Two-phase flow injector replacing refrigerator throttling element

A throttling element and ejector technology, which is used in refrigerators, ejectors, refrigeration and liquefaction, etc., can solve the problems that refrigerants are prone to shock waves, reduce nozzle efficiency, reduce ejector efficiency, etc., and achieve significant social benefits and Economic benefit, efficiency improvement, effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

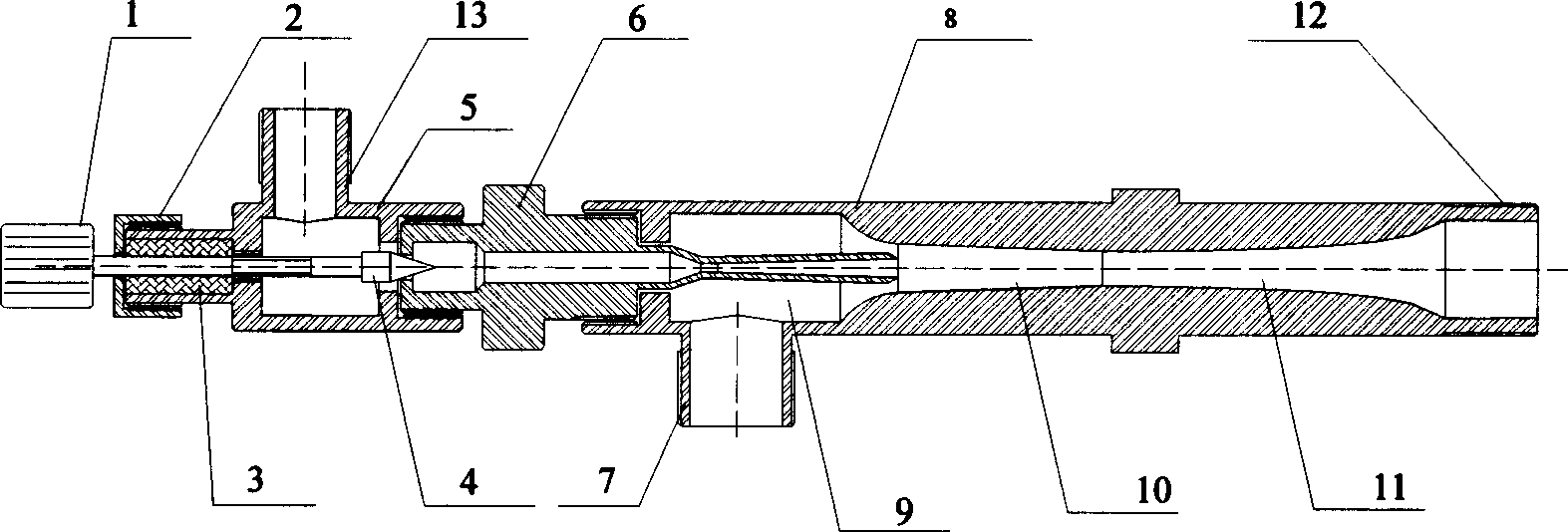

[0011] Such as figure 1 As shown, the present invention includes: stepper motor 1, sealing nut 2, sealing packing 3, regulating valve stem 4, regulating valve body 5, nozzle 6, injection fluid inlet joint 7, injector housing 8, suction chamber 9 , Mixing chamber 10, diffuser chamber 11, mixed fluid outlet joint 12, mainstream fluid inlet joint 13. One end of the regulating valve stem 4 is connected with the output shaft of the stepping motor 1, and the other end is made into a cone shape, and extends into the regulating valve body 5 after passing through the sealing nut 2 and the sealing packing 3, and the middle part of the regulating valve stem 4 is in contact with the regulating valve body. The contact part of the body 5 is threaded, the mainstream fluid inlet joint 13 is integrated with the regulating valve body 5, the inlet of the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com