Patents

Literature

1356 results about "Expansion chamber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

On a two-stroke engine, an expansion chamber or tuned pipe is a tuned exhaust system used to enhance its power output by improving its volumetric efficiency.

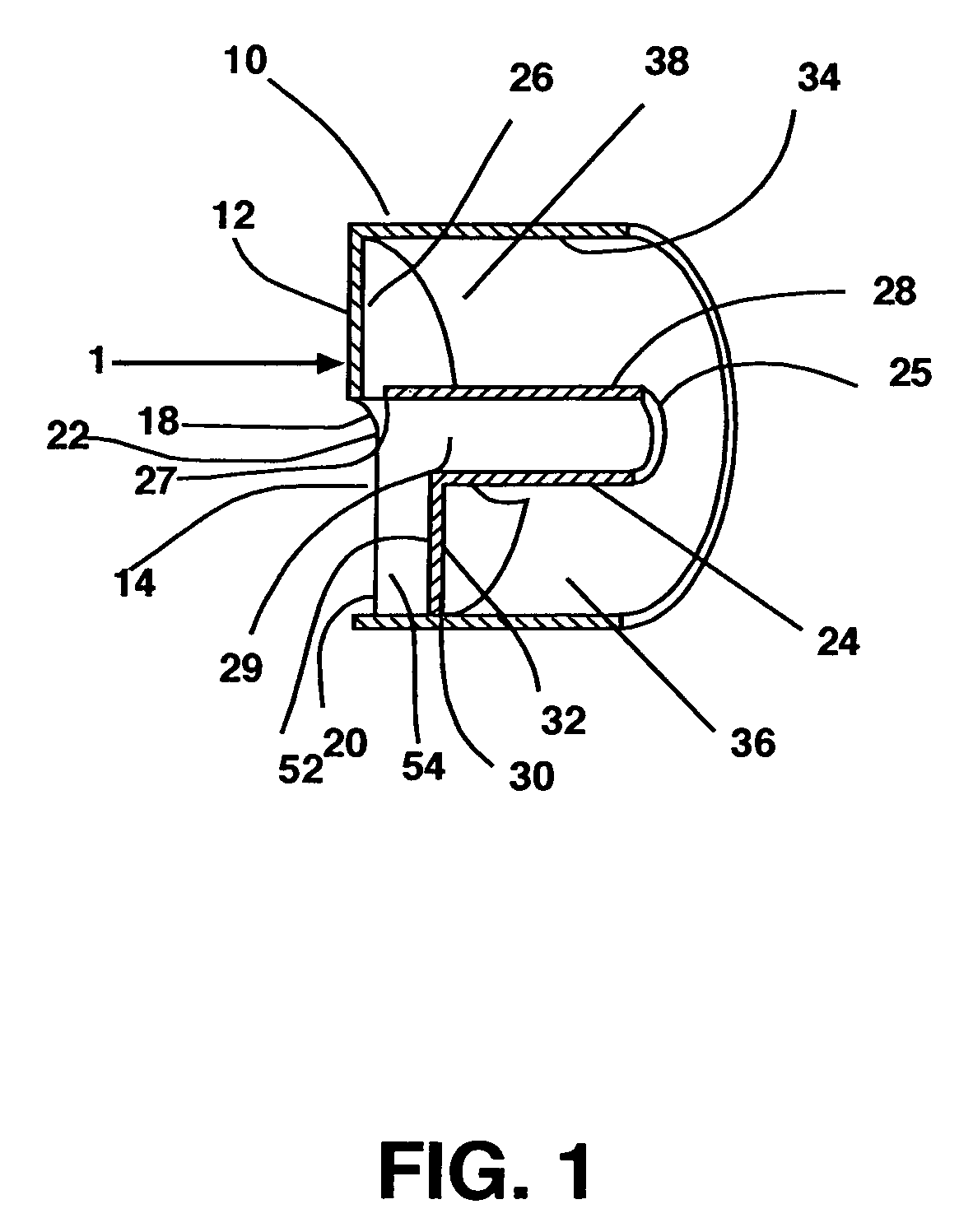

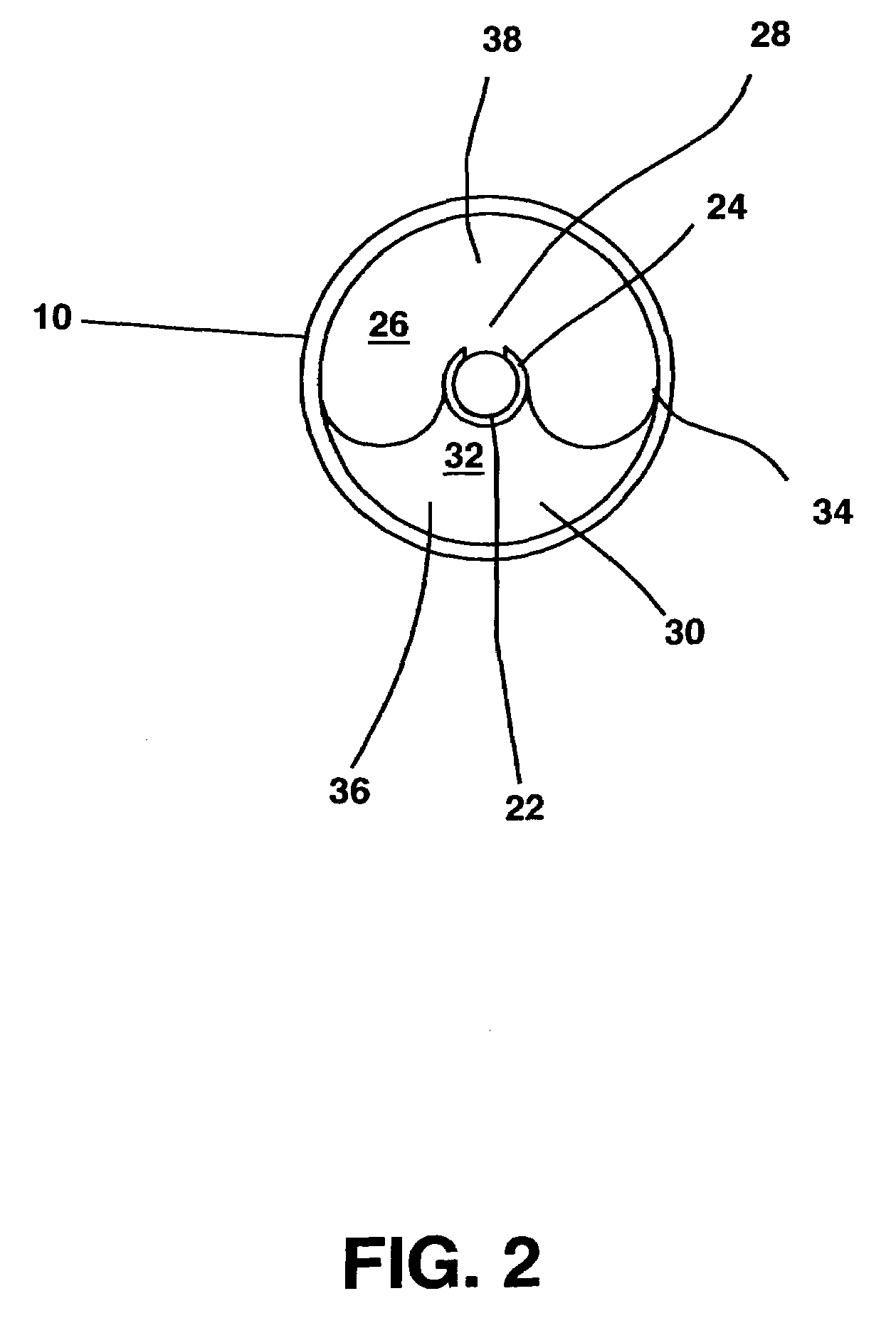

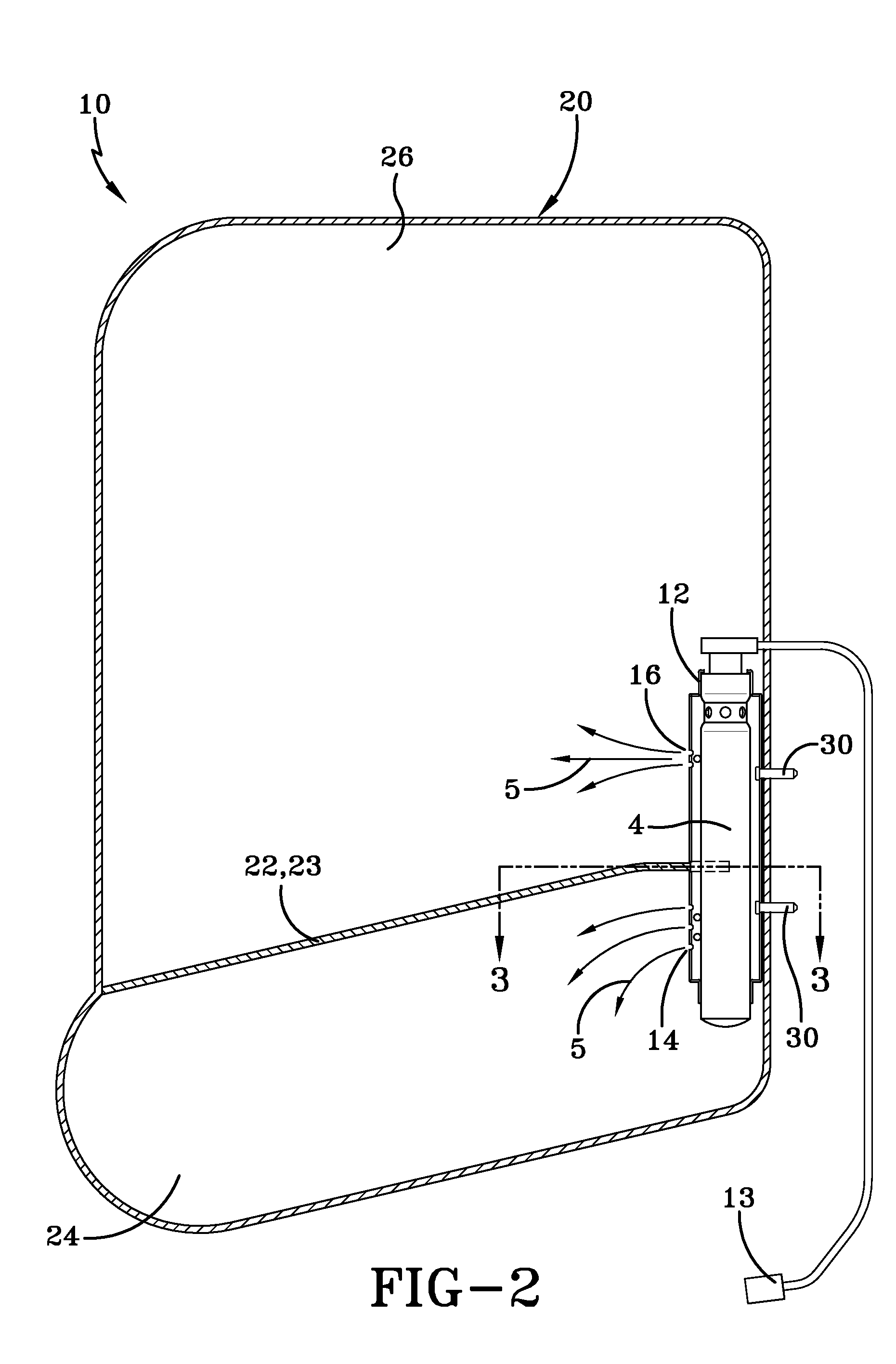

Omega firearms suppressor

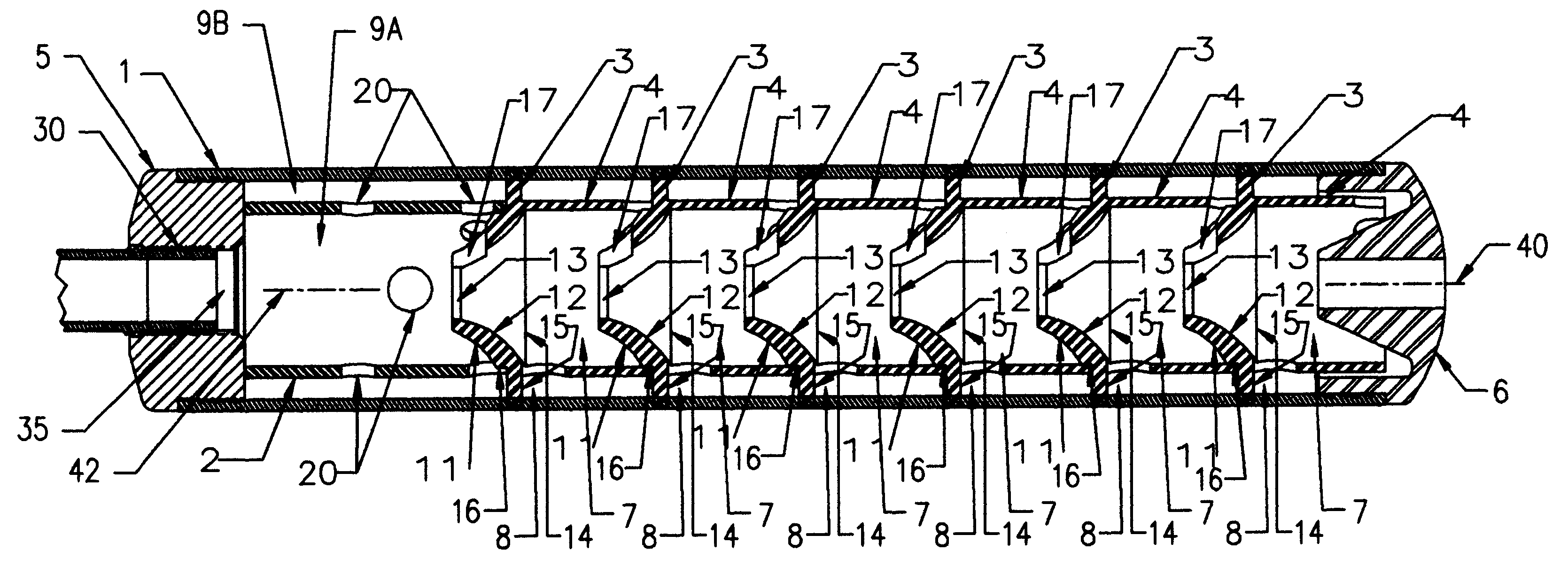

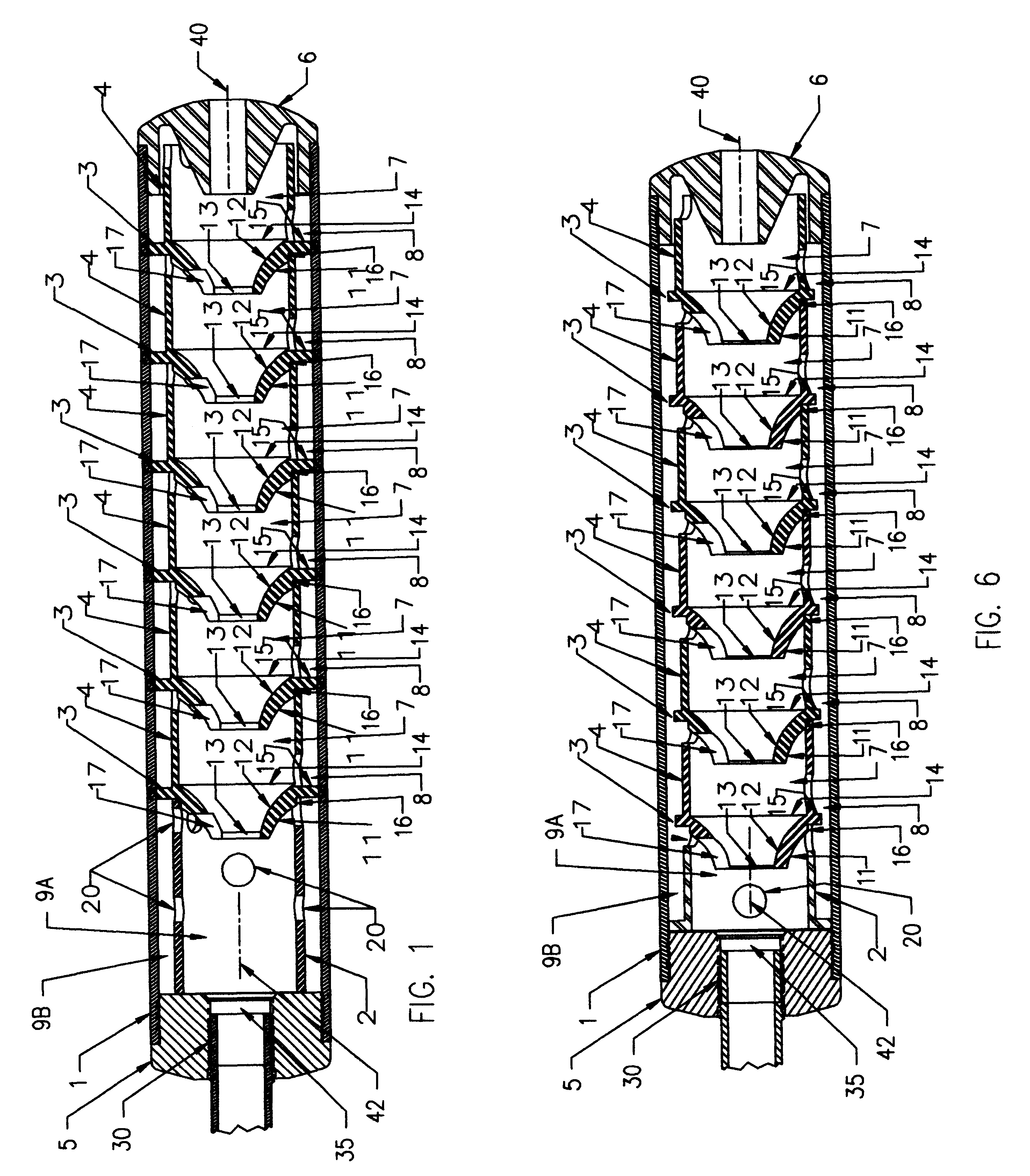

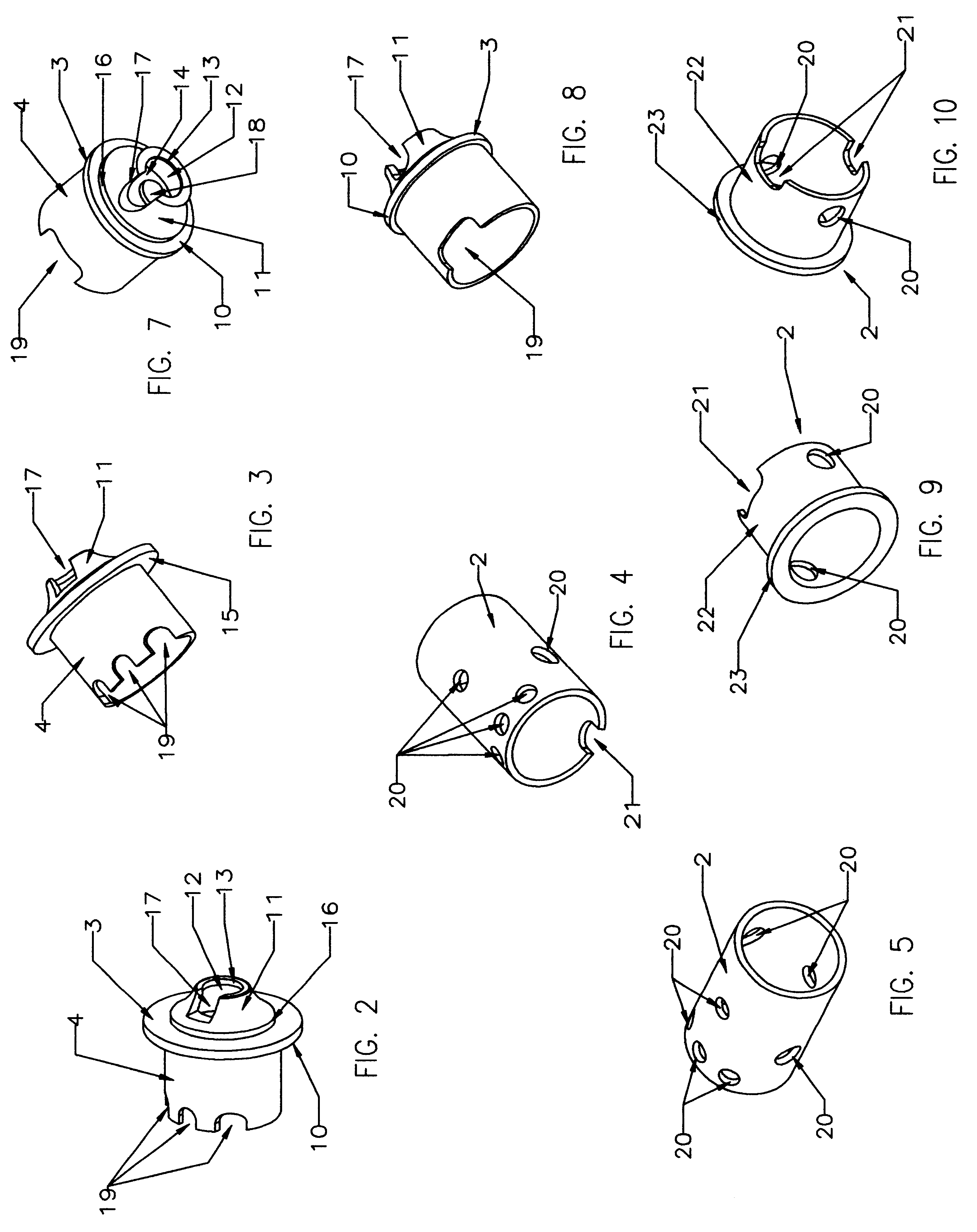

A sound suppressor for a firearm comprises a cylindrical housing having a rear end cap attached to the housing and having means for mounting to the muzzle of a firearm, a front end cap attached to the housing and having a centrally positioned aperture, and at least one baffle element positioned within the housing between the rear end cap and front end cap. The baffle element comprises a flat plate with an integral rearward-protruding cone with the cone having an entrance aperture and an exit aperture, with the cone having an elongated aperture that extends from the entrance aperture toward the flat plate. An initial coaxial spacer element is positioned between the rear end cap and the baffle element, with the initial coaxial spacer element having at least one gas port and at least one notch at an edge of the initial coaxial spacer element. Inner and outer expansion chambers are formed between the rear end cap, the initial coaxial spacer element and the baffle element. A coaxial spacer element is positioned between the front end cap and the baffle element, and the coaxial spacer element has at least one gas port and at least one notch at an edge of the coaxial spacer element. Inner and outer expansion chambers are formed between the baffle element, the coaxial spacer element and the front end cap.

Owner:GADDINI JOSEPH D

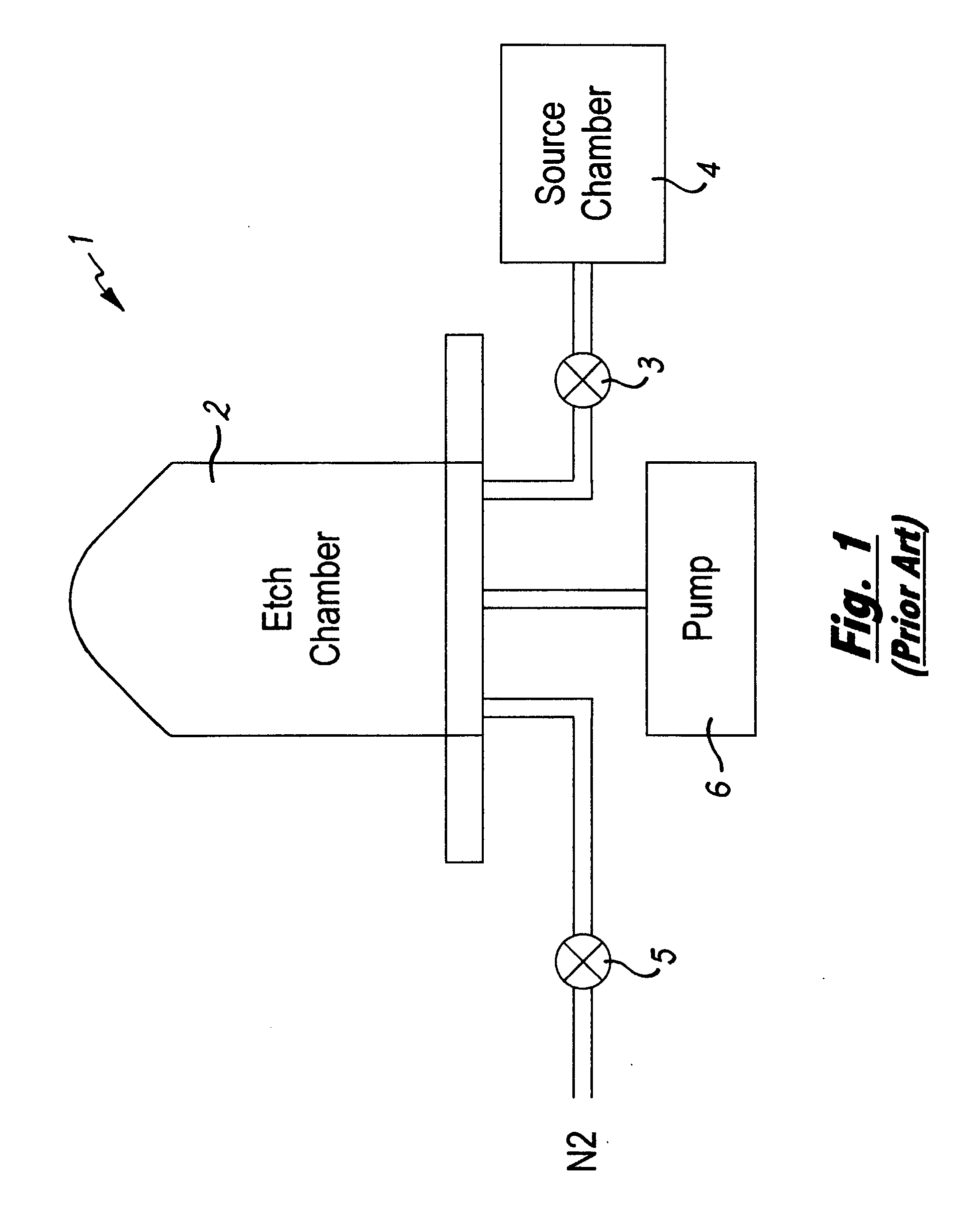

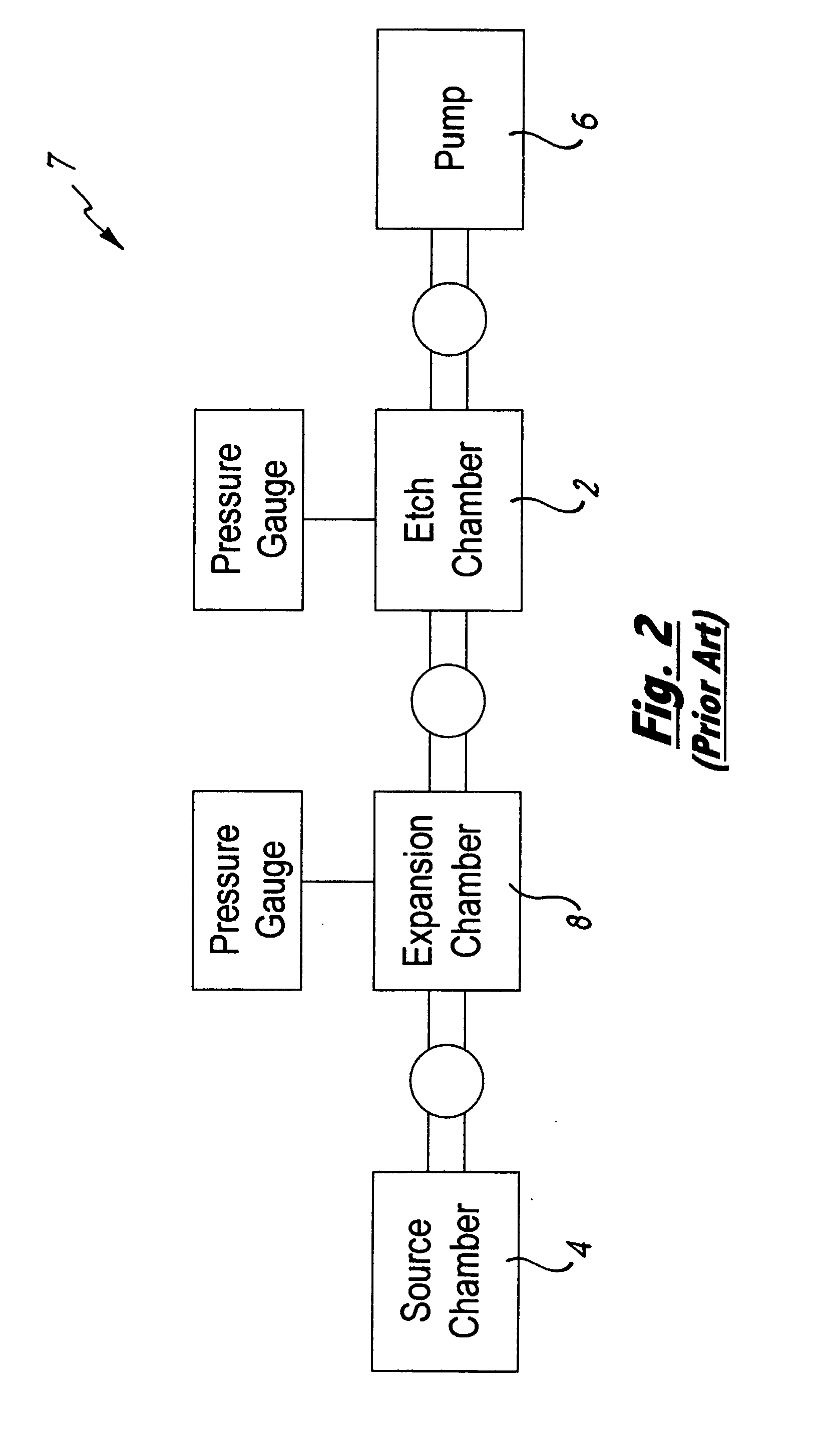

Method and Apparatus for the Etching of Microstructures

InactiveUS20080035607A1Increase partial pressureIncrease ratingsElectric discharge tubesDecorative surface effectsEtchingContinuous flow

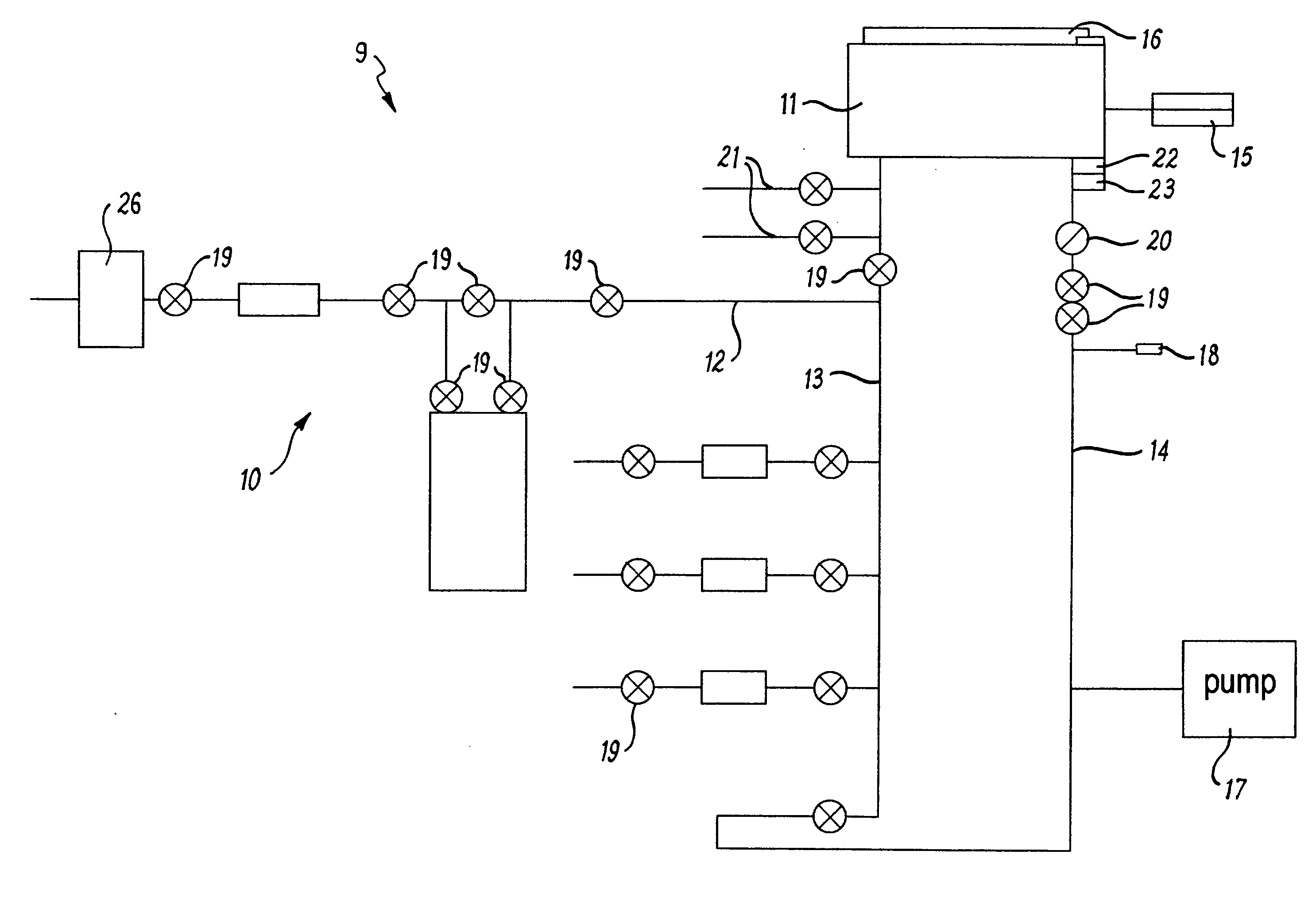

An apparatus and method for providing an etching gas source for etching one or more microstructures located within a process chamber. the apparatus has a gas source supply line attached to a gas source and one or more chambers for containing an etching material. In use, the etching material is transformed into an etching material vapor within one or more of the chamber and the gas supply line provides a supply of carrier gas to the etching material vapor and also supplies the etching material vapor transported by the carrier gas to the process chamber. Advantageously, the apparatus of the invention does not require the incorporation of any expansion chambers or other complicated mechanical features in order to achieve a continuous flow of etching gas.

Owner:MEMSSTAR

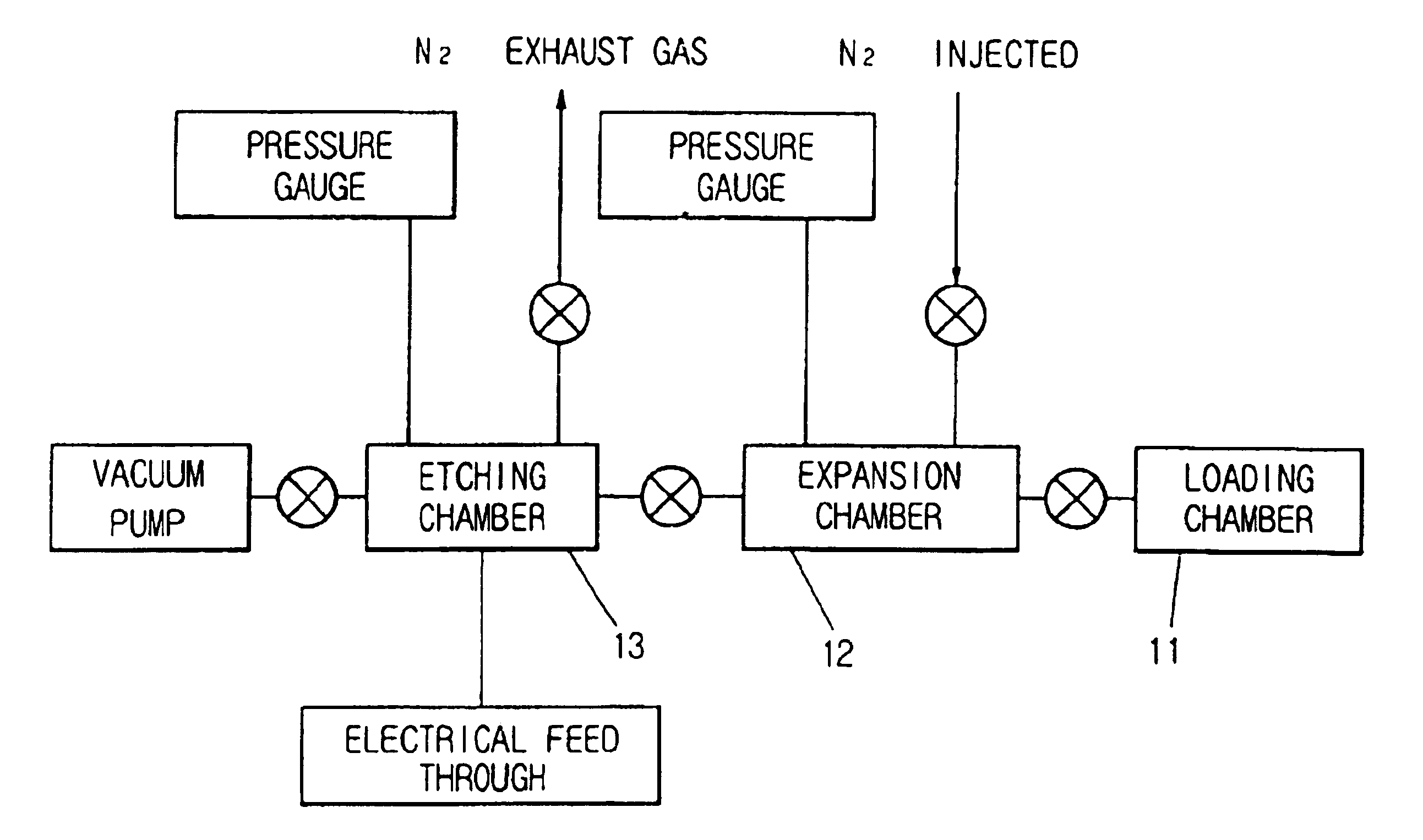

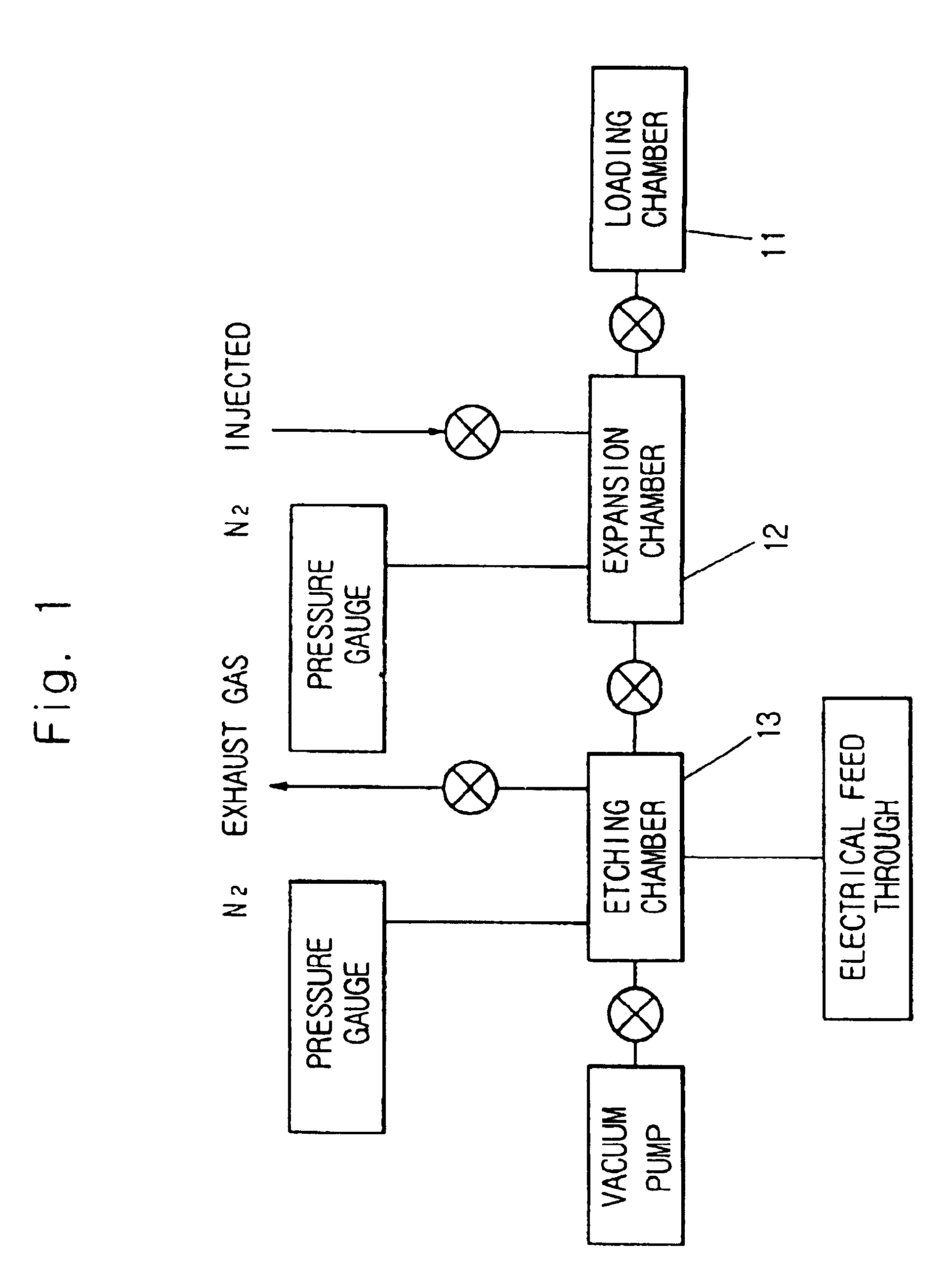

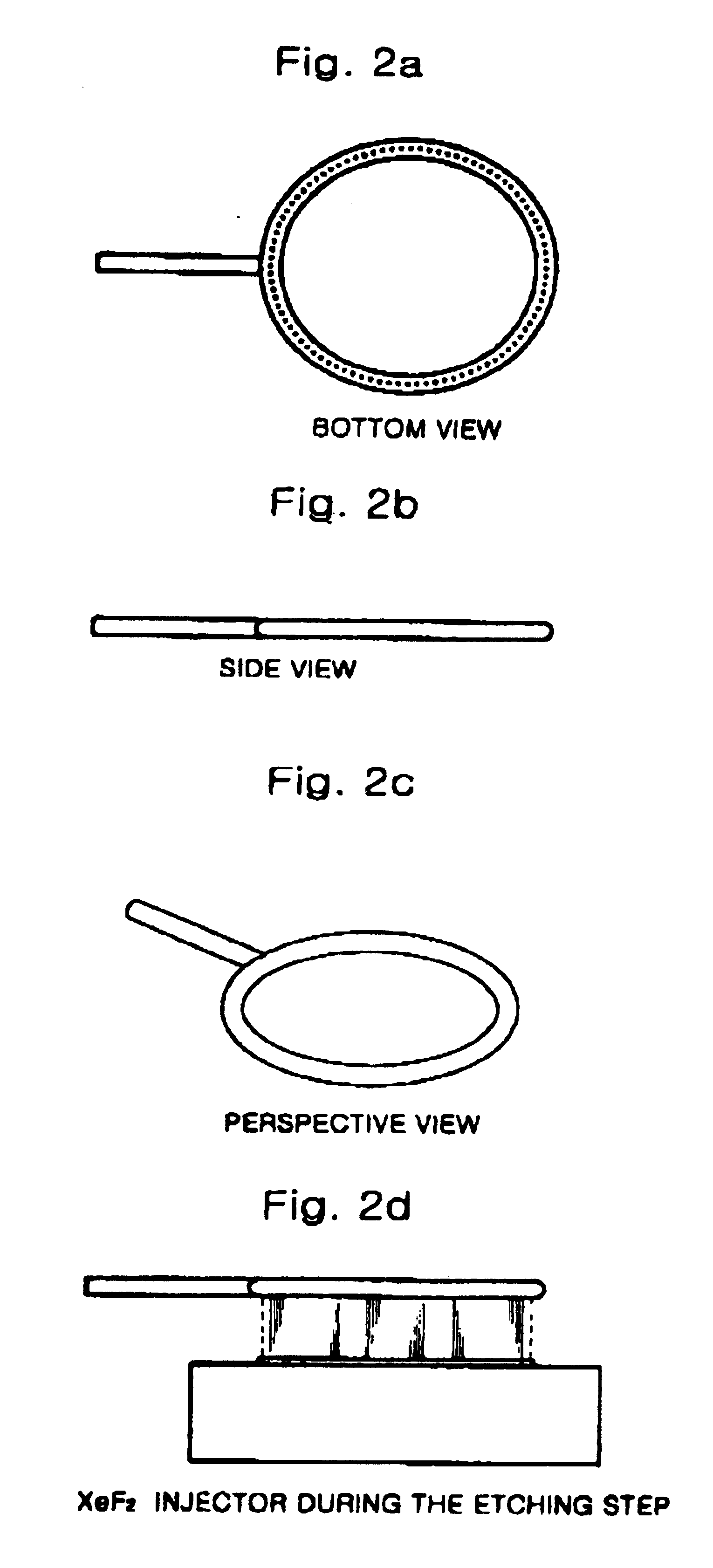

Silicon etching apparatus using XeF2

InactiveUS6736987B1Minimize damageUniform etchingVacuum gauge using ionisation effectsDecorative surface effectsInternal pressureFeedback controller

The silicon etching apparatus using XeF2 includes: a basic structure composed of a loading chamber tot loading XeF2, an expansion chamber for collecting sublimated XeF2 gas, and an etching chamber for performing an etching process; and a means for injecting nitrogen prior to the etching process to eliminate air moisture in the apparatus and thus preventing the formation of HF. The silicon etching apparatus using XeF2 further includes: an injector having a predefined shape provided in the etching chamber for uniformly injecting the XeF2 gas downward on to surface of a wafer; a feedback controller for feedback controlling the internal pressure of the loading chamber in order to prevent sublimation of the residual XeF2 in the loading chamber; and a weight scale for measuring the weight of XeF2 in the loading chamber.

Owner:TECHBANK

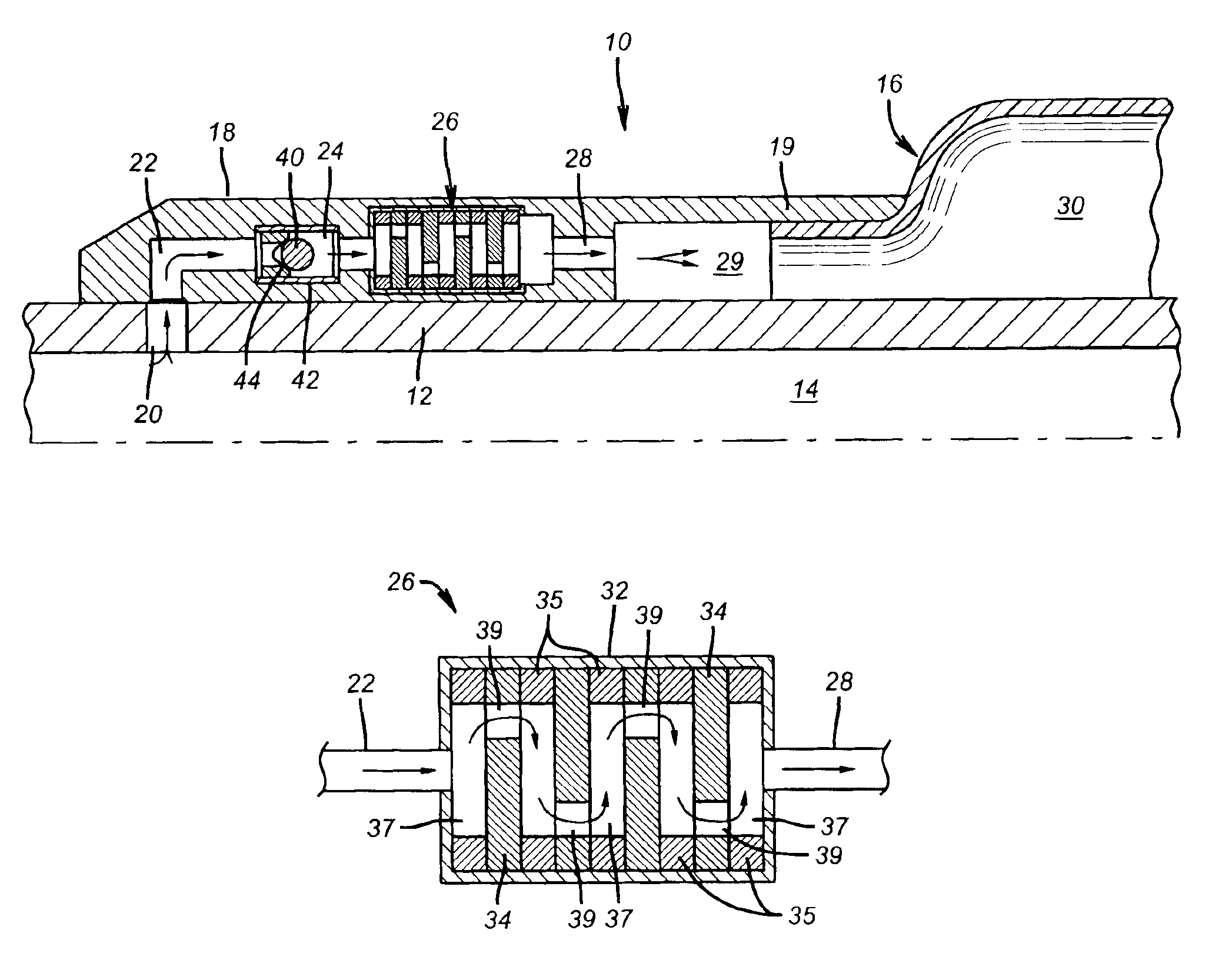

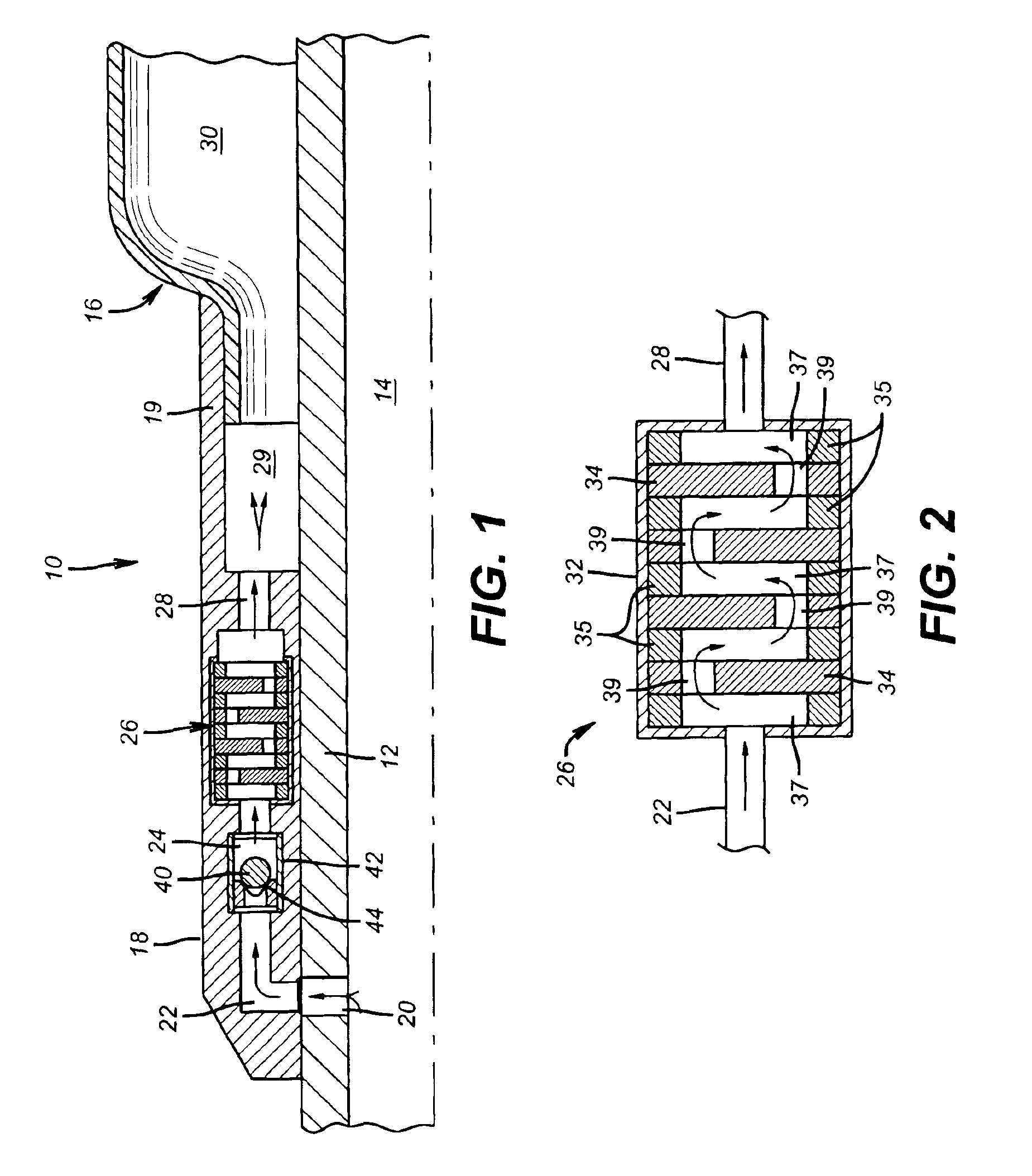

Shear activated inflation fluid system for inflatable packers

A subterranean well packer is inflated by a pumped transfer of rheotropic fluid through a tortuous flow channel into a packer sealing element expansion chamber. The tortuous flow channel and fluid delivery pressure are coordinated with the fluid properties to impose sufficient fluid shear stress for inducement of a substantial phase change in said rheotropic fluid after entry into expansion chamber.

Owner:BAKER HUGHES INC

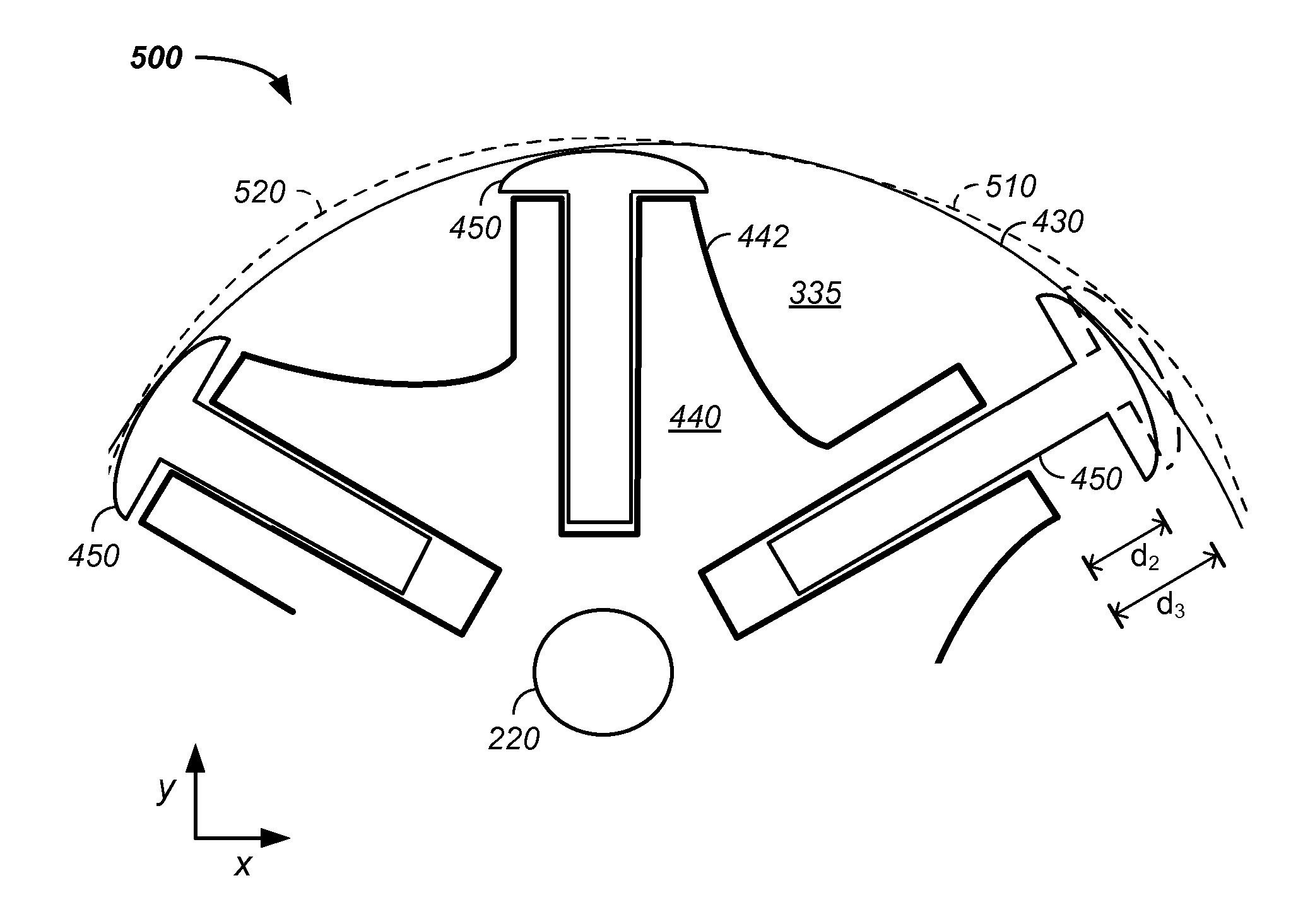

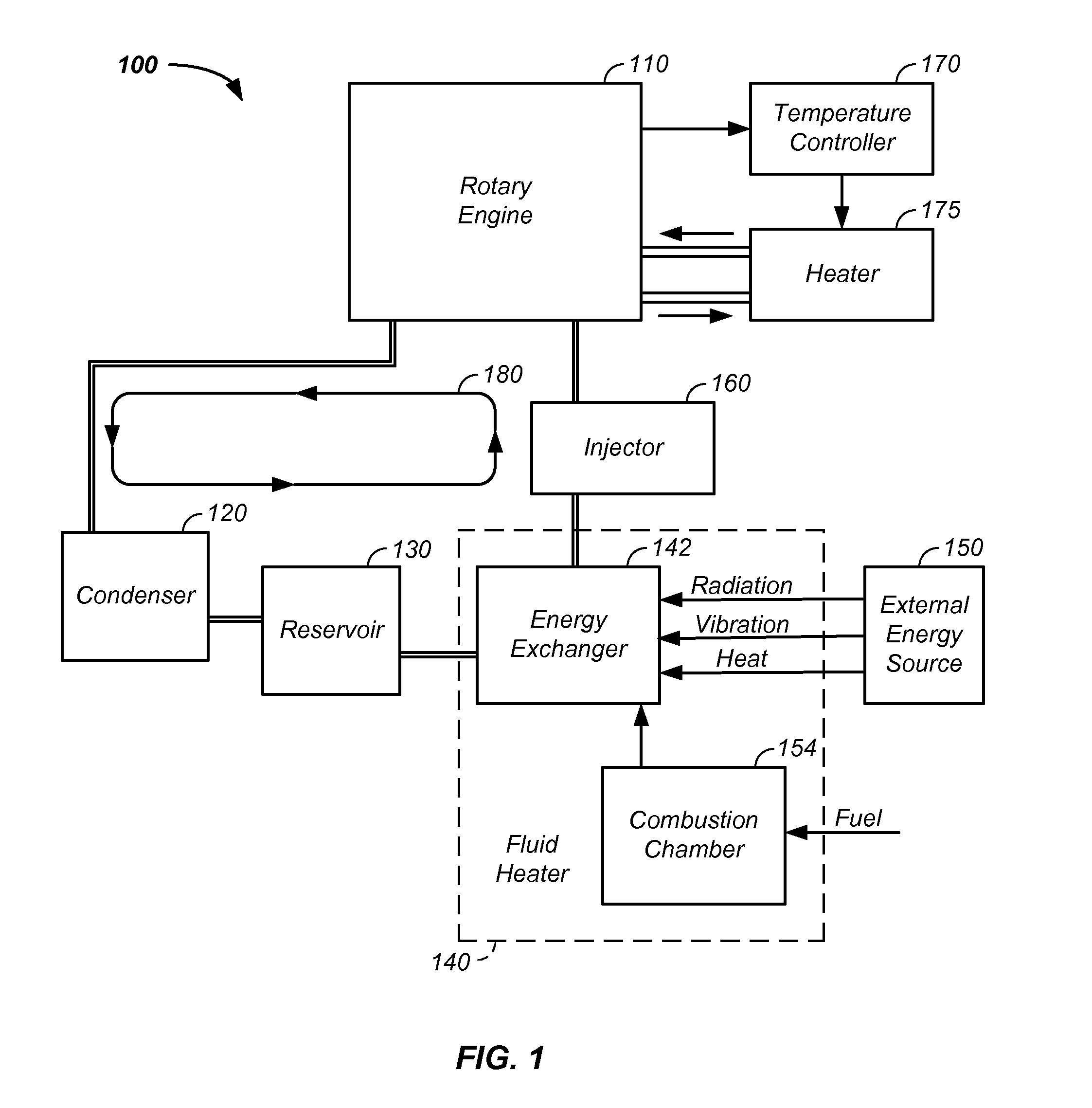

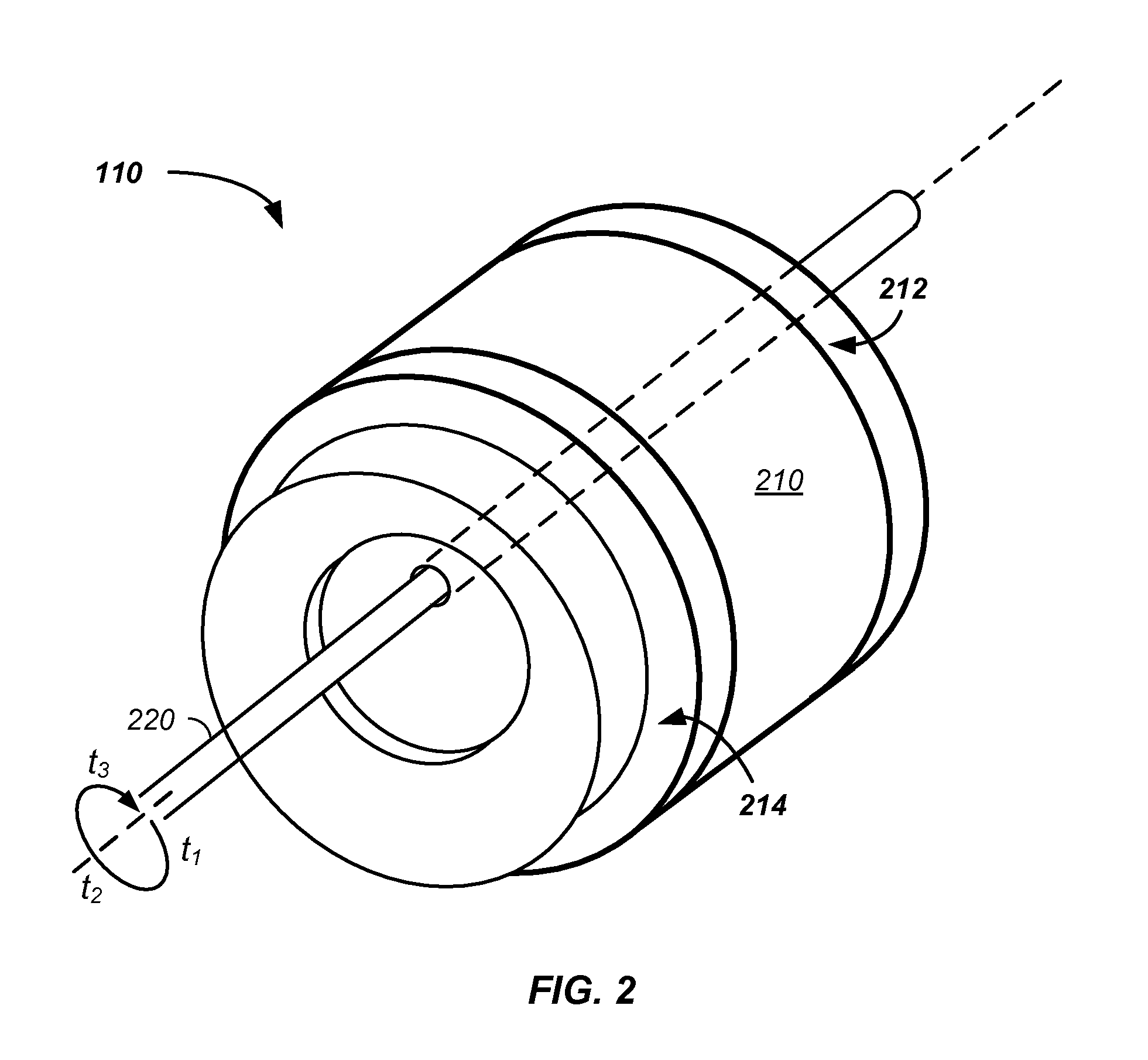

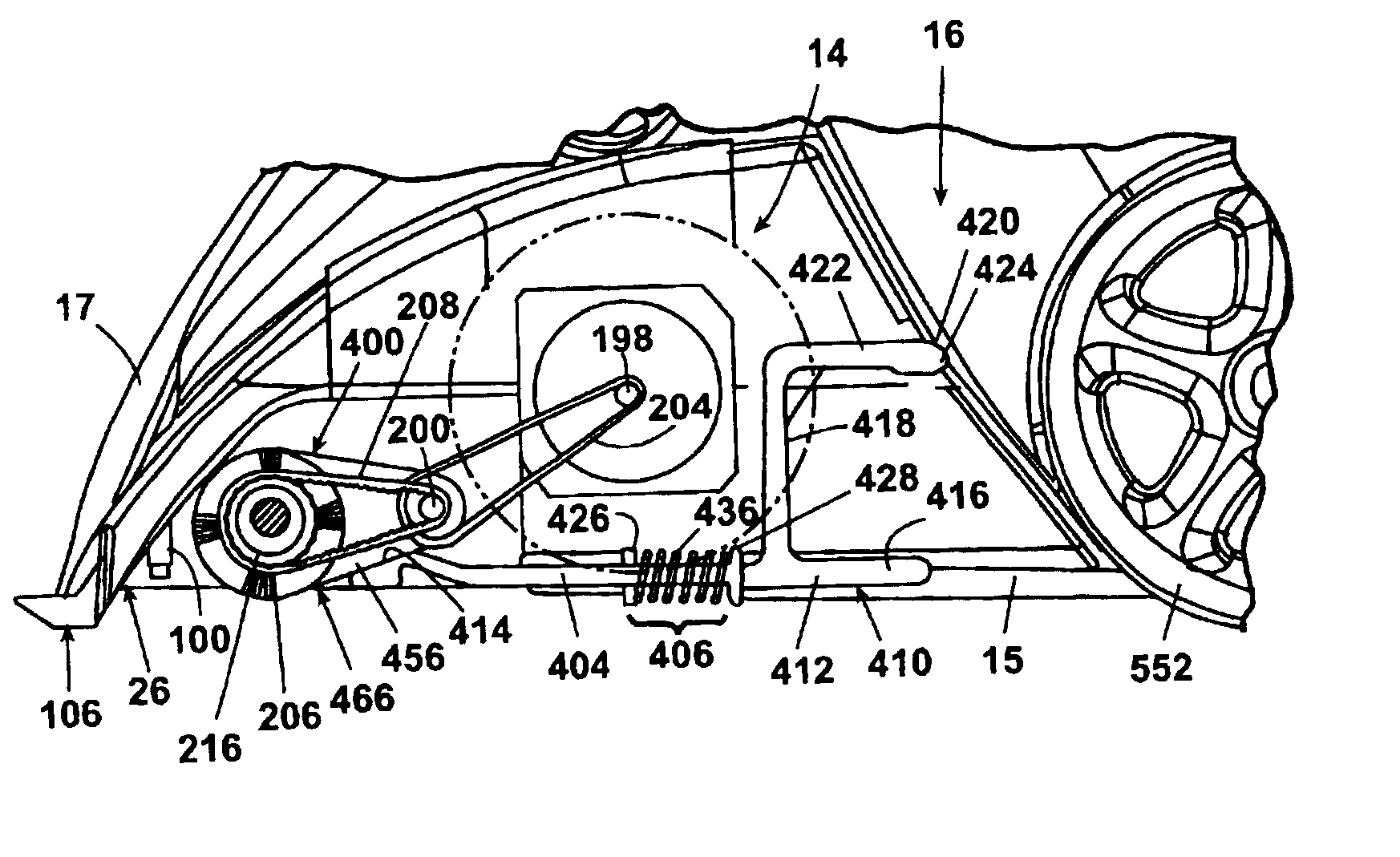

Rotary engine expansion chamber apparatus and method of operation therefor

ActiveUS8523547B2Internal combustion piston enginesOscillating piston enginesRotary engineExpansion chamber

Owner:PEKRUL MERTON W

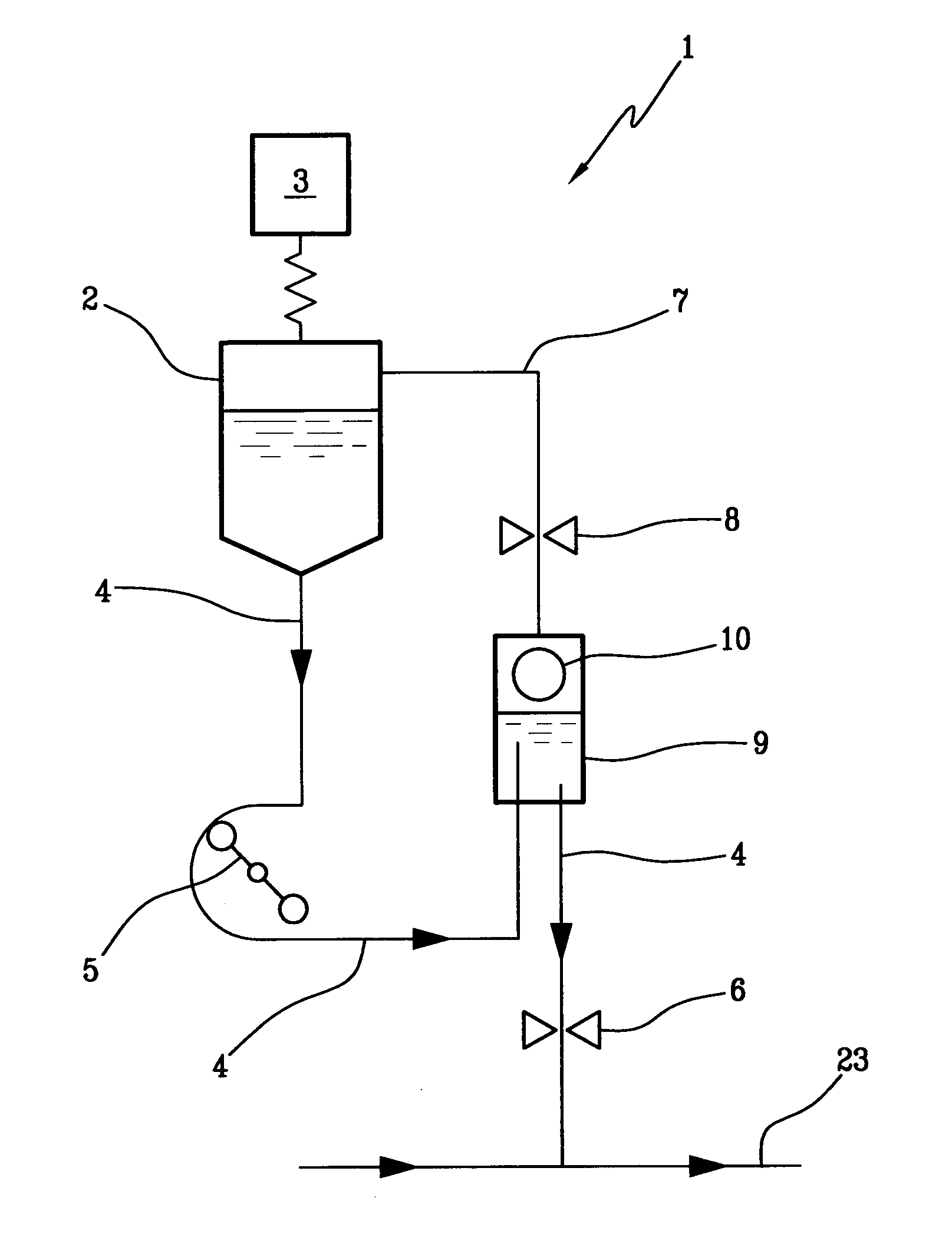

Infusion apparatus

ActiveUS20100280430A1Reduce need for interventionReduce riskMedical devicesPressure infusionEngineeringExpansion chamber

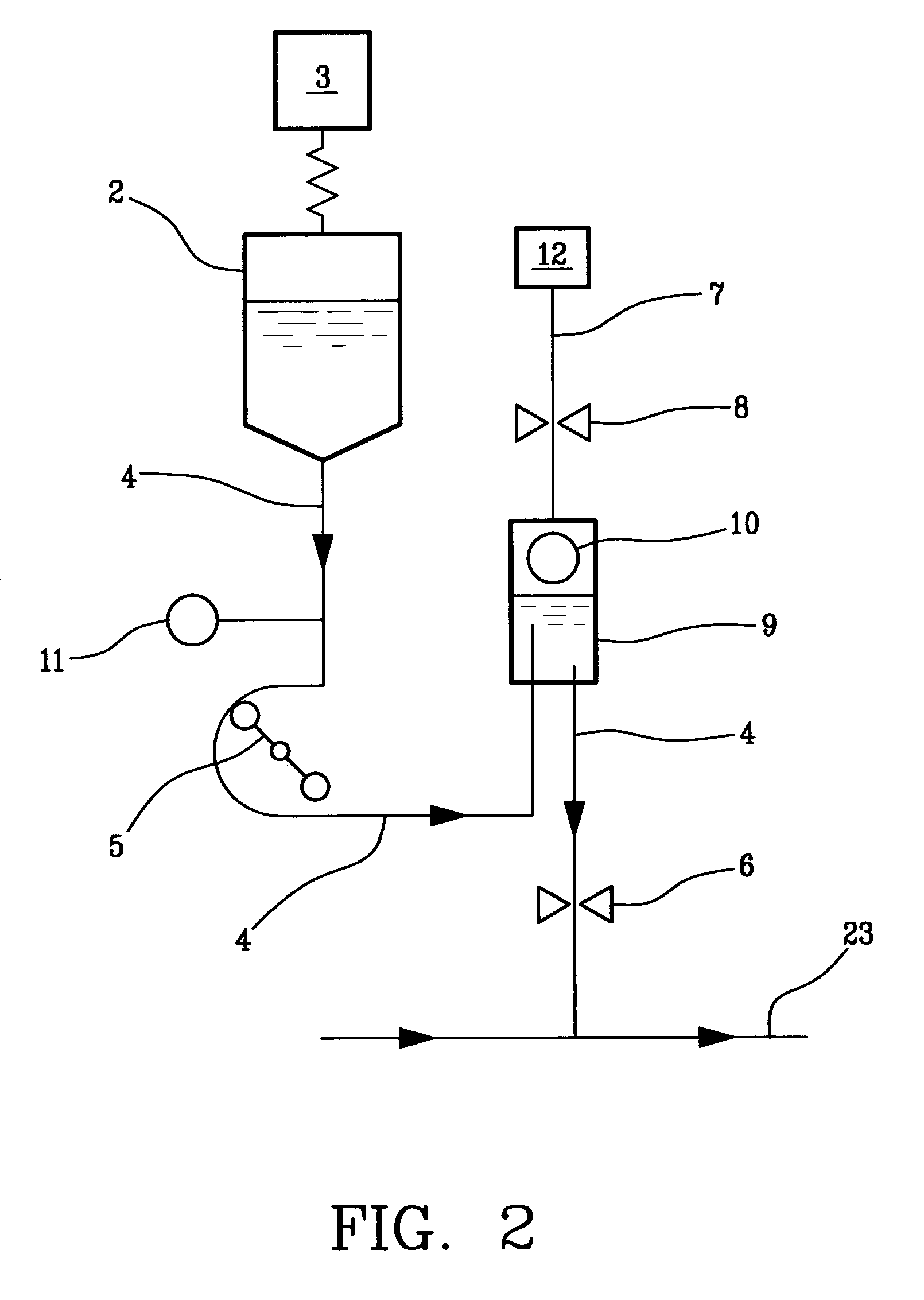

In an infusion apparatus, an infusion line (4) connects a container (2) of an infusion fluid to an extracorporeal blood circuit (23). A first valve (6) closes the infusion line downstream of an infusion pump (5). An expansion chamber (9), provided with a pressure sensor (10), is arranged between the infusion pump and the first valve. A second valve (8) closes a vent line (7) of the expansion chamber. The processor closes the first valve when the container is emptied. After replacement with a new and full container, the processor restarts the pump and selectively opens the first valve or the second valve according to the increase in pressure measured in the expansion chamber.

Owner:GAMBRO LUNDIA AB

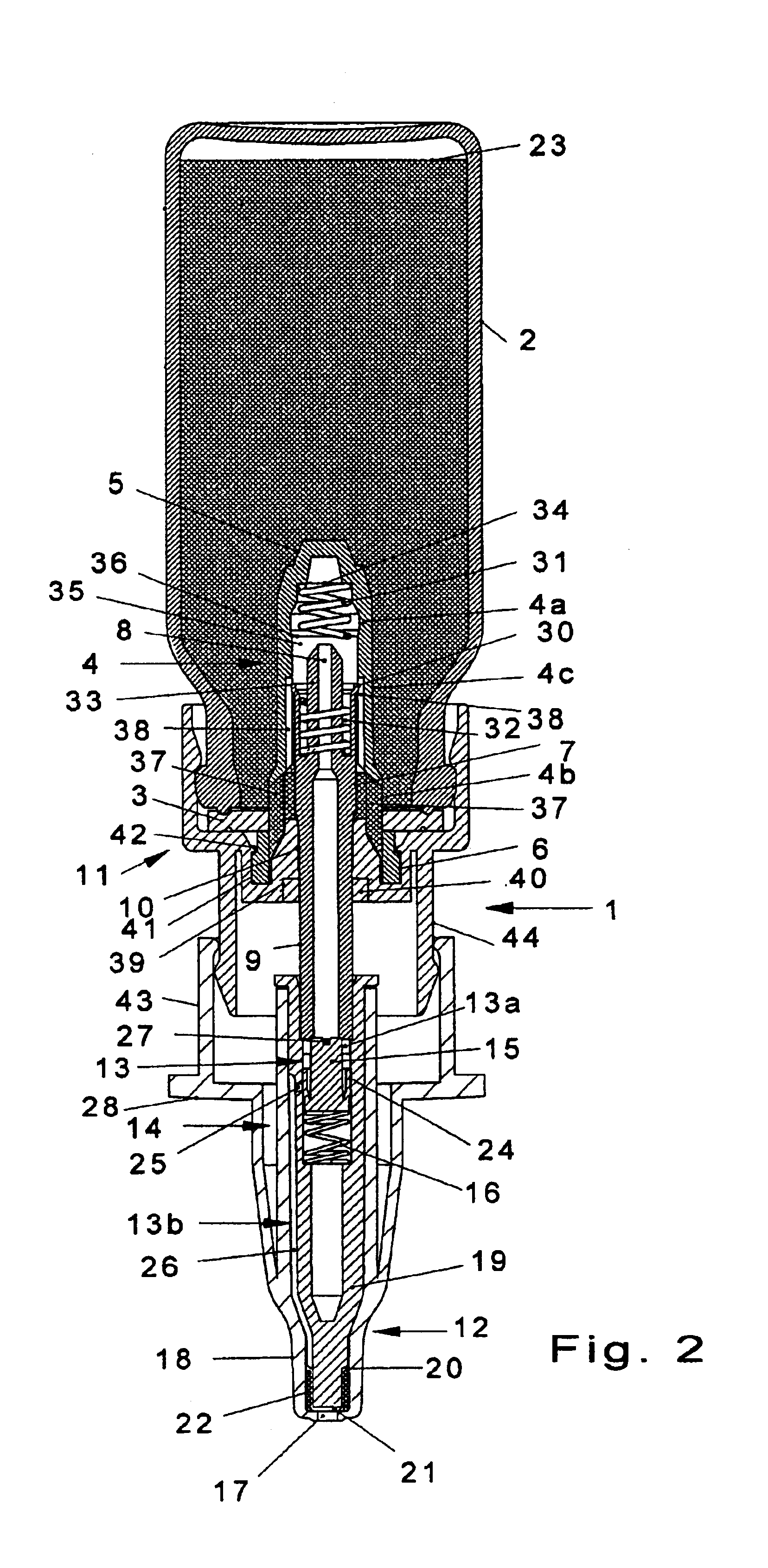

Pneumatically driven setting tool

ActiveUS20070045377A1Reduce the amount of constructionAdvantageously actuatedStapling toolsNailing toolsCompression deviceEngineering

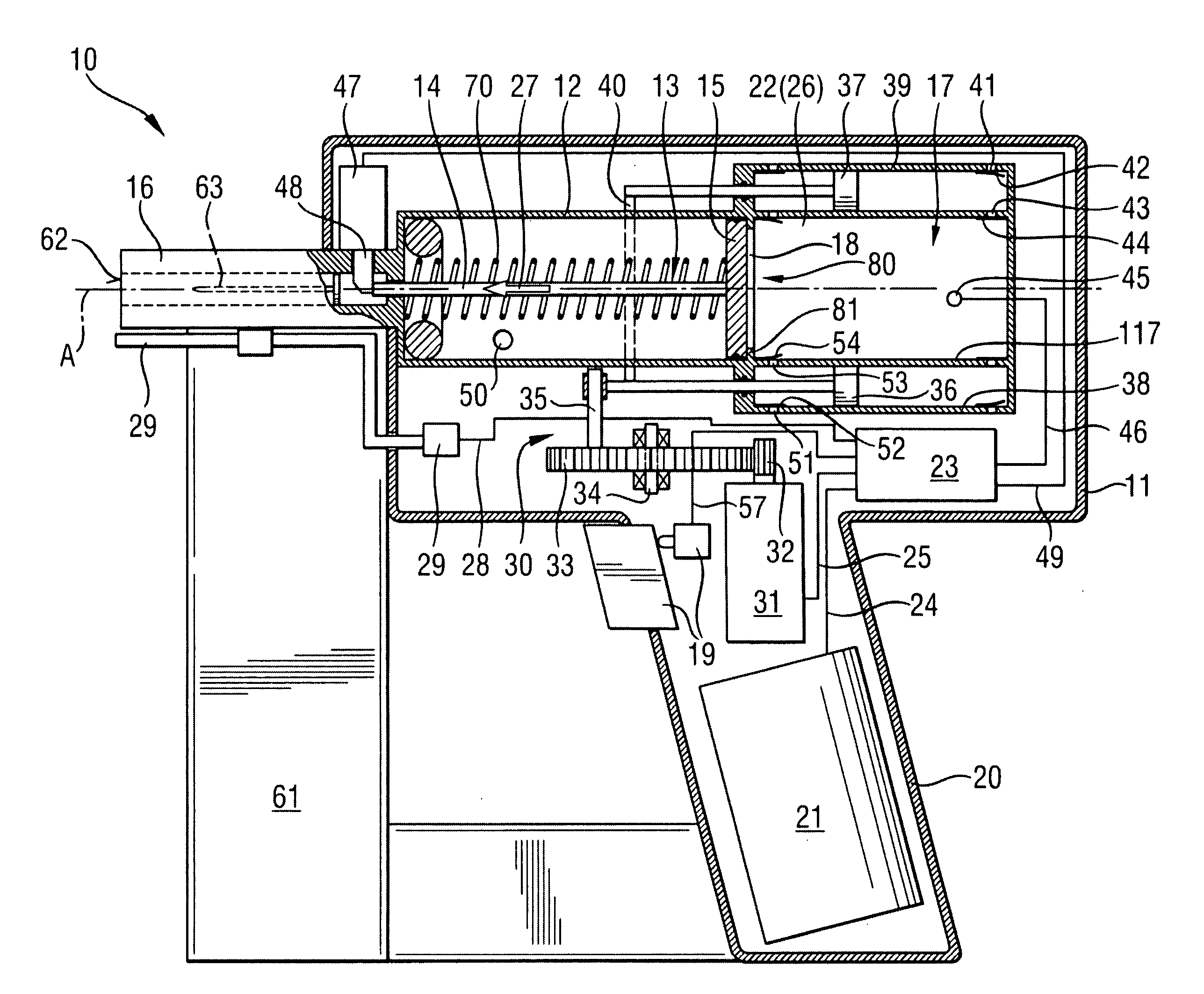

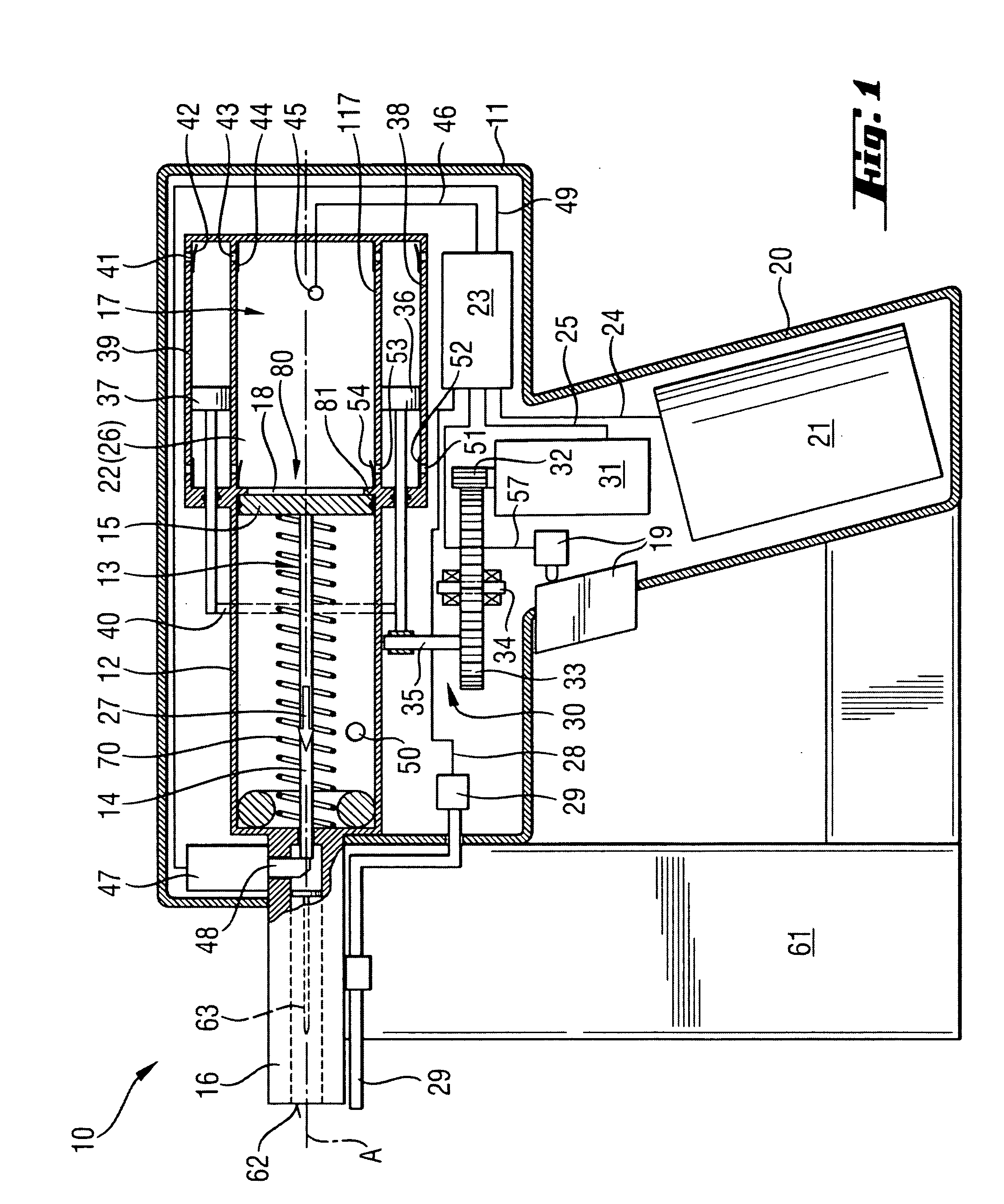

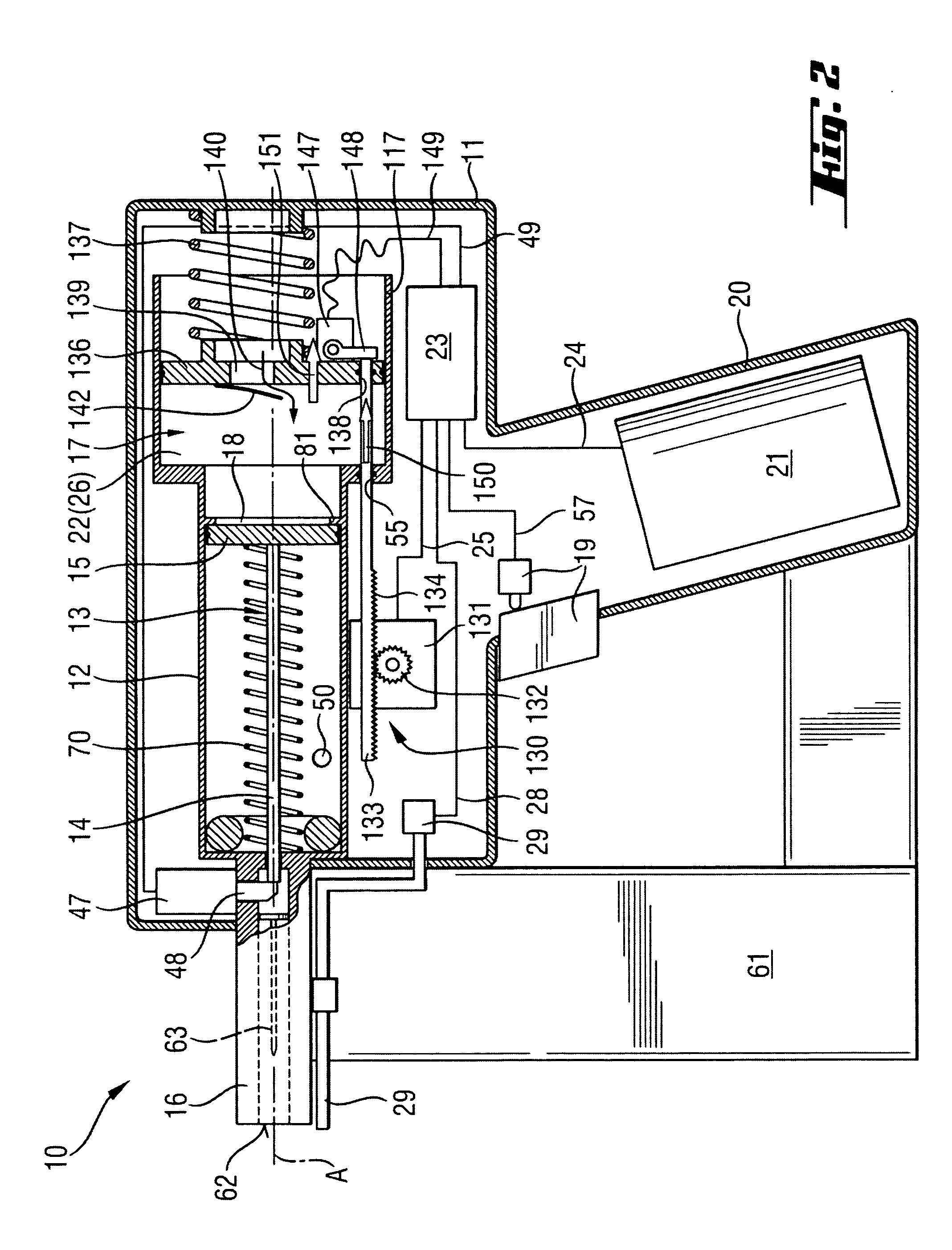

A pneumatically driven setting tool for driving in fastening elements, includes a chamber (17) forming a storage chamber (22) for storing the pressure medium produced by the compression device (30, 130) and an expansion chamber (26) adjoining the drive-in piston (13), which is displaceable in a guide (12), at a side of the drive-in piston (13) remote from the piston stem (14), communicating with the storage chamber (22), and having an opening (18) connecting the expansion chamber (26) with the drive-in piston (13), at least one check valve (44, 54, 142) arranged between the compression device (30, 130) and the chamber (17), and a piston retaining device (47) for retaining the drive-in piston (13) in its initial position (80) in which the chamber (17) is sealed against the guide (12).

Owner:HILTI AG

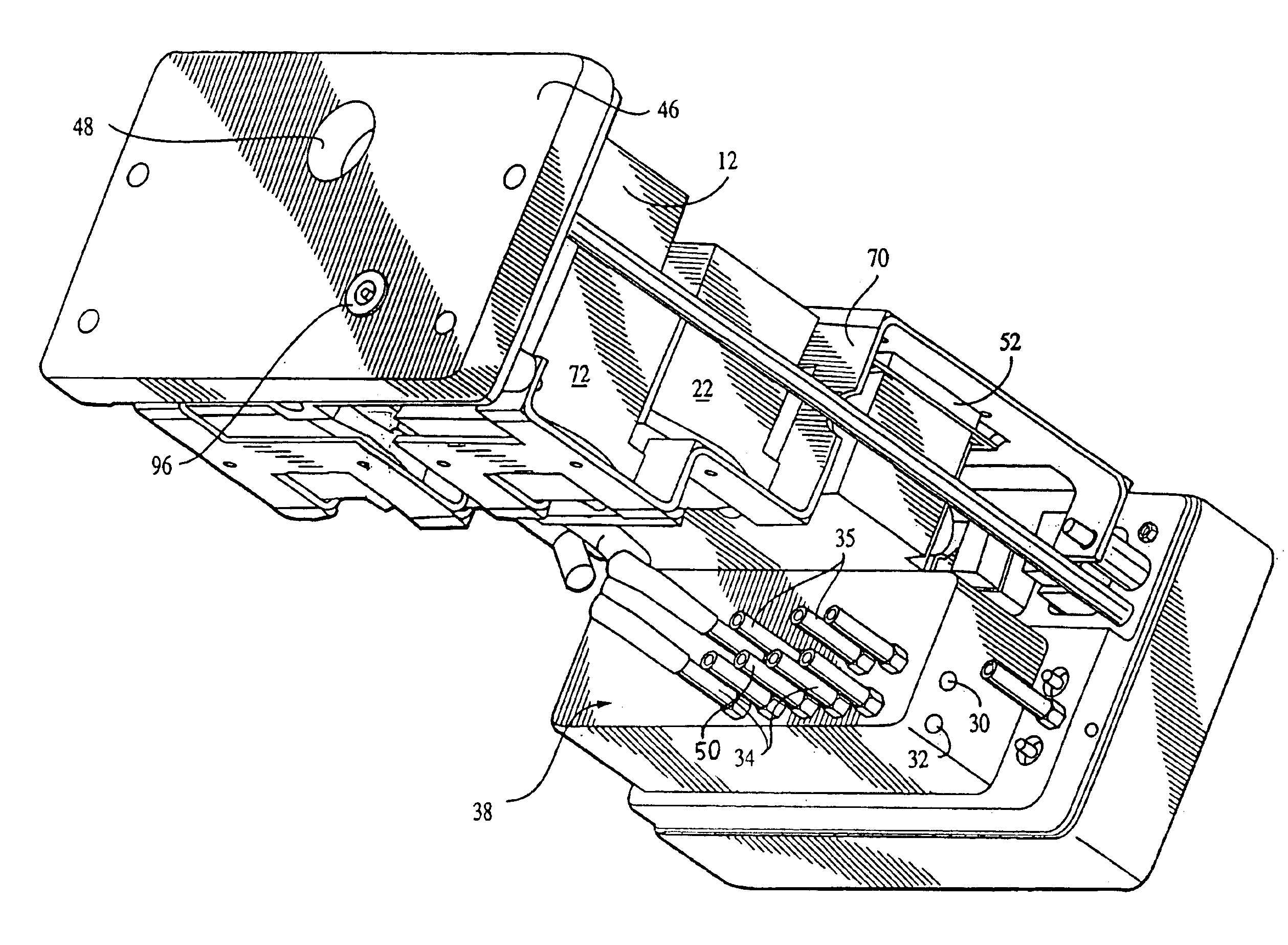

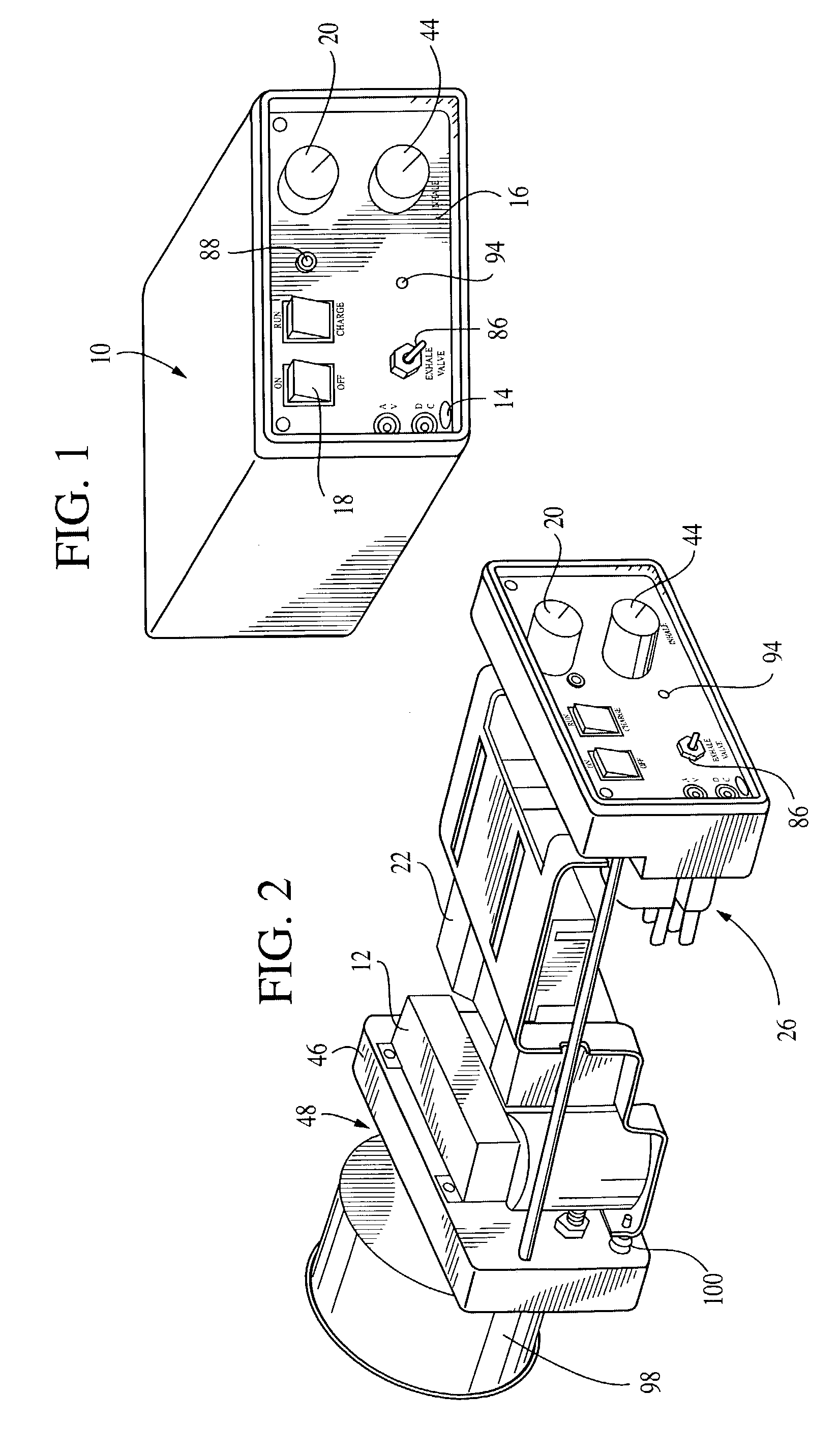

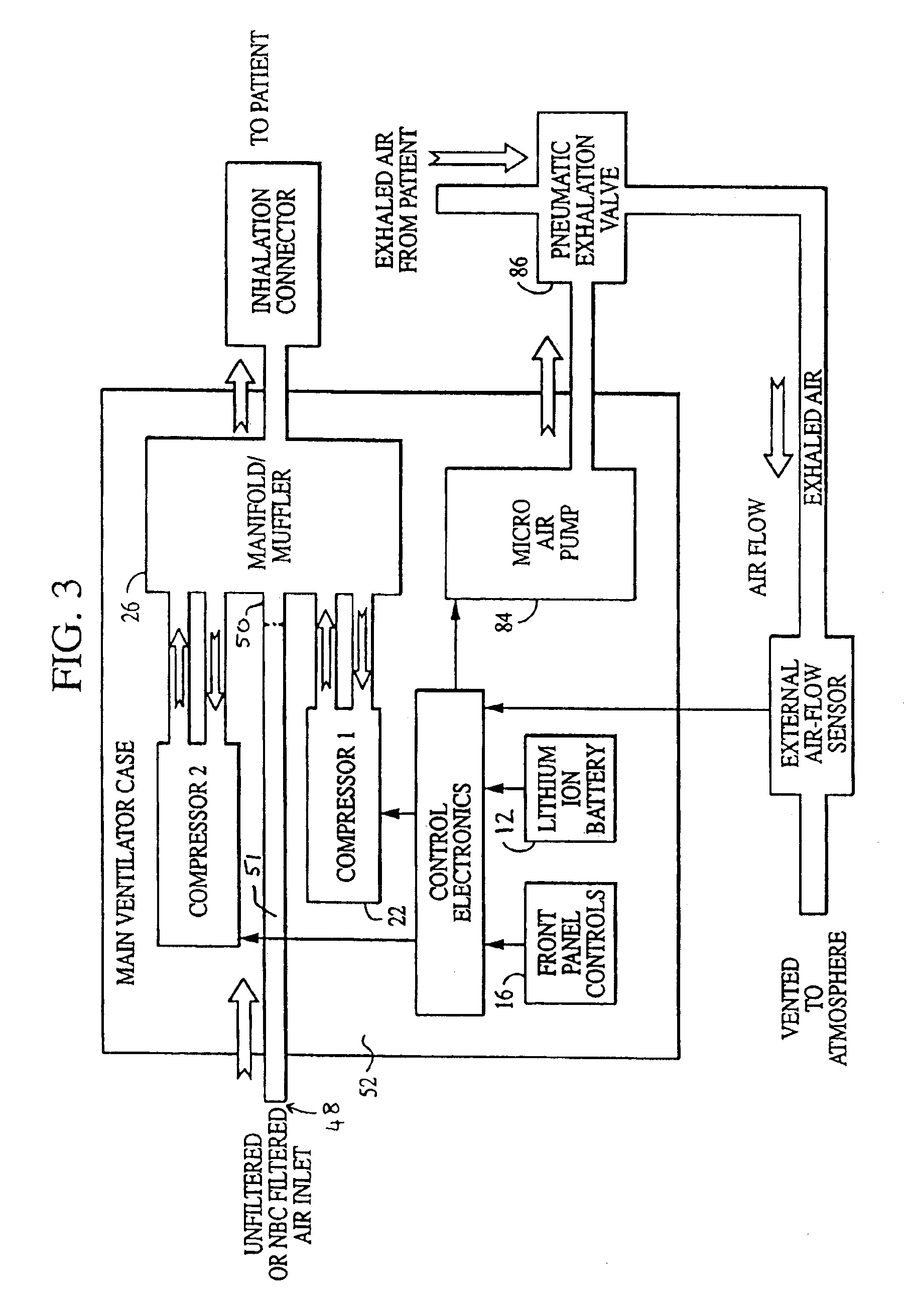

Portable ventilator

ActiveUS7032589B2Speed up the flowReduce audible noiseExhaust apparatusBreathing masksPortable ventilatorsEngineering

A portable ventilator for providing an air-recipient with compulsory respiration is provided with an outlet manifold and a single-expansion-chamber muffler configured so that airflow through an inhale outlet port of the muffler is pulse-free and a transmission loss, defined as the ratio of sound power generated by the at least one compressor and incident on the muffler to the sound power transmitted by the muffler, is sufficient to deaden the sound power of the compressor.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

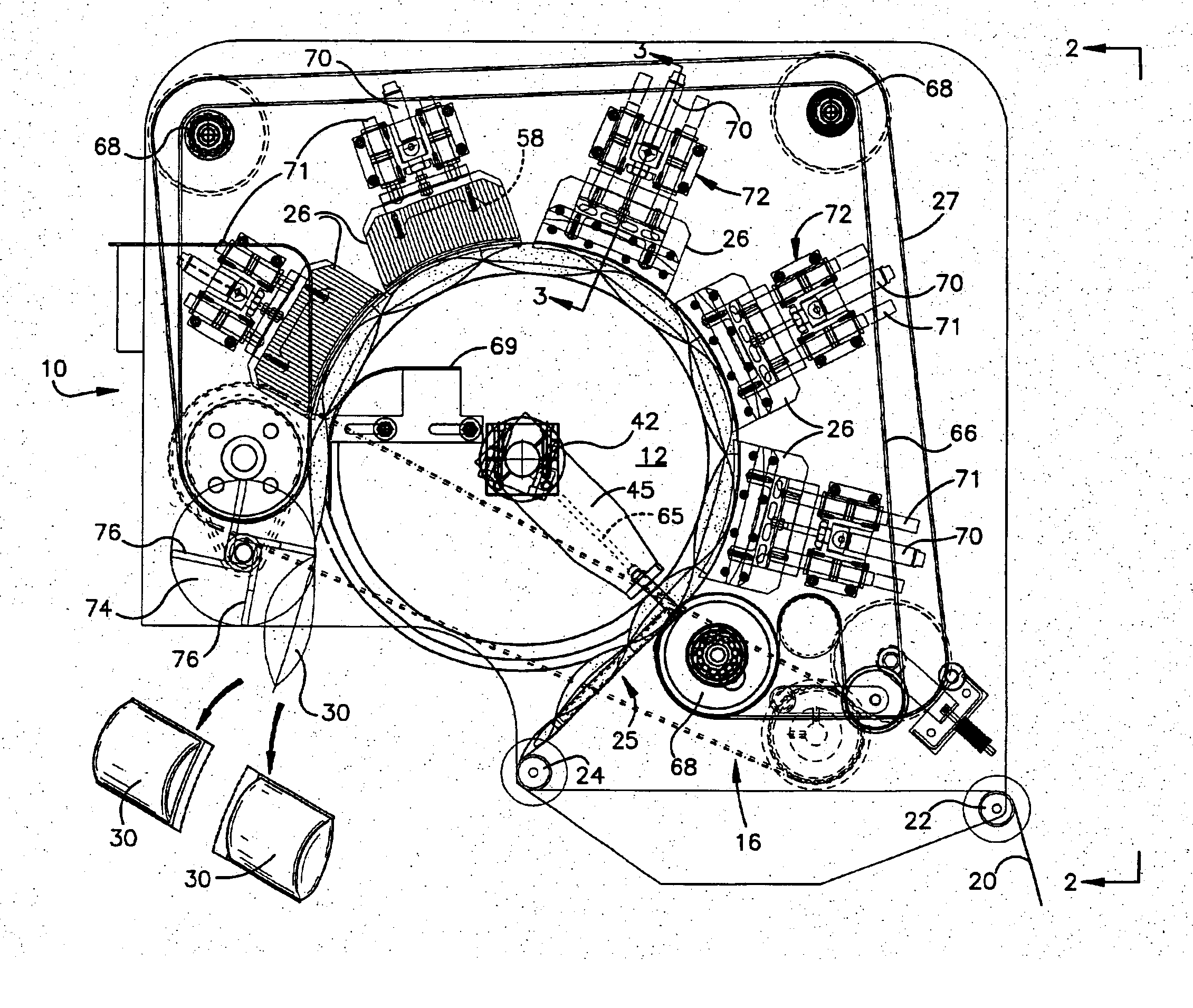

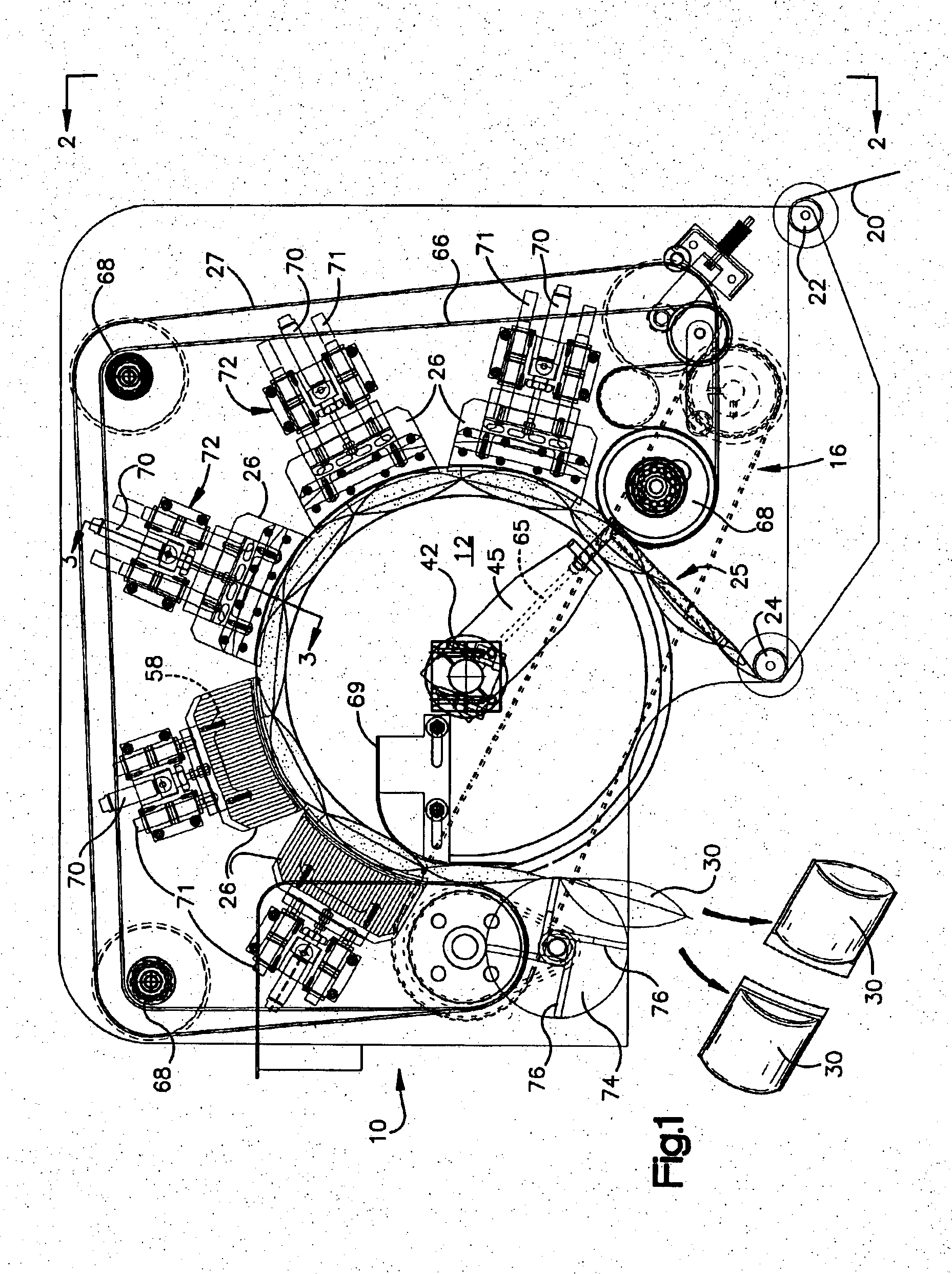

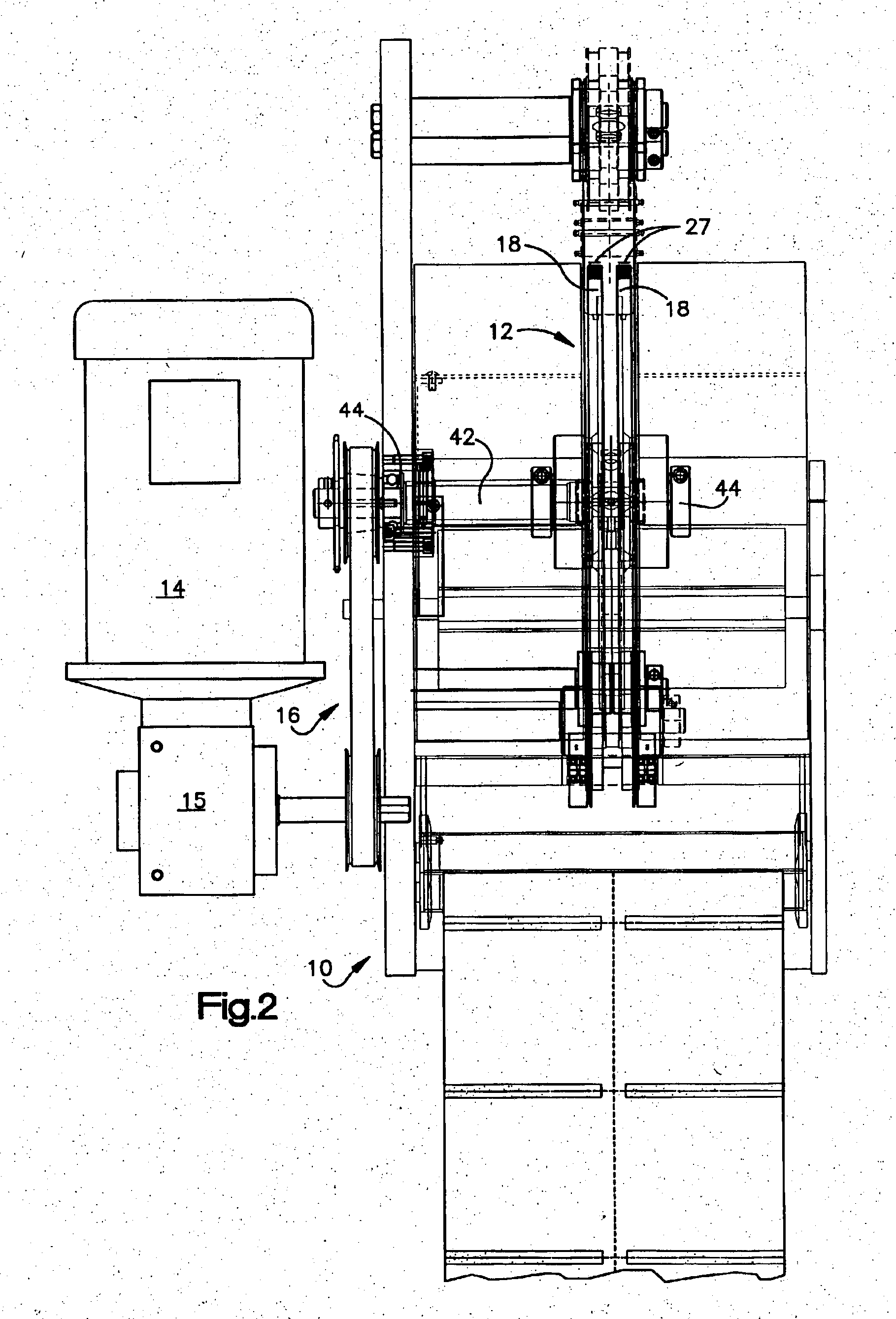

Fluid filled unit formation machine and process

A machine for the manufacture of inflated plastic dunnage and other fluid filled units is disclosed. In a disclosed and pictured dunnage embodiment, the machine includes a hollow shaft rotatably mounted on a frame. In the preferred embodiment the shaft is solid. With either embodiment a drive is operably connected to the shaft for causing the shaft to rotate about its axis and a drum mounted on the shaft to rotate with the shaft. The drum is in the form of a pair of closely spaced discs having perimetral, cylindrically contoured sealing surfaces for support and, in cooperation with driven metal belts, transport of a web being formed into dunnage units. Sets of heating and cooling shoes having spaced arcuate surfaces are complementally positioned adjacent the drum surfaces with the cooling shoes downstream from the heating shoes in the direction of dunnage formation rotation. A nozzle is mounted generally tangentially of the drum at a location midway between the discs. Each of the cooling shoes includes an air expansion chamber communicating through a shoe inlet when in use with a supply of air under pressure. In the hollow shaft embodiment one cooling shoe chamber has an outlet in communication with the nozzle via the shaft.

Owner:AUTOMATED PACKAGING SYST

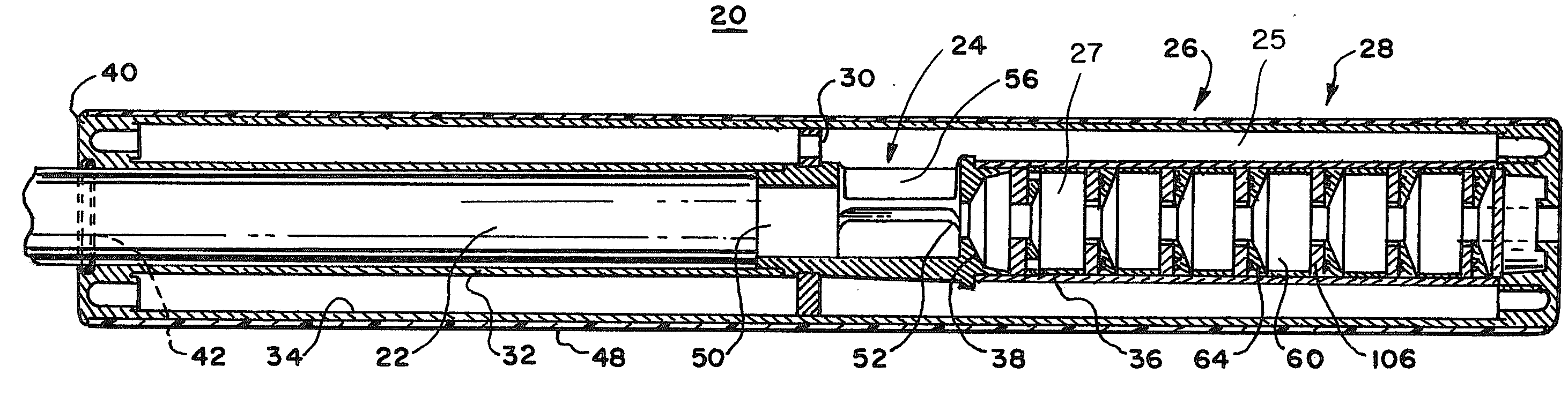

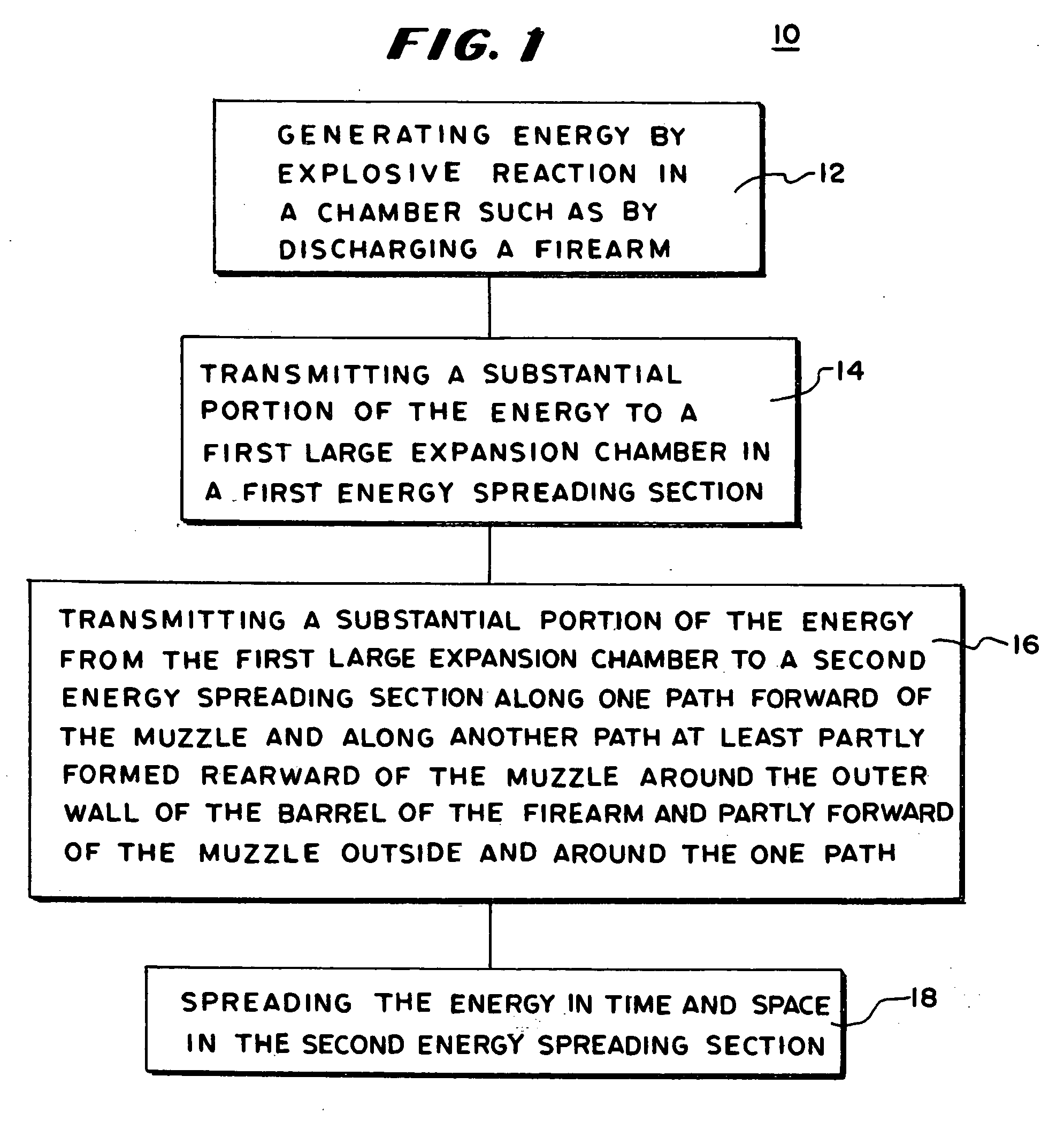

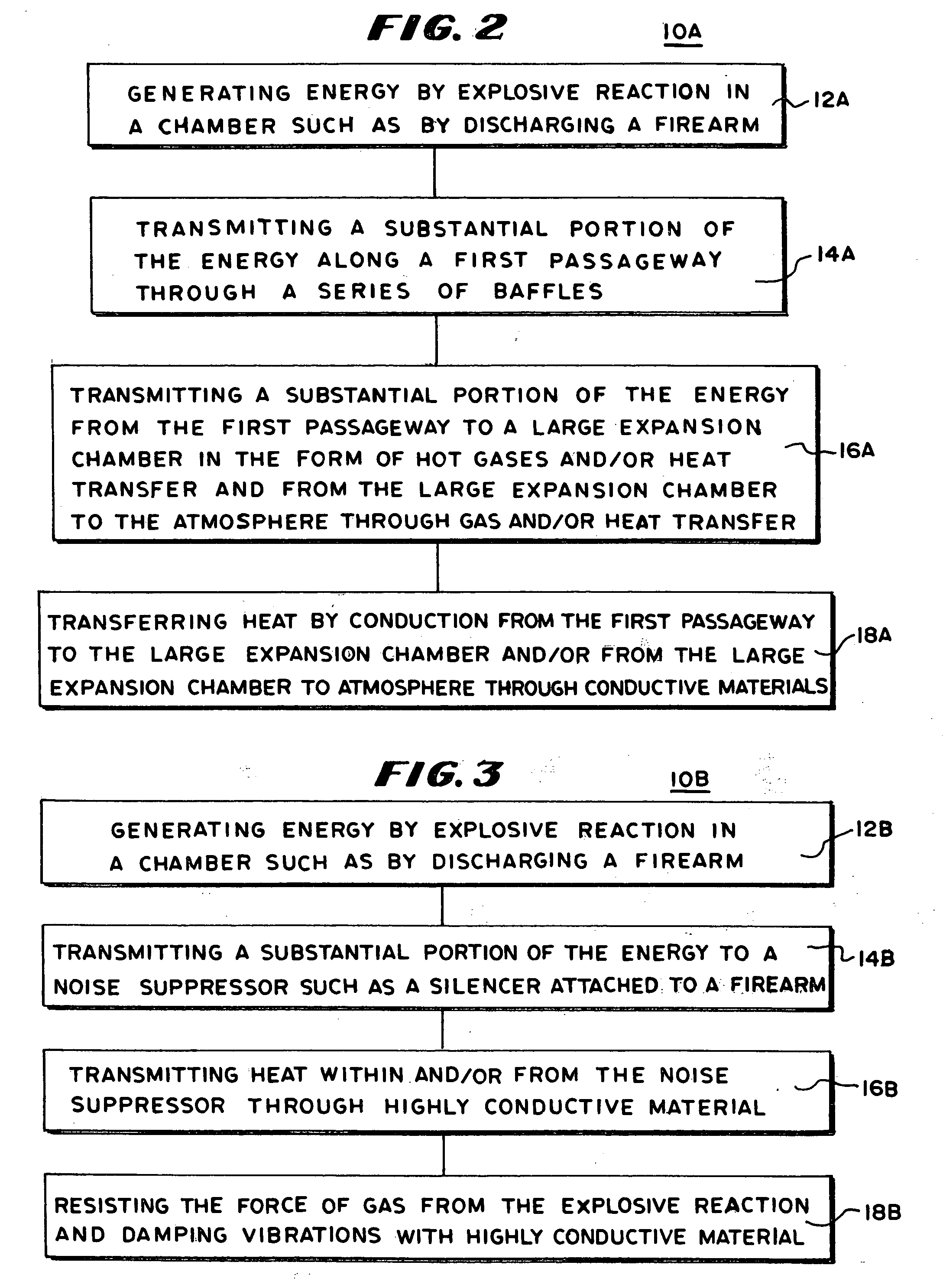

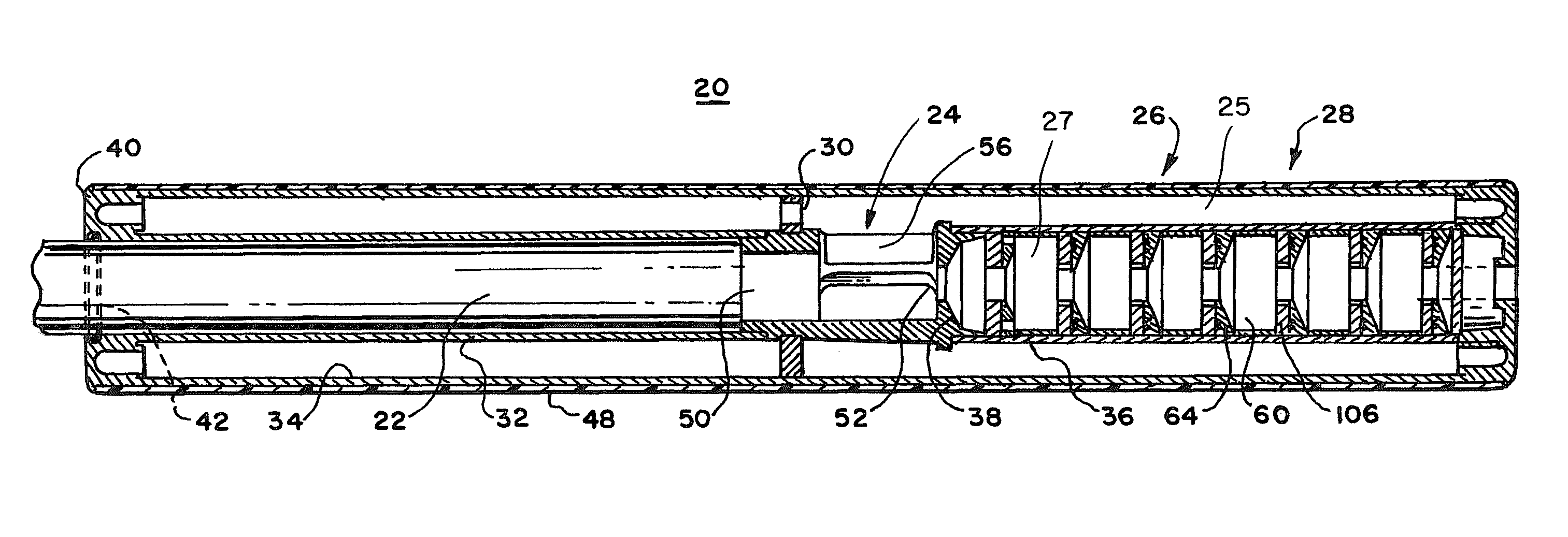

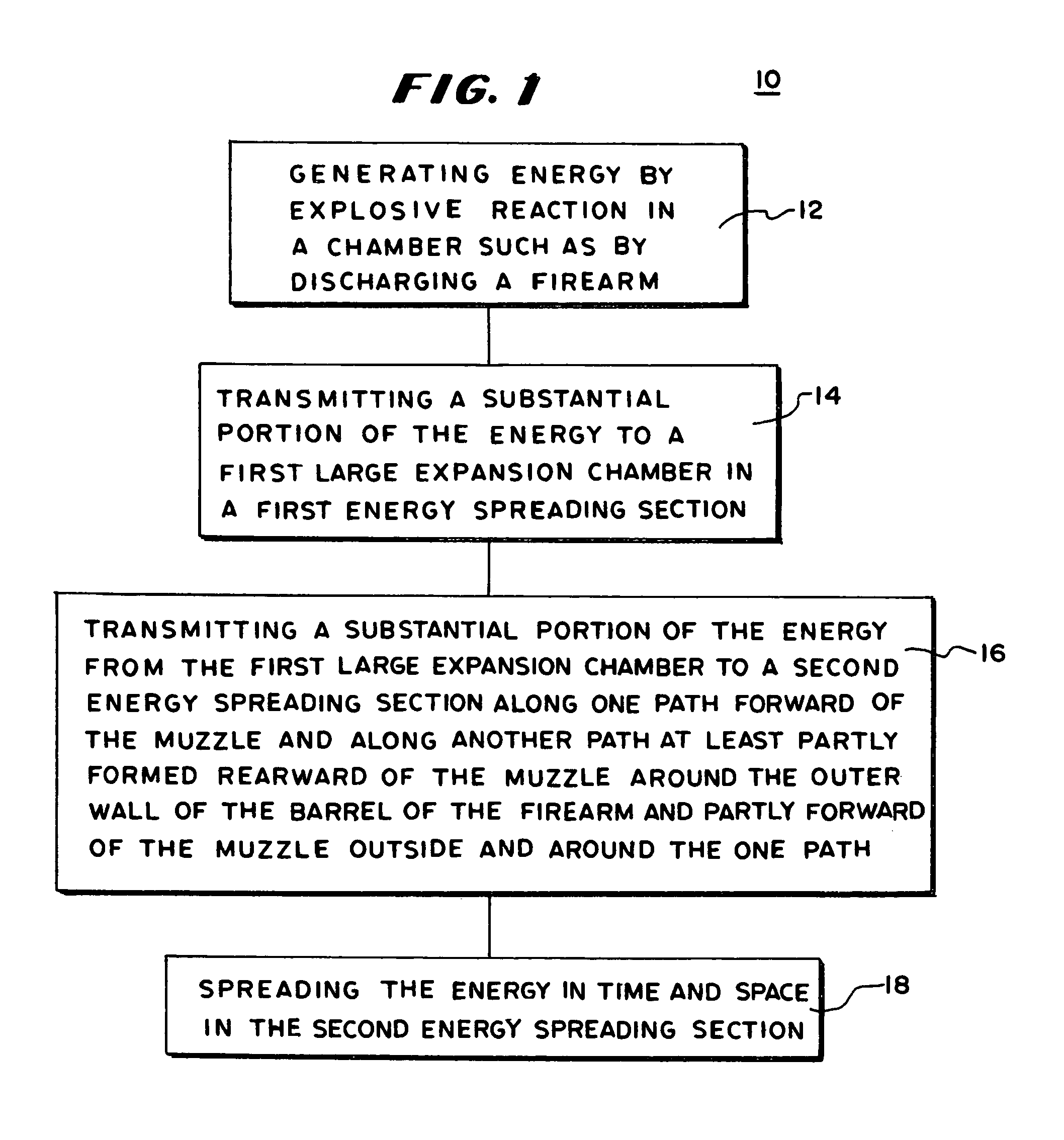

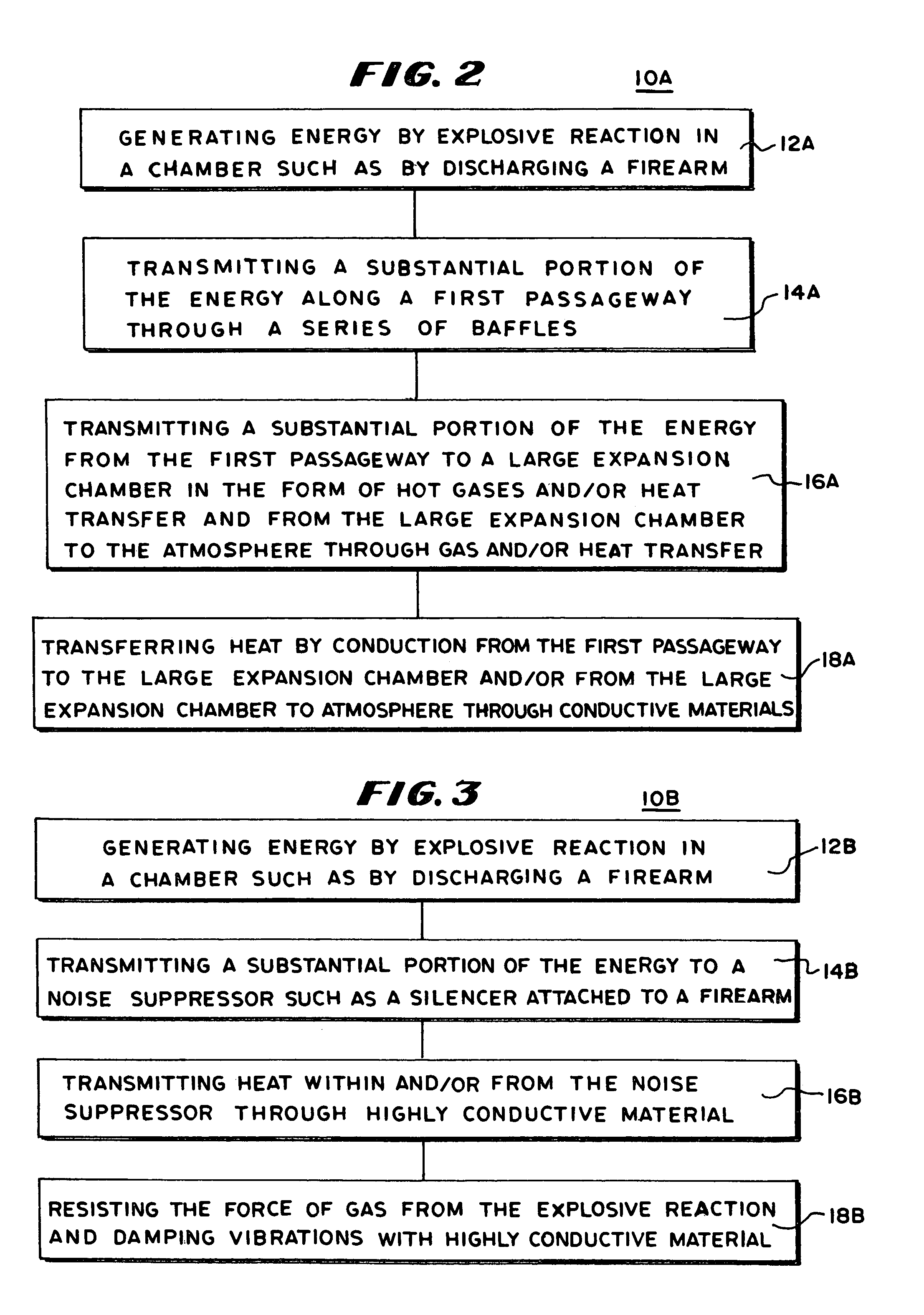

Energy suppressors

A suppressor for a firearm includes a first gas expansion section of relatively large size sufficient to reduce the temperature and pressure of the gas expelled from a muzzle during discharge of the firearm to a level that avoids rapid degrading of structural members such as baffles in the suppressor that are downstream of the muzzle. The gas is channeled through multiple paths to distribute its energy more equally. Preferably, the suppressor is formed with a lightweight, thermally-conductive composite portion. The composite portion provides lightweight, bursting strength with good thermal conductivity and little contribution to vibrational instability of the muzzle to which it is attached. The composite portion may be of a carbon fiber, silicon, boron, or metallic base. In one embodiment, a first expansion chamber is in communication with the muzzle and with a second expansion chamber and in another embodiment, the first expansion chamber communicates with the muzzle and with the second expansion chamber The composite portions of the suppressor provide good bursting strength and heat conductivity with light weight. In some embodiments, a series of baffles creates turbulence in the gas, slowing its motion and distributing the energy more evenly over space.

Owner:PETERSEN BYRON S

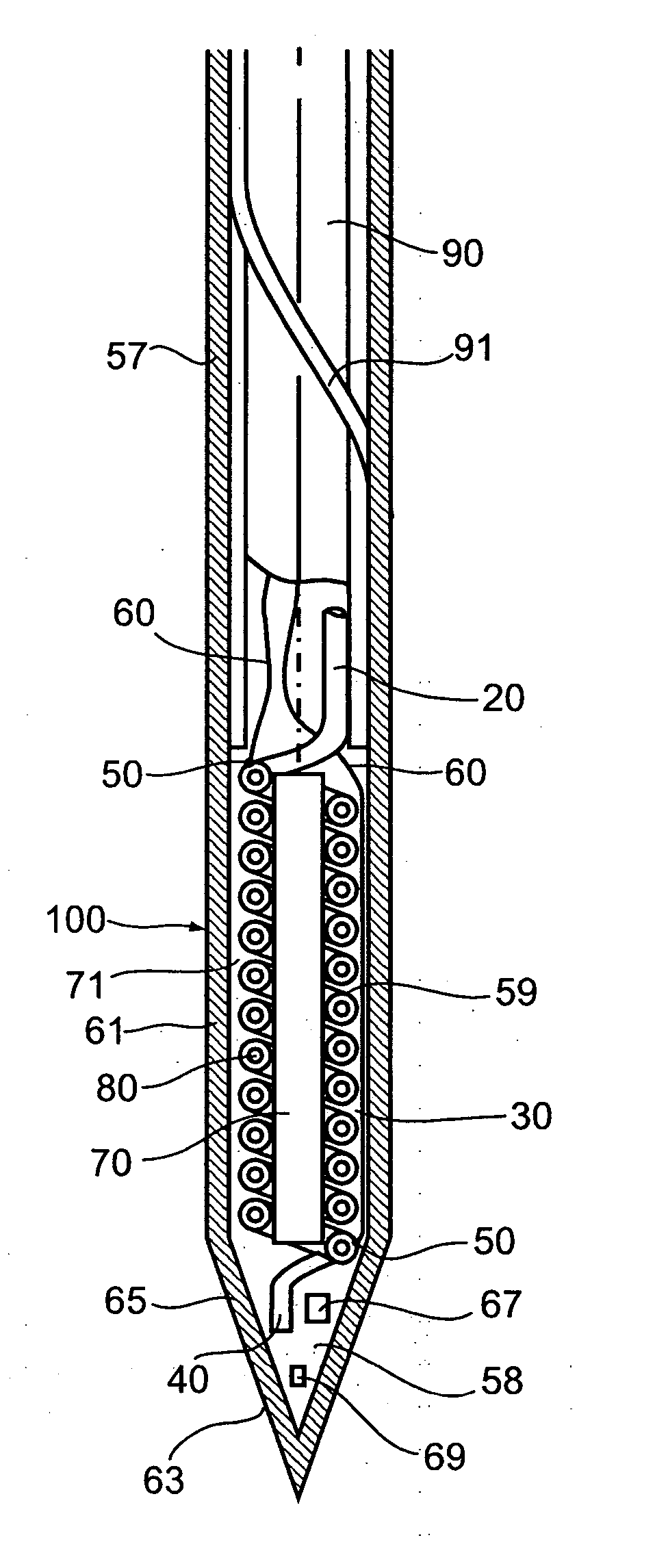

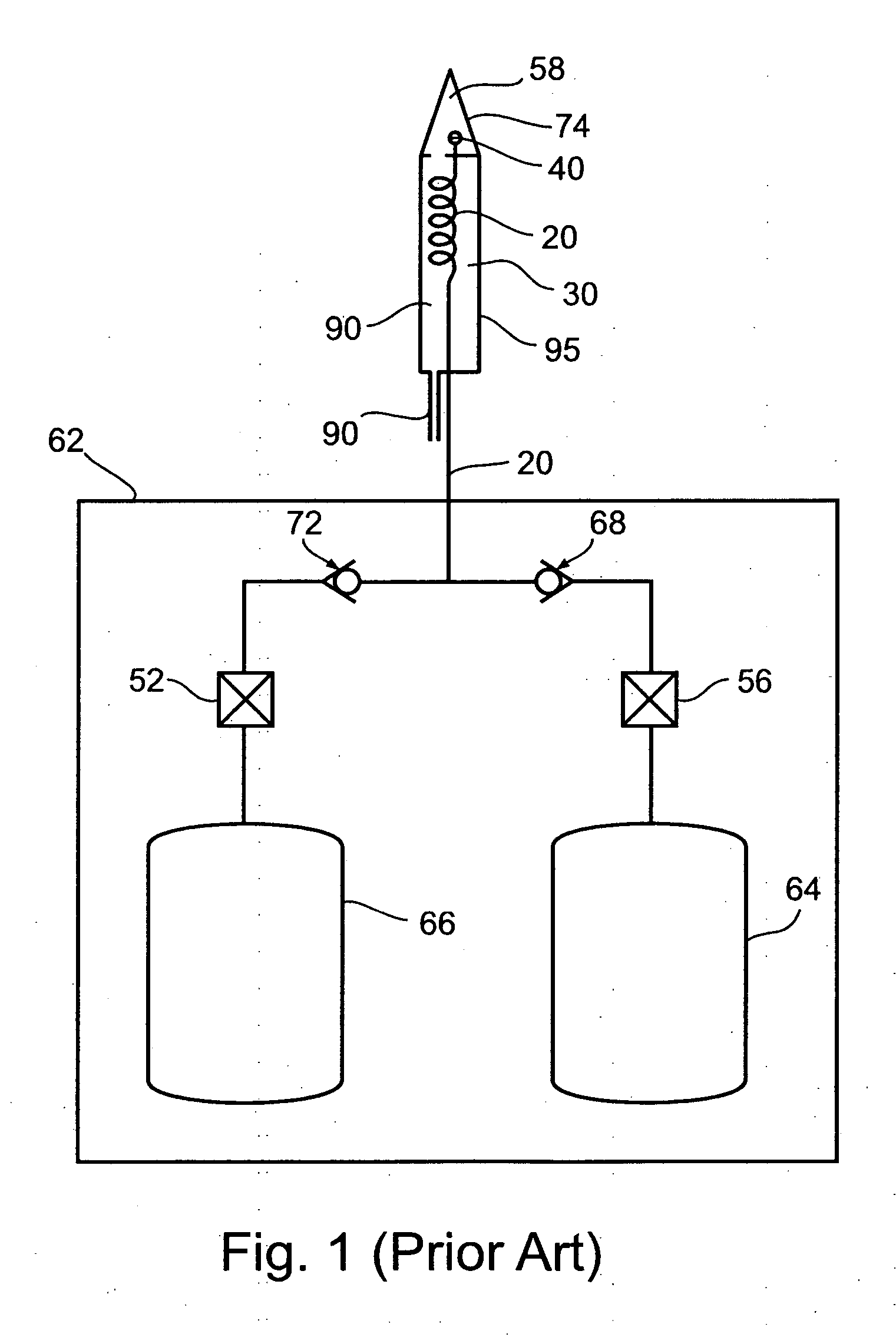

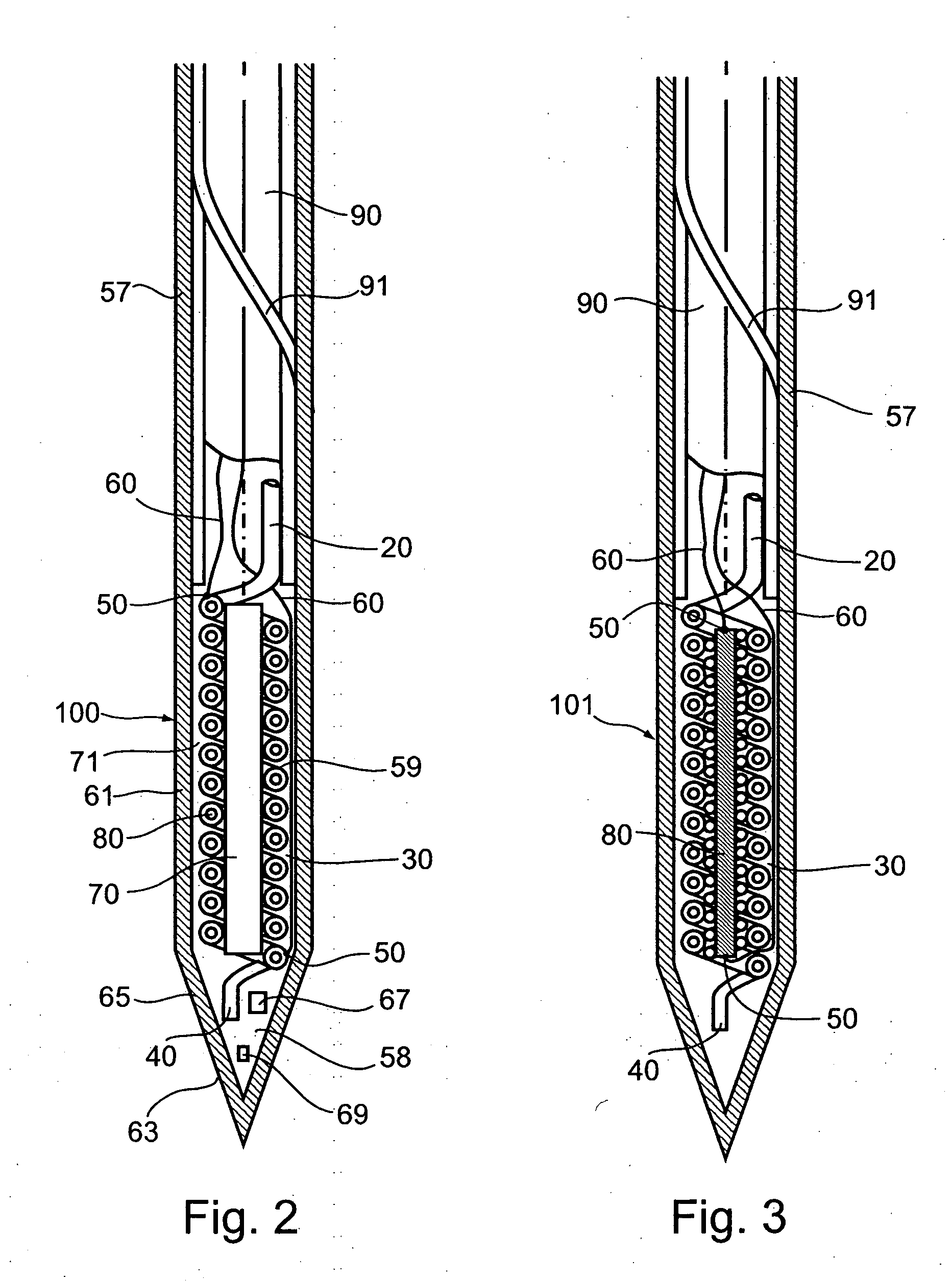

Gas-heated gas-cooled cryoprobe utilizing electrical heating and a single gas source

ActiveUS20060122590A1Quick switchHeating fastSurgical instruments for coolingElectrical resistance and conductanceElectricity

The present invention is of device, system, and method for cooling and heating an operating tip of a cryoprobe using a single source of compressed gas. Cooling of the operating tip is effected by Joule-Thomson expansion of a high-pressure cooling gas through a Joule-Thomson orifice into an expansion chamber. Heating of the operating tip is effected by electrical resistance heating. In preferred embodiments, heating of the operating tip is effected by electrical resistance heating of low-pressure gas flowing towards the operating tip. Preferably, gas from a single gas source is supplied to the probe during both cooling and heating phases, a cooling gas being supplied at high pressure when used for cooling and at low pressure when used for heating. Low-pressure gas supplied during the heating phase is heated as it flows towards the operating tip, preferably by electrical resistance heating within the body of the probe. A single gas input lumen is used during both cooling and heating phases to transport gas into the probe, and a single gas exhaust lumen is used during both cooling and heating phases to conduct gas out of the probe.

Owner:GALIL MEDICAL

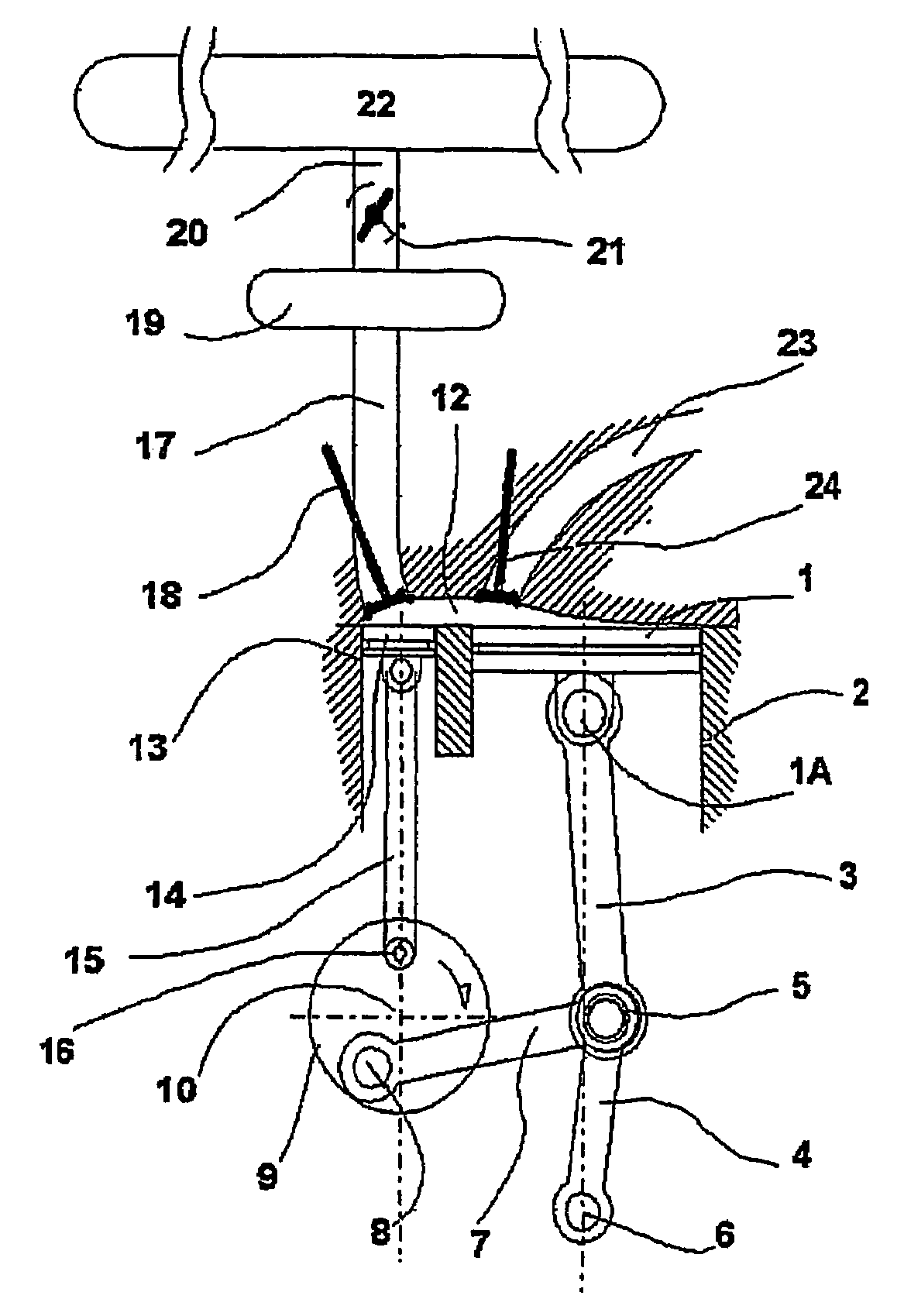

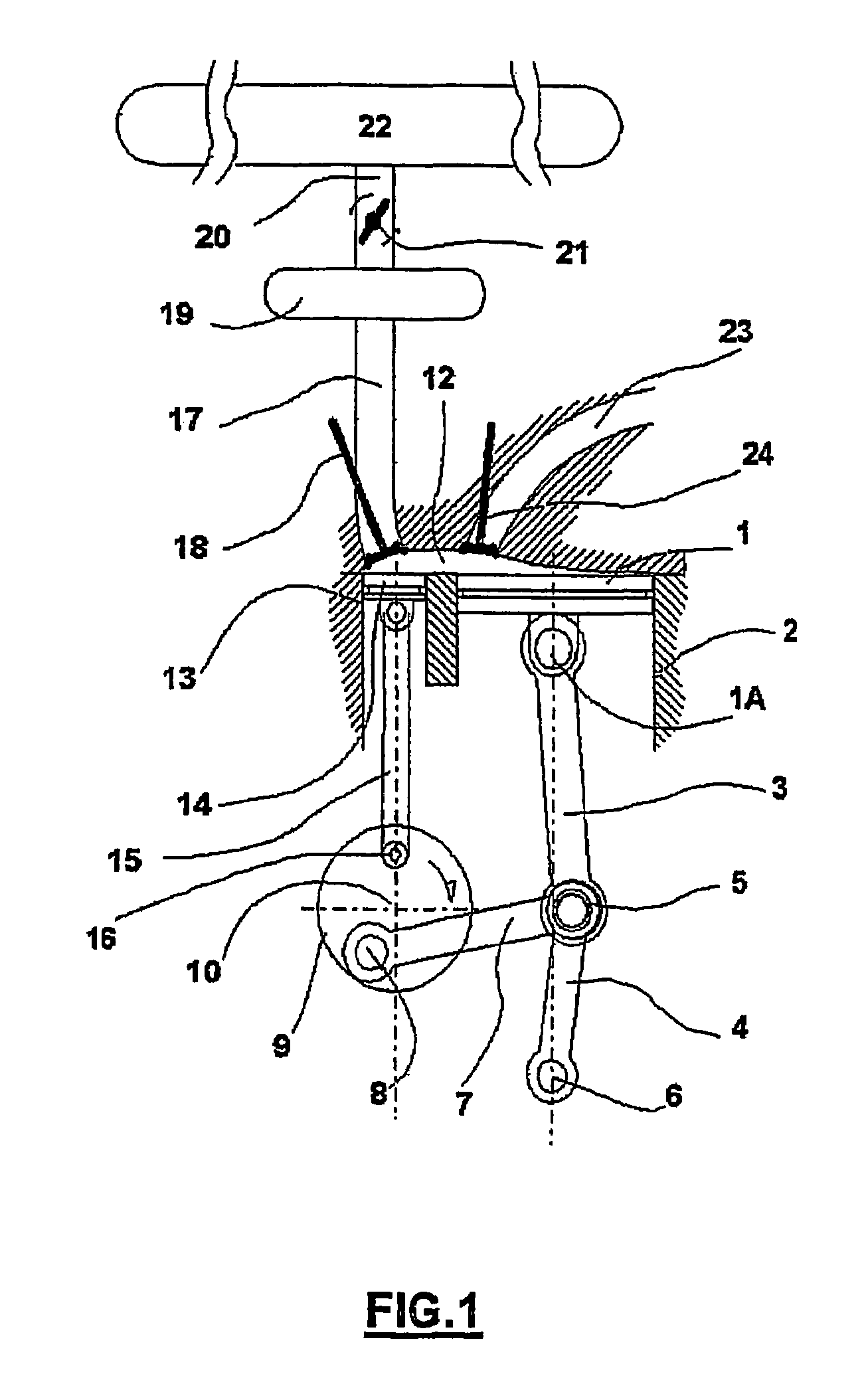

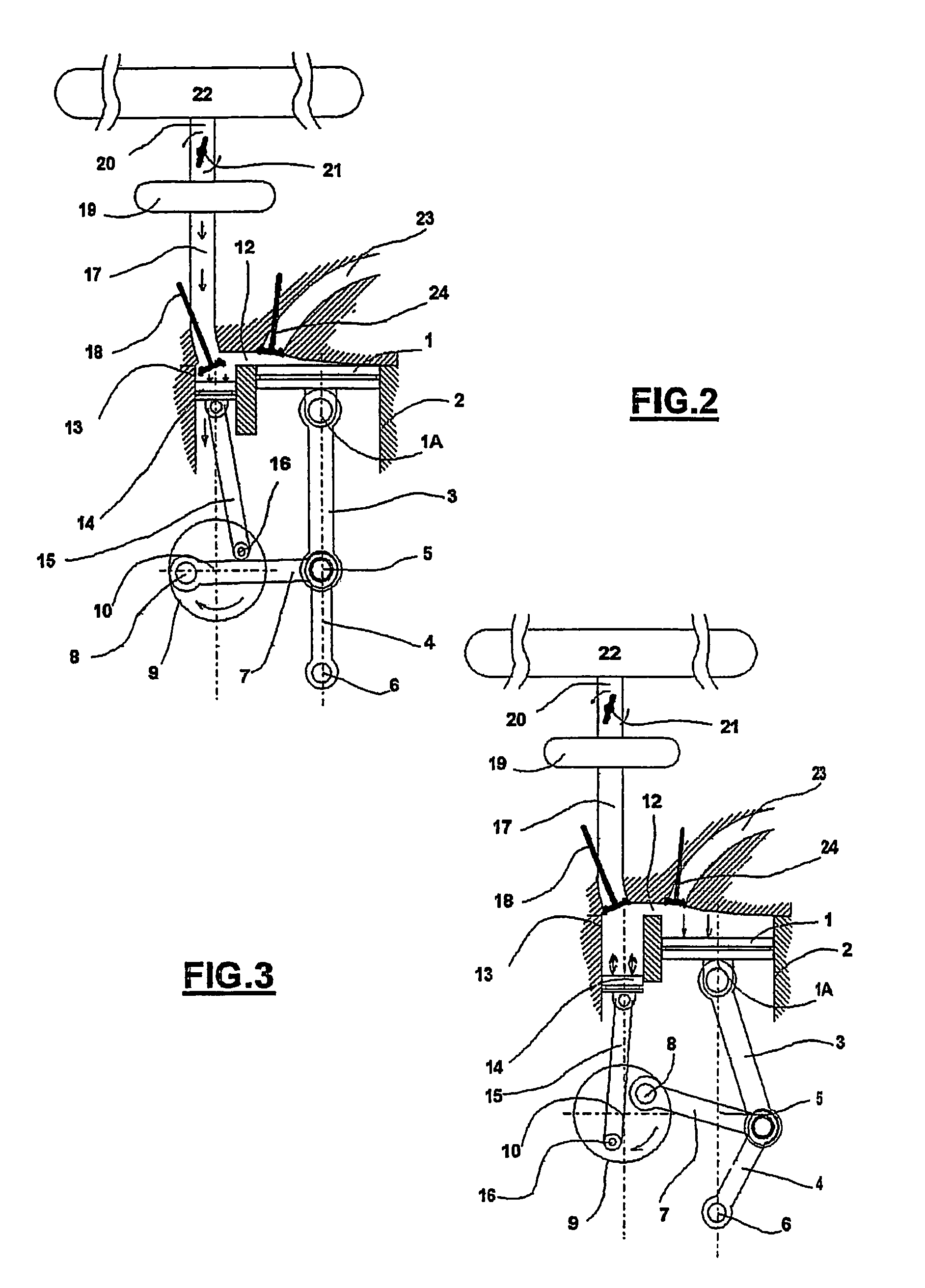

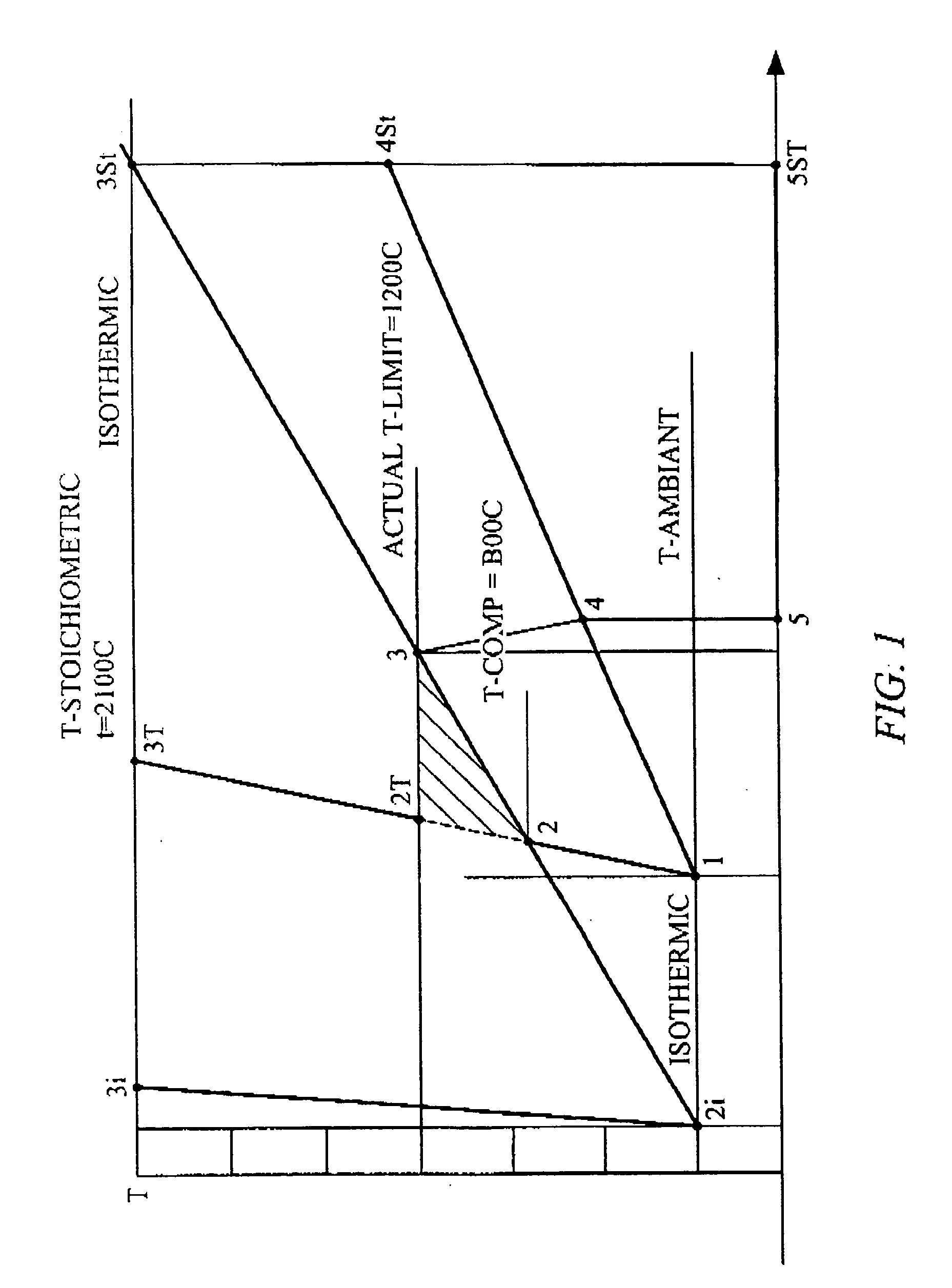

Engine with an active mono-energy and/or bi-energy chamber with compressed air and/or additional energy and thermodynamic cycle thereof

ActiveUS7469527B2Usable and available energyQuantity of usable and availableFlexible wall reciprocating enginesCombustion enginesTop dead centerEngineering

An engine uses a top dead center piston stop device. It is fed by compressed air, via a working capacity, which, in the bi-energy version, includes a device for heating the air supplied by additional energy. The active expansion chamber consists of a variable volume or charge piston sliding in a cylinder, coupled to a space above the engine piston via a passage. When stoped at upper dead center, the pressurized air is admitted into the expansion chamber with the smallest volume thereof and, under the effect of thrust, increases the volume thereof by producing work; the expansion chamber is then kept at a maximum volume during expansion of the engine cylinder driving back the engine piston in its downward stroke, providing work of its own. During exhaust, the two pistons travel in an upward stroke and simultaneously reach top dead center in order to resume a new cycle.

Owner:MDI MOTOR DEV INT SA

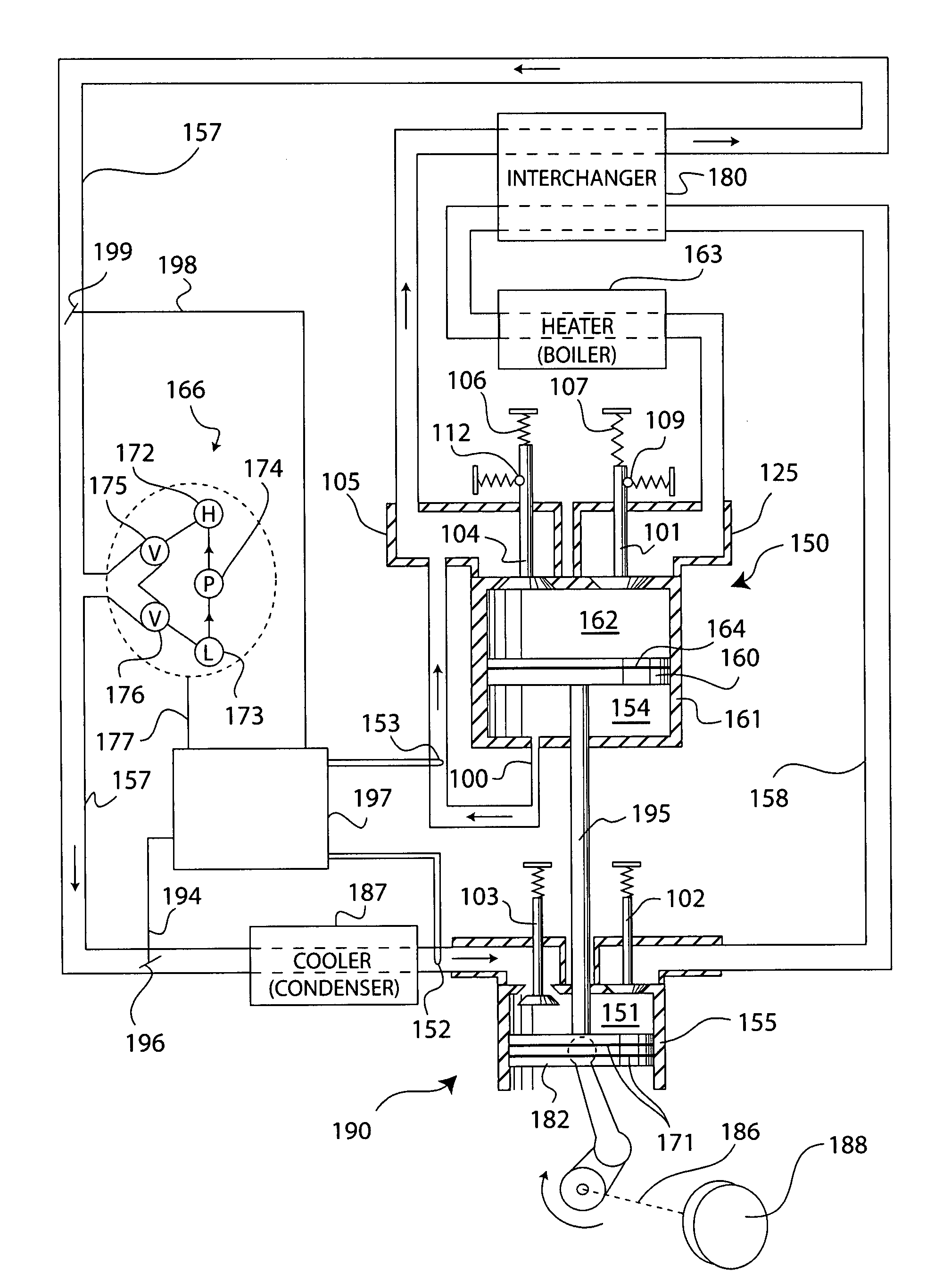

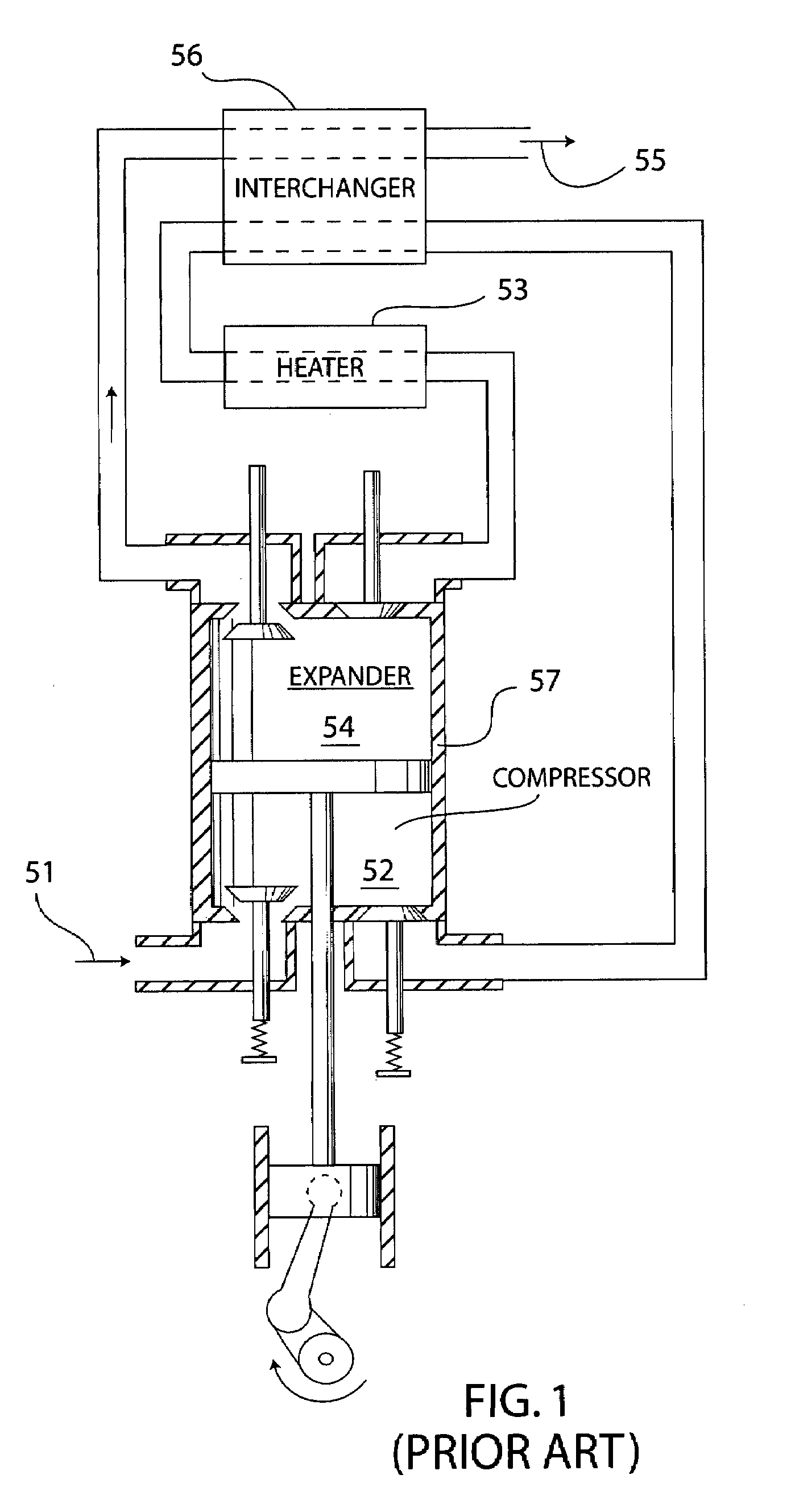

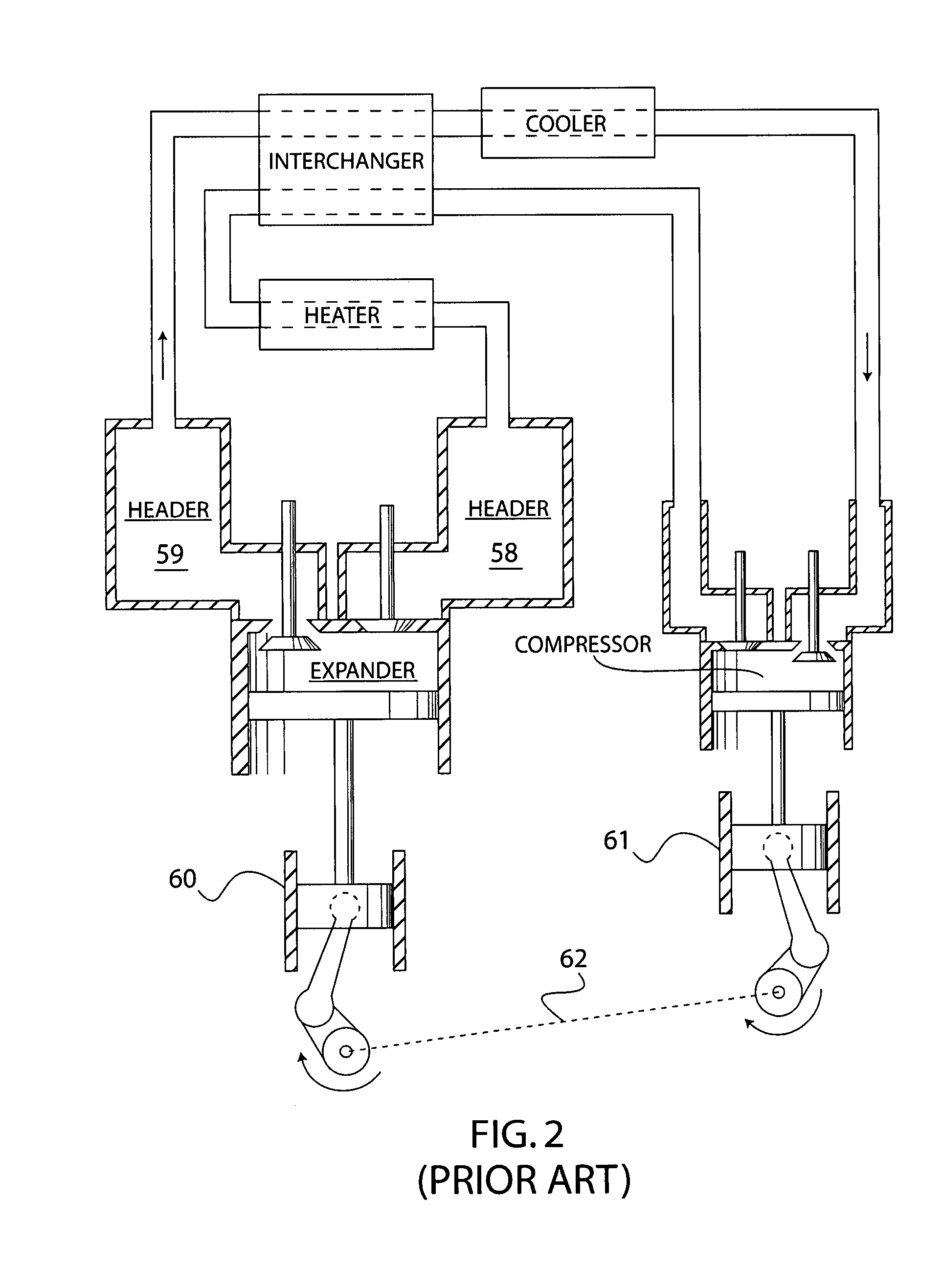

Harmonic engine

A high efficiency harmonic engine based on a resonantly reciprocating piston expander that extracts work from heat and pressurizes working fluid in a reciprocating piston compressor. The engine preferably includes harmonic oscillator valves capable of oscillating at a resonant frequency for controlling the flow of working fluid into and out of the expander, and also preferably includes a shunt line connecting an expansion chamber of the expander to a buffer chamber of the expander for minimizing pressure variations in the fluidic circuit of the engine. The engine is especially designed to operate with very high temperature input to the expander and very low temperature input to the compressor, to produce very high thermal conversion efficiency.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

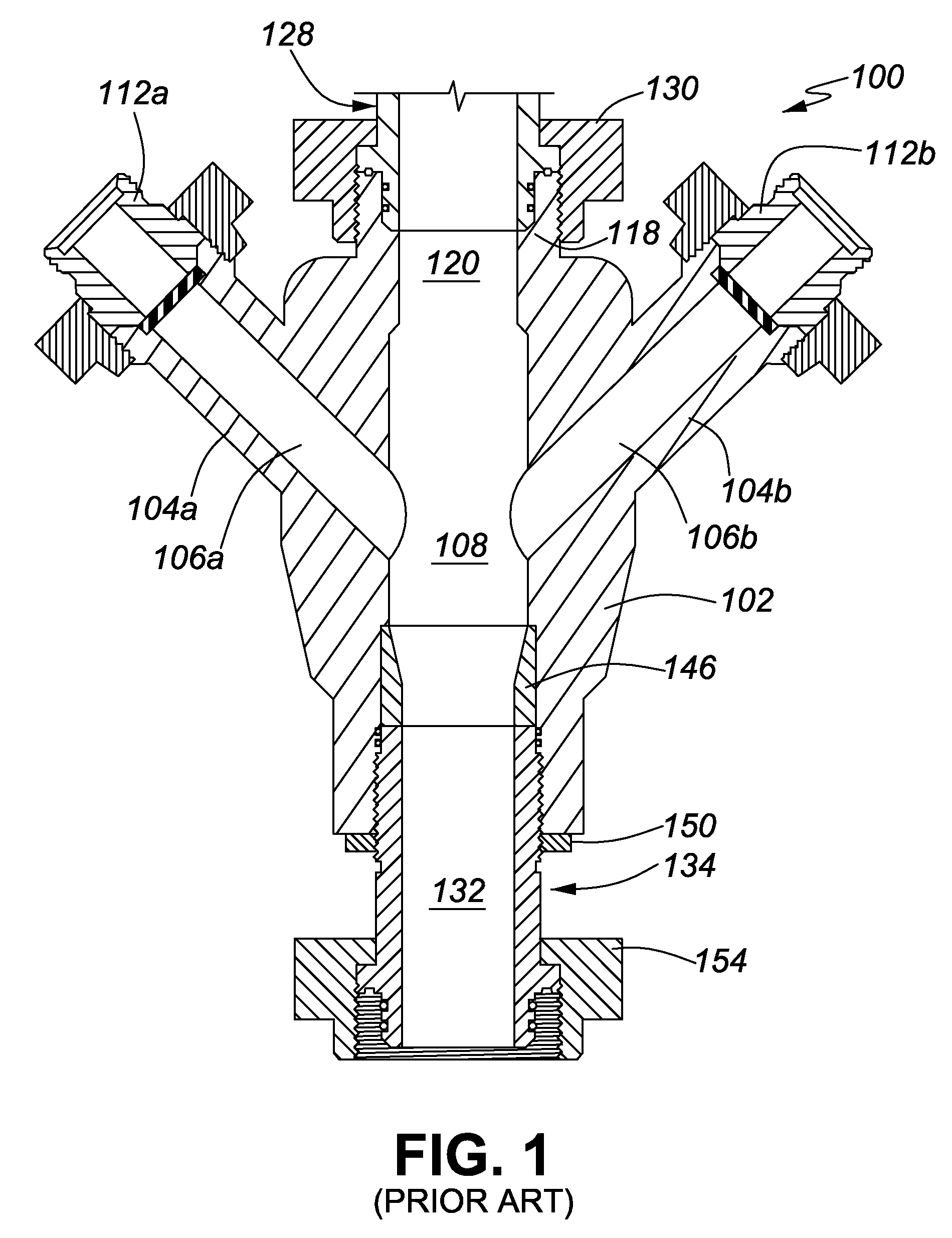

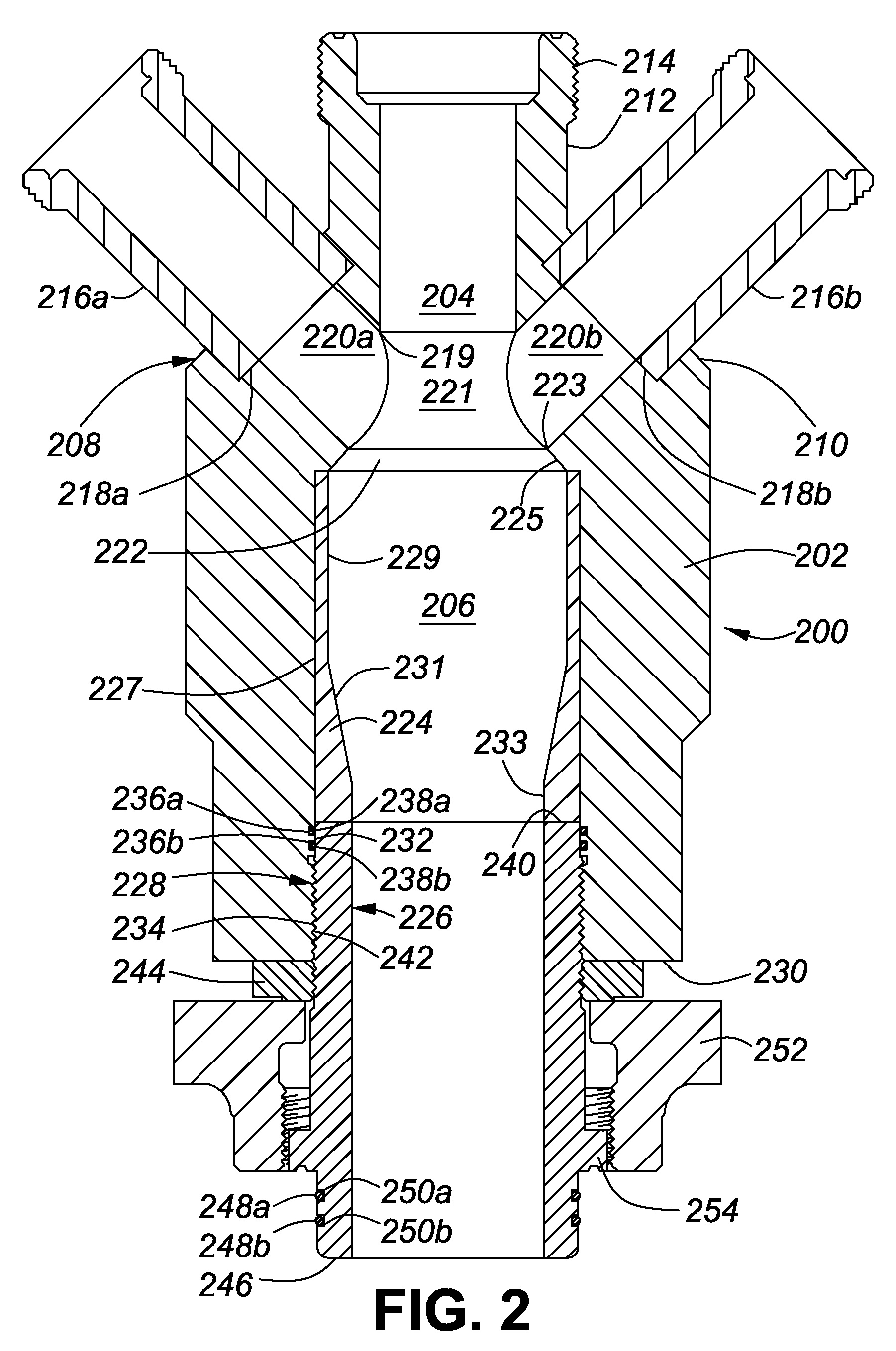

Erosion resistant frac head

ActiveUS7789133B2Easy and fast constructionResist erosionDrilling rodsFluid removalEngineeringExpansion chamber

Owner:WELLS FARGO BANK NAT ASSOC +1

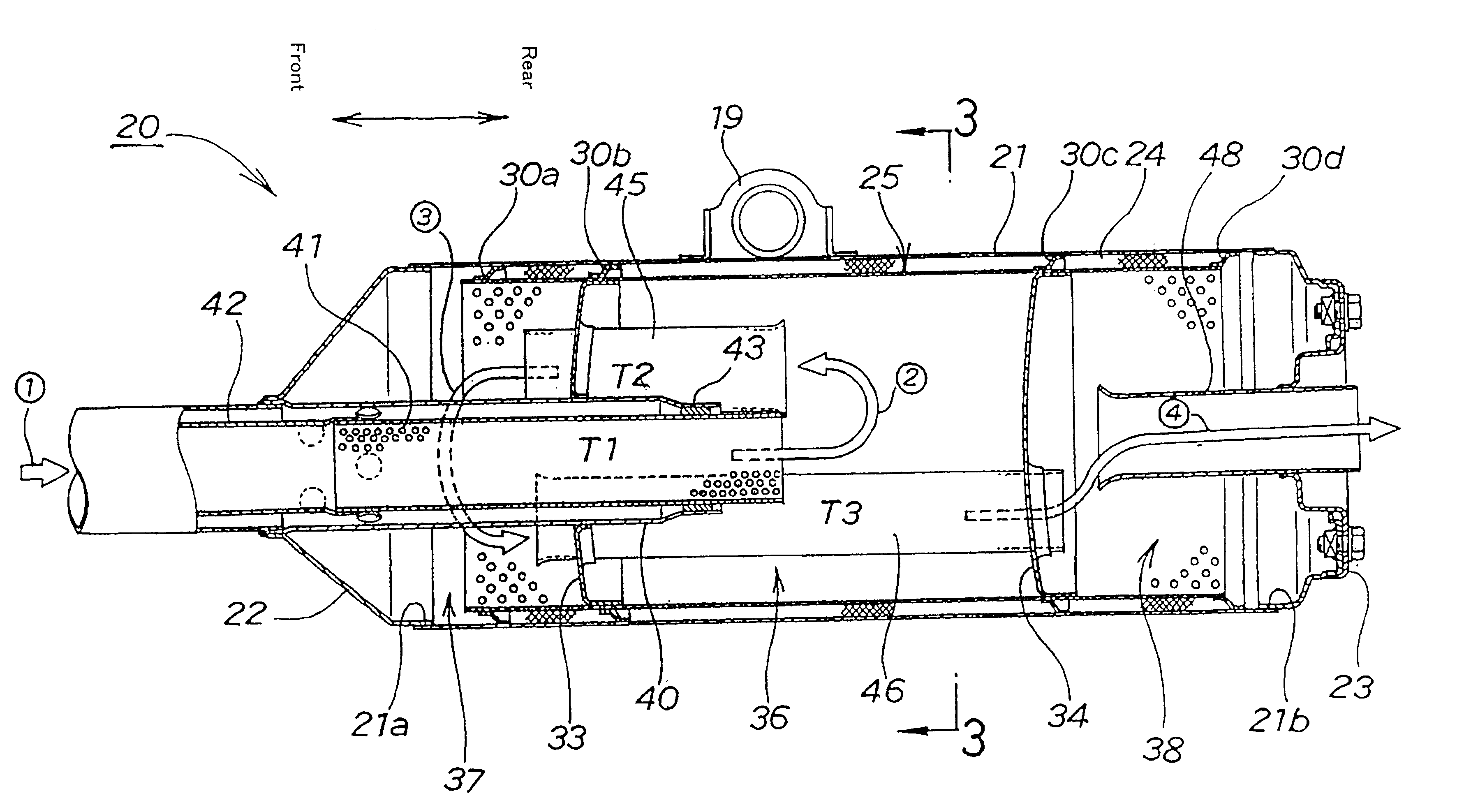

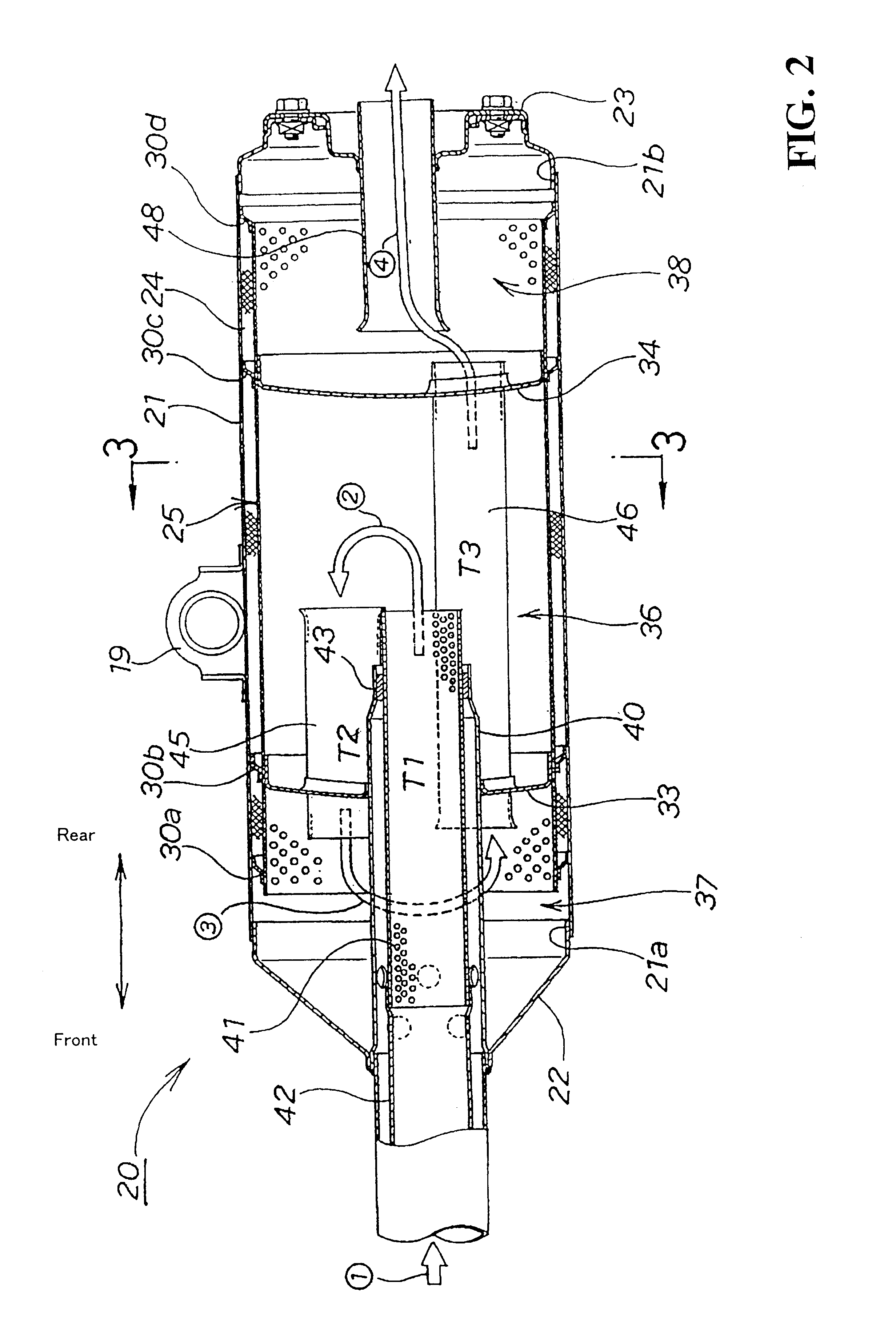

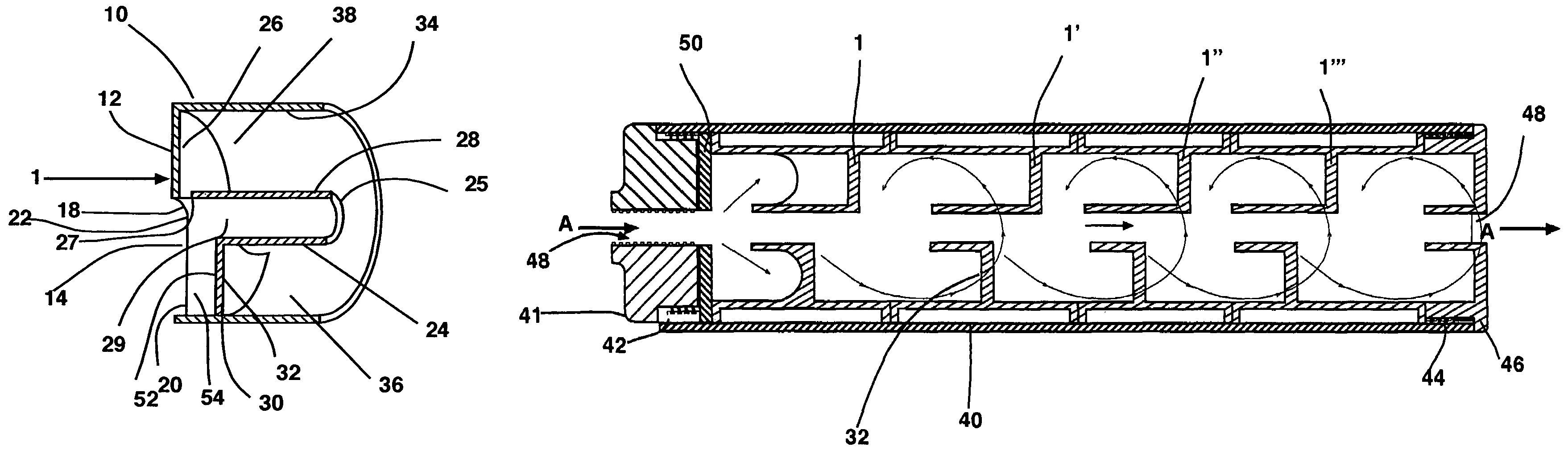

Muffler structure

To provide a muffler structure capable of lowering muffler cost. A muffler structure is provided in which a sound absorbing material is laid on the inside surface of an outer tube. The sound absorbing material is retained by an inner tube made of a metal that is punched with a plurality of holes. The inner tube is divided into a plurality of expansion chambers. Exhaust gas from an engine is led into the fiat expansion chamber by an inlet pipe. The exhaust gas is discharged out after being supplied to the second and third expansion chambers in succession through the connecting pipes. In the muffler structure, the inner tube is made of an approximately flat metal that is punched with a plurality of holes by bending the metal into circular form until its opposite edges are butted to each other, and is fitted in the outer tube, with the butt portions not jointed, so that the butt portions will come behind the connecting pipe when viewed from the inlet pipe side.

Owner:HONDA MOTOR CO LTD

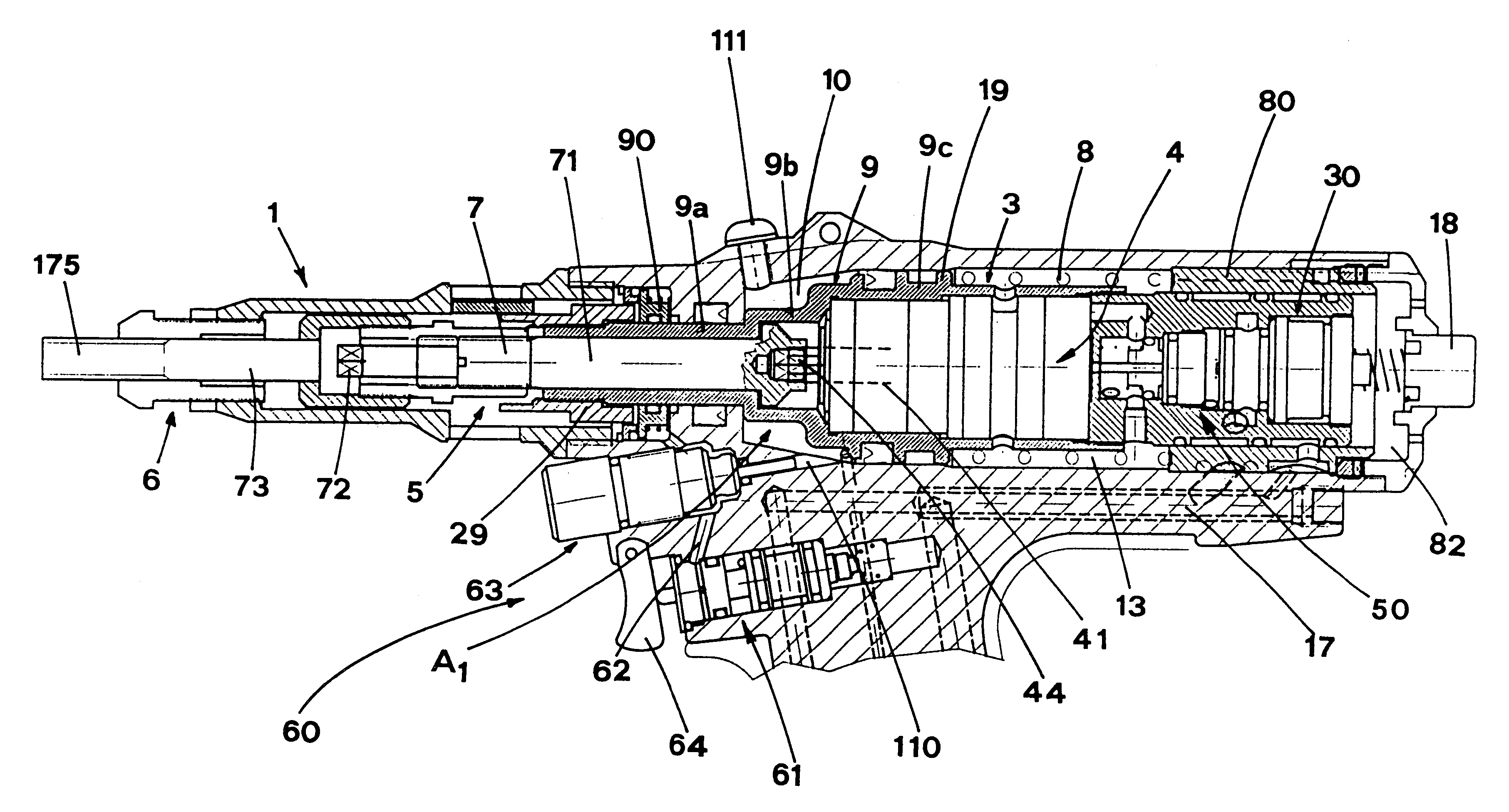

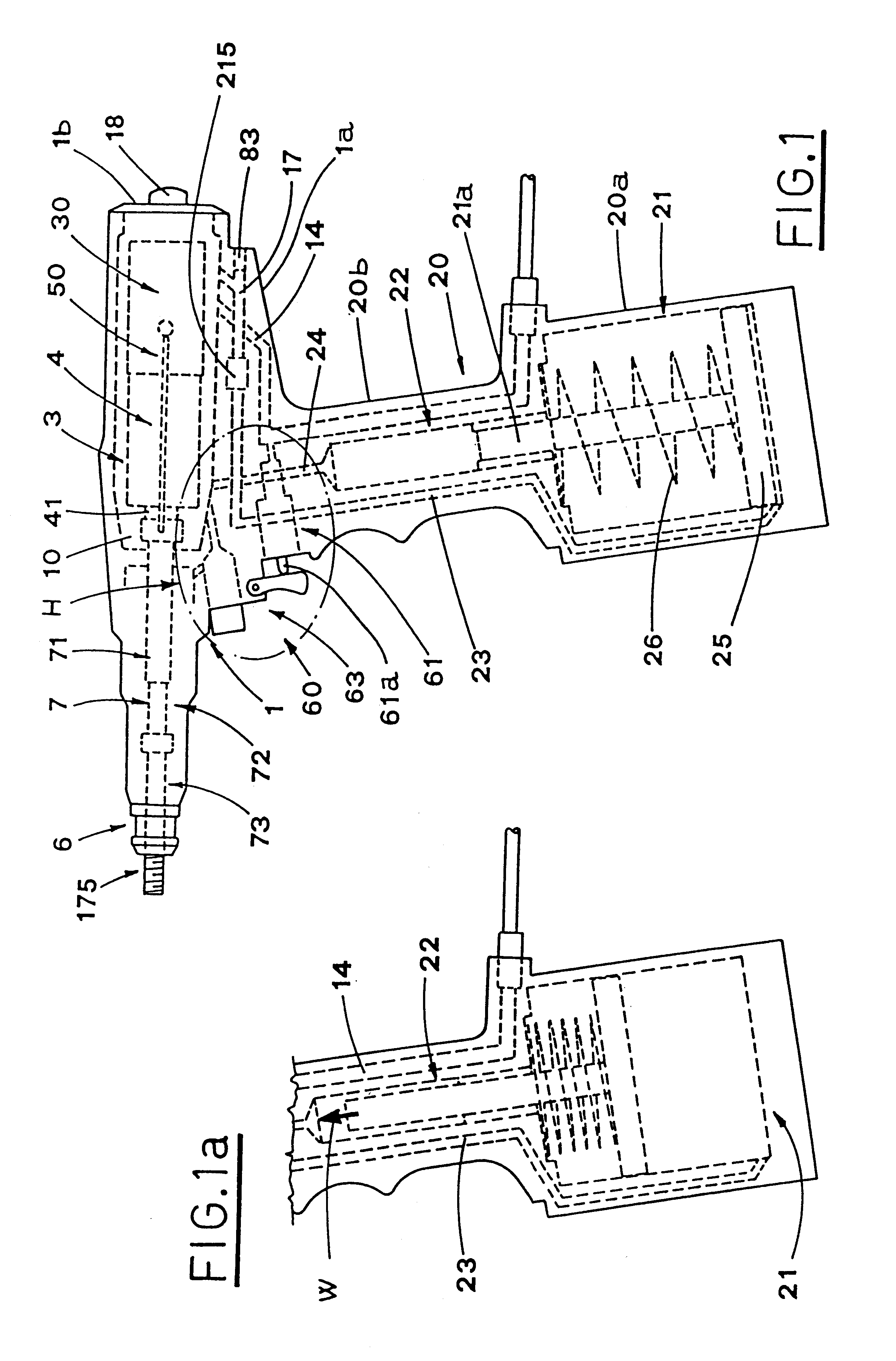

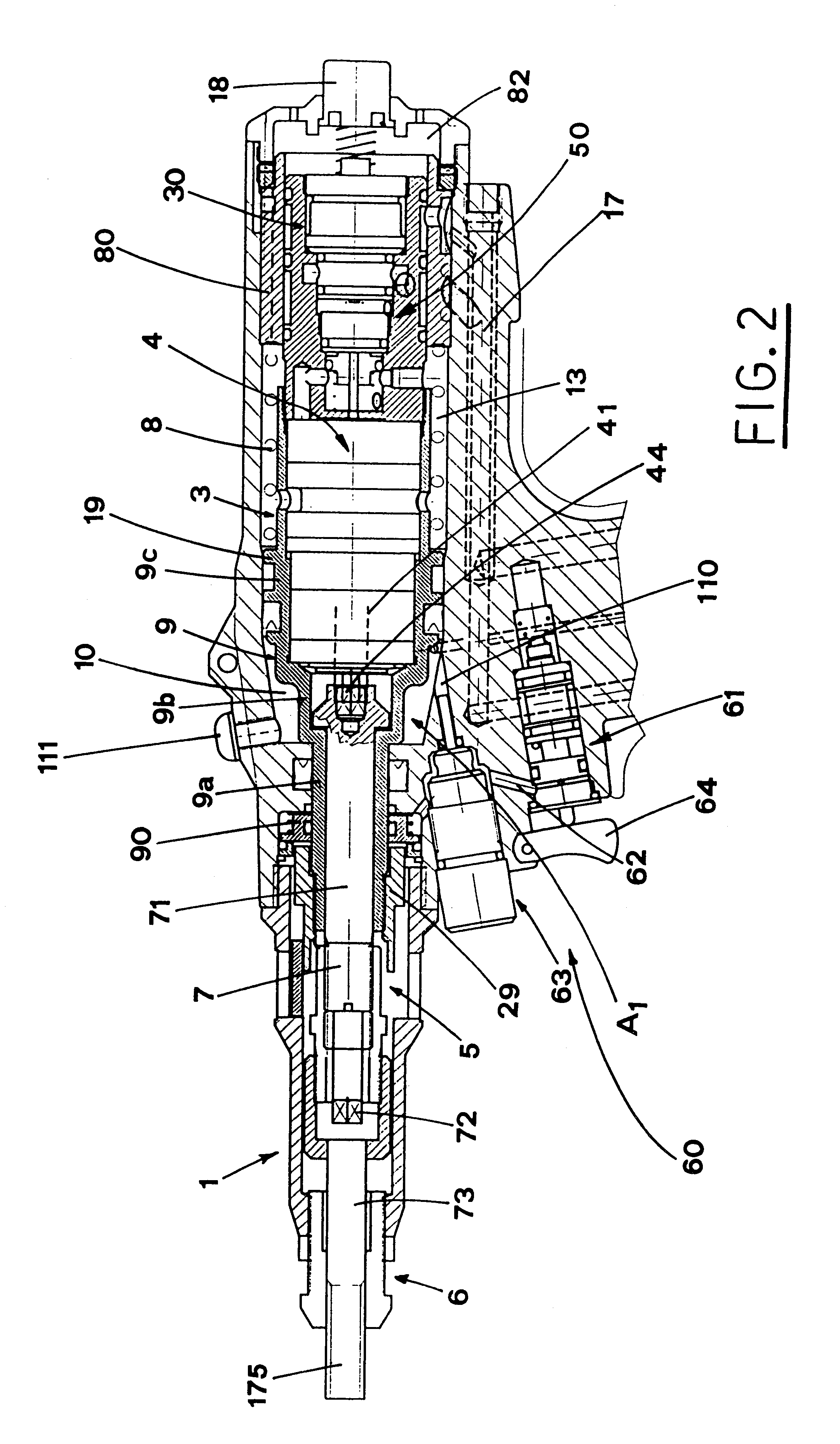

Pneumatic-hydraulic rivet gun

InactiveUS6272899B1Simple and quick controlEasy to handlePortable power-driven toolsMetal working apparatusHydraulic cylinderInlet valve

A rivet gun includes a pneumatic motor (4), that drives a segment stem 7. A pneumatic cylinder (21) actuates a hydraulic cylinder (22) which sends oil under pressure to an expansion chamber (10) provided for moving back the segment stem (7) and buckling the rivet (2) fixing it to a laminate structure (100). The rivet gun also includes a change-over switching device (30) linked to controls (50,60) for reversing rotation of the motor (4). The controls (60) include an inlet valve (61) operated by a trigger (64) for connecting a compressed air infeed duct 14 with a feed-discharge duct (23) leading to the pneumatic cylinder (21). A discharge valve (63) is disposed in series with the inlet valve (61) and has an adjustment ring (176) for adjusting of the maximum traction force. Another discharge valve (90) is disposed in series with the discharge valve (63) previously mentioned and is provided for adjustment of the stroke of the segment stem (7).

Owner:OBER UTENSILI PNEUMATICI

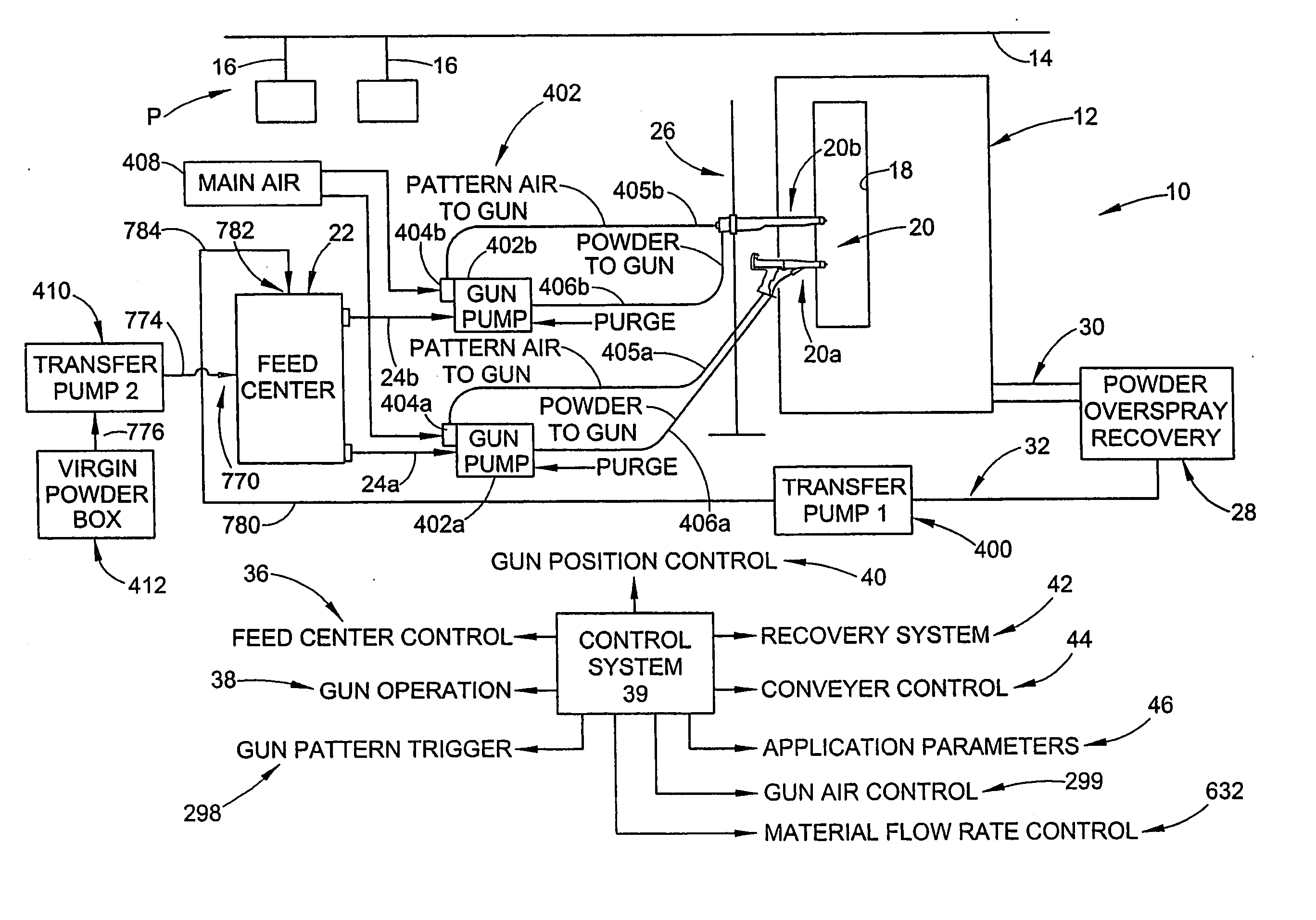

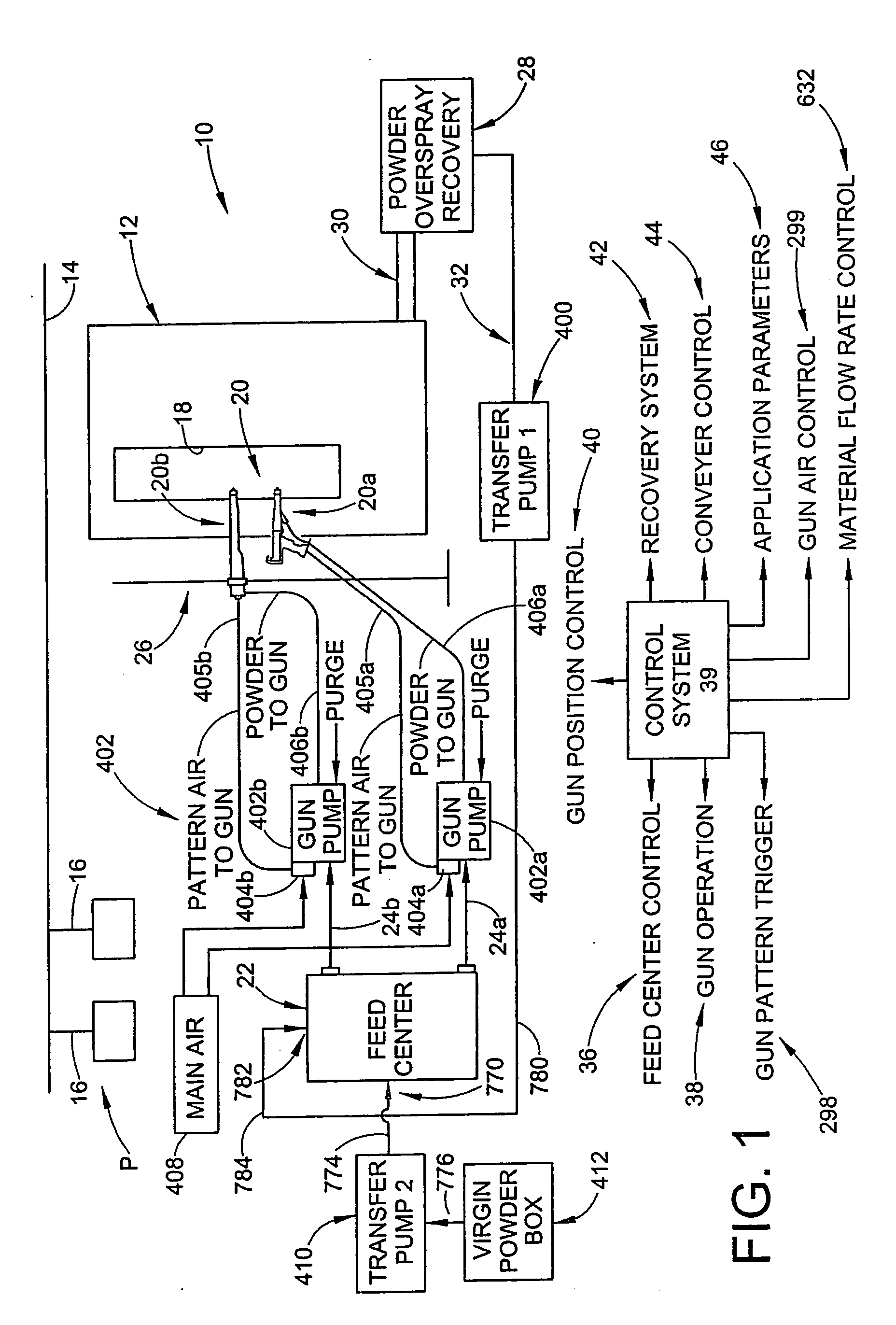

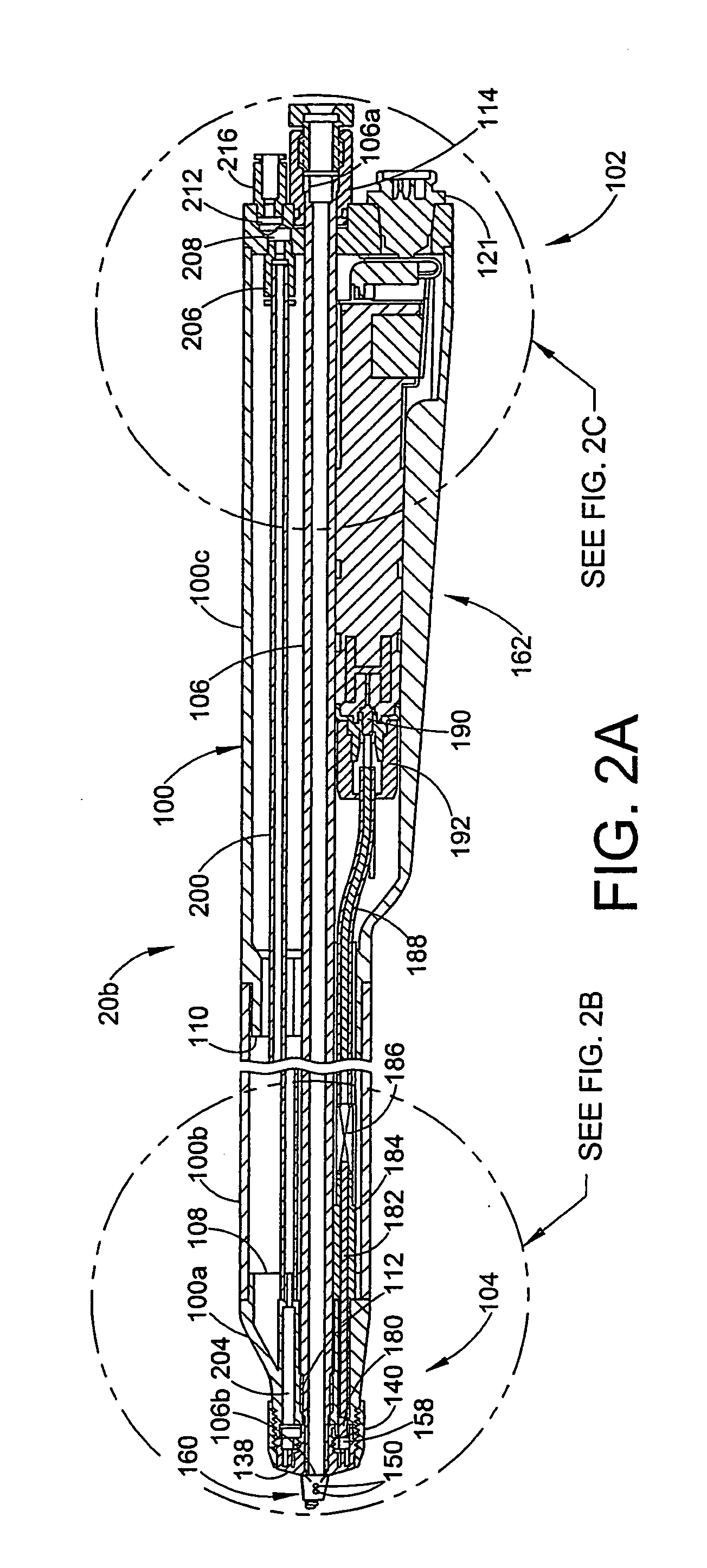

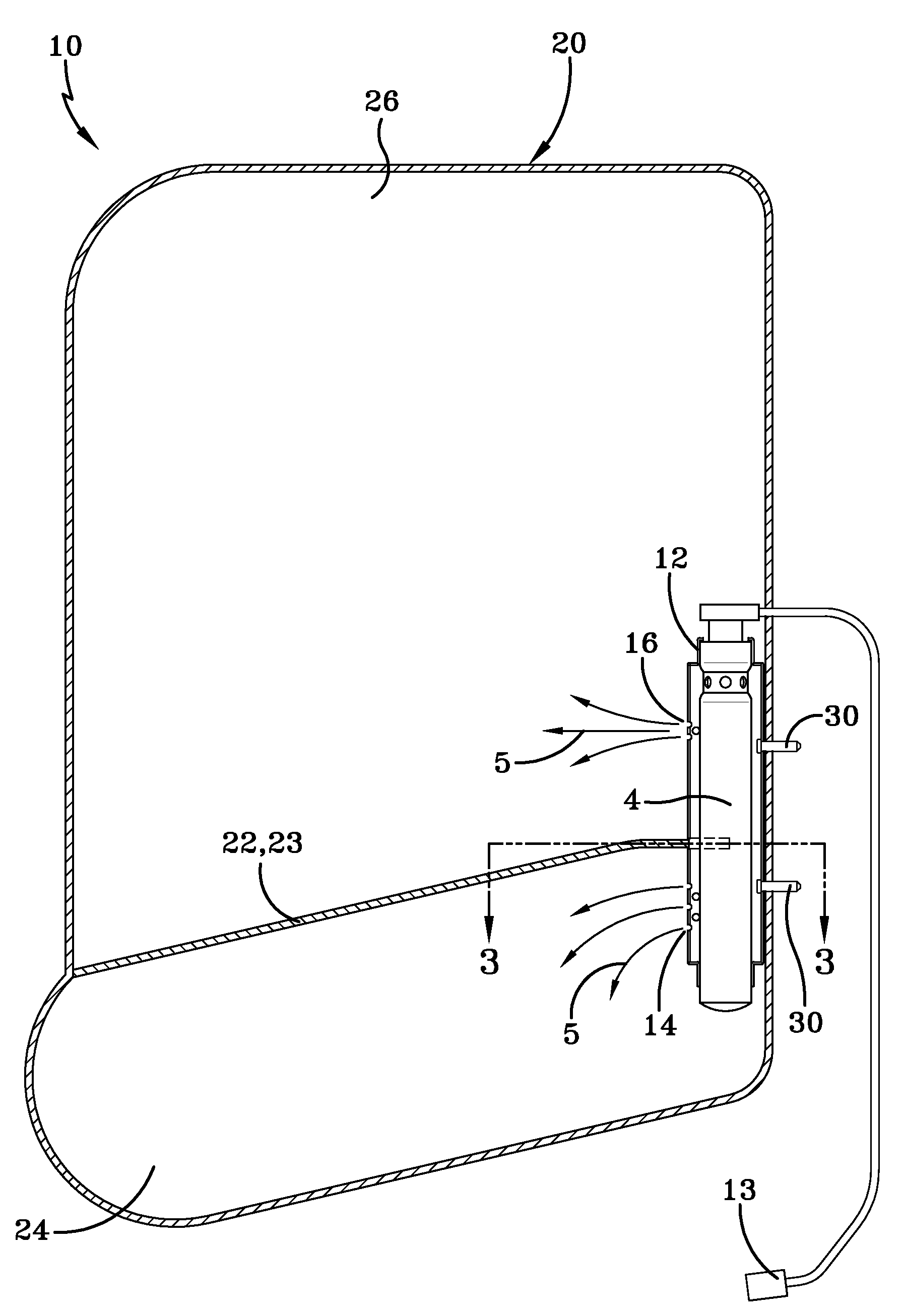

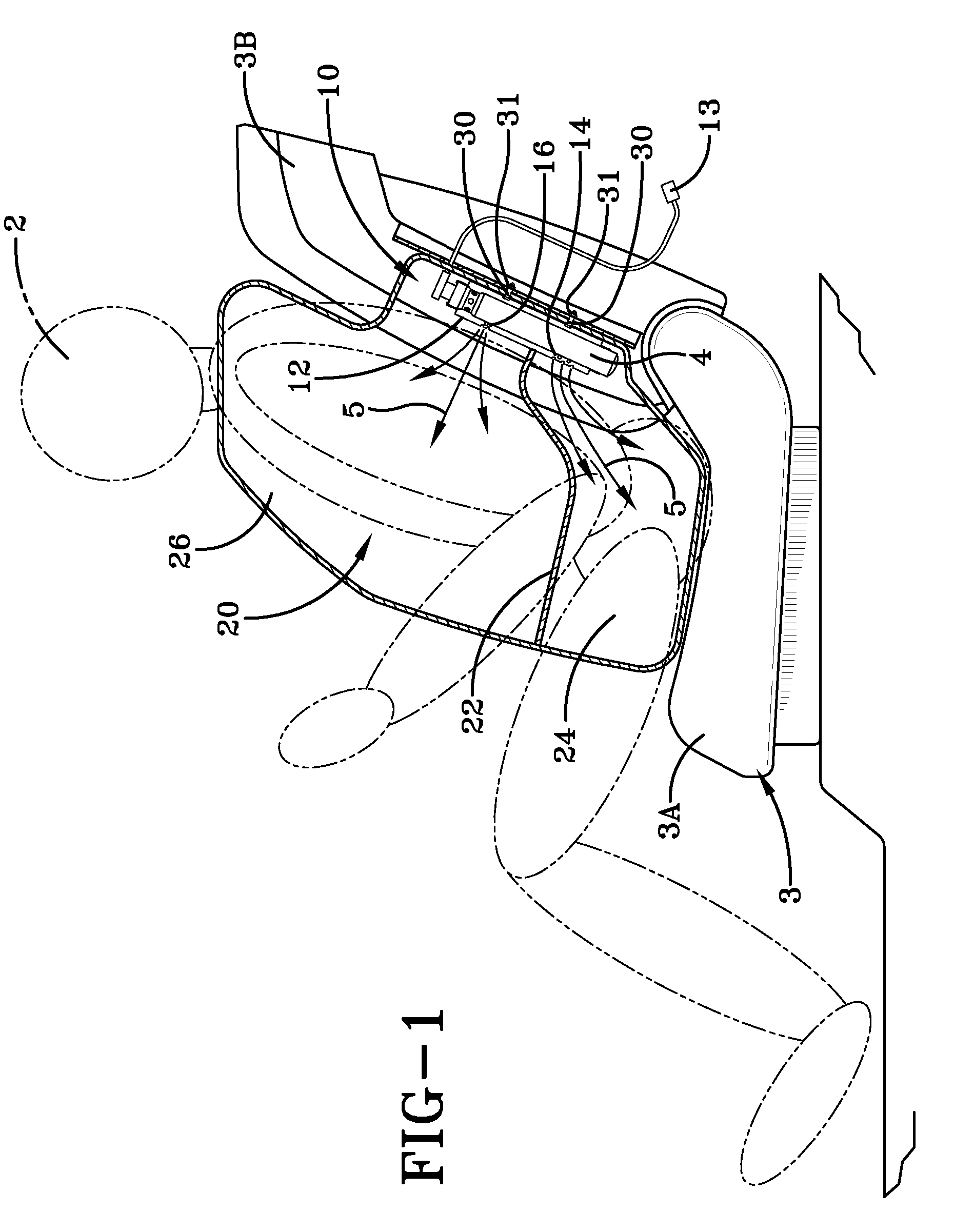

Particulate material applicator and pump

InactiveUS20050229845A1Good cleanabilityShorten color change timeLiquid surface applicatorsLiquid supply arrangementsEngineeringExpansion chamber

A nozzle assembly for a material application device includes an expansion chamber for slowing down the velocity of powder fed to the nozzle from a dense phase pump. The nozzle assembly includes a nozzle insert that forms the expansion chamber and provides air assist function. The nozzle includes an integral deflector, and further includes a passageway for a charging electrode so that the electrical path is routed away from the powder path, while permitting the electrode tip to be centered in the powder spray pattern from the nozzle. The nozzle also includes air wash for the electrode. The nozzle outlet orifice has a cross-sectional area that is equal to or greater than the inlet cross-sectional area so that a slow moving dense phase powder cloud is produced by the nozzle.

Owner:NORDSON CORP

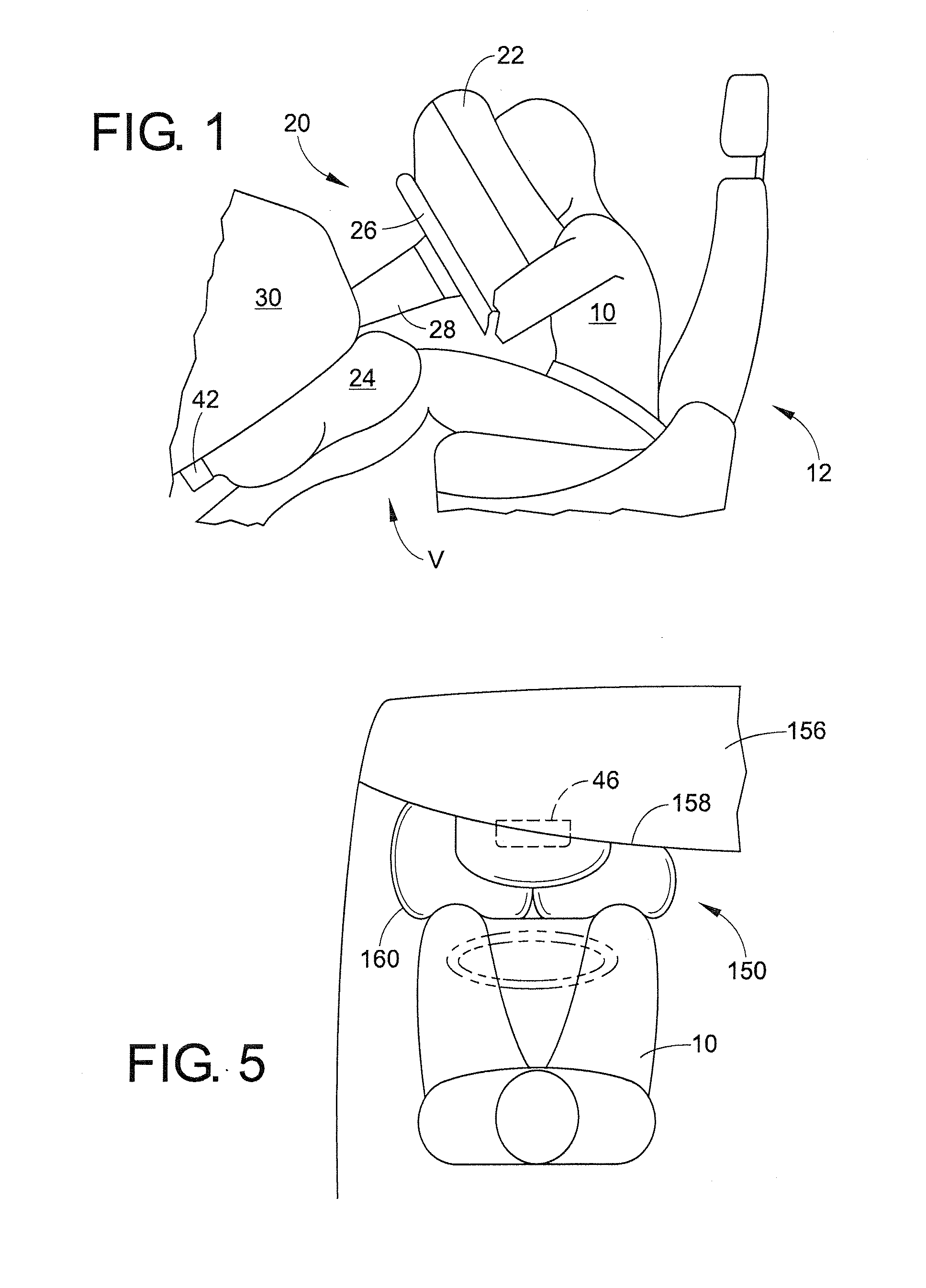

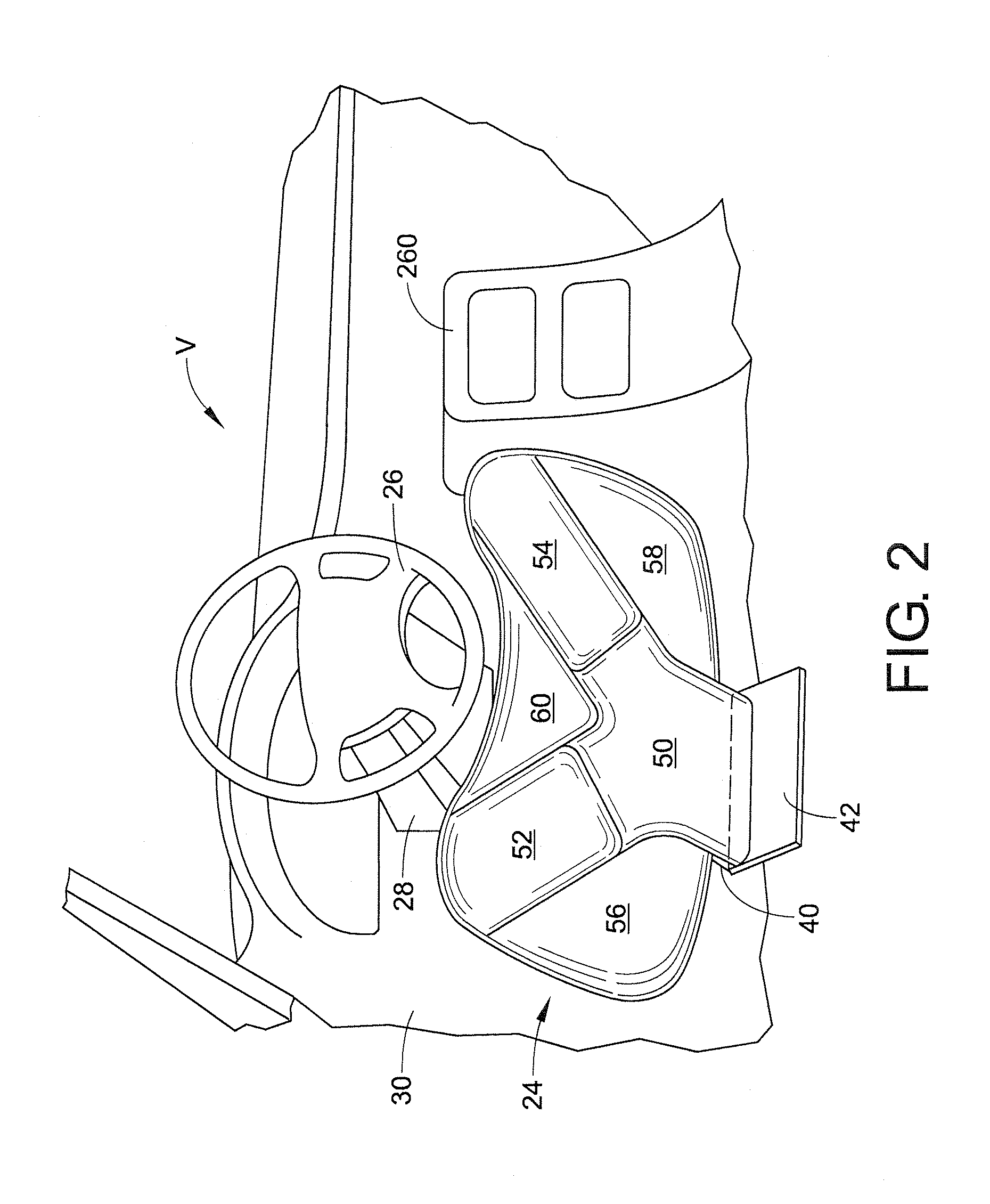

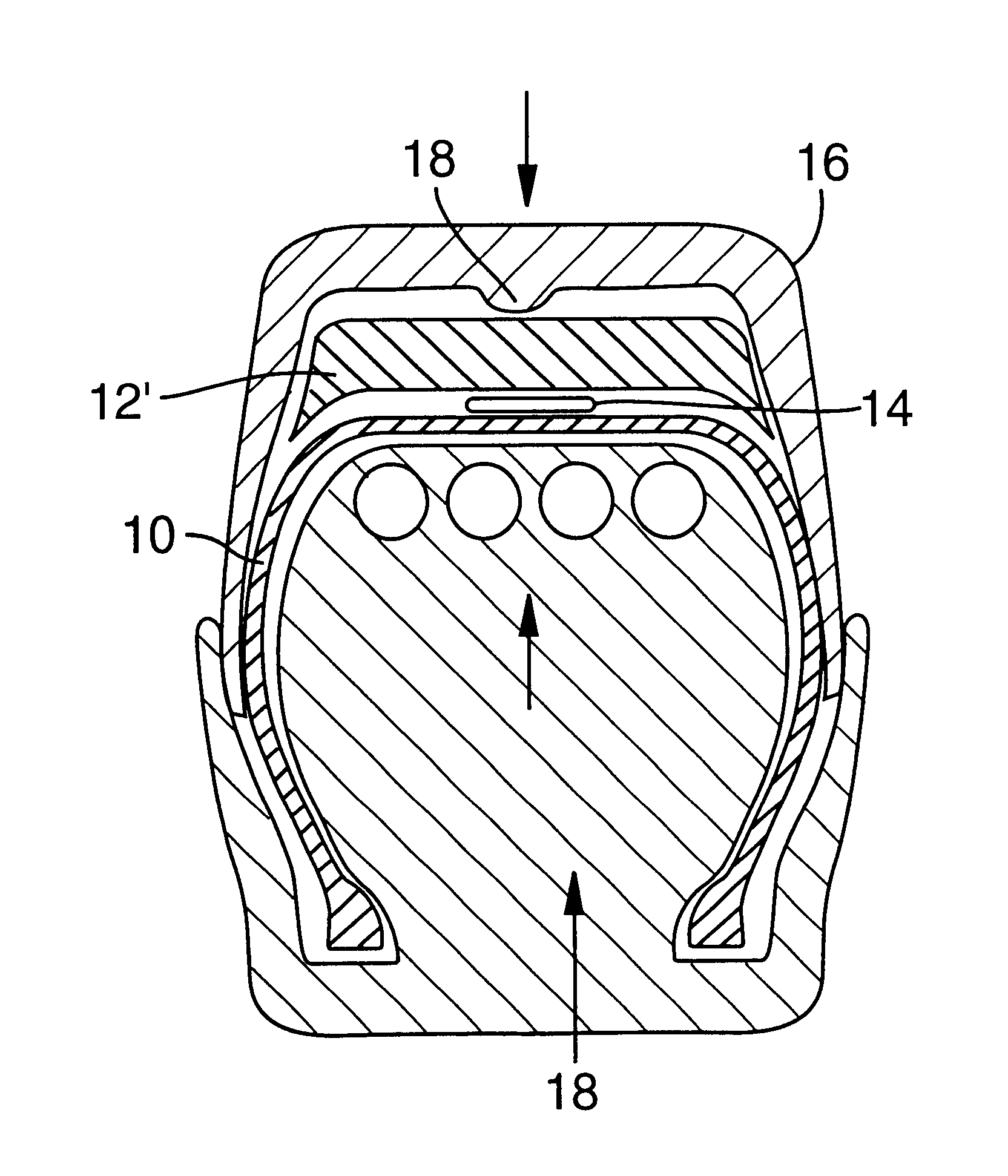

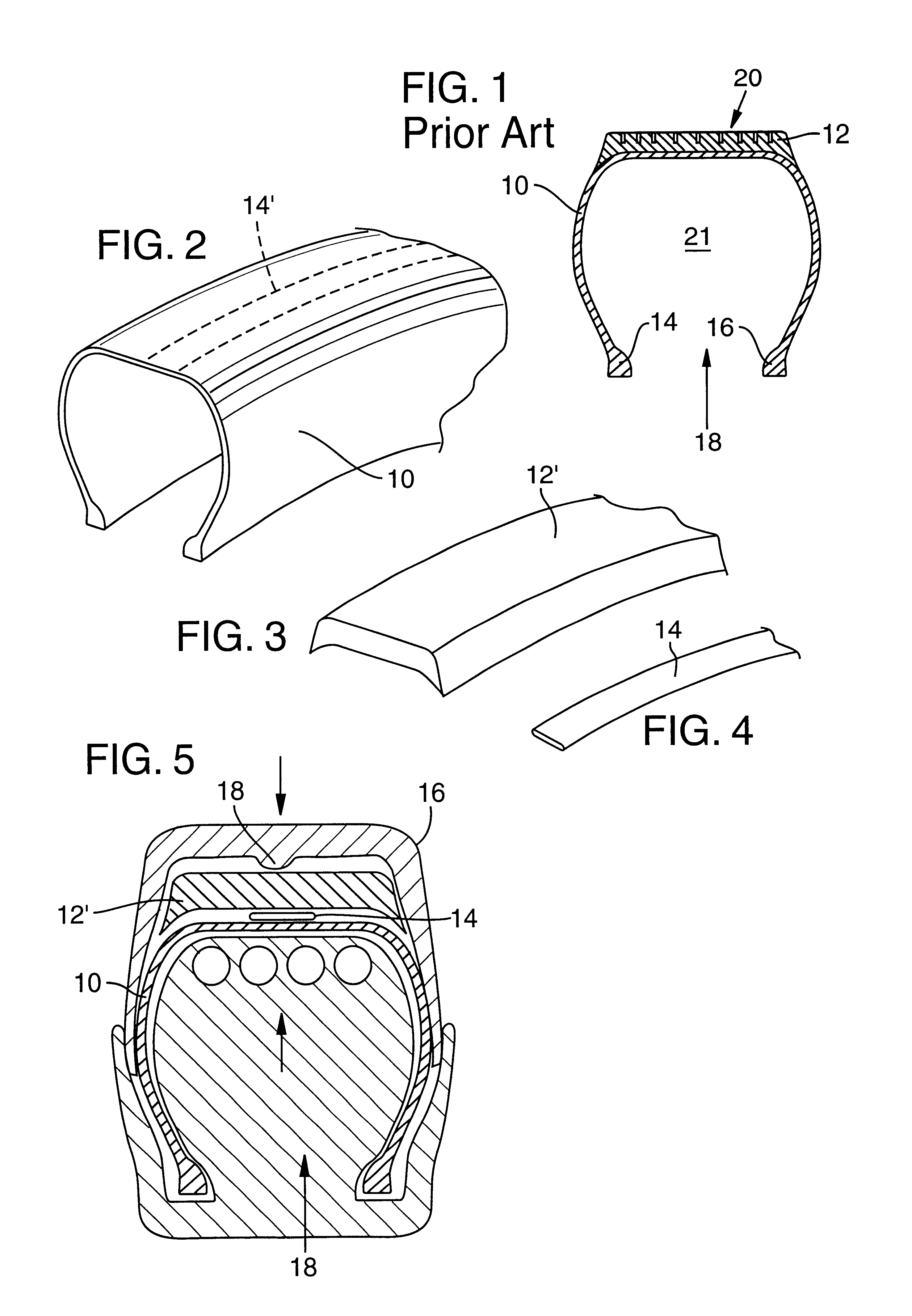

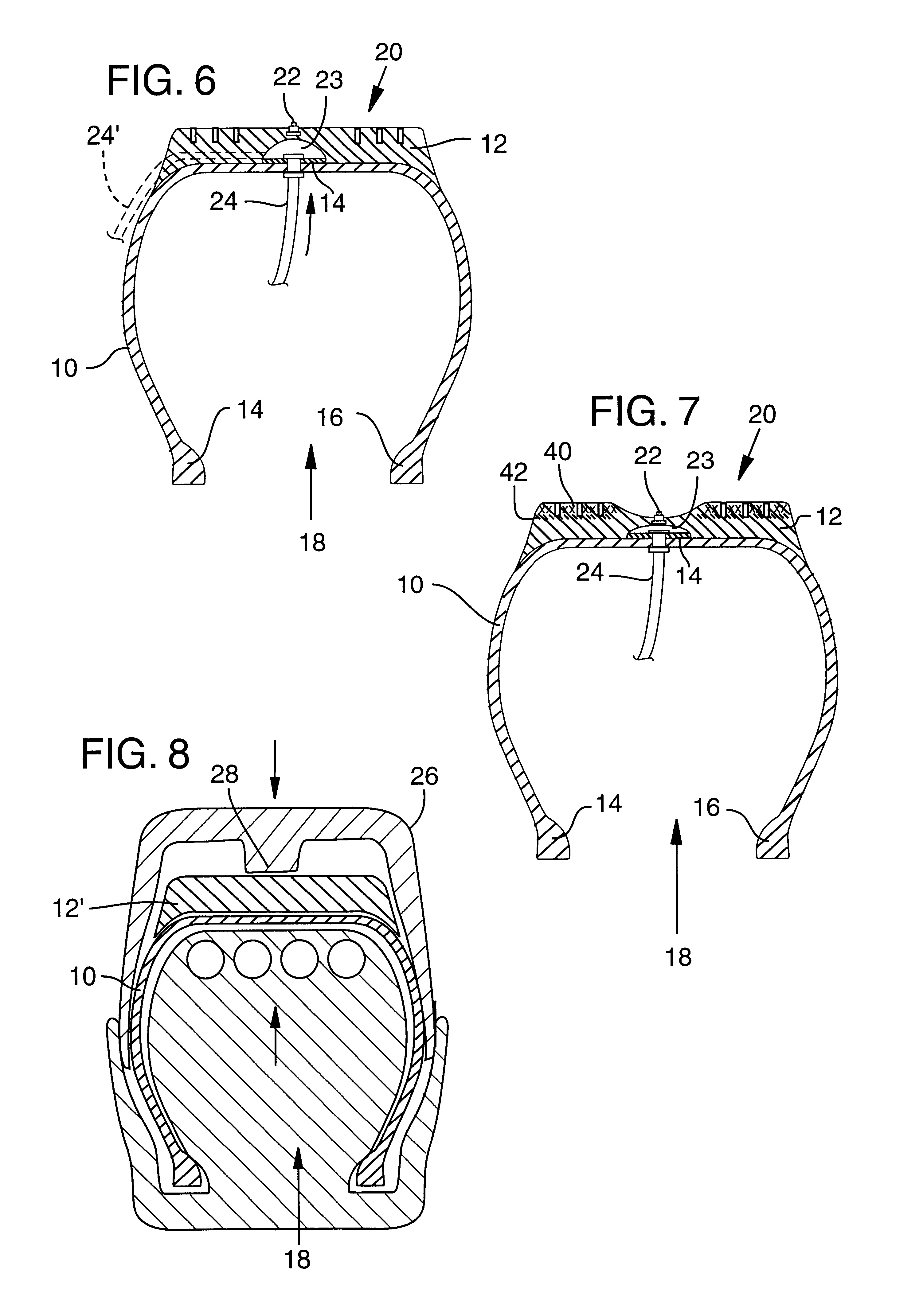

Multi-chamber knee airbag

ActiveUS20110175334A1Increase pressurePedestrian/occupant safety arrangementEngineeringExpansion chamber

An airbag module for a vehicle includes a gas generator for generating a gas and a multi-chamber airbag operatively connected to the gas generator for receiving the gas. The airbag defines a first inflation chamber, at least one second inflation chamber, at least one third inflation chamber and a fourth inflation chamber. The airbag includes internal vents configured to allow selective communication between the first chamber and each of the at least one second chamber and the at least one third chamber and selective communication between the at least one second chamber and the fourth chamber. The internal vents are configured to maintain a higher pressure in selective chambers by restricting ability of the gas to escape the selective chamber. The order of internal venting between the respective inflation chambers controls the pressure and timing of inflation of the multi-chamber airbag.

Owner:HONDA MOTOR CO LTD

Sound suppressor silencer baffle

ActiveUS7412917B2Reduces sound and flash levelReduce the amount of noiseWeapon componentsSuppressorEngineering

A baffle for use in a firearm suppressor, which increases the amount of sound and flash that are perceived upon the firing of a firearm upon which a suppressor is placed without substantial alteration to the power or accuracy of the firearm upon which the suppressor is attached. The baffle is made up of a generally hollow, central core defining open topped tube that is dimensioned so as to allow passage of a projectile through this core. This tube extends from an open front end backwards to an intersection with an inside surface of a rear wall, as well as to an intersection with a forward bulkhead. The bulkhead and the inside surface of the rear wall are located in different vertical and horizontal planes and define expansion chambers and reflection surfaces that alter the escape pattern of gasses out of the suppressor.

Owner:VAIS GEORGE

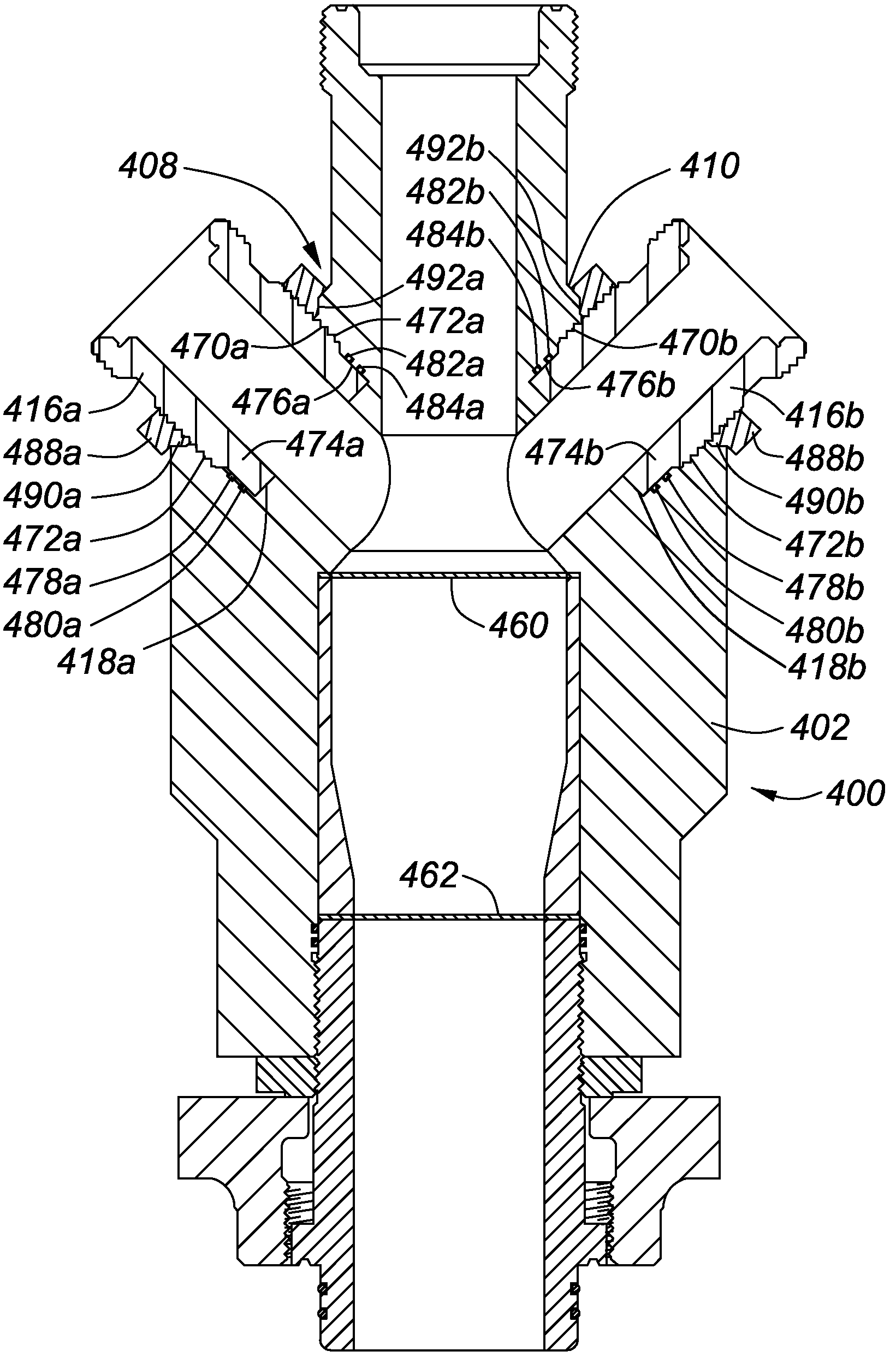

Energy suppressors

ActiveUS7789008B2Good noise suppression characteristicsReduce the amplitudeWeapon componentsBursting strengthFiber

A suppressor for a firearm includes a first gas expansion section of relatively large size sufficient to reduce the temperature and pressure of the gas expelled from a muzzle during discharge of the firearm to a level that avoids rapid degrading of structural members such as baffles in the suppressor that are downstream of the muzzle. The gas is channeled through multiple paths to distribute its energy more equally. Preferably, the suppressor is formed with a lightweight, thermally-conductive composite portion. The composite portion provides lightweight, bursting strength with good thermal conductivity and little contribution to vibrational instability of the muzzle to which it is attached. The composite portion may be of a carbon fiber, silicon, boron, or metallic base. In one embodiment, a first expansion chamber is in communication with the muzzle and with a second expansion chamber and in another embodiment, the first expansion chamber communicates with the muzzle and with the second expansion chamber The composite portions of the suppressor provide good bursting strength and heat conductivity with light weight. In some embodiments, a series of baffles creates turbulence in the gas, slowing its motion and distributing the energy more evenly over space.

Owner:PETERSEN BYRON S

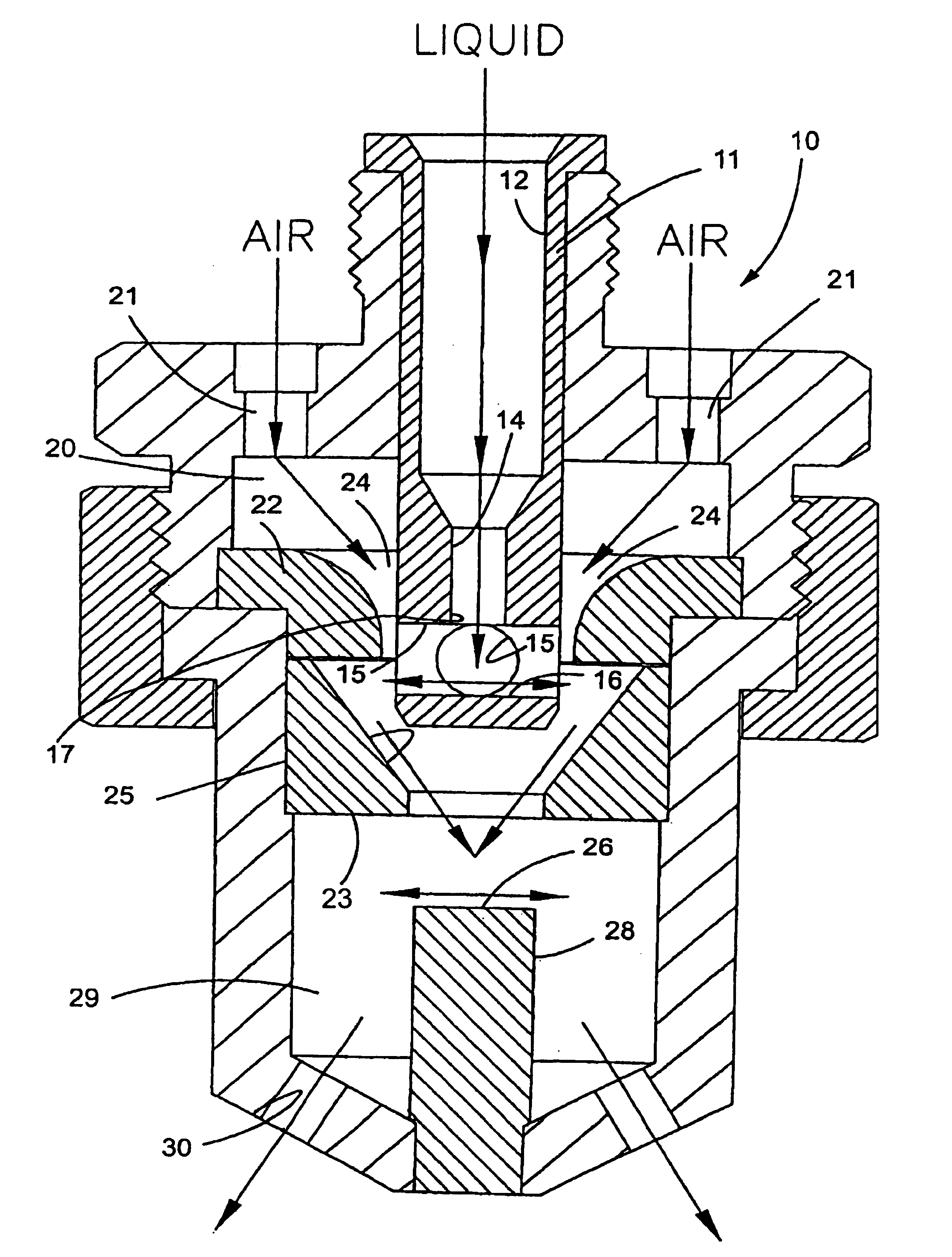

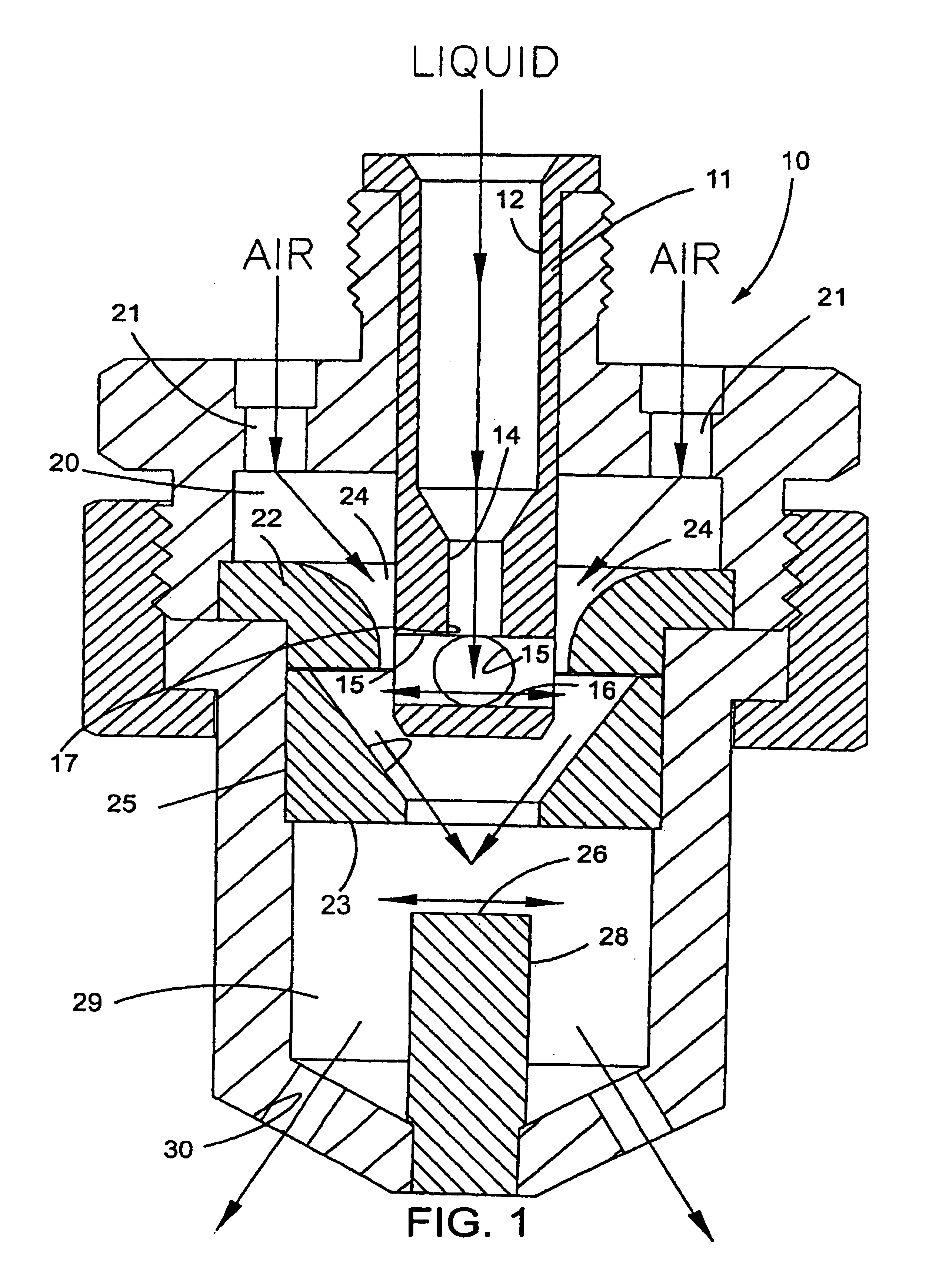

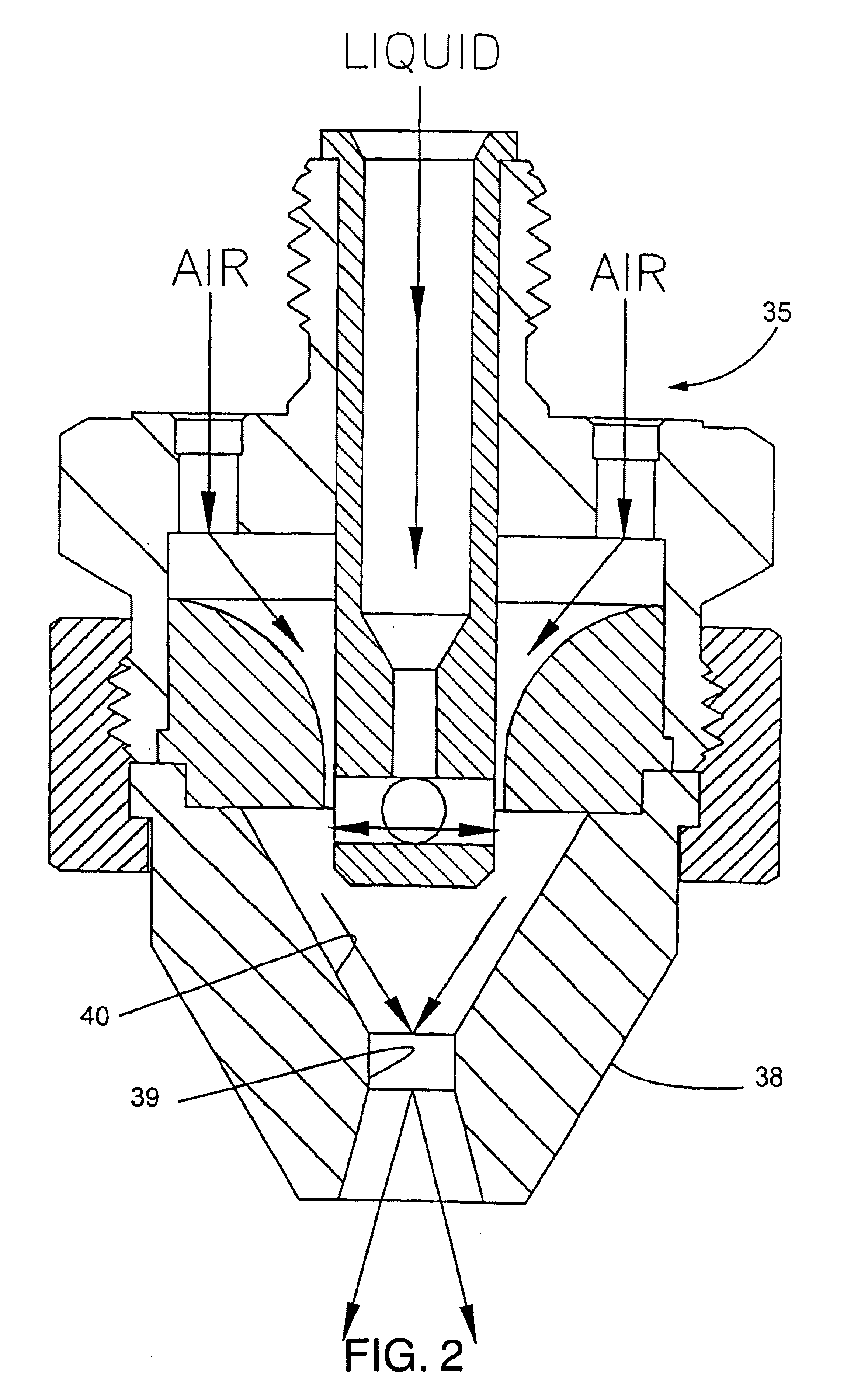

Internal mixing atomizing spray nozzle assembly

InactiveUS7036753B2Effectively atomizing liquid spraysReduce air pressureLighting and heating apparatusSpray nozzlesEngineeringExpansion chamber

A nozzle for atomizing and spraying liquid is provided. The nozzle includes a longitudinal liquid flow passageway that terminates in a liquid orifice for directing a stream of liquid along a predetermined axis. A plurality of intersecting, transverse passageways extend perpendicular to and intersect the predetermined axis. Each of the transverse passageways terminates at either end in an outlet. The transverse passageways define a first impingement surface downstream of the liquid orifice for breaking up a stream of liquid impinging thereon into a laterally spreading dispersion which disperses through the transverse passageways. An air annulus is arranged in surrounding relation to the outlets of the transverse passageways and oriented to discharge air in a downstream direction so as to strike the fluid dispersed through the outlets of the transverse passageways. An expansion chamber is arranged downstream of the transverse passageways and air annulus. The expansion chamber communicates with a nozzle discharge orifice.

Owner:SPRAYING SYST

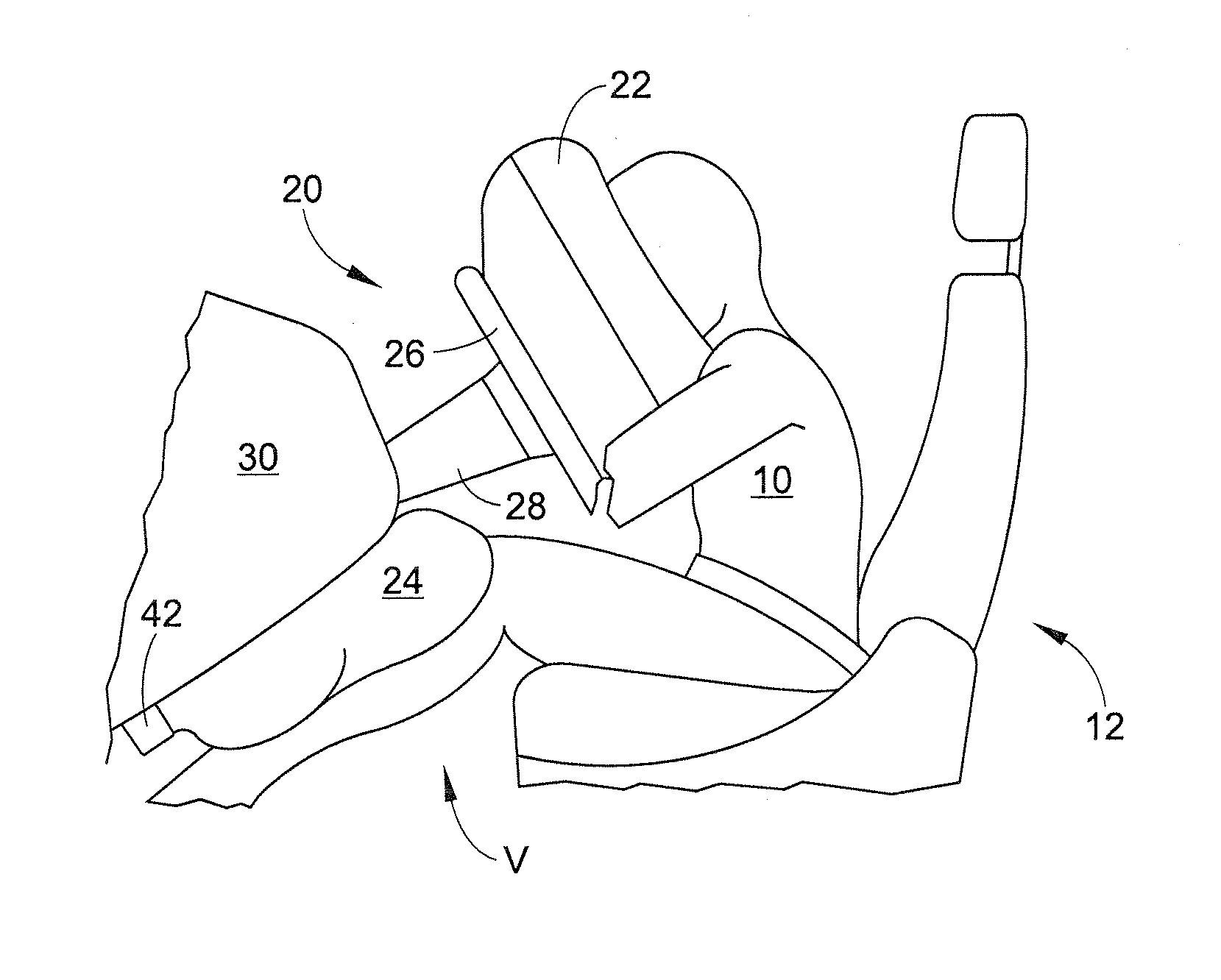

Seat mounted side impact airbag module

InactiveUS7278656B1Protect the occupantsPedestrian/occupant safety arrangementLateral airbagThoracic region

A seat mounted side impact airbag module for protecting an occupant of a vehicle has an airbag with a first inflation chamber for engaging the pelvic region of the vehicle occupant and a second inflation chamber for engaging the thoracic region of the vehicle occupant. The inflation chambers are separated by a chamber separator. An inflator provides inflation gas to fill the airbag housed in a tubular housing manifold having a first aperture and a second aperture. The housing manifold is shaped to retain the inflator and create two discrete flows of inflation gas. A first flow of inflation gas goes into the first inflation chamber via the first aperture and a second flow of inflation gas goes into the second inflation chamber via the second aperture. The chamber separator is tightly sealed around the housing manifold to prevent the first flow and second flow to pass into the other inflation chamber. The chamber separator may be rubber coated with the housing manifold having a recess adapted to accept and hold the chamber separator sealed in a gas tight manner around the exterior of the housing manifold.

Owner:KEY SAFETY SYST

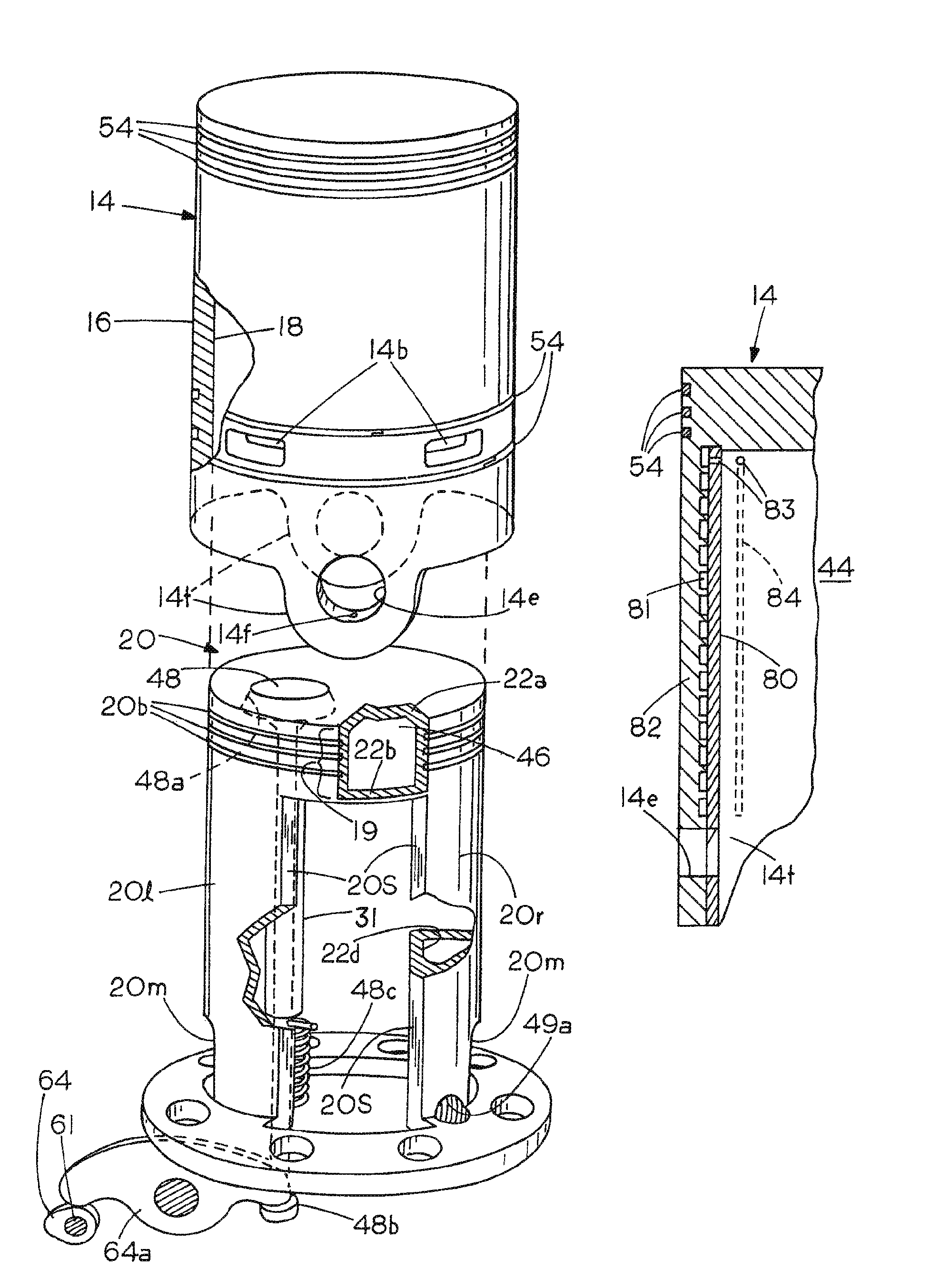

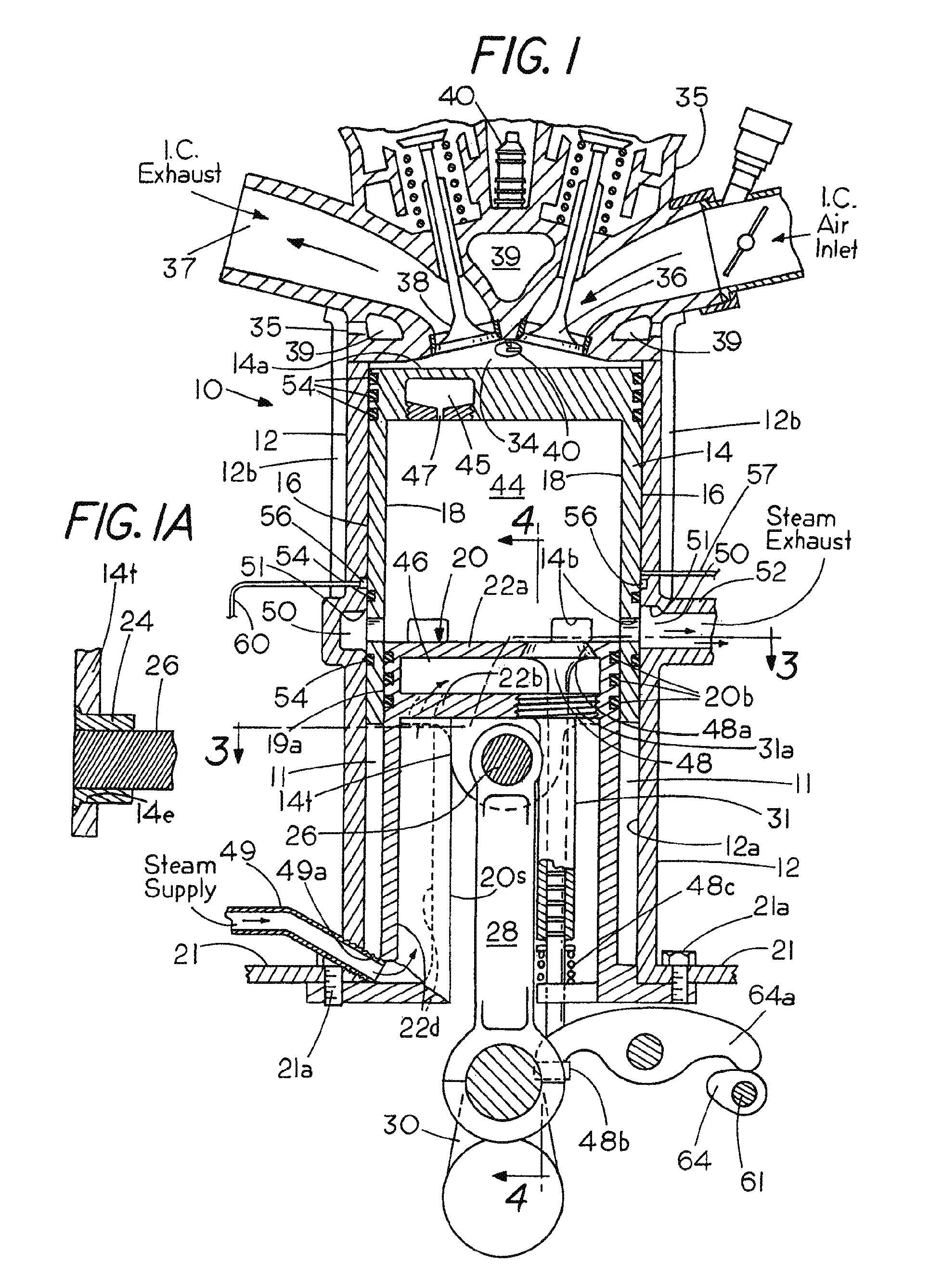

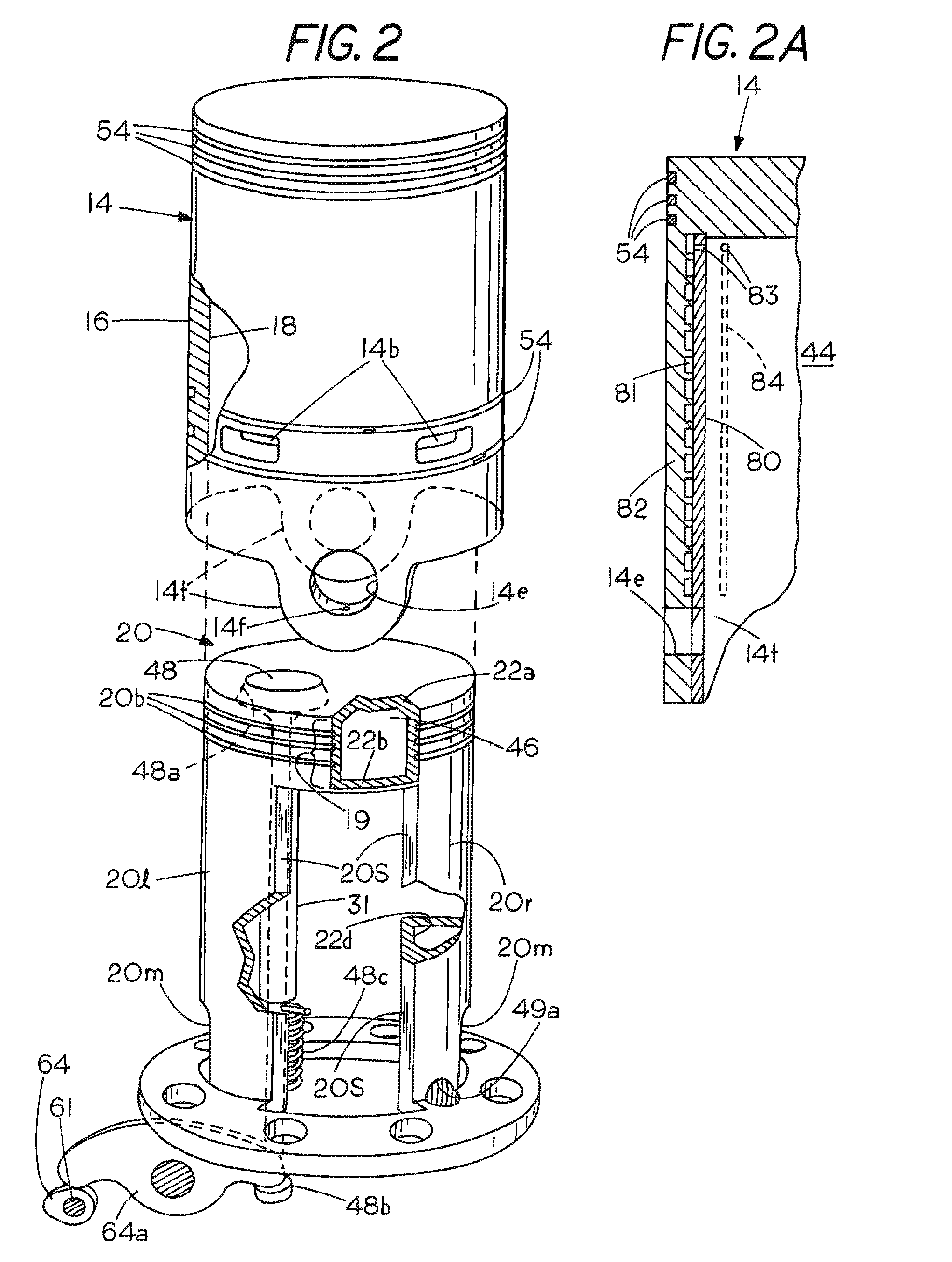

High efficiency multicycle internal combustion engine with waste heat recovery

ActiveUS8061140B2Effective recoveryIncrease enthalpyReciprocating combination enginesInternal combustion piston enginesCombustion chamberInlet valve

A high efficiency combined cycle internal combustion and steam engine includes a cylinder and a piston with an internal combustion chamber outward of the piston, a fixed cylinder cap and a steam expansion chamber inside the piston. The cylinder cap can be heated to reduce condensation of steam entering from a steam generator fired by waste combustion heat. Following exhaust, residual steam can be recompressed prior to admitting the next charge of steam. A wrist pin connected to an inner end of the piston skirt inwardly of the cylinder cap is coupled to a connecting rod secured to a crankshaft. One valve or a pair of steam inlet valves are connected to communicate in series within the cylinder cap inside the piston. The steam mass admitted is regulated to reduce fuel consumption. Coolant can be superheated in the combustion exhaust manifold.

Owner:THERMAL POWER RECOVERY

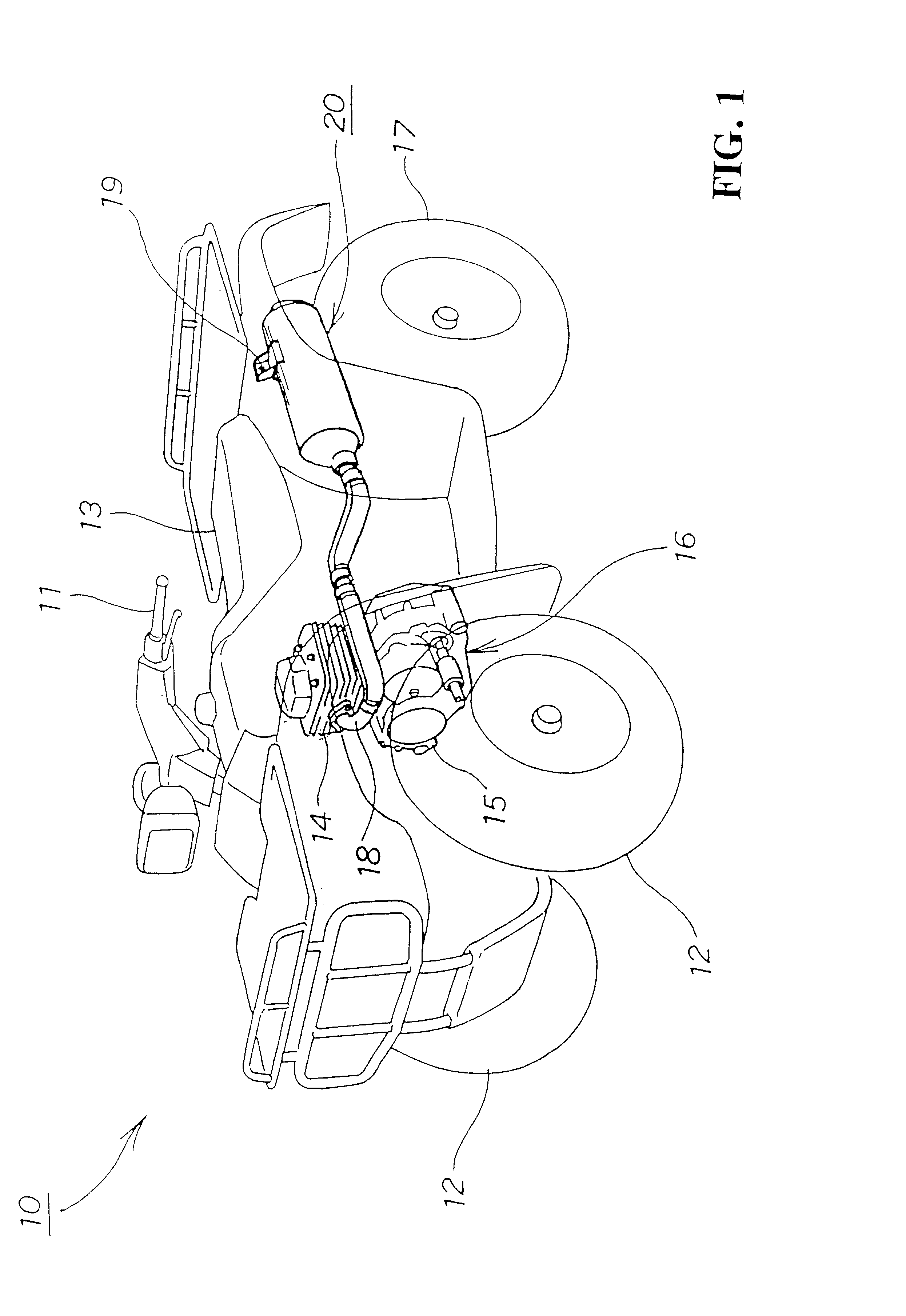

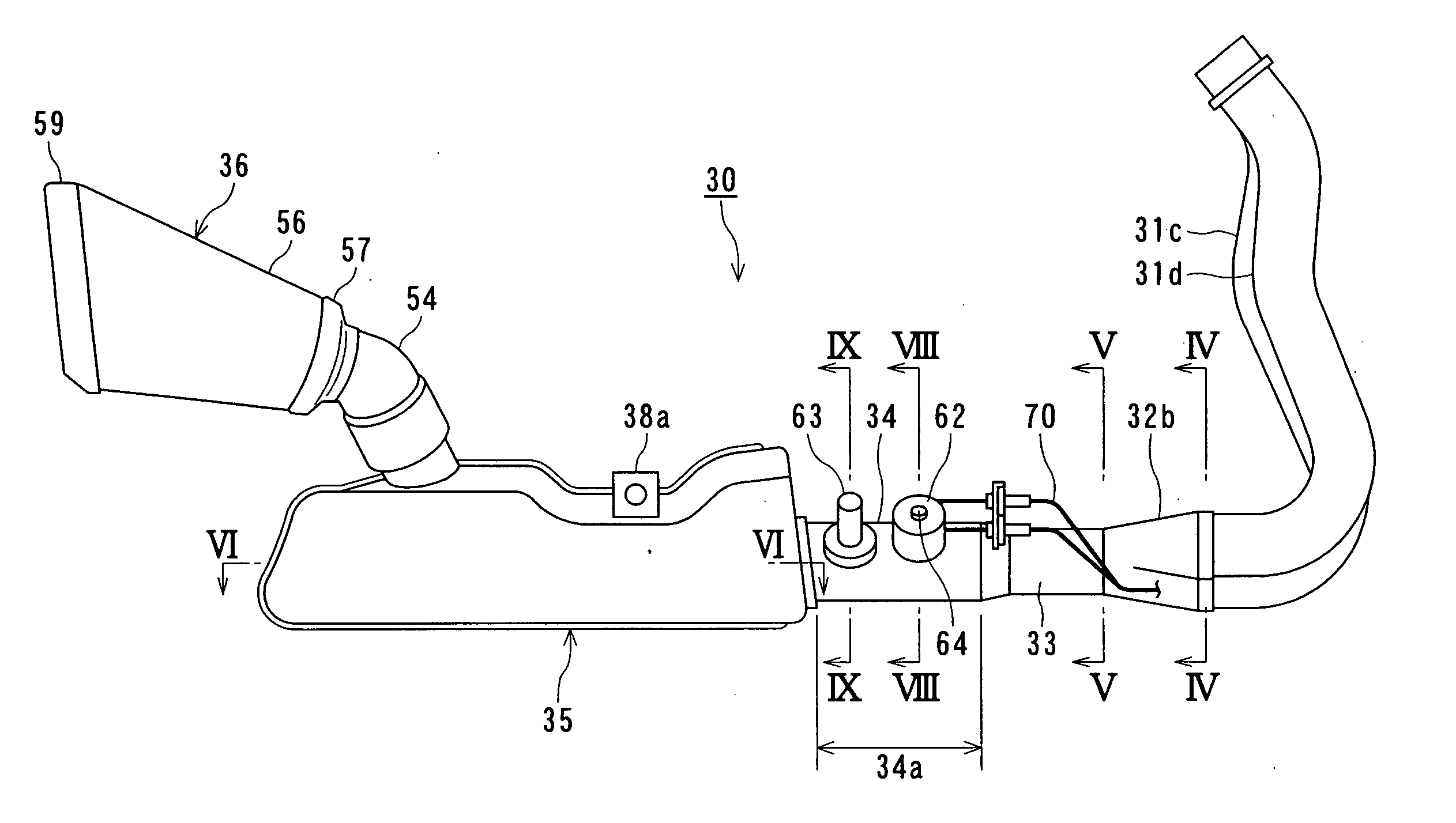

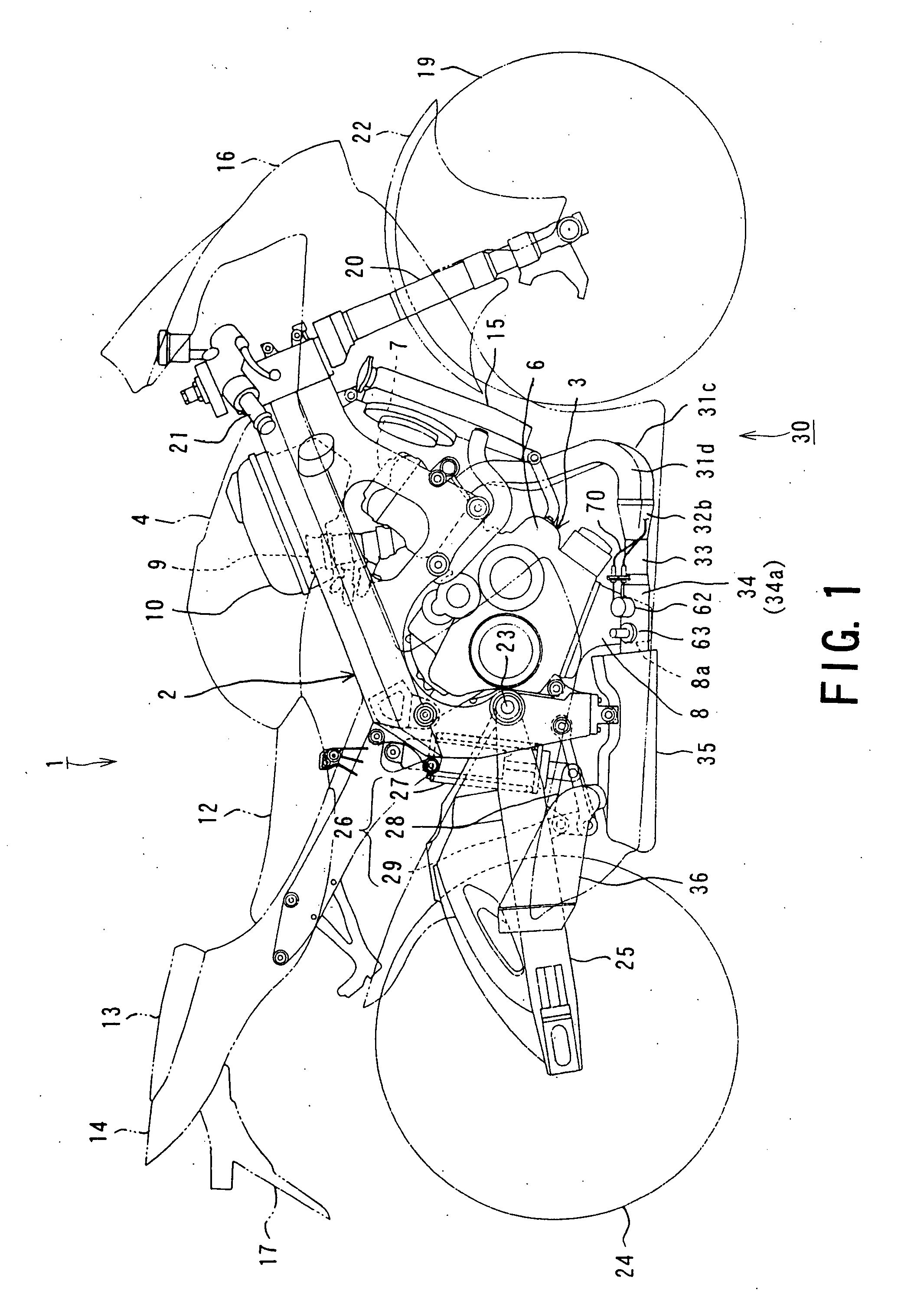

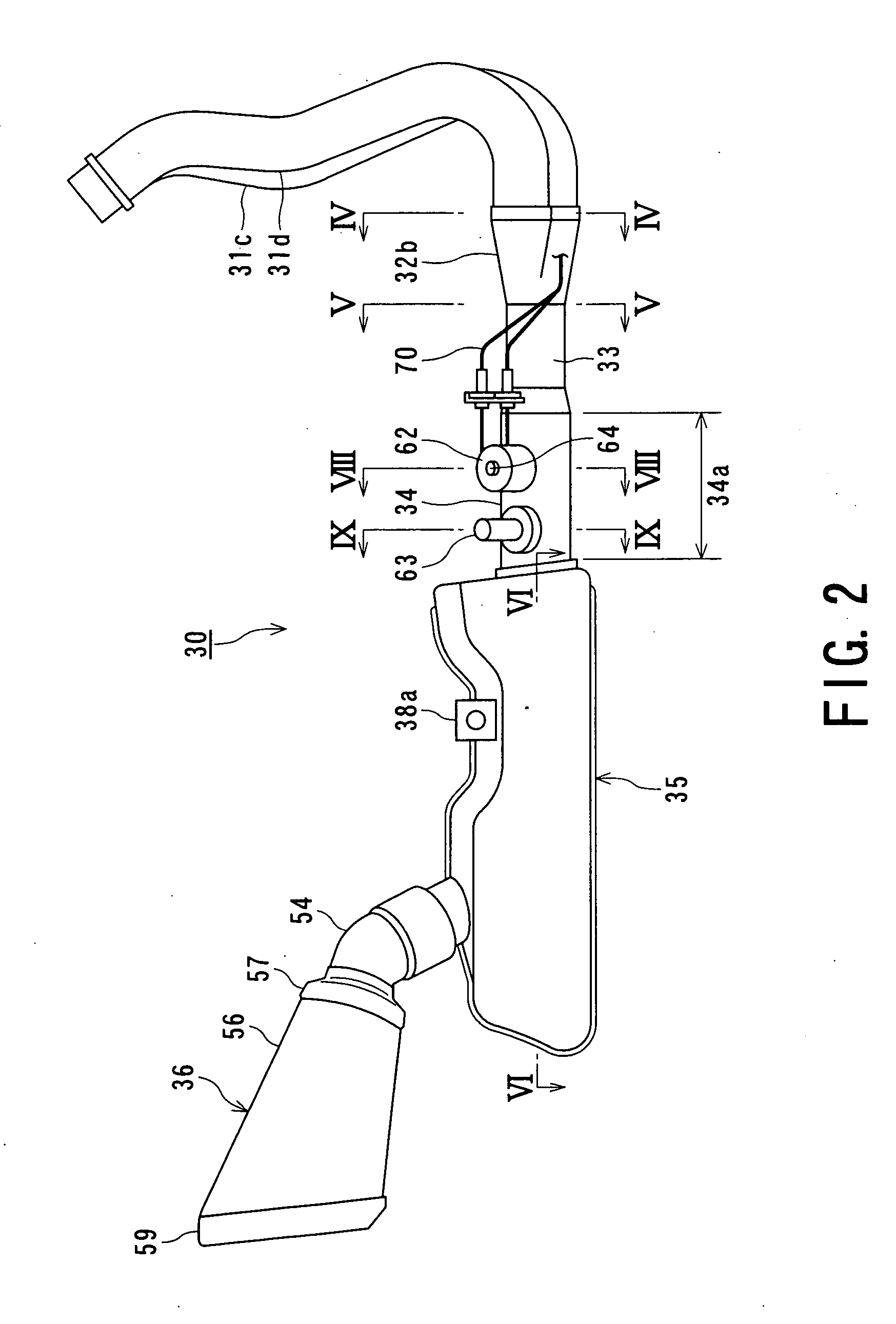

Exhaust system for motorcycle

ActiveUS20060242952A1Operation efficiency can be improvedImpairing running stabilityExhaust apparatusSilencing apparatusCrankcaseExpansion chamber

An exhaust system for a motorcycle having an engine mounted on a front half of a body frame of the motorcycle includes a plurality of first exhaust pipes extending from exhaust ports of the engine, a collecting section at which the first exhaust pipes are collected, a second exhaust pipe including a substantially straight portion connected to a downstream side of the collecting section and disposed under a crankcase of the engine, an expansion chamber connected to a downstream side of the second exhaust pipe and located under a rear wheel suspension arranged behind the engine, an exhaust outlet disposed on a most downstream portion of the expansion chamber, and an exhaust throttle valve and an exhaust gas sensor disposed on the straight portion of the second exhaust pipe.

Owner:SUZUKI MOTOR CORP

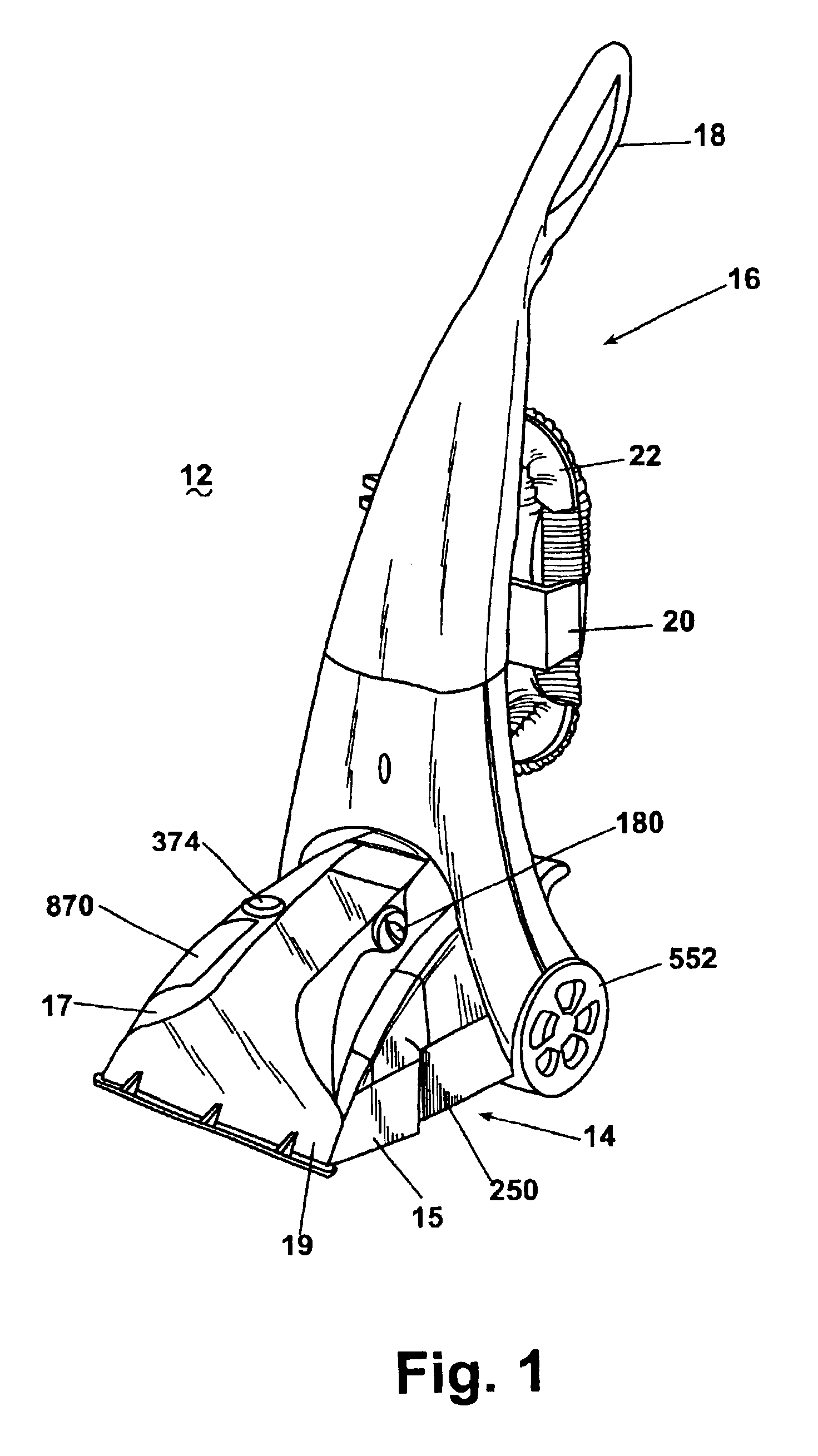

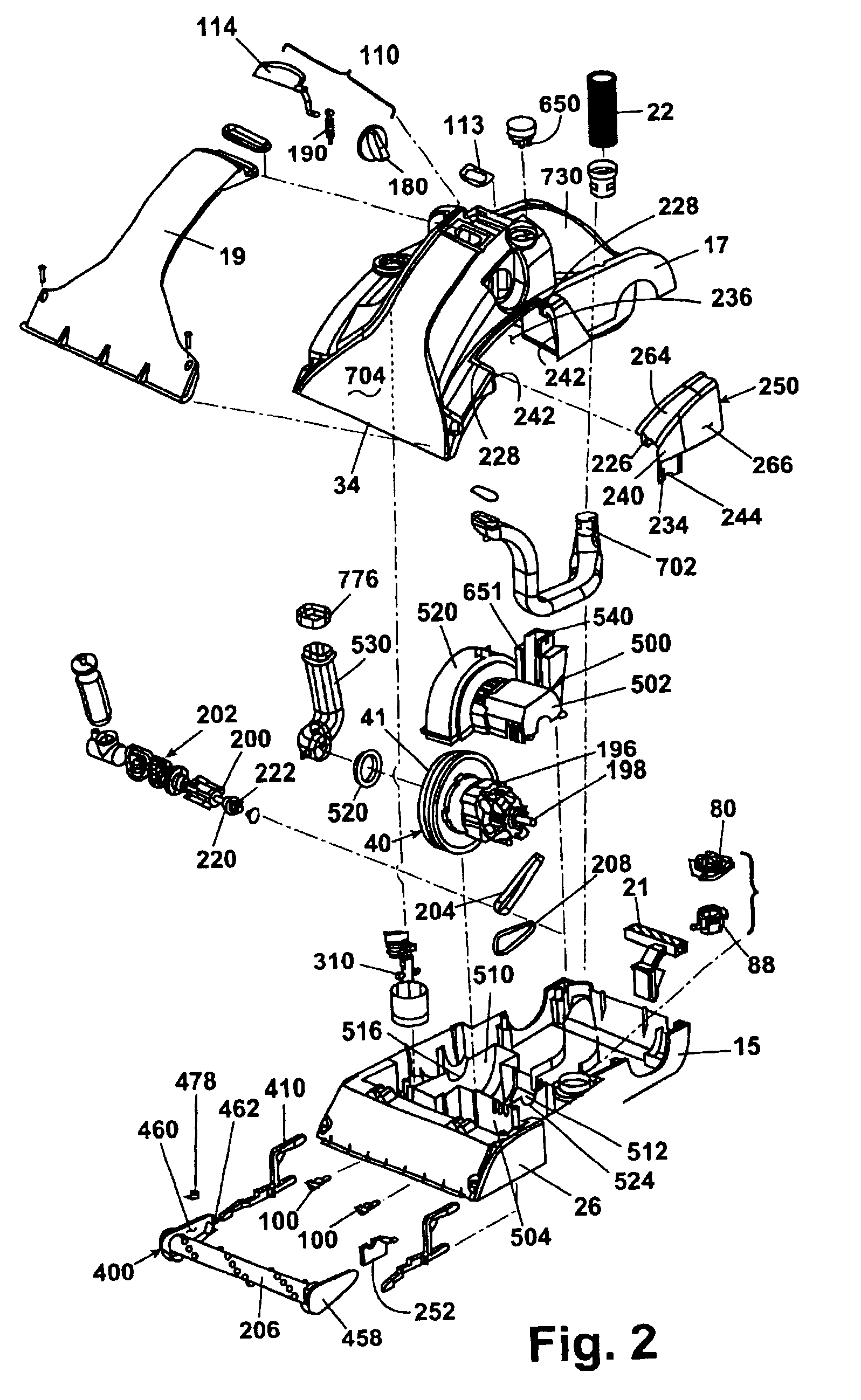

Upright extraction cleaning machine

A portable surface cleaning apparatus including a base module for movement along a surface , an upright handle pivotally attached to the base module, a liquid dispensing system including a flexible bladder defining a fluid supply chamber for holding a supply of cleaning fluid , a fluid recovery system including a tank on the base module having a fluid recovery chamber for holding recovered fluid and housing the flexible bladder, and a fluid passageway between the fluid supply chamber and the recovery chamber, whereby the recovery chamber is in fluid communication with the fluid supply chamber and the pressure in the flexible bladder is equalized with the pressure in the tank as the cleaning fluid is dispensed from the supply chamber and the dirty liquid is collected in the recovery chamber. In a further embodiment the tank has an outlet opening in a bottom portion thereof and a drain plug is removably mounted in the outlet opening. In another embodiment a lid mounted on the tank defines an expansion chamber having an inlet opening, an outlet passage, and first and second diverters against which the working air flow reverses direction twice between the inlet opening of the expansion chamber and the tank. In another embodiment the working air conduit includes a manual actuator knob having an over-center linkage mechanism connected to a conversion valve for movement between first and second positions and thereby selectively moving the conversion valve between open and closed positions, whereby fluid communication between the tank and the suction nozzle is selectively opened and closed. In a further embodiment, a flow indicator is mounted to the base module and has a visibility window observable to a user and the flow indicator is disposed in the fluid supply conduit and is responsive to the flow of fluid through the fluid supply conduit to visually indicate the flow of fluid through the supply conduit to the user. Another embodiment includes a pump primer connected to the pump and having a housing defining a priming chamber with a valved opening connected to the vacuum source, an inlet opening connected to the fluid supply chamber, and an outlet opening connected to an inlet for the pump. A further embodiment includes a first mechanical connector extending between the motor drive shaft and the pump drive shaft, whereby the motor drives both the agitation brush and the pump. In a further embodiment, the base module includes an upper housing portion and a lower housing portion and an upright handle is pivotably mounted to the rear portion of the base module through at least one bearing for rotatable reception in the housing. In another embodiment , an elevator assembly is reciprocally mounted to the base module and movable in response to movement of the upright handle from an operative position to the upright position for upwardly pivoting a pivot arm mounting an agitation brush.

Owner:BISSELL HOMECARE

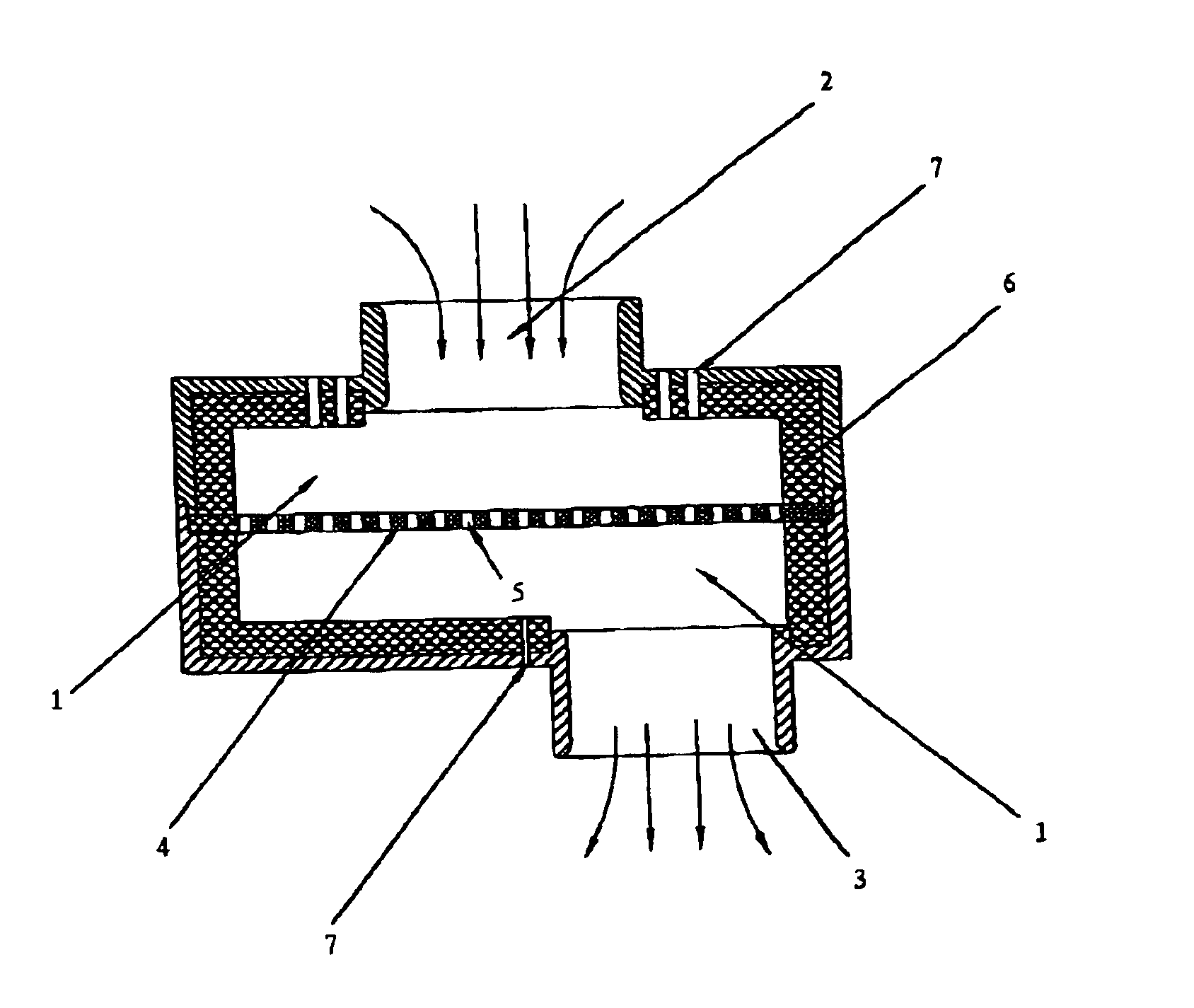

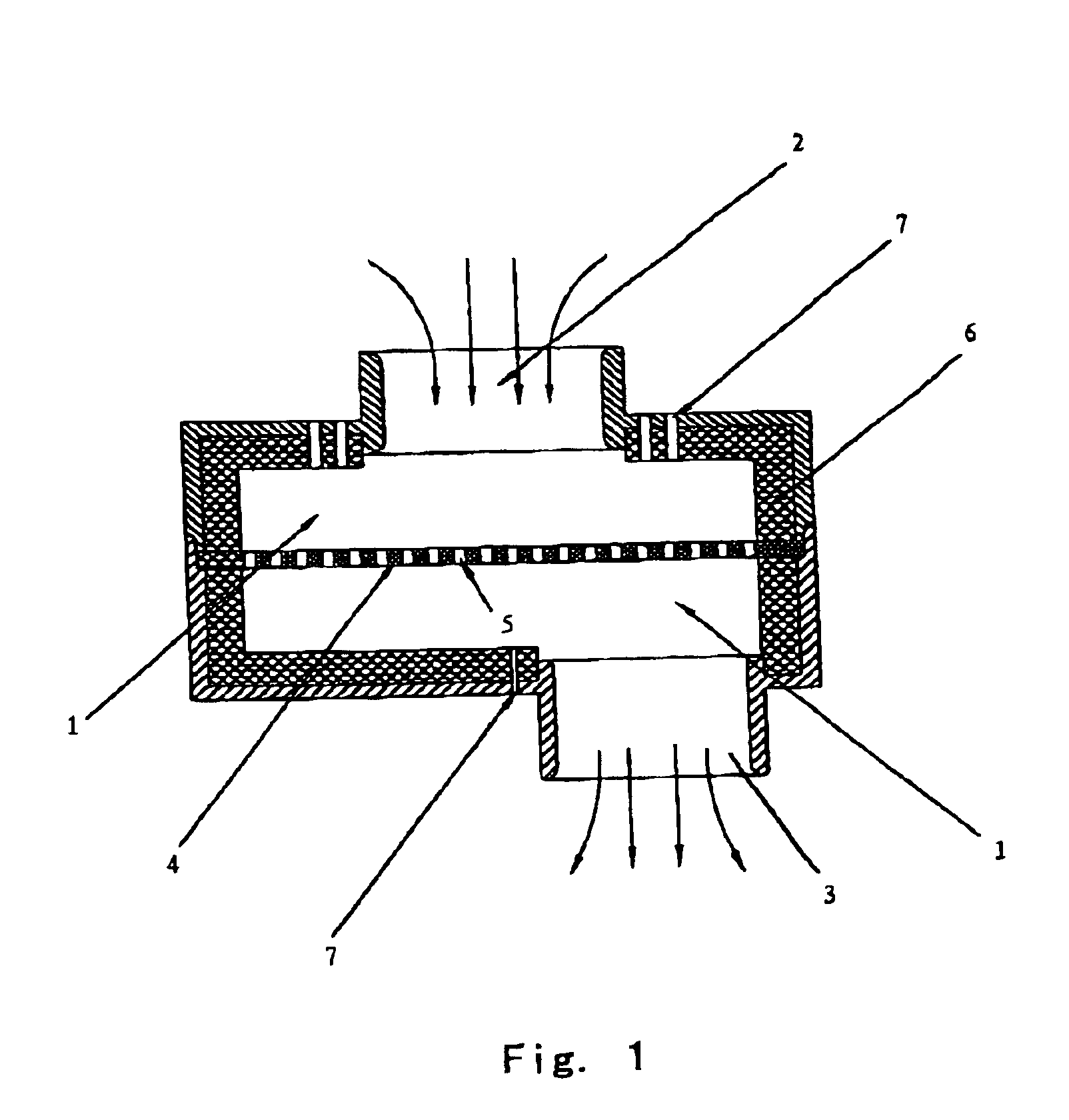

Silencer for vacuum cleaner

InactiveUS6932188B2Reduce noiseImprove noise reductionCombination devicesSuction filtersExpansion chamberMuffler

A silencer for a vacuum cleaner is provided and includes at least one hermetic expansion chamber mounted in an exhaust channel of the vacuum cleaner and allowing an exhaust airflow from the vacuum cleaner to pass through. The expansion chamber at its two sides has an inlet and an outlet connected to the exhaust channel. A silencing board is mounted in the expansion chamber, separating the inlet from the outlet. Pores are distributed throughout in the silencing board. The silencer integrates several different silencing structures together, and, when mounted to the exhaust port of the vacuum cleaner, can considerably diminish the noise generated by the vacuum cleaner in operation.

Owner:SUZHOU KINGCLEAN FLOORCARE

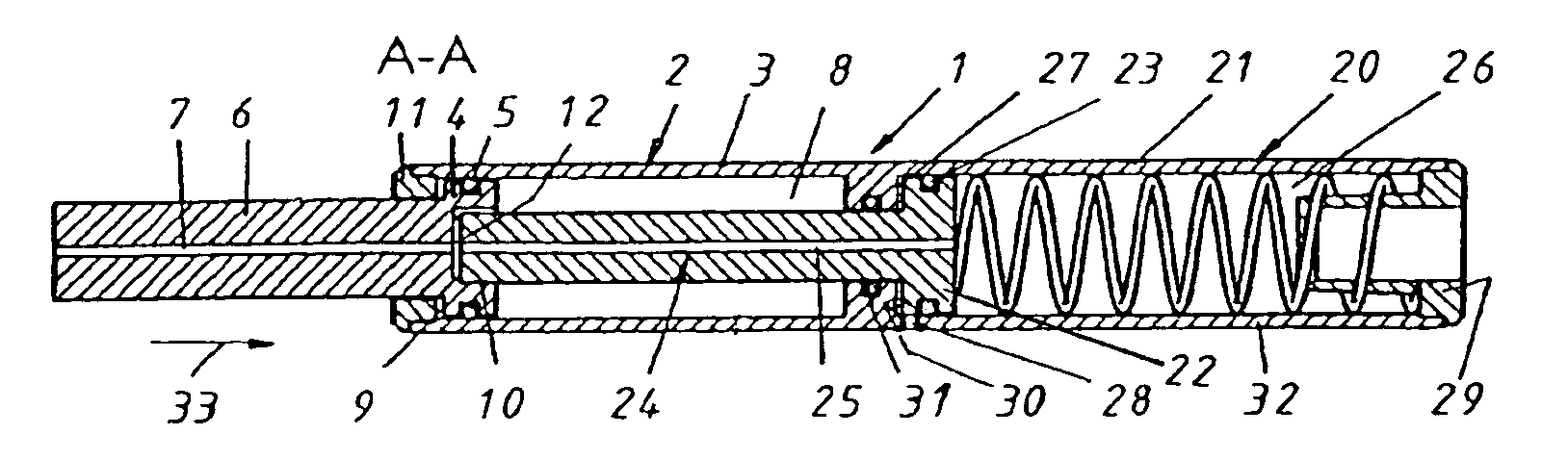

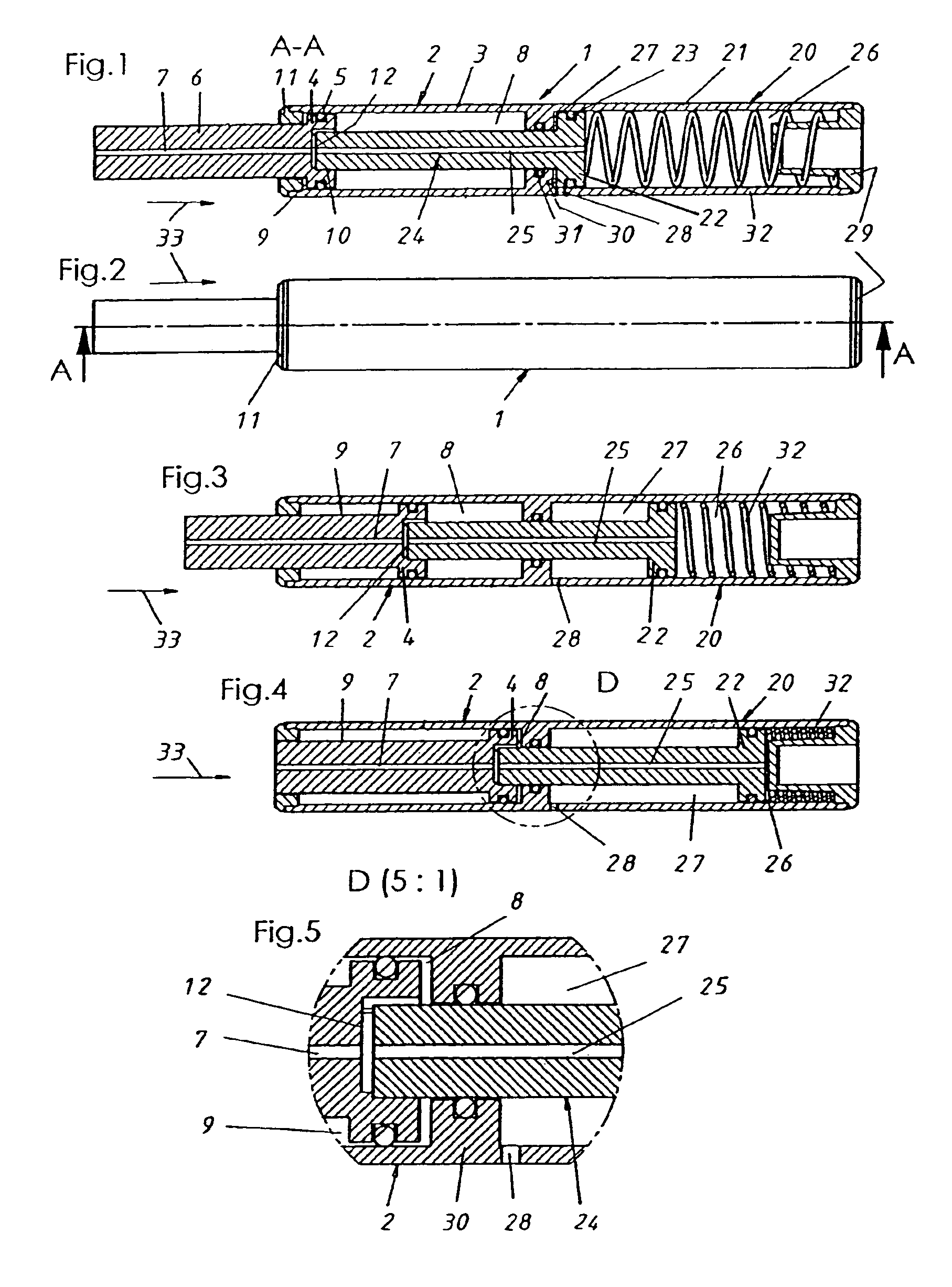

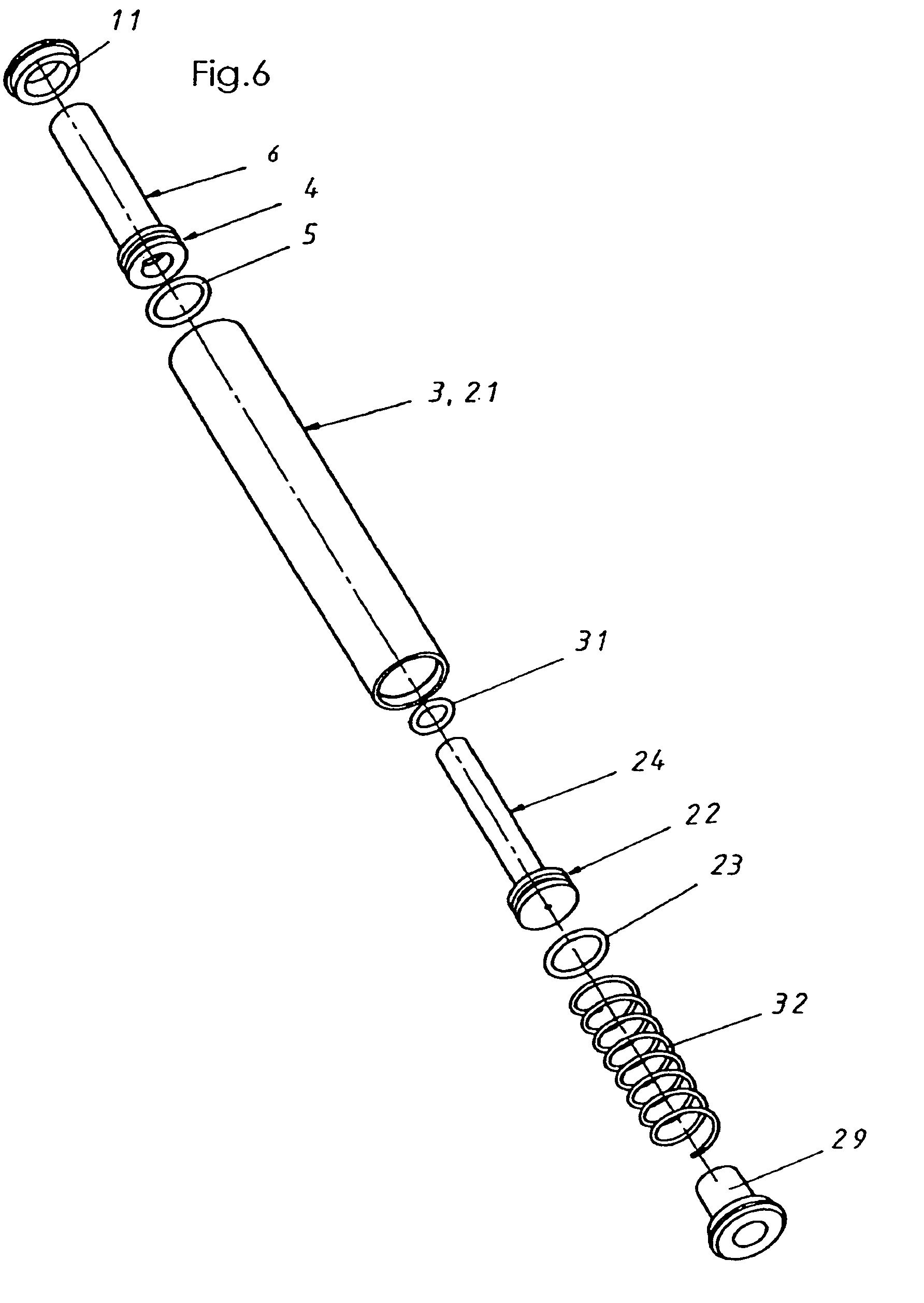

Damping device

InactiveUS6957807B2Compact formWide rangePortable framesBuilding braking devicesEngineeringExpansion chamber

The invention concerns a damping device for damping the kinetic energy of movable cabinet components, which has a first damping element with a first cylinder that has a first piston, which slides lengthwise in it, and at least one more (second) damping element with a second cylinder that has a second piston, which slides lengthwise in it. Both damping elements are located one behind the other in a serial arrangement and form an integral system. The invention is characterized by the fact that each of the two damping elements are each designed as pneumatic (air) dampers, and a compression chamber and an expansion chamber respectively contain variable volumes; whereby, the damping effects of the damping elements are affected by the guide canals, which control the air distribution and air flow within and between the compression chambers and / or expansion chambers.

Owner:GRASS GMBH

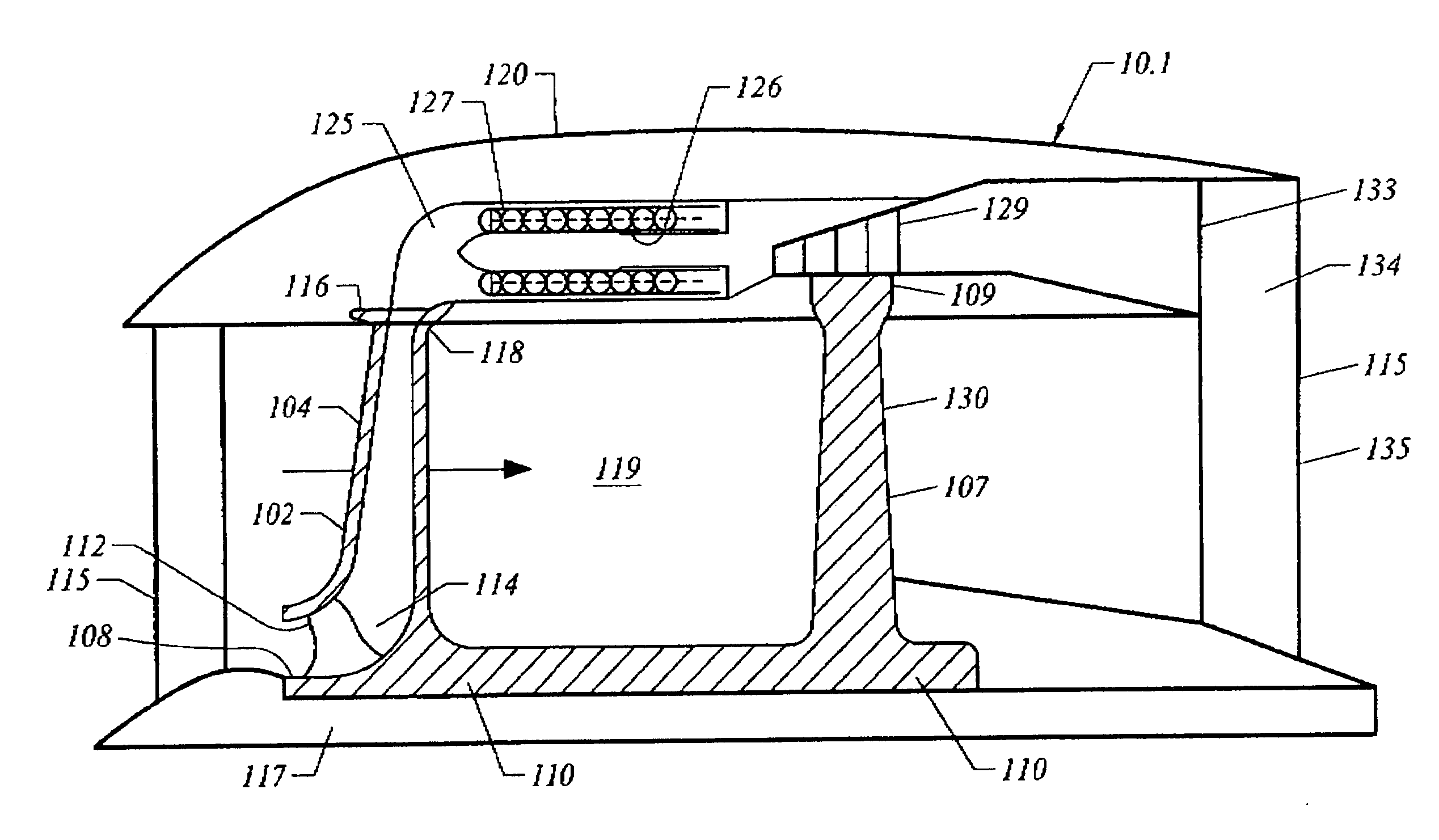

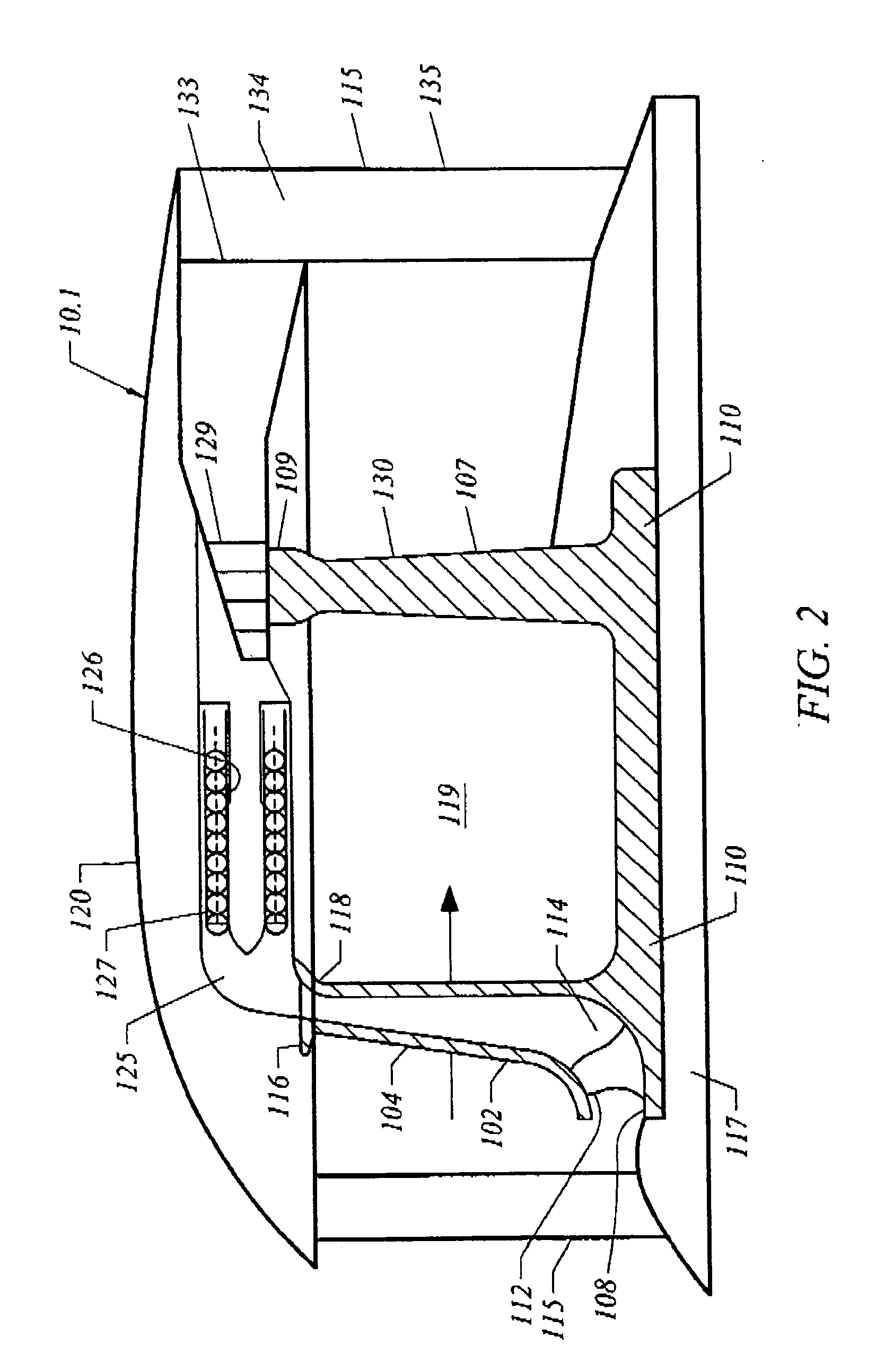

Universal Carnot propulsion systems for turbo rocketry

InactiveUS20060086078A1Maximum efficiencyLarge rangeWorking fluid for enginesGas turbine plantsJet engineCombustion

Turbofan jet engines utilizing the Carnot cycle for improved performance with isothermal compression of combustion air and, in part, isothermal expansion of thermally heated air, the engines having a turbofan compressor rotor with hollow fan blades in a core bypass passage through the engine and an annular, peripheral thermal chamber with staged turbine blades in an expansion chamber where heated gases are supplied to multiple stages to maintain peak temperatures.

Owner:PAUL MARIUS A

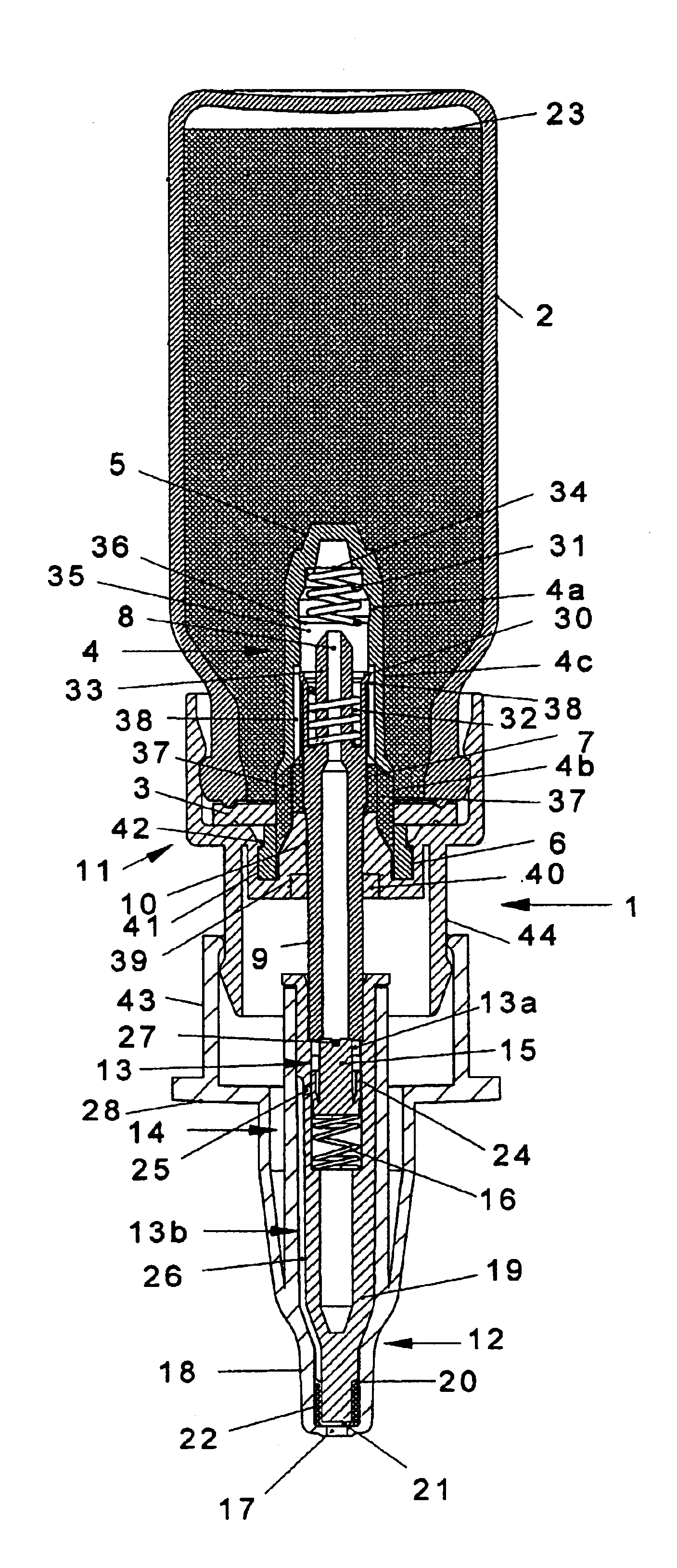

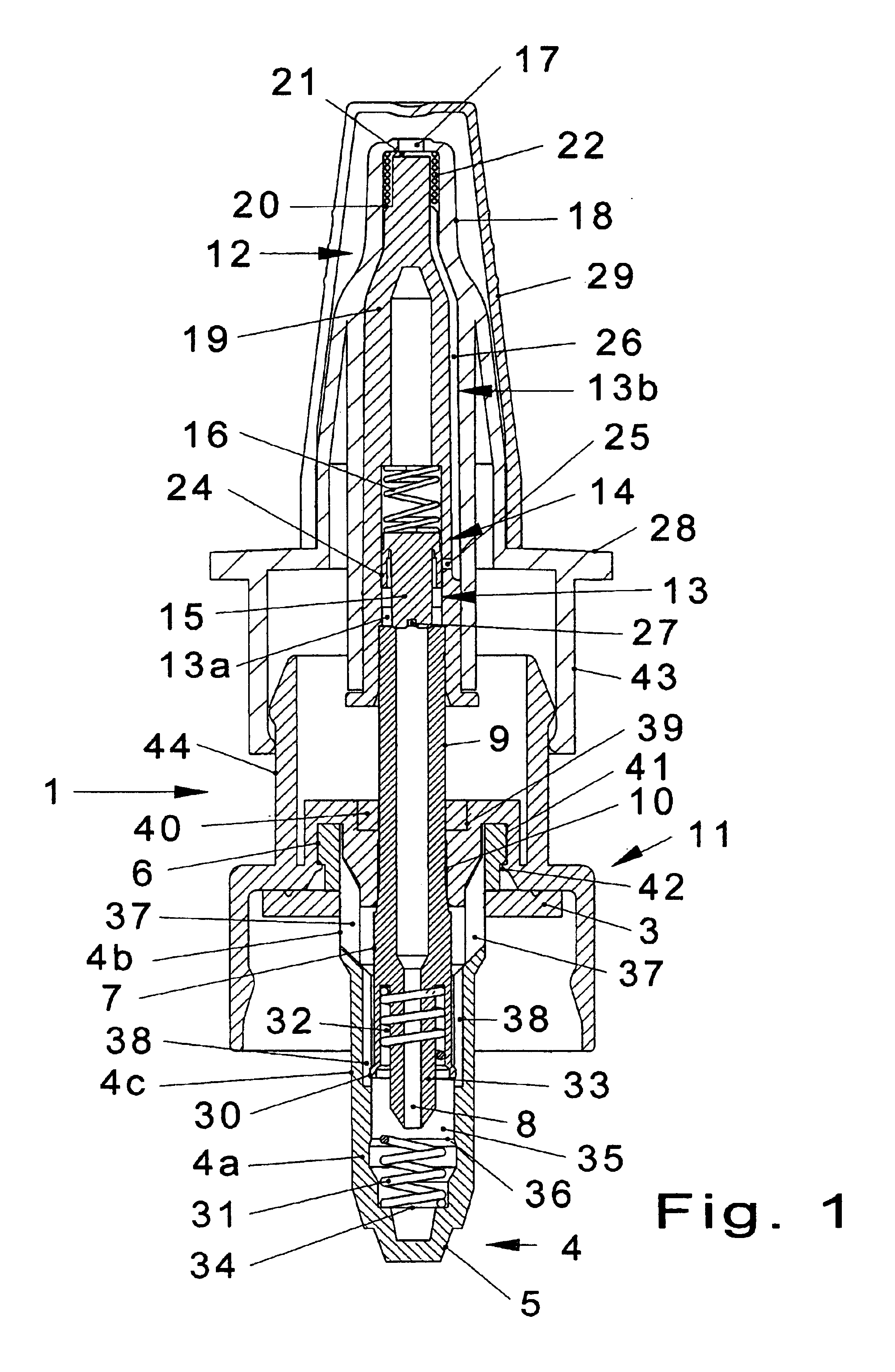

Double-acting pump for ejecting a product from a container

InactiveUS6851583B2Avoid pollutionEasy to assembleClosuresCoin-freed apparatus detailsEngineeringExpansion chamber

A double-acting pump for ejecting a product from a container includes a piston which is axially slideable in a housing and is sealed by the housing. A hollow piston rod extends the axial bore of the piston and is slideable in a closing cap and has an actuating head, wherein, when the actuating head is actuated, the piston builds up a pressure in a pressure chamber against a restoring force of a spring. An outlet duct extends through the actuating head to an outlet opening. When subjected to the restoring force of the spring, the piston releases a passage between the pressure chamber and openings of a second housing portion. A medium which kills germs and bacteria is arranged in an expansion chamber. The dispensing stroke volume of the piston corresponds to the volume of a drop of the liquid.

Owner:AERO PUMP

Process for creating expandable tire chamber

InactiveUS6905564B1Improve gripTelevision system scanning detailsAuxillary traction increasing equipmentRoad surfaceEngineering

A process for producing a tire having an expandable chamber utilized for extending and retracting studs provided in the periphery of the tire. In one embodiment, a non-stick film is strategically positioned between the casing and the tread prior to curing the tread onto the casing. The interface at either side of the film forms the sides of an expandable chamber. The tread side of the chamber is inset and studs are affixed thereto. Expansion of the chamber extends the studs out of the inset and into engagement with a road surface. Alternative processes provide a channel in the tread and the expansion chamber formed in the channel.

Owner:Q TIRES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com