Upright extraction cleaning machine

a cleaning machine and upright technology, applied in the direction of valve operating means/release devices, carpet cleaners, detergent compounding agents, etc., can solve the problems of inconvenient cleaning solution inclusion of detergents and the like in the cleaning solution, the inability to simply convert the current upright extraction cleaning machine, and the inability to fill and empty the fluid supply chamber and the fluid recovery chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

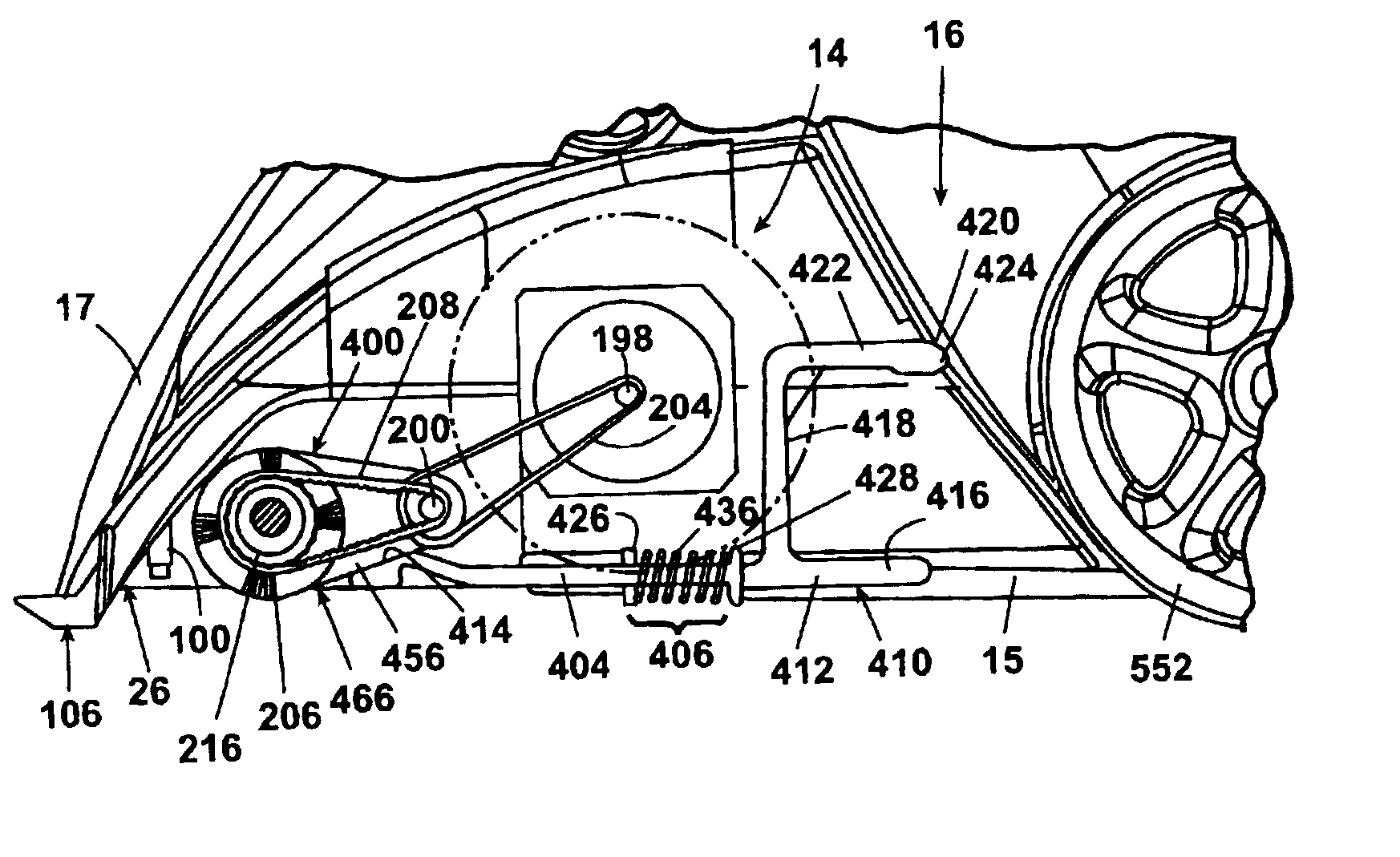

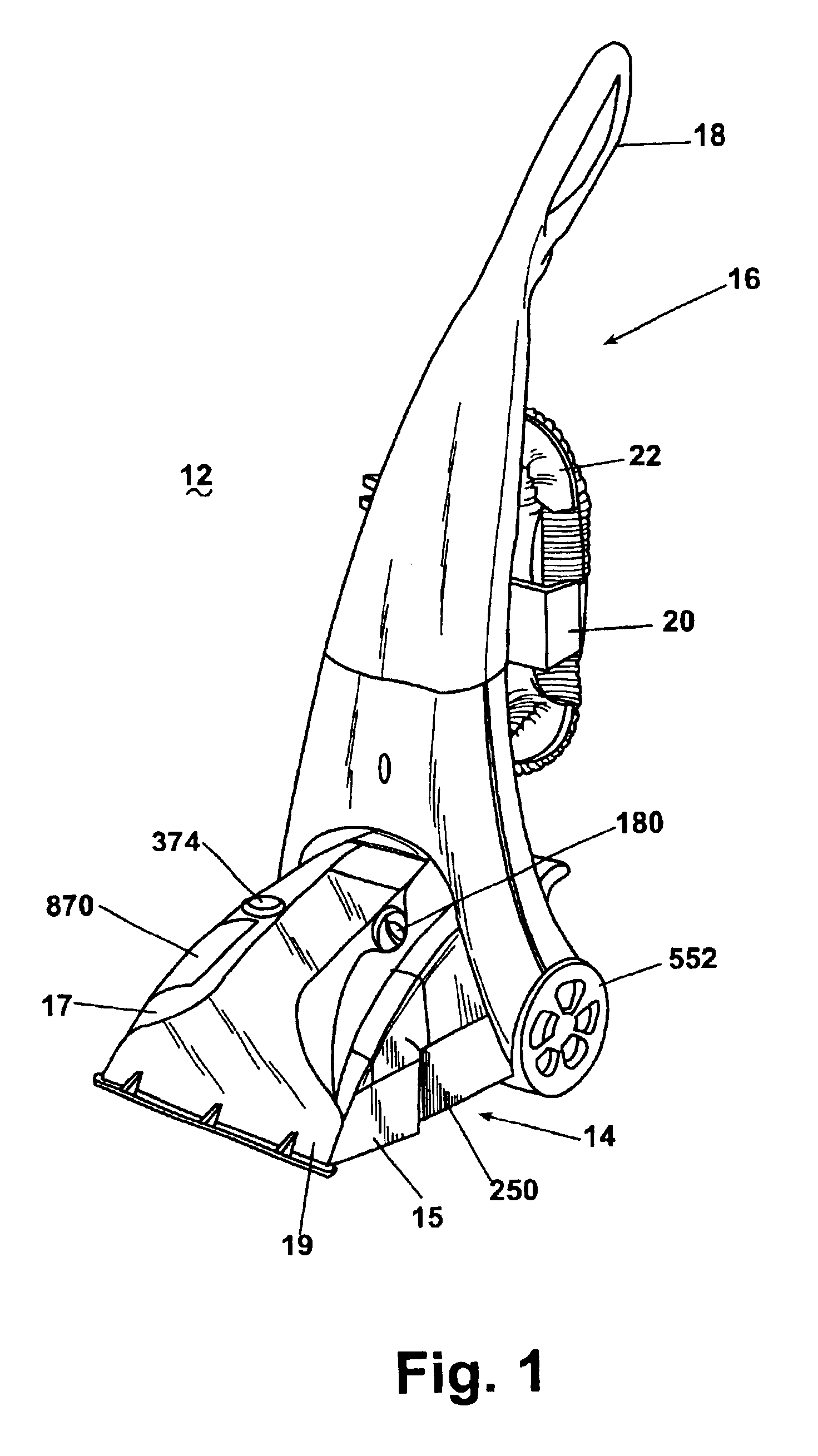

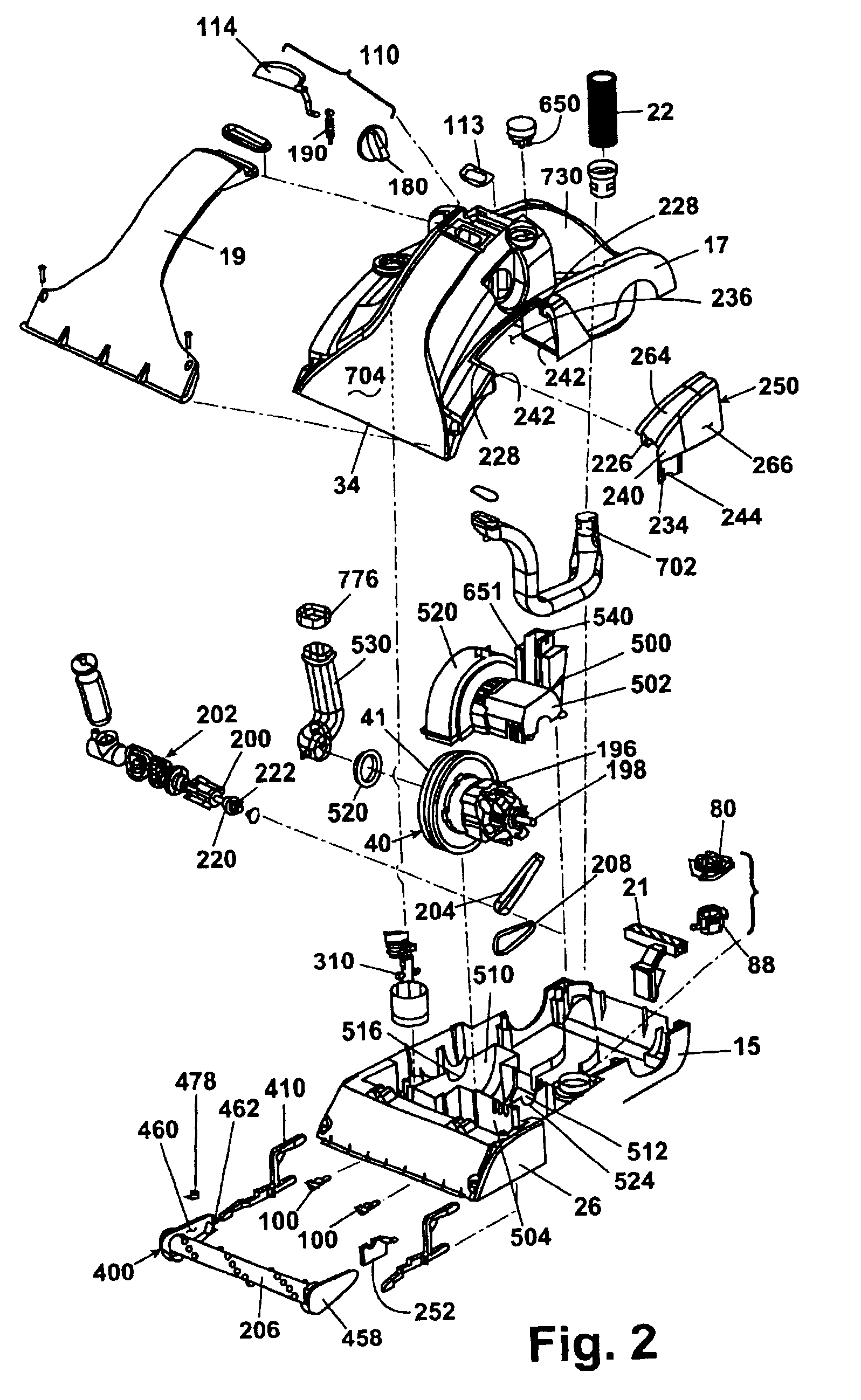

[0047]Referring now to the drawings and to FIG. 1 in particular, an upright extraction cleaning machine 12 according to the invention is shown. The machine 12 is a portable surface cleaning apparatus including a base module 14 adapted to roll across a surface to be cleaned and an upright handle assembly 16 pivotably mounted to a rear portion of the base module 14.

[0048]As best shown in FIGS. 1-3, the base module 14 includes a lower housing portion 15 and an upper housing portion 17, which together define an interior for housing components and a well 730 for receiving a tank assembly 50. Further, a well 732 in the upper housing portion 17 receives a detergent supply tank 870, as best shown in FIG. 3. The upper housing portion 17 receives a transparent facing 19 for defining a first working air conduit 704 and a suction nozzle 34, which is disposed at a front portion of the base module 14 adjacent the surface being cleaned for recovering fluid therefrom. The handle assembly 16 has a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| surface heights | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com