Patents

Literature

646 results about "Gas expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gas expansion. In reservoir systems with little or no water drive, gas expansion often provides the energy necessary to move hydrocarbons to the wellbore. Free gas in a gas reservoir or in the gas cap of an oil reservoir expands to replace produced hydrocarbons.

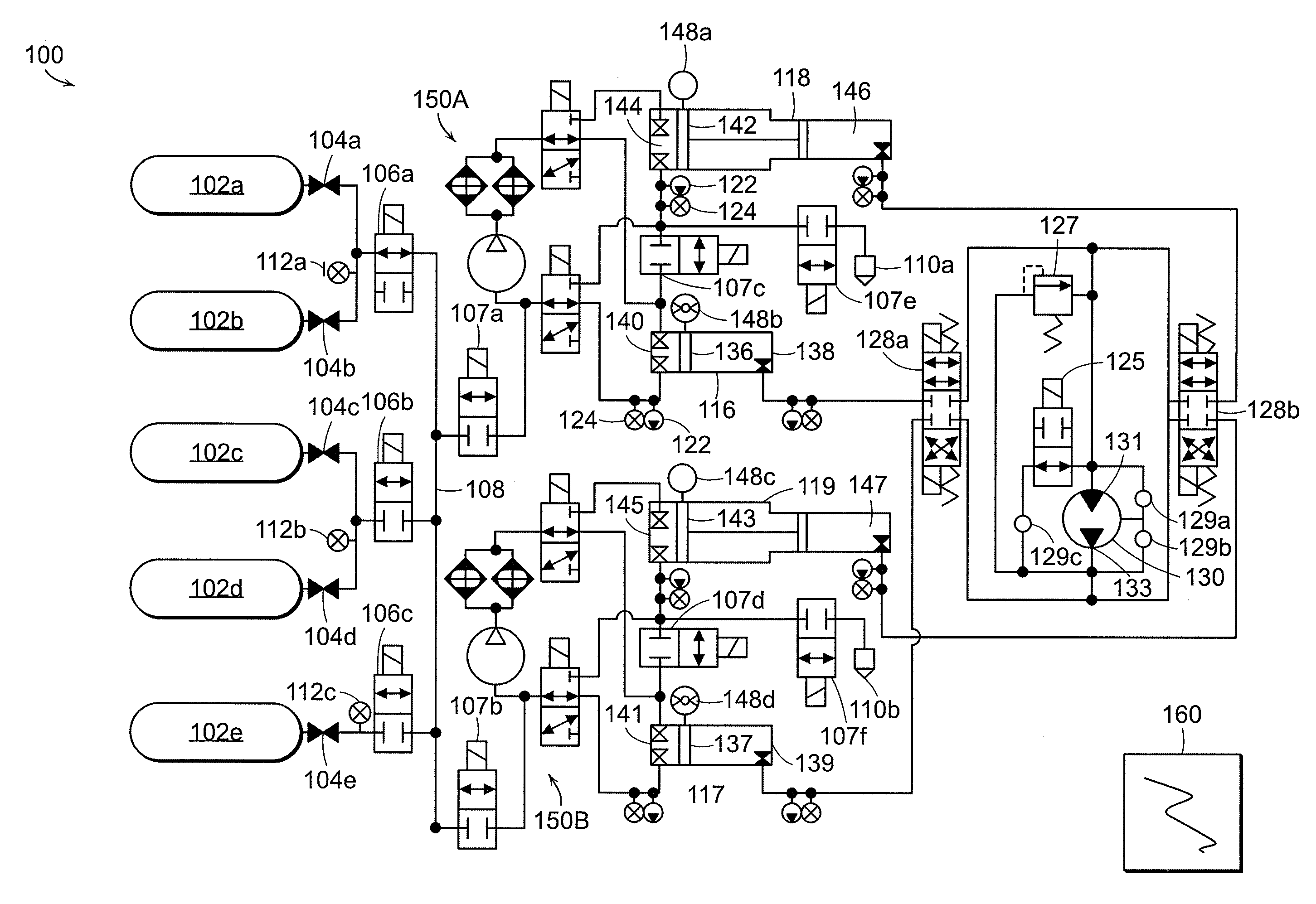

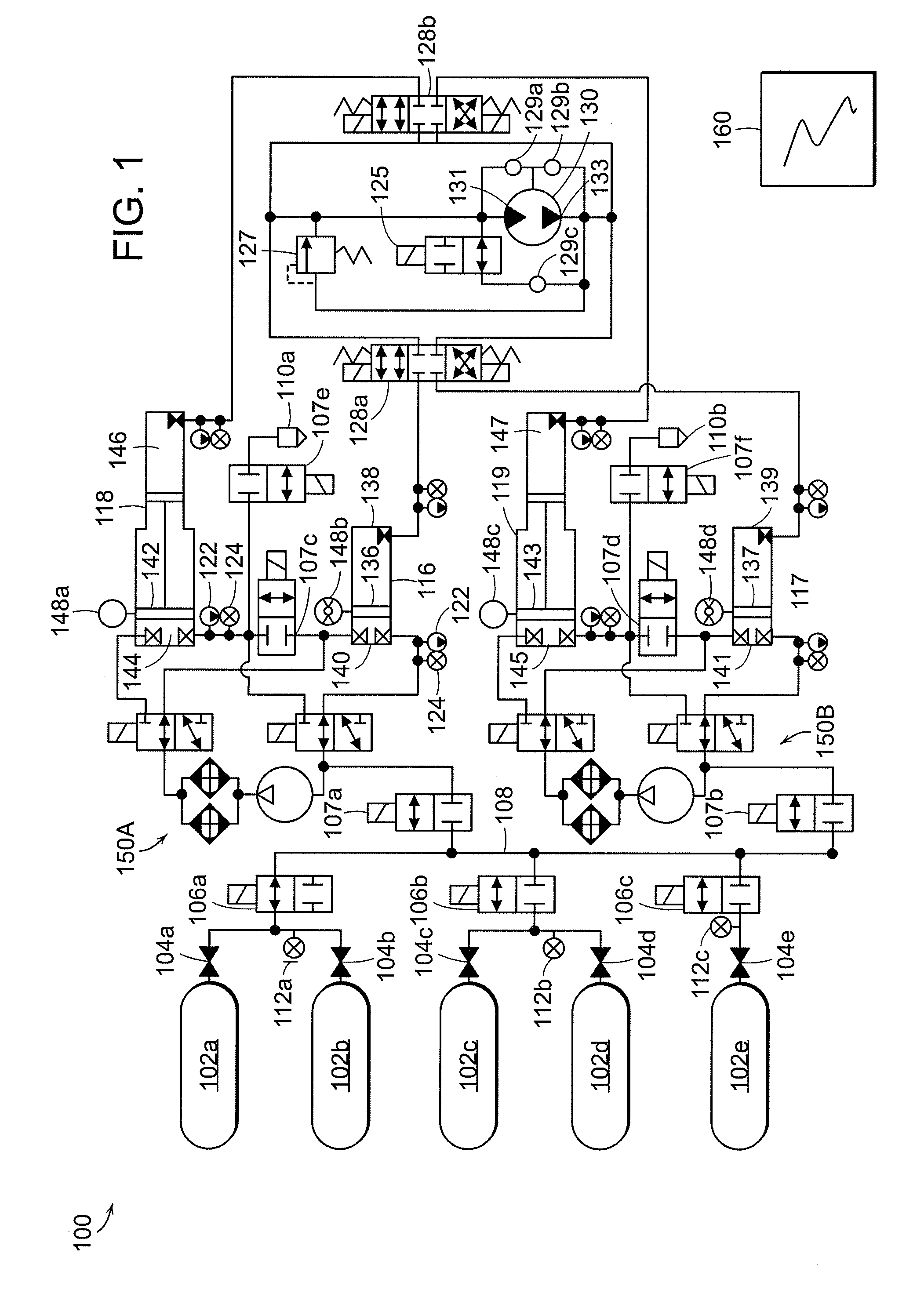

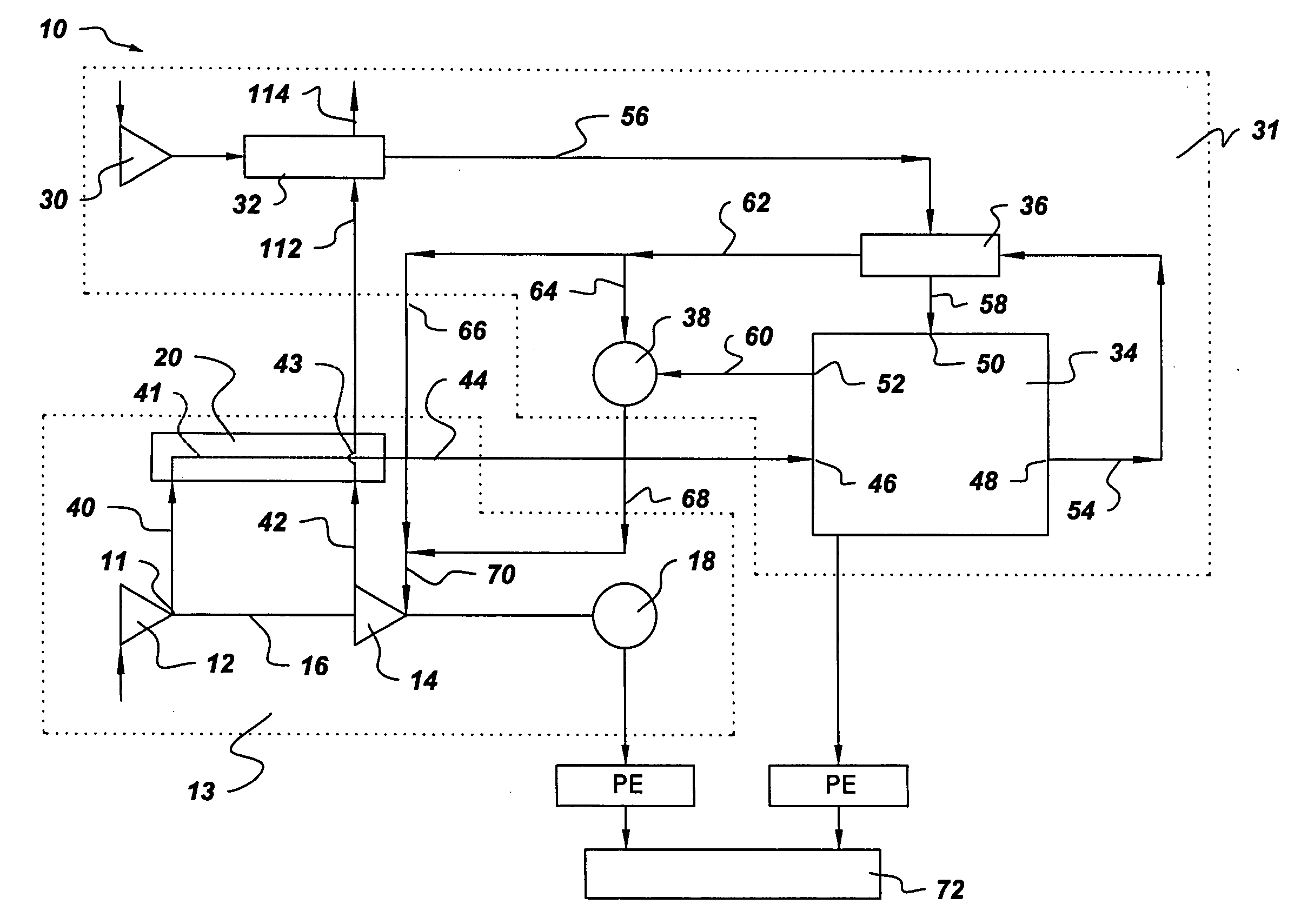

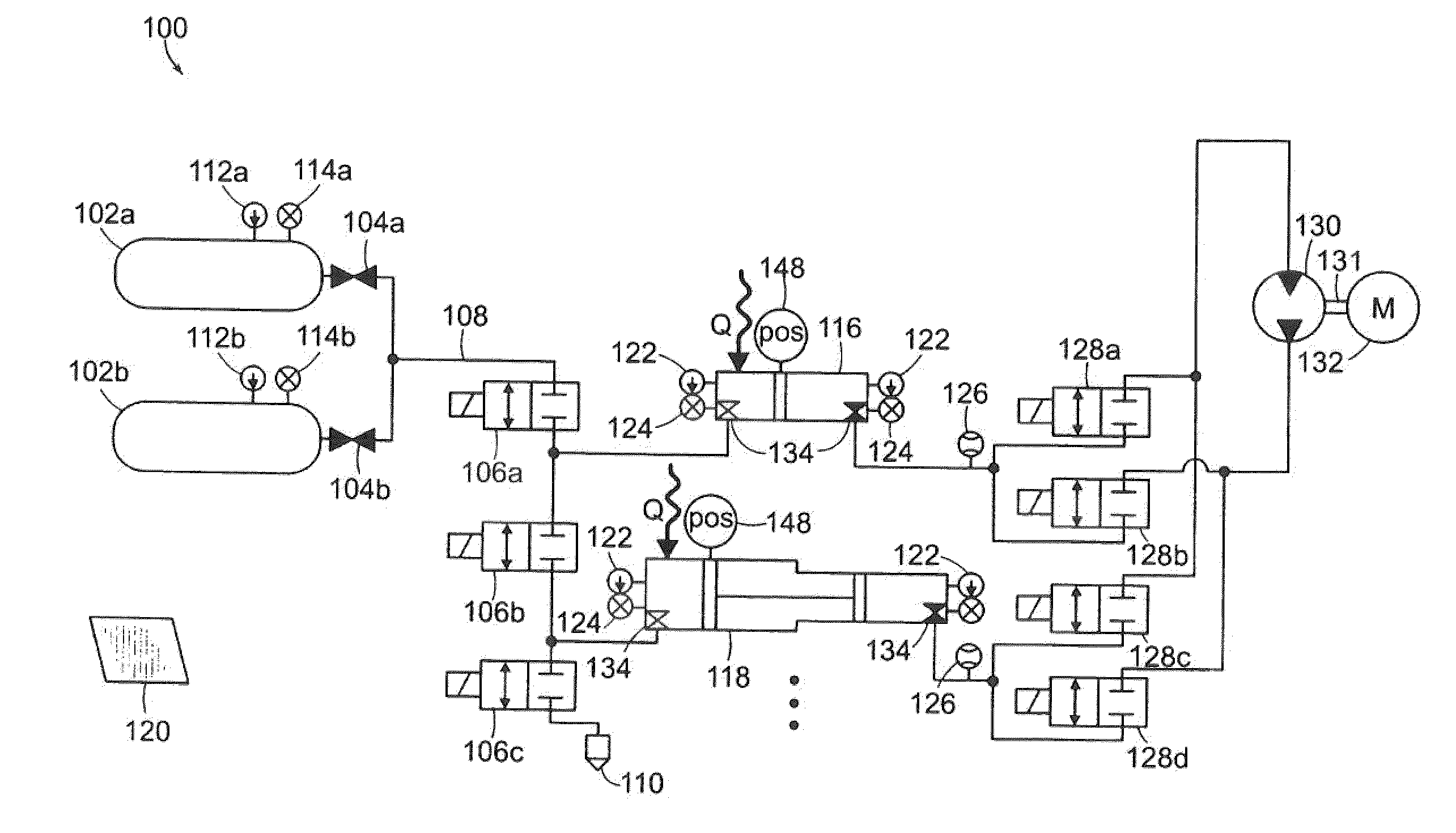

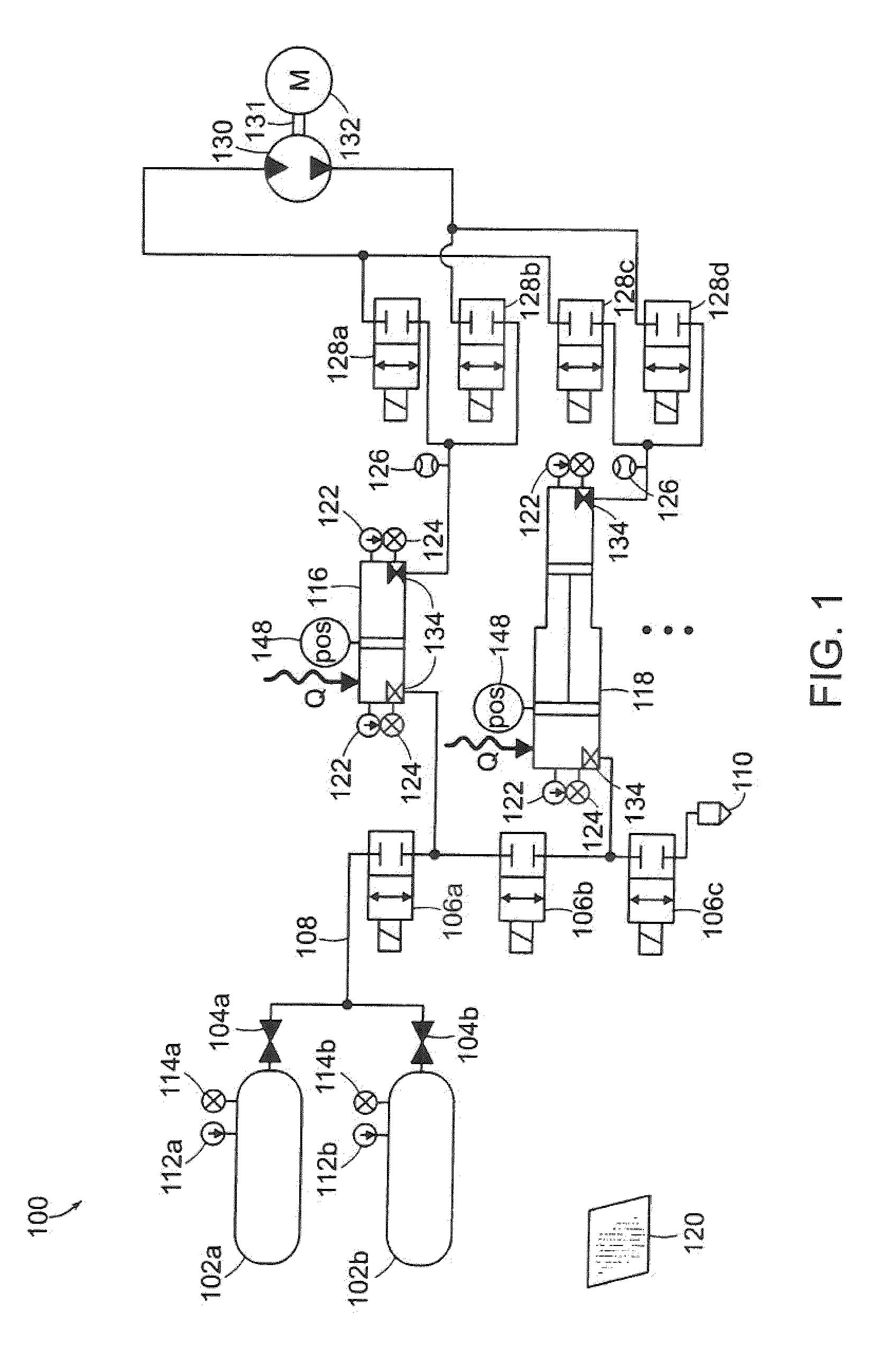

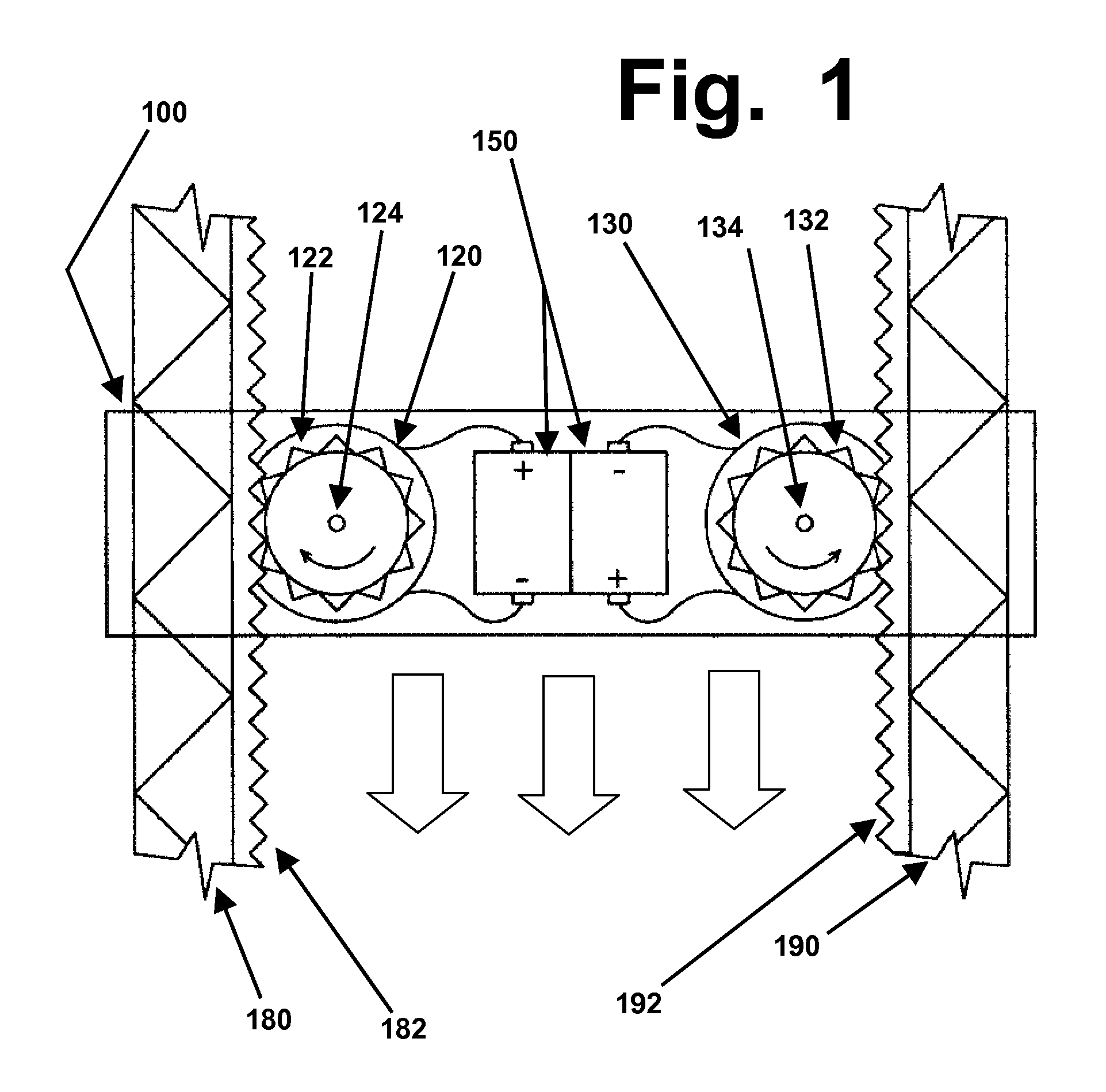

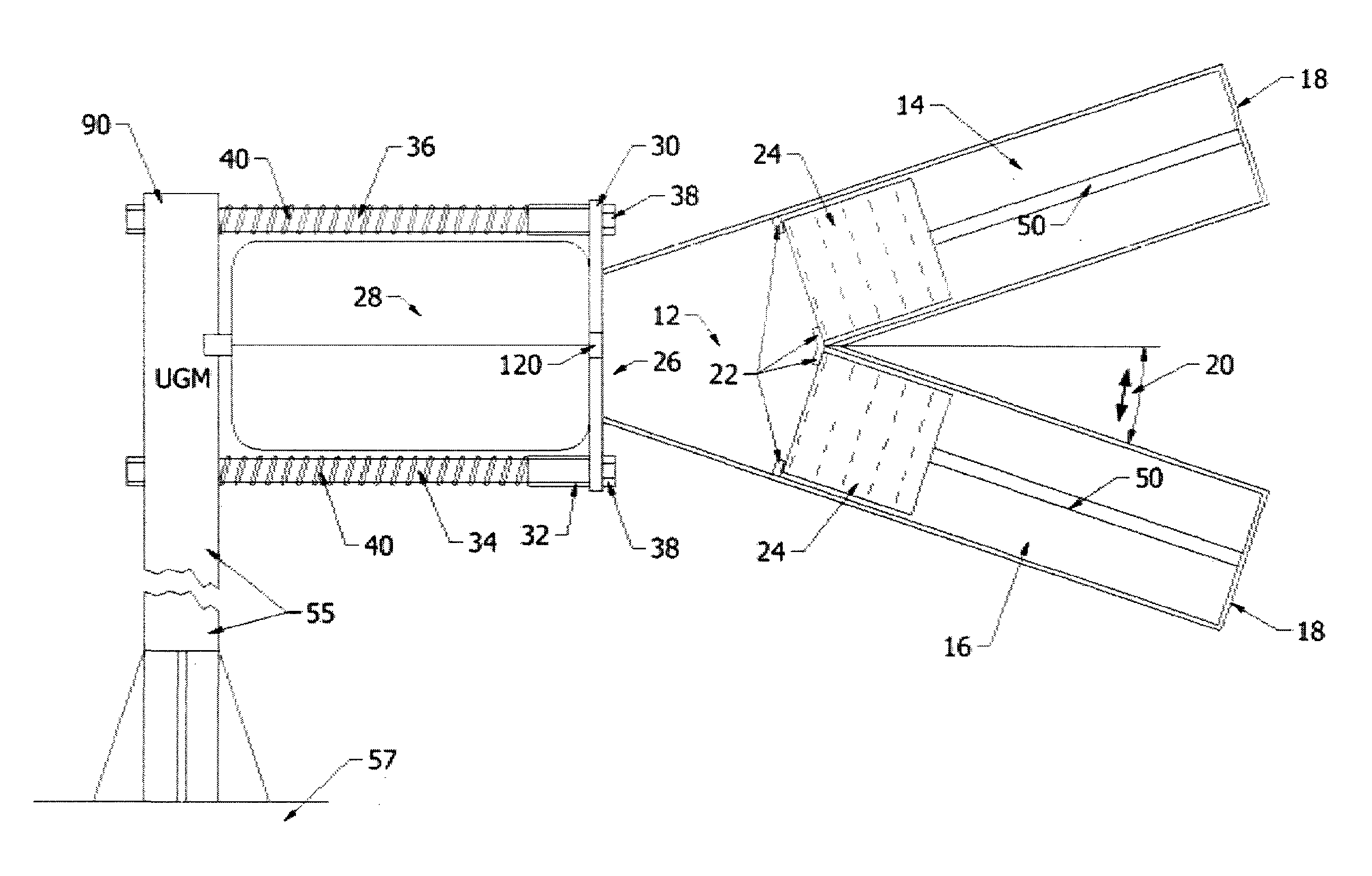

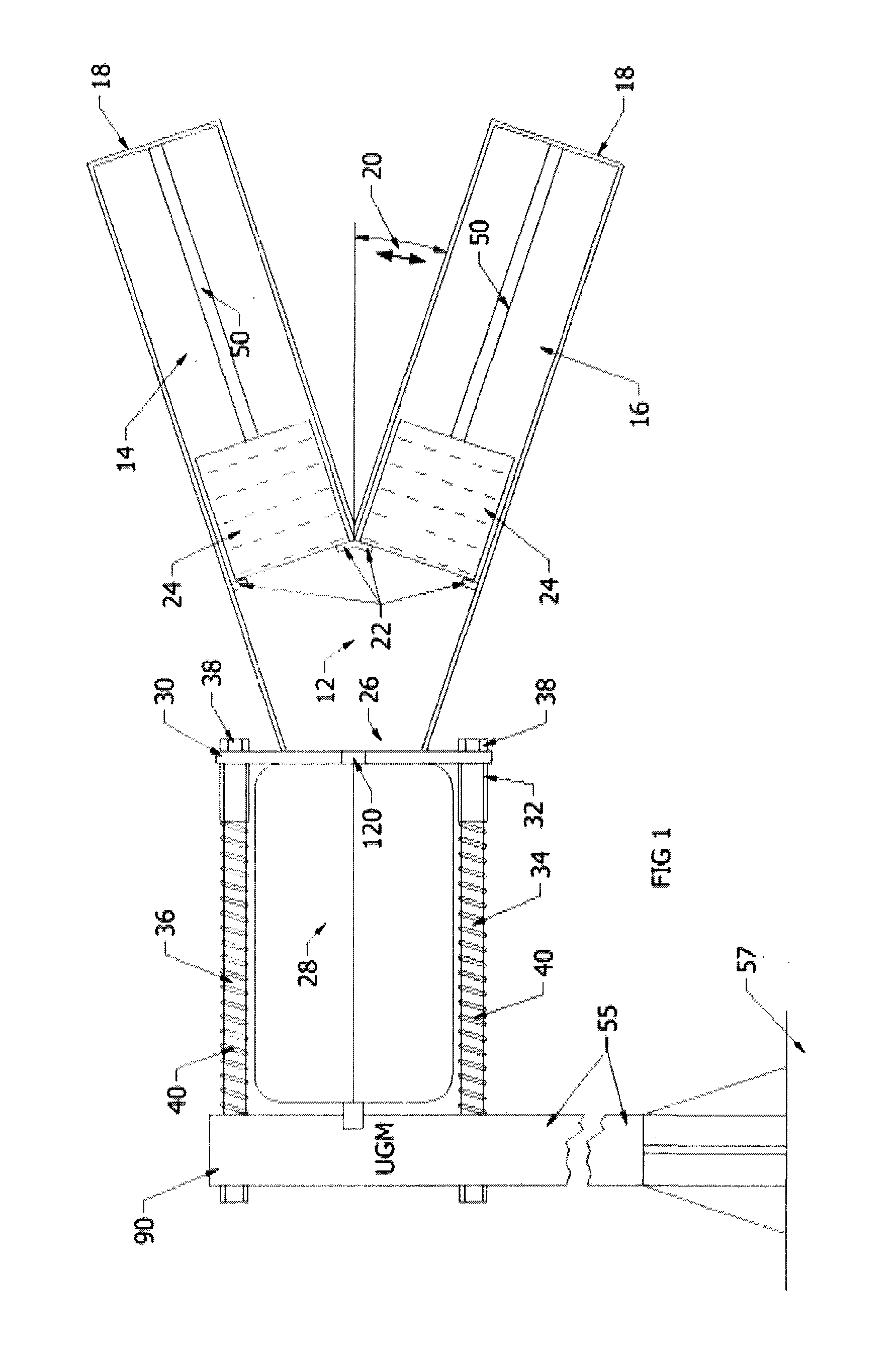

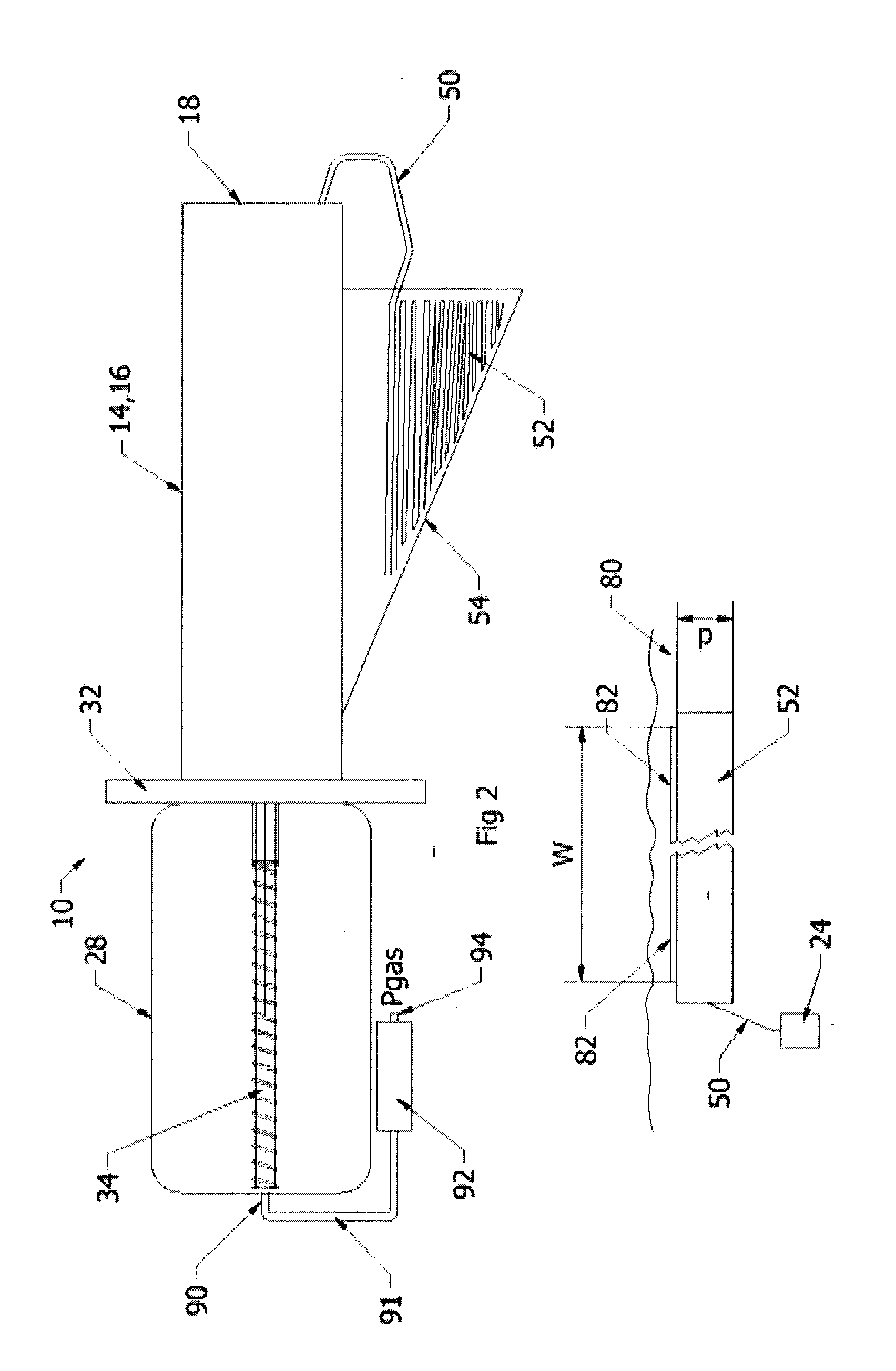

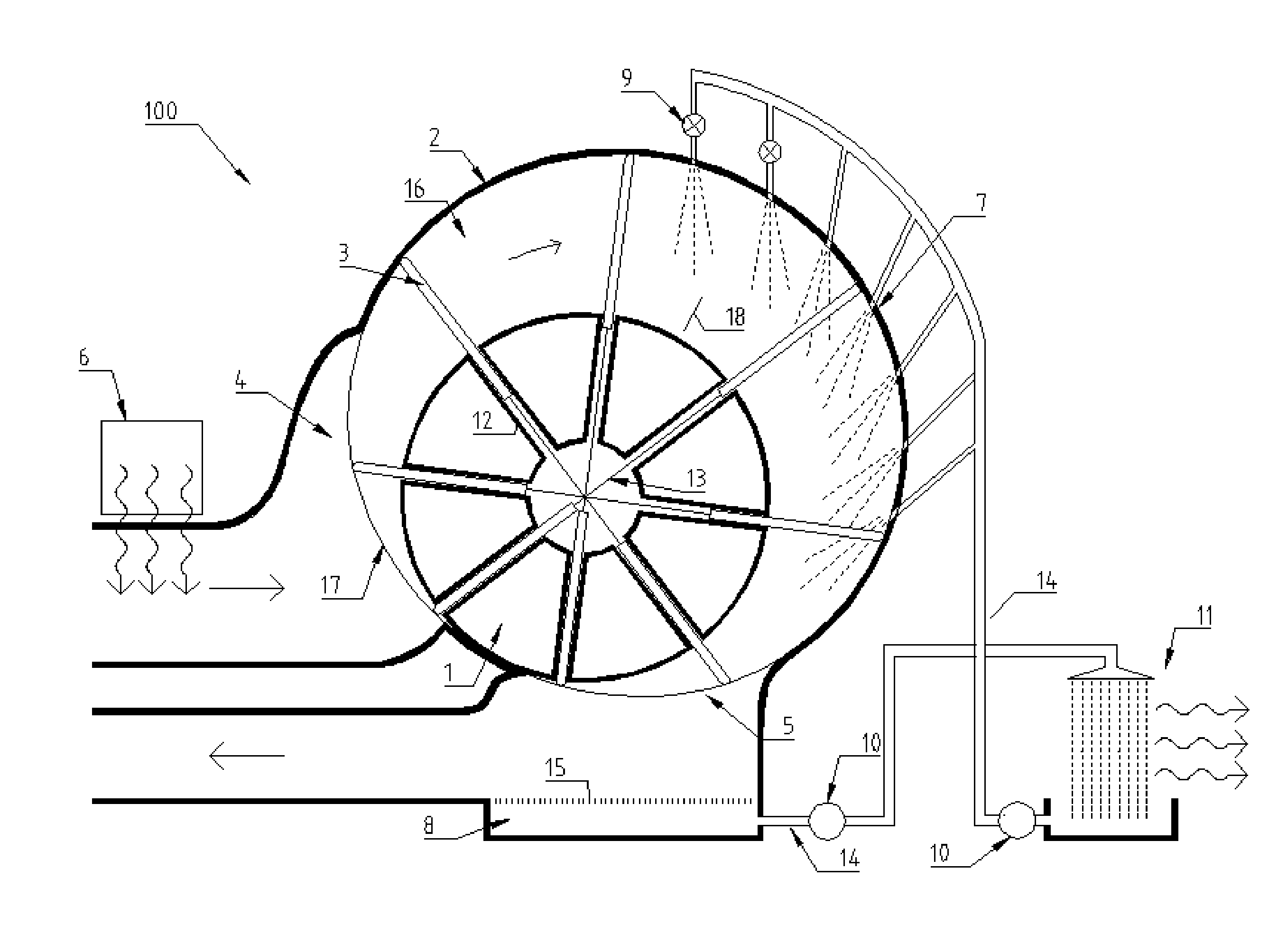

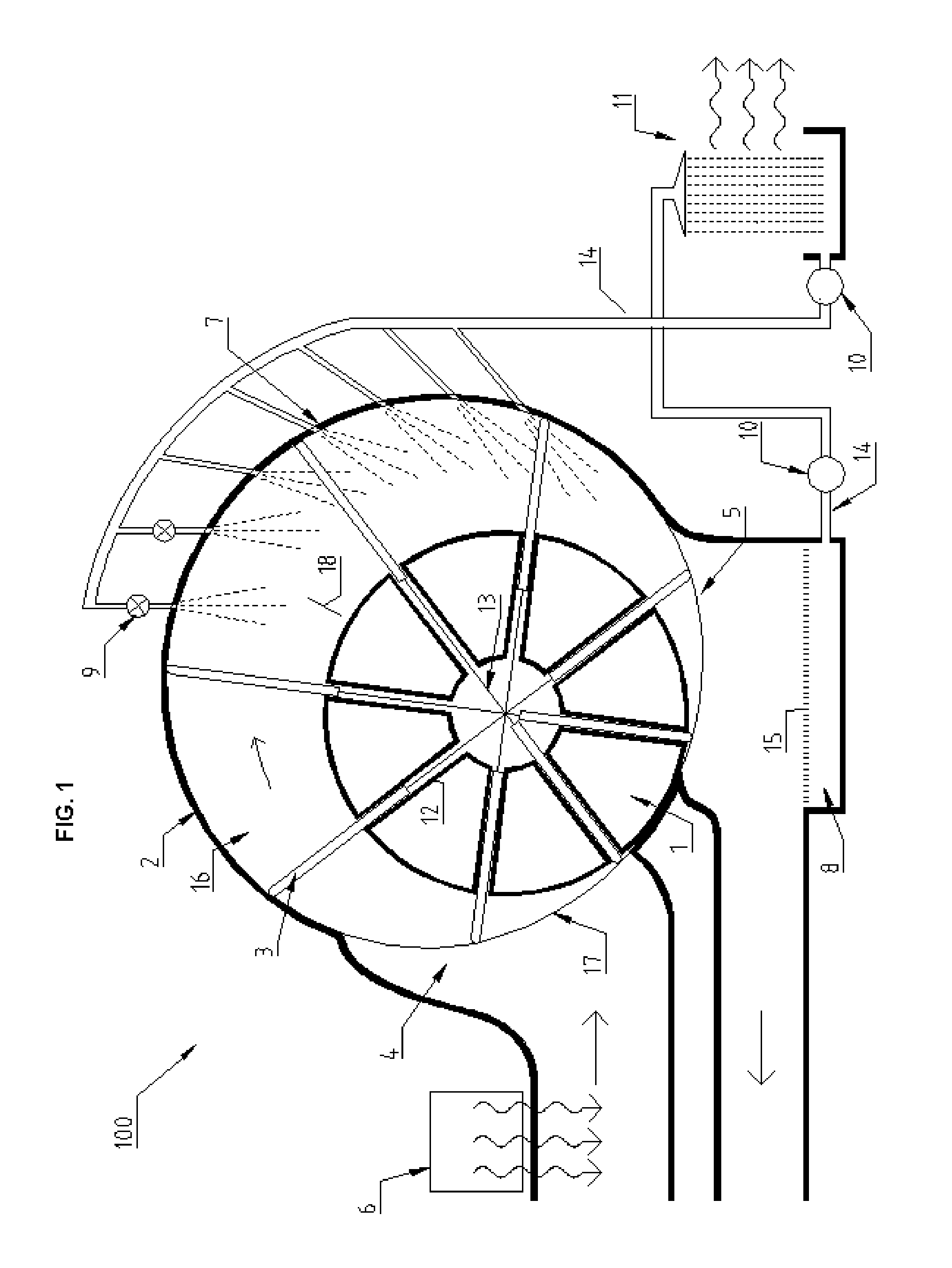

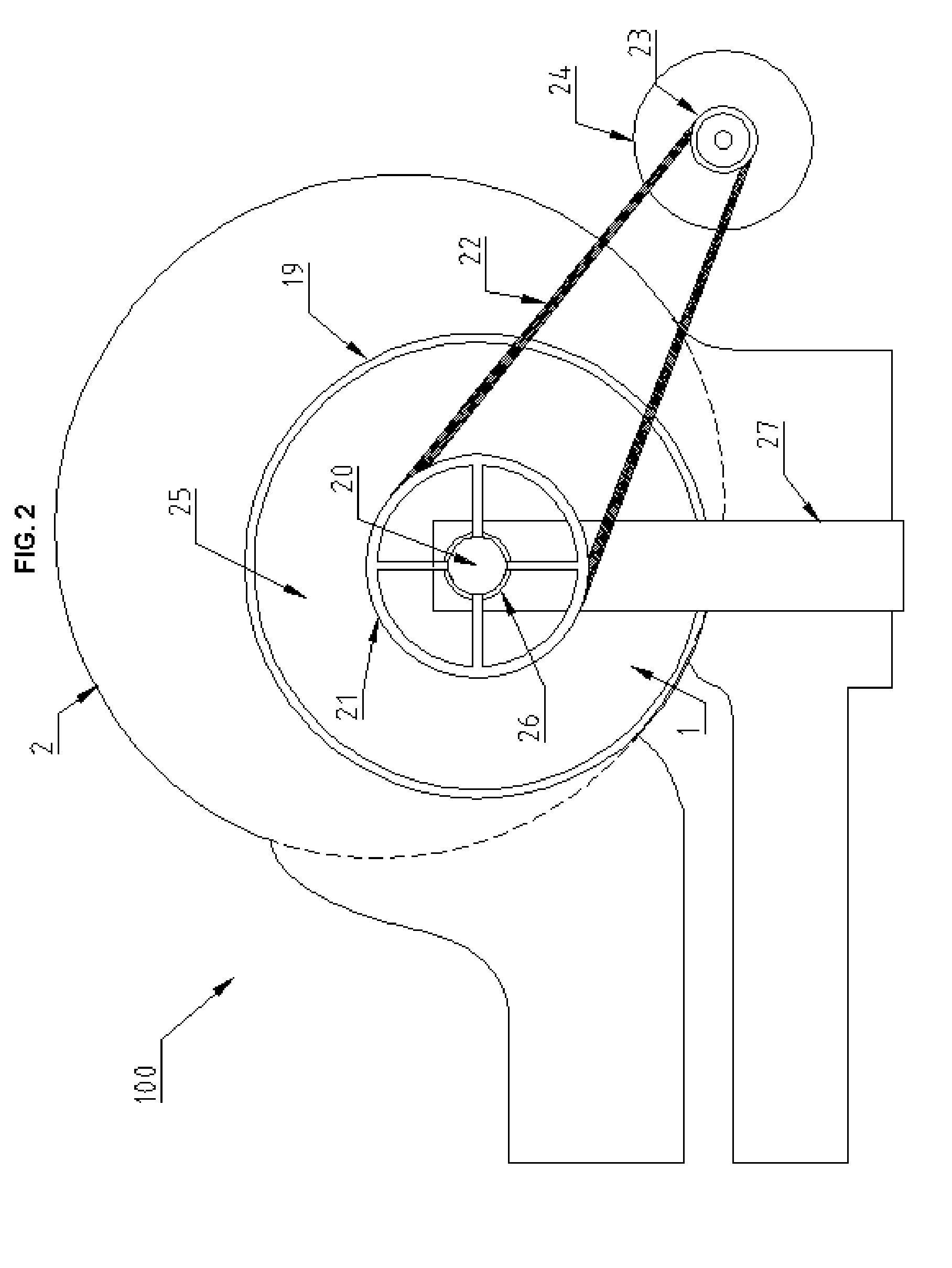

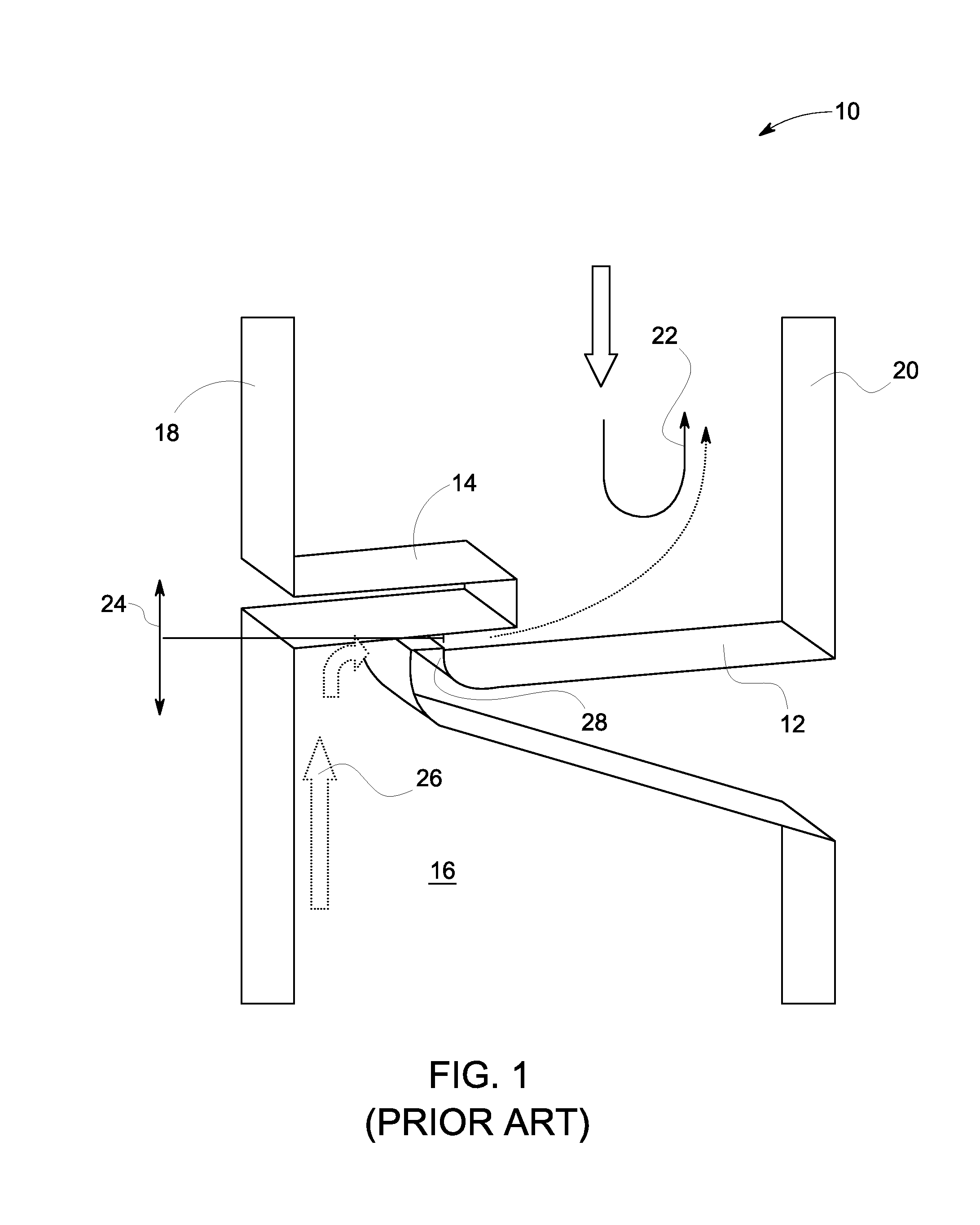

Systems and Methods for Energy Storage and Recovery Using Rapid Isothermal Gas Expansion and Compression

InactiveUS20100089063A1Increase energy densityHigh outputElectrical storage systemInternal combustion piston enginesProduct gasEngineering

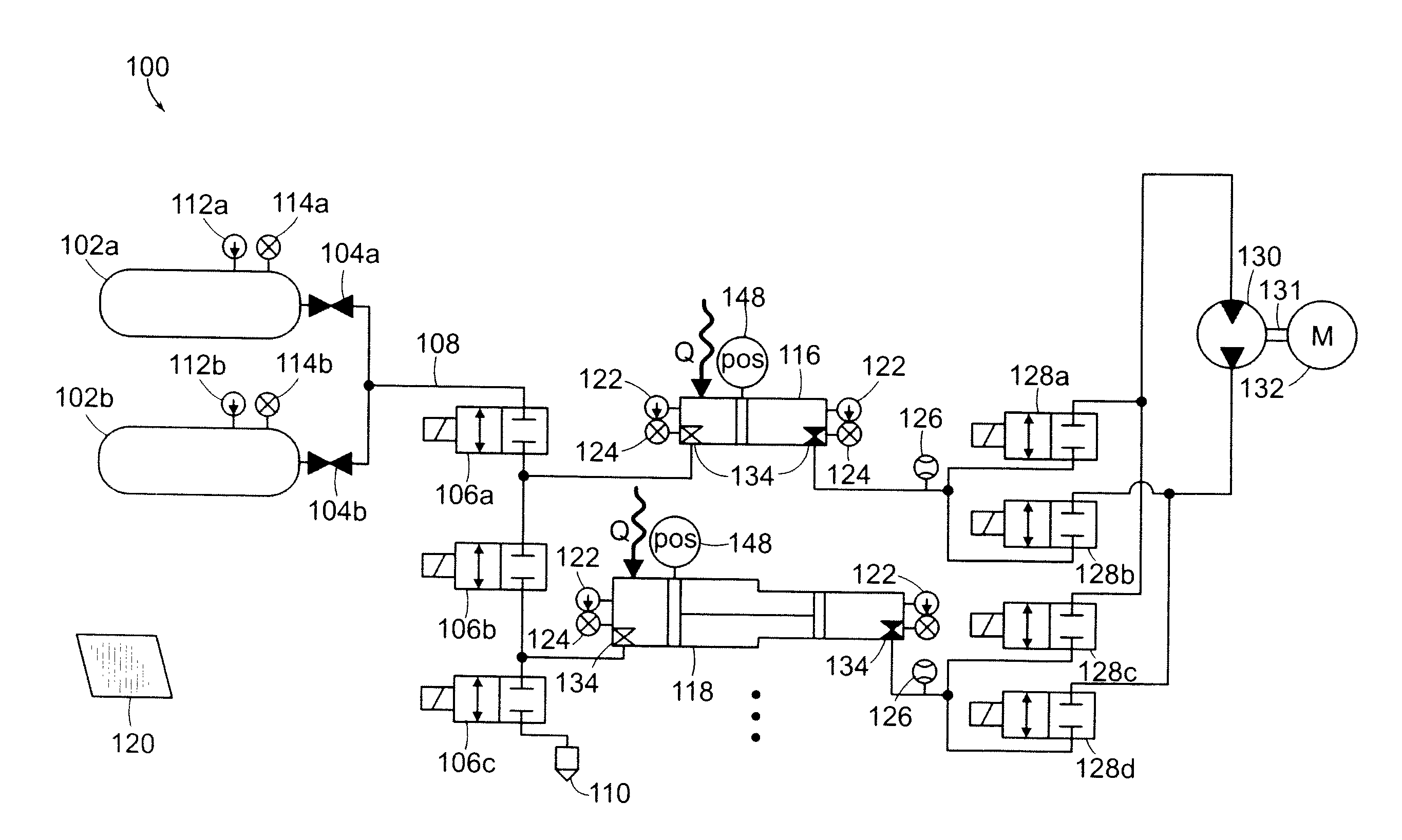

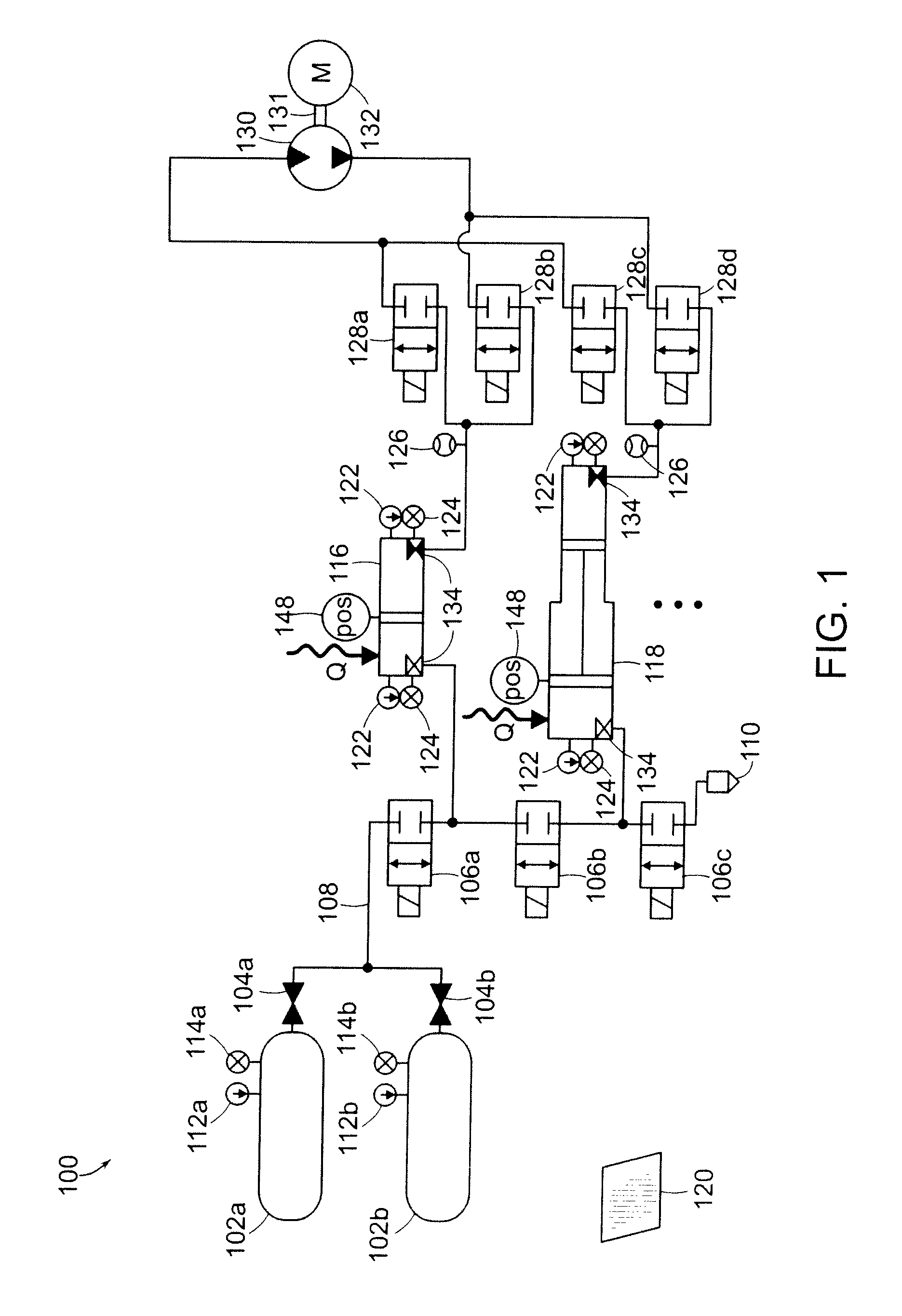

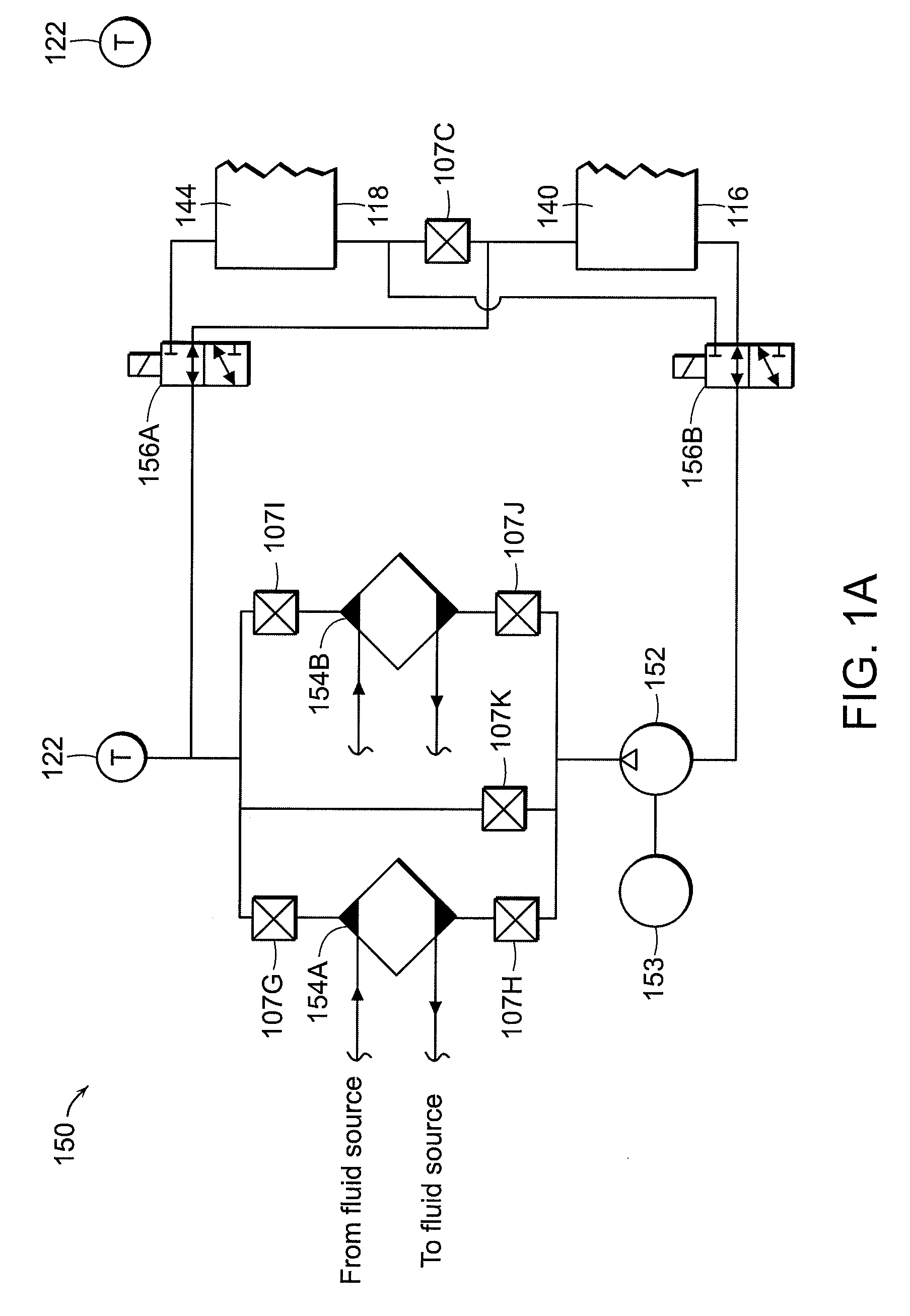

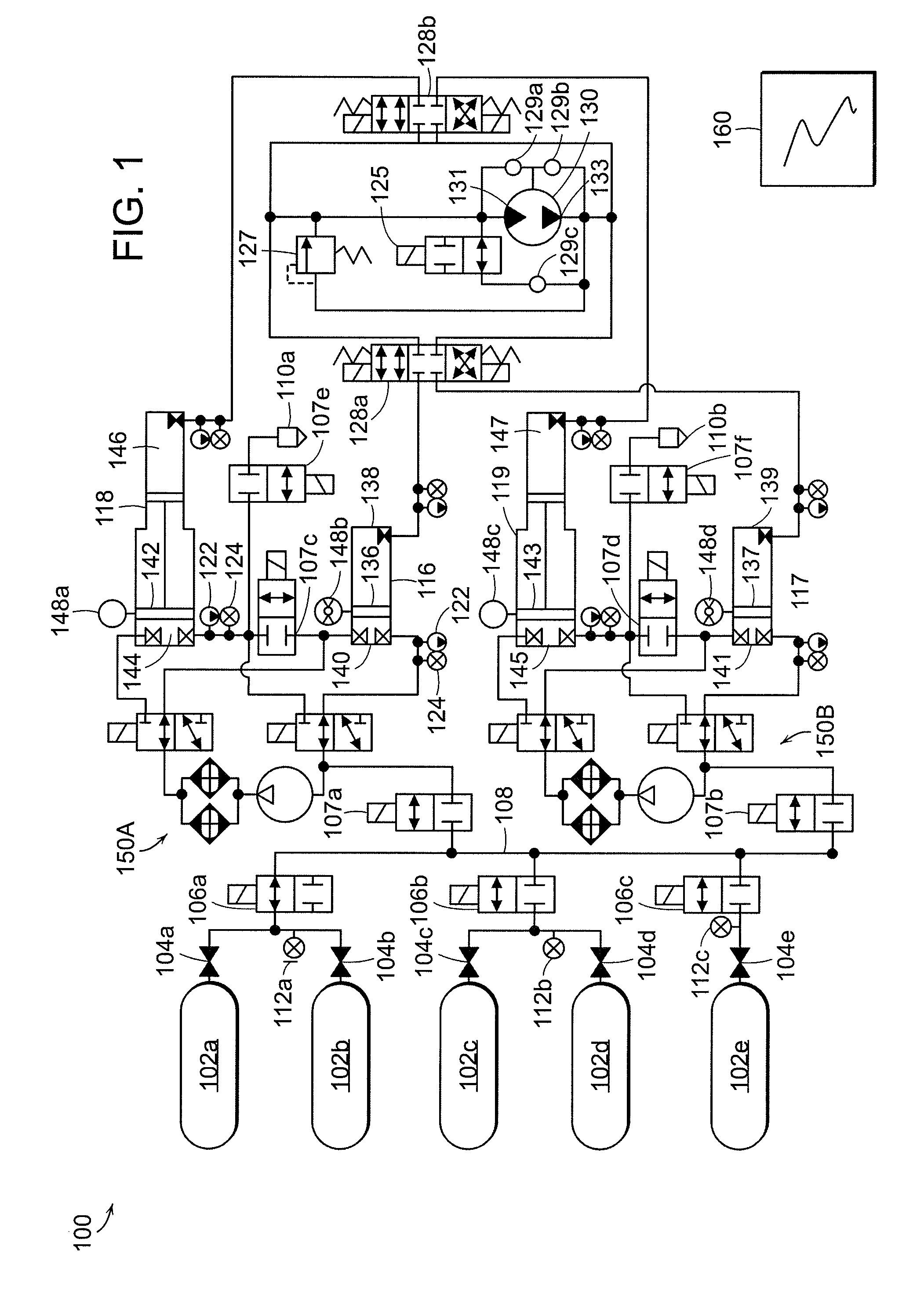

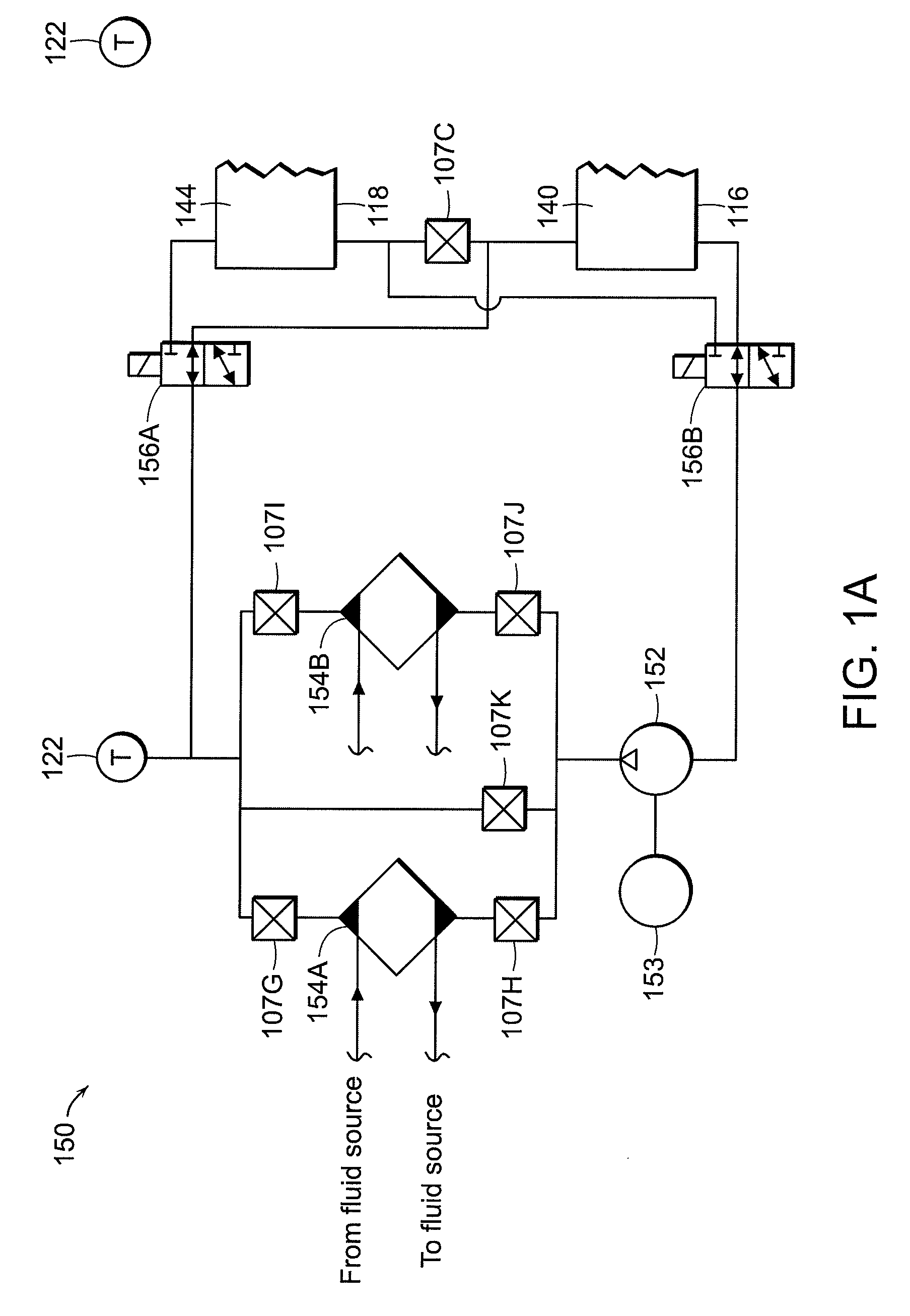

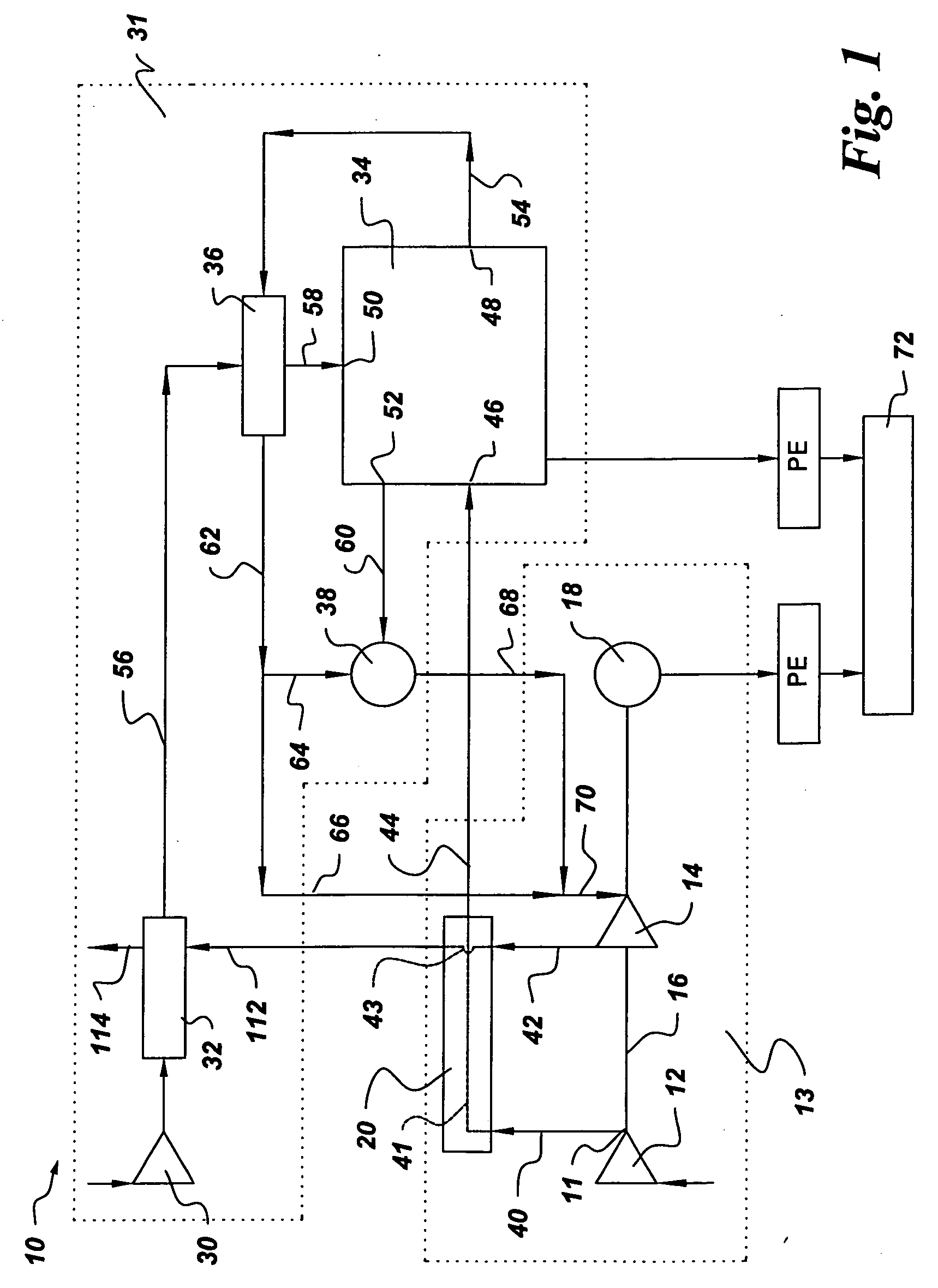

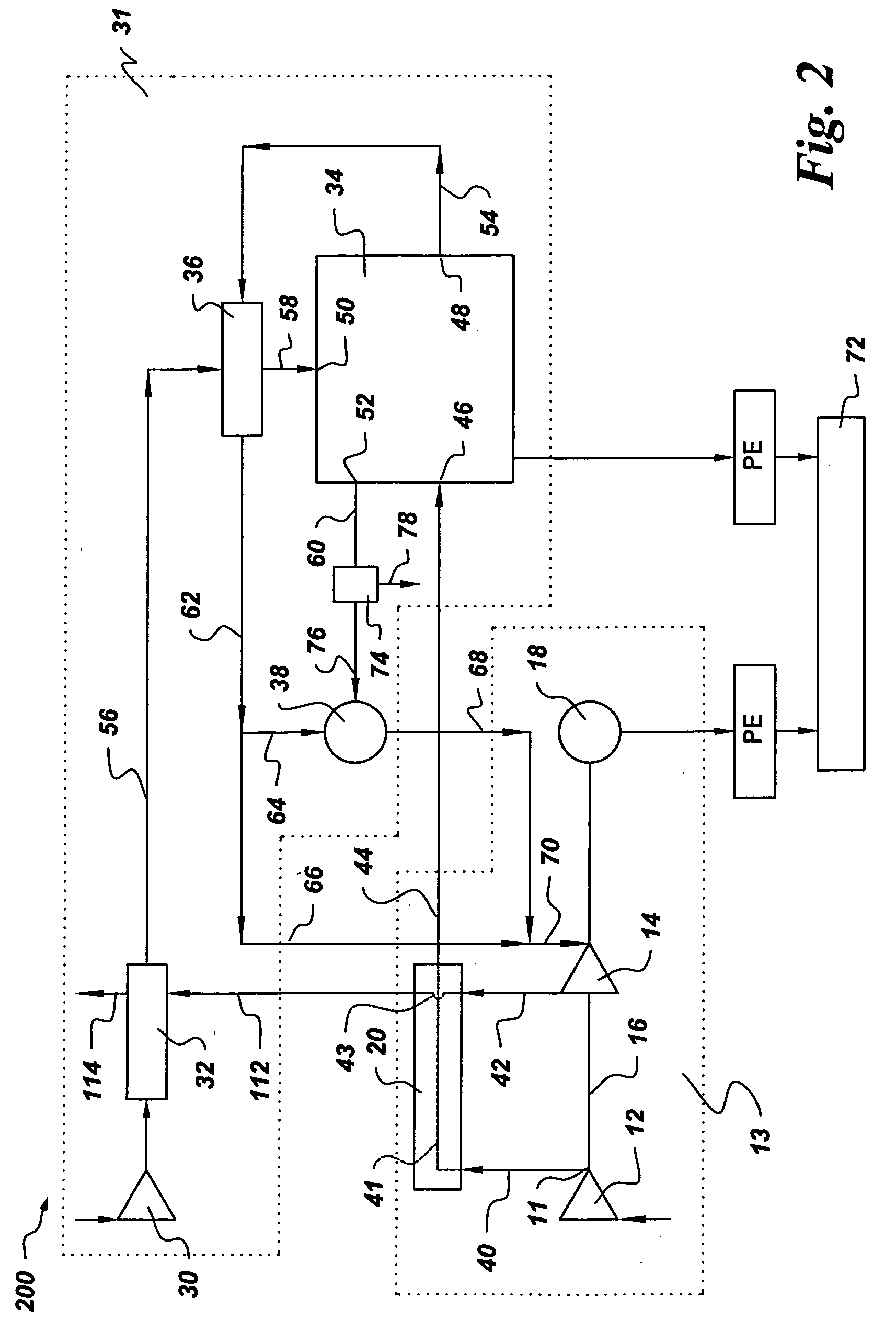

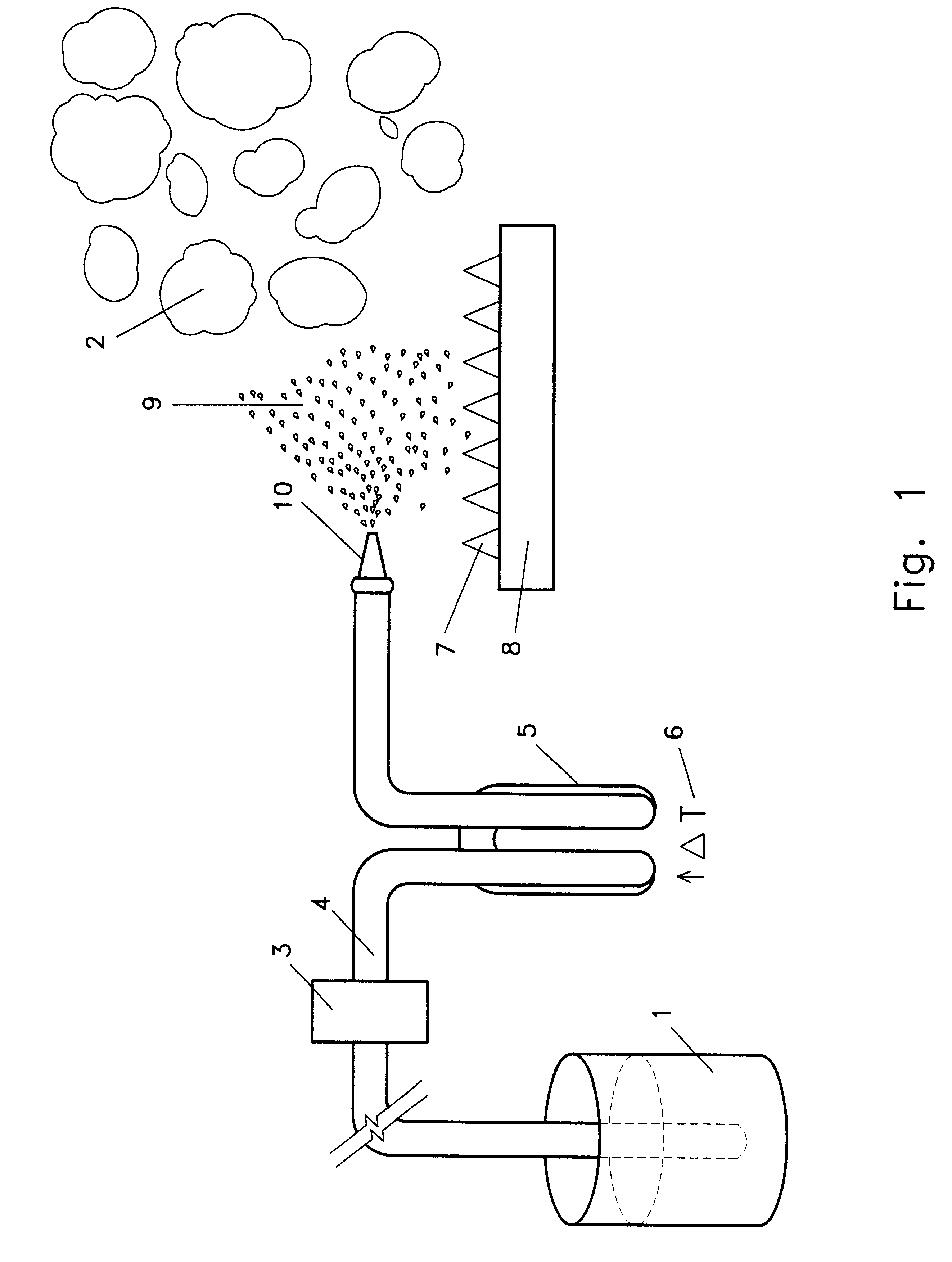

The invention relates to systems and methods for rapidly and isothermally expanding and compressing gas in energy storage and recovery systems that use open-air hydraulic-pneumatic cylinder assemblies, such as an accumulator and an intensifier in communication with a high-pressure gas storage reservoir on a gas-side of the circuits and a combination fluid motor / pump, coupled to a combination electric generator / motor on the fluid side of the circuits. The systems use heat transfer subsystems in communication with at least one of the cylinder assemblies or reservoir to thermally condition the gas being expanded or compressed.

Owner:SUSTAINX

Isothermal reciprocating machines

InactiveUS20060248886A1High materialIncrease heating capacityPositive displacement pump componentsMulti-stage pumpsWorking fluidGas compressor

A reciprocating gas compressor is described operating according to an extended cycle of 4,6 or more strokes, wherein the first two strokes are sequential induction and compression strokes using a low pressure gas as working fluid and compressing it to a high pressure gas, and the remaining strokes are pairs of sequential filling and emptying strokes using more of the low pressure gas as heat transfer fluid for transferring heat from inside the gas compressor to outside the gas compressor. The gas compressor also contains an in-cylinder heat regenerator for absorbing heat from the compressed gas and releasing heat to the heat transfer fluid thus achieving near-isothermal compression. Using parallel principles, a reciprocating gas expander is also described for achieving near-isothermal expansion. Also described are reciprocating machines using the near-isothermal gas compressor and near-isothermal gas expander in combination according to the Ericsson heat engine cycle, the Stirling heat engine cycle and the Stirling refrigeration cycle.

Owner:MA THOMAS TSOI HEI

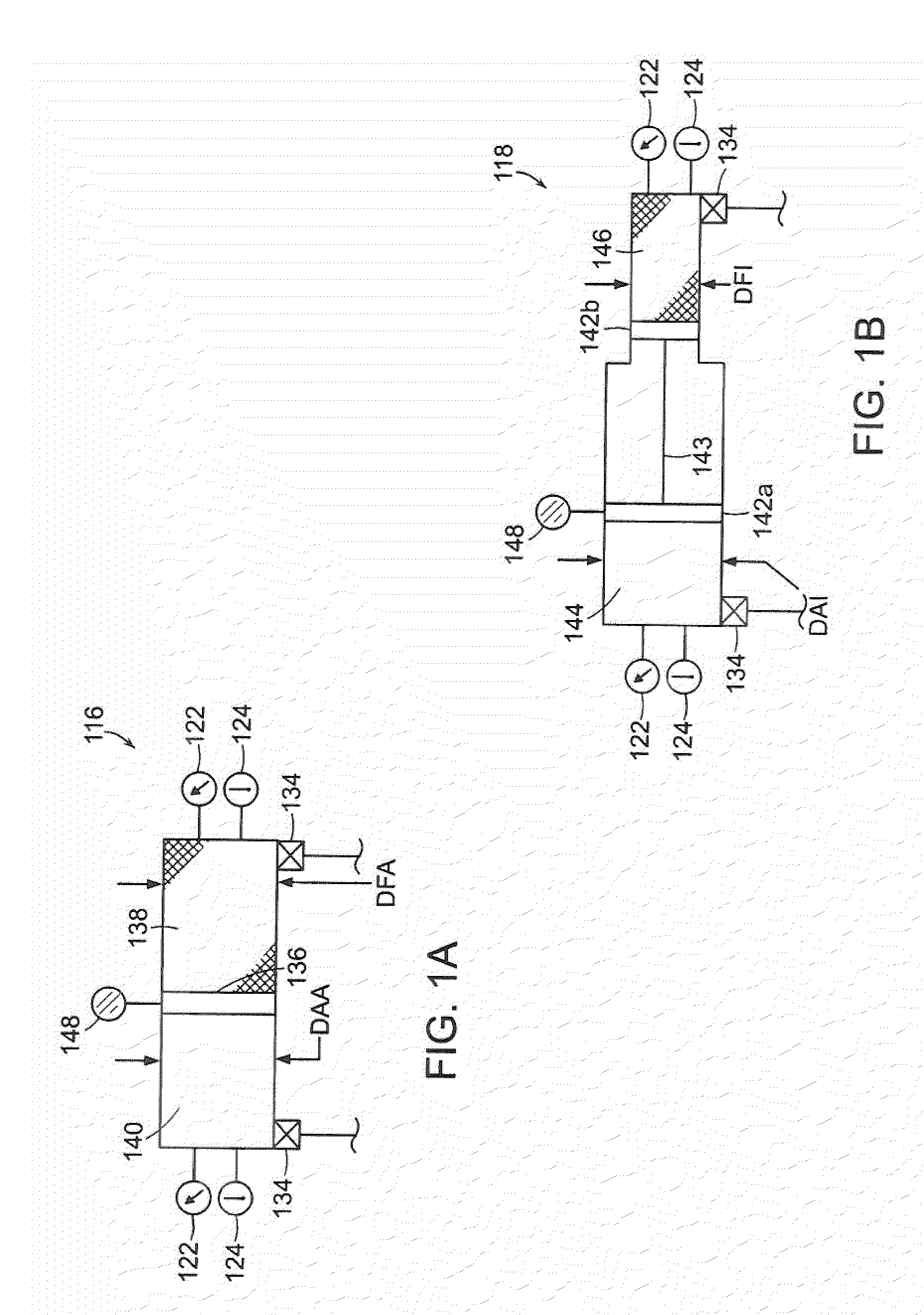

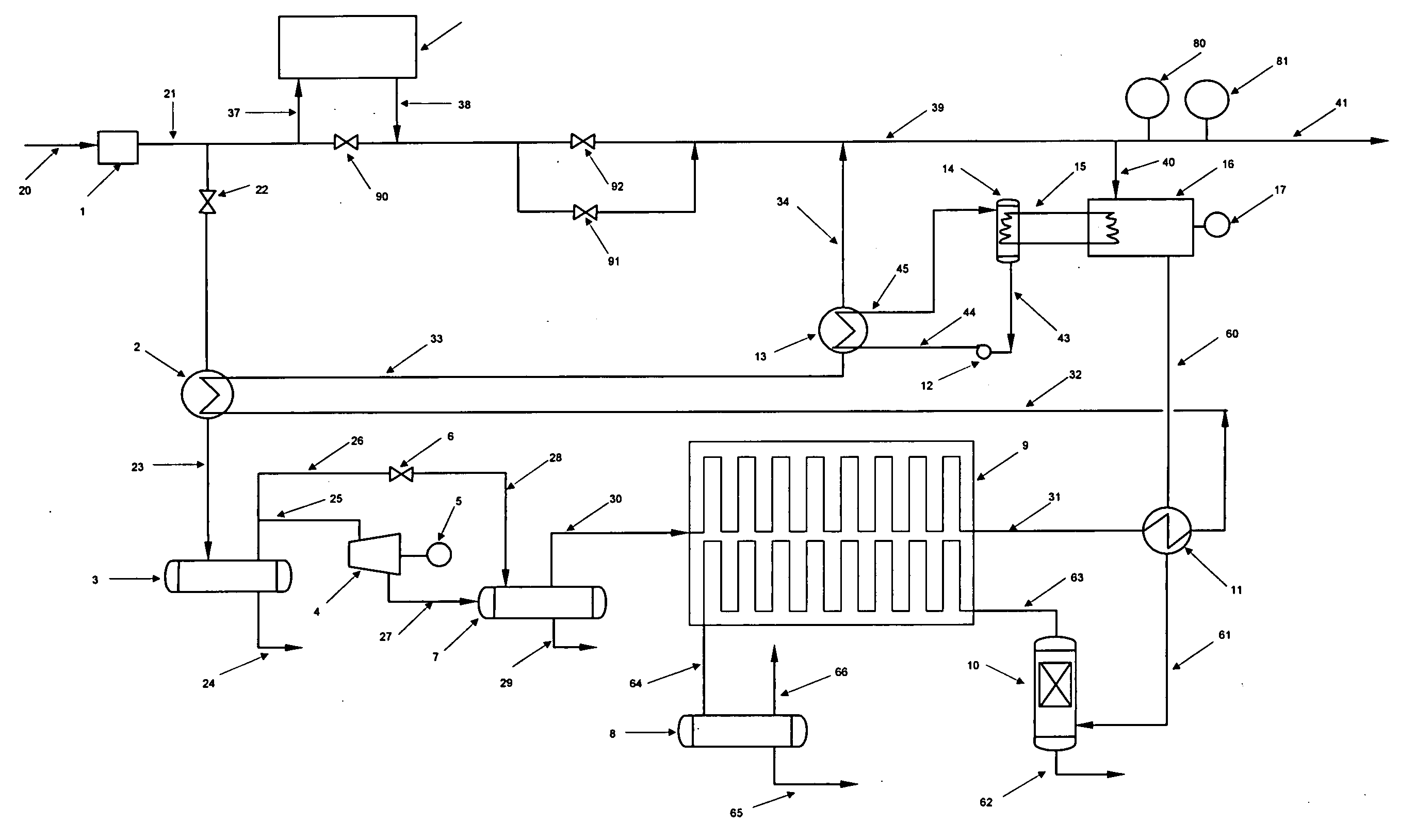

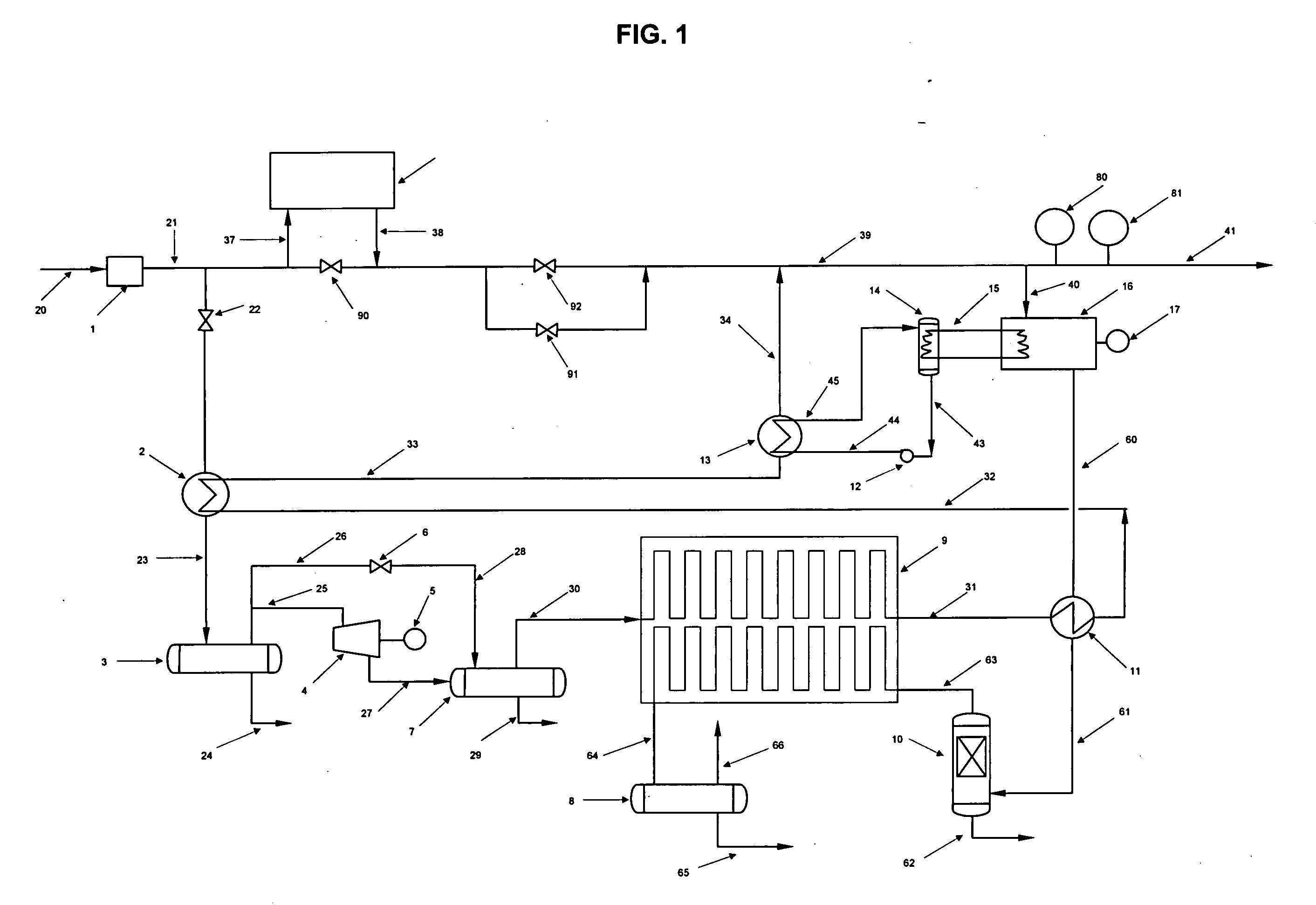

System and Method for Rapid Isothermal Gas Expansion and Compression for Energy Storage

InactiveUS20090301089A1Overcome disadvantagesInhibit migrationElectrical storage systemFluid couplingsCounter flowEngineering

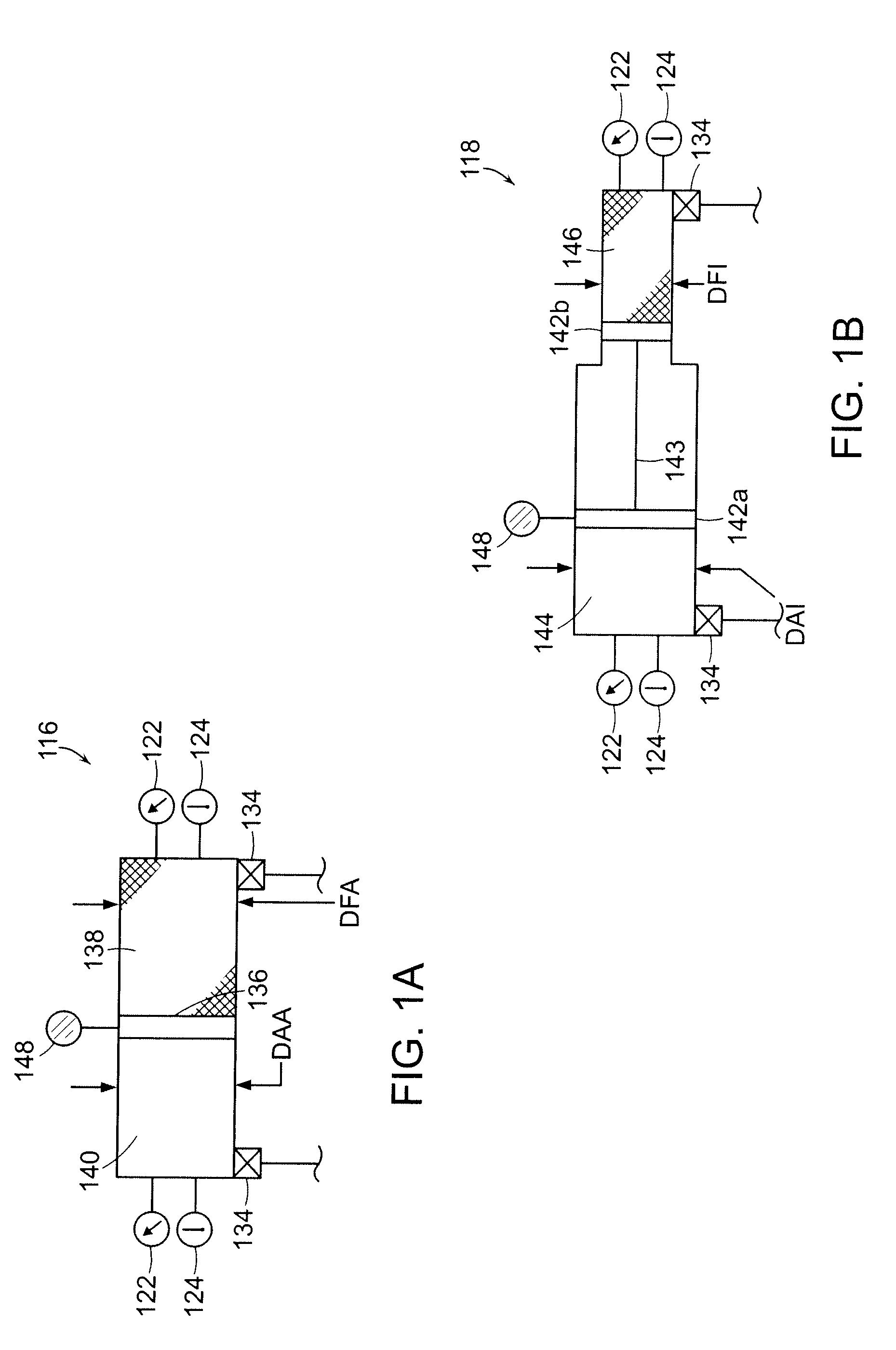

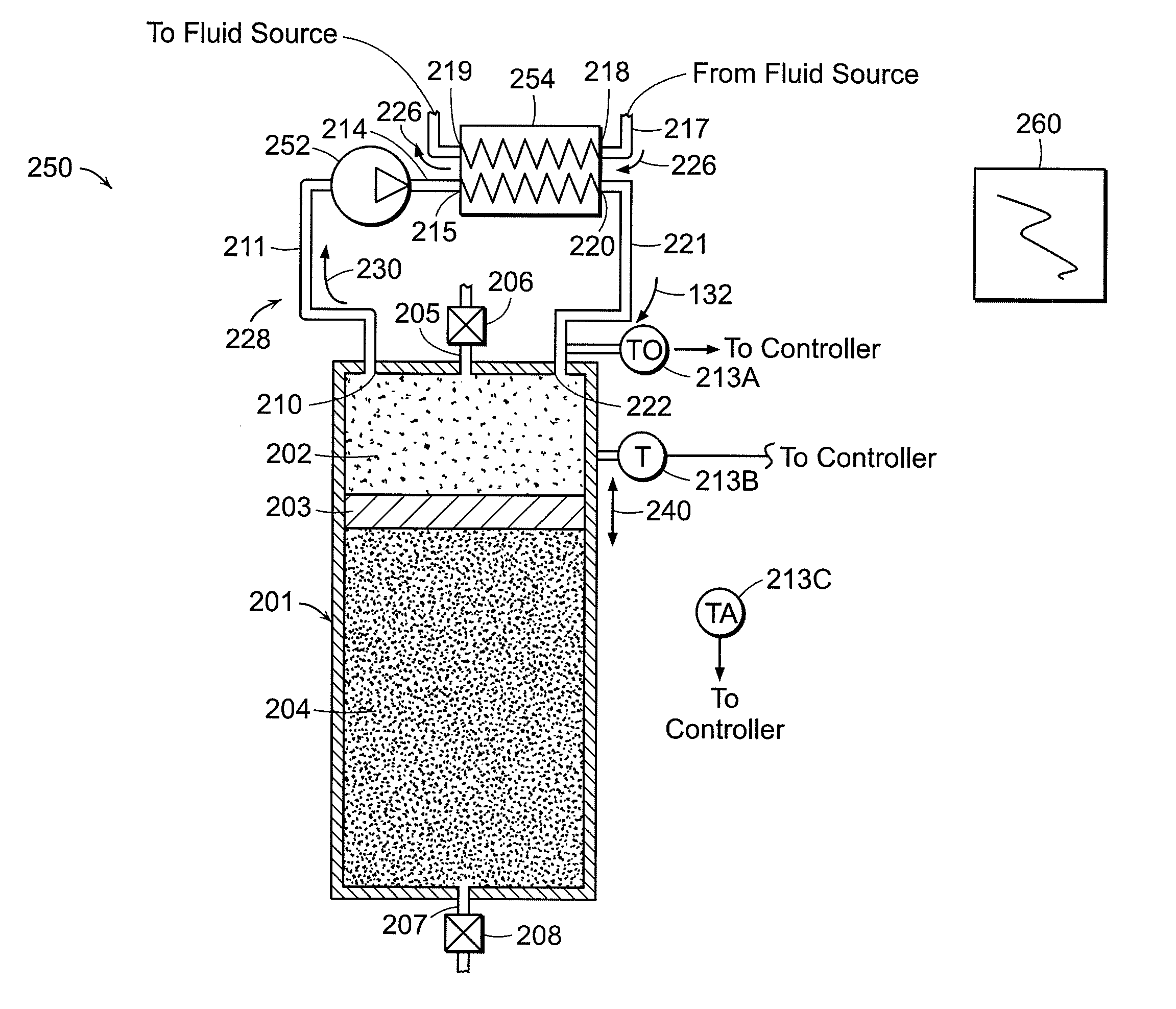

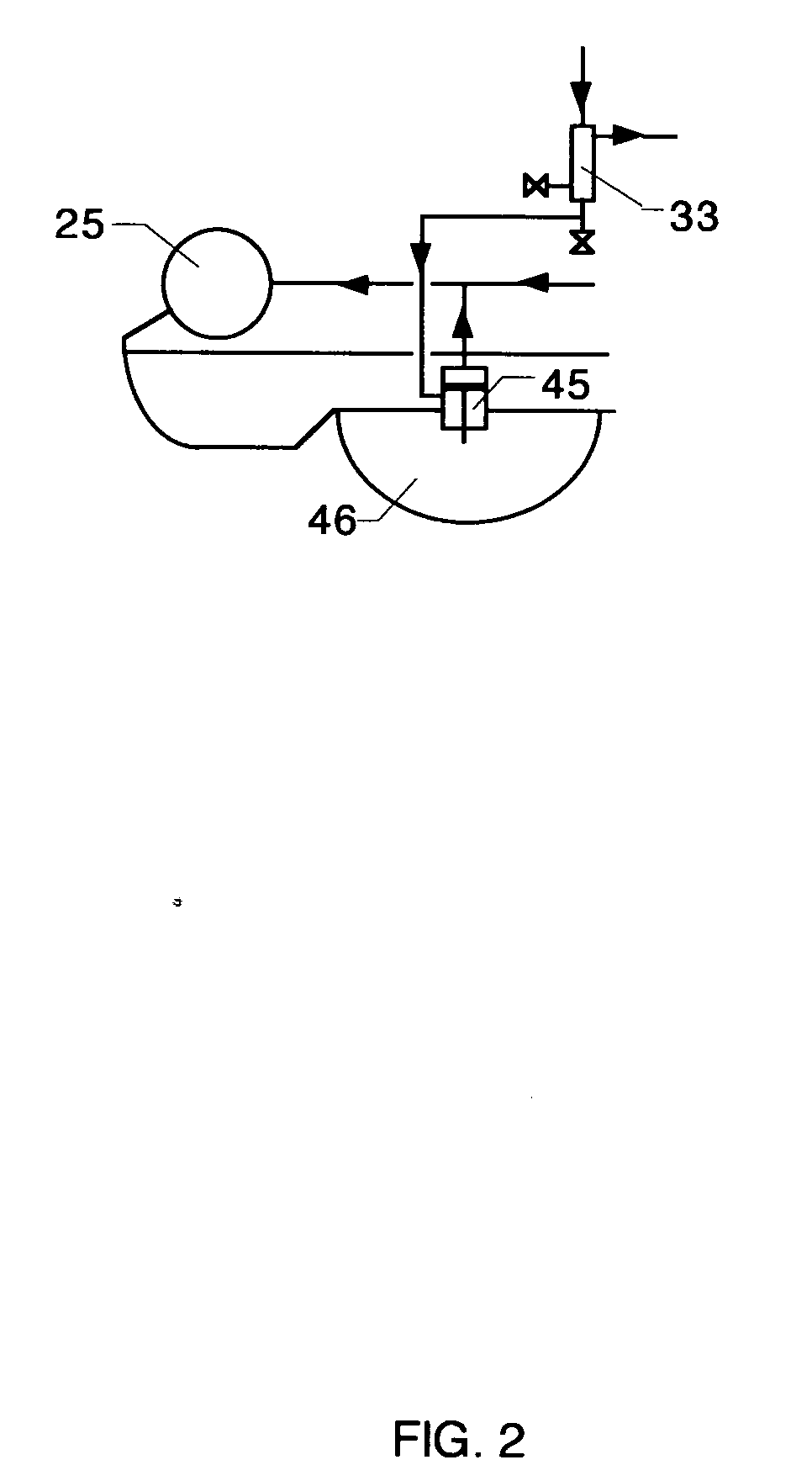

The invention relates to systems and methods for rapidly and isothermally expanding gas in a cylinder. The cylinder is used in a staged hydraulic-pneumatic energy conversion system and includes a gas chamber (pneumatic side) and a fluid chamber (hydraulic side) and a piston or other mechanism that separates the gas chamber and fluid chamber while allowing the transfer of force / pressure between each opposing chamber. The gas chamber of the cylinder includes ports that are coupled to a heat transfer subassembly that circulates gas from the pneumatic side and exchanges its heat with a counter flow of ambient temperature fluid from a reservoir or other source.

Owner:SUSTAINX

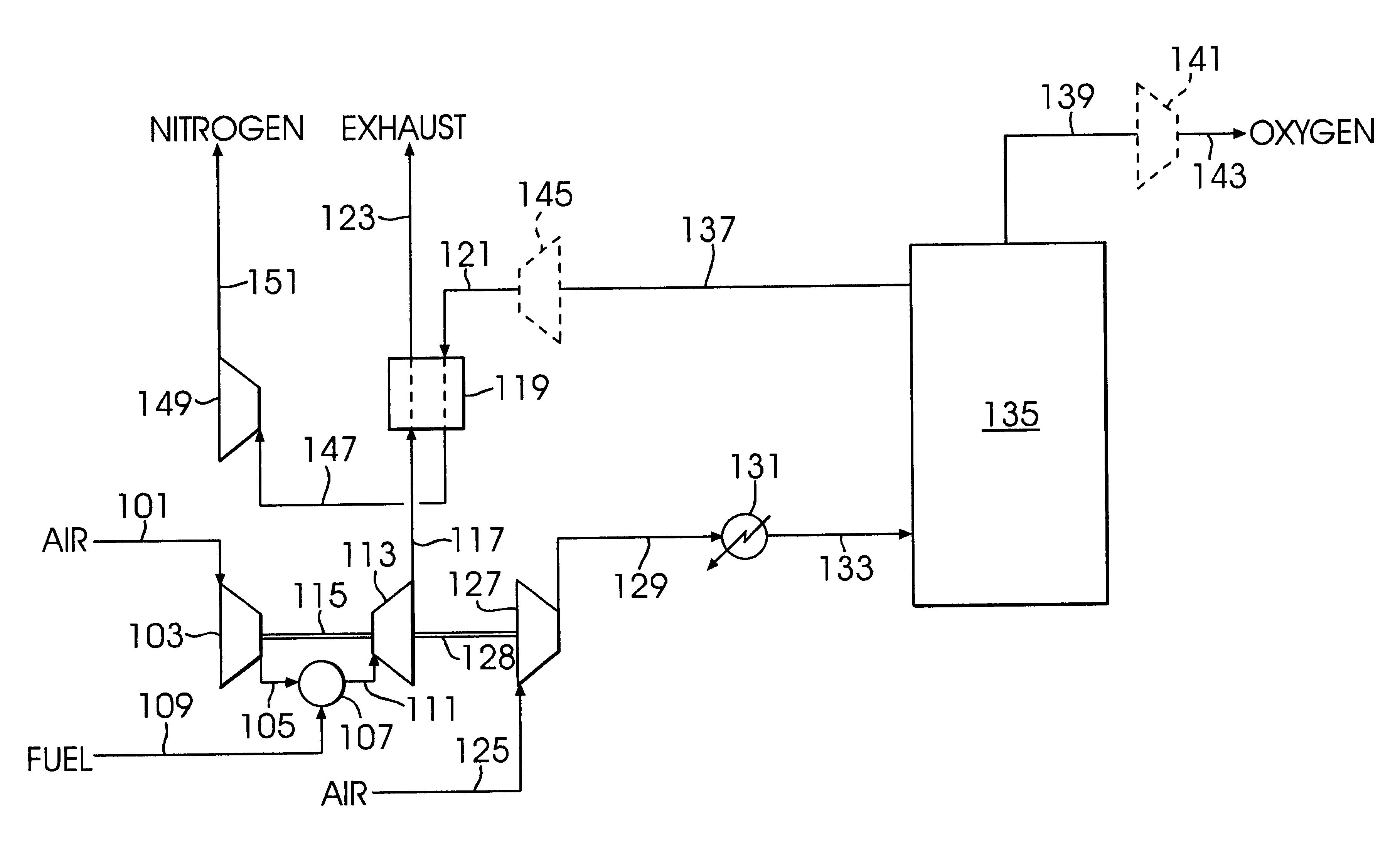

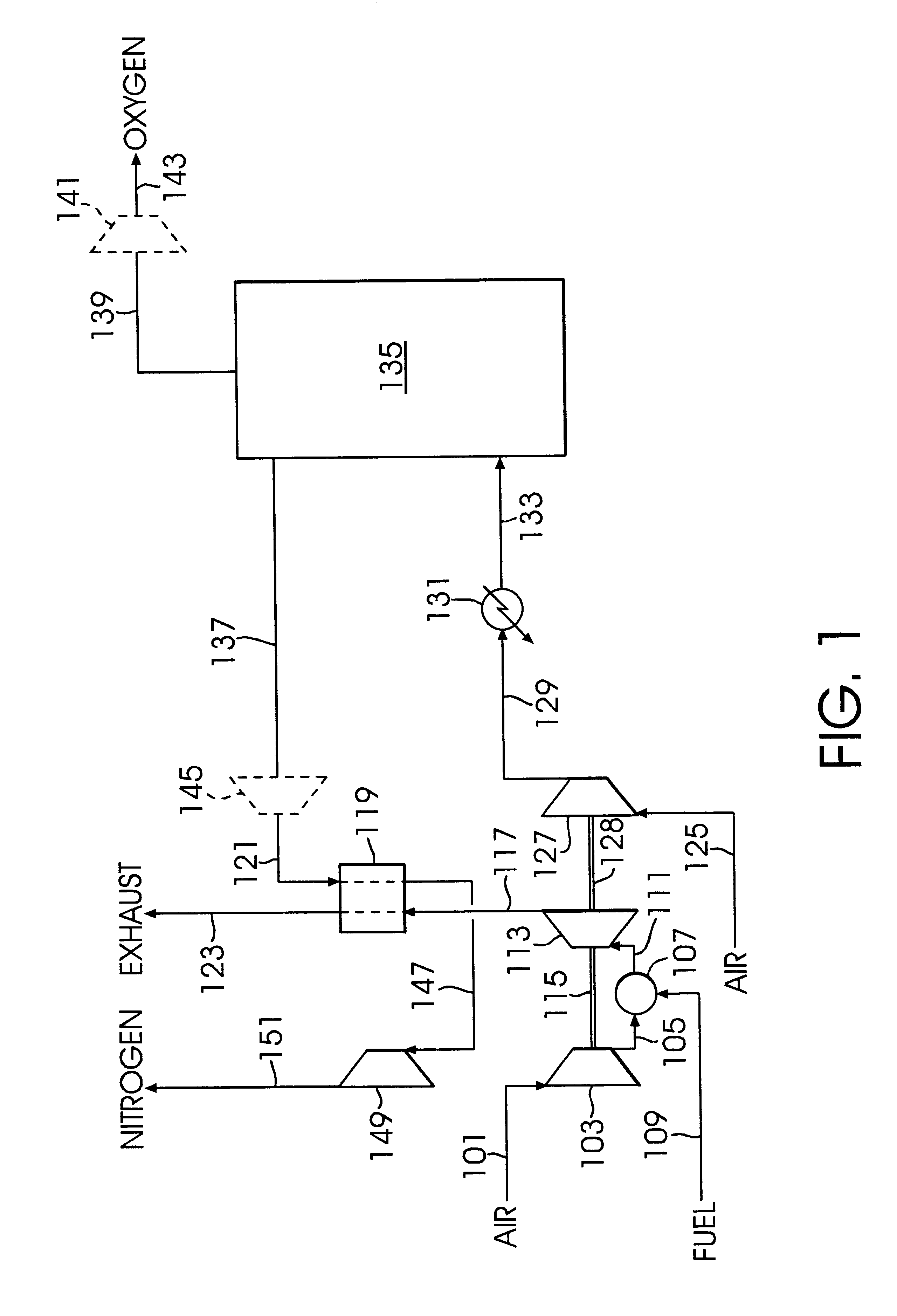

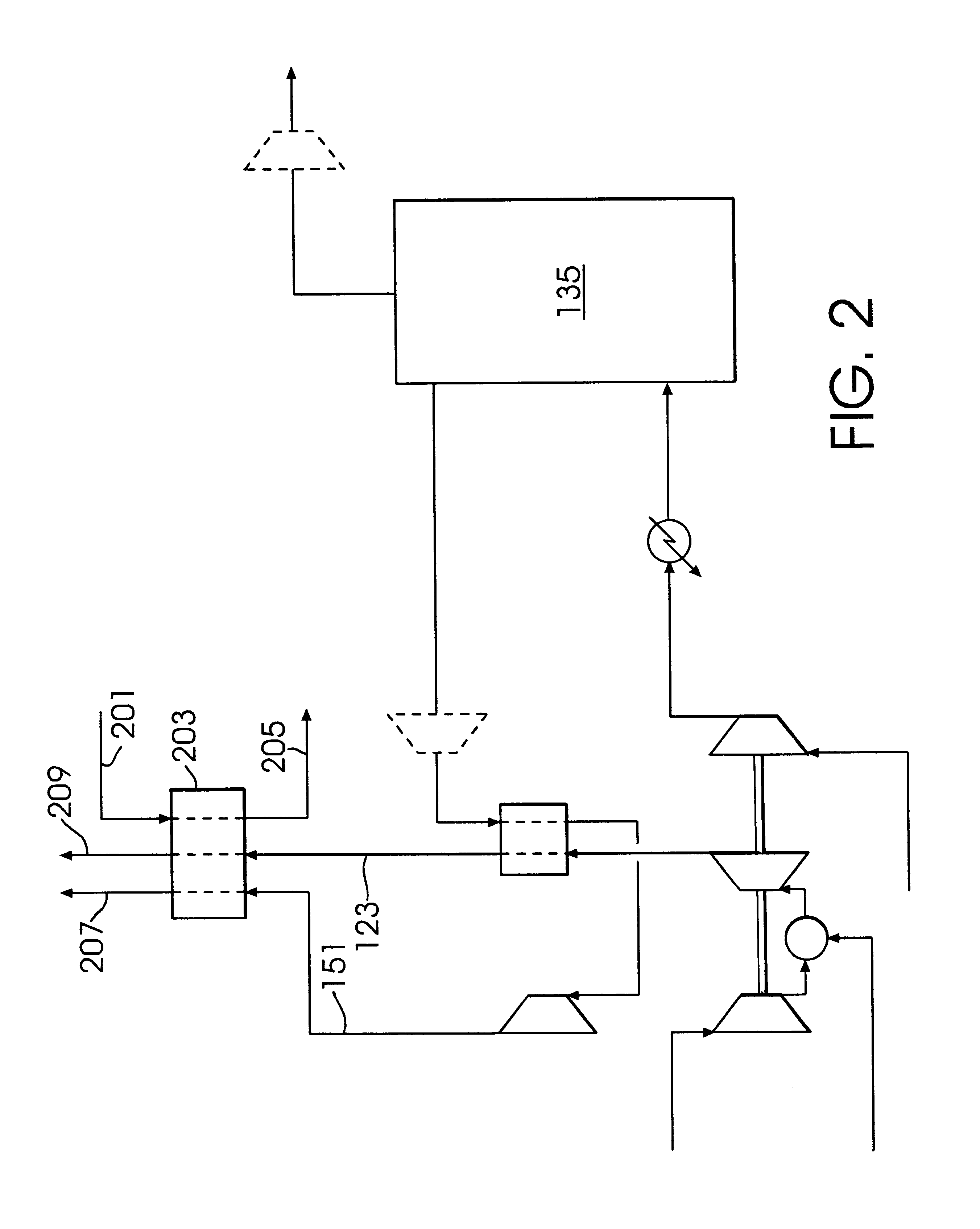

Air separation process integrated with gas turbine combustion engine driver

A method for the separation of a feed gas mixture comprising oxygen and nitrogen in which an oxidant gas and fuel are combusted in a combustion engine to generate shaft work and a hot exhaust gas, the feed gas mixture comprising oxygen and nitrogen is compressed, and the resulting compressed feed gas mixture is separated into two or more product gas streams with differing compositions. The shaft work of the combustion engine is utilized to provide at least a portion of the work required for compressing the feed gas mixture, one of the product gas streams by is heated by indirect heat exchange with the hot exhaust gas from the combustion engine, and the resulting heated product gas is work expanded to generate shaft work and yield an expanded product gas stream. The combustion engine may be a gas turbine combustion engine.

Owner:AIR PROD & CHEM INC

System and method for rapid isothermal gas expansion and compression for energy storage

InactiveUS7802426B2Overcome disadvantagesInhibit migrationElectrical storage systemServomotorsCounter flowEngineering

The invention relates to systems and methods for rapidly and isothermally expanding gas in a cylinder. The cylinder is used in a staged hydraulic-pneumatic energy conversion system and includes a gas chamber (pneumatic side) and a fluid chamber (hydraulic side) and a piston or other mechanism that separates the gas chamber and fluid chamber while allowing the transfer of force / pressure between each opposing chamber. The gas chamber of the cylinder includes ports that are coupled to a heat transfer subassembly that circulates gas from the pneumatic side and exchanges its heat with a counter flow of ambient temperature fluid from a reservoir or other source.

Owner:SUSTAINX

Energy Storage Systems

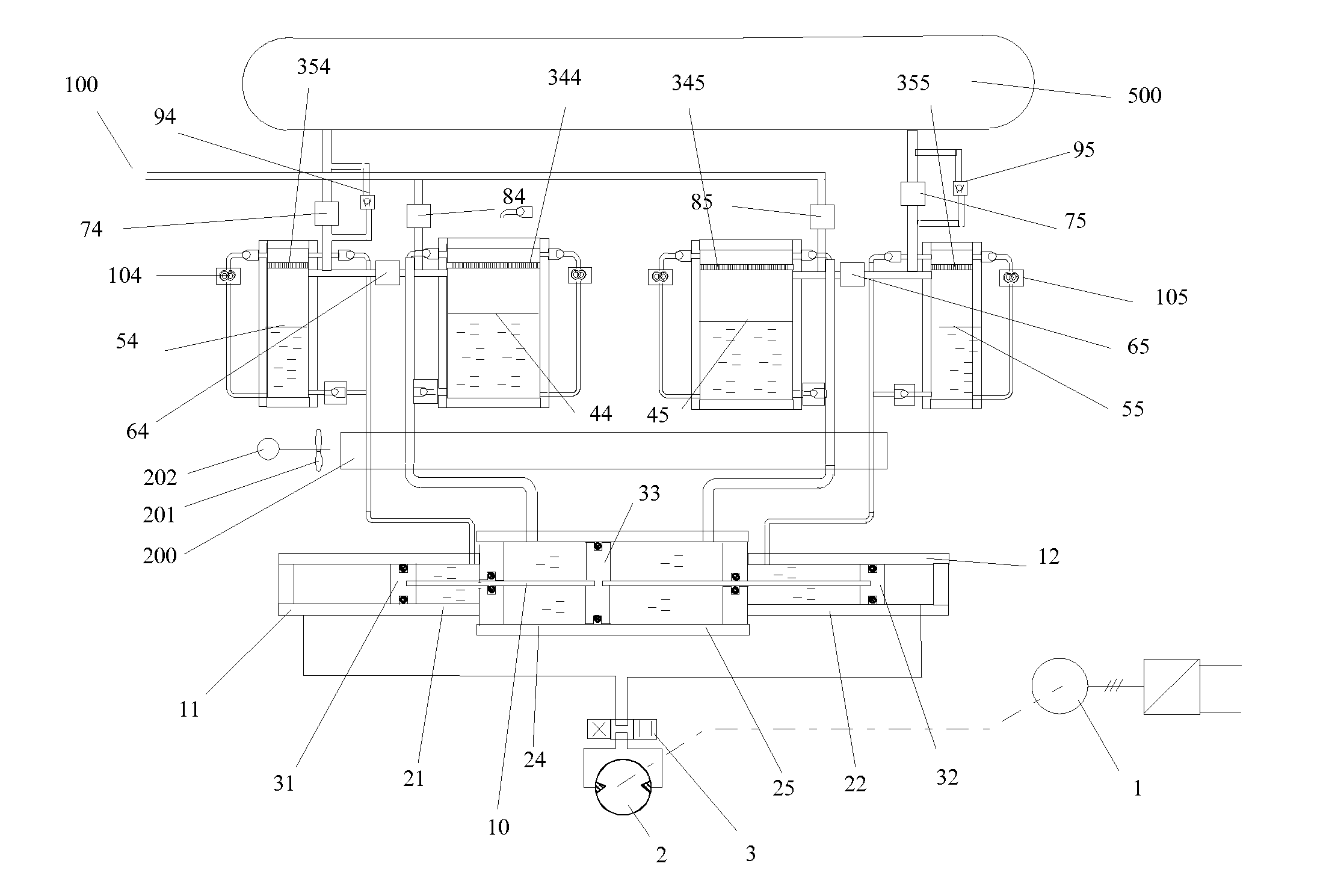

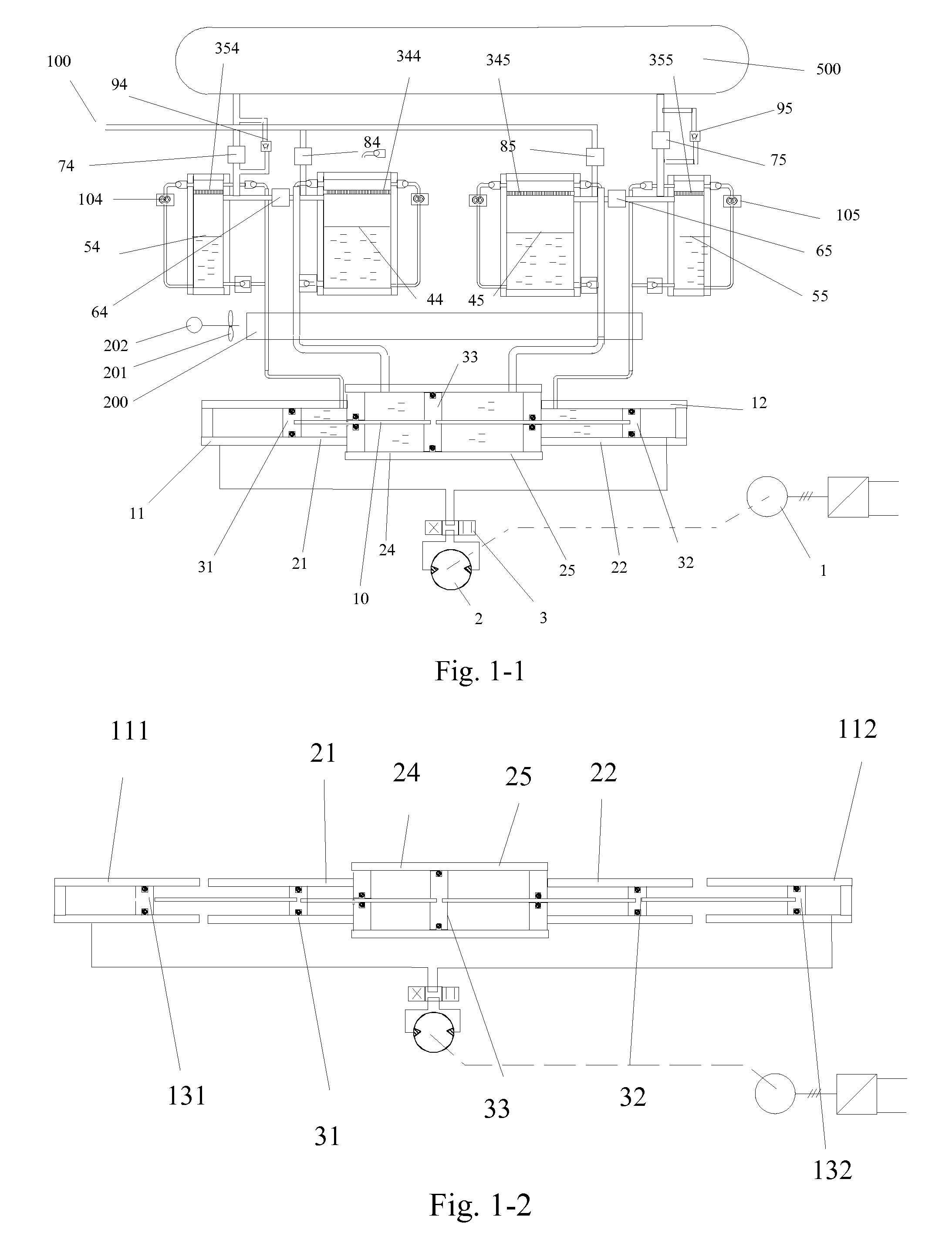

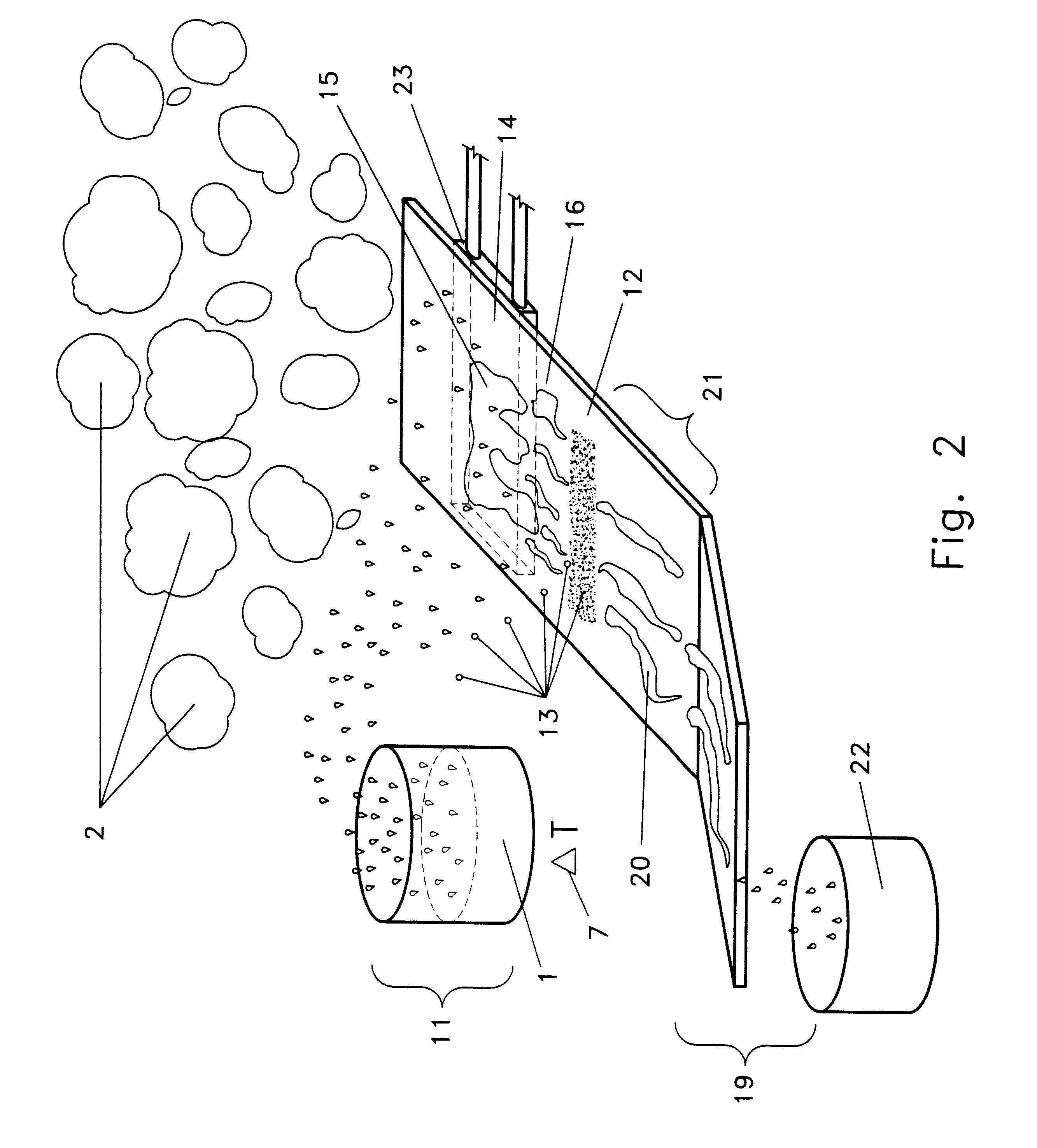

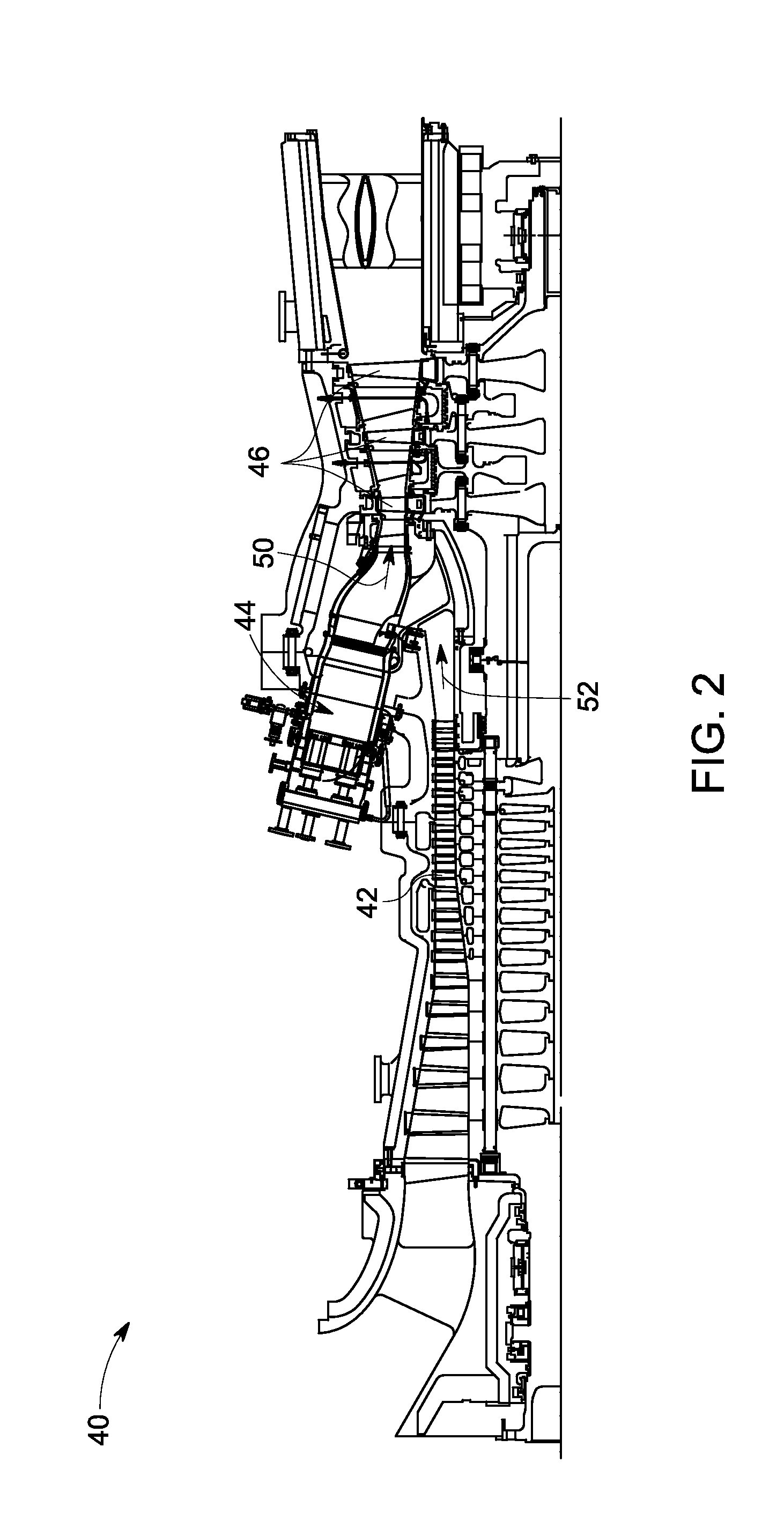

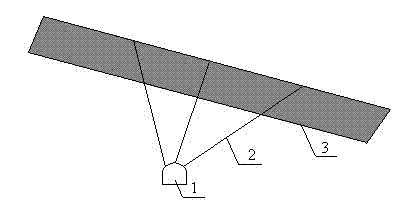

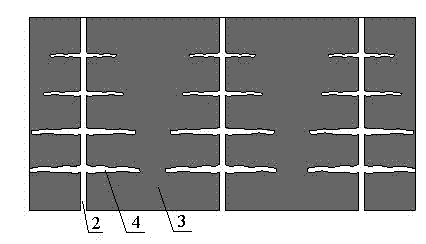

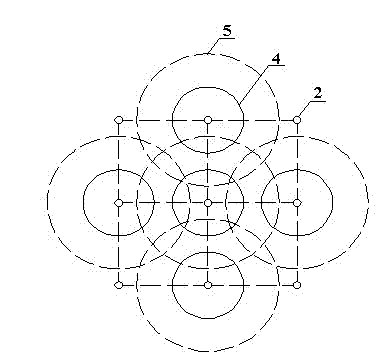

Different types of energy storage systems are described, in particular hydro-pneumatic storage systems. In one, energy is stored by compressing gas in a chamber (44,45,54,55) with a liquid piston and released by gas expansion. A spray head or grid at the top of the chamber (44,45,54,55) supplies liquid as a shower through the gas being compressed or expanding in the cylinder (11,12) to maintain an isothermal condition. In another, energy is stored from an array of solar cells connected to an array of supercapacitors forming an auxiliary storage, and a main energy storage device such as a hydro-pneumatic storage system, for supply to an AC or DC network. The efficiency is improved by connecting the solar cells via the array of supercapacitors to the AC or DC network. An immersed hydro-pneumatic storage device for off-shore / on-shore power generation systems comprises a cylinder that is immersed in a liquid mass, wherein energy is stored by compressing gas with a liquid piston and energy is released by gas expansion. The mass of liquid maintains an isothermal condition in the cylinder during compression and expansion.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

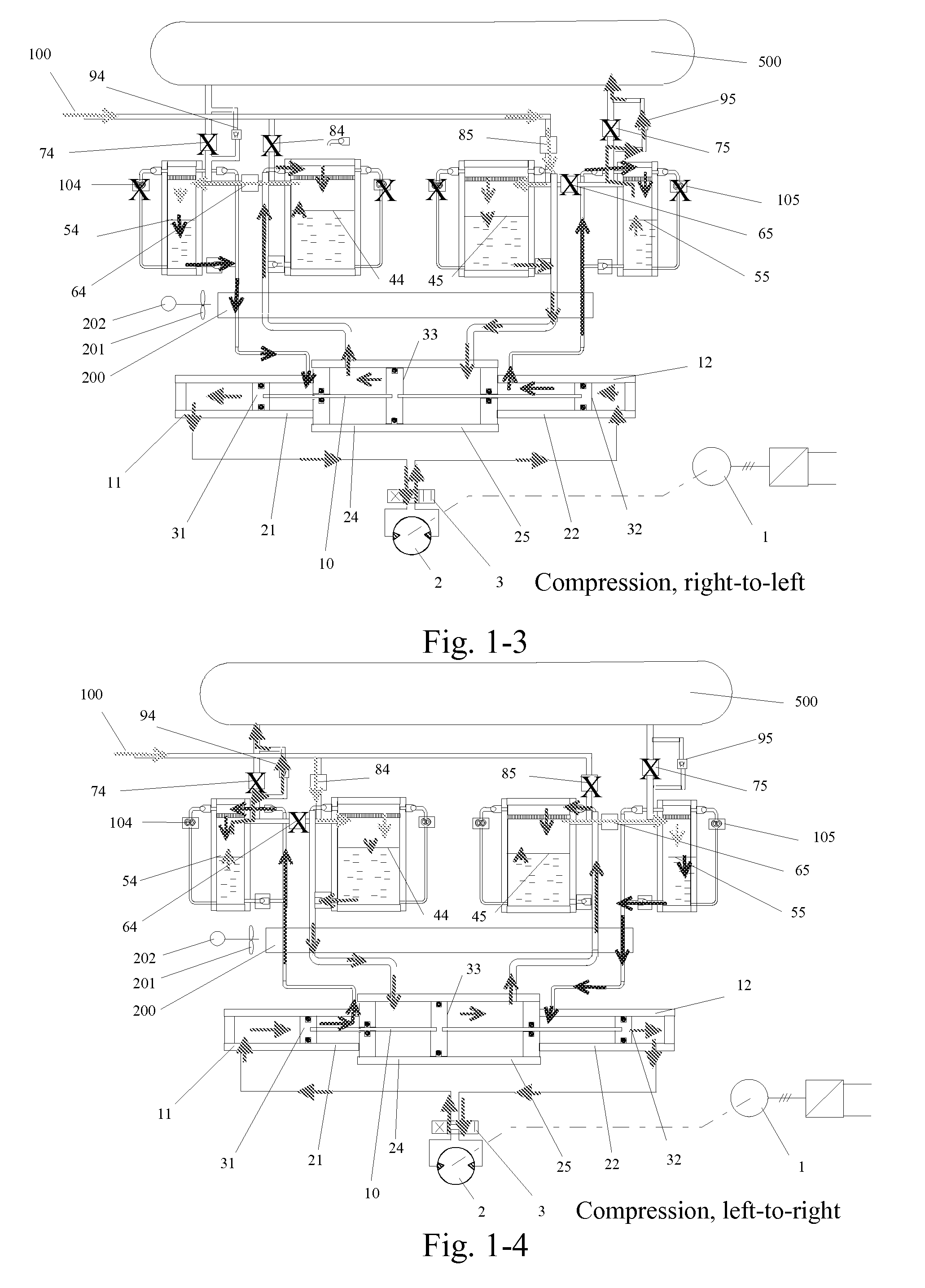

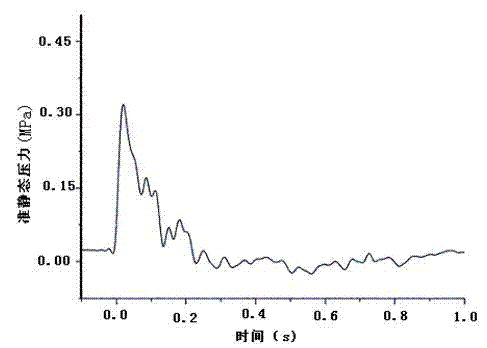

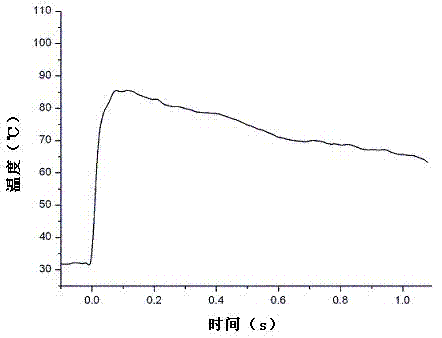

Detonation performance test method for high-energy imploding explosive

InactiveCN102253083AFlexible simulationRealize synchronized measurementsMaterial exposibilityDetonatorExplosive Agents

The invention discloses a detonation performance test method for high-energy imploding explosive. The method is characterized in that: a explosive grain with a detonator is placed in a sealed explosion vessel; quasi-static pressure of the explosive, transient temperature of the explosive, detonation velocity of the explosive and gas components of the explosive are detected; a temperature sensor is arranged on the sealed explosion vessel, and is provided for monitoring the temperature changing in the sealed explosion vessel during the test process, a pressure sensor is arranged on the sealed explosion vessel, and is provided for monitoring the pressure changing in the sealed explosion vessel during the test process; the sealed explosion vessel is further connected with a gas collection andtest system, a firing device, a detonation velocity test device, a mechanical vacuum pump and a gas cylinder. The method is applicable for the performance tests of various imploding explosives, and can be provided for performing laboratory quantitative evaluation to the gas expansion working.

Owner:XIAN MODERN CHEM RES INST

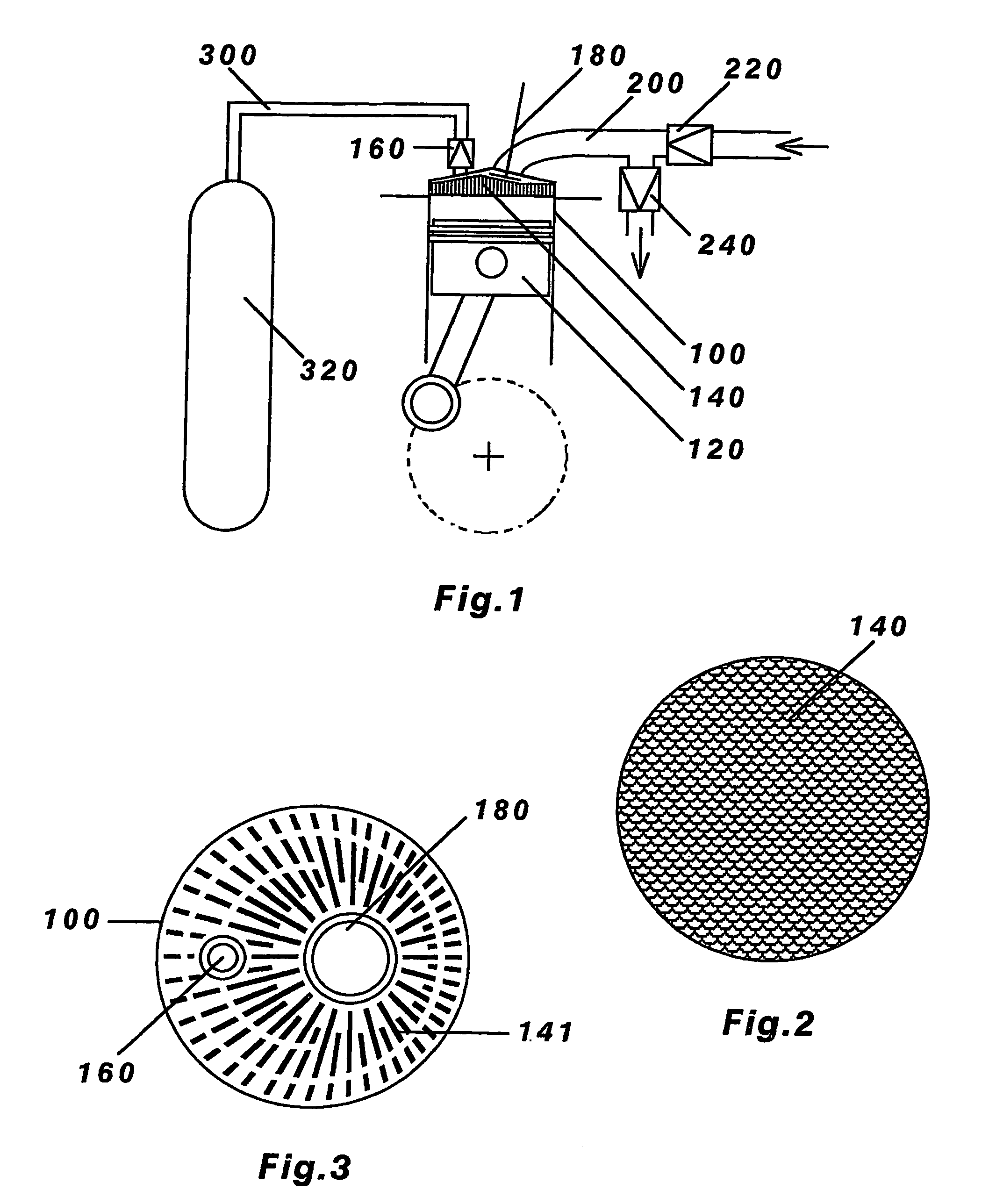

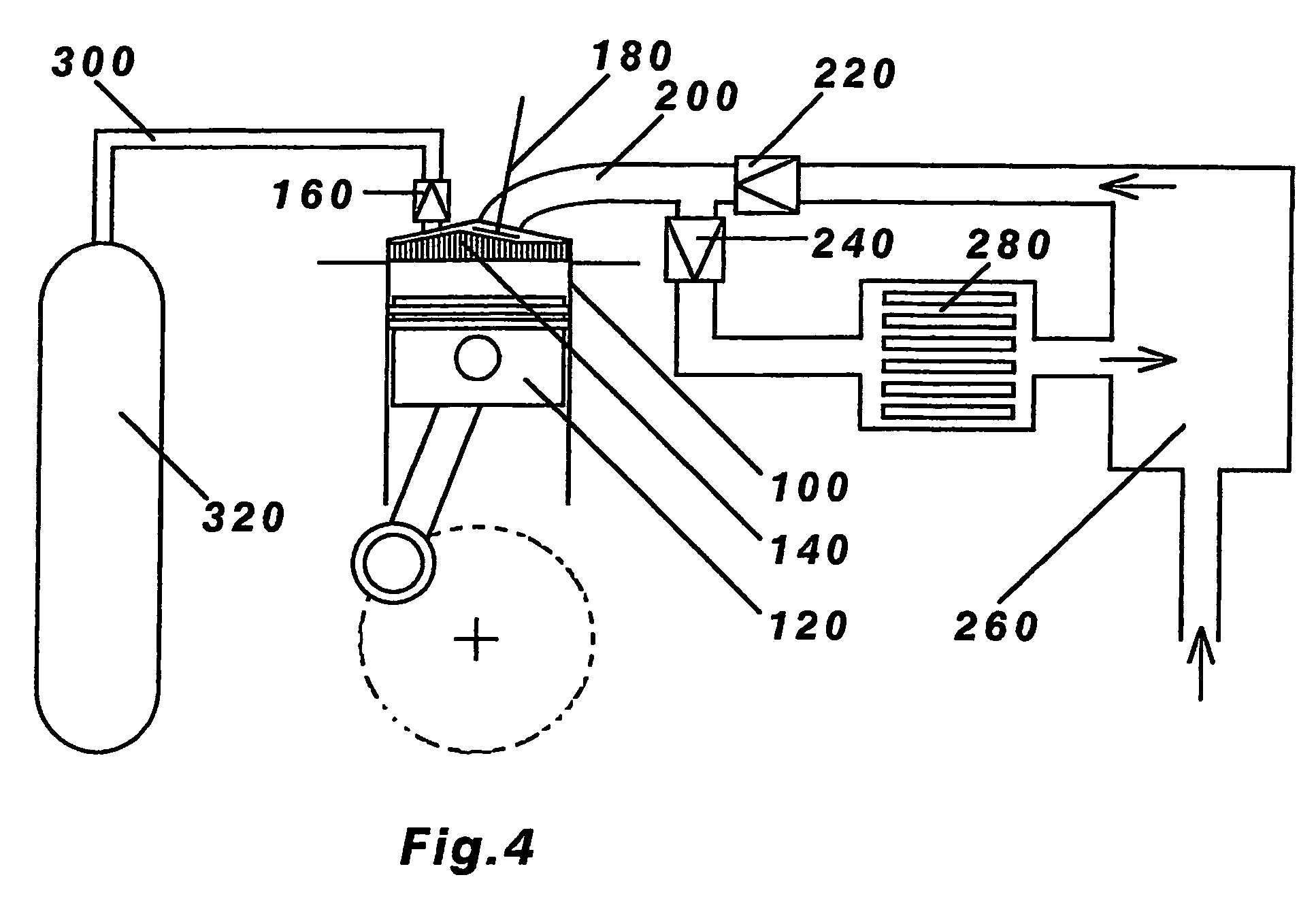

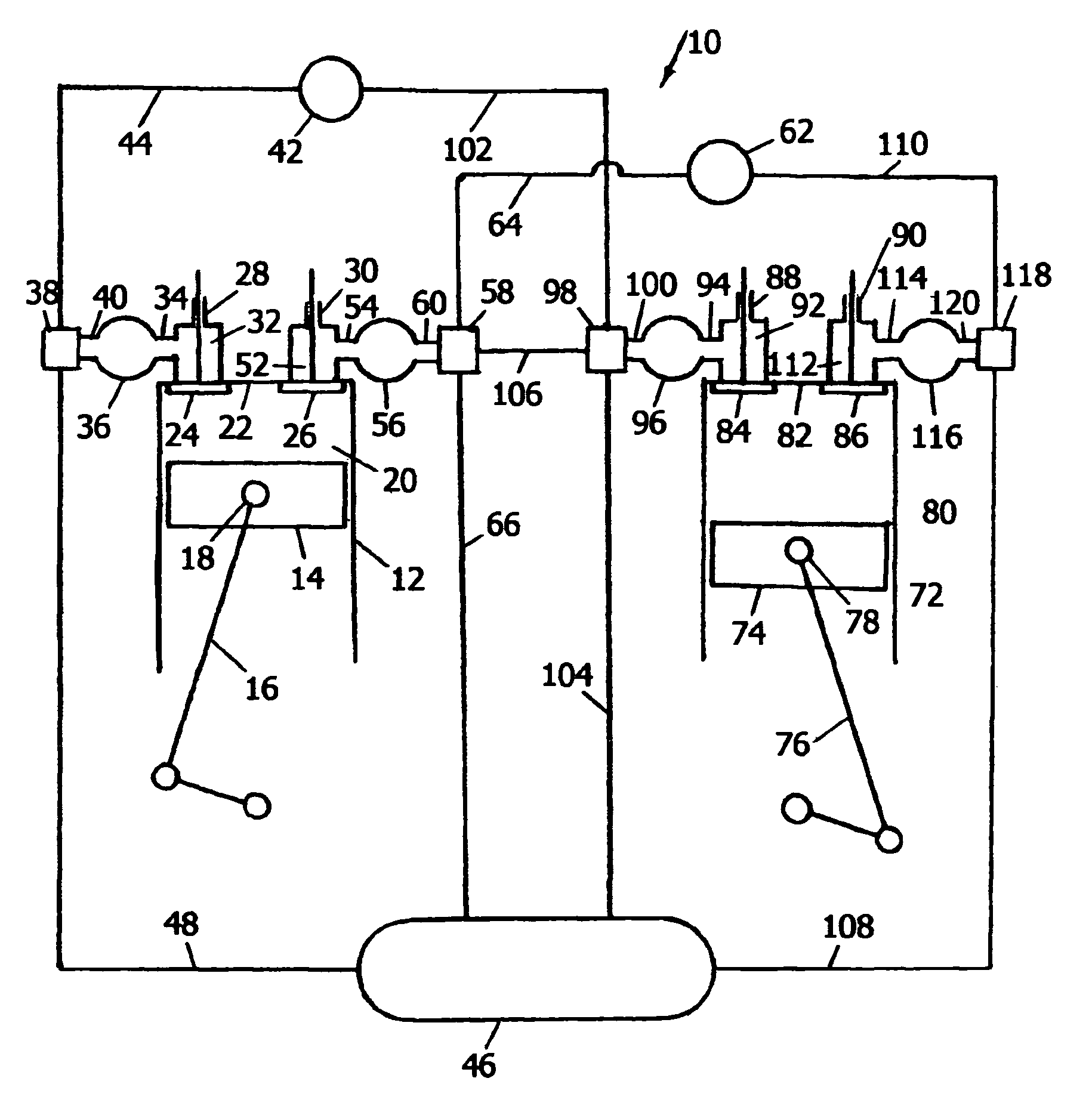

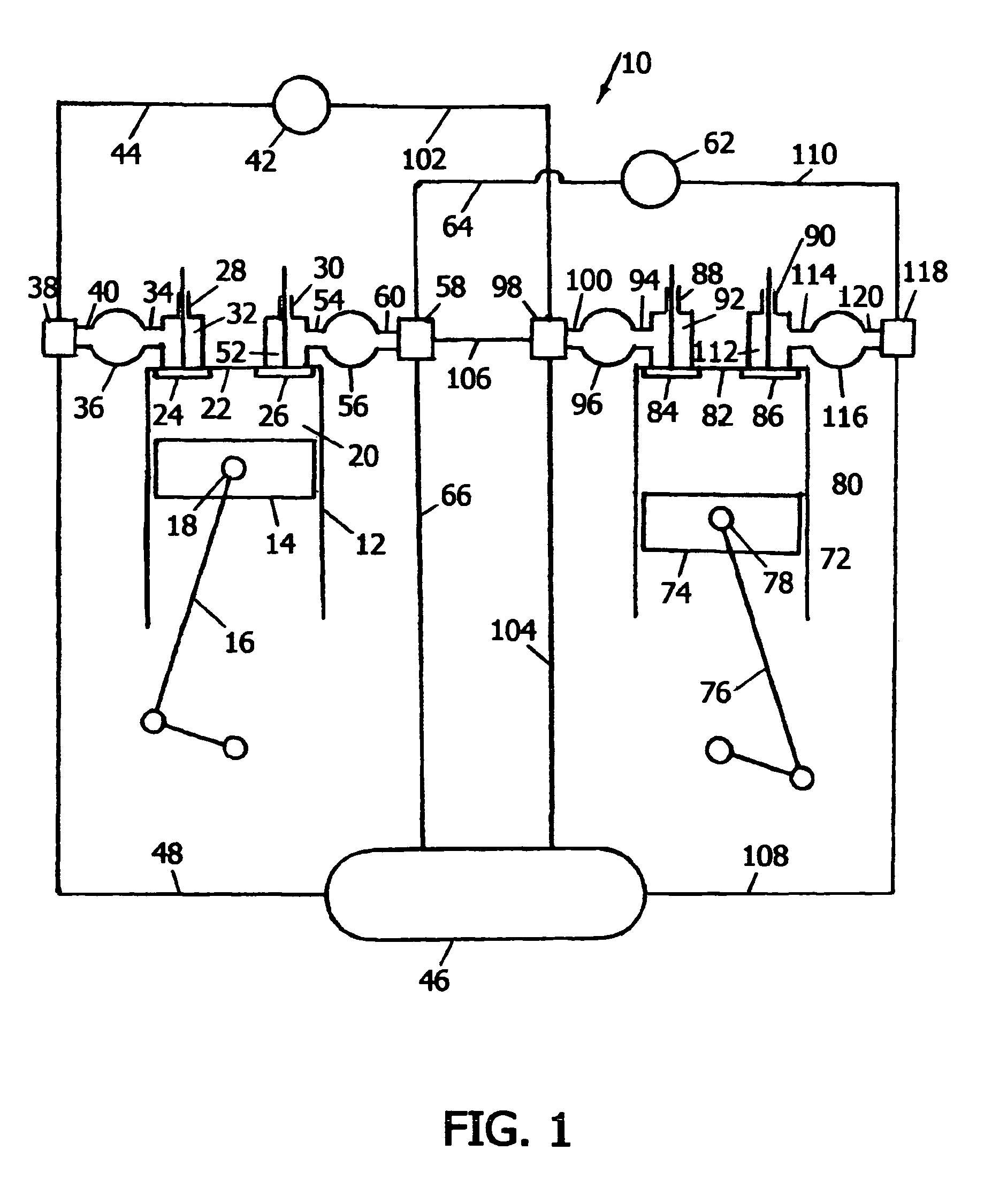

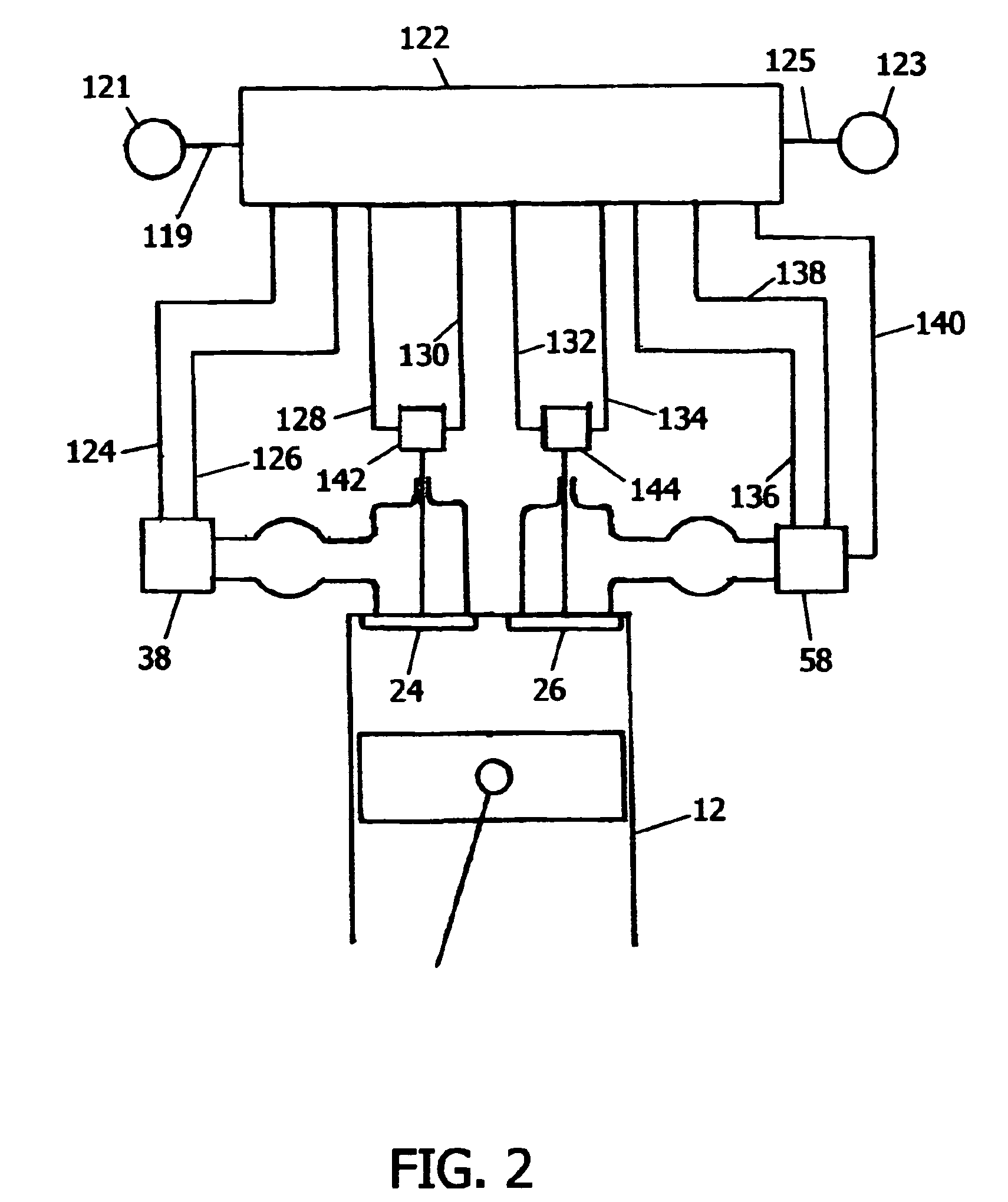

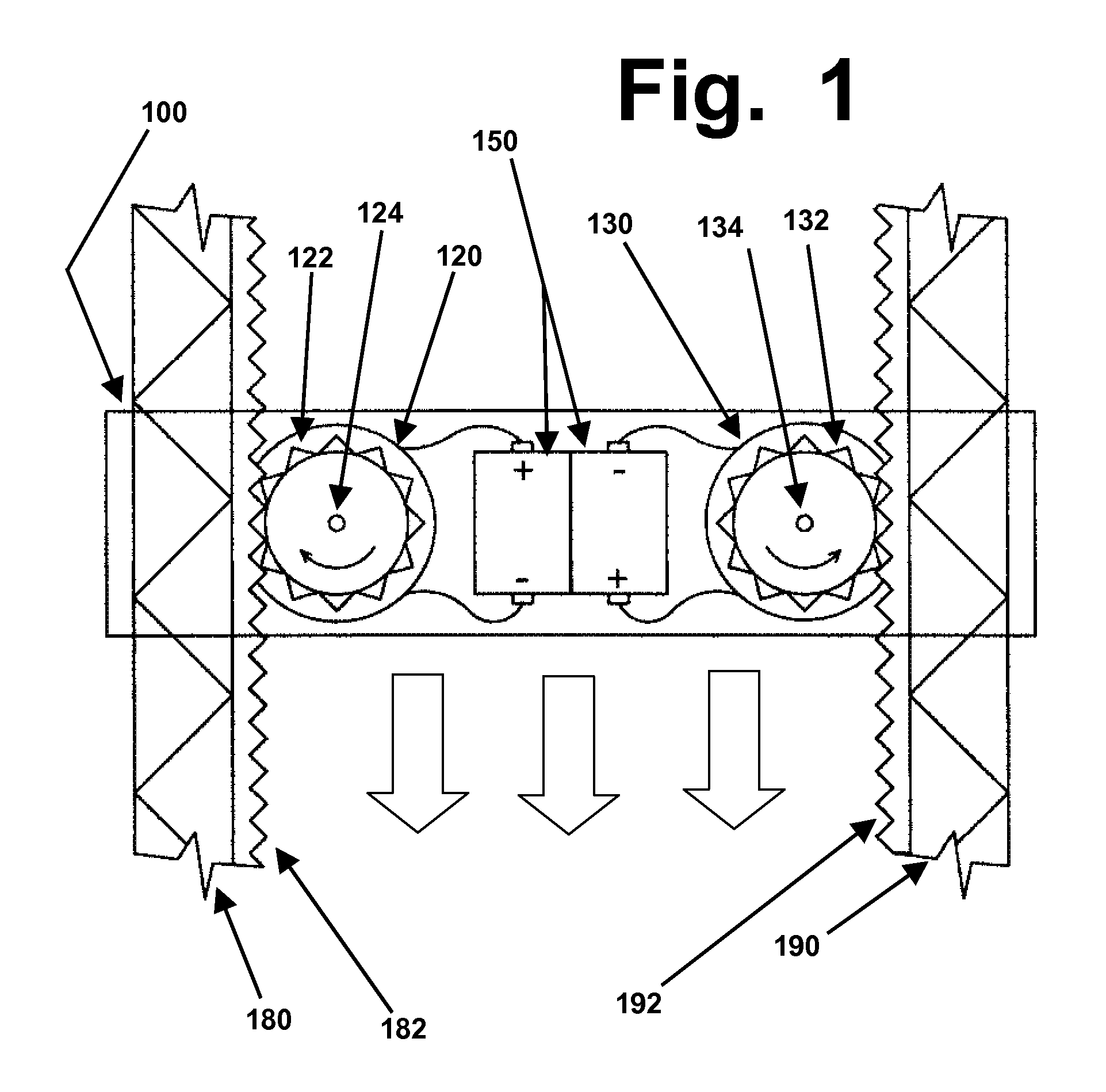

Operating a vehicle with high fuel efficiency

InactiveUS7607503B1Increase fuel consumptionReduce fuel consumptionAuxillary drivesRailway vehiclesCombustionEngine efficiency

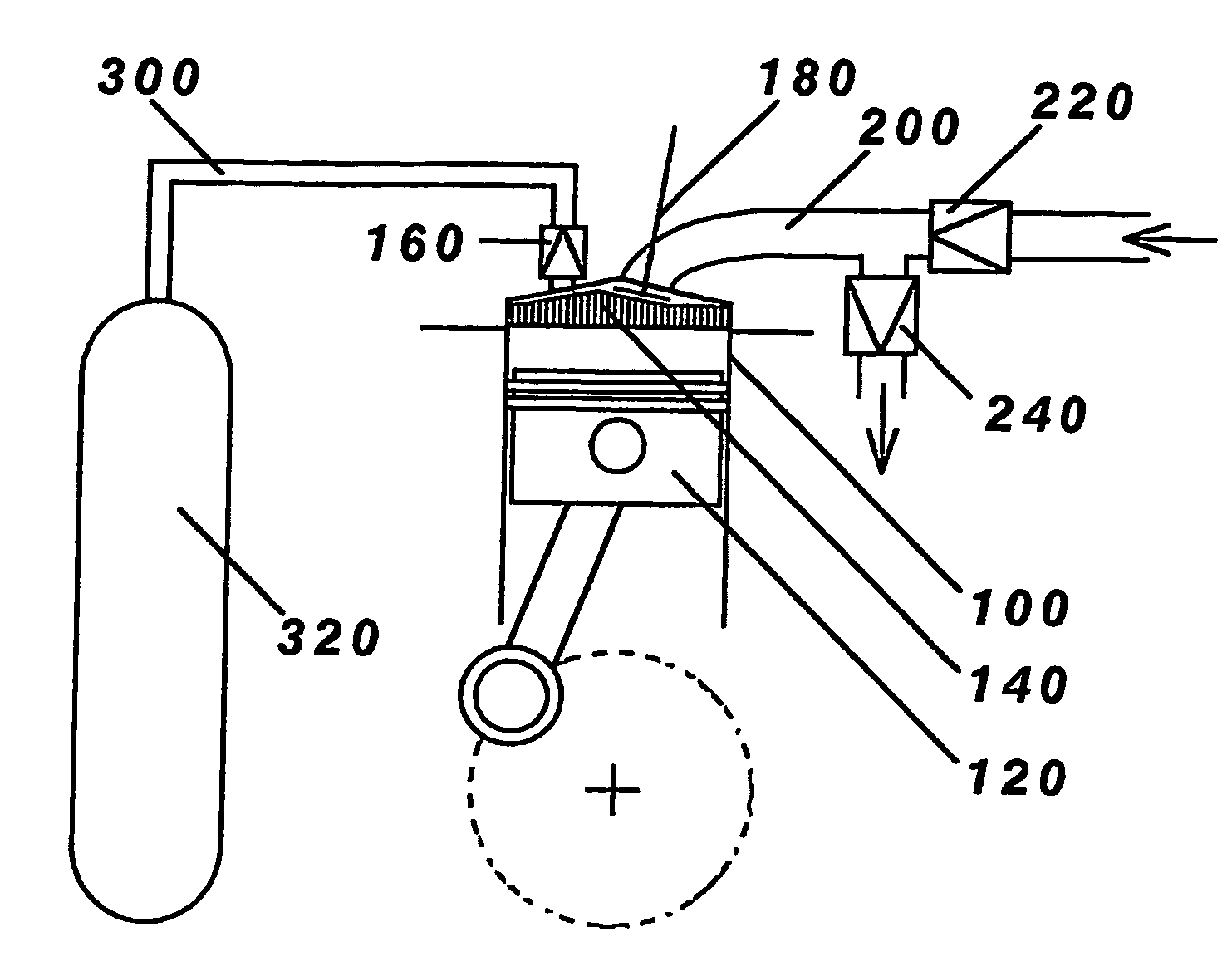

High vehicle fuel efficiency is achieved by reducing fuel consumption during driving both in the city and on the highway. During driving in the city, the system accumulates the energy derived from vehicle motion during braking, and uses it to assist in vehicle propulsion at a later time. The energy can be stored either in a compressed-air reservoir or in an electric battery. During cruising on the highway, the engine operates in a two-stage gas-expansion cycle. The engine has primary and secondary cylinders. Only primary cylinders operate in internal-combustion mode. After expansion in primary cylinders, combustion gas is subjected to a second stage of expansion in secondary cylinders. This substantially improves the engine efficiency. Whenever heavy engine load is needed, all cylinders operate in internal-combustion mode.

Owner:SCHECHTER MICHAEL MOSES

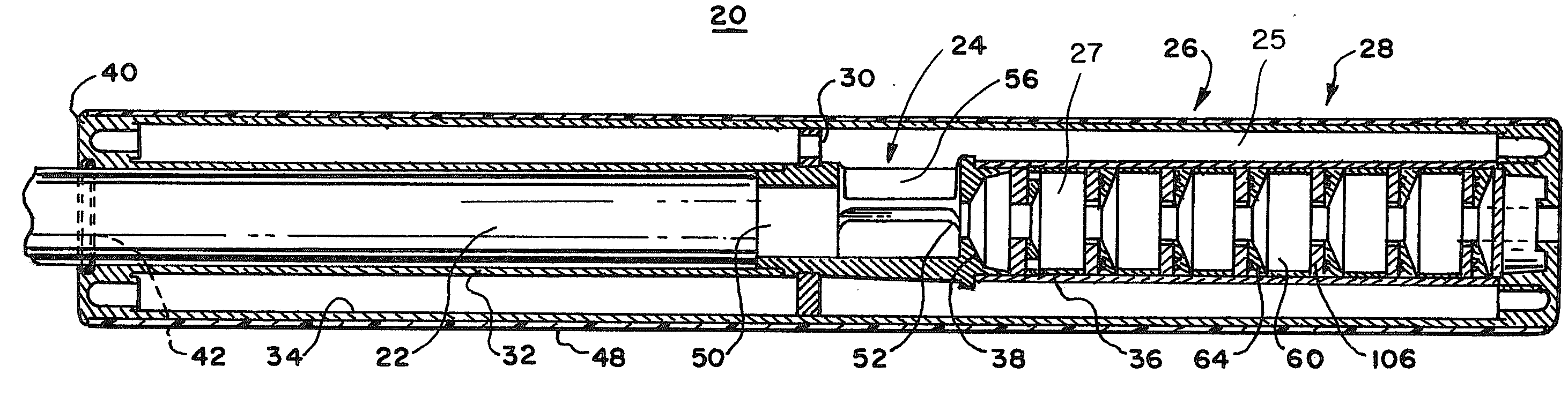

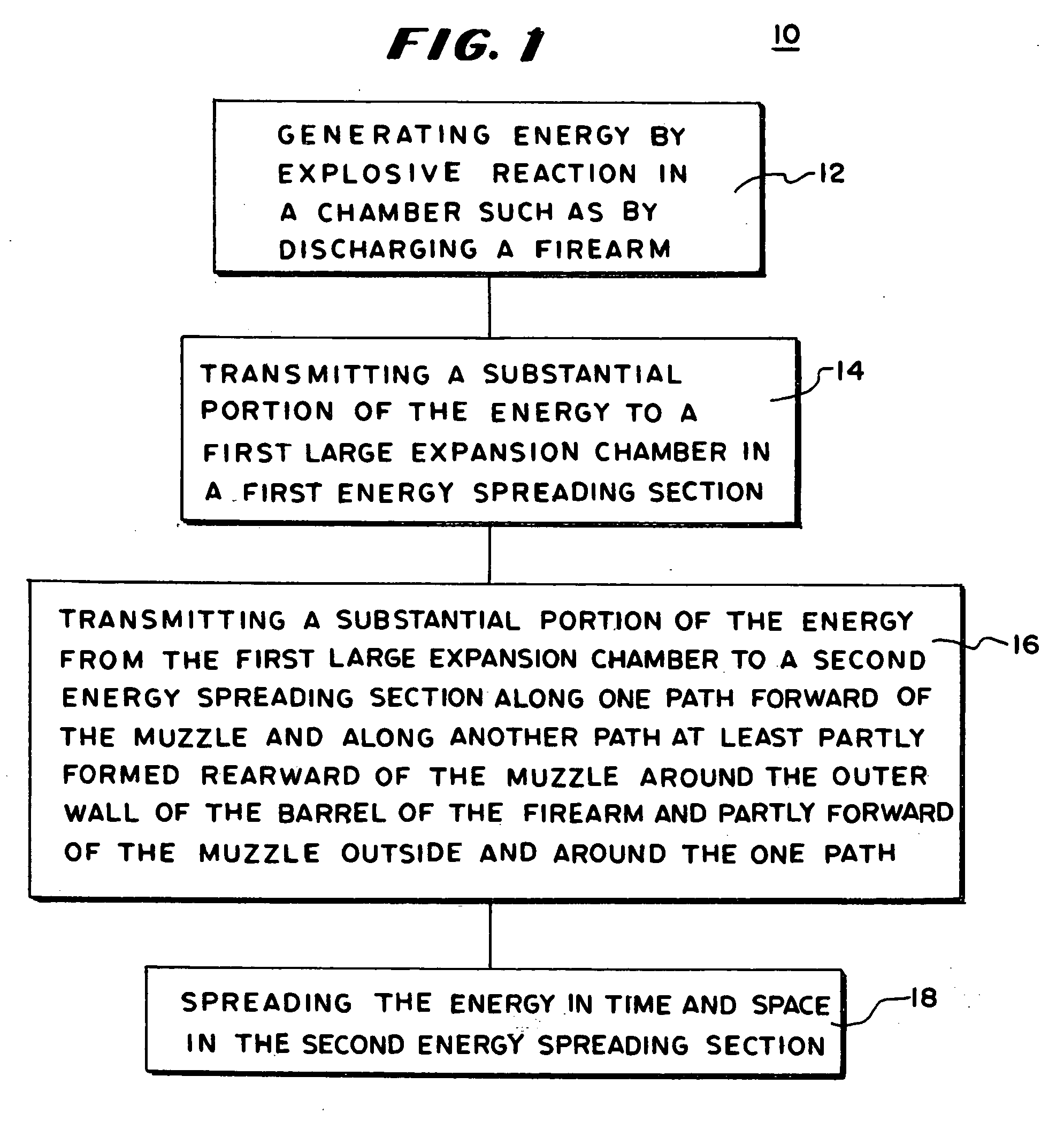

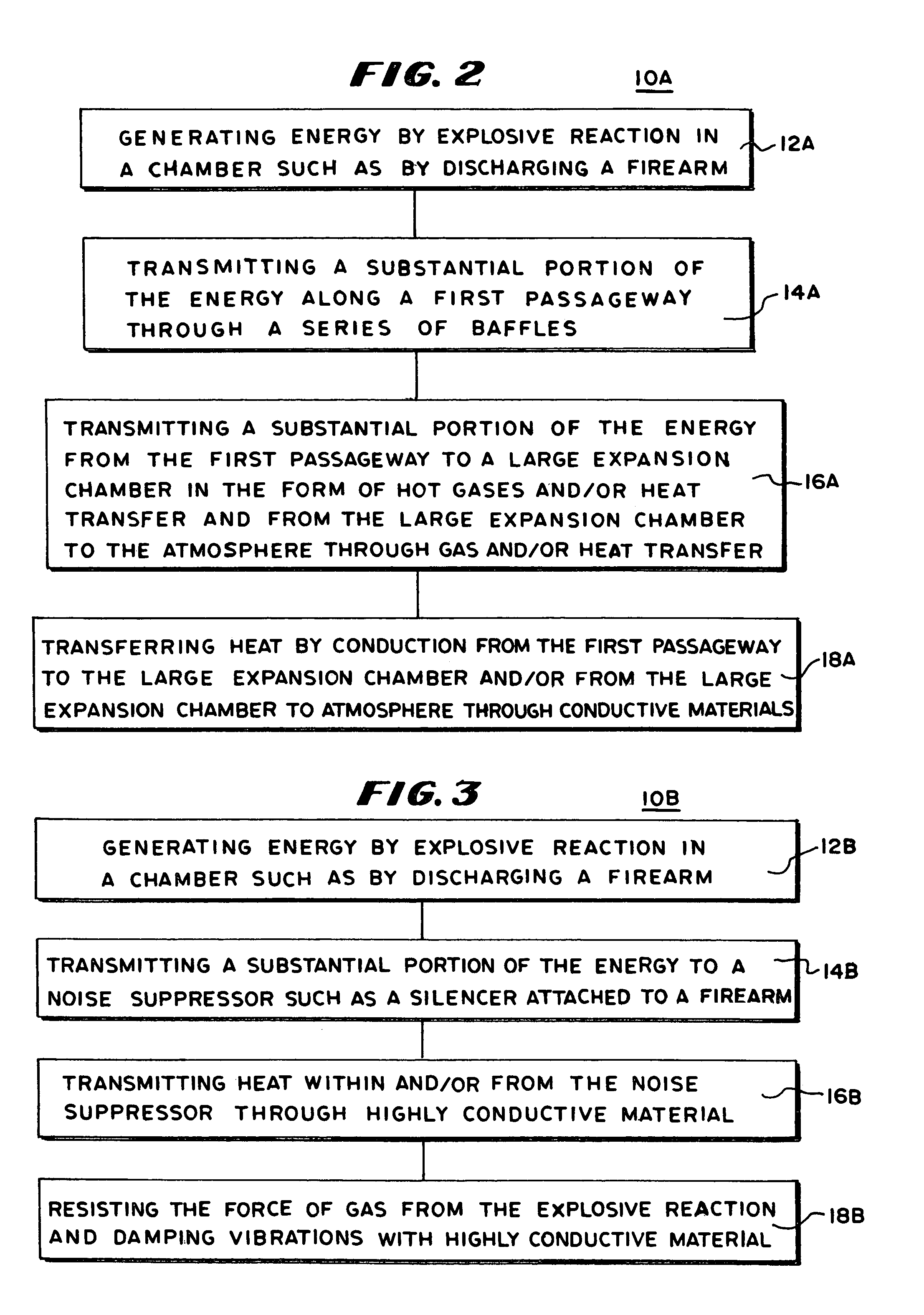

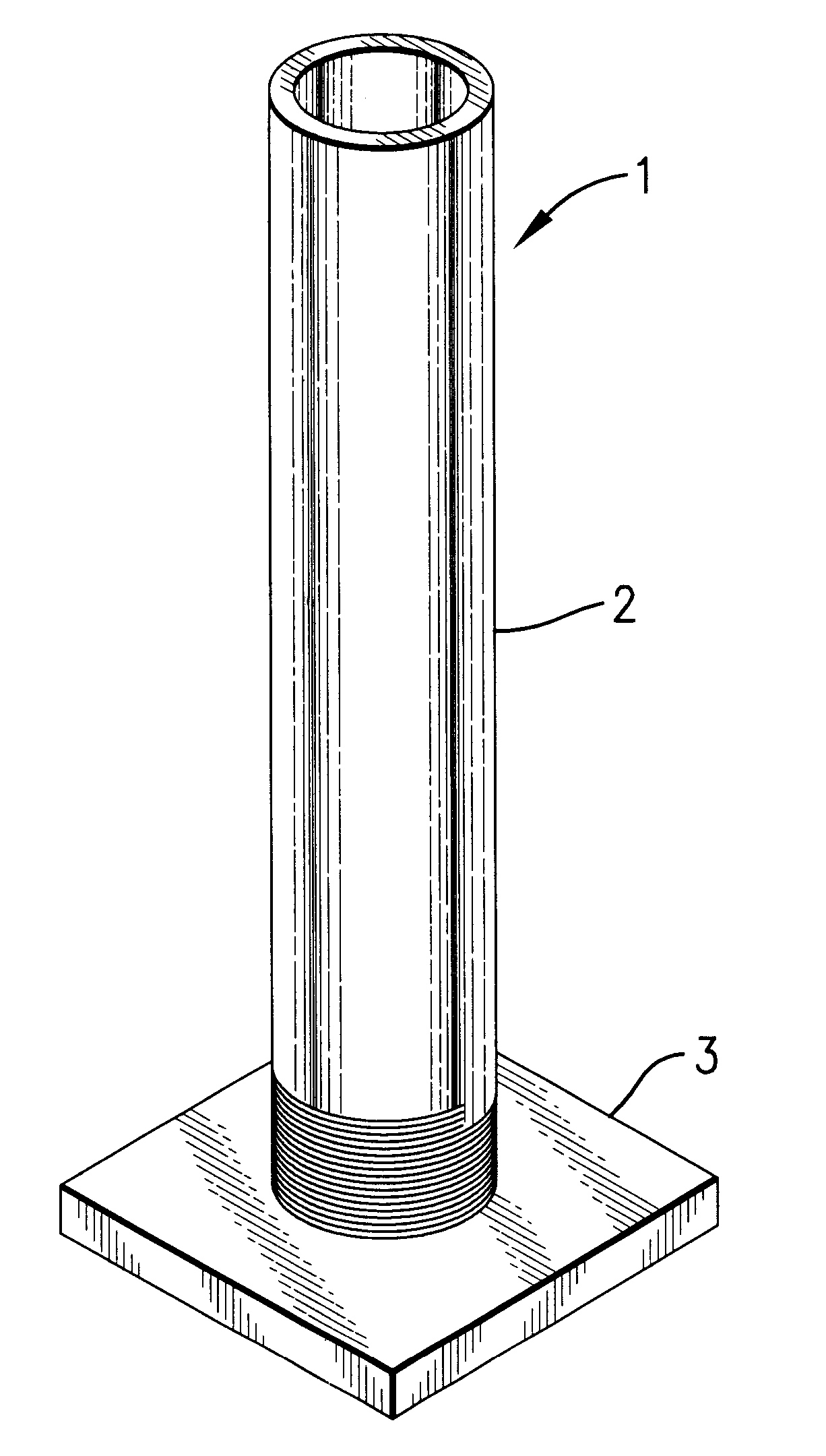

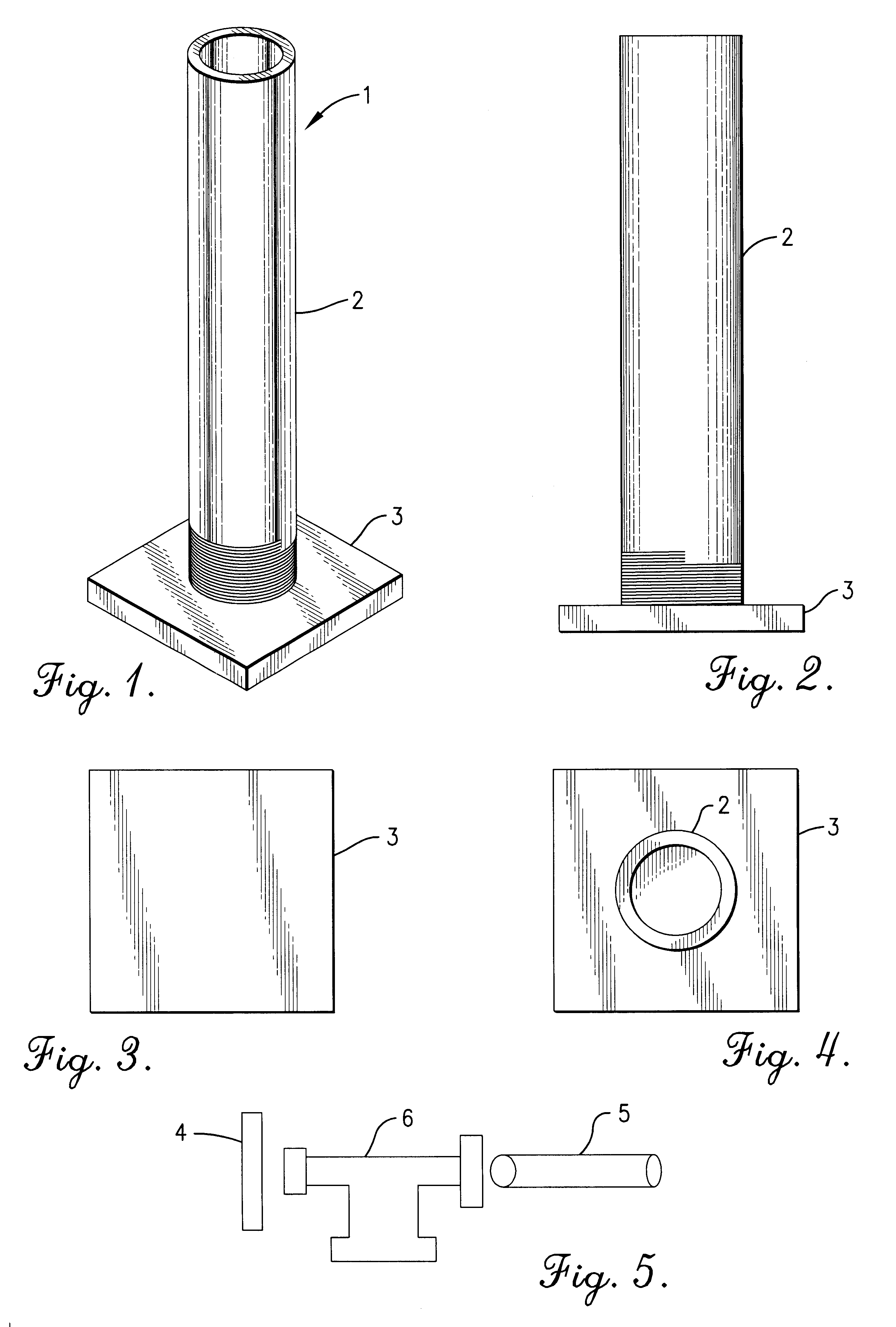

Energy suppressors

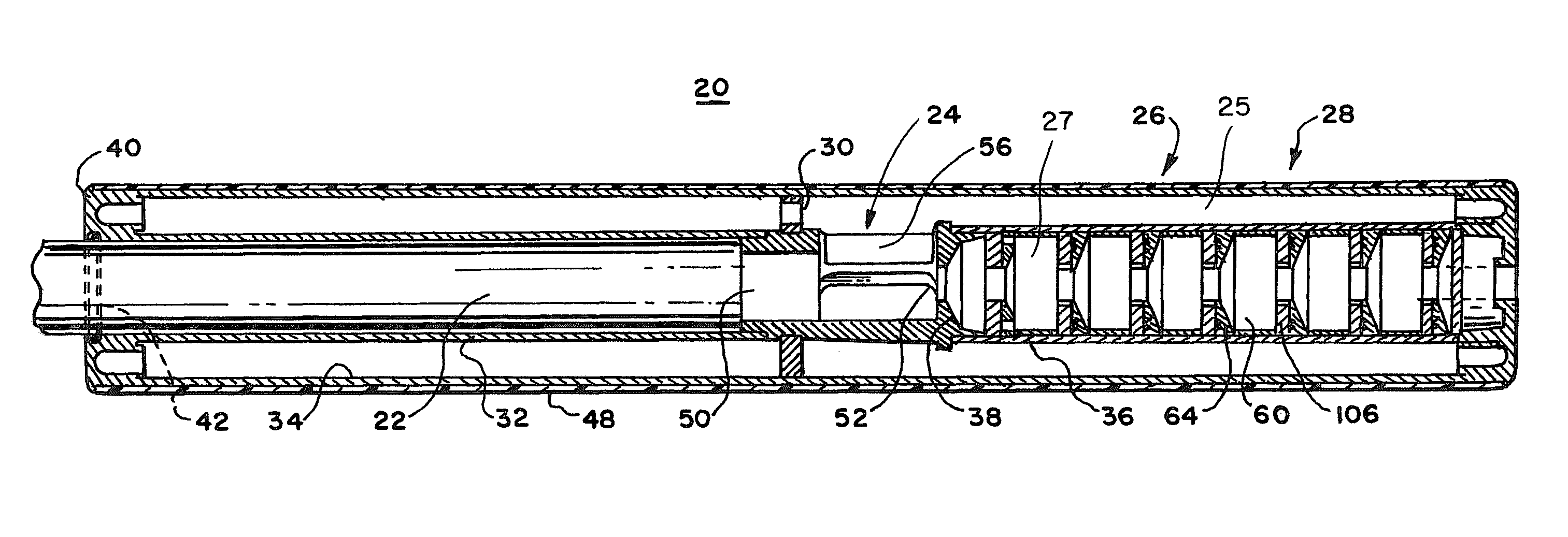

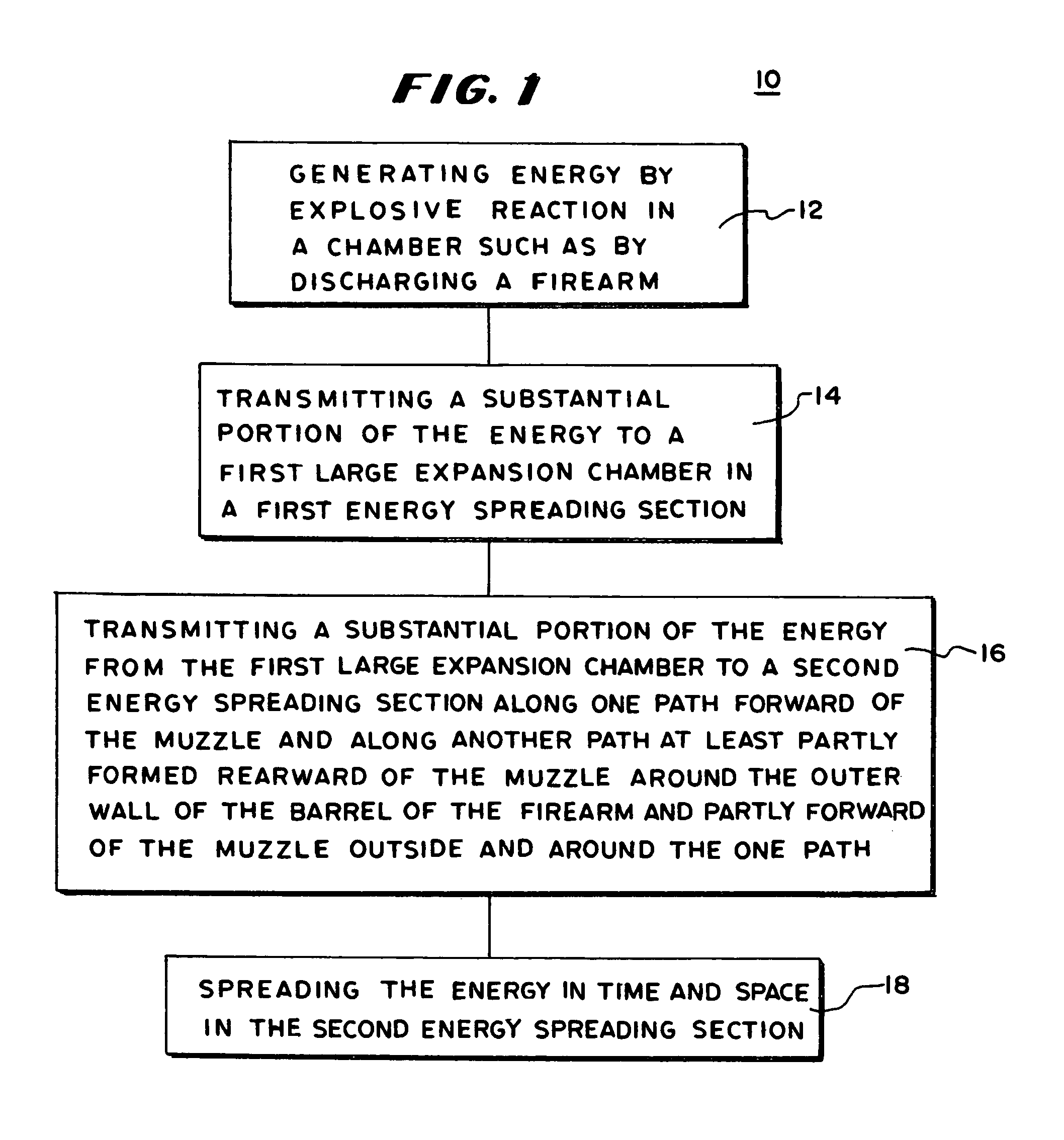

A suppressor for a firearm includes a first gas expansion section of relatively large size sufficient to reduce the temperature and pressure of the gas expelled from a muzzle during discharge of the firearm to a level that avoids rapid degrading of structural members such as baffles in the suppressor that are downstream of the muzzle. The gas is channeled through multiple paths to distribute its energy more equally. Preferably, the suppressor is formed with a lightweight, thermally-conductive composite portion. The composite portion provides lightweight, bursting strength with good thermal conductivity and little contribution to vibrational instability of the muzzle to which it is attached. The composite portion may be of a carbon fiber, silicon, boron, or metallic base. In one embodiment, a first expansion chamber is in communication with the muzzle and with a second expansion chamber and in another embodiment, the first expansion chamber communicates with the muzzle and with the second expansion chamber The composite portions of the suppressor provide good bursting strength and heat conductivity with light weight. In some embodiments, a series of baffles creates turbulence in the gas, slowing its motion and distributing the energy more evenly over space.

Owner:PETERSEN BYRON S

Integrated fuel cell hybrid power plant with controlled oxidant flow for combustion of spent fuel

InactiveUS20050079395A1Reduction of fuelReduction of carbon monoxide emissionFuel cells groupingFuel cell auxillariesElectric forceRecuperator

A hybrid power generation system for generating electrical power comprises a compressor for producing a compressed oxidant and a recuperator in flow communication with the compressor. The hybrid power generation system further comprises a fuel cell assembly comprising a plurality of fuel cells in flow communication with the recuperator to provide the compressed oxidant for the fuel cell assembly. The fuel cell assembly further comprises a cathode inlet for receiving the compressed oxidant, an anode inlet for receiving a fuel stream, an anode outlet in flow communication with an anode exhaust stream and a cathode outlet in flow communication with a cathode exhaust stream, wherein at least a portion of the fuel reacts with the oxidant to produce electrical power. The hybrid power generation system further comprises a tail gas burner in flow communication with the anode outlet and the cathode outlet. The tail gas burner is configured for combusting a mixture of at least a portion of the anode exhaust stream and at least a portion of the cathode exhaust stream and producing a hot compressed gas. A control system is used for controlling the amount of the cathode exhaust stream introduced in the tail gas burner for stable combustion and reduction of fuel and carbon monoxide emission. The hot compressed gas from the tail gas burner is introduced to a turbine, where the hot compressed gas is expanded, thereby producing electrical power and an expanded gas.

Owner:GENERAL ELECTRIC CO

Energy suppressors

ActiveUS7789008B2Good noise suppression characteristicsReduce the amplitudeWeapon componentsBursting strengthFiber

A suppressor for a firearm includes a first gas expansion section of relatively large size sufficient to reduce the temperature and pressure of the gas expelled from a muzzle during discharge of the firearm to a level that avoids rapid degrading of structural members such as baffles in the suppressor that are downstream of the muzzle. The gas is channeled through multiple paths to distribute its energy more equally. Preferably, the suppressor is formed with a lightweight, thermally-conductive composite portion. The composite portion provides lightweight, bursting strength with good thermal conductivity and little contribution to vibrational instability of the muzzle to which it is attached. The composite portion may be of a carbon fiber, silicon, boron, or metallic base. In one embodiment, a first expansion chamber is in communication with the muzzle and with a second expansion chamber and in another embodiment, the first expansion chamber communicates with the muzzle and with the second expansion chamber The composite portions of the suppressor provide good bursting strength and heat conductivity with light weight. In some embodiments, a series of baffles creates turbulence in the gas, slowing its motion and distributing the energy more evenly over space.

Owner:PETERSEN BYRON S

Systems and methods for energy storage and recovery using gas expansion and compression

InactiveUS20110296823A1Increase energy densityElectrical storage systemFluid couplingsEngineeringAtmospheric pressure

In various embodiments, energy-storage systems are based upon an open-air arrangement in which pressurized gas is expanded in small batches from a high pressure of, e.g., several hundred atmospheres to atmospheric pressure. The systems may be sized and operated at a rate that allows for near isothermal expansion and compression of the gas.

Owner:SUSTAINX

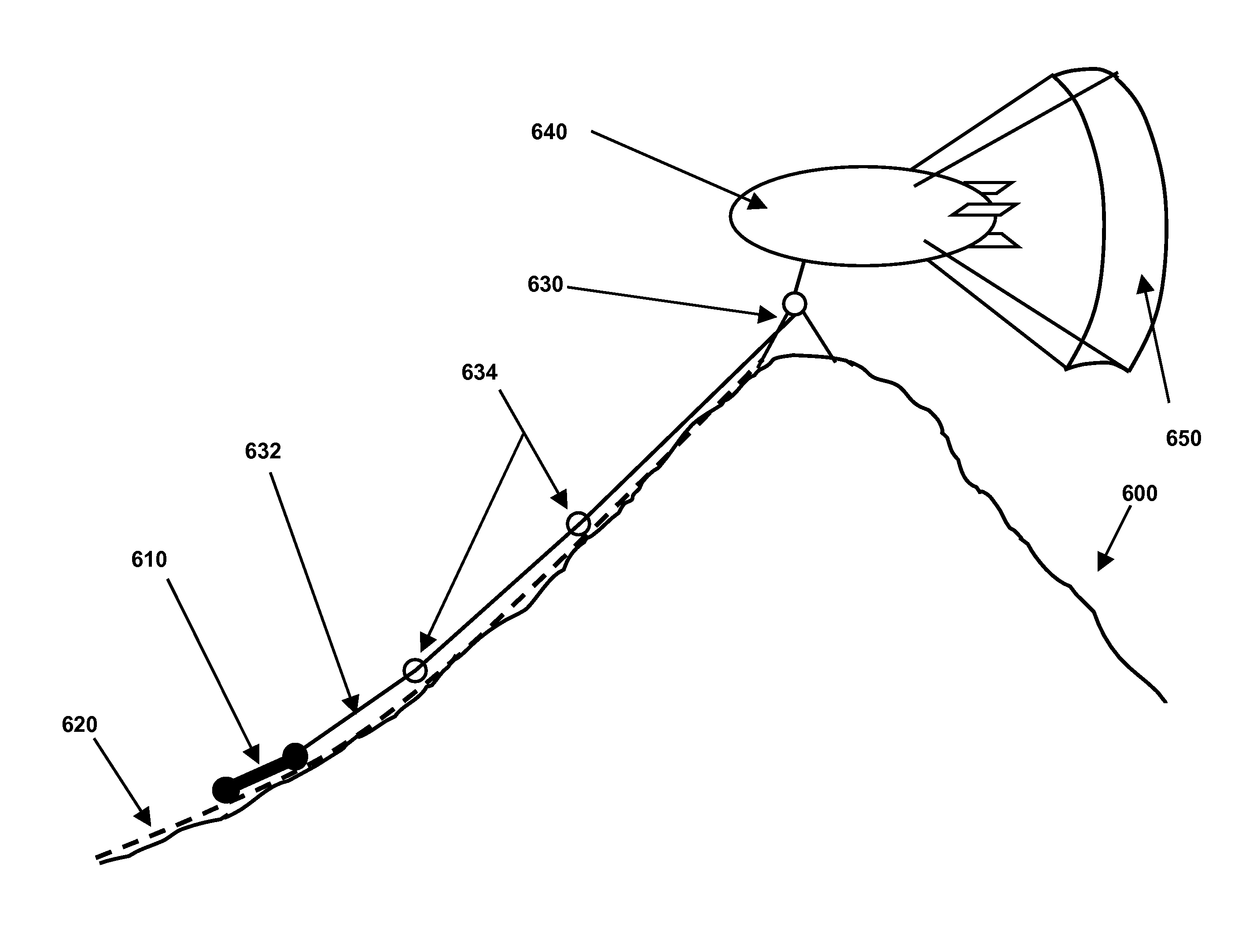

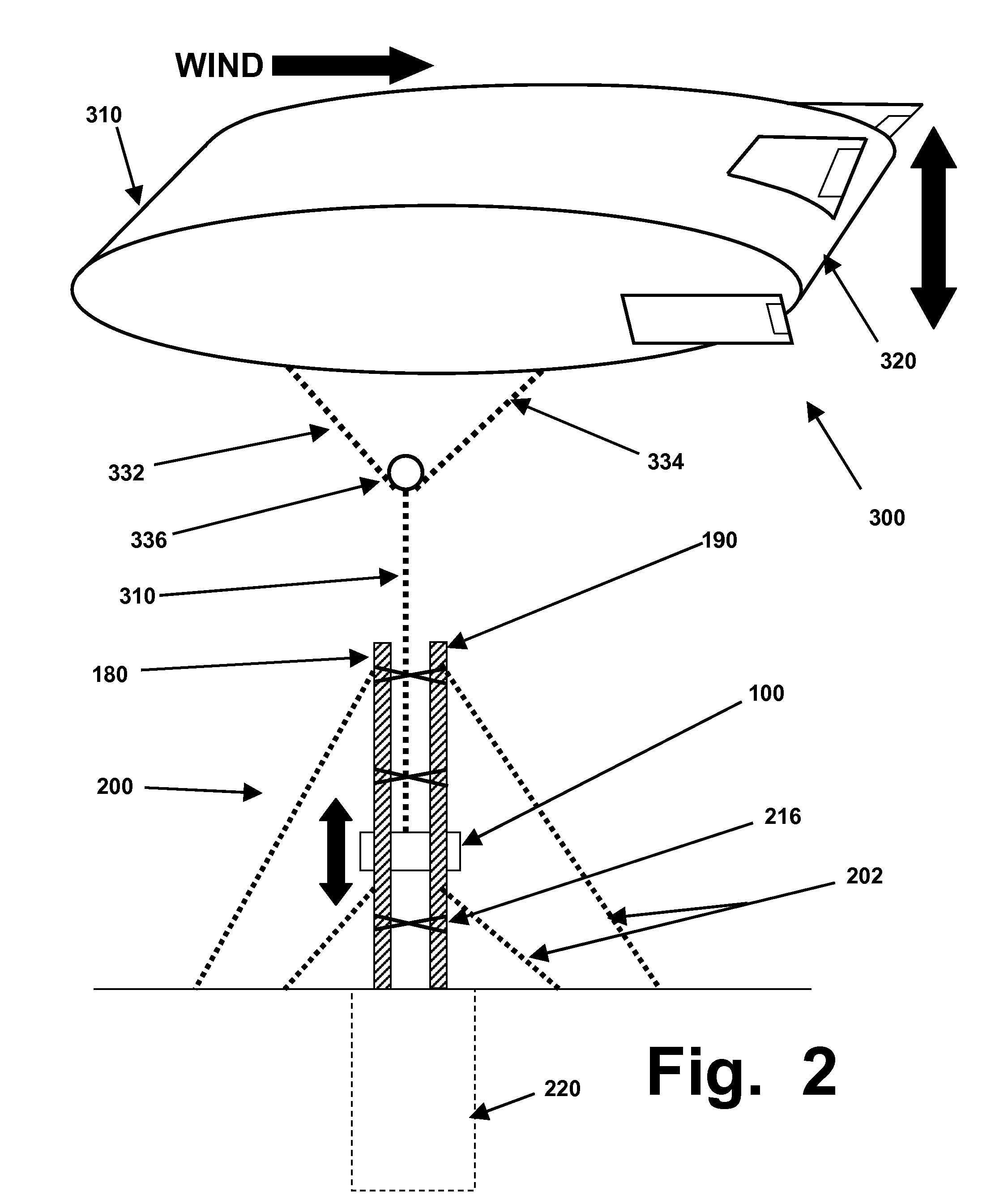

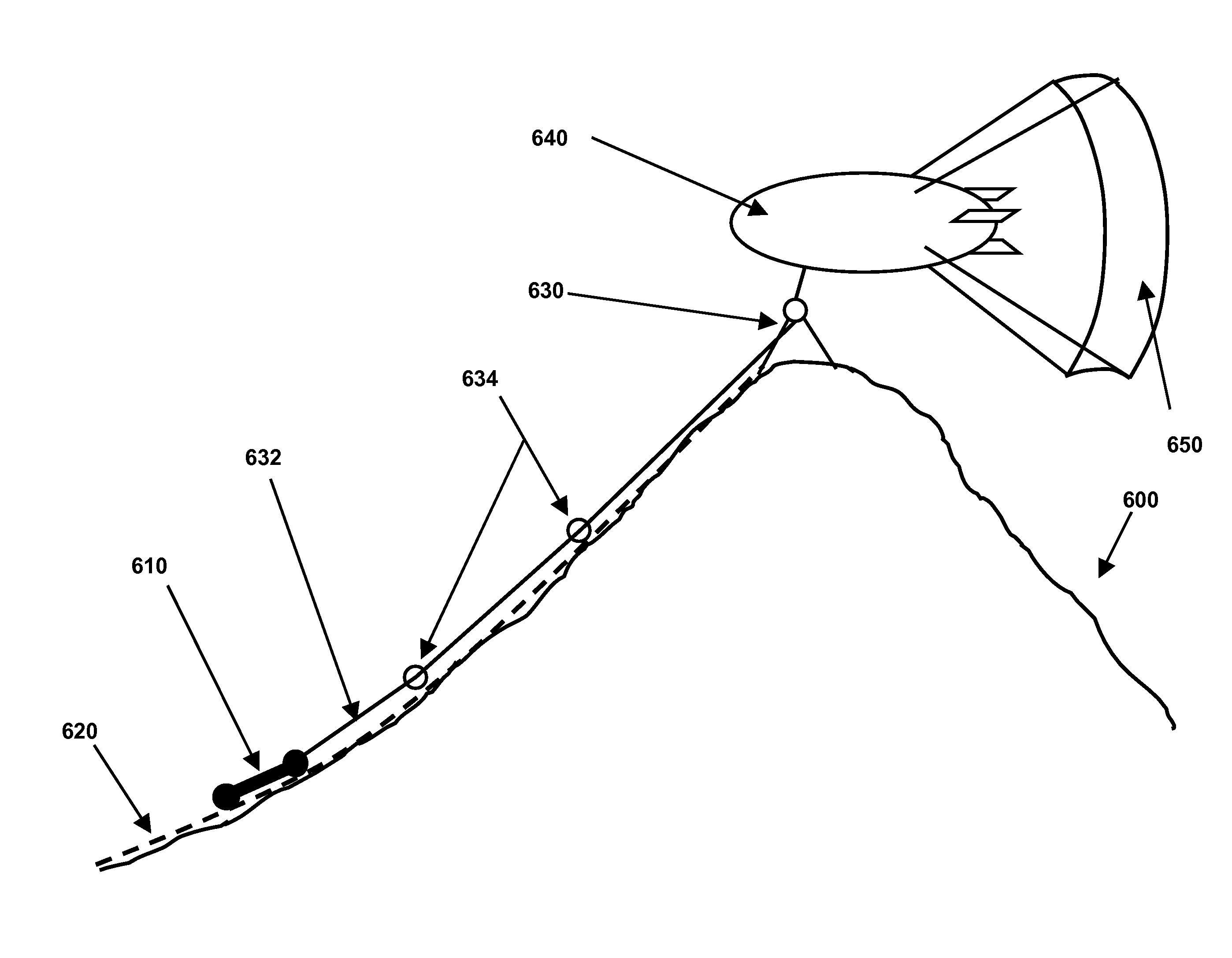

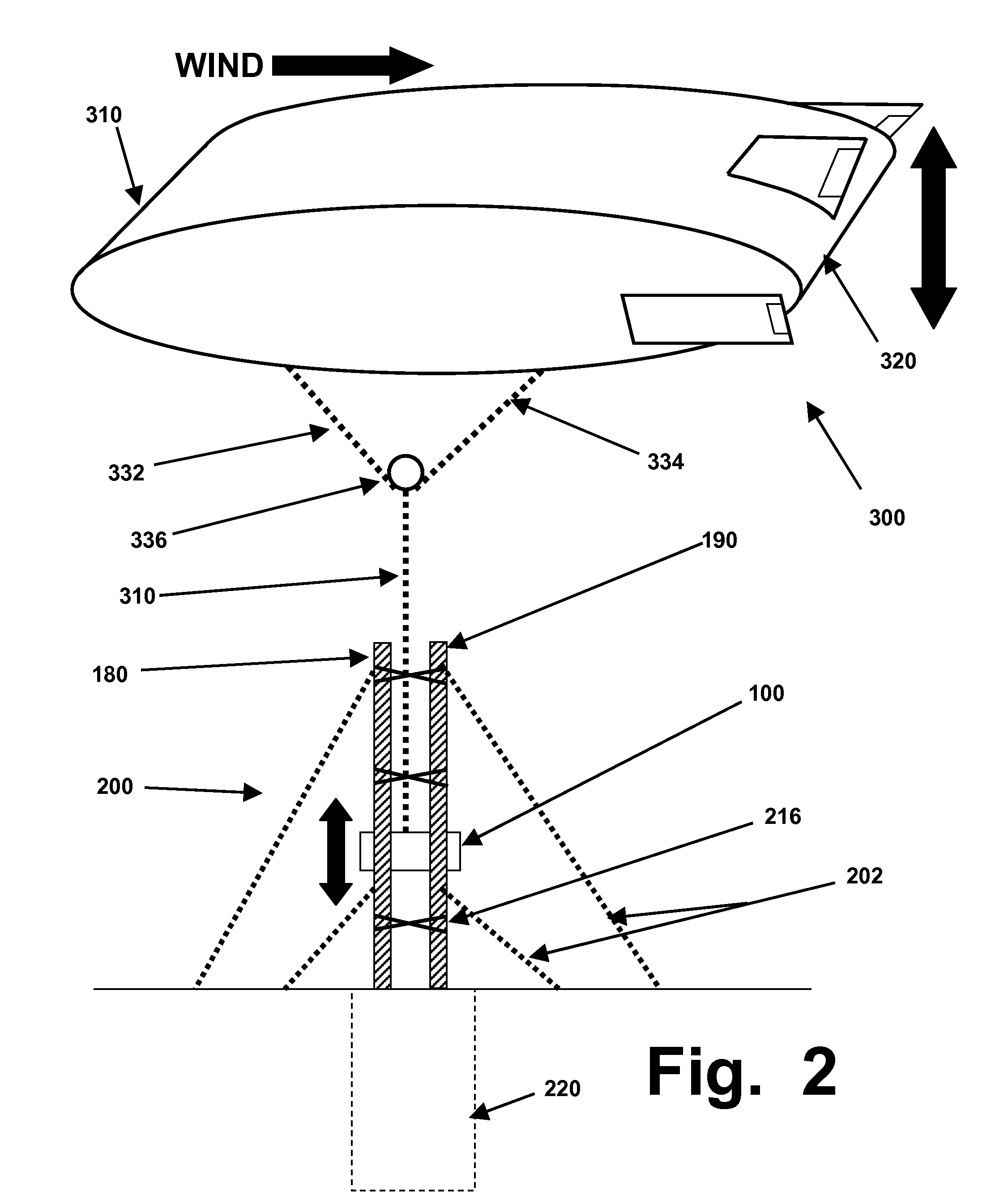

Reciprocating system with buoyant aircraft, spinnaker sail, and heavy cars for generating electric power

InactiveUS8018079B2Large power inputLow efficiencyWind energy with electric storageEnergy storageHydrogenElectric power system

An electric generating system uses a zeppelin filled with helium or hydrogen, and a spinnaker sail, to provide pulling power that will lift a heavy railcar to an elevated height on a track, such as on a hill or mountainside, or in an elevator-type shaft in a tall building. When the heavy car reaches the top of the track, it is released, and its descent drives an electric generator. The generator can be carried by the car, and can send the power to batteries on the car, or to conductive rails. Alternately, if the car is inert weight, cables can drive stationary generators. The zeppelin will be inflated and deflated repeatedly, using equipment to recapture energy during each gas expansion, to help drive subsequent recompression into high-pressure tanks. The spinnaker sail will use a cable-handling device and spreader bars to deploy the sail and keep it at an elevated height. Various advantages are provided compared to wind turbines and pumped-storage hydroelectric facilities.

Owner:TETRAHEED

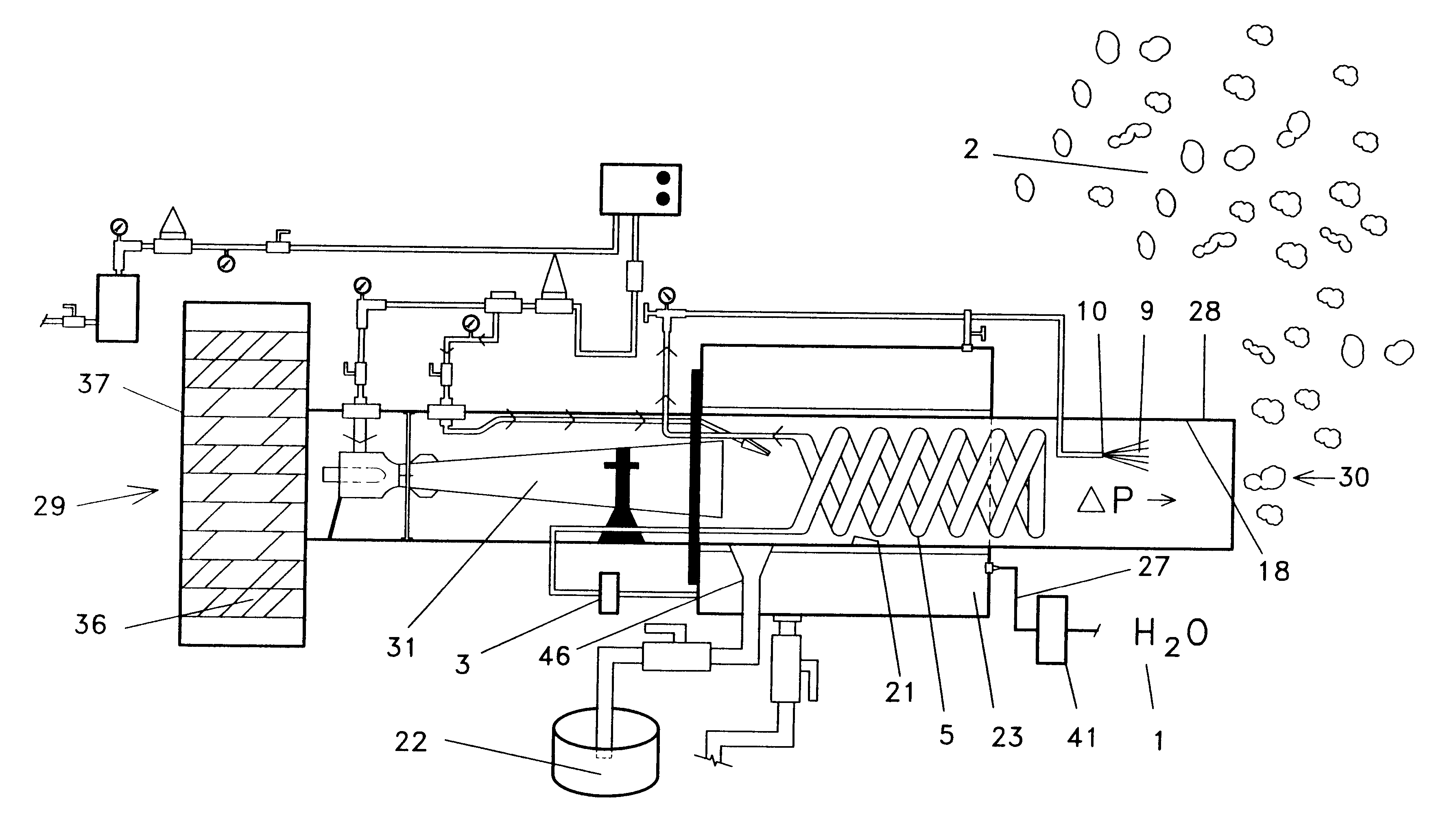

Accelerated water evaporation system

InactiveUS6637379B2Lower the volumeCost effectiveCombustion enginesFlash steam boilersGas to liquidsEvaporation

A liquid to gas converter to convert liquids (1) to gas (2) that can include a liquid pressurization element (3), a liquid preheating element (5), and a nozzle (10) to disperse liquids into energy (7) generated by an energy source (8). The gas to liquid converter can be located inside an enclosure (17) and substances dissolved in the liquid can accumulate as solids (13) on deposition surface (12) of the enclosure as the liquid (1) converts to gas Cis (2). Condensation of a portion of the gas (2) generated can be combined with the solids (13) for continuous removal of such solids (13) from the enclosure (17). A gas expansion compensator can generate a pressure gradient (24) to move the volume of gas generated from the liquid from the enclosure (17).

Owner:RESOURCE WEST

Reciprocating system with buoyant aircraft, spinnaker sail, and heavy cars for generating electric power

ActiveUS20100213718A1Large power inputImprove the forceWind energy with electric storageEnergy storageHydrogenElectric power system

An electric generating system uses a zeppelin filled with helium or hydrogen, and a spinnaker sail, to provide pulling power that will lift a heavy railcar to an elevated height on a track, such as on a hill or mountainside, or in an elevator-type shaft in a tall building. When the heavy car reaches the top of the track, it is released, and its descent drives an electric generator. The generator can be carried by the car, and can send the power to batteries on the car, or to conductive rails. Alternately, if the car is inert weight, cables can drive stationary generators. The zeppelin will be inflated and deflated repeatedly, using equipment to recapture energy during each gas expansion, to help drive subsequent recompression into high-pressure tanks. The spinnaker sail will use a cable-handling device and spreader bars to deploy the sail and keep it at an elevated height. Various advantages are provided compared to wind turbines and pumped-storage hydroelectric facilities.

Owner:TETRAHEED

Air cannon and associated launch canister for a line-fouling system

ActiveUS20160161225A1Rapidly deployableDirect forceDefence devicesPeptide/protein ingredientsCouplingEqualization

FIG. 7 shows an air cannon system loaded with a launch canister containing a prop-fouler. A pressure vessel (28) contains an inlet including a poppet valve (100) that, upon command, can be selectively placed in either a one-way flow position to permit charging of the pressure vessel or otherwise opened to trigger rapid discharge through pressure equalization with the ambient environment. The air cannon may include multiple splayed barrels or a single barrel (158). A launch canister (202), realized in the form of a tube, has a driving plate (350) that closes an end of the launch tube. The driving plate is the first point loaded into the barrel. Within the launch canister (202) a first portion of a floating prop-fouling line is stored. The prop-fouling line, such as made from Dyneema®, has at its ends two drogues that, upon entry into the water, fill with water to produce drag resistance to movement of the prop-fouling line. To avoid undue stress on canopy panels of each drogue and to avoid twisting of shroud lines (312) to the canopy, a rotating shackle (310a, 310b) acts as a coupling point between the shroud lines (312) and the prop-fouling line. Only one drogue (306), its associated coupling and a selected length prop-fouling line are loaded into the launch canister, with the other drogue and its rotating shackle (310b) loaded into a cradle (166). Upon firing, gas expansion causes the rapid acceleration and ejection of the launch tube (202) and generally straight line deployment of the prop-fouling line (302).

Owner:BCB INT

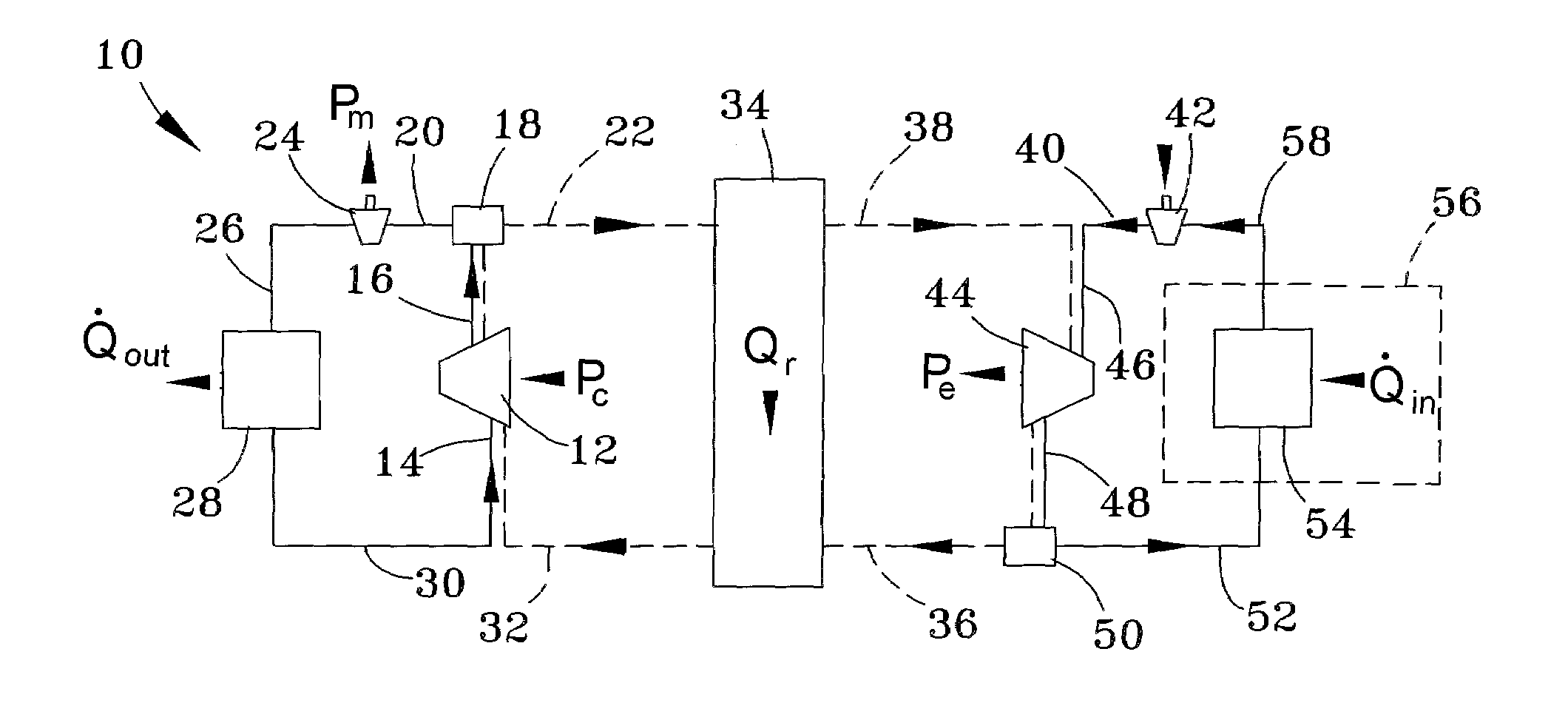

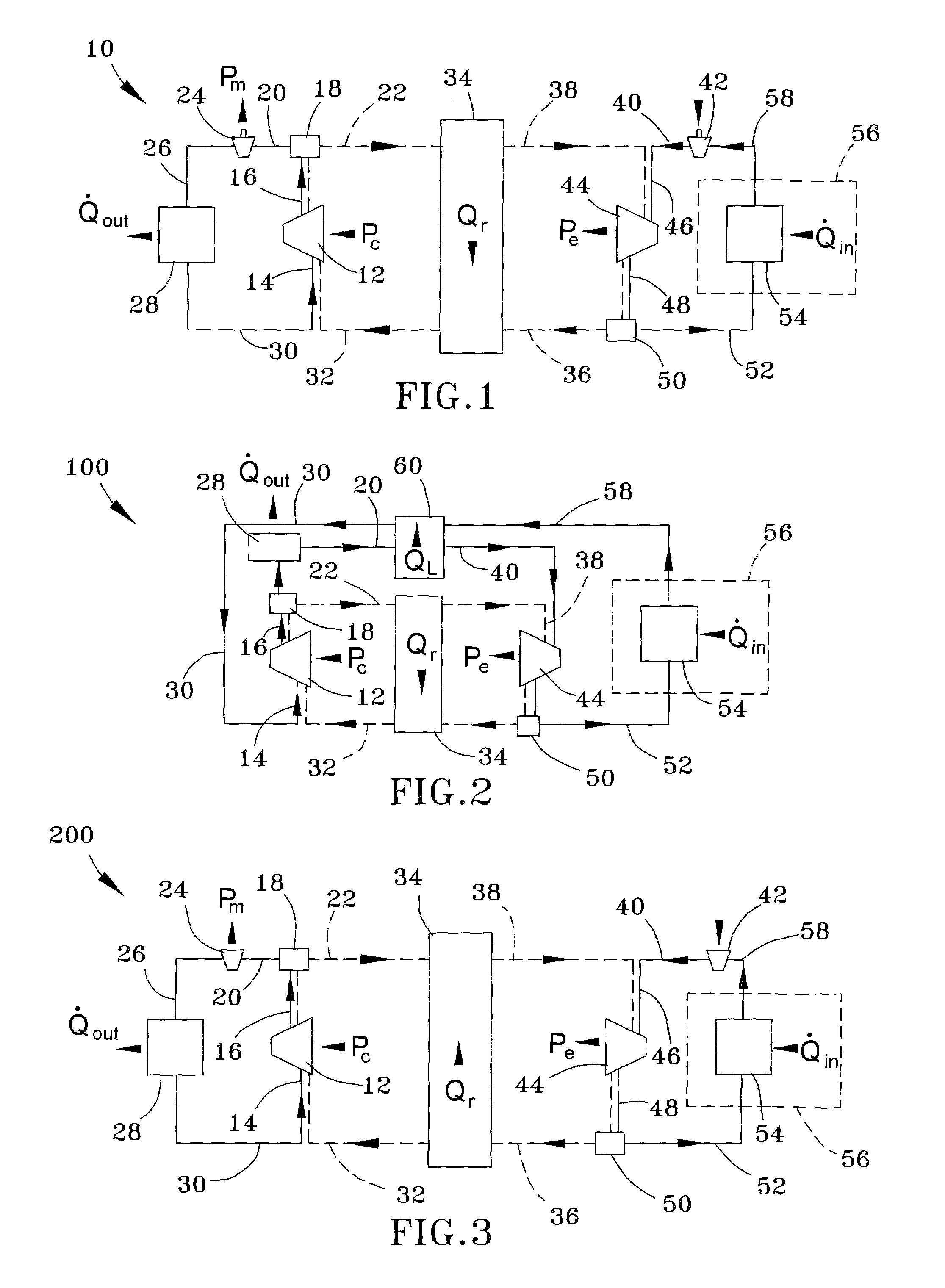

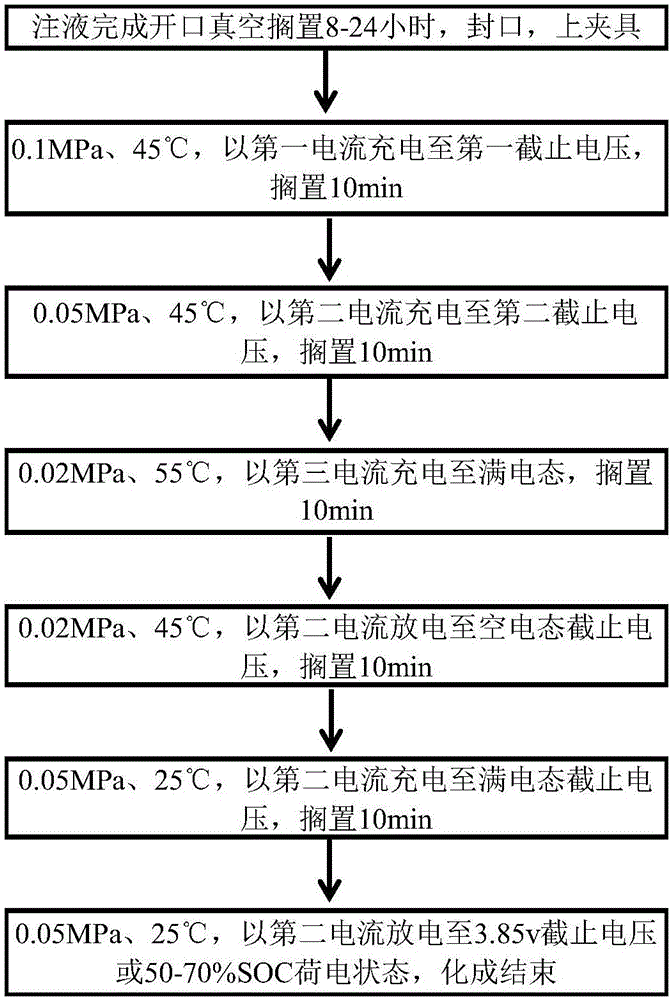

Thermodynamic systems operating with near-isothermal compression and expansion cycles

InactiveUS7401475B2Engine of arcuate-engagement typeCompression machines with non-reversible cycleBrayton cycleProduct gas

A thermodynamic system that can approximate the Ericsson or Brayton cycles and operated in reverse or forward modes to implement a cooler or engine, respectively. The thermodynamic system includes a device for compressing a first fluid stream containing a first gas-liquid mixture having a sufficient liquid content so that compression of the gas within the first gas-liquid mixture by the compressing device is nearly isothermal, and a device for expanding a second fluid stream containing a second gas-liquid mixture having a sufficient liquid content so that expansion of the gas within the second gas-liquid mixture by the expanding device is nearly isothermal. A heat sink is in thermal communication with at least the liquid of the first gas-liquid mixture for transferring heat therefrom, and a heat source is in thermal communication with at least the liquid of the second gas-liquid mixture for transferring heat thereto. A device is provided for transferring heat between at least the gas of the first gas-liquid mixture after the first fluid stream exits the compressing device and at least the gas of the second gas-liquid mixture after the second fluid stream exits the expanding device. The compressing and expanding devices are not liquid-ring compressors or expanders, but instead are devices that tolerate liquid flooding, such as scroll-type compressors and expanders.

Owner:PURDUE RES FOUND INC

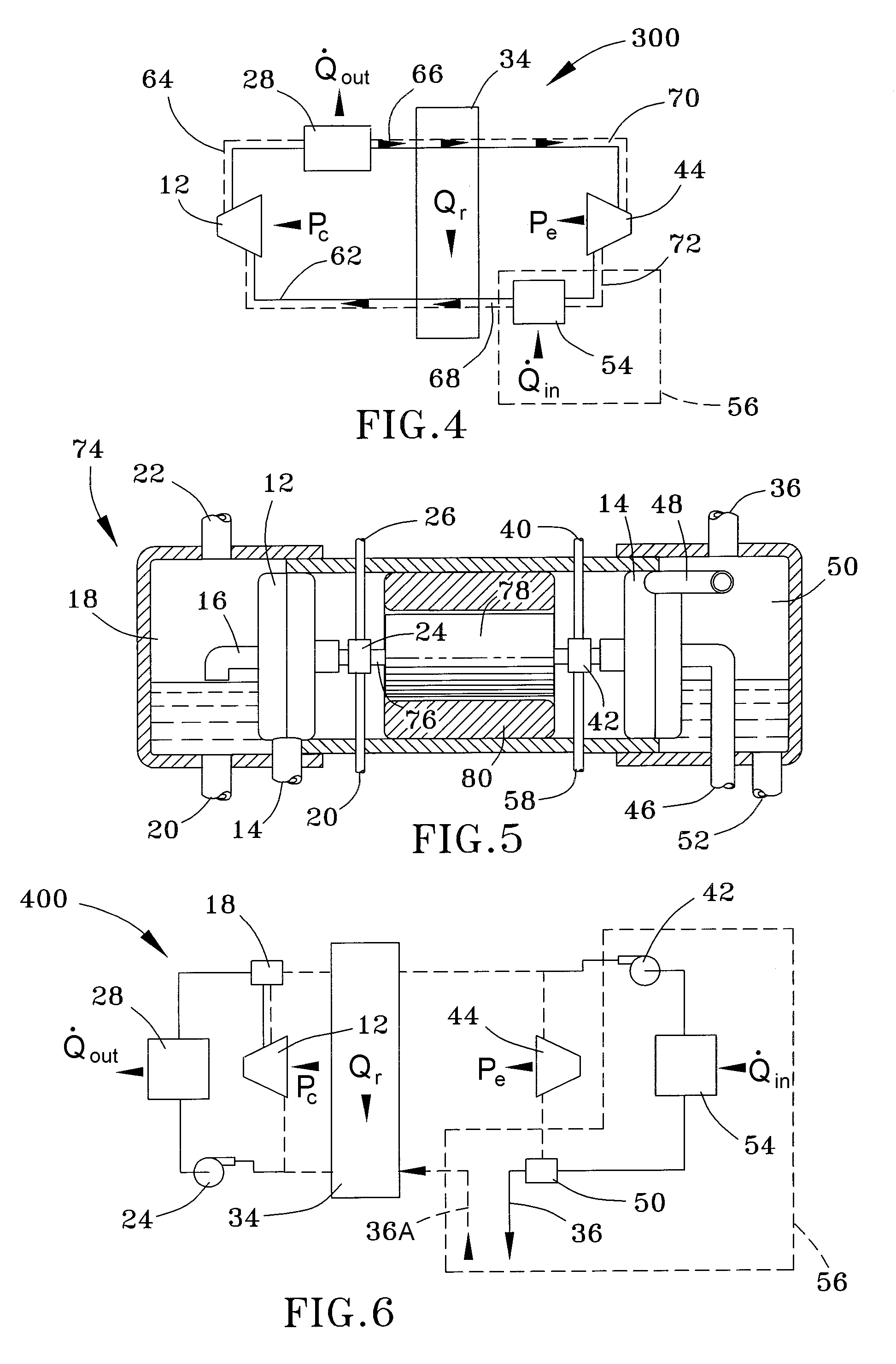

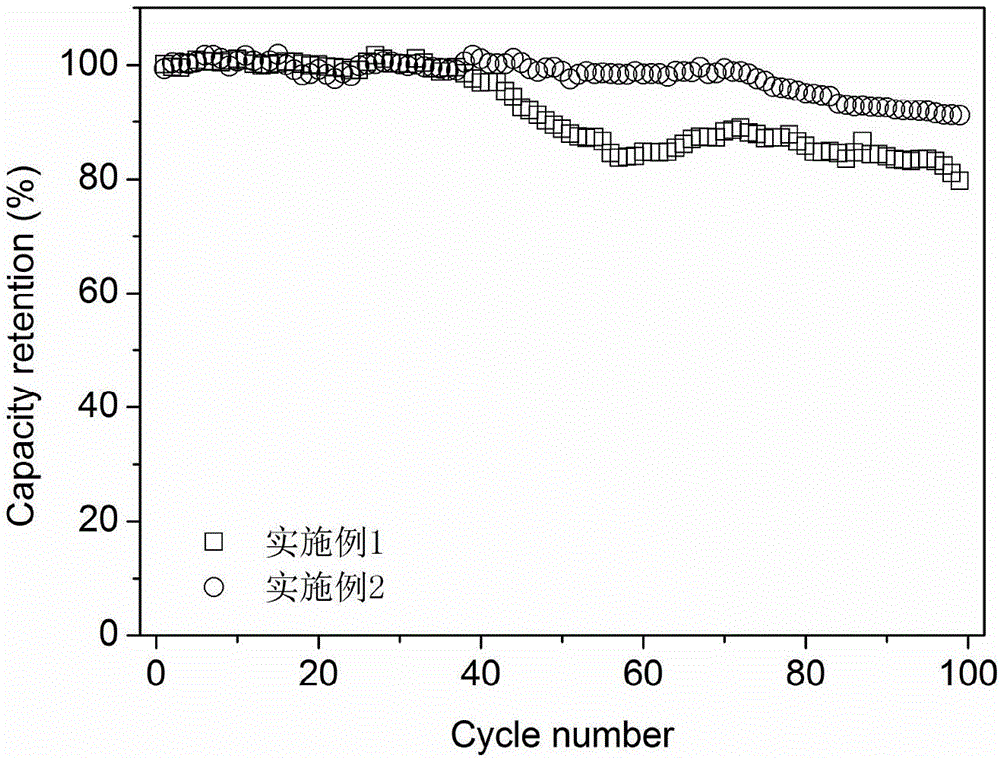

Formation method for high-voltage lithium ion flexibly packaged battery

ActiveCN106684457ASolve flatulenceImprove cycle performanceFinal product manufactureElectrolyte accumulators manufactureLithium-ion batteryHigh voltage

The invention provides a formation method for a high-voltage lithium ion flexibly packaged battery, and relates to the technical field of a lithium ion battery. The formation method comprises the steps of forming an opening in a flexibly packaged cell after the cell is completely injected with an electrolyte, and laying up the cell in a vacuum state for 8-24h, then sealing the opening, mounting a clamp, adjusting pressure and temperature, taking a first current for charging until reaching a first cut-off voltage, and laying up; then adjusting the pressure and temperature, performing two times of charging, discharging, re-charging and re-discharging, and then completing the formation. By adoption of the formation method for the high-voltage lithium ion flexibly packaged battery, a relatively uniform solid electrolyte interphase film (SEI film) can be formed on the surface of the electrode, the problem of battery gas expansion is solved, and the cycling performance of the battery can be improved.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Method to condense and recover carbon dioxide from fuel cells

A method to condense and recover carbon dioxide. A first step involve providing at more than one heat exchanger, with each heat exchanger having a first flow path for passage of a first fluid and a second flow path for passage of a second fluid. A second step involves passing a stream of very cold natural gas sequentially along the first flow path of each heat exchanger until it is heated for distribution and concurrently passing a gaseous stream rich in carbon dioxide sequentially along the second flow path of each heat exchanger, allowing a gaseous portion of the gaseous stream rich in carbon dioxide to pass to a next sequential heat exchanger and capturing in a collection vessel the condensed carbon dioxide. This processes results in a cryogenic heat exchange in which natural gas at Metering and Pressure ReductionStations is first cooled by reducing its pressure through a gas expander or a pressure reducing valve and then heated in a series of stages and the gaseous stream rich in carbon dioxide stream is separated in a series of stages through sequential cryogenic carbon dioxide separation and recovery.

Owner:1304338 ALBERTA

External heat engine of the rotary vane type and compressor/expander

InactiveUS20080041056A1Efficient thermal energyLow costOscillating piston enginesSealing arrangement for pumpsThermal energyMechanical energy

A heat engine of the rotary vane type and thermodynamic cycle is disclosed. The engine converts thermal energy contained within relatively low temperature hot gasses into mechanical energy. The engine operates by expanding a hot gas to a sub-atmospheric pressure, cooling the gas at a roughly constant volume and then cooling the gas further while compressing it back to atmospheric pressure. Possible sources of hot gasses for powering the engine include exhaust gasses from other engines and air heated by solar collectors. A novel compressor and expander comprised of the primary components of the engine is also disclosed.

Owner:CARNAHAN ERIC SCOTT

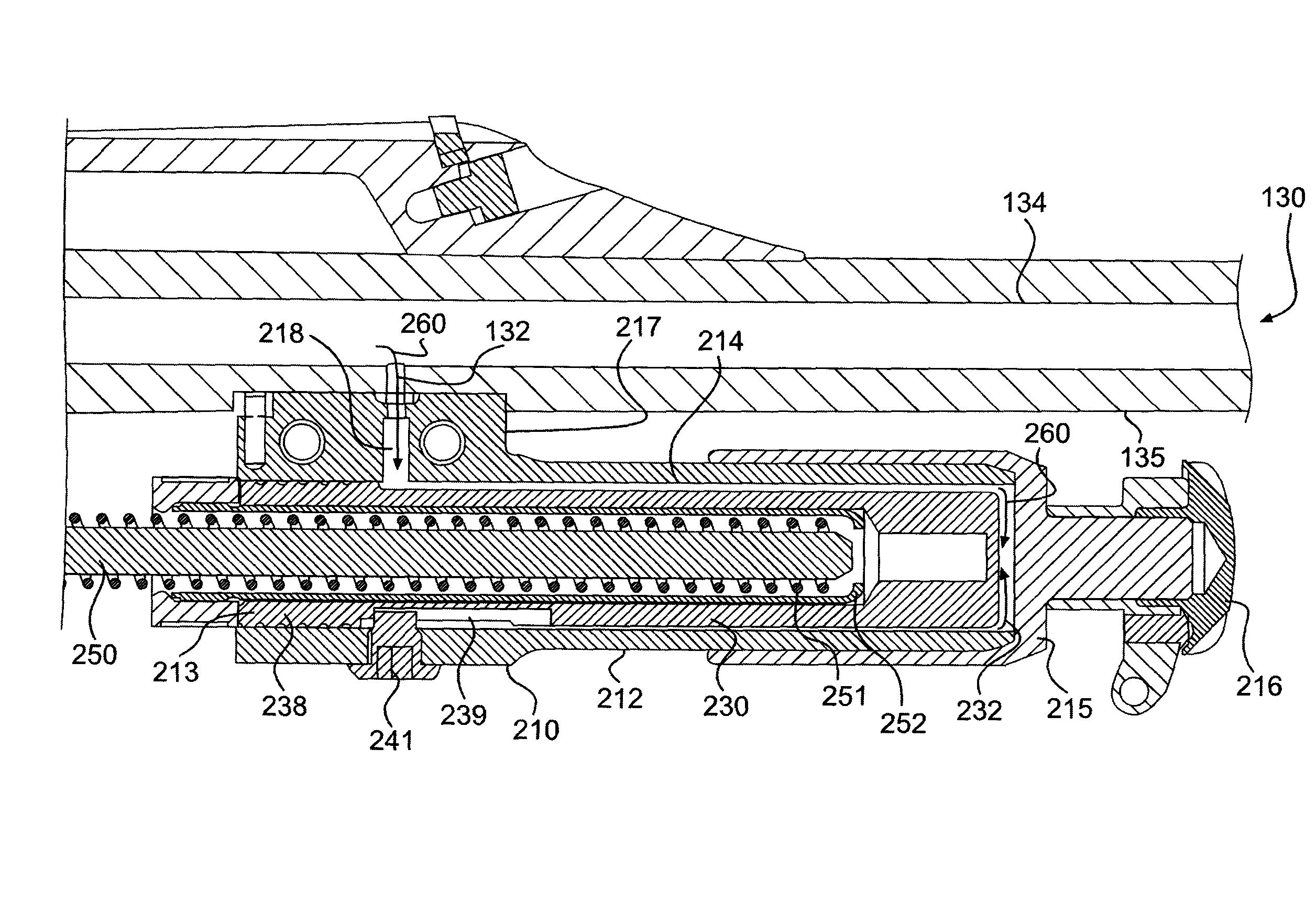

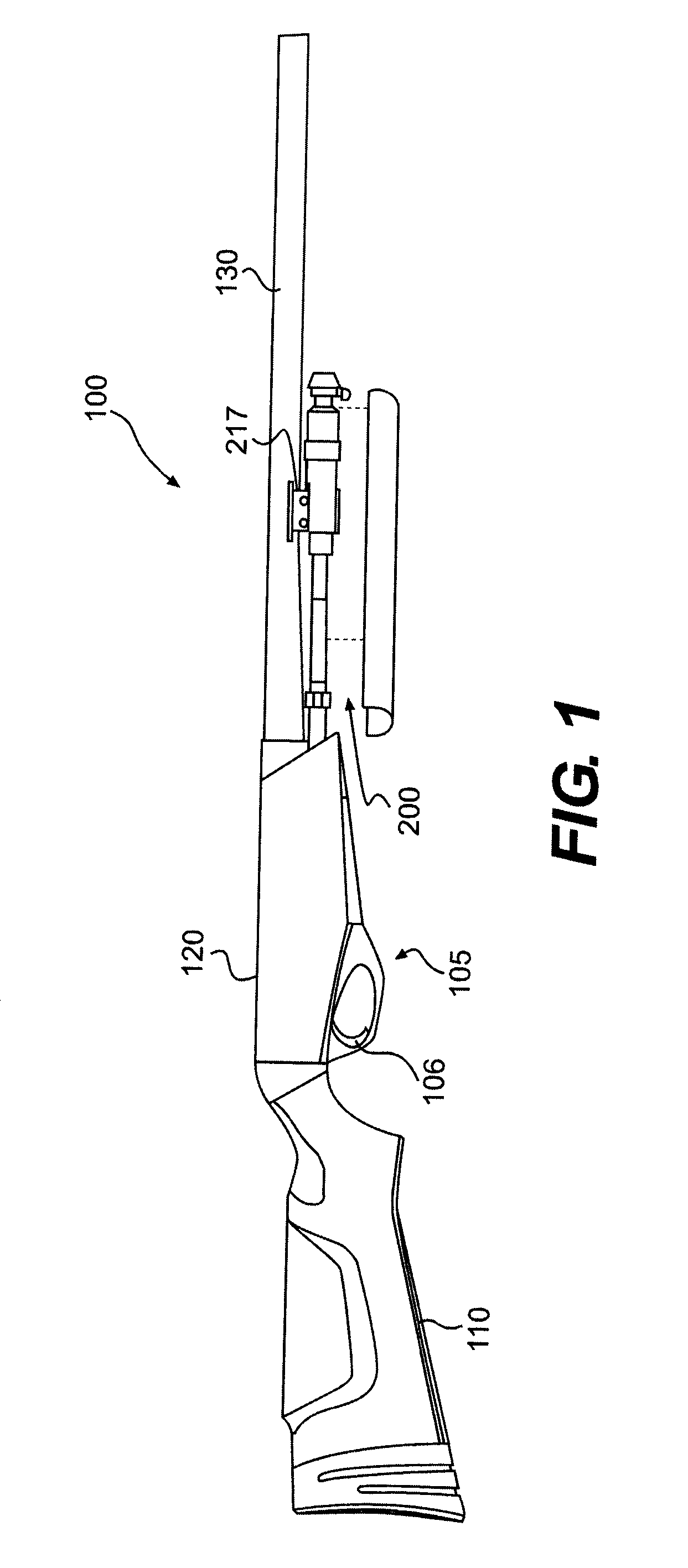

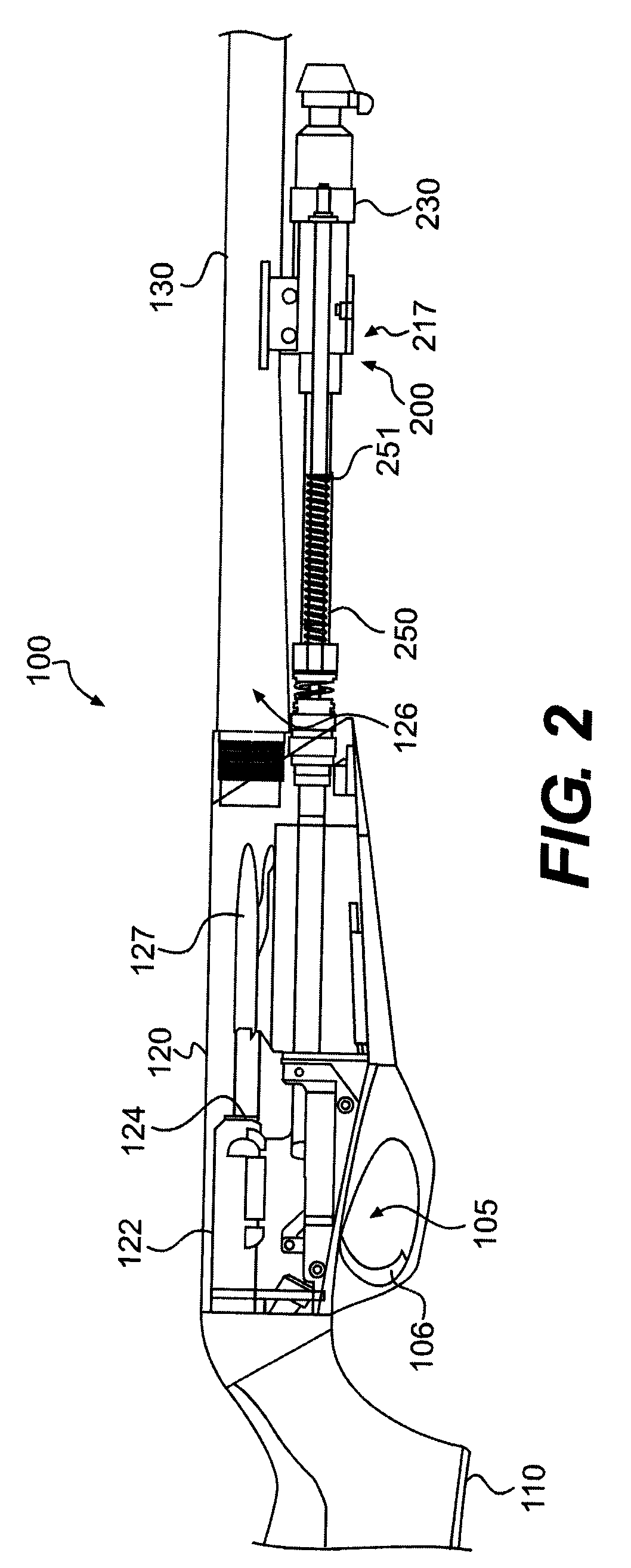

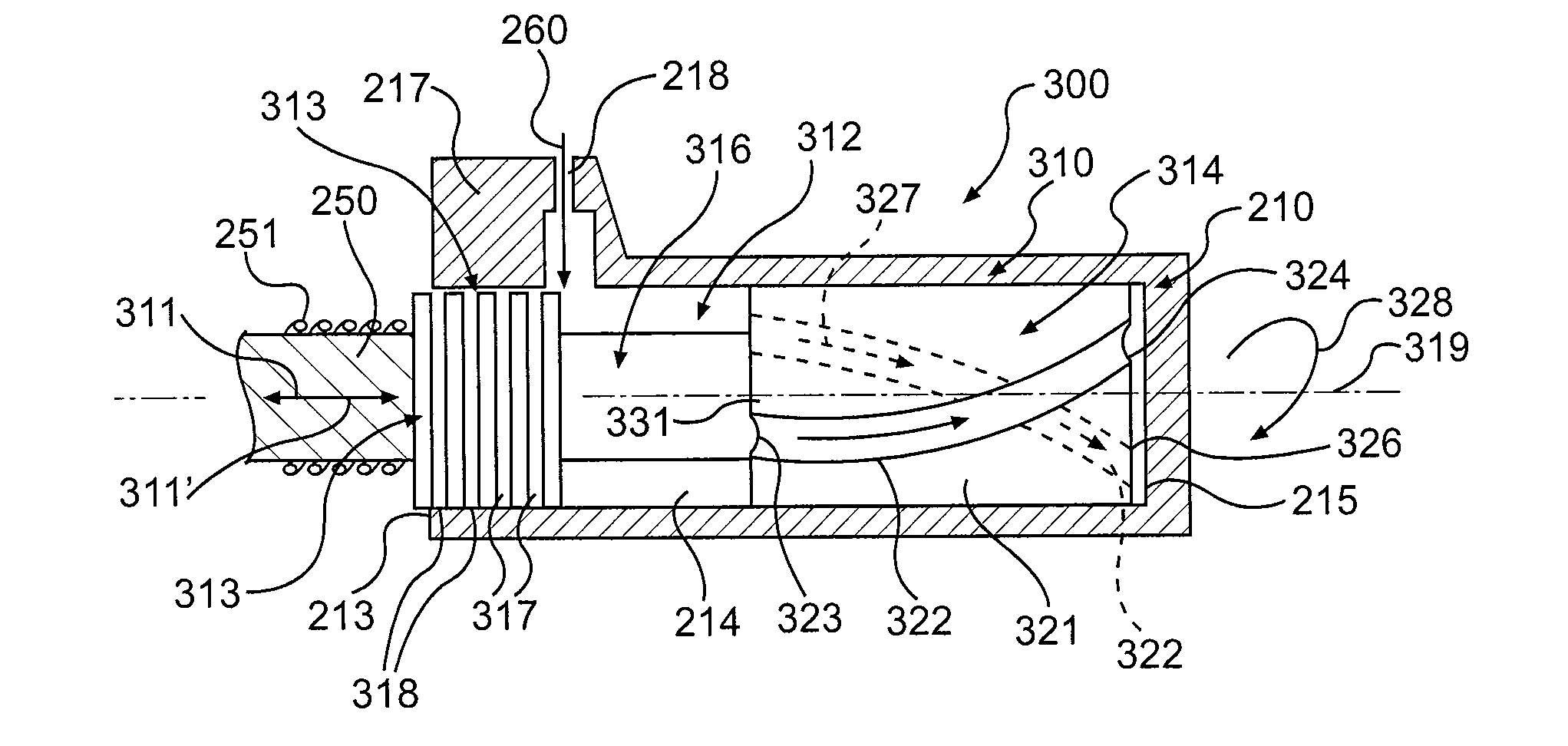

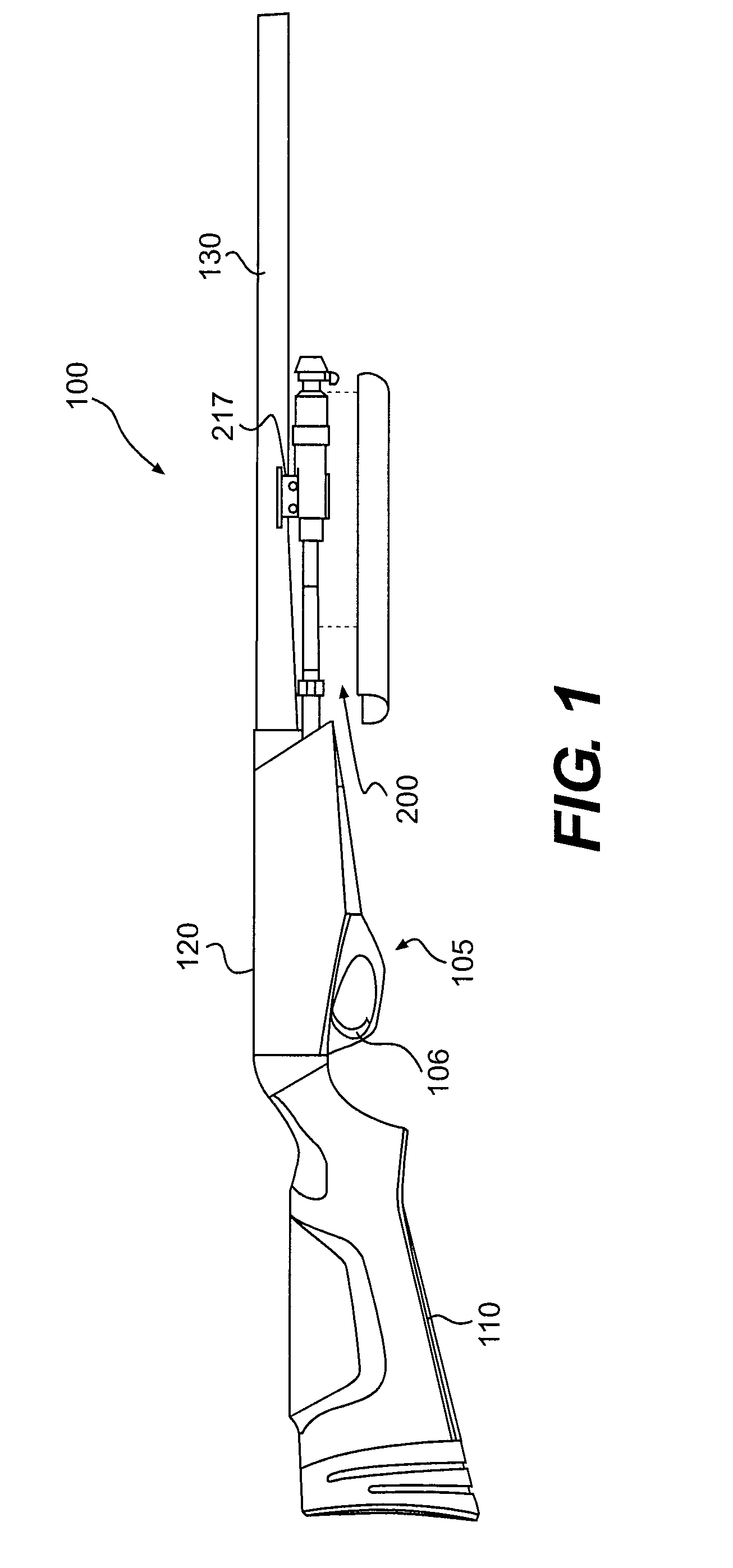

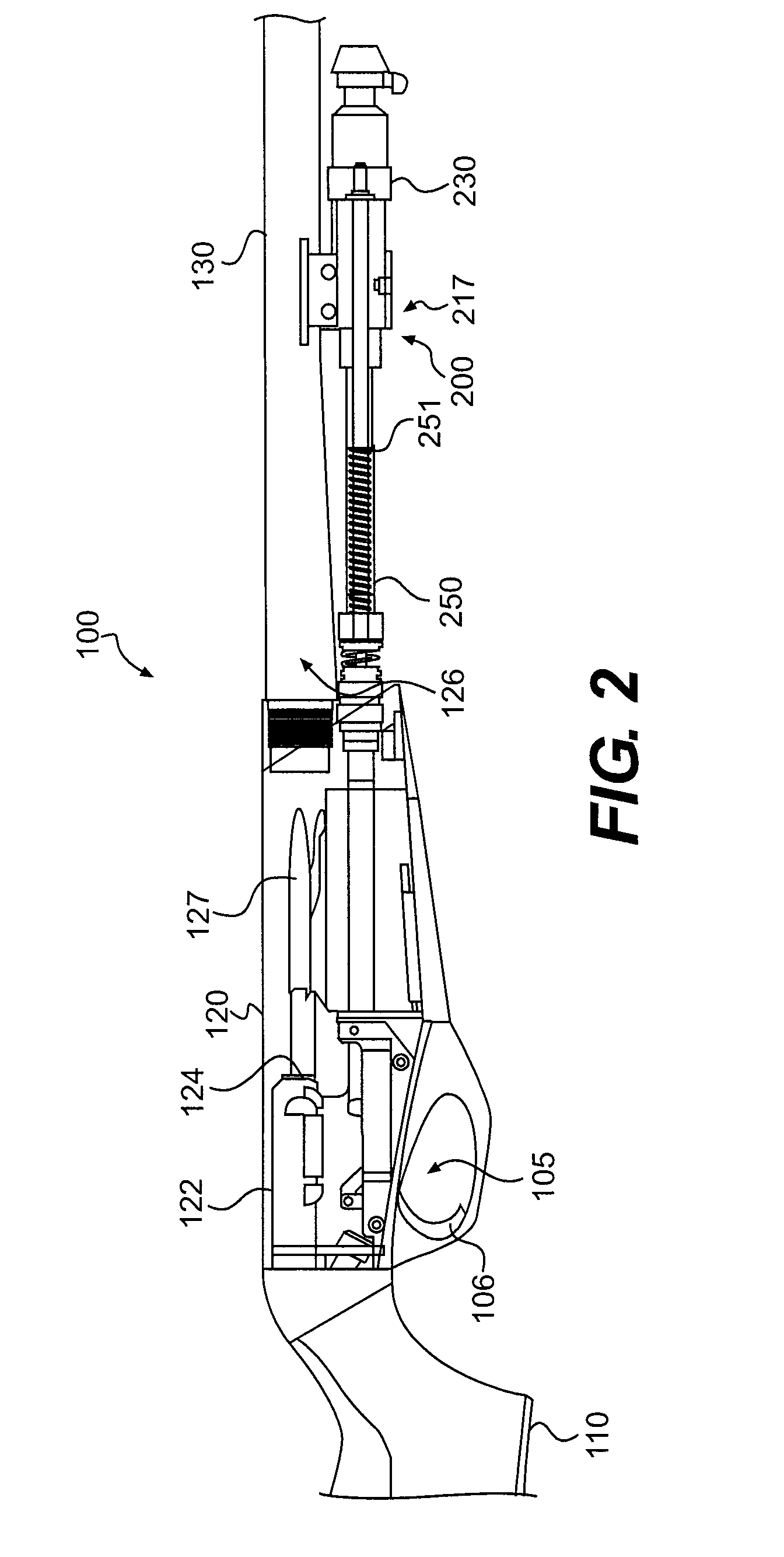

Gas system for firearms

InactiveUS7946214B2Reduced dampingLimit axial travelWeapon componentsEngineeringMechanical engineering

A piston assembly is provided for a gas-operated firearm of the type having a chamber and a barrel. The piston assembly includes a gas expansion housing and a piston mounted within the gas expansion housing. An annular recess is formed in the outer wall of the piston to receive exhaust gases diverted from the barrel upon firing of the firearm. At least one longitudinally extending groove extends from the annual recess to the head of the piston and forms a pathway for diverting the exhaust gases to the head of the piston. During firing, pressurized gases are diverted into the annular recess and expand longitudinally from the annular recess to the piston head, whereupon the pressurized exhaust gas drives the gas piston rearwardly along the housing.

Owner:REM TML HLDG LLC

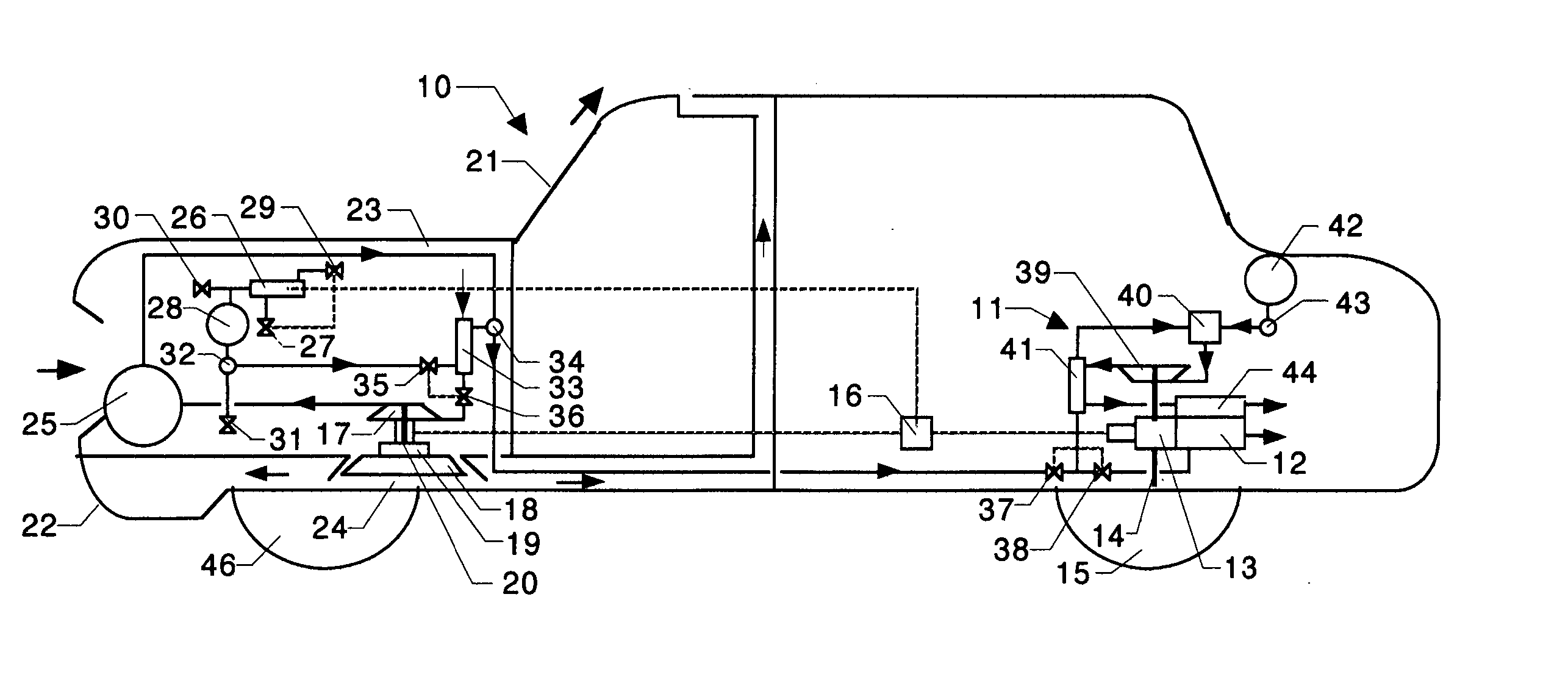

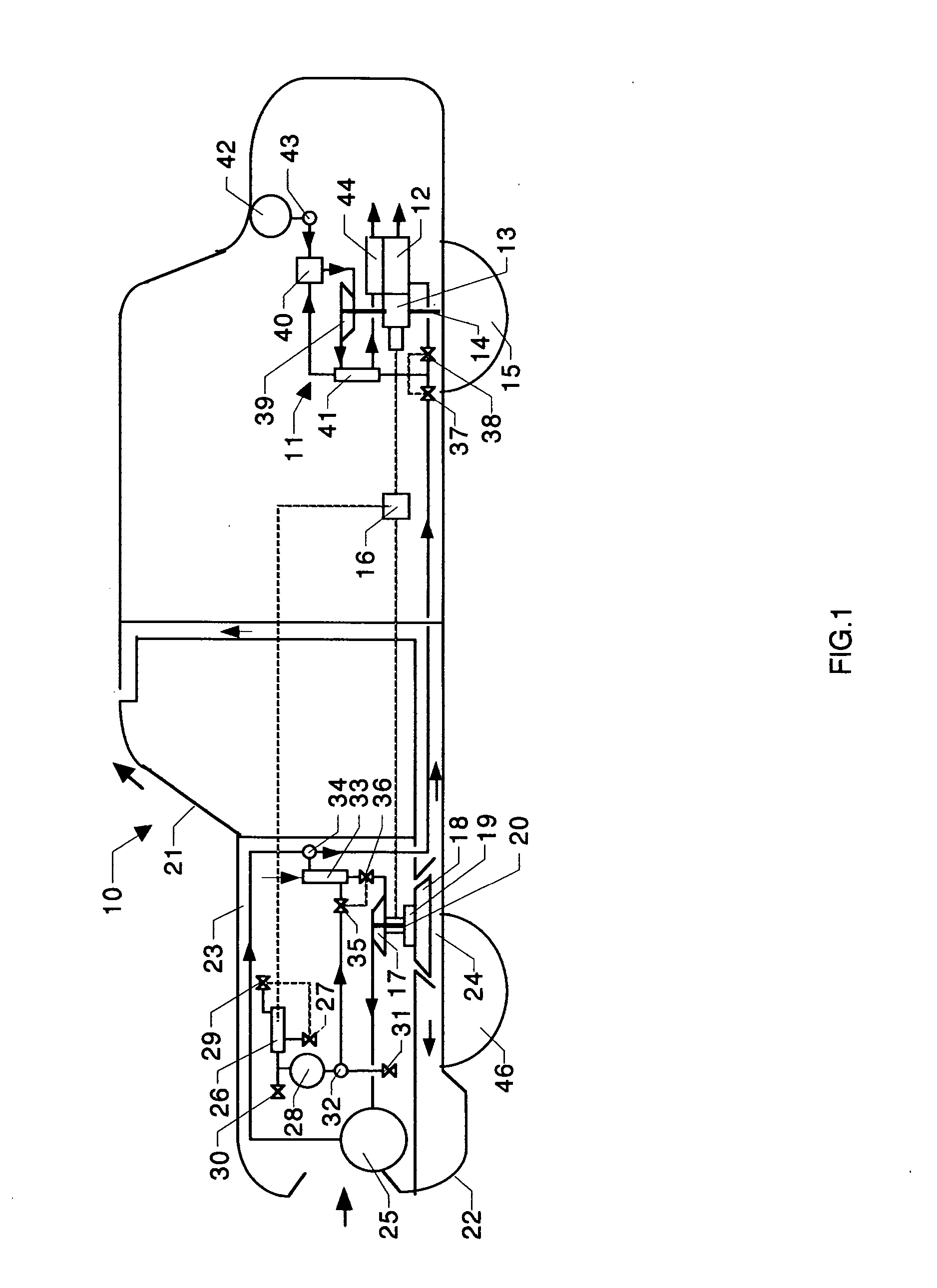

Motor vehicle energy recovery, storage, transfer and consumption system

InactiveUS20050252696A1Reduced turbine inletReduce exhaust temperatureAuxillary drivesVehicle sub-unit featuresWorking fluidAtmospheric air

An energy conversion apparatus and method using recovered energy sources including motor vehicle kinetic energy (deceleration and shock) and wind resistance, supplemented by liquefied air transferred to the vehicle and by solar radiation thereto. The energy sources are combined, as available, to drive a compressor for supplying intake working fluid of a motor vehicle prime mover, wherein liquefied air provides pre-compression cooling of an atmospheric air portion of the working fluid. The liquefied air is made by recovered energy, stored and transferred between vehicles and between vehicles and stationary sites. In a hybrid version of the vehicle, exhaust heat from a combustion engine part of the prime mover increases working fluid temperature in a gas expander part, thereof; the engine and expander operating independently or together for improved vehicle propulsion efficiency.

Owner:KAUFMAN JAY STEPHEN

Green mining method and mining device for submarine shallow non-diagenetic natural gas hydrate

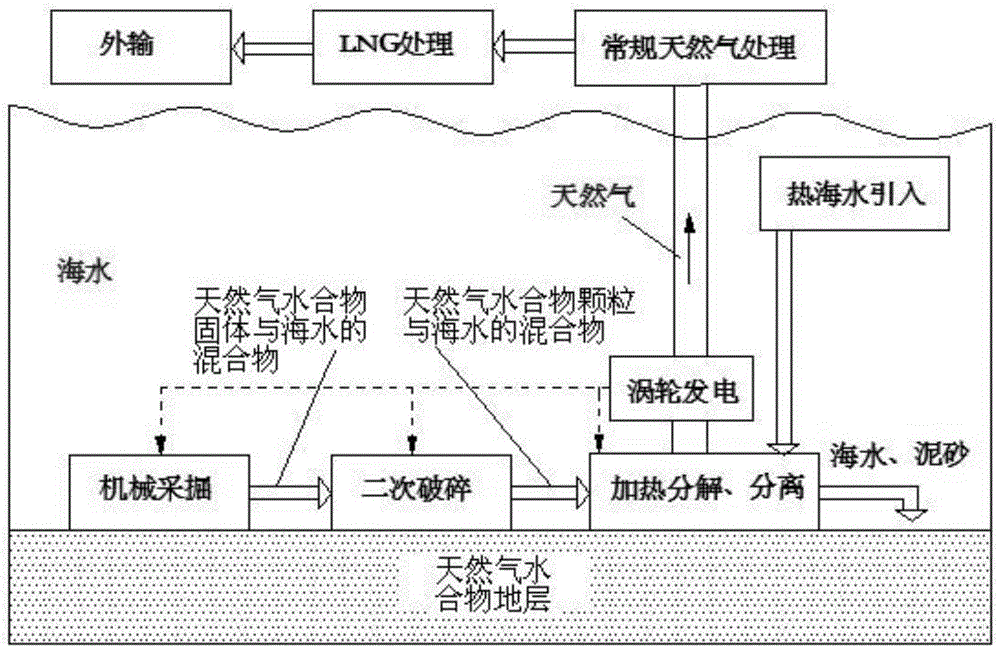

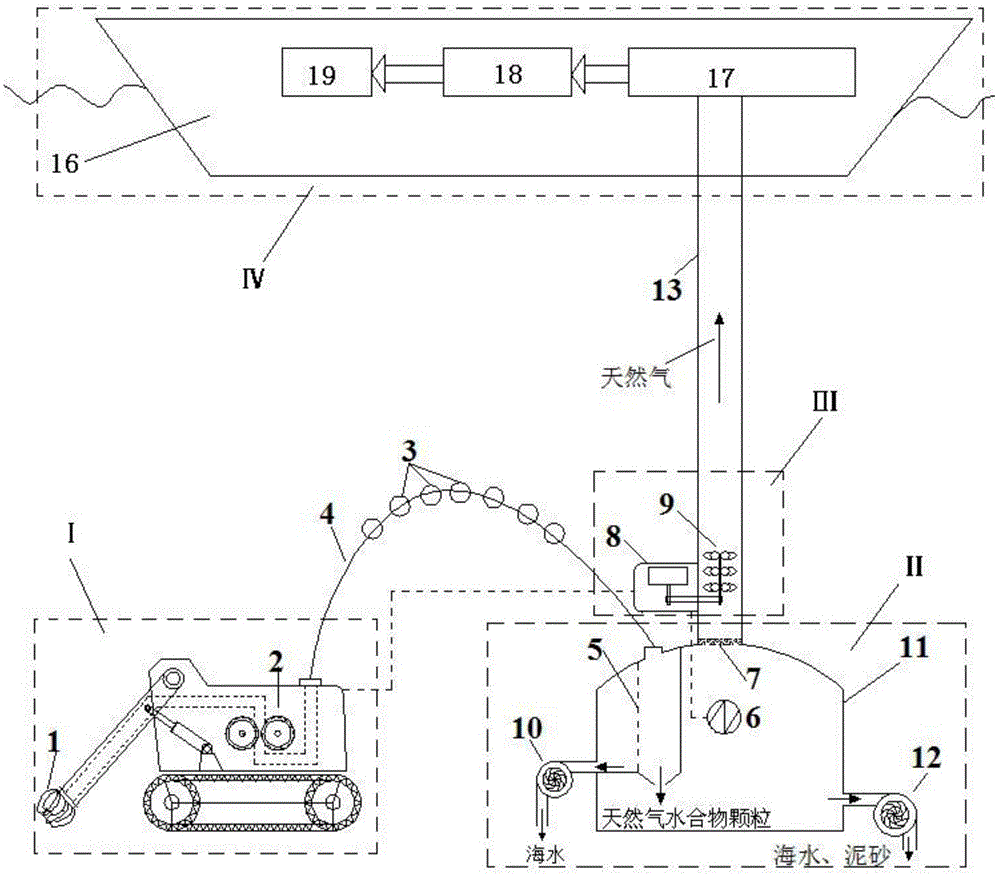

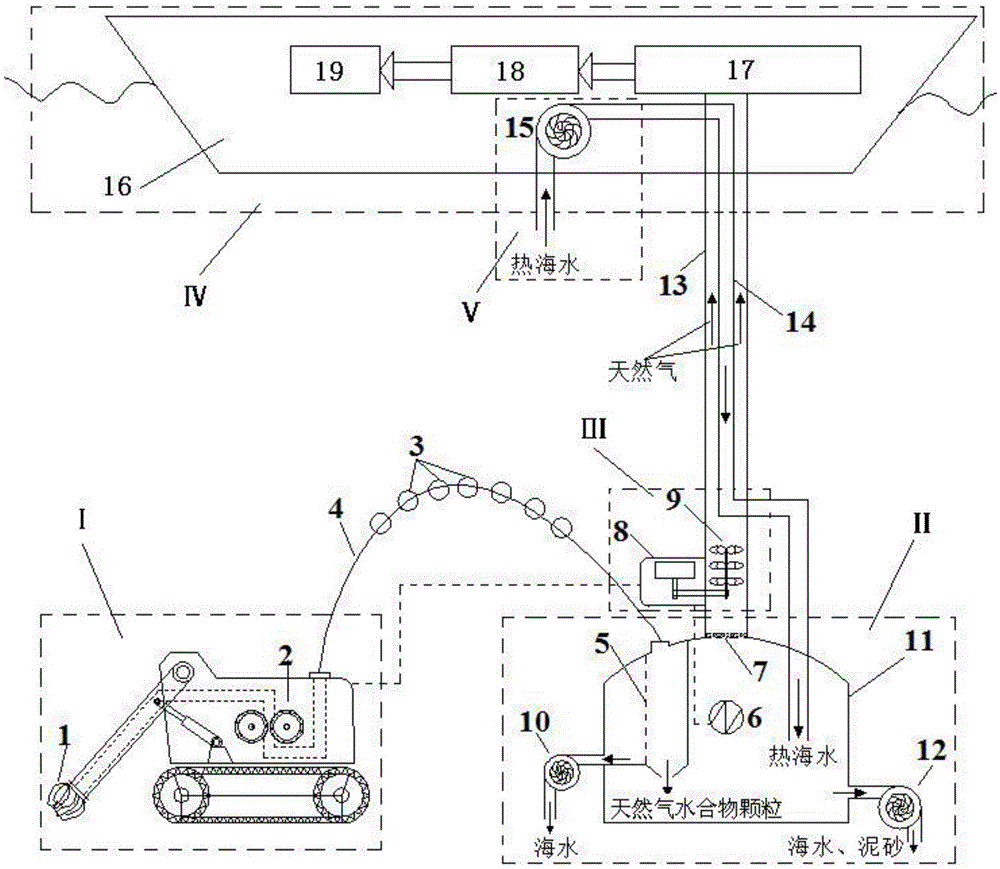

ActiveCN105587303ADoes not change temperatureDoes not change the pressureConstructionsFluid removalDecompositionEnergy supply

The invention discloses a green mining method and mining device for submarine shallow non-diagenetic natural gas hydrate. The green mining method comprises the following steps that on the condition that the ambient temperature and pressure of a submarine natural gas hydrate stratum are not changed, the natural gas hydrate is mined in a submarine mining mode and broken for two times to obtain a mixture of natural gas hydrate particles and seawater; thermal decomposition is directly performed on the mixture of the natural gas hydrate particles and the seawater at the bottom of sea in a sealed environment to obtain natural gas, wherein energy needed by thermal decomposition comes from energy generated through gas expansion work during thermal decomposition of the natural gas hydrate; the natural gas is delivered to the sea surface to be subjected to aftertreatment, and liquefied natural gas is obtained. The green mining device comprises a mining and breaking unit, a first transportation pipe, a decomposition unit, a natural gas transportation pipe, an energy supplying unit and a sea surface supporting unit.

Owner:SOUTHWEST PETROLEUM UNIV

System and method for recovering exhaust gas in olefin polymer production

ActiveCN103520946AHigh recovery rateReduce energy consumptionVapor condensationEthylene productionPolyolefinGas phase

The invention provides a system for recovering the emission of an olefin polymerization process. The system comprises a devolatilization device, a compression cooling unit, a first gas-liquid separation device, a first gas separation device and a second gas separation device, wherein the devolatilization device is used for receiving the emission and fresh purge gas from the olefin polymerization process and outputting a first fluid and polyolefin resin; the compression cooling unit comprises a compression device and a first heat exchange device and is used for receiving the first fluid and outputting a first gas-liquid mixture; the first gas-liquid separation device is used for performing gas-liquid separation on the first gas-liquid mixture and outputting a first recovery product and a first gas-phase component; the first gas separation device is used for receiving the first gas-phase component and removing small-molecular substances therein and outputting a component rich in small-molecular gases and a second gas-phase component rich in hydrocarbon substances; the second gas separation device comprises a second heat exchange device, a second gas-liquid separation device and a first gas expansion device.

Owner:HANGZHOU SHUANGAN SCI TECH +1

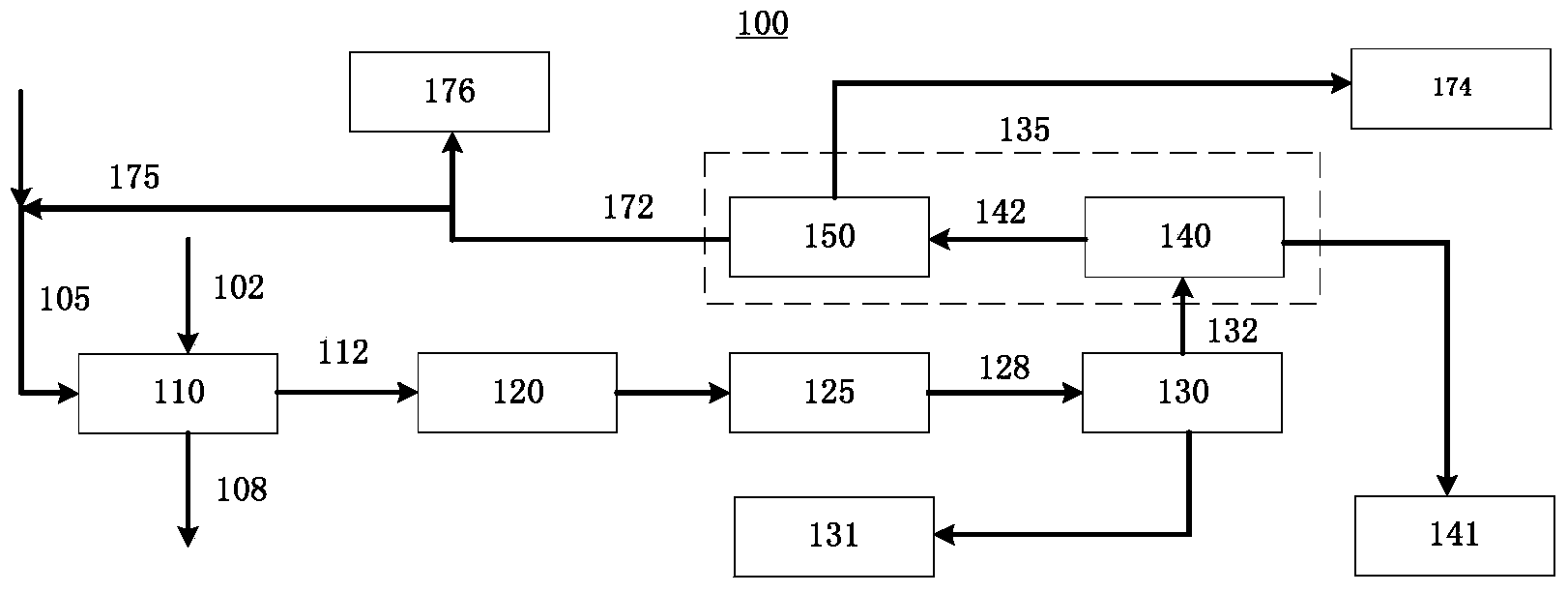

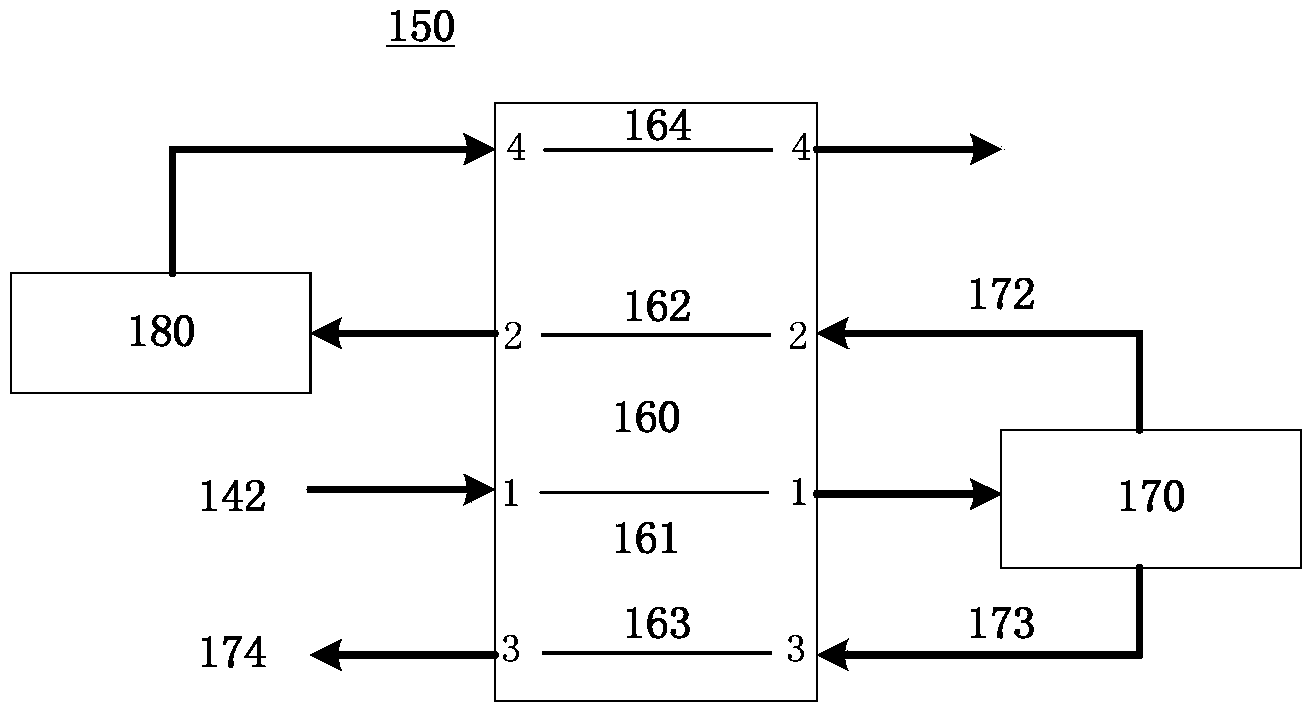

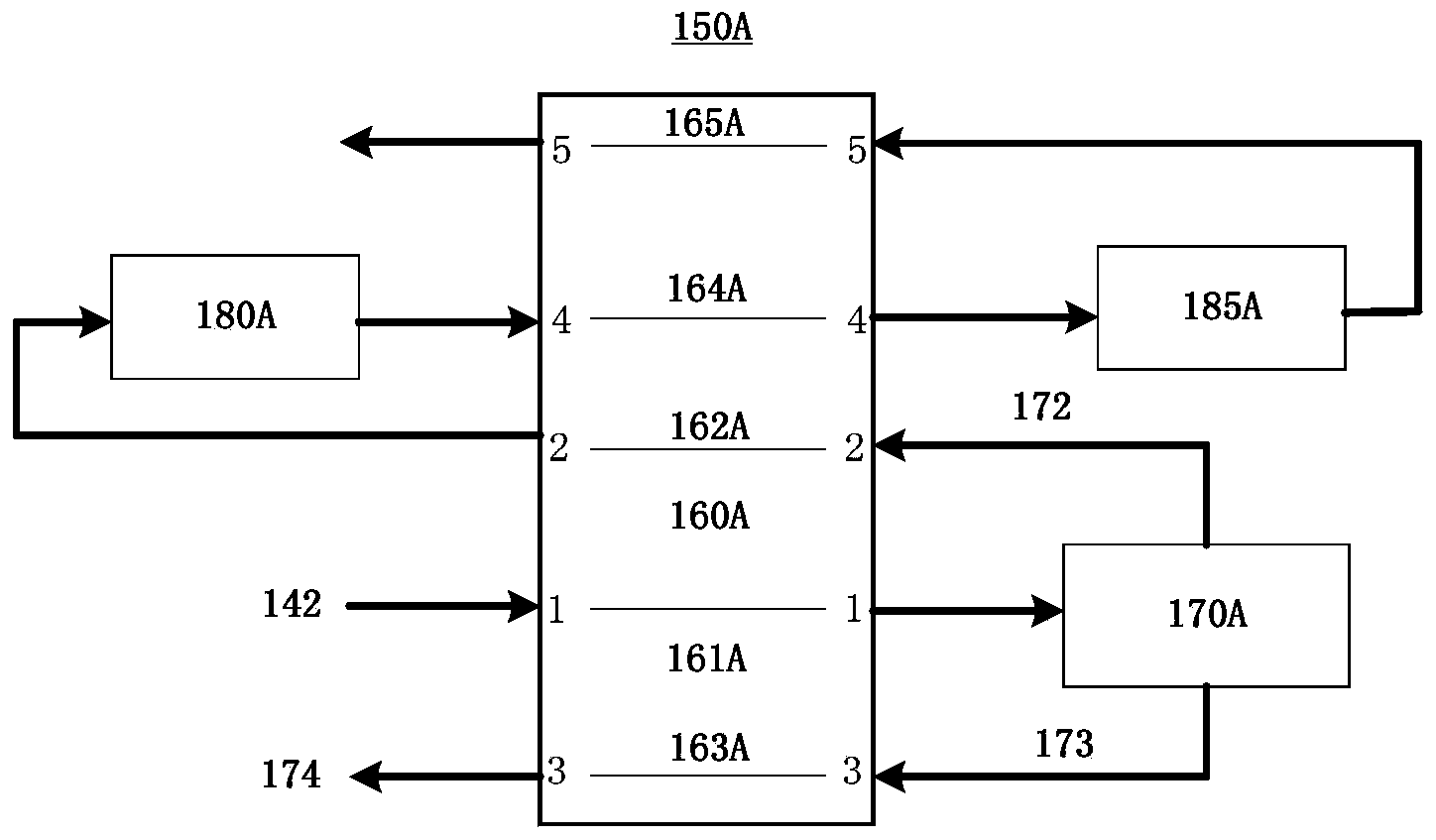

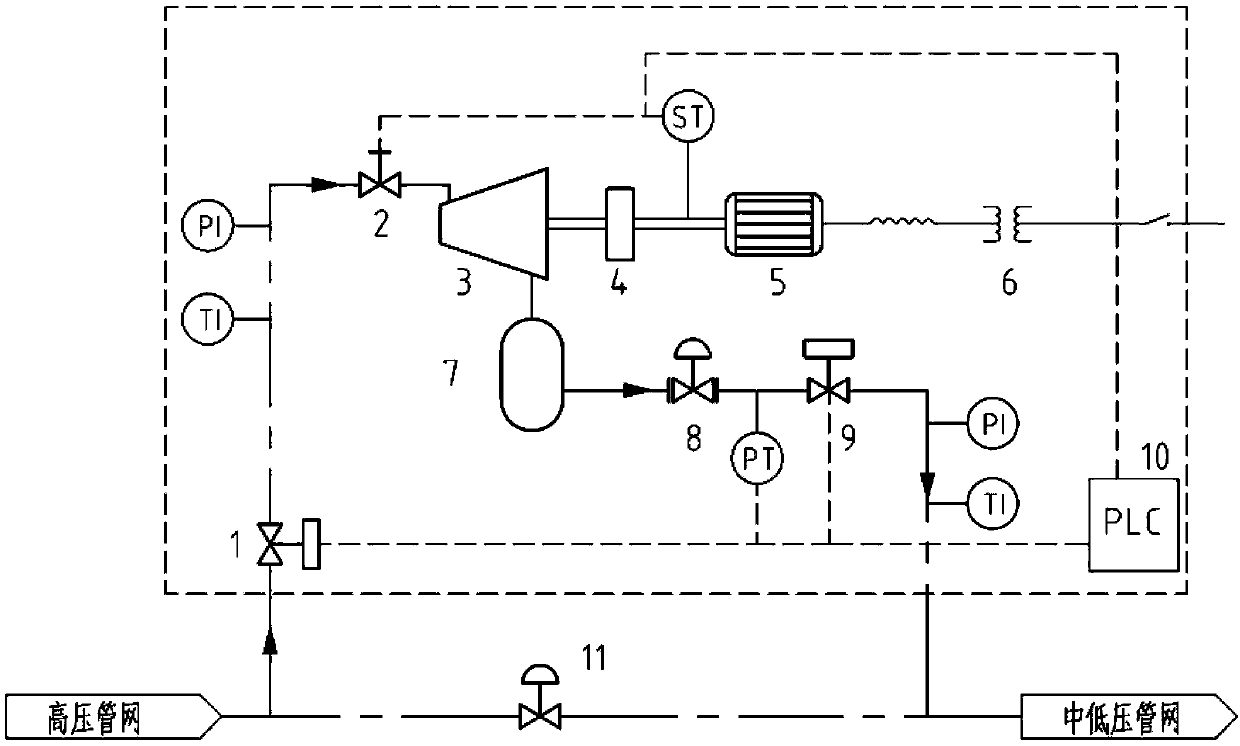

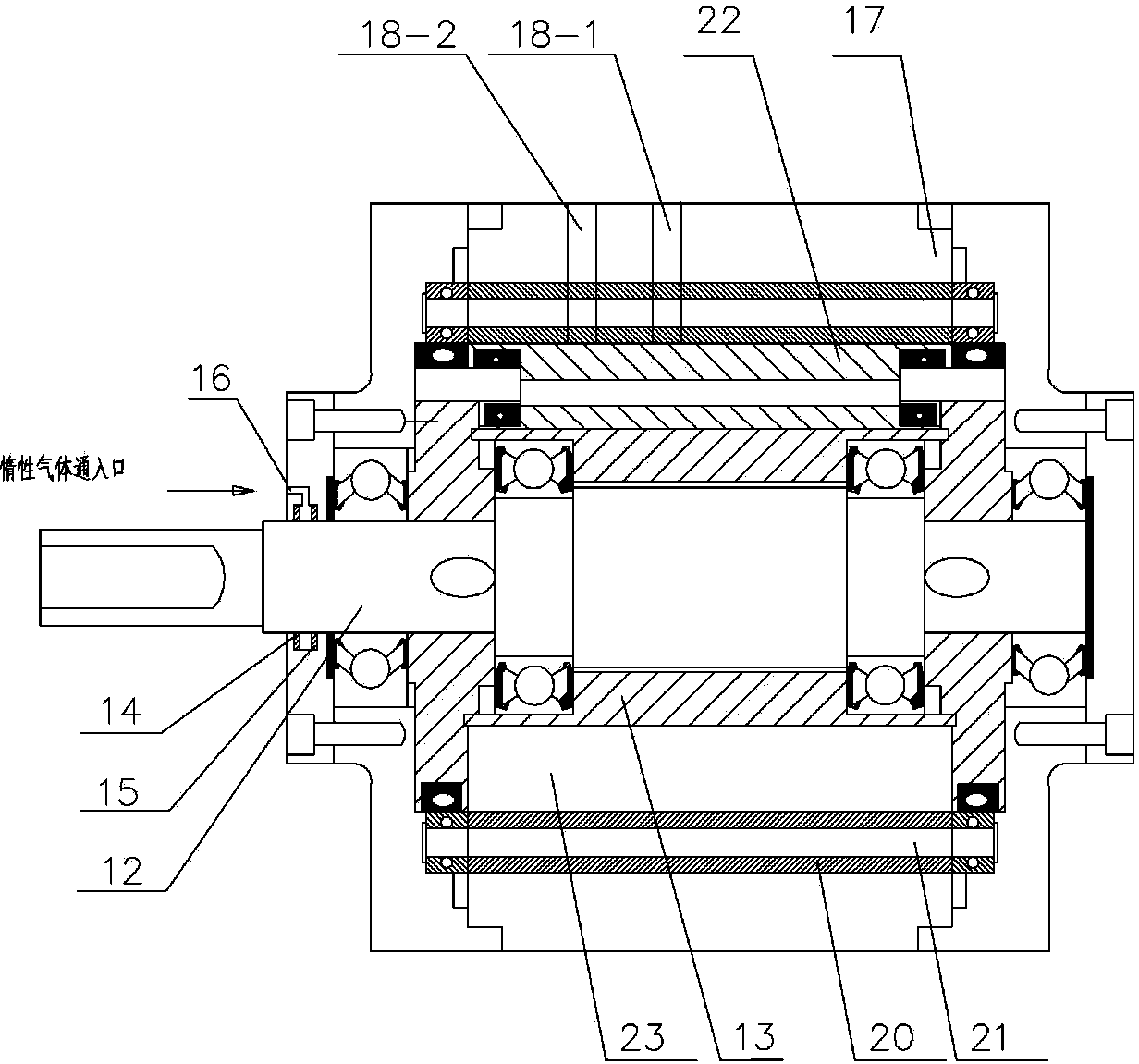

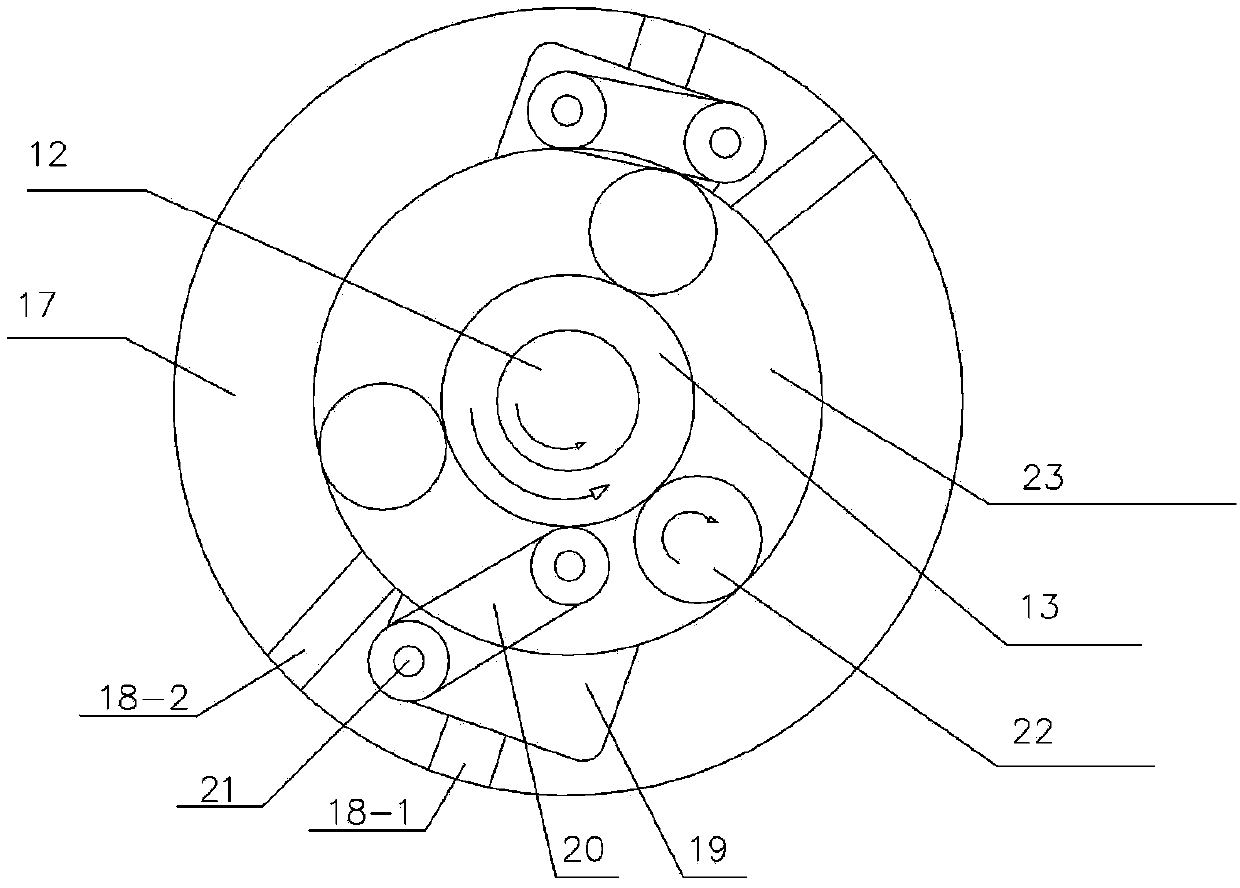

Process and device for generating power by pressure energy of small natural gas pipeline network

InactiveCN103422899ALeak will notSolve the problem that cannot be explosion-proofSealing arrangements for enginesMachines/enginesGas cylinderPower user

The invention discloses a process and a device for generating power by pressure energy of a small natural gas pipeline network. A high-pressure pipeline network of the device is connected with a gas inlet of an expansion machine through a pipeline; a gas outlet of the expansion machine is connected with a gas inlet of a temperature balancer through a pipeline; an outlet of the temperature balancer is connected with a low and medium-pressure gas pipeline network through a pipeline; a main shaft of the expansion machine is connected with a gearbox; the gearbox is connected with a power generator; the power generator is connected with a transformer synchronizer; the expansion machine adopts an improved AT15-65 type gas expansion machine; one end of the main shaft is connected with an air cylinder in a totally-closed way; a first seal ring and a second seal ring, which have sealing effects, are arranged between the other end of the main shaft and a wheel drum; a flow guide pipe is arranged in a closed cavity between the two seal rings; the flow guide pipe is connected with an inert gas bottle. The device can be used for continuously and stably providing a 220 V / 380 V stable power supply for an interruptible and closed 1-5 kW low-power user.

Owner:SOUTH CHINA UNIV OF TECH +1

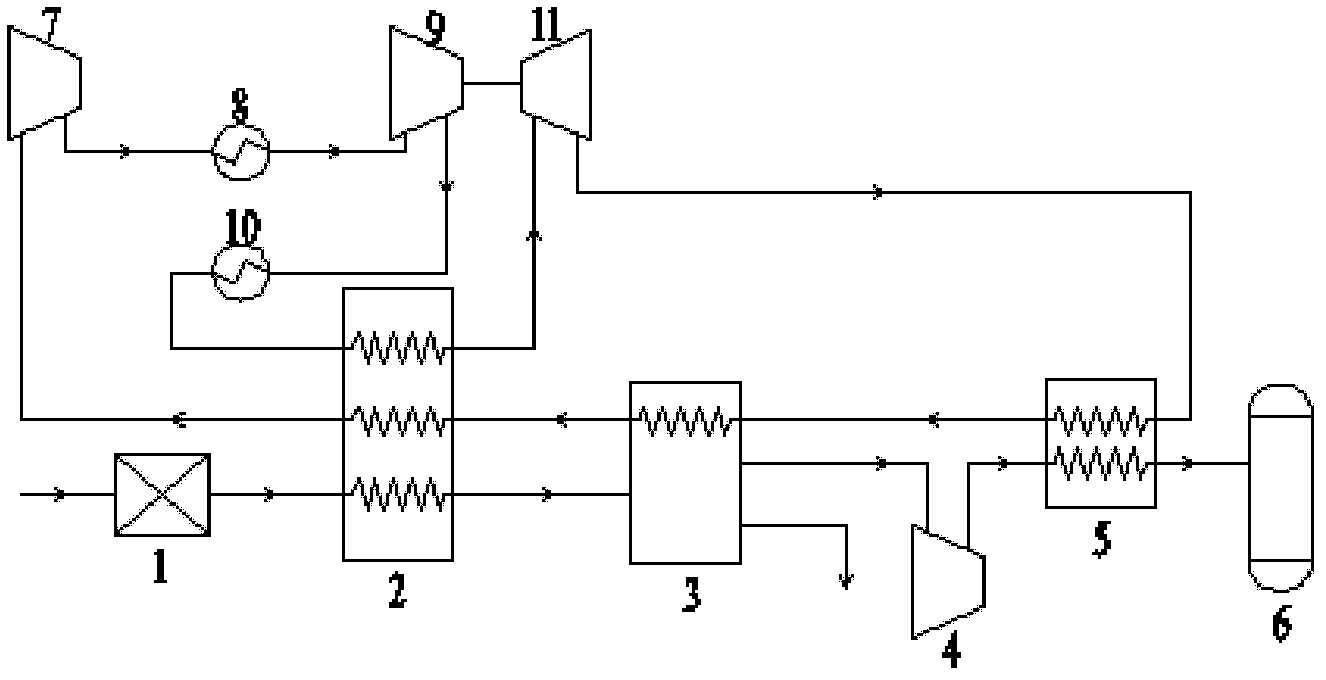

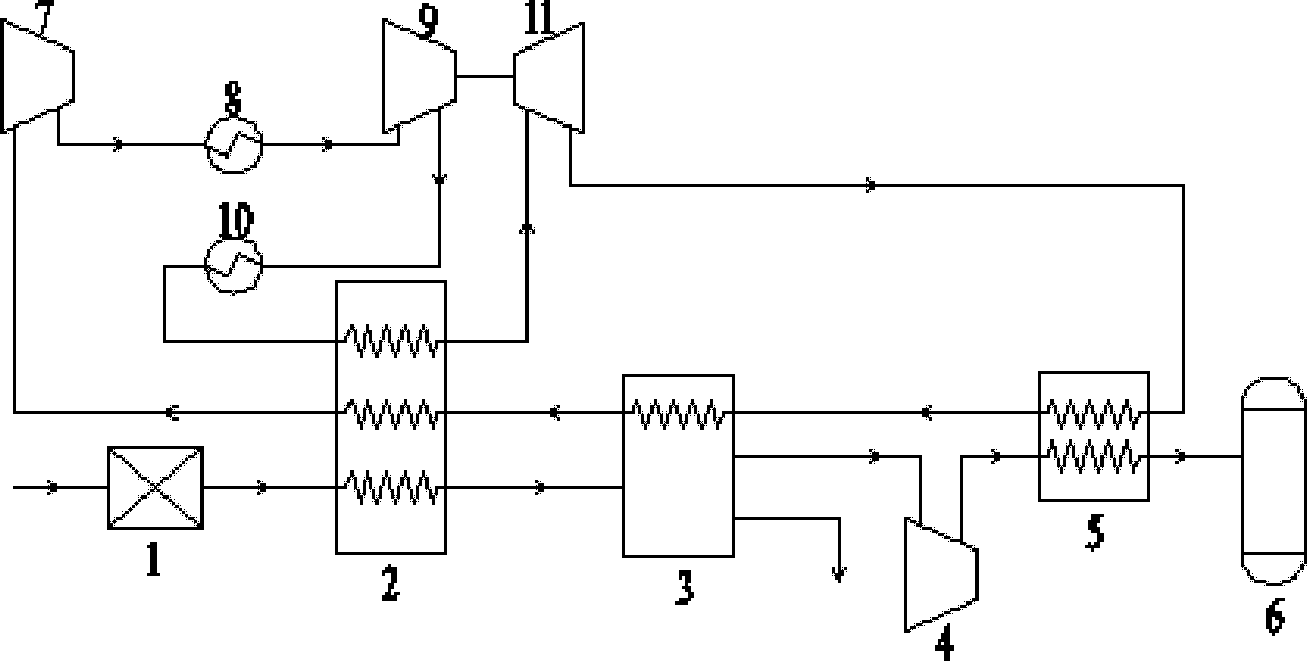

Gas expansion natural gas pressurized liquefying technique with function of condensing and removing carbon dioxide (CO2)

InactiveCN102628635AImprove toleranceReduce unit energy consumptionSolidificationLiquefactionDry icePre treatment

The invention relates to a gas expansion natural gas pressurized liquefying technique with a function of condensing and removing carbon dioxide (CO2), which comprises the steps of: precooling natural gas at a gaseous state in a precooler, continuously cooling the natural gas in a crystallizing device, condensing and separating solid dry ice while lowering the content of the CO2 to 0.5 percent, then pressurizing the natural gas in a low-temperature compressor, then introducing the natural gas in a liquefying device and liquefying the natural gas under higher pressure and then introducing the liquefied natural gas into a storage tank for storing. The cold capacity needed by the liquefying process is supplied by an independent gas expansion refrigeration circulation. Compared with the prior art, the gas expansion natural gas pressurized liquefying technique has the advantages that: a CO2 pretreatment device occupying a large floor area in the conventional natural gas liquefying process can be saved, so that the investment cost for liquefying the natural gas on an offshore platform in high price can be greatly reduced. Meanwhile, the energy loss of the refrigeration circulation can be reduced when the natural gas is liquefied at a higher temperature.

Owner:SHANGHAI JIAO TONG UNIV

Fireworks launcher

InactiveUS6286429B1Reduce manufacturing costProvide strengthRocket launchersFirework flares/torchesFireworksEngineering

A longitudinal launcher tube made substantially of polyurethane resin or plastic having a rear end closed by a transverse rear wall and an open front end. The invention allows a projectile to be housed in the tube and adapted to slide longitudinally inside it towards the front, to be expelled from it via the front end tube, means for defining with the tube and projectile a rear gas expansion chamber immediately to the rear of the projectile, and an impulse cartridge adapted on command to develop gas pressure in the rear chamber to cause the expulsion of the projectile via the front end of the tube. The apparatus is a pyrotechnic device for rigidly supporting fireworks such as mortar-type, rocket-type, projectile-type, and other pyrotechnic devices so that the launcher device is reusable, whereby the launcher substantially retains its integrity after each launch to minimize harm caused to persons and the environment.

Owner:MARIETTA JOHN +1

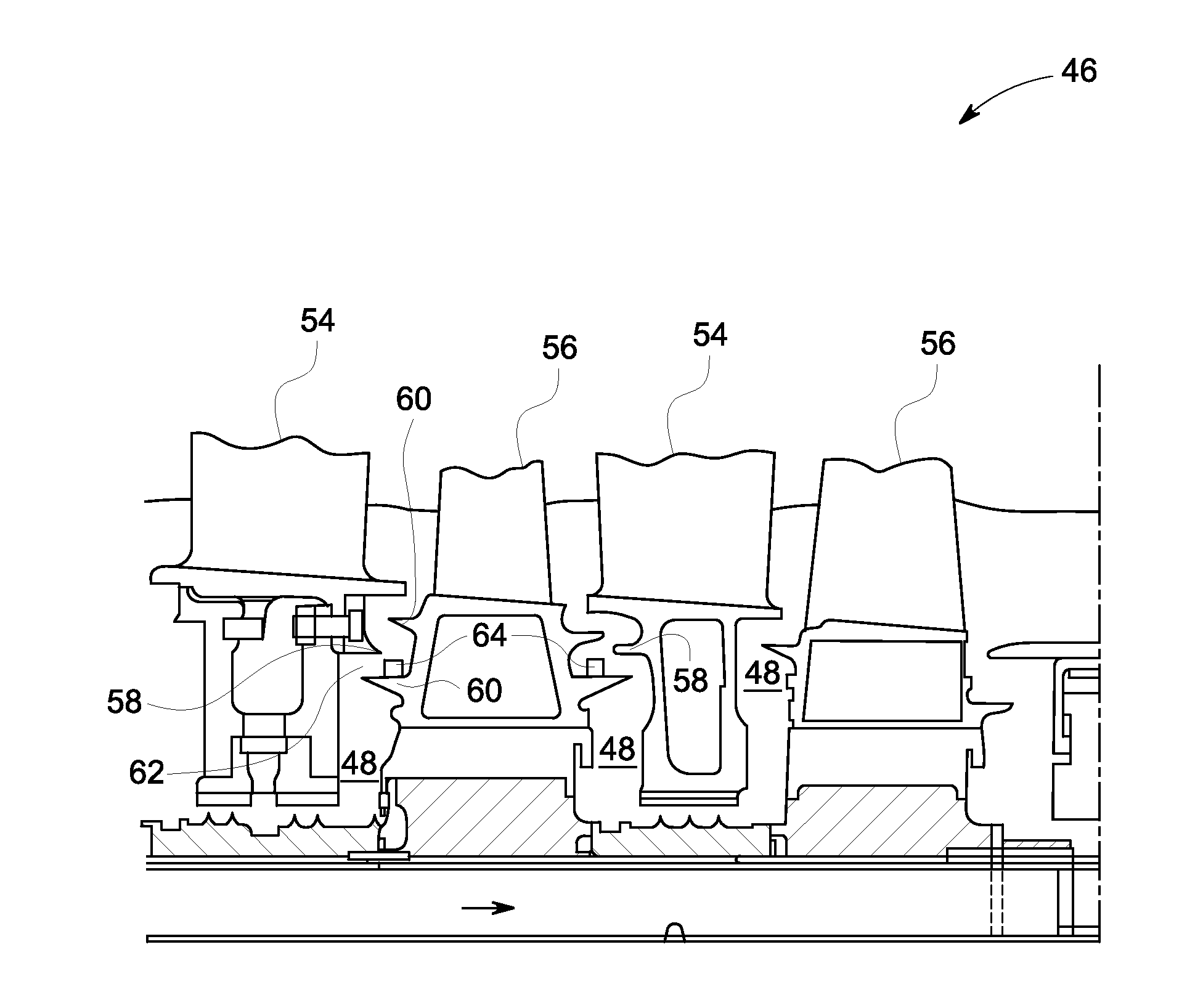

System and method to eliminate a hard rub and optimize a purge flow in a gas turbine

InactiveUS20120163955A1Reduce temperatureLimit ingestionPump componentsBlade accessoriesStatorGas turbines

A system and method to eliminate hard rub and optimize a purge flow in a gas turbine is provided. The gas turbine includes a stator configured to guide a flow of an incoming gas. The gas turbine also includes a rotor configured to expand the incoming gas and extract kinetic energy from the incoming gas. The gas turbine further includes a purge flow bled from a compressor and configured to reduce a temperature of a wheel space by limiting ingestion of the incoming gas. The gas turbine also includes an angel wing disposed between the rotor and the stator and configured to act as a sealing surface between the rotor and the stator. The gas turbine further includes a fan blade disposed on a surface of the angel wing at an axial position and configured to generate a recirculation zone of the purge flow, wherein the recirculation zone is reduces a volume of successive purge flows entering the wheel space.

Owner:GENERAL ELECTRIC CO

Slotting induced-flow pressure-relief anti-reflection method for complicated seam

ActiveCN102966372AAchieving safe miningImprove extraction efficiencyFluid removalGas removalSocial benefitsDesorption

A slotting induced-flow pressure-relief anti-reflection method for a complicated seam is suitable for gas control of high-gas high-ground-stress complicated seam regions, can improve the gas permeability and gas desorption rate of coal, solves the difficult problems of low exhausting and mining efficiencies of coal-bed gas, high drilling construction load and the like, and realizes efficient gas exhausting and mining as well as fast outburst elimination of the complicated seam. High-pressure water is jetted into drilled holes to cut and destroy the coal in a rotary manner, and the coal in the radial direction of the drilled holes is destroyed and disturbed, so that buckling failures of the coal are induced and the coal and the gas are enabled to be spouted out of the drilled holes, as a result, the gas expansion energy of the coal is released, coal cracks are expanded and the exposure surface area of the coal is increased. therefore, the gas exhausting and mining efficiencies of coal are improved, coal and gas burst risks are eliminated, the effective influence range of drilling gas exhausting and mining is improved by 1-3 times, the air permeability coefficient of coal around the drilled holes is improved by 100-200 times, the drilling methane gas exhausting and mining quantity is improved by 2-5 times within hundreds of meters, and the outburst elimination time of the coal bed is shortened by 30-50 percent. The slotting induced-flow pressure-relief anti-reflection method for the complicated seam has very good field application value and social benefits.

Owner:CHINA UNIV OF MINING & TECH

Gas system for firearms

A piston assembly is provided for a gas-operated firearm of the type having a chamber and a barrel. The piston assembly includes a gas expansion housing and a piston mounted within the gas expansion housing. An annular recess is formed in the outer wall of the piston to receive exhaust gases diverted from the barrel upon firing of the firearm. At least one longitudinally extending groove extends from the annual recess to the head of the piston and forms a pathway for diverting the exhaust gases to the head of the piston. During firing, pressurized gases are diverted into the annular recess and expand longitudinally from the annular recess to the piston head, whereupon the pressurized exhaust gas drives the gas piston rearwardly along the housing.

Owner:REM TML HLDG LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com