Patents

Literature

225 results about "Liquid piston" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Energy Storage Systems

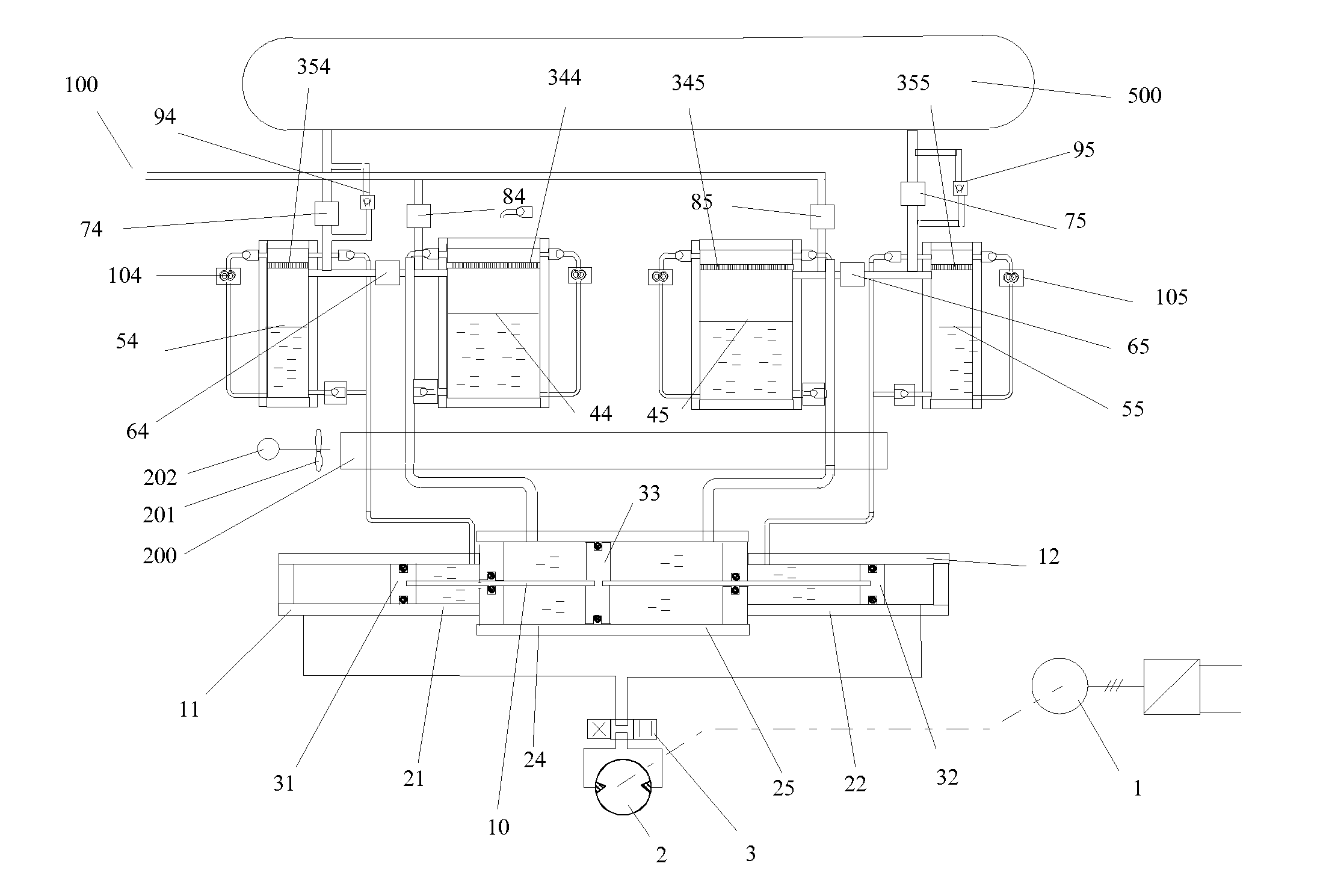

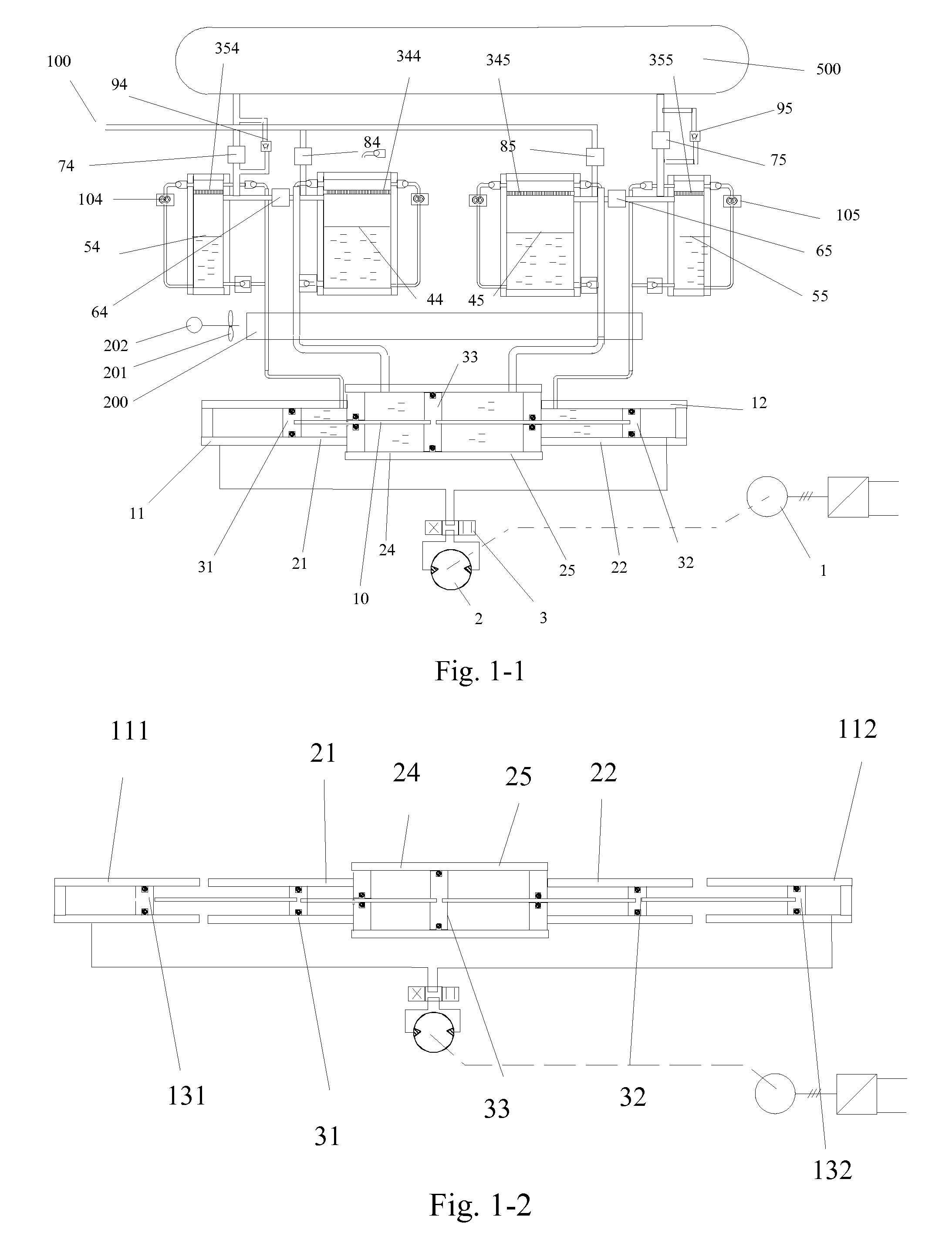

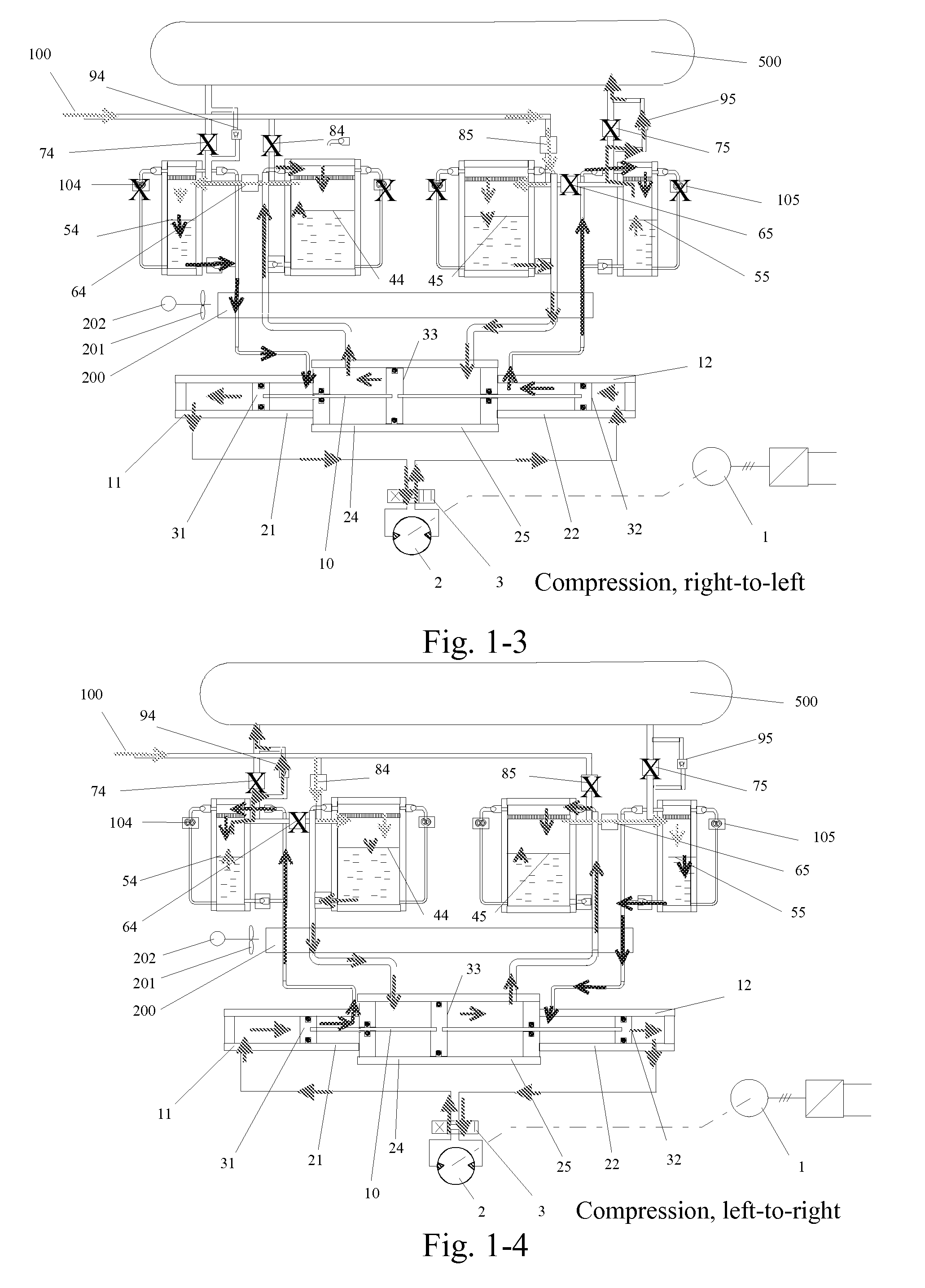

Different types of energy storage systems are described, in particular hydro-pneumatic storage systems. In one, energy is stored by compressing gas in a chamber (44,45,54,55) with a liquid piston and released by gas expansion. A spray head or grid at the top of the chamber (44,45,54,55) supplies liquid as a shower through the gas being compressed or expanding in the cylinder (11,12) to maintain an isothermal condition. In another, energy is stored from an array of solar cells connected to an array of supercapacitors forming an auxiliary storage, and a main energy storage device such as a hydro-pneumatic storage system, for supply to an AC or DC network. The efficiency is improved by connecting the solar cells via the array of supercapacitors to the AC or DC network. An immersed hydro-pneumatic storage device for off-shore / on-shore power generation systems comprises a cylinder that is immersed in a liquid mass, wherein energy is stored by compressing gas with a liquid piston and energy is released by gas expansion. The mass of liquid maintains an isothermal condition in the cylinder during compression and expansion.

Owner:ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL)

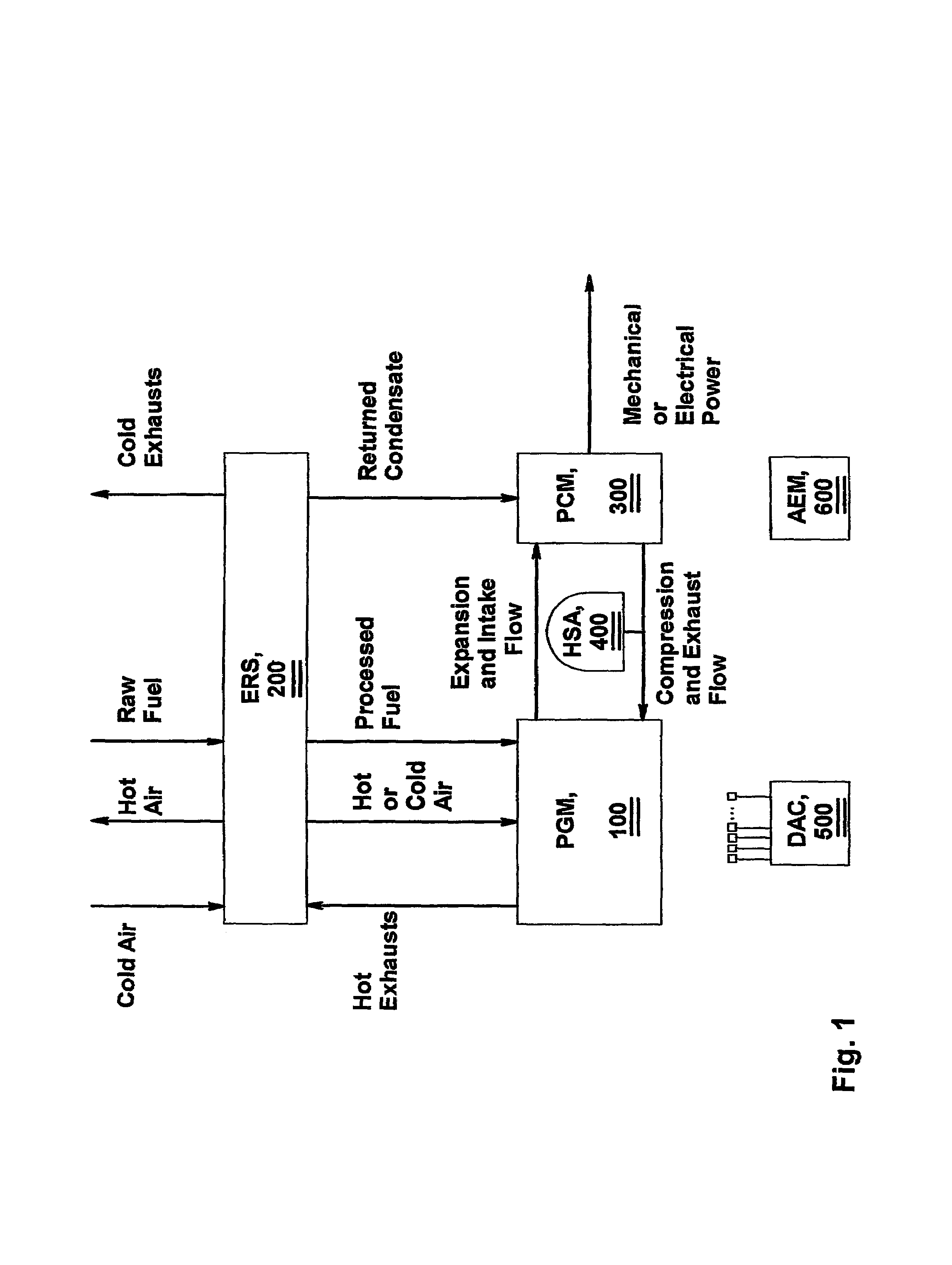

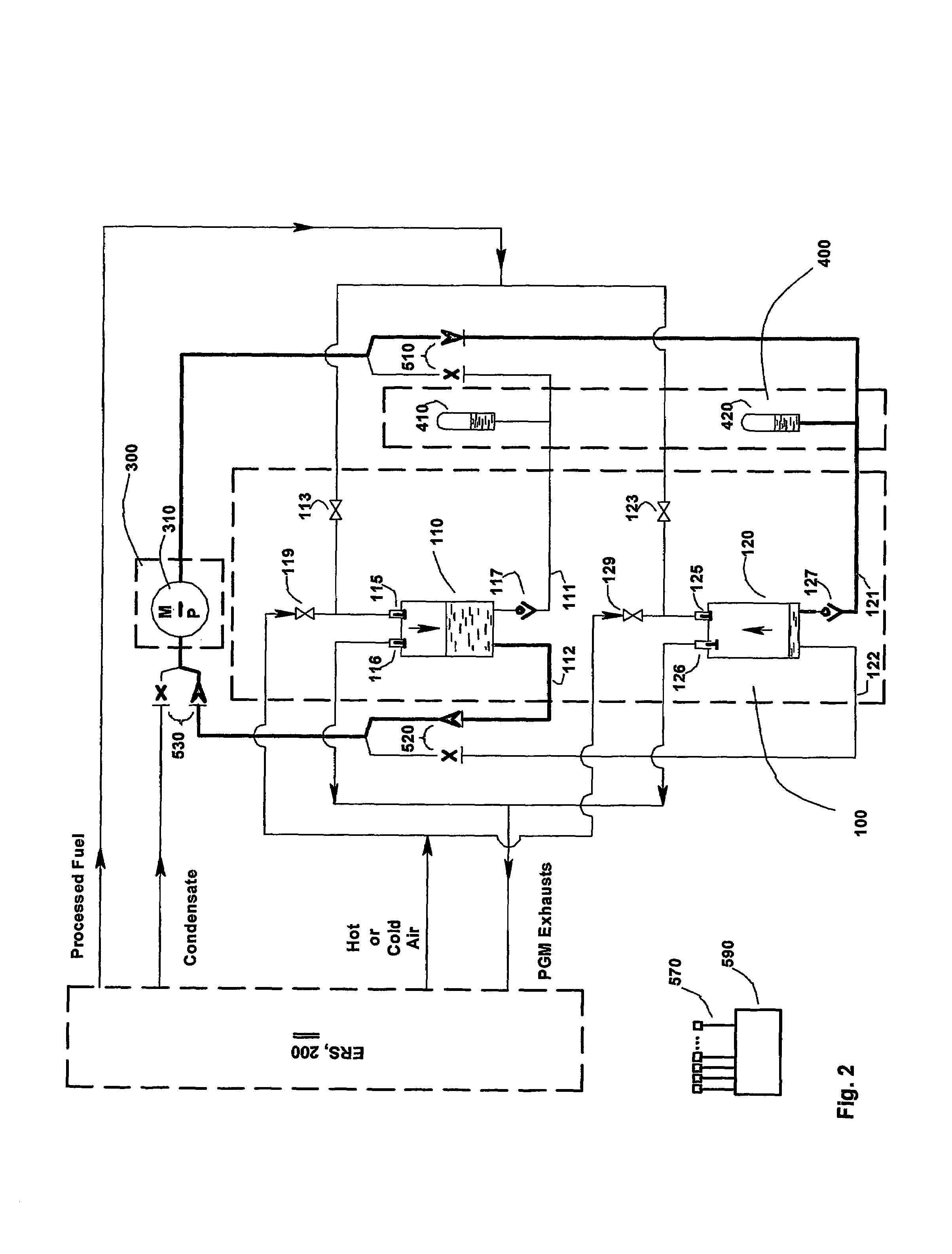

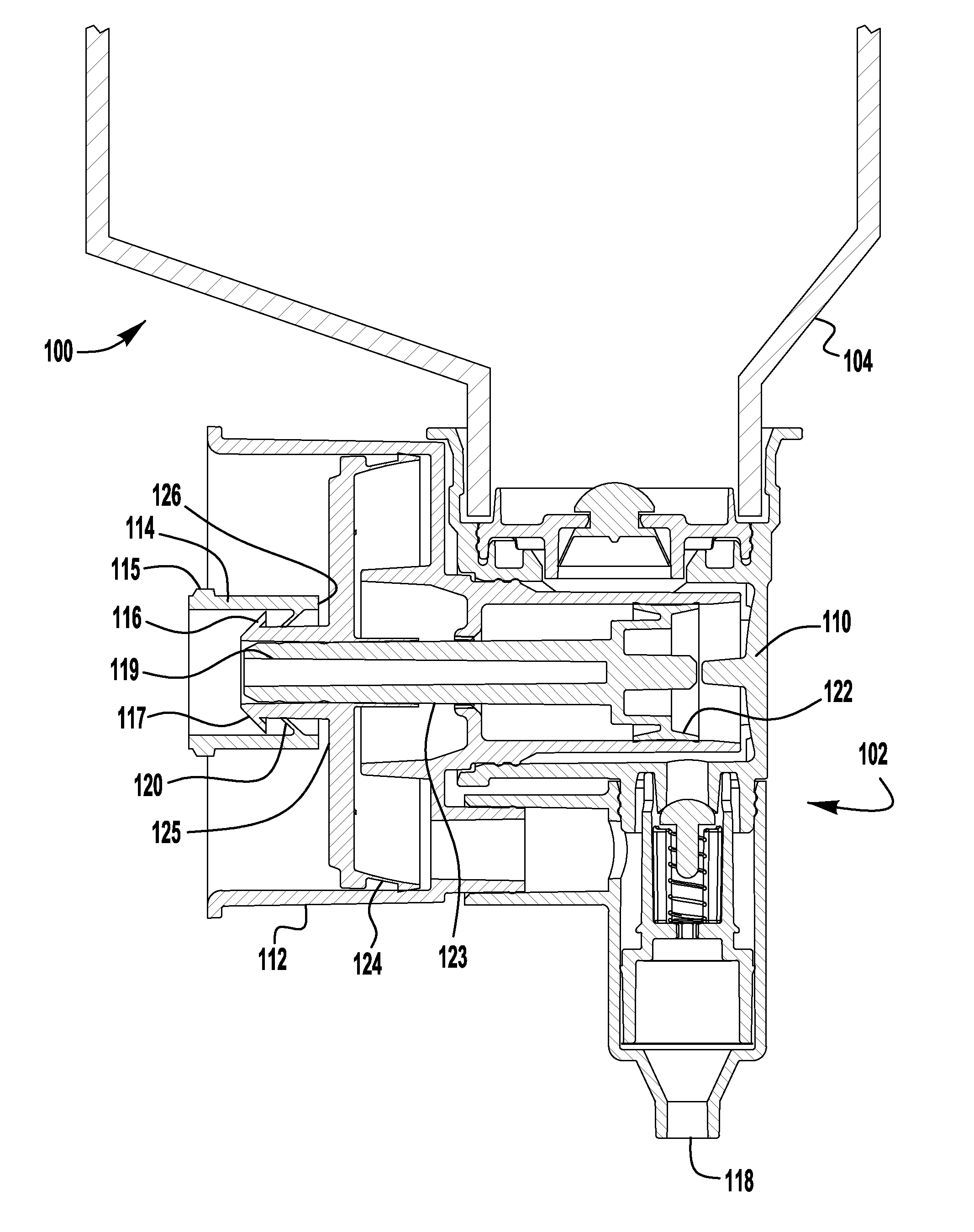

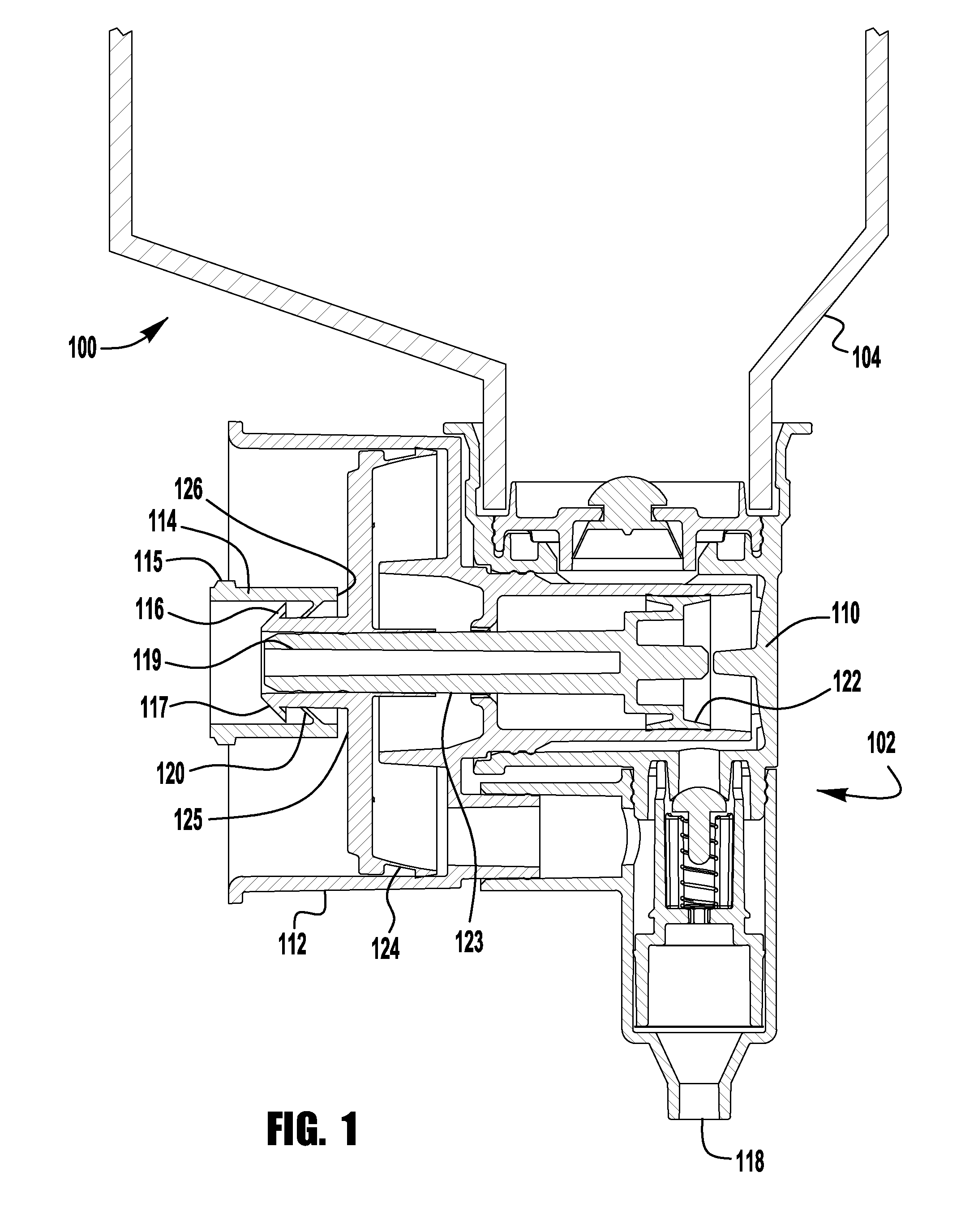

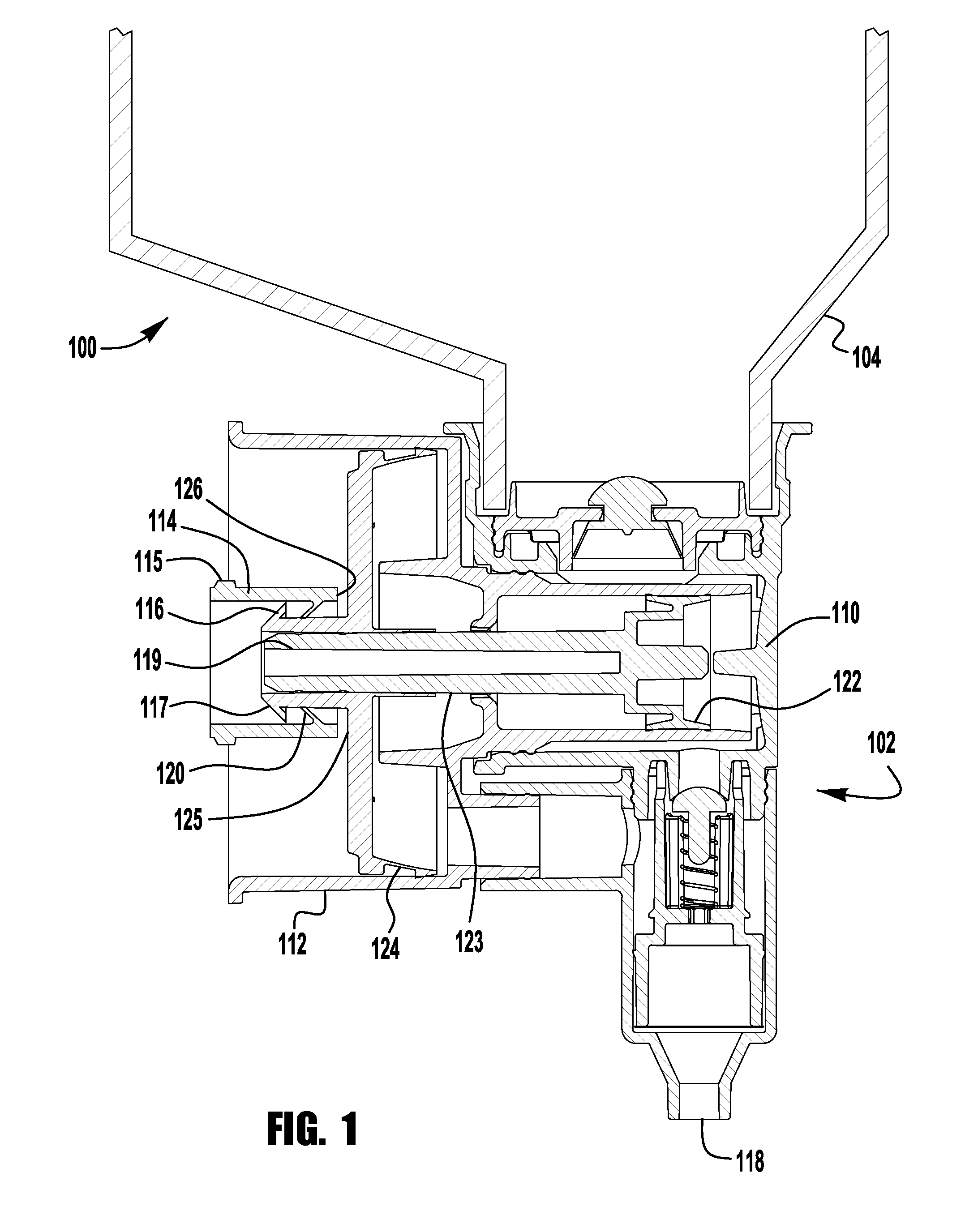

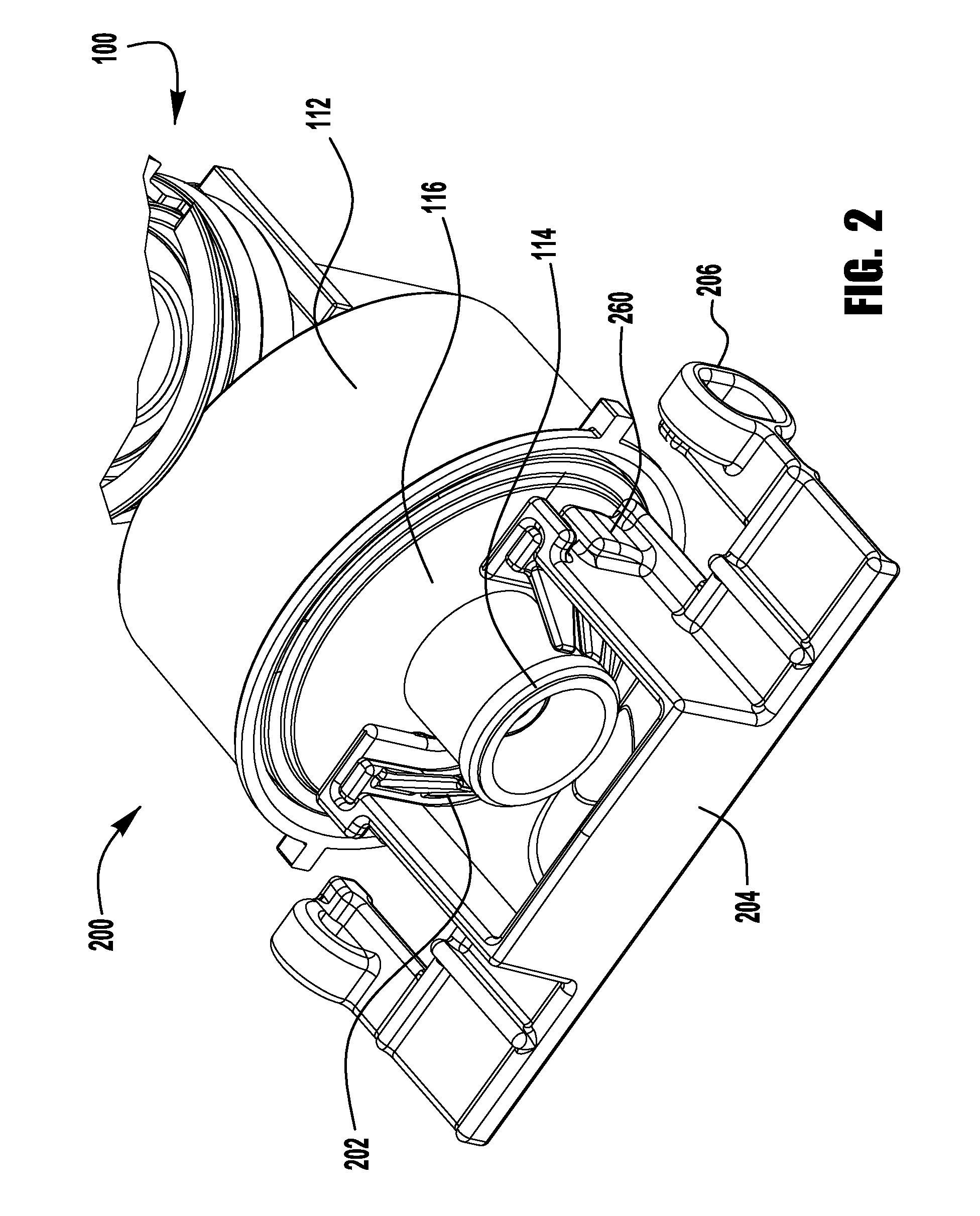

Liquid piston internal combustion power system

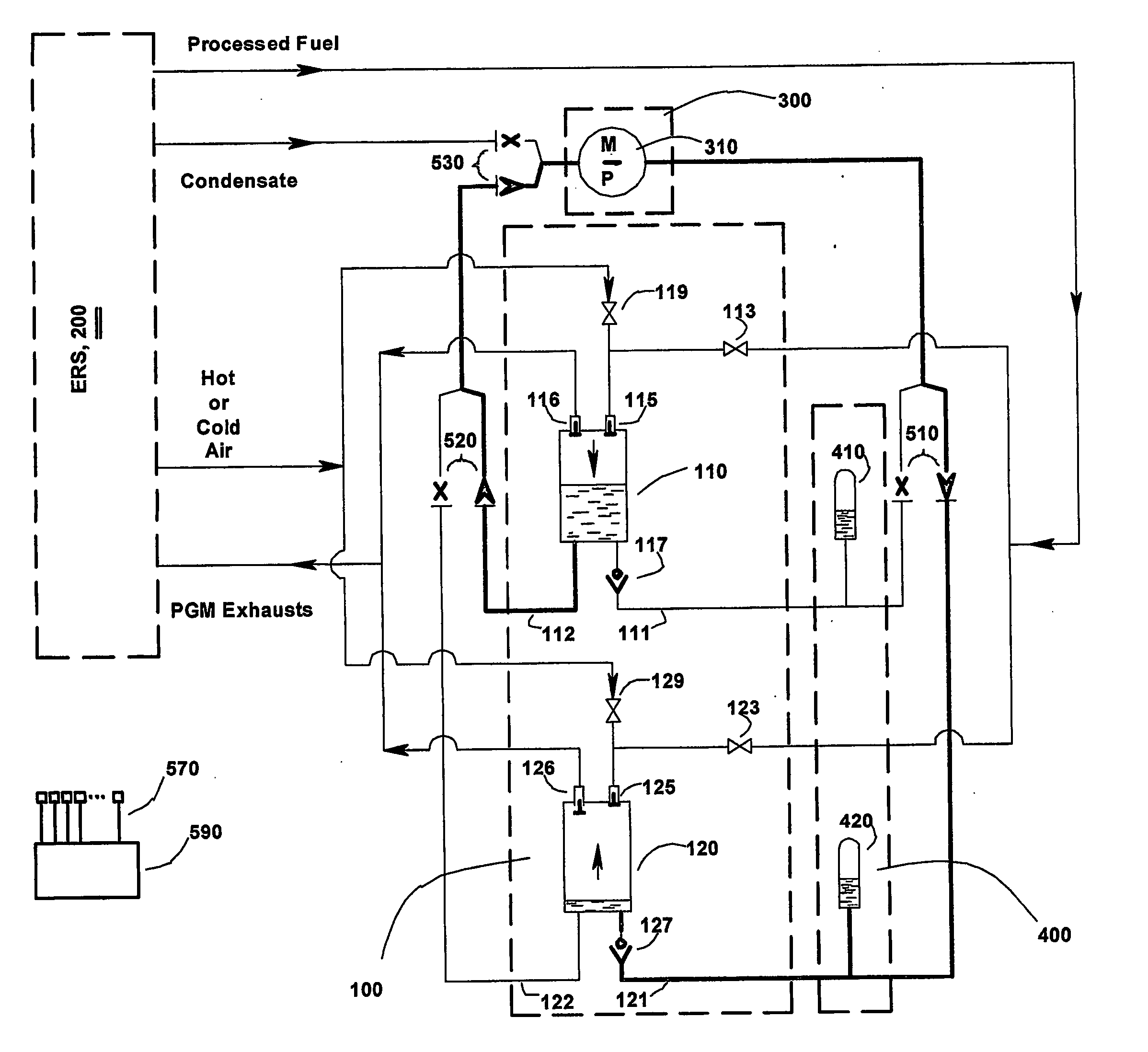

InactiveUS20050166869A1Reduce pollutionRotary slide valveSteam engine plantsLiquid pistonEnergy recovery

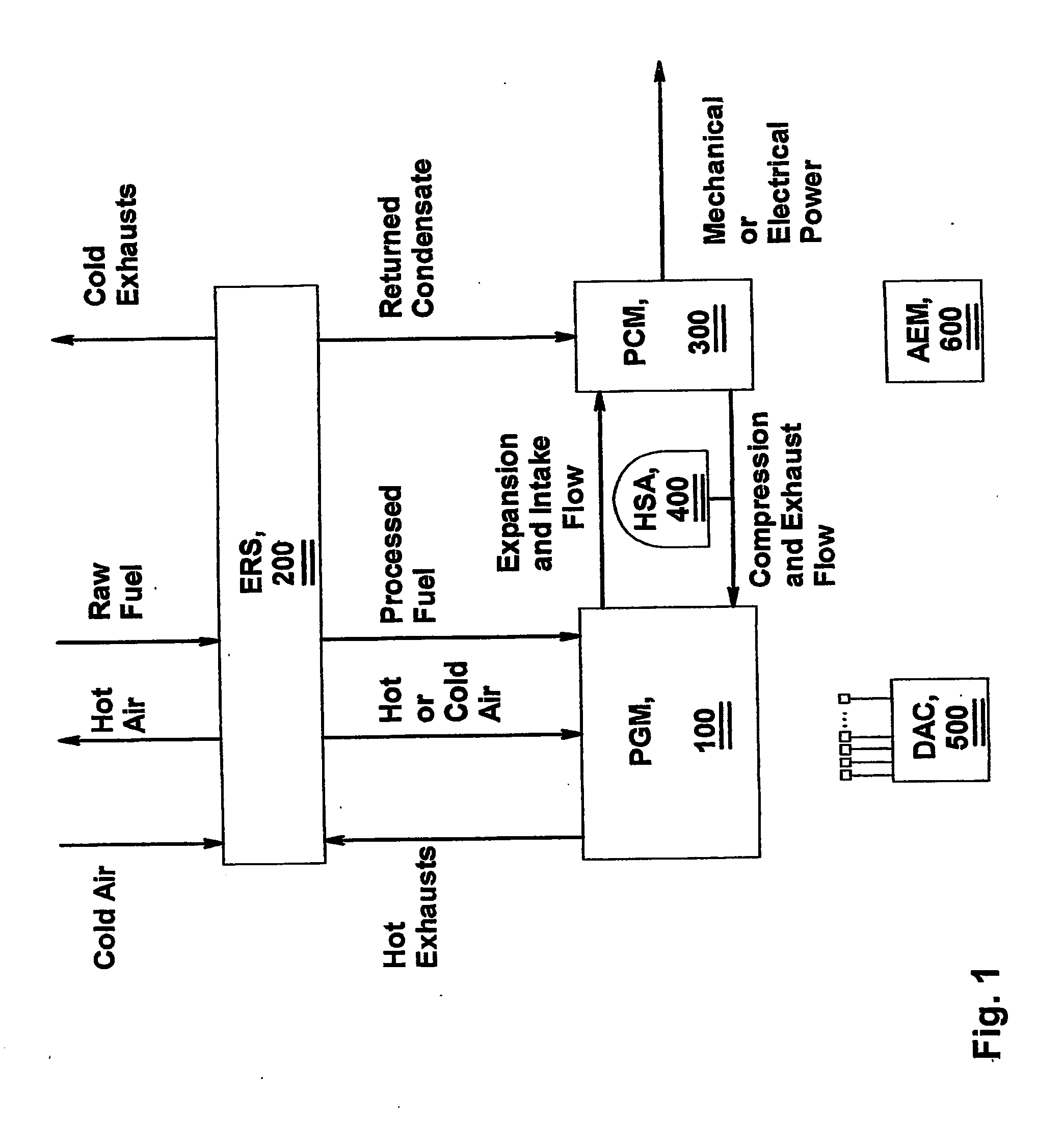

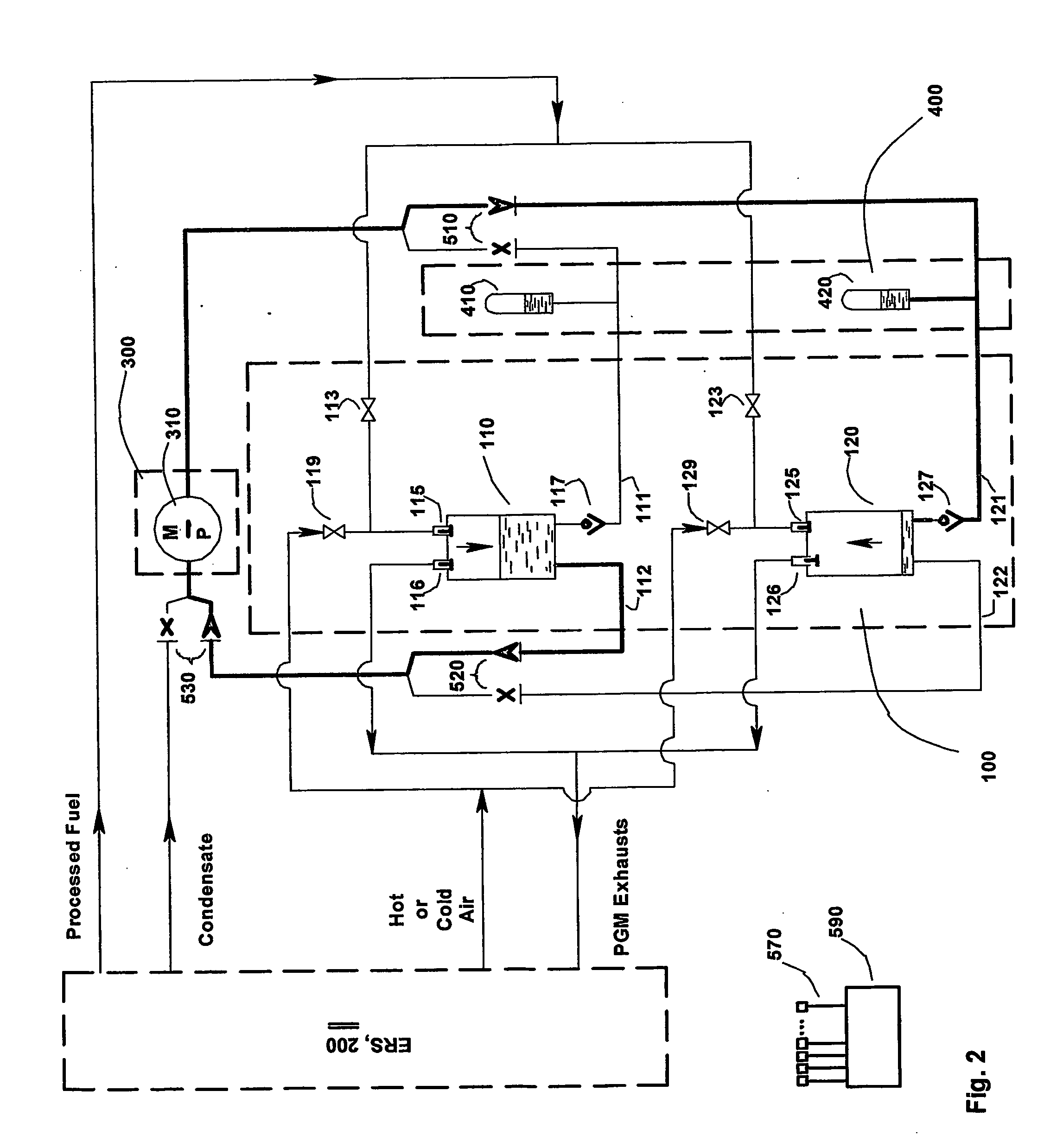

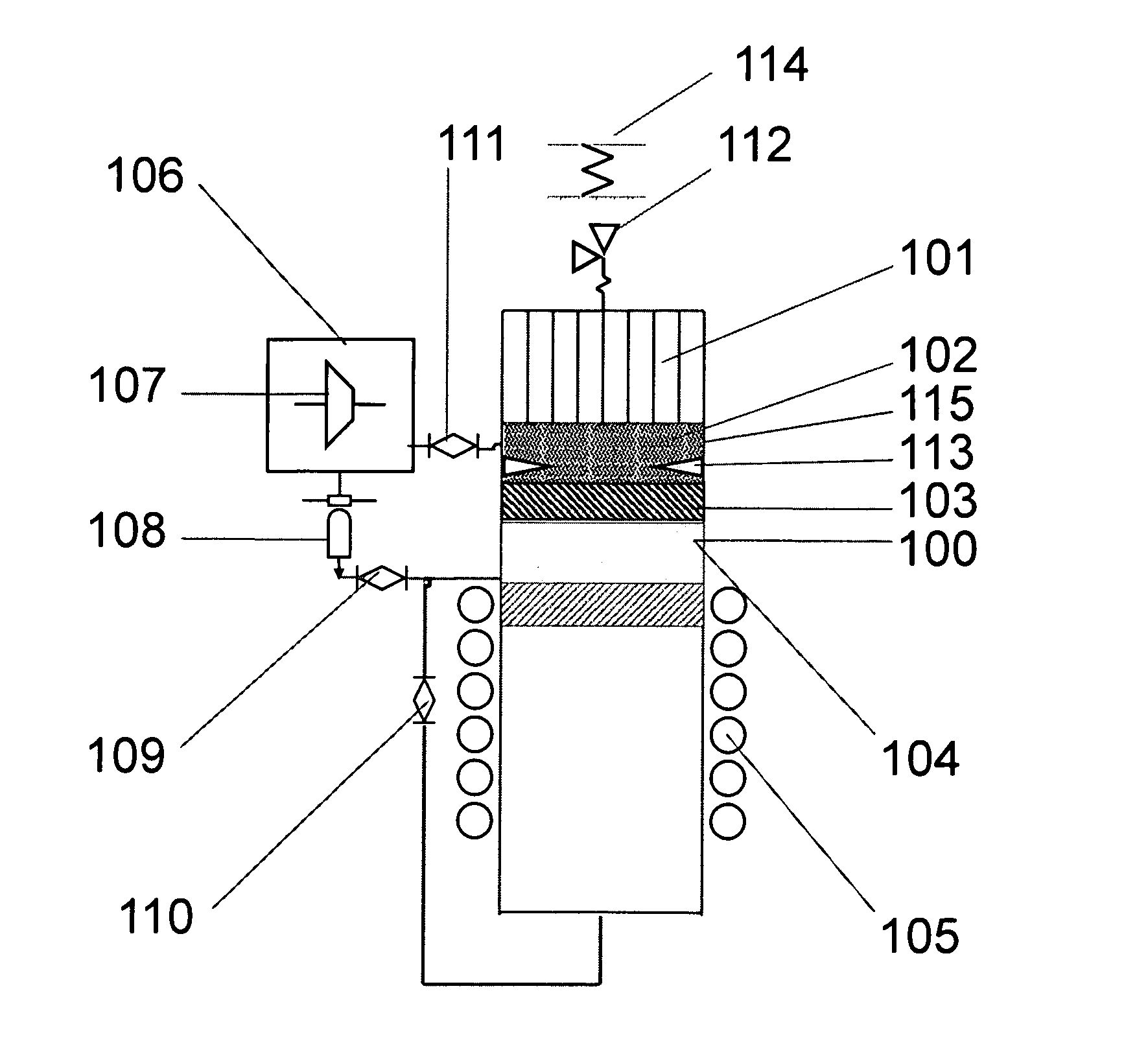

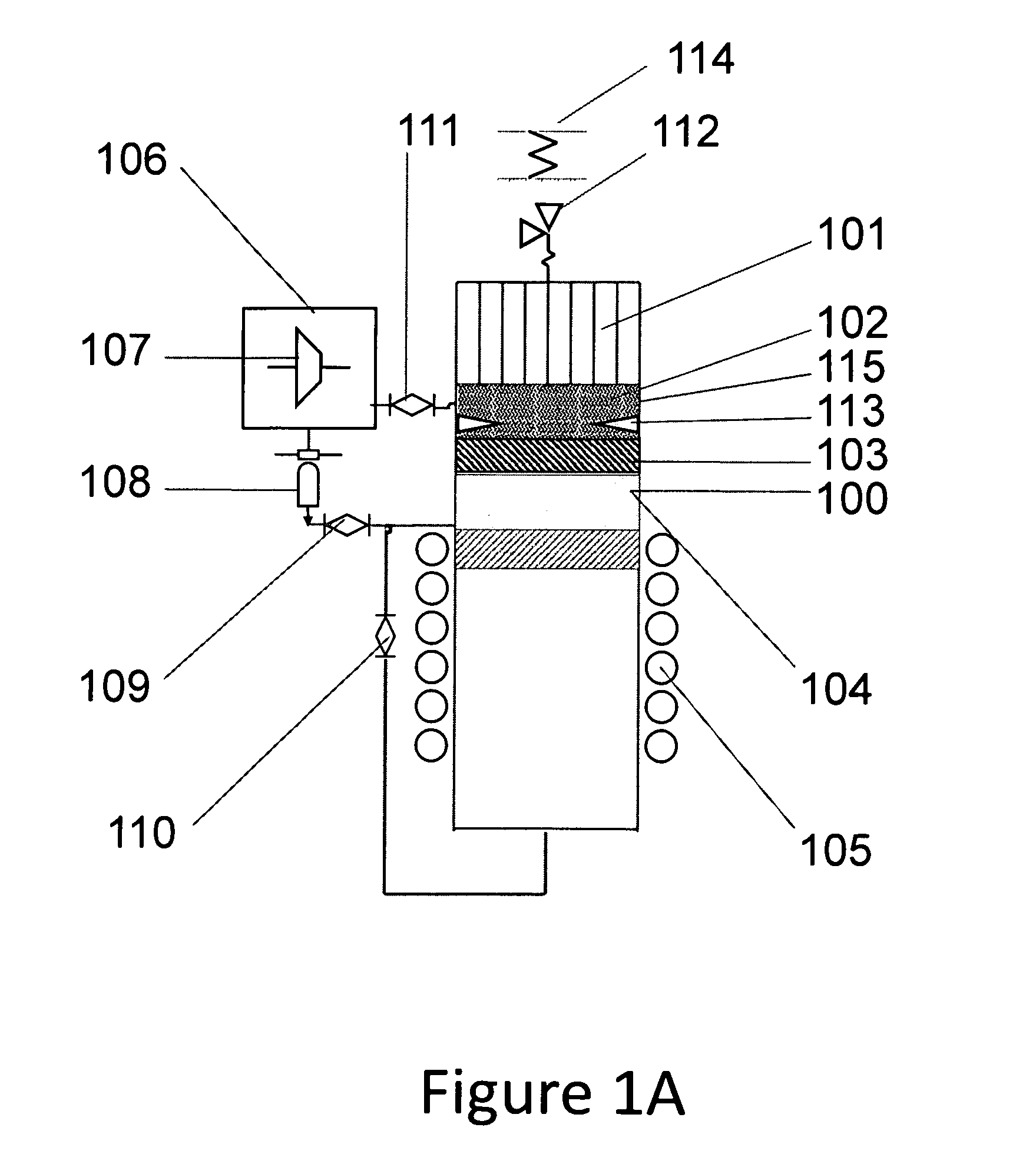

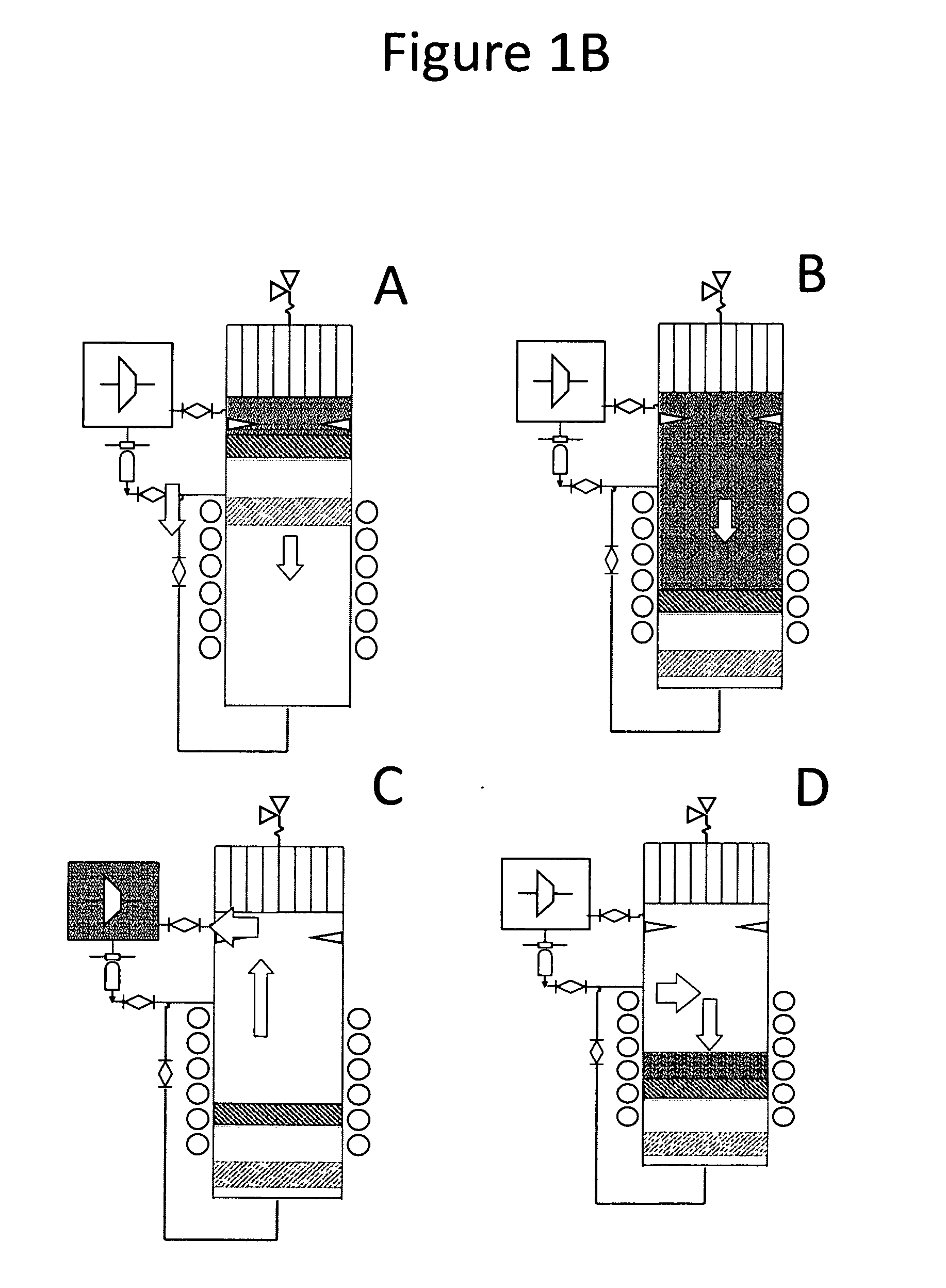

Methods, devices and systems for power generation through liquid piston internal combustion engine. The liquid piston internal combustion engine of the invention, utilizes a novel, synergetic combination of internal combustion and steam piston engines within the framework of one and the same system. The engine may comprise or a plurality of cylinders, each having a liquid piston. The ICE (Internal Combustion Engine) system comprises six modules viz PGM (Power Generating Module) (100), ERS (Energy Recovery System) (200), PCM (Power Conversion Module) (300), HAS (Hydraulic Shock Absorbers Module) (400), DAC (Data Acquisition & Control Module) (500) and AEM (Auxiliary Equipment Module) (600).

Owner:LIQUIDPISTON INC

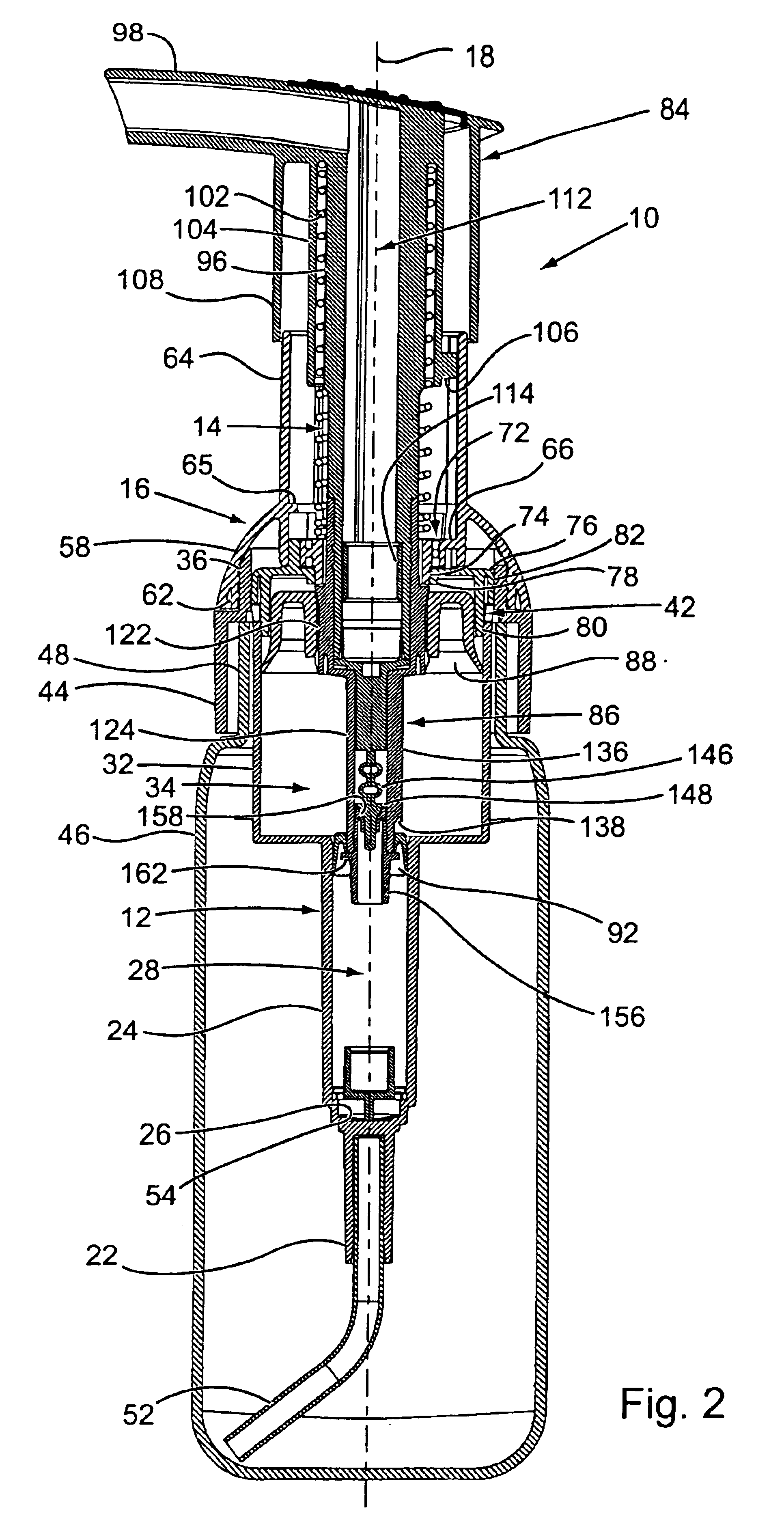

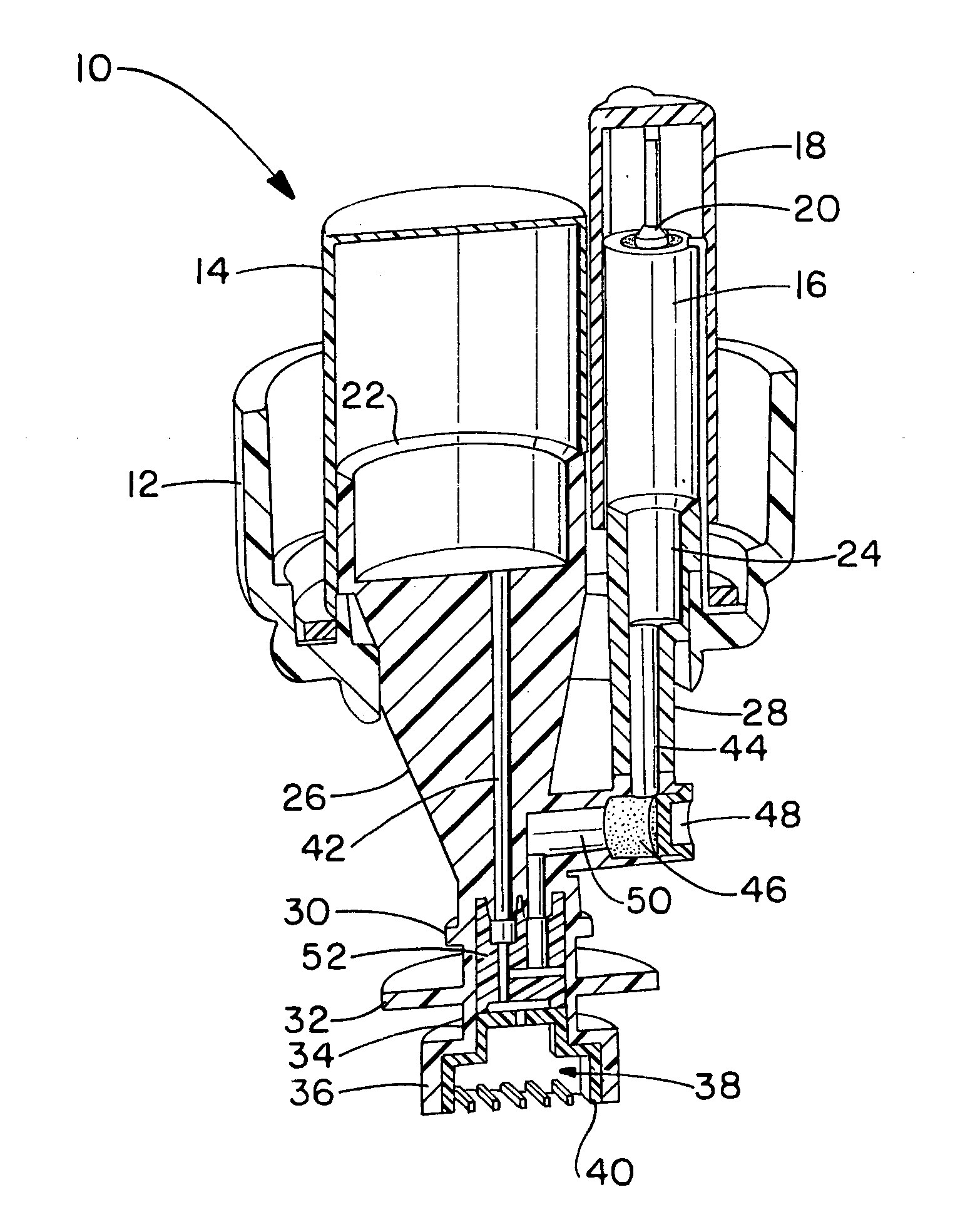

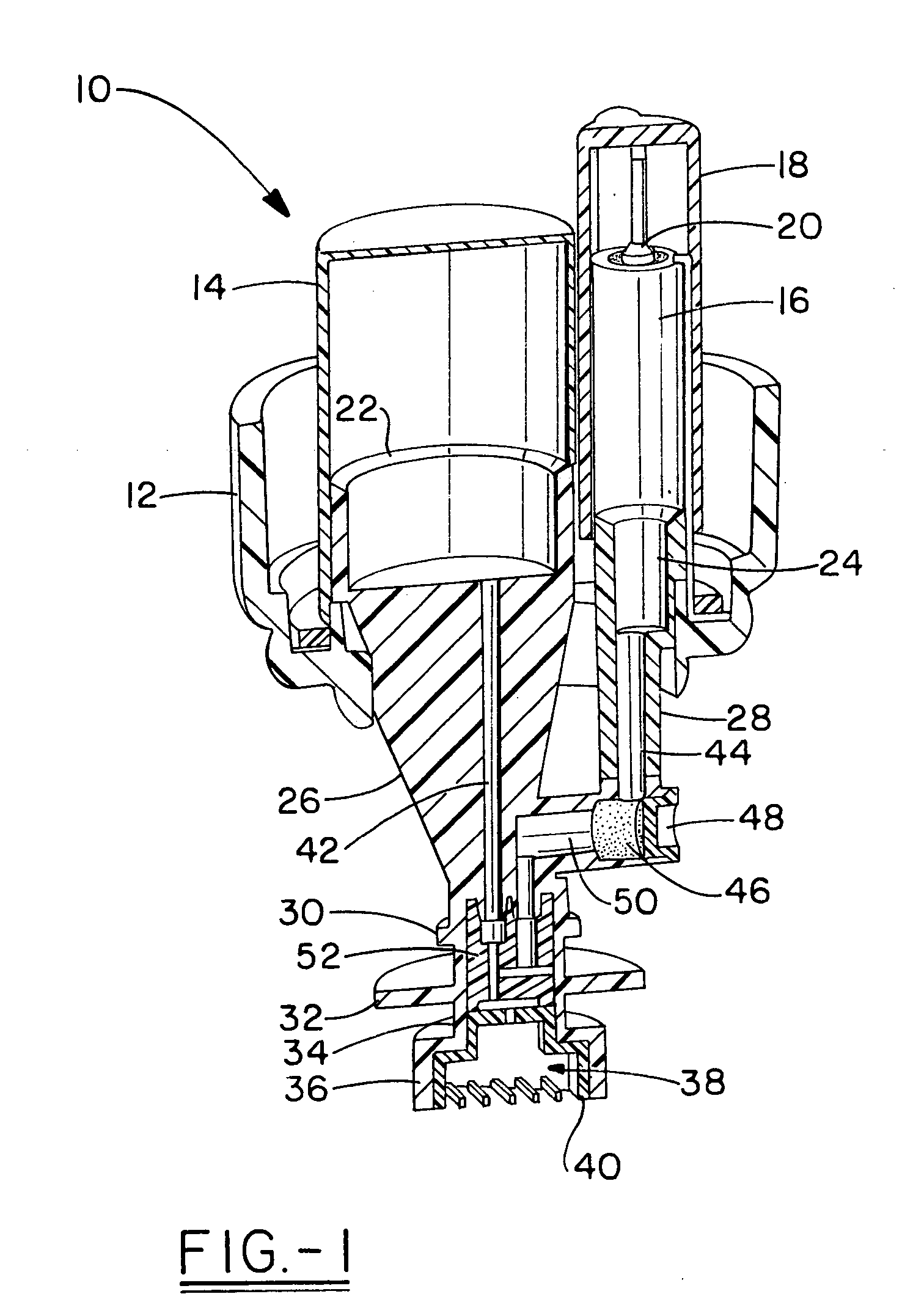

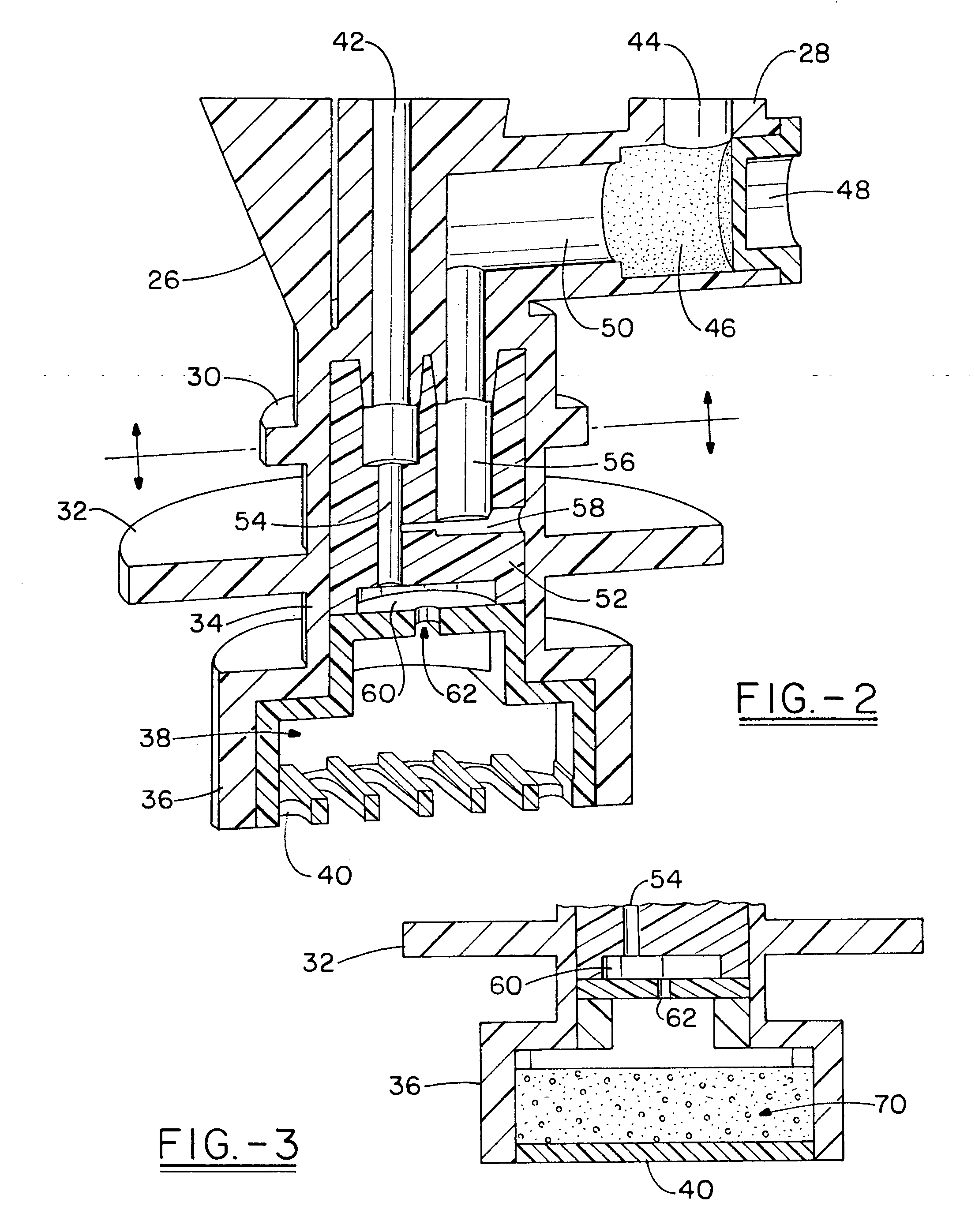

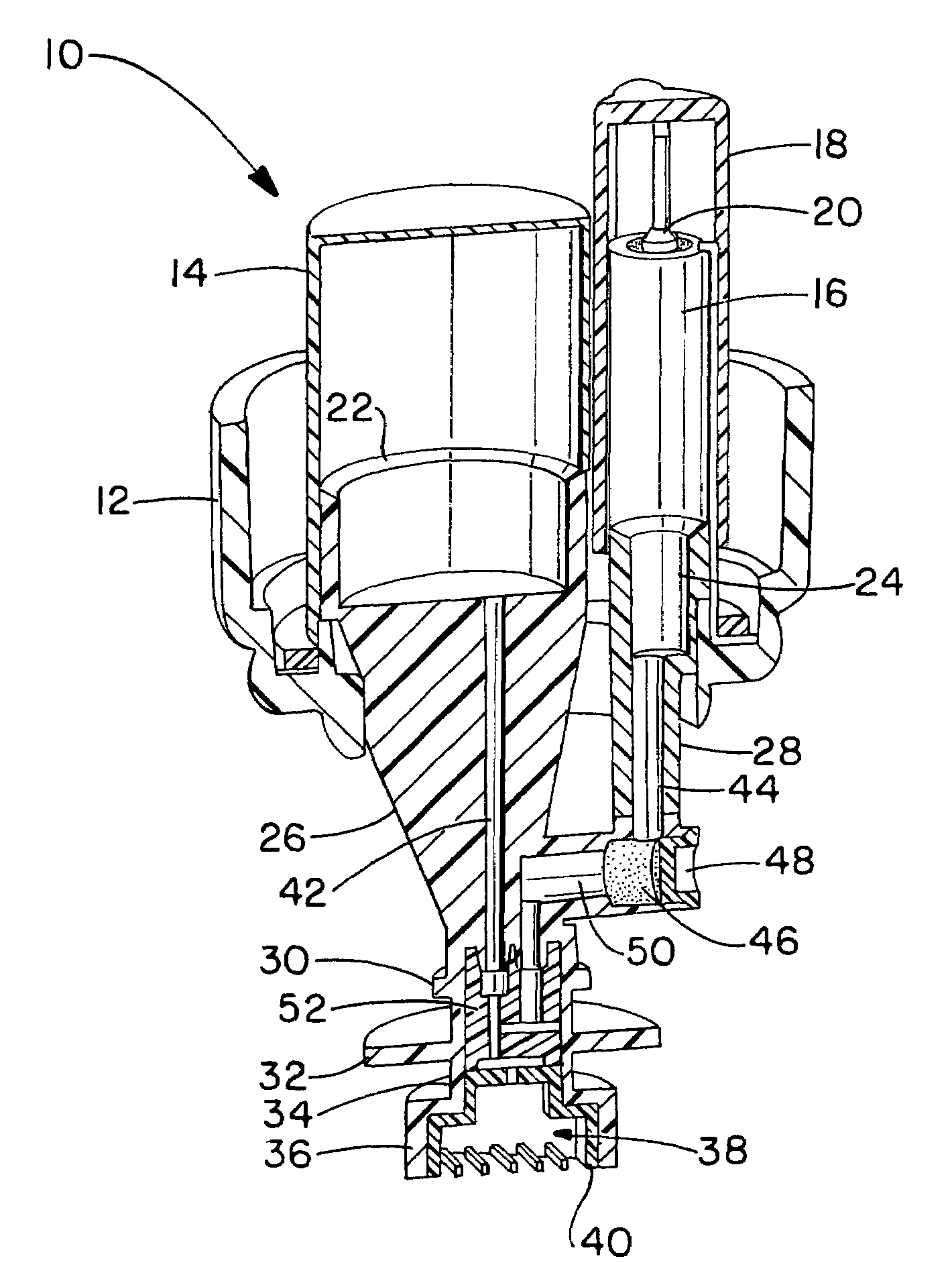

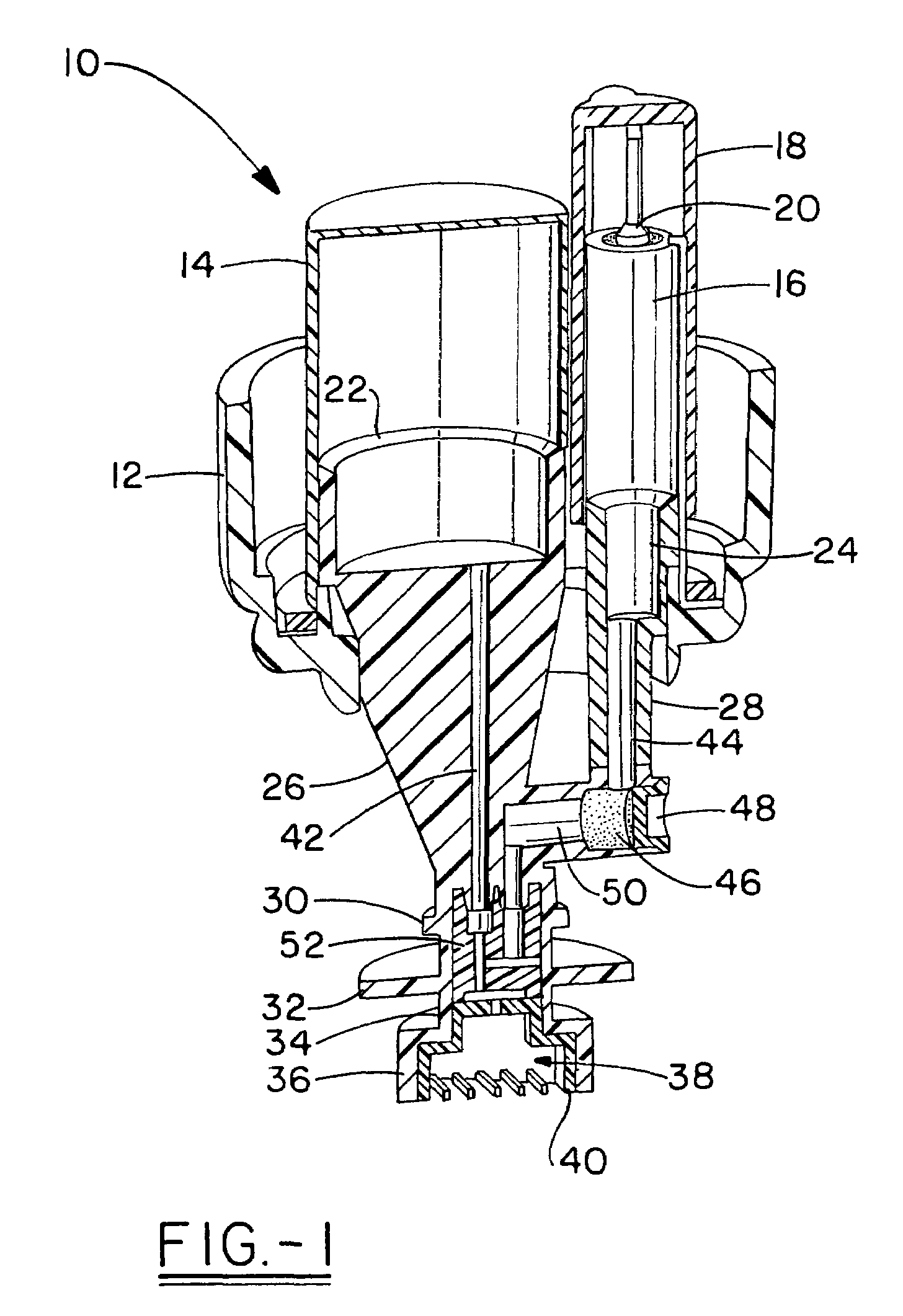

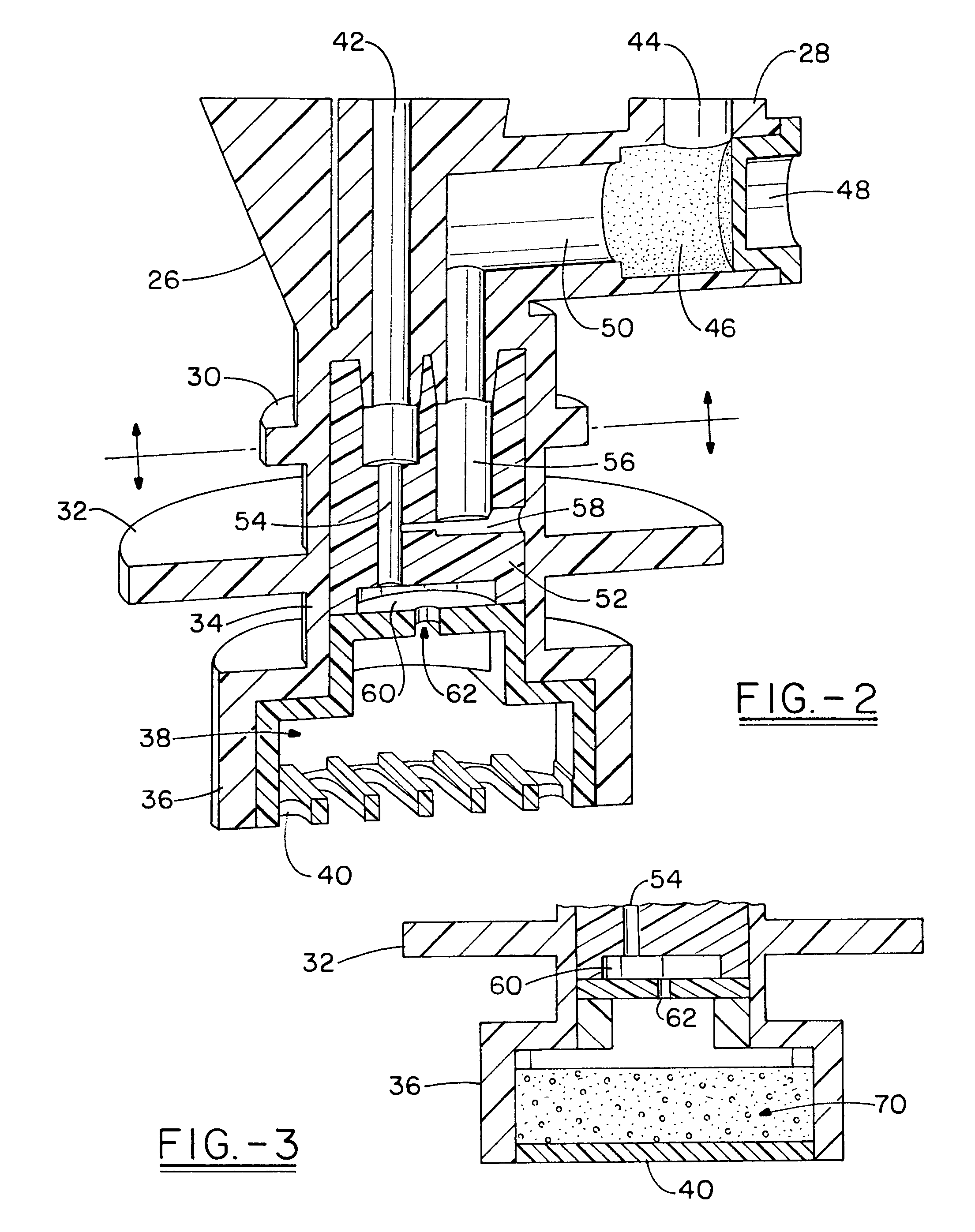

Air foam pump with shifting air piston

InactiveUS6840408B1Reduce in quantityReduce valve costContracting/expanding measuring chambersLarge containersReciprocating motionPump chamber

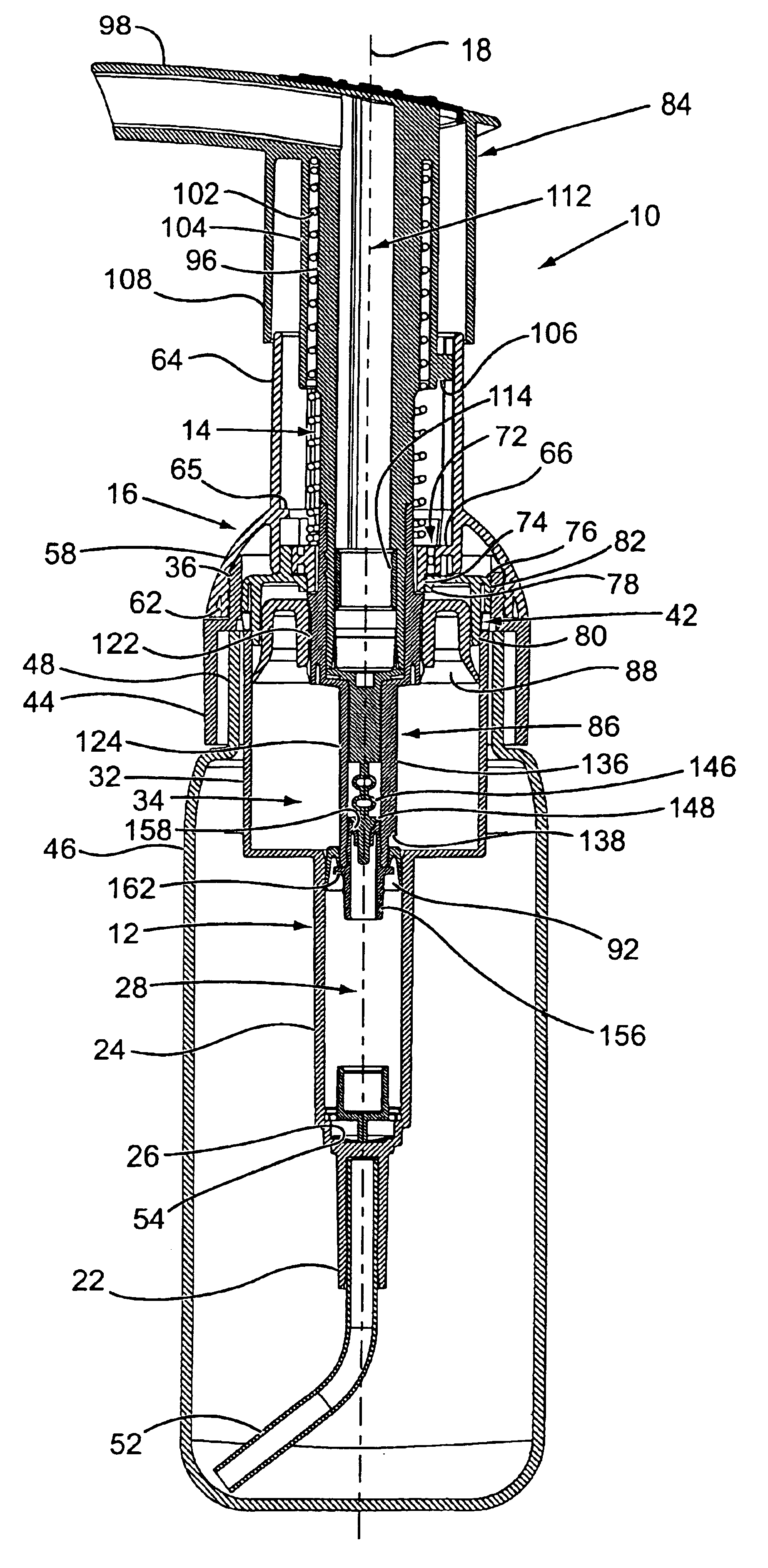

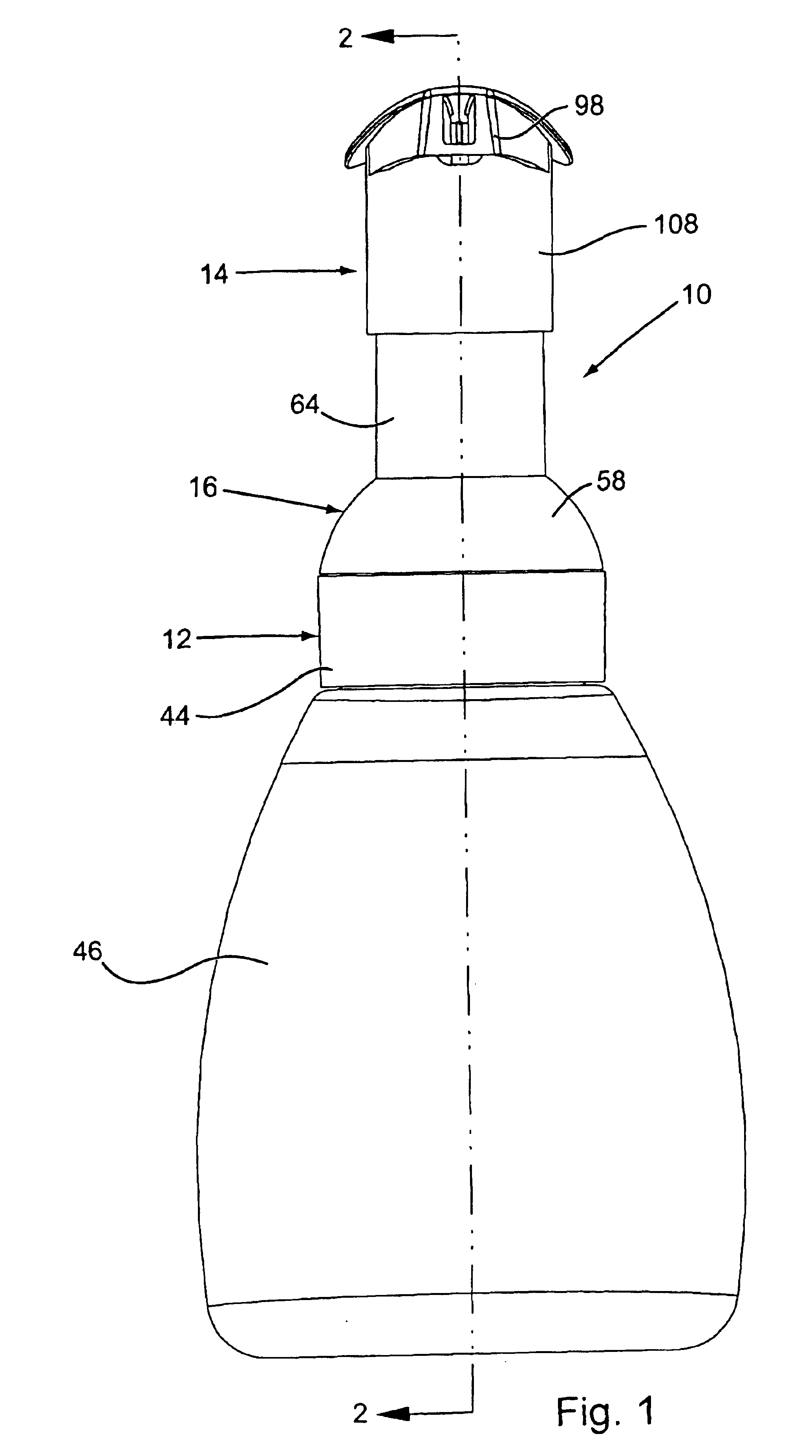

A manually operated liquid foaming dispenser is attached to a bottle of liquid and pumps and mixes both the liquid and air to create a foam from the liquid and to dispense the foam. The dispenser includes a pump housing containing an air pump chamber and a liquid pump chamber, and a pump plunger that is manually reciprocated in both the air pump chamber and the liquid pump chamber. An air piston and a liquid piston are mounted on the plunger and are reciprocated by the plunger in the respective air pump chamber and liquid pump chamber. The air piston is mounted on the pump plunger for relative movement of the air piston on the plunger that enables an interior volume of the air pump chamber to be vented to an exterior environment of the dispenser on manual reciprocation of the pump plunger.

Owner:SILGAN DISPENSING SYST CORP

Liquid piston internal combustion power system

InactiveUS7191738B2Reduce pollutionRotary slide valveSteam engine plantsFree-piston engineCombustion

Methods, devices, and systems for power generation through liquid piston internal combustion engine. The liquid piston internal combustion engine of the invention utilizes a novel, synergetic combination of internal combustion and steam piston engines within the framework of one and the same system. The engine may comprise a plurality of cylinders, each having a liquid piston.

Owner:LIQUIDPISTON INC

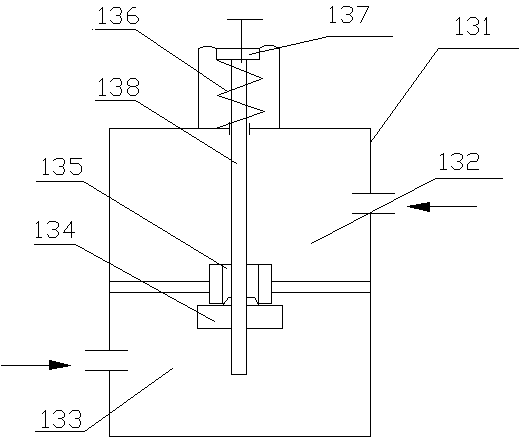

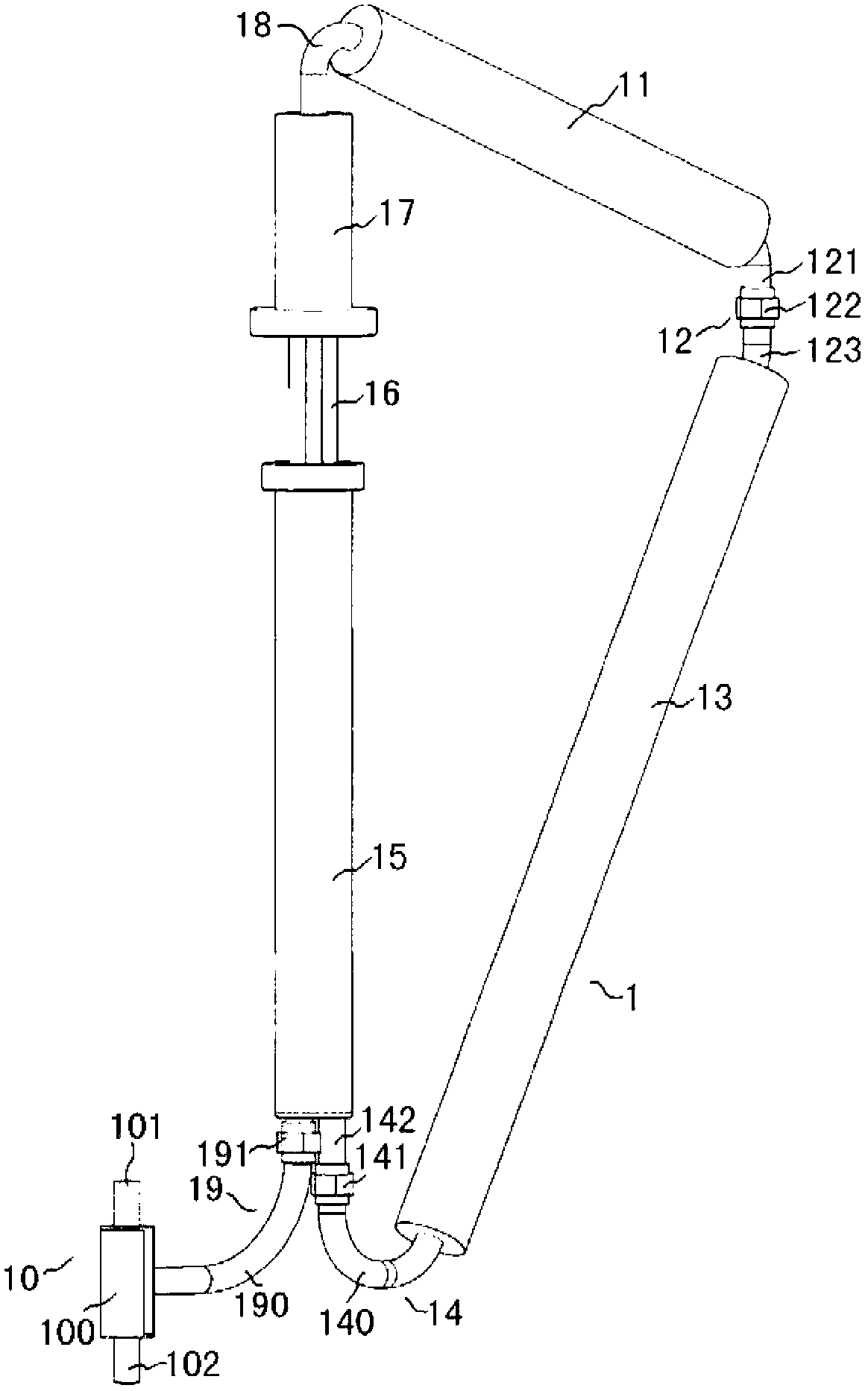

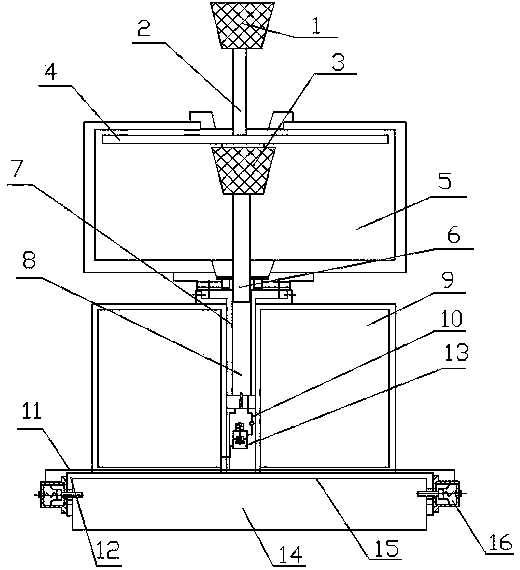

Positive-pressure pneumatic type automatic water sample sampler

ActiveCN103439146AIncrease buoyancyLarge capacityWithdrawing sample devicesPositive pressureEngineering

The invention discloses a positive-pressure pneumatic type automatic water sample sampler comprising a sampling water storage bin, a counter weight bin and a high-pressure gas storage pot, wherein the upper part of the sampling water storage bin is provided with a sampling port; a gas-liquid piston cylinder is arranged under the sampling port and separated into an upper gas cavity and a lower liquid cavity through a piston plate; the cylinder wall at the bottom of the lower liquid cavity is provided with a liquid outlet; the liquid outlet is provided with a liquid drainage one-way valve; the upper gas cavity of the gas-liquid piston cylinder and the high-pressure gas storage pot are connected through a pipeline; the pipeline is provided with an environment pressure control valve; the bin wall of the counter weight bin is provided with a seawater inlet / outlet through hole; a gas bag is arranged in the counter weight bin; a gas inlet of the gas bag and the high-pressure gas storage tank are connected through a gas inlet pipeline; the gas inlet pipeline is provided with a gas inlet control valve of the gas bag; the cylinder wall at the bottom of the lower liquid cavity is provided with a pressure triggering button matched with the gas inlet control valve of the gas bag. By adopting the underwater pneumatic technology, a water sample with the set depth can be automatically sampled, the positive-pressure pneumatic type automatic sampler can automatically reset and can be applied to a variety of occasions, and a collected sample can be taken out.

Owner:HUAIHAI INST OF TECH

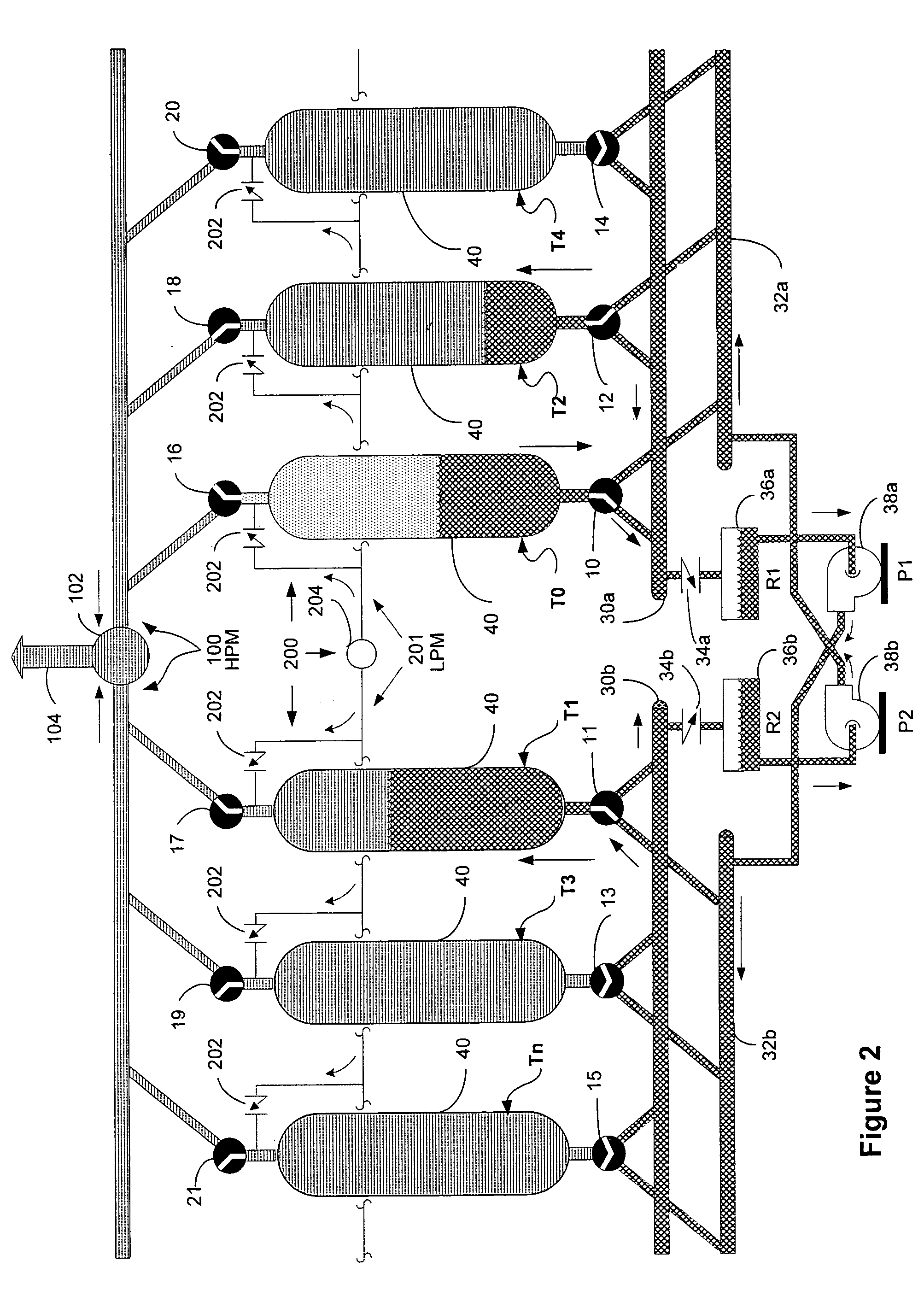

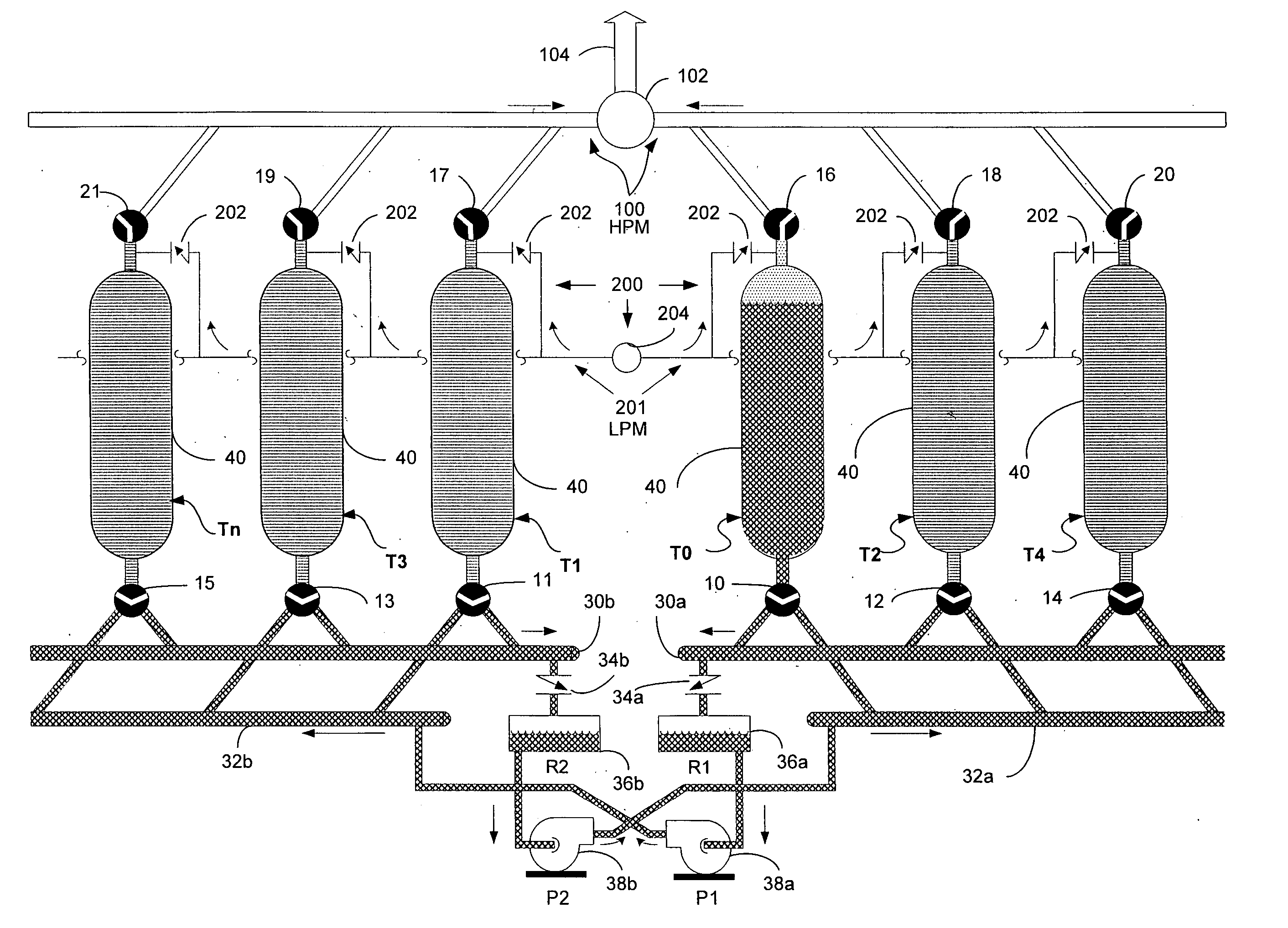

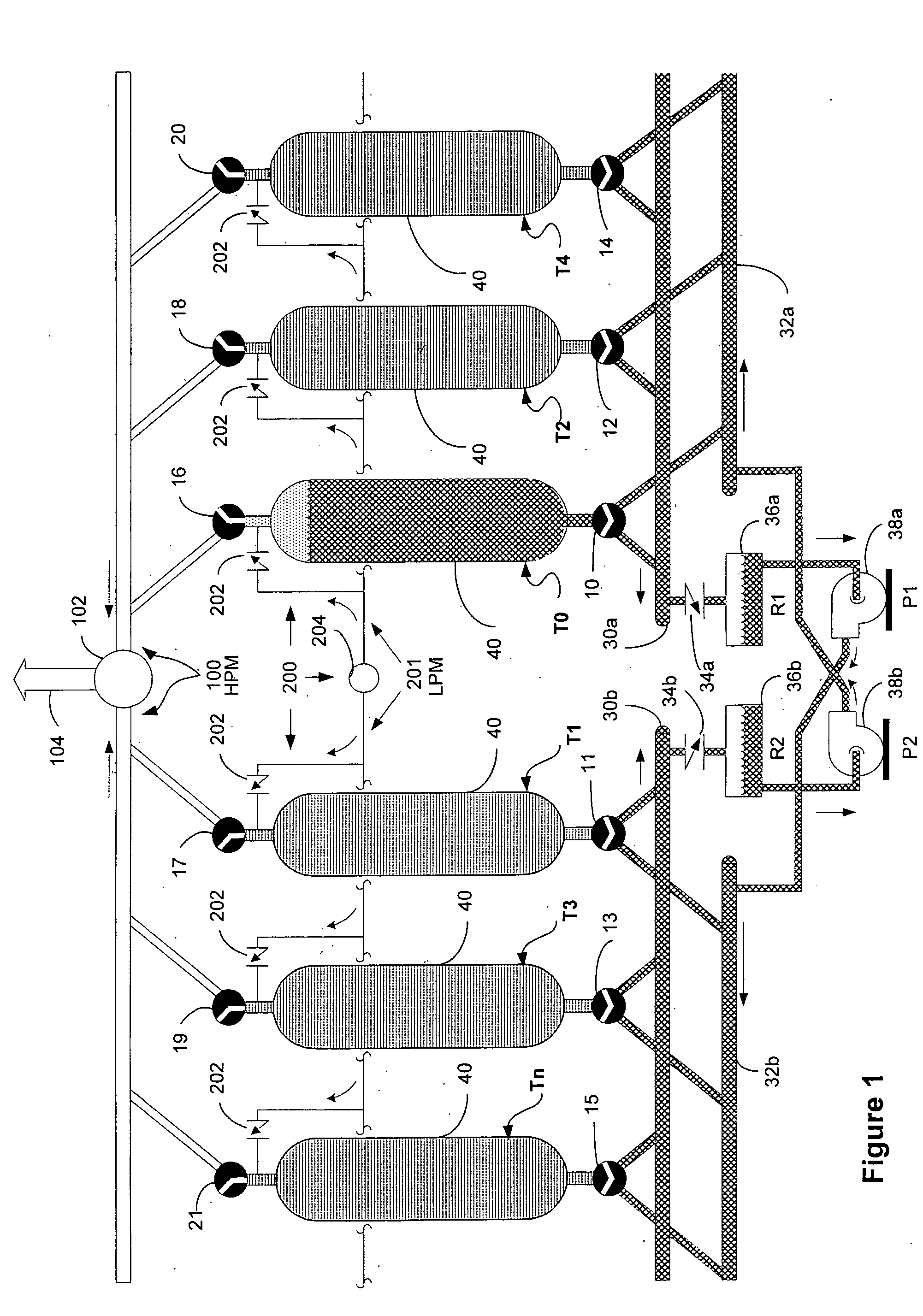

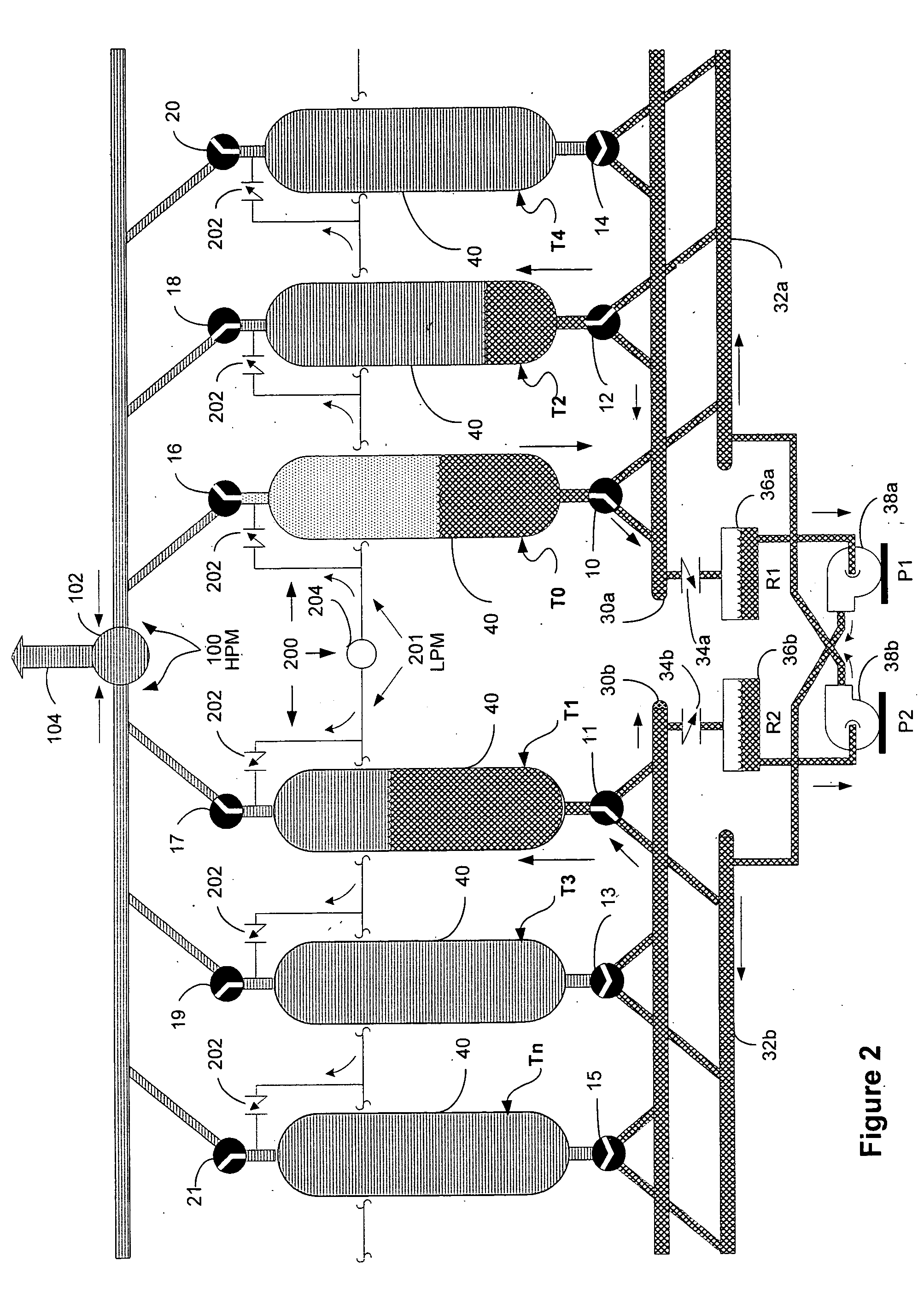

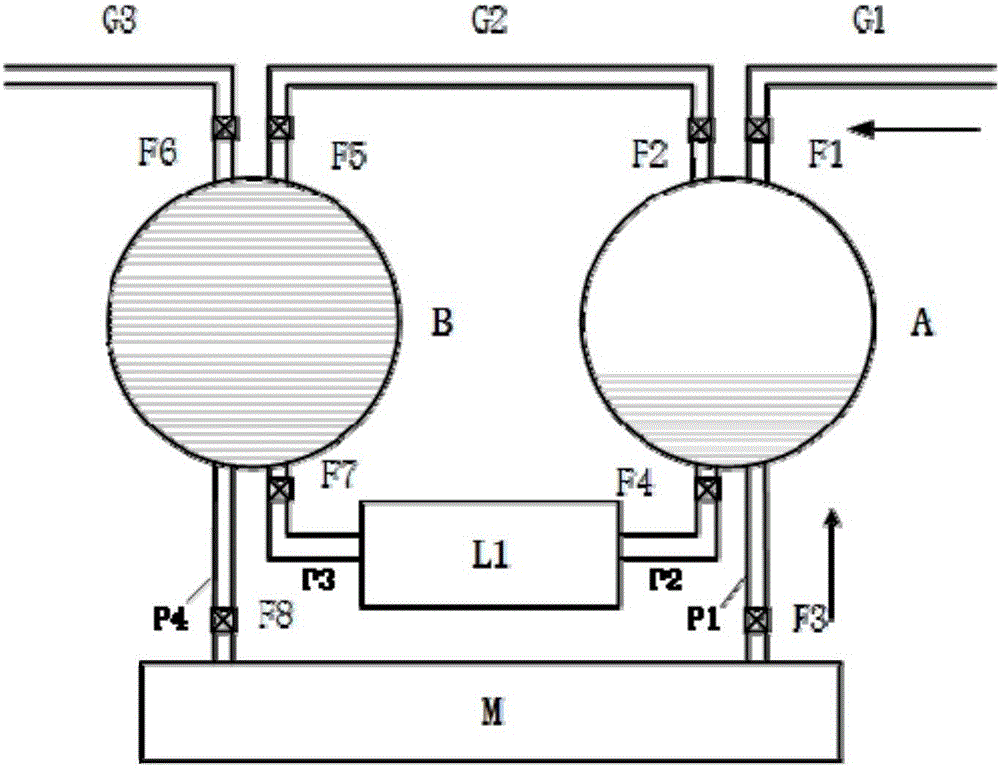

Liquid displacement shuttle system and method

A multi-vessel gas storage system and liquid displacement shuttle system that utilizes a liquid-piston shuttled to alternate reservoirs and tank banks to evacuate stored gas or other fluids from storage vessels. Preferably, the gas storage and fluid displacement shuttle system includes multiple pressure storage vessels or tanks arranged in tank banks that are preferably coupled in parallel at one end to a high pressure gas manifold to exhaust the stored gas or other fluids from the vessels and coupled in parallel at another end to separate fluid shuttle circuits. The fluid shuttle circuits include cross-piped fluid fill and drain manifolds that are fluidly linked through interposing reservoirs and pumps. In operation, the stored gas or other fluids are evacuated from the storage vessels by shuttling the volume of displacement liquid between alternating banks of storage tanks and reservoirs with alternating pumps.

Owner:SEAONE HLDG

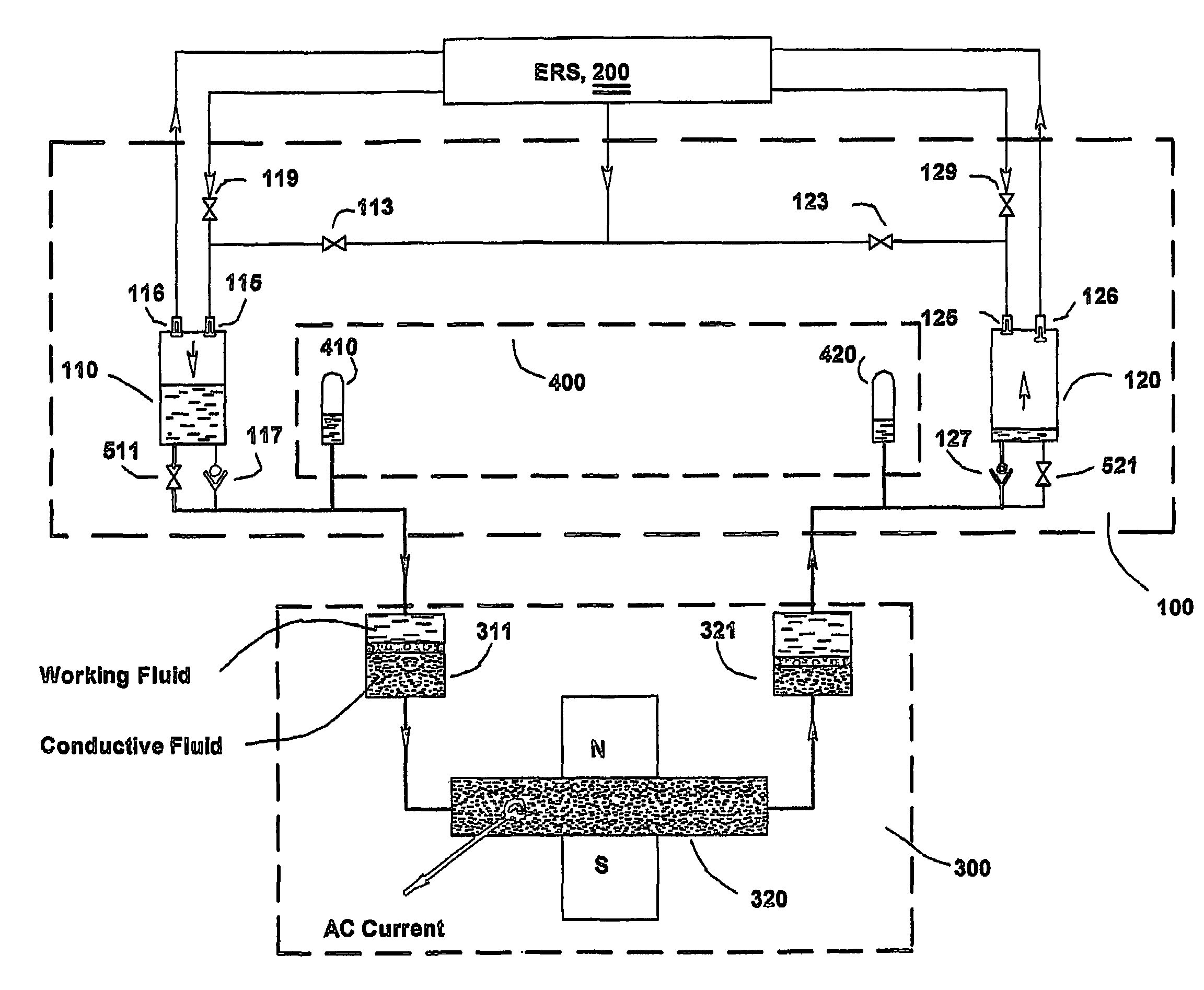

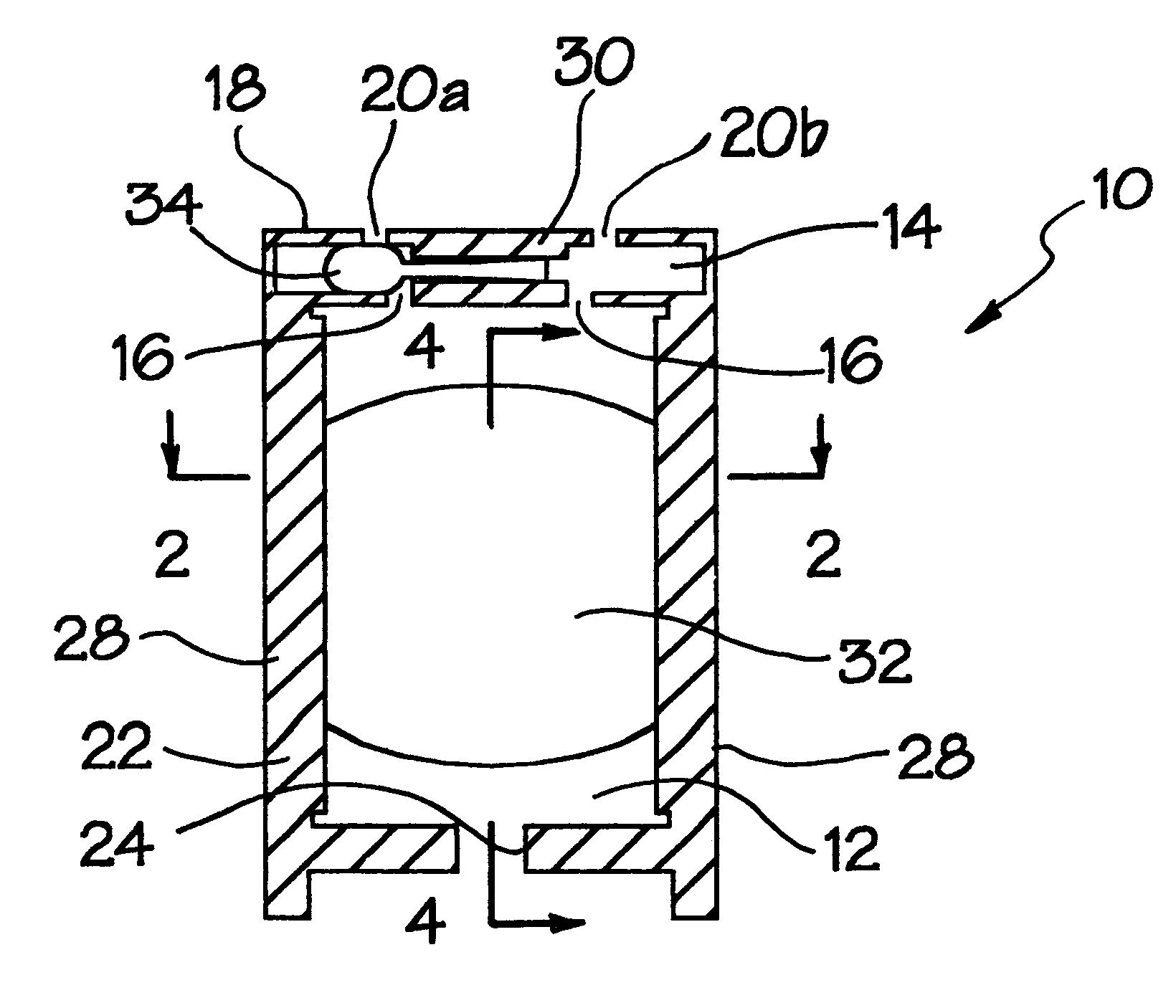

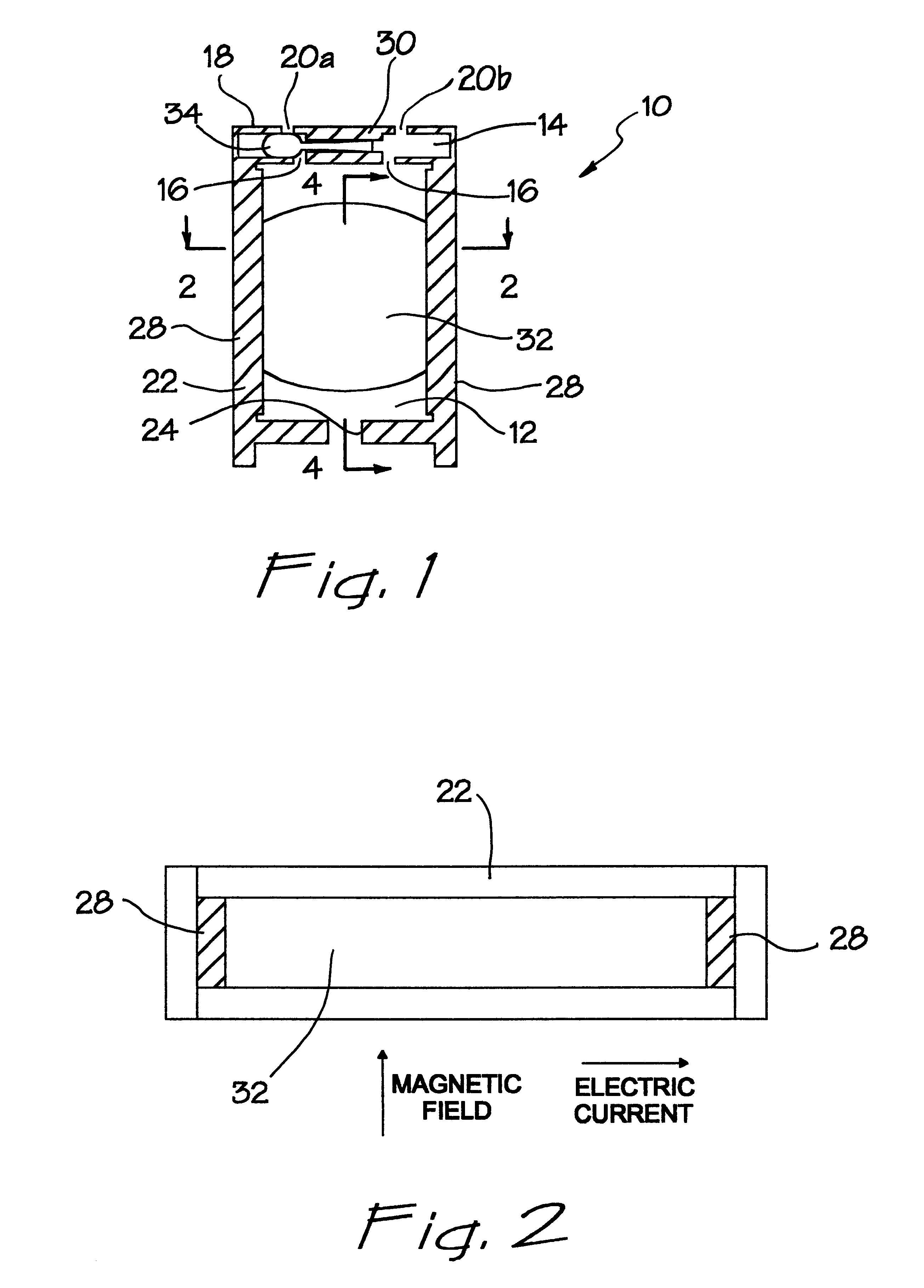

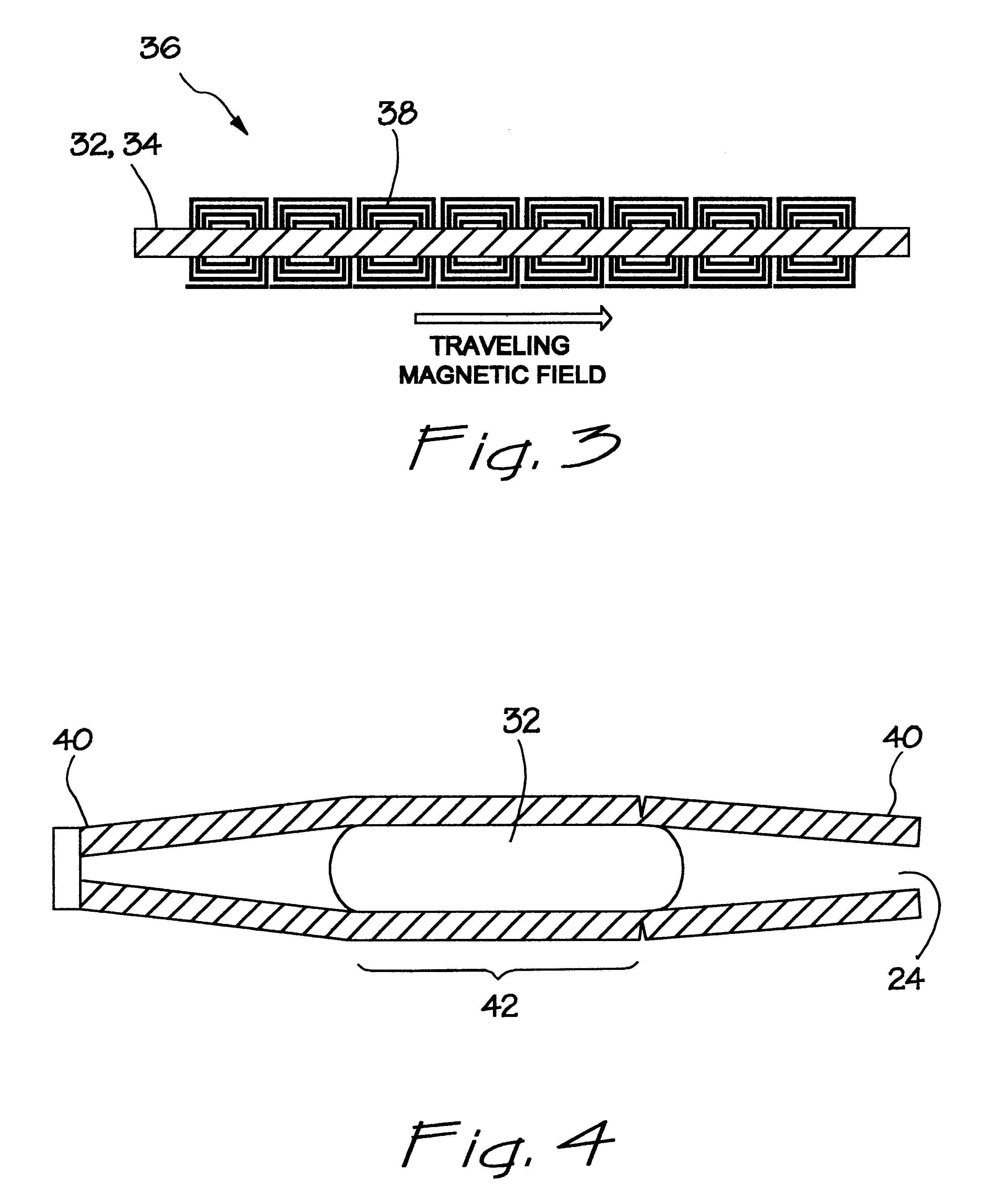

Micro-magnetohydrodynamic pump and method for operation of the same

InactiveUS6241480B1Simple and effective energy transfer meanLow working voltagePositive displacement pump componentsPiston pumpsWorking fluidPump chamber

A micropump fabricated in a planar substrate is provided with a valving chamber which is communicated to a pumping chamber. The valving chamber has an inlet and outlet port. Both the valving chamber and pumping chamber have a liquid, electrically conductive piston disposed therein, which liquid piston is nonmiscible with the pumped working fluid and nonreactive with the substrate in which the chambers are formed. The valving piston is magnetohydrodynamically driven to selectively close either the inlet port or the outlet port. The pumping piston is magnetohydrodynamically driven to pull or push the working fluid through one of the inlet or outlet ports, through the valving chamber, into the pumping chamber, back out of the pumping chamber and through the other one of the inlet or outlet ports after activation of the valving piston. Both direct current and inductive magnetohydrodynamic drives are contemplated. The valving and / or pumping chambers may be shaped or narrowed in their dimensions to impose a mechanical bias on the respective valving and / or pumping pistons to assume a preferred position in their respective chambers when the magnetohydrodynamic drive is turned off.

Owner:RGT UNIV OF CALIFORNIA

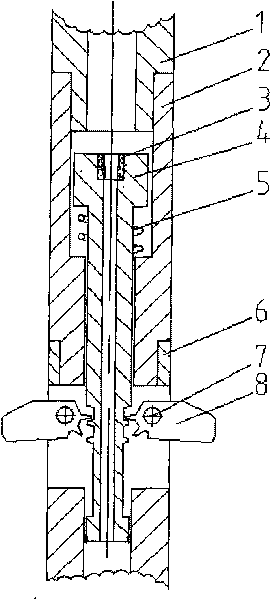

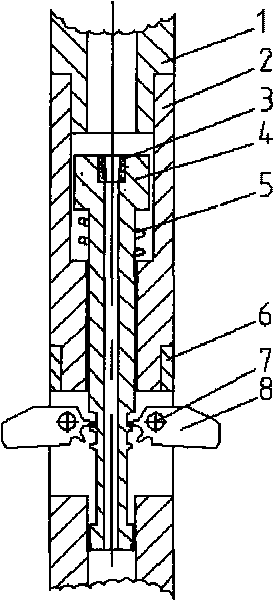

Drill-following reamer

A drill-following reamer comprises an upper joint, a reamer body, a piston nozzle, a piston, a compression spring, a blade, a pin shaft and a limit stop. The upper part of the whole set of device is connected with a drilling tool through the upper joint, while the lower part is connected with a drill bit through a screw thread. During drill-following reaming operation, the liquid piston nozzle pumped on the ground produces pressure drop to push the piston to move downwards, a groove on the piston pushes a gear structure on the blade to rotate the blade outwards by using the pin shaft as the center when the piston moves downwards till the blade is limited by the limit stop, and then the blade is expanded to reach the maximum outside diameter to start the drill-following reaming operation. 78.6 percent of drill hole expansion rate can be achieved by using the drill-following reamer, so the drill hole expansion rate is high; the blade has the mechanical locking function and is not retracted due to the extrusion of the well wall, so the diameter of the reamed drill hole is regular; and because the drilling and the reaming are carried out at the same time, the drilling cost is saved.

Owner:SHENGLI PETROLEUM ADMINISTRATION BUREAU DRILLING TECH ACAD SINOPEC

Thermoacoustically-driven thermally-coupled two-stage pulse tube cooling system

InactiveCN101706169ALow mass inertiaMass inertiaCompression machinesGas cycle refrigeration machinesPower flowThermoacoustics

The invention discloses a thermoacoustically-driven thermally-coupled two-stage pulse tube cooling system, which comprises a U-shaped double side-drive thermoacoustic engine, connecting pipes and a thermally-coupled two-stage pulse tube cooler, which are connected sequentially. The system is characterized in that: a U-shaped resonating tube connects two thermoacoustic cores; acoustic power flows flow out from the directions of a cold end and a hot end of a thermoacoustic plate stack to drive an acoustic oscillator and the pulse tube cooler in the U-shaped resonating tube respectively; the backward pressure waves output by the two thermoacoustic cores drive the two stages of the thermally-coupled two-stage pulse tube cooler through the connecting pipes respectively, the pulse tube cooler is connected to the pressureantinode positions on the two ends of the thermoacoustic engine, and a larger output pressure ratio is favorable for the acquisition of optimal lower cooling performance of the pulse tube cooler; the operation method of combining the thermoacoustic plate stack and a thermoacoustic regenerator is adopted to improve the acoustic power output capacity and the vehicle efficiency; and a liquid piston is introduced into the U-shaped resonating tube to form a gas-liquid coupled oscillation system so as to reduce resonance frequency and increase pressure ratio and consequentially improve the performance of the driven pulse tube cooler.

Owner:ZHEJIANG UNIV

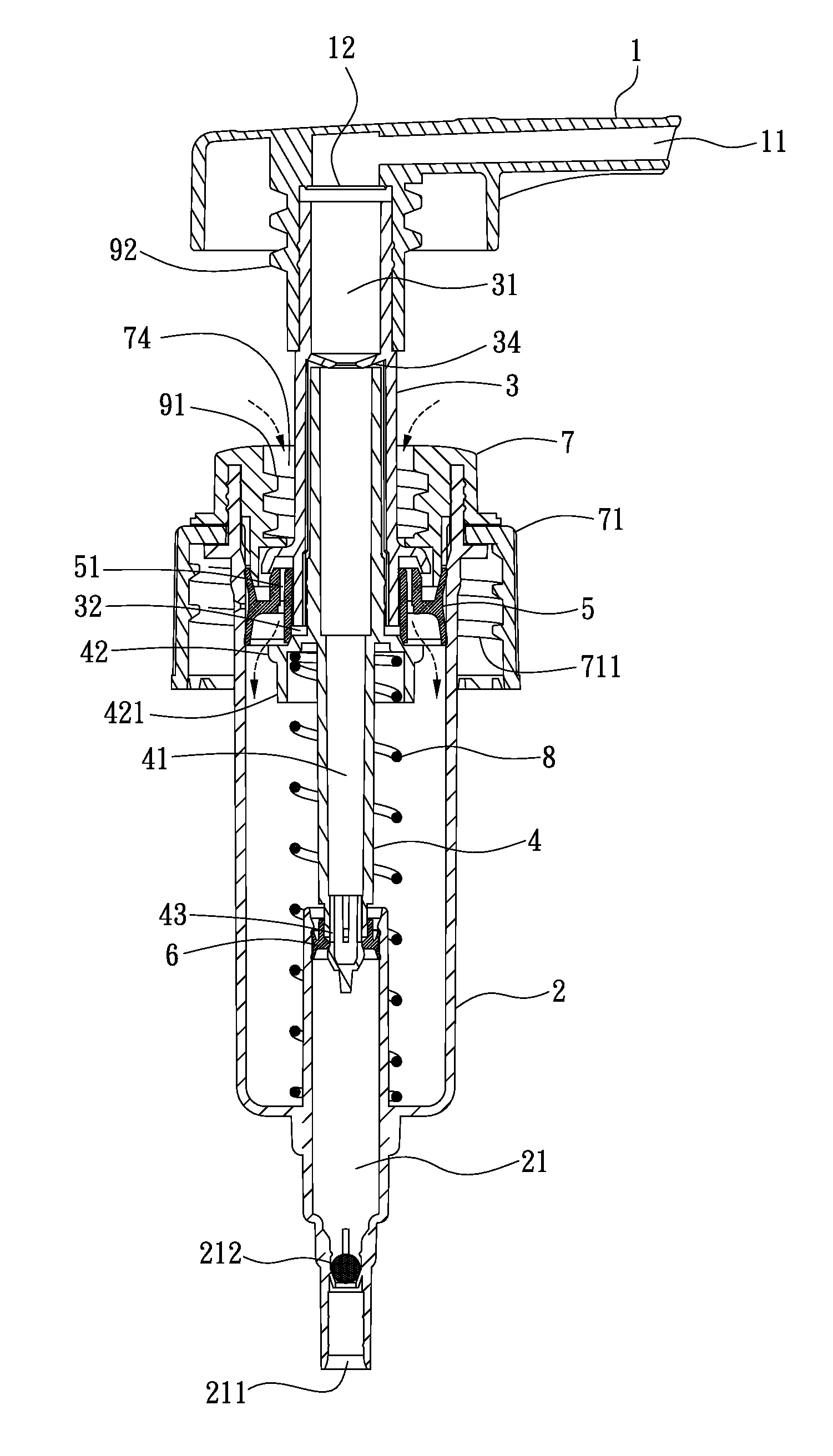

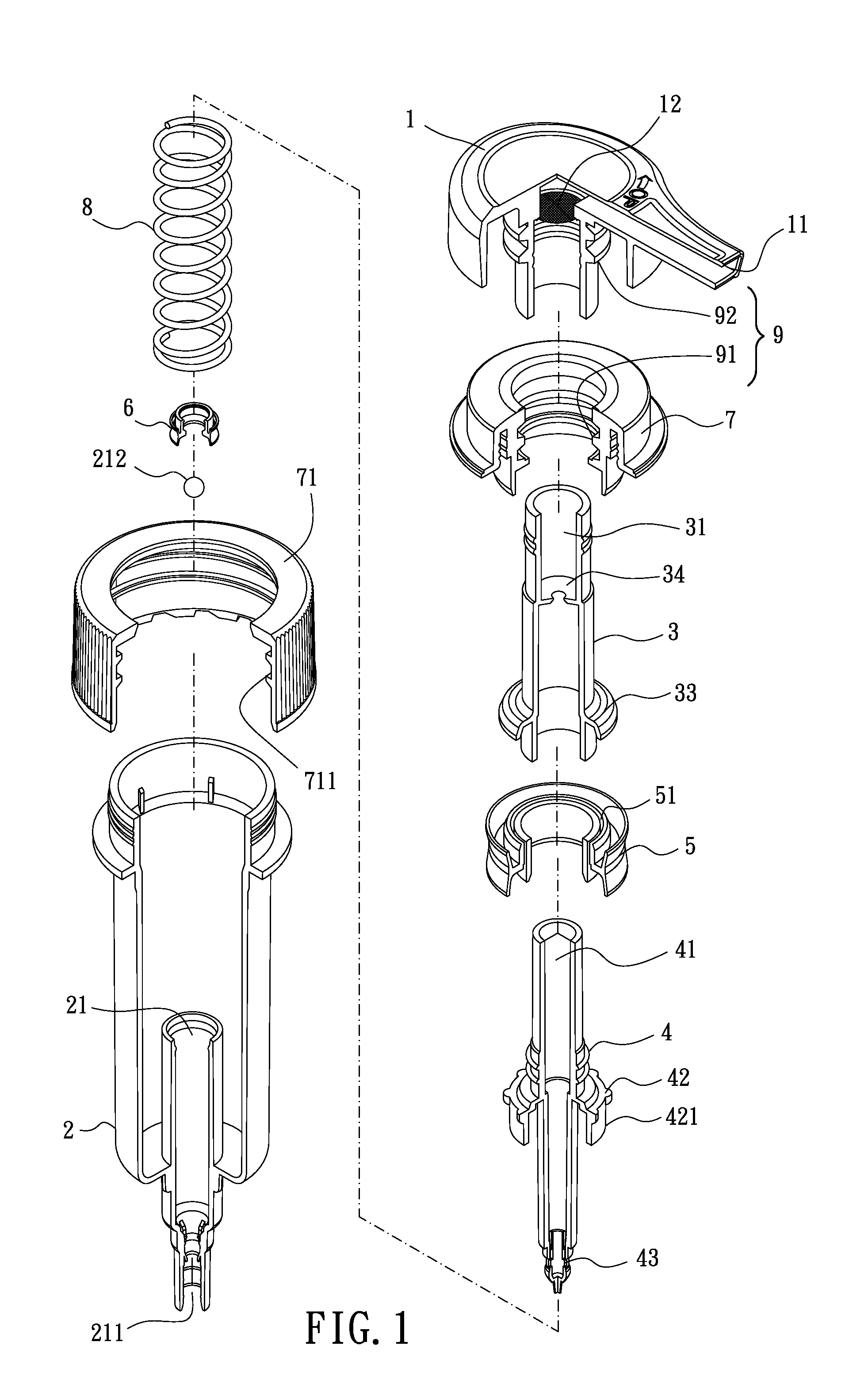

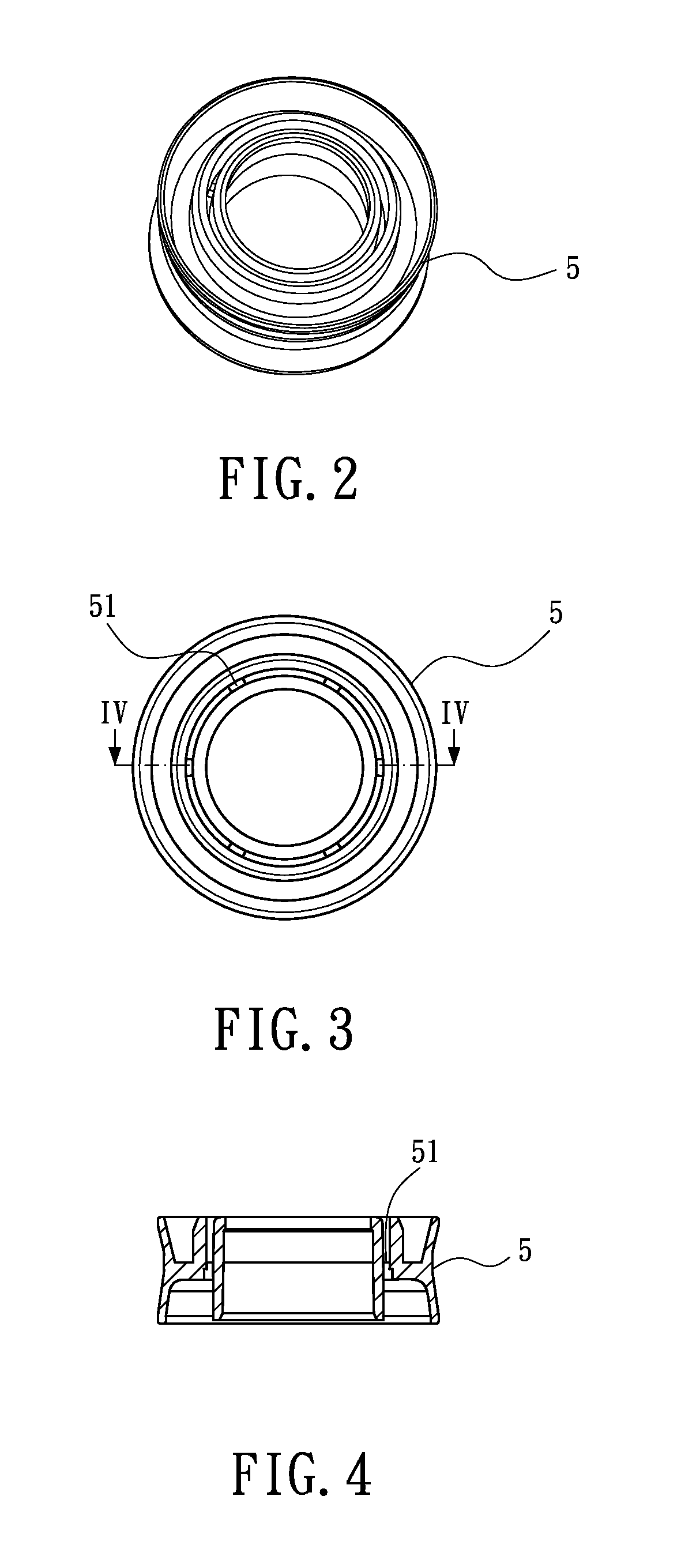

Foam dispensing device

InactiveUS20120104048A1Prevent backflowHolders and dispensersLiquid transferring devicesLiquid pistonMixing chamber

A foam dispensing device includes an outer tube connecting with a liquid container. A lower tube and an upper tube are partially received in the outer tube. The lower tube has a guide chamber defined therein which has a second inlet defined therein. A liquid piston is connected with the lower tube for selectively sealing the second inlet. A spring is compressibly received in the outer tube and abuts against the lower tube. The upper tube sleeves on the lower tube and has a mixing chamber defined therein for communicating with the guide chamber. An air piston movably sleeves on the upper tube and has at least one air hole defined therein for guiding air into the outer tube. A dispensing head is connected with the upper tube and has a nozzle formed thereon.

Owner:HSIH TUNG TOOLING

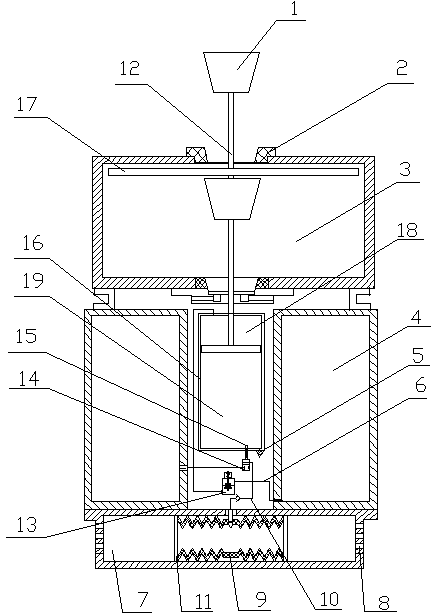

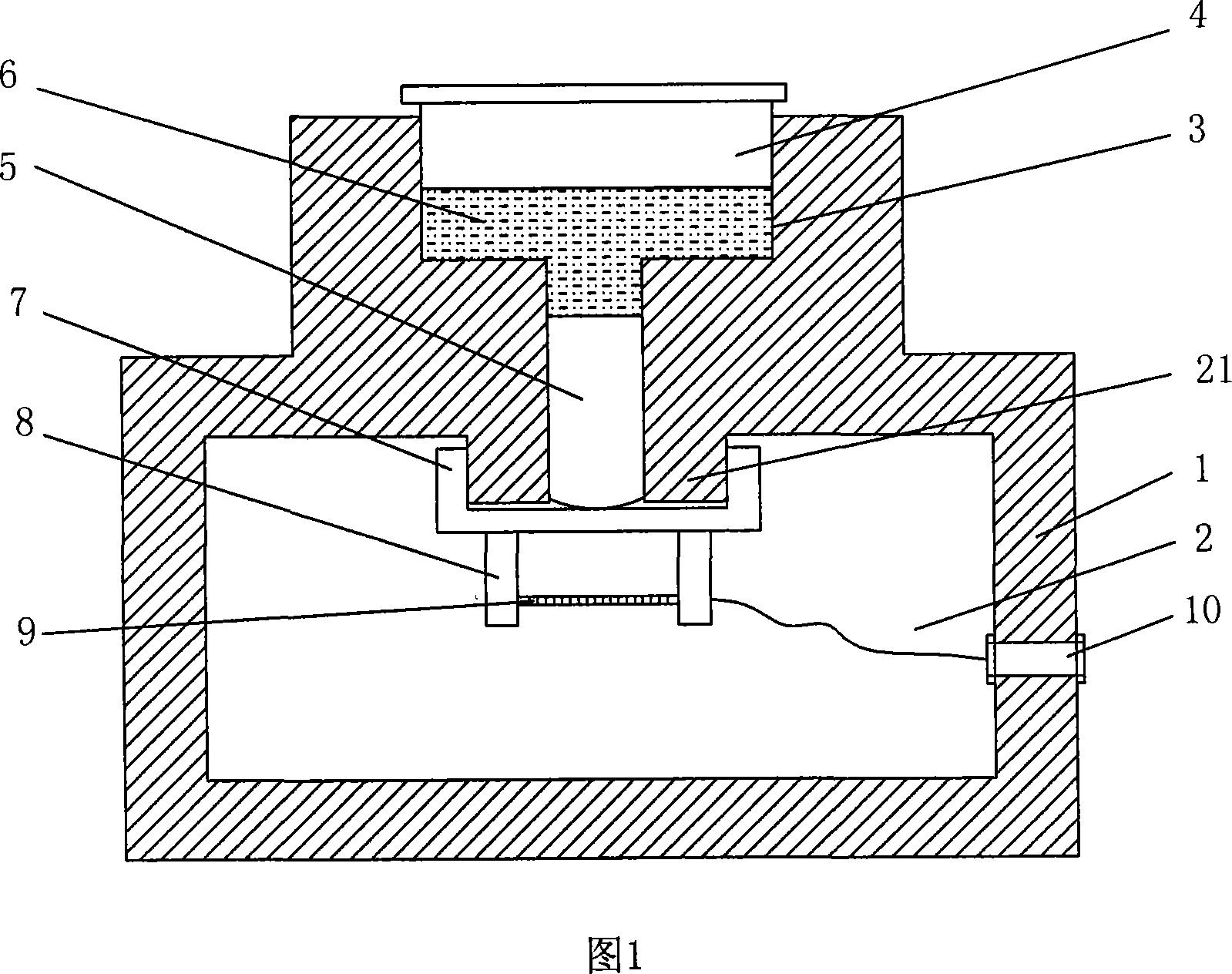

Boiler and liquid piston thermomotor thereof

ActiveCN103321775AReduce noiseImprove sealingEngine componentsHot gas positive displacement engine plantsEngineeringLiquid piston

The invention discloses a liquid piston thermomotor and a boiler using the liquid piston thermomotor. The liquid piston thermomotor comprises a first cylinder, a second cylinder, a heater, a heat regenerator and a cooler. Liquid pistons with the bottoms communicated are arranged in the first cylinder and the second cylinder, the heater, the heat regenerator and the cooler are sequentially connected, the first cylinder is connected with the heater, and the second cylinder is connected with the cooler. The liquid piston thermomotor further comprises a power output pipe. The first end of the power output pipe is provided with a power output port and stretches into the first cylinder or is connected with the bottom of the first cylinder, so that reciprocating power can be output to the external through the second end of the power output pipe. The liquid piston thermomotor and the boiler using the liquid piston thermomotor are low in cost, small in noise and environmentally friendly and save energy.

Owner:BORTALA MONGOLIA AUTONOMOUS PREFECTURE WANLIYUAN SCI & TECH DEV

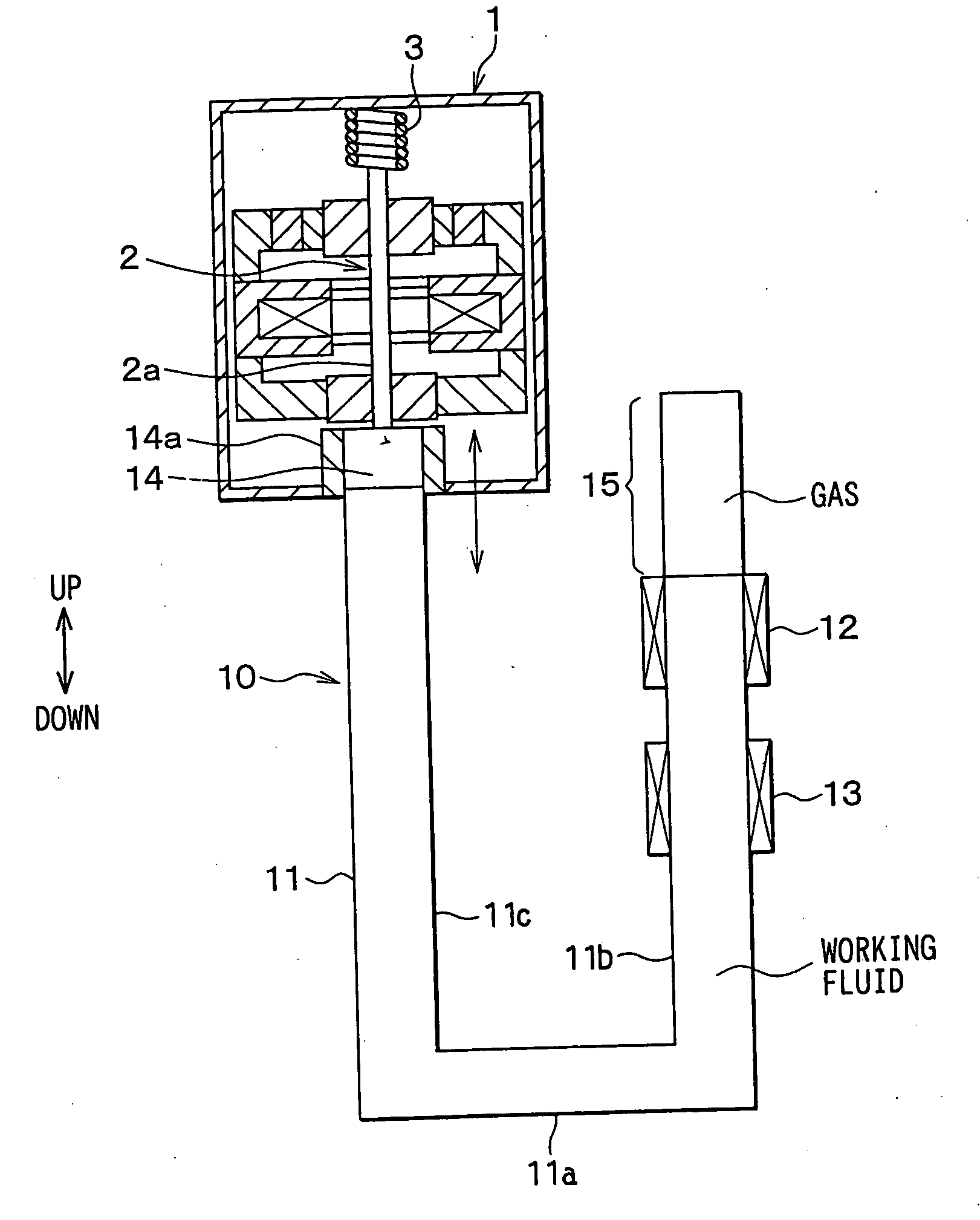

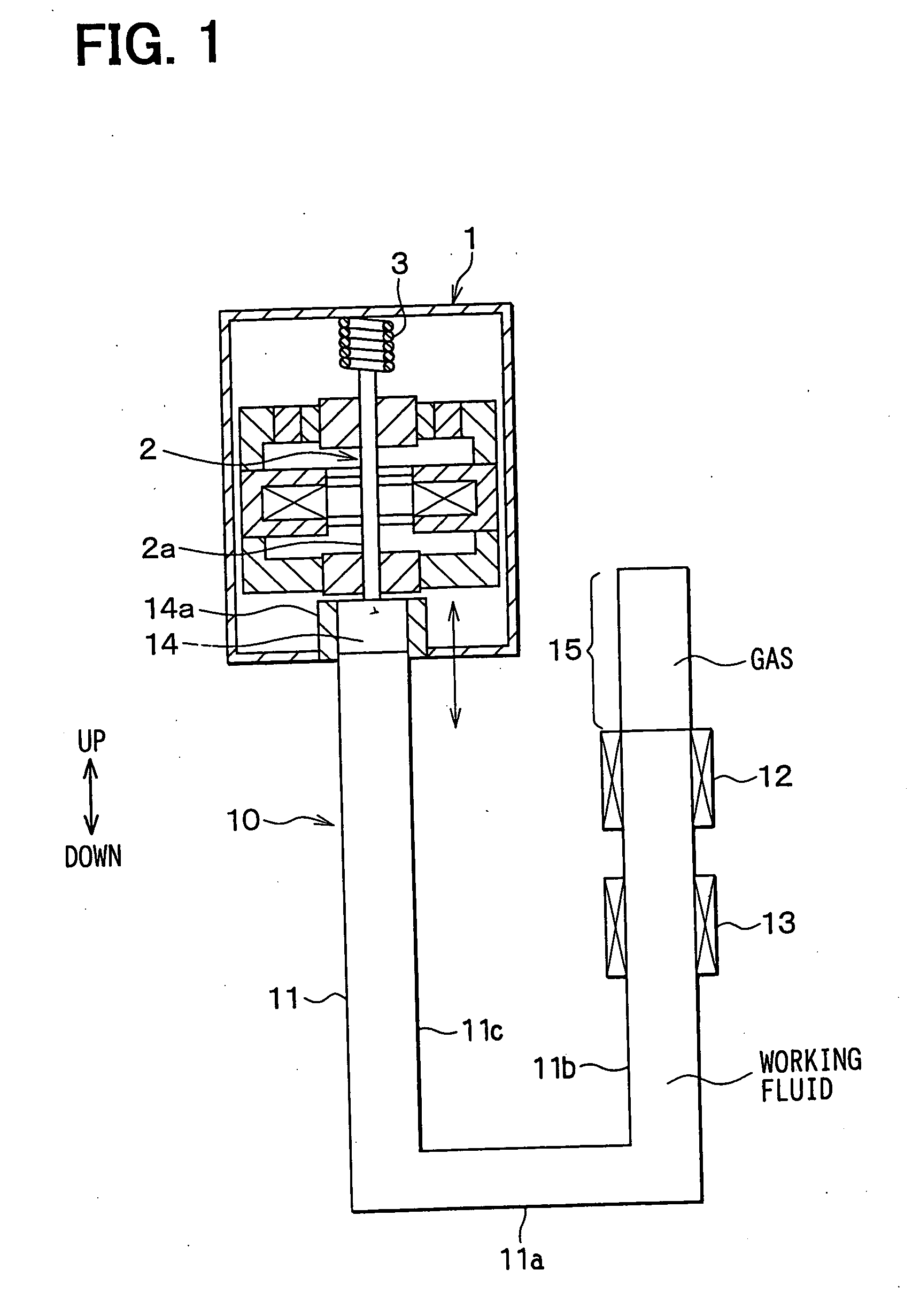

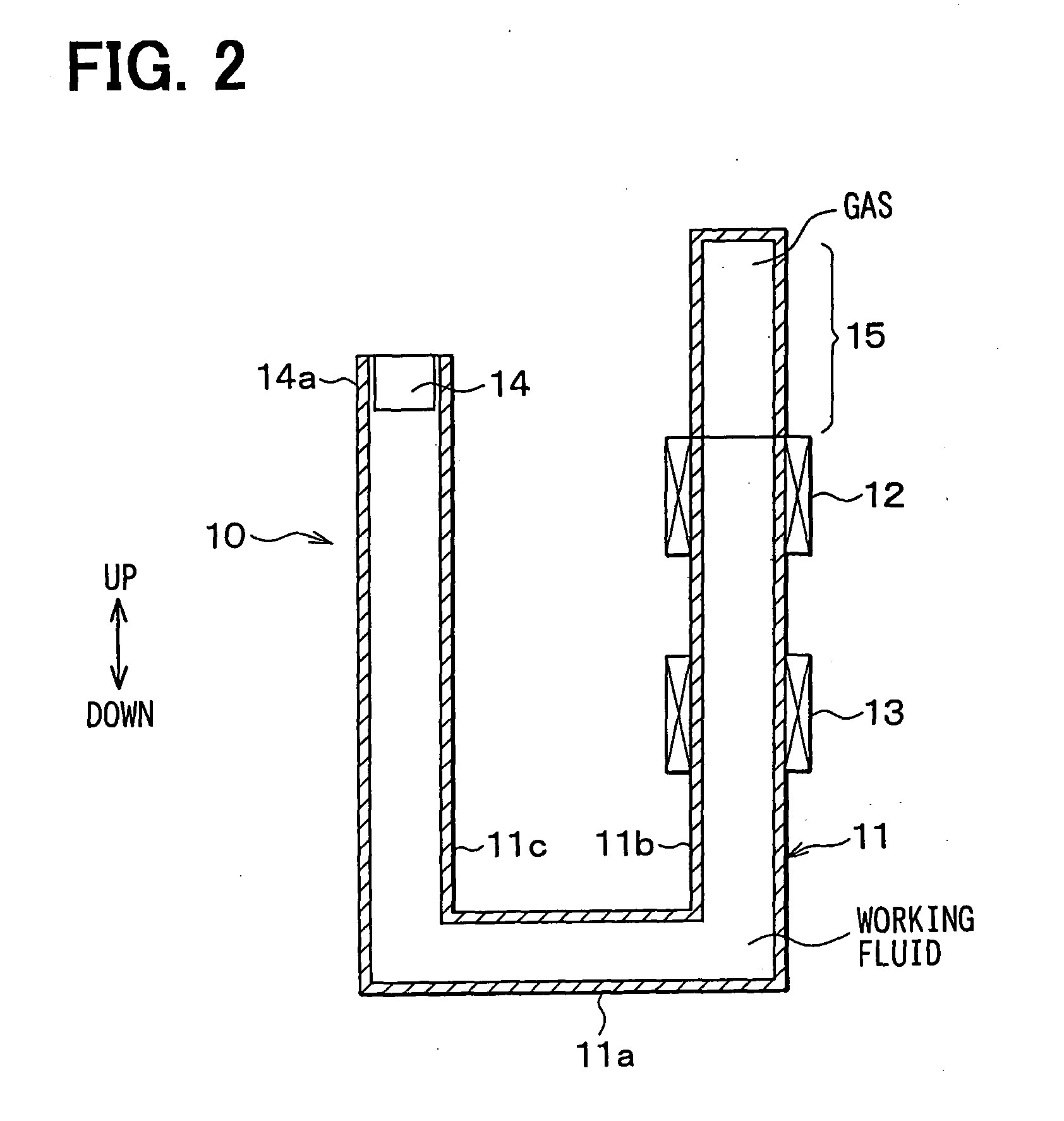

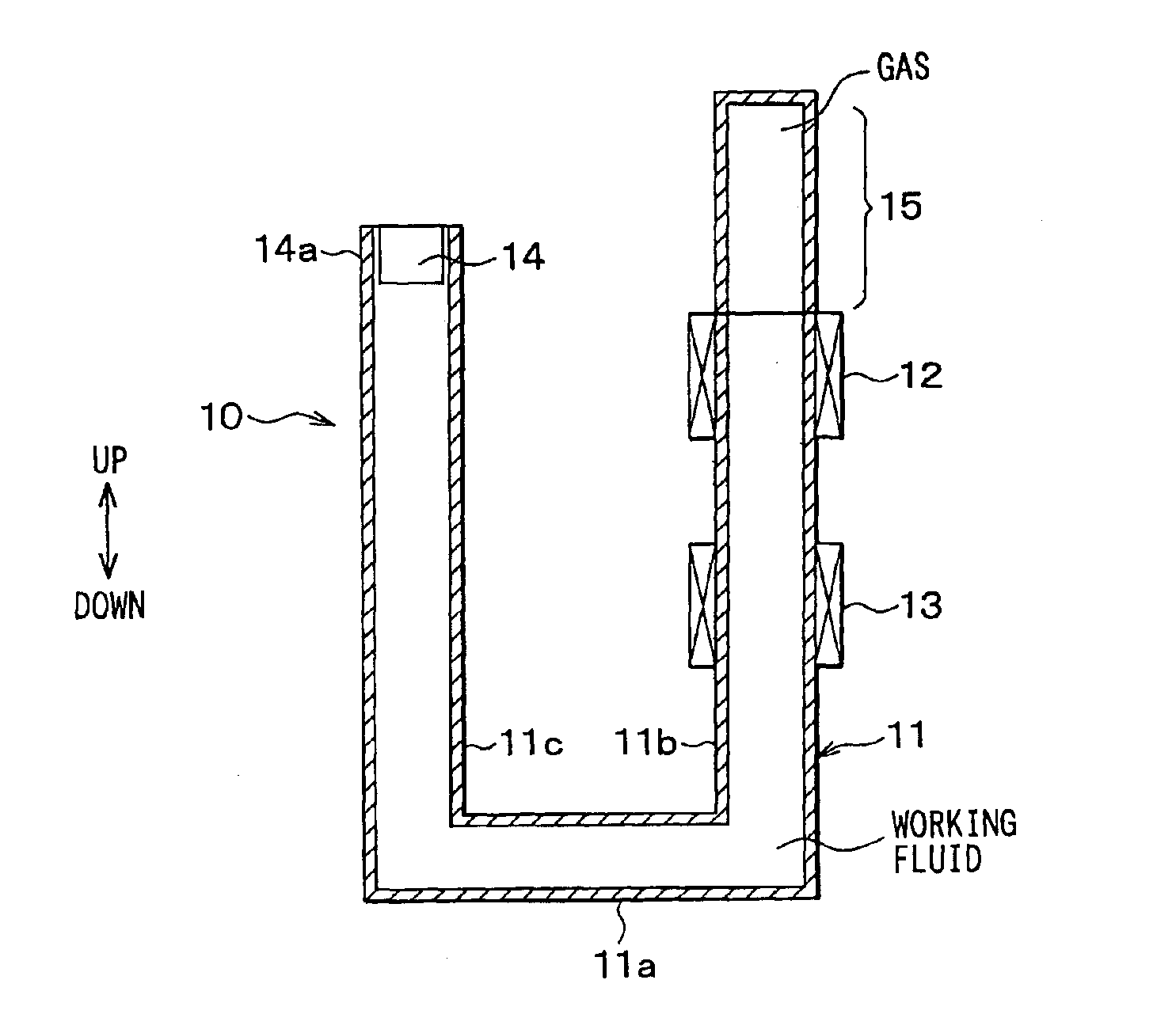

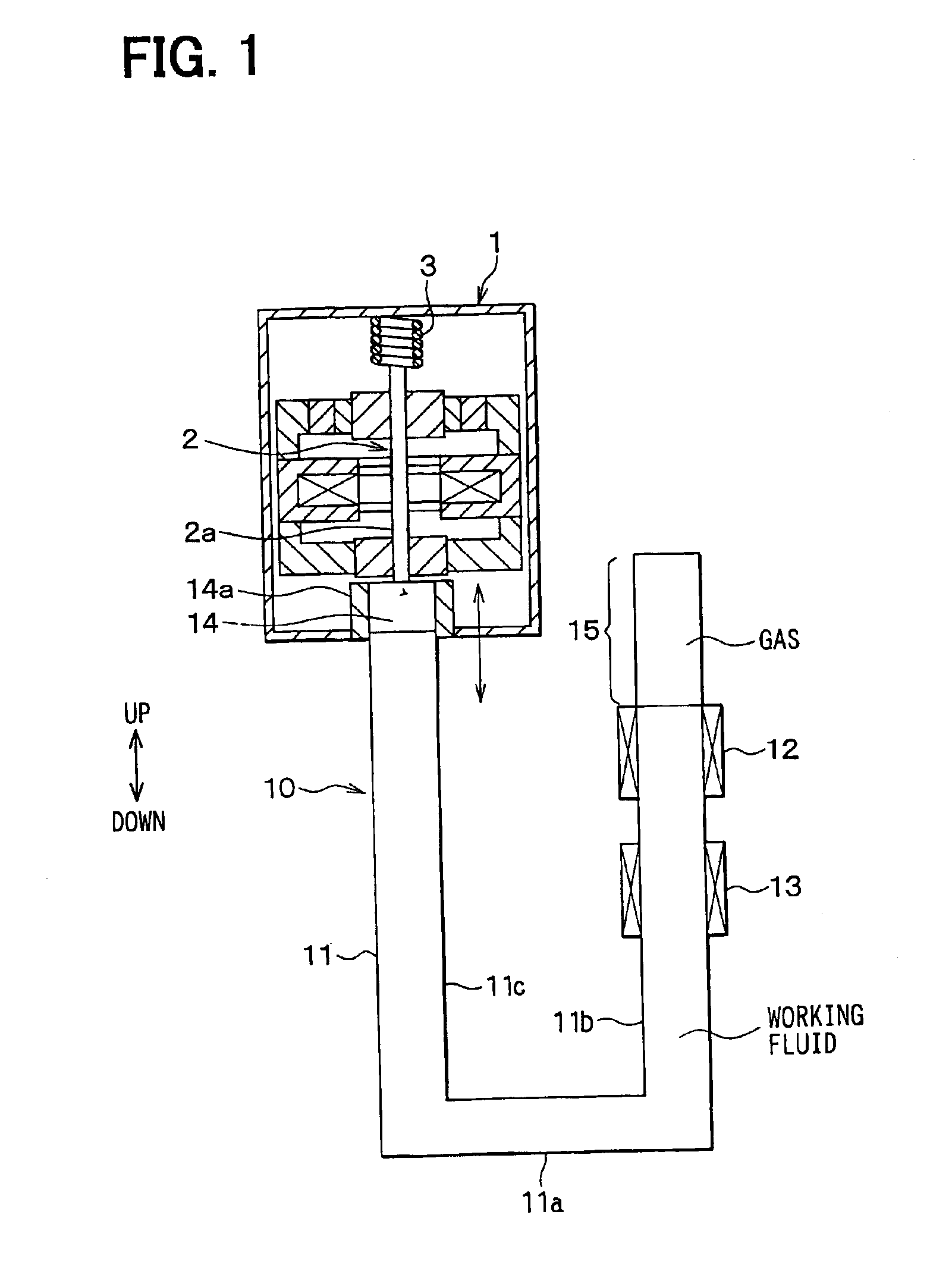

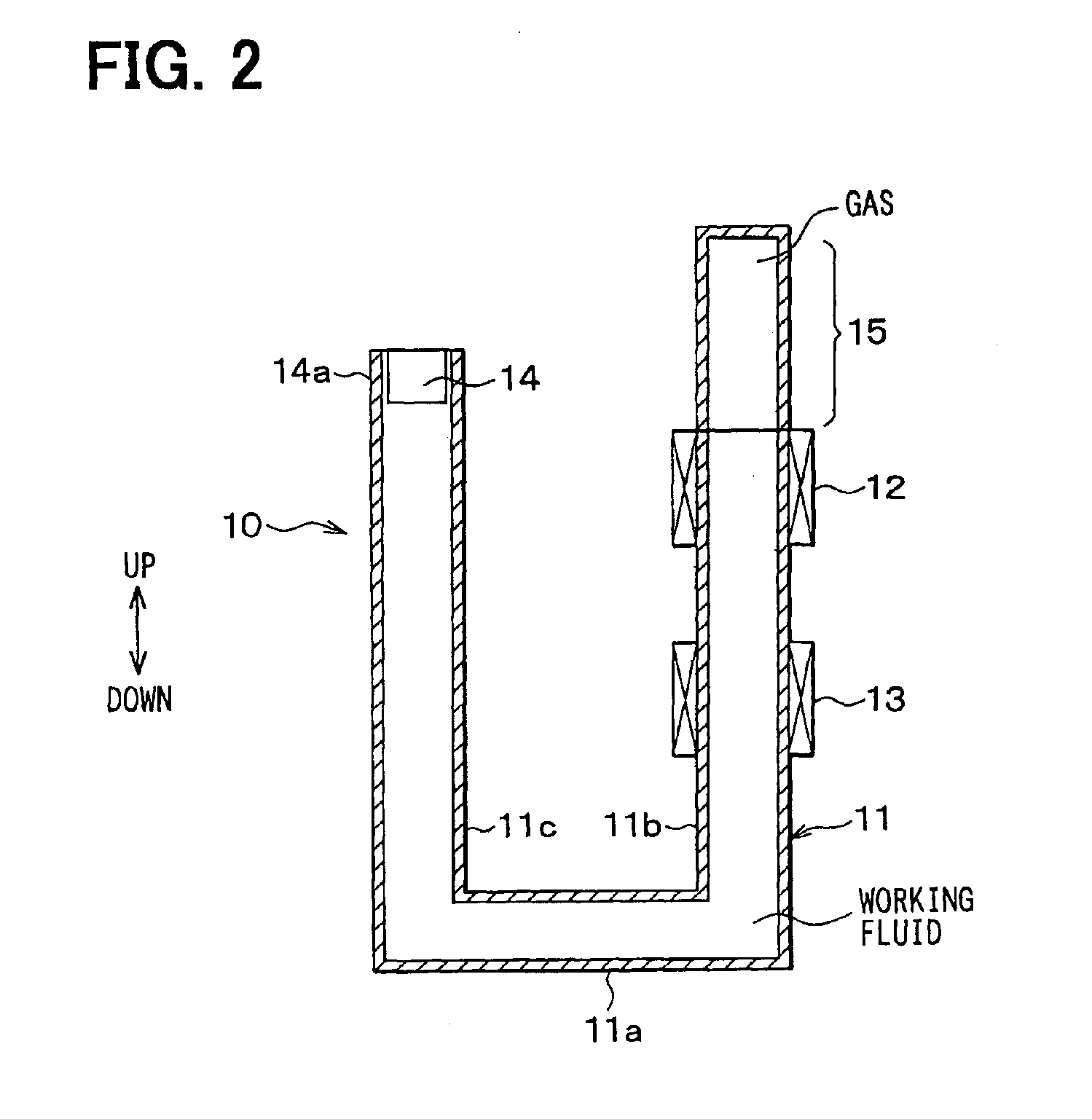

Steam engine

ActiveUS20040060294A1Avoid it happening againAvoid abrasionsSteam accumulatorsEngine componentsSteam pressureWorking fluid

A steam engine increases efficiency and prevents corrosion, abrasion, and the like in a part receiving steam pressure. A heater and a cooler are provided on one side of a U-shaped fluid container, and a piston for output is provided on its other side. The heater heats working fluid to vaporize the fluid. The expansion pressure of steam of the working fluid depresses a fluid level in a first vertical pipe. The liquid component of the working fluid flows from the first vertical pipe into a second vertical pipe, thereby applying pressure to the piston in an upward direction. Then, the liquid component of the working fluid functions as a liquid piston directly receiving the expansion pressure of the steam, so that it is possible to prevent the occurrence of corrosion, abrasion and the like in the part receiving steam pressure.

Owner:DENSO CORP

Steam engine

A steam engine increases efficiency and prevents corrosion, abrasion, and the like in a part receiving steam pressure. A heater and a cooler are provided on one side of a U-shaped fluid container, and a piston for output is provided on its other side. The heater heats working fluid to vaporize the fluid. The expansion pressure of steam of the working fluid depresses a fluid level in a first vertical pipe. The liquid component of the working fluid flows from the first vertical pipe into a second vertical pipe, thereby applying pressure to the piston in an upward direction. Then, the liquid component of the working fluid functions as a liquid piston directly receiving the expansion pressure of the steam, so that it is possible to prevent the occurrence of corrosion, abrasion and the like in the part receiving steam pressure.

Owner:DENSO CORP

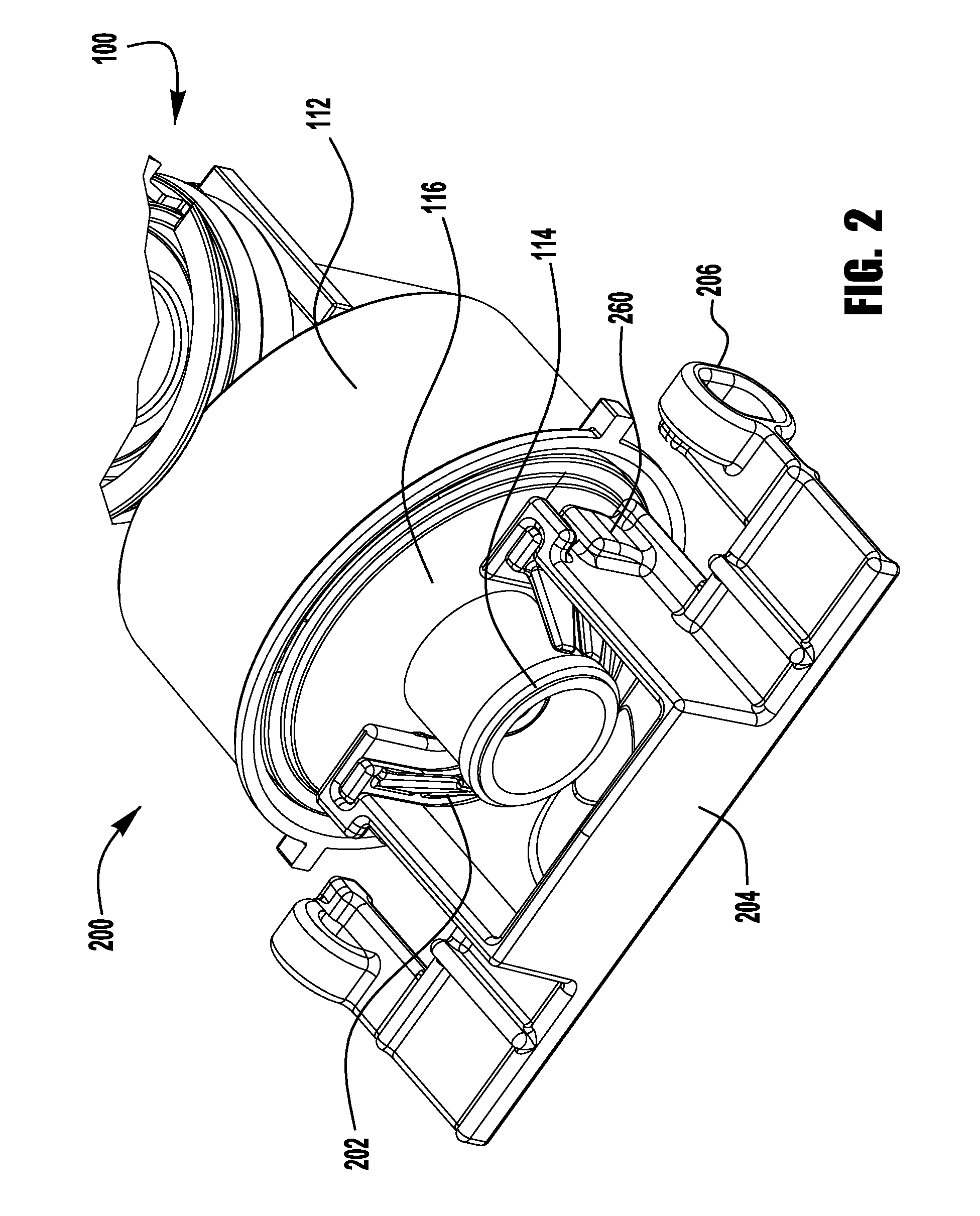

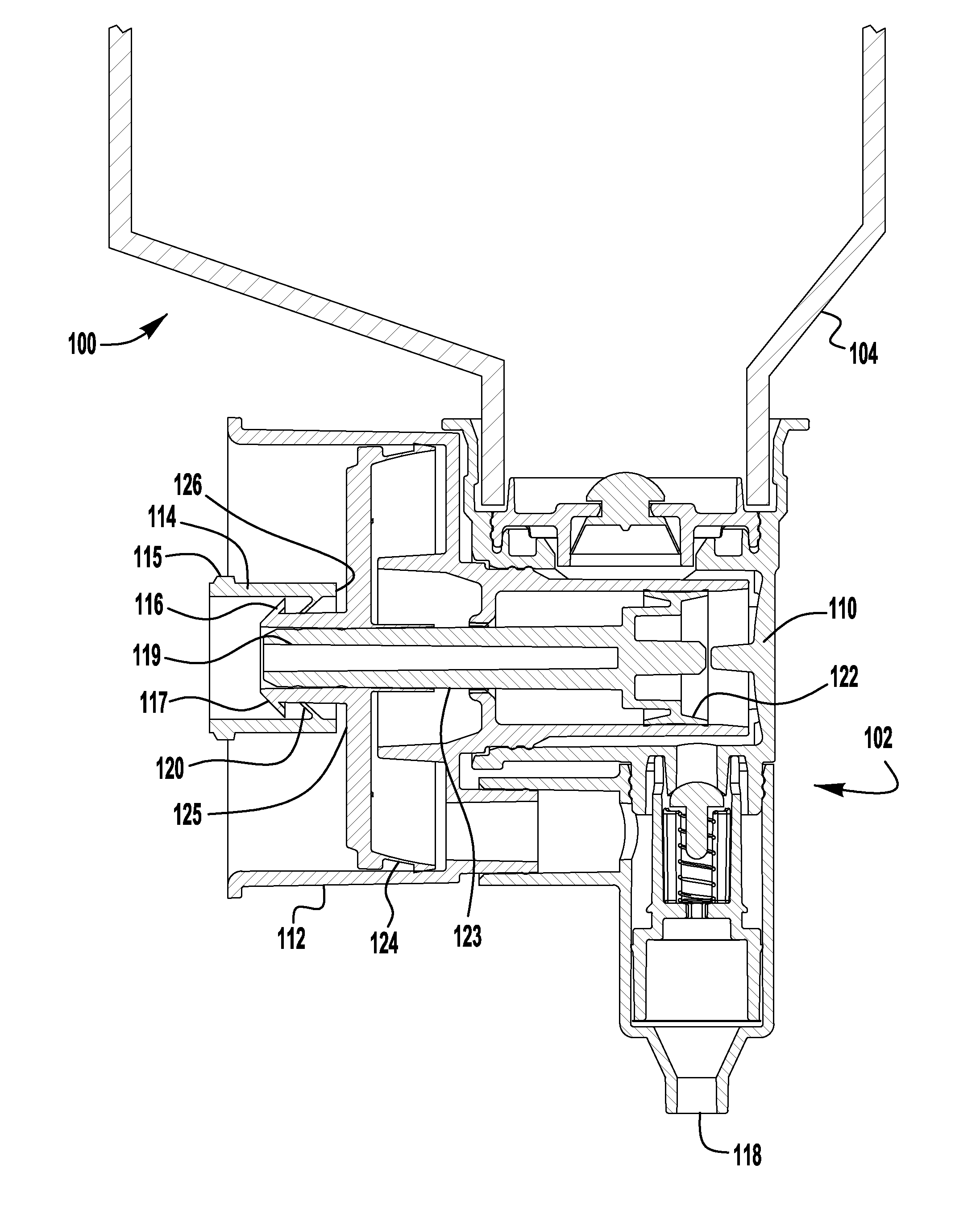

Foam pumps with lost motion and adjustable output foam pumps

Embodiments of lost motion foam pumps are disclosed herein. One exemplary embodiment includes a liquid chamber, a liquid piston movable in the liquid chamber, an air chamber and an air piston movable in the air chamber. The air piston is linked to the liquid piston. A connector is linked to the air piston or the liquid piston. The connector includes an engagement member for connecting to an actuator of a foam dispenser. Movement of the actuator in a first direction moves the liquid and air pistons to contract the liquid chamber and the air chamber. Movement of the actuator a first distance in a second direction does not move the liquid piston or the air piston; however, continued movement of the actuator a second distance in the second direction moves the liquid piston and the air piston and expands the liquid and air chambers.

Owner:GOJO IND INC

Fluid machine

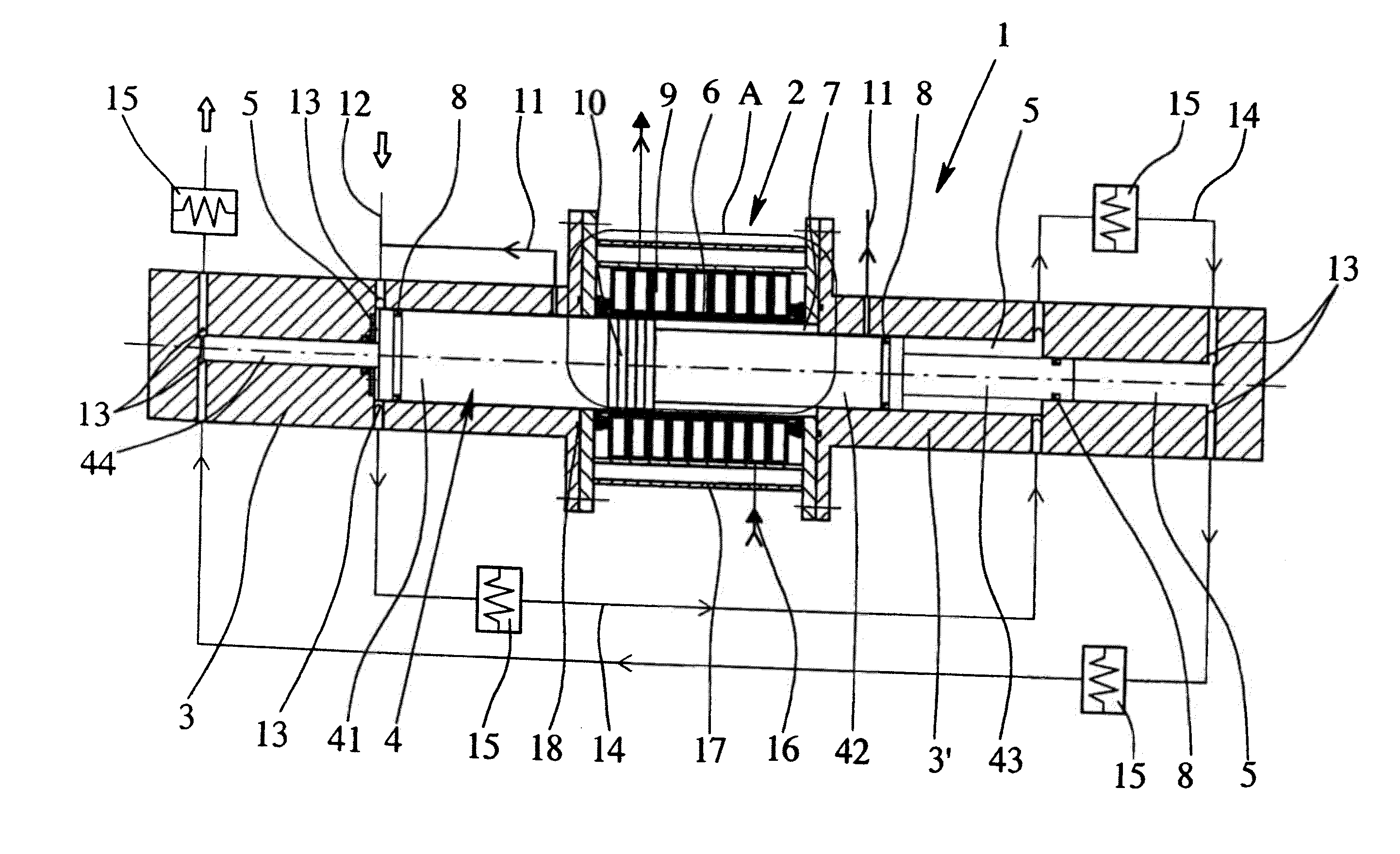

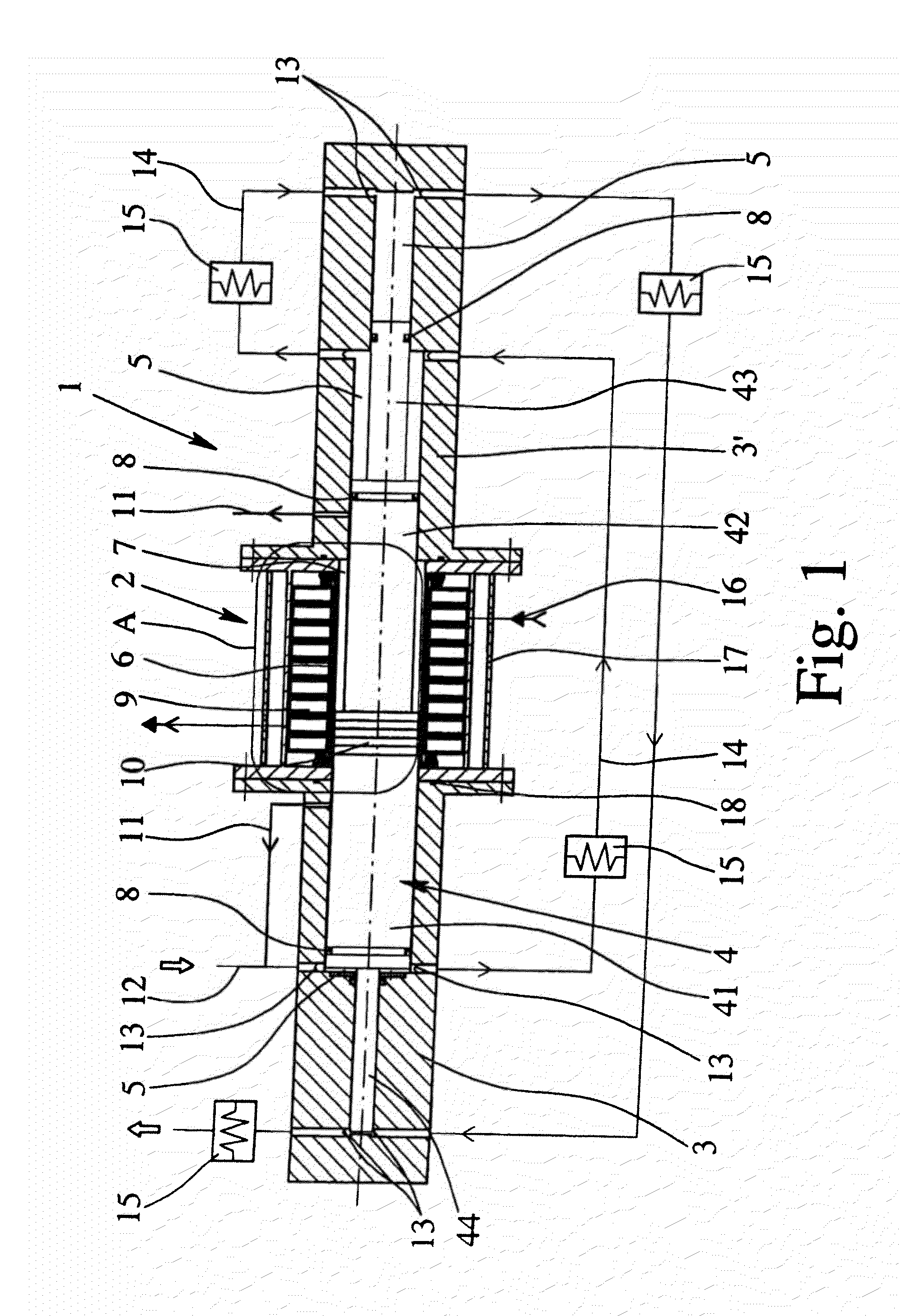

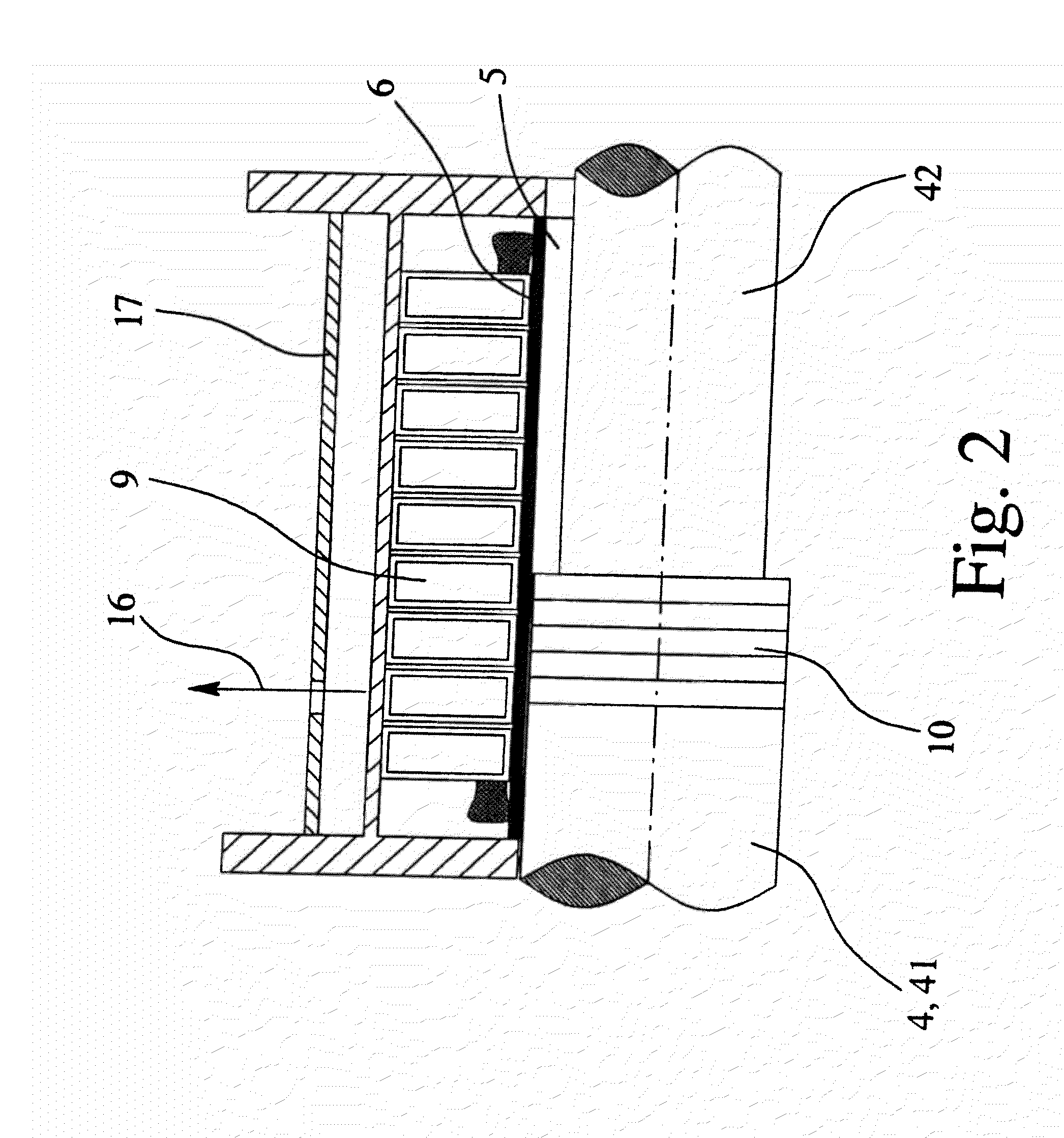

InactiveUS20110052430A1Simple structurePrevention of leakage to atmospherePositive displacement pump componentsPressure pumpsLiquid pistonHigh pressure

A fluid machine for compressing or conveying fluids, in particular for compressing gases to high pressures, has a linear motor (2), at least one cylinder (3), a solid or liquid piston (4, 4′) which can be moved axially in the cylinder (3), and at least one compression space (5) which is formed between the cylinder (3) and the solid or liquid piston (4, 4′), wherein the linear motor (2) applies translational driving force to the solid or liquid piston (4, 4′). For such a fluid machine, the leakage-free and lubricant-free compression and conveying of fluids, in particular a compression of gases to high pressures, and a rather simple construction is made possible owing to the fact that the solid or liquid piston (4, 4′) is surrounded in the area of the linear motor (2) by a firmly attached pipe section (6).

Owner:ANDREAS HOFER HOCHDRUCKTECHN +1

Foam soap generator and pump

InactiveUS20070051748A1Reduce drippingHolders and dispensersLiquid transferring devicesEngineeringLiquid piston

A foam soap generator and pump is provided for receipt by a liquid soap container in a foam soap dispenser. The foam soap generator and pump comprise an air cylinder and a liquid cylinder, integral with each other, and in parallel arrangement. Each receives a respective air and liquid piston, again of integral construction. The pistons are provided with arms having passages therethrough that ultimately bring the liquid and air together under pressure for the generation of foam and extrude of the same through an appropriate screen or open cell foam disk.

Owner:KANFER JOSEPH S

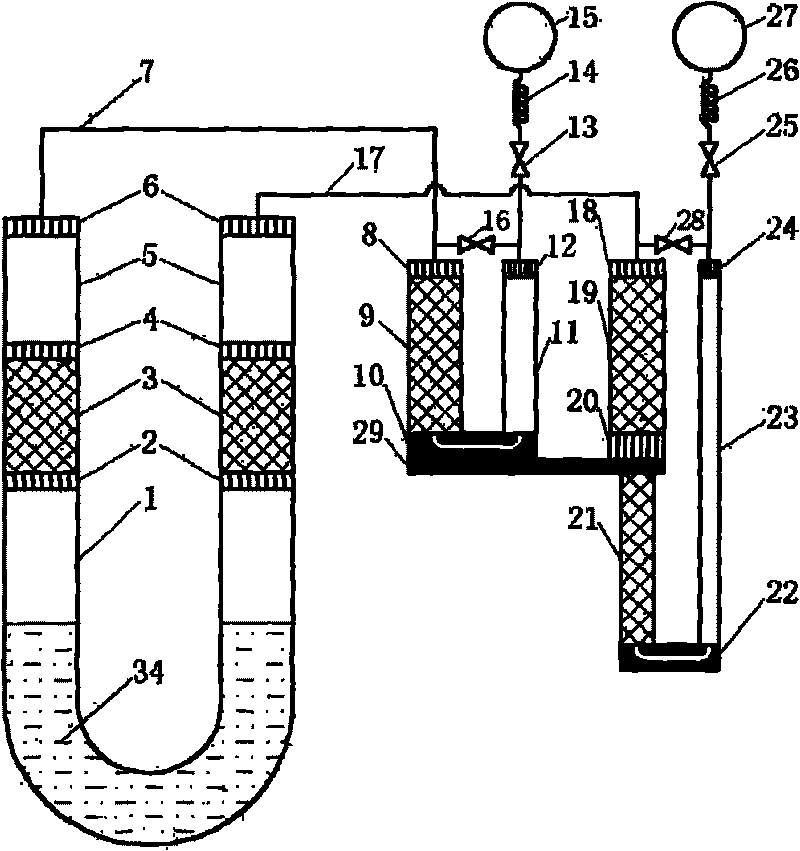

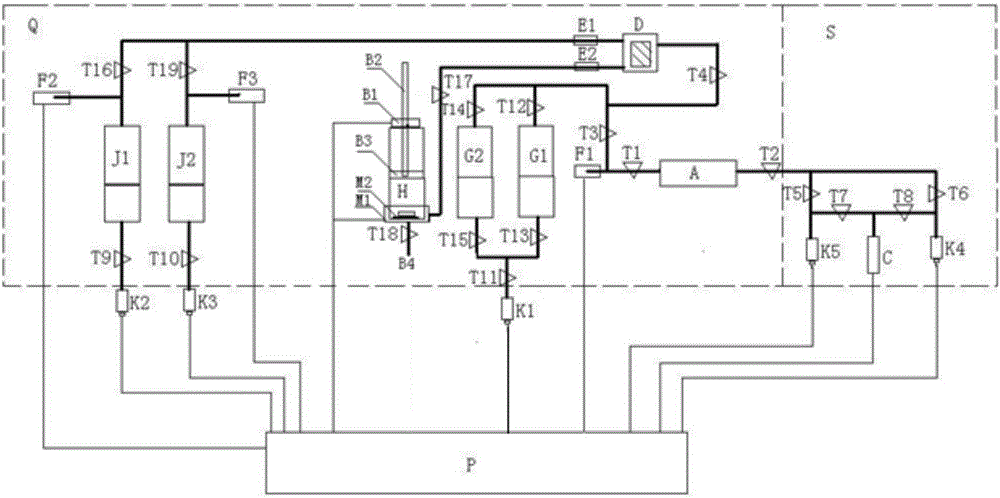

Foam flooding physical simulation device and foam flooding physical simulation method

The invention provides a foam flooding physical simulation device and a foam flooding physical simulation method. The device comprises a model part, an injecting part and an outflow liquid collecting part, wherein the model part is used for simulating an oil reservoir, the injecting part is used for injecting crude oil or a high-pressure displacing medium into the model part, and the outflow liquid collecting part is used for collecting outflow liquid from the model part; the injecting part comprises a gas piston container / gas piston containers (J1 or / and J2), a liquid piston container and a foam generating device, wherein the gas piston container / gas piston containers (J1 or / and J2) is / are used for storing a gas medium, the liquid piston container is used for storing foaming solution, and the foam generating device is used for producing foam by matching with the liquid piston container and constant-pressure and constant-speed pumps (K2 and K3); and the bottom part of the liquid piston container is provided with a magnetic stirring device and a magnetic rod. According to the foam flooding physical simulation device and the foam flooding physical simulation method provided by the invention, accurate control over injection rate and injection pressure is performed on high-pressure gas by adopting the constant-pressure and constant-speed pumps, so that accuracy is high, and the foam flooding physical simulation device is stable to work; the lower part of the liquid piston container is equipped with the magnetic stirring device, and liquid outflows from the side face of the lower part of the liquid piston container, so that the injected liquid is enabled to be uniform, and meanwhile, precipitates can be prevented from entering a core holder.

Owner:PETROCHINA CO LTD +1

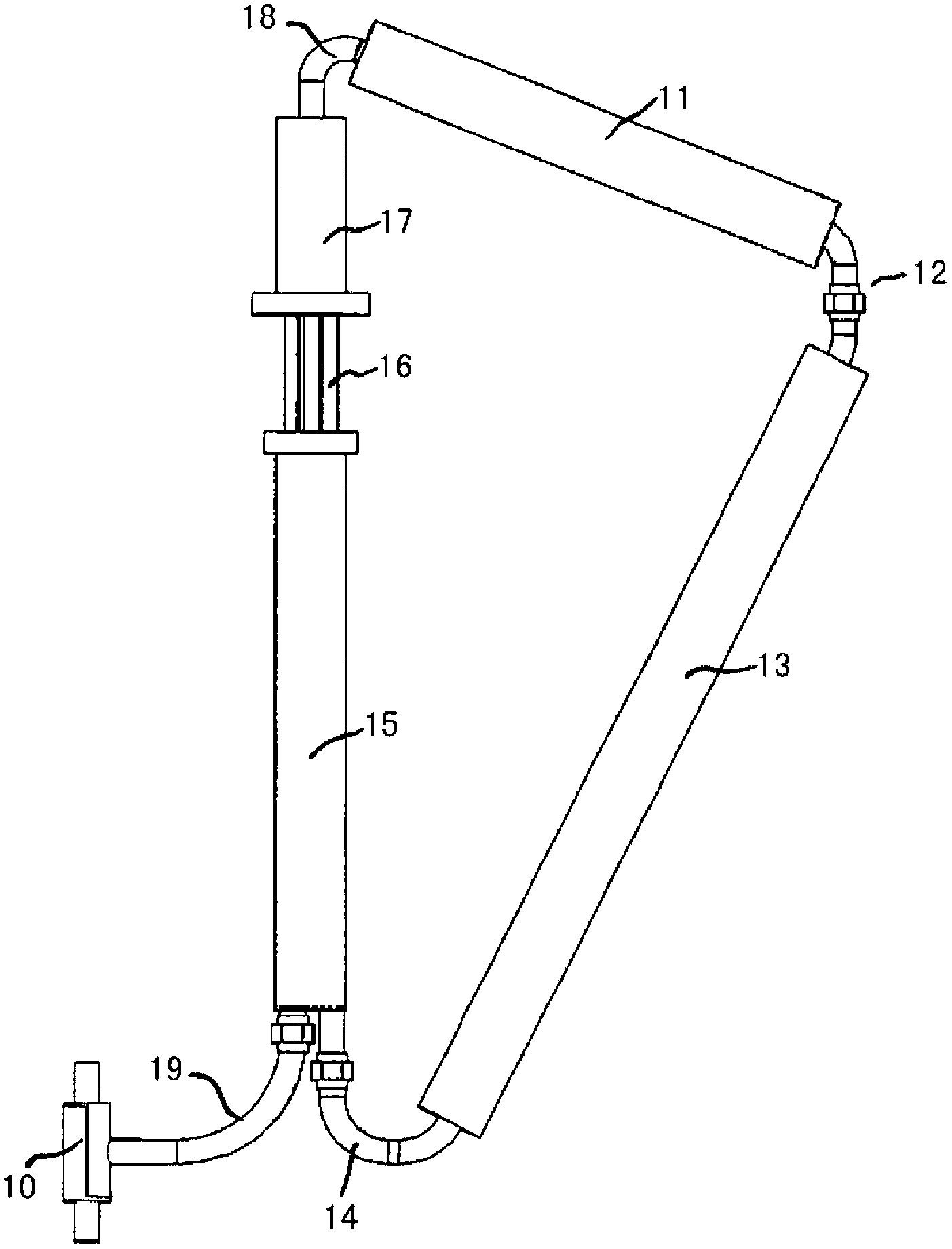

Negative pressure pneumatic type automatic sampler for water sample in medium-deep layer

InactiveCN103439149AIncrease buoyancyRealize automatic returnWithdrawing sample devicesWater storageLiquid piston

The invention discloses a negative pressure pneumatic type automatic sampler for a water sample in a medium-deep layer. The negative pressure pneumatic type automatic sampler comprises a sampling water storage chamber, a balance weight device and a gas-liquid tank, wherein a sampling hole is formed in the upper part of the sampling water storage chamber, a gas-liquid piston cylinder is arranged below the sampling hole, a liquid storage cavity of the gas-liquid piston cylinder is connected with the gas-liquid tank through a pipeline, an environmental pressure control valve is arranged on the pipeline, a balancing weight of the balance weight device is fixed on a balancing weight frame through a balancing weight fixed releasing control valve, the balancing weight fixed releasing control valve is connected with the gas-liquid tank through a water returning pipeline, a water returning control valve is arranged on the water returning pipeline, and a pressure trigger button matched with a water returning control valve is arranged at the bottom of the liquid storage cavity. The negative pressure pneumatic type automatic sampler submerges in water under the action of gravity of the balancing weight, so that the water sample in the medium-deep layer with the depth of below 10-30m is automatically acquired, the balancing weight is discarded, a device automatically returns and the acquired sample is brought out due to the adoption of an underwater negative pressure pneumatic technology.

Owner:HUAIHAI INST OF TECH

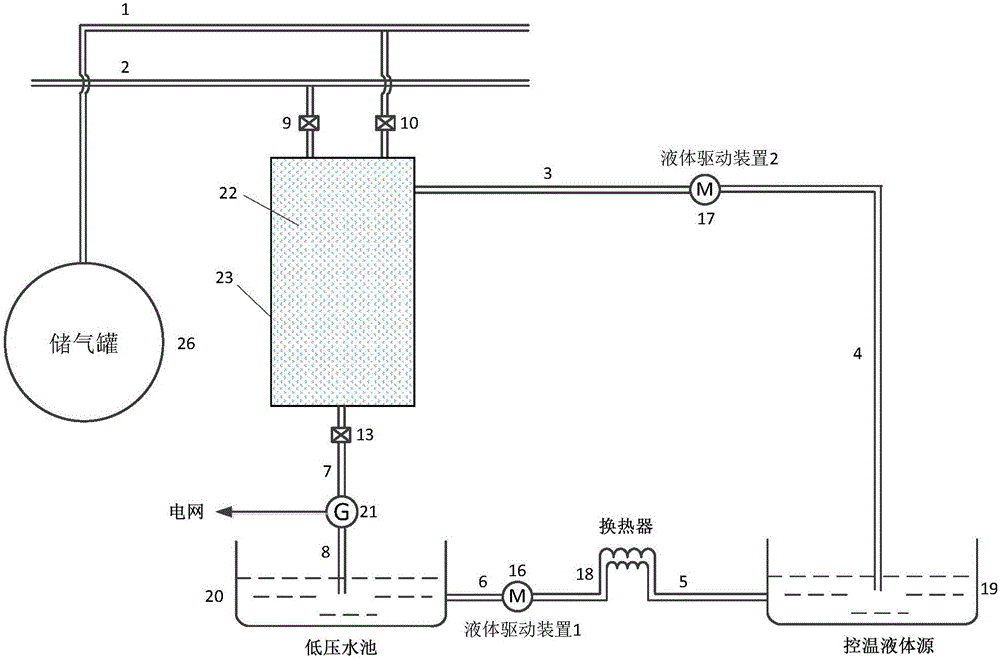

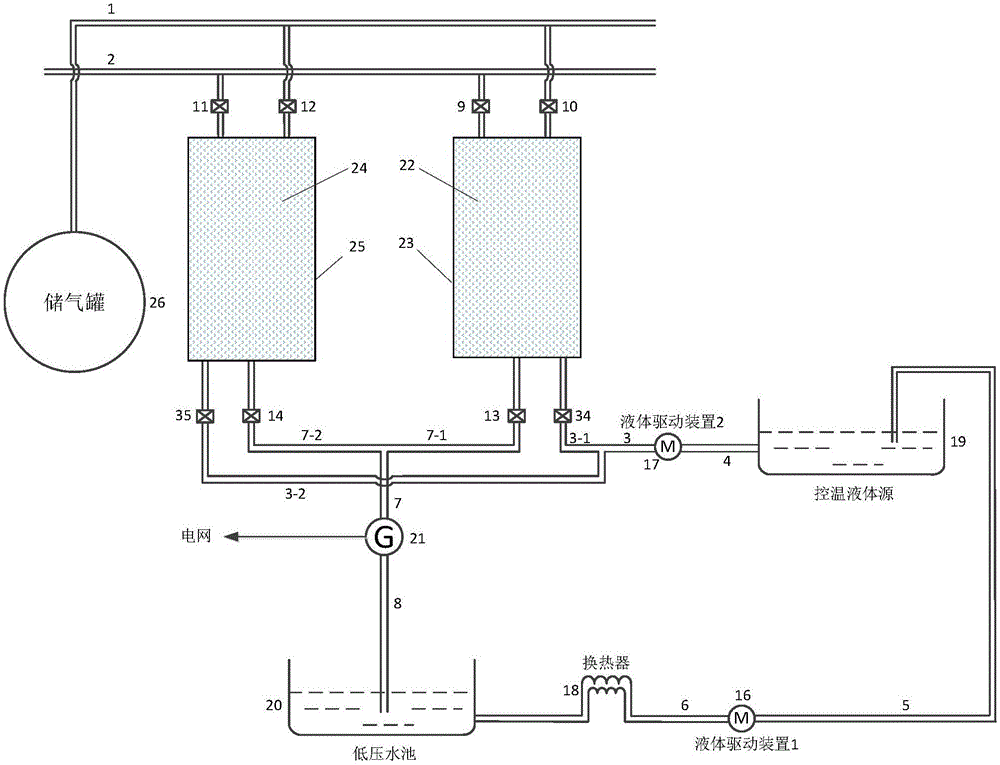

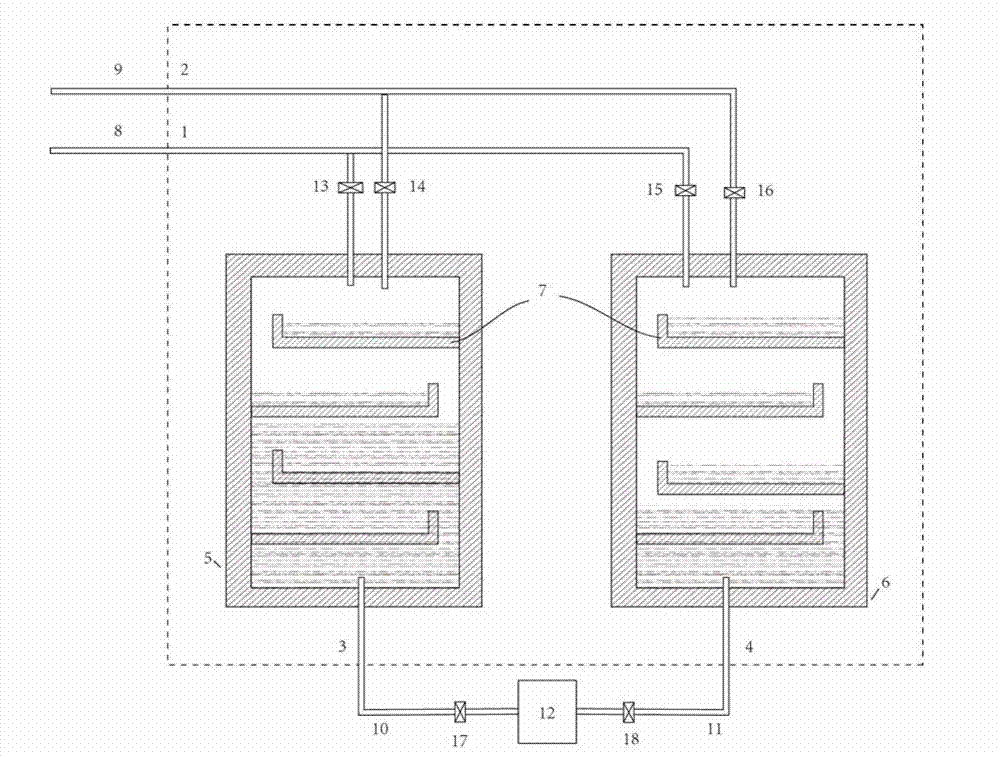

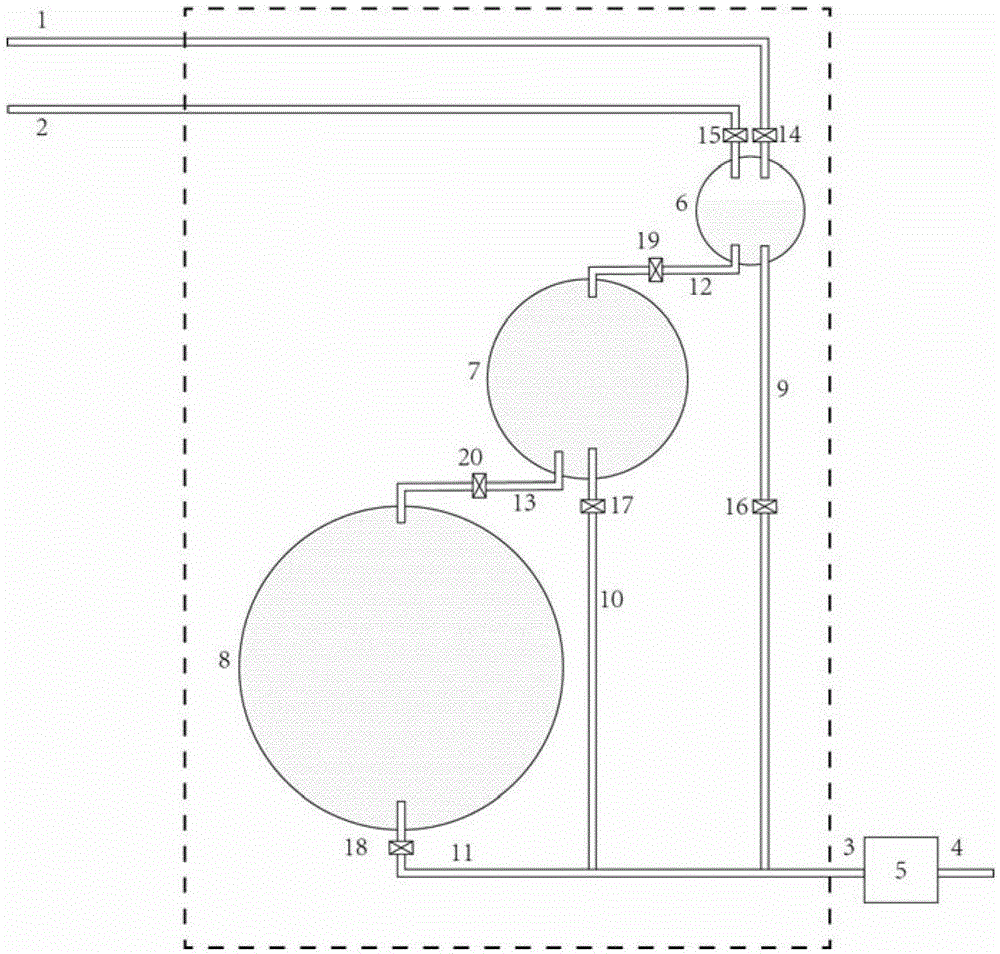

Isothermal compression air energy storage power generation system based on liquid temperature control and method thereof

ActiveCN106321343ARelease completelyReduce frictionHydro energy generationEngine componentsLiquid temperatureEngineering

The invention belongs to the technical field of compressed air energy storage, and in particular, relates to an isothermal compression air energy storage power generation system based on liquid temperature control and a method thereof. The system consists of an internal temperature control liquid piston, hydraulic power generation equipment, a gas storage tank, a low-pressure pool, a temperature control liquid source, an external temperature adjusting facility, a liquid driving device and a valve; in energy storage, the hydraulic power generation equipment converts electric energy to liquid potential energy, gas is compressed in the internal temperature control liquid piston, generated heat is stored by liquid, and high-pressure gas is fed in the gas storage tank; in power generation, high-pressure gas is expanded for acting in the internal temperature control liquid piston, and the heat is absorbed from the liquid to push the hydraulic power generation equipment to generate electricity; and the liquid in the temperature control liquid source replaces original liquid of the internal temperature control liquid piston to control the temperature of the gas in the liquid piston, so that the liquid temperature control of the temperature control liquid source is realized, and four working modes of an open direct supply operating mode, a closed direct supply operating mode, an afterheat utilization mode and an efficient power generation mode are realized.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

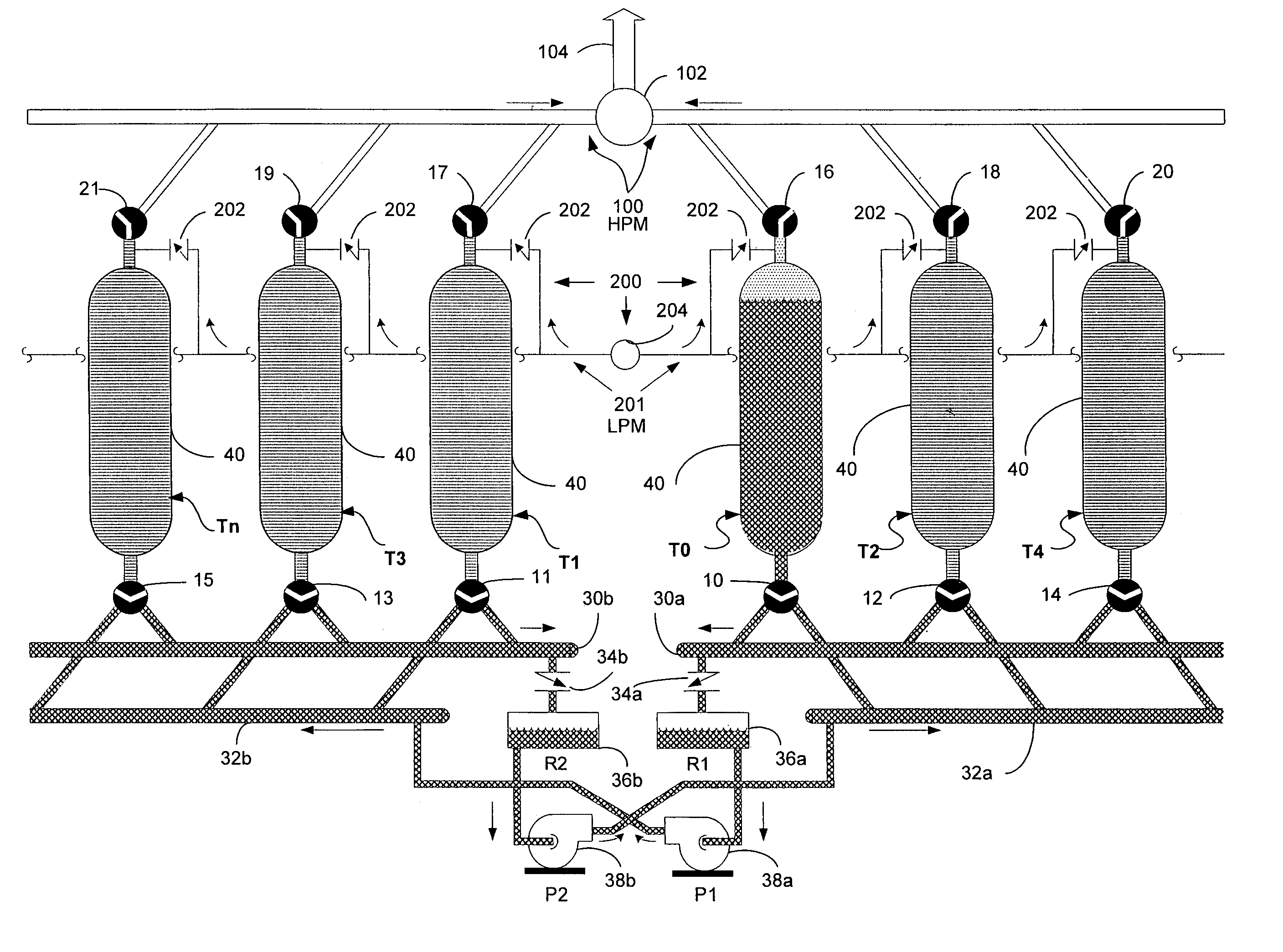

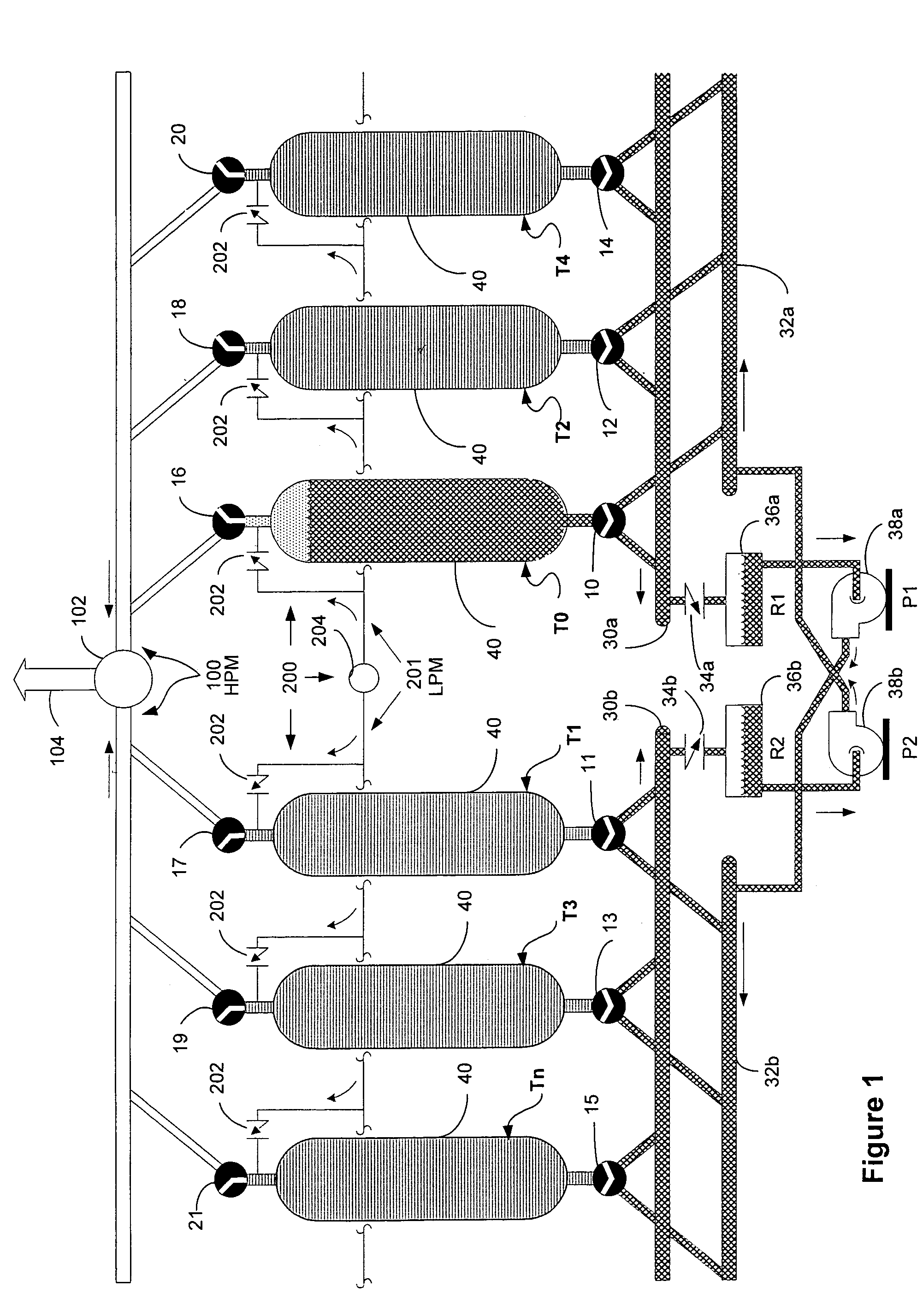

Liquid displacement shuttle system and method

ActiveUS20060042692A1Large storage capacityVessel mounting detailsVessel geometry/arrangement/sizeEngineeringLiquid piston

A multi-vessel gas storage system and liquid displacement shuttle system that utilizes a liquid-piston shuttled to alternate reservoirs and tank banks to evacuate stored gas or other fluids from storage vessels. Preferably, the gas storage and fluid displacement shuttle system includes multiple pressure storage vessels or tanks arranged in tank banks that are preferably coupled in parallel at one end to a high pressure gas manifold to exhaust the stored gas or other fluids from the vessels and coupled in parallel at another end to separate fluid shuttle circuits. The fluid shuttle circuits include cross-piped fluid fill and drain manifolds that are fluidly linked through interposing reservoirs and pumps. In operation, the stored gas or other fluids are evacuated from the storage vessels by shuttling the volume of displacement liquid between alternating banks of storage tanks and reservoirs with alternating pumps.

Owner:SEAONE HLDG

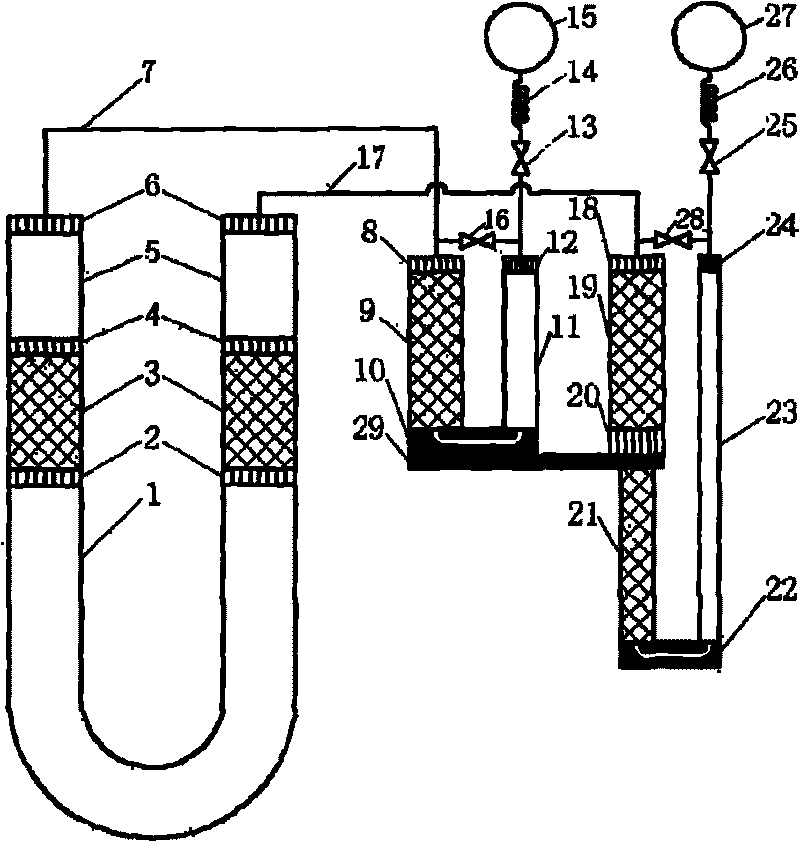

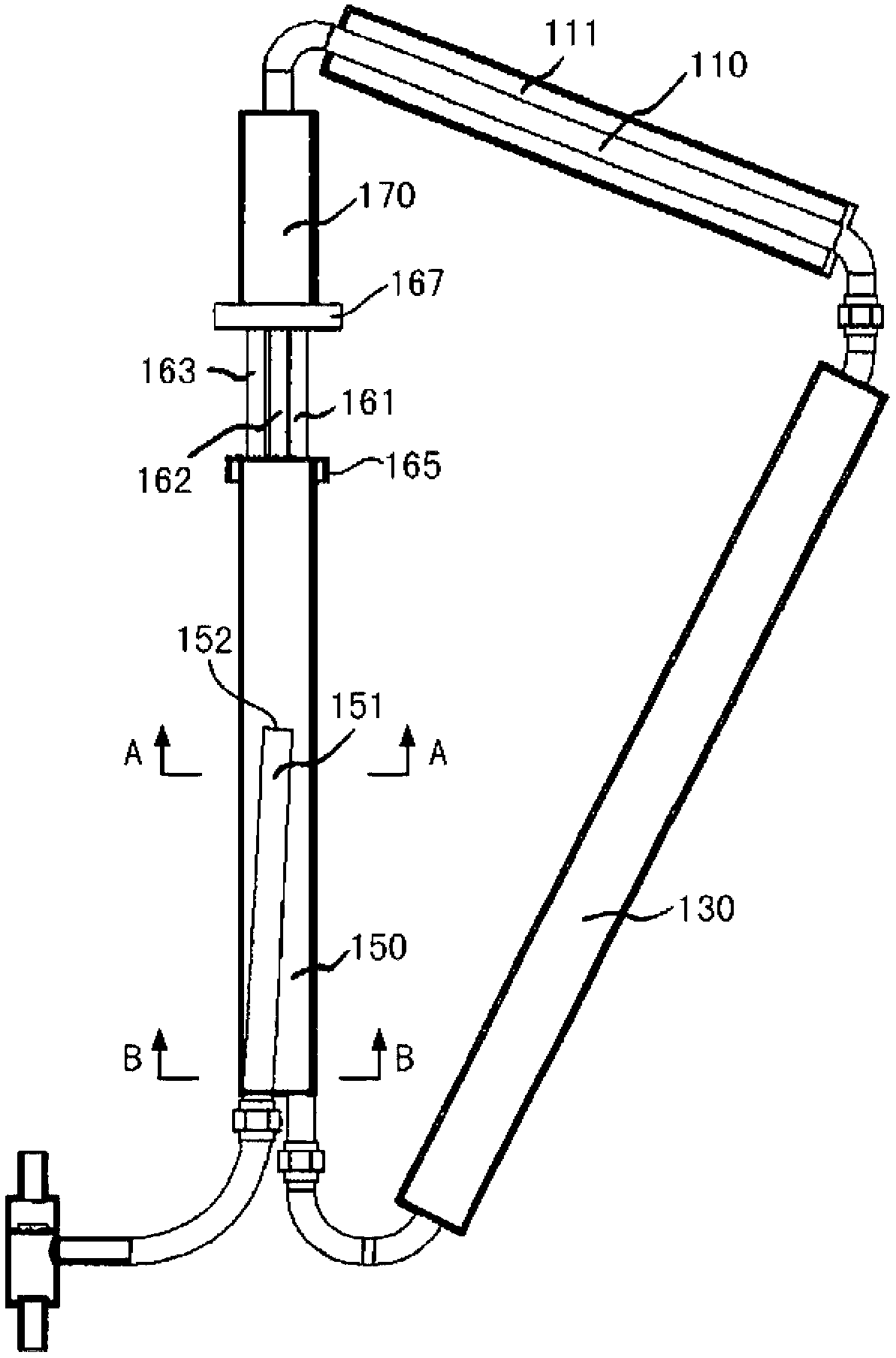

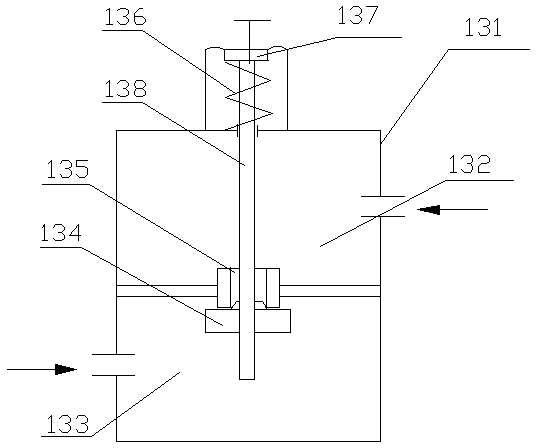

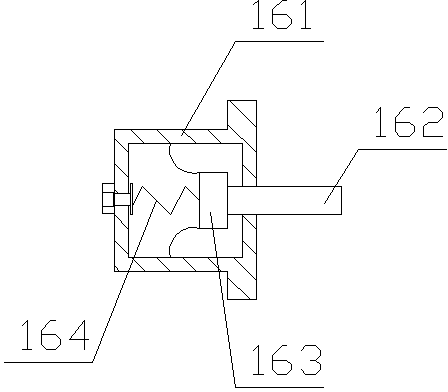

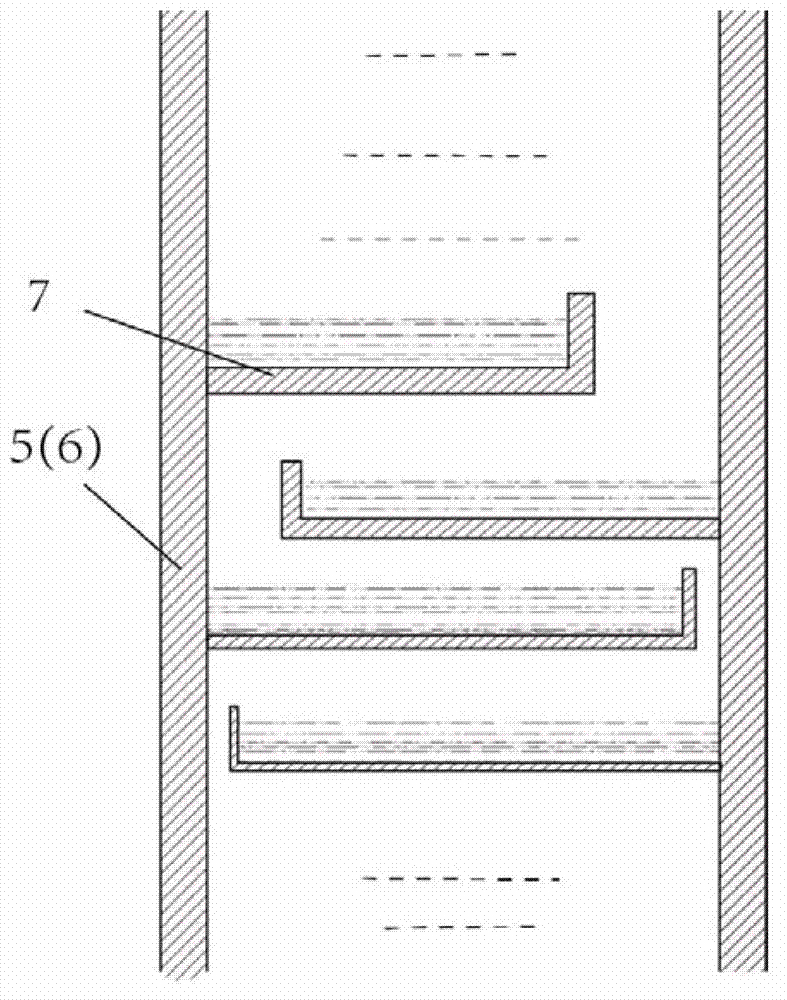

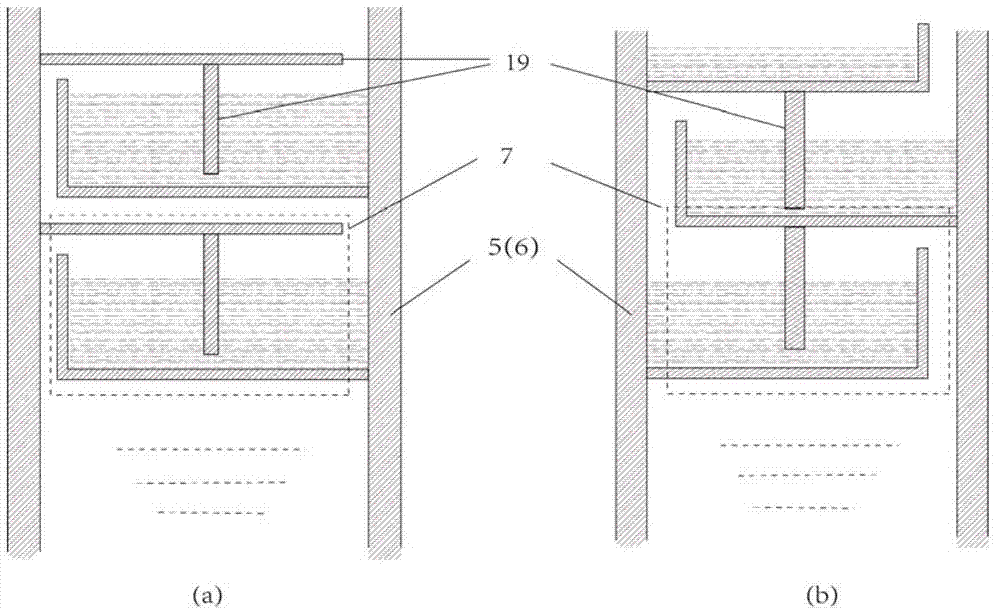

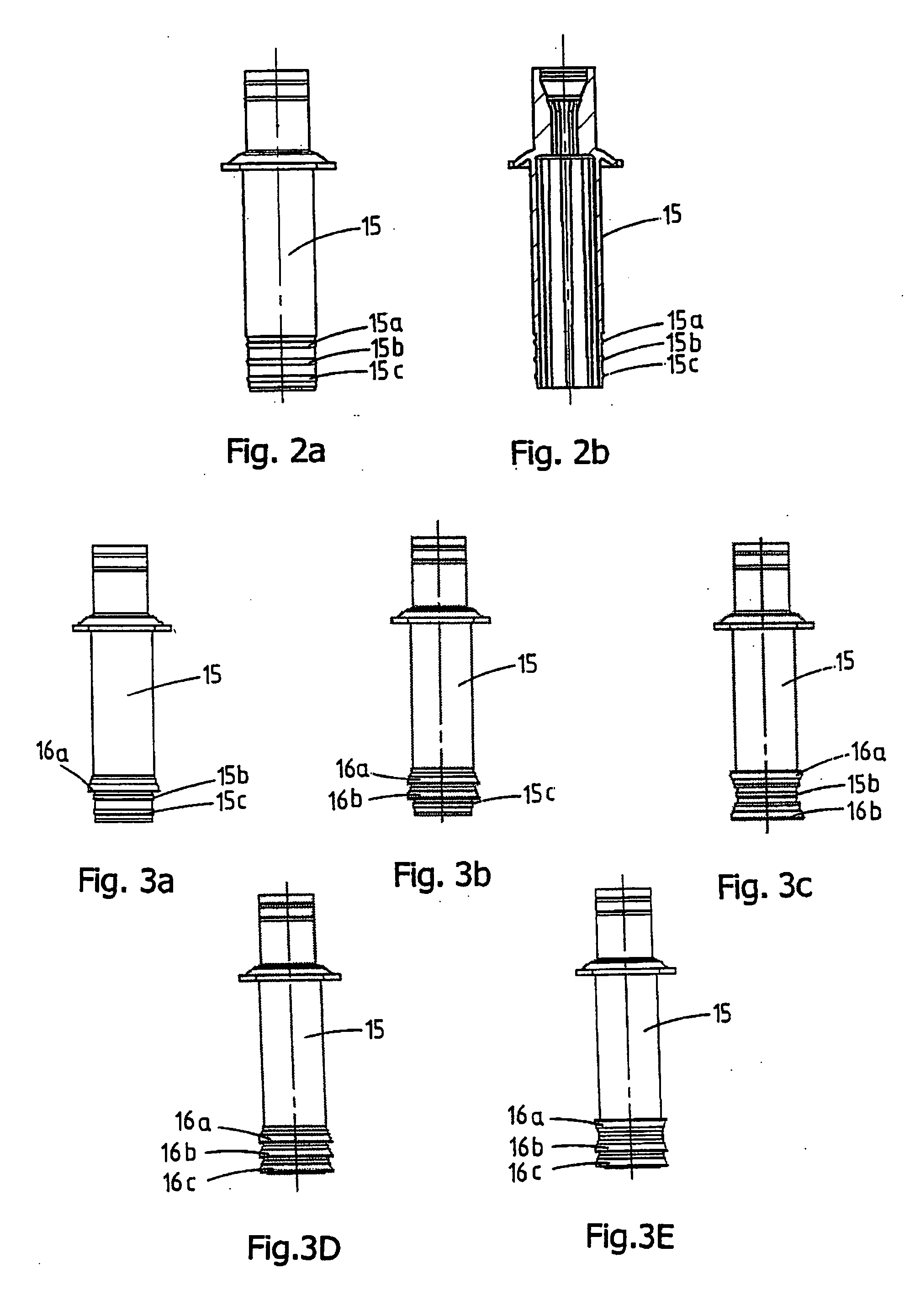

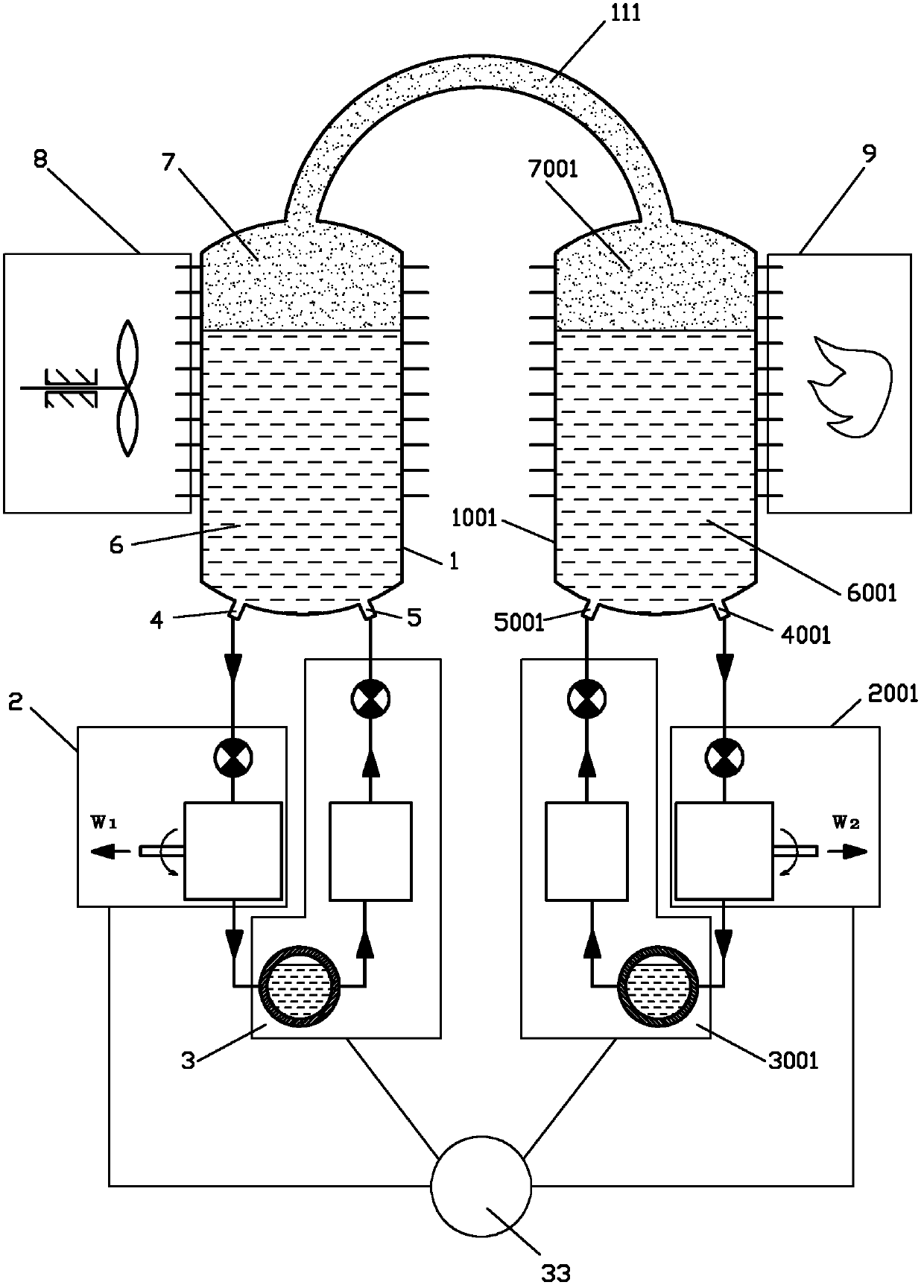

Liquid piston device with isothermy scaling of air achievable and with temperature controlled inside

ActiveCN103161774ARelease completelyImprove utilization efficiencyPressure pumpsMachines/enginesLiquid temperatureAir filter

The invention belongs to the technical field of liquid pistons, and particularly relates to a liquid piston device with isothermy scaling of air achievable and with temperature controlled inside. According to the liquid piston device with the isothermy scaling of the air achievable and with the temperature controlled inside, the top portions of two liquid piston chambers are respectively connected with a high pressure gas pipeline and a low pressure gas pipeline, the bottom portions of the two liquid piston chambers are both connected with an external hydraulic set through respective liquid pipelines, and a plurality of intracavity liquid storage units are arranged in the liquid piston chambers. When the liquid piston device operates, liquid stays in the intracavity liquid storage units, and the liquid storage units are used for increasing the contact area between the liquid and the air to improve heat exchange speed between the liquid and the air, and liquid temperature is used for controlling air temperature to achieve the isothermy scaling of the air. The intracavity liquid storage units are of two basic structures, have multiple enhancement type temperature control modes such as the spraying mode, the liquid circulation mode, and the air filtering mode, and can be realized through one or multiple combination types.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Foam pumps with lost motion and adjustable output foam pumps

ActiveUS20140117053A1Positive displacement pump componentsHolders and dispensersLiquid pistonActuator

Embodiments of lost motion foam pumps are disclosed herein. One exemplary embodiment includes a liquid chamber, a liquid piston movable in the liquid chamber, an air chamber and an air piston movable in the air chamber. The air piston is linked to the liquid piston. A connector is linked to the air piston or the liquid piston. The connector includes an engagement member for connecting to an actuator of a foam dispenser. Movement of the actuator in a first direction moves the liquid and air pistons to contract the liquid chamber and the air chamber. Movement of the actuator a first distance in a second direction does not move the liquid piston or the air piston; however, continued movement of the actuator a second distance in the second direction moves the liquid piston and the air piston and expands the liquid and air chambers.

Owner:GOJO IND INC

Pressure-measuring fiber grating process and device

InactiveCN101046418ASize rangeSmall rangeSpectrum generation using diffraction elementsForce measurement by measuring optical property variationFiberGrating

The present invention discloses one kind of pressure-measuring fiber grating process and device. After linear conversion of the measured force in a 'piston-liquid-piston' converter in the conversion ratio equal to the upper and the lower piston area ratio, the converted force is transmitted by the lower piston to the fiber grating with relatively small measuring range. The change in force causes the axial strain in the fiber grating, and change of fiber grating in parameters, including Bragg wavelength. After the mathematic model between the pressure and the central wavelength of the grating, measuring the wavelength can obtain the corresponding pressure. The present invention has the advantages of great measurement range, high precision, etc.

Owner:SHANDONG UNIV OF SCI & TECH

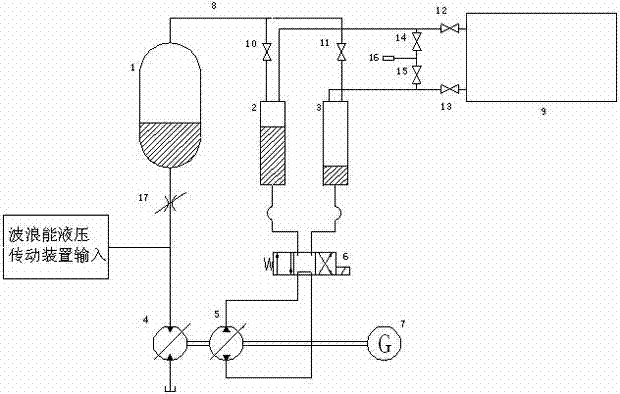

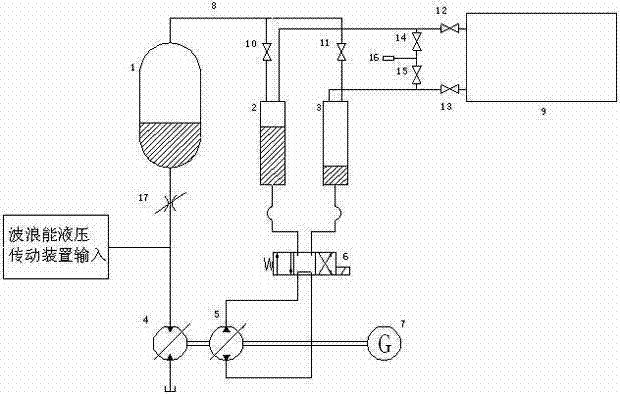

Compressed air type energy accumulation stable power generation device adopting liquid piston

InactiveCN102506004AImprove storage densityImprove conversion efficiencyMachines/enginesEngine componentsHydraulic pumpEngineering

The invention discloses a compressed air type energy accumulation stable power generation device adopting a liquid piston. A variable hydraulic motor is connected with an alternating-current generator by a variable hydraulic pump; one path of the input port of the hydraulic motor is connected with an opened type energy accumulator by an adjustable throttling value, and the other path of the input port of the hydraulic motor is connected with the input of a wave energy hydraulic transmission device; the outlet of the hydraulic pump passes through an electromagnetic diverting valve and is respectively connected with two liquid piston cavities; the two liquid piston cavities are respectively connected with the opened type energy accumulator by a common pipeline through the first and second check valves, and are respectively connected with a gas storage chamber through third and fourth check valves; and fifth and sixth check valves are connected in series between two pipelines at the inlet ends of the third and fourth check valves, and the serial connection points are connected with an air inlet. According to the invention, the energy conversion efficiency is increased by combining hydraulic and air compression; the gas leakage and friction brought by mechanical sliding seal are reduced by adopting liquid piston type air compression; and the capability for stabilizing the input energy fluctuation is increased by adopting the opened type energy accumulator, and is adjusted according to the working condition.

Owner:ZHEJIANG UNIV

Foam soap generator and pump

InactiveUS7543722B2Reduce drippingHolders and dispensersLiquid transferring devicesEngineeringLiquid piston

A foam soap generator and pump is provided for receipt by a liquid soap container in a foam soap dispenser. The foam soap generator and pump comprise an air cylinder and a liquid cylinder, integral with each other, and in parallel arrangement. Each receives a respective air and liquid piston, again of integral construction. The pistons are provided with arms having passages therethrough that ultimately bring the liquid and air together under pressure for the generation of foam and extrude of the same through an appropriate screen or open cell foam disk.

Owner:KANFER JOSEPH S

Methods of pulsed nuclear energy generation using piston-based systems

InactiveUS20130005200A1High heat transfer rateIncrease heatNuclear energy generationPropulsive elements of non-rotary typeWorking fluidNuclear engineering

The invention describes a method of nuclear energy transformation into electric and / or mechanical energy by triggering criticality in a working cylinder by an approach of a piston with a neutron reflector layer to fissile heat elements. Optionally, liquid moderator should fill the heating element to provide for an additional condition of such triggering. The pulse reaction initiates a heat cycle by expanding working fluid, extracting mechanical work and compressing the working fluid using lower amount of energy. The energy released in reaction can drive a column of water as a liquid piston propelling a highly efficient hydraulic turbine and producing a simple economical method of energy conversion. The piston movements can also be converted in laser and electromagnetic pulses. Self-regulation of nuclear reaction by a reflector piston linked to a resilient spring can be used in marine propulsion. In one method, the approach of the reflector piston triggers a reaction that evaporates water in the pressure chamber and produces a reactive thrust in a noozle. A fraction of the steam is diverted to produce steam bubble envelope on the surface of the vessel to minimize drag. Another fraction of the diverted steam drives a pump, pumping sea water into the heating elements. Other practical and novel applications of the method are disclosed.

Owner:MAYBURD ANATOLY

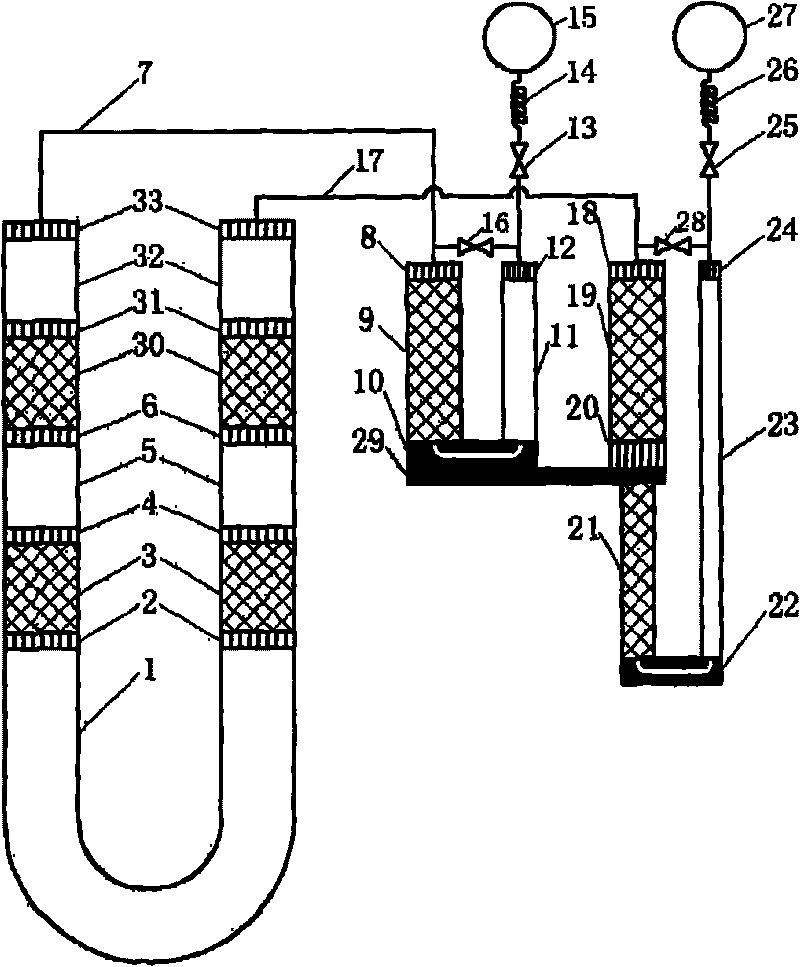

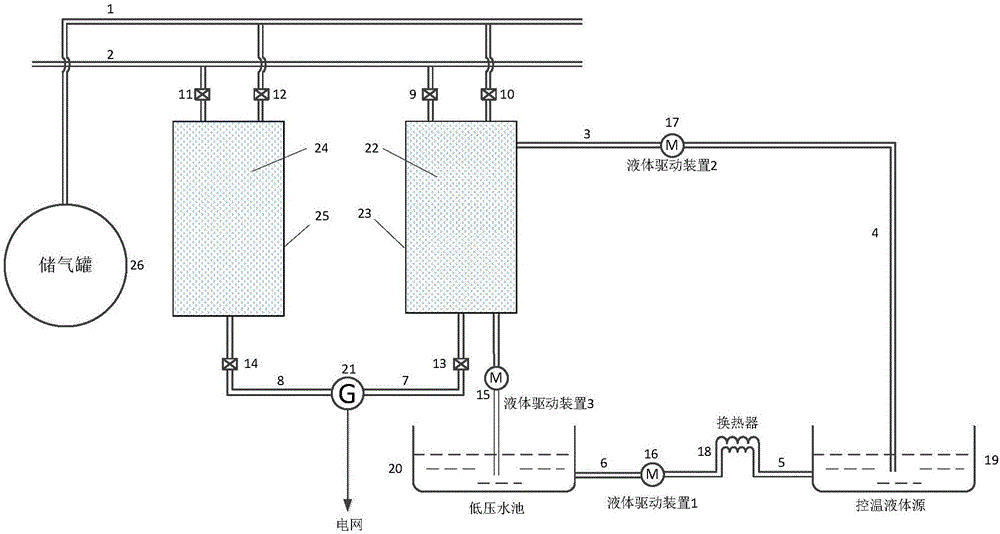

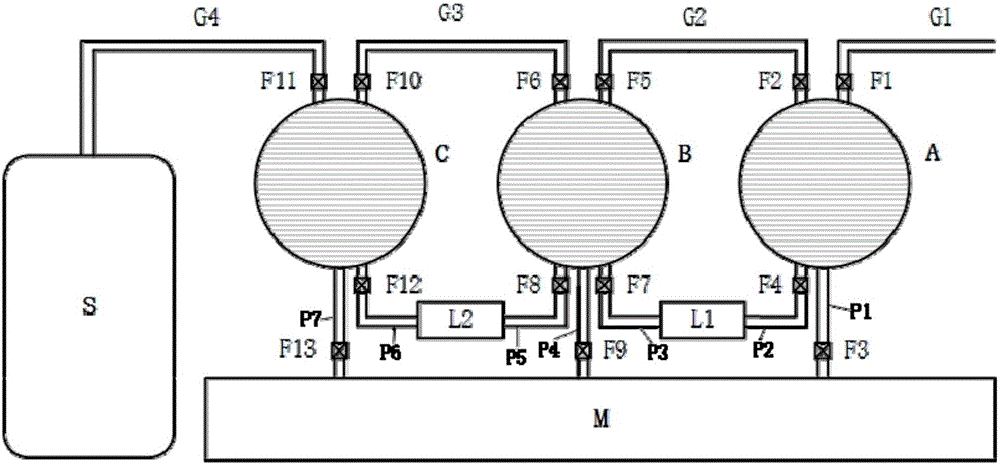

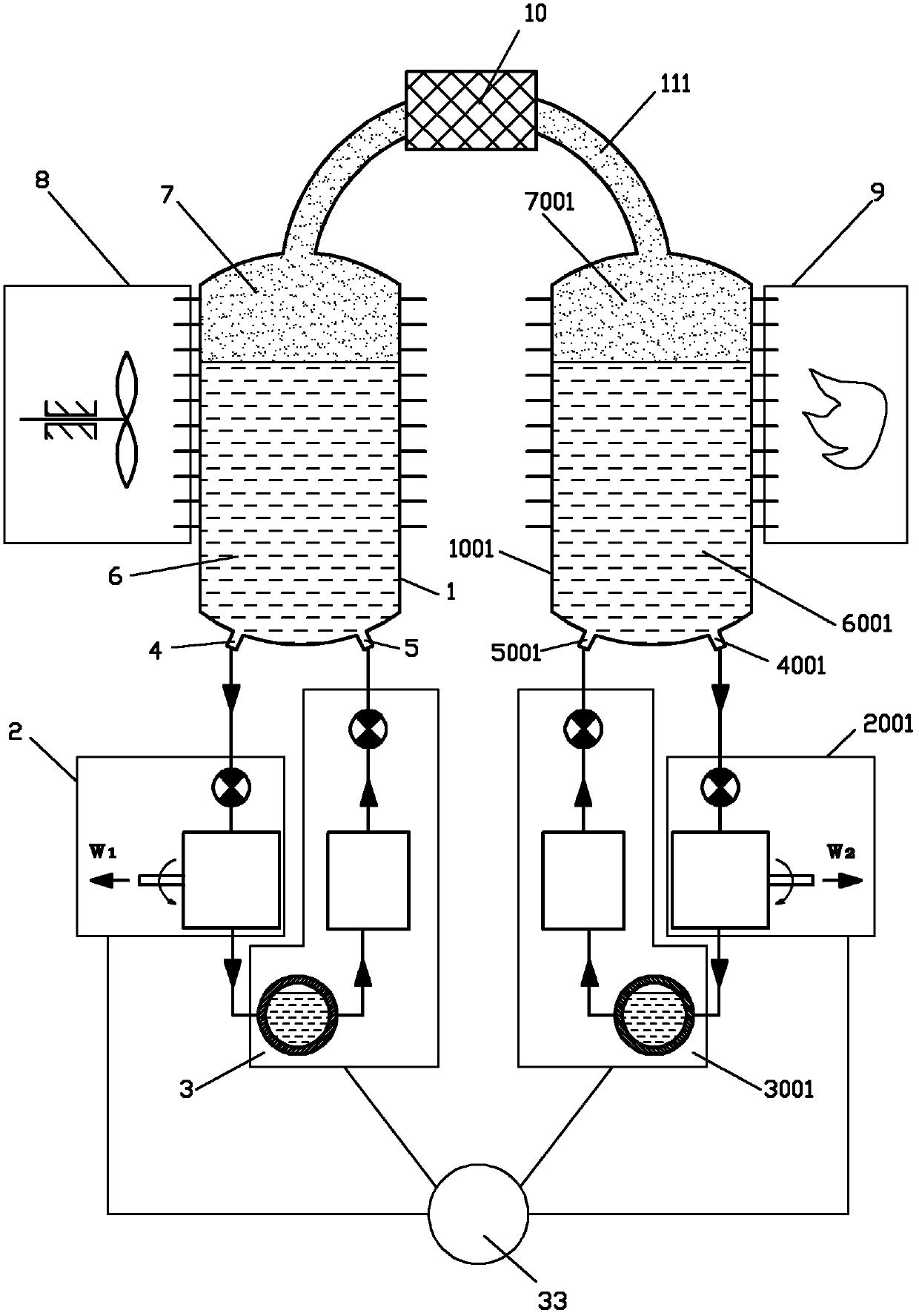

Compressed air energy storage system capable of achieving stepped gas compression and expansion

ActiveCN106089657AReduce the pressure rangeLower manufacturing requirementsPositive displacement pump componentsPump installationsThermal energy storageHydraulic equipment

The invention belongs to the technical field of large-capacity electric energy storage and particularly relates to a compressed air energy storage system capable of achieving stepped gas compression and expansion through the equal-pressure migration technology. Liquid pistons are sequentially connected according to pressure-resisting level, the upper portions of every two adjacent liquid pistons are connected through a gas pipeline, and the lower portions of every two adjacent liquid pistons are connected through a liquid driving device. Each liquid piston is connected to external hydraulic equipment through a pipeline. The liquid piston with the lowest pressure-resisting level is connected with a low-pressure gas pipeline, and the liquid piston with the highest pressure-resisting level is connected with a gas storage system. According to the compressed air energy storage system, the stepped compression and expansion processes of gas in the liquid pistons are achieved, the gas is transferred between the liquid pistons with different levels through the equal-pressure migration technology, the pressure bearing change range of the liquid pistons is reduced, the equipment safety is improved, the service life of the liquid pistons is prolonged, and the manufacturing cost of equipment can be greatly reduced.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

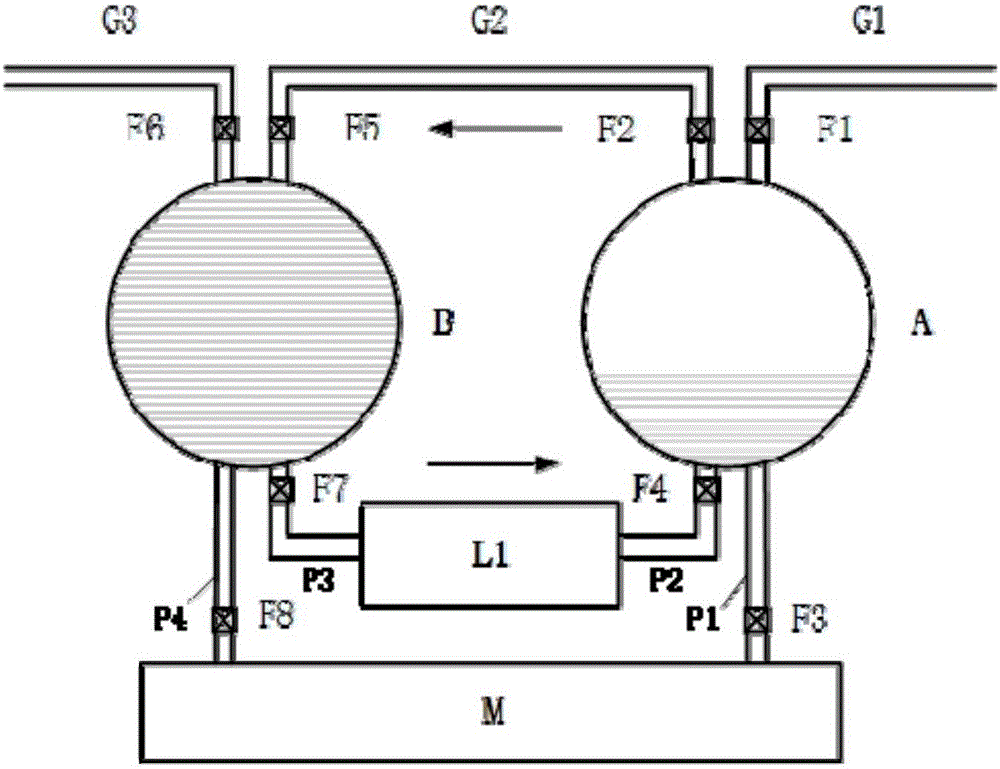

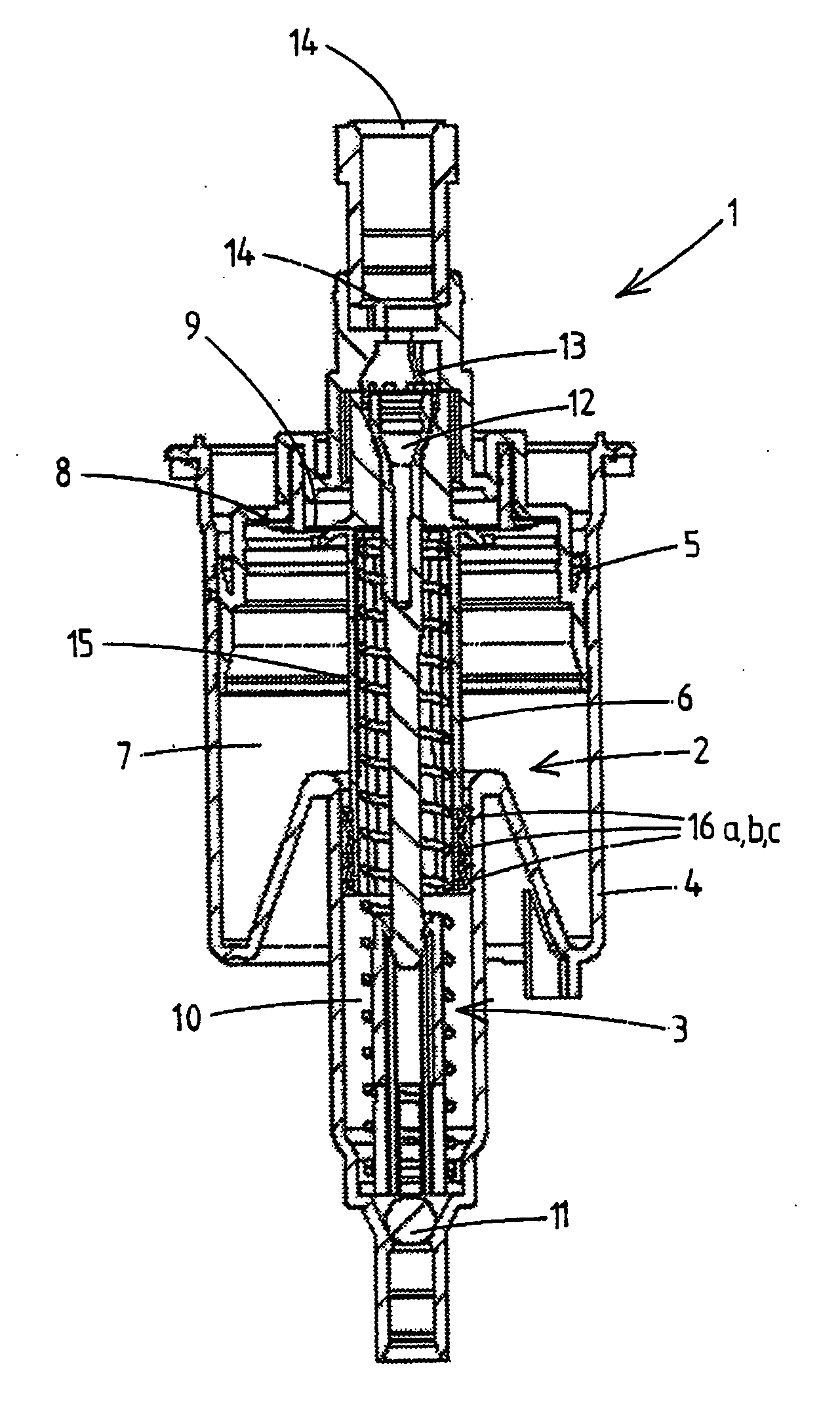

Dispensing device with piston pump

InactiveUS20060157512A1Easy to adaptSufficient freedomLiquid transferring devicesSingle-unit apparatusAir pumpEngineering

The invention relates to a foam-dispensing device for dispensing a foam, comprising a manually operated pump assembly. The pump assembly comprises a liquid piston pump for pumping the liquid, and an air pump for pumping air, the liquid and air to be pumped being mixed together to form a foam which is dispensed through a dispensing aperture. The liquid piston pump comprises a pump housing, for example a cylinder, a liquid piston which is movable telescopically in the pump housing, and one or more sealing elements to be fixed on the liquid piston in order to seal the liquid piston in the pump housing. The liquid piston comprises at least two locations for fixing the one or more sealing elements. The invention further relates to a kit for producing a piston with one or more sealing elements for such a dispensing device, and a method for producing a piston pump for such a dispensing device.

Owner:REXAM AIRSPRAY

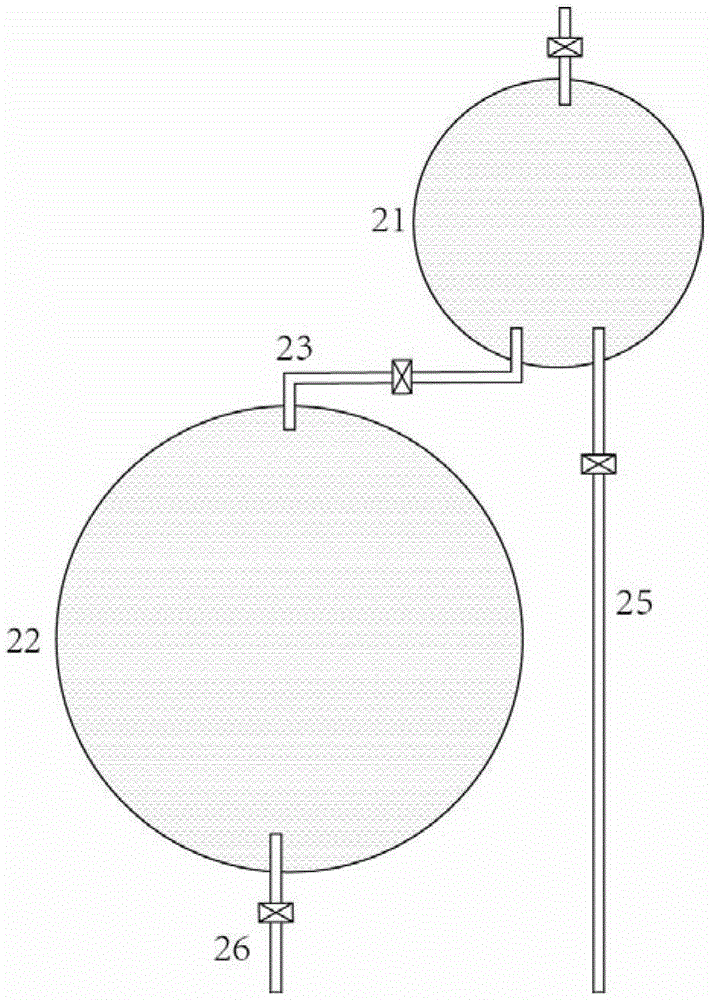

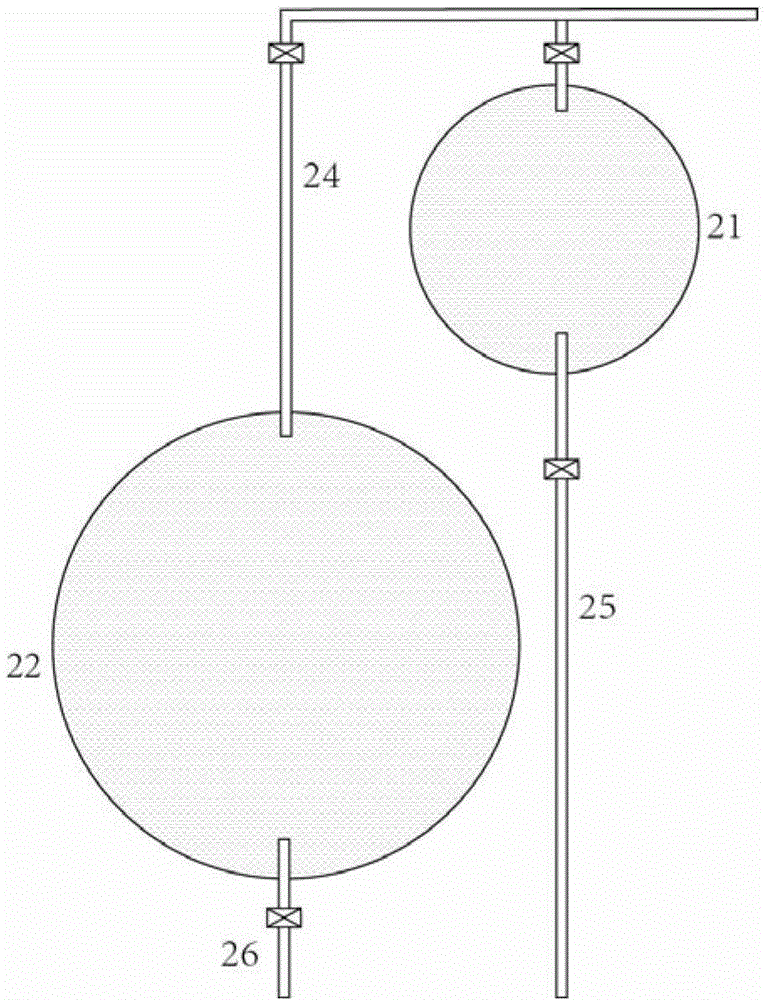

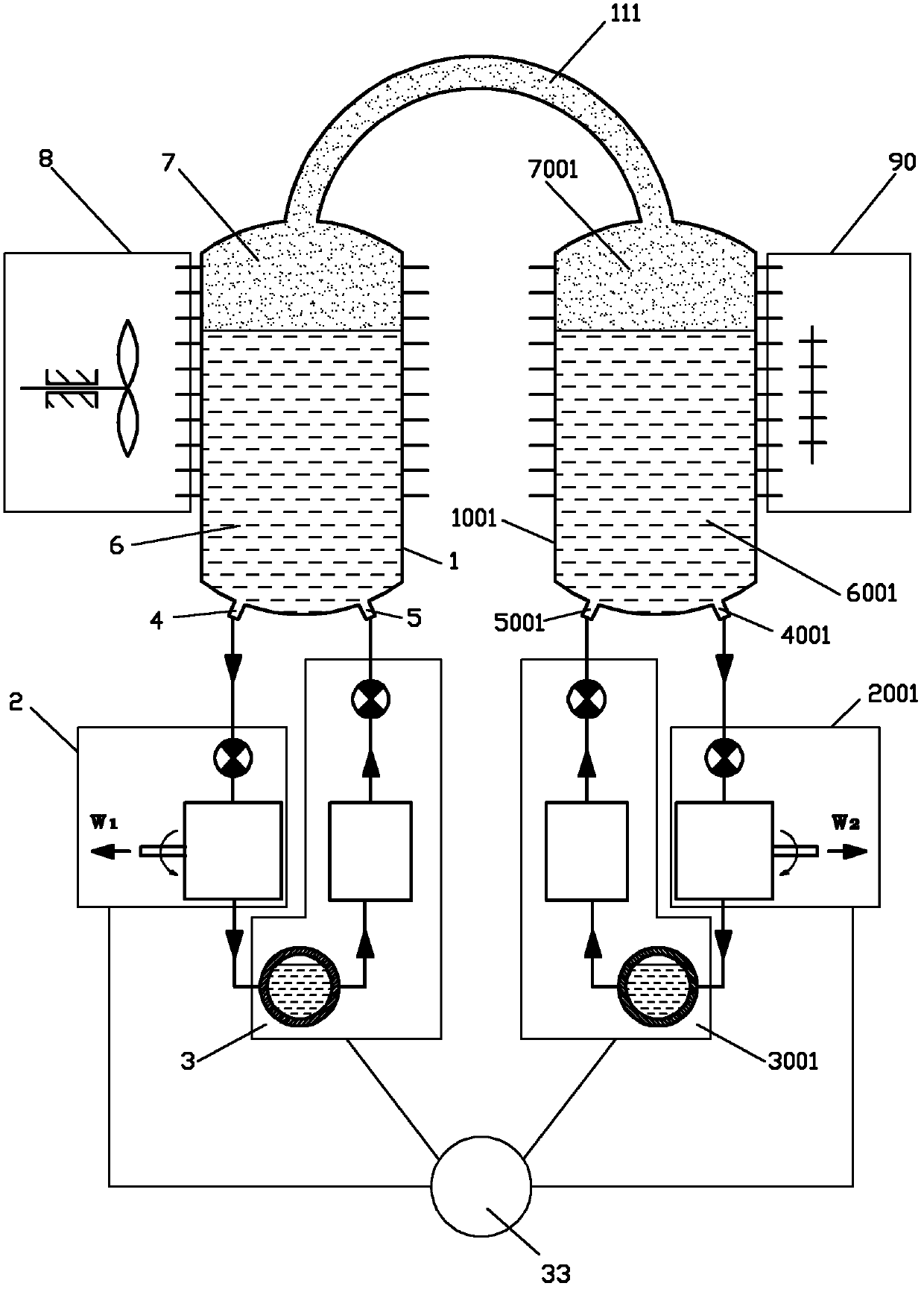

Variable pressure-resistant cascading liquid piston device

ActiveCN103334899ADoes not increase overall volumeWork is not affectedPositive displacement pump componentsMechanical power devicesEngineeringHydraulic equipment

The invention belongs to the technical field of liquid pistons, and provides a variable pressure-resistant cascading liquid piston device. The device is formed by combining two or more pressure vessels with different pressure-resistant values in a series or parallel connection manner; all the pressure vessels equal to or higher than a certain pressure-resistant grade can be combined into a pressure vessel group with a large volume by controlling valves on connecting pipelines; and a specific liquid piston can be formed. A combination mode can be changed continuously according to requirements of gas expansion or compression during running to form a high-pressure and small-volume liquid piston cavity or a low-pressure and large-volume liquid piston cavity. The device has all functions of the liquid piston, can achieve energy conversion between internal energy of compressed air and potential energy of a liquid, guarantees a volume of a piston cavity required when the gas is at low pressure, avoids a situation that all the pressure vessels adopt the highest pressure-resistant grade, and effectively lowers the cost. When hydraulic equipment adopts corresponding hydraulic pistons with different pressure-resistant grades, the pressure vessels and the hydraulic pistons in the same grade can be connected directly for improving the running efficiency.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Liquid piston heat engine

InactiveCN102434311ARealize stepless speed changeImplement speed changesInternal combustion piston enginesHot gas positive displacement engine plantsHydraulic cylinderCold air

The invention discloses a liquid piton heat engine which comprises a cold air hydraulic cylinder, a hot air hydraulic cylinder, a cold hydraulic power mechanism, a hot hydraulic power mechanism, a cold liquid medium return system and a hot liquid medium return system, wherein the cold air hydraulic cylinder is communicated with the hot air hydraulic cylinder through an air medium communicating pipeline, a cooler is arranged on the cold air hydraulic cylinder, a heater is arranged on the hot air hydraulic cylinder, a cold liquid medium outlet of the cold air hydraulic cylinder is communicated with a cold liquid medium return hole through the cold hydraulic power mechanism and the cold liquid medium return system, a hot liquid medium of the hot air hydraulic cylinder is communicated with a hot liquid medium return hole through the hot hydraulic power mechanism and the hot liquid medium return system, and the cold hydraulic power mechanism, the cold liquid medium return system, the hot hydraulic power mechanism and the hot liquid medium return system are controlled by a progress control mechanism. According to the invention, a piston crank connecting rod mechanism of an engine is omitted, and a large-power thermomotor with high efficiency and small volume and light weight can be manufactured.

Owner:ZEROQ SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com