Compressed air energy storage system capable of achieving stepped gas compression and expansion

A gas classification and gas technology, applied in the direction of liquid variable displacement machinery, variable displacement pump components, pump devices, etc., can solve the problems of redundant liquid piston capacity and pressure resistance, increase operating costs, etc., to improve equipment safety performance, reduce manufacturing requirements, and reduce the effect of pressure variation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments will be described in detail below in conjunction with the accompanying drawings.

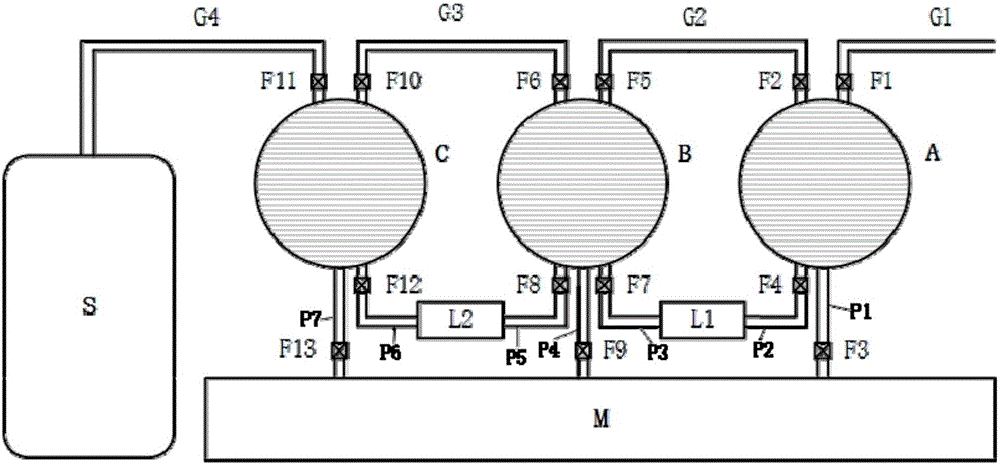

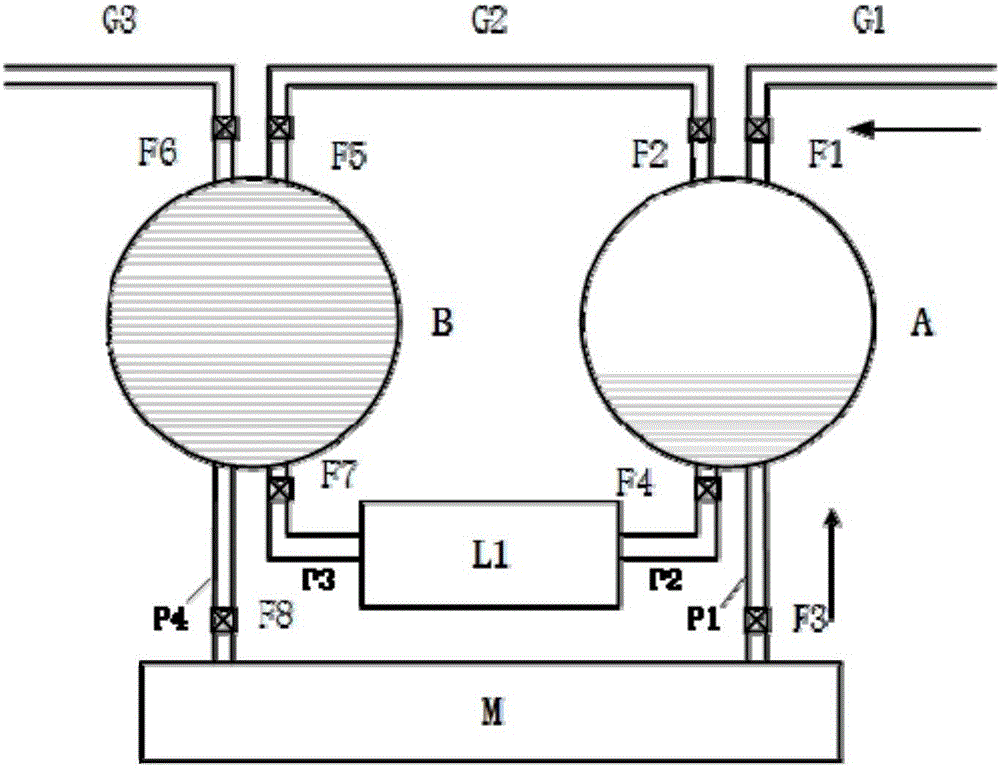

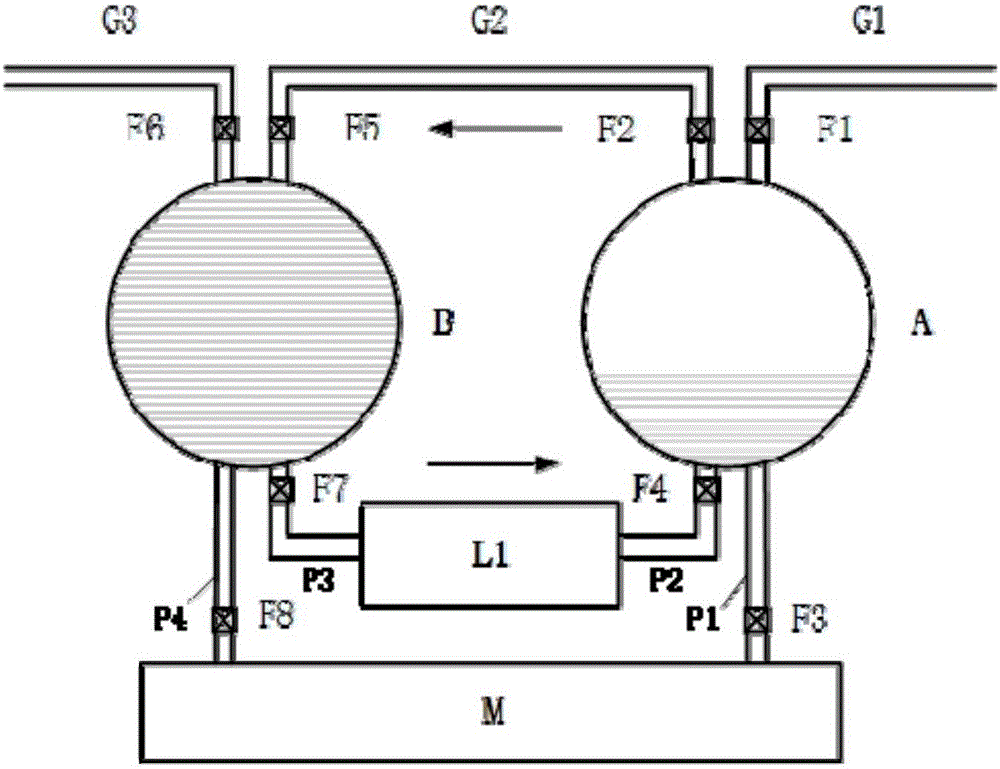

[0029] The basic structure of the compressed air energy storage system of the present invention is as follows: figure 1As shown: A, B, and C are three liquid pistons with increasing pressure levels in sequence, which are connected sequentially through gas pipelines G2 and G3. Liquid piston A with the lowest pressure level is set to connect low-pressure gas pipeline G1 to an external low-pressure gas source, and the liquid piston C is connected to the gas storage system S through the gas pipeline G4, the liquid pistons A and B, B and C are connected through the liquid driving devices L1 and L2 respectively, and A, B and C are connected to the outside through the liquid pipelines P1, P4 and P7 respectively Hydraulic equipment M. There are valves on each pipeline to control the operation of the system.

[0030] Liquid piston A is the liquid piston with the lowest pressure r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com