Patents

Literature

95 results about "Longwall mining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Longwall mining is a form of underground coal mining where a long wall of coal is mined in a single slice (typically 0.6–1.0 m (2 ft 0 in–3 ft 3 in) thick). The longwall panel (the block of coal that is being mined) is typically 3–4 km (1.9–2.5 mi) long and 250–400 m (820–1,310 ft) wide.

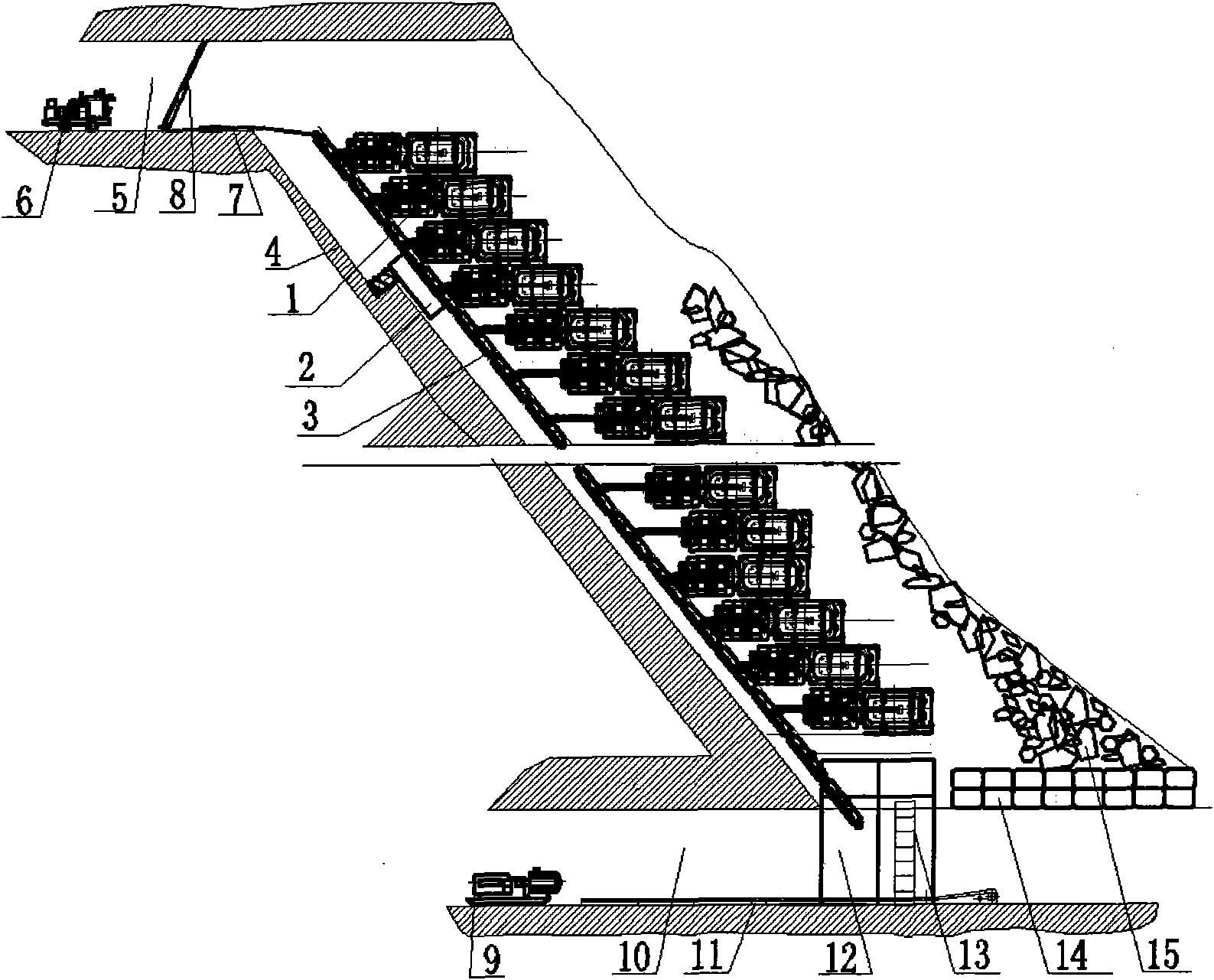

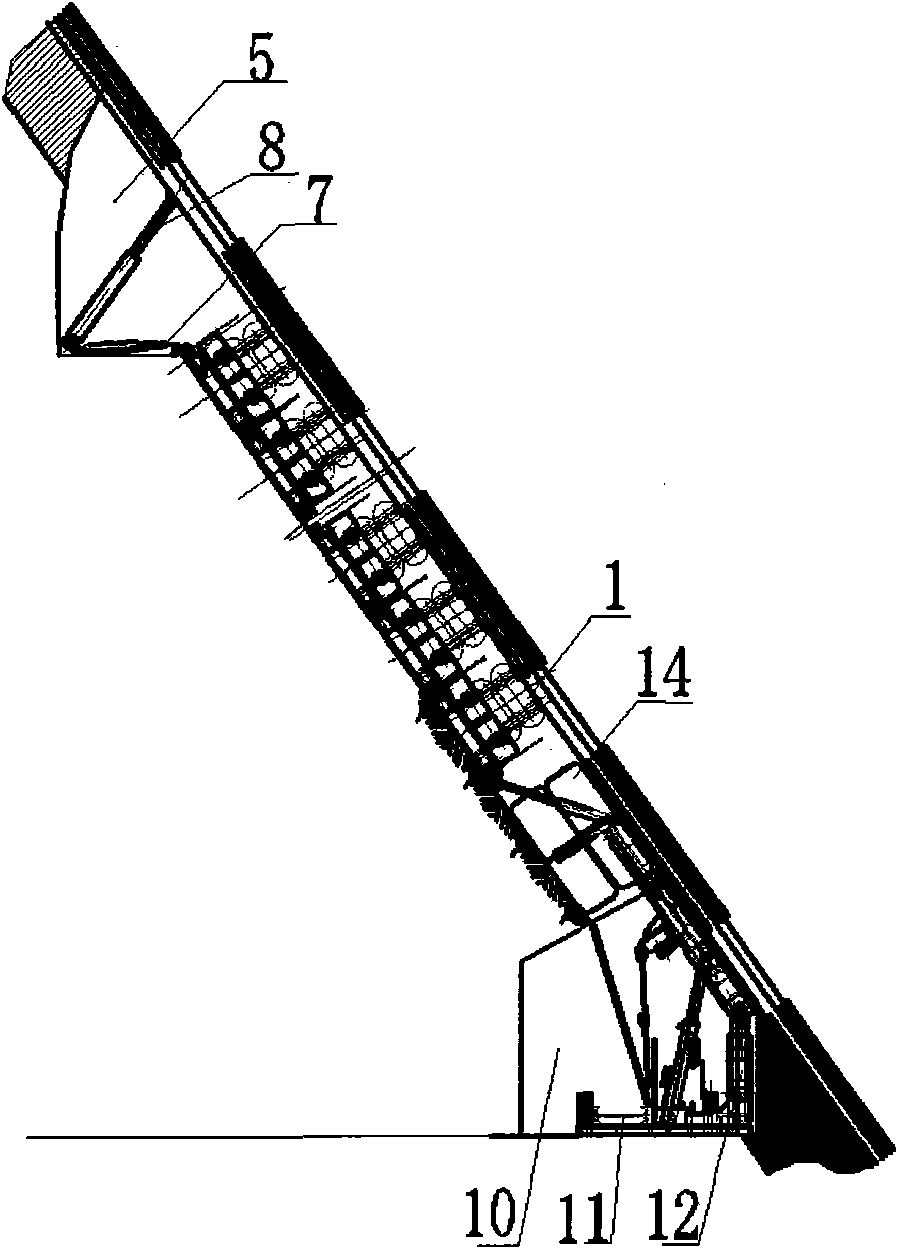

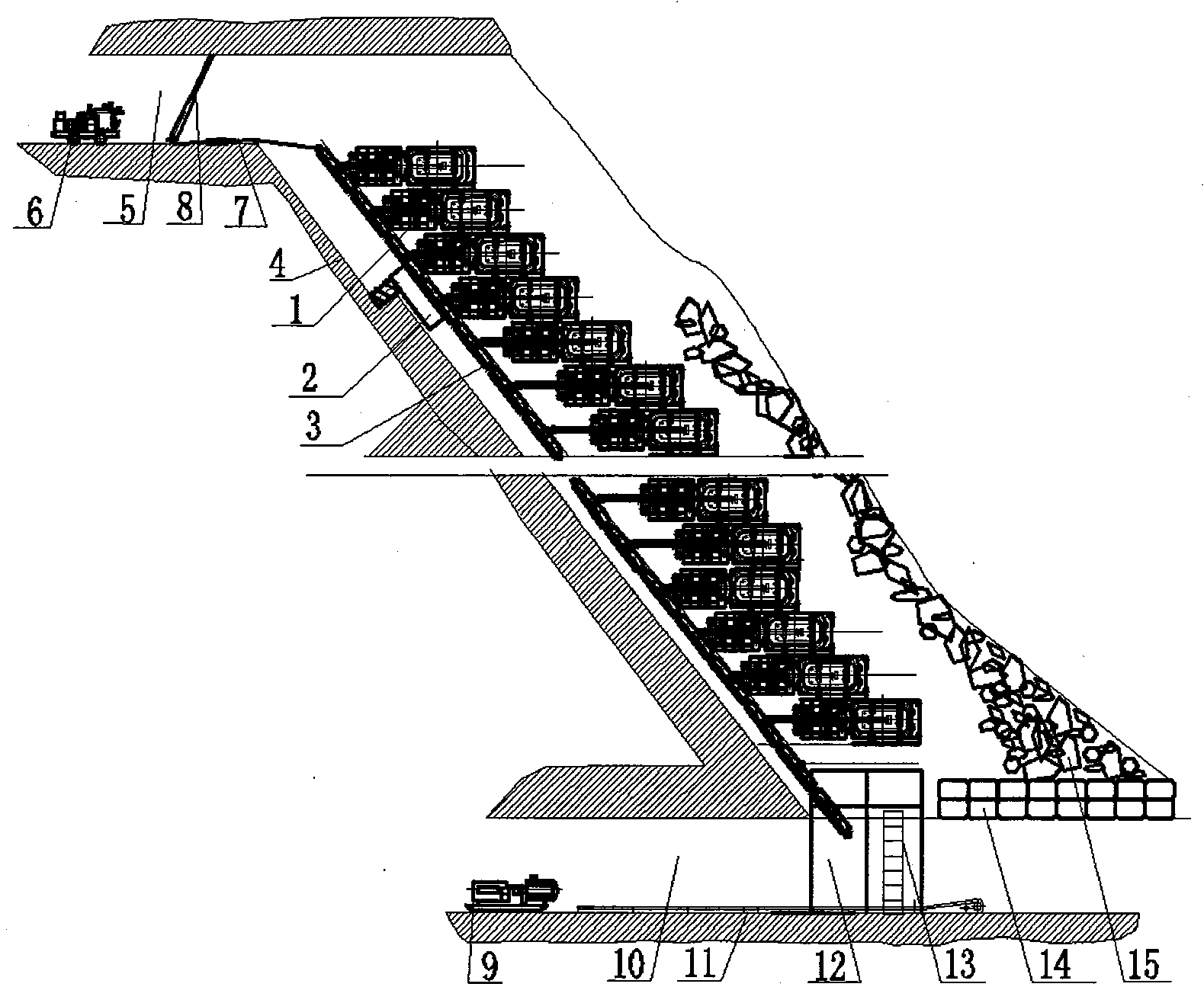

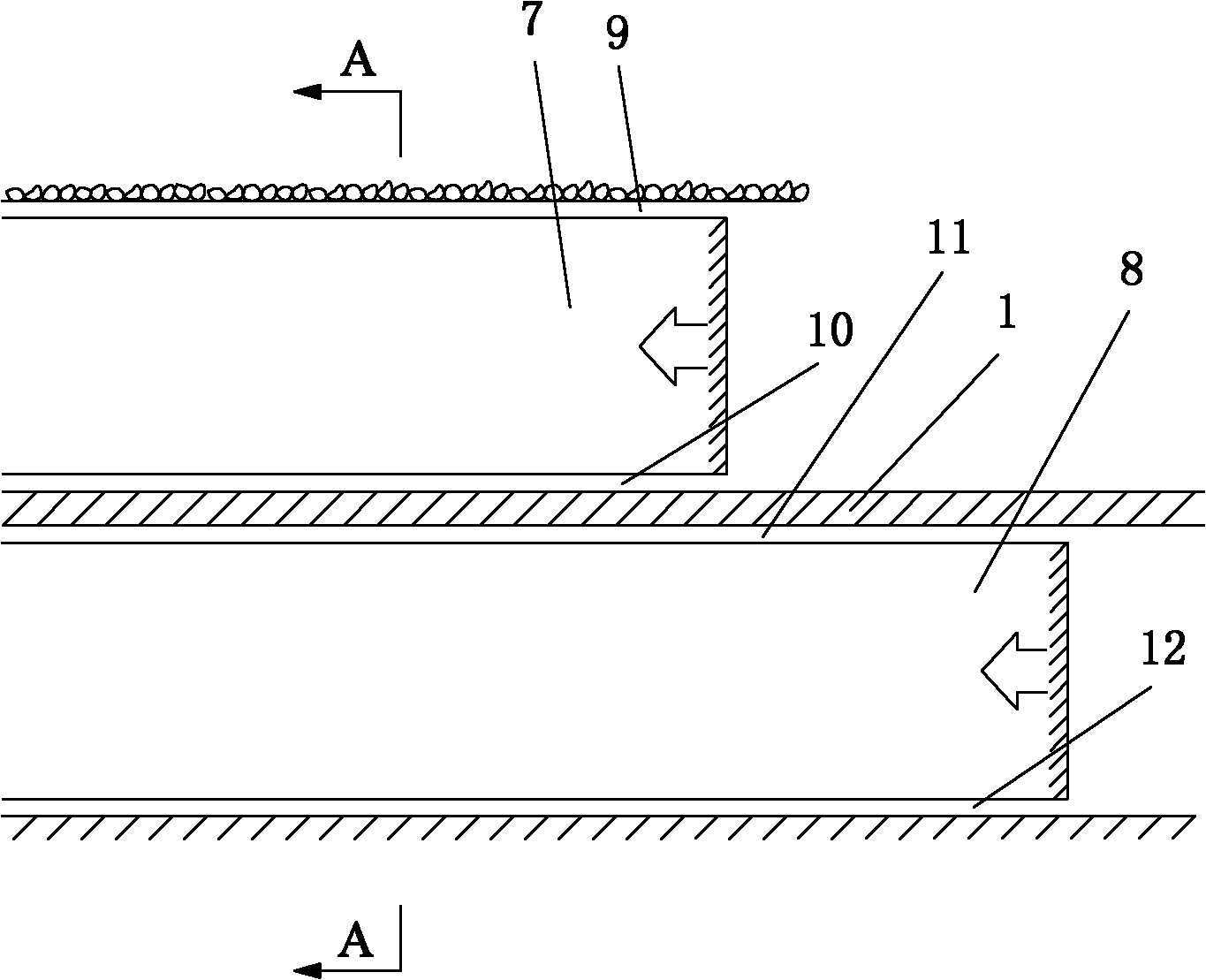

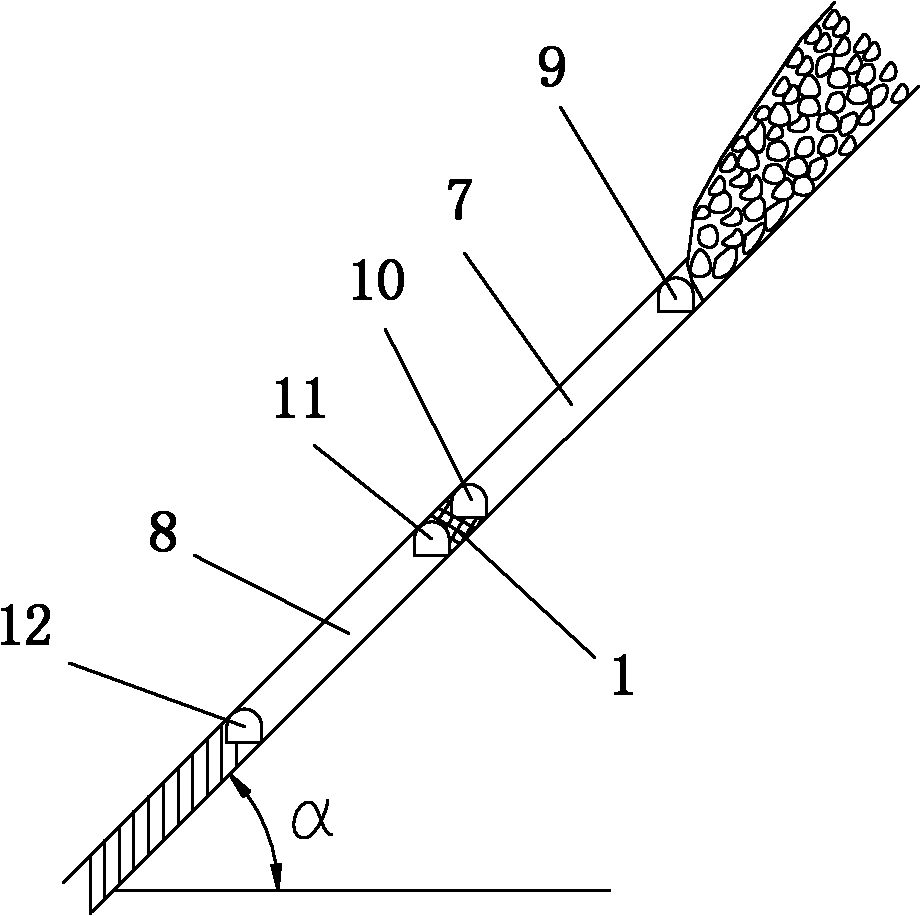

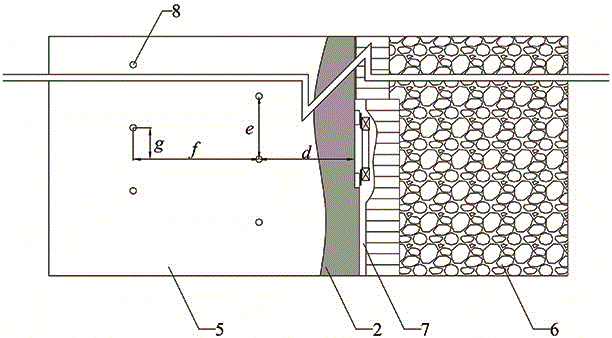

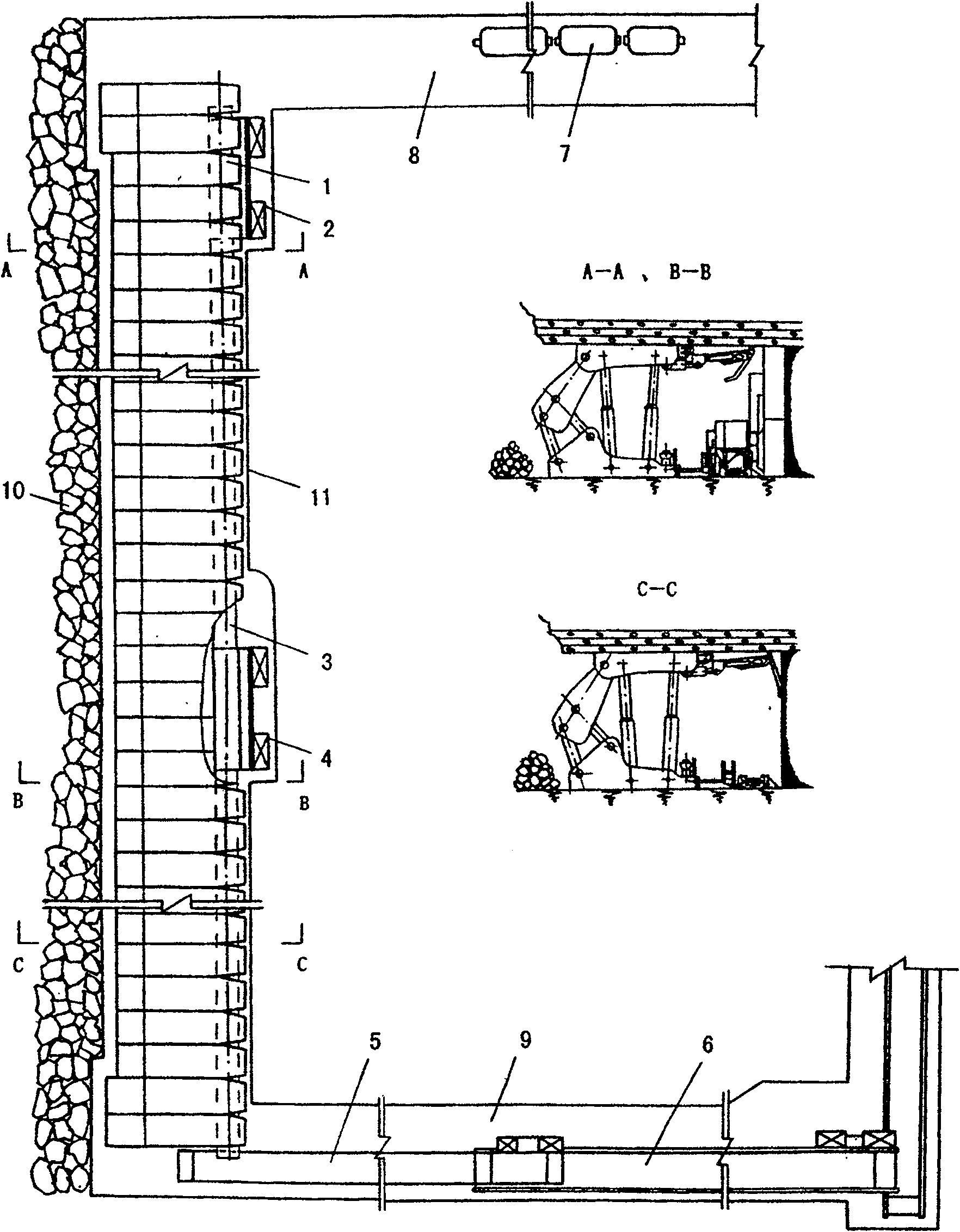

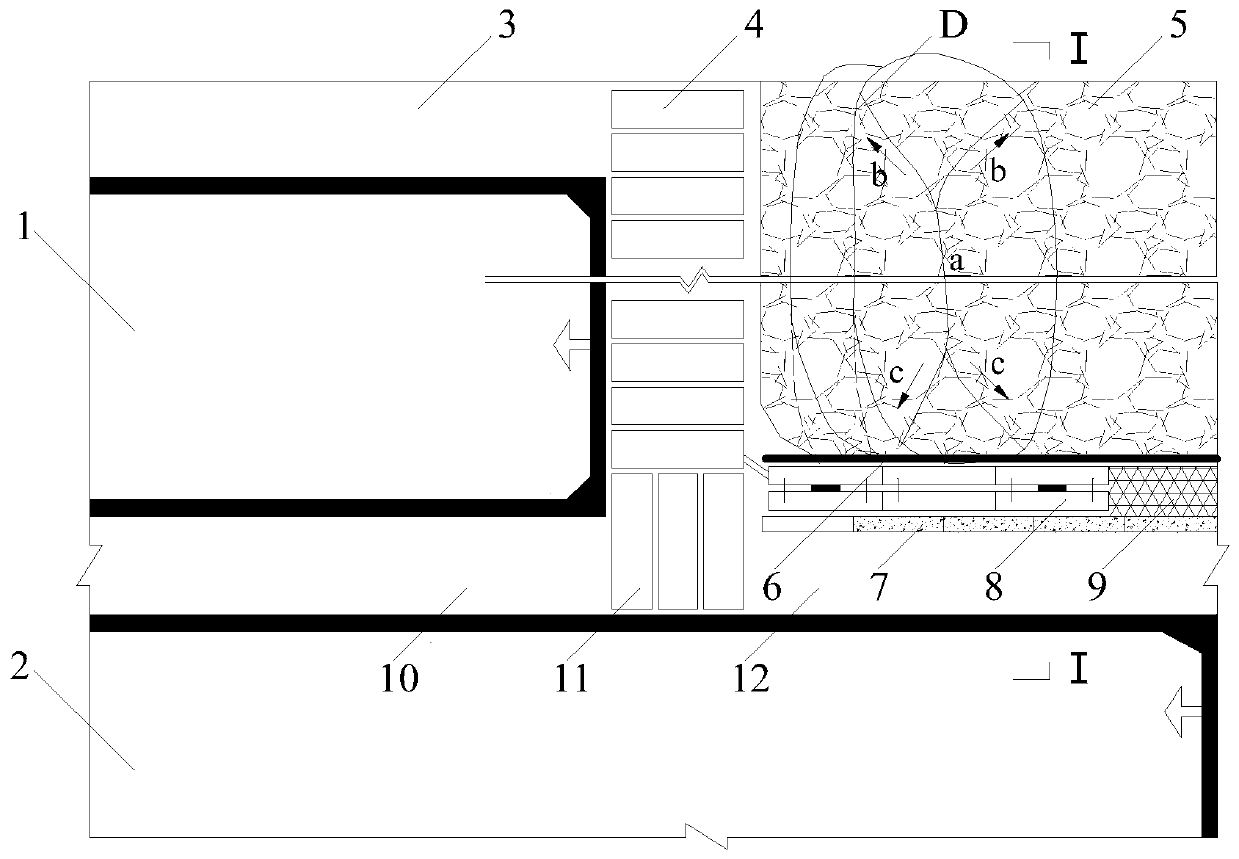

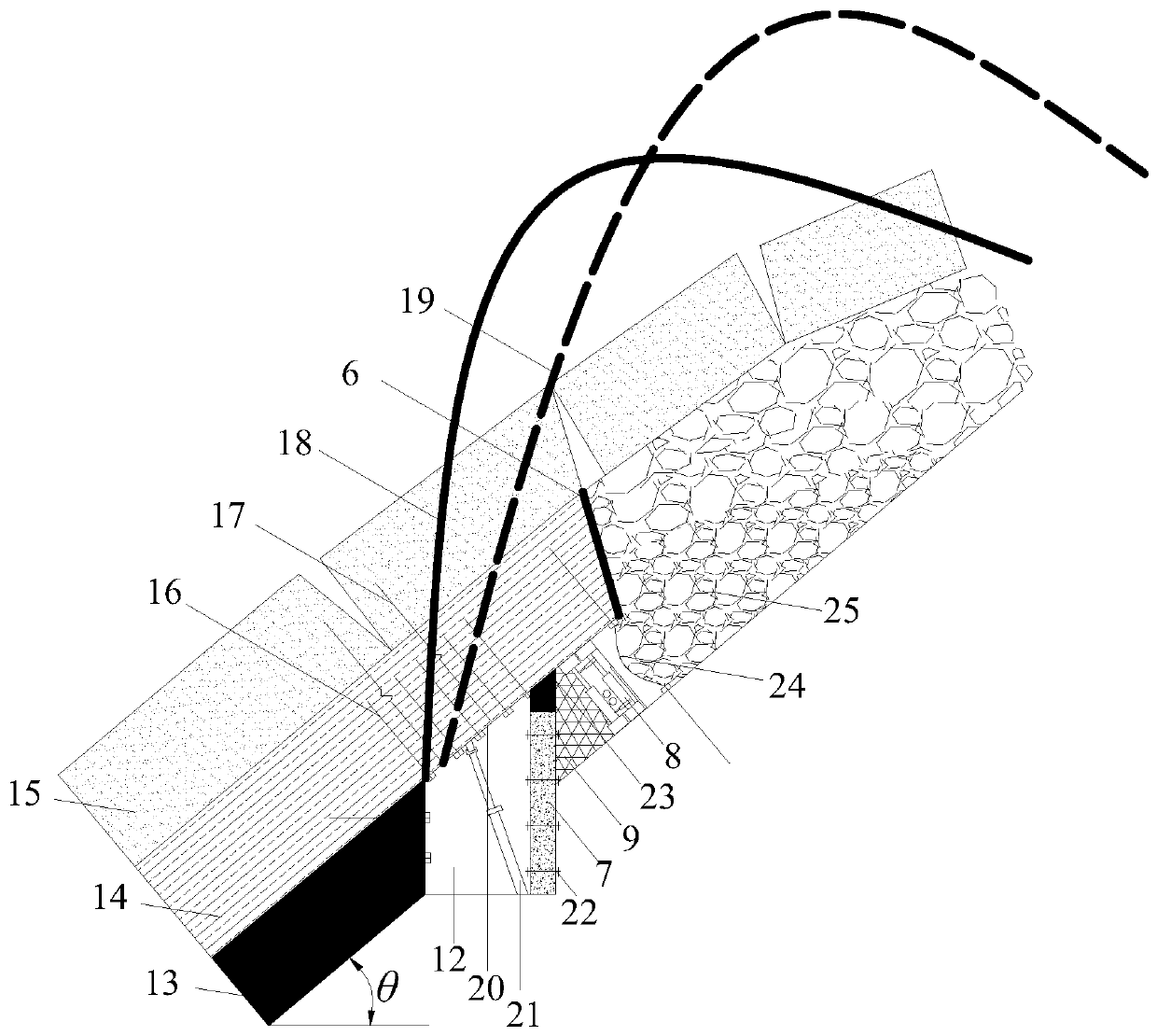

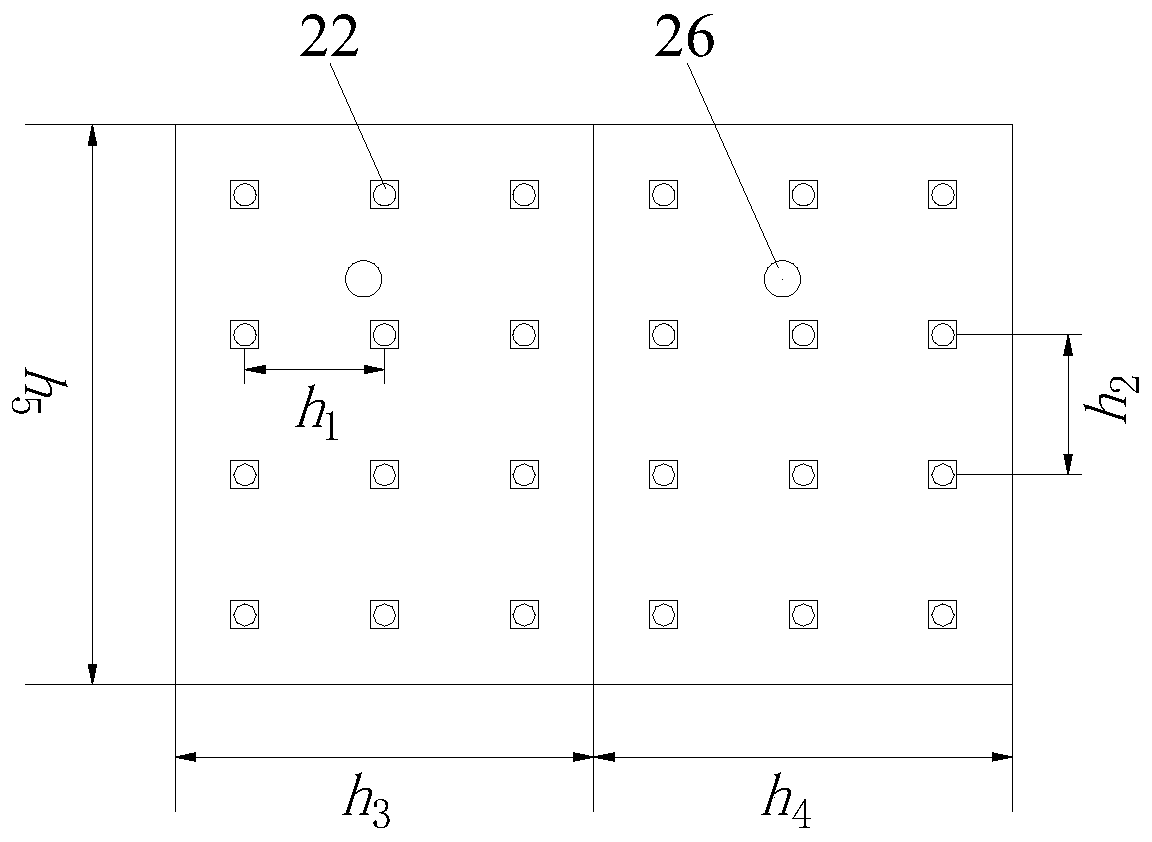

Coal mining method for high-dipping low seam

InactiveCN101942999AAchieve mechanical propertiesIncrease productionUnderground miningSurface miningLongwall miningMining engineering

The invention relates to a coal mining method for a high-dipping low coal seam by long-wall mining. The method comprises the following steps of: supporting a roof by a self-advancing air bag support; arranging a working surface in a mode of advancing to the dip; mining coal by drilling and blasting or using an off-pan shearer; transporting the coal in a mode of gravity haulage; filling a goaf with gangue or sand; and filling a lower end with gangue bags, precast concrete blocks or solidified macromolecular foaming slurry. The coal mining method has the advantages of realizing mechanical coal mining for the high-dipping low coal seam, improving the yield per unit and efficiency of the working surface, effectively protecting the exploited ground, improving the recovery rate of mines, and guaranteeing the coal seam mining safety.

Owner:TIANDI SCI & TECH CO LTD

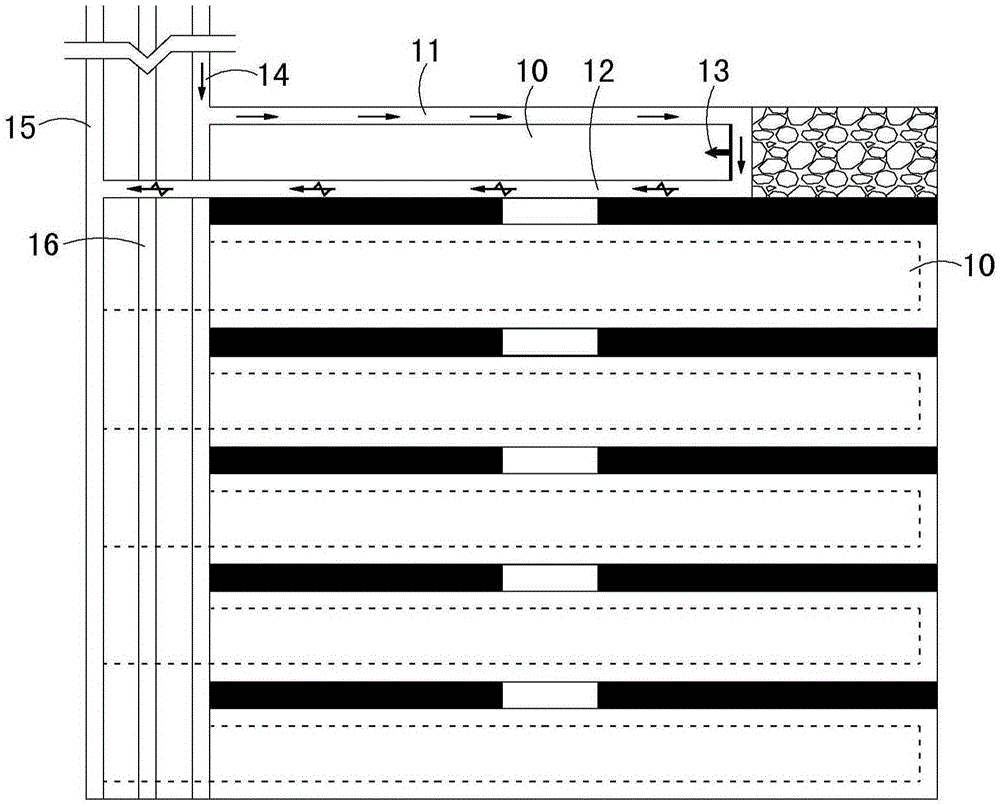

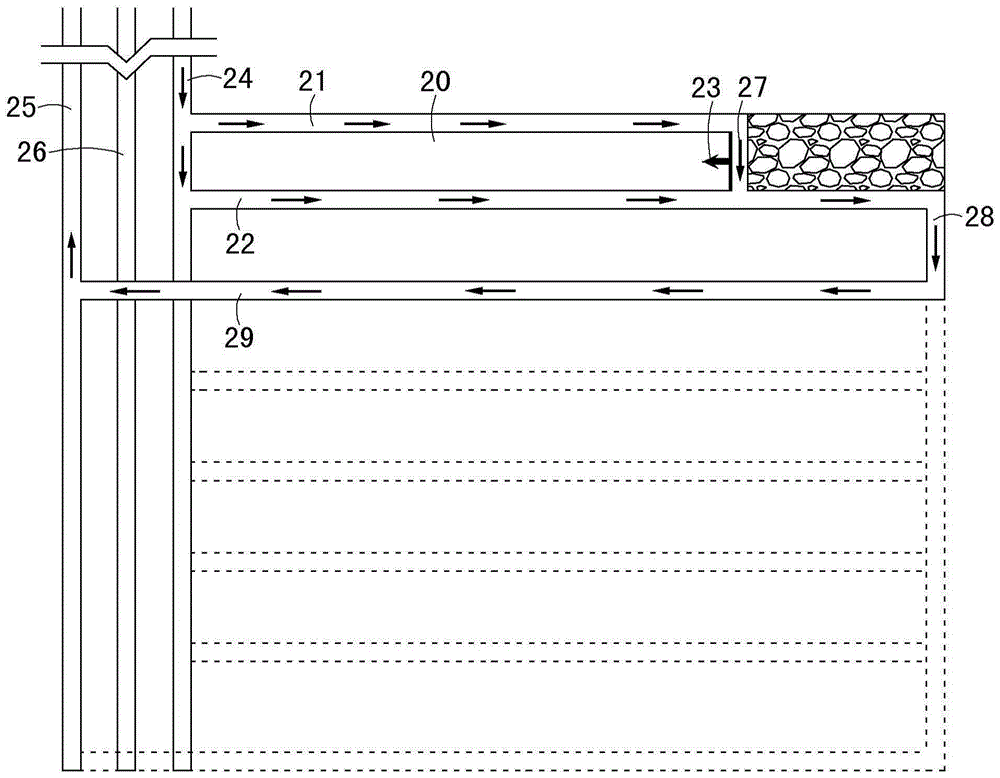

Longwall mining N00 construction method

ActiveCN105240013AGuaranteed ventilation effectSave resourcesUnderground miningTunnel/mines ventillationLongwall miningCoal pillar

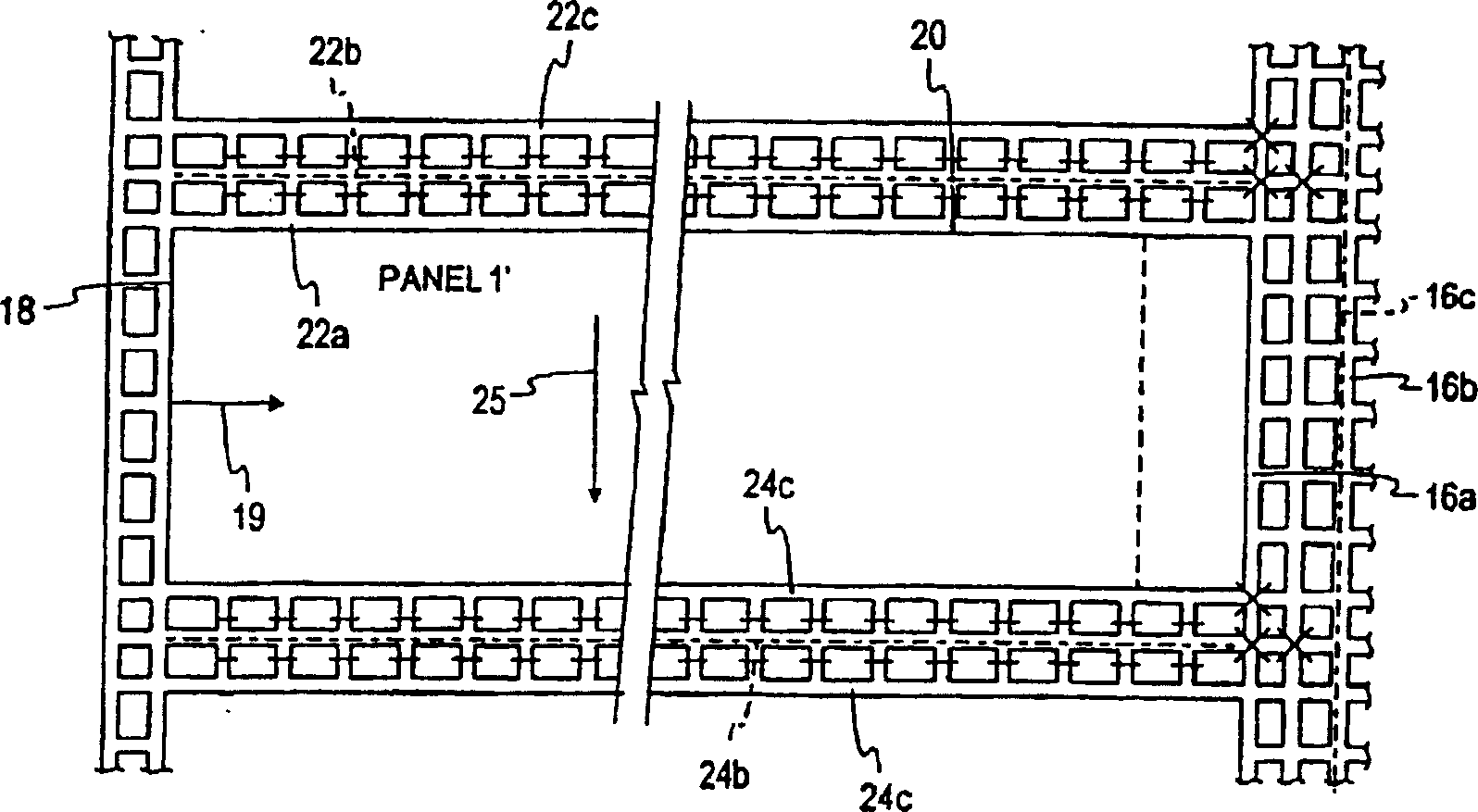

The invention discloses a longwall mining N00 construction method, which is characterized in that roadway-free tunneling and coal-pillar-free mining are performed in N working faces of a bran-new panel; the whole panel is provided with an air return downhill passage, a belt downhill passage and a rail downhill passage; the air return downhill passage and the rail downhill passage are positioned at one end of the panel; and the belt downhill passage is communicated with the other end of the panel and is communicated with the air return downhill passage. The longwall mining N00 construction method has the advantages that the ventilation of the whole coal mining region can be ensured; during the mining of each working face in the panel, one part of a goaf is used for implementing roof cutting and pressure relief automatic roadway forming; any crossheading roadway does not need to be tunneled; and coal pillars do not need to be reserved, so that resources are saved, and the efficiency is improved.

Owner:何满潮

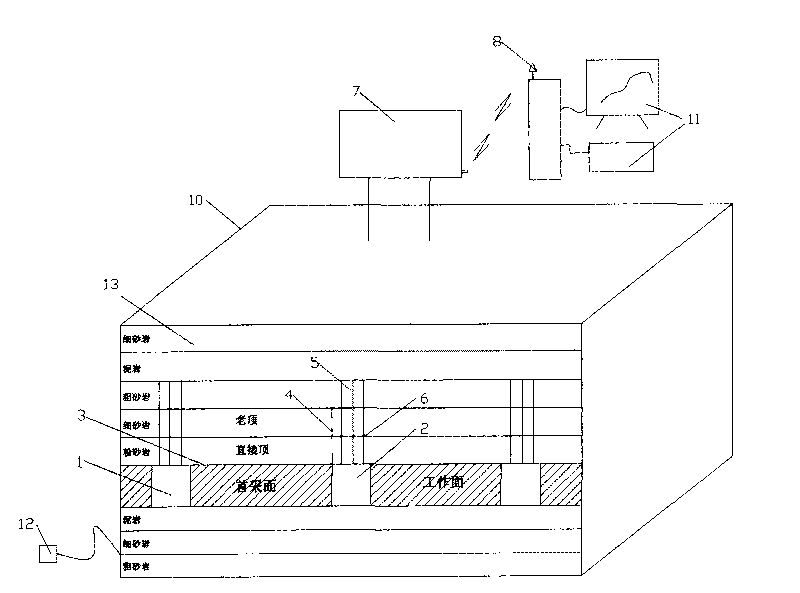

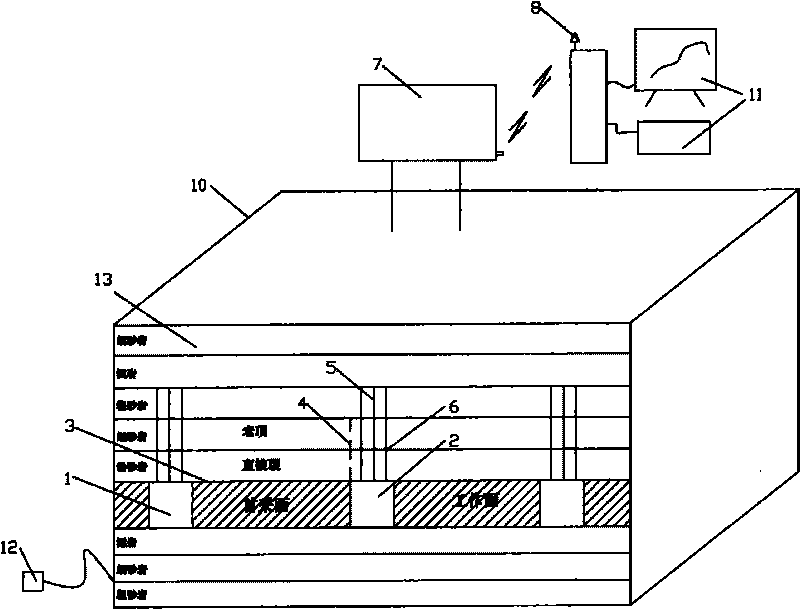

Deep stope automatic lane forming physical simulation test method and device

ActiveCN101737056AReduce stress concentrationReduce wasteForce measurementTunnelsStress concentrationLongwall mining

The invention discloses a novel lane forming method for mining a long wall, namely a deep stope automatic lane forming physical simulation test method which changes the traditional mode of mining the long wall through a single face and double lanes. An oriented pre-cracking top-cutting lane-reserving technique is adopted; and a return mining lane of a gate road under a primary work face is reserved and serves as one of return mining lanes of the next new work face so as to mine through a single face and a single lane. The method has the advantages of removing concentrated stress above the coal on adjacent working faces, reducing the mining ratio, improving the production efficiency and reducing the resource waste, and belongs to a novel, safe, efficient, economic and scientific mining technique. At the same time, the invention designs a deep stope automatic lane forming physical simulation test device based on the principle so as to prove the reliability of the method and ensure the authenticity and the availability of the test process.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

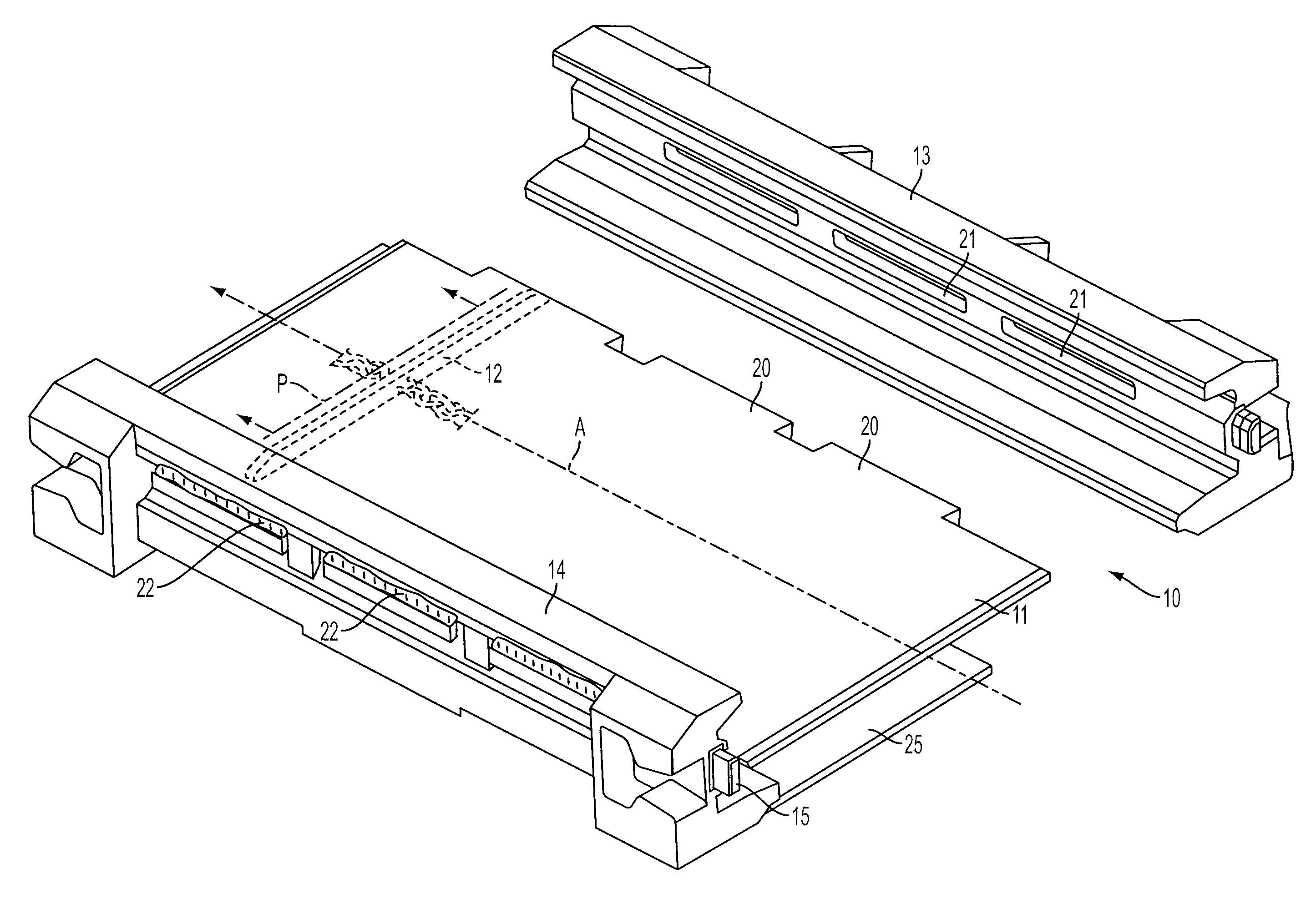

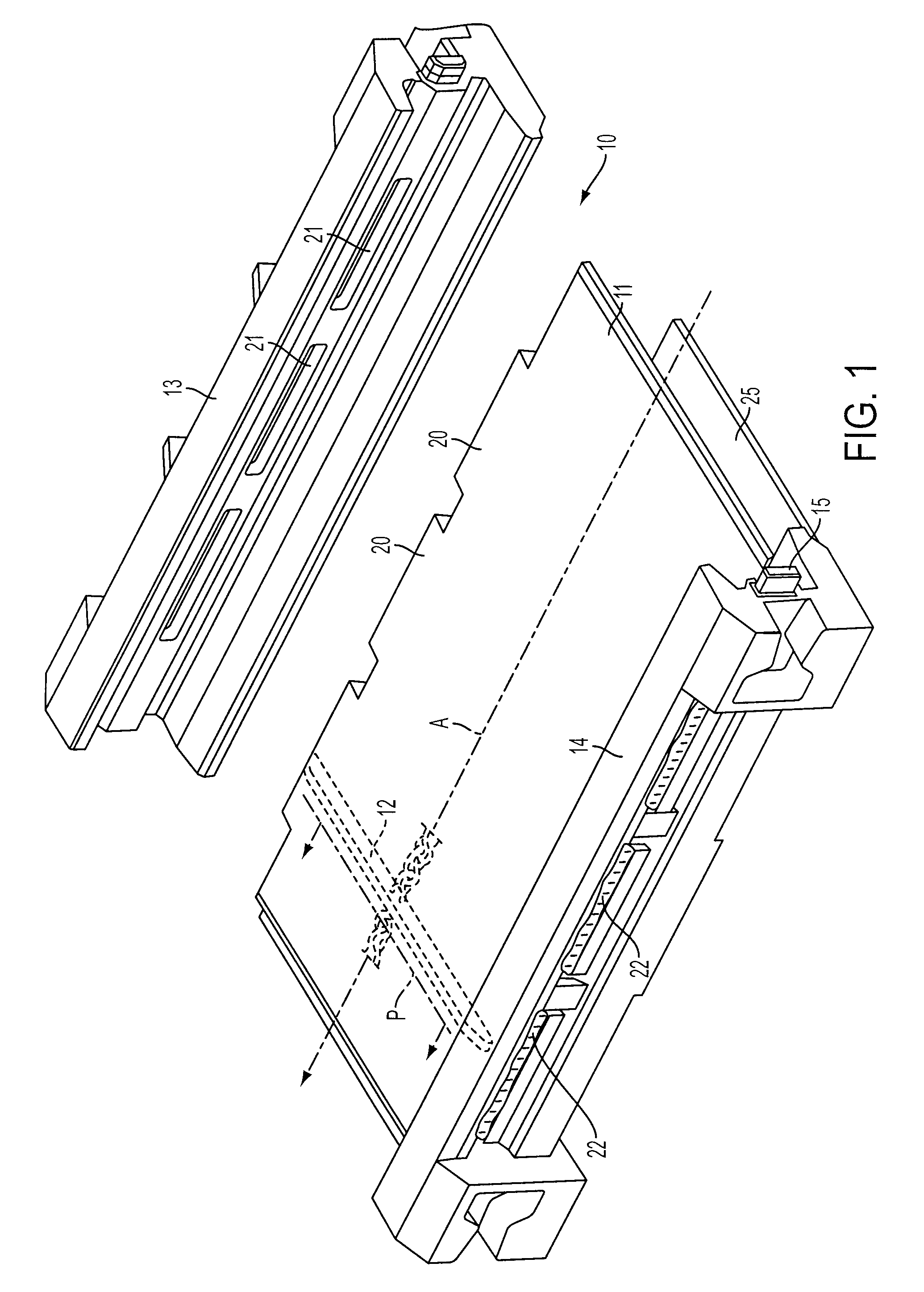

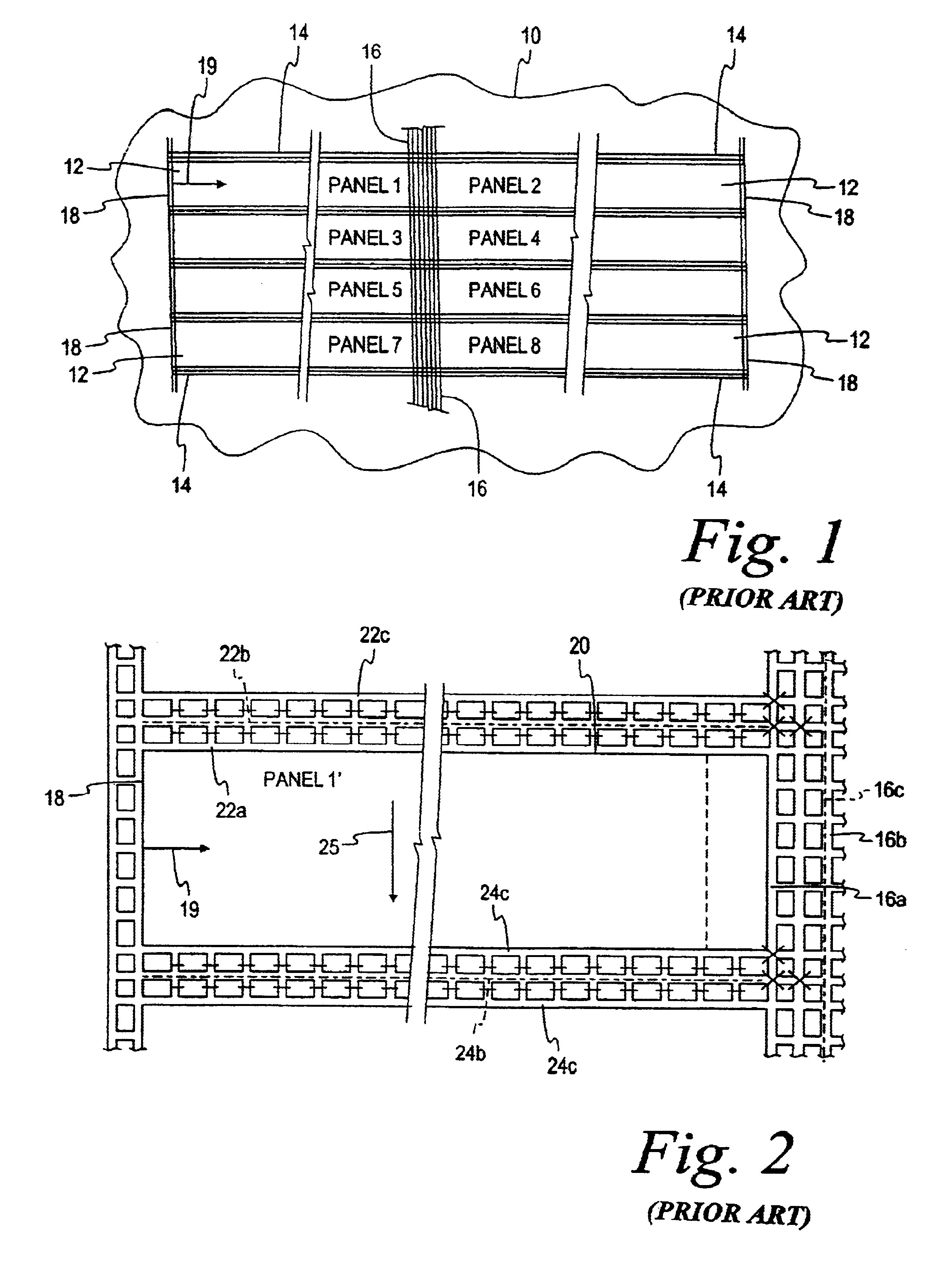

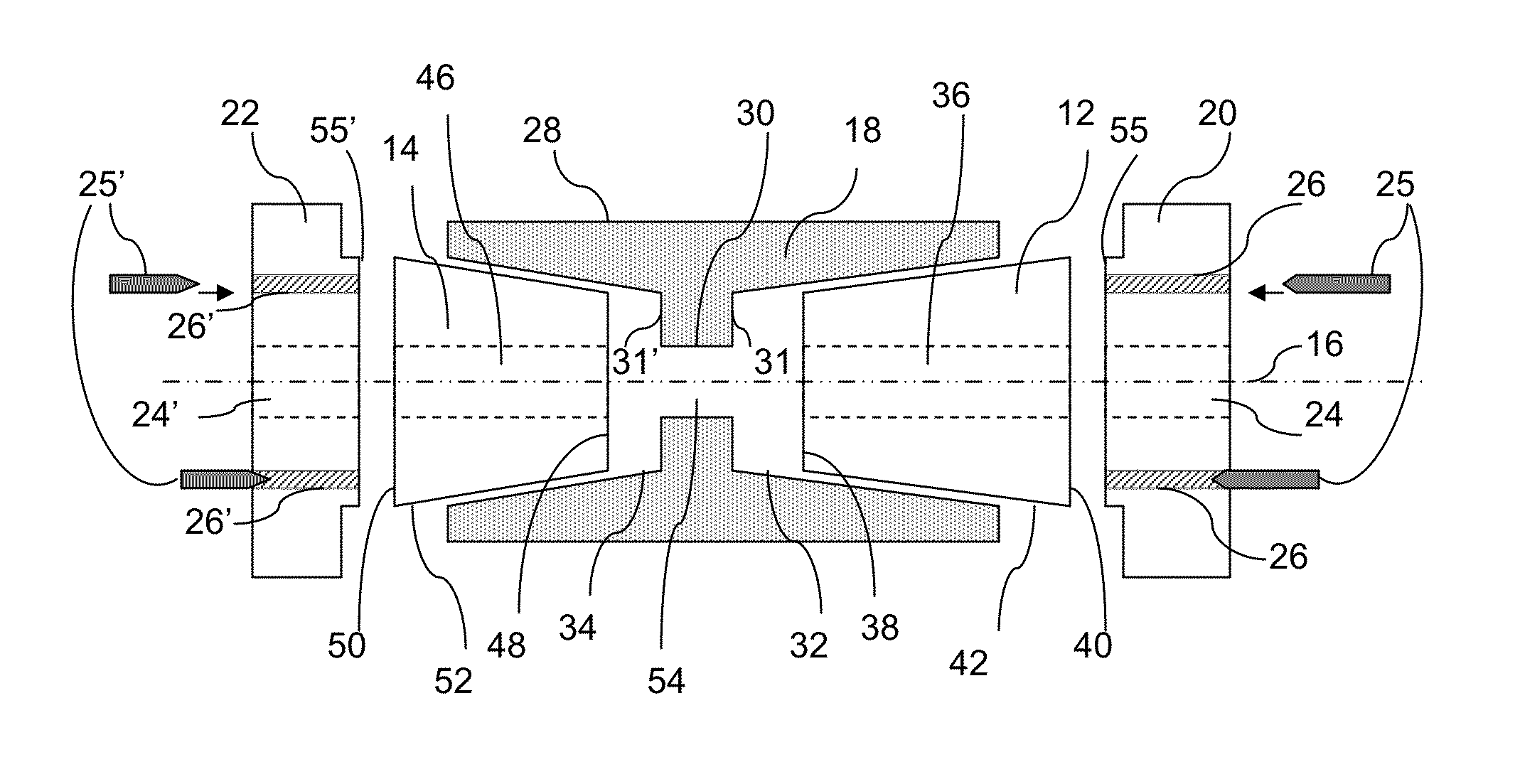

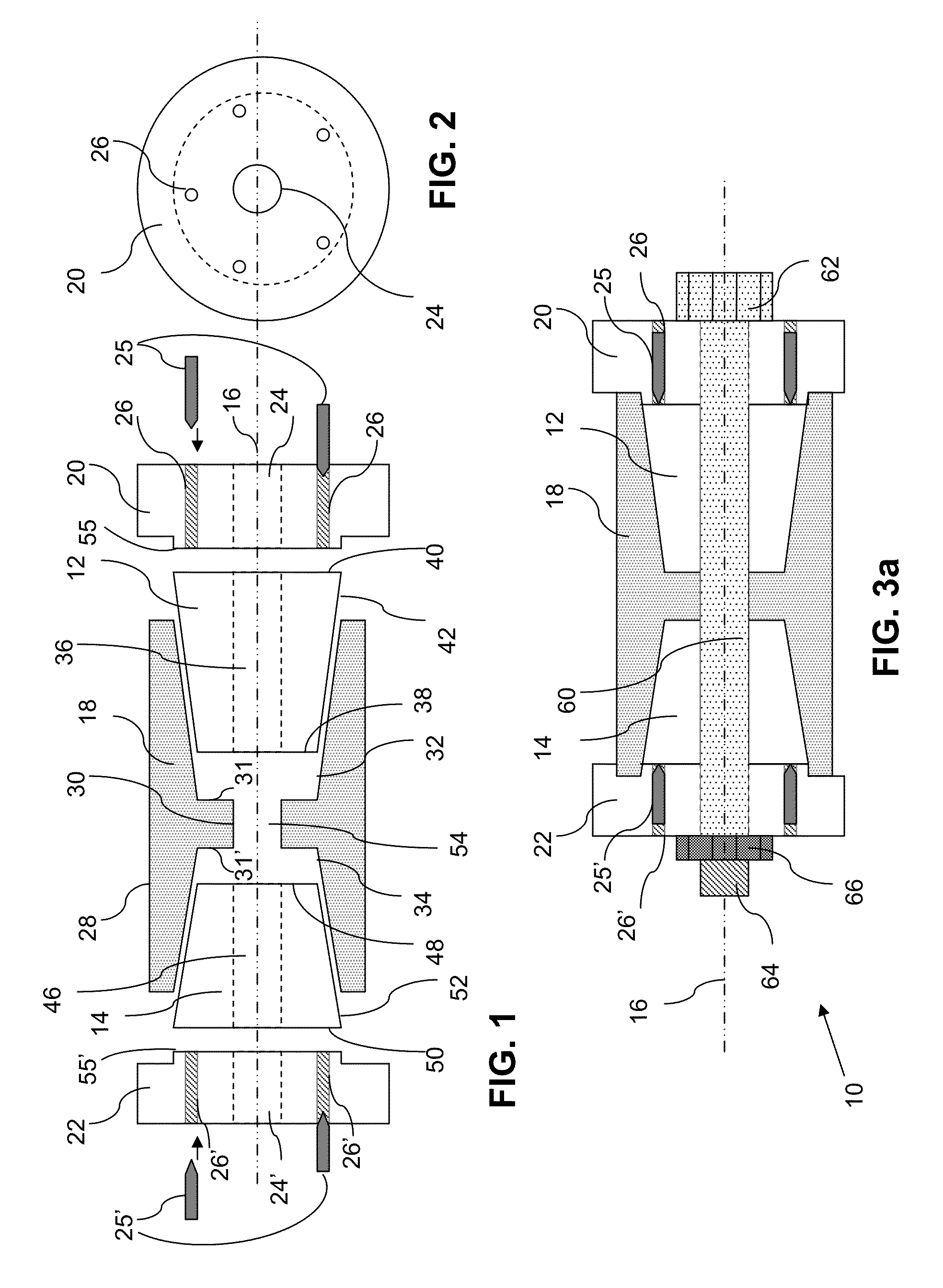

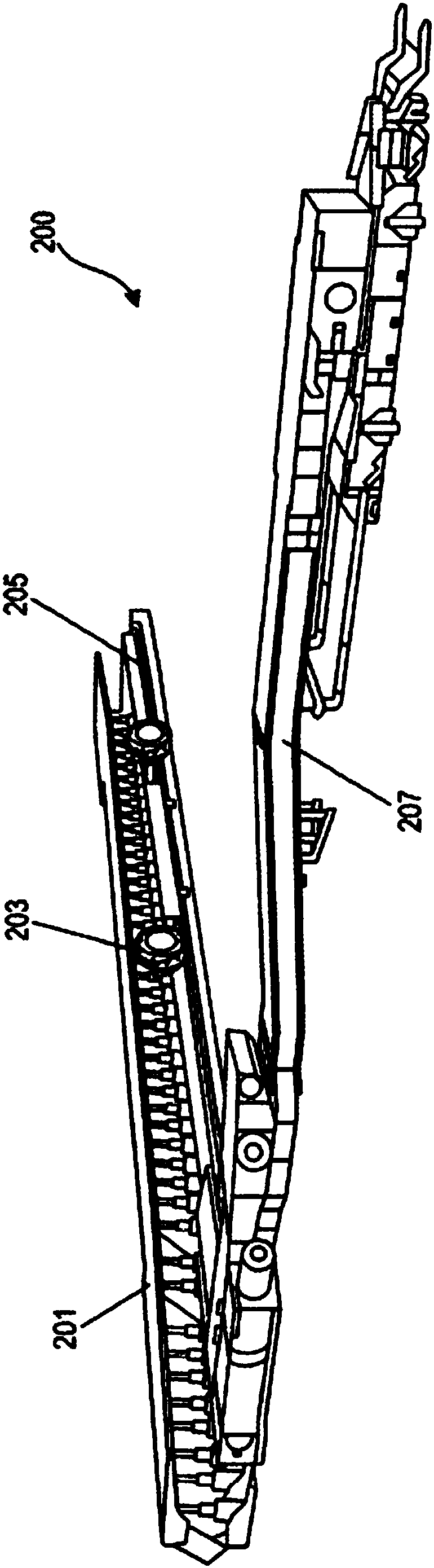

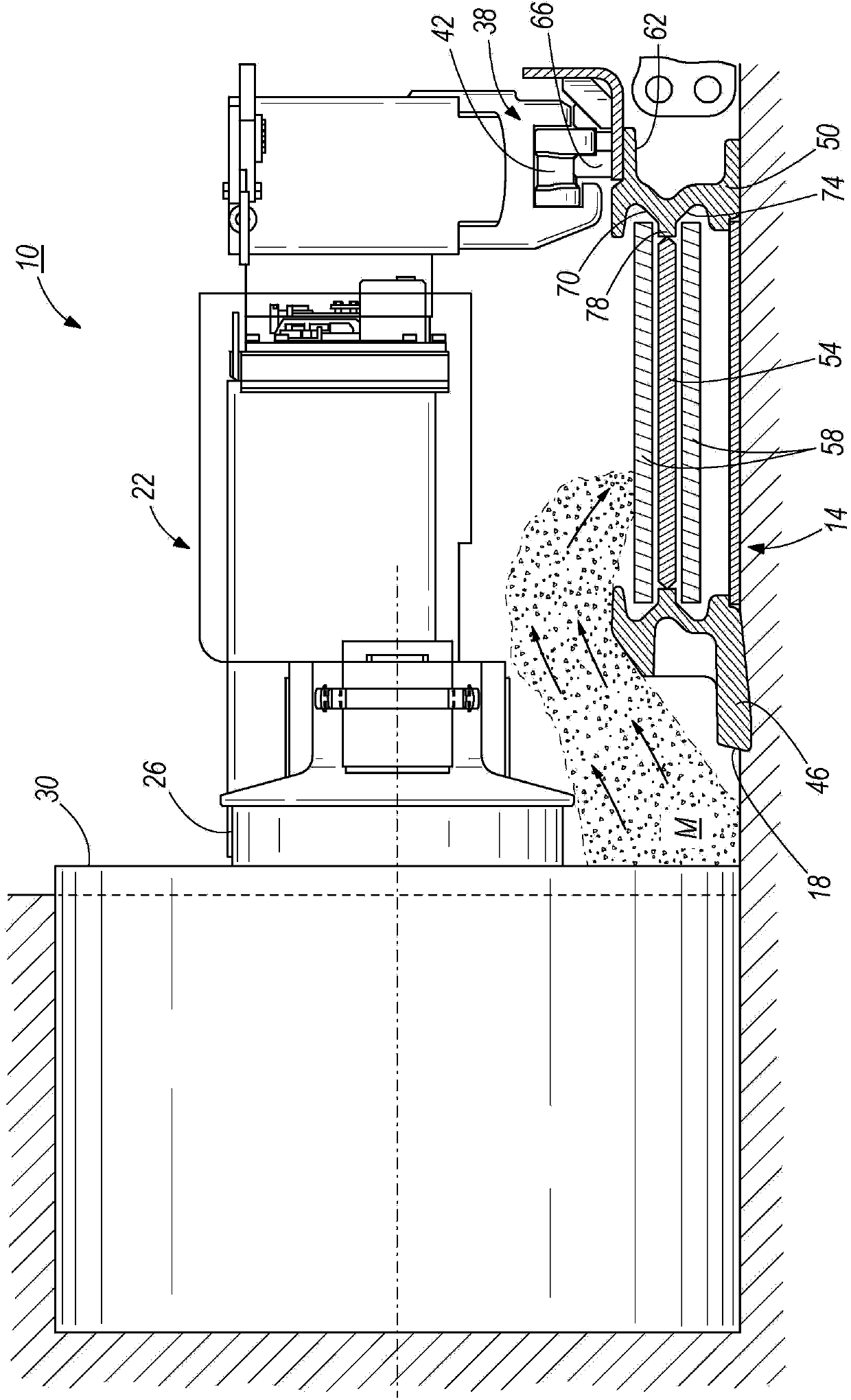

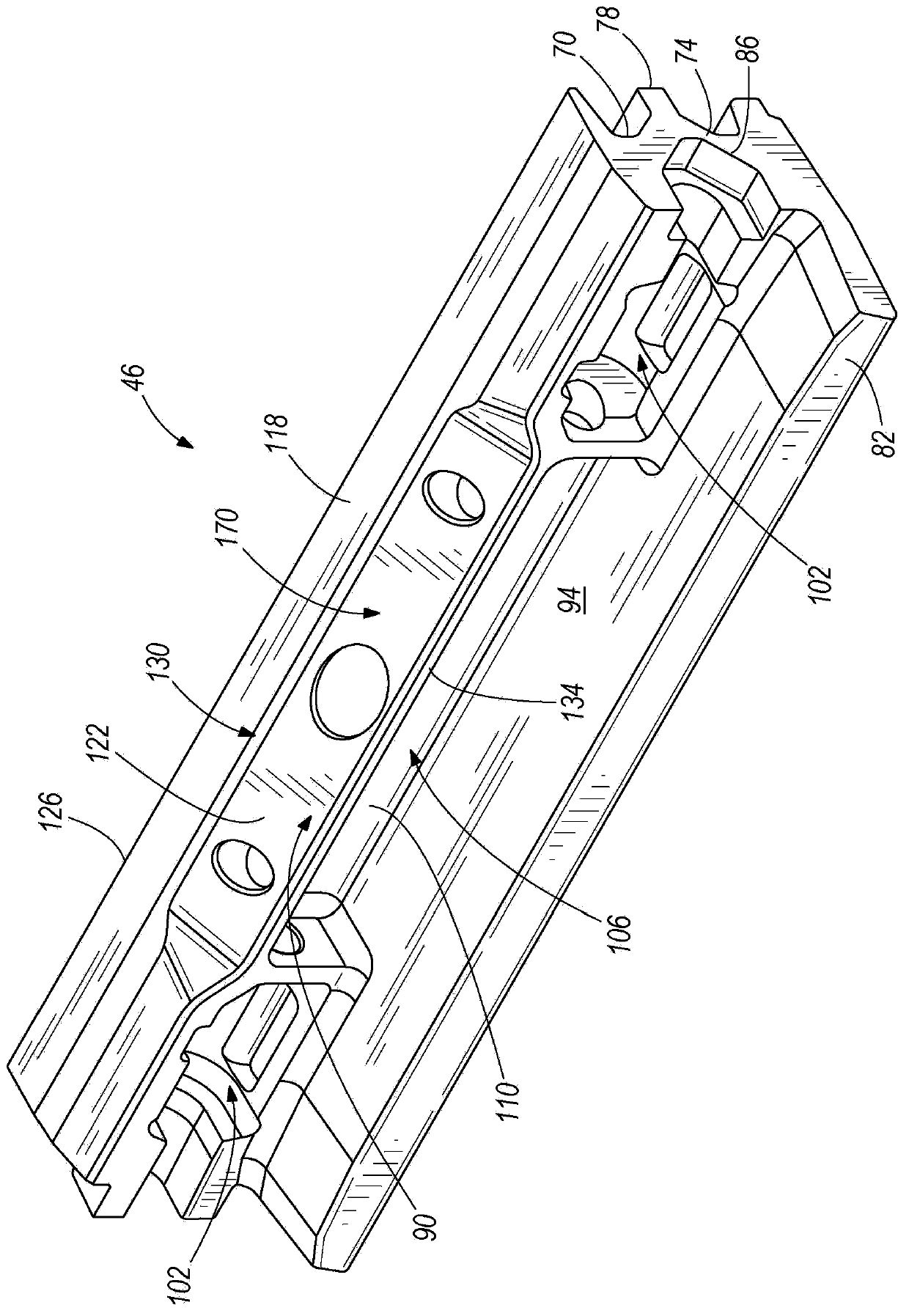

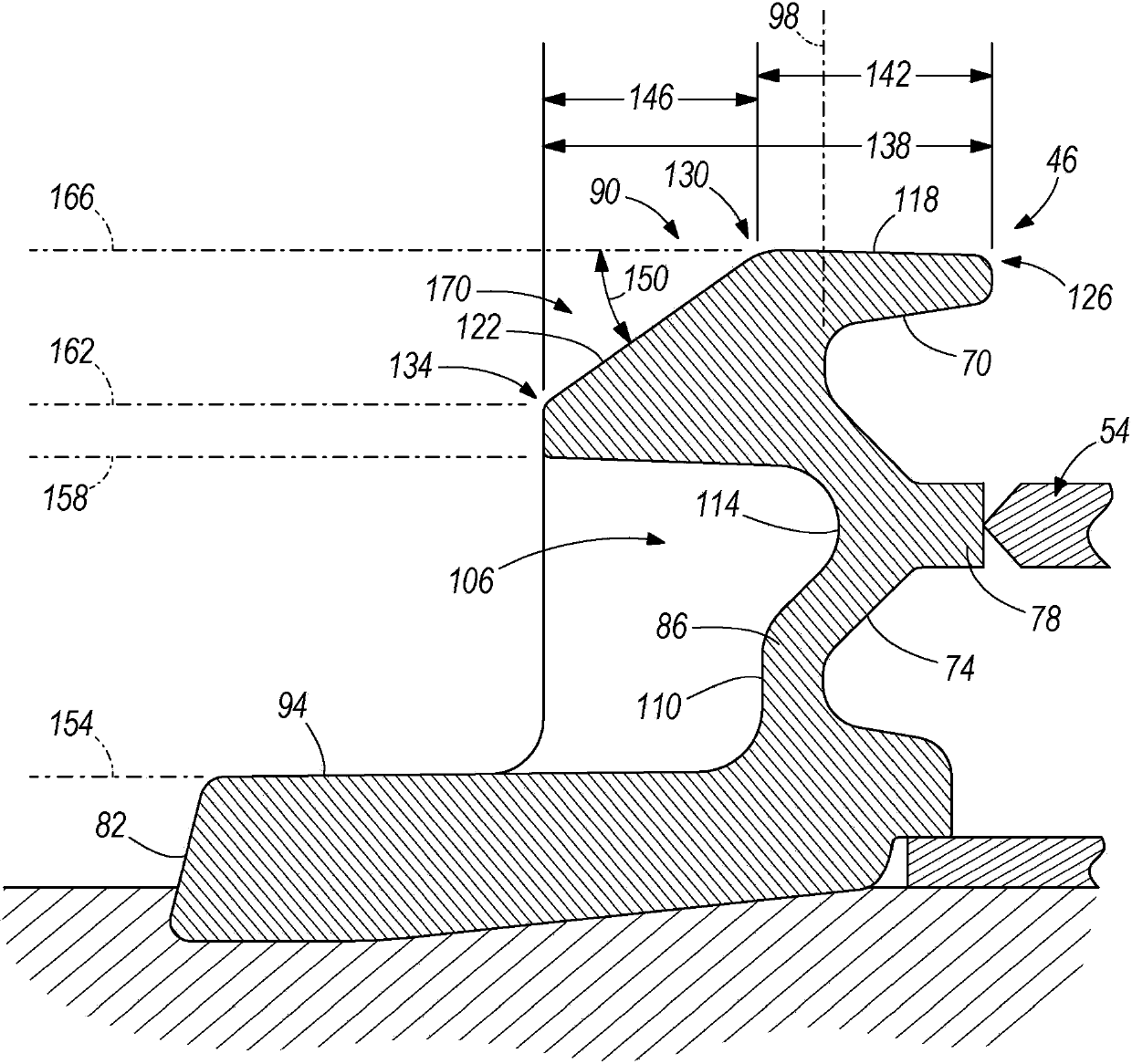

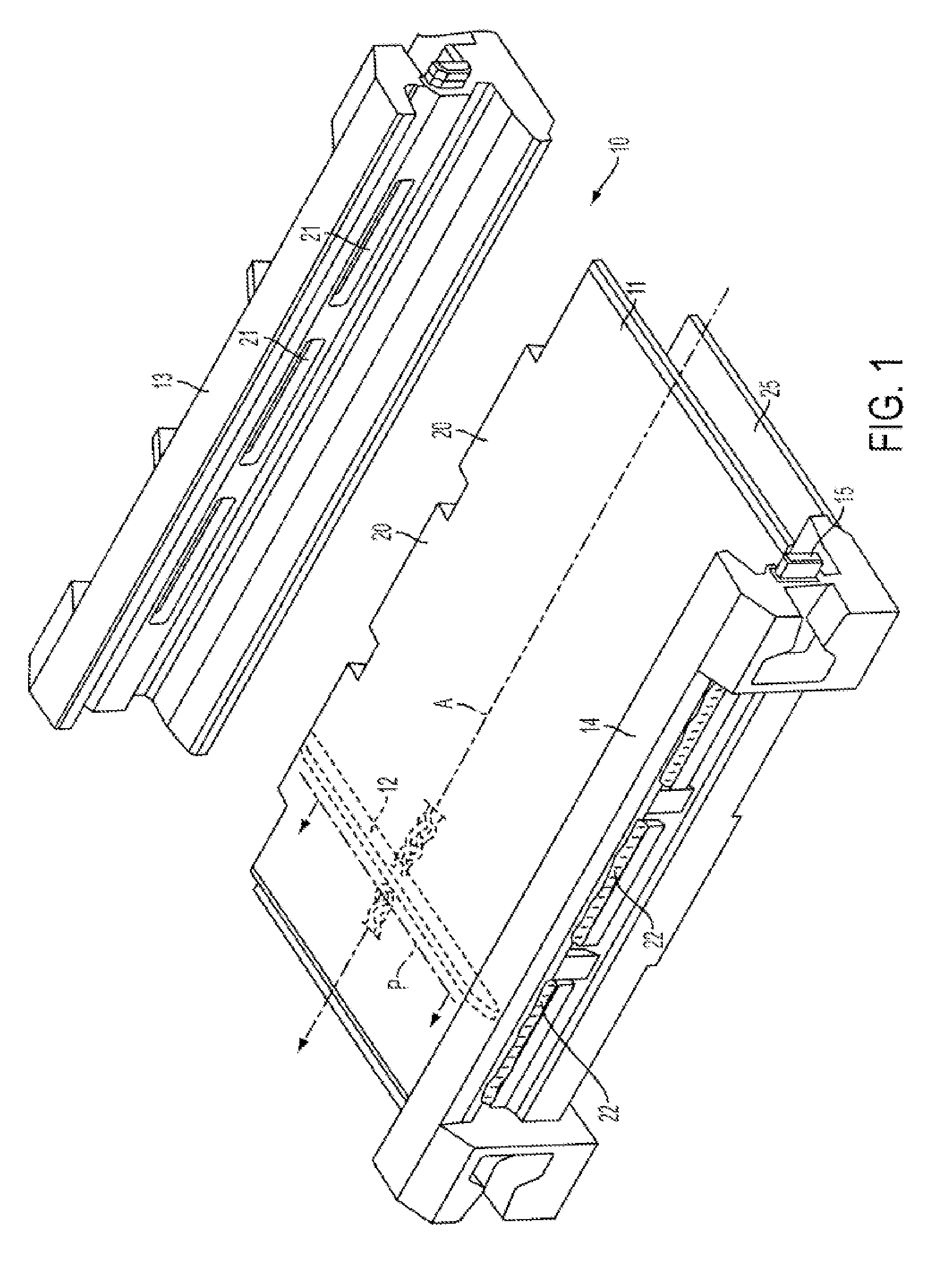

Conveyor pan with improved edge shaping

ActiveUS20090066147A1Low stress levelImprove conveyor pan fatigue lifeConveyorsSlitting machinesLongwall miningVertical plane

A conveyor pan for use with a shearer with a skid-type shoe in a longwall mining operation, the conveyor pan including a side member having a surface adapted to be engaged by the shearer skid-type shoe, the surface being formed by a piece of the side member that extends horizontally for the length of the side member. The piece has a first end and a second end, each piece end having a top, a rear, a front and an edge. The first end edge and the second end edge are each formed by each edge being between 45 degrees removed from a vertical plane extending at 90 degrees to the horizontal plane formed by the side member surface.

Owner:JOY GLOBAL UNDERGROUND MINING LLC

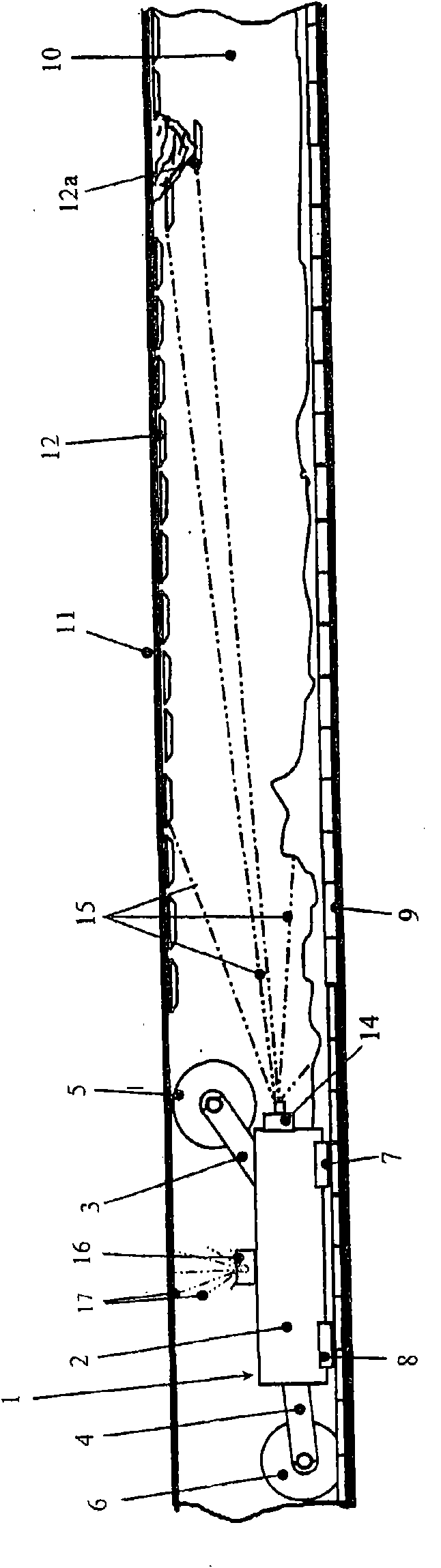

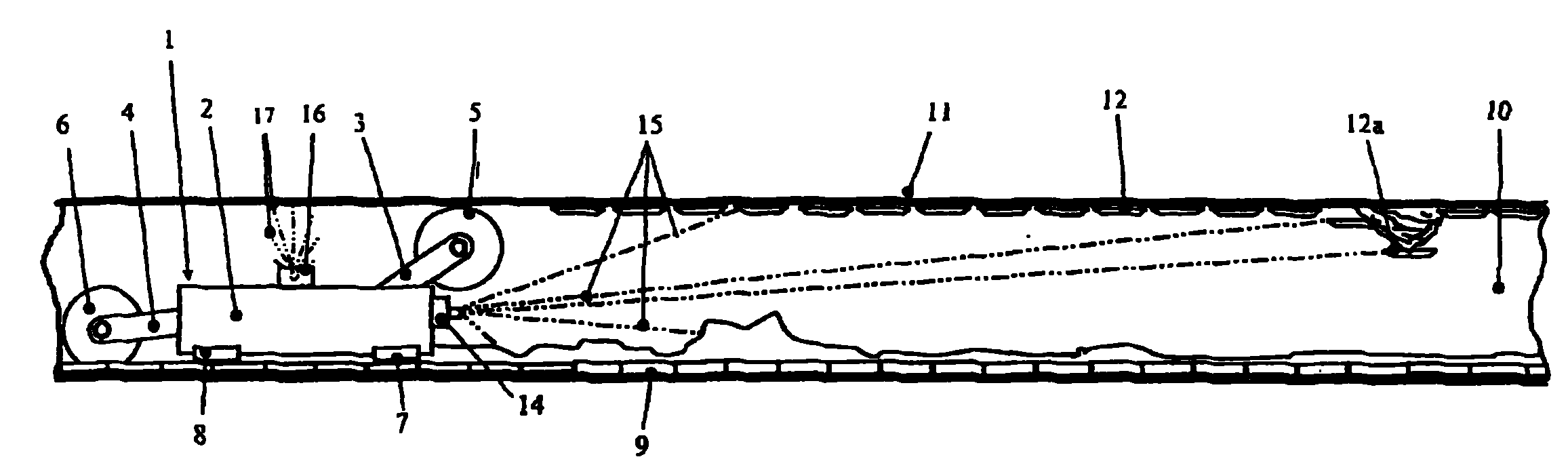

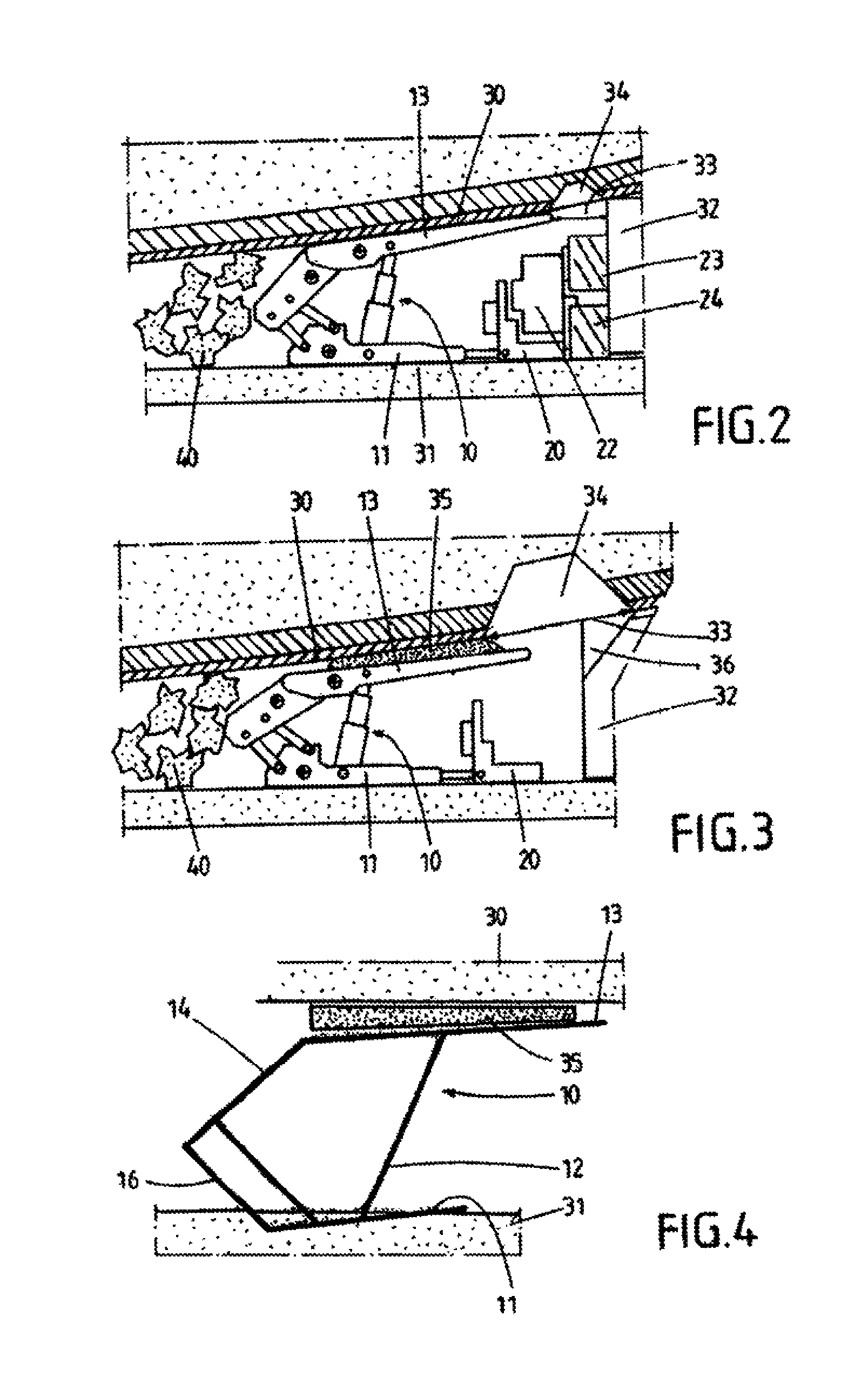

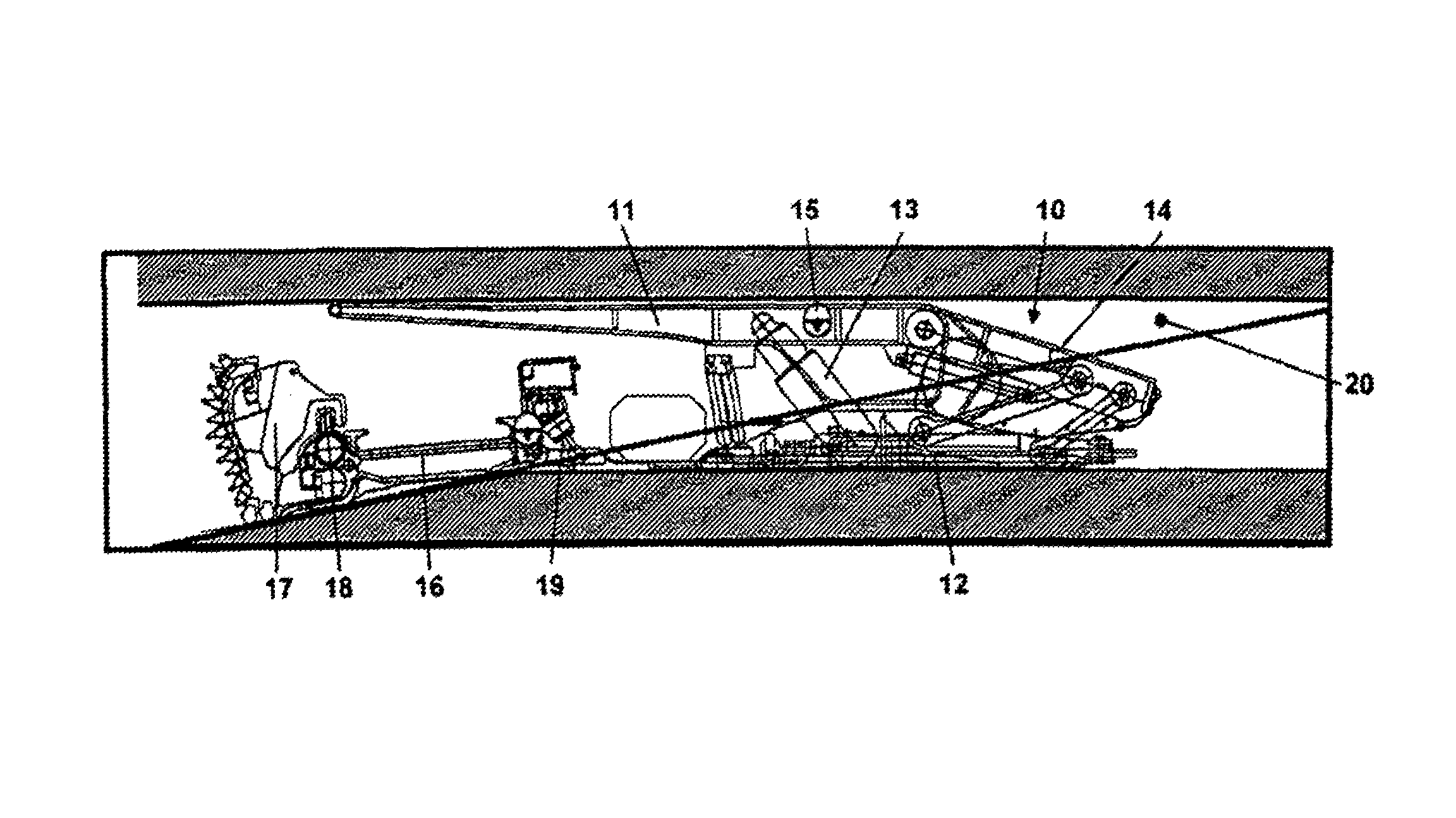

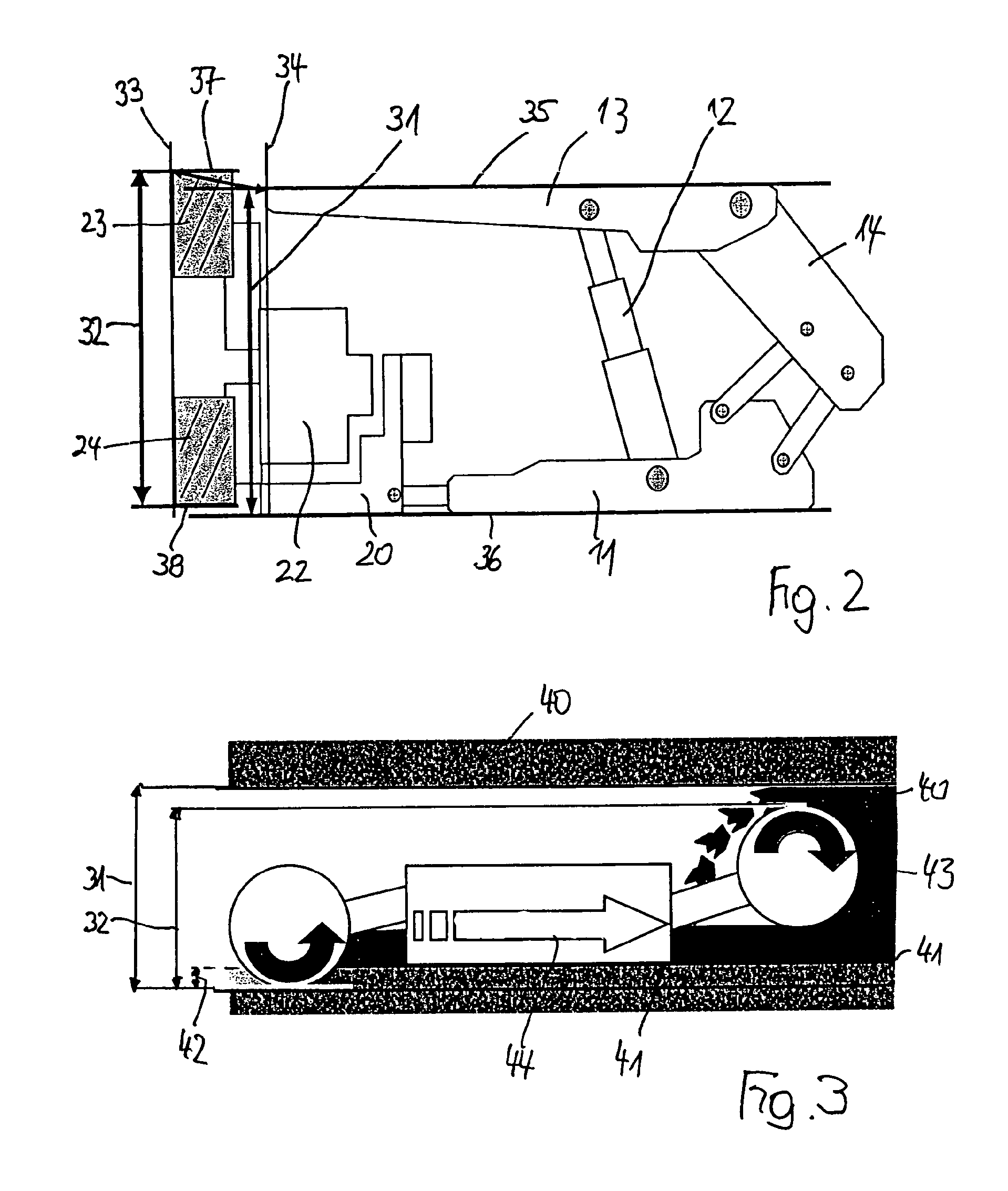

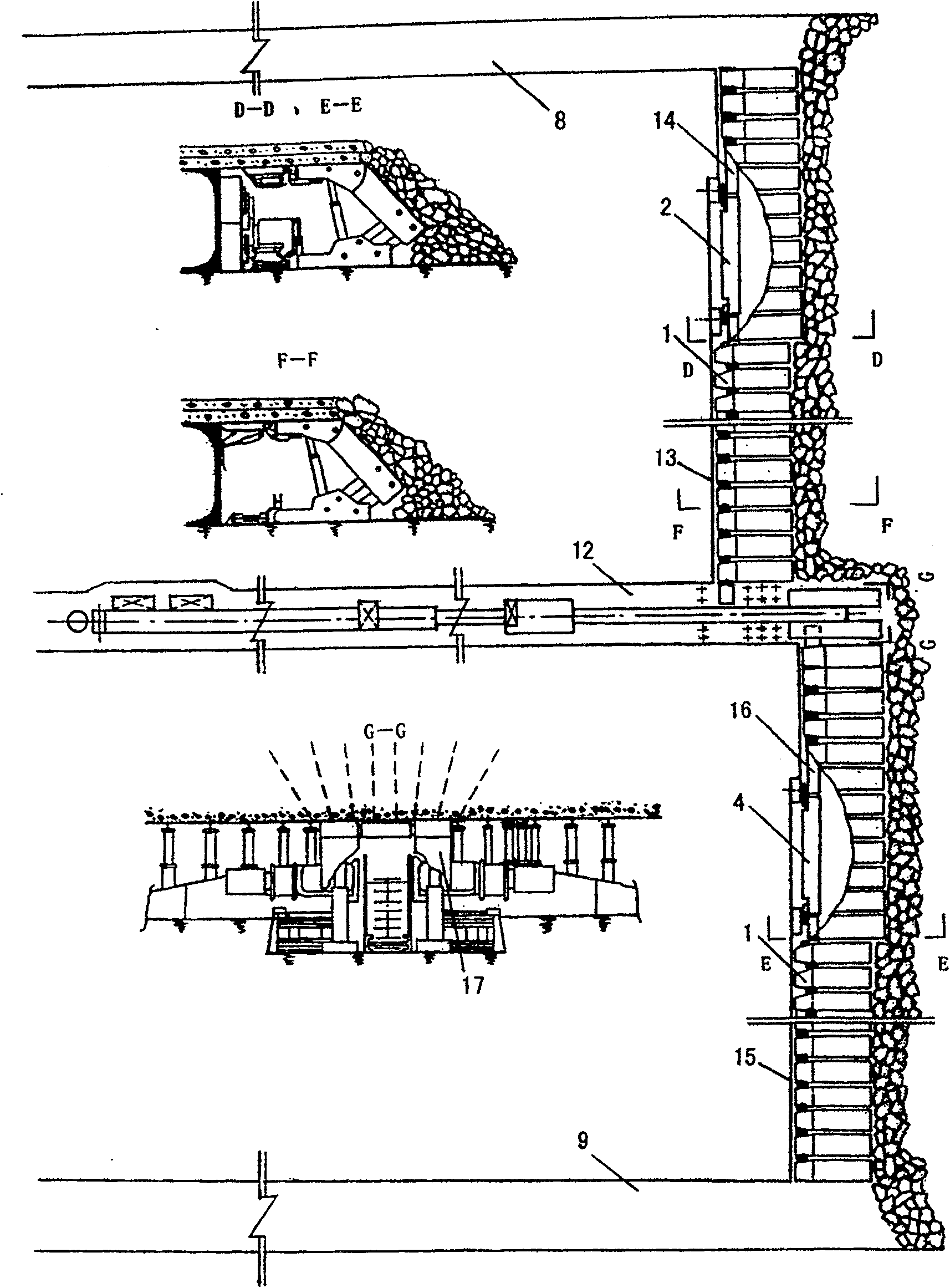

Method and device for monitoring a cutting extraction machine

The invention relates to a method and to a device for monitoring the track of a cutting extraction machine (1), which is used in particular in coal mining and can be displaced during longwall mining in a longwall face equipped with face conveyors (9) and longwall advancing (12, 13) along the face (10). The underlying object of the invention is to create a method and a device which make it possible, despite extremely poor visibility conditions, for example in the track of the extraction machine, to detect present obstacles in the form of lowered canopies or drooping folding canopies, sliding canopies or other additions to the lining or overloads of the conveyor in order to take measures for avoiding interruptions in the operation in a timely manner. In order to achieve this object, according to the invention the track of the extraction machine (1) is scanned using a radar measuring device (14) associated with the extraction machine (1) and upon detection of an obstacle an alarm is triggered and / or an invention in the controller of the extraction machine (1) takes place.

Owner:EICKHOFF BERGBAUTECHN

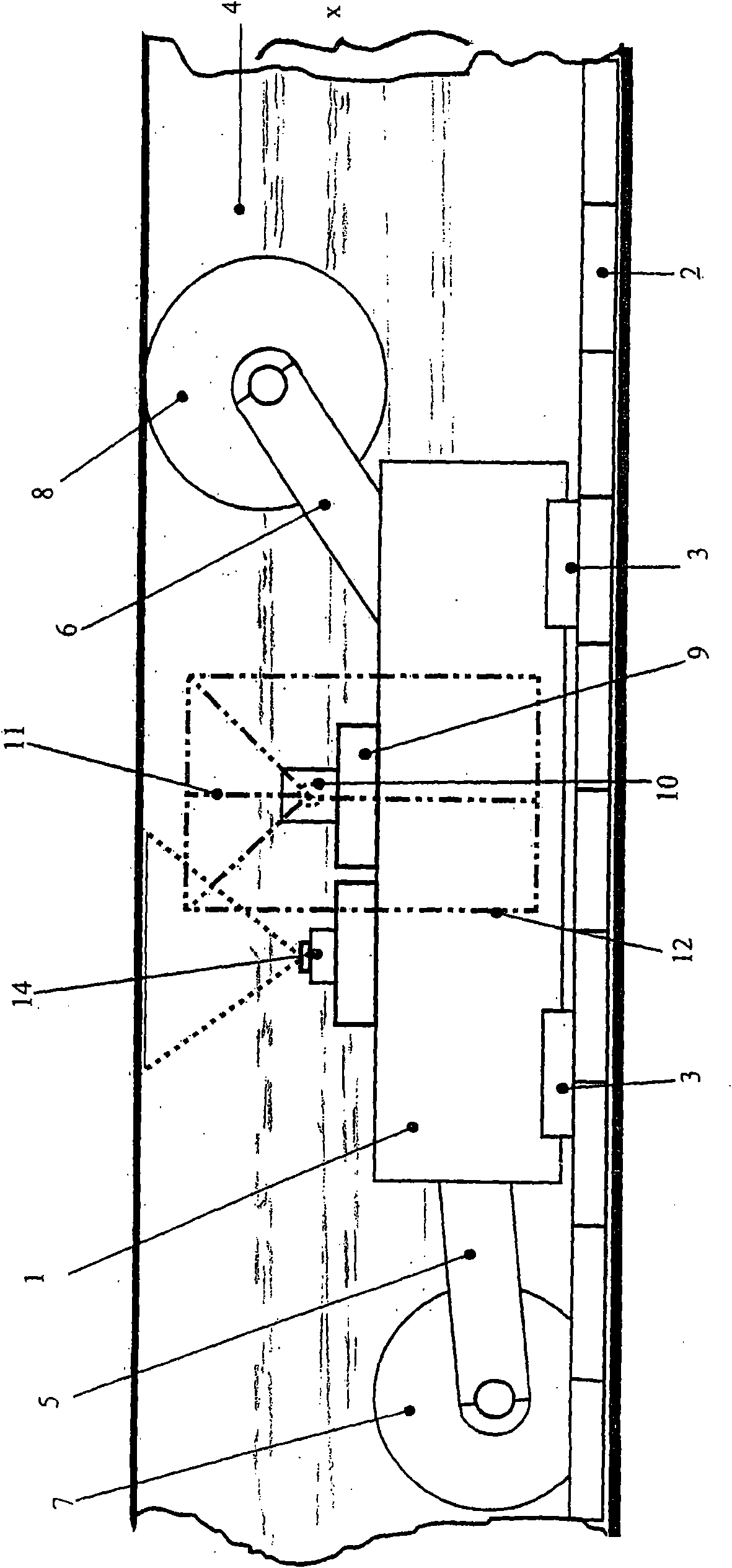

Method for controlling a cutting extraction machine

The invention relates to a method for controlling a cutting extraction machine that can be displaced along a coal face in longwall mining, wherein the radiated heat of the working face (4) newly exposed by the extraction machine is observed by means of an infrared camera (10), and control data for the subsequent extraction travel is generated using said observation. In order to make said method error-free and better suited for practical application, the invention proposes that the observation of the radiated heat is done perpendicular to the working face (4) at a minimum distance from the cutting tools of the extraction machine, and that a guiding layer package (X) having a characteristic sequence of boundaries between layers of differing heat conductivity is determined, and that the course of said guide layer package (X) relative to the boundaries of the face is determined at the end of each extraction travel using the heat images, and that the control data for the next extraction travel of the extraction machine is generated using said course of the guide layer package.

Owner:EICKHOFF BERGBAUTECHN

Method for automatically producing a defined face opening in plow operations in coal mining

A method for automatically producing a defined face opening in a longwall mining operation in underground coal mining, using a face conveyor, at least one plow, as an extraction machine, guided on the face conveyor, and respective hydraulic shield support frames having, as main components, a floor skid arrangement, a gob shield, a top canopy and support connection rods. Inclination sensors are disposed on at least three of the floor skid arrangements, the gob shield, the support connection rods and a gob-side region of the top canopy. From the sensors, an inclination relative to a horizontal is ascertained. From the inclination data, by comparison with base data defining a geometrical orientation of the components and movement thereof during a stepping process, a respective shield height of the shield support frames perpendicular to a bed thereof is calculated and is compared with a machine-dependent fixed cutting height of the plow to establish if deviations exist. By means of a boom controller disposed between the shield support frame and the face conveyor, a height control of the plow is initiated to correct established deviations and is maintained, in the sense of a location-synchronized evaluation, until the shield support frame, which trails the plow with a time delay, has reached the position at which the plow was located at the point in time when the height control of the plow was initiated.

Owner:RAG AG

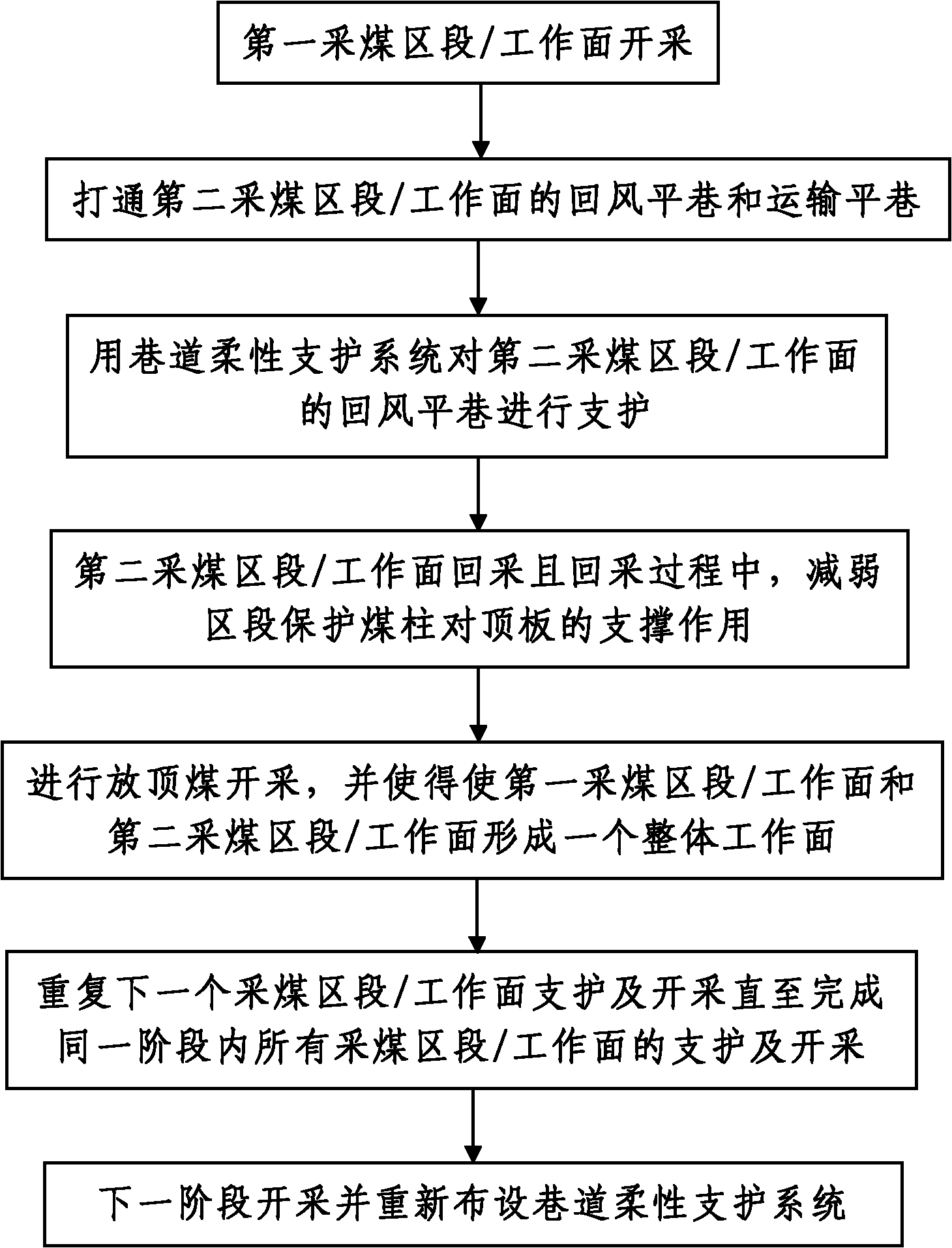

Integral high-strength flexible support method of roadway at large-inclined angle coal-seam longwall mining section

InactiveCN102094660AReasonable designSimple methodProps/chocksAnchoring boltsLongwall miningSupporting system

The invention discloses an integral high-strength flexible support method of a roadway at a large-inclined angle coal-seam longwall mining section. The method comprises the following steps: 1. mining a first coal-mining section / working face; 2. supporting and mining a second coal-mining section / working face: opening up a return-air driftway and a haulage driftway, supporting the return-air driftway by a flexible roadway support system, stoping the second coal-mining section / working face and weakening the supporting action of protective coal pillars at the section on a roof, and carrying out top coal caving mining so that the two coal-mining sections / working faces form an integral working face; 3. supporting and mining next coal-mining section / working face; 4. repeatedly supporting and mining until all the coal-mining sections / working faces are completely supported and mined at the same stage; and 5. mining for next stage and rearranging the flexible roadway support system. The flexible support method has the advantages of reasonable design and low cost, and the flexible roadway support system has a good application effect, thus solving the instability problem of a 'roof-support-floor' system in an upper area of the working face during the large-inclined angle coal-seam mining process.

Owner:XIAN UNIV OF SCI & TECH +1

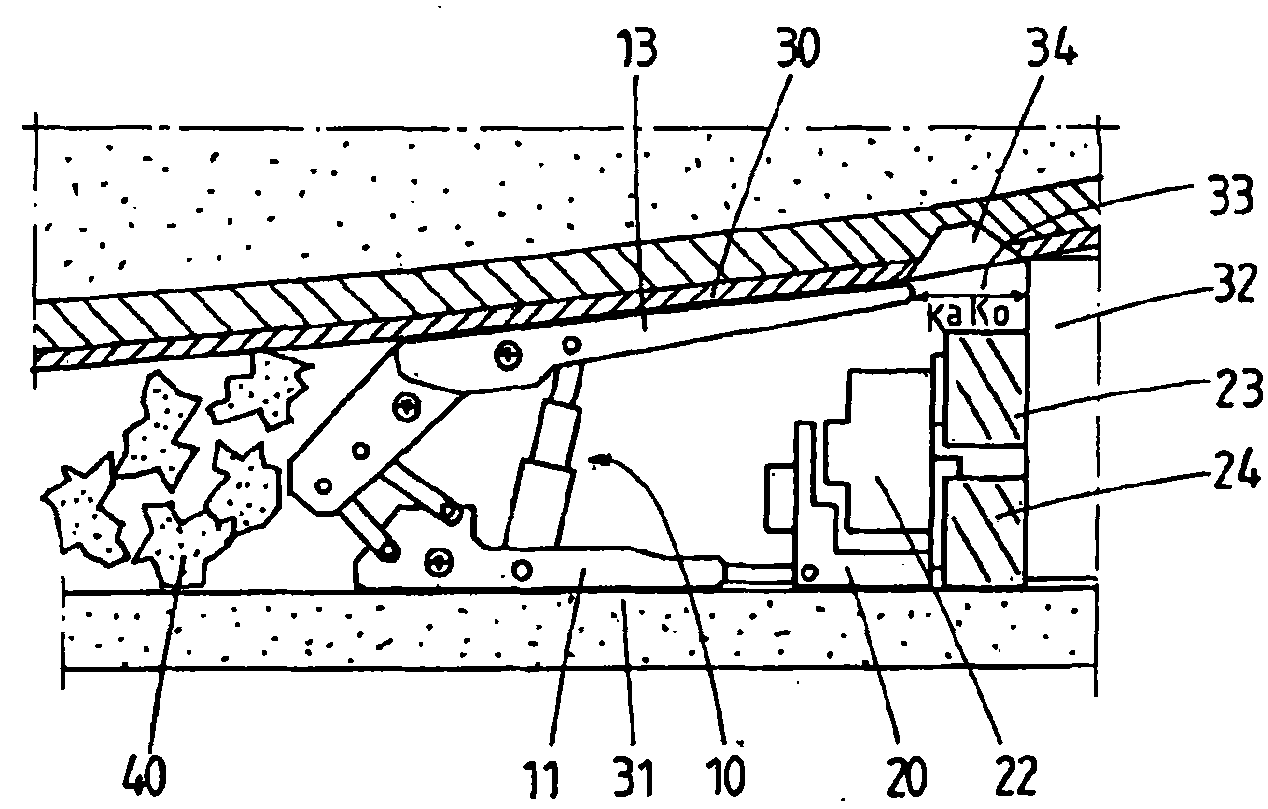

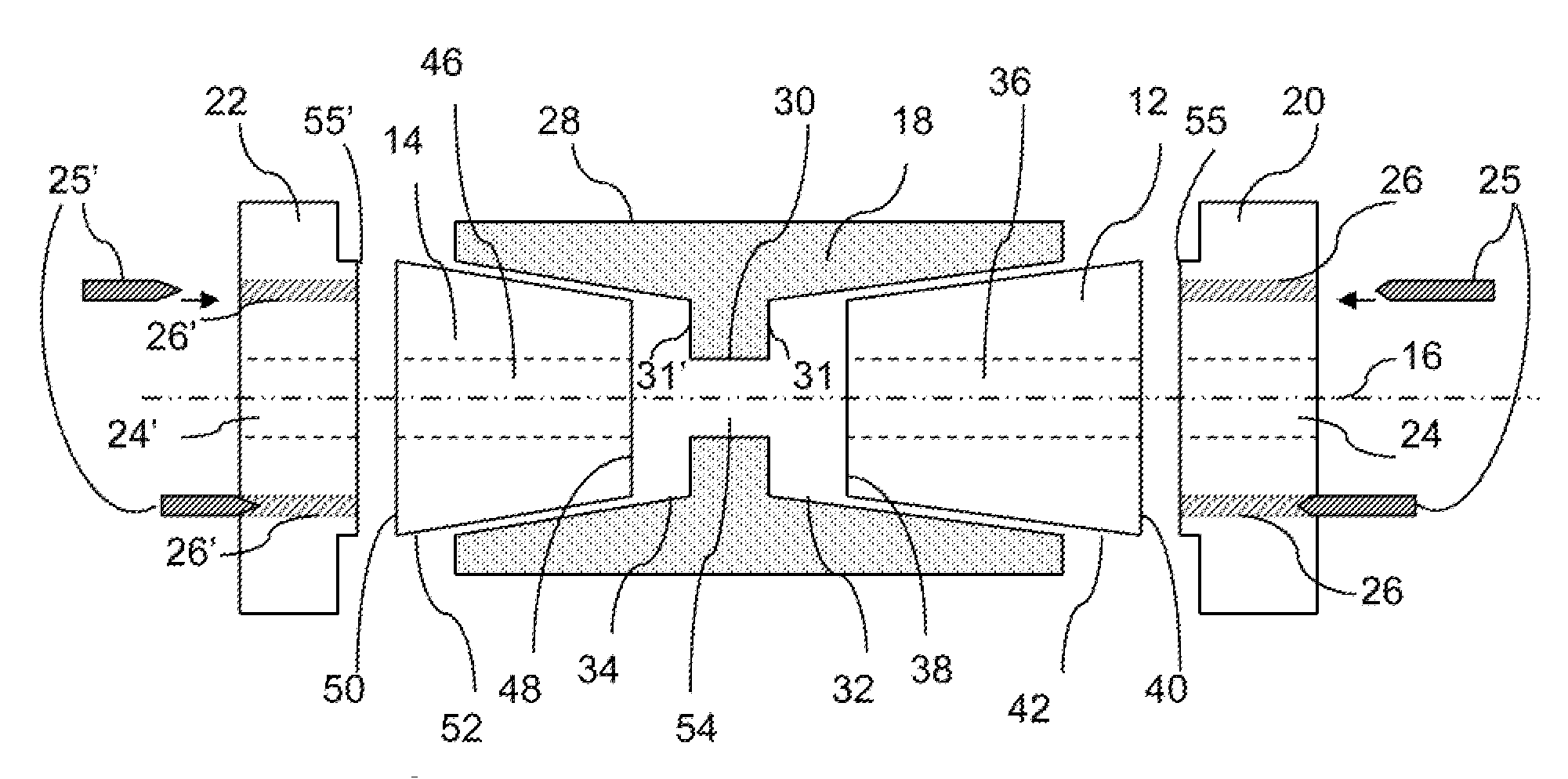

Method for the controlled maintaining of a distance between the top canopy and the coal face in longwall mining operations

ActiveUS8567870B2Limit CaCoWidth of cutUnderground miningSlitting machinesLongwall miningBraced frame

A method for maintaining, in a controlled manner, a top canopy / coal-face distance expedient for rock mechanics, in longwall mining operations in underground coal mining, using a face conveyor, at least one extraction machine, and a hydraulic shield support frame. Inclination sensors are disposed on at least three of the four main components of the shield support frame, including floor skid, gob shield, support connection rods and gob-side area of the top canopy. An inclination of the top canopy and floor skid are ascertained via the sensors. From the ascertained inclination data, in a computer, the effects on a top canopy / coal face distance are determined when changes in an angle of inclination of the top canopy occur. An automatic adjustment of decisive cycle parameters of the shield support frame are carried out, wherein the work cycle comprises retraction, advancement and setting processes.

Owner:BEIJING CCRI TIANMA AUTOMATION TECH CO LTD +1

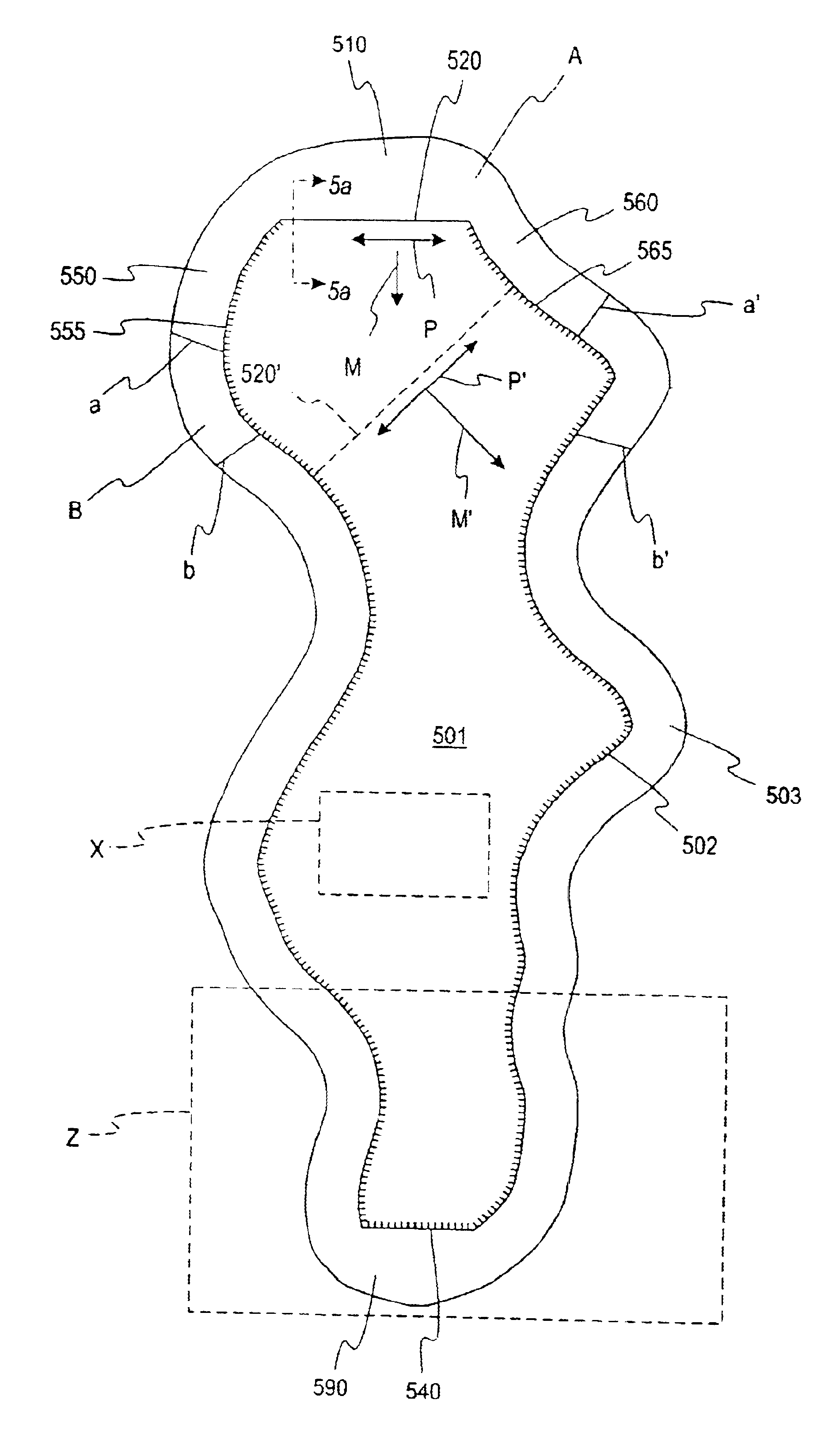

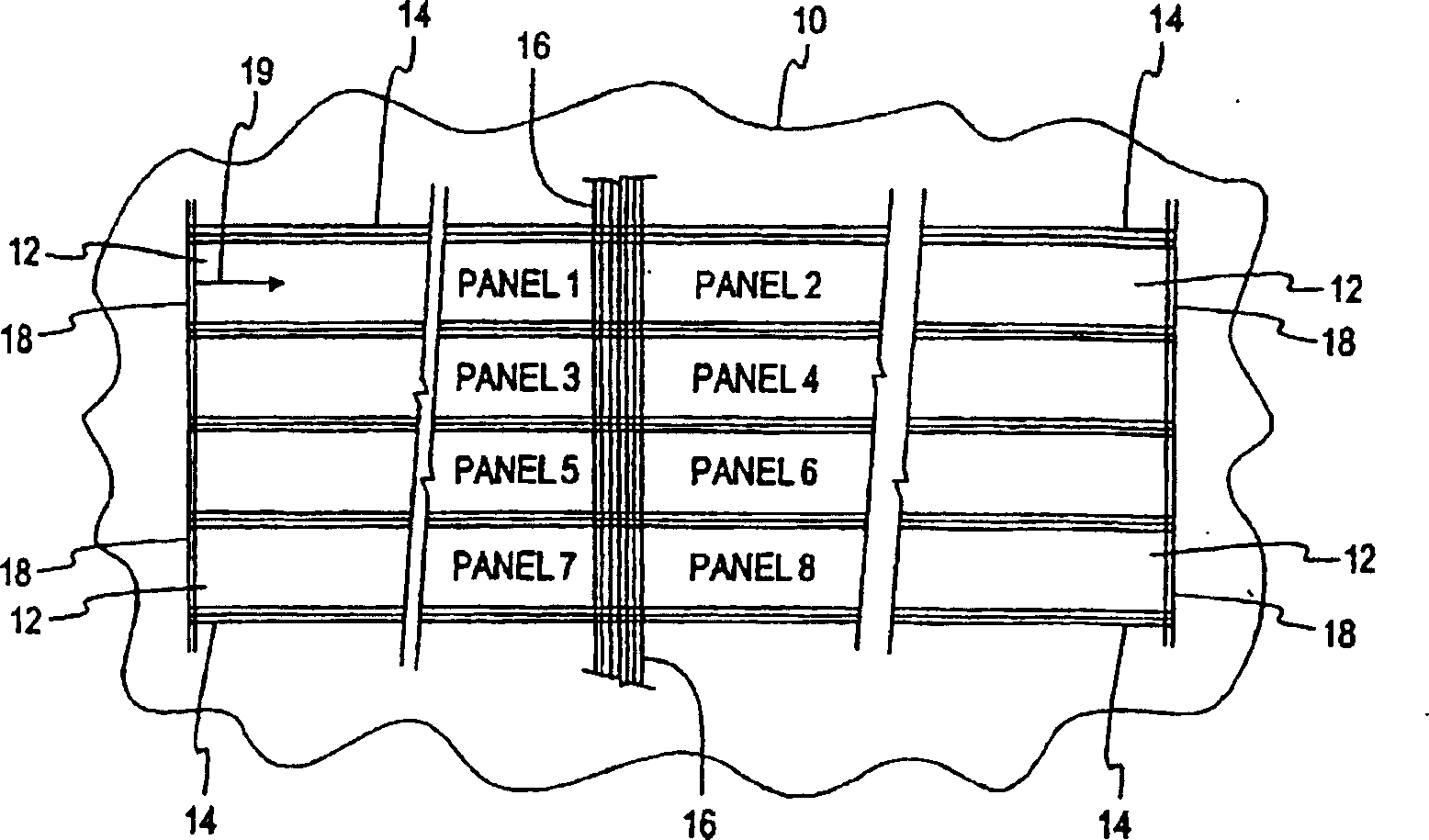

Mining system

InactiveUS6913321B2Easy accessEasy to insertDisloding machinesUnderground miningLongwall miningEngineering

A method for extracting mineral deposits in a mineral reserve, a portion being accessible from a sloping surface and the remaining portion being inaccessible, is disclosed. The sloping surface is mined to create a bench and highwall for providing access to the mineral reserve around the accessible portion. Then, a surface is formed in the highwall to create an insertion highwall between an endwall extending from the insertion highwall and the inaccessible portion of the mineral reserve. A starter entry is created for cutting into the mineral reserve across the entire length of the insertion highwall from the endwall to the inaccessible portion of the mineral reserve. Roof supports are advanced into the starter entry with spoil added to form a starter passage from the endwall to the inaccessible portion of the mineral reserve. Shortwall or longwall mining techniques are then used to mine the mineral reserve along the starter passage. Canopies are positioned at both ends of the starter passage to seal the passage and provide ventilation of the active mining area by the introduction of air along the face of the mineral seam. A single-gate passage is formed extending from the insertion highwall adjacent the inaccessible portion of the mineral reserve to allow the continuous miner to form another opposing endwall. Mining then continues in the starter passage along the insertion highwall from the single-gate passage to the opposing endwall, thereby forming a production passage into which the roof supports are farther advanced with gob forming behind.

Owner:CLECO CORP

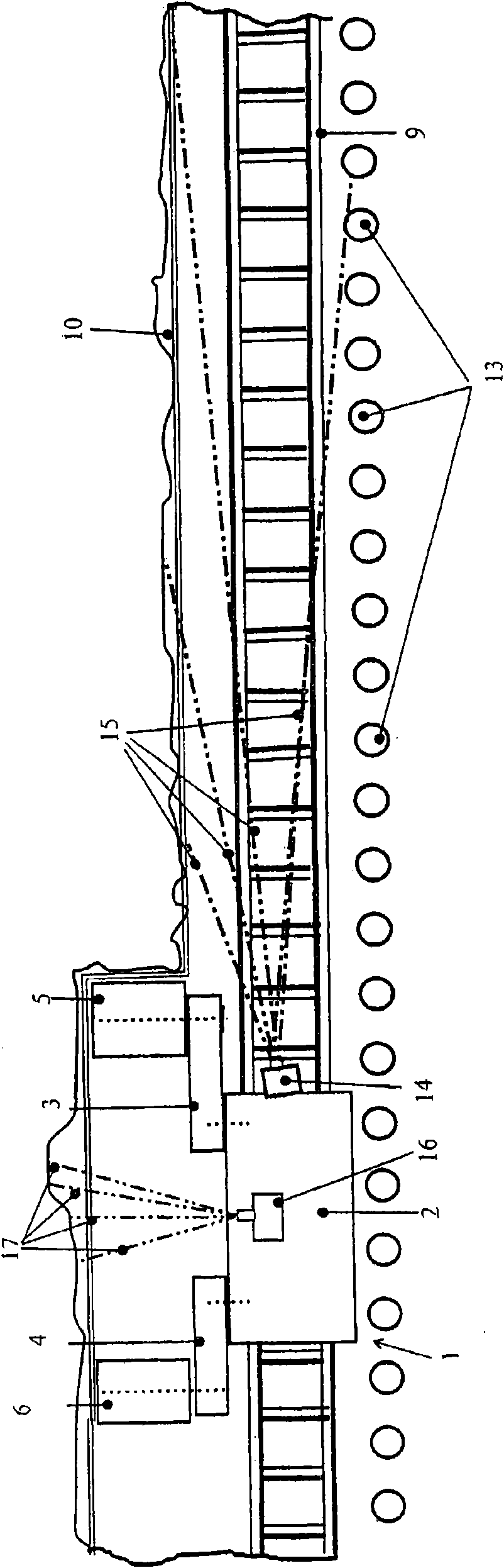

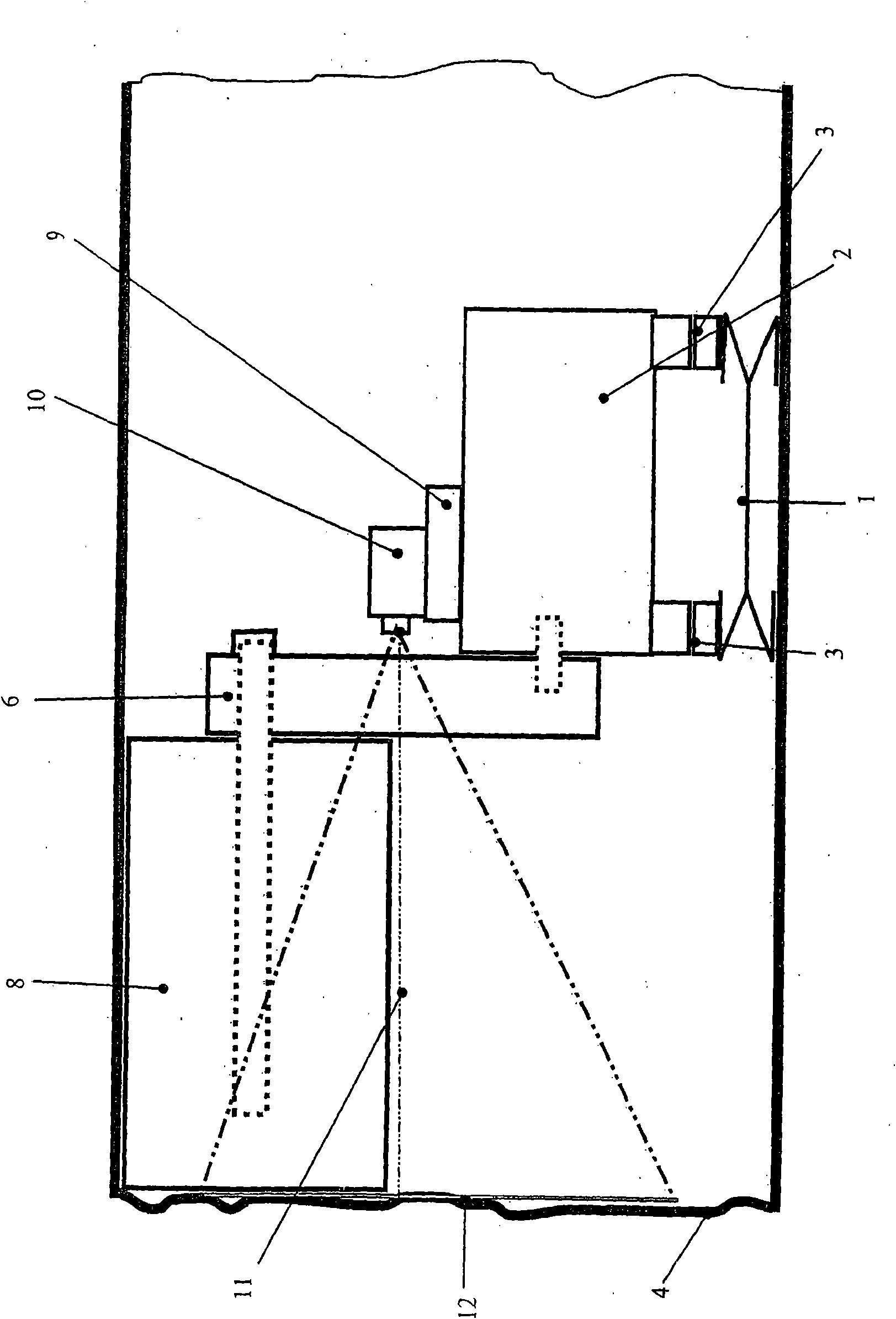

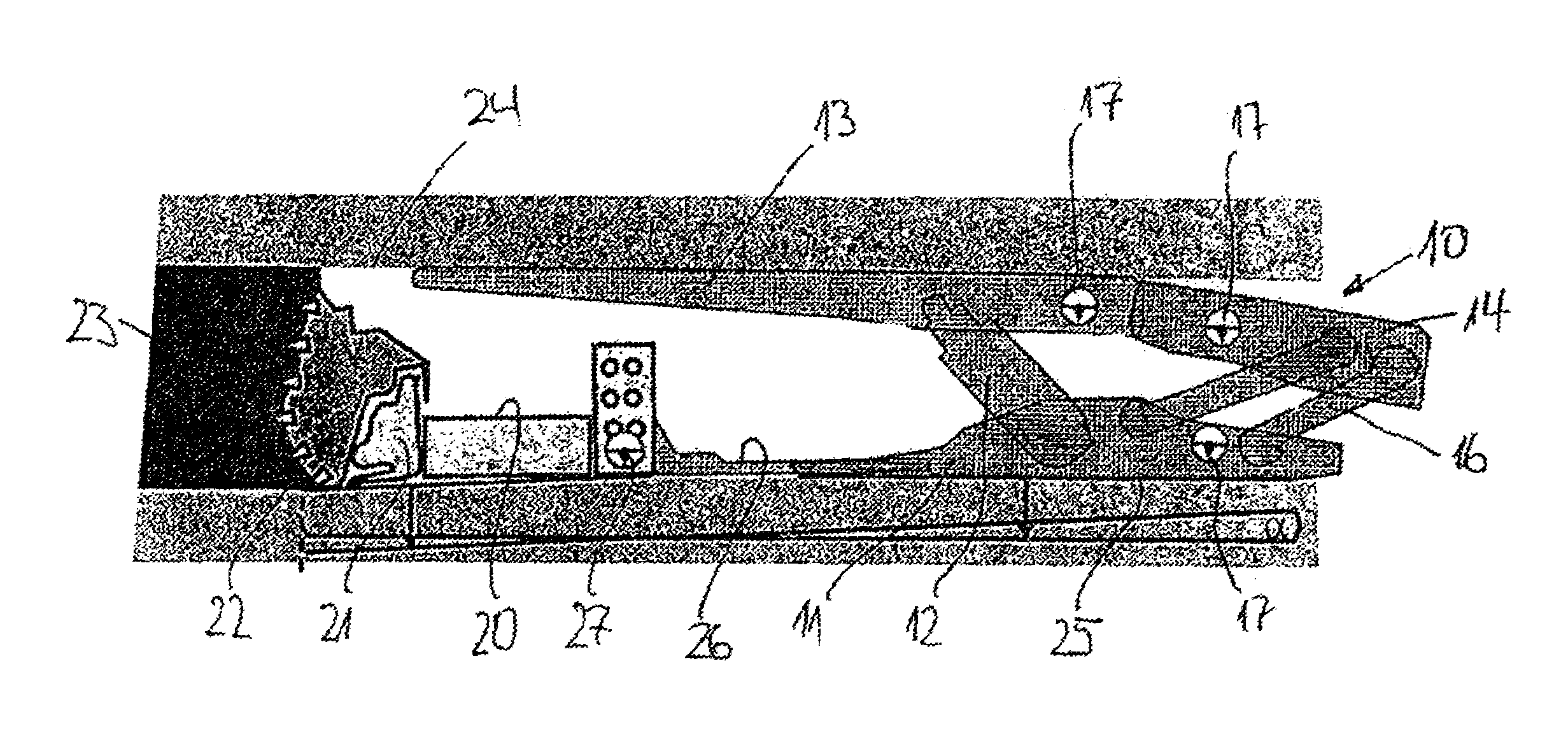

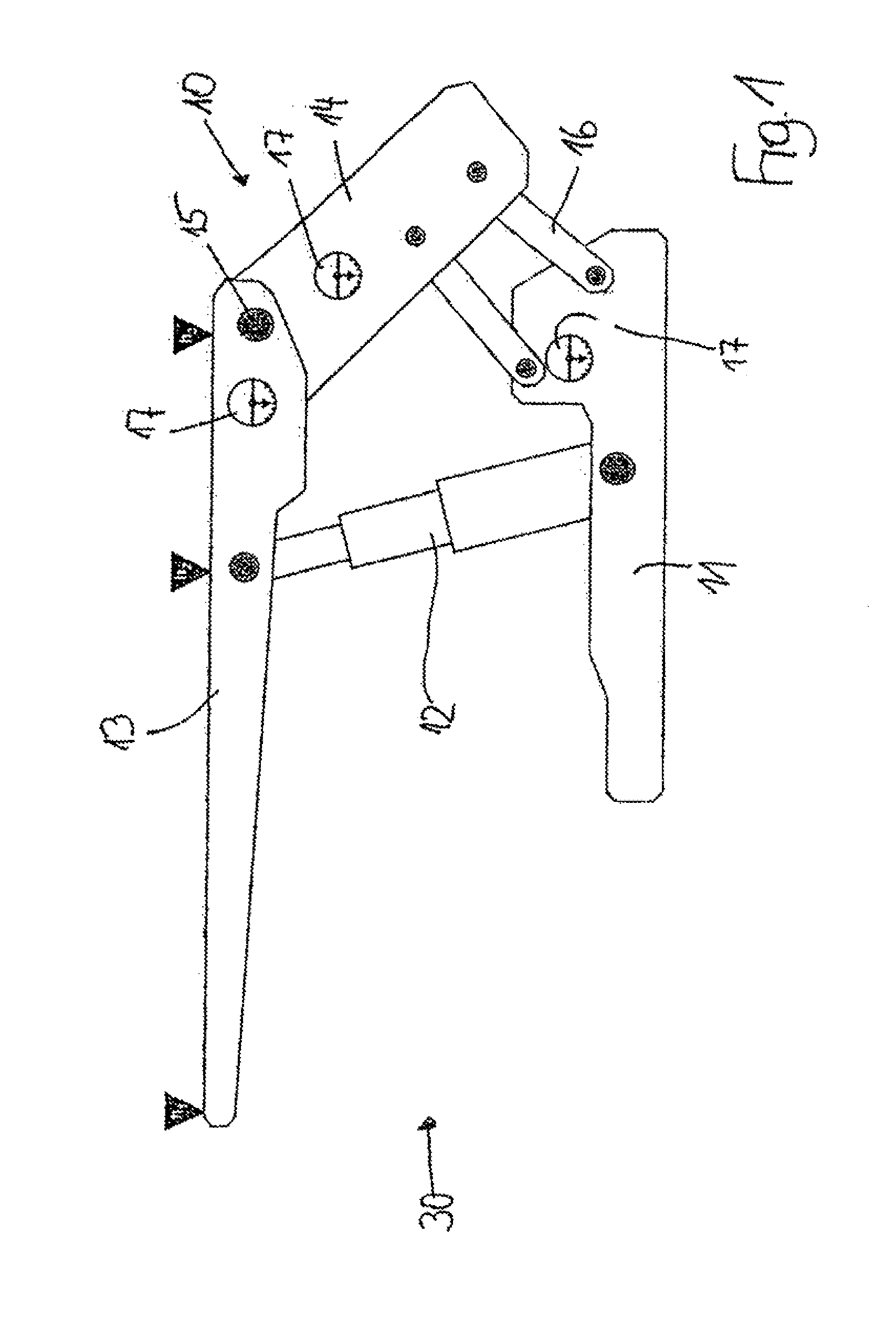

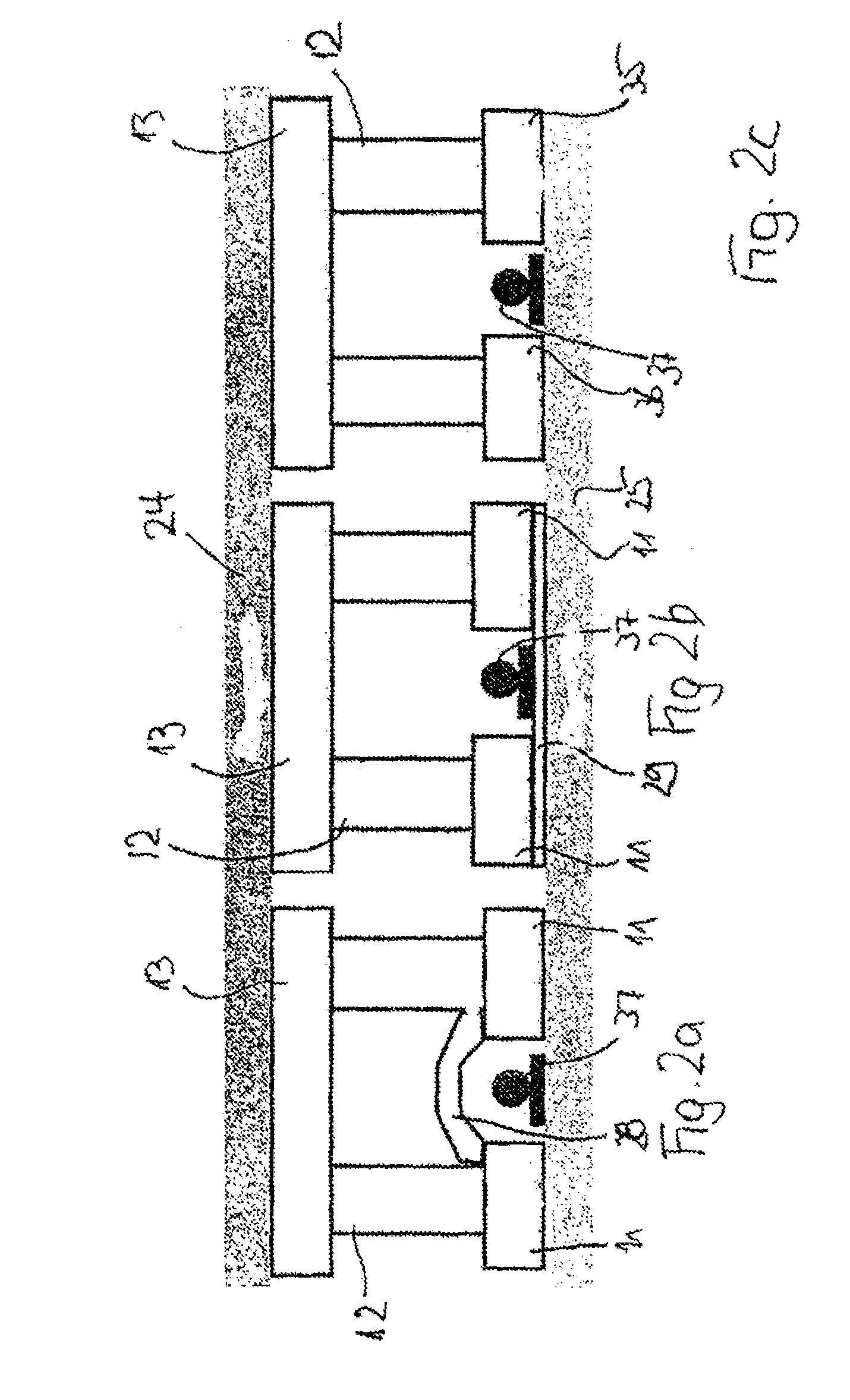

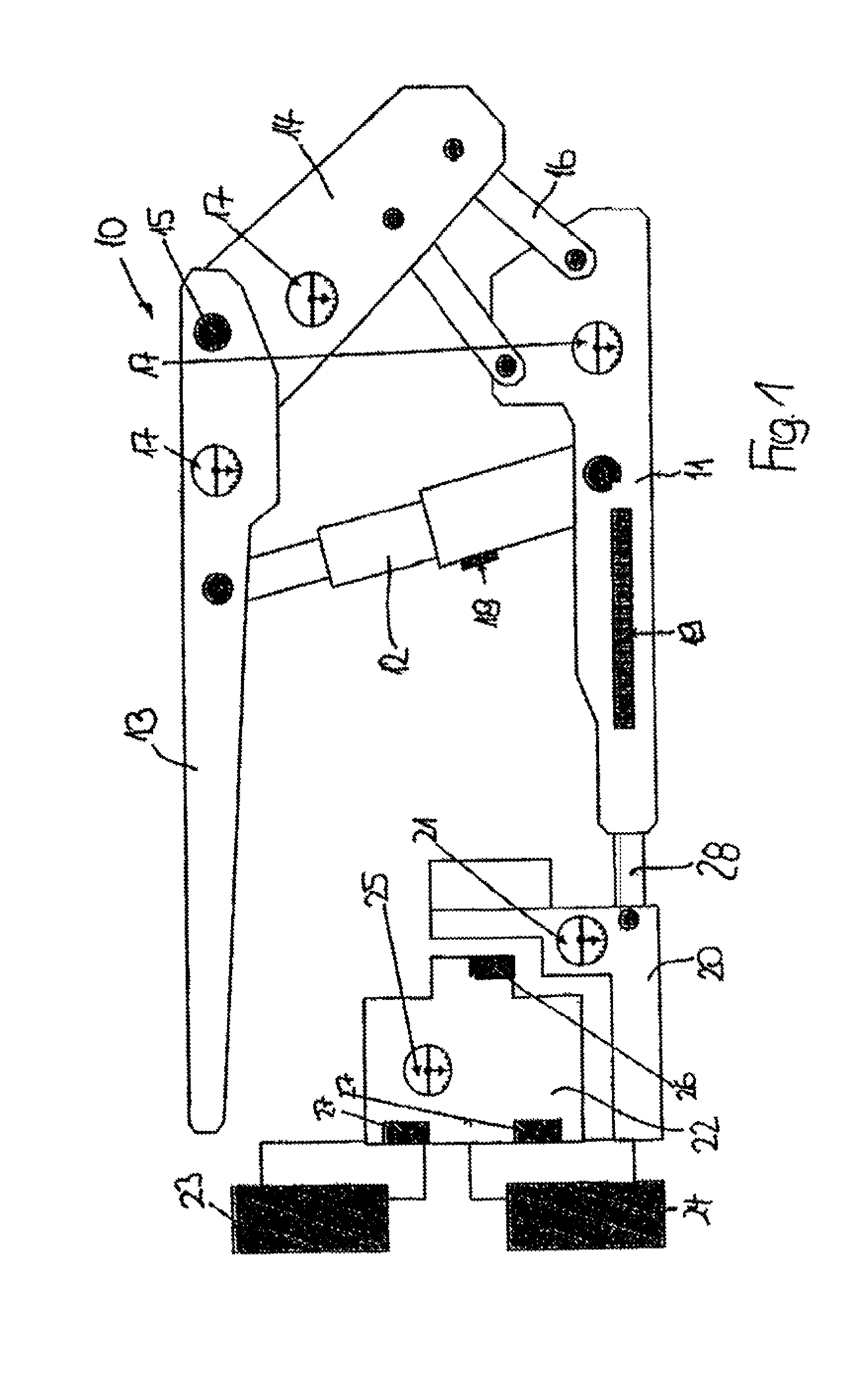

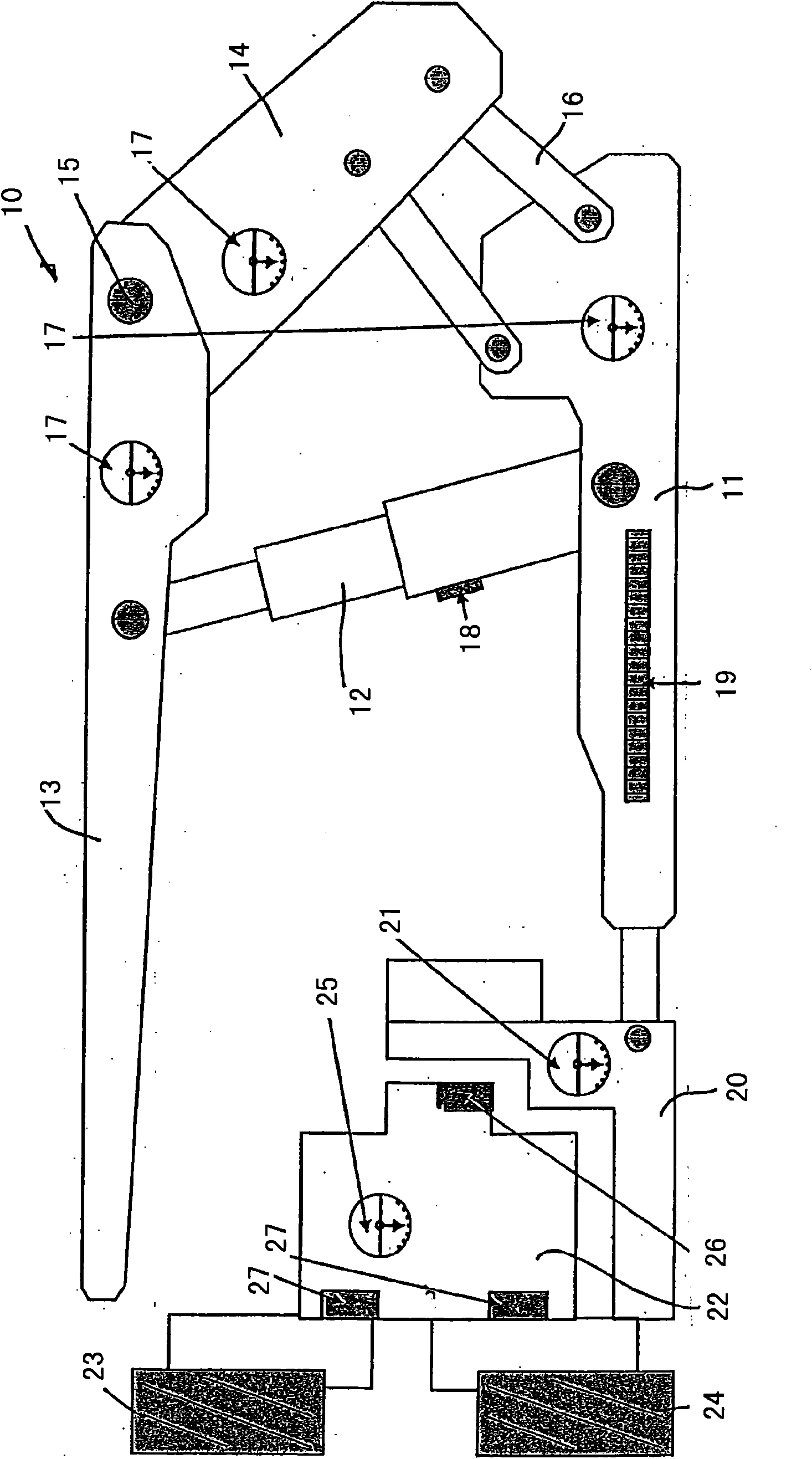

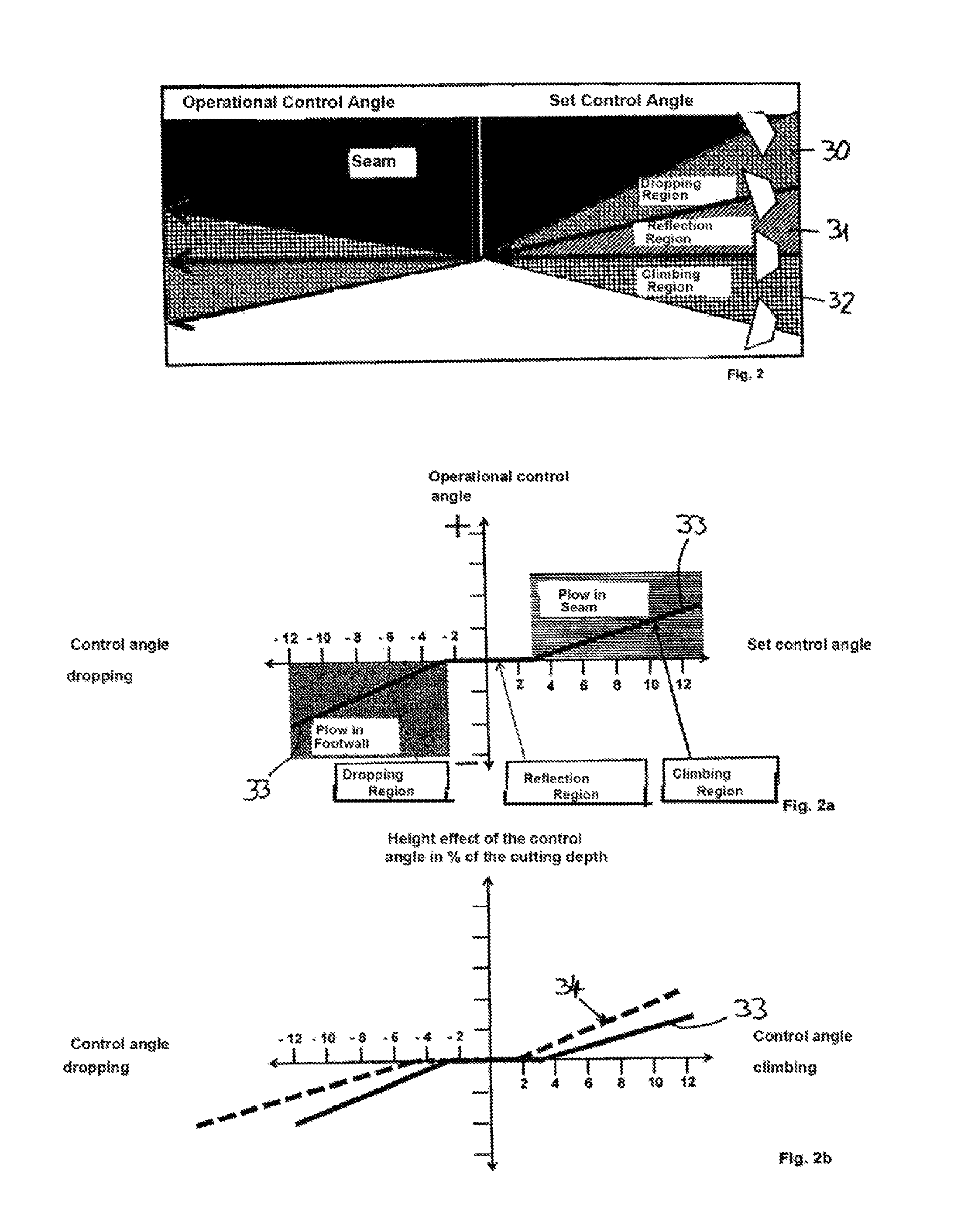

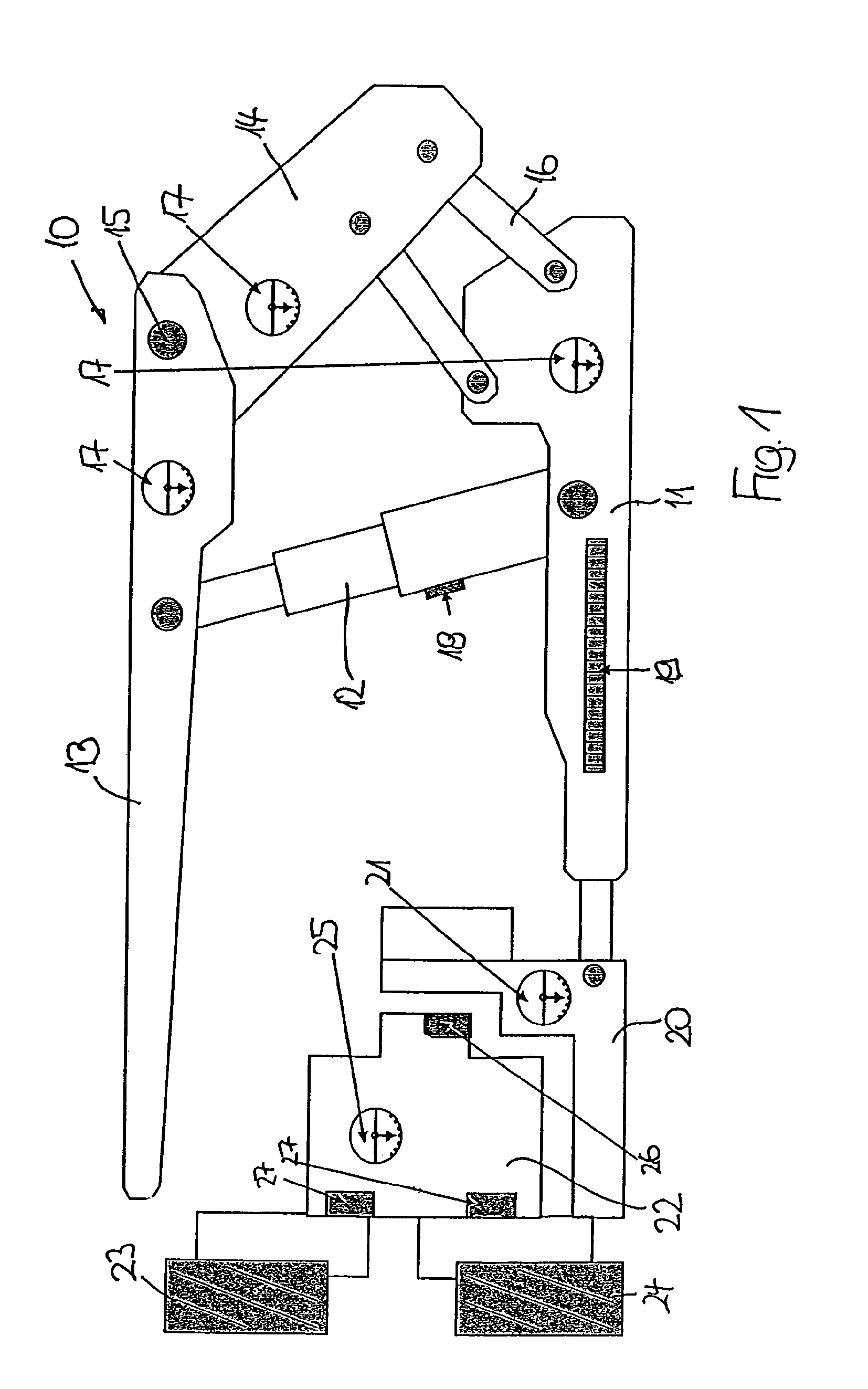

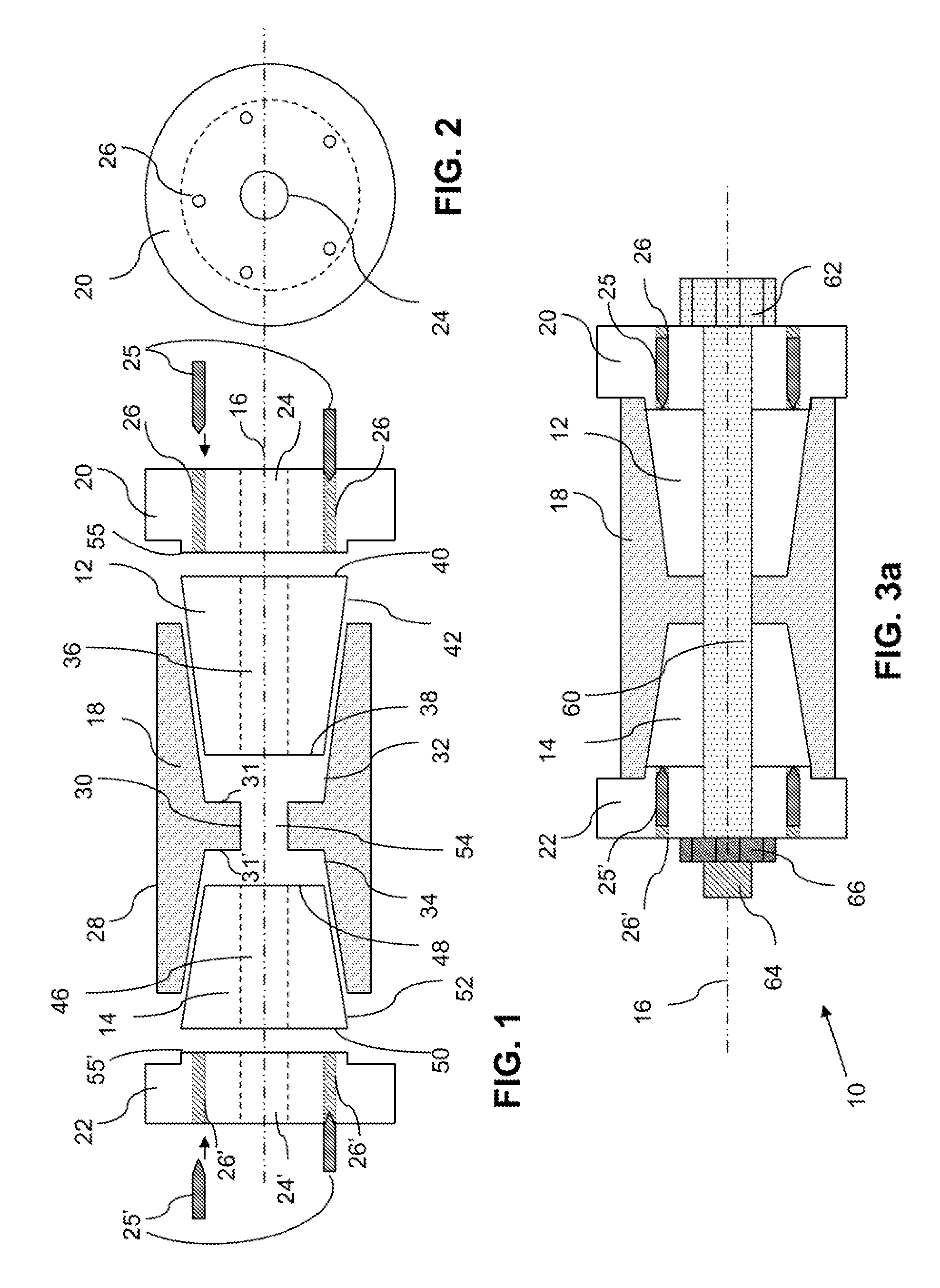

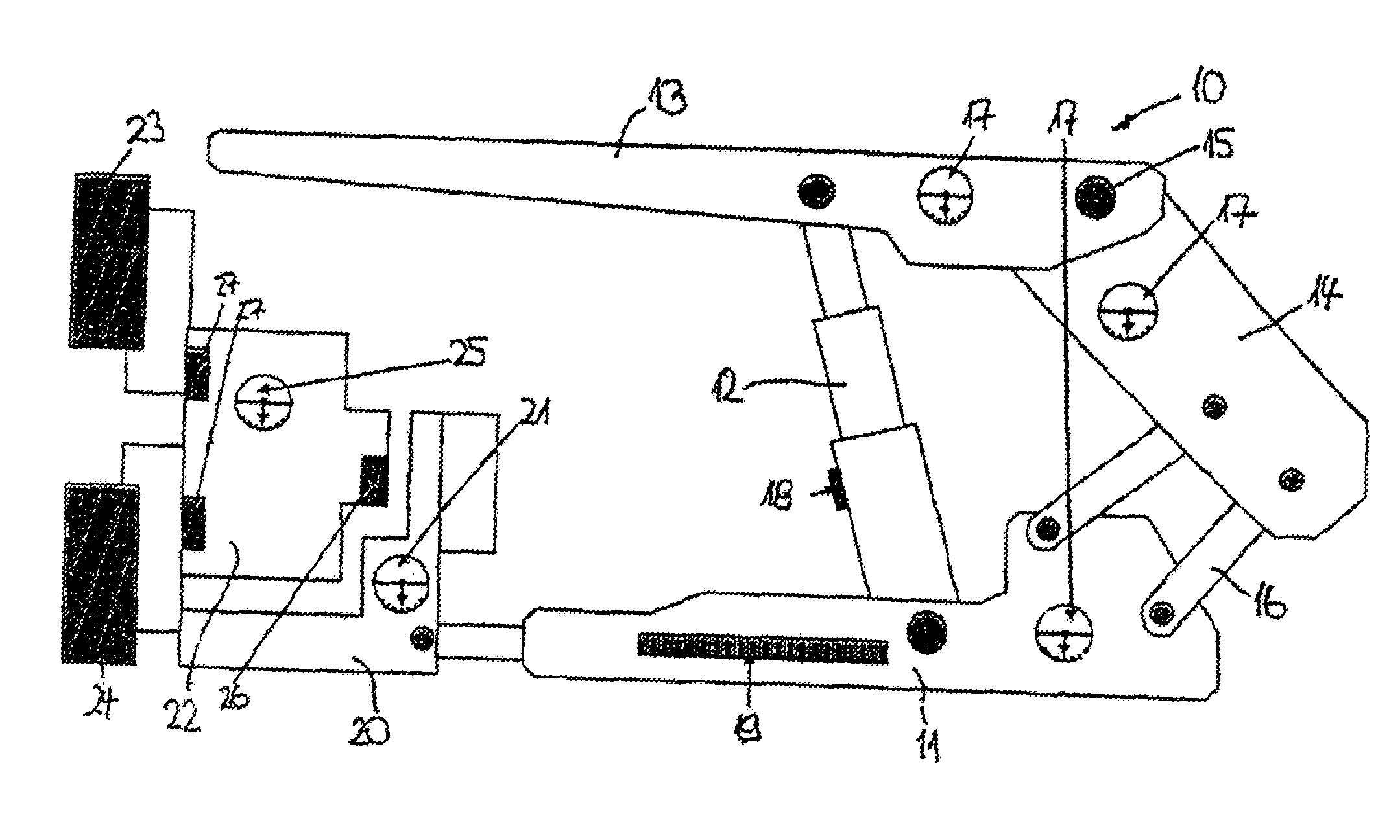

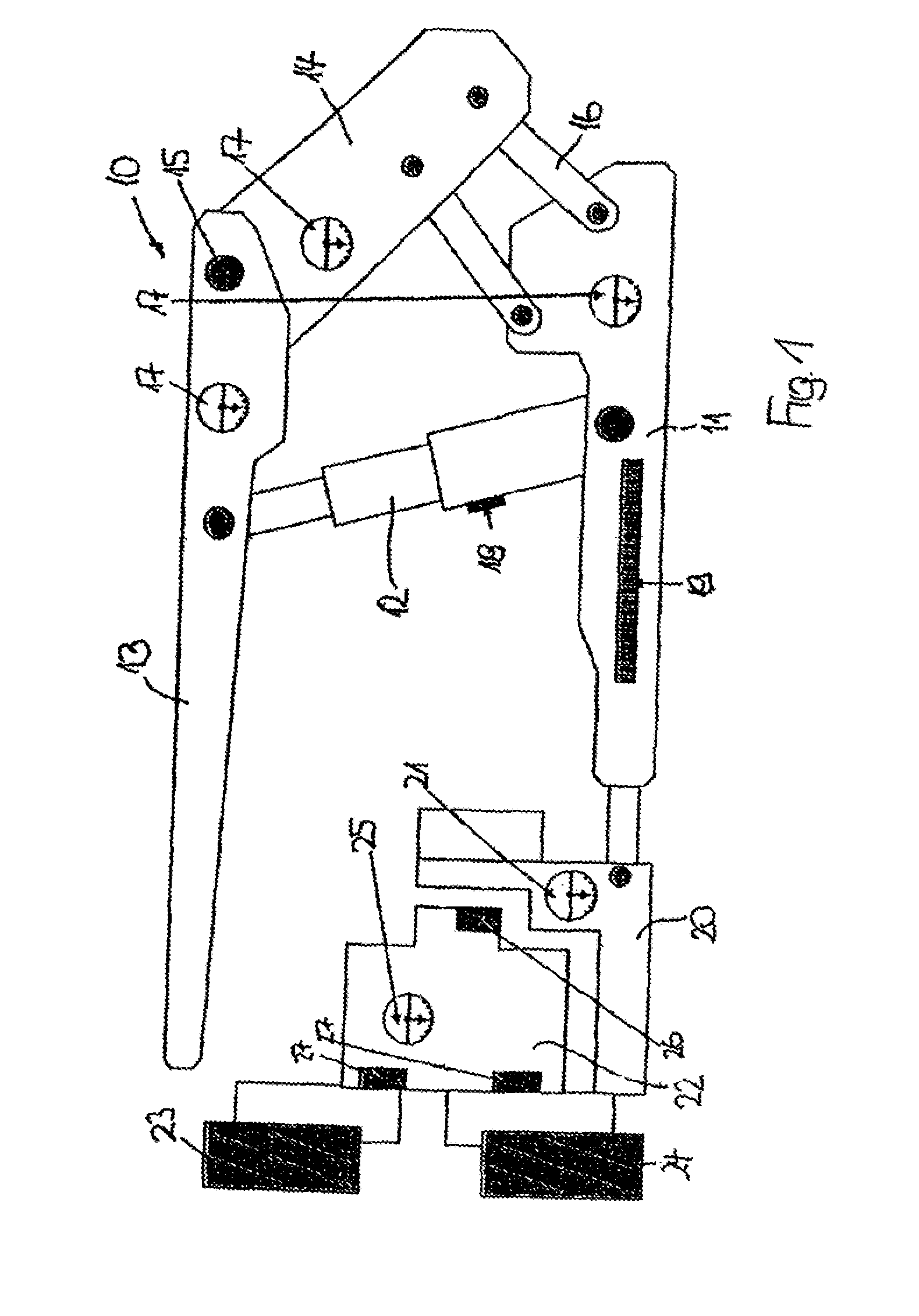

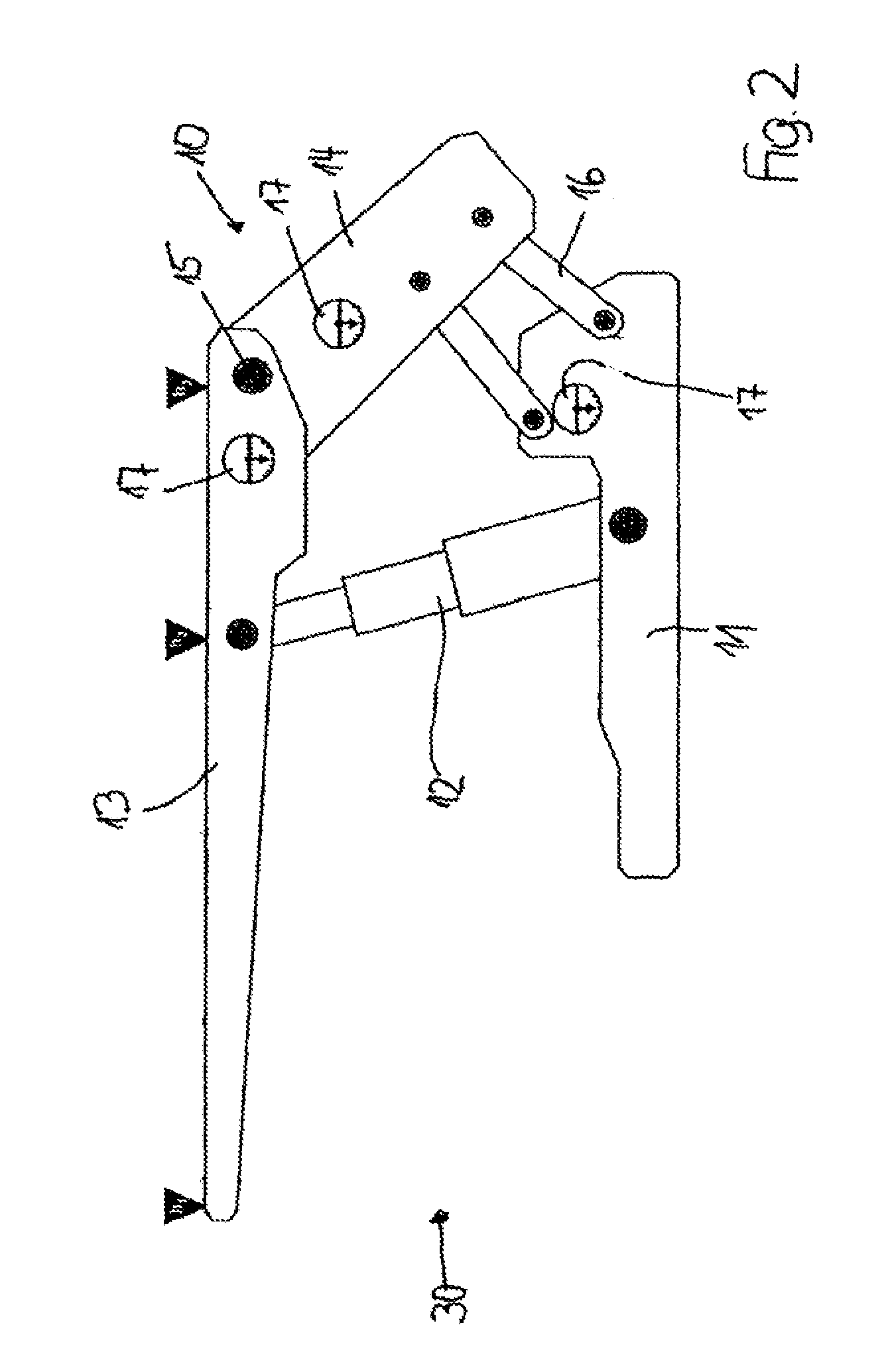

Method for controlling longwall mining operations

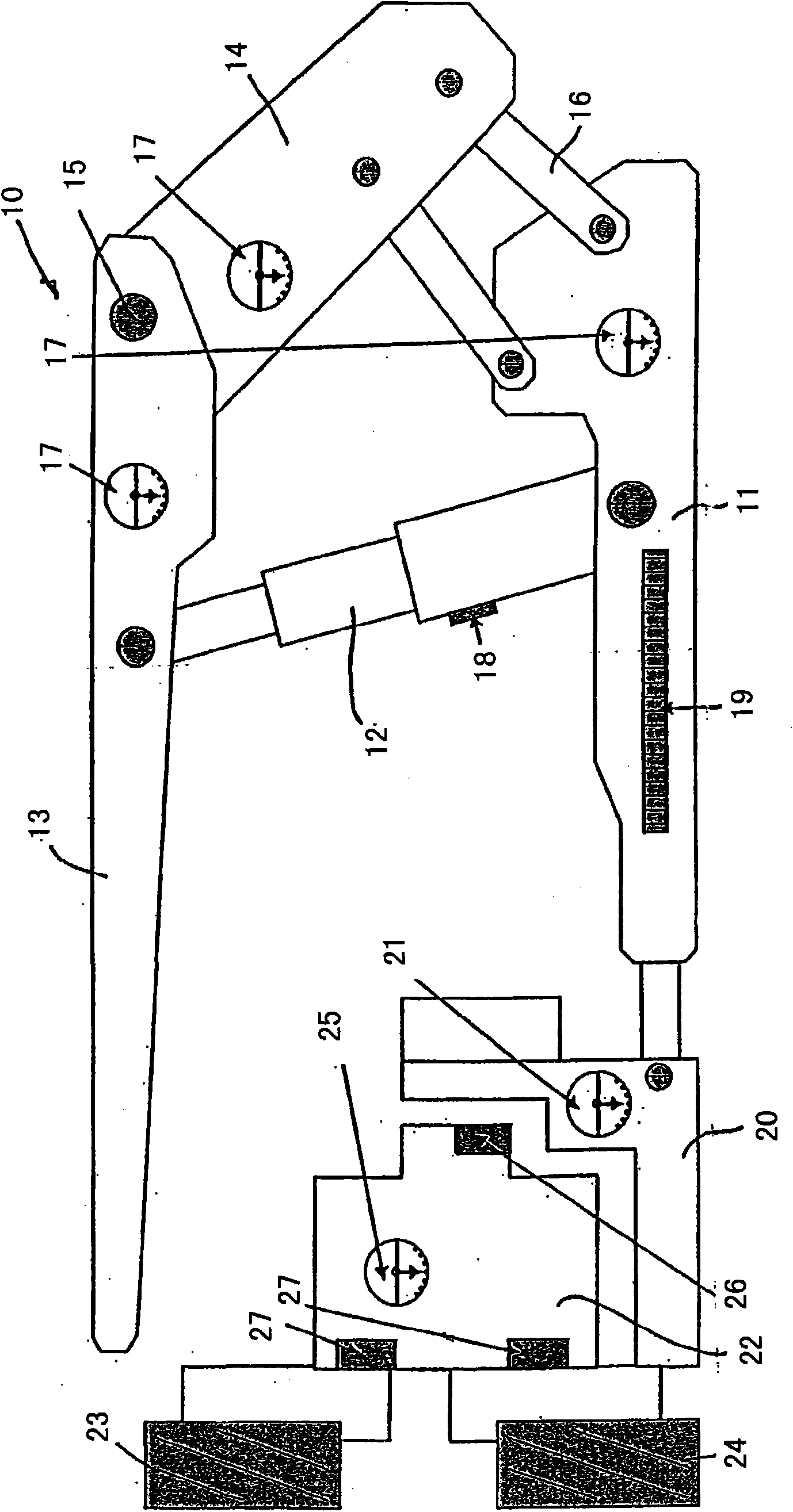

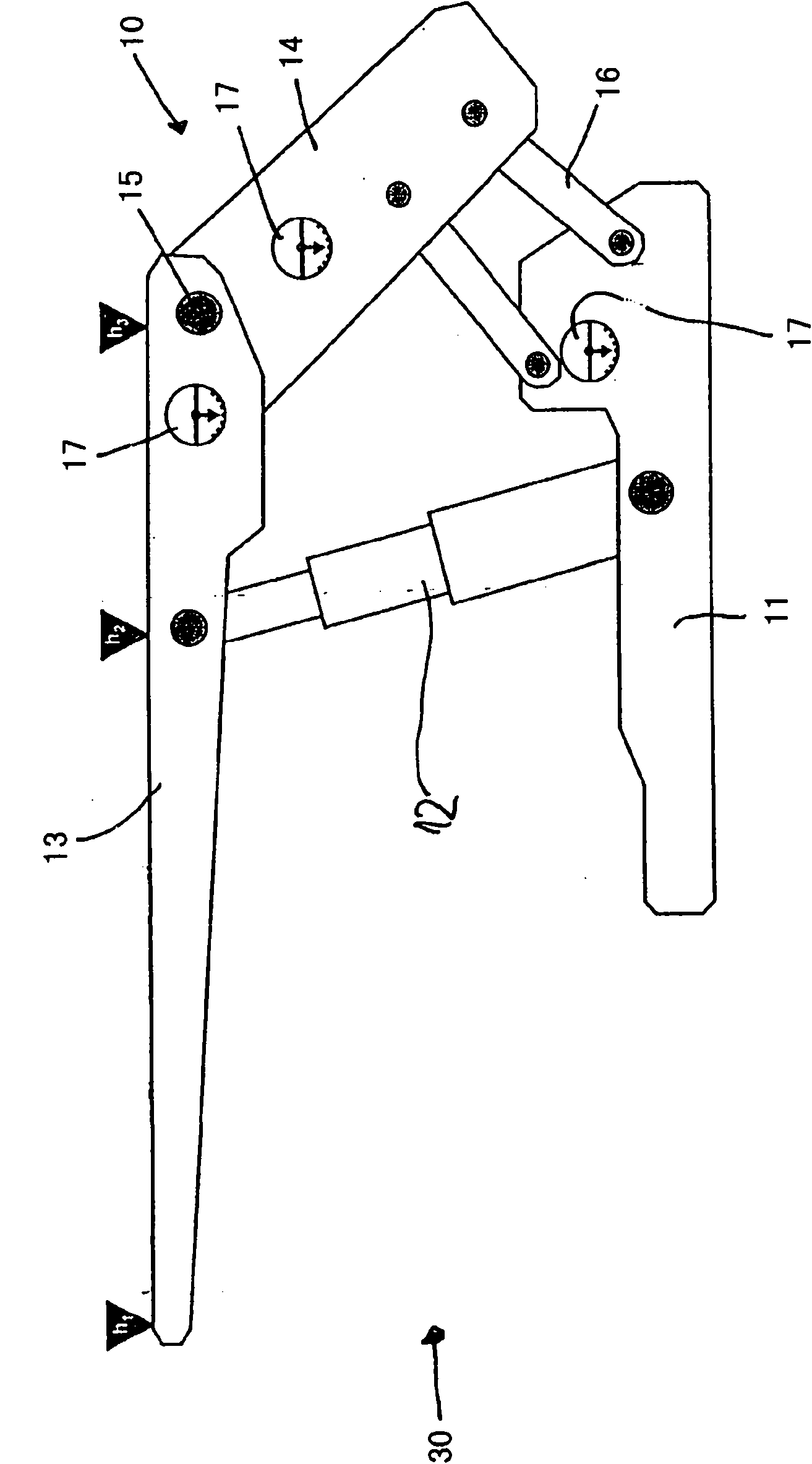

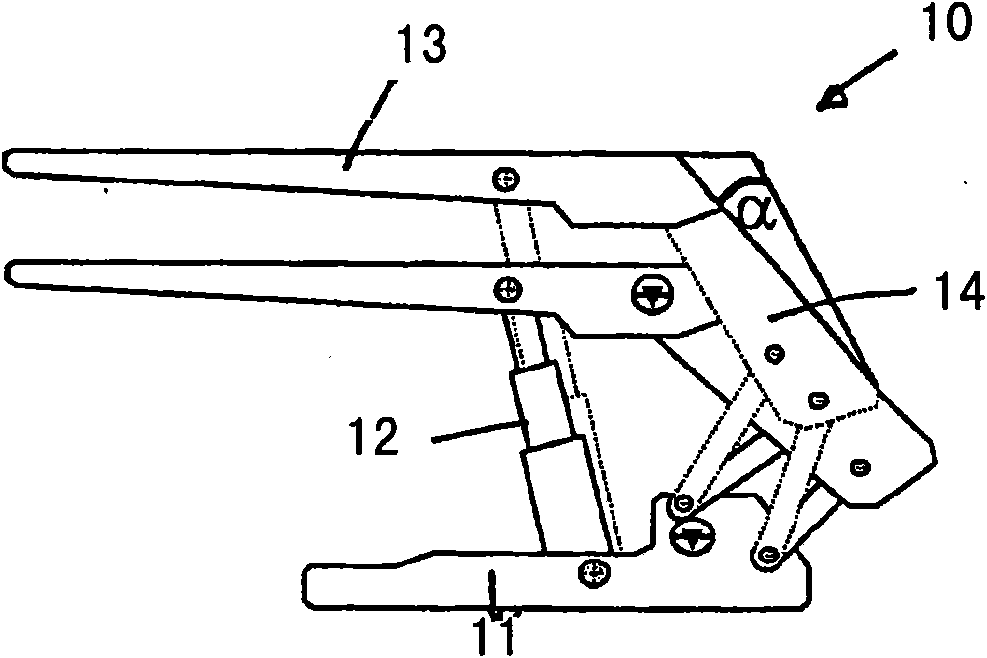

ActiveCN101970795AReduce retracted heightLocation matchSlitting machinesMine roof supportsLongwall miningEngineering

Disclosed is a method for controlling longwall coal mining operations comprising a face conveyor (20), at least one extraction machine (22), and a hydraulic shield support. In said method, the inclination of the shield components relative to the horizontal line in the direction of advance is determined by means of inclination sensors (17) mounted on at least three of the four main components of each shield support frame (10), such as the floor skid (11), the gob shield (14), the supporting connection rods (16), and in the gob zone of the top canopy (13), and the height (h1) of the shield support frame (10) perpendicular to the bed at the forward end of the top canopy (13) is calculated as a measure of the face opening (30) from the measured data in a computer unit by comparing said measured data with the basic data that is stored in the computer unit and defines the geometrical orientation of the components and the movement thereof during the advance.

Owner:BEIJING TIANMA INTELLIGENT CONTROL TECH CO LTD +1

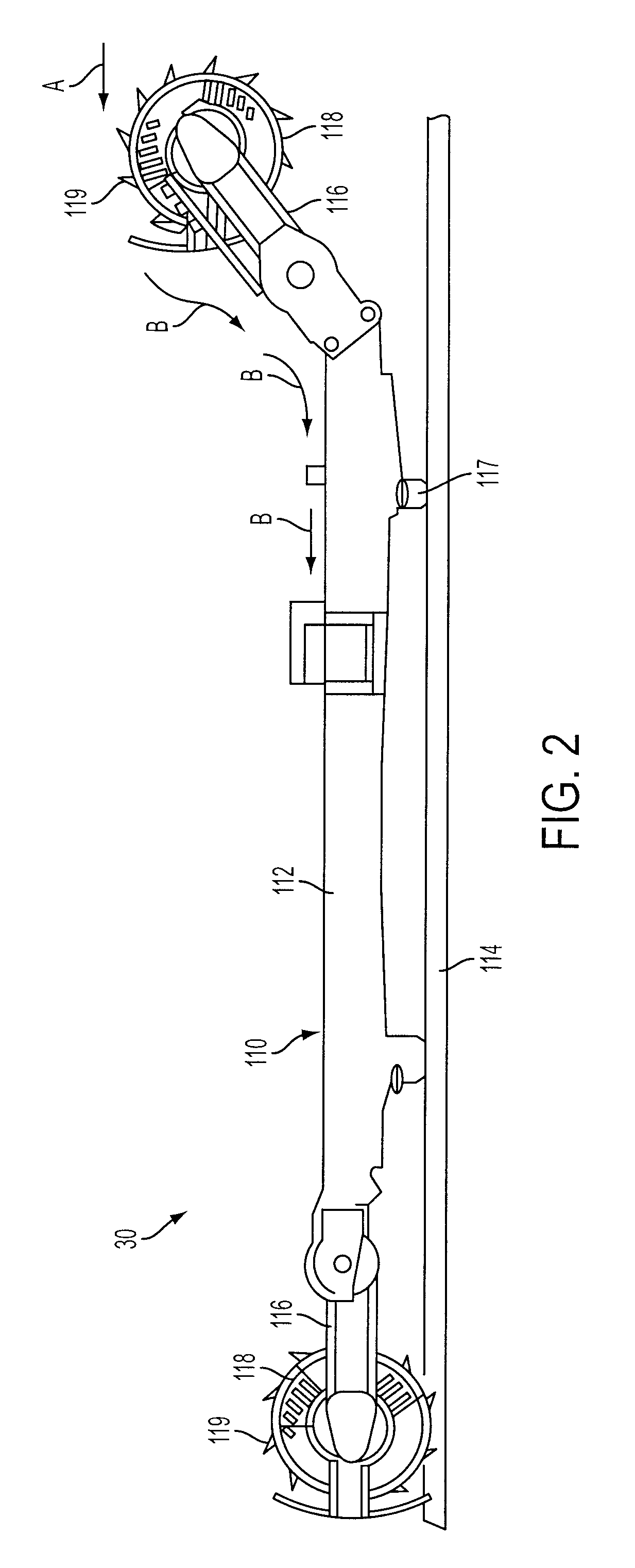

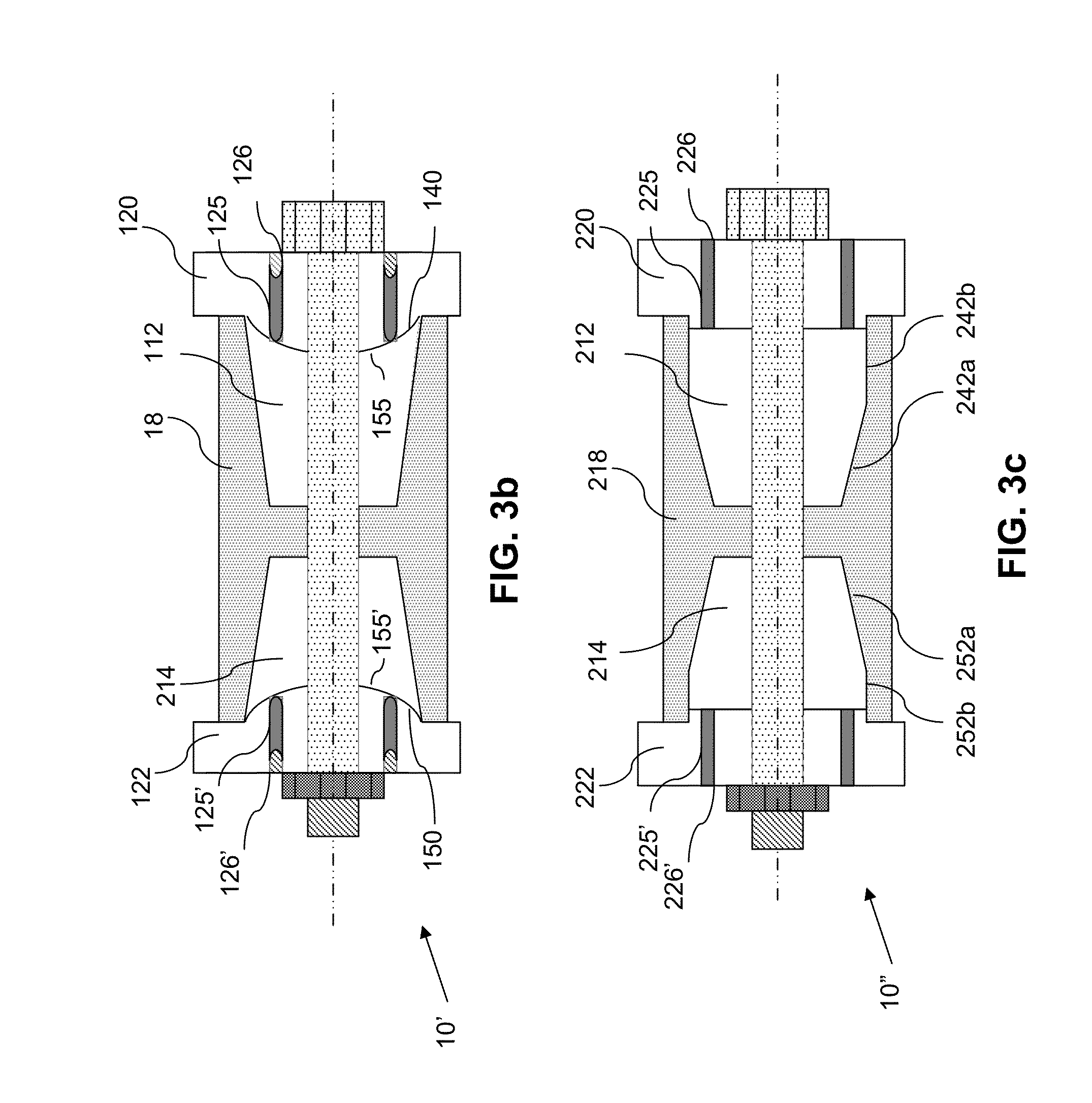

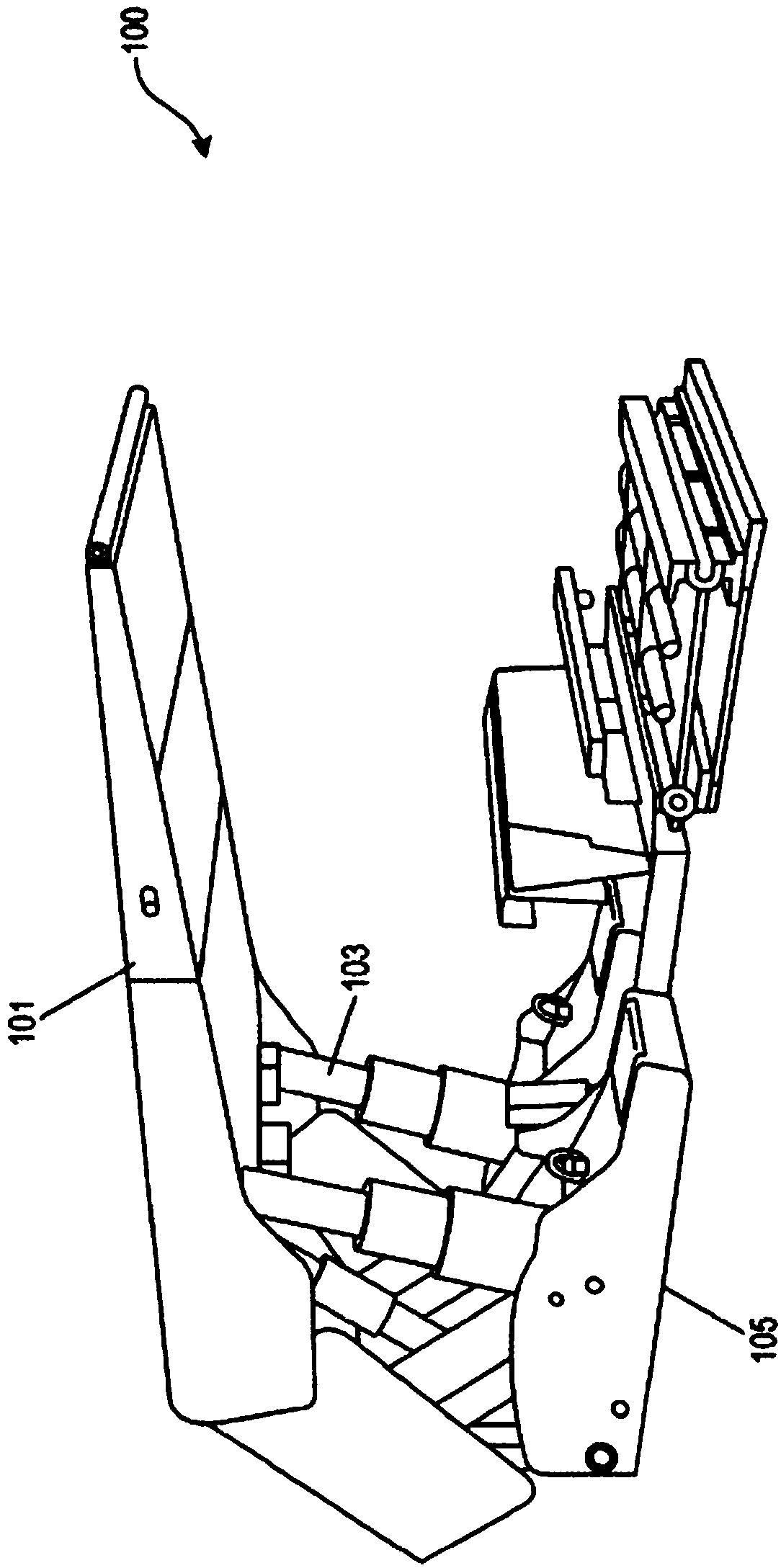

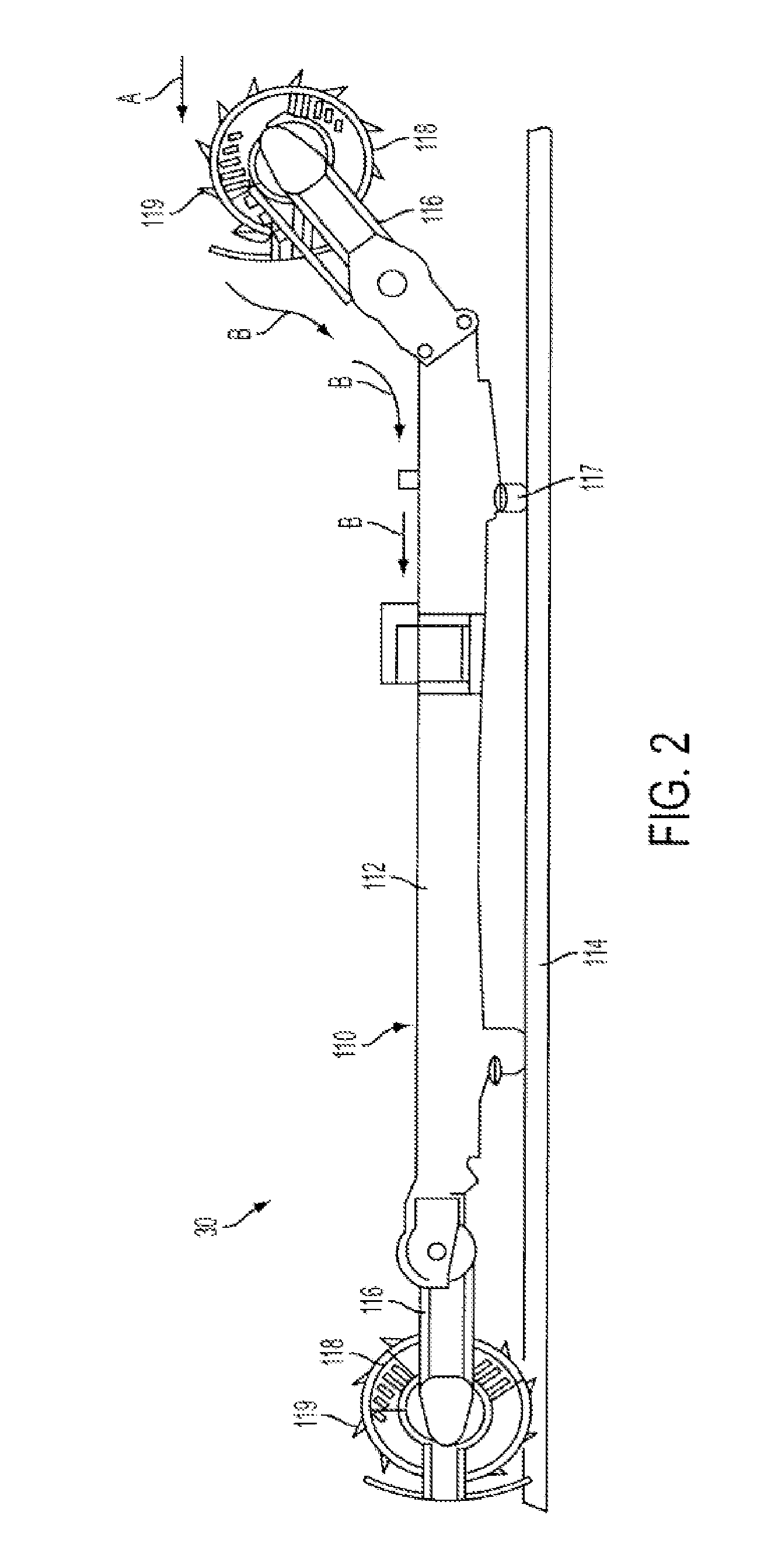

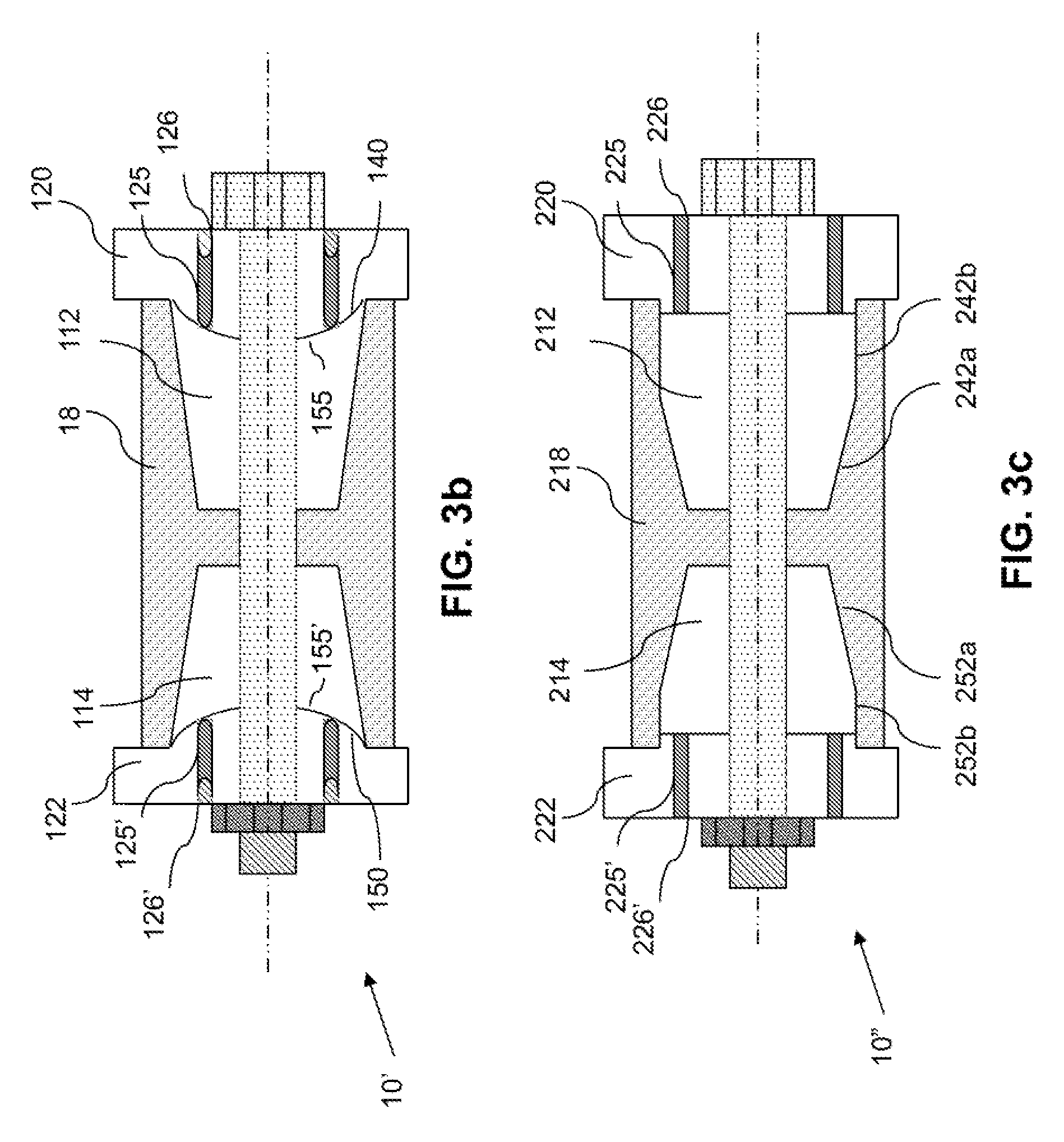

Demountable Pin and Collet Assembly and Method to Securely Fasten a Ranging Arm to a Longwall Shearer Using Such Assembly

A pin-and-collet assembly, a longwall shearer comprising a ranging arm attached to a lifting bracket with such assembly, a method for the secure fastening of one piece to another, such as securely fastening the ranging arm to the lifting bracket of a longwall shearer using such assembly as a bushing, and a method for longwall mining of ore, such as trona, using such longwall shearer. This assembly is easy to install, does not have to be tightened during longwall operation of an ore panel, and is also demountable when it is time to stop the longwall mining operation and time to remove / replace the ranging arm for maintenance and / or when the end of the ore panel is reached.

Owner:SOLVAY CHEM INC

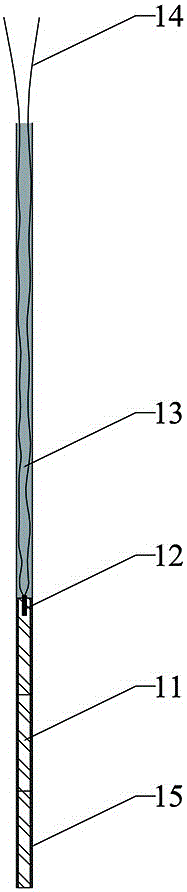

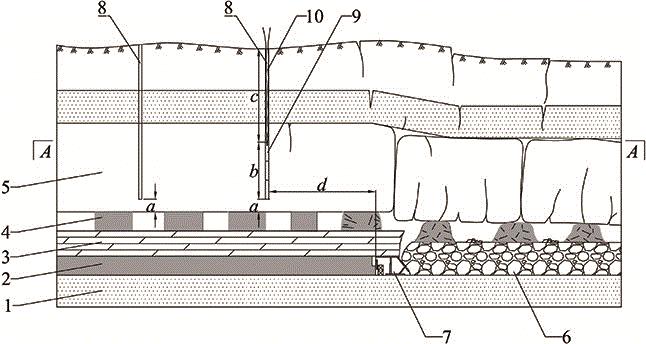

Surface drilling pre-splitting blasting shallow burying method for room type goaf roof

ActiveCN106705773APrevent crushingSafe miningUnderground miningBlastingLongwall miningShortest distance

The invention discloses a surface drilling pre-splitting blasting shallow burying method for a room type goaf roof and belongs to a roof disaster preventing and controlling method for mining of a short distance coal bed below a shallowly-buried goaf. During long wall mining of the short distance coal bed below the shallowly-buried room type goaf, main roof large-area pressure coming happens easily, the yielding damage happens to a small-size coal column under the fracture load of a main roof, a large-size coal column has an elastic kernel and acts the concentrated stress on a lower coal bed work face hydraulic support, and collapse of a work face inner roof, pushing down of a support, hurricane impacting and other disasters are caused. According to the method, drilling pre-splitting blasting of the roof is performed on the ground, the problems that construction is difficult and the effective distance of drilling is short during forced caving of room penetrating type drilling pre-splitting blasting of the goaf are solved, roof large-area pressure coming, roof collapse, pushing down of the support and other disasters can be effectively prevented, and the method is also applicable tomining of lower coal beds of concentrated coal columns of a shallowly-buried long-wall goaf. The method is simple in implementation process, safe and efficient and has wide applicability.

Owner:CHINA UNIV OF MINING & TECH

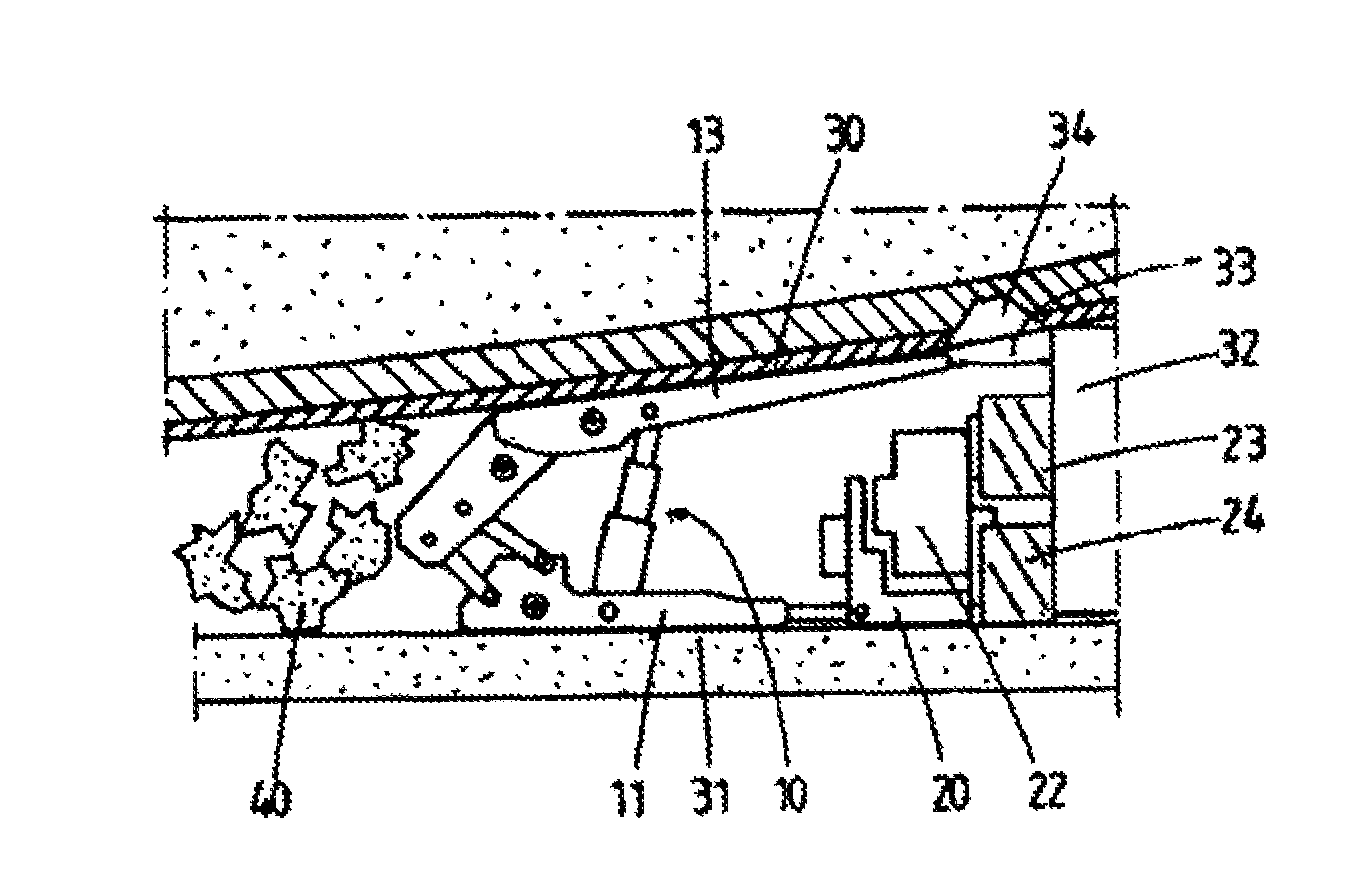

Method for the controlled maintaining of a distance between the roof and the face in longwall mining operations

Disclosed is a method for the controlled maintaining of a mechanically favorable distance (33) between the roof and the face in longwall coal mining operations comprising a face conveyor (20), at least one extraction machine (22), and a hydraulic shield support. In said method, the inclination of the top canopy (13) and the floor skid (11) in the mining direction is determined by means of inclination sensors (17) mounted on at least three of the four main components of each shield support frame (10), such as the floor skid (11), the gob shield (14), the supporting connection rods (16), and in the gob zone of the top canopy (13), the effects on the distance (33) between the roof and the face are determined in a computer unit on the basis of the measured data when the angle of inclination of the top canopy (13) changes, and the parameters that are crucial for the working cycle of the shield support frame (10) are automatically adjusted, said working cycle consisting of a retracting, advancing, and setting process.

Owner:BEIJING TIANMA INTELLIGENT CONTROL TECH CO LTD +1

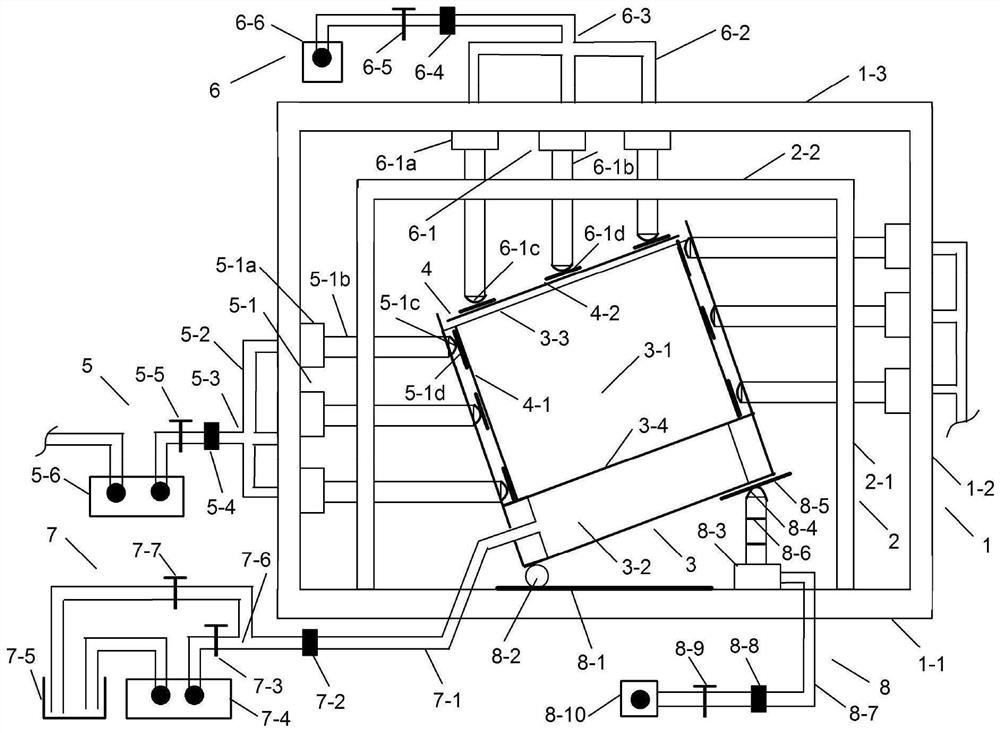

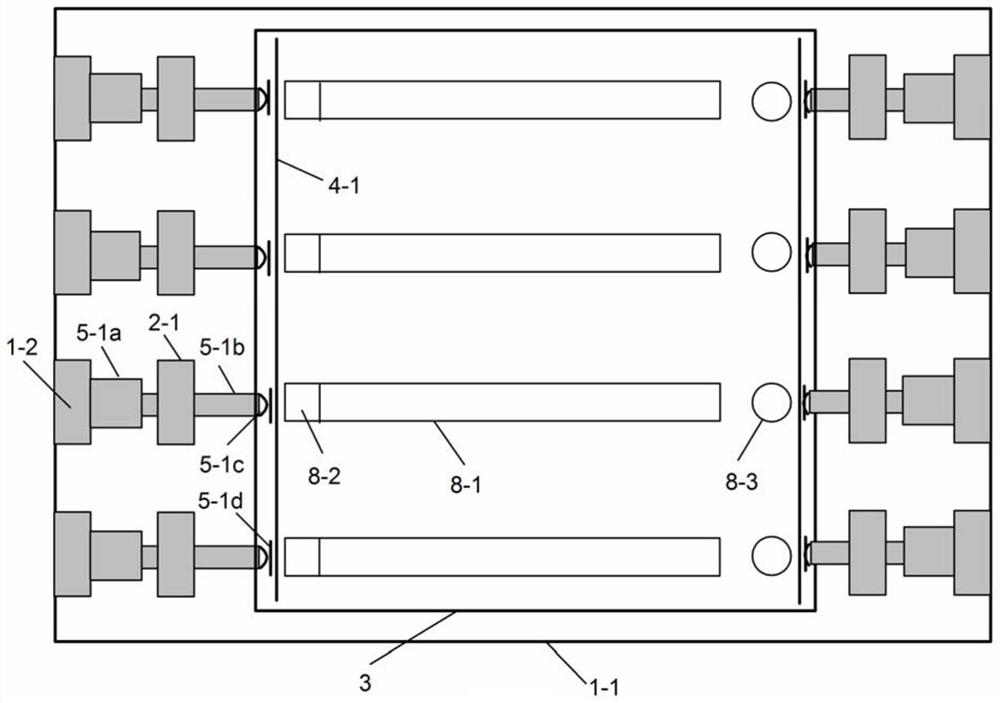

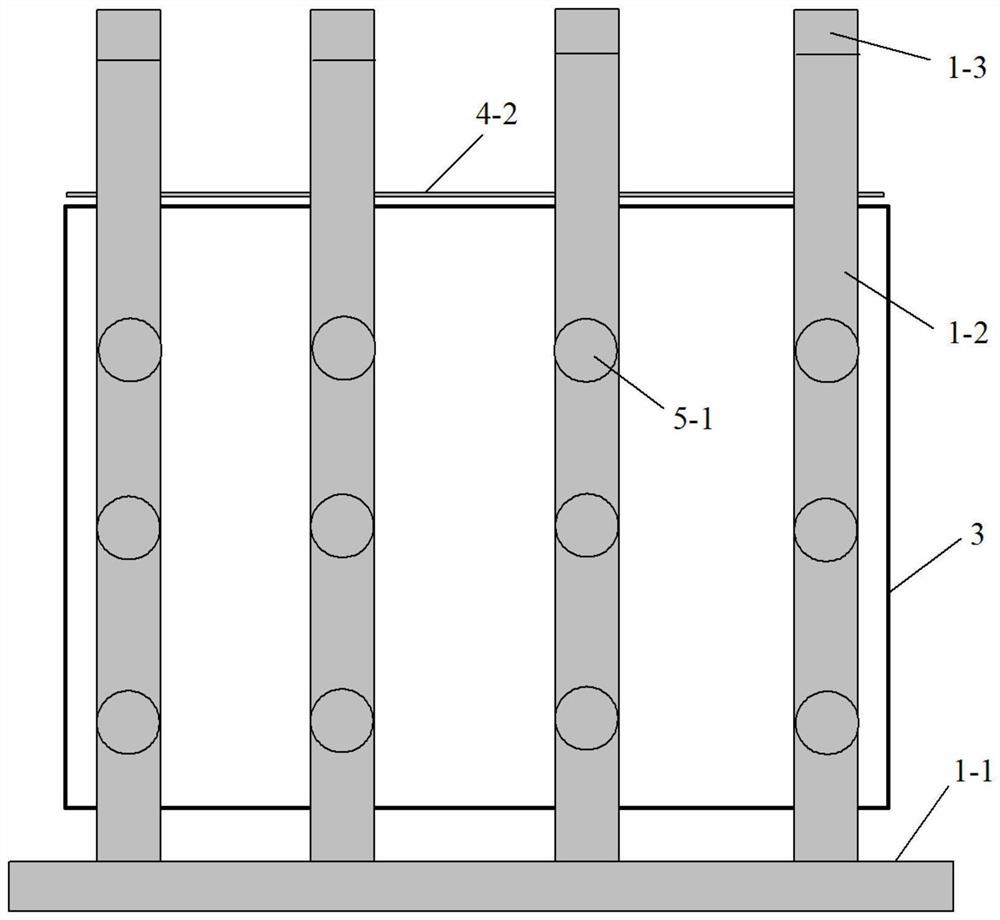

Three-dimensional similarity test device and test method for mining of inclined coal seam with adjustable confined aquifer inclination angle

PendingCN112269015AReal step-by-step excavationReal segmental excavationEarth material testingLongwall miningMining engineering

The invention discloses a three-dimensional similarity test device and test method for mining of an inclined coal seam with an adjustable confined aquifer inclination angle, and relates to the field of confined water inclined coal seam mining similarity tests. The three-dimensional similarity test device comprises a test support, an internal frame, a model storage cavity, a loading plate, a horizontal loading system, a vertical loading system, a water pressure loading system, an inclination angle adjusting system, a signal acquisition and processing system, a three-dimensional test model and acoal seam mining simulation system. The test device realizes the adjustability of the inclination angle of the confined aquifer, the gradient distribution of the water pressure load of the aquifer and the authenticity of the stress state of the inclined coal seam in the vertical direction and the horizontal direction, and realizes the segmental and step-by-step excavation simulation of the coal seam in the closed space of the three-dimensional similar model; and the test device can truly invert generation, expansion and penetration of rock stratum fractures of the mining floor of the inclinedcoal seam on the confined water to finally form a dynamic evolution process of a water guide channel, and can better carry out prediction research on water inrush of the mining floor of the inclinedcoal seam with different inclination angles on the confined water in the strike of long-wall mining.

Owner:ANHUI UNIV OF SCI & TECH

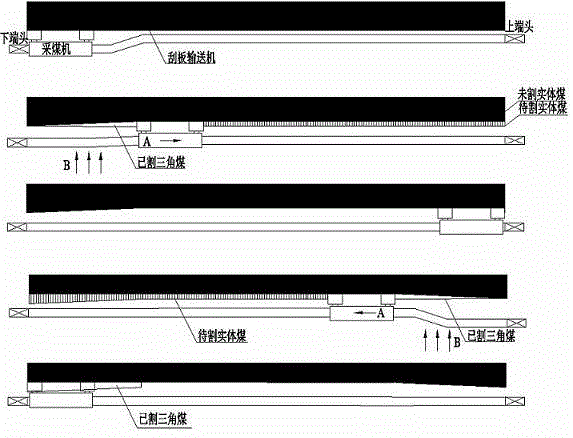

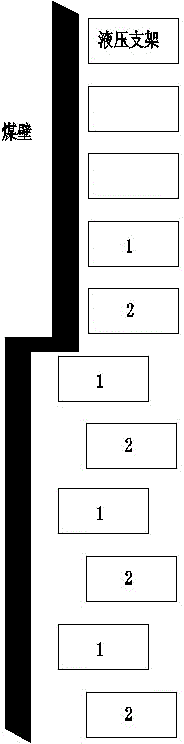

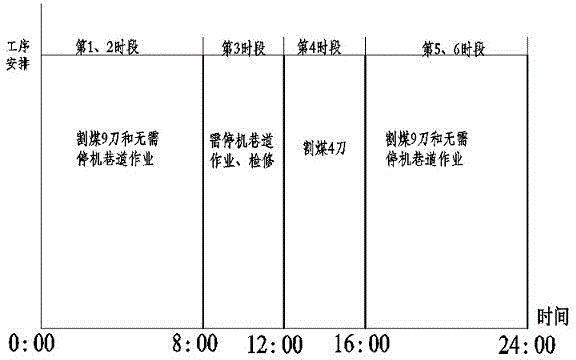

High-speed cutting longwall-mining method for low coal seams and medium-thickness coal seams

ActiveCN104564073AImprove boot rateExtension of timeUnderground miningSurface miningLongwall miningEngineering

The invention discloses a high-speed cutting longwall-mining method for low coal seams and medium-thickness coal seams. The cutting resistance is reduced by reducing a web, so that a normal coal cutting speed reaches 15-40 m / min; by using a low-web bidirectional high-speed coal cutting process for left triangular coals, after triangular coals are completely cut, returning to cut the other half of triangular coals is not required, but continuing to carry out ascending (descending) coal cutting is performed; and reciprocating mining is performed in such a way. By adopting the spaced quick moving of brackets, every two circulating brackets move at a synchronized interval. Through the timing optimization of production takts, by using a space-time coordinated continuous operating method, each workday is uniformly divided into six (or eight) time intervals, a maintenance operation and a shutdown-required roadway operation are arranged in the third time interval, and coal cutting and non-shutdown-required roadway operations are arranged in the rest of time intervals. According to the invention, the low-web bidirectional high-speed coal cutting process for left triangular coals, moving brackets in a grouped, spaced and staggered mode, and the space-time coordinated continuous operating method are adopted, so that the shortcomings of slow advance speed and low mining efficiency of low coal seams and medium-thickness coal seams are made up, thereby providing a feasible mining method for the high-speed cutting of low coal seams and medium-thickness coal seams.

Owner:TIANDI SCI & TECH CO LTD +1

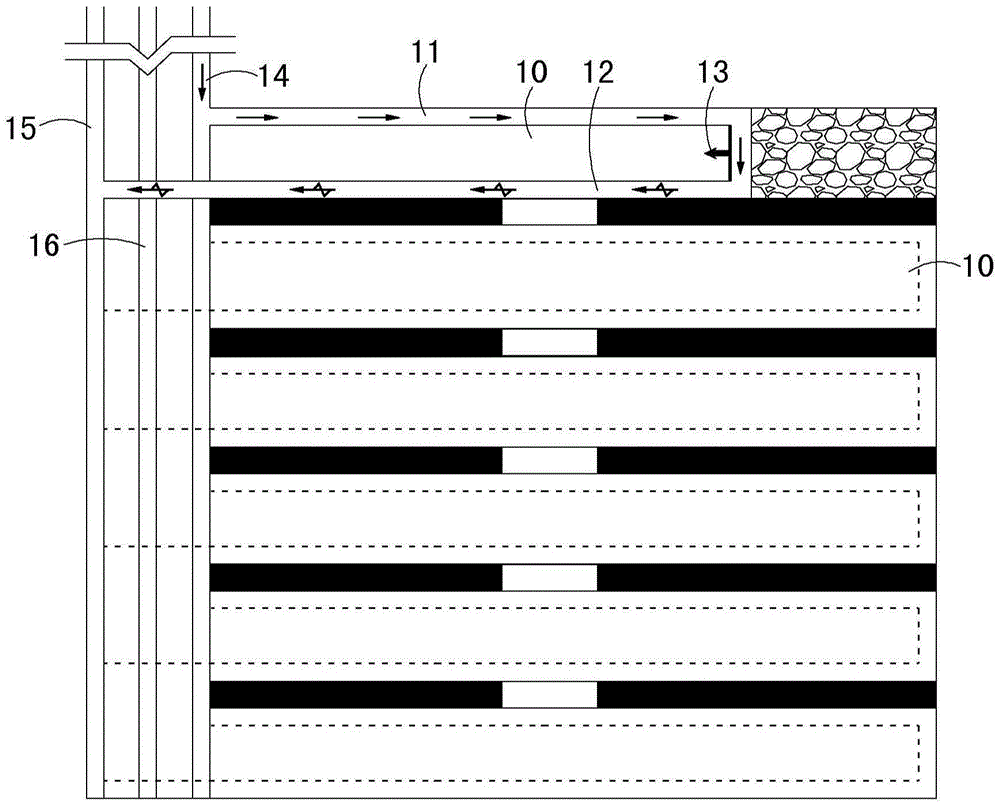

Longwall mining method 110

InactiveCN105178962AImprove securityImprove ventilationUnderground miningSlitting machinesLongwall miningCoal

The invention discloses a longwall mining method 110. The longwall mining method 110 is characterized in that a belt downhill channel, an air return downhill channel and a track downhill channel are arranged, the whole panel is provided with a plurality of working faces, an upper gate road and a lower gate road of each working face which is being mined are communicated with the belt downhill channel, the lower gate road is left in a roadway after the working face is mined to serve as the upper gate road of the next working face, and the lower gate road of the next working face is communicated with the air return downhill channel. According to the longwall mining method 110, as the upper gate road and the lower gate road of each working face which is being mined are communicated with the belt downhill channel, and the lower gate road of the next working face is communicated with the air return downhill channel, ventilation of the working face which is being mined is realized by not only the upper gate road and the lower gate road of the working face but also the lower gate road of the next working face, the ventilation quantity of the working face which is being mined is increased, the ventilation speed is also increased, and accordingly, the ventilation performance is improved to further improve the coal mine production security.

Owner:何满潮

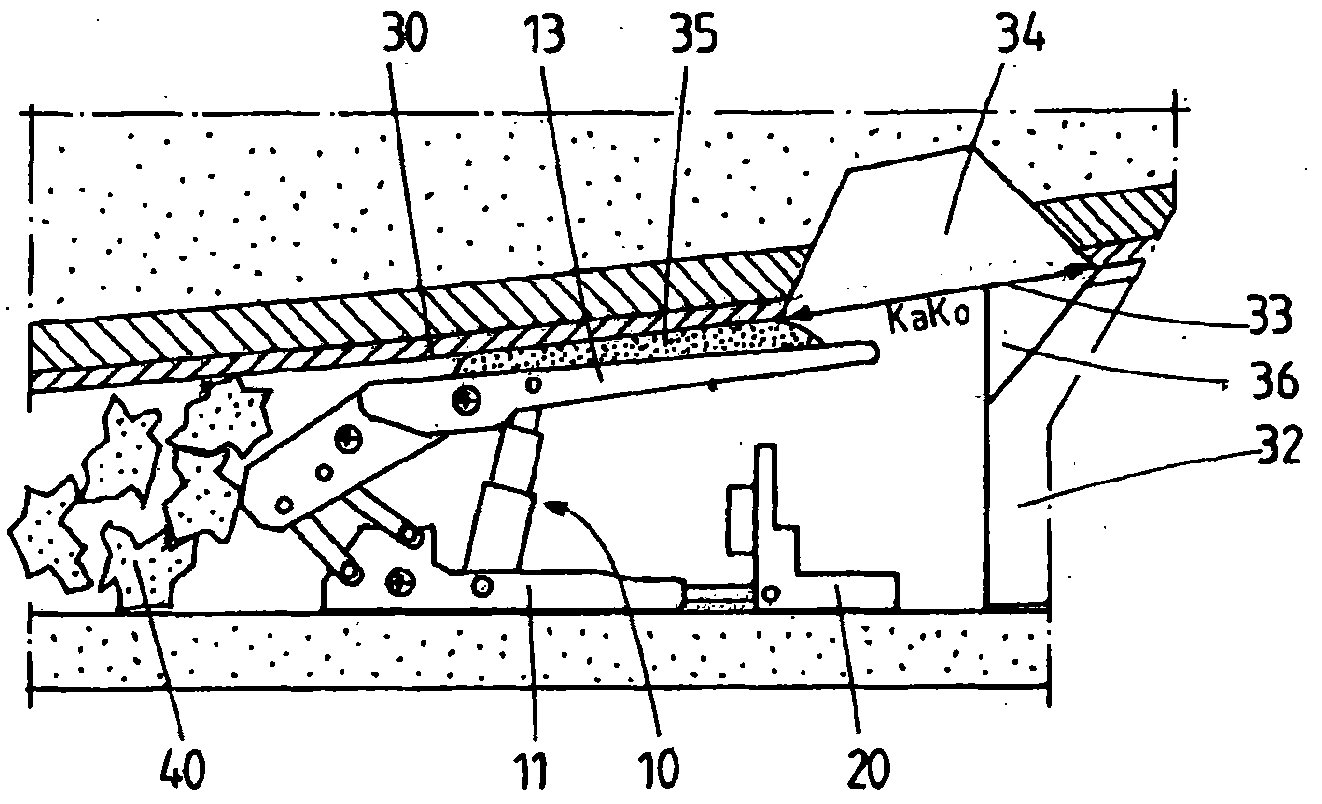

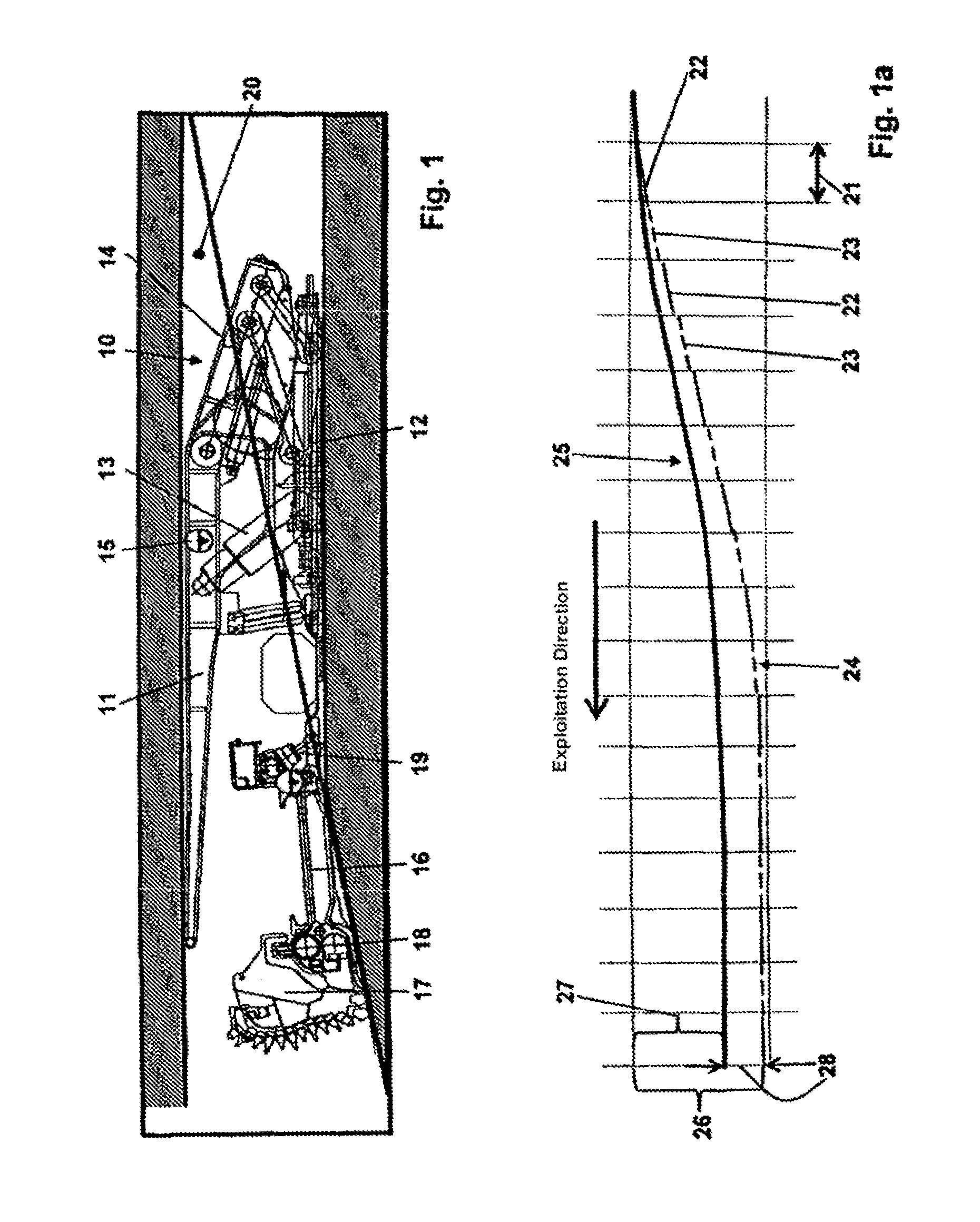

Method of setting an automatic level control of the plow in plowing operations of coal mining

InactiveUS8562077B2Quality improvementGuaranteed functionSlitting machinesMine roof supportsLongwall miningAutomatic control

A method of setting an automatic level control of a plow in longwall mining operations. By means of a boom control mechanism, a control angle for setting motion of the plow, which is guided on a face conveyor, in an exploitation direction as a climbing, plunging or neutral motion is set. For each plow stroke, a cutting depth and the control angle, derived as a differential angle between inclinations of the face conveyor and of a top canopy of a shield support frame are determined. In a calculating unit, a face height change per plow stroke is calculated therefrom and a face height, as a projected height, is associated with each face position of the face conveyor. When a shield support frame that trails behind the plow in terms of a time delay reaches a respective face position, an actual height of the face is calculated and compared with the store projected height. For subsequent plow strokes, a height differential value between the projected and actual heights, determined for a respective face position, in the sense of a self-learning effect of the calculating unit when the control angle that is to be set to achieve a projected height of the face is prescribed, is taken into consideration.

Owner:RAG AG

Method and system for determining structural changes in a longwall mine

InactiveUS20130269453A1Useful commercial choiceMining devicesSlitting machinesLongwall miningControl theory

A system for determining structural changes in a longwall mine, including a modulator wheel operatively coupled to a longwall mining machine, and a controller in communication with the modulator wheel; wherein the controller determines a movement of the longwall mining machine according to a signal received from the modulator wheel.

Owner:CUT COAL TECH HLDG

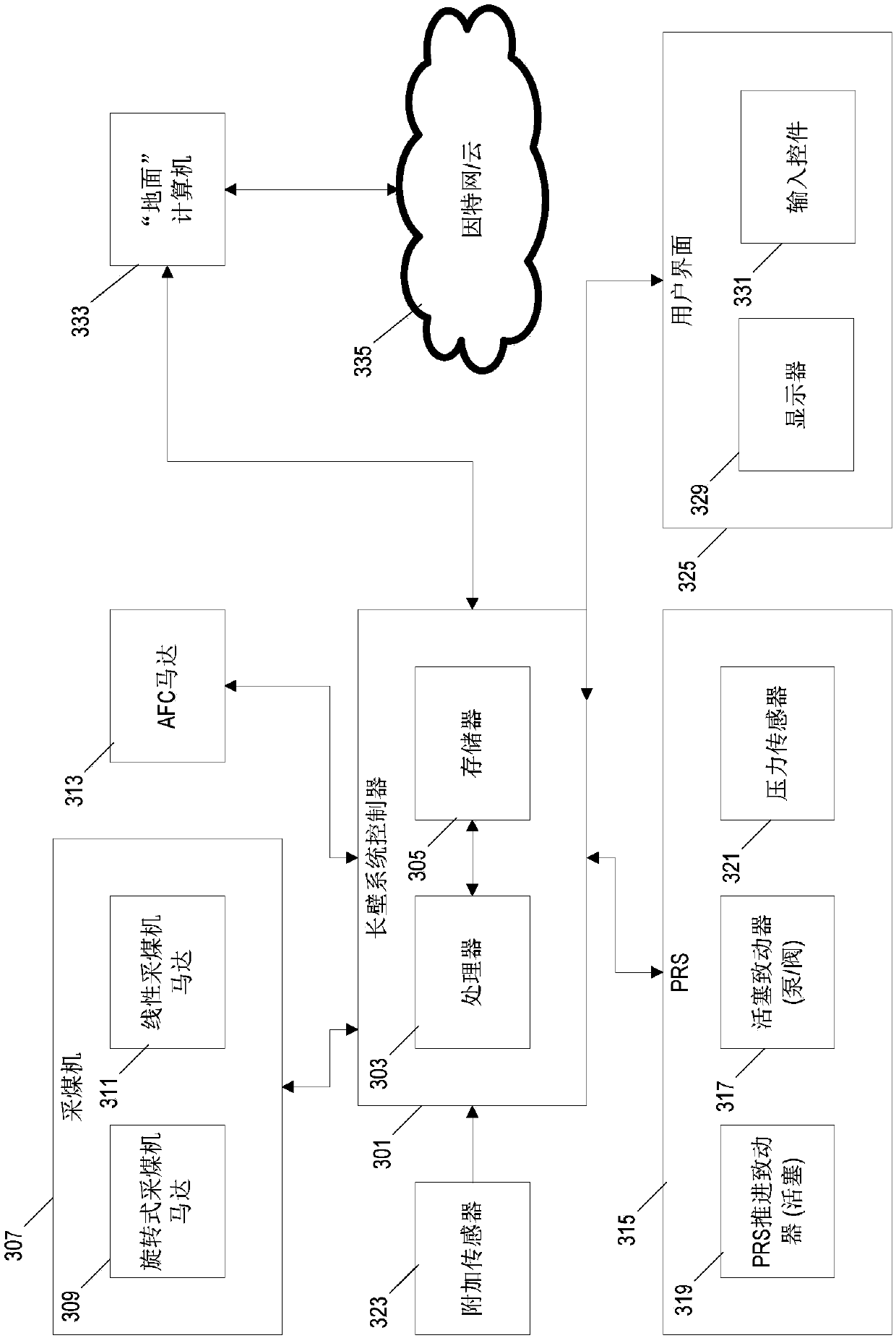

Systems and methods for monitoring longwall mine roof stability

Systems and methods are described for monitoring a condition of a mine roof using a longwall mining system. A plurality of powered roof supports are controlled to apply an adjustable support pressureon a mine roof. A condition of the mine roof is monitored based on the adjustable support pressure applied to the roof by a respective actuator of each powered roof support. In some implementations, the condition of the mine roof is monitored by generating and analyzing a graphical pressure map based on the adjustable support pressure applied by each powered roof support and a relative position ofa shearer moving across the mine face. In some implementations, roof collapse events are detected based on temporally similar changes in the adjustable support pressure applied by multiple adjacent powered roof supports as indicated by the graphical pressure map.

Owner:JOY GLOBAL UNDERGROUND MINING LLC

Method for automatically creating a defined face opening in longwall mining operations

ActiveUS8567871B2Sufficient precision and reliabilityError componentUnderground miningSlitting machinesLongwall miningEngineering

A method for automatically producing a defined face opening in a longwall mining operation, in underground coal mining, having a face conveyor, at least one extraction machine and hydraulic shield support frames. Inclination sensors are disposed on at least three of the four main components of each shield support frame, such as floor skid, gob shield, support connection rods and gob-side area of the top canopy. From ascertained inclination data, by comparison with base data defining a geometrical orientation of the components and a movement thereof during stepping, a respective shield height of the shield support frames perpendicular to a bed thereof is calculated. From further sensors on the extraction machine, a cutting height thereof is acquired as a face opening. In terms of a location-synchronous analysis, for possible adjustment purposes the cutting height is compared with the shield height when the shield support frame, which trails the extraction machine with a time delay, has reached the position to which relates that cutting height which was used in the comparison.

Owner:BEIJING CCRI TIANMA AUTOMATION TECH CO LTD +1

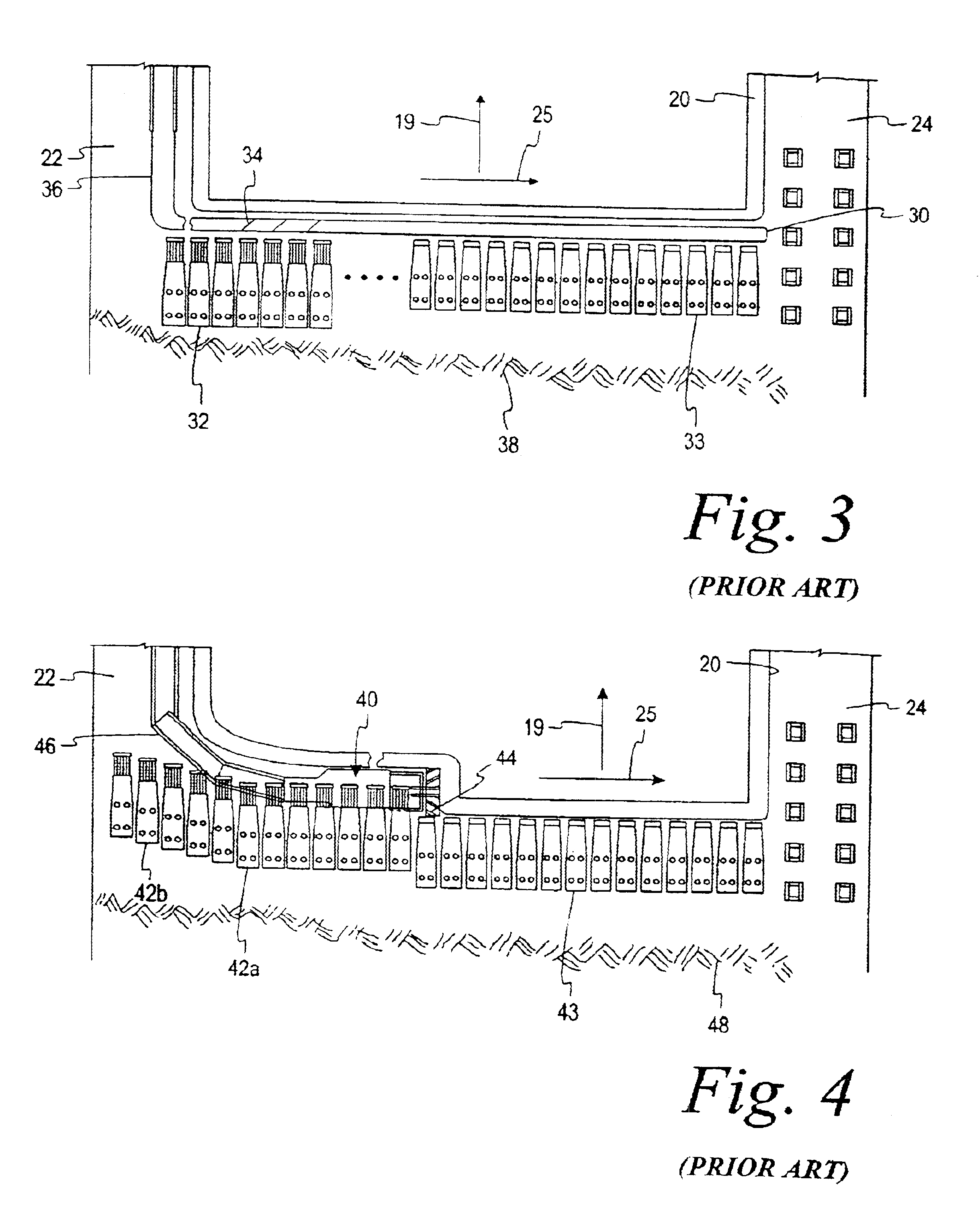

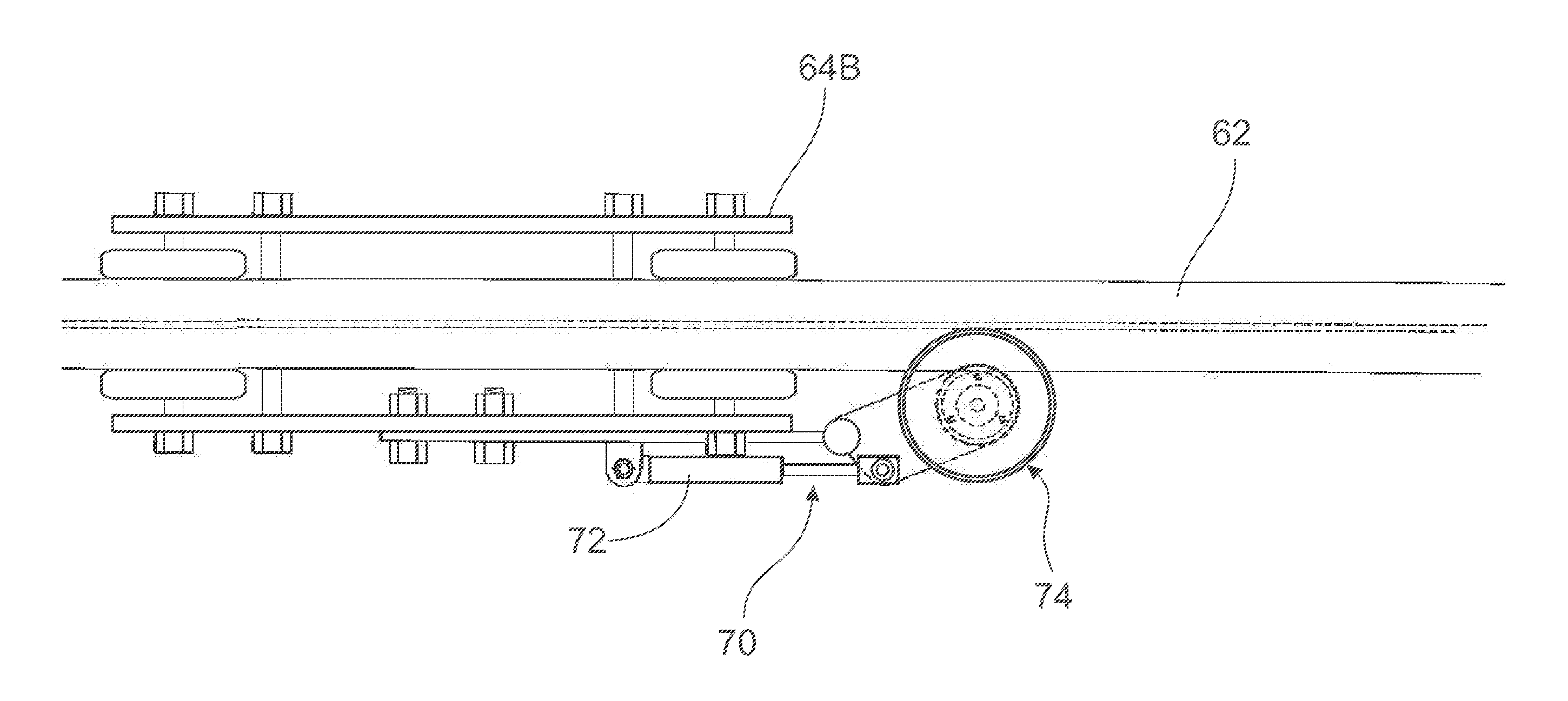

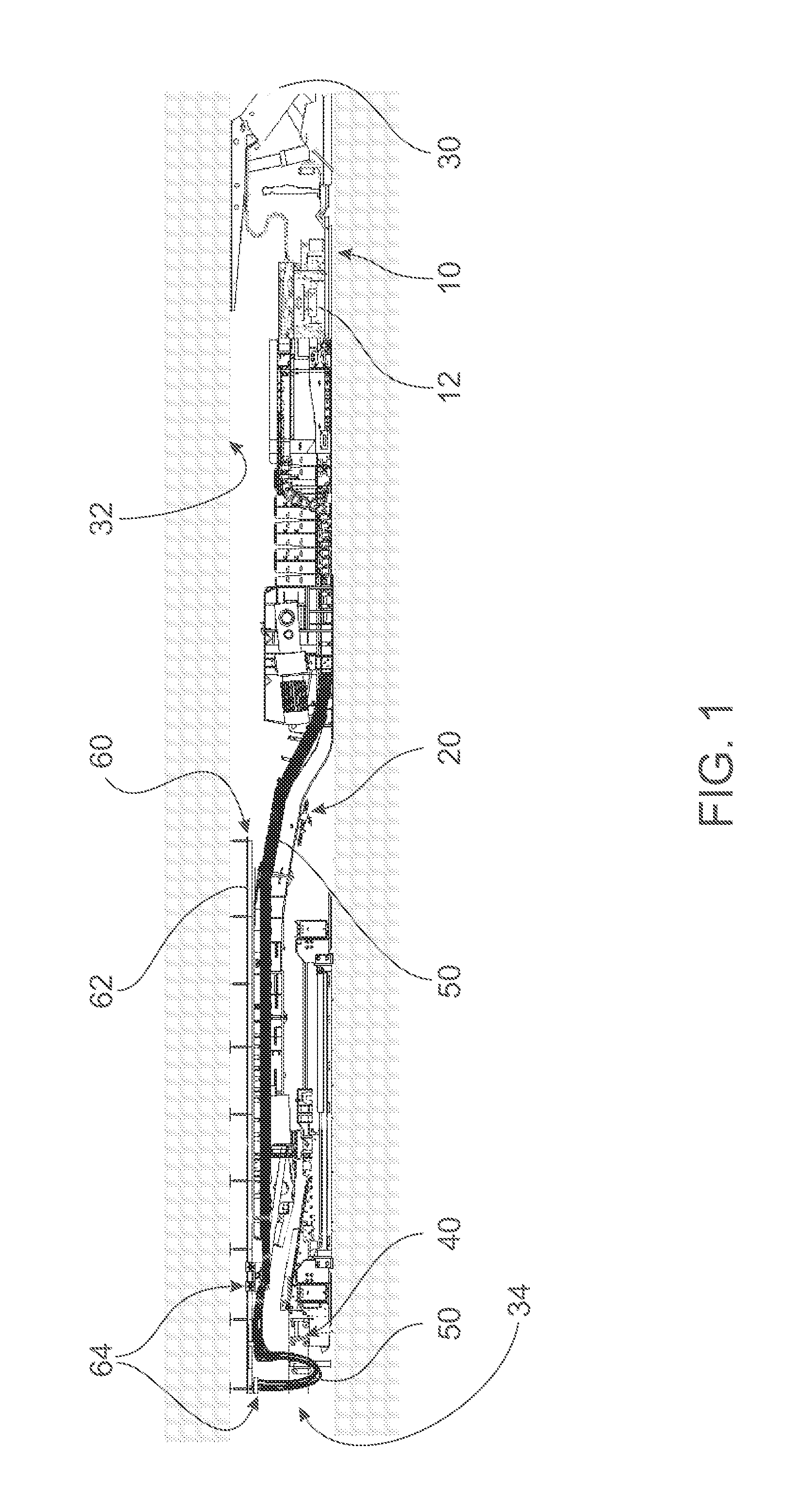

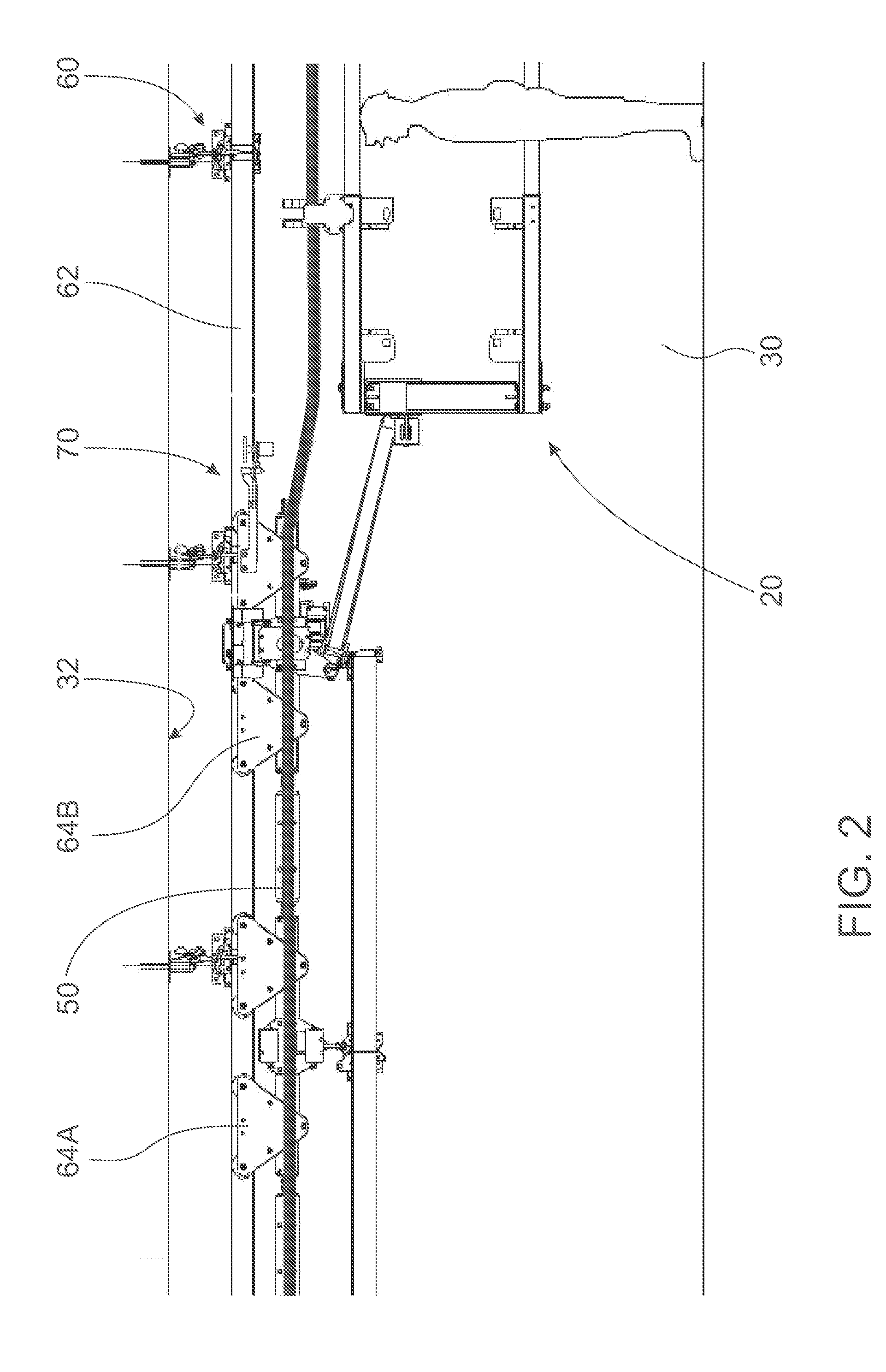

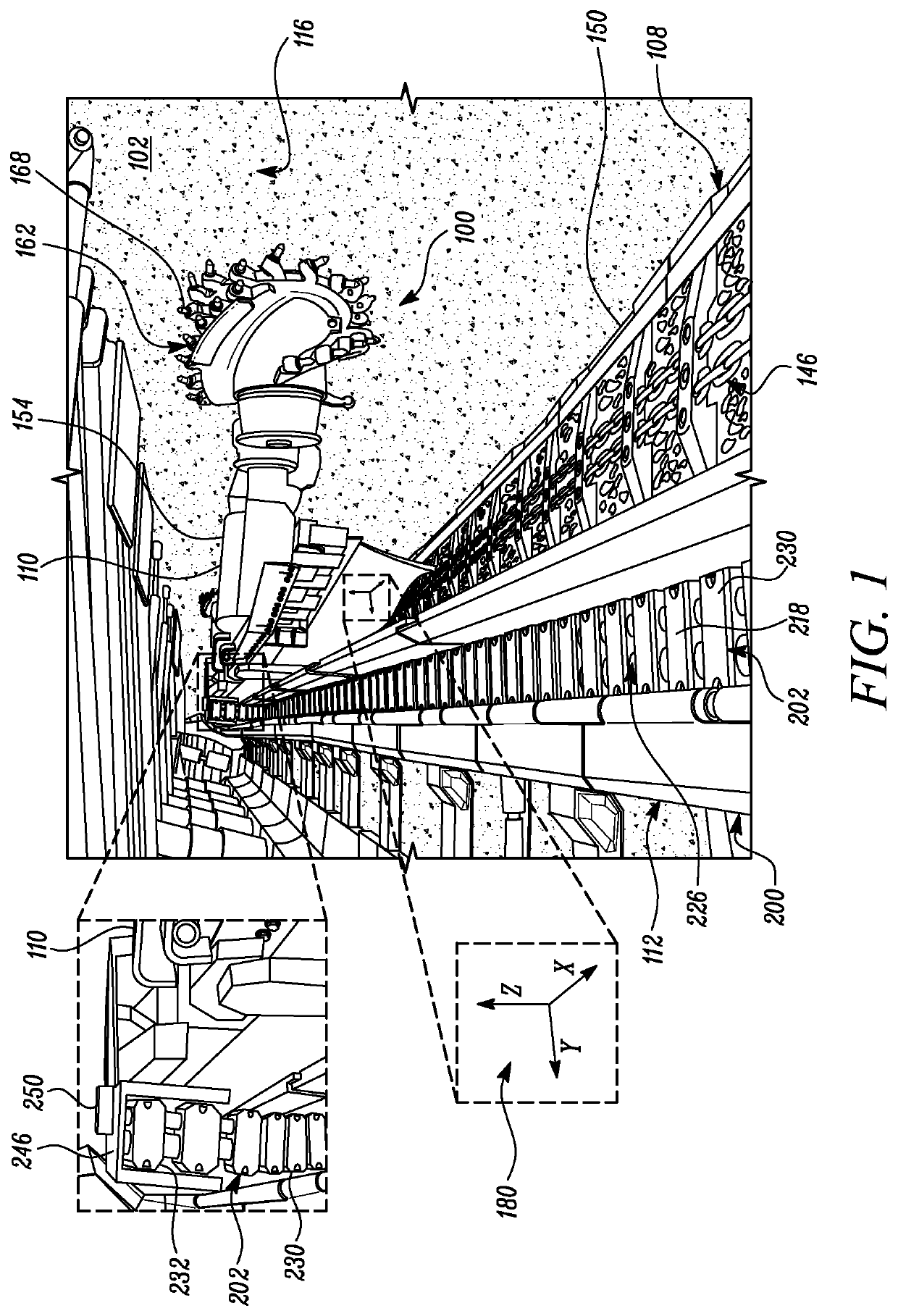

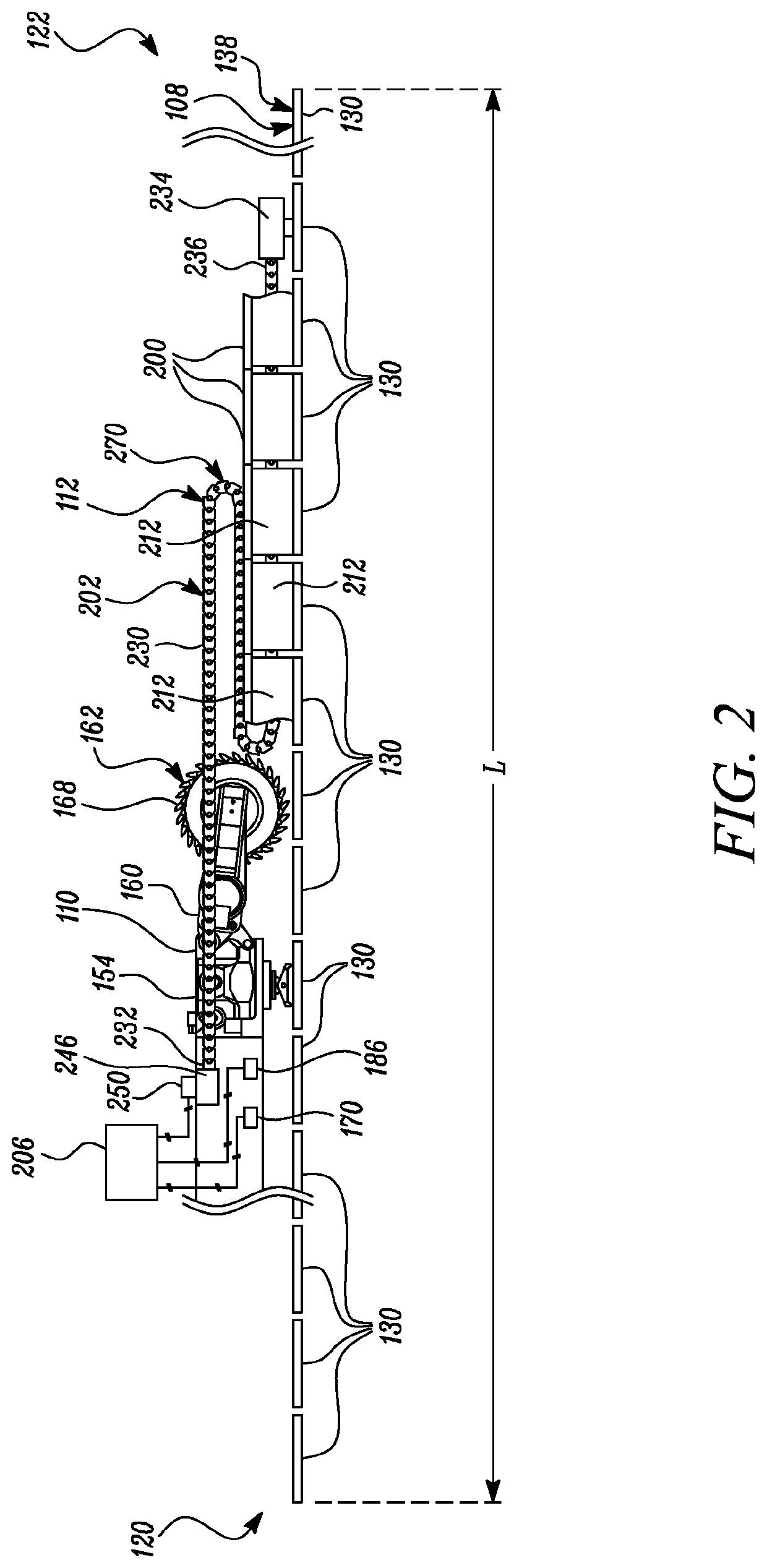

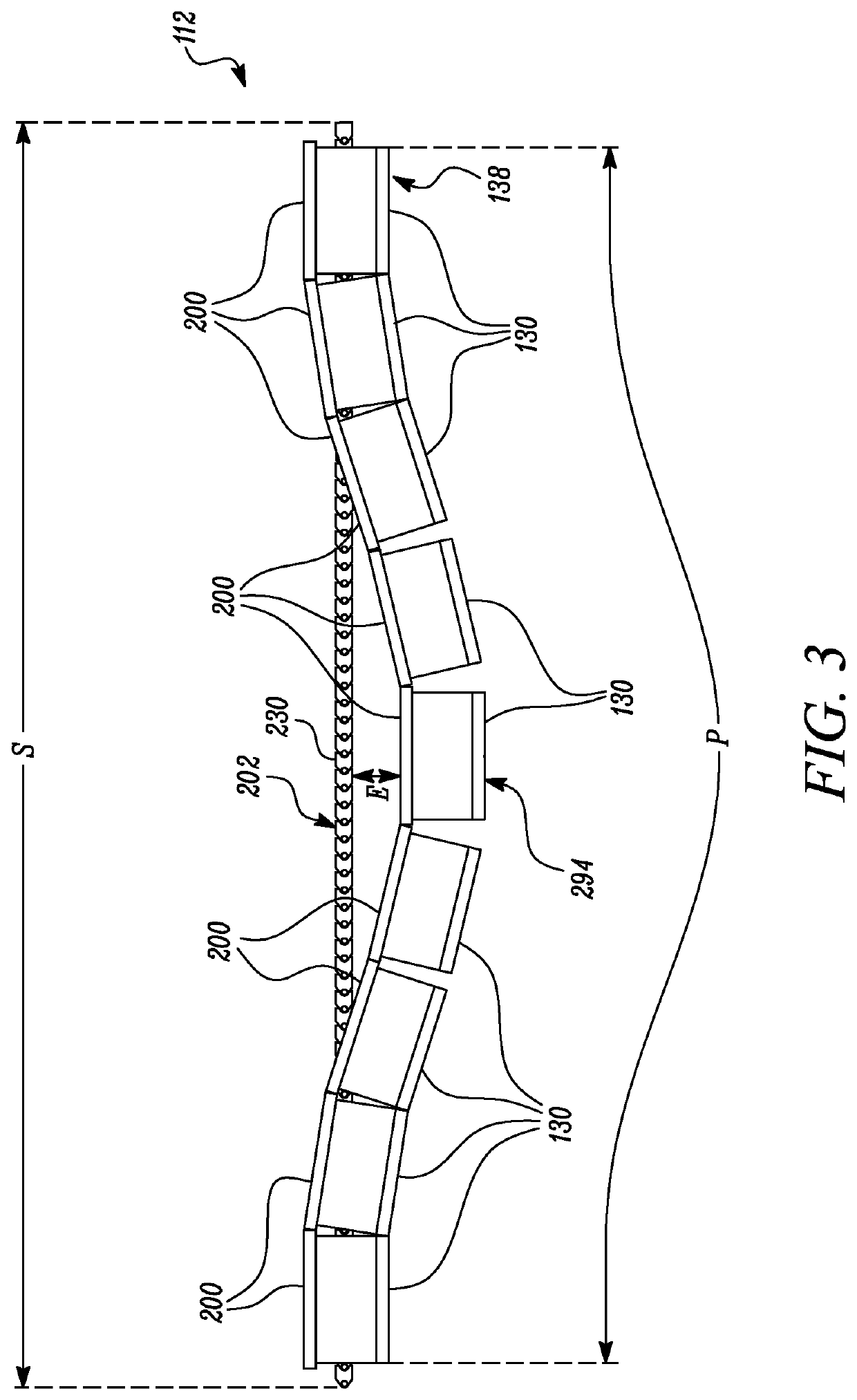

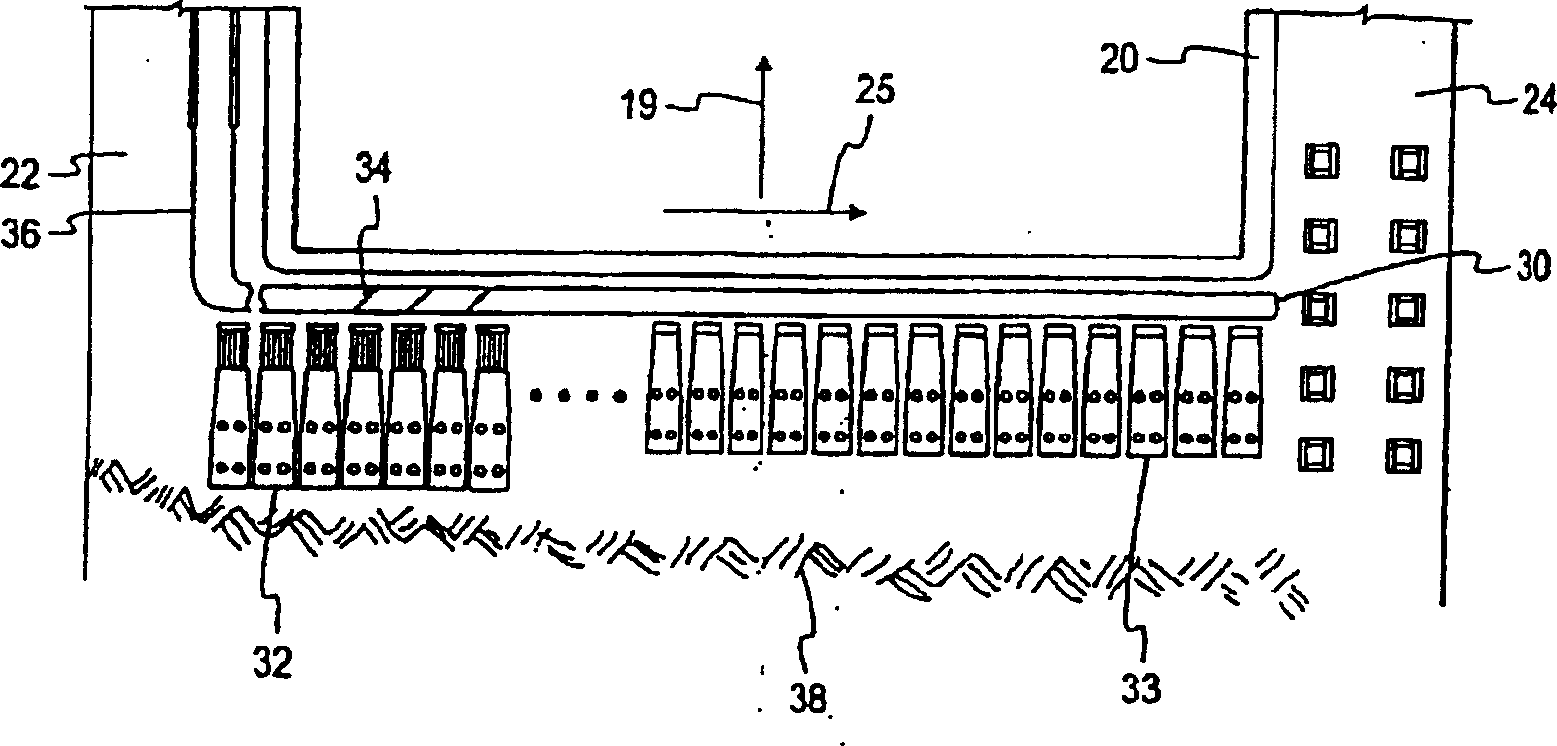

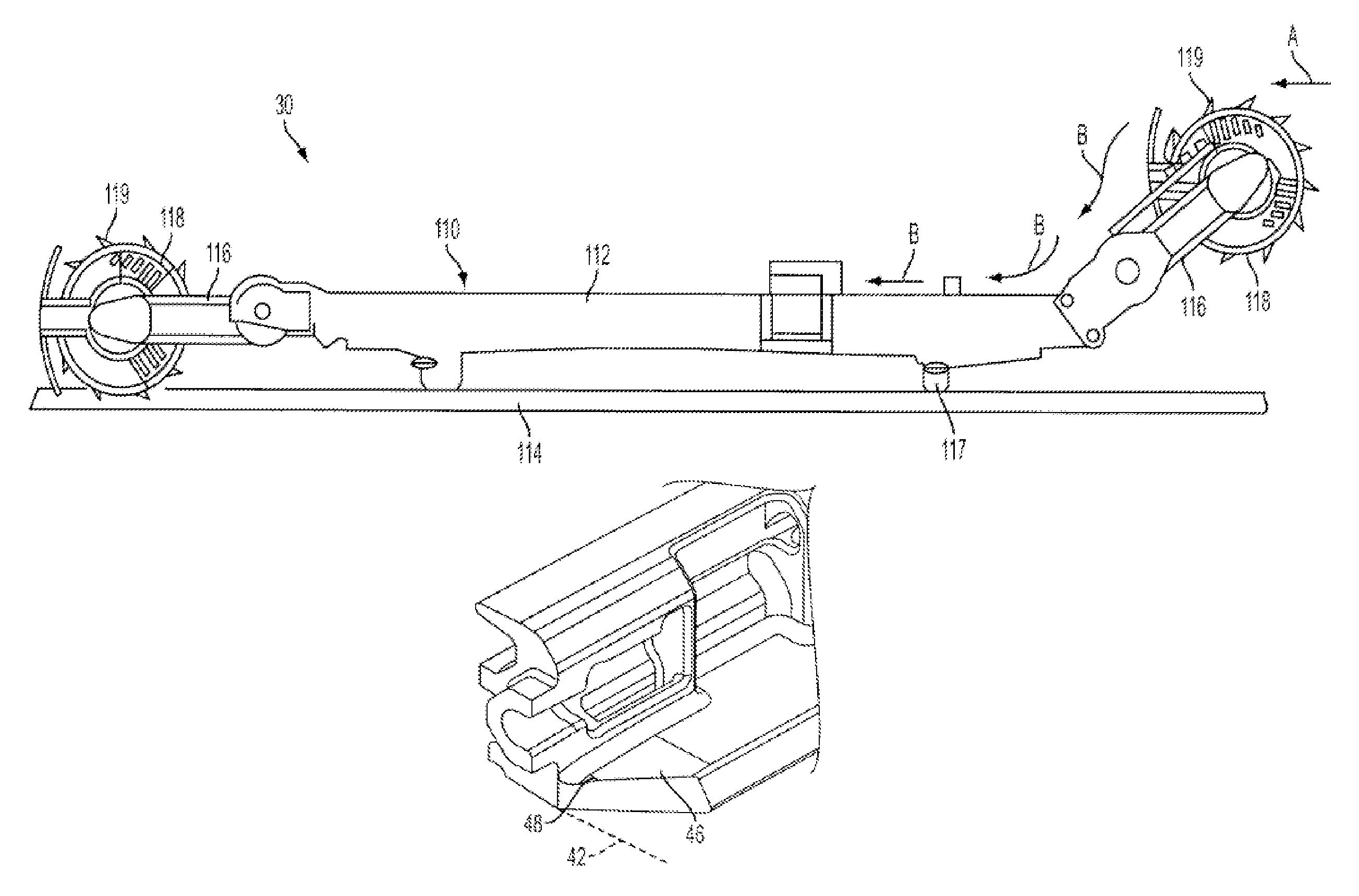

Cable handling system for longwall mining machines

ActiveUS20200024943A1Facilitating shearer operationPipe supportsMining devicesLongwall miningMining engineering

A cable handling system for a longwall mining machine is disclosed. The longwall mining machine includes a shearer configured to move along a pan line to mine material along a mine face. The cable handling system includes a service line configured to carry one or more supply lines to the shearer for facilitating shearer operation. Further, a plurality of interconnected trays accommodates the service line. Moreover, a controller is configured to determine a profile of the pan line; detect one or more parameters associated with the service line in relation to the profile of the pan line; and determine a likelihood of at least a portion of the service line dislodging from the plurality of interconnected trays based on the one or more parameters exceeding a predefined threshold.

Owner:CATERPILLAR INC

Mining system

InactiveCN1745226AShorten movement timeEliminates the need for ingressUnderground miningSurface miningLongwall miningEngineering

A method for extracting mineral deposits in a mineral reserve (1501), a portion being accessible from a sloping surface and the remaining portion being inaccessible, is disclosed. The sloping surface is mined to create a bench (1515) and highwall for providing access to the mineral reserve around the accessible portion. A surface is formed in the highwall to create an insertion highwall (1520) between an endwall extending from the insertion highwall and the inaccessible portion (PB) of the mineral reserve. A starter entry (1580) is created for cutting into the mineral reserve across the entire length of the insertion highwall from the endwall to the inaccessible portion of the mineral reserve (1501). Roof supports are advanced into the starter entry with spoil added to form a starter passage from the endwall to the inaccessible portion of the mineral reserve. Shortwall or longwall mining techniques are then used to mine the mineral reserve along the starter passage.

Owner:乔伊・W・哈曼 +1

Comprehensive coal-mining process by using long wall mining method

InactiveCN100567703CLow costReduce in quantityUnderground miningSurface miningLongwall miningResource recovery

The utility model relates to a longwall coal mining method fully mechanized mining technology, which involves underground coal mining, and is suitable for longwall mining of stable coal seams, hard roofs, no faults, gently dipping medium-thick coal seams and thick coal seams. Arrange hydraulic supports, scraper conveyors, and roller shearers on the longwall fully mechanized mining face, and arrange trough loaders and retractable belt conveyors on the transport lane. The fully mechanized mining face adopts super-long layout, that is, the face length is arranged according to the length of two fully mechanized mining faces. Two shearers are used, riding on the same scraper conveyor, to cut the coal walls of the upper half and the lower half respectively. The middle roadway can also be arranged in the middle of the super-long fully mechanized mining face as a transportation roadway; a scraper conveyor is arranged on the upper half and lower half of the fully mechanized mining face for opposite transportation to form a fully mechanized mining face. The invention further excavates the production potential of the longwall fully mechanized mining face, improves the output and work efficiency, and makes the production centralized; while realizing high output and high efficiency, it reduces the roadway excavation rate, reduces the loss of coal pillars, and improves the resource recovery rate; full mining is beneficial to the ground surface sink.

Owner:YANKUANG GRP CO LTD

Longwall mining machine and a linepan section

This invention discloses a longwall mining machine and a linepan section. The linepan section may include a face-side rail, a gob-side rail opposite the face-side rail, and a conveyor pan between the face-side rail and the gob-side rail. The face-side rail may have a generally horizontal top surface at a top surface height and with a top surface width, an angled loading surface extending toward the mining face and the ground surface and arranged at an oblique angle relative to the top surface, the loading surface being at a loading height and with a loading surface width, the loading surface width being at least about 25 percent of the total width, and a material cavity defined in the face surface below the loading surface and recessed toward a gob-side.

Owner:JOY GLOBAL UNDERGROUND MINING LLC

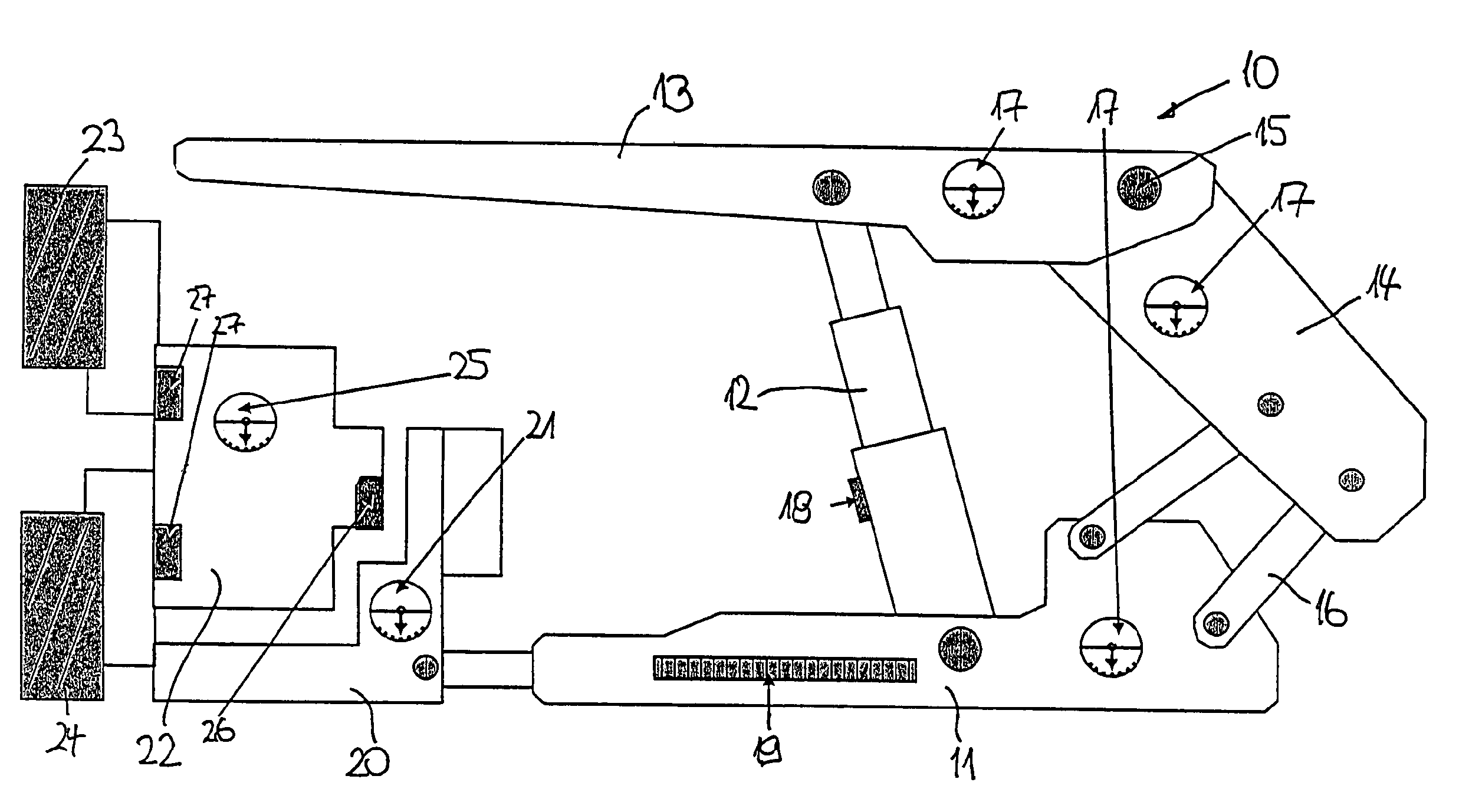

Conveyor pan with improved edge shaping

ActiveUS7896444B2Reduce decreaseConvenient to accommodateConveyorsSlitting machinesLongwall miningVertical plane

A conveyor pan for use with a shearer with a skid-type shoe in a longwall mining operation, the conveyor pan including a side member having a surface adapted to be engaged by the shearer skid-type shoe, the surface being formed by a piece of the side member that extends horizontally for the length of the side member. The piece has a first end and a second end, each piece end having a top, a rear, a front and an edge. The first end edge and the second end edge are each formed by each edge being between 45 degrees removed from a vertical plane extending at 90 degrees to the horizontal plane formed by the side member surface.

Owner:JOY GLOBAL UNDERGROUND MINING LLC

Demountable pin and collet assembly and method to securely fasten a ranging arm to a longwall shearer using such assembly

A pin-and-collet assembly, a longwall shearer comprising a ranging arm attached to a lifting bracket with such assembly, a method for the secure fastening of one piece to another, such as securely fastening the ranging arm to the lifting bracket of a longwall shearer using such assembly as a bushing, and a method for longwall mining of ore, such as trona, using such longwall shearer. This assembly is easy to install, does not have to be tightened during longwall operation of an ore panel, and is also demountable when it is time to stop the longwall mining operation and time to remove / replace the ranging arm for maintenance and / or when the end of the ore panel is reached.

Owner:SOLVAY CHEM INC

Method for controlling longwall mining operations

InactiveUS8672414B2Eliminate errorsEasy to controlSlitting machinesMine roof supportsLongwall miningEngineering

A method for controlling a longwall mining operation, including a face conveyor, at least one extraction machine, and a hydraulic shield support, in underground coal mining. Using inclination sensors disposed on at least three of the four main components of each shield support frame, such as floor skid, gob shield, support connection rods, and gob-side region of the top canopy, the inclination of the shield components relative to horizontal is ascertained in the direction of step. In a computer, the ascertained inclination data is compared with base data stored in the computer that defines the geometrical orientation of the components and their movement during stepping. From the comparison, a respective height of the shield support frame, at the forward end of the top canopy, is calculated as a measure for the face opening.

Owner:RAG AG

Method for reserving and supporting special-shaped gob-side roadway for longwall mining along strike of large-inclination medium-thick coal seam

ActiveCN110925017AGood deformabilityReduce sedimentation rateMaterial fill-upAnchoring boltsLongwall miningMining engineering

The invention provides a method for reserving and supporting a special-shaped gob-side roadway for longwall mining along the strike of a large-inclination medium-thick coal seam. The method comprisesthe following steps: 1, reserving of the gob-side roadway of the large-inclination medium-thick coal seam; 2, flexible formwork concrete and flexible cushion layer strong-weak combined roadside filling support; and 3, single prop and full-anchor system rigid-flexible combined roadway interior support. By means of the method, the stability of gob-side entry retaining of the large-inclination medium-thick coal seam can be achieved, the coal recovery rate is improved, the labor intensity of workers is reduced, and the construction safety is greatly improved.

Owner:XIAN UNIV OF SCI & TECH

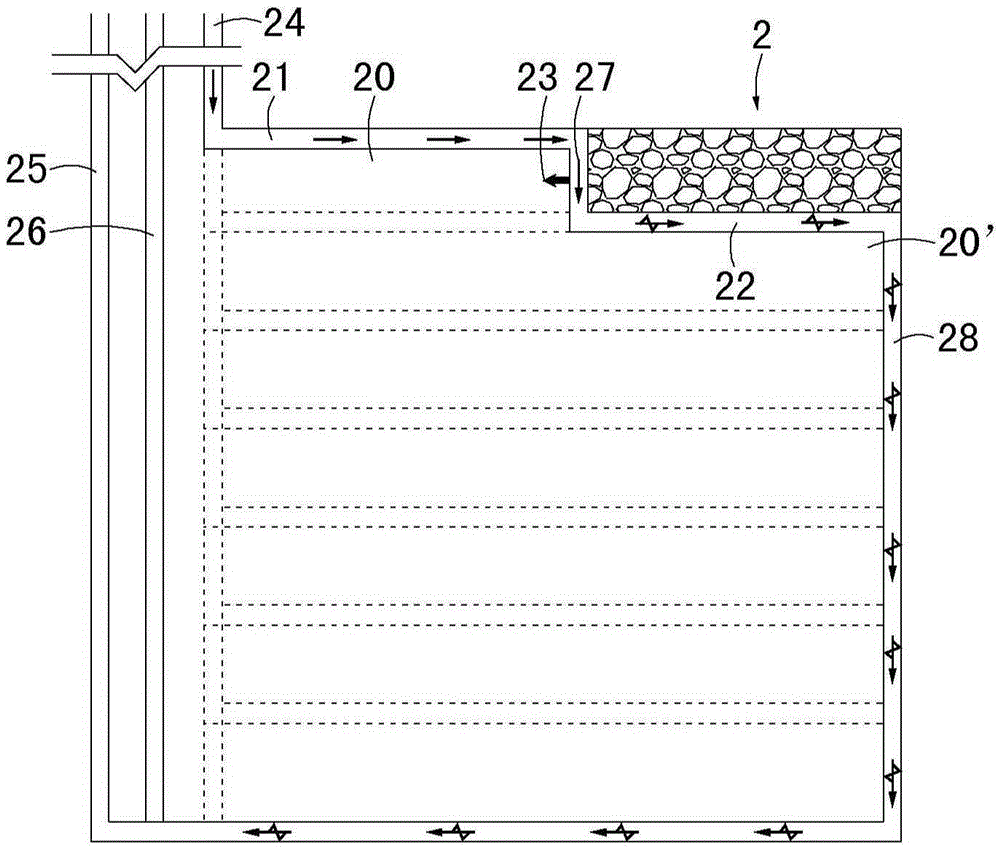

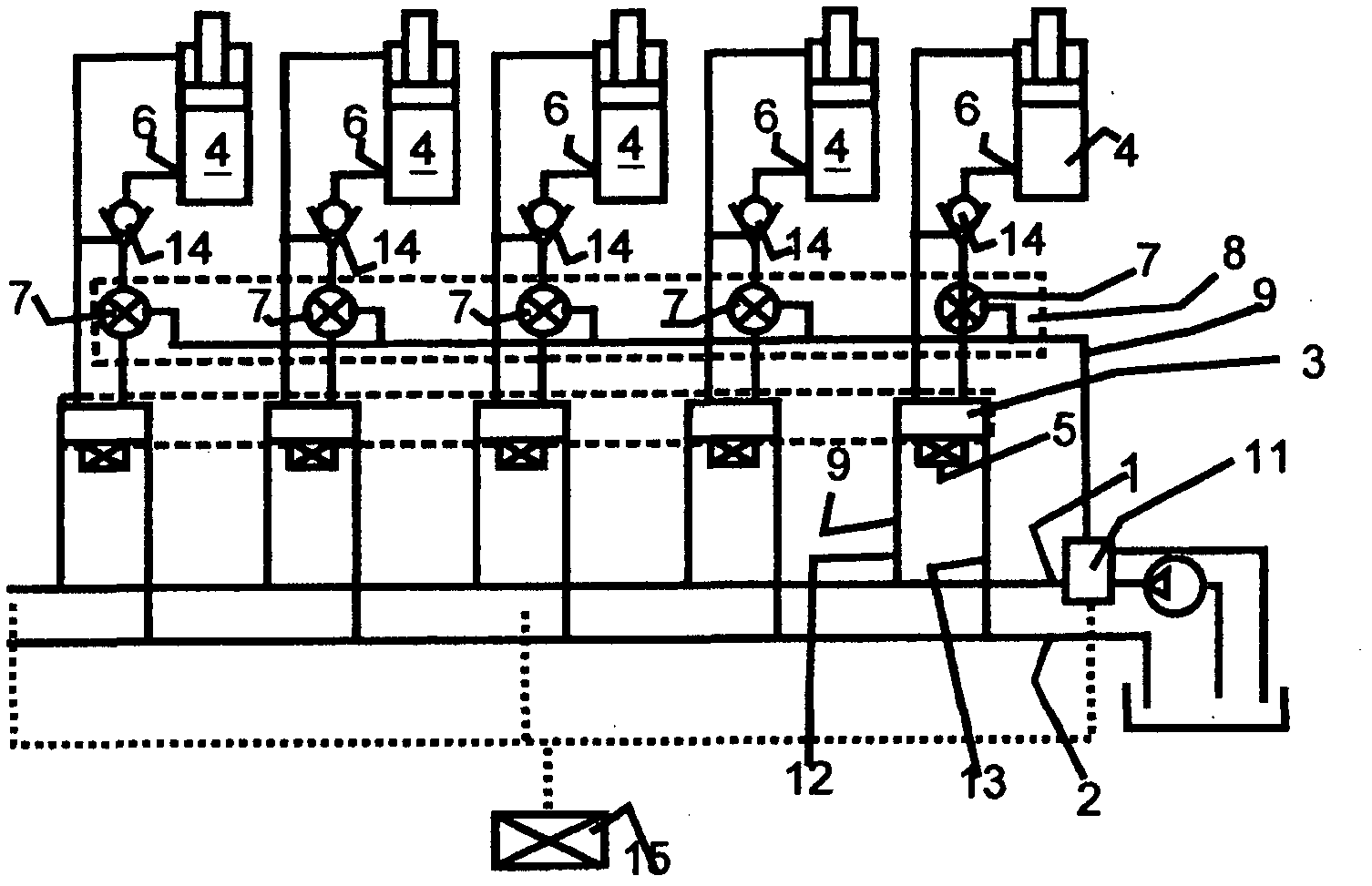

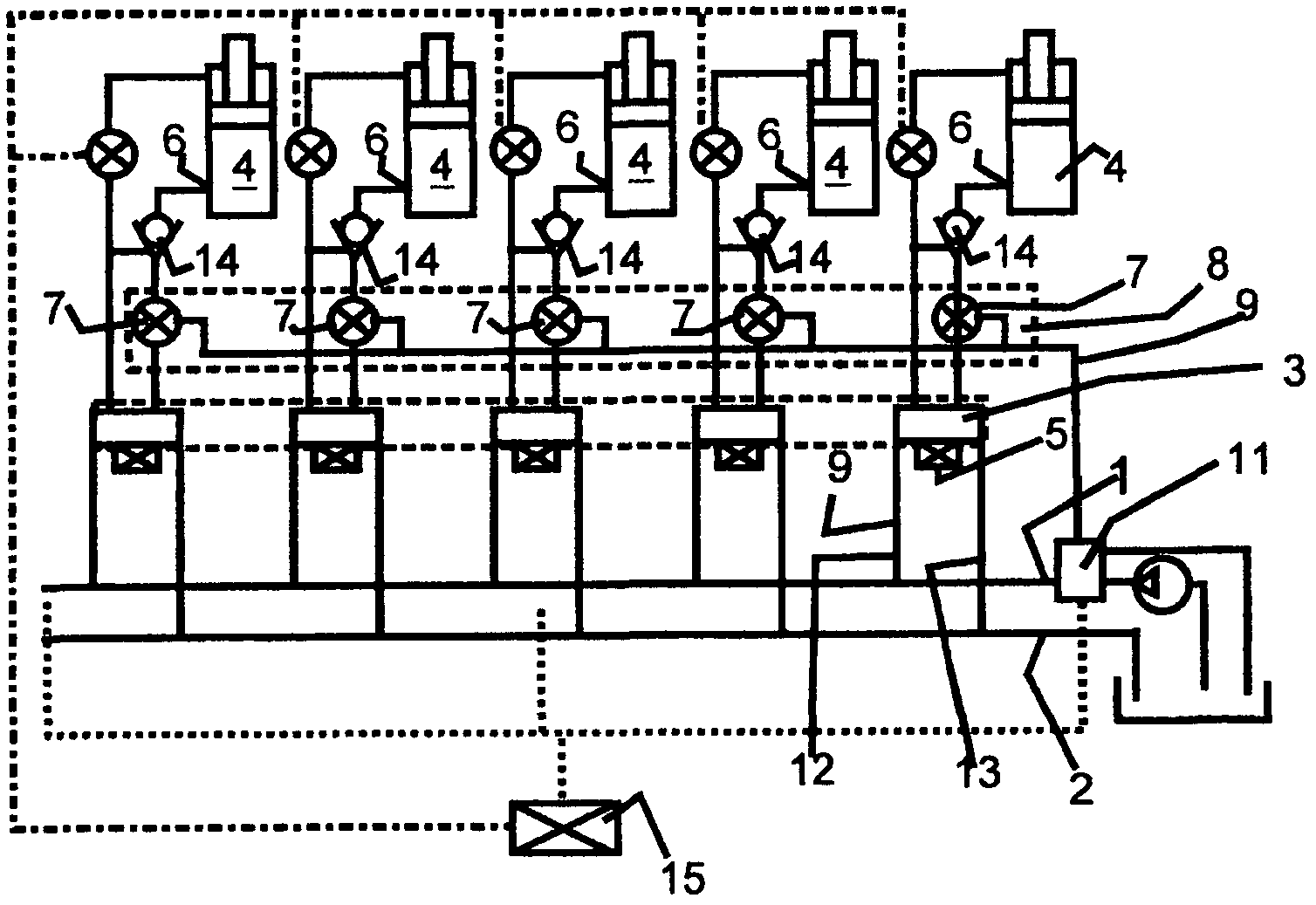

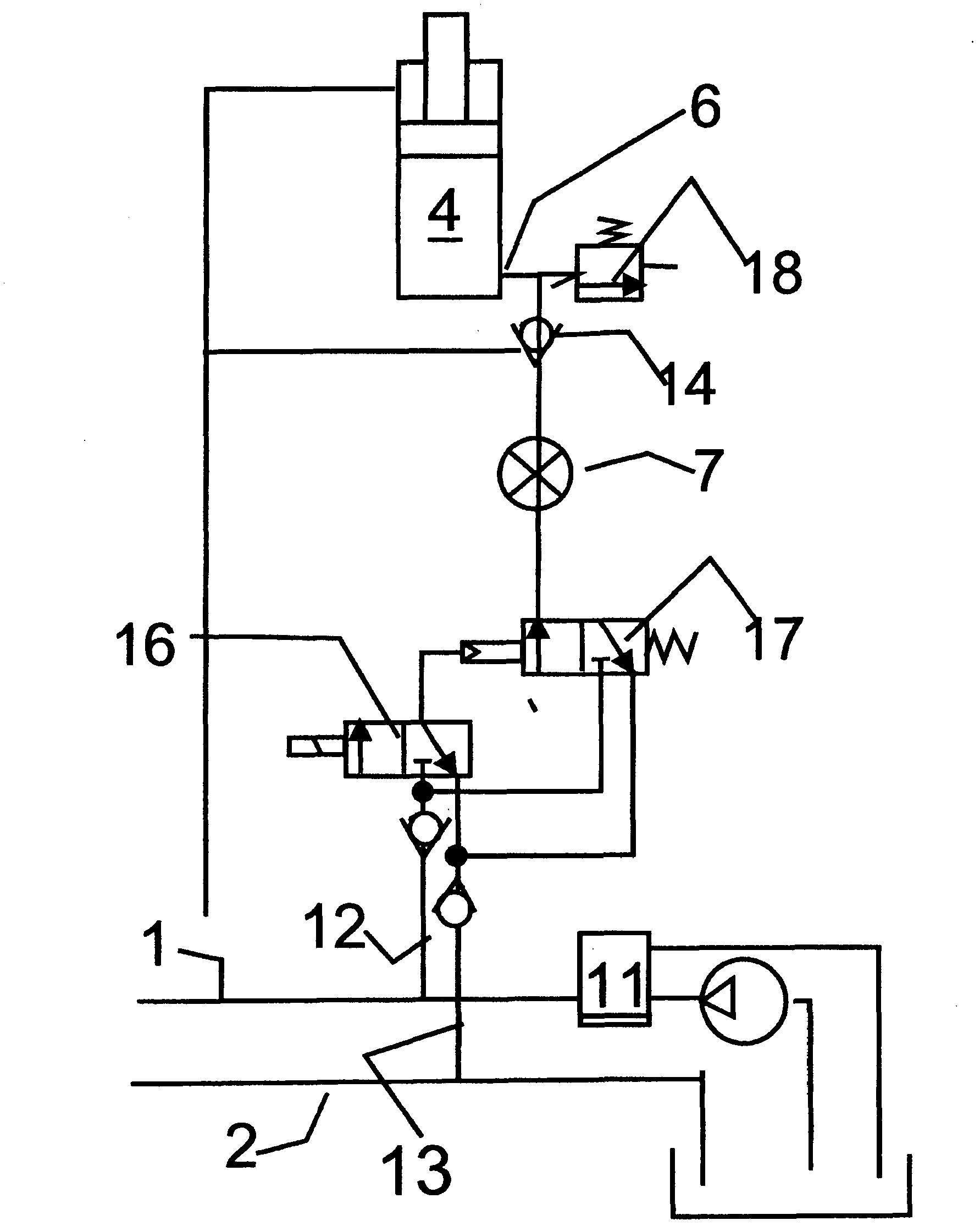

Hydraulic circuit for longwall mining

InactiveCN102713149AEasy to interveneMeet safety requirementsFluid-pressure actuator testingMine roof supportsLongwall miningHydraulic circuit

A hydraulic circuit for longwall support for use in underground mining for supporting a longwall by means of a plurality of support shields comprises a pressure monitoring device in the pressure line between the load maintaining valve and the shield control valve. Said pressure monitoring device can be a device for monitoring the piston position of the shield control valve which device signals a deviation of the set position predetermined by the shield control device from the measured actual position of the piston of the shield control valve in the form of a deviation signal. It may also be a pressure sensor which signals the deviation of the set pressure predetermined by the shield control device from the measured actual pressure in the form of a deviation signal. Signaling can be acoustic or optical.

Owner:TIEFENBACH CONTROL SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com