Patents

Literature

3307results about "Mine roof supports" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Quick supporting method for large-deformation roadway easy to fall, break and loosen and apparatus thereof

InactiveCN101852083AImprove stress statusStop looseningUnderground chambersMine roof supportsFiberSupporting system

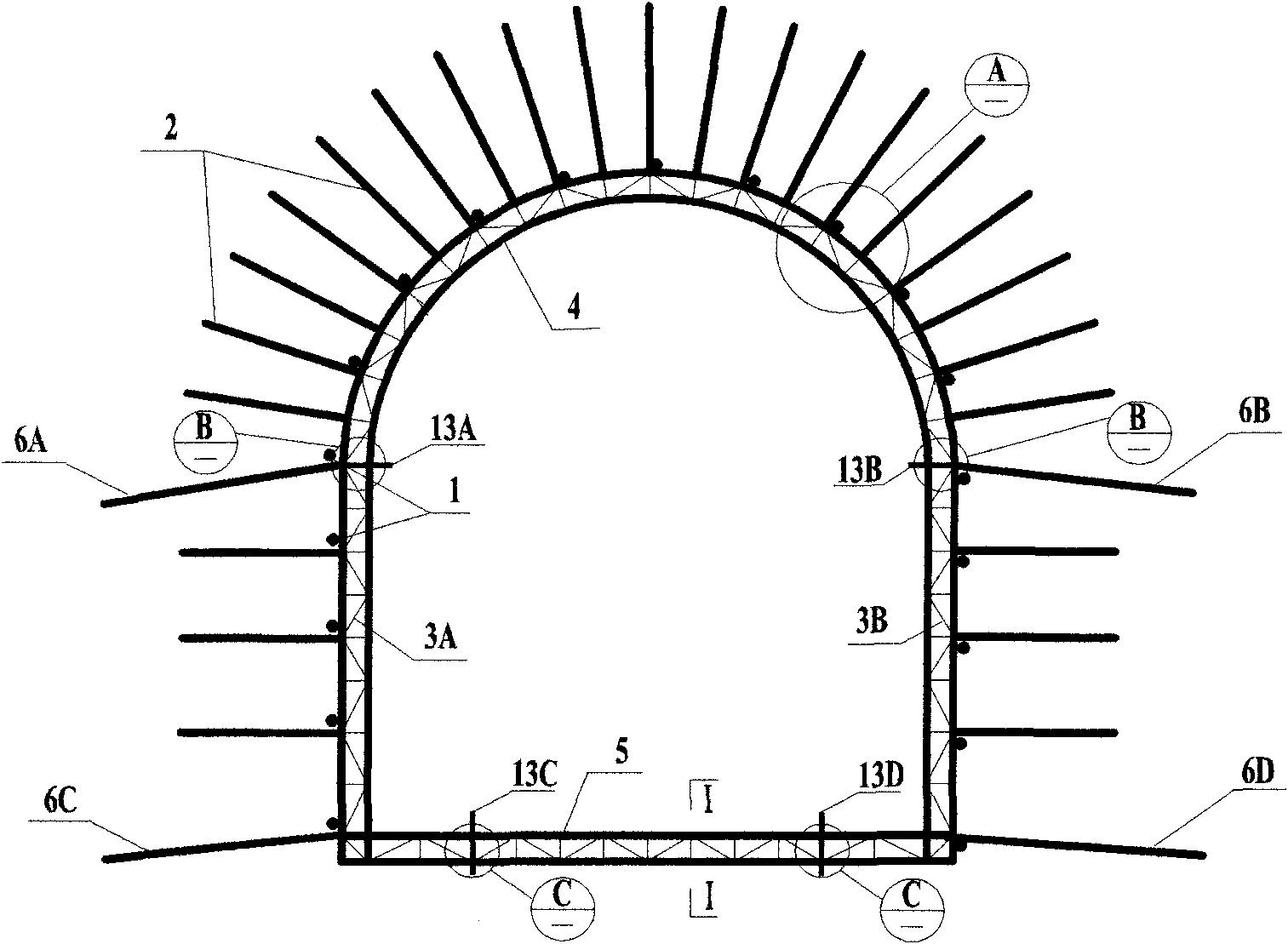

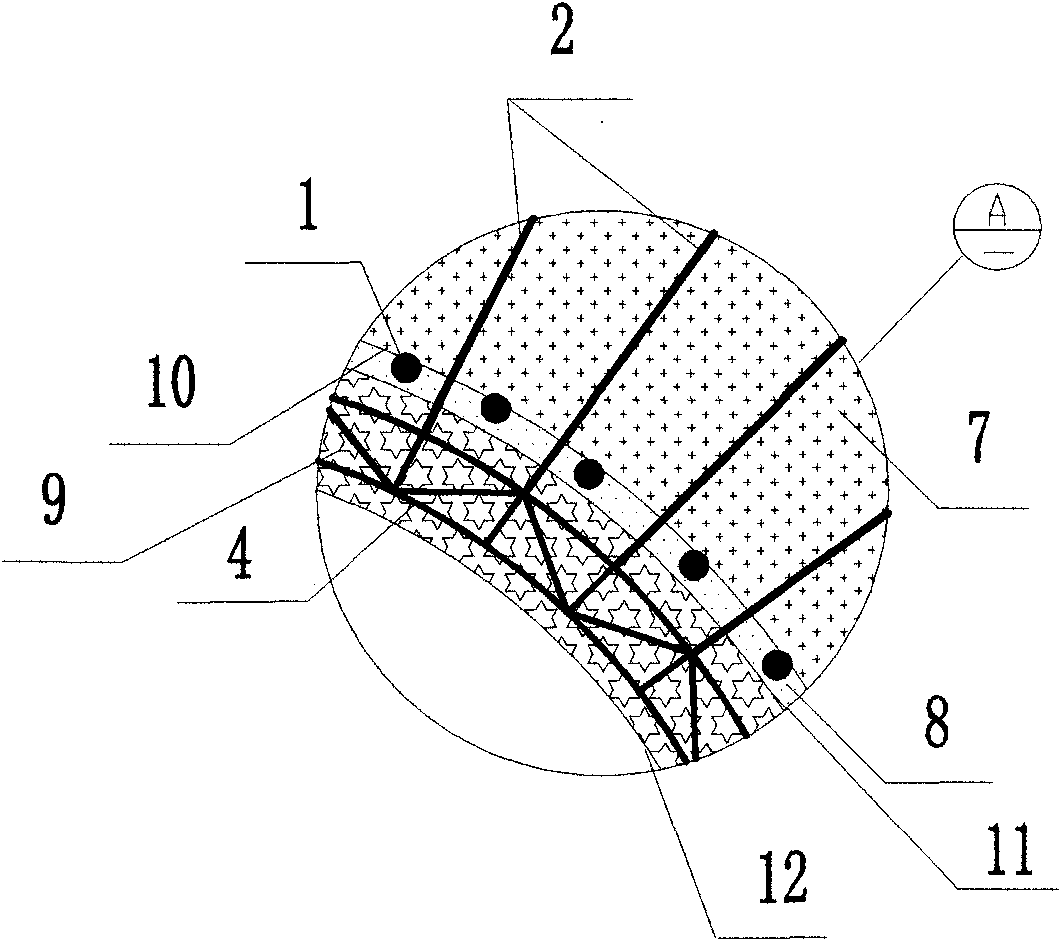

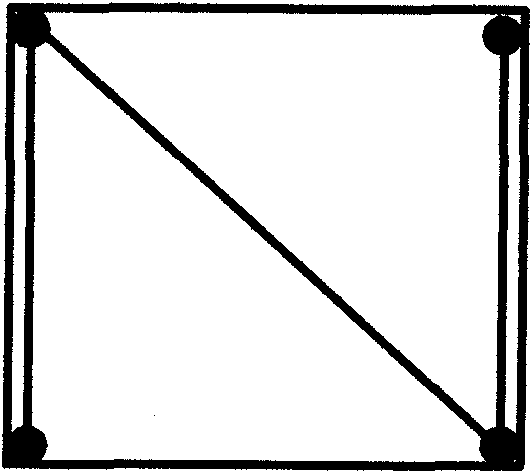

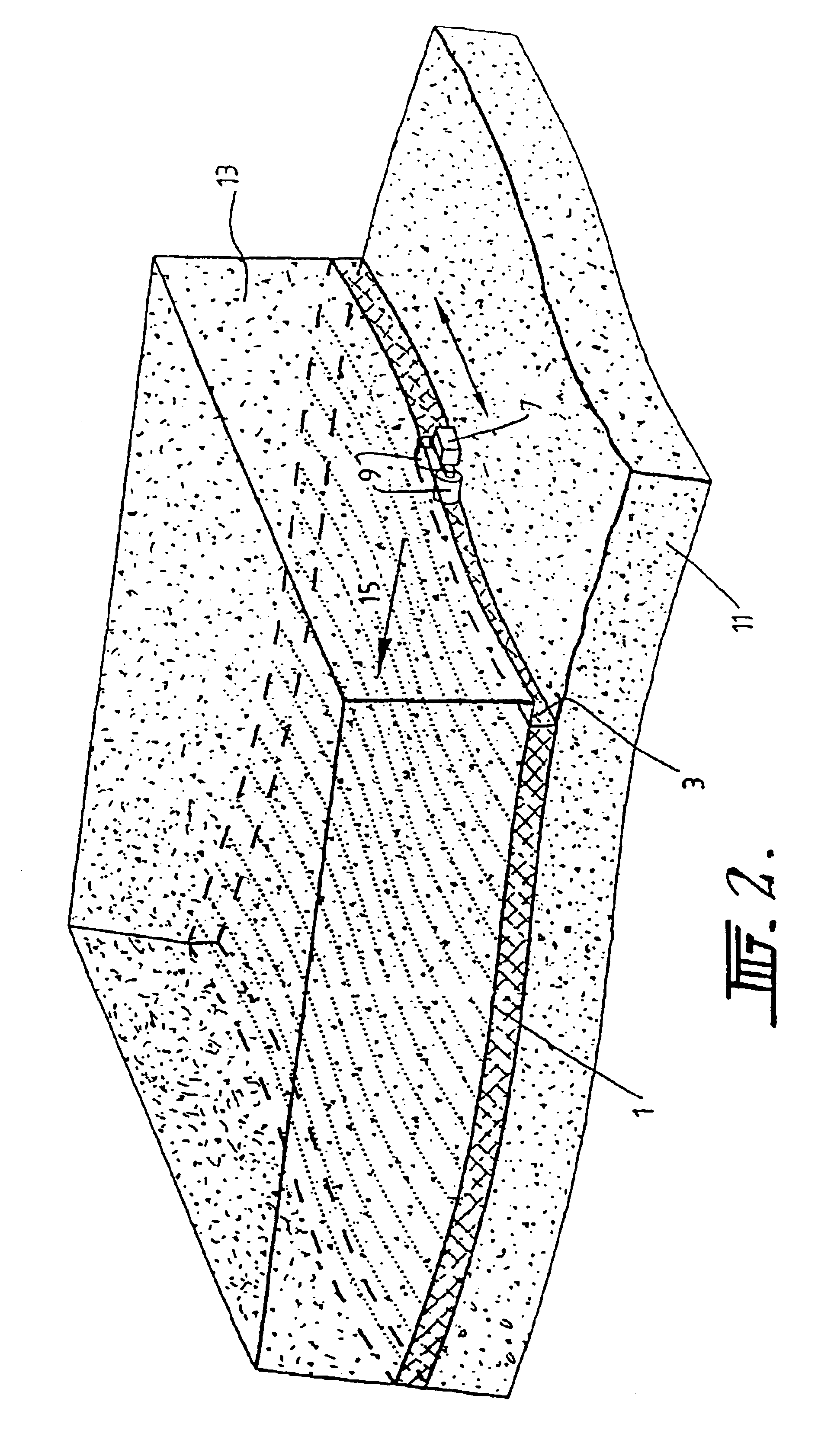

The invention discloses a quick supporting method for large-deformation roadway easy to fall, break and loosen and an apparatus thereof. The method comprises the following steps of: (1) clearing away the loose stones on the wall of the surrounding rock of the roadway; (2) hanging a reinforcing steel bar mesh along the digging outline of the roadway and initially spraying one thin concrete layer; (3) arranging an anchor rod in the drill hole of the roadway wall; (4) arranging a side-wall steel grating arch to support the surrounding rock of the side wall; (5) arranging a top-supporting steel grating arch, touching the top and supporting the upper surrounding rock; (6) clearing away the floating slag at the bottom of the roadway, arranging a steel grating arch of the inverted arch, supporting and sealing the system into a ring; (7) carrying out the cement injection construction on the anchor rod; (8) welding the exposed part of the cement injected anchor rod on the steel grating arch to form a whole structure; and (9) multi-spraying concrete or steel fiber concrete along the roadway wall. The apparatus comprises an anchor rod, a side-wall steel grating arch, a steel grating arch of top arch, a steel grating arch of inverted arch, and a concrete spray layer of reinforcing steel bar. The invention has the advantage of remarkable support effect, simple method and convenient operation and solves the problem that the bracket and the surrounding rock are not adhered tightly.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

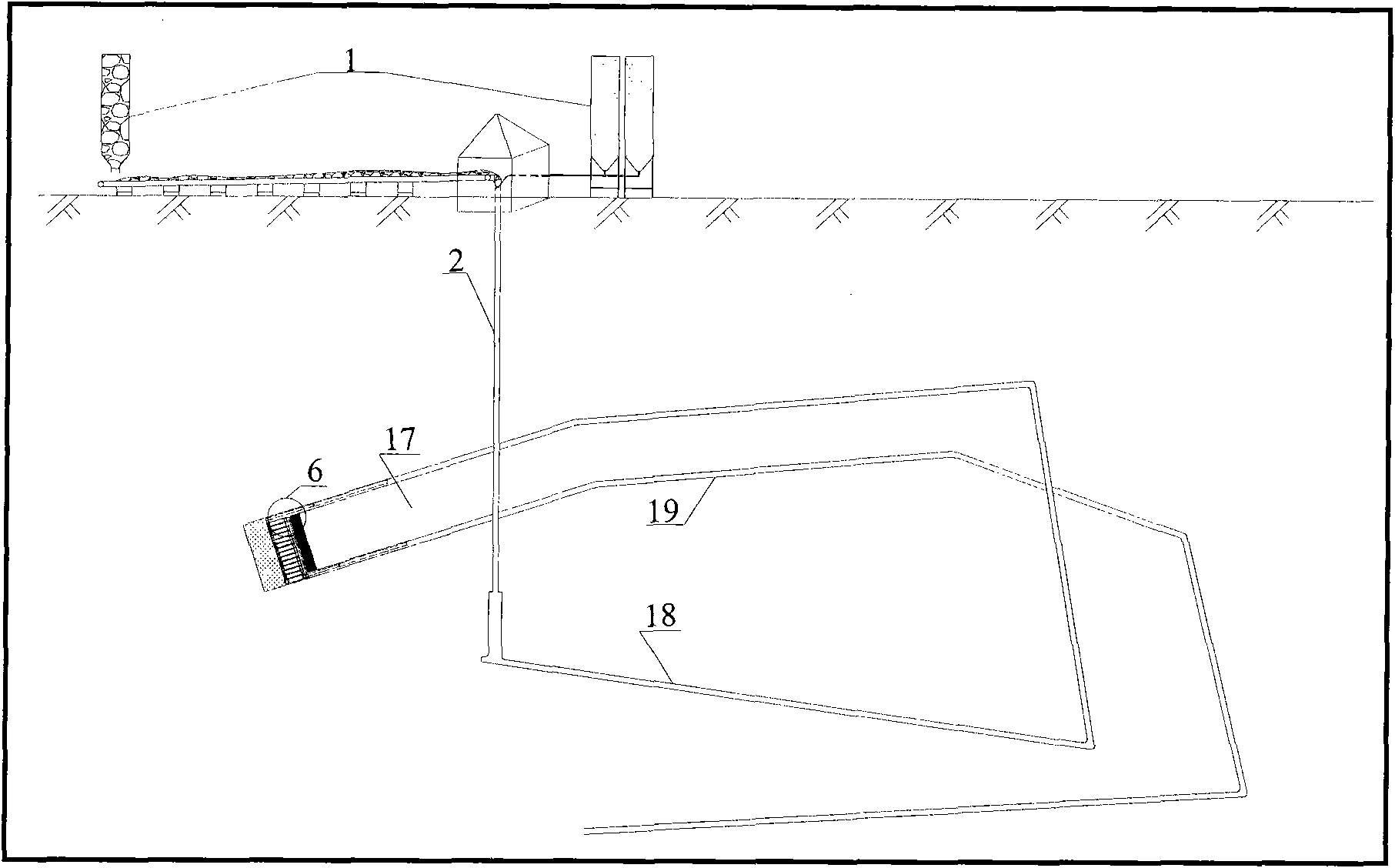

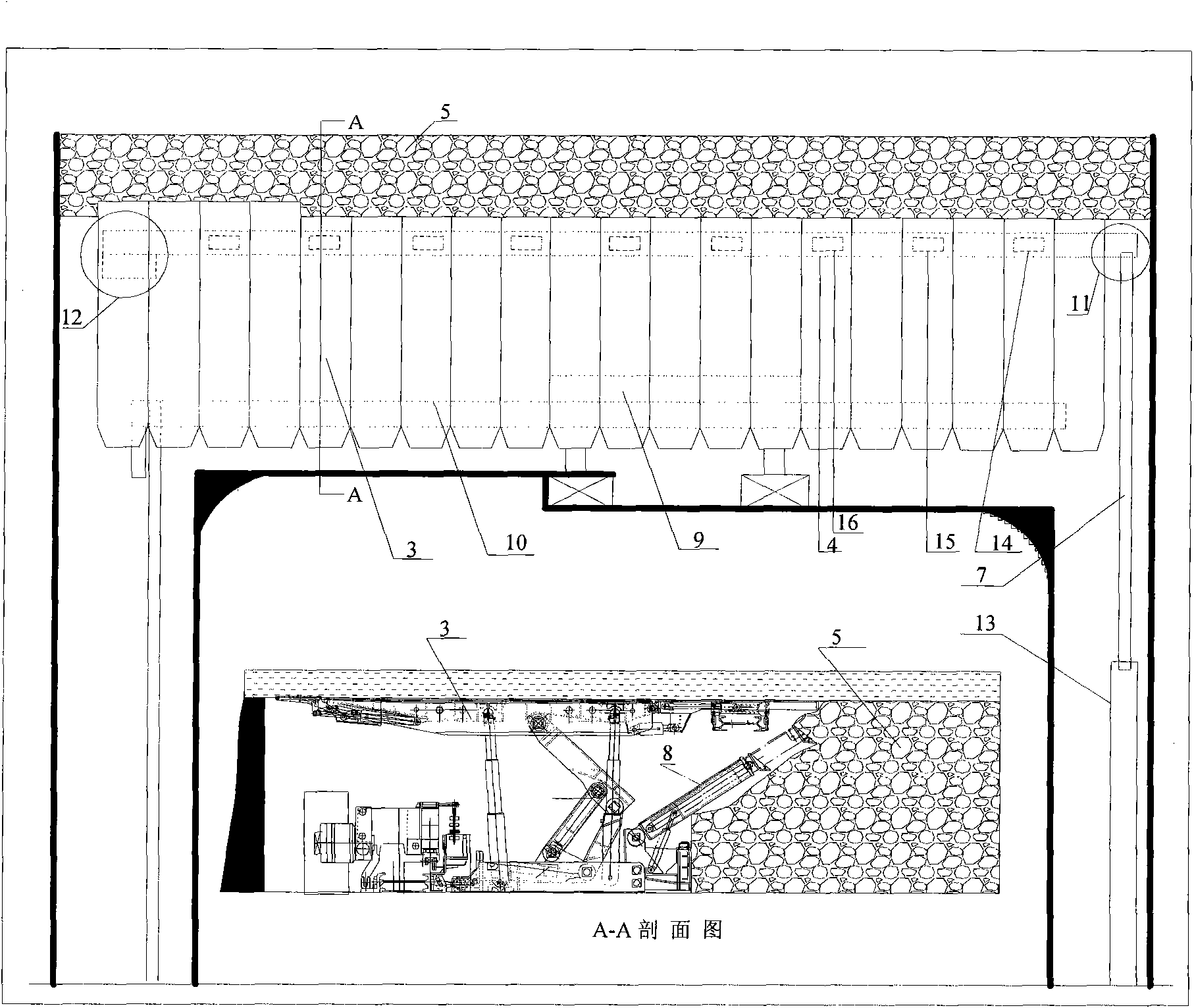

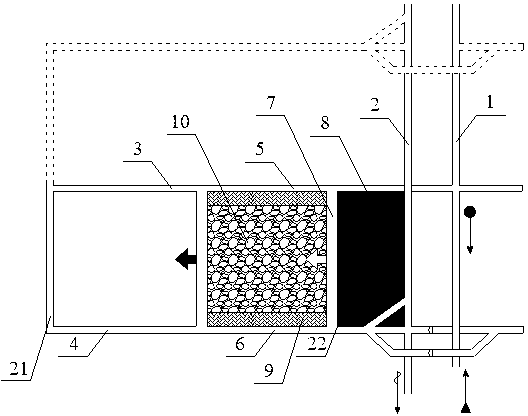

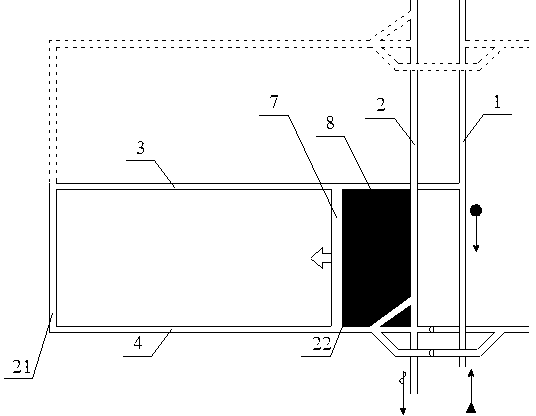

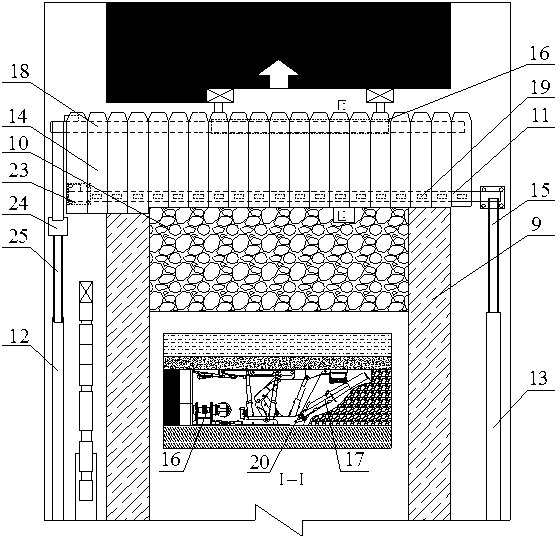

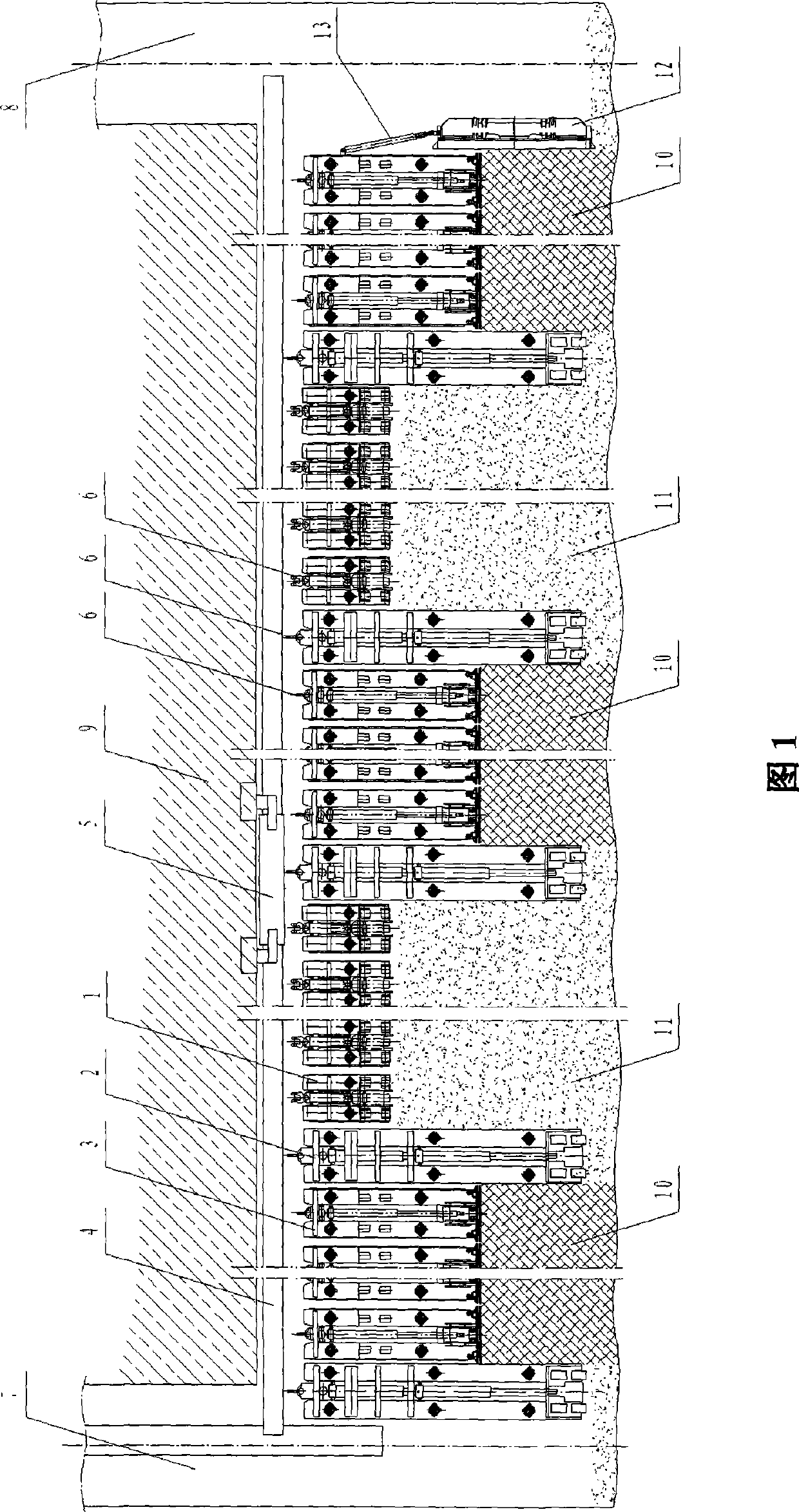

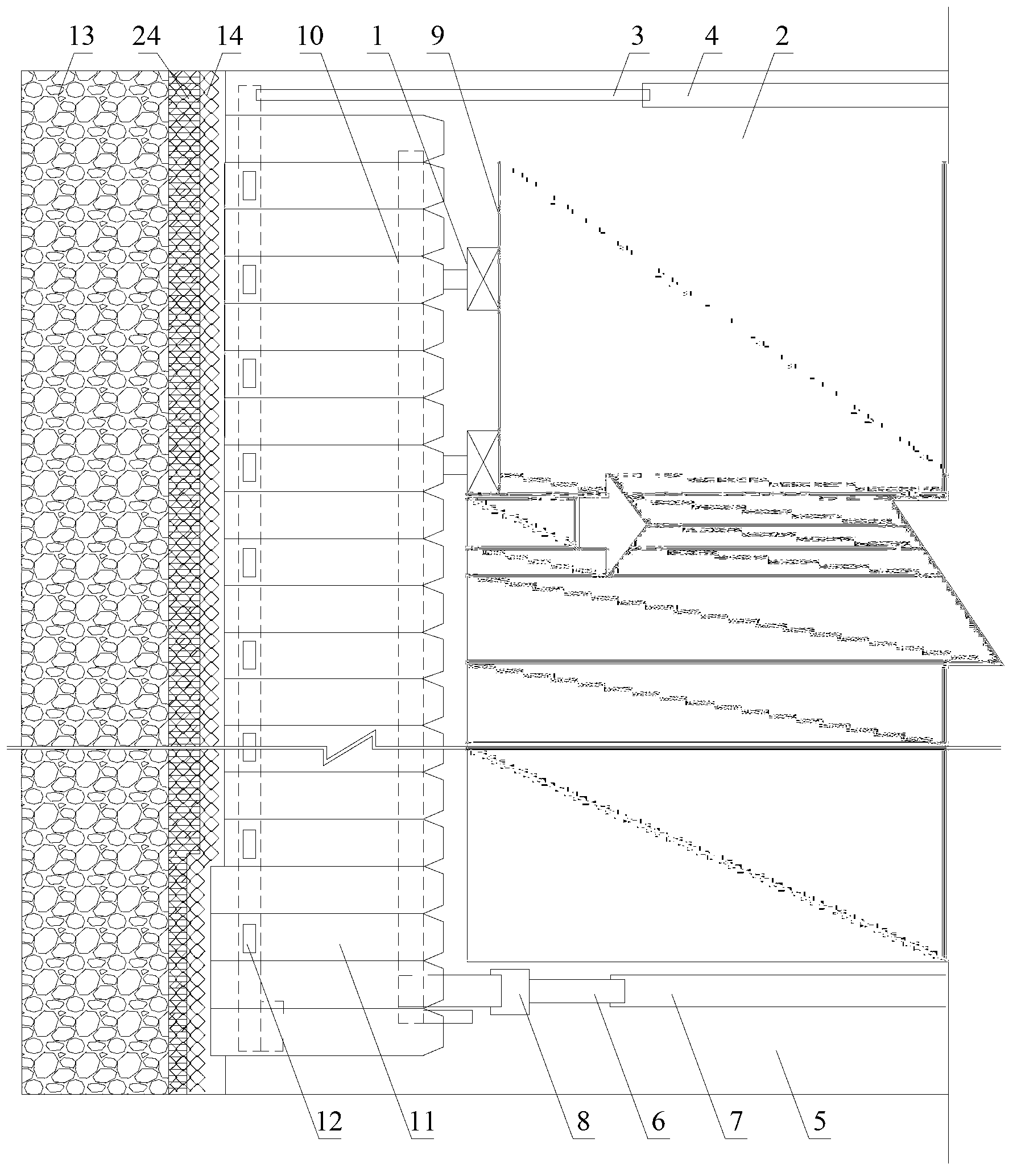

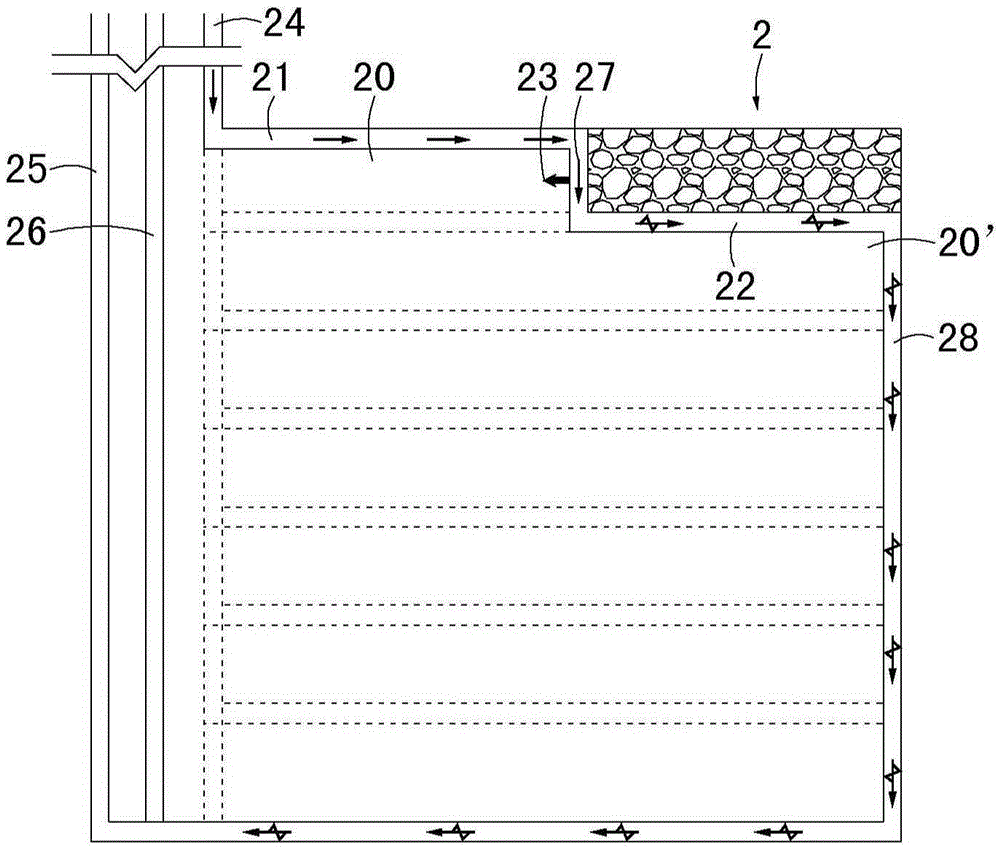

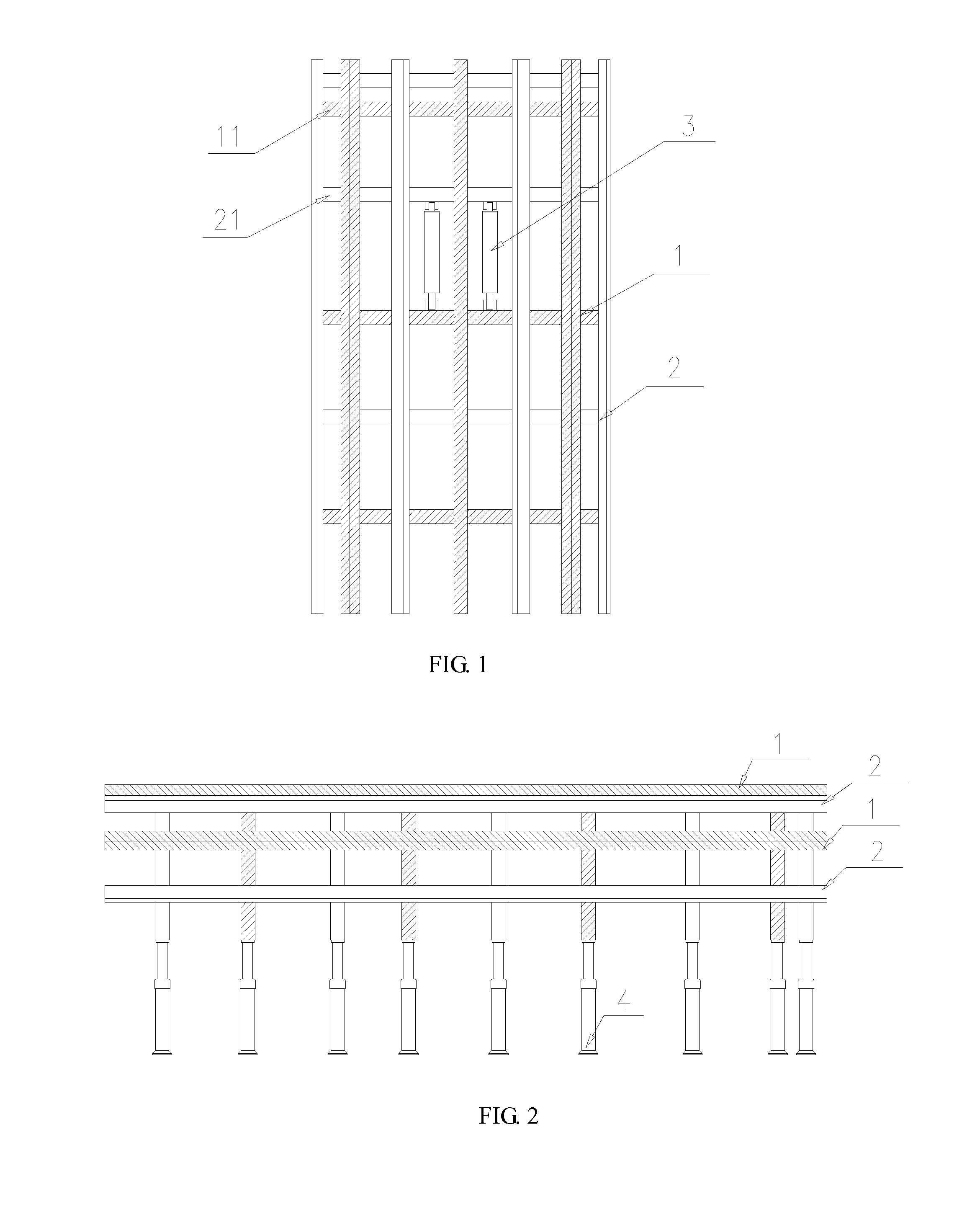

Coal mining solid filling method

InactiveCN101586460AHelps control sinkingEasy to useUnderground miningSurface miningSolid massFilling materials

A coal mining solid filling method comprises following steps: using the stacked solids on the ground as the filling materials for the working surface goaf, directly putting the solid filling materials from the ground to a belt conveyor in the underworkings by a perpendicular feeding well, transporting to the end of a coal face through the underground belt conveyor, reloading the solid filling materials to a solid filling mining conveyor hung under a back tail beam of a self-impacting type filling hydraulic support by a self-moving type filling material reloading machine. In the process of mining work, the coal is mined and the filling materials are filled on the bottom; and the solid filling materials are compacted by means of a compactor of the self-impacting type filling hydraulic support. The method solves the problem of coal compaction under the building and low coal recovery.

Owner:CHINA UNIV OF MINING & TECH +1

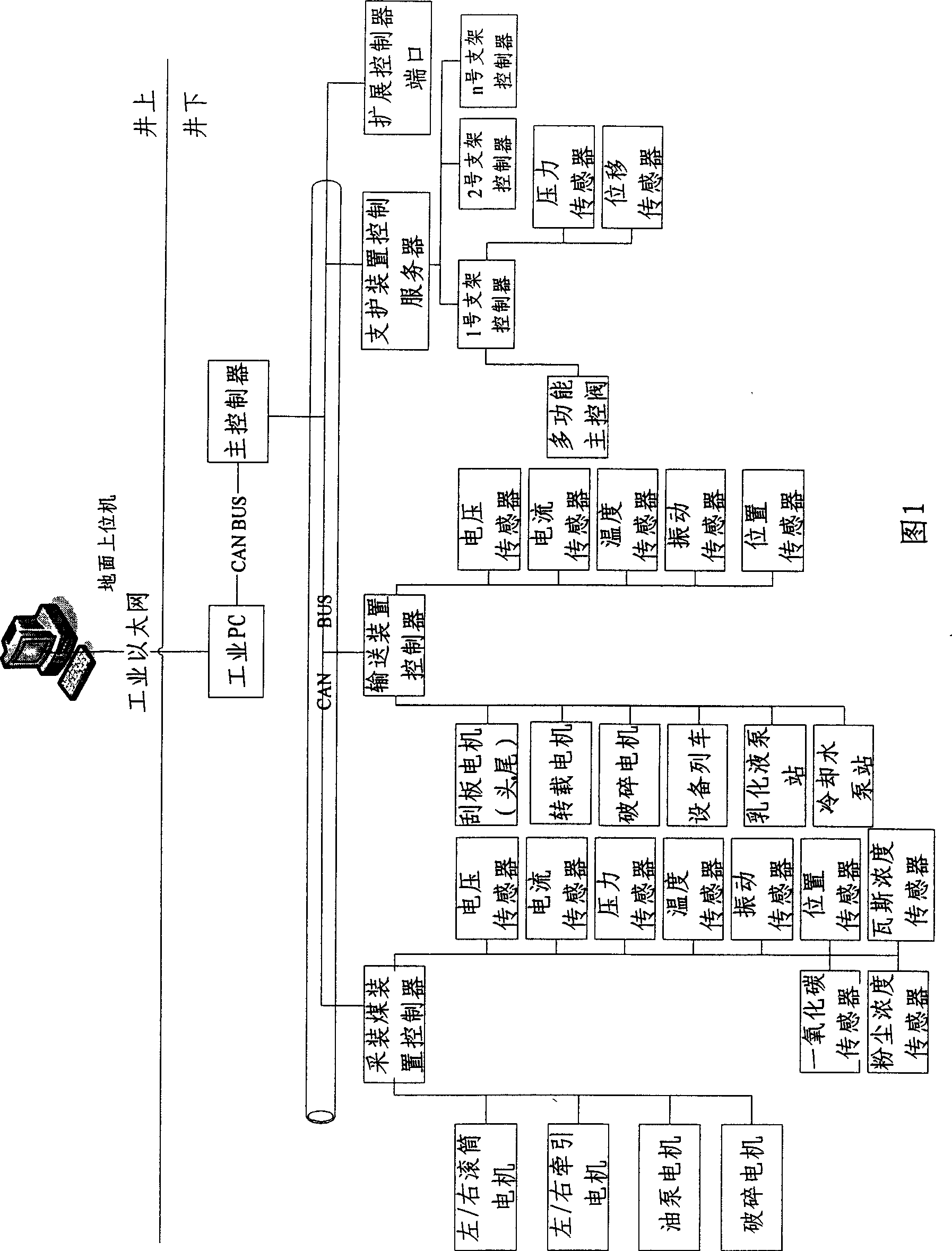

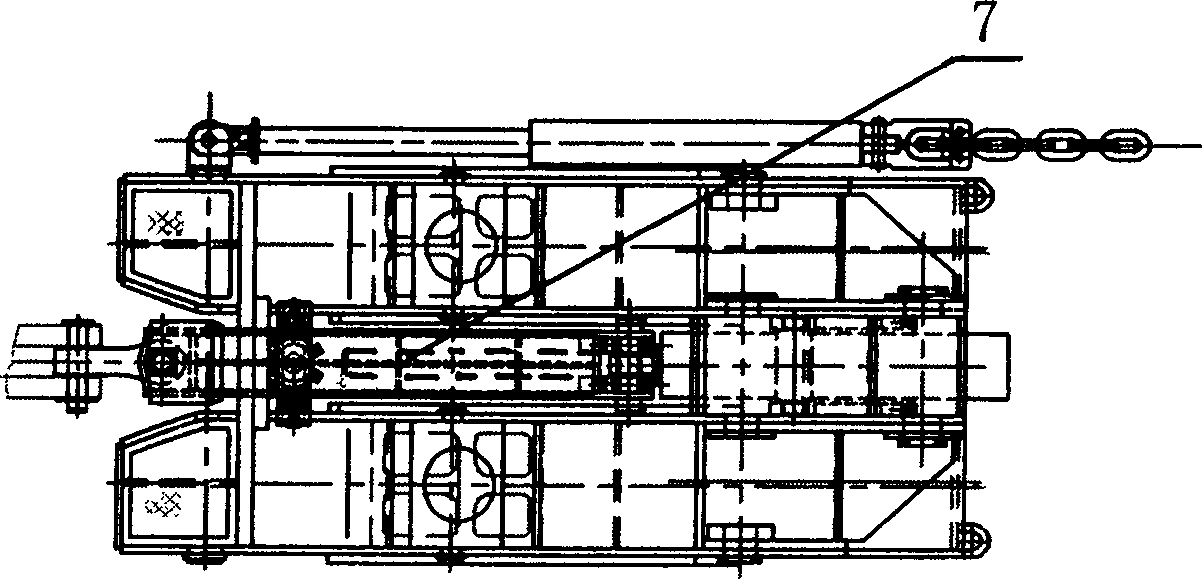

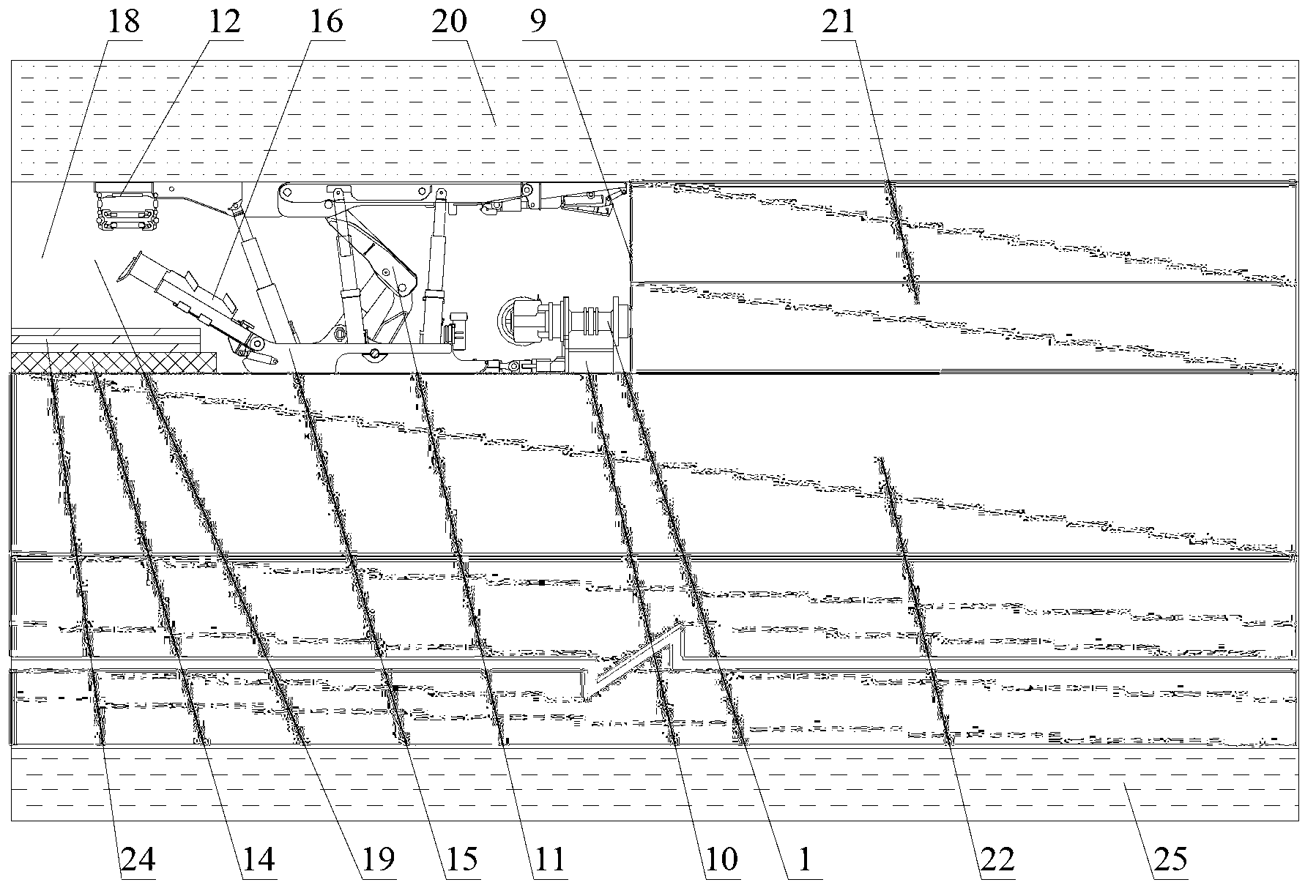

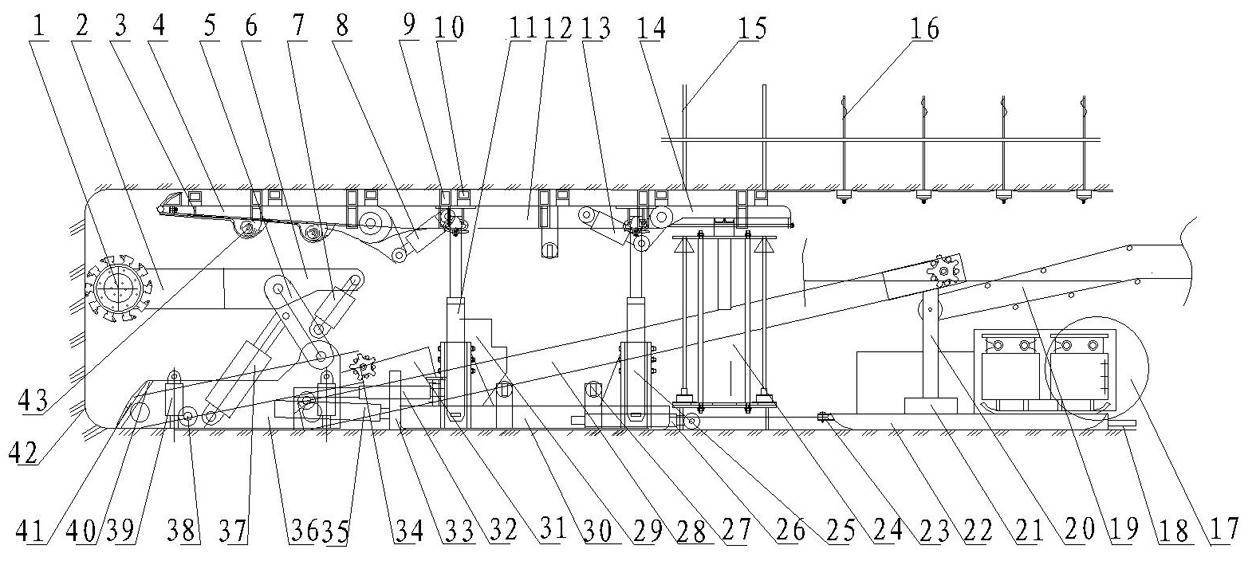

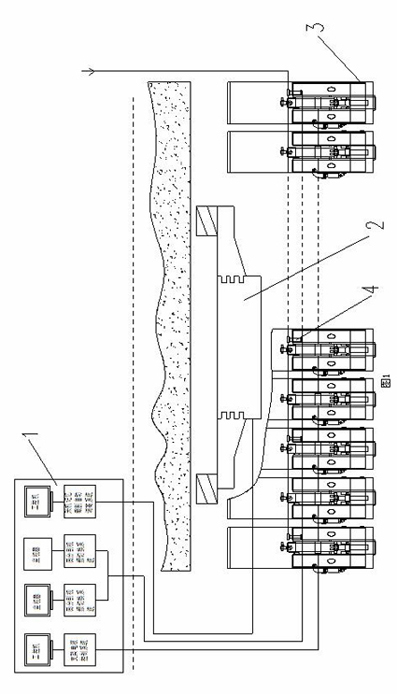

Intelligent full automatic combine coal mining system

ActiveCN101418688ARealize comprehensive applicationImprove completenessMining devicesUnderground miningProcess engineeringControl equipment

The invention relates to an intelligent type full-automatic combined coal mining system, which comprises a coal mining and loading device, a conveying device, a supporting device, and an equipment train, and is mounted in the working face and crossheading in the coal mine well. The coal mining and loading device is mounted on the conveying device, the coal conveying port of the conveying device is conveyed to the outside of the well or the coal bunker through a belt type conveyor in the crossheading, the supporting device is arranged behind the conveying device for supporting the top plate of the coal seam and linking with the conveying device, the equipment train comprises a central control chamber of a central control equipment, a starter, a power device, and a lifesaving cabin, the central control equipment monitors and controls the coordination operation of the devices, the equipment train, and the power device of the equipment train, the power device provide power source for the devices and the equipment train, and the equipment train moves freely in the crossheading with the feeding of the working faces. The invention improves system complete ability and execution efficiency, and has strong function, high intelligent degree, high safety, high production efficiency, and the like.

Owner:SANY HEAVY EQUIP

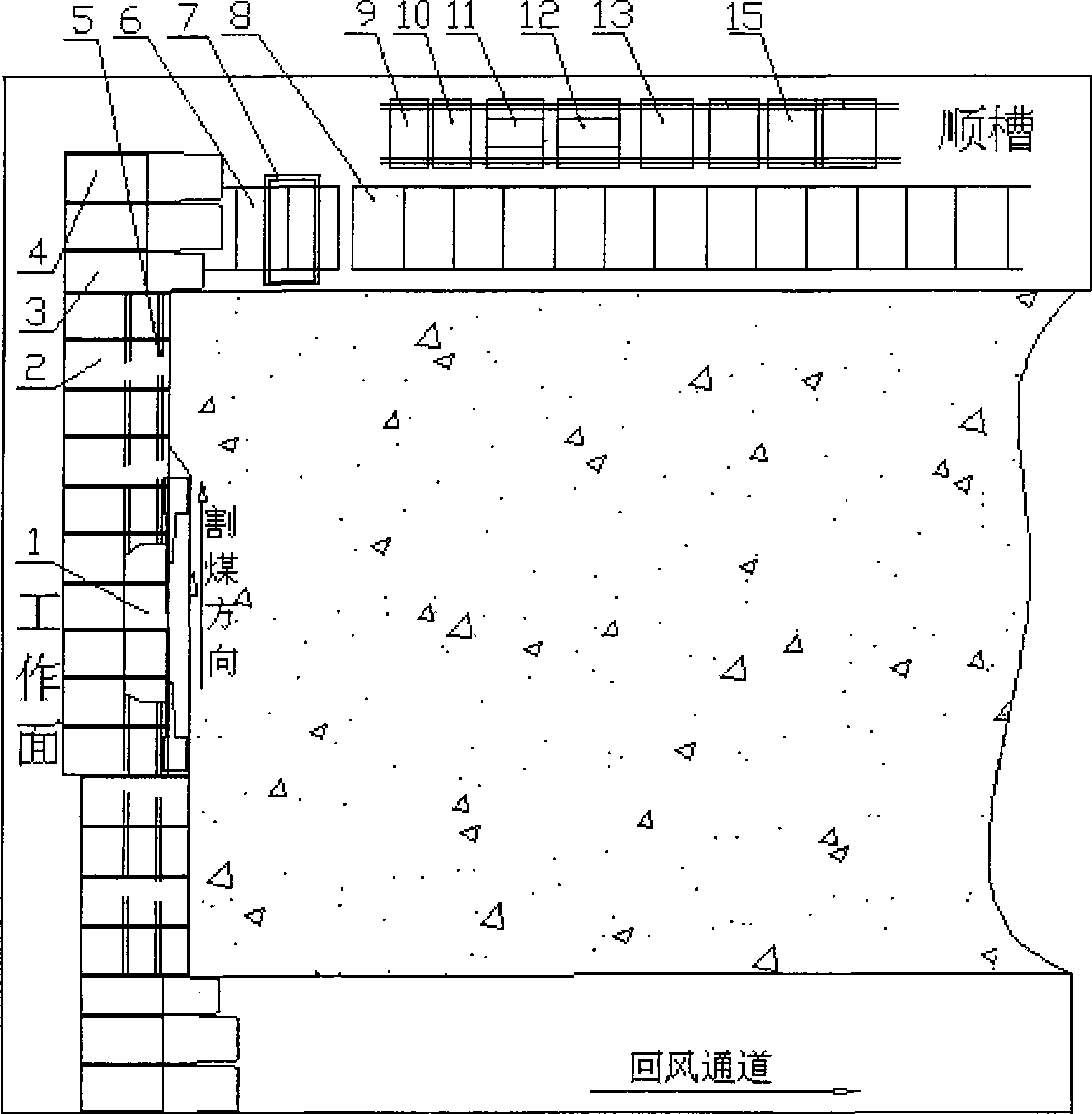

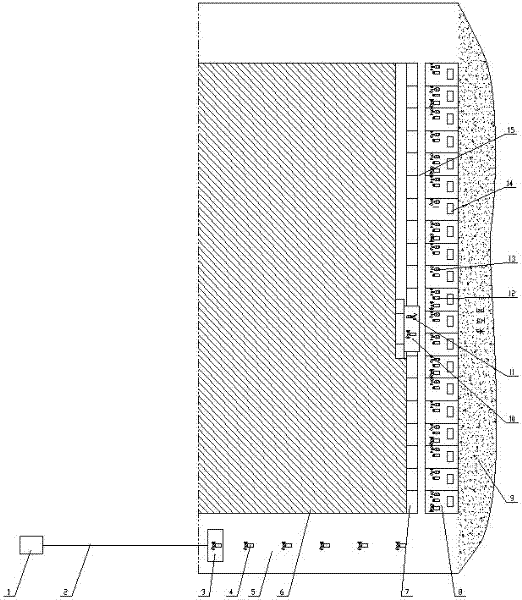

Solid-filling coal mining method with two pre-excavating tunnels for advancing

ActiveCN102996131ASolve the technical problems that cannot guarantee the filling effectEasy to useUnderground miningSurface miningFilling materialsMining engineering

The invention discloses a solid-filling coal mining method with two pre-excavating tunnels for advancing. A mining roadway adopts an arrangement mode that the pre-excavating tunnels are taken as air return and inlet roadways and a gob-side entry retaining roadway is taken as a roadway for transporting filling materials and coal; coal extraction and gob backfilling are carried out by a comprehensive mechanical solid-filling coal mining process; and according to the coal mining method, a mining sequence is propelled by making a filling coal mining work surface be back to the direction for transporting the coal to a mountain in a mining area. The pre-excavating tunnels are formed before the extraction of the work surface by tunneling, and the gob-side entry retaining roadway is formed by optimally designed filling bodies beside the roadway along with the implementation of advancing filling coal mining operation along the work surface. The coal mining method is simple in process and technically and completely realizes coal milling without pillars, and the resource extraction rate of the coal is high. The coal mining method can not only solve the technical problems that a draw-back-type down-mining and up-filling work surface cannot ensure a filling effect during a filling milling process of a mine with shortage of resources, but also materialize the comprehensive mechanical solid-filling coal mining of mines with limited geological conditions by virtue of an advancing up-milling and down-filling work surface.

Owner:CHINA UNIV OF MINING & TECH

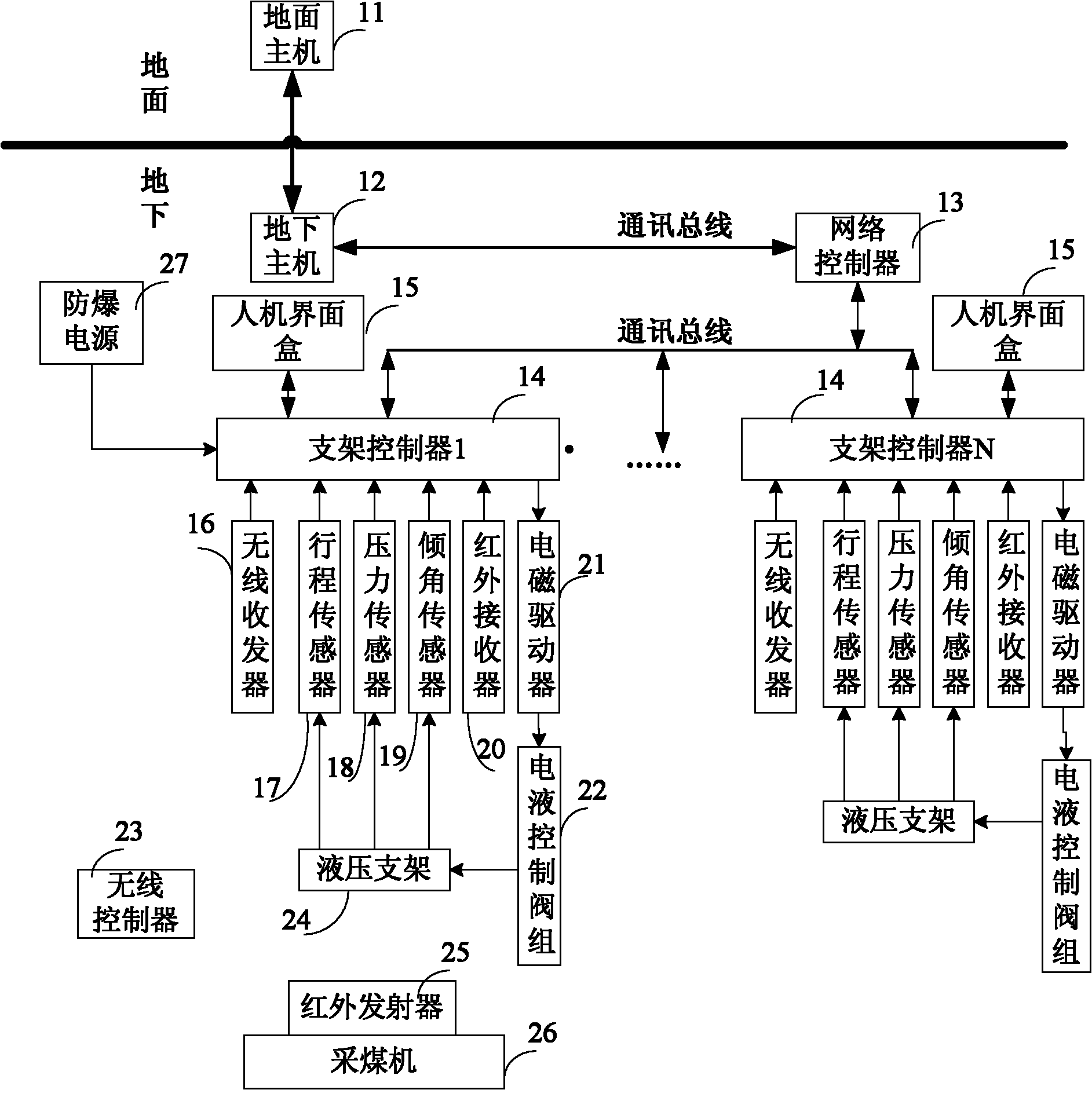

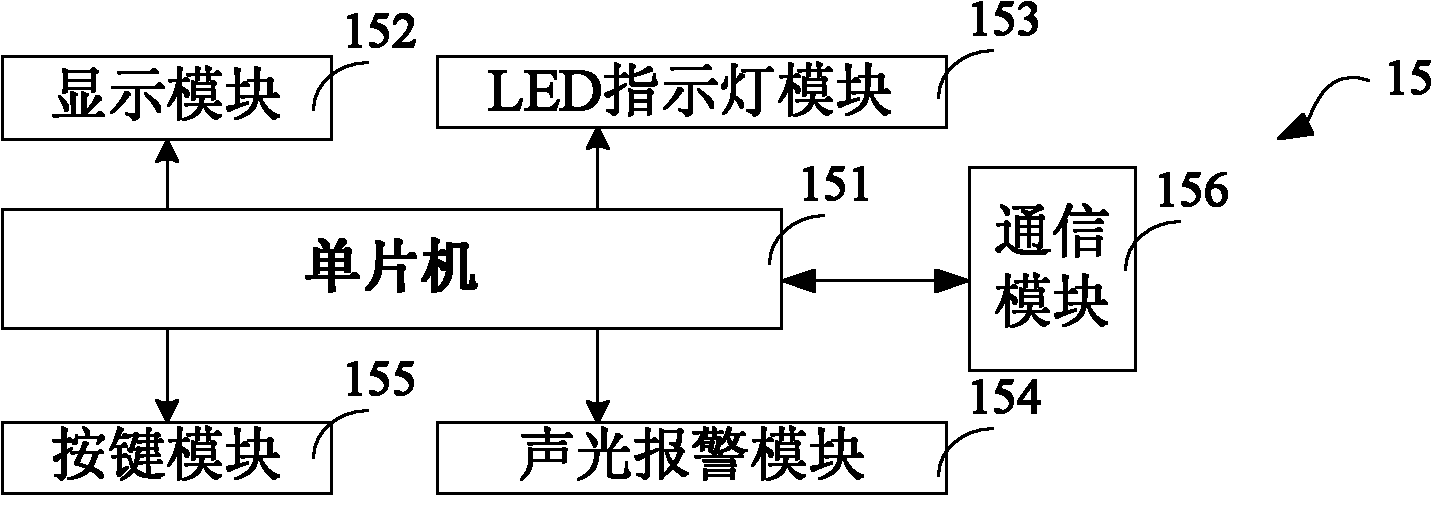

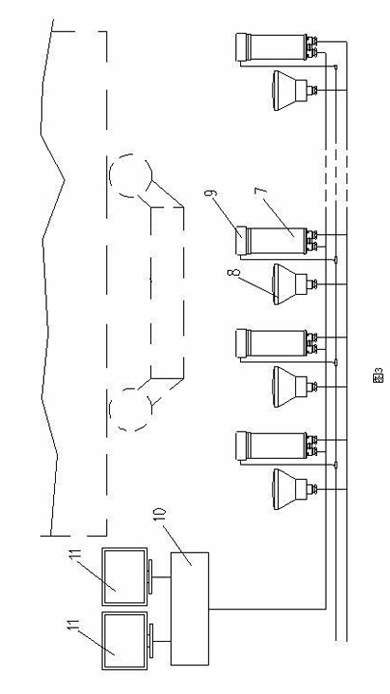

Thin coal seam unmanned automated mining mode

The invention discloses a drum-coal-mining-machine-based thin coal seam unmanned automated mining technology. The technology has the characteristics that: persons do not exist on an operating surface; operators know about conditions of the operating surface through video in a control center far from the operating surface and simultaneously complete various kinds of operation; video signals and control instructions are transmitted through a wireless switch; a coal mining machine has a function of memory cutting and is provided with a position monitoring device and an infrared transmitter at the same time, coal is automatically cut according to a preprogram, and operation parameters such as positions, directions and the like are sent out at any time; a bracket controller receives the parameters, automatically drives an electric hydraulic control valve to do actions of column lowering, frame moving, pushing, column erecting and the like according to the preprogram, and a hydraulic bracket is pushed to move forward along with the coal mining machine, so that the unmanned automated mining on the operating surface is realized; and when the thickness of coal seams, and top and bottom boards are changed, the operators regulate operation programs and the parameters in the control center and perform manual intervention on the coal mining machine and the hydraulic bracket, so that the remote-control unmanned automated mining on the operating surface is realized.

Owner:TIANDI SCI & TECH CO LTD

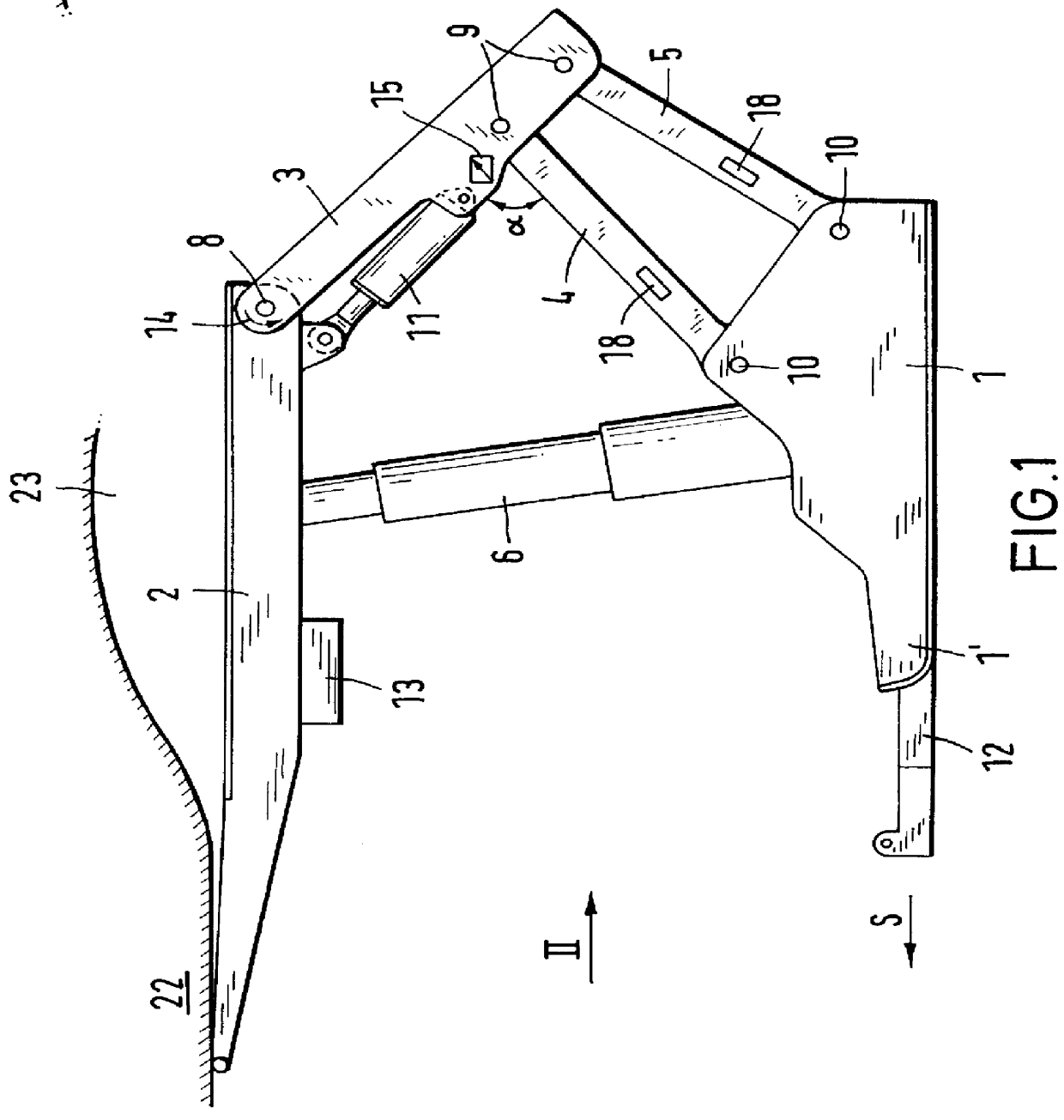

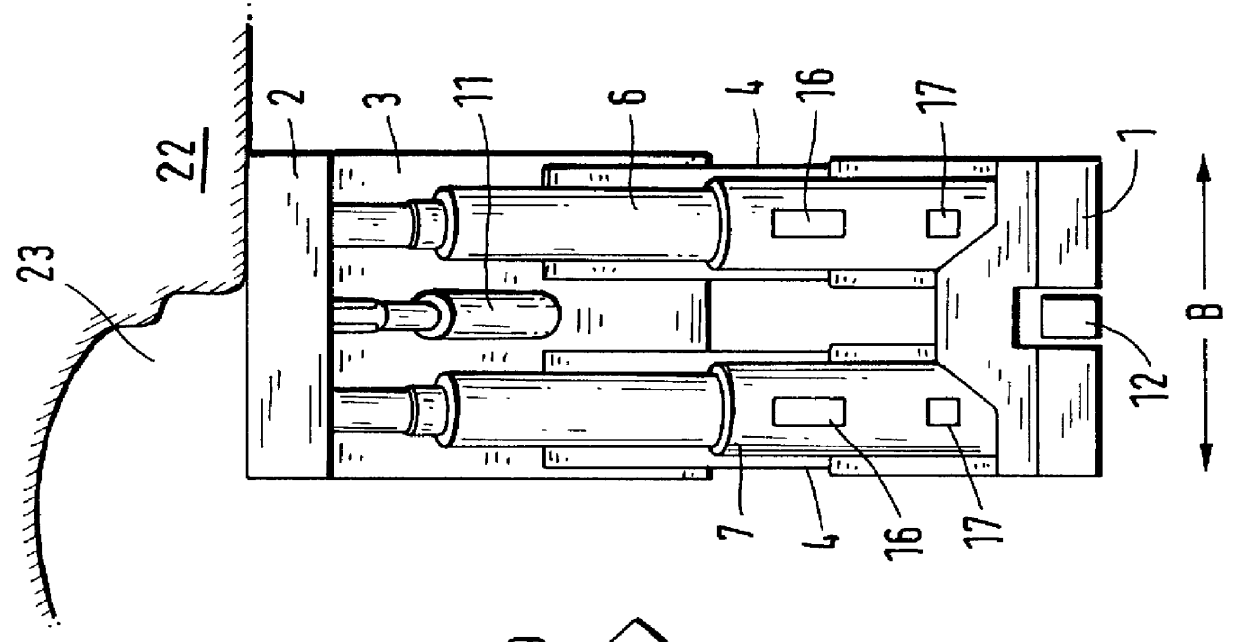

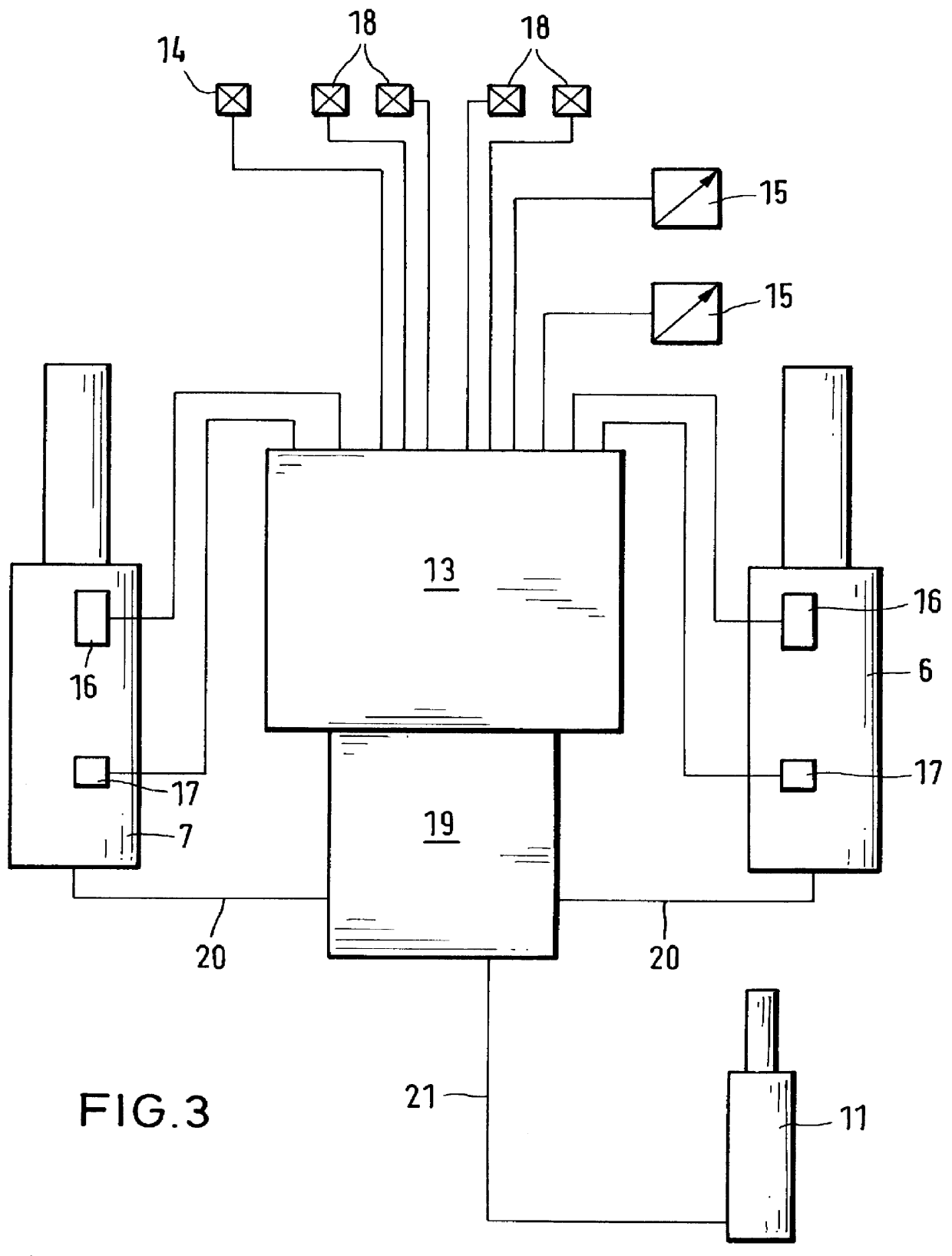

Method and device for monitoring the load on hydraulic powered shield supports for underground mining

InactiveUS6056481AReduce weightExtended service lifeArtificial islandsMine roof supportsMicroelectronicsElectricity

According to the invention, monitoring the load on hydraulic powered shield supports in underground use is performed by using the controller (13) serving for extraction control, which is equipped with microelectronics for load monitoring and load control, the components of the powered shield support being assigned sensors (14 to 18) whose electric measured values are used by the controller (13) for evaluating the measured signals and for driving the hydraulic rams (6, 7) and / or the angle cylinder (11) assigned to the powered shield support. The load control is preferably designed here in such a way that the critical load situations "one-sided loading" and / or "tip-toeing" are detected as early as during the setting operation, with the aid of appropriate sensors, and are rendered non-damaging in their effect by appropriately driving the hydraulic rams and / or the angle cylinder.

Owner:CATERPILLER GLOBAL MINING EURO GMBH

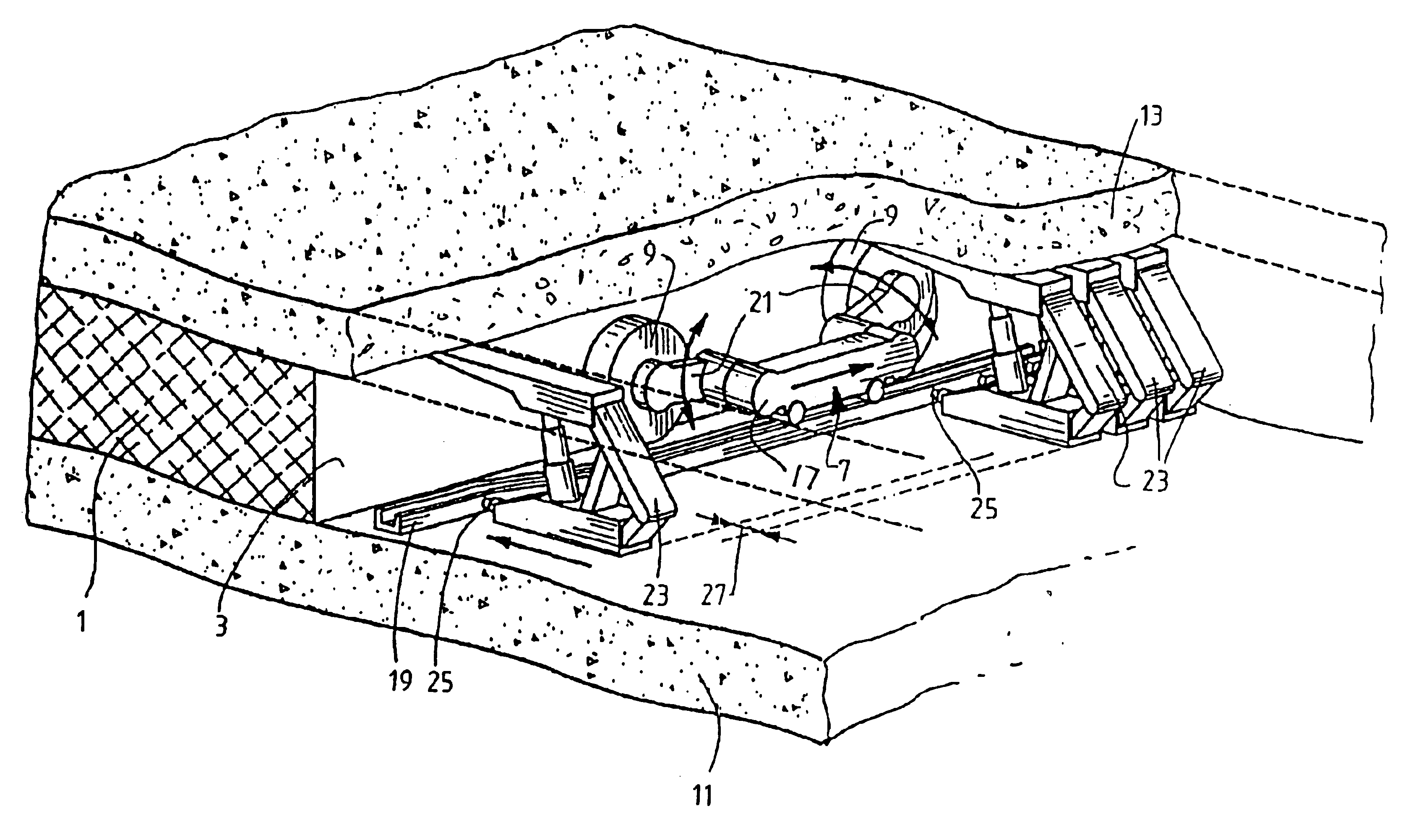

Strip filling integral backstopping coal mining method

ActiveCN101372891AHigh recovery rateMining operation safetyUnderground miningSurface miningResource recoveryBand shape

A band filling stoping mining method effectively solves the problems in the prior stoping mining of a 'three-low' coal bed, such as the sedimentation and distortion of the earth surface, the low recycling rate of coal and charcoal resources, the existence of safety hazards, etc. The method comprises the following steps: a transporter and a coal mining machine are laid on the working face of the mining area; in the direction perpendicular to the direction of the transporter movement, a timbering device which is composed of a hydraulic bracket of the working face, a side molding board bracket for filling beside the lane and a back molding board bracket for filling beside the lane, and connected with the connecting head of the transporter is arranged; after the brackets are pushed along the working face, paste concrete is injected through a pipeline into a filling mold cavity enclosed by the brackets, so as to form a band-shaped filling wall which is supported between the top plate above the goaf and the bottom plate of the coal bed. By the method, safe and convenient mining operation is ensured; the recycling rate for coal and charcoal is increased; meanwhile, the sedimentation and distortion of the overlying strata of the coal bed and the earth surface can be controlled in a very small range of deformation permitted by a building, thereby minimizing the amount of gentle sedimentation of the earth surface, and protecting buildings and attachments on the earth surface.

Owner:沈阳天安特种机器人有限公司

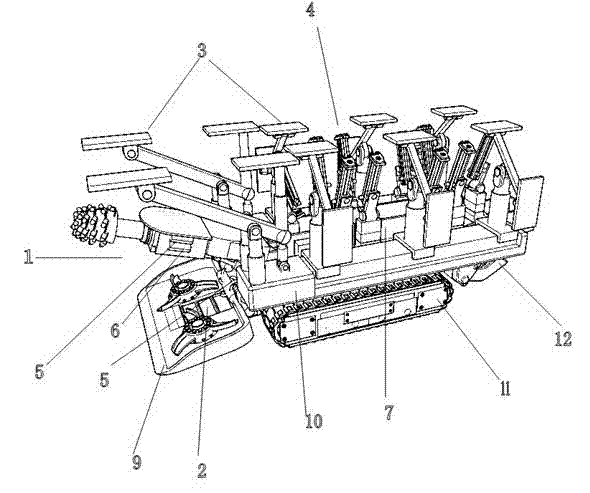

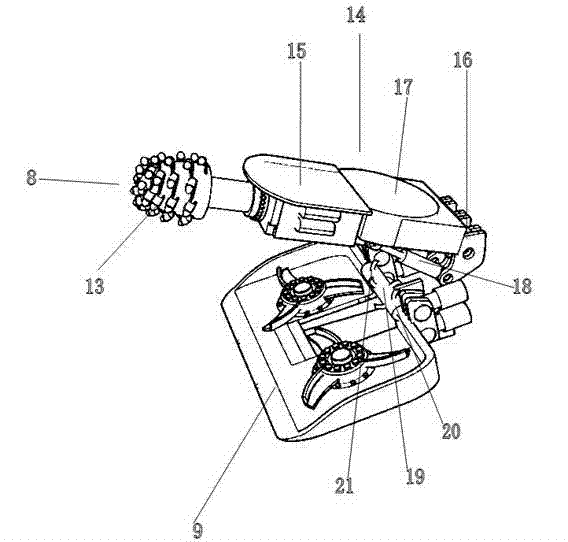

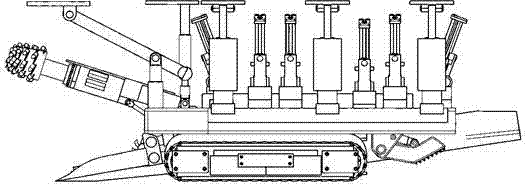

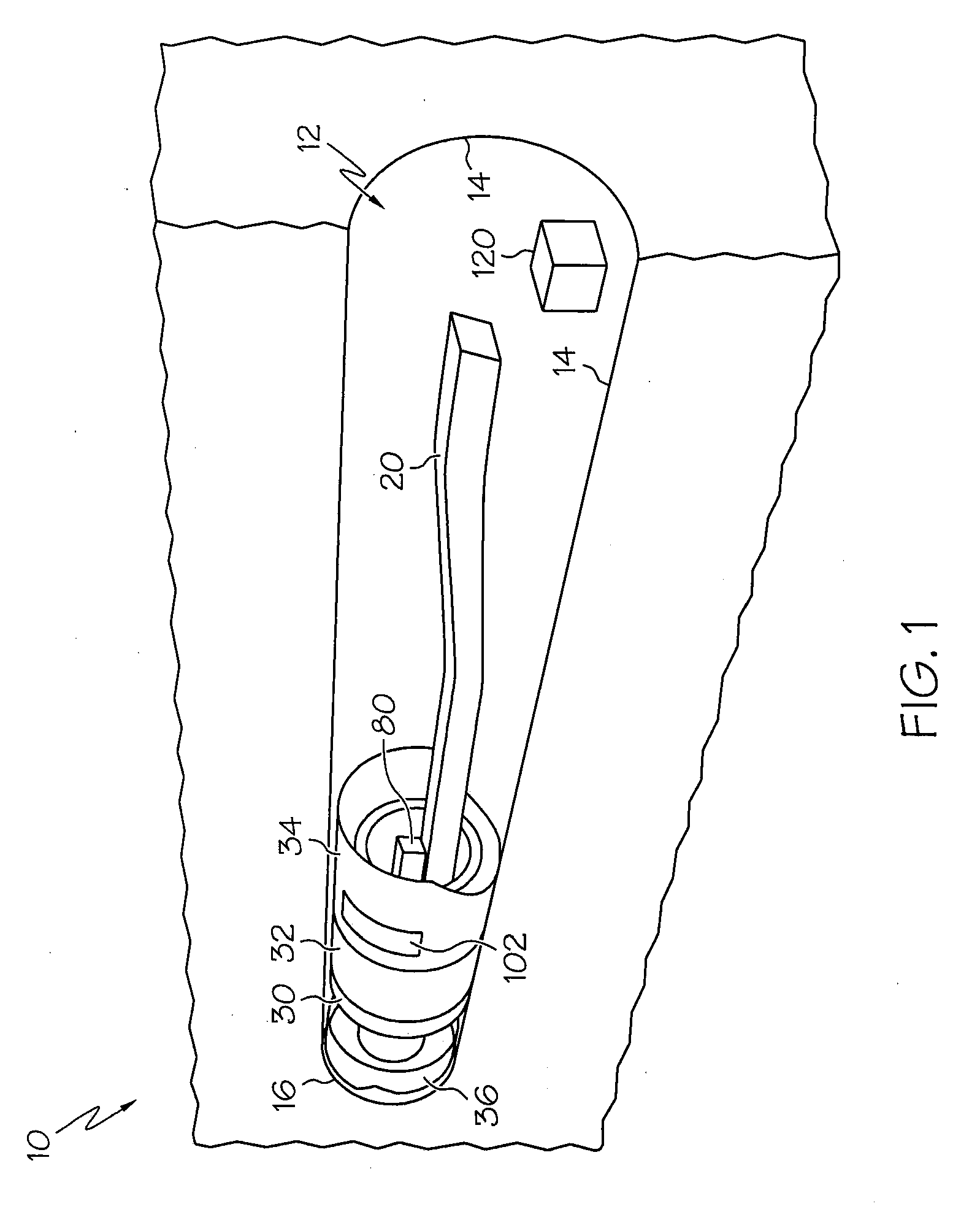

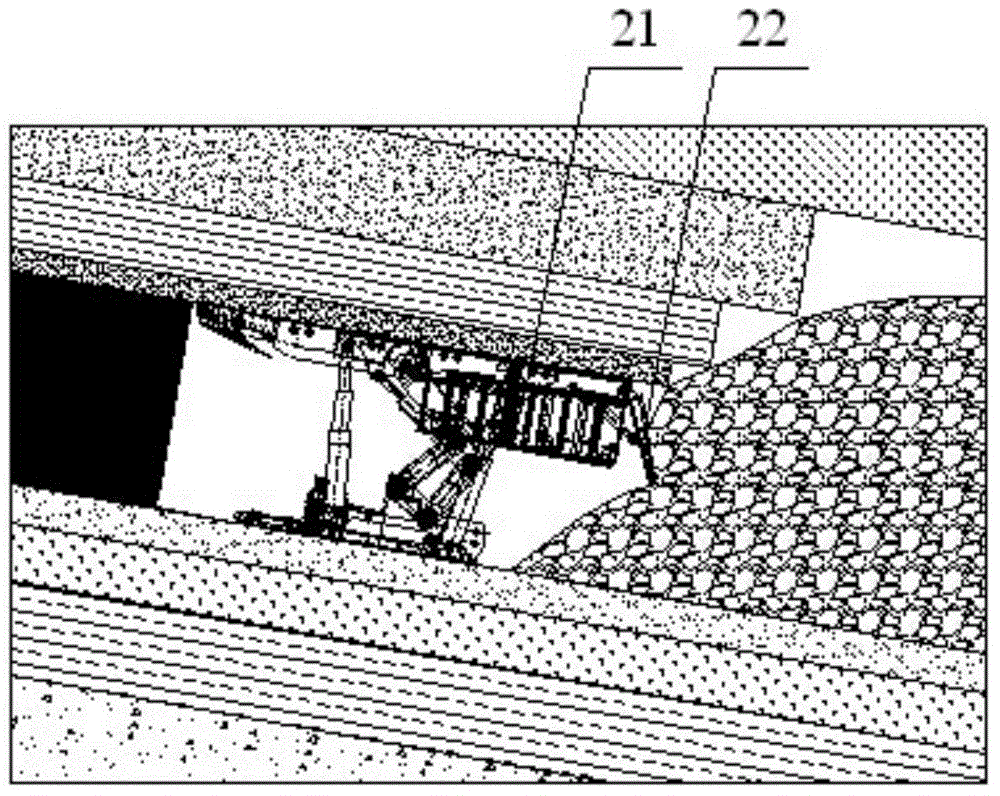

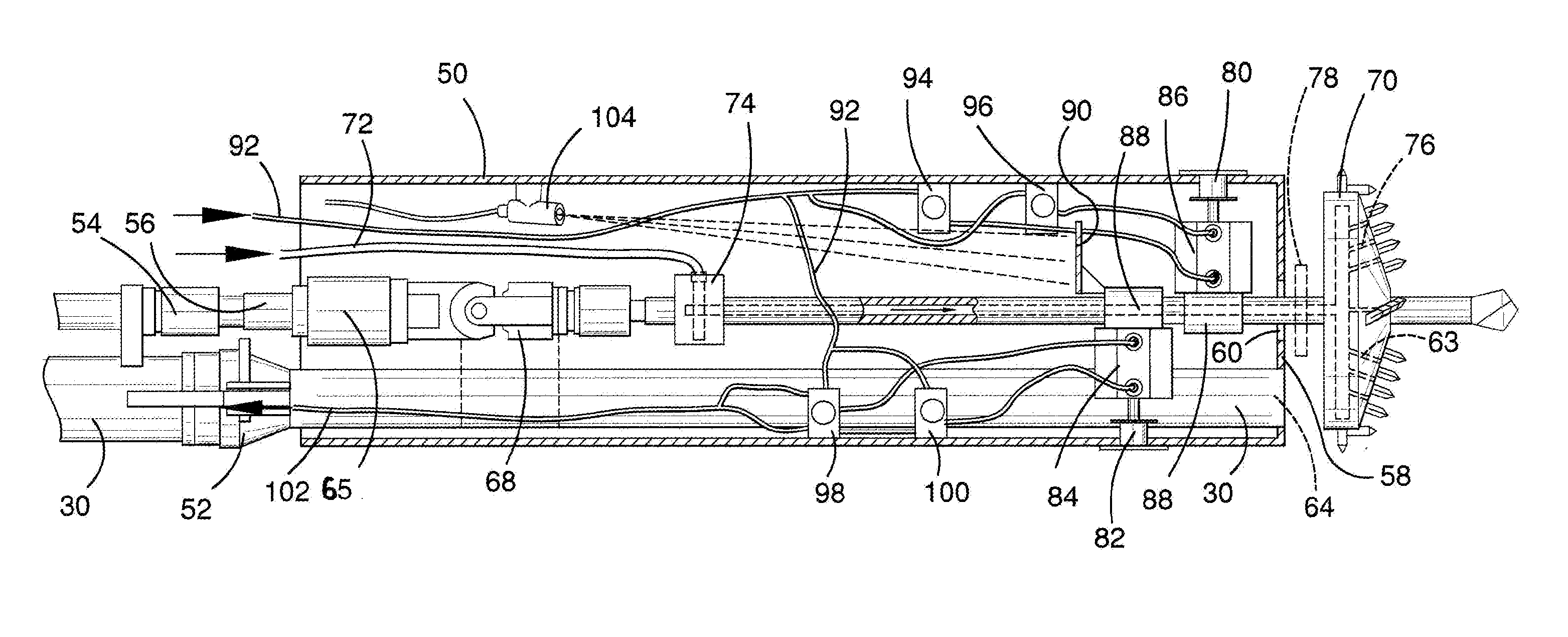

Unmanned roadway driving and anchoring all-in-one machine

InactiveCN104500086AImprove adjustabilityFlexible cuttingMine roof supportsTunnelsSupporting systemControl system

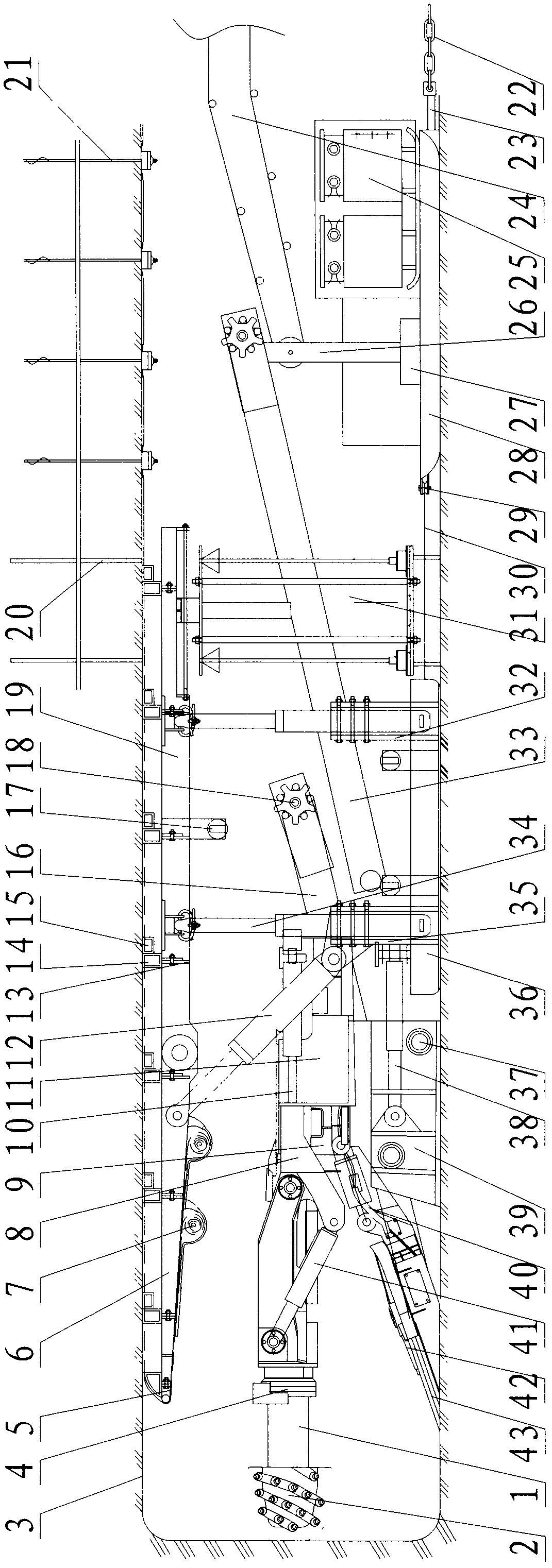

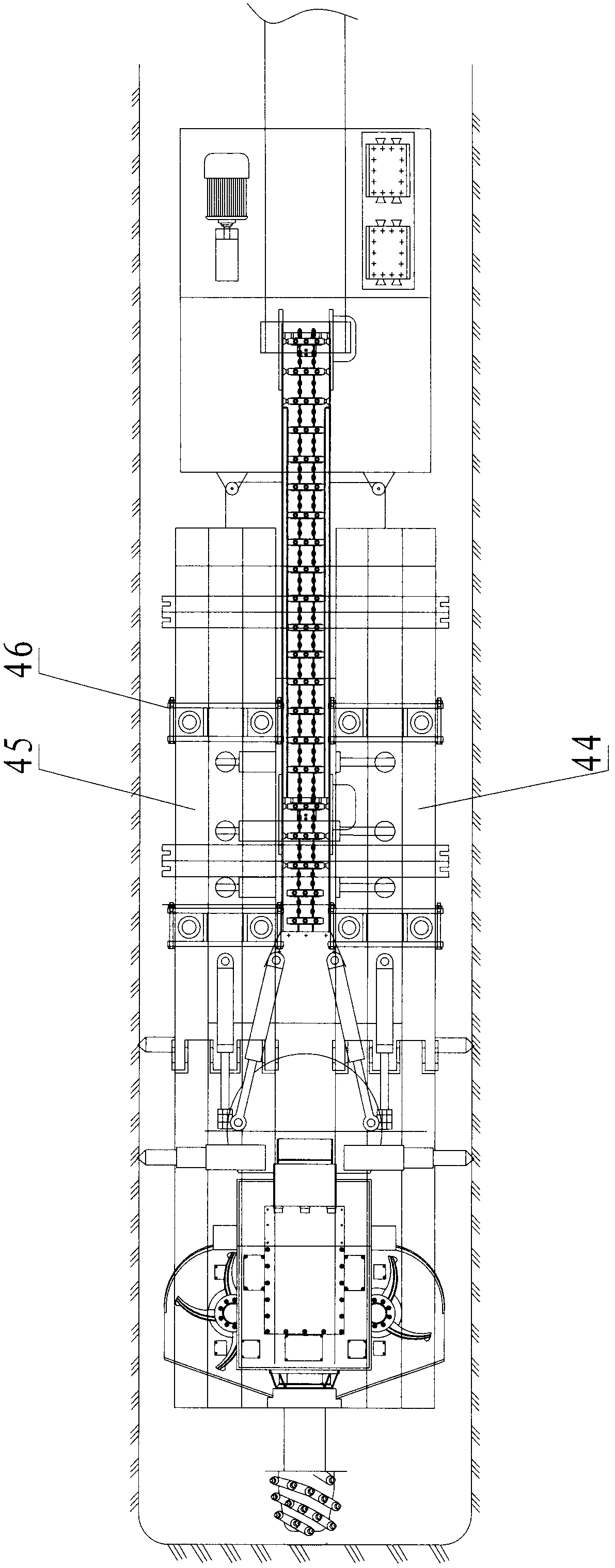

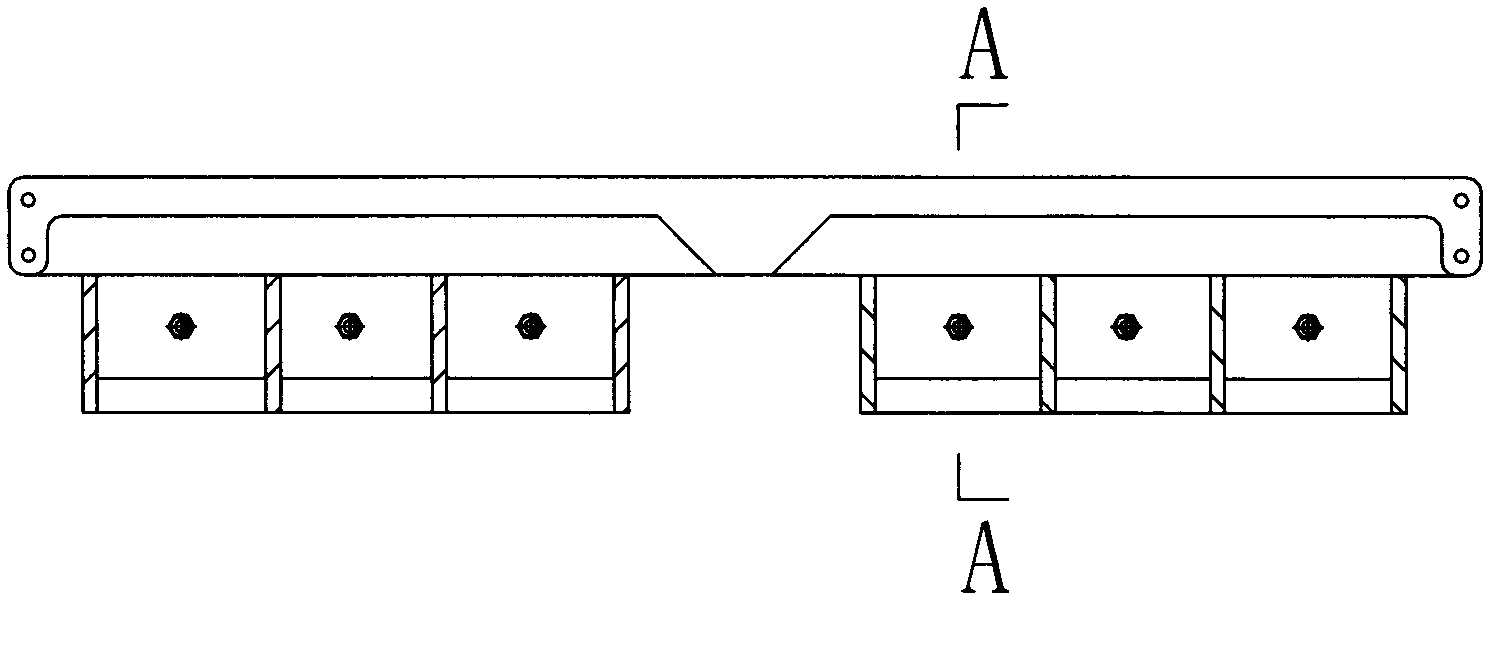

The invention discloses an unmanned roadway driving and anchoring all-in-one machine. The unmanned roadway driving and anchoring all-in-one machine comprises a driving system, a conveying system, a temporary support system, an anchoring system, a driving all-in-one machine water system, a sensing system and an electrical control system. A feed moving roller at the connection portion between a shovel of the driving system and the front end of the conveying system can prevent feed clogging at the shovel and the front end of a scraper conveyor. The temporary support system is uniform in supporting, can move relative to the driving and anchoring all-in-one machine to achieve no-deferring synchronization of driving, supporting and anchoring and can be adapted to the round, uprightly oval, approximately oval or rectangular cross section of a roadway to be applicable to driving and supporting operations of roadways of a variety of ground pressure and directions. The sensing system and the electrical control system of the driving and anchoring all-in-one machine can effectively collect and process information such as, light, distance, humidity and gas and the electrical control system performs automatic or remote manual analysis so as to achieve unattended operations in the working process and greatly improve the safety factor of the operations.

Owner:SHANXI DATONG UNIV

Electric hydraulic controlled caving coal method and it hydraulic supporter

ActiveCN1786420AAdd controlAdapt to process requirementsMine roof supportsProps/chocksControl systemElectro hydraulic

The invention relates to coal mine synthesizing exploiting caving top coal technique. Electro-hydraulic control caving top coal method is adopted hydraulic support to finish support caving top coal each procedure. The hydraulic support is made up of low order caving top coal hydraulic support and electro-hydraulic control system. In the electro-hydraulic control system, top beam incline sensor is added. The flash board jack is adopted travel sensor. The length of the flash board is increased, and the size of the coal discharging is adjusted in order to keep top beam horizontal and increase supporting stability. The coal discharging method includes the following steps: top coal sufficient crashing: adopting single sequence sublevel discharging; top coal middling crashing: adopting the same; top coal difficult crashing: adopting double sequence sublevel discharging. The invention can increase coal discharging control type, improve caving top coal technique adaptability, and realize high yield and high efficiency.

Owner:兖矿能源集团股份有限公司

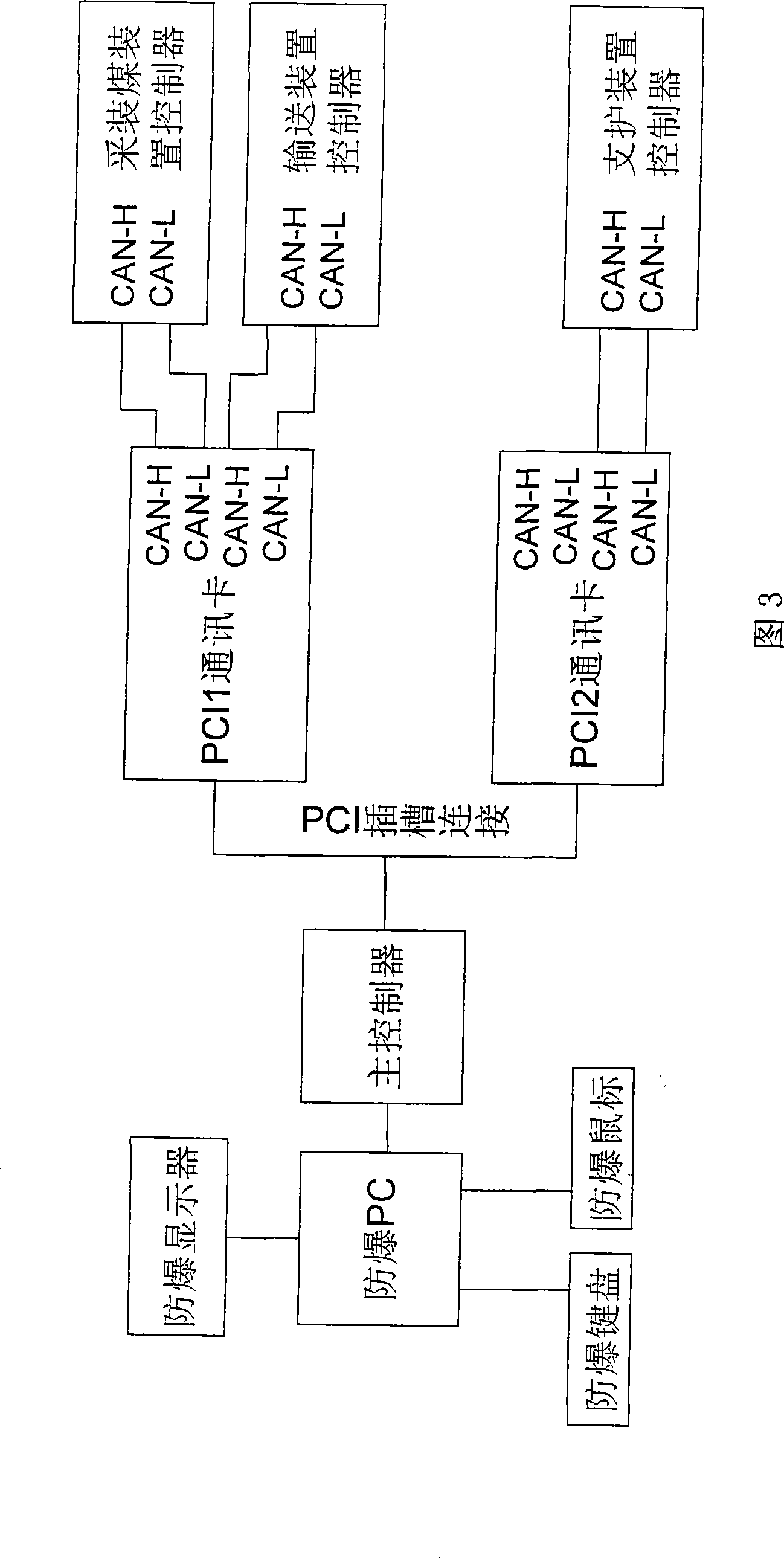

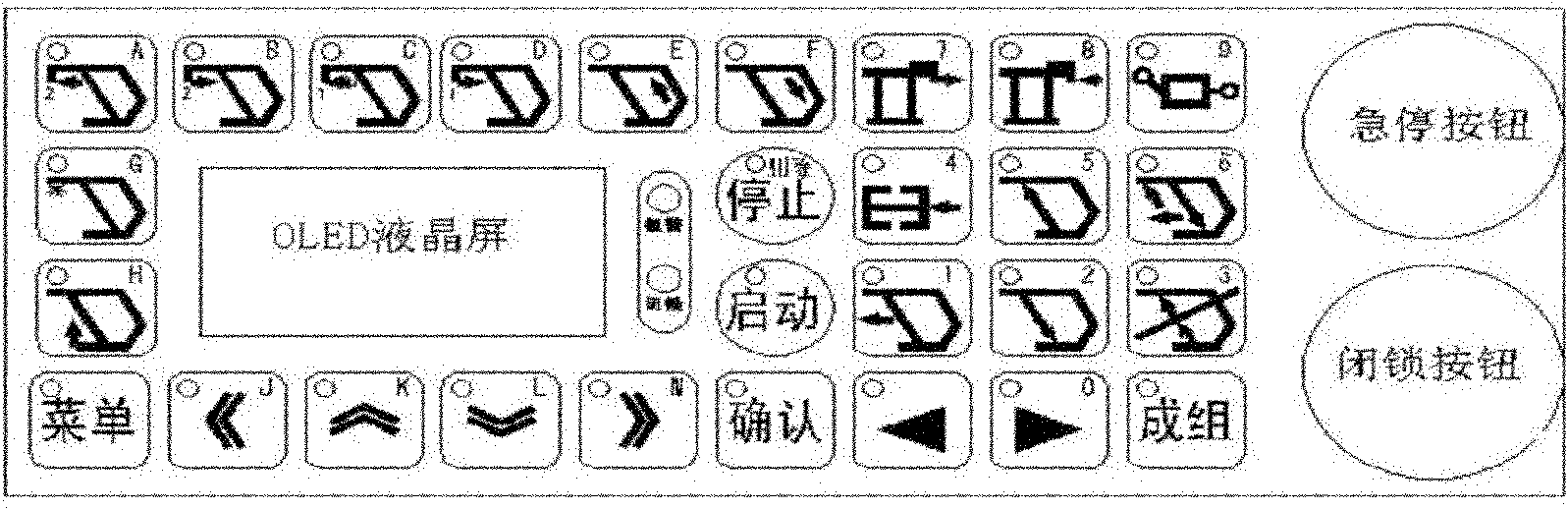

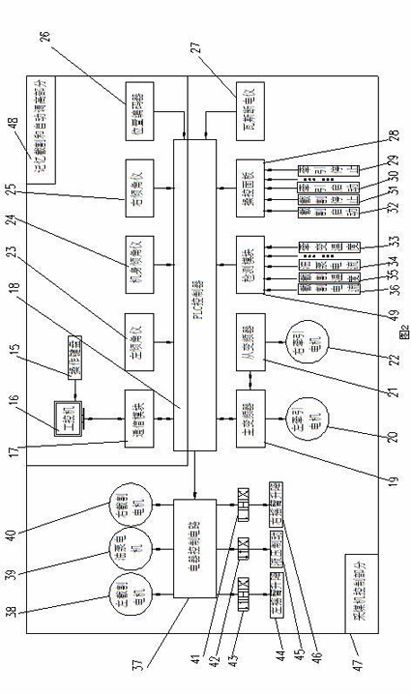

Electro-hydraulic control system for working surface hydraulic support

InactiveCN102071956AImprove the automation level of fully mechanized miningRich in compositionMine roof supportsControl systemData information

Owner:BEIJING ZHONGKE LINZHONG TECH

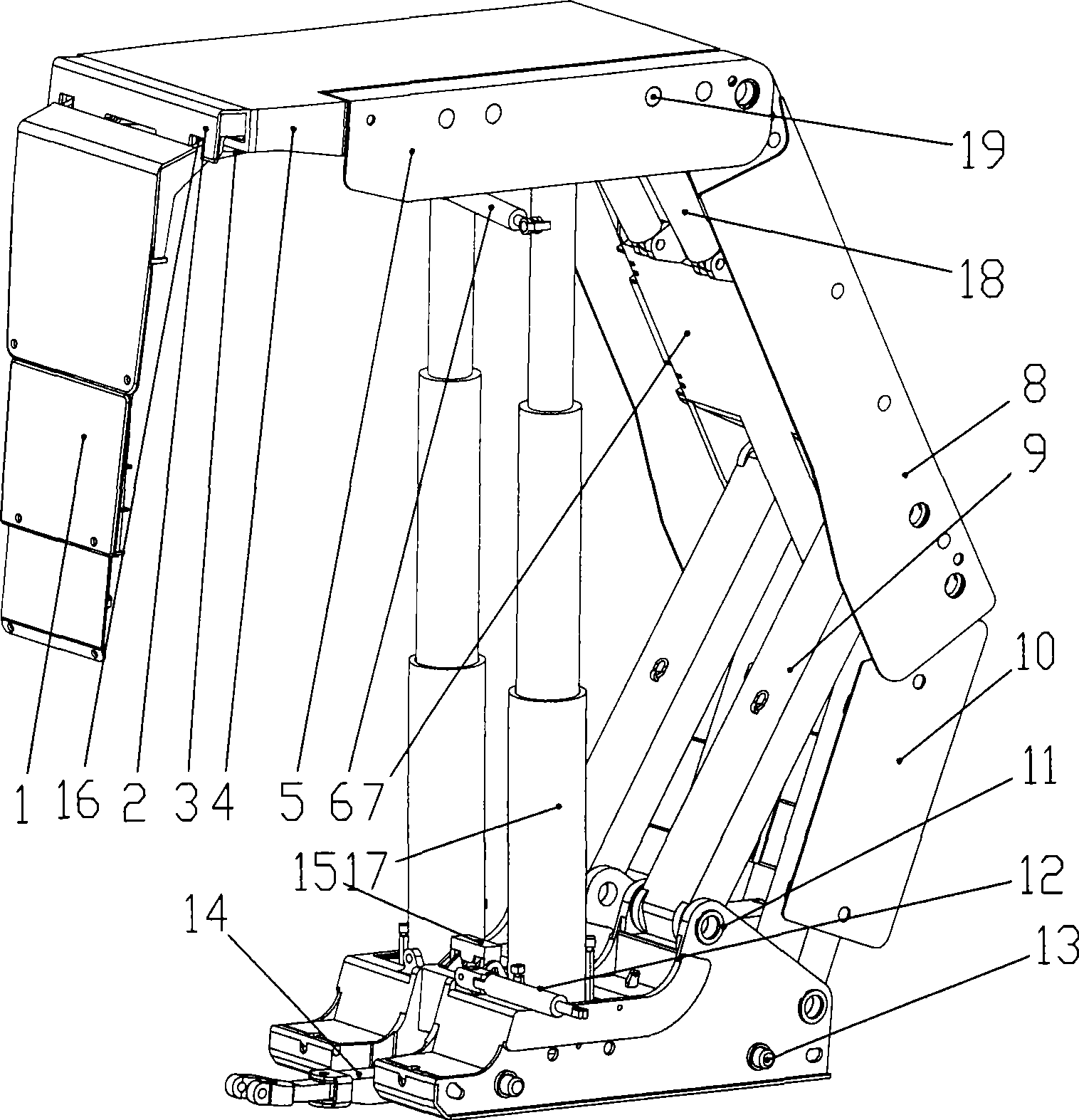

Overlarge mining height hydraulic support

The invention relates to a super large mining height hydraulic support which comprises an opened rigid integrated base, wherein, two double-telescopic hydraulic upright posts are arranged on the base, and the upper ends of the upright posts are connected with a top beam; the rear of the top beam is connected with a screening beam; an edge protection device is connected with the telescopic beams which are in inner extension connection with the top beam; a balance jack is arranged between the top beam and the screening beam; the screening beam and the base are respectively connected with the front and rear connecting rods; a push jack is arranged on the base and is connected with a push rod; the front part of the top beam is provided with the telescopic beams, the middle part of the top beam is provided with a falling prevention device for the support, and bottom lifting, skid prevention and support regulation devices are arranged on the base; and a levelling device is arranged on a cross binding head on the front end of the push rod; the support adopts 2-meter width between centers, the maximum height ranges from 6.3 meters to 7.5 meters, and the front end of the telescopic beam is provided with a third-stage edge protection device which is not lower than half of the mining height. The support has obvious effects of controlling the wall caving of the coal wall of a super thick coalseam, the roof fall of the ceiling, and the stability of the hydraulic support.

Owner:CCTEG COAL MINING RES INST

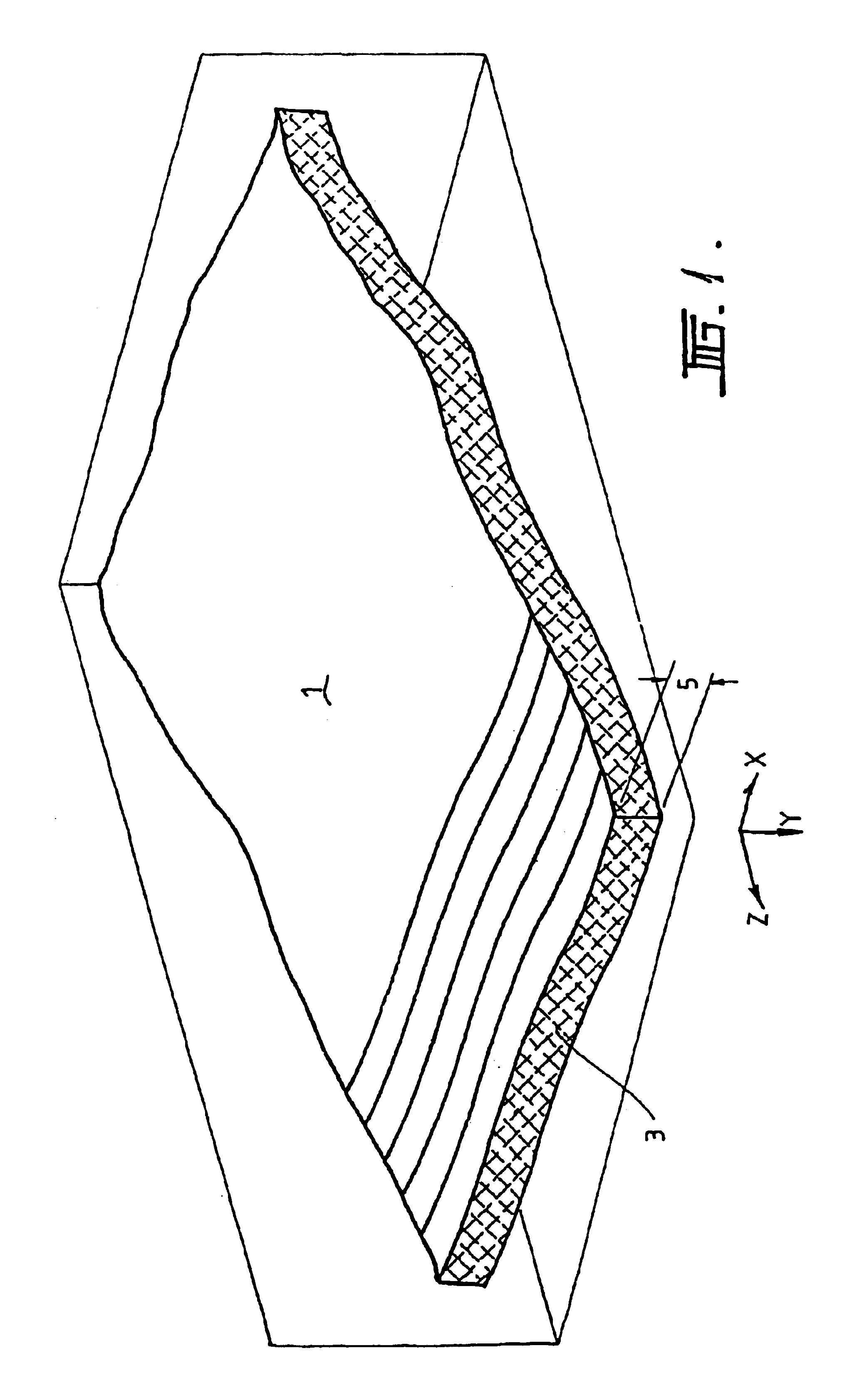

Inclined separated layer solid filling coal mining method for super thick coal seam

ActiveCN103306720ASolve sinkingFree resourcesUnderground miningSurface miningSolid massEarth surface

The invention discloses an inclined separated layer solid filling coal mining method for a super thick coal seam, which is suitable for the exploitation of an 'under three' super thick coal seam. The method comprises the following steps: determining the number of inclined separated layers according to the principle that thickness of each separated layer is 2.5-4.5 m; adopting a exploitation sequence that mining layer by layer, and filling at a next row; arranging tunnels and equipment according to the conventional solid filling coal mining method; carrying out a circulating sequence that coal mining firstly, metal nets and bamboo fences paving secondly, and filling finally to complete the filling exploitation of a first mining surface and a first separated layer; meanwhile, mining according to the same filling coal mining method under the shield of a manual false roof formed by the first separated layer at the corresponding position of a second separated layer 4 months after a working face of the first separated layer finishes mining; circulating in the way that the exploitation of one separated layer is performed under the shield of a manual false roof manufactured by an upper separated layer continuously until the whole super thick coal seam is mined out. Through the adoption of the method, resources of the 'under three' super thick coal seam can be utilized, the rock formation movement and earth surface sinking can be effectively controlled; and the recovery ratio is high, the production efficiency is high, the cost is low, and the method has wide practicability in the field of thick coal seam filling exploitation.

Owner:CHINA UNIV OF MINING & TECH

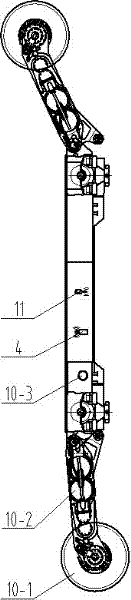

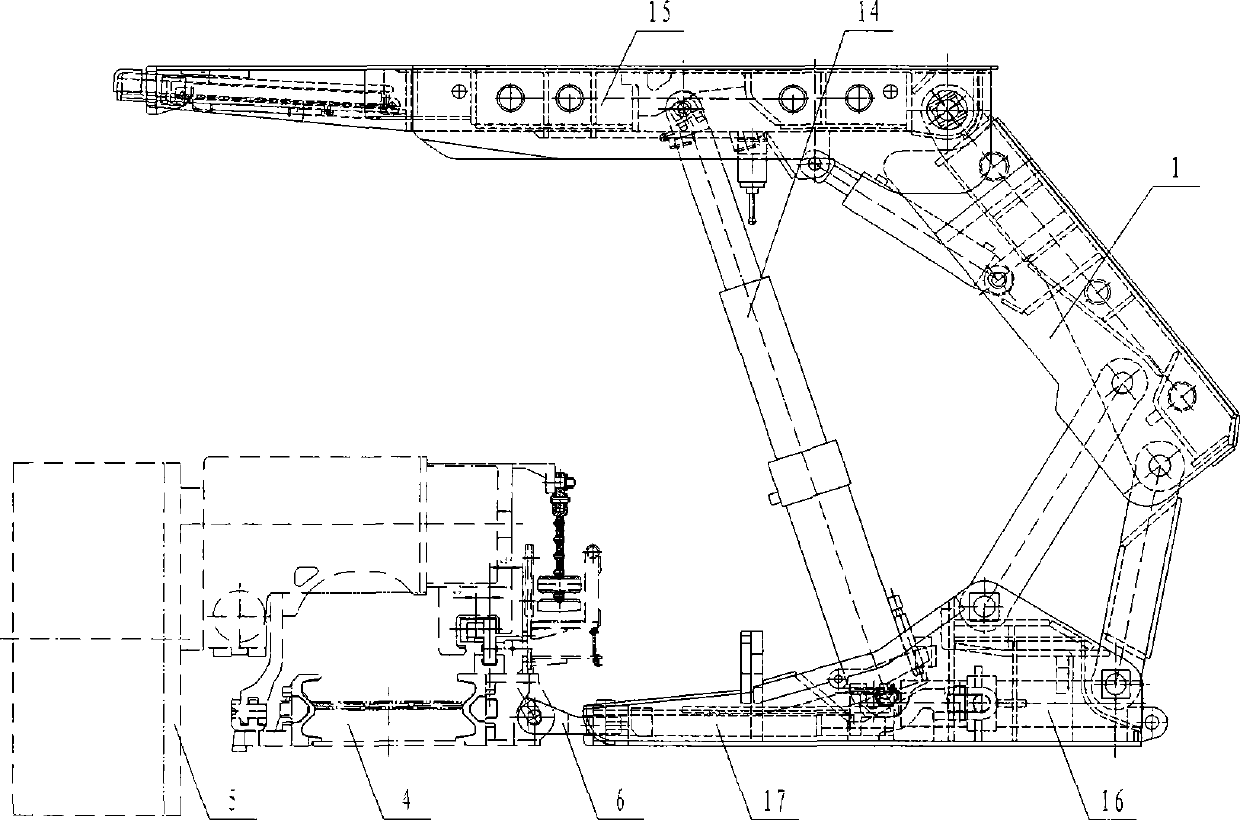

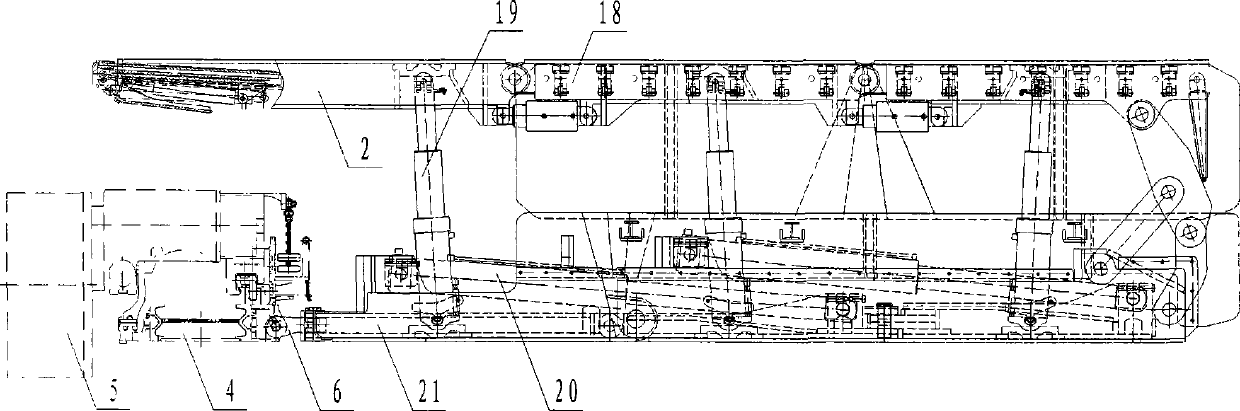

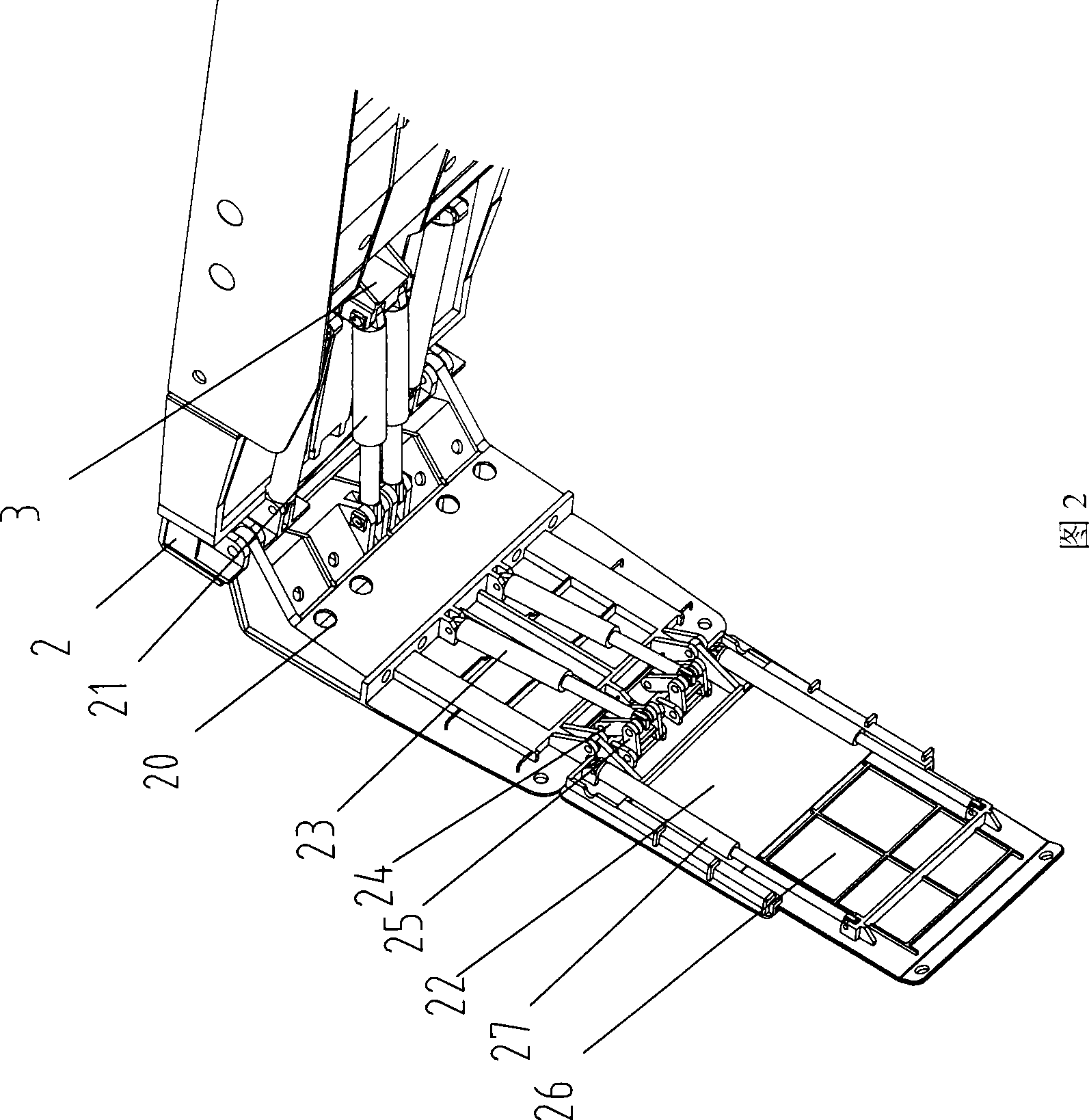

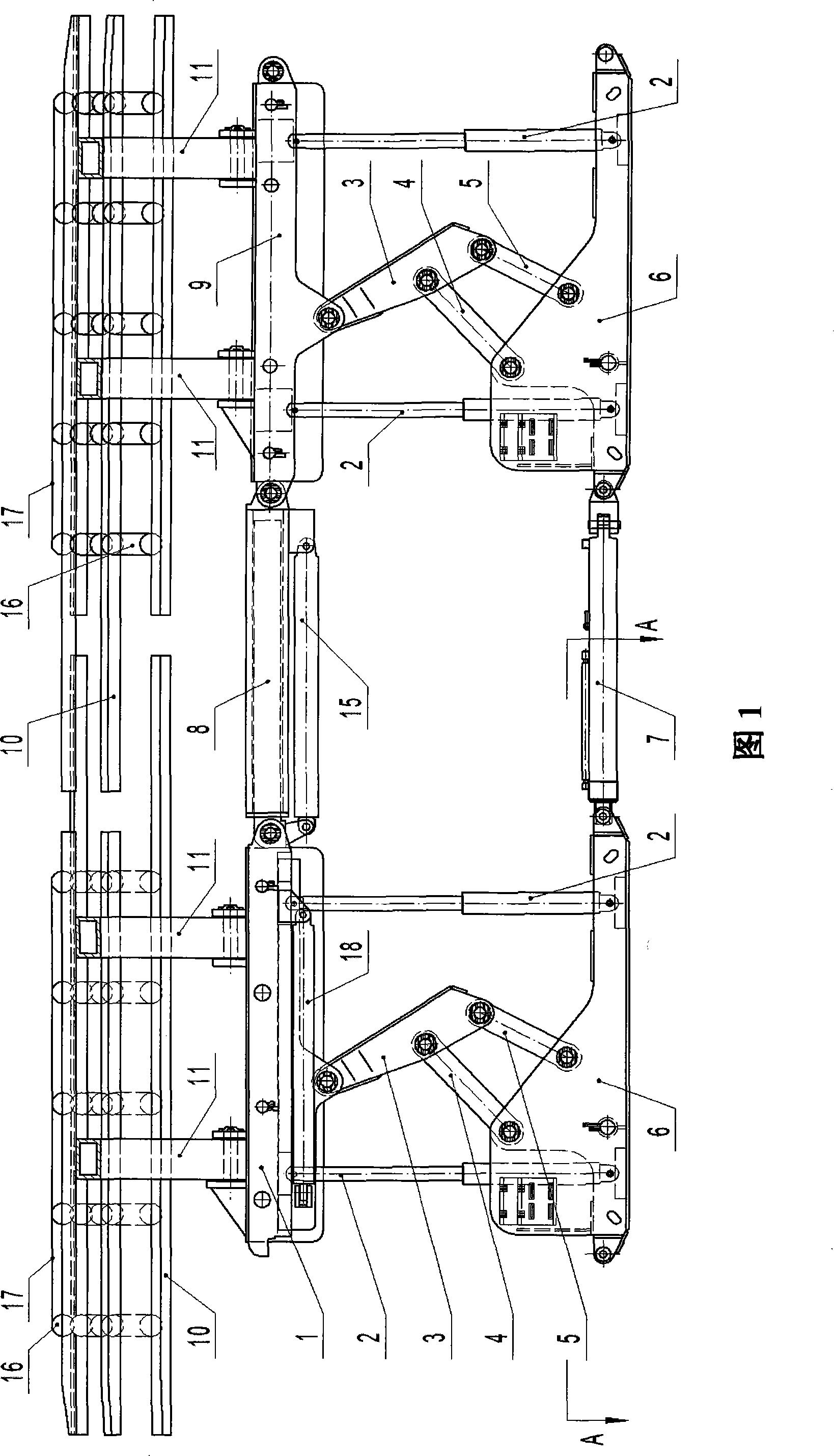

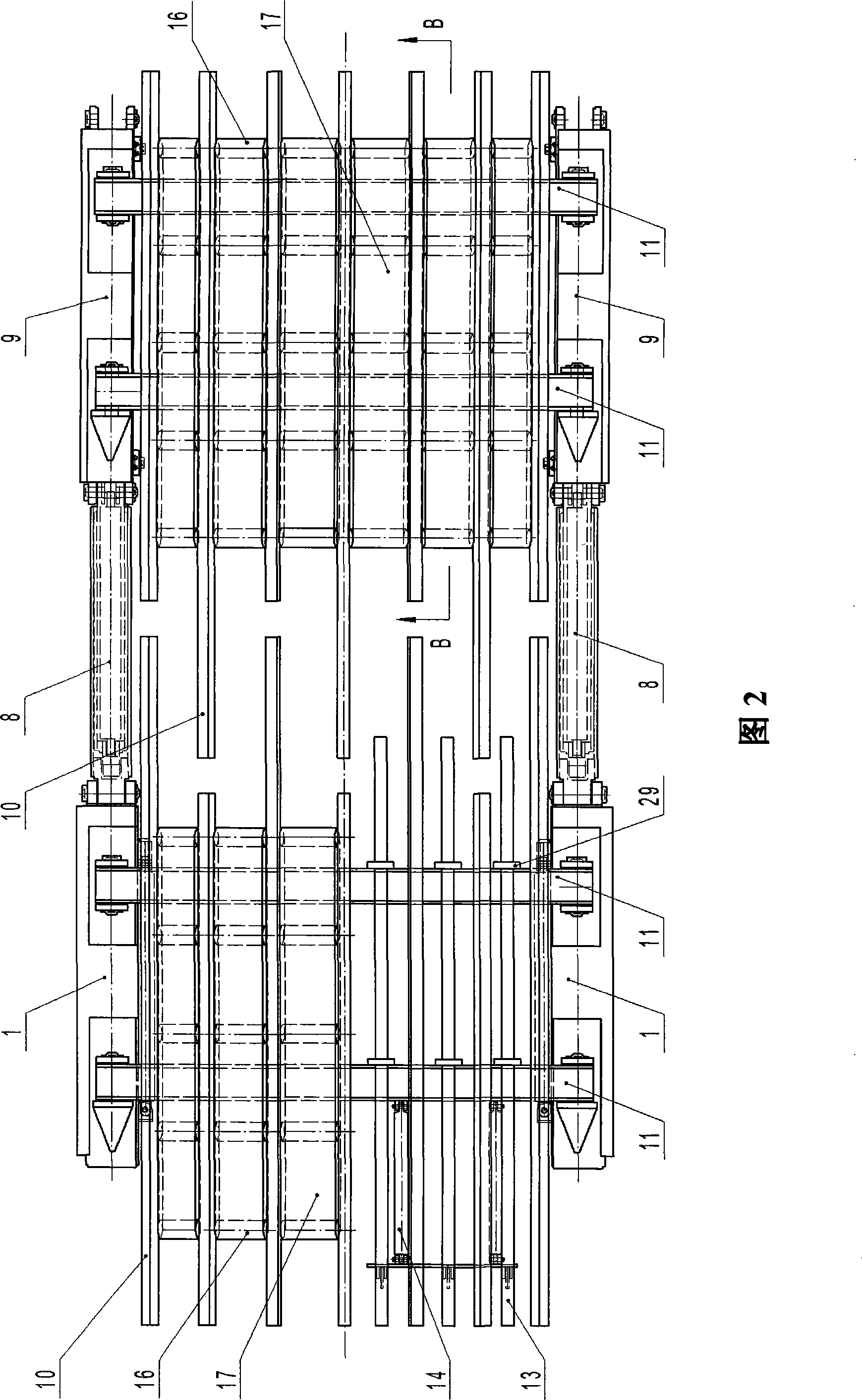

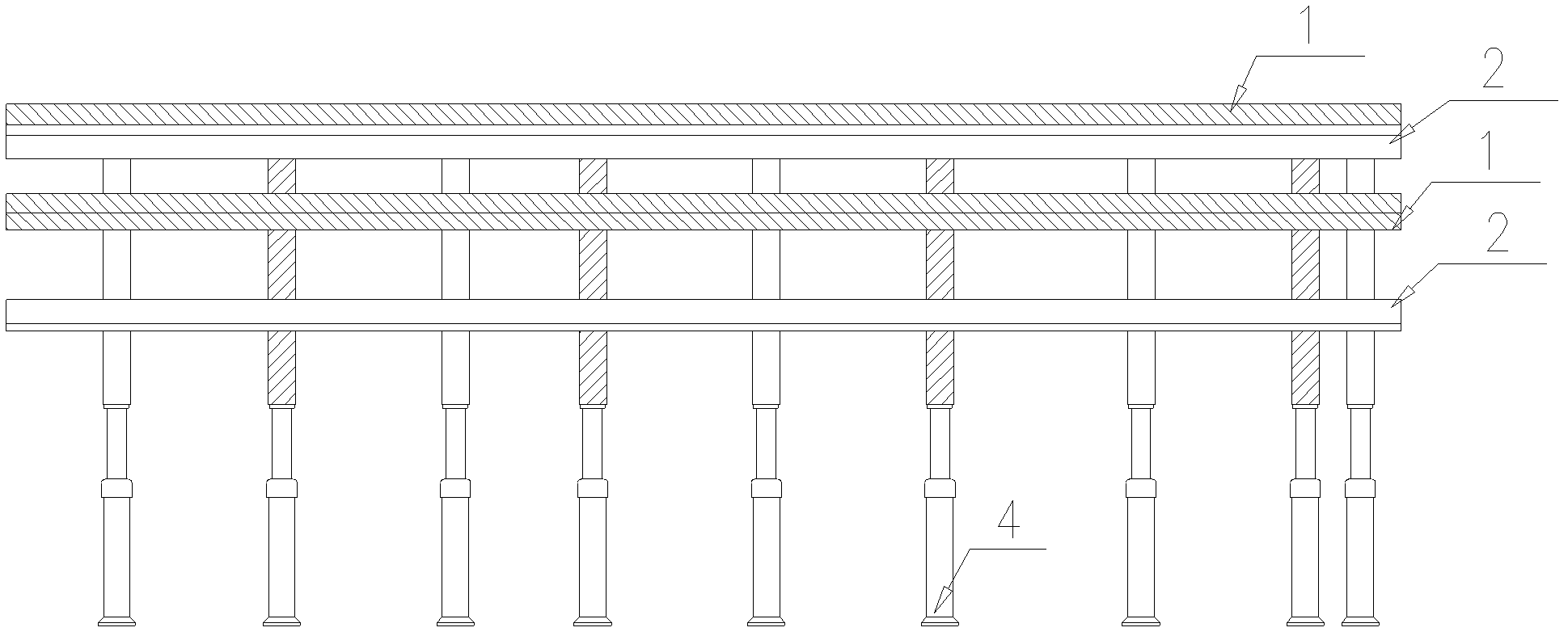

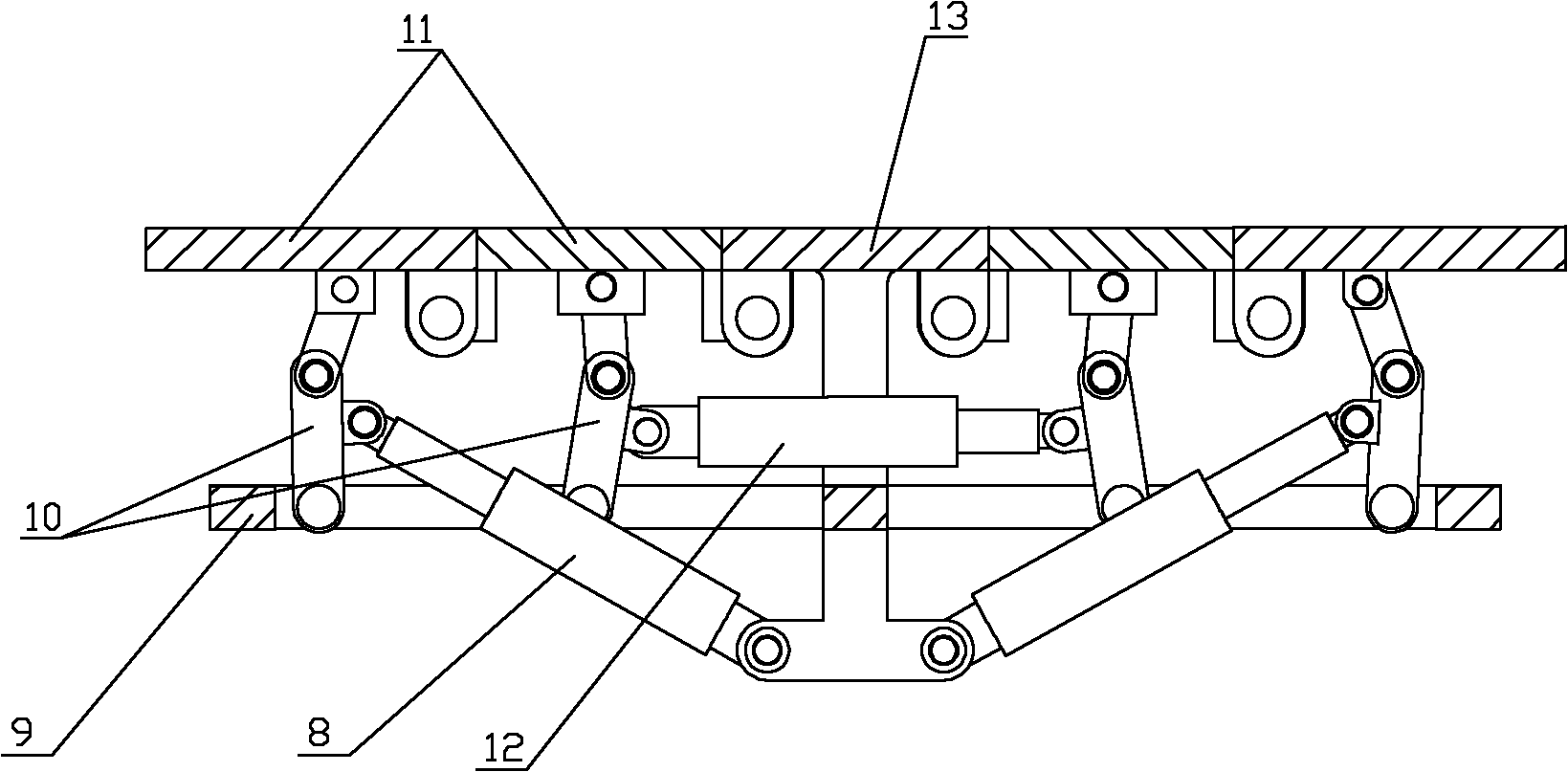

Immediate support device for digging machine

ActiveCN101251022AAvoid distortionAvoid out of syncMine roof supportsHydraulic cylinderContinuous operation

The invention relates to an in-time supporting device for a fully-mechanized coal mining machine, comprising a pedestal, a top beam, a hydraulic upright post which connects the pedestal and the top beam, side frames which consist of four link mechanisms, and a telescopic connecting beam and a hydraulic cylinder which are hinged between two side frames. The invention adopts the technical key points that: top beams of the side frames adopt front top beams or continuous top beams; the side frames which are arranged in parallel and provided with the front top beams or the continuous top beams are hinged into a front support or a continuous support through an arched beam or a horizontal beam; shun beams are arranged on the arched beam or the horizontal beam at intervals; belt guard beams or telescopic shun beams are arranged between adjacent shun beams. The in-time supporting device for the fully-mechanized coal mining machine effectively solves the problems in the prior art of lagged supporting means, difficult frame movement, requirement of stop operation, low efficiency and so on, is reasonable in structural design, stable in supporting operation, convenient in assembly and disassembly and maintenance, and safe and reliable in use, preferably meets the requirements of matched operation of underworkings and the fully-mechanized coal mining machine, realizes in-time mechanical support of a just exposed roof of a tunneling work surface of a laneway, and shields the fully-mechanized coal mining machine to realize continuous operation.

Owner:SHENYANG TIAN AN TECH CO LTD

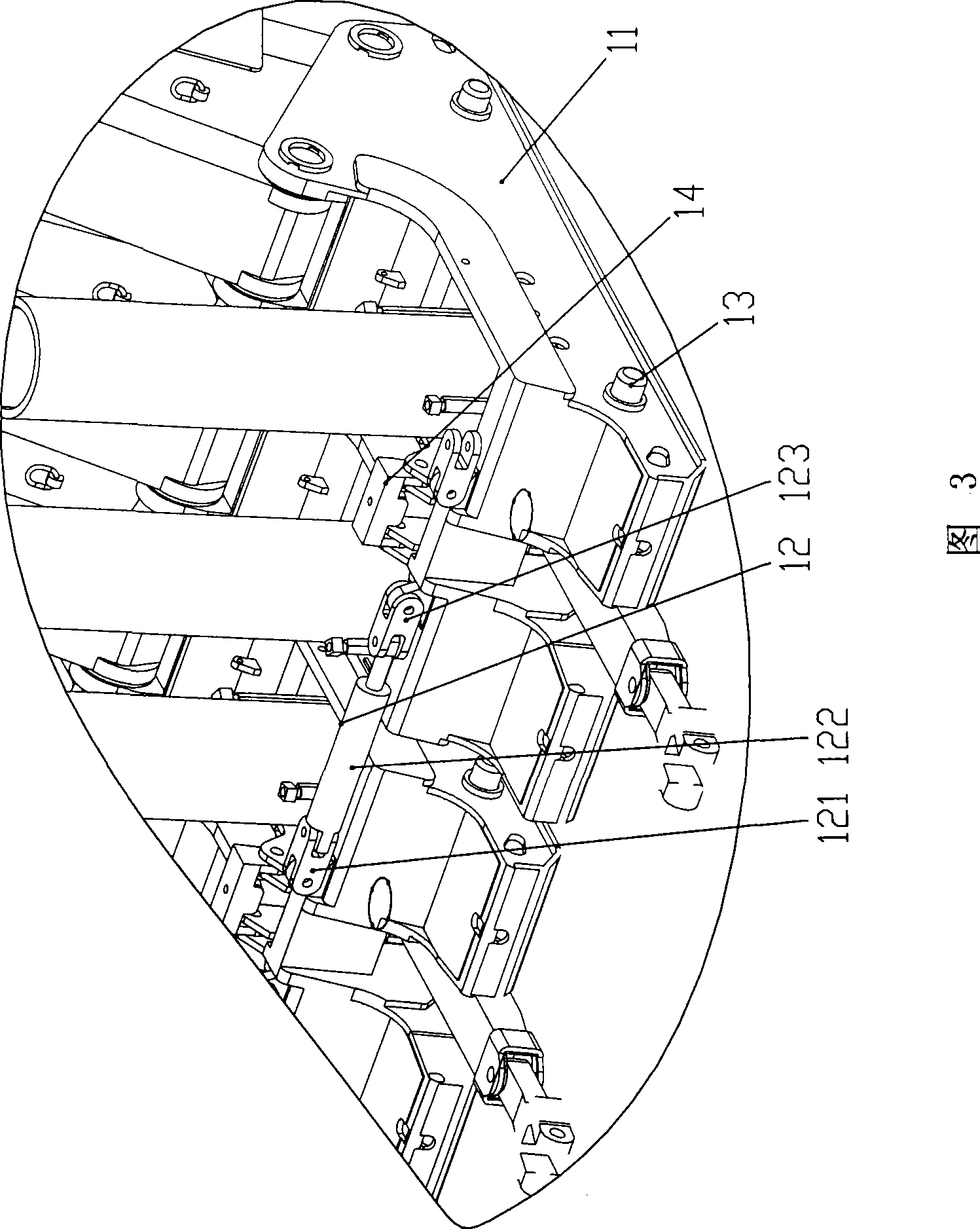

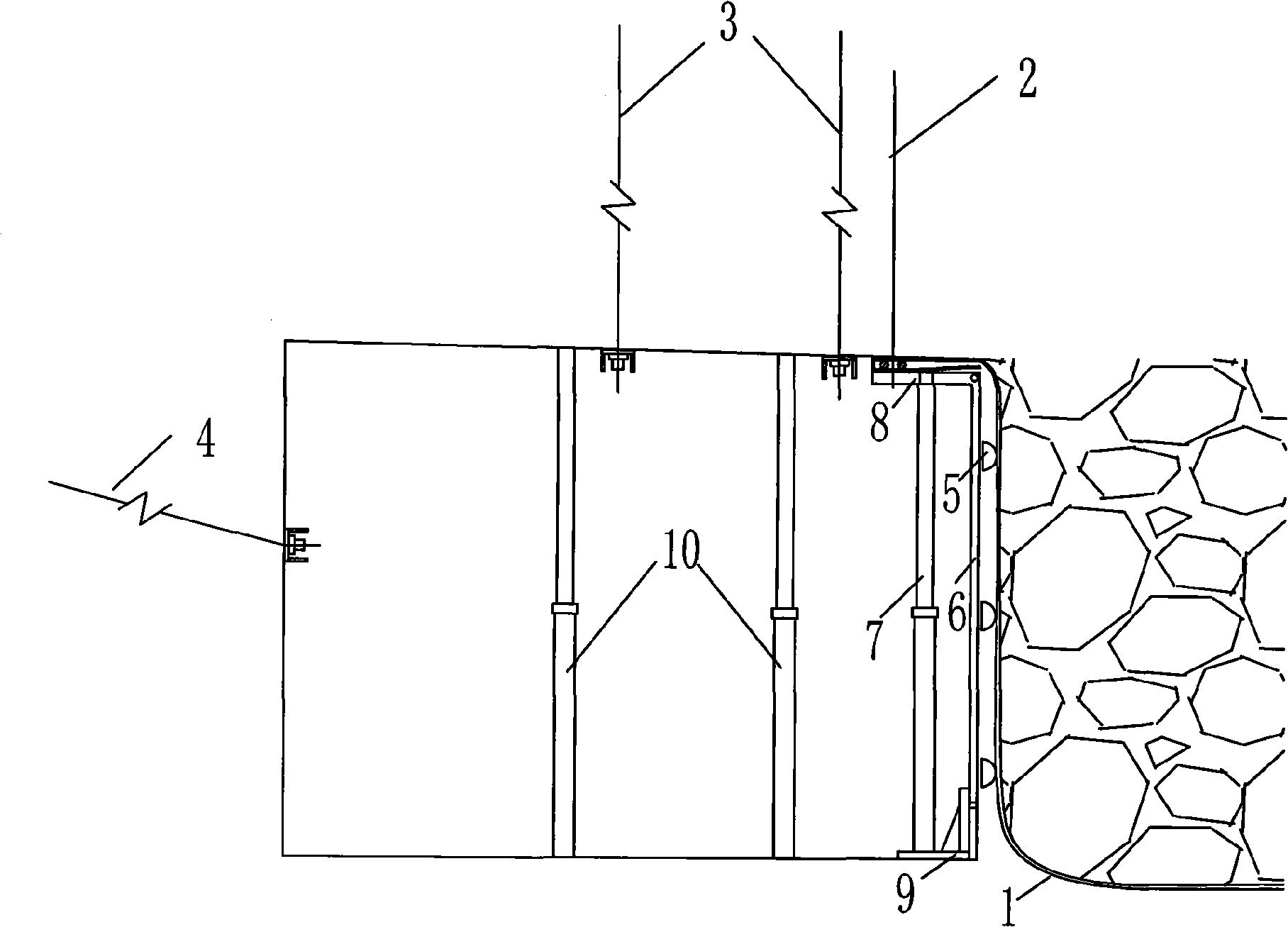

Integrated suspension device for retaining a lane for next sublevel

ActiveCN101289939AMining operation safetyEasy to operateMaterial fill-upMine roof supportsCoal pillarMechanical engineering

The invention relates to a gob-site entry retaining comprehensive support device, which effectively solves the problems not solved in the prior art that how mechanized formwork erection and whole support are carried out, and realizes difficult problem that filling and coal-mining production are carried out at the same time. The technical key points of the device are as follows: a roadway advancing and retaining support is arranged in a transportation roadway or a return airway; a roadway filling back formwork support, a roadway side filling formwork support and a set of working face hydraulic supports are arranged parallelly in sequence along a roadway; and all supports are vertically connected along the running direction of a transporter; the roadway side filling back formwork support, the roadway side filling formwork support which is arranged on the left of the roadway side filling back formwork support, and an adjustable hydraulic formwork which is arranged on the right of the roadway side filling back formwork support to surround a filling mould cavity which forms a gob-site entry retaining and filling wall. The device has the advantage that the device is favorable for mining a no-coal pillar, is safe and convenient to operate, and is strong in adaptability, can form an insulating gob area in the roadway side and a shield concrete filling wall which is solidified and hardened into a regular wall body, and can shield and match a working face transporter, a coal mining machine and a formwork support to perform normal coal-mining production.

Owner:SHENYANG TIAN AN TECH CO LTD +1

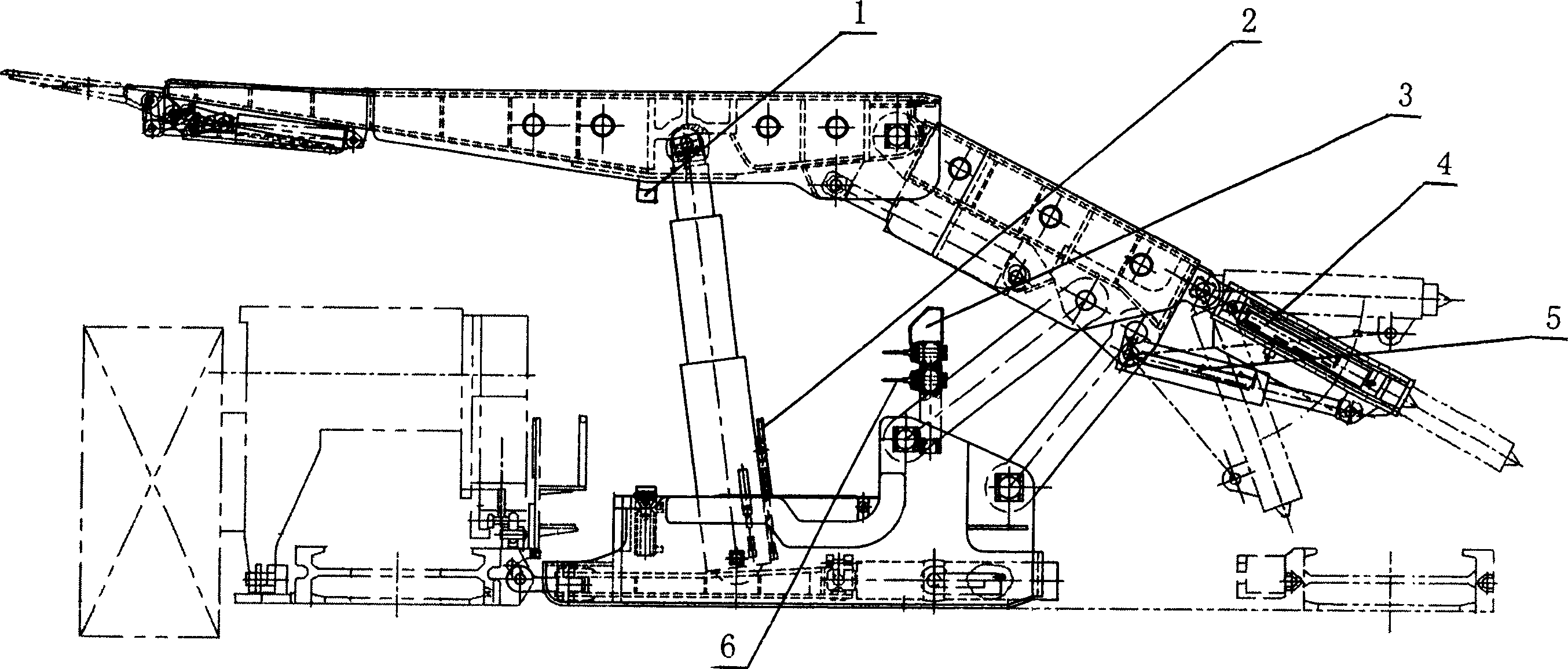

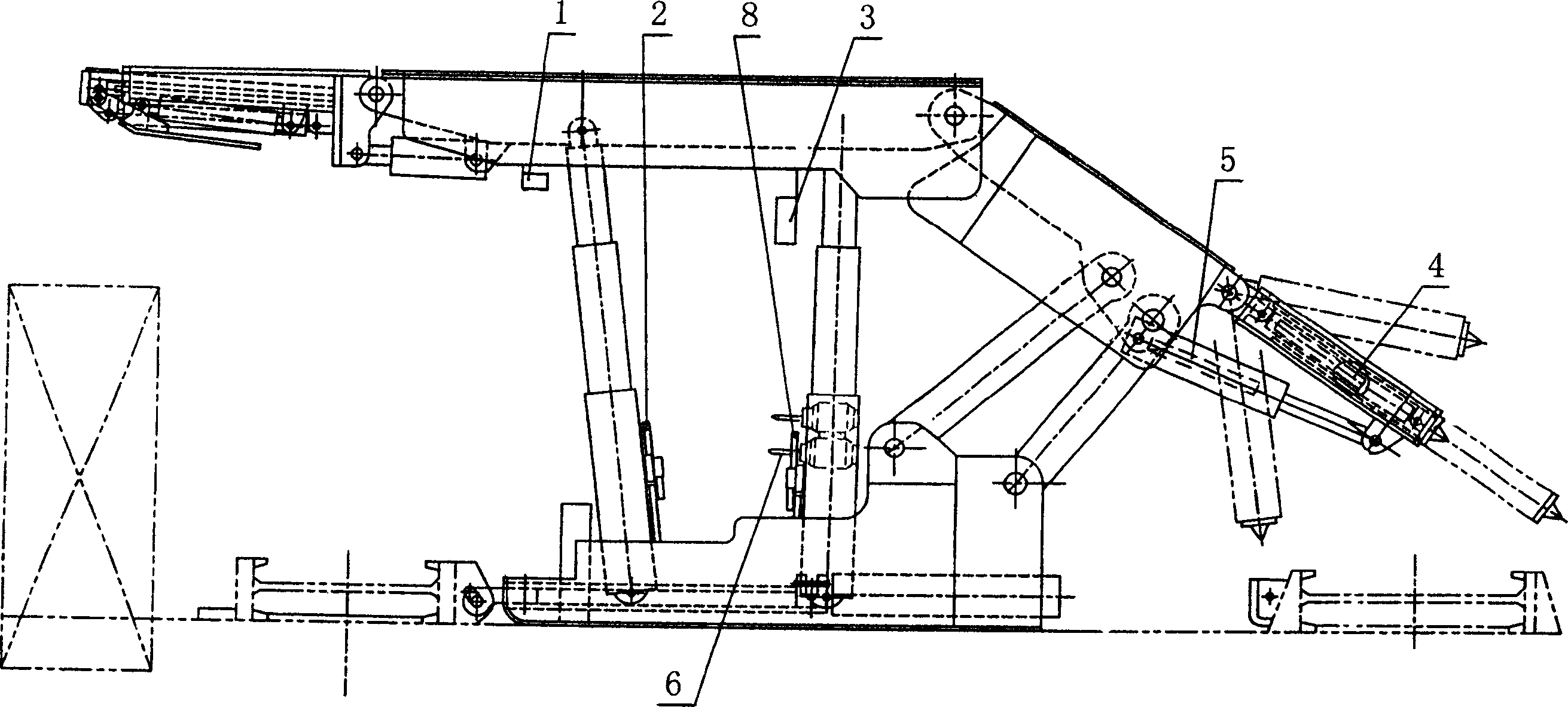

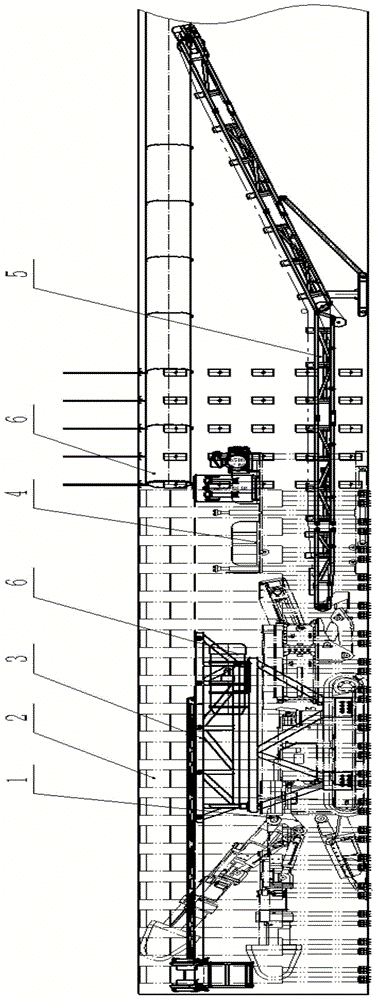

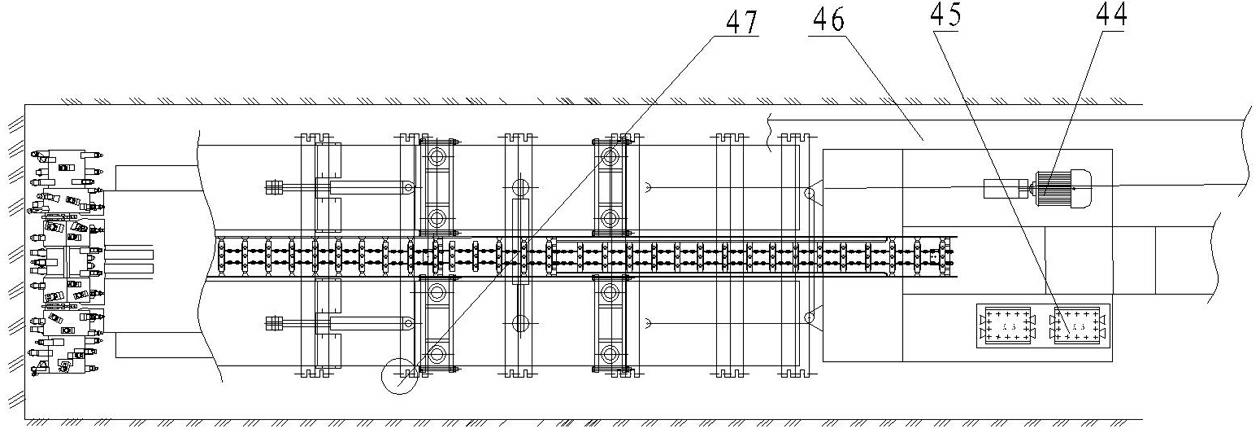

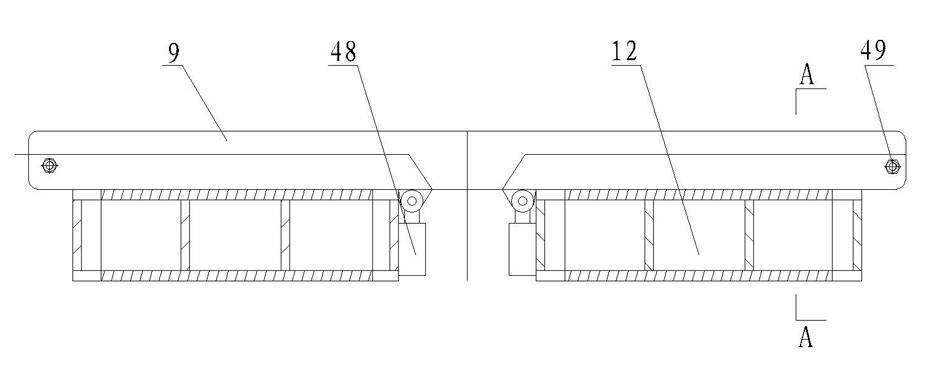

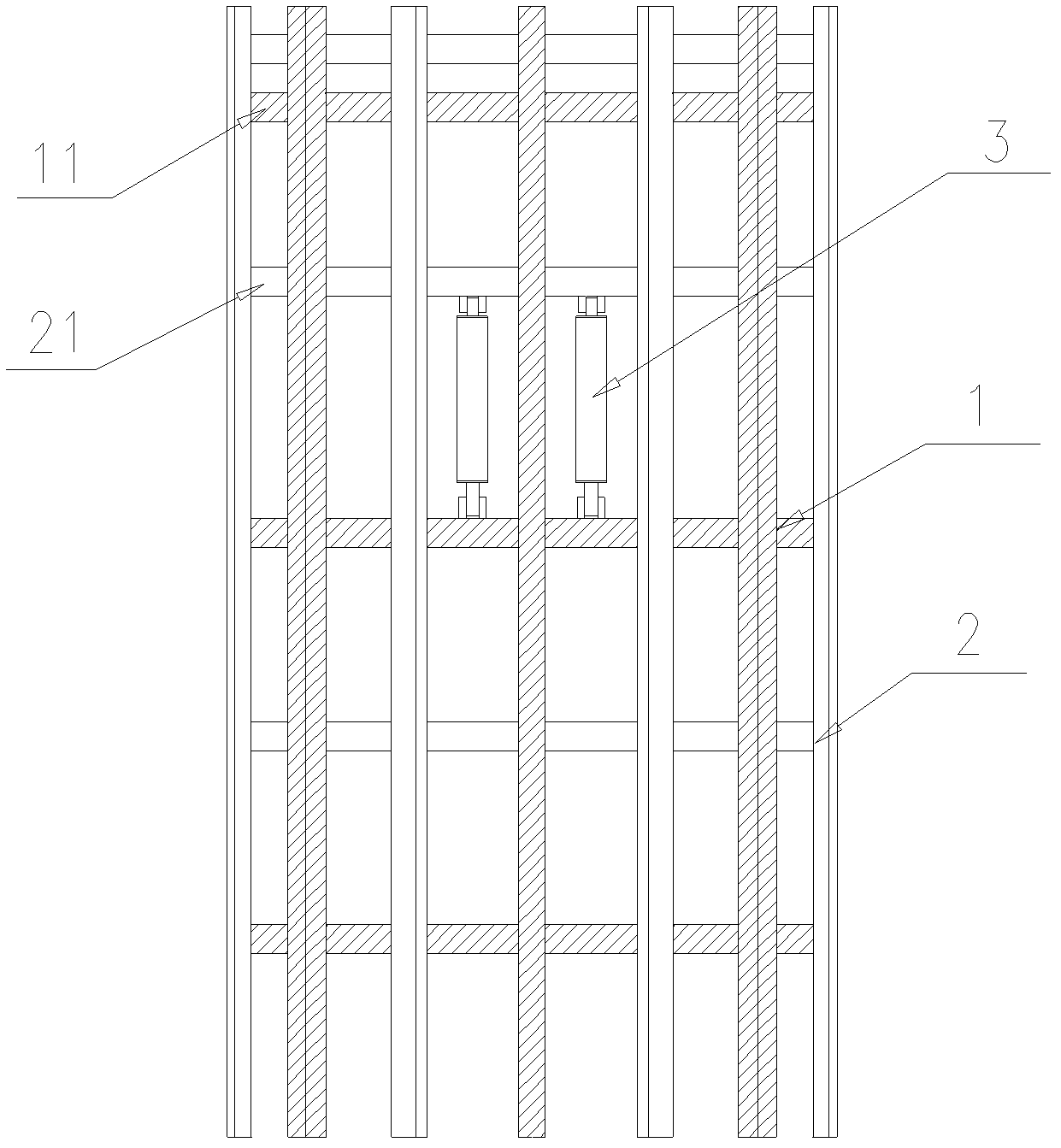

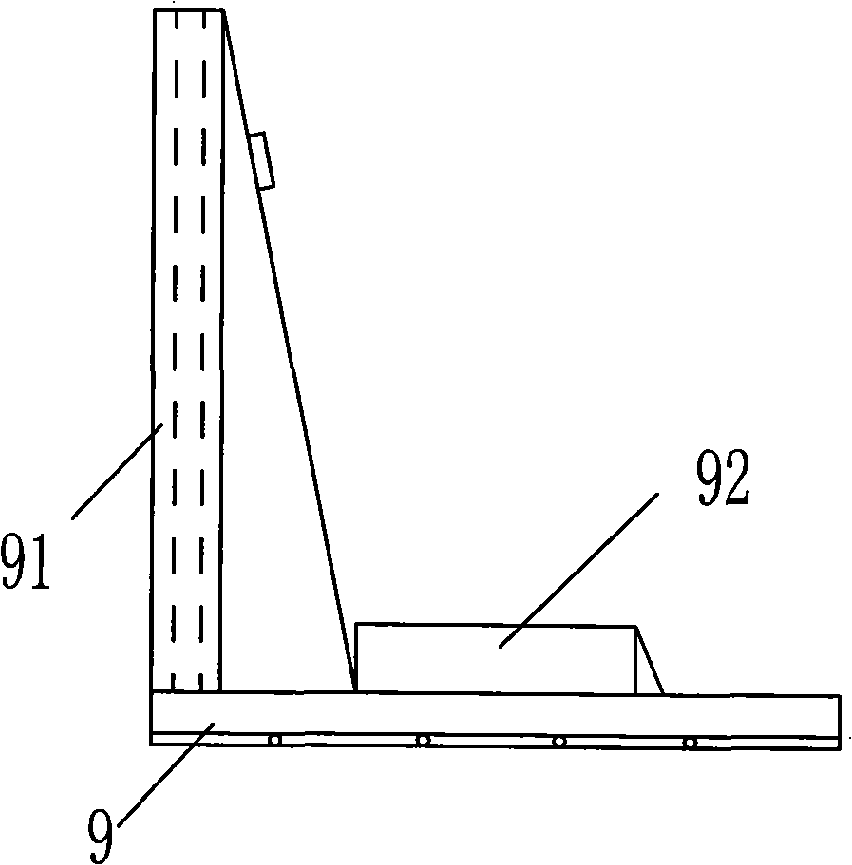

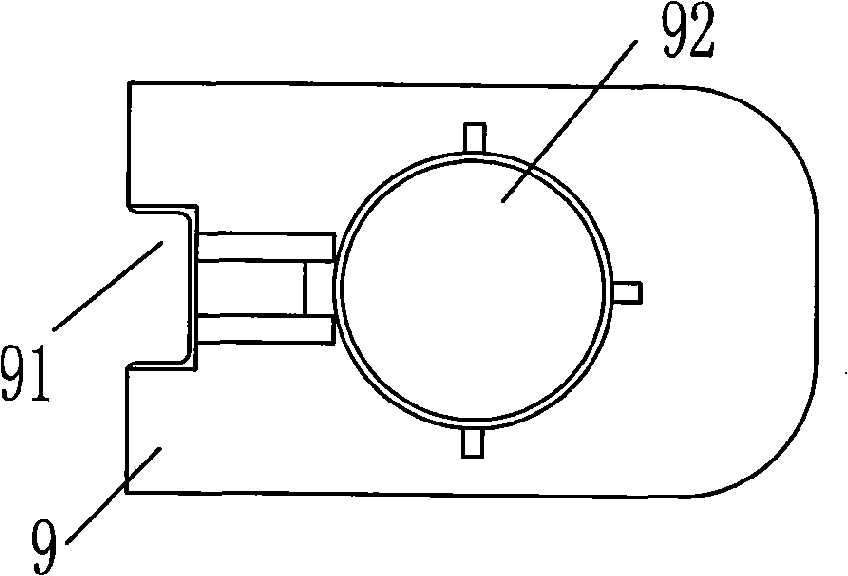

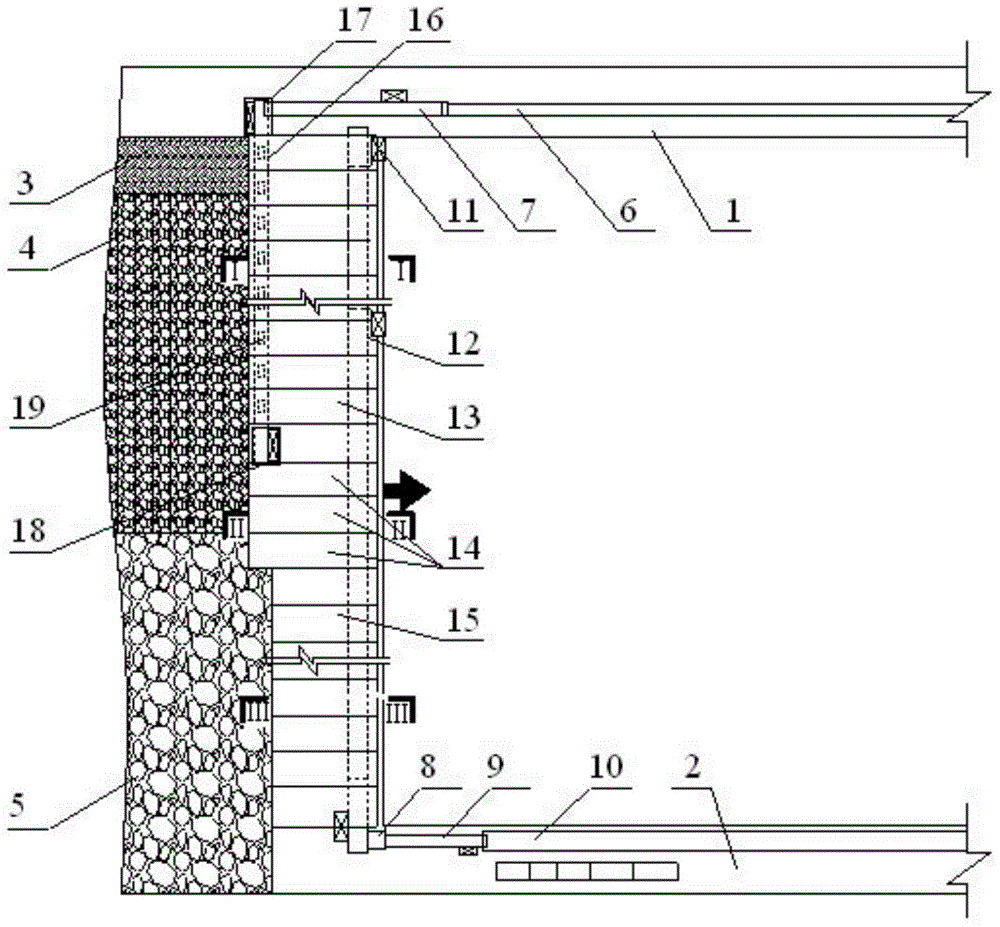

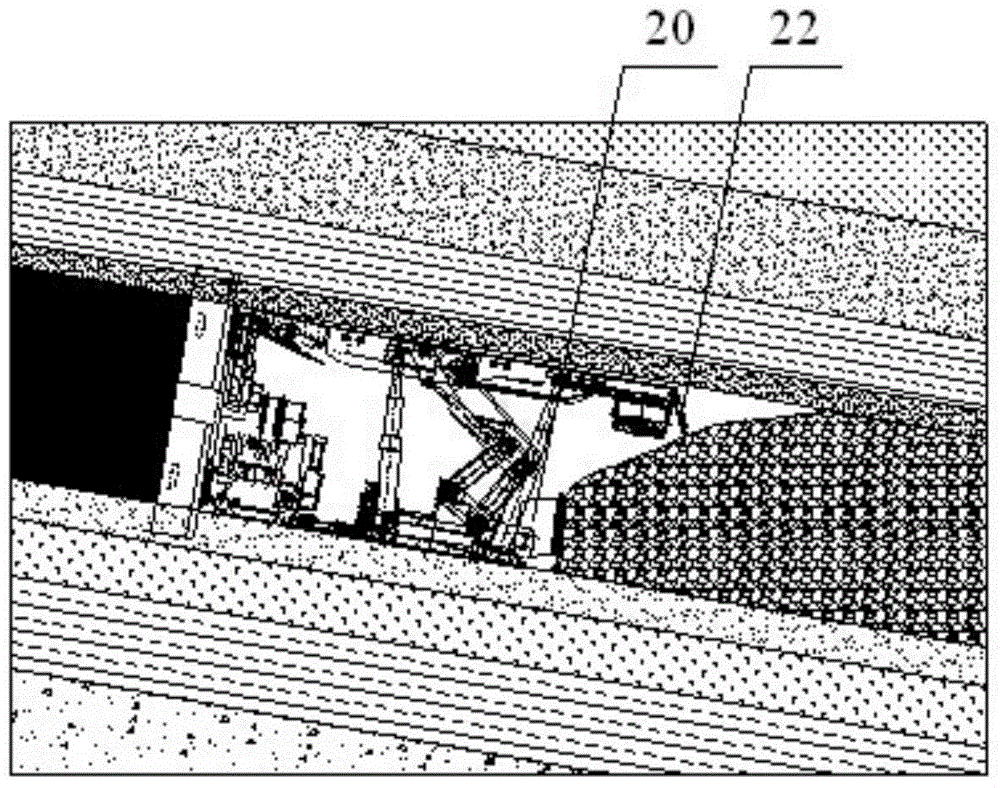

Process method and equipment for heading and anchoring parallel operation construction

ActiveCN104564050AImprove boot rateRaise the level of single advance in tunnelingSlitting machinesMine roof supportsComputer scienceBuilding construction

The invention discloses process method and equipment for heading and anchoring parallel operation construction. According to the process, a heading face is divided into a heading machine operation area and an anchoring support area, wherein the heading machine operation area ranges from a heading head to a heading machine tail, a heading machine post-anchoring operation range serves as the anchoring support area, the heading machine operation area and the anchoring support area are collectively called as a temporary support area, temporary support is carried out in the temporary support area by adopting folding telescopic laneway hydraulic support frames, and heading machine cutting and permanent support are parallelly operated; when the heading machine cutting and anchoring support are completed for one step pitch, the hydraulic support frames positioned on the tail ends of the temporary support area are withdrawn and carried to the heading head through an auxiliary support frame lifting and carrying device, and the hydraulic support frames are lifted to complete the temporary support so as to be subjected to heading and anchoring parallel operation in a next cycle. The heading and anchoring parallel operation construction comprises a heading machine, a plurality of laneway hydraulic support frames, the auxiliary support frame lifting and carrying device, an anchoring support operation platform, a machine back transportation system and a machine tracking ventilating dustproof facility.

Owner:郑东风 +1

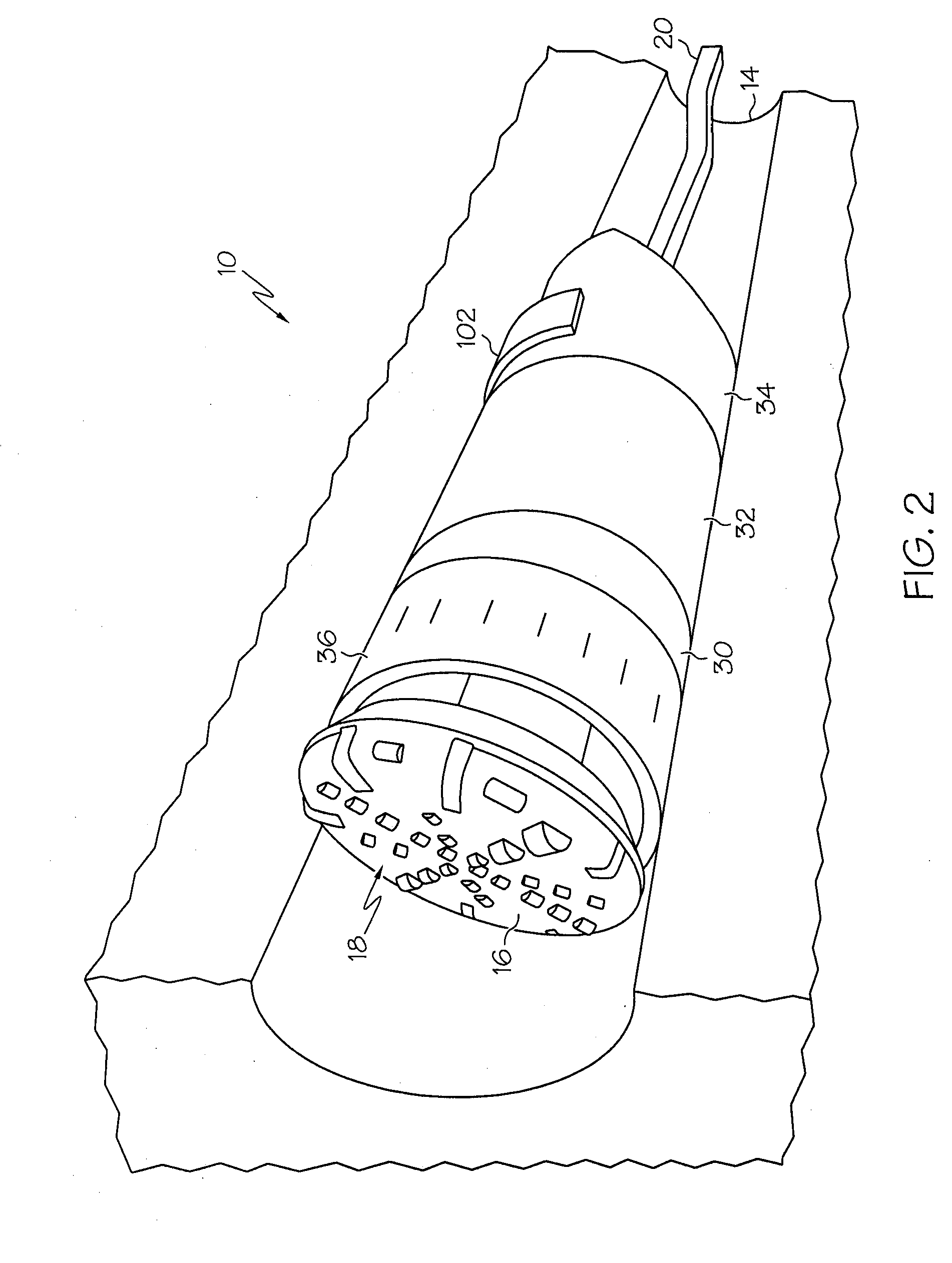

All-conditions tunnel boring machine

A tunnel boring machine is provided comprising a cutter head, a main beam, a first, second, and third shield; and a ground conditioning work zone within the first shield, a gripper assembly, a segment erector arm for lining the tunnel, and at least one propulsion mechanism. The ground conditioning work zone includes at least one probing device for probing the terrain ahead of the cutter head. The first shield is configured to be retracted relative to the second shield to provide access for the ground conditioning work zone to apply at least one ground support device. The at least one propulsion mechanism moves the cutter head, the first and the second shield forward while the third shield and the gripper assembly remain stationary. The ground support devices can include filling a hole with a ground conditioning agent; and placing a bolt, ring beam, mesh, or shotcrete in / on the tunnel wall.

Owner:THE ROBBINS CO

Mining machine and method

A control system for a mining machine which moves in passes across a seam to be mined using absolute coordinates is disclosed. The machine is carried on rail and co-ordinates of the rail are measured along the length of rail. The rail is then moved to a new position for a next pass, and the distance of moving is determined from the co-ordinates previously measured. By knowing the co-ordinates, the rail can be moved to assume a desired profile, so that a desired profile of the seam can be achieved on the next pass. Co-ordinates of the up and down movement of a shearing head can also be measured and stored with the co-ordinates along the rail to provide a profile of the seam being cut, and so that on a next pass the intended position of the shearing head can be predicted and moved accordingly.

Owner:COMMONWEALTH SCI & IND RES ORG

Support-type comprehensive tunneler

ActiveCN102022122AOvercome the disadvantages of not being able to drill holes and support at the same timeIncrease the speed of excavationMine roof supportsTunnelsEngineeringMetal mesh

The invention relates to a support-type comprehensive tunneler which comprises a non-tracked tunneler, a tunneler chassis, a left hydraulic support, a right hydraulic support, a drilling rig and scraper conveyors, wherein the tunneler is arranged on the tunneler chassis, and two advancing jacks are arranged on the tunneler chassis; the other ends of the two advancing jacks are respectively connected with the left hydraulic support and the right hydraulic support, and the two sides of the tunneler chassis are respectively provided with a lateral pushing oil cylinder; forestopes of the left andright hydraulic supports are respectively provided with a group of metal mesh storages, and the tail of a main top beam of the support is hung with the drilling rig; the tail of a first scraper conveyor is arranged on a spade plate of the tunneler, and the head of the first scraper conveyor and the tail of a second scraper conveyor are overlapped; and the head of the second scraper conveyor and the tail of a belt loader are overlapped, and sleds are arranged at the back of the two hydraulic supports. The tunneler has the advantage that the drilling support and the coal cutting of the tunnelerare simultaneously carried out, and also has the automatic lapping function, thus reducing labor intensity and increasing the coal mining efficiency by over 4 times.

Owner:DATONG COAL MINE GRP CO LTD HENGAN EQUIP CO LTD

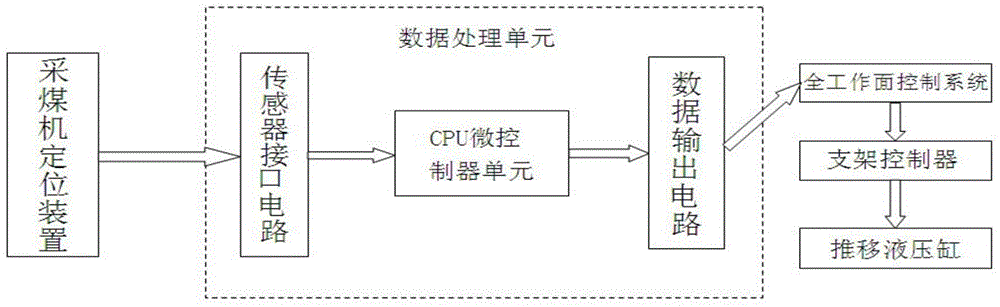

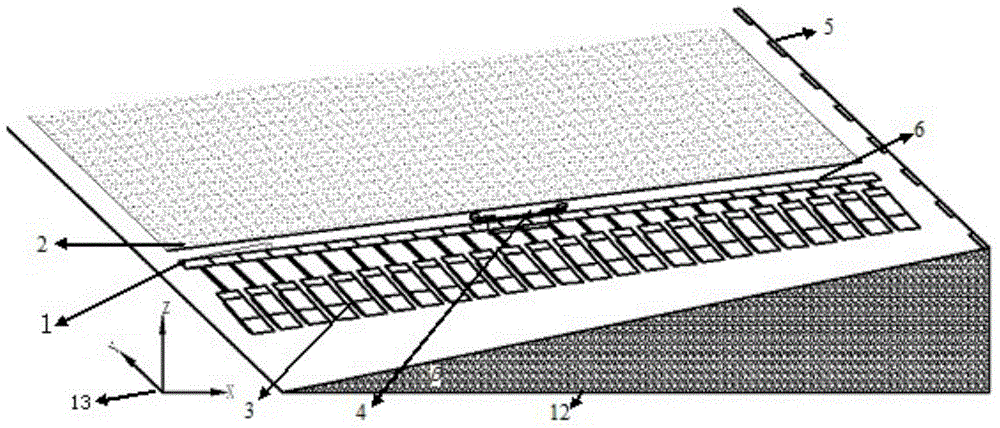

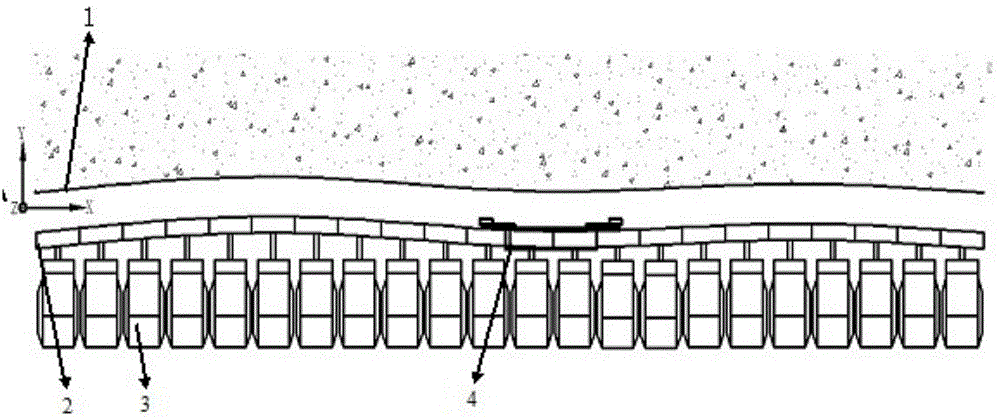

Scrapping plate conveyor dynamic straightening method based on absolute motion trajectory of coal cutter

ActiveCN104058215ARealize false tiltAchieve alignmentConveyorsMine roof supportsTerrainSignal processing circuits

The invention provides a scrapping plate conveyor dynamic straightening method based on the absolute motion trajectory of a coal cutter and belongs to a scrapping plate conveyor dynamic straightening method for a full-mechanized mining face. In the dynamic straightening method, a positioning device mounted on the coal cutter is utilized, so as to conduct real-time monitoring to the moving trajectory of the coal cutter along the scrapping plate conveyor; a signal processing circuit analyzes the dynamic position data of the coal cutter moving along the scrapping plate conveyor under the set spatial coordinate system; the absolute motion trajectory curve of the coal cutter and target reference motion trajectory of the quire under the geographical spatial coordinate system are concluded; a micro controller draws a target reference motion trajectory of a next quire according to the target reference trajectory and the working face coal bed terrain; the displacement distance of each hydraulic support is calculated; the micro controller controls an electro hydraulic control system via an output circuit; the electro hydraulic control system controls each bracket controller, so as to push a jack forward and enables the scrapping plate conveyor to meet the linear requirement. The positioning device on the coal cutter detects the orientation of the full-mechanized mining face in the geographical spatial coordinate system, so that adjusting false inclination of the full-mechanized mining face can be achieved.

Owner:CHINA UNIV OF MINING & TECH

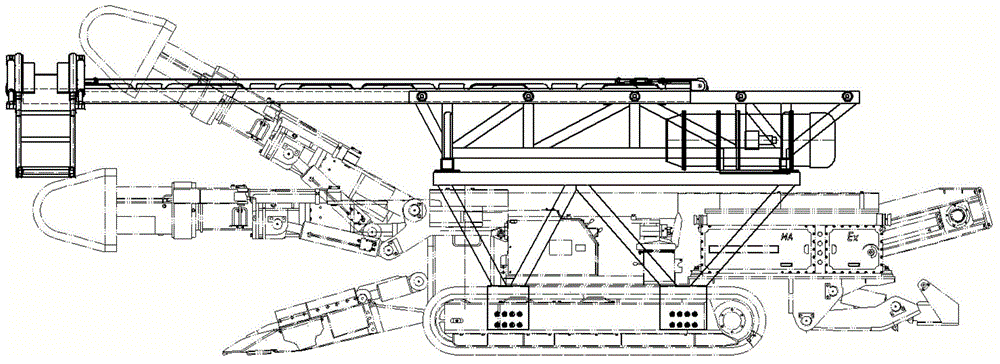

Comprehensive dredging machine

ActiveCN102155219AOvercome the disadvantages of not being able to drill holes and support at the same timeIncrease the speed of excavationMine roof supportsTunnelsPush and pullEngineering

The invention discloses a comprehensive dredging machine. The comprehensive dredging machine comprises a crawler-free type dredging machine, a hydraulic support, a drilling machine, a scraper conveyor, a runner and the like. The upper end of the hydraulic support is provided with a main top beam, a front canopy, a back canopy and a cross beam; the dredging machine is arranged on a foundation; thefront and rear ends of the foundation are provided with a slope regulation jack respectively; one end of a front pushing and pulling jack is connected with the foundation of the dredging machine, andthe other end of the front pushing and pulling jack is connected with the hydraulic support; the rear of the dredging machine is provided with a self-advancing jack, and two sides of the foundation are provided with a side push cylinder respectively; and the drilling machine is arranged below the main top beam or the back canopy; and the runner is arranged behind the hydraulic support and is connected with a rear push and pull jack arranged on the hydraulic support by an anchor chain and a pulley. The comprehensive dredging machine has the advantages of parallel operation of hole drilling andsupporting, and coal cutting of a development machine, a roadway turns flexibly, the turning radius is small, the turning speed is high, the tunneling speed is high, and the safety is guaranteed.

Owner:DATONG COAL MINE GRP CO LTD HENGAN EQUIP CO LTD

Longwall mining N00 construction method

ActiveCN105240013AGuaranteed ventilation effectSave resourcesUnderground miningTunnel/mines ventillationLongwall miningCoal pillar

The invention discloses a longwall mining N00 construction method, which is characterized in that roadway-free tunneling and coal-pillar-free mining are performed in N working faces of a bran-new panel; the whole panel is provided with an air return downhill passage, a belt downhill passage and a rail downhill passage; the air return downhill passage and the rail downhill passage are positioned at one end of the panel; and the belt downhill passage is communicated with the other end of the panel and is communicated with the air return downhill passage. The longwall mining N00 construction method has the advantages that the ventilation of the whole coal mining region can be ensured; during the mining of each working face in the panel, one part of a goaf is used for implementing roof cutting and pressure relief automatic roadway forming; any crossheading roadway does not need to be tunneled; and coal pillars do not need to be reserved, so that resources are saved, and the efficiency is improved.

Owner:何满潮

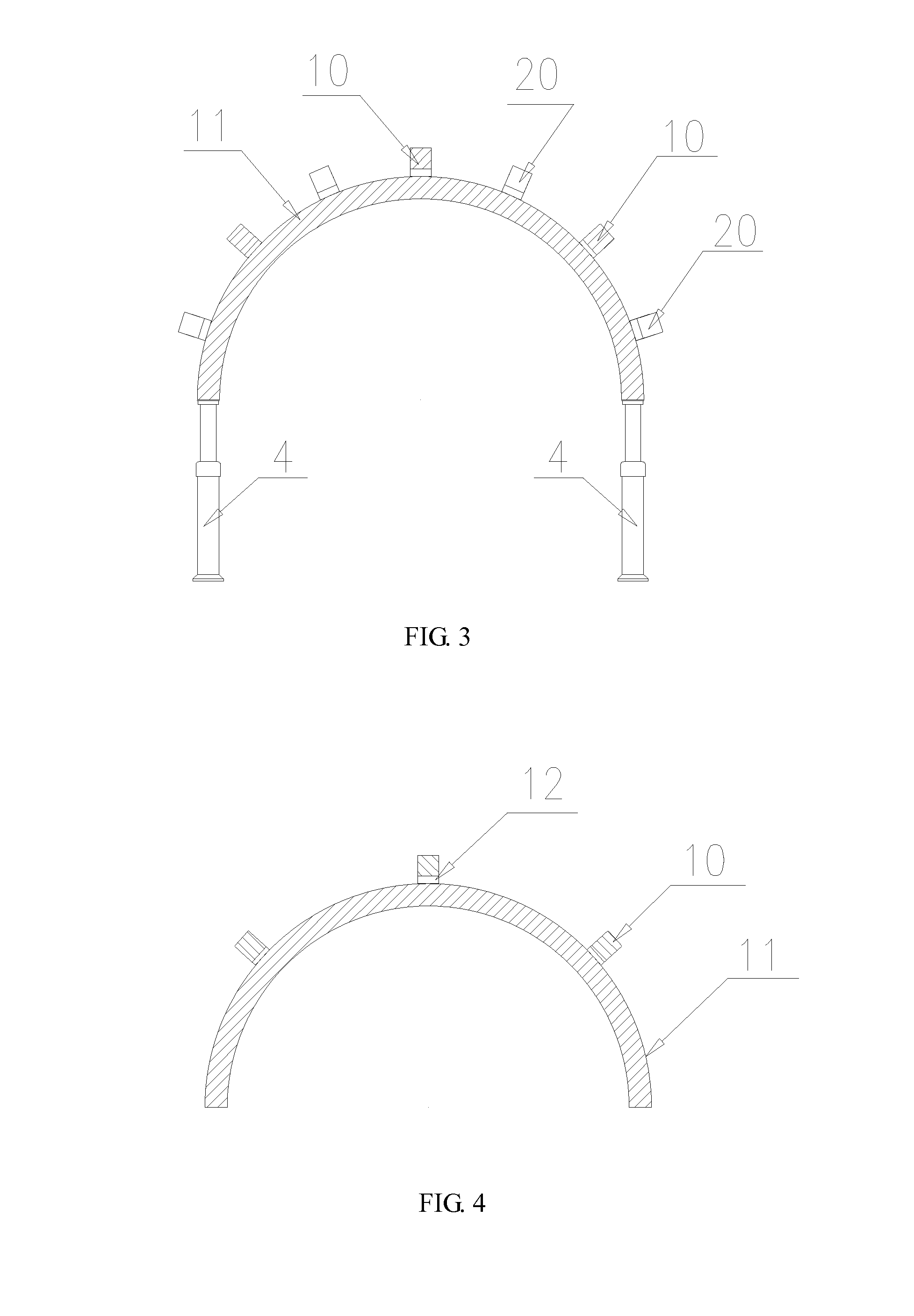

Tunnel self-advancing support shed

ActiveCN102628368ATo achieve the effect of safety supportTimely supportMine roof supportsTunnel liningStructural engineering

Owner:李信斌

Non-roadside supporting gob-side entry retaining process

InactiveCN101514633AEasy to operateImprove construction efficiencyMaterial fill-upMine roof supportsEngineeringCantilever

The invention discloses a non-roadside supporting gob-side entry retaining process comprising the following processing steps: 1) additionally constructing anchor rods, anchor craning beams and side anchor craning beams and mounting metal mesh in an entry to be retained in front of the stope face, wherein, one end of the metal mesh is fixed on the entry top which is 0.4m from the stope face side through the anchor rods, and the anchor cable of each anchor cable beam is anchored on the stable layer of a coal seam roof; 2) laying the metal mesh on a head beam of a support on a fully-mechanized face, mounting Pi-shaped steel legs and roof-cutting mono-blocks on the edge of a gob area at the back of the support, and mounting mono-blocks in the entry at the same time; 3) carrying out the roof-cutting with the roof-cutting mono-blocks, then, the immediate roof of the gob area is fully broken down, and the metal mesh is compacted on the floor by the broken gangue, so as to form a 'mesh-gangue' wall; and 4) withdrawing mono-blocks of roof-cutting mono-blocks in the retained entry and part in the later period of stoping, so as to form a stable cantilever beam structure. The invention is characterized in that the roof of the entry is supported mainly by an anchor cable, an anchor net and the 'mesh-gangue' wall to form and retain the stable cantilever beam structure. The process has the advantages of simple operation, high construction efficiency and speed, low impact on the working surfaces, low cost, safety and reliability, therefore, the process has wide practicability.

Owner:冀中能源股份有限公司葛泉矿

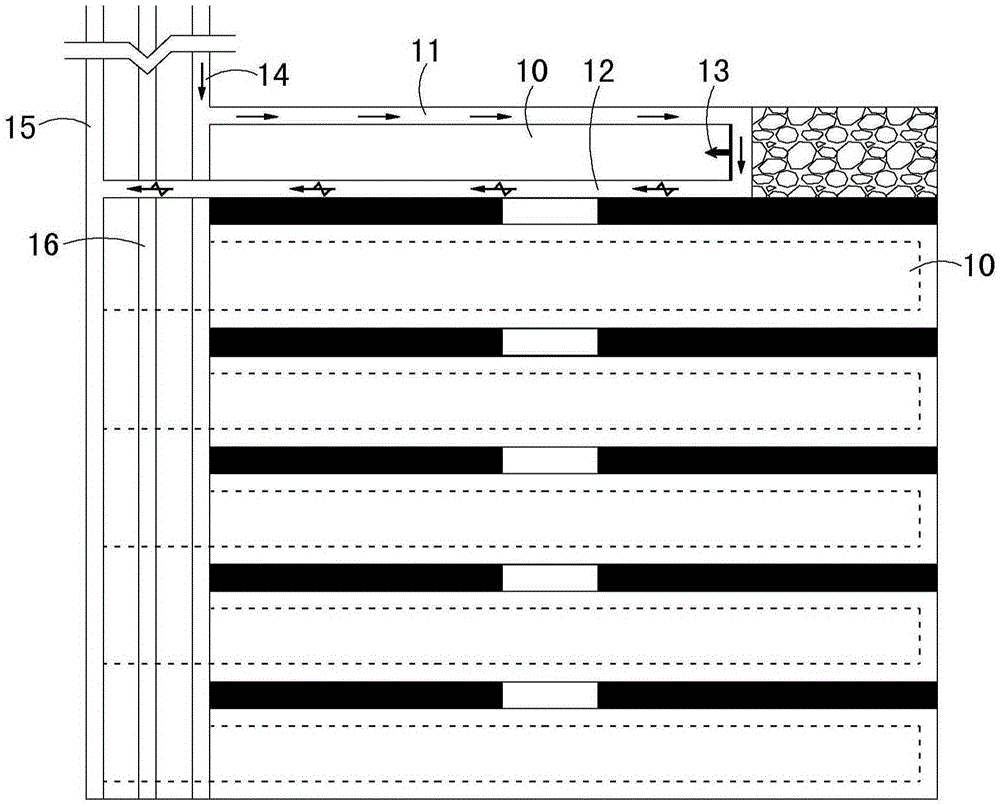

Mining method employing solid filling and fully-mechanized coal mining hybrid working face

ActiveCN104405437AAvoid pollutionSolve the tunnelingUnderground miningSurface miningSolid massFilling materials

The invention discloses a mining method employing a solid filling and fully-mechanized coal mining hybrid working face, namely a method for carrying out coordinated and combined mining by combining solid filling with fully-mechanized coal mining on the same coal face. Coal mining is carried out by adopting a strike retreating-longwall mode; coal cutting, coal charging and coal handling procedures are the same as those of a fully-mechanized coal mining process; a solid filling section of the hybrid working face is used for supporting a roof by virtue of a filling and mining hydraulic support; solid filling materials are backfilled to a goaf management roof by virtue of a porous hopper conveyor which is suspended behind and below of the filling and mining hydraulic support; a fully-mechanized coal mining section is used for supporting the roof by virtue of a fully-mechanized coal mining hydraulic support; the goaf is managed by adopting a caving method. The mining method is beneficial for giving play to dual advantages of solid filling and fully-mechanized coal mining; the problem of environmental pollution caused by accumulation of solid wastes such as gangue, coal ashes and construction wastes on the ground is reduced by solid filling; the working face is lengthened by combining with fully-mechanized coal mining; tunneling of a mining roadway is reduced; the single yield and single effect of the working face are improved; the requirements of a modern mine on production capacity are met.

Owner:CHINA UNIV OF MINING & TECH +1

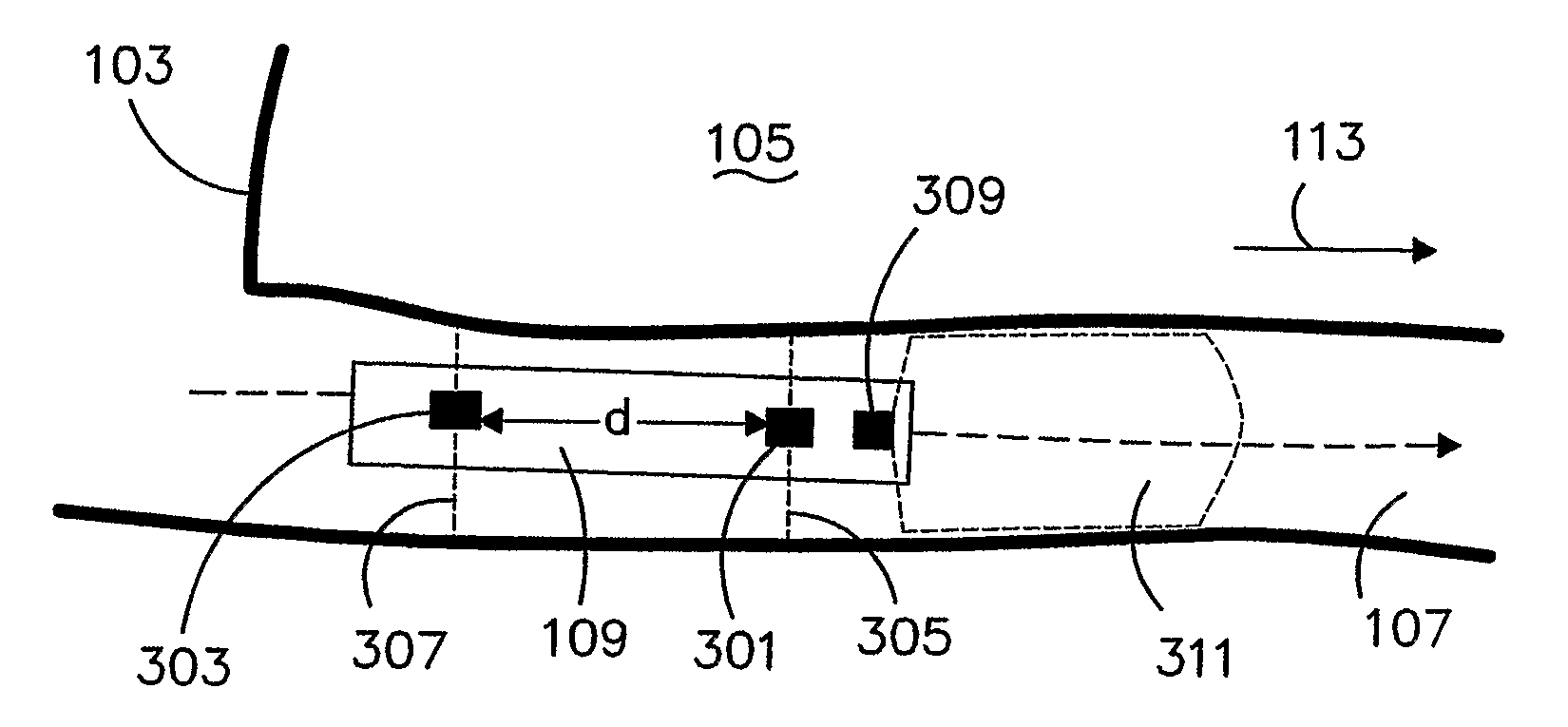

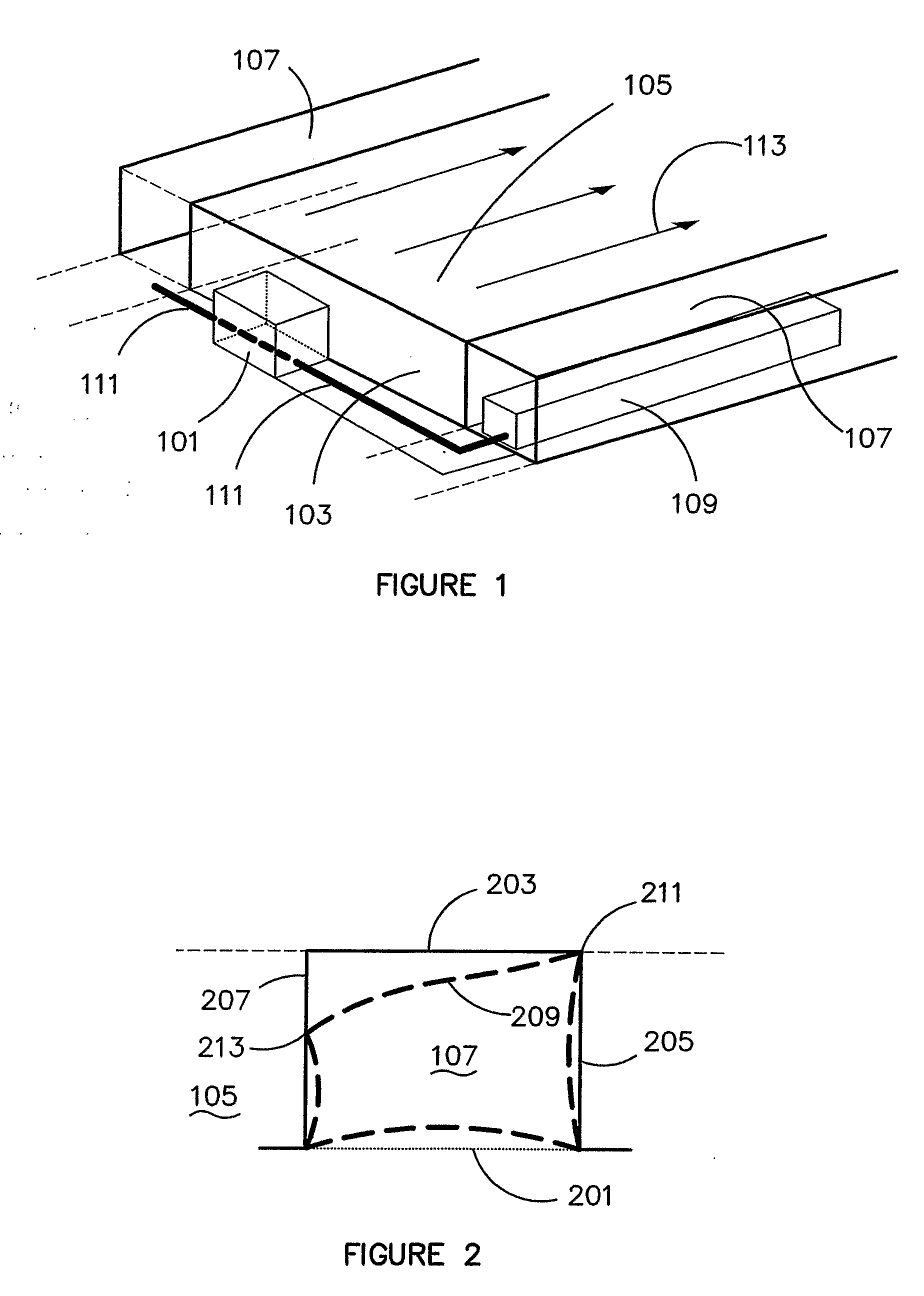

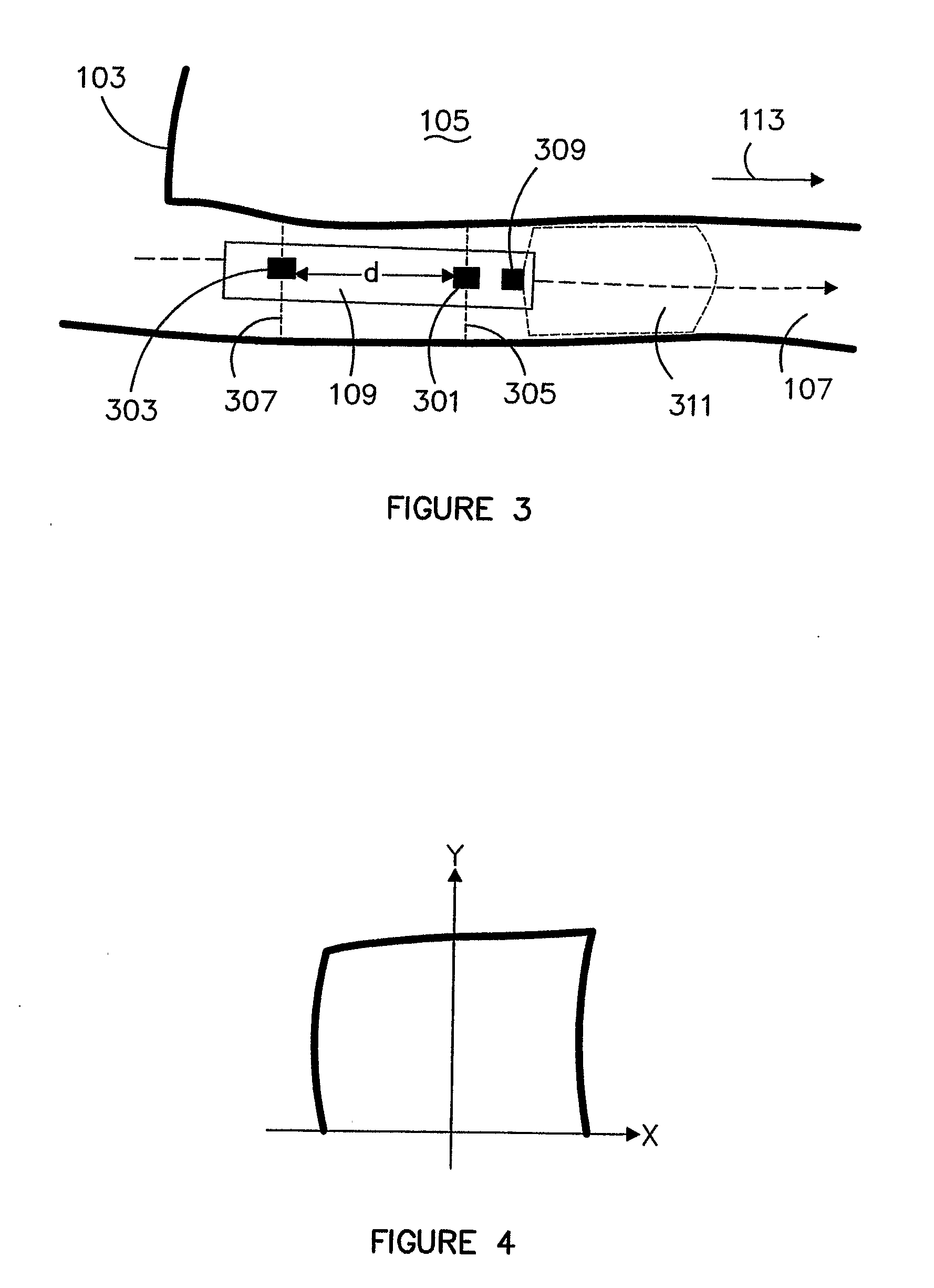

Method and apparatus for monitoring gateroad structural change

ActiveUS20090134692A1Overcome problemsElectric/magnetic detection for well-loggingMining devicesMultiple sensorEngineering

Owner:COMMONWEALTH SCI & IND RES ORG

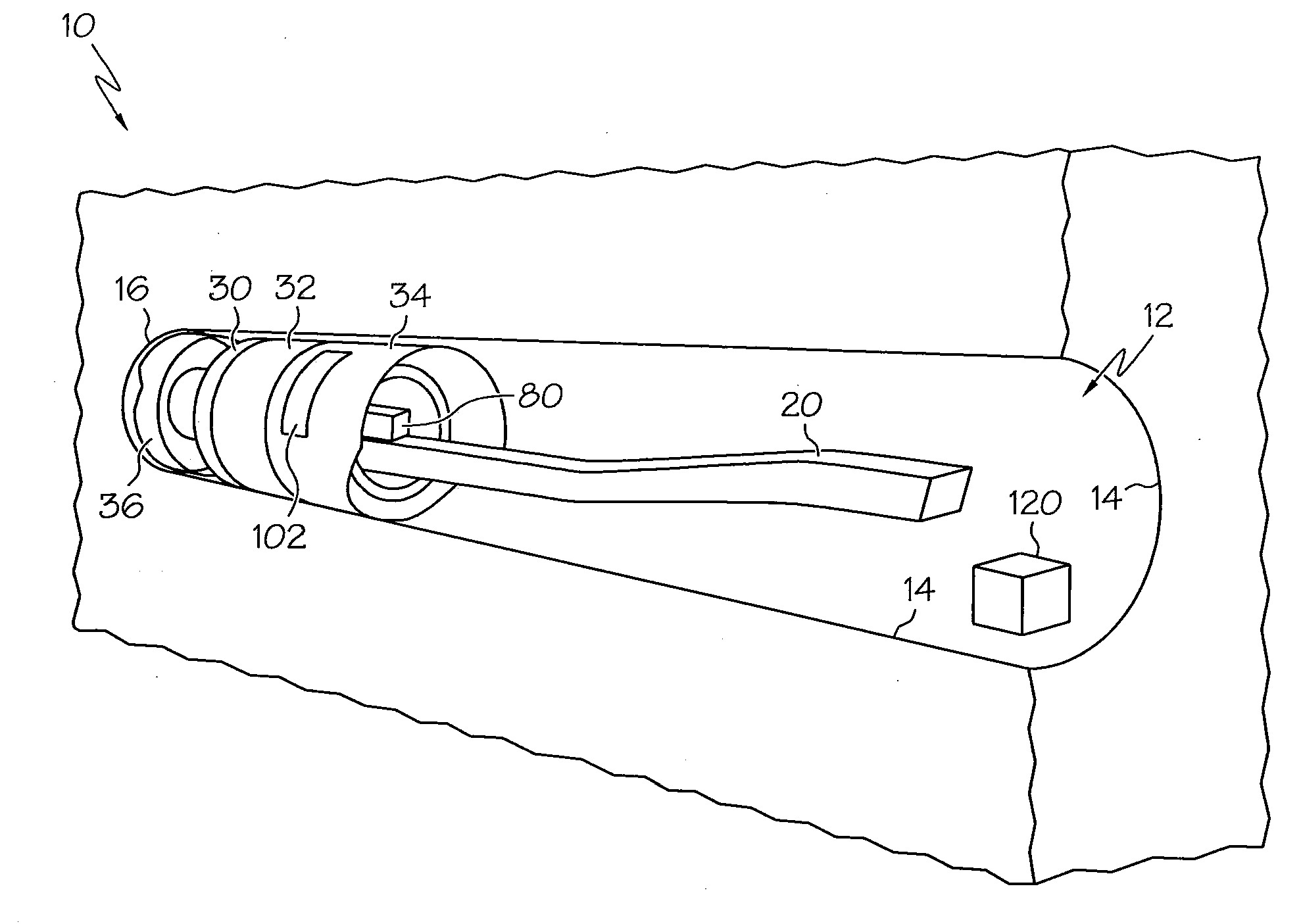

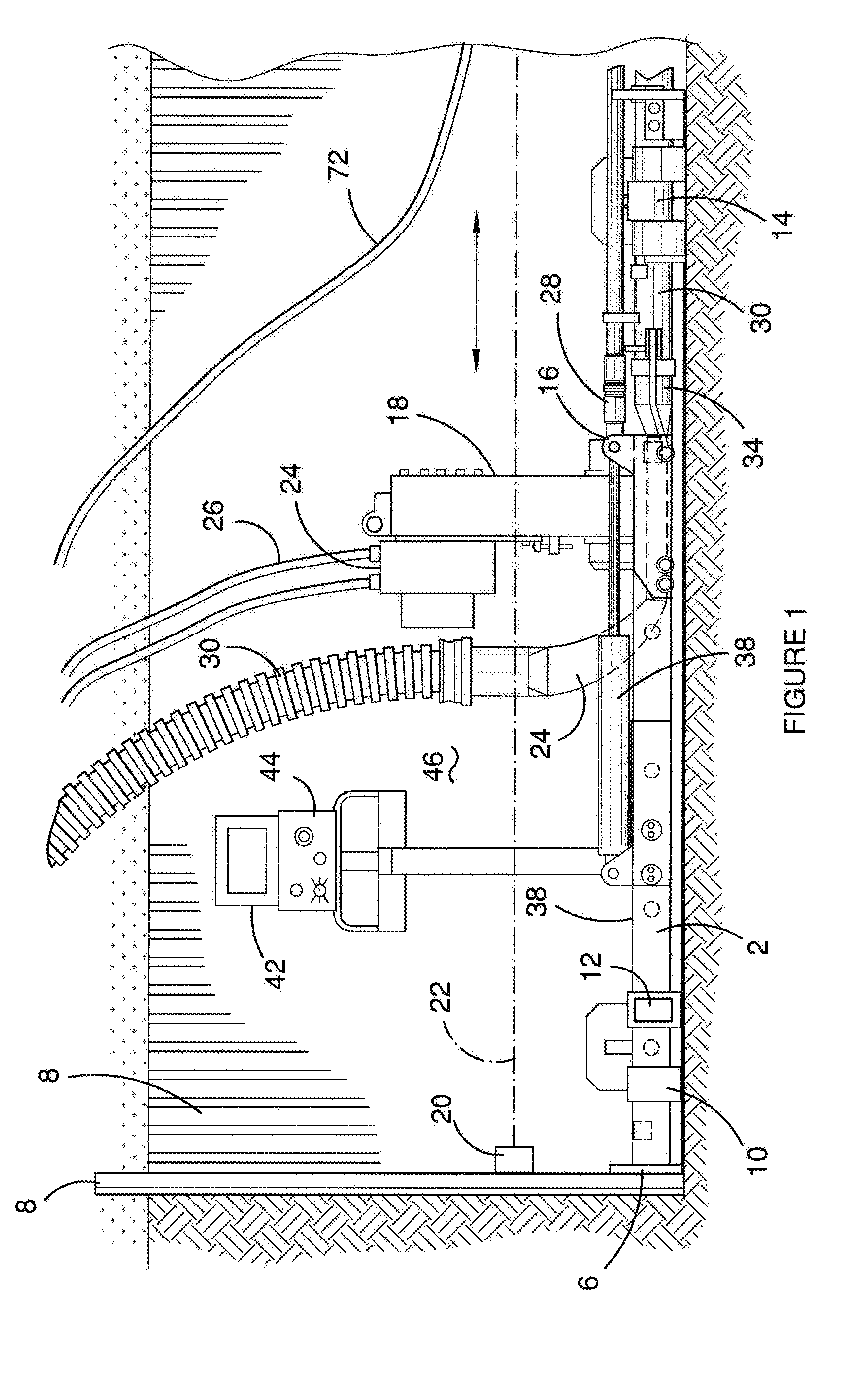

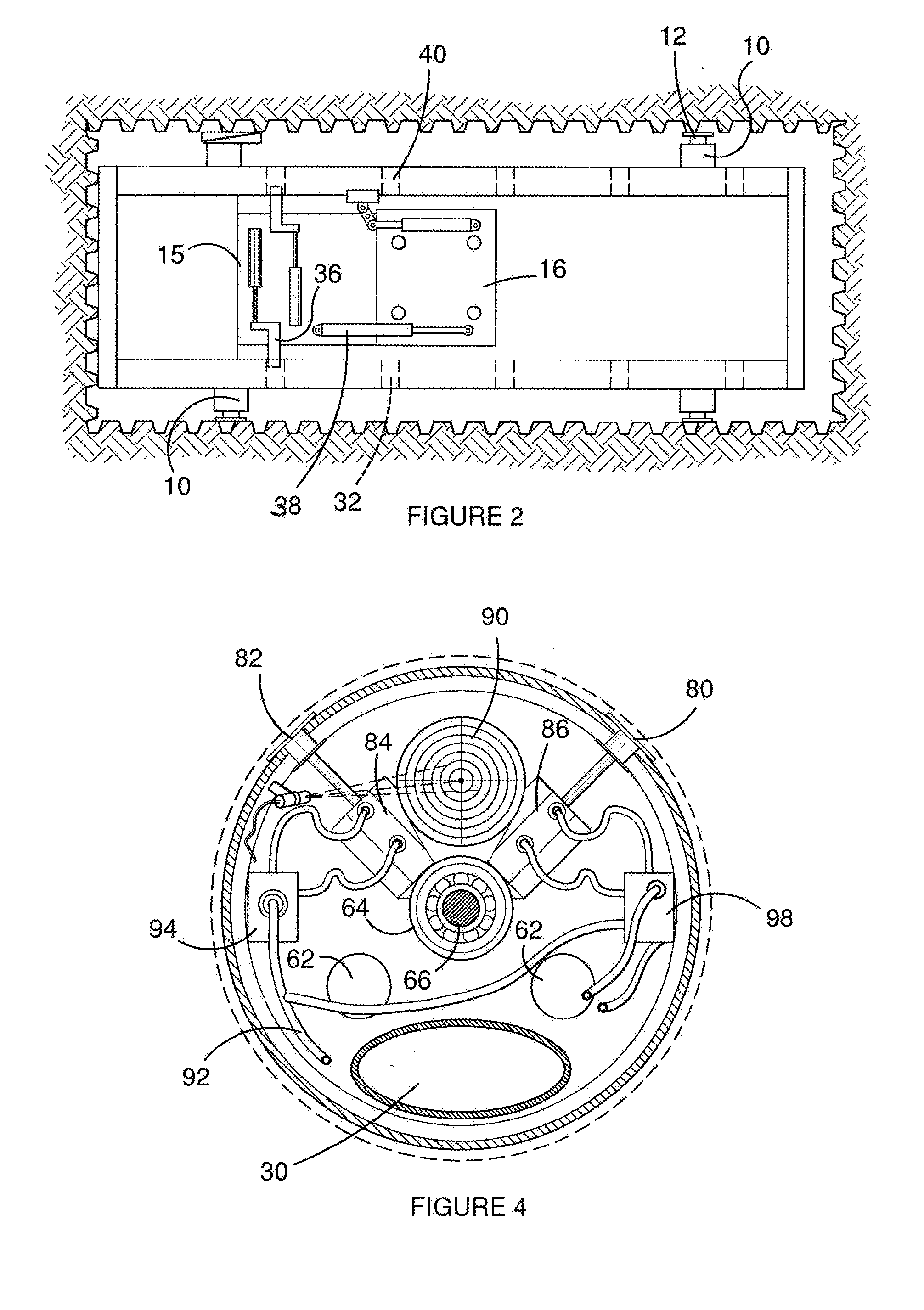

Boring machine

InactiveUS20070089906A1Simplifies and constructionUnderground chambersSlitting machinesDrive shaftEngineering

A micro tunnelling machine has a tunnelling head with a boring bit which is forced in a horizontal direction by a hydraulic thruster. The direction of the head is laser guided. The beam strikes a target in the head and a camera relays an image of the target to an operator located at the tunnel entrance. The operator adjusts the direction by admitting water and draining water from a pair of rams inside the head which move the boring bit up and down or left and right. Water is introduced into the boring bit through the drive shaft of the boring bit. The water forms a slurry which is extracted by a vacuum pipe which enters the slurry as droplets and particles and conducts them away from the tunnelling head.

Owner:DAVIES RODNEY JOHN

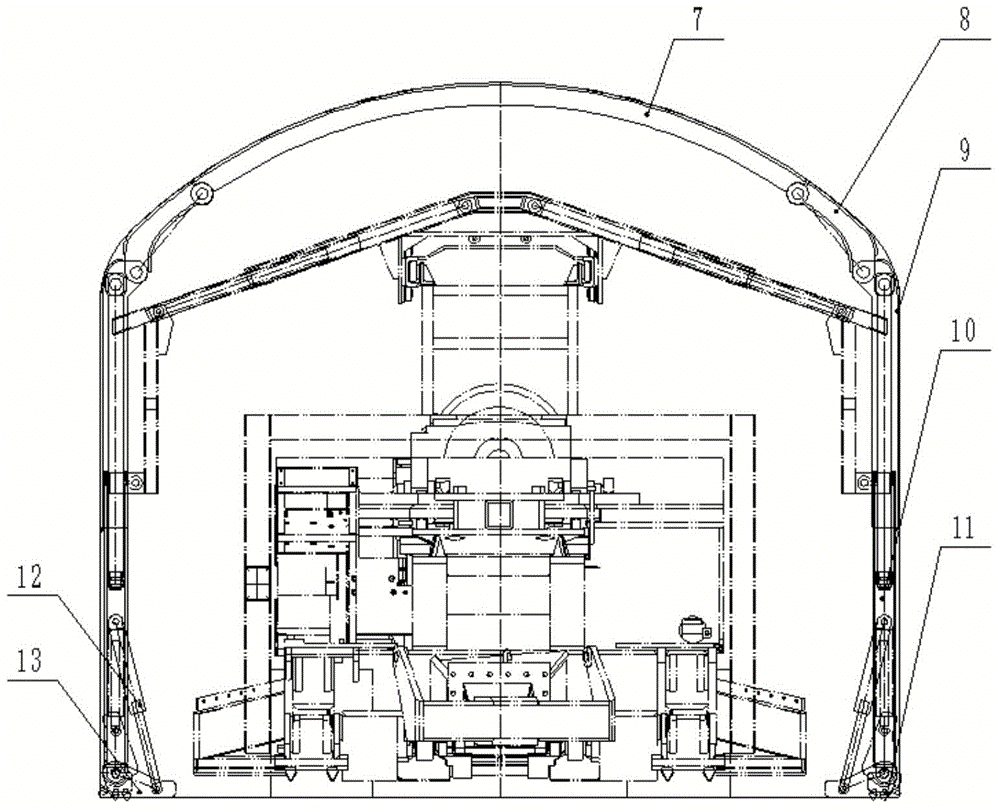

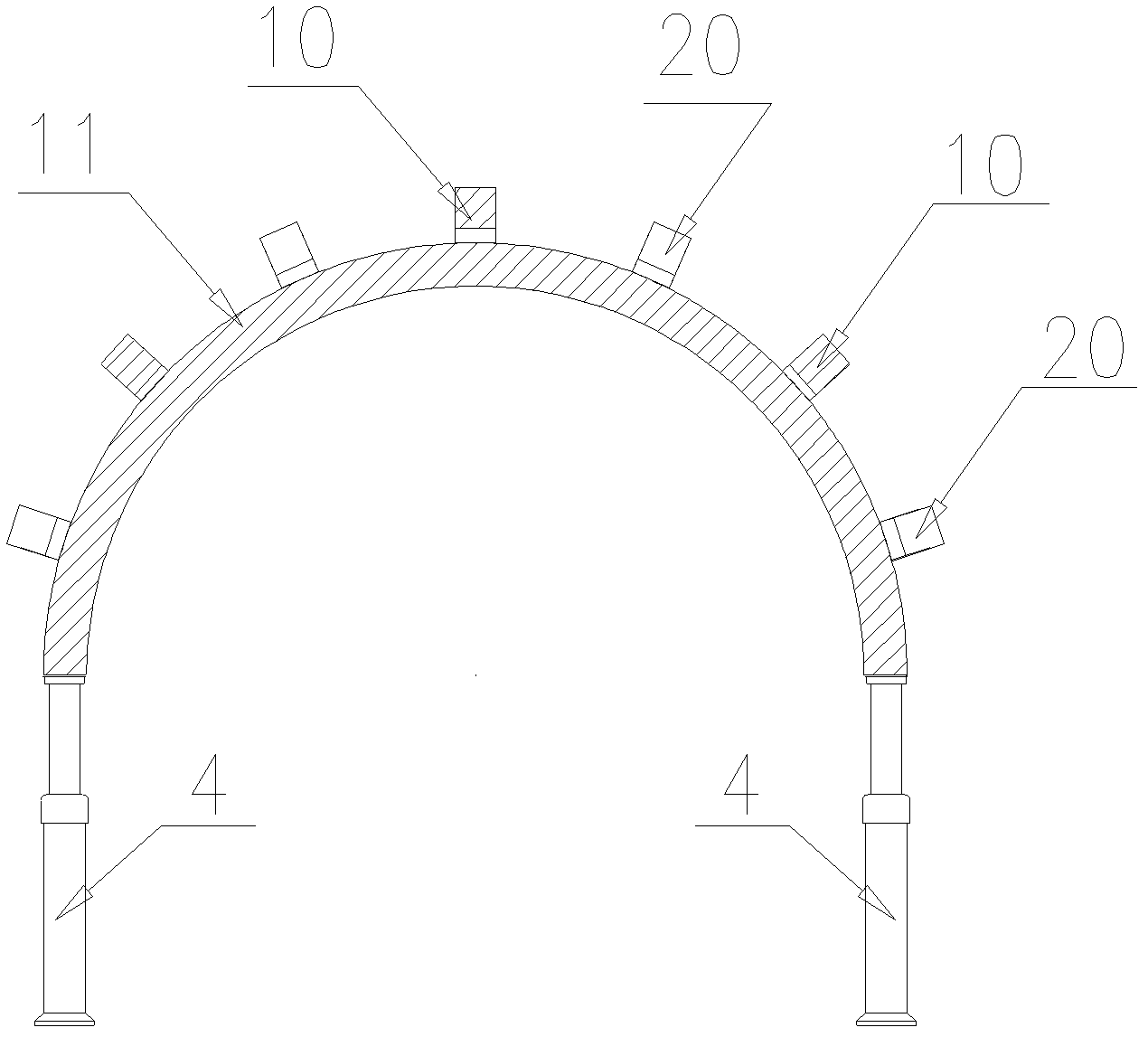

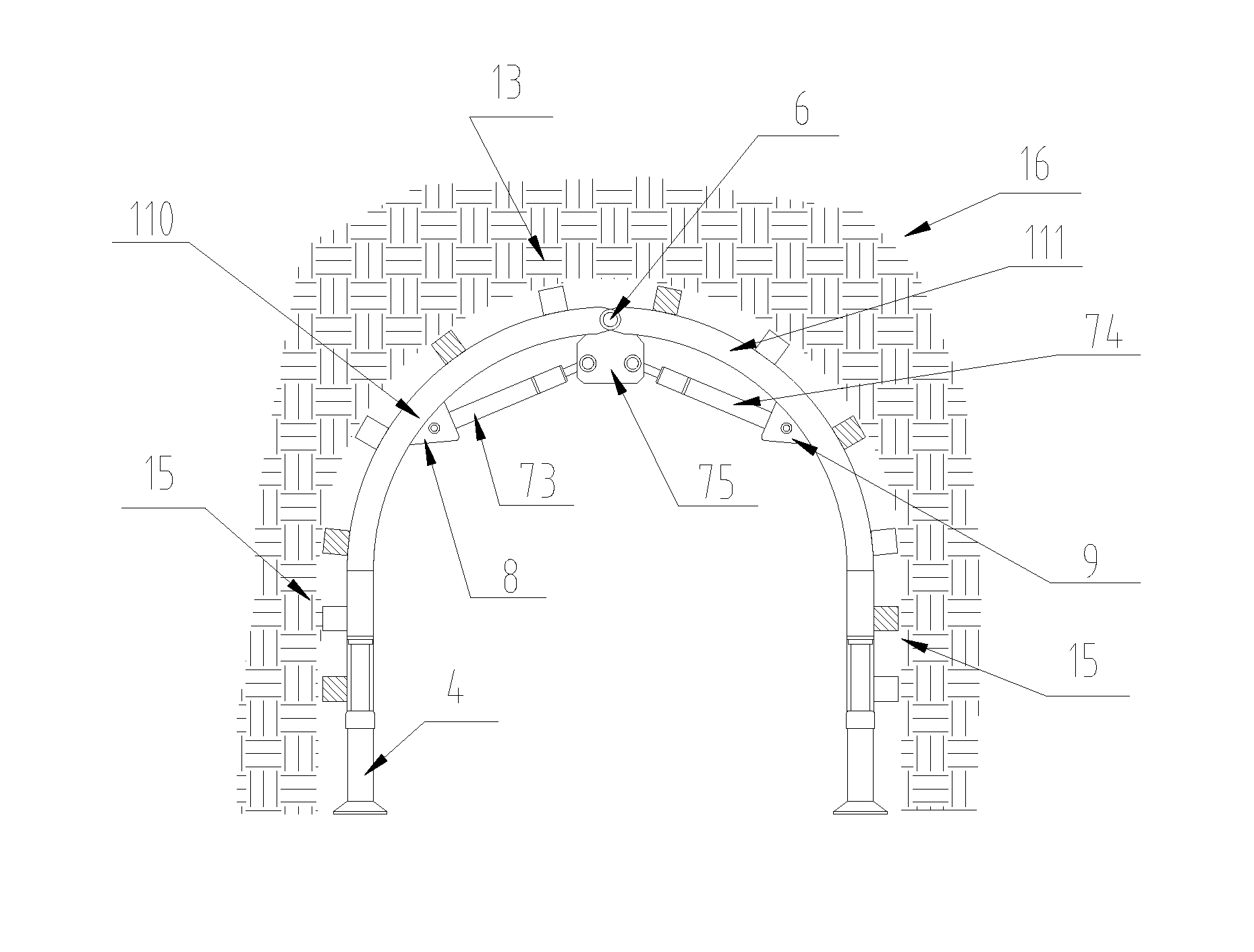

Self-moving tunnel support canopy

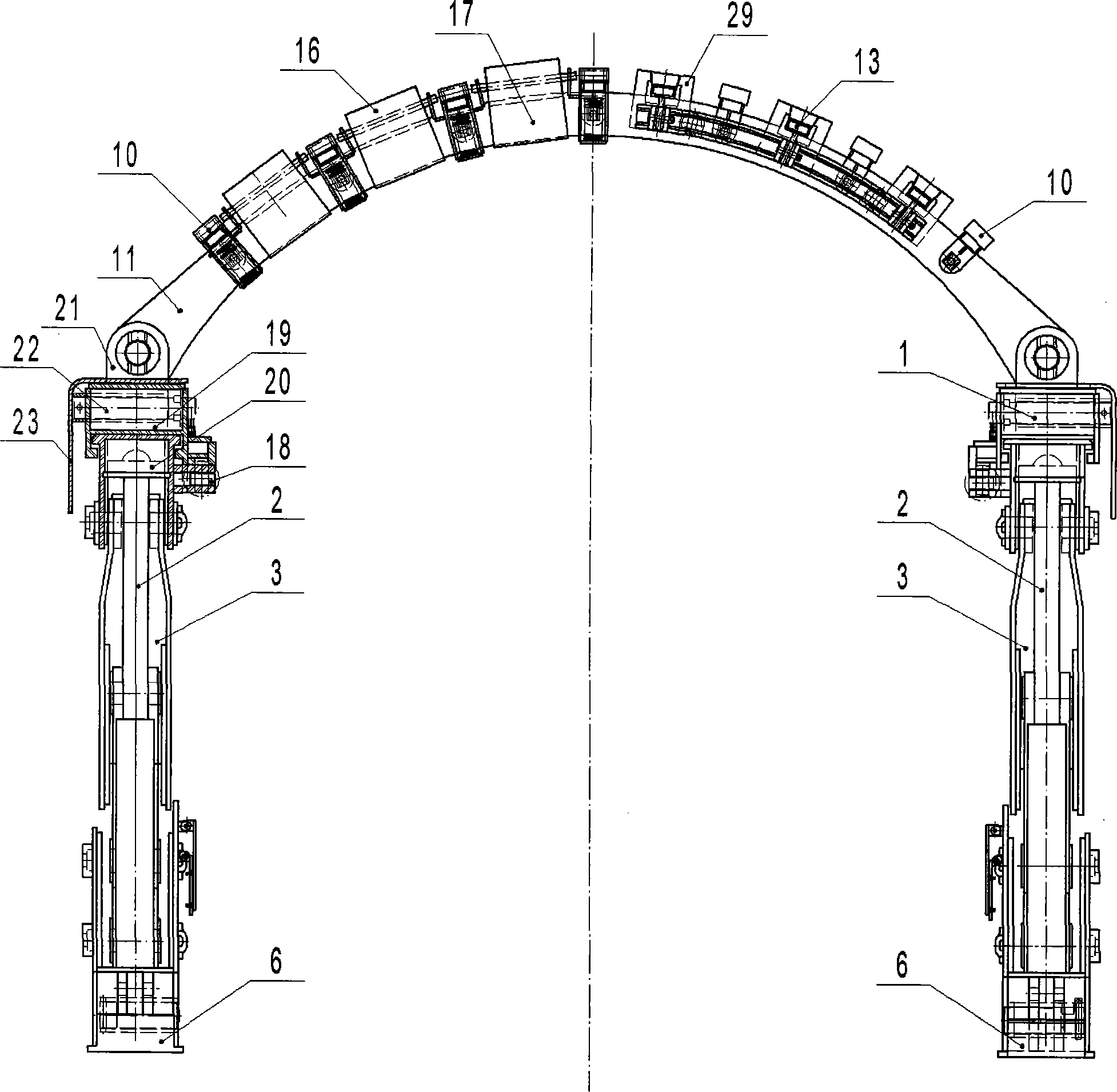

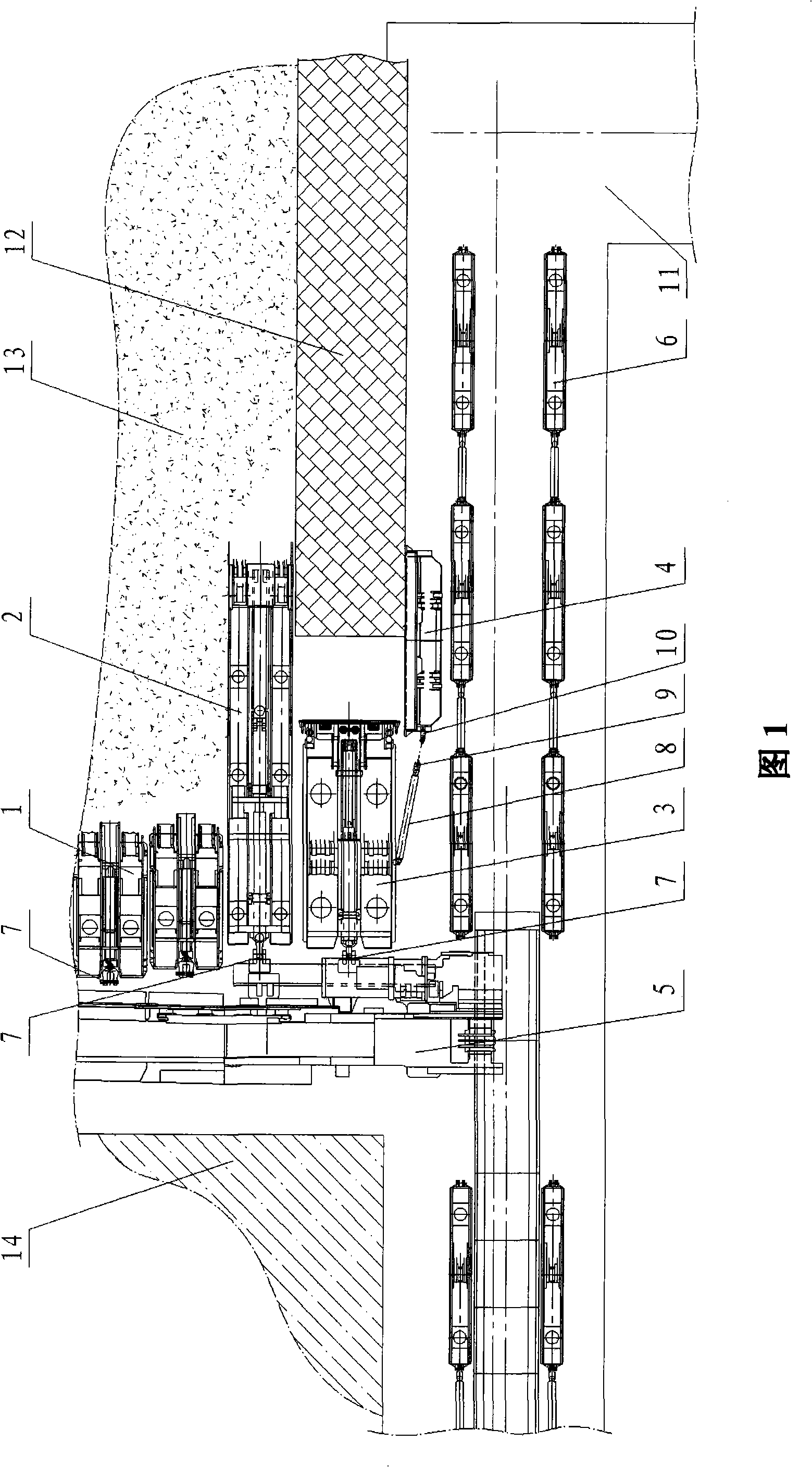

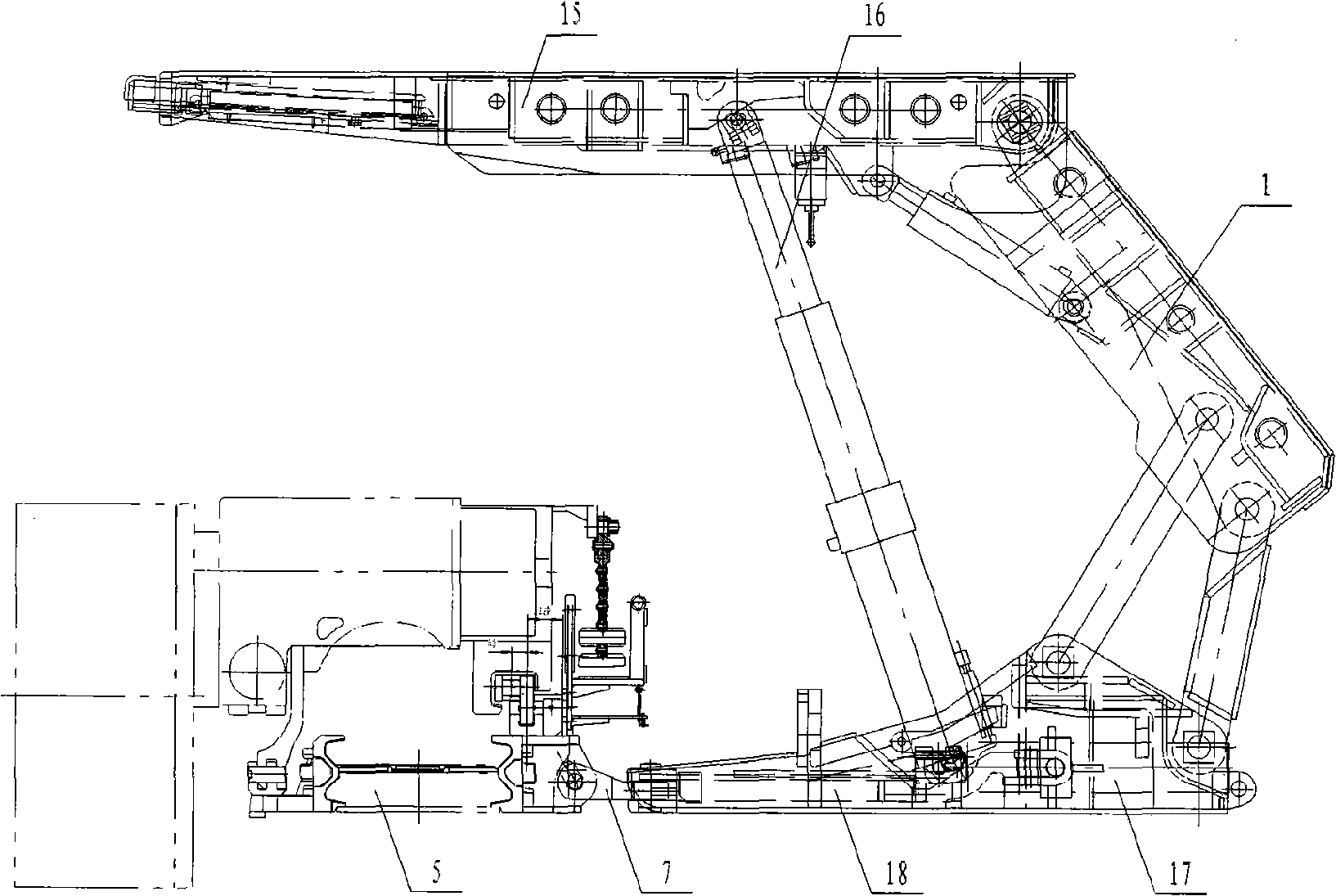

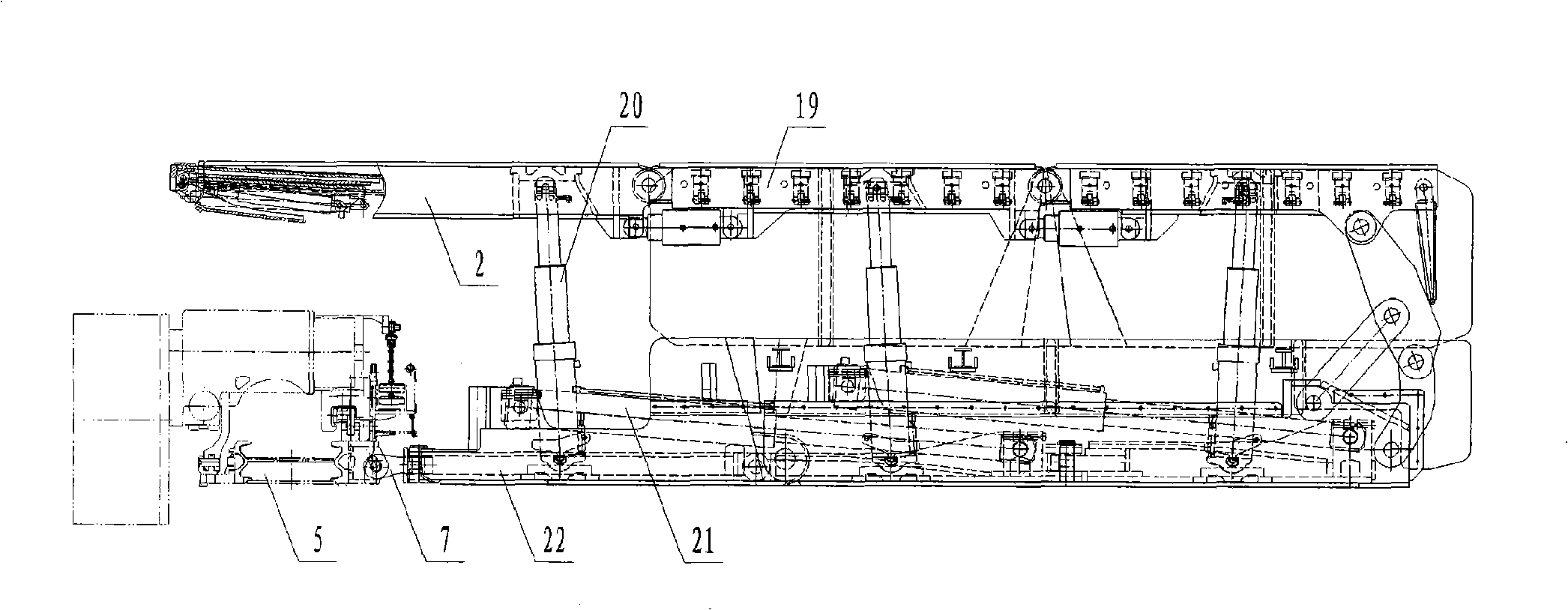

ActiveUS20150086272A1Safe and reliableSecure supportUnderground chambersMine roof supportsShaped beamStructural engineering

A self-moving tunnel support canopy includes front arch frame, rear arch frame, forward jack, and support jack disposed under the front arch frame. The front arch frame has front arch beams and front longitudinal beams longitudinally disposed along arch upper surfaces of front arch beams and coupled to all the front arch beams. The rear arch frame has rear arch beams and rear longitudinal beams longitudinally disposed along arch upper surfaces of the rear arch beams and coupled to all the rear arch beams. The front longitudinal beams and the rear arch beams are spacedly disposed, and a spacing is configured between the front arch beam and a front-adjacent rear arch beam. One end is coupled to the front arch frame, and the other end of the forward jack is coupled to the rear arch frame. The front arch beam and the rear arch beam are both arch-shaped beams.

Owner:LI XINBIN

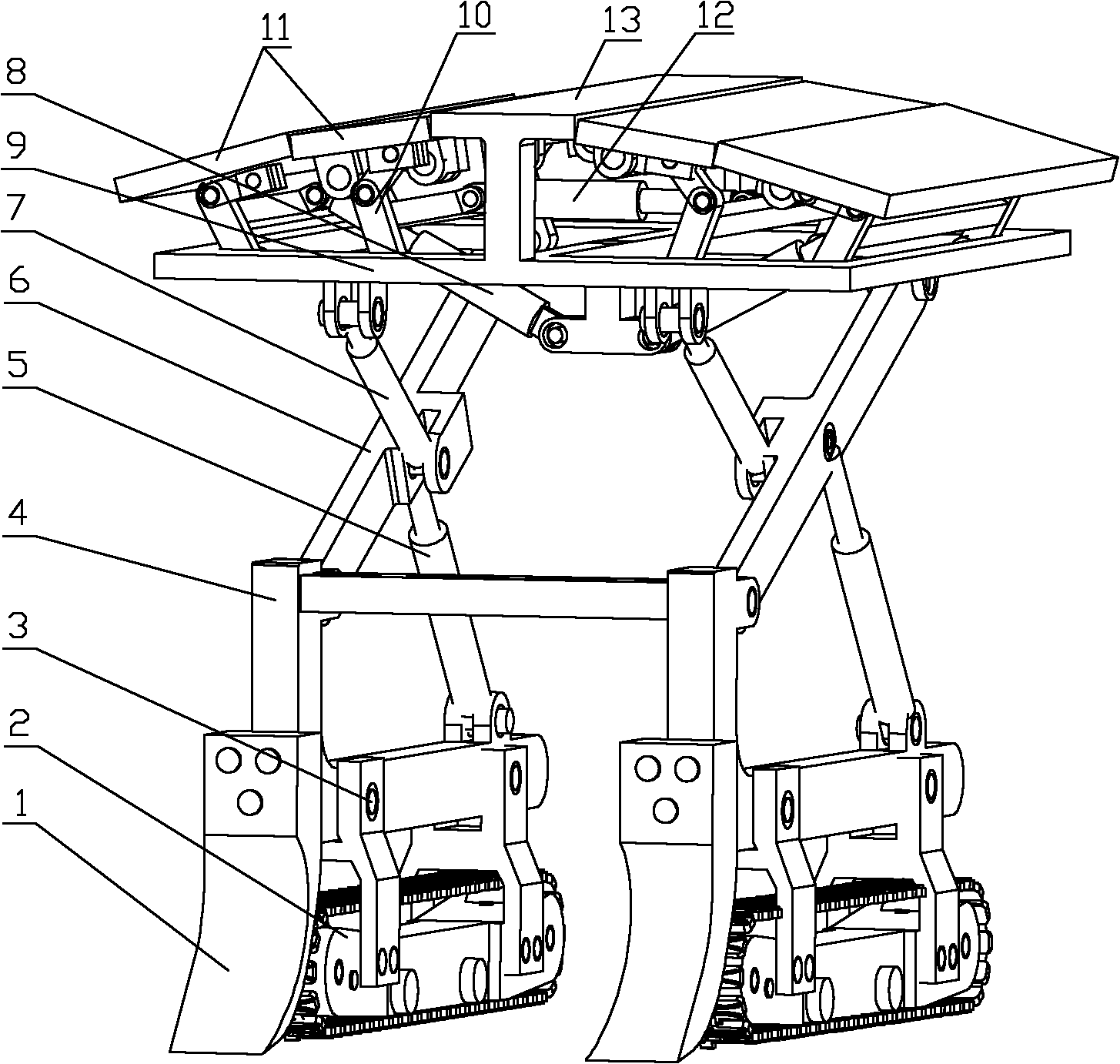

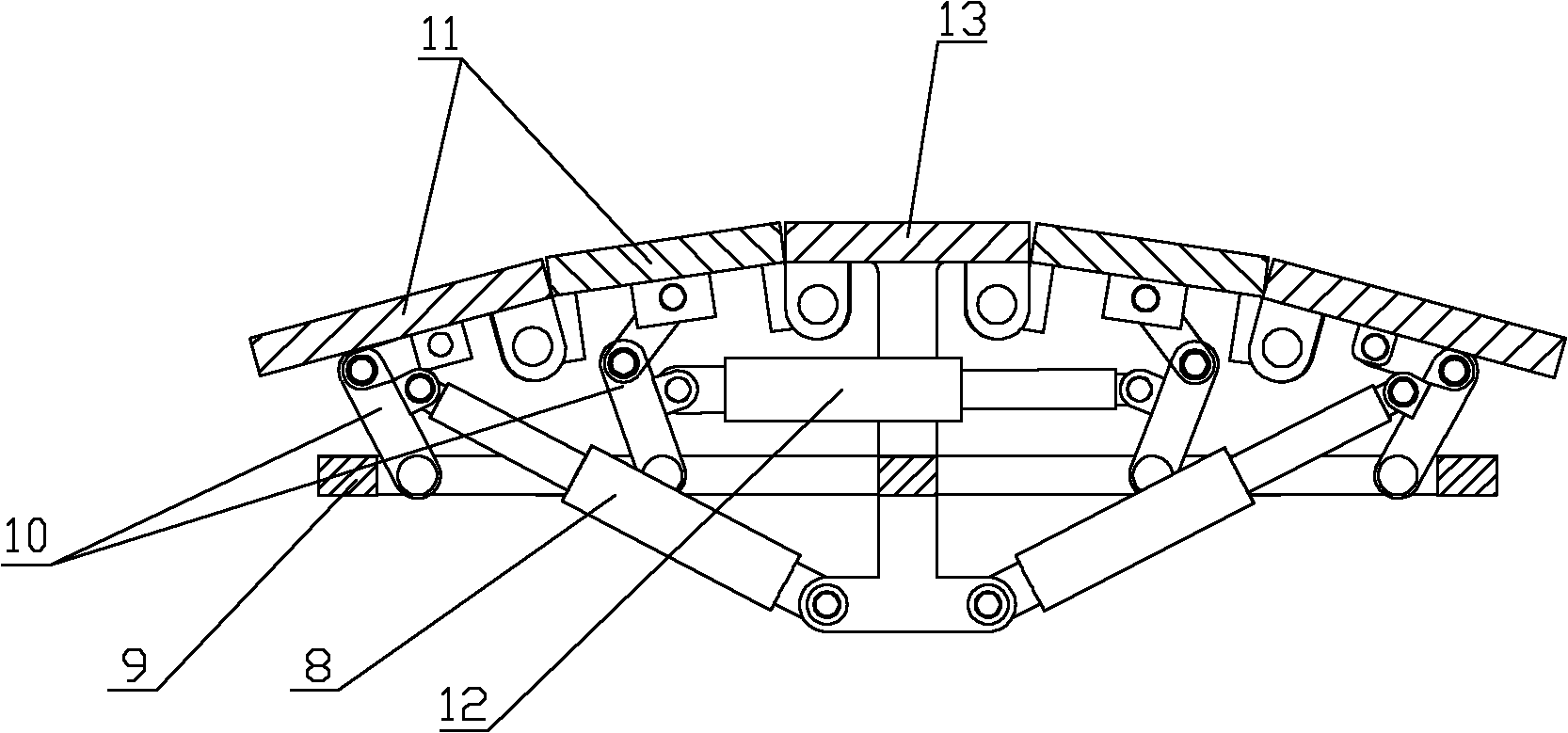

Temporary supporting device for roadway drifting

The invention relates to a temporary supporting device for roadway drifting. The key technical points of the temporary supporting device for roadway drifting are as follows: a middle support plate is fixedly connected with the upper part of a top beam frame; two side support plates are respectively arranged at two sides of the middle support plate; the support plates are mutually hinged; the sidesupport plates are hinged with the top beam frame through a link mechanism below the side support plates; the top beam frame is also hinged with two bracing cylinders; the other ends of the two bracing cylinders are hinged with a longitudinal connecting beam of the link mechanism of the two side support plates; and a longitudinal connecting beam of a link mechanism below another two side support plates is hinged with a floating cylinder. The lower end of the top beam frame is hinged with the top part of a rack; and the rack is a component of a foldstool with a shape that two supporting feet are crossed. The rack comprises a left L-shaped girder, a right L-shaped girder, a stay bar, a lift cylinder, and an adjusting cylinder. A caterpillar mechanism is connected with the bottom of the rackin a dismountable way; and a road clearing shovel is arranged at the lower part of the front end of the rack. The temporary supporting device for roadway drifting has simple and flexible structure, is safe and reliable, and can adapt to changes of sizes and shapes of roadway roofs in a certain scope.

Owner:HUNAN UNIV OF SCI & TECH

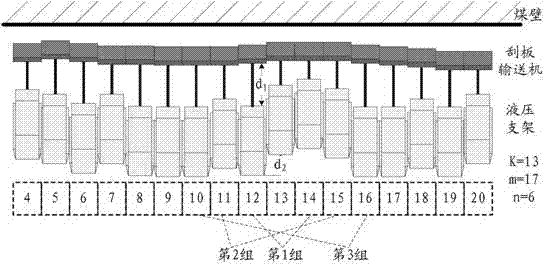

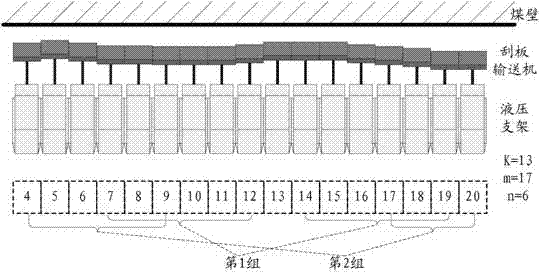

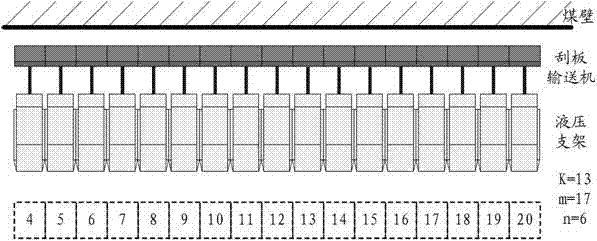

Automatic straightening method and system for hydraulic supports and scraper conveyors of fully-mechanized coal mining working faces

ActiveCN103114867AGuarantee "Three Directions and One Equalization"Orderly rowsMine roof supportsEngineeringCoal mining

The invention provides automatic straightening method and system for hydraulic supports and scraper conveyors of fully-mechanized coal mining working faces. The automatic straightening method includes steps of during continuous propelling of the fully-mechanized coal mining working faces, acquiring relative positions between every two hydraulic supports by first travel sensors mounted on the hydraulic supports; acquiring a relative position between each hydraulic support and one scraper conveyor; utilizing the appointed hydraulic support as reference, and straightening the hydraulic supports within an appointed range according to the relative positions between every two hydraulic supports until readings of the first travel sensors are zero; and utilizing the relative position of the appointed hydraulic support and the scraper conveyor as reference, and straightening the scraper conveyors within an appointed range according to the relative position between each hydraulic support and each scraper conveyor. By the automatic straightening method and system, the scraper conveyors and the hydraulic supports can be guaranteed to arrange orderly, and 'keeping the hydraulic supports, the scraper conveyors and cut coal walls straight and flat' of the fully-mechanized coal mining working faces is guaranteed.

Owner:HITACHI BUILDING TECH GUANGZHOU CO LTD +1

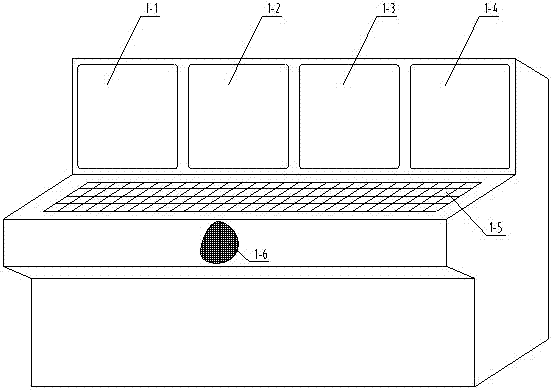

Fully-mechanized mining digital manless working face control system

InactiveCN102004483ARealize on-site operatorsReduce on-site operatorsSlitting machinesMine roof supportsVideo monitoringControl system

The invention discloses a fully-mechanized mining digital manless working face control system which mainly comprises a centralized control console, a coal mining combine control system, a hydraulic rack control system and a video monitoring system, wherein the centralized control console is respectively connected with the coal mining combine control system, the hydraulic rack control system and the video monitoring system through mine communication cables. The fully-mechanized mining digital manless working face control system has a plurality of flexible and reliable control modes, and can be used for remotely centrally controlling equipment of a coal mining combine, a hydraulic rack and the like, thereby reducing the quantity of site operators of the coal mining combine and the hydraulic rack, realizing automatic, manless or few man mining of a fully-mechanized working face, improving the mining efficiency of coal resources, and avoiding or reducing serious loss of life and personal injury in a mine.

Owner:HEBEI SHENFENG HEAVY MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com