Process method and equipment for heading and anchoring parallel operation construction

A technology of parallel operation and construction technology for digging and bolting, which is applied to mining equipment, bolt installation, cutting machinery, etc., which can solve the problems of heavy support workload, high labor intensity, unsafe operation, etc. Level, reduce labor intensity, high degree of automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention is described in detail below in conjunction with accompanying drawing:

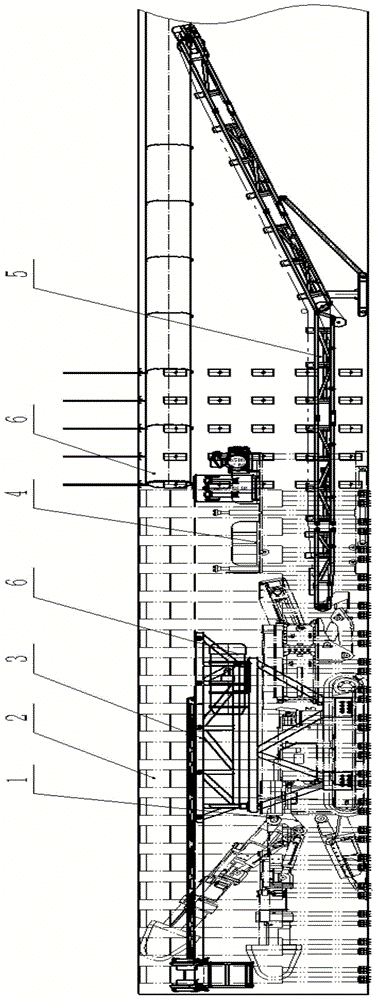

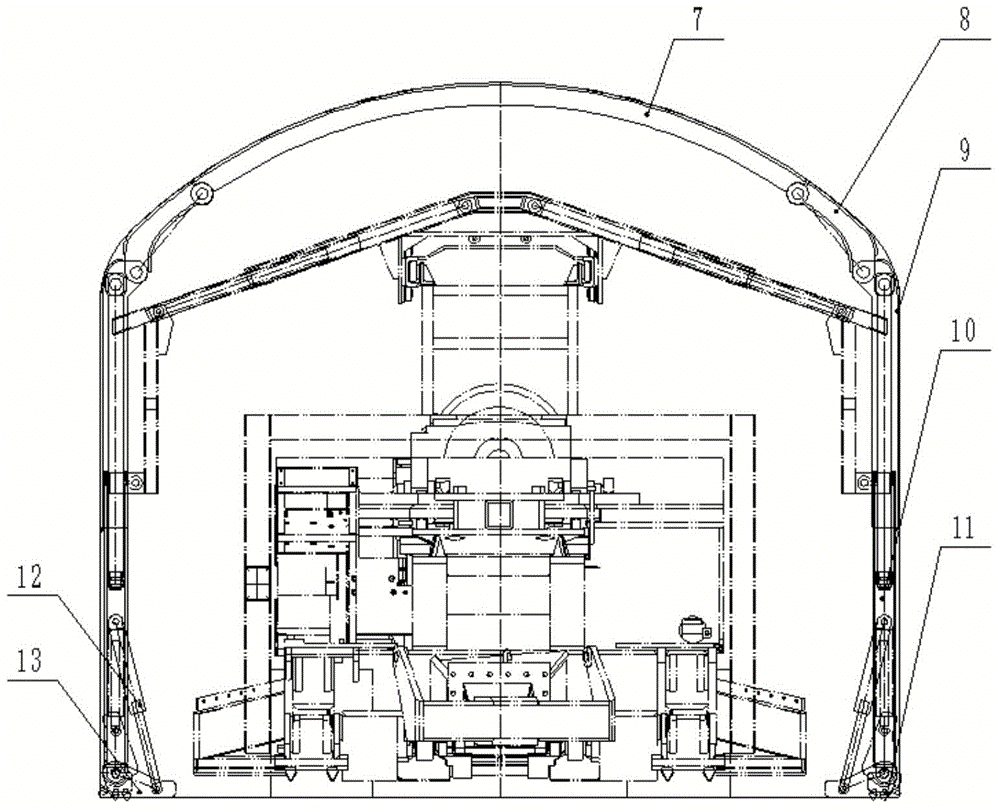

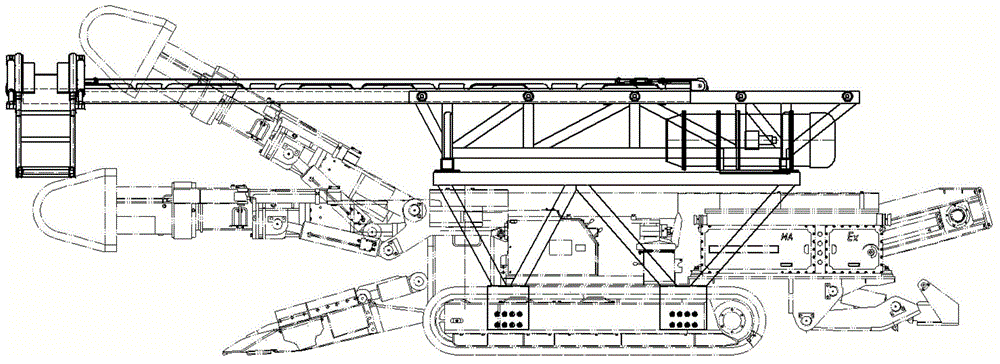

[0049] A construction method for excavating and anchoring parallel operations, which divides the excavating working face into the working area of the roadheader and the anchoring support area, the working area of the roadheading machine from the front of the excavation to the tail of the roadheading machine, and the anchoring operation area behind the roadheader is the anchoring support area The roadheader operation area and anchor support area are collectively referred to as the temporary support area. The temporary support area adopts folding telescopic roadway hydraulic supports for temporary support. The roadheader cutting and permanent support work in parallel. When the roadheader cutting After completing a step with the anchor support, the hydraulic support at the end of the temporary support area is retracted and transported to the front of the excavation through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com