Patents

Literature

2087 results about "Roadheader" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

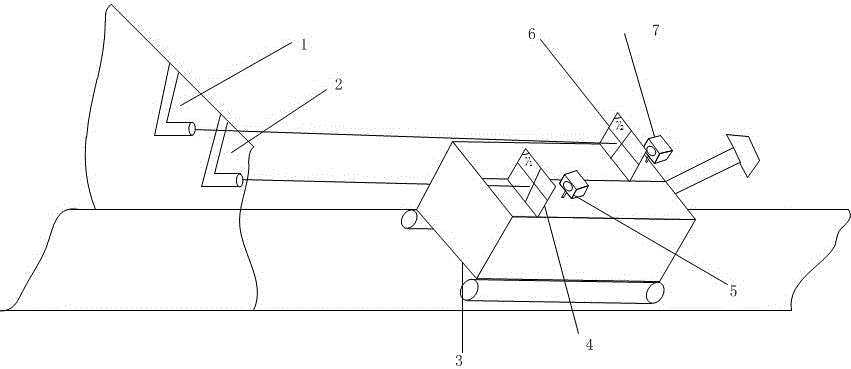

A roadheader, also called a boom-type roadheader, road header machine, road header or just header machine, is a piece of excavating equipment consisting of a boom-mounted cutting head, a loading device usually involving a conveyor, and a crawler travelling track to move the entire machine forward into the rock face.

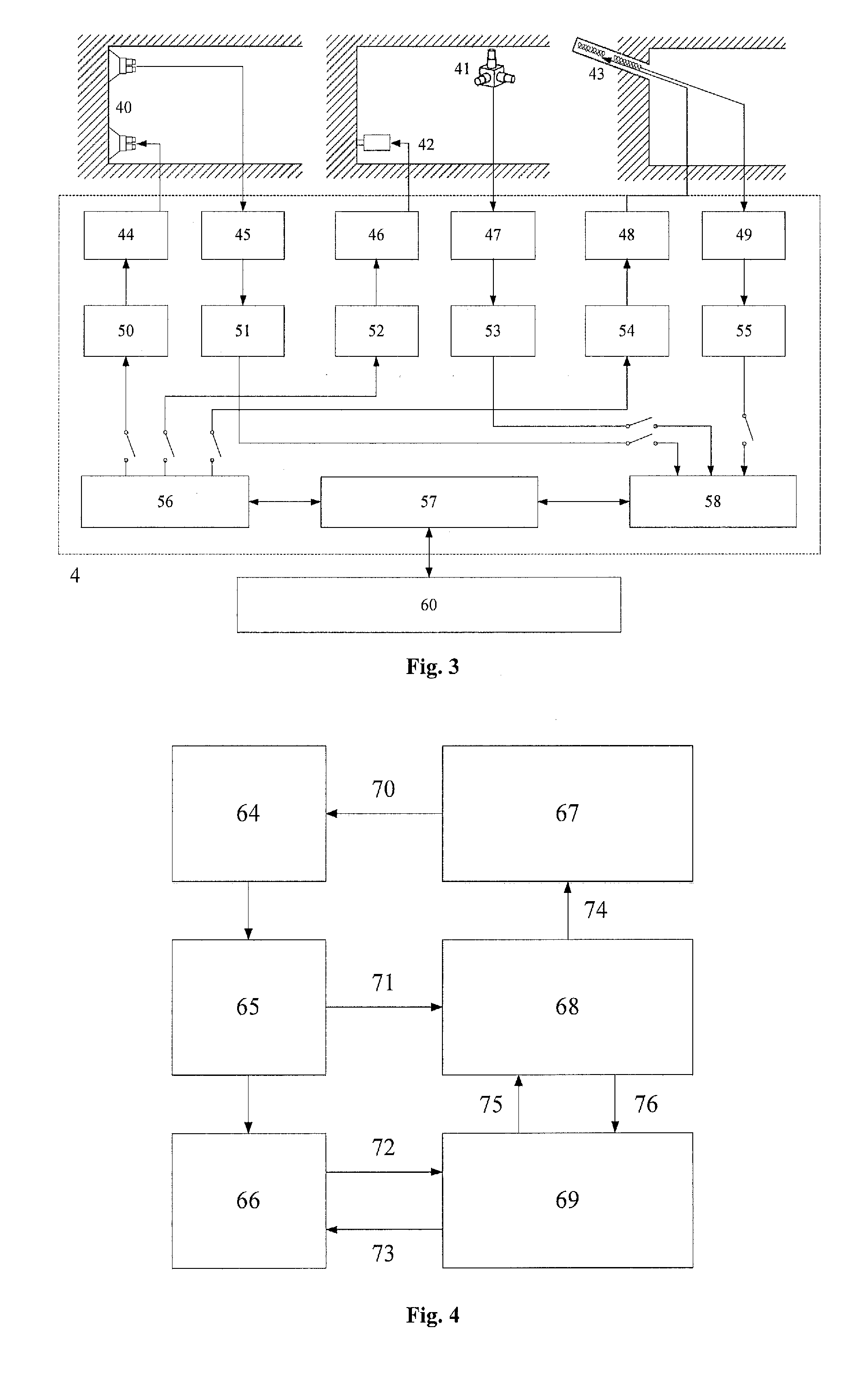

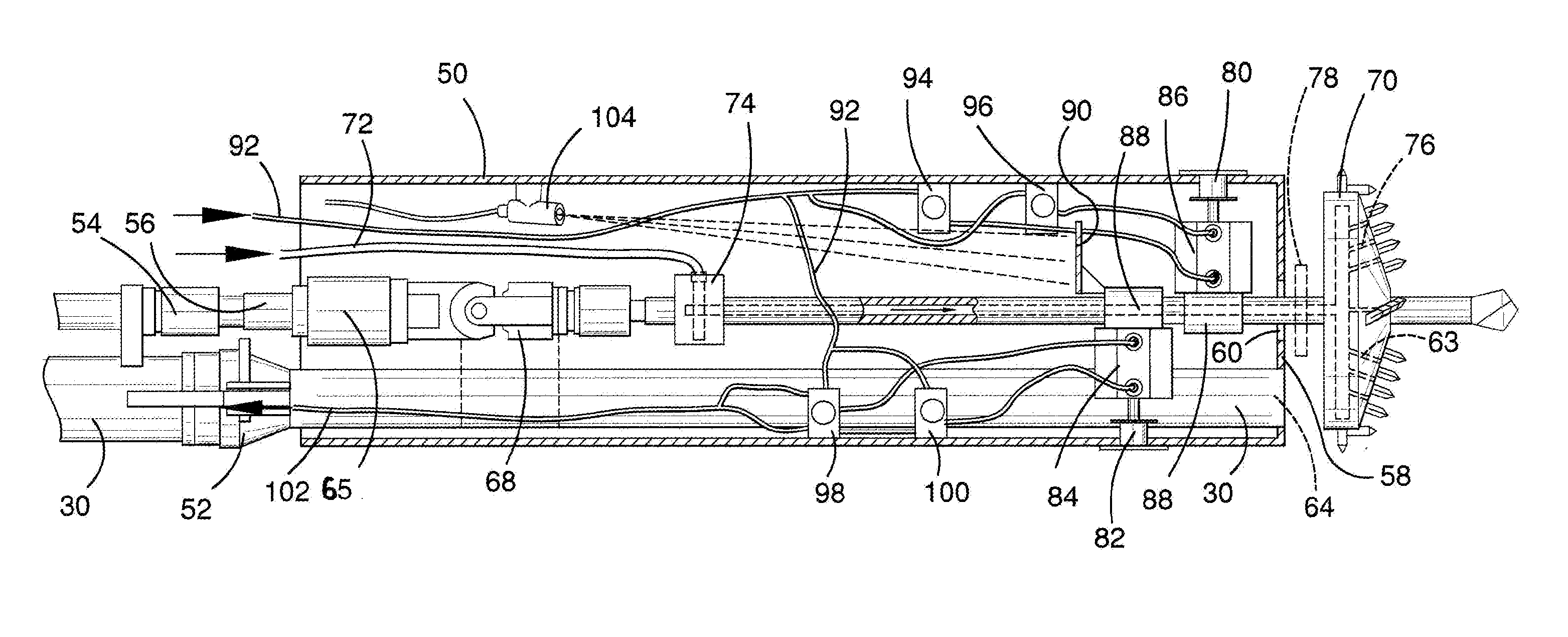

Comprehensive advanced geological detection system carried on tunnel boring machine

ActiveUS20150233242A1Improve accuracyImprove efficiencySeismic signal processingTunnelsDecision systemComputer module

The present invention presents a comprehensive advanced geological detection system carried on a tunnel boring machine. The comprehensive advanced geological detection system includes a multifunctional combination main frame, an induced polarization detection device, a seismic wave detection device, an integrated junction device, a borehole ground penetrating radar detection device and a comprehensive interpretation and decision system; the multifunctional combination main frame includes a time division multiplexing control module, an excitation source control module and a parallel data acquisition module; the excitation source control module outputs trigger signals to the three detection devices respectively, and the three detection devices respectively output measurement data and feedback signals to the time division multiplexing control module through the parallel data acquisition module; and the comprehensive interpretation and decision system supports geological interpretations and decisions through the inversion / migration imaging joint inversion of three detection methods.

Owner:SHANDONG UNIV

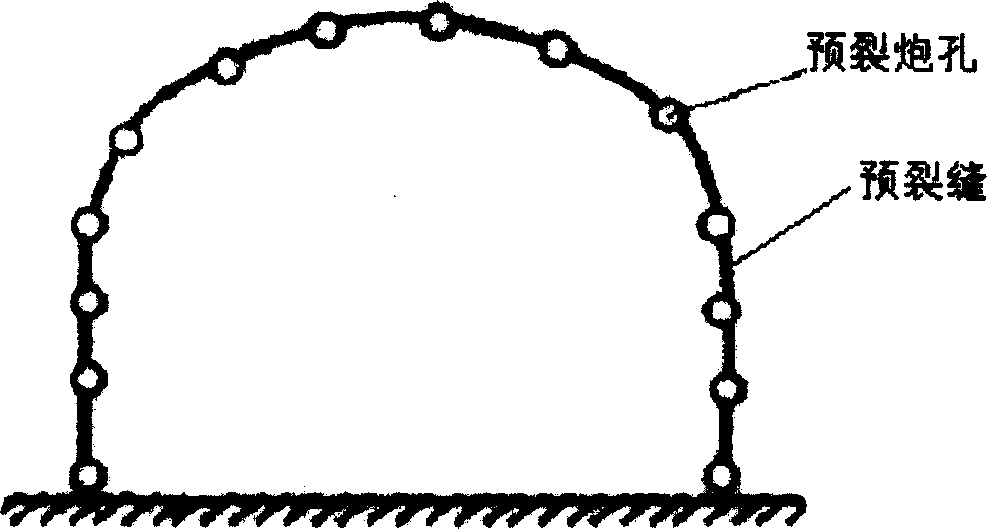

Rock lane digging method

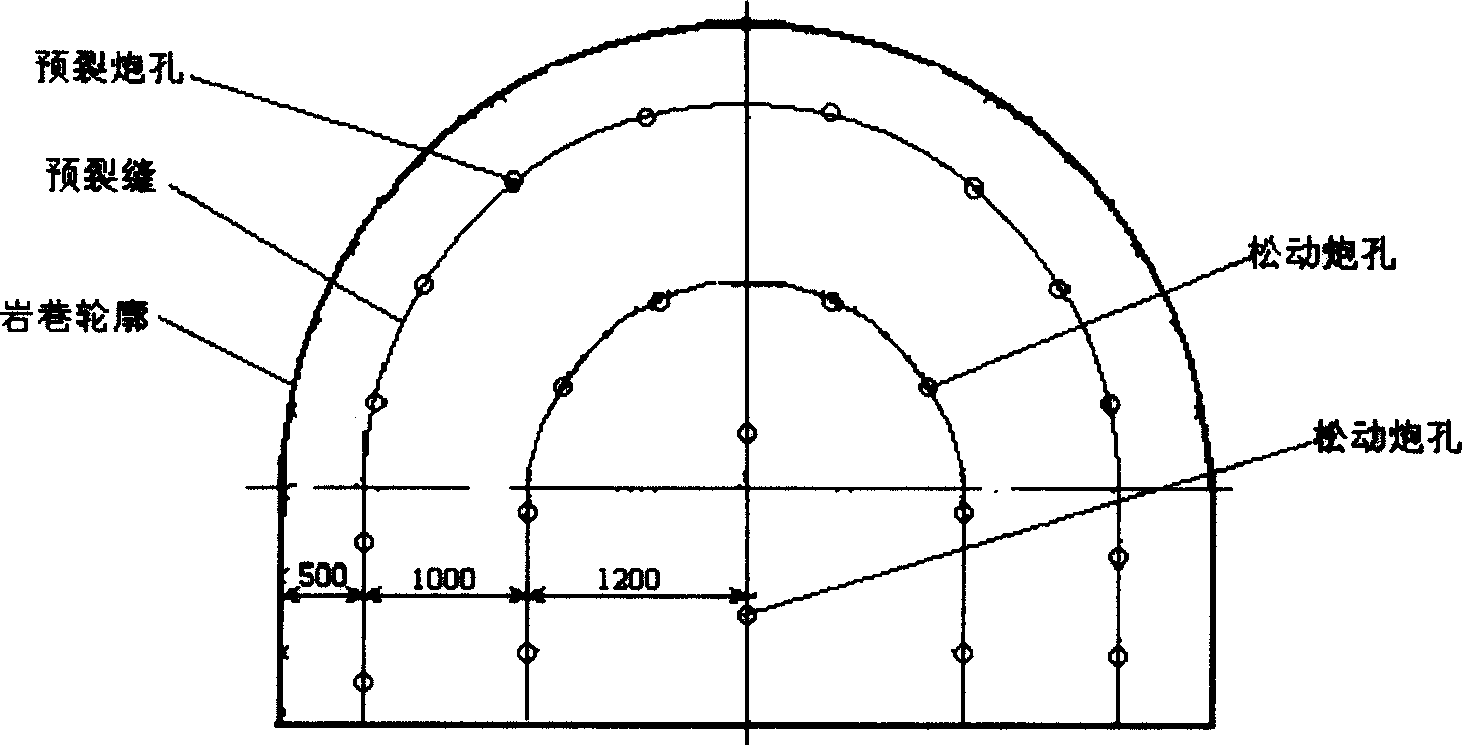

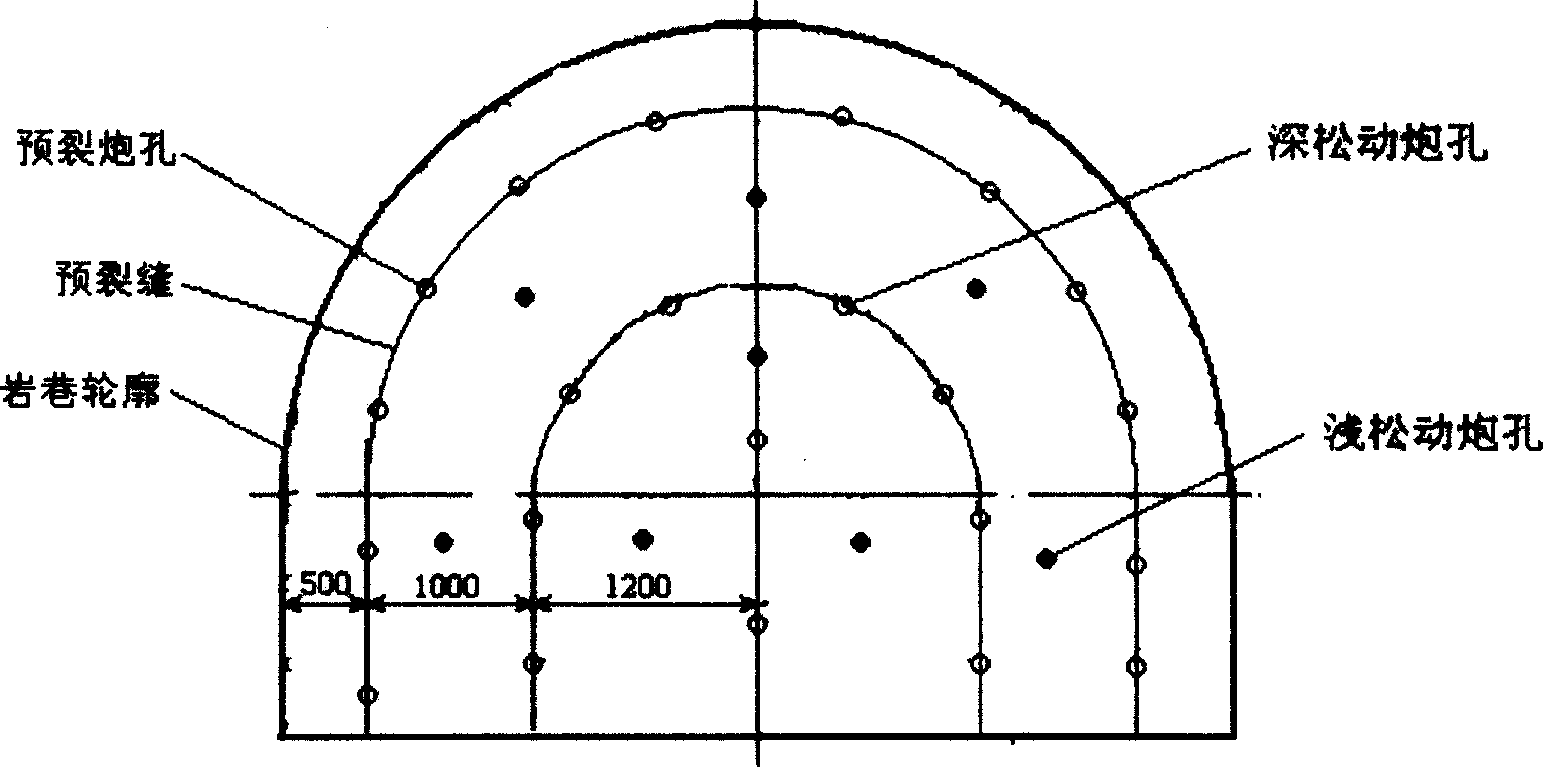

The invention discloses a rock gangway drifting method. Firstly, directional blasting technology is adopted, and presplitting cracks are arranged close to the periphery of a rock gangway through blasting. Secondly, loosening blasting technology is adopted to break rocks in the presplitting cracks; directional blasting and loosening blasting can be performed separately and also can be performed synchronously and initiated in sequence; the directional blasting is initiated before the loosening blasting. Finally, a rock gangway drifting machine is adopted to drill broken rocks. By adoption of combination of drifting of the drifting machine and controlled blastings, the invention has the advantages of great reduction of damage on surrounding rocks, increase of safety, improvement of drifting speed and reduction of cost, and is a rock gangway drifting method having the advantages of high efficiency, safety, low cost, good operating environment and low labor intensity. The invention is suitable for drifting various rock gangways and particularly suitable for drifting rock drifts with high hardness.

Owner:杨仁树

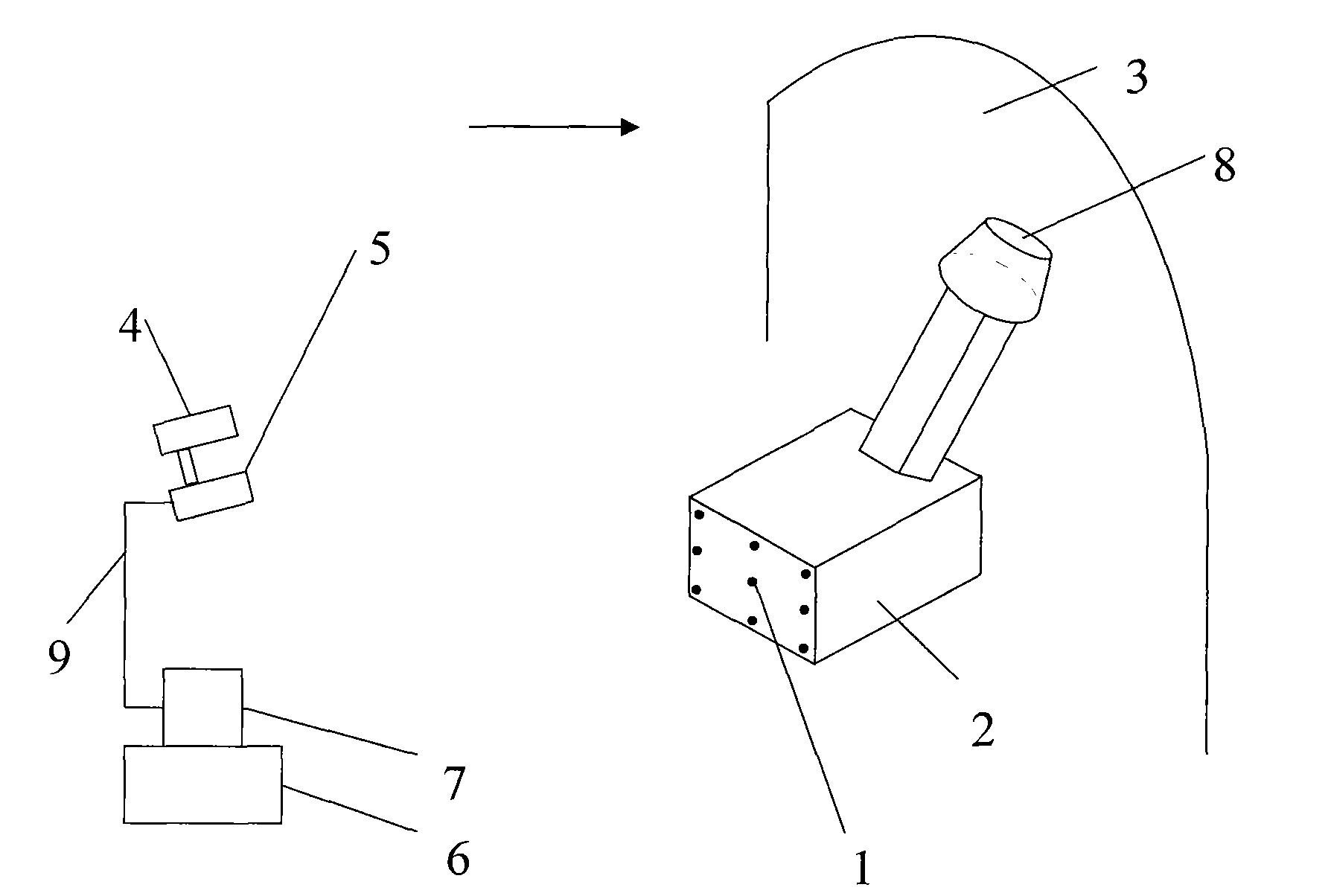

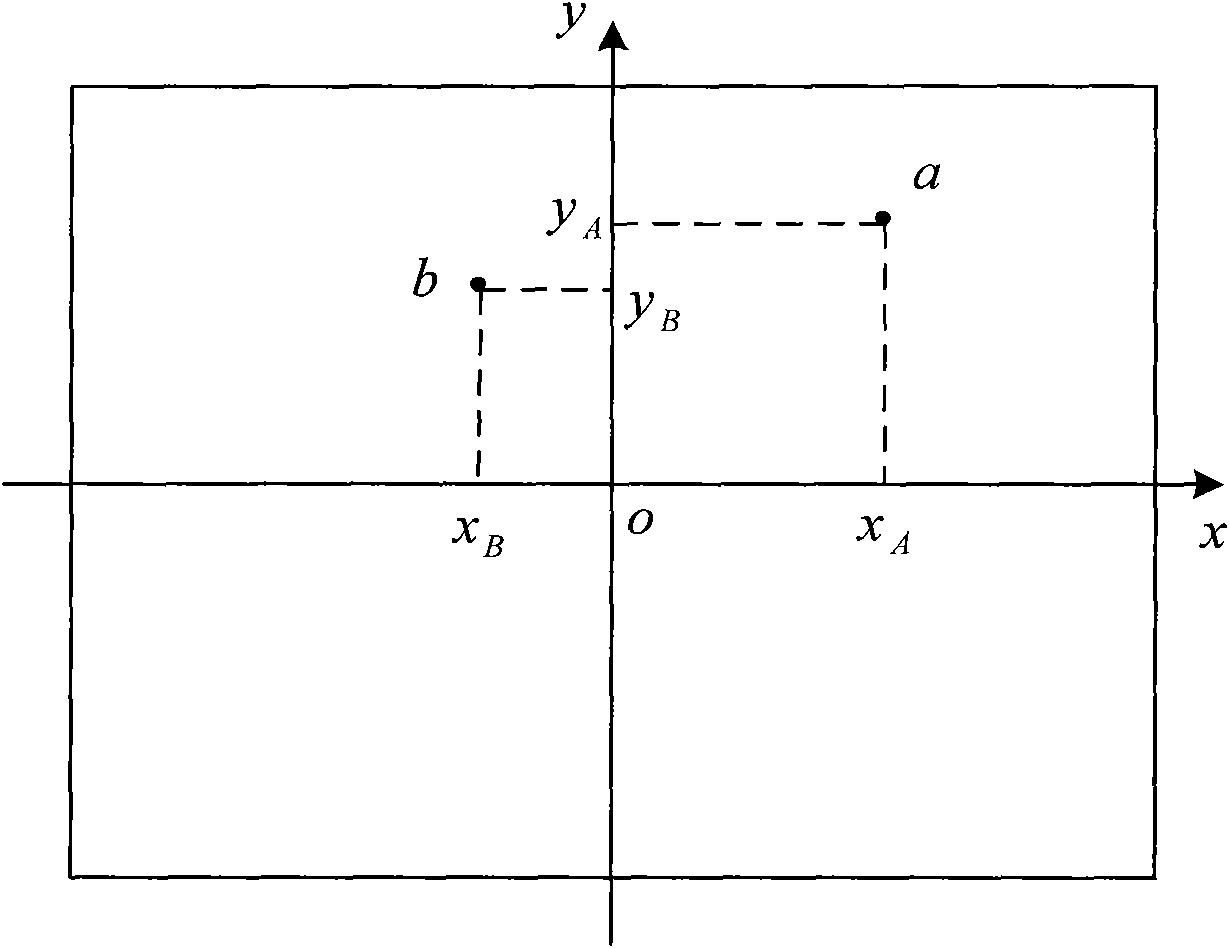

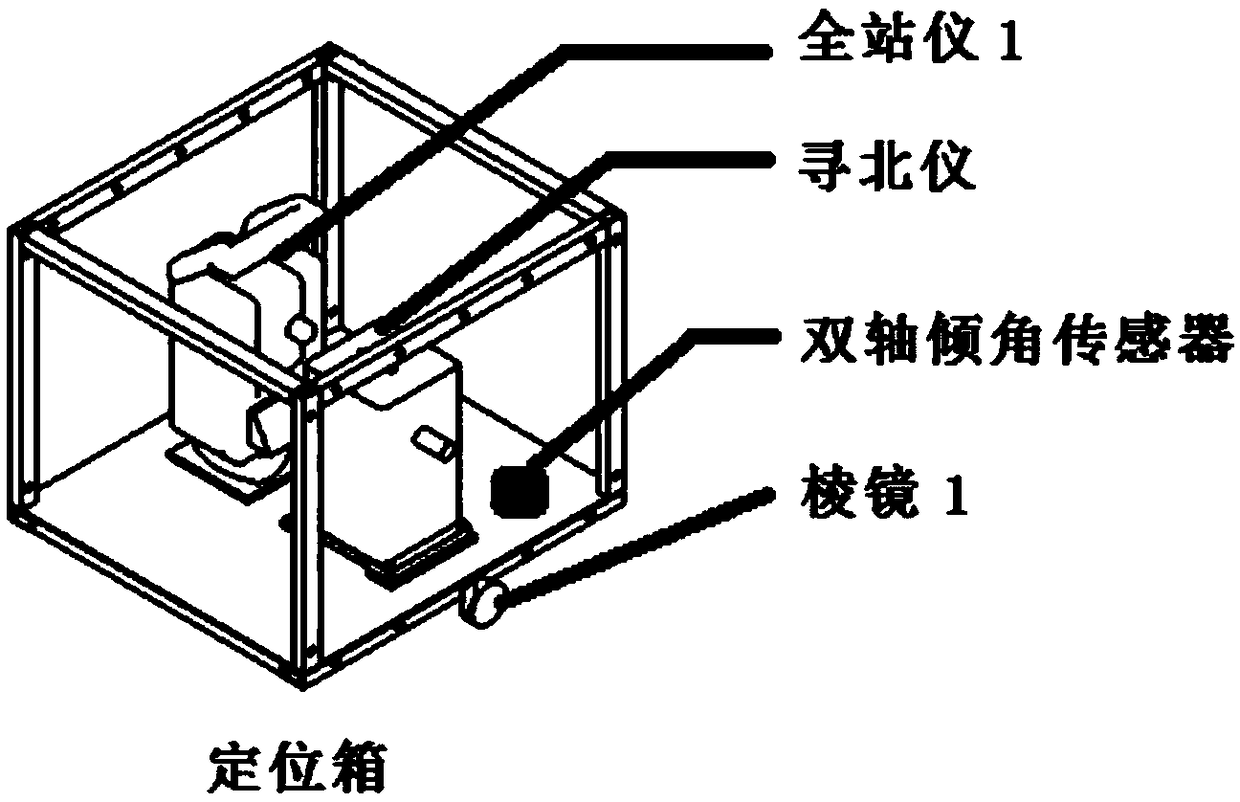

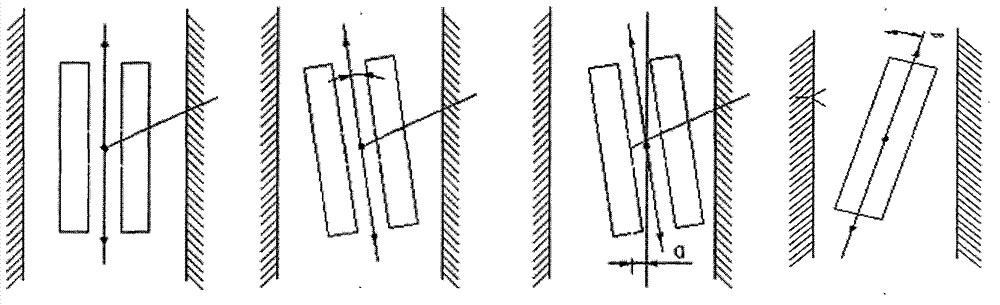

Method for automatically measuring special position of tunnel boring machine

ActiveCN101819036AIdeal mining pose measurement methodAdvancedAngle measurementView cameraTunnel boring machine

The invention relates to a method for automatically measuring the special position of a tunnel boring machine. According to the practical situation of the tunneling operation of the tunnel boring machine in a small underground space of a coal mine, an industrial view camera, an industrial computer, a laser orientation instrument and an image acquisition card are arranged on the back part of the tunnel boring machine. The position of the tunnel boring machine on a coal petrography cross section is measured and calculated, the most reasonable position of a machine body is determined, a command on an excavating operation is made and operators are far away from hazardous areas so as to reduce sudden accidents, enhance excavating safety and keep the tunnel boring machine on a best and most reasonable position and in a best and most reasonable state. A maximum cover angle is + / -60 degrees, a displacement detection deviation is less than 10 millimeters, the detection accuracy of a deflection angle is + / -12 gon, the detection accuracy of a pitch angle is + / -6 gon and the detection accuracy of a roll angle is + / -6 gon so as to improve excavating quality and efficiency. The method is advanced, reasonable and correct, is a very ideal method for measuring the excavation position of a coal extraction tunnel boring machine and can be used in tunnel excavation operation.

Owner:TAIYUAN INST OF COAL SCI RES INST +1

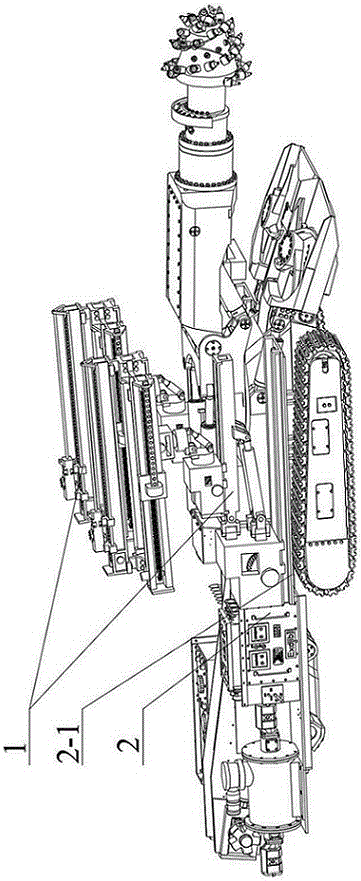

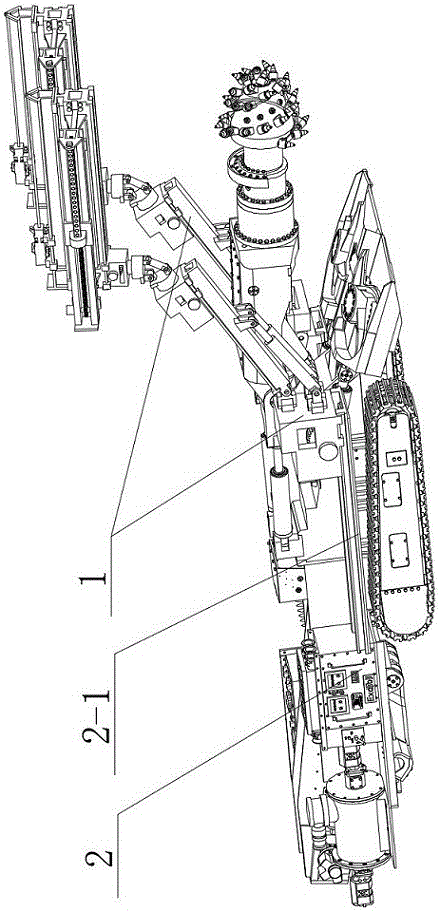

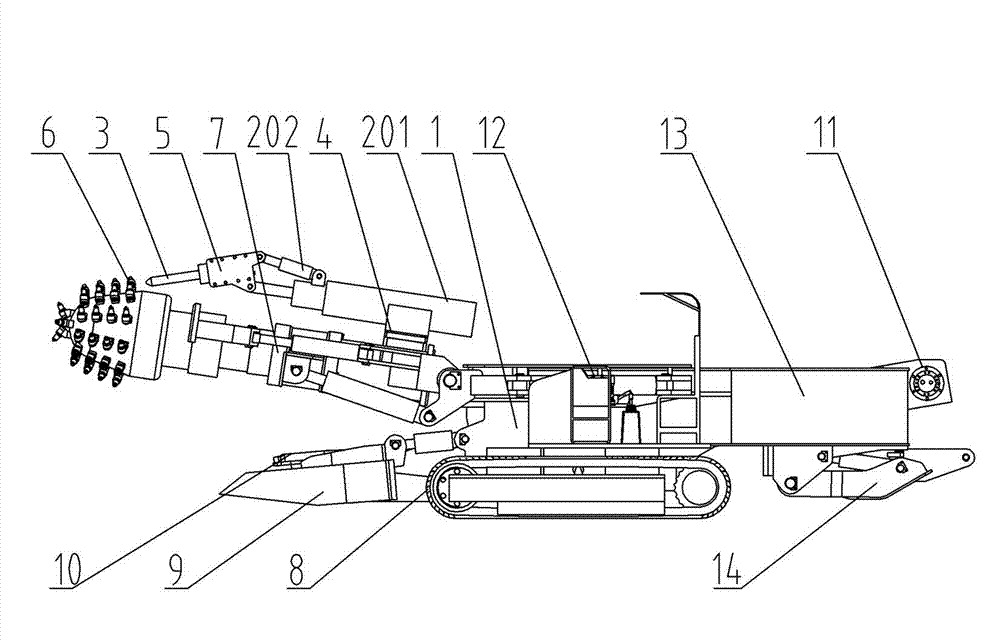

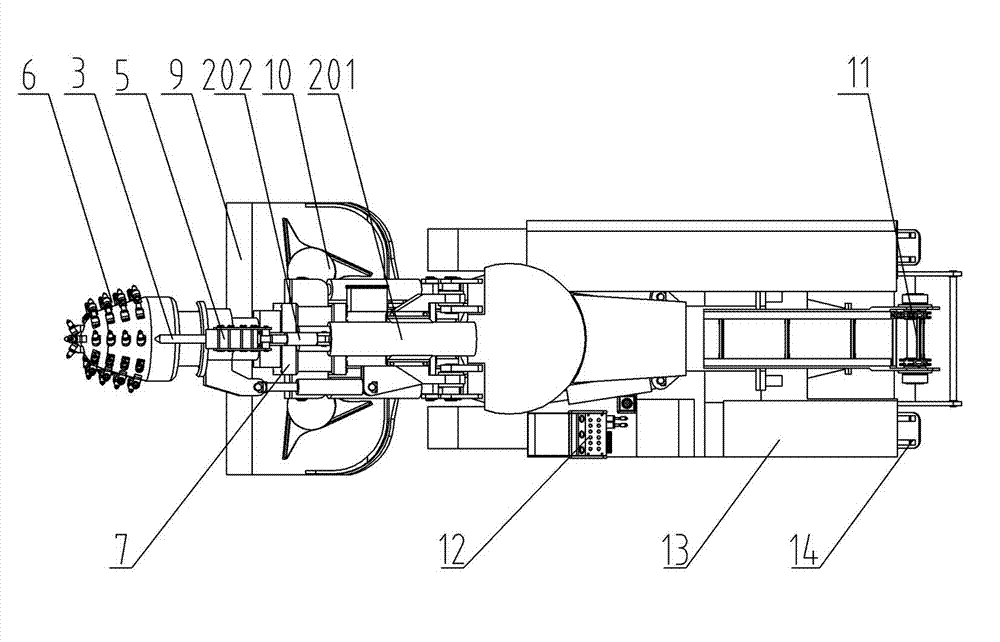

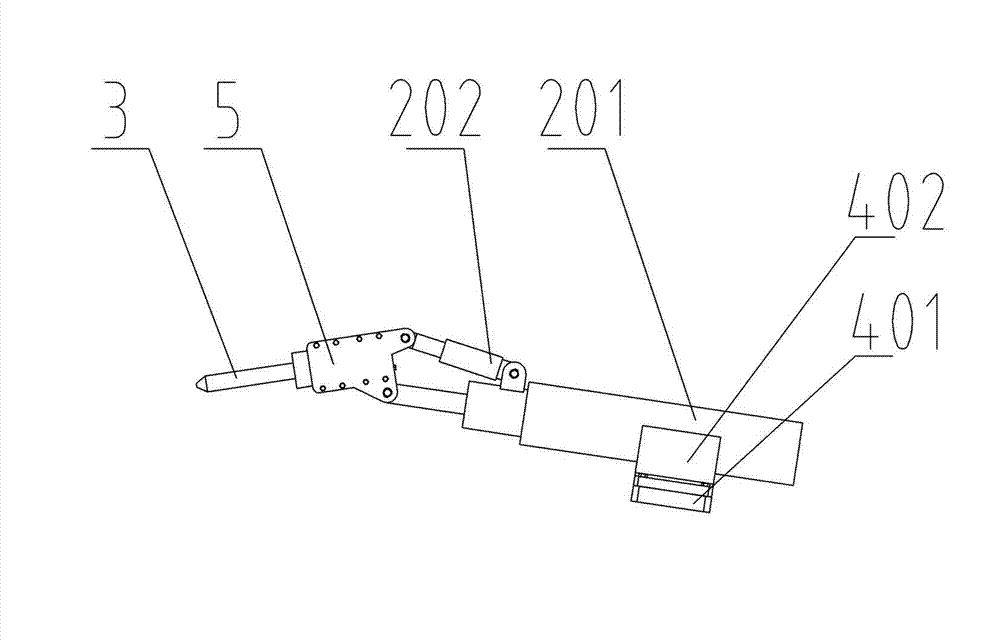

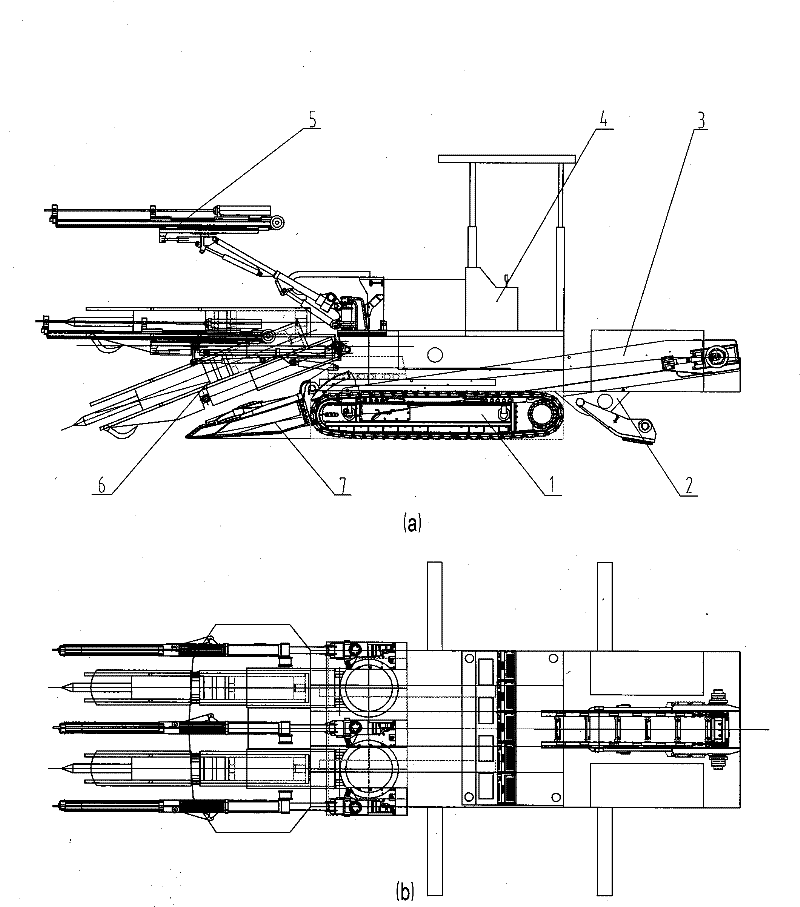

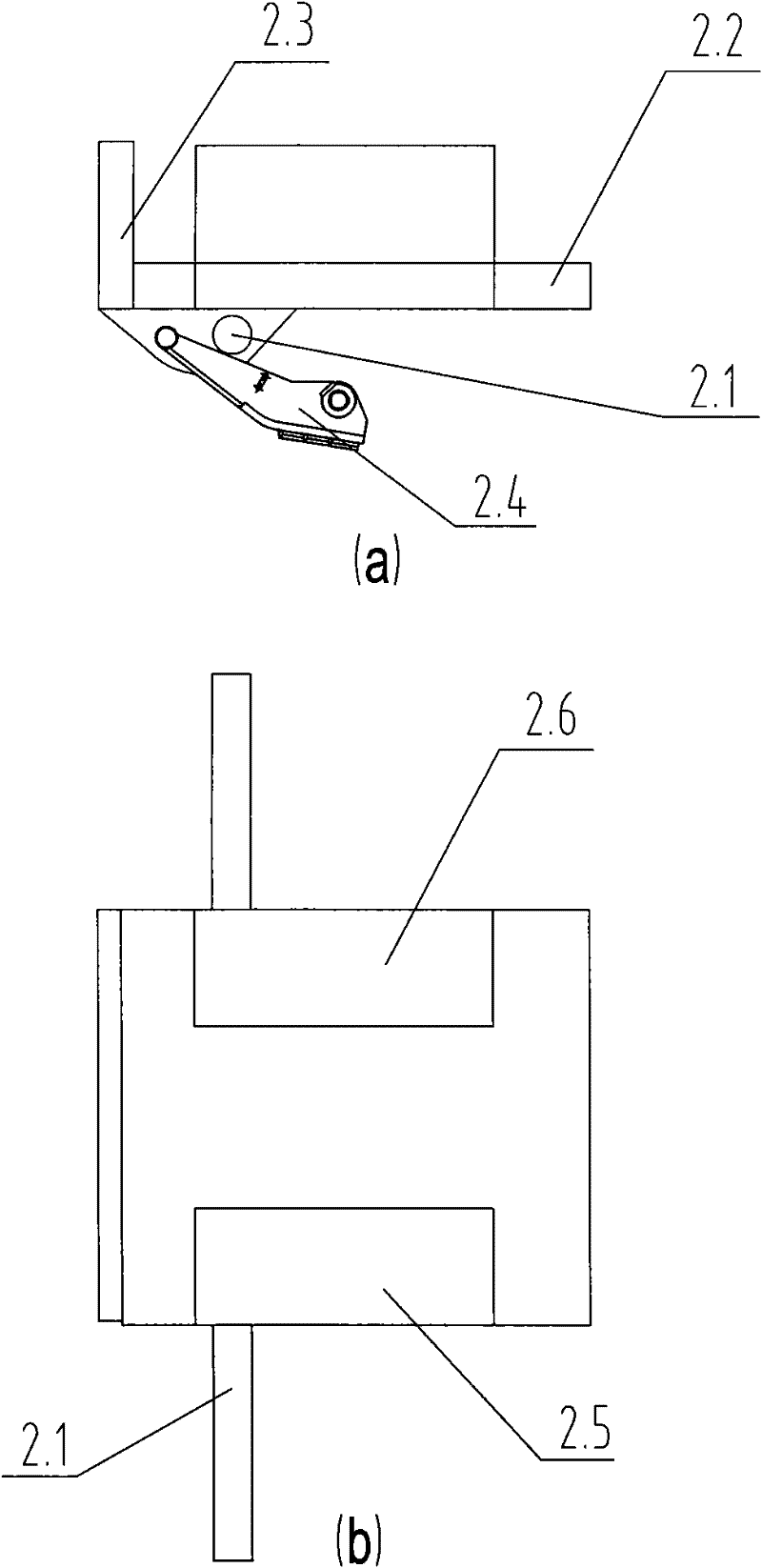

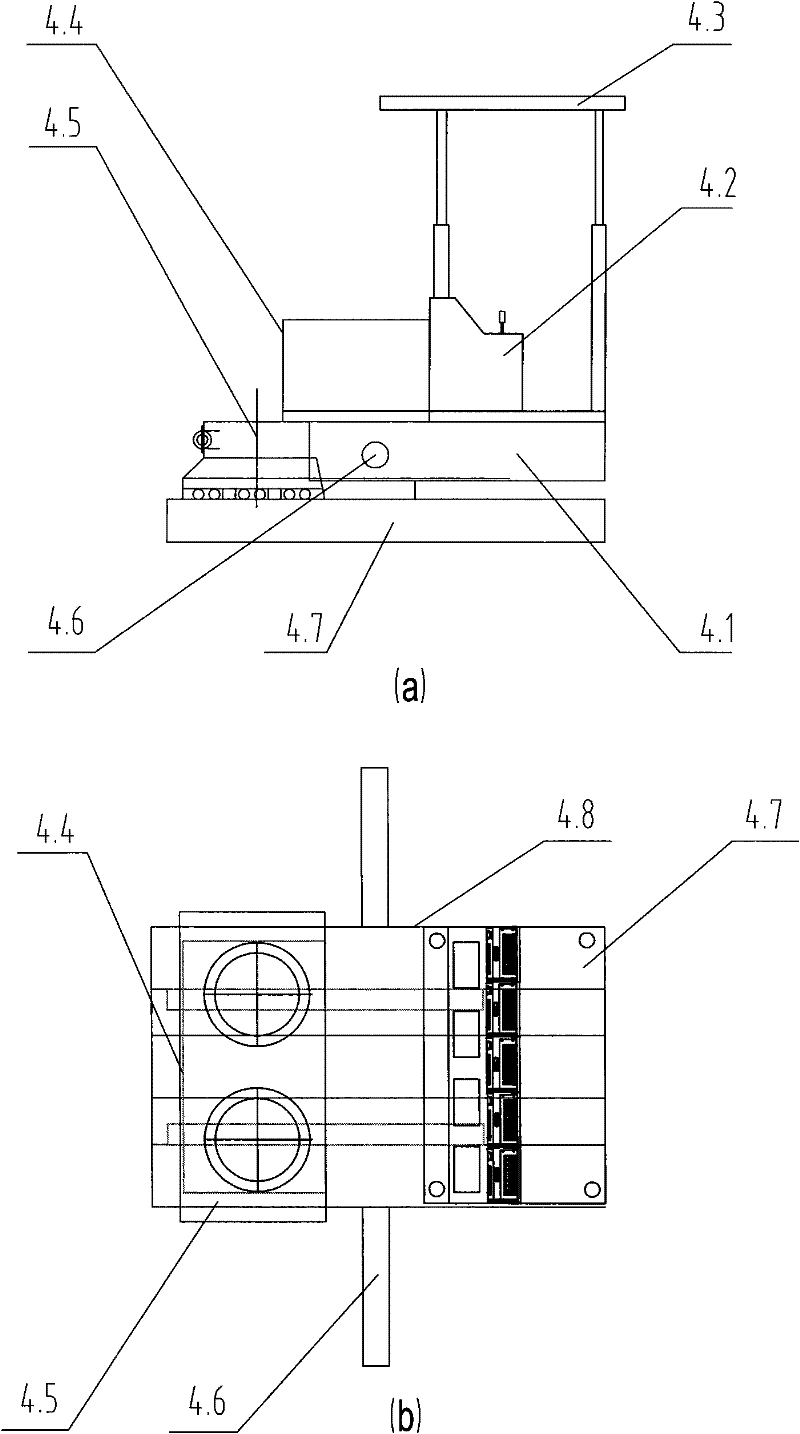

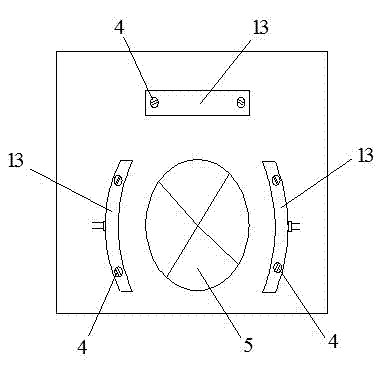

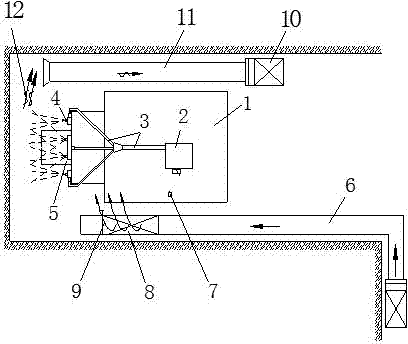

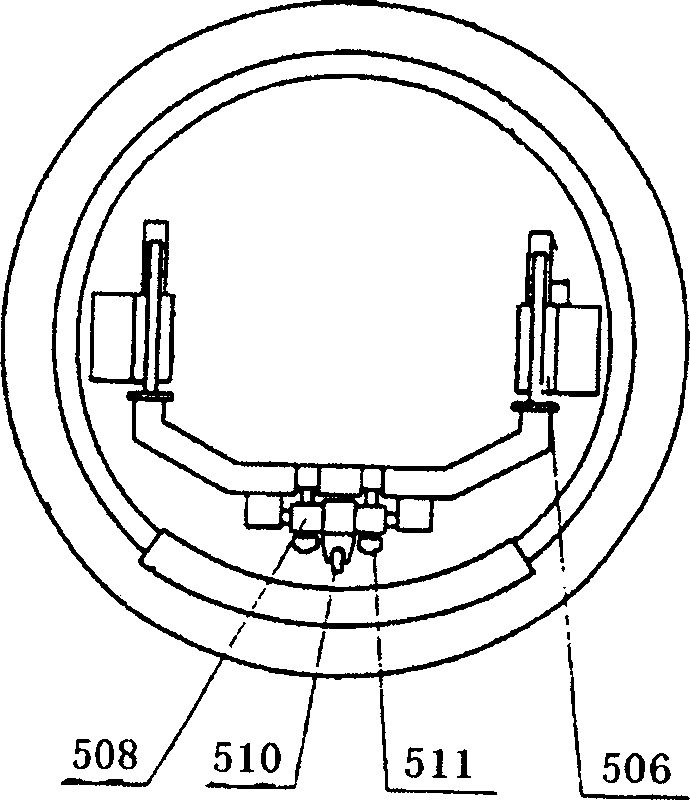

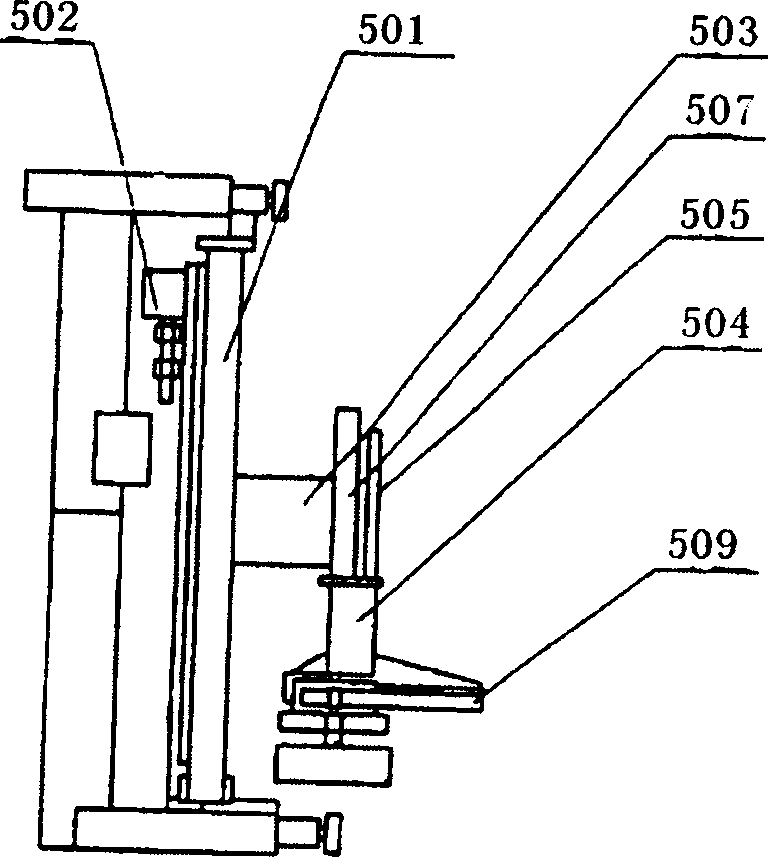

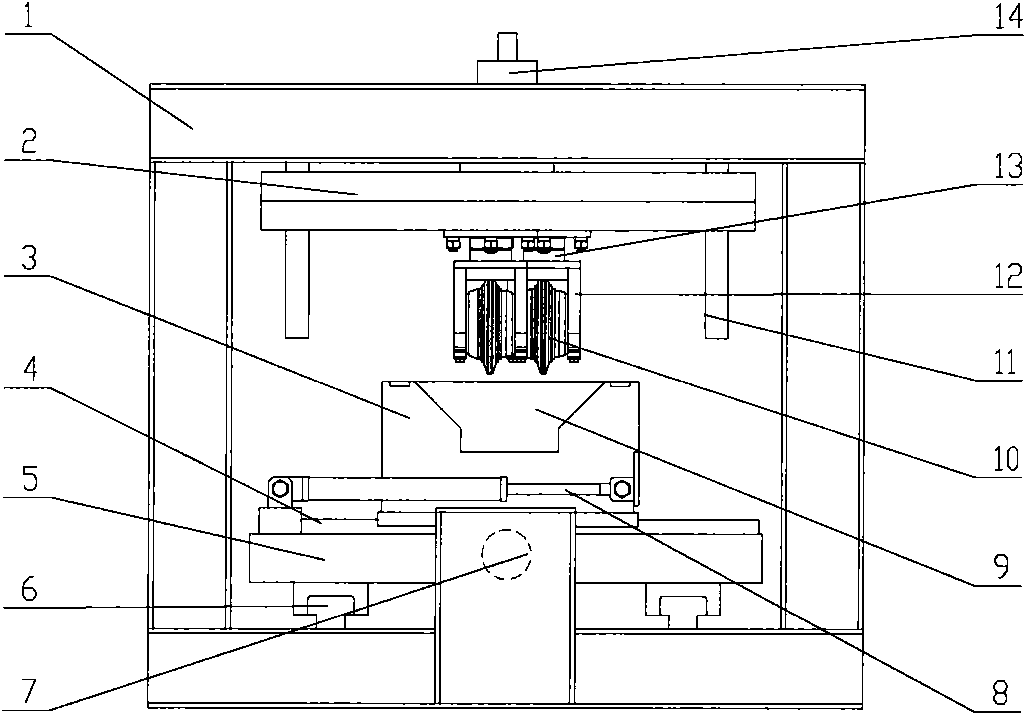

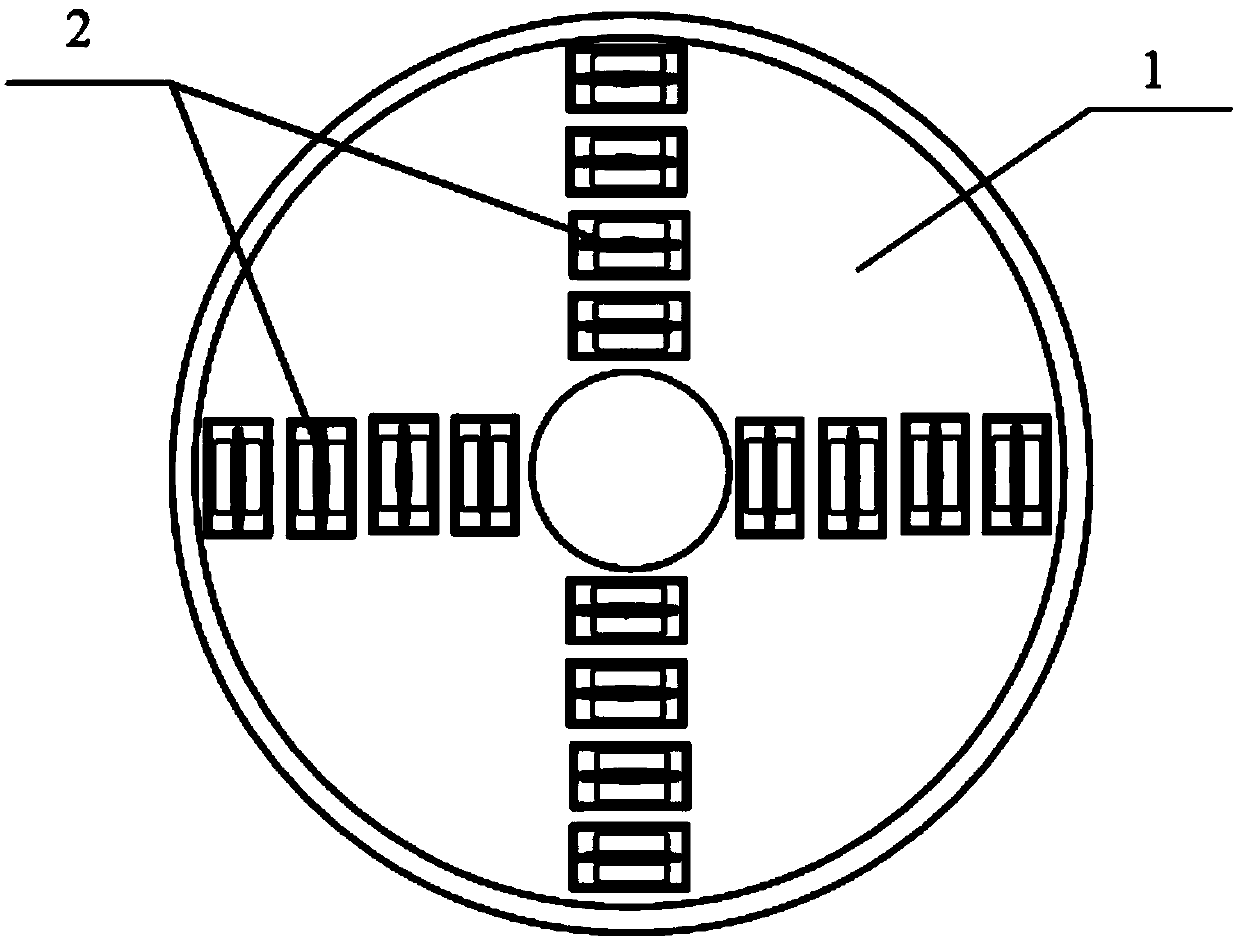

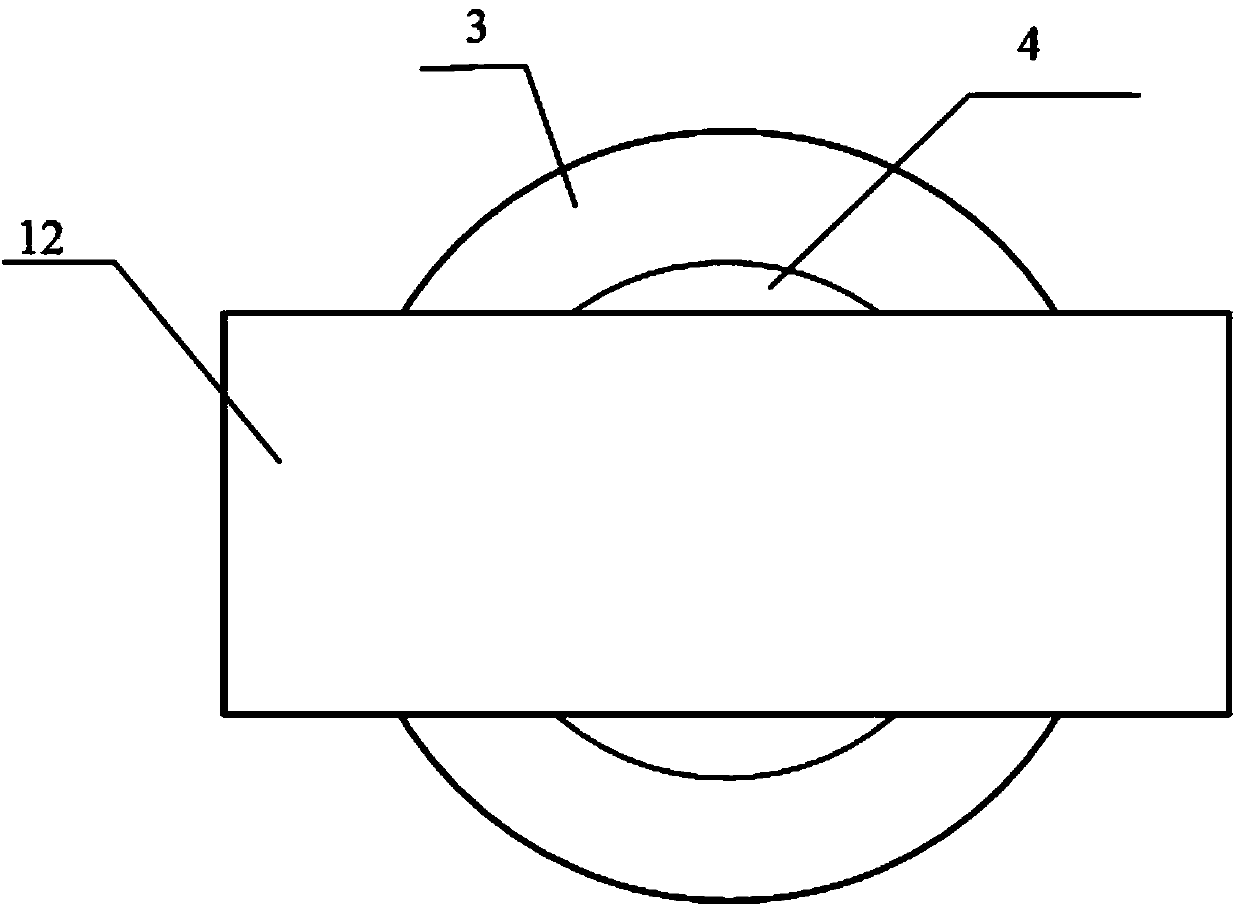

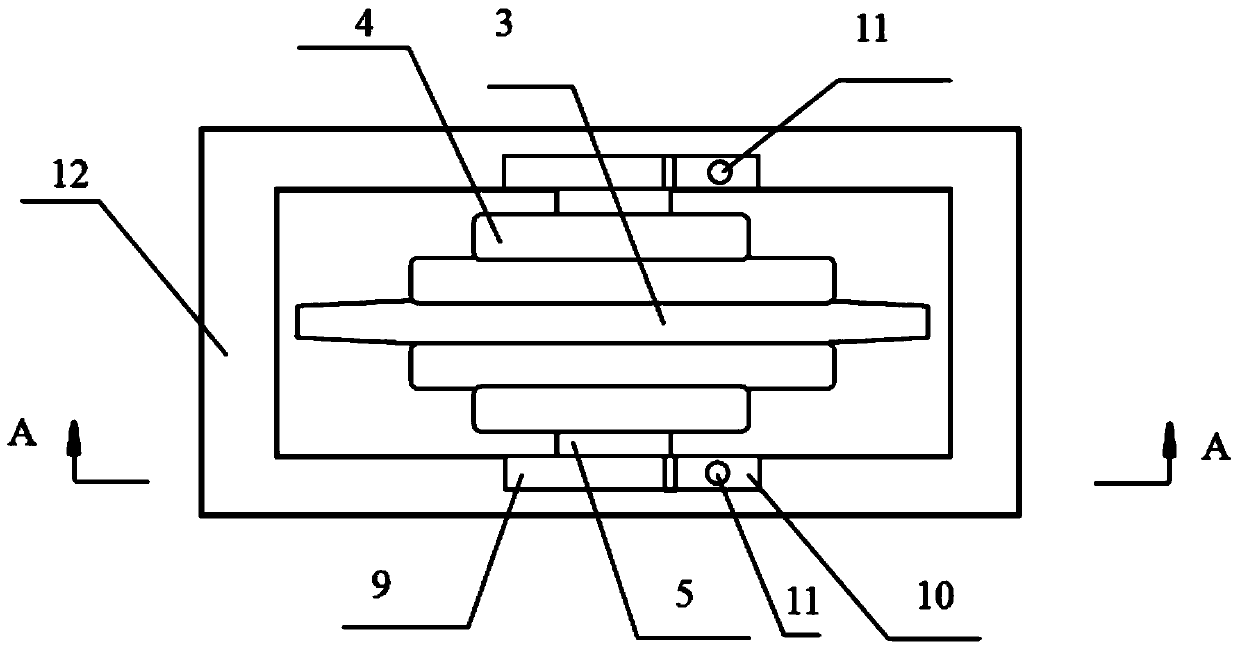

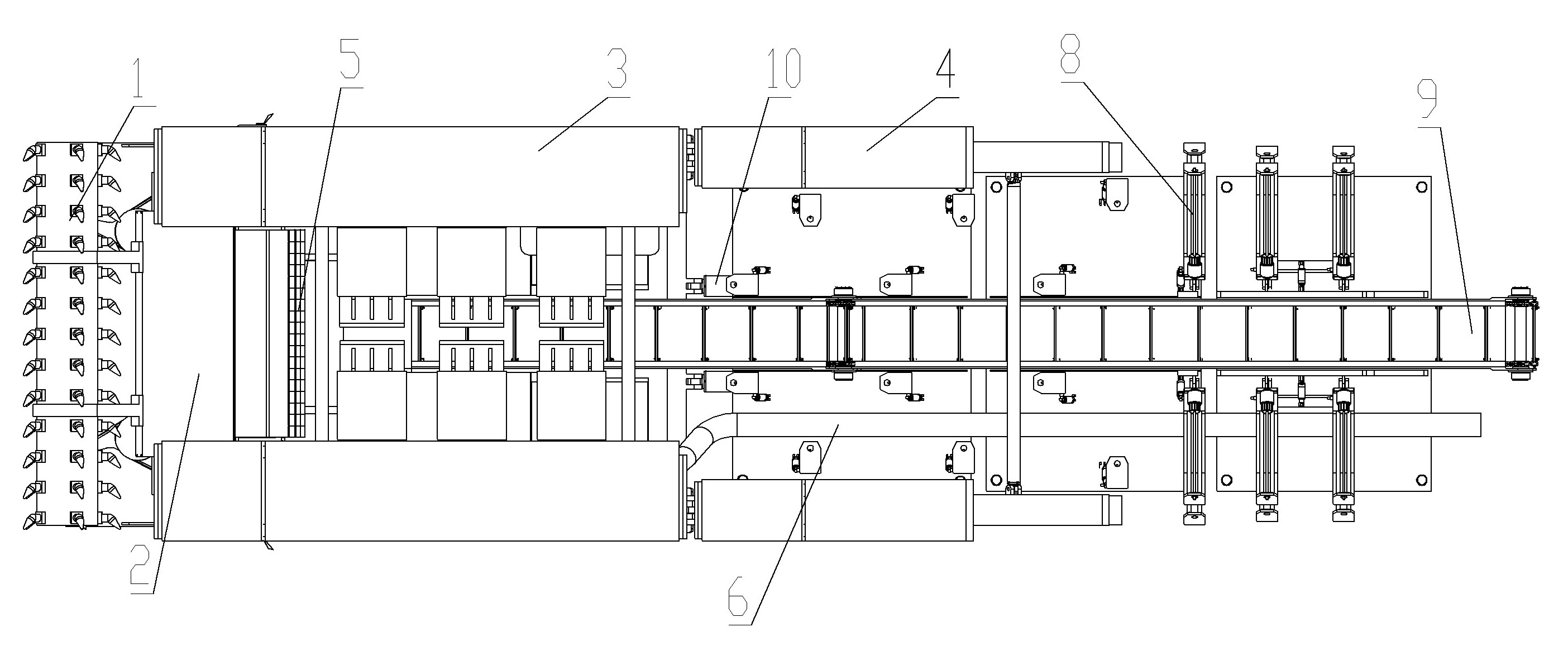

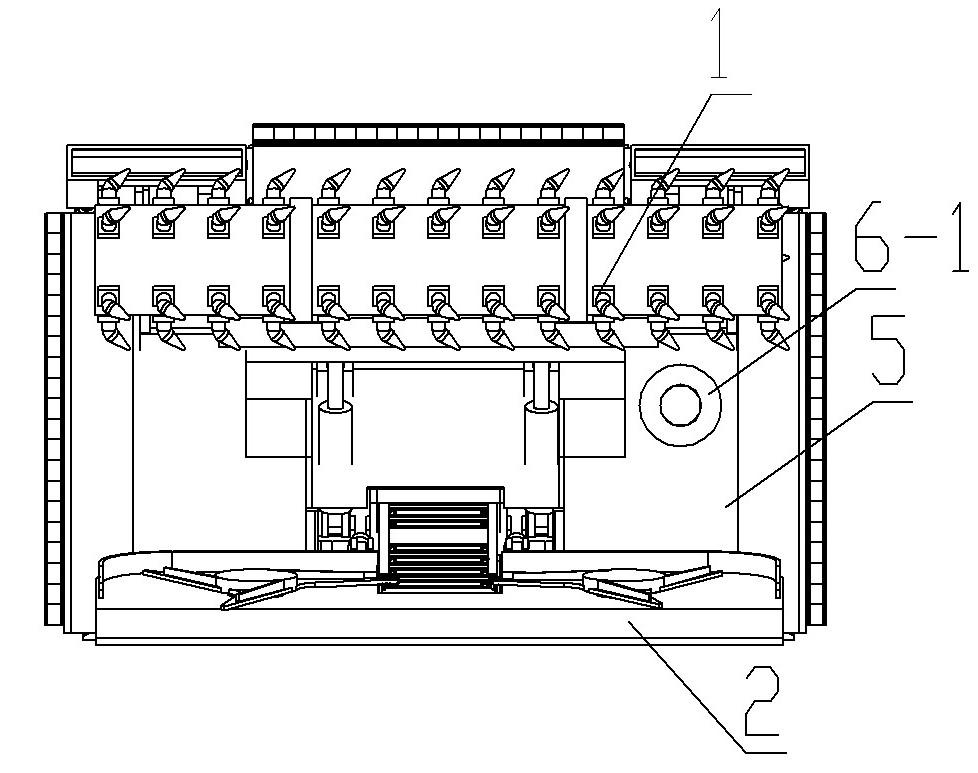

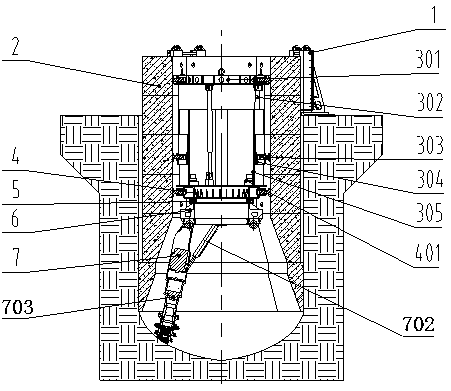

Drilling and bursting type heading machine

ActiveCN105804764AImprove drilling efficiencyLow drilling efficiencyDisloding machinesSlitting machinesHydraulic motorHydraulic cylinder

The invention discloses a drilling and bursting type heading machine which comprises a drilling and bursting device, an angle control device, a front-back telescopic device and a cantilever type heading machine body. The drilling and bursting device is installed on a front-back moving component of the front-back telescopic device. The front-back telescopic device is installed on the cantilever type heading machine body. The drilling and bursting device comprises a fixing frame, a rock drill component and a bursting device component, wherein the rock drill component and the bursting device component are fixed to and installed on the fixing frame. The angle control device comprises an installation base, an auxiliary rotary hydraulic motor, an adjusting hydraulic cylinder and a main rotary hydraulic motor. When the front-back moving component of the front-back telescopic device completely stretches out, the distance between the front end of the drilling and bursting device and a working surface is smaller than the distance between the front end of a cutting head of the cantilever type heading machine body and the working surface. The drilling and bursting type heading machine is compact in structure, a hard rock stratum with the rock stratum hardness being larger than 10 can be rapidly drilled and burst on the premise that the energy consumption is not increased, and accordingly the purposes of improving the heading efficiency and reducing potential safety hazards are achieved.

Owner:CHINA UNIV OF MINING & TECH

Compound cantilever excavator

InactiveCN102733803AImprove drilling abilityImprove work efficiencySlitting machinesCutting machinesHydraulic cylinderClassical mechanics

The invention relates to an excavating machine, and especially relates to a compound cantilever excavator. The excavator comprises an excavator body, an excavating mechanism, a travelling mechanism, a hydraulic system, an electrical system, a conveying mechanism and a dedusting system, wherein the excavating mechanism comprises cutting heads and a cutting arm, the cutting heads are positioned on the top of the cutting arm, and the lower part of the cutting arm is movably fixed on the body of the excavator; the travelling mechanism comprises a power machine and a crawler belt positioned under two sides the body of the excavator; and the upper part of the excavating mechanism is provided with an impact fragmenting mechanism, and the impact fragmenting mechanism comprises a hydraulic cylinder and a fragmenting hammer positioned on the top of the hydraulic cylinder. According to the compound cantilever excavator of the invention, service lives of cutting teeth can be prolonged, so the cost of the whole excavator is reduced; the working environment of workers is improved, so the body health of the workers is protected; and the application range of the cantilever excavator is substantially widened, so the cantilever excavator has a wide market prospect.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

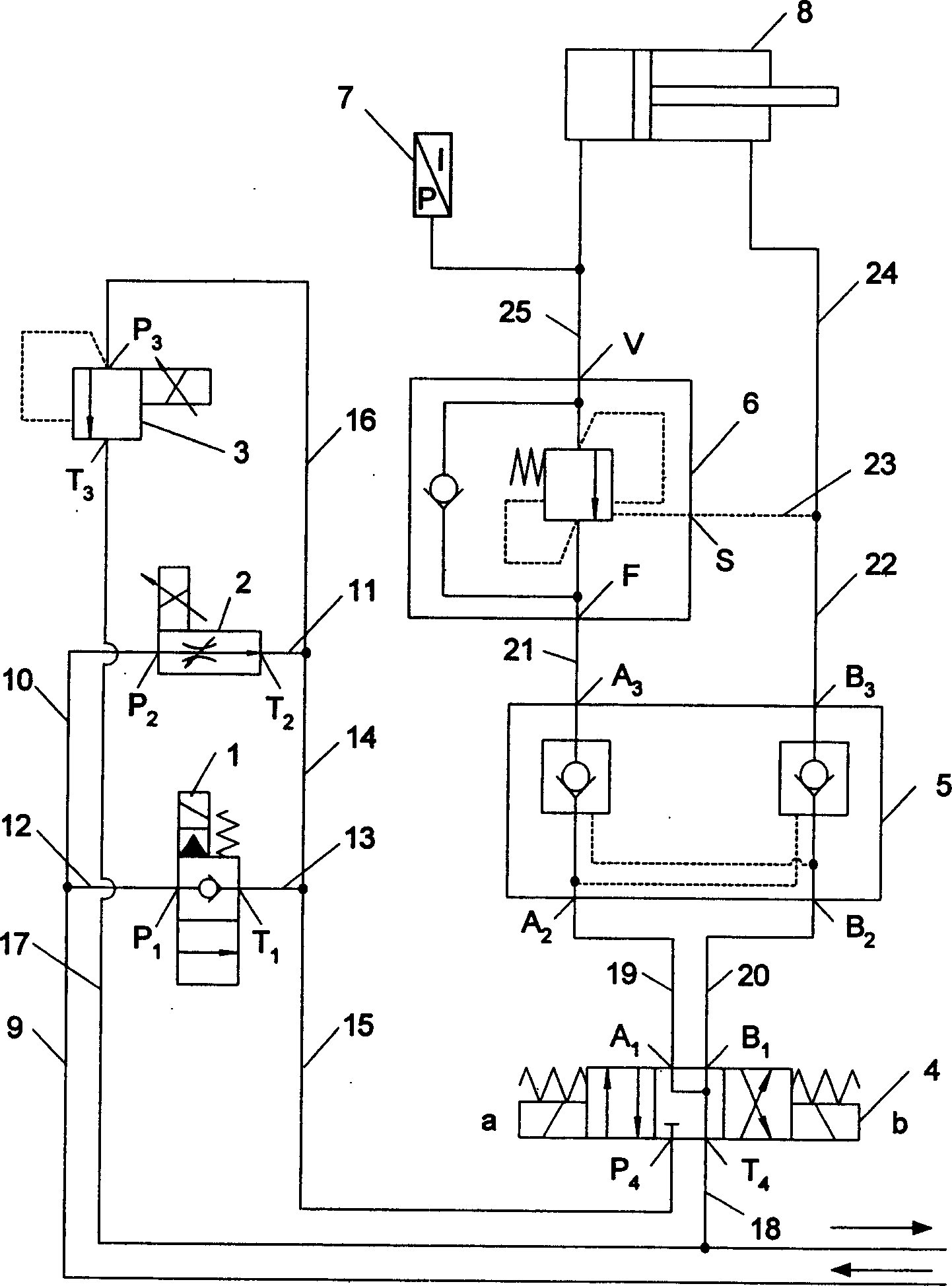

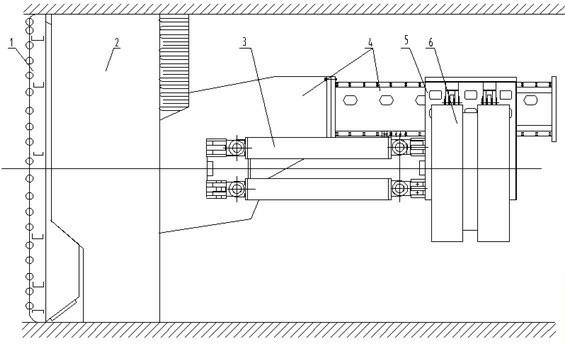

Hydraulic propelling system for mining tunnel driving machine controlled by ratio flow pressure

InactiveCN1560482AReal-time adjustment of propulsion speedAdjust pressure in real timeServomotor componentsTunnelsMachine controlEarth surface

The invention discloses a shield development machine hydraulic advancing system with proportion flow pressure compound control. It includes two bits two-way electromagnetic ball valve, proportion adjusting valve, proportion overflow valve, and three-bit four-way electromagnetic change valve, hydraulic lock, balancing valve, pressure sensor and hydraulic oil cylinder with inner shift sensor. The advancing system uses the proportion adjusting valve to control the advancing speed, uses proportion overflow valve to control the advancing pressure, it realizes the compound control of advancing speed and pressure with proper control tactics. Because the invention uses the compound control technology of the proportion flow pressure, it can realize the control to the advancing speed and advancing pressure in the advancing process of the shield development in real-time, thus realizes the control to the soil barn pressure, stratum stability and the ground sedimentation. The system in the invention can be adapted to each kind of stratums, realizes the control to the posture and direction precisely, the energy-saving effect of the system is good.

Owner:ZHEJIANG UNIV

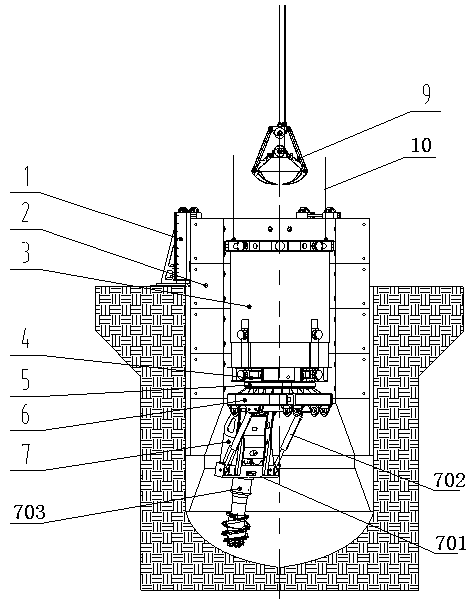

A hard rock hydraulic crushing roadheader

The invention relates to hard rock excavation equipment, in particular to a hard rock hydraulic crushing type excavation machine. It integrates the functions of drilling, rock breaking, material collection, transportation, walking and dust removal, and can realize fast and efficient excavation of all-rock roadways above f10 and above. The roadheader includes a running part, a rear support part, a transport part, a main body part, a rock drilling part, a rock breaking part and a shoveling part. Part, the rear part of the body part is provided with a rear support part and a transport part. The invention can solve the problems of low operation efficiency, harsh working environment and the like existing in the prior art. The whole equipment can realize the efficient, safe and high-quality rapid excavation of the whole hard rock roadway, replacing the more dangerous drilling and blasting method commonly used in hard rock excavation and the comprehensive excavation method with low efficiency in hard rock excavation.

Owner:SANY HEAVY EQUIP

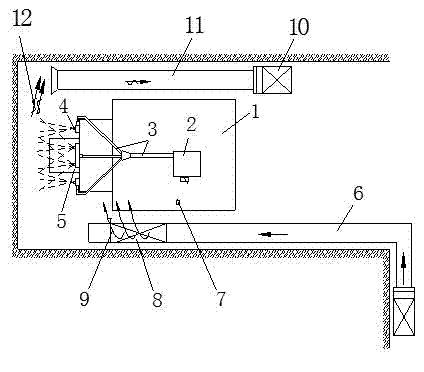

Settling, isolating and removing integrated dust prevention method of fully mechanized excavation face

ActiveCN102536236AInfluence motion trajectoryImprove governance effectSlitting machinesCoalWind flow

The invention relates to a settling, isolating and removing integrated dust prevention method of a fully mechanized excavation face, and is applicable to dust prevention and control of a coal mine underground fully mechanized excavation face. The method comprises the steps that: a foam generator is installed on a fully-mechanized roadheader, a pneumatic dedusting fan is arranged at one side of a laneway, and a wall attaching wind drum is installed at the front end of a pressed-in type wind drum; when the fully-mechanized roadheader works, the foam generator is operated to prepare foam, and the foam is sprayed by a spraying head to a dust source at the cutting part of the fully-mechanized roadheader so as to rapidly settle the dust; the axial air flow in the pressed-in type wind drum is changed by the wall attaching wind drum into a spiral type air flow and then sprayed, so as to prevent the air flow from directly blowing to the foam spraying region to influence the foam track; an air curtain dust isolating region is formed in front of the driver of the fully-mechanized roadheader, so as to effectively prevent dust from diffusing out; and the residual dust in the dust isolating region is removed by starting the pneumatic dedusting fan. According to the invention, foam dust settling, air curtain dust isolating and pneumatic fan dedusting are organically integrated, thus the dust prevention effect of the fully mechanized excavation face is significantly improved, the potential safety hazard brought by using of an electric dedusting fan is avoided, and the method has wide practicability.

Owner:CHINA UNIV OF MINING & TECH

Shield segment splicing machine with six-freedom degree

InactiveCN1837578AIncrease loadReduce adverse effectsUnderground chambersTunnel liningEngineeringSystem stability

The invention relates to a shield construction tube assembler with six freedoms, which comprises a rotational disc, a driving device, two suspending beams, two translation cylinders, two guide sheathes, two guide inner sheathes, two lifting cylinders, a lifting beam, a tube clamper, a tube weight, a rotational platform, a central ball joint bearing, a tube incline cylinder, a tube rotational cylinder, a fixed disc and a rolling wheel. The invention has six freedoms to meet the demand of assemble different spatial positions; and a middle beam and a tube clamper, etc, are arranged between two suspending beams to improve the system stability.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

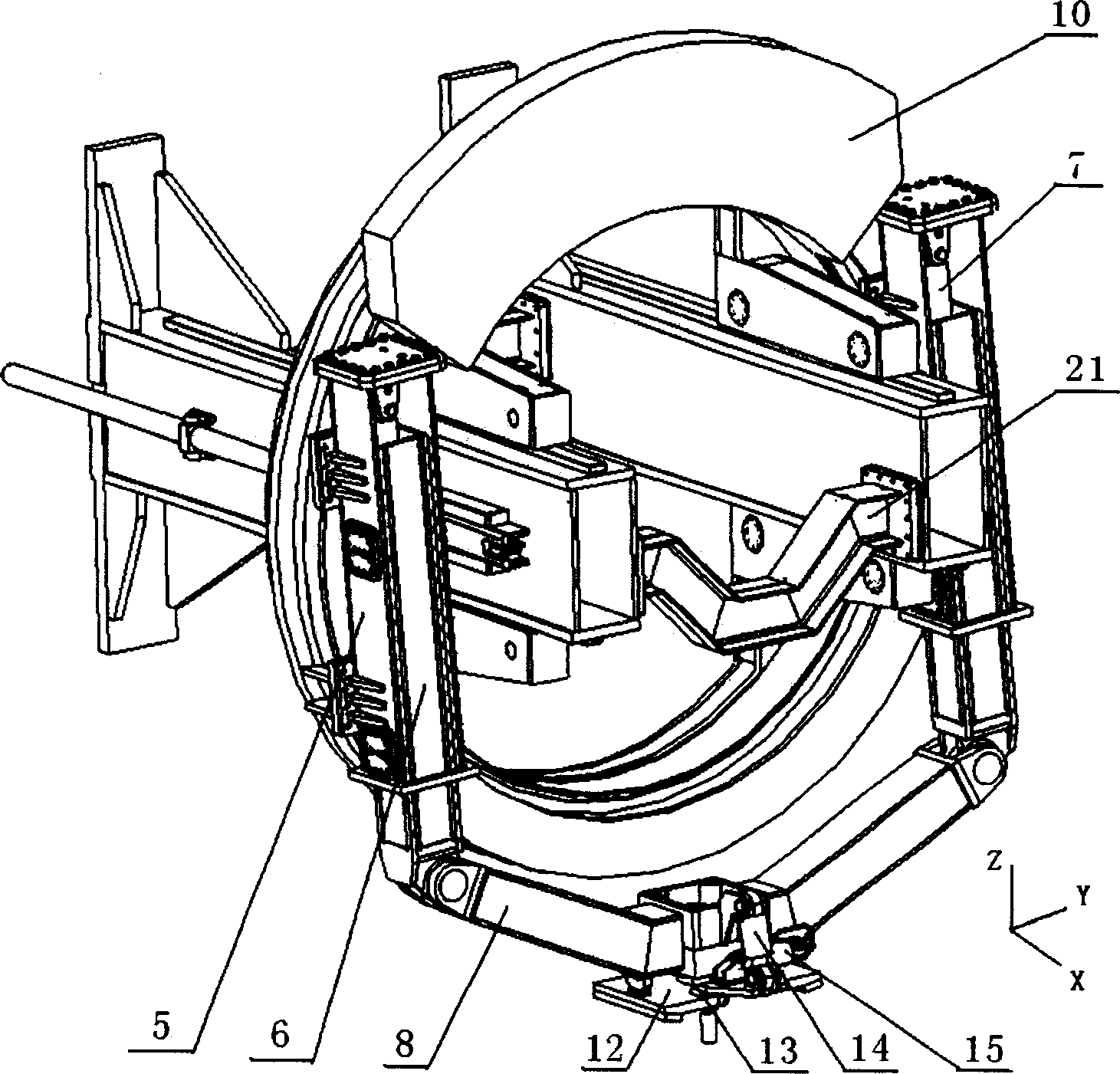

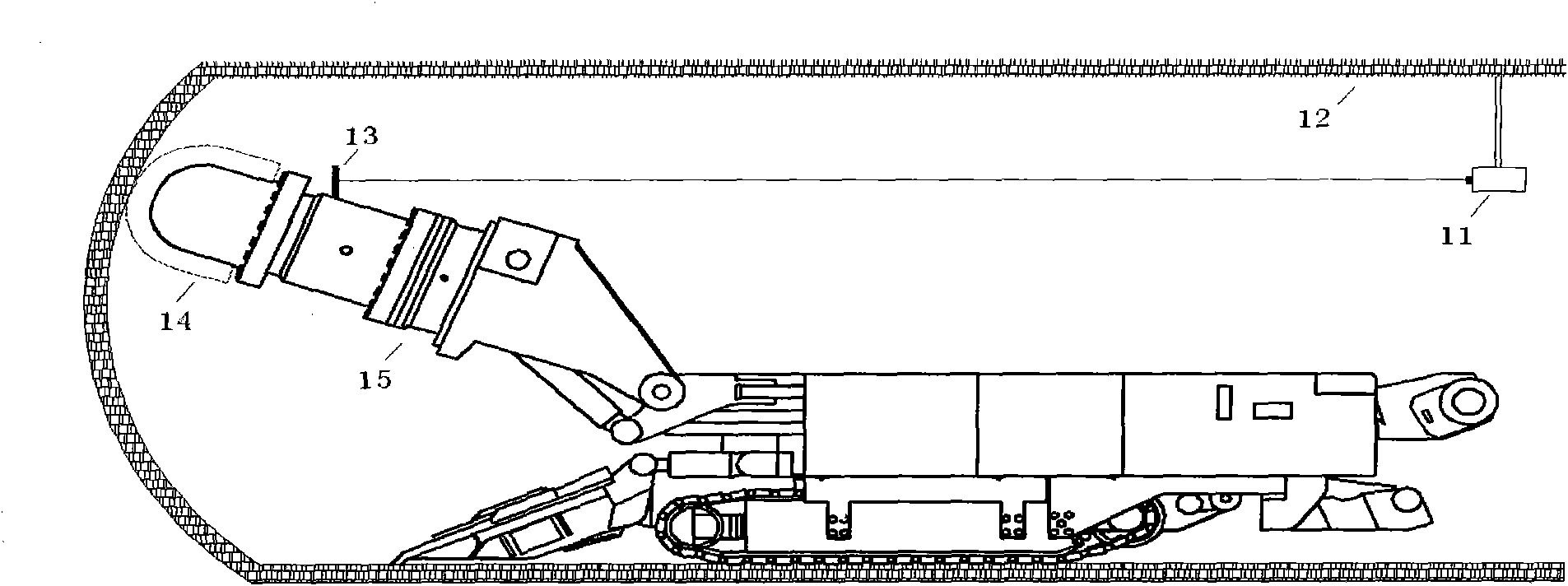

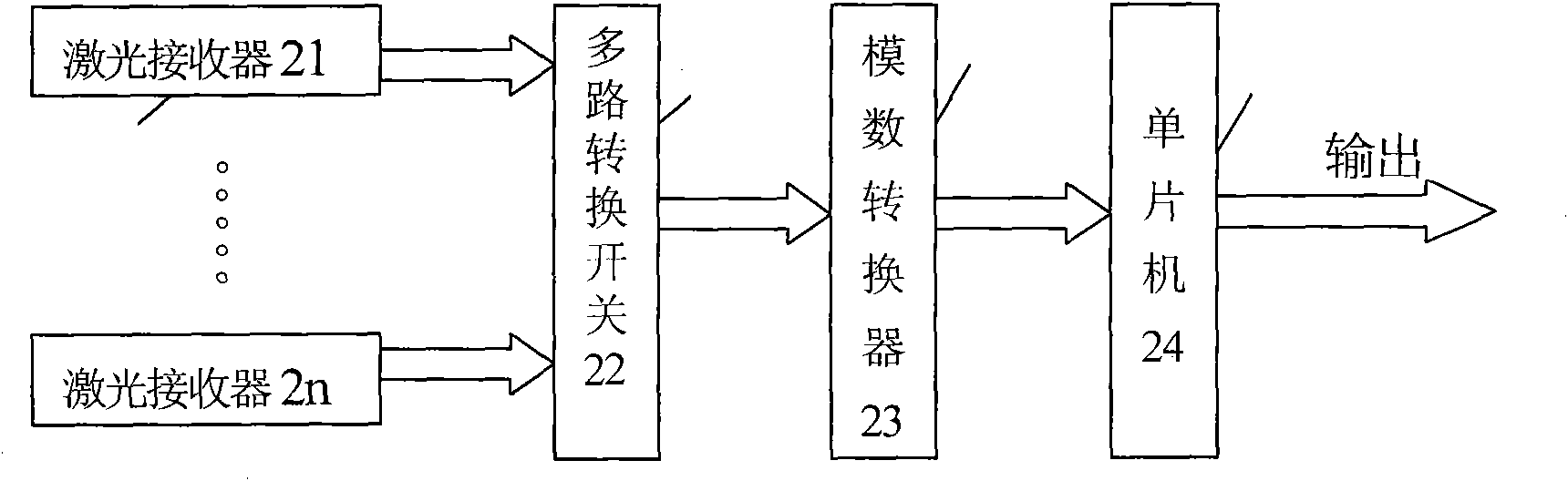

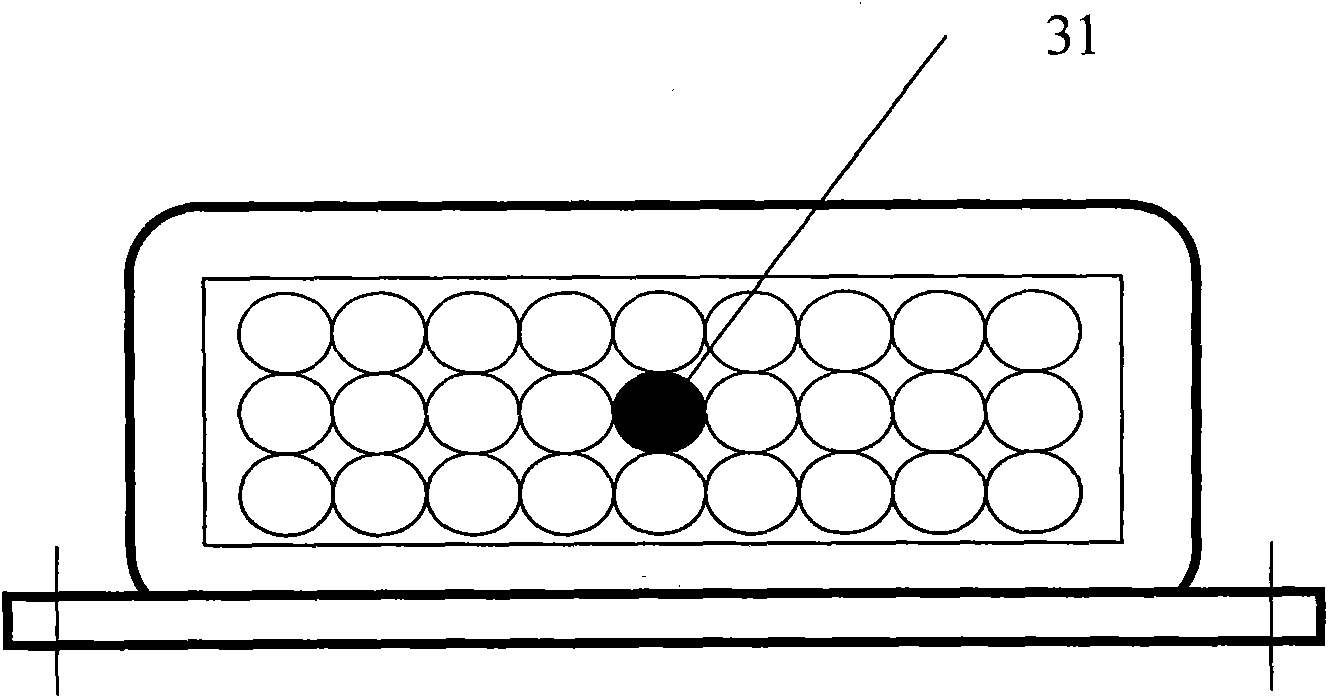

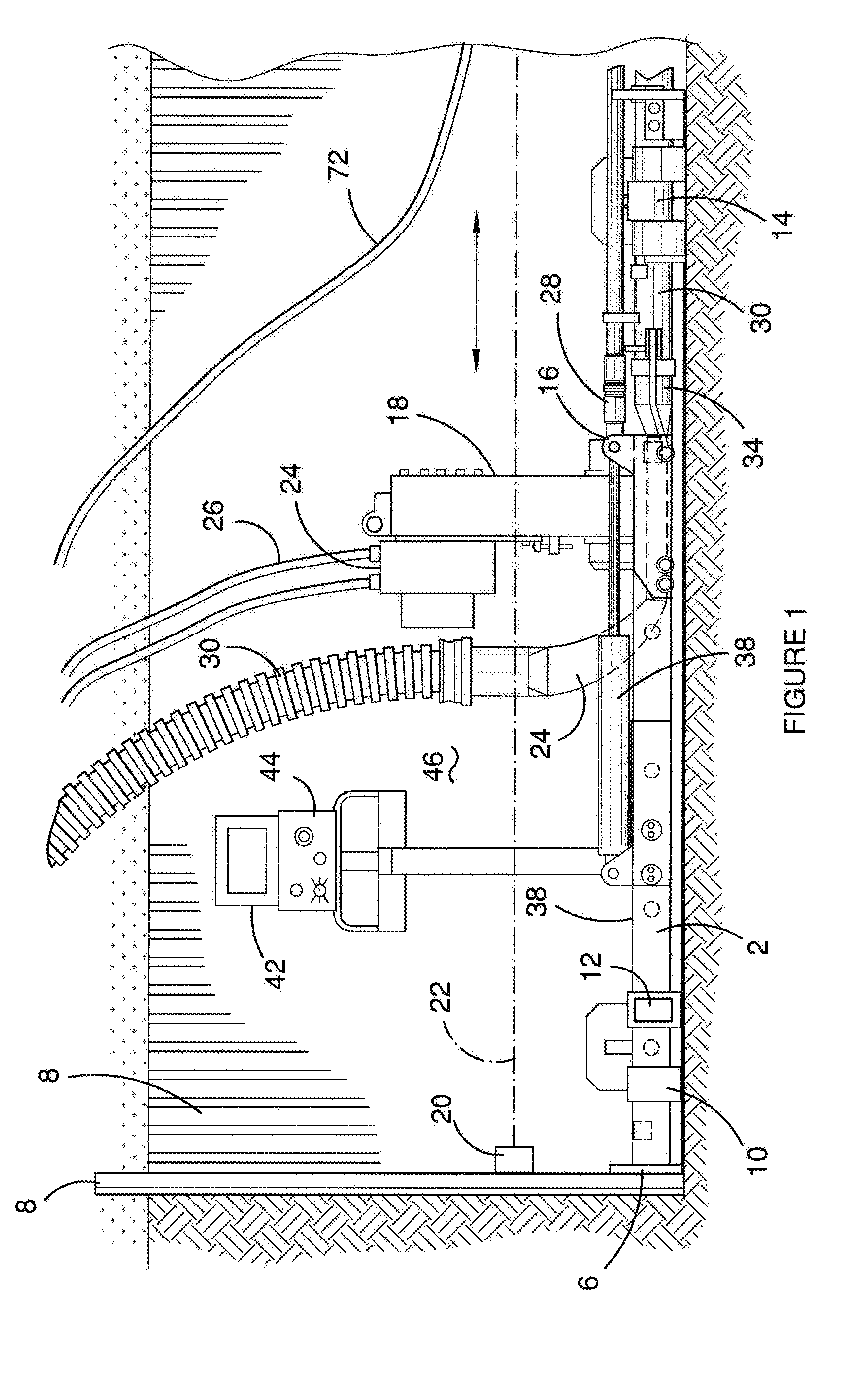

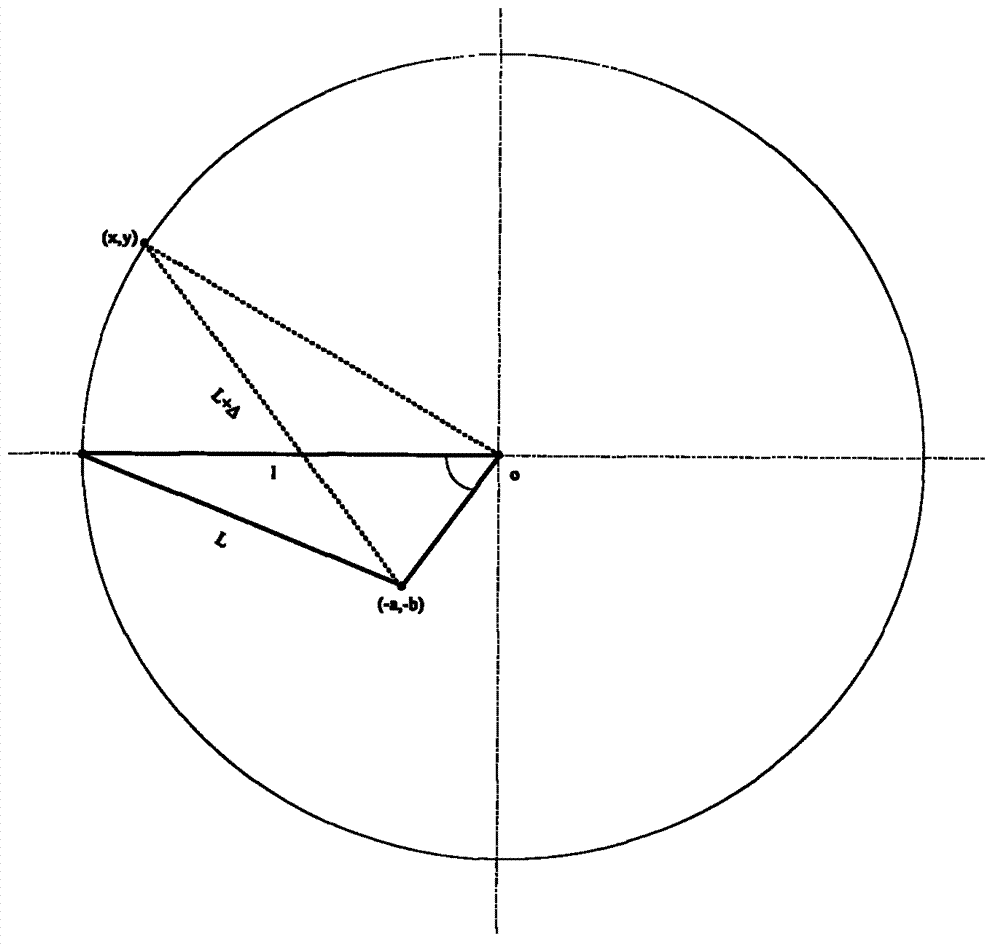

Laser guided positioning and orientation device and method of roadheader

InactiveCN101975063AGuaranteed Directional DrillingShorten adjustment timeSlitting machinesSurveying instrumentsMicrocontrollerControl system

The invention provides a laser guided positioning and orientation device and a method of a roadheader. A detector thereof is composed of a laser guiding device, a laser receiver, a multicircuit switch, an analog-to-digital converter, a singlechip and a control system, wherein the laser guiding device is arranged on a tunnel roof at the back of the roadheader, and the laser receiver and the multicircuit switch are arranged on a cantilever. In the detection method, the laser guiding device is arranged on the tunnel roof at the back of the roadheader, the laser receiver is arranged on the cantilever, the laser receiver is used for converting received optical signals into voltage signals and amplifying the voltage signals, the analog to digital converter is used for converting the amplified voltage signals into digital signals, and then the digital signals are operated and processed by the program of the singlechip, thus deviation that the roadheader deviates from the laser guiding direction and information that the excavated cantilever aligns with the center coordinate of an excavated section can be output, thereby positioning the cutting head of the cantilever, being capable of fast calibrating the central point of the reference coordinate, shortening the adjustment time, improving the excavating speed, and ensuring the orientated excavation of the roadheader in laser guiding direction.

Owner:CHINA UNIV OF MINING & TECH

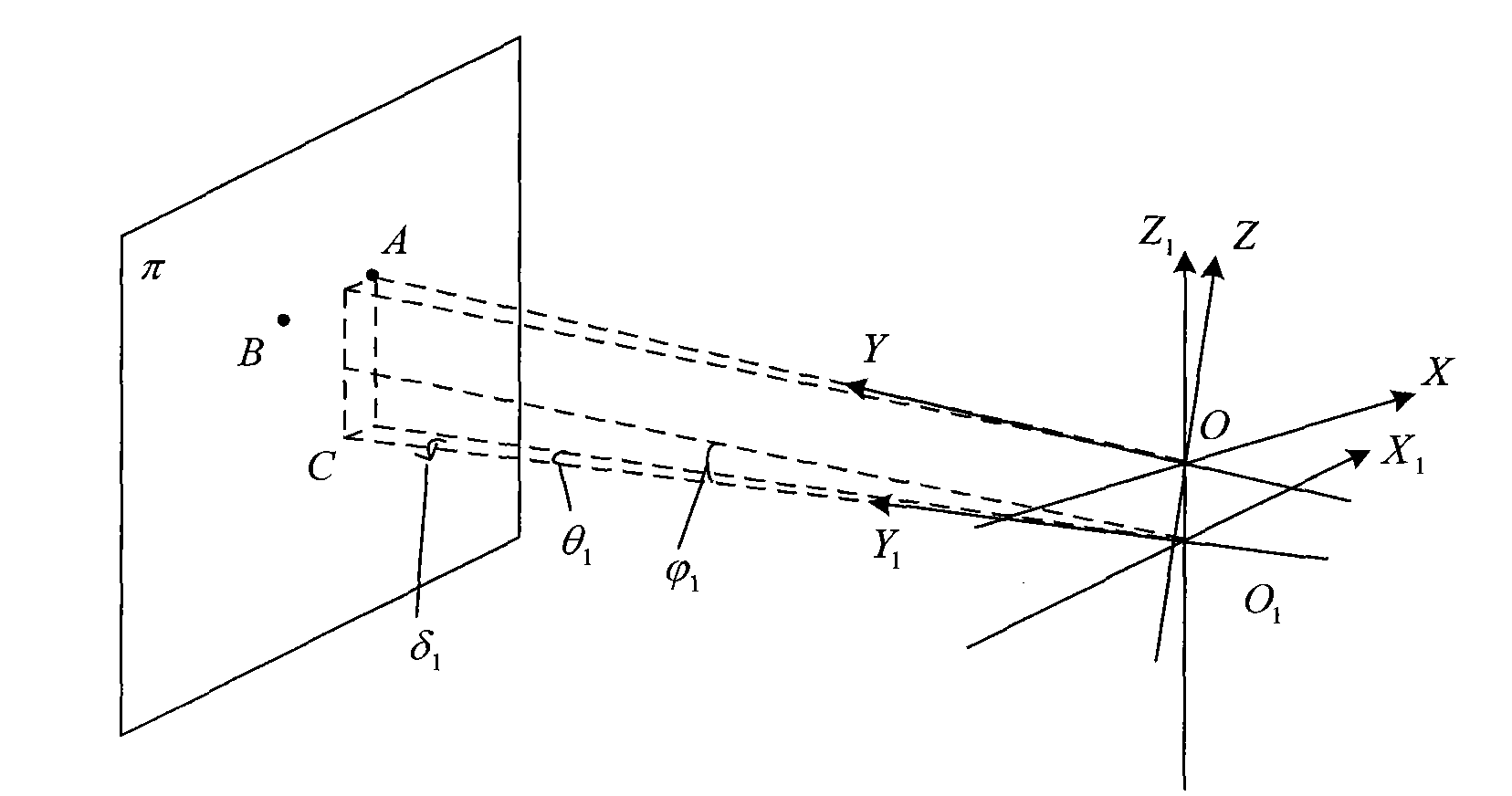

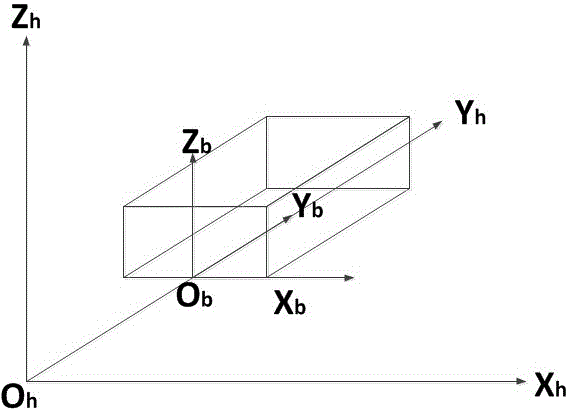

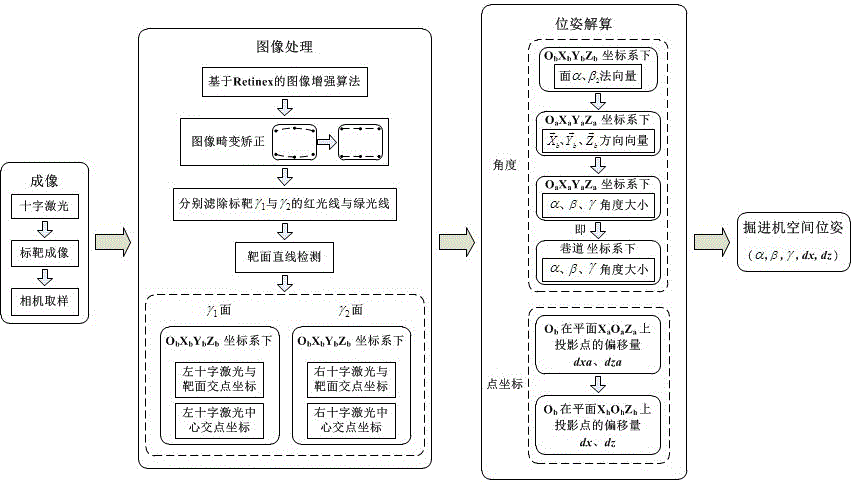

Real-time detection system and method for spatial pose of boom-type roadheader

InactiveCN106052645AFix stability issuesSolve the resultPhotogrammetry/videogrammetryLaser transmitterLaser target

The invention provides a real-time detection system and method for the spatial pose of a boom-type roadheader. The real-time detection system comprises two cross laser transmitters, an industrial control computer, two Internet protocol cameras and two laser targets. Machine vision technology is used as an acquisition manner for pose parameters; a mathematic model for resolving the pose of the roadheader is established so as to obtain the yaw angle, pitch angle, roll angle of the roadheader in heading process and the offset of a fixed point on the body of the roadheader on the cross section of a tunnel, i.e., the spatial pose of the roadheader, and the spatial pose can be used for deviation rectification in automatic heading of the roadheader. Experimental results show that the precision of an angle detected by the system is within 0.5 DEG and the precision of offset is better than 20 mm; an interval between processing time and displaying time for each frame of an image is about 5 s; so requirements of tunnel construction for automation, precision and real-time positioning are met.

Owner:CHINA UNIV OF MINING & TECH

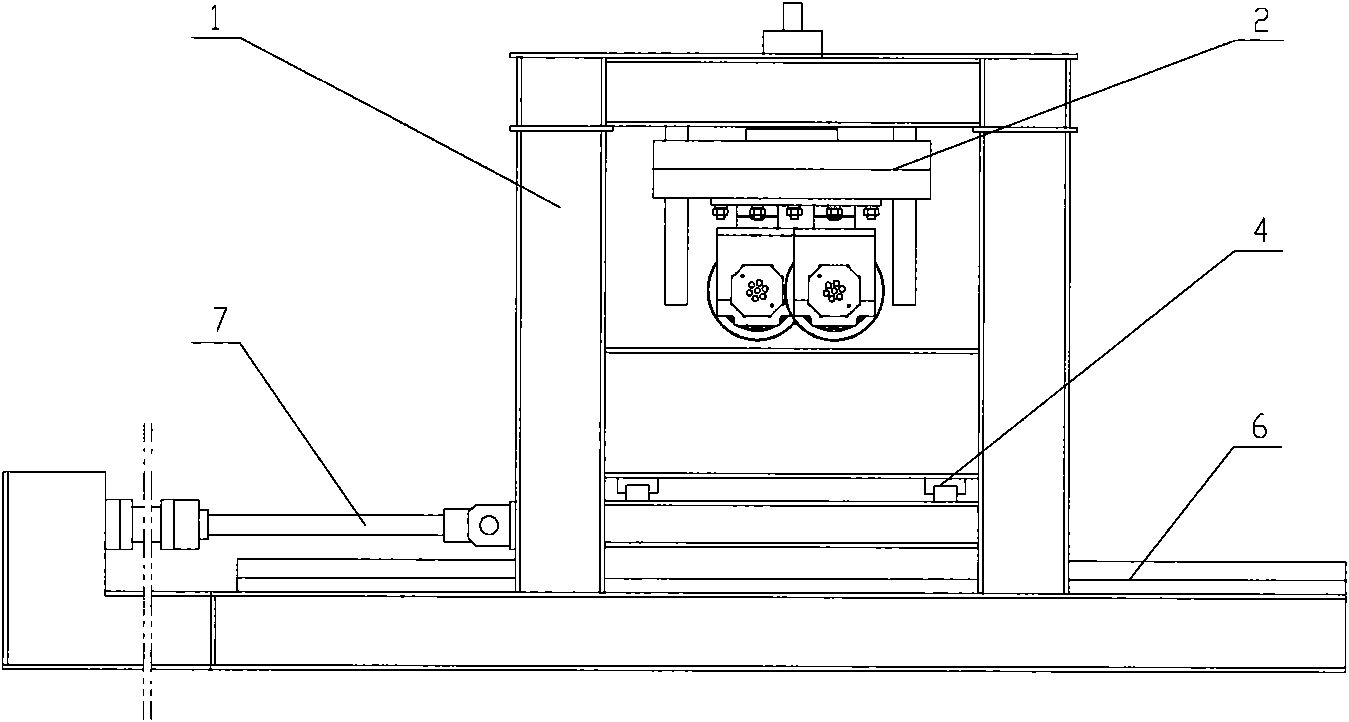

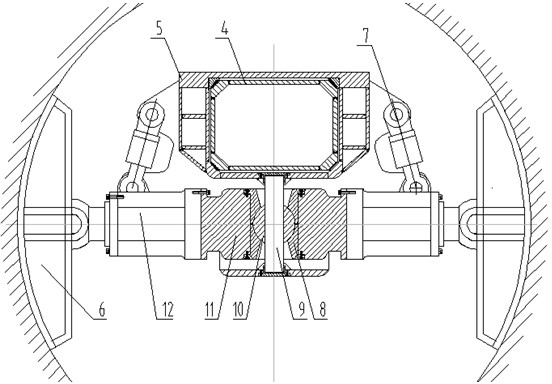

Synchronous detection test device for multi-item parameters of linear TBM hobs

InactiveCN101592533ARock breaking test data is accurateShorten the development and design cycleForce measurementMechanical clearance measurementsHydraulic cylinderPhase difference

The invention provides a synchronous detection test device for multi-item parameters of linear TBM hobs applied in the full-section hard-rock tunneling machine industry. The whole device consists of a self-counterforce frame, a regulate tool rest, an X-direction moving worktable, an X-direction linear guide rail, a Y-direction moving worktable, a Y-direction linear guide rail, an X-direction hydraulic cylinder, a rock sample, a hob, a four-rod guide mechanism, three-direction pressure sensors, a Z-direction hydraulic cylinder and the like, wherein the lateral movement direction of the rock sample is set as an X axis; the axial direction of the hob is set as a Y axis; the direction perpendicular to the surface of the rock sample is set as a Z axis; the rock sample is fixed on a trolley; the regulate tool rest is arranged on the four-rod guide mechanism; the X-direction moving worktable and the Y-direction moving worktable are arranged on a horizontal linear guide rail; the hob is arranged in a hob seat and is connected with the regulate tool rest through the three-direction pressure sensors; the rock sample is arranged and clamped on the X-direction moving worktable; and the three direction hydraulic cylinders are fixed with the fixed self-counterforce frame respectively. The device has the advantage of more precise function of simulating the process of breaking rocks through the hob, and is used for the synchronous detection of three-direction force, tool interval, penetration degree, wear degree, phase difference and other parameters of the hob in the states of linear paths and high-speed rotation of a plurality of hobs.

Owner:SHENYANG HEAVY MACHINERY GROUP

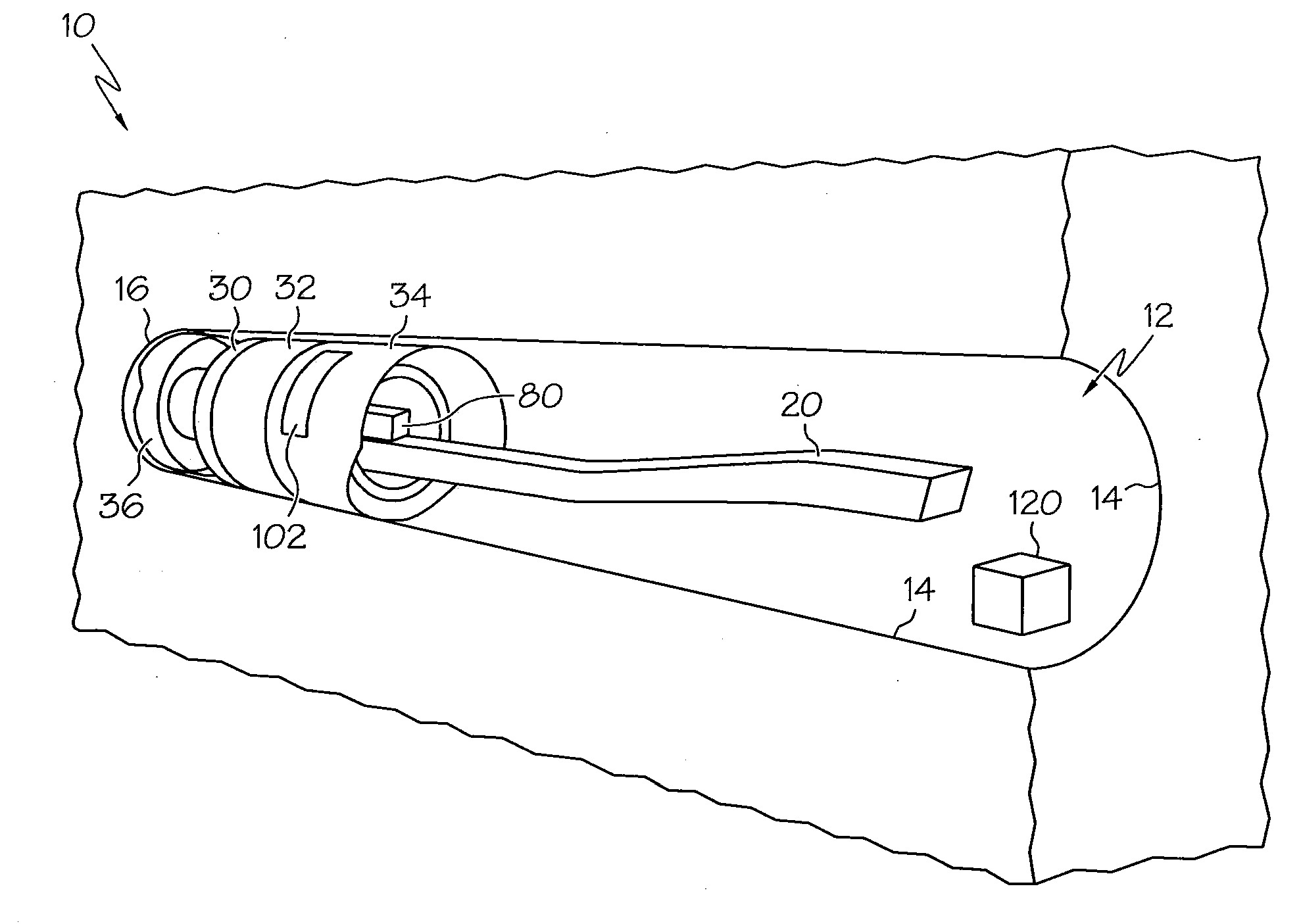

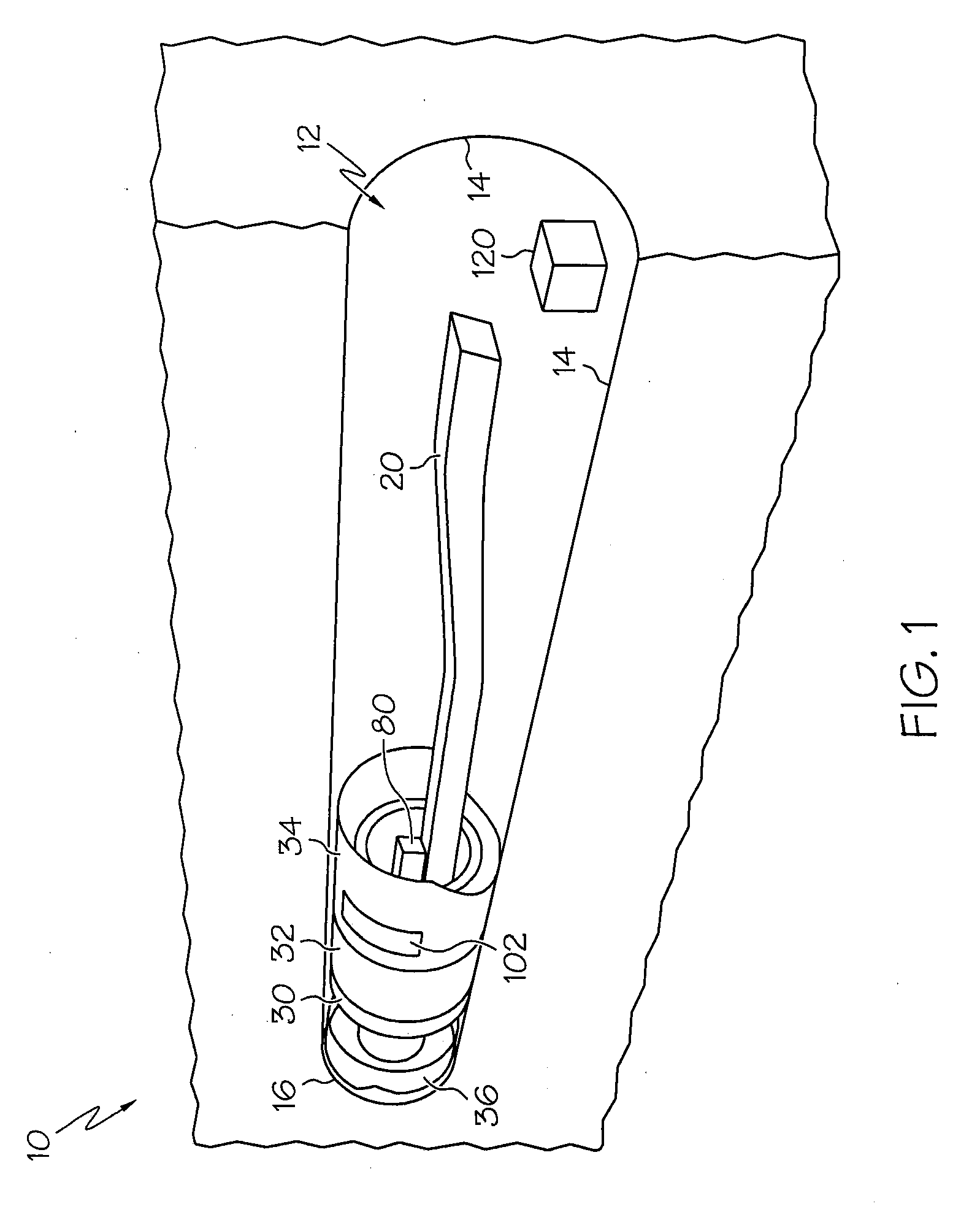

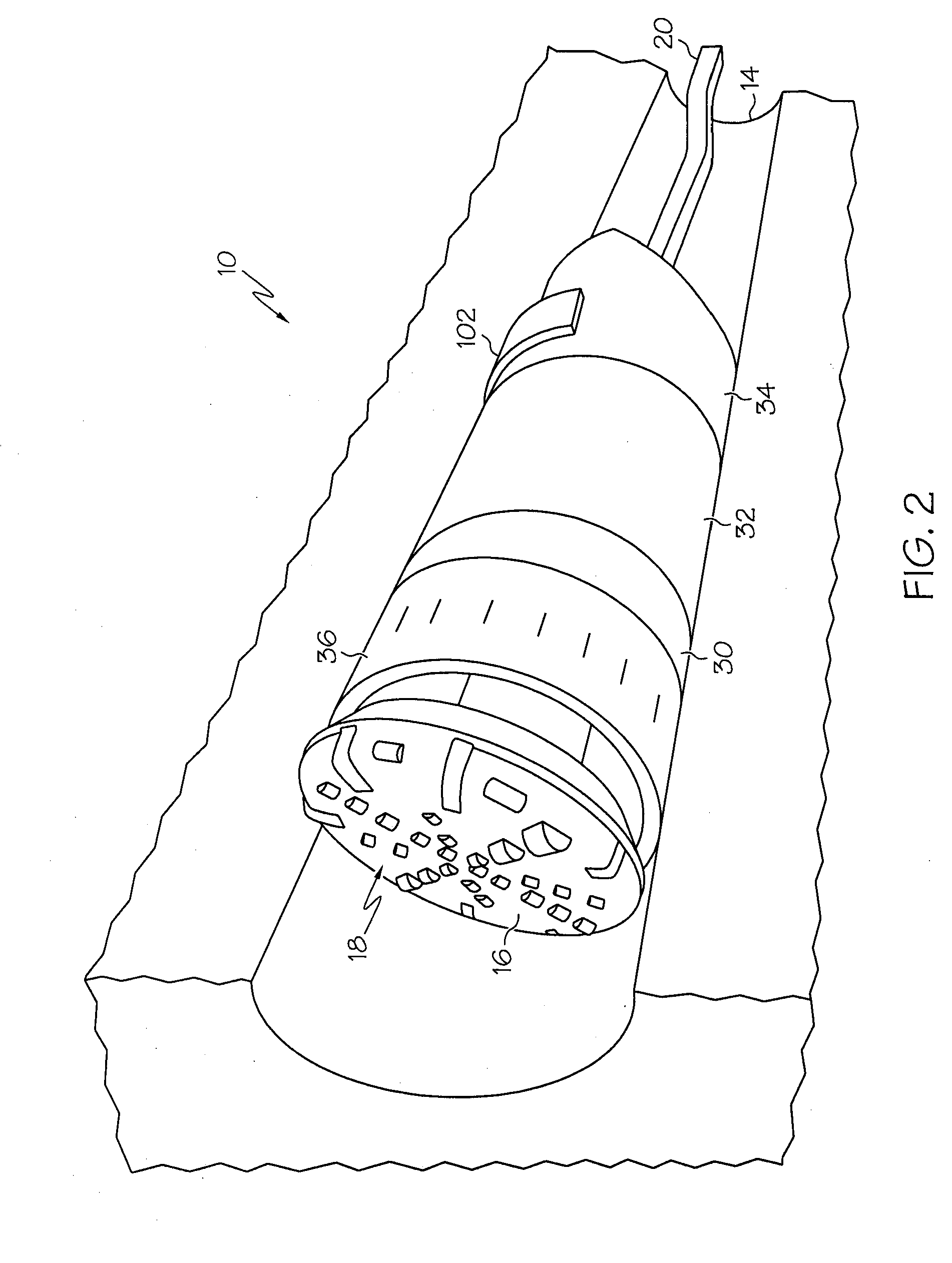

All-conditions tunnel boring machine

A tunnel boring machine is provided comprising a cutter head, a main beam, a first, second, and third shield; and a ground conditioning work zone within the first shield, a gripper assembly, a segment erector arm for lining the tunnel, and at least one propulsion mechanism. The ground conditioning work zone includes at least one probing device for probing the terrain ahead of the cutter head. The first shield is configured to be retracted relative to the second shield to provide access for the ground conditioning work zone to apply at least one ground support device. The at least one propulsion mechanism moves the cutter head, the first and the second shield forward while the third shield and the gripper assembly remain stationary. The ground support devices can include filling a hole with a ground conditioning agent; and placing a bolt, ring beam, mesh, or shotcrete in / on the tunnel wall.

Owner:THE ROBBINS CO

Device for online detection for stress of hobbing cutter of tunnel boring machine

ActiveCN103698075AGrasp the working status in timeExtended service lifeMeasurement of force componentsElastomerAudio power amplifier

The invention discloses a device for online detection for stress of a hobbing cutter of a tunnel boring machine. The device comprises a shaft end supporting structure of a cutter central shaft, a sensor for detecting the stress of the hobbing cutter, a signal amplifier, a transmitting antenna, a signal receiving device and a monitoring computer, wherein the shaft end supporting structure of the cutter central shaft comprises a shaft end structure of the cutter central shaft, a supporting wedge and a locking wedge, and the sensor is formed on the supporting wedge. The supporting wedge is used as an elastomer, the sensor for detecting the stress of the hobbing cutter is formed through pasting a resistance strain piece on the elastomer, and when the heading machine works, the sensor can be used for online detecting stress in three directions borne by a cutting edge of the hobbing cutter, so that the tunneling operation scheme can be adjusted according to the condition, the service life of the cutter is prolonged, and further good tunneling efficiency can be obtained. The device can also be used for identifying whether string wear occurs or not and timely grasping the working state of the hobbing cutter, and the tunneling efficiency can be ensured due to the fact that when the cutting edge is subjected to string wear, the cutter can be timely replaced.

Owner:TIANJIN UNIV

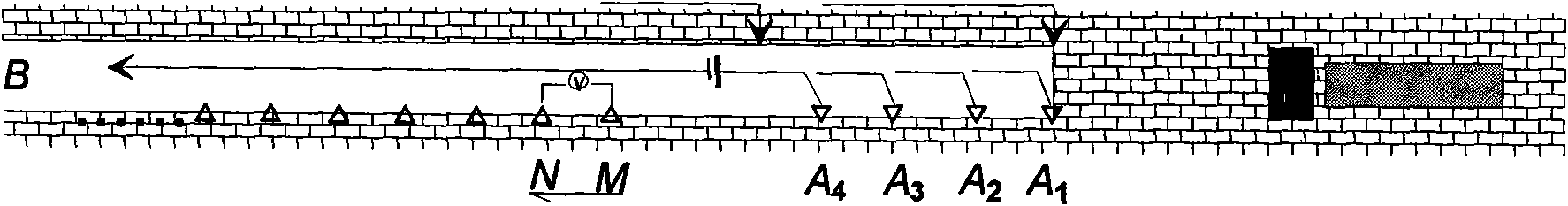

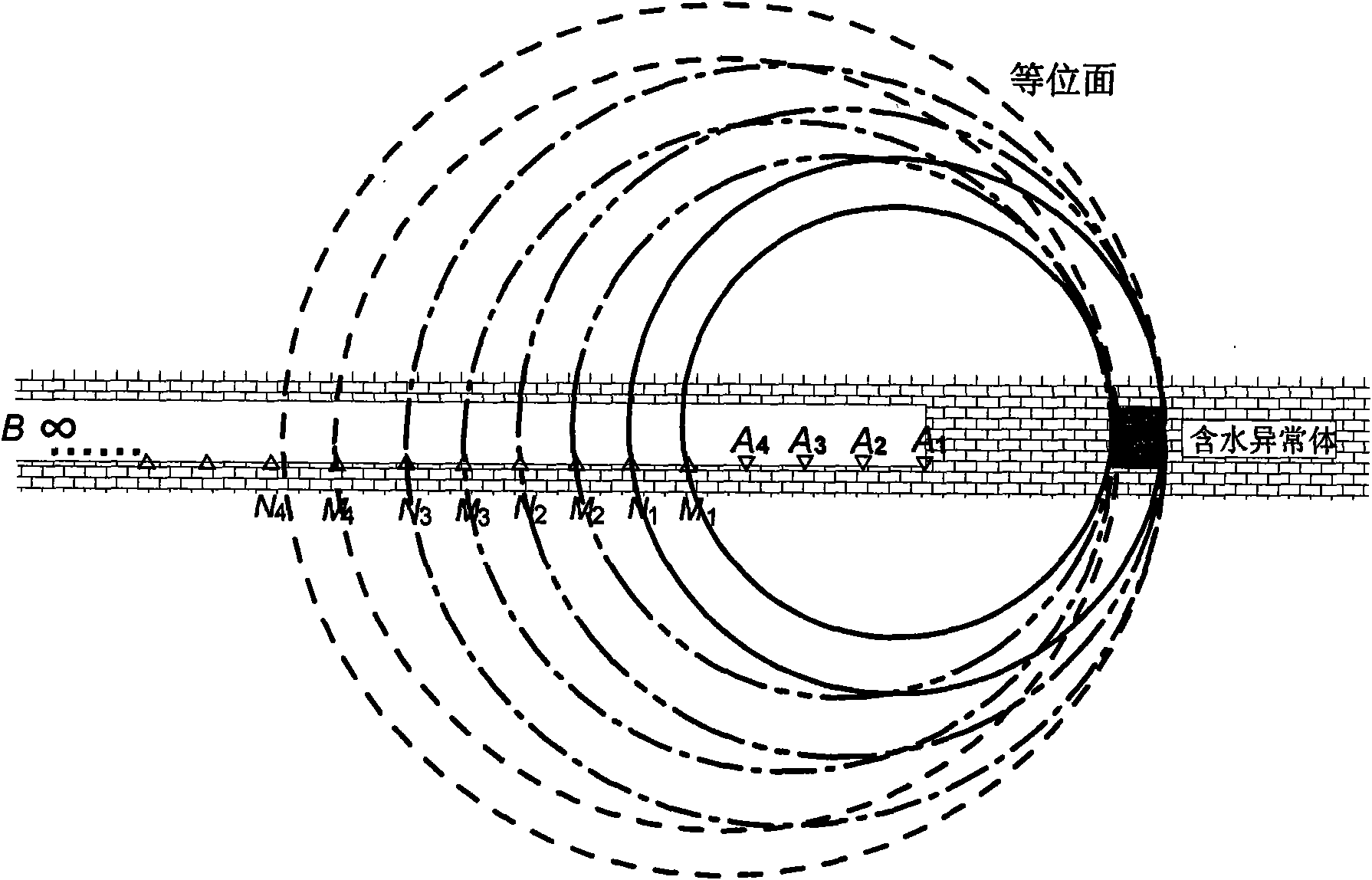

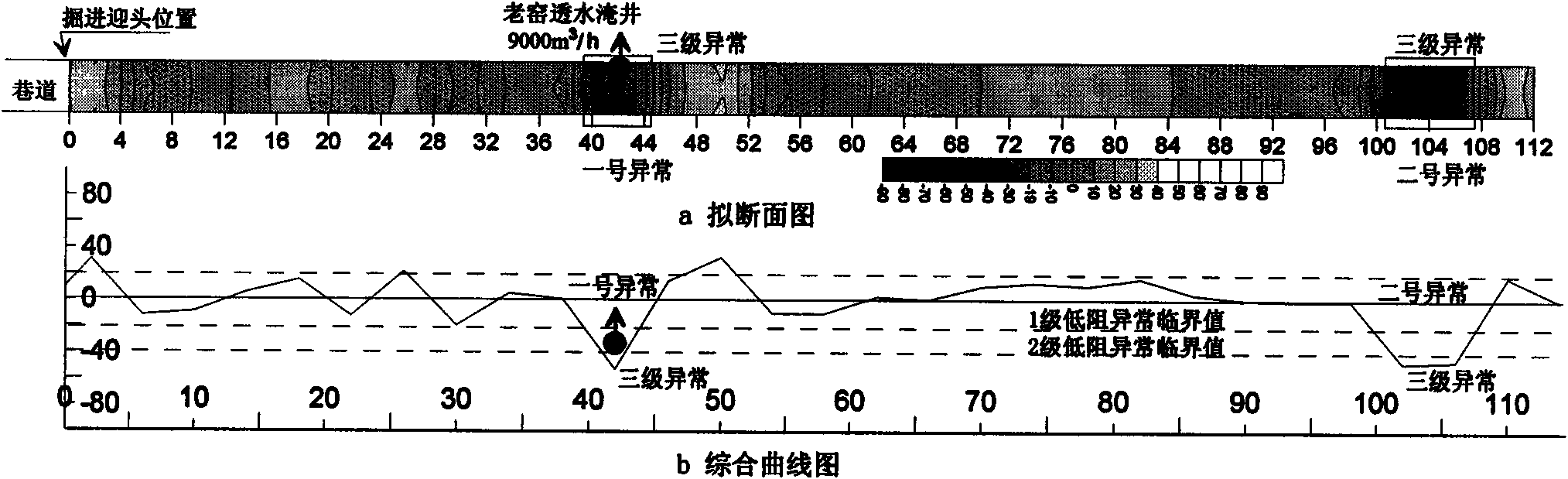

Direct current method for bed-parallel advanced detection of water bearing structure in mine tunnel

ActiveCN101603423AQuick detectionExplain quicklyElectric/magnetic detection for well-loggingWater resource assessmentProperty distributionElectric field

The invention discloses a direct current method for bed-parallel advanced detection of water bearing structure in mine tunnel. Common advanced detection technology comprises a seismic reflection wave method, a Rayleigh wave method and the like, but with the extensive application of a fully-mechanized roadheader, the above methods are harder to adapt to the present production task requirements. The method of the invention is as follows: a mine direct current method seven-electrode series detecting device is used to arrange four current-emitting electrodes of A1, A2, A3 and A4 which are arranged on one straight line near a mine tunnel heading end, and the four current-emitting electrodes respectively form a loop with another current-emitting electrode B arranged at infinity to supply direct current under the ground, so that a direct current field is built; meanwhile, two electrodes M and N with relatively fixed distance behind the tunnel are used for measuring the distribution rule of the electric field; after treatment with special mating interpreting technology, electrical property distribution information in a geologic body 0-140m ahead a drifting tunnel or a tunnel is obtained. The invention has the advantages of small workload, high speed, small possibility of influence by personal factors, high objectivity and high accuracy, and belongs to a non-destructive detection method.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

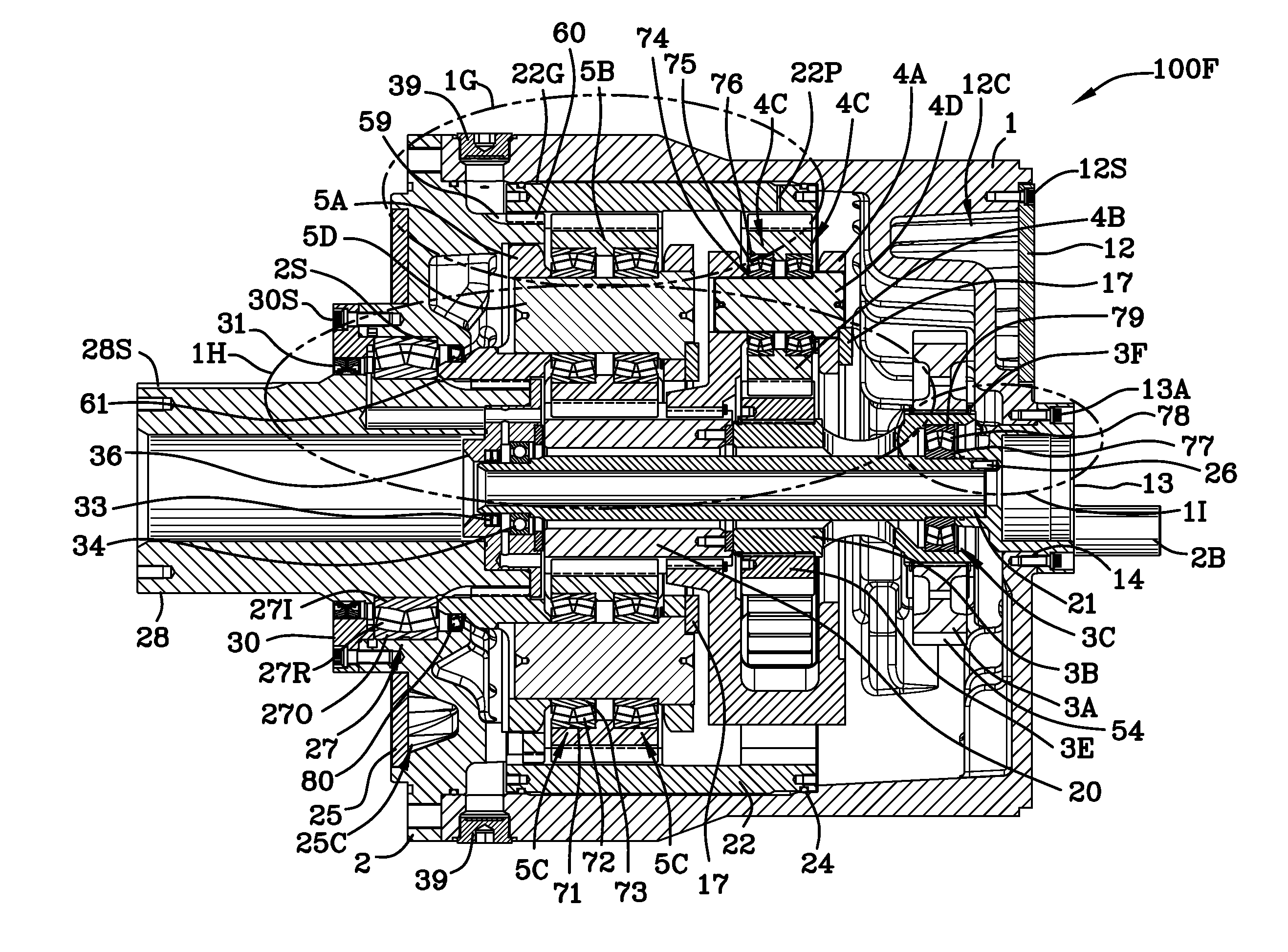

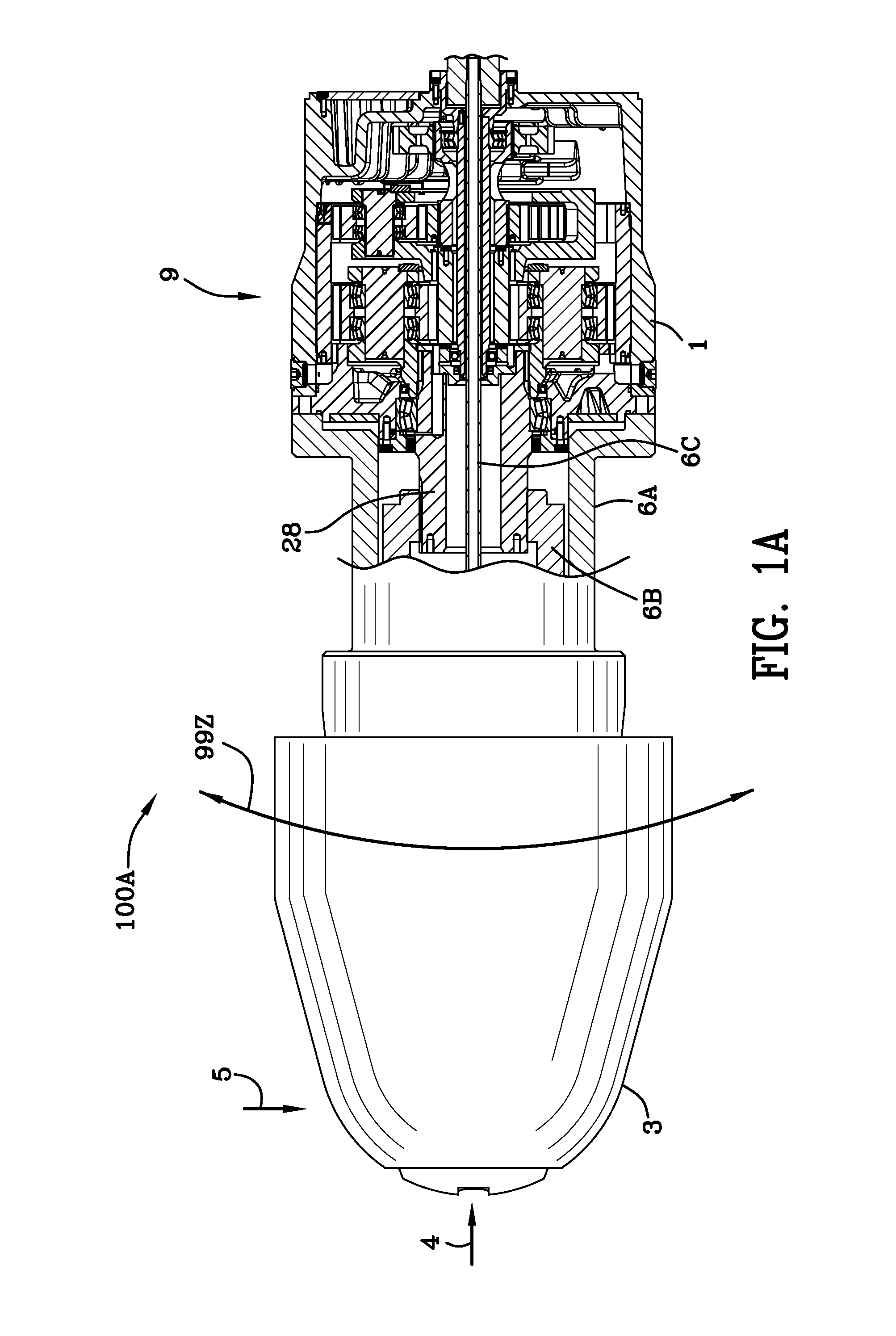

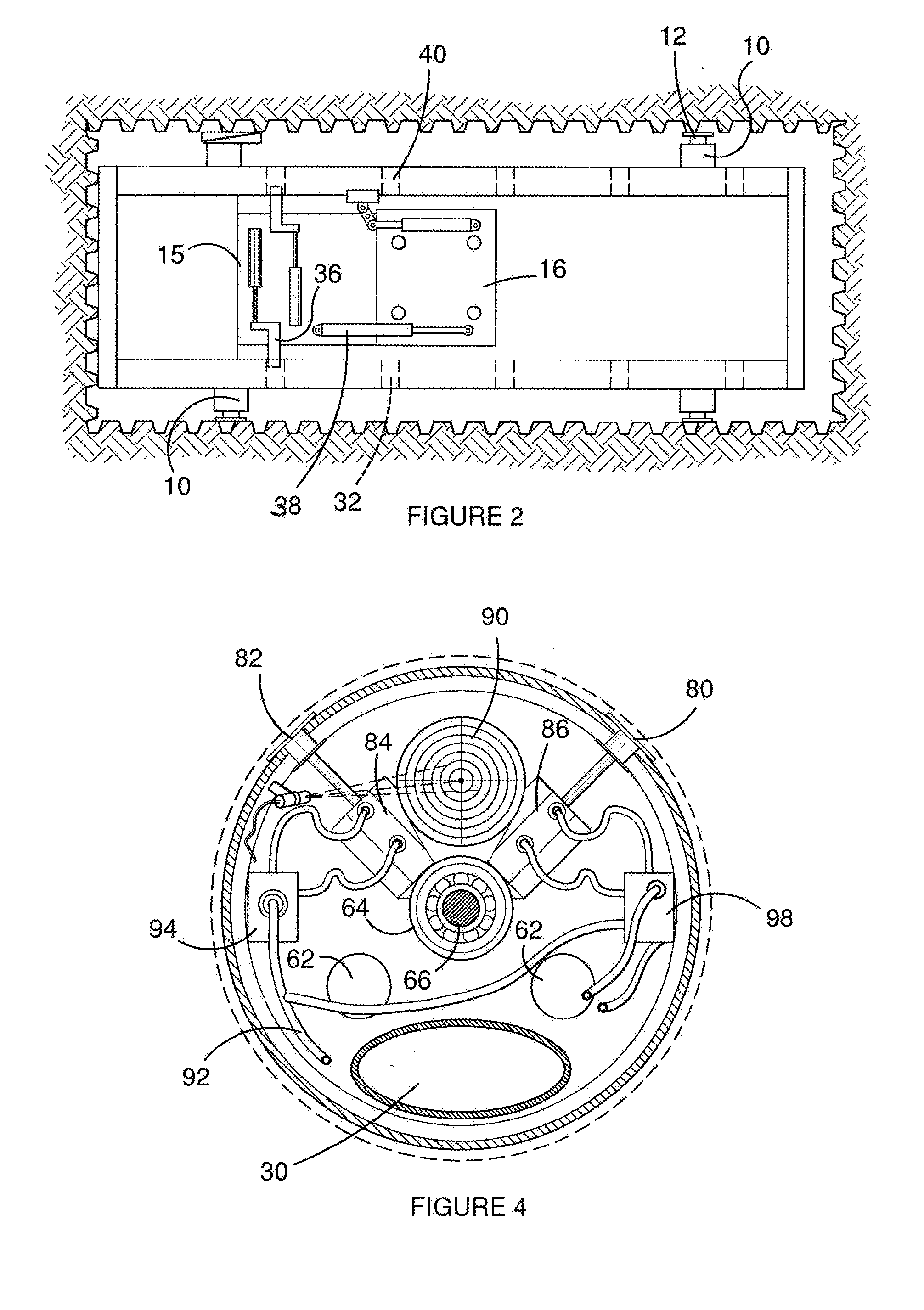

Roadheader gearbox

InactiveUS20130324354A1Precise positioningToothed gearingsGearing detailsSpherical bearingGear system

A gearbox includes a shaft input spherical bearing and a shaft output spherical bearing enabling the ring gear to float within the housing and not engage the housing. The shaft output spherical bearing permits angular displacement of the output shaft with respect to the longitudinal axis of said output shaft. A spline connection enables the ring gear to pivot with respect to the cover. Loads transmitted to the housing of the gearbox are not transferred to the gear systems and the gear systems self-align within the housing.

Owner:FAIRFIELD MFG CO INC

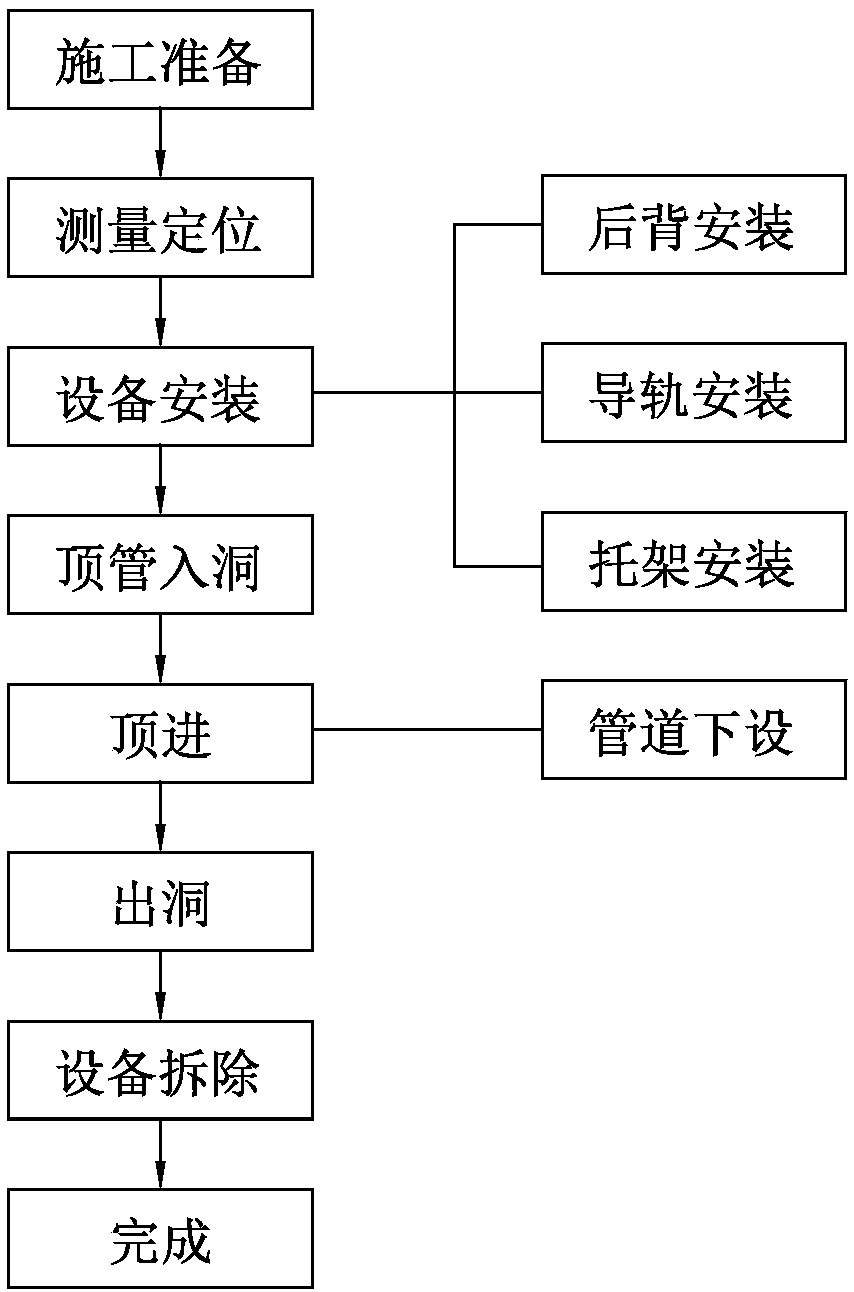

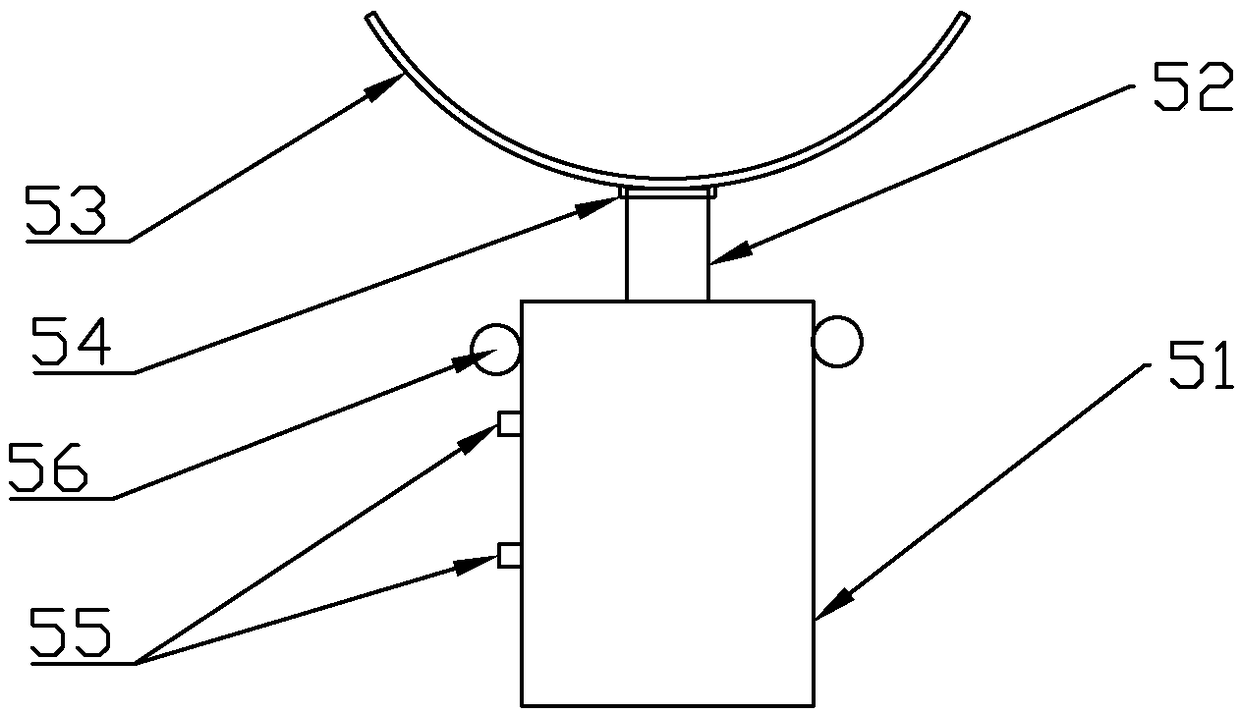

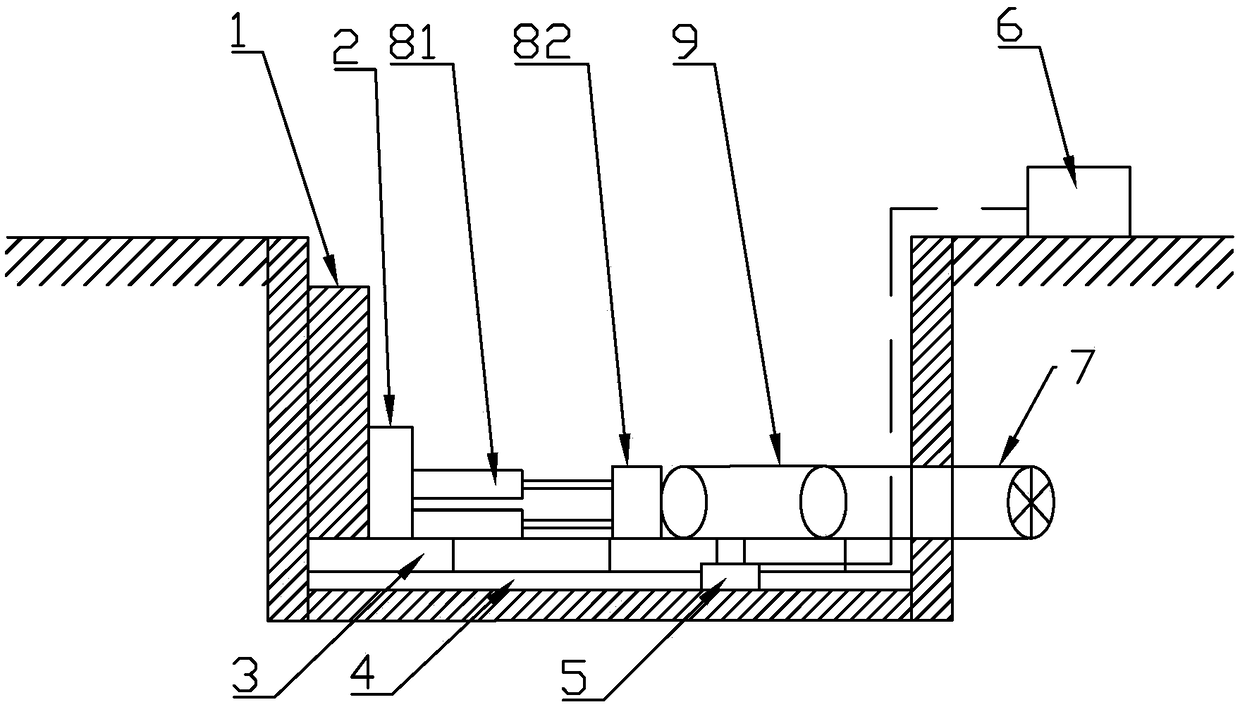

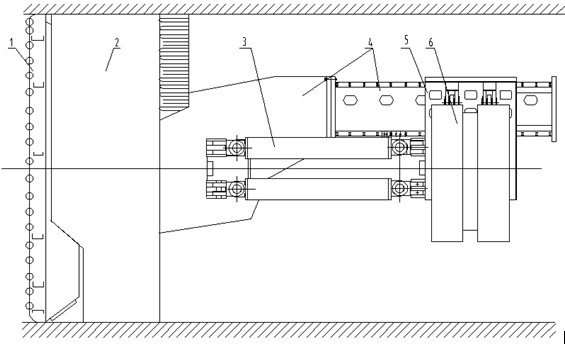

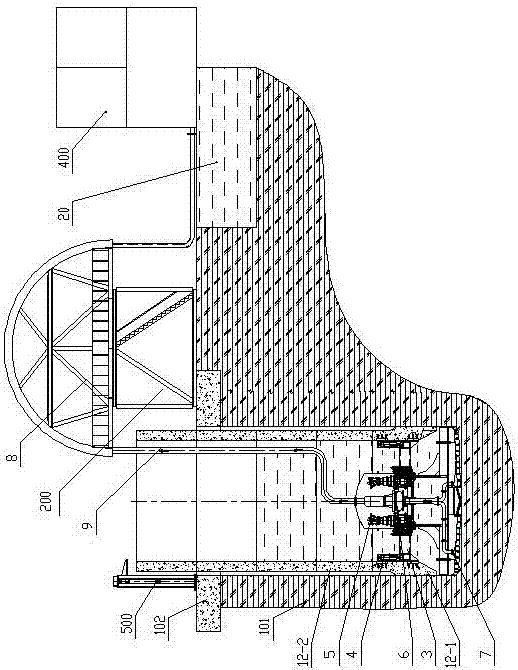

Pipe jacking construction structure and pipe jacking construction method

PendingCN108412505AFacilitate withdrawalAvoid damagePipe laying and repairTunnelsArchitectural engineeringSynergy

The invention provides a pipe jacking construction structure and a pipe jacking construction method. After the foundation pit is formed, the back wall, the back steel plate, the pipe jacking machine,the guide rail, the hydraulic jack bracket and the roadheader are installed in the foundation pit from the back to the front. By using a hydraulic jack bracket, the pipe can be smoothly transported into place, which is beneficial to withdraw the sling to prevent damage to the surface of the pipe. Through the synergy of the pipe jacking machine and the roadheader, the pipe is pushed forward one byone to complete the pipe jacking construction.

Owner:北京清河水利建设集团有限公司

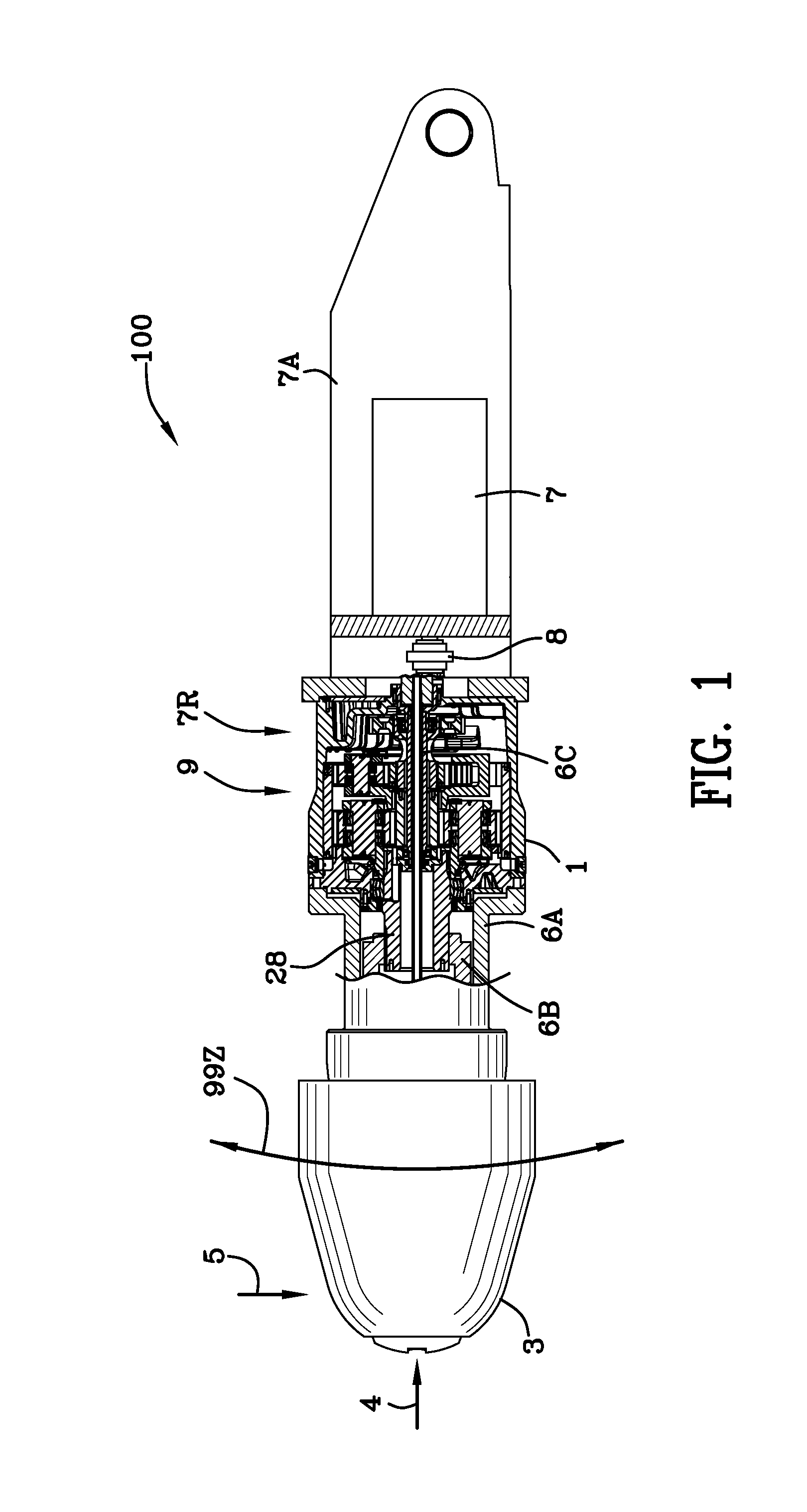

Boring machine

InactiveUS20070089906A1Simplifies and constructionUnderground chambersSlitting machinesDrive shaftEngineering

A micro tunnelling machine has a tunnelling head with a boring bit which is forced in a horizontal direction by a hydraulic thruster. The direction of the head is laser guided. The beam strikes a target in the head and a camera relays an image of the target to an operator located at the tunnel entrance. The operator adjusts the direction by admitting water and draining water from a pair of rams inside the head which move the boring bit up and down or left and right. Water is introduced into the boring bit through the drive shaft of the boring bit. The water forms a slurry which is extracted by a vacuum pipe which enters the slurry as droplets and particles and conducts them away from the tunnelling head.

Owner:DAVIES RODNEY JOHN

Spherical support girder turning mechanism for open-type hard-rock boring machines

InactiveCN102691506AEasy to operateExcellent anti-vibration performanceTunnelsEngineeringRock tunnel

The invention discloses a spherical support girder turning mechanism for open-type hard-rock boring machines, which is applied to the field of full-face hard-rock tunnel boring machines. The spherical support girder turning mechanism comprises a cutterhead, a shield, a thrust cylinder, a girder, torque cylinders, an articulated ball gland and horizontal support cylinders and the like, wherein the cutterhead, the shield and the girder of the full-face hard-rock tunnel boring machine are connected into a whole through bolts, the girder and a saddle are assembled together through a box structure with a guide slideway, the two ends of the thrust cylinder are respectively articulated on the girder and a bracing shoe, the four corners of the girder and the saddle are respectively provided with a guide slideway, the saddle is connected with the horizontal support cylinders through the torque cylinders on both sides of the saddle, a central pin shaft is arranged in an articulated ball, the two ends of the central pin shaft are fixed on upper and lower plates of the saddle, and a central block is fastened with the two horizontal support cylinders through a bolt. The most striking design characteristic of the invention focuses on the central pin shaft and the articulated ball; and the spherical support girder turning mechanism disclosed by the invention is easy to operate, safe and reliable, good in vibration-resistant effect and uneasy to damage.

Owner:NORTHERN HEAVY IND GRP CO LTD

Roadheader, system and method

ActiveCN109356608AAchieve positioningSolve the fast-moving puzzleMining devicesTesting machinesAutomatic controlRemote control

The invention provides a roadheader, a system and a method. According to the roadheader, the system and the method, three-dimensional space coordinates of the roadheader can be tracked and measured inreal time to realize the millimeter levelpositioning accuracy of the set distance within the visual range, remote control operation and automatic control over the roadheader are facilitated, and themovement path and the speed of a cutting head as well as the direction, position and posture of a roadheader body can be automatically adjusted according to the position change of the roadheader and the rock wall hardness change of a heading working face roadway.

Owner:山东新矿信息技术有限公司

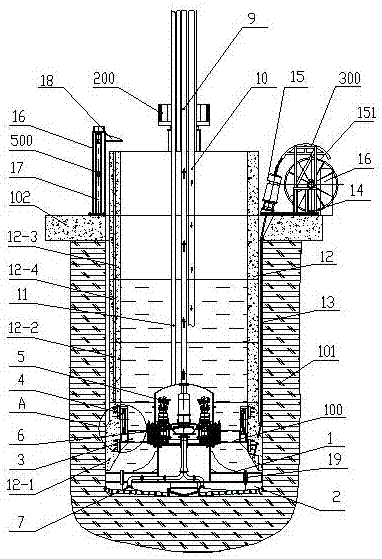

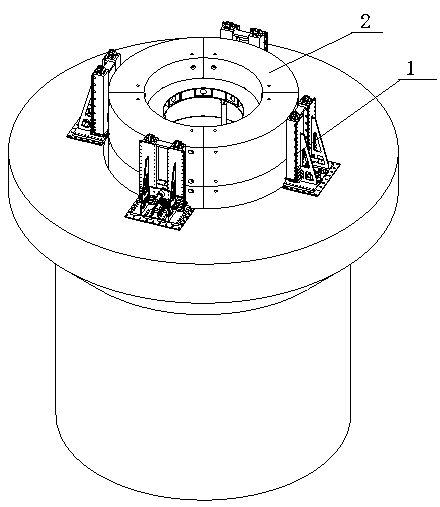

Vertical shaft tunnel boring machine by shaft sinking method and construction method of tunnel boring machine

ActiveCN107461197AChange the method of excavationReduce construction riskHydro energy generationShaft sinkingSludgeArchitectural engineering

The invention provides a vertical shaft tunnel boring machine by a shaft sinking method and a construction method of the tunnel boring machine, and solves the problems of low mechanization degree and efficiency, high risk and the like of devices and construction methods in the prior art. The tunnel boring machine comprises a tunneling mechanism, a pipe arrangement mechanism, a shaft lifting mechanism, a slurry separation system and an auxiliary pressure mechanism are mutually connected, the pipe arrangement mechanism, the shaft lifting mechanism, the slurry separation system and the auxiliary pressure mechanism are positioned on an over-ground wellhead ring beam, the tunneling mechanism comprises a tunneling shell, a cutter head is arranged at the front end of the tunneling shell, a driving fixing frame is arranged at the rear end of the tunneling shell, a feeding device and a driving device are arranged on the driving fixing frame, and the feeding device and the cutter head are connected with the driving device. The tunnel boring machine has mechanized excavation, sludge discharge and support functions and is operated on the ground, safe and reliable, underground operators are omitted in the working process of the vertical shaft tunnel boring machine, traditional shaft bottom excavation modes are changed, construction risks are greatly reduced, and operating efficiency is improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

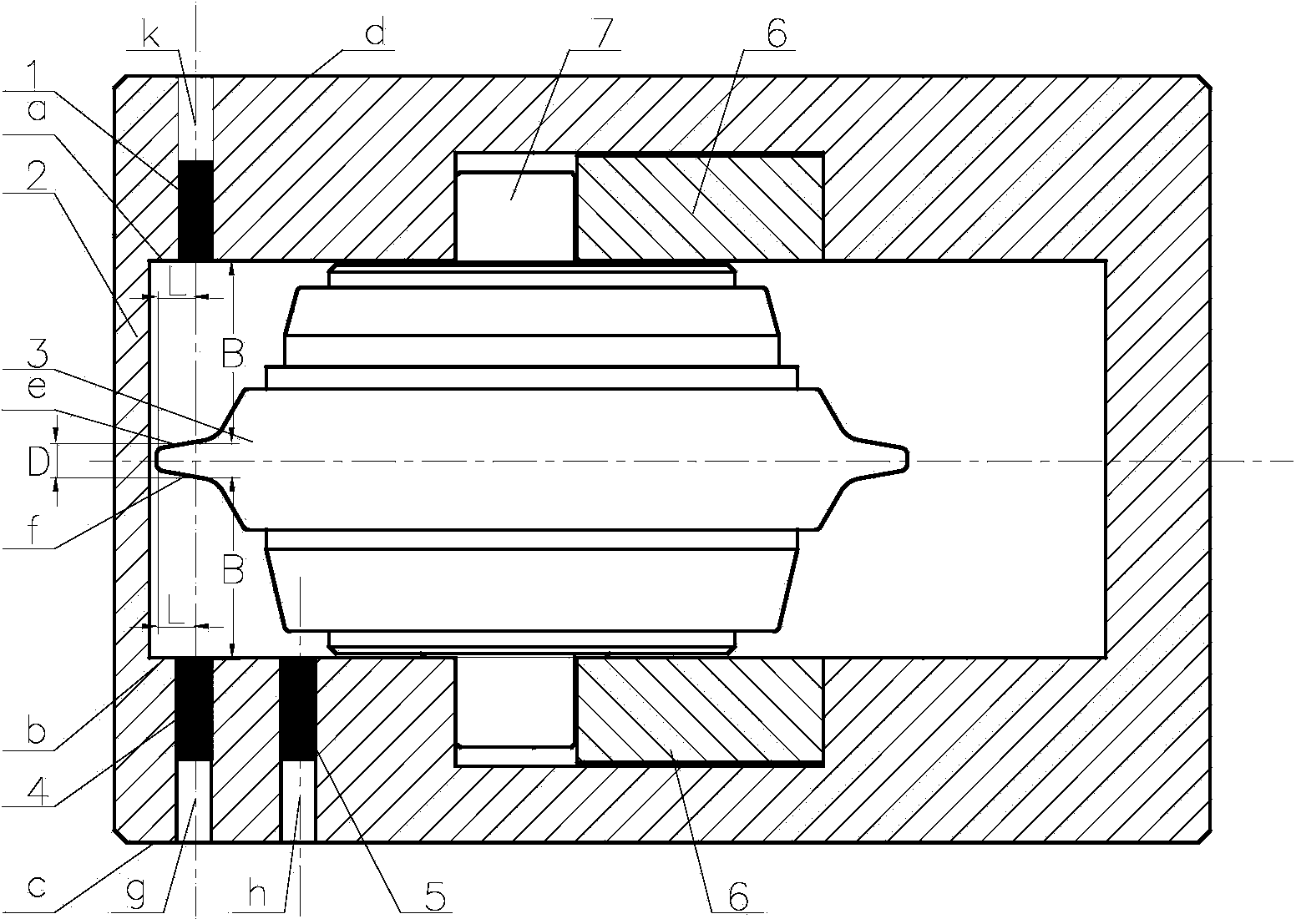

On-line hob cutter abrasion detection method for boring machine

InactiveCN103969139AExtend working lifeImprove work efficiencyInvestigating abrasion/wear resistanceAgricultural engineeringEngineering

The invention discloses an on-line hob cutter abrasion detection method for a boring machine, belongs to the field of tunnel construction machine, and relates to the on-line hob cutter abrasion detection method for the boring machine, which adopts various sensor devices. The detection method can determine and detect normal hob cutter abrasion and various abnormal abrasion states; according to a detection device adopted by the detection method, an upper displacement sensor device is bonded to or screwed with an upper left groove in a tool apron; a lower displacement sensor device is bonded to or screwed with a lower left groove in the tool apron; a speed sensor device is bonded to or screwed with a lower right groove in the tool apron. The on-line hob cutter abrasion detection method, provided by the invention, can detect so as to timely discover abrasion failure and reaching limit abrasion during the using process of the hob cutter, so as to timely replace the hob cutter and increase the excavation efficiency; therefore, the on-line hob cutter abrasion detection method has important significance to prolong the service life of tunnel excavation equipment.

Owner:DALIAN UNIV OF TECH

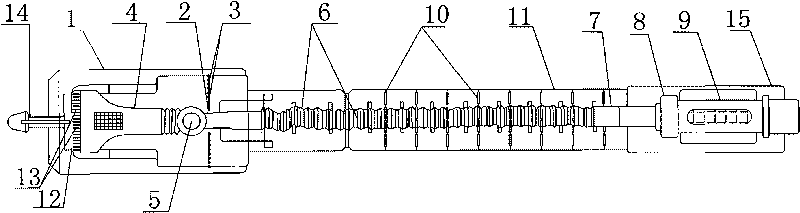

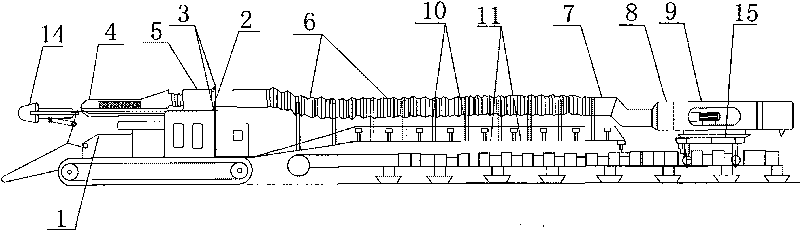

Tunneling, anchoring and drilling composite machine

InactiveCN101086205ARealize an integrated structureImprove reliabilityConstructionsRotary drillingEngineeringRock bolt

The invention involves a composite machine which integrals the boring machine, the bolting machine and the drilling machine into one unit, specifically it is a boring surveying operation which uses the boring machine cutting part armor plate as the working platform of drilling machine, uses the cutting head as the main support of drilling machine, achieves the integration of drilling machine and the boring machine cutting part and completes the boring surveying work of tunnel deep hole through the lifting , swinging of cutting part and the self-functions; at the same time, it also uses that the boring machine panoramic table side wall can be installed folded bolting machine device to achieve the tunnel-dislodging anchor bar anchor-installing operation of automatic hydraulic control anchor bar machine. The installation of 'three machines' into one unit: the drilling machine is installed on the boring machine through rail connection; the bolting machine is positioned and installed on the side wall of boring machine panoramic table through straight pins and high strength bolt connection, the bolting machine and the drilling machine both use the lifting and the swinging functions of boring machine cutting part fully, greatly simplify the design structure of boring machine bolting machine, reduces the space size of boring, bolting and drilling composite machine on the maximum extent.

Owner:SANY HEAVY EQUIP

Novel quick digging and anchoring integrated machine for rectangular coal roadway

ActiveCN102606152AAvoid destructionImprove efficiencySlitting machinesAnchoring boltsSupporting systemHydraulic cylinder

The invention discloses a novel quick digging and anchoring integrated machine for a rectangular coal roadway, which comprises a heading machine, a temporary support system, an anchoring system, a conveying system and a dust removing system, and also comprises a support system, wherein a sealing device is arranged between the head of the heading machine and the front of the support system; the sealing device comprises a main body plate, a movable sealing plate and left and right movable sealing plates; support hydraulic cylinders are arranged on the main body plate and an upper movable sealing plate bracket; support hydraulic cylinders are arranged on the main body plate and left and right movable sealing plate brackets as well; meanwhile, an upper movable sealing plate, the left and right movable sealing plates are provided with flexible sealing belts; the front end of a dust removing pipeline of the dust removing system is installed on the main body plate of the sealing device; and the dust removing pipeline is communicated with the space in the front part of the sealing device. The novel quick digging and anchoring integrated machine for the rectangular coal roadway, provided by the invention, employs a novel telescopic cylinder to cut and mold the width of a roadway in one step, therefore, the high efficiency is achieved, and in addition, the damage to a base plate due to repeated displacement is avoided; through cooperation of adjusting oil cylinders with flexible sealing, a top plate and lateral walls are very adaptive, so that dust is prevented from rushing into a rear working space; and meanwhile, a working environment is improved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

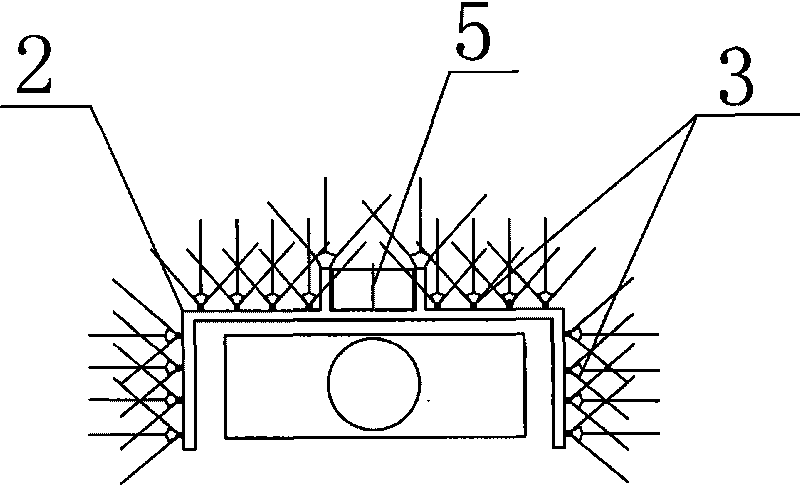

Air curtain sealing dedusting system on fully-mechanized excavating face

InactiveCN101761337AReduce spreadReduce dust concentrationDust removalFire preventionEngineeringOperation safety

The invention discloses an air curtain sealing dedusting system on a fully-mechanized excavating face, comprising a fully-mechanized roadheader body. The fully-mechanized roadheader body is provided with an air curtain generating device; the air curtain generating device is positioned between an excavating head and a driver of the fully-mechanized roadheader body and can spray air flows to the left side and the right side of the fully-mechanized roadheader body in an upright upward direction so as to form a closed air curtain perpendicular to the excavating direction of a fully-mechanized roadheader; a closed space used for accommodating dust generated when the fully-mechanized roadheader body excavates is formed by the closed air curtain and the excavating face of the fully-mechanized roadheader body; and the fully-mechanized roadheader body is also provided with a dedusting device used for absorbing the dust inside the closed space. By arranging the ari curtain generating device on and the dedusting device on the fully-mechanized roadheader to effectively seal the dust in a space with unattended operation, the invention enhances the dust absorption efficiency of the dust positioned on the excavating head, reduces the influence on a visual line of an operator and enhances the operation safety because the operator can clearly view evacavating.

Owner:SHANDONG UNIV OF SCI & TECH

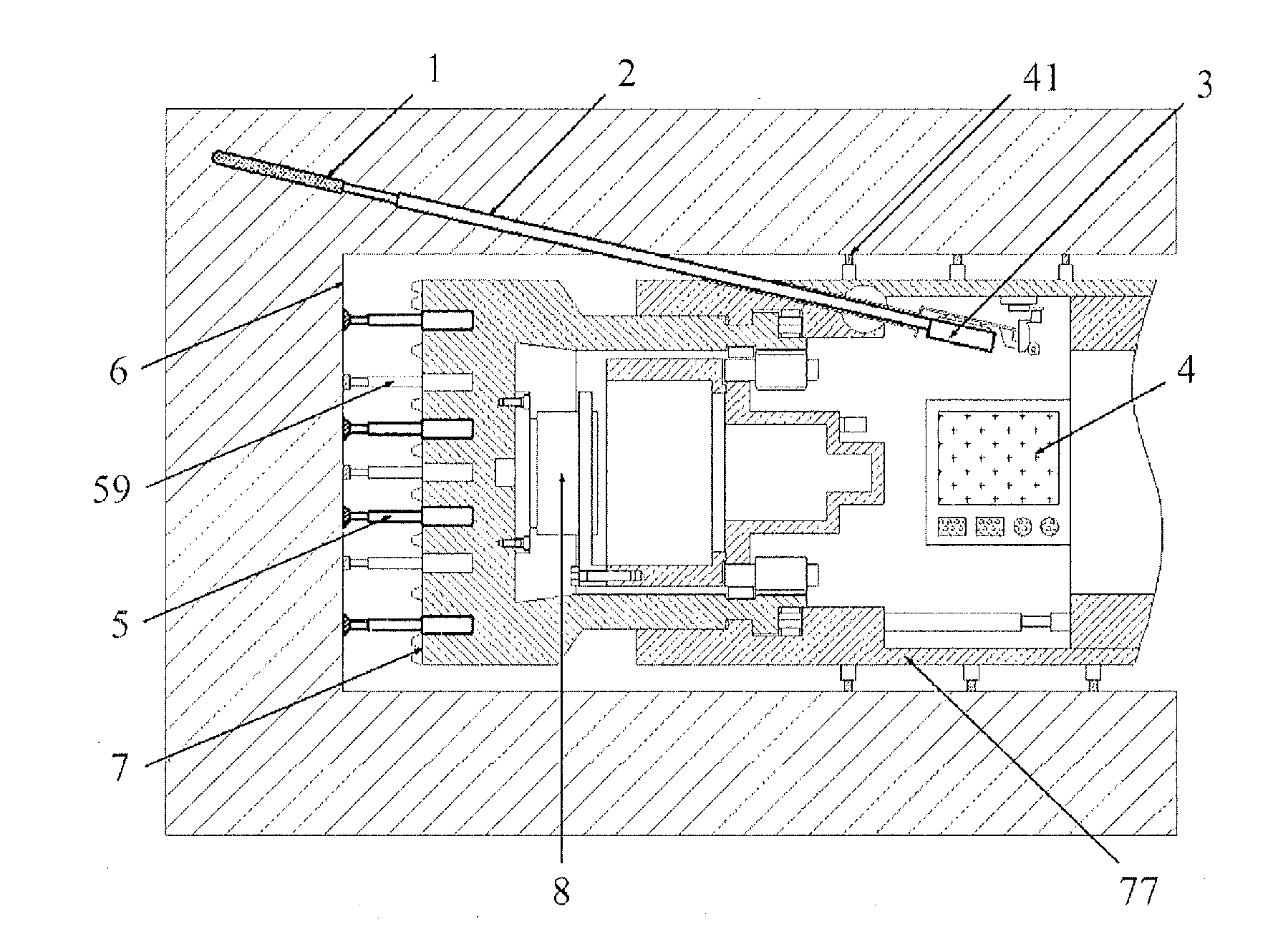

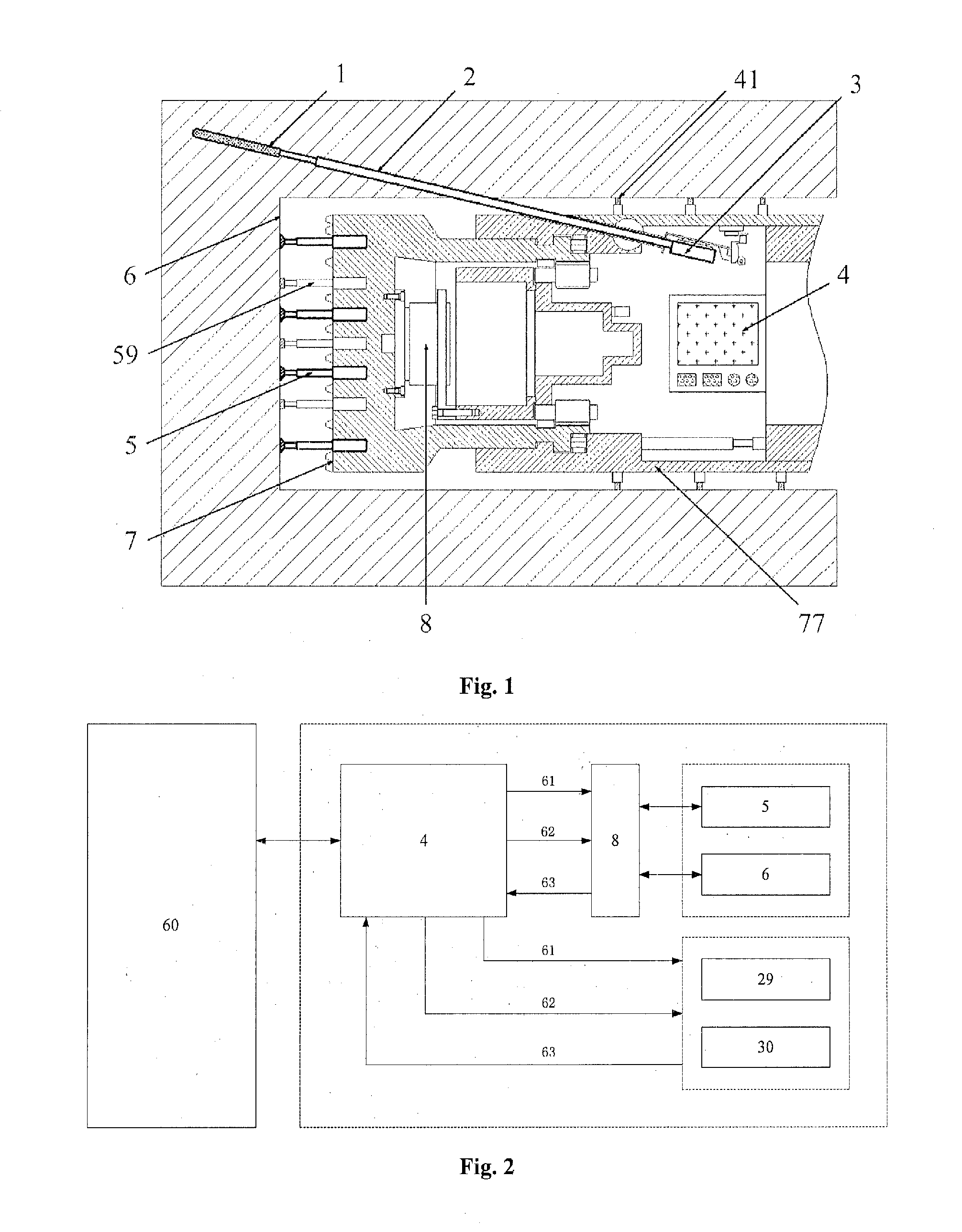

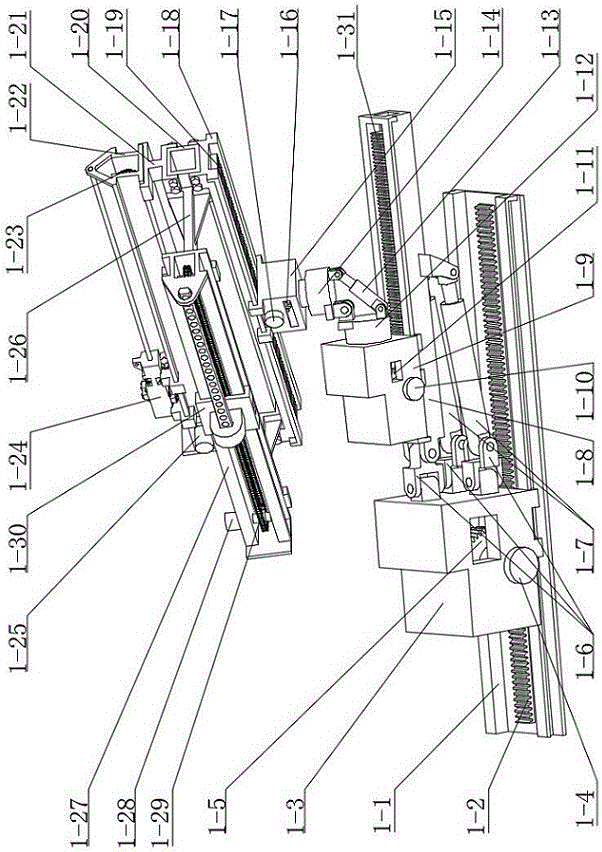

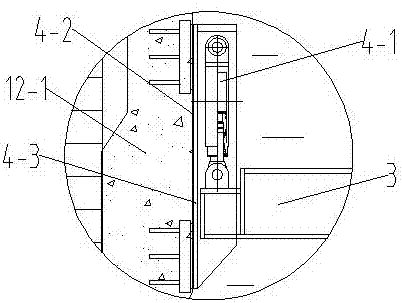

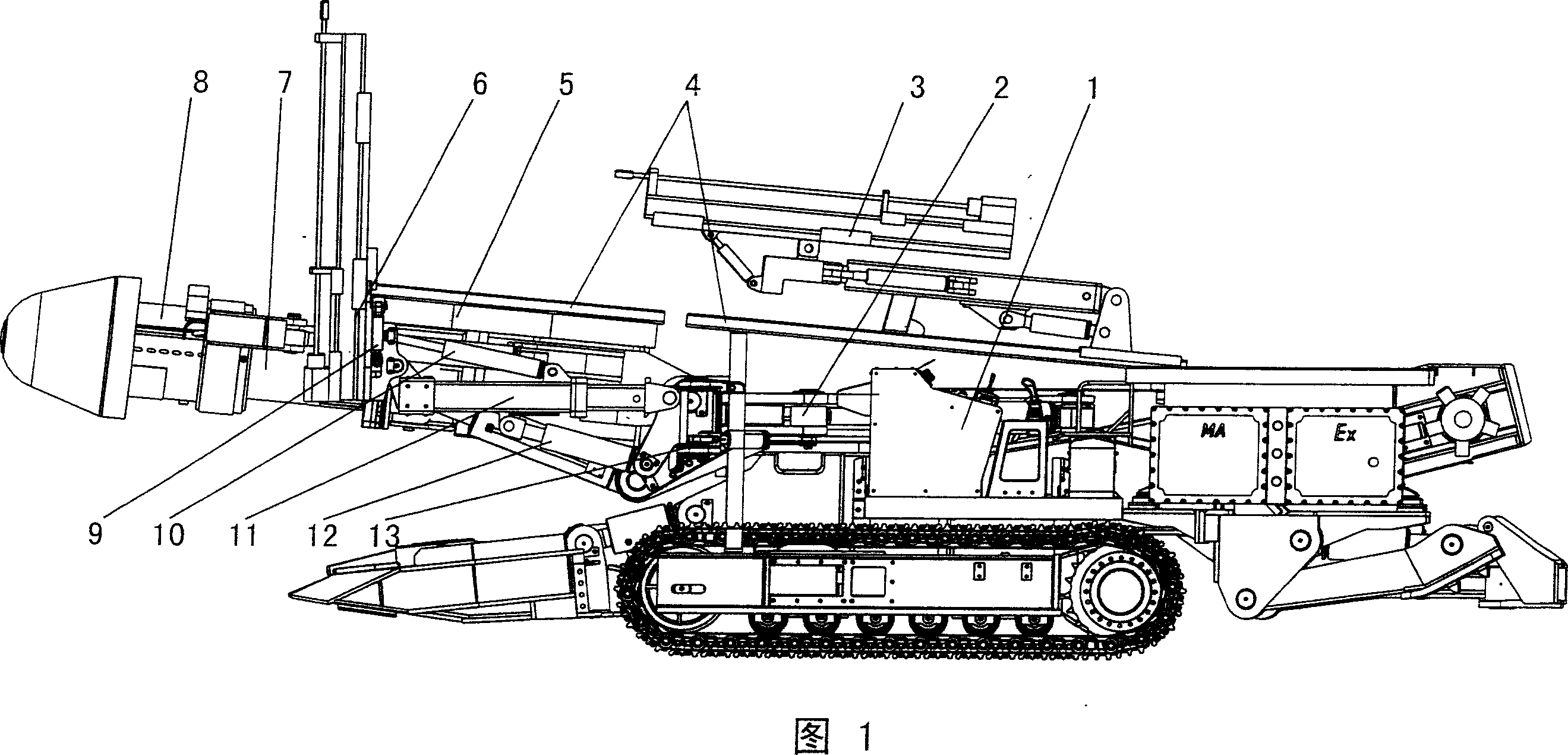

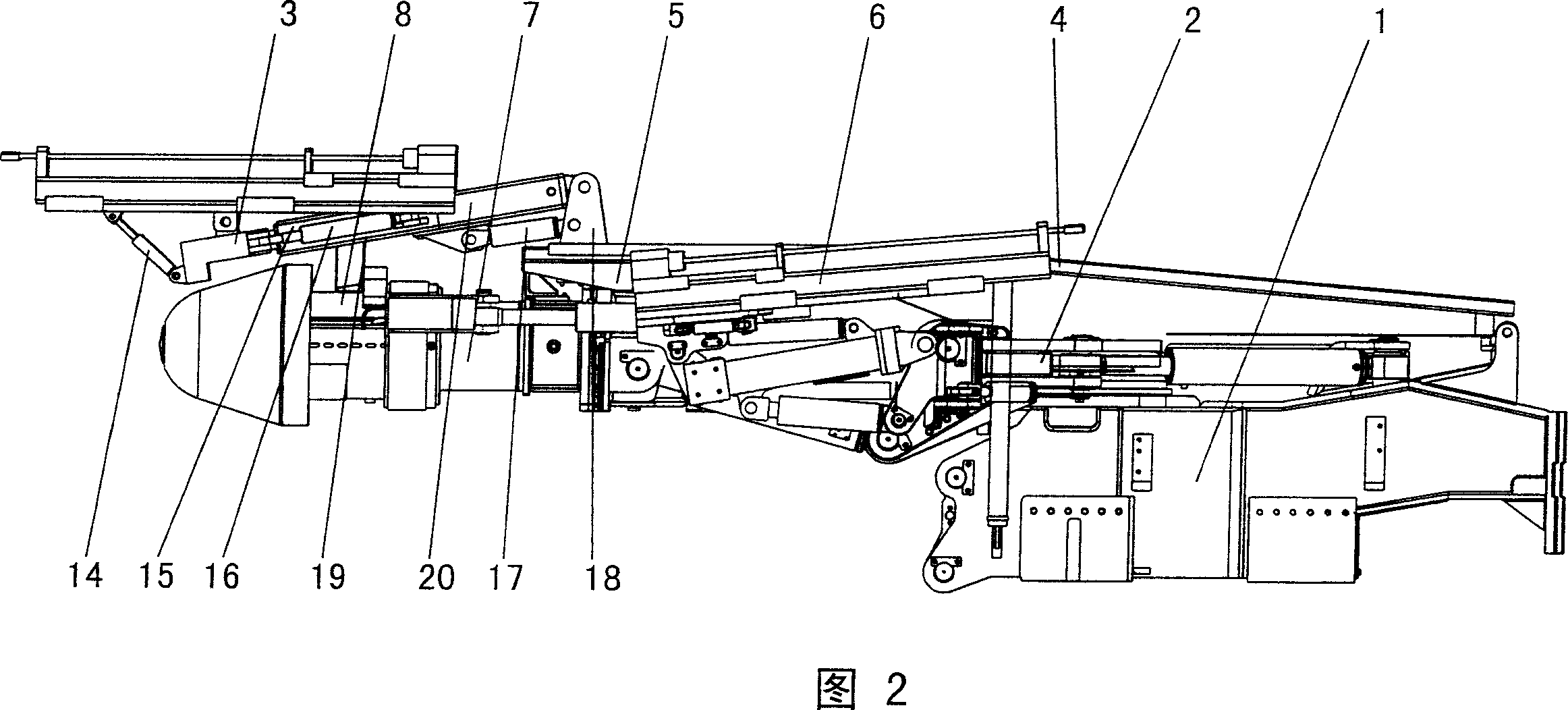

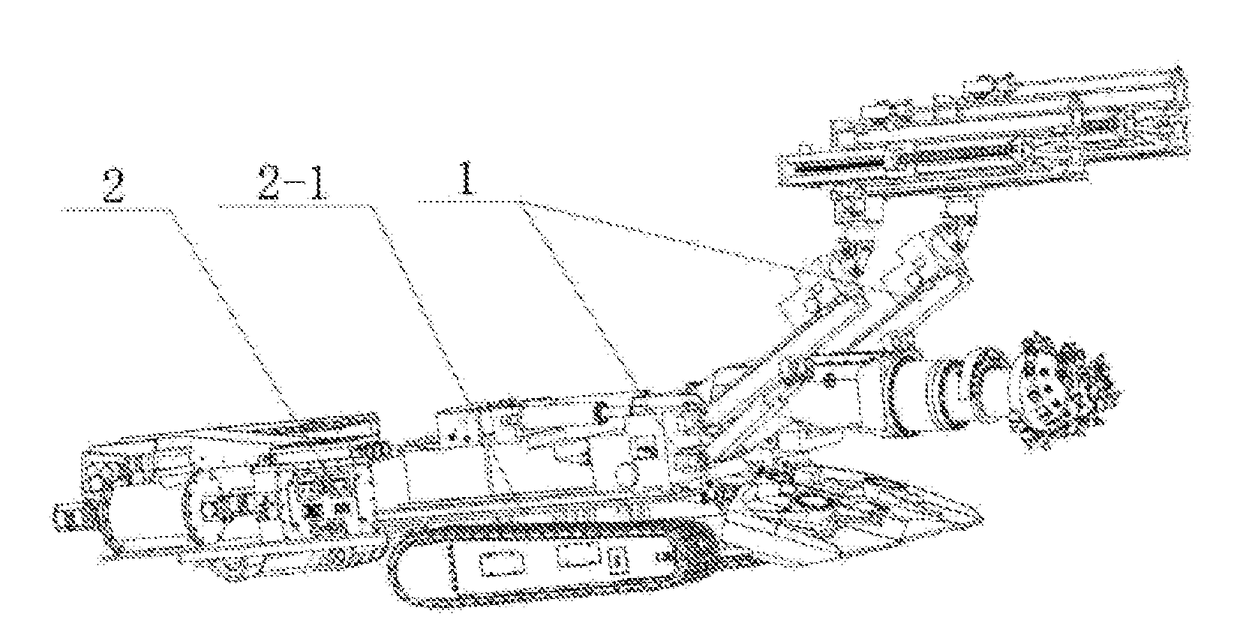

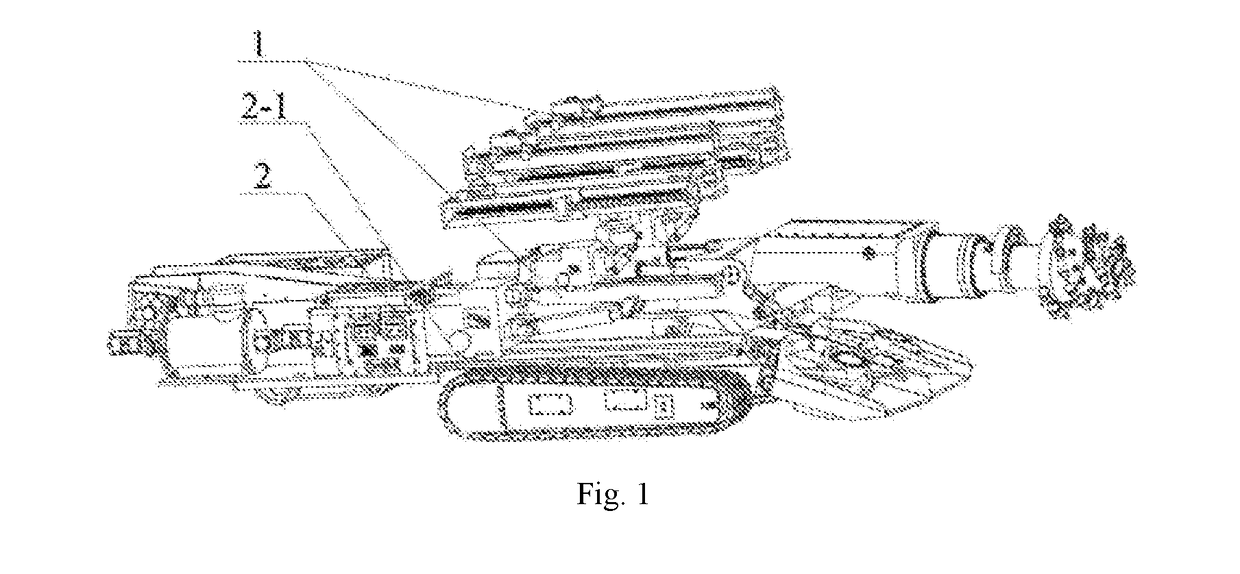

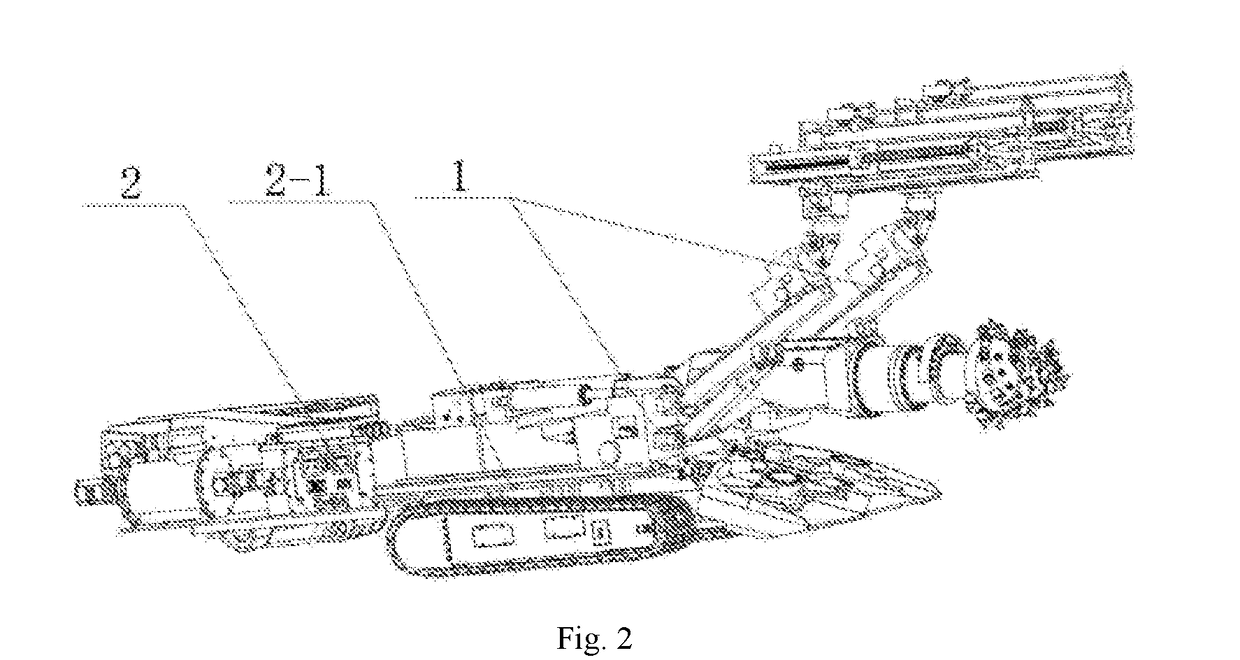

Drilling and Bursting Heading Machine

InactiveUS20180195388A1Compact structureImprove energy consumptionDisloding machinesSlitting machinesHydraulic cylinderHydraulic motor

A drilling and bursting heading machine, comprising a drilling and bursting device (1), an angle control device, a forward-backward telescopic device and a cantilever type heading machine (2), wherein the drilling and bursting device (1) is mounted on a forward-backward moving component of the forward-backward telescopic device by means of the angle control device, and the forward-backward telescopic device is mounted on the cantilever type heading machine (2); the drilling and bursting device (1) comprises a fixing support (1-20), as well as a rock drill component and a bursting component fixedly mounted on the fixing support (1-20) respectively; the angle control device comprises a mounting base (1-15), an auxiliary rotary hydraulic motor (1-14), an adjustment hydraulic cylinder (1-13) and a main rotary hydraulic motor (1-12); and when the forward-backward moving component of the forward-backward telescopic device completely extends out, the distance from a front end of the drilling and bursting device (1) to a working plane is shorter than the distance from a front end of a cutting head of the cantilever type heading machine (2) to the working plane. The drilling and bursting heading machine has a compact structure and is able to implement quick drilling and bursting on a hard rock stratum having a rock hardness f greater than 10 without increasing the energy consumption, so that the heading efficiency is improved and potential safety risks are reduced.

Owner:CHINA UNIV OF MINING & TECH

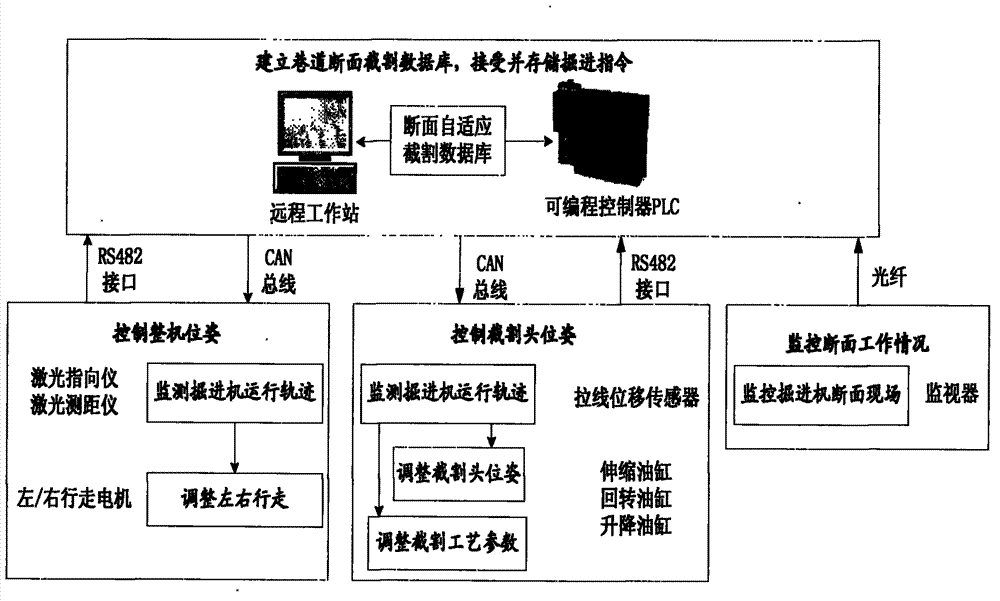

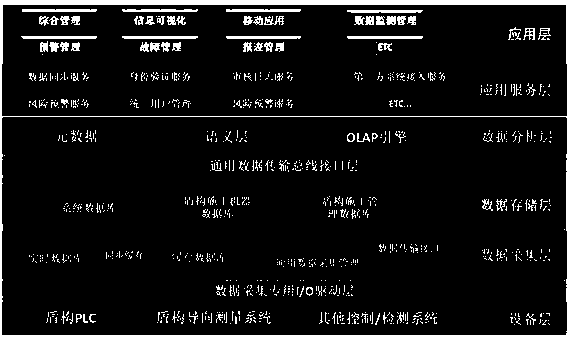

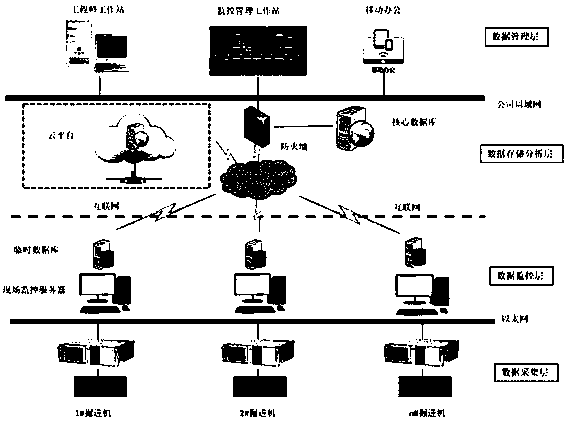

Tunnel self-adaptation cutting system and self-adaptation remote control method for roadheader

ActiveCN102854838AImprove tunneling efficiencyStrong reliabilityNumerical controlRemote controlMonitoring system

The invention relates to a tunnel self-adaptation cutting system and a self-adaptation remote control method for a roadheader and belongs to the technical field of coal mining equipment application. The method includes building a tunnel cross section self-adaptation cutting database, using a software application system to monitor moving trajectory of the roadheader, and storing poses and operating data of a cutter and the whole roadheader; using a remote monitoring system to display work condition of a tunneling cross section in real time, and combining with a PLC (programmable logic unit) of the field roadheader to finish remoter wired control of tunnel self-adaptation cutting operations. The poses of the cutter and the whole roadheader can be displayed in real time, adjusting of poses of the whole roadheader and cross section circulating cutting are finished automatically, tunneling efficiency is high, and reliability is high. By remoter control of cross section cutting by the roadheader, an operator is far away from a dangerous sectional operation environment, working environments for the operator is improved, injury accidents of the operator is reduced, and safety is high.

Owner:INNER MONGOLIA NORTH HEAVY INDS GROUP

Shaft boring machine by open caisson method and construction method thereof

PendingCN109630124AImprove securityImprove construction safetyDrilling rodsShaft sinkingSlagMechanization

The invention discloses a shaft boring machine by an open caisson method and a construction method thereof, and solves the problems of low mechanization degree, difficult disassembly and assembly andlow working efficiency of a shaft excavation device in the prior art. The shaft boring machine by the open caisson method comprises a tunneling system, a control detection system and a slag dischargesystem. A pipe joint pressure lifting device is arranged on a wellhead ring beam on the ground. The tunneling system comprises a propulsion device, a rotary support, a rotary platform and an excavation device. The upper part of the propulsion device is connected with a hydraulic power system on the ground, and the lower part of the propulsion device is provided with an equipment platform. The equipment platform is connected with the rotary support, and the rotary support is connected with a driving device arranged on the equipment platform. The upper part of the rotary platform is connected with the rotary support, and the excavation device is arranged at the lower part of the rotary platform. According to the shaft boring machine by the open caisson method, the step-by-step excavation ofthe excavation device is realized through the propulsion device, and the efficient and safe excavation is realized through the tightening and stabilization of the excavation device. The shaft boring machine can be quickly disassembled and assembled in the process of entering and exiting the well, thereby saving the construction period and improving the well-forming efficiency.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

A remote monitoring platform of tunnel boring machine based on big data

ActiveCN109376194AImprove service efficiencyReduce riskDatabase management systemsResourcesData displayData acquisition

The invention provides a remote monitoring platform of tunnel boring machine based on big data, include a data acquisition module, data transmission module, The data acquisition module is connected with the data storage and processing module through the data transmission module, the data storage and processing module is connected with the data analysis module, and the data analysis module is connected with the data display module. The invention can visually supervise the whole life cycle of the shield machine, optimize the design of the tunnel boring machine according to the big data technology, intelligently excavate, predict the risk, early warning the state, intelligent operation and maintenance, health management, quality early warning, cost control and the like, improve the service efficiency of the tunnel boring machine, and effectively reduce various risks in the construction process.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

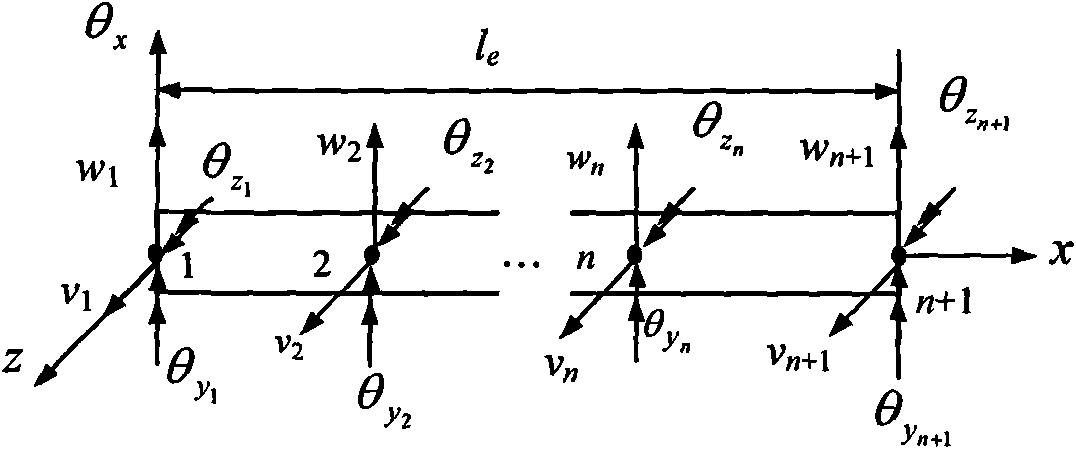

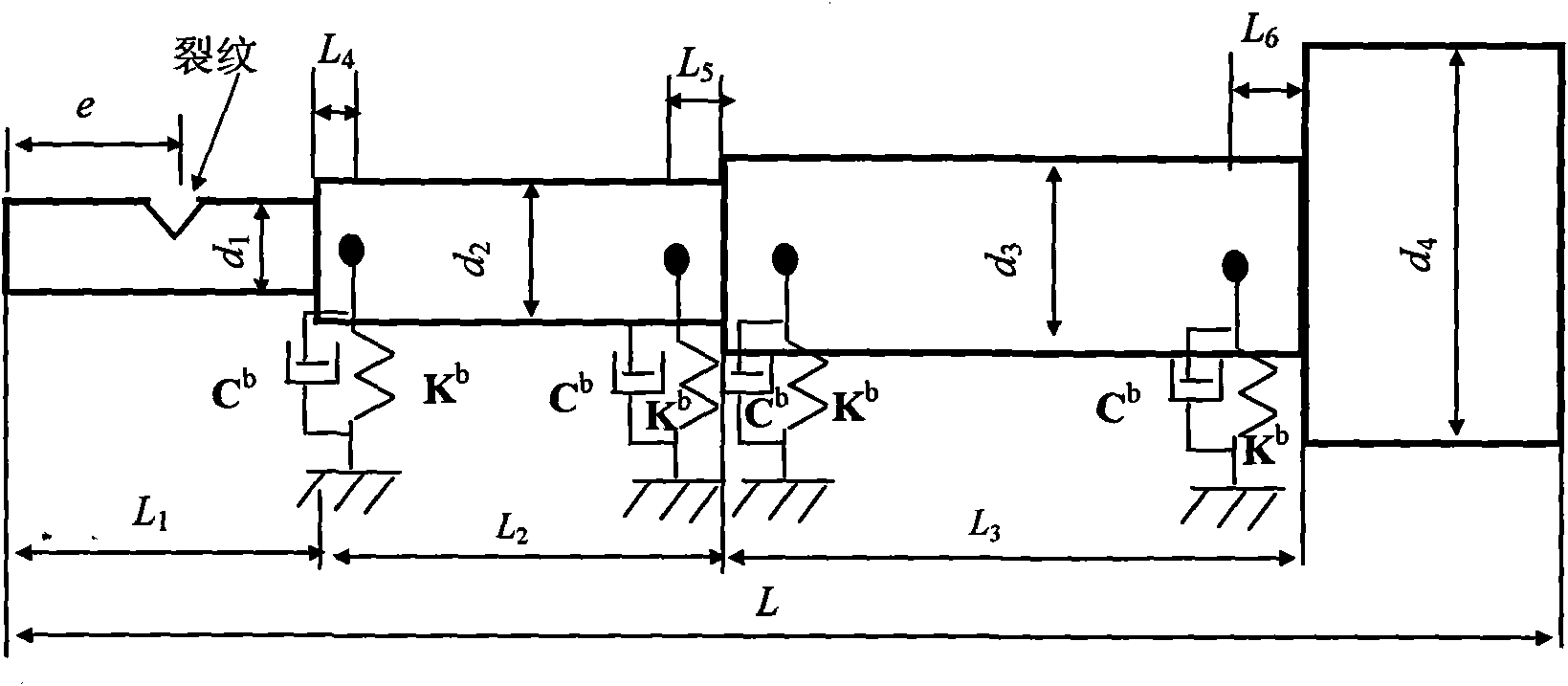

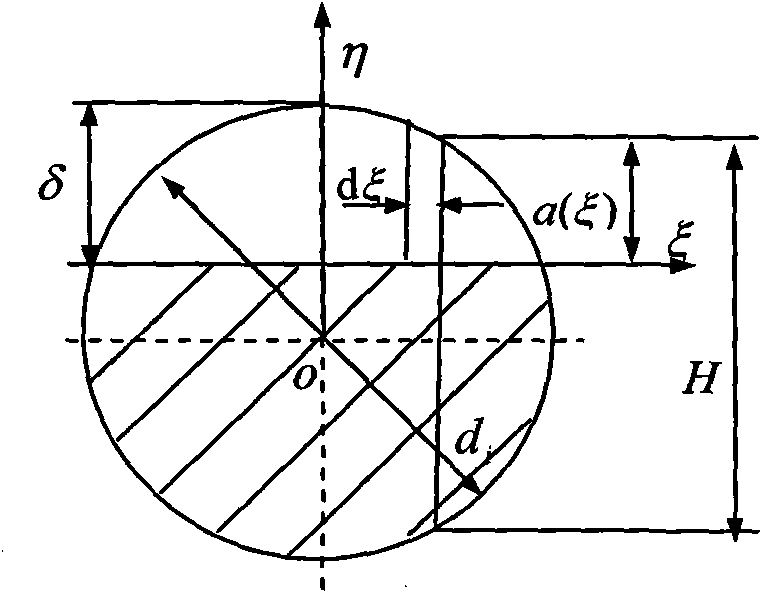

Crack identification method of main shaft of boring machine

InactiveCN101852681AOvercomes the drawback of being only available in a stationary stateSuitable for online monitoring and diagnosisMachine part testingSubsonic/sonic/ultrasonic wave measurementElement modelEngineering

The invention relates to a crack identification method of a main shaft of a boring machine, the method comprises the following steps: the first step: establishing a wavelet finite element model of the main shaft of cracks of the boring machine under the running state; the second step: adopting the wavelet finite element model of the first step to calculate a forward problem solution crack quantitative diagnosis database which takes the first three-order forward whirling frequency as the target, applying the operational mode analysis method to measure the actual forward whirling frequency of the main shaft of the cracks of the boring machine under the running state, utilizing the mixed optimization algorithm of the genetic algorithm and a back propagation neural network to solve, and quantitatively identifying the positions and the severities of the cracks of the main shaft of the boring machine. The method is effective and reliable, is applicable to quantitative diagnosis of the cracks of the main shaft of the running boring machine, can overcome the defect that the common method can only be used for the static state and is suitable for on-line monitoring and diagnosis.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com