Crack identification method of main shaft of boring machine

A roadheader and crack technology, which is applied in the field of mechanical structure fault diagnosis, can solve problems such as high environmental vibration and noise, no application, and poor working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with accompanying drawing, the content of the method embodiment of this roadheader main shaft crack identification is described in further detail:

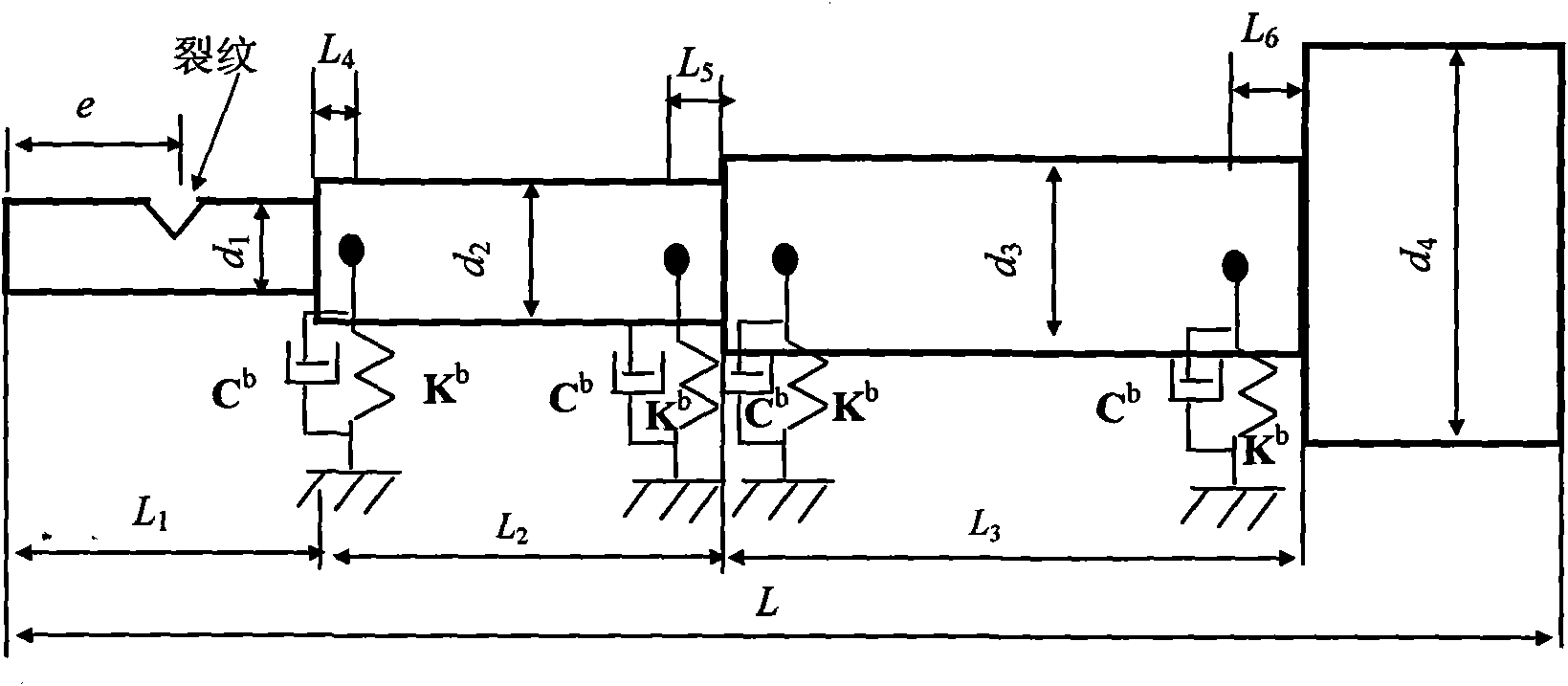

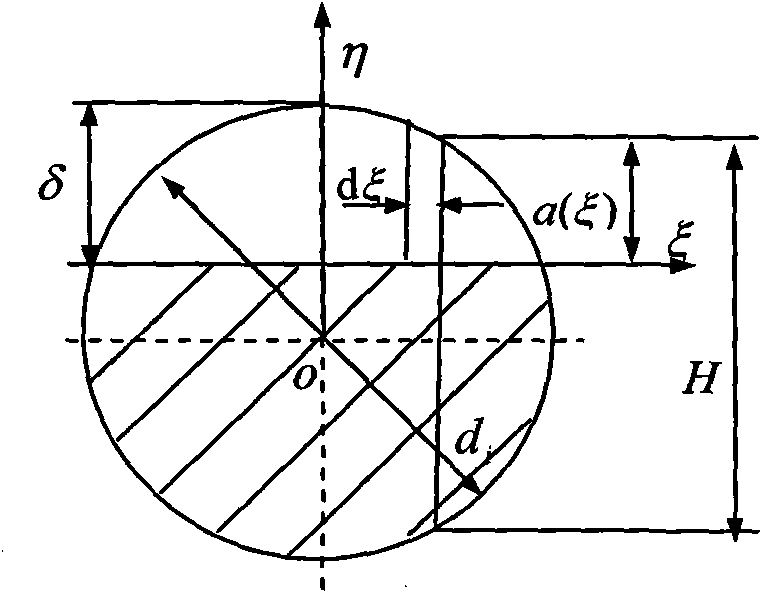

[0047] The first step is to establish the wavelet finite element model of the cracked spindle of the high-precision roadheader under the running state, including the following specific steps:

[0048] I. According to the gyro torque, transverse shear deformation, moment of inertia of the main shaft, material hysteresis and viscous damping, cross stiffness and cross damping of the roadheader main shaft, the wavelet finite element calculation model of the main shaft of the roadheader obtains the first three orders of positive whirl frequency.

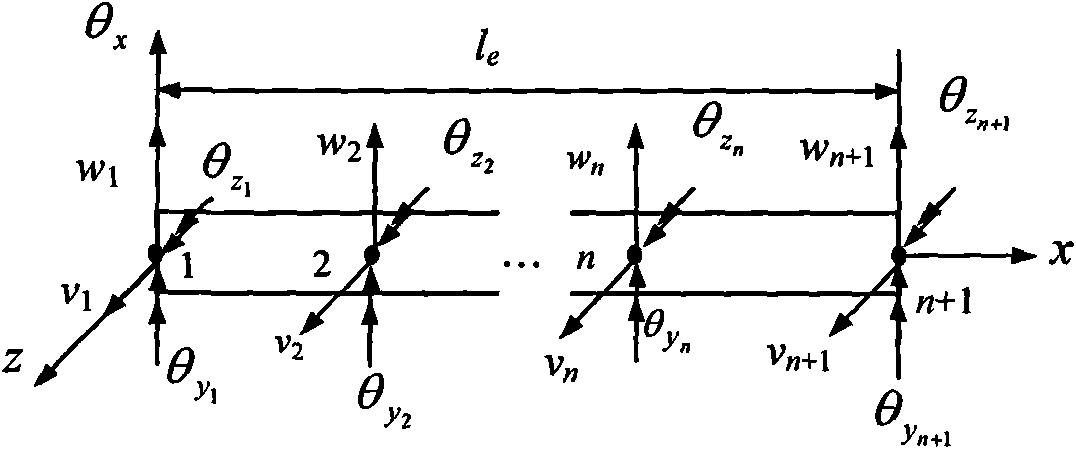

[0049] refer to figure 1 As shown, the interval B-spline wavelet BSWI scaling function whose order is m and scale is j is adopted, which is abbreviated as BSWIm j The scaling function, as the construction unit of the interpolation basis function, can be used as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com