Patents

Literature

744 results about "Fracture process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

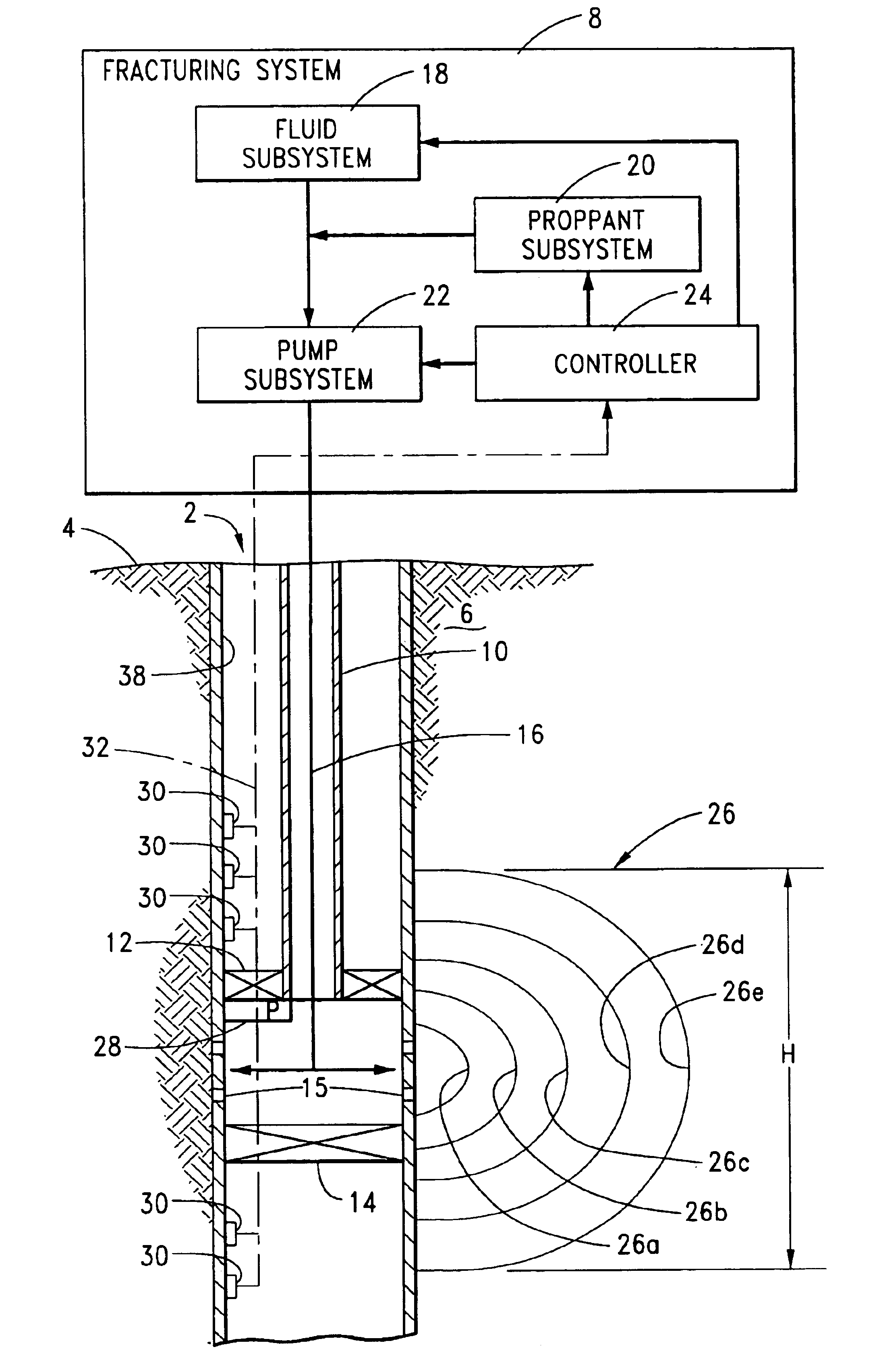

Hydraulic fracturing system and method

ActiveUS9840897B2Multiple-effect/fractional condensationSteam/vapor condensersDistilled waterHydraulic fracturing

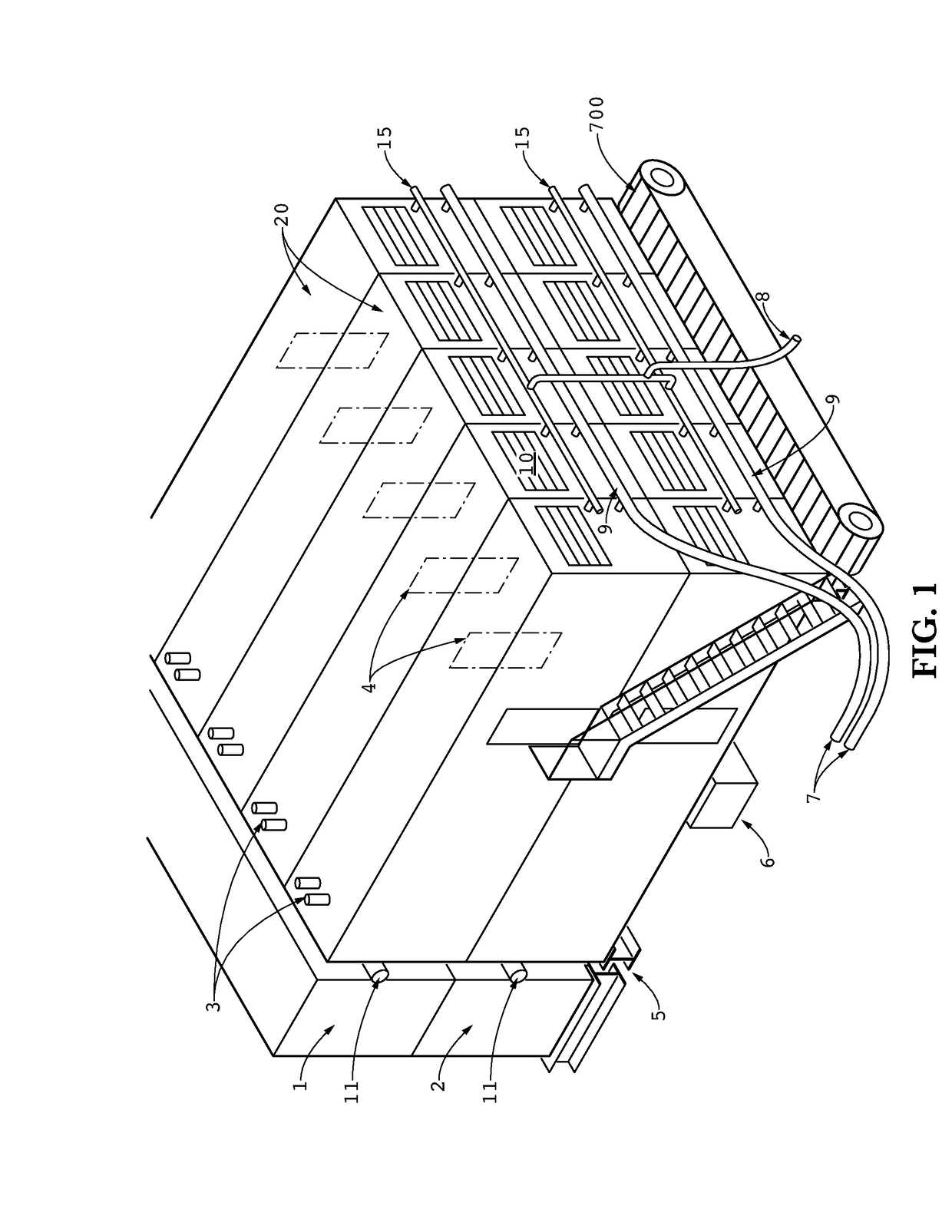

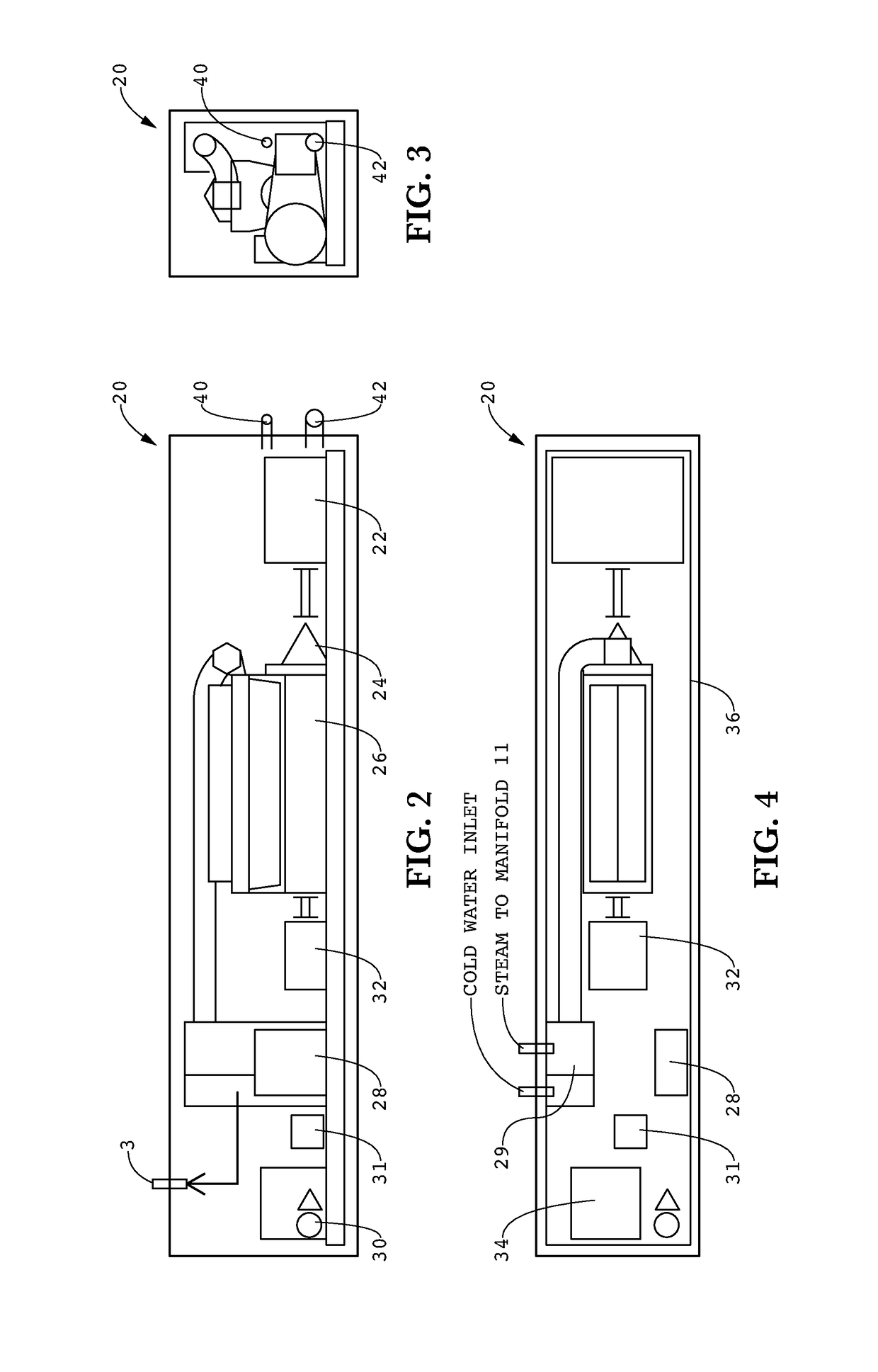

Disclosed herein is a fracturing unit for hydraulic fracturing having an engine and a fracturing pump connected to the engine through a variable speed torque converter. Also disclosed is a hydraulic fracturing system using multiple fracturing units which are sized similar to ISO containers. A hydraulic fracturing system may also force flow back water, produced water, or fresh water through a heat exchanger so that heat from the fracturing engines can be transferred to these liquids in order to vaporize them. A force cooled fractioning unit then can accept the vapor / steam in order to condense the various components and produce distilled water for re-use in the fracturing process or for release into the environment.

Owner:LARSON KEVIN

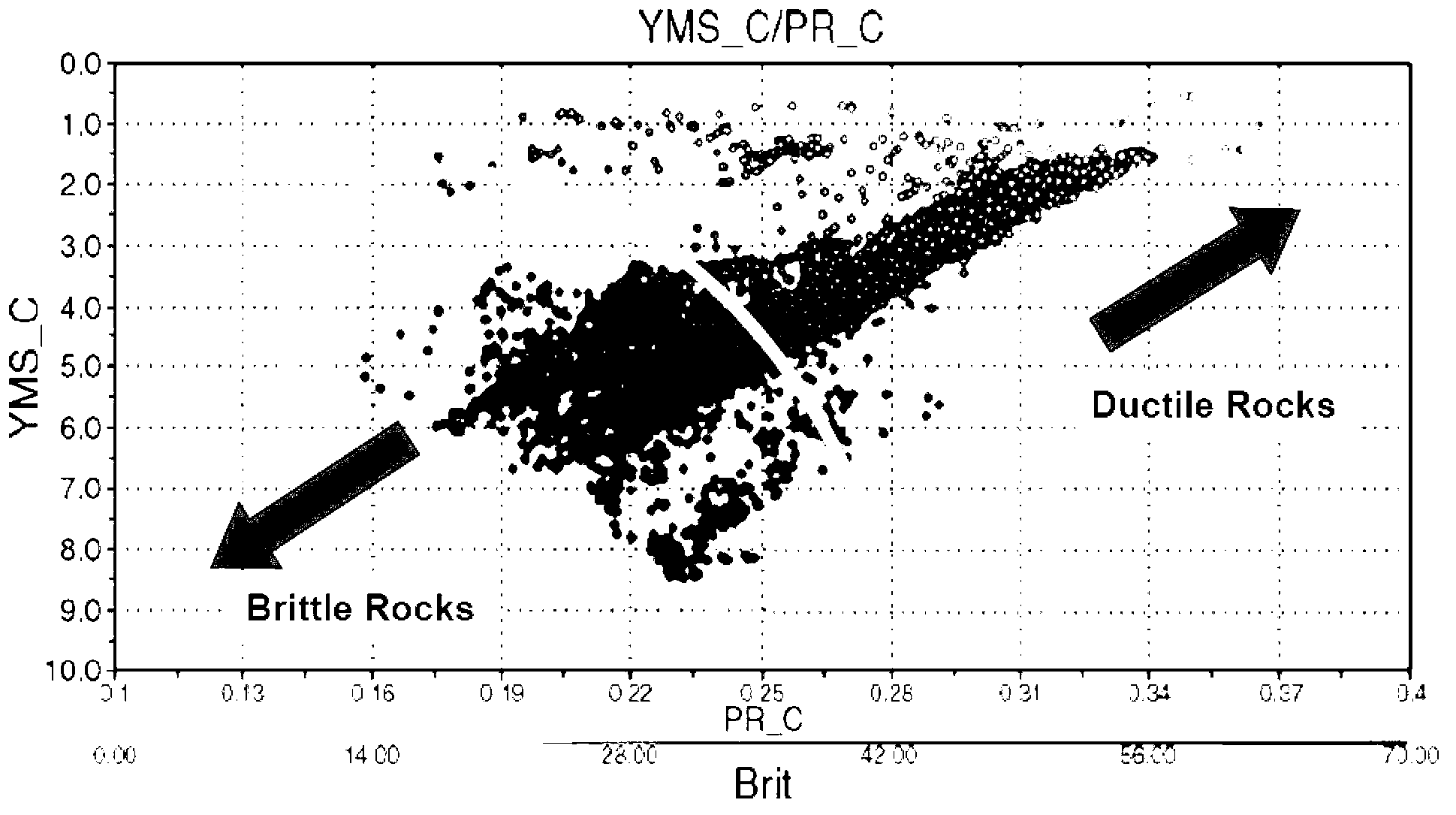

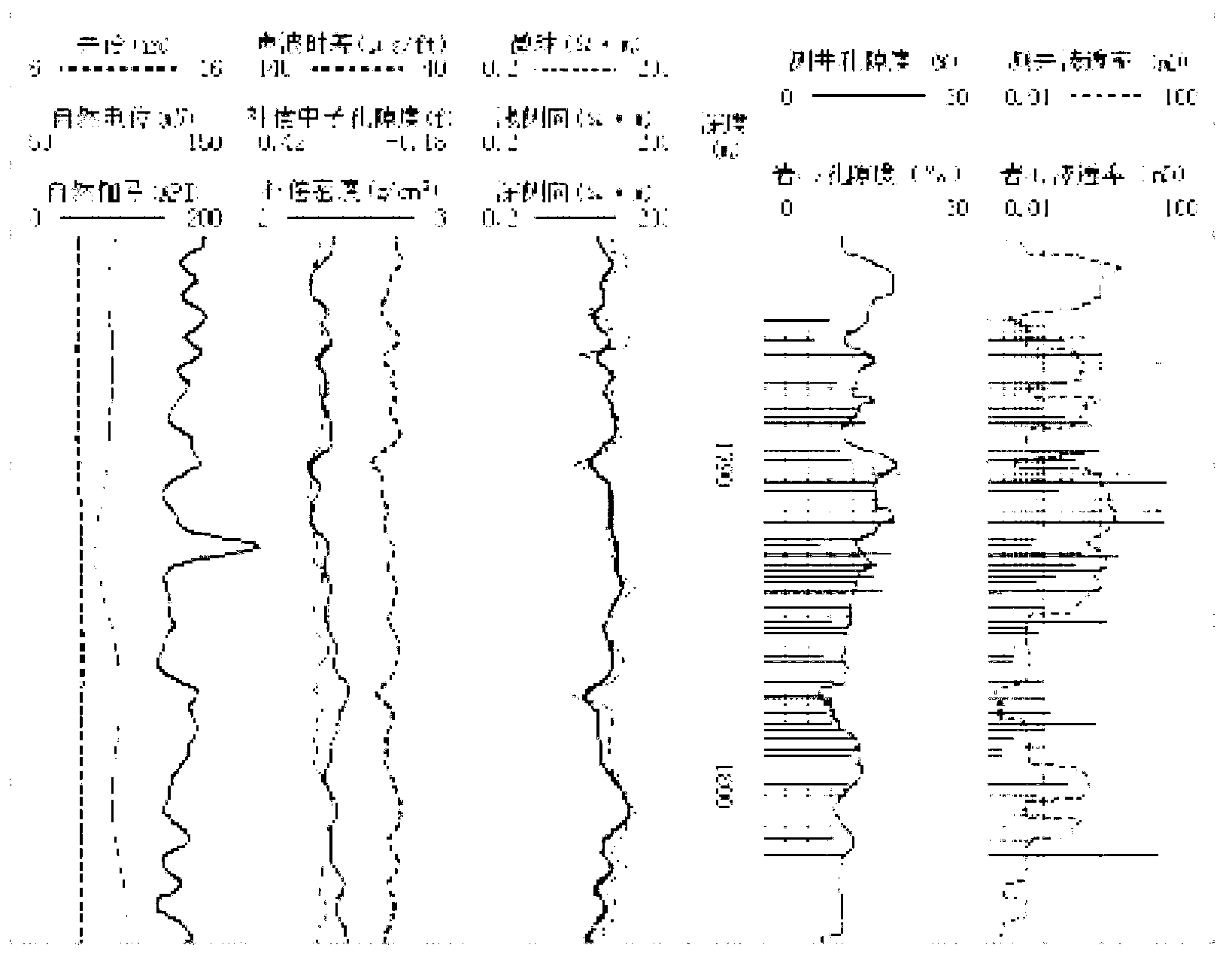

Unconventional oil and gas reservoir horizontal well section full-fracture-length fracturing parameter analog method and device

InactiveCN103256046ASolve the problem that interwell information cannot be obtainedEasy accessBorehole/well accessoriesThree-dimensional spaceYoung's modulus

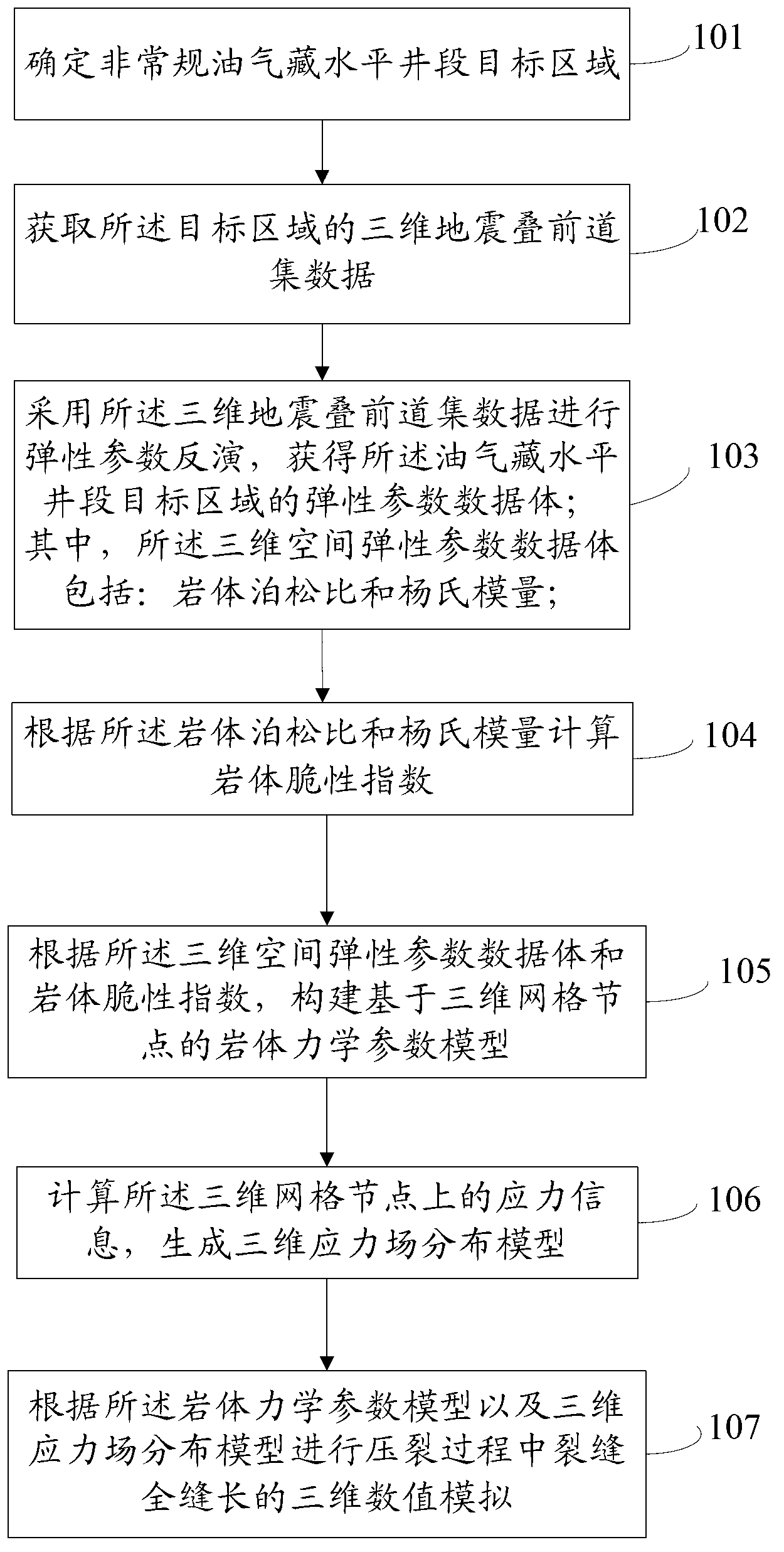

The invention provides an unconventional oil and gas reservoir horizontal well section full-fracture-length fracturing parameter analog method and device. The method includes the steps of determining an unconventional oil and gas reservoir horizontal well section object region; obtaining three-dimensional earthquake prestack gathered data in the object region, conducting elastic parametric inversion and obtaining a three-dimensional space elastic parameter data body, wherein the three-dimensional space elastic parameter data body comprises a rock mass poisson ratio and Young modulus; calculating a rock mass brittleness index according to the rock mass poisson ratio and the Young modulus; establishing a rock mass mechanical parameter model based on three-dimensional grid nodes according to the three-dimensional space elastic parameter data body and the rock mass brittleness index; calculating stress information on the three-dimensional grid nodes, and generating a three-dimensional stress field distribution model; conducting full- fracture-length three-dimensional numerical simulation of fractures in the fracturing process according to the rock mass mechanical parameter model and the three-dimensional stress field distribution model. The unconventional oil and gas reservoir horizontal well section full-length-fracture fracturing parameter analog method and device can improve effectiveness and accuracy of unconventional oil and gas reservoir horizontal well section full-fracture-length fracturing parameter analog, and improve the reserve utilization degree of a reservoir stratum.

Owner:PEKING UNIV

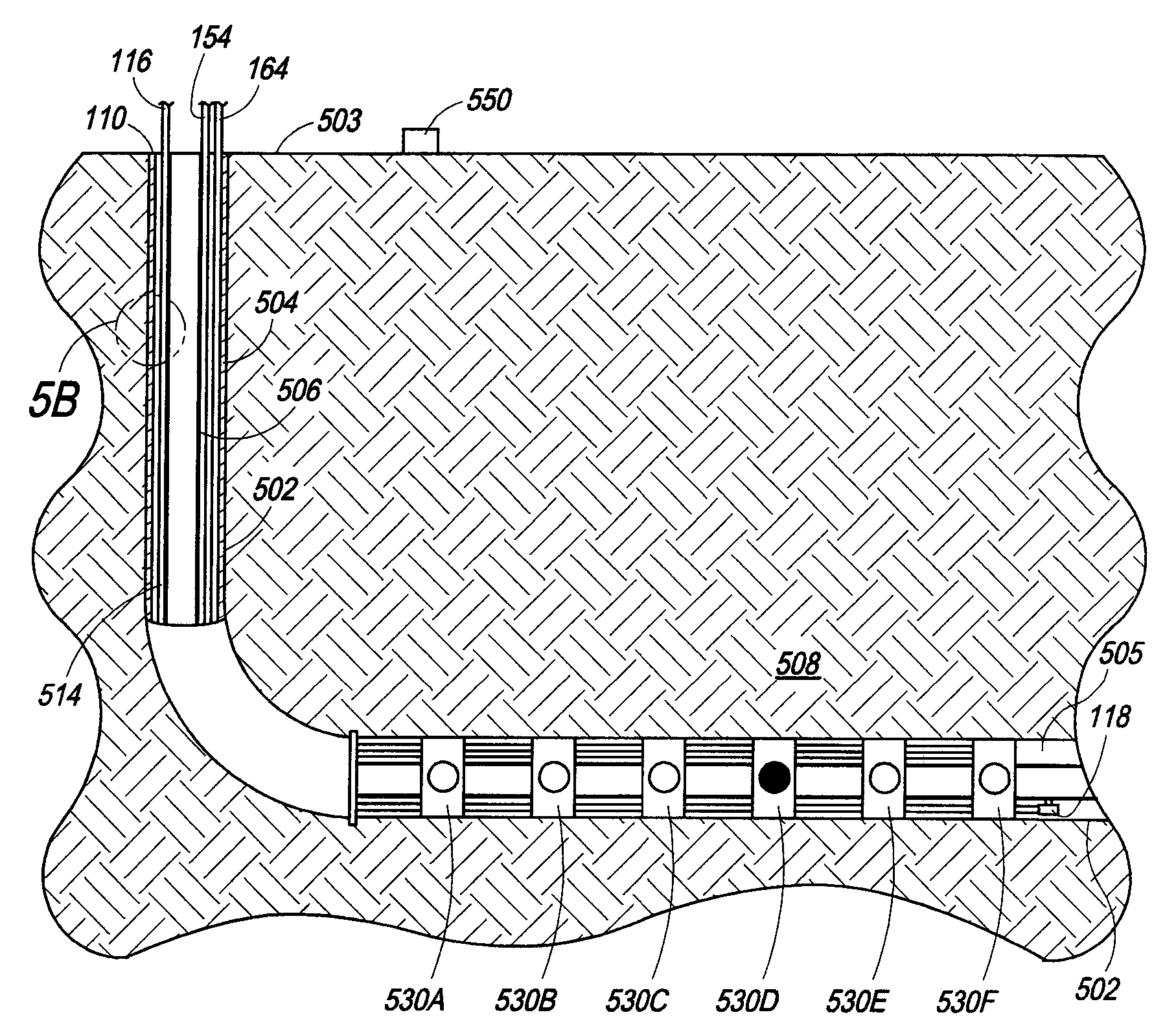

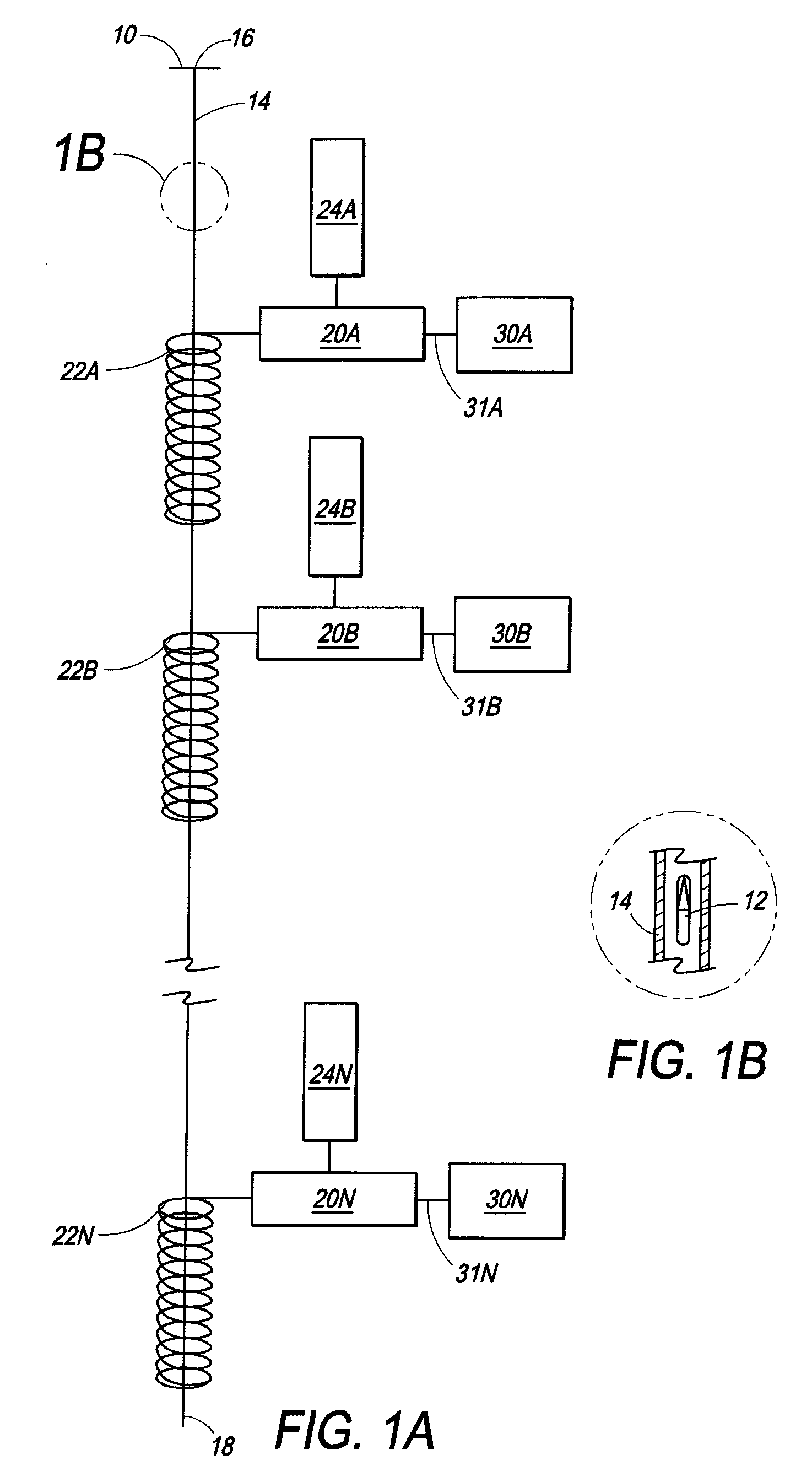

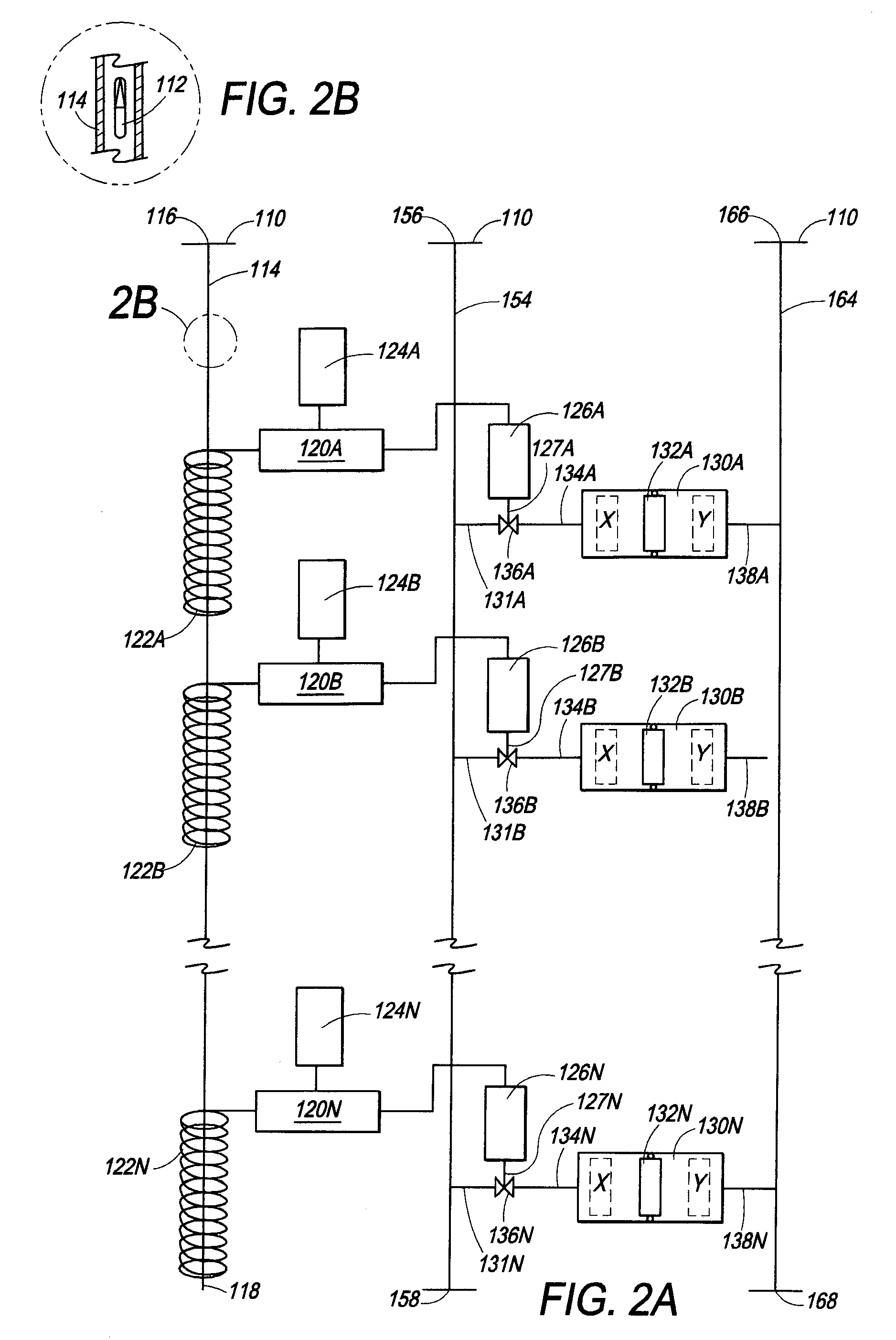

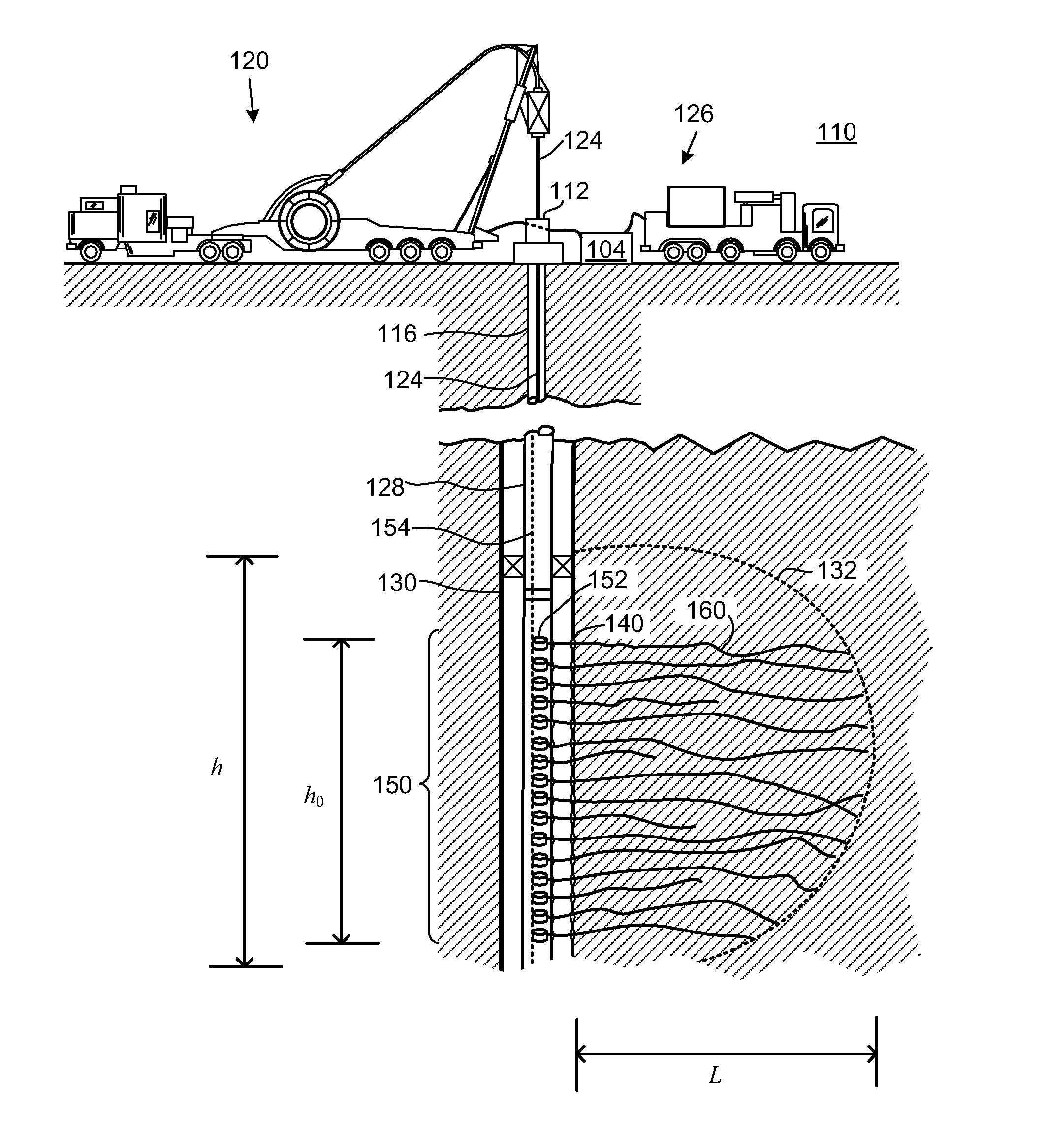

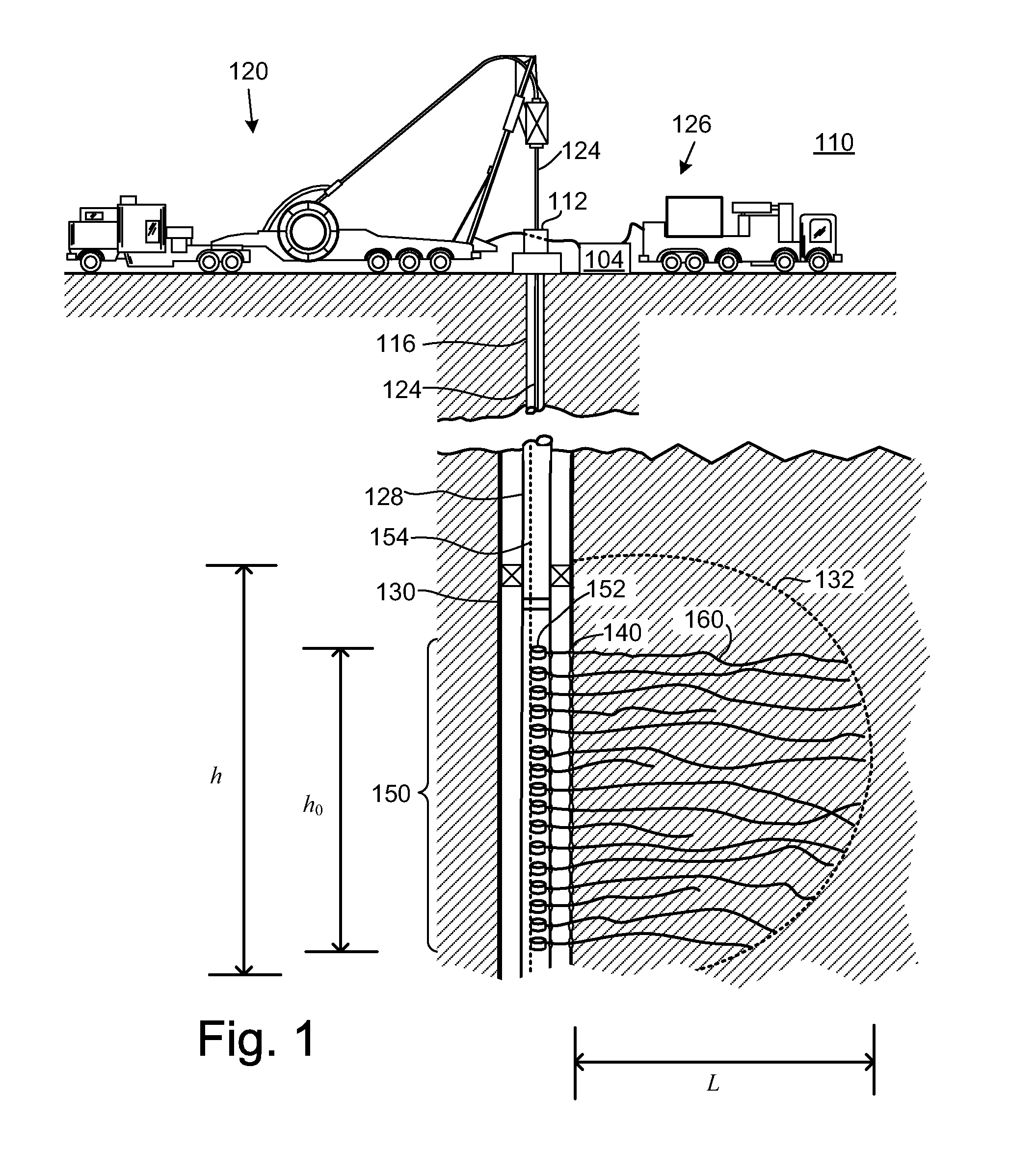

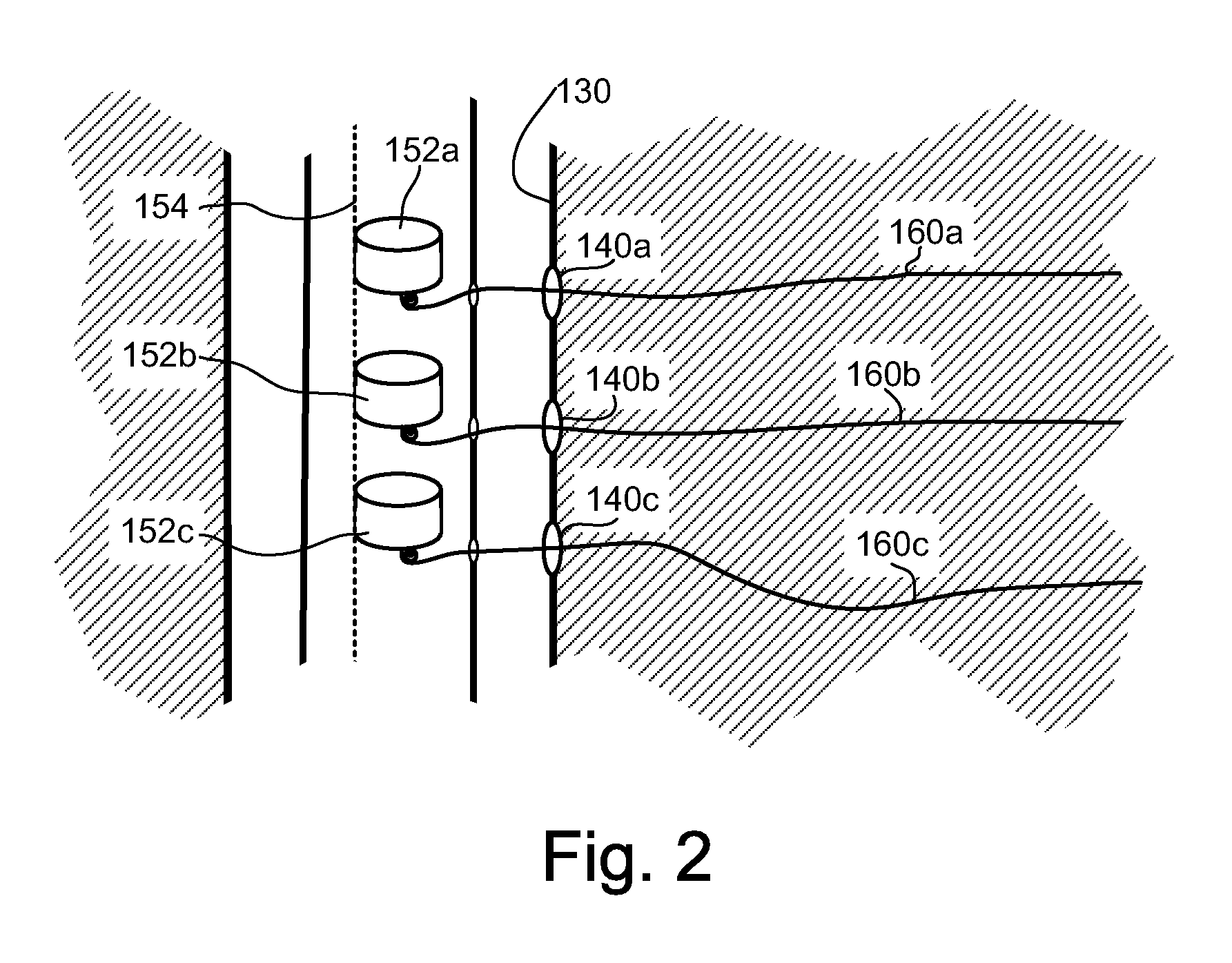

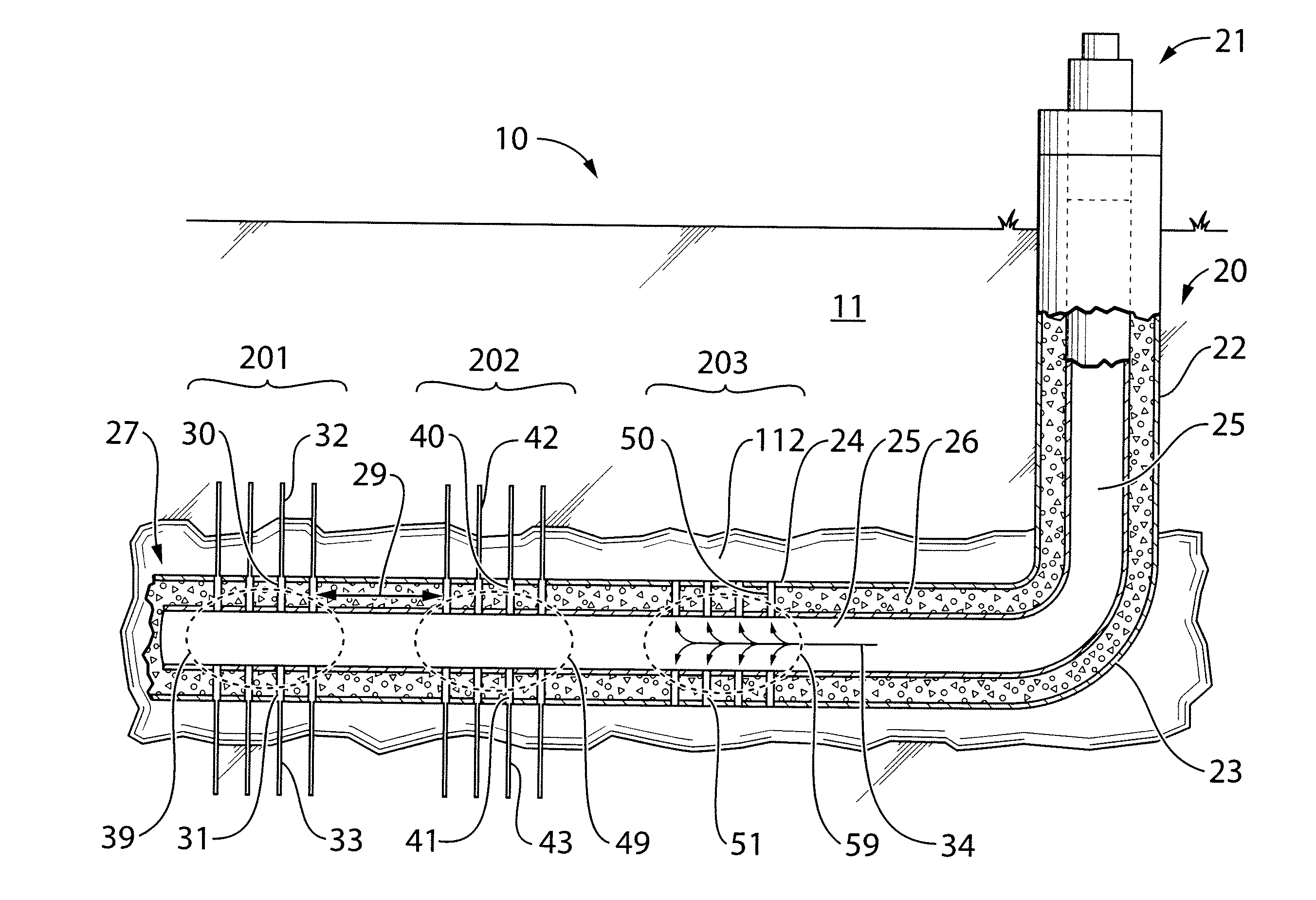

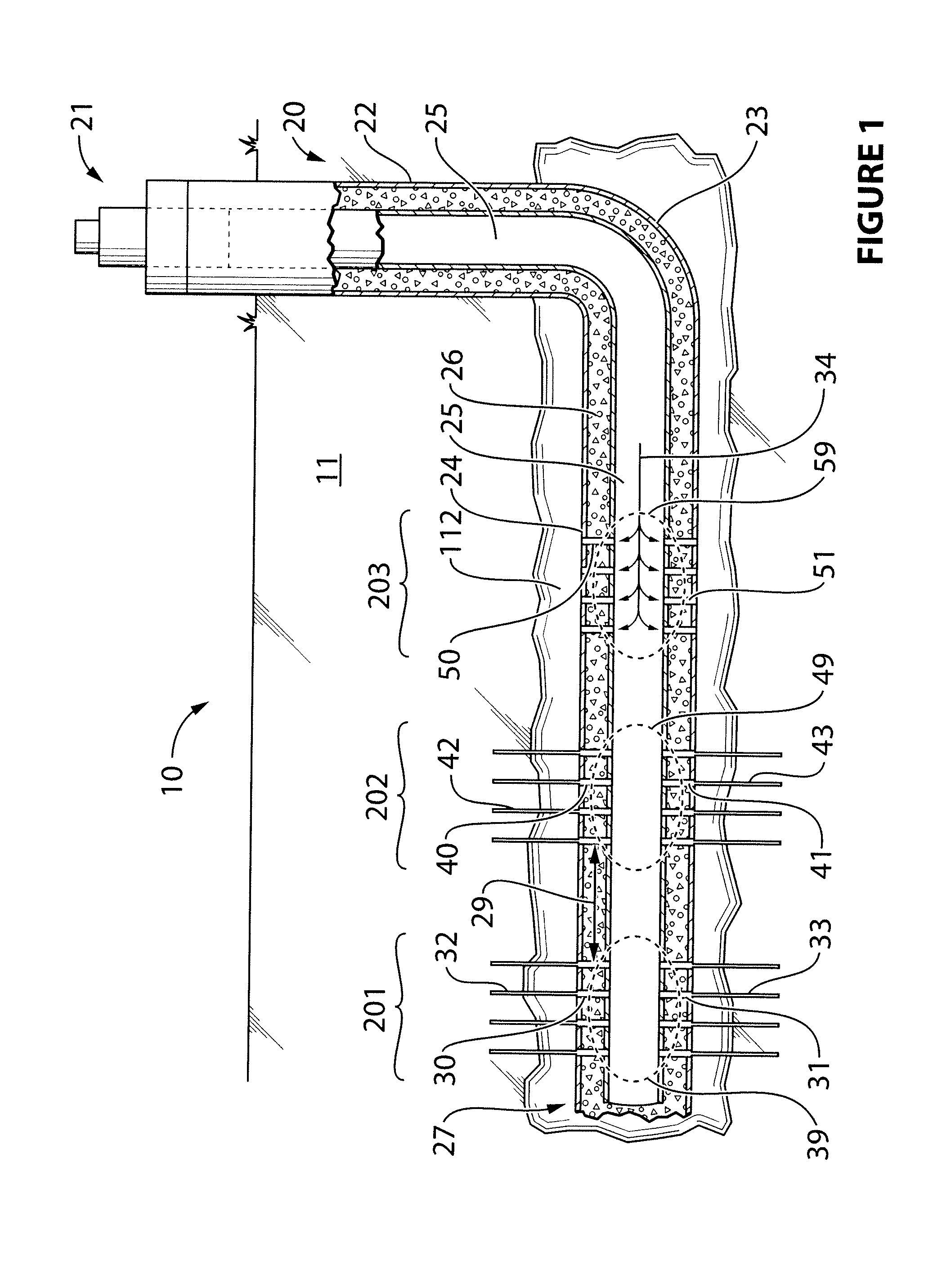

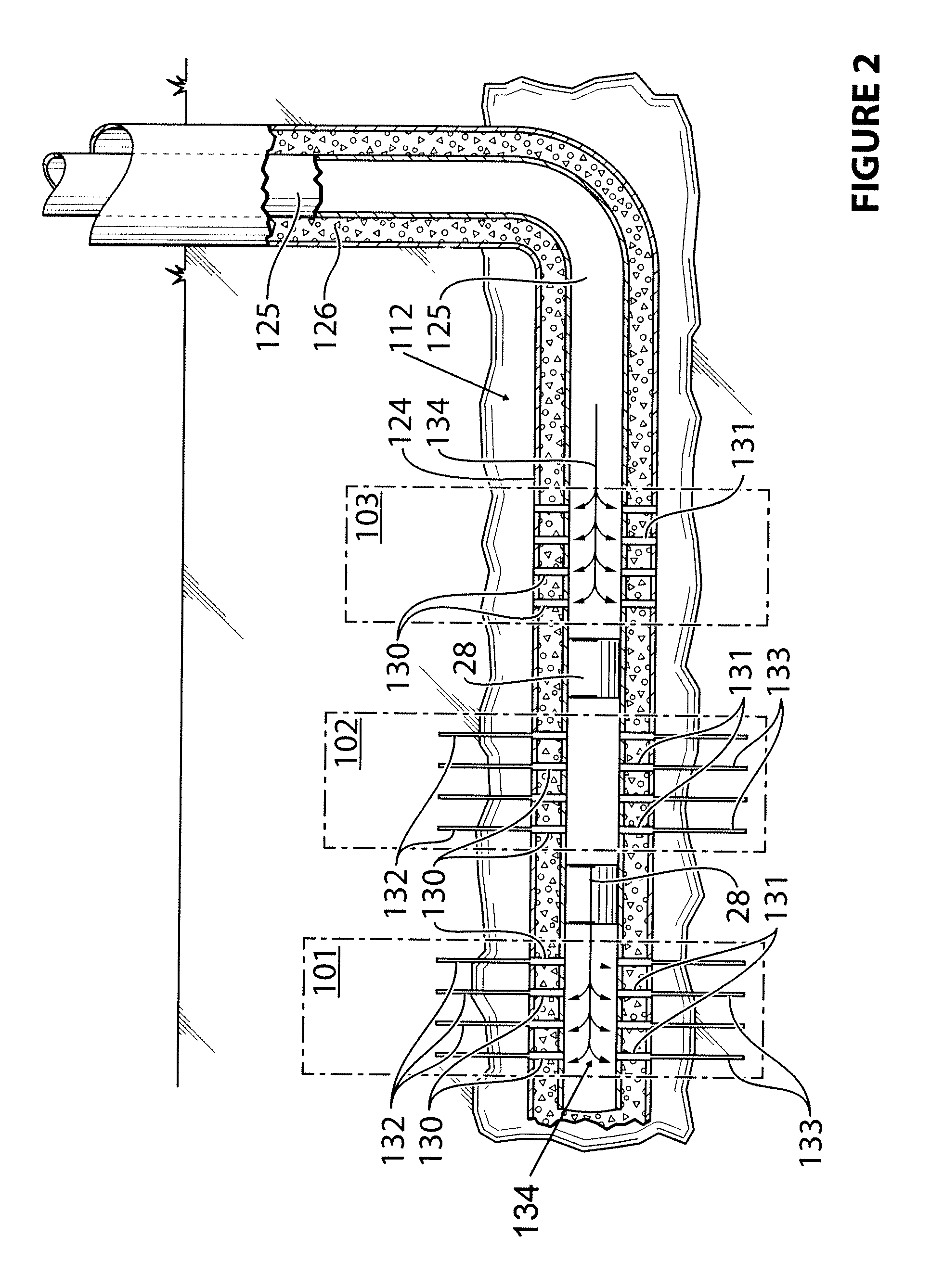

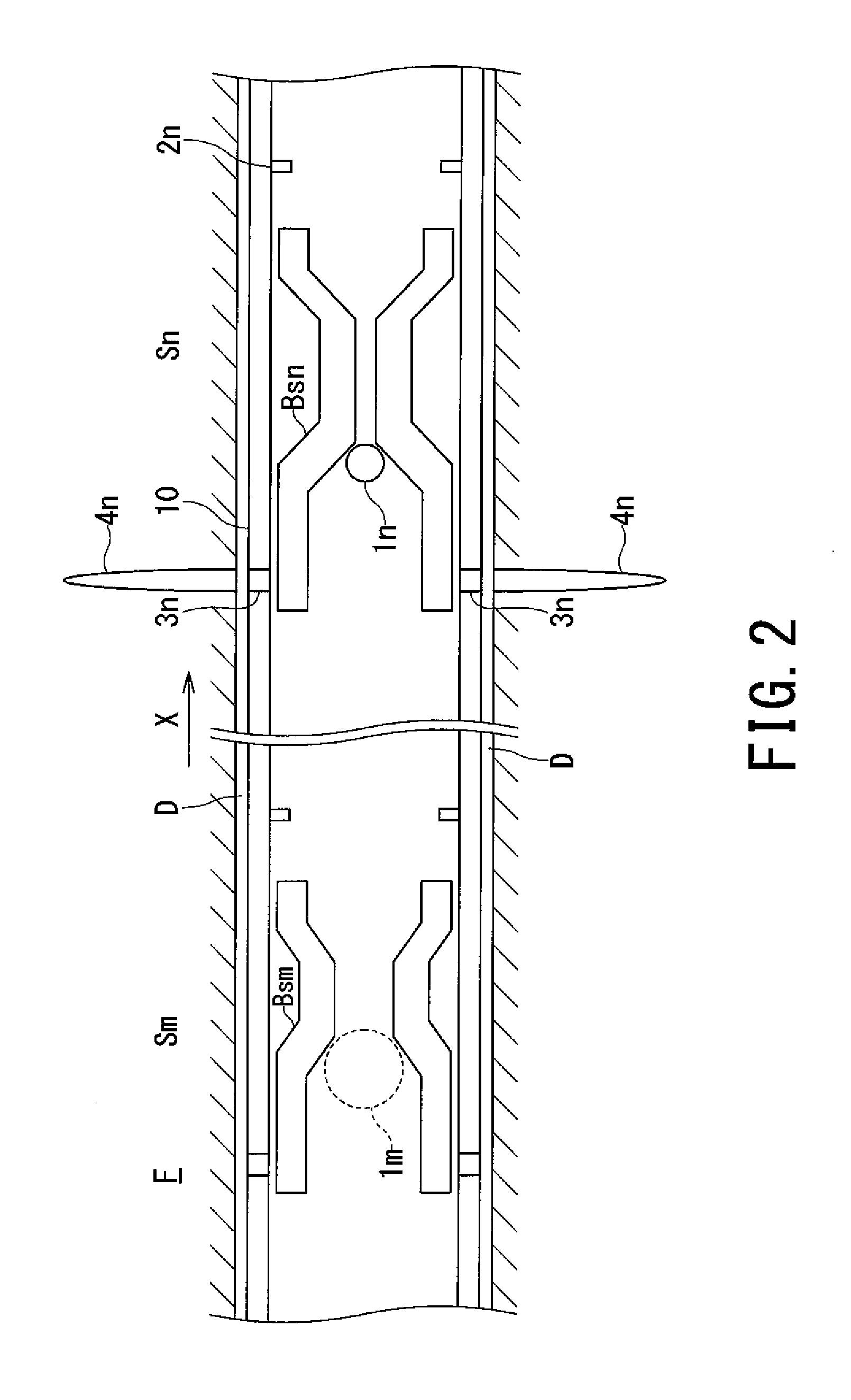

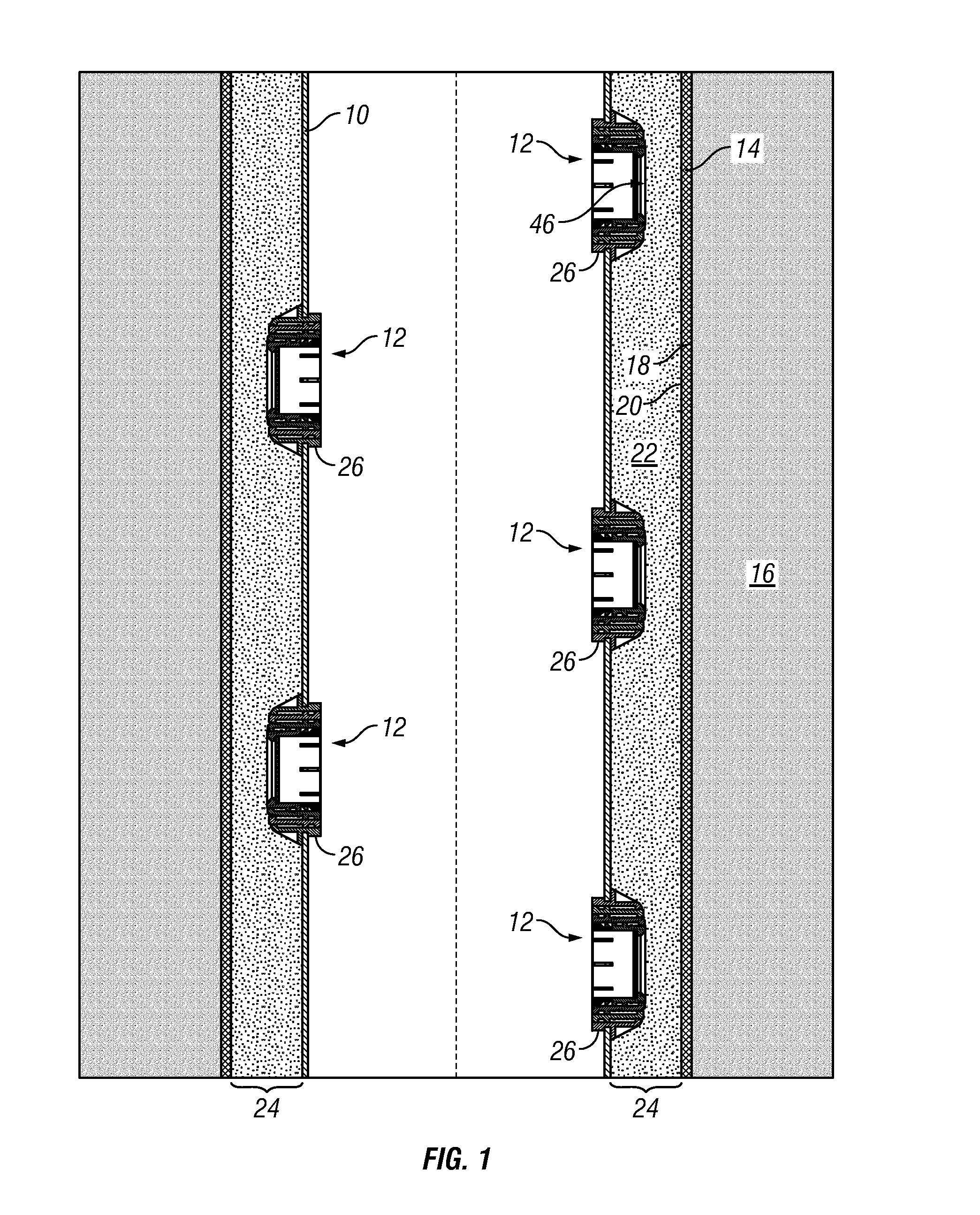

Systems, assemblies and processes for controlling tools in a well bore

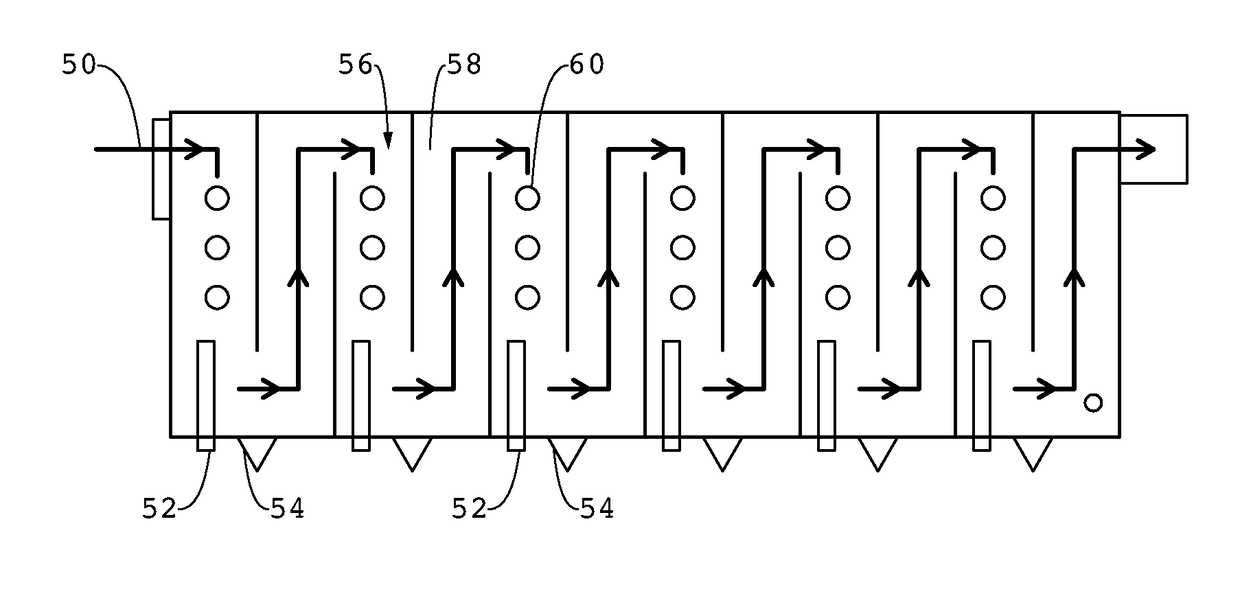

A dedicated hydraulic line for transmission of a signal device capable of generating one or more unique signals to one or more tools within a subterranean well. Each tool can be equipped with a reader device for receiving signals from and transmitting signals to the signal device. Each reader device can control operation of the tool associated therewith if the reader device is programmed to respond to signals received from the control device. Hydraulic fluid used to operate the tool can be conveyed via the dedicated hydraulic line or a separate hydraulic line. A separate hydraulic line can be used to reset the tool. Where the tools include sliding sleeves, the tools can be used to hydraulically fracture subterranean environs at spaced apart locations along a well bore in any desired sequence and without removing the tools from the well during the fracturing process.

Owner:WEATHERFORD TECH HLDG LLC

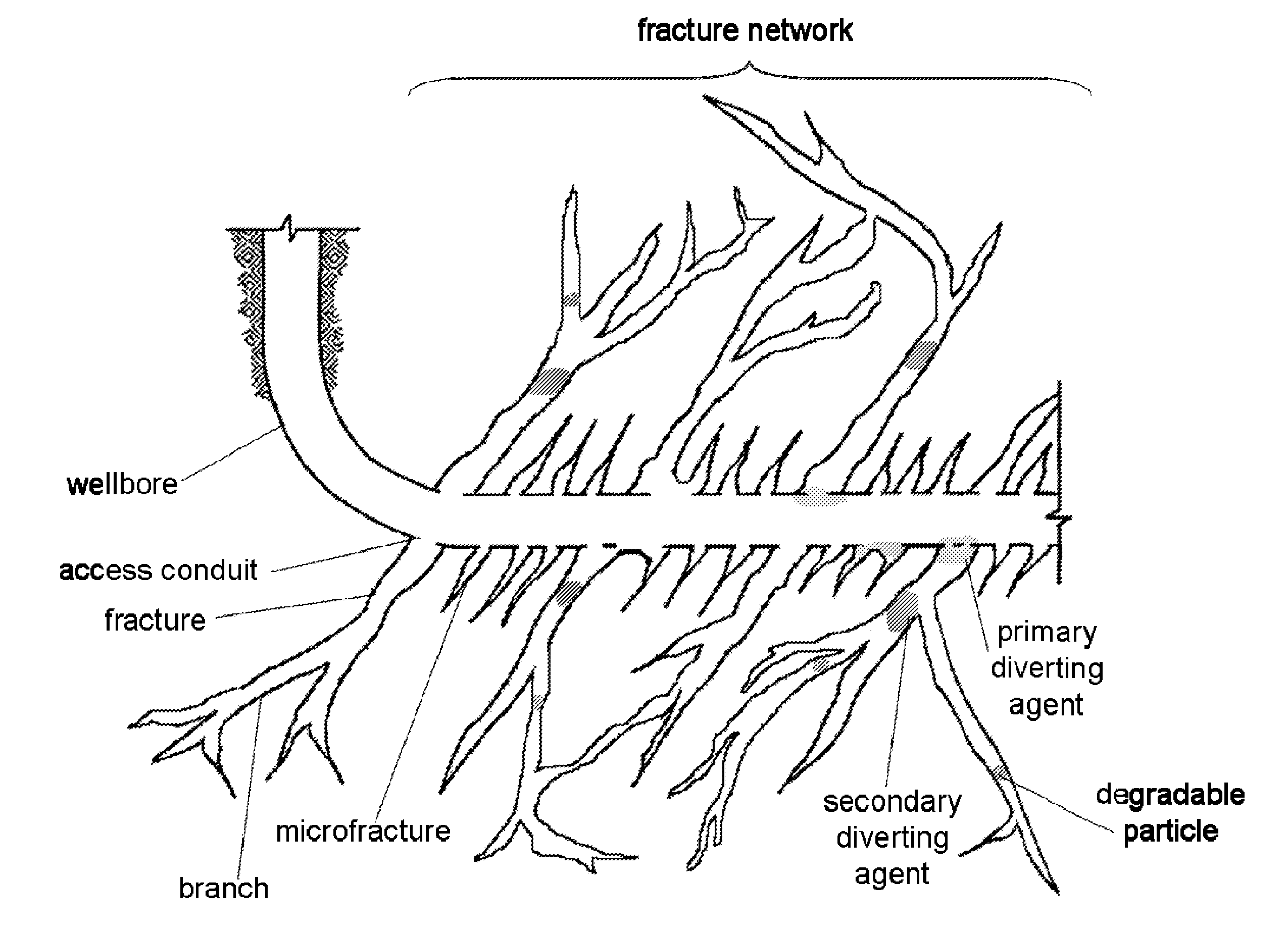

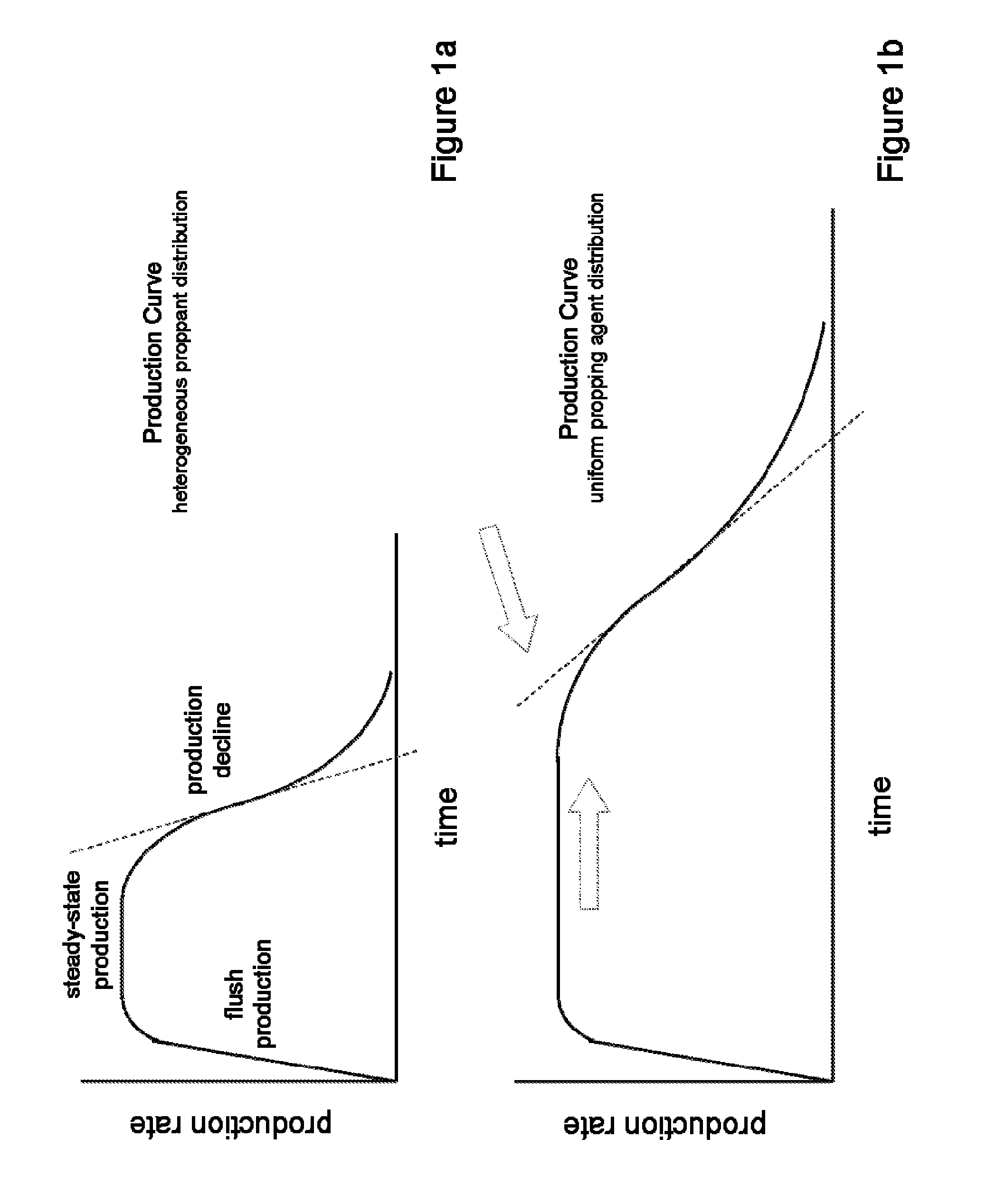

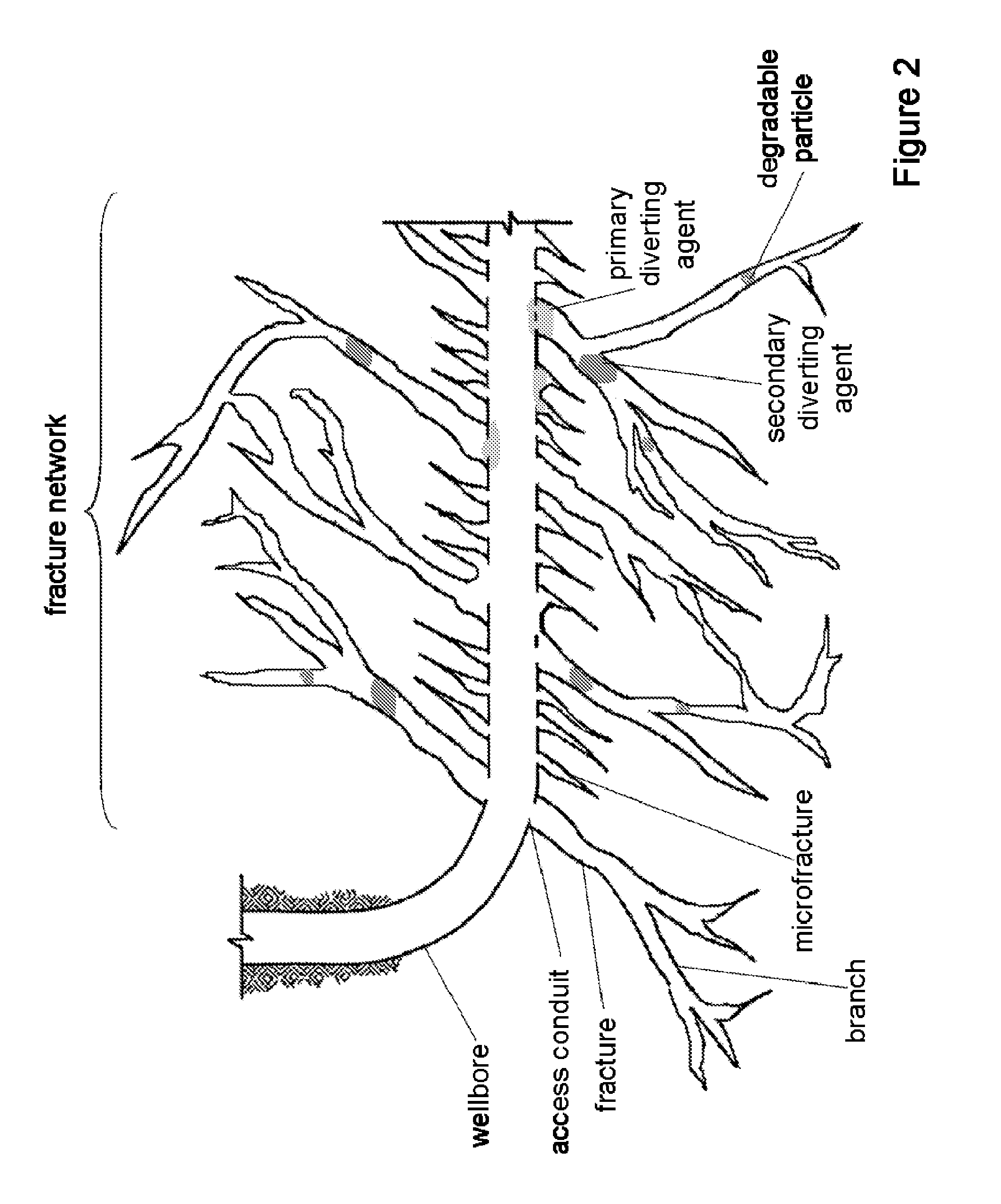

Fracturing Process to Enhance Propping Agent Distribution to Maximize Connectivity Between the Formation and the Wellbore

InactiveUS20130048282A1Enhancing propping agent distributionMaximize connectivityFluid removalFolding cabinetsWellboreFracture process

A method of treating a subterranean formation may include placing a first treatment fluid into a subterranean formation through an access conduit connecting the subterranean formation to a wellbore at a pressure sufficient to form at least a portion of a fracture network; pumping a second treatment fluid comprising a propping agent into the fracture network such that the propping agent forms a proppant pack in at least a portion of the fracture network; placing a third treatment fluid comprising a secondary diverting agent into the fracture network so as to substantially inhibit fluid flow through at least a portion of the fracture network without substantially inhibiting fluid flow through the access conduit; and placing a fourth treatment fluid comprising a primary diverting agent into the wellbore such that the primary diverting agent substantially inhibits fluid flow through the access conduit.

Owner:HALLIBURTON ENERGY SERVICES INC

Continuous fibers for use in hydraulic fracturing applications

InactiveUS7926562B2Facilitate deployment of and communicationSufficient redundancySurveyConstructionsFiberGeomorphology

Methods and related systems are described for use with hydraulic fracturing and other oilfield applications. A tool body is positioned in a wellbore at a location near a subterranean rock formation being fractured. The tool body contains a plurality of deployable continuous fibers. At least some of the deployable continuous fibers are deployed into fractures within a subterranean rock formation. Each deployed fiber is continuous from the tool body to the rock formation. The number of deployable continuous fibers provides sufficient redundancy to make at least a target measurement relating to the fracturing process.

Owner:SCHLUMBERGER TECH CORP

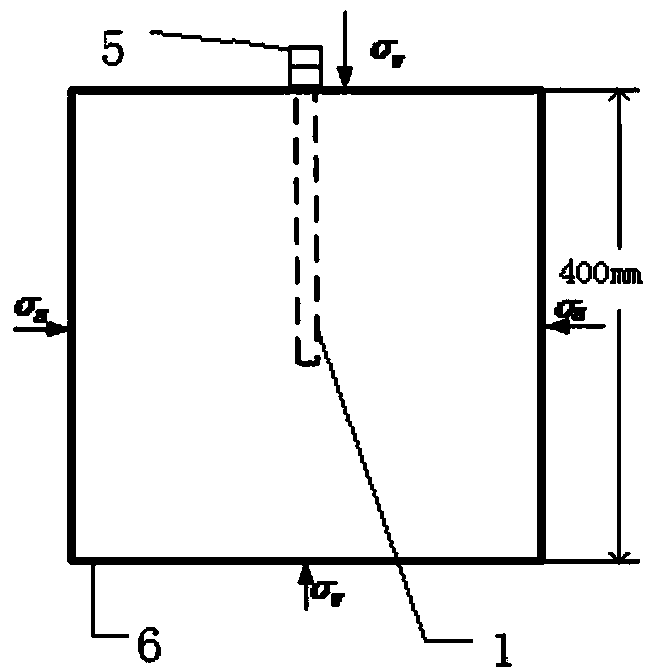

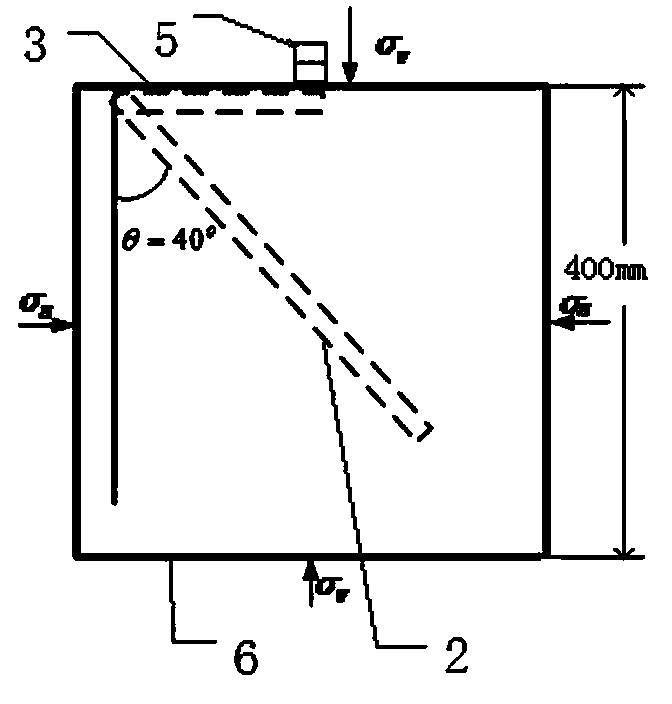

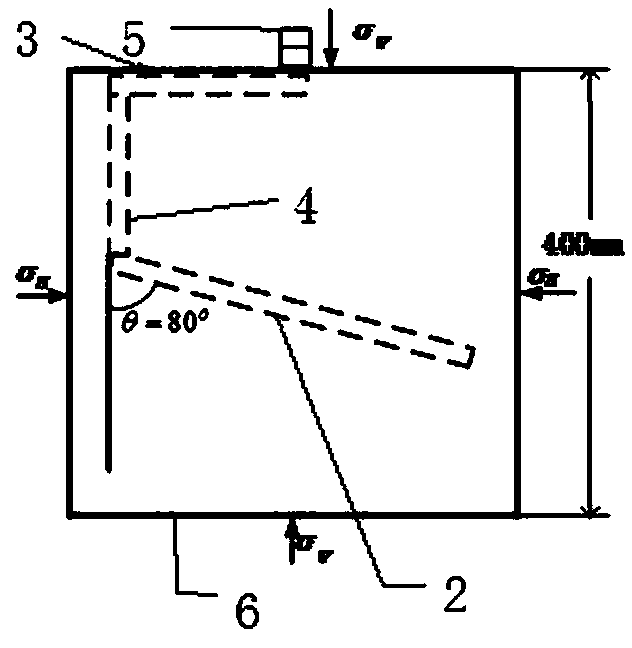

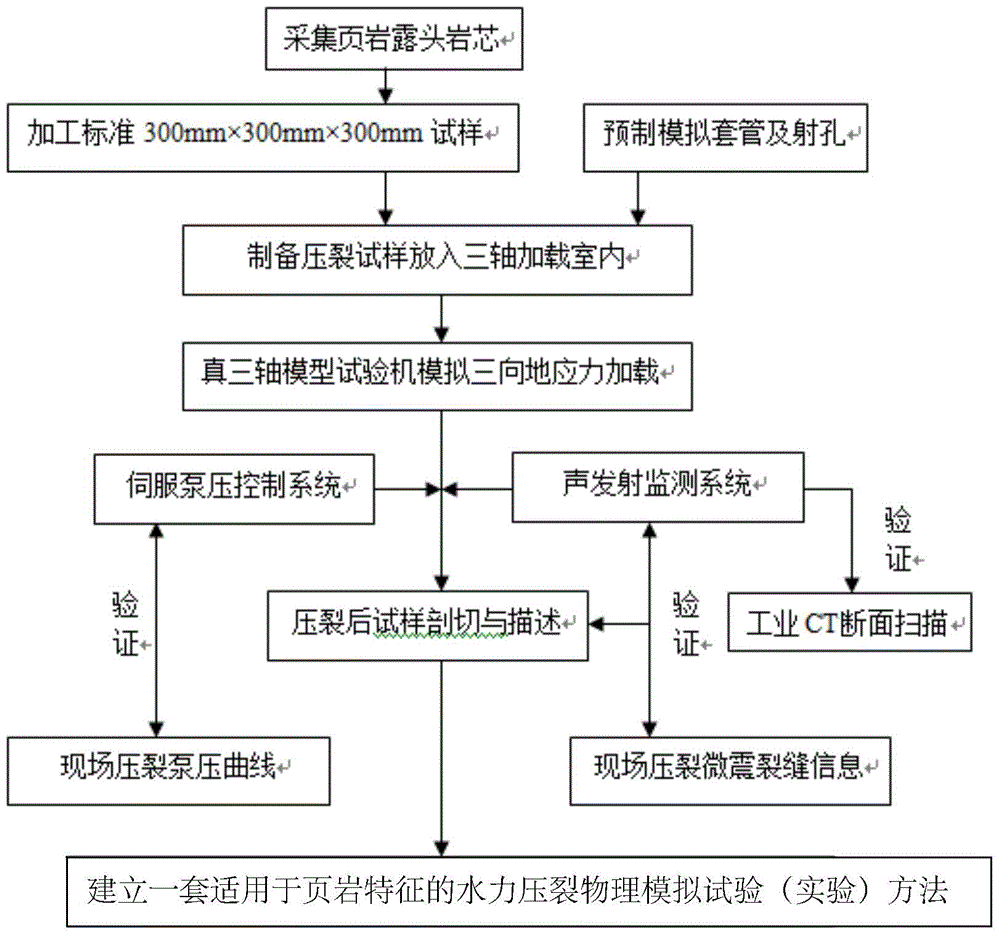

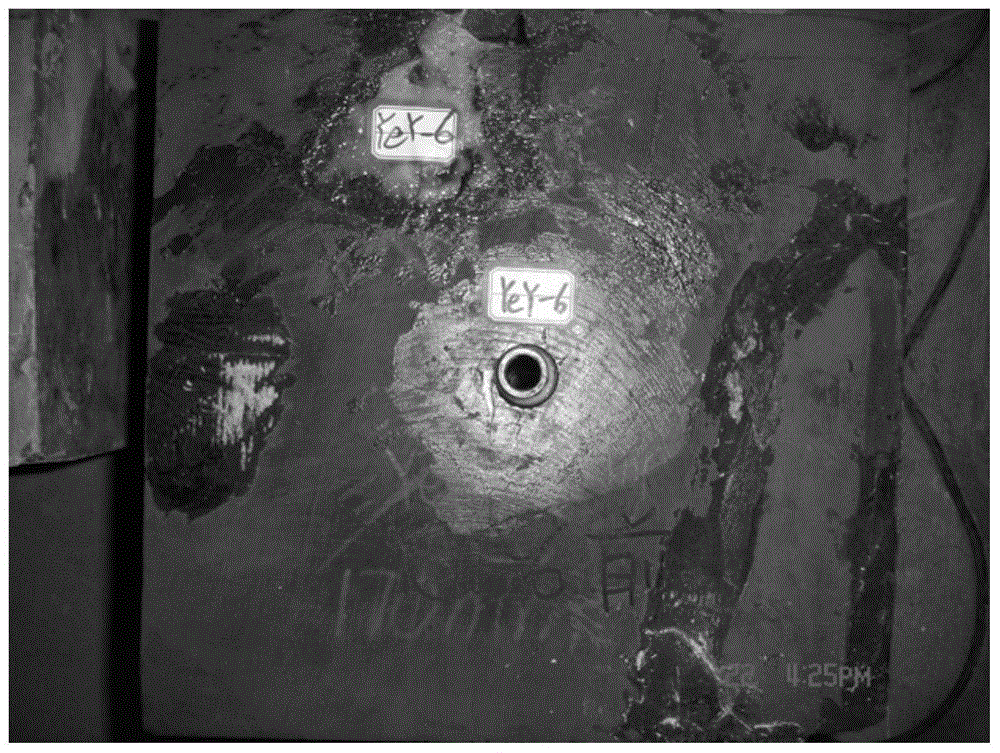

Method for physically simulating sectional hydrofracture of different well types of perforated well shafts

ActiveCN104060976AEfficient developmentSimple materialFluid removalTechnological researchHydraulic fracturing

The invention belongs to the field of technical research on oil and gas reservoir development and particularly relates to a method for physically simulating sectional hydrofracture of different well types of perforated well shafts. The method comprises the following steps of: (1) processing a simulated shaft and arranging bullet holes on the well wall of the simulated shaft; (2) prefabricating the simulated shaft in the step (1) into an artificial core test sample and developing a hydrofracture physical simulation experiment by utilizing a true triaxial hydrofracture device system; and (3) observing fracture initiation and extension forms of hydraulic fractures at the positions of the bullet holes on the well wall of the simulated shaft by the hydrofracture physical simulation experiment in the step (2). According to the method, aiming at geological development blocks with different reservoir structures, different well types and fracture processes can be selected to carry out effective indoor simulation evaluation research; and the theoretical foundation is provided for design and scheme optimization of the hydrofracture process of conventional or unconventional dense oil and gas reservoirs and complex oil-gas blocked deposits.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

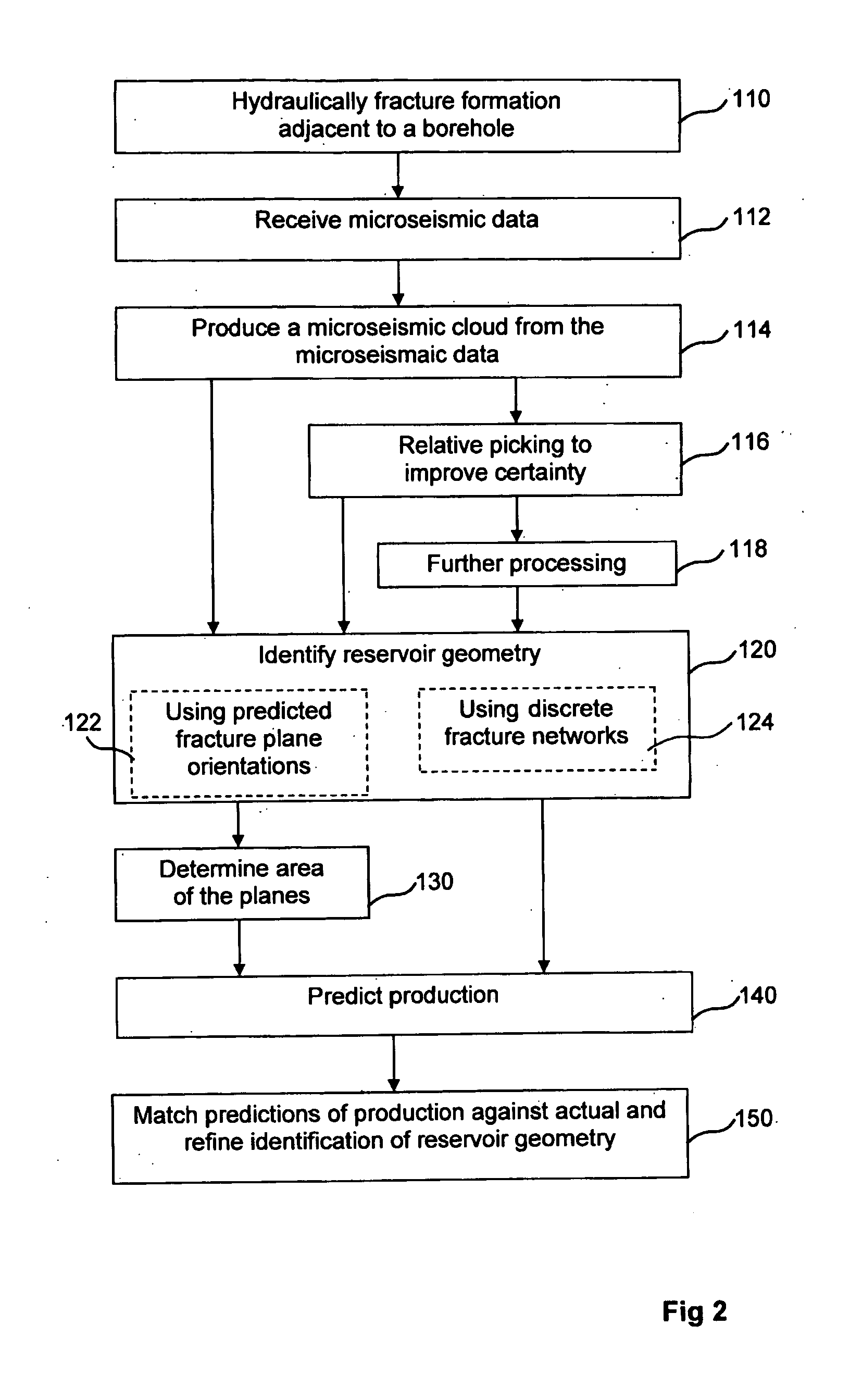

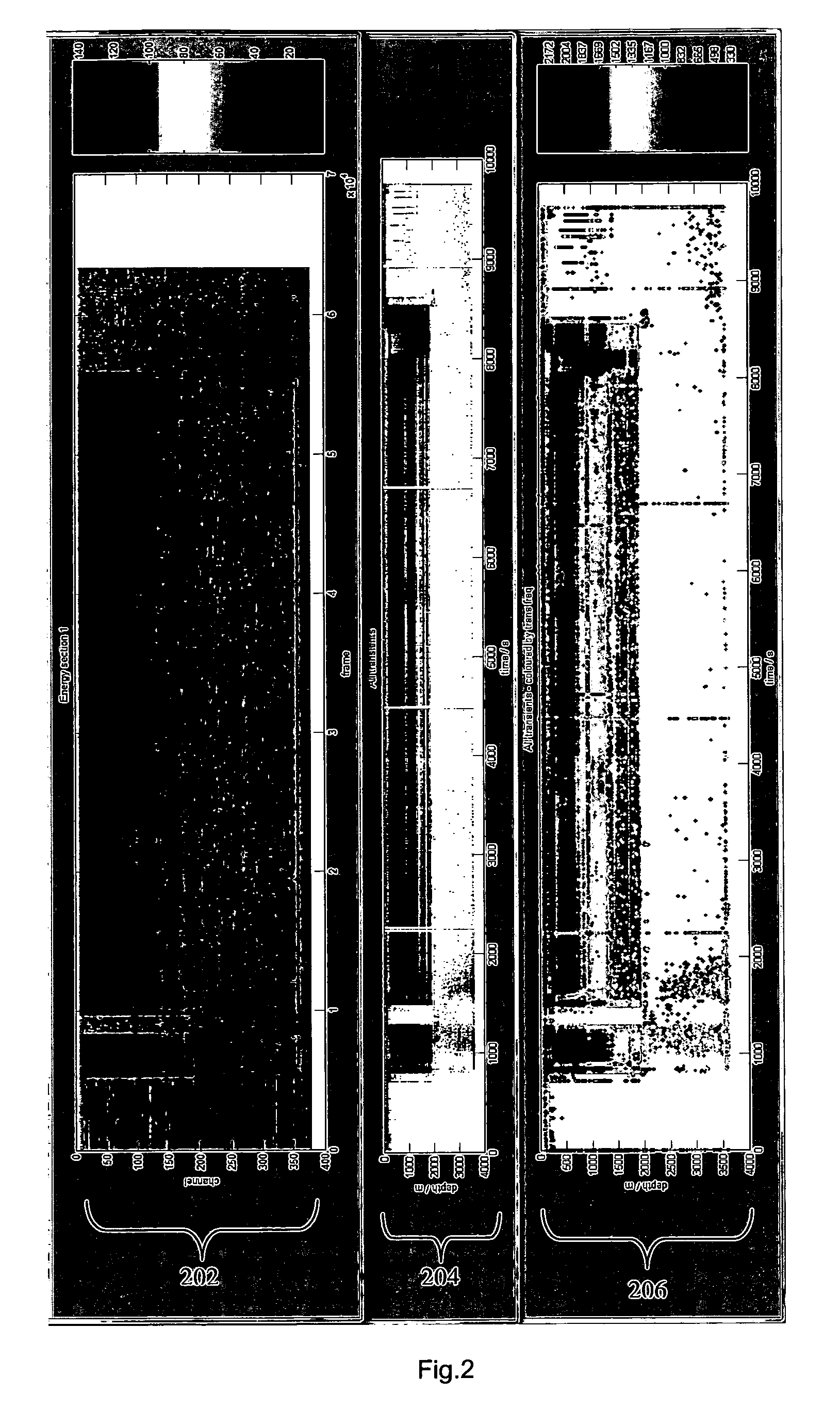

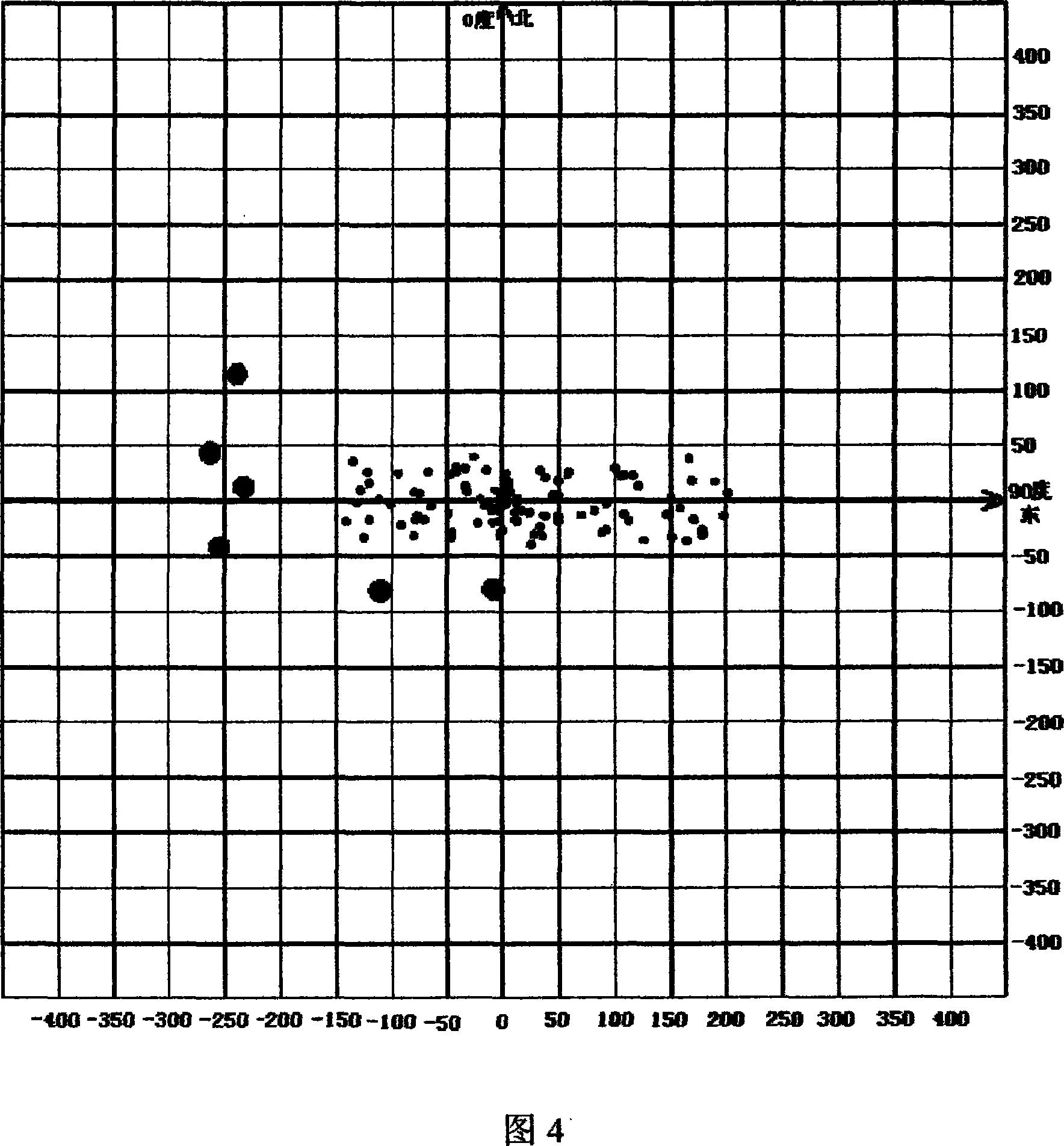

Identification of reservoir geometry from microseismic event clouds

InactiveUS20130144532A1Provide benefitsElectric/magnetic detection for well-loggingSeismic signal processingNumber densityHydraulic fracturing

A method for characterizing fracture planes generated during a hydraulic fracturing process, comprises receiving microseismic data from the hydraulic fracturing process and processing a microseismic event cloud from the received microseismic data. This is followed by determining at least one reservoir geometry from the microseismic event cloud. The determination of geometry may consist of determining multiple candidate geometries and probability of each. In some forms of the invention the method may comprise postulating a set of candidate geometries with differing numbers of fracture planes, determining the most probable locations of the postulated fracture planes in each member of the set of candidate geometries and also determining relative probabilities of the candidate geometries in the postulated set. Determining a location of a fracture plane may comprise calculating a number density for each microseismic event, dependent on distance from some possible location of a fracture plane or fracture network. Finding the location of a plane may then be finding the location for which the number density is greatest. The determination of reservoir geometry may be followed by determination of the area of the fracture planes and / or by a prediction of production.

Owner:SCHLUMBERGER TECH CORP

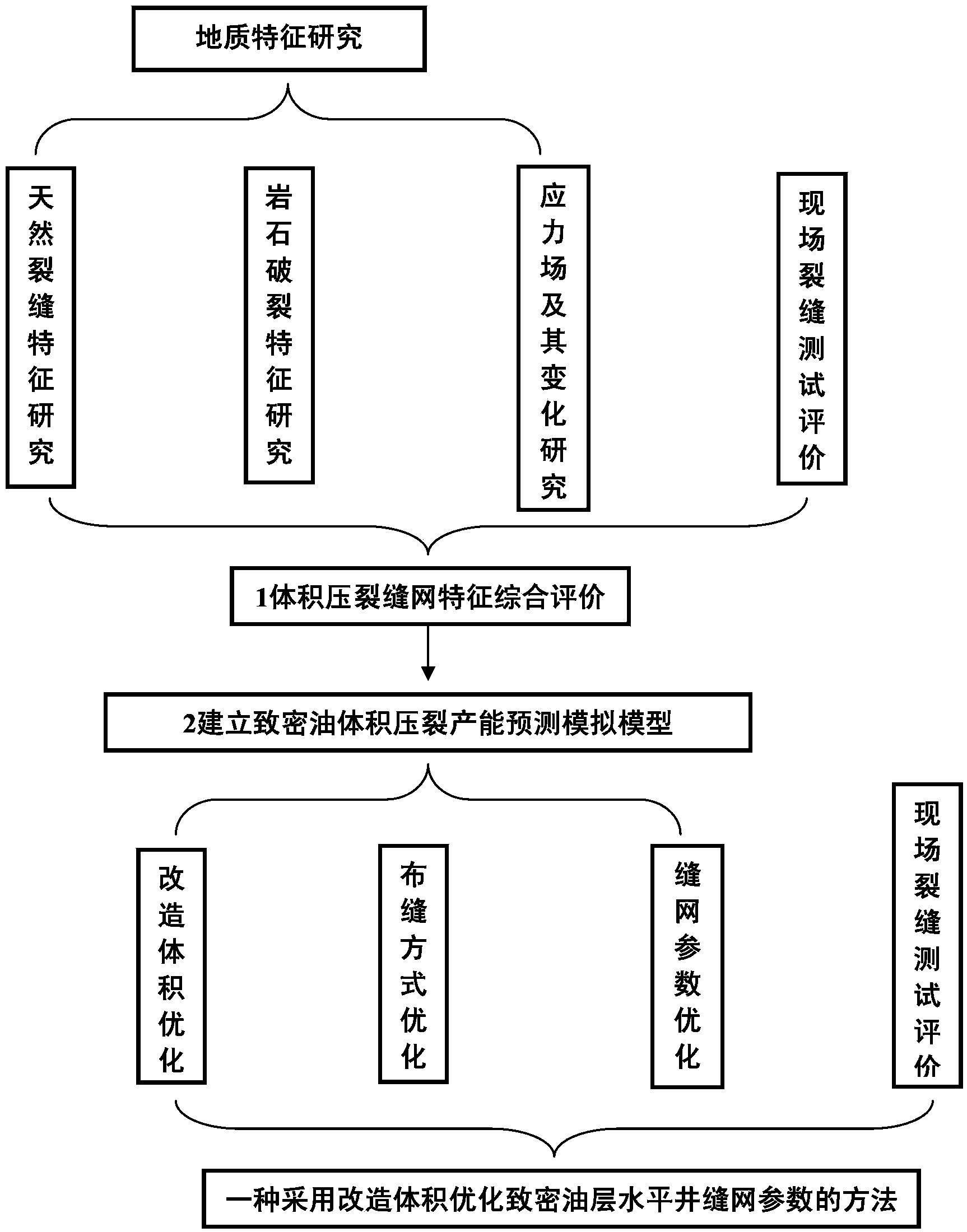

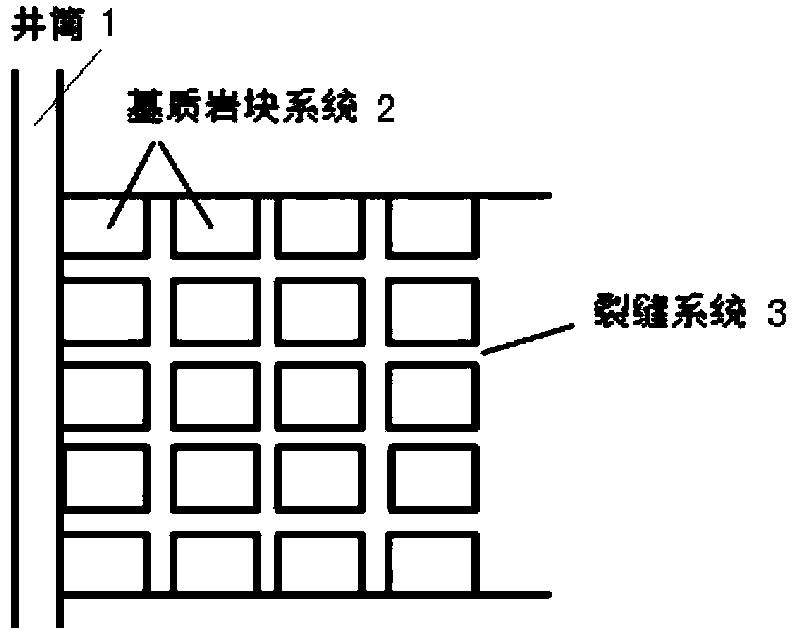

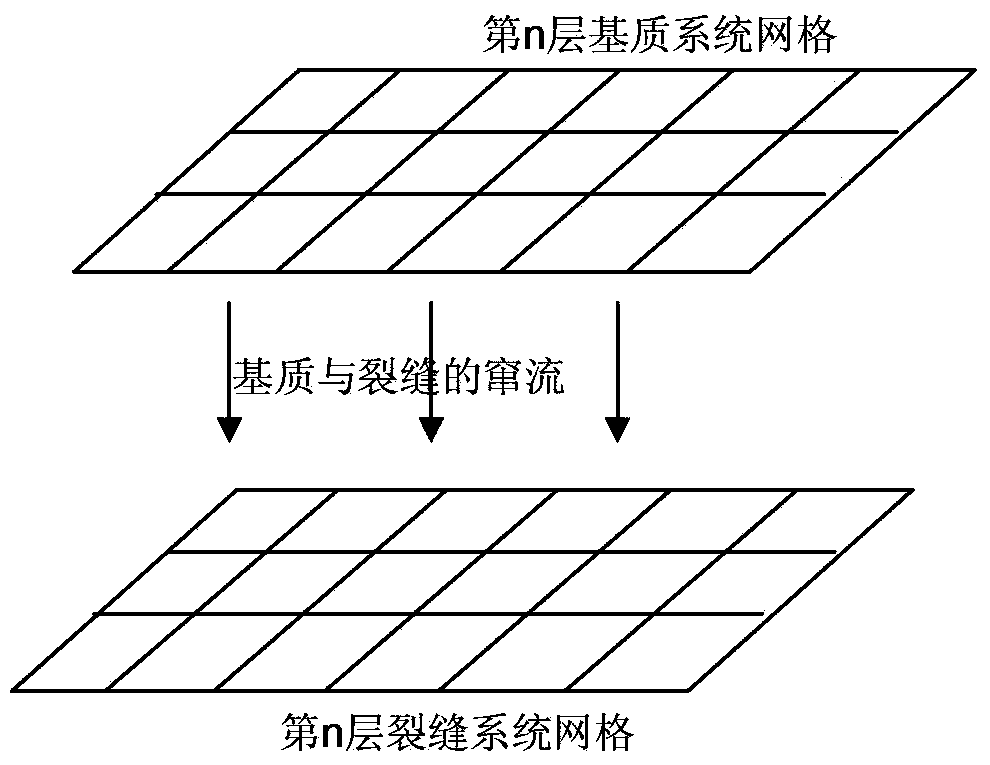

Method for optimizing tight oil horizontal well crack network parameters through transformation volume

The invention discloses a method for optimizing tight oil horizontal well crack network parameters through the transformation volume, and belongs to the field of tight oil horizontal well reservoirs. According to the method, according to a tight reservoir, firstly, the geologic feature of the reservoir is evaluated, the specific reservoir condition for volume fracture to form a volume crack network system is explicated, then, the influences of different transformation volumes and crack arrangement modes of horizontal well volume fracture on capacity are studied, and the specific crack network parameters are optimized. The method at least includes the steps that firstly, a basic crack network feature comprehensive evaluation method for tight reservoir volume fracture is established; secondly, a capacity prediction and simulation model method for tight oil volume fracture is established. The tight oil layer horizontal well fracture crack network parameters are optimized through the transformation volume formed in the fracture process, the transformation volume is formed in a tight oil layer, a matrix seeps towards a crack at the shortest distance, the driving pressure of effective flow is greatly reduced, and flow under the extremely-low permeability condition is achieved; the single well capacity can be greatly improved.

Owner:PETROCHINA CO LTD

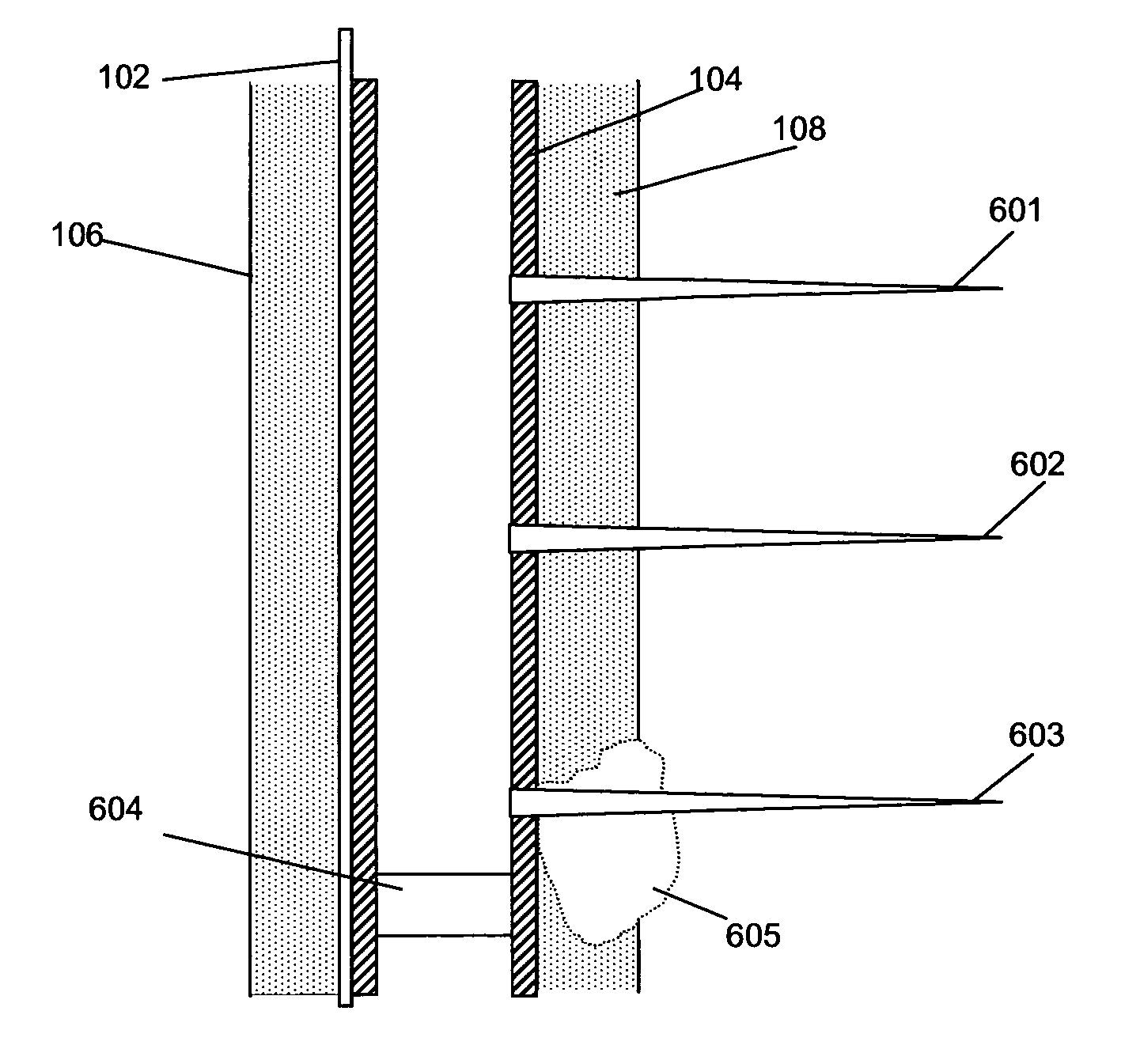

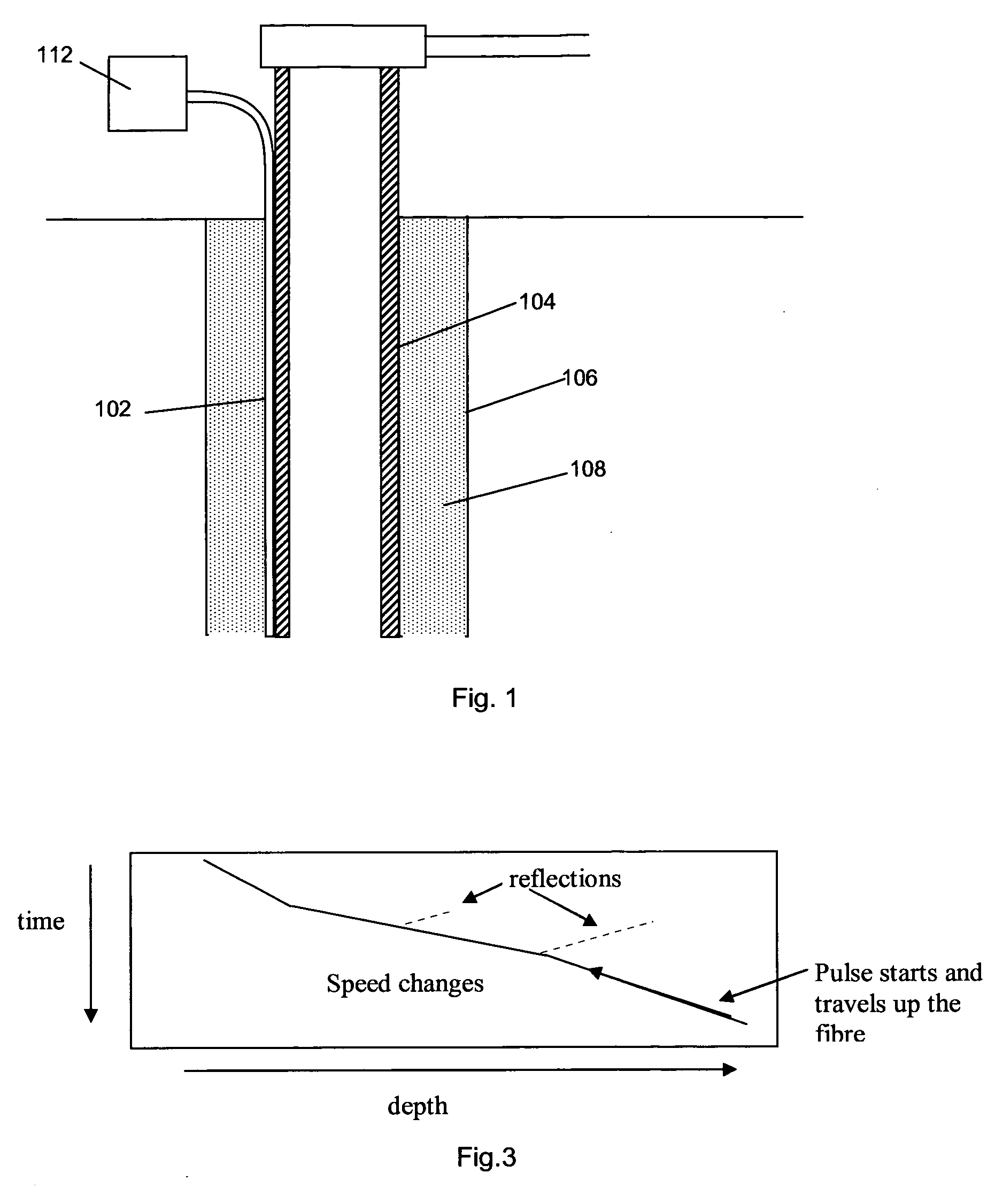

Fracture monitoring

ActiveUS8950482B2Effectively acoustically exciteIncrease productionMaterial analysis using sonic/ultrasonic/infrasonic wavesSurveyDistributed acoustic sensingFiber

This application relates to methods and apparatus for monitoring hydraulic fracturing during oil / gas well formation. A fiber optic cable (102) deployed down a well bore (106), which may be the well bore in which fracturing is performed, is interrogated to provide a distributed acoustic sensor. Data is sampled from at least one longitudinal sensing portion of the fiber and processed to provide at least fracturing characteristic. The fracturing characteristic may comprise the characteristics of high frequency transients indicative of fracturing events (606). The intensity, frequency, duration and signal evolution of the transients may be monitored to provide the fracturing characteristic. Additionally or alternatively the fracturing characteristic may comprise the longer term acoustic noise generated by fracture fluid flow to the fracture sites. The intensity and frequency of the noise may be analyzed to determine the fracturing characteristic. The method allows real-time control of the fracturing process.

Owner:OPTASENSE HLDG LTD

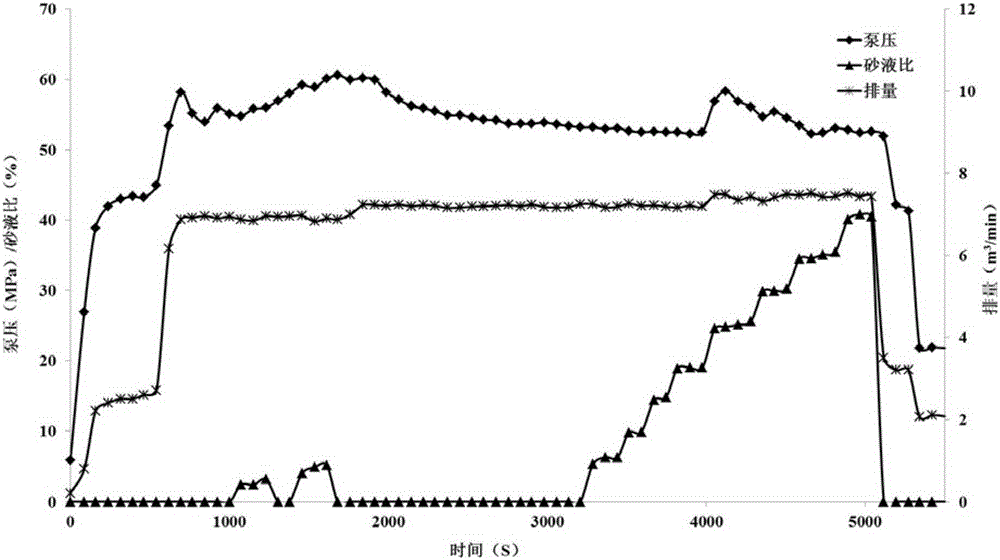

Volume transformation process of low permeability reservoir

ActiveCN102913221AImprove permeabilityAchieve transformationFluid removalMulti clusterCurrent limiting

The invention discloses a volume transformation process of a low permeability reservoir, and the volume transformation process sequentially comprises the following steps of (1) selecting a coal bed, shale, tight sand or other low-permeability reservoir; and (2) adopting a pitching current-limiting hydraulic fracturing way after perforating a plumb shaft; adopting a segmental multi-cluster perforation hydraulic fracturing way after perforating a horizontal well; and varying displacement, propping agent, fracturing fluid and sand ratio in the pumping process in both fracturing ways. Due to adopting the measures for varying the displacement, the sand ratio, the propping agent and the fracturing fluid in the hydraulic fracturing process, pitching current limitation can be adopted when the plumb shaft is fractured or the segmental multi-cluster perforation fracturing process is adopted for the horizontal well, and a netted crack system is formed in the reservoir. Due to adopting the volume transformation process, the volume transformation effect is realized, the weakness of the traditional hydraulic fracturing process that a single crank cannot conform to the commercial production capacity or the later yield is reduced too fast can be avoided, and technical support can be provided for the oil-gas resource development of the low-permeability reservoir.

Owner:HENAN POLYTECHNIC UNIV

Hydraulic Fracturing Process for Deviated Wellbores

InactiveUS20140096950A1Improved stimulated reservoir volumeProcess safetyFluid removalDrinking water installationHydraulic fracturingHydrocarbon

A method of stimulating an interval in a hydrocarbon reservoir equipped with a deviated wellbore having a casing, wherein said interval comprises at least two sequential stages in said wellbore without isolation means, said method comprising:i) introducing a first stageii) introducing a second stage in the same wellborewherein said first stage, and second stage are not separated by any isolation means; and optionallyiii) recovering hydrocarbon from said hydrocarbon reservoir to a surface.

Owner:CNOOC PETROLEUM NORTH AMERICA ULC

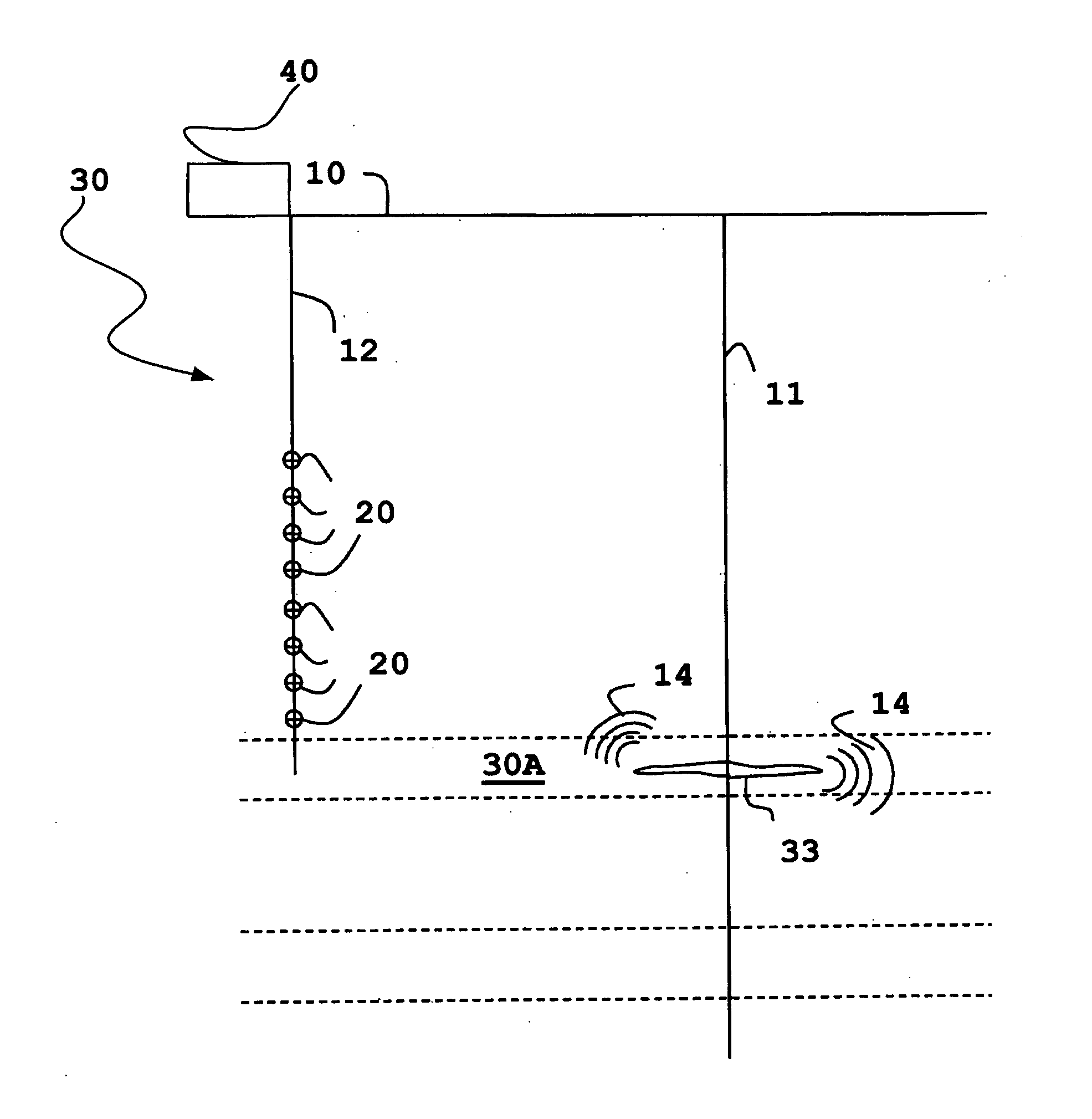

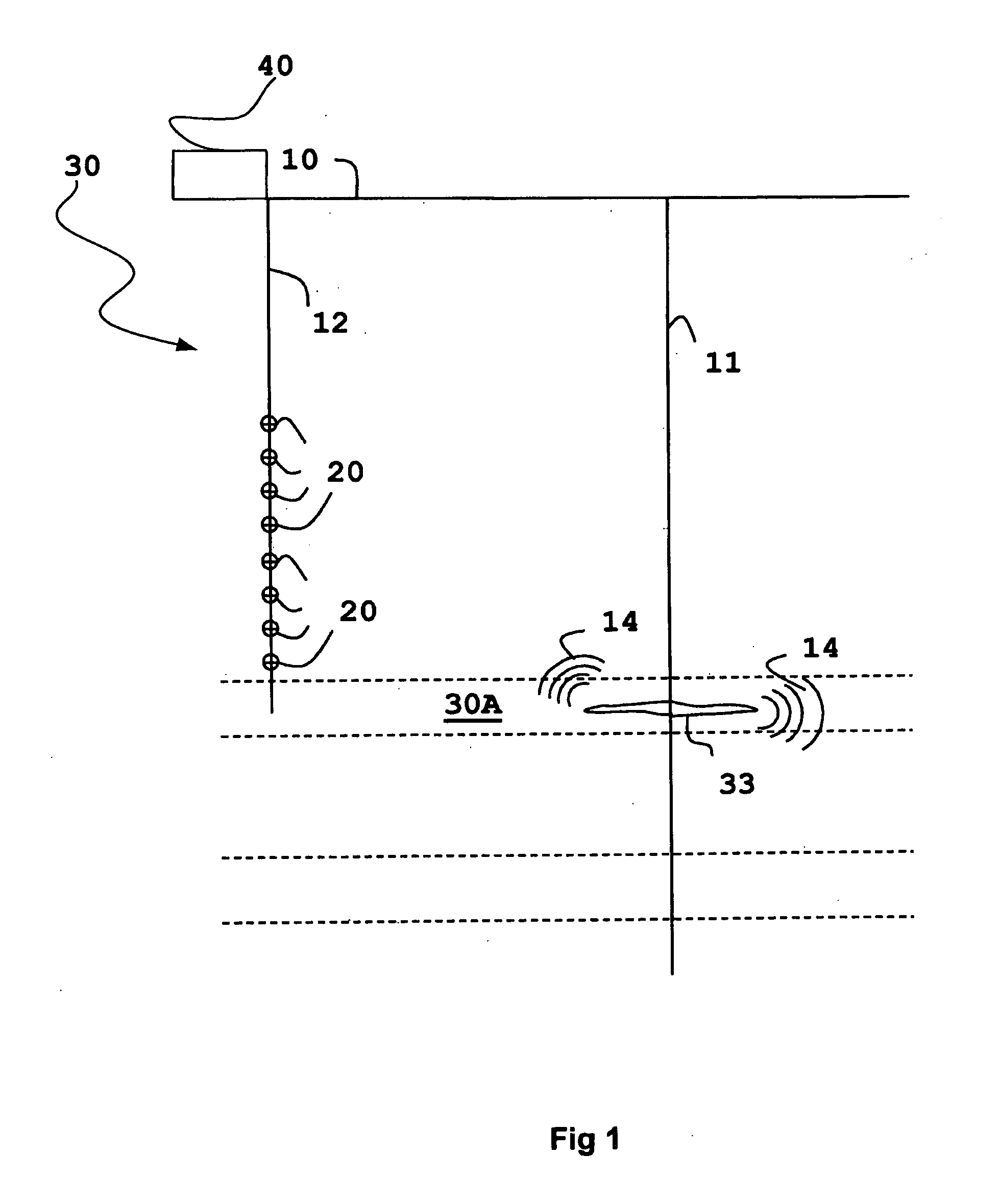

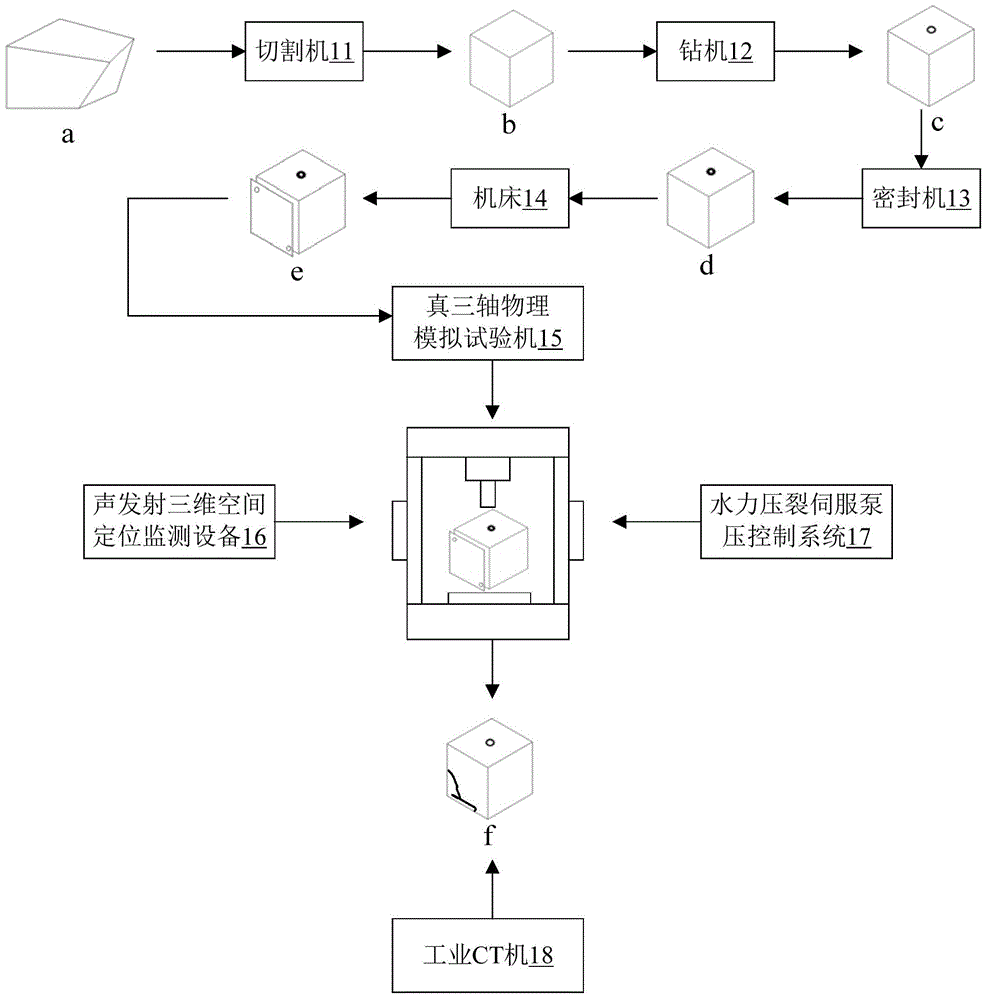

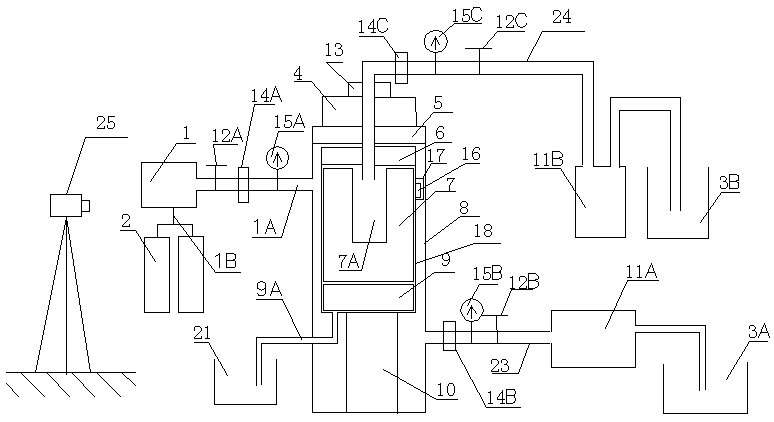

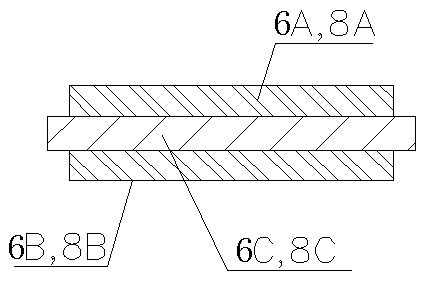

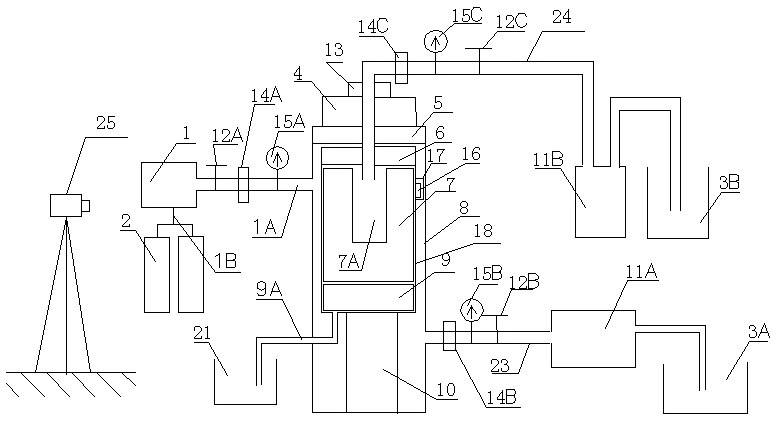

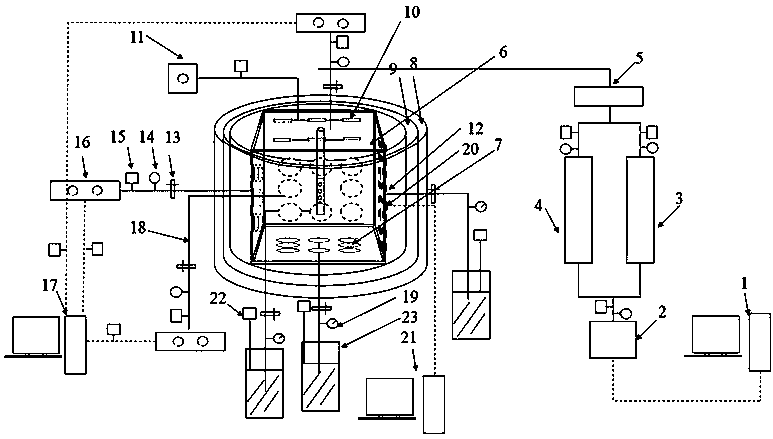

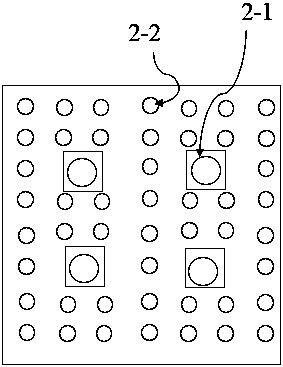

Physical simulation system and method for fracture propagation in shale

InactiveCN105756645AAccurate discriminationTo achieve the purpose of increasing productionFluid removalFracturing fluidHydraulic fracturing

The invention discloses a physical simulation system and method for fracture propagation in shale. The system comprises a drilling rig, a sealing machine, a machine tool, a true triaxial physical simulation testing machine, a hydraulic fracturing servo pump pressure control system, acoustic emission three-dimensional space location monitoring equipment and an industrial CT (computed tomography) machine, wherein the drilling rig, the sealing machine and the machine tool are jointly used for processing acquired shale into a fracturing sample; the true triaxial physical simulation testing machine is used for loading simulated three-dimensional ground stress to the fracturing sample; the hydraulic fracturing servo pump pressure control system is used for providing a fracturing fluid for the fracturing sample, so that a hydraulic fracturing process can be simulated; the acoustic emission three-dimensional space location monitoring equipment is used for monitoring the simulated hydraulic fracturing process in real time; the industrial CT machine is used for preforming tomography scanning on the fracturing sample before and after hydraulic fracturing. The physical simulation system for fracture propagation in the shale can be used for researching fracture initiation, expansion and extension laws of anisotropic shale in the hydraulic fracturing process, so that fracture information can be distinguished more accurately, high-precision basic data are provided for fracturing construction design, technical support is provided for site fracturing construction, and the yield is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

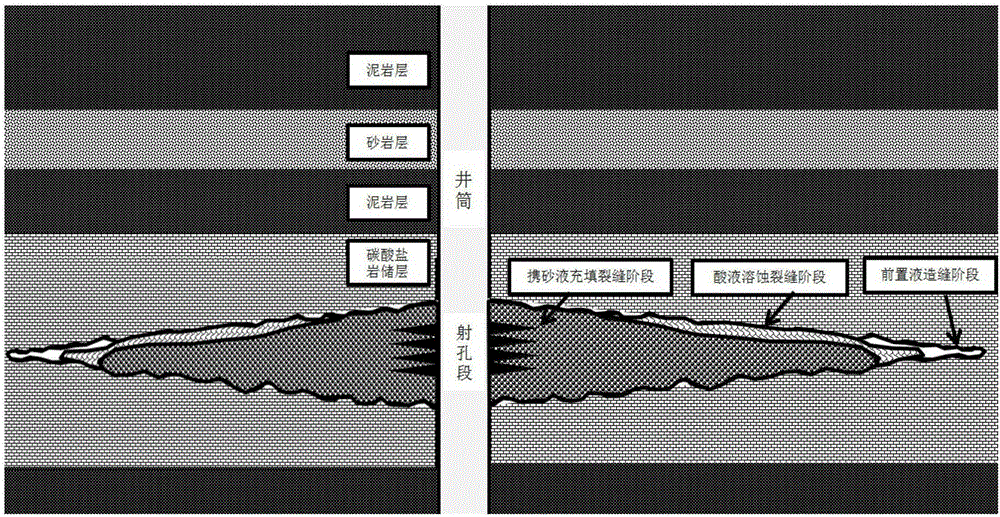

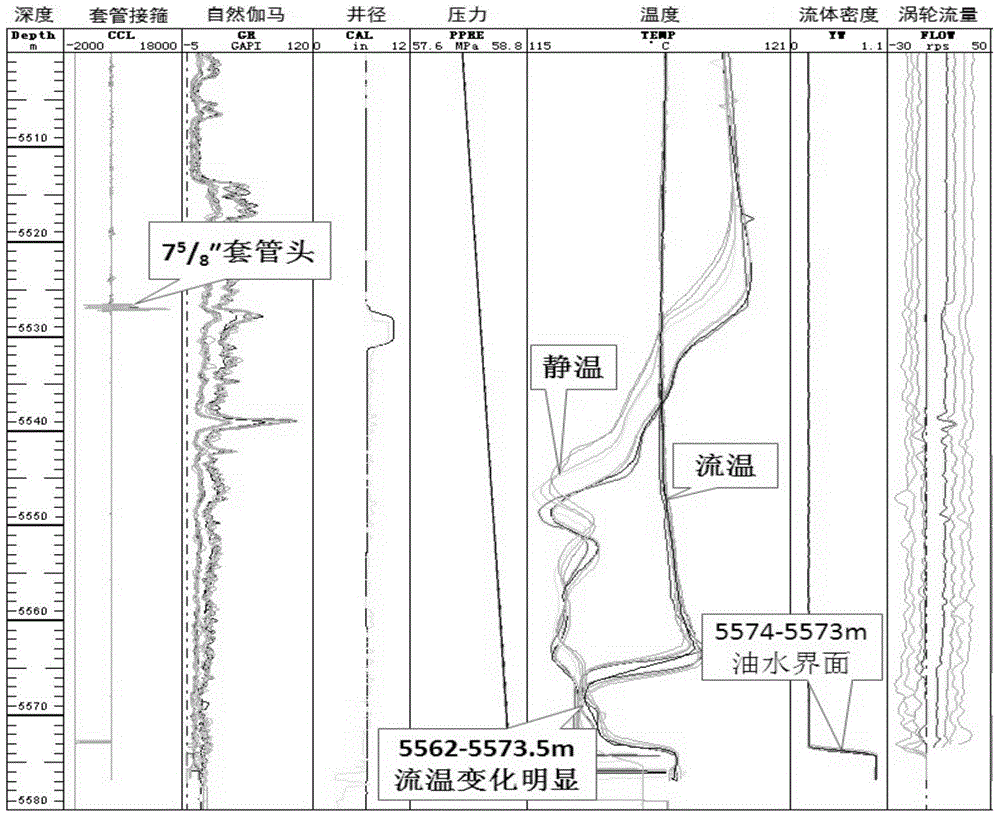

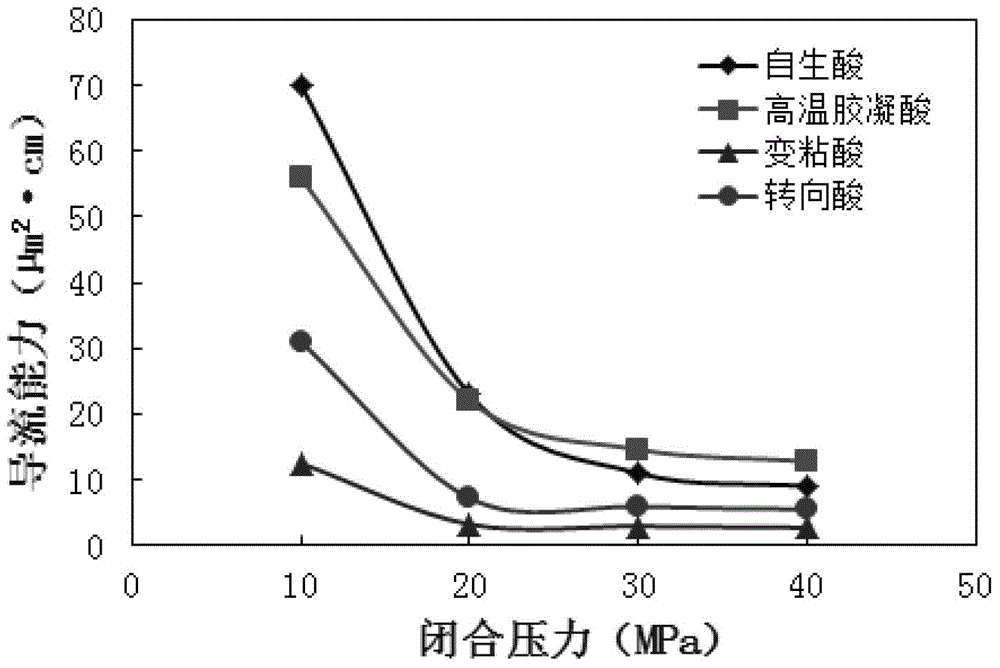

High-flow-conductivity acid fracturing method for carbonate rock reservoirs

The invention discloses a high-flow-conductivity acid fracturing method for carbonate rock reservoirs, and belongs to the field of reservoir reconstruction technologies. The high-flow-conductivity acid fracturing method includes applying acid fracturing processes for corroding crack by acid fluid and hydraulic fracturing processes for filling the crack with added sand in a combined manner, to be more specific, forming the crack in the carbonate rock reservoirs by the aid of non-reactive ahead fluid and reducing the surrounding temperatures of wall surfaces of the crack; injecting high-concentration acid fluid systems to corrode the wall surfaces of the artificial crack and forming uneven grooves in the wall surfaces of the crack by means of corroding to allow the crack to have certain flow-conductivity after the crack is closed; enabling high-viscosity sand-carrying fluid to carry proppants and flow into crack systems and filling the crack with the high-viscosity sand-carrying fluid to further improve the flow-conductivity of the crack. The high-flow-conductivity acid fracturing method has the advantages that the high-flow-conductivity acid fracturing method is reasonable in design, simple in process and convenient to implement in fields, the high-flow-conductivity crack systems with the acid-corroded crack and crack closing supporting functions can be formed, oil and gas flow resistance can be reduced, the acid fracturing reconstruction effects can be improved for the carbonate rock reservoirs, and the high-flow-conductivity acid fracturing method can be widely used for acid fracturing reconstruction construction for limestone, dolomite and carbonate rock oil and gas reservoirs with mud.

Owner:CHINA PETROLEUM & CHEM CORP +1

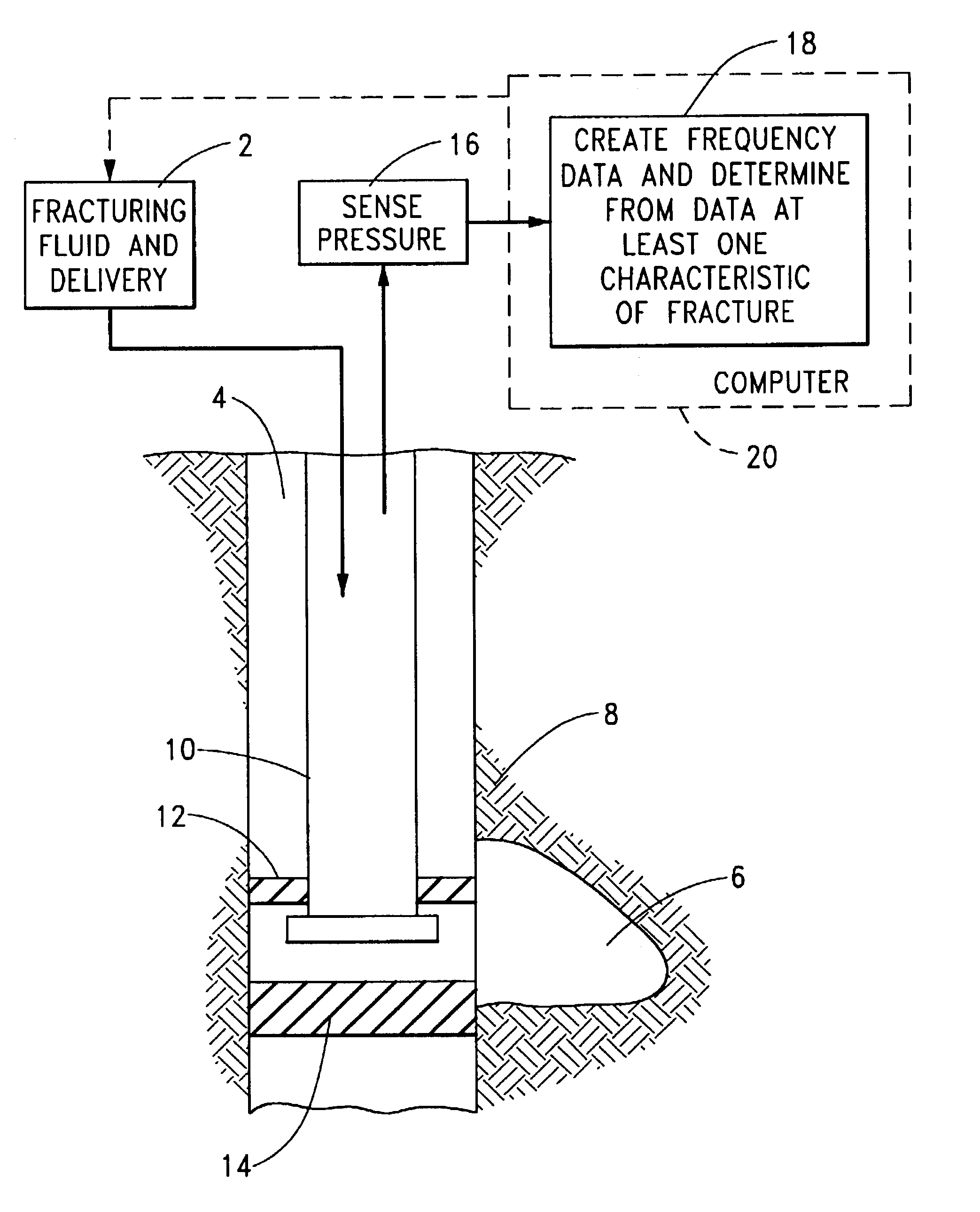

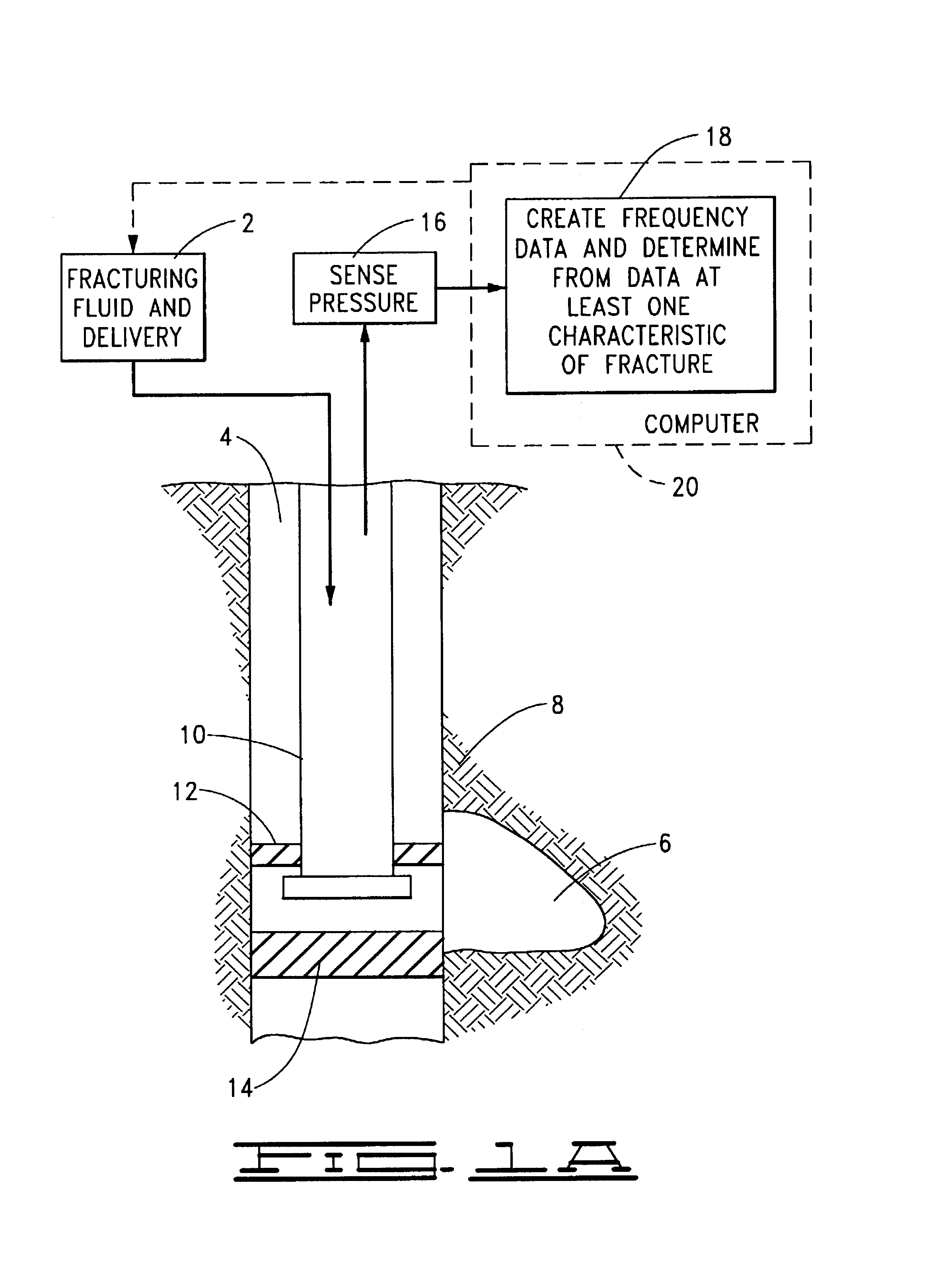

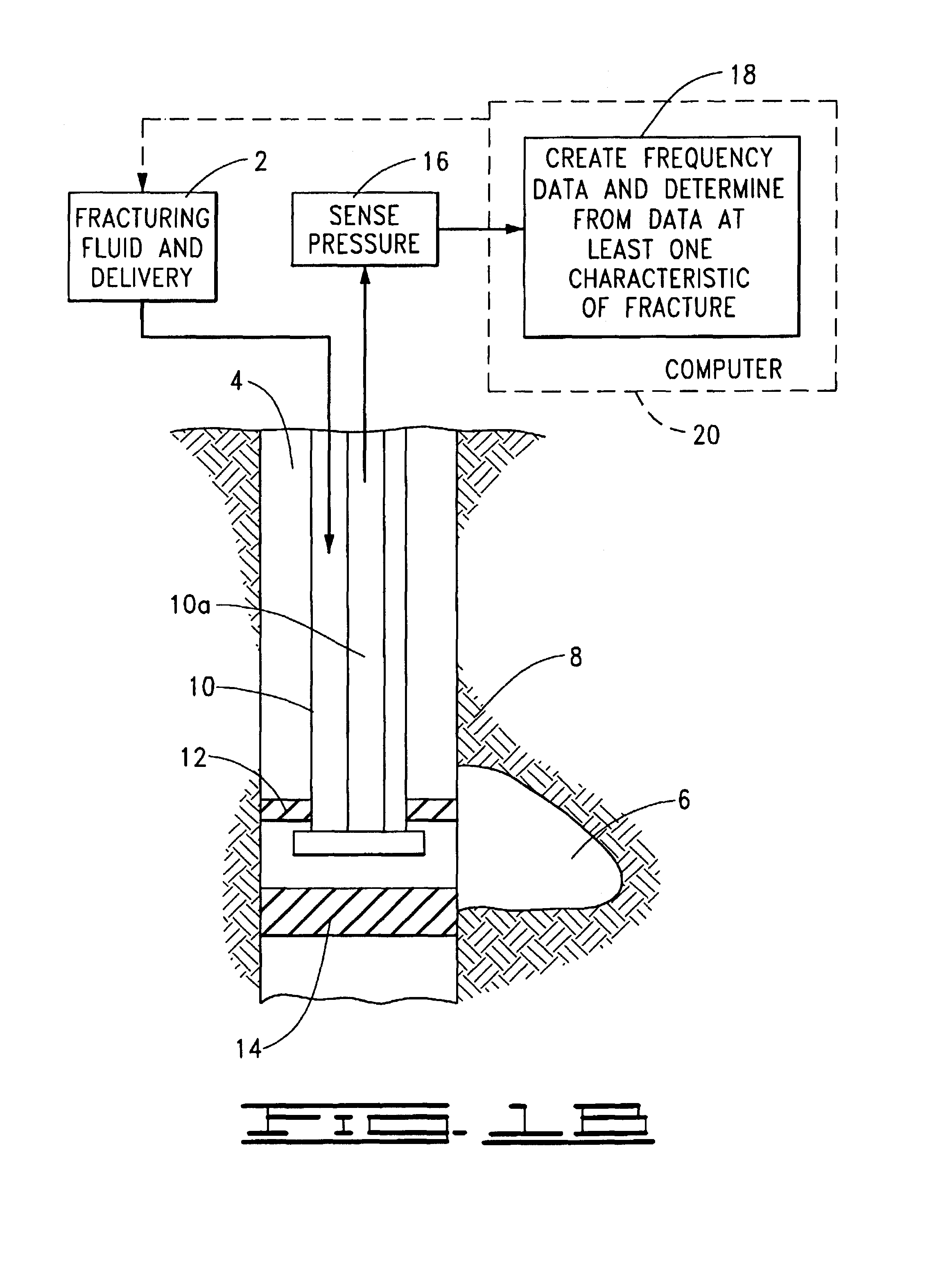

Fracture monitoring using pressure-frequency analysis

ActiveUS7100688B2Electric/magnetic detection for well-loggingSurveyFrequency spectrumTime–frequency analysis

Changes occurring downhole during a fracturing process can create or reflect pressure signals. Capturing and evaluating such pressure waves during fracturing enables personnel to monitor, in real time or later, what happens downhole. When a fracture extends, a burst of acoustic noise is embodied in a pressure wave or signal, as is noise coming from other sources. By transforming time-based pressure signals to a frequency base, one can monitor this acoustic noise. In a particular implementation, a waterfall plot of frequency spectra at successive time slices of the original signal is used to determine frequency ridges, such as a ridge of decreasing frequencies indicates fracture extension and a ridge of increasing frequencies indicates either closure or proppant backing up in the fracture. Filtering, such as wavelet filtering, can be used. A fracturing process can be controlled in response to determining whether the fracture is extending.

Owner:HALLIBURTON ENERGY SERVICES INC

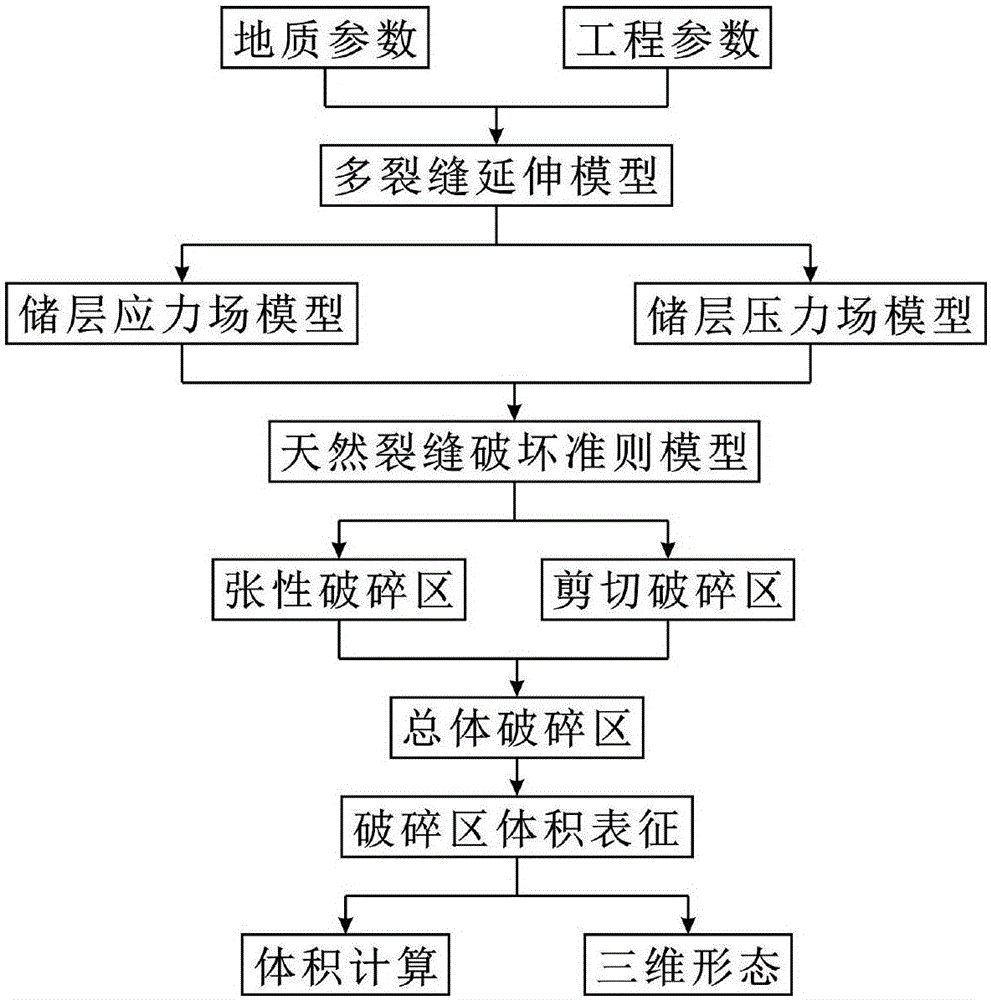

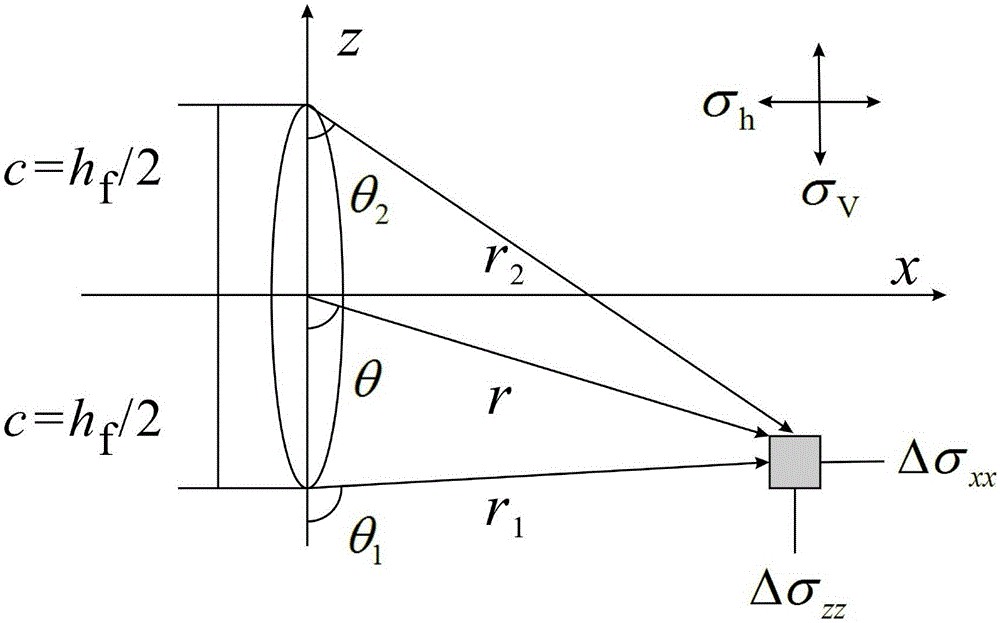

Calculating method for size of fracturing and broken region of horizontal well for shale

ActiveCN105019877AAccurate quantitative evaluationSolve problems that cannot be widely promoted and appliedFluid removalCalculation methodsPoromechanics

The invention discloses a calculating method for the size of a fracturing and broken region of a horizontal well for shale. The calculating method comprises following steps of: A, utilizing the theory of crack propagation available to establish a hydraulic fracture extension model during a shale fracturing process; B, utilizing the theory of rock mechanics available to establish a model for stress field variation during a shale fracturing process; C, utilizing the theory of seepage mechanics available to establish a model for pressure field variation during a shale fracturing process; D, utilizing the rock breaking theory available to establish a rule model for natural fractures; E, combining the above four steps to calculate and represent the size of the fracturing and broken region by means of a calculation flow. The calculating method for the size of the fracturing and broken region of the horizontal well for shale has following beneficial effects: time and money spent on calculating the size of the broken region during fracture of the horizontal well for shale are saved so that the valuation of the size of the fracturing and broken region can be extensively prompted and applied.

Owner:SOUTHWEST PETROLEUM UNIV

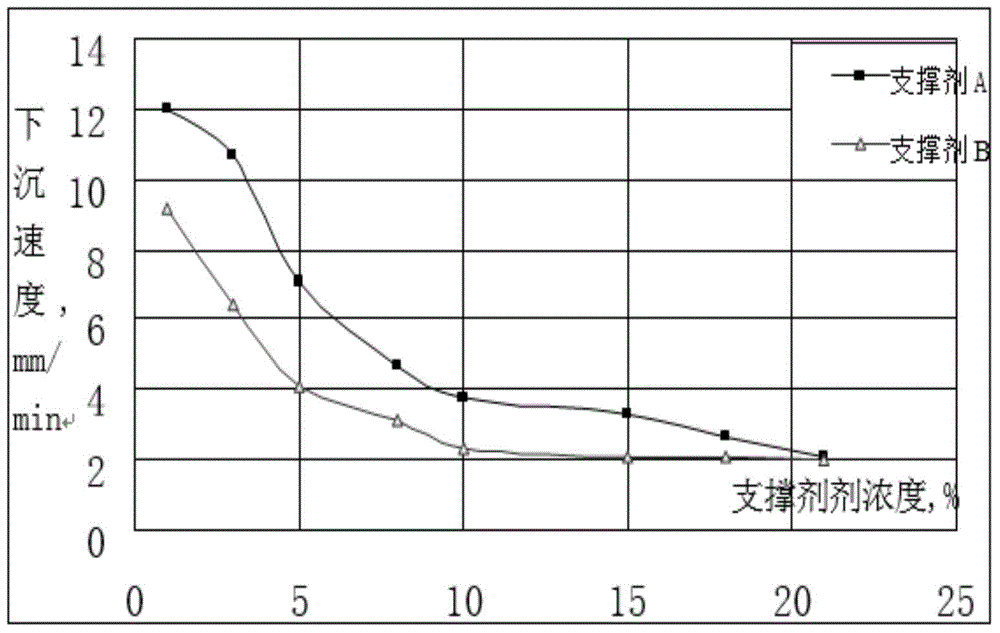

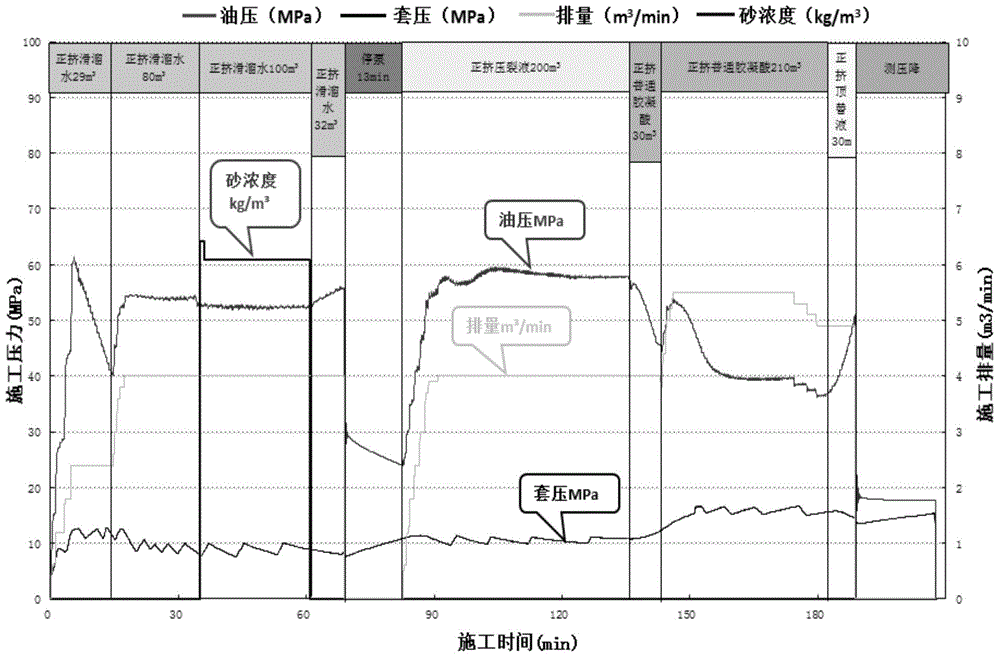

Pumping stop sand setting fracture-height-controlling acid fracturing process method applicable to carbonate reservoir

InactiveCN104564002AReduce fluid lossIncrease the lengthFluid removalAcid fracturingFracturing fluid

The invention relates to a pumping stop sand setting fracture-height-controlling acid fracturing process method applicable to a carbonate reservoir. The method comprises the following work procedures that before the normal fracturing, low-viscosity slickwater is adopted for fracture making, and the initial fracture height is controlled; then, after the slickwater enters the stratum in a way of carrying support agent sand, the pumping stop is adopted for prompting the support agent sand to be settled near a fracture opening, so that each stage of support agent sand shields the back section in advance, a high-intensity artificial separation layer is formed, the stress state is changed, and the goal of effectively controlling the lower fracture height extending to prevent the communication with the lower part water body is achieved; low-viscosity fracturing fluid is injected for fracture making at a stable discharge capacity; after the fracturing fluid enters the stratum, acid liquid is injected for etching the stratum, and high-flow-guide capability artificial fractures are formed; after the acid liquid is extruded into the stratum, the pumping is stopped for measuring the pressure drop, and the construction is completed. The process has the advantages that the artificial separation layer can be formed, the fracture height vertical direction extending can be controlled, the stress state is changed, and the goals of effectively controlling the lower fracture height extending and preventing the communication with the lower part water body are achieved.

Owner:CHINA PETROLEUM & CHEM CORP

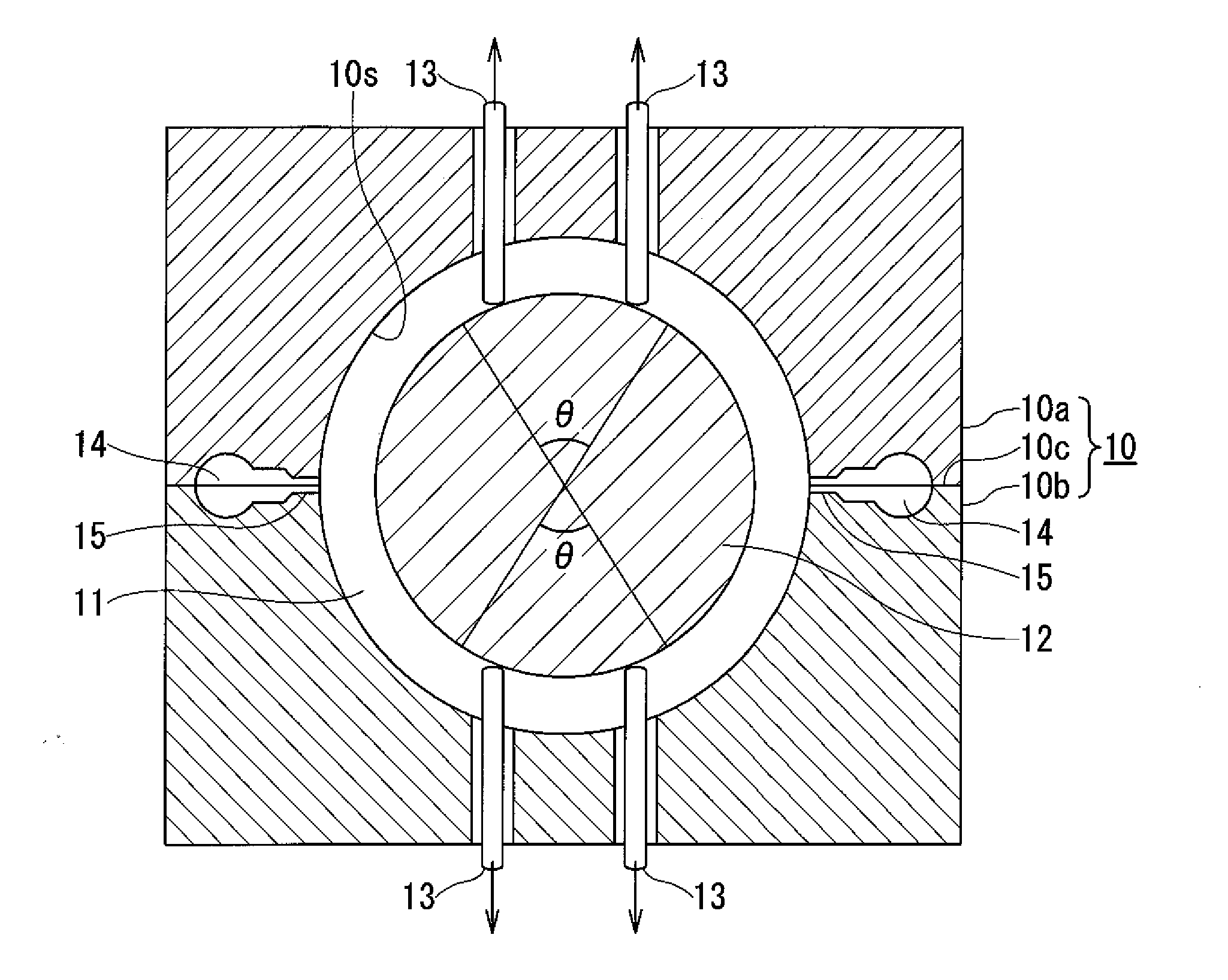

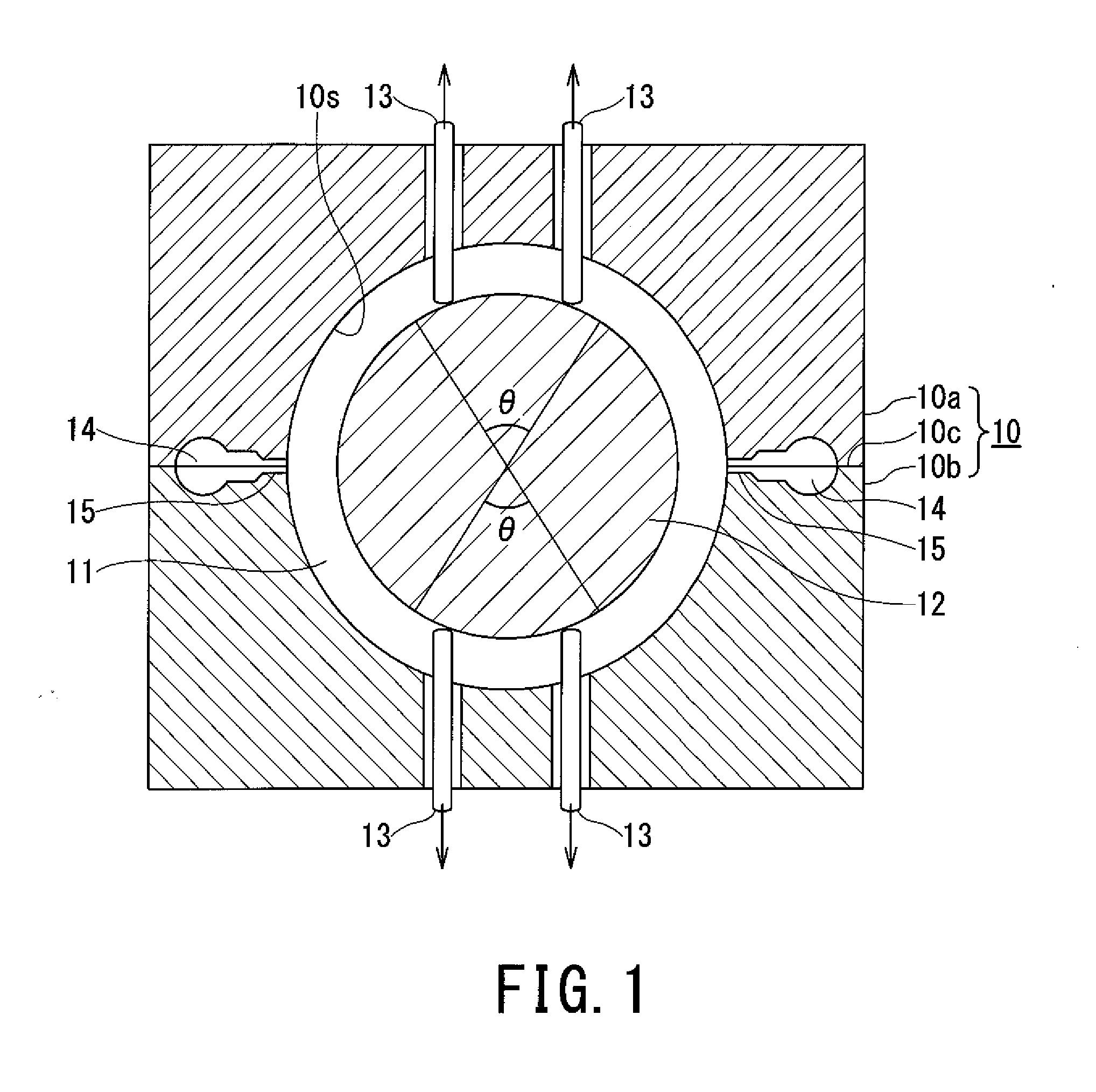

Ball sealer for hydrocarbon resource collection as well as production method therefor and downhole treatment method using same

ActiveUS20150144348A1High mechanical strengthSimple stepsSynthetic resin layered productsFluid removalResource recoveryHydraulic fracturing

A ball sealer for hydrocarbon resource recovery, comprising: a generally spherical entire structure including at least two layers of a spherical core and a surface resin layer covering the spherical core, of which at least the surface resin layer comprises a polyglycolic acid resin; and having a diameter of at least about 25 mm (1 inch). The ball sealer is produced through a process comprising the steps of: disposing a spherical core by a support pin at a substantially central position within a mold cavity, injecting a surface resin comprising a polyglycolic acid resin into the cavity surrounding the spherical core, causing the support pin to retreat up to a wall surface of mold cavity in synchronism with a completion of the injection of the surface resin, and then hardening the surface resin. As a result, it is possible to produce a large-diameter ball sealer suitable for use in the hydraulic fracturing process (hydraulic fracturing) widely used for recovery of hydrocarbon resources by using a polyglycolic acid resin which is a biodegradable resin having good mechanical strengths and a good size designability at least as a surface-forming resin, through relatively simple steps and with good dimensional accuracy.

Owner:KUREHA KAGAKU KOGYO KK

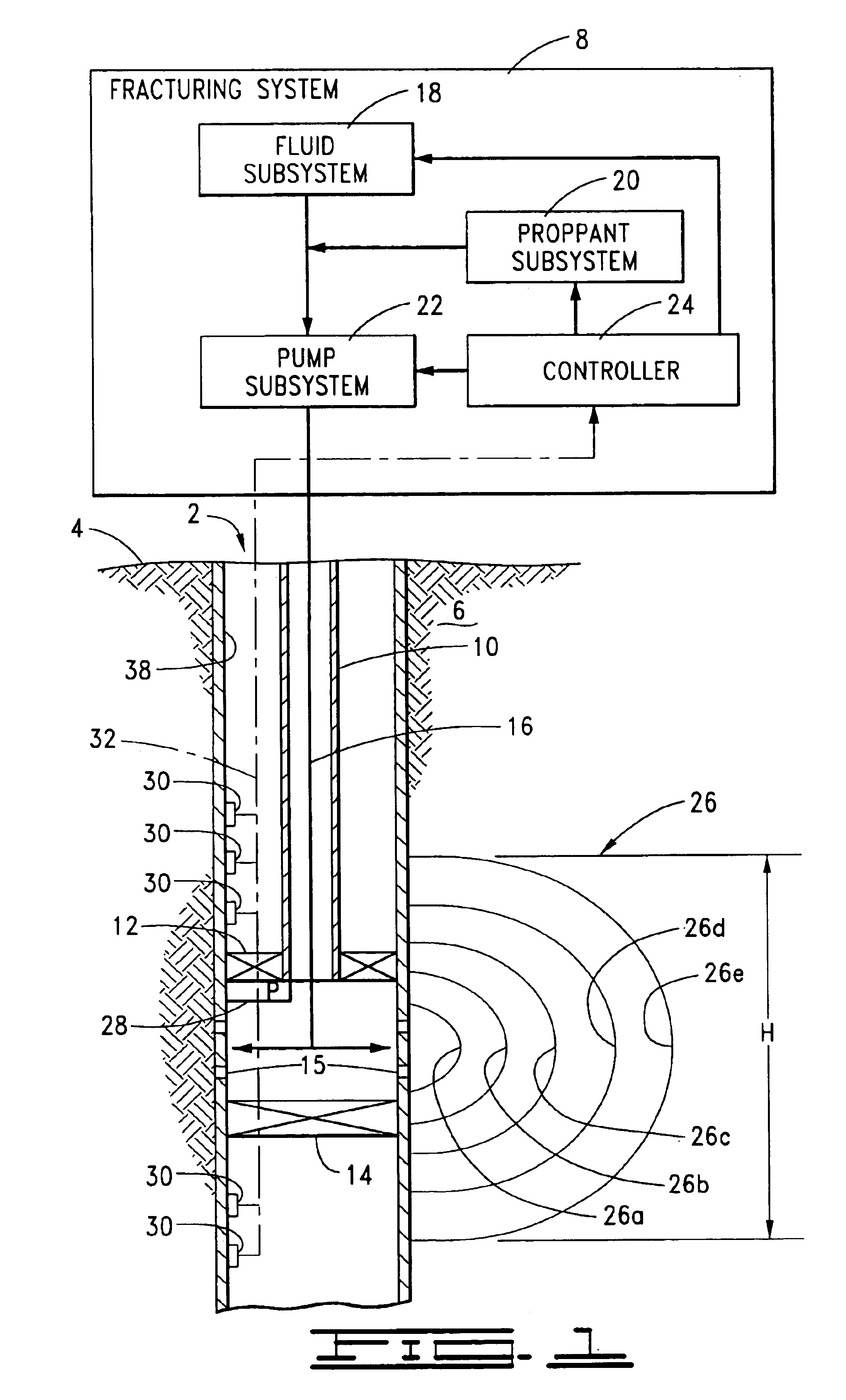

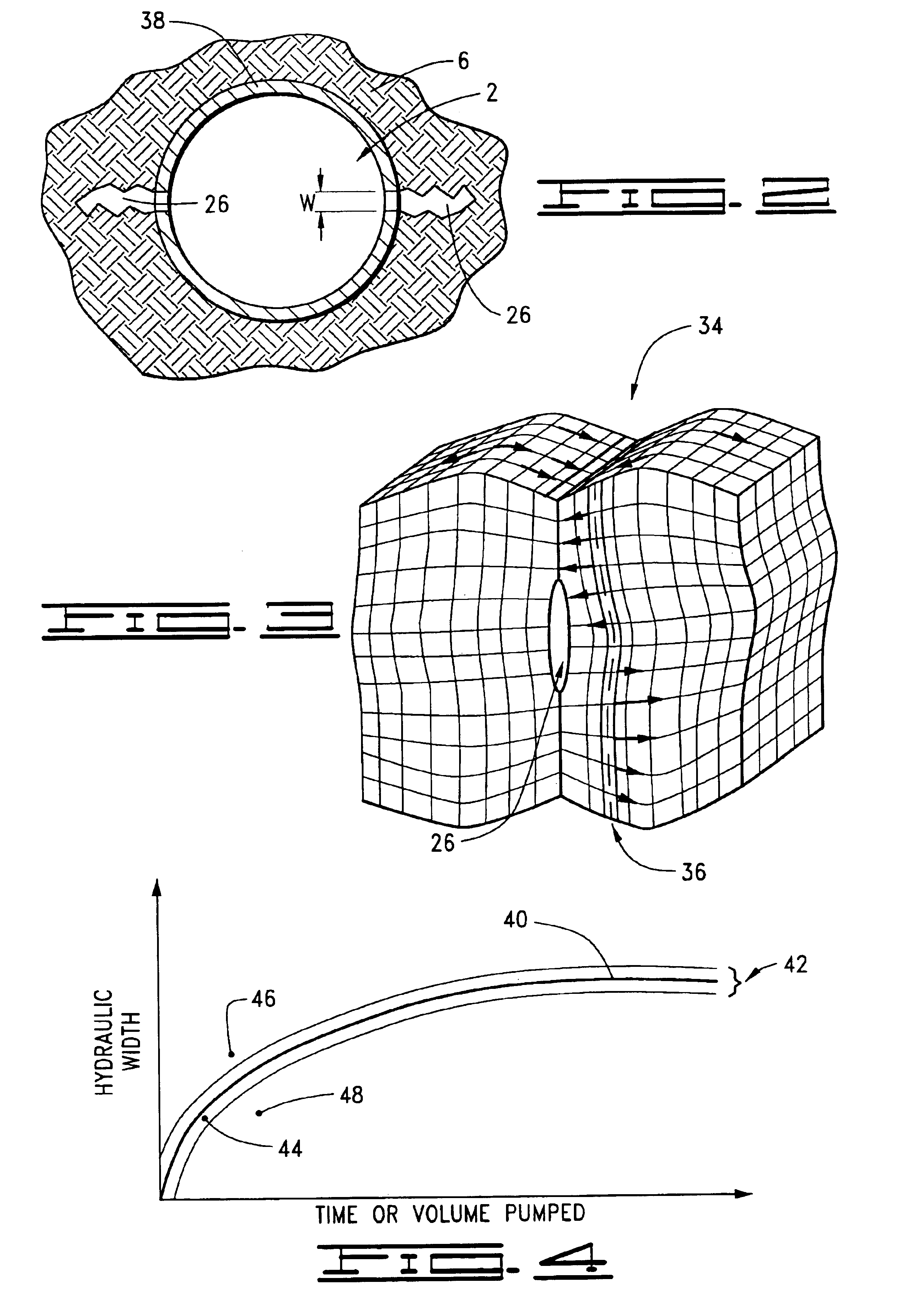

Mitigating risk by using fracture mapping to alter formation fracturing process

A formation fracturing method with which to mitigate risk to hydrocarbon productivity includes pumping fracturing fluid, during at least part of a fracturing job time period, into a well to fracture a formation; generating signals, within the fracturing job time period, in response to at least one dimension of the fracture; and further pumping fracturing fluid, within the fracturing job time period, into the well in response to the generated signals. Further pumping includes controlling at least one of a pump rate of the further pumping and a viscosity (either fluid viscosity or particulate concentration) of the further pumped fracturing fluid. Control can include comparing a measured magnitude of at least one dimension of the fracture represented by the generated signals with a predetermined modeled magnitude of the same dimension. Tiltmeters can be used to sense fracture height and width, for example.

Owner:HALLIBURTON ENERGY SERVICES INC

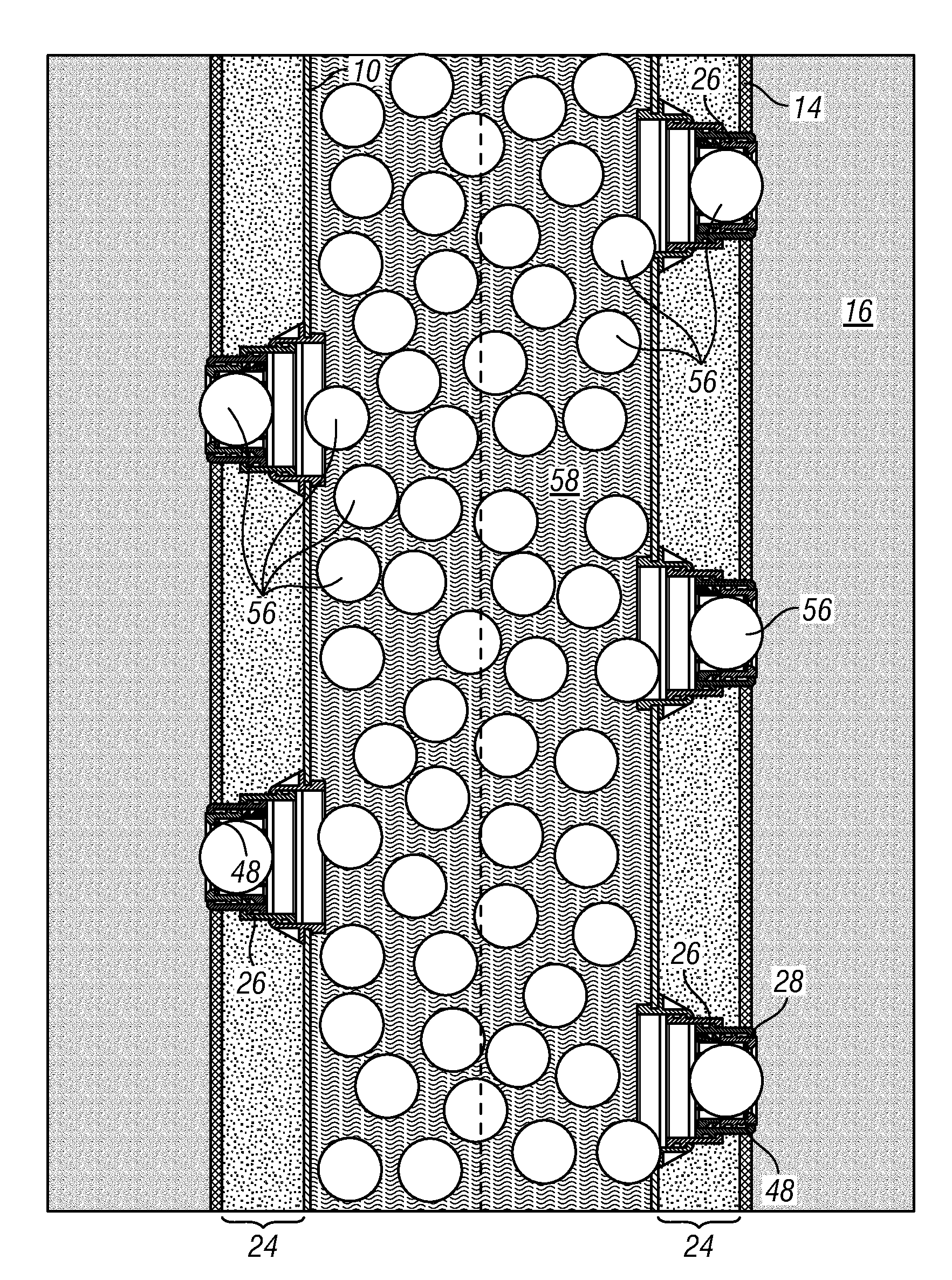

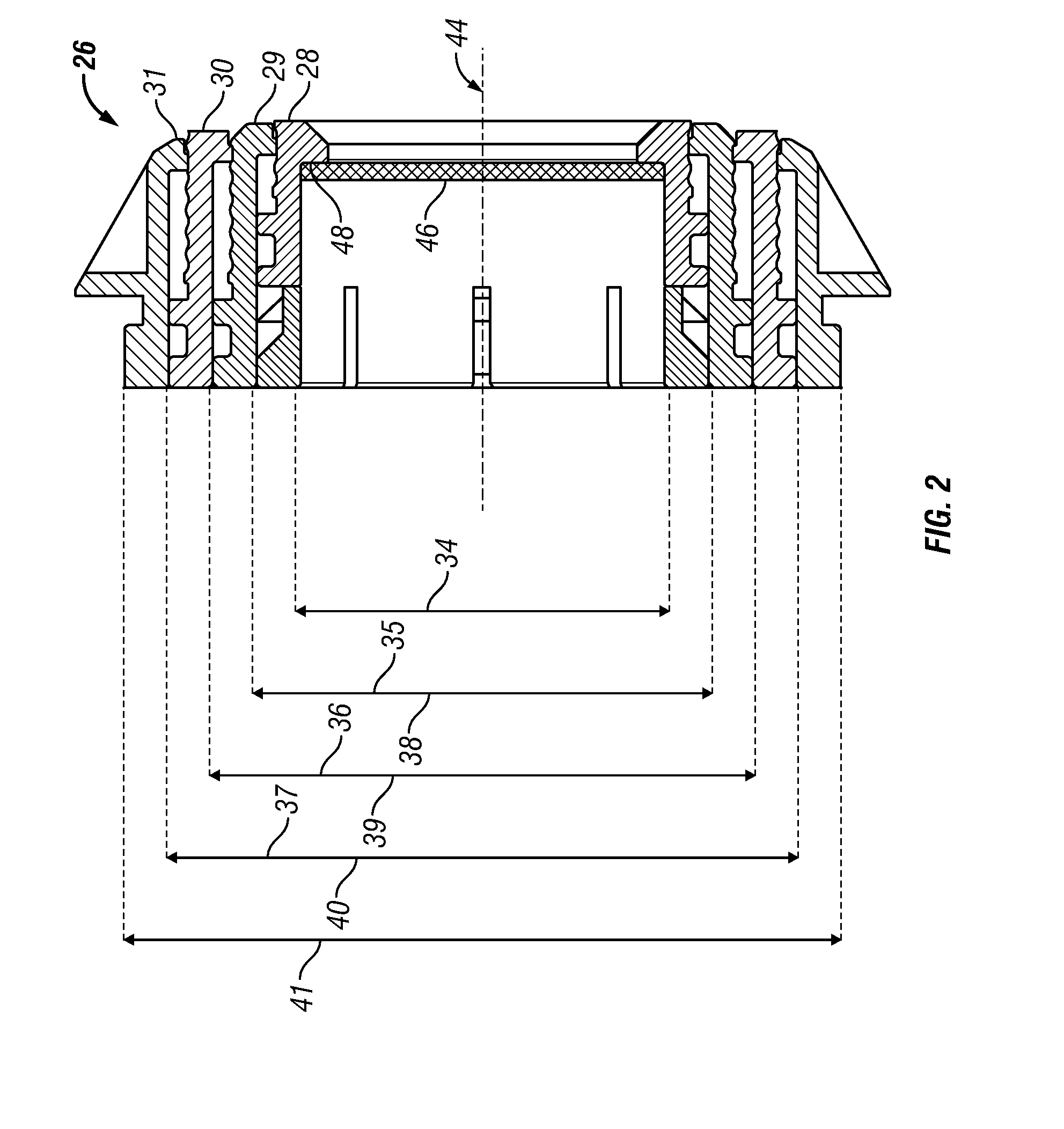

Method and Materials for Proppant Flow Control With Telescoping Flow Conduit Technology

ActiveUS20110220362A1Control flowInhibits and prevents flowFluid removalWell/borehole valve arrangementsHydraulic fracturingEngineering

Porous objects, such as porous balls, may be employed within telescoping devices to control proppant flowback through a completed well during production. The telescoping devices may connect a reservoir face to a production liner without perforating. Acid-soluble plugs initially disposed within the telescoping devices may provide enough resistance to enable the telescoping devices to extend out from the production liner under hydraulic pressure. The plugs may then be dissolved in an acidic solution, which may also be used as the hydraulic extension fluid. After the plugs are substantially removed from the telescoping devices, the reservoir may be hydraulically fractured using standard fracturing processes. The porous balls may then be inserted into the telescoping devices to block proppant used in the fracturing process from flowing out of the reservoir with the production fluids.

Owner:BAKER HUGHES INC

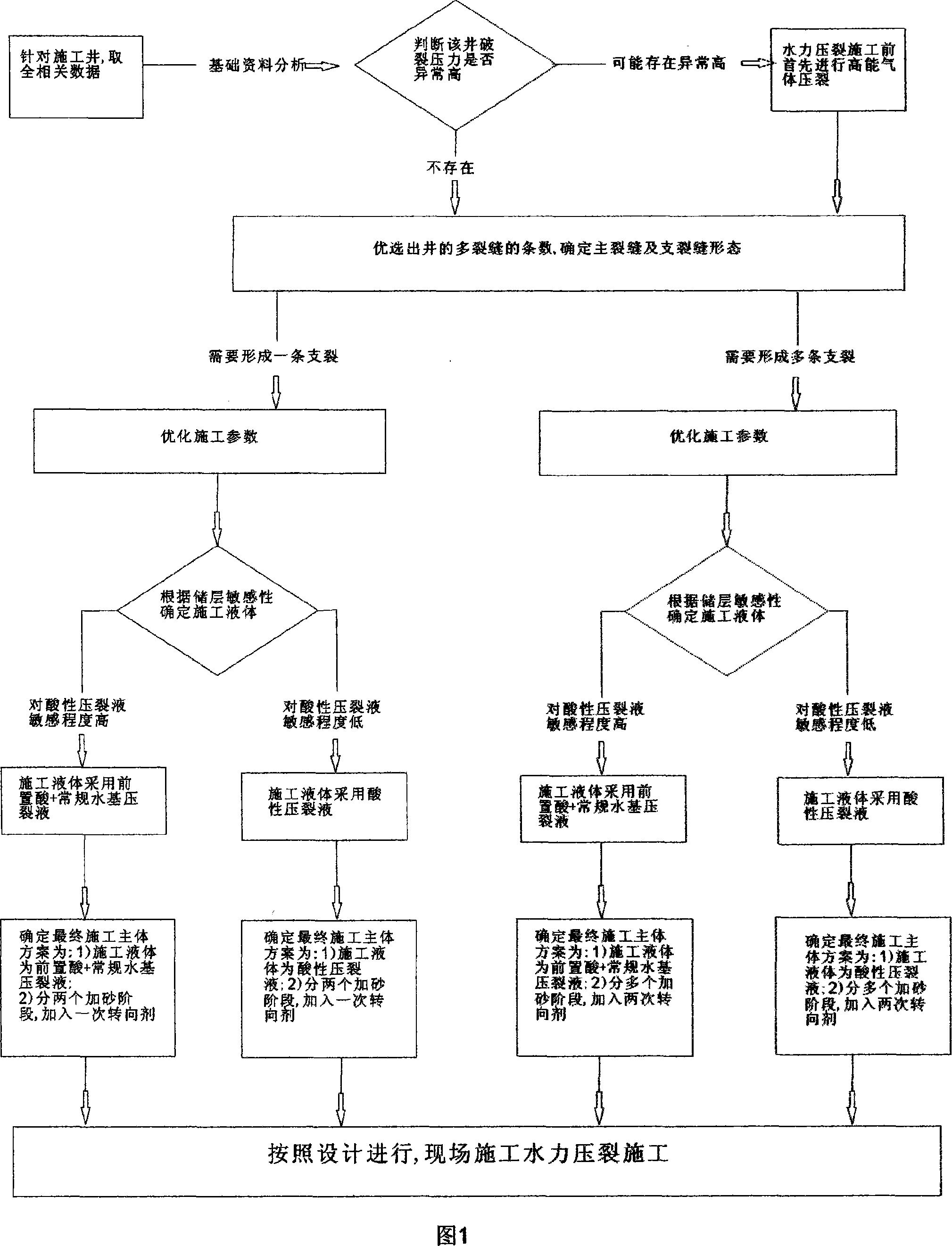

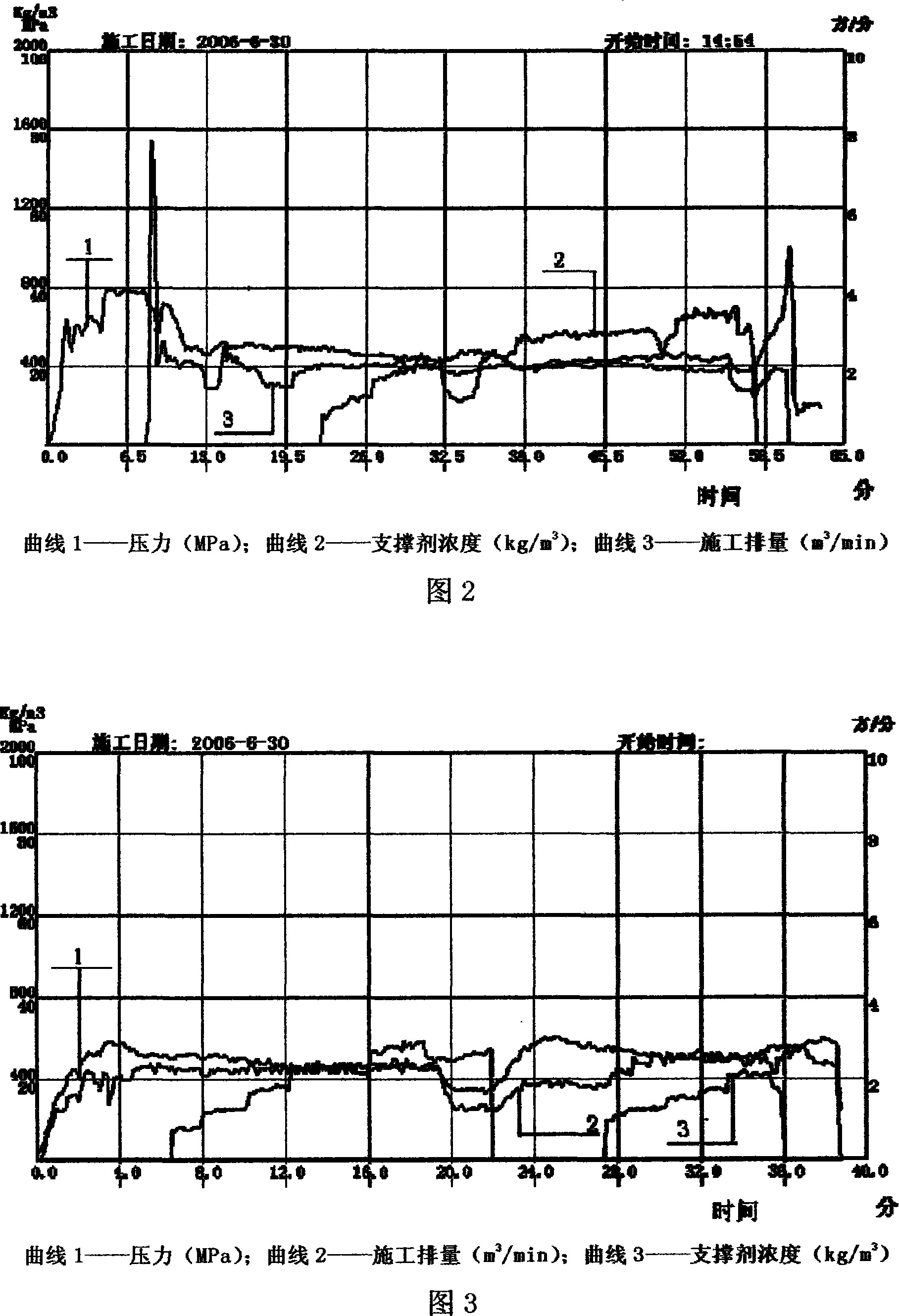

Fracturing process for enhancing low permeability reservoir deliverability

ActiveCN101113669AGuaranteed permeabilityIncreased productivity after pressingFluid removalAcid fracturingClay minerals

The invention relates to an oil field production technique, in particular to a fracturing method applied under the oil well to improve new well production capacity of low permeability reservoir before being brought into production. The fracturing reformation course at least comprises common fracturing technique and is characterized in that the method uses a compound application of more than two techniques of the use of acid fracturing liquid, or diversion agent or acid liquid and diversion agent by adopting high-energy gas fracturing technique; the upper sealed fracturing pipe is adopted during the working of hydraulic fracturing; the acid liquid is adopted during a pad fluid stage as the working liquid; the diversion agent is added for one or more times to seal fractured cracks; an increasing working flow rate is adopted before and after the adding of the diversion agent. The method of the invention can increase oil discharging area after fracturing, reduce expansion rate of clay minerals in fractured reservoir and improve completion of oil well reformation, fracturing effect and production capacity of low permeability reservoir after fracturing.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

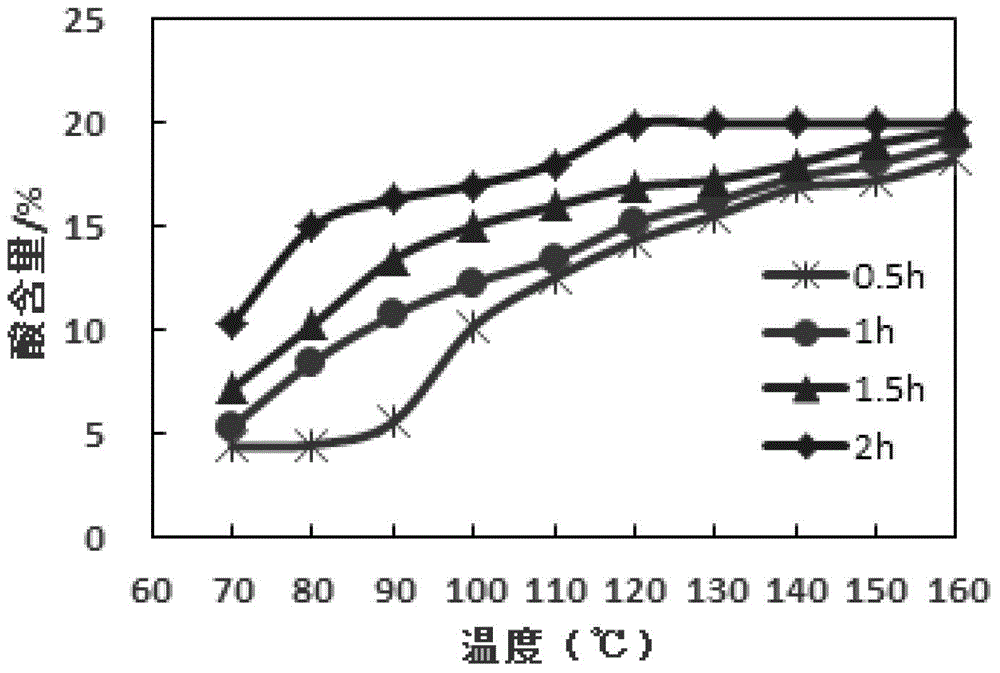

Acid fracturing process of oil gas well mining temperature control various mucic acid

ActiveCN101353958AReduce fluid lossEasy to form non-uniform etchingFluid removalDrilling compositionAcid etchingMucic acid

The invention relates to an acid fracturing method of a temperature-control and variable-viscosity acid in the exploitation of an oil-gas well, which comprises the steps that: a common chlorohydric acid pickling process is firstly used for removing the pollution of an embrasure; then, the temperature-control and variable-viscosity acid fracturing process, or an ahead-fluid temperature-control and variable-viscosity acid fracturing process, or a temperature-control and variable-viscosity acid fracturing enclosed acidizing process, or an ahead-fluid temperature-control and variable-viscosity acid fracturing enclosed acidizing process is adopted; the weight ratio of the components of the temperature-control and variable-viscosity acid are as follows: 100 portions of basic acid solution, 0.5 portion to 1.5 portions of the main agent of the temperature-control and variable-viscosity acid, 1 portion to 3 portions of a corrosion inhibitor of the temperature-control and variable-viscosity acid, 0.5 portion to 1 portion of an emulsion breaker, 0.5 portion to 1 portion of a ferric ion stabilizer and 0.5 portion to 1 portion of a high efficient discharge aiding agent; 2-percent KCL clear water is used for displacing the temperature-control and variable-viscosity acid into the stratum. The temperature-control and variable-viscosity acid is easily prepared on site, with low friction drag and strong pumpability, thereby being capable of being applied to high-discharge construction; under the high temperature condition of a storing layer, both the fresh acid and the residue acid have high viscosity, thus increasing the length of acid-etching cracks. After the construction is finished, the viscosity of the residue acid is reduced, which is beneficial to the back discharge of the residue acid.

Owner:PETROCHINA CO LTD

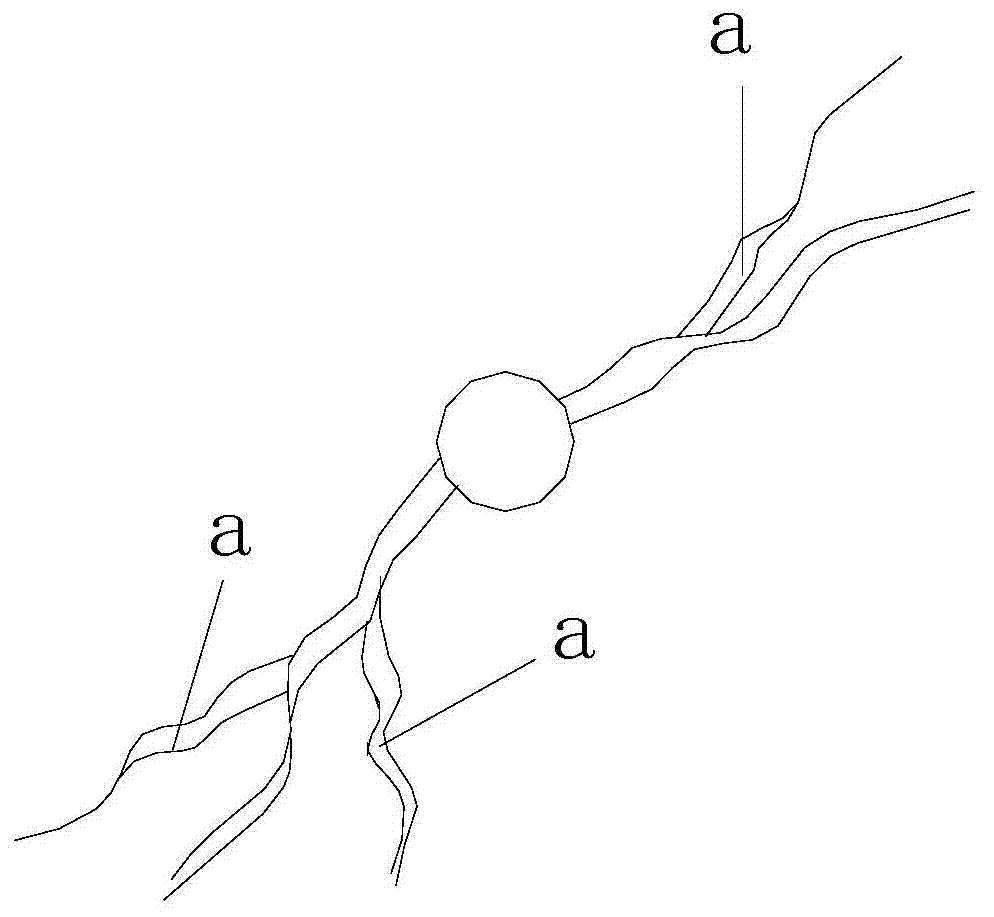

Temporary plugging and fracturing process in degradable fiber clearance

The invention relates to a novel temporary plugging and fracturing process in a degradable fiber clearance. According to the temporary plugging and fracturing process, work liquid composed 1.0%-2.0% of degradable polyester fibers, 0.45% of linear glue and 20%-35% of propping agents is poured into a fracturing layer section, and a plurality of branch cracks are generated. The temporary plugging and fracturing process has the advantages that operability of the construction process is strong, the branch cracks are formed in a fracturing mode, the oil drainage area is expanded, fracturing yield is improved, an effective driving system can be built through a formed branch crack system and a well, cost is low, and the exploitation benefit of an oilfield is greatly improved, and the problems that permeability is low, exploitation is hard and the reserve fracturing reforestation effect is poor are solved.

Owner:PETROCHINA CO LTD +1

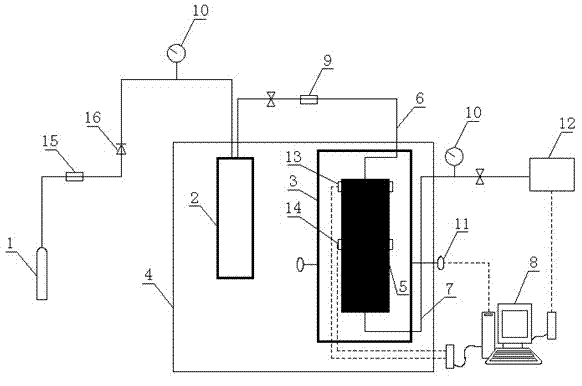

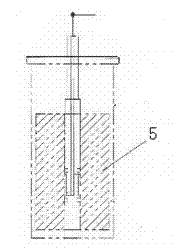

Coal and rock bore hydraulic fracture experimental apparatus

InactiveCN102031954AImprove fracturing effectEasy to take pictures and recordEarth material testingFluid removalPressure systemAcoustic emission

The invention discloses a coal and rock bore hydraulic fracture experimental apparatus, which comprises a sample device system, a confining pressure system, a fracture system, a sealing system and a monitoring system, wherein the sample device system comprises a sample cylinder, the bottom in the sample cylinder is provided with a screen drum of which the bottom is provided with a water outlet pipe, a sample is accommodated in the sample cylinder above the screen drum, and a simulated bore is formed in the sample; the confining pressure system comprises an air filling subsystem and a water filling subsystem; the fracture system comprises a fracture high-pressure water pump of which a water outlet is communicated with the simulated bore through a fracture pipeline; the sealing system comprises a sample cylinder sealing device and an experimental cylinder sealing device; and the monitoring system comprises an acoustic emission sensor arranged on an external wall of the sample cylinder. By the coal and rock bore hydraulic fracture experimental apparatus, a simulated experiment can be performed in a laboratory to investigate the change rules of crack initiation, expansion and extension in the hydraulic fracture process of a coal mine underground coal seam bore, and know a crack extending direction so as to guide field fracture; therefore, the fracture effect is greatly improved.

Owner:HENAN POLYTECHNIC UNIV

Experimental device for improving permeability of shale gas storage layer in supercritical CO2 fracturing process

The invention discloses an experimental device for increasing the permeability of a shale gas storage layer in the supercritical CO2 fracturing process, which comprises a gas source supply system, a gas supercharger, a pressure chamber, a temperature controller and a data automatic acquisition system. A shale test piece of which the center is drilled is arranged in the pressure chamber; the gas source supply system is communicated with a gas inlet pipe of the pressure chamber by the gas supercharger; both the gas supercharger and the pressure chamber are arranged in the temperature controller; and the data automatic acquisition system is used for carrying out real-time acquisition on the stress-strain relation, the pressure, the temperature, an acoustic emission signal and the like in the shale fracturing process and measuring the seepage characteristics of shales before and after the supercritical CO2 fracturing. The device disclosed by the invention can be used for simulating the dynamic variation of the permeability of the shale gas storage layer in the supercritical CO2 fracturing process under the multifield (the ground stress, the temperature and the pressure) coupling conditions and provides an experimental platform for researching the mechanism of increasing the permeability of the shale gas storage layer in the supercritical CO2 fracturing process.

Owner:CHONGQING UNIV

Hydraulic fracturing simulation experimental device and method of hot dry rock enhanced type geothermal system

InactiveCN107893652AAccurate calculation of hydraulic fracturing heat transfer efficiencySimulation is accurateSurveyFluid removalHydraulic fracturingHigh pressure

The invention relates to a hydraulic fracturing simulation experimental device and method of a hot dry rock enhanced type geothermal system. A hot dry rock high-pressure and high-temperature generating environment is simulated, precise stress is applied to a rock core by designing a multistage piston, the permeability of hot dry rock fluid is maintained by adopting a pressureproof and temperature-resistant perforated plate, the hot dry rock fluid is externally connected to a fluid collection chamber through a flow guiding groove, and meanwhile an adjustable sound emission probe is embedded into a true-triaxial high-pressure axe to monitor a sound emission event happening when a fracture expands in the hydraulic fracturing process, integrated collection of information of rock hydraulic fracturing, sound emission, heat energy recovery efficiency and the like under the triaxial confining pressure condition can be achieved by utilizing the device, and therefore the fracture initiation andexpanding situations of the hot dry rock hydraulic fracture can be studied. The hydraulic fracturing simulation experimental device and method have the beneficial effects that warming and heat preservation effects are good, a sealed part is simple to replace and convenient to maintain, a sound emission embedded part can be adjusted according to the requirements for the probe sizes, in addition, the whole device further has the characteristics that operation is convenient, and the protection and maintenance period is short, and the device is an important technological innovation at the aspect of dry hot rock enhanced type geothermal system hydraulic fracturing testing device detection.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

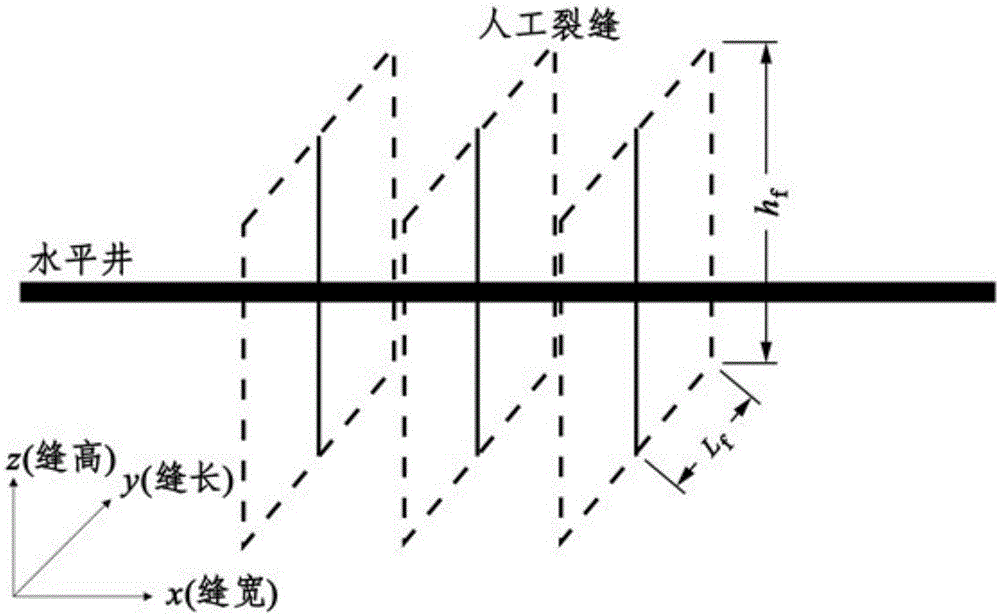

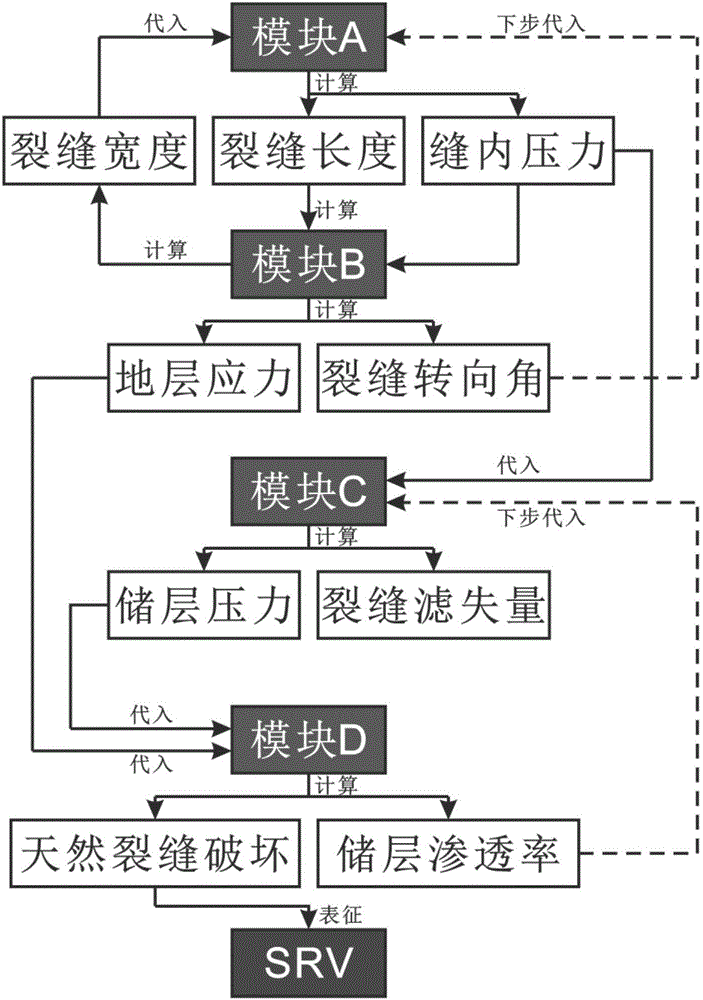

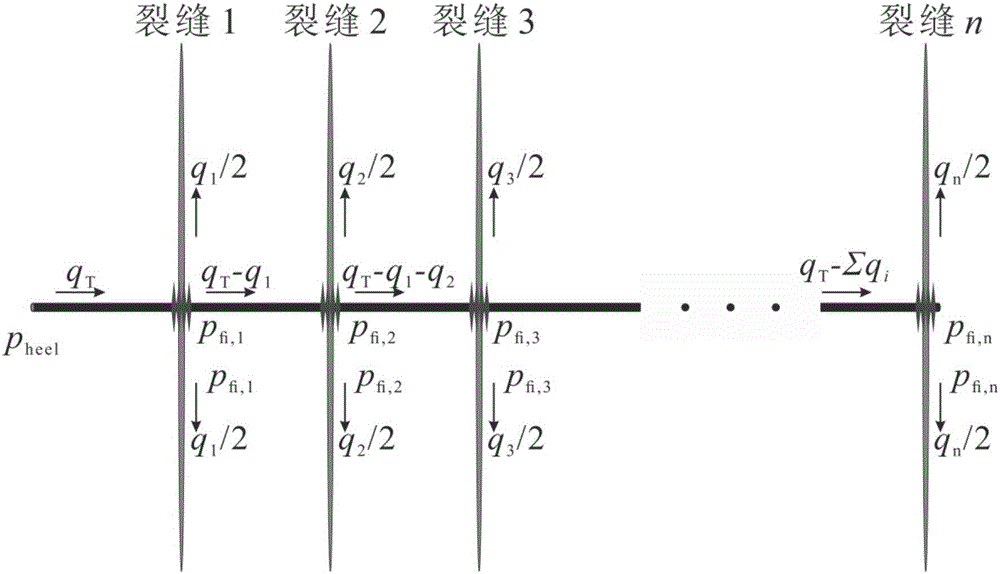

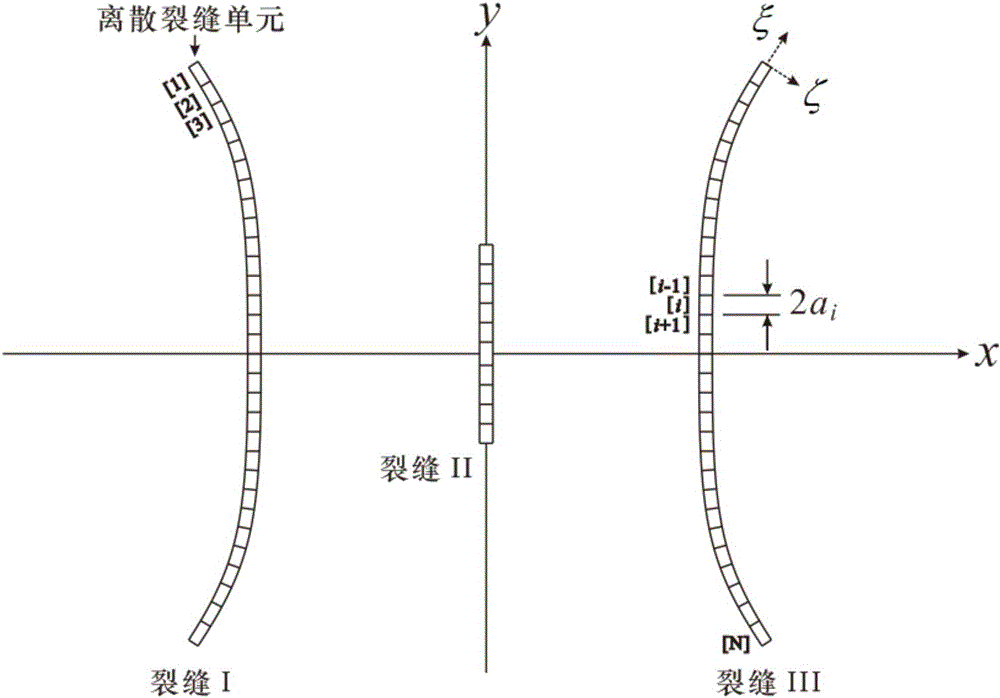

Method for calculating tight reservoir fracturing transformation volume area

ActiveCN106844909AFastSolve the problem of failure to widely promote and apply in the mining fieldGeometric CADDesign optimisation/simulationReservoir pressureChange model

The invention discloses a method for calculating a tight reservoir fracturing transformation volume area. The method comprises the following steps that multiple hydraulic fracture non-planar turning extension models, a formation stress field change model, a reservoir pressure file change model and a natural fracture failure criterion in the tight reservoir horizontal well fracturing process are established, geological parameters, horizontal well fracturing construction parameters and the total fracturing time are obtained, an initial fracture filter loss value, an initial fracture half-length value, an initial in-fracture pressure value, an initial fracture extension turning angle, initial permeability and an initial fracturing time value are endowed, all the models are calculated, and natural fracture failure point coordinate data is calculated; a spatial and numerical integration method is utilized to calculate tension failure transformation area volume and shear failure transformation area volume in a reservoir respectively, and the spaces of the two parts are united and regarded as a total transformation volume area. By adopting the method, accurate, economic and rapid tight reservoir horizontal well fracturing evaluation can be achieved, and the problem that effort, money and time are wasted in the existing tight reservoir horizontal well fracturing transformation volume area calculating process is solved.

Owner:SOUTHWEST PETROLEUM UNIV

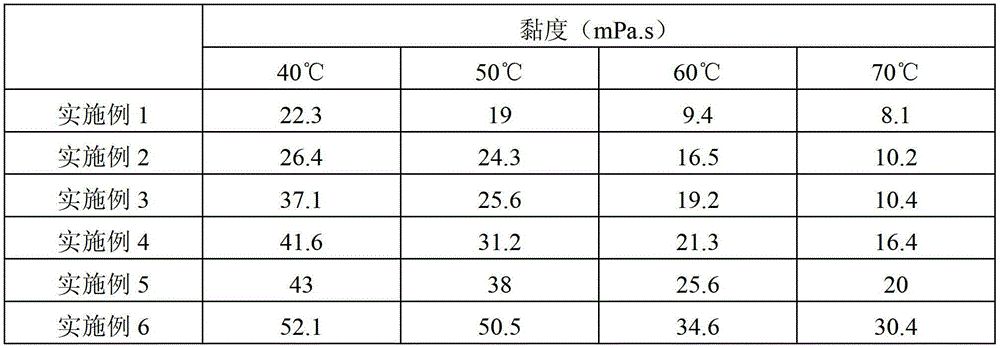

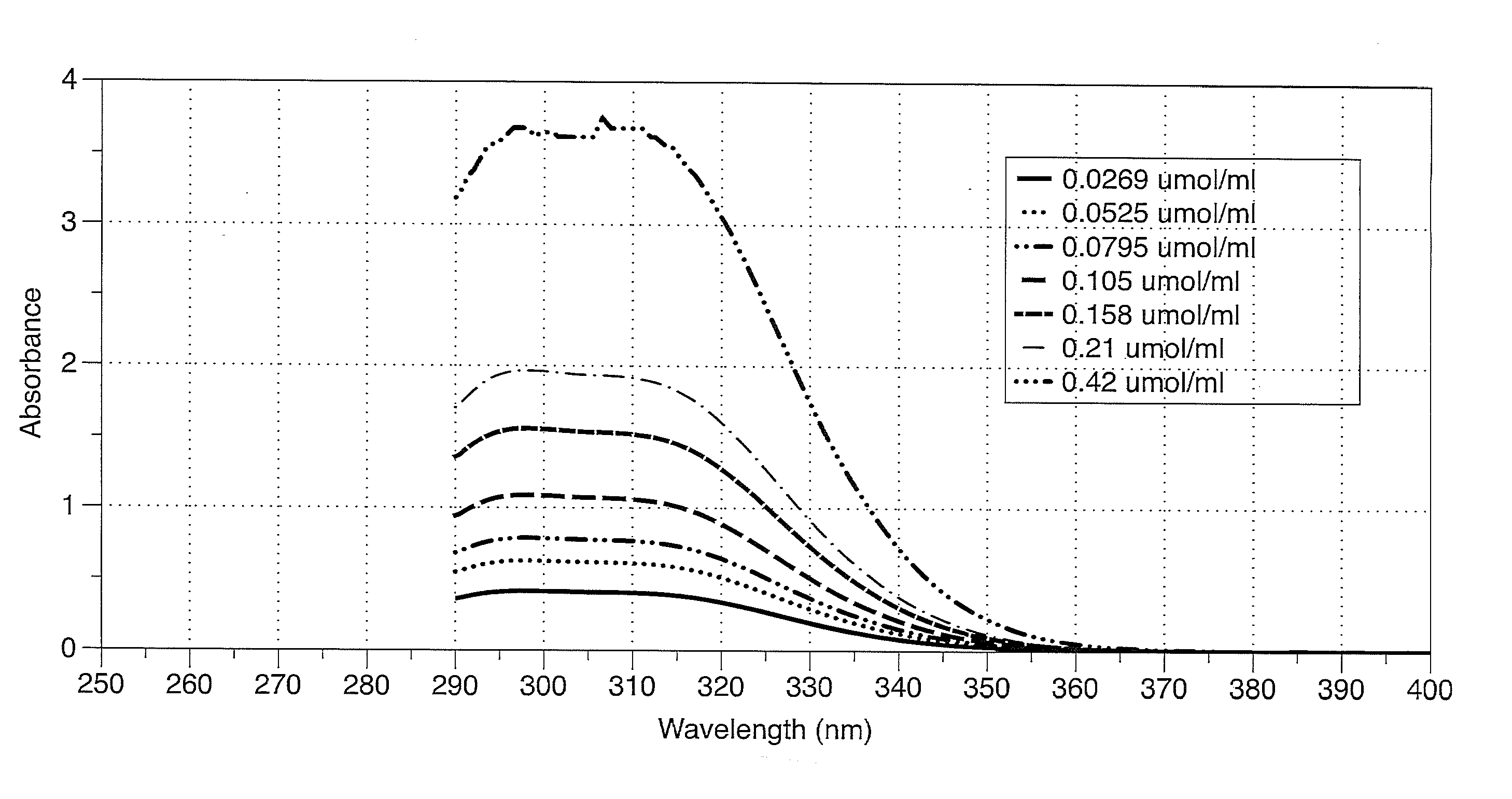

Carbon dioxide fracturing fluid and preparation method thereof

InactiveCN104152133ANo pollution in the processImprove protectionDrilling compositionBulk chemical productionFracturing fluidShear rate

The invention provides a carbon dioxide fracturing fluid and a preparation method thereof. The carbon dioxide fracturing fluid is a non-water fracturing fluid, and the fracturing fluid contains carbon dioxide, a thickening agent and a multi effect additive used to reduce the interfacial tension between underground fluids and the fracturing fluid. The carbon dioxide fracturing fluid has high viscosity at a certain temperature and in a certain shear rate, the viscosity temperature performance is mainly controlled by temperature, and is in nonsignificant relationship with shear time, and the carbon dioxide fracturing fluid can satisfy the fracturing fluid crack making and sand carrying technical requirements of the fracturing process on the fracturing fluid. The non-water fracturing fluid provided by the invention can greatly reduce the environment stress of the fracturing technology on fresh water and waste liquid processing, can be used for production increase and development of oil and gas fields, and is especially suitable for the development of severe water sensitive reservoirs and non conventional resources.

Owner:CHINA PETROLEUM & CHEM CORP +1

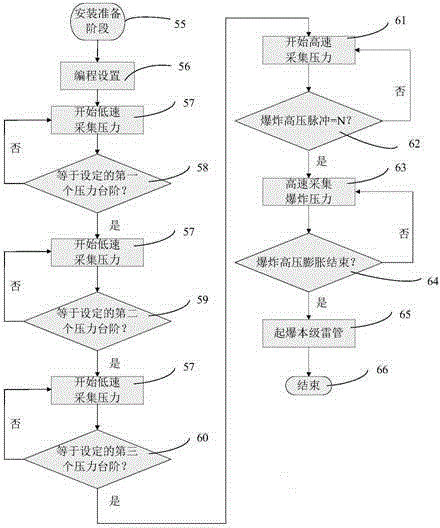

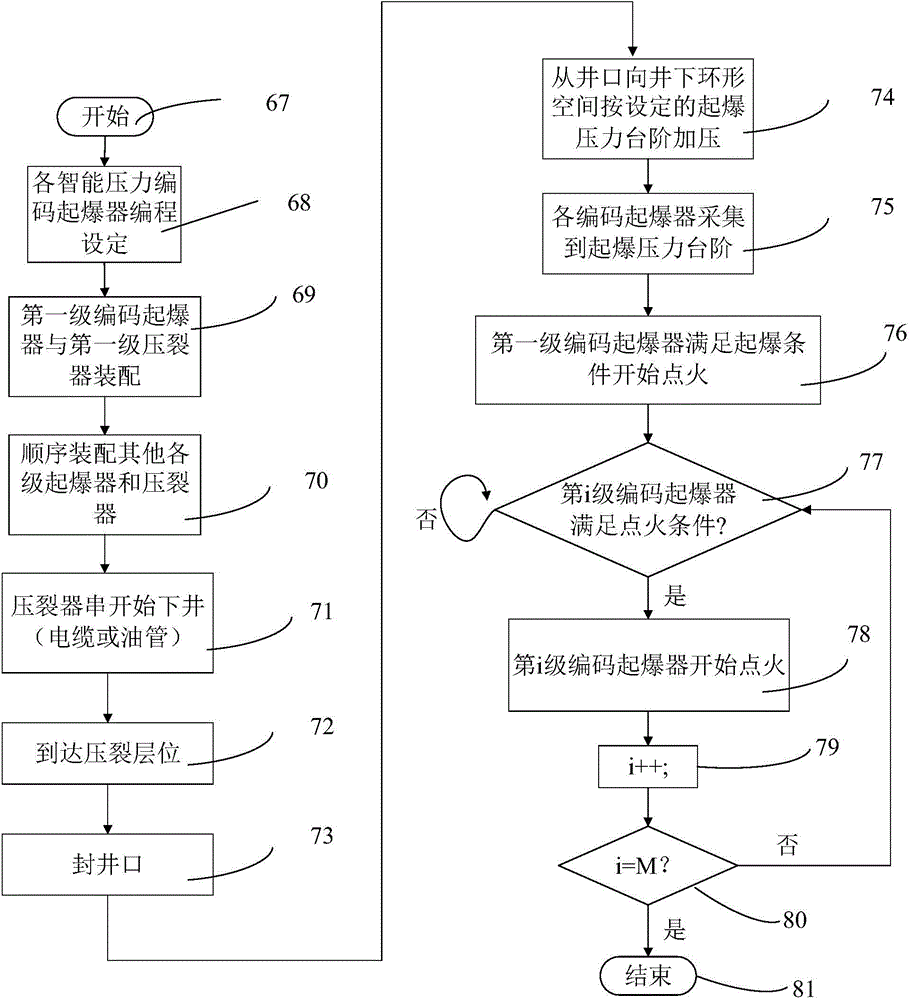

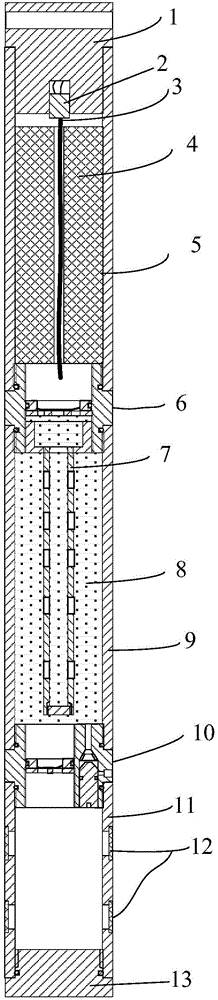

Underground multi-stage intelligent high pressure gas pulse formation fracturing device and method thereof

The invention discloses an underground multi-stage intelligent high pressure gas pulse formation fracturing device and a method thereof, belongs to the technical field of fracturing completion of oil and gas wells, and particularly relates to two technical sachems of the device and the method. The method is used for fracturing the underground layer by the underground multi-stage intelligent high pressure gas pulse formation fracturing device. The device is controlled by each stage of intelligent pressure encoding detonator to gradually detonate by stages at proper time to generate a large amount of high pressure gas according to the set working mode, the dynamic high pressure pulse pressure is formed in the well or holes of a formation, the formation is fractured to form a plurality of cracks, and the permeability of fluid in the formation is increased, so the oil and gas are easily produced. The device and the method have the advantages that the cyclic multiple pressure pulses which are controlled at proper pressure can be generated, so the formation can generate the compression-expansion-compression alternating 'resonance', the cracks are promoted to effectively extend, and a new fracturing network is formed, so the permeability of the formation is improved; the pollution to the formation and environment in the fracturing process is avoided; the method is suitable for the water-sensitive and acid-sensitive formation; the construction cycle is short, the cost is low, the equipment is simple and convenient, and the limitation by terrain and water sources is avoided.

Owner:ZHONGBEI UNIV

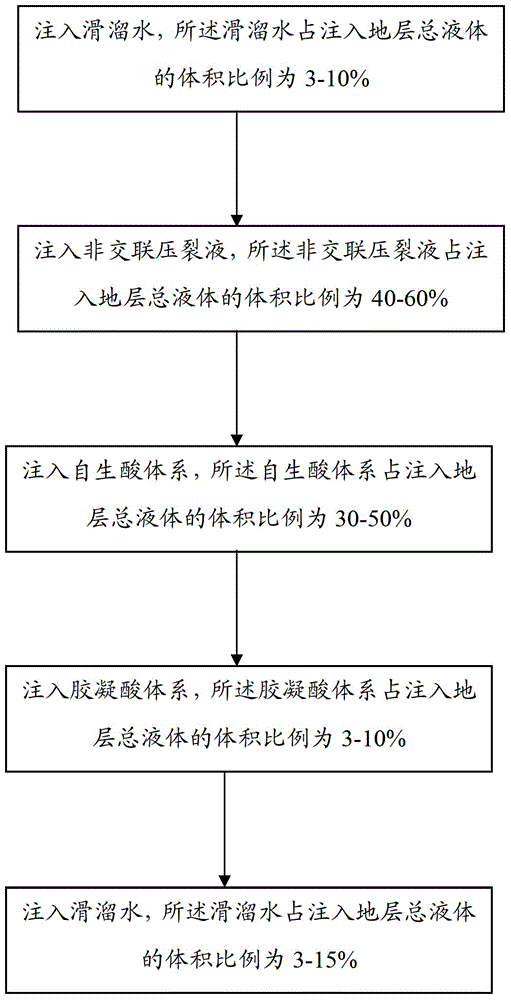

Self-born acid composite acid fracturing process for high-temperature deep well carbonate rock reservoir

ActiveCN104975840AImprove diversion capacityReduce corrosion rateFluid removalAcid fracturingHot Temperature

The invention relates to a self-born acid composite acid fracturing process for a high-temperature deep well carbonate rock reservoir. The process comprises the following work procedures of: (1) injecting slick water into a stratum through an oil pipe; (2) injecting non-crosslinked fracturing liquid into the stratum through the oil pipe; (3) injecting a self-born acid system into the stratum through the oil pipe; (4) injecting a gelled acid system into the stratum through the oil pipe in a low-displacement mode; and (5) injecting the slick water into the stratum through the oil pipe, wherein the volume proportions of liquid, accounting for the total liquid injected into the stratum, injected in the first to fifth work procedures are shown as follows: the slick water in the first work procedure accounts for 3 to 10 percent; the non-crosslinked fracturing liquid in the second work procedure accounts for 40 to 60 percent; the self-born acid system in the third work procedure accounts for 30 to 50 percent; the gelled acid system in the fourth procedure accounts for 3 to 10 percent; the volume proportion of the slick water in the fifth work procedure is 3 to 15 percent; and the volume unit is m<3>. Through the self-born acid composite acid fracturing process, the flow guide capability is improved by more than 140md.m, and the deep penetration effect of the high-temperature deep well carbonate rock reservoir is obvious.

Owner:CHINA PETROLEUM & CHEM CORP

Shale oil and gas fracturing fluids containing additives of low environmental impact

InactiveUS20140090850A1Less harmfulLess harmful to the environmentFluid removalFlushingParticulatesFracturing fluid

The present invention relates to improved chemical additives for use in hydraulic fracturing fluids for the recovery of oil or natural gas entrained in deep-layer shale formations. Many chemical agents currently in use in such water / sand (or other proppants) mixtures could pose human and animal health risks if these chemicals migrate from the shale beds into the environment contaminating the water table, rivers, streams and lakes. The fracturing fluid chemical additives of this invention are designed to be retained or anchored in or near the deep shale layers and are prevented, or greatly delayed from upward migration. Specifically, many chemical additives required for proper fracturing fluid performance can be chemically bonded to inert particulate materials before incorporation into said fluids. The fracturing fluid chemical additives are able to perform their function in the shale fracturing process, and then become nearly permanently trapped in the shale layers protecting the environment above.

Owner:BATTELION ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com