Patents

Literature

154 results about "Distributed acoustic sensing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

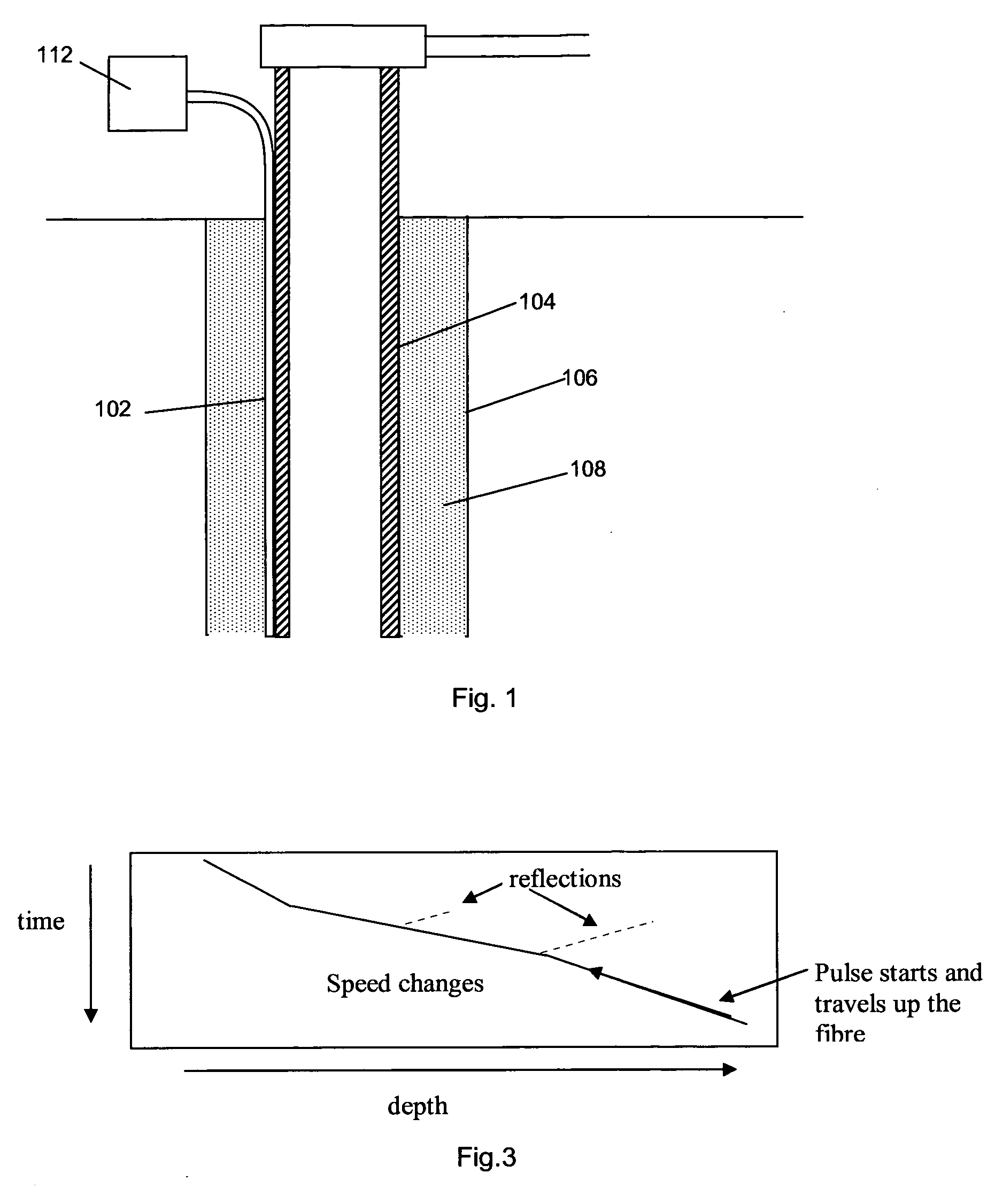

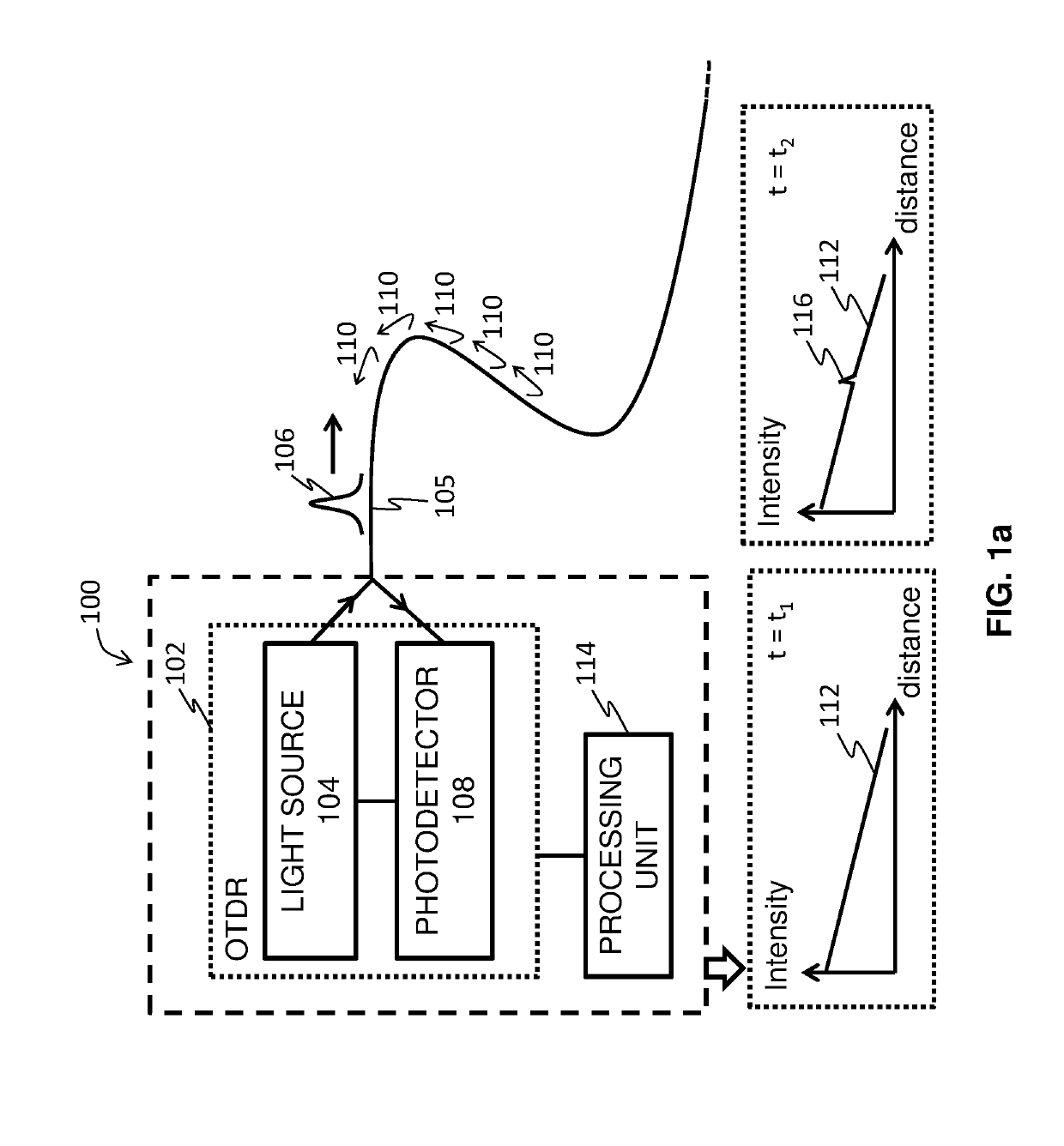

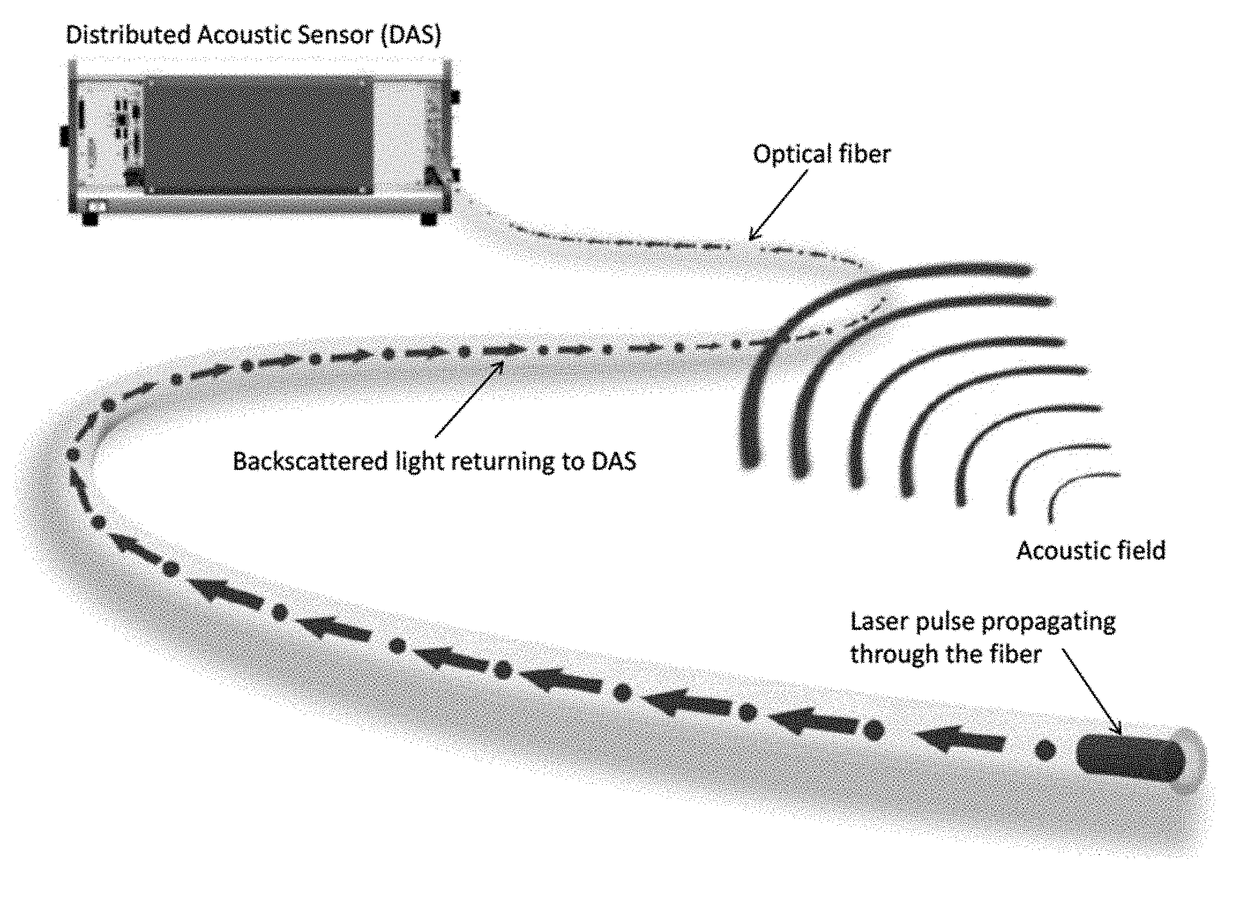

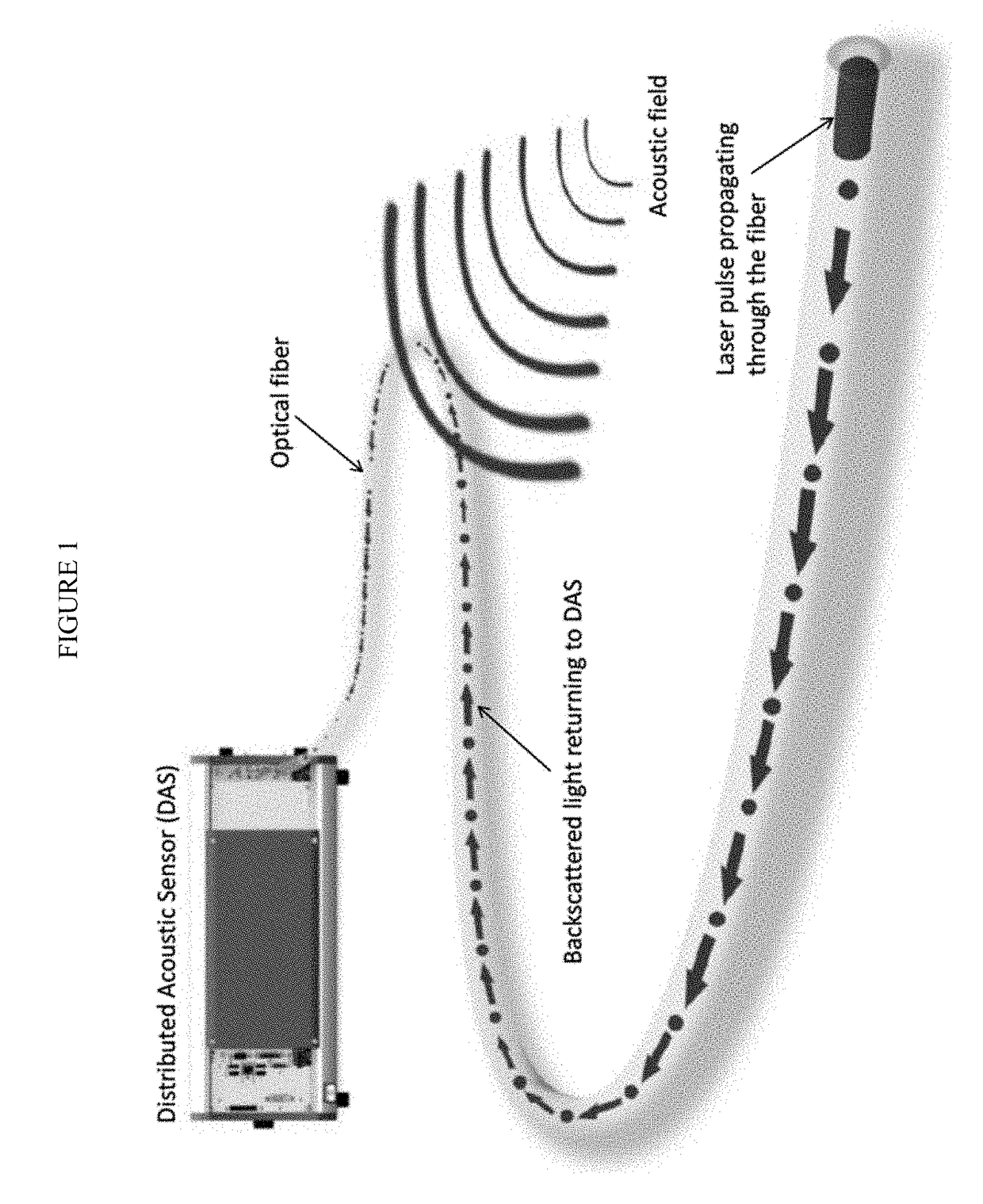

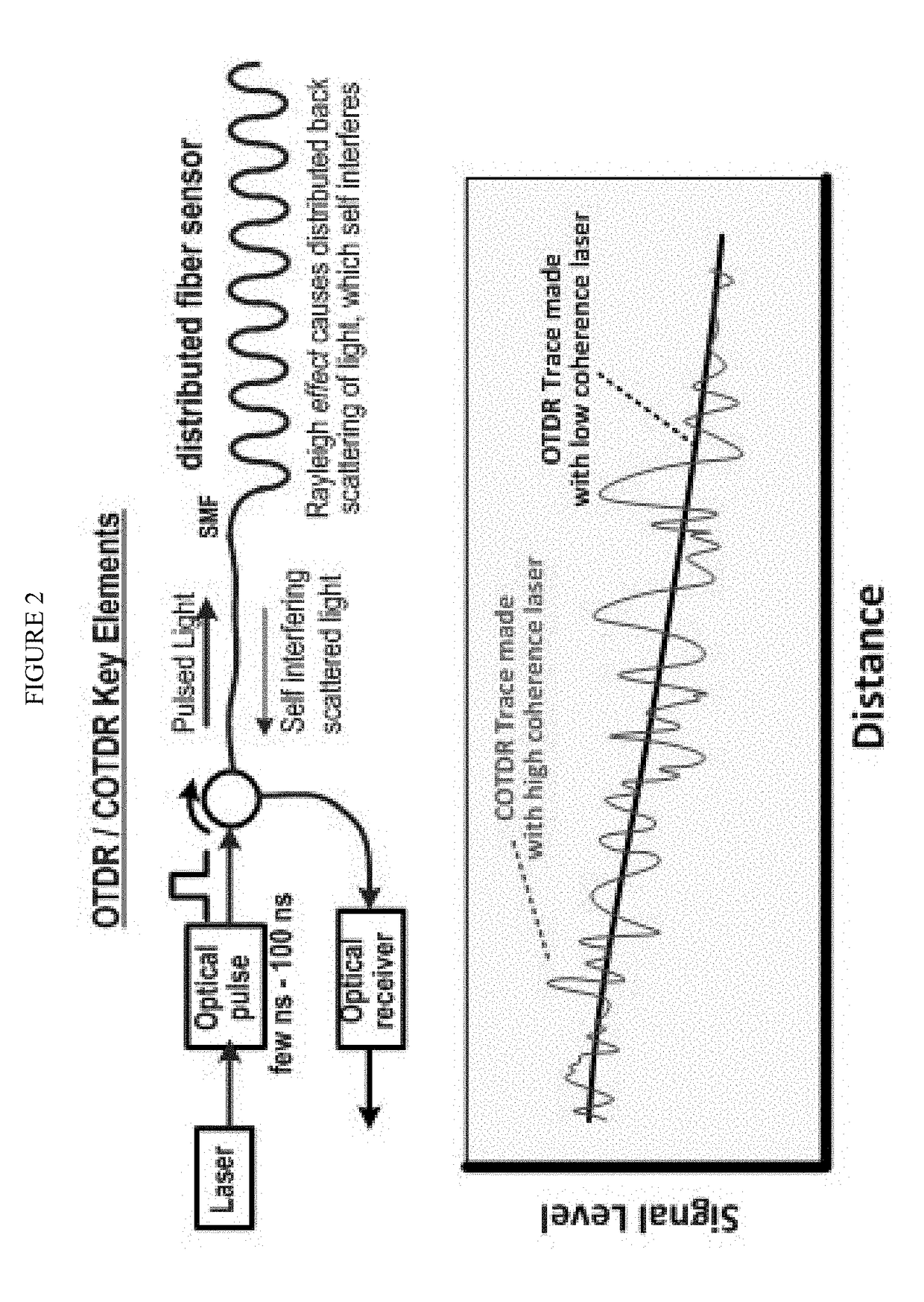

Rayleigh scattering based distributed acoustic sensing (DAS) systems use fiber optic cables to provide distributed strain sensing. In DAS, the optical fiber cable becomes the sensing element and measurements are made, and in part processed, using an attached optoelectronic device. Such a system allows acoustic frequency strain signals to be detected over large distances and in harsh environments.

Distributed acoustic sensing with fiber bragg gratings

ActiveUS20100200744A1High sensitivityInexpensive to acquireOptical detectionSeismic signal receiversDistributed acoustic sensingFiber

A method for obtaining information about a subsurface formation from acoustic signals that contain information about to the subsurface formation, comprises: providing a fiber optic having a proximal end and a remote end, with the proximal end being coupled to a light source and a proximal photodetector, wherein said fiber optic cable includes randomly spaced impurities and selectively placed Bragg gratings and wherein the fiber optic cable is acoustically coupled to the subsurface formation so as to allow the acoustic signals to affect the physical status of at least one grating: transmitting at least one light pulse into the cable; receiving at the photodetector a first light signal indicative of the physical status of at least one first section of the cable, and outputting at least one item of information to a display.

Owner:SHELL USA INC

Sonic/acoustic monitoring using optical distributed acoustic sensing

ActiveUS20110280103A1ConstructionsSubsonic/sonic/ultrasonic wave measurementMultiplexingDistributed acoustic sensing

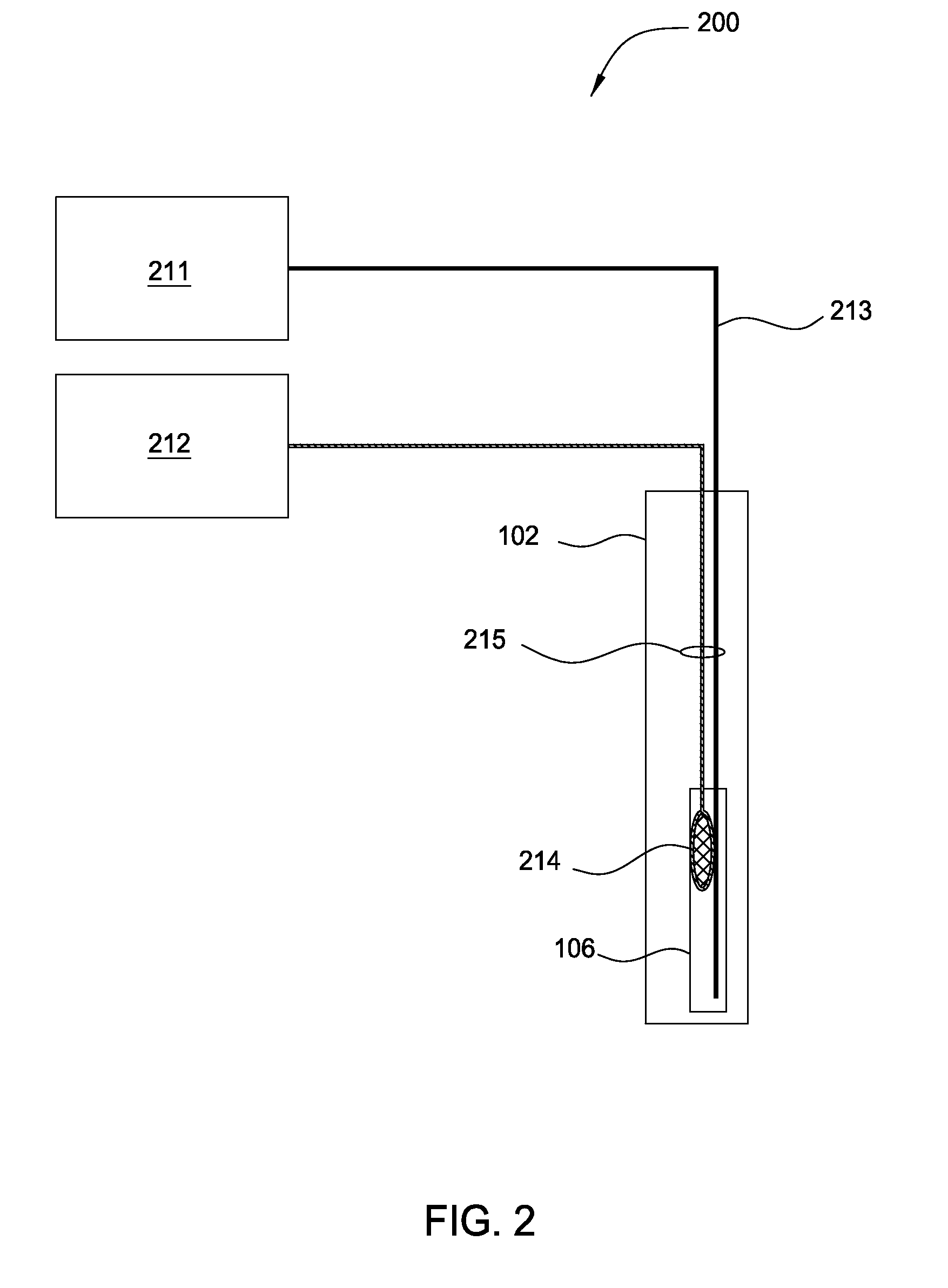

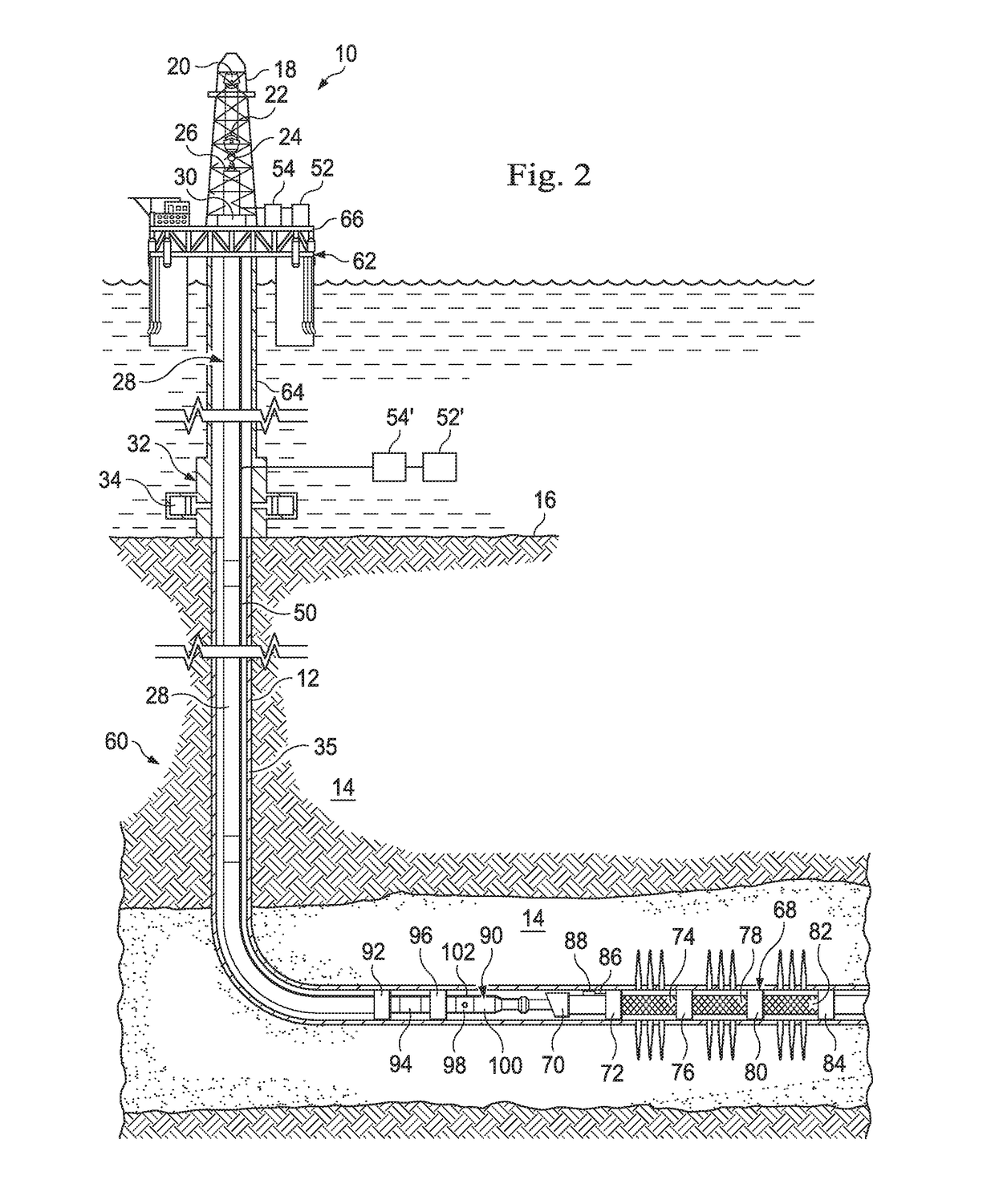

Methods and apparatus for performing sonic well logging within a wellbore based on optical Distributed Acoustic Sensing (DAS) are provided. A sonic well logging system based on DAS may be capable of producing the functional equivalent of tens, hundreds, or even thousands of acoustic sensors. In this manner, the emplacement of the sonic well logging system based on DAS may not be nearly as complex or expensive as emplacing a sonic well logging system based on traditional methods. Furthermore, multiplexing may be simpler, downhole electronics need not be used, and the sonic well logging system may be used in extreme, high temperature environments.

Owner:WEATHERFORD TECH HLDG LLC

Fracture monitoring

ActiveUS8950482B2Effectively acoustically exciteIncrease productionMaterial analysis using sonic/ultrasonic/infrasonic wavesSurveyDistributed acoustic sensingFiber

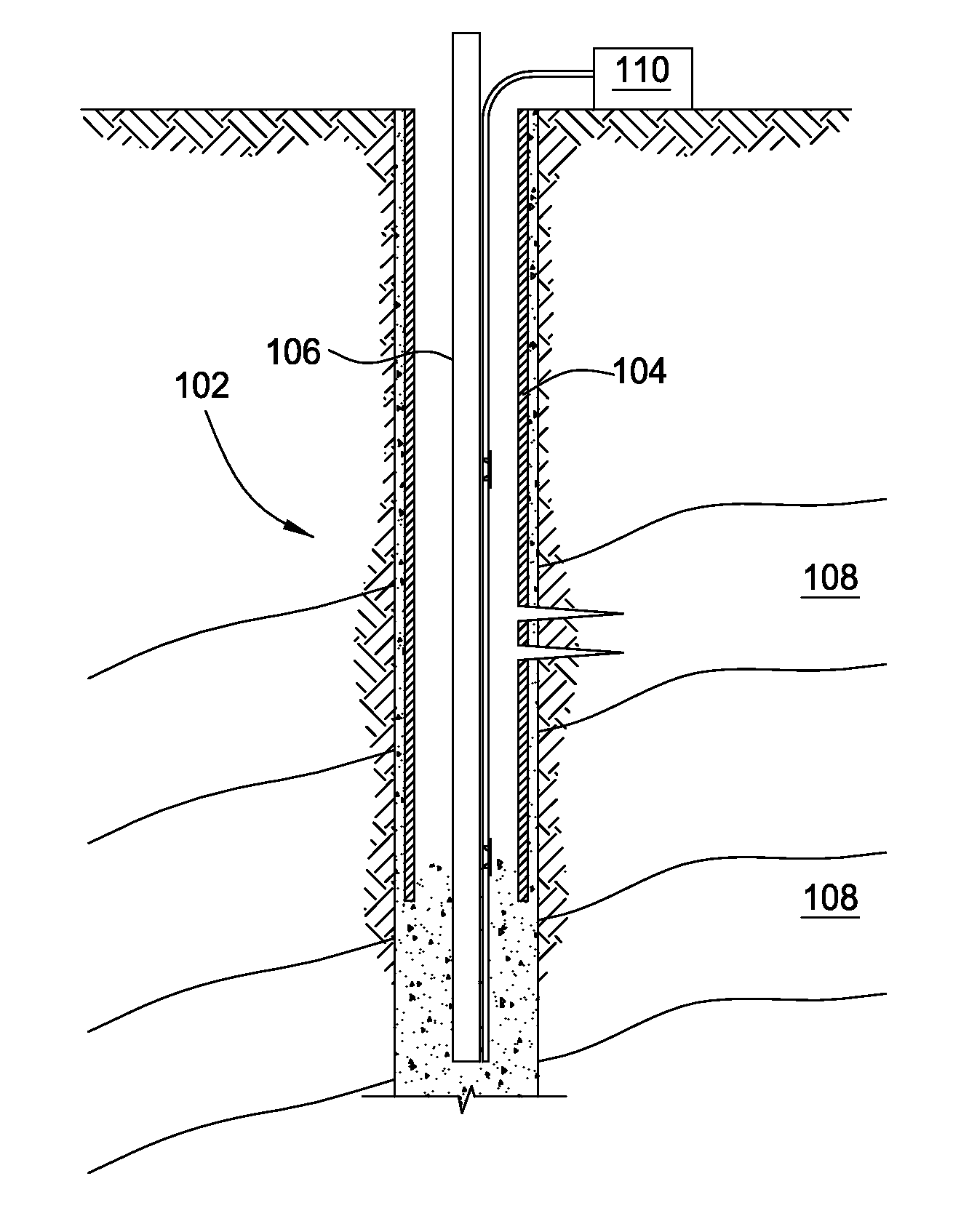

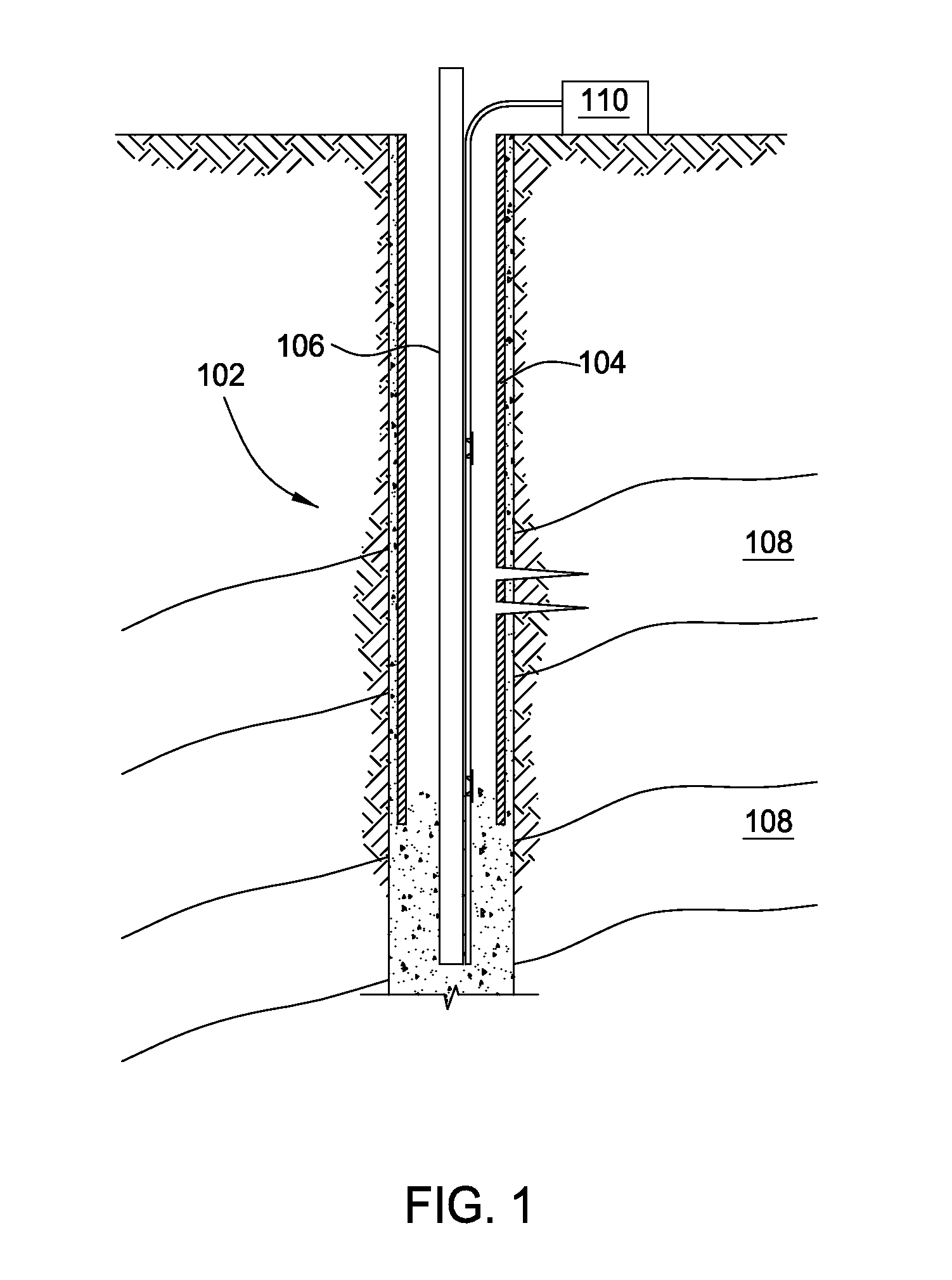

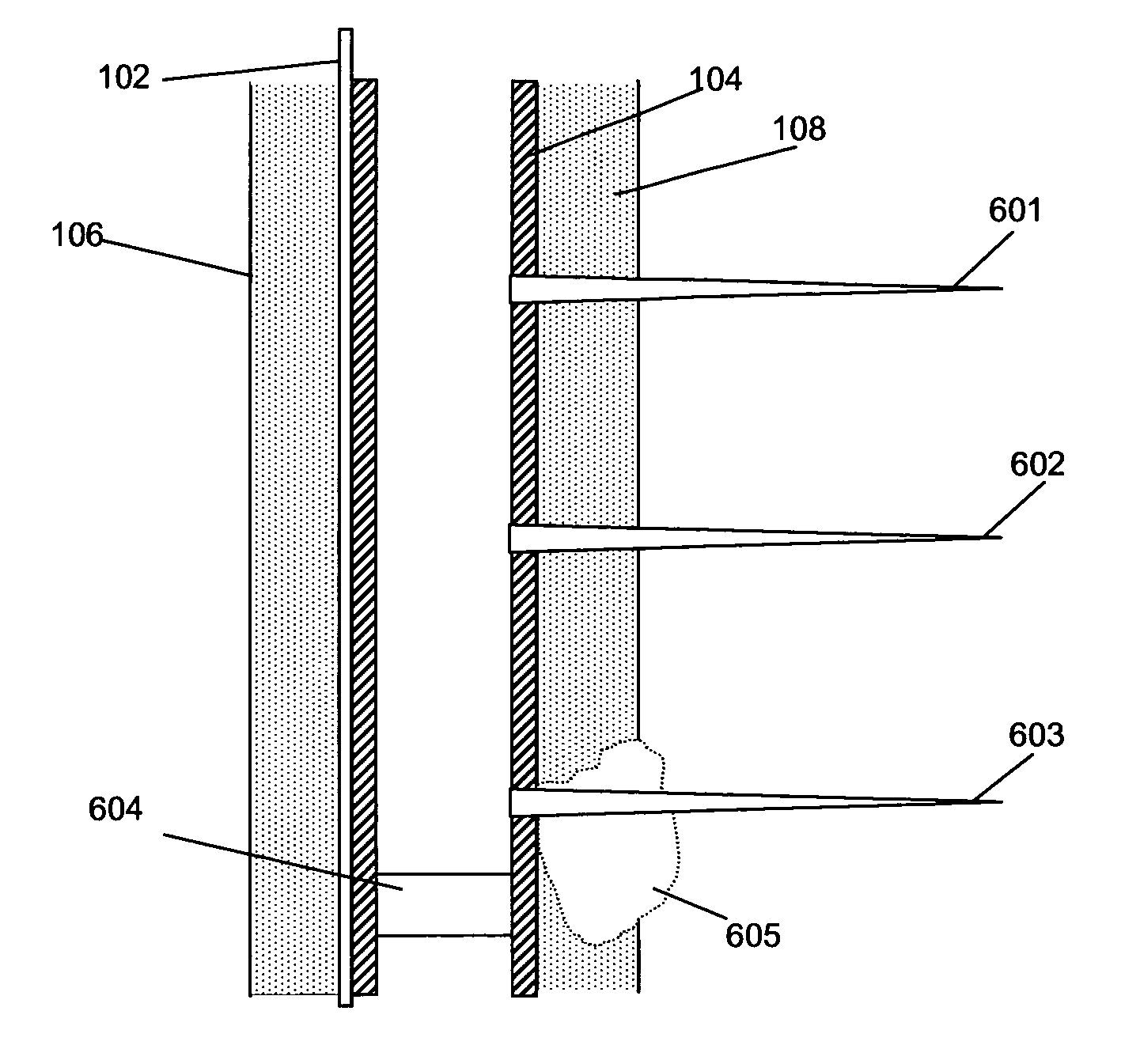

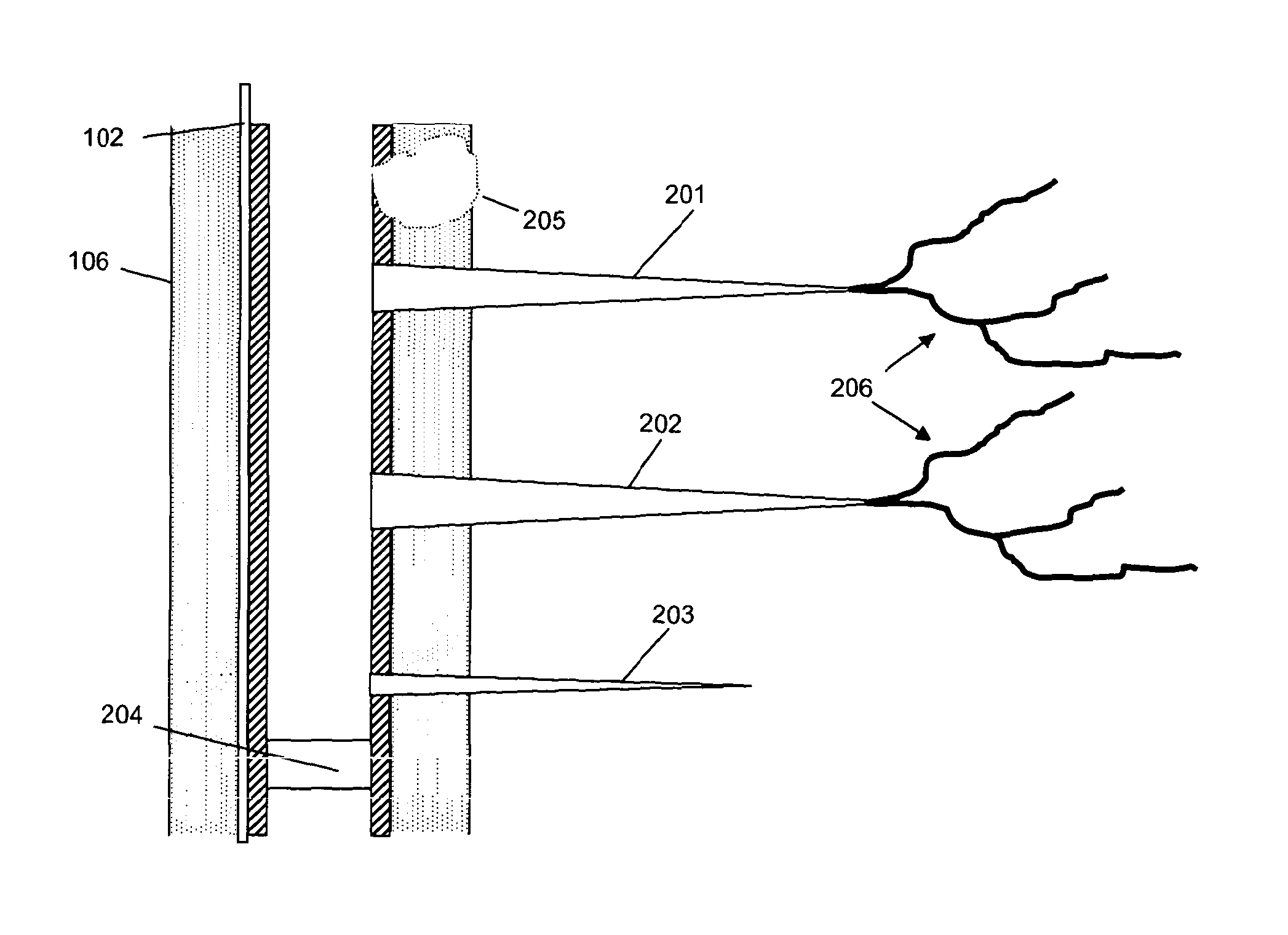

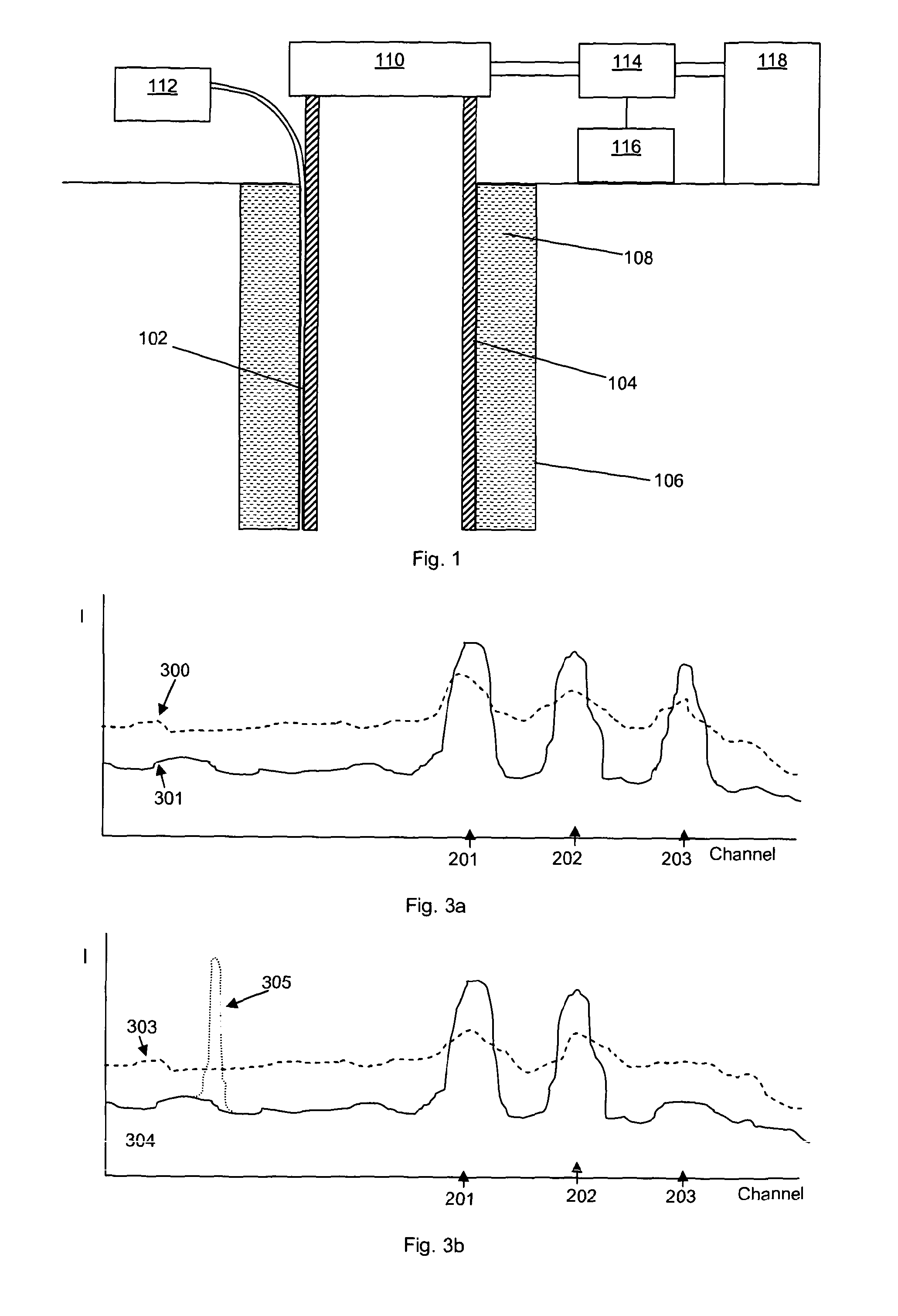

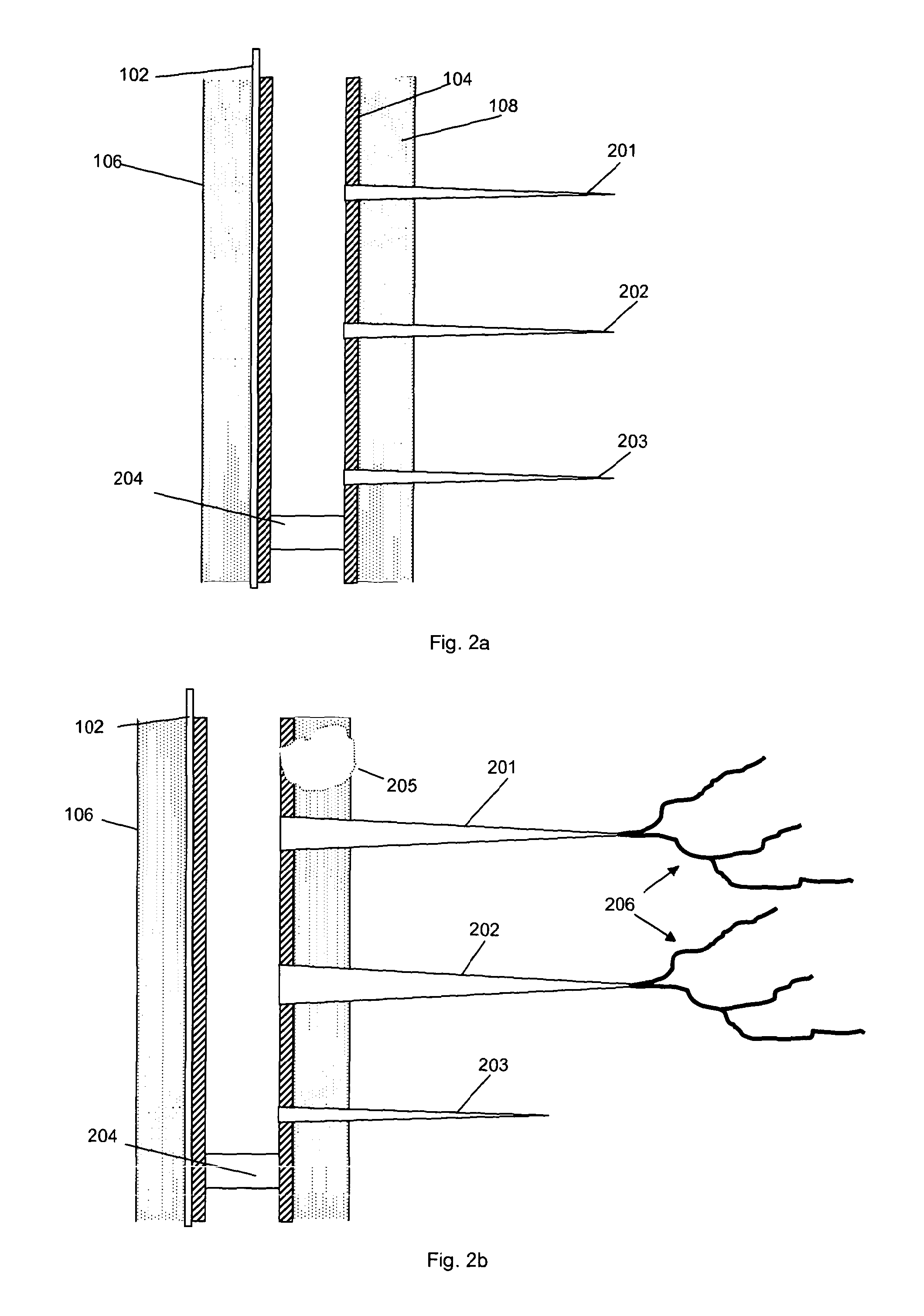

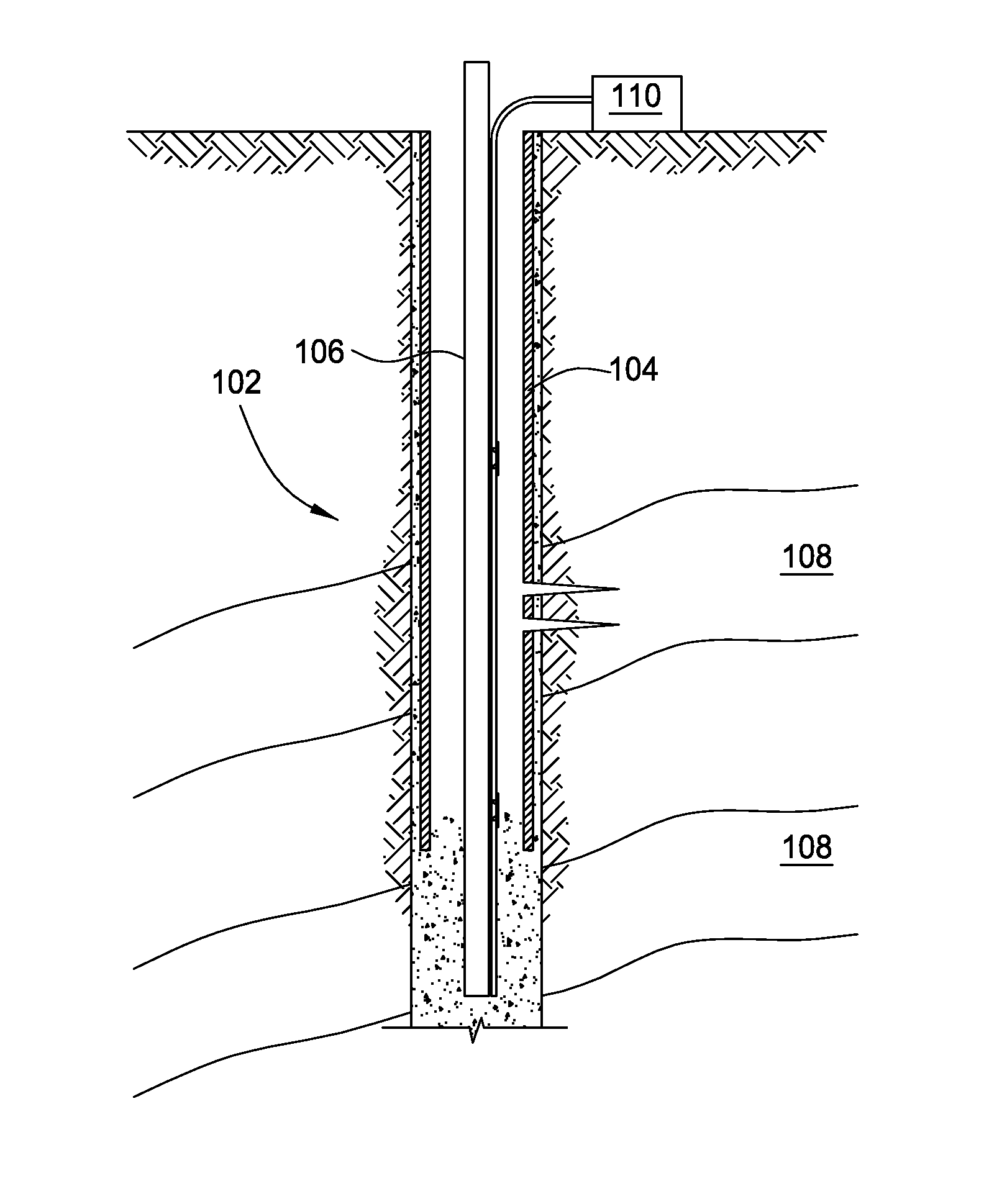

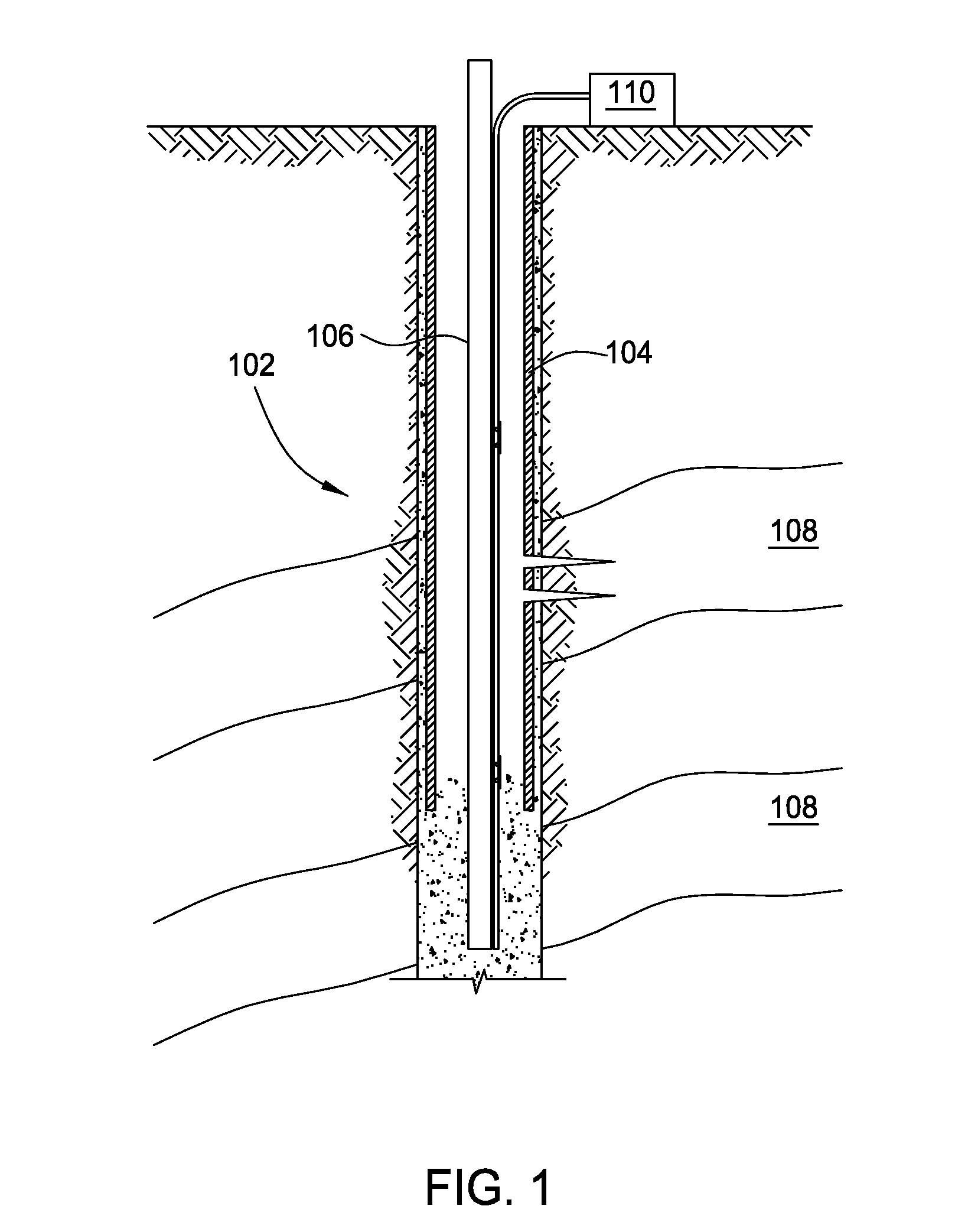

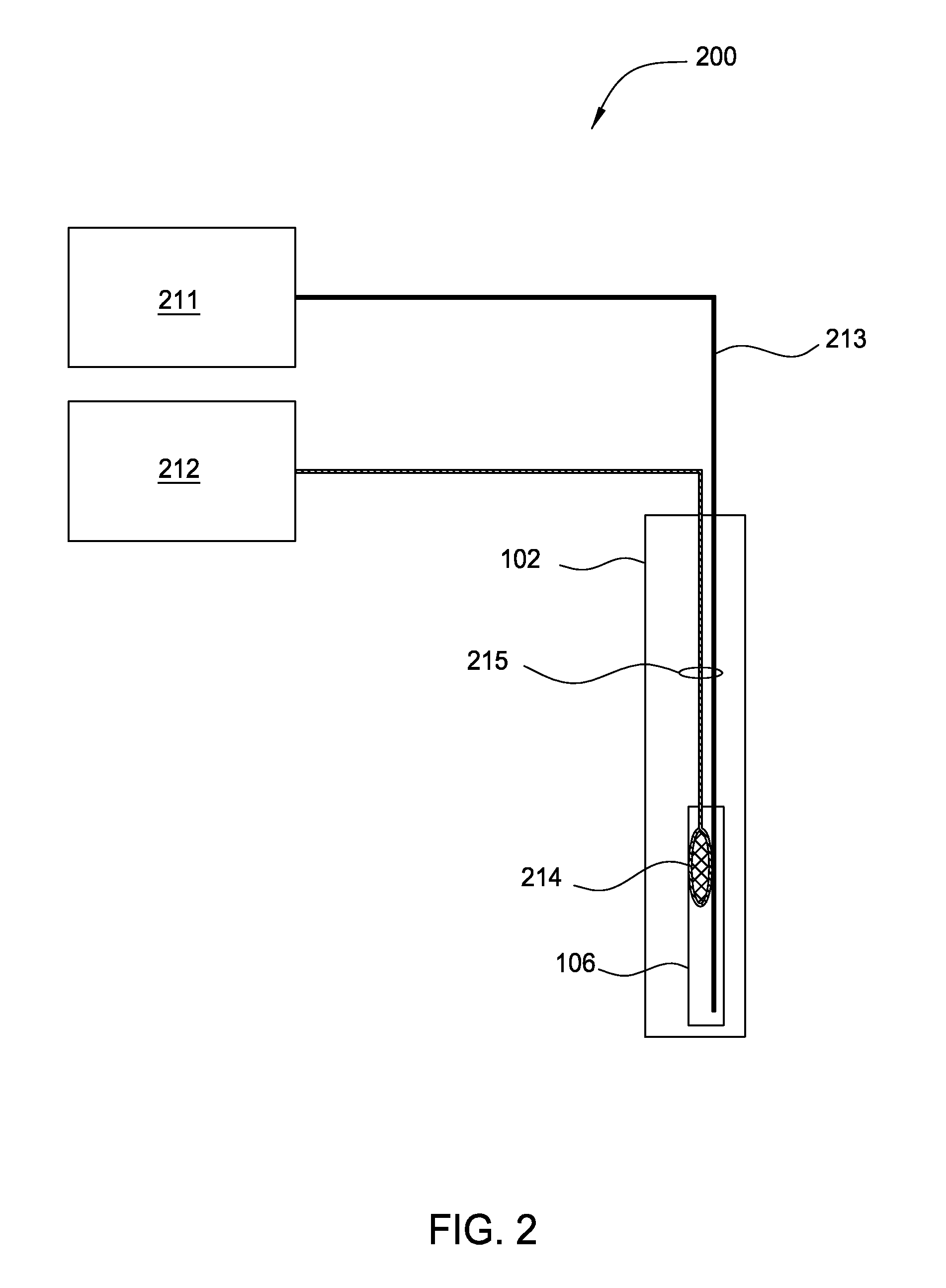

This application relates to methods and apparatus for monitoring hydraulic fracturing during oil / gas well formation. A fiber optic cable (102) deployed down a well bore (106), which may be the well bore in which fracturing is performed, is interrogated to provide a distributed acoustic sensor. Data is sampled from at least one longitudinal sensing portion of the fiber and processed to provide at least fracturing characteristic. The fracturing characteristic may comprise the characteristics of high frequency transients indicative of fracturing events (606). The intensity, frequency, duration and signal evolution of the transients may be monitored to provide the fracturing characteristic. Additionally or alternatively the fracturing characteristic may comprise the longer term acoustic noise generated by fracture fluid flow to the fracture sites. The intensity and frequency of the noise may be analyzed to determine the fracturing characteristic. The method allows real-time control of the fracturing process.

Owner:OPTASENSE HLDG LTD

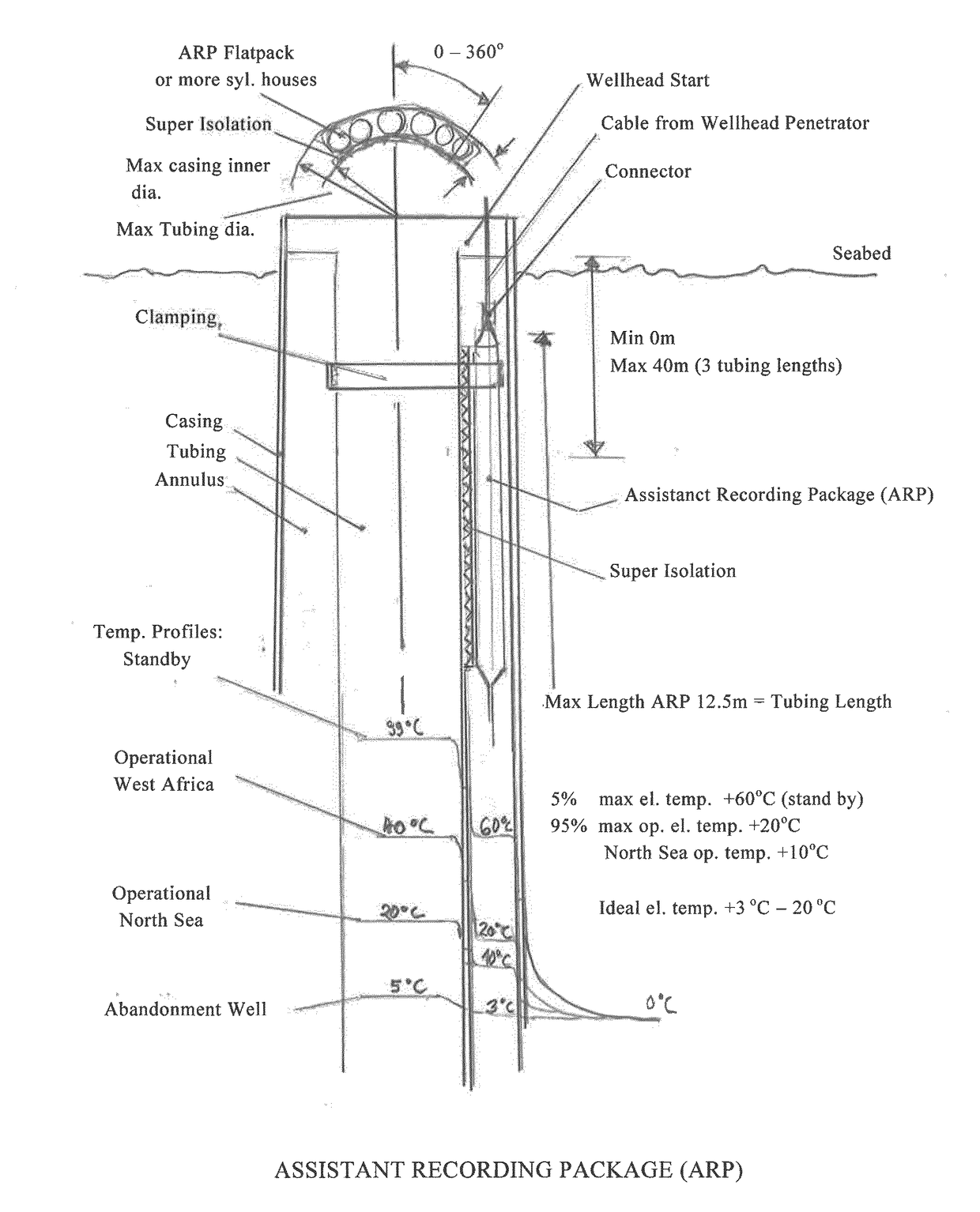

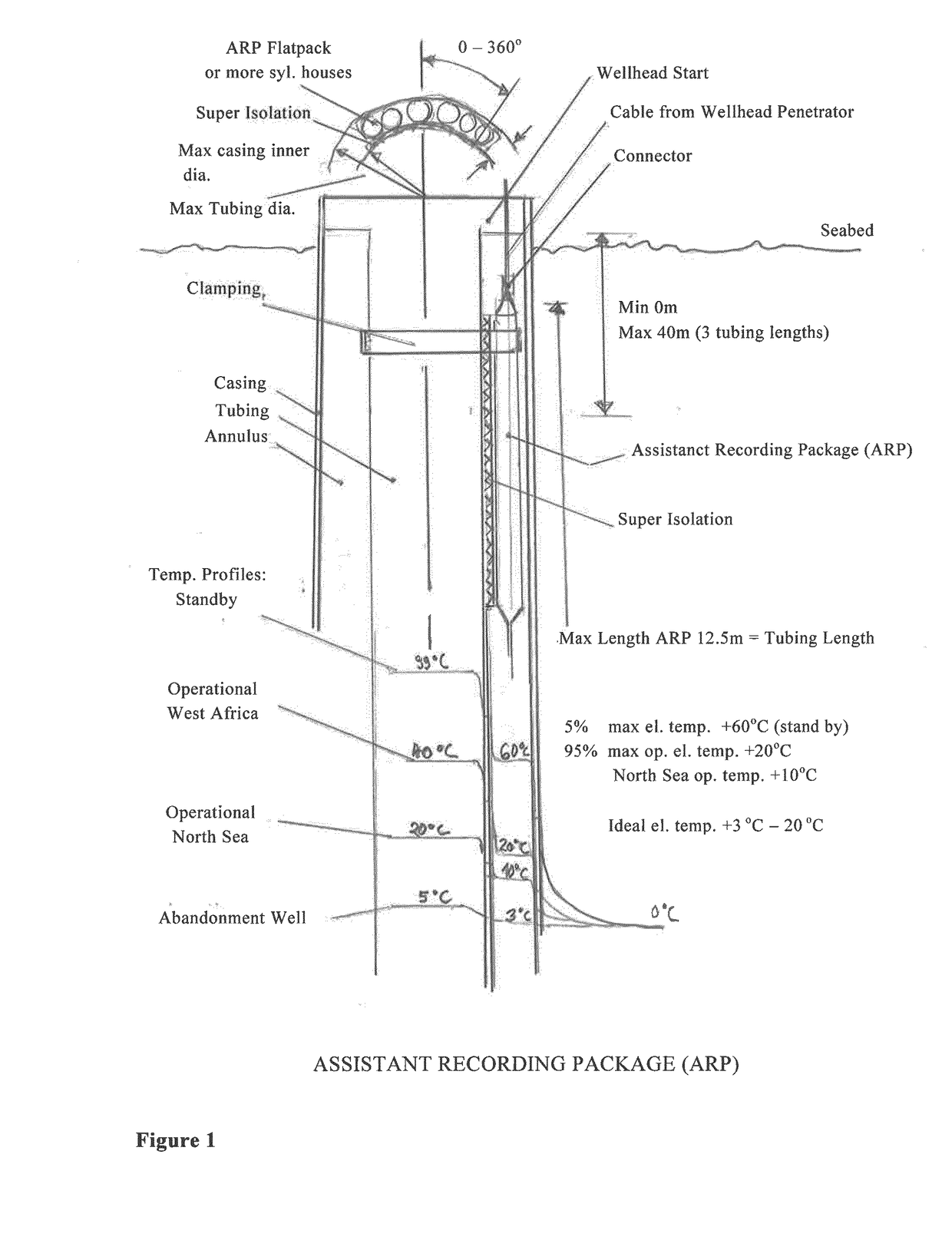

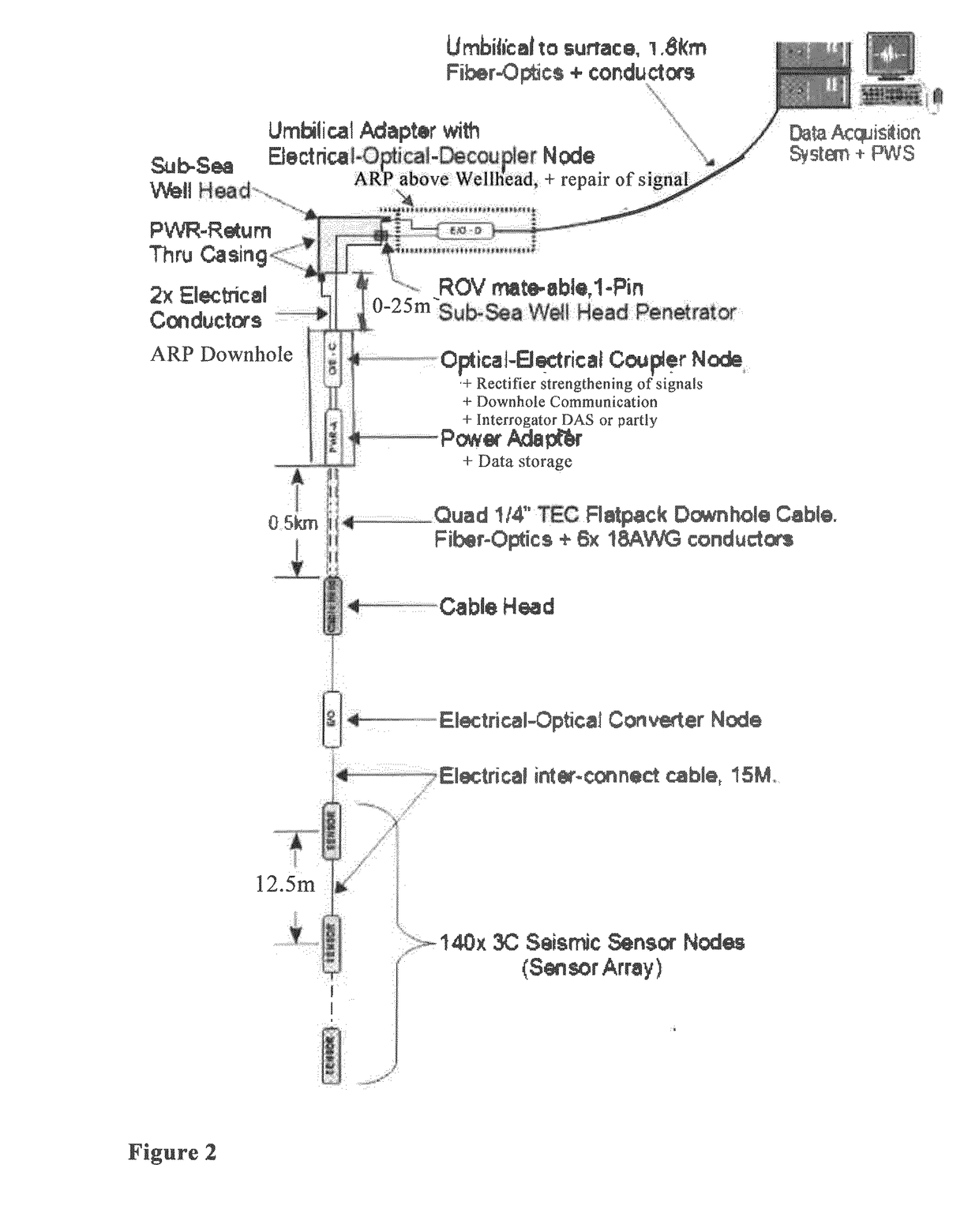

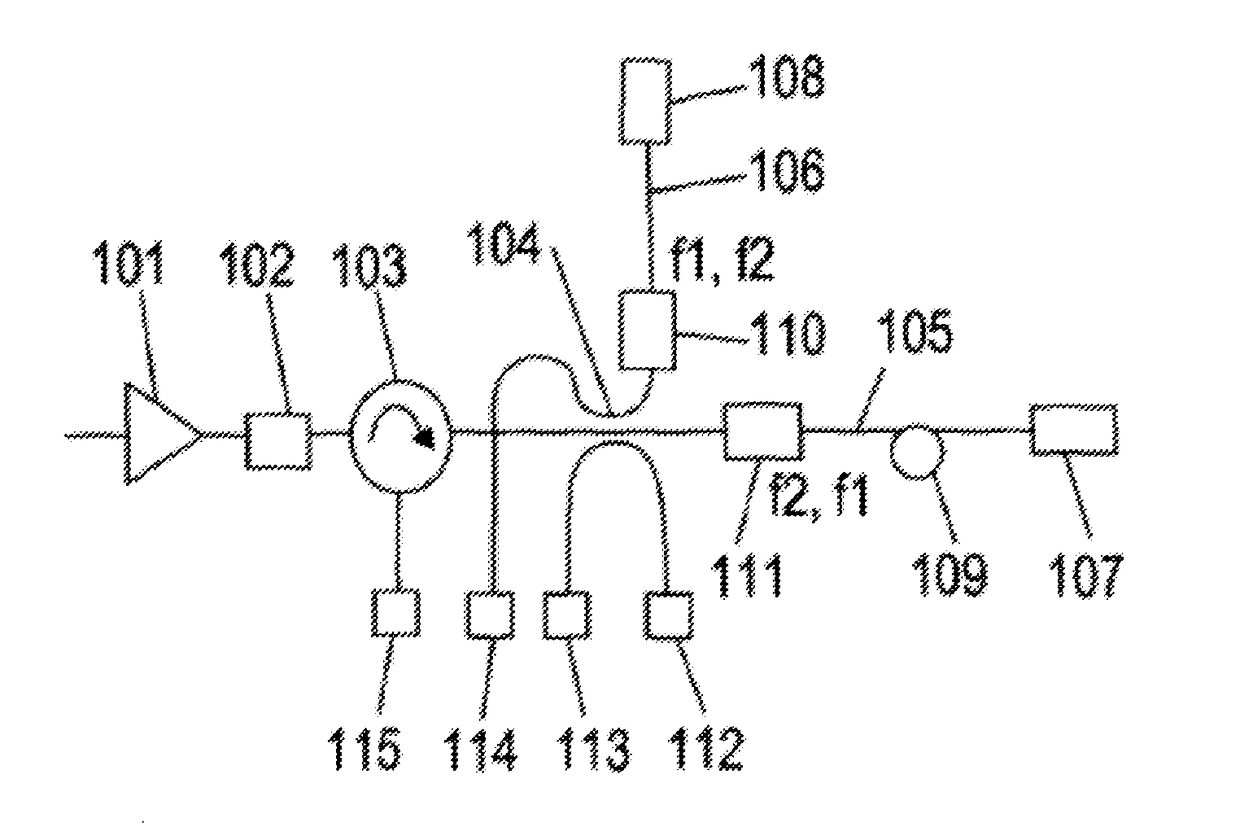

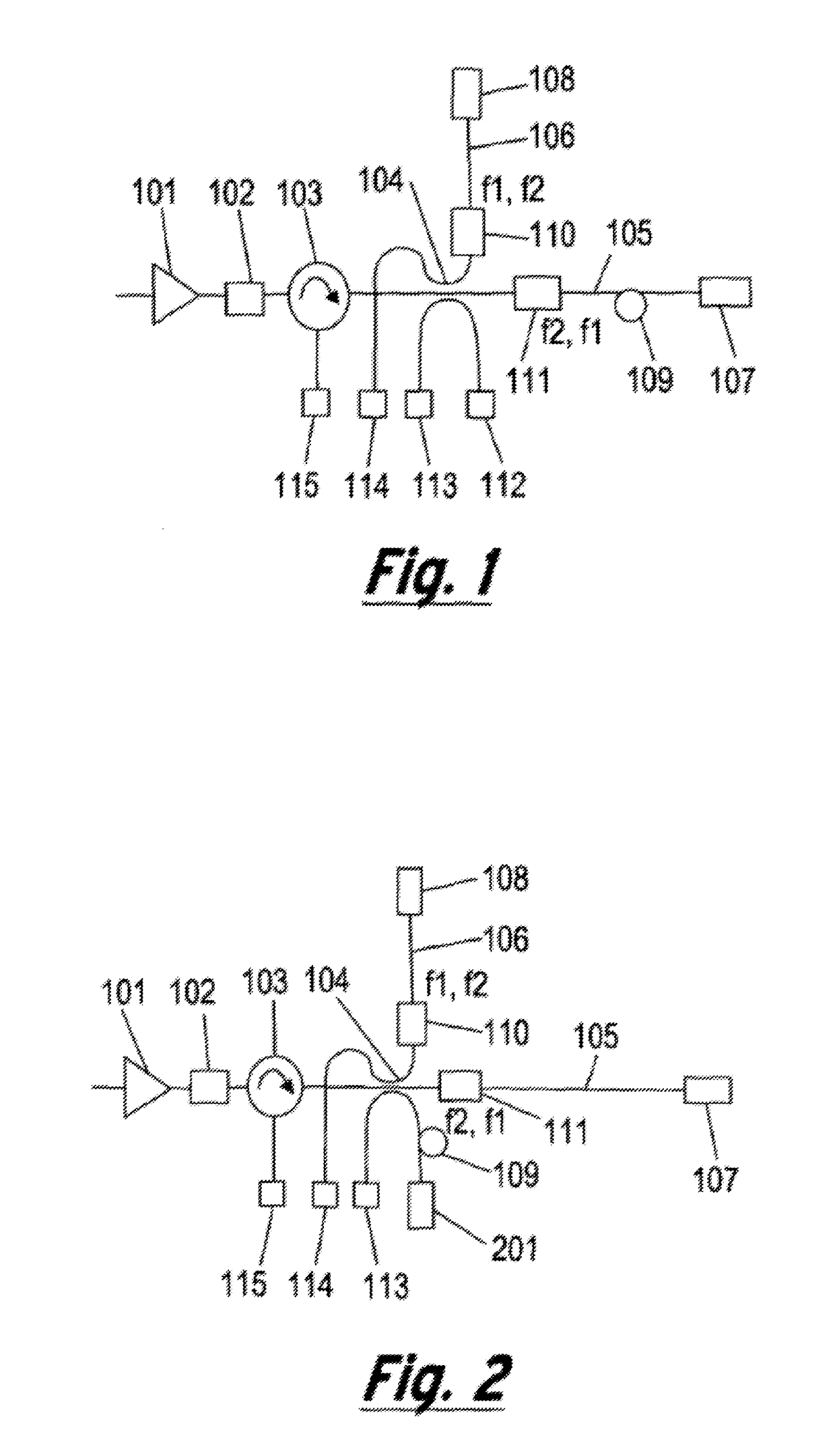

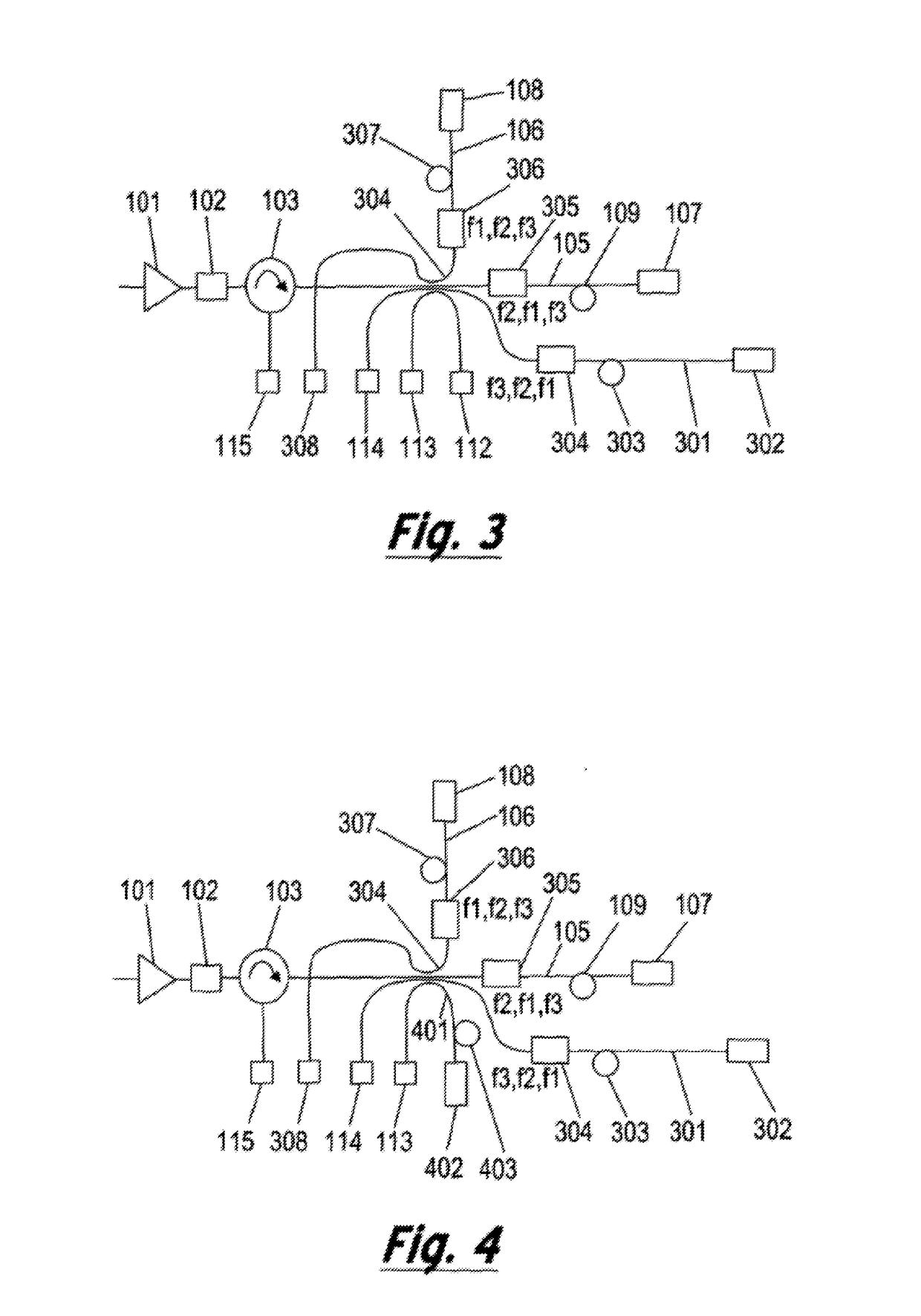

Method and system for transmitting signals from a distributed acoustic sensor through a one pin solution of a subsea wellhead

A method and system for transmitting signals from a distributed acoustic sensor, DAS, into a well through at least one pin penetrator running from a downhole side to a top side of a subsea wellhead, and without degrading quality of the signals. The method includes: connecting a first assistant recording package, ARP, between the DAS and the at least one pin penetrator on a downhole side of the wellhead; connecting a second ARP between a data acquisition system and the at least one pin penetrator on the topside of the well head; converting DAS signals to electrical signals by the first ARP and performing signal conditioning; transmitting signals received from the DAS sensors, from the first ARP and through the wellhead to the second ARP. The system implements the method.

Owner:RIIDO

Method and Apparatus for Optical Sensing

ActiveUS20180045543A1High sensitivityReduce reflectivityConstructionsSubsonic/sonic/ultrasonic wave measurementFiberGrating

An optical fiber distributed acoustic sensor system includes weak broadband reflectors inserted periodically along the fiber. The reflectors reflect only a small proportion of the light from the DAS incident thereon back along the fiber, typically in the region of 0.001% to 0.1%, but preferably around 0.01% reflectivity per reflector. In addition, to allow for temperate compensation to ensure that the same reflectivity is obtained if the temperature changes, the reflection bandwidth is relatively broadband. In some embodiments the reflectors are formed from a series of fiber Bragg gratings, each with a different center reflecting frequency, the reflecting frequencies and bandwidths of the gratings being selected to provide the broadband reflection. A chirped grating may also be used to provide the same effect. In preferred embodiments, the reflectors are spaced at half the gauge length i.e. the desired spatial resolution of the optical fiber DAS.

Owner:SILIXA

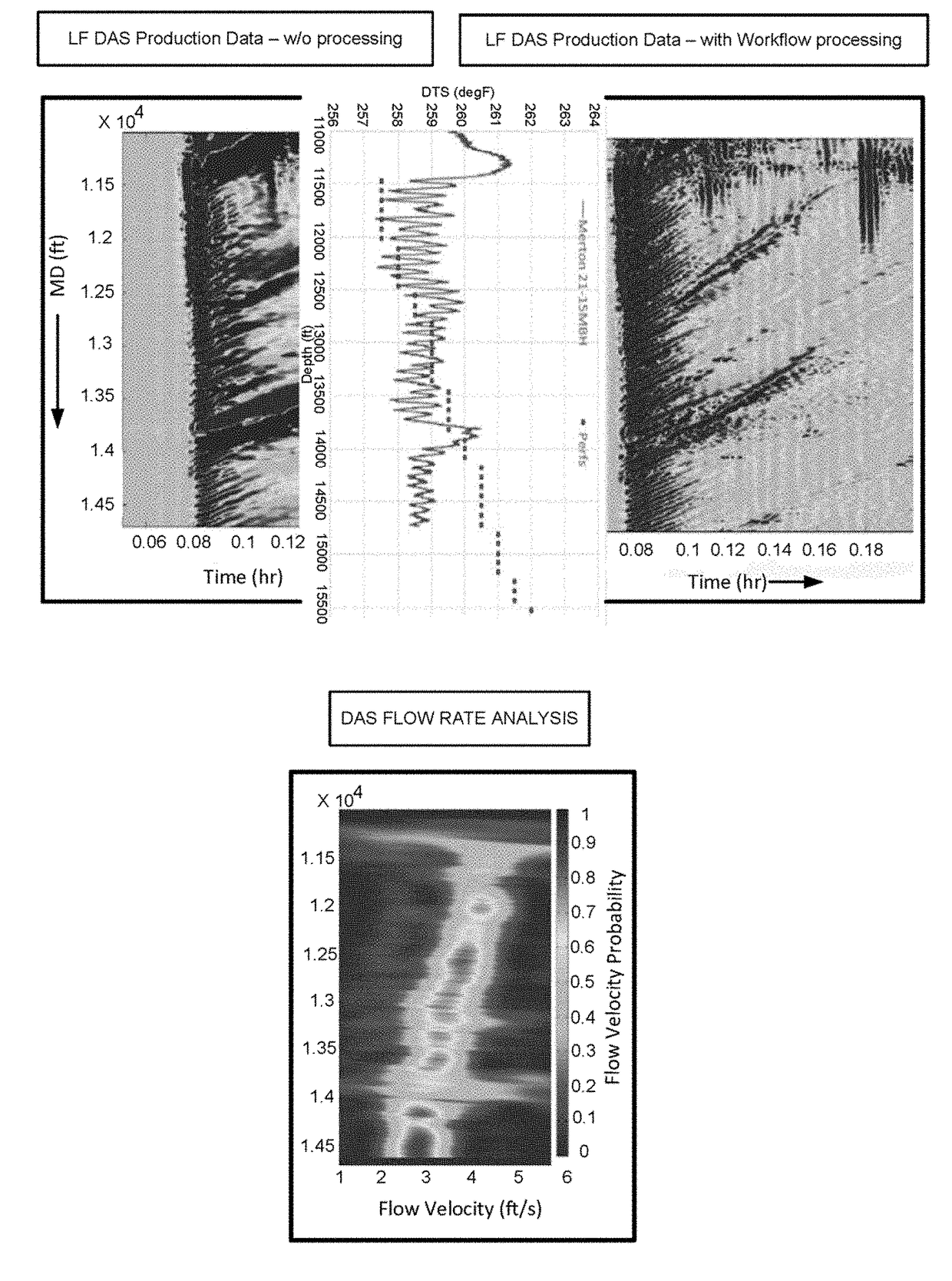

Low-frequency das snr improvement

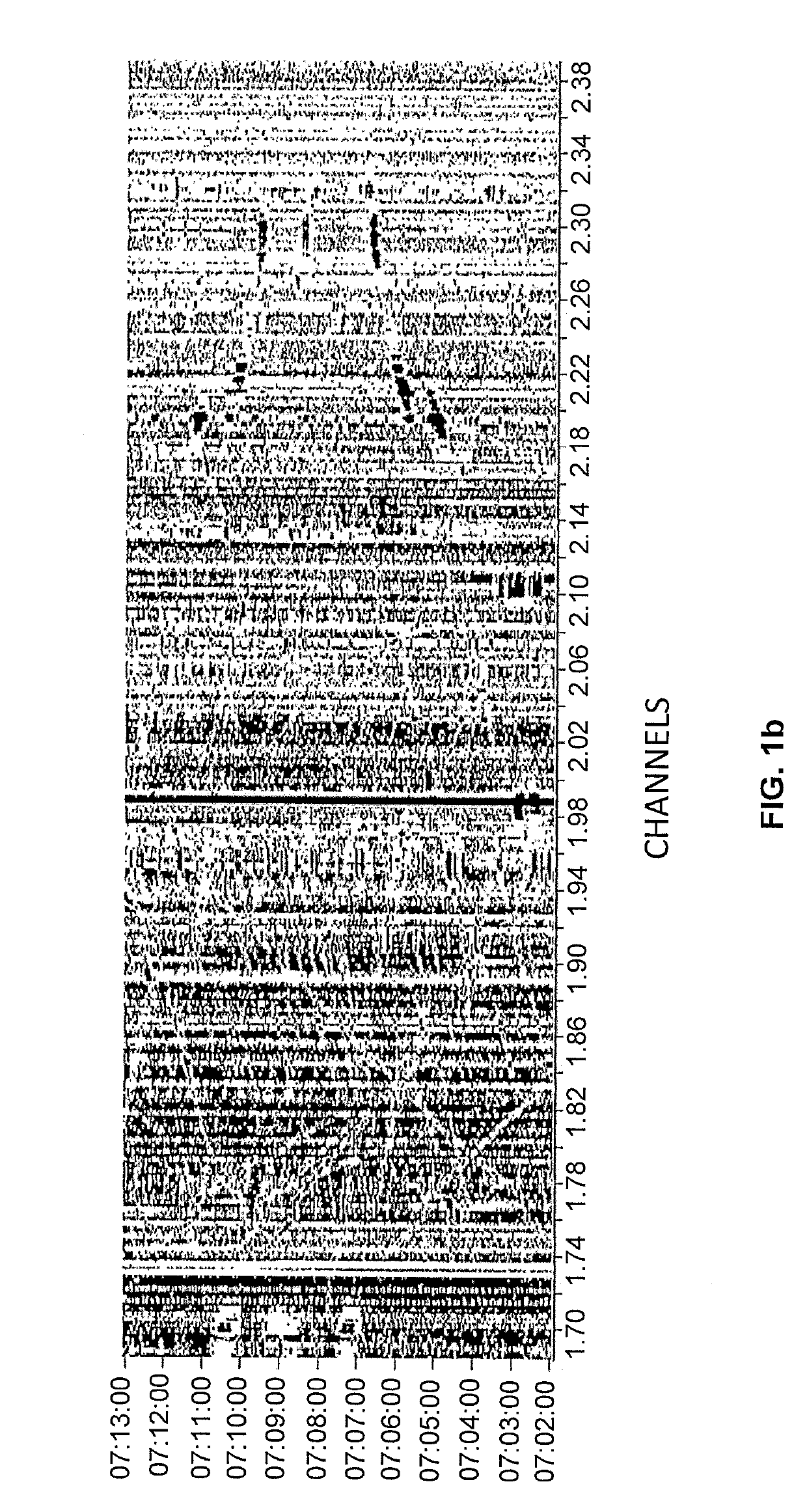

ActiveUS20170342814A1Increase calculated semblance accuracyShorten the timeSurveySubsonic/sonic/ultrasonic wave measurementDistributed acoustic sensingSignal-to-noise ratio (imaging)

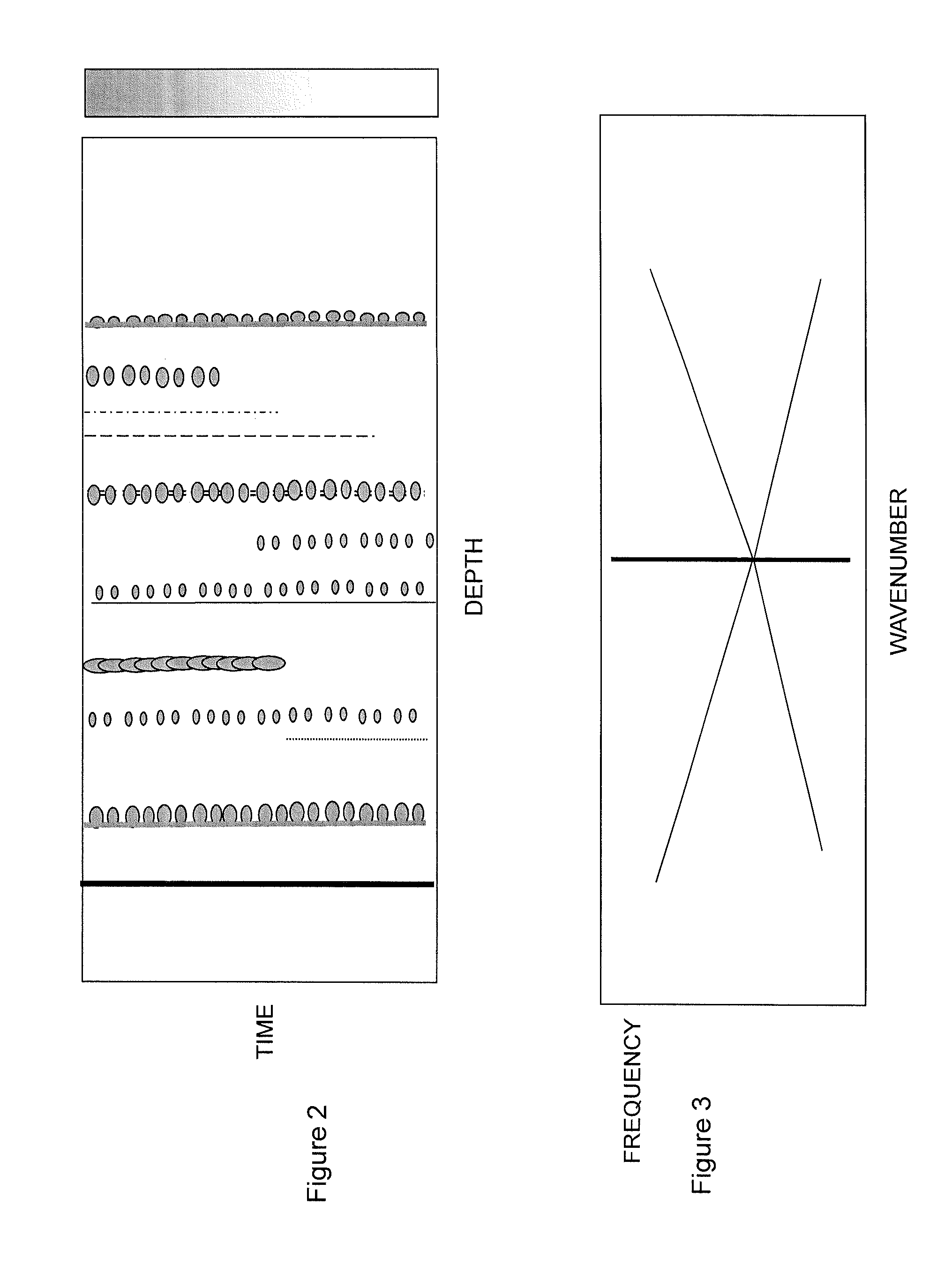

A workflow using techniques for improving signal-to-noise ratio and decreasing interferences for Low-Frequency Distributed Acoustic Sensing is described.

Owner:CONOCOPHILLIPS CO

Fracture characterization

ActiveUS9416644B2Easy to identifyReduce the amount requiredSurveyConstructionsFiberDistributed acoustic sensing

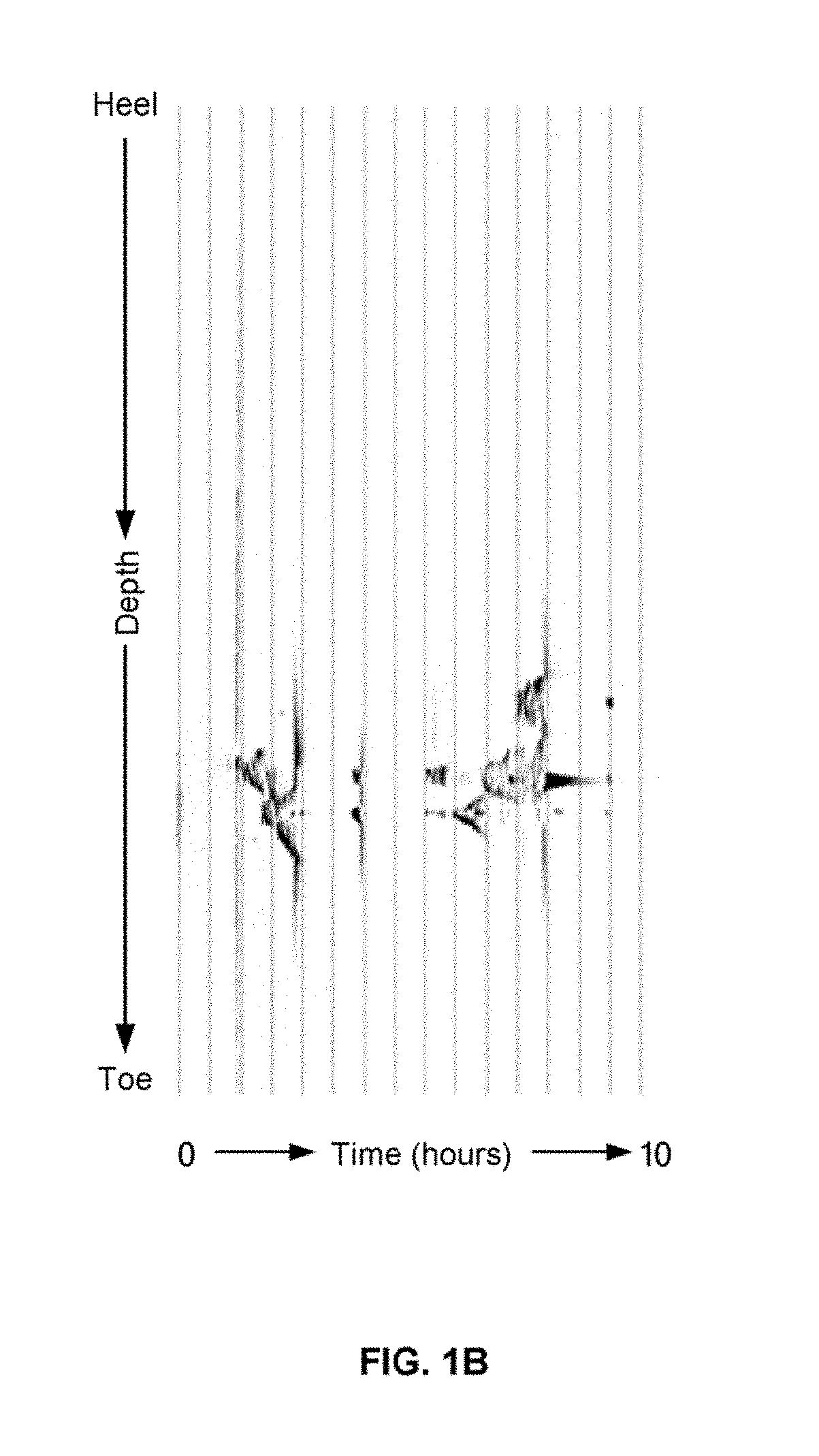

This application relates to methods and apparatus for monitoring hydraulic fracturing in well formation and fracture characterization using distributed acoustic sensing (DAS). The method involves interrogating a optic fiber (102) arranged down the path of a bore hole (106) to provide a distributed acoustic sensor and also monitoring flow properties of fracturing fluid pumped (114) into the well. The acoustic data from the distributed acoustic sensor is processed together with the flow properties data to provide an indication of at least one fracture characteristic.

Owner:OPTASENSE HLDG LTD

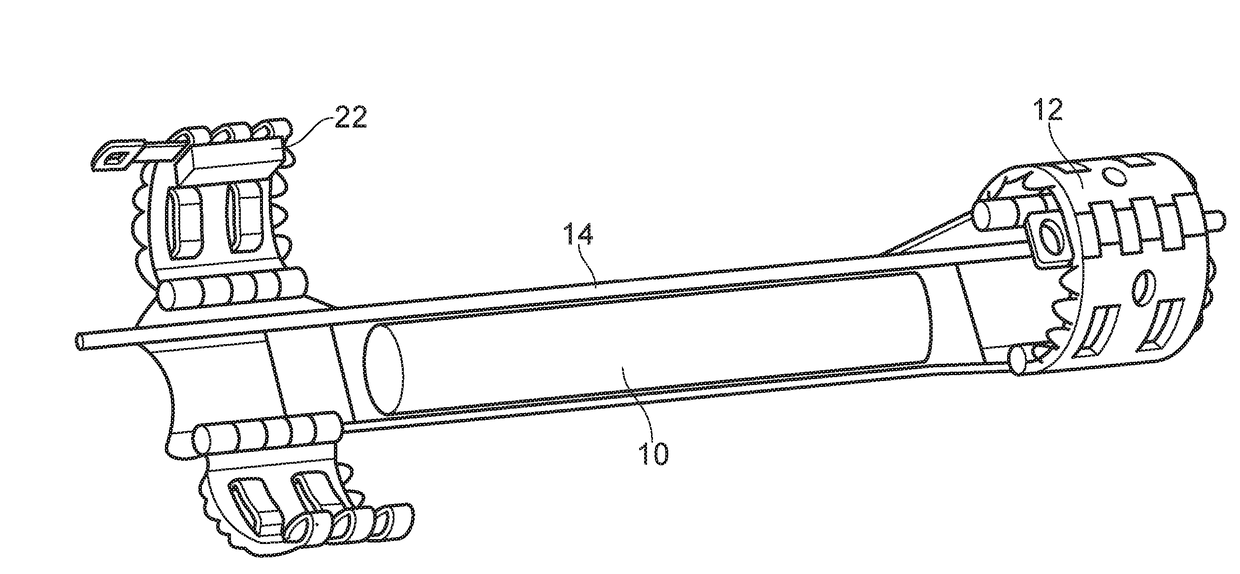

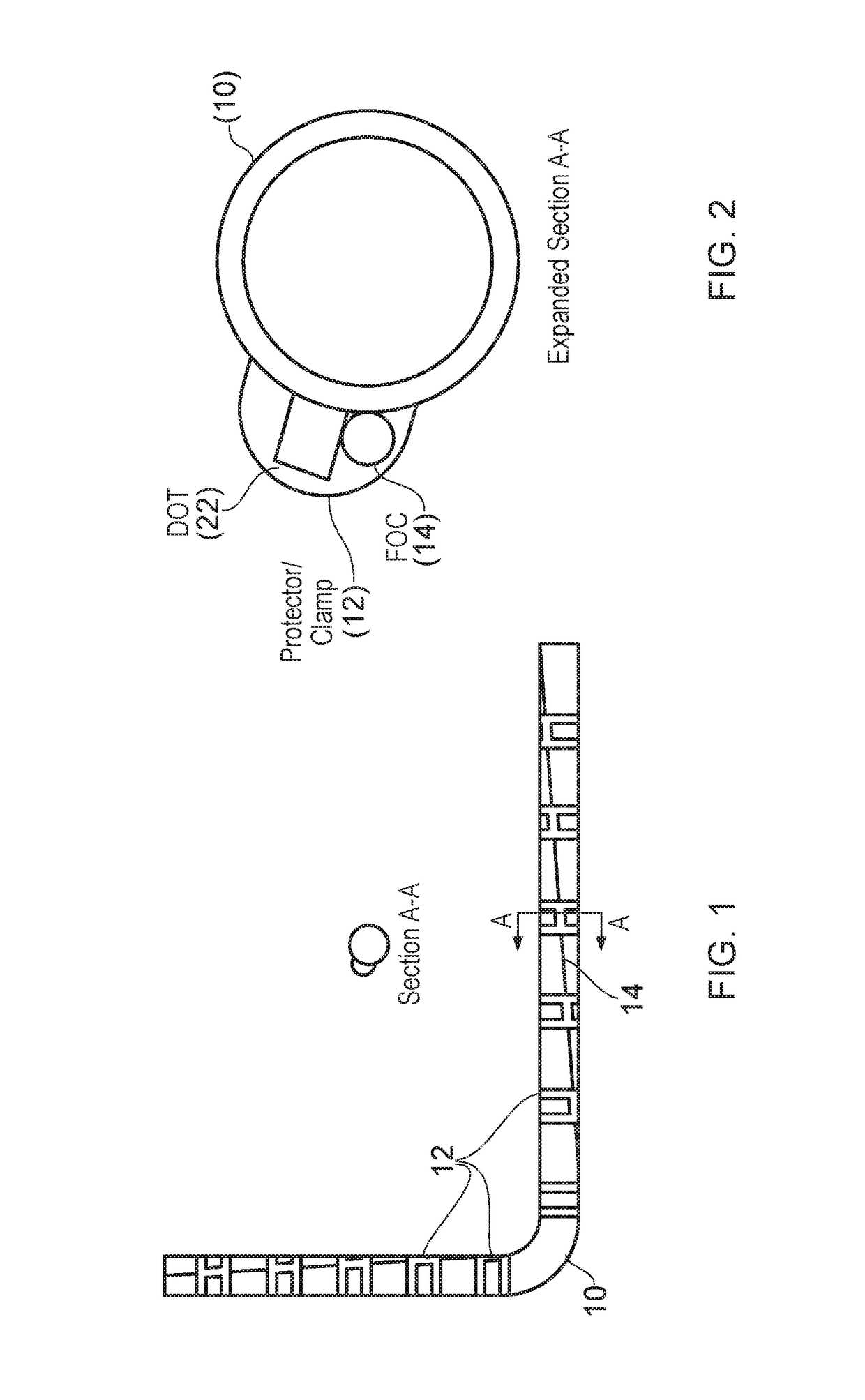

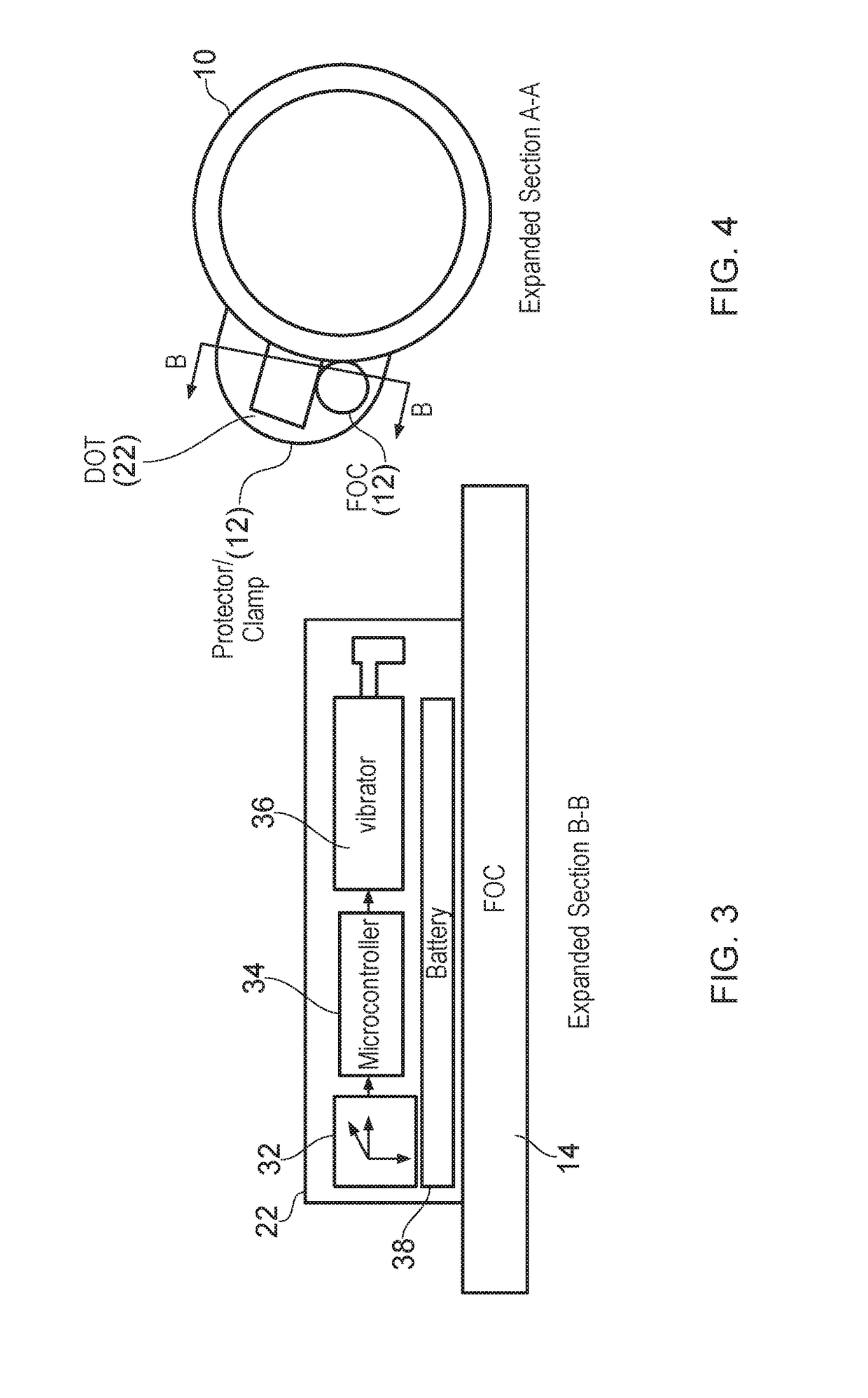

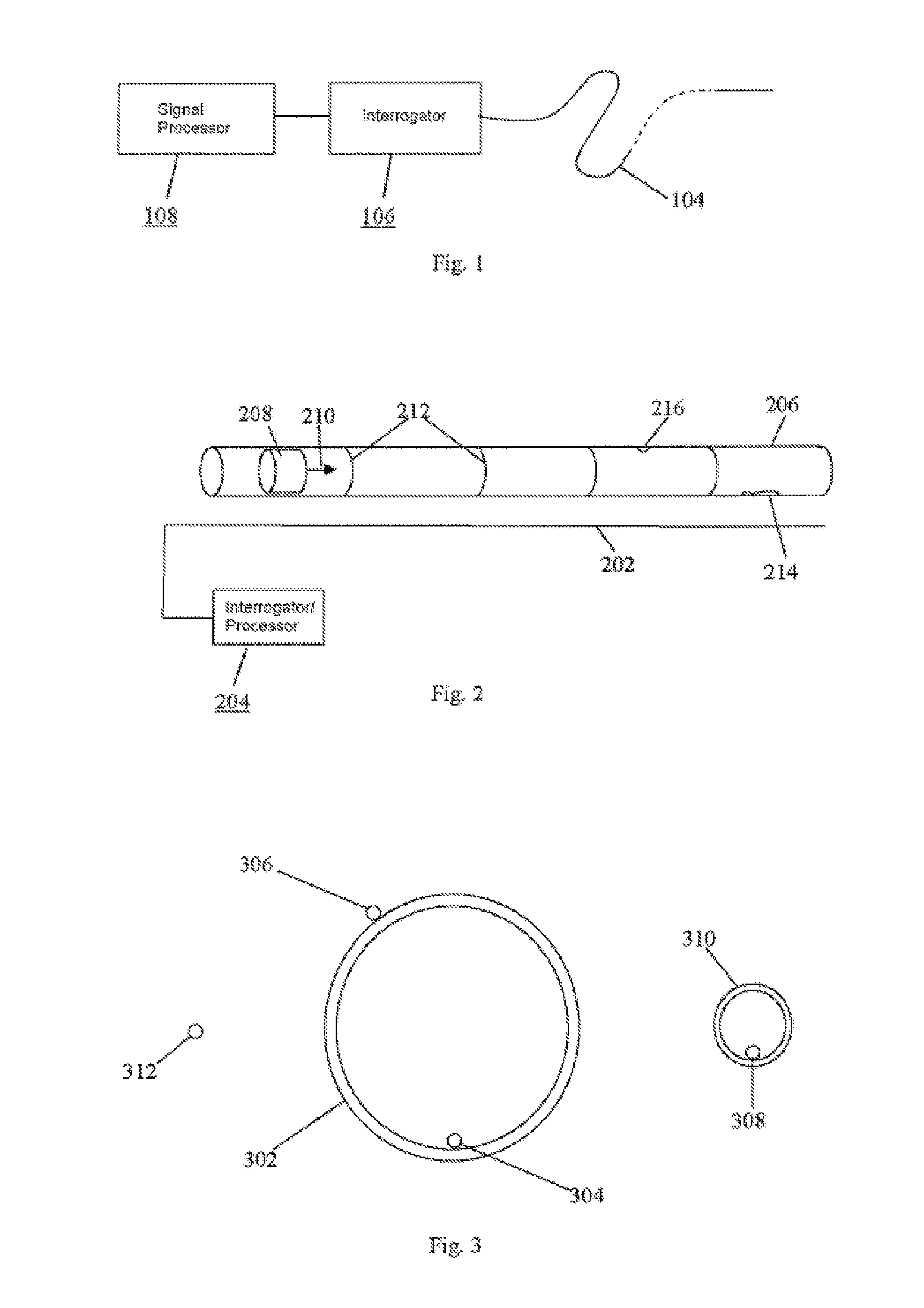

Method and system for downhole object location and orientation determination

A downhole device is provided that is intended to be co-located with an optical fiber cable to be found, for example by being fixed together in the same clamp. The device has an accelerometer or other suitable orientation determining means that is able to determine its positional orientation, with respect to gravity. A vibrator or other sounder is provided, that outputs the positional orientation information as a suitable encoded and modulated acoustic signal. A fiber optic distributed acoustic sensor deployed in the vicinity of the downhole device detects the acoustic signal and transmits it back to the surface, where it is demodulated and decoded to obtain the positional orientation information. Given that the device is co-located with the optical fiber the position of the fiber can then be inferred. As explained above, detecting the fiber position is important during perforation operations, so that the fiber is not inadvertently damaged.

Owner:SILIXA

Enhanced seismic surveying

InactiveUS20140126325A1ConfidenceImprove accuracySubsonic/sonic/ultrasonic wave measurementConstructionsDistributed acoustic sensingSeismic survey

Embodiments of the present invention help in the processing and interpretation of seismic survey data, by correlating or otherwise comparing or associating seismic data obtained from a seismic survey with flow information obtained from a well or borehole in the surveyed area. In particular, embodiments of the present invention allow for flow data representing a flow profile along a well that is being monitored by a distributed acoustic sensor to be determined, such that regions of higher flow in the well can be determined. For example, in the production zone the well will be perforated to allow oil to enter the well, but it has not previously been possible to determine accurately where in the production zone the oil is entering the well. However, by determining a flow rate profile along the well using the i)AS then this provides information as to where in the perforated production zone oil is entering the well, and hence the location of oil bearing sands. This location can then be combined or otherwise correlated, used, or associated with petroleum reservoir location information obtained from the seismic survey, to improve the confidence and / or accuracy in the determined petroleum reservoir location.

Owner:SILIXA +1

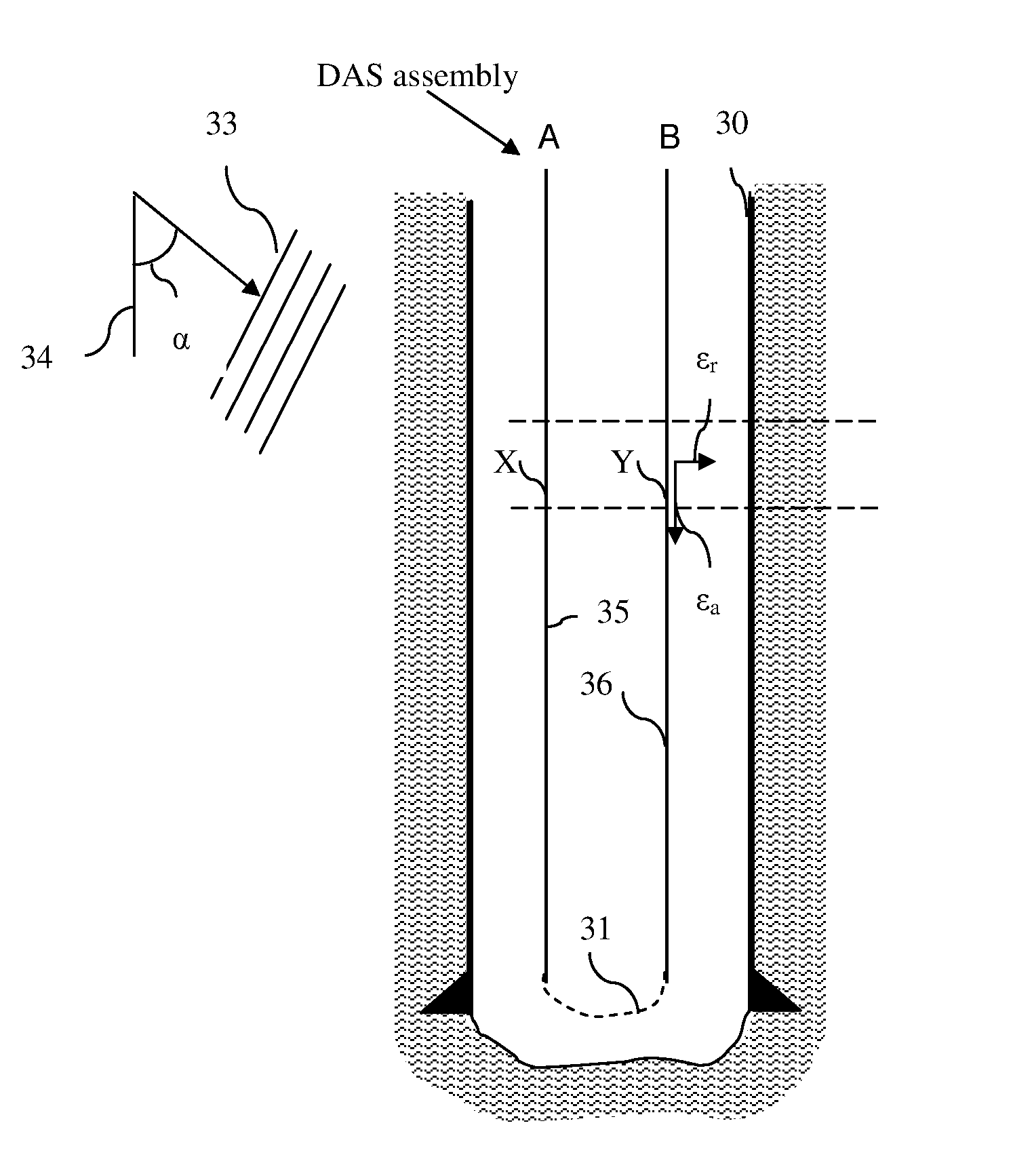

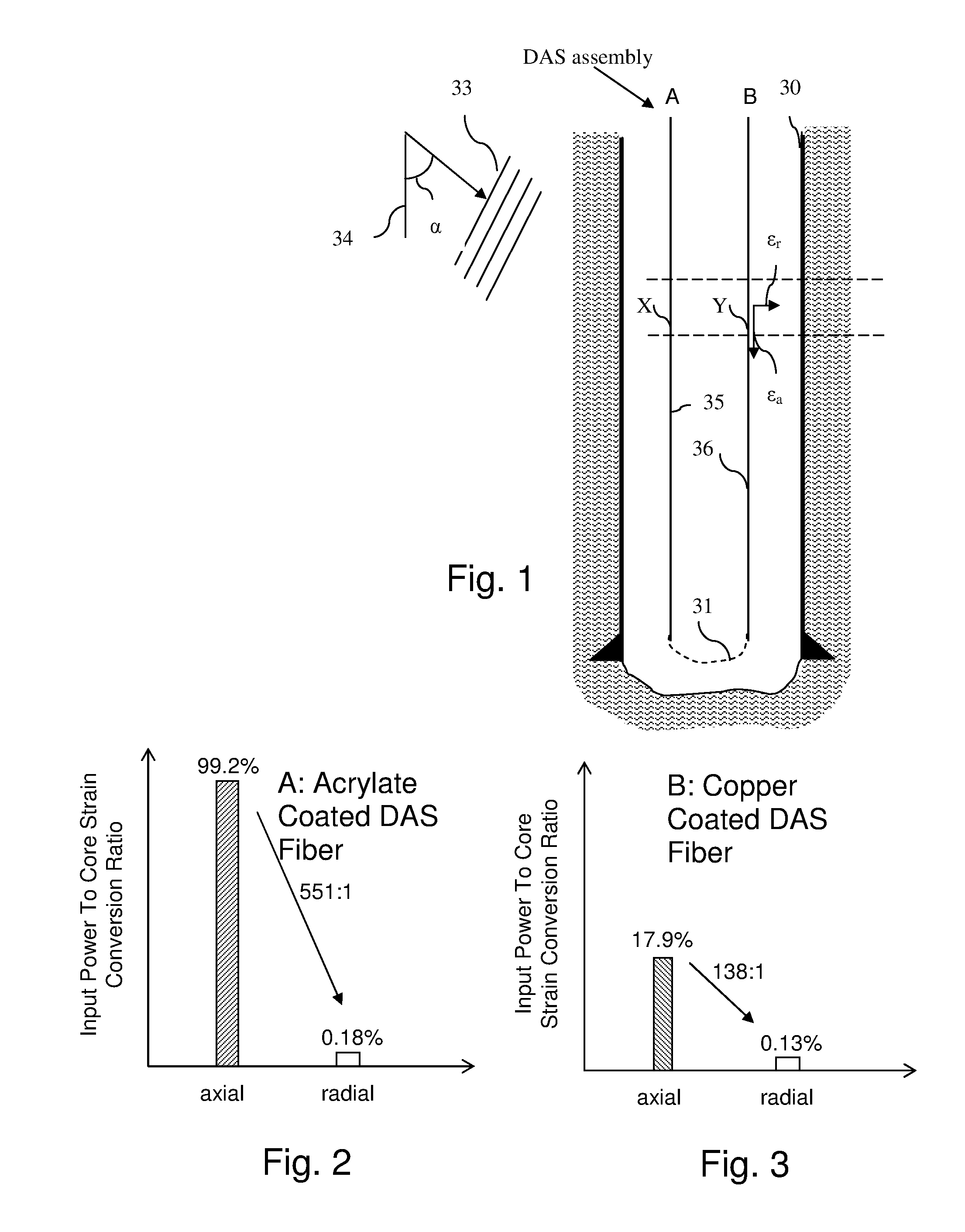

Detecting broadside and directional acoustic signals with a fiber optical distributed acoustic sensing (DAS) assembly

ActiveUS20130211726A1Vibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesFiberDistributed acoustic sensing

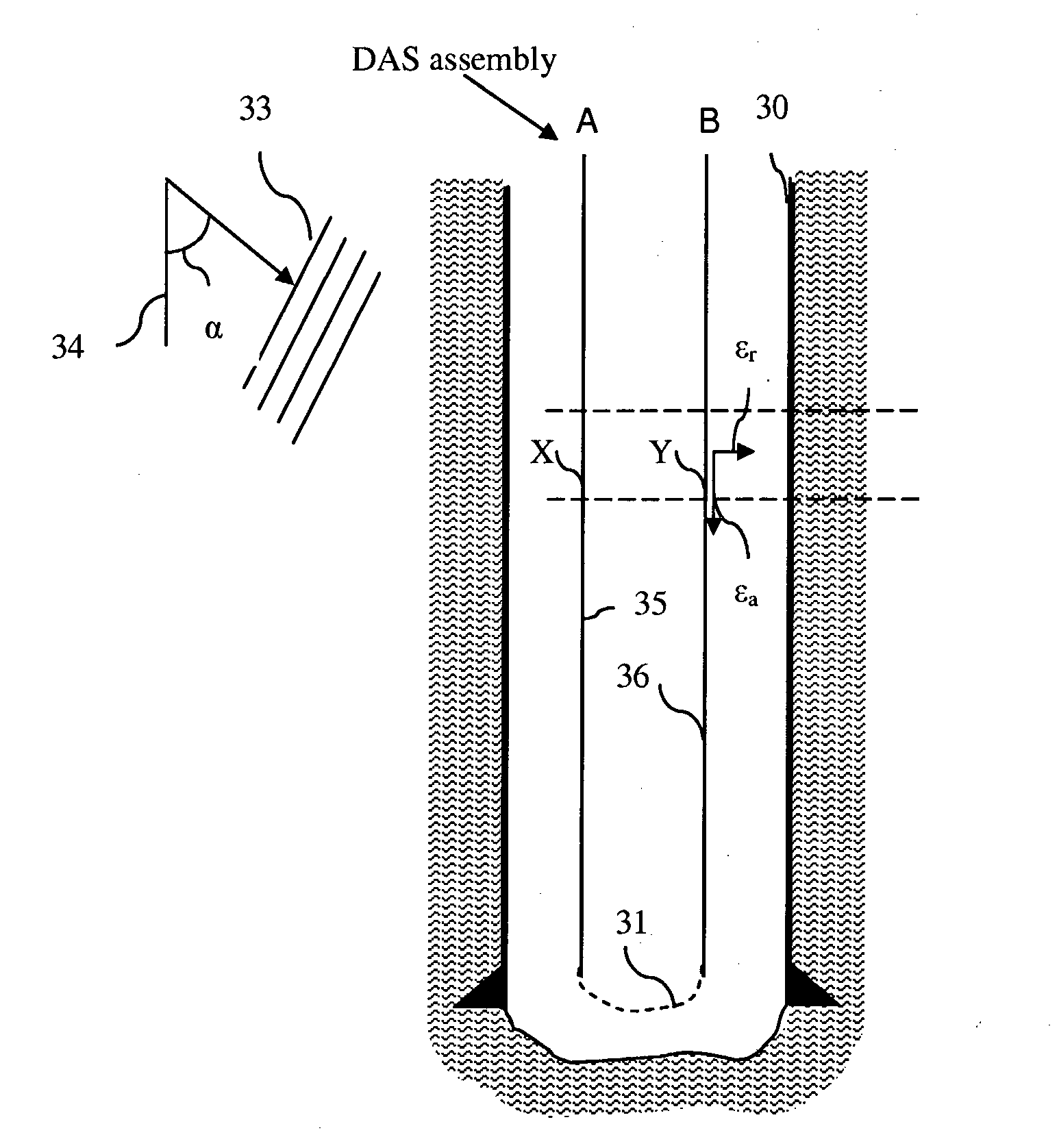

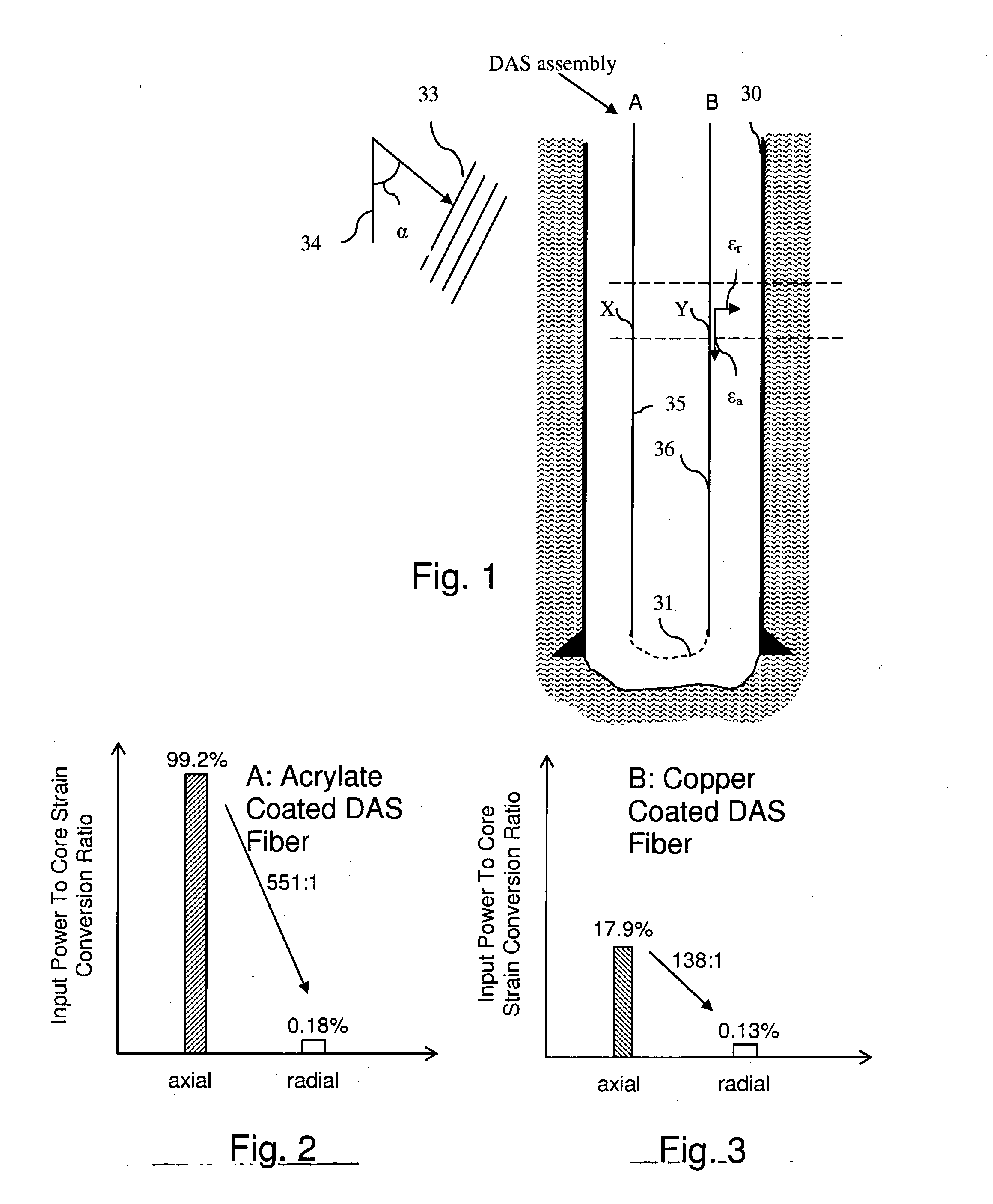

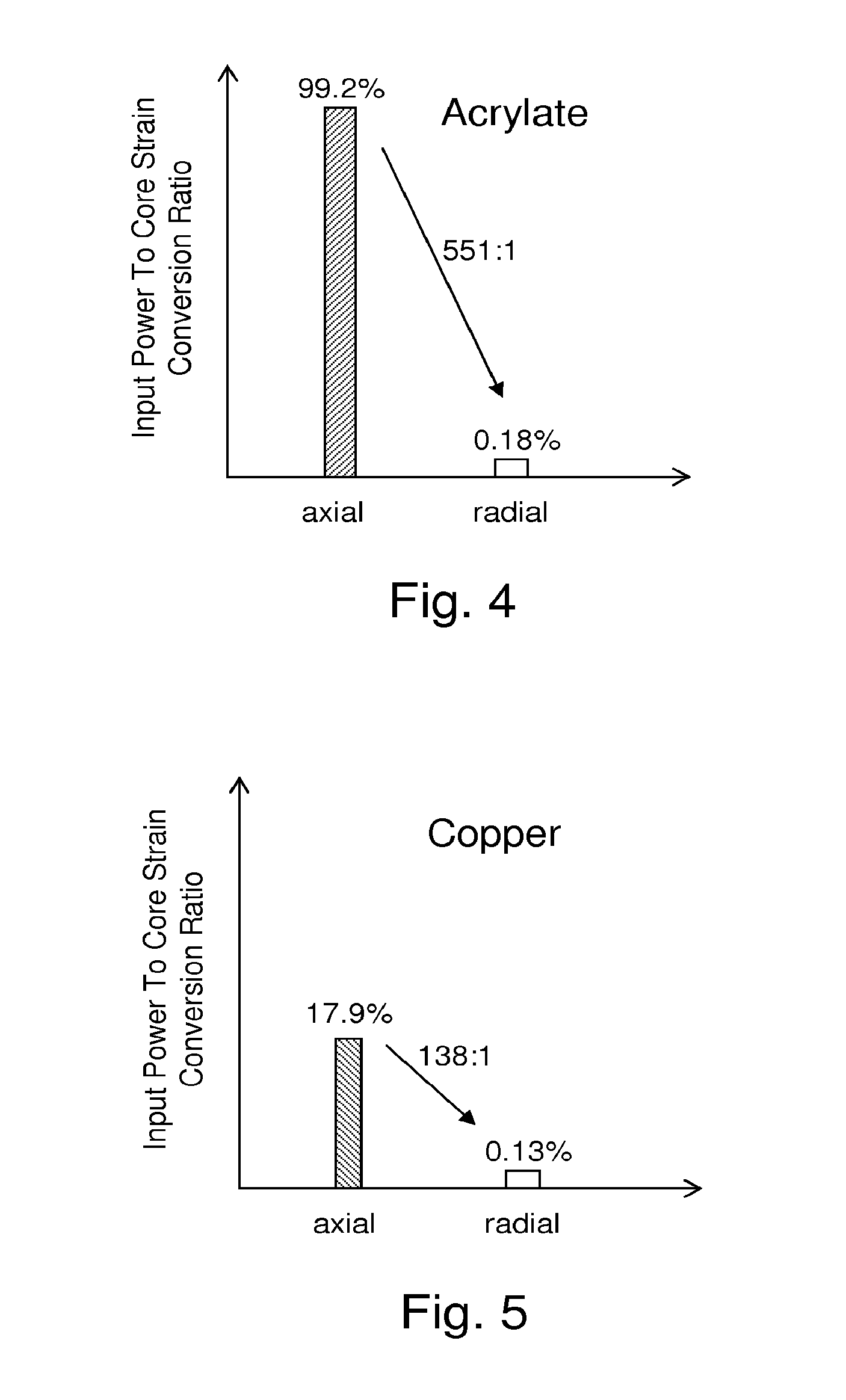

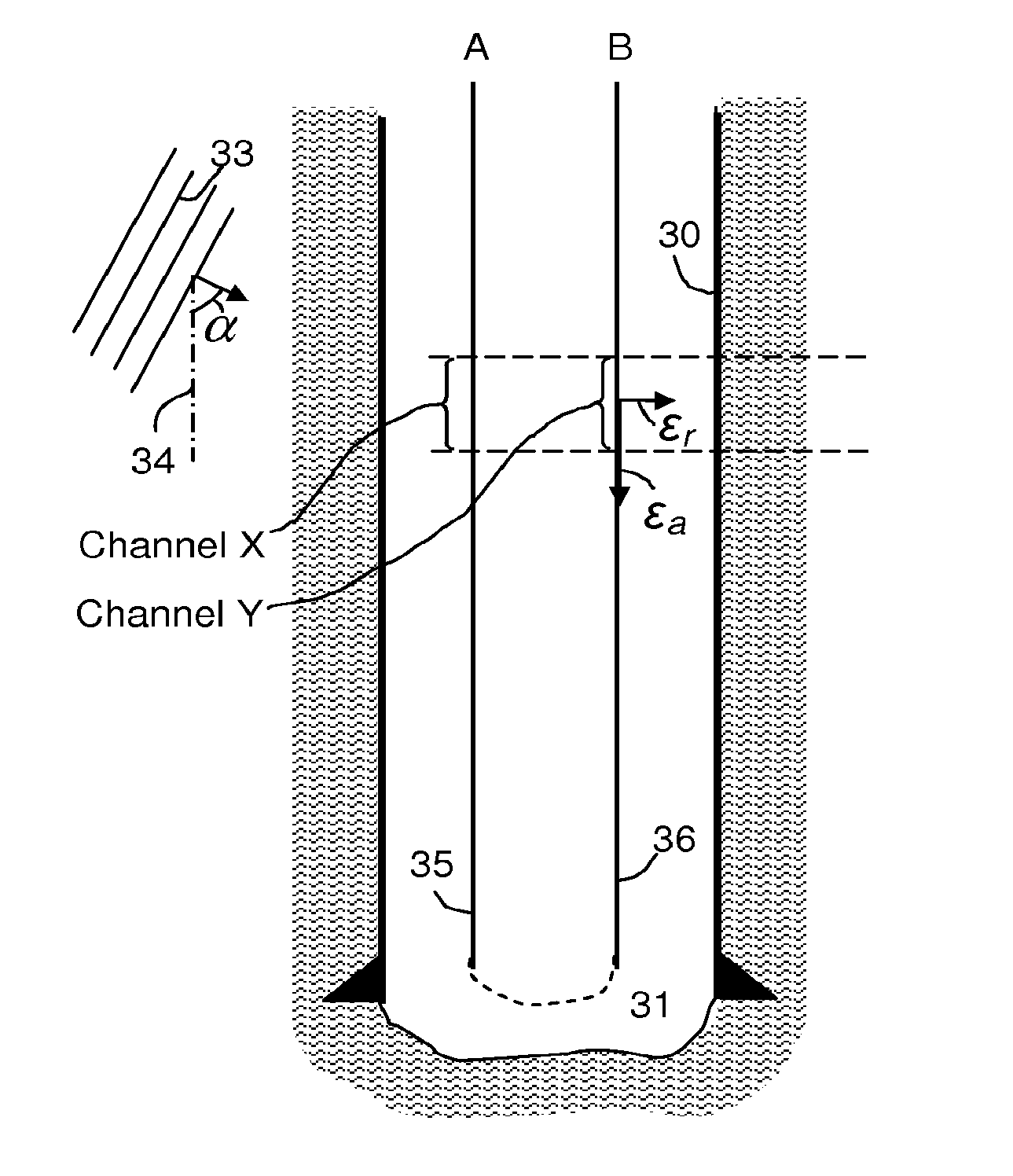

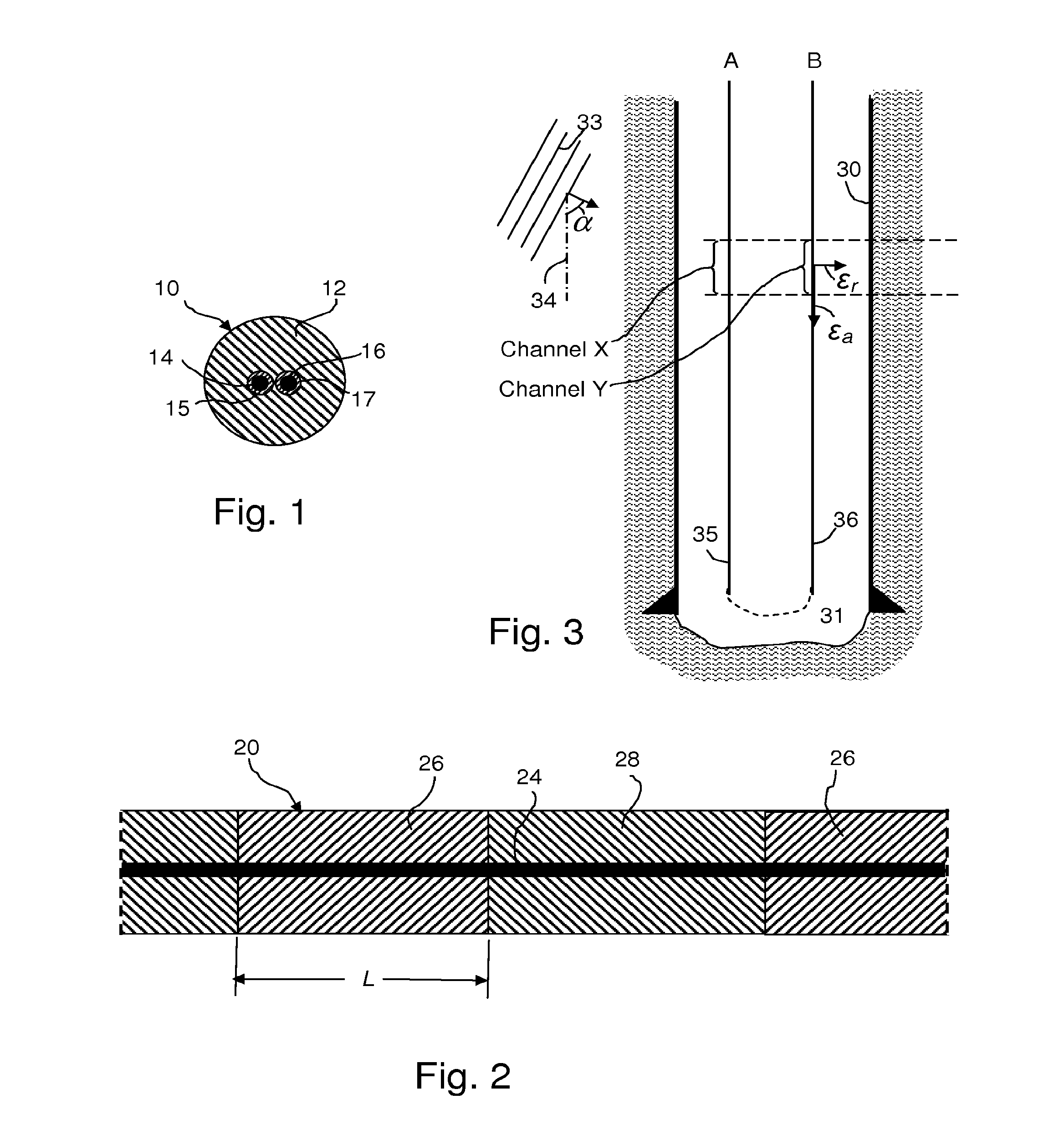

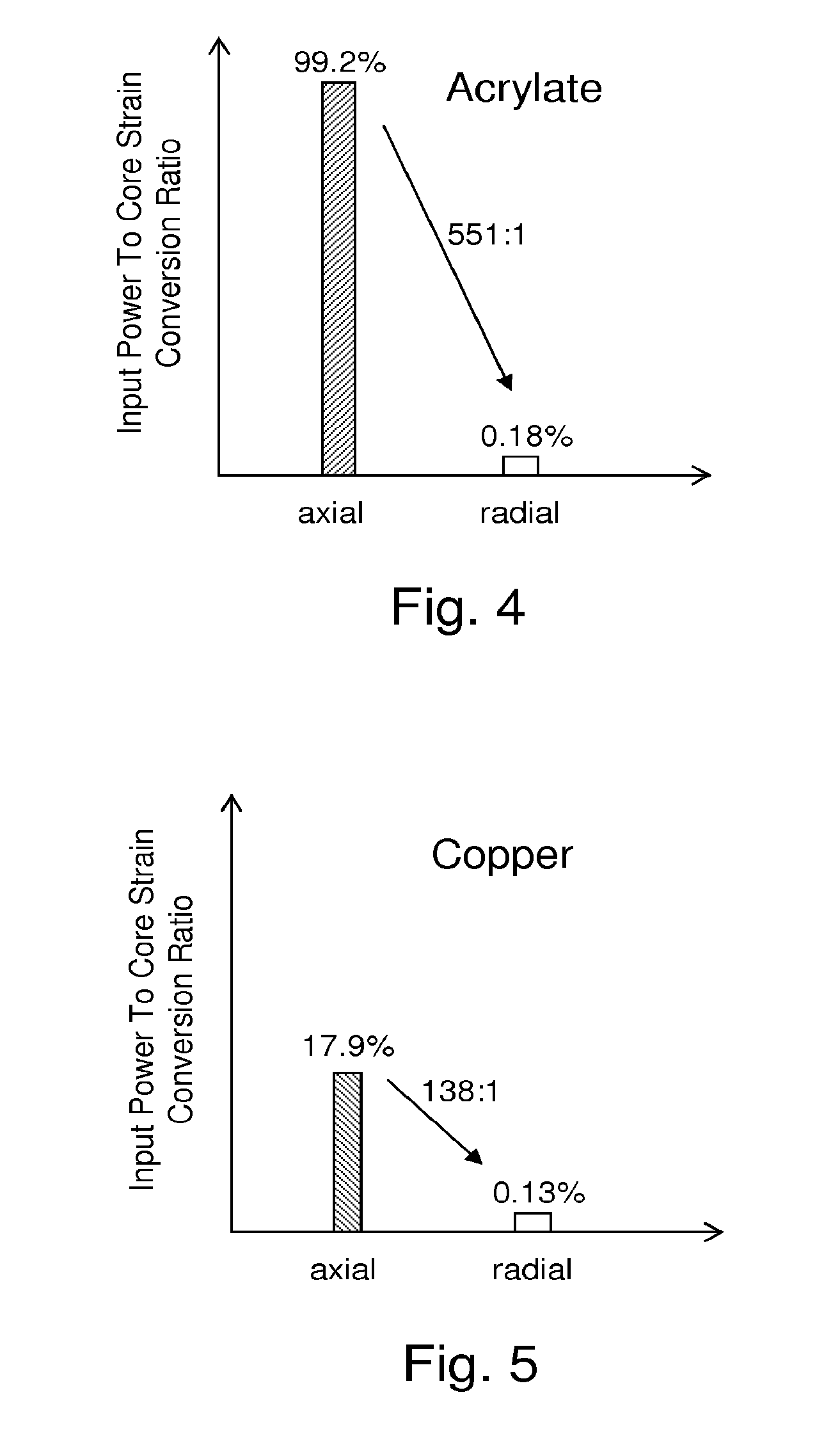

A Distributed Acoustic Sensing (DAS) fiber optical assembly comprises adjacent lengths of optical fiber A, B with different directional acoustic sensitivities, for example by providing the first length of optical fiber A with a first coating 35, such as acrylate, and the second length of optical fiber B with a second coating 36, such as copper, wherein the first and second coatings 35 and 36 may be selected such that the Poisson's ratio of the first length of coated fiber A is different from the Poisson's ratio of the second length of coated fiber B. The different Poisson's ratios and / or other properties of the adjacent lengths of optical fiber A and B improve their directional acoustic sensitivity and their ability to detect broadside (radial) acoustic waves.

Owner:SHELL USA INC

Method of acoustic surveying

ActiveUS20140163889A1Electric/magnetic detection for well-loggingSurveyDistributed acoustic sensingSurveyor

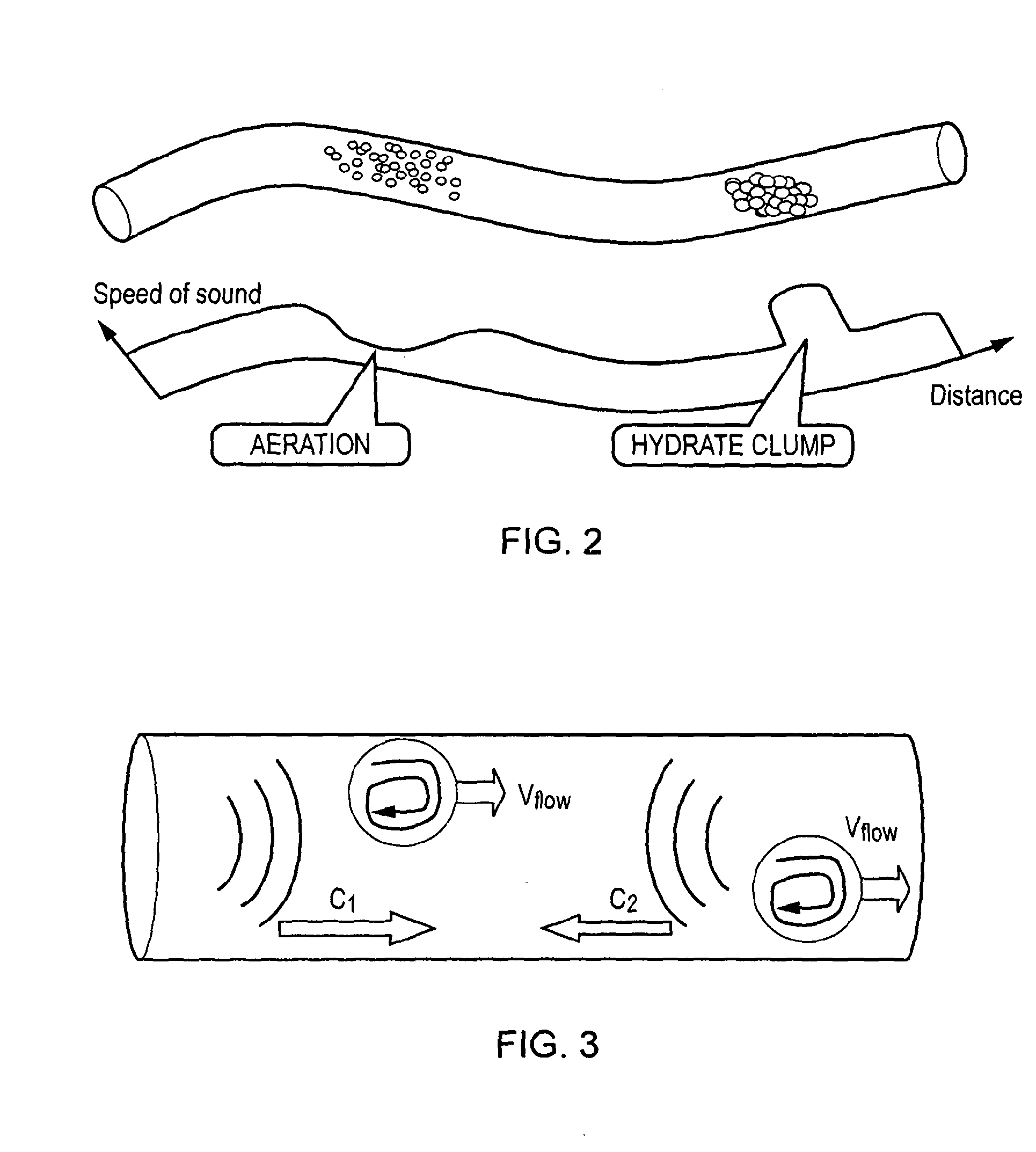

The invention relates to the use of distributed optical fibre sensors for distributed acoustic sensing, and in particular, modal analysis of distributed acoustic data obtained in-well to monitoring well integrity. By determining one or more acoustic modes corresponding to distributed speed of sound measurements within the wellbore, and analysing variations in the distributed speed of sound measurement it is possible to derive information relating to a formation and / or fluid in the wellbore.

Owner:SILIXA

Method and system for distributed acoustic sensing

ActiveUS20190197846A1Accurate frequencyPrecise positioningOptical signal transducersSubsonic/sonic/ultrasonic wave measurementDistributed acoustic sensingFiber

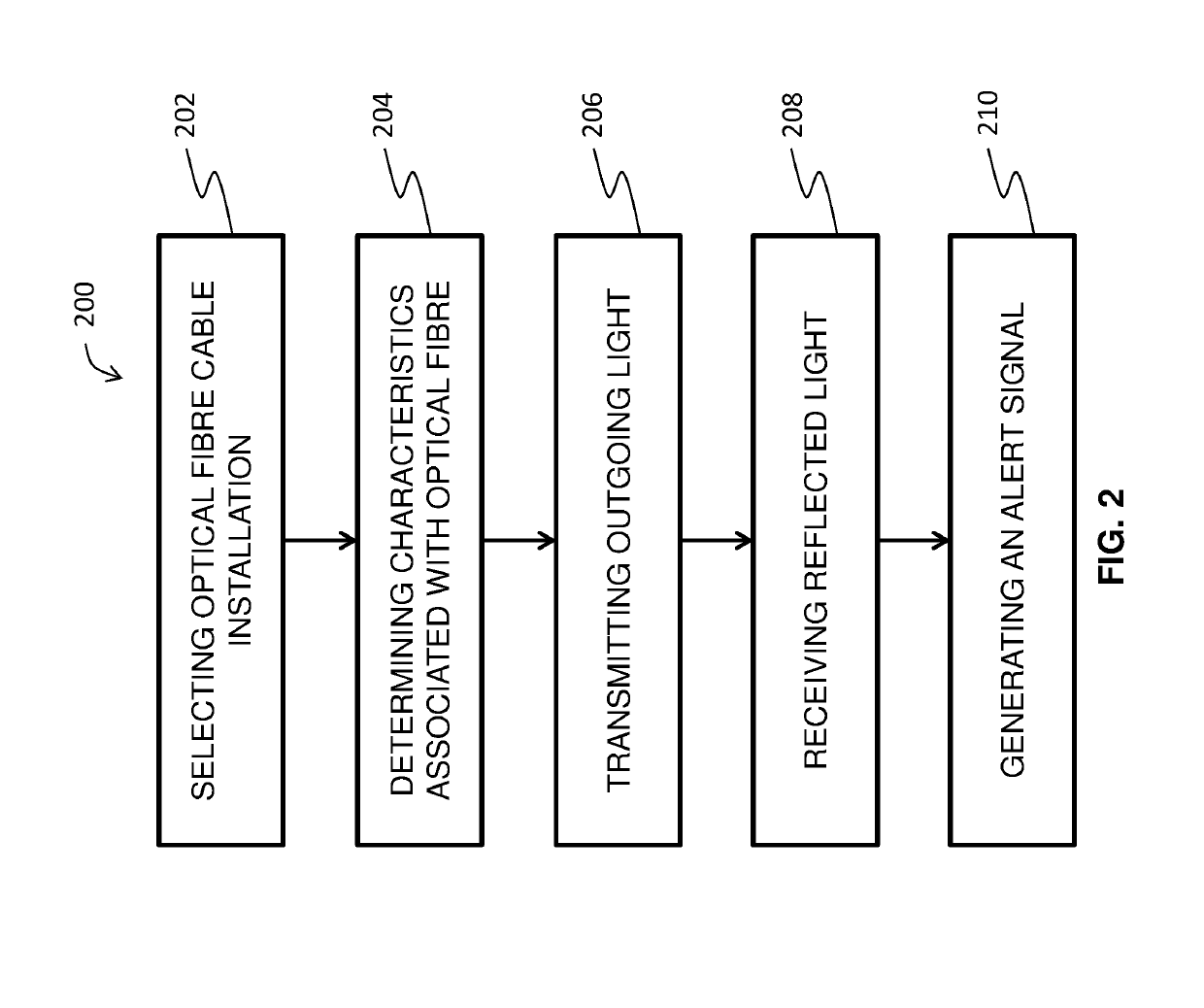

Described herein is a method and system of distributed acoustic sensing, such as in an urban or metropolitan area involving a dedicated and established fibre optic communications network including a data centre. In general, the disclosed method and system includes the steps of (a) selecting an optical fibre cable installation having a path extending across a selected geographical area, the optical fibre cable installation including a bundle of optical fibres and forming part of a fibre-optic communications network, (b) determining characteristics associated with the optical fibre and / or the selected optical fibre installation, (c) transmitting outgoing light in the optical fibre, (d) receiving reflected light back scattered along the optical fibre, and (e) based on the reflected light and the determined characteristics, generating an alert signal representative of an acoustic event. The disclosed method and system may be useful in the detection of acoustic events near or within the selected geographical area.

Owner:FIBER SENSE LTD

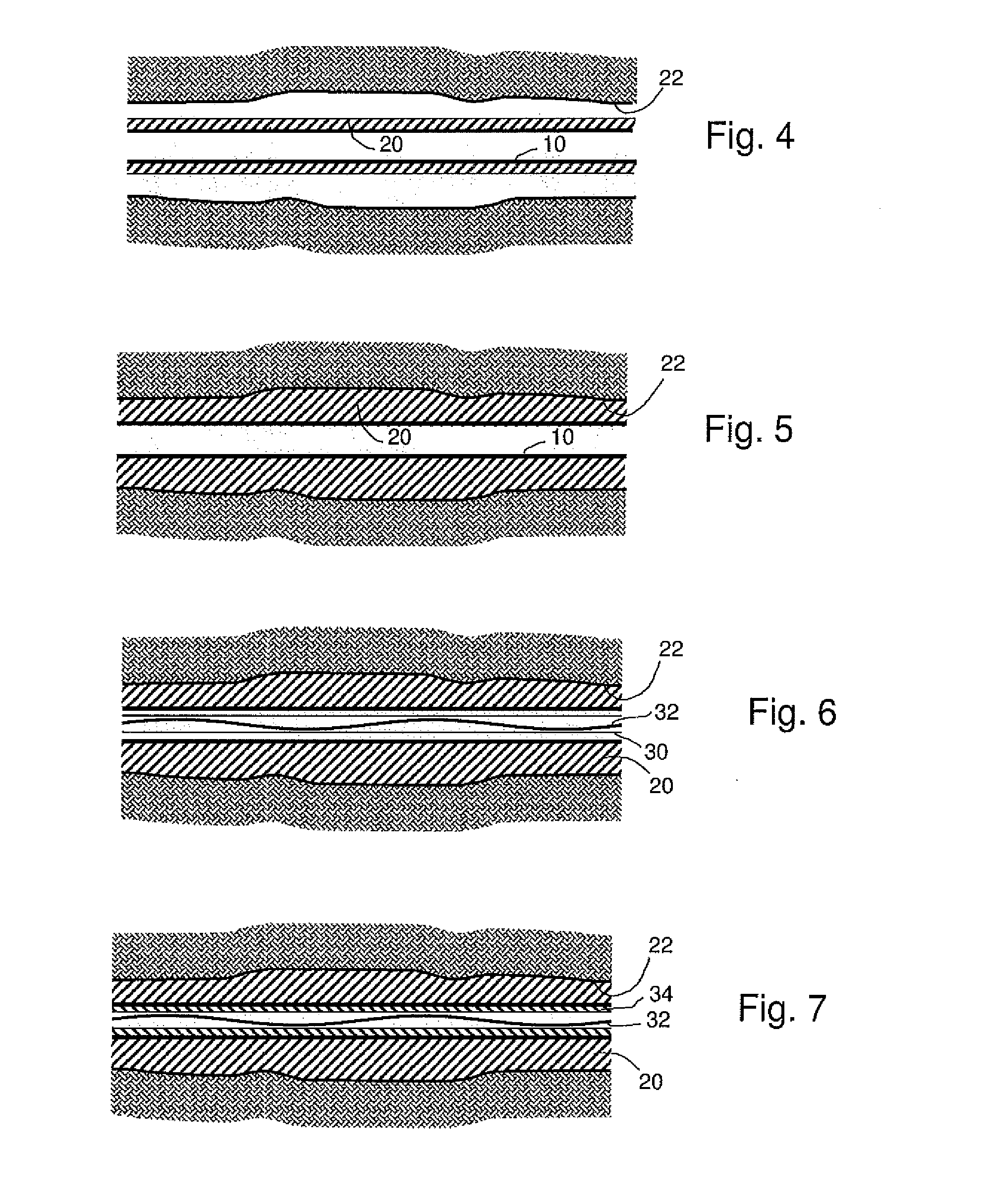

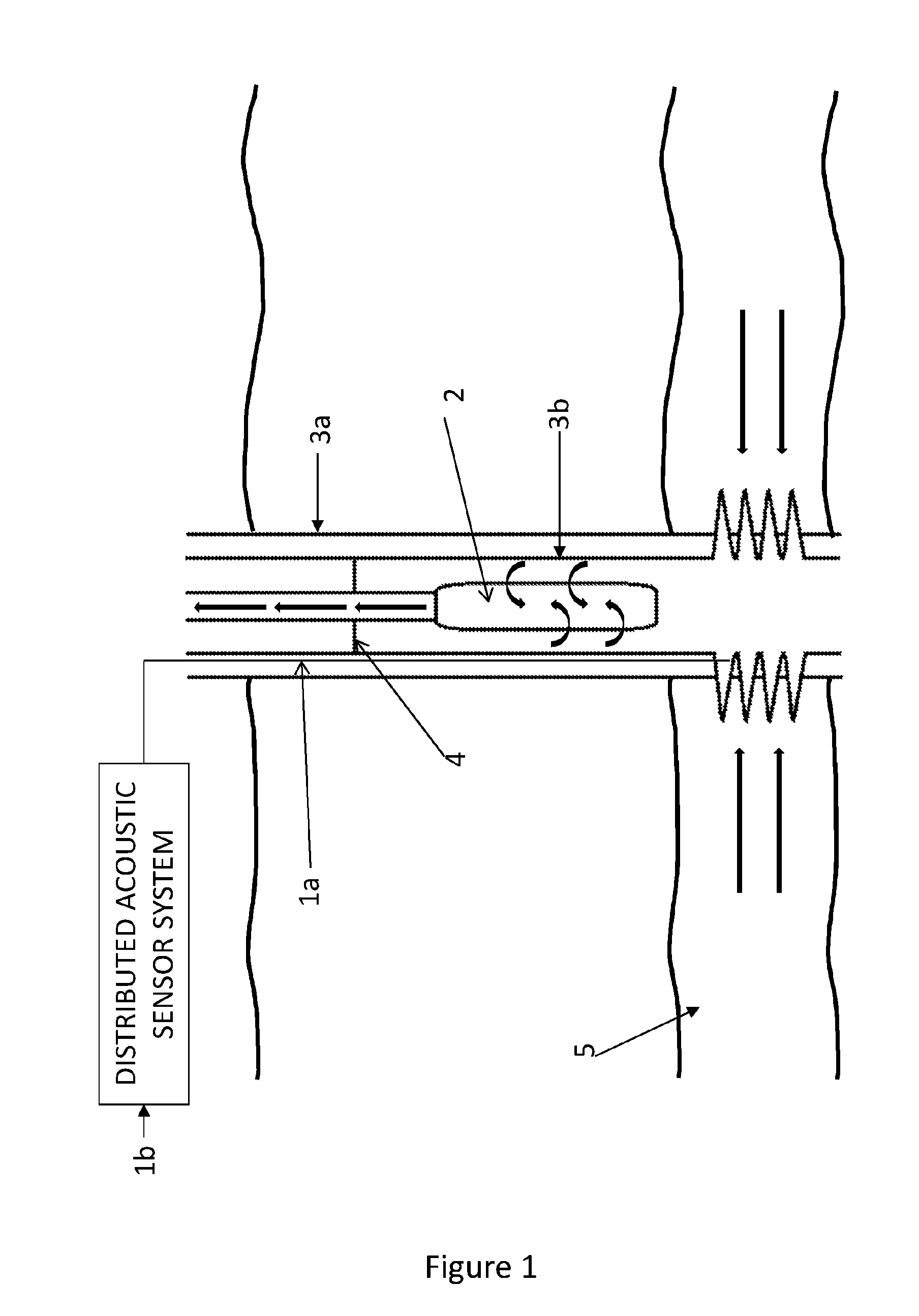

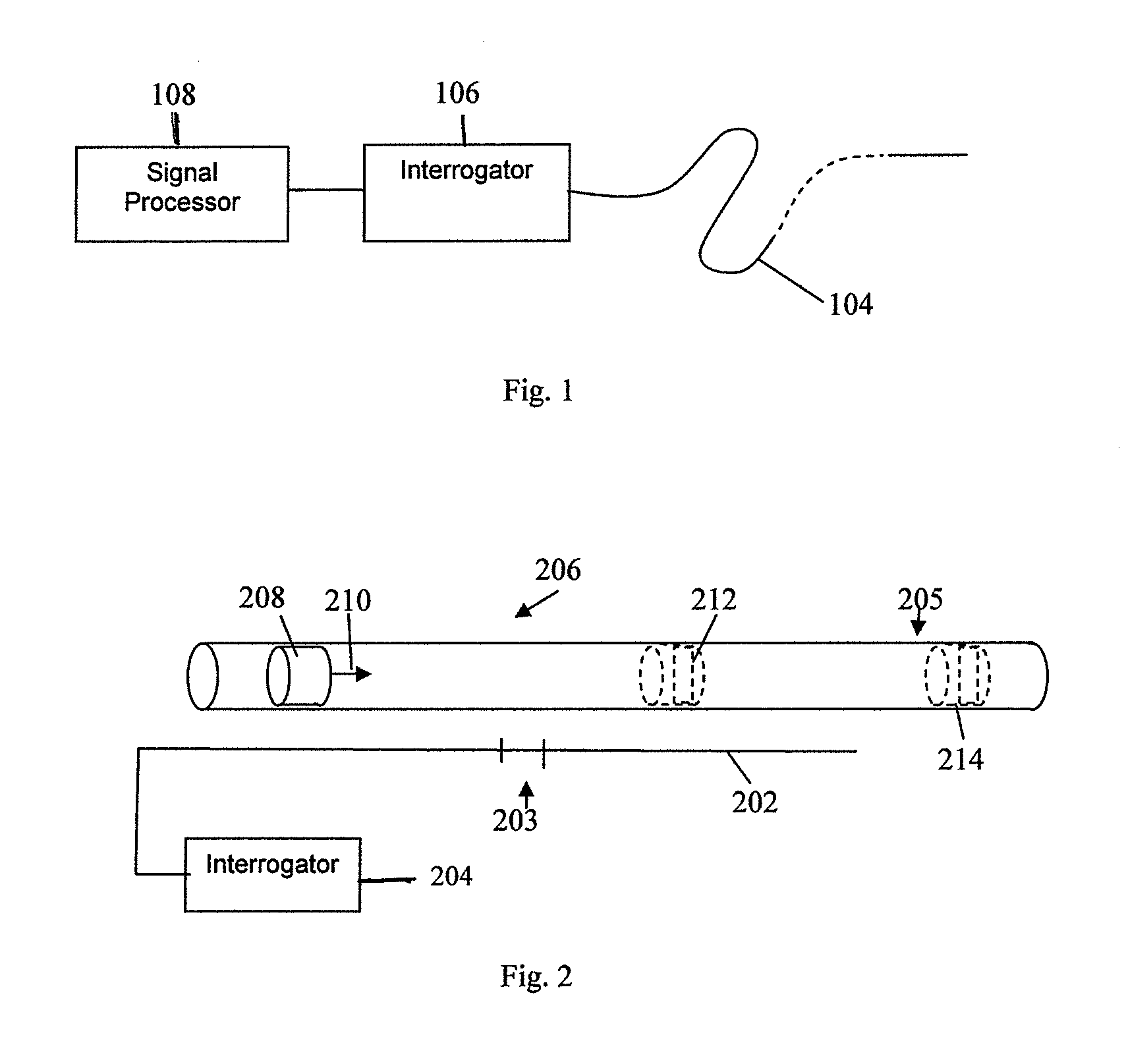

Method and system for monitoring fluid flow in a conduit

ActiveUS20160265345A1Sensitive in up thermal and acoustic noiseLower overall pressure dropSurveySubsonic/sonic/ultrasonic wave measurementFiberDistributed acoustic sensing

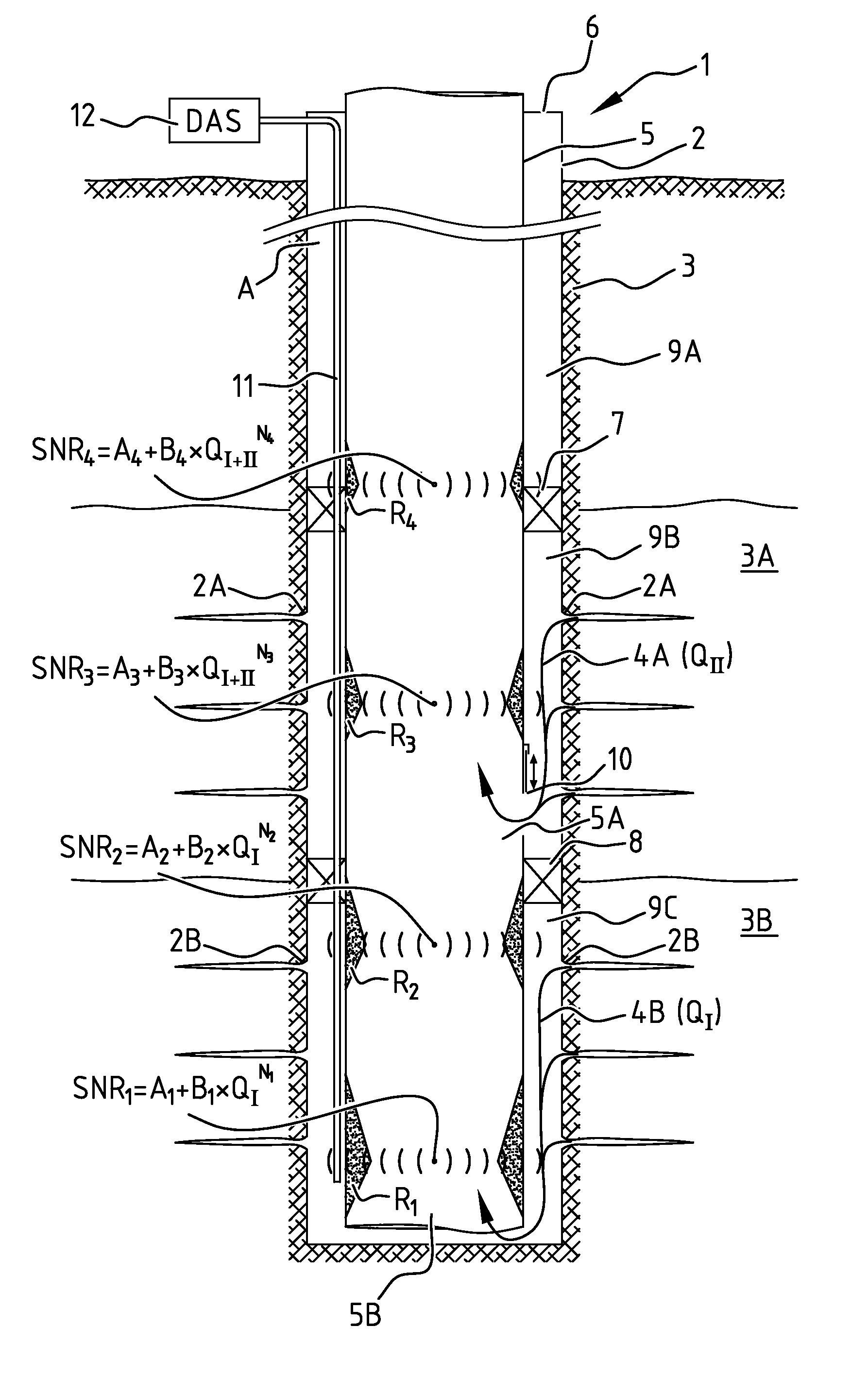

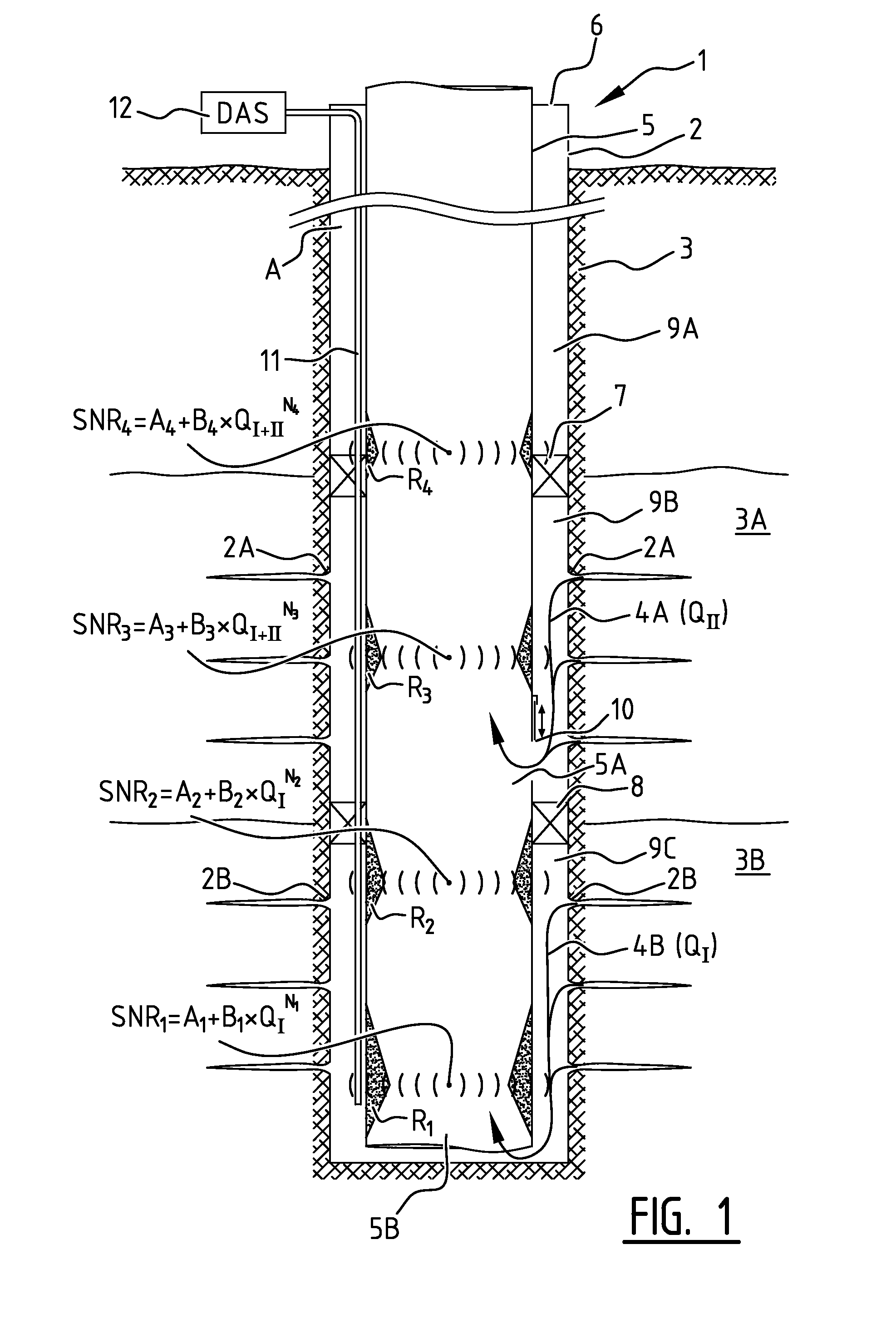

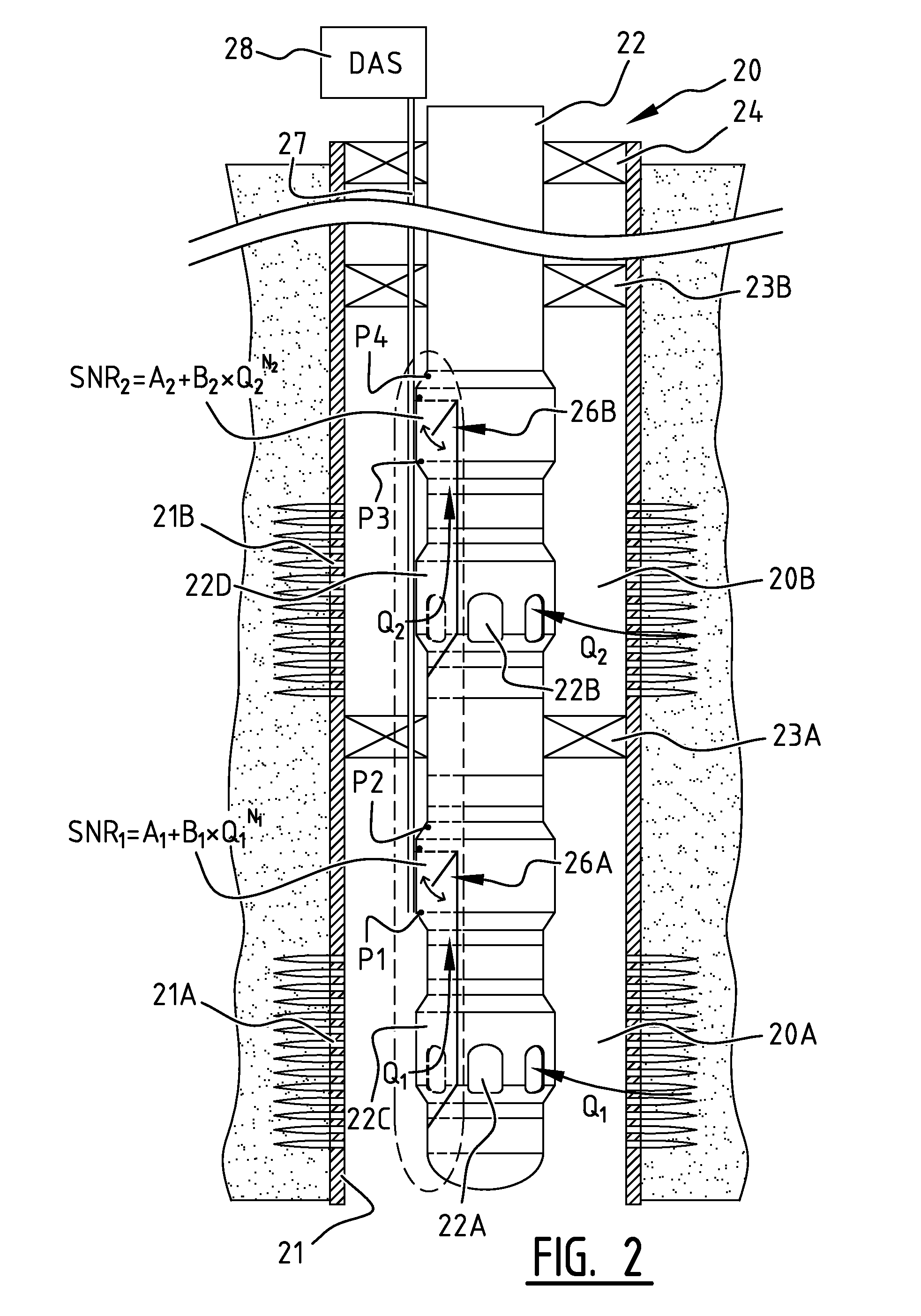

A method for monitoring fluid flow in a conduit comprises:acoustically coupling an optical fiber to the conduit adjacent one or more flow restrictions (R1-R4) in the conduit;inducing a Distributed Acoustic Sensing (DAS) assembly to measure an acoustic noise signature (SNR1-4) generated in the fiber by the fluid flowing through each flow restriction (R1-R4);deriving the fluid flow rate of the fluid (QI, QI+II) flowing through each flow restriction (R1-R4) from the measured acoustic noise signature (SNR1-4); anddisplaying the derived fluid flow rate (QI, QI+II) at a fluid flow rate monitoring display.

Owner:SHELL USA INC

Fiber optic cable for distributed acoustic sensing with increased acoustic sensitivity

Owner:WEATHERFORD TECH HLDG LLC

Signal stacking in fiber optic distributed acoustic sensing

ActiveUS9140815B2Improve signal-to-noise ratioLow costSeismic signal receiversSeismic signal processingFiberDistributed acoustic sensing

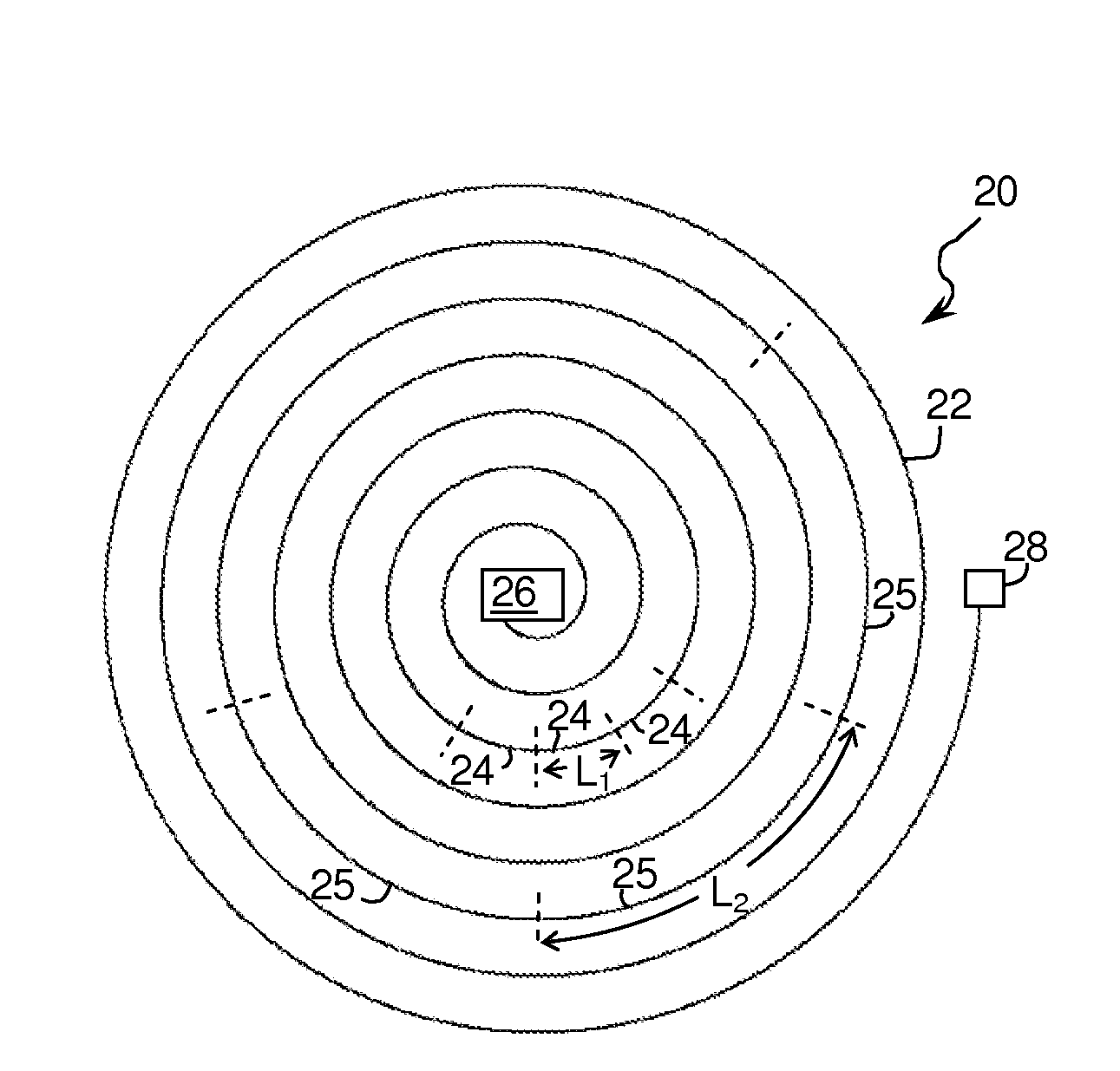

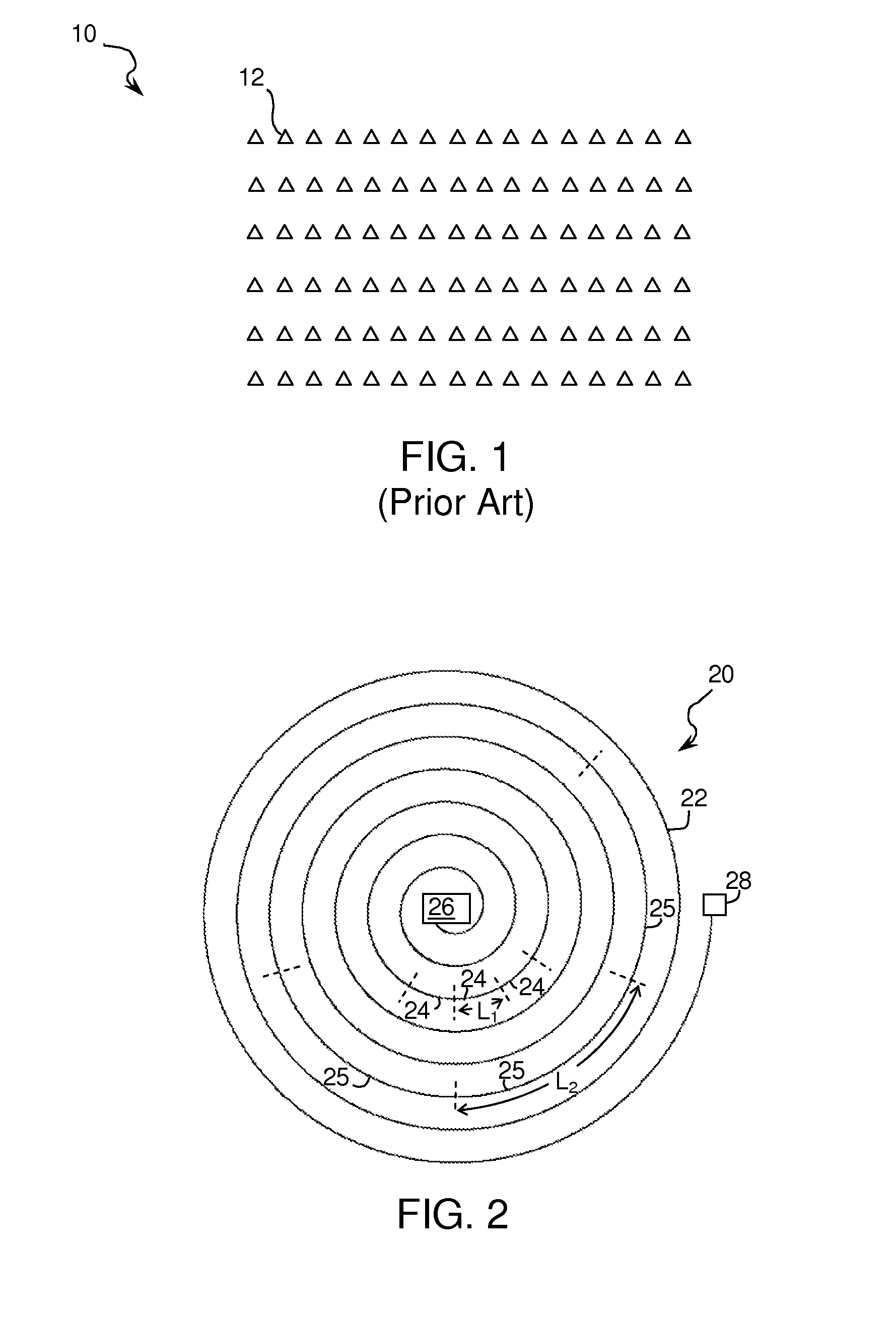

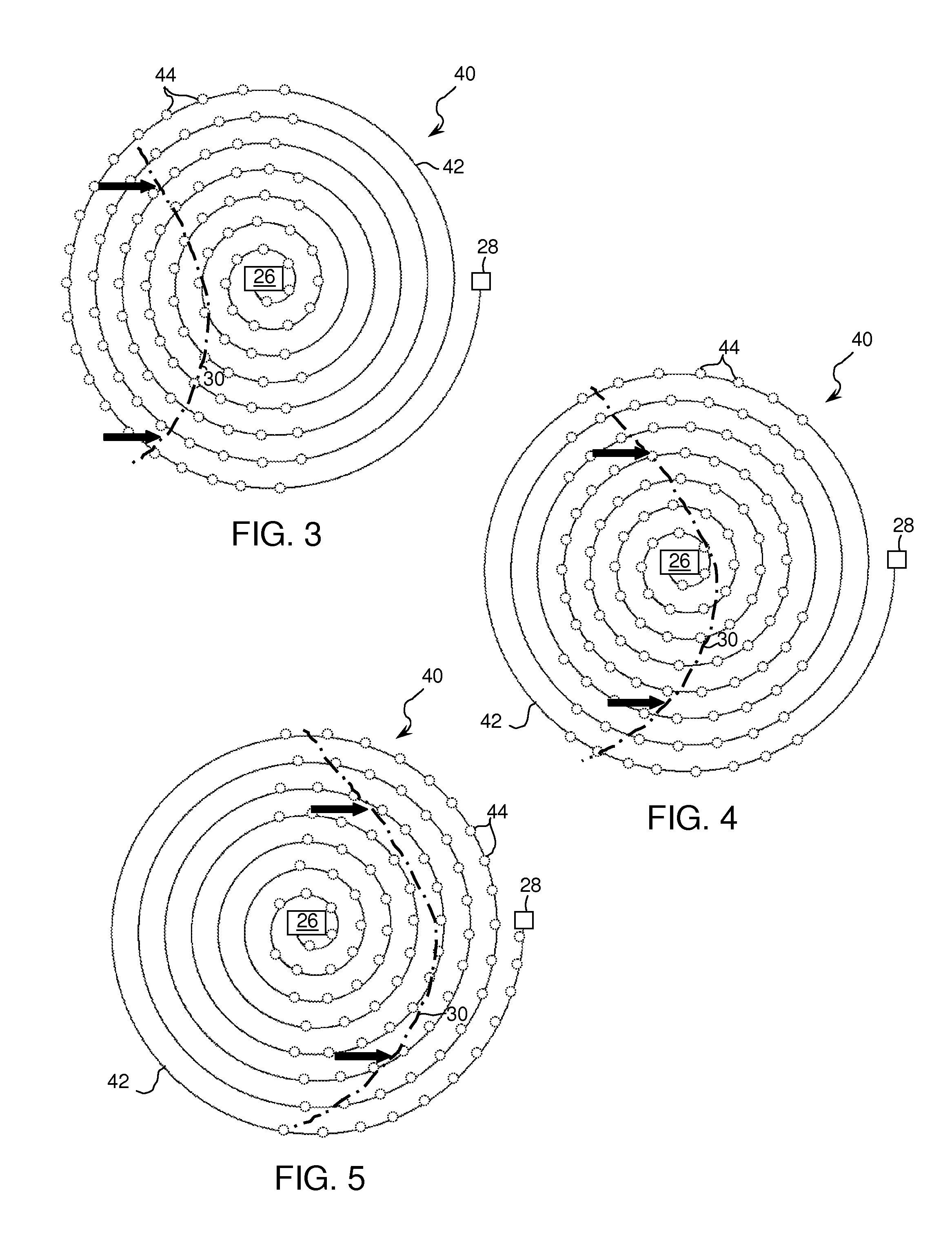

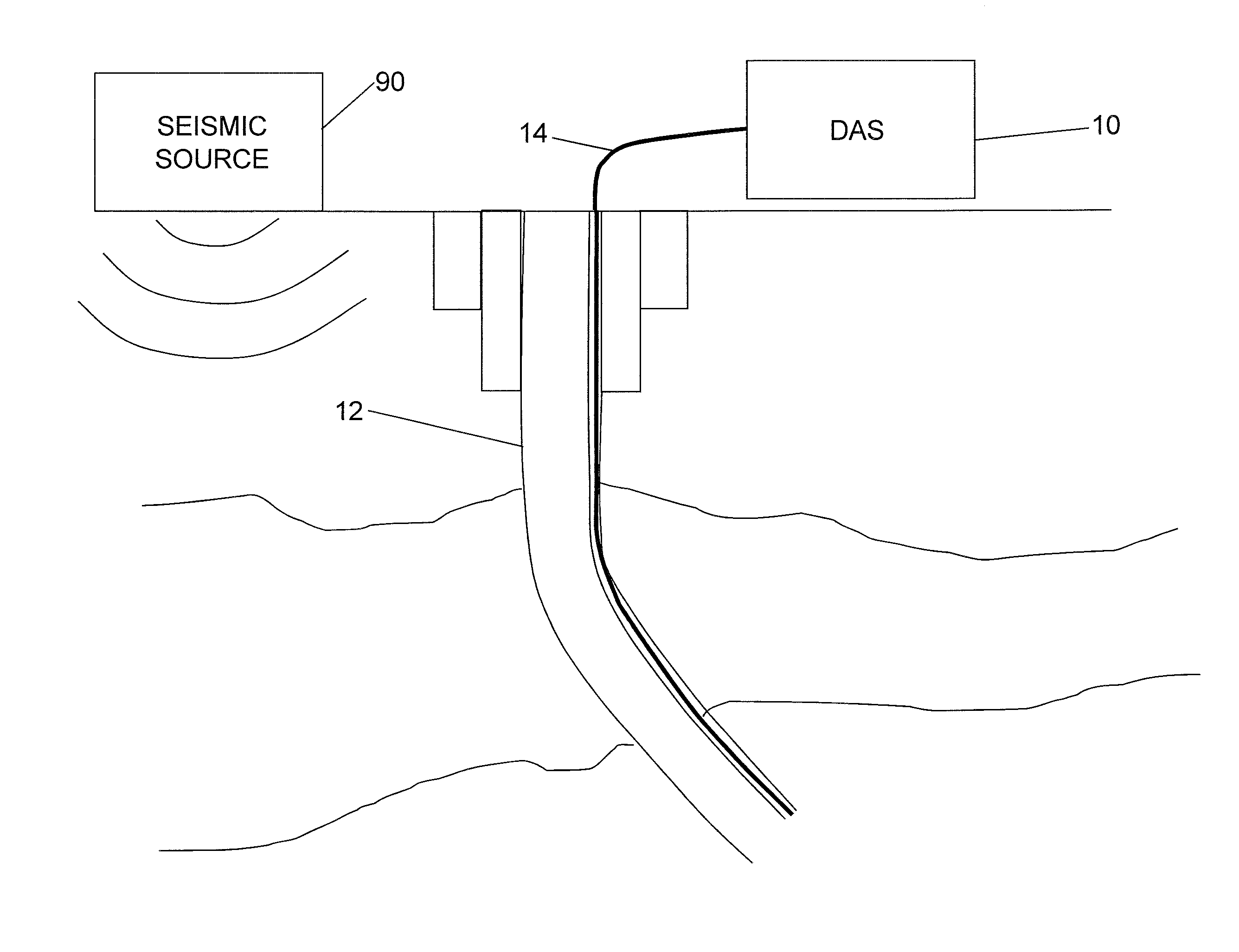

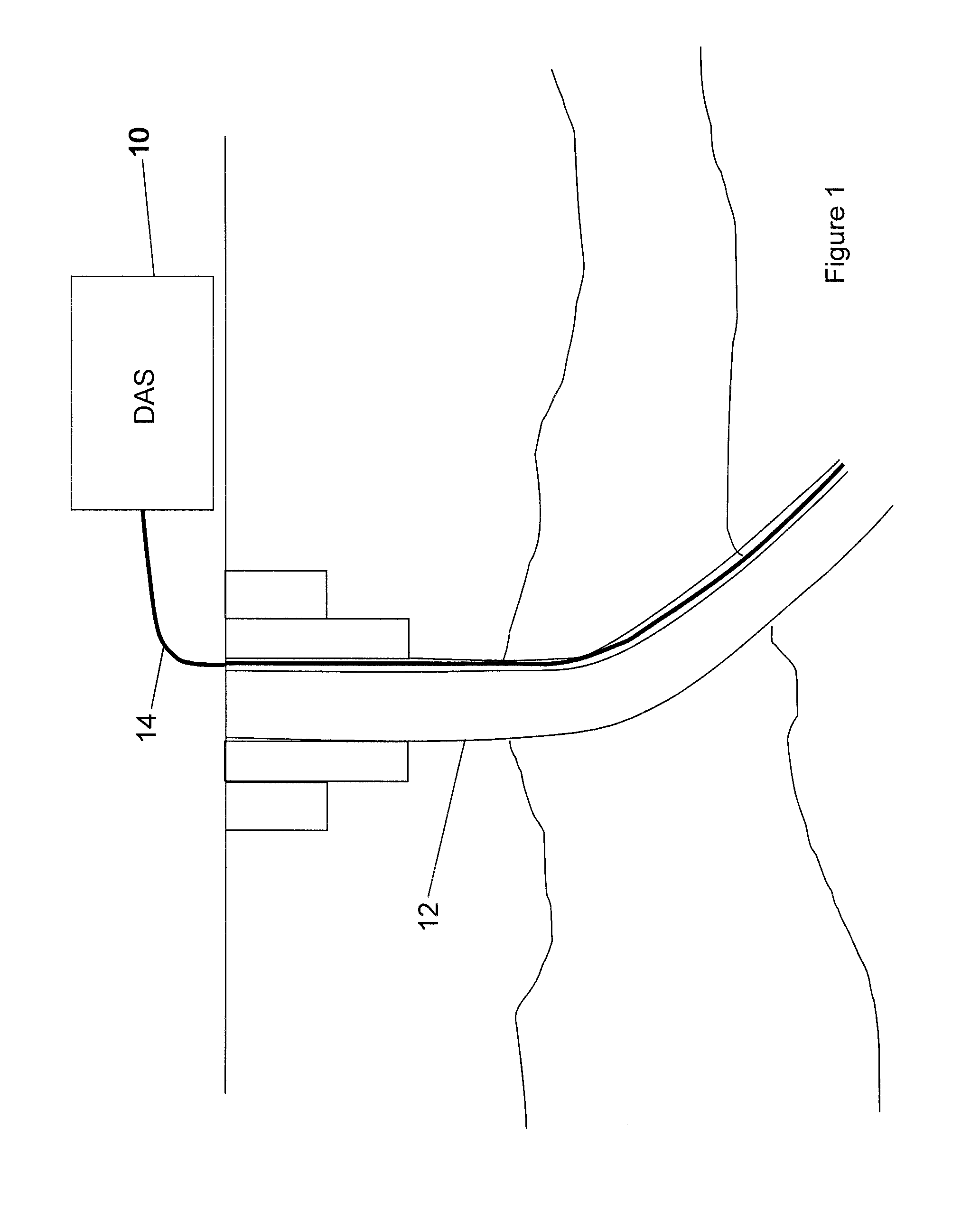

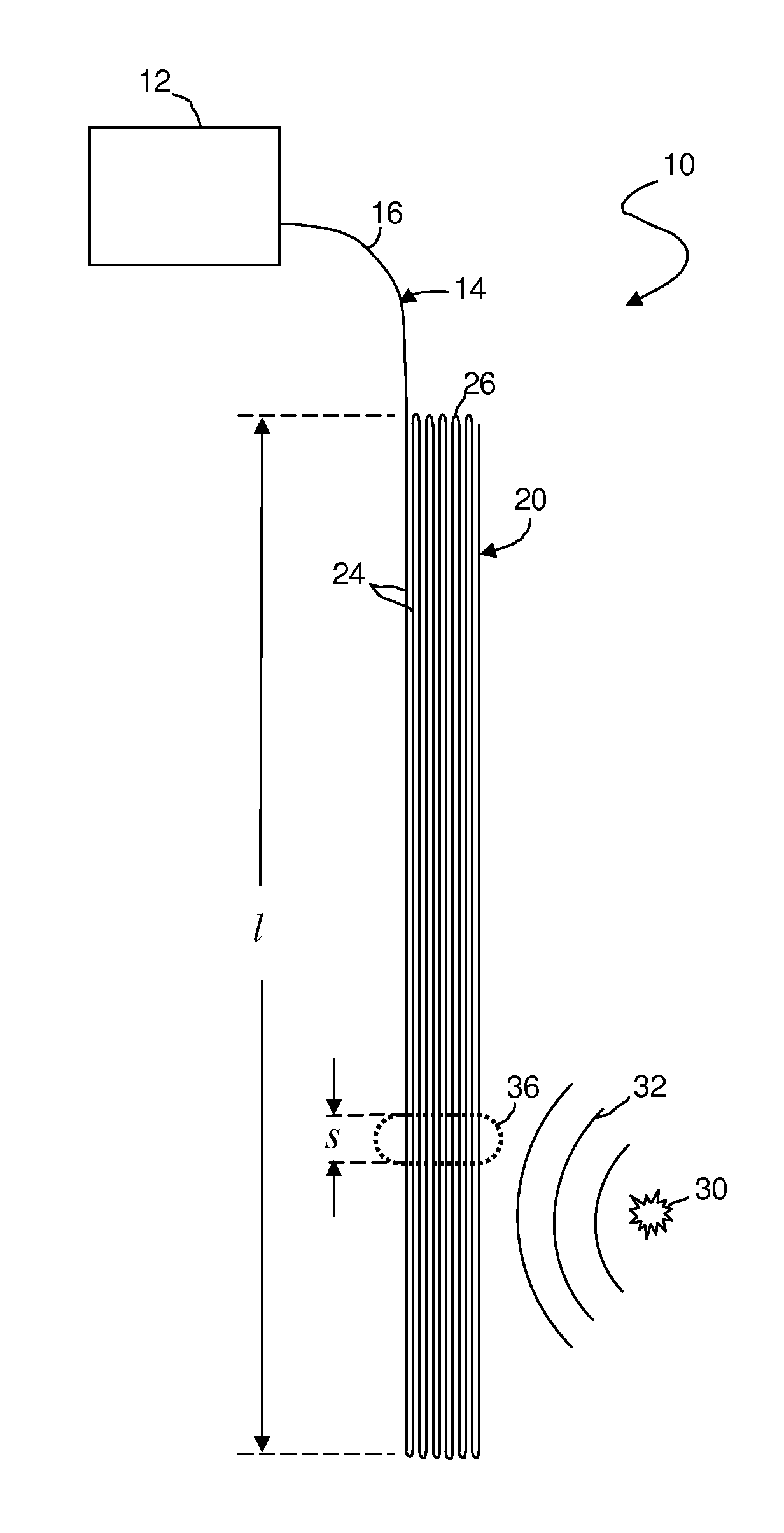

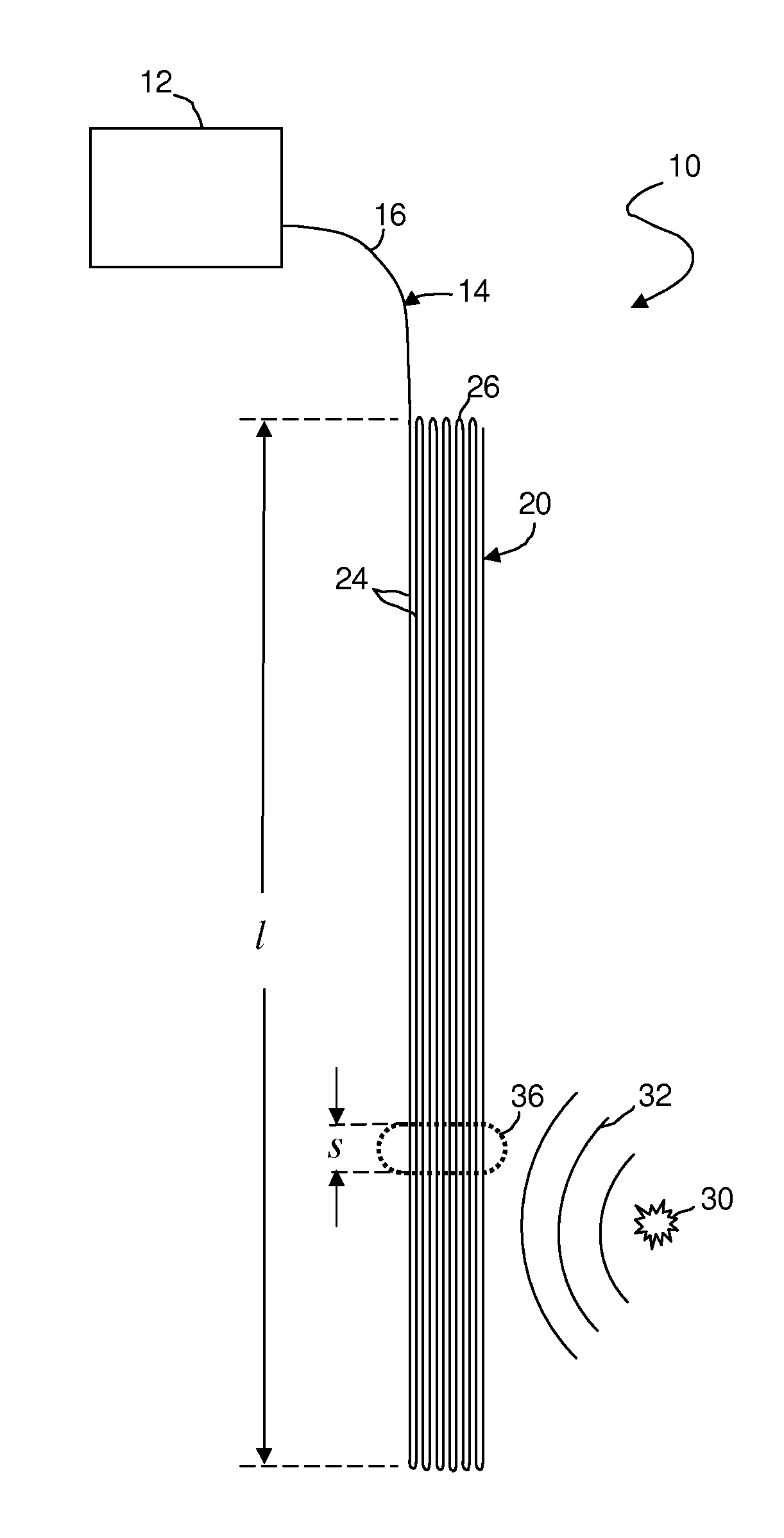

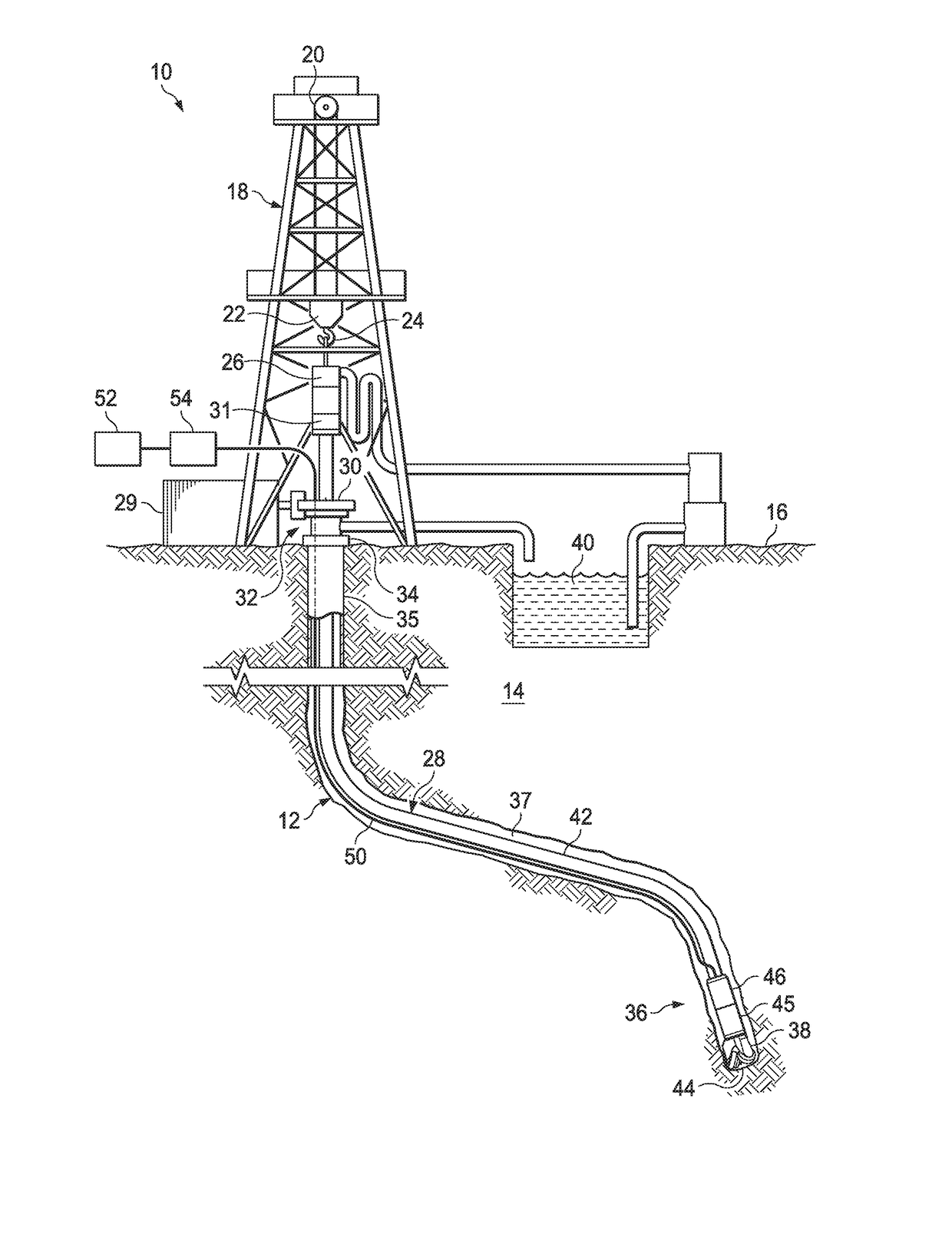

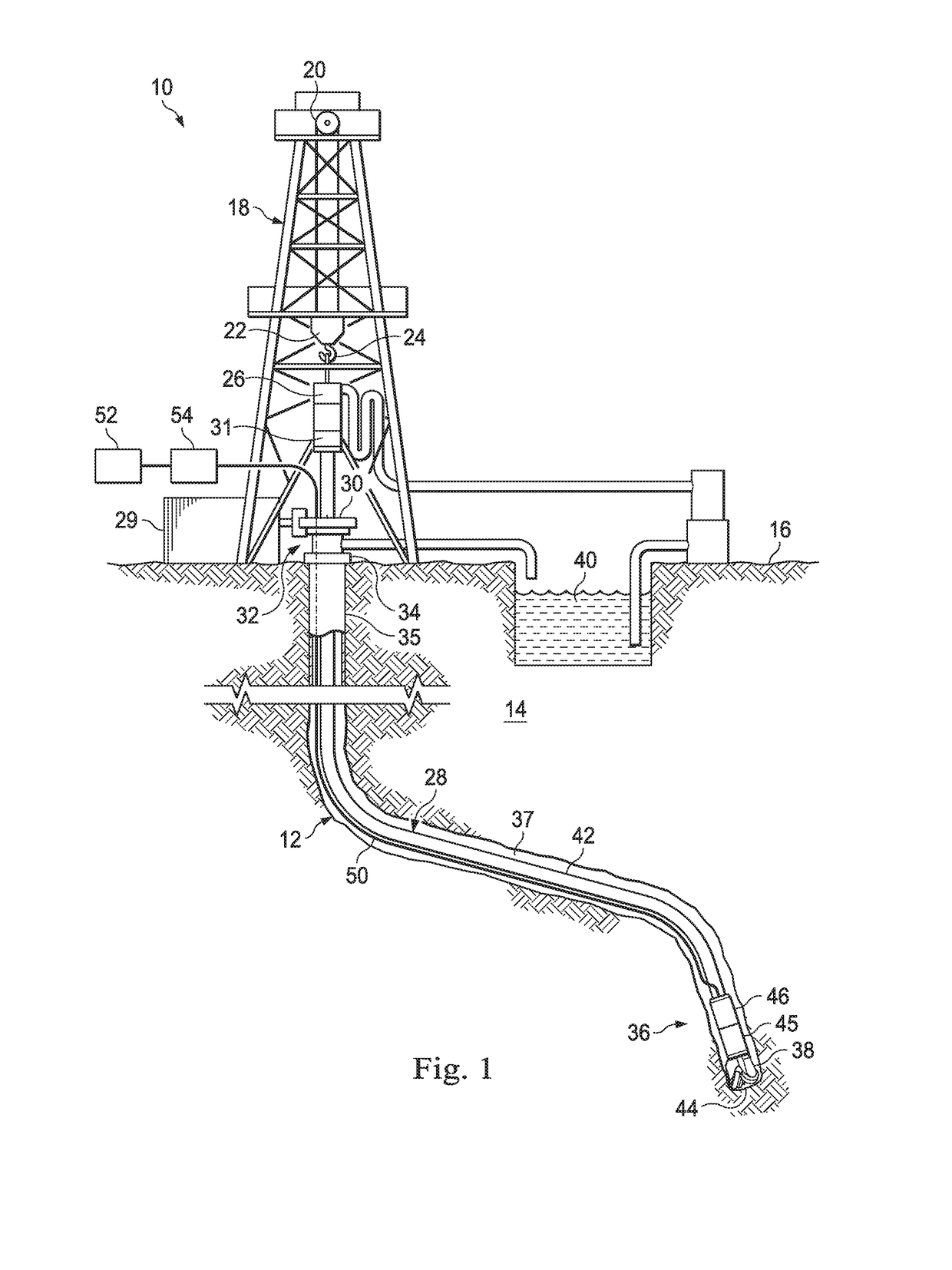

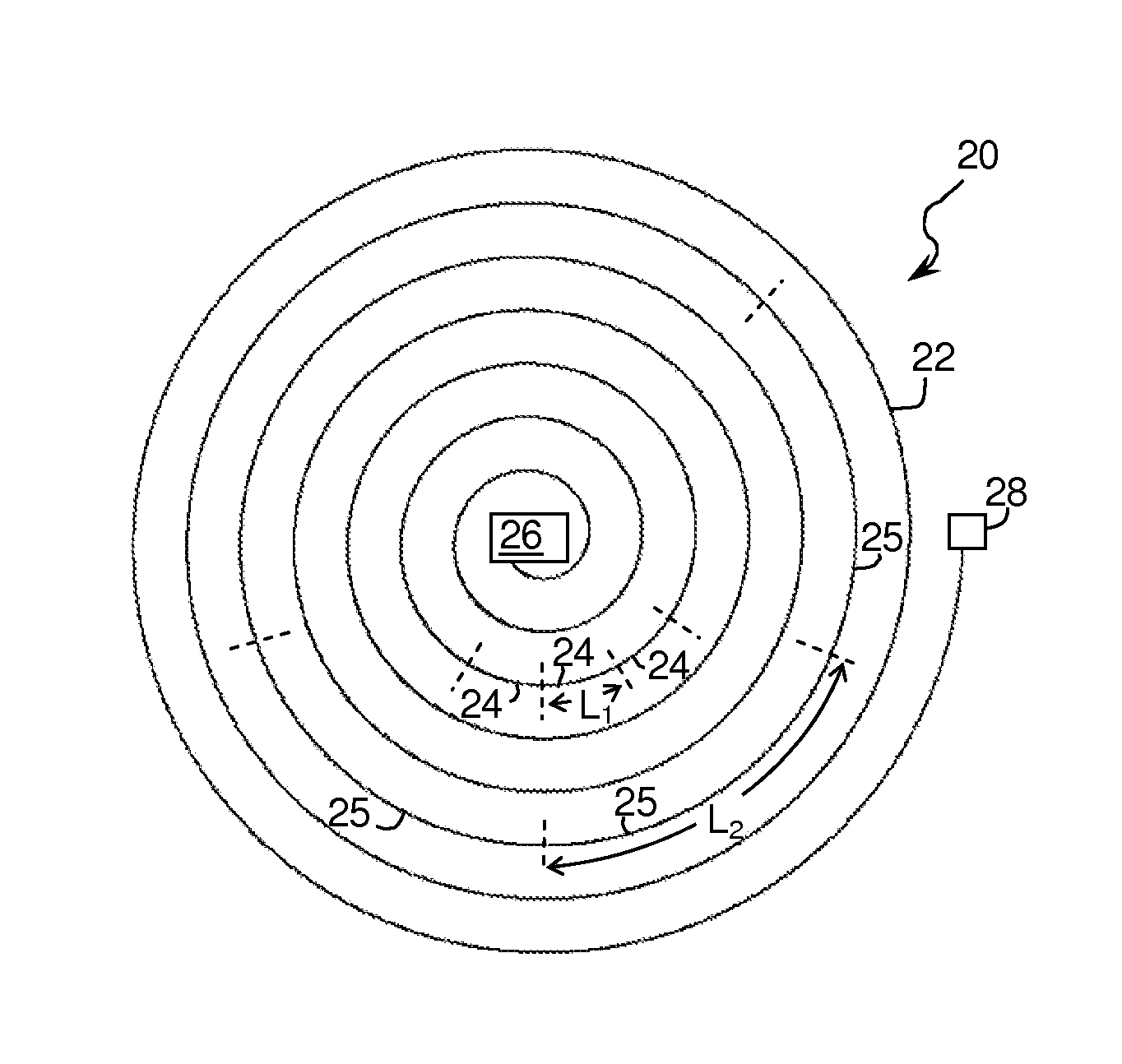

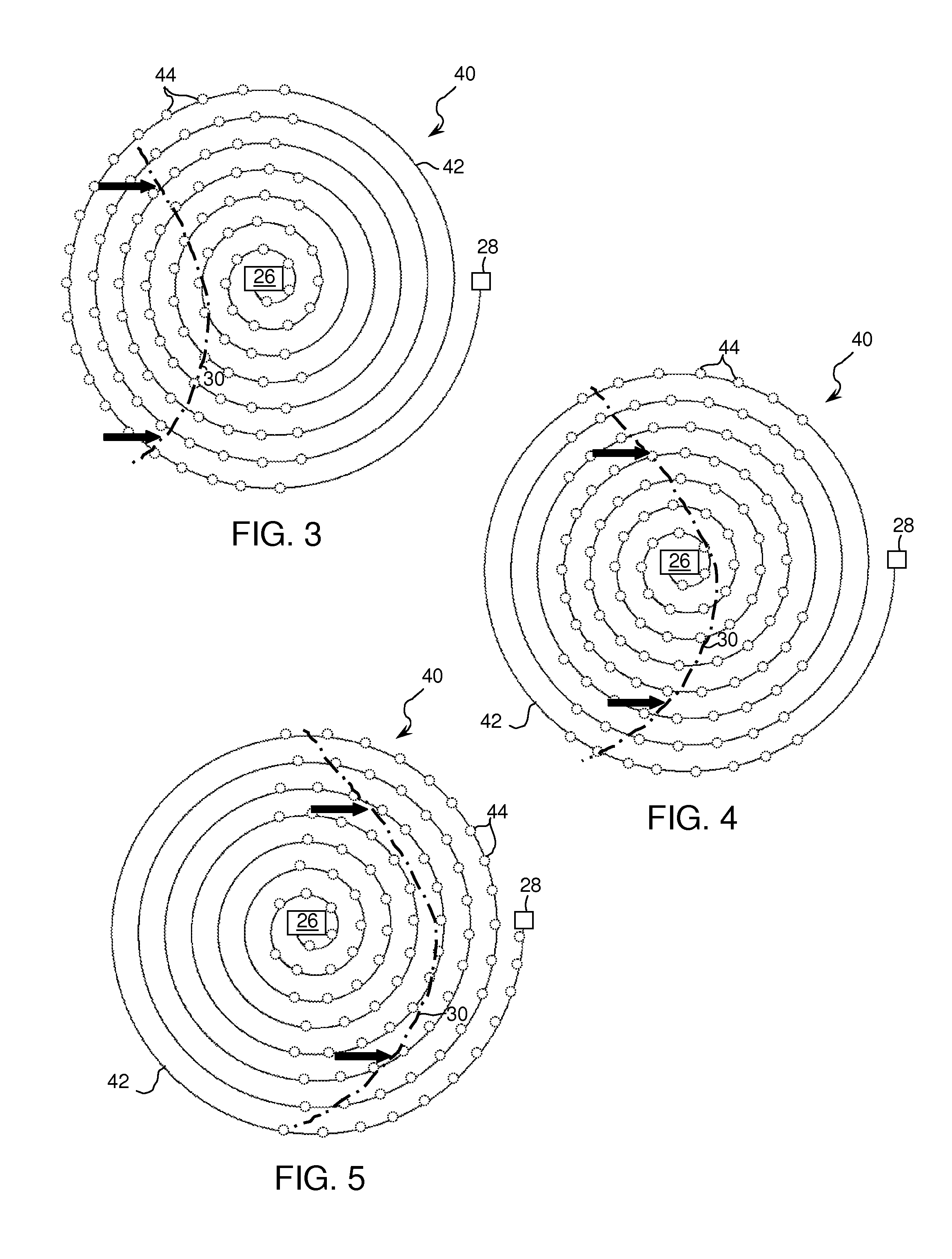

A method for obtaining information about a subsurface formation from acoustic signals that contain information about the subsurface formation, comprises a) transmitting an optical signal into a fiber optic cable (14) that includes a sensing apparatus (20) comprising a plurality of substantially parallel fiber lengths (24), b) collecting from the sensing apparatus a plurality of received optical signals, each received signal comprising a portion of the transmitted signal that has been reflected from a different segment of a cable length, wherein the different segments are each in different cable lengths and correspond to a single selected location along the sensing cable, and c) processing the collected signals so as to obtain information about an acoustic signal received at the different segments. The cable may be ribbon cable and the lateral distance between the different segments may be less than 10 meters.

Owner:SHELL USA INC

Das for well ranging

InactiveUS20170260839A1Low costHigh acquisition rateSurveySubsonic/sonic/ultrasonic wave measurementDistributed acoustic sensingFiber

Owner:CONOCOPHILLIPS CO

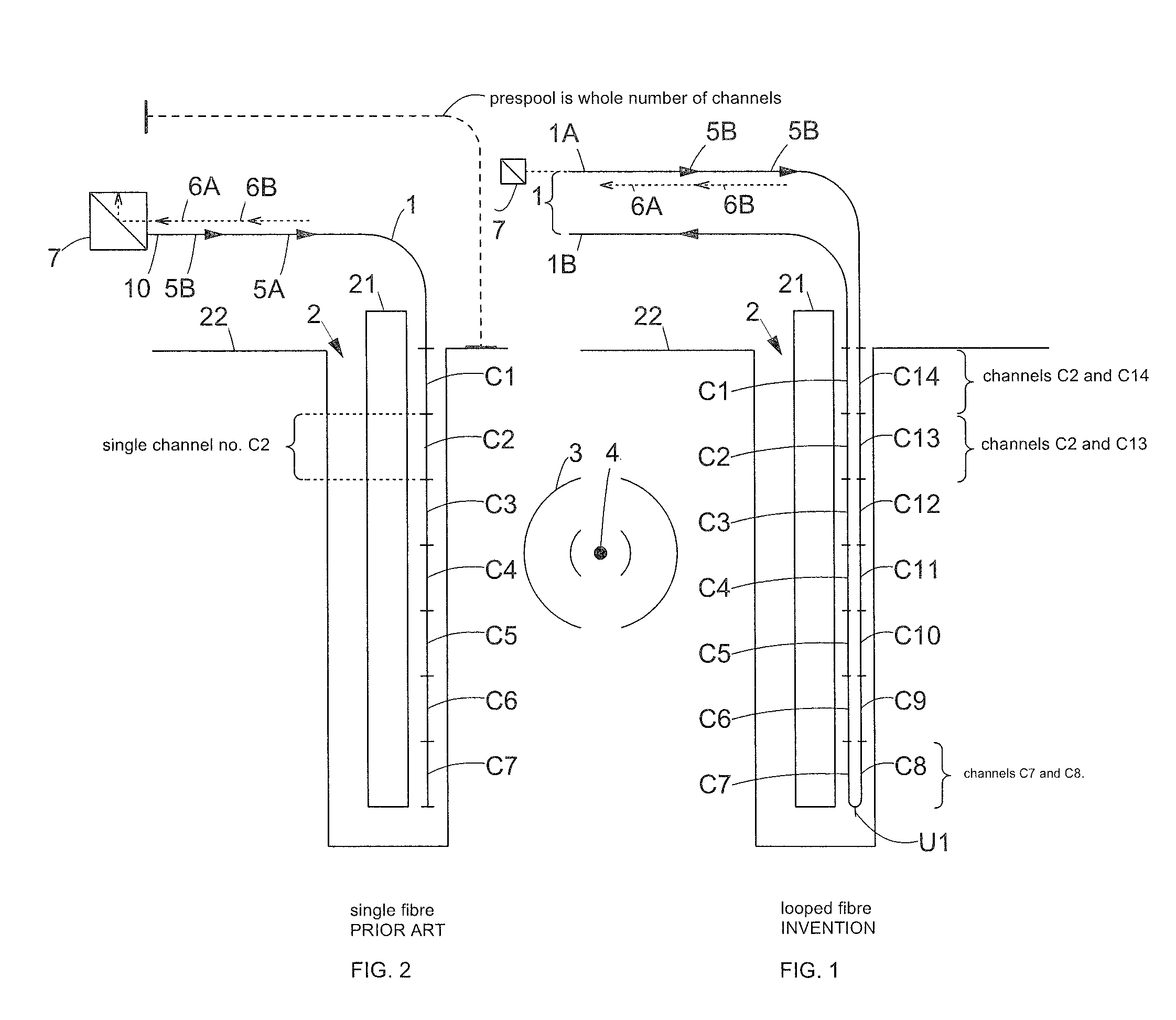

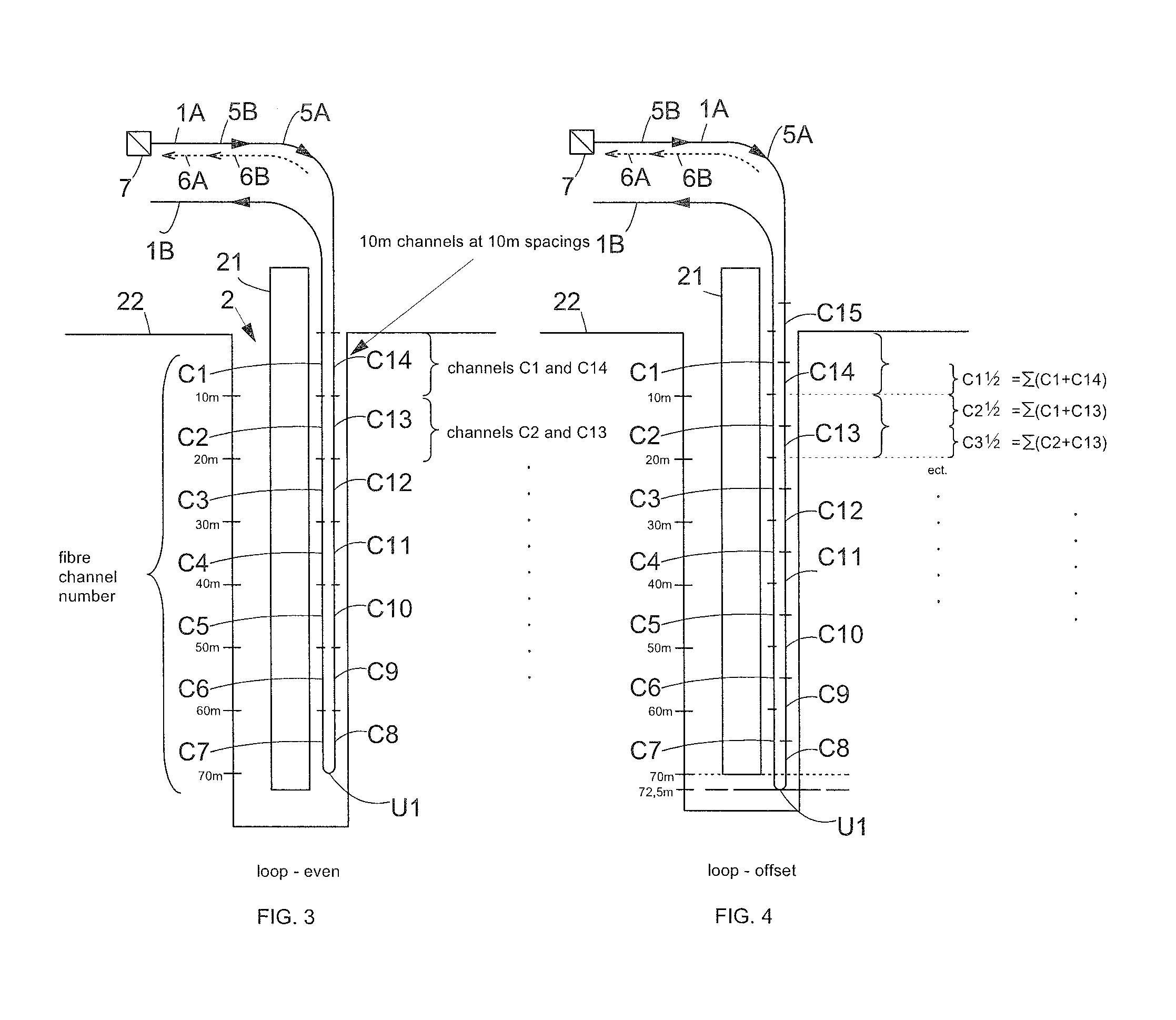

Method and system for enhancing the spatial resolution of a fiber optical distributed acoustic sensing assembly

ActiveUS20120255362A1Vibration measurement in solidsSubsonic/sonic/ultrasonic wave measurementFiberDistributed acoustic sensing

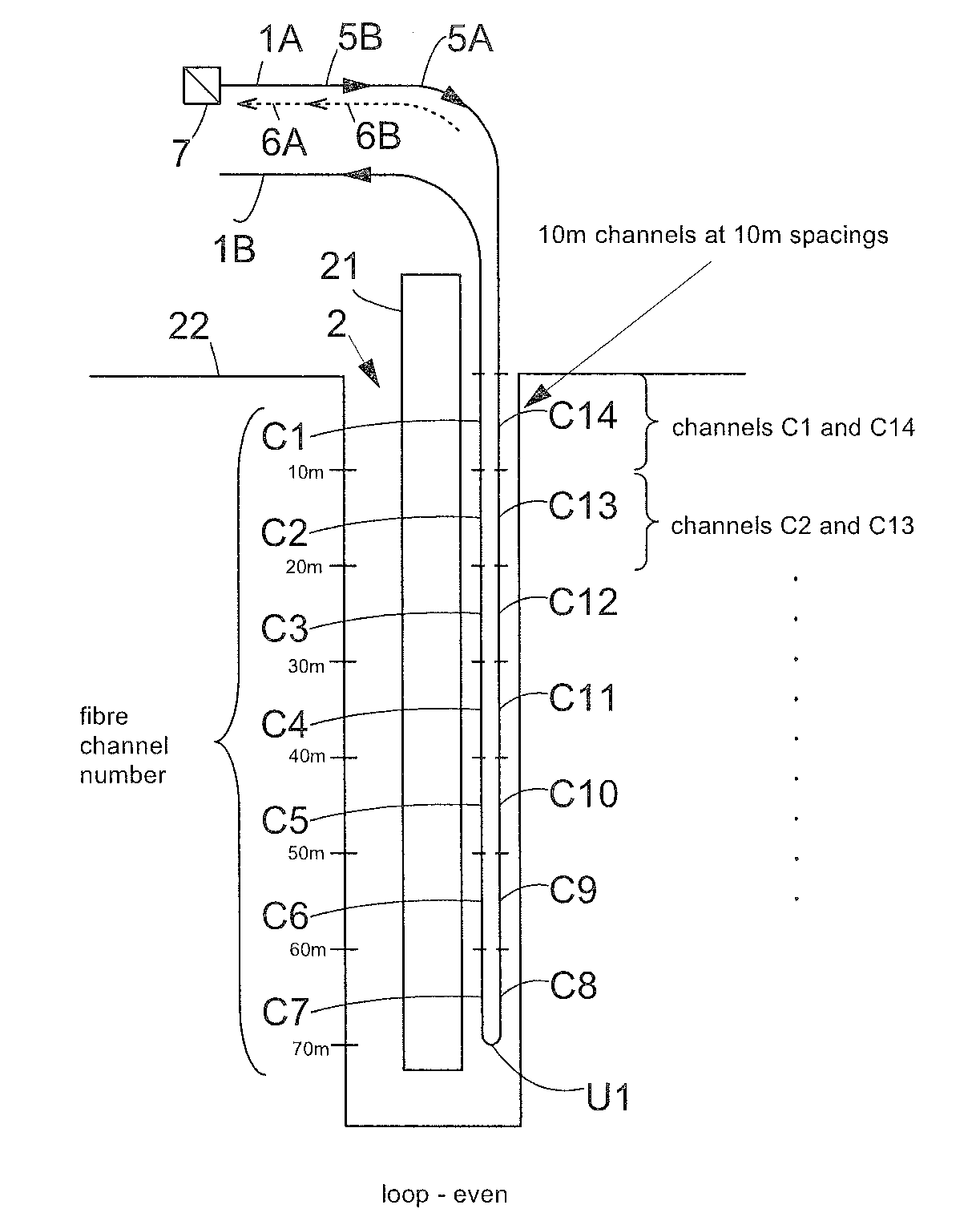

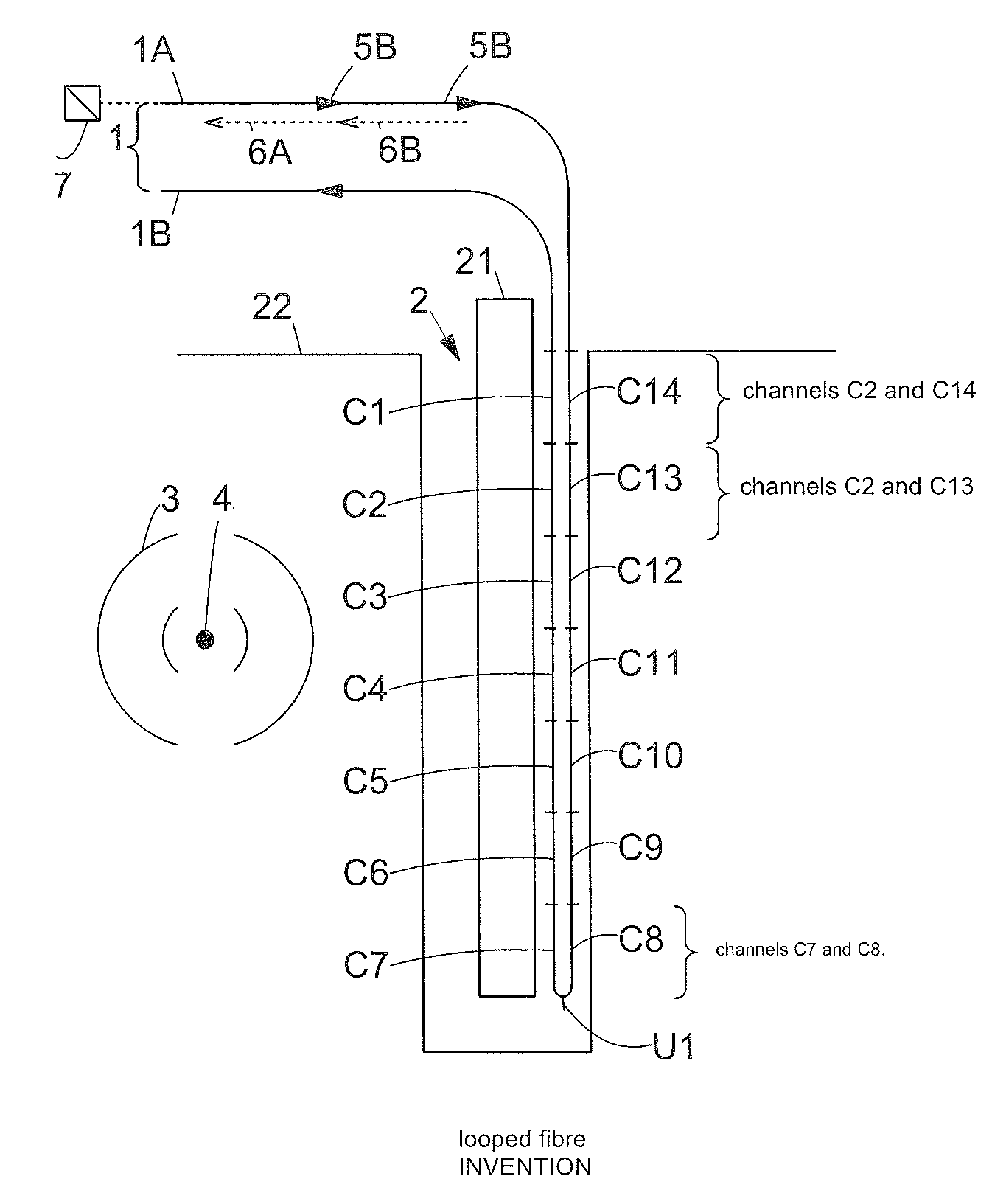

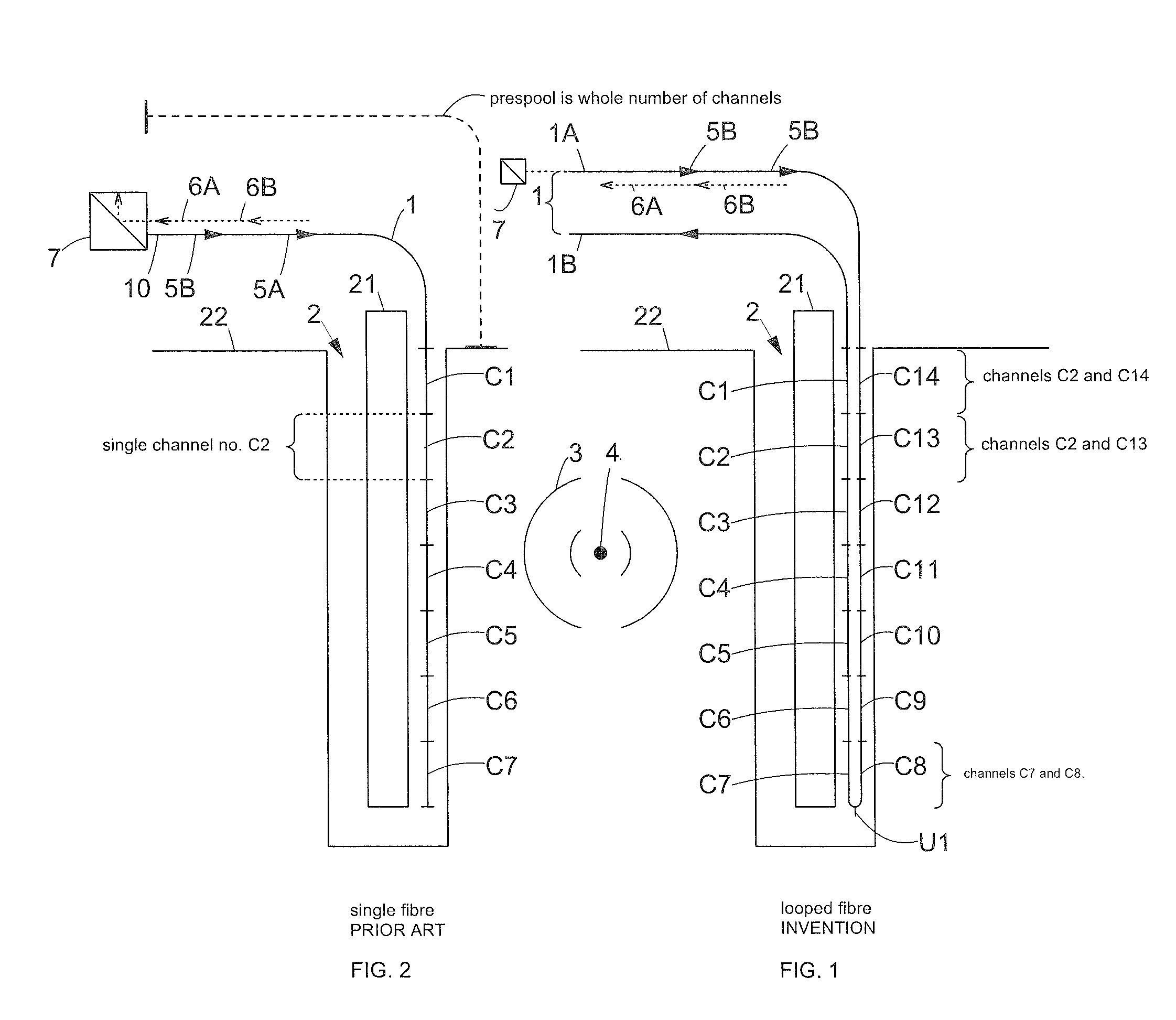

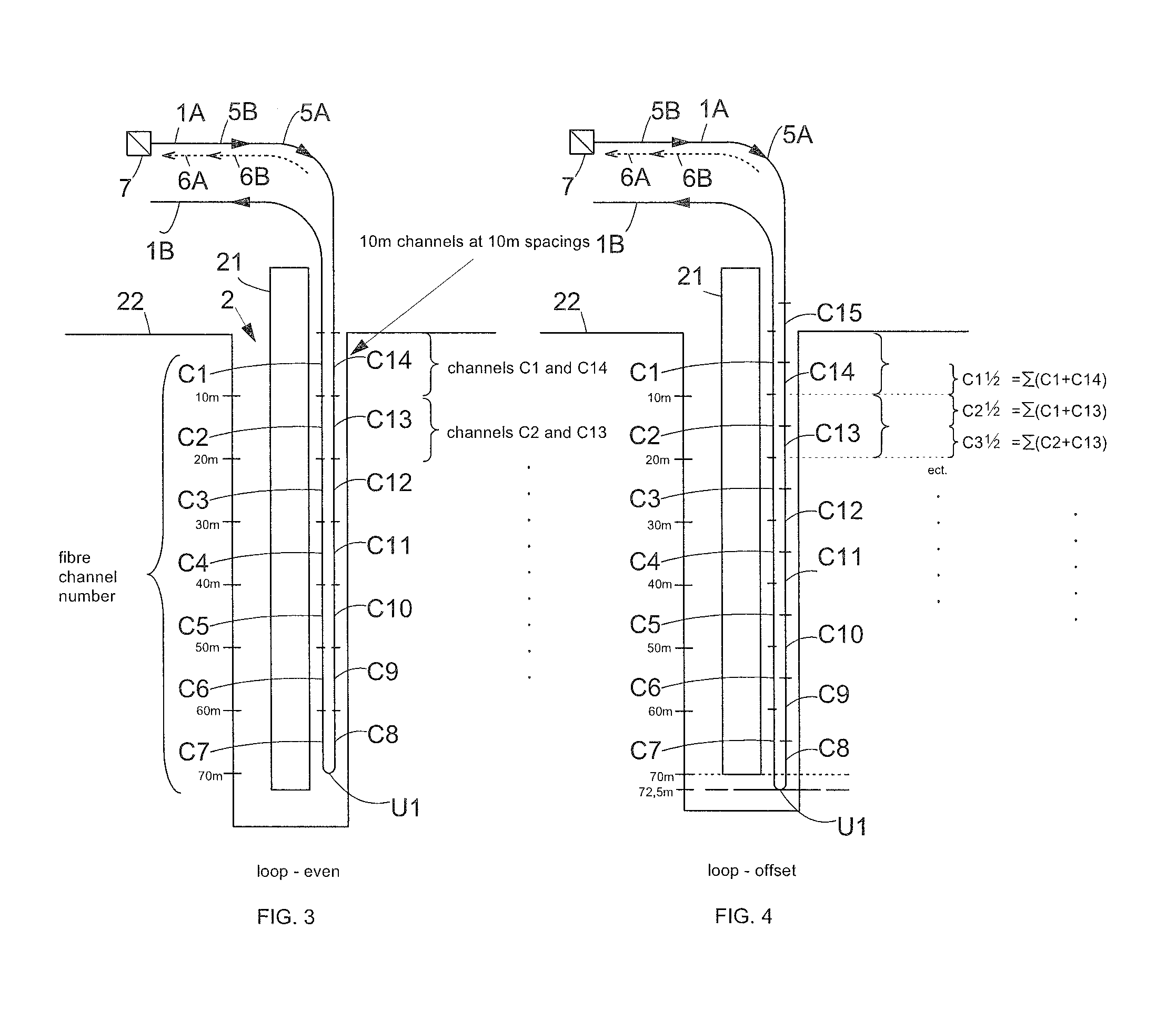

The spatial resolution of a fiber optical Distributed Acoustic Sensing (DAS) assembly is enhanced by:arranging an optical DAS fiber (1) with a series of contiguous channels (C1-C14) that are sensitive to vibration in a U-shaped loop (U1) such that substantially parallel fiber sections (IA, IB) comprise pairs of channels (C1&C14, C2&C13,C3&C12 . . . etc) that are arranged at least partially side by side;transmitting a series of light pulses (5A, 5B) through the optical fiber (1) and receiving back reflections (6A, 6B) of said light pulses (5A, 5B) by a light transmission and receiving assembly (7); andprocessing the received back reflections (6A, 6B) such that back reflections stemming from at least one pair of channels (C1, C14; C2,C13) that are arranged at least partially side by side are correlated to each other.

Owner:SHELL USA INC

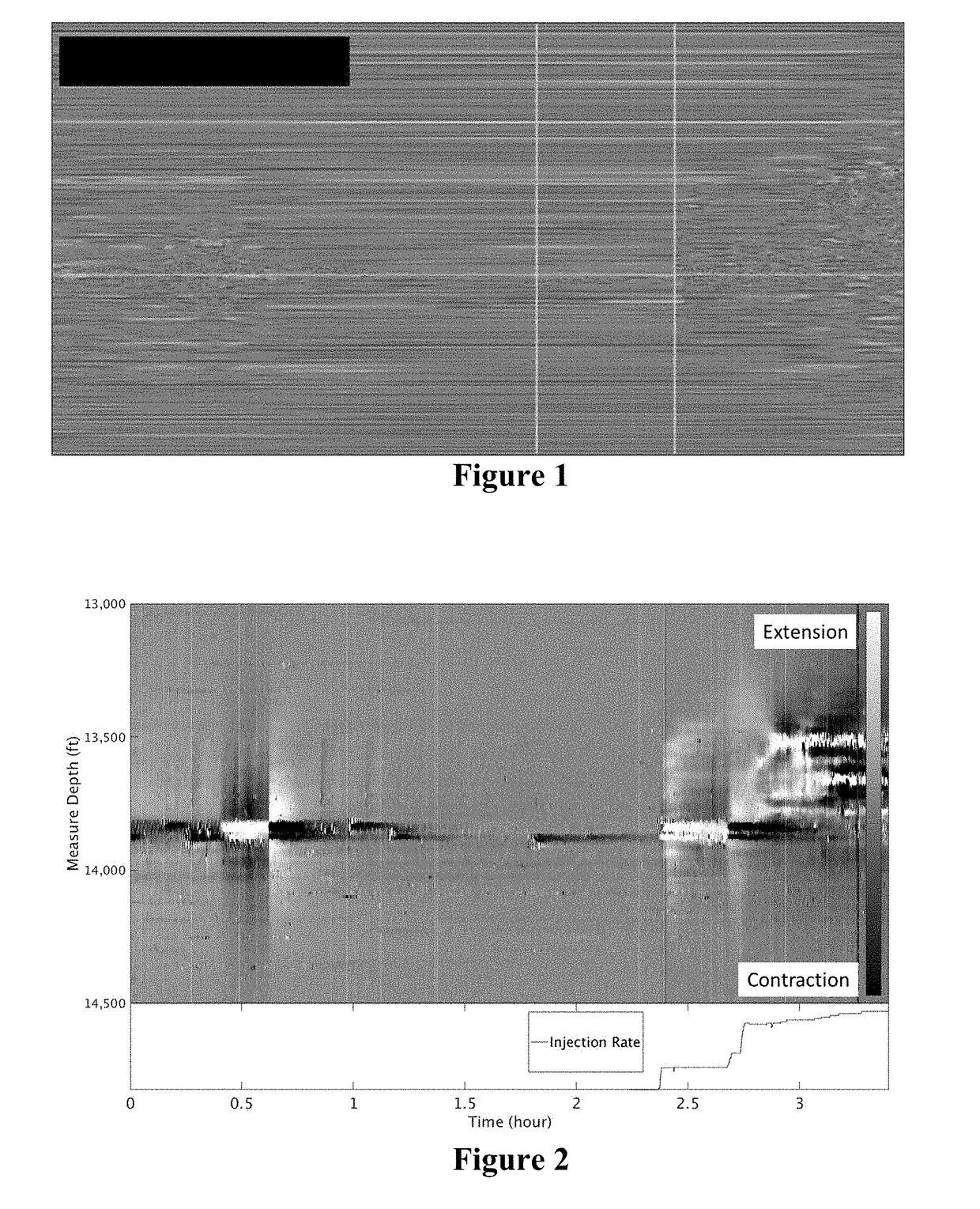

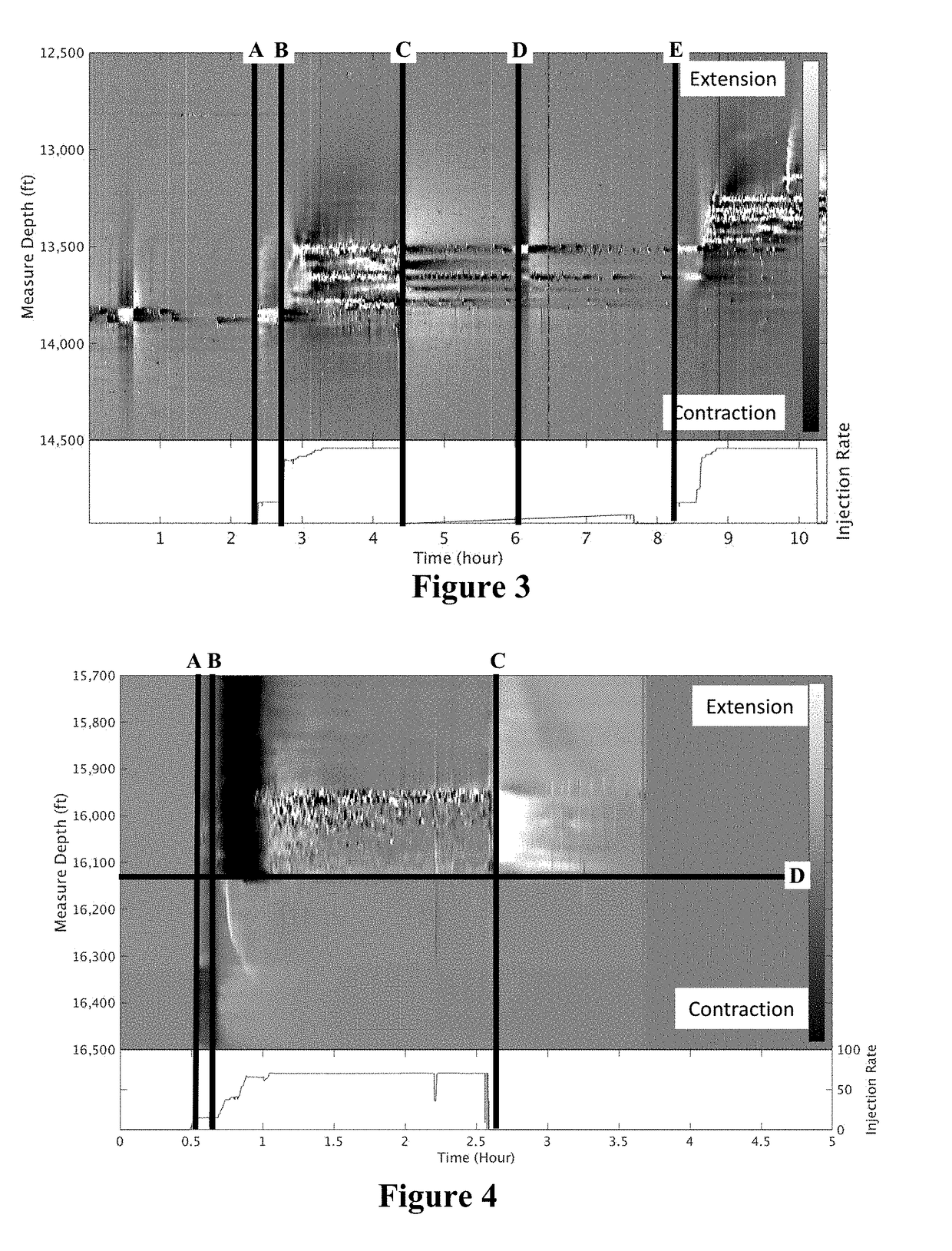

Low frequency distributed acoustic sensing

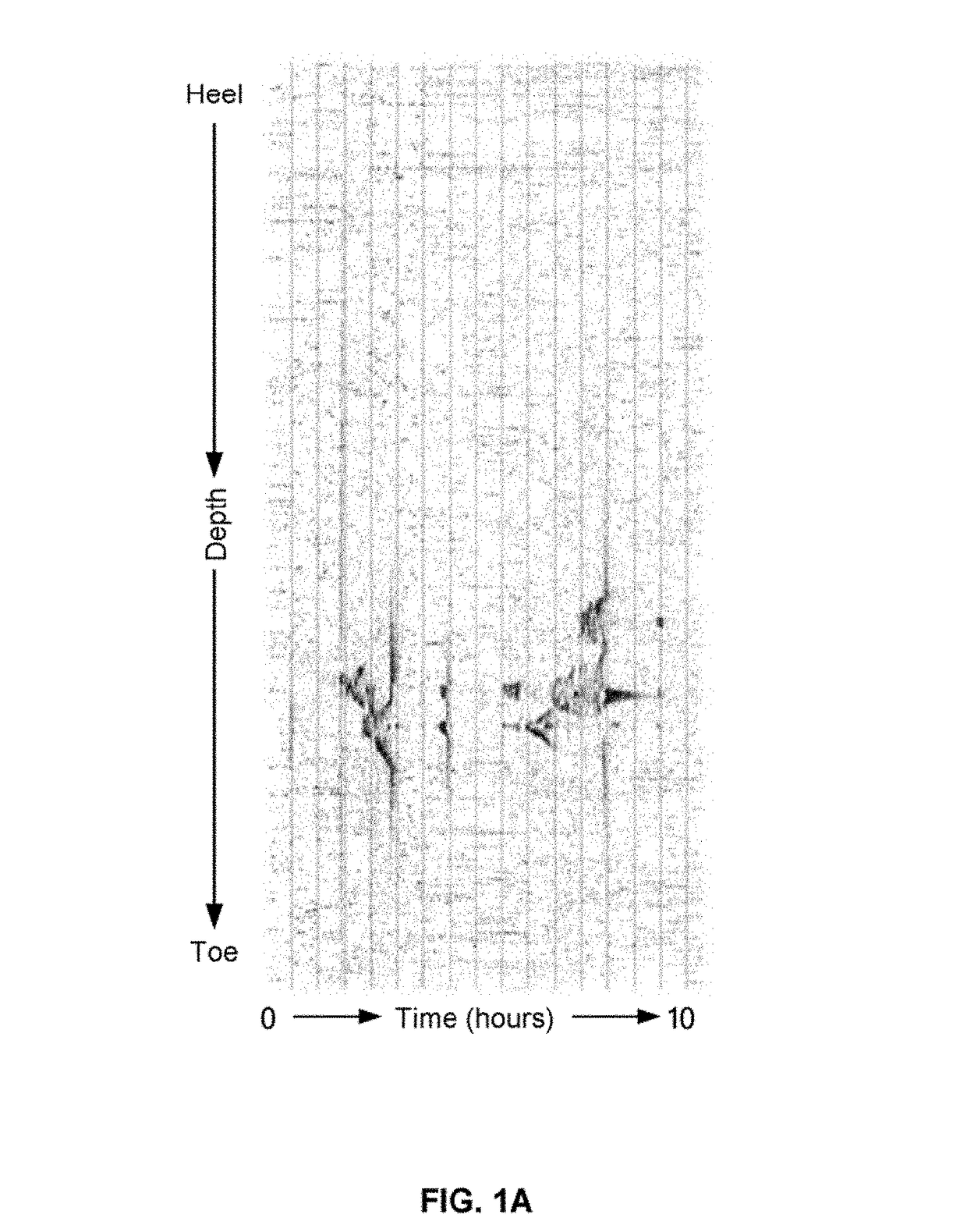

ActiveUS20170260842A1Increasing hydrocarbon productionSurveyConstructionsDistributed acoustic sensingData set

The invention relates to DAS observation has been proven to be useful for monitoring hydraulic fracturing operations. While published literature has shown focus on the high-frequency components (>1 Hz) of the data, this invention discloses that much of the usable information may reside in the very low frequency band (0-50 milliHz). Due to the large volume of a DAS dataset, an efficient workflow has been developed to process the data by utilizing the parallel computing and the data storage. The processing approach enhances the signal while decreases the data size by 10000 times, thereby enabling easier consumption by other multi-disciplinary groups for further analysis and interpretation. The polarity changes as seen from the high signal to noise ratio (SNR) low frequency DAS images are currently being utilized for interpretation of completions efficiency monitoring in hydraulically stimulated wells.

Owner:CONOCOPHILLIPS CO

Method and system for enhancing the spatial resolution of a fiber optical distributed acoustic sensing assembly

ActiveUS9109944B2Vibration measurement in solidsMaterial analysis by observing immersed bodiesDistributed acoustic sensingFiber

The spatial resolution of a fiber optical Distributed Acoustic Sensing (DAS) assembly is enhanced by:arranging an optical DAS fiber with a series of contiguous channels that are sensitive to vibration in a U-shaped loop such that substantially parallel fiber sections include pairs of channels that are arranged at least partially side by side;transmitting a series of light pulses through the optical fiber and receiving back reflections of said light pulses by a light transmission and receiving assembly; andprocessing the received back reflections such that back reflections stemming from at least one pair of channels that are arranged at least partially side by side are correlated to each other.

Owner:SHELL USA INC

Detecting broadside acoustic signals with a fiber optical distrubuted acoustic sensing (DAS) assembly

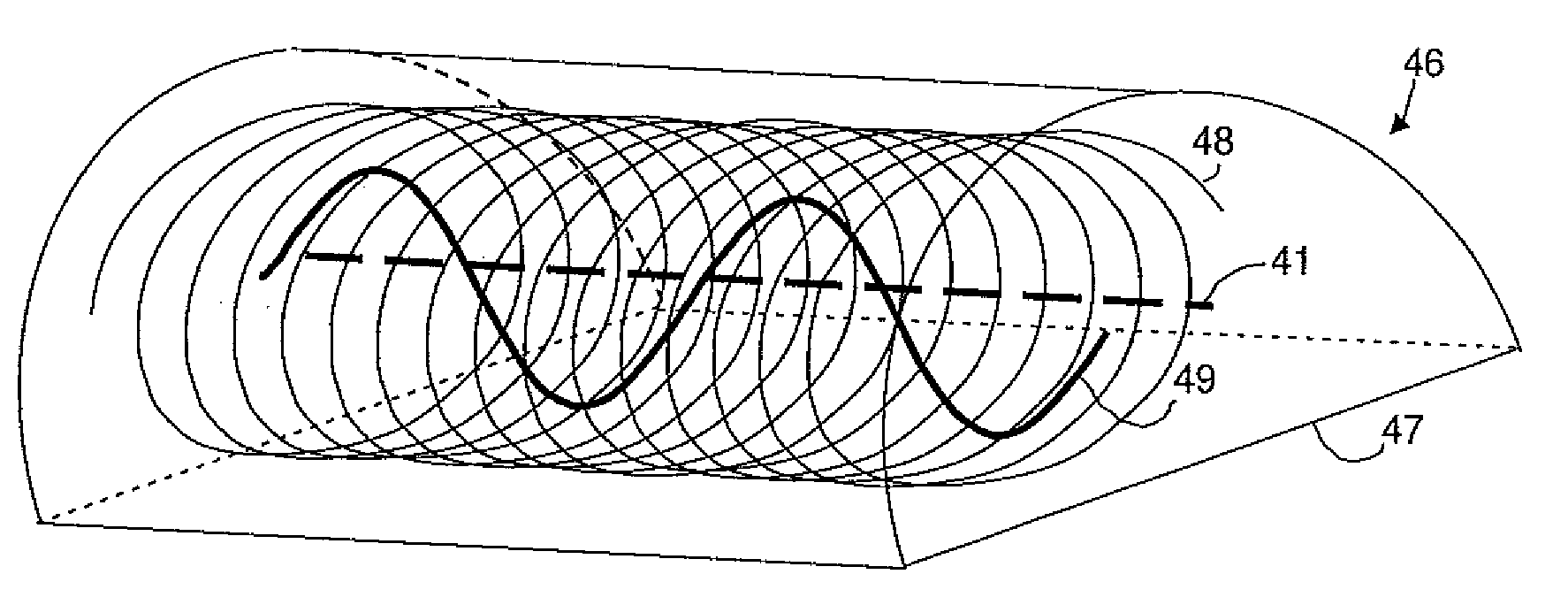

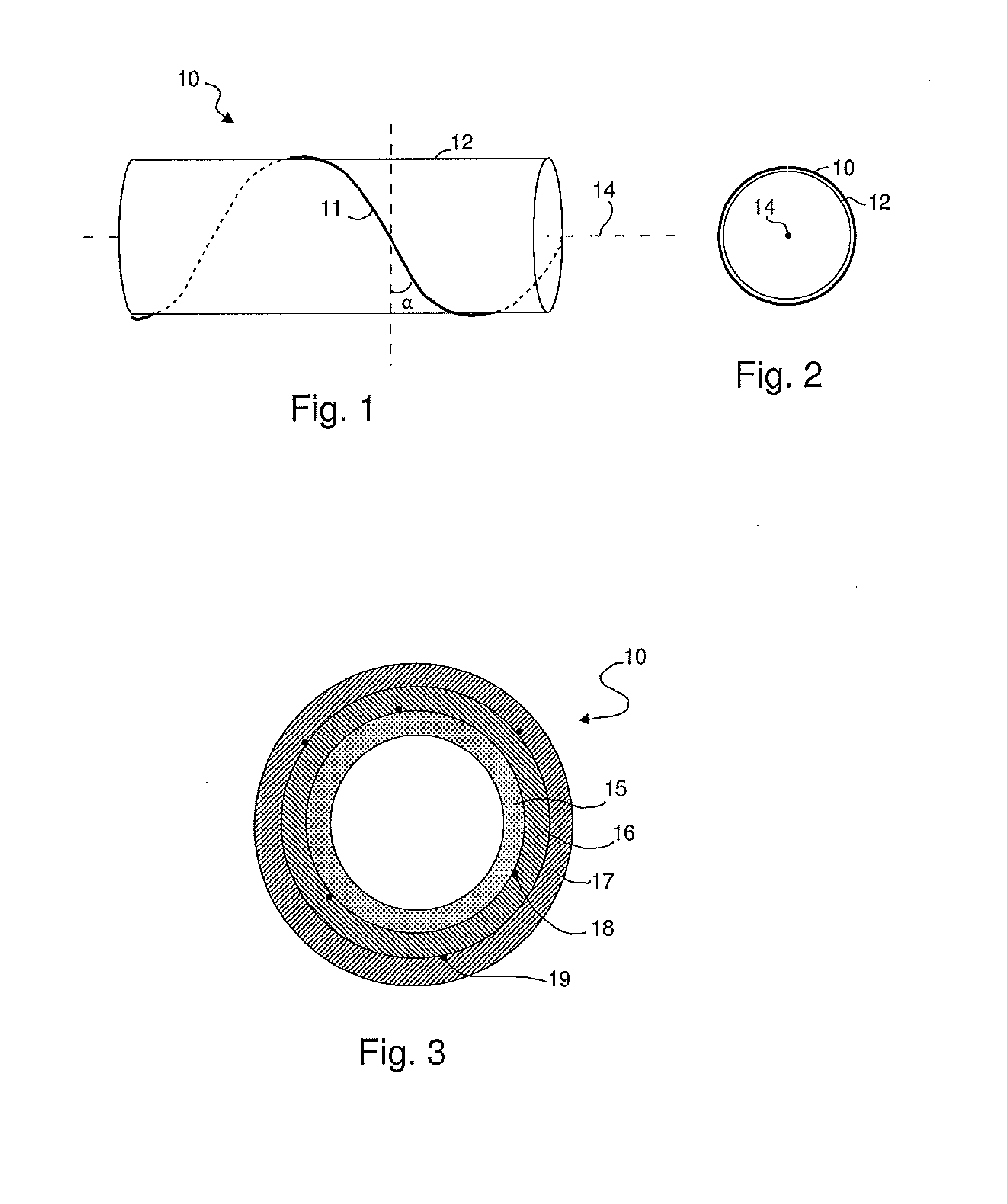

ActiveUS20140345388A1Easy to distinguishVibration measurement in solidsSubsonic/sonic/ultrasonic wave measurementElastomerFiber

A distributed fiber optic acoustic sensing system comprises an elongate body having an outer surface, an optical fiber disposed on the outer surface at a first predetermined wrap angle, and light transmitting and receiving means optically connected to the fiber for. The elongate body may include at least one substantially flat face, and / or a layer of swellable elastomer surrounding the body, and / or an outer elastomeric tube surrounding the elastomer layer. There may be at least one sensor pad disposed in the outer layer, the sensor pad comprising a stiffener and at least one longitudinal fiber affixed thereto or embedded therein. There may be a body of protective material surrounding the tube, which may have an outer surface that includes at least one substantially flat face and at least one sensor pad disposed in the body.

Owner:SHELL USA INC

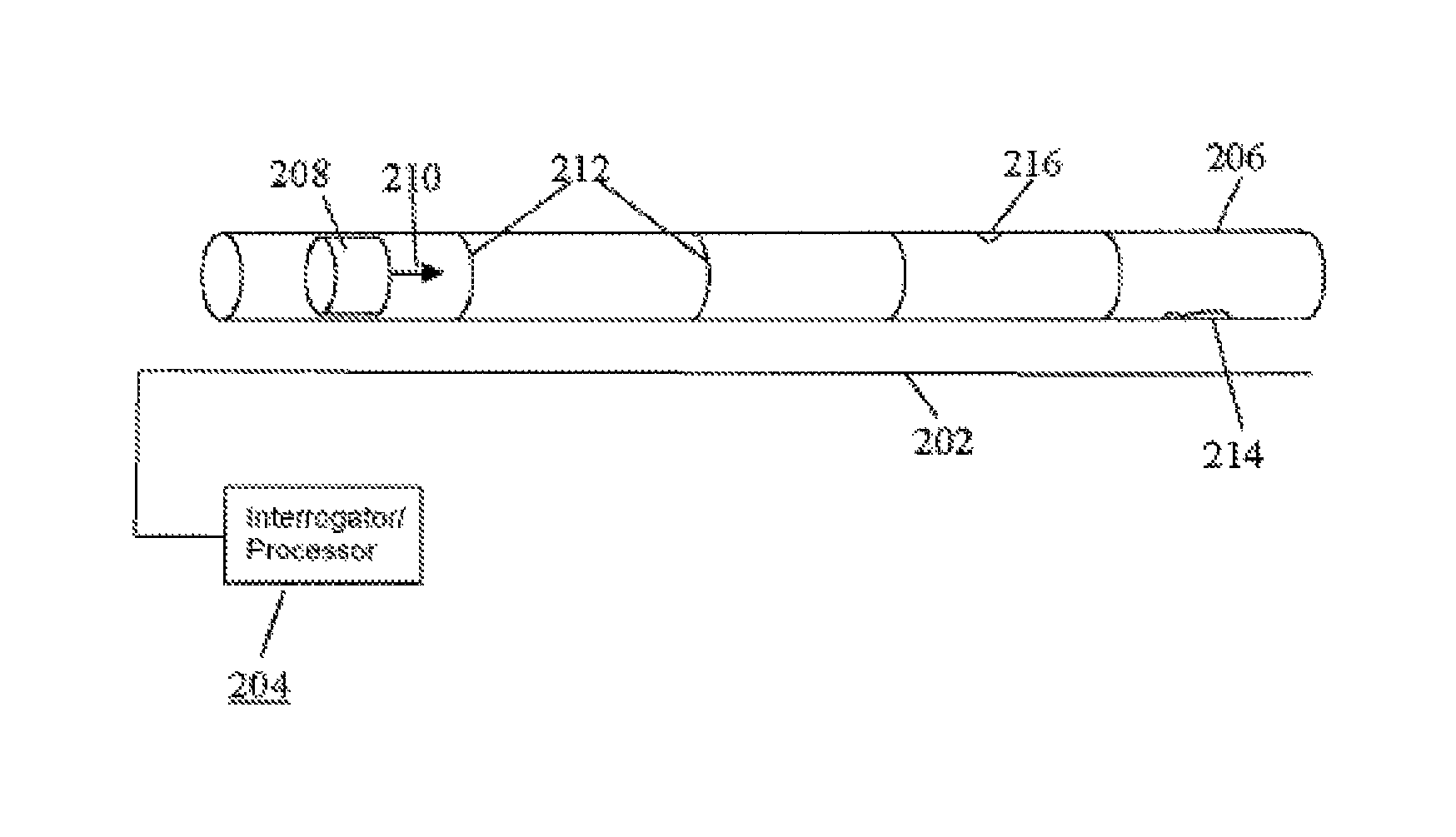

Tracking objects in conduits

ActiveUS8973444B2Simple methodDetection of fluid at leakage pointAnalysing solids using sonic/ultrasonic/infrasonic wavesFiberDistributed acoustic sensing

Methods and apparatus for tracking objects in conduits, especially for tracking the movement of a pig in a pipeline, are disclosed. Distributed acoustic sensing is used to obtain signal returns from a plurality of discrete longitudinal sensing portions of a fibre optic cable which is laid along the length of the conduit. The method involves detecting an acoustic signature corresponding to the object moving in the conduit. The acoustic signature may comprise a series of pressure pulses caused by the object traversing joints etc. in the conduit. Preferably the method involves detecting pressure waves caused by the object as it moves through the conduit. Detecting the characteristic pressure wave signal provides discrimination of the object from other acoustic disturbances. In pipeline applications a pig can be tracked in real time, if the pig stops moving an alert can be generated and the location of the pig will be known.

Owner:OPTASENSE HLDG LTD

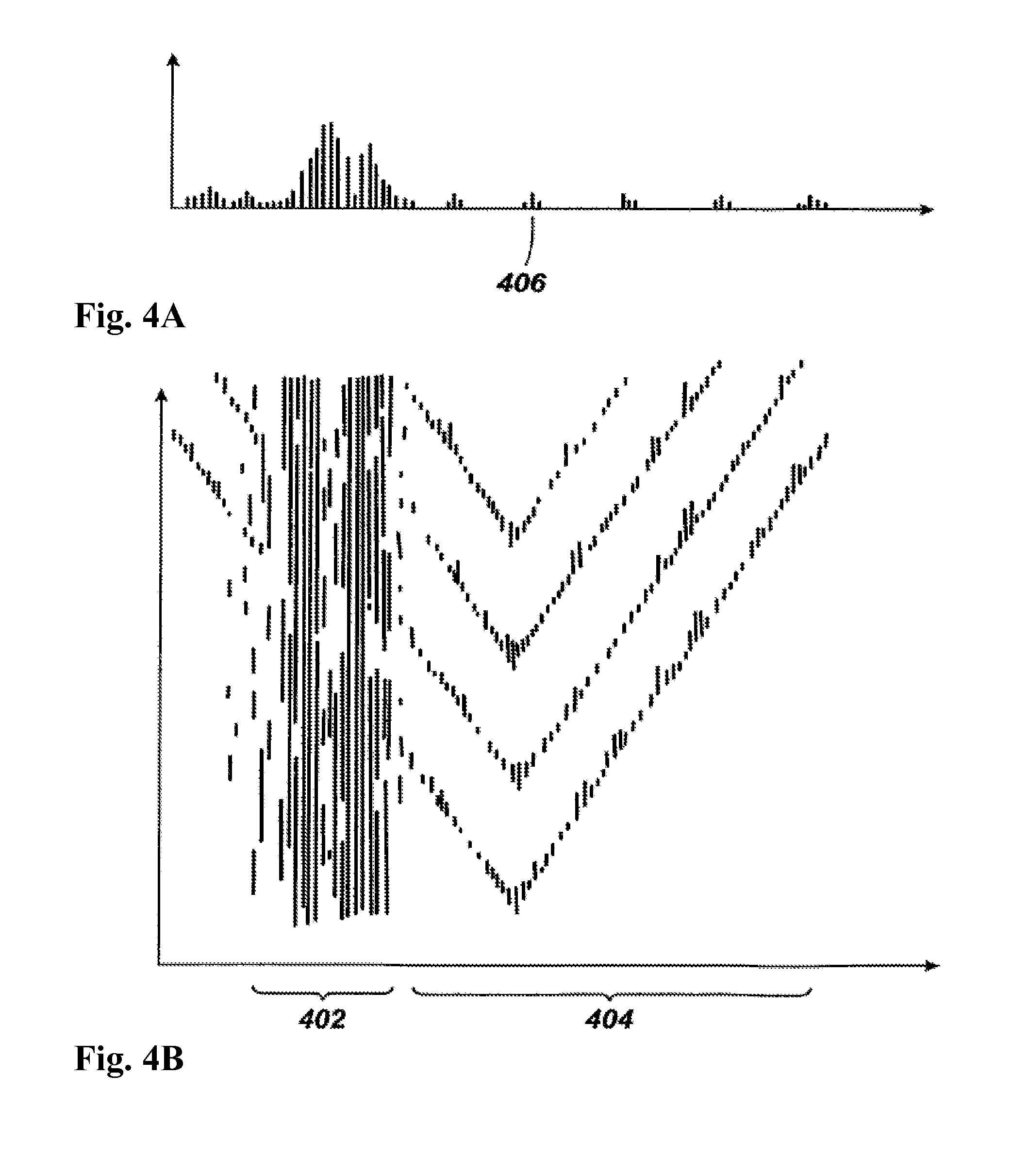

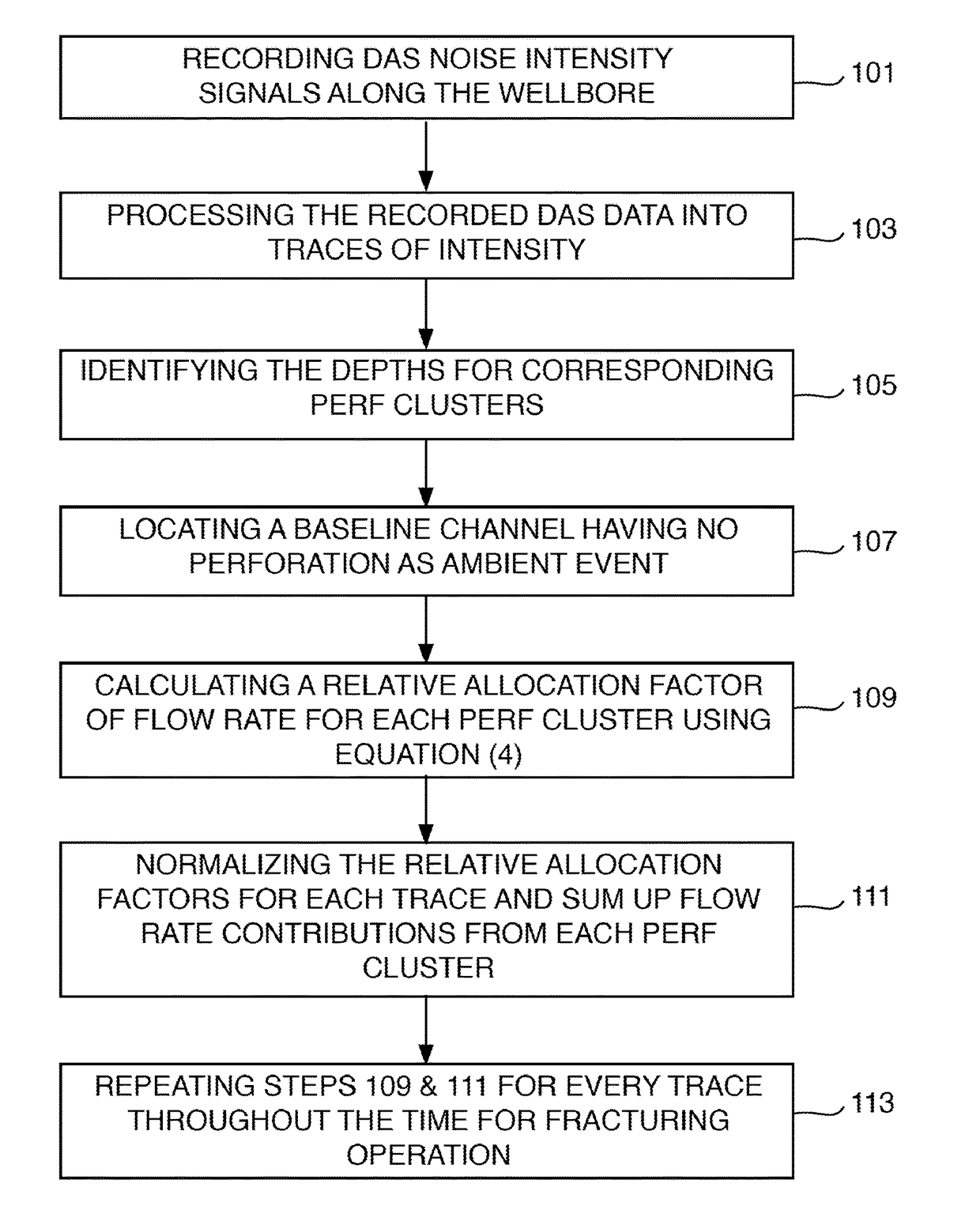

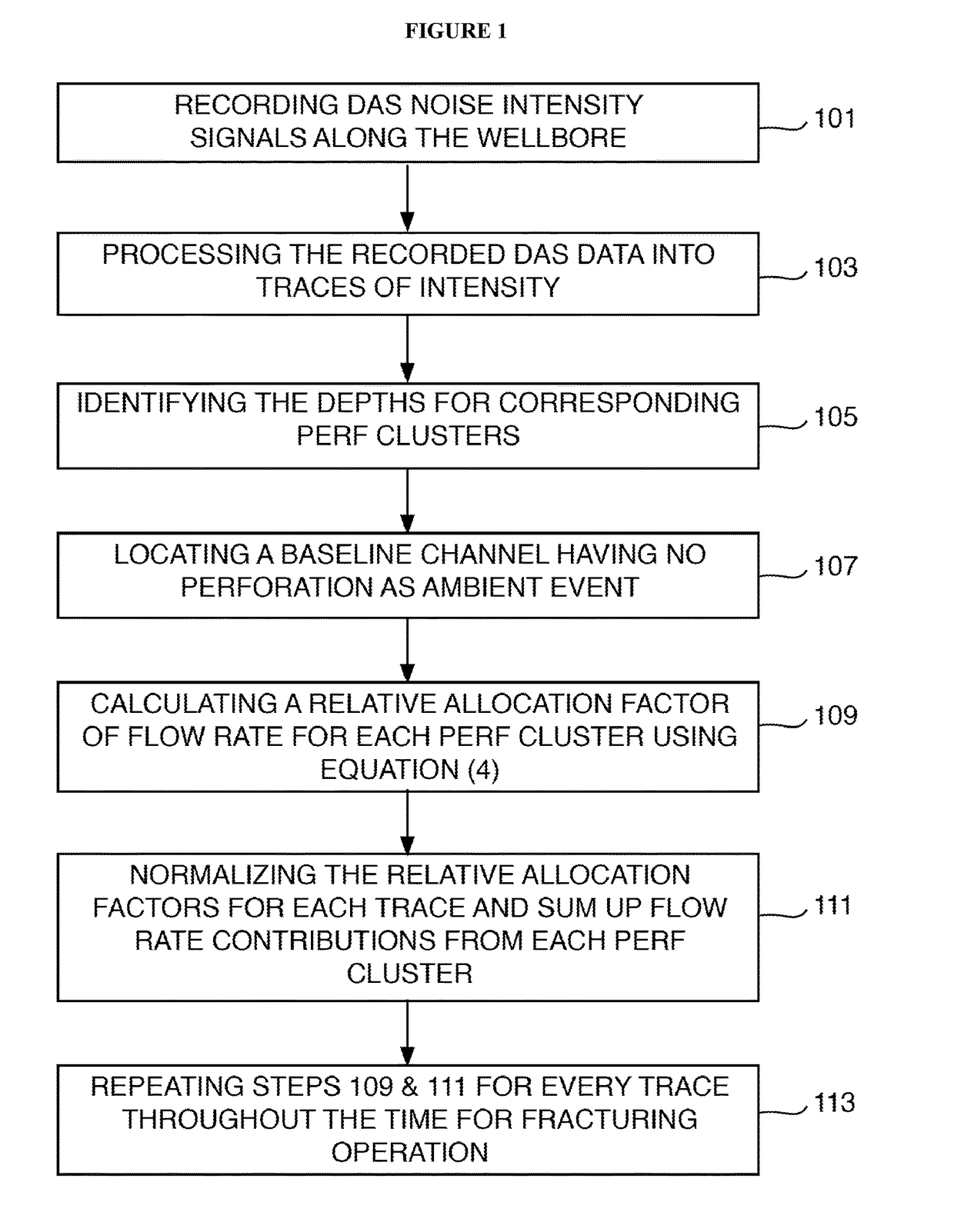

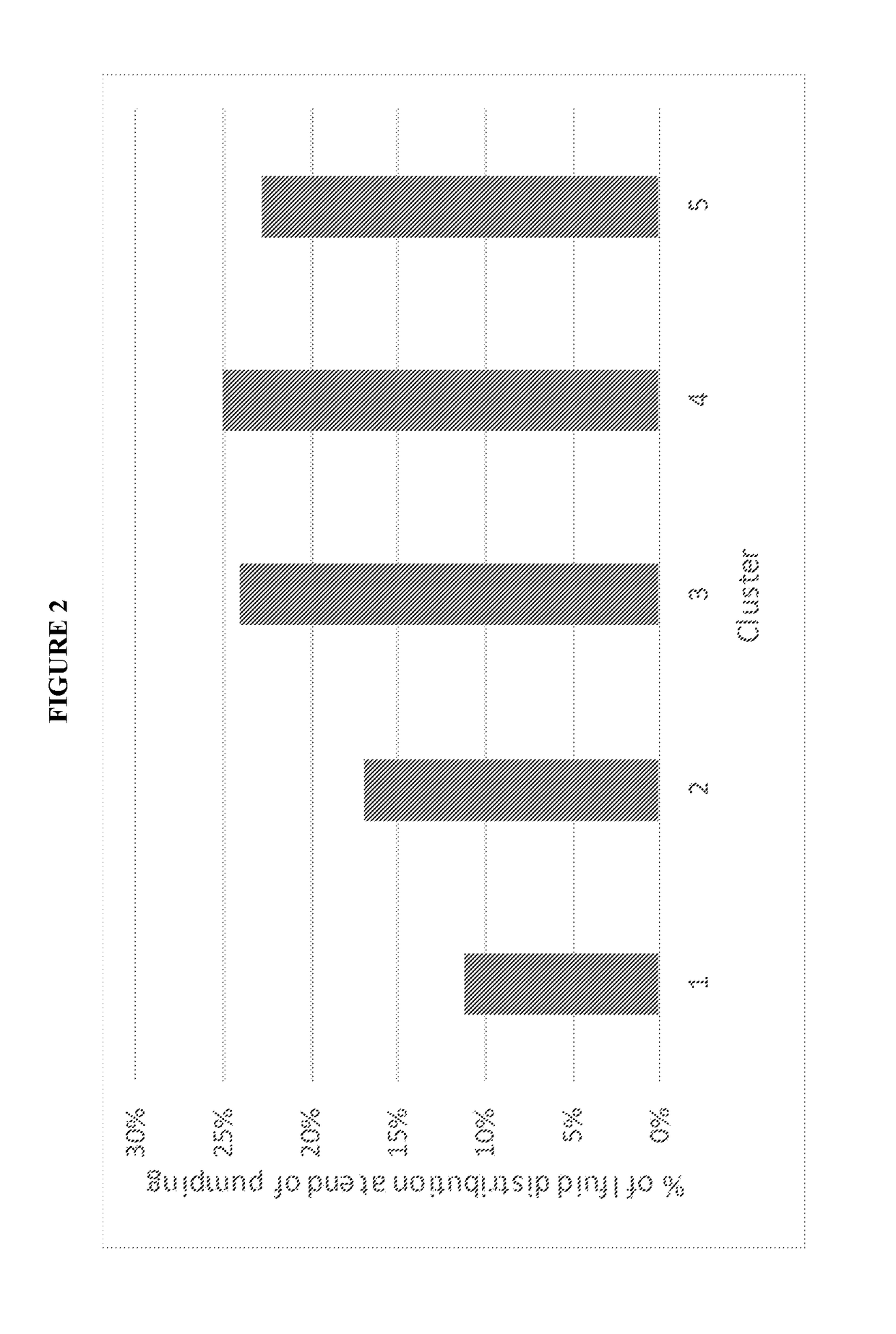

Das method of estimating fluid distribution

ActiveUS20170260849A1Easy to optimizeSurveyConstructionsDistributed acoustic sensingHydraulic fracturing

This disclosure describes a method of calculating fluid distribution from a hydraulically fractured well, especially during a plug-and-perf hydraulic fracturing operation. The Distributed Acoustic Sensing (DAS) data is used to quantify the fluid distribution in separate perf clusters during fracturing, and the result can be used for completion design and optimization, hydraulic fracturing, and ultimately for oil and gas production.

Owner:CONOCOPHILLIPS CO

A Strain Sensitive Optical Fiber Cable Package for Downhole Distributed Acoustic Sensing

InactiveUS20170260847A1SurveySubsonic/sonic/ultrasonic wave measurementFiberDistributed acoustic sensing

A distributed acoustic sensing cable package having a polymer composite extruded over an optical waveguide to encase the waveguide and to form a crystalline matrix layer acoustically coupled to the waveguide. The crystalline matrix includes reinforcement fibers to further enhance transmission of a cable strain to the optical waveguide. During manufacture of the cable, the polymer composite may be extruded over the optical waveguide and subsequently subjected to heat treatment to increase the crystallinity of the polymer composite and increase the elastic modulus. Both axial and radial strain fields are effectively interact with cased fiber waveguide for producing measurable phase shift signal for distributed acoustic noise detection.

Owner:HALLIBURTON ENERGY SERVICES INC

Detecting broadside and directional acoustic signals with a fiber optical distributed acoustic sensing (DAS) assembly

ActiveUS9080949B2Vibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesFiberDistributed acoustic sensing

A Distributed Acoustic Sensing(DAS) fiber optical assembly comprises adjacent lengths of optical fiber A, B with different directional acoustic sensitivities, for example by providing the first length of optical fiber A with a first coating 35, such as acrylate, and the second length of optical fiber B with a second coating 36, such as copper, wherein the first and second coatings 35 and 36 may be selected such that the Poisson's ratio of the first length of coated fiber A is different from the Poisson's ratio of the second length of coated fiber B. The different Poisson's ratios and / or other properties of the adjacent lengths of optical fiber A and B improve their directional acoustic sensitivity and their ability to detect broadside (radial) acoustic waves.

Owner:SHELL USA INC

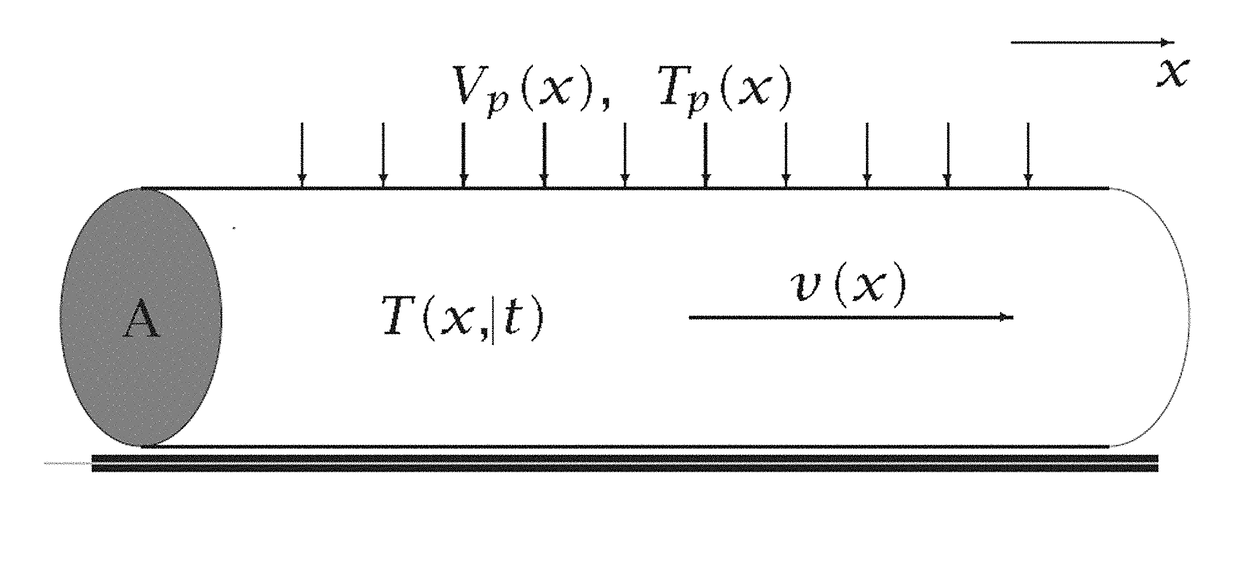

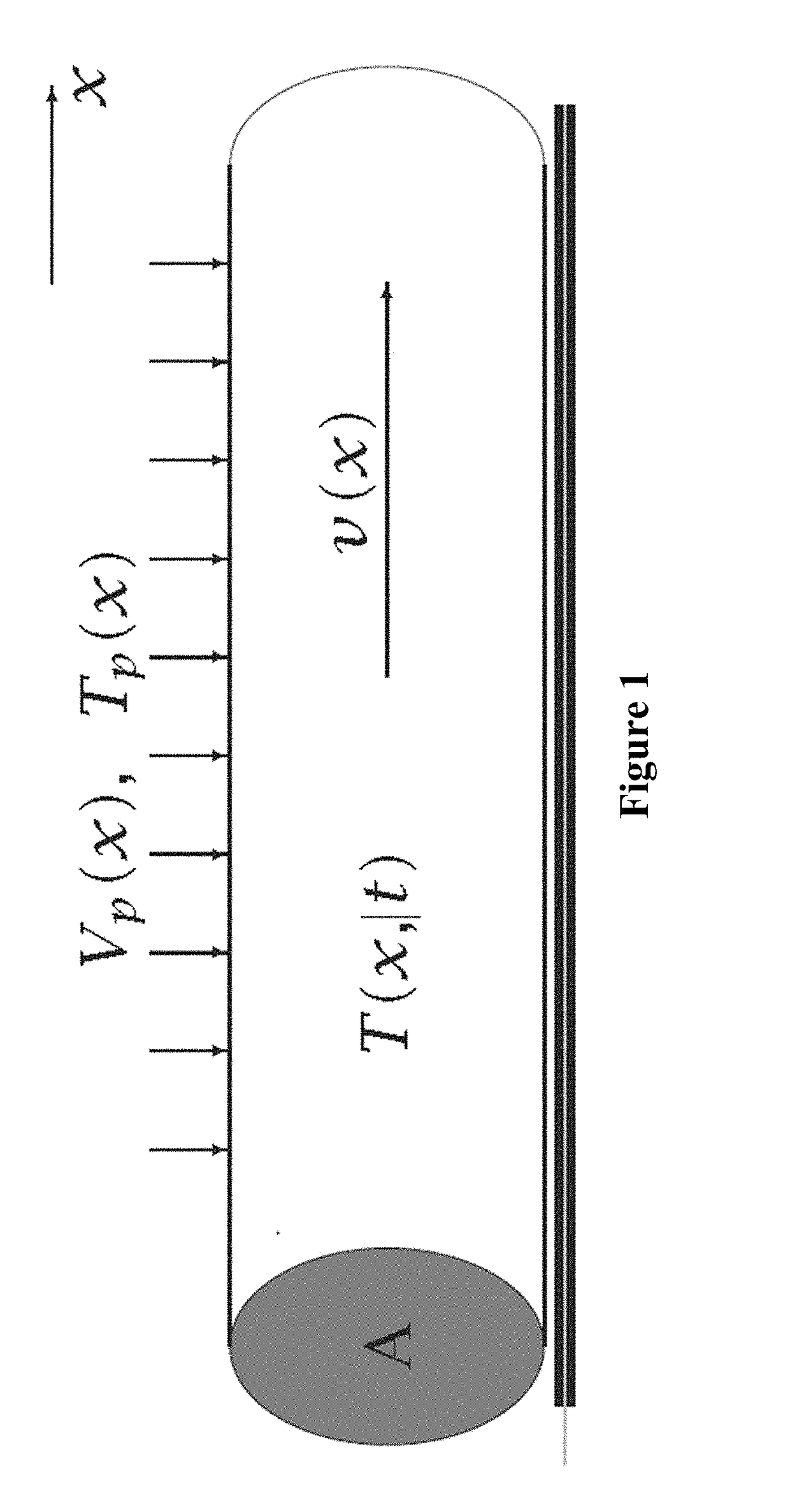

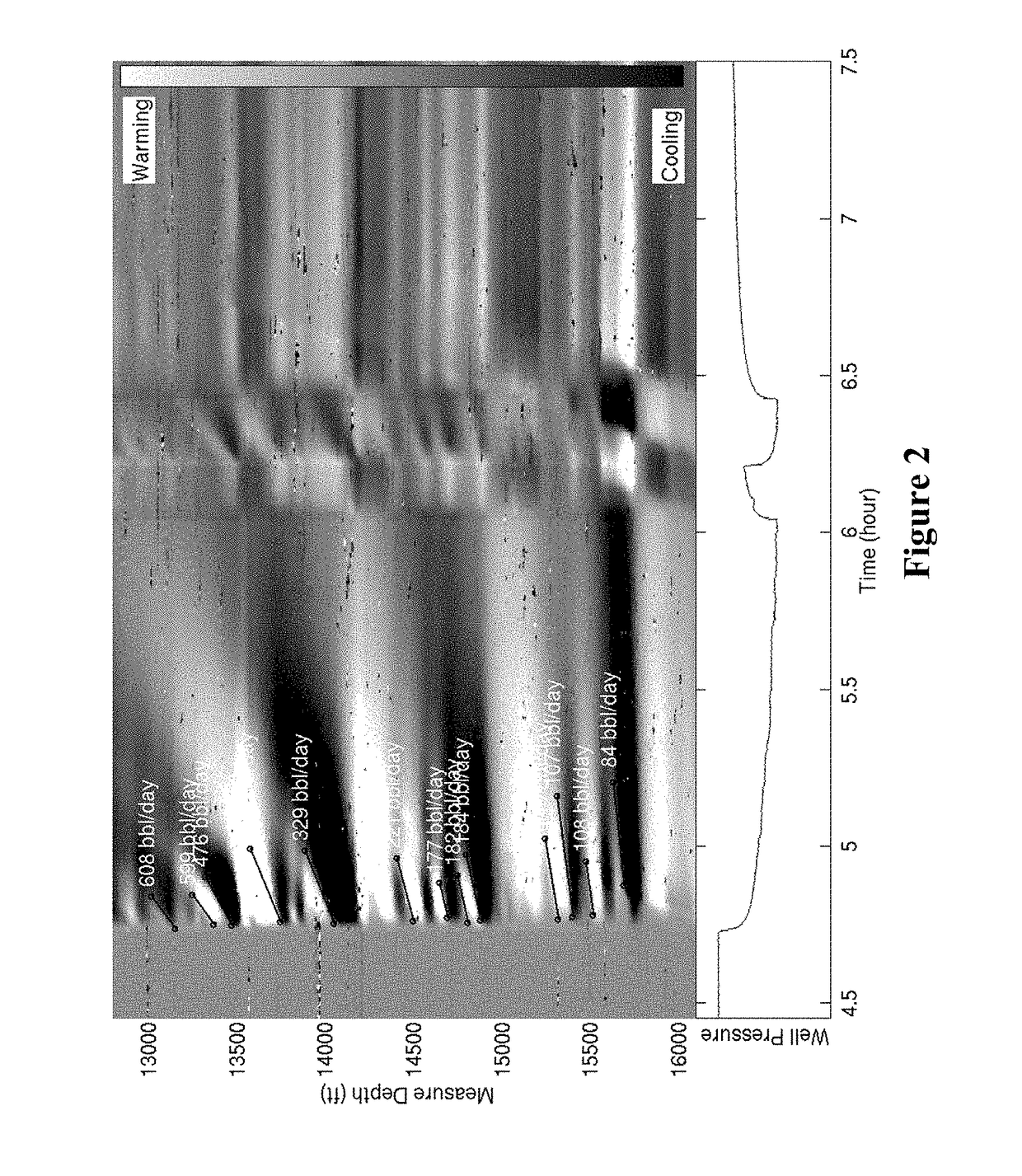

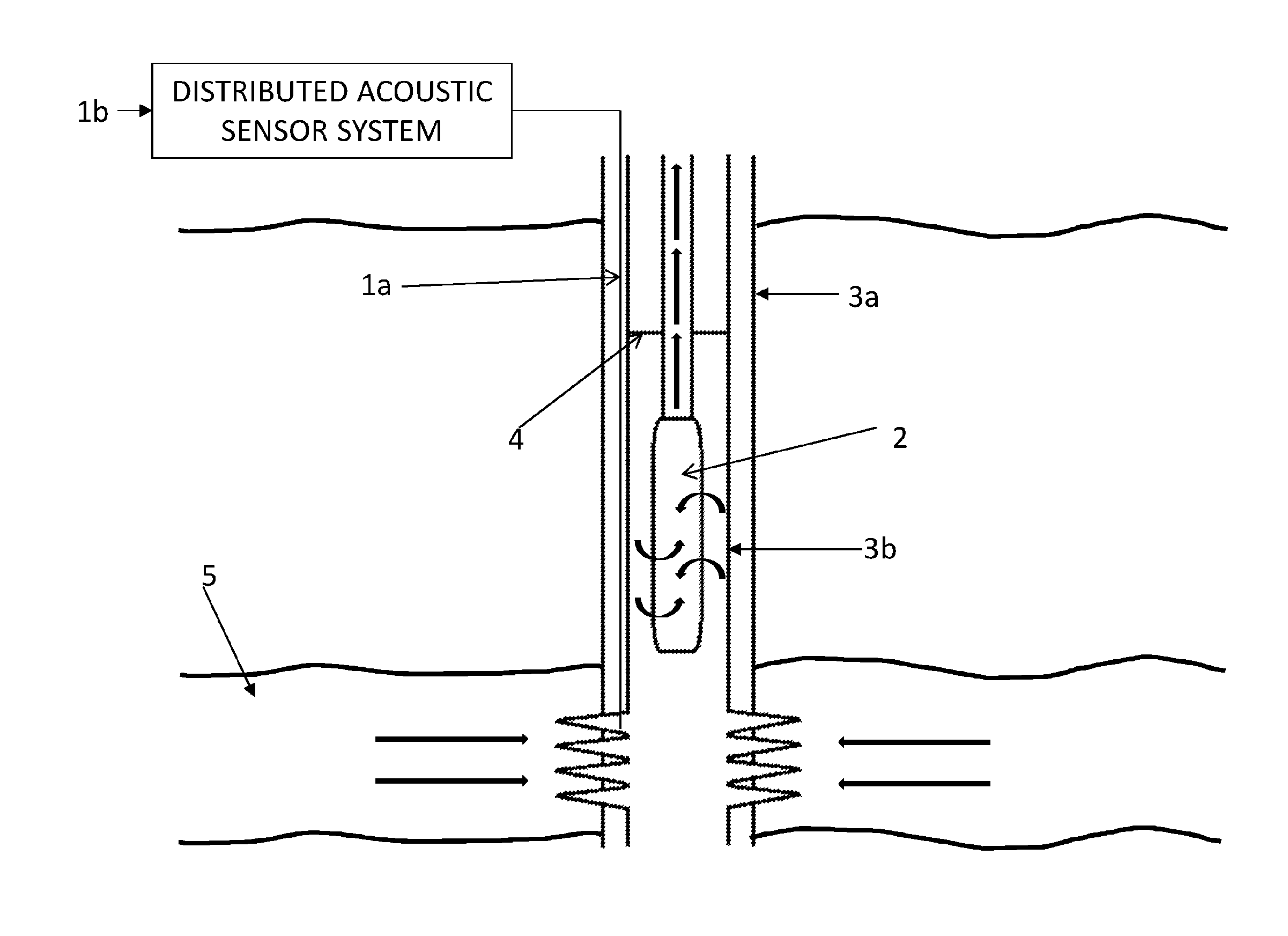

Production logs from distributed acoustic sensors

ActiveUS20180045040A1High data resolutionMinimizing misfitSurveyConstructionsFiberDistributed acoustic sensing

A system and method for monitoring oil flow rates along a producing oil or gas well using a Distributed Acoustic Sensing fiber is described. This system uses the low-frequency component of the acoustic signal as a measurement of temperature variations within the well. The relative flow contributions can then be inferred from these temperature fluctuations.

Owner:CONOCOPHILLIPS CO

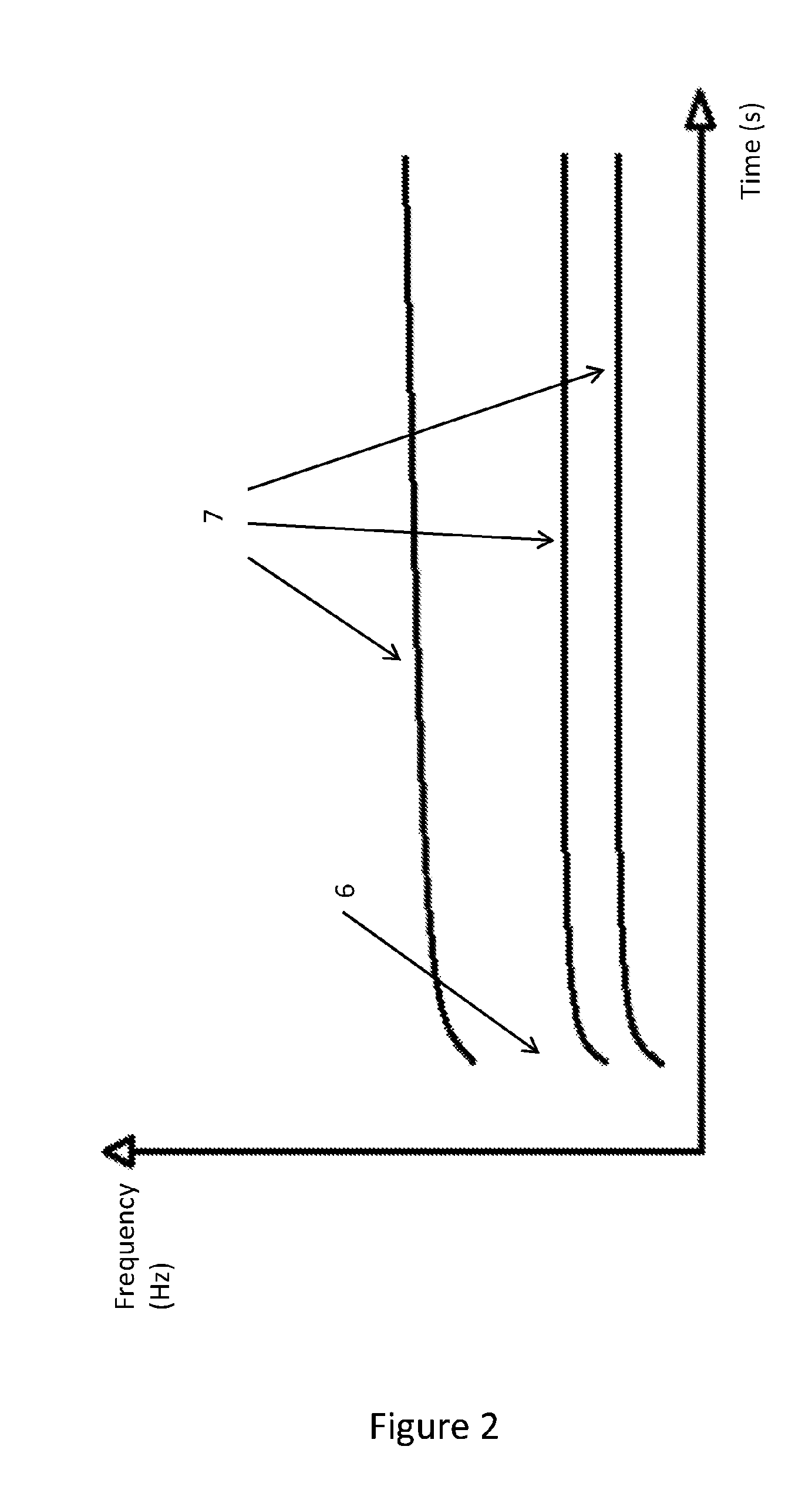

Submersible Pump Monitoring

ActiveUS20170016312A1Determine efficiencySurveySubsonic/sonic/ultrasonic wave measurementFiberDistributed acoustic sensing

In order to address the above noted problems, embodiments of the present invention use distributed acoustic sensing to monitor the fluid level in an ESP activated well so as to monitor the condition and performance of the ESP. Embodiments of the invention use the ESP as an acoustic source in order to monitor the annulus fluid level within the well and to monitor the frequency of the ESP. Additionally, embodiments of the present invention may use distributed acoustic sensing to monitor the flow rates of the production fluid above and below the ESP to determine the pump's efficiency. In particular, some embodiments utilise one or more optical fibers to measure the acoustic waves generated by the ESP, wherein the fiber cabling has already been deployed along the length of the well. As such, the present invention is a non-invasive, in-situ method for monitoring the condition and performance of an ESP.

Owner:SILIXA

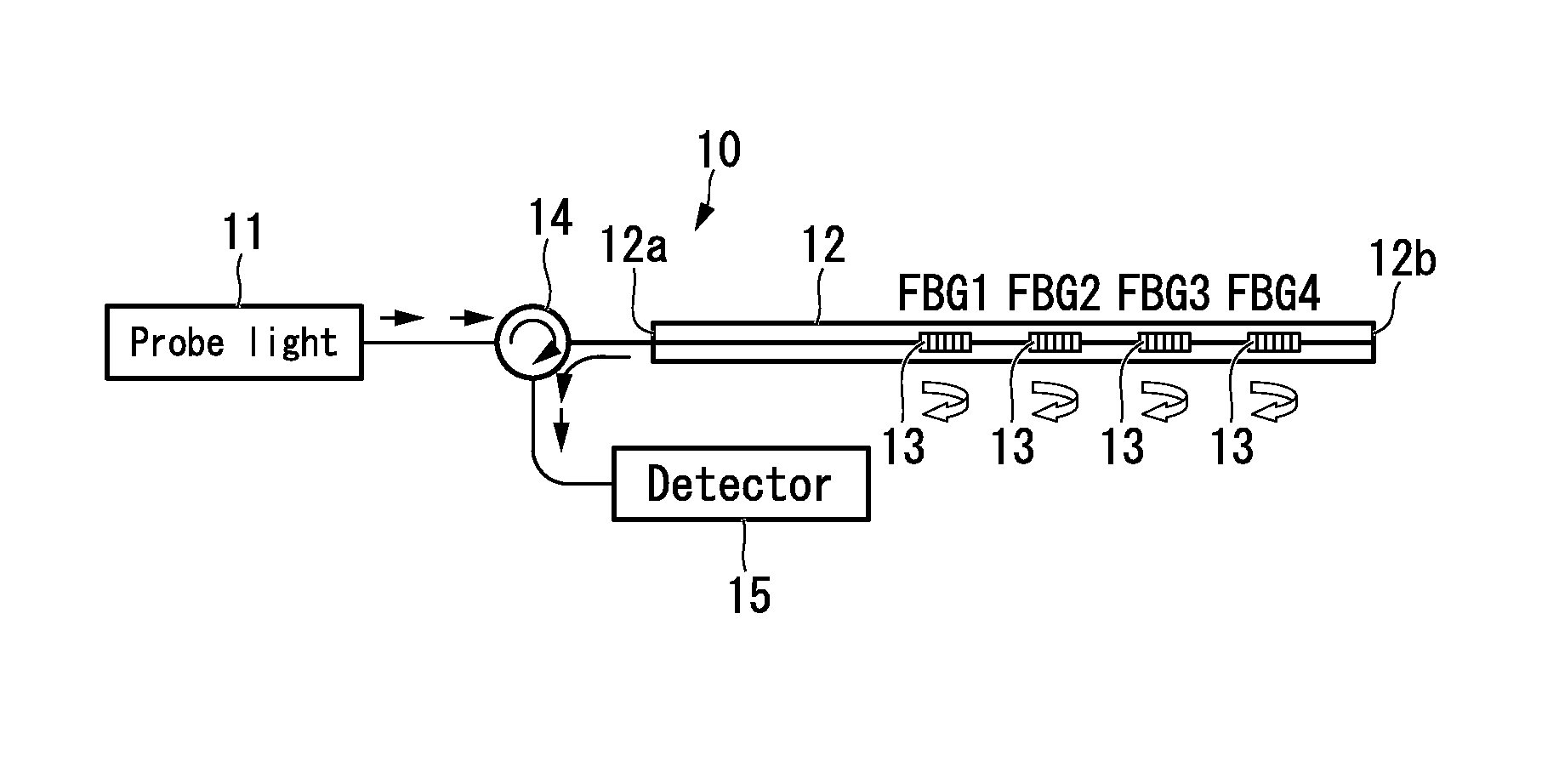

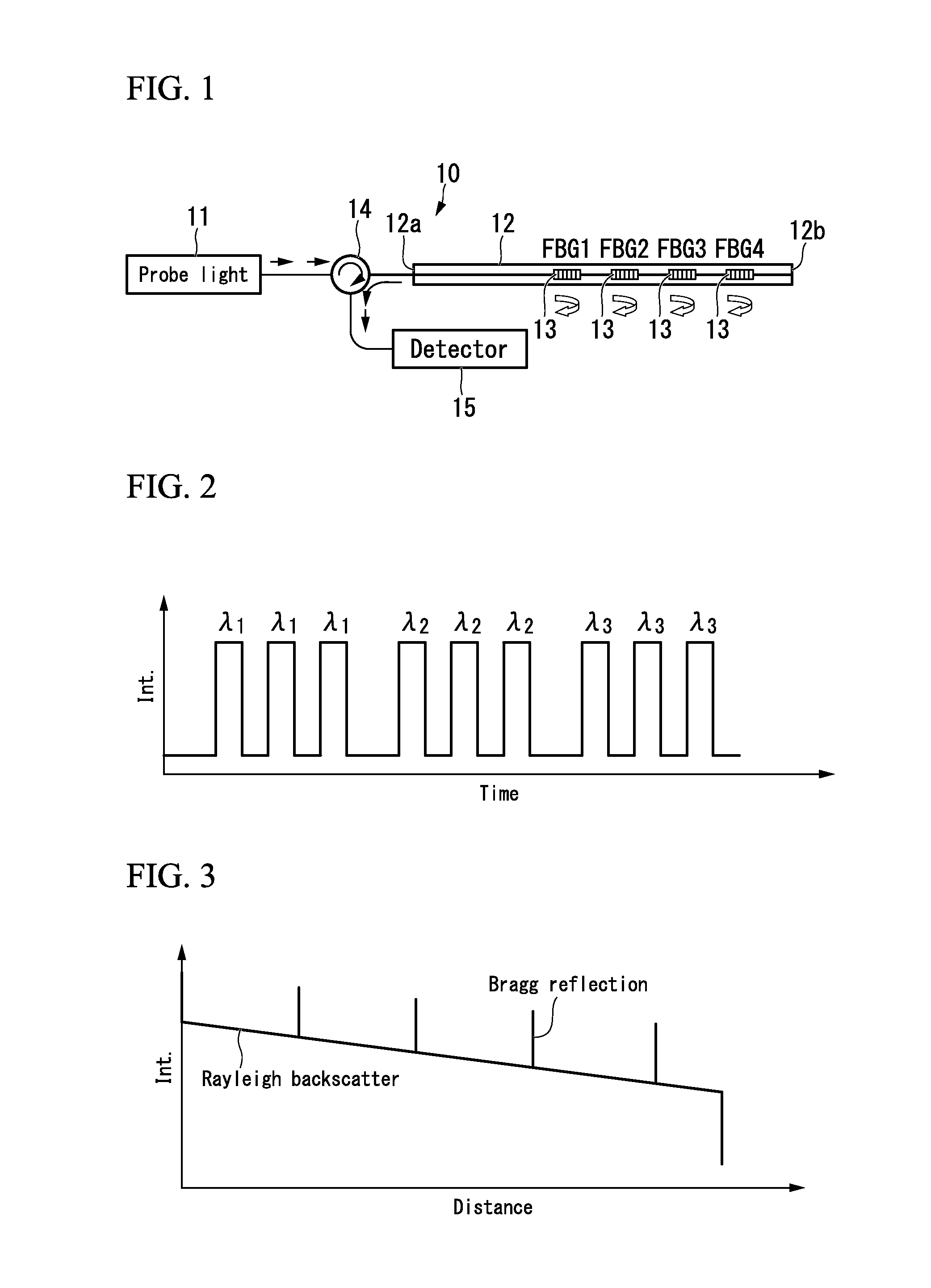

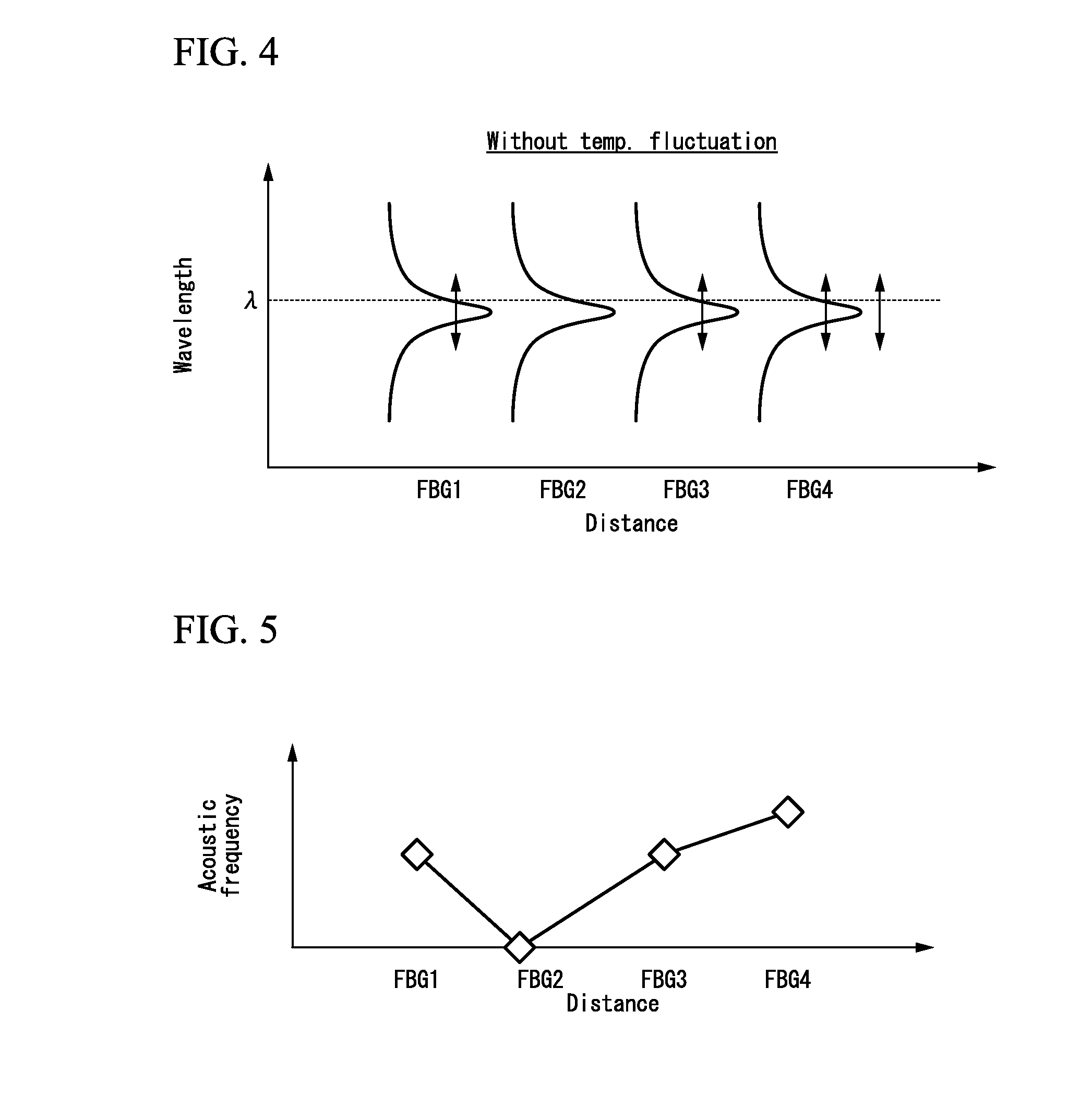

Method of measuring acoustic distribution and distributed acoustic sensor

ActiveUS20130333476A1Vibration measurement in solidsSubsonic/sonic/ultrasonic wave measurementFiberDistributed acoustic sensing

Optical pulses are output from a light source to an optical fiber at one selected emission wavelength, a reflection light reflected at a fiber Bragg grating at the optical fiber is received at an optical receiver and is converted to a reflection signal by an optical to electrical conversion, a fiber Bragg grating which reflects the reflection light is identified by the signal processing unit when an intensity of the reflection signal obtained by the optical receiver is over a predetermined threshold value, and a measurement step that calculates acoustic frequencies at the fiber Bragg grating based on a temporal change of the intensity of the reflection signal at the fiber Bragg grating is repeated more than two times while changing an emission wavelength of the light source. The acoustic frequency at each fiber Bragg grating is calculated to determine an acoustic distribution along a longitudinal direction of the fiber.

Owner:THE FUJIKURA CABLE WORKS LTD

Detecting the direction of acoustic signals with a fiber optical distributed acoustic sensing (DAS) assembly

ActiveUS20130291643A1Vibration measurement in solidsSubsonic/sonic/ultrasonic wave measurementFiberDistributed acoustic sensing

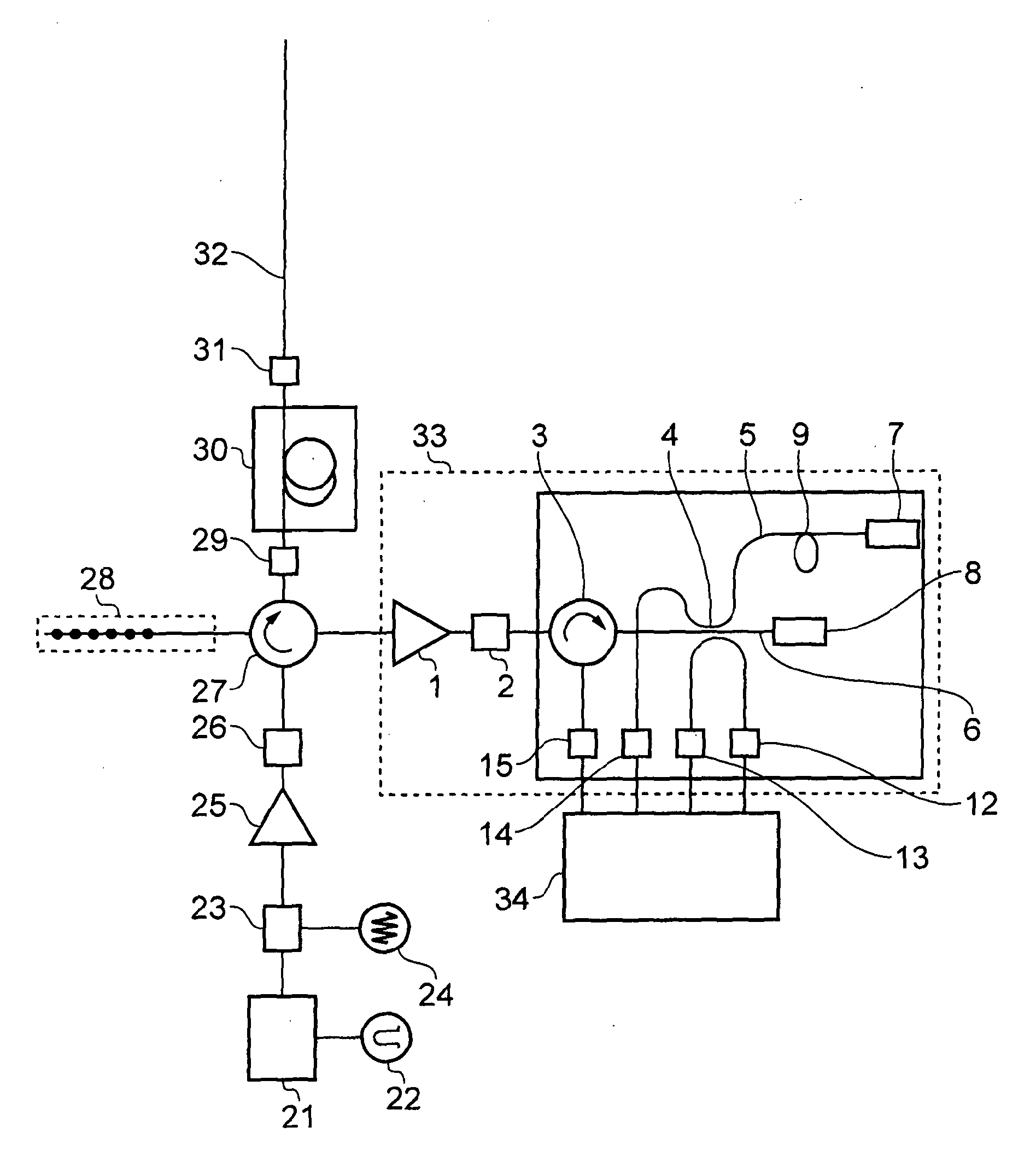

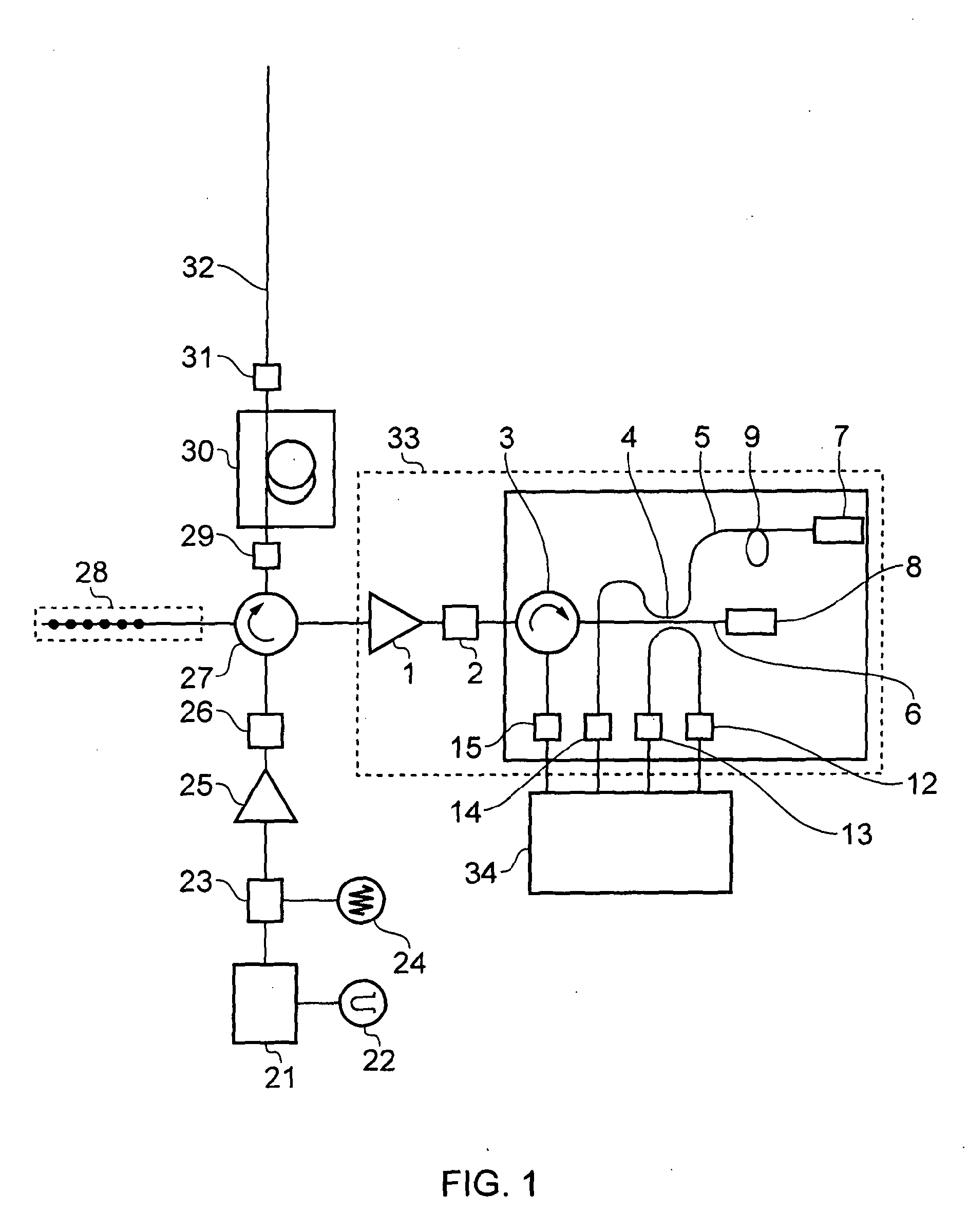

A directionally sensitive Distributed Acoustic Sensing (DAS) fiber optical assembly comprises adjacent lengths of optical fiber (A,B) with different directional acoustic sensitivities, which are used to detect the direction (a) of acoustic signals relative to the lengths of optical fiber (A, B).

Owner:SHELL OIL CO

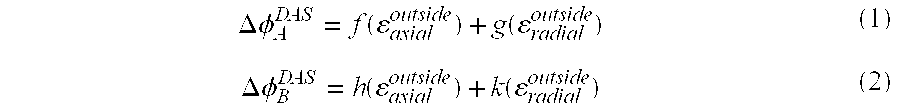

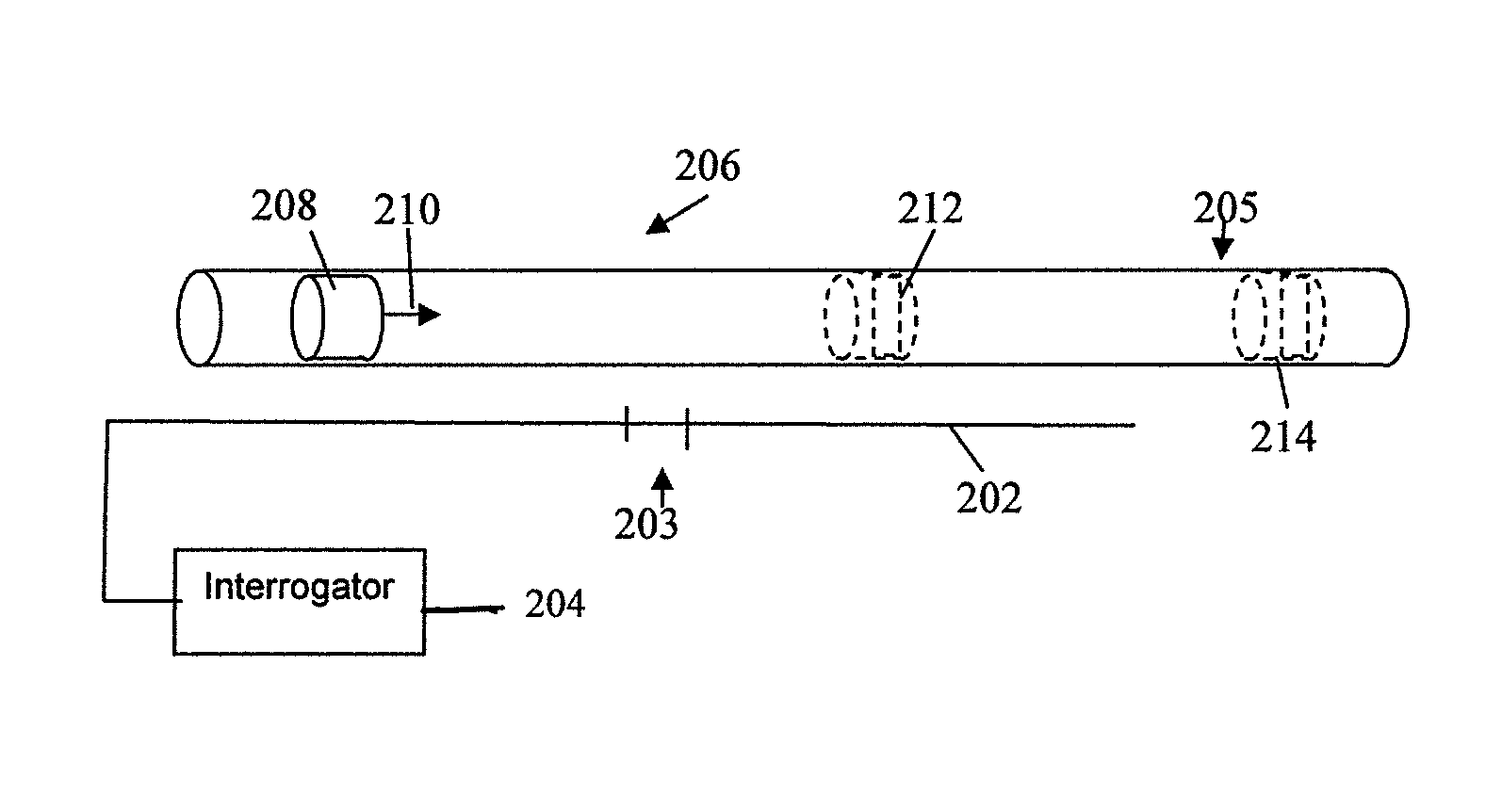

Monitoring of conduits

ActiveUS9453821B2Improve Sensing PerformanceImprove noise levelDetection of fluid at leakage pointAnalysing solids using sonic/ultrasonic/infrasonic wavesFiberDistributed acoustic sensing

This application relates to methods and apparatus for monitoring of conduits, especially oil or gas pipelines, as an object such as pipeline pig moves within the conduit. The method comprises monitoring at least part of a conduit (206) using a fibre optic (202) distributed acoustic sensor (204) as the object (208) passes along the conduit. The acoustic signals detected from at least one sensing location (203) as the object moves along the conduit are analysed so as to discriminate acoustic signals received at said sensing location from different locations. The method allows the contributions to the acoustic signal at a given sensing portion from different locations to be separately identified, and can allow the detection of the location of acoustic sources along the conduit even if the source is outside the section of conduit which is monitored. The method provides a method of leak detection that can extend the monitoring of the pipeline beyond the location of the optical fibre.

Owner:OPTASENSE HLDG LTD

Distributed acoustic sensing with fiber Bragg gratings

ActiveUS8315486B2Inexpensive to acquireInexpensive to deployOptical detectionSeismic signal receiversFiberDistributed acoustic sensing

Owner:SHELL USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com