Patents

Literature

2659 results about "Speed of sound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The speed of sound is the distance travelled per unit time by a sound wave as it propagates through an elastic medium. At 20 °C (68 °F), the speed of sound in air is about 343 metres per second (1,235 km/h; 1,125 ft/s; 767 mph; 667 kn), or a kilometre in 2.9 s or a mile in 4.7 s. It depends strongly on temperature, but also varies by several metres per second, depending on which gases exist in the medium through which a soundwave is propagating.

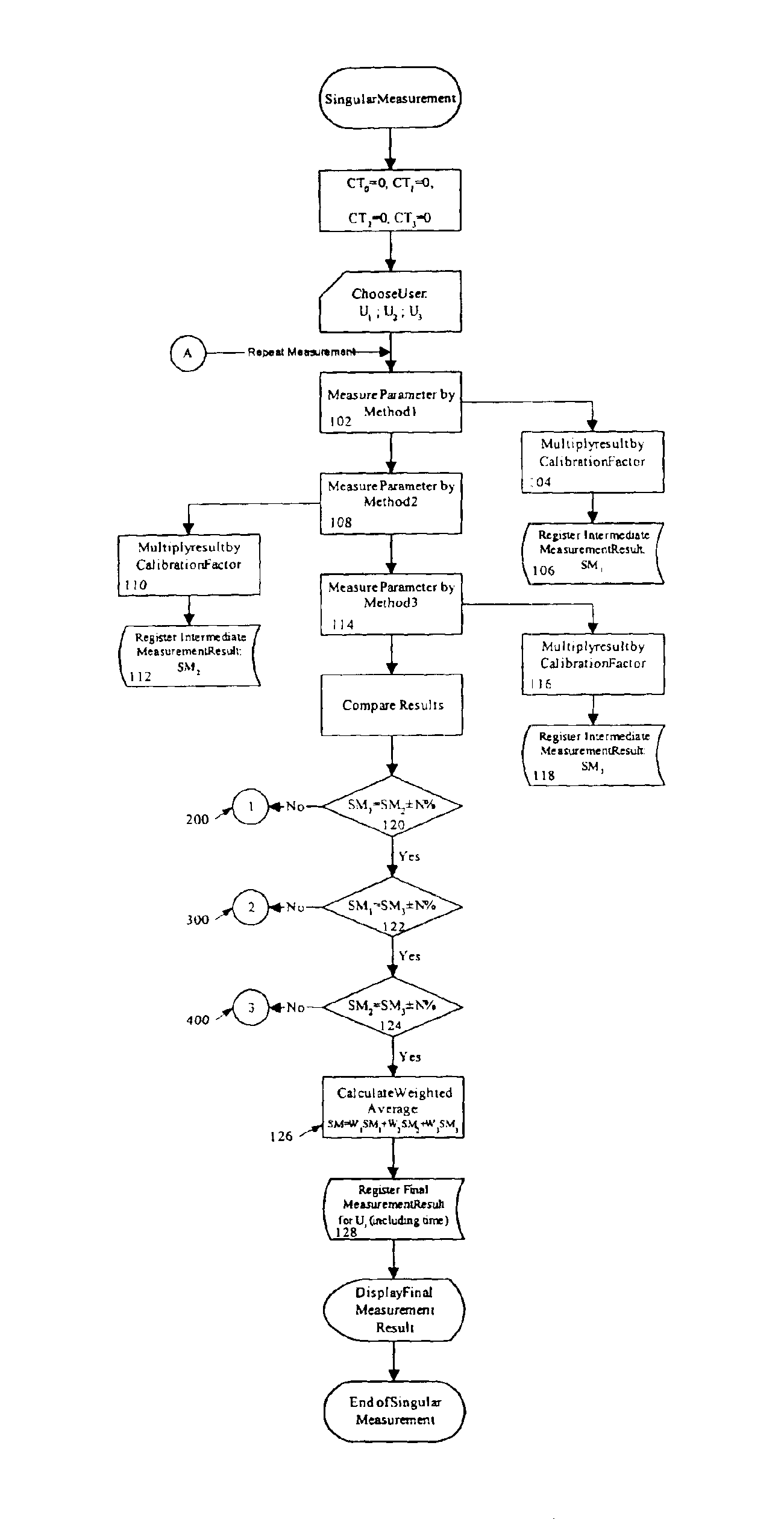

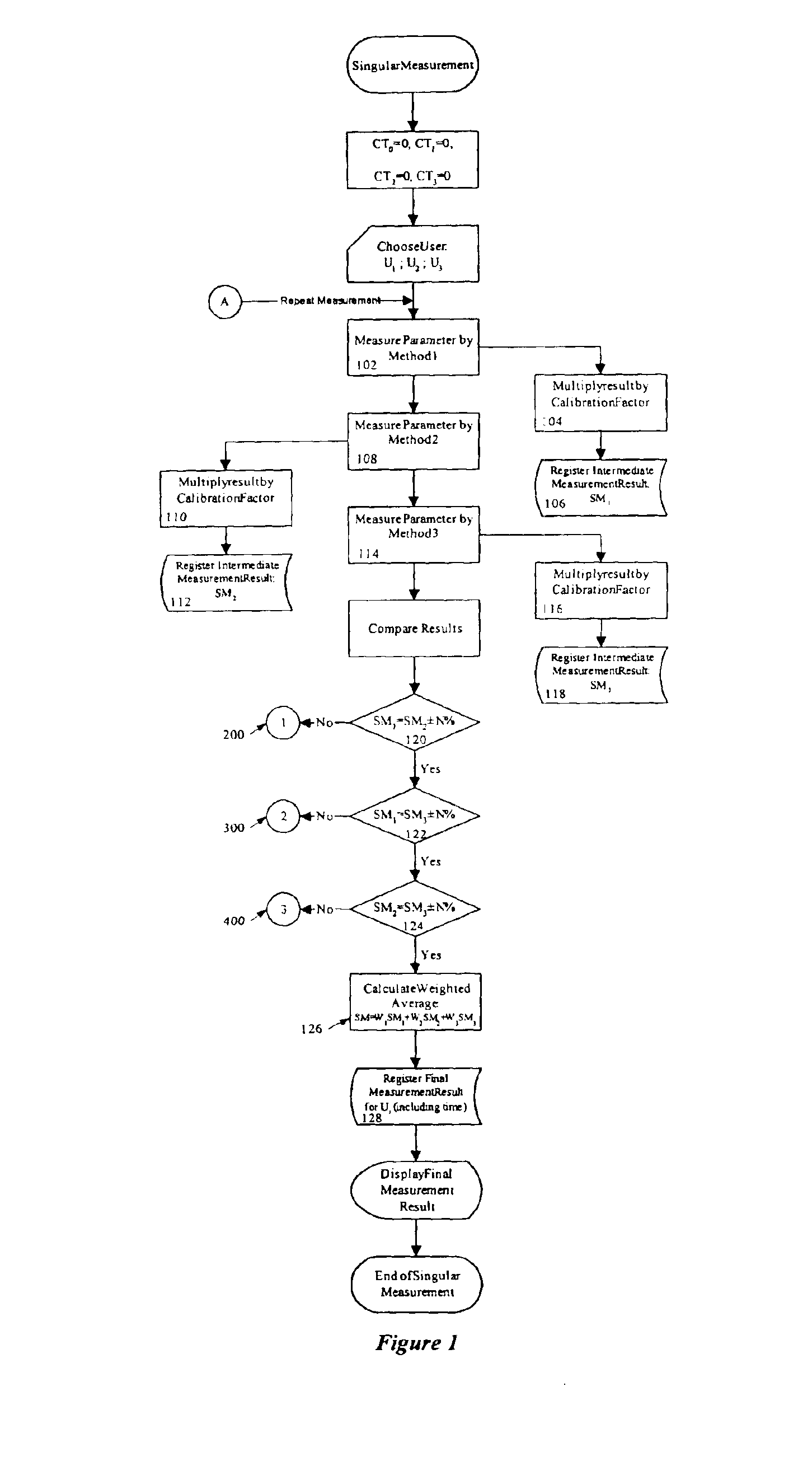

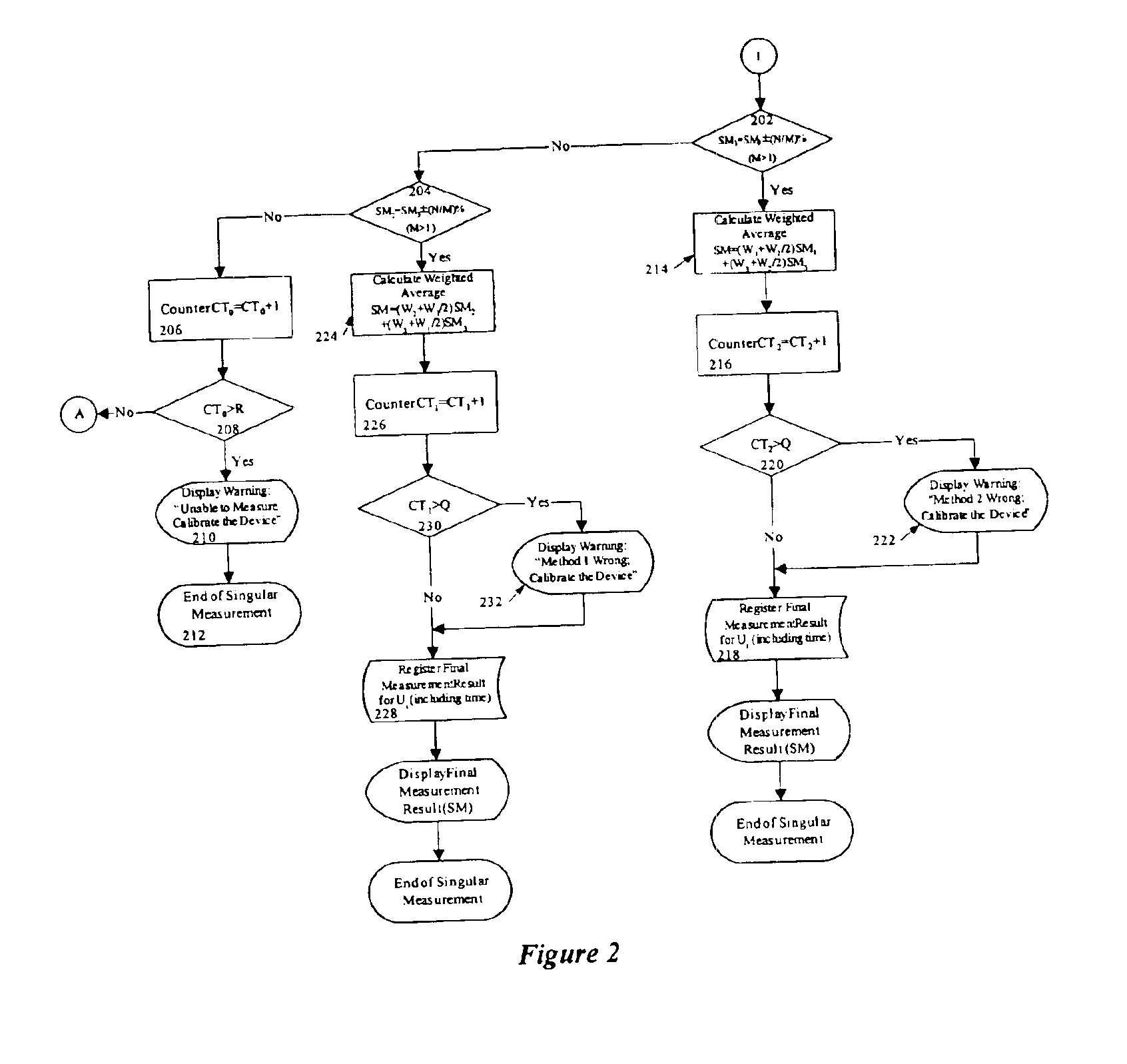

Method of monitoring glucose level

The method of monitoring or measuring the concentration of glucose level in human and animal blood uses a non-invasive technique and includes measurements of the speed of sound through the blood, the conductivity of the blood, and the heat capacity of the blood, or by non-invasive measurement of any other parameters that can be used to calculate the glucose level. Thereafter, the glucose level for each of the three measurements is calculated and the final glucose value is determined by a weighted average of the three calculated glucose values.

Owner:JMS DIVERSIFIELD HLDG

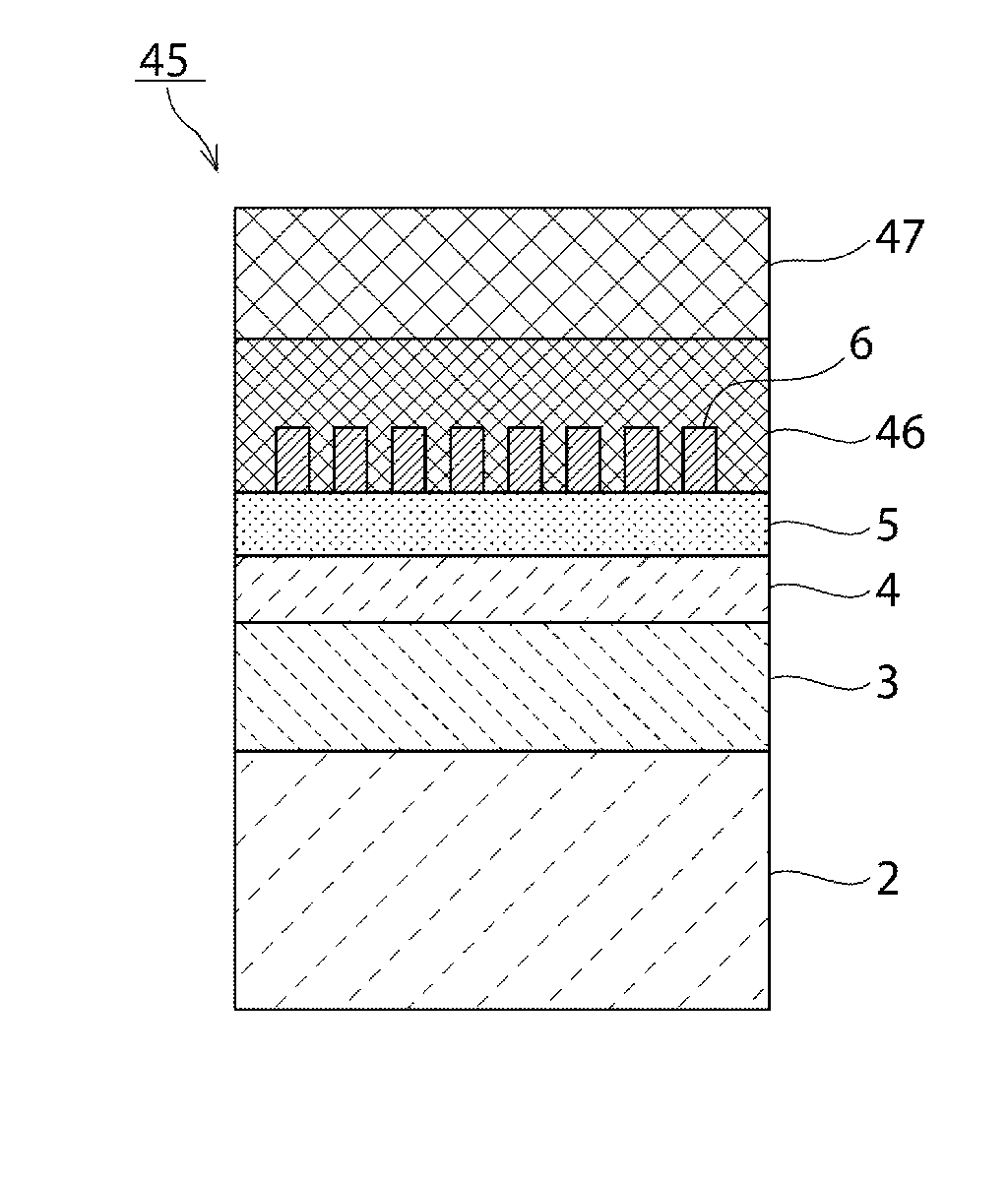

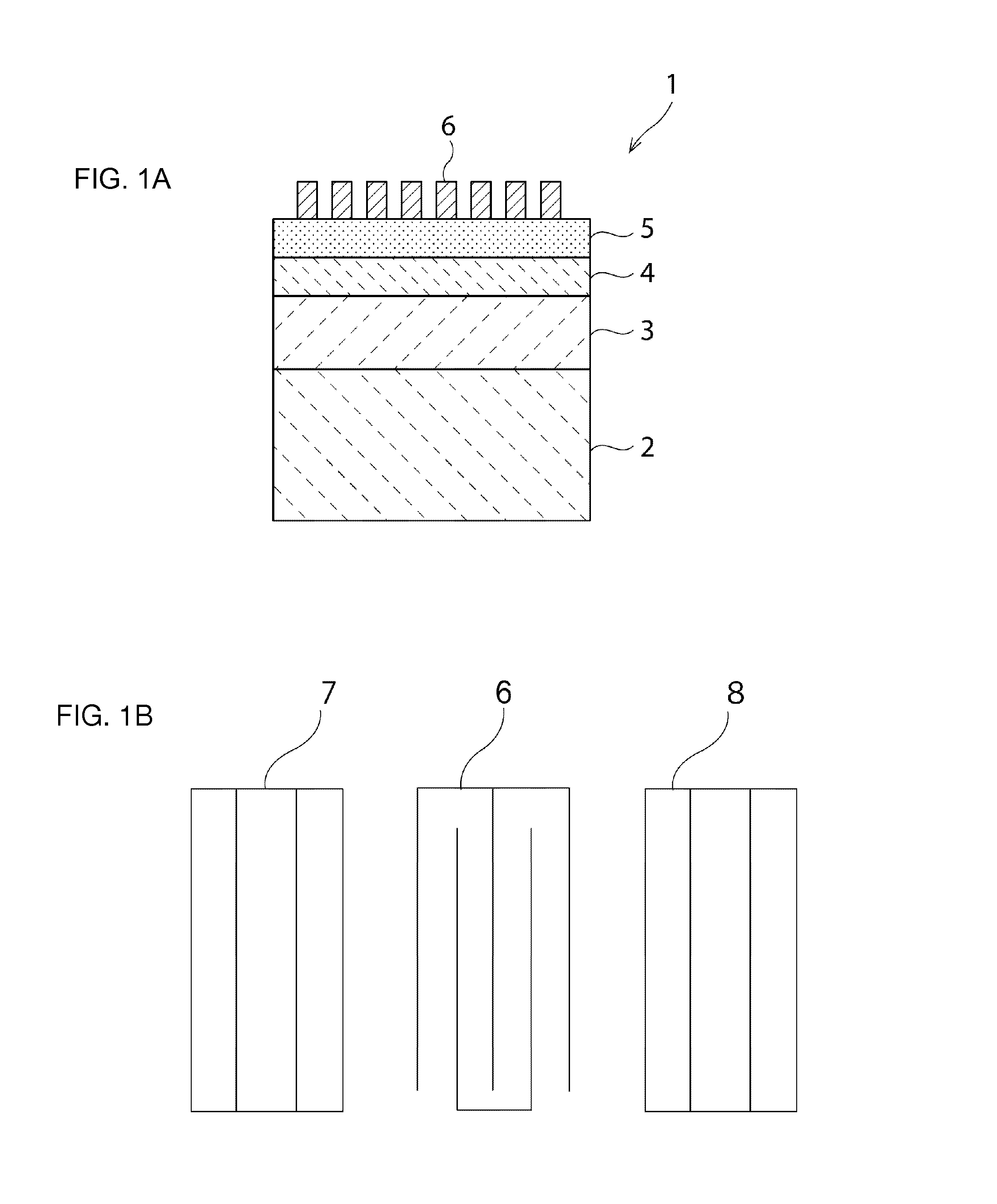

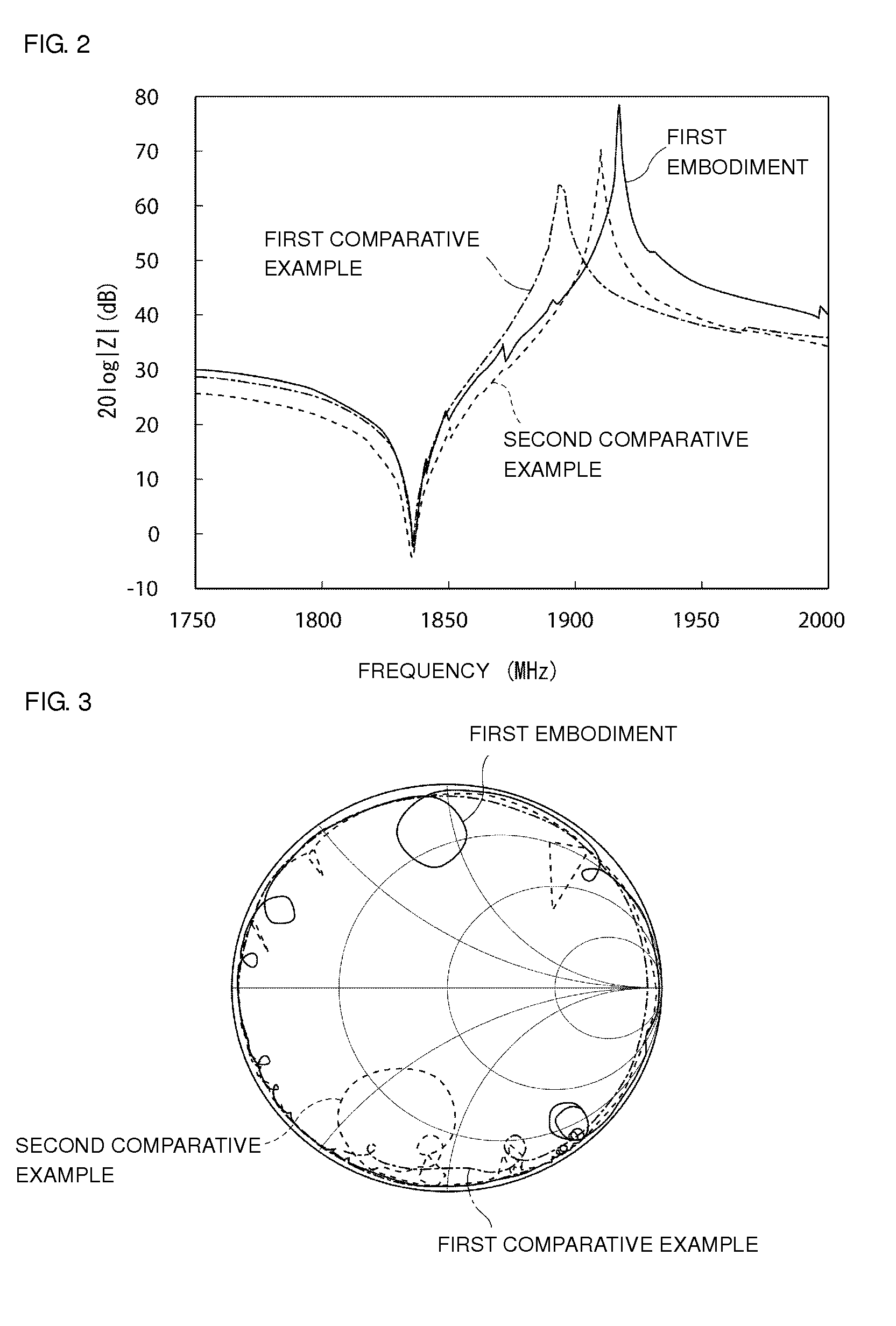

Elastic wave device and method for manufacturing the same

ActiveUS20130285768A1Recover piezoelectricityImprove featuresImpedence networksSpeed of soundElectrode

An elastic wave device includes a supporting substrate, a high-acoustic-velocity film stacked on the supporting substrate and in which an acoustic velocity of a bulk wave propagating therein is higher than an acoustic velocity of an elastic wave propagating in a piezoelectric film, a low-acoustic-velocity film stacked on the high-acoustic-velocity film and in which an acoustic velocity of a bulk wave propagating therein is lower than an acoustic velocity of a bulk wave propagating in the piezoelectric film, the piezoelectric film is stacked on the low-acoustic-velocity film, and an IDT electrode stacked on a surface of the piezoelectric film.

Owner:MURATA MFG CO LTD

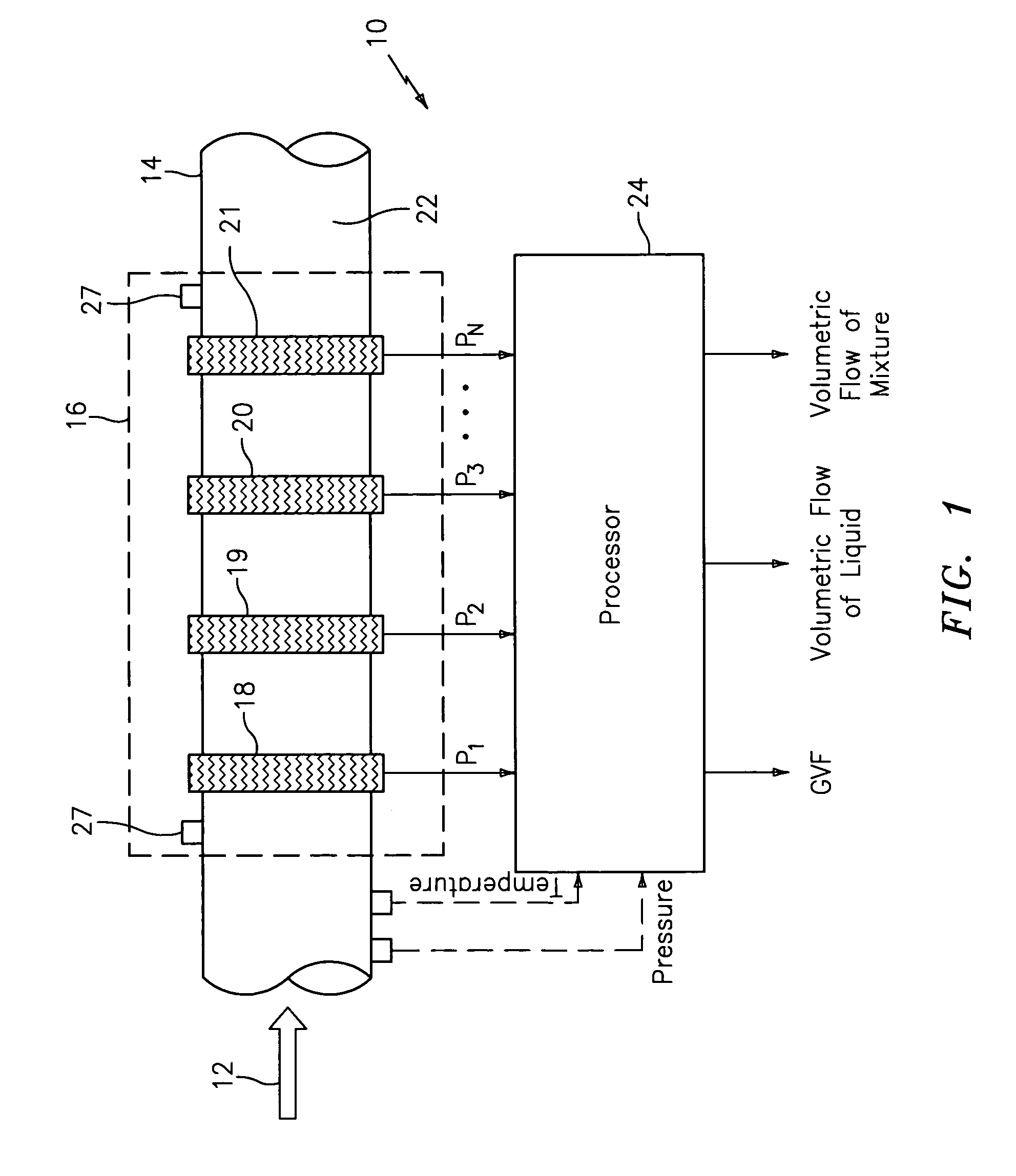

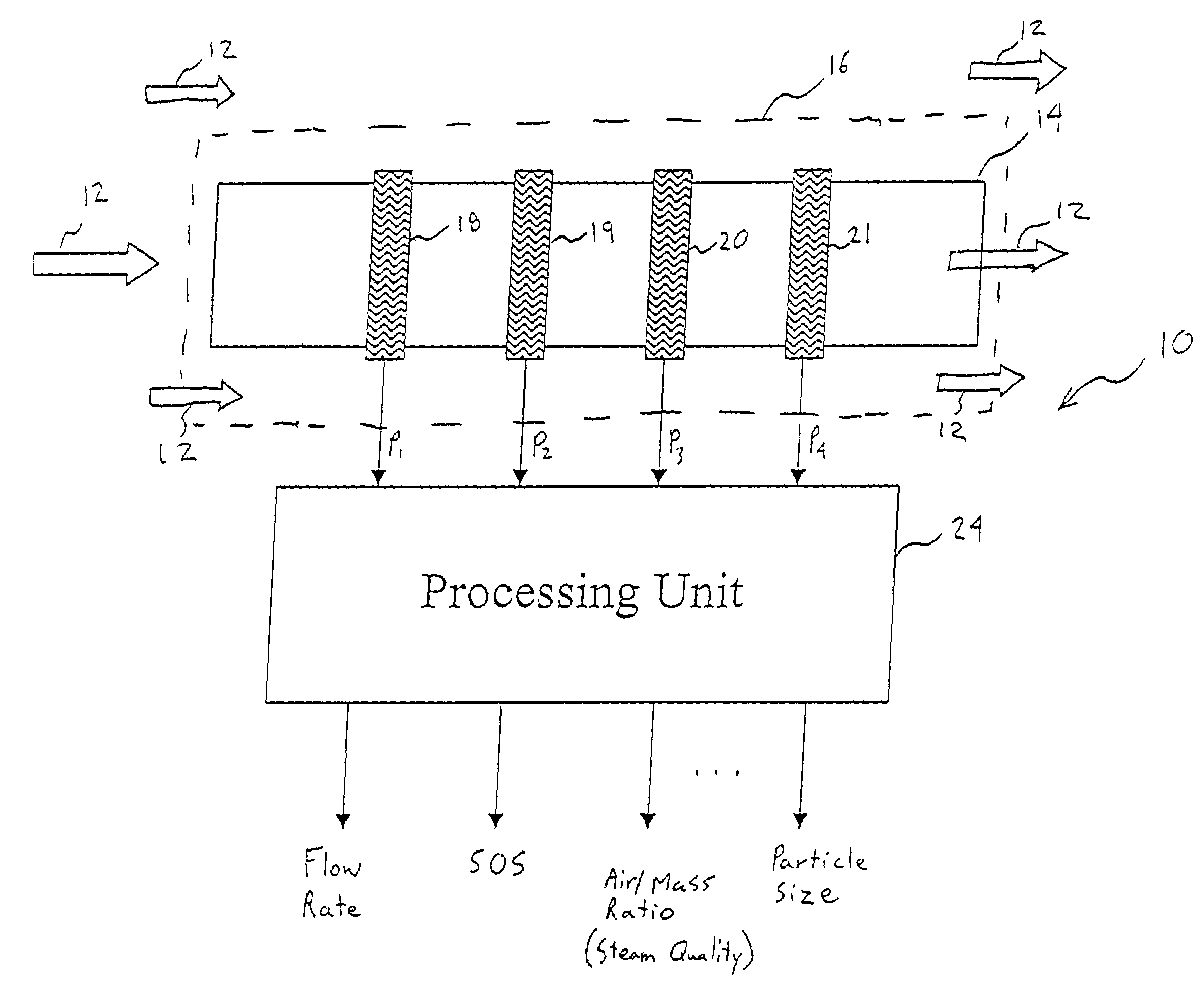

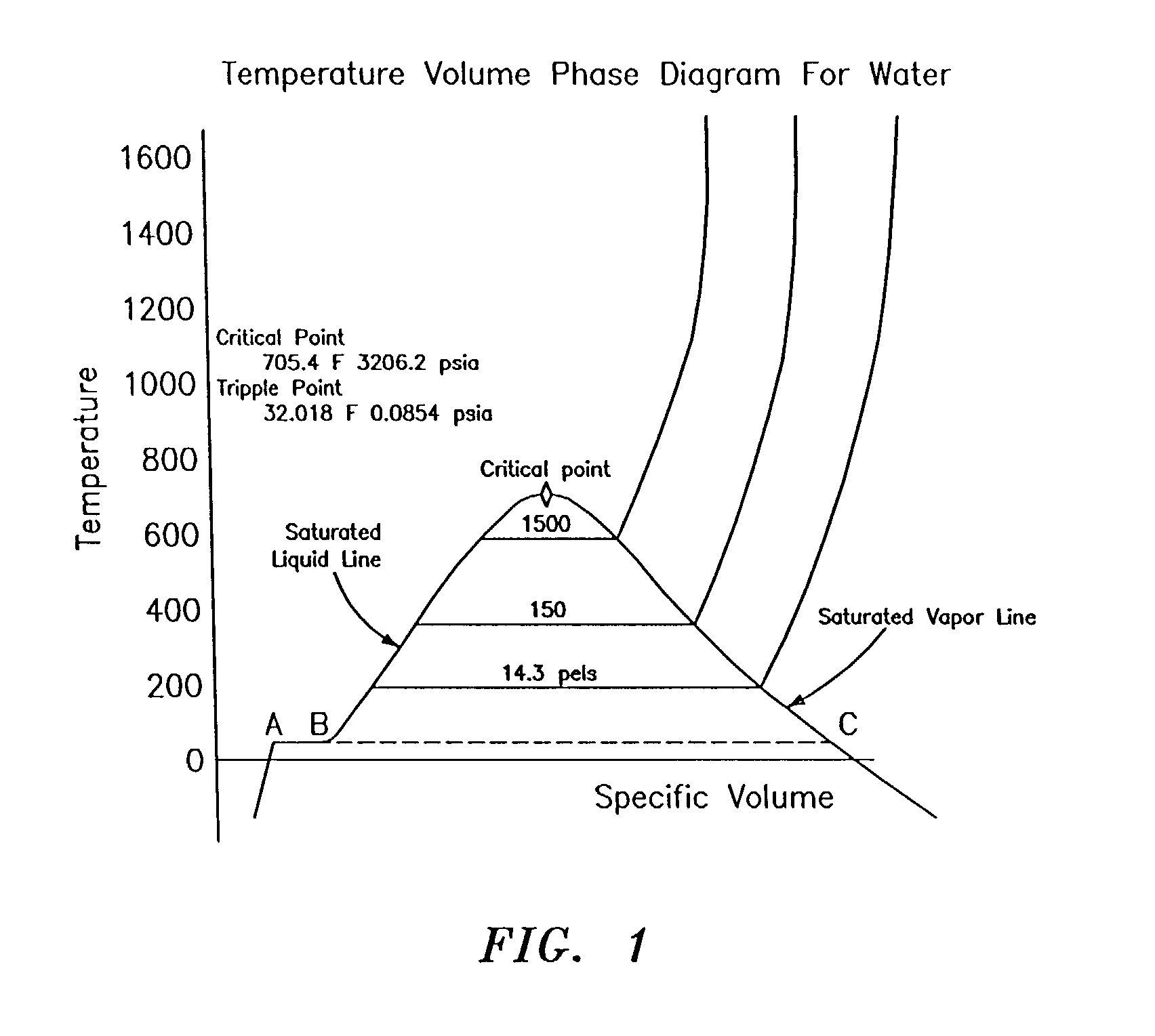

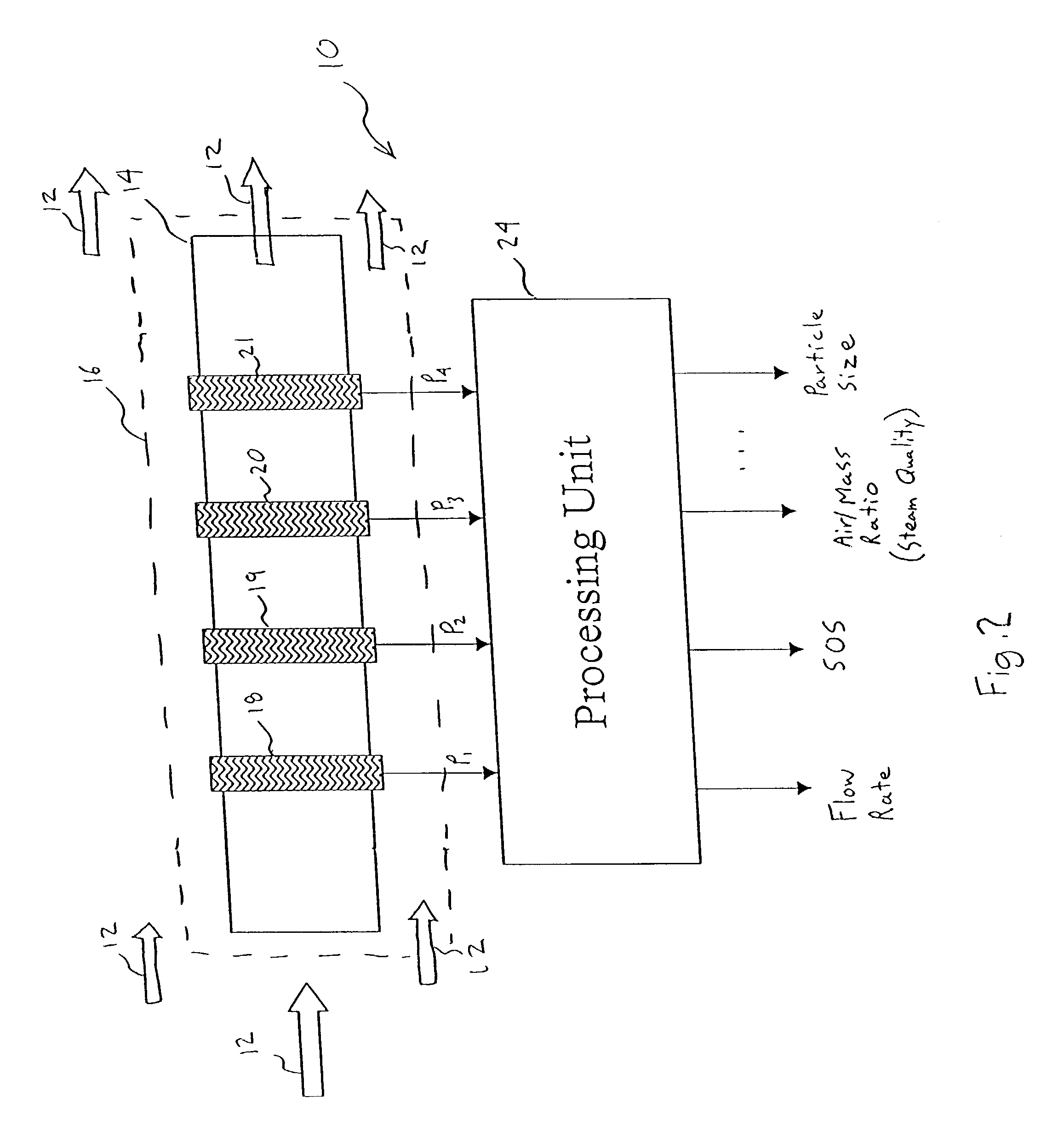

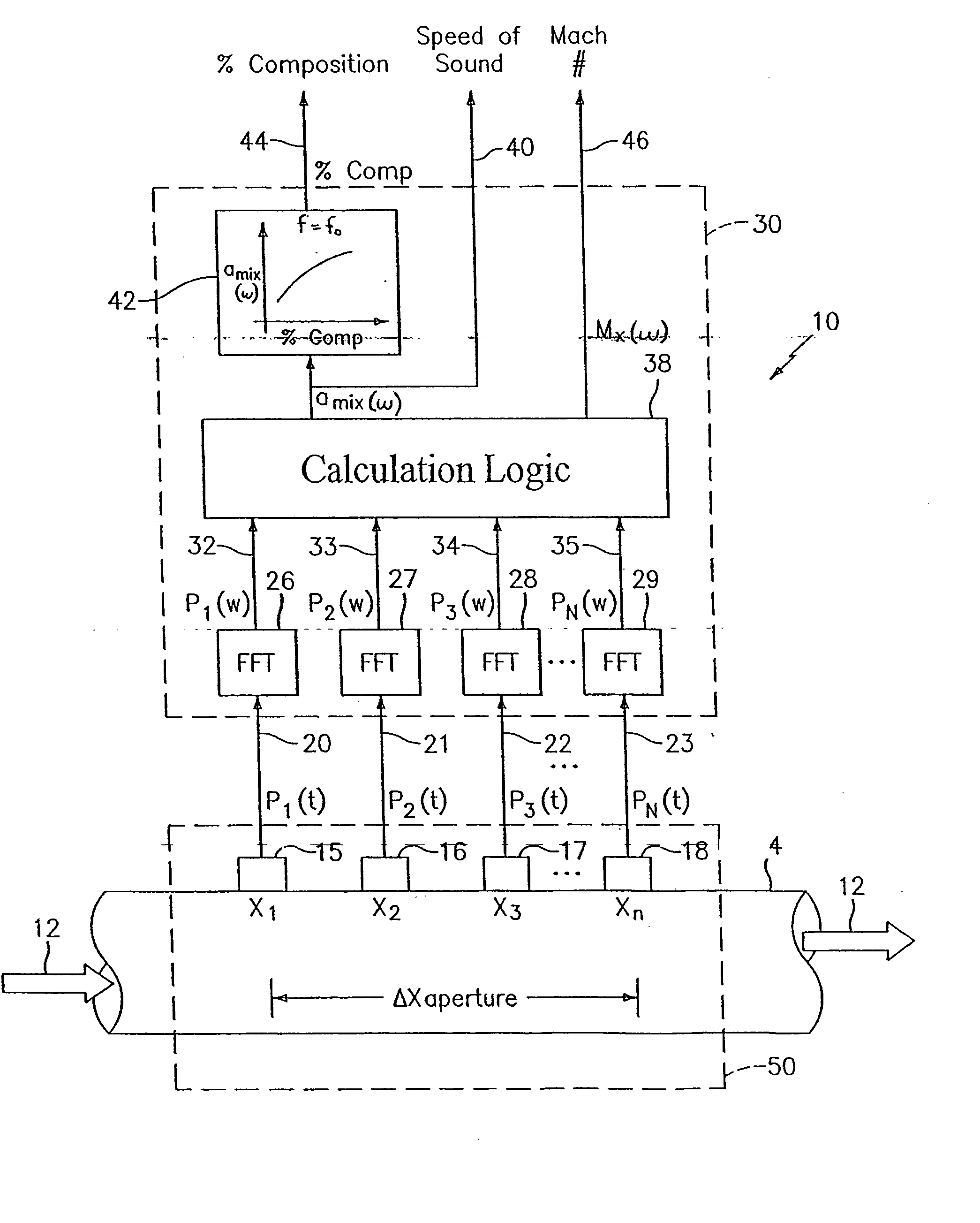

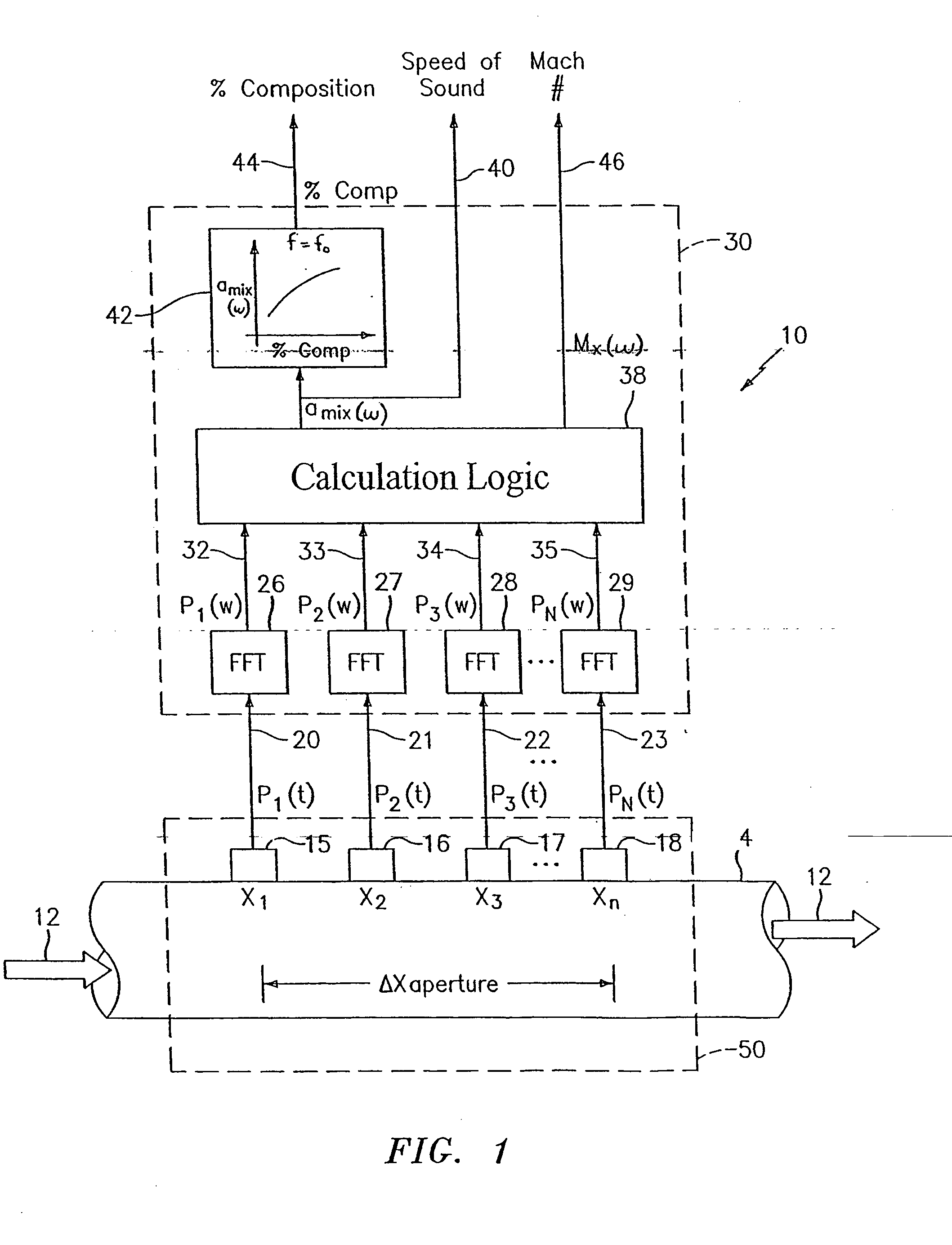

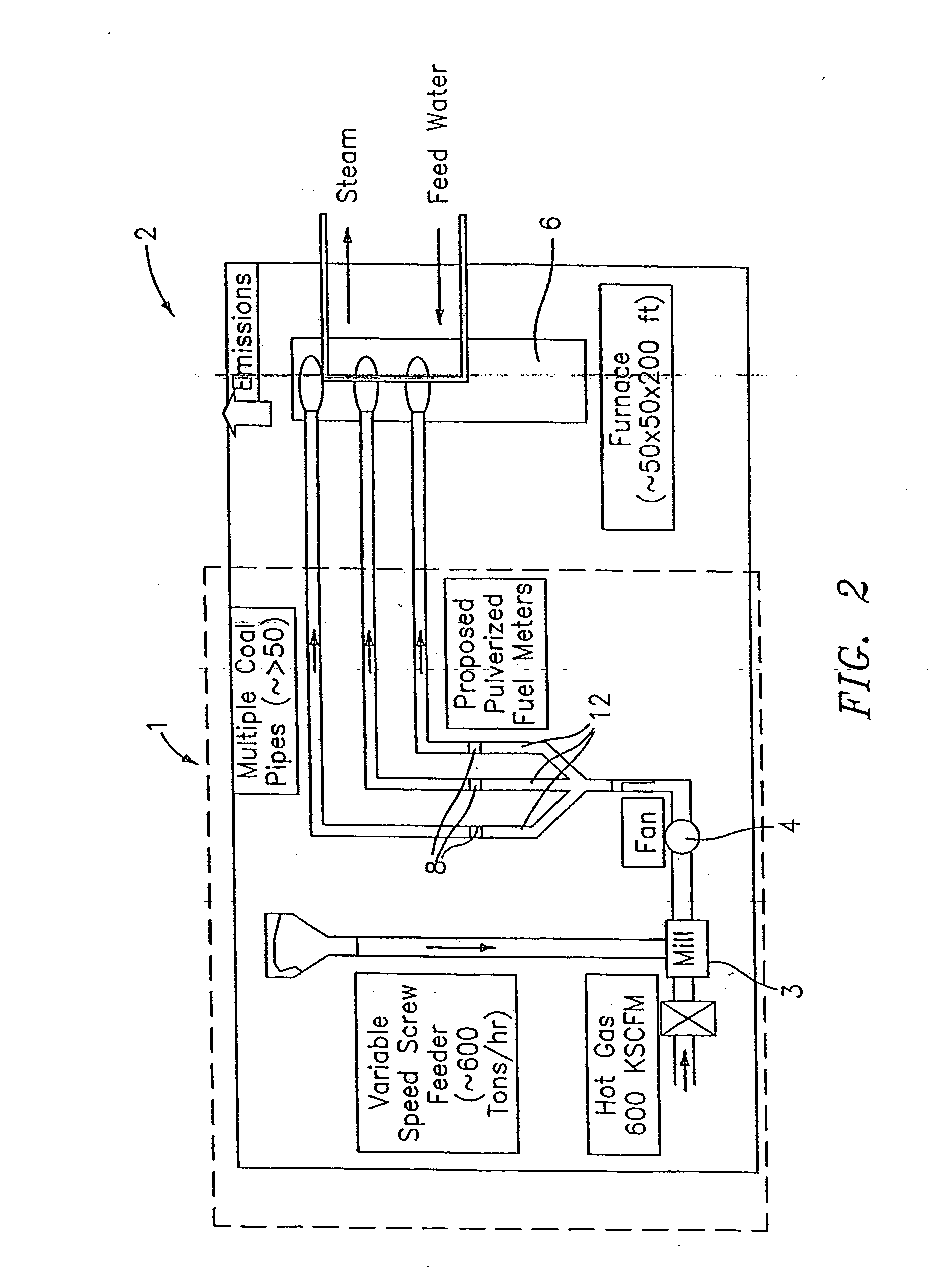

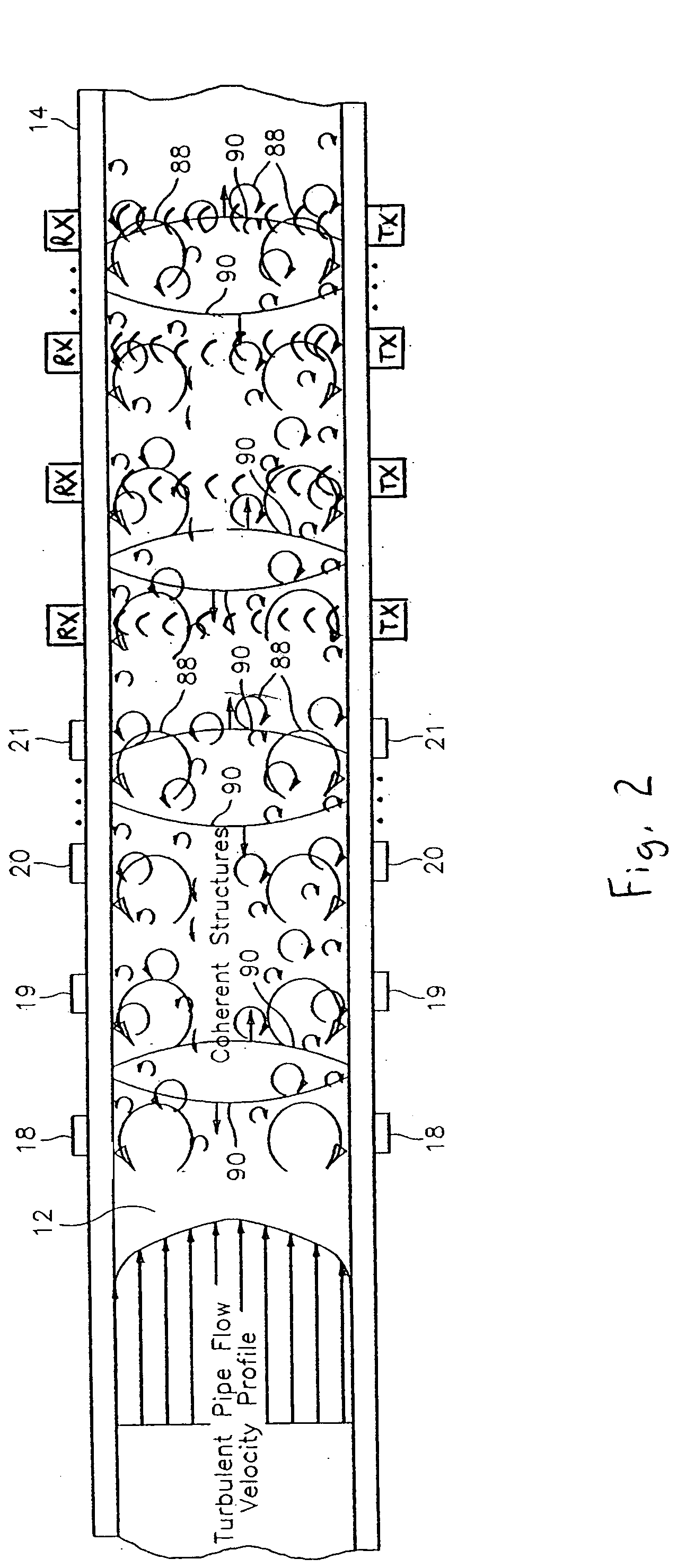

Fluid parameter measurement in pipes using acoustic pressures

InactiveUS6862920B2Less sensitive to static shifts (or errors) in sensingImprove measurement reliabilityAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringWater fraction

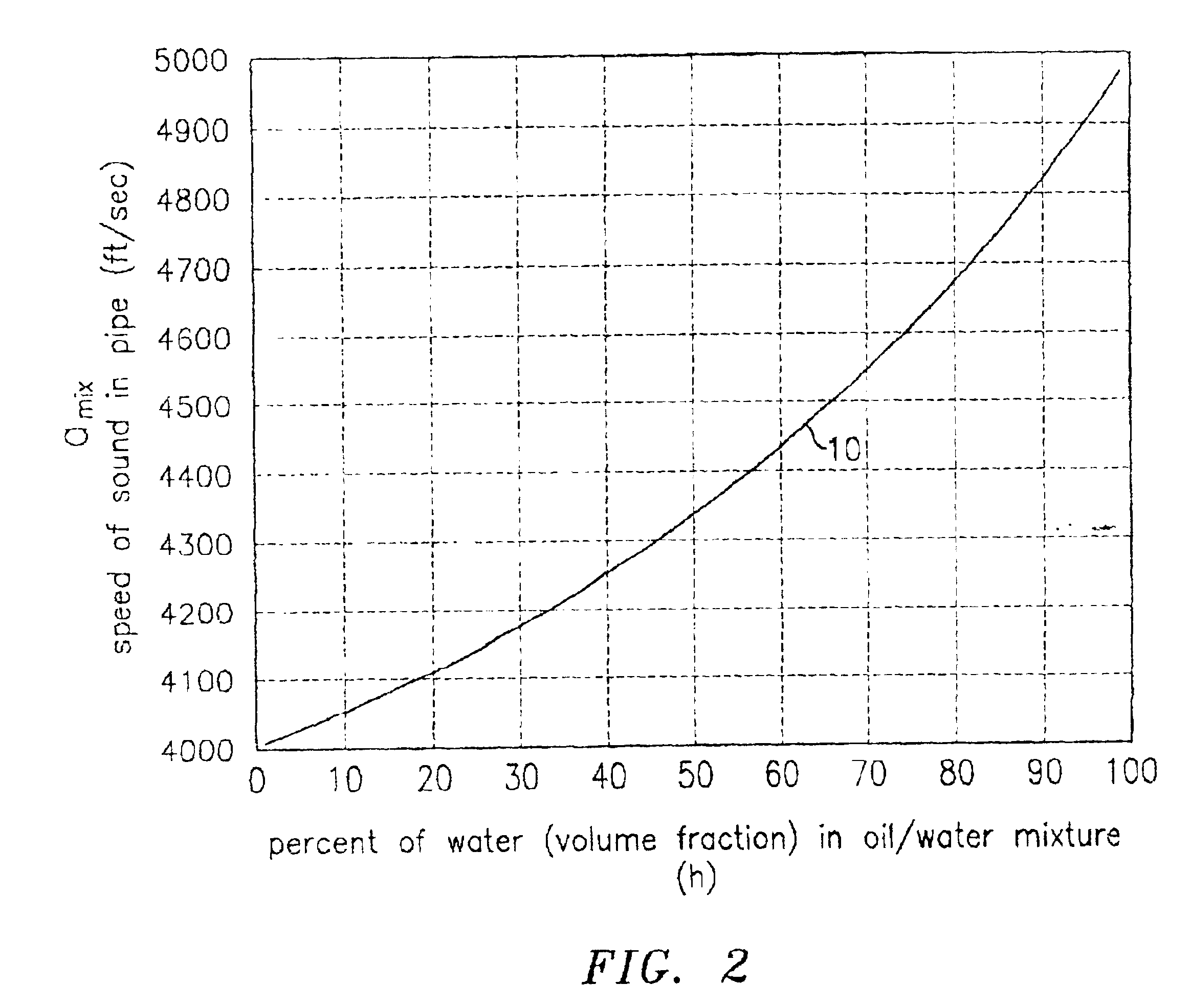

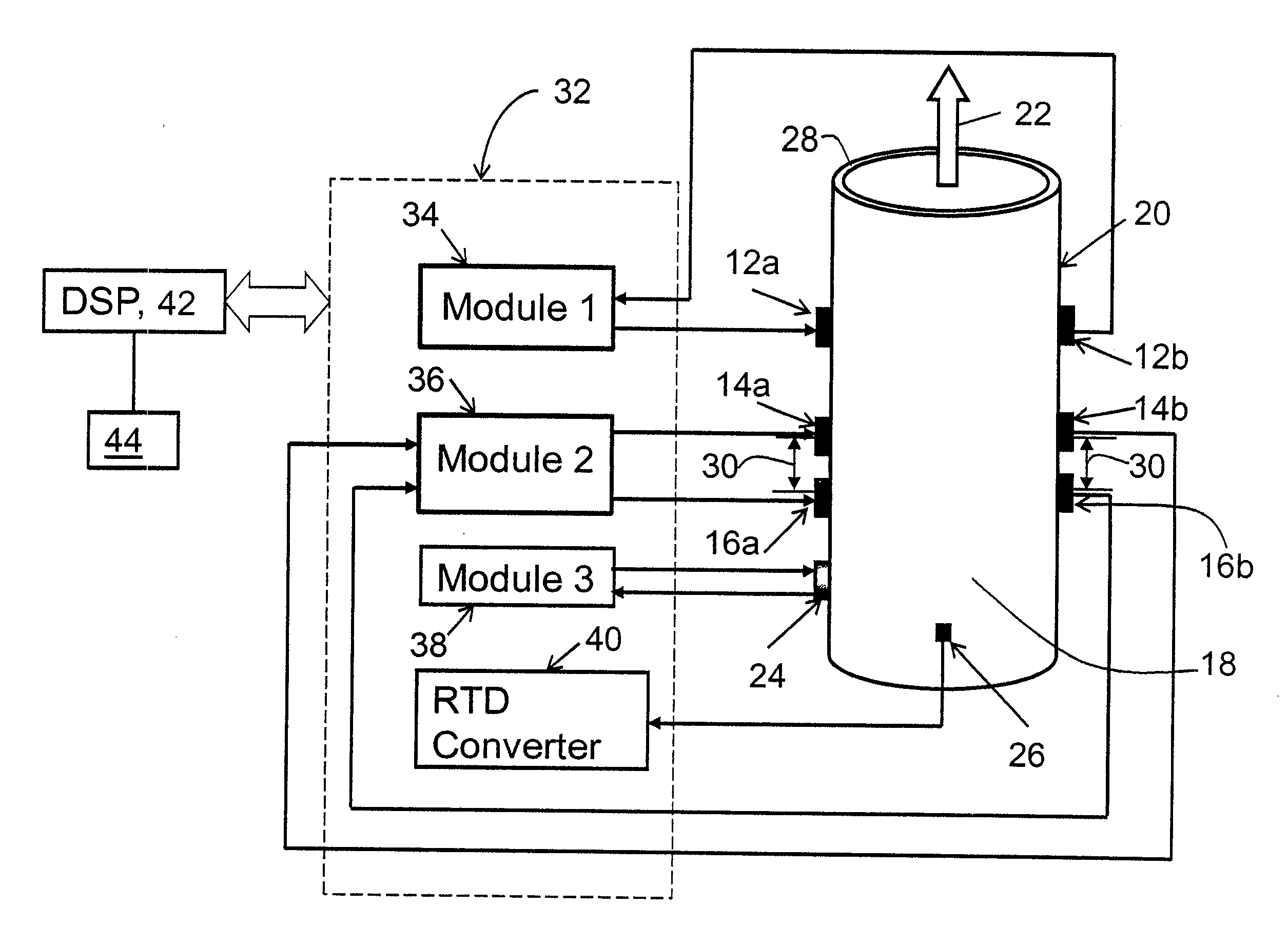

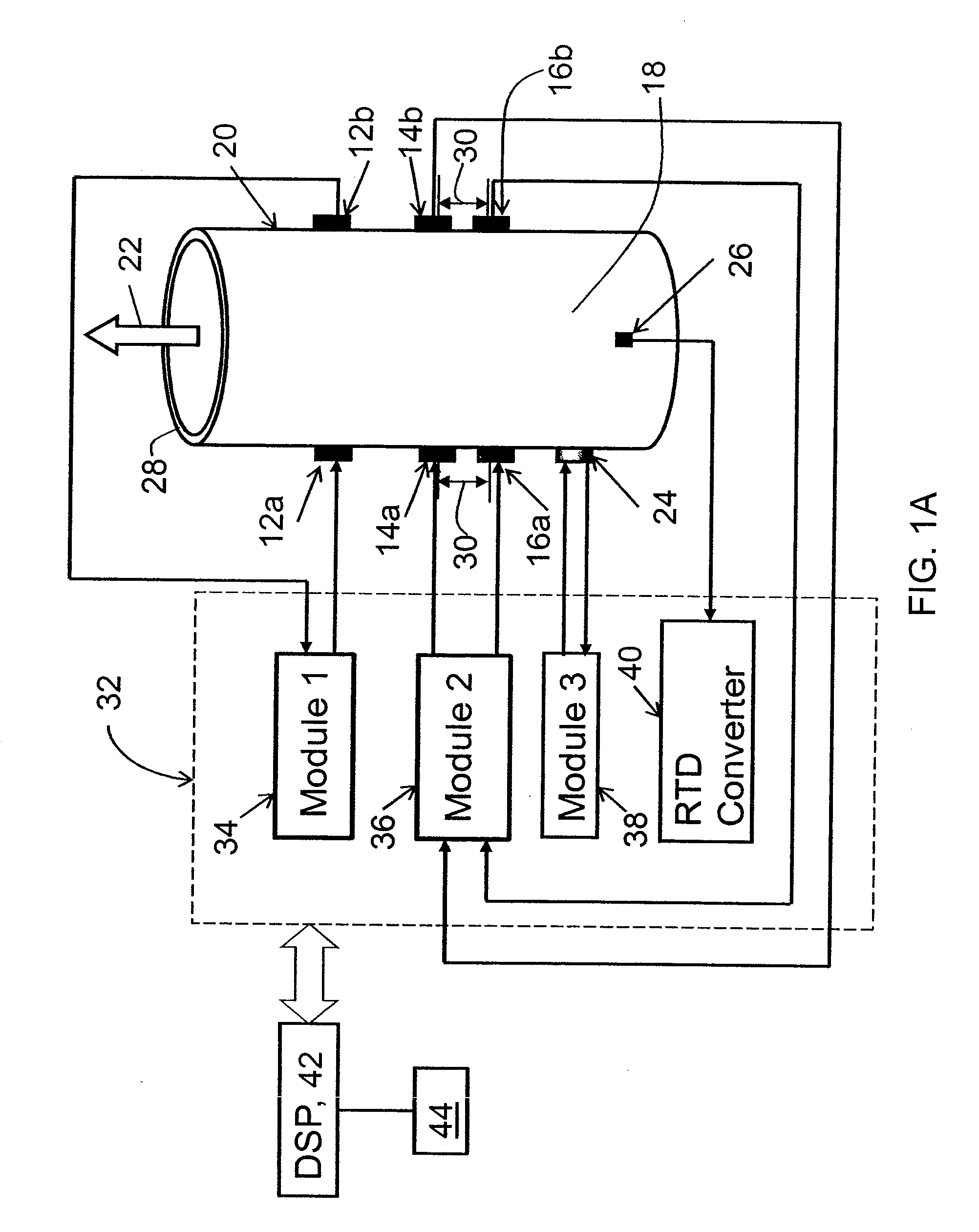

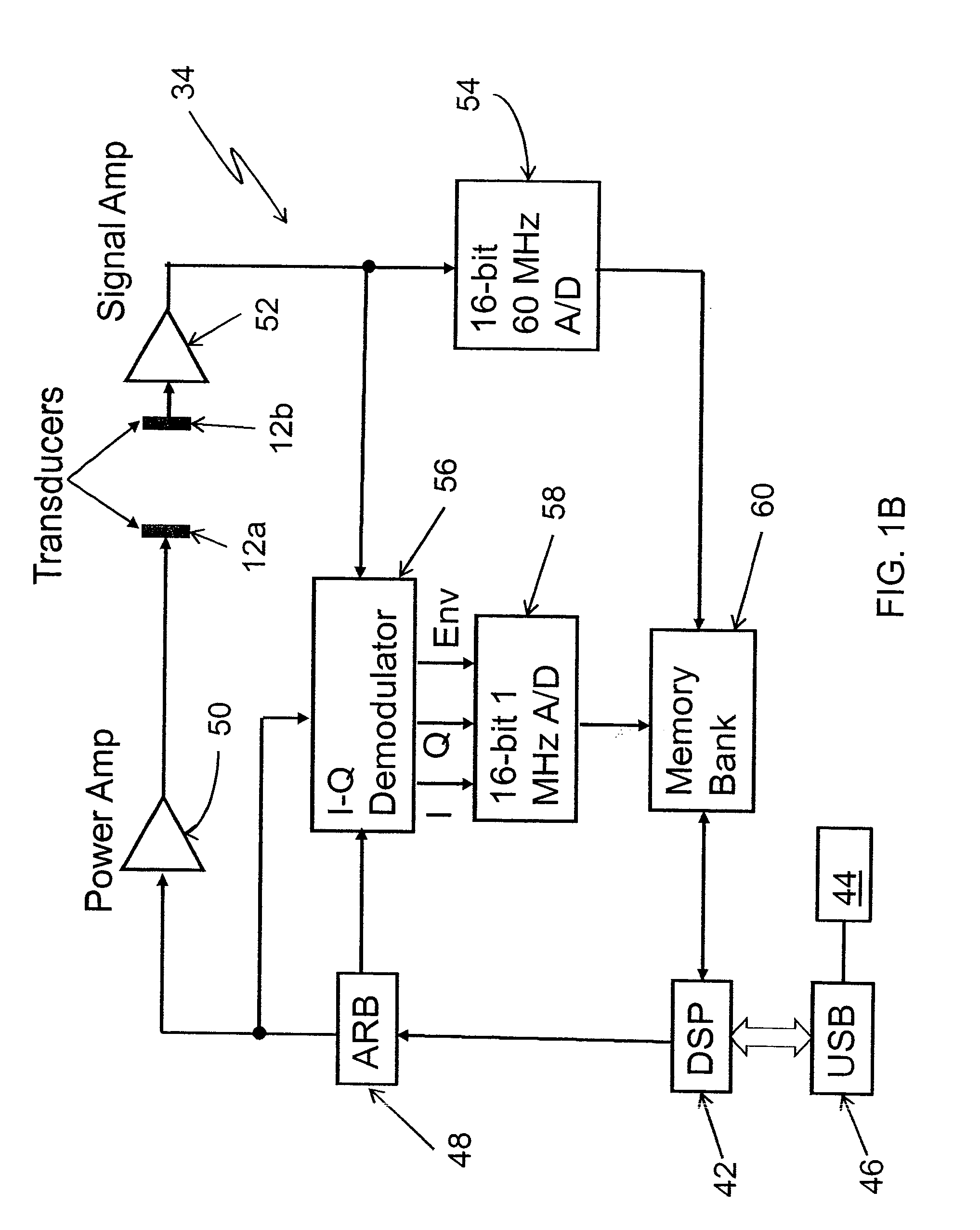

At least one parameter of at least one fluid in a pipe is measured using a spatial array of acoustic pressure sensors placed at predetermined axial locations along the pipe 12. The pressure sensors provide acoustic pressure signals, which are provided to a signal processing system that determines the speed of sound amix of the fluid (or mixture) in the pipe 12 using acoustic spatial array signal processing techniques. Numerous spatial array processing techniques may be employed to determine the speed of sound amix. The speed of sound amix is provided to another logic system that calculates the percent composition of the mixture, e.g., water fraction, or any other parameter of the mixture or fluid which is related to the sound speed amix. The signal processing system may also determine the Mach number Mx of the fluid. The acoustic pressure signals measured are lower frequency (and longer wavelength) signals than those used for ultrasonic flow meters, and thus are more tolerant to inhomogeneities in the flow. No external source is required and thus may operate using passive listening. The invention will work with arbitrary sensor spacing and with as few as two sensors if certain information is known about the acoustic properties of the system.

Owner:WEATHERFORD TECH HLDG LLC

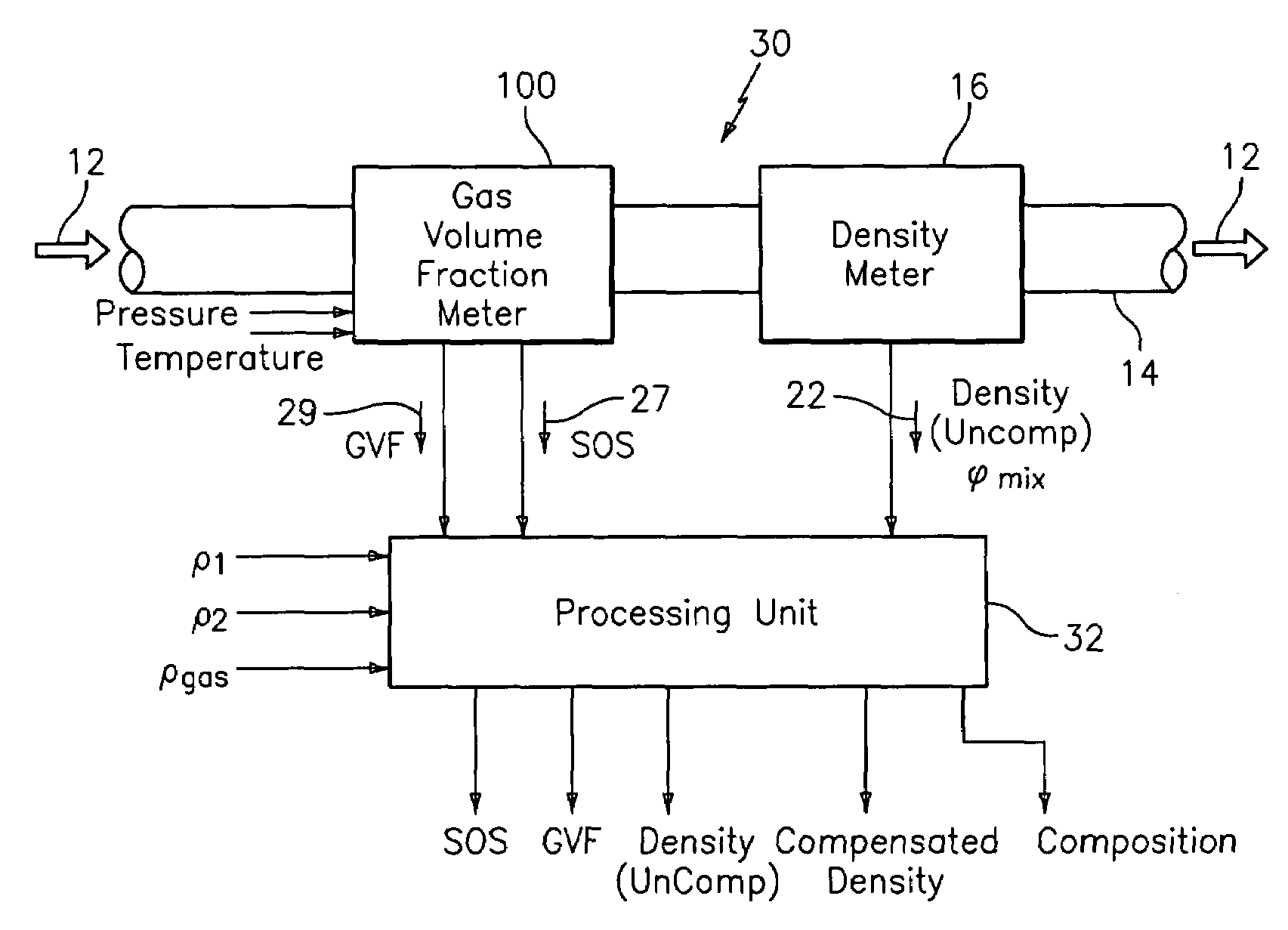

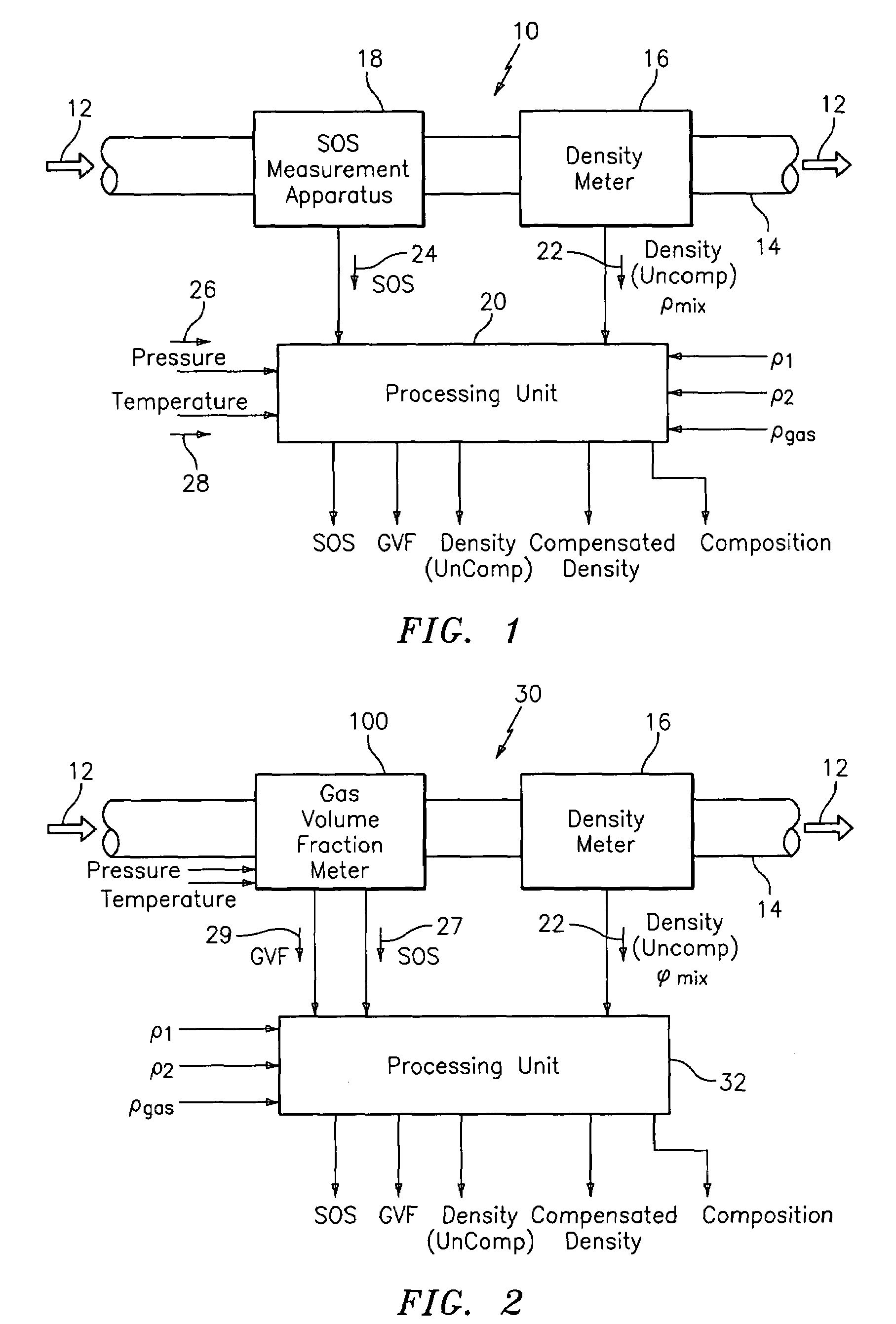

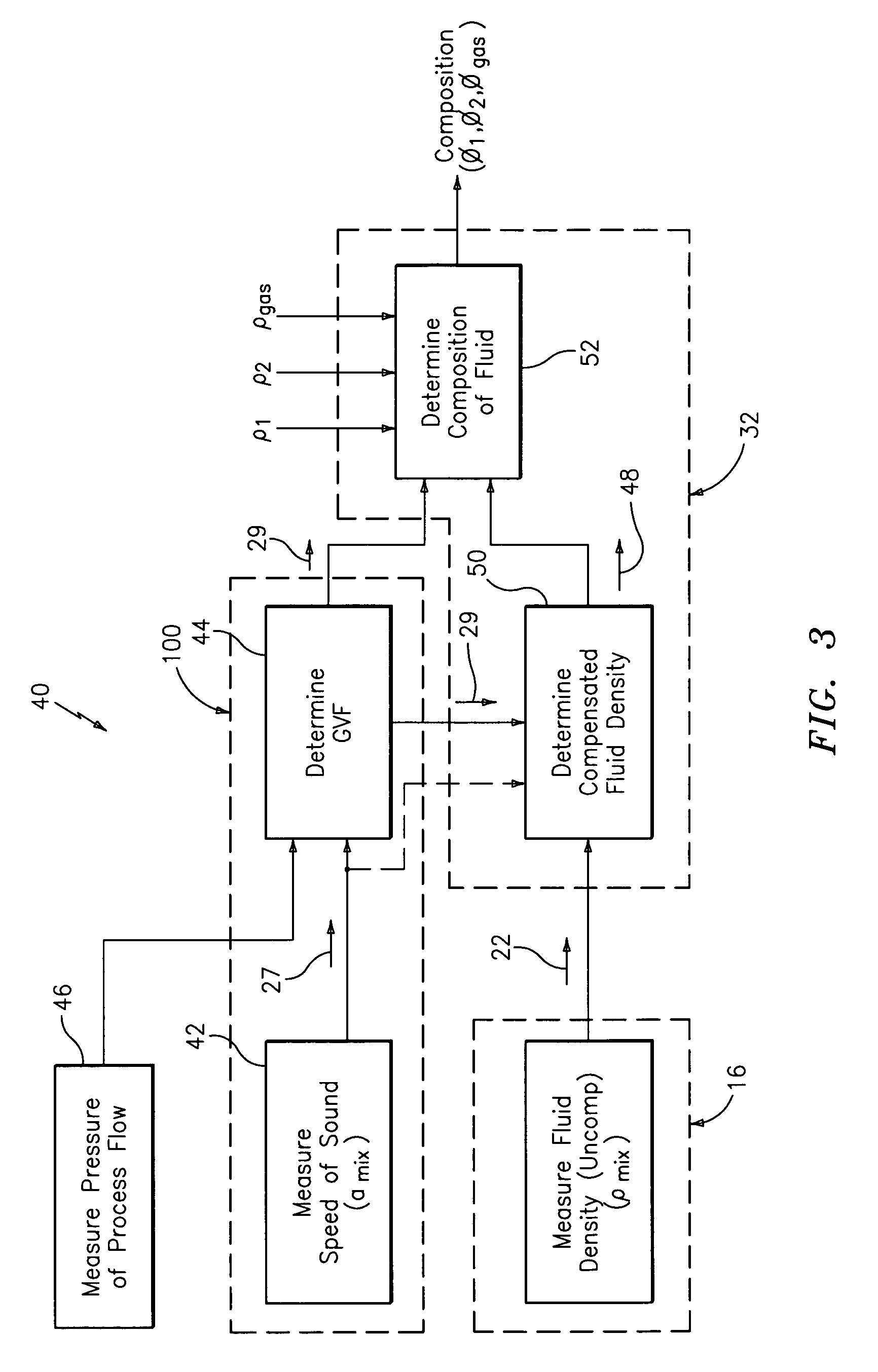

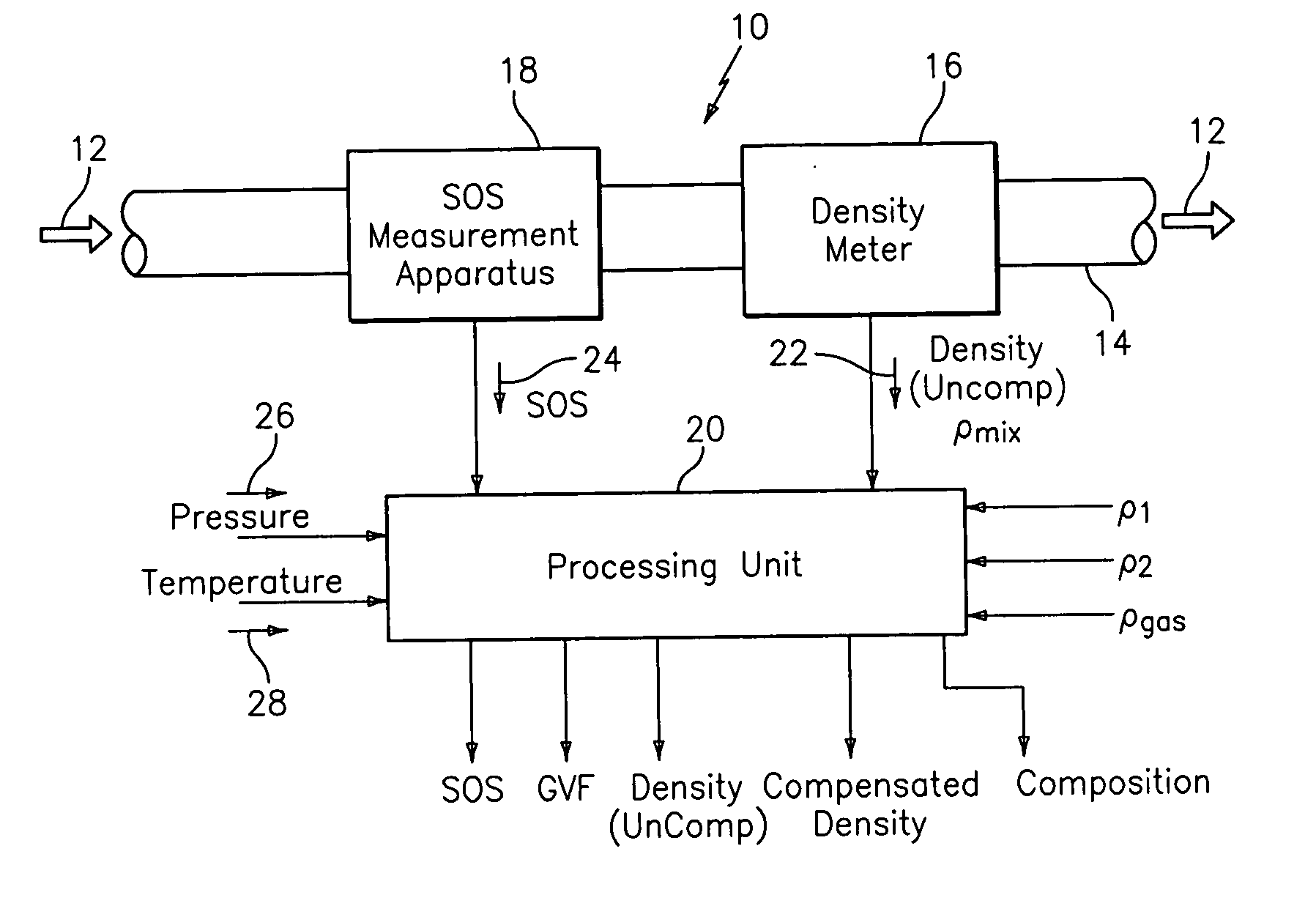

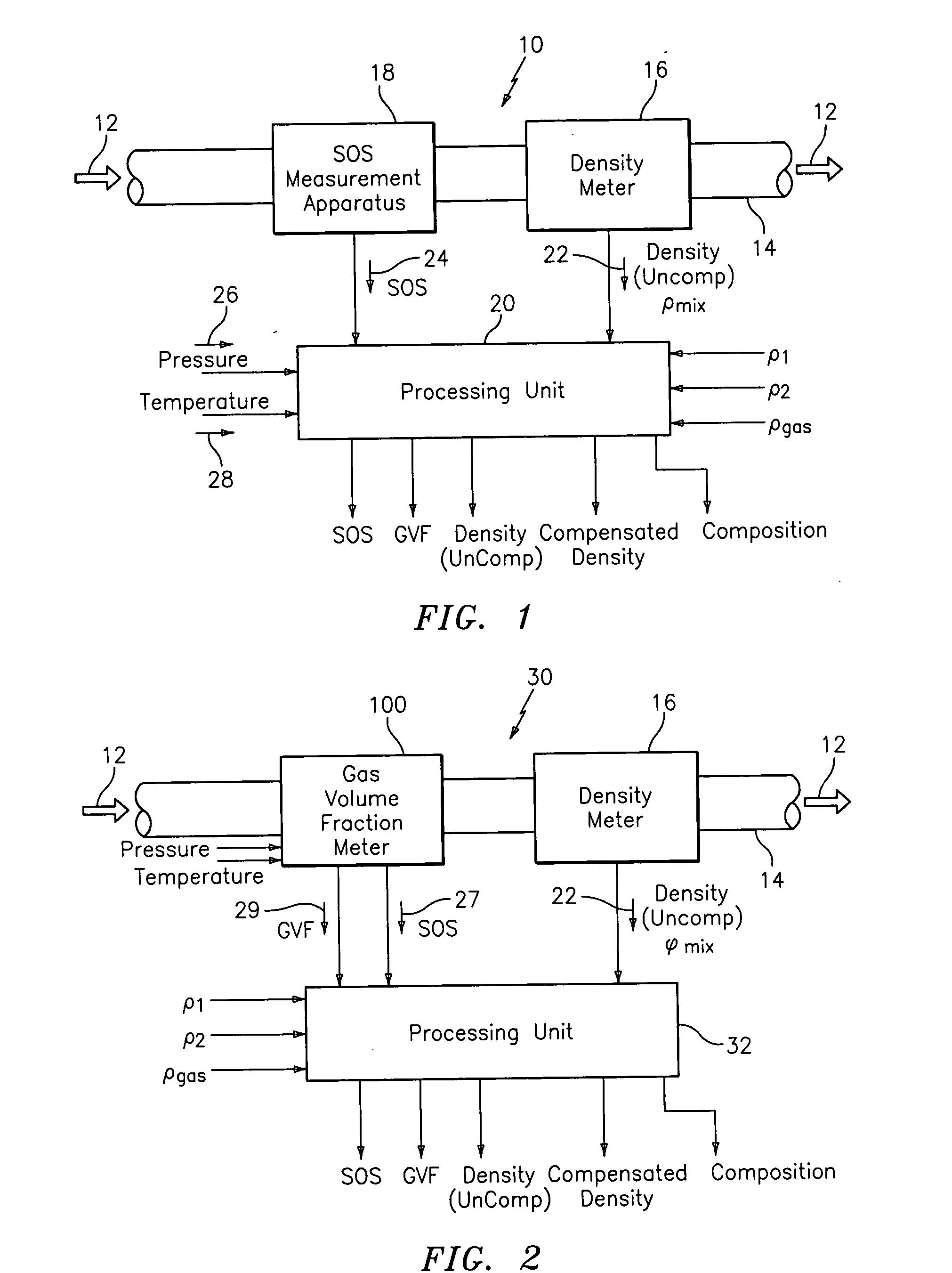

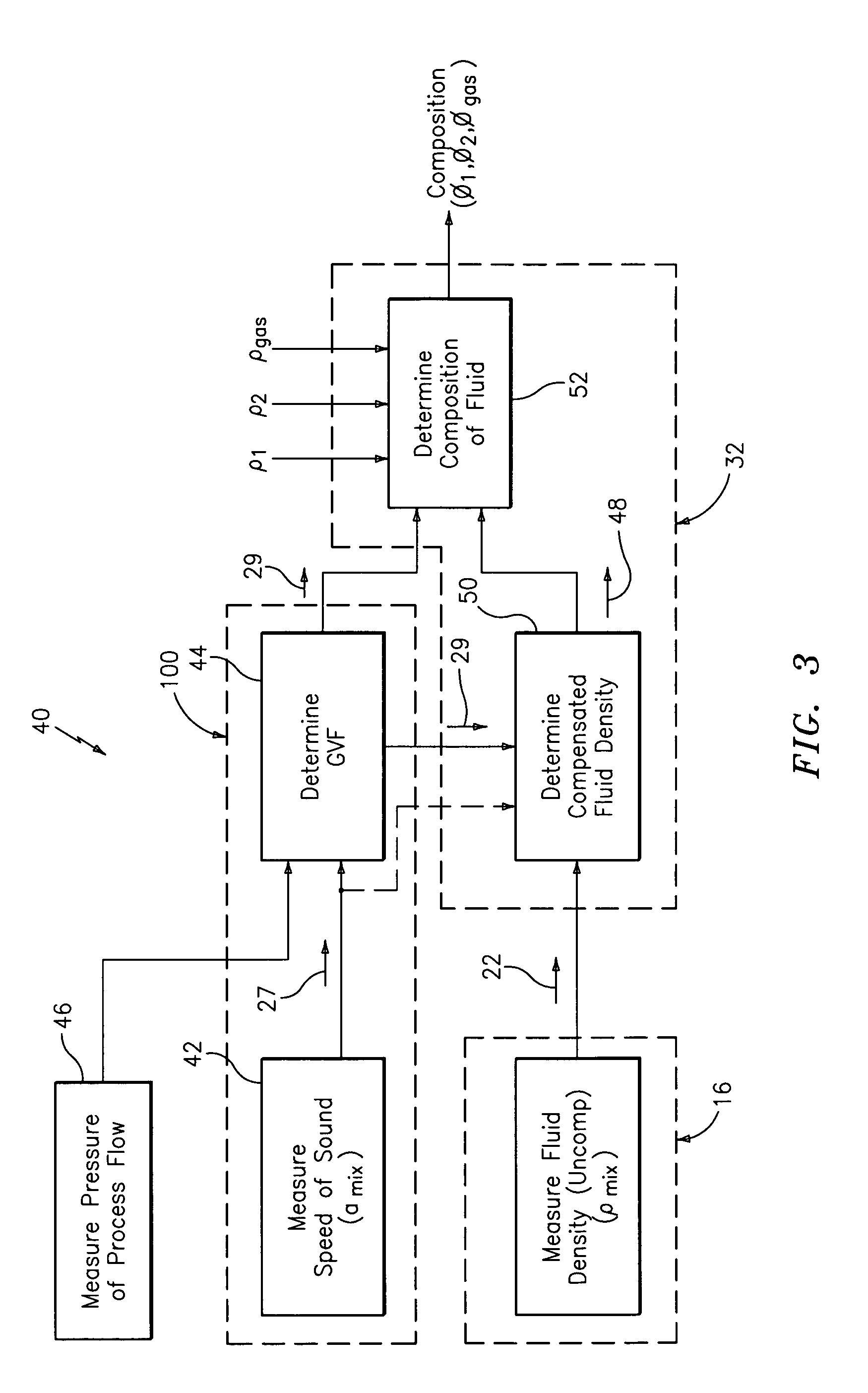

Apparatus and method for providing a density measurement augmented for entrained gas

A flow measuring system combines a density measuring device and a device for measuring the speed of sound (SOS) propagating through the fluid flow and / or for determining the gas volume fraction (GVF) of the flow. The GVF meter measures acoustic pressures propagating through the fluids to measure the speed of sound αmix propagating through the fluid to calculate at least gas volume fraction of the fluid and / or SOS. In response to the measured density and gas volume fraction, a processing unit determines the density of non-gaseous component of an aerated fluid flow. For three phase fluid flows, the processing unit can determine the phase fraction of the non-gaseous components of the fluid flow. The gas volume fraction (GVF) meter may include a sensing device having a plurality of strain-based or pressure sensors spaced axially along the pipe for measuring the acoustic pressures propagating through the flow.

Owner:EXPRO METERS

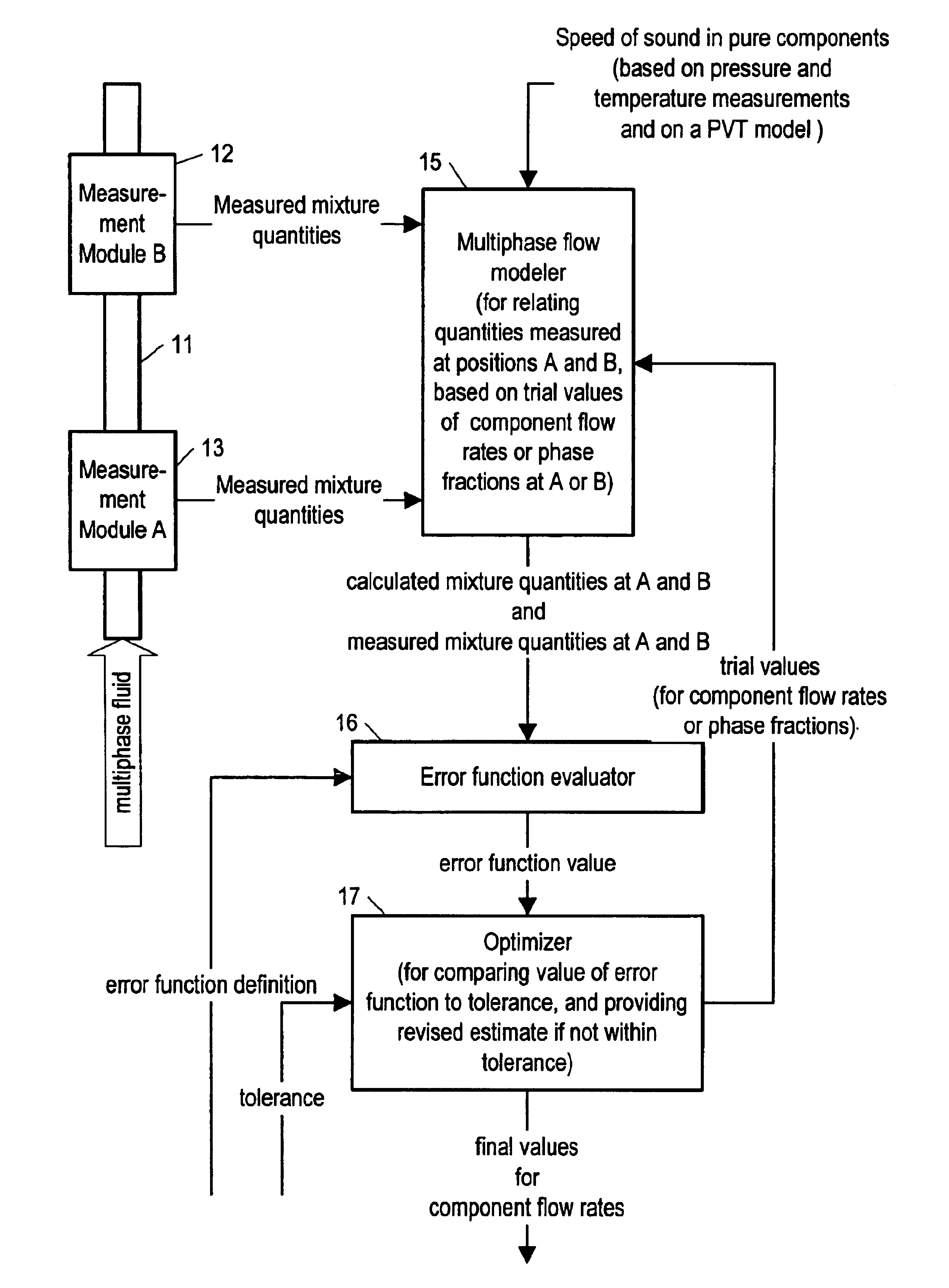

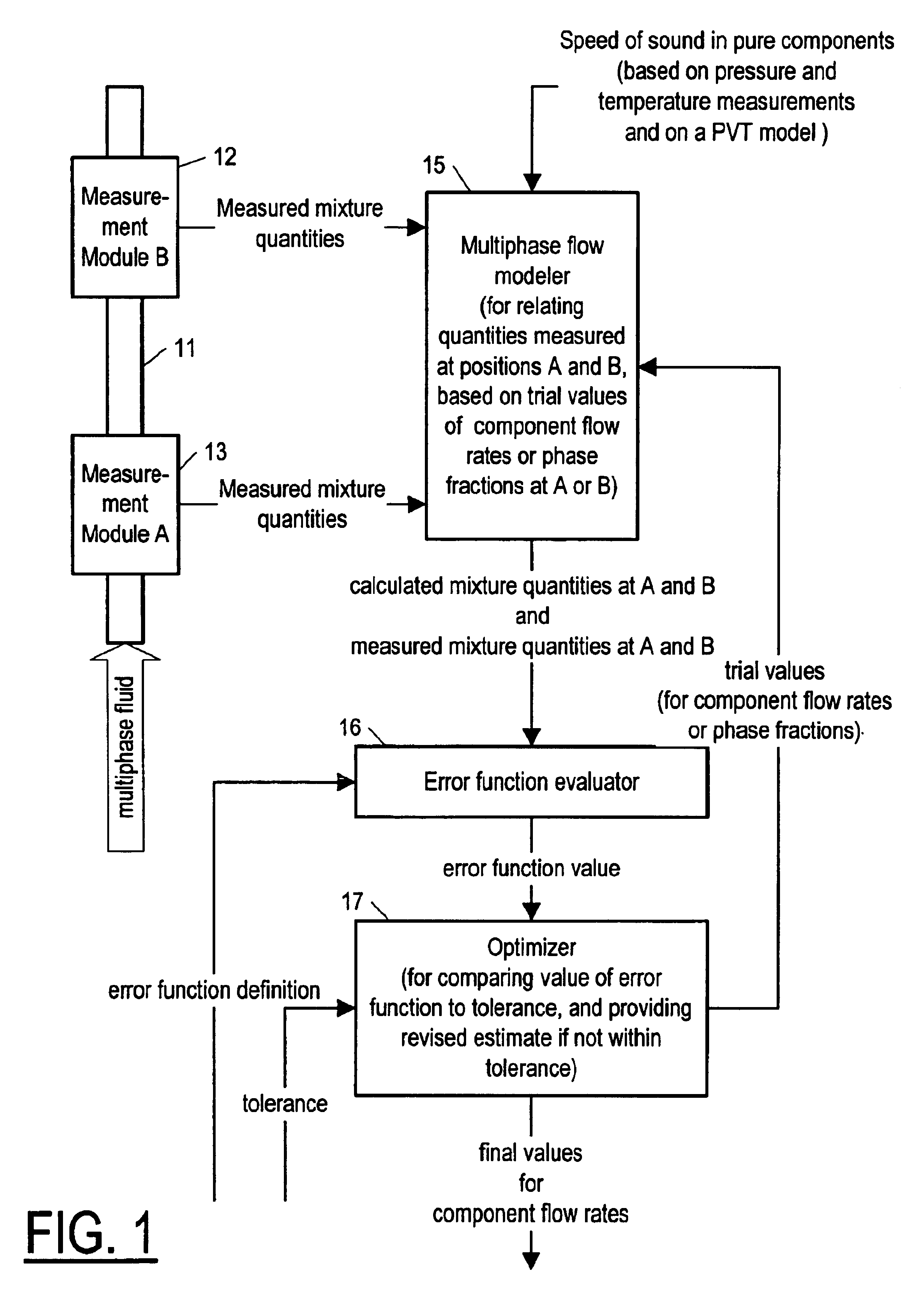

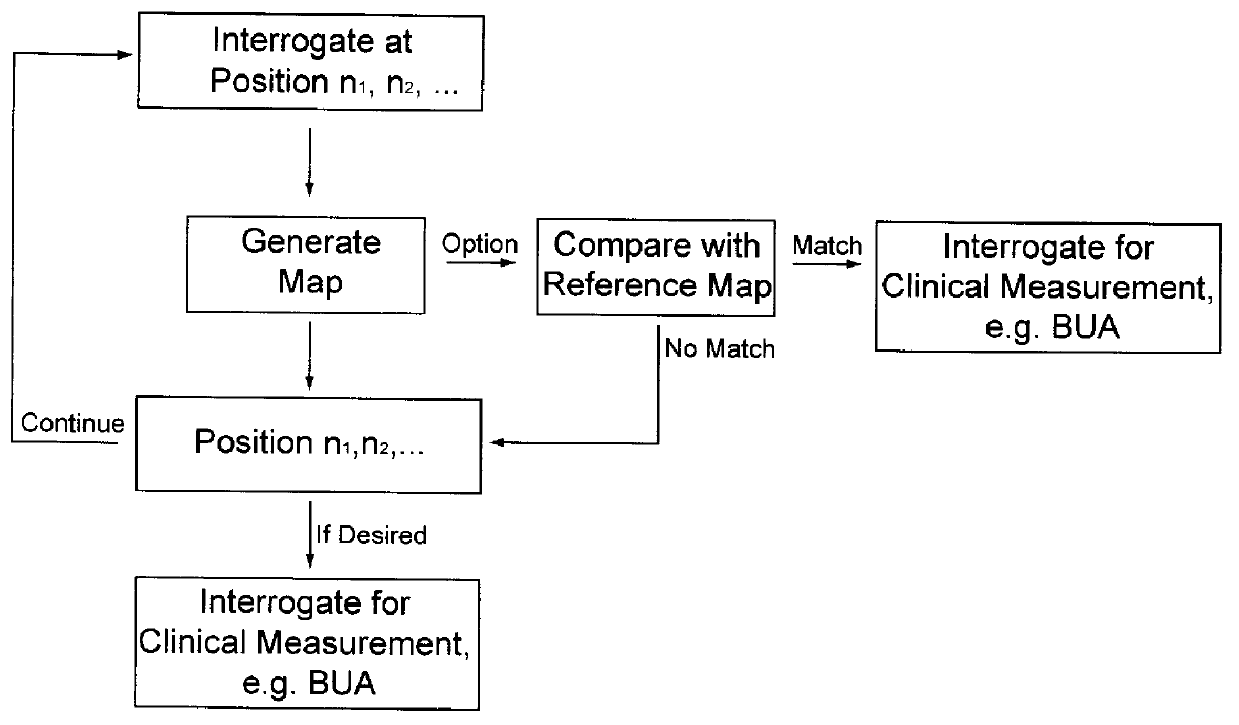

Method and apparatus for determining component flow rates for a multiphase flow

An apparatus and corresponding method for determining component flow rates of a multiphase fluid in a conduit, the fluid consisting of at least three known components, the method including the steps of: measuring at each of two different positions along the conduit at least four mixture quantities, typically the sound speed, the flow velocity of the multiphase fluid, the pressure and the temperature; providing a speed of sound in each of the components at the measured pressures and temperatures; providing a trial value for each of either the component flow rates or the phase fractions; using a predetermined model to calculate values for the measured mixture quantities based on the trial values for each of either the component flow rates or the phase fractions; using a predetermined error function to determine an error value; and using a predetermined optimizing algorithm to determine whether the calculated values are acceptable, and, if they are not, to provide a new trial value for each of either the component flow rates or the phase fractions. In some applications, the error function is the sum of the squares of the difference between the measured and calculated values at each point.

Owner:WEATHERFORD TECH HLDG LLC

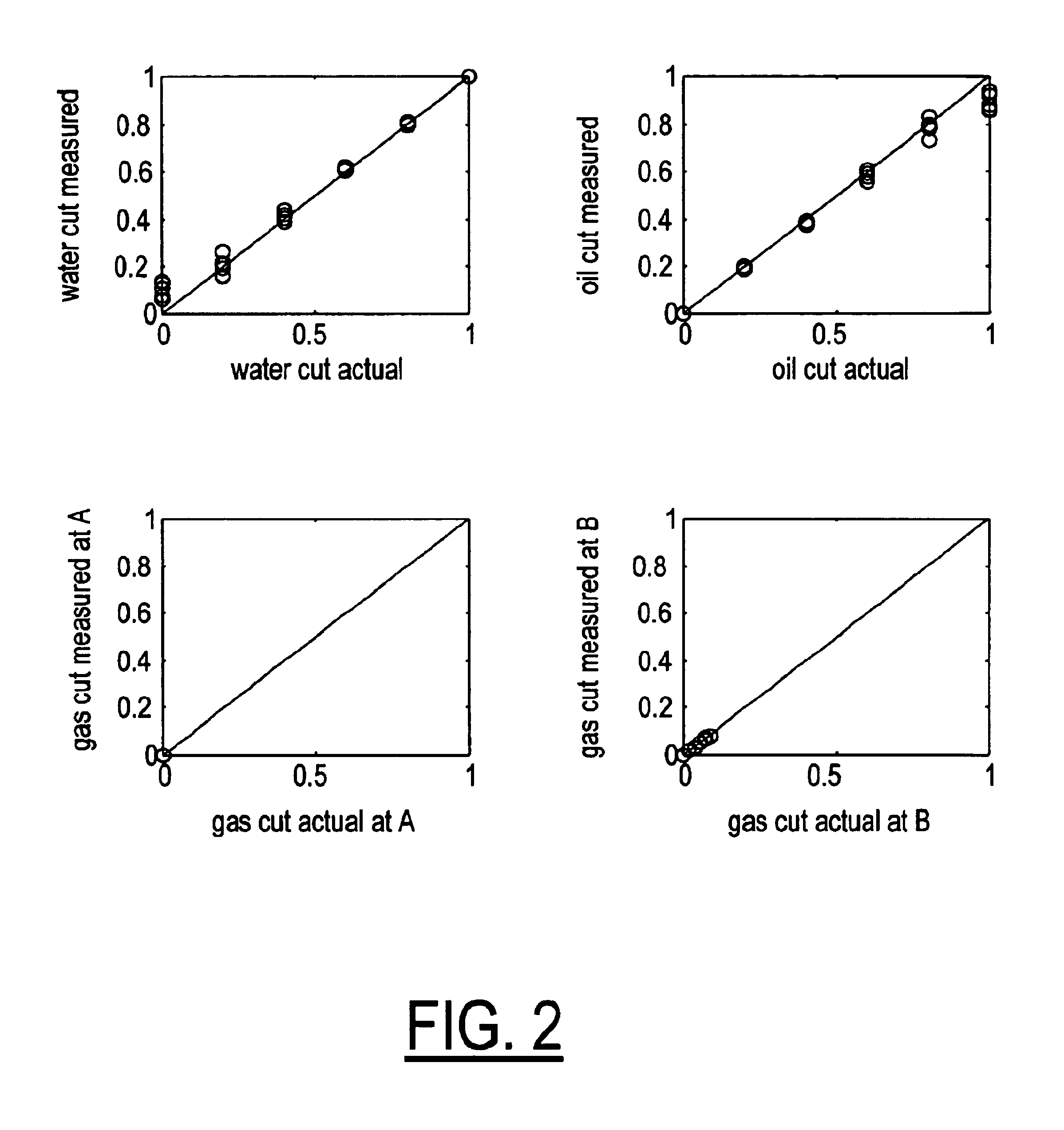

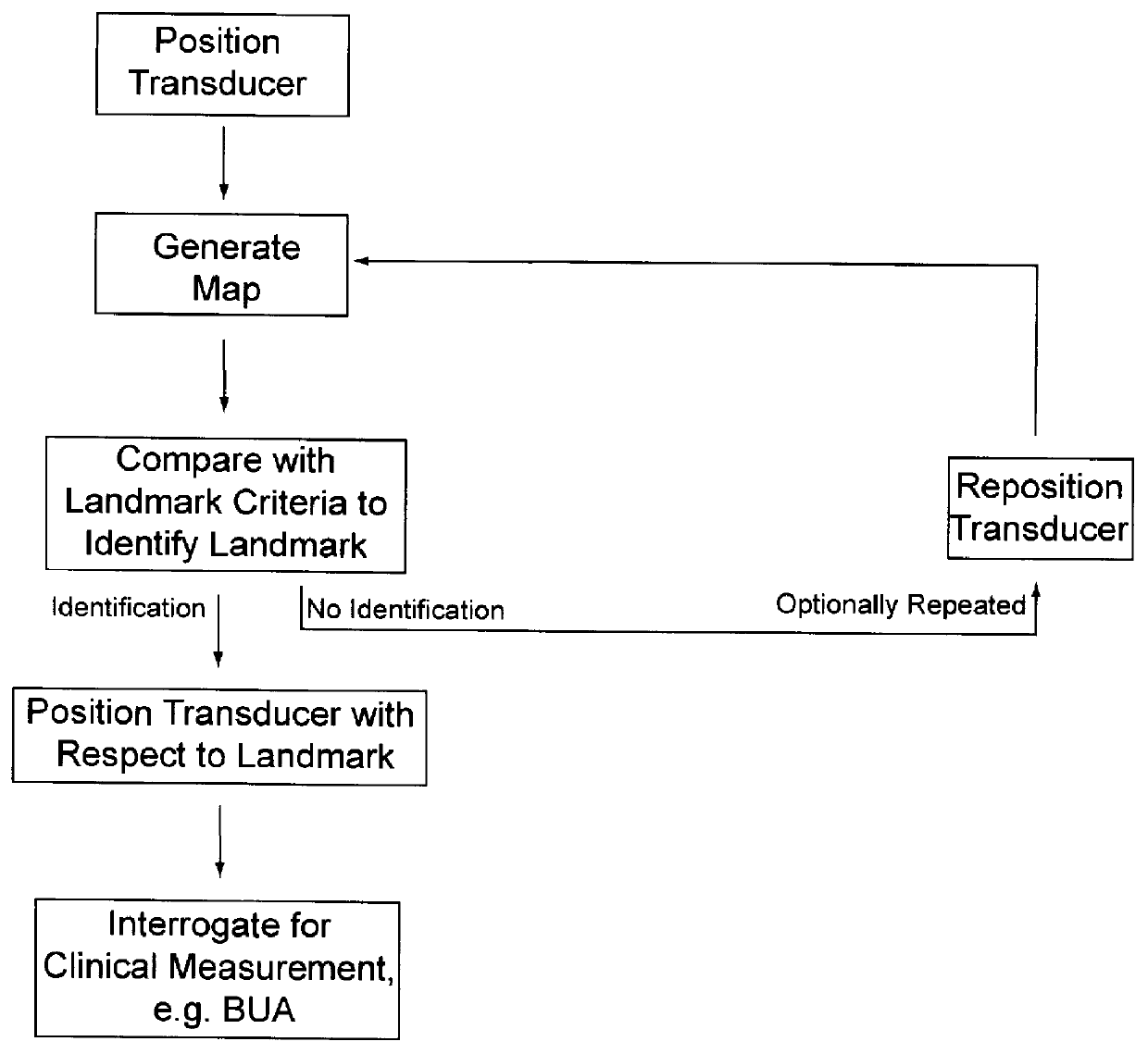

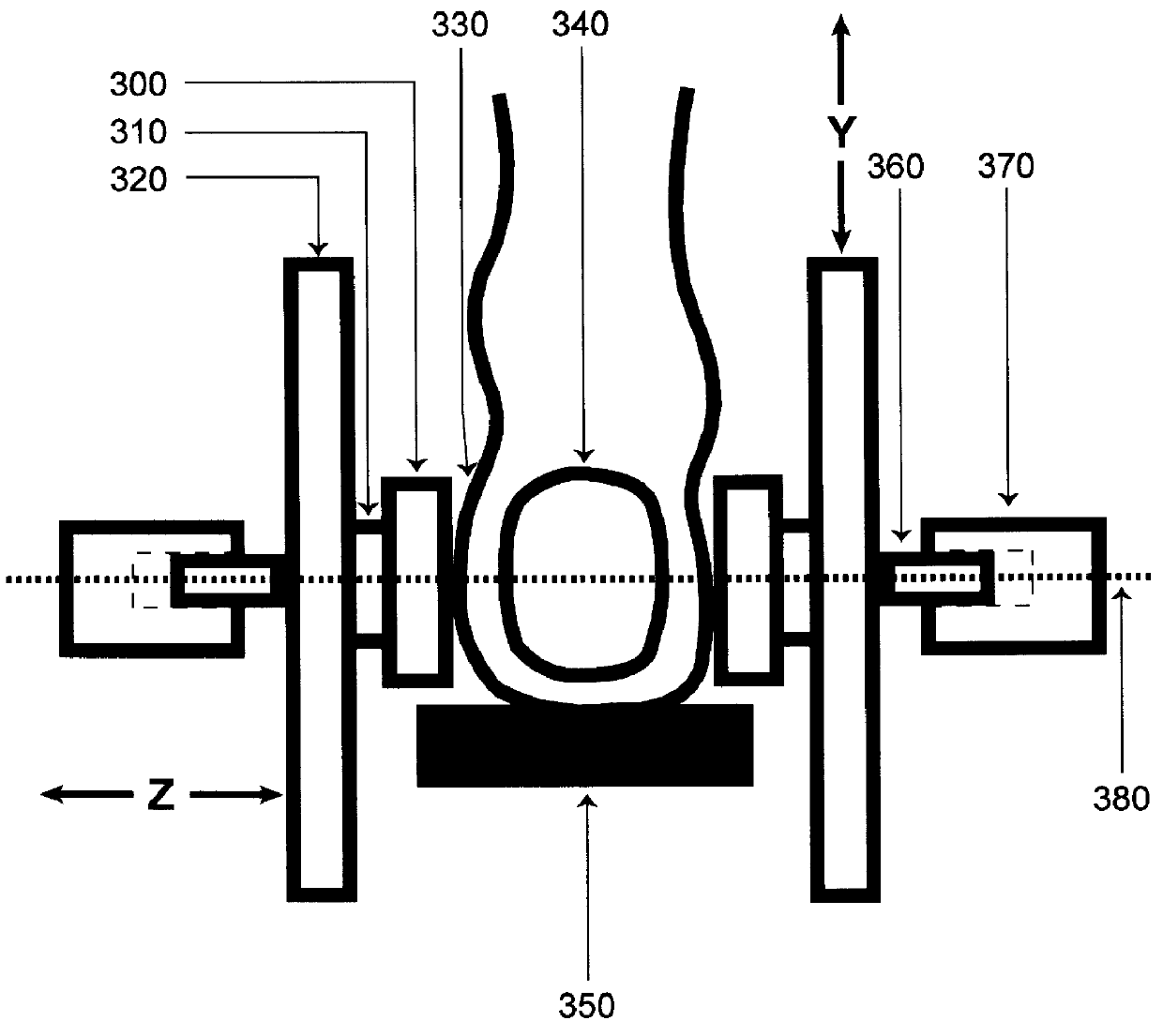

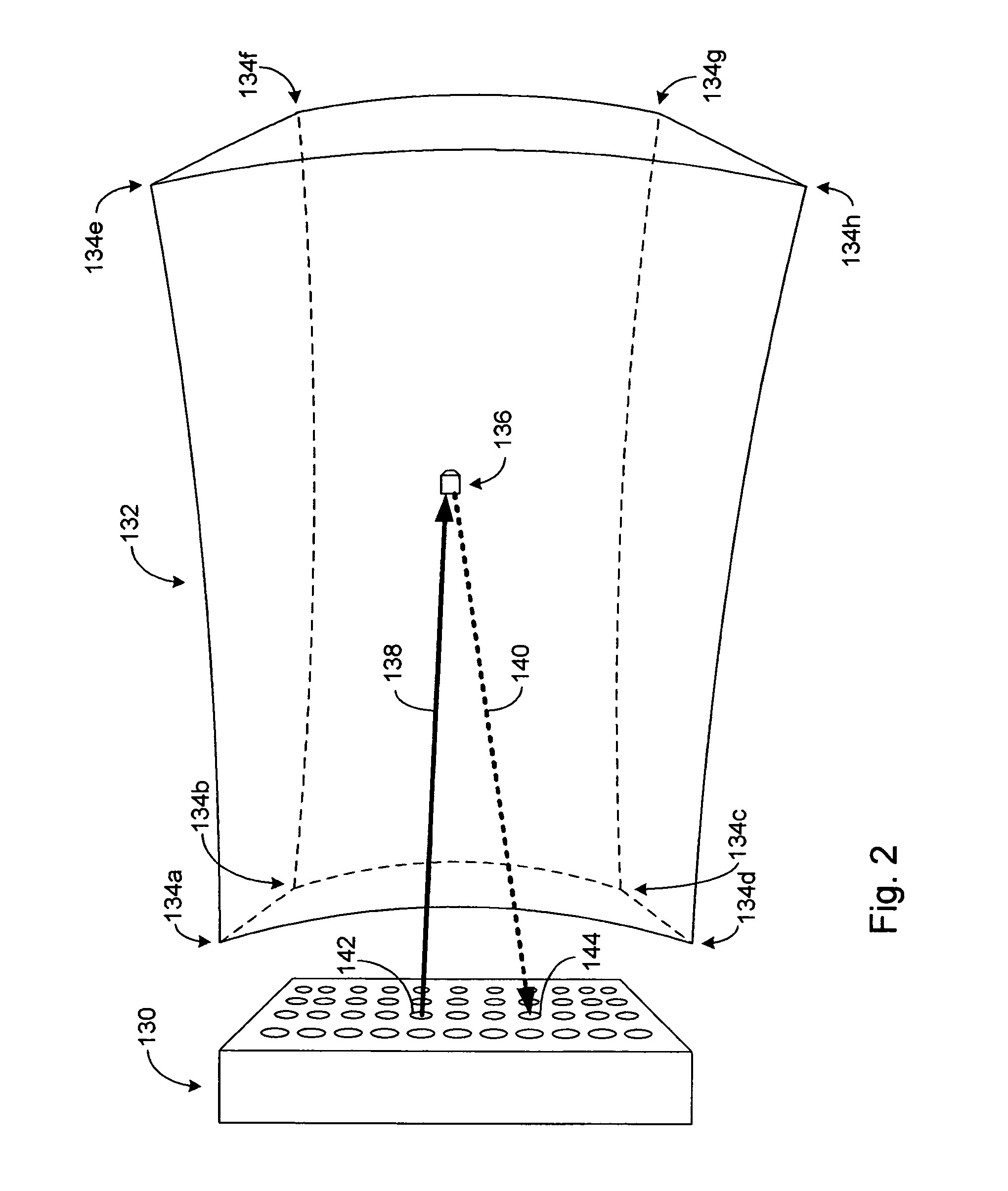

Methods and device for improving broadband ultrasonic attenuation and speed of sound measurements using anatomical landmarks

InactiveUS6077224AOrgan movement/changes detectionInfrasonic diagnosticsAnatomical landmarkSonification

The invention provides for ultrasonic methods and devices that provide for reproducible positioning of an ultrasonic transducer(s) in the heel using anatomic landmarks for broadband ultrasonic attenuation or speed of sound measurements. The invention provides for improved interrogation devices that reproducibly position transducer(s) over an interrogation site in the heel.

Owner:LANG PHILIPP +1

Apparatus and method for providing a density measurement augmented for entrained gas

ActiveUS20050061060A1Improve accuracySpecific gravity using flow propertiesVolume/mass flow by dynamic fluid flow effectThree-phaseDischarge measurements

A flow measuring system combines a density measuring device and a device for measuring the speed of sound (SOS) propagating through the fluid flow and / or for determining the gas volume fraction (GVF) of the flow. The GVF meter measures acoustic pressures propagating through the fluids to measure the speed of sound αmix propagating through the fluid to calculate at least gas volume fraction of the fluid and / or SOS. In response to the measured density and gas volume fraction, a processing unit determines the density of non-gaseous component of an aerated fluid flow. For three phase fluid flows, the processing unit can determine the phase fraction of the non-gaseous components of the fluid flow. The gas volume fraction (GVF) meter may include a sensing device having a plurality of strain-based or pressure sensors spaced axially along the pipe for measuring the acoustic pressures propagating through the flow.

Owner:EXPRO METERS

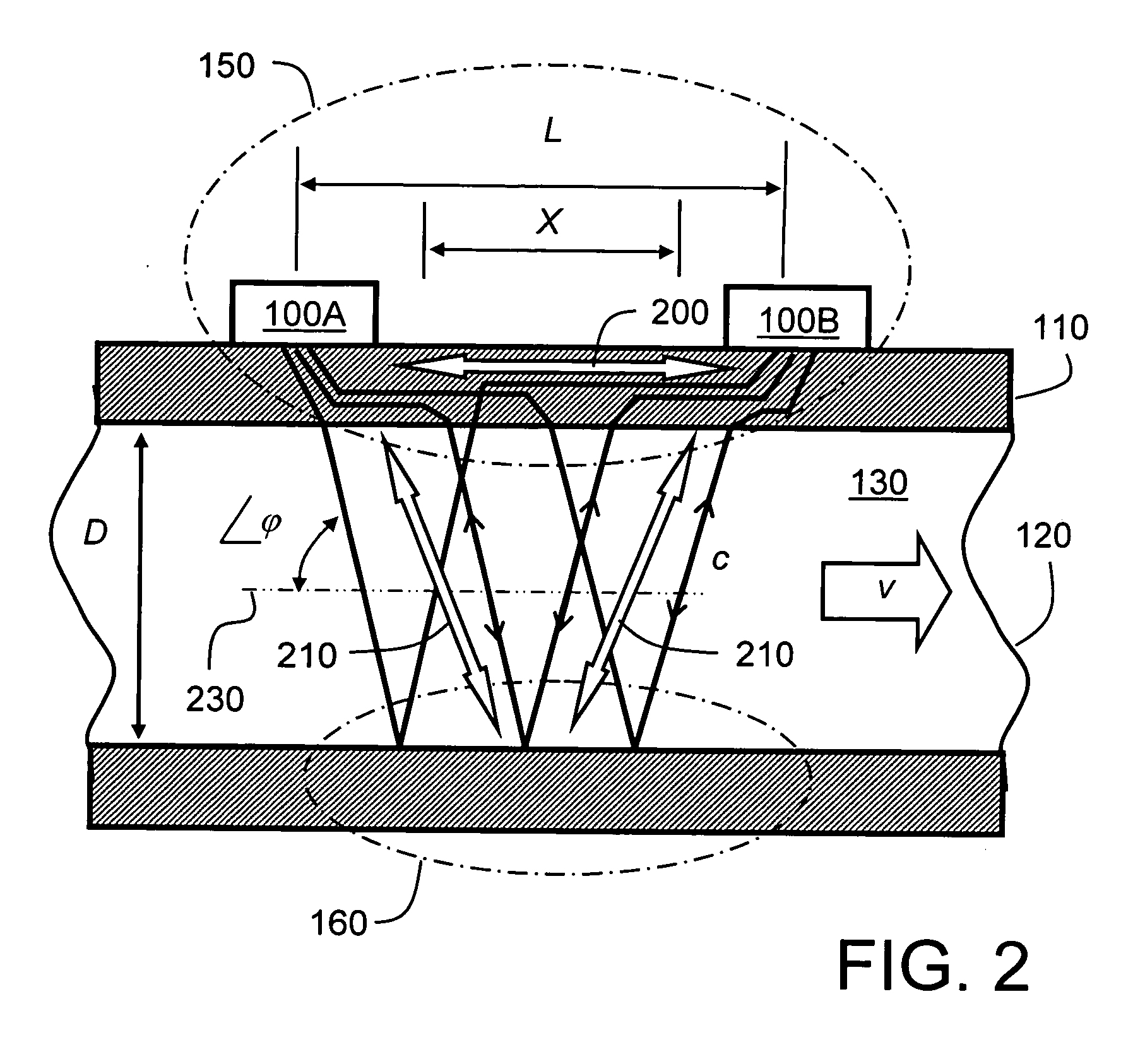

Flow measuring apparatus

ActiveUS20110271769A1Reliable and accurate measurementImprove energy transferFlow propertiesVolume flow measuring devicesPropagation timeUltrasonic radiation

A flow measuring apparatus (300, 500) measures a fluid flow (130) within a conduit (120) including a wall (110). The apparatus (300, 500) includes a transducer arrangement including at least two transducers (100A, 100B) for alternately emitting and receiving ultrasonic radiation through the conduit wall (110) and the flow (130). The apparatus (300, 500) also includes a signal processing arrangement (310) for generating signals to excite the transducer arrangement (100A, 100B) and for processing received signals provided by the transducer arrangement (100A, 100B) for generating output signals from the signal processing arrangement (310) indicative of properties of the flow. The transducer arrangement (100A, 100B) in cooperation with the conduit (120) provides a first path (200) for Lamb-wave ultrasonic radiation coupling directly from a first of the at least two transducers (100A, 100B), to a second of said at least two transducers to generate a first received signal. The transducer arrangement (100A, 100B) in cooperation with the conduit (120) provides at least one second path (210) for ultrasonic propagation along the wall (100) via Lamb waves coupling to at least a portion of the flow (130) from a first of the at least two transducers (100A, 100B) to a second of the at least two transducers (100A, 100B) to generate a second received signal. The signal processing arrangement (310) determines from said first and second received signals ultrasonic radiation propagation time periods through the first path (200) and through the at least one second path (210), and to perform computational operations on the propagation time periods to determine properties of the flow including, but not limited to, at least one of: fluid flow velocity (v) in the conduit (120), a sound velocity (c) through the fluid (130).

Owner:XSENS

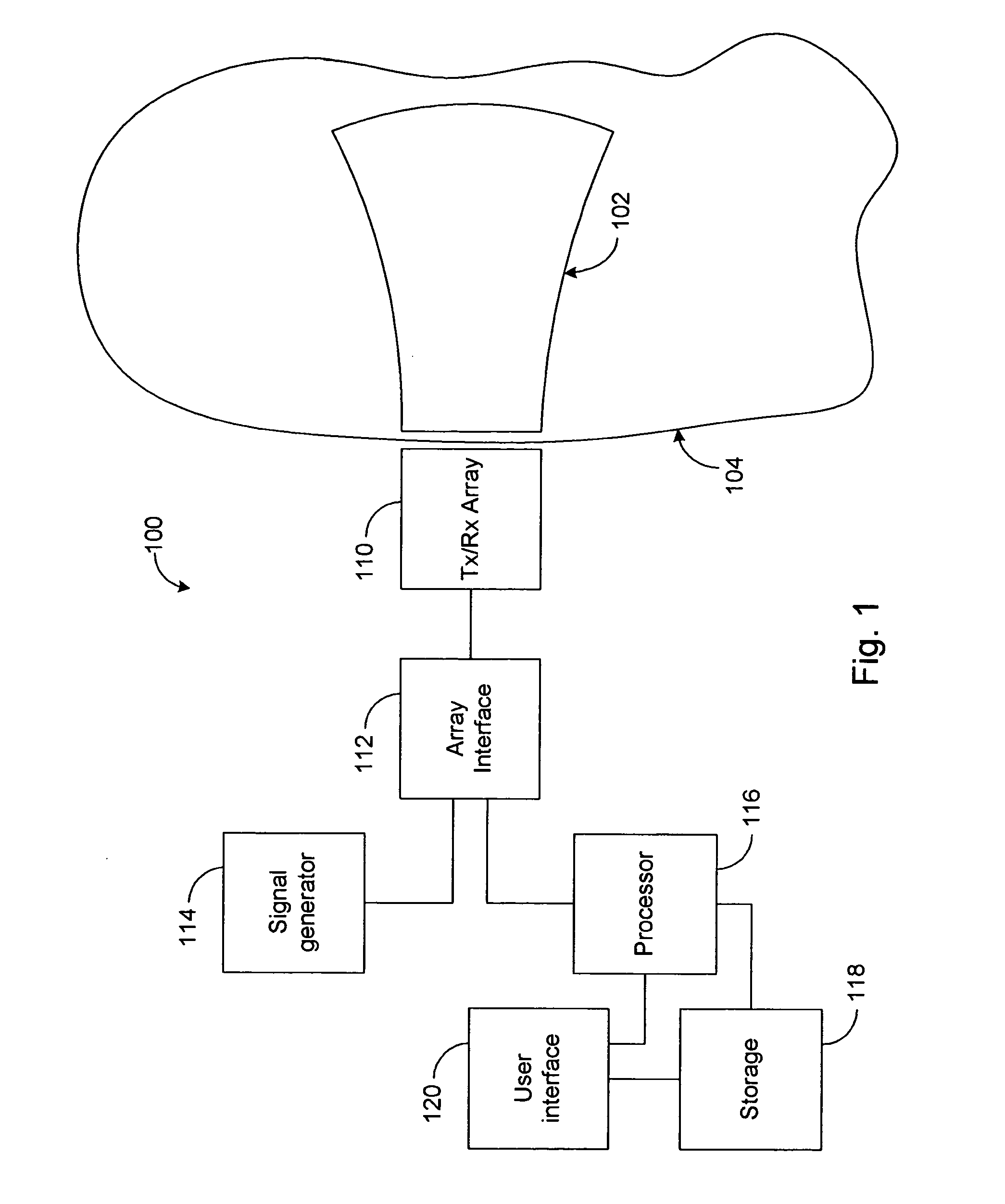

Systems and methods for ultrasound imaging

InactiveUS7862508B2Improve resolutionQuality improvementOrgan movement/changes detectionInfrasonic diagnosticsUltrasound imagingSonification

Systems and methods are disclosed for improving the resolution and quality of an image formed by signals from an array of receivers. Multiple receivers introduce variations in arrival times that can be less than the period of an operating signal, and also less than the period associated with a sampling operation. Thus, multiple receivers allow sampling of fine features of reflected signals that would be considered beyond the resolution associated with the operating signal. Use of multiple receivers also provides an effective sampling rate that is greater than the sampling rate of an individual receiver. Similar advantages can be obtained using multiple transmitters. Such advantageous features can be used to obtain high resolution images of objects in a medium in applications such as ultrasound imaging. Sub-Nyquist sampling is discussed. Accounting for the effects of refraction on pathlengths as a signal passes between two regions of different sound speed allows improved calculation of focus distances. Extending the analysis to account for additional layers or sub-layers allows further improvement.

Owner:CARESTREAM HEALTH INC

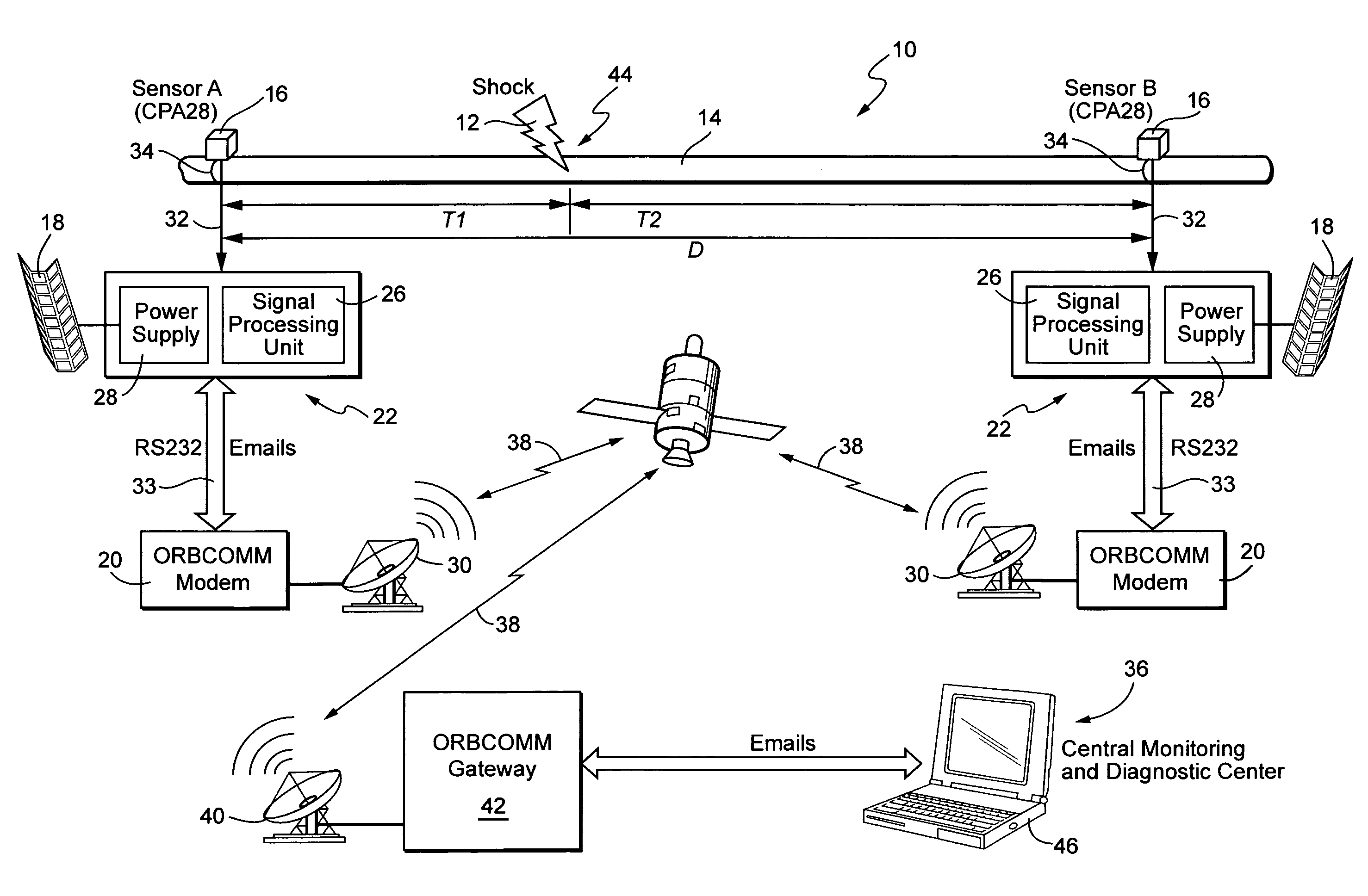

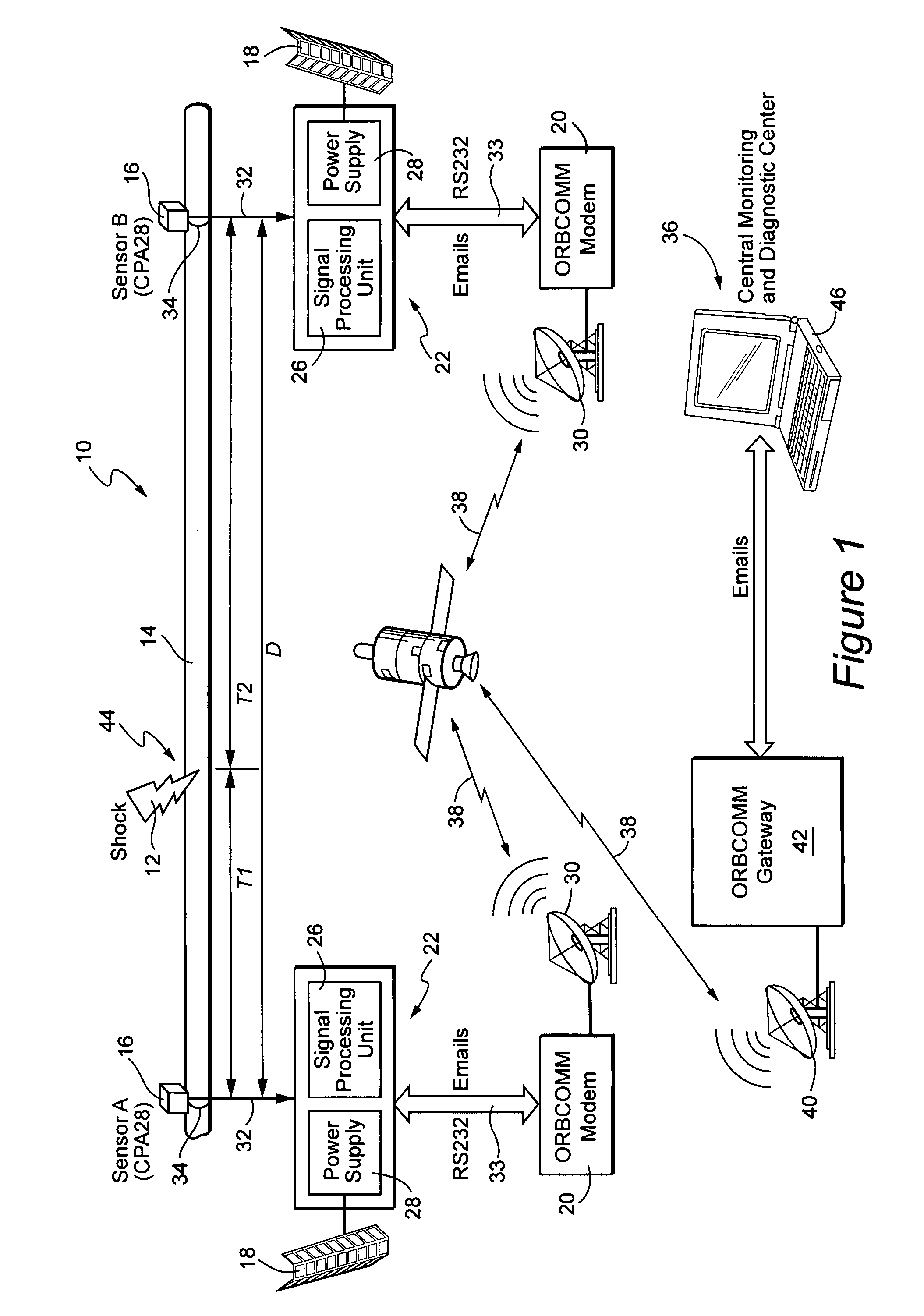

Acoustic impact detection and monitoring system

ActiveUS7607351B2Cost effectiveQuick checkMultiple-port networksVibration measurement in fluidHydrophoneTelecommunications link

A system is disclosed for detecting and locating harmful impacts to pipelines using sensors placed along the pipeline. The exact spacing of sensors is site specific and is set with the goal of maximizing sensor spacing without reducing system performance and reliability. At each sensor location, preferably there are four basic components, i.e., a hydrophone, solar power components, and data processing and communications equipment. Each hydrophone directly measures the acoustic noise fluctuation in a pipe section, which propagates at long distances in the pipeline at the specific speed of sound for the particular type of pipe. If specific signal parameters exceed a programmed threshold, a detection message is generated and transmitted via a communications link to a central monitoring and diagnostic center.

Owner:GENERAL ELECTRIC CO

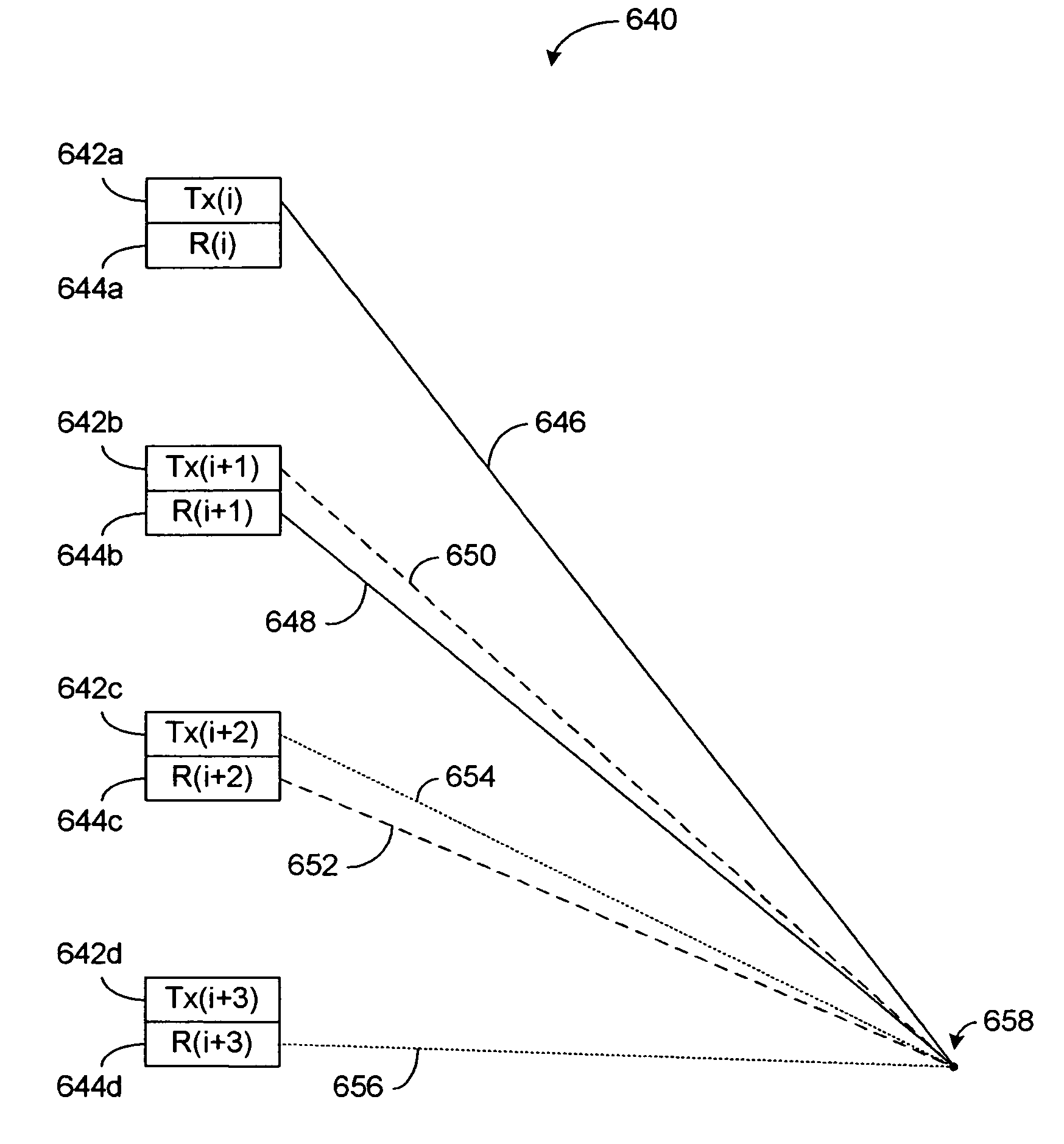

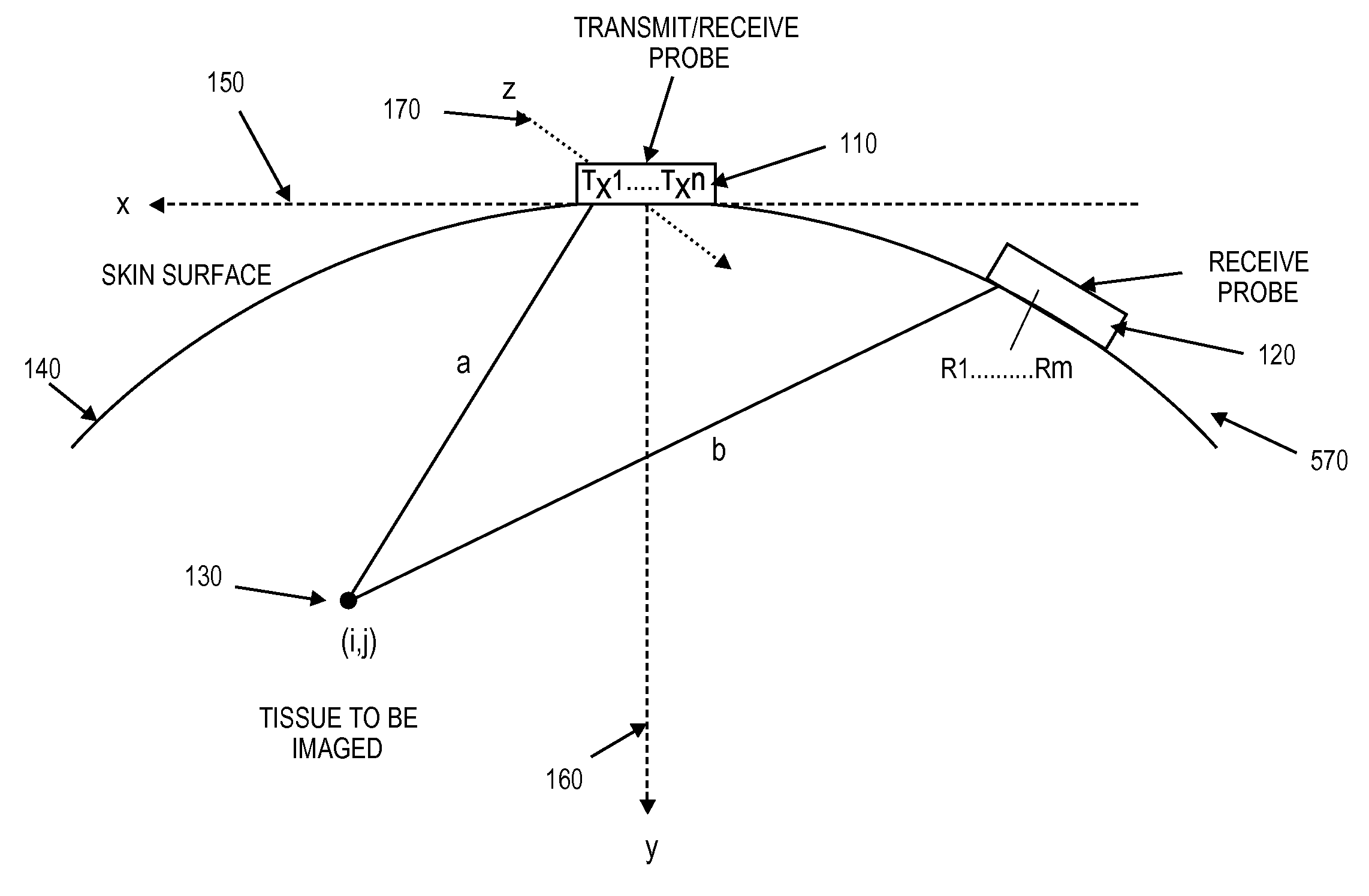

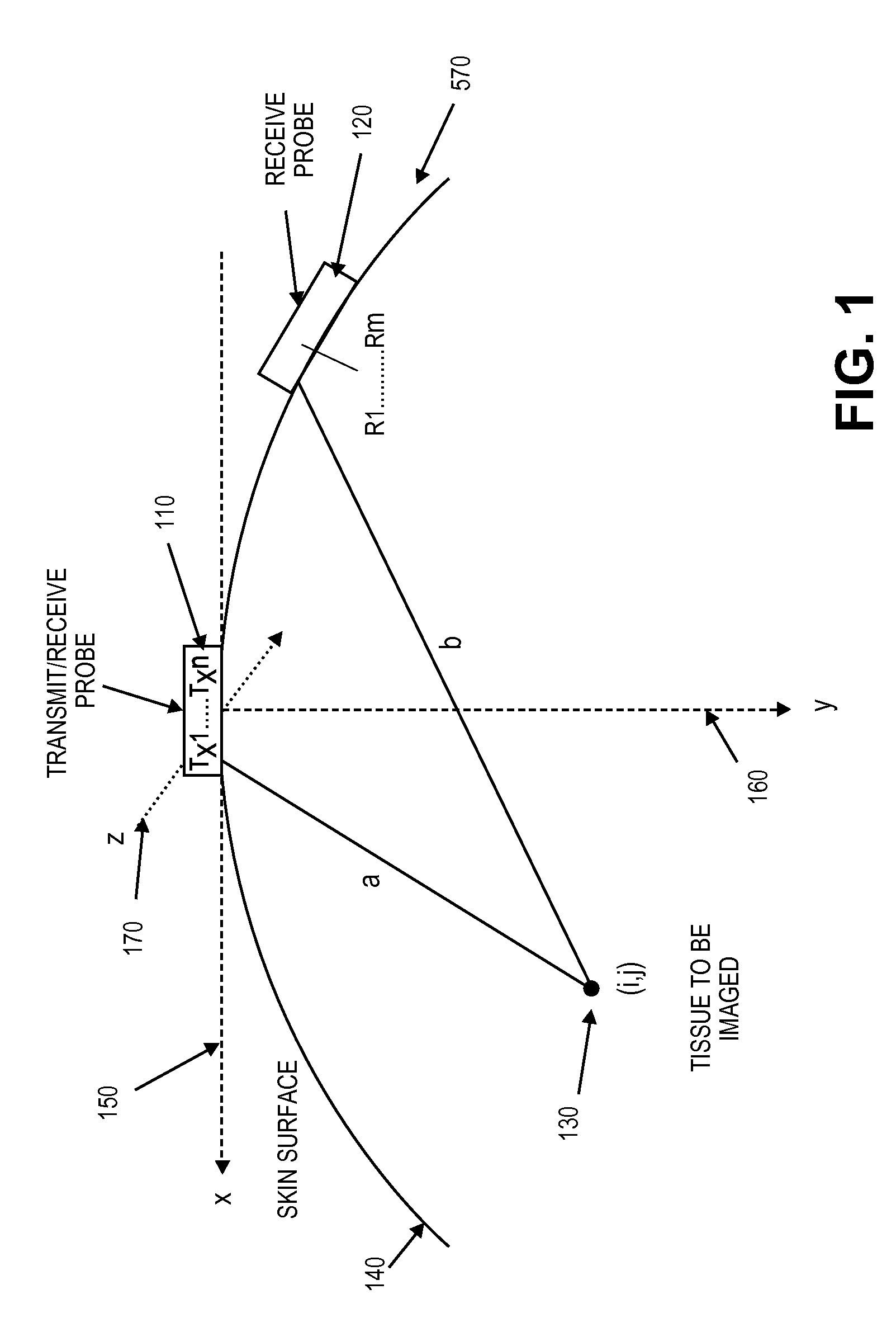

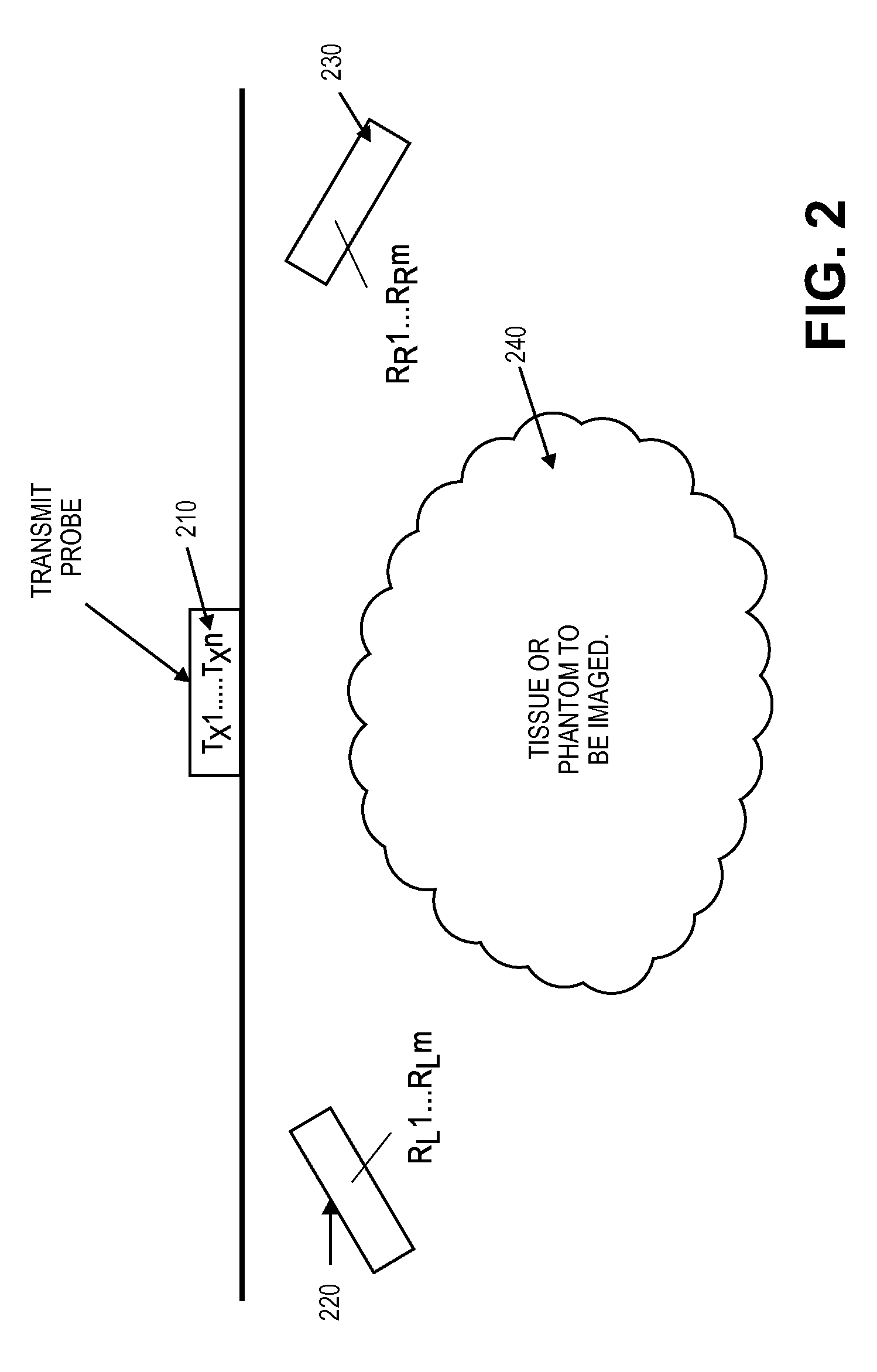

Universal Multiple Aperture Medical Ultrasound Probe

InactiveUS20100262013A1Material analysis using sonic/ultrasonic/infrasonic wavesOrgan movement/changes detectionUltrasonographyPhysical point

A Multiple Aperture Ultrasound Imaging (MAUI) probe or transducer is uniquely capable of simultaneous imaging of a region of interest from separate physical apertures. Construction of probes can vary by medical application. That is, a general radiology probe can contain multiple transducers that maintain separate physical points of contact with the patient's skin, allowing multiple physical apertures. A cardiac probe may contain only two transmitters and receivers where the probe fits simultaneously between two or more intracostal spaces. An intracavity version of the probe can space transmit and receive transducers along the length of the wand, while an intravenous version can allow transducers to be located on the distal length the catheter and separated by mere millimeters. Algorithms can solve for variations in tissue speed of sound, thus allowing the probe apparatus to be used virtually anywhere in or on the body.

Owner:MAUI IMAGING

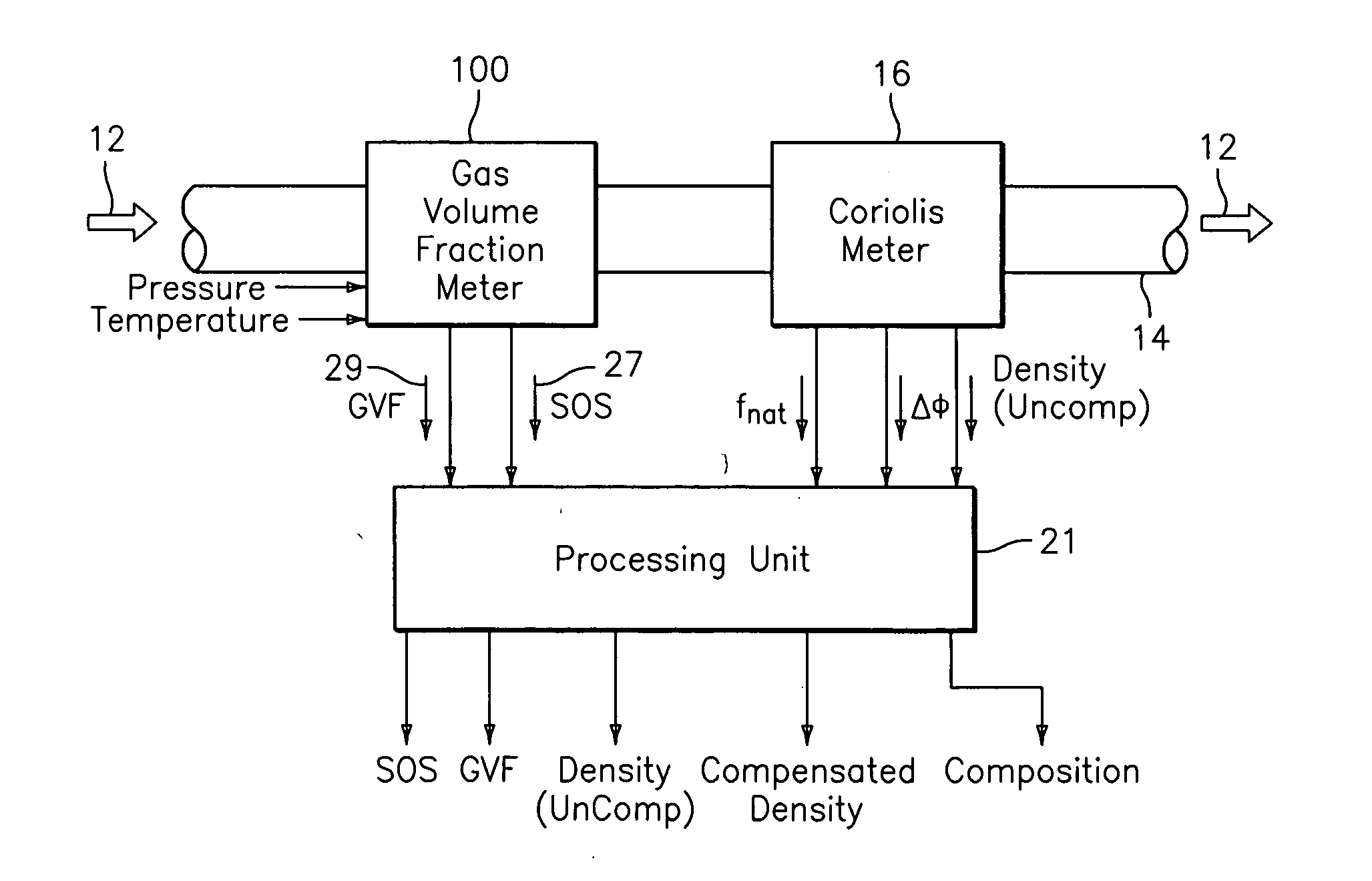

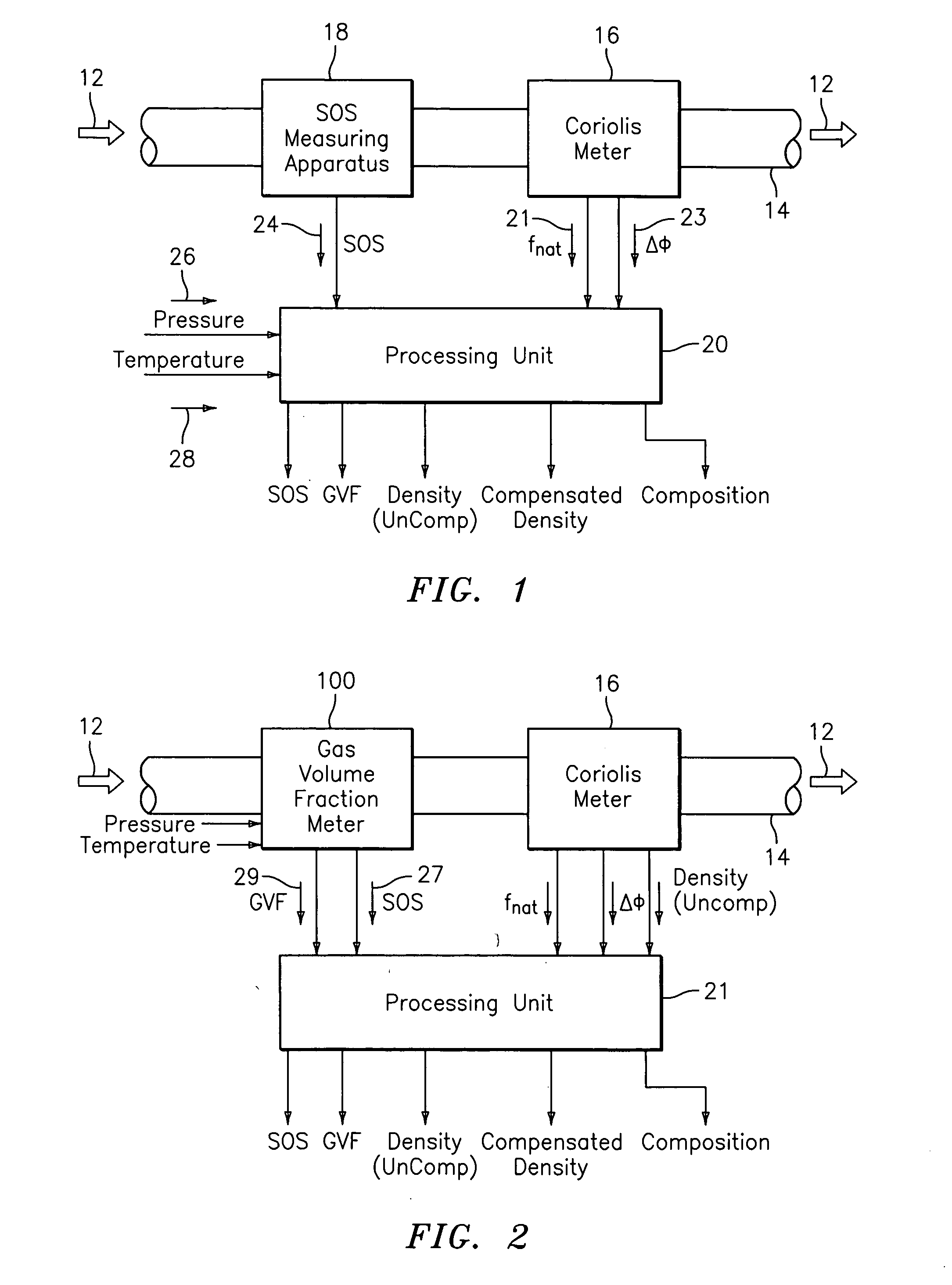

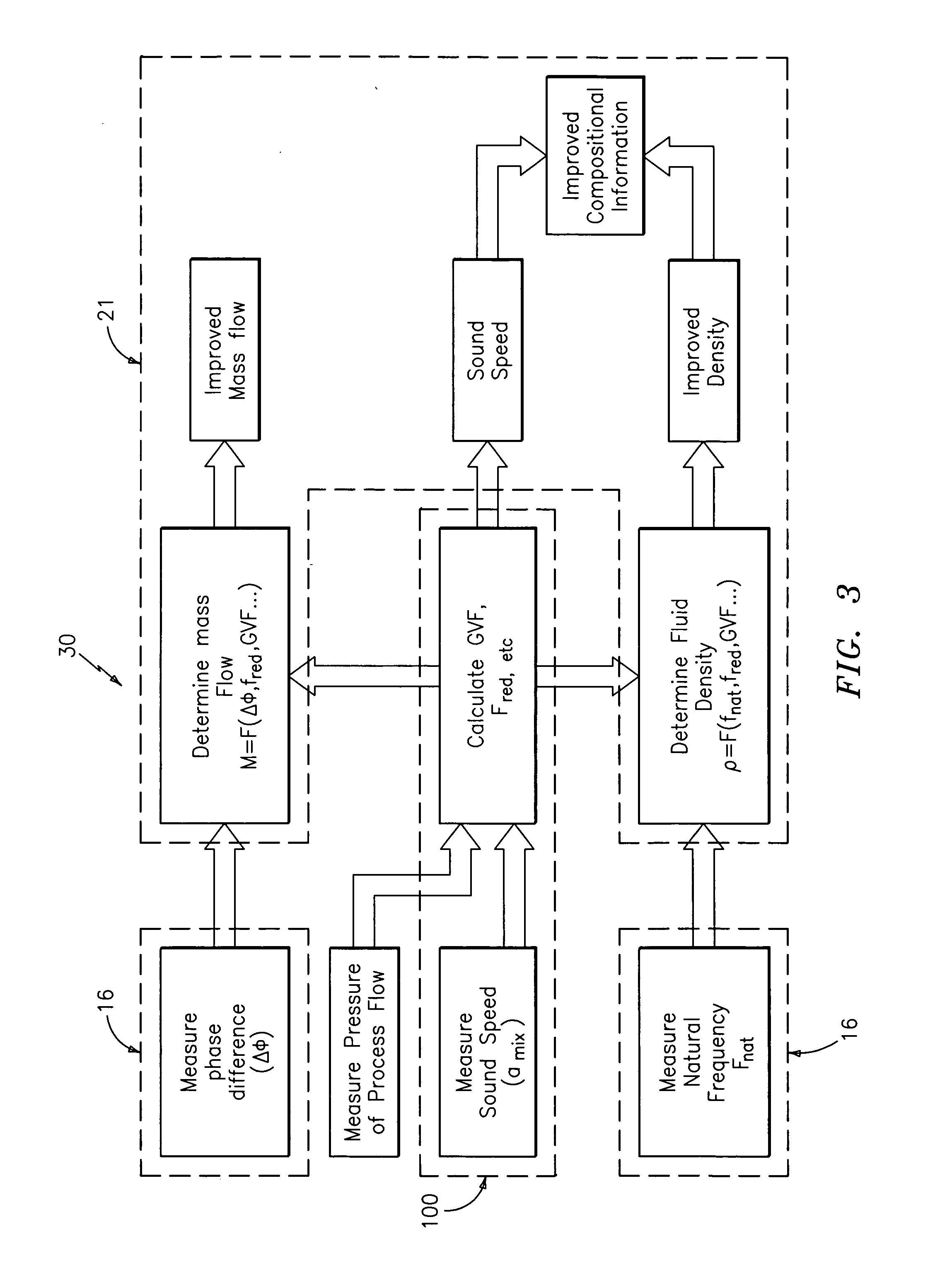

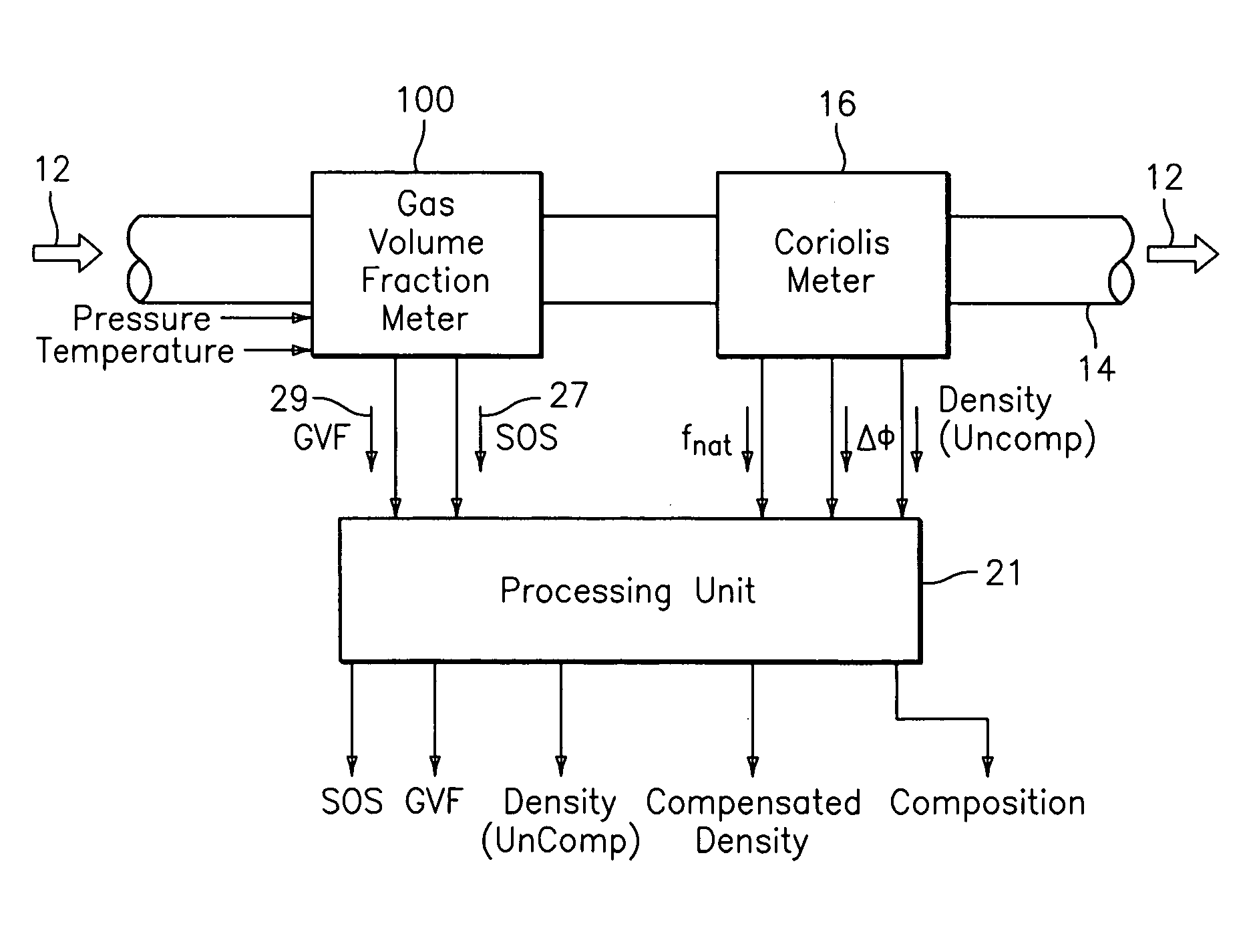

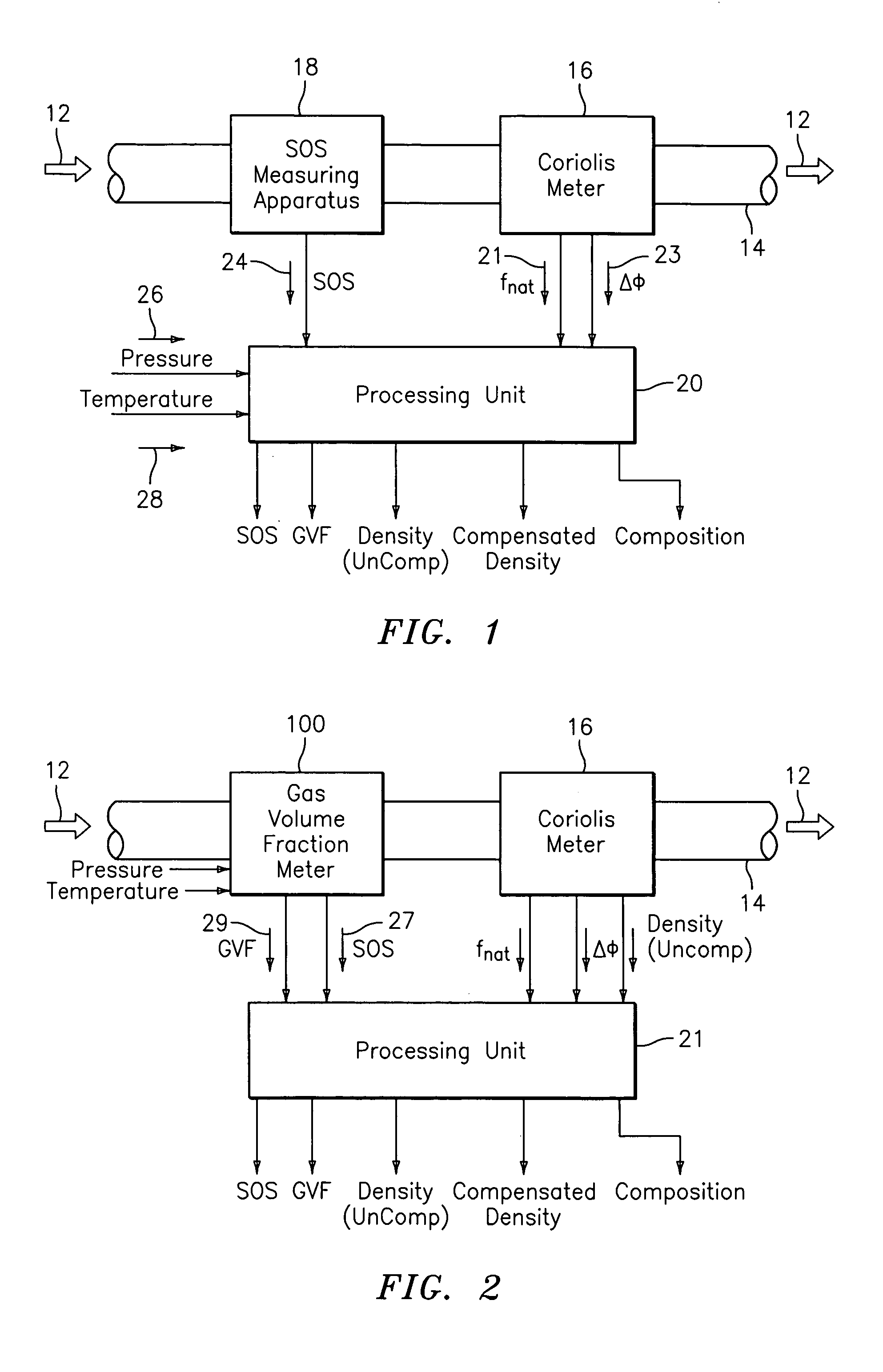

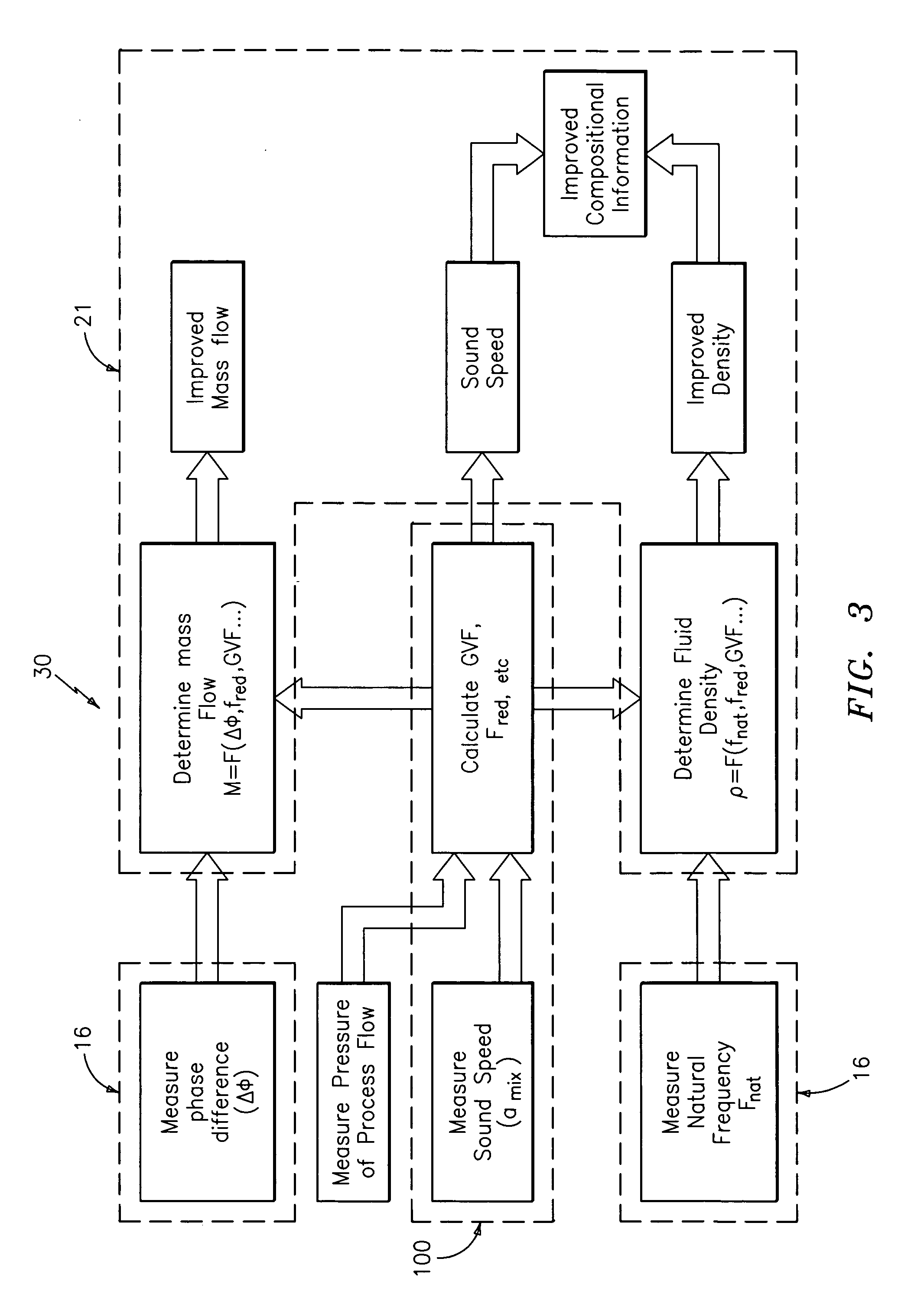

Apparatus and method for compensating a coriolis meter

ActiveUS20050044929A1High densityAdd additional massVolume/mass flow by dynamic fluid flow effectVolume meteringVolumetric Mass DensityDischarge measurements

A flow measuring system is provided that provides at least one of a compensated mass flow rate measurement and a compensated density measurement. The flow measuring system includes a gas volume fraction meter in combination with a coriolis meter. The GVF meter measures acoustic pressures propagating through the fluids to measure the speed of sound αmix propagating through the fluid to calculate at least gas volume fraction of the fluid and / or the reduced natural frequency. For determining an improved density for the coriolis meter, the calculated gas volume fraction and / or reduced frequency is provided to a processing unit. The improved density is determined using analytically derived or empirically derived density calibration models (or formulas derived therefore), which is a function of the measured natural frequency and at least one of the determined GVF, reduced frequency and speed of sound, or any combination thereof. The gas volume fraction (GVF) meter may include a sensing device having a plurality of strain-based or pressure sensors spaced axially along the pipe for measuring the acoustic pressures propagating through the flow.

Owner:EXPRO METERS

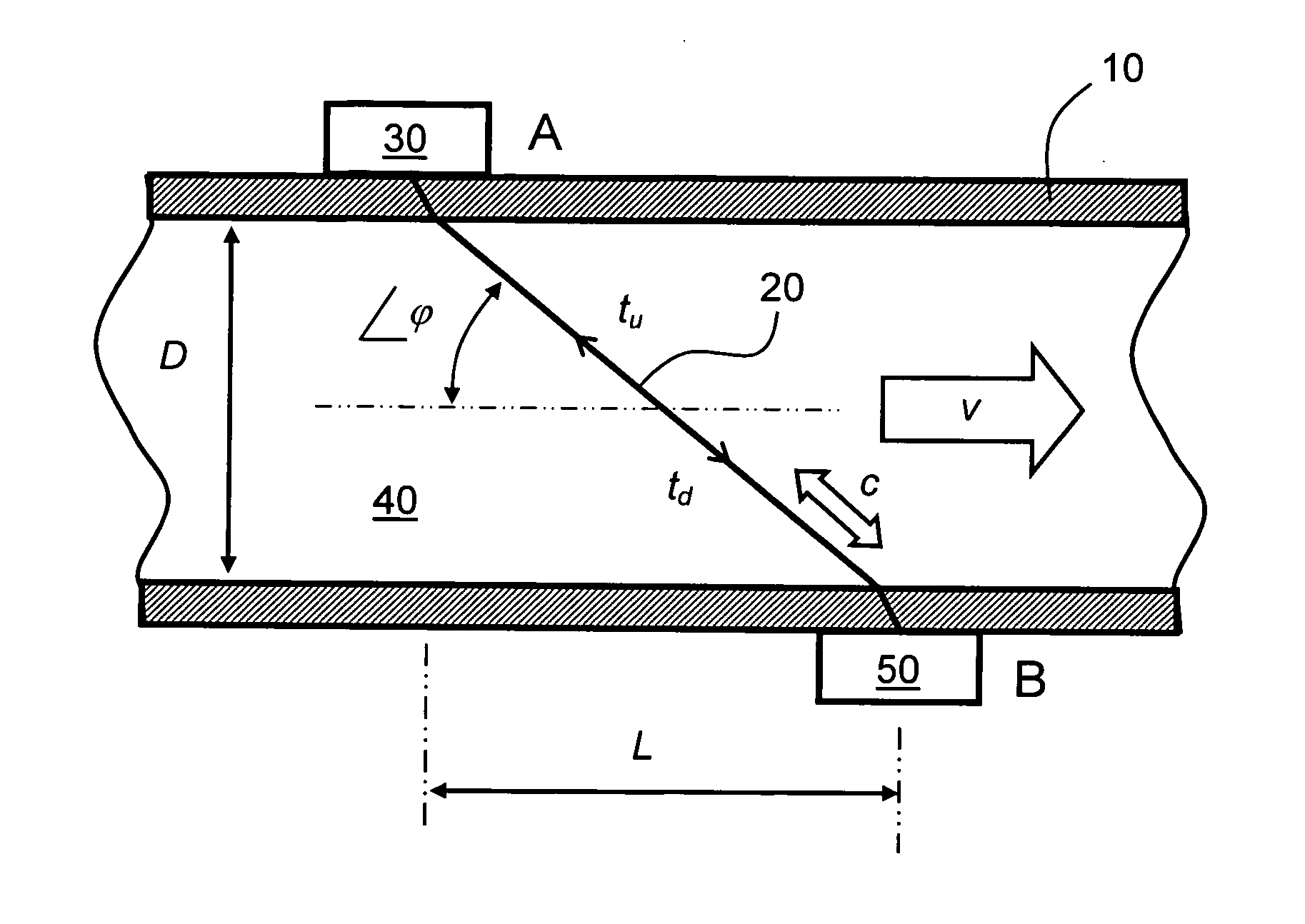

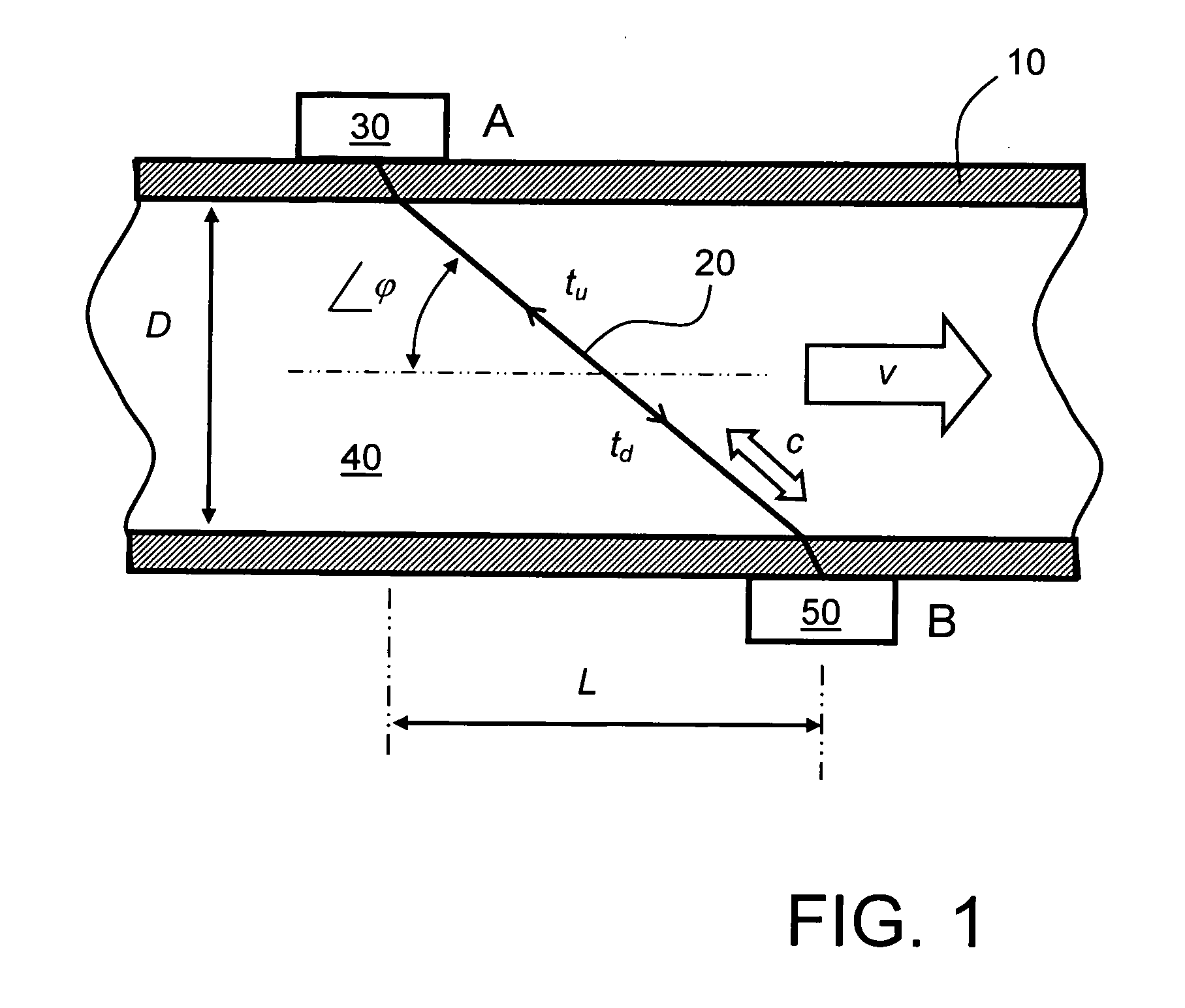

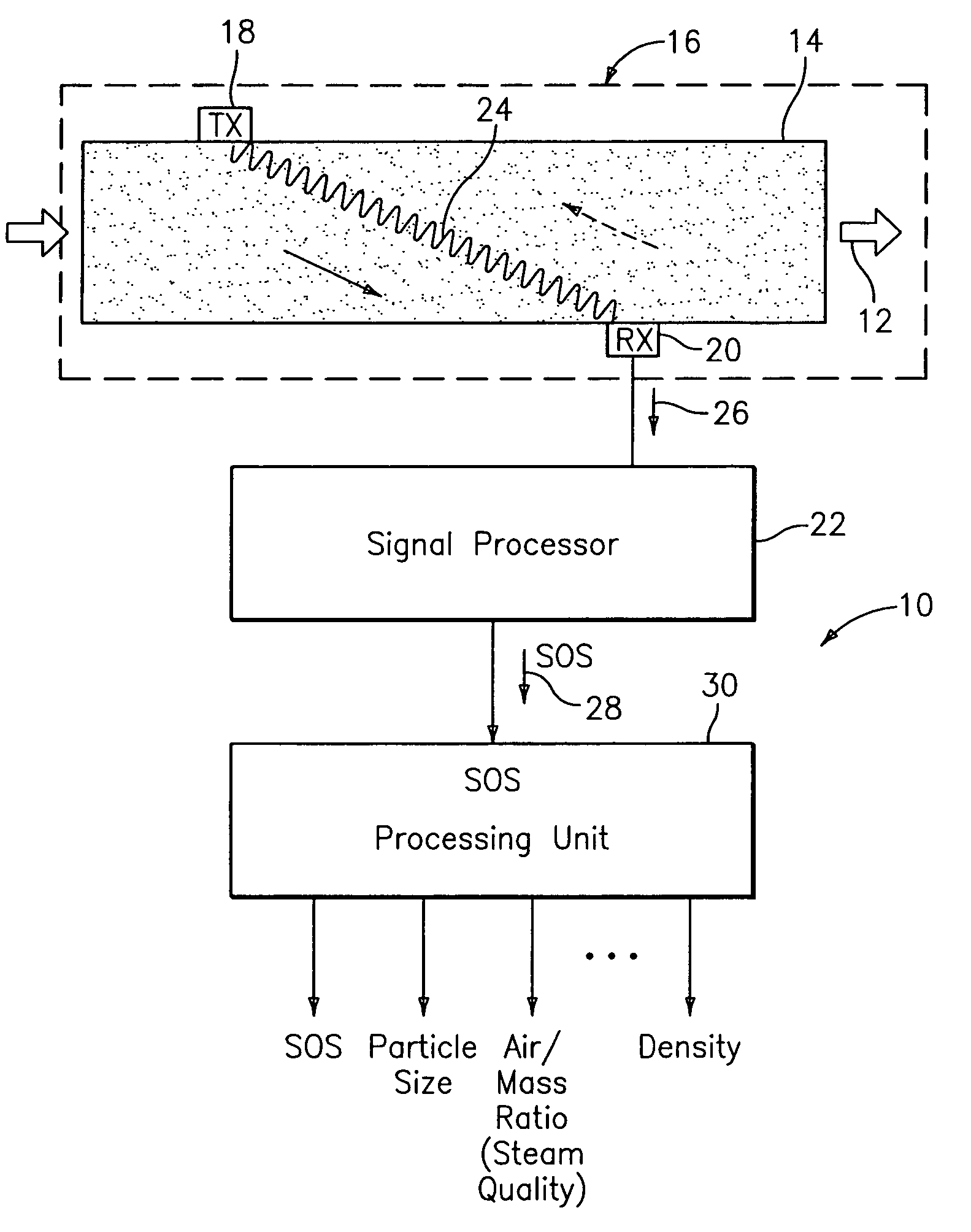

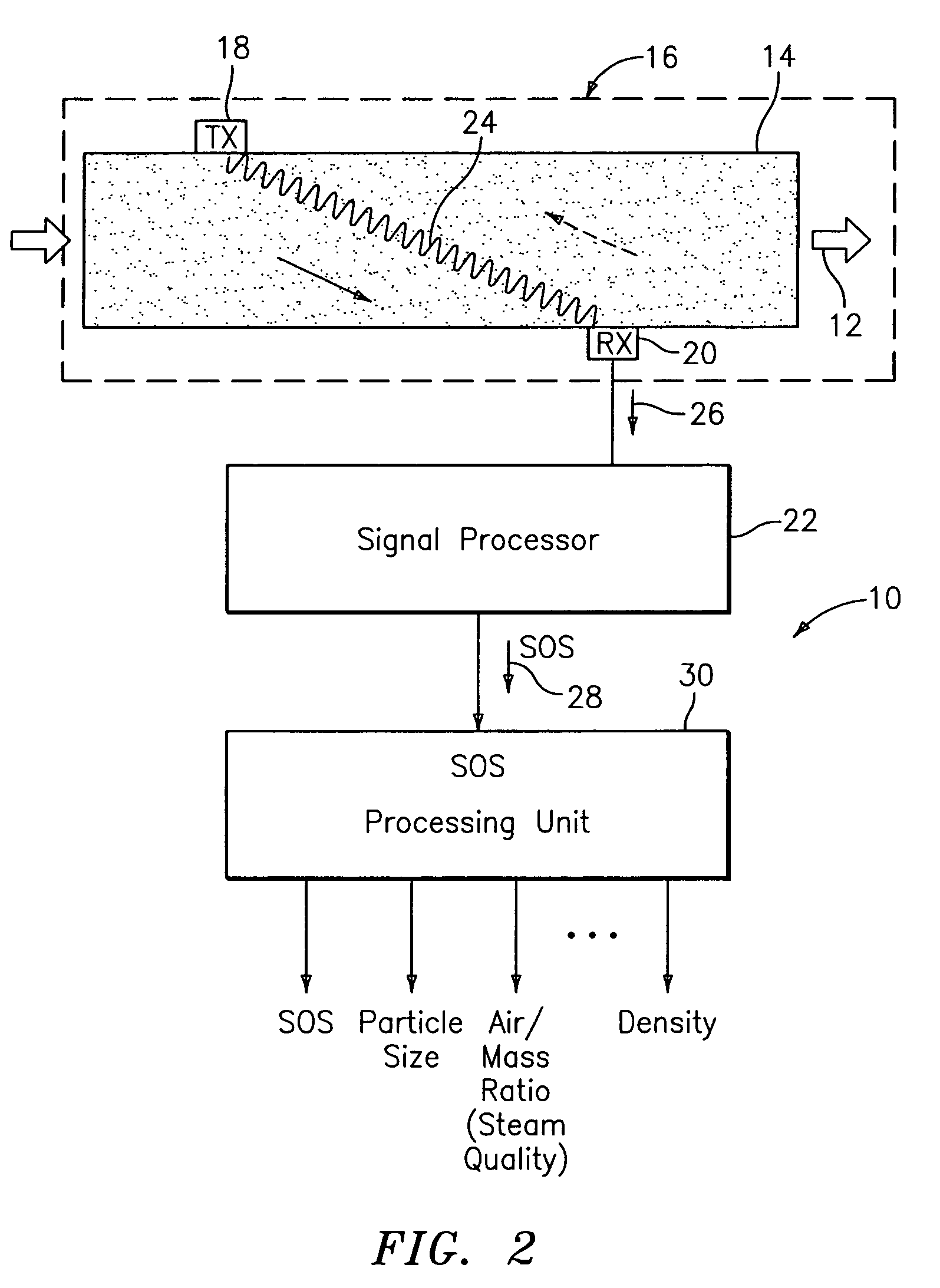

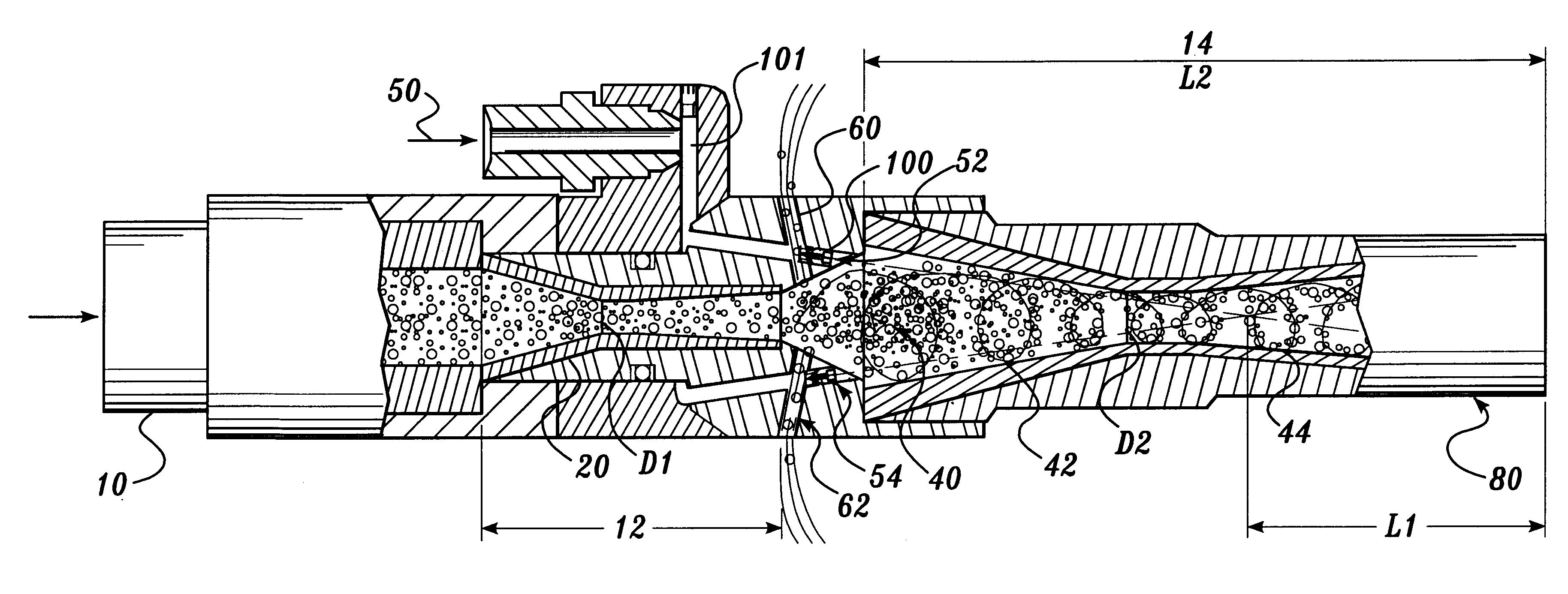

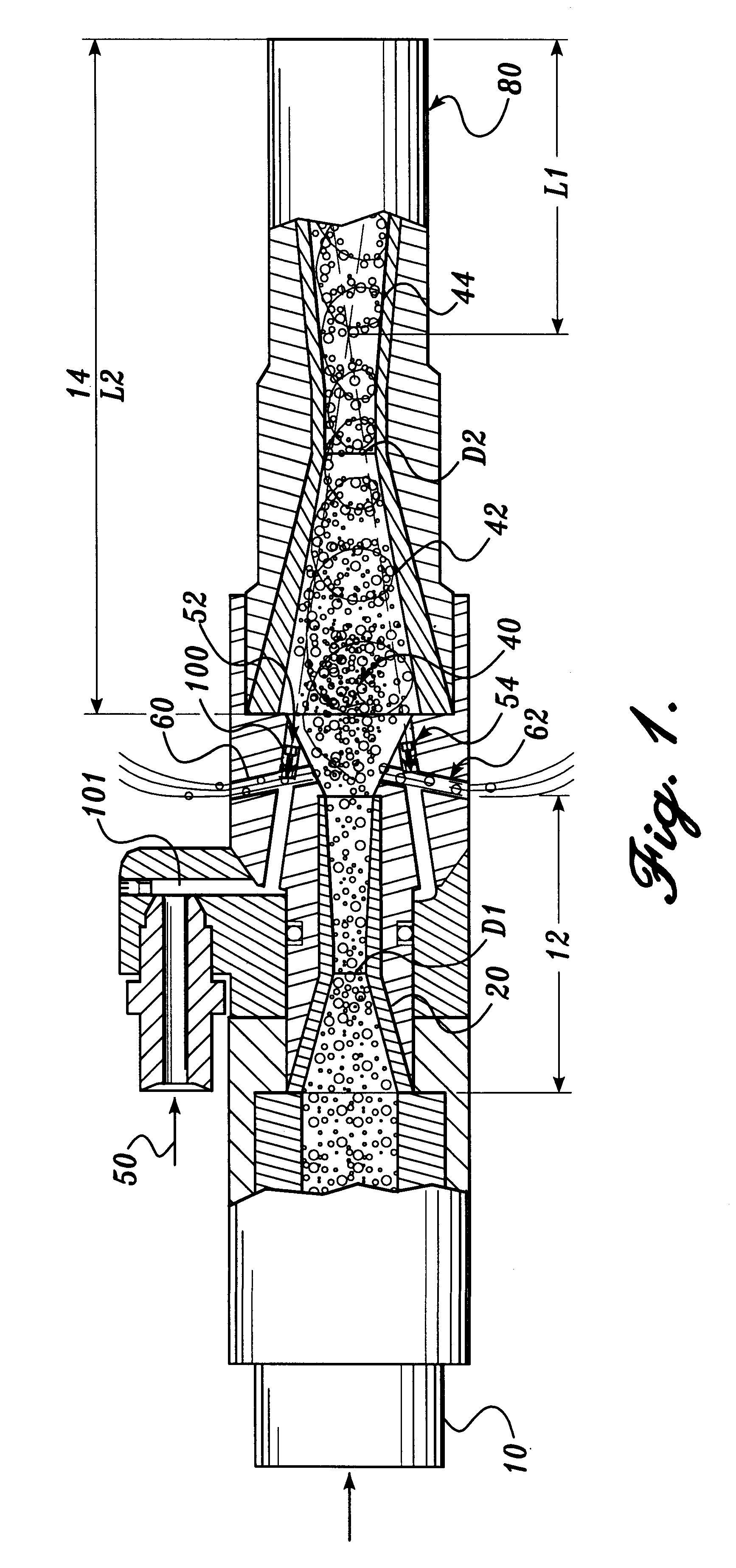

Apparatus for measuring parameters of a flowing multiphase mixture

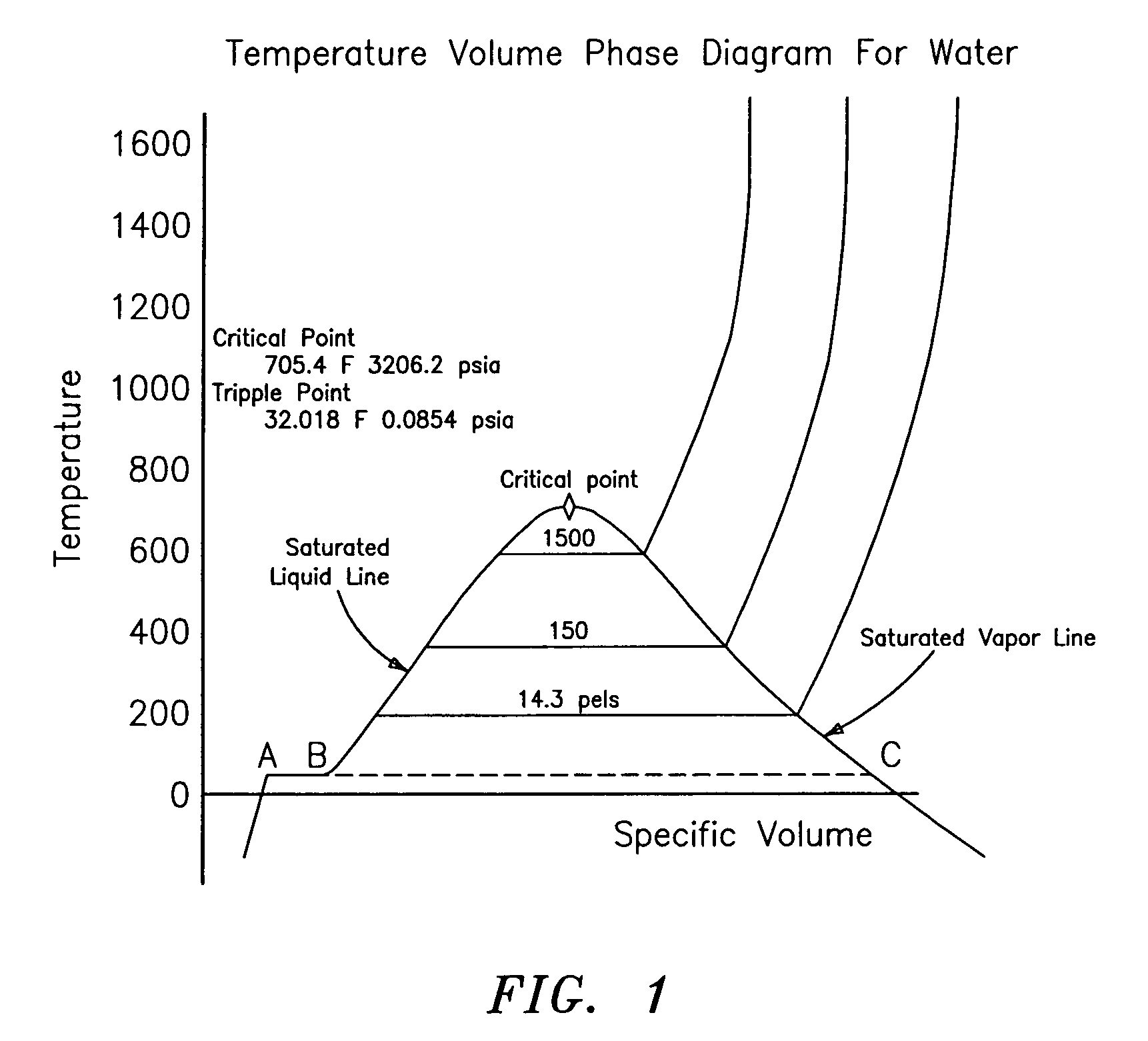

ActiveUS7096719B2Analysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesUltrasonic sensorMass ratio

An apparatus 10 is provided that measures the speed of sound propagating in a multiphase mixture to determine parameters, such as mixture quality, particle size, vapor / mass ratio, liquid / vapor ratio, mass flow rate, enthalpy and volumetric flow rate of the flow in a pipe or unconfined space, for example, using acoustic and / or dynamic pressures. The apparatus includes a pair of ultrasonic transducers disposed axially along the pipe for measuring the transit time of an ultrasonic signal to propagate from one ultrasonic transducer to the other ultrasonic transducer. A signal process, responsive to said transit time signal, provides a signal representative of the speed of sound of the mixture. An SOS processing unit then provides an output signal indicative of at least one parameter of the mixture flowing through the pipe. The frequency of the ultrasonic signal is sufficiently low to minimize scatter from particle / liquid within the mixture. The frequency based sound speed is determined utilizing a dispersion model to determine the at least one parameter of the fluid flow and / or mixture.

Owner:CIDRA CORP SERVICES

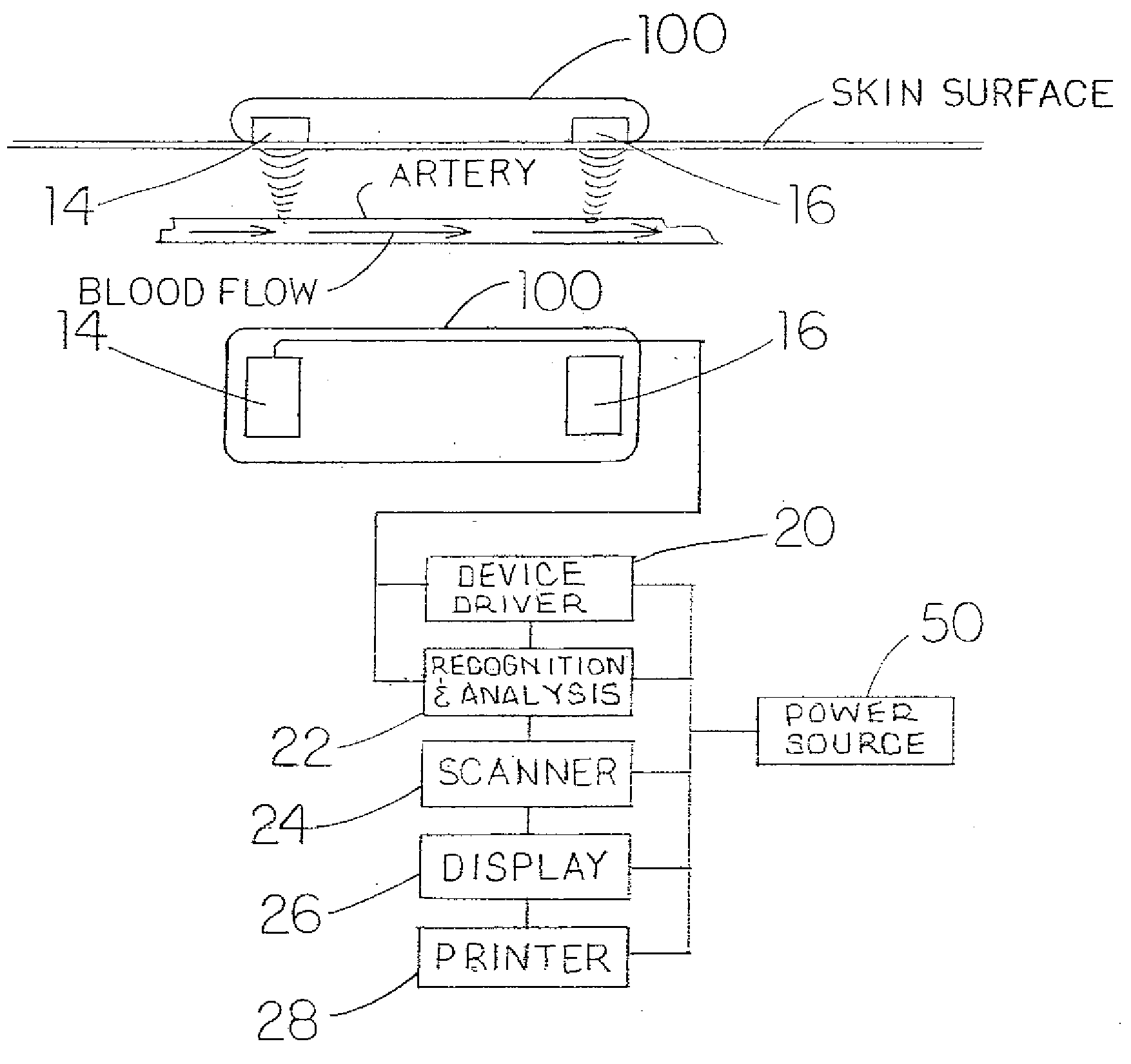

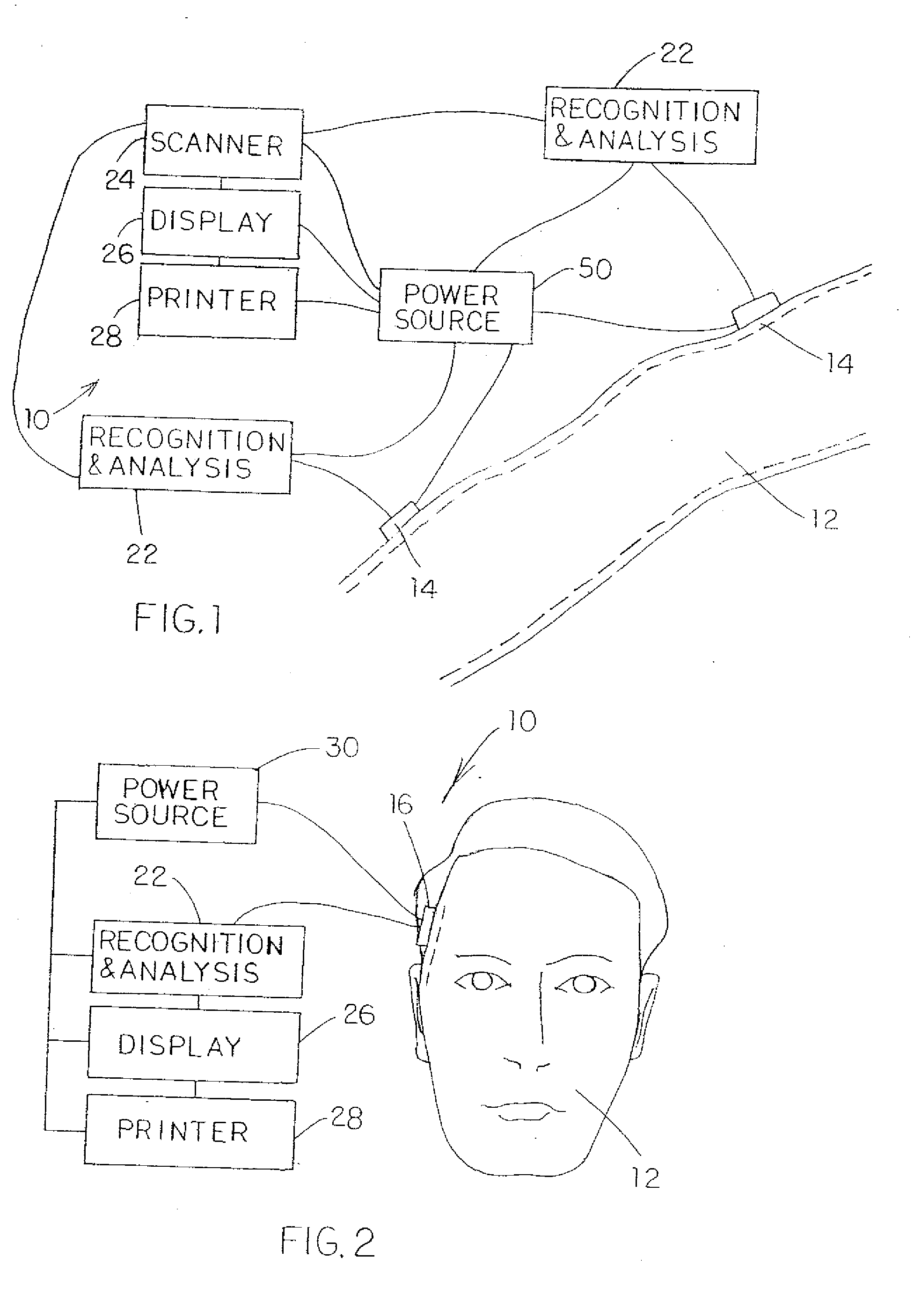

Multiparameter whole blood monitor and method

InactiveUS20090270695A1Increase turnaround timeRemove uncertaintyBlood flow measurement devicesEvaluation of blood vesselsPulse pressureIntravascular catheter

Owner:NEW PARADIGM CONCEPTS

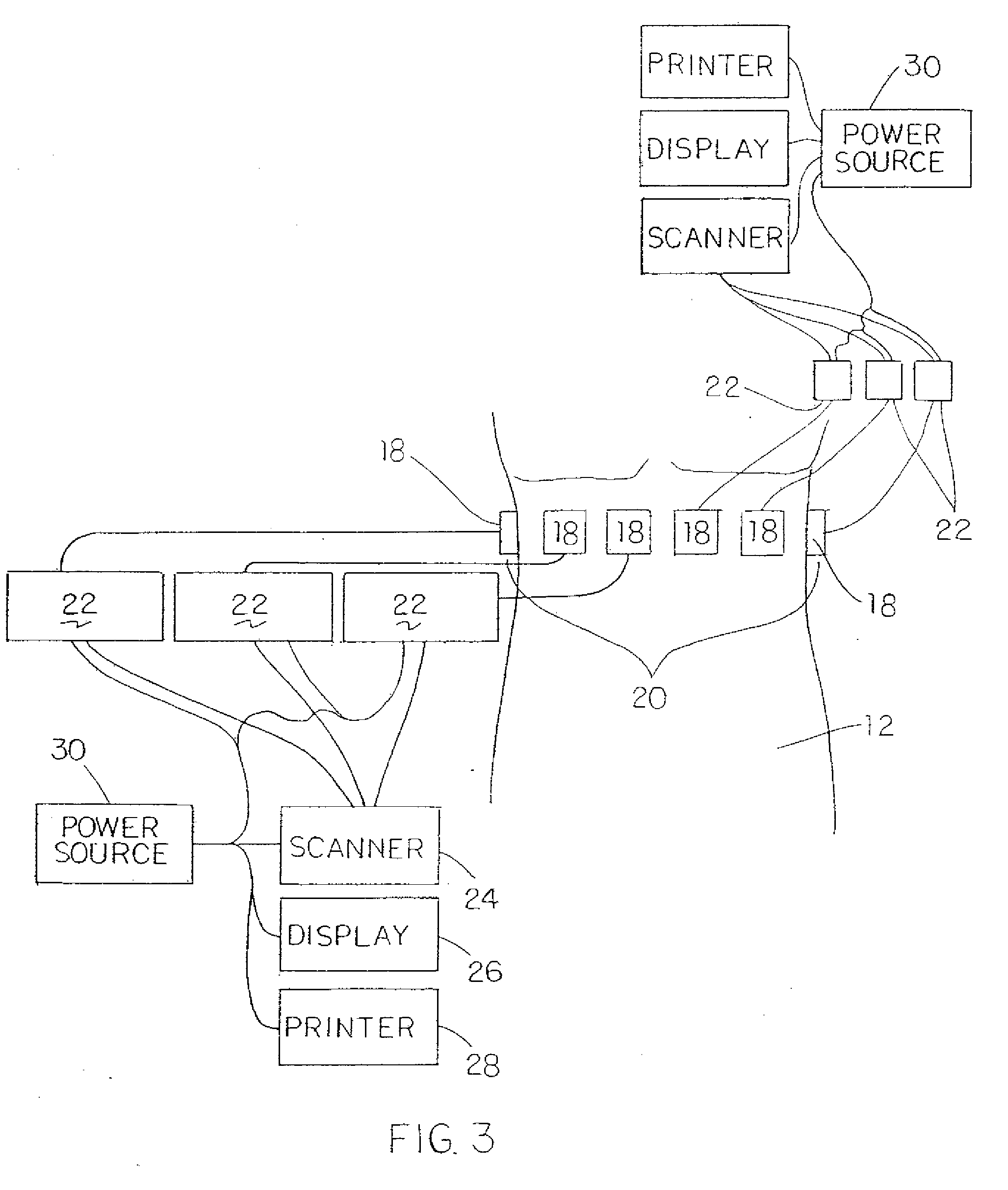

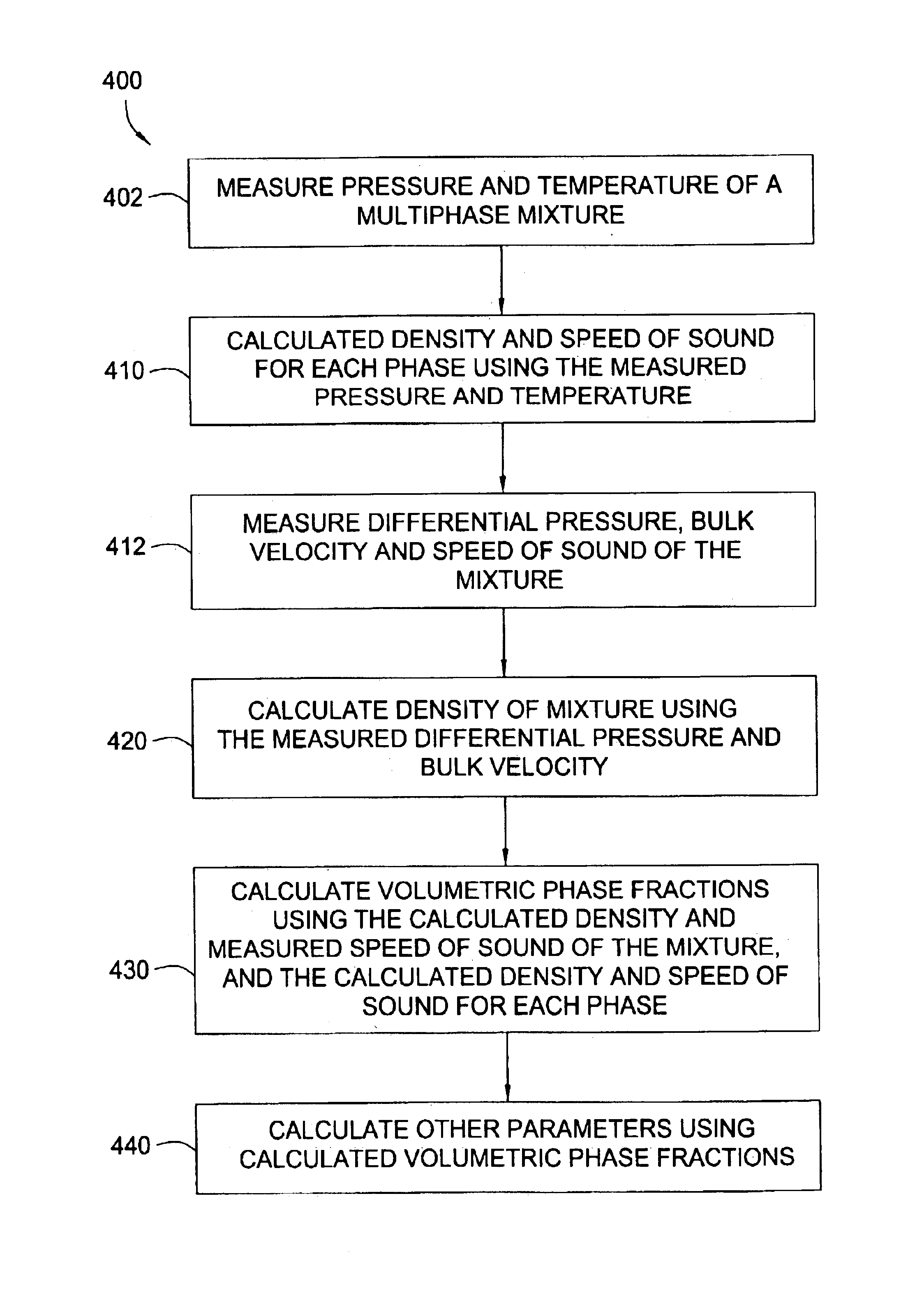

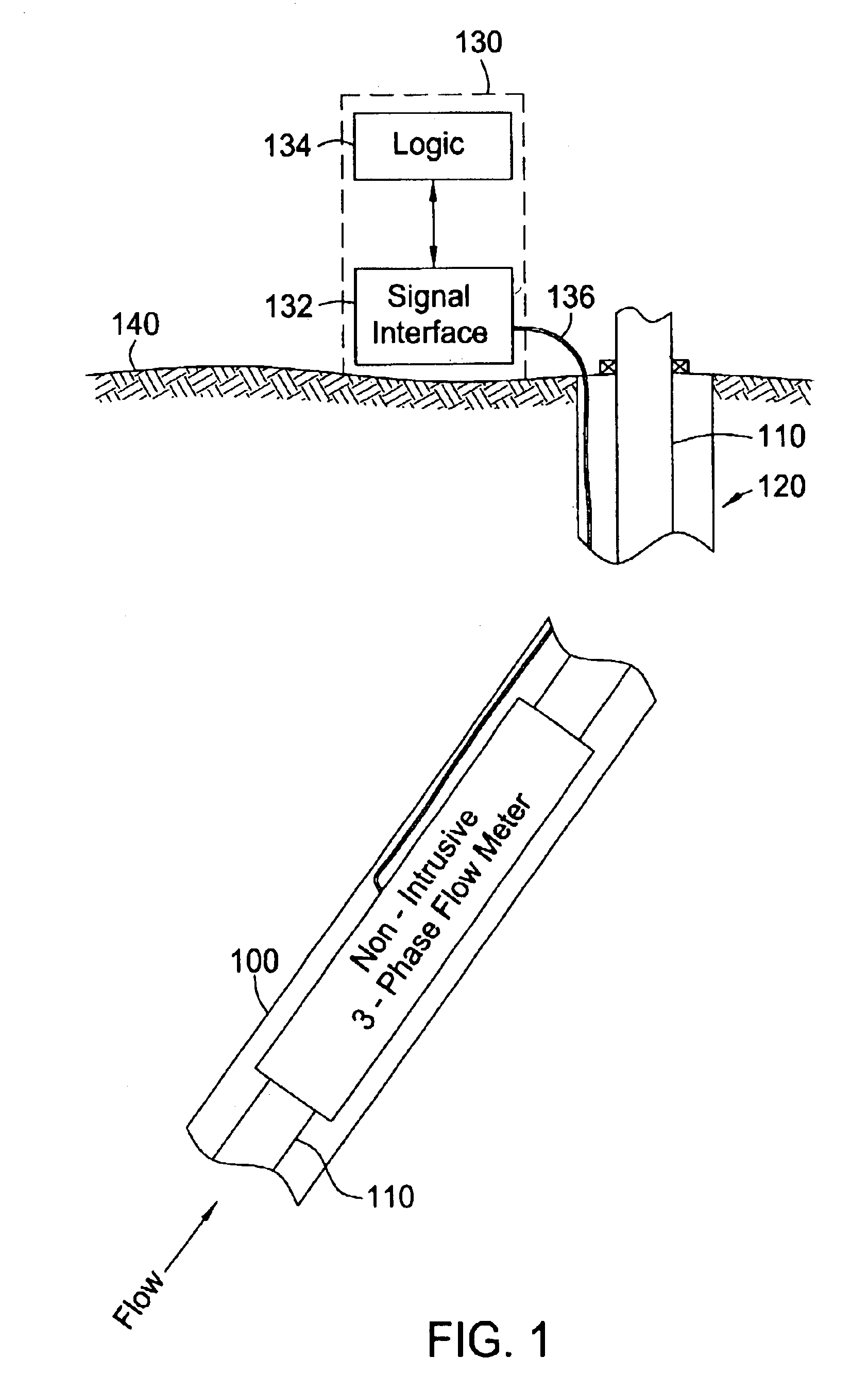

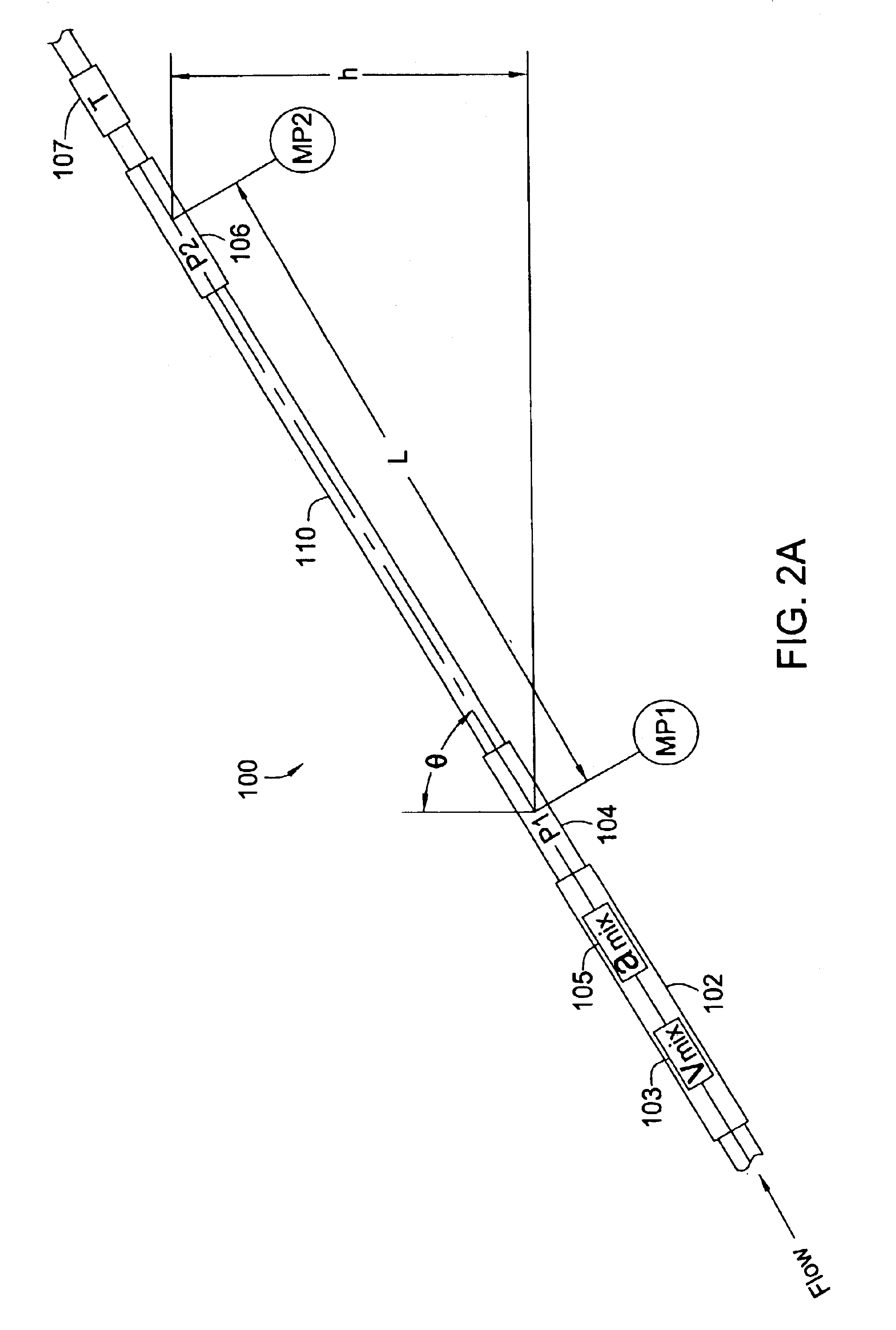

Non-intrusive multiphase flow meter

InactiveUS6945095B2SurveyMaterial analysis using sonic/ultrasonic/infrasonic wavesFiberDifferential pressure

Embodiments of the present invention generally provide methods, apparatus, and systems for determining void fractions of individual phase components of a multiphase mixture. The void fractions may be determined based on measured parameters of the mixture as a whole, such as differential pressure, bulk velocity of the mixture and speed of sound in the mixture. According to some embodiments, the mixture parameters may be measured using non-intrusive fiber optic based sensors. Various other parameters may also be derived from the void fractions, such as individual phase flow rates, liquid holdup and watercut parameters (for oil and gas mixtures).

Owner:WEATHERFORD TECH HLDG LLC

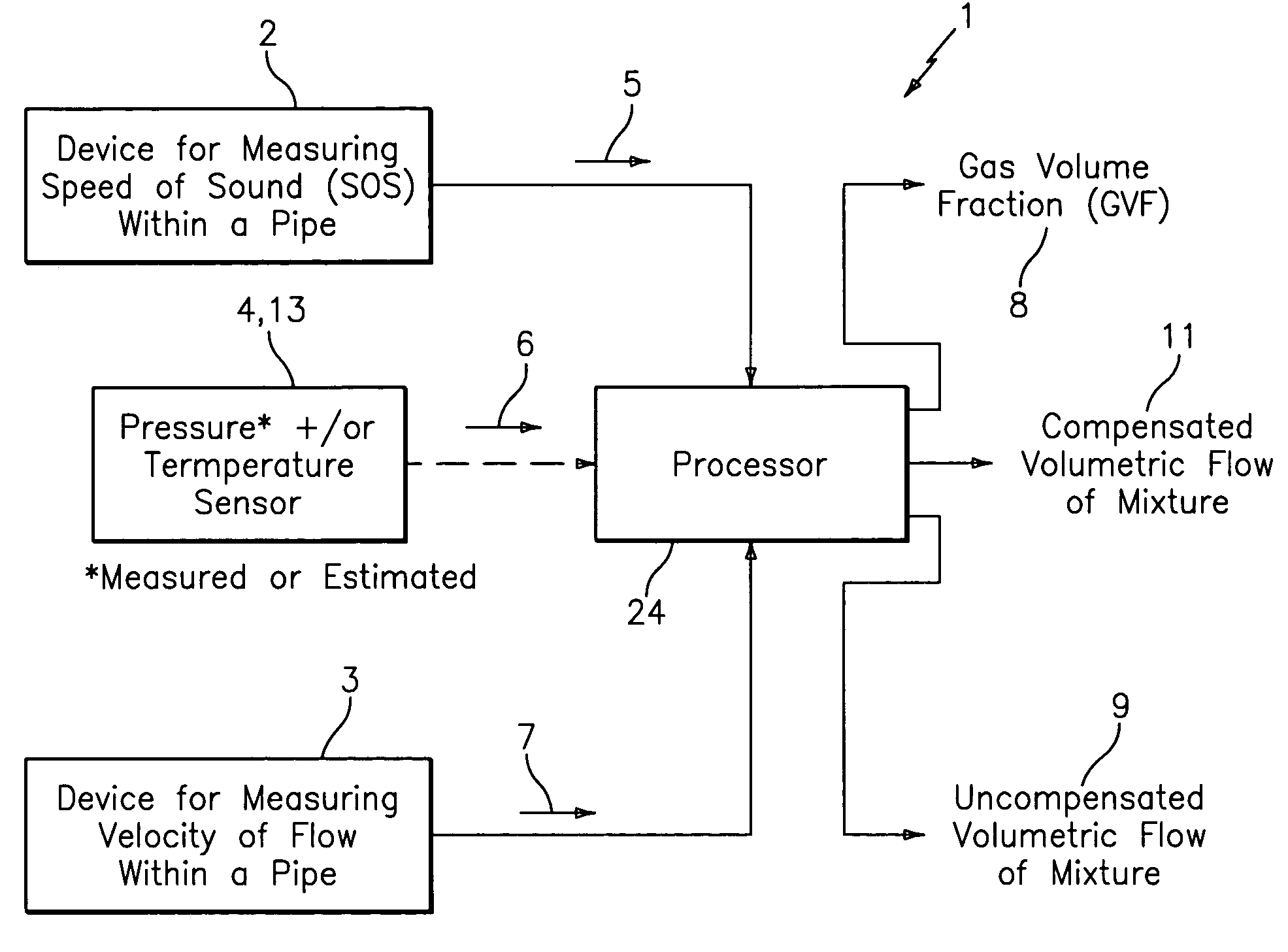

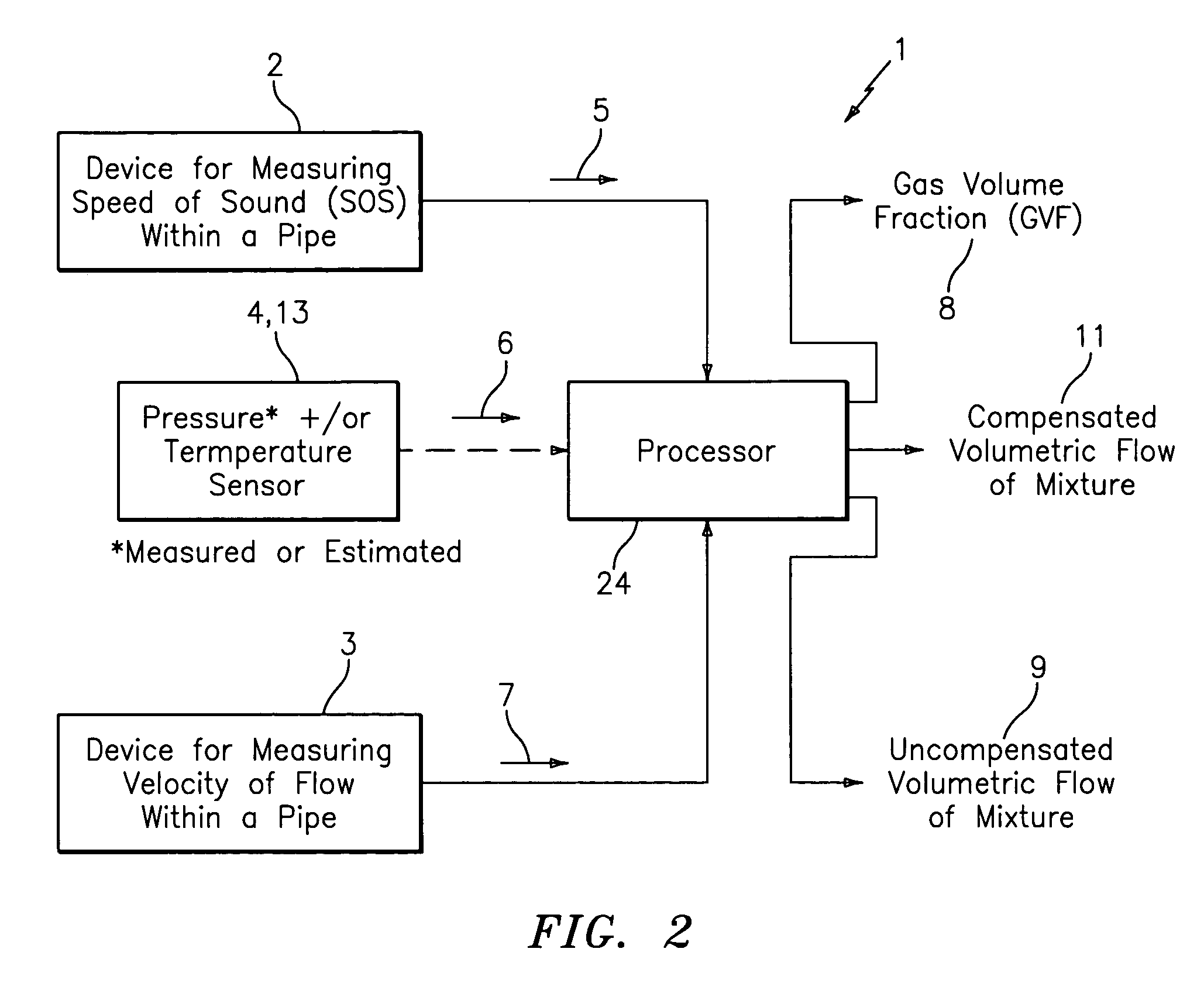

Apparatus and method for providing a flow measurement compensated for entrained gas

ActiveUS7165464B2Material analysis using sonic/ultrasonic/infrasonic wavesMaterial analysis using microwave meansSensor arrayAir entrainment

A apparatus 10,110 is provided that measures the speed of sound and / or vortical disturbances propagating in a fluid or mixture having entrained gas / air to determine the gas volume fraction of the flow 12 propagating through a pipes and compensating or correcting the volumetric flow measurement for entrained air. The GVF meter includes and array of sensor disposed axially along the length of the pipe. The GVF measures the speed of sound propagating through the pipe and fluid to determine the gas volume fraction of the mixture using array processing. The GVF meter can be used with an electromagnetic meter and a consistency meter to compensate for volumetric flow rate and consistency measurement respective, to correct for errors due to entrained gas / air.

Owner:EXPRO METERS

Apparatus and method for compensating a coriolis meter

ActiveUS7152460B2High densityAdd additional massMaterial analysis using microwave meansVolume/mass flow by dynamic fluid flow effectDischarge measurementsVolumetric Mass Density

A flow measuring system is provided that provides at least one of a compensated mass flow rate measurement and a compensated density measurement. The flow measuring system includes a gas volume fraction meter in combination with a coriolis meter. The GVF meter measures acoustic pressures propagating through the fluids to measure the speed of sound αmix propagating through the fluid to calculate at least gas volume fraction of the fluid and / or the reduced natural frequency. For determining an improved density for the coriolis meter, the calculated gas volume fraction and / or reduced frequency is provided to a processing unit. The improved density is determined using analytically derived or empirically derived density calibration models (or formulas derived therefore), which is a function of the measured natural frequency and at least one of the determined GVF, reduced frequency and speed of sound, or any combination thereof. The gas volume fraction (GVF) meter may include a sensing device having a plurality of strain-based or pressure sensors spaced axially along the pipe for measuring the acoustic pressures propagating through the flow.

Owner:EXPRO METERS

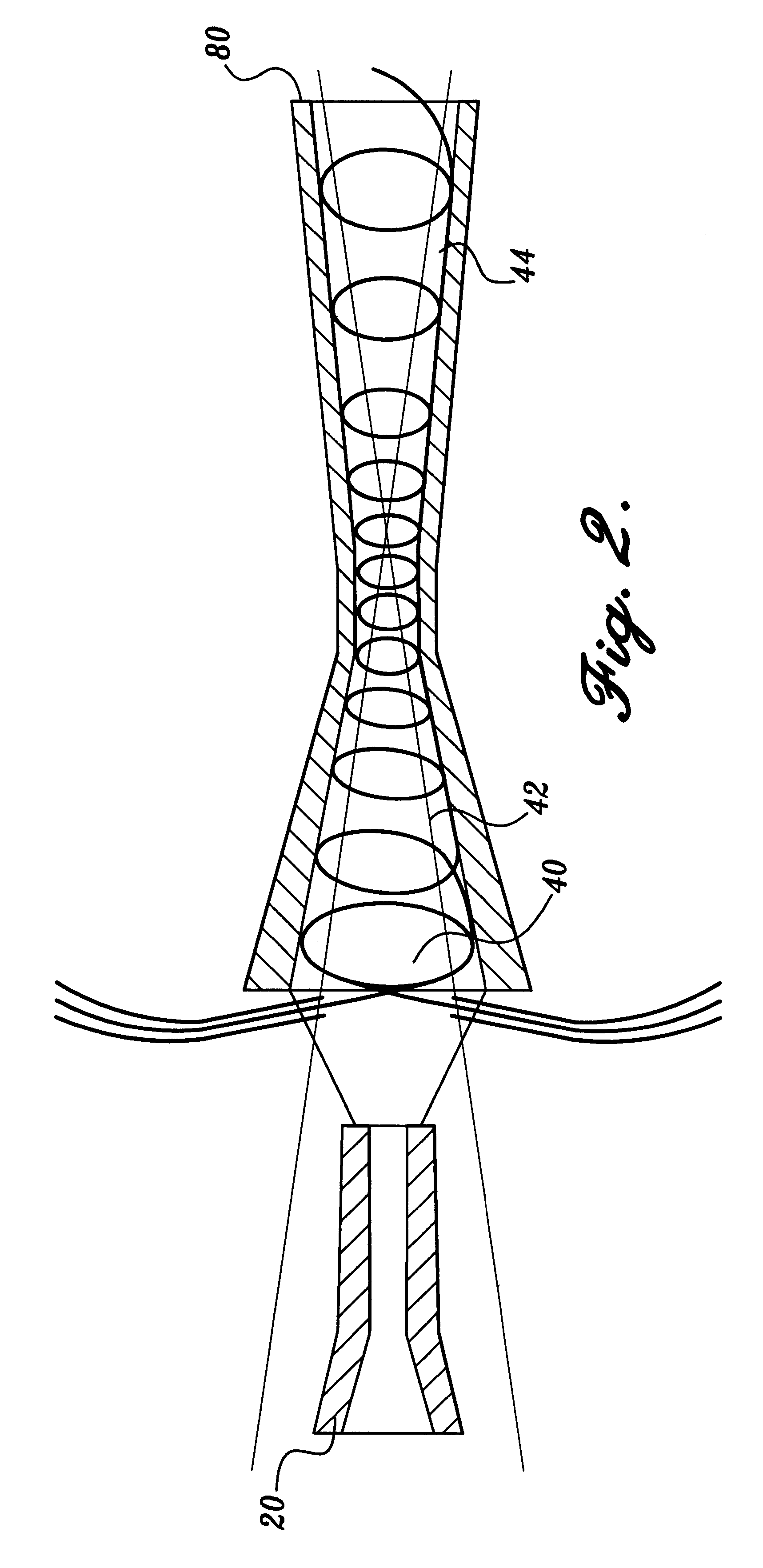

Method and apparatus for producing a high-velocity particle stream

InactiveUS6283833B1Uniform particle spreadingImprove productivityBlast gunsLiquid spraying apparatusJet flowClassical mechanics

A method and apparatus for producing a high-velocity particle stream at low cost through multi-staged acceleration using different media in each stage. The particles are accelerated to a subsonic velocity (with respect to the velocity of sound in air) using one or more jets of gas at low cost, then further accelerated to a higher velocity using jets of water. Additionally, to enhance particle acceleration, a vortex motion is created, and the particles introduced into the fluid having vortex motion, thereby enhancing the delivery of particles to the target.

Owner:FLOW INT

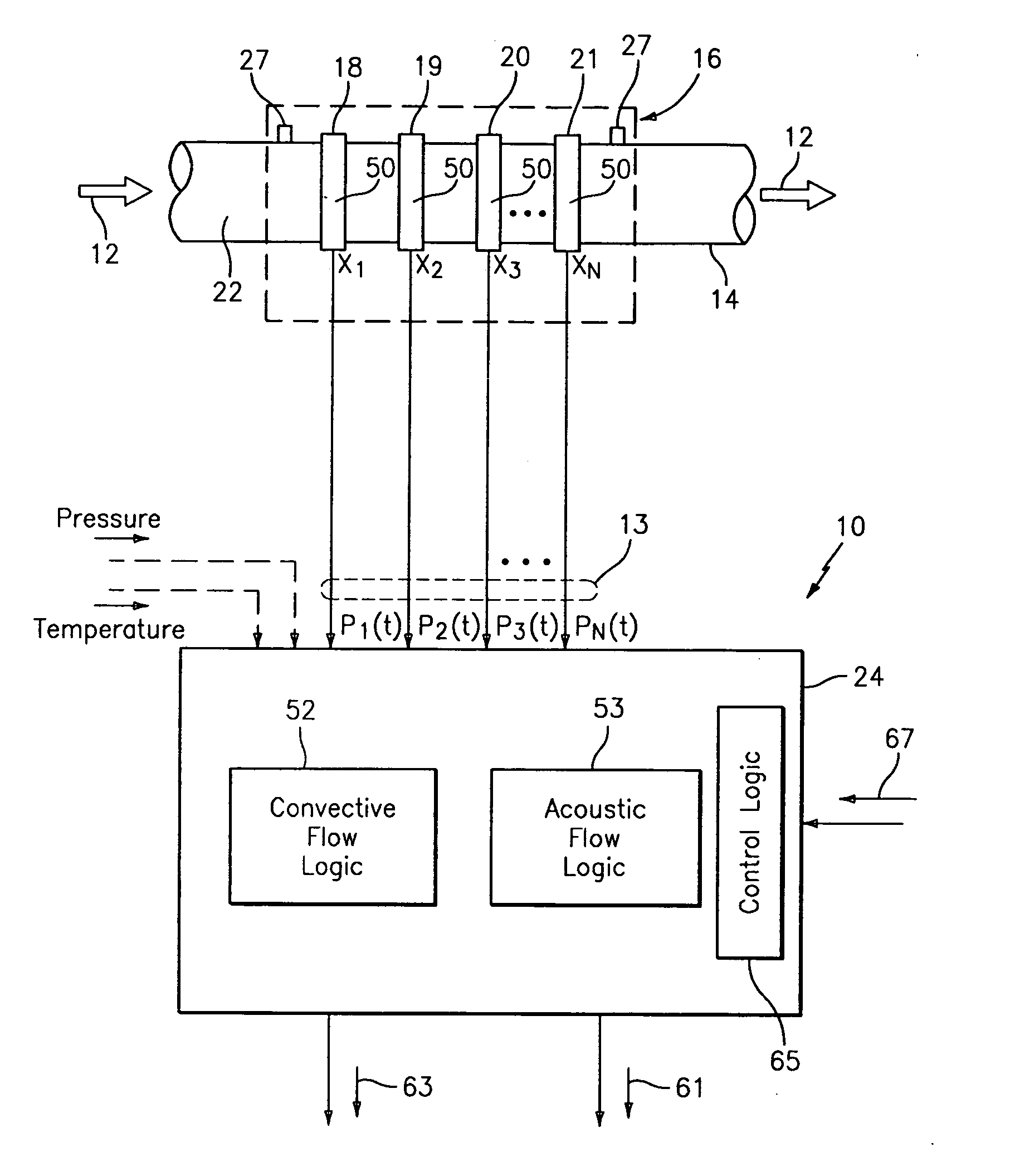

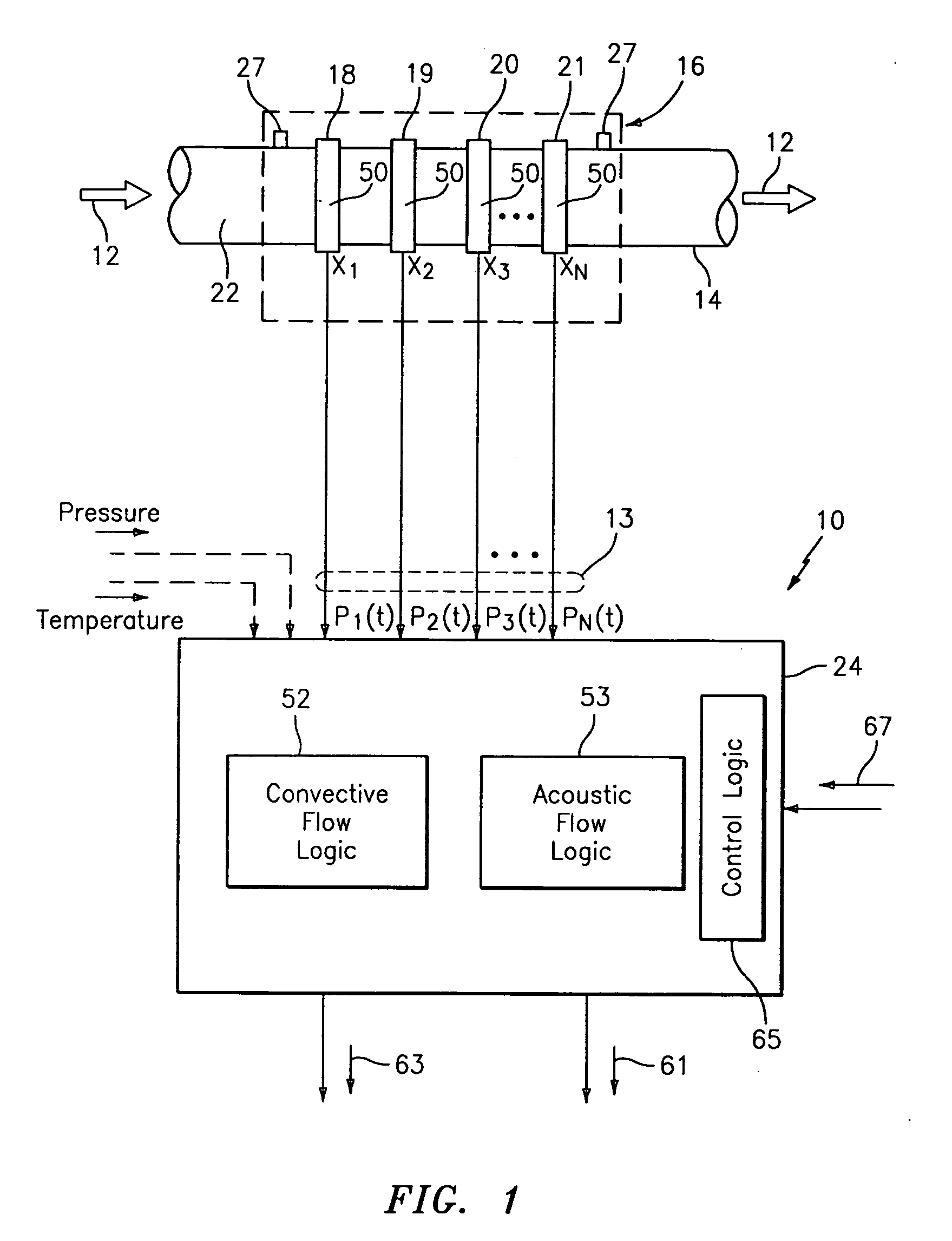

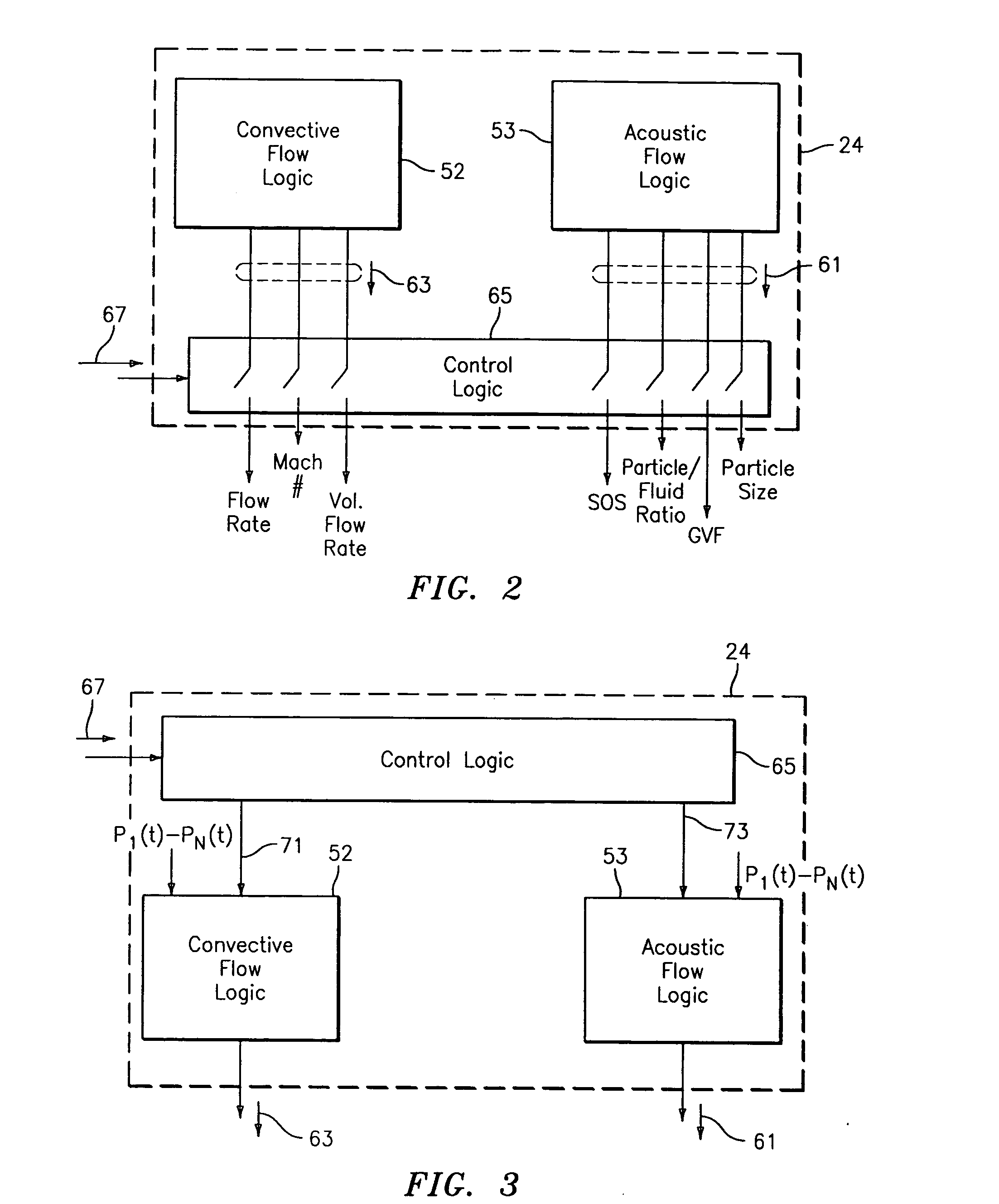

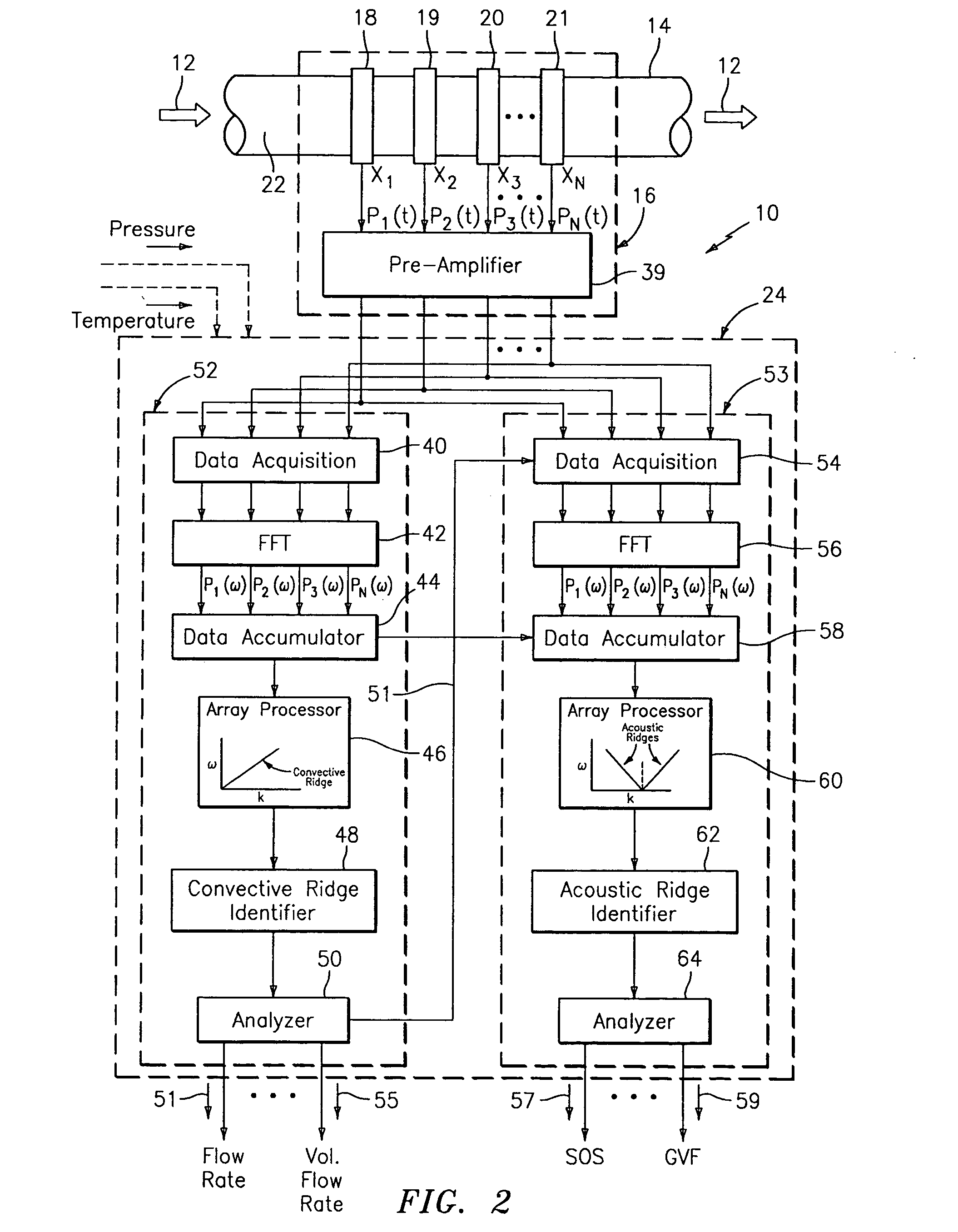

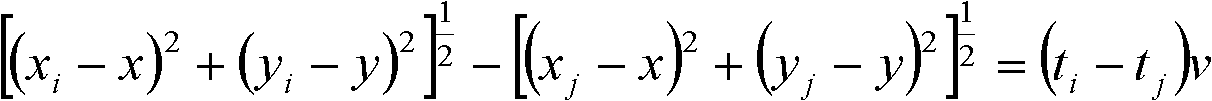

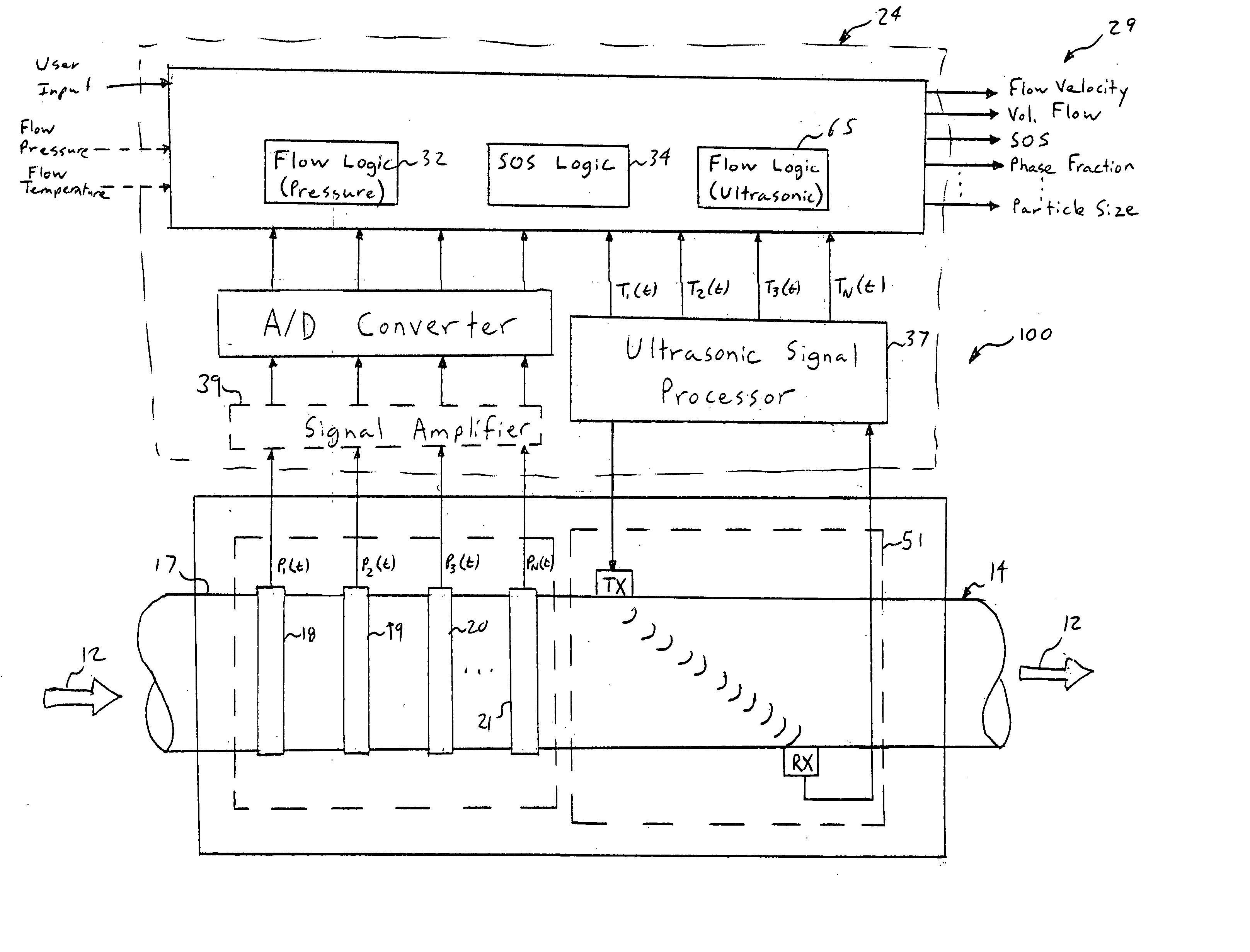

Configurable multi-function flow measurement apparatus having an array of sensors

ActiveUS20050011283A1Testing/calibration apparatusVolume/mass flow by thermal effectsSensor arrayMeasurement device

A configurable multi-function flow measurement apparatus is provided that can selectably function to measure the speed of sound propagating through a fluid flowing within a pipe and / or to measure pressures disturbances (e.g. vortical disturbances or eddies) moving with a fluid to determine respective parameters of the flow propagating through a pipe and detects the health of an industrial process. The configurable flow measurement device can also be selectable to function as a system diagnostic meter that provides a diagnostic signal indicative of the health of the industrial process, namely health of pumps, valves, motors and other devices in an industrial flow loop. The apparatus includes a sensing device that includes an array of strained-based or pressure sensors used to measure the acoustic and convective pressure variations in the flow to determine desired parameters. In response to a remote or local configuration signal, a control logic selects the desired function of the flow measurement apparatus.

Owner:EXPRO METERS

Multiphase fluid characterization system

ActiveUS20120055239A1Analysing fluids using sonic/ultrasonic/infrasonic wavesTesting/calibration for volume flowUltrasound attenuationResonance

A measurement system and method for permitting multiple independent measurements of several physical parameters of multiphase fluids flowing through pipes are described. Multiple acoustic transducers are placed in acoustic communication with or attached to the outside surface of a section of existing spool (metal pipe), typically less than 3 feet in length, for noninvasive measurements. Sound speed, sound attenuation, fluid density, fluid flow, container wall resonance characteristics, and Doppler measurements for gas volume fraction may be measured simultaneously by the system. Temperature measurements are made using a temperature sensor for oil-cut correction.

Owner:TRIAD NAT SECURITY LLC

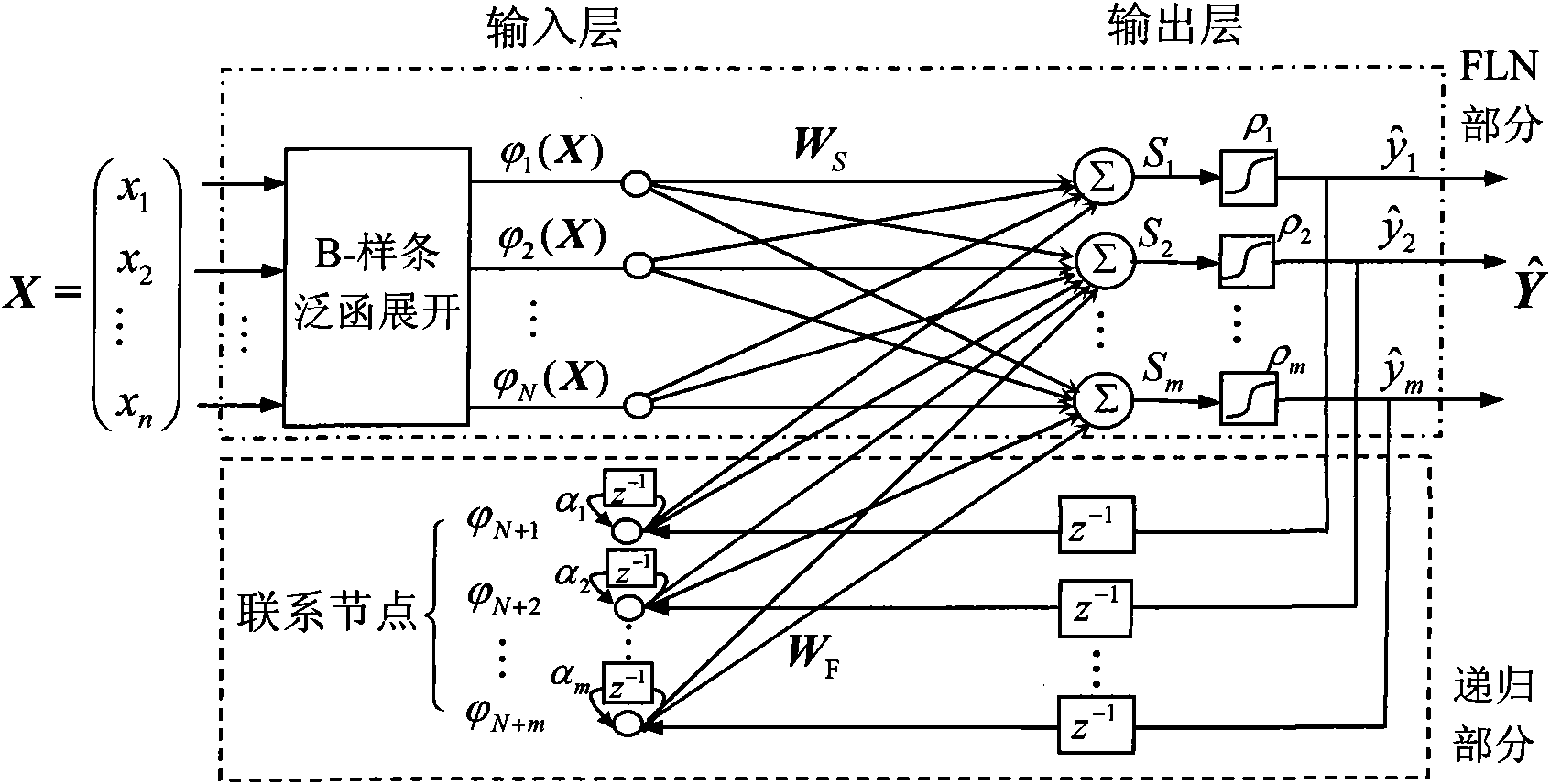

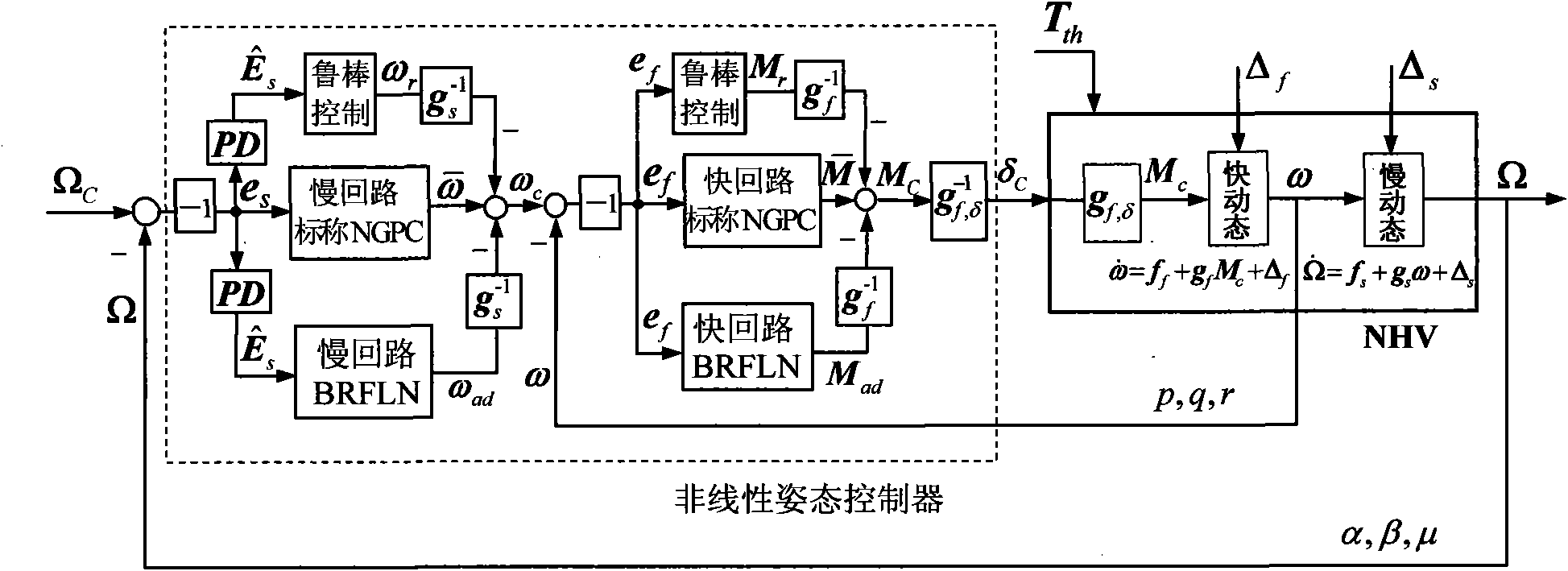

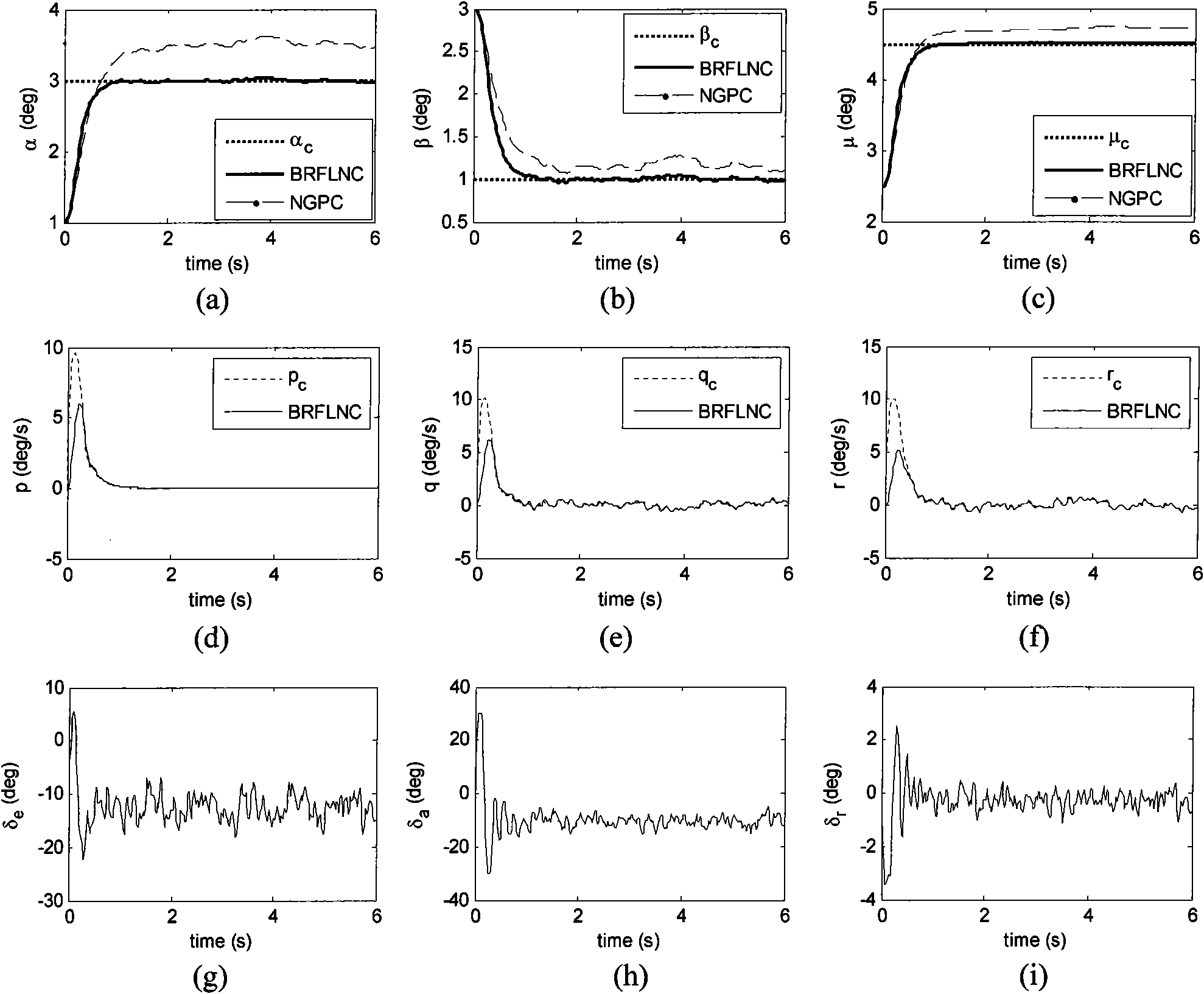

Nonlinear self-adaption control method of near-space hypersonic vehicle

InactiveCN101937233ATake advantage ofLighten the computational burdenAttitude controlAdaptive controlAviationNonlinear adaptive control

The invention discloses a nonlinear self-adaption control method of near-space hypersonic vehicle (NHV), which belongs to a flight control method in the technical field of aerospace. The control method mainly comprises three control law parts: a nominal nonlinear generalized predictive control law (NGPC), a B-spline recursive functional linkage network (BRFLN) self-adaption control law, and a robust control law of gain self-adaption adjustment. The invention integrates the simplicity of the NGPC method and the effectiveness of dynamic uncertainty of the BRFLN learning, targets the immeasurable dynamic uncertainty and fast interference of an attitude system in the flight of the NHV, brings favorable learning effect, and realizes the nonlinear accurate control to the attitude angle.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Dual function flow measurement apparatus having an array of sensors

ActiveUS20050011284A1Testing/calibration apparatusVolume/mass flow by thermal effectsSensor arrayMeasurement device

A dual function flow measurement apparatus is provided that combines the functionality of an apparatus that measures the speed of sound propagating through a fluid flowing within a pipe, and measures pressures disturbances (e.g. vortical disturbances or eddies) moving with a fluid to determine respective parameters of the flow propagating through a pipe. The apparatus includes a sensing device that includes an array of pressure sensors used to measure the acoustic and convective pressure variations in the flow to determine desired parameters. The measurement apparatus includes a processing unit the processes serially or in parallel the pressure signals provided by the sensing array to provide output signals indicative of a parameter of the fluid flow relating to the velocity of the flow and the speed of sound propagating through the flow, respectively.

Owner:EXPRO METERS

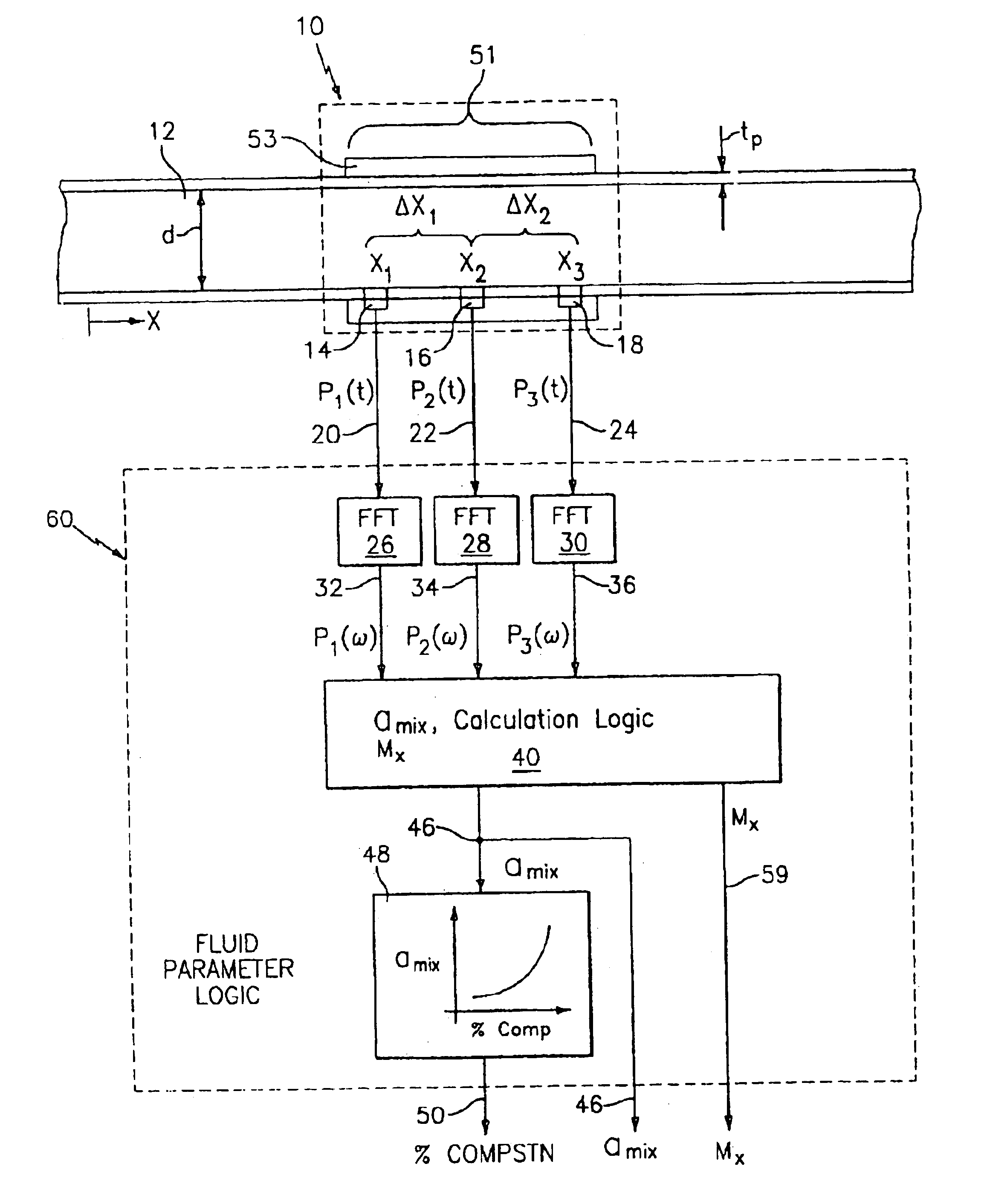

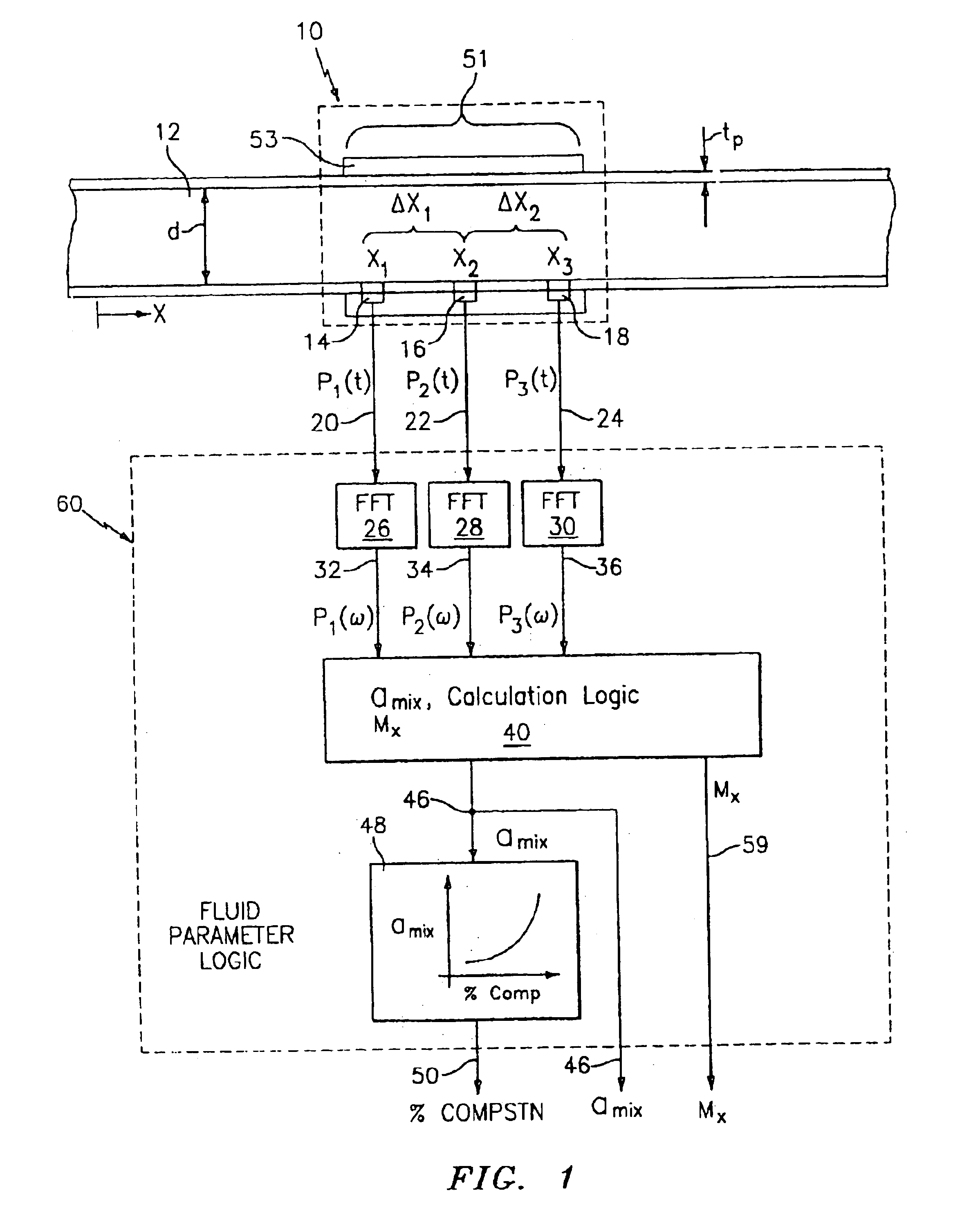

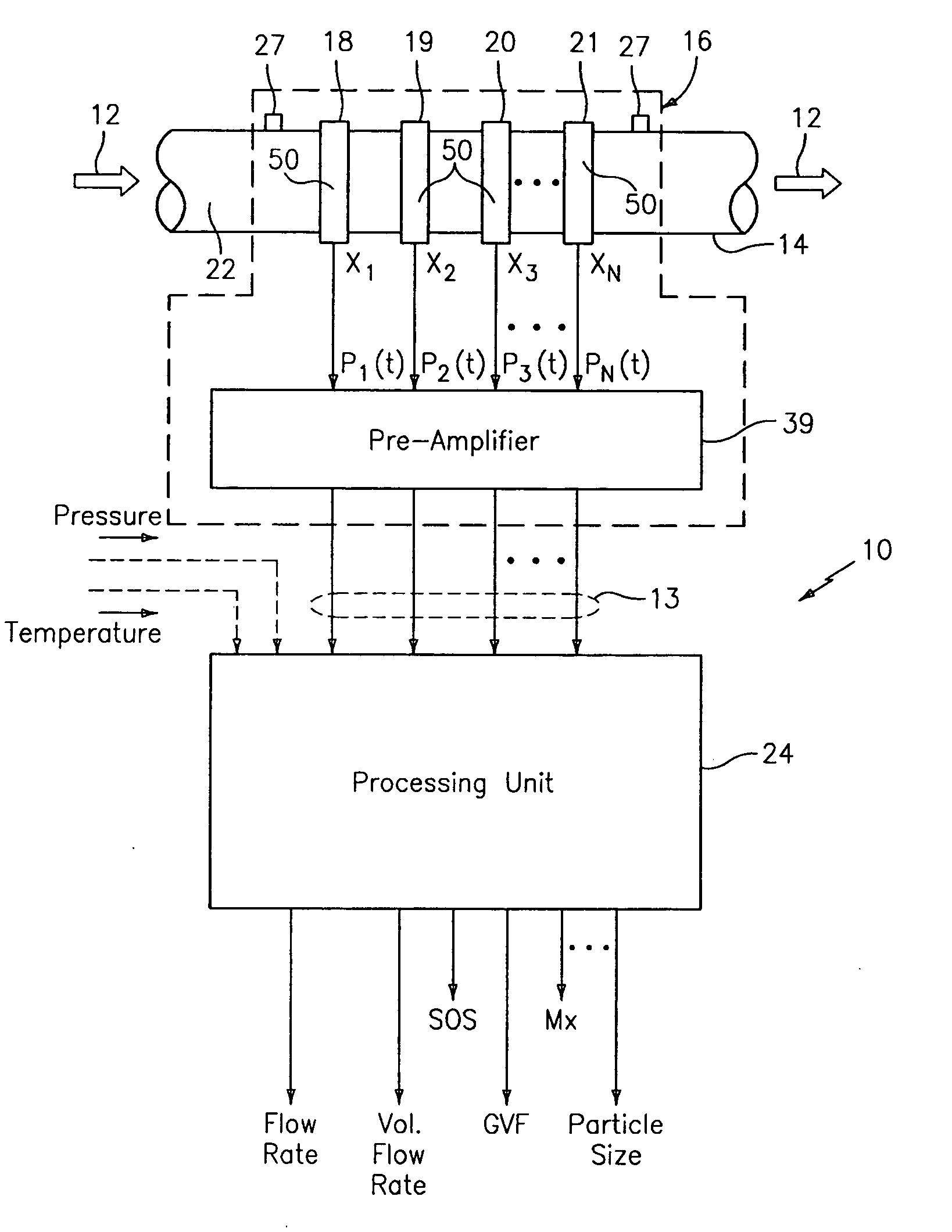

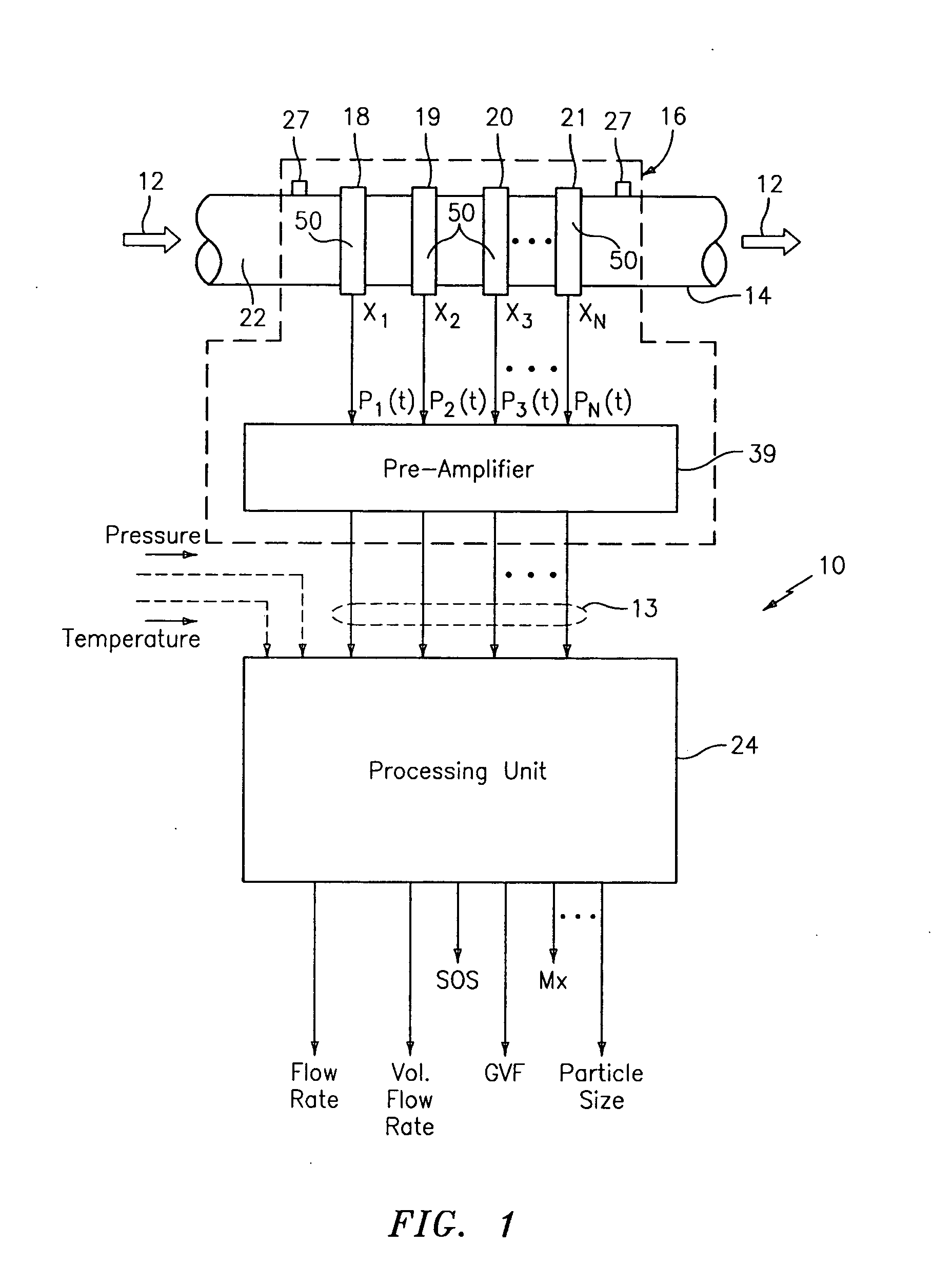

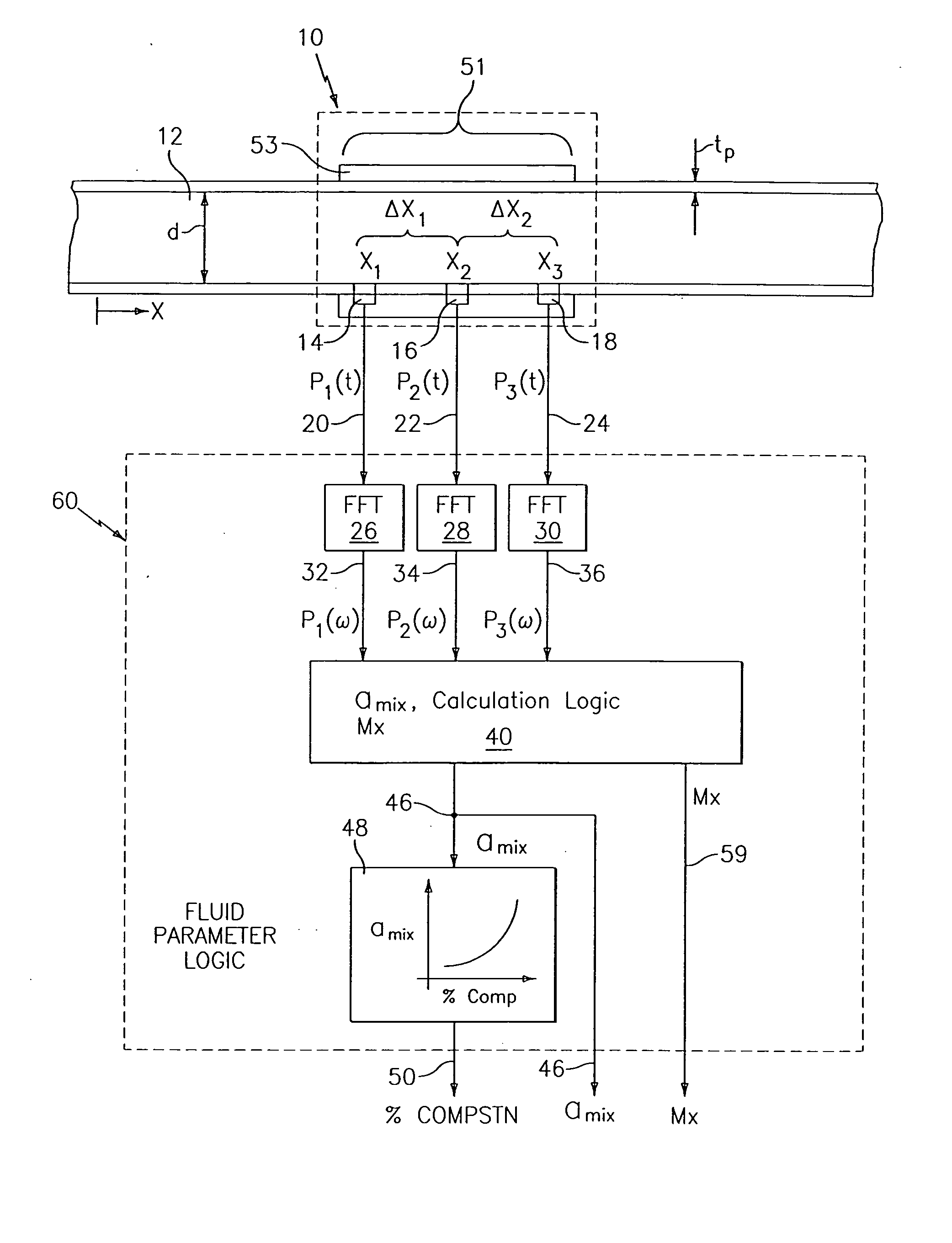

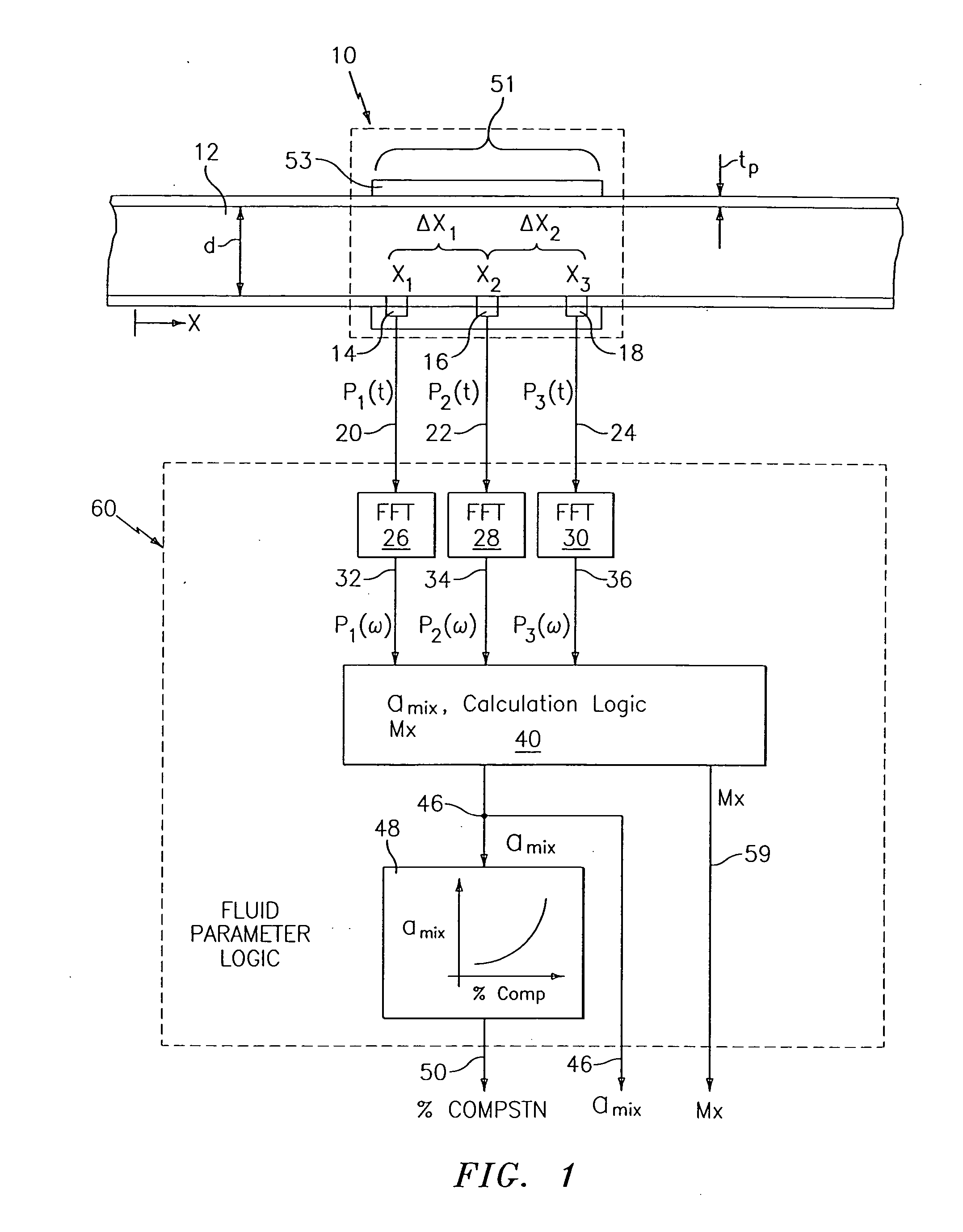

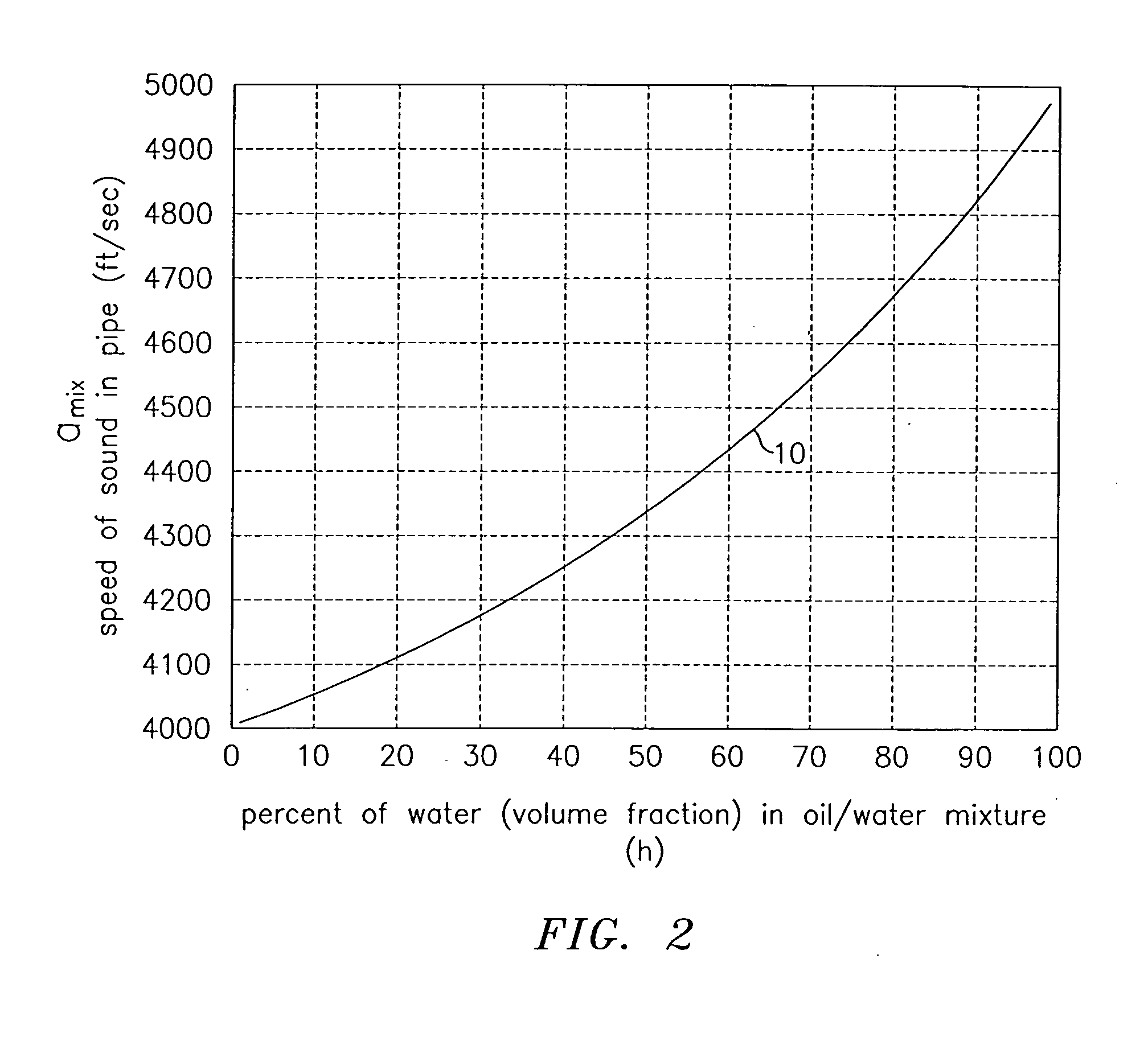

Fluid parameter measurement for industrial sensing applications using acoustic pressures

InactiveUS20050000289A1Less sensitiveImprove measurement reliabilityVibration measurement in solidsVibration measurement in fluidEngineeringOpto electronic

In industrial sensing applications at least one parameter of at least one fluid in a pipe 12 is measured using a spatial array of acoustic pressure sensors 14,16,18 placed at predetermined axial locations x1, x2, x3 along the pipe 12. The pressure sensors 14,16,18 provide acoustic pressure signals P1(t), P2(t), P3(t) on lines 20,22,24 which are provided to signal processing logic 60 which determines the speed of sound amix of the fluid (or mixture) in the pipe 12 using acoustic spatial array signal processing techniques with the direction of propagation of the acoustic signals along the longitudinal axis of the pipe 12. Numerous spatial array-processing techniques may be employed to determine the speed of sound amix. The speed of sound amix is provided to logic 48, which calculates the percent composition of the mixture, e.g., water fraction, or any other parameter of the mixture, or fluid, which is related to the sound speed amix. The logic 60 may also determine the Mach number Mx of the fluid. The acoustic pressure signals P1(t), P2(t), P3(t) measured are lower frequency (and longer wavelength) signals than those used for ultrasonic flow meters, and thus is more tolerant to inhomogeneities in the flow. No external source is required and thus may operate using passive listening. The invention will work with arbitrary sensor spacing and with as few as two sensors if certain information is known about the acoustic properties of the system. The sensor may also be combined with an instrument, an opto-electronic converter and a controller in an industrial process control system.

Owner:EXPRO METERS

Probe for measuring parameters of a flowing fluid and/or multiphase mixture

A probe 10,170 is provided that measures the speed of sound and / or vortical disturbances propagating in a single phase fluid flow and / or multiphase mixture to determine parameters, such as mixture quality, particle size, vapor / mass ratio, liquid / vapor ratio, mass flow rate, enthalpy and volumetric flow rate of the flow in a pipe or unconfined space, for example, using acoustic and / or dynamic pressures. The probe includes a spatial array of unsteady pressure sensors 15-18 placed at predetermined axial locations x1-xN disposed axially along a tube 14. For measuring at least one parameter of a saturated vapor / liquid mixture 12, such as steam, flowing in the tube 14. The pressure sensors 15-18 provide acoustic pressure signals P1(t)-PN(t) to a signal processing unit 30 which determines the speed of sound amix propagating through of the saturated vapor / liquid mixture 12 in the tube 14 using acoustic spatial array signal processing techniques. Frequency based sound speed is determined utilizing a dispersion model to determine the parameters of interest.

Owner:EXPRO METERS

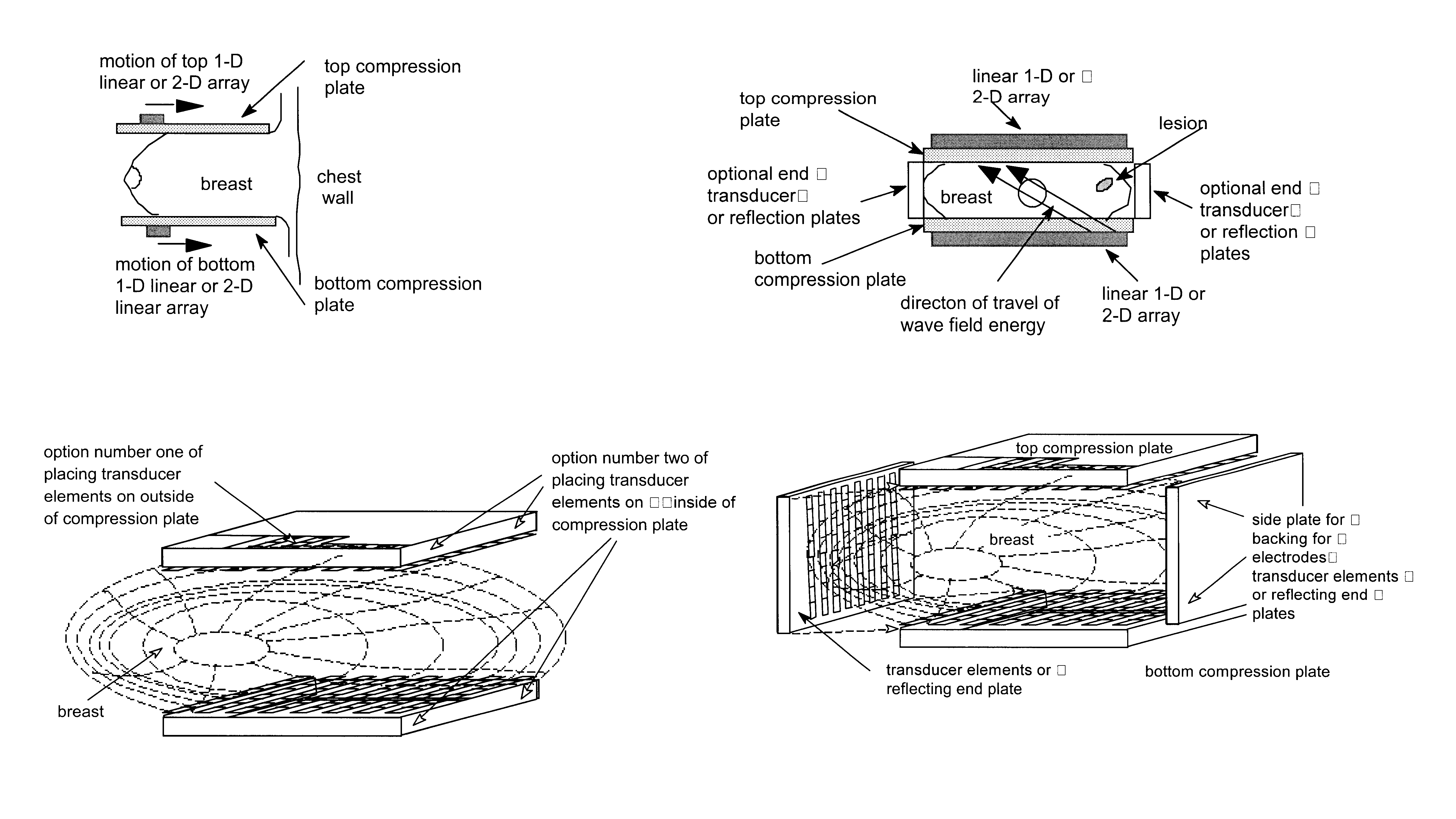

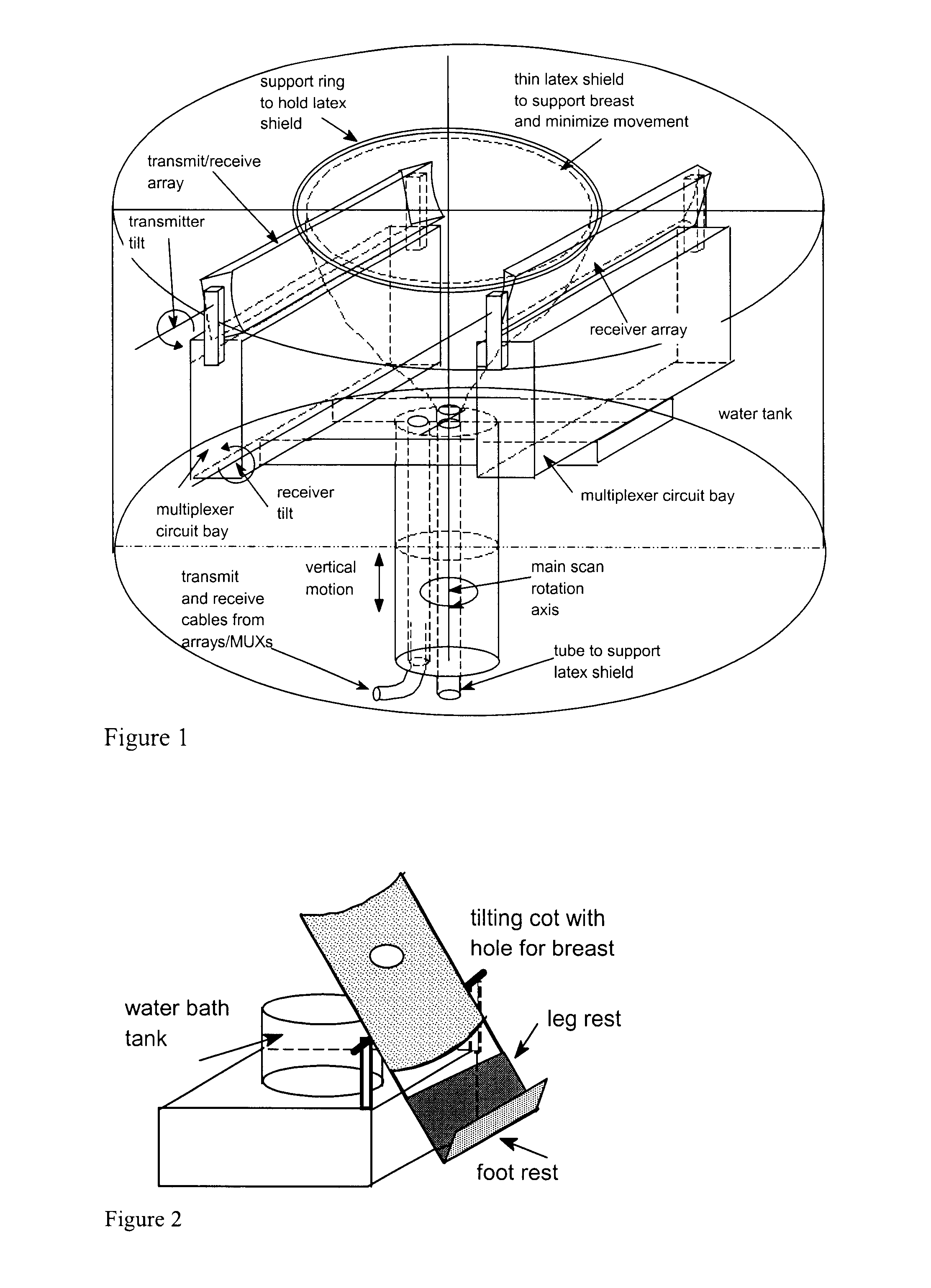

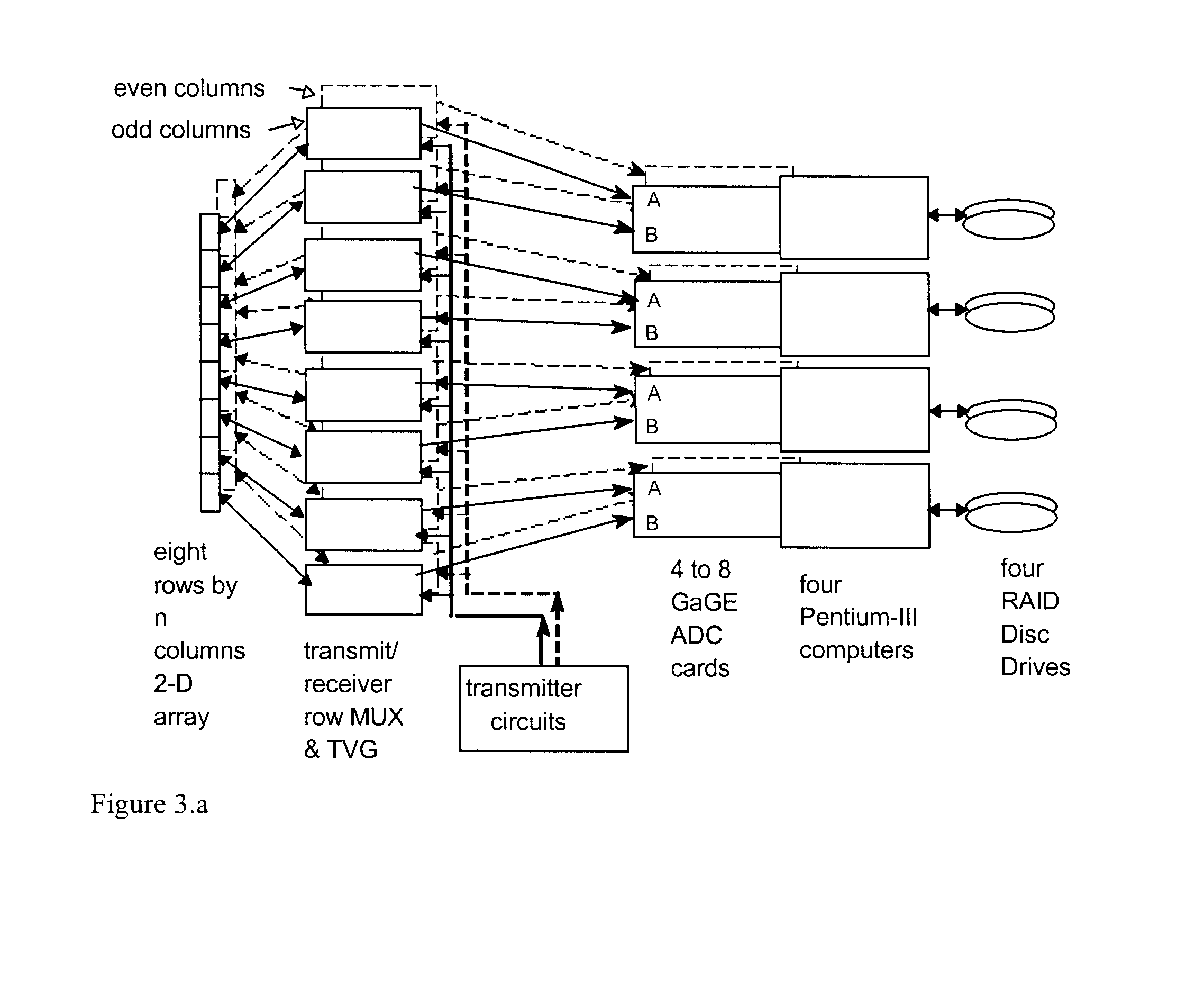

Apparatus and method for imaging objects with wavefields

This invention describes a method for increasing the speed of the parabolic marching method by about a factor of 256. Firstly, to form true 3-D images or 3-D assembled from 2-D slices. Secondly, the frequency of operation can be increased to 5 MHz to match the operating frequency of reflection tomography. This allow the improved imaging of speed of sound which in turn is used to correct errors in focusing delays in reflection tomography imaging. This allows reflection tomography to reach or closely approach its theoretical spatial resolution of ½ to ¾ wave lengths. A third benefit of increasing the operating frequency of inverse scattering to 5 MHz is the improved out of topographic plane spatial resolution. This improves the ability to detect small lesions. It also allow the use of small transducers and narrower beams so that slices can be made closer to the chest wall.

Owner:TECHNISCAN

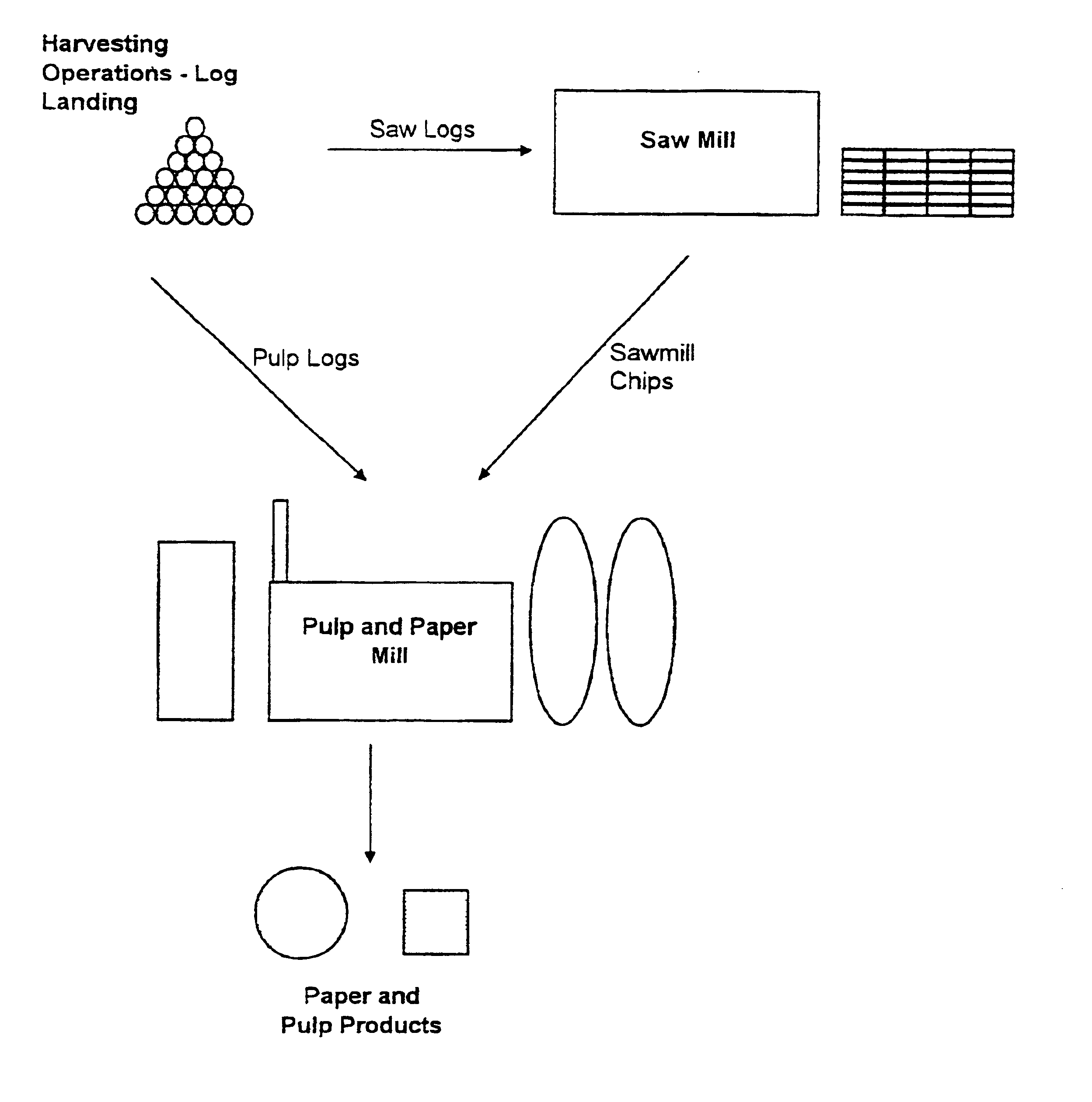

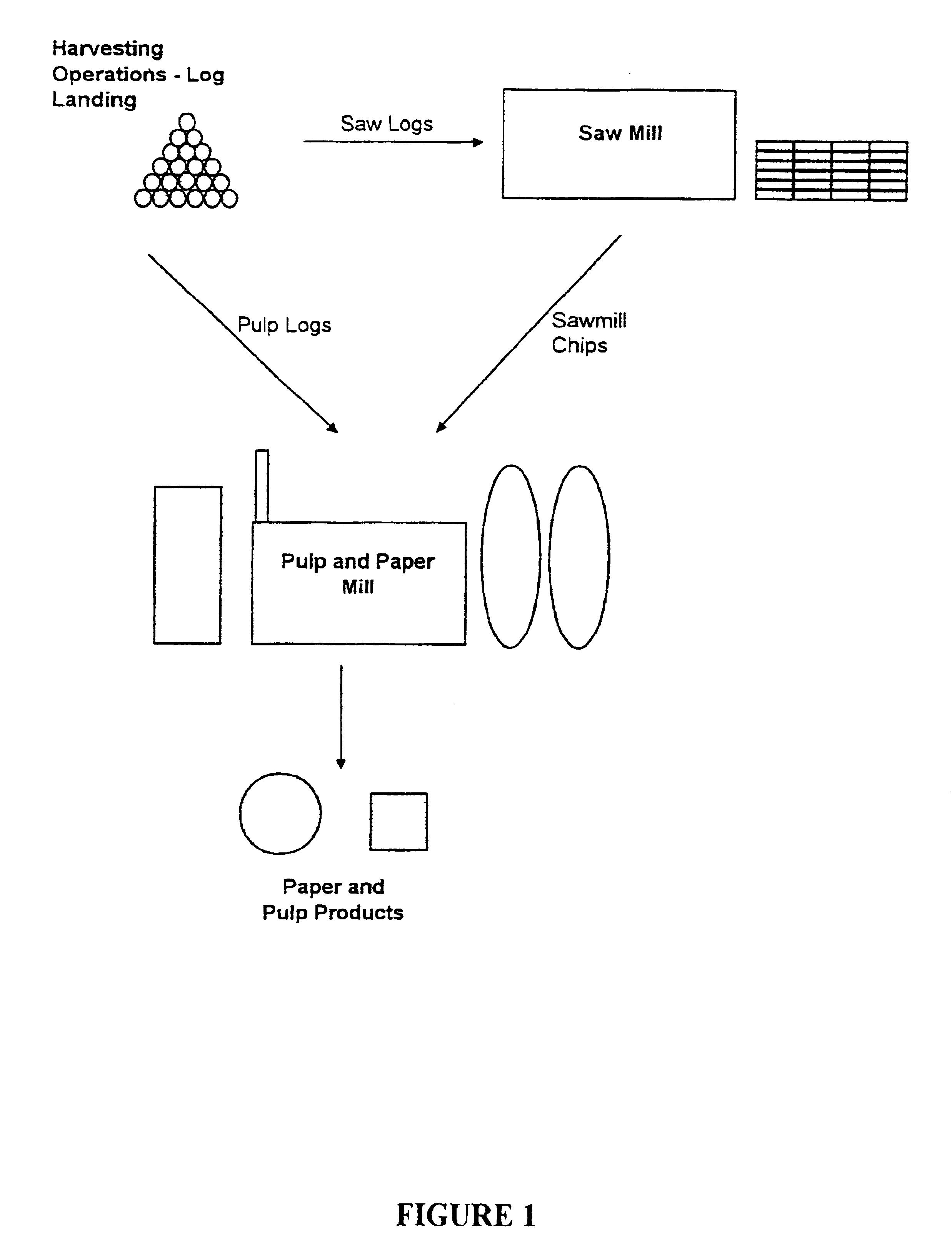

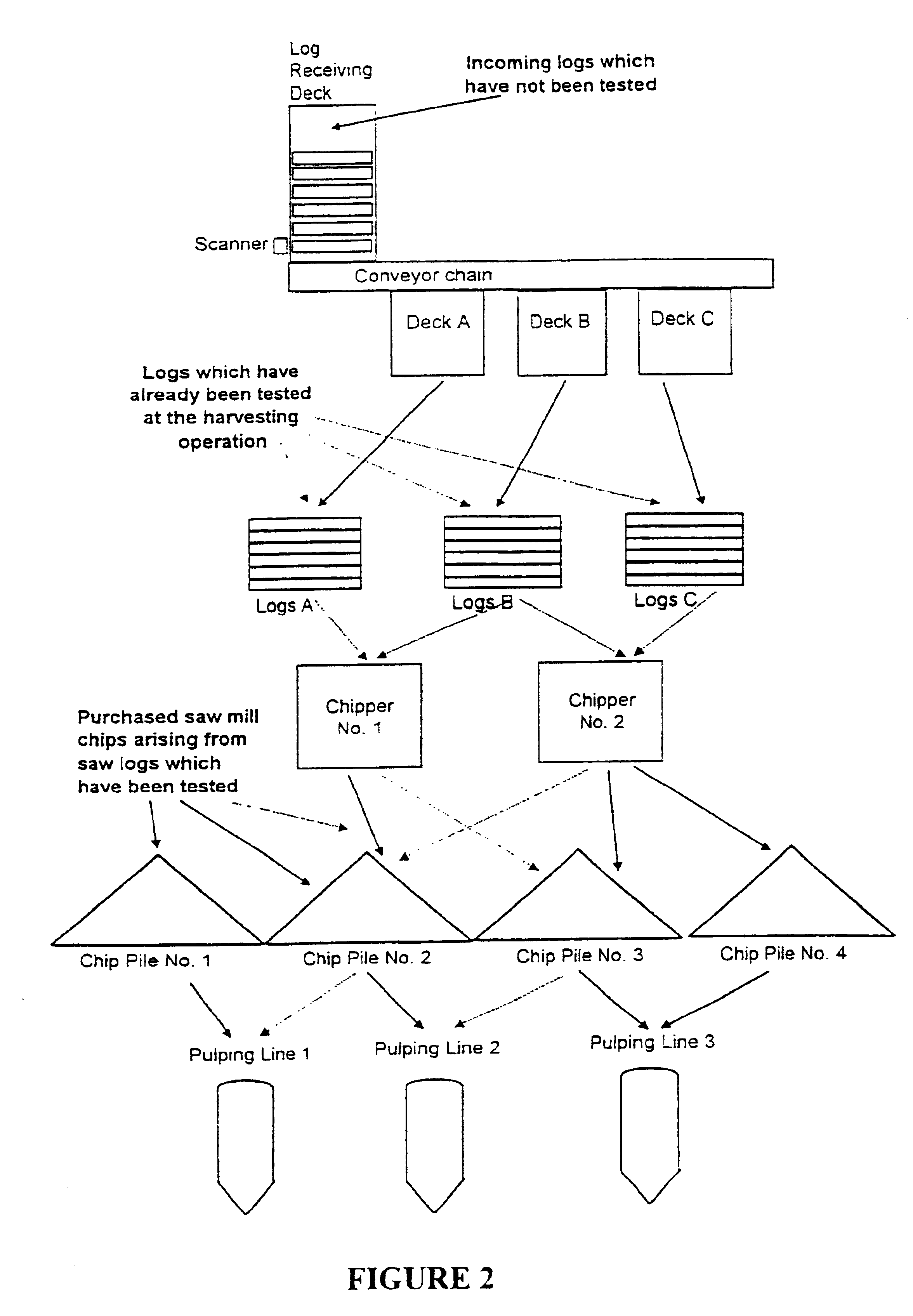

Method of selecting and/or processing wood according to fibre characteristics

InactiveUS6773552B1Analysing solids using sonic/ultrasonic/infrasonic wavesDigestersSolid woodWood fibre

The invention provides a method for predictively assessing one or more characteristics of wood pulp produced from solid wood. The method comprises the steps of determining the velocity of sound through the solid wood, and assessing characteristic(s) of wood fiber or wood pulp produced from the wood by reference to the velocity of sound through the solid wood. The method may also comprise the steps of causing a sound wave to be transmitted through the wood, determining the velocity of the sound wave through the wood, and comparing the result to stored information on fiber characteristic(s) versus sound velocity through the wood-type to determine the fiber characteristic(s) for the wood.

Owner:FIBER GEN INSTR

Apparatus and method for measuring parameters of a mixture having solid particles suspended in a fluid flowing in a pipe

InactiveUS20050171710A1Analysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesEngineeringSolid particle

An apparatus 10 and method is provided that includes a spatial array of unsteady pressure sensors 15-18 placed at predetermined axial locations x1-xN disposed axially along a pipe 14 for measuring at least one parameter of a solid particle / fluid mixture 12 flowing in the pipe 14. The pressure sensors 15-18 provide acoustic pressure signals P1(t)-PN(t) to a signal processing unit 30 which determines the speed of sound amix(ω) of the particle / fluid mixture 12 in the pipe 14 using acoustic spatial array signal processing techniques. The primary parameters to be measured include fluid / particle concentration, fluid / particle mixture volumetric flow, and particle size. Frequency based sound speed is determined utilizing a dispersion model to determine the parameters of interest. the calculating the at least one parameter uses an acoustic pressure to calculate

Owner:EXPRO METERS

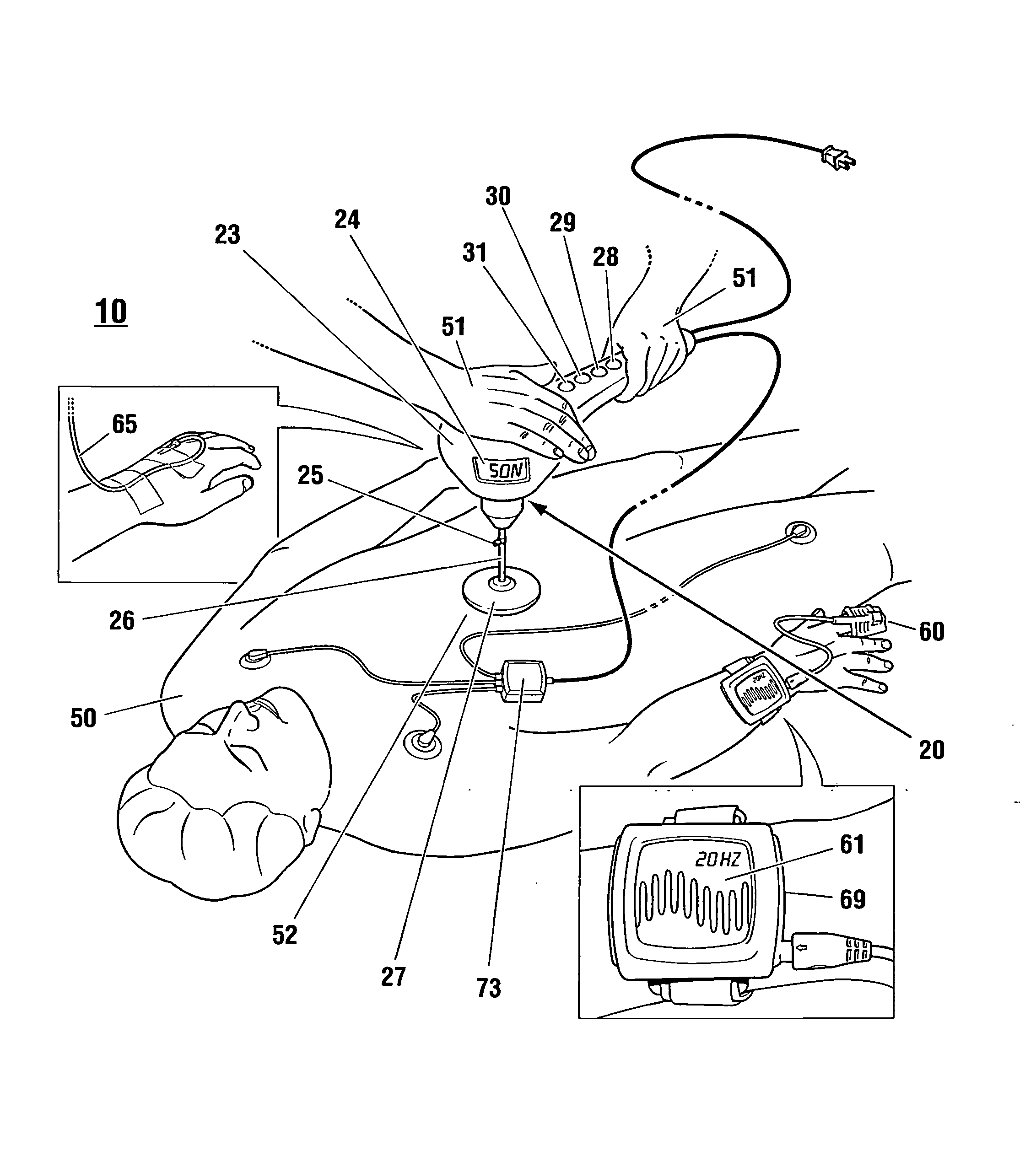

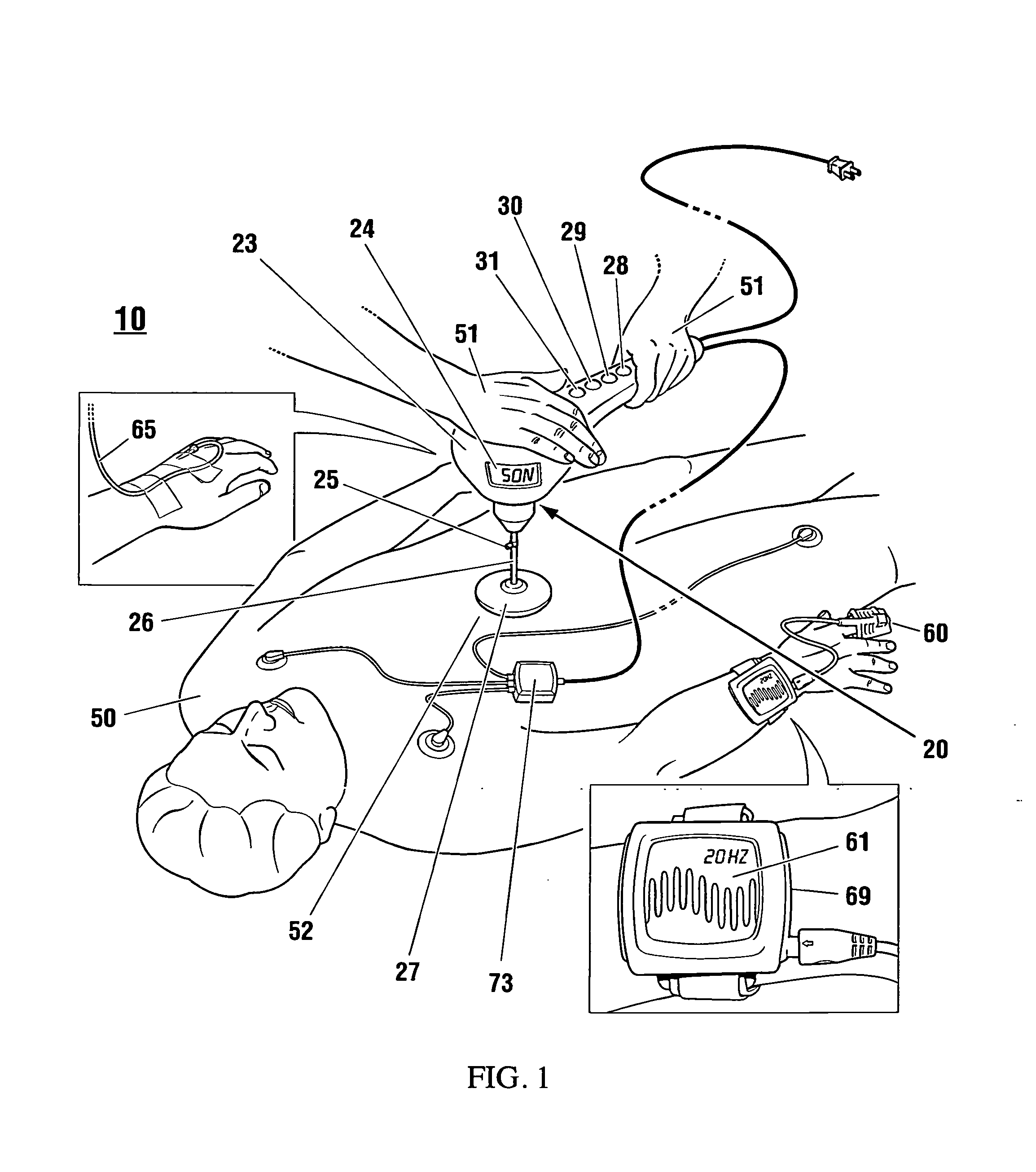

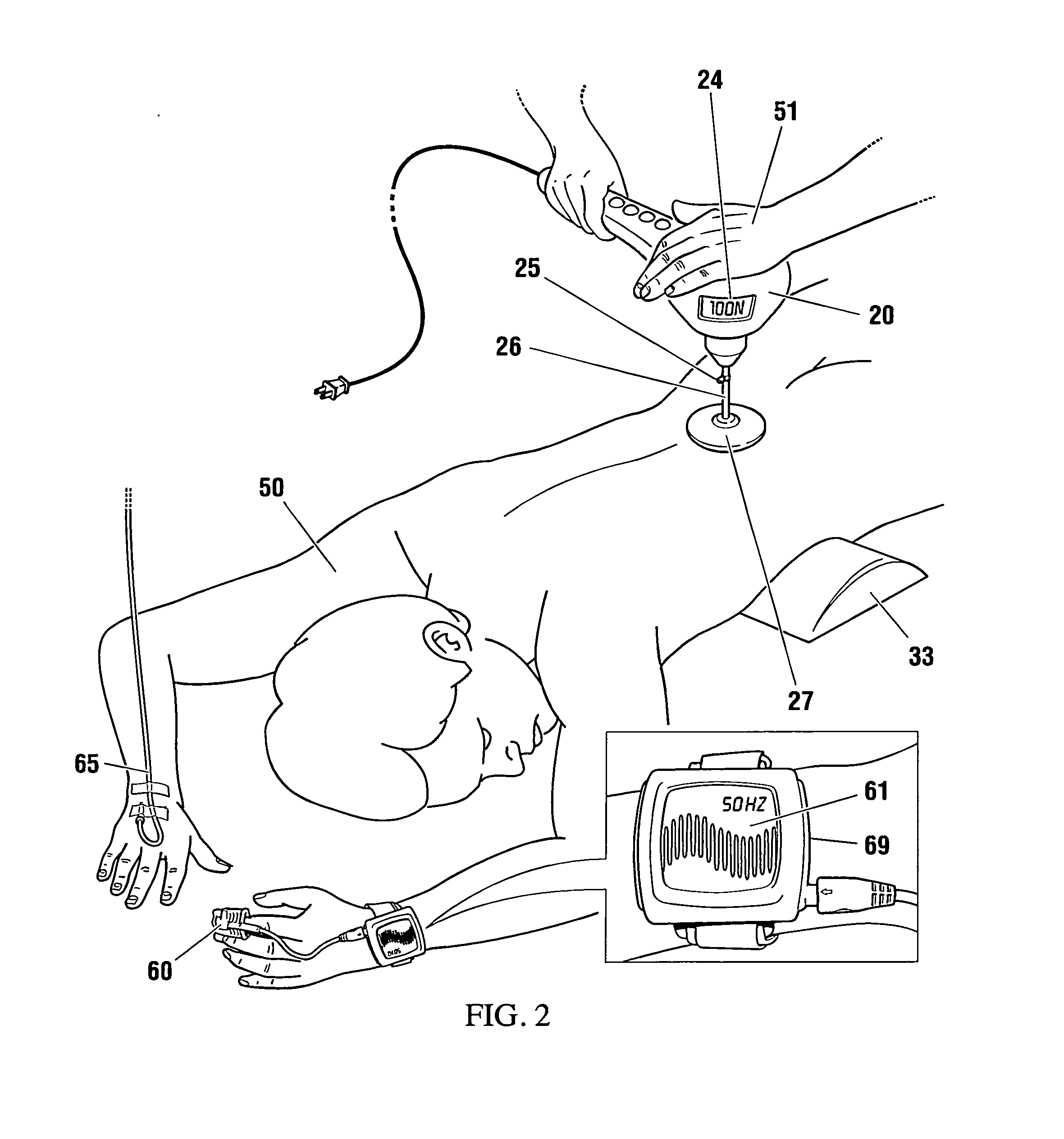

Non-invasive reperfusion system by deformation of remote, superficial arteries at a frequency much greater than the pulse rate

InactiveUS20130281897A1Effective researchEffective clinical toolUltrasound therapyOrgan movement/changes detectionPULMONARY EMBOLUSThrombus

Preferred systems for assisting clearance of an acutely thrombosed artery substantially surrounded by boney external body surfaces which are resistant to deformative displacement relative to the thrombosed artery by the application of external percussive force are described. The method consists of applying targeted, localized, non-invasive, high infrasonic to low sonic frequency vibratory percussion with a serial impact frequency much greater than the pulse rate of a patient being treated, the percussion directed towards a remote, preferably superficial “target vessel” residing palpably close to the skin surface. Marked vessel deformations with resultant blood pressure and flow fluctuations are thereby induced by the percussion within the target vessel which propagate to the acutely thrombosed artery to provide localized agitation and turbulence to assist thrombolytic and / or IV microbubble delivery and effectiveness in facilitating reperfusion. Preferred apparatus for treatment of ST elevation myocardial infarction, acute ischemic stroke and acute pulmonary embolus are presented.

Owner:AHOF BIOPHYSICAL SYST

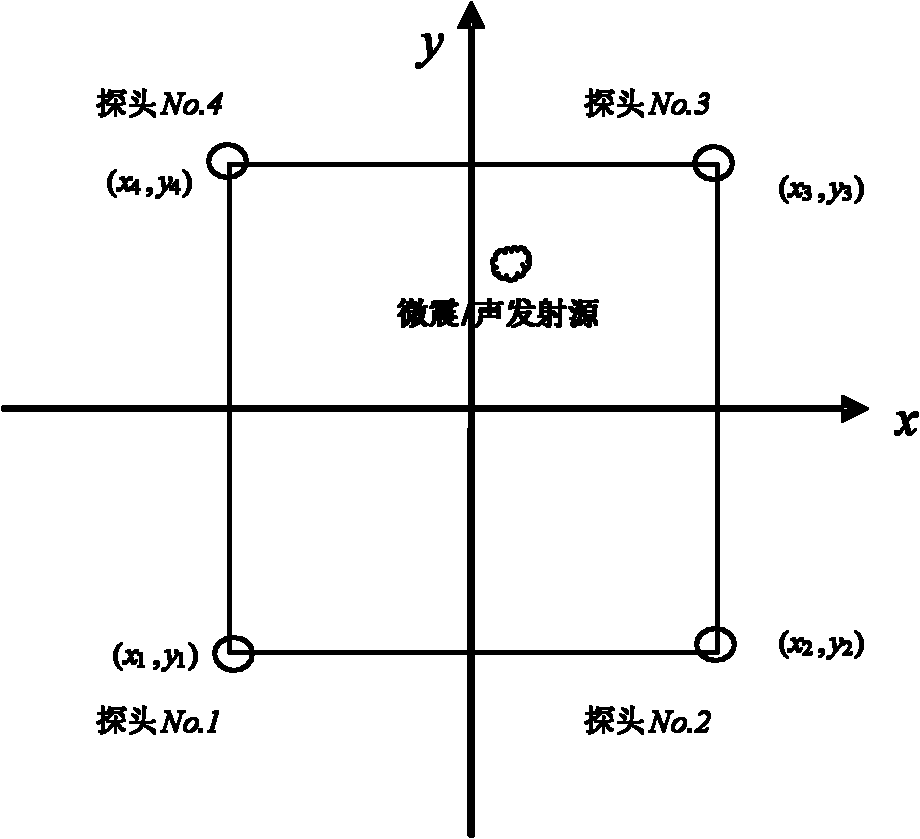

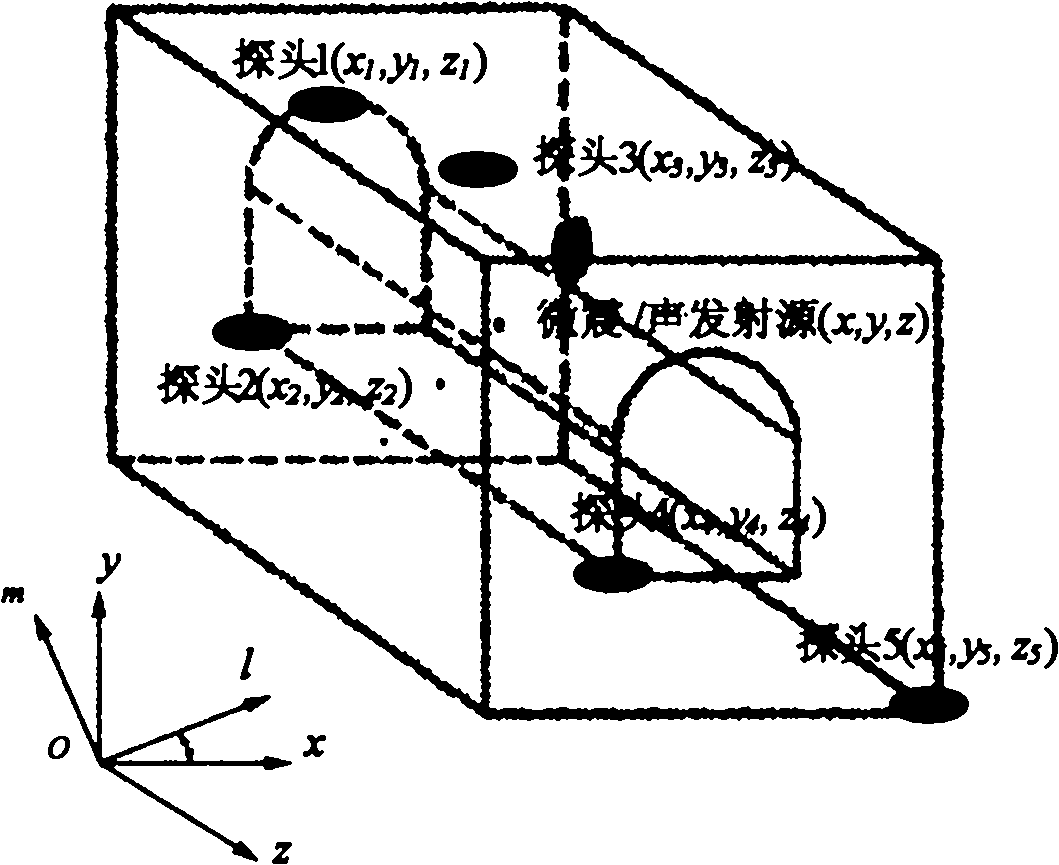

Method for positioning micro seismic source or acoustic emission source

The invention discloses a method for positioning a micro seismic source or an acoustic emission source, which comprises the following steps of: placing a plurality of acoustic emission transducers nearby an object to be detected, and solving position coordinates of the micro seismic source or the acoustic emission source by using a nonlinear least square regression method, such as a simplex acceleration method or a Marquardt method or the like, according to the coordinate values and the time difference of the positions of the known transducers and according to a distance operational formula. The acoustic emission positioning method disclosed by the invention does not need to measure or preset acoustic velocity, can avoid the influence of acoustic velocity measurement on positioning, improves the positioning precision, and is convenient and practical in practical engineering application compared with a traditional method.

Owner:CENT SOUTH UNIV

Flow measurement apparatus having strain-based sensors and ultrasonic sensors

ActiveUS20050125170A1More robustMaterial analysis using sonic/ultrasonic/infrasonic wavesVolume/mass flow measurementUltrasonic sensorMeasurement device

A flow measurement apparatus is provided that combines the functionality of an apparatus that uses strain-based sensors and ultrasonic sensors to measure the speed of sound propagating through a fluid flowing within a pipe, and measure pressures disturbances (e.g. vortical disturbances or eddies) moving with a fluid to determine respective parameters of the flow propagating through a pipe. The apparatus includes a sensing device that includes an array of pressure sensors used to measure the acoustic and convective pressure variations in the flow to determine desired parameters and an ultrasonic meter portion to measure the velocity and volumetric flow of the fluid. In response to an input signal or internal logic, the processor can manually or dynamically switch between the pressure sensors and ultrasonic sensors to measure the parameters of the flow. The flow measurement apparatus thereby provides a robust meter capable of measuring fluid flows having a wide range of different characteristics and flows exposed to different environmental conditions.

Owner:EXPRO METERS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com