Patents

Literature

232results about "Specific gravity using flow properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device for measuring density of a liquid

InactiveUS20080223130A1Improve accuracyMinimal roughnessMaterial analysis by observing immersed bodiesSpecific gravity using centrifugal effectsLiquid densityEngineering

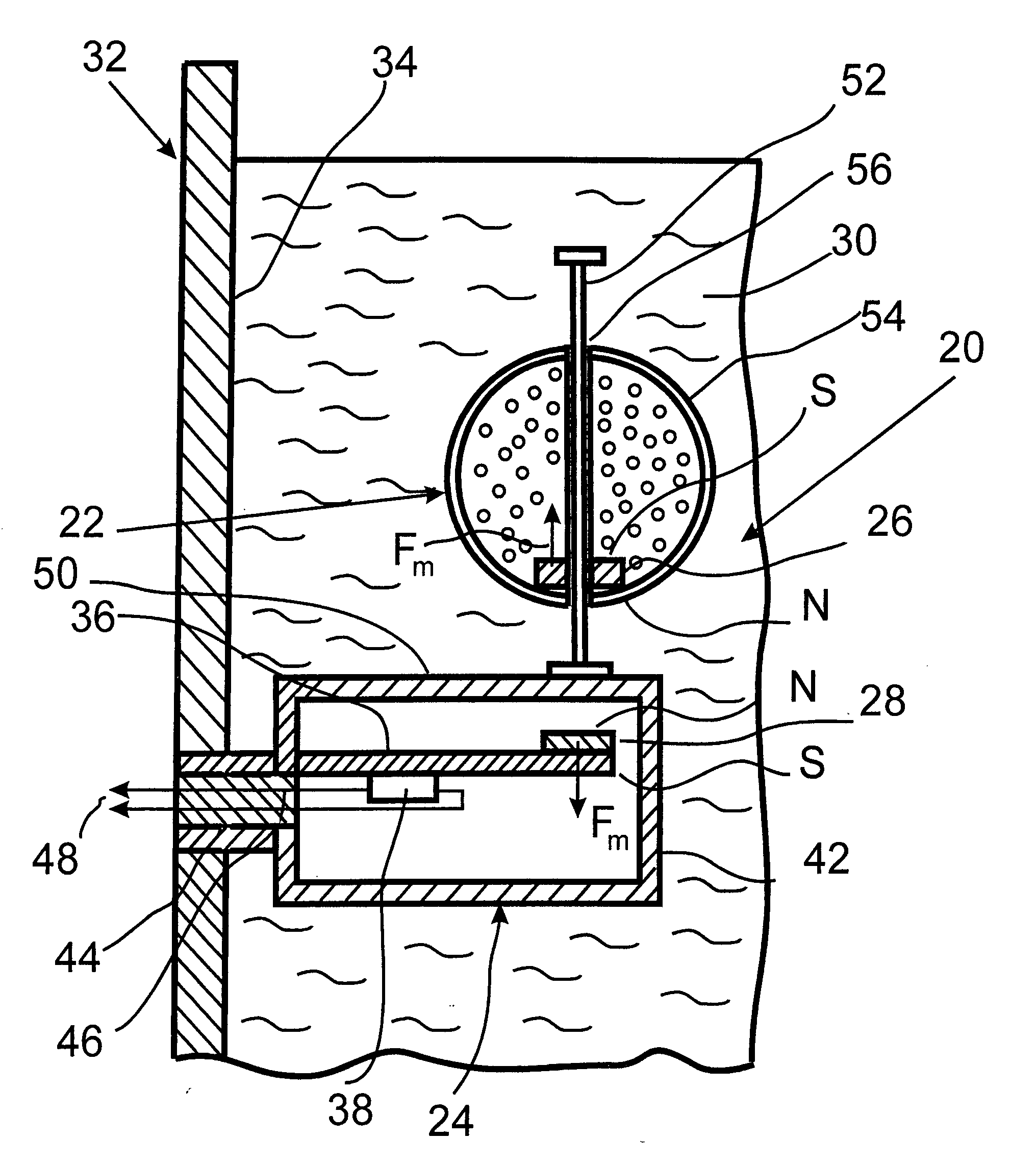

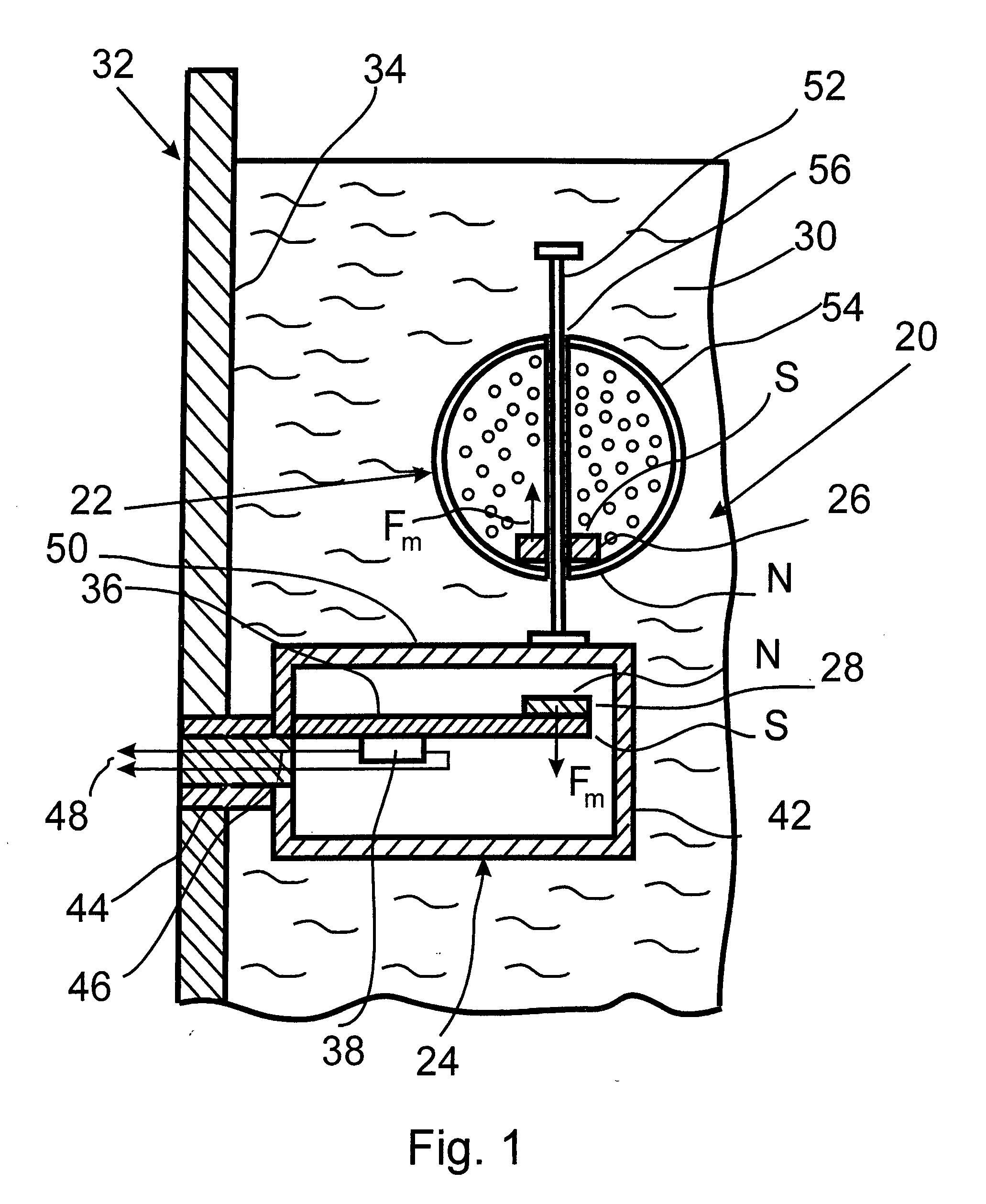

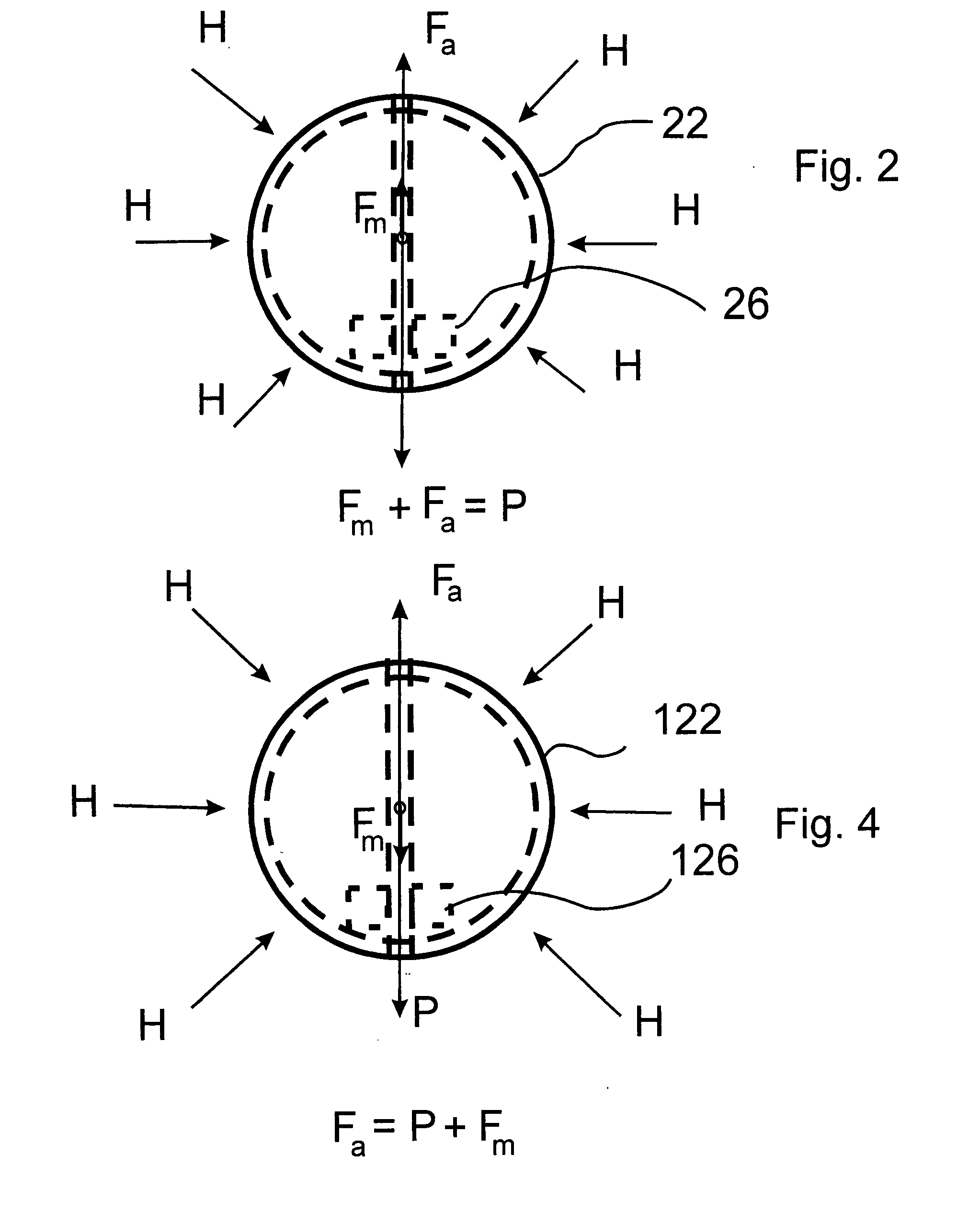

A sensor for measuring density of a liquid that comprises a float unit having a sealed hollow casing that contains a first magnet and a strain-gauge unit having a sealed hollow casing that contains a strain gauge and a second magnet arranged coaxially to the first magnet. Coaxiality of the magnets is provided by means of a guide rod installed on the casing of the strain-gauge unit and used to guide the float unit by inserting the guide rod into the central opening of the float unit casing. A characteristic feature of the sensor is that changes in the density of the liquid that cause displacement of the float cause detectable deformations of the strain gauge via forces of magnetic interaction between the first and second magnets without physical contact between the magnets. Since the elements of the sensor are located in sealed casings, they are not subject to damage and do not require maintenance.

Owner:PROVINA

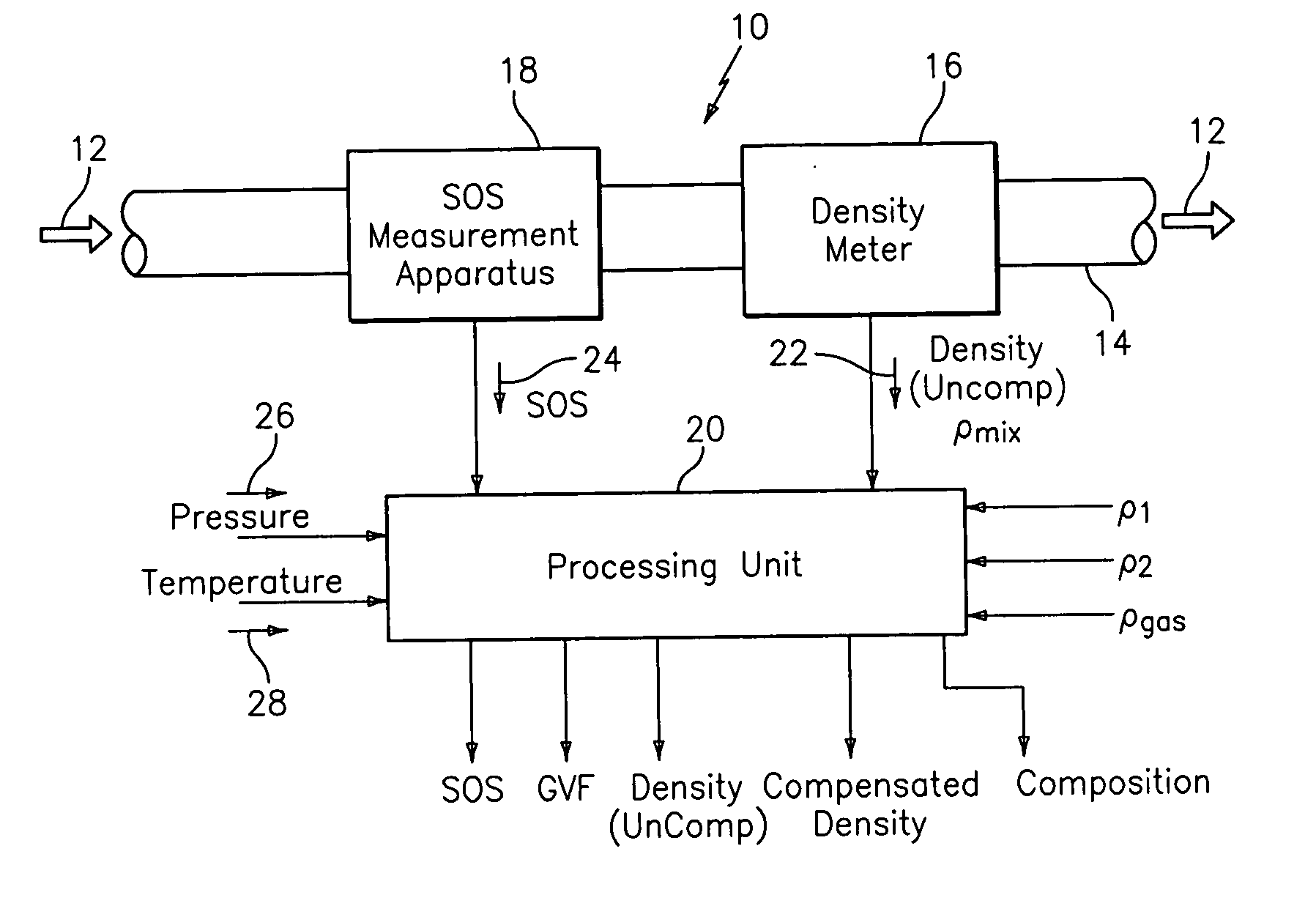

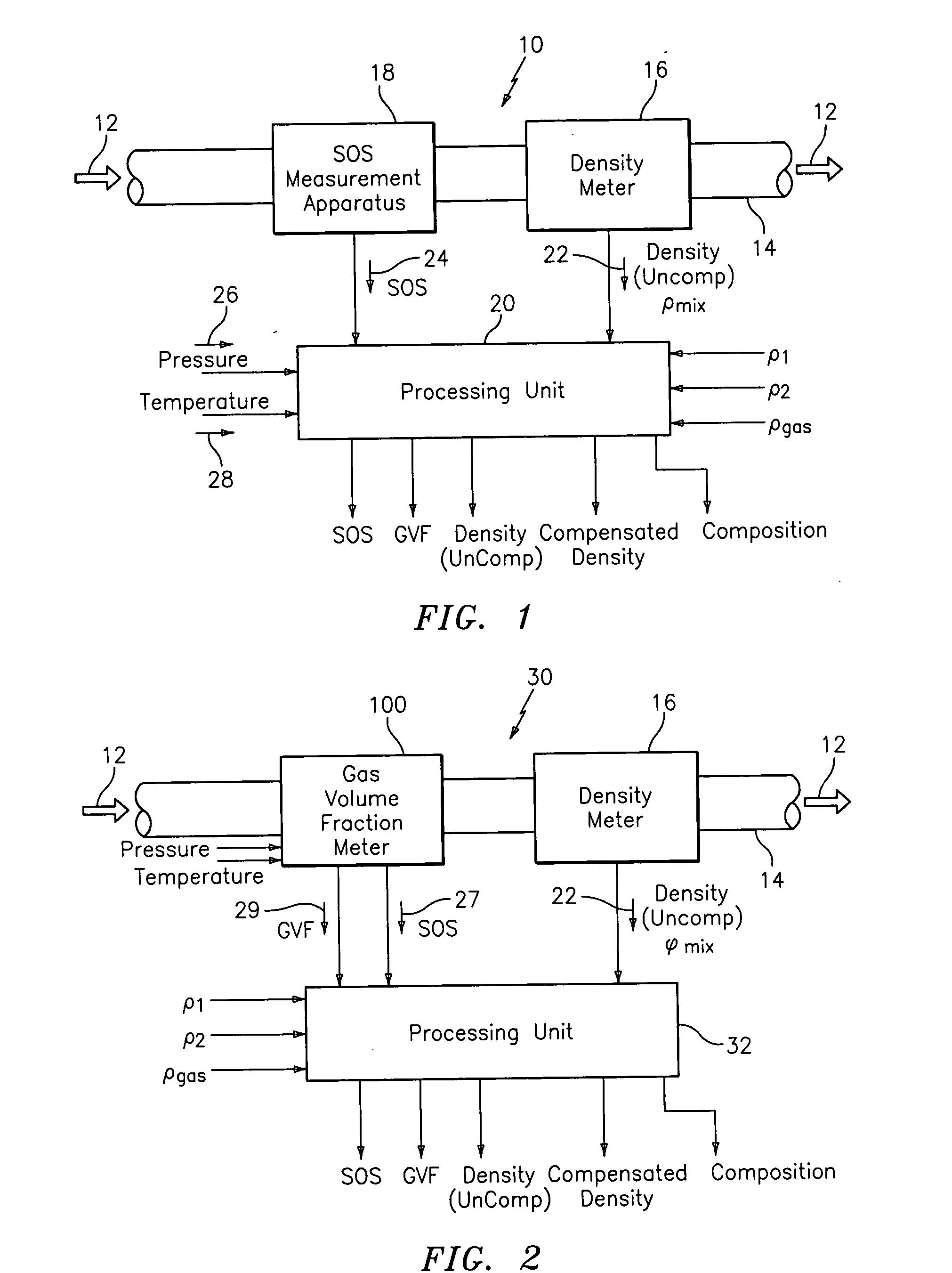

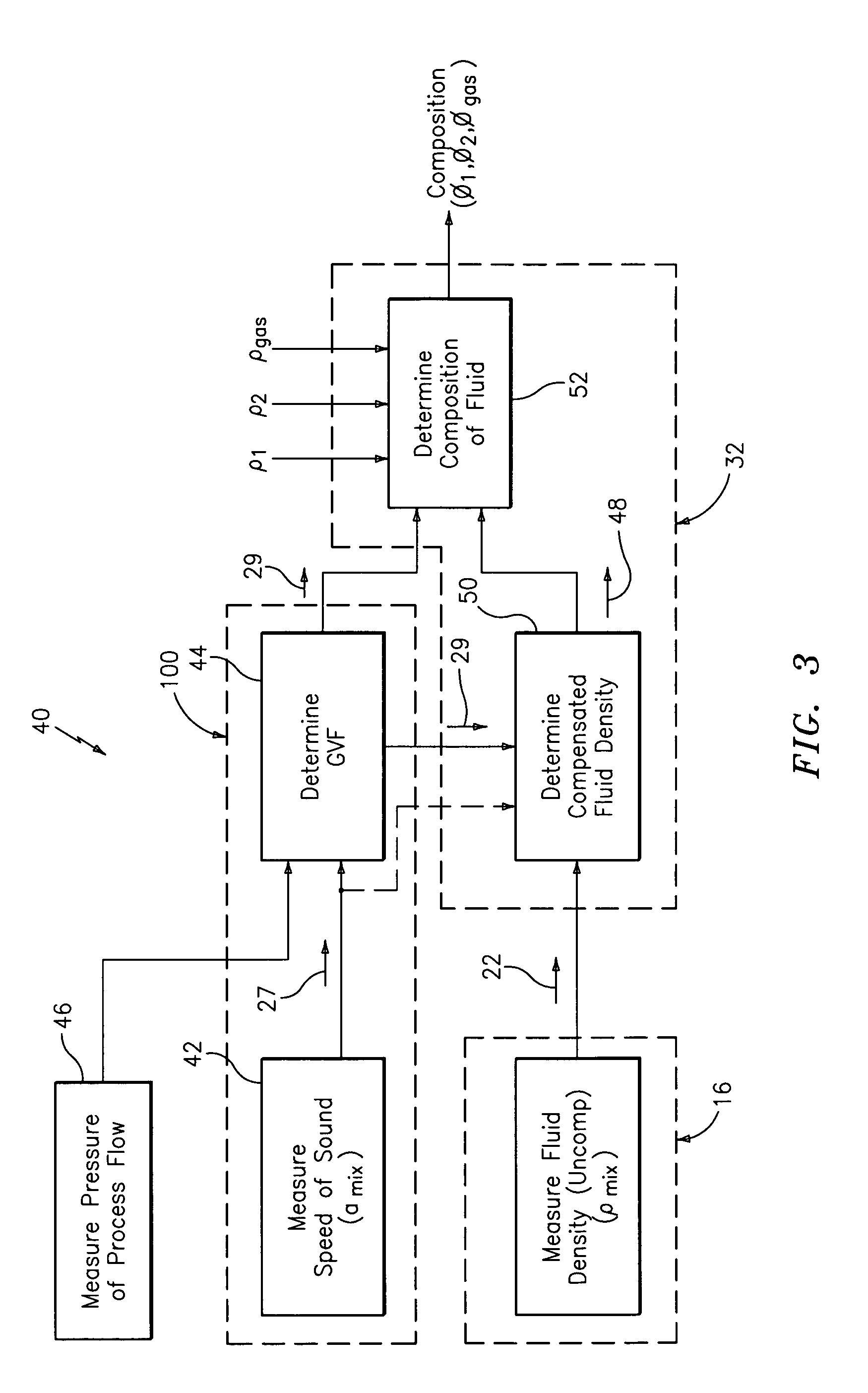

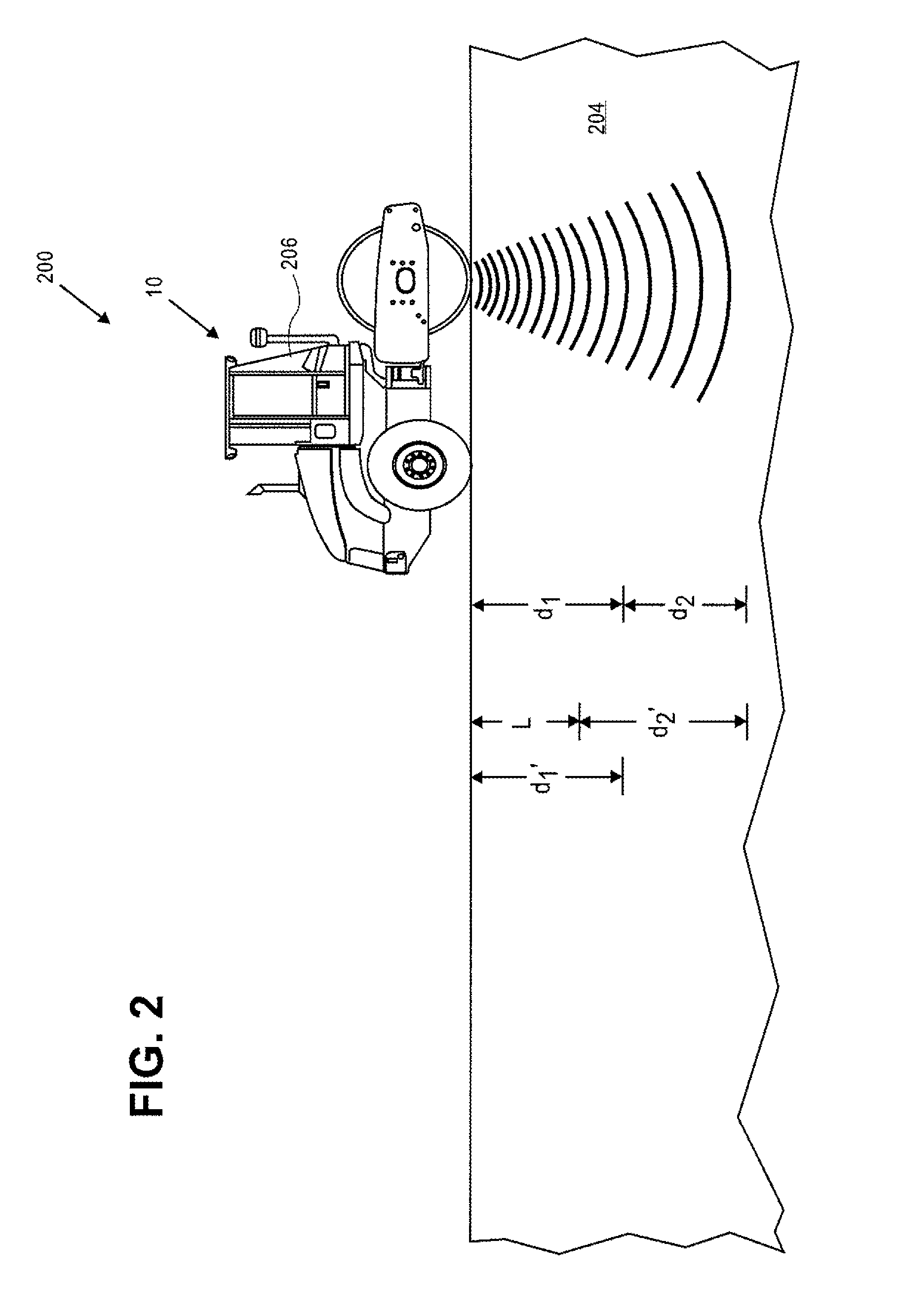

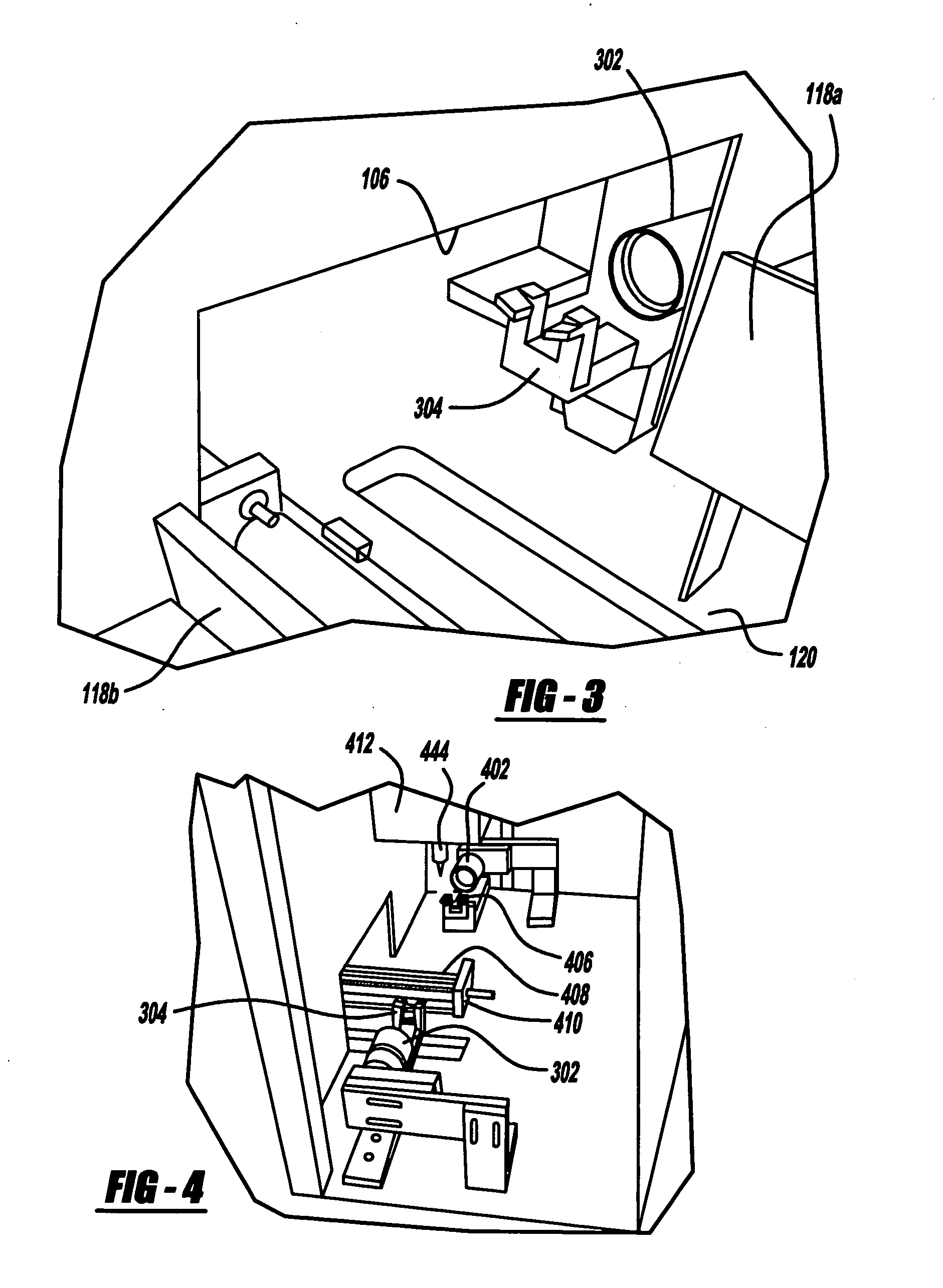

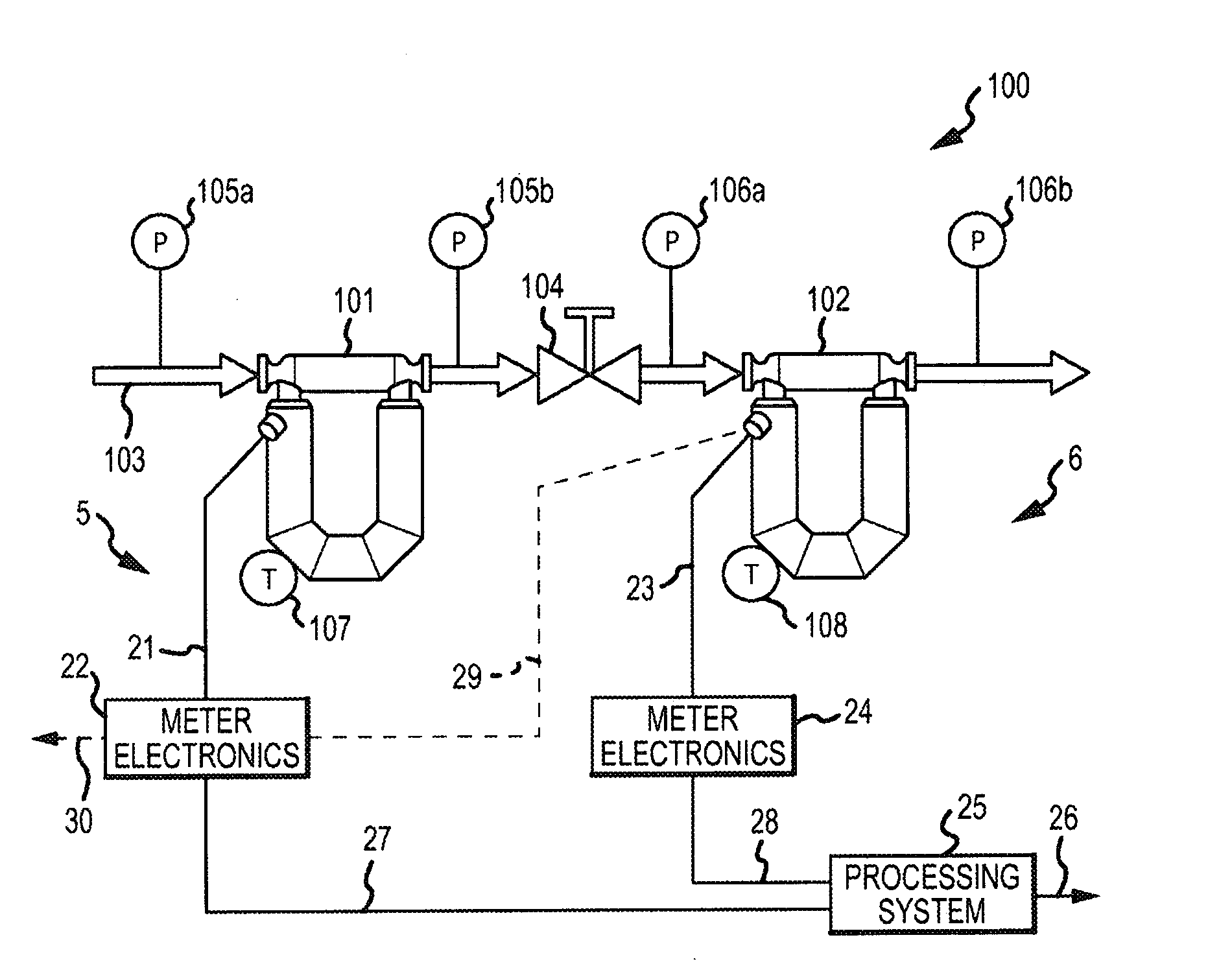

Apparatus and method for providing a density measurement augmented for entrained gas

ActiveUS20050061060A1Improve accuracySpecific gravity using flow propertiesVolume/mass flow by dynamic fluid flow effectThree-phaseDischarge measurements

A flow measuring system combines a density measuring device and a device for measuring the speed of sound (SOS) propagating through the fluid flow and / or for determining the gas volume fraction (GVF) of the flow. The GVF meter measures acoustic pressures propagating through the fluids to measure the speed of sound αmix propagating through the fluid to calculate at least gas volume fraction of the fluid and / or SOS. In response to the measured density and gas volume fraction, a processing unit determines the density of non-gaseous component of an aerated fluid flow. For three phase fluid flows, the processing unit can determine the phase fraction of the non-gaseous components of the fluid flow. The gas volume fraction (GVF) meter may include a sensing device having a plurality of strain-based or pressure sensors spaced axially along the pipe for measuring the acoustic pressures propagating through the flow.

Owner:EXPRO METERS

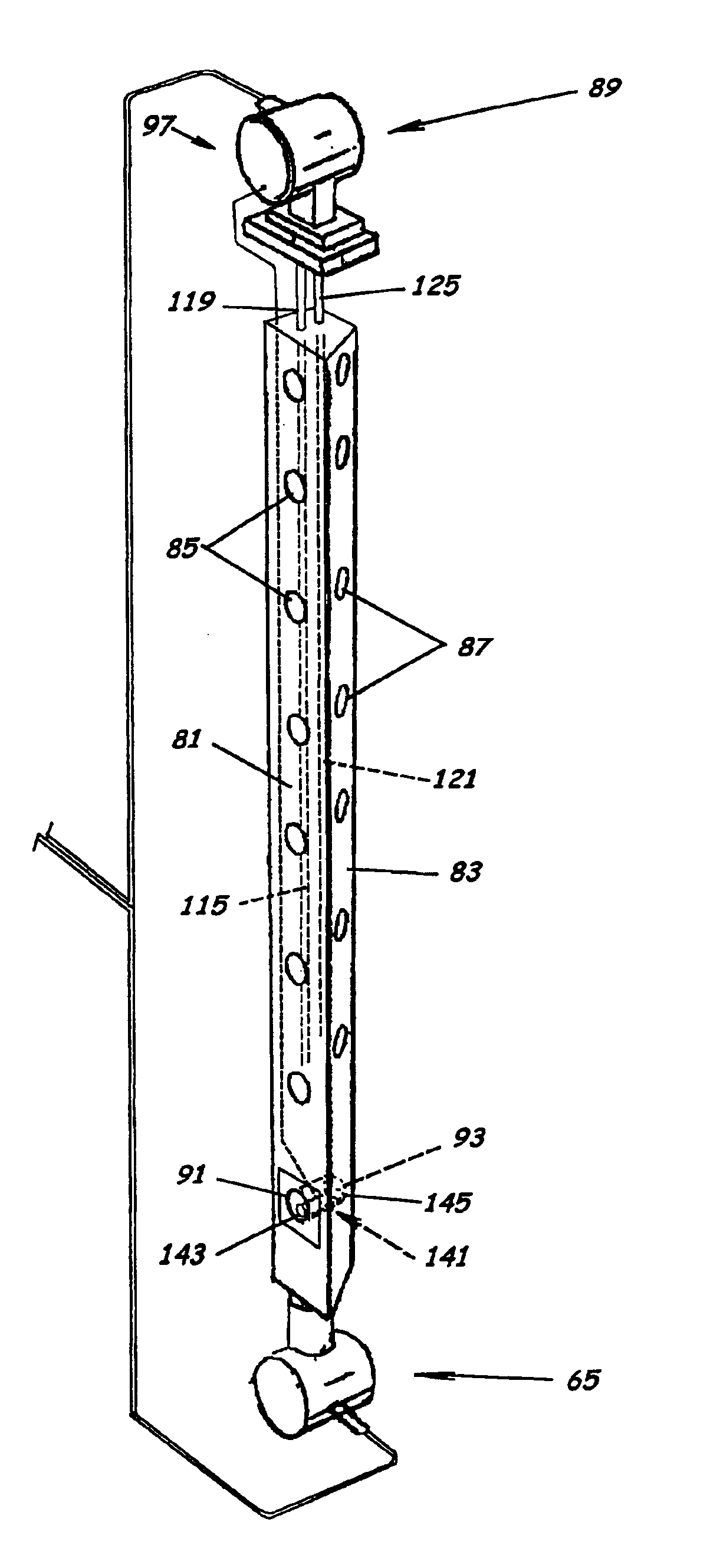

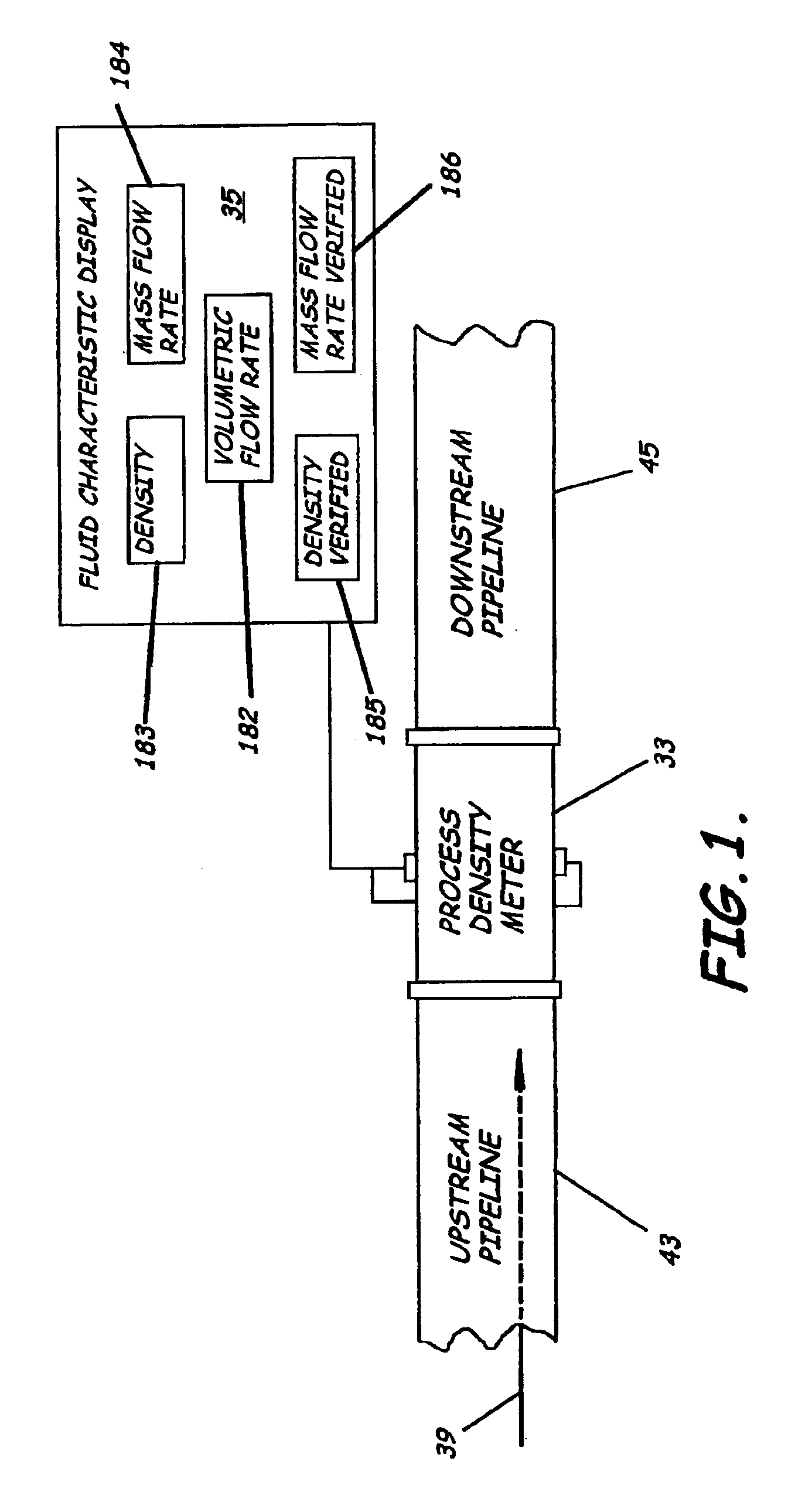

System to measure density, specific gravity, and flow rate of fluids, meter, and related methods

ActiveUS6957586B2Little maintenanceMinimization needsVolume/mass flow by thermal effectsSpecific gravity using flow propertiesDifferential pressureDisplay device

A system to measure fluid flow characteristics in a pipeline, meter, and methods includes a pipeline having a passageway to transport flowing fluid therethrough, a process density meter including at least portions thereof positioned within the pipeline to provide flowing fluid characteristics including volumetric flow rate, fluid density, and mass flow rate of the flowing fluid, and a fluid characteristic display to display the fluid characteristics. The process density meter includes a vortex-shedding body positioned within the pipeline to form vortices and a vortex meter having a vortex frequency sensor to measure the frequency of the vortices and to determine the volumetric flow rate. The process density meter further includes a differential pressure meter positioned adjacent the vortex-shedding body to produce a differential pressure meter flow rate signal indicative of the density of fluid when flowing through the pipeline. The process density meter also includes a thermal flow meter positioned adjacent the vortex-shedding body to produce a mass flow rate signal indicative of the mass flow rate of fluid when flowing through the pipeline. The process density meter produces an output of a volumetric flow rate, a flowing fluid density, and a mass flow rate to be displayed by the fluid characteristic display.

Owner:SAUDI ARABIAN OIL CO

Flow detectors having mechanical oscillators, and use thereof in flow characterization systems

ActiveUS20030000291A1Ability to useNormalize signalAnalysing fluids using sonic/ultrasonic/infrasonic wavesComponent separationTuning forkEngineering

An improved system, device and method for characterizing a fluid sample that includes injecting a fluid sample into a mobile phase of a flow characterization system, and detecting a property of the fluid sample or of a component thereof with a flow detector comprising a mechanical resonator, preferably one that is operated at a frequency less than about 1 MHz, such as a tuning fork resonator.

Owner:MEAS FRANCE

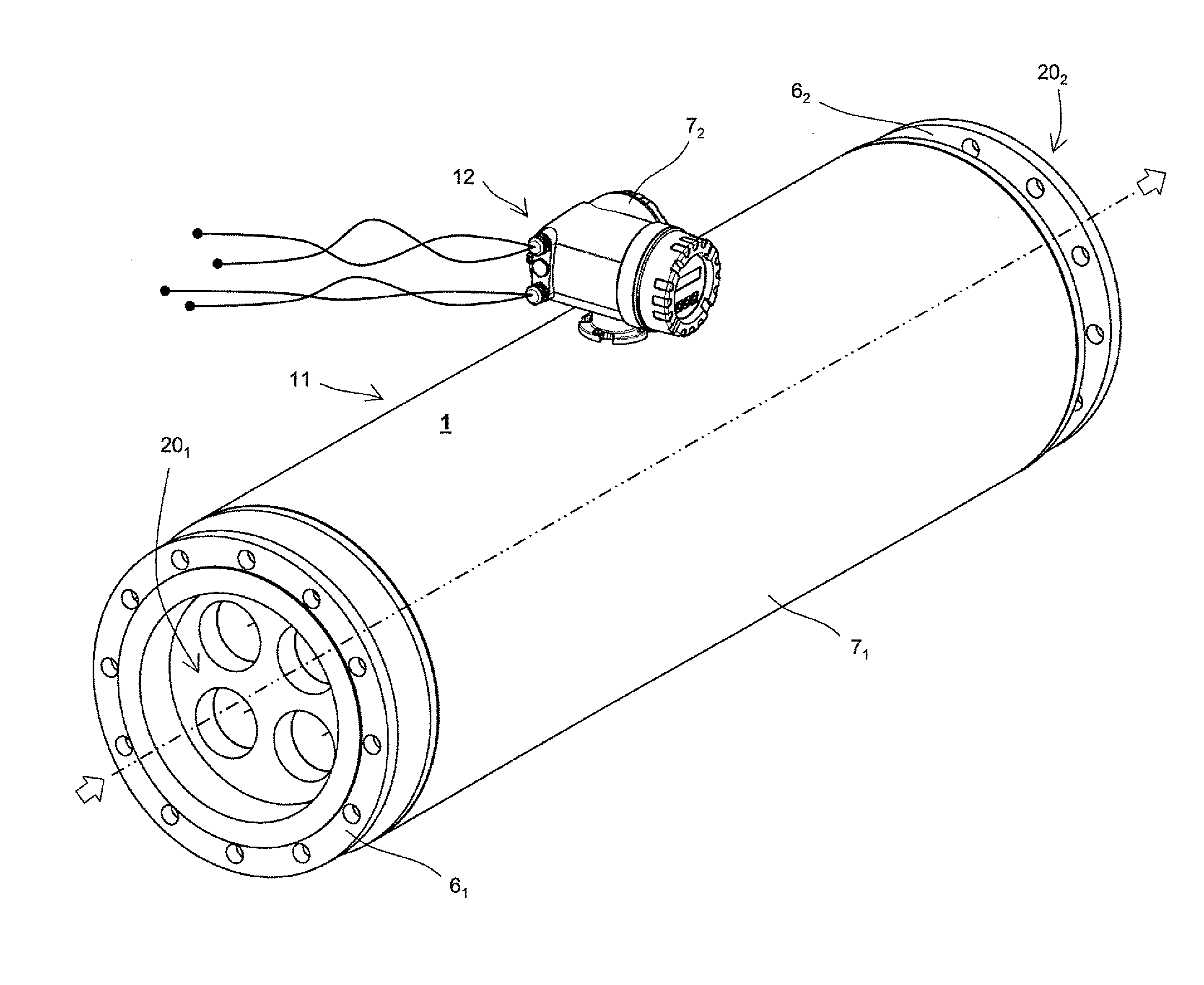

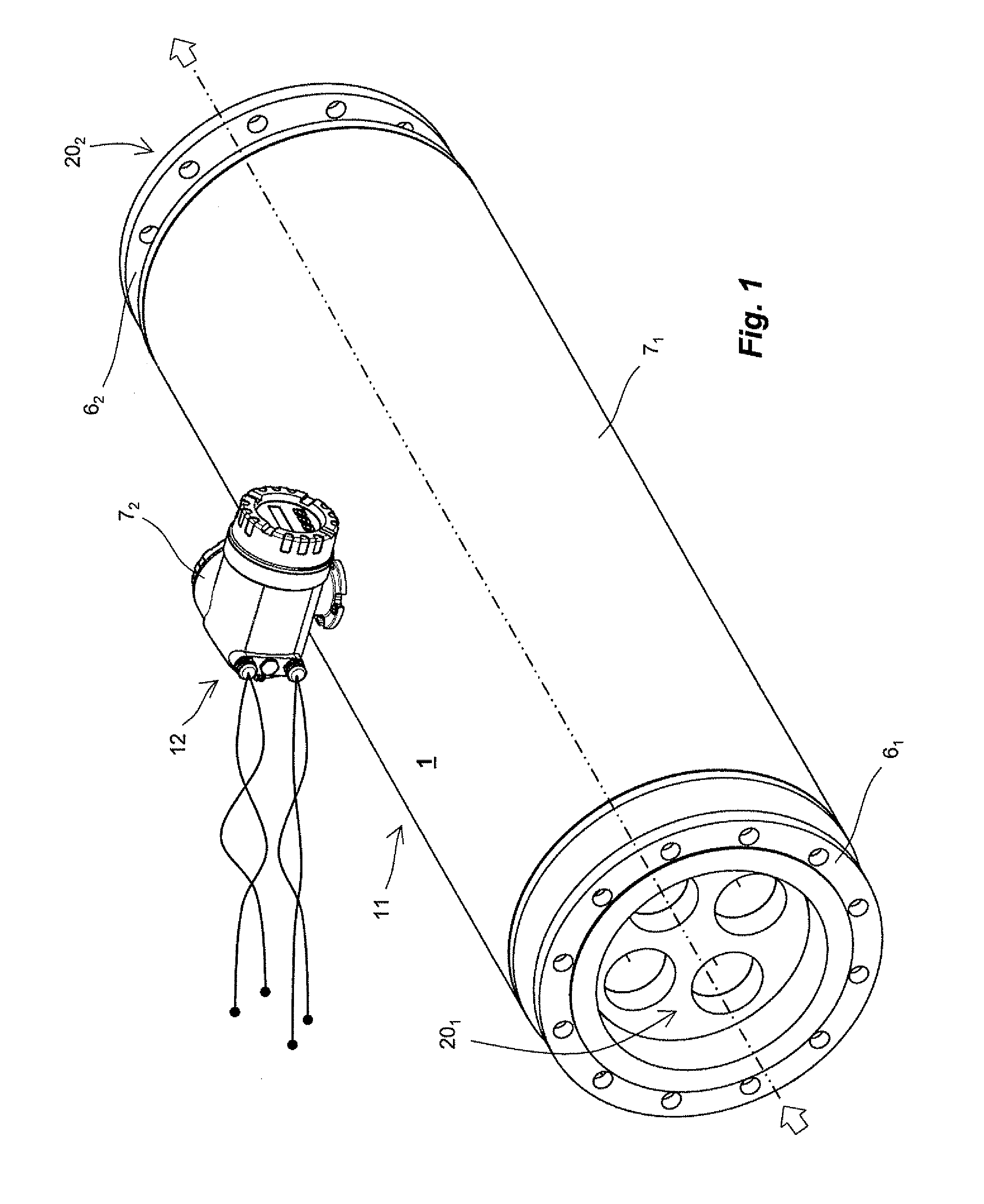

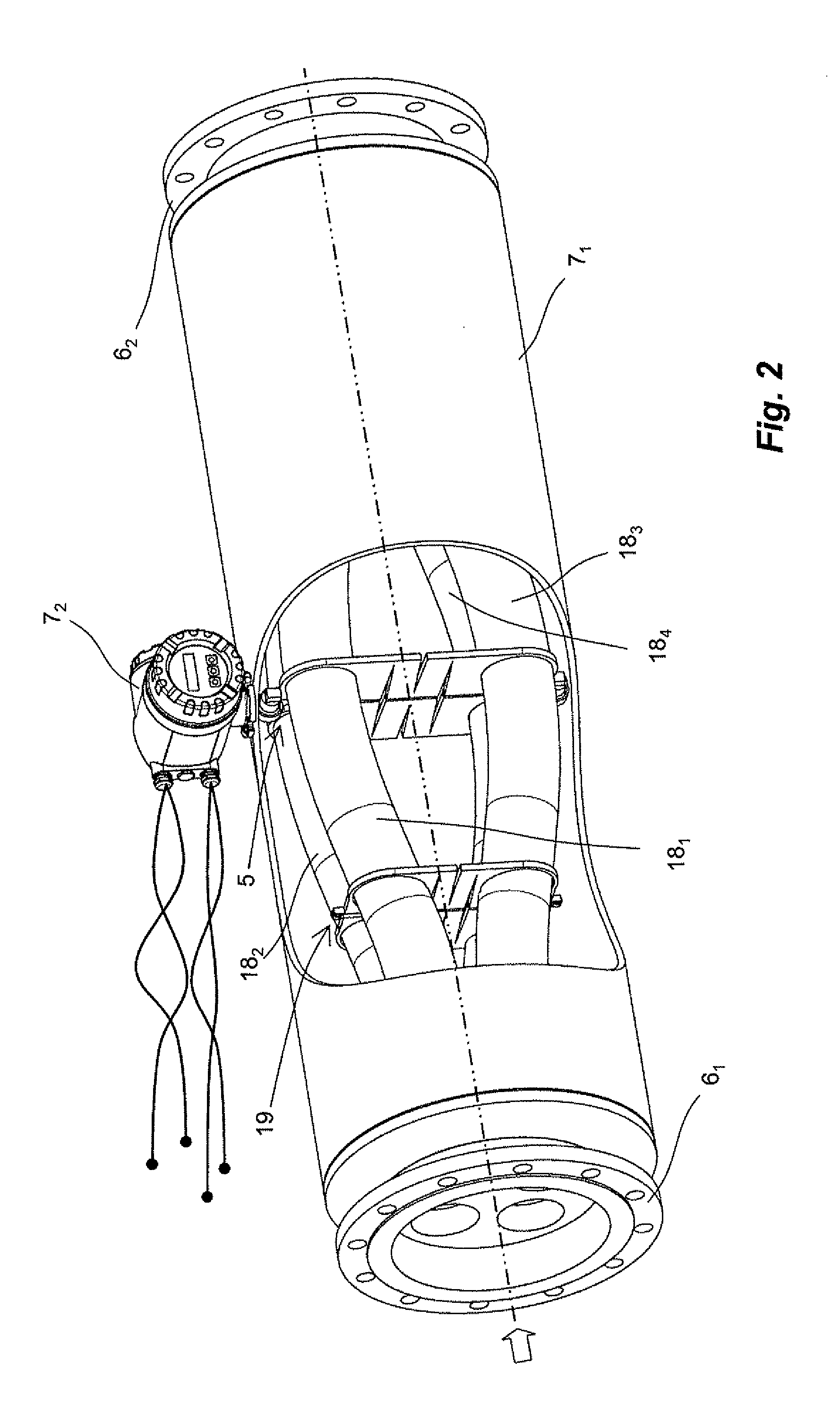

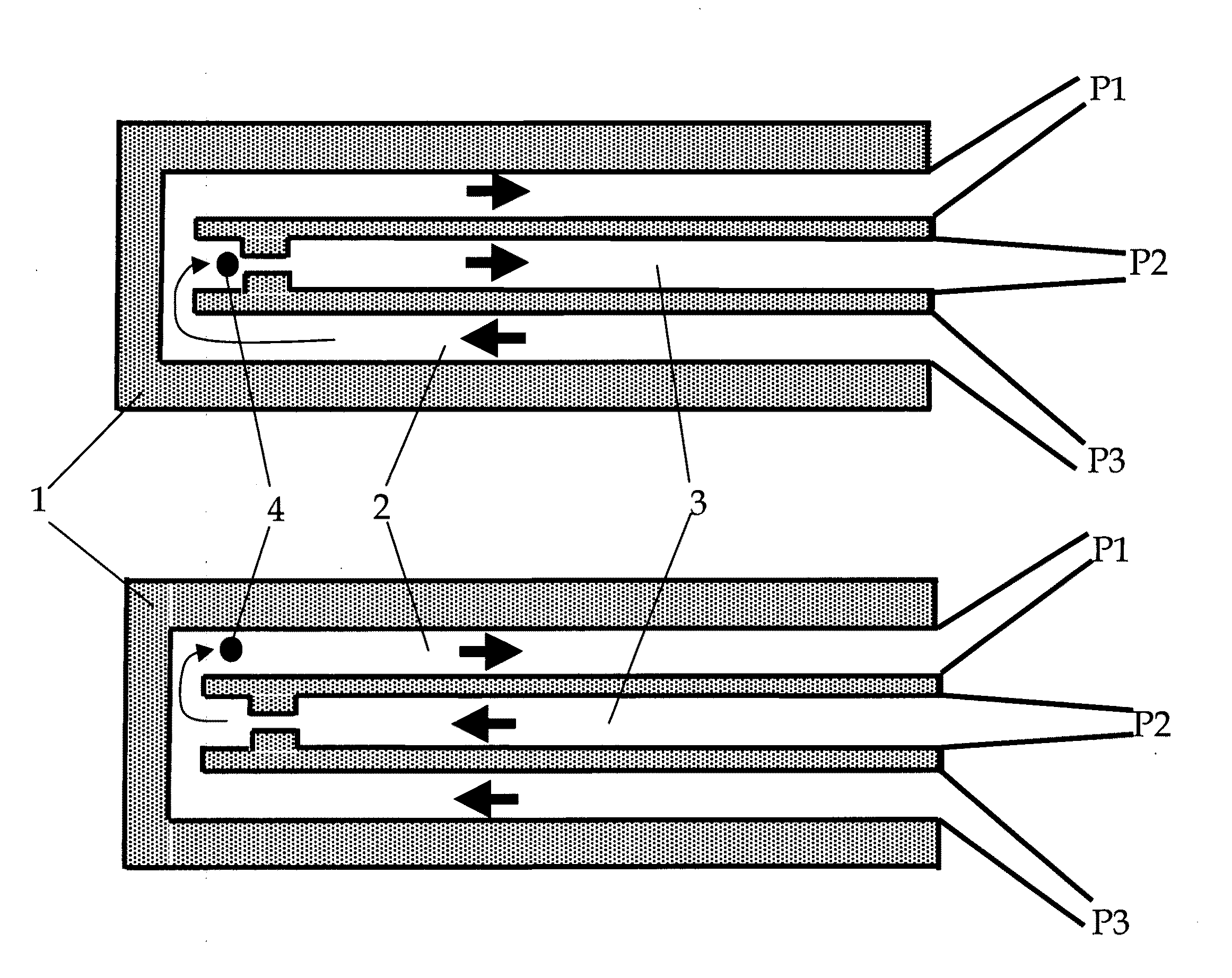

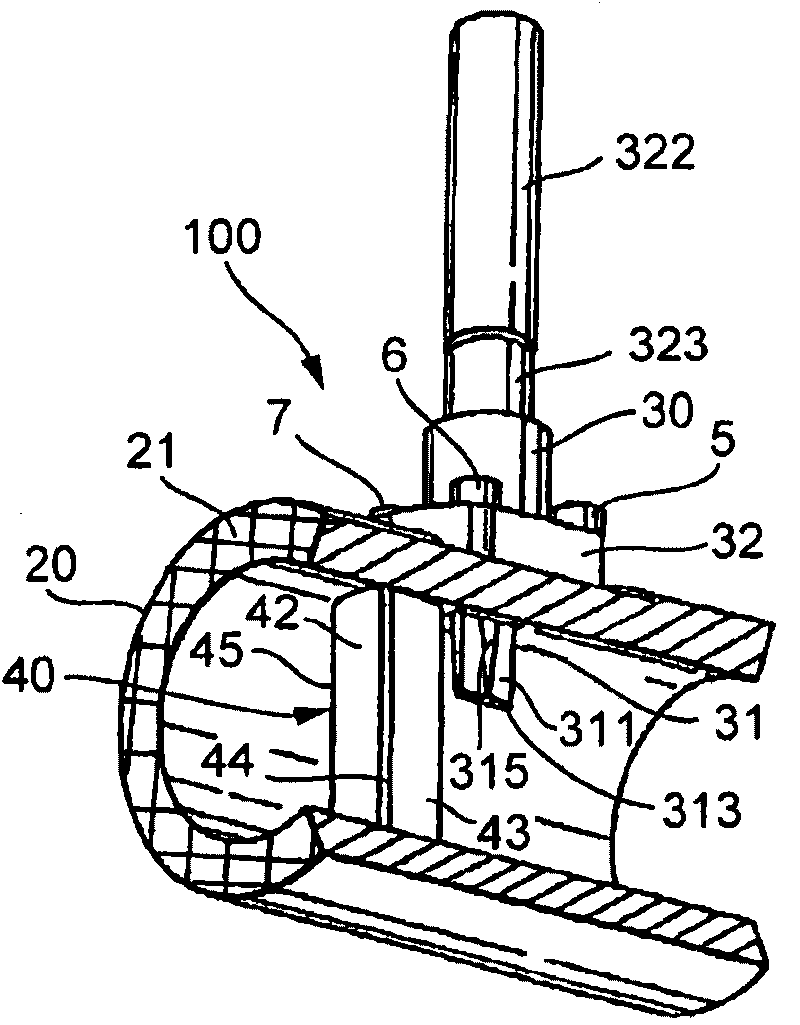

Measuring transducer of vibration-type

ActiveUS20110167907A1Impairs accuracy of measurementMeasurement accuracySpecific gravity using flow propertiesVolume variation compensation/correction apparatusSection planeTransducer

The measuring transducer comprises: a transducer housing, of which an inlet-side, housing end is formed by means of a flow divider including four flow openings spaced, and an outlet-side, formed by means of a flow divider including four flow openings spaced, from one another. A tube arrangement including four curved measuring tubes connected to the flow dividers for guiding flowing medium along flow paths connected in parallel. Each measuring tubes opens with an inlet-side, measuring tube end into one of the flow openings of the flow divider and with an outlet-side, measuring tube end into one the flow openings of the flow divider. The two flow dividers are embodied and arranged in the measuring transducer, so that the tube arrangement extends both between a first and a second of the measuring tubes and between a third and a fourth of the measuring tubes. An imaginary longitudinal-section plane, with respect to which the tube arrangement is mirror symmetric and perpendicular to the imaginary longitudinal-section plane, an imaginary longitudinal-section plane, with respect to which the tube arrangement likewise is mirror symmetric. An electromechanical exciter mechanism of the measuring transducer serves for producing and / or maintaining mechanical oscillations of the four measuring tubes.

Owner:ENDRESS HAUSER FLOWTEC AG

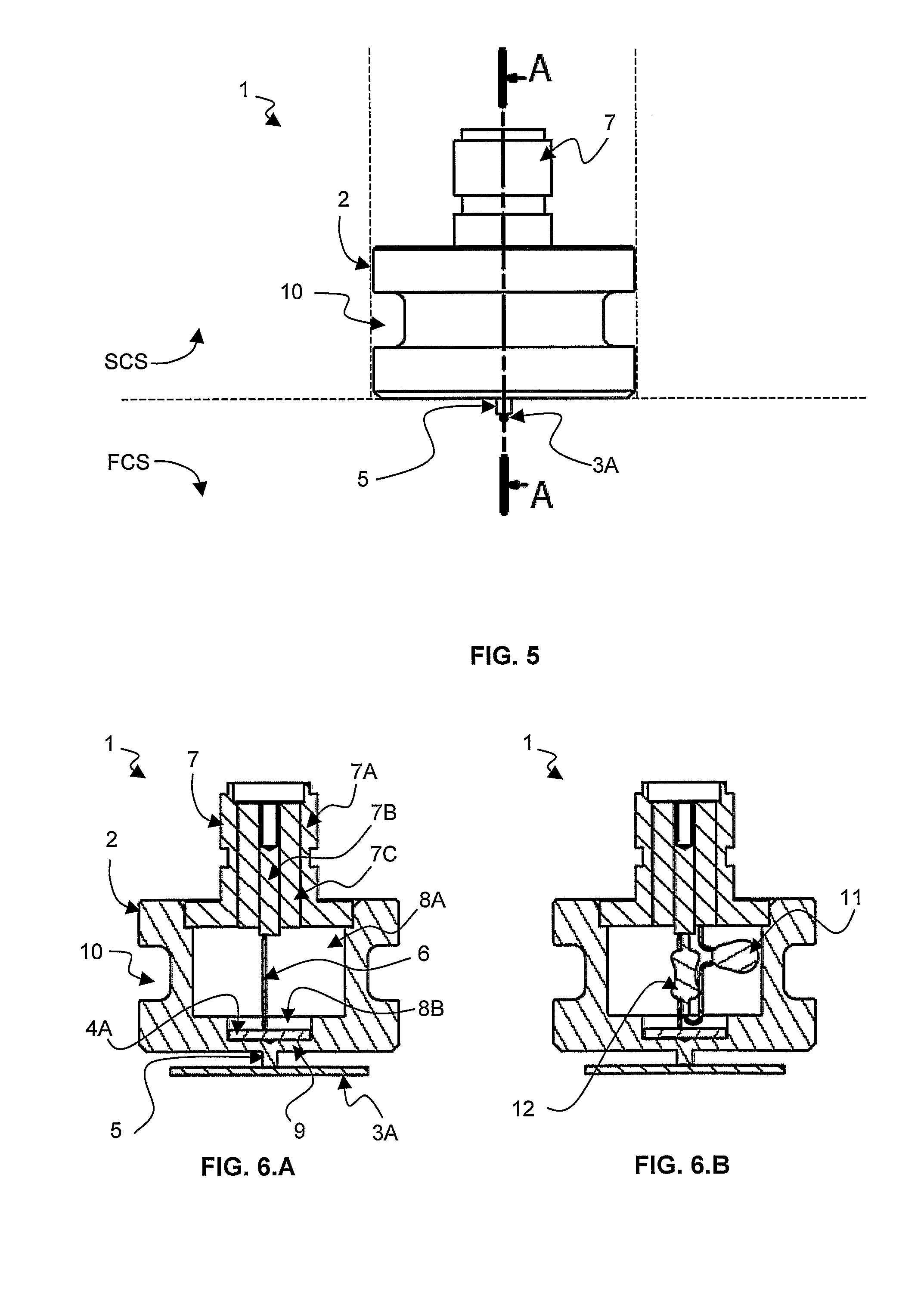

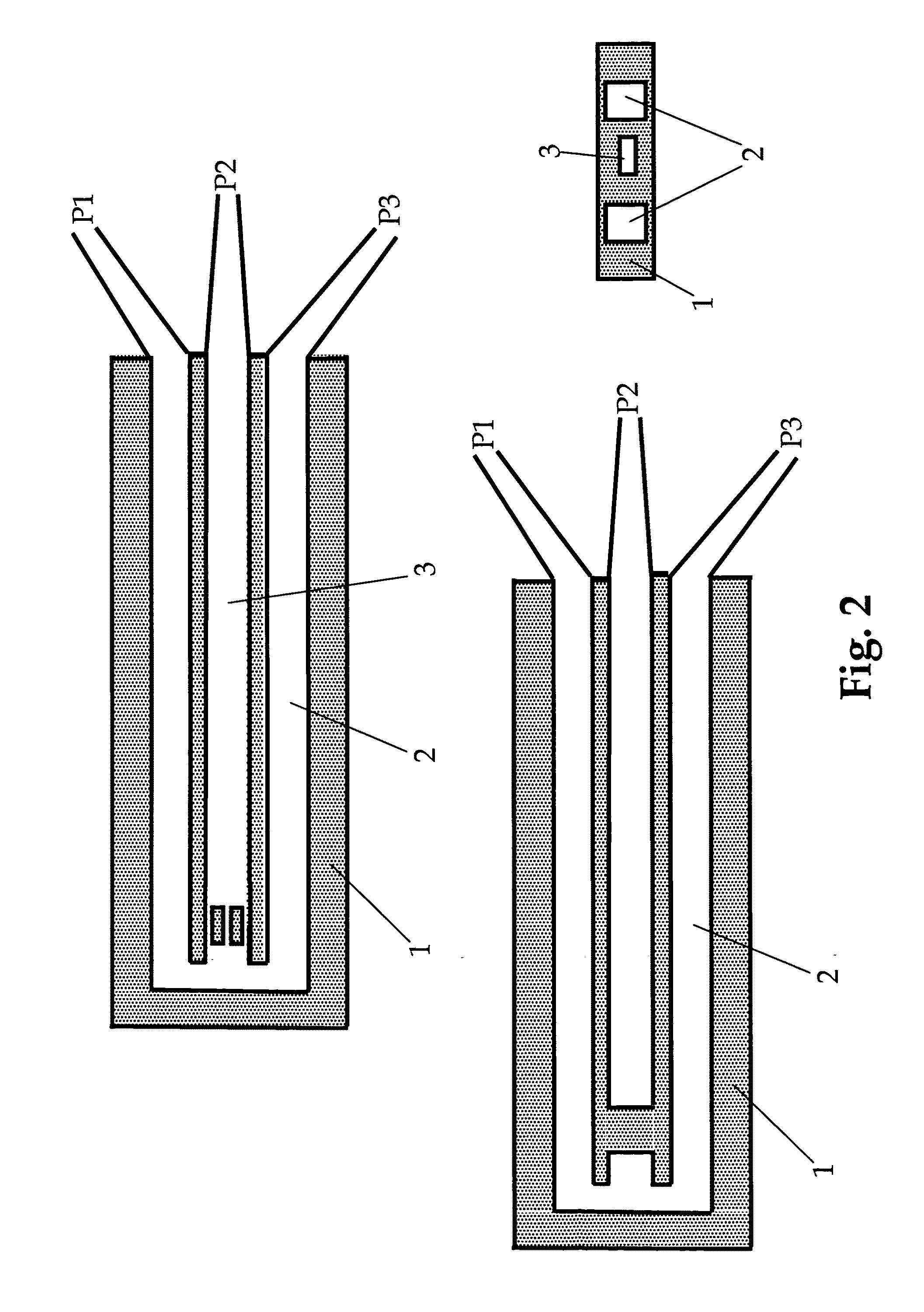

Density and Viscosity Sensor

ActiveUS20080257036A1Efficient excitationRegard to overcoming effectsFlow propertiesSpecific gravity using flow propertiesResonanceEngineering

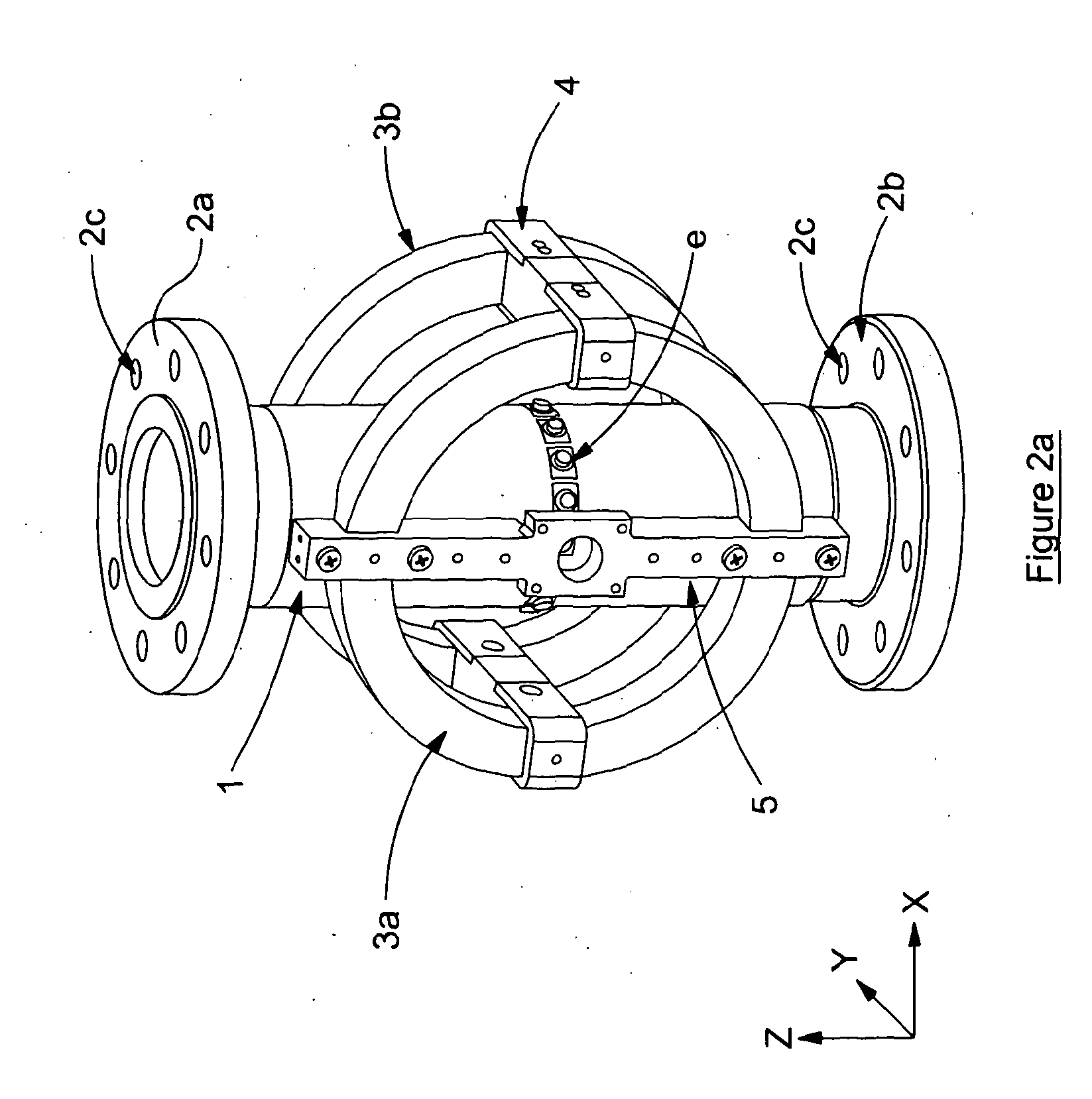

A density and viscosity sensor 1 for measuring density and viscosity of fluid F, the sensor 1 comprising:a resonating element 3, 3A, 3B, 3C, 3D, 3E, 3F, 3G arranged to be immersed in the fluid F,an actuating / detecting element 4, 4A, 4B coupled to the resonating element,a connector 7 for coupling to the actuating / detecting element 4, 4A, 4B,a housing 2 defining a chamber 8A isolated from the fluid F, the housing 2 comprising an area of reduced thickness defining a membrane 9 separating the chamber 8A from the fluid F, the membrane 9 having a thickness enabling transfer of mechanical vibration between the actuating / detecting element 4, 4A, 4B and the resonating element 3, 3A, 3B, 3C, 3D, 3E, 3F, 3G,the actuating / detecting element 4, 4A, 4B is positioned within the chamber so as to be isolated from the fluid F and mechanically coupled to the membrane 9, the resonating element 3, 3A, 3B, 3C, 3D, 3E, 3F, 3G arranged to be immersed in the fluid F is mechanically coupled to the membrane 9, wherein the resonating element 3, 3A, 3B, 3C, 3D, 3E, 3F, 3G has a shape defining a first resonance mode and a second resonance mode characterized by different resonant frequencies F1, F2 and different quality factors Q1, Q2, the first resonance mode moving a volume of fluid, the second mode shearing a surrounding fluid.

Owner:SCHLUMBERGER TECH CORP

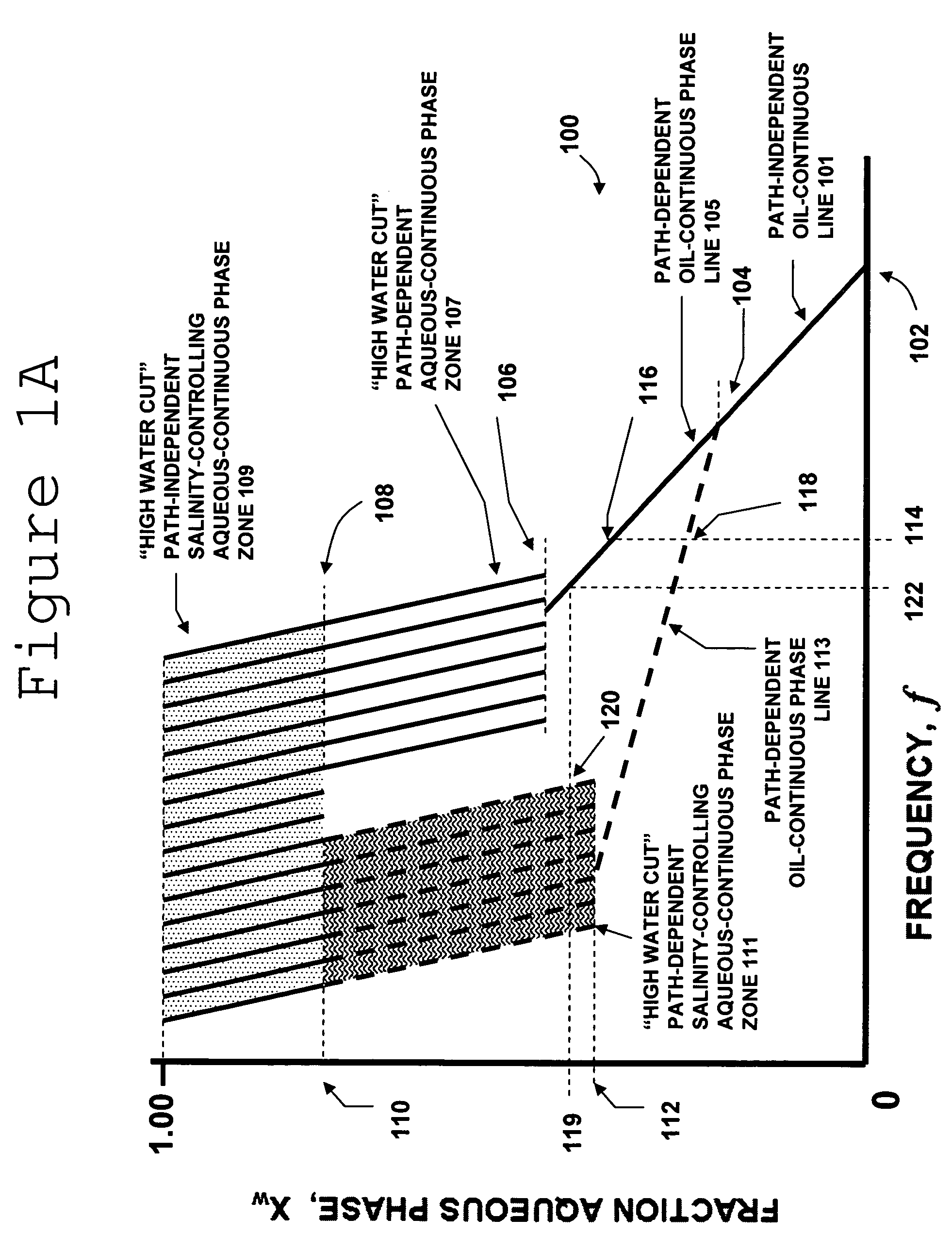

Multiphase fluid characterization

ActiveUS7523647B2Accurate measurementGreat advantageMaterial analysis by electric/magnetic meansSpecific gravity using flow propertiesPermittivityPetroleum oil

Methods for determining and validating a first phase fraction of a gravitationally-separated multiphase fluid by conducting physical and electrical property measurements on samples of the fluid. The water content of crude petroleum oil is determined after the oil and water have begun to separate into phase layers such as occurs during un-agitated holding of the crude petroleum oil. A series of measurements of electrical properties such as permittivity and physical properties such as density is collected. The density minima can be used to generate hindsight determinations of average properties, such as the dry oil phase density, which in turn can be used to increase the accuracy of the water percentage in the oil determined by the permittivity and density methods. Flow weighted averages of water percentages by each method can be used to determine and validate the water content of the crude petroleum oil.

Owner:PHASE DYNAMICS

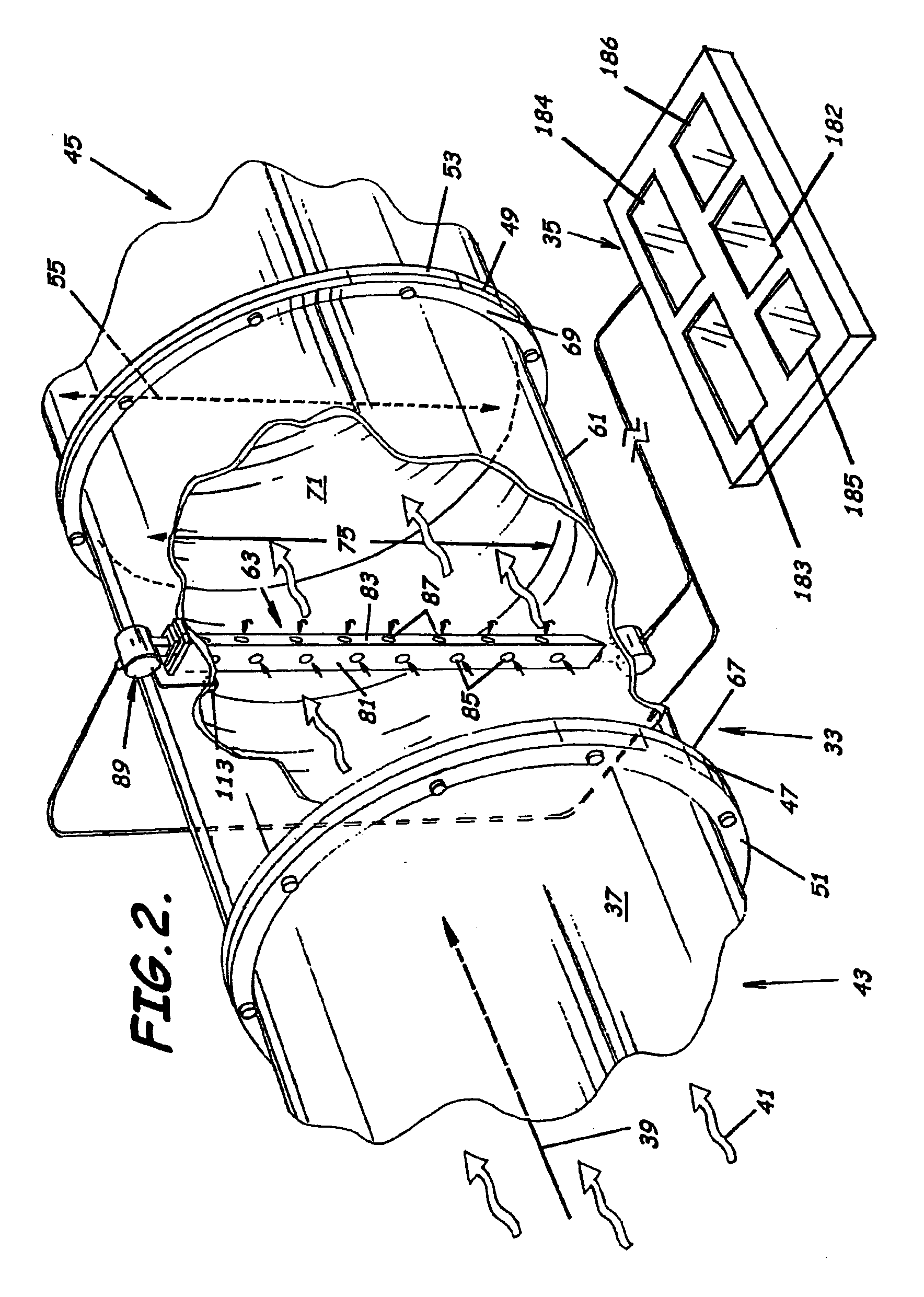

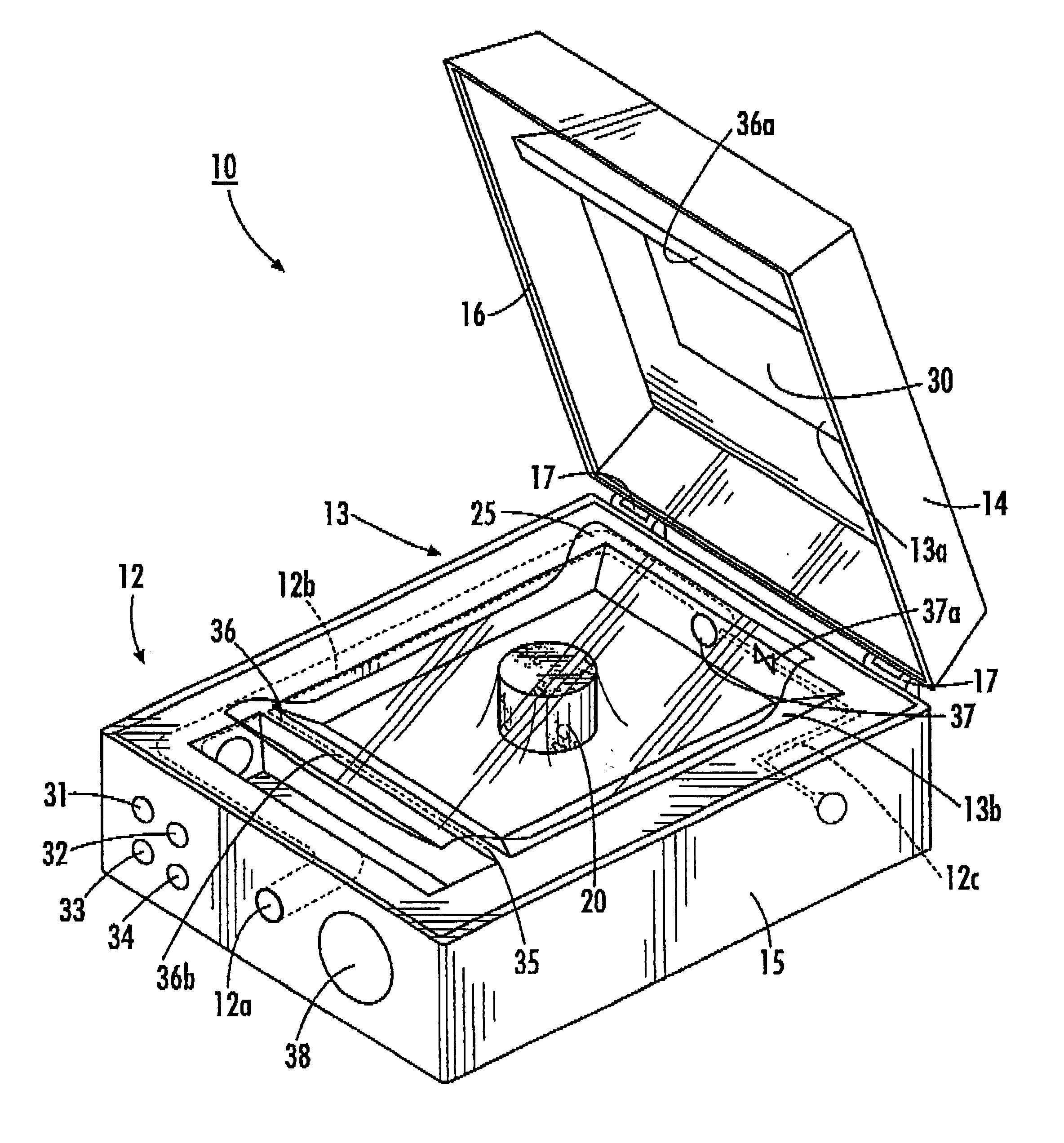

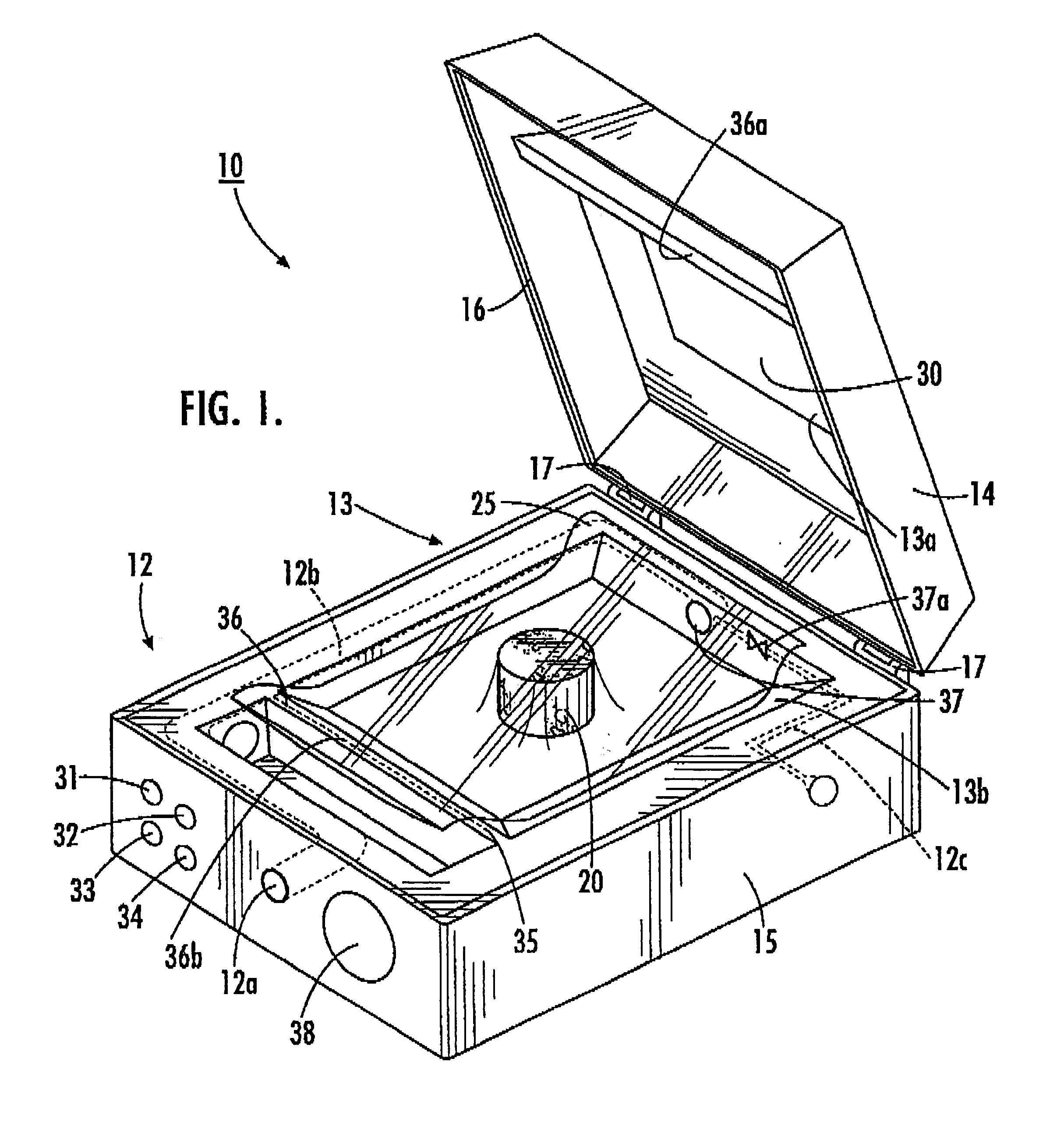

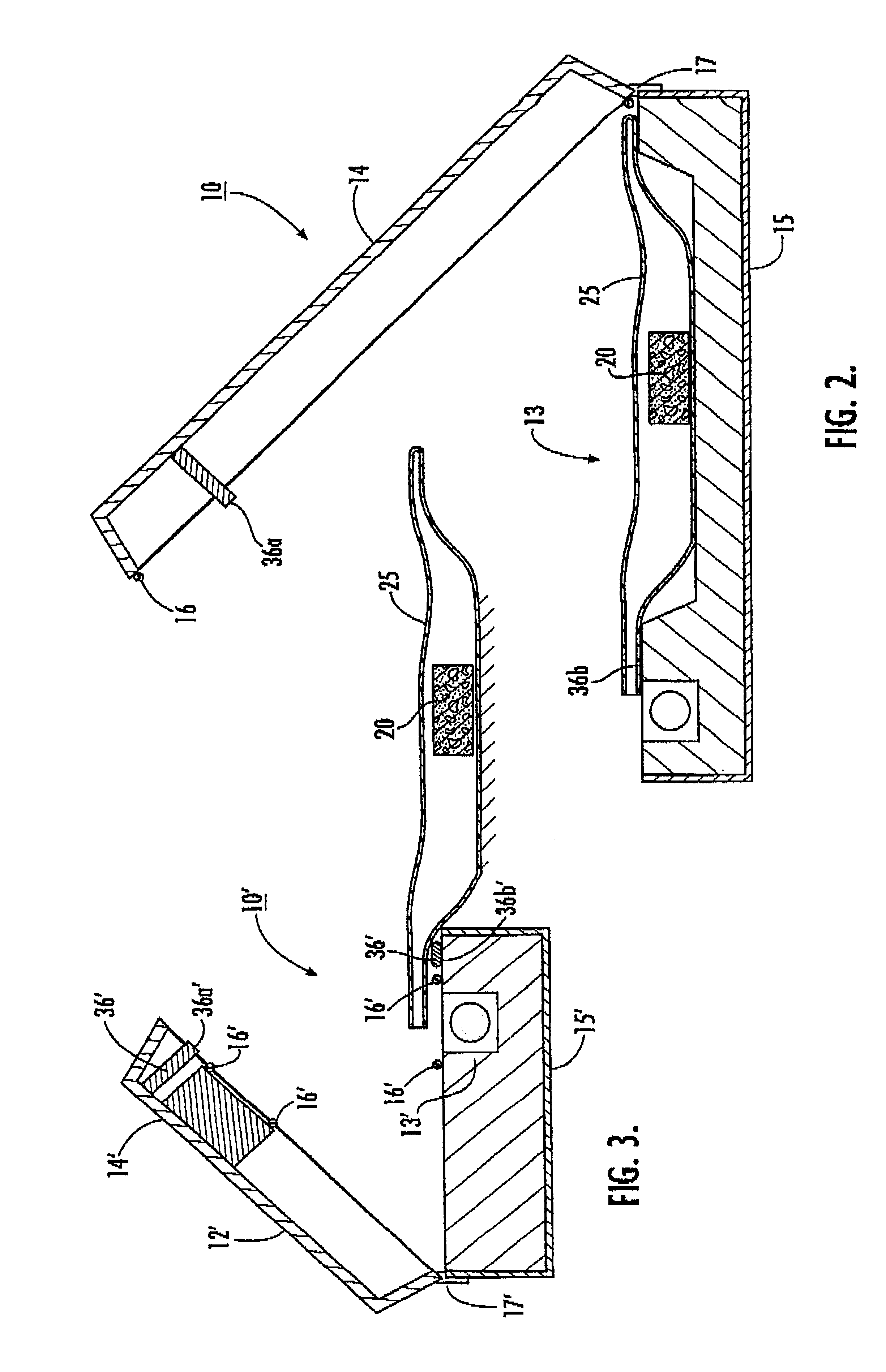

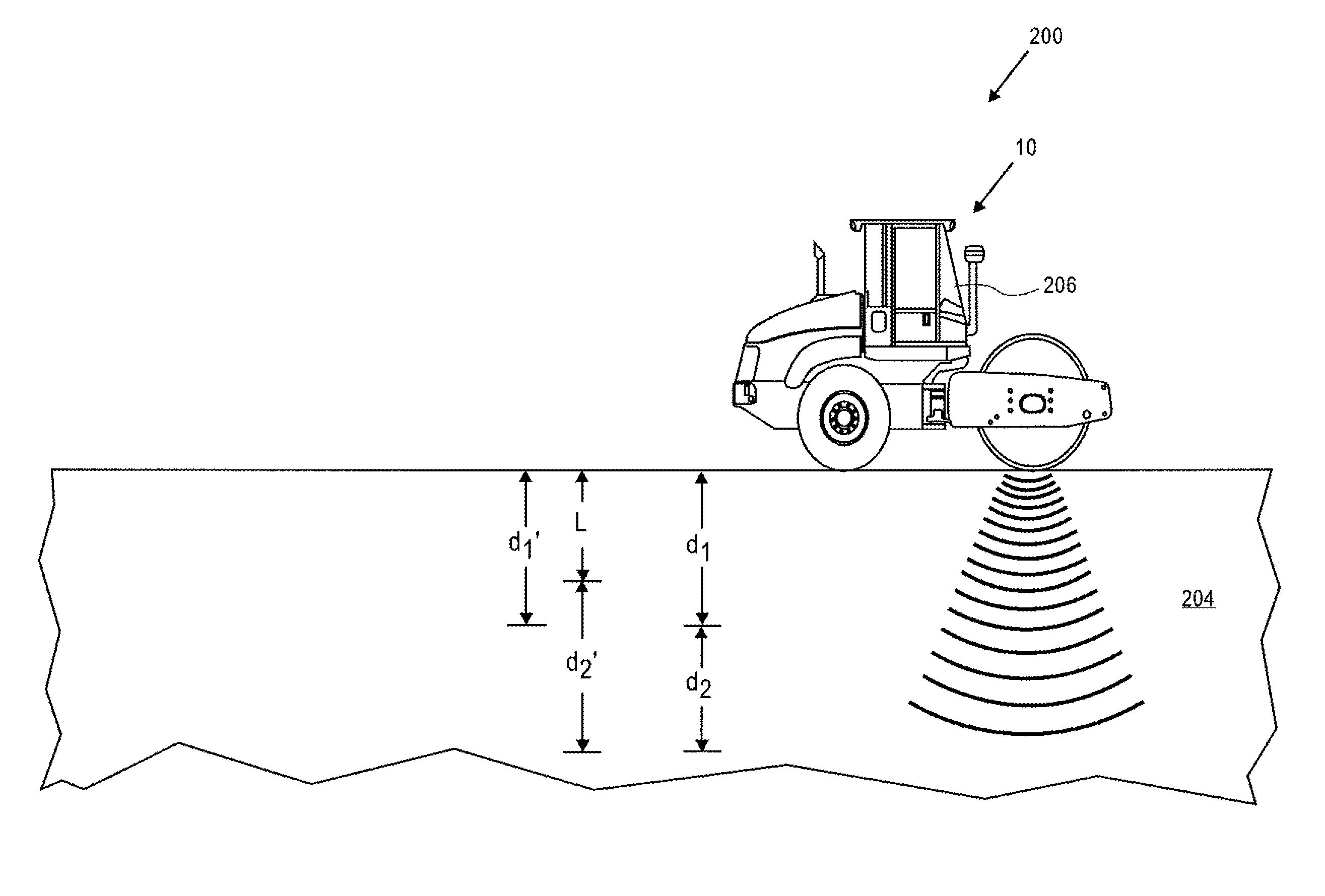

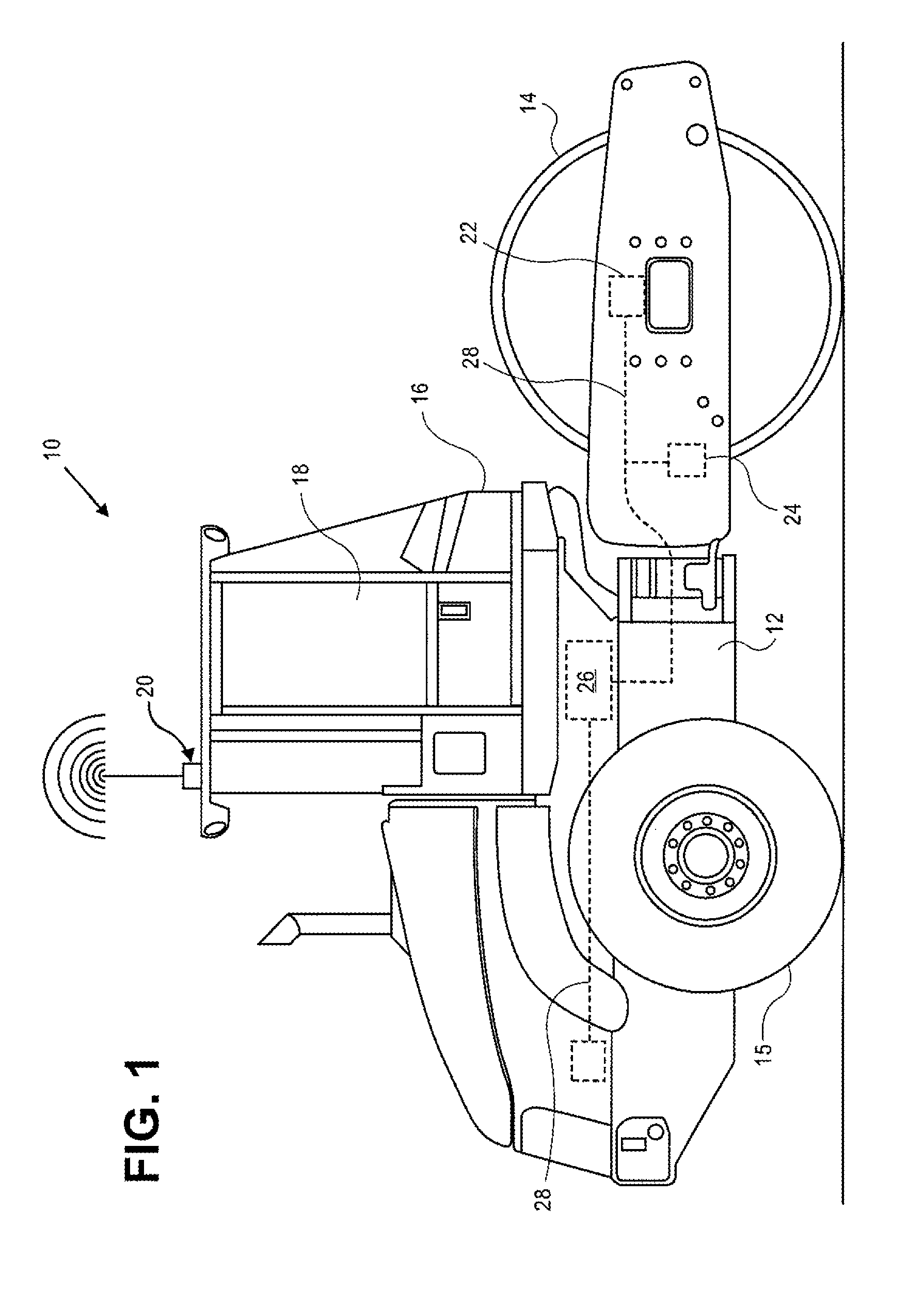

Methods and apparatus for sealing a porous material sample for density determination using water displacement methods and associated surface conformal resilient compressible bags

InactiveUS6321589B1Easy to useReduce operator-induced variation on sealed configurationMaterial analysis by measuring buoyant forcesMaterial analysis by observing immersed bodiesPorosityVacuum pressure

Water-resistant preformed resilient bags are applied to a porous material specimen having a coarse external surface to provide for more consistent measurement results in water displacement tests. The preformed bag is configured to collapse and substantially conform to the material specimen's external surface and to provide planar collapsed portions extending away from the specimen. The preformed bags are precision manufactured and each applied to a respective specimen in a manner in which the bag consistently displaces the same volume of water when used in water displacement tests over many specimens. The volume of the bag can be accounted for when obtaining the volume of the specimen. The method of sealing the specimen includes inserting the specimen into a preformed bag and collapsing and sealing the bag such that is conformal to the external surface of the specimen. The method can provide a preferred operating vacuum pressure corresponding to the specimen type (such as porosity or coarseness) which can automatically direct the operational parameters of the bag sealing operation. The system includes a preformed bag configured to receive a material specimen therein, a vacuum apparatus for removing the air from the bag, and a sealing means for sealing the bag. In one embodiment the vacuum apparatus includes an integrated scale for measuring various weights associated with the specimen for liquid density determinations.

Owner:INSTROTEK

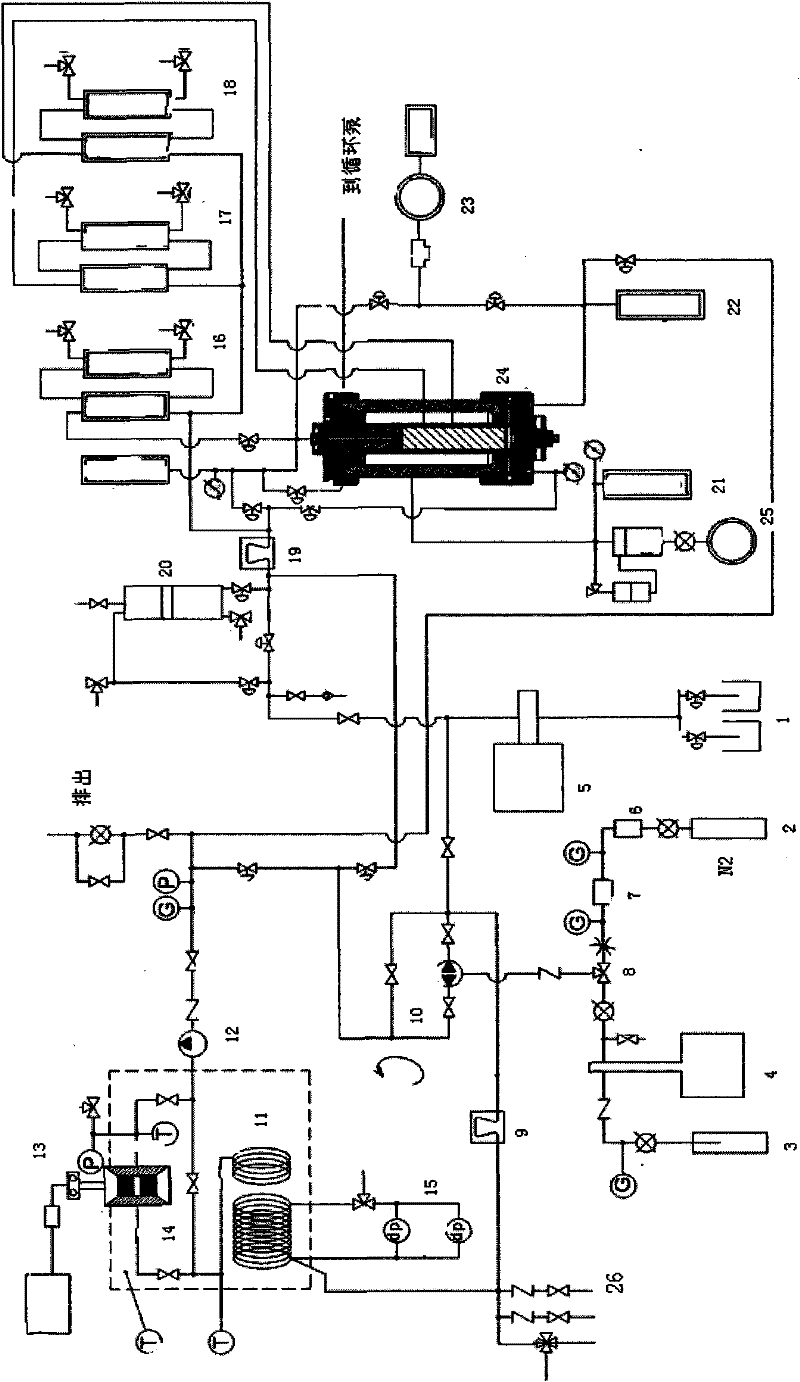

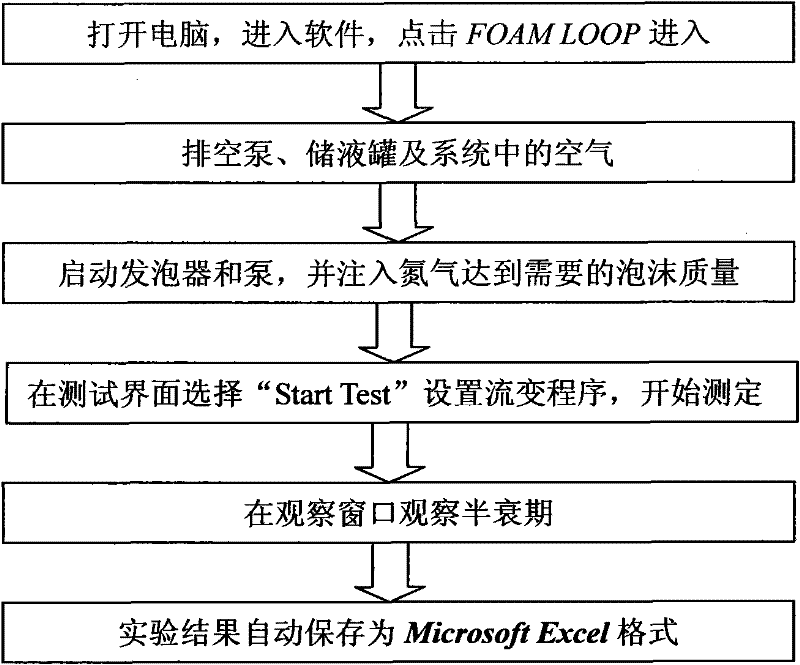

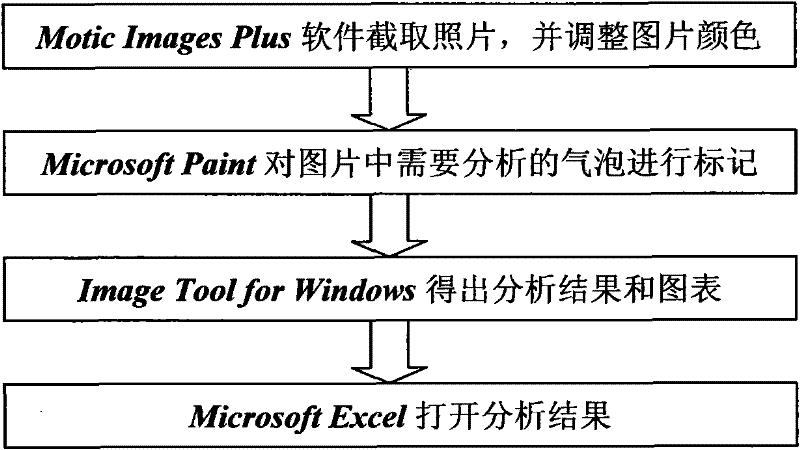

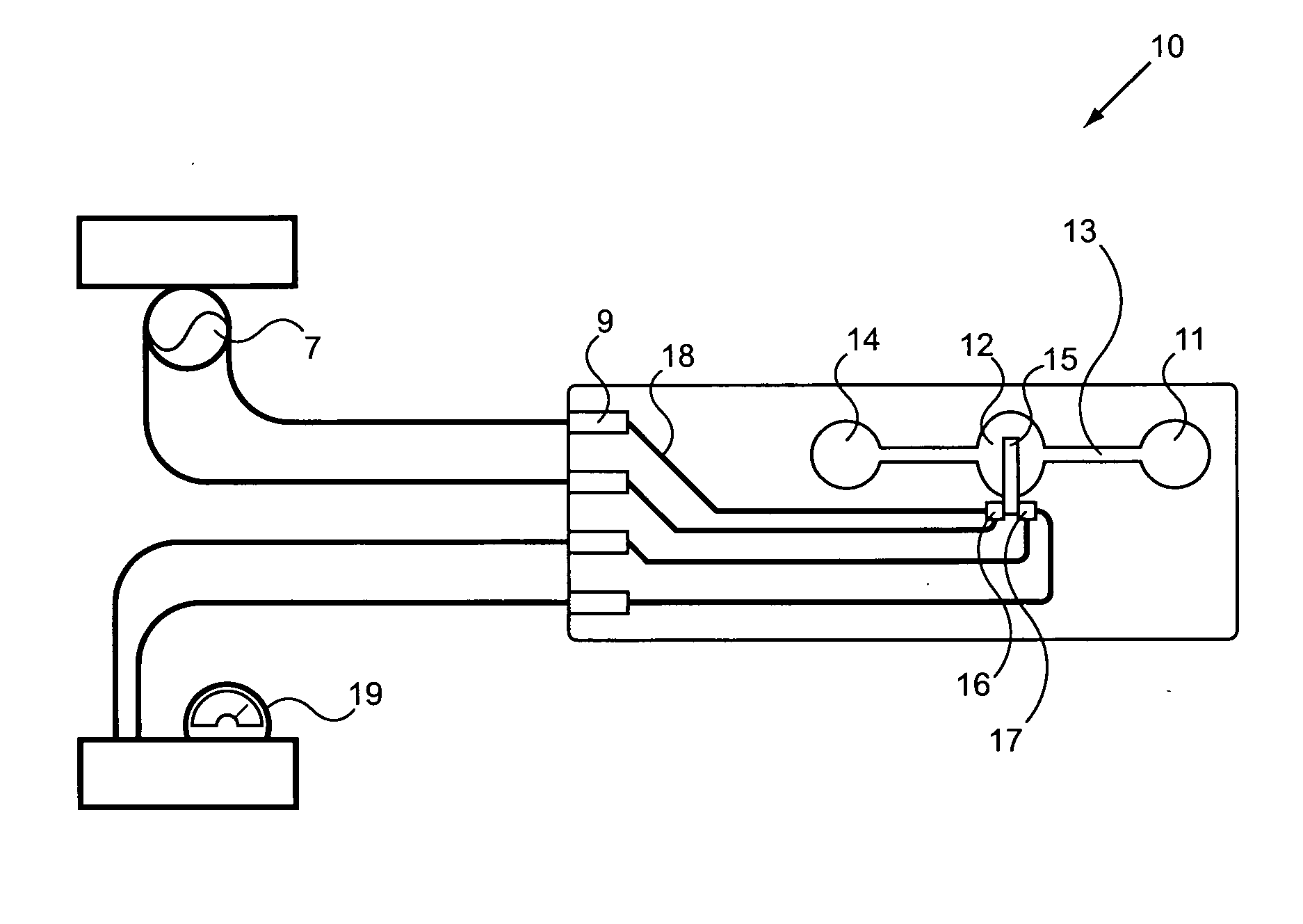

High-temperature, high-pressure, and acid-resisting apparatus for foam generating and dynamic evaluating

ActiveCN102192864AFlow propertiesSpecific gravity using flow propertiesDifferential pressureFiltration

The invention relates to a high-temperature, high-pressure, and acid-resisting apparatus for foam generating and dynamic evaluating. According to the invention, a liquid tank A with a heating coat is communicating with a foam generator, a nitrogen supplying apparatus A is connected to the foam generator, and a liquid carbon dioxide supplying apparatus is connected to the foam generator. The foam generator is connected to a coil heating furnace, the coil heating furnace is provided with a viewing window, and a data collecting system composed of a microscope and a camera is connected outside ofthe viewing window. The coil heating furnace is connected to a flow temperature and density meter, a differential pressure sensor A, and a washing system. The liquid tank A with a heating coat is connected to a liquid tank B with a heating coat, and the connected liquid tanks are connected to a rock core holder with a heating apparatus. The rock core holder with a heating apparatus is connected to an ambient pressure system, a back pressure system, and the differential pressure sensor. The apparatus provided by the present invention is capable of simulating the temperature and the pressure under stratum conditions, testing the rheological characteristics and the viscosities of foam liquids, and testing the performances of the foam liquids, such as foam quality, particle diameter distribution, half life period and dynamic filtration, foam liquid damage, and acidifying effect.

Owner:PETROCHINA CO LTD

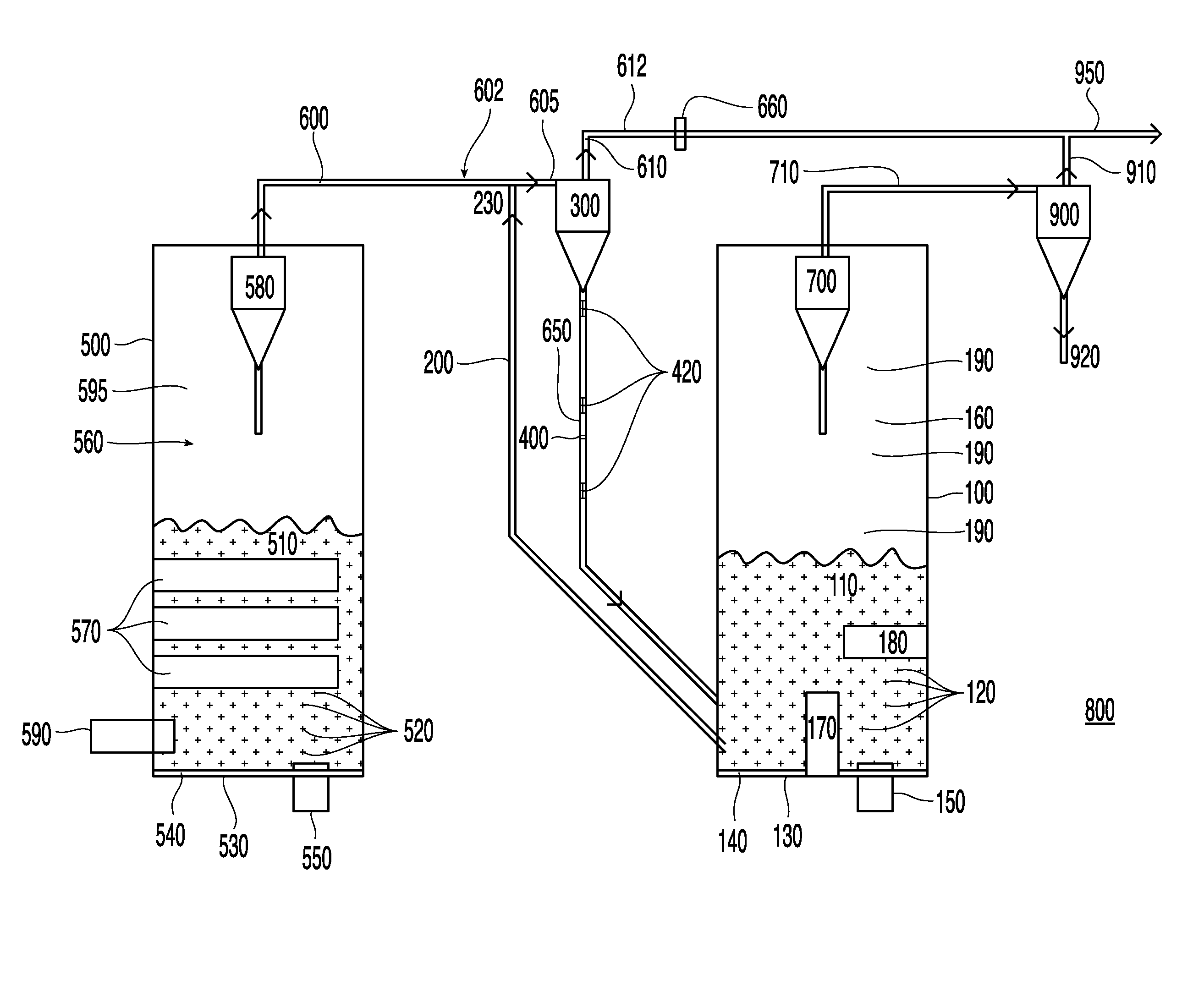

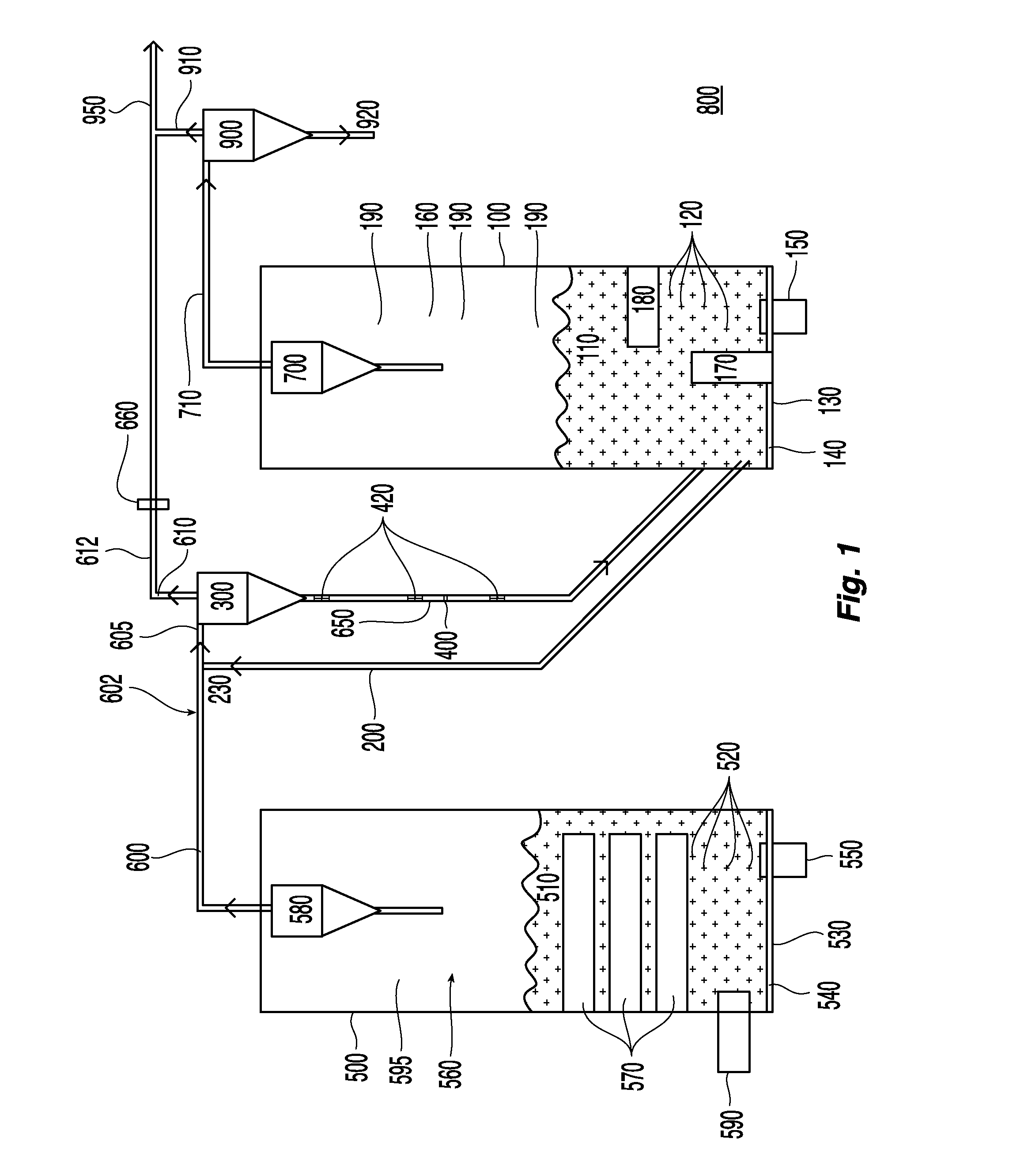

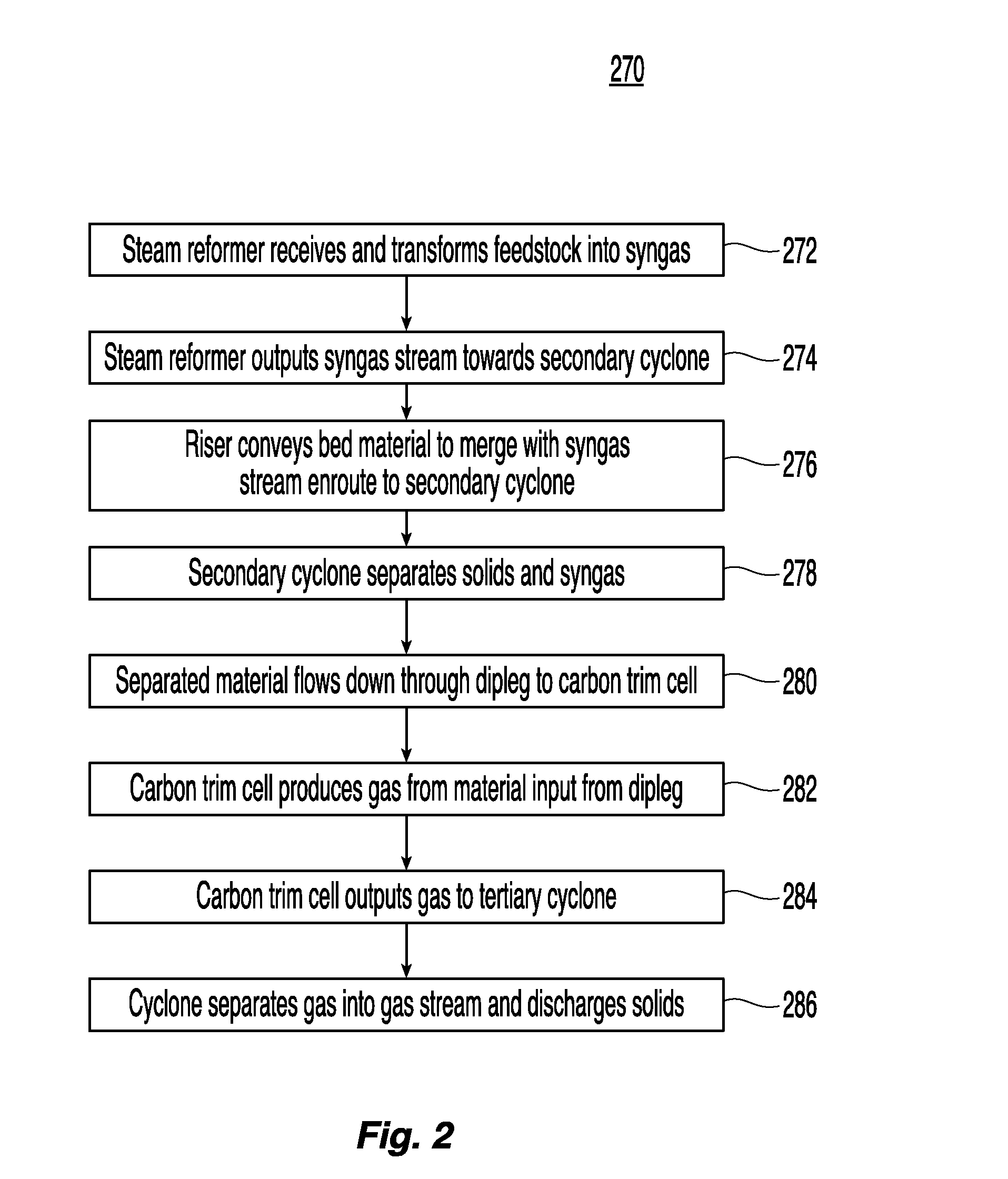

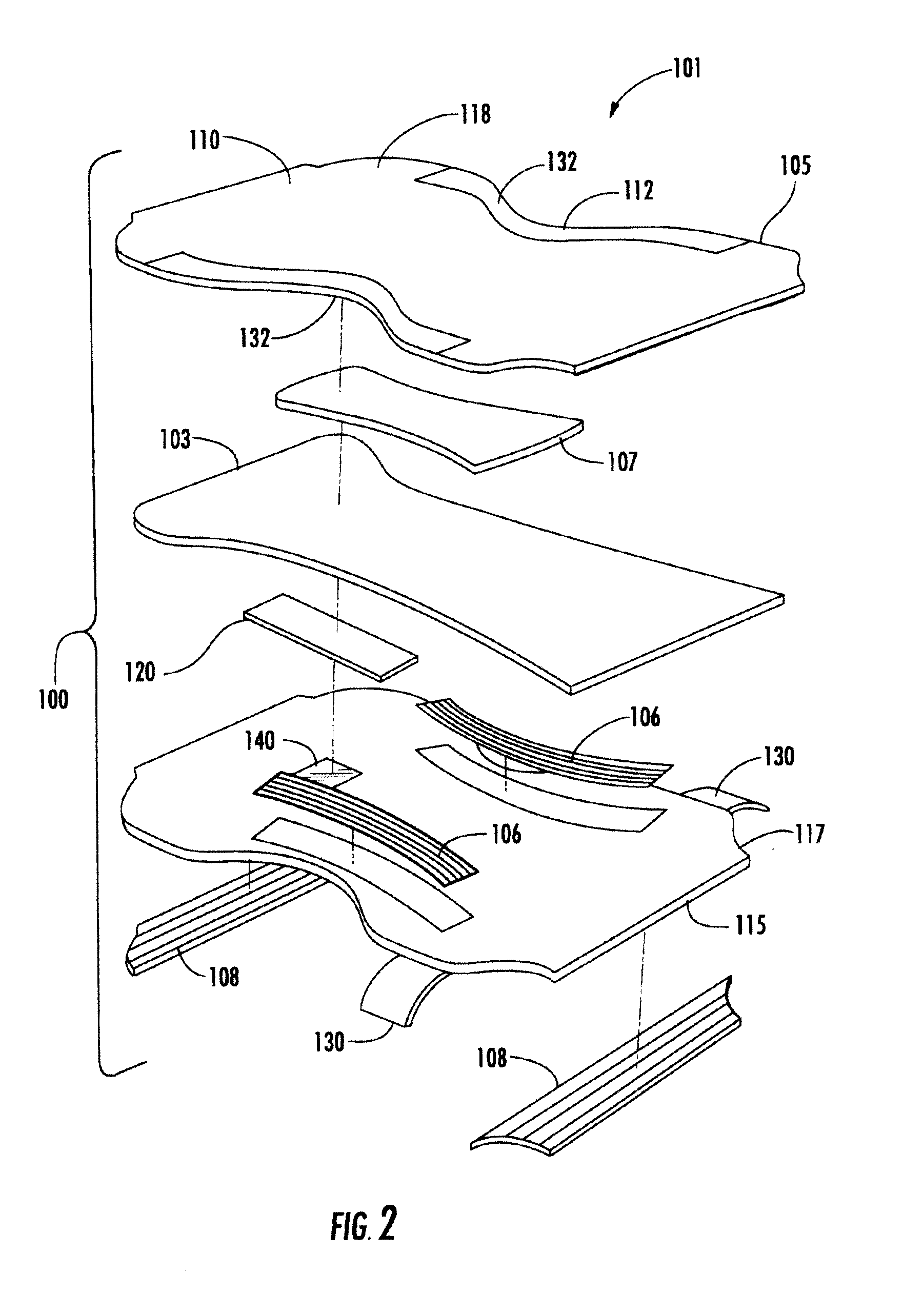

Solids Circulation System and Method for Capture and Conversion of Reactive Solids

ActiveUS20120111109A1Specific gravity by measuring pressure differencesGasifier mechanical detailsCycloneFluid transport

A solids circulation system receives a gas stream containing char or other reacting solids from a first reactor. The solids circulation system includes a cyclone configured to receive the gas stream from the first reactor, a dipleg from the cyclone to a second reactor, and a riser from the second reactor which merges with the gas stream received by the cyclone. The second reactor has a dense fluid bed and converts the received materials to gaseous products. A conveying fluid transports a portion of the bed media from the second reactor through the riser to mix with the gas stream prior to cyclone entry. The bed media helps manipulate the solids that is received by the cyclone to facilitate flow of solids down the dipleg into the second reactor. The second reactor provides additional residence time, mixing and gas-solid contact for efficient conversion of char or reacting solids.

Owner:THERMOCHEM RECOVERY INT

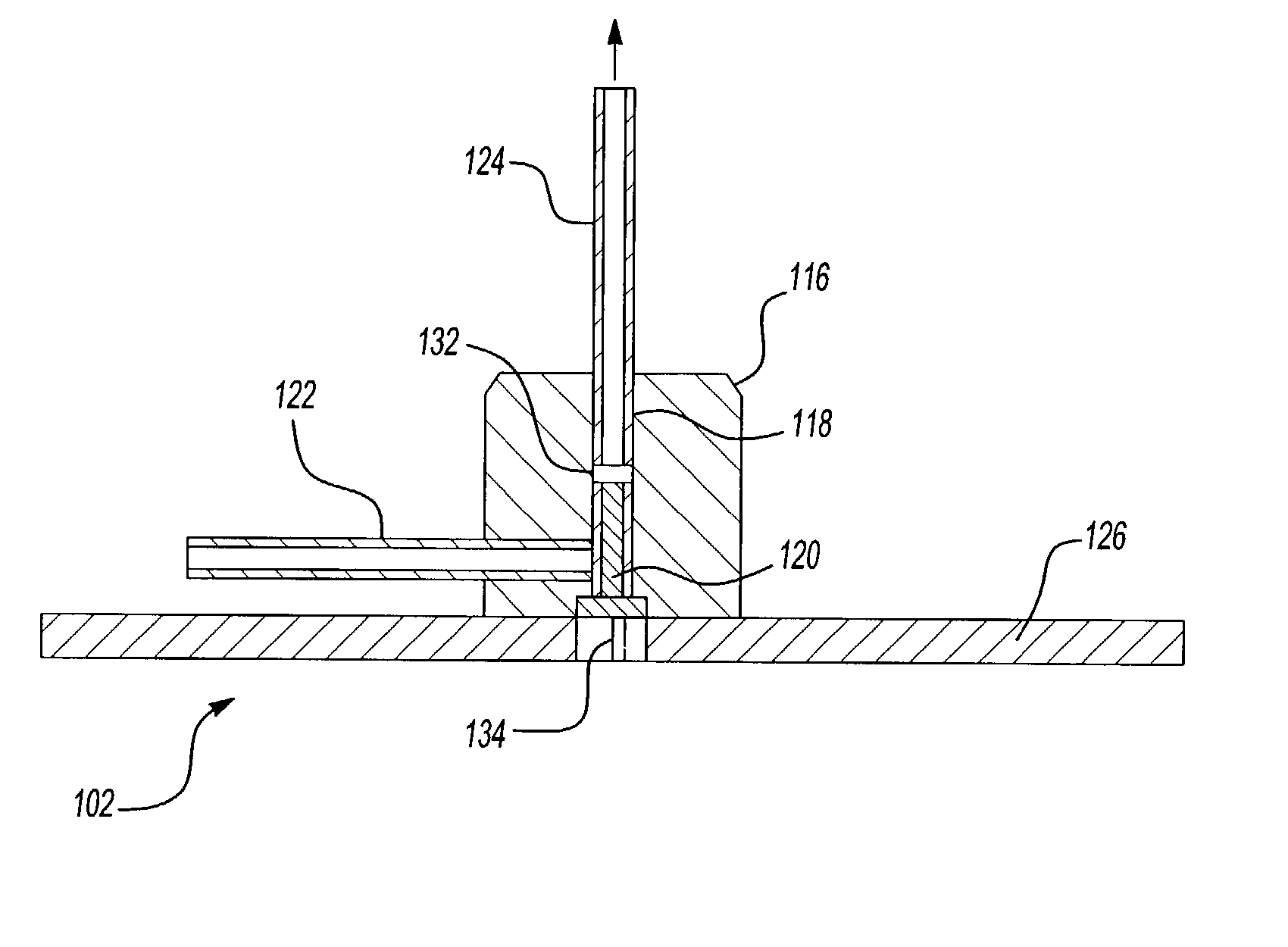

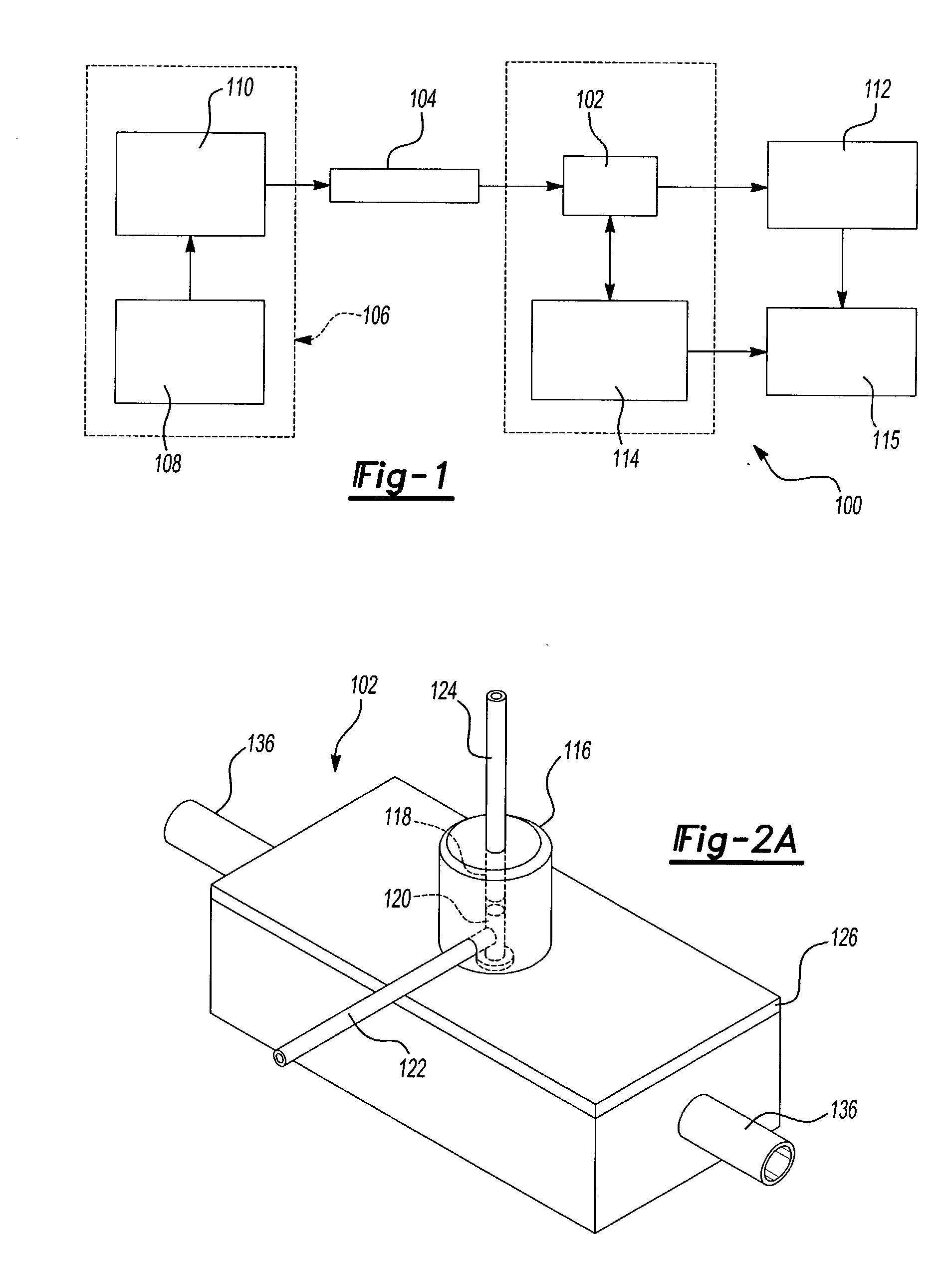

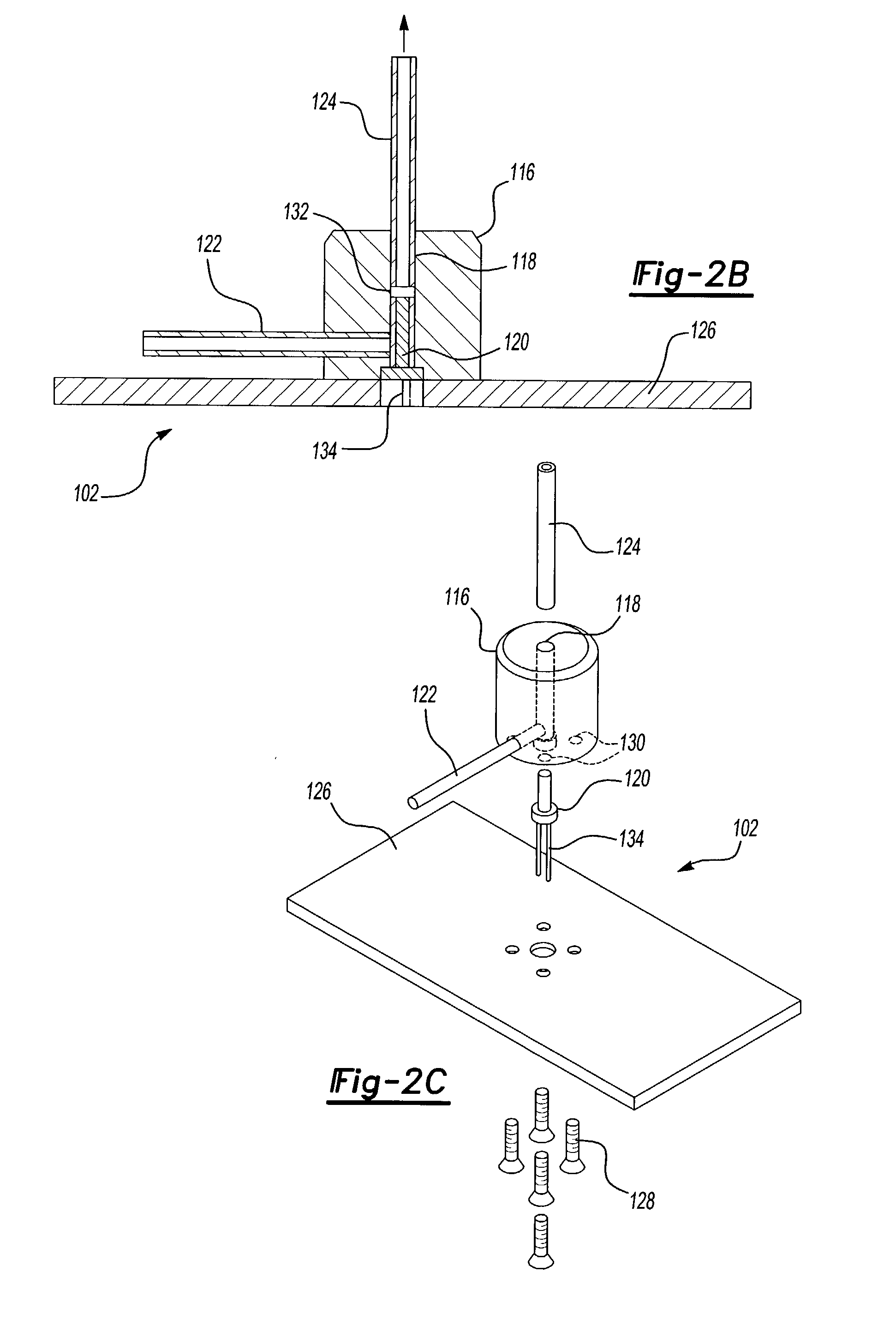

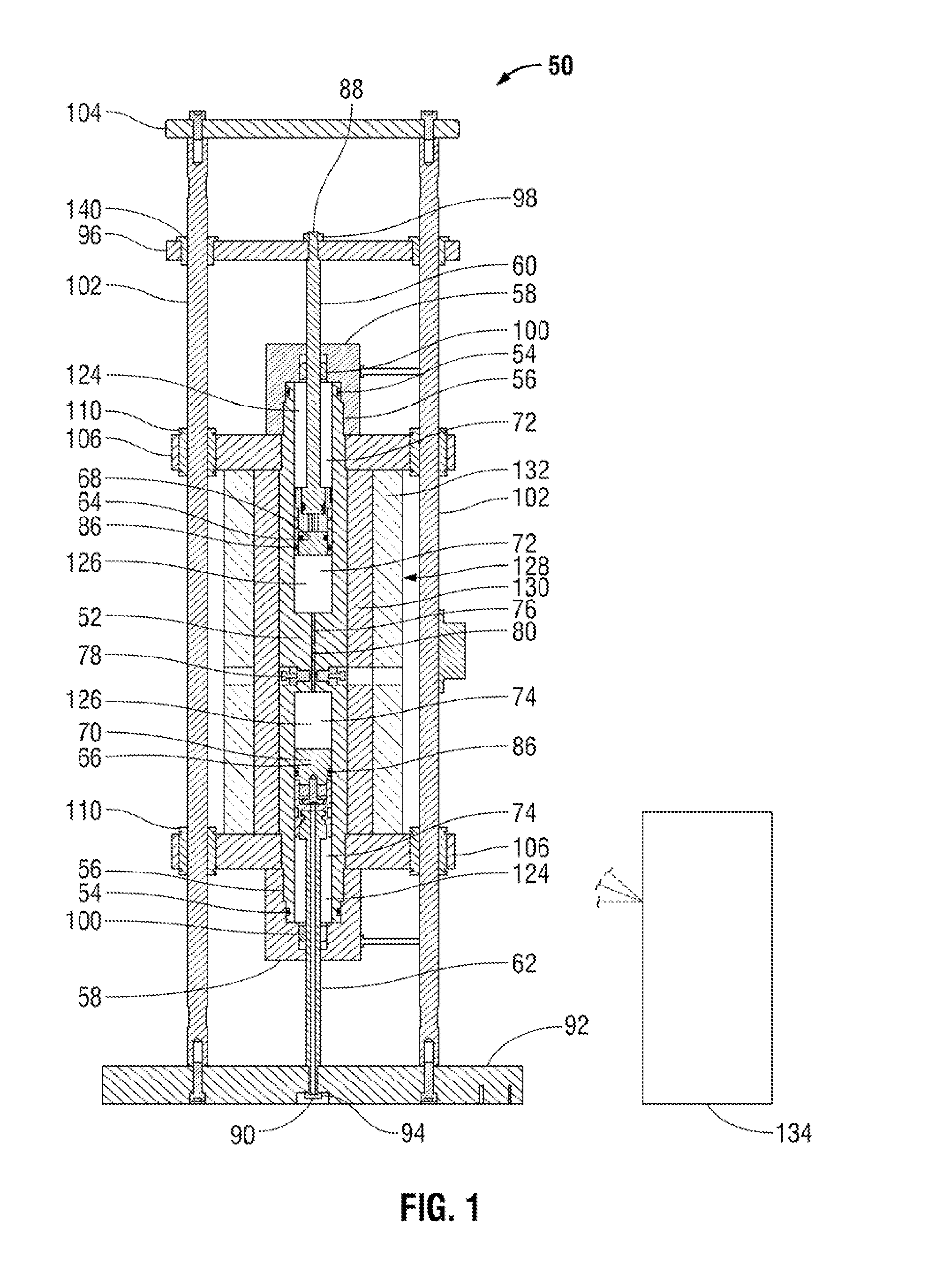

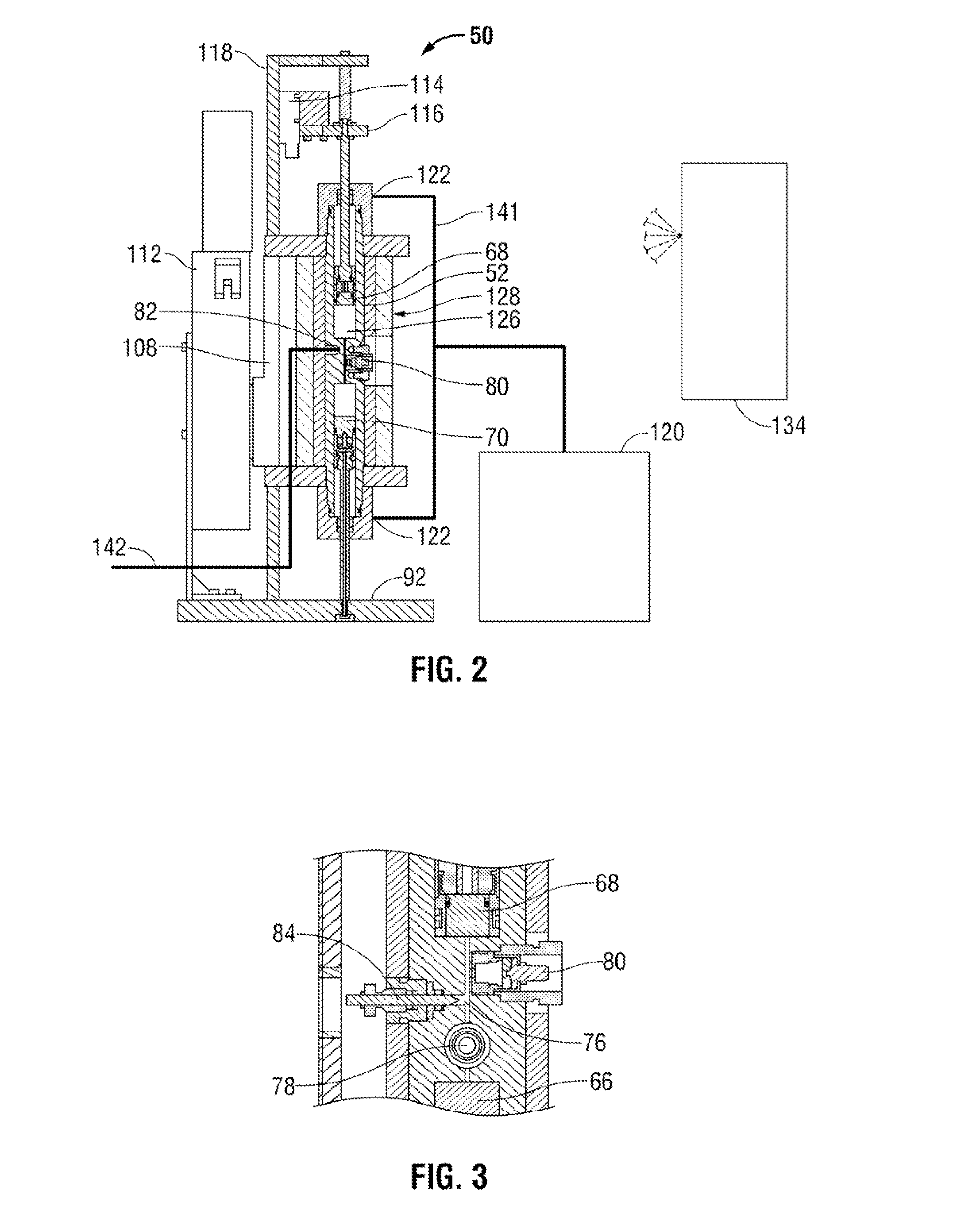

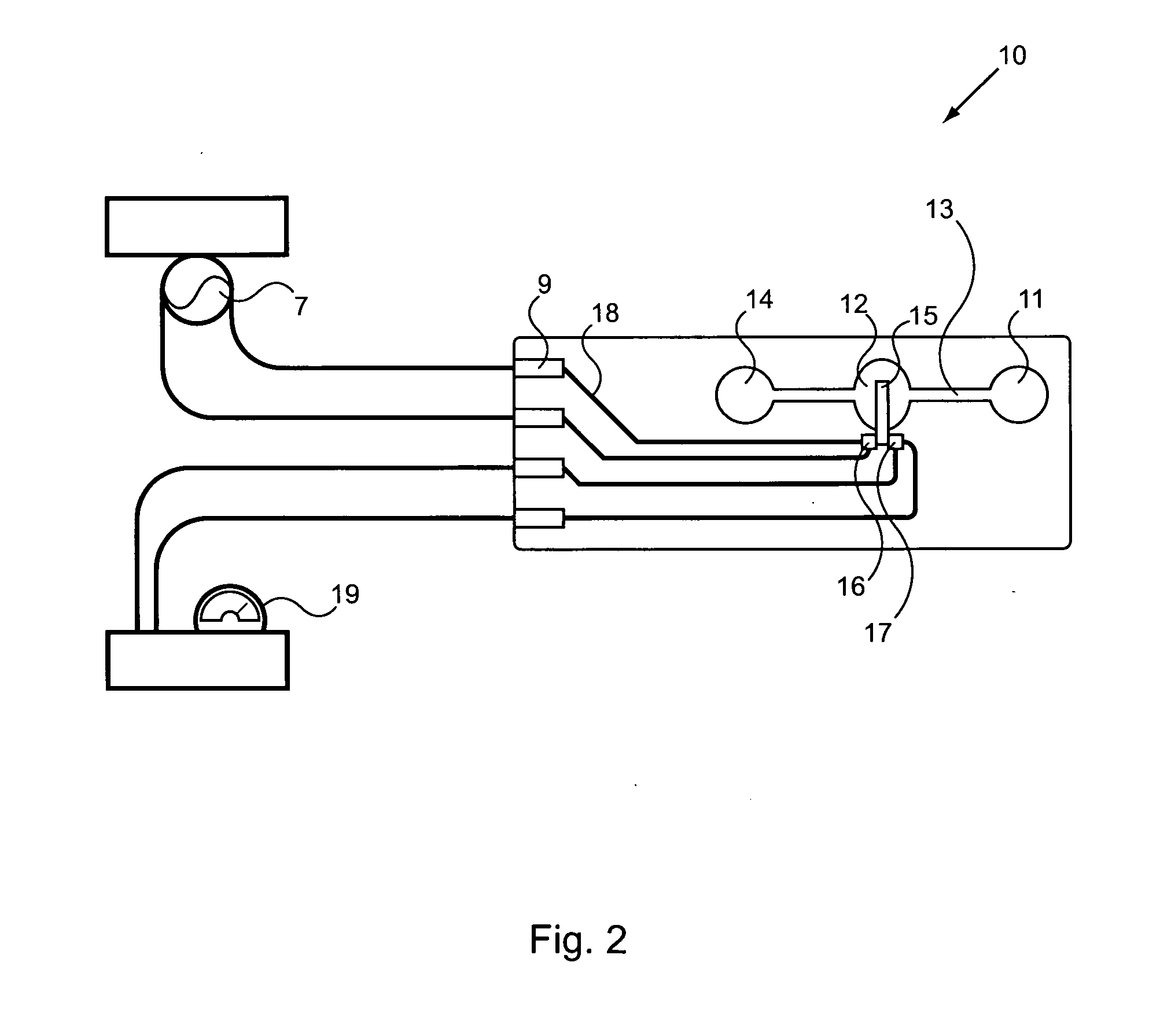

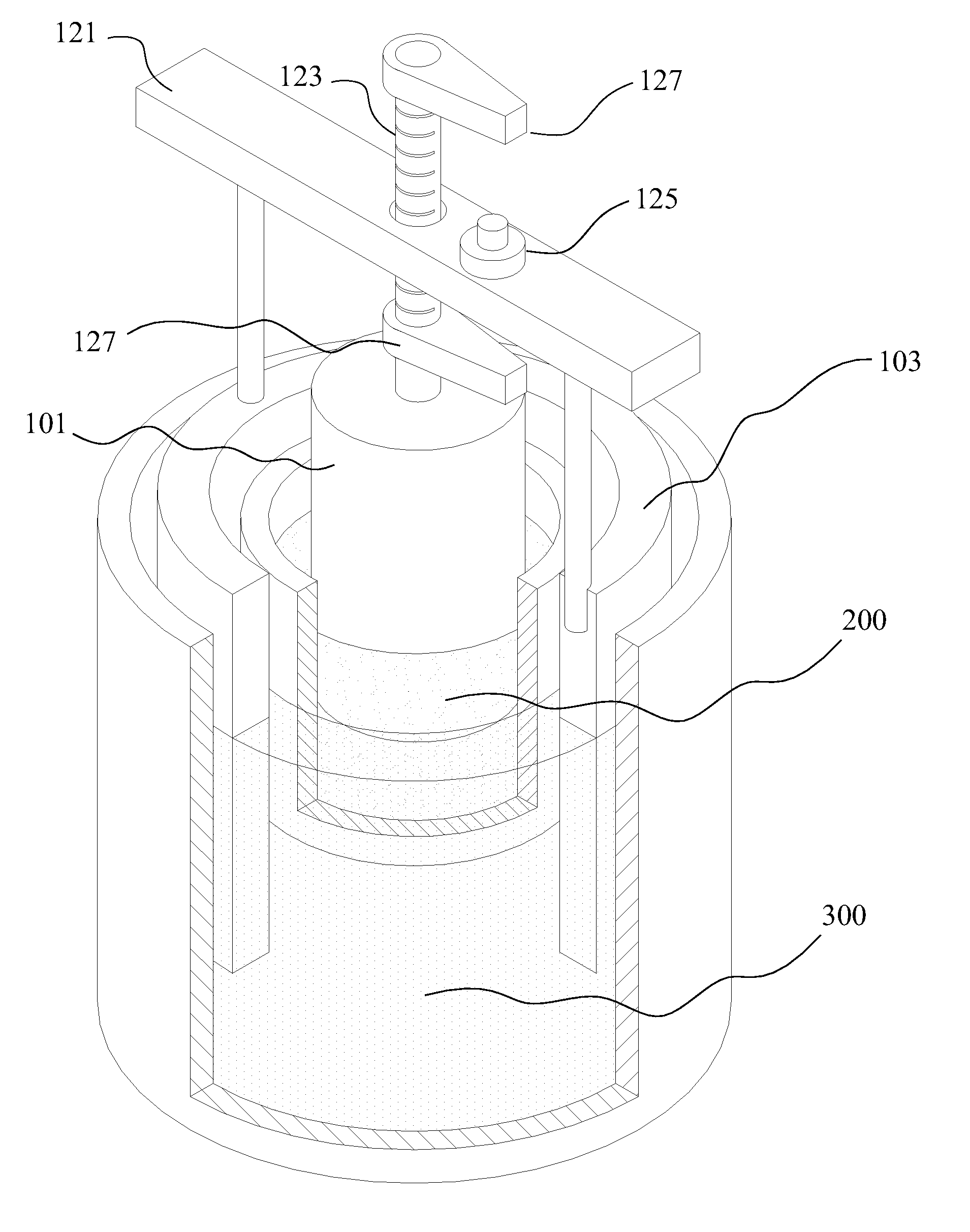

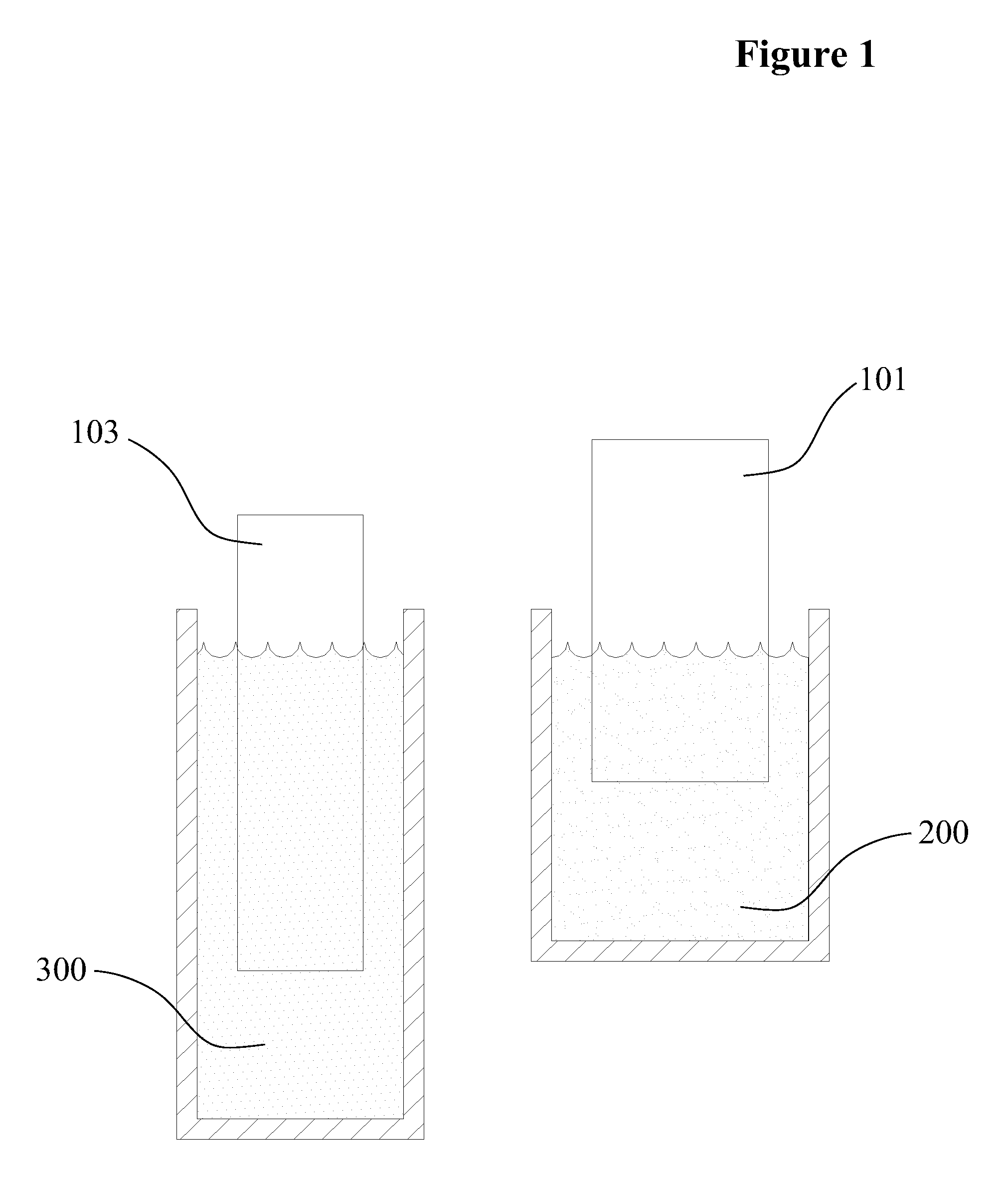

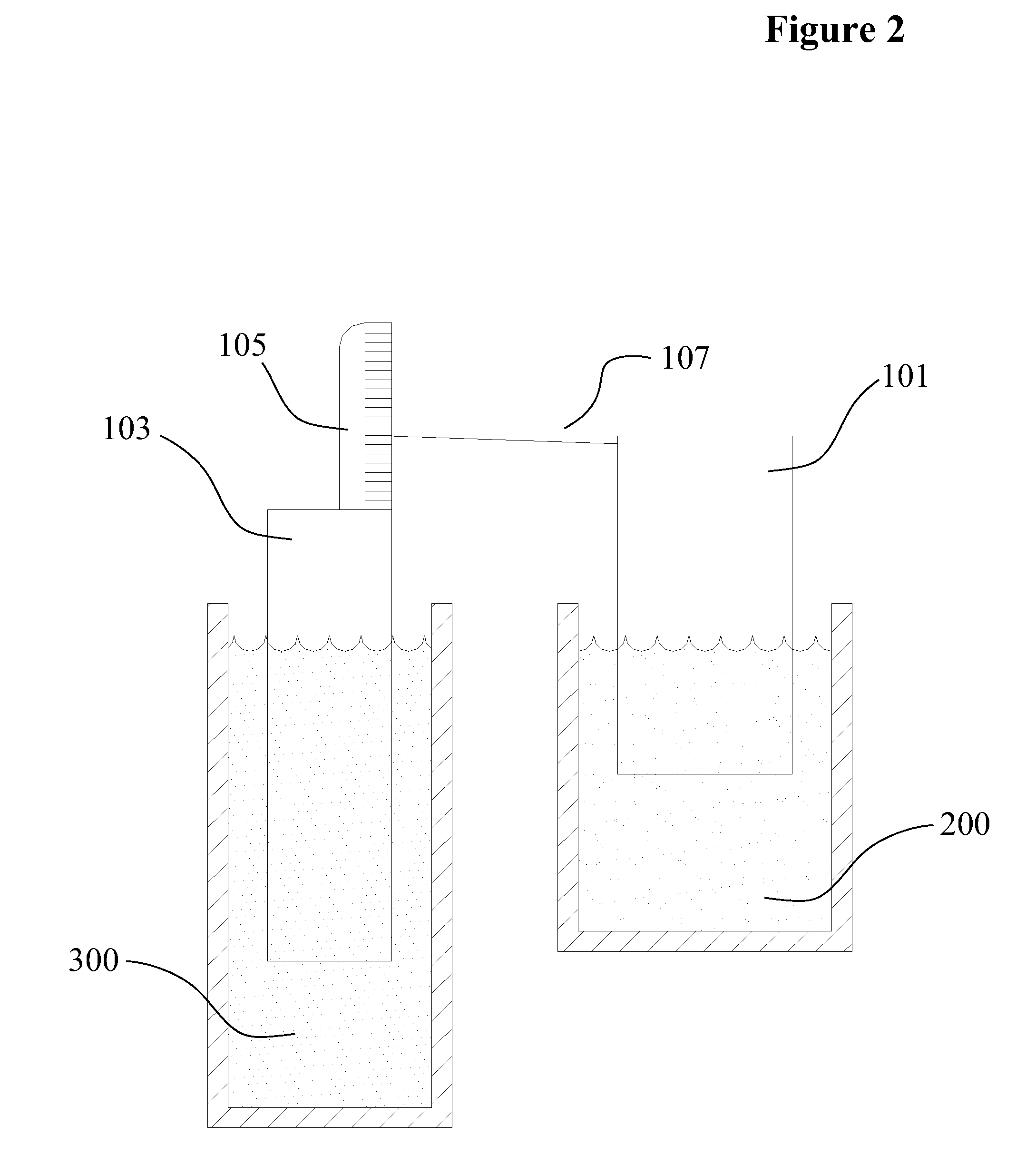

Apparatus and method for phase equilibrium with in-situ sensing

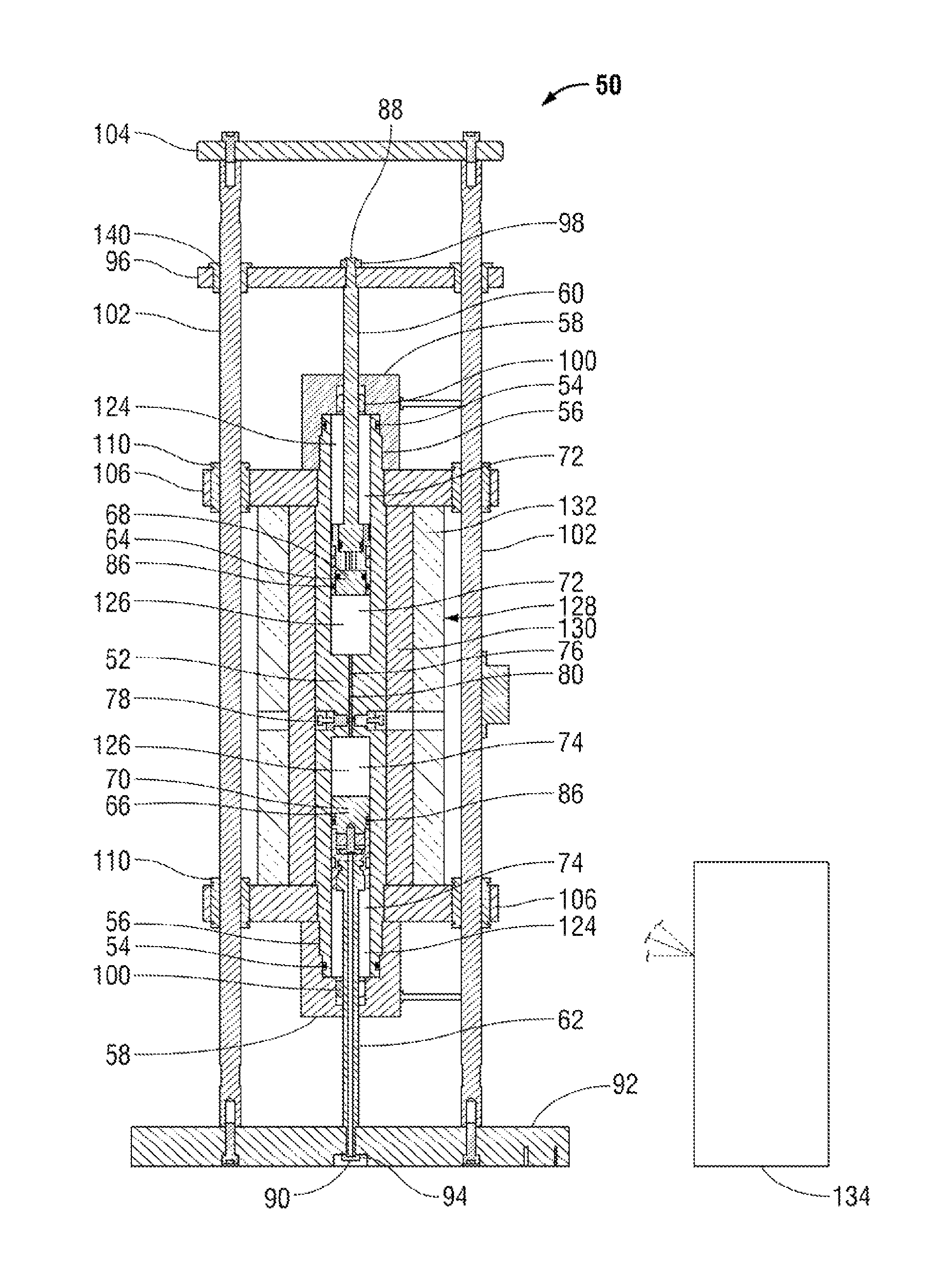

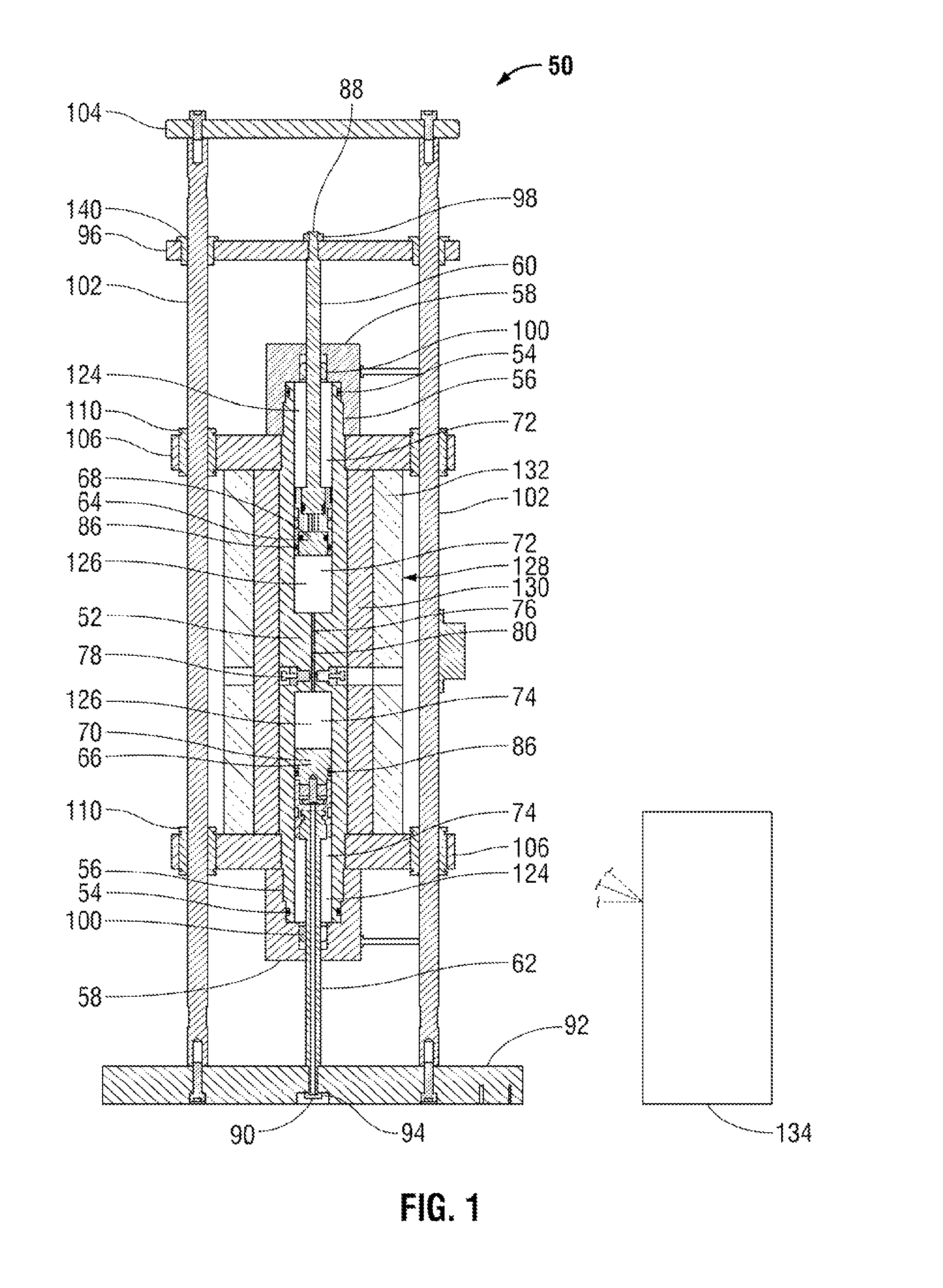

ActiveUS20130243028A1Efficient measurementMaterial heat developmentSpecific gravity using flow propertiesEngineeringReservoir fluid

A technique facilitates the monitoring of thermodynamic properties of reservoir fluids. The technique utilizes a modular sensor assembly designed to evaluate a sample of a hydrocarbon-containing fluid within a cell body. A variety of sensors may be selectively placed into communication with a sample chamber within the cell body to evaluate the sample at potentially high pressures and temperatures. The sensors may comprise a density-viscosity sensor located in-situ to efficiently measure both the density and viscosity of the sample as a function of pressure and temperature. Other sensors, such as an optic sensor, may also be positioned to measure parameters of the sample while the sample is retained in the sample chamber.

Owner:SCHLUMBERGER TECH CORP

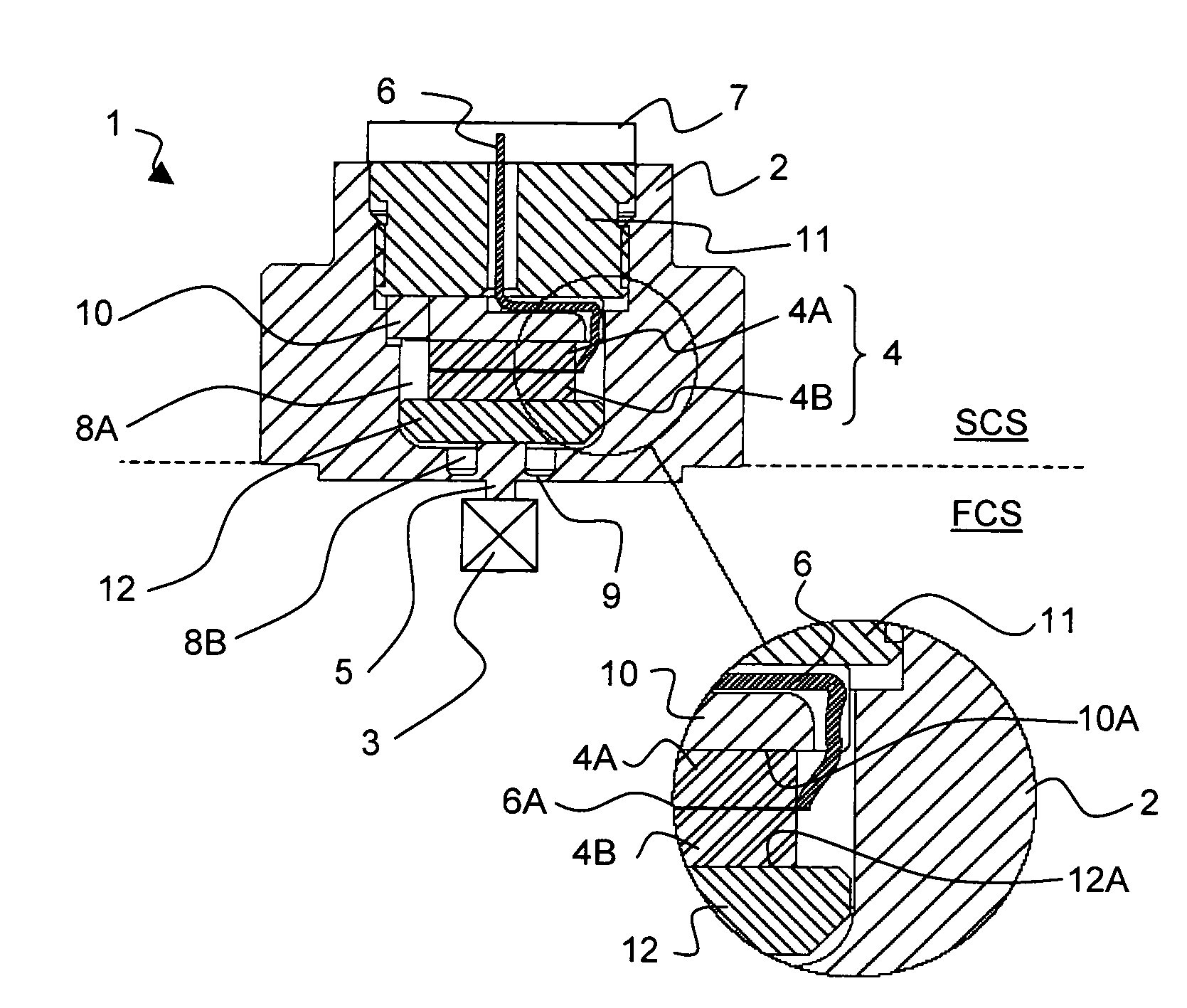

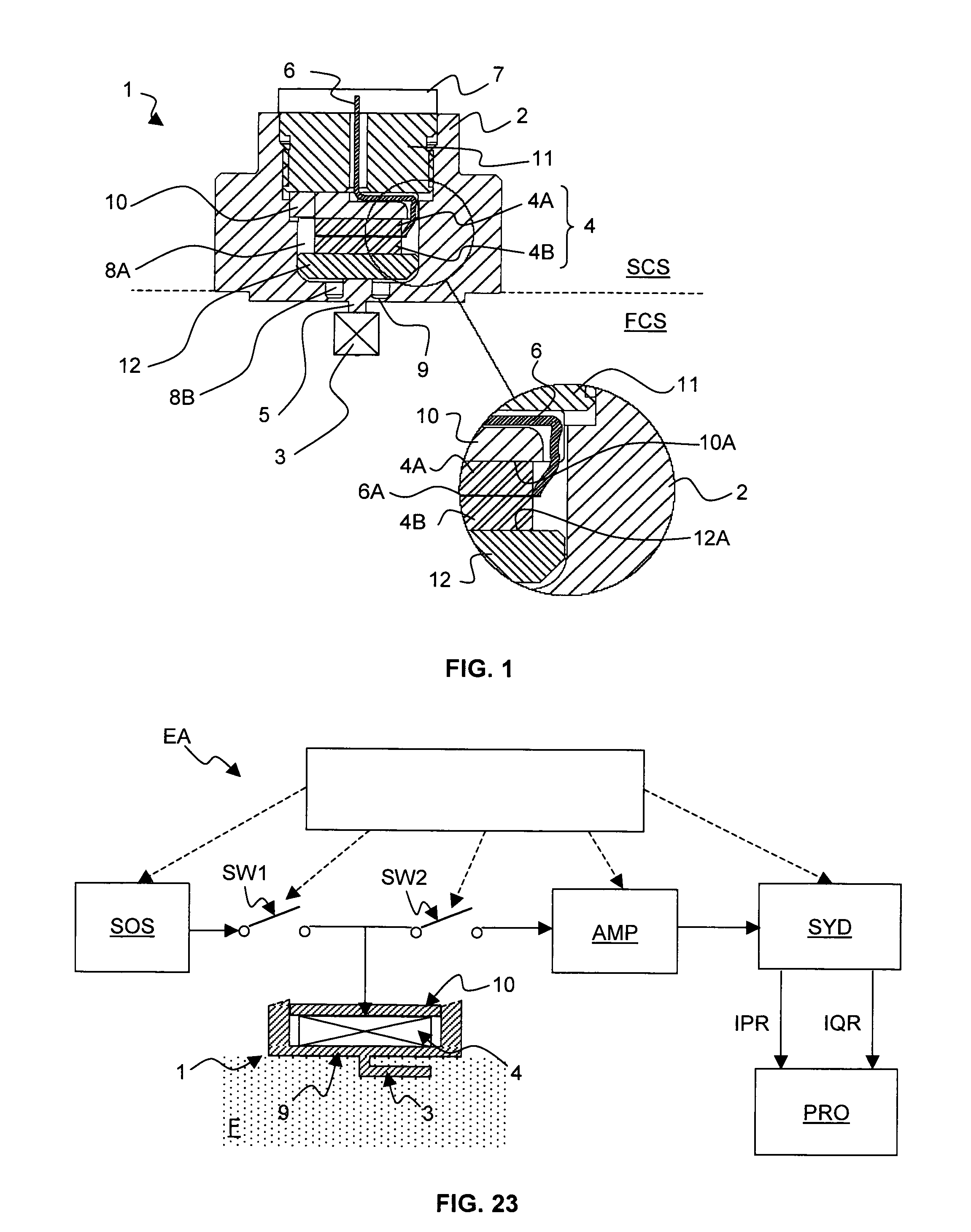

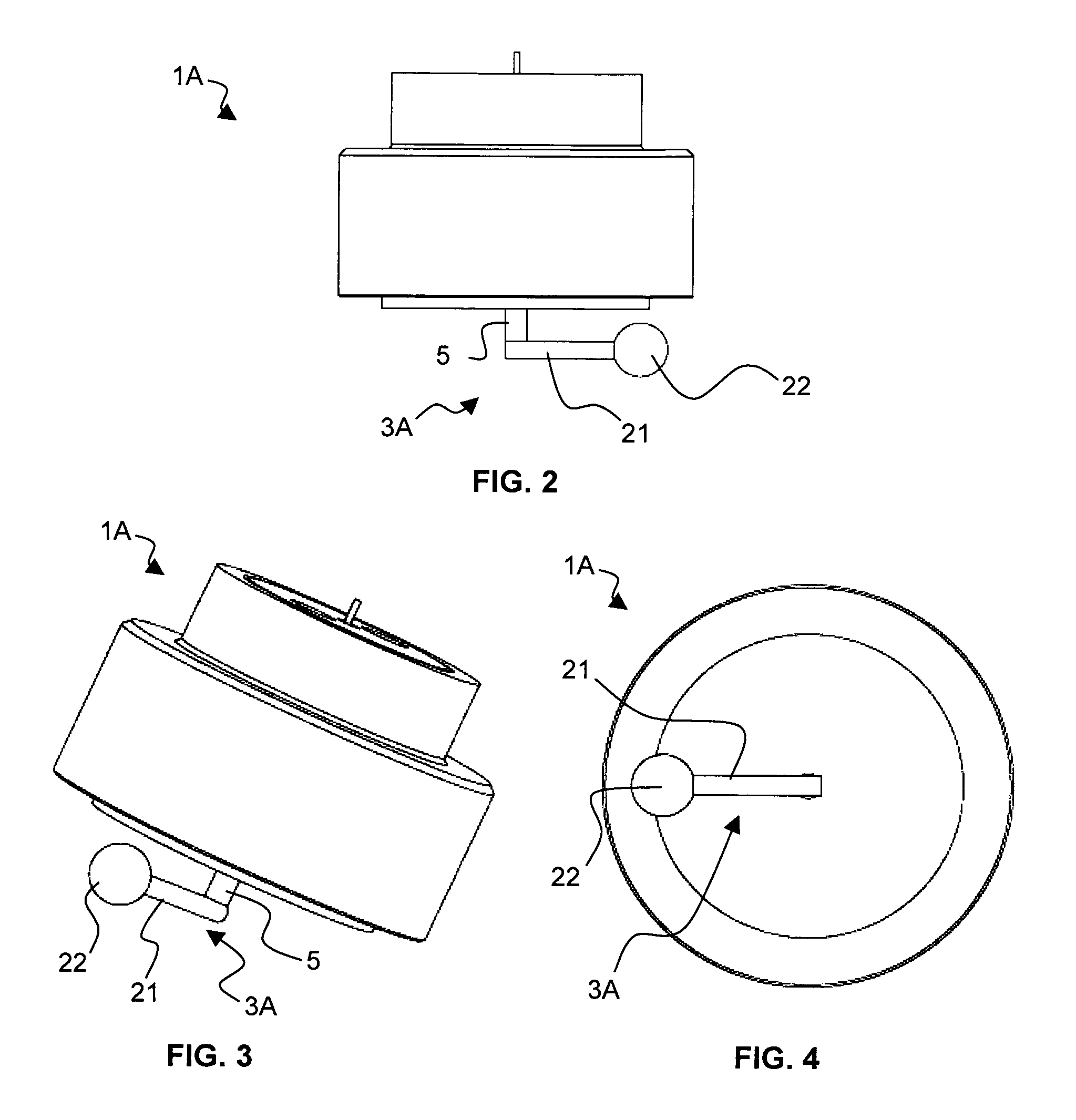

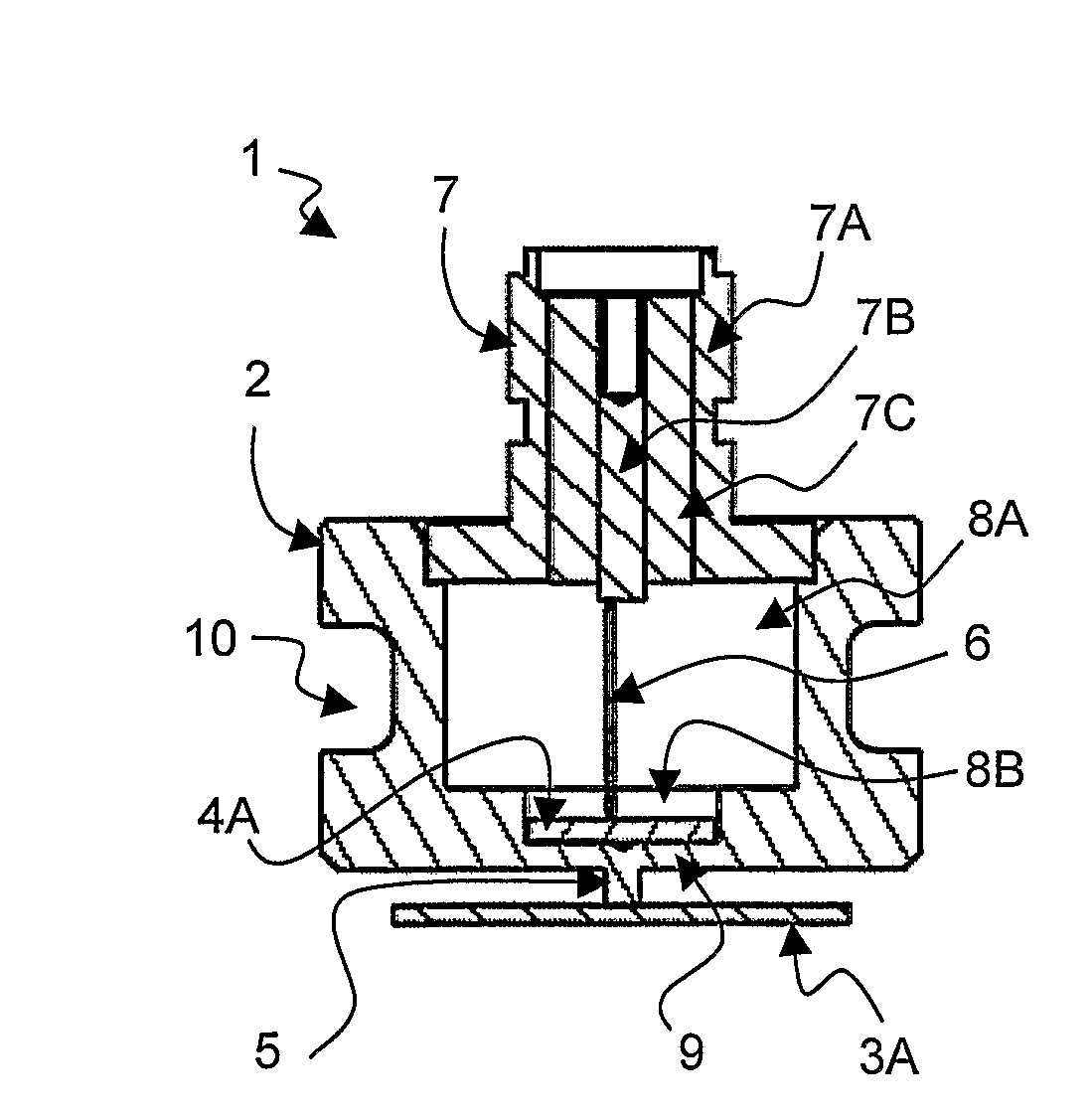

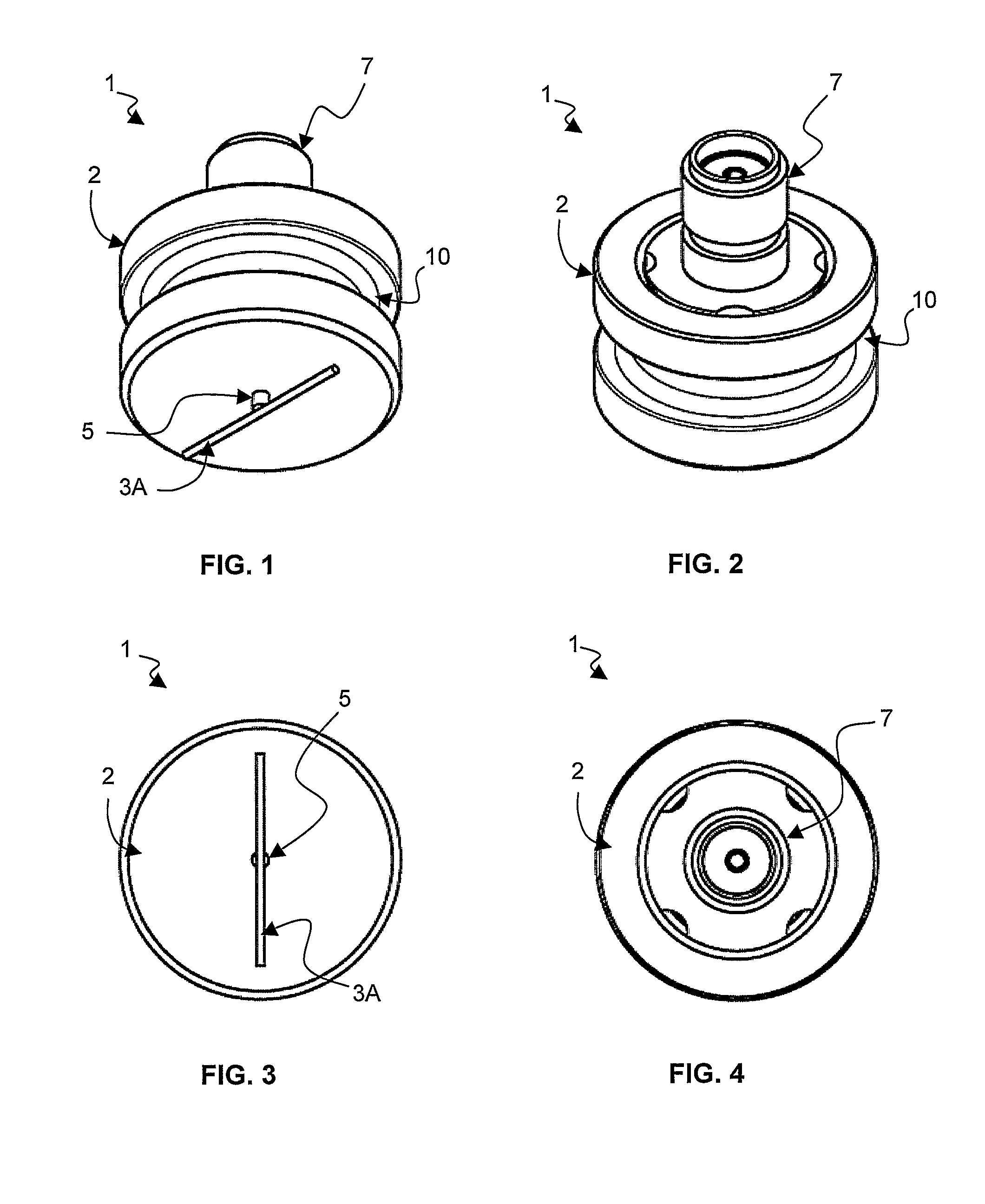

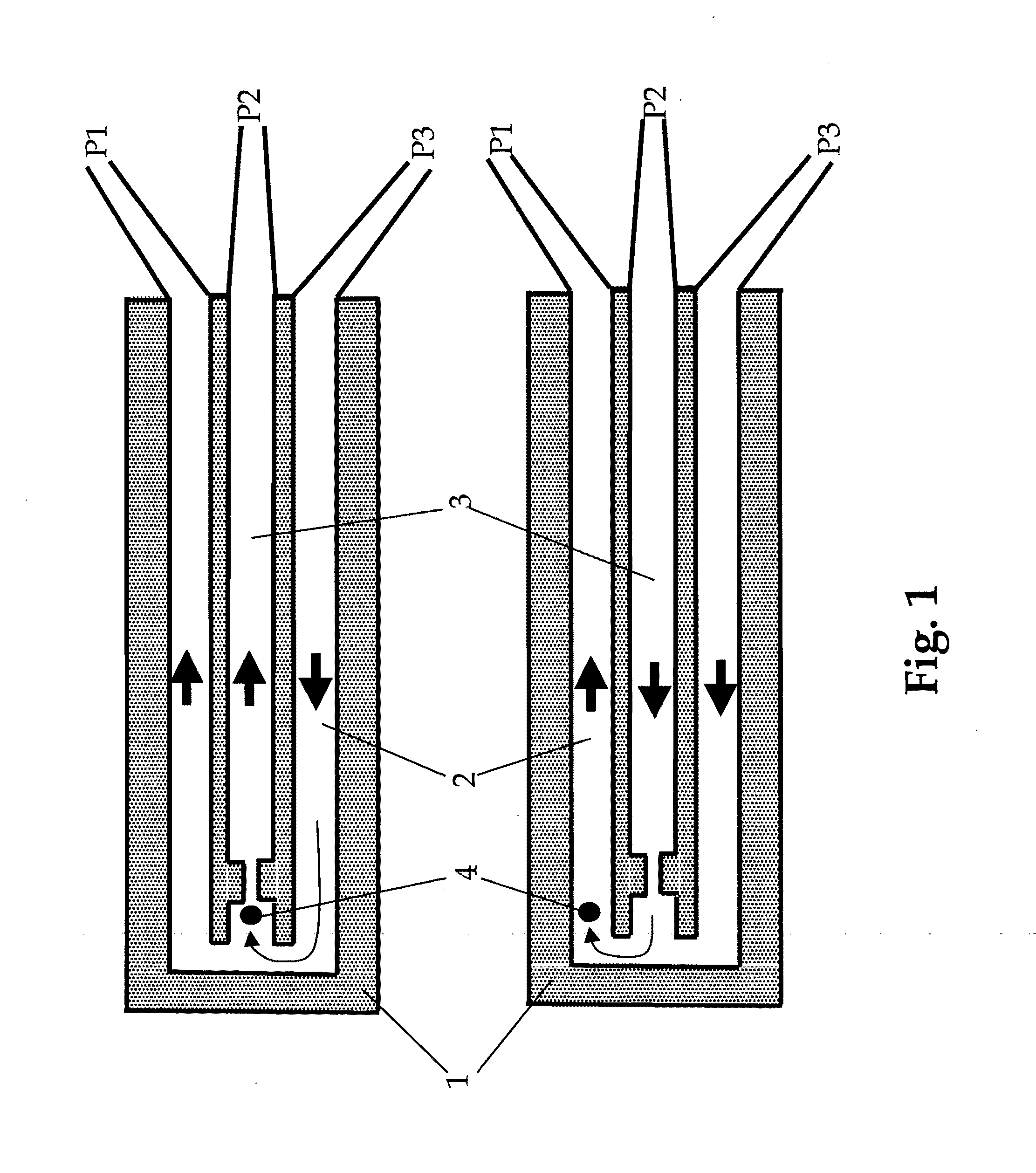

Density and viscosity sensor

ActiveUS7958772B2Reduce thicknessEnabling pressure resistanceFlow propertiesSpecific gravity using flow propertiesIsolation housingMechanical engineering

A density and viscosity sensor 1 for measuring density and viscosity of fluid F, the sensor 1 comprising a resonating element 3, 3A, 3B, 3C, 3D arranged to be immersed in the fluid F, an actuating / detecting element 4A, 4B coupled to the resonating element, and a connector 7 for coupling to the actuating / detecting element 4A, 4B. The sensor 1 further comprises a housing 2 defining a chamber 8A isolated from the fluid F, the housing 2 comprising an area of reduced thickness defining a membrane 9 separating the chamber 8A from the fluid F. The actuating / detecting element 4A, 4B is positioned within the chamber so as to be isolated from the fluid F and mechanically coupled to the membrane 9. The resonating element 3, 3A, 3B, 3C, 3D arranged to be immersed in the fluid F is mechanically coupled to the membrane 9. The membrane 9 has a thickness enabling transfer of mechanical vibration between the actuating / detecting element 4A, 4B and the resonating element 3, 3A, 3B, 3C, 3D.

Owner:SCHLUMBERGER TECH CORP

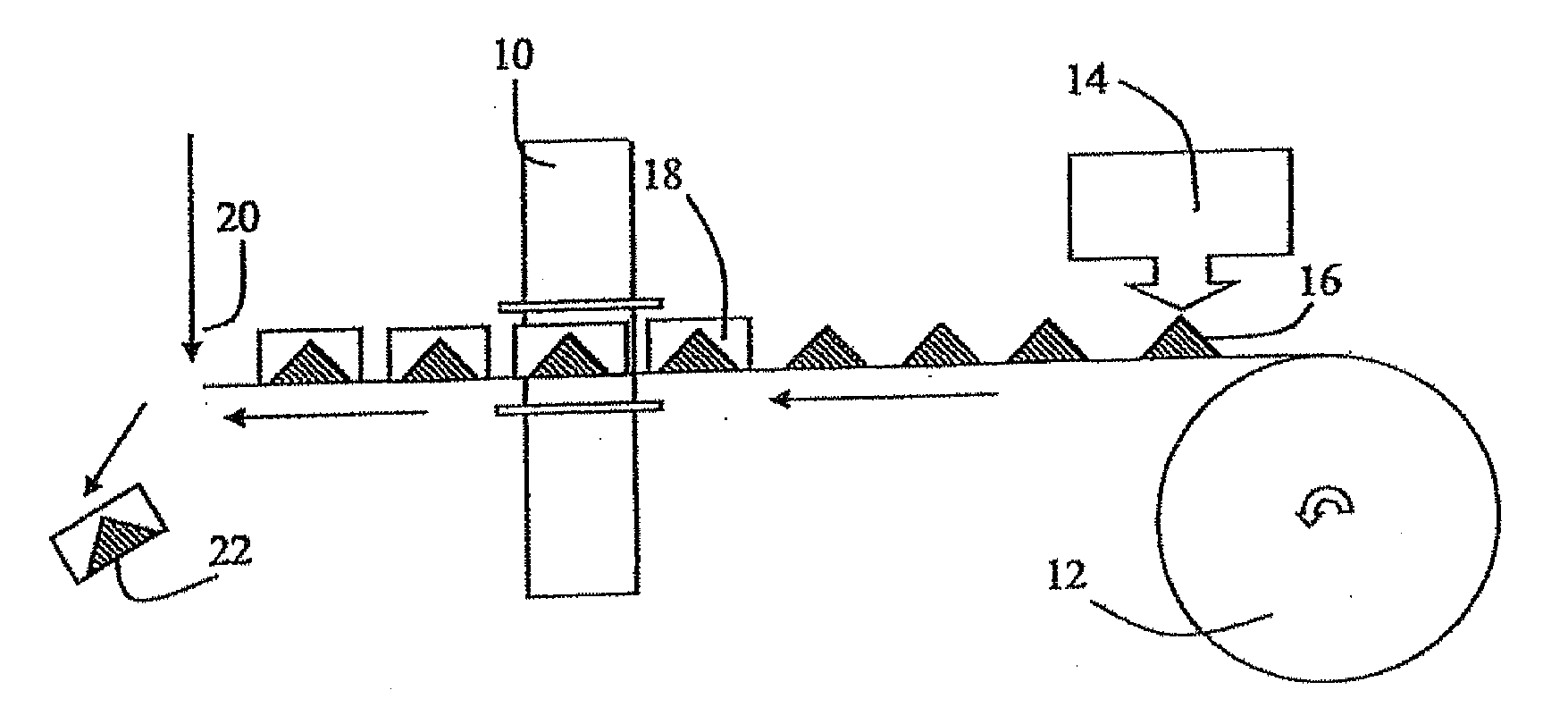

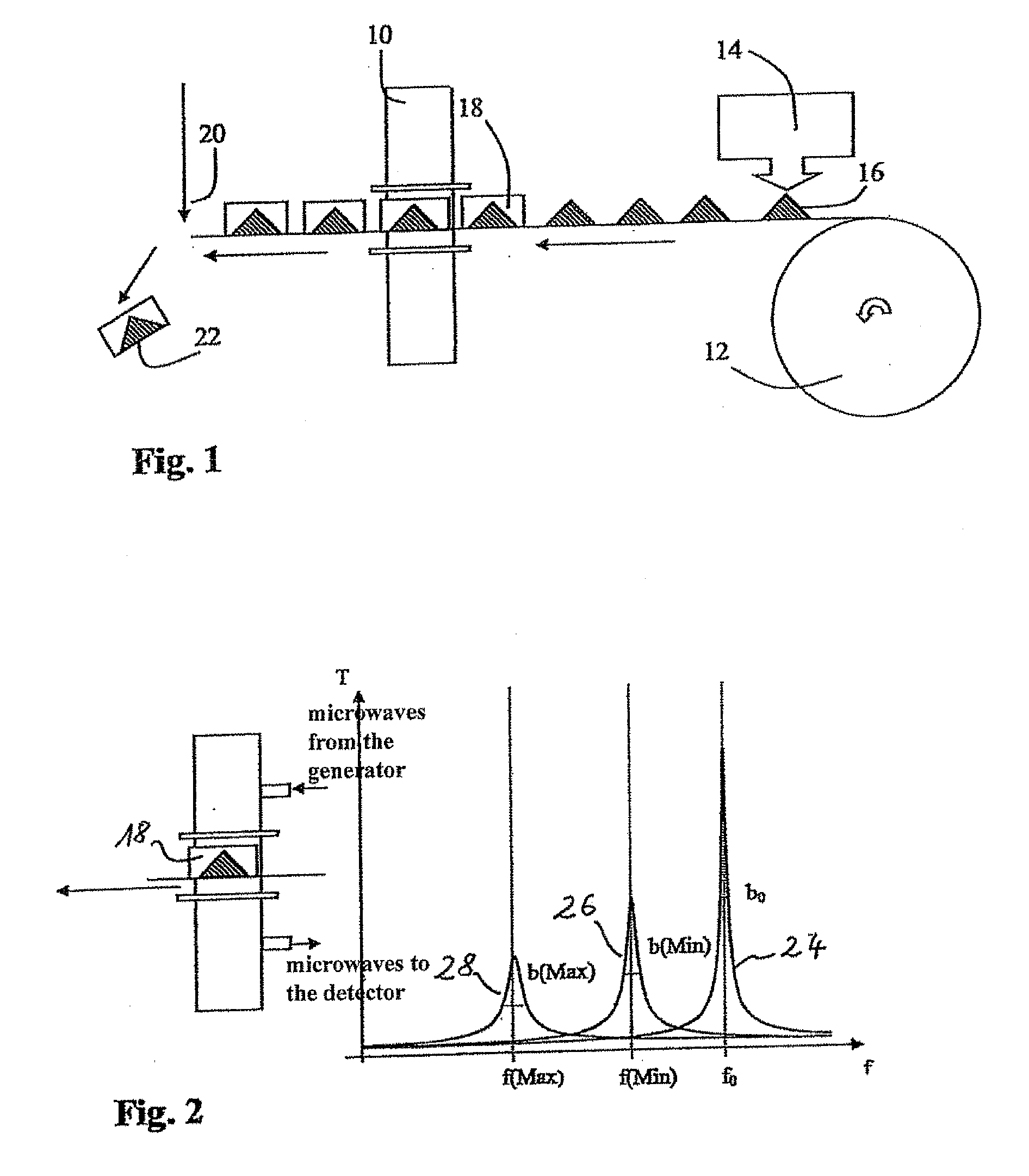

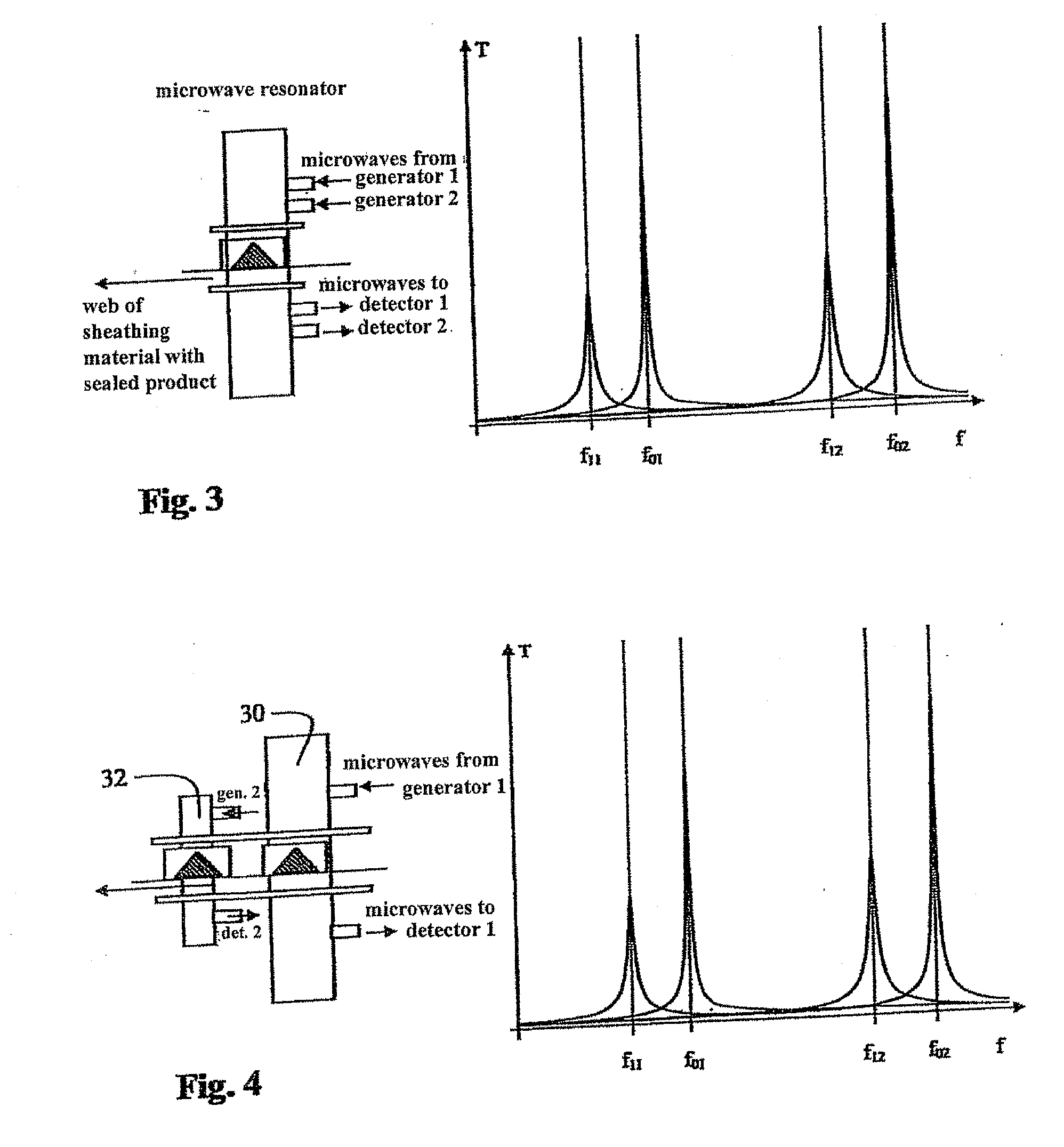

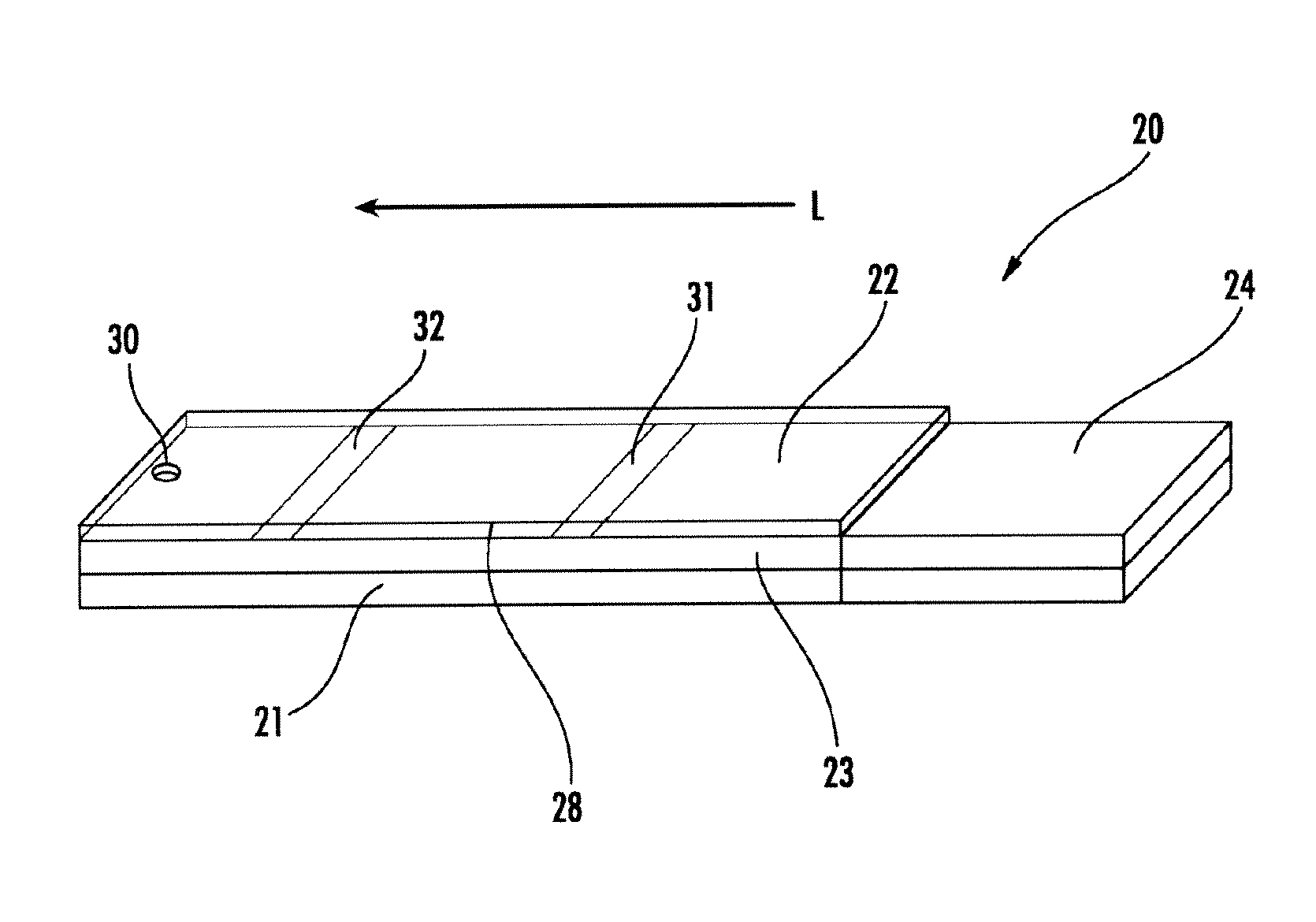

Apparatus and method for the measurement of mass and density and/or for the measurement of the humidity of portioned units

ActiveUS20100176818A1Guaranteed continuous supplyDurable propertyResistance/reactance/impedenceTobacco smoke filtersMeasuring instrumentResonance

Method and apparatus for the measurement of mass or density and / or for the measurement of the humidity in a plurality of portioned units in a non-metallic carrier material, which provides the following: a microwave measuring instrument, consisting of at least one microwave resonator for generating at least one resonance mode in a spatially limited measurement area and an analysing unit for analysing at least one variable of the at least one resonance mode, a conveying device for the carrier material, which transports the carrier material with the portioned units through the measurement area, the microwave measuring instrument measures at least one variable of the at least one resonance mode at a time when only the carrier material without portioned unit is in the measurement area, and at a time when the portioned unit is at least partially in the measurement area, the analysing unit subtracts the variable measured for the carrier material from the measurement values for the portioned unit, and determines a value of the humidity and / or of the mass or density of the portioned unit from at least one difference by way of an input-output map.

Owner:TEWS ELEKTRONIK GMBH & CO KG

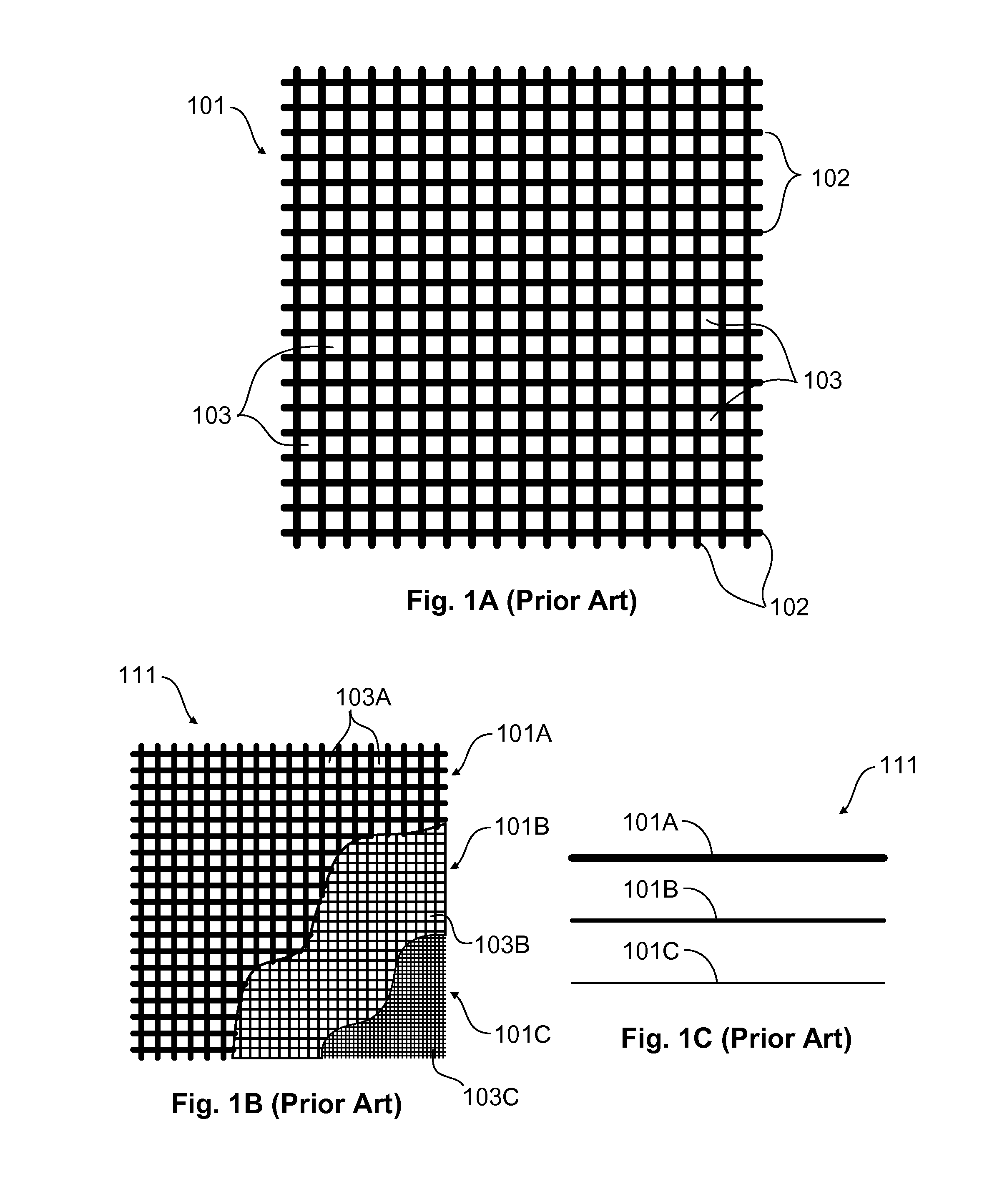

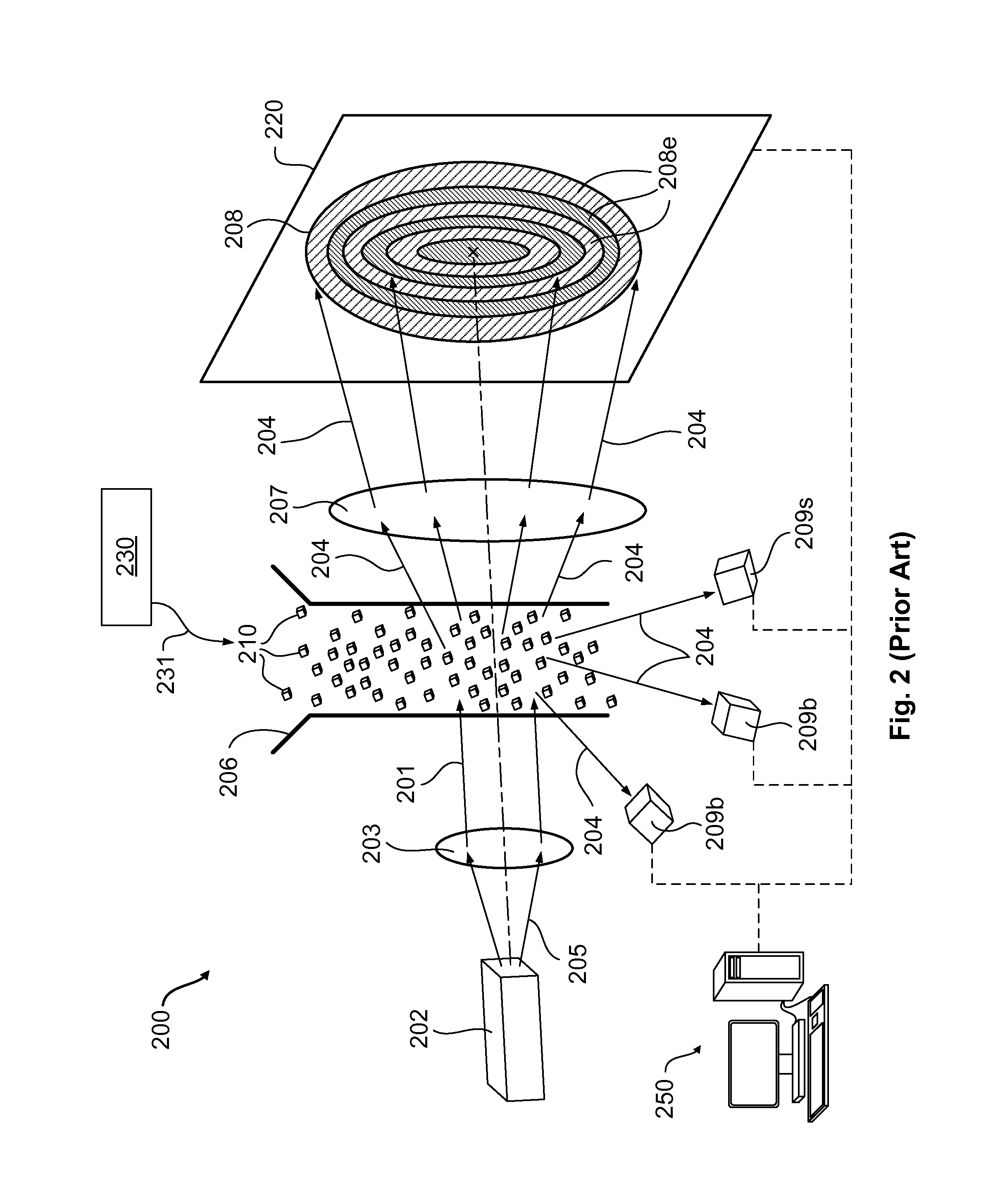

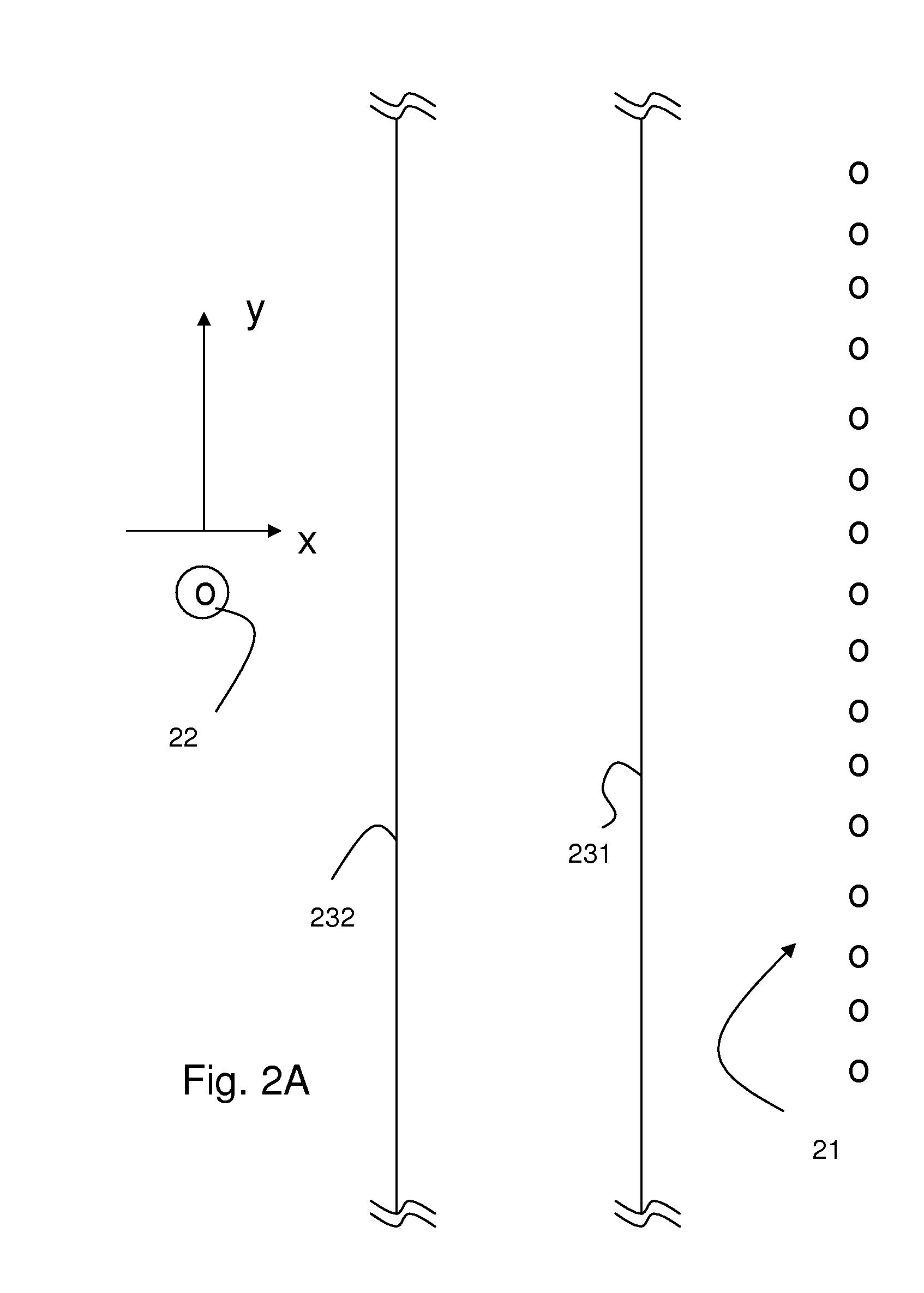

Systems and methods for determining specific gravity and minerological properties of a particle

InactiveUS20150020588A1Well formedMaterial analysis by observing immersed bodiesSpecific gravity using flow propertiesChemical physicsParticulate material

A system includes a particulate material sample that contains a fluid medium and a plurality of particles dispersed in the fluid medium. The system further includes a particle analysis apparatus having a sample cell and sample delivery means for delivering the particulate material sample to the sample cell, wherein the particle analysis apparatus is adapted to obtain particle information on at least one particle in that particulate material sample while the at least one particle is in the sample cell. Furthermore, the system also includes fluid manipulation means for manipulating movement of the fluid medium while the particle analysis apparatus is obtaining the particle information on the at least one particle, and a data processing apparatus that is adapted to determine a specific gravity of the at least one particle based on the obtained particle information.

Owner:NAT OILWELL VARCO LP

Piezoelectric coagulation sensors

ActiveUS20110203367A1Analysing fluids using sonic/ultrasonic/infrasonic wavesFlow propertiesPiezoelectric actuatorsTransducer

This invention provides methods and devices to measure physical characteristics of sample fluids. Samples are introduced into a sample chamber in contact with a mechanically oscillating working member. The vibrations are received by a piezoelectric sensor transducer and correlated to a sample characteristic, such as viscosity or density. The devices include a sample chamber in contact with one or more working members actuated by a piezoelectric actuator and / or monitored by a piezoelectric sensor.

Owner:MICROPOINT BIOTECHNOLOGIES CO LTD

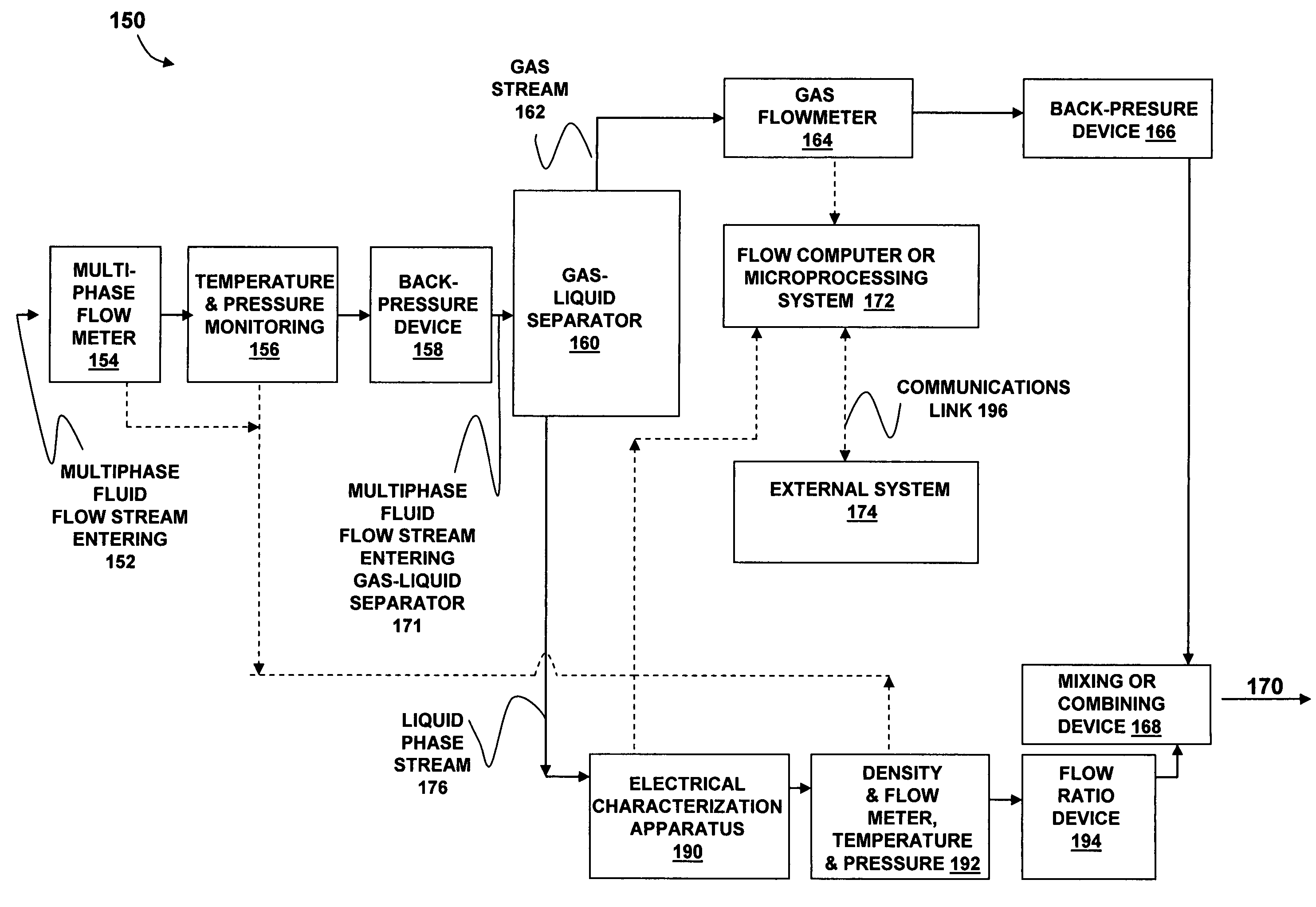

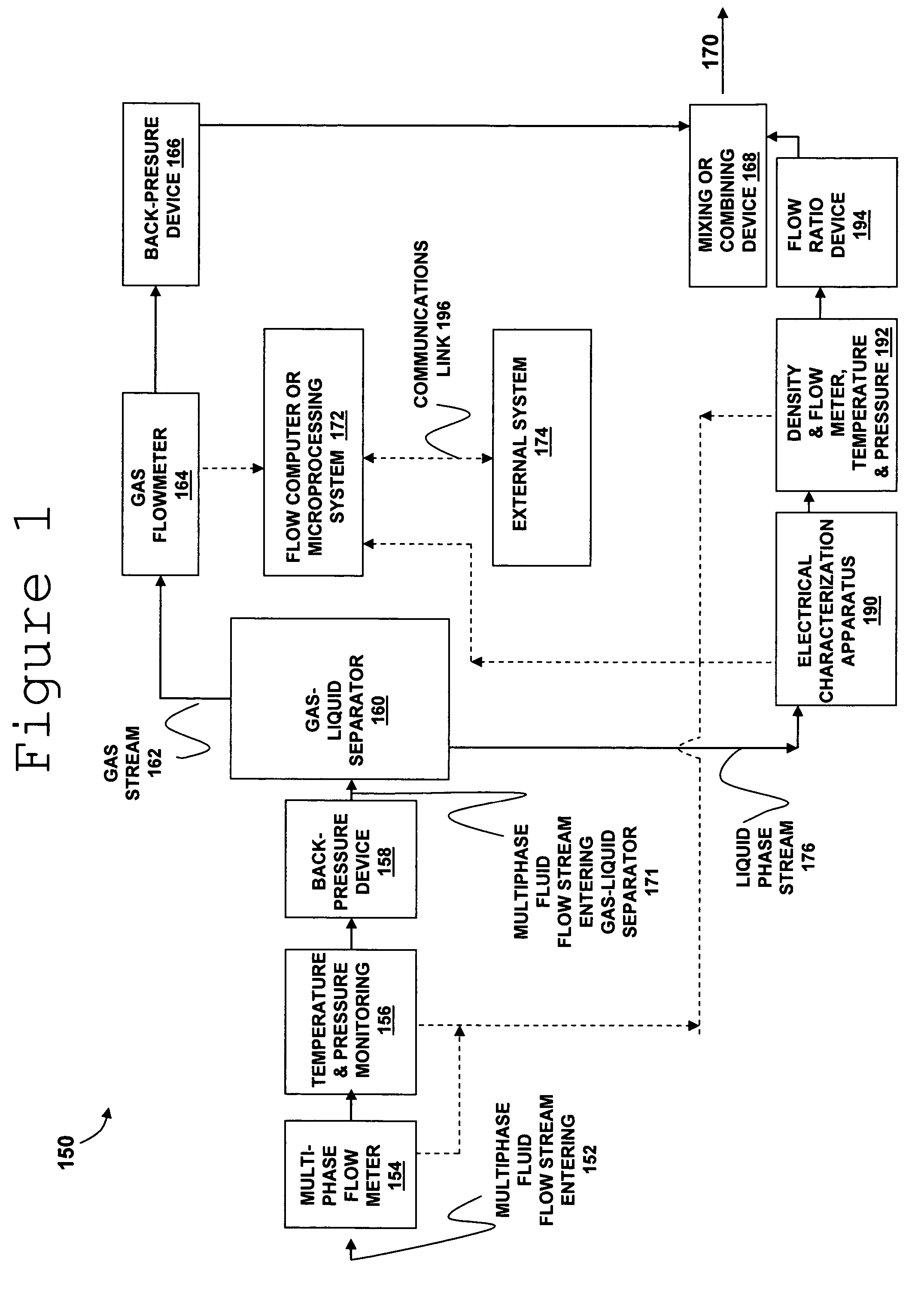

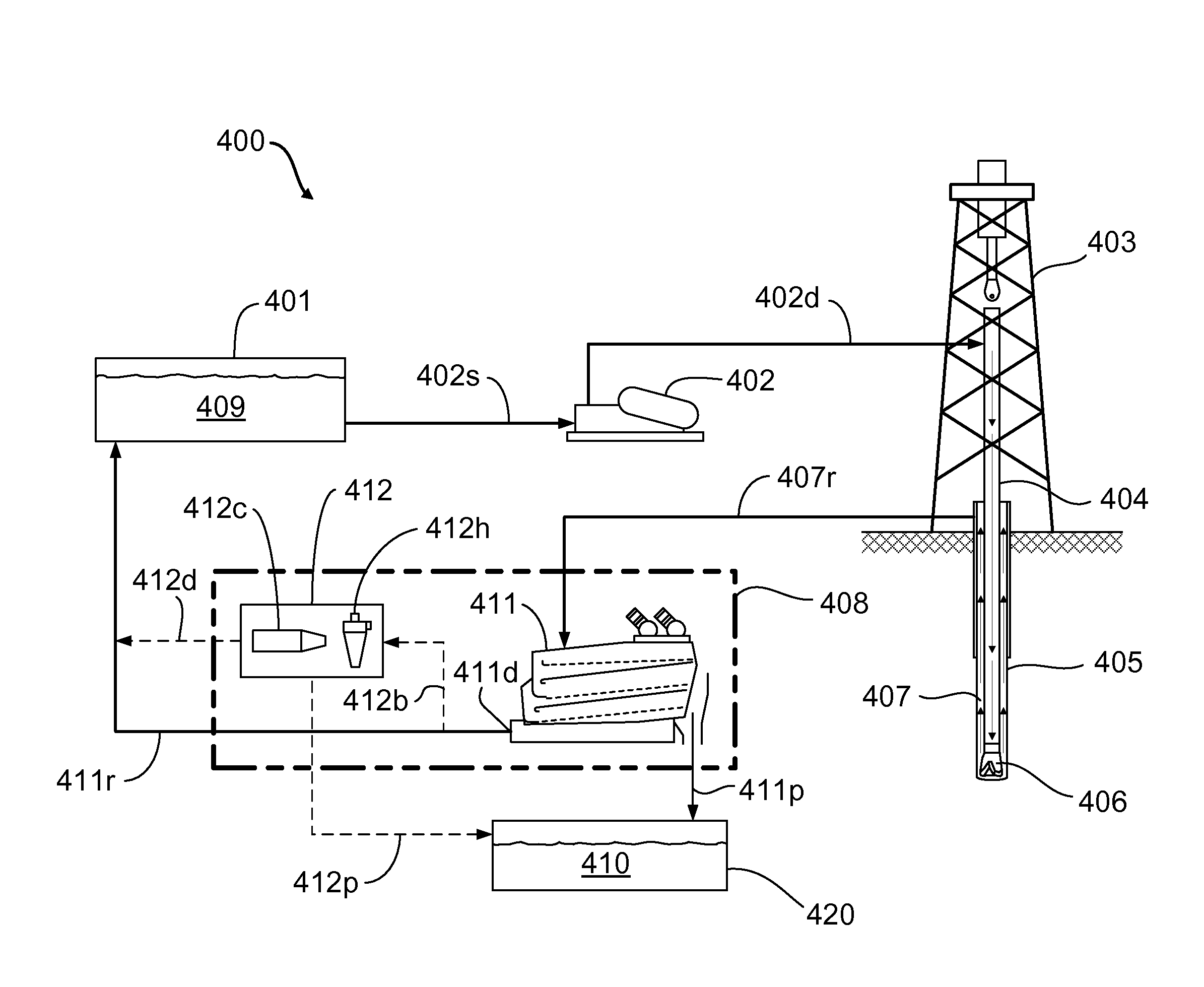

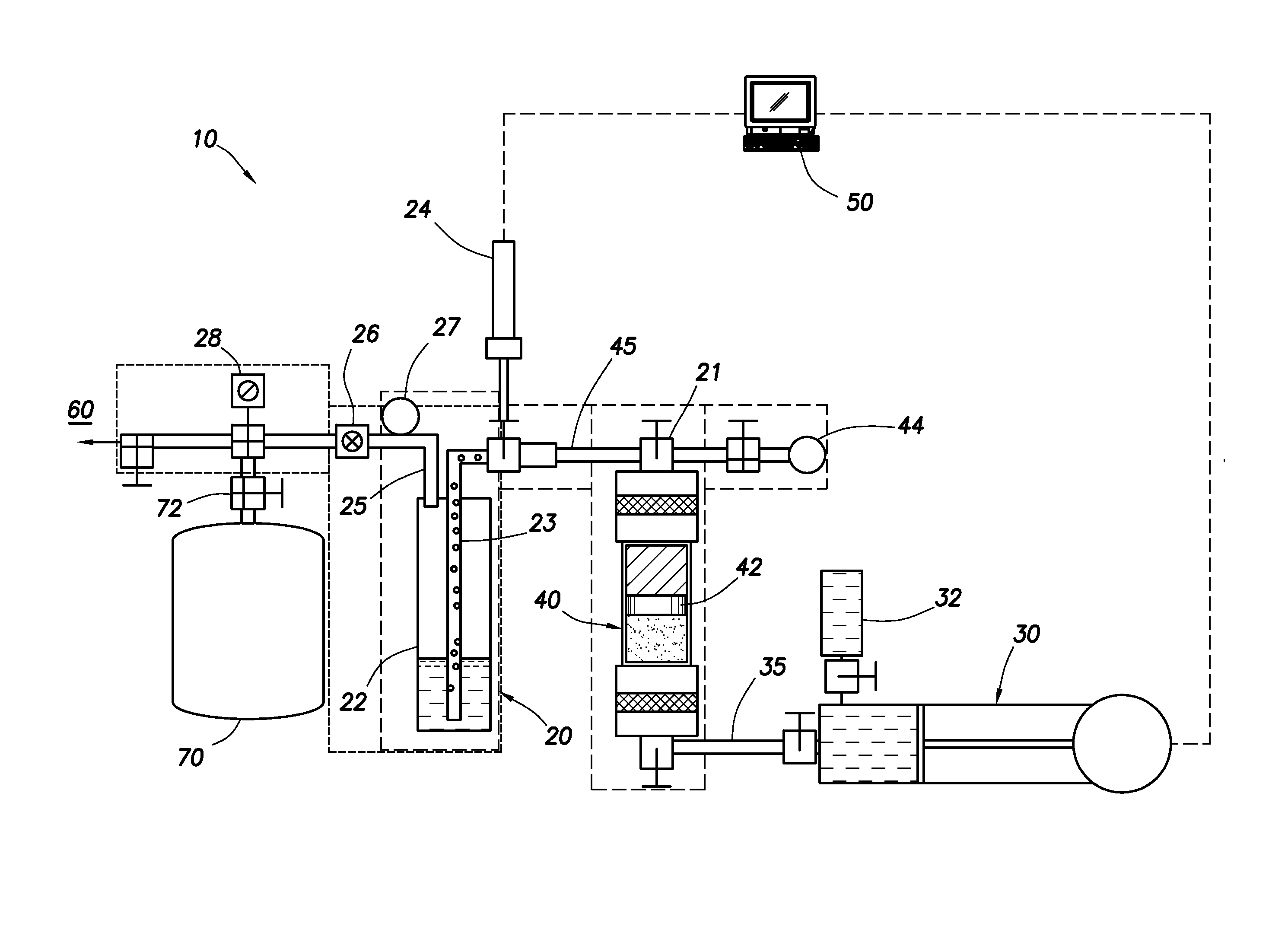

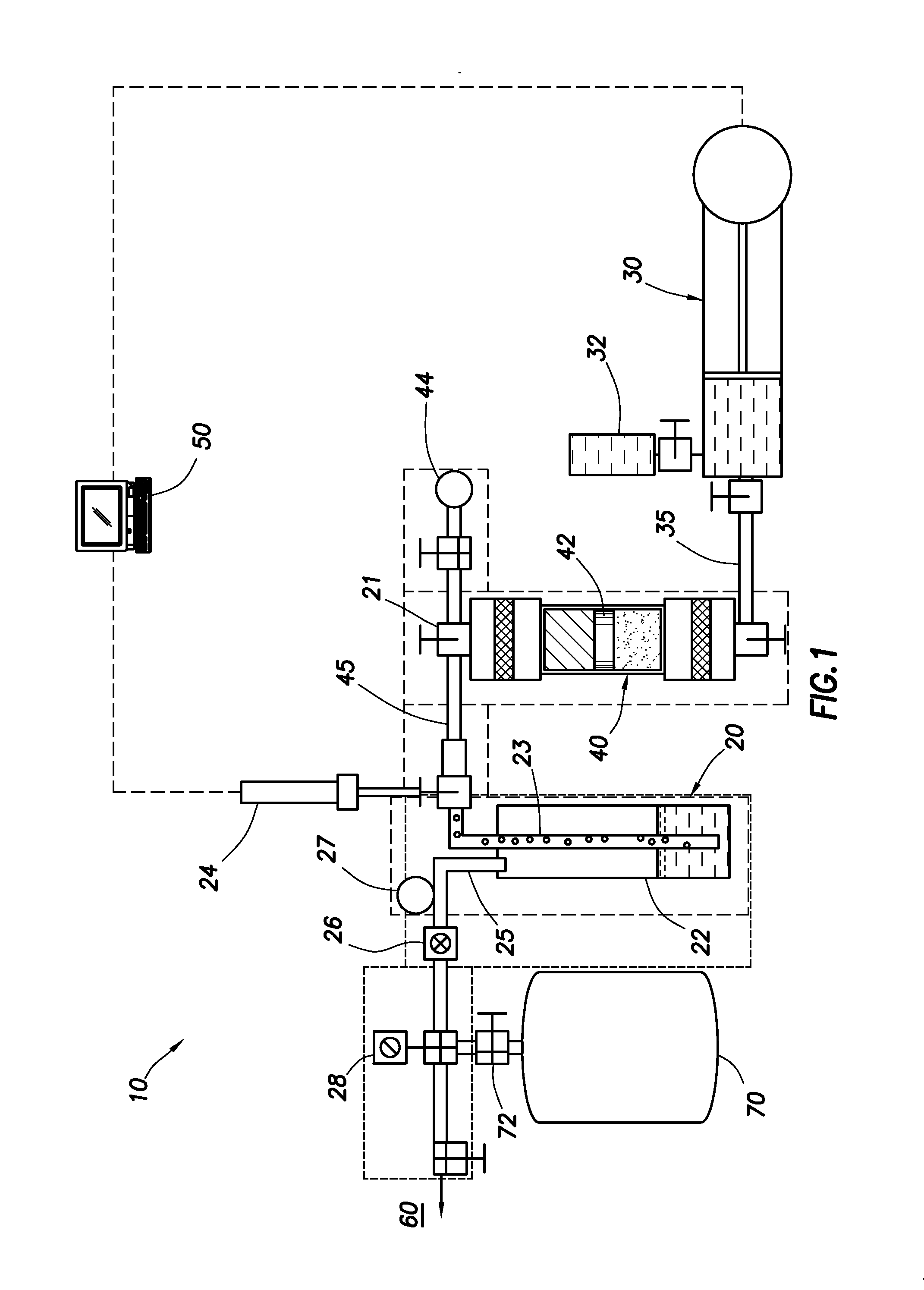

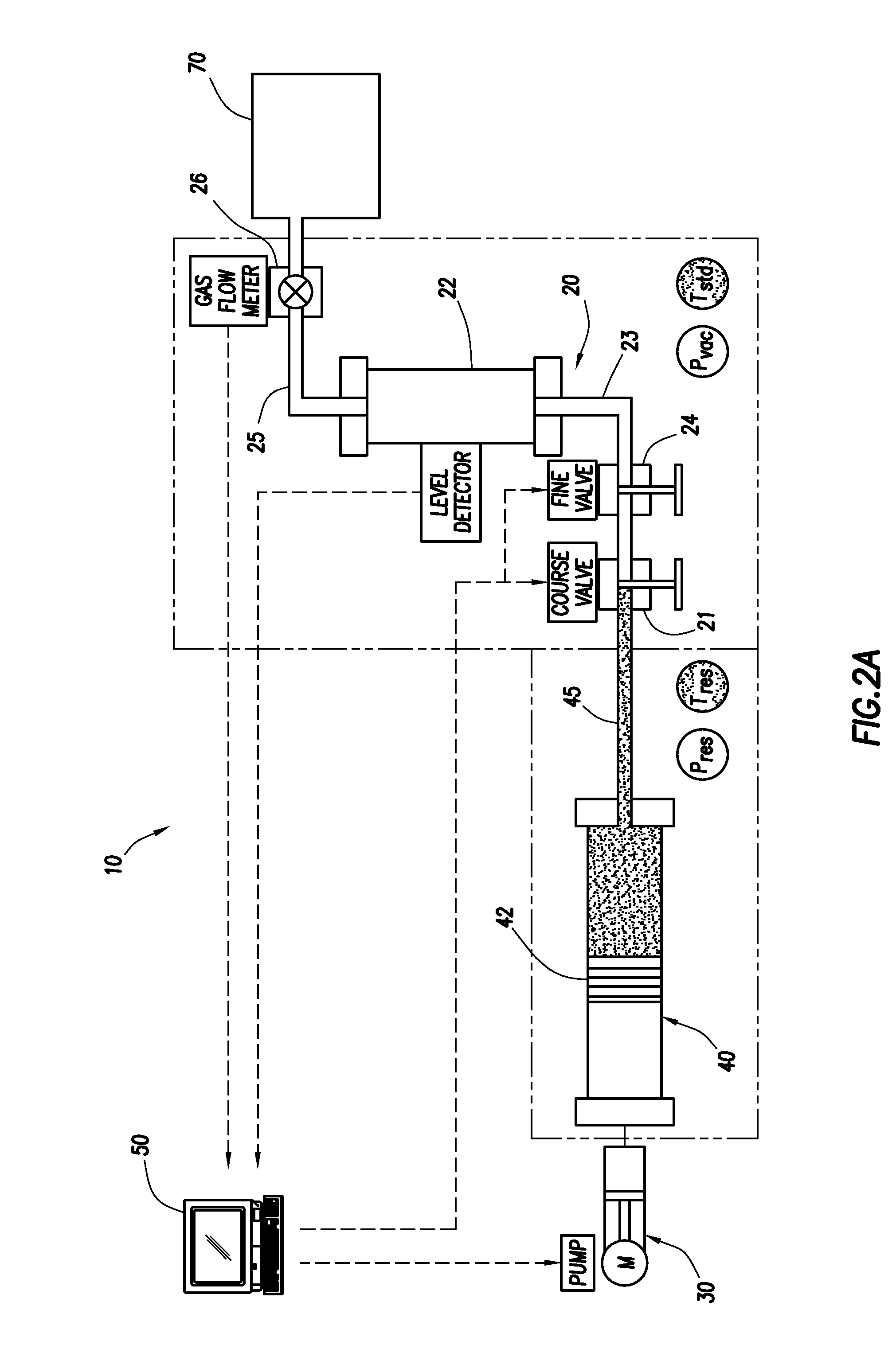

Universal flash system and apparatus for petroleum reservoir fluids study

A flash system and method is disclosed to control the rate of flashing a reservoir fluid sample from reservoir conditions to a given pressure and temperature in order to produce a liquid and a gas phase of the sample. The flash system comprises a flash apparatus including a separating chamber, a metering valve positioned at an inlet of the separating chamber, and a gas flow meter positioned at an outlet of the separating chamber. A pump is provided to displace the sample from a sample chamber to the flash apparatus, wherein the pump speed and the discharge rate of the metering valve can be automatically controlled. The flash system may be used in a laboratory environment and at the site of an oilfield reservoir. The present disclosure provides a universal flash system and method that can limit operator actions to a minimum of simple operations to ensure the repeatability of the process independent of the operator's skill.

Owner:SCHLUMBERGER TECH CORP

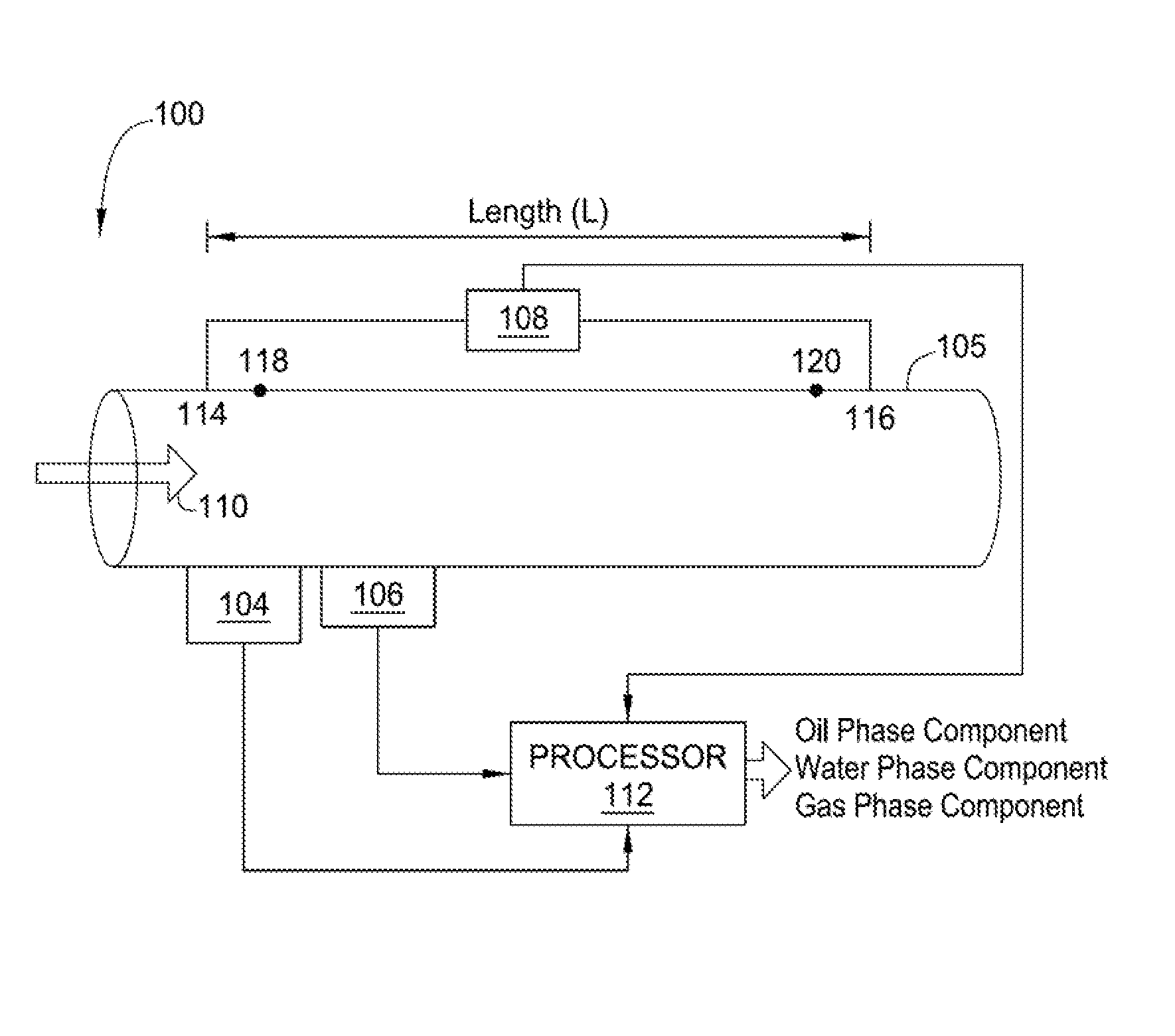

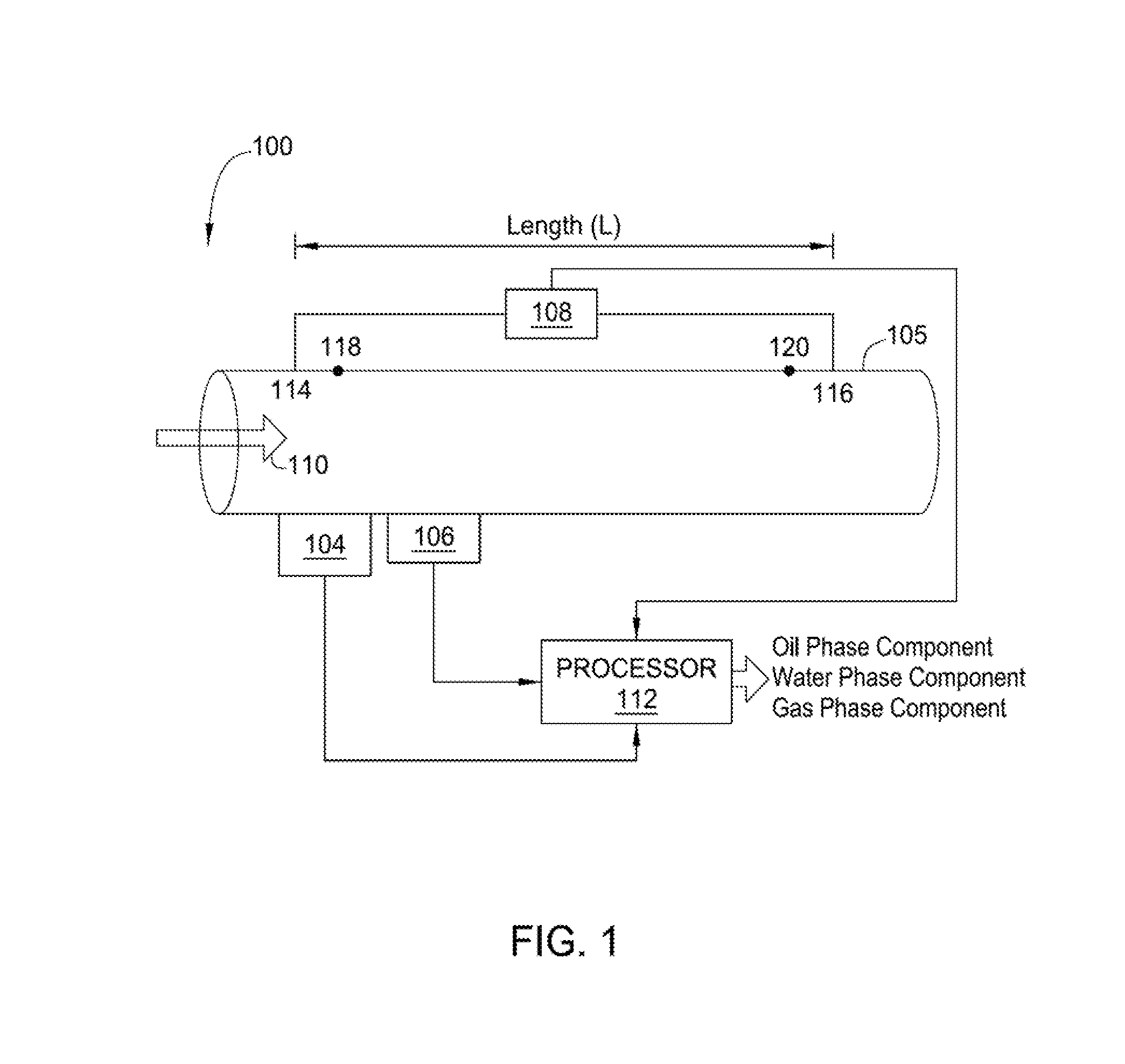

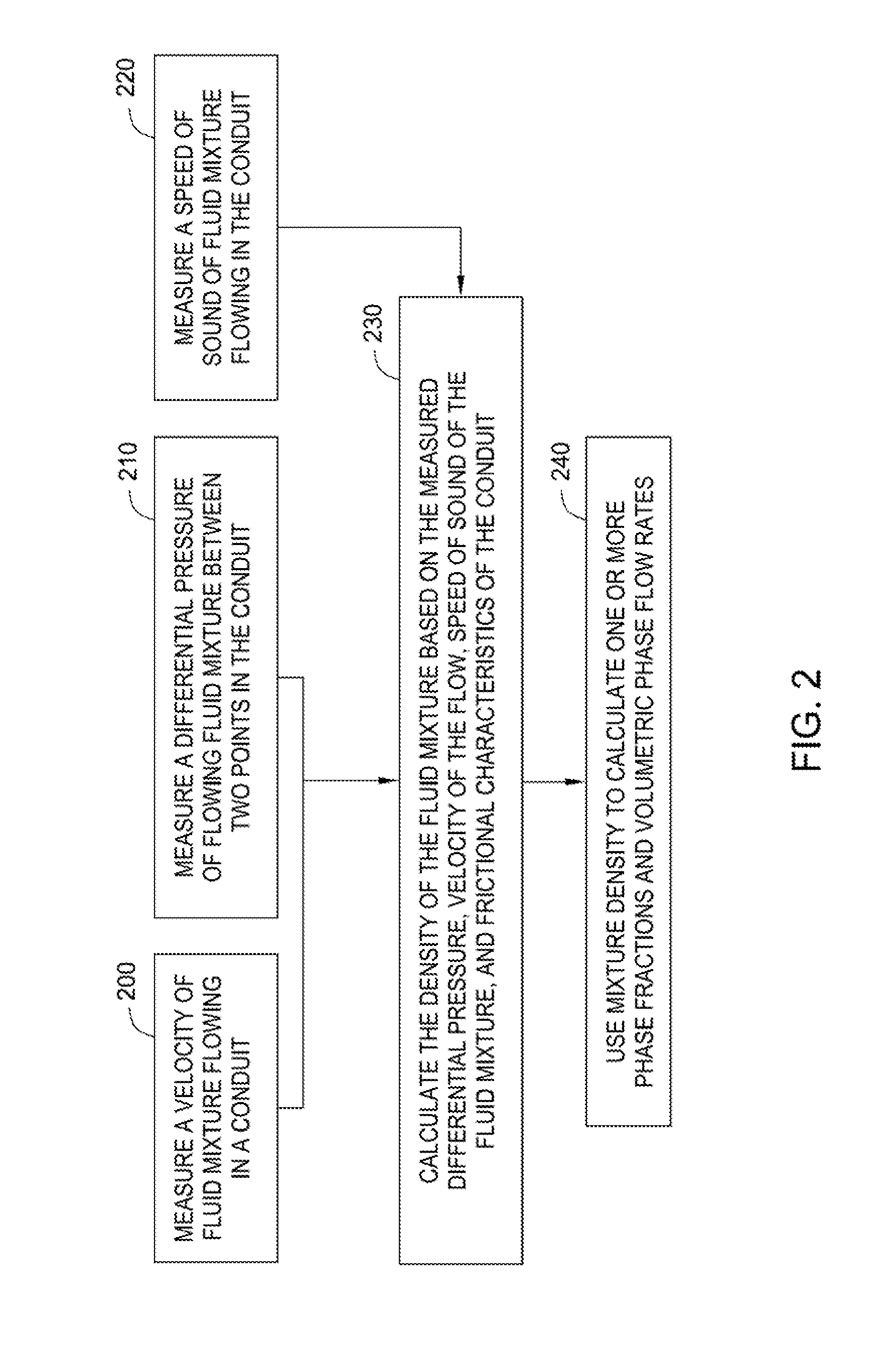

In-well full-bore multiphase flowmeter for horizontal wellbores

ActiveUS20140012507A1Electric/magnetic detection for well-loggingMaterial analysis using sonic/ultrasonic/infrasonic wavesMomentumSurface roughness

Methods and apparatus for measuring individual phase fractions and phase flow rates in a multiphase flow based on velocity of the flow, speed of sound through the fluid mixture, and the density of the fluid mixture. Techniques presented herein are based on measuring frictional pressure drop across a flowmeter conduit, determining a surface roughness term for the conduit during initial flow tests or through other mechanical means, implementing a correction method to balance the momentum equation, and calculating the fluid mixture density using the measured pressure drop. The techniques may be applicable to measuring flow parameters in horizontally oriented conduits and, more generally, conduits of any orientation.

Owner:WEATHERFORD TECH HLDG LLC

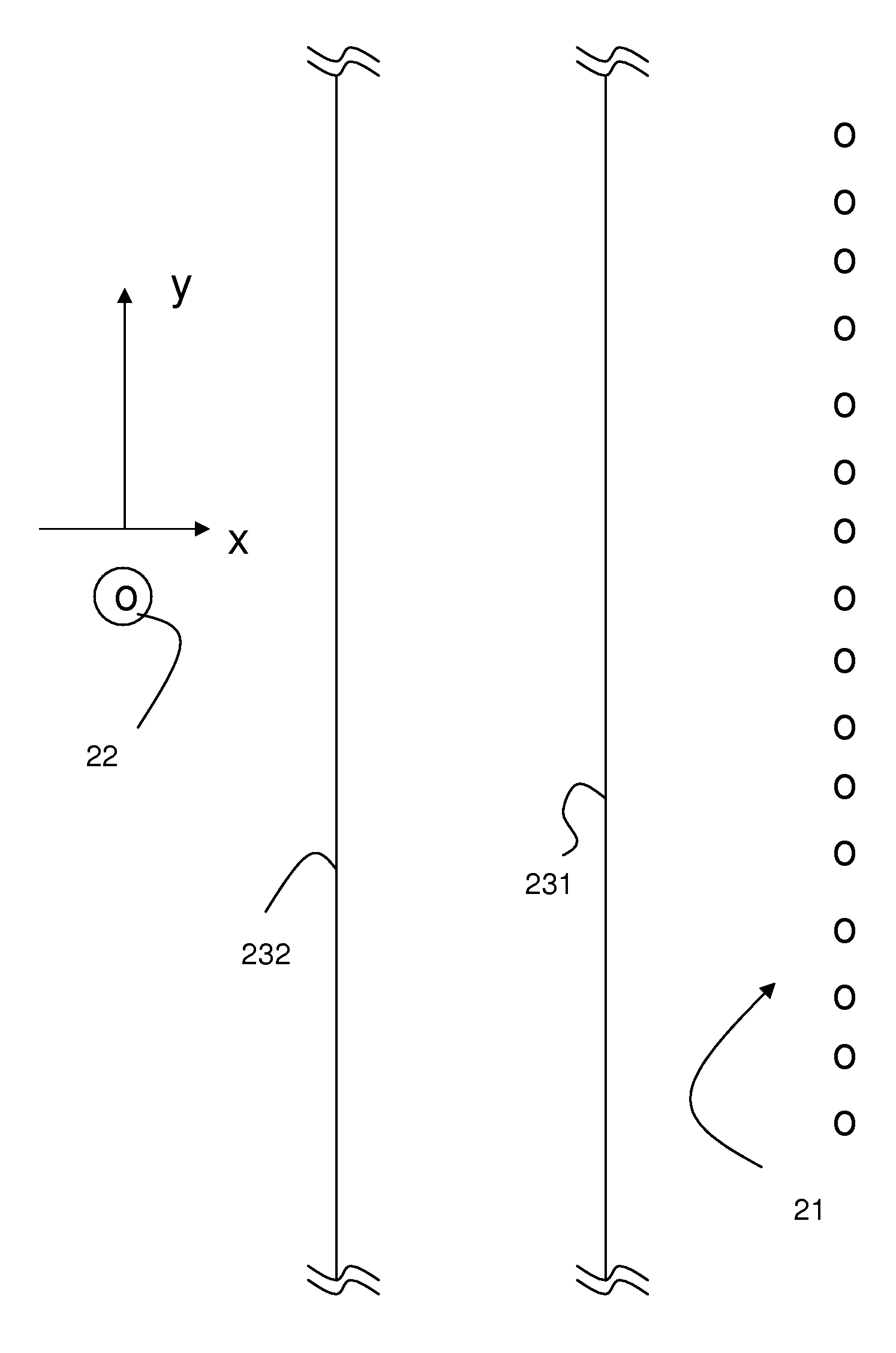

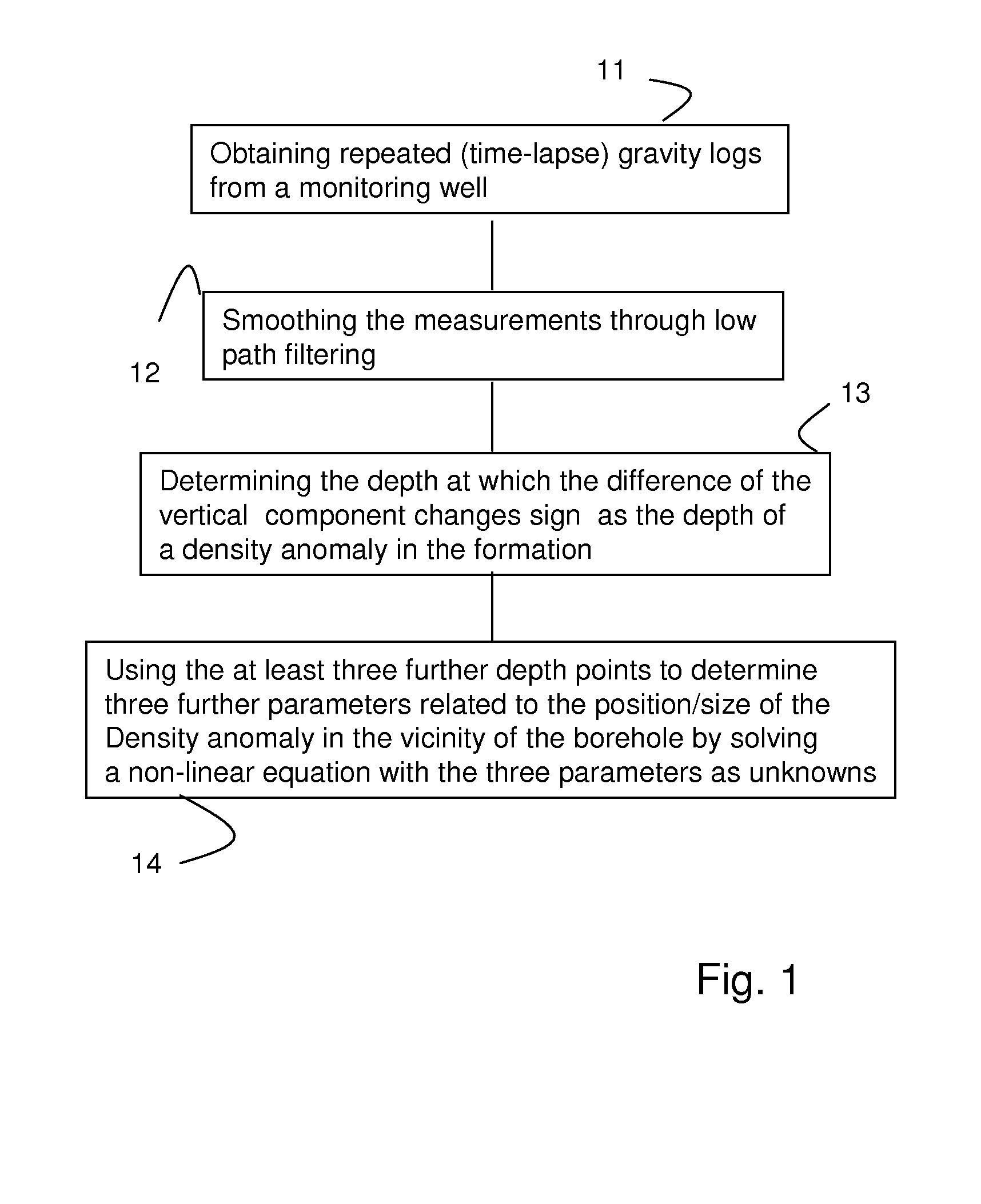

Gravity measurement methods for monitoring reservoirs

ActiveUS20090223291A1Reduce computing costRapid responseSurveySpecific gravity using flow propertiesGravitationWellbore

A method of performing gravity surveys in a wellbore is described including performing a time-lapse measurement in a monitoring well in the vicinity of injector wellbores, determining a depth for which the difference of the time lapse measurements changes sign or crosses zero as depth of the anomaly; and using said measurements at other depth points to further determine one or more parameters relating to the location and / or size of a density anomaly caused by injecting fluids through said injector wellbores, thus enabling the sweep of an injected fluid including the occurrence of fingering in the formation.

Owner:SCHLUMBERGER TECH CORP +1

Temperature compensated density sensing process and device

InactiveUS20100095763A1Intuitive monitoringMaterial analysis by observing immersed bodiesSpecific gravity using flow propertiesTotal dissolved solidsBuoyancy function

A total dissolved solids measurement process and device are provided that facilitates total dissolved solids sensing of a subject fluid via relative buoyancy levels of separate float bodies; one buoyed by the subject fluid of varying total dissolved solids and temperatures and another buoyed by a reference fluid of constant total dissolved solids but of a varying temperature matching the subject fluid. The equal temperature baths of the subject fluid and the reference fluid as well as geometrical shape and weighting of the floats conveys the total dissolved solids as the difference in buoyancy levels of the floats. This difference in buoyancy levels is of further benefit for activation of sundry controls.

Owner:LAYNE CHRISTENSEN COMPANY

Method and apparatus for trapping single particles in microfluidic channels

ActiveUS20100154535A1Material analysis using sonic/ultrasonic/infrasonic wavesComponent separationDifferential measurementParticle physics

Methods and apparatus for improving measurements of particle or cell characteristics, such as mass, in Susppended Microchannel Resonators (SMR's). Apparatus include in particular designs for trapping particles in SMR's for extended measurement periods. Methods include techniques to provide differential measurements by varying the fluid density for repeated measurements on the same particle or cell.

Owner:MASSACHUSETTS INST OF TECH

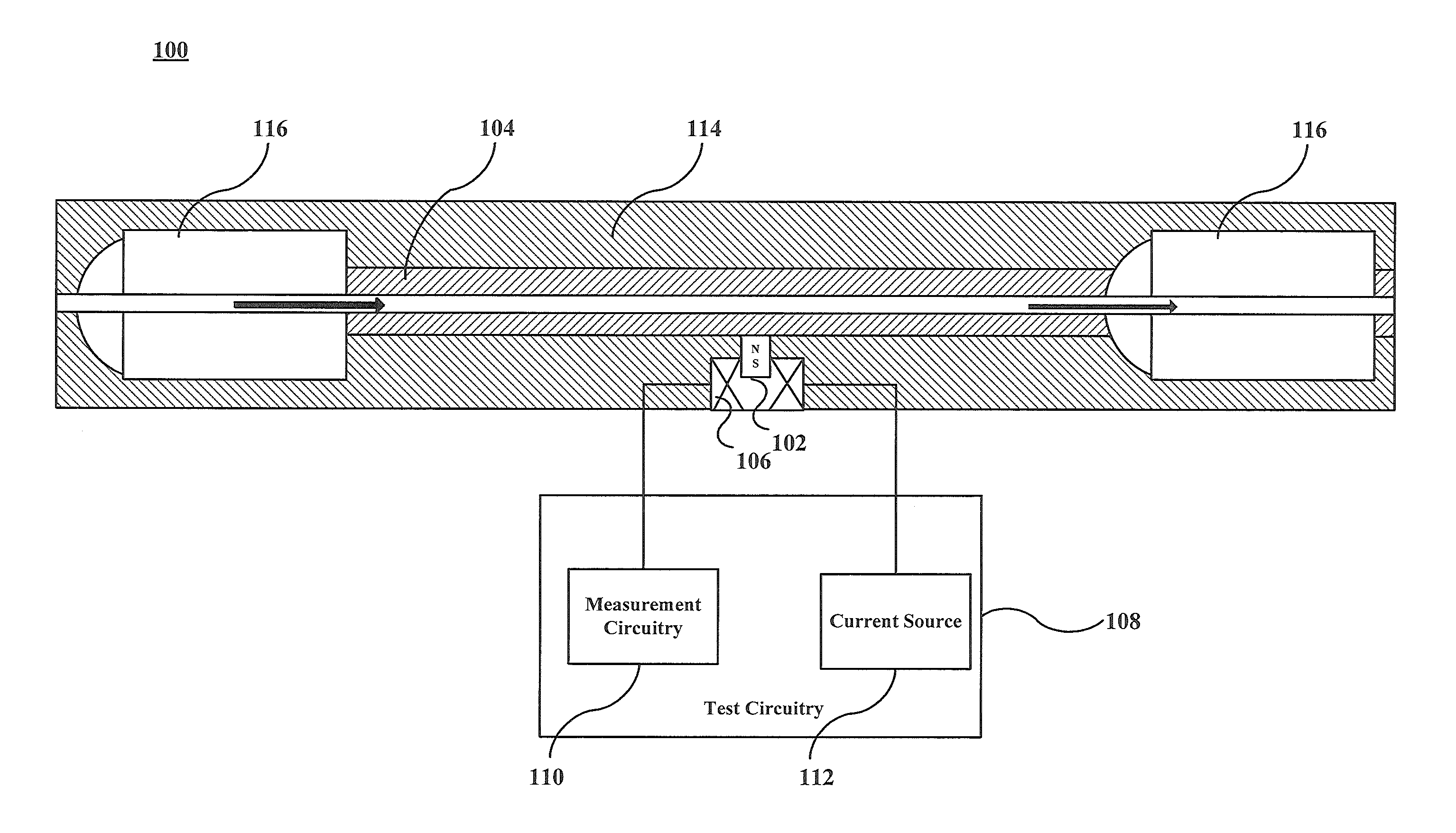

Fluid densitometer with temperature sensor to provide temperature correction

ActiveUS20130180330A1Thermometer detailsSpecific gravity using flow propertiesThermodynamicsFluid density

A sensor for measuring a density of a fluid is provided. The sensor (200) includes a flow tube (104) for receiving the fluid and a vibration driver (102) coupled to the flow tube, the vibration driver configured to drive the flow tube to vibrate. The sensor also includes a vibration detector (106) coupled to the flow tube, the vibration detector detecting characteristics related to the vibrating flow tube, and a distributed temperature sensor (202) coupled to the flow tube, the distributed temperature sensor measuring a temperature of the flow tube as the flow tube vibrates. The sensor further includes measurement circuitry (110) coupled to the vibration detector and the distributed temperature sensor, the measurement circuitry determining a density of the fluid from the detected characteristics related to the vibrating flow tube and the measured temperature of the flow tube.

Owner:HALLIBURTON ENERGY SERVICES INC

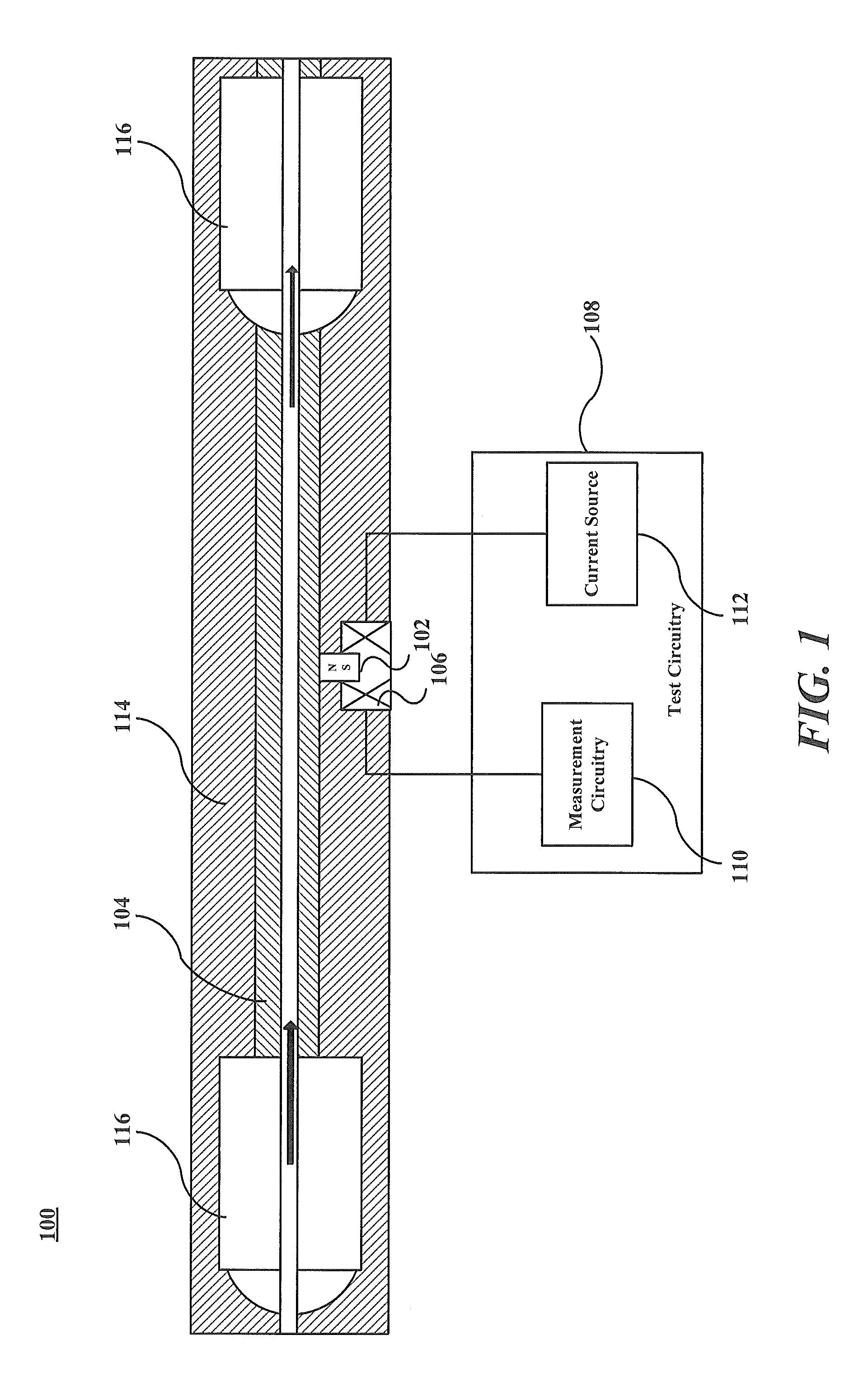

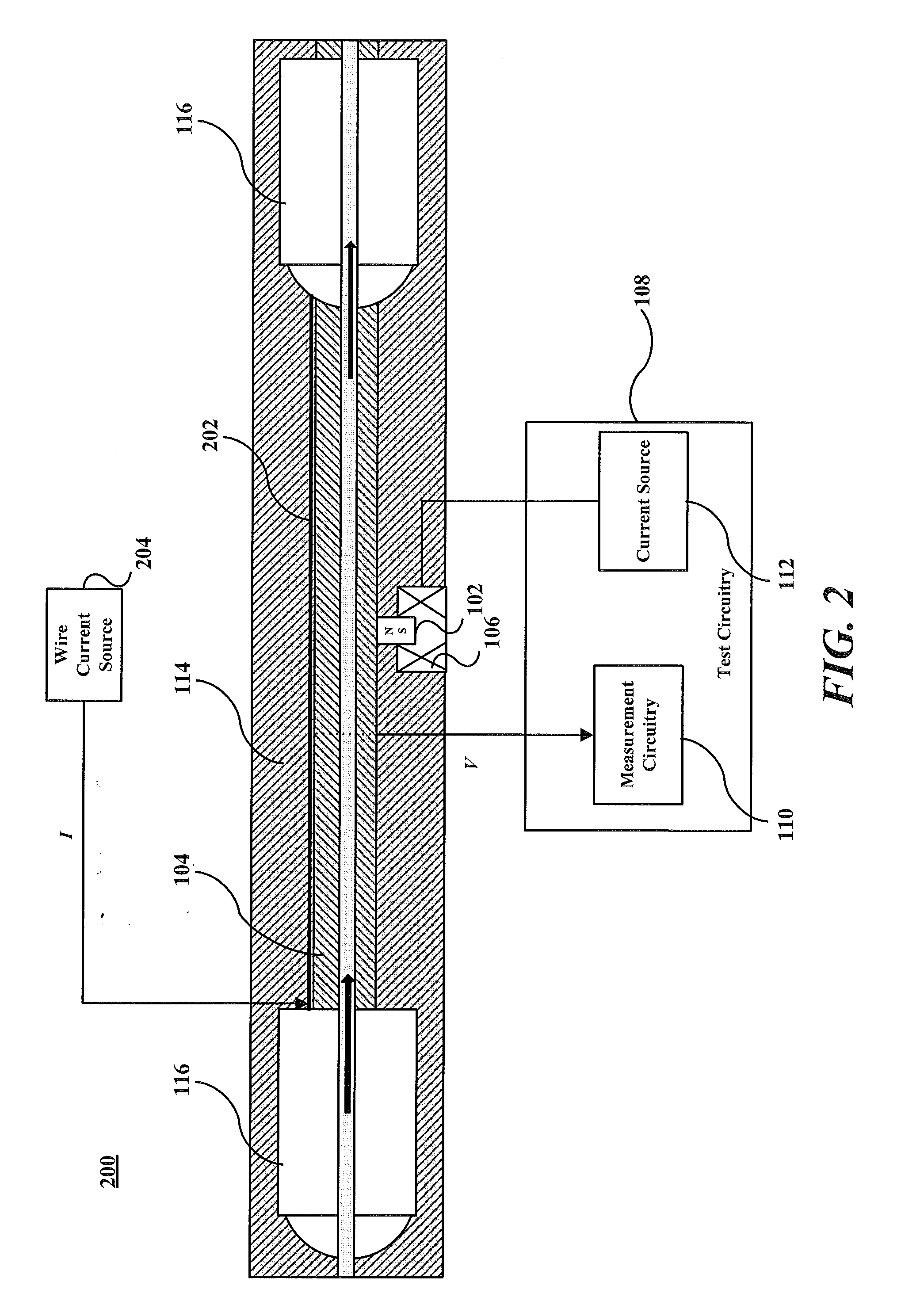

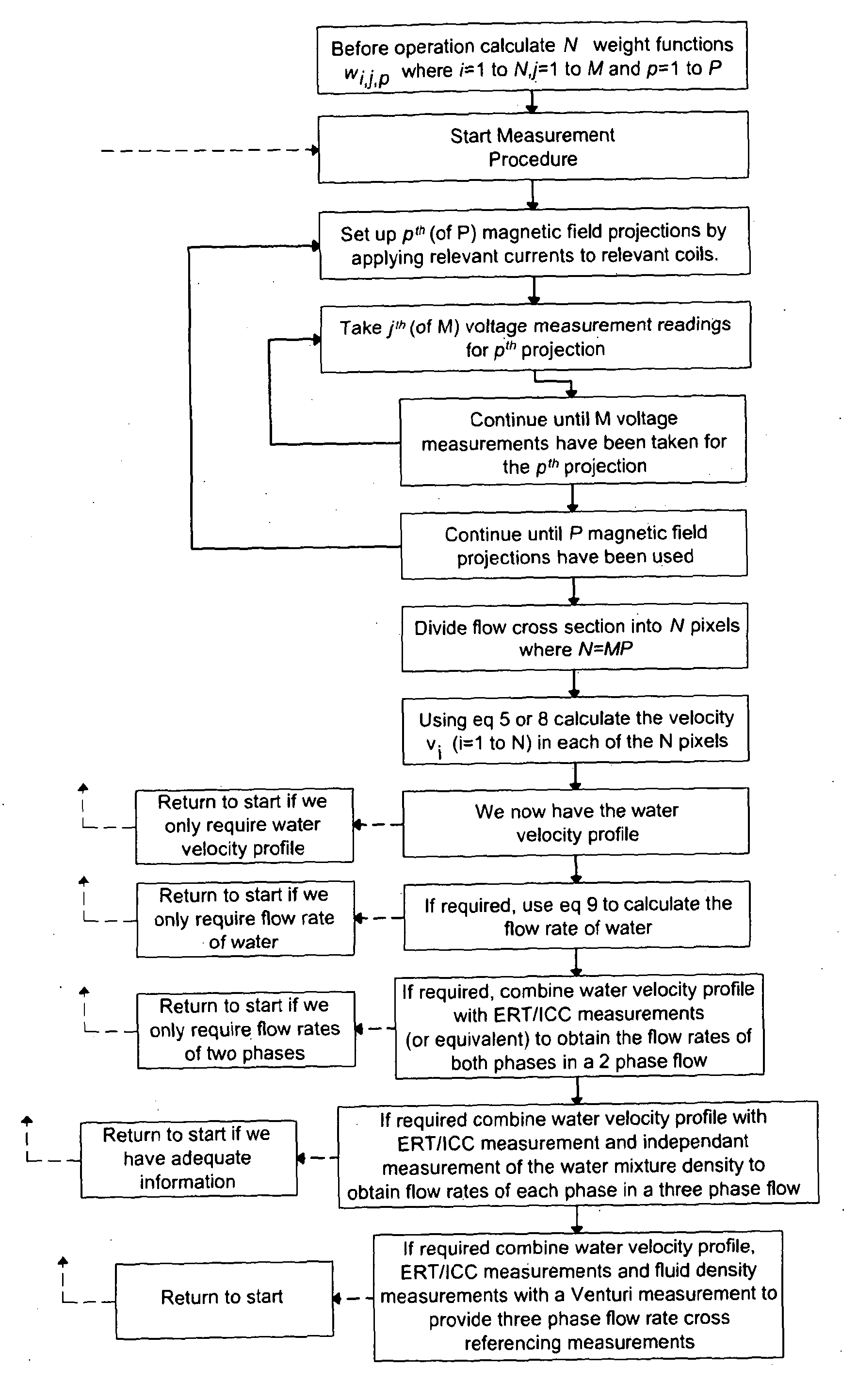

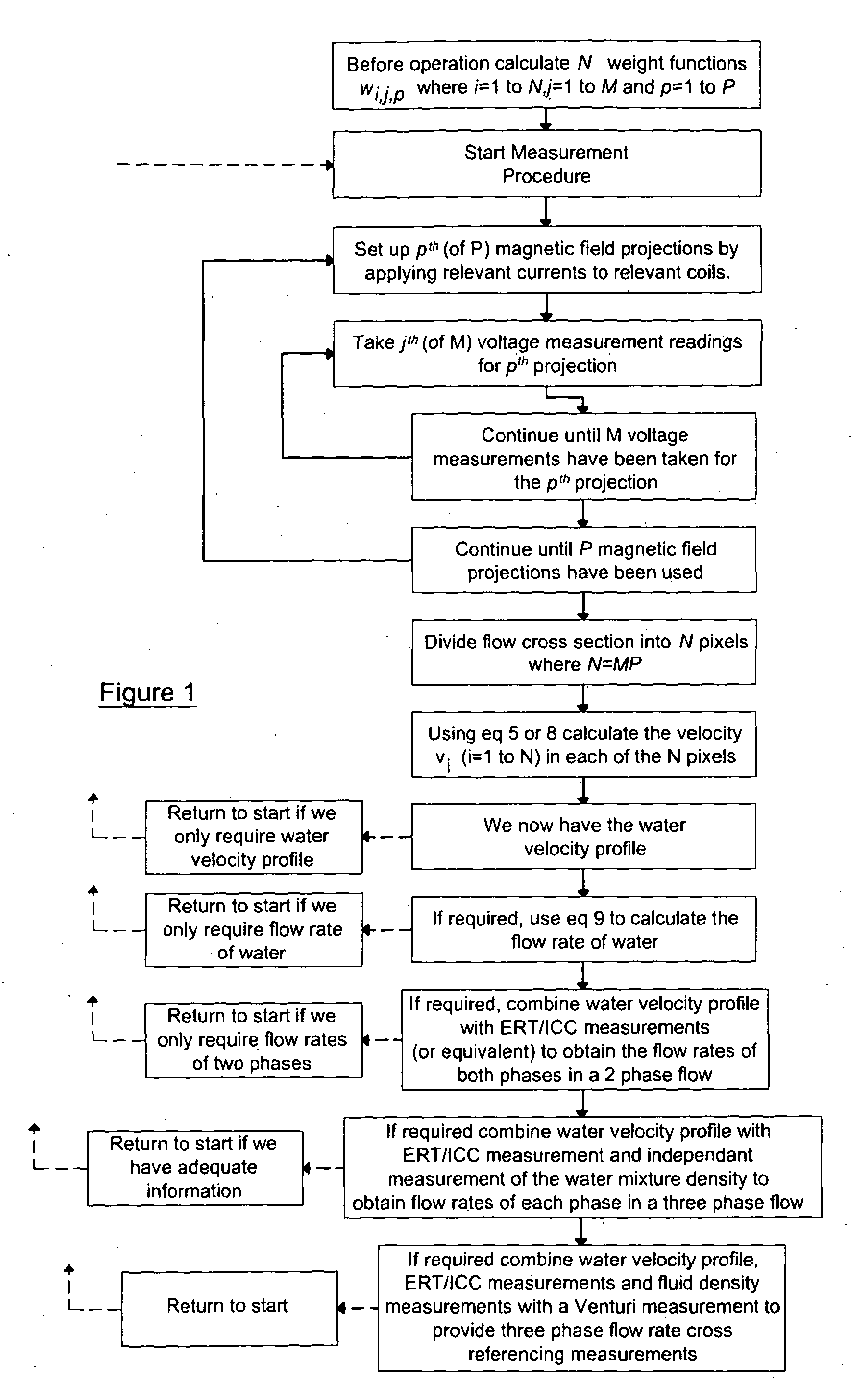

Means and method for monitoring the flow of fluid

ActiveUS20130036817A1Cheap manufacturingGuaranteed economical operationSpecific gravity using flow propertiesVolume/mass flow by electromagnetic flowmetersEngineeringElectromagnetic flow

The invention relates to an means and method for monitoring the flow of a fluid. The invention relates to an electromagnetic flow meter and method for measuring the axial velocity profile of a conducting fluid. The conducting fluid may be a conducting single phase fluid or a conducting continuous phase of a multiphase fluid. The conducting fluid may have a uniform flow profile or a non-uniform flow profile. The electromagnetic flow meter and method measure the axial velocity profile of a conducting fluid by dividing the flow cross section into multiple pixels and determining the axial velocity of the conducting fluid in each pixel. Having. derived the axial velocity profile, the electromagnetic flow meter and method may further derive the volumetric flow rate of the conducting fluid. The electromagnetic flow meter and method may be suitable for measuring the axial velocity profile and optionally the volumetric flow rates of each phase of a multiphase fluid.

Owner:UNIVERSITY OF HUDDERSFIELD

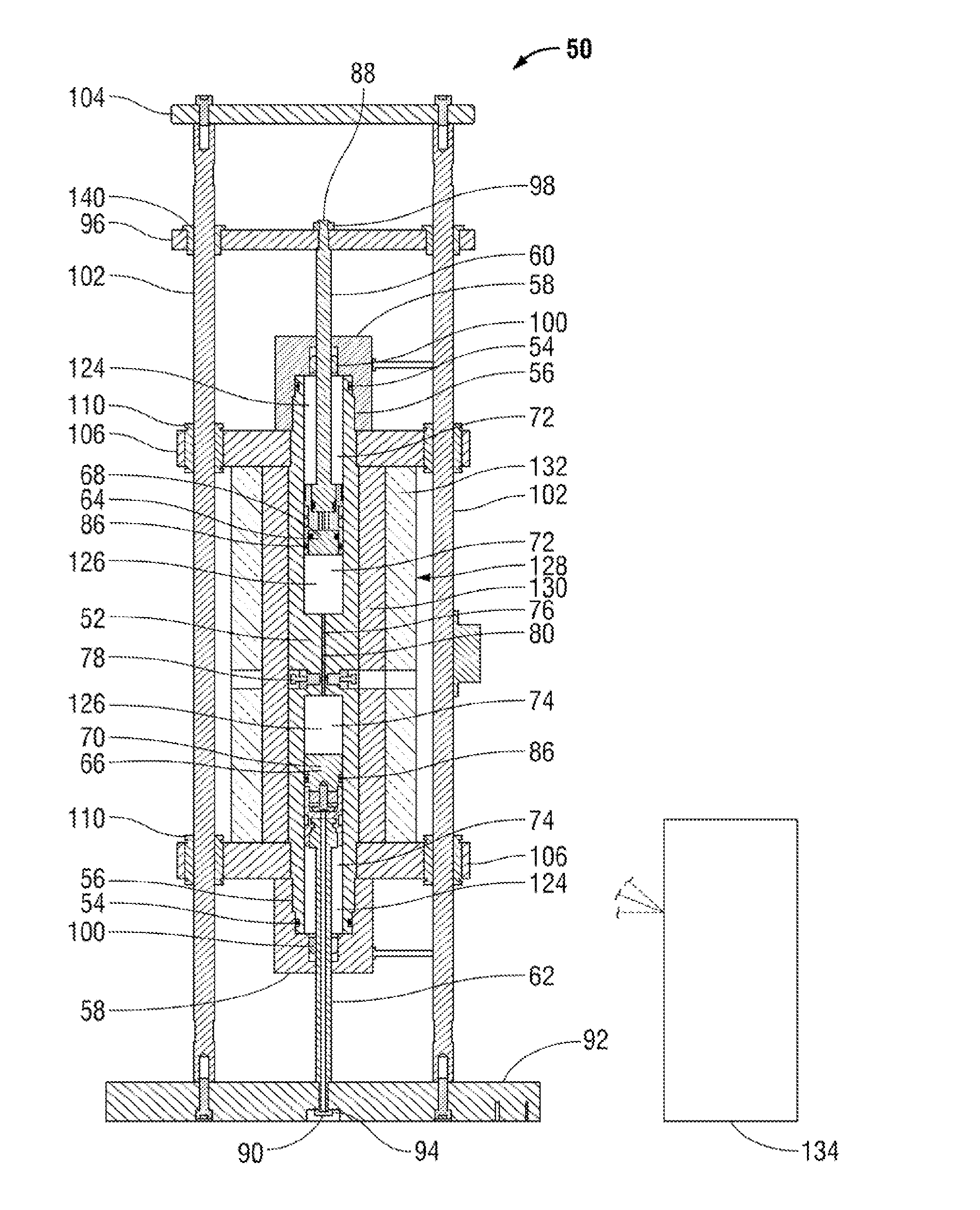

Apparatus and method for phase equilibrium with in-situ sensing

ActiveUS9291585B2Efficient measurementMaterial heat developmentSpecific gravity using flow propertiesEngineeringReservoir fluid

A technique facilitates the monitoring of thermodynamic properties of reservoir fluids. The technique utilizes a modular sensor assembly designed to evaluate a sample of a hydrocarbon-containing fluid within a cell body. A variety of sensors may be selectively placed into communication with a sample chamber within the cell body to evaluate the sample at potentially high pressures and temperatures. The sensors may comprise a density-viscosity sensor located in-situ to efficiently measure both the density and viscosity of the sample as a function of pressure and temperature. Other sensors, such as an optic sensor, may also be positioned to measure parameters of the sample while the sample is retained in the sample chamber.

Owner:SCHLUMBERGER TECH CORP

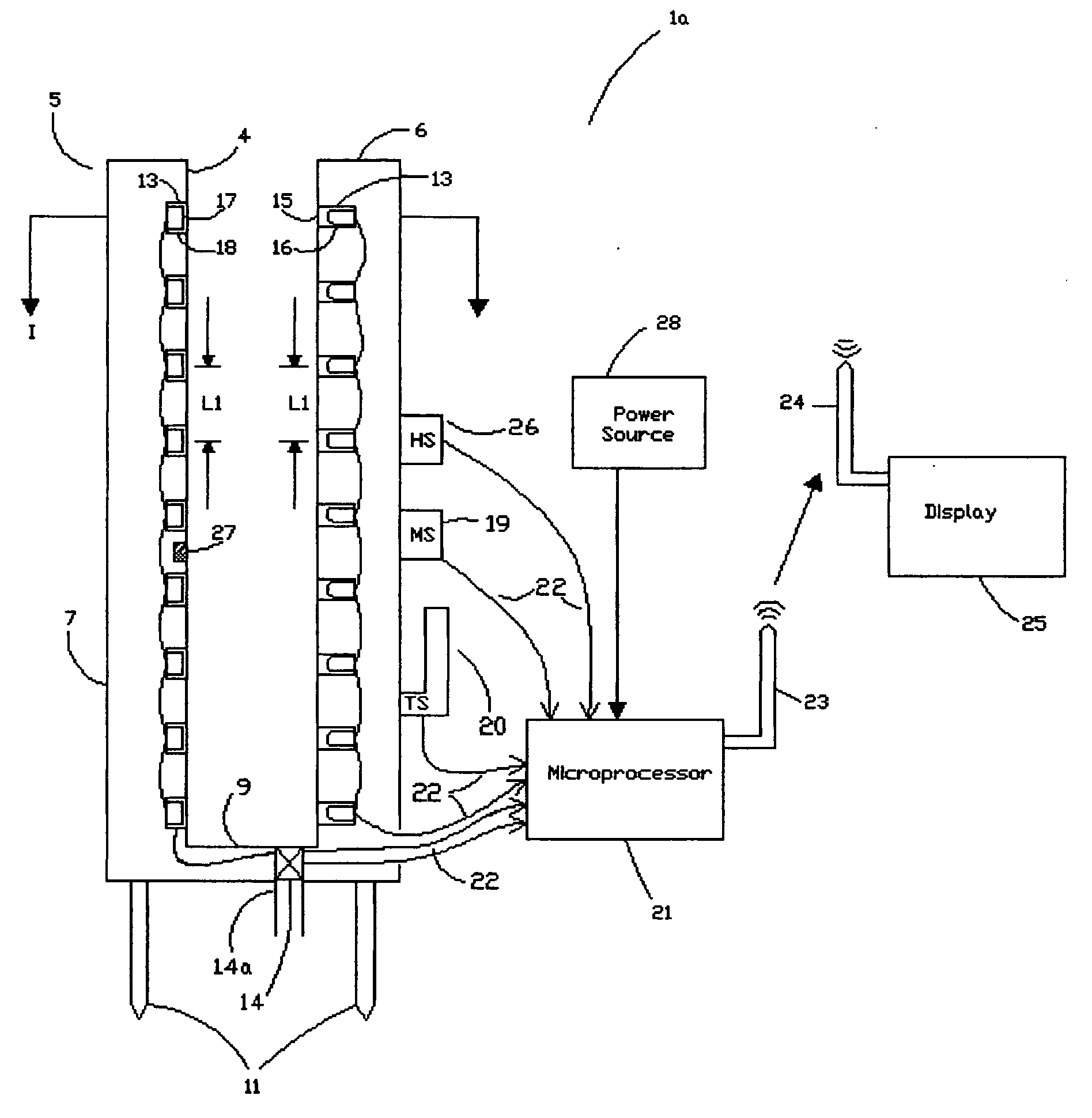

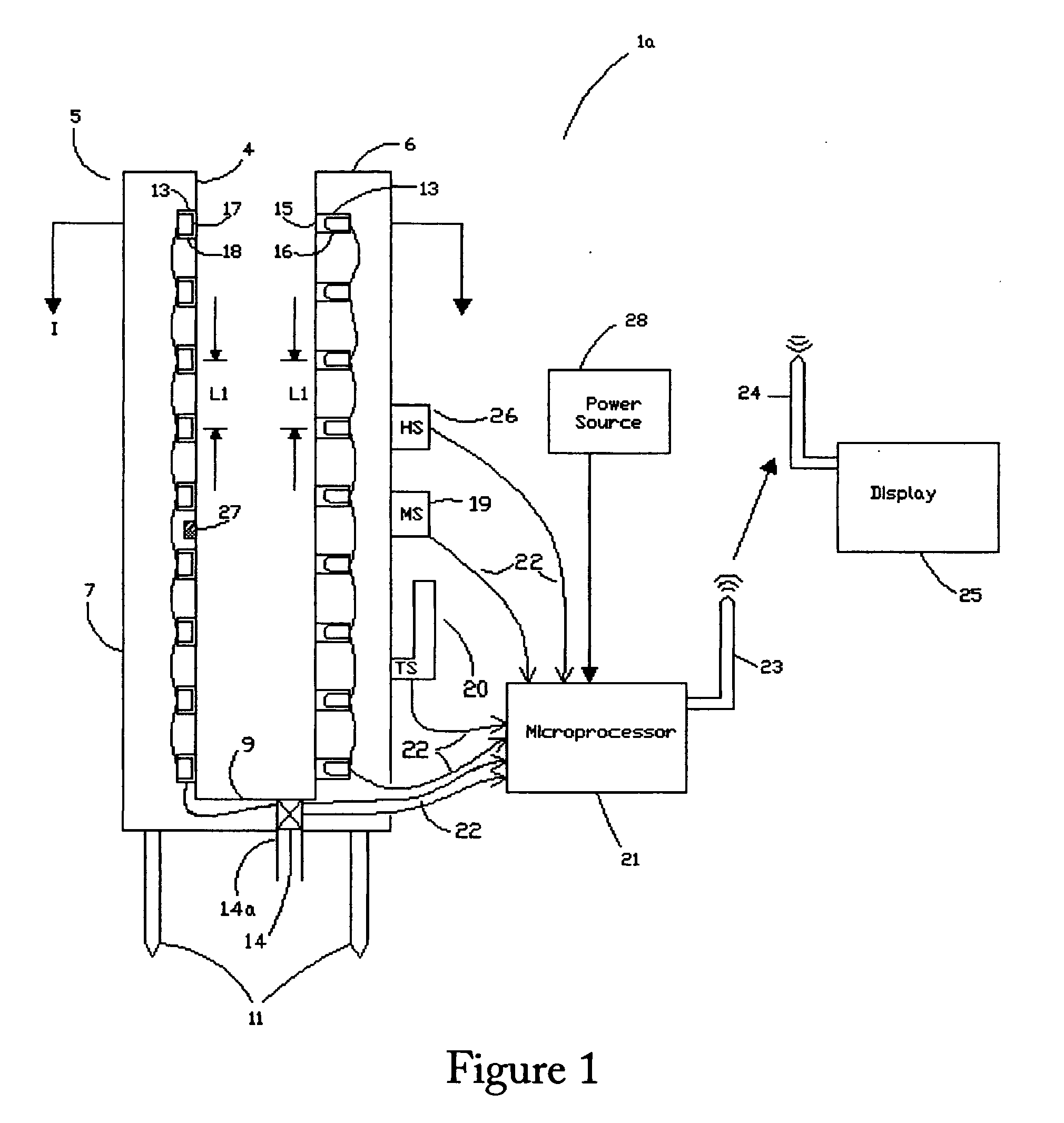

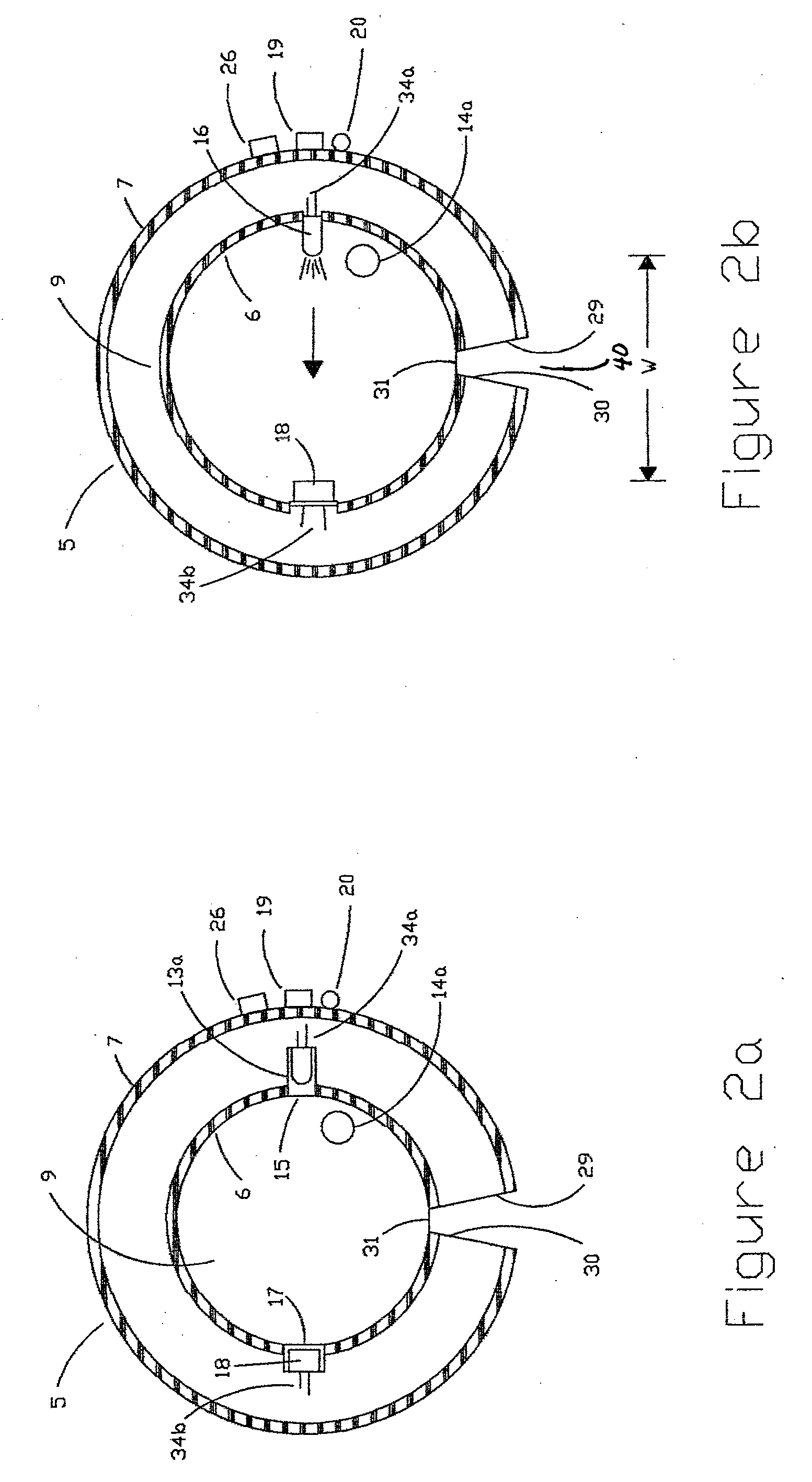

Apparatus and method for measuring precipitation

InactiveUS20100169017A1The process is convenient and fastConveniently and efficiently determinedRainfall/precipitation gaugesSpecific gravity using flow propertiesOptoelectronicsMoisture sensor

A precipitation gauge for measuring liquid and frozen precipitation is provided according to the present invention that includes a support structure having at least one light sensor, or pair of electrodes, and at least one light source disposed thereon so that the light sensor may receive light that is emitted from the light source. The light sensor or light sensors and the light source or light sources generally extend a substantial height of the support structure. The light sensor or light sensors generate an output signal in response to the amount of light received from the light source. A microprocessor receives the output signal or output signals from the light sensor or light sensors and determines whether precipitation is present between the light sensor or light sensors and the light source or light sources. Based on the output signal or output signals, the microprocessor determines and displays the level of precipitation. The microprocessor may also determine the density of frozen precipitation. A heating element is disposed on the support structure to melt frozen precipitation. The microprocessor determines the density of the frozen precipitation from the amount of frozen precipitation and the amount of liquid that results from melting the frozen precipitation. Alternatively, the microprocessor determines the density of frozen precipitation from the amount of frozen precipitation and the weight of the frozen precipitation. A temperature sensor, a moisture sensor, and / or a humidity sensor are located at or near the support structure and are connected to the microprocessor. A method for measuring the amount of precipitation and the density of frozen precipitation is also disclosed.

Owner:NOONAN TECH

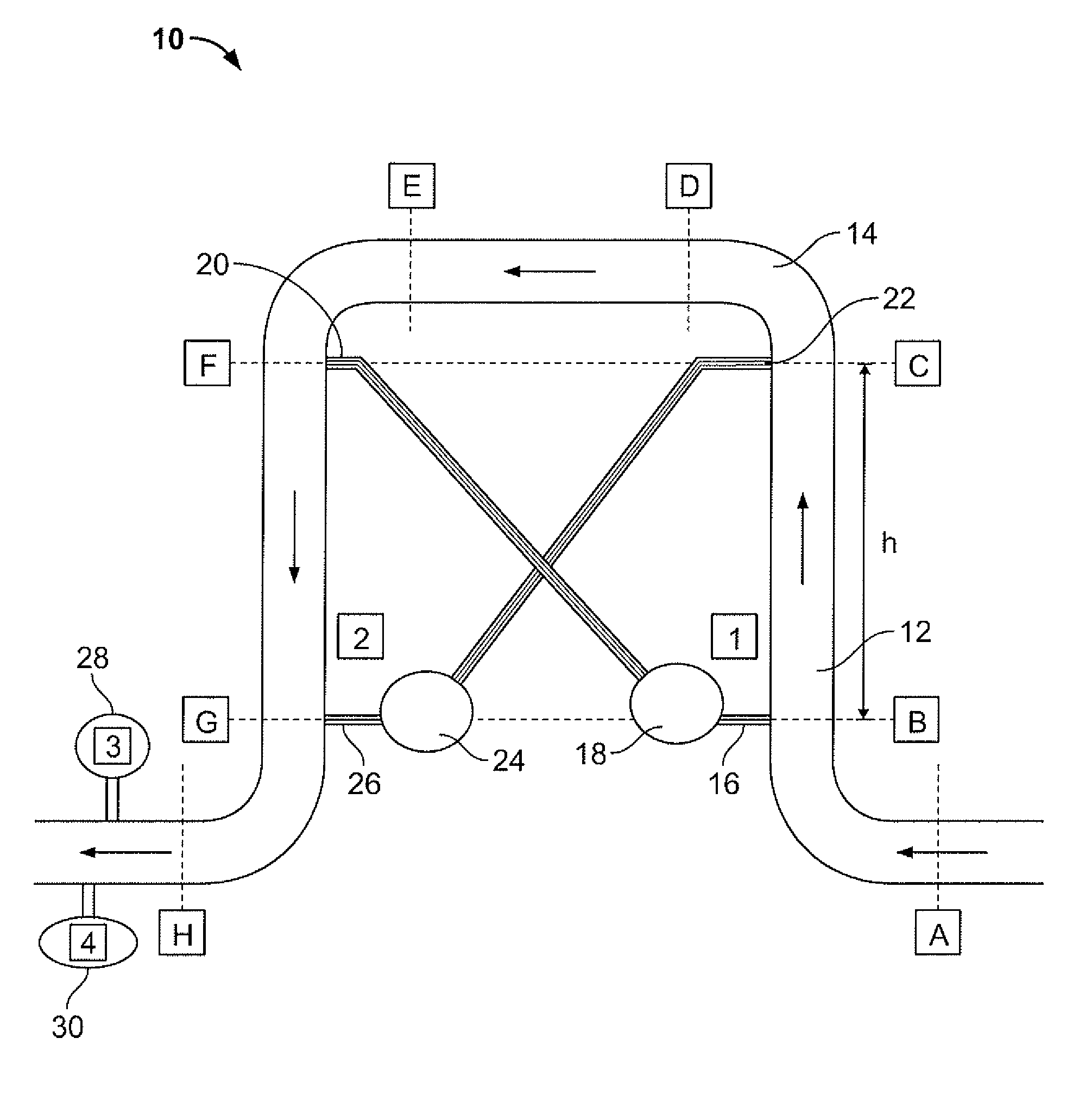

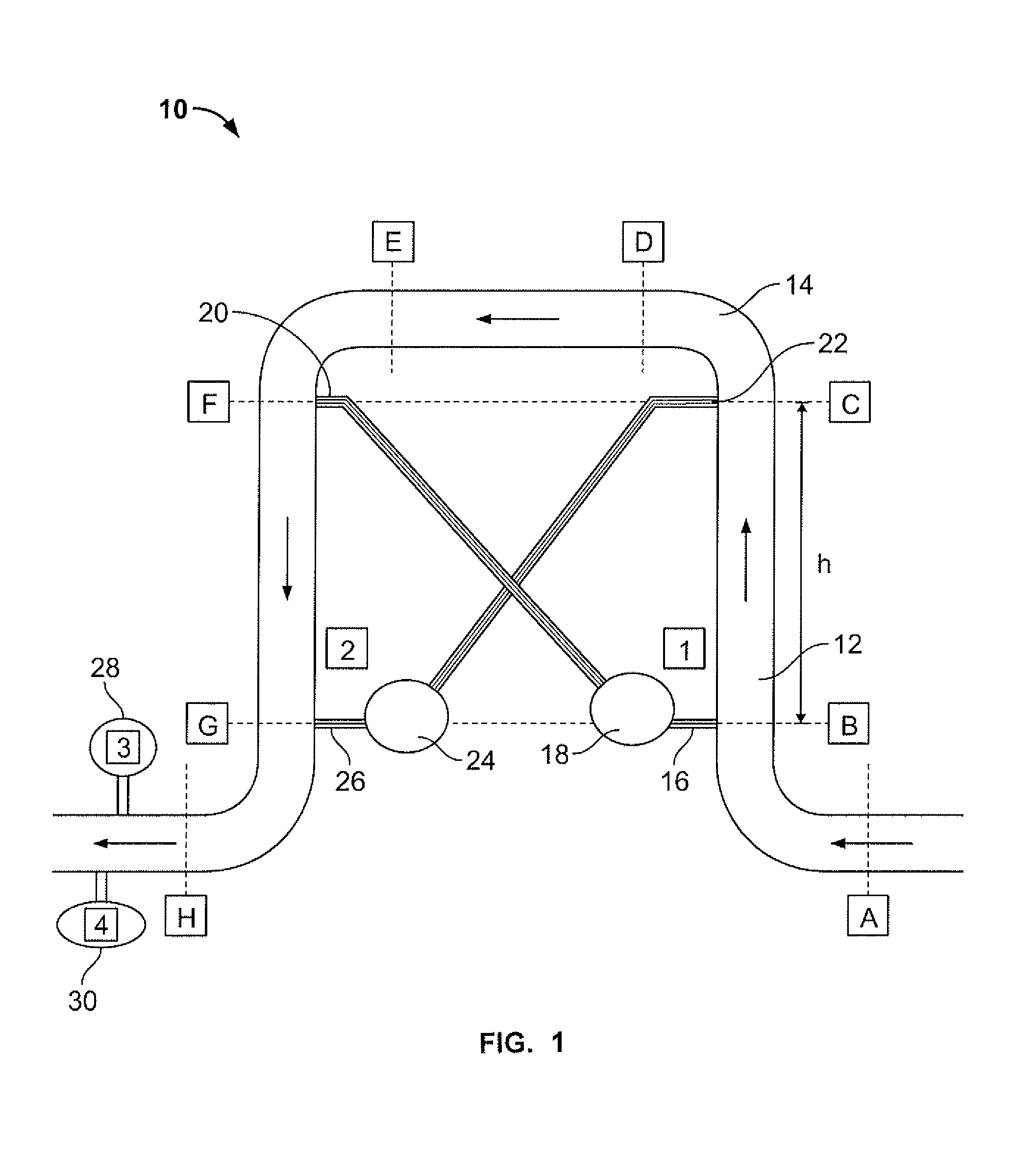

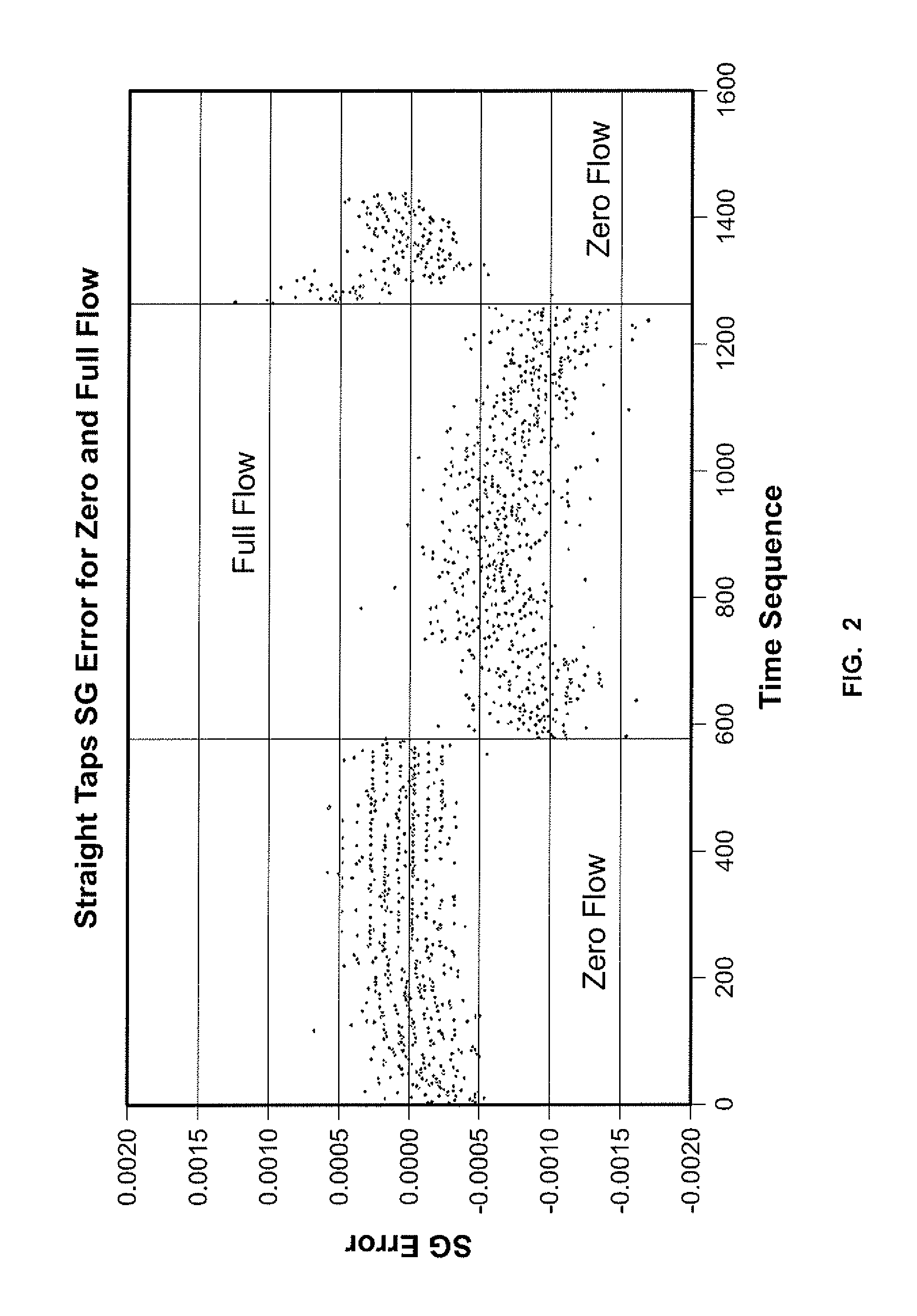

Method and apparatus for measuring the density of a flowing fluid in a conduit using differential pressure

InactiveUS20110296911A1Eliminates elbow effectAvoid the needSpecific gravity by measuring pressure differencesSpecific gravity using flow propertiesDifferential pressureEngineering

A method and apparatus for determining the specific gravity of a monophasic or polyphasic fluid flowing in a conduit. The apparatus employs an square wave shaped tube known for its effectiveness in differential pressure measurements. The apparatus is configured such that the differential pressure is measured in crosswise manner Pressure taps comprising high and low pressure taps for a respective pressure sensing device are associated with a different leg. The apparatus has also been found to be effective for determining flow rate of the fluid in the conduit using differential pressure measurements.

Owner:MOORE BARRY +1

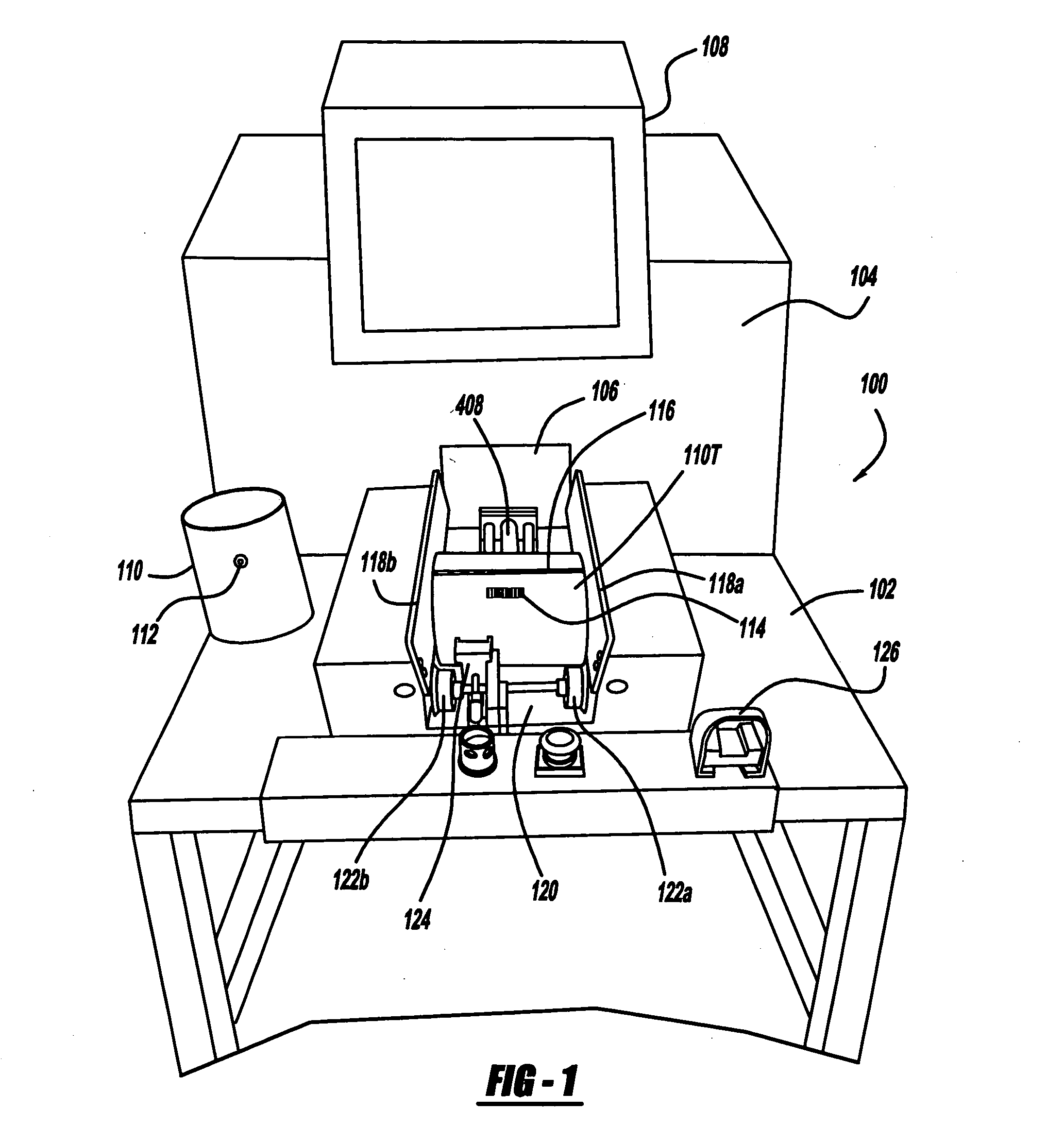

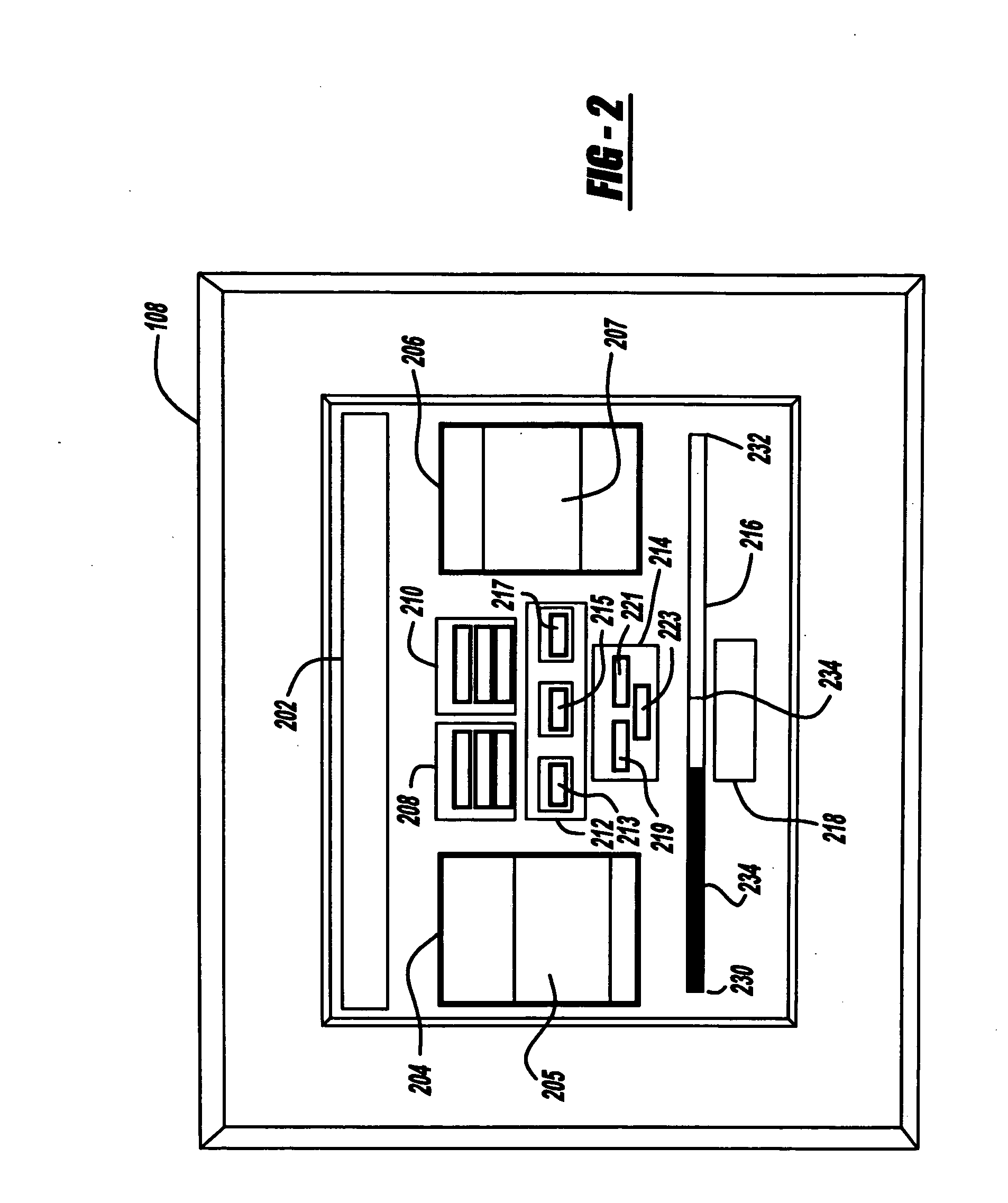

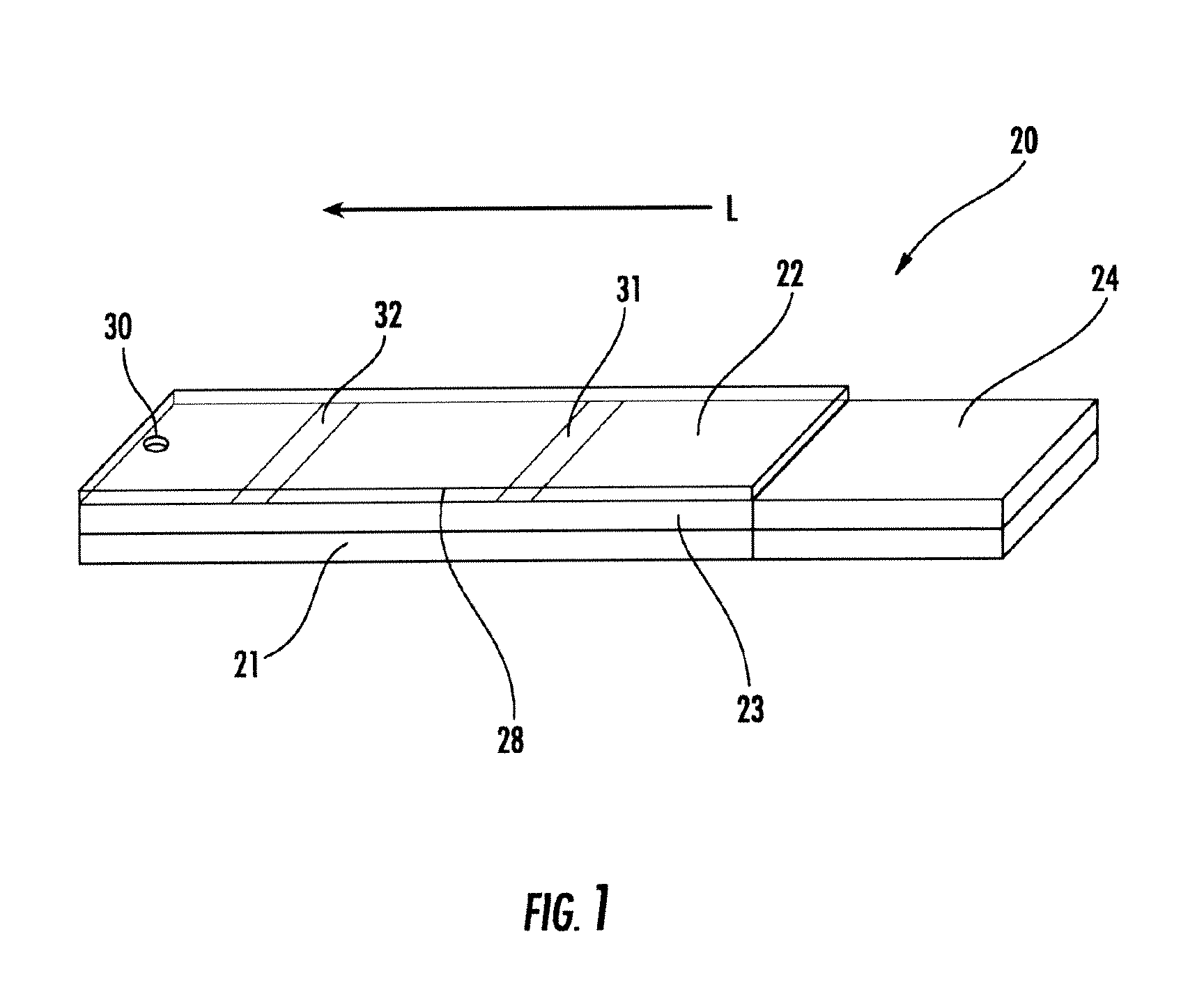

Apparatus and method for measuring gap bulk density of a catalytic converter support mat

InactiveUS20060156794A1Specific gravity using flow propertiesMeasurement/indication equipmentsBarcodeEngineering

Gap bulk density (GBD) of a support mat surrounding a catalyst substrate in a catalytic converter is calculated using an average gap width optically determined by a camera system. Mat weight determined at an assembly station is bar coded and placed in a bar code label attached to the converter under test. A programmable controller calculates an average gap width from a plurality of camera readings. GBD is then calculated using mat weight and dimensions, and the GBD is compared to an acceptable range to determine pass / failure of the converter.

Owner:TENNECO AUTOMOTIVE OPERATING CO INC

Dehydration Sensors with Ion-Responsive and Charged Polymeric Surfactants

ActiveUS20120042722A1Improve wettabilityReduce solubilityAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorPolymeric surfaceIonic strength

A lateral flow assay device for determining the relative ionic strength of urine is described. The device includes a buffering zone having a polyelectrolyte disposed therein, and an indicator zone having a pH indicator non-diffusively immobilized therein, the indicator zone being separate from the buffering zone and positioned adjacent to and in fluid communication with the buffering zone. A detection zone is part of the buffering zone, and has a buffering component comprising a weak polymeric acid and weak polymeric base with a pKa≦10−3, and a class of charged polymeric surfactants that are responsive to relative ion concentrations in a sample solution, and a charged pH indicator with a charge opposite to that of the charged polymeric surfactant. The charged polymeric surfactant is soluble in amounts of greater than or equal to about 1% by weight (≧1 wt. % solute) in water and aqueous solutions of low ionic concentration of ≦0.1 wt. % salts, but insoluble (<1 wt. % solute) in aqueous solution of high ionic concentrations of >0.1 wt. % salts. The present invention also describes absorbent articles incorporating such an assay device and methods of monitoring dehydration or testing ion strength of a urine sample using such a test format.

Owner:KIMBERLY-CLARK WORLDWIDE INC

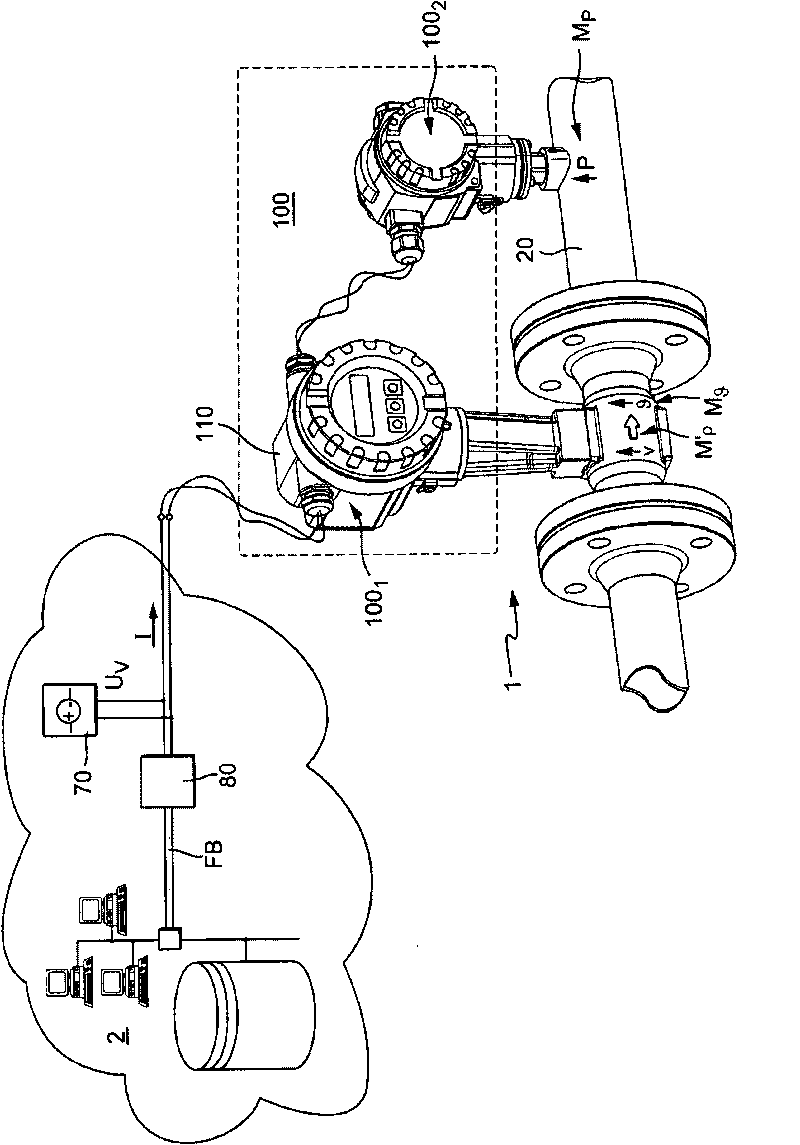

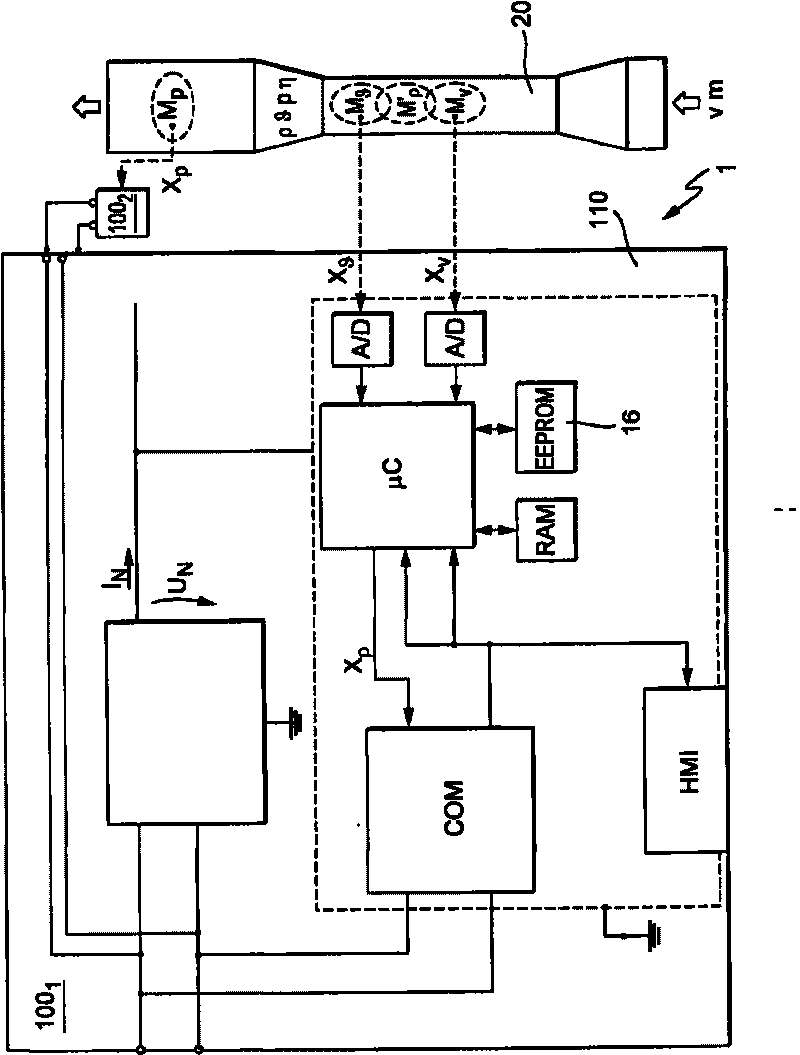

Measuring system for a medium flowing in a process line

ActiveCN101711351AHigh measurement accuracySpecific gravity by measuring pressure differencesSpecific gravity using flow propertiesLine tubingMeasurement point

The invention relates to a measuring system for measuring a density of a medium flowing in a process line, said medium being variable regarding its thermodynamic state, especially at least being proportionally compressible, along an imaginary axis of flow of the measuring system. The measuring system comprises at least one temperature sensor that is located in a temperature measuring point and that primarily reacts to a local temperature, theta, of a medium flowing past, said temperature sensor supplying at least one temperature measurement signal that is influenced by the local temperature of the medium to be measured, at least one pressure sensor that is located in a pressure measuring point and that primarily reacts to a local, especially static, pressure, p, of a medium flowing past, said pressure sensor supplying at least one pressure measurement signal that is influenced by the local pressure, p, in the medium to be measured, and at least one electronic measuring unit that at least temporarily communicates with at least the temperature sensor and the pressure sensor. The electronic measuring unit generates a provisional density value, using the temperature measurement signal and at least the pressure measurement signal, said density value representing a density which the flowing medium only apparently has in a virtual density measuring point that is especially interspaced from the pressure measuring point and / or the temperature measuring point along the axis of flow at a defined distance. The electronic measuring unit further generates at least temporarily at least one especially digital density value, which is different from the provisional density value, using the provisional density value and at least one correctional density value that depends on a flow speed of the medium and on the local temperature prevailing in the temperature measuring point, said correctional value being determined during operation time.

Owner:ENDRESS HAUSER FLOWTEC AG

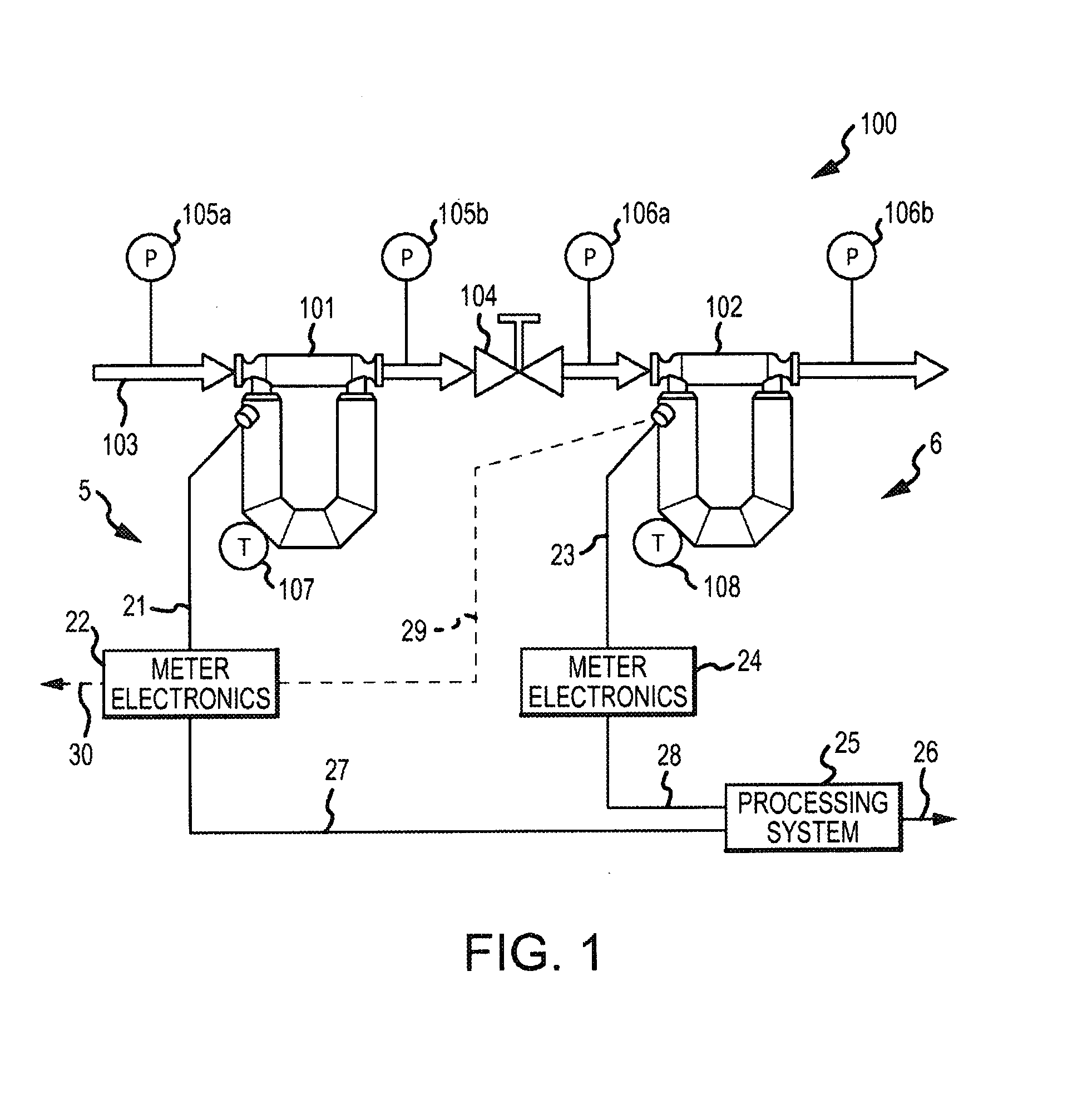

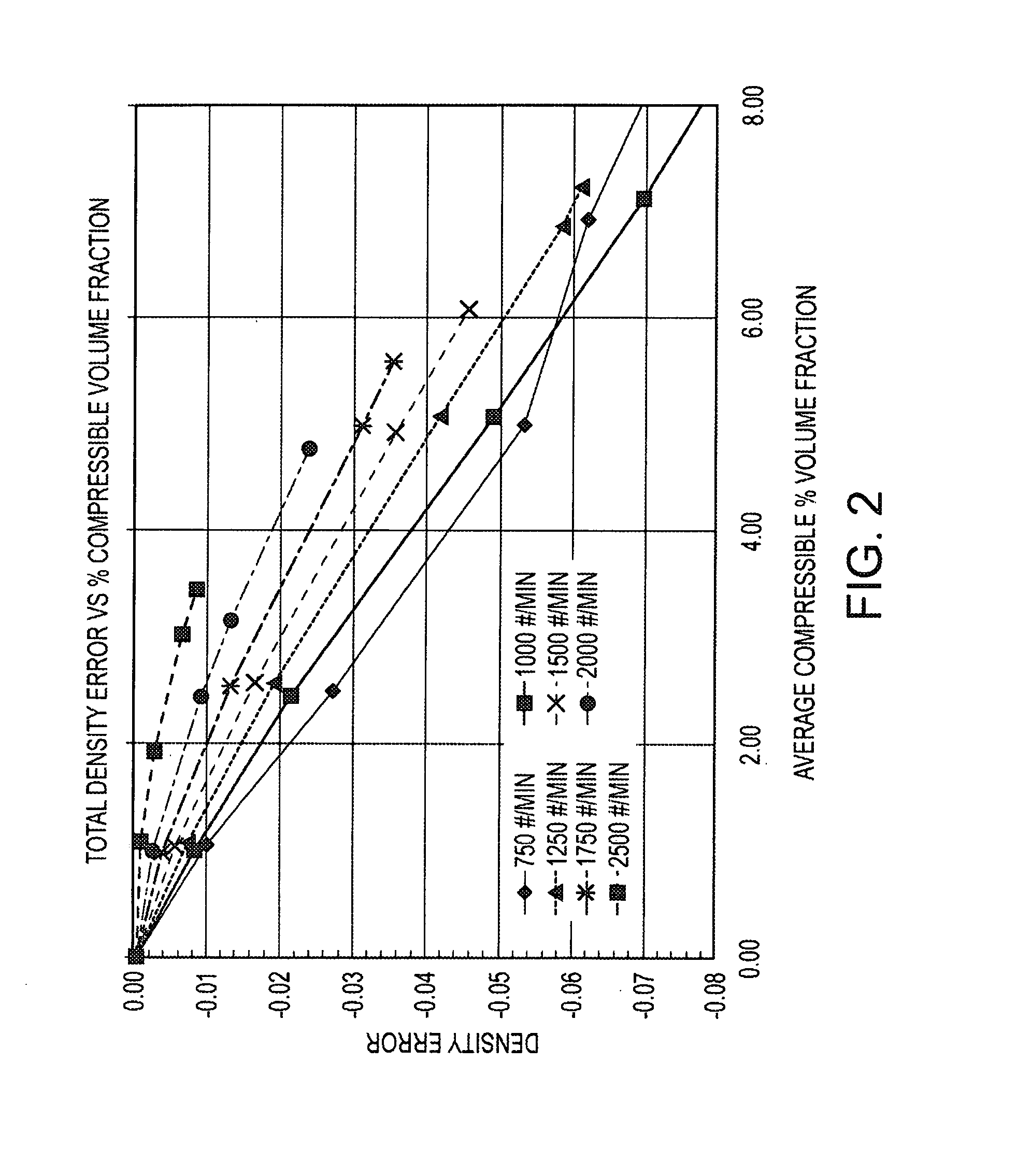

Fluid characteristic determination of a multi-component fluid with compressible and incompressible components

ActiveUS20150160056A1Specific gravity by measuring pressure differencesSpecific gravity using flow propertiesEnvironmental geologyFluid property

Owner:MICRO MOTION INC

Popular searches

Testing metals Volume metering Testing/calibration for volume flow Direct mass flowmeters Volume/mass flow by differential pressure Indirect mass flowmeters Ultrasonic/sonic/infrasonic wave generation Processing detected response signal Material analysis by optical means Moisture content investigation using microwaves

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com