Patents

Literature

1413results about "Direct mass flowmeters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

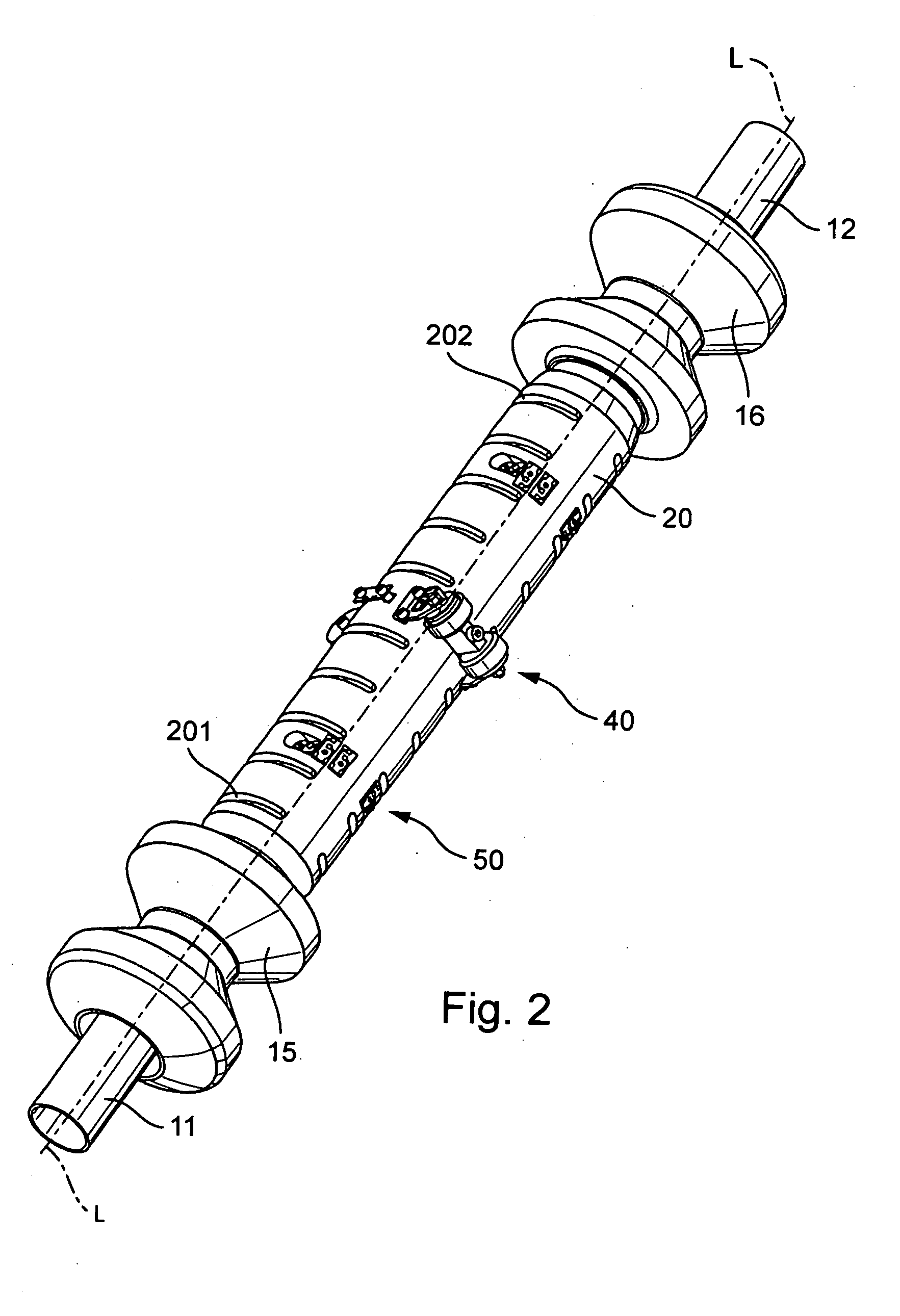

Vibratory transducer

InactiveUS6840109B2Simple and robust mannerSimplifies isolationVibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesTransducerEngineering

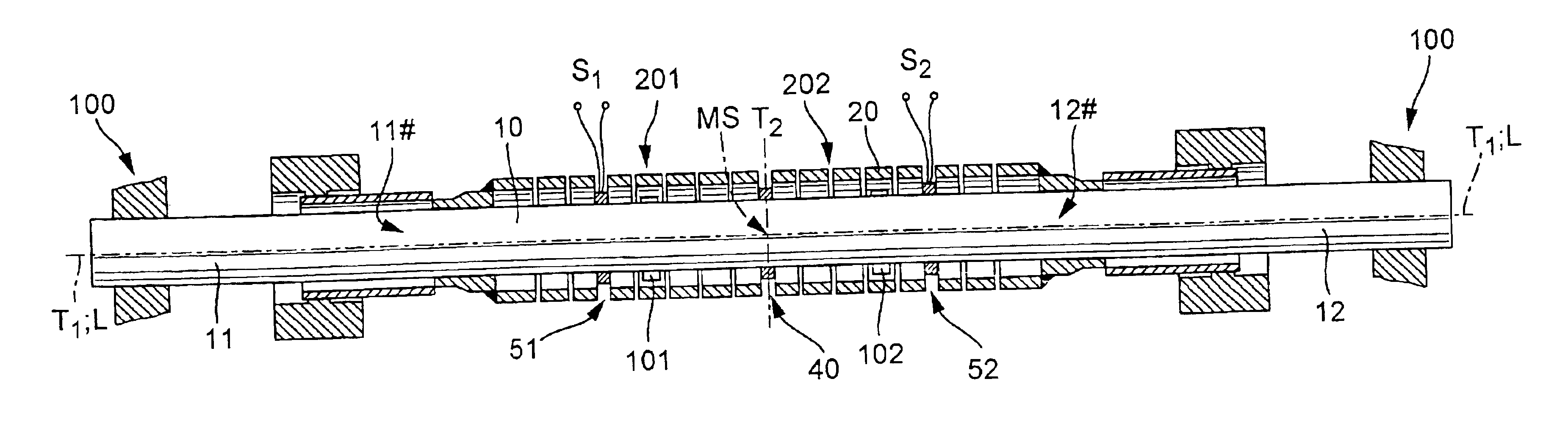

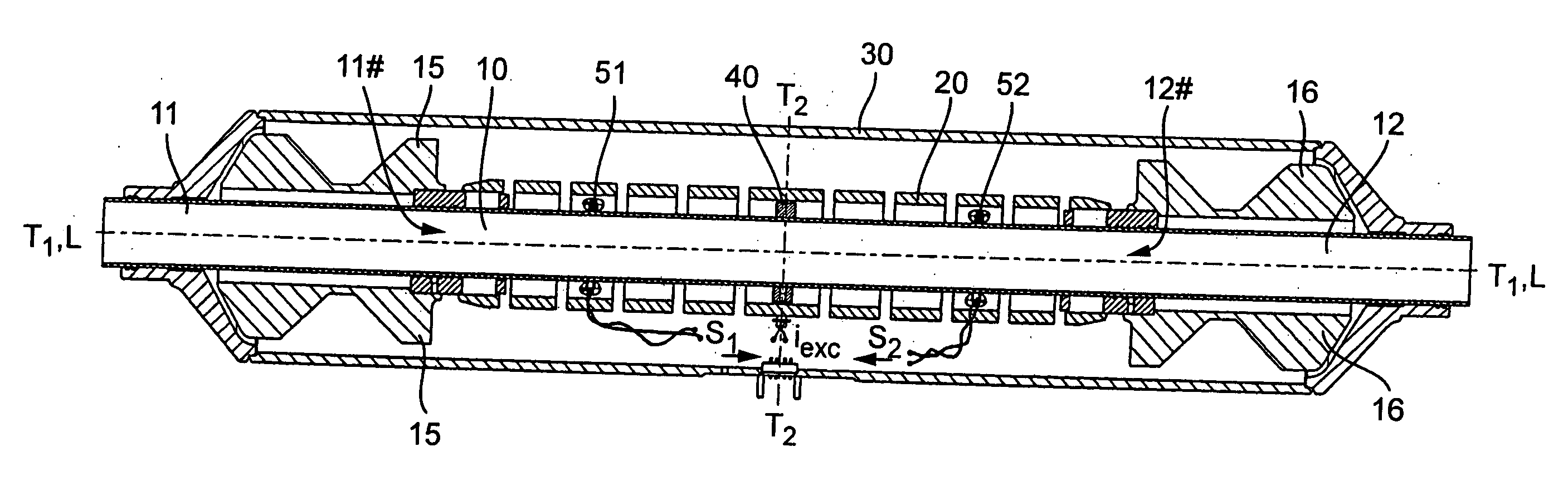

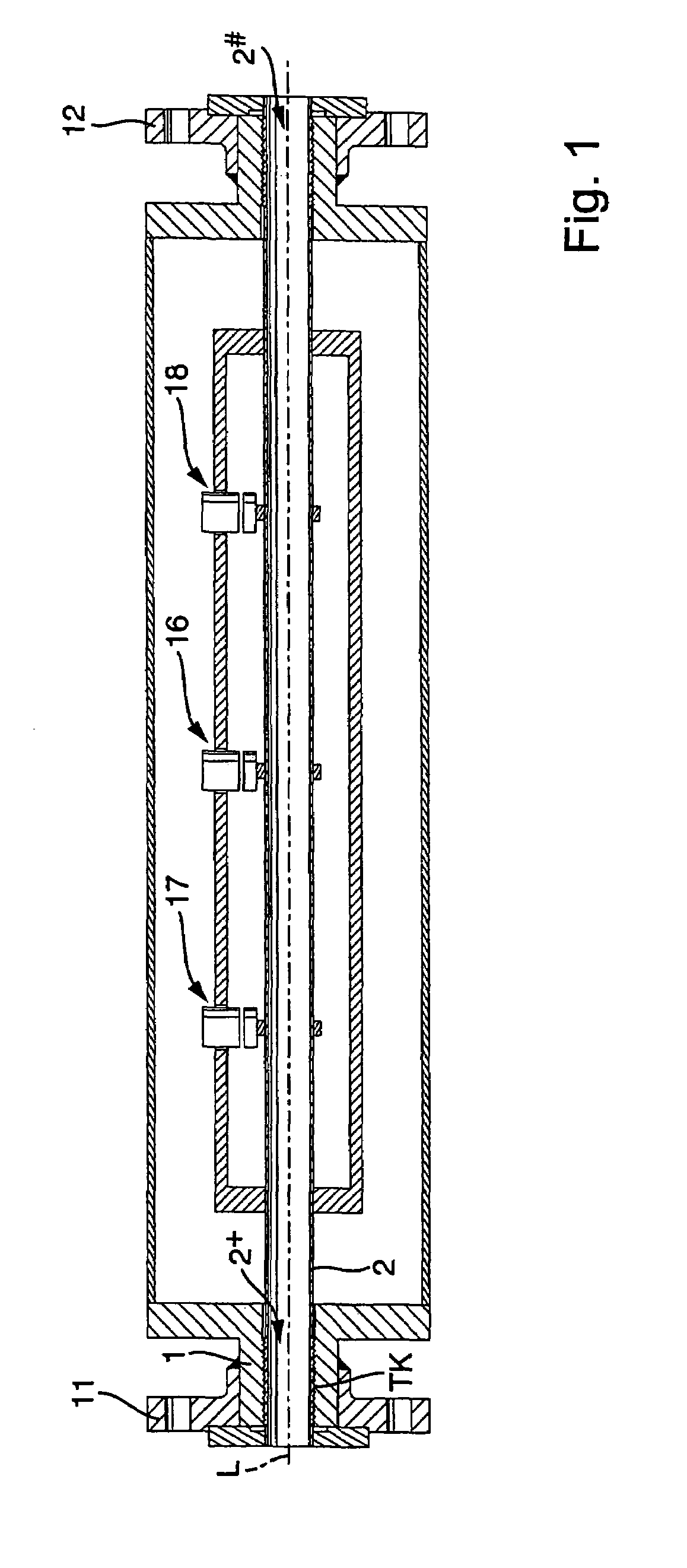

To conduct a fluid, the transducer has a flow tube which in operation vibrated by an excitation assembly. Inlet-side and outlet-side vibrations of the flow tube are sensed by means of a sensor arrangement. To produce shear forces in the fluid, the flow tube is at least intermittently excited into torsional vibrations about a longitudinal flow-tube axis. An internal portion of the transducer, formed at least by the flow tube, an antivibrator, the sensor arrangement, and the excitation assembly and mounted at least on the inlet and outlet tube sections, has a centroid which is located inside the flow tube. The transducer is suitable for use in viscometers or Coriolis mass flowmeter-viscometers. In spite of using only a single straight flow tube, it is dynamically well balanced in operation, and the development of bending moments by the torsionally vibrating flow tube is largely prevented. This also effectively prevents the transducer case or the connected pipe from being excited into sympathetic vibration. Measurement signals representative of mass flow rate are readily distinguishable from measurement signals representative of viscosity, particularly if the sensors used for the viscosity measurement are also used for the mass flow measurement.

Owner:ENDRESS HAUSER FLOWTEC AG

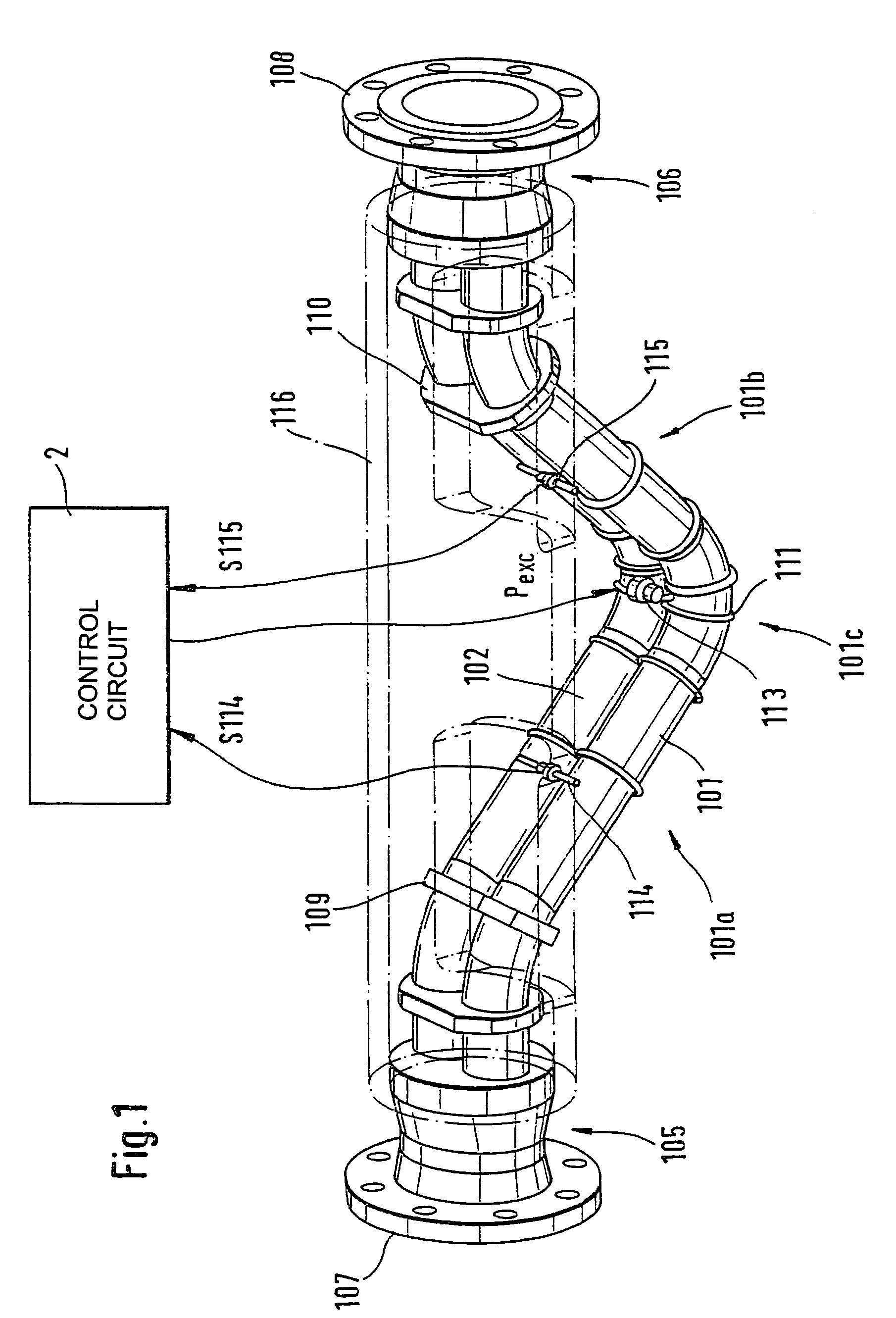

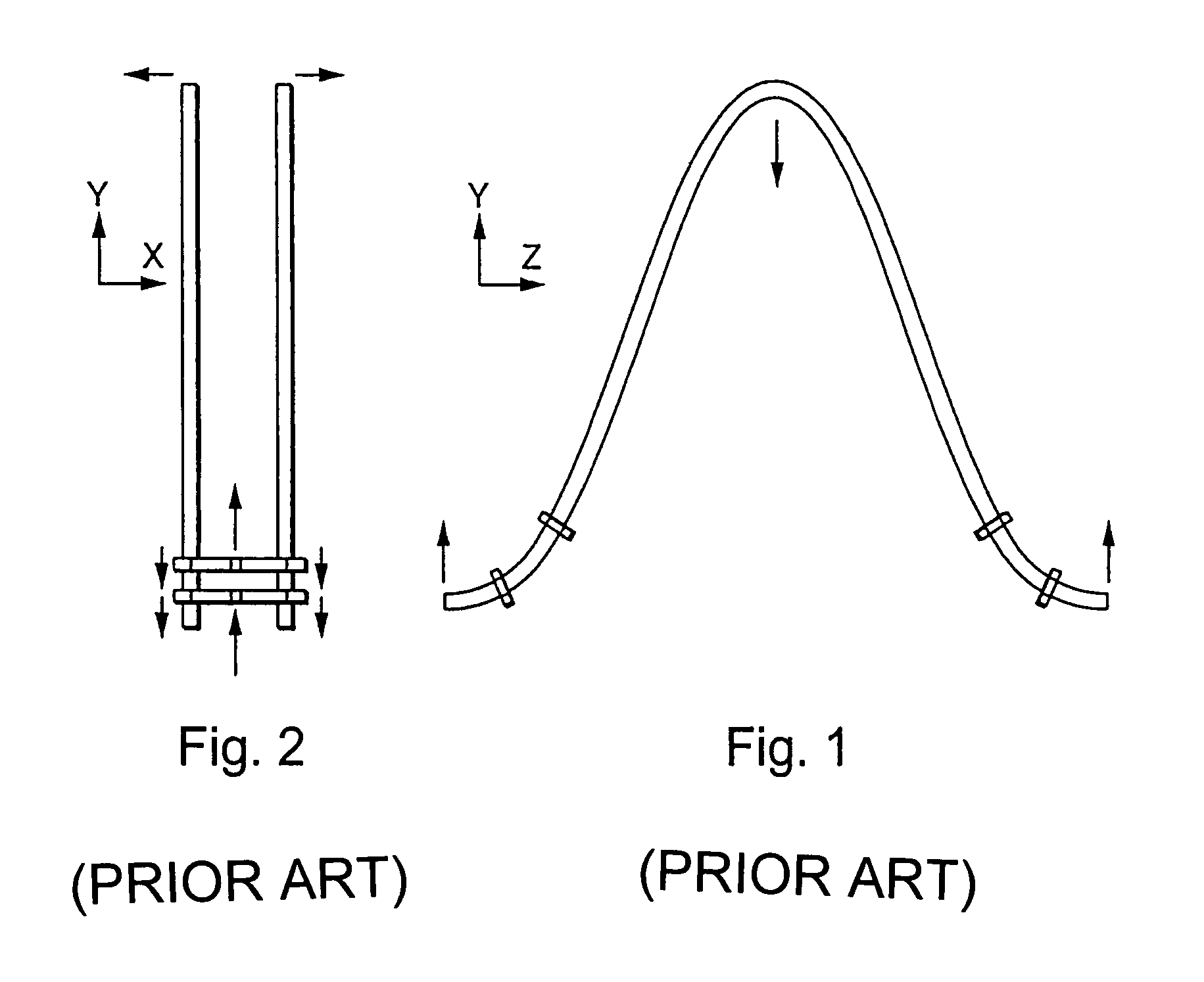

Vibratory transducer

InactiveUS6920798B2Easy to manufactureEasy to bendMaterial analysis using sonic/ultrasonic/infrasonic wavesWeather/light/corrosion resistanceCross sensitivityStraight tube

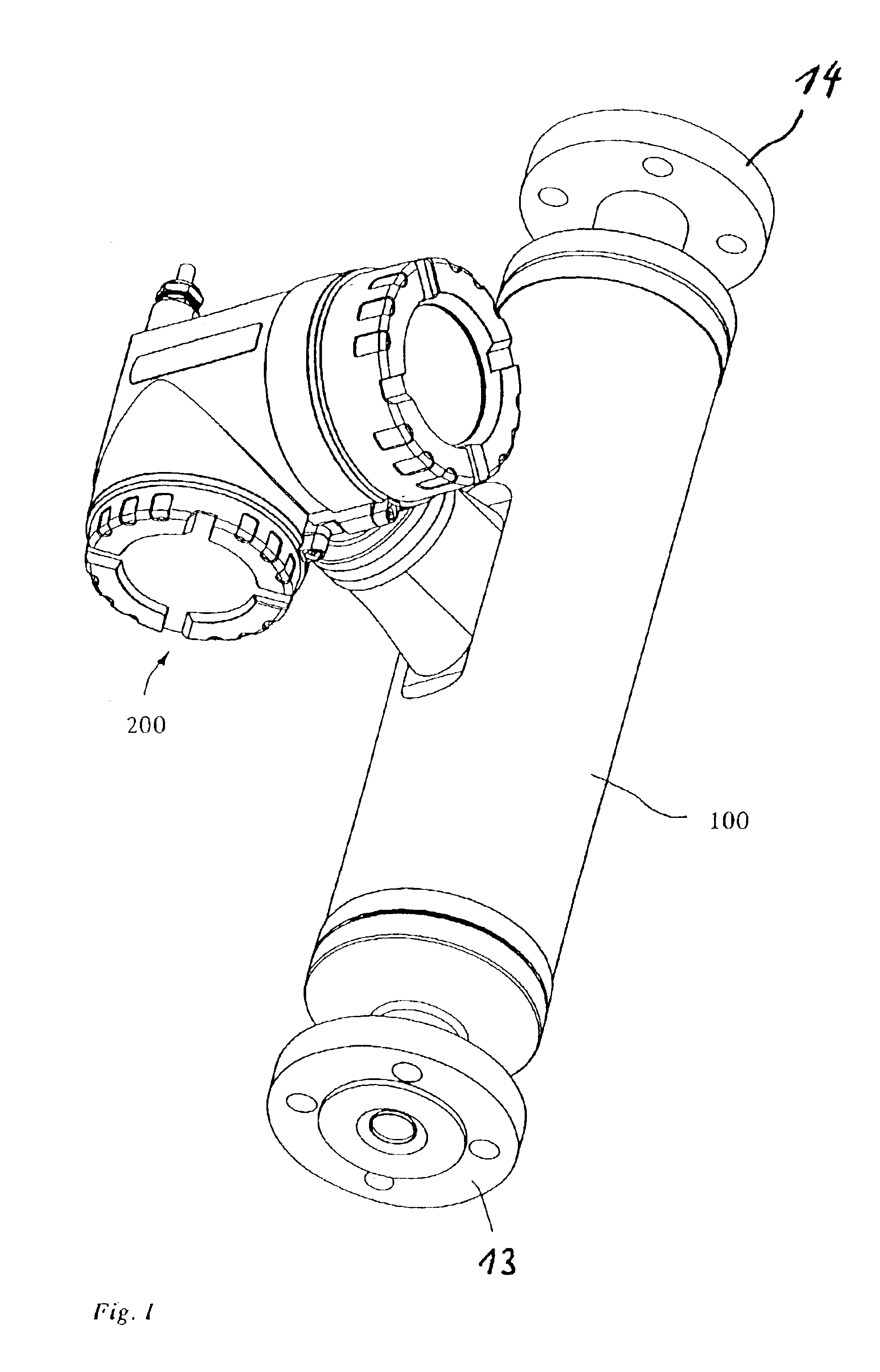

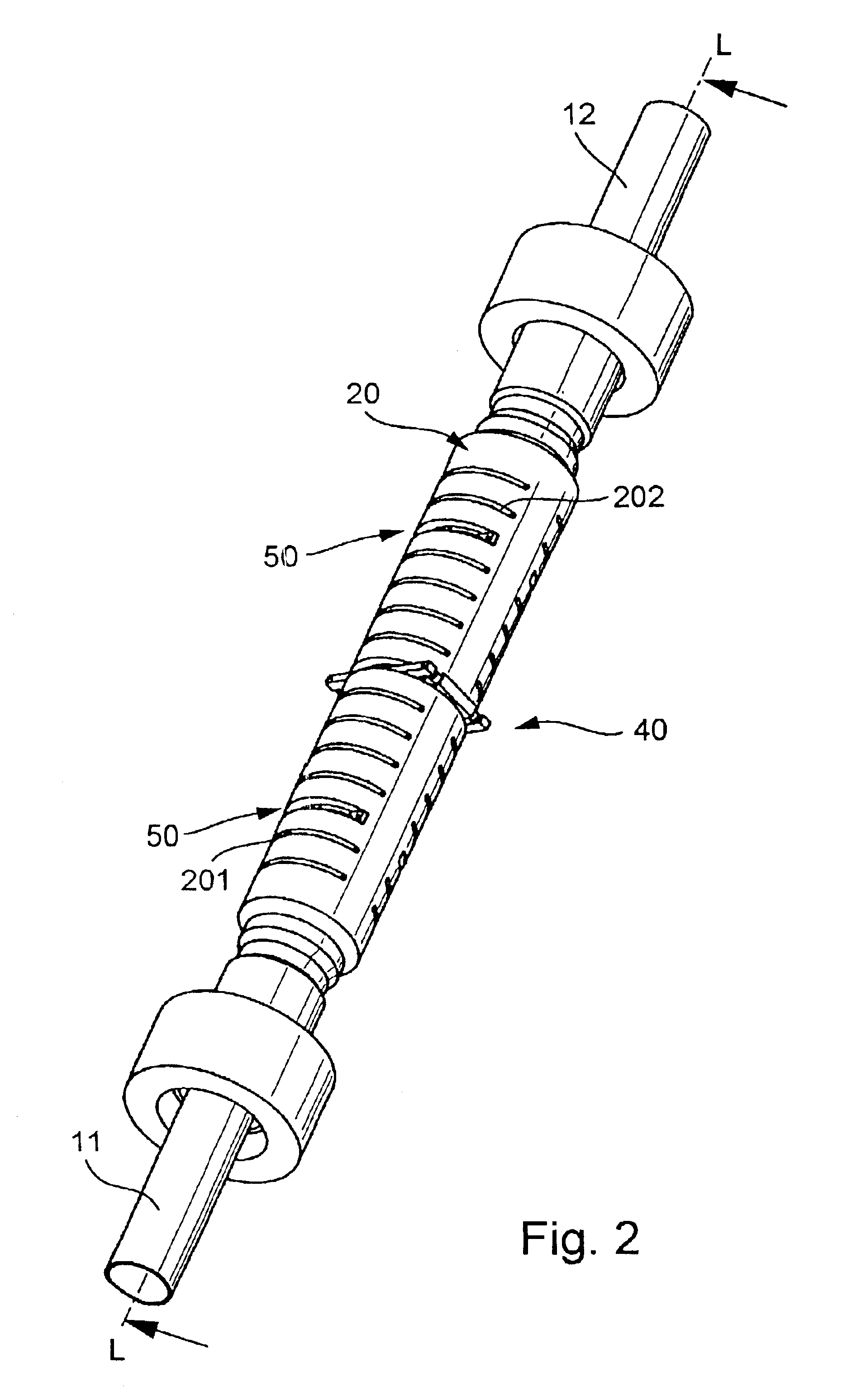

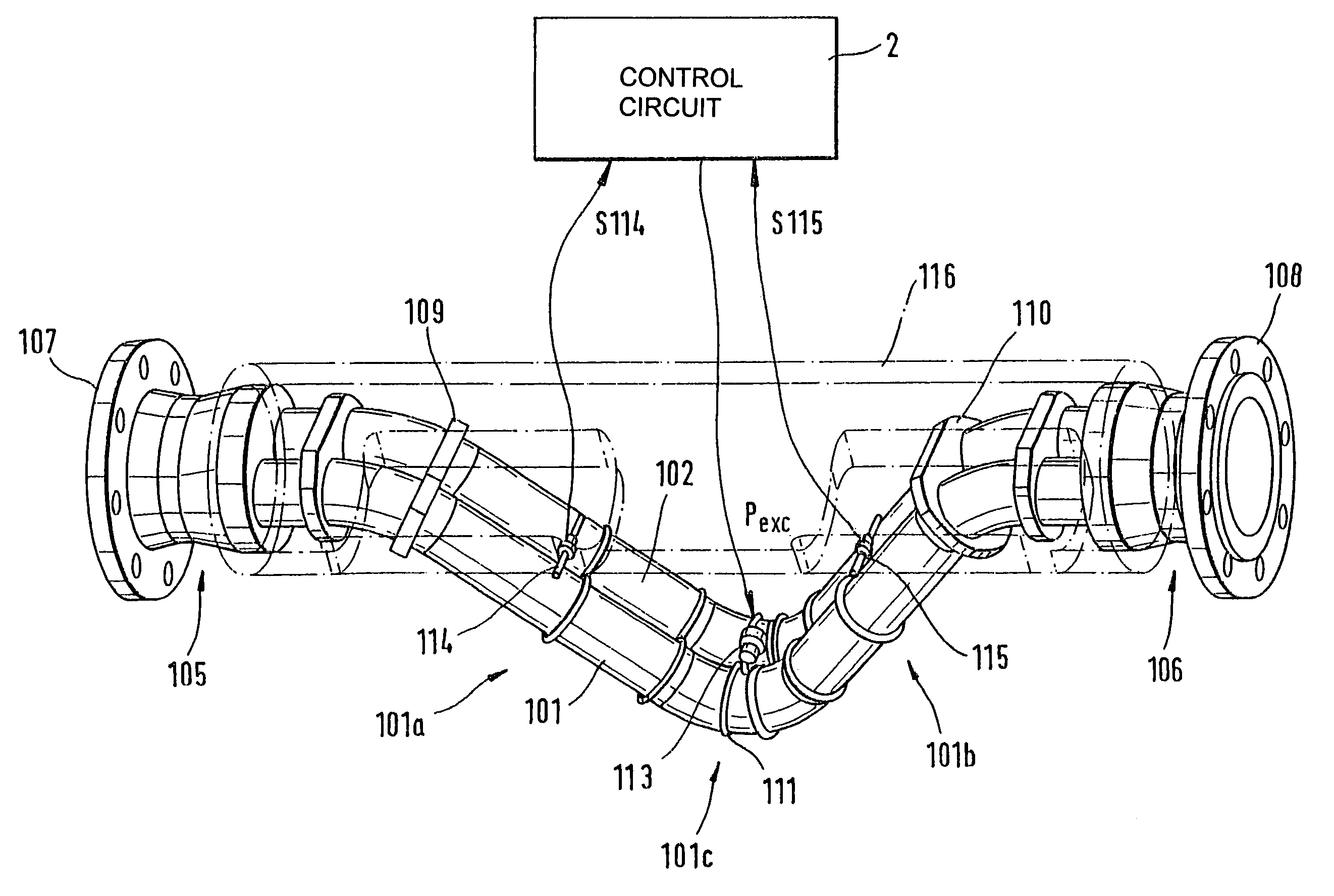

The transducer (1) has at least one at least temporarily vibrating flow tube (101) of predeterminable lumen for conducting a fluid. The flow tube (101) communicates with a connected pipe via an inlet tube section (103), ending in an inlet end, and an outlet tube section (104), ending in an outlet end, and in operation performs flexural vibrations about an axis of vibration joining the inlet and outlet ends. The flow tube (101) has at least one arcuate tube section (101c) of predeterminable three-dimensional shape which adjoins a straight tube segment (101a) on the inlet side and a straight tube segment (101b) on the outlet side. At least one stiffening element (111, 112) is fixed directly on or in close proximity to the arcuate tube segment (101c) to stabilize the three-dimensional shape. By means of the at least one stiffening element (111, 112), the cross sensitivity of the transducer (1) is greatly reduced, so that cross talks from pressure to mass flow signals are minimized and the accuracy of the transducer is improved.

Owner:ENDRESS HAUSER FLOWTEC AG

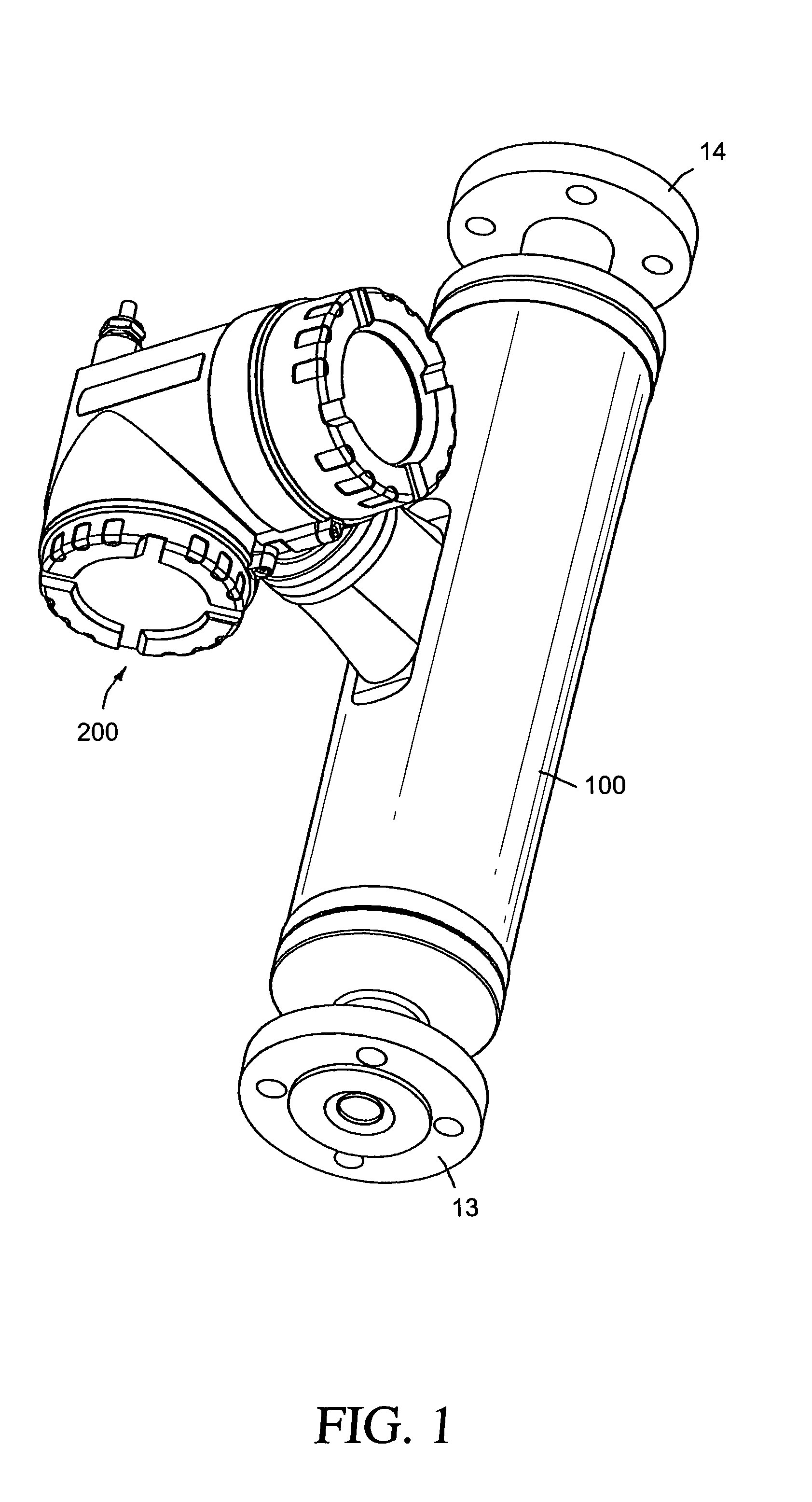

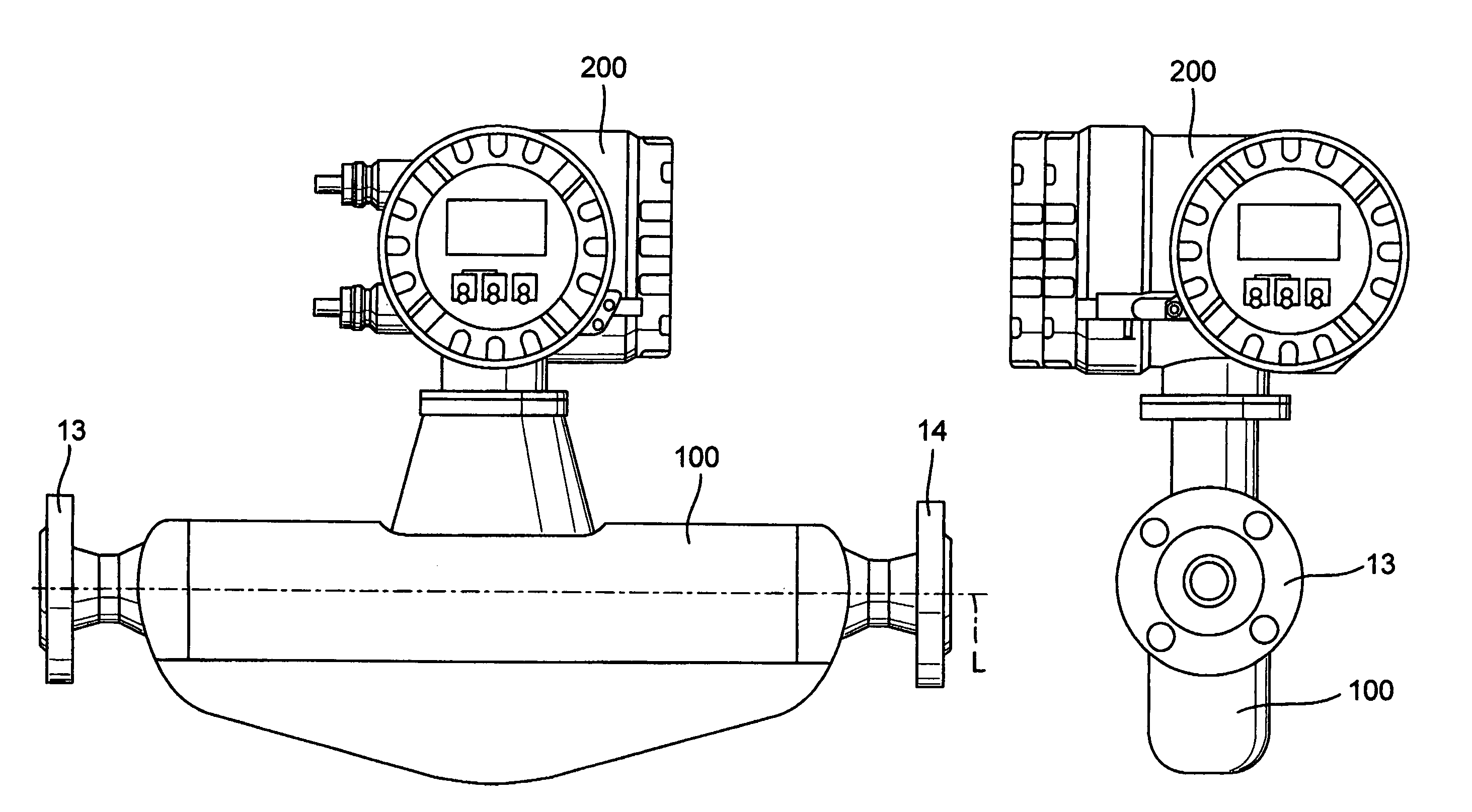

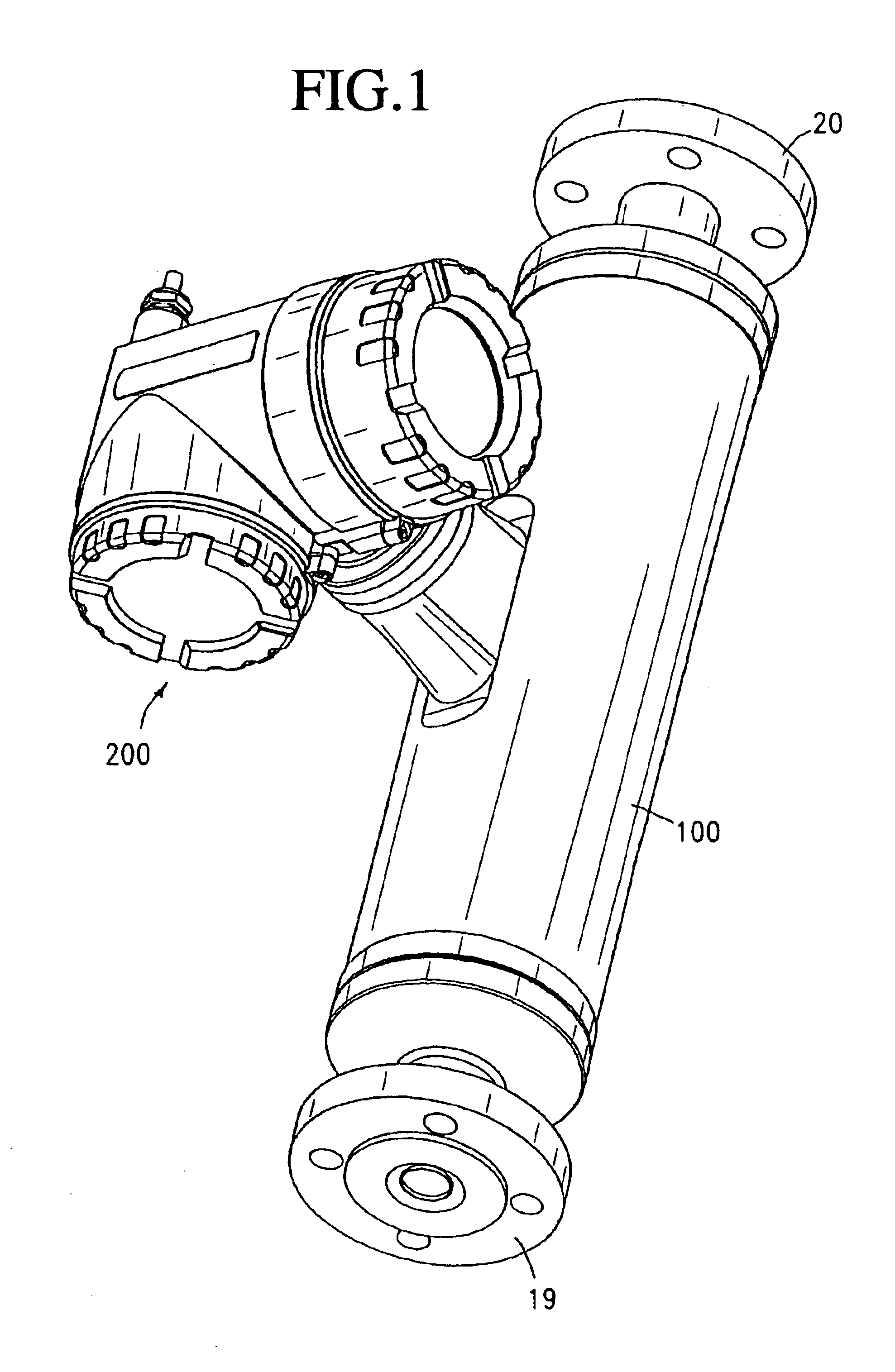

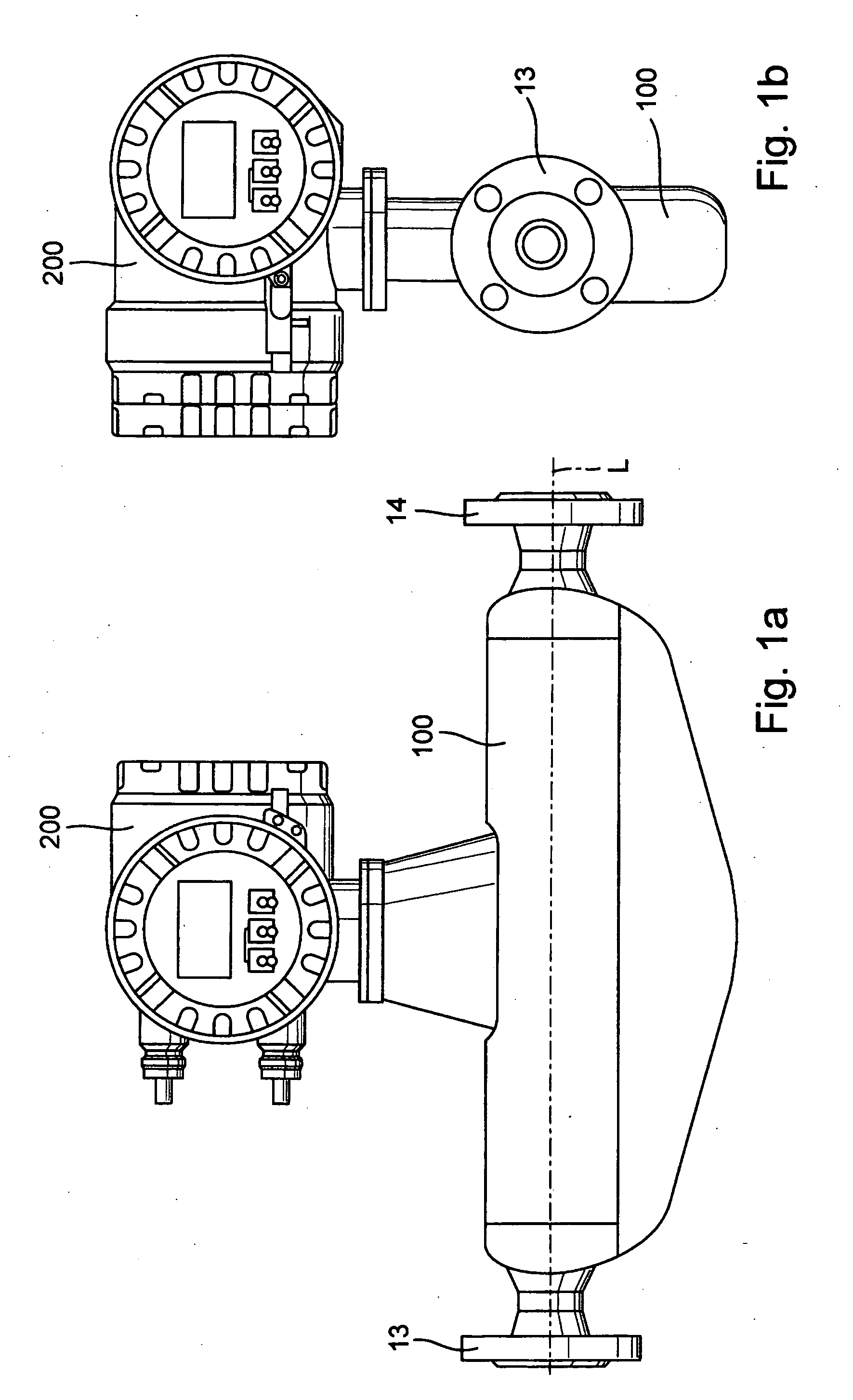

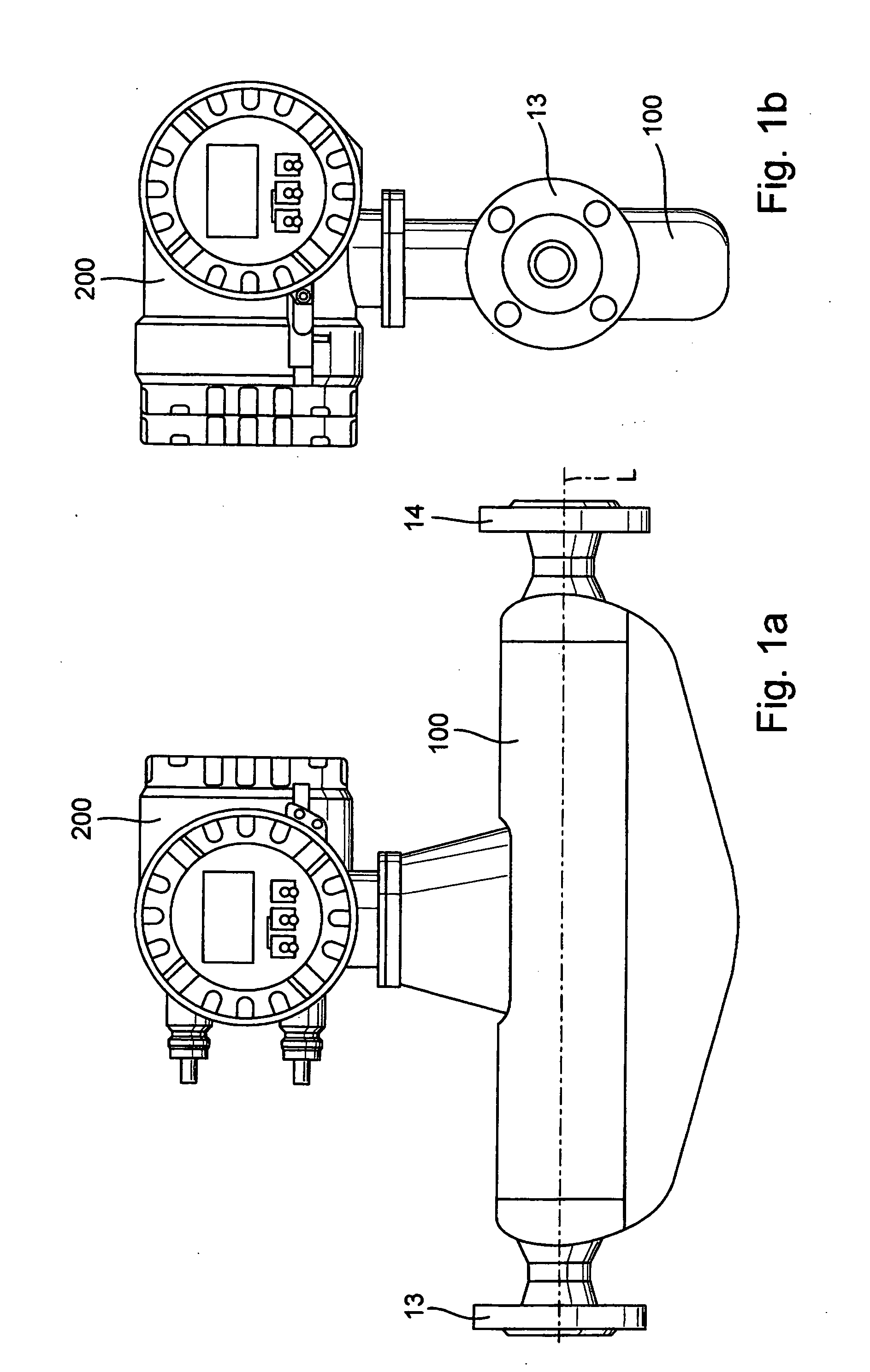

Inline measuring device with a vibration-type measurement pickup

An inline measuring device serves for measuring a medium, especially a gaseous and / or liquid medium, in a pipeline. It includes, a vibration-type measurement pickup and a measuring device electronics electrically coupled with the measurement pickup. The measurement pickup has at least one measuring tube vibrating during operation and communicating with the pipeline, an electromechanical, especially electrodynamic, exciter mechanism acting on the at least one measuring tube for producing and maintaining mechanical oscillations of the measuring tube, a sensor arrangement for producing at least one oscillation measurement signal representing oscillations of the measuring tube and having at least one oscillation sensor arranged on the measuring tube or in its vicinity, and a measurement pickup housing. In an inline measuring device of the invention, it is additionally provided that the measuring device electronics monitors a static internal pressure within the measurement pickup housing and / or a hermeticity of the at least one measuring tube.

Owner:ENDRESS HAUSER FLOWTEC AG

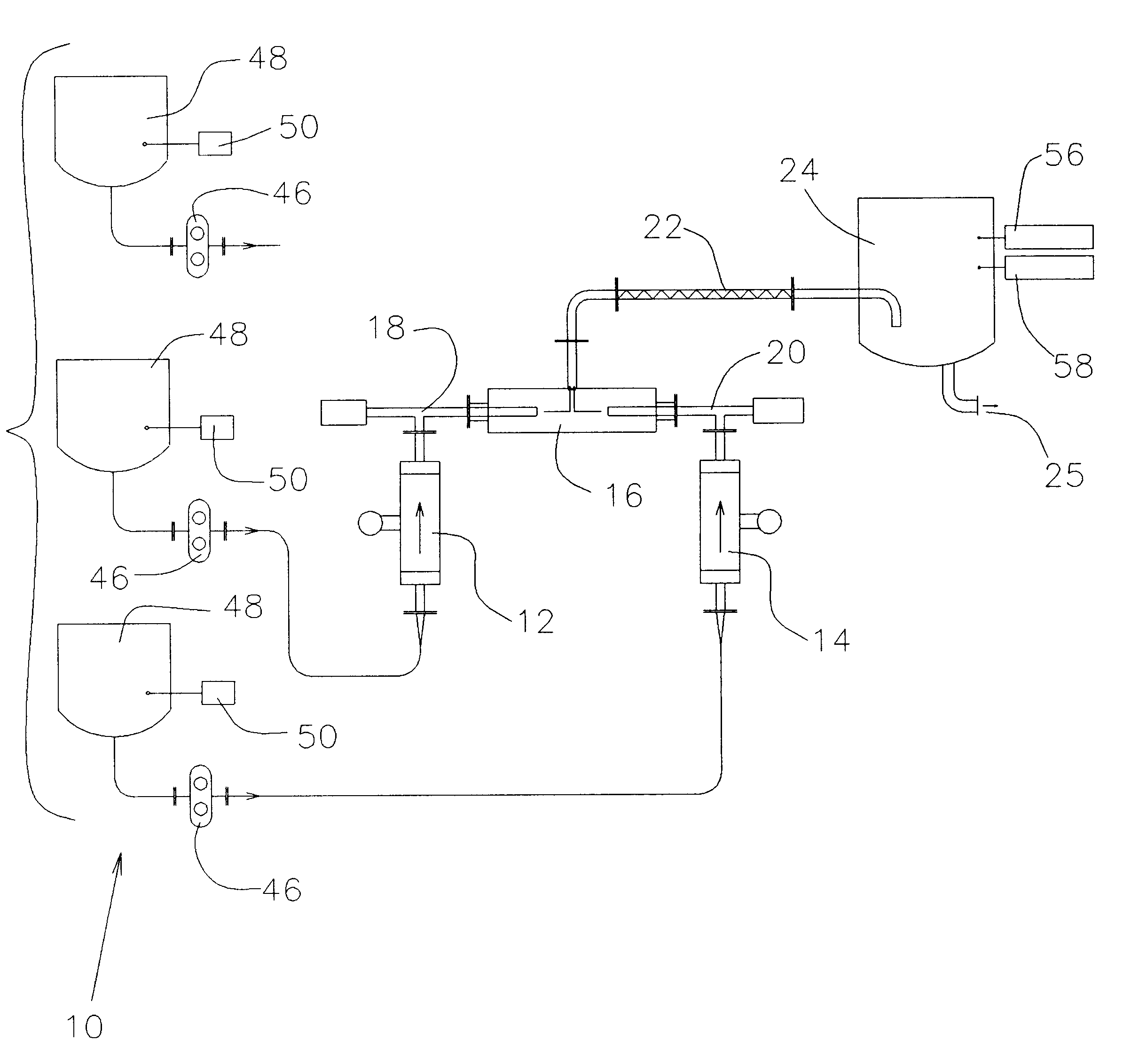

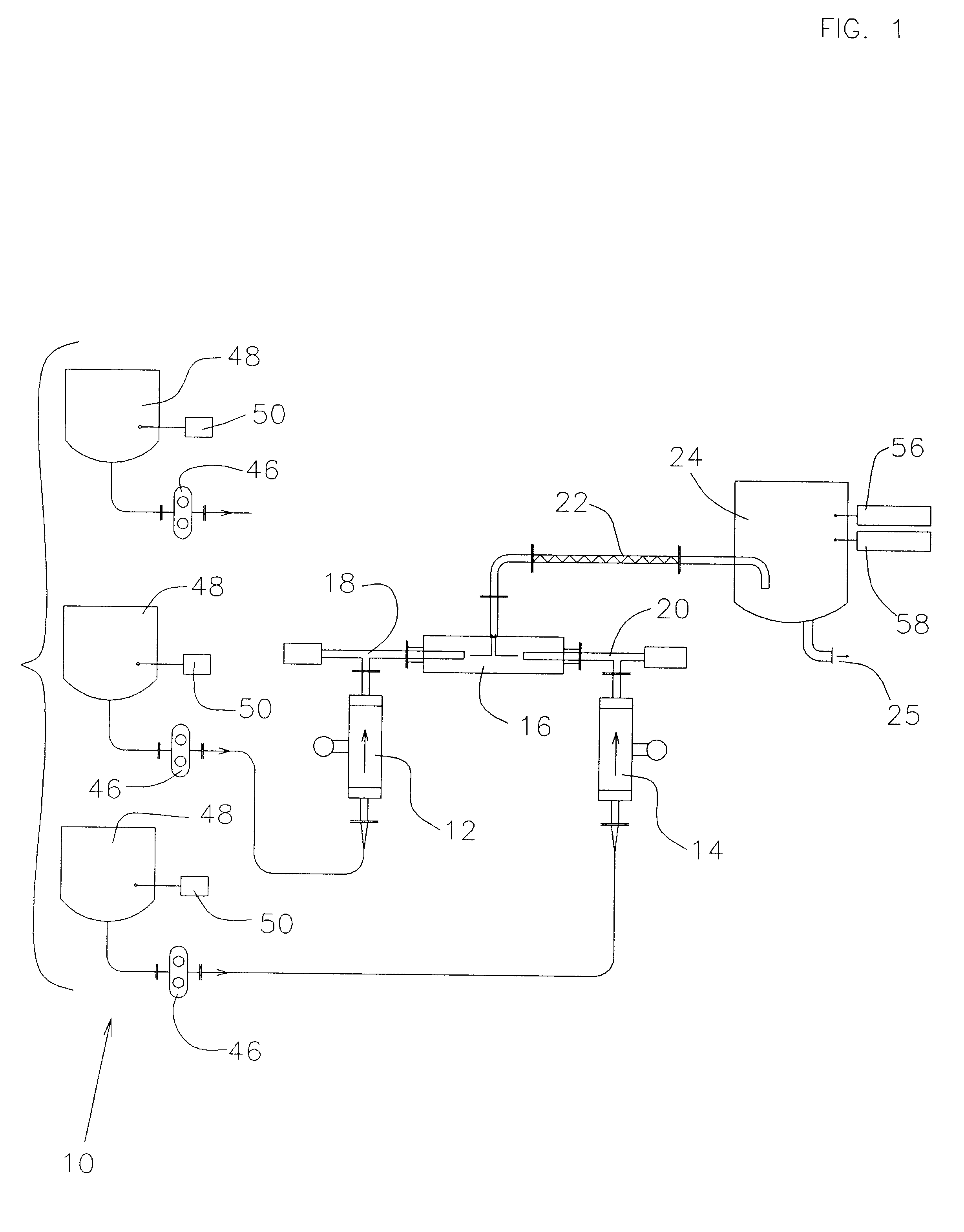

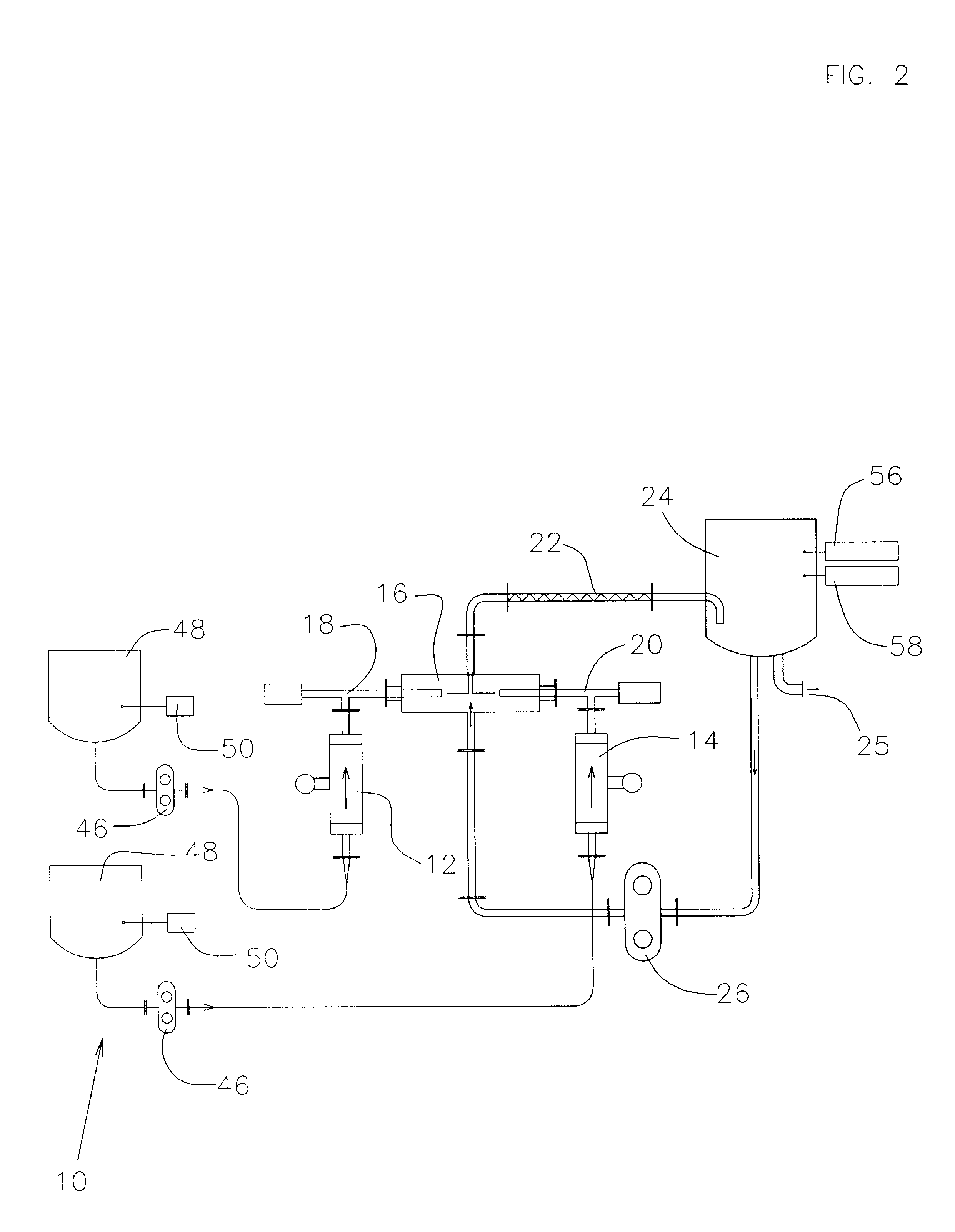

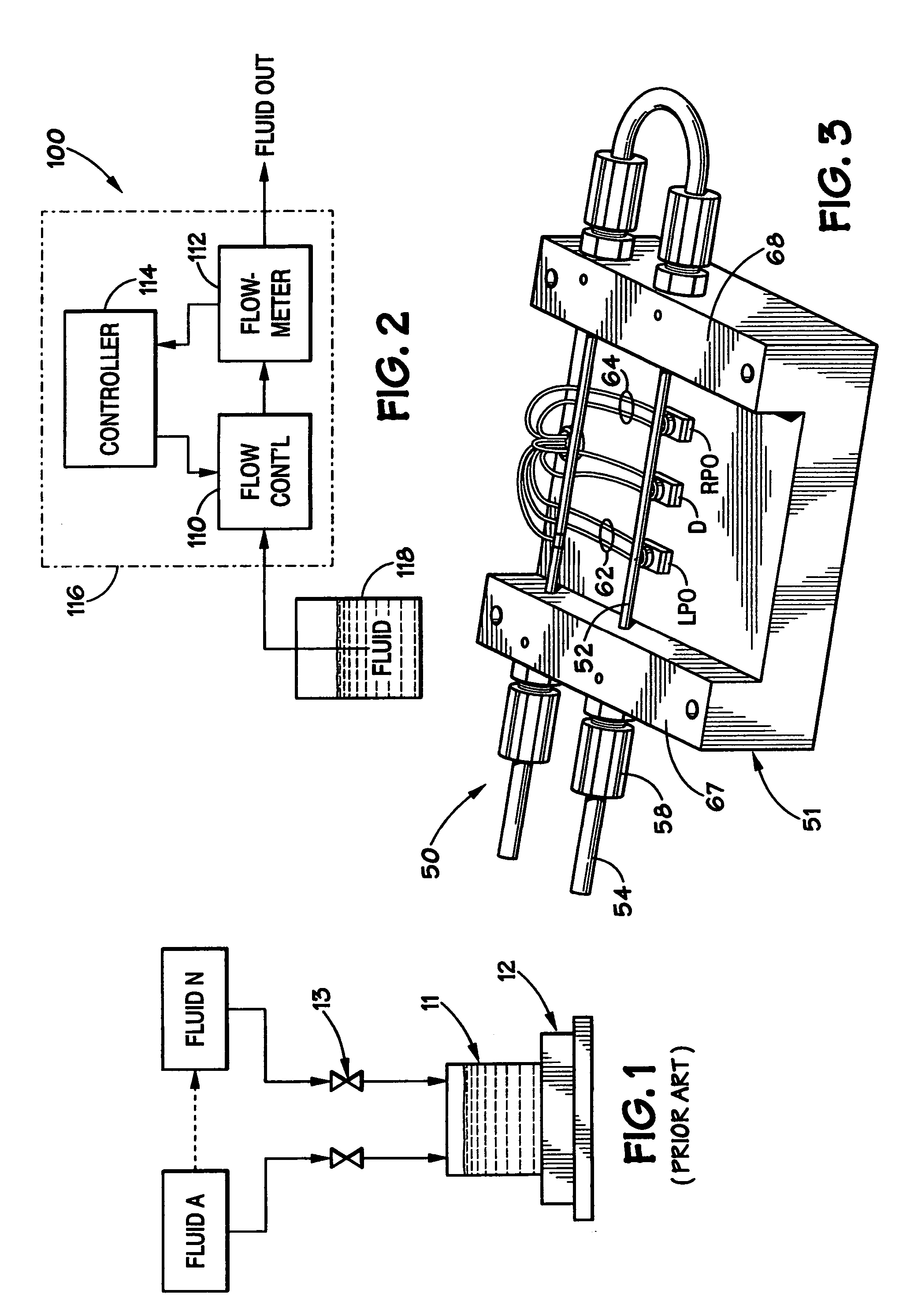

Continuous liquid stream digital blending system

InactiveUS6186193B1More disadvantageSimplifies software and set-up computationLiquid fillingControlling ratio of multiple fluid flowsHybrid systemDigital clock

The present invention consists of a method and apparatus providing for the continuous stream blending, preferably on a mass ratio basis, of two or more liquids. Each individual liquid stream is synchronously dosed in precise mass ratio to a common mixing point. The flow of each stream is on-off or digital. Repeated mass ratio doses of defined and matching flow interval, referred to as synchronous digital flow, interspersed with a defined interval of no flow, constitutes digital flow at a net rate sufficient to meet or exceed some required take-away of the blended liquids. In one preferred embodiment, each dose stream flow is produced and measured by a four element apparatus preferably consisting of a servo motor and controller, a precision positive displacement pump, a Coriolis mass meter and a precision flow stream shut-off device. The servo motor and controller establish and control a periodic and intermittent flow rate necessary to displace a defined mass dose in a precisely defined flow interval. The flow interval is measured against a precision millisecond digital clock. The Coriolis mass meter is used only to totalize mass flow to define the desired mass dose during the defined digital flow interval. The flow stream shut-off device ensures precise delivery of the mass dose to the common mixing point. The flow rate of a stream is automatically adjusted by the control electronics until the required mass dose is delivered in the defined flow interval.

Owner:ODEN MACHINERY

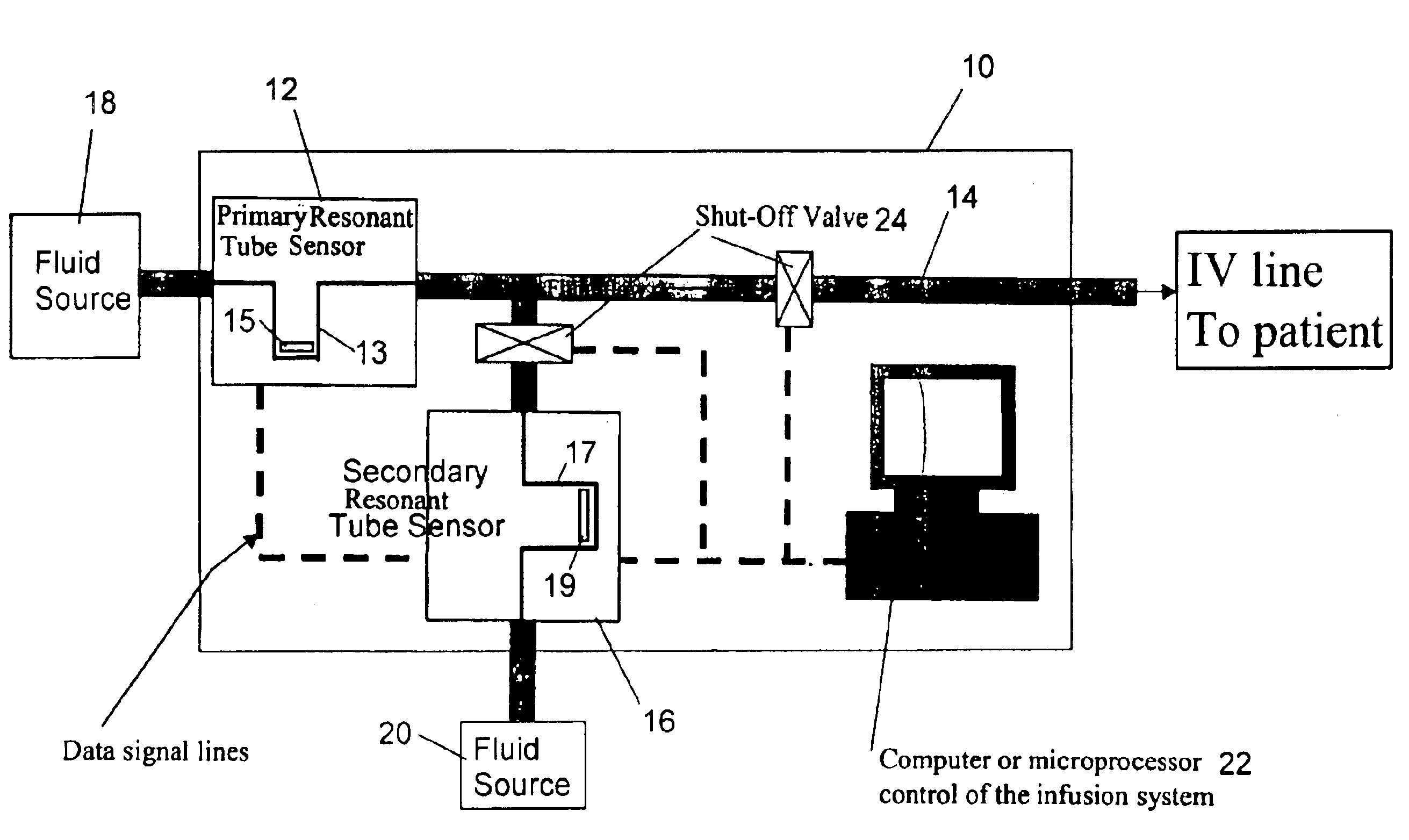

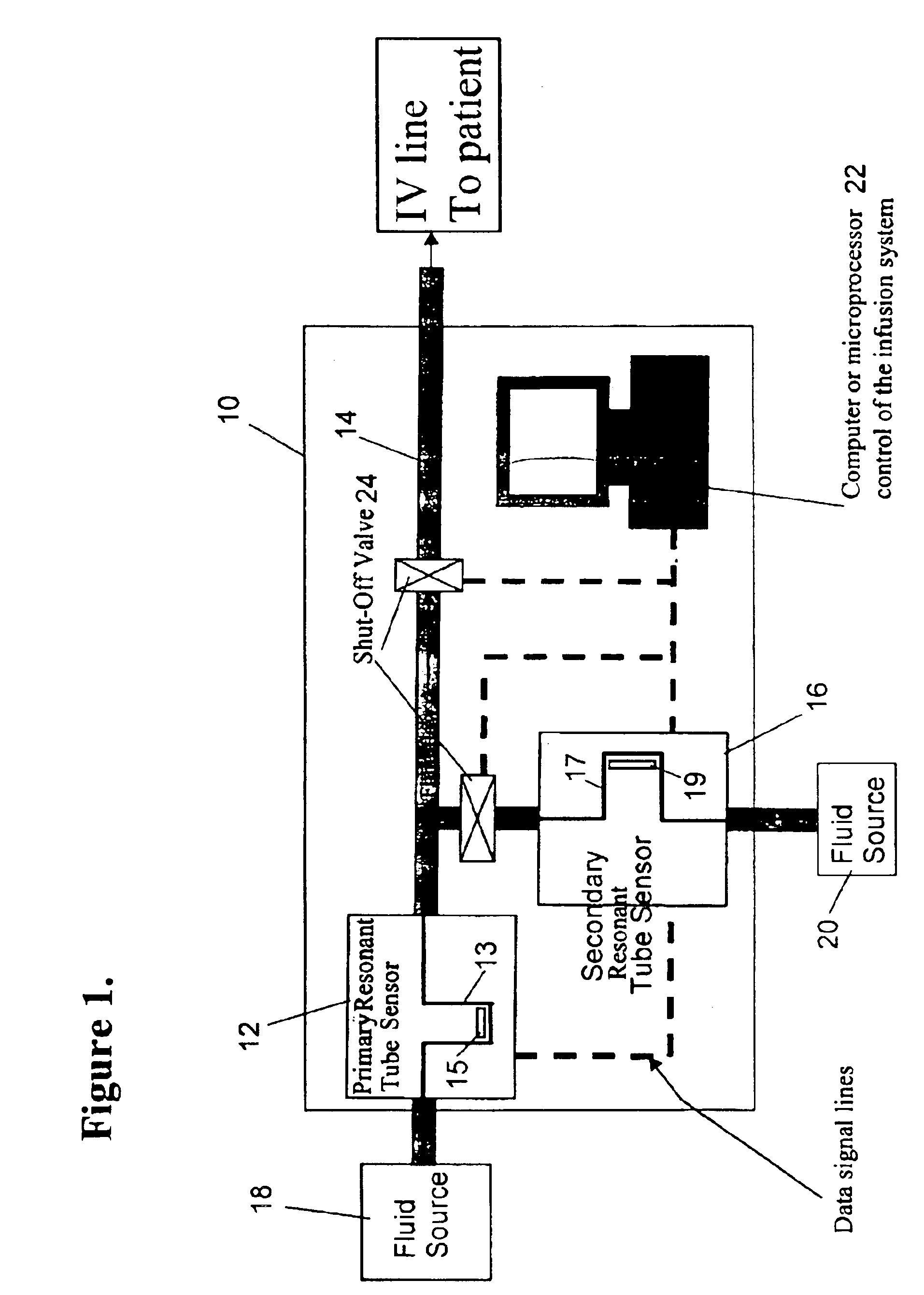

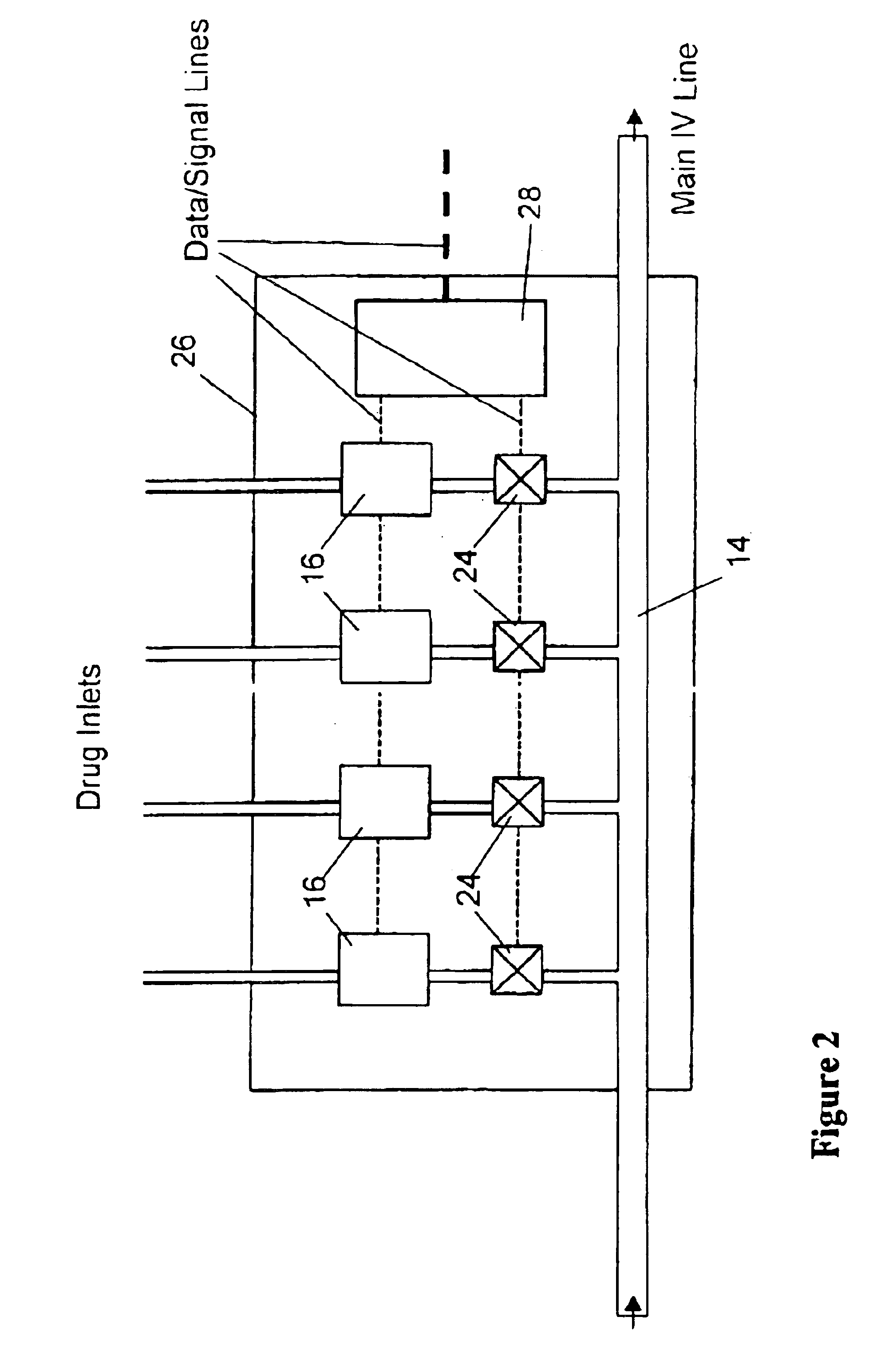

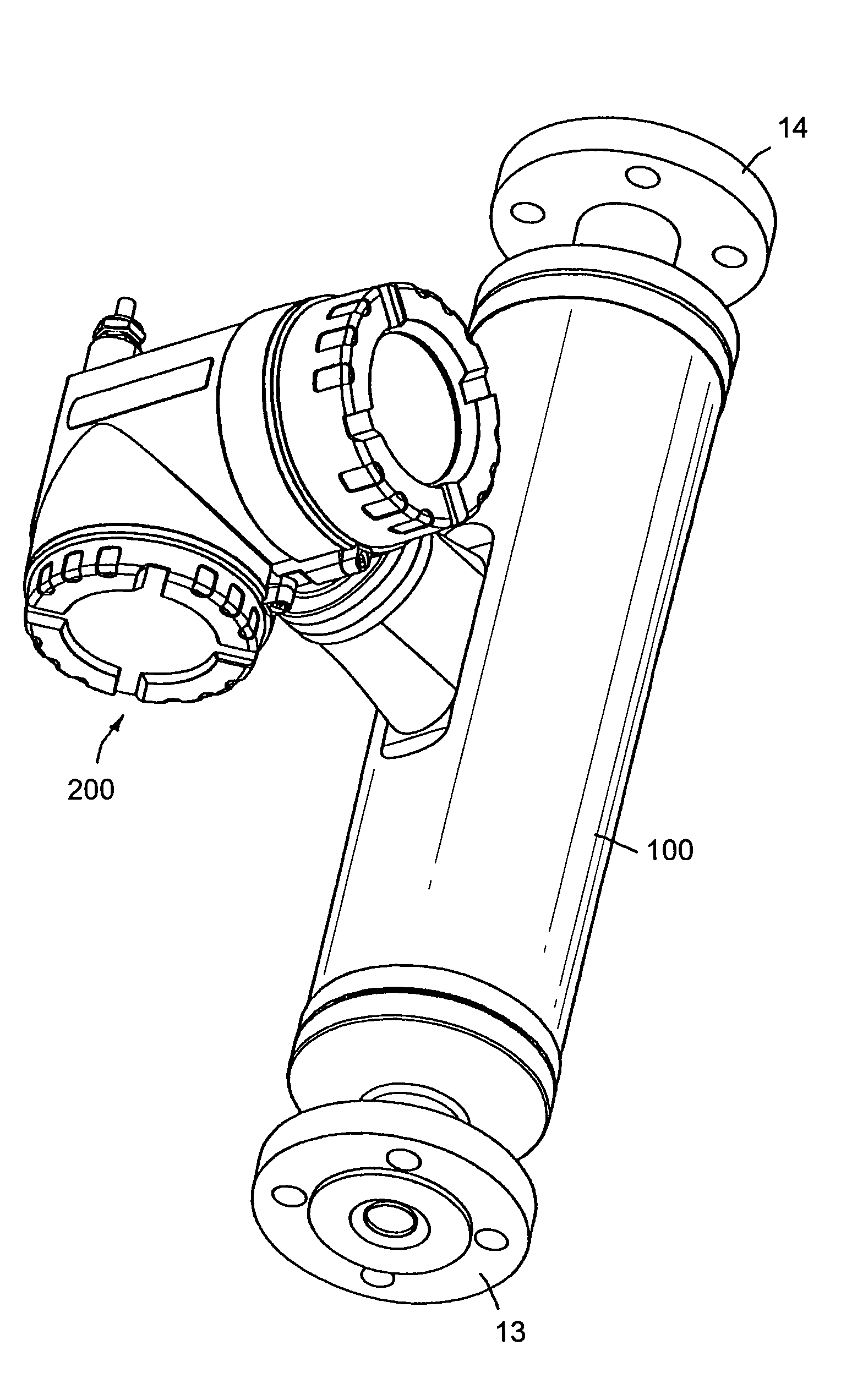

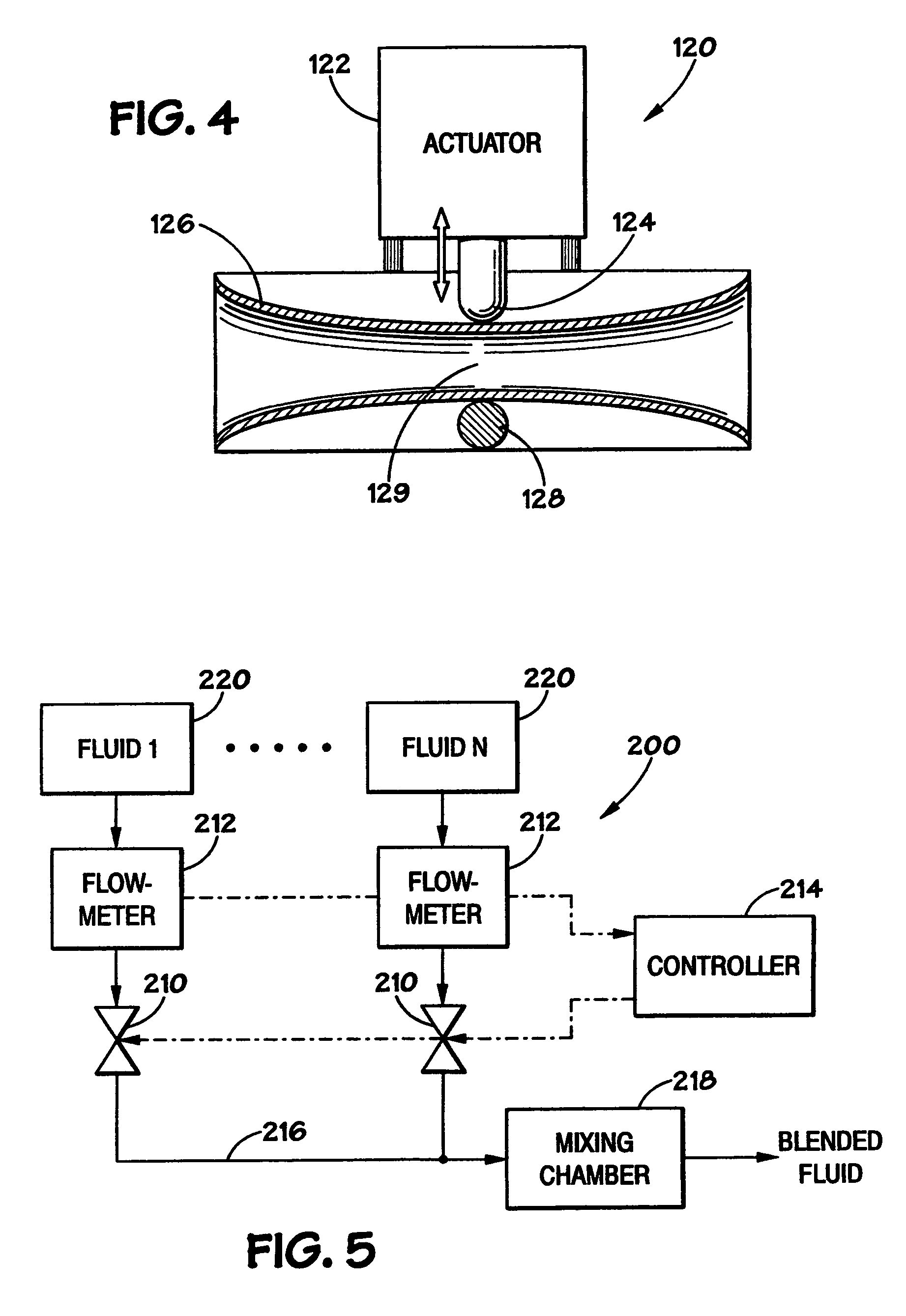

Fluid delivery system and method

InactiveUS6932114B2The right amountSafe deliveryCircuit elementsVolume measurement and fluid deliveryEngineeringDelivery system

A fluid delivery system capable of delivering a precise amount of fluid and monitor certain properties of the fluid so that the correct fluid is safely delivered to its intended destination. The system makes use of a flow sensor comprising a freestanding tube portion vibrated at a resonant frequency, wherein the resonant frequency corresponds to the density of the fluid flowing through the tube portion and the tube portion exhibits a degree of twist that varies with the mass flow rate of the fluid flowing therethrough. Movement of the tube portion is then sensed to produce a first output signal corresponding to the fluid density and a second output signal corresponding to the mass flow rate. The system is also equipped to measure elapsed time and to stop fluid flow in response to either of the first and second output signals.

Owner:INTEGRATED SENSING SYST INC

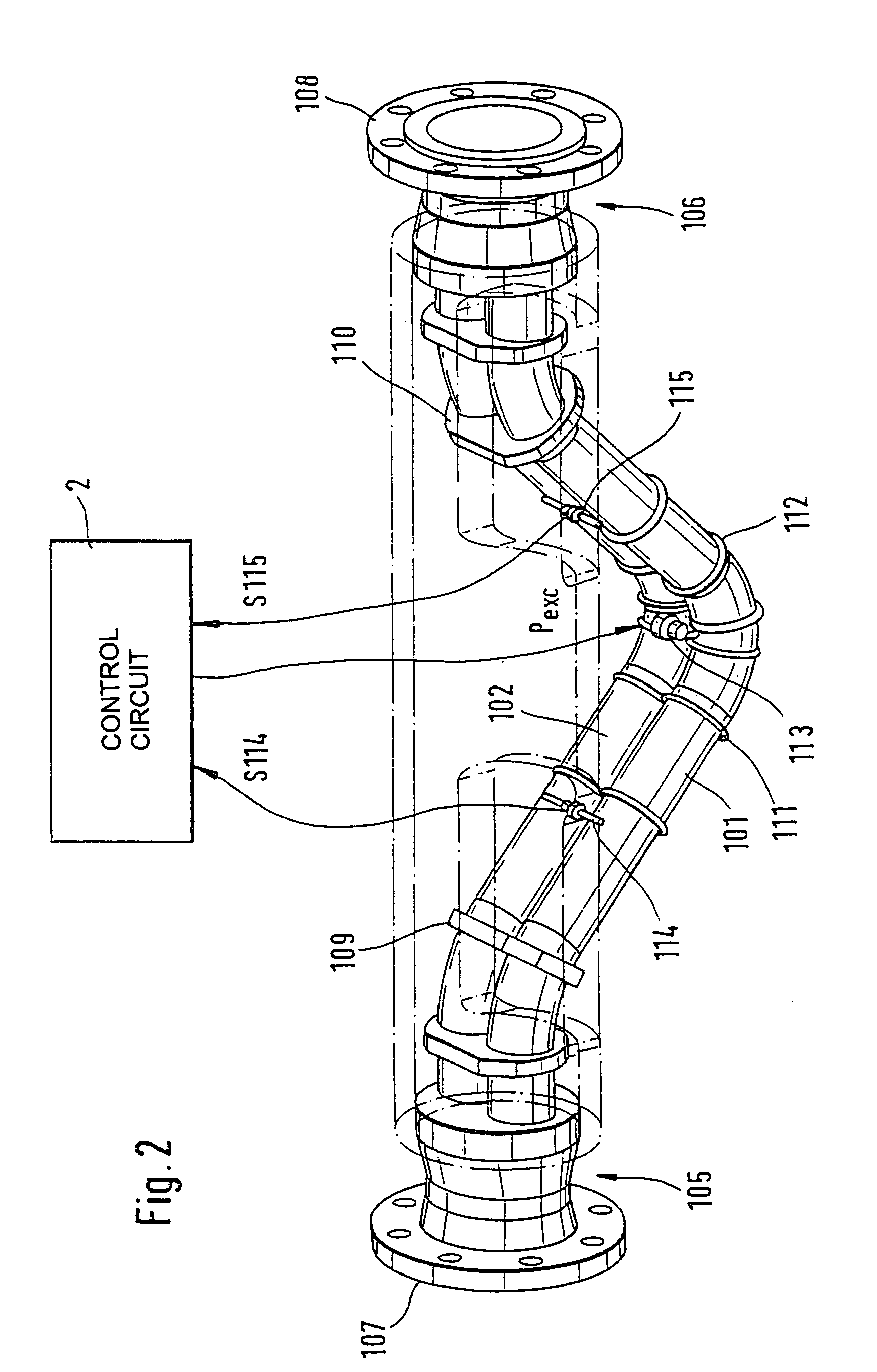

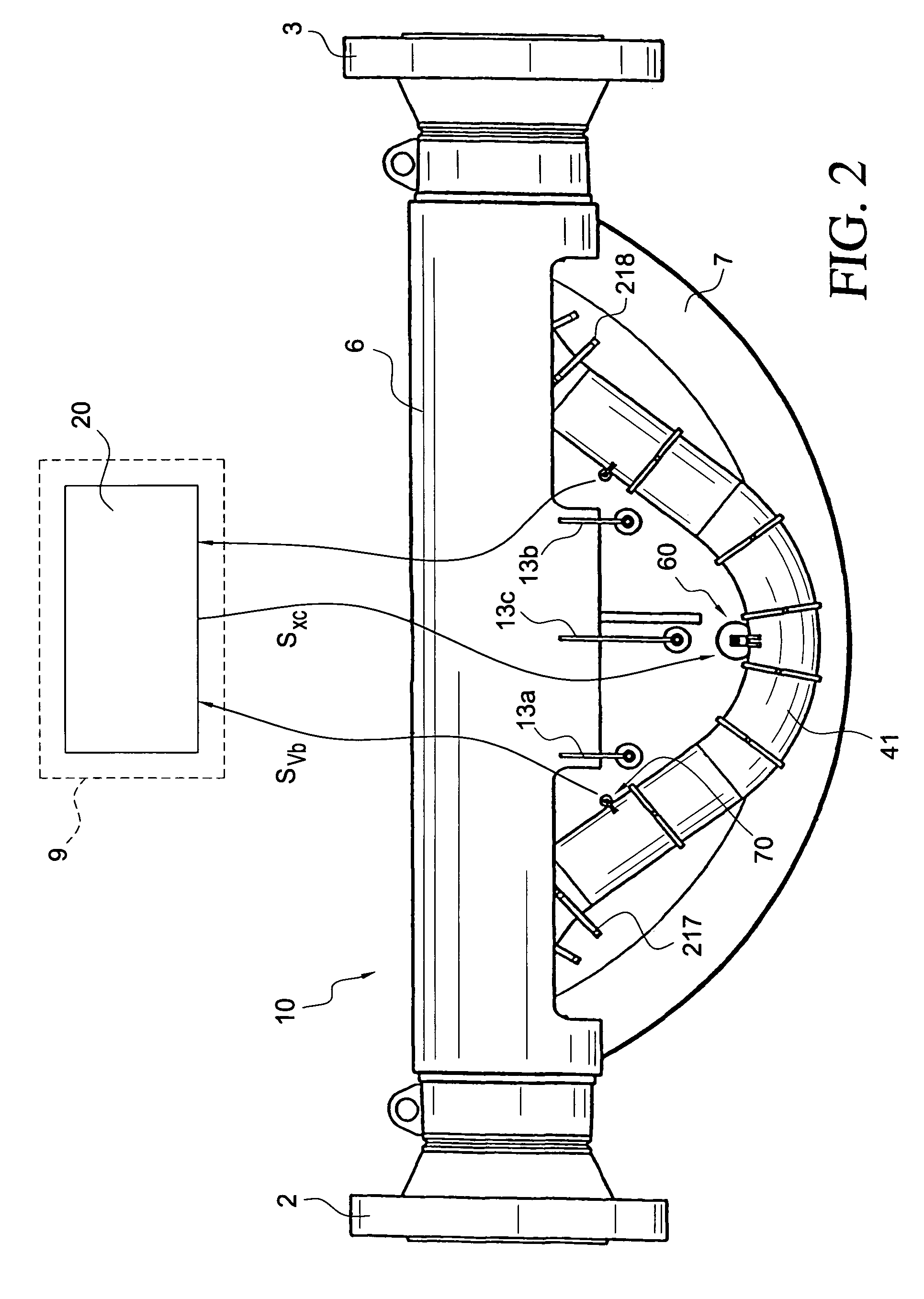

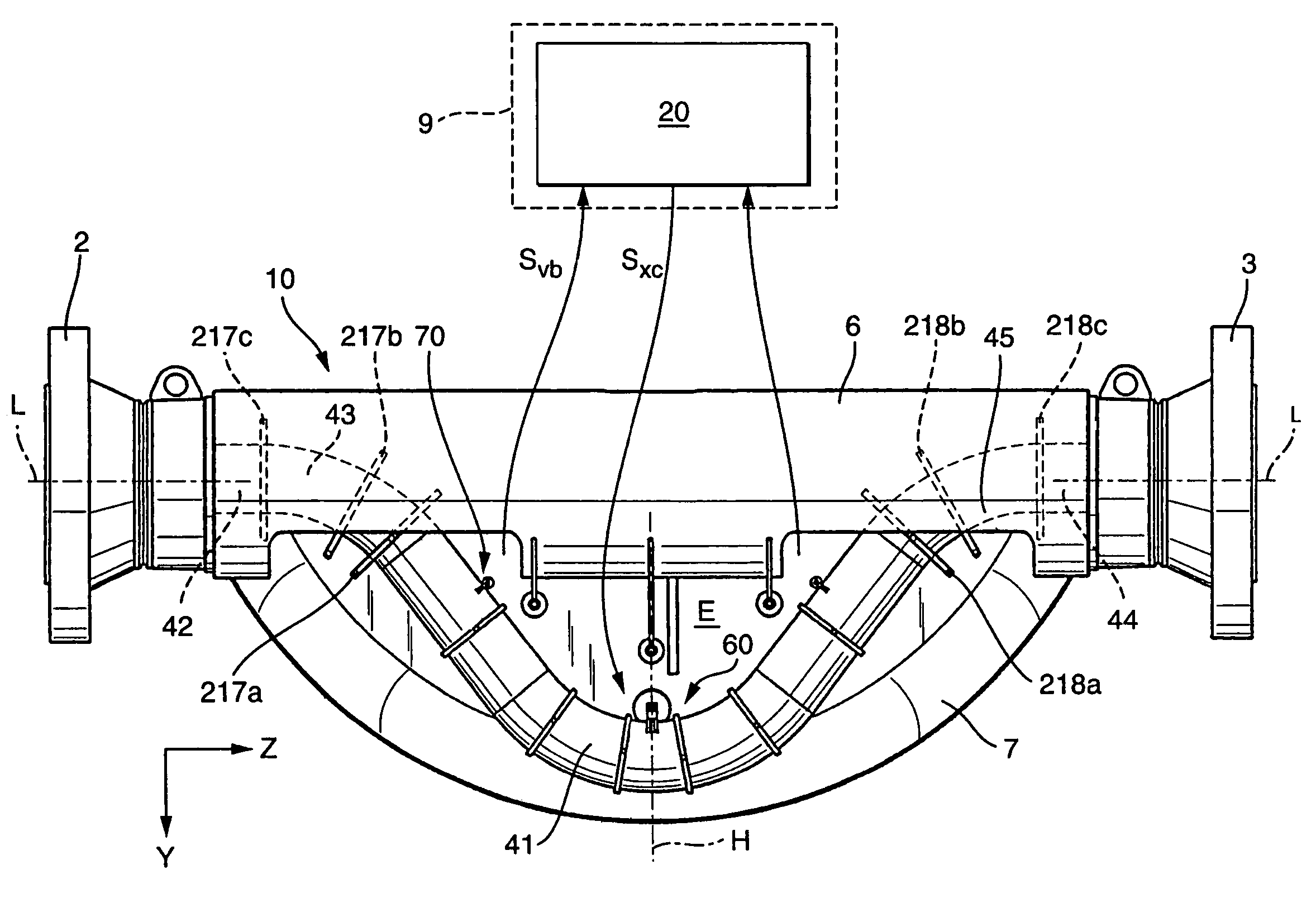

Vibration-type measuring transducer

For conveying a fluid, the measuring transducer is equipped with a measuring tube, which is held oscillatably in a support element and vibrates during operation. The measuring tube executes, during operation, at least over part of its length, driven by an exciter arrangement, bending oscillations about an oscillation axis. These bending oscillations predominantly assume an oscillation form having at least three bending oscillation antinodes. Inlet-end and outlet-end oscillations are registered by means of a sensor arrangement. Additionally provided in the measuring transducer is a coupler arrangement connected with measuring tube and with support element and having at least one coupling element interacting mechanically, especially resiliently, with the vibrating measuring tube and the support element. By suitable choice of the effective spring constant, c60, of the coupler arrangement, this can cancel transverse forces produced, during operation, on the part of the vibrating measuring tube, for example due to fluctuating fluid density.

Owner:ENDRESS HAUSER FLOWTEC AG

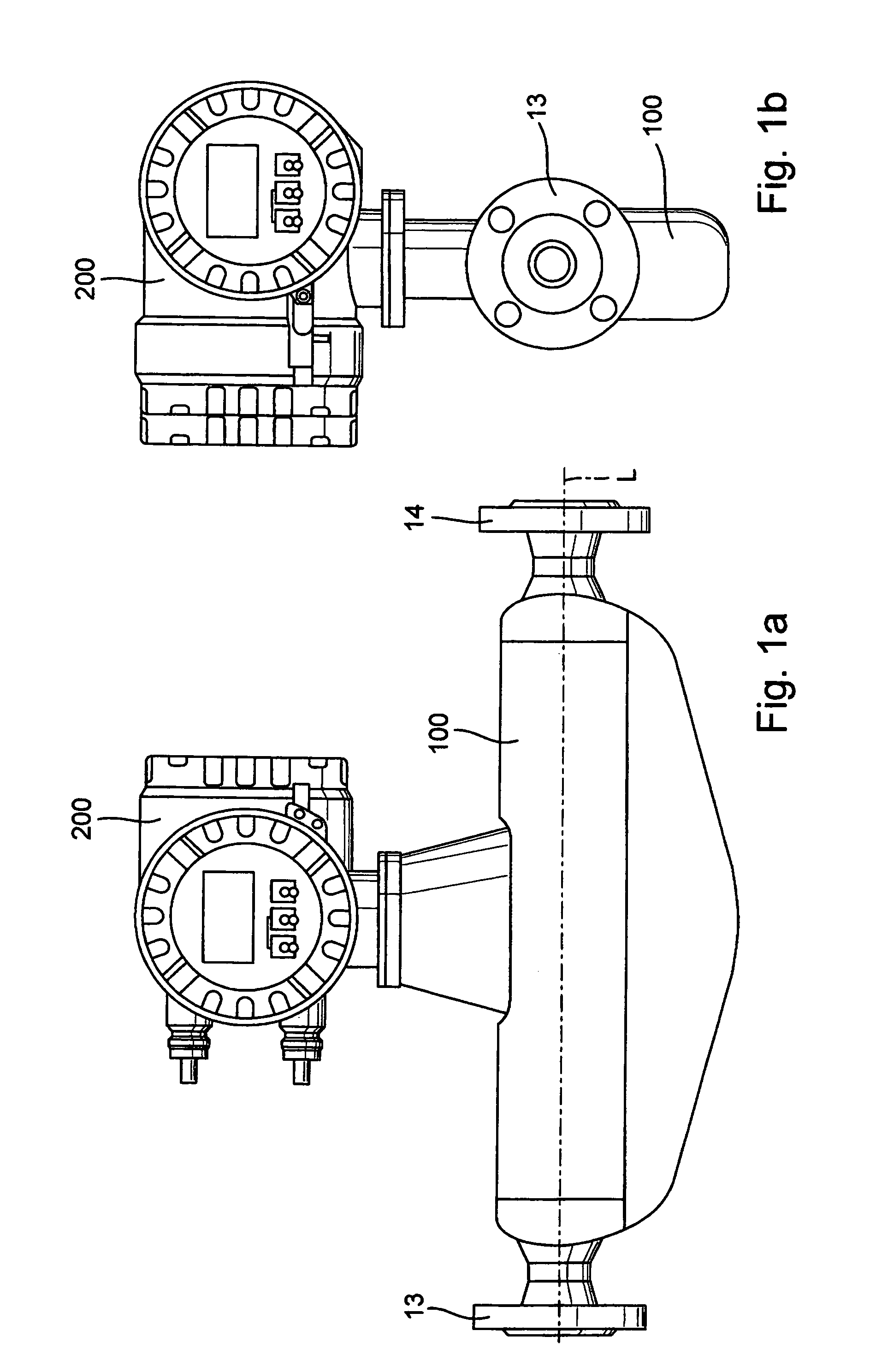

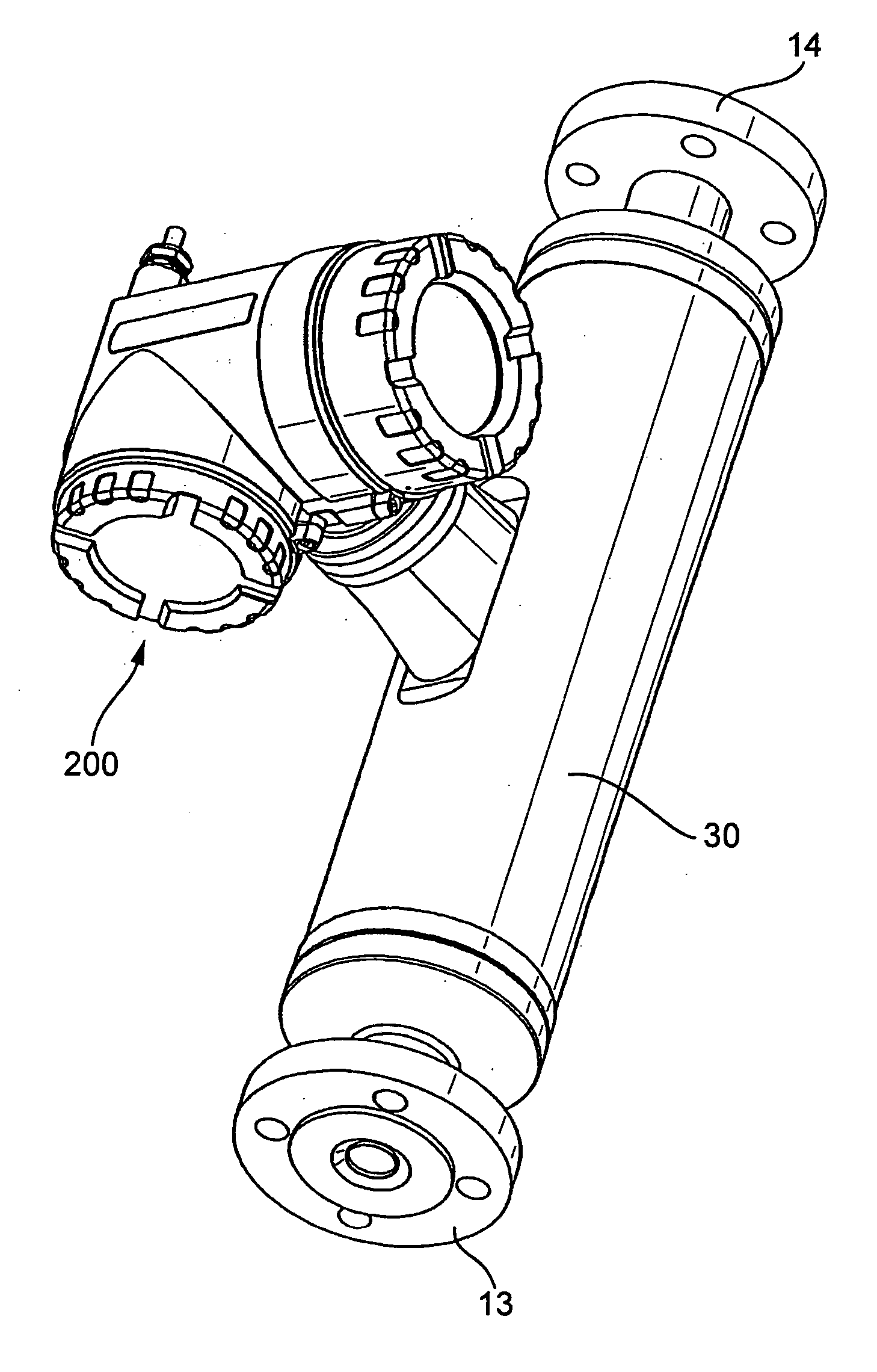

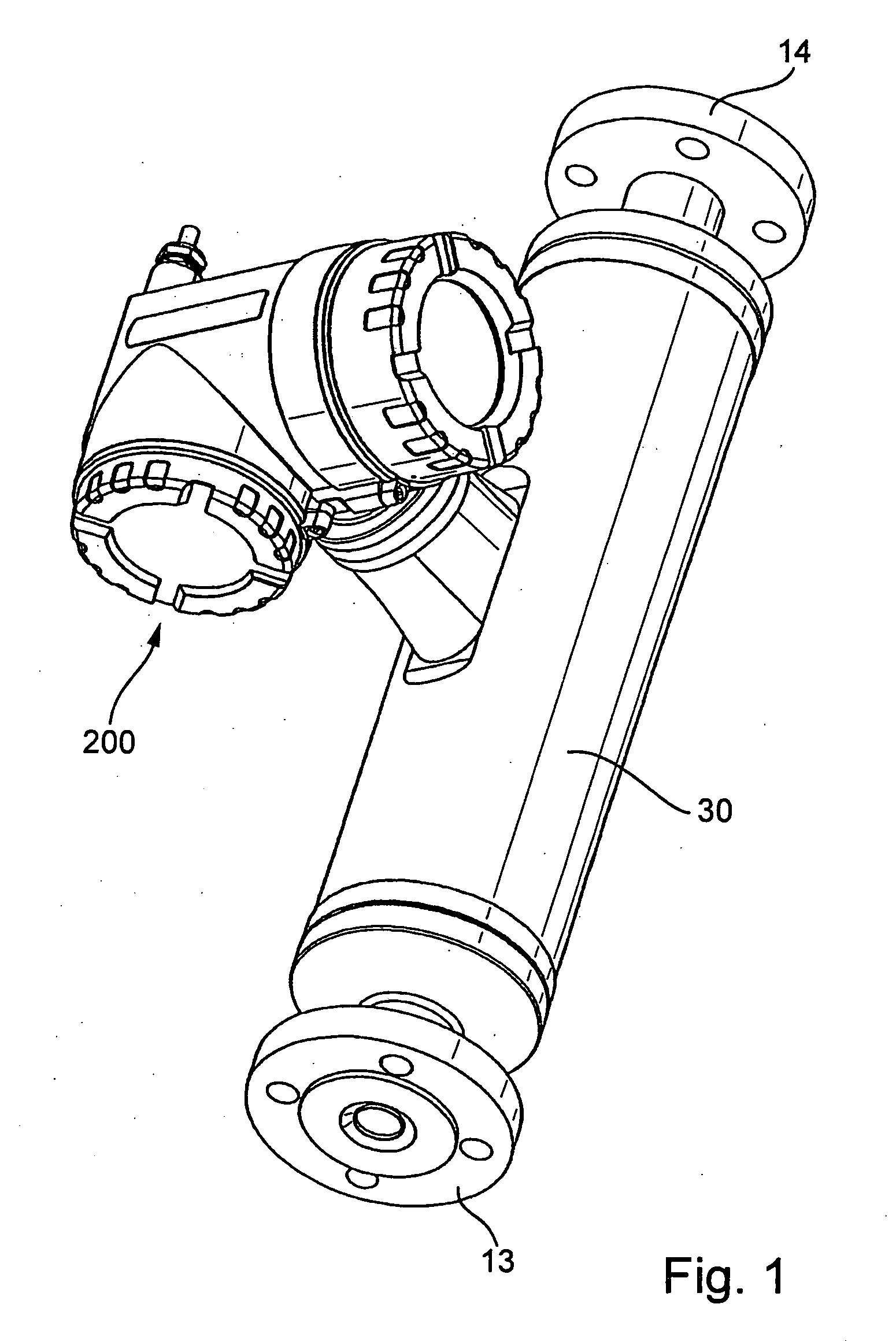

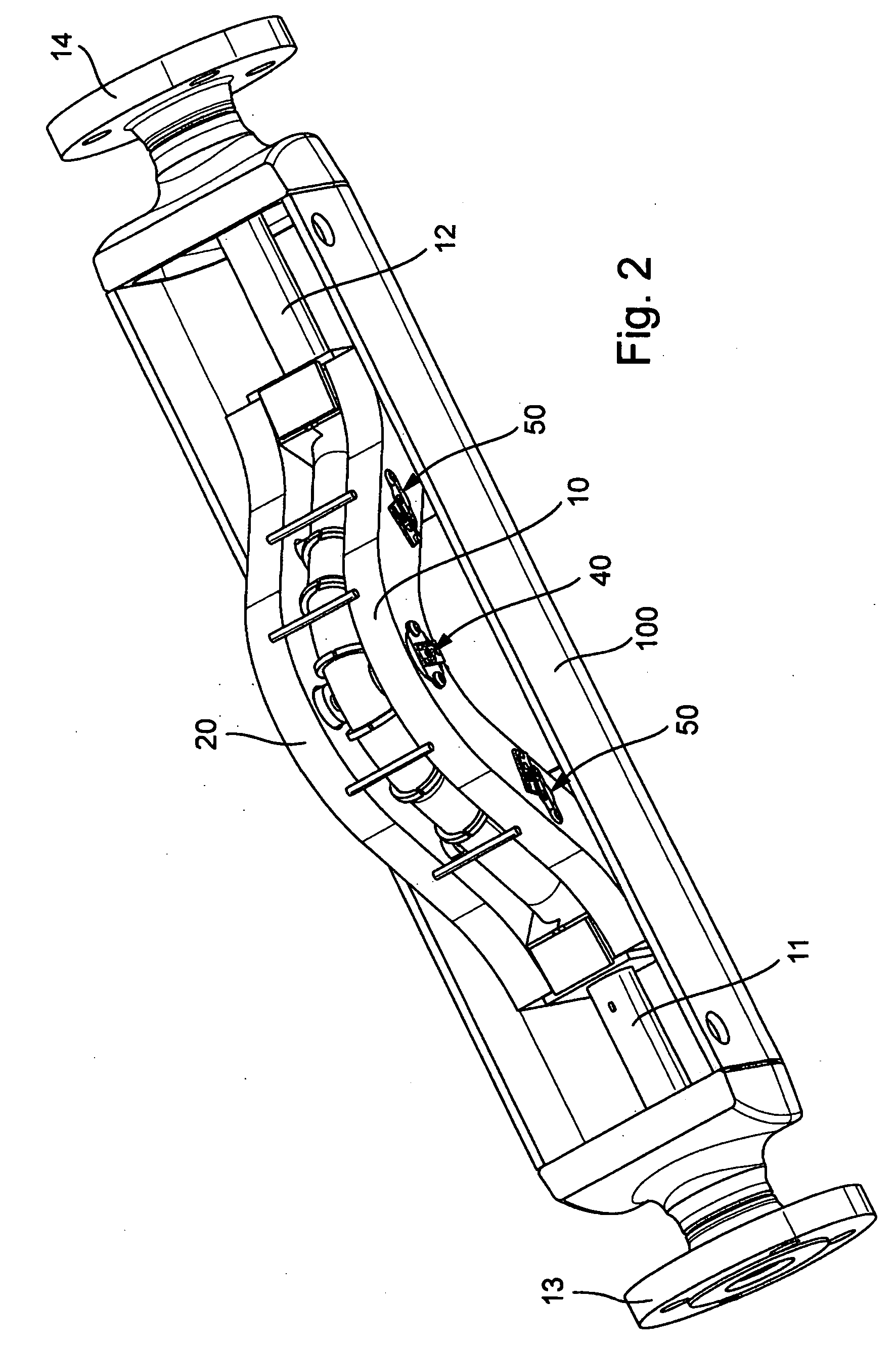

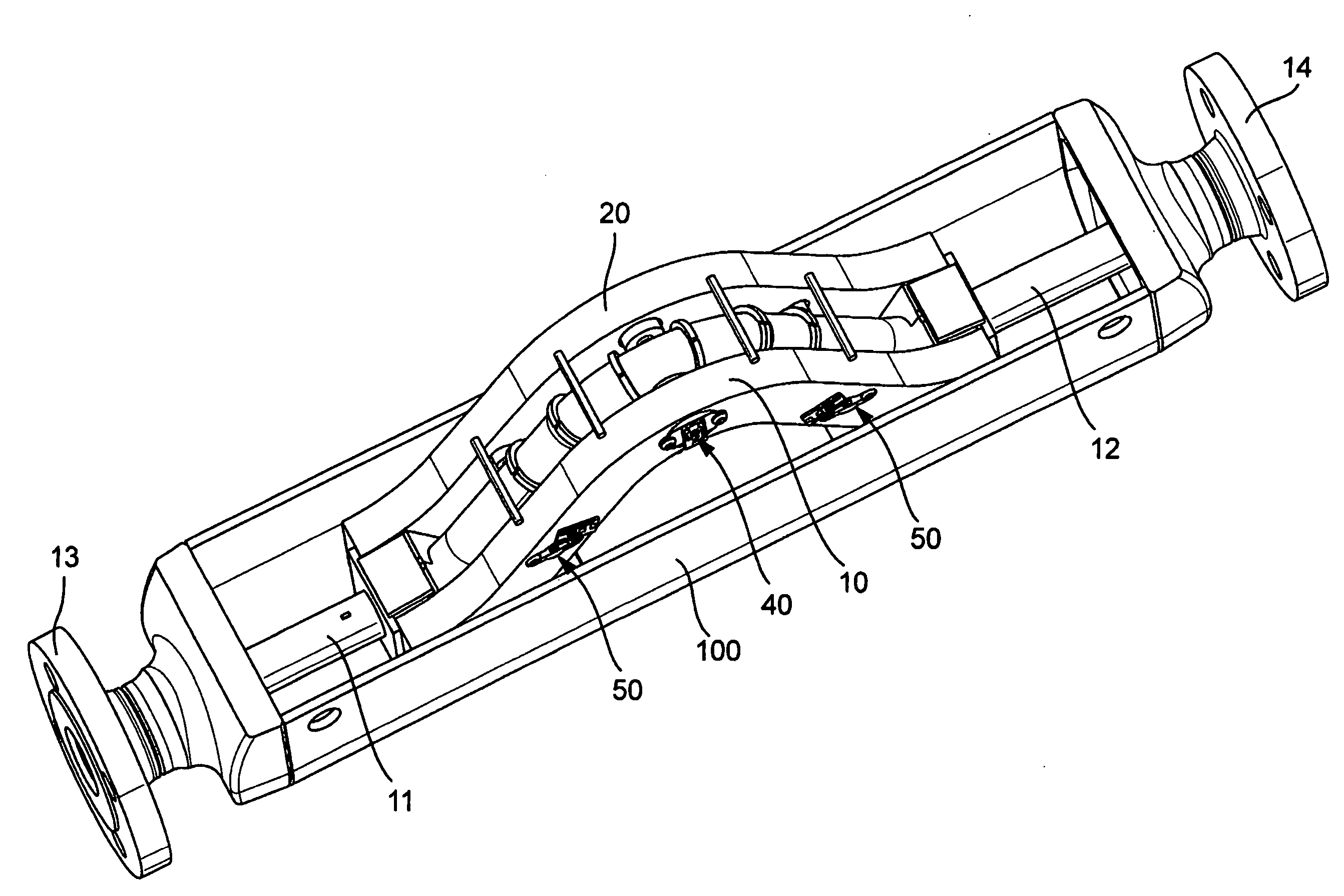

Measuring transducer of vibration-type

ActiveUS7360451B2Improve density dependence of zero-pointWorking range of the measuring transducer can,Direct mass flowmetersDirect flow property measurementCouplingTransducer

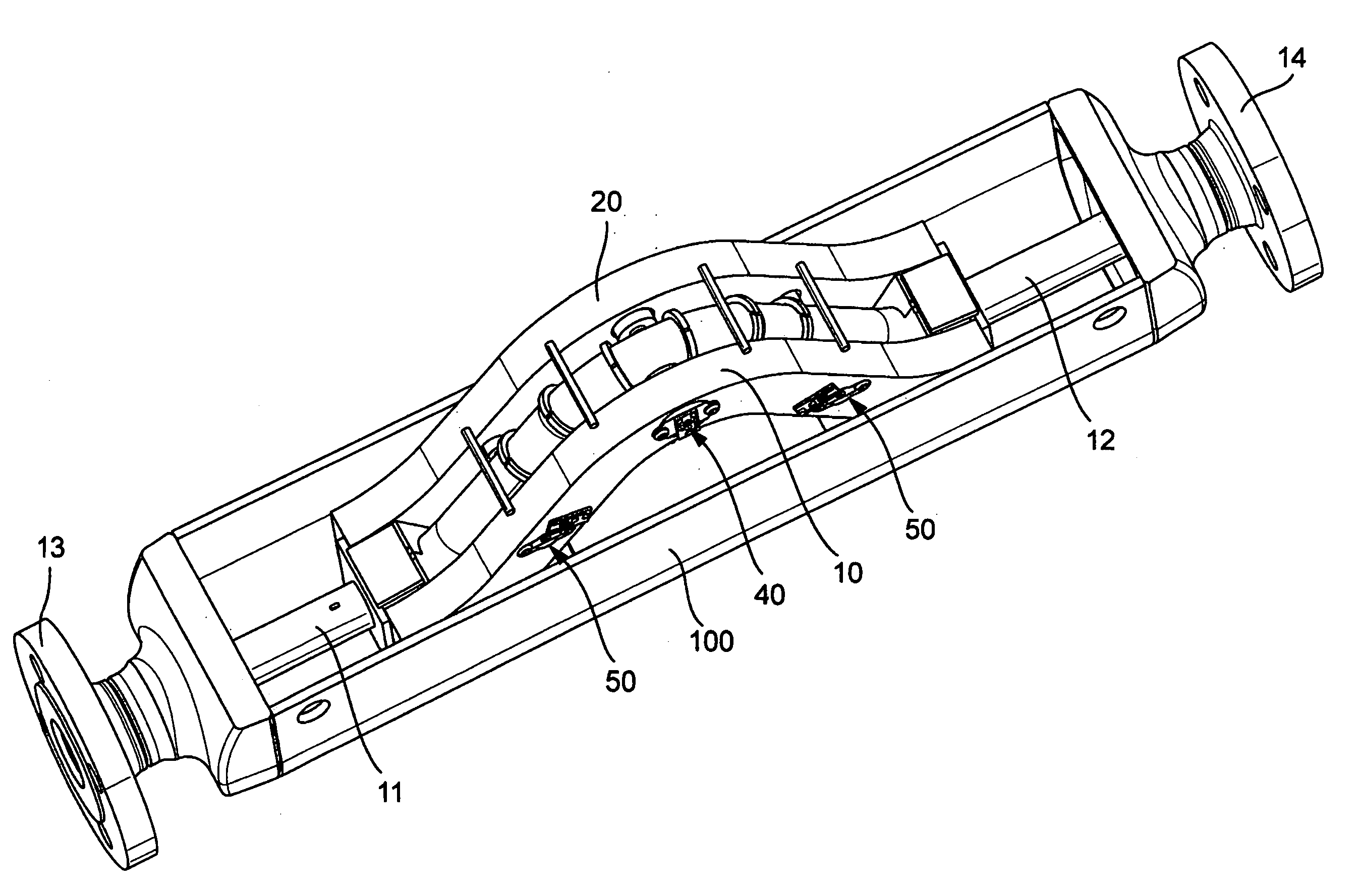

A measuring transducer includes a transducer housing, as well as an internal part arranged in the transducer housing. The internal part includes at least one curved measuring tube vibrating, at least at times, during operation and serving for conveying the medium, as well as a counteroscillator affixed to the measuring tube on the inlet-side, accompanied by formation of a coupling zone, and to the measuring tube on the outlet-side, accompanied by the formation of a coupling zone. The internal part is held oscillatably in the transducer housing, at least by means of two connecting tube pieces, via which the measuring tube communicates during operation with the pipeline and which are so oriented with respect to one another, as well as with respect to an imaginary longitudinal axis of the measuring transducer, that the internal part can move during operation in the manner of a pendulum about the longitudinal axis. The measuring tube and the counteroscillator are additionally so embodied and so oriented with respect to one another that both a center of mass spaced from the imaginary longitudinal axis of the measuring tube, as well as also a center of mass of the counteroscillator spaced from the imaginary longitudinal axis, lie in a common region of the measuring transducer spanned by the imaginary longitudinal axis and the measuring tube, and that the center of mass of the measuring tube is spaced farther from the longitudinal axis than the center of mass of the counteroscillator.

Owner:ENDRESS HAUSER FLOWTEC AG

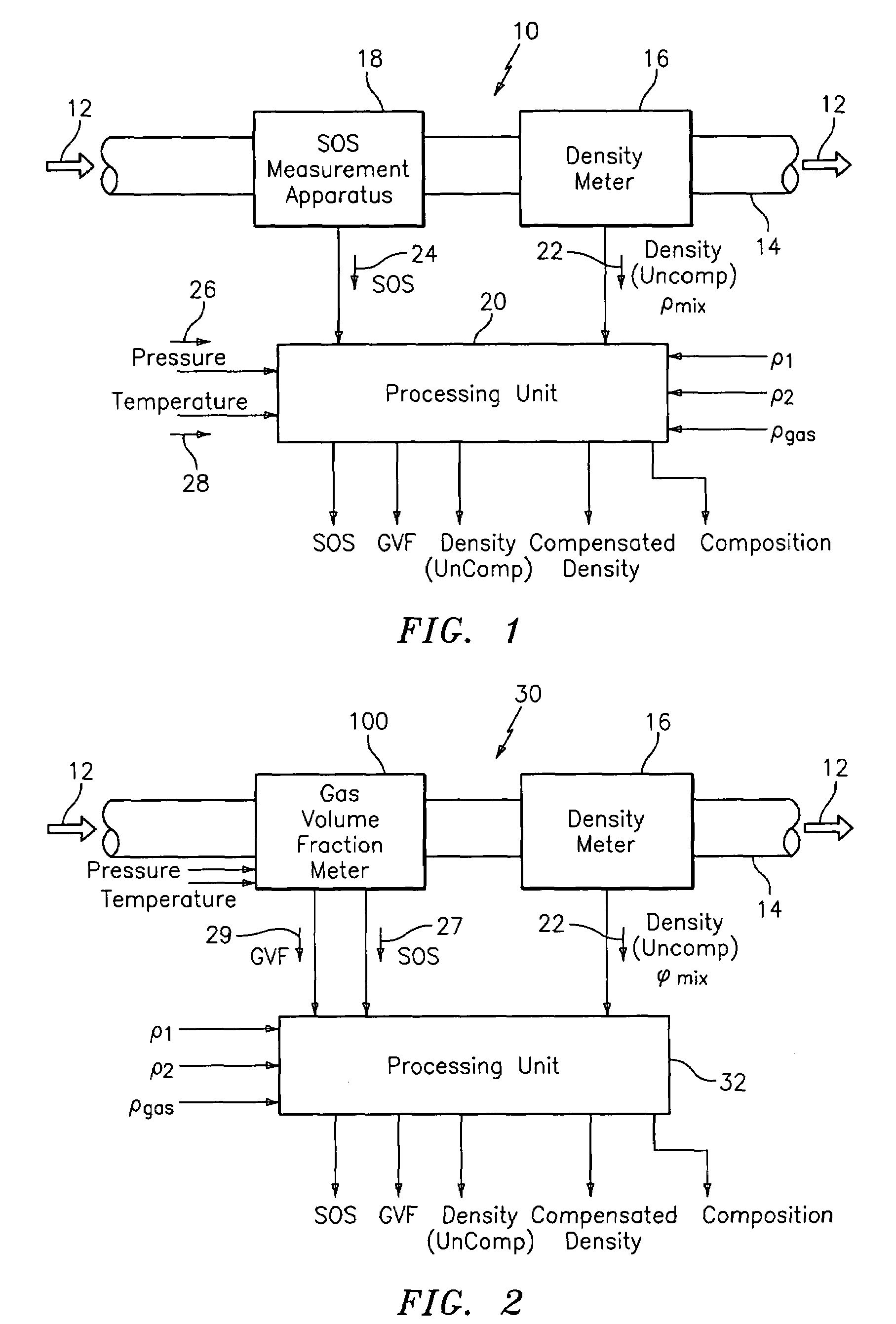

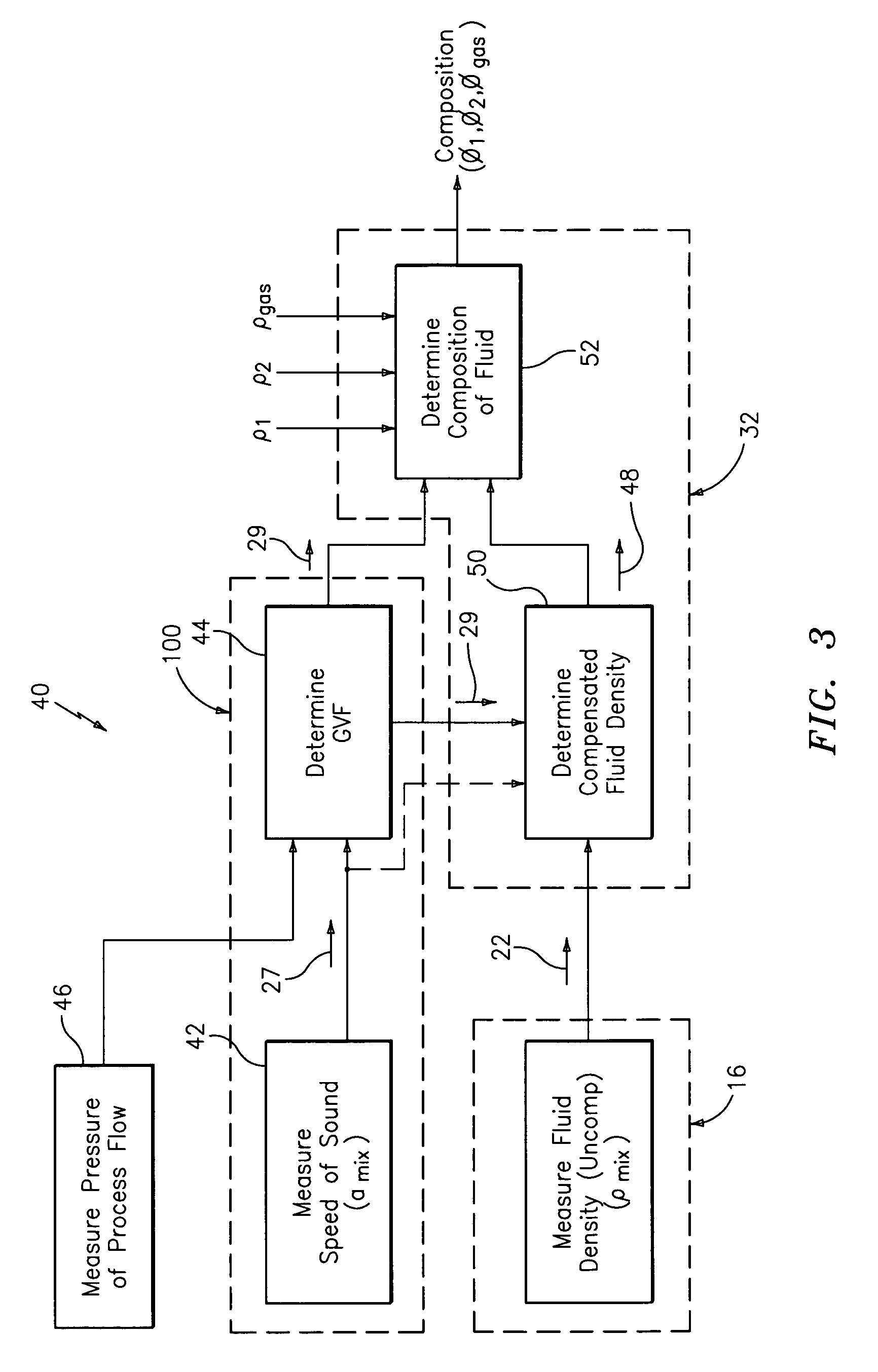

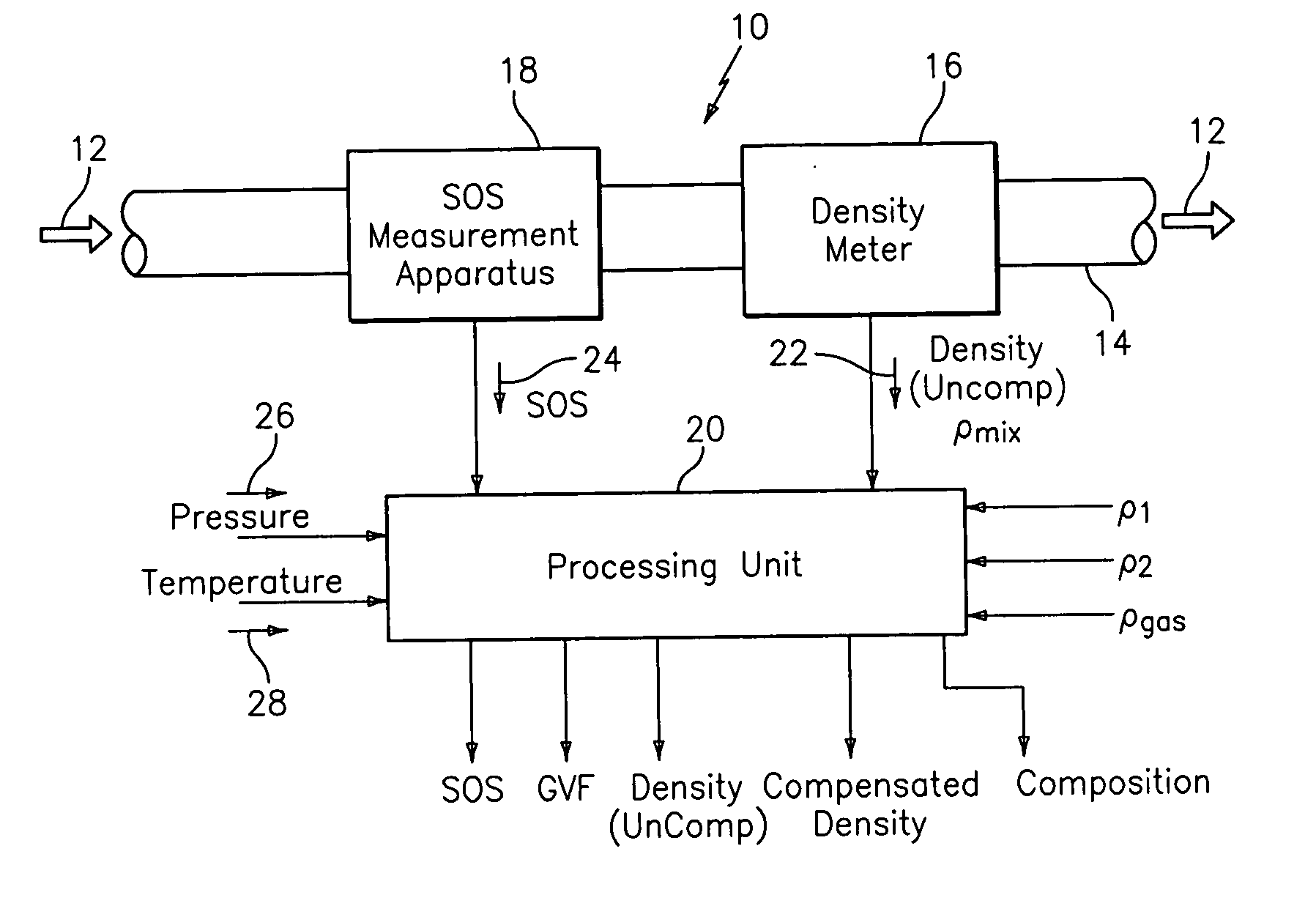

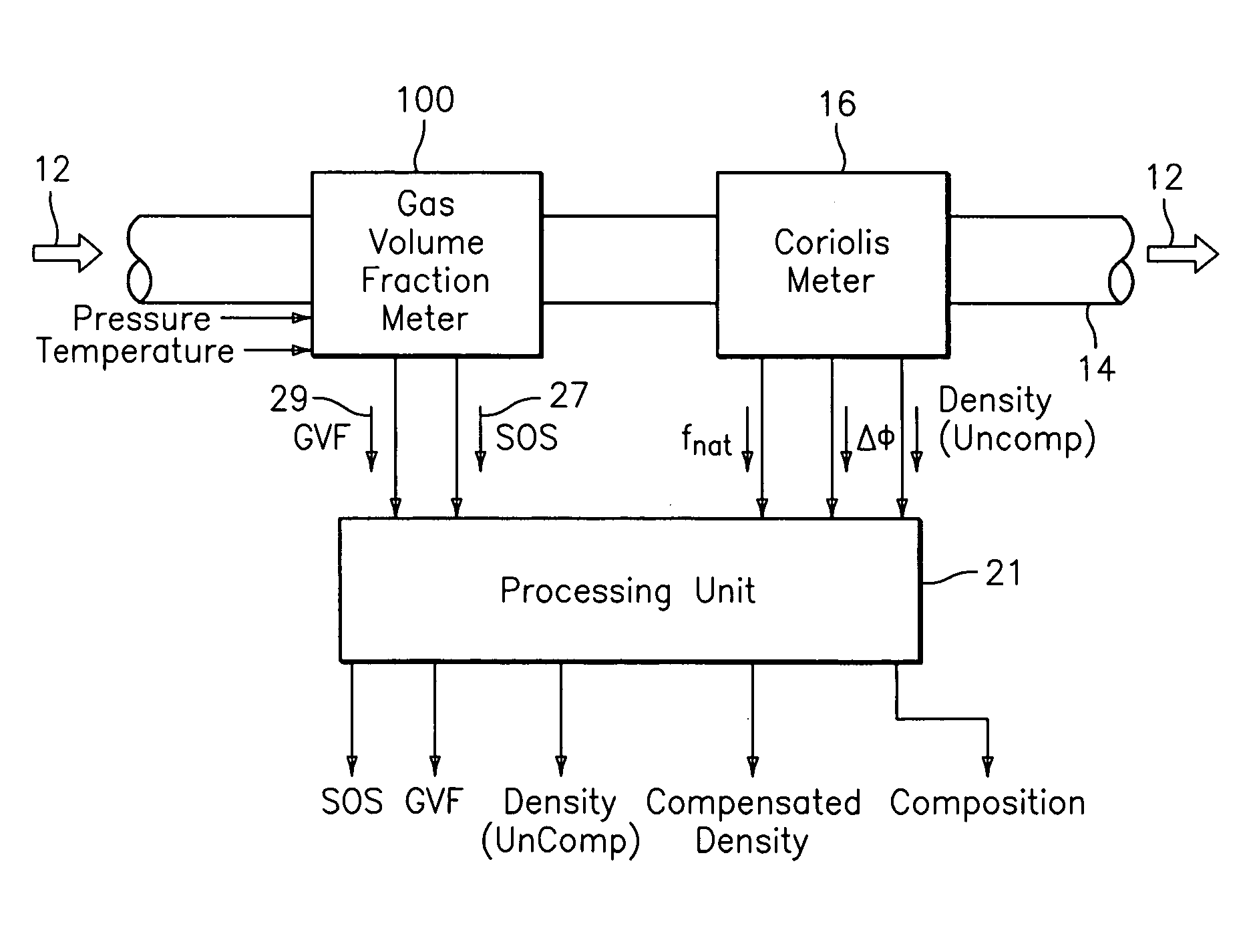

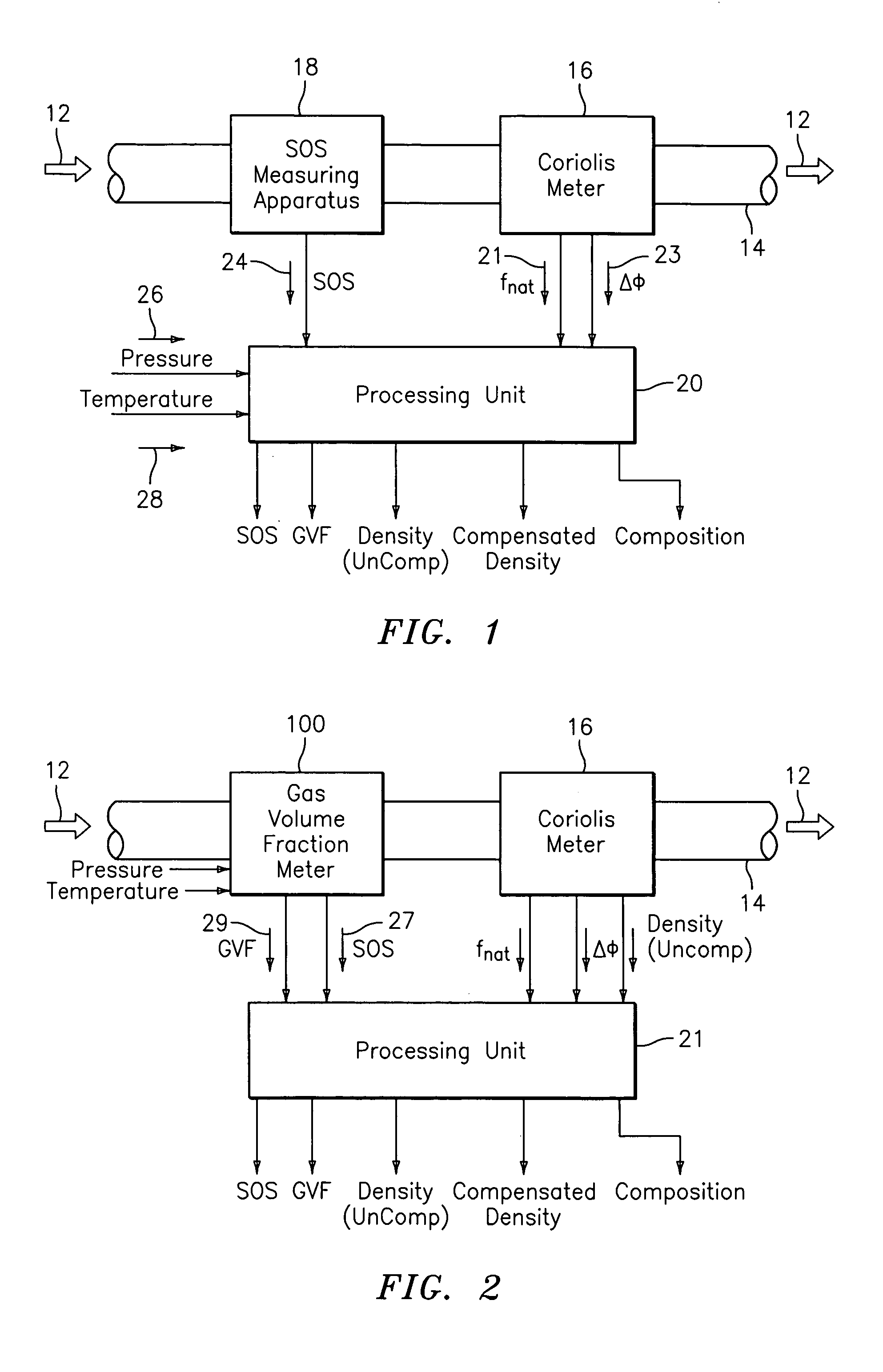

Apparatus and method for providing a density measurement augmented for entrained gas

A flow measuring system combines a density measuring device and a device for measuring the speed of sound (SOS) propagating through the fluid flow and / or for determining the gas volume fraction (GVF) of the flow. The GVF meter measures acoustic pressures propagating through the fluids to measure the speed of sound αmix propagating through the fluid to calculate at least gas volume fraction of the fluid and / or SOS. In response to the measured density and gas volume fraction, a processing unit determines the density of non-gaseous component of an aerated fluid flow. For three phase fluid flows, the processing unit can determine the phase fraction of the non-gaseous components of the fluid flow. The gas volume fraction (GVF) meter may include a sensing device having a plurality of strain-based or pressure sensors spaced axially along the pipe for measuring the acoustic pressures propagating through the flow.

Owner:EXPRO METERS

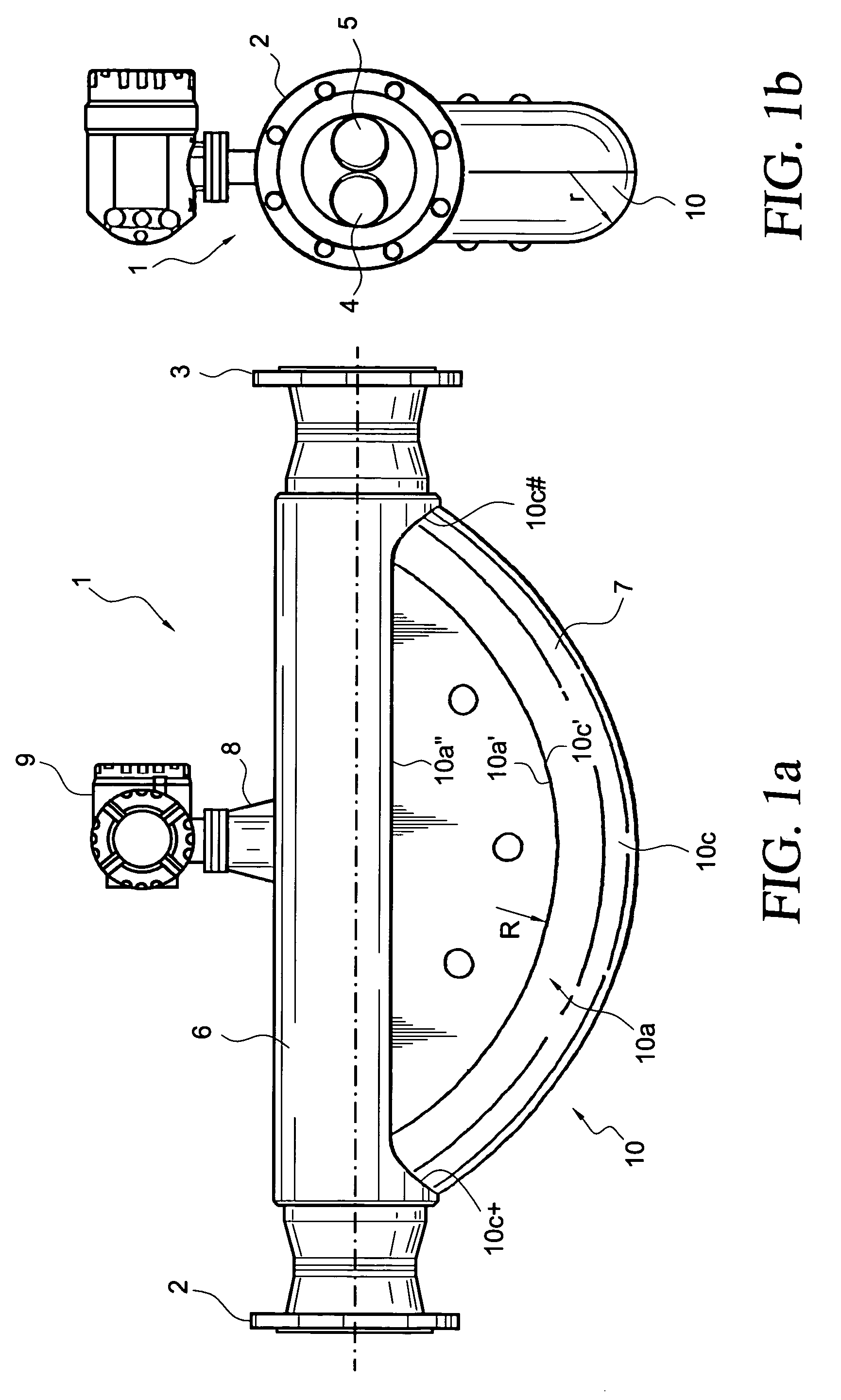

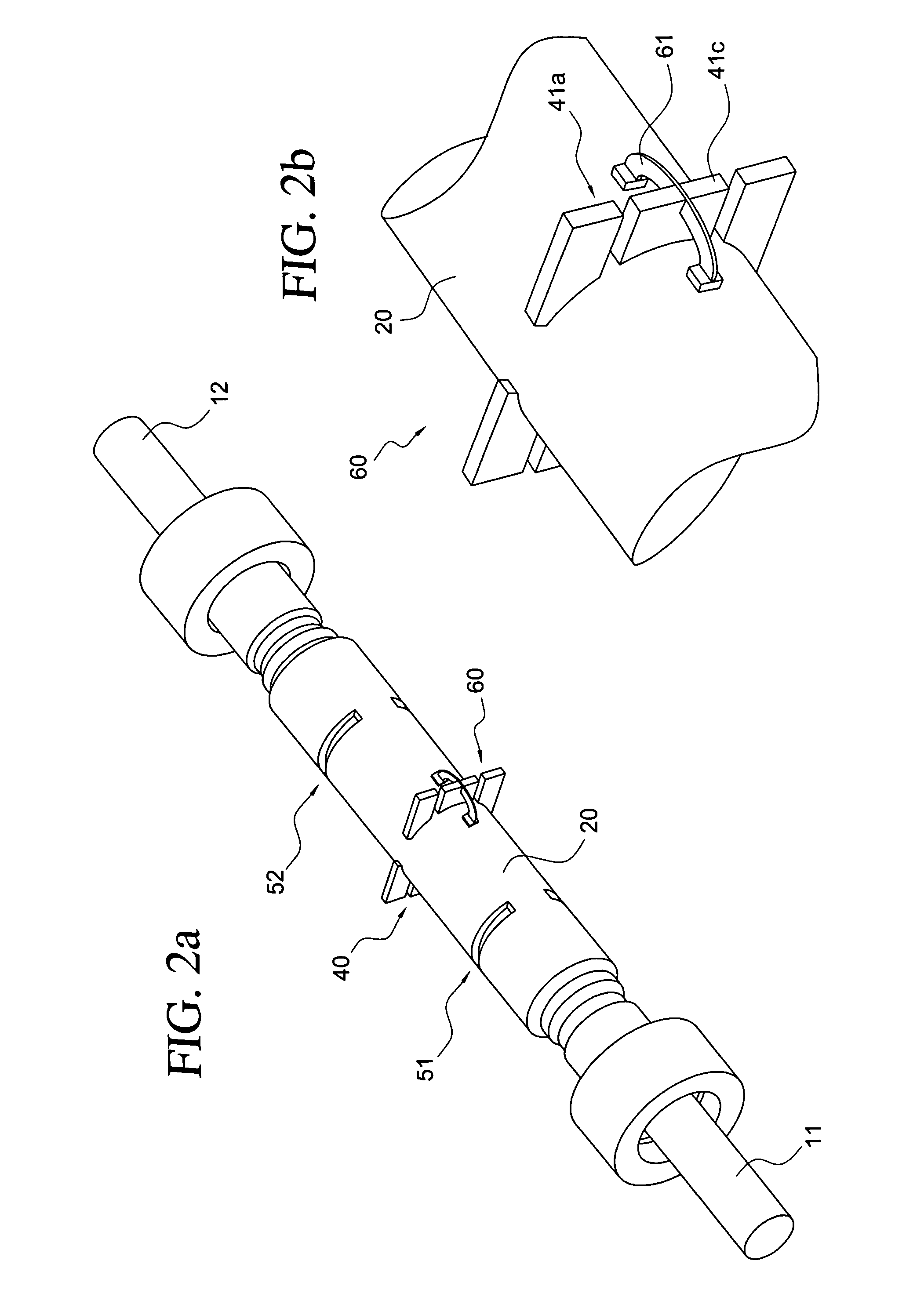

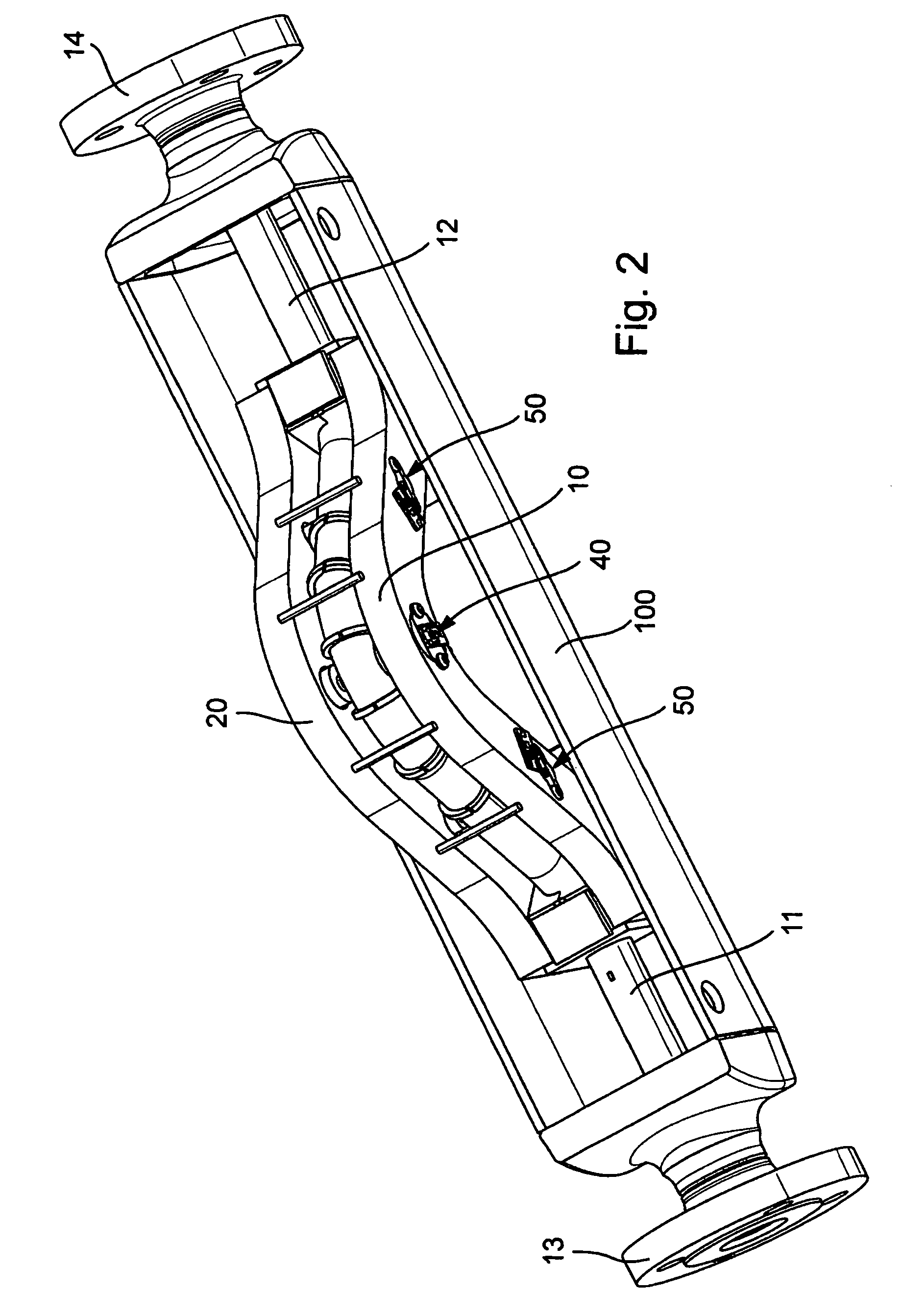

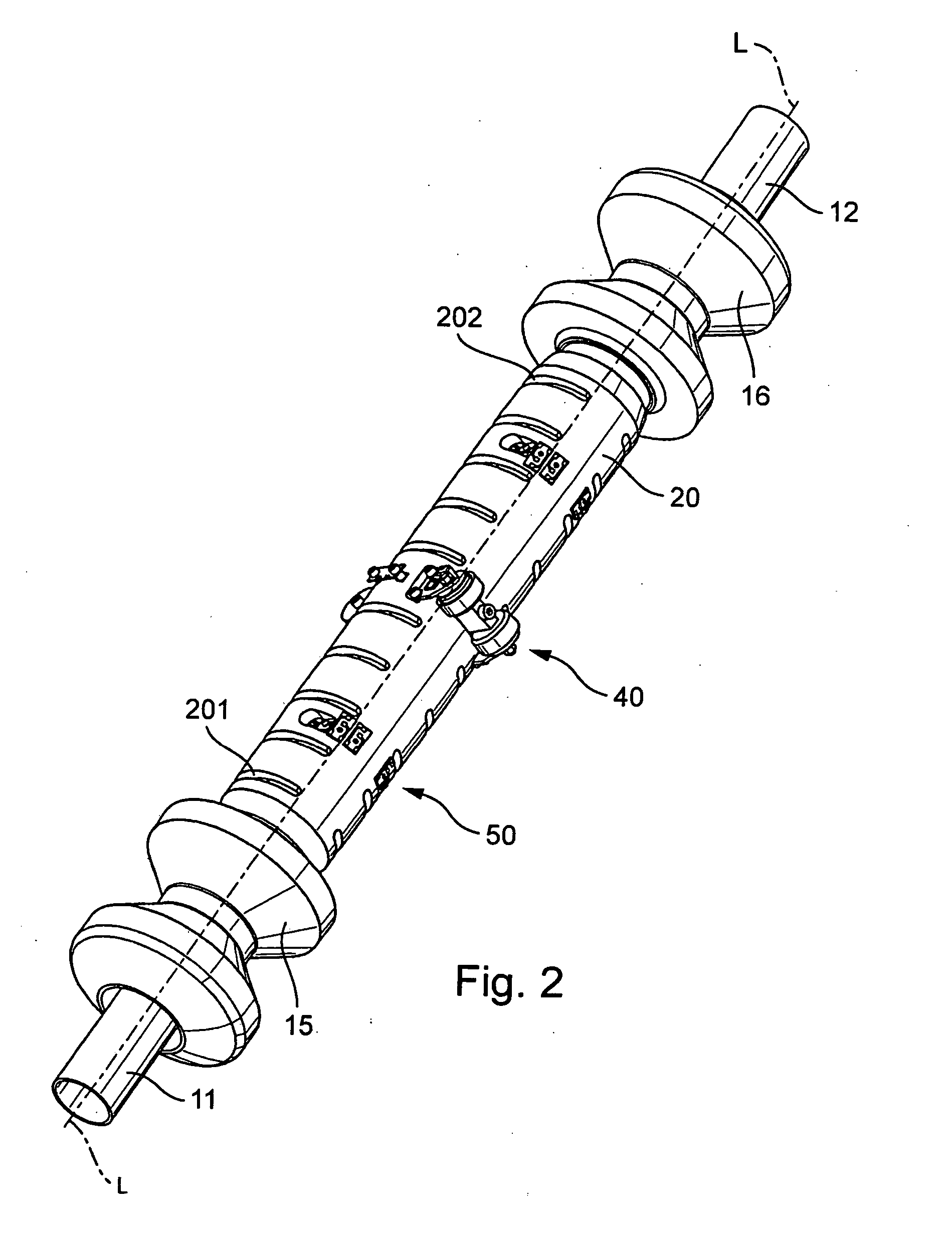

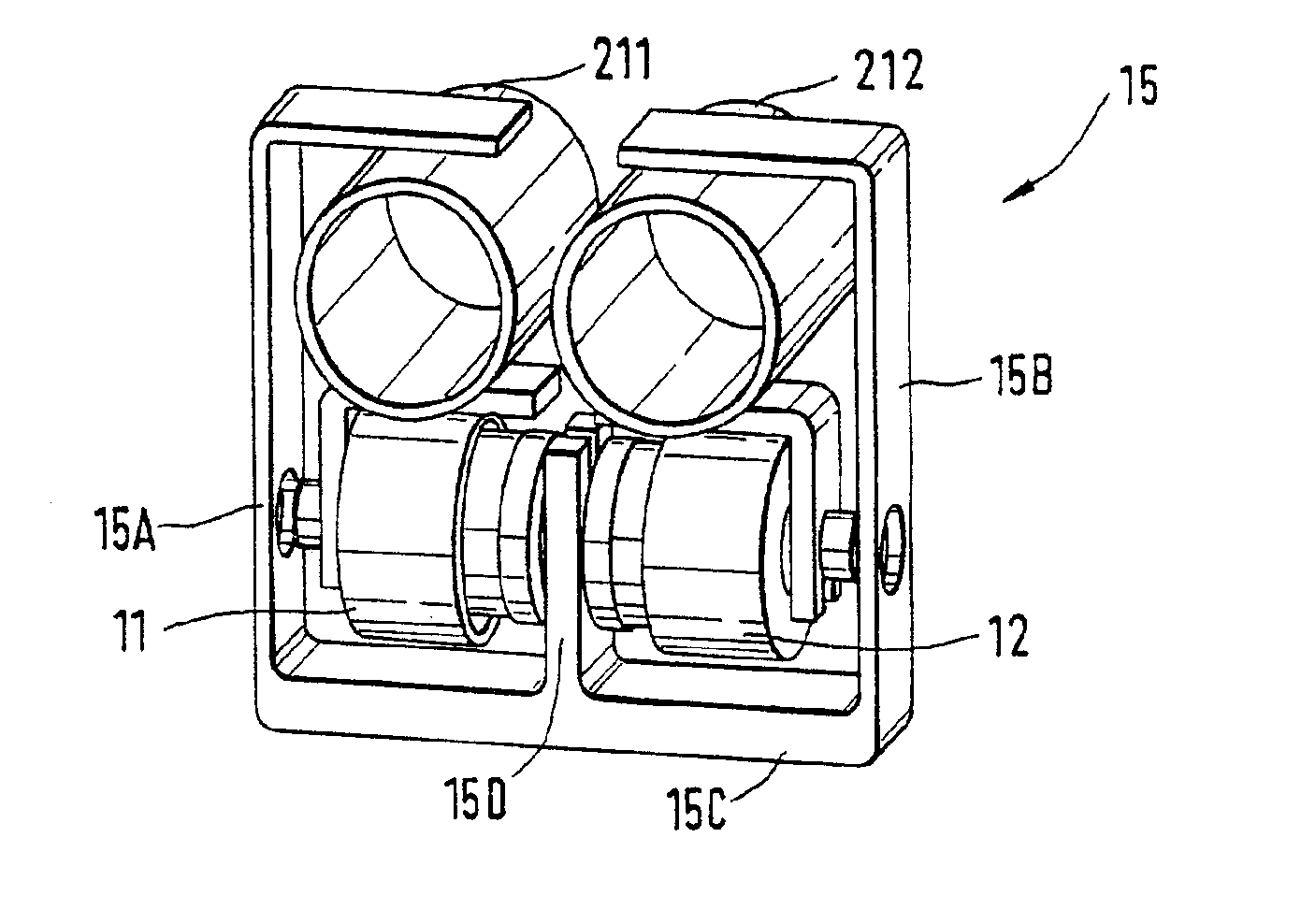

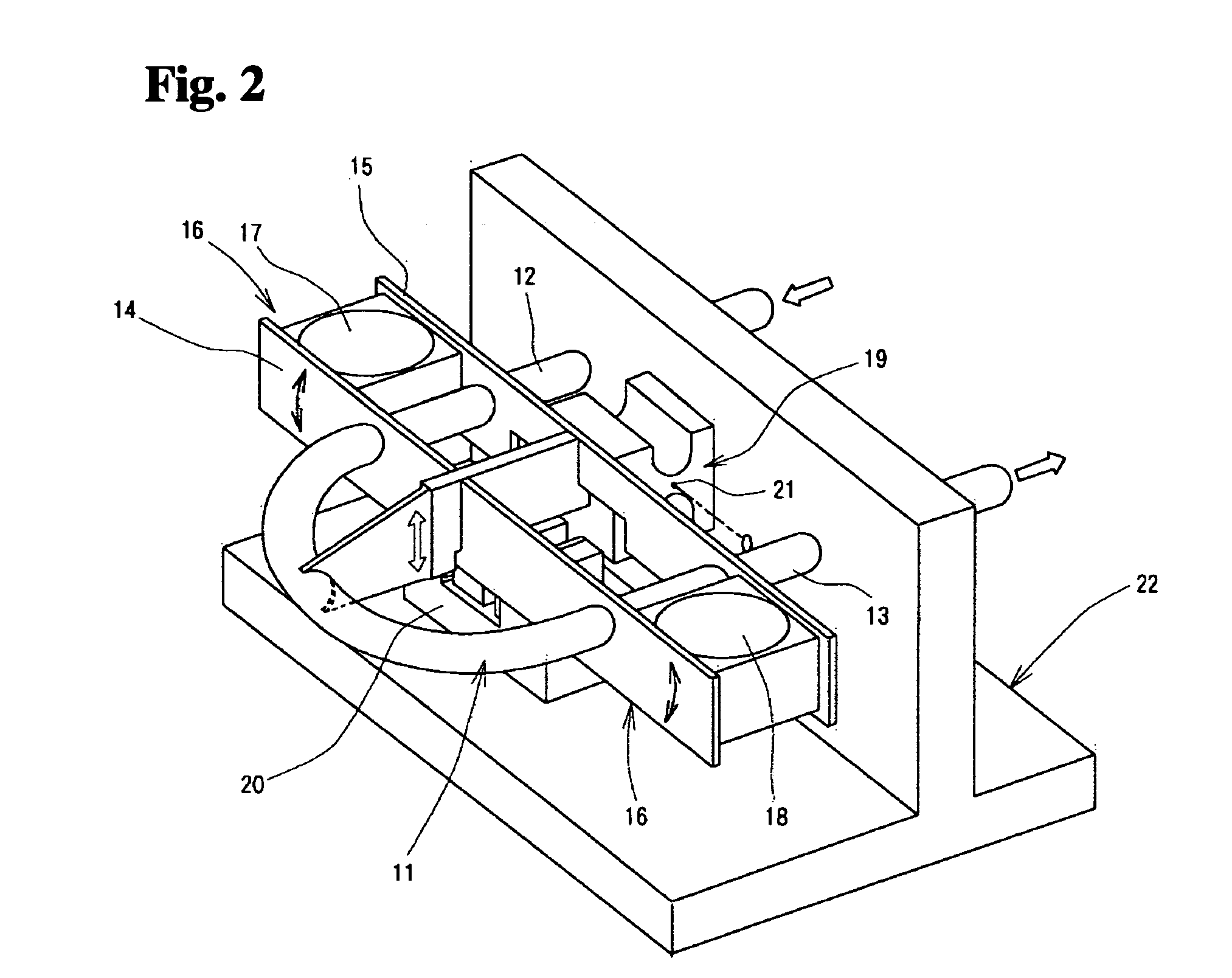

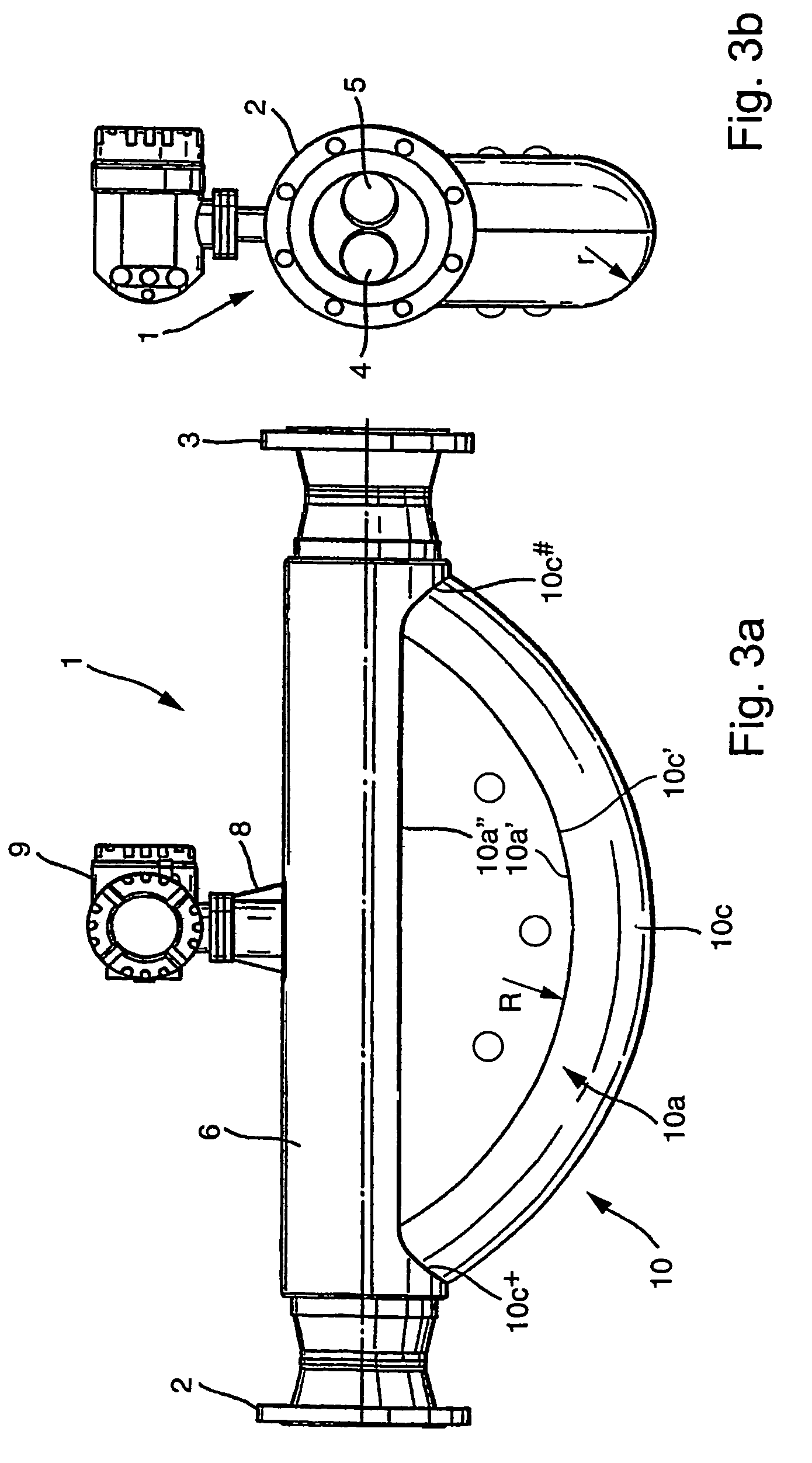

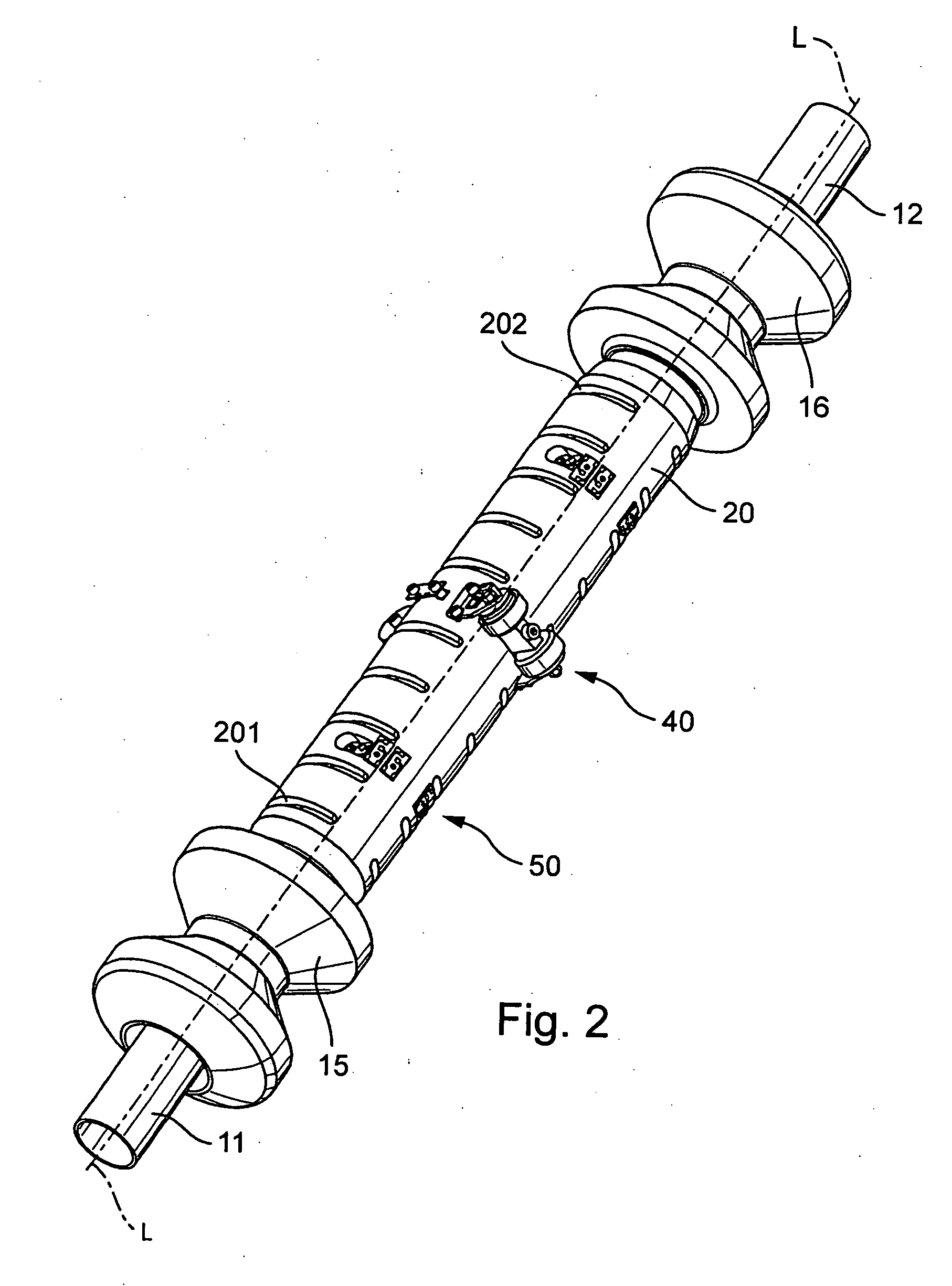

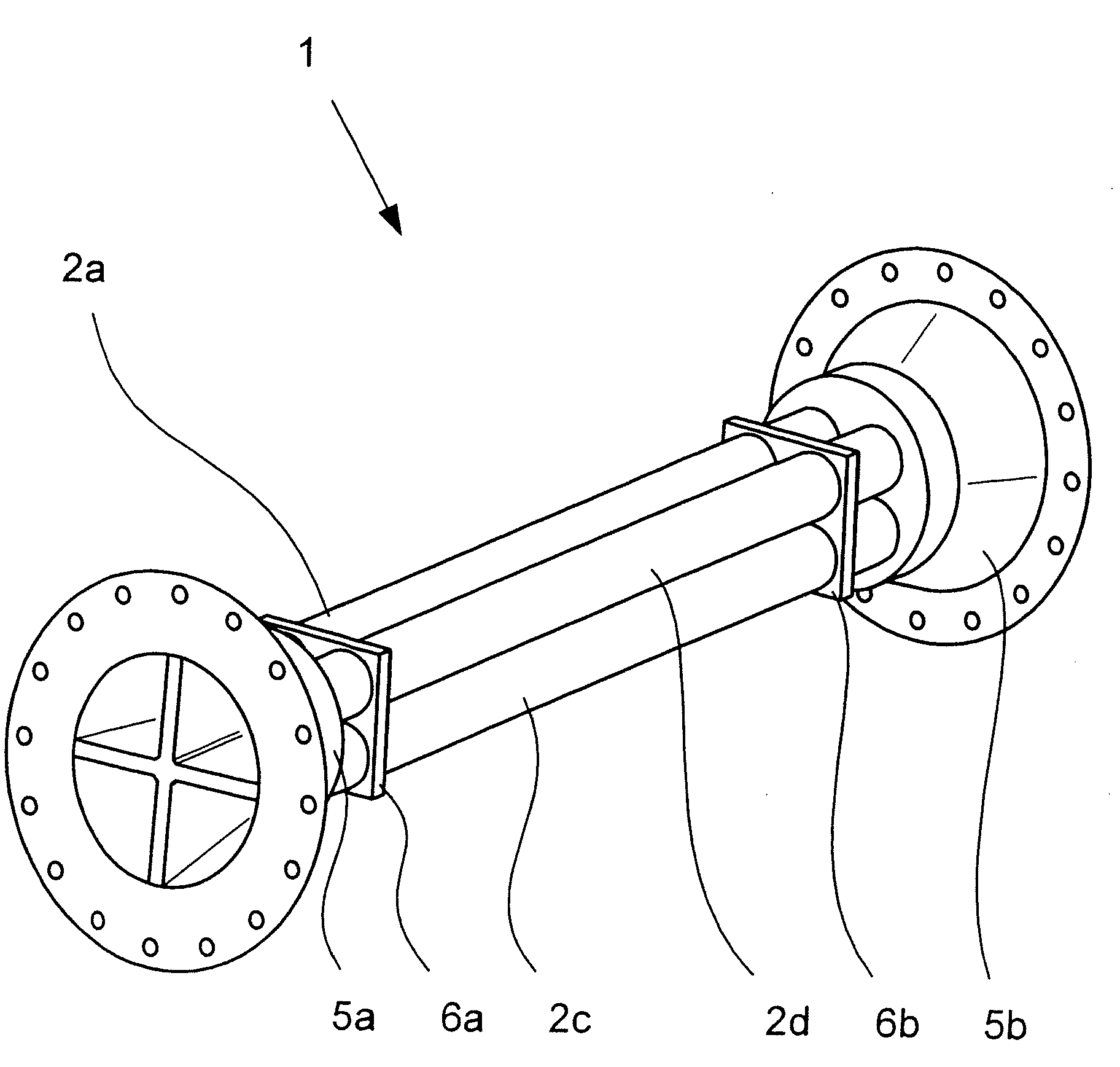

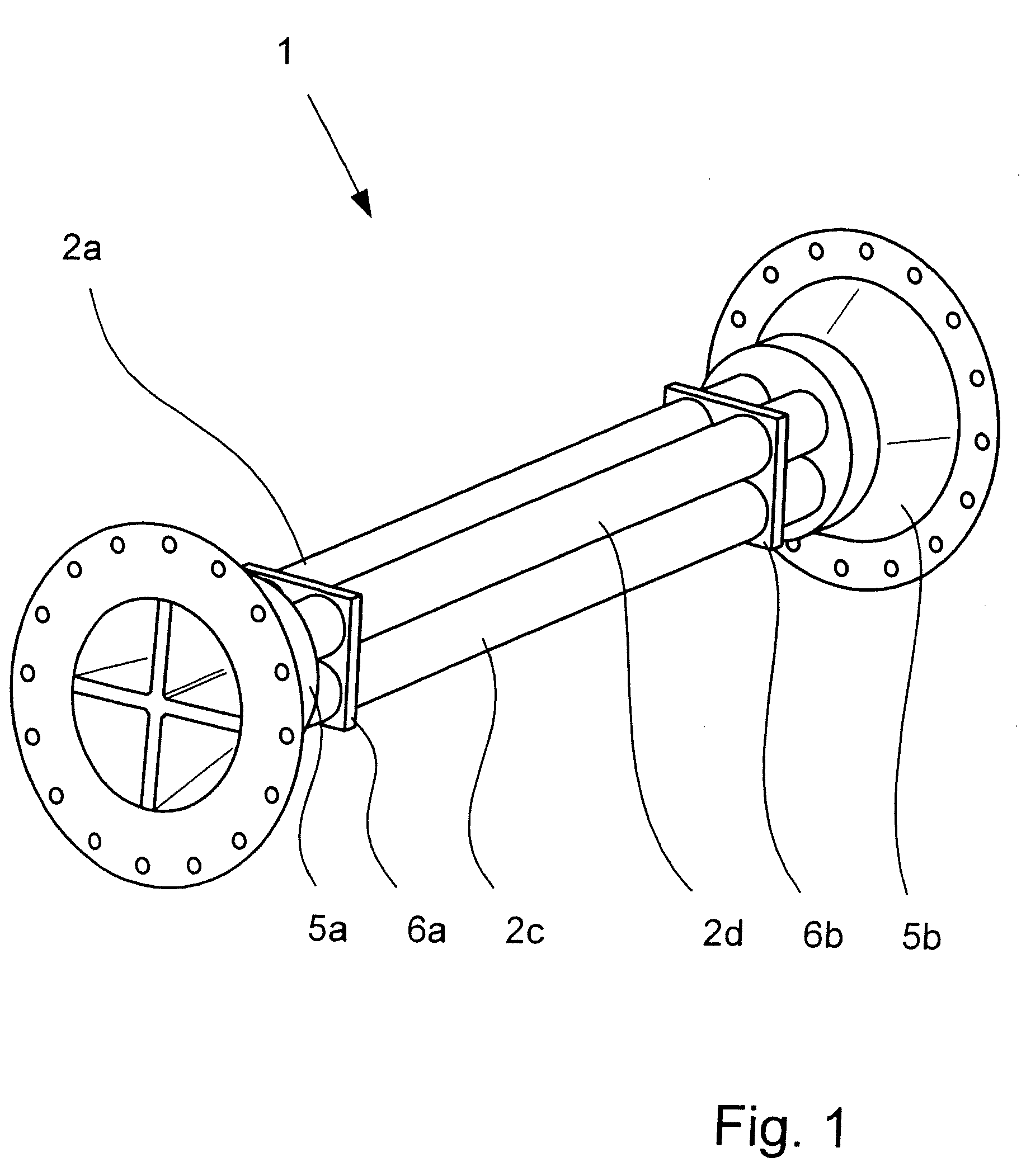

Measurement transducer of vibration-type

ActiveUS20070119264A1Improve balanceReduce quality problemsDirect mass flowmetersCantilevered beamCoupling

The measurement transducer includes: A measuring tube vibrating at least at times during operation and serving for the conveying of a medium, wherein the measuring tube communicates with a pipeline via an inlet tube piece at an inlet end and an outlet tube piece at an outlet end; a counteroscillator, which is affixed to the measuring tube on the inlet end to form a first coupling zone and affixed to the measuring tube on the outlet end to form a second coupling zone; and a first cantilever for producing bending moments in the inlet tube piece and coupled with the inlet tube piece and the measuring tube essentially rigidly in the area of the first coupling zone and having a center of mass lying in the region of the inlet tube piece, as well as a second cantilever for producing bending moments in the outlet tube piece and coupled essentially rigidly with the outlet tube piece and the measuring tube in the region of the second coupling zone and having a center of mass lying in the region of the outlet tube piece. The measurement transducer of the invention is especially suited also for measuring tubes having large nominal diameters of more than 50 mm.

Owner:ENDRESS HAUSER FLOWTEC AG

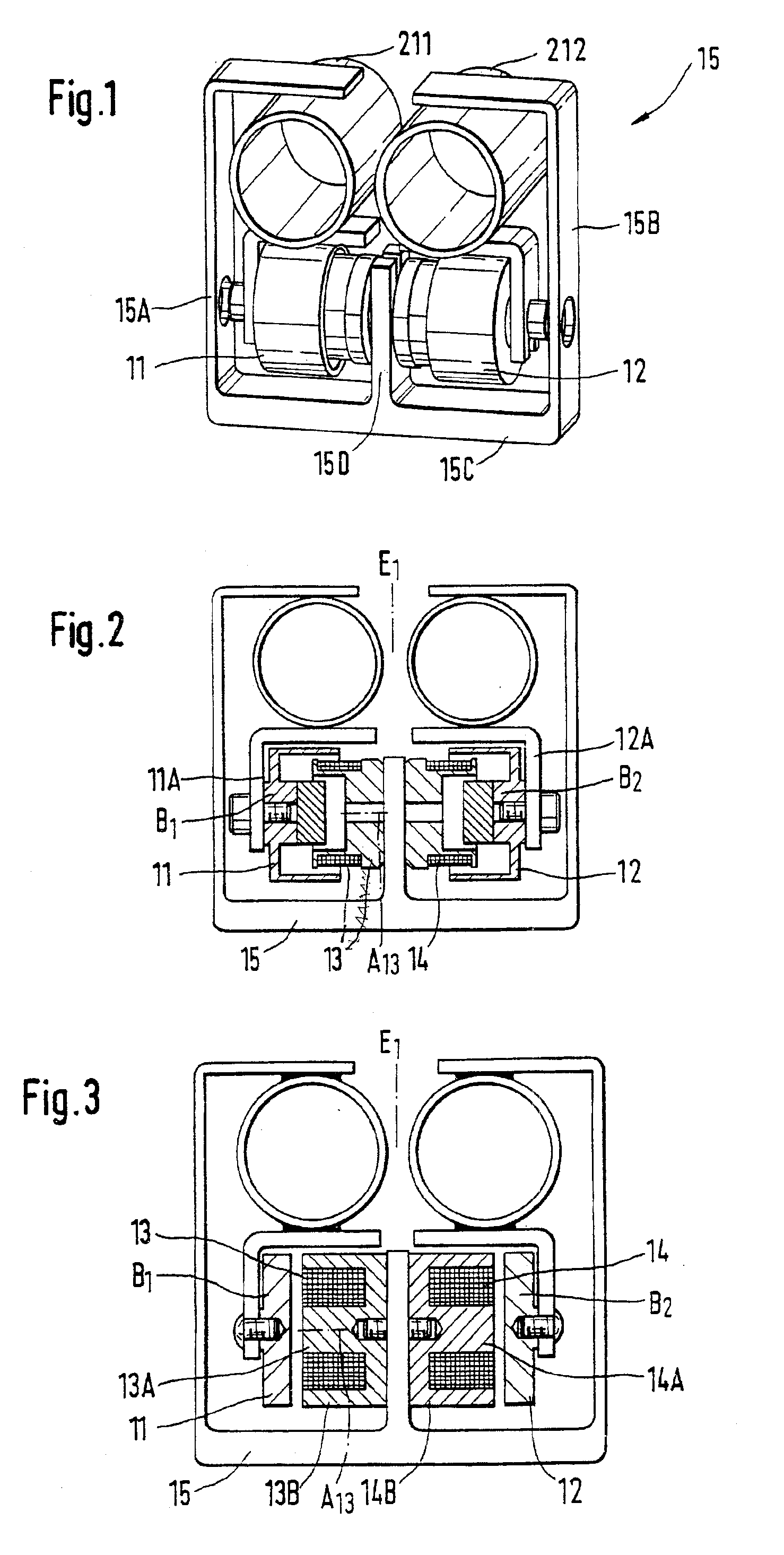

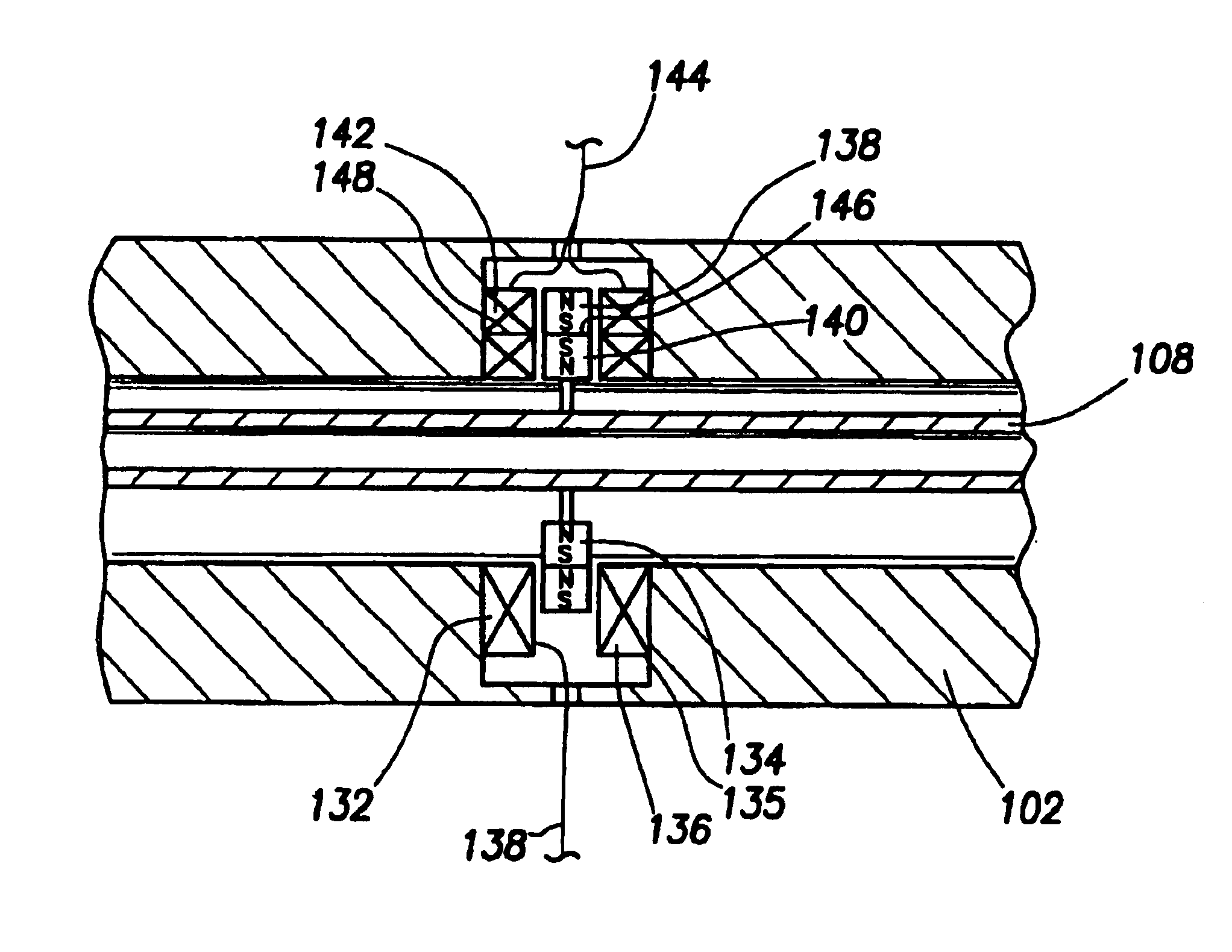

Magnetic circuit arrangement for a transducer

The magnetic circuit arrangement, which is preferably used in a fluid-measuring transducer, comprises at least one coil which is traversed in operation by a current. It further comprises two armatures that are fixed to two flow tubes vibrating in phase opposition. The coil is float-mounted by means of a holder to a double flow tube configuration formed by the flow tubes. The armatures are shaped and aligned relative to each other in such a manner that magnetic fields produced by means of the magnetic circuit arrangement are essentially concentrated within the magnetic circuit arrangement, whereby the latter is also largely insensitive to extraneous magnetic fields. The magnetic circuit arrangement is marked by a long service life and, particularly if the transducer is used for fluids with high and / or varying temperatures, by constantly high accuracy in operation.

Owner:ENDRESS HAUSER FLOWTEC AG

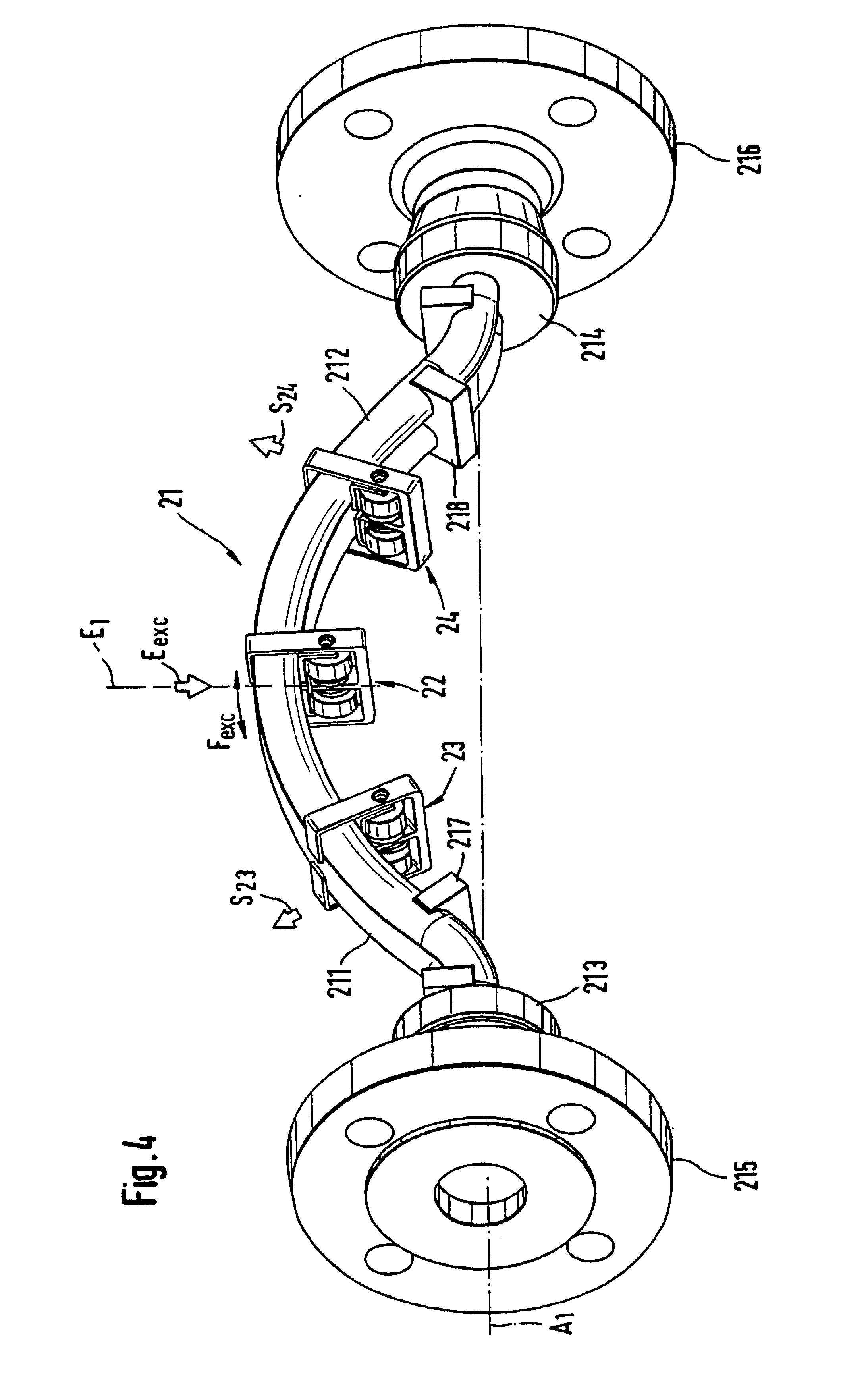

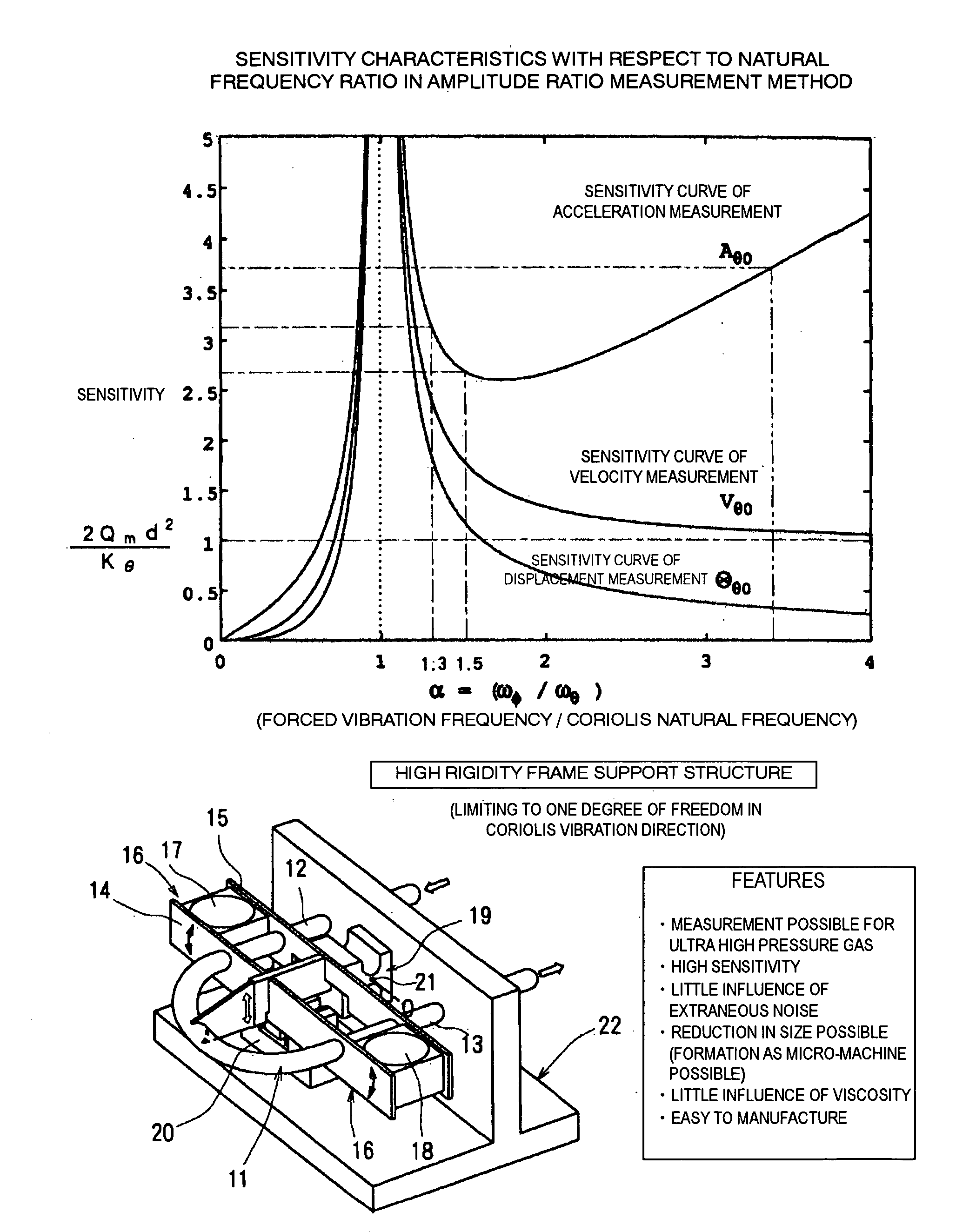

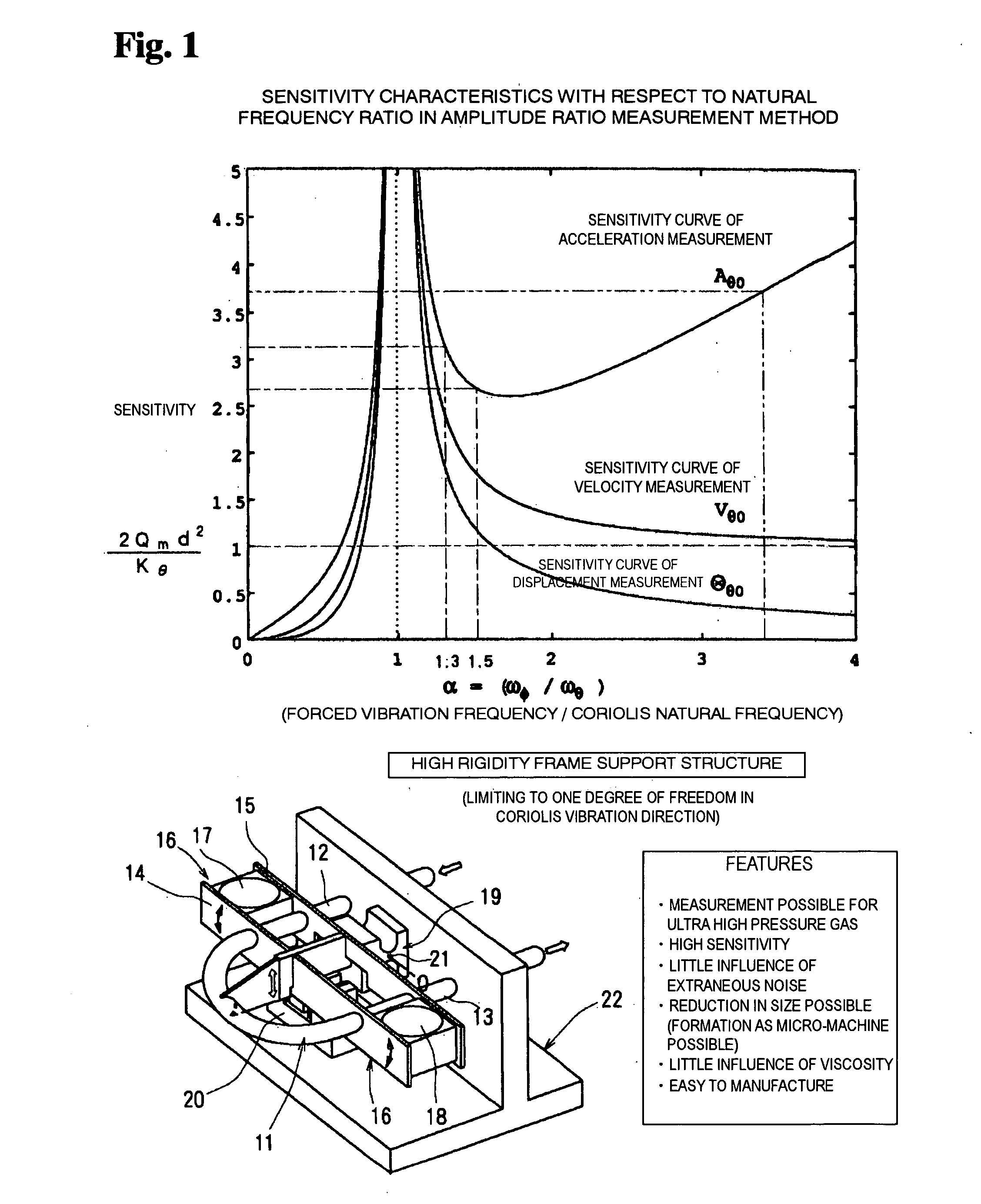

Coriolis flowmeter

ActiveUS20070034019A1Efficient removalReduce the impactDirect mass flowmetersPhase differenceClassical mechanics

When outputs from two vibration detection sensors are measured by a Coriolis flowmeter in a form of phase difference time, a tube must be thinned to increase a sensitivity of the flowmeter to enable measurement and accordingly flow velocity and pressure loss increase, and a thickness of the flowmeter must be reduced and therefore a pressure resistance cannot be readily enhanced. In particular, the sensitivity of signals to flow rate is difficult to increase and, accordingly, a flow rate of a low-density gas cannot be accurately measured. In the present invention, a Coriolis vibration frame 16 carrying a U-shaped tube is swingably fixed to a forced vibration frame 19 fixed to a support base 22 to form a highly rigid frame structure limiting a vibrating direction to one degree of freedom in a Coriolis vibration direction. The forced vibration frame 19 is vibrated by a vibration exciter 20 so that a ratio of a forced vibration frequency to the Coriolis frequency of a pipeline is at least 1 to 10. The ratio of the amplitude of the forced vibration to the amplitude of the Coriolis vibration is calculated based on signals from two vibration sensors such as acceleration sensors 17 and 18 to measure the mass flow rate of a fluid flowing in the pipeline.

Owner:NAT INST OF ADVANCED IND SCI & TECH

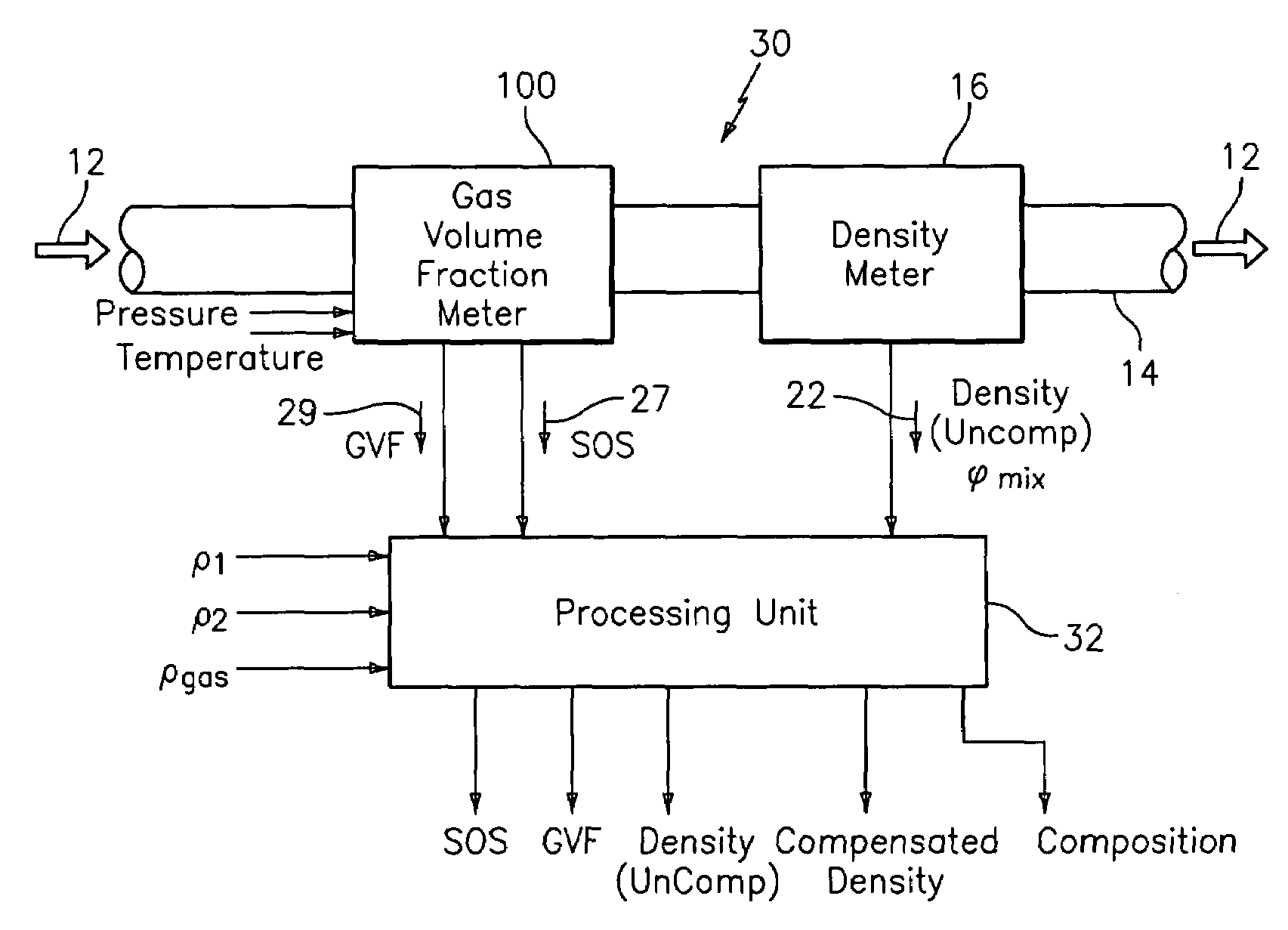

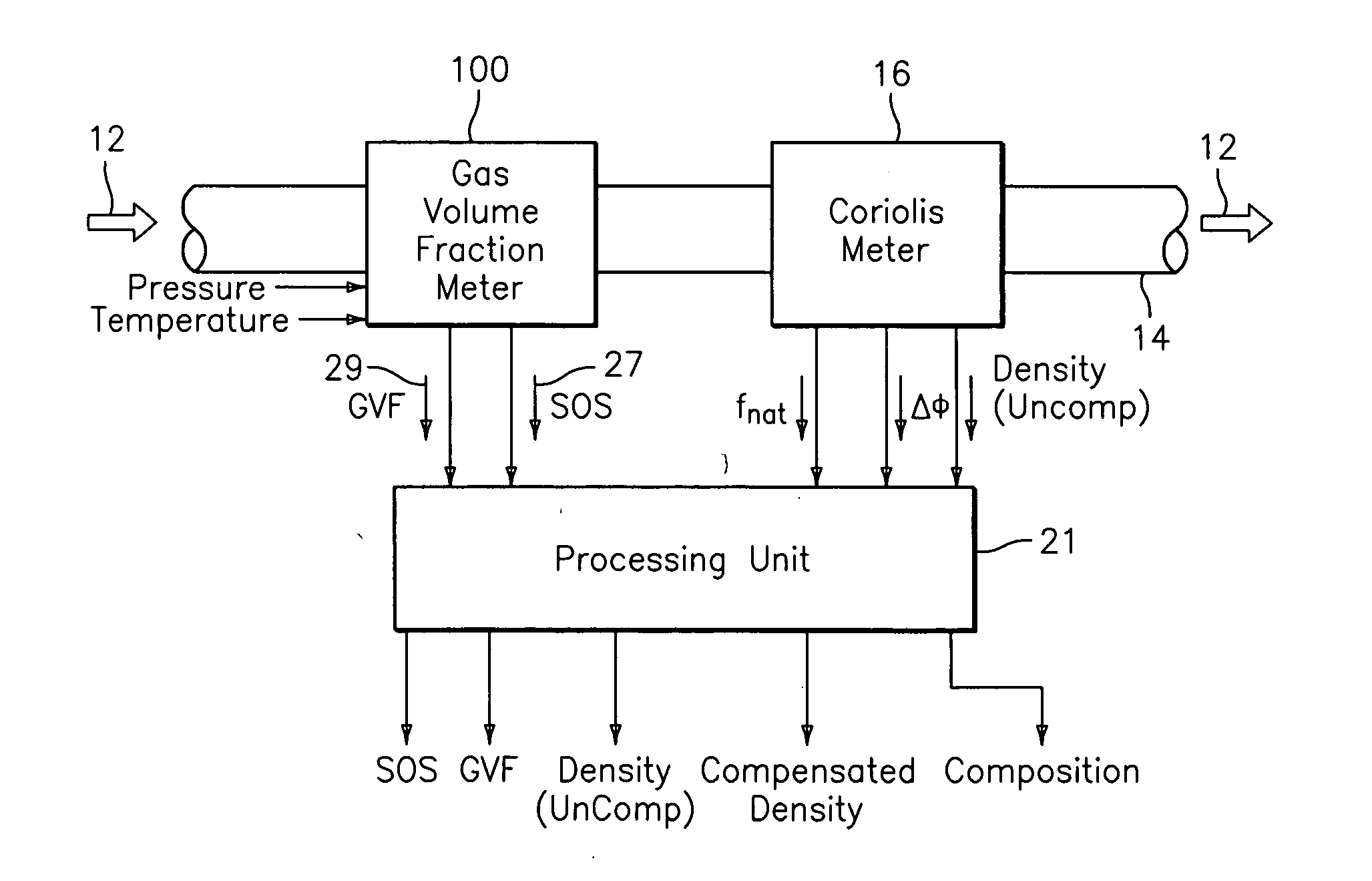

Apparatus and method for providing a density measurement augmented for entrained gas

ActiveUS20050061060A1Improve accuracySpecific gravity using flow propertiesVolume/mass flow by dynamic fluid flow effectThree-phaseDischarge measurements

A flow measuring system combines a density measuring device and a device for measuring the speed of sound (SOS) propagating through the fluid flow and / or for determining the gas volume fraction (GVF) of the flow. The GVF meter measures acoustic pressures propagating through the fluids to measure the speed of sound αmix propagating through the fluid to calculate at least gas volume fraction of the fluid and / or SOS. In response to the measured density and gas volume fraction, a processing unit determines the density of non-gaseous component of an aerated fluid flow. For three phase fluid flows, the processing unit can determine the phase fraction of the non-gaseous components of the fluid flow. The gas volume fraction (GVF) meter may include a sensing device having a plurality of strain-based or pressure sensors spaced axially along the pipe for measuring the acoustic pressures propagating through the flow.

Owner:EXPRO METERS

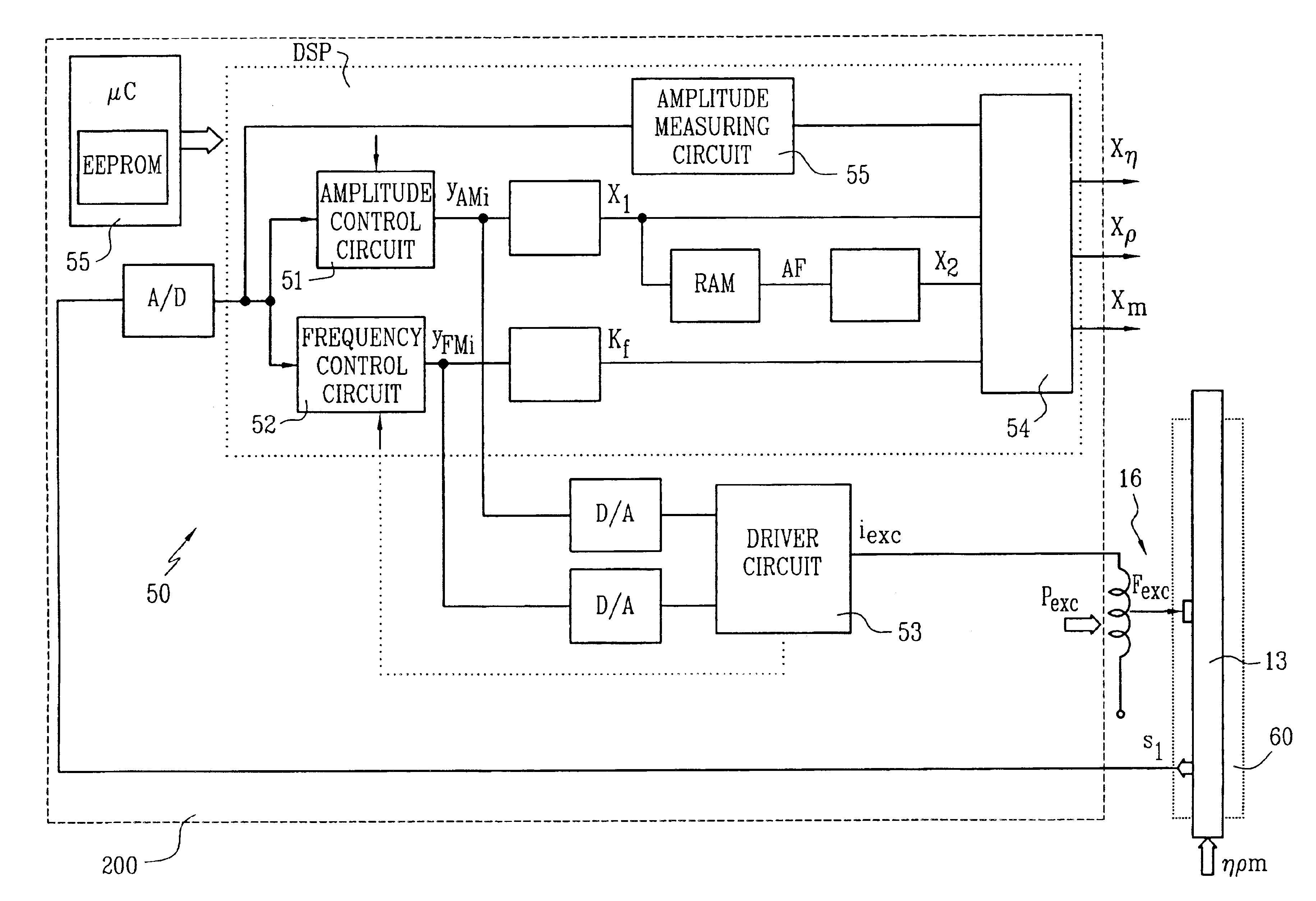

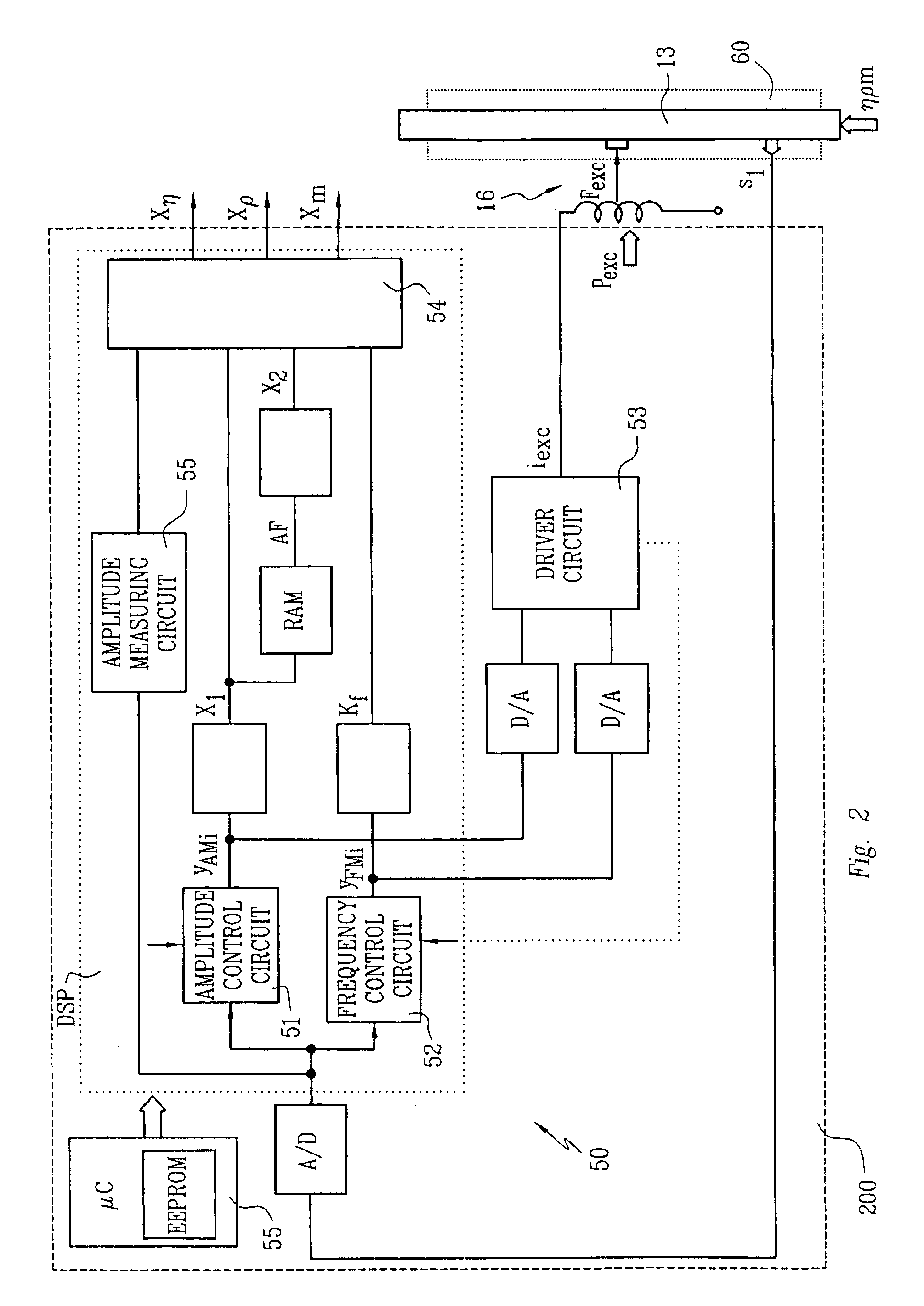

Viscometer

The viscometer provides a viscosity value (Xη) which represents the viscosity of a fluid flowing in a pipe connected thereto. It comprises a vibratory transducer with at least one flow tube for conducting the fluid, which communicates with the pipe. Driven by an excitation assembly, the flow tube is vibrated so that friction forces are produced in the fluid. The viscometer further includes meter electronics which feed an excitation current (iexc) into the excitation assembly. By means of the meter electronics, a first internal intermediate value (X1) is formed, which corresponds with the excitation current (iexc) and thus represents the friction forces acting in the fluid. According to the invention, a second internal intermediate value (X2), representing inhomogeneities in the fluid, is generated in the meter electronics, which then determine the viscosity value (Xη) using the two intermediate values (X1, X2). The first internal intermediate value (X1) is preferably normalized by means of an amplitude control signal (yAM) for the excitation current (iexc), the amplitude control signal corresponding with the vibrations of the flow tube. As a result, the viscosity value (Xη) provided by the viscometer is highly accurate and robust, particularly independently of the position of installation of the flow tube.

Owner:ENDRESS HAUSER FLOWTEC AG

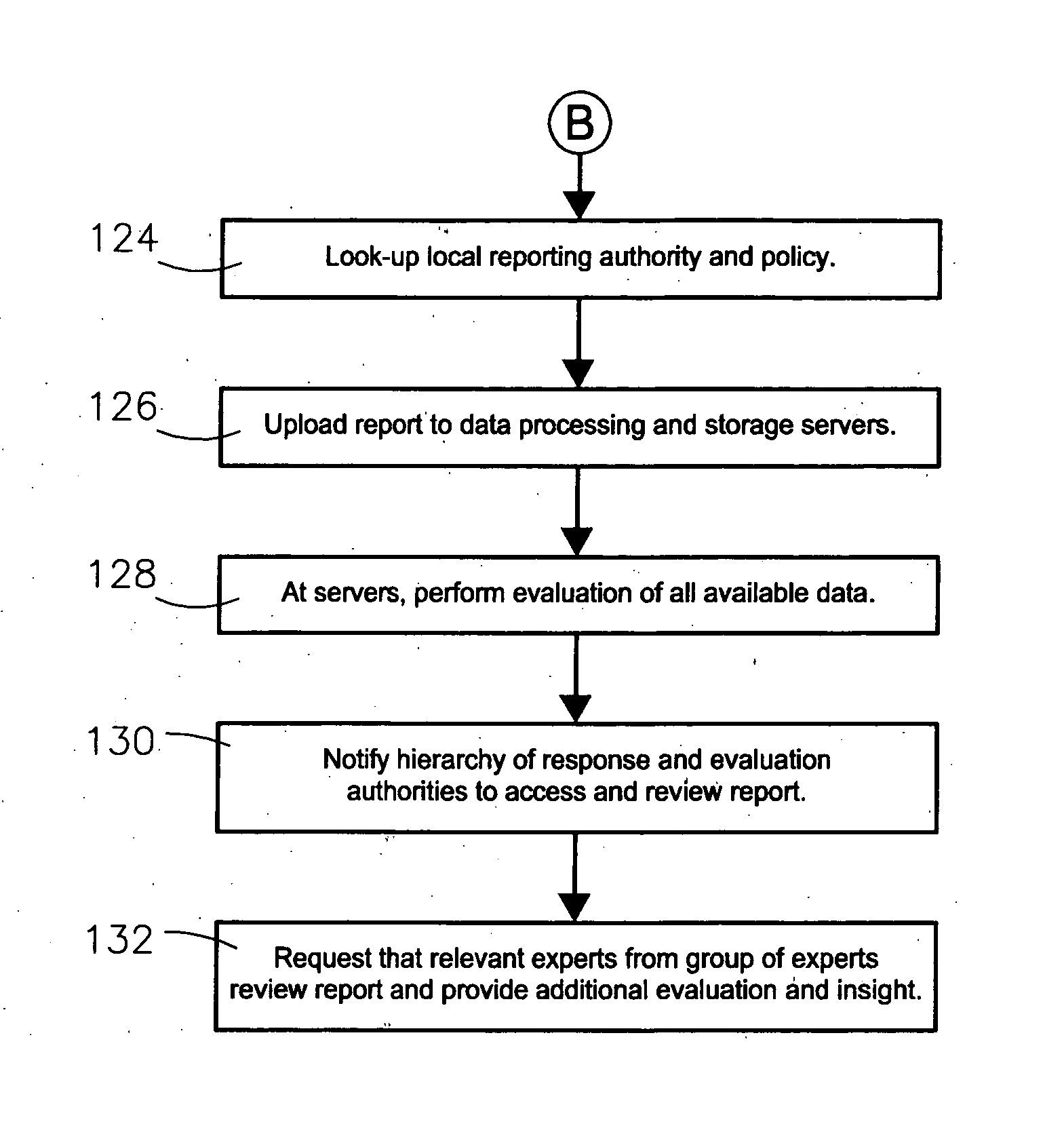

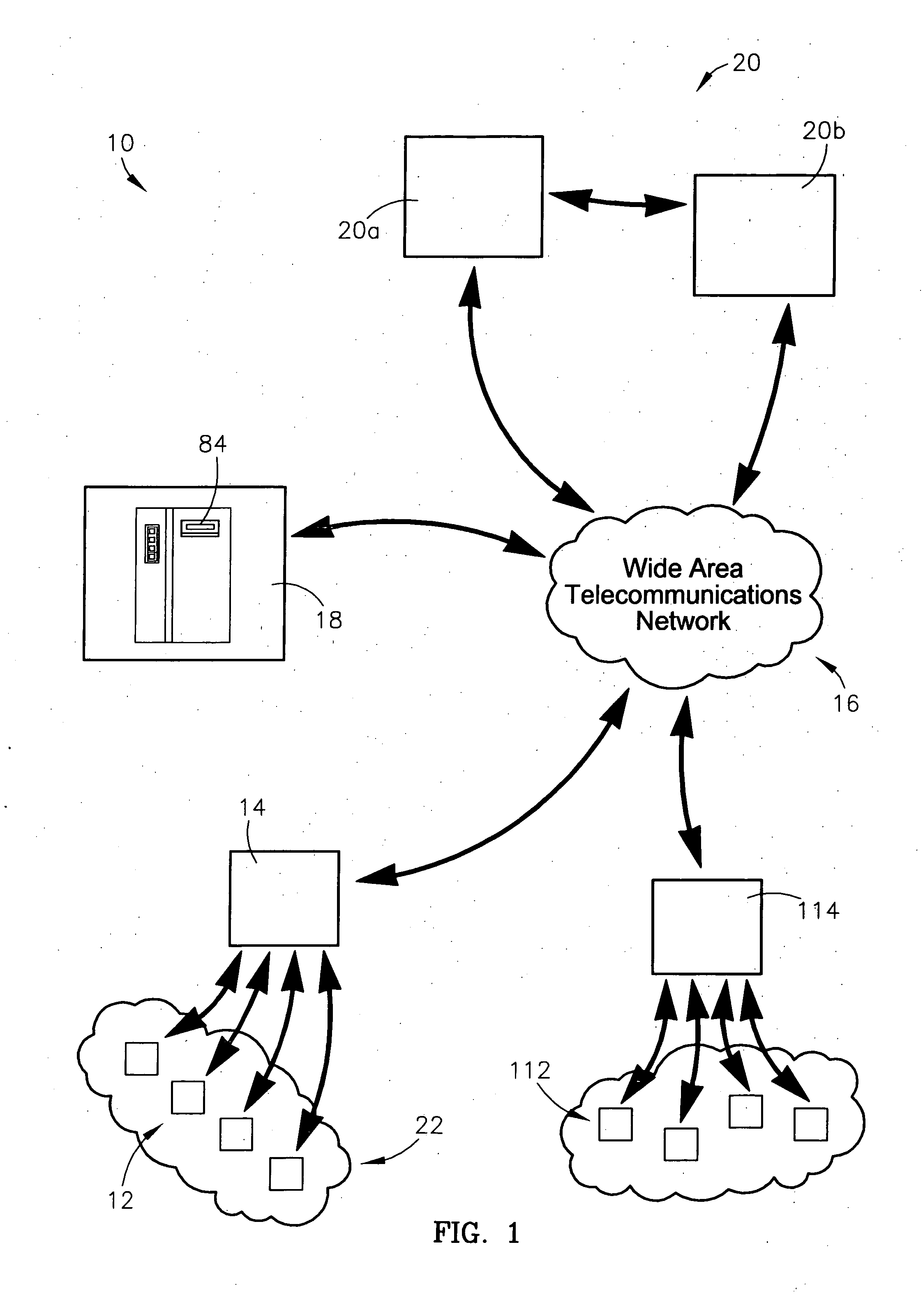

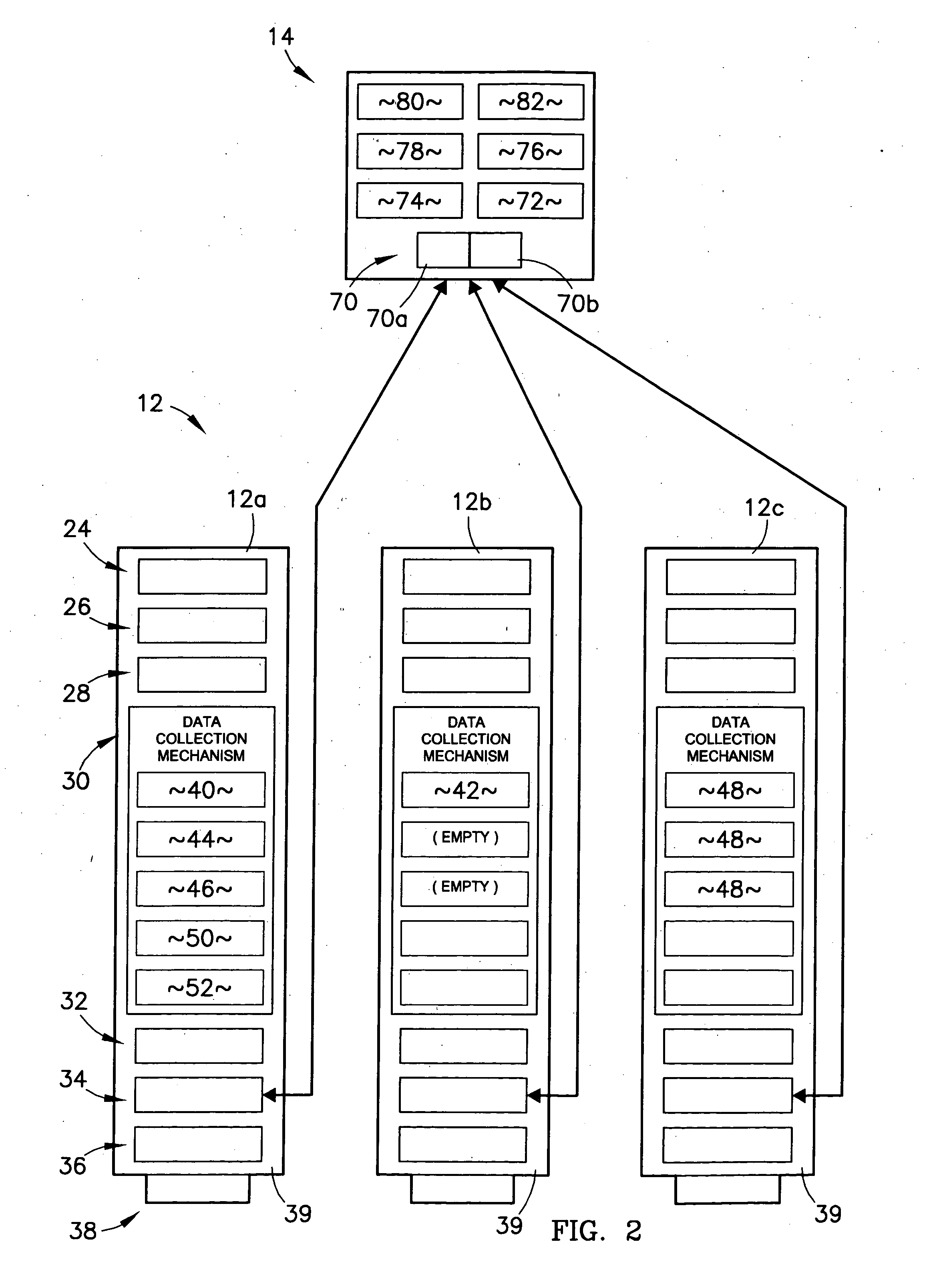

System and method for identifying, reporting, and evaluating presence of substance

ActiveUS20120030130A1Rapid deploymentEliminates exposure riskComponent separationDigital data processing detailsRadioactive agentComputer science

A system and method for identifying, reporting, and evaluating a presence of a solid, liquid, gas, or other substance of interest, particularly a dangerous, hazardous, or otherwise threatening chemical, biological, or radioactive substance. The system comprises one or more substantially automated, location self-aware remote sensing units; a control unit; and one or more data processing and storage servers. Data is collected by the remote sensing units and transmitted to the control unit; the control unit generates and uploads a report incorporating the data to the servers; and thereafter the report is available for review by a hierarchy of responsive and evaluative authorities via a wide area network. The evaluative authorities include a group of relevant experts who may be widely or even globally distributed.

Owner:HONEYWELL FED MFG & TECHNOLOGI

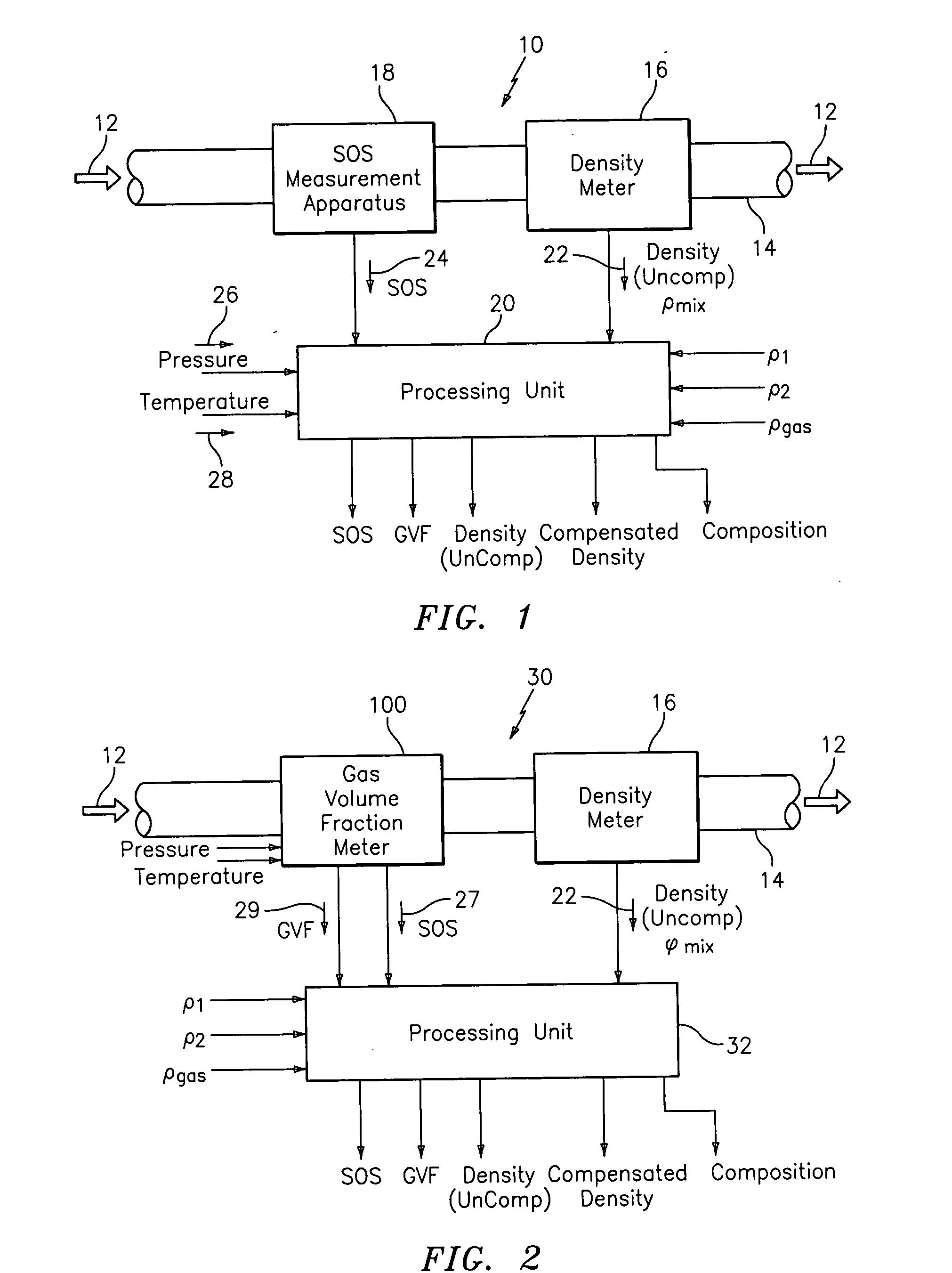

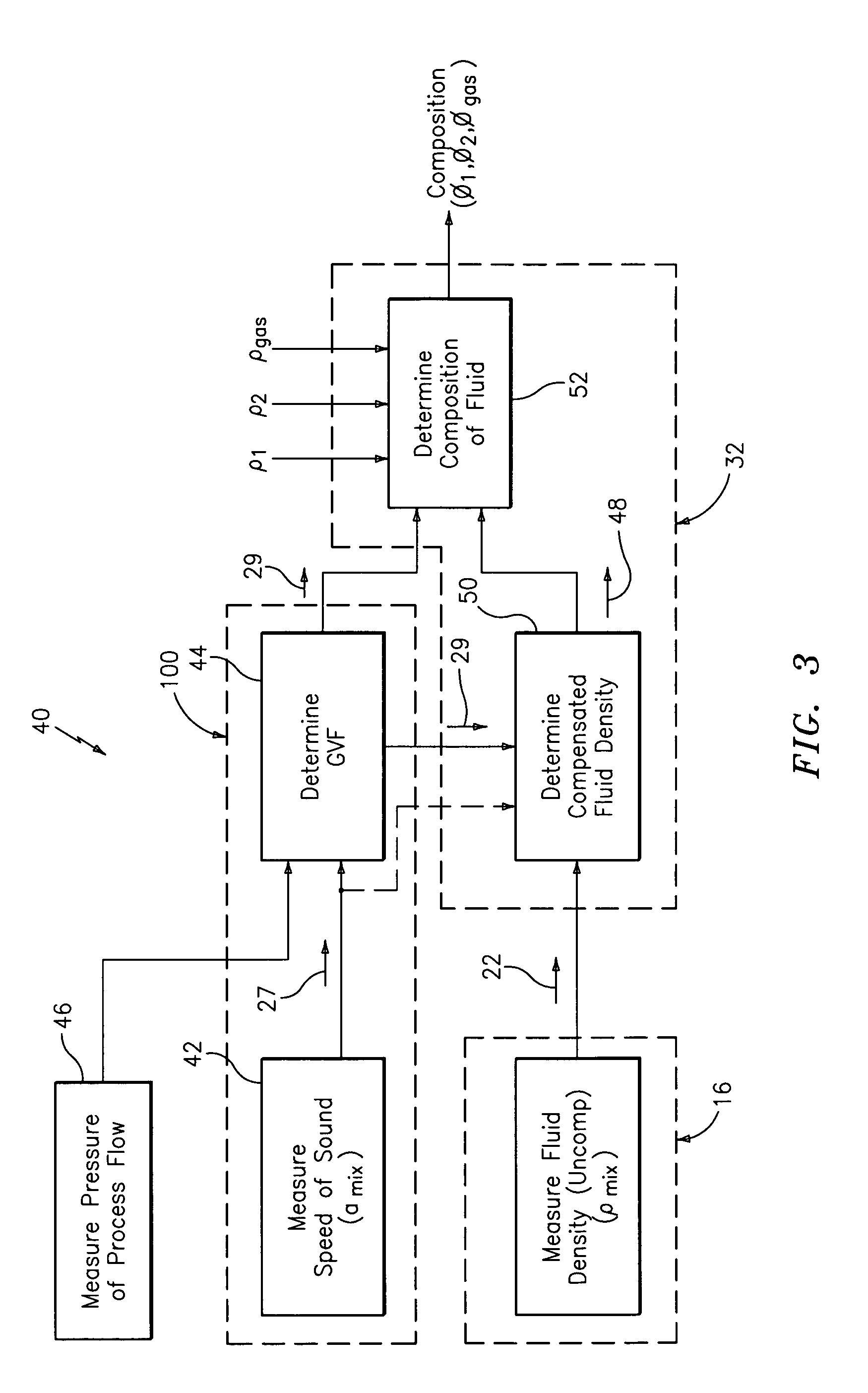

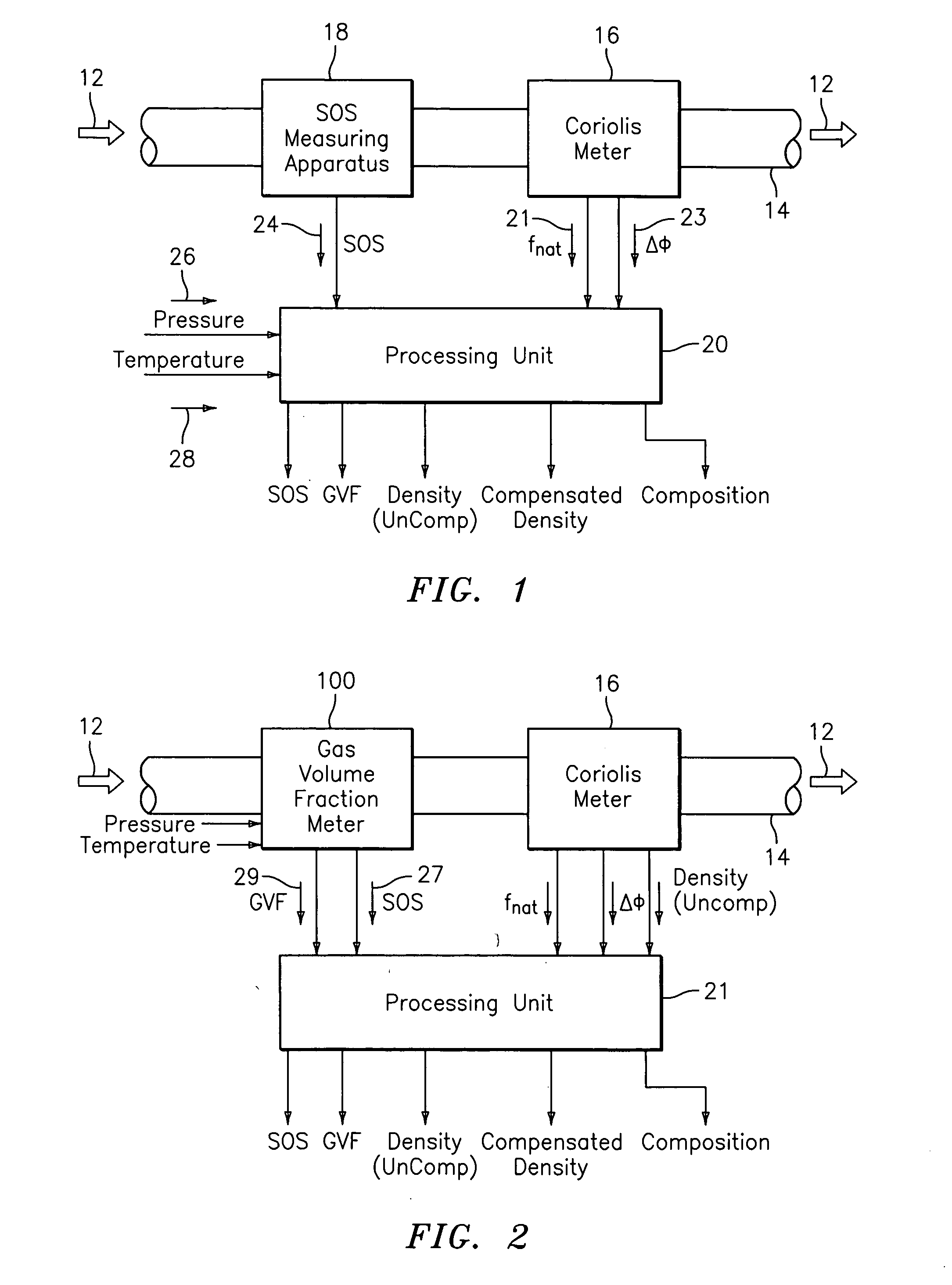

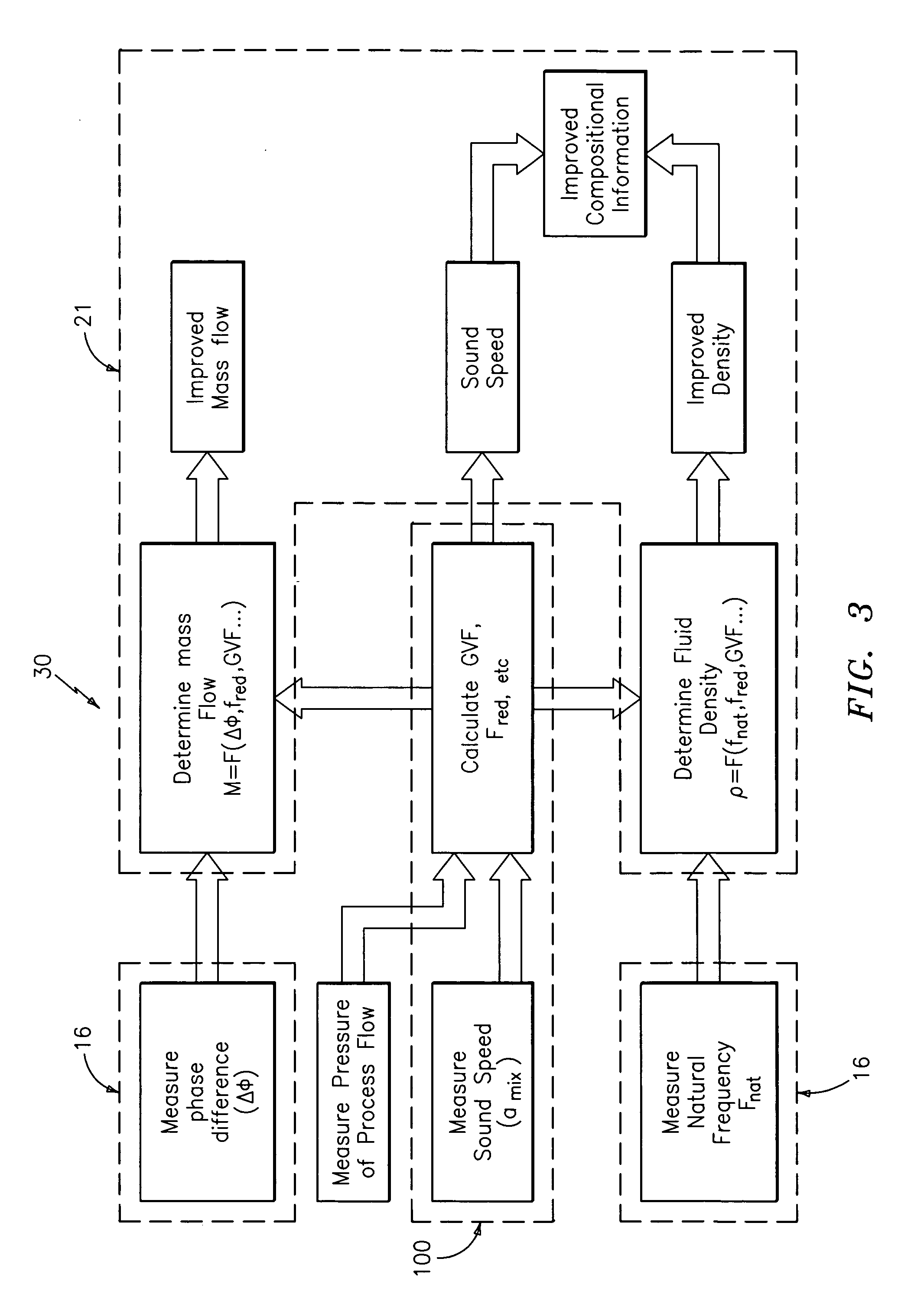

Apparatus and method for compensating a coriolis meter

ActiveUS20050044929A1High densityAdd additional massVolume/mass flow by dynamic fluid flow effectVolume meteringVolumetric Mass DensityDischarge measurements

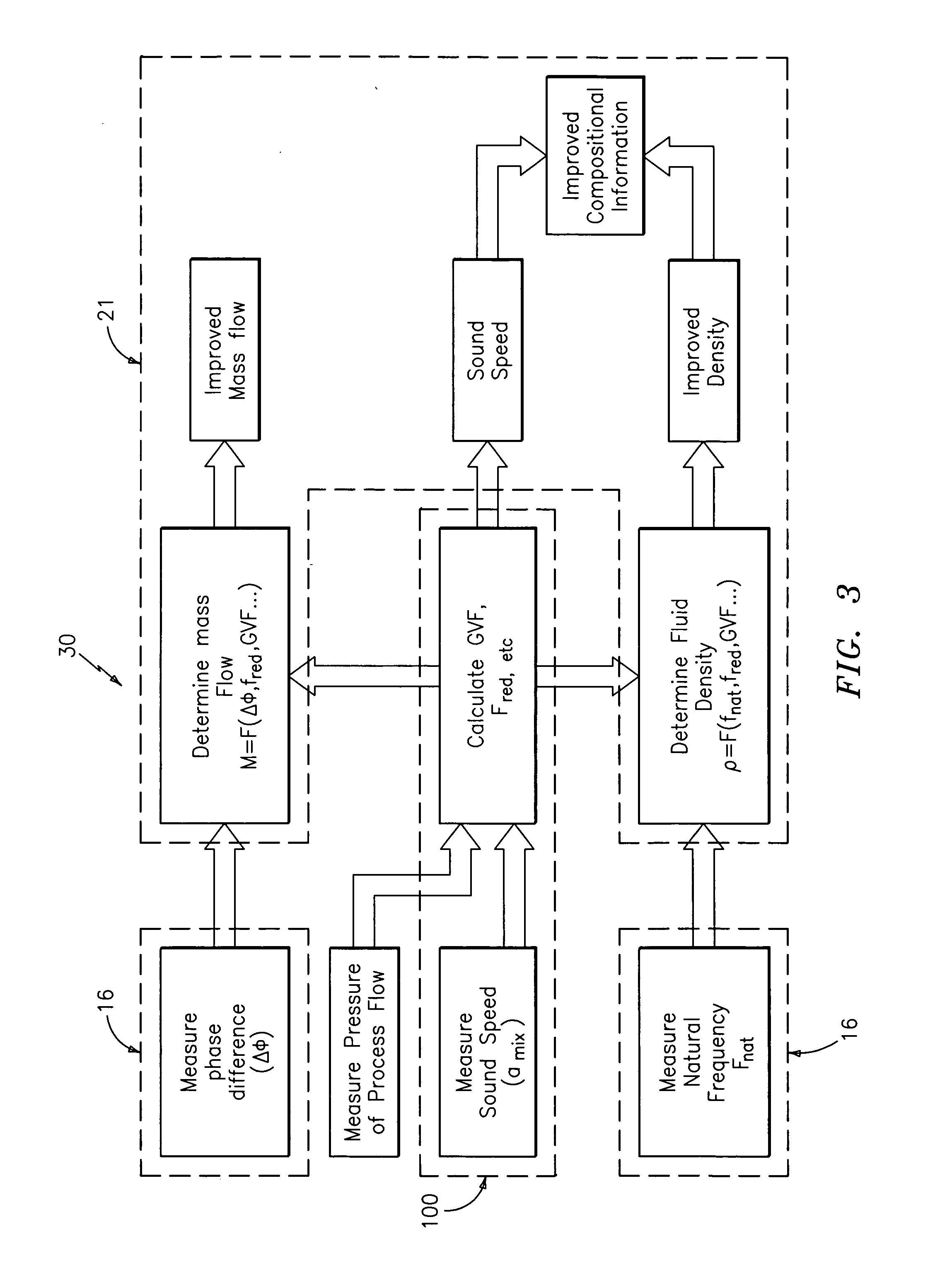

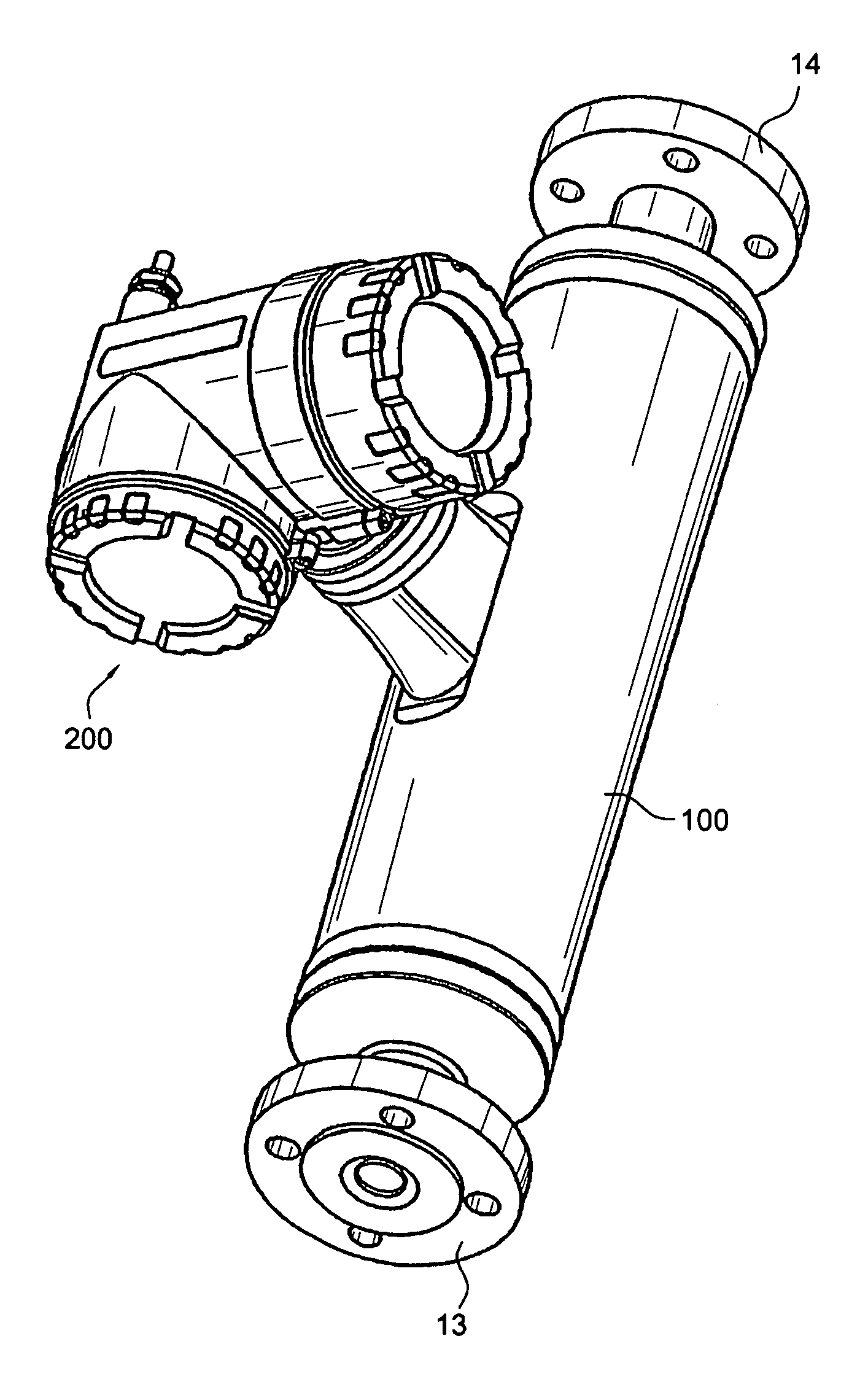

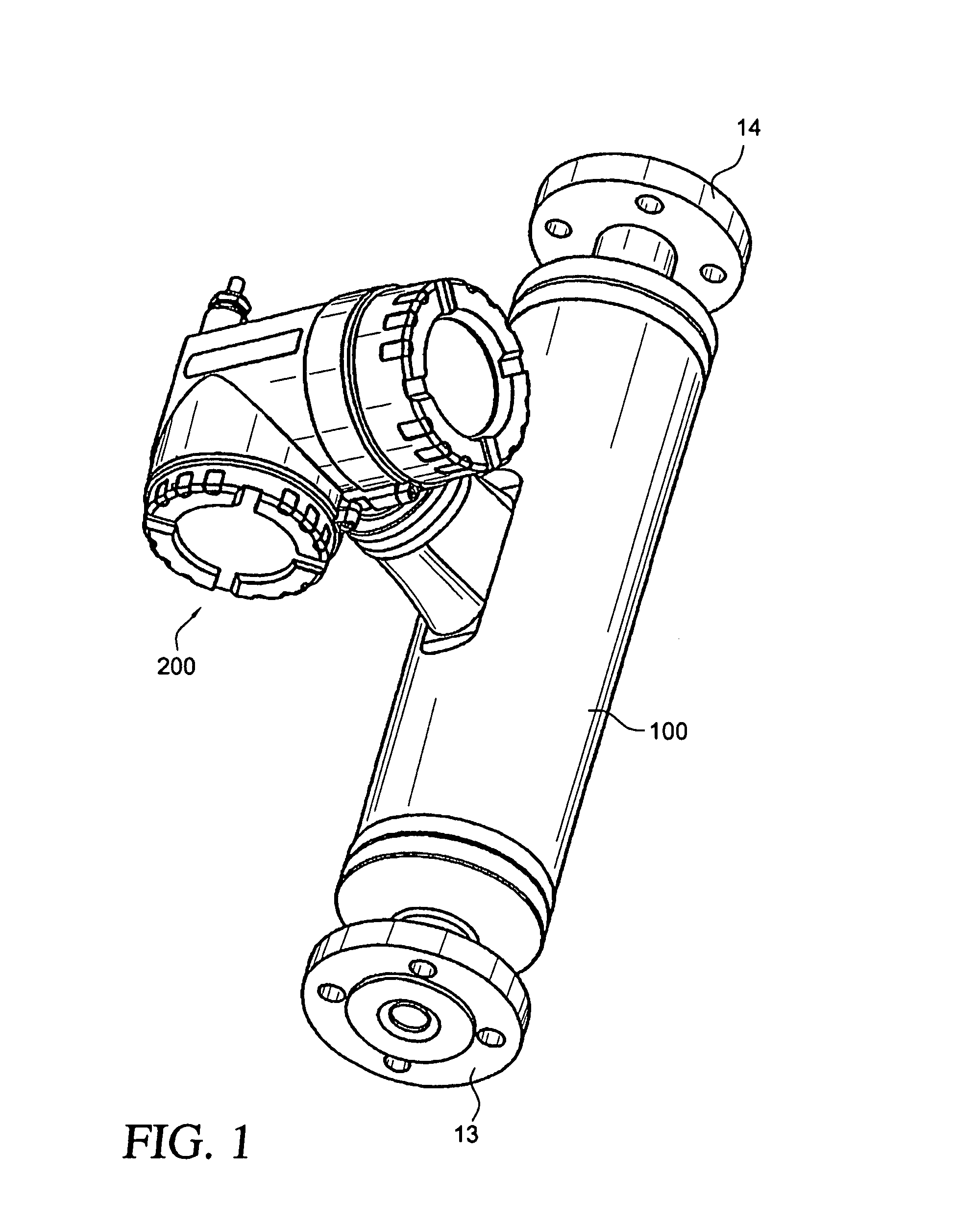

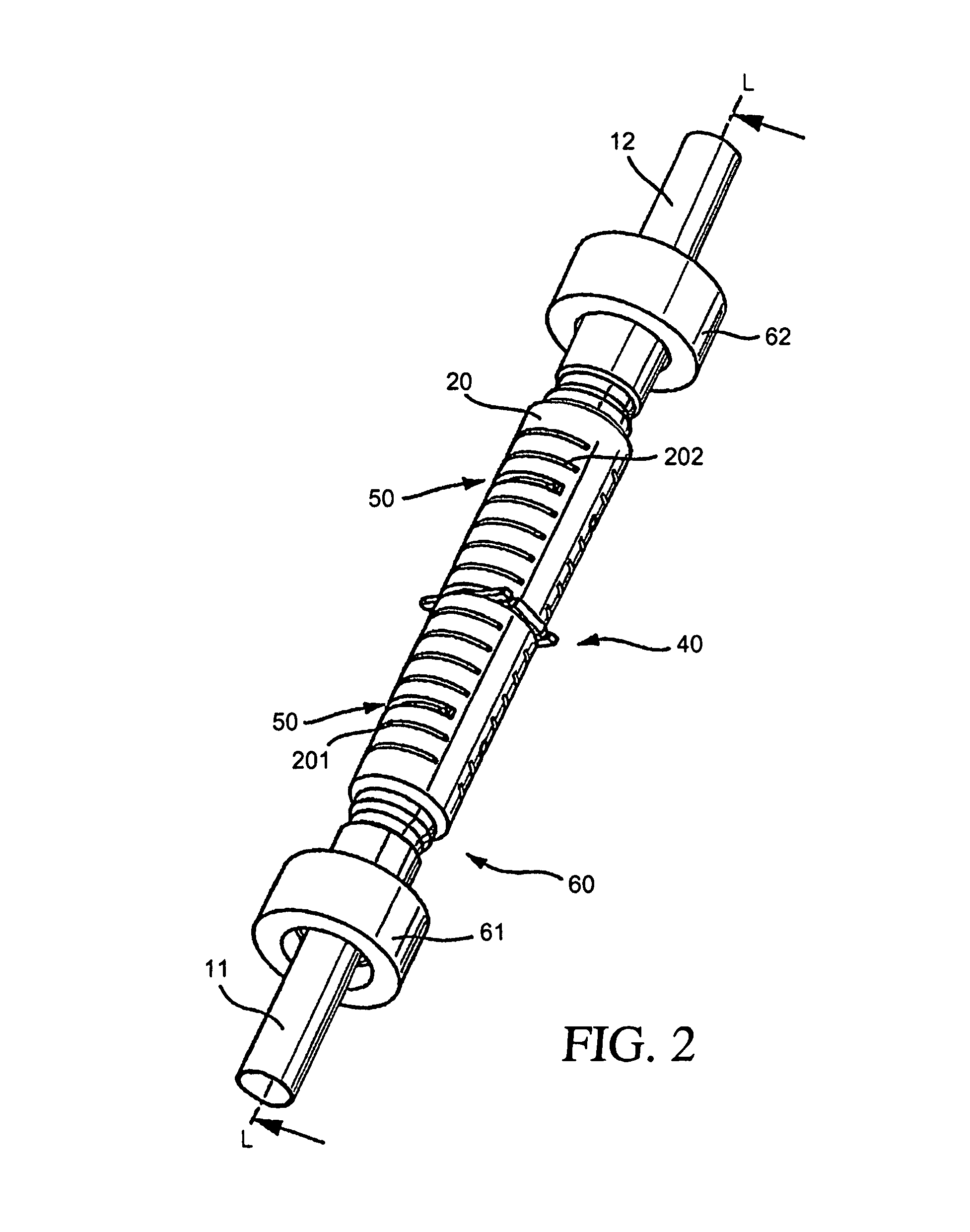

A flow measuring system is provided that provides at least one of a compensated mass flow rate measurement and a compensated density measurement. The flow measuring system includes a gas volume fraction meter in combination with a coriolis meter. The GVF meter measures acoustic pressures propagating through the fluids to measure the speed of sound αmix propagating through the fluid to calculate at least gas volume fraction of the fluid and / or the reduced natural frequency. For determining an improved density for the coriolis meter, the calculated gas volume fraction and / or reduced frequency is provided to a processing unit. The improved density is determined using analytically derived or empirically derived density calibration models (or formulas derived therefore), which is a function of the measured natural frequency and at least one of the determined GVF, reduced frequency and speed of sound, or any combination thereof. The gas volume fraction (GVF) meter may include a sensing device having a plurality of strain-based or pressure sensors spaced axially along the pipe for measuring the acoustic pressures propagating through the flow.

Owner:EXPRO METERS

In-line measuring device

ActiveUS7284449B2Little effortFlow propertiesVolume meteringTorsional oscillationsElectrical current

An inline measuring device includes a vibration-type measurement pickup having at least one measuring tube, which has a medium to be measured flowing through it during operation. The measuring tube is made by means of an exciter arrangement to execute, at least at times and / or at least in part, lateral oscillations and, at least at times and / or at least in part, torsional oscillations about an imaginary measuring tube longitudinal axis. The torsional oscillations alternate with the lateral oscillations or are, at times, superimposed thereon. Also included is a sensor arrangement for producing oscillation measurement signals correspondingly representing oscillations of the measuring tube. Measuring device electronics controlling the exciter arrangement generates, by means of at least one of the oscillation measurement signals and / or by means of the exciter current, at least at times, at least one measured value, which represents the at least one physical quantity to be measured. Additionally, the measuring device electronics also determines a first intermediate value, which corresponds to the lateral current component of the exciter current serving to maintain the lateral oscillations of the measuring tube and / or to a damping of the lateral oscillations of the measuring tube, as well as a second intermediate value, which corresponds to a torsional current component of the exciter current serving to maintain the torsional oscillations of the measuring tube and / or to a damping of the torsional oscillations of the measuring tube. With the goal of producing the measured value at high accuracy, such value is determined also taking into consideration these two intermediate values. The measured value obtained in this way is distinguished especially by high accuracy also in the case of media of two, or more, phases.

Owner:ENDRESS HAUSER FLOWTEC AG

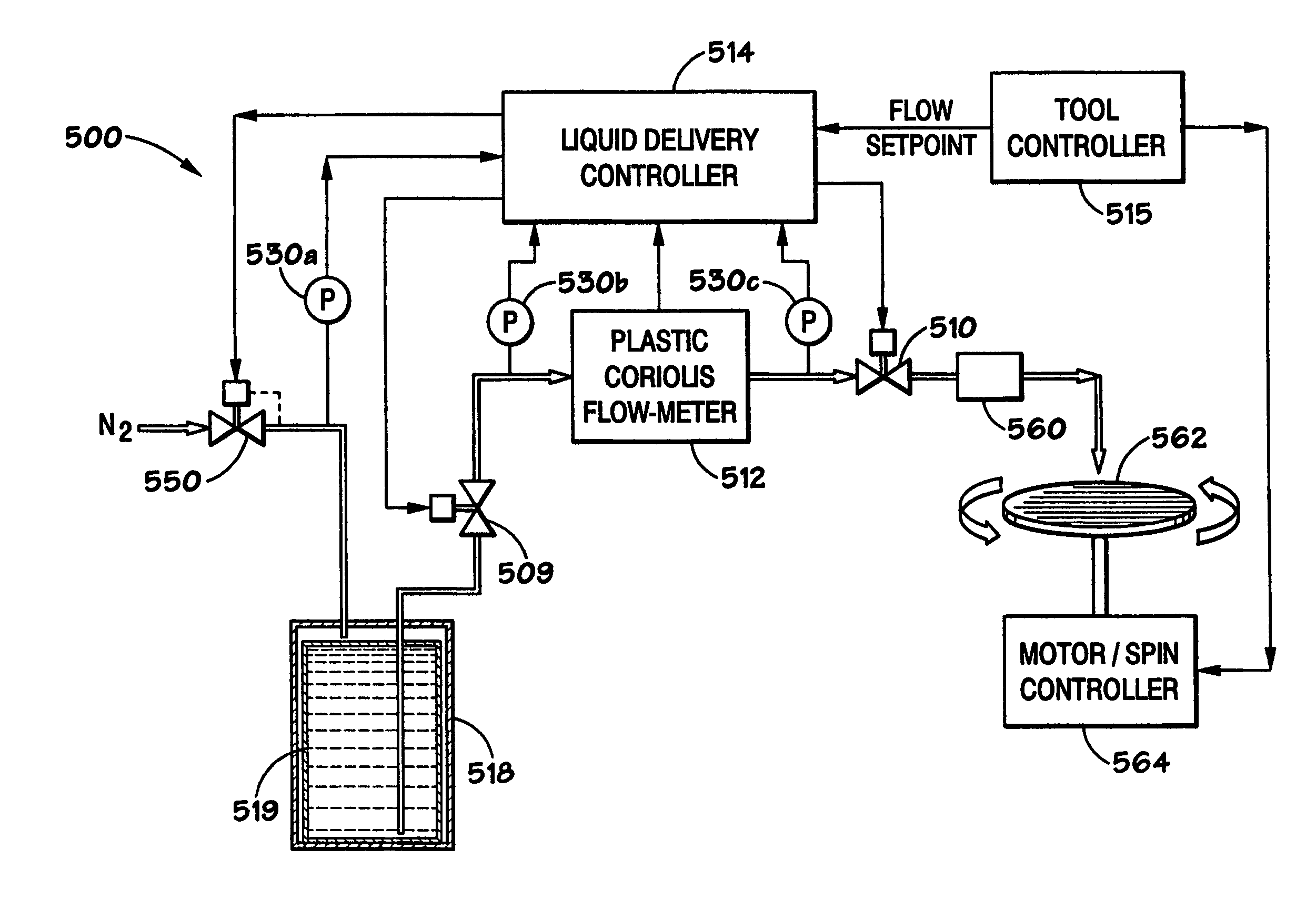

High purity fluid delivery system

InactiveUS7114517B2Operating means/releasing devices for valvesFlow control using electric meansPlastic materialsPinch valve

A fluid delivery system includes a flow control device and a Coriolis mass flowmeter in fluid communication with the flow control device. The Coriolis flowmeter has a flow-tube made of a high-purity plastic material, such as PFA, making the delivery system suitable for high purity applications. A controller provides a control output signal to the flow control device, which may comprise a pinch valve, so as to vary the flow control device output in response to a setpoint signal and measurement signals received from the flowmeter.

Owner:EMERSON ELECTRIC CO

Apparatus and method for compensating a coriolis meter

ActiveUS7152460B2High densityAdd additional massMaterial analysis using microwave meansVolume/mass flow by dynamic fluid flow effectDischarge measurementsVolumetric Mass Density

A flow measuring system is provided that provides at least one of a compensated mass flow rate measurement and a compensated density measurement. The flow measuring system includes a gas volume fraction meter in combination with a coriolis meter. The GVF meter measures acoustic pressures propagating through the fluids to measure the speed of sound αmix propagating through the fluid to calculate at least gas volume fraction of the fluid and / or the reduced natural frequency. For determining an improved density for the coriolis meter, the calculated gas volume fraction and / or reduced frequency is provided to a processing unit. The improved density is determined using analytically derived or empirically derived density calibration models (or formulas derived therefore), which is a function of the measured natural frequency and at least one of the determined GVF, reduced frequency and speed of sound, or any combination thereof. The gas volume fraction (GVF) meter may include a sensing device having a plurality of strain-based or pressure sensors spaced axially along the pipe for measuring the acoustic pressures propagating through the flow.

Owner:EXPRO METERS

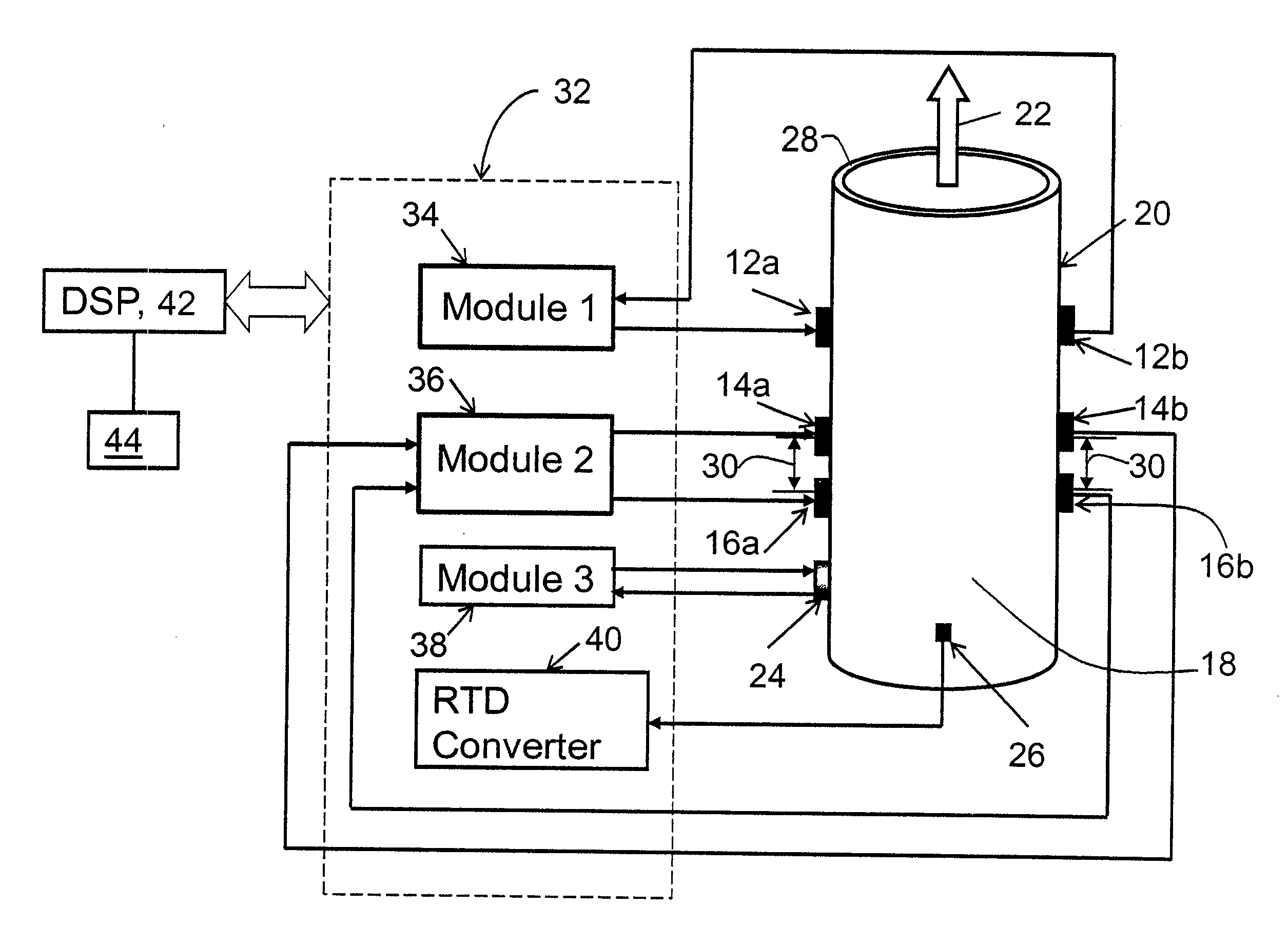

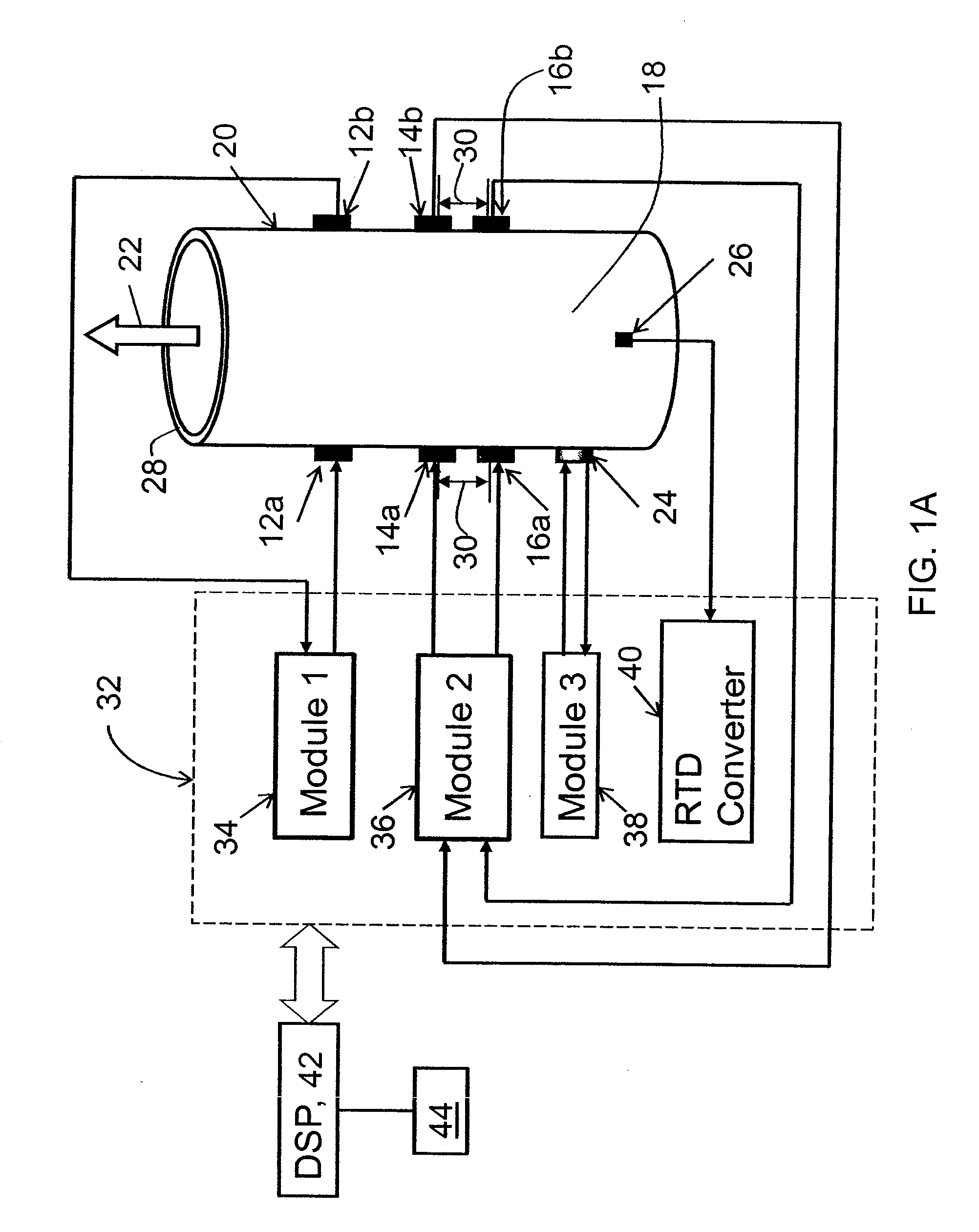

Multiphase fluid characterization system

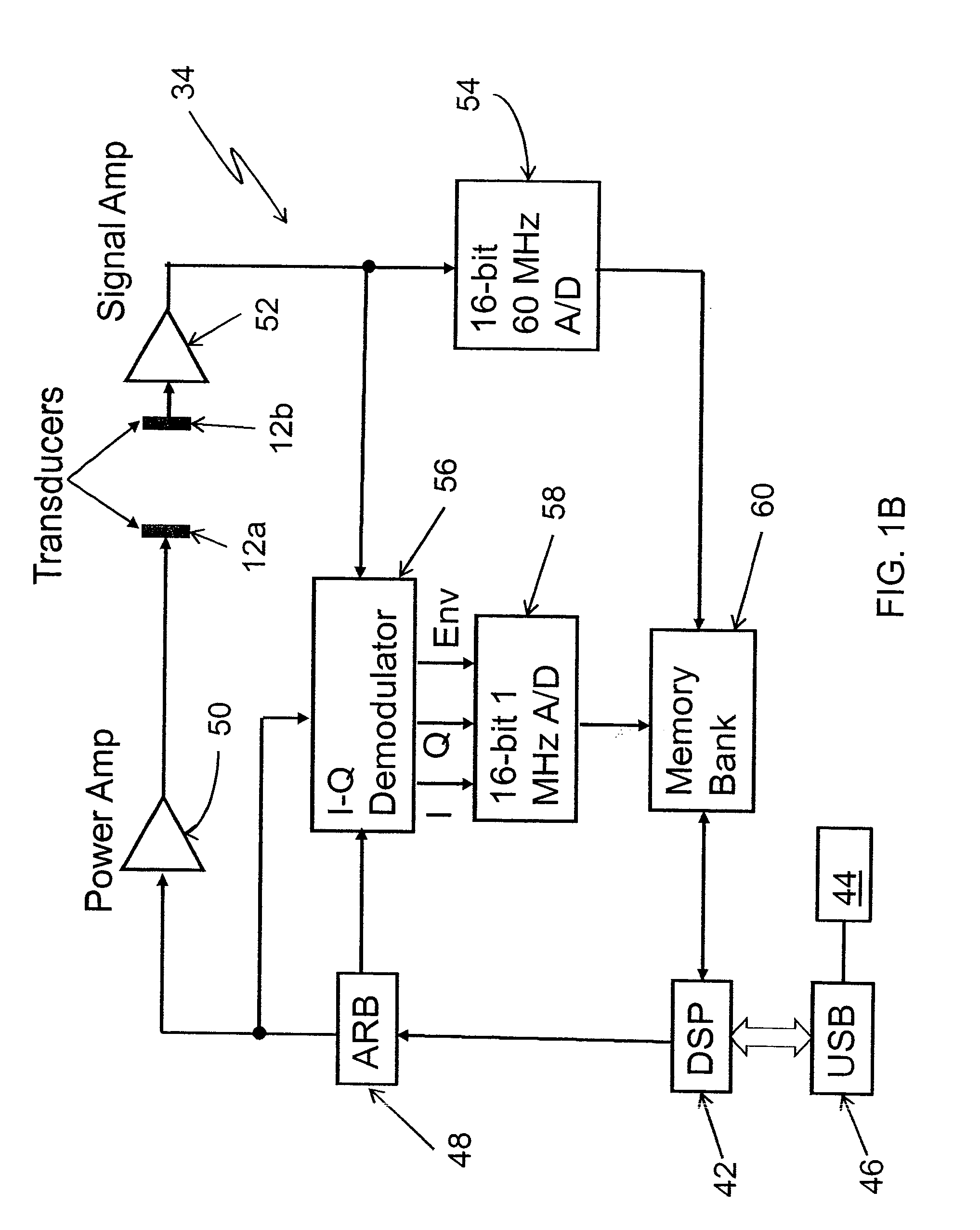

ActiveUS20120055239A1Analysing fluids using sonic/ultrasonic/infrasonic wavesTesting/calibration for volume flowUltrasound attenuationResonance

A measurement system and method for permitting multiple independent measurements of several physical parameters of multiphase fluids flowing through pipes are described. Multiple acoustic transducers are placed in acoustic communication with or attached to the outside surface of a section of existing spool (metal pipe), typically less than 3 feet in length, for noninvasive measurements. Sound speed, sound attenuation, fluid density, fluid flow, container wall resonance characteristics, and Doppler measurements for gas volume fraction may be measured simultaneously by the system. Temperature measurements are made using a temperature sensor for oil-cut correction.

Owner:TRIAD NAT SECURITY LLC

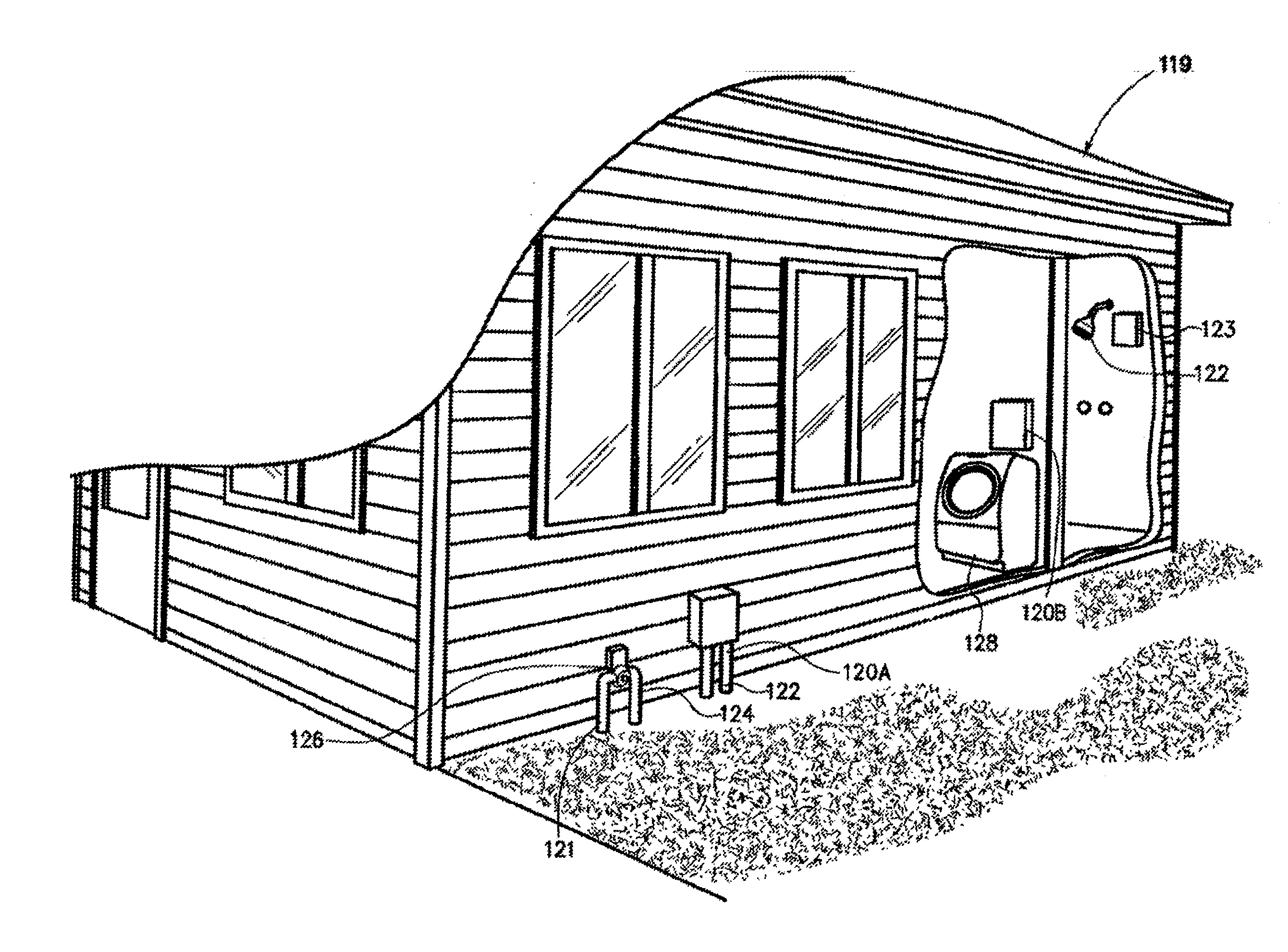

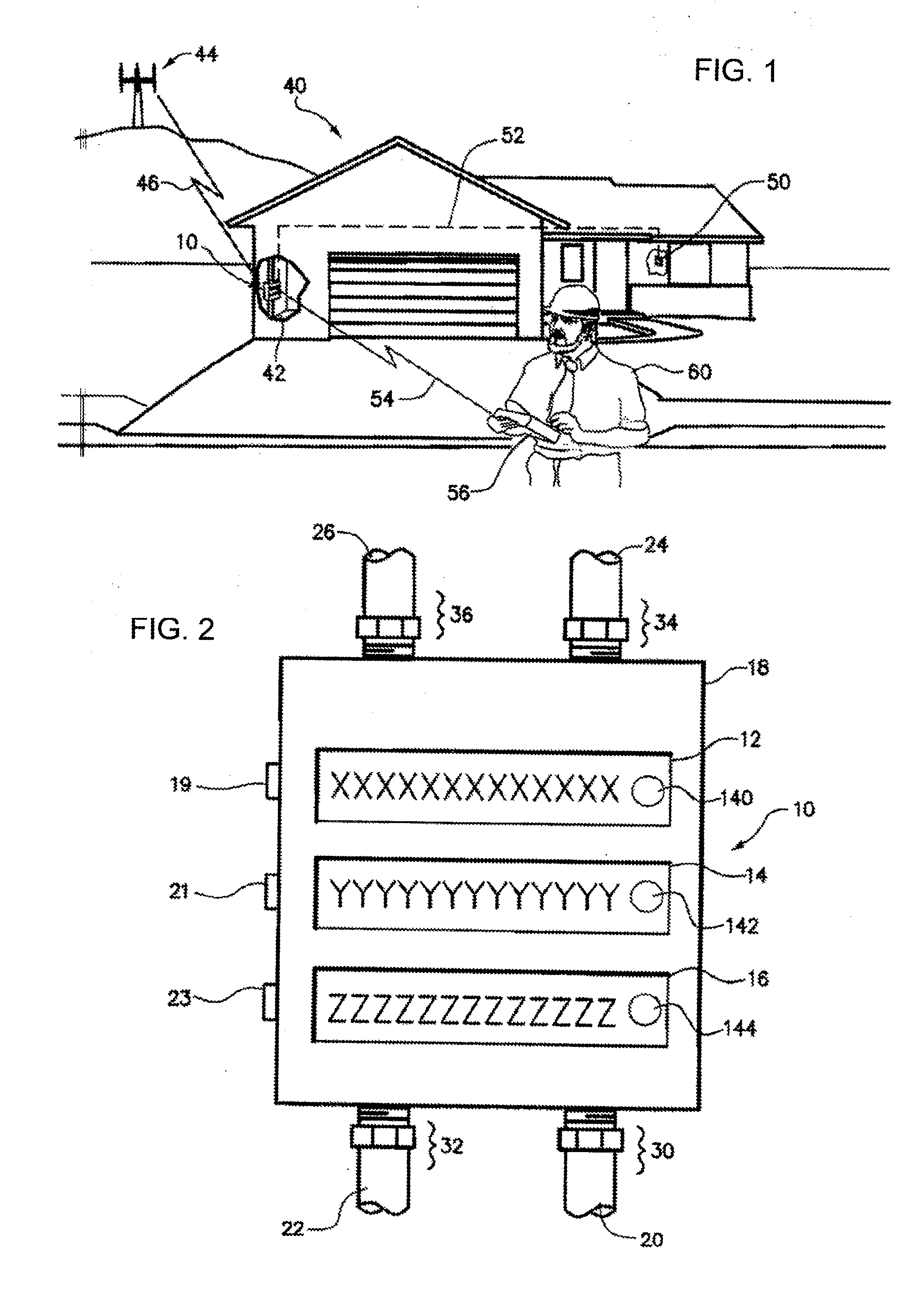

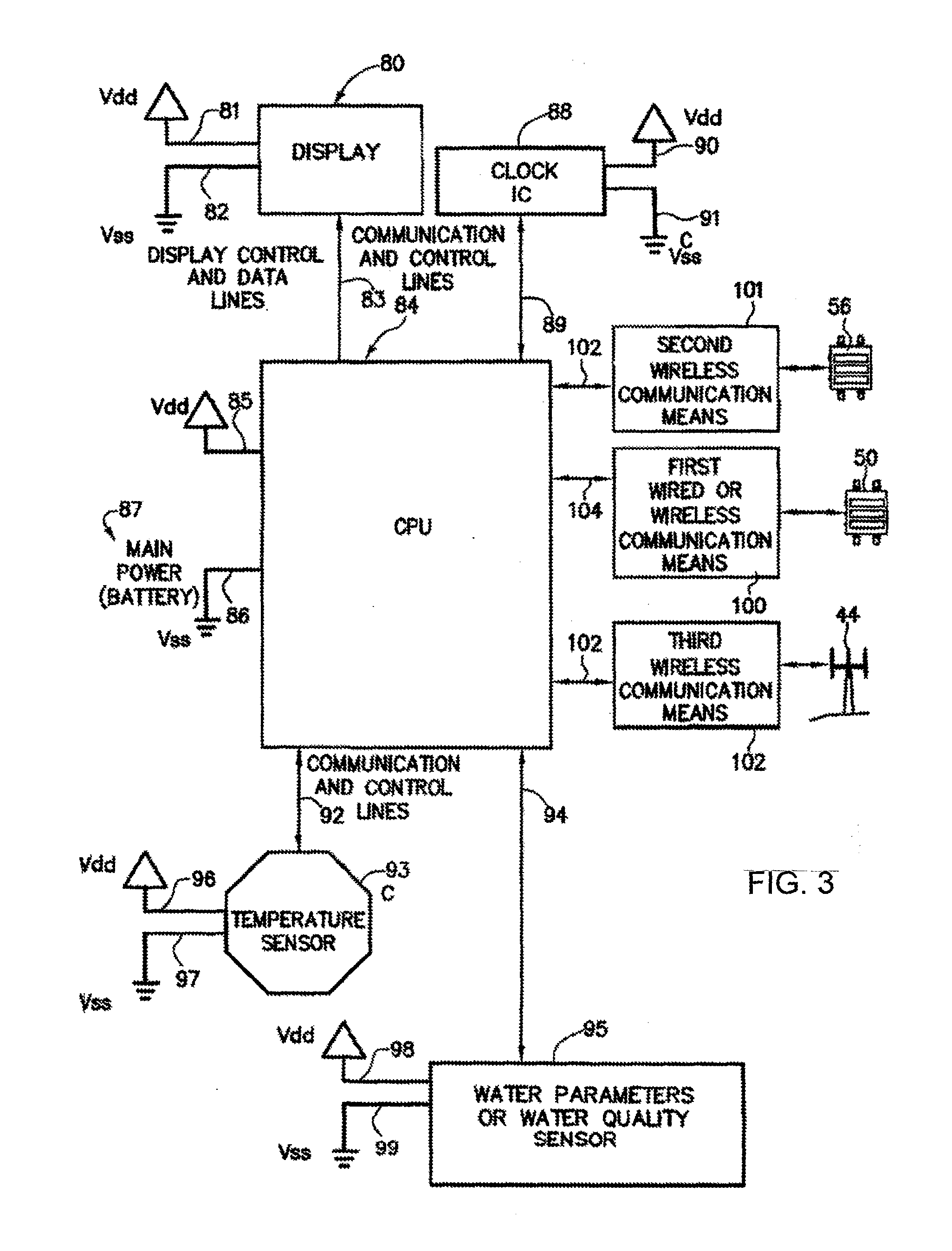

Water Use Monitoring Apparatus

ActiveUS20160076909A1Easy to observeGeneral water supply conservationVolume/mass flow by thermal effectsWater useTechnology communication

The present invention is a water use and / or a water energy use monitoring apparatus that is affixed to the hot and cold water supply piping for continuously (or on demand) monitoring displaying the water and water energy (hot vs. ambient) use within a residential or commercial building. A first wire or wireless means is incorporated to communicate with a remote display for viewing by the owner of a commercial building or occupier / resident of a home. A second optional wire or wireless means can be incorporated that can be monitored by civil, commercial, governmental or municipal operators or agencies, using a remote display and / or recorder means or by a secure wire or wireless communication network (e.g. cell phone, smart phone or other similar technology communication means). A third wireless means communicates water parameter data utilizing typical cell tower technology and / or mesh network technology. The water use monitor apparatus includes a power generation, a microprocessor, temperature and water flow sensors, optional water quality sensors, timing circuits, wireless circuitry, and a display means. A wired or wireless means is designed to electronically communicate water use, water energy use and / or water quality information to a remotely located display apparatus or typical cell phone, smart phones, or similar apparatus for convenient observation by a commercial, operator or occupier, resident, municipal or government agency.

Owner:REIN TECH INC

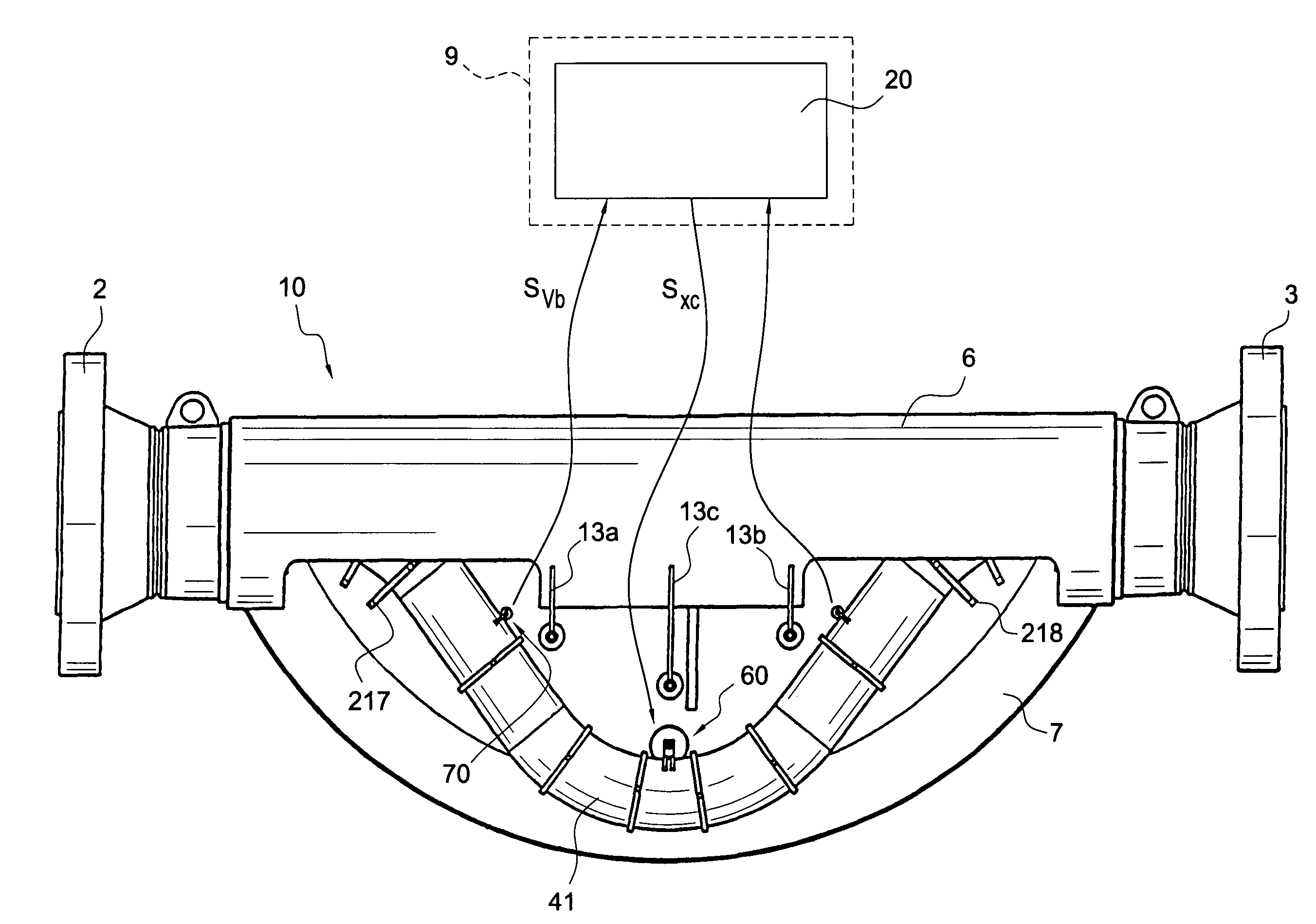

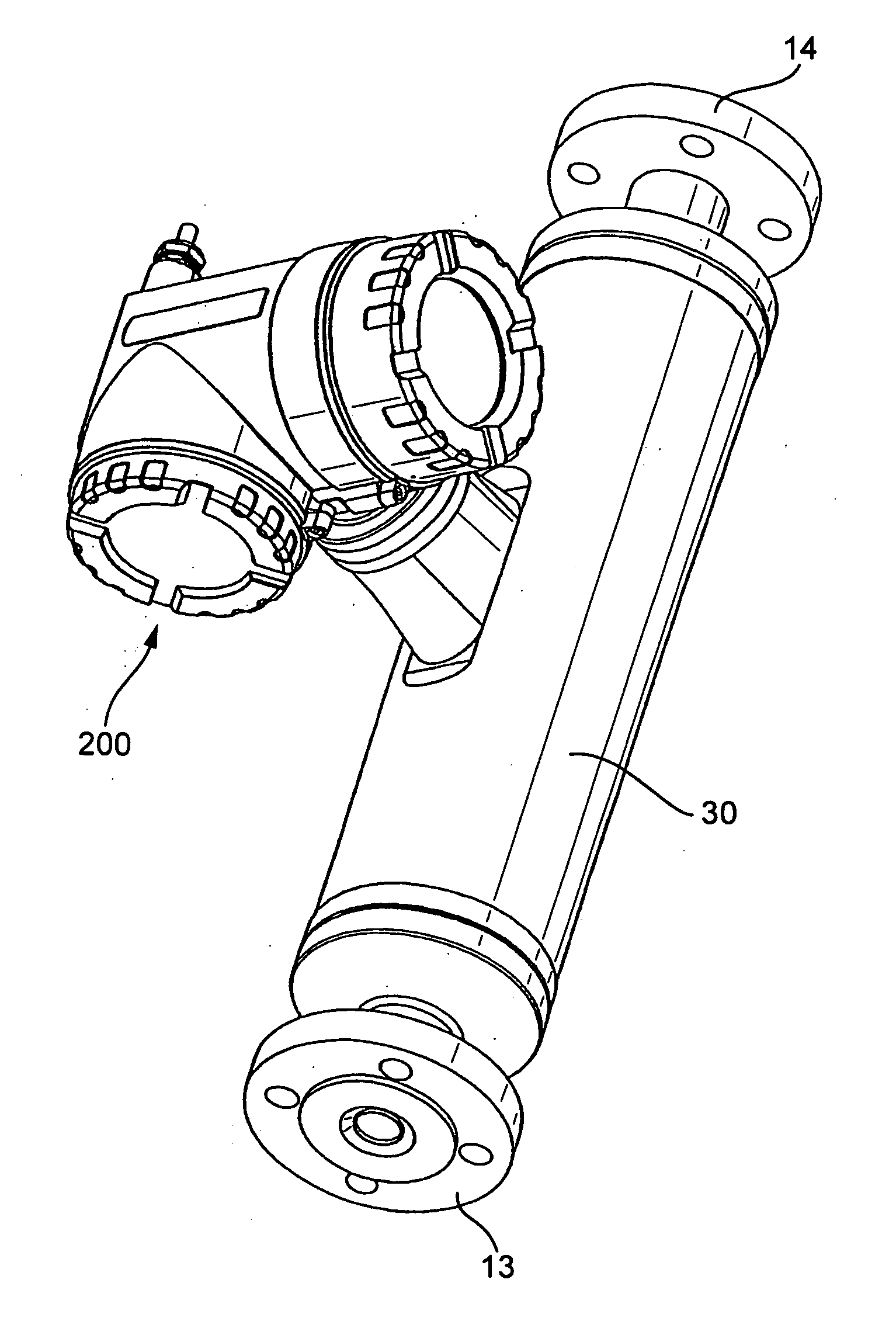

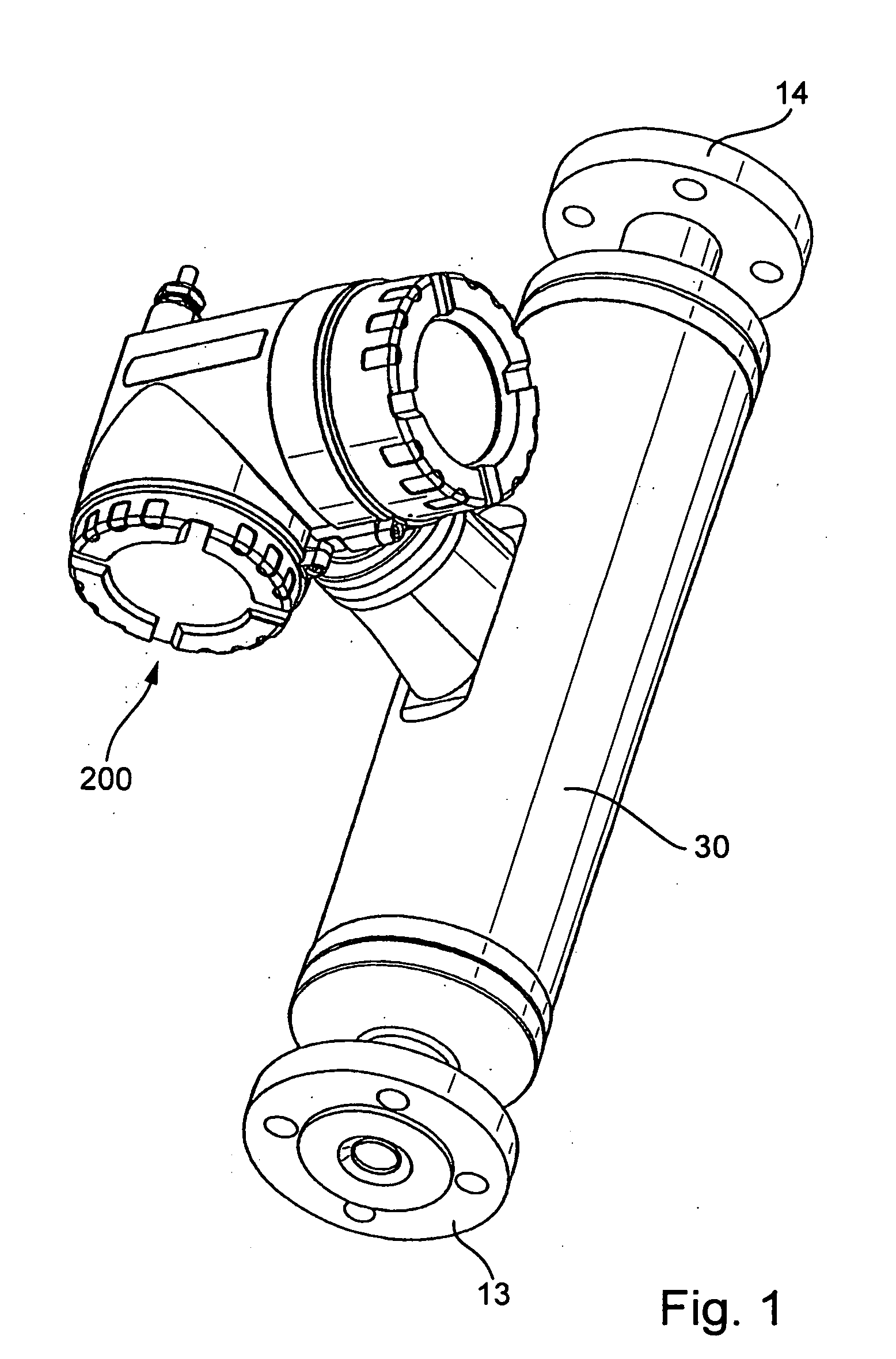

Measuring transducer of vibration-type

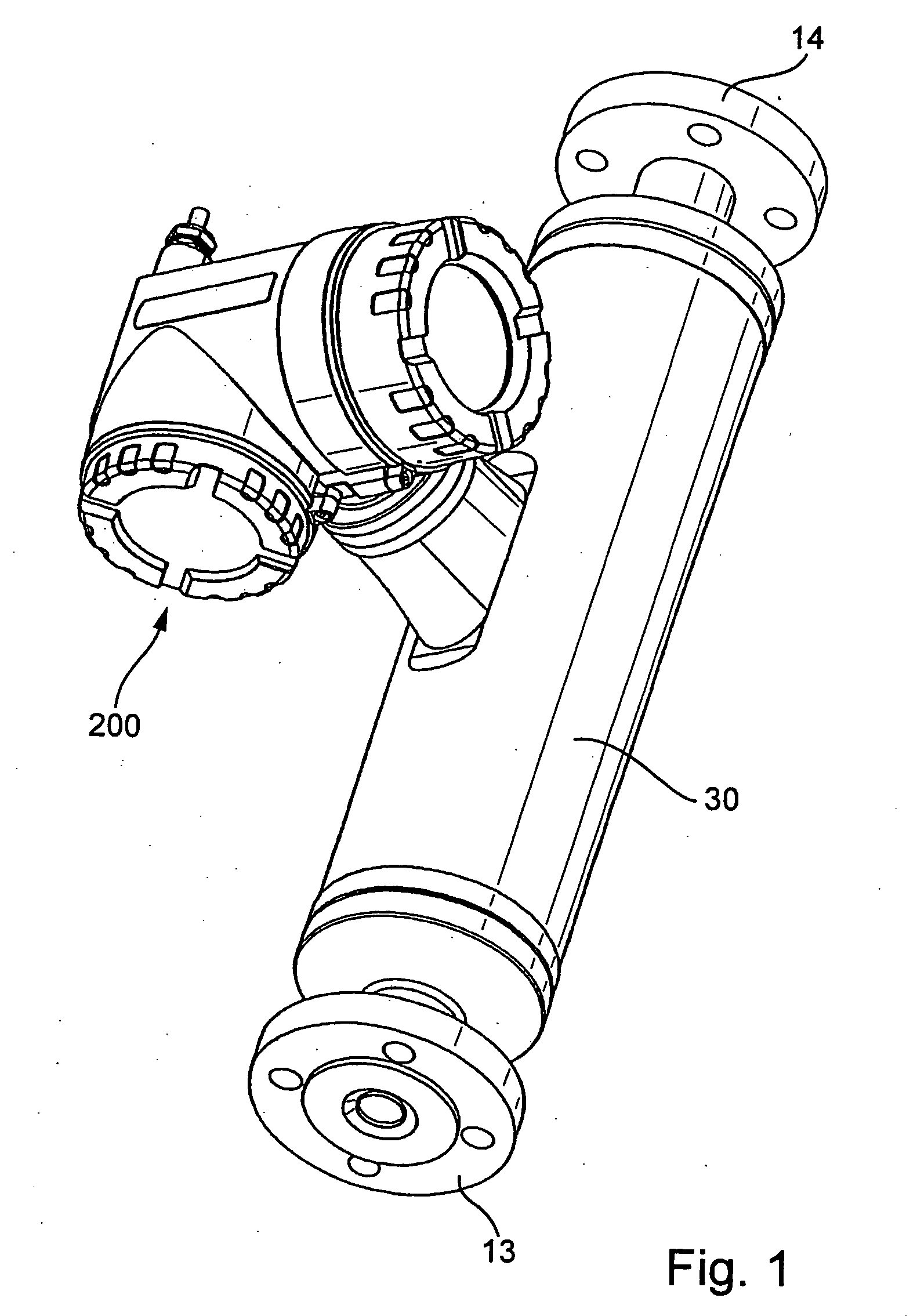

ActiveUS20070151370A1Simple mechanical structureReduce complexityDirect mass flowmetersCouplingTransducer

The measuring transducer includes a transducer housing, as well as an internal part arranged in the transducer housing. The internal part includes at least one curved measuring tube vibrating, at least at times, during operation and serving for conveying the medium, as well as a counteroscillator affixed to the measuring tube on the inlet-side, accompanied by formation of a coupling zone, and to the measuring tube on the outlet-side, accompanied by the formation of a coupling zone. The internal part is held oscillatably in the transducer housing, at least by means of two connecting tube pieces, via which the measuring tube communicates during operation with the pipeline and which are so oriented with respect to one another, as well as with respect to an imaginary longitudinal axis of the measuring transducer, that the internal part can move during operation in the manner of a pendulum about the longitudinal axis. Counteroscillator of the measuring transducer of the invention is formed by means of two counteroscillator plates, of which a first counteroscillator plate is arranged on the left side of the measuring tube and a second counteroscillator plate is arranged on the right side of the measuring tube.

Owner:ENDRESS HAUSER FLOWTEC AG

Single tube densitometer

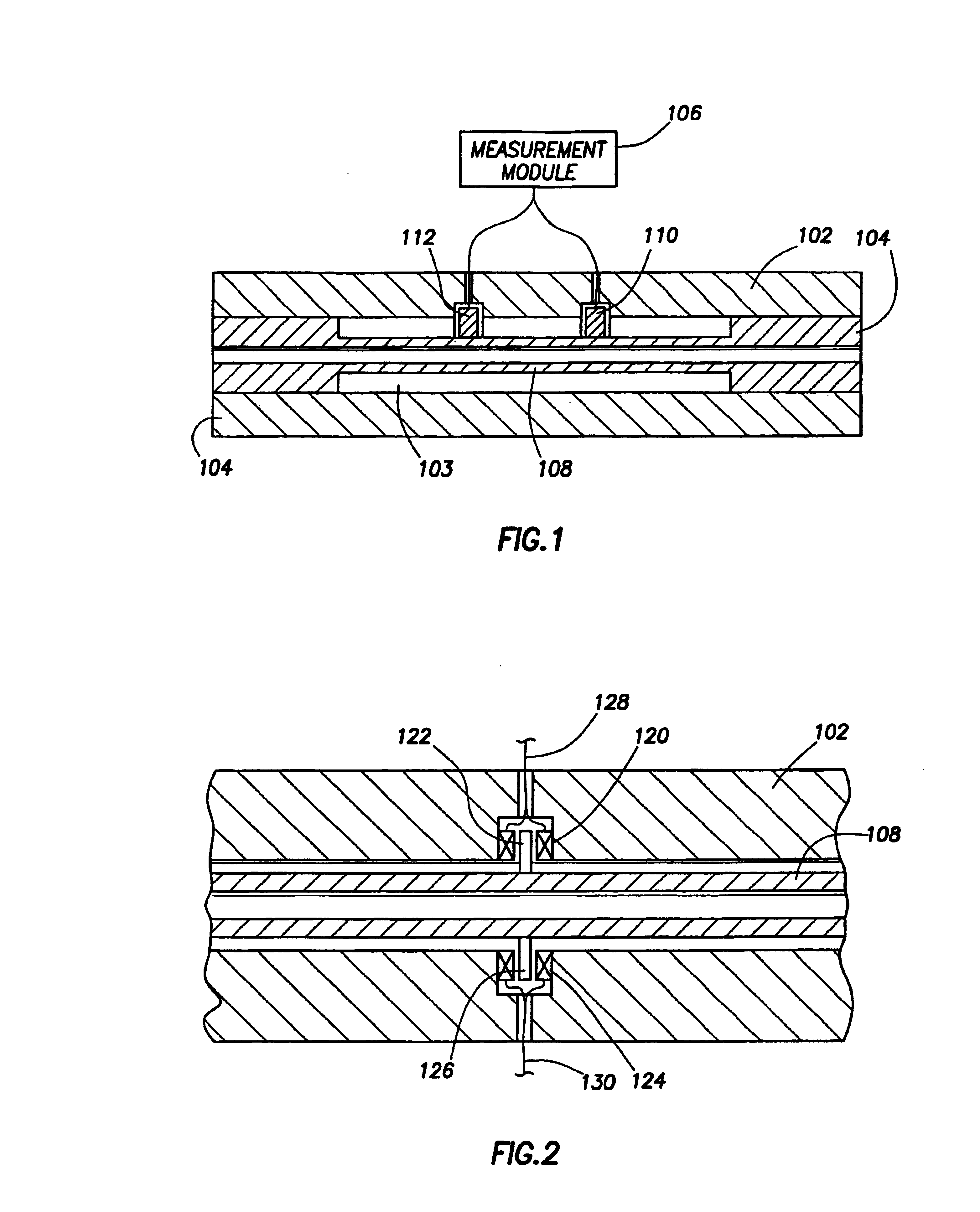

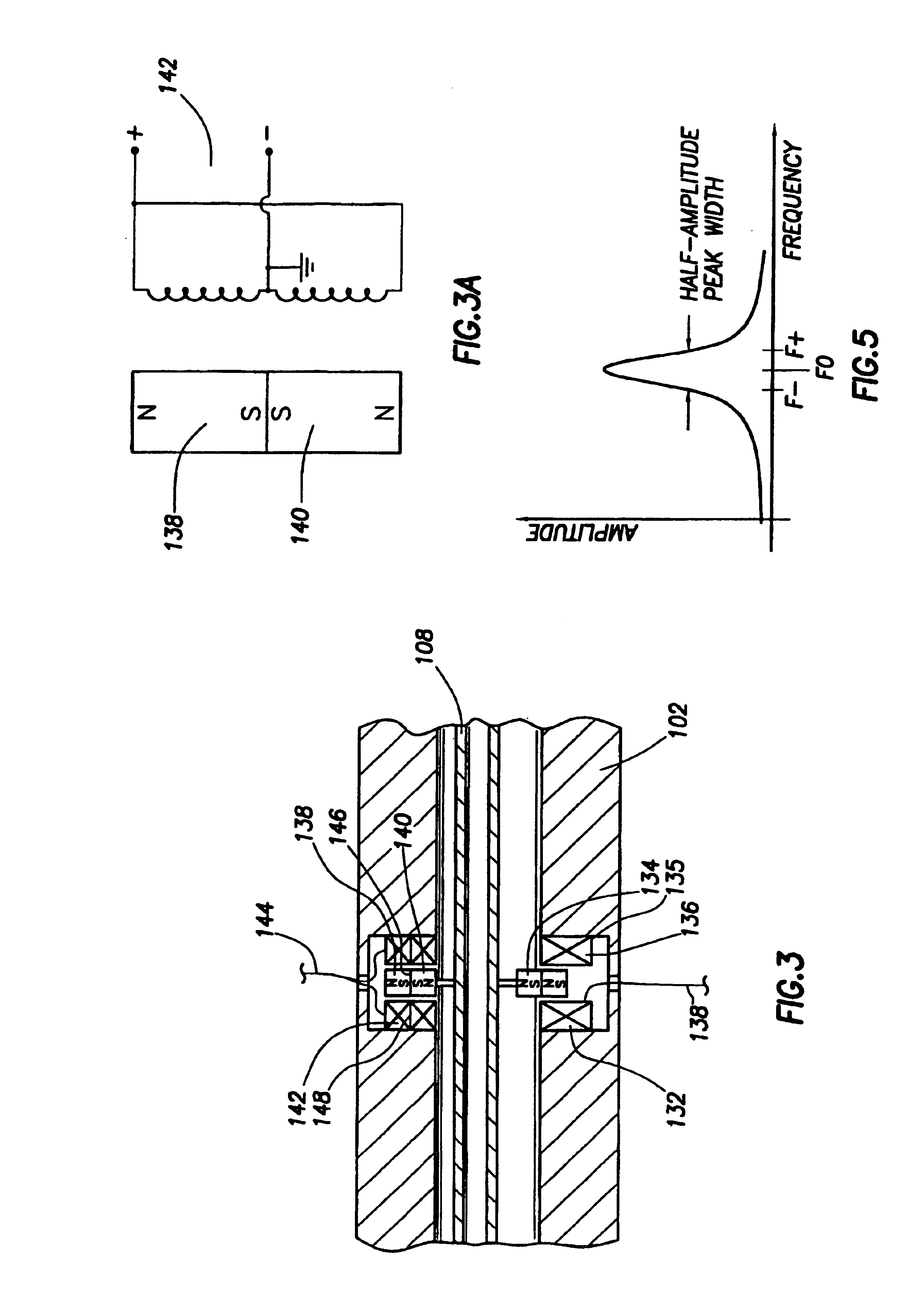

InactiveUS6912904B2Improve accuracyImprove reliabilityVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesMeasurement deviceComputer module

A measurement device is provided that determines fluid properties from vibration frequencies of a sample cavity. In one embodiment, the measurement device includes a sample flow tube, vibration source and detector mounted on the tube, and a measurement module. The sample flow tube receives a flow of sample fluid for characterization. The measurement module employs the vibration sources to generate vibrations in the tube. The measurement module combines the signals from the vibration detector on the tube to determine properties of the sample fluid, such as density, viscosity, compressibility, water fraction, and bubble size. The measurement module may further detect certain flow patterns such as slug flow, for example. To measure the sample fluid density, the measurement module determines the resonant frequency of the sample flow tube. The density can then be calculated according to a formula that compensates for the temperature and pressure of the system.

Owner:HALLIBURTON ENERGY SERVICES INC

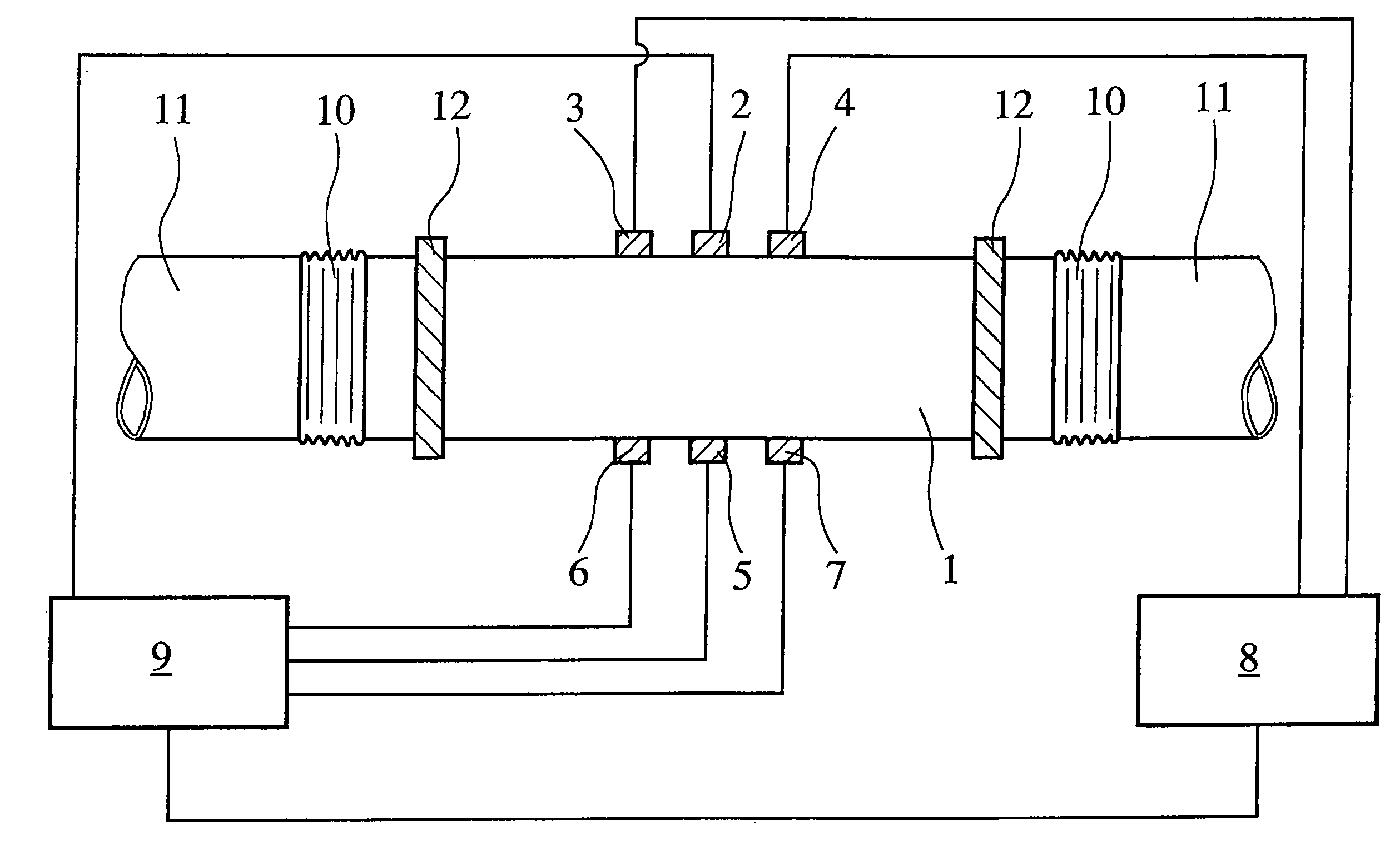

Coriolis mass flowmeter

InactiveUS7073396B2High measurement accuracyImprove vibrationVolume meteringDirect mass flowmetersClassical mechanicsAccuracy and precision

A Coriolis mass flowmeter incorporates a measuring tube for guiding a flowing medium, a first oscillator for the oscillatory stimulation of the measuring tube, as well as a first oscillation sensor and a second oscillation sensor for picking up Coriolis oscillations of the measuring tube. The first oscillator, the first oscillation sensor and the second oscillation sensor are mutually spaced apart in the longitudinal direction of the measuring tube and the first oscillator is activated by an oscillation-stimulating control device. A third oscillation sensor is provided and positioned opposite the first oscillator at the same longitudinal distance of the measuring tube. Additionally or alternatively, a second oscillator and a third oscillator may be provided, with the second oscillator positioned opposite the first oscillation sensor and the third oscillator positioned opposite the second oscillation sensor, in each case at the same longitudinal distance on the measuring tube. All mutually opposite oscillators and oscillation sensors are of the same size, resulting in a “balanced” measuring tube while opening up various possibilities for improving the evaluation and control of the flowmeter, which in turn provides greater reproducibility and measuring accuracy.

Owner:KRONE GMBH

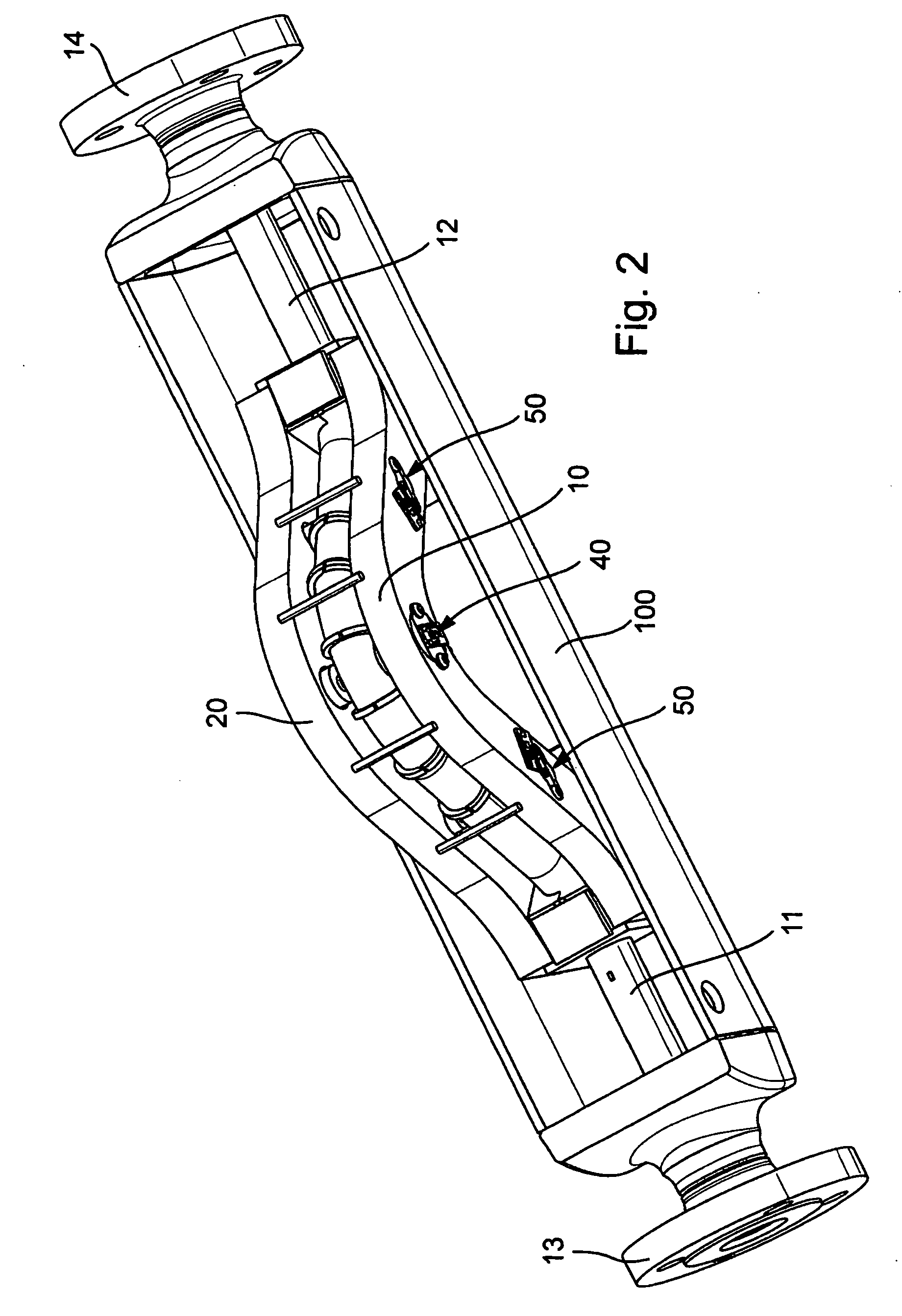

Measuring transducer of vibration-type

ActiveUS20070151371A1Improve density dependence of zero-pointEffective applicationDirect mass flowmetersDirect flow property measurementCouplingTransducer

A measuring transducer includes a transducer housing, as well as an internal part arranged in the transducer housing. The internal part includes at least one curved measuring tube vibrating, at least at times, during operation and serving for conveying the medium, as well as a counteroscillator affixed to the measuring tube on the inlet-side, accompanied by formation of a coupling zone, and to the measuring tube on the outlet-side, accompanied by the formation of a coupling zone. The internal part is held oscillatably in the transducer housing, at least by means of two connecting tube pieces, via which the measuring tube communicates during operation with the pipeline and which are so oriented with respect to one another, as well as with respect to an imaginary longitudinal axis of the measuring transducer, that the internal part can move during operation in the manner of a pendulum about the longitudinal axis. The measuring tube and the counteroscillator are additionally so embodied and so oriented with respect to one another that both a center of mass spaced from the imaginary longitudinal axis of the measuring tube, as well as also a center of mass of the counteroscillator spaced from the imaginary longitudinal axis, lie in a common region of the measuring transducer spanned by the imaginary longitudinal axis and the measuring tube, and that the center of mass of the measuring tube is spaced farther from the longitudinal axis than the center of mass of the counteroscillator.

Owner:ENDRESS HAUSER FLOWTEC AG

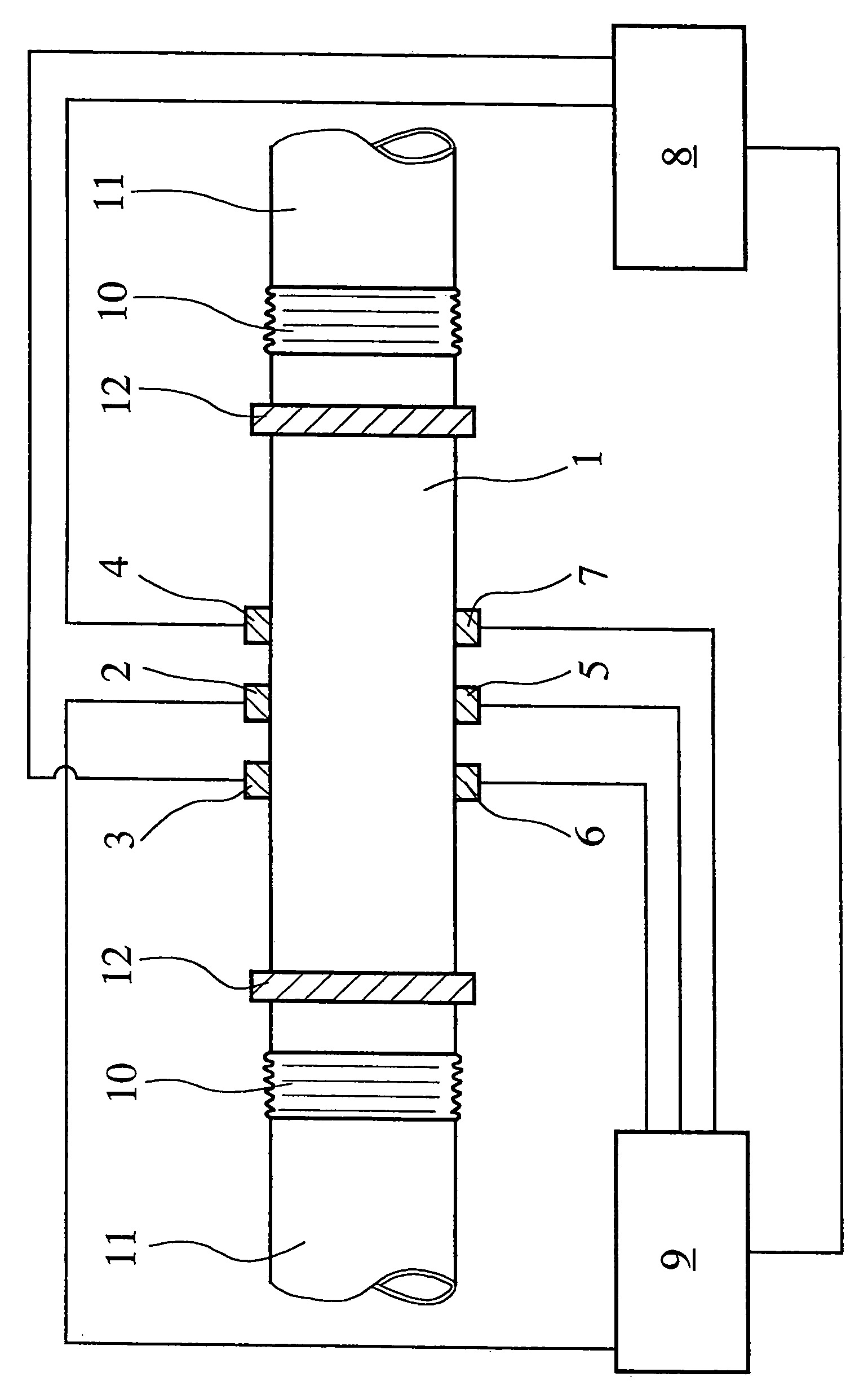

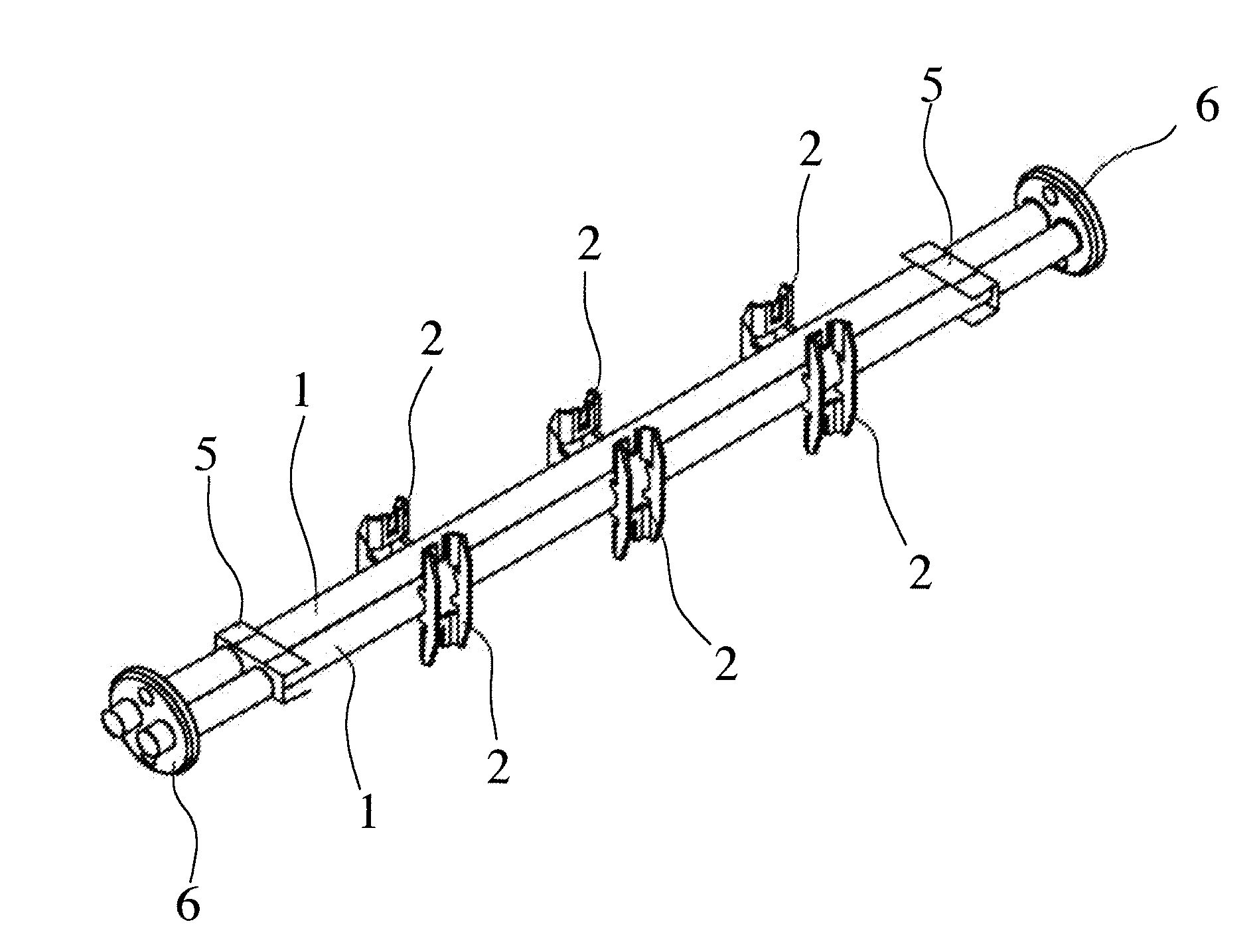

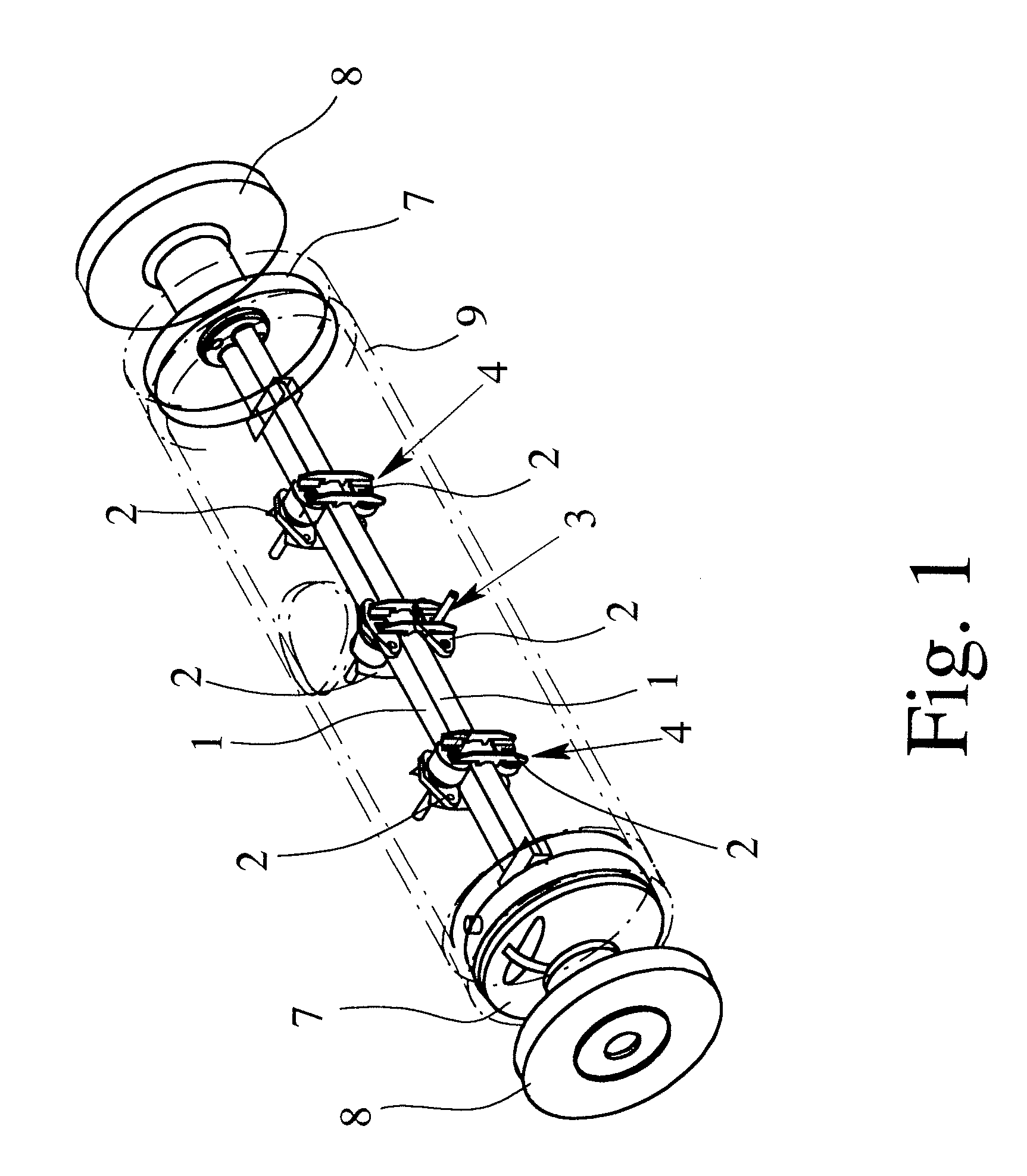

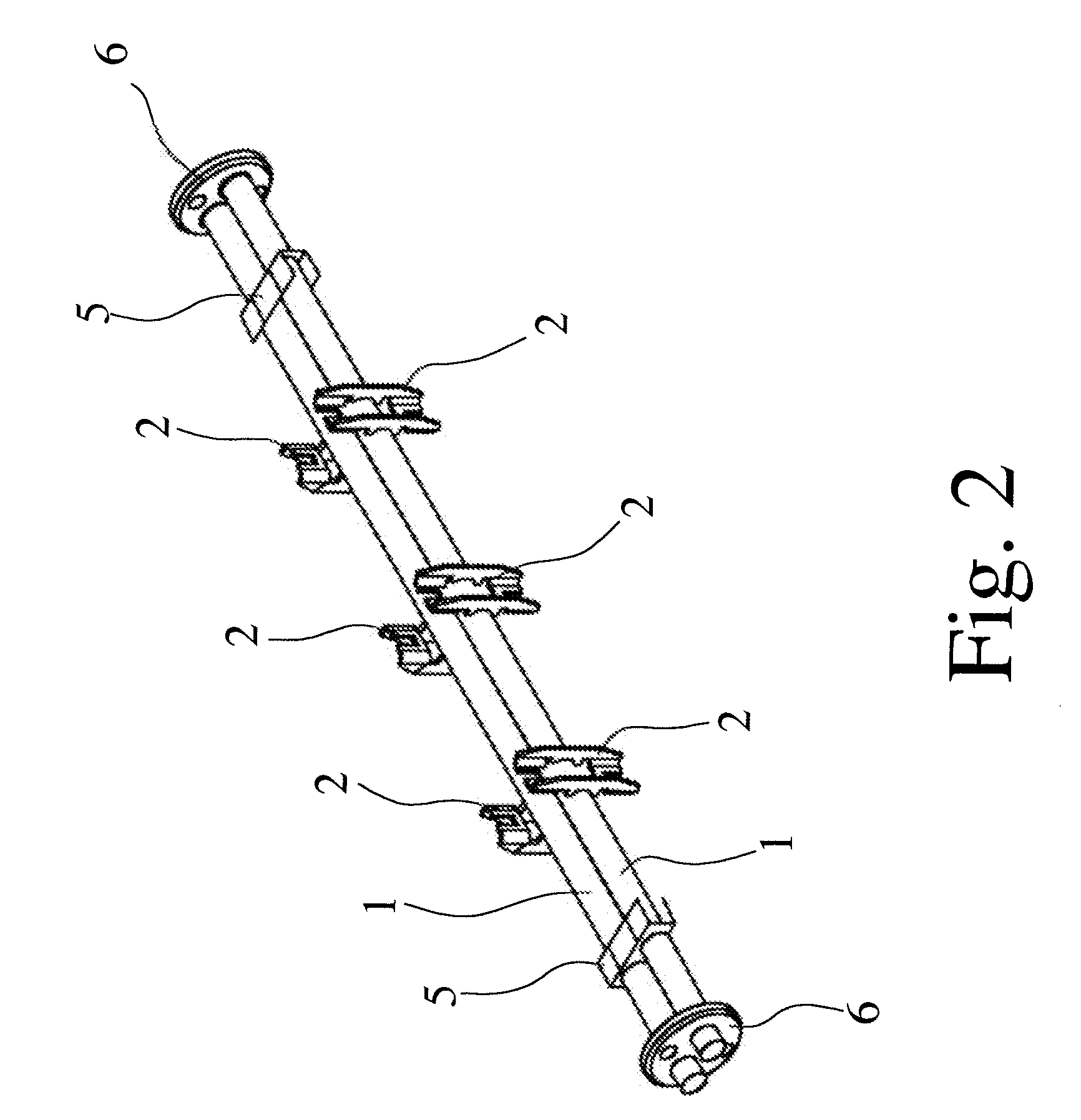

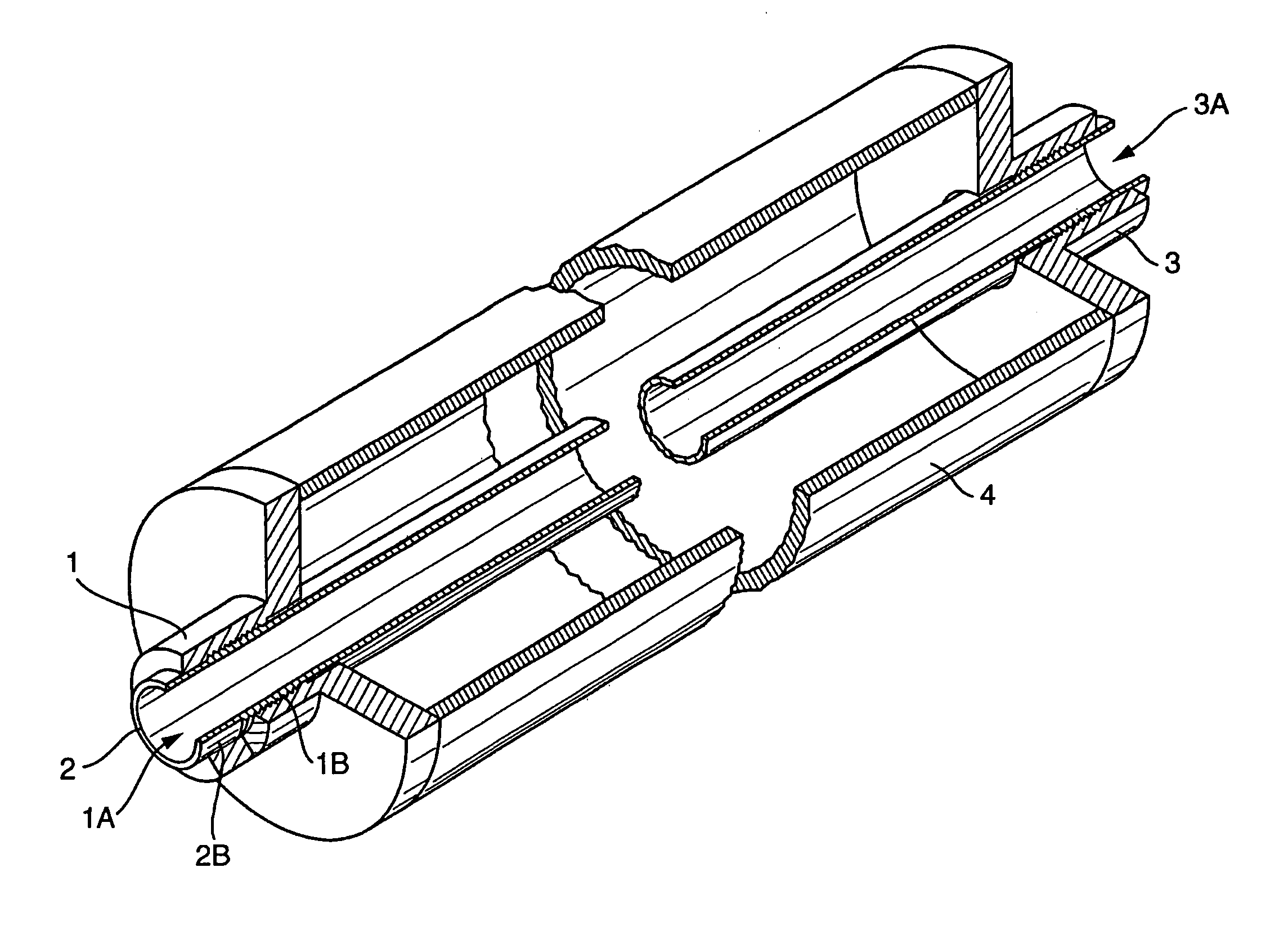

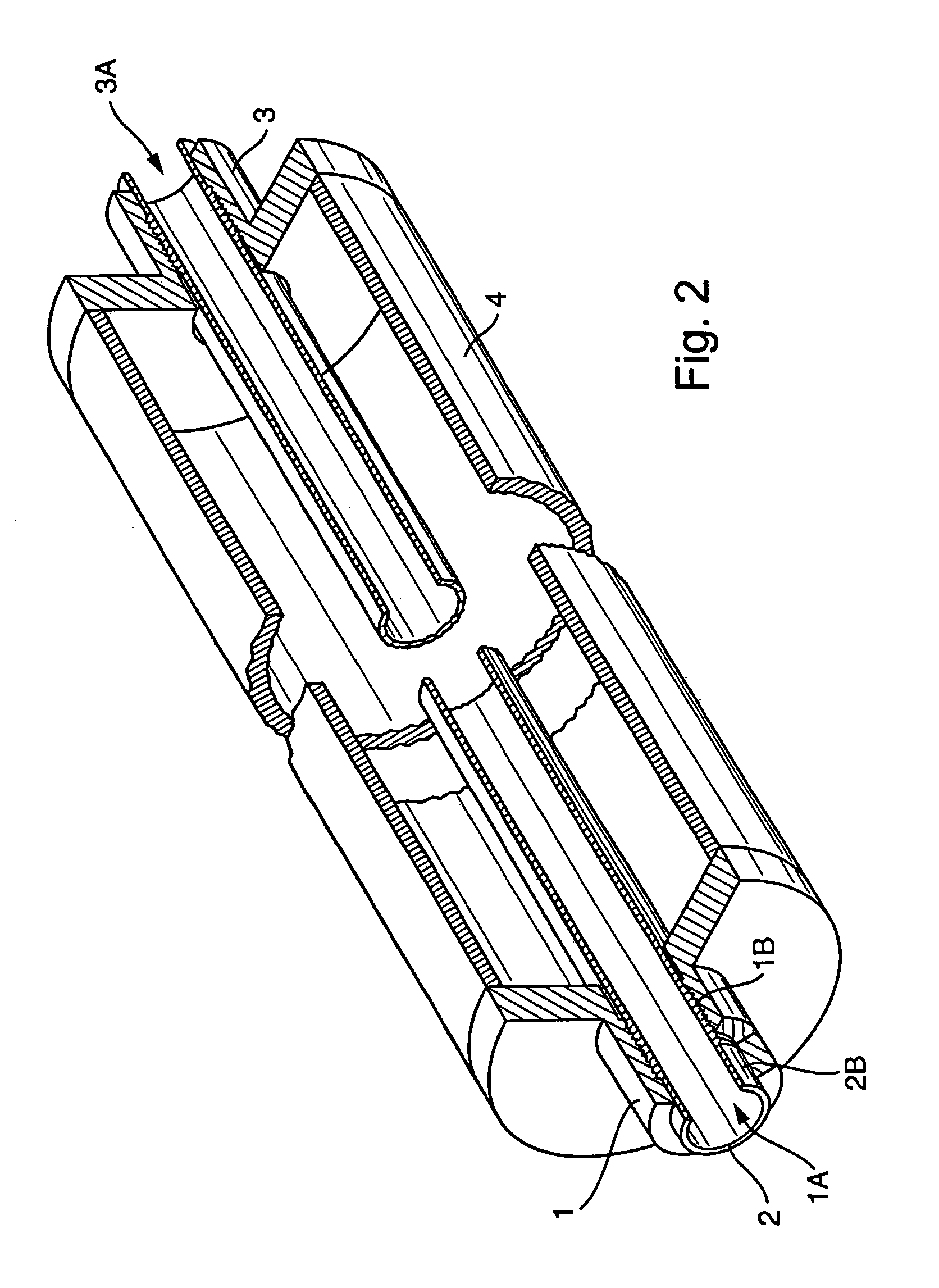

Device for measuring the mass rate of flow

ActiveUS20070151368A1Easy to produceImprove accuracyDirect mass flowmetersMeasurement deviceStream flow

A mass flow rate measurement device which works according to the coriolis principle, and has two measurement tubes (1) and a vibration converter. It is provided that a carrier (2) is mounted on each of the measurement tubes (1) as a pair of carriers, and the vibration converter is made and arranged such that it acts between the pair carriers (2). In this way, a coriolis mass flow rate measurement device which is simple to produce is attained, with measurement tubes (1) which can be located extremely close to one another.

Owner:KRONE GMBH

Measurement transducer of vibration type

ActiveUS20070186685A1Improve balanceReduce quality problemsDirect mass flowmetersCantilevered beamCoupling

The measurement transducer includes: A measuring tube vibrating at least at times during operation and serving for the conveying of a medium, wherein the measuring tube communicates with a pipeline via an inlet tube piece at an inlet end and an outlet tube piece at an outlet end; a counteroscillator, which is affixed to the measuring tube on the inlet end to form a first coupling zone and affixed to the measuring tube on the outlet end to form a second coupling zone; and a first cantilever for producing bending moments in the inlet tube piece and coupled with the inlet tube piece and the measuring tube essentially rigidly in the area of the first coupling zone and having a center of mass lying in the region of the inlet tube piece, as well as a second cantilever for producing bending moments in the outlet tube piece and coupled essentially rigidly with the outlet tube piece and the measuring tube in the region of the second coupling zone and having a center of mass lying in the region of the outlet tube piece. The measurement transducer of the invention is especially suited also for measuring tubes having large nominal diameters of more than 50 mm.

Owner:ENDRESS HAUSER FLOWTEC AG

Vibratory measurement transducer

The measurement transducer includes a transducer housing, which exhibits a plurality of natural oscillation modes, as well as at least one first flow tube held oscillatably in the transducer housing, vibrating at least at times, and conveying at least a portion of the medium to be measured. Additionally, the measurement transducer includes an electromechanical, especially electrodynamic, exciter arrangement acting on the at least one flow tube for producing and / or maintaining mechanical oscillations of the at least one flow tube, and a sensor arrangement reacting to movements of the flow tube, especially bending oscillations, for producing at least one oscillation measurement signal representing oscillations of the flow tube. Additionally, for improving the oscillation properties and, consequently, also the measurement accuracy of the measurement transducer, at least three coupling elements are provided for connecting the first and second flow tubes together at the inlet end, as well as at least three coupling elements for connecting the first and second flow tubes together at the outlet end. By using at least six coupling elements, it is possible to produce vibration-type measurement transducers of high measuring accuracy even at large nominal diameters of more than 150 mm, especially also while largely maintaining already established and proven forms of construction.

Owner:ENDRESS HAUSER FLOWTEC AG

Measurement transducer of vibration type

ActiveUS20070119265A1Improve balanceReduce quality problemsDirect mass flowmetersCantilevered beamCoupling

The measurement transducer includes: A measuring tube vibrating at least at times during operation and serving for the conveying of a medium, wherein the measuring tube communicates with a pipeline via an inlet tube piece at an inlet end and an outlet tube piece at an outlet end; a counteroscillator, which is affixed to the measuring tube on the inlet end to form a first coupling zone and affixed to the measuring tube on the outlet end to form a second coupling zone; and a first cantilever for producing bending moments in the inlet tube piece and coupled with the inlet tube piece and the measuring tube essentially rigidly in the area of the first coupling zone and having a center of mass lying in the region of the inlet tube piece, as well as a second cantilever for producing bending moments in the outlet tube piece and coupled essentially rigidly with the outlet tube piece and the measuring tube in the region of the second coupling zone and having a center of mass lying in the region of the outlet tube piece. The measurement transducer of the invention is especially suited also for measuring tubes having large nominal diameters of more than 50 mm.

Owner:ENDRESS HAUSER FLOWTEC AG

Composite system, method for its manufacture, and measurement pickup using such a composite system

ActiveUS7299699B2Stable, high-strength and lasting,Increased pull-out strengthMaterial analysis using sonic/ultrasonic/infrasonic wavesPig casting plantsEngineeringCompound system

A composite system includes a first component, for instance of metal, and a second component extending at least partly through the first component along an imaginary longitudinal axis of the composite system. The second component contacts, with an at least partially curved, especially cylindrical, outer surface, an inner surface of the first component flushly such that the first component at least sectionally, at least partly, grips around the second component. Joining surfaces of the composite system, which are formed by the mutually contacting surfaces of the two components, are formed in such a manner that the two components exhibit contour portions in the area of these joining surfaces embodied as self-closing, peripheral surfaces. The contour portions fit at least partly into one another, to form a mechanical interference locking effective, at least in part, likewise in the direction of the longitudinal axis. Additionally, the second component, with its outer surface, contacts the inner surface of the first component flushly, such that the two components are mechanically tightly connected together also by means of a frictional locking effective at least partly in the direction of the longitudinal axis. Alternatively, or in supplementation thereof, at least one of the components is subjected at least partly to lastingly elastic, especially mixed plastic-elastic, deformations. The composite system is distinguished by a high pull-out strength, even in the presence of repeatedly arising vibrations in one of the components and is, therefore, especially suited also for use in a vibration-type measurement pickup.

Owner:ENDRESS HAUSER FLOWTEC AG

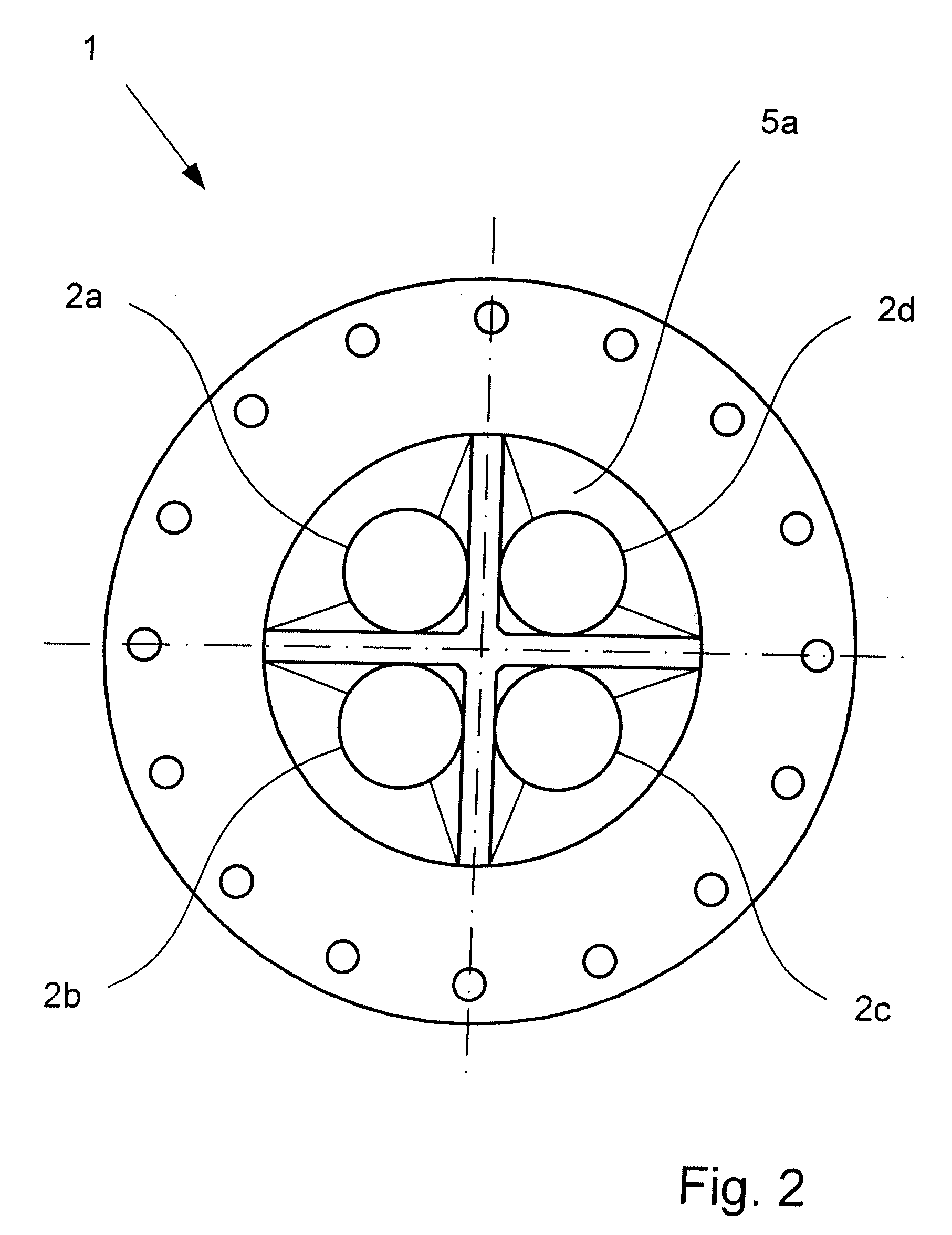

Mass flowmeter

A mass flowmeter is provided which operates on the Coriolis principle, having (1) at least four measurement tubes which can oscillate and through which a medium can flow, (2) at least one oscillation generator for excitation of the oscillations of the measurement tube, and (3) at least one oscillation sensor for detection of the excited oscillations of the measurement tubes. The measurement tubes are preferably arranged closely in parallel such that the flow cross section covered by the measurement tubes covers as small an area as possible. The use of four or more compactly arranged measurement tubes advantageously allows for the measurement of a high mass flow rate with measurement tubes having a relatively small cross section and length, resulting in a mass flowmeter having compact length and width dimensions, and which requires only a relatively low energy oscillation generator for excitation of the oscillations of the measurement tubes.

Owner:KRONE GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com