Patents

Literature

9843results about "Volume metering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

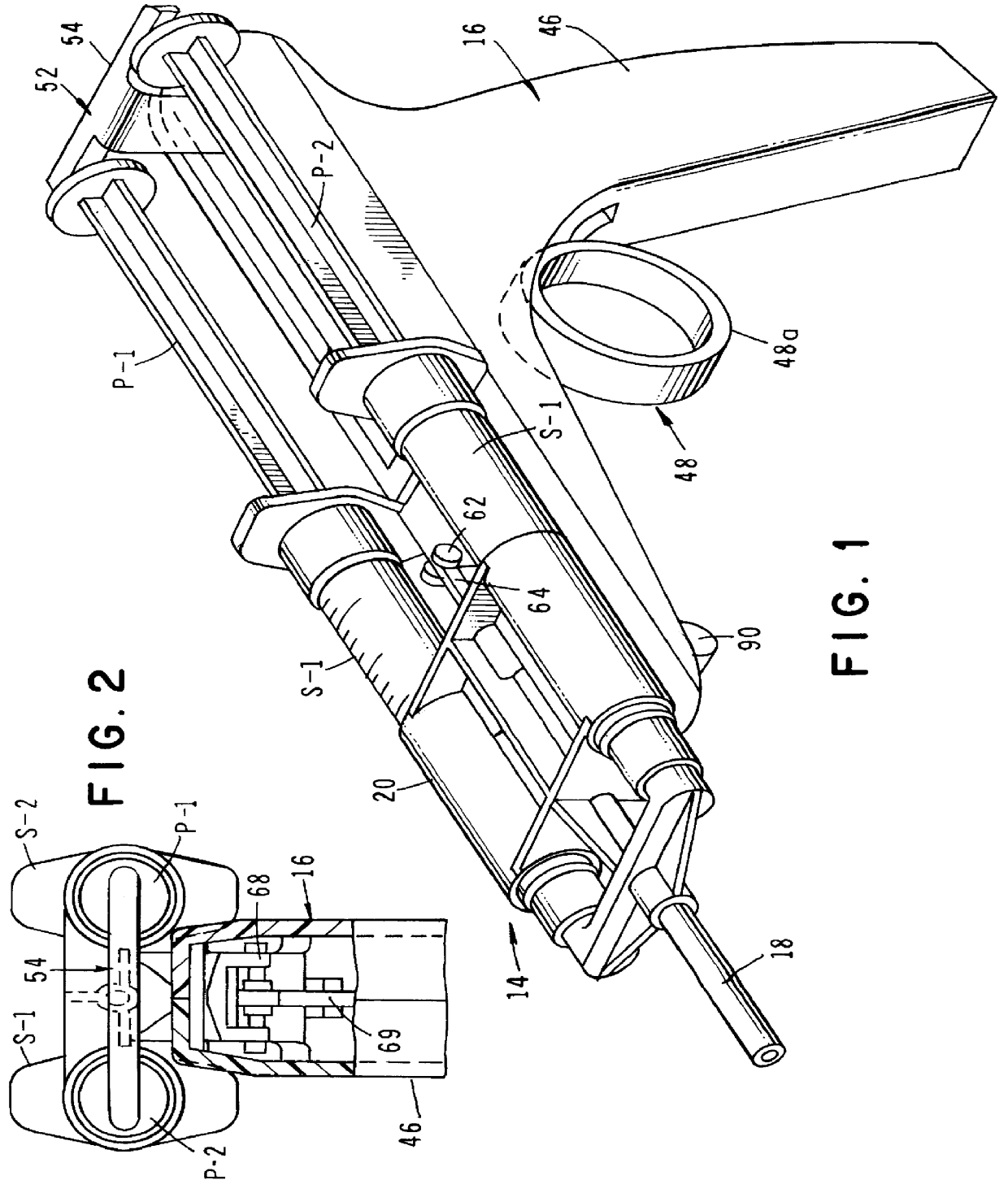

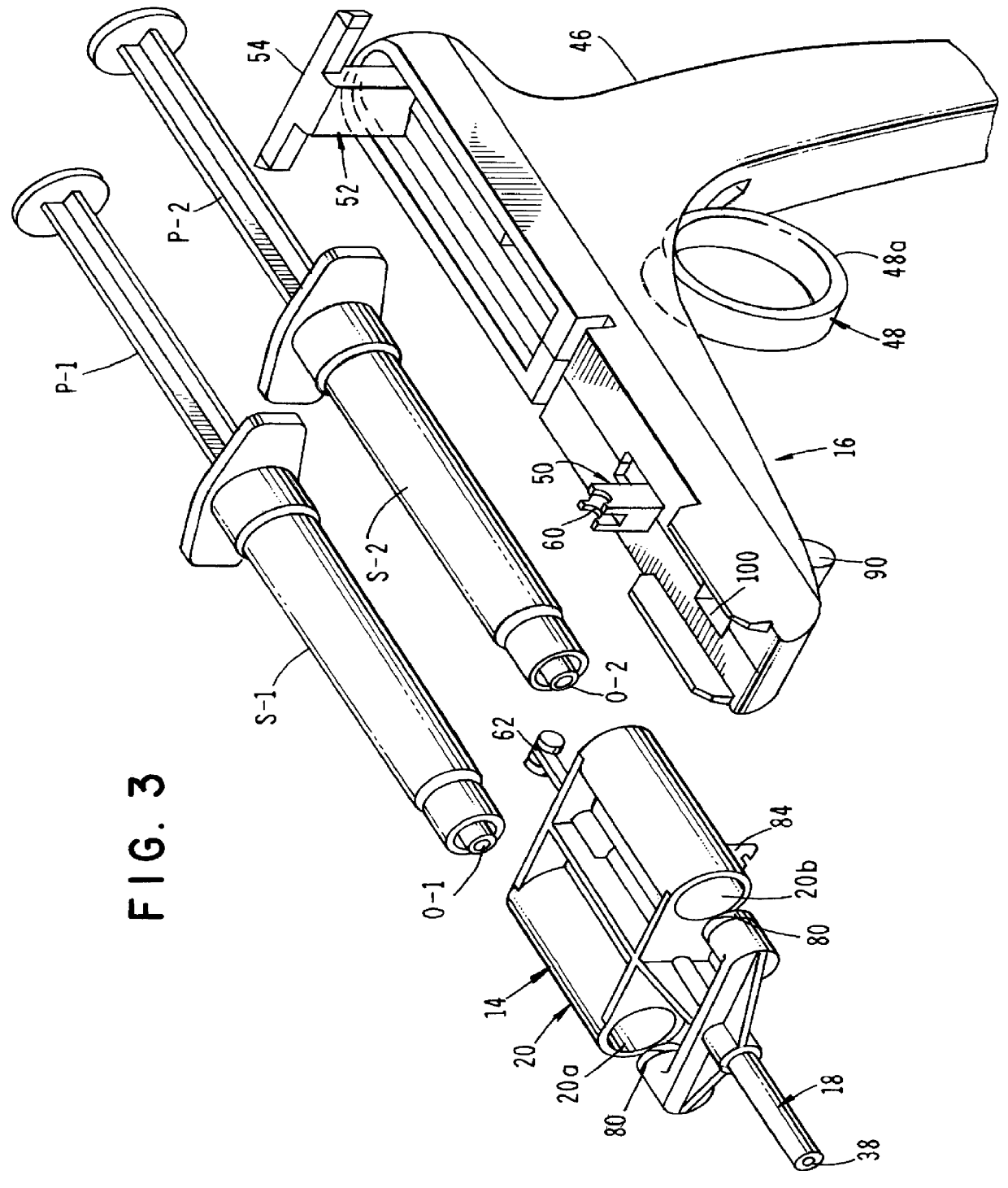

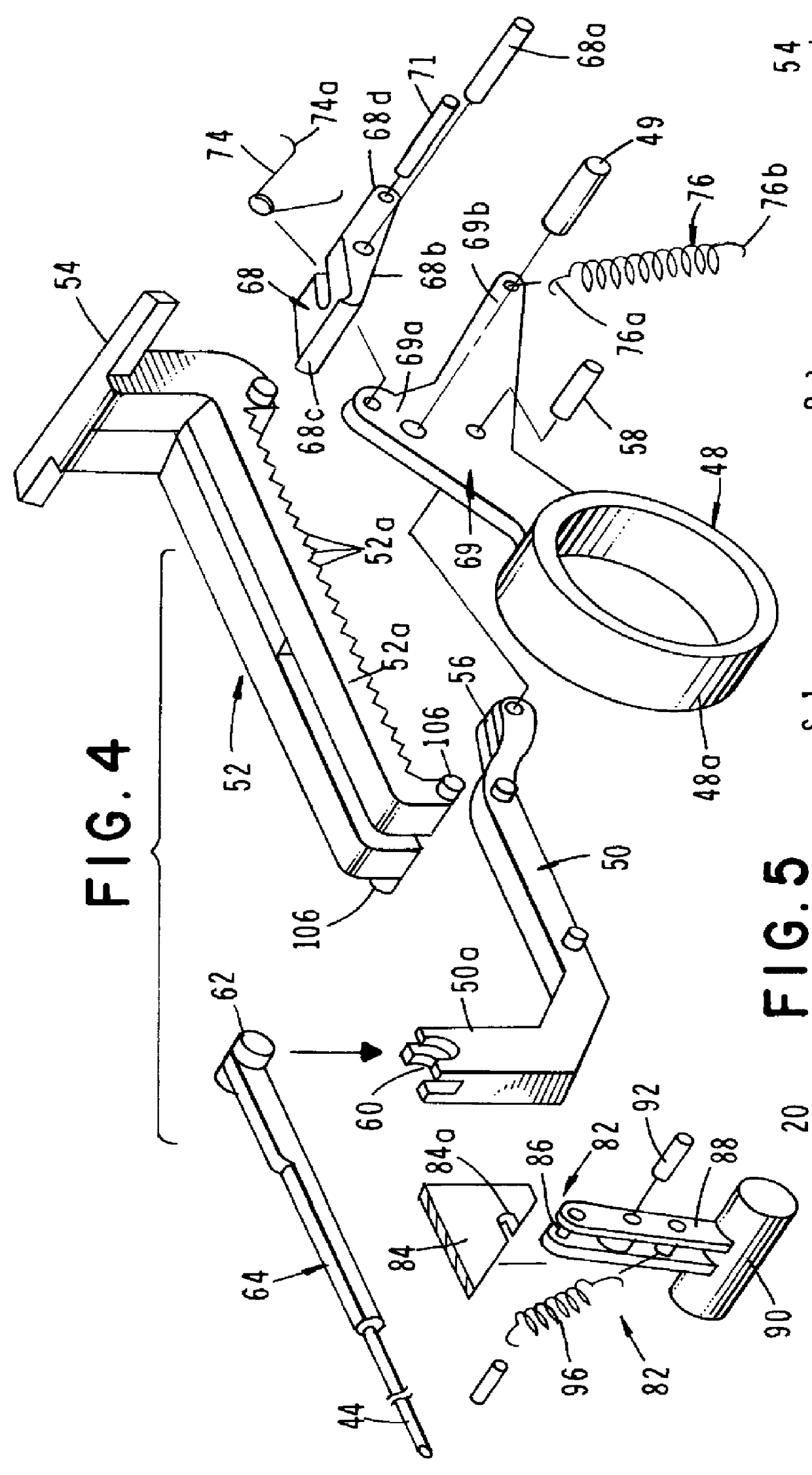

Two component fluid dispenser

InactiveUS6047861AEnhanced couplingSecurely holdLiquid surface applicatorsSurgeryEngineeringViscosity

A two-component fluid dispenser which can accurately mix two liquids of varying viscosity and then precisely deliver the mixture formed in discrete amounts. The mixture of the two components is delivered from a single delivery tube in a manner such that none of the mixture remains within the delivery tube at the completion of each mixing and delivery cycle. In one form of the apparatus, the single delivery tube of the apparatus is operably coupled with conventional hypodermic syringes of various sizes so that different fluids can be mixed in different ratios.

Owner:BAXTER INT INC

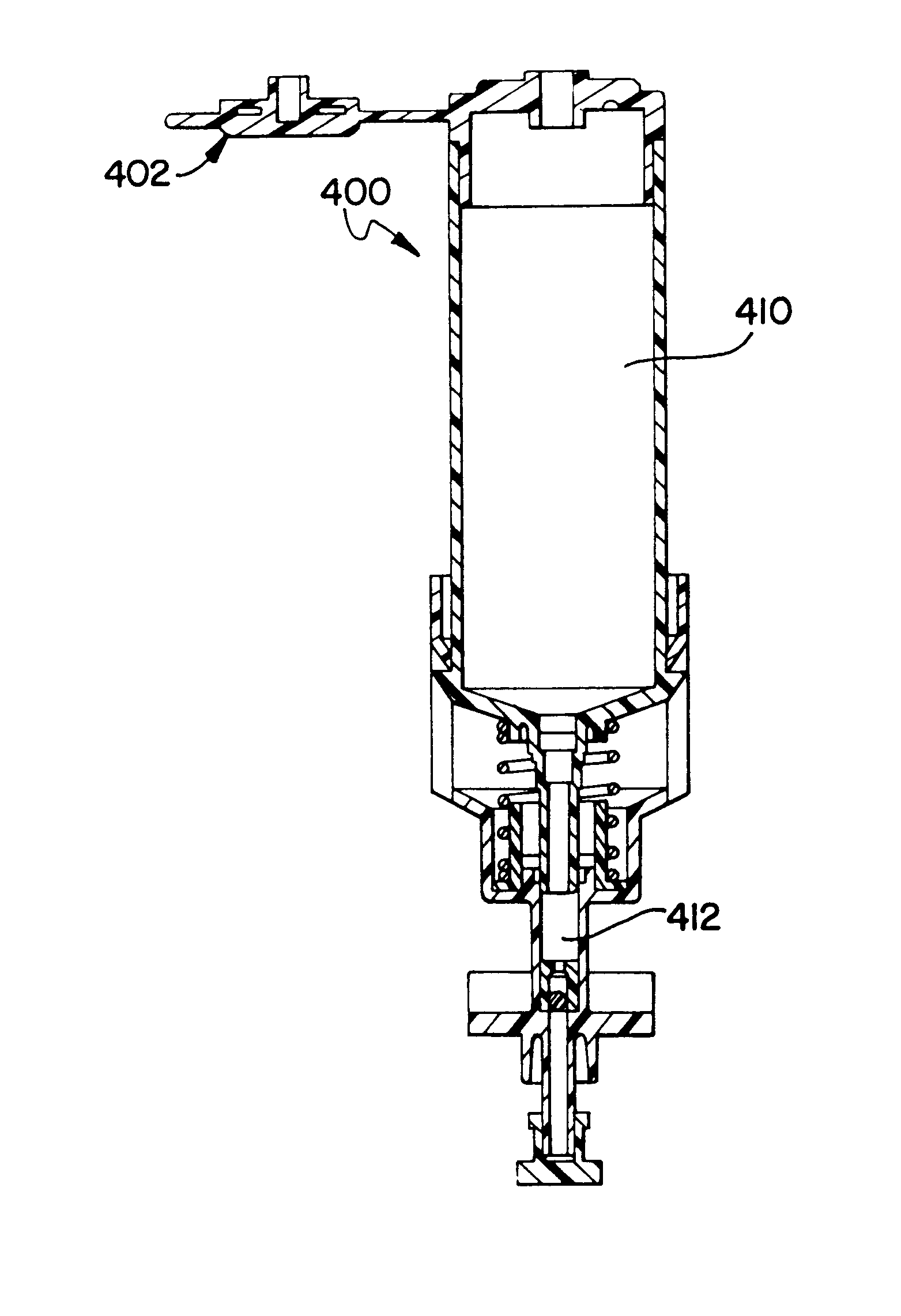

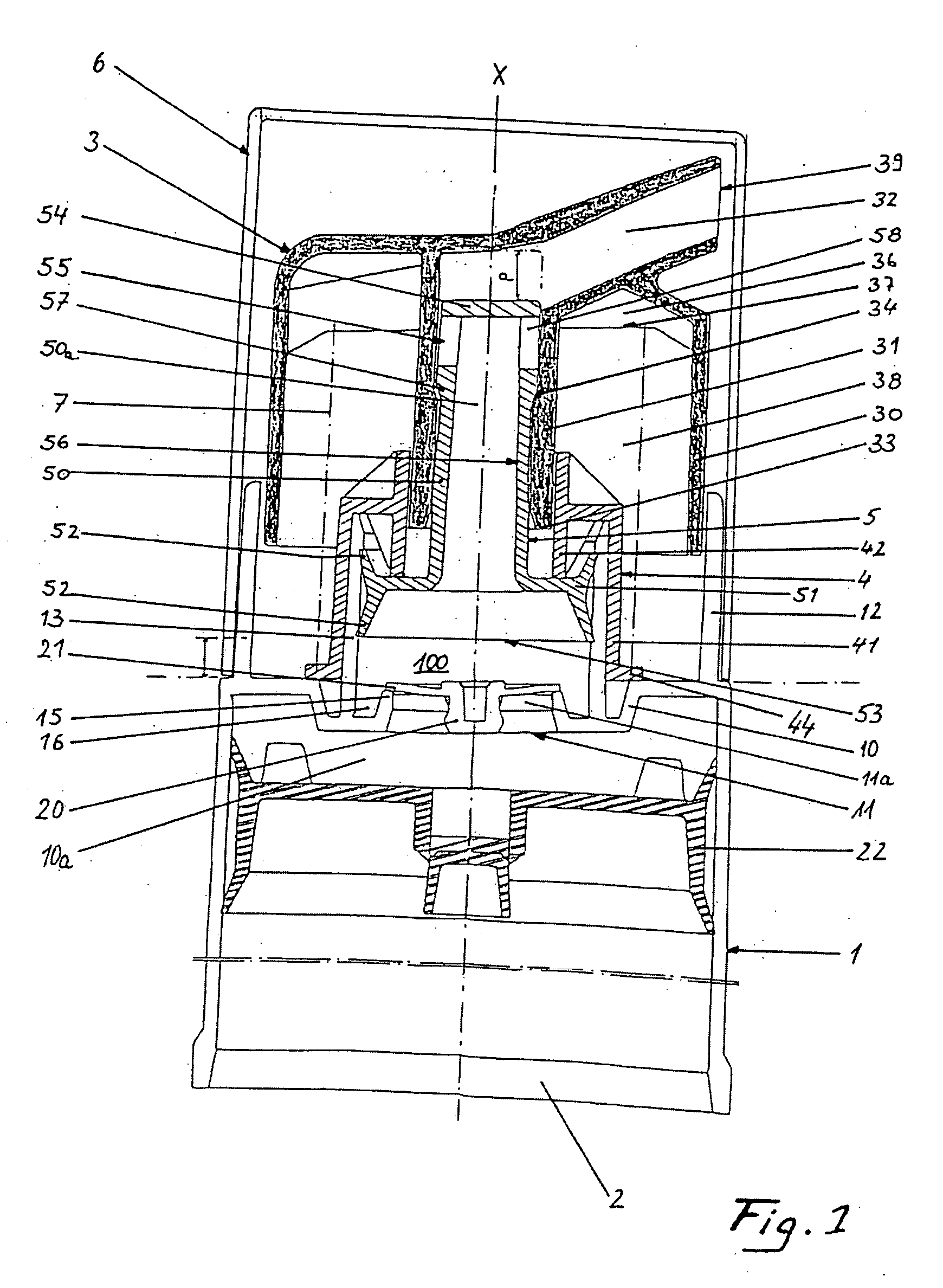

Vertebroplasty injection device

InactiveUS7008433B2Small sizeIncrease pressurePowder deliveryShaking/oscillating/vibrating mixersInjectable biomaterialBone cement

This invention relates to a mixing and delivery device suitable for delivering injectable biomaterials, and to preferred bone cement formulations.

Owner:DEPUY ACROMED INC

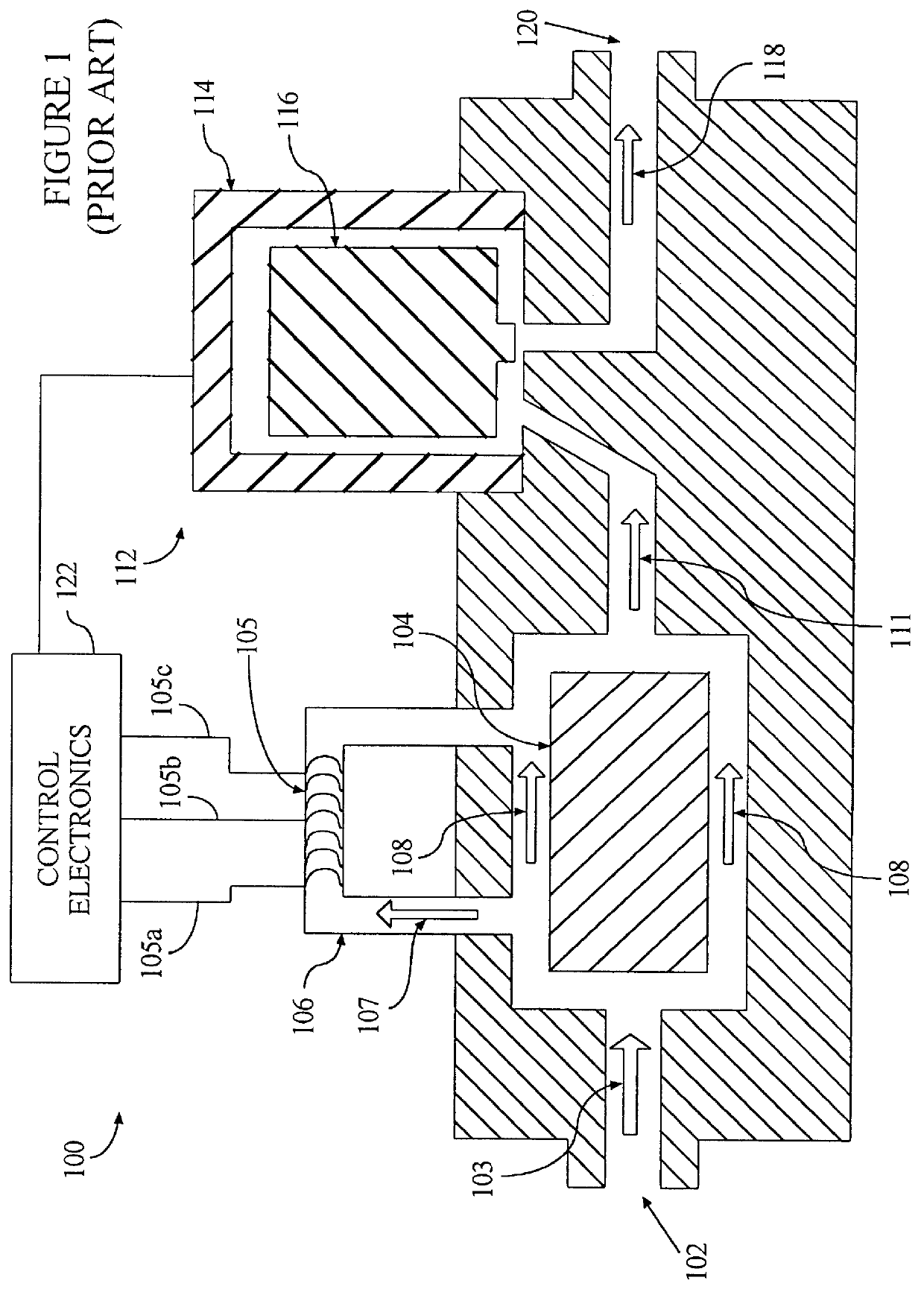

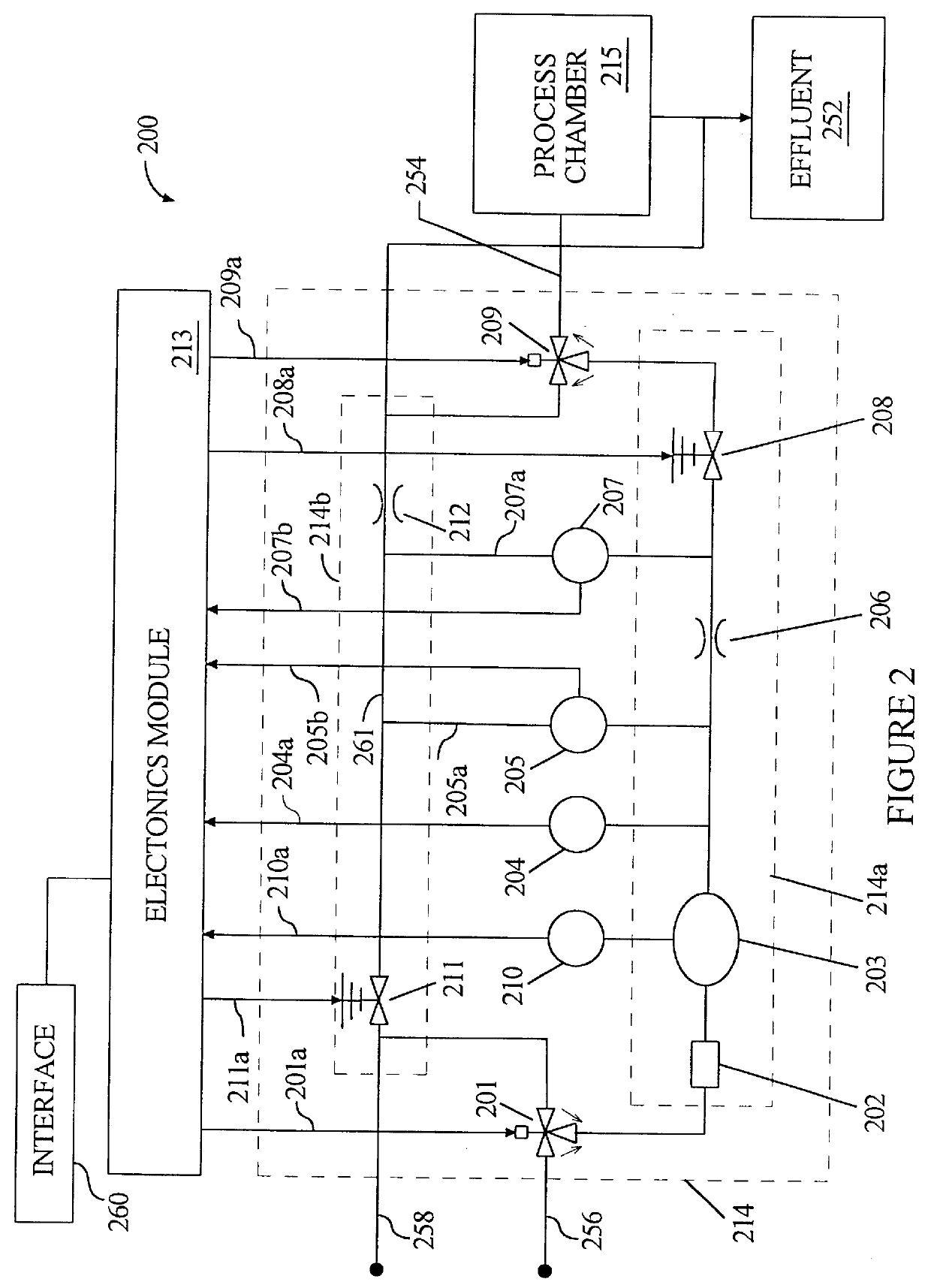

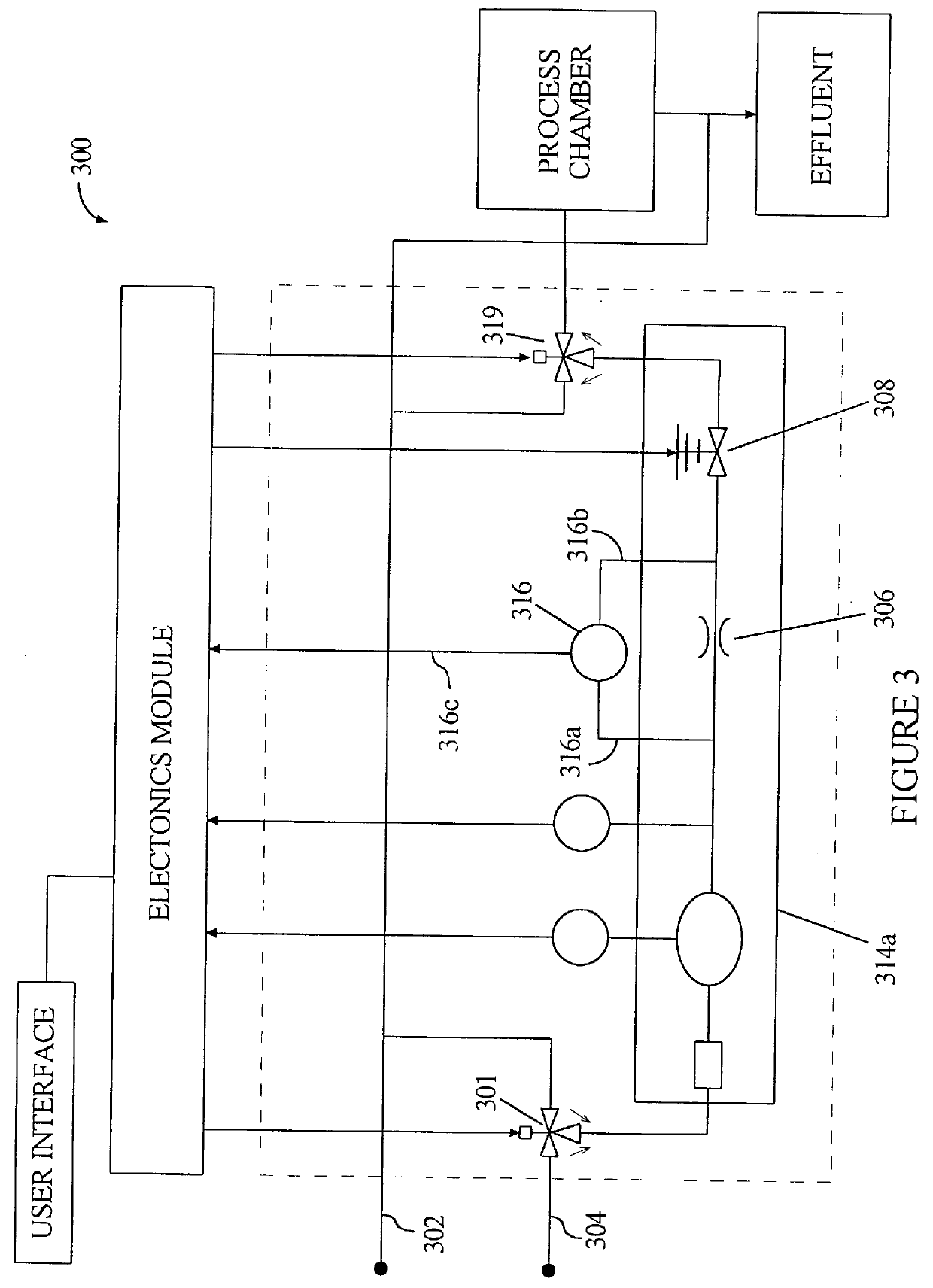

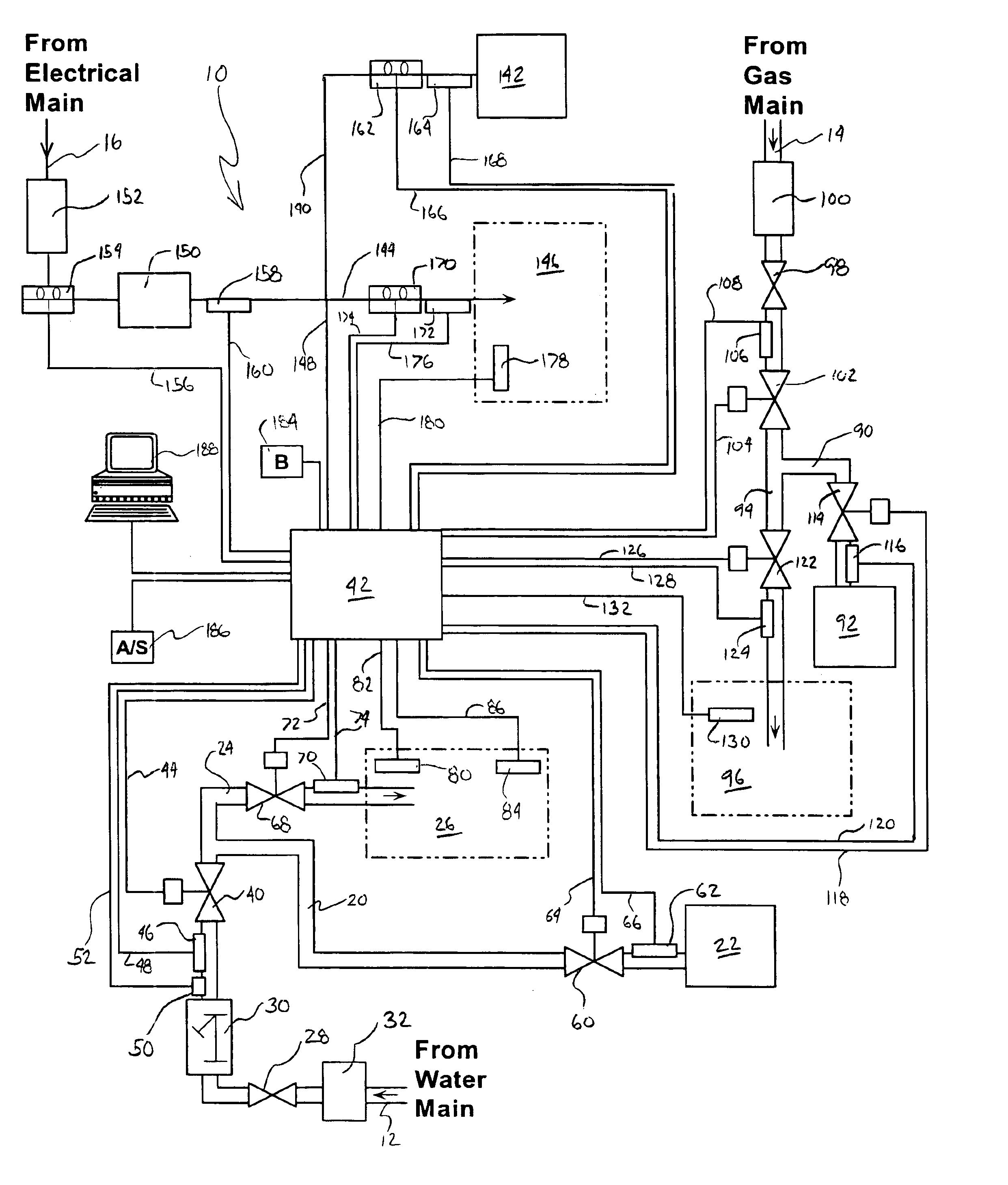

Method for wide range gas flow system with real time flow measurement and correction

InactiveUS6119710AAccurate measurementAccurate flowOperating means/releasing devices for valvesVolume/mass flow by thermal effectsDifferential pressureInlet valve

A gas delivery system accurately measures and optionally regulates mass flow rate in real time. A fluid conduit connects an inlet valve, calibration volume, flow restrictor, and outlet valve in series. Pressure and temperature sensors are coupled to the calibration volume. One or more pressure sensors may be attached across the flow restrictor. Alternatively, an absolute pressure sensor may be attached upstream of the flow restrictor. One embodiment of differential pressure sensors comprises a floating reference differential pressure sensor, including a first transducer attached to the fluid conduit upstream of the flow restrictor and a second transducer attached to the conduit downstream of the flow restrictor. In this embodiment, each transducer receives a reference pressure from a reference source, and optionally, after the calibration volume is charged, the floating reference differential pressure transducers are calibrated. When gas flow is initiated, differential and / or absolute pressure measurements are repeatedly taken, and a measured mass flow rate calculated thereon. Gas flow is adjusted until the measured mass flow rate reaches a target mass flow. Using the temperature / pressure sensors at the calibration volume, repeated calculations of actual flow rate are made to uncover any discrepancy between actual and measured mass flow rates. Whenever a discrepancy is found, the manner of calculating measured mass flow is conditioned to account for the discrepancy; thus, the measured mass flow rate more accurately represents the actual mass flow rate thereby providing an actual mass flow rate more accurately achieving the target mass flow rate.

Owner:CYBER INSTR TECH LLC AN ARIZONA LIMITED LIABILITY +1

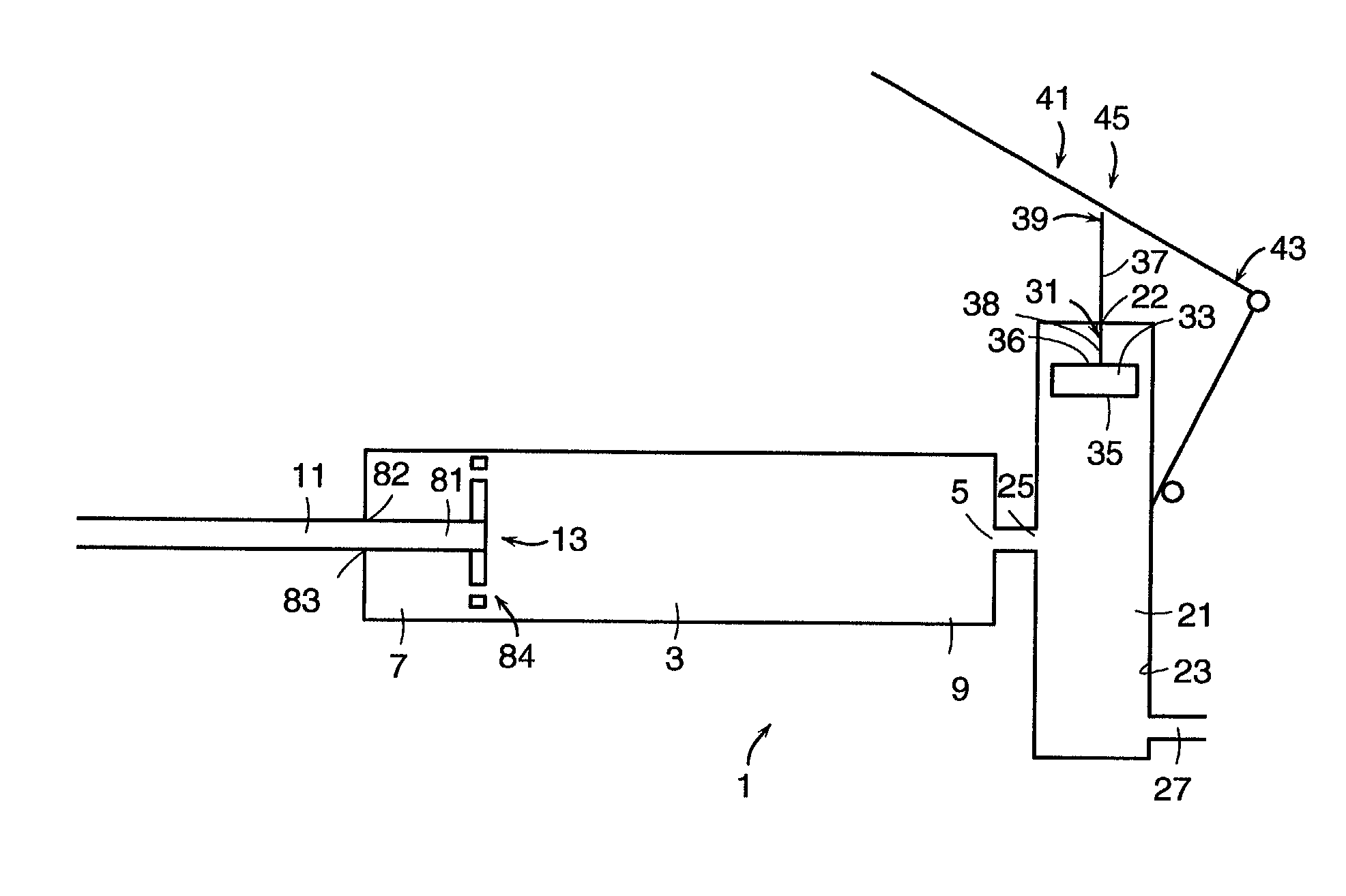

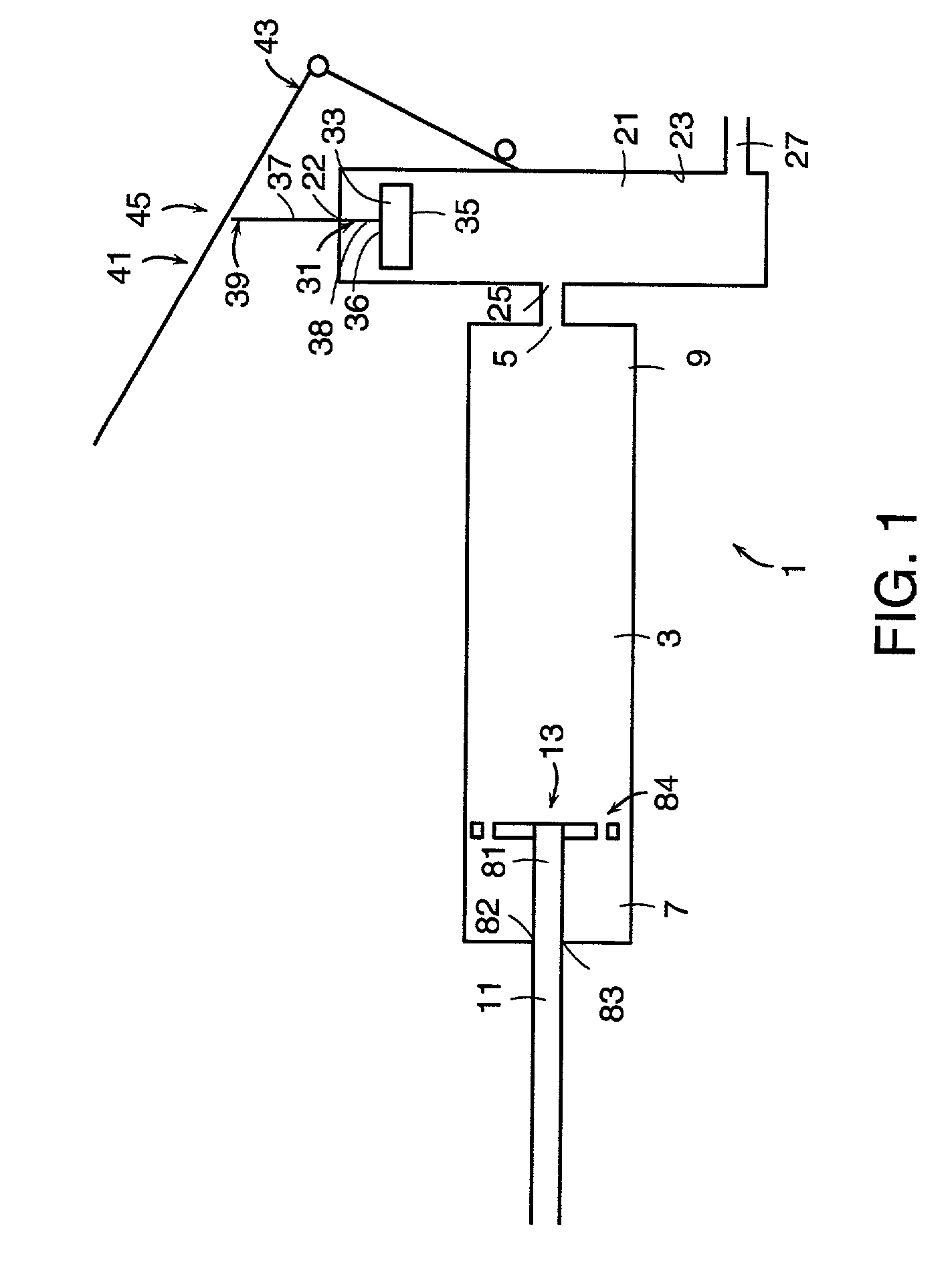

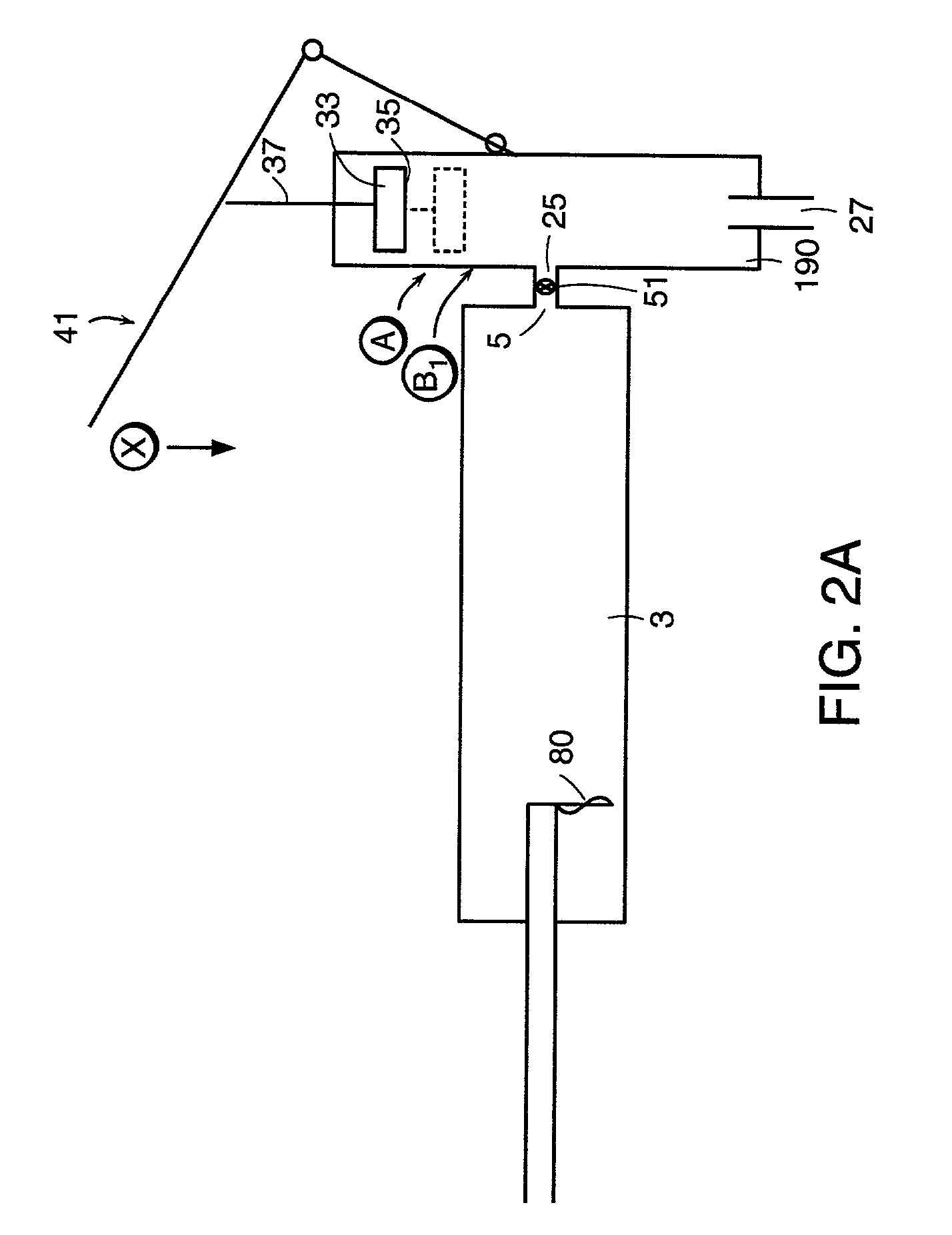

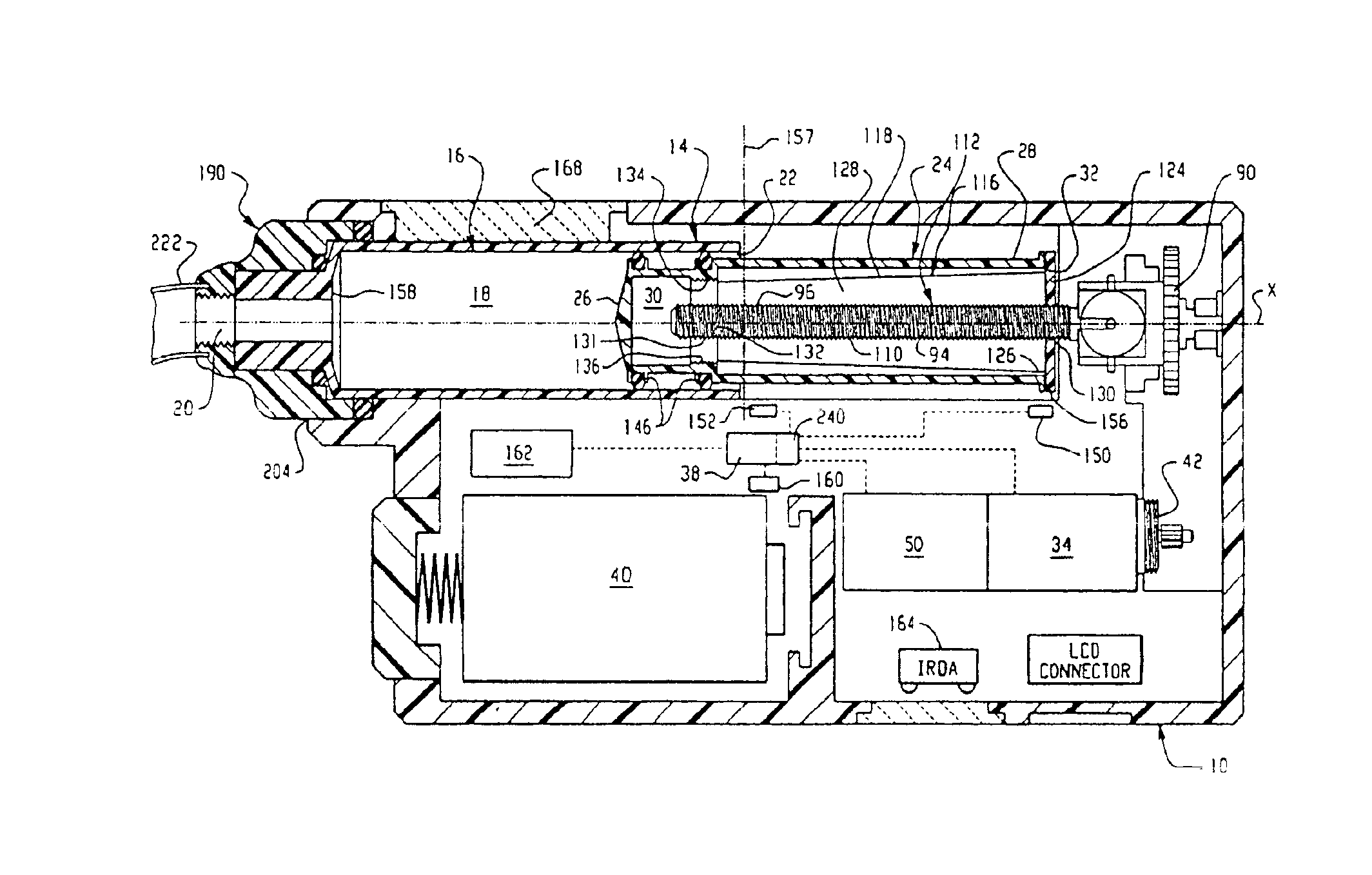

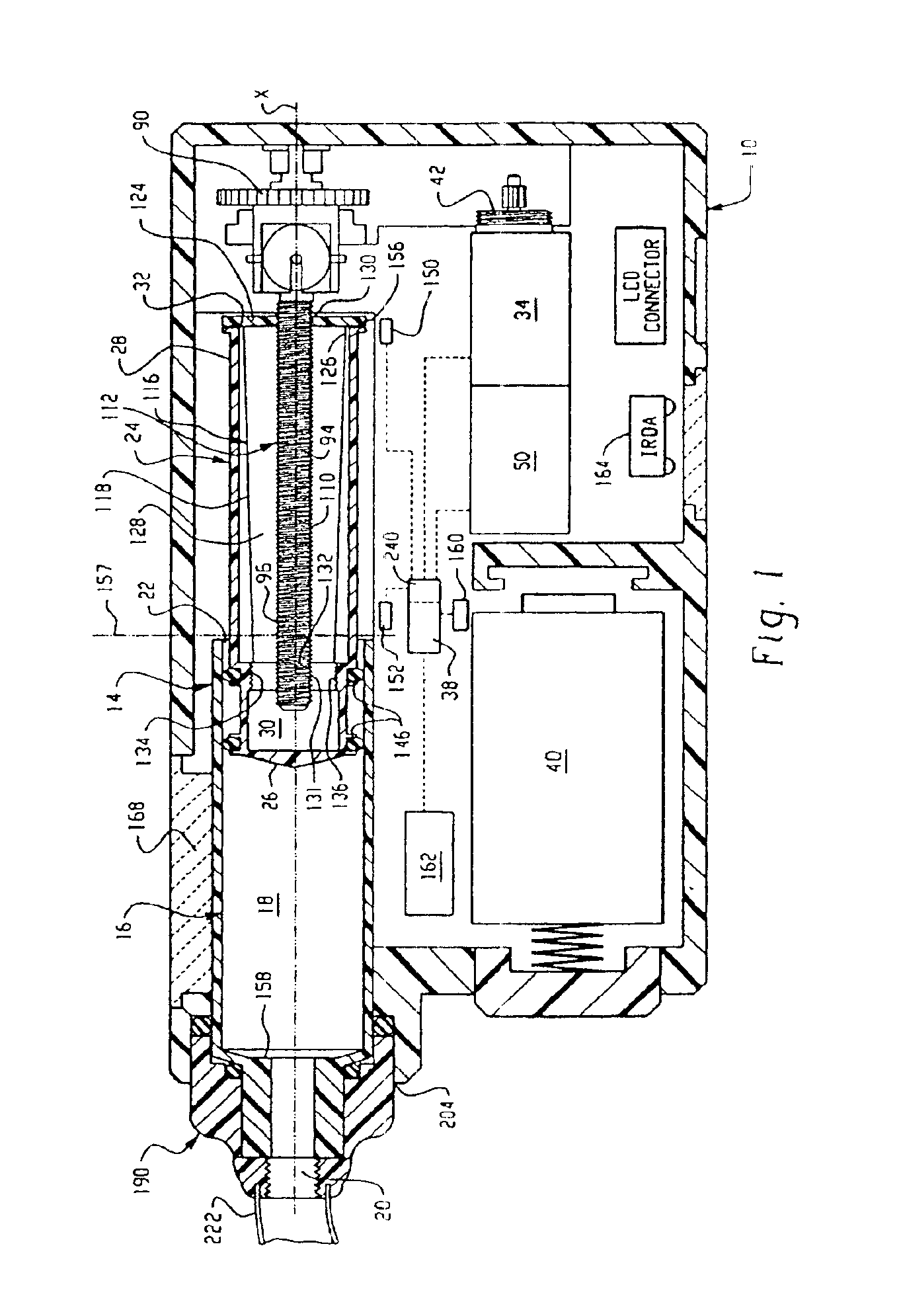

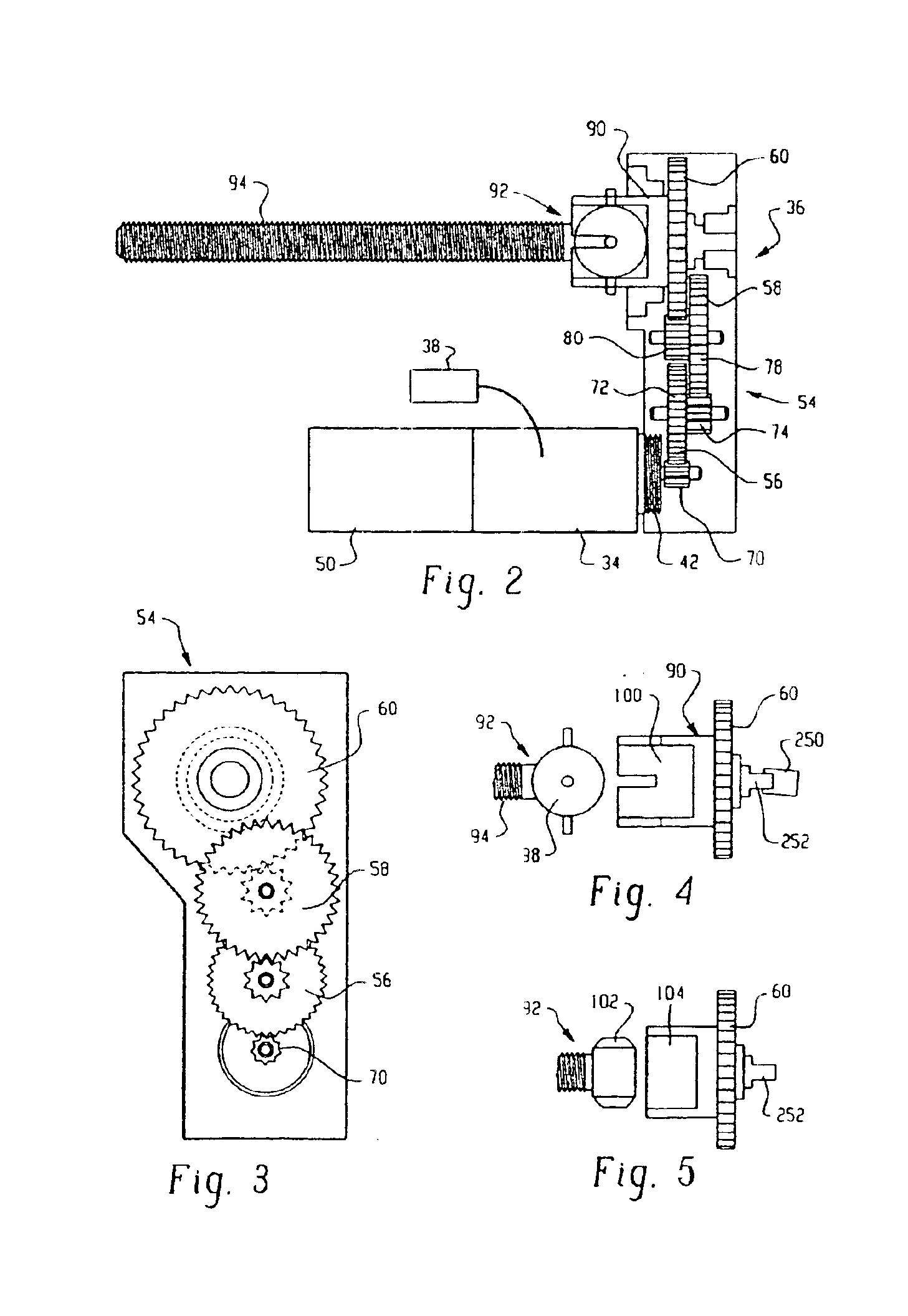

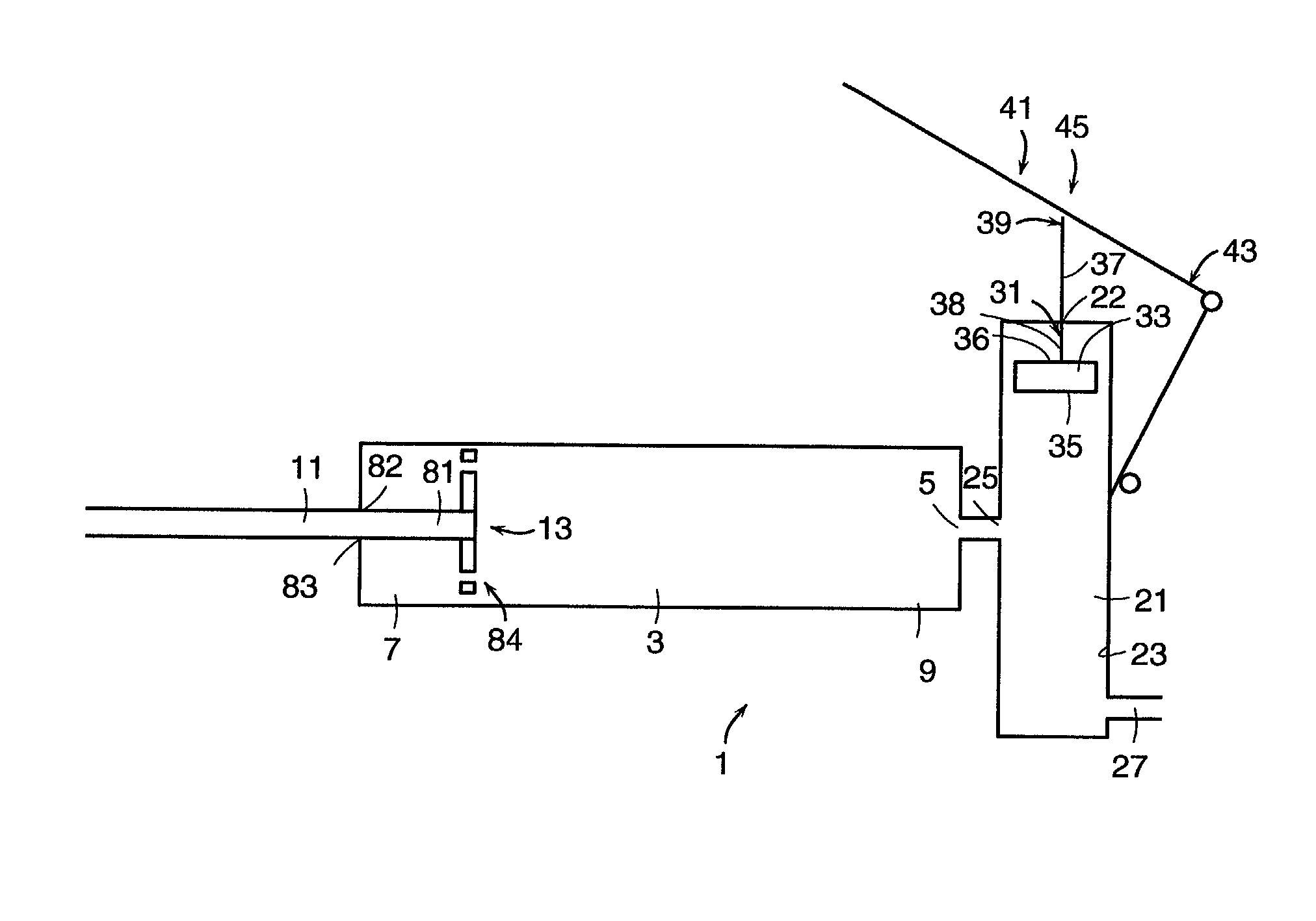

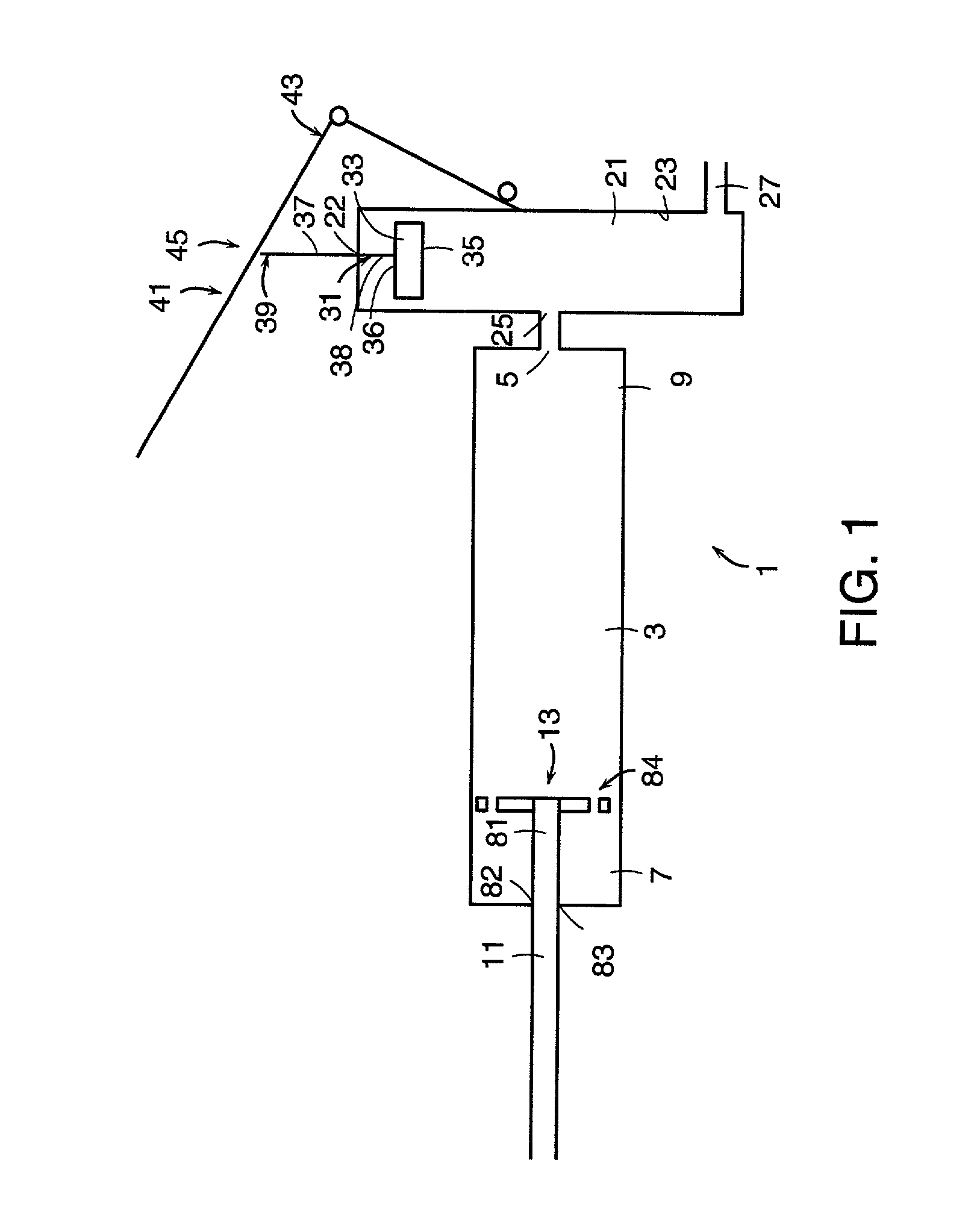

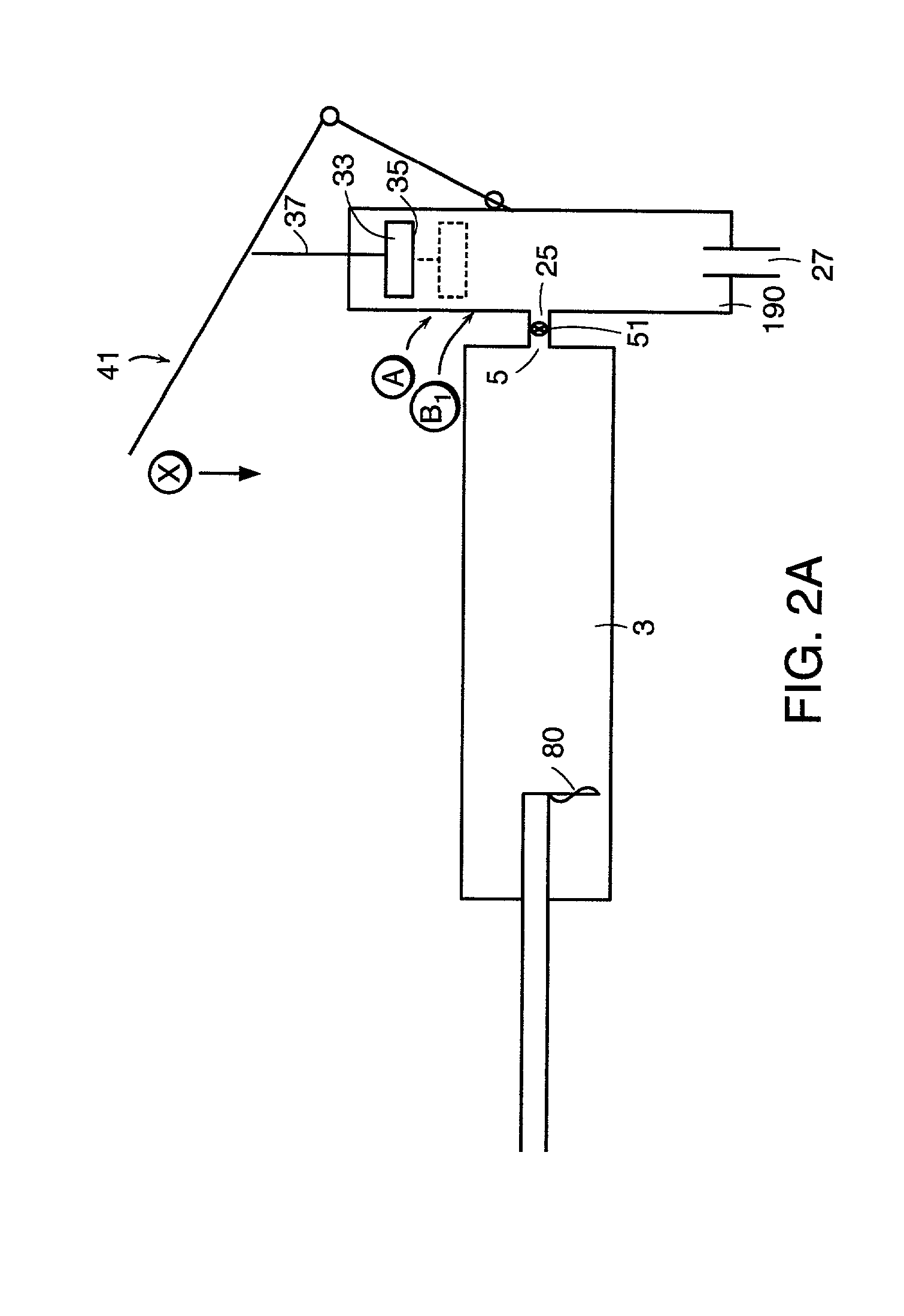

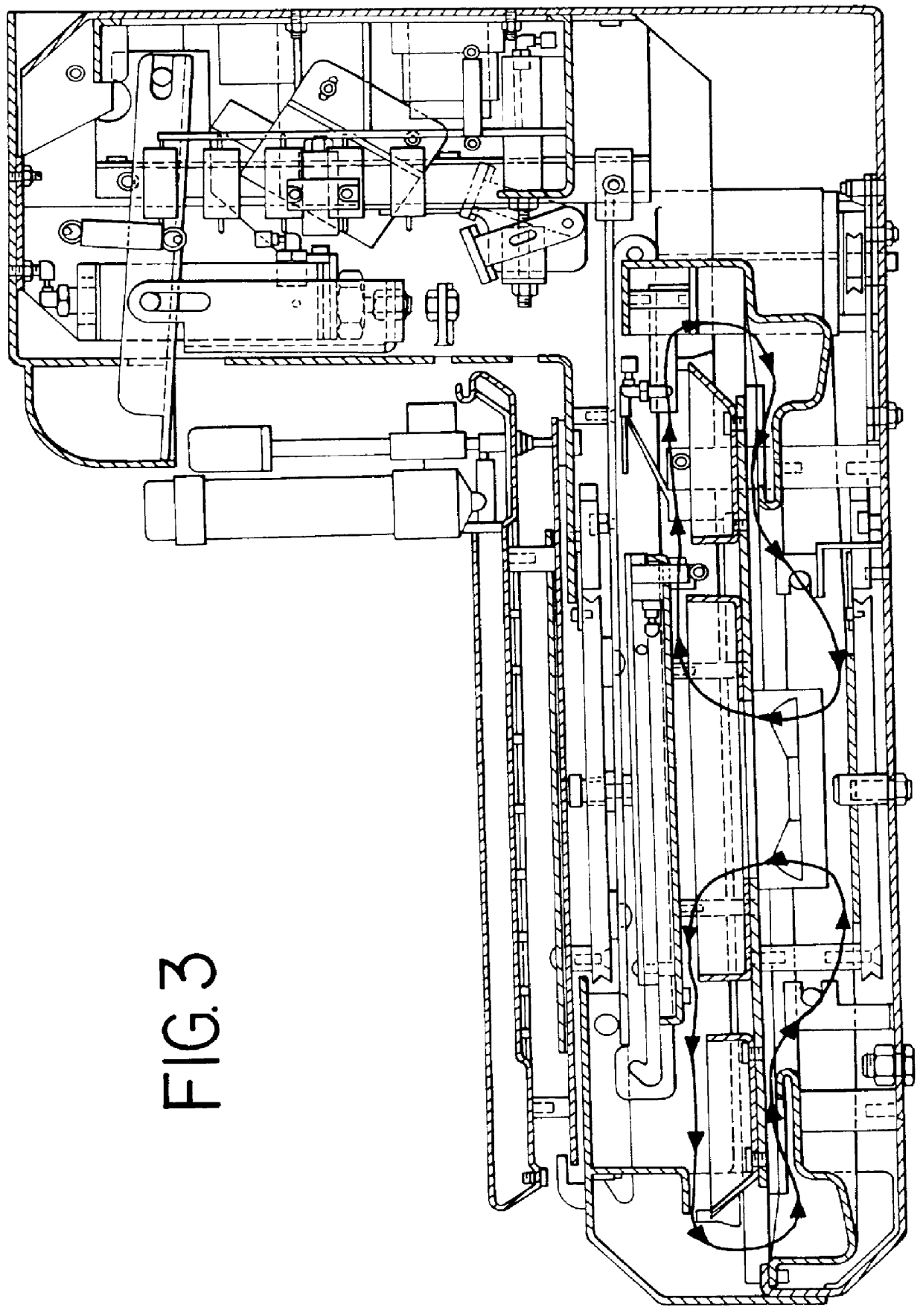

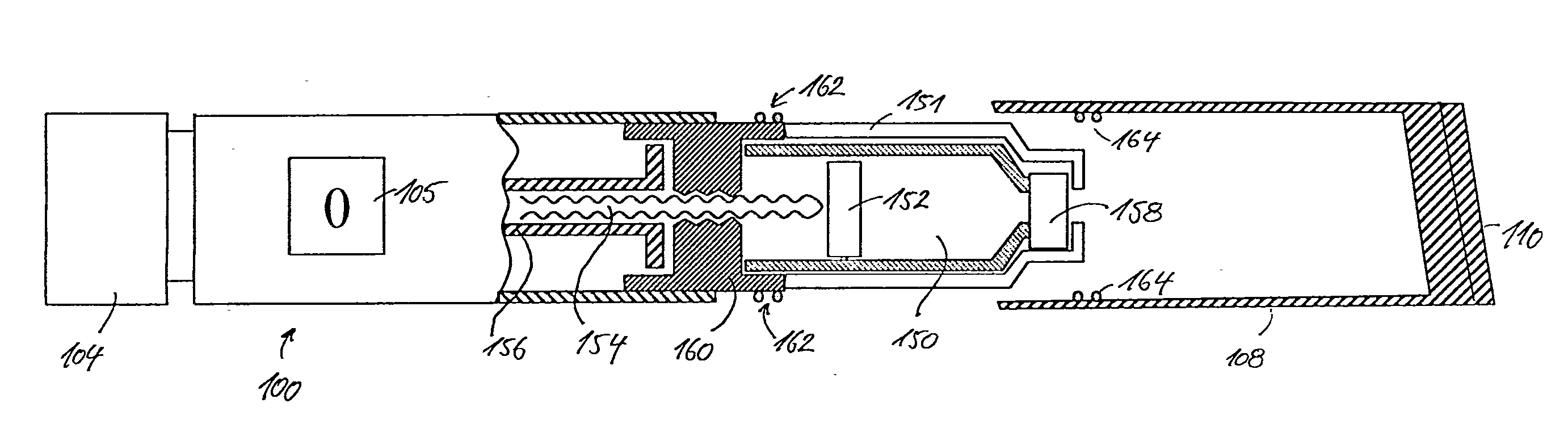

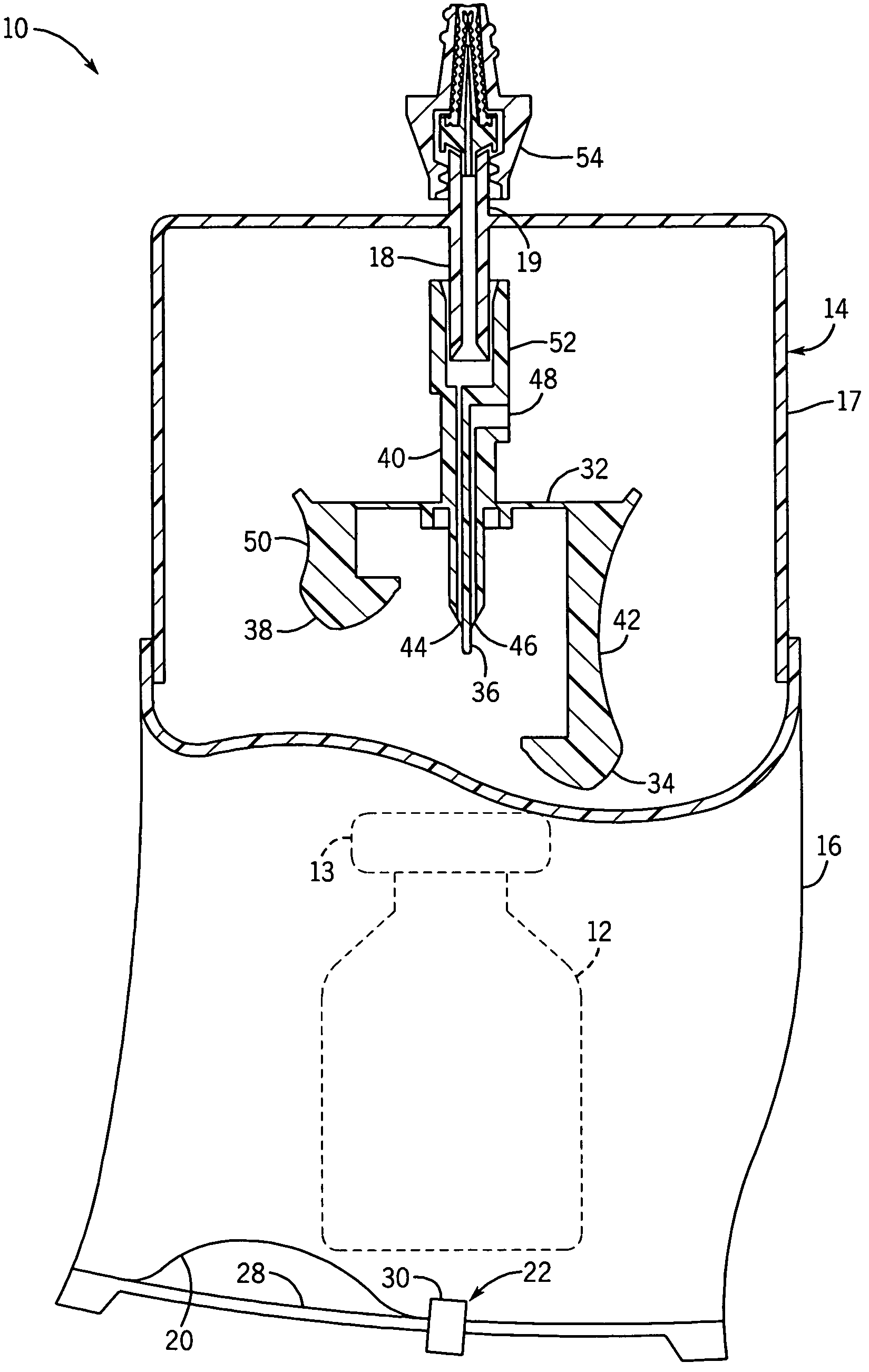

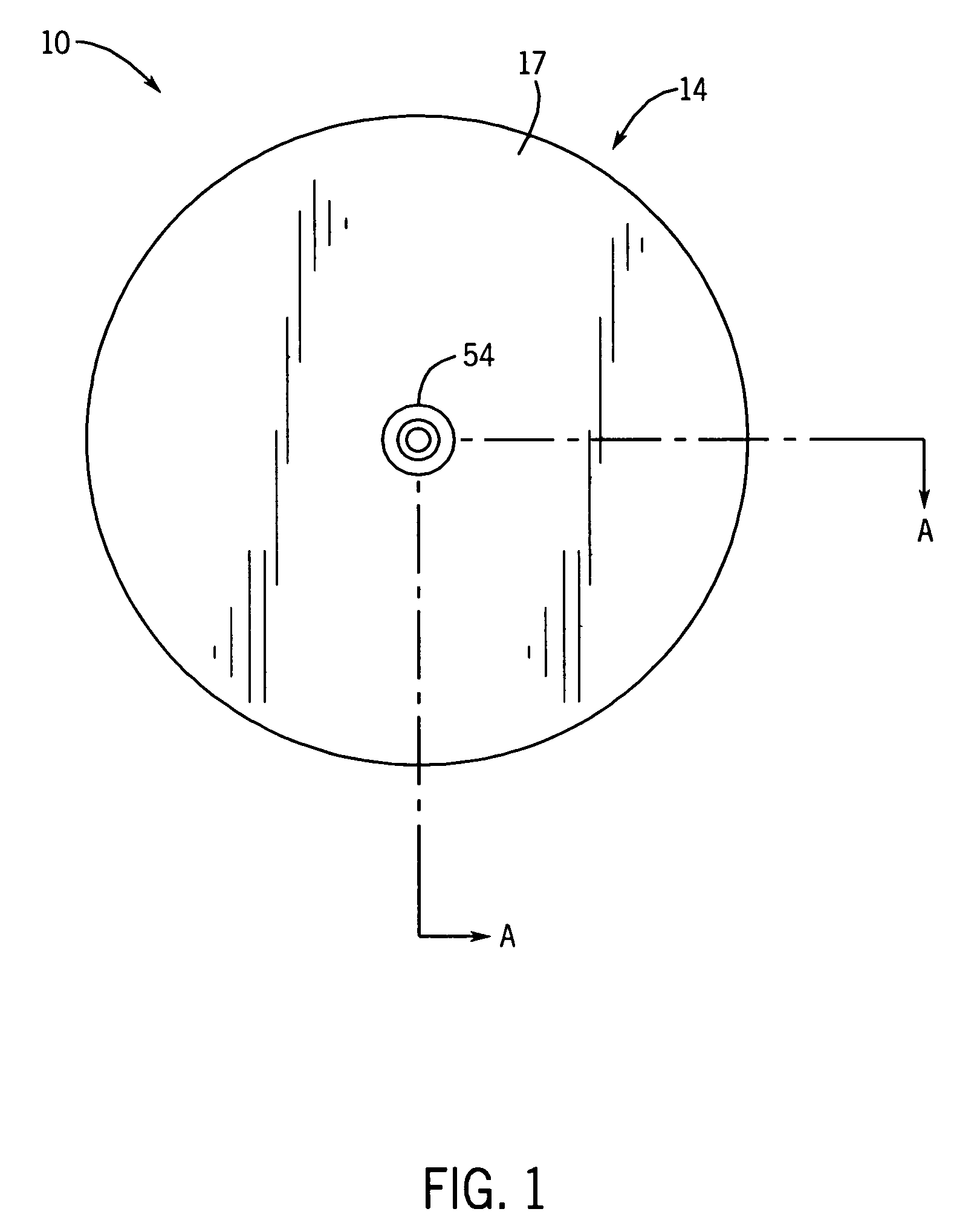

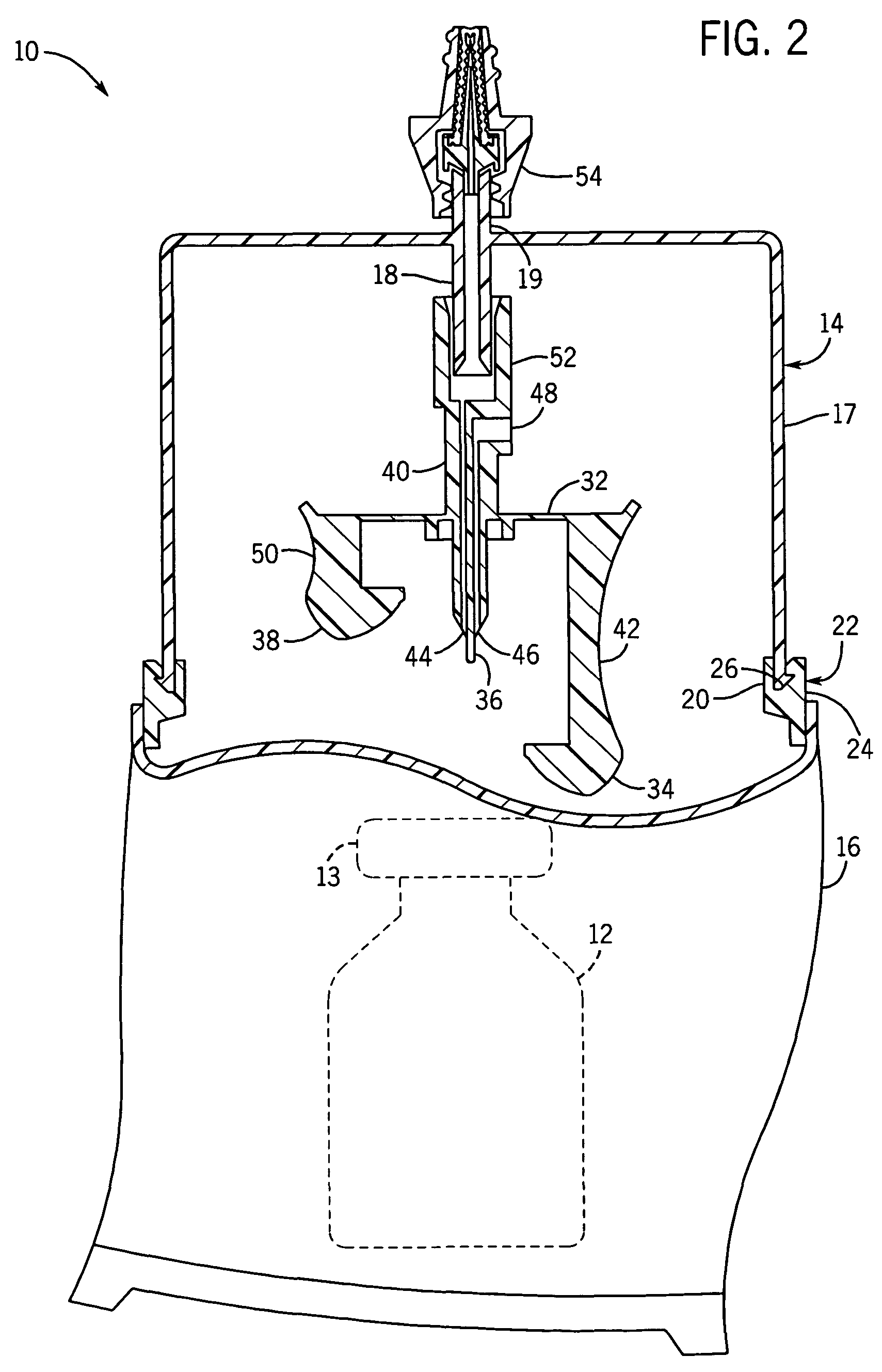

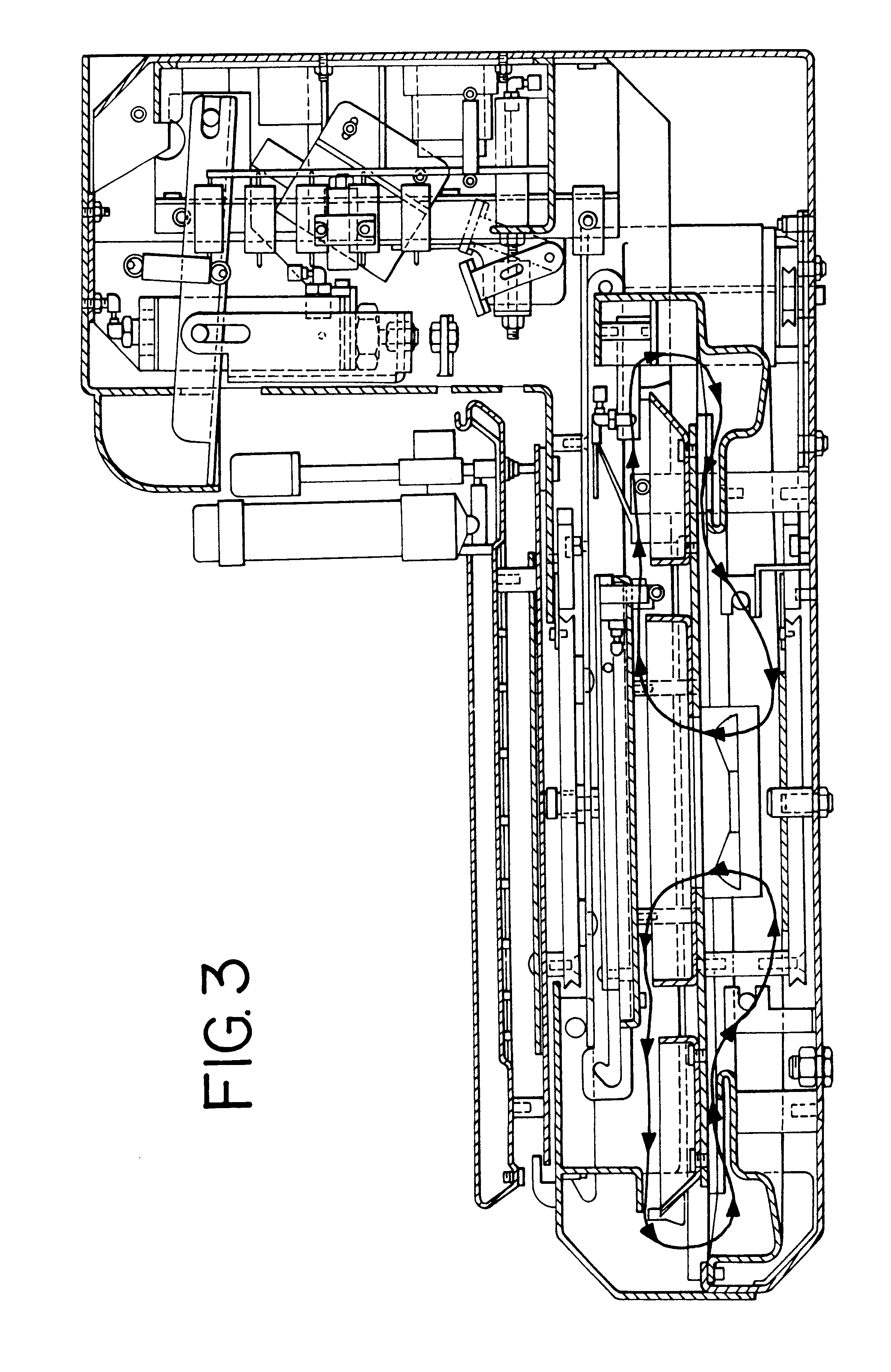

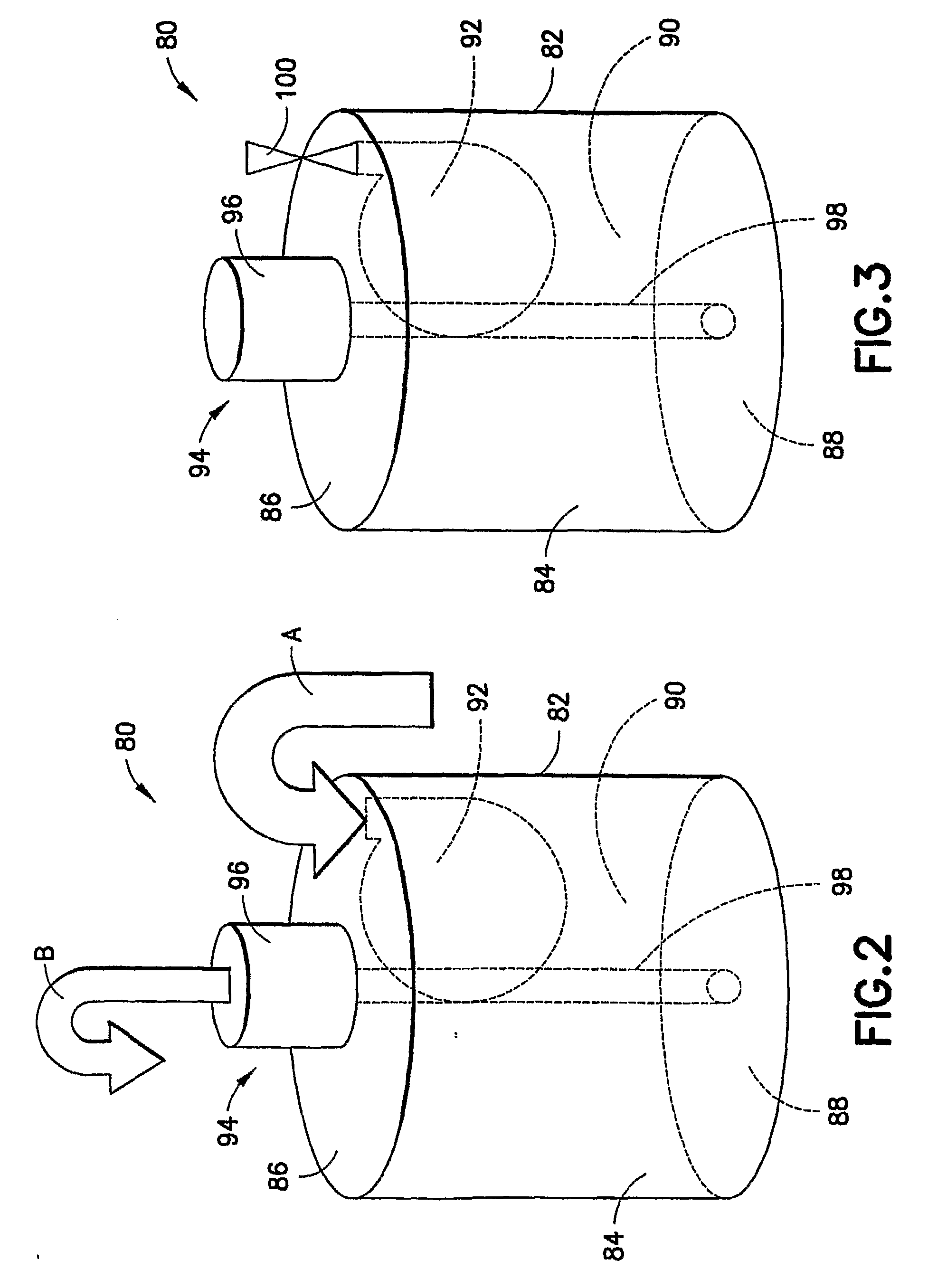

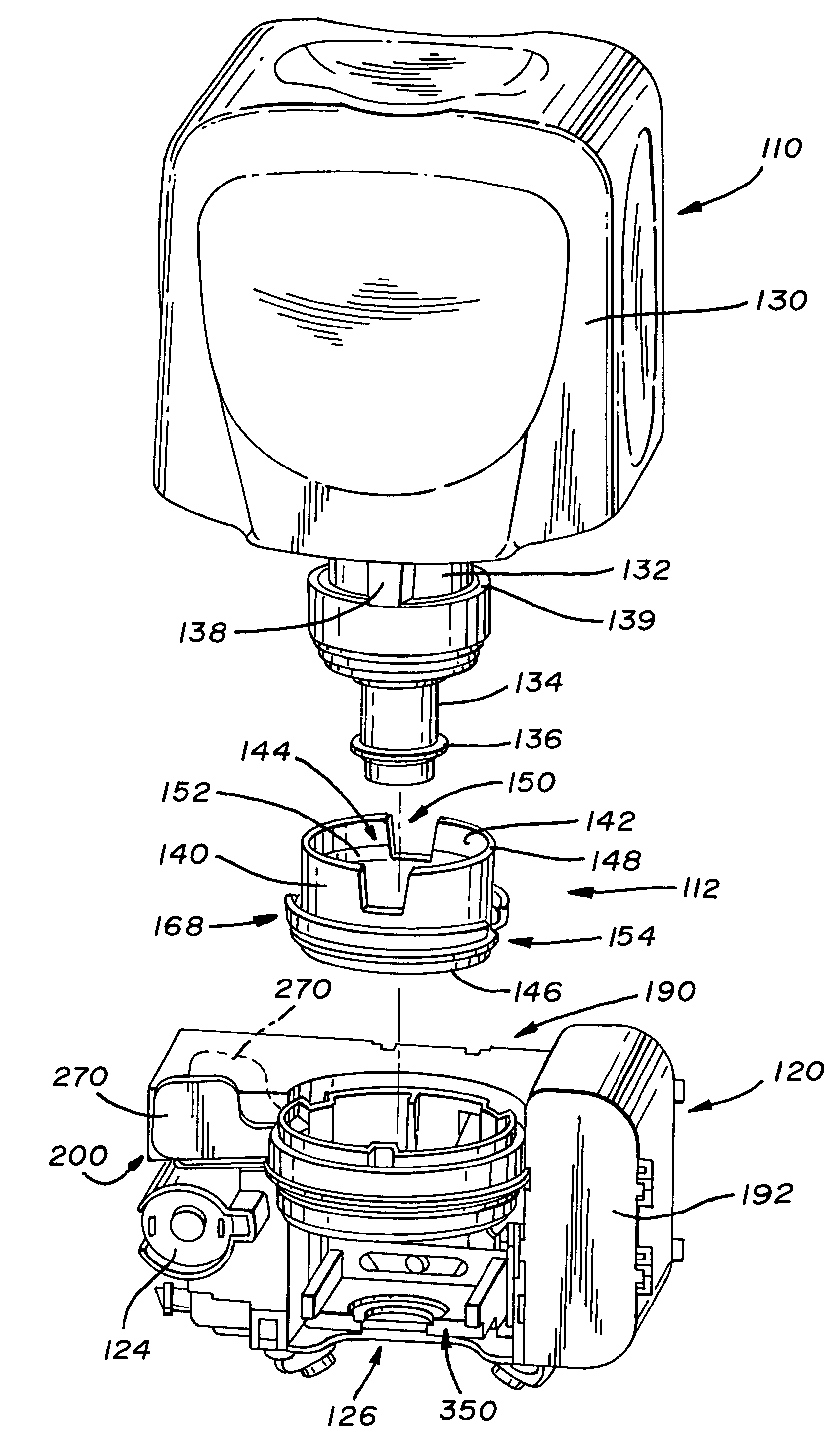

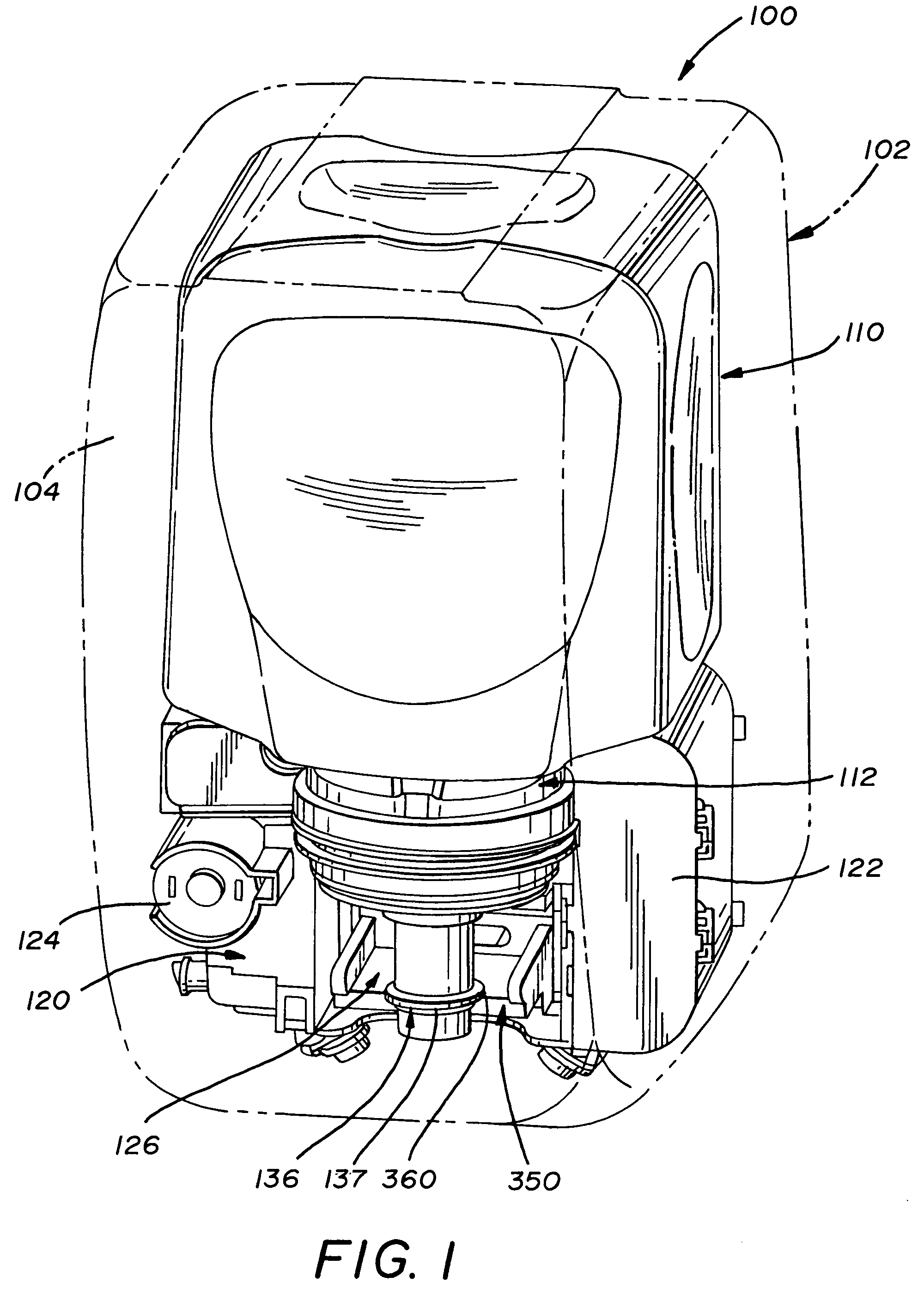

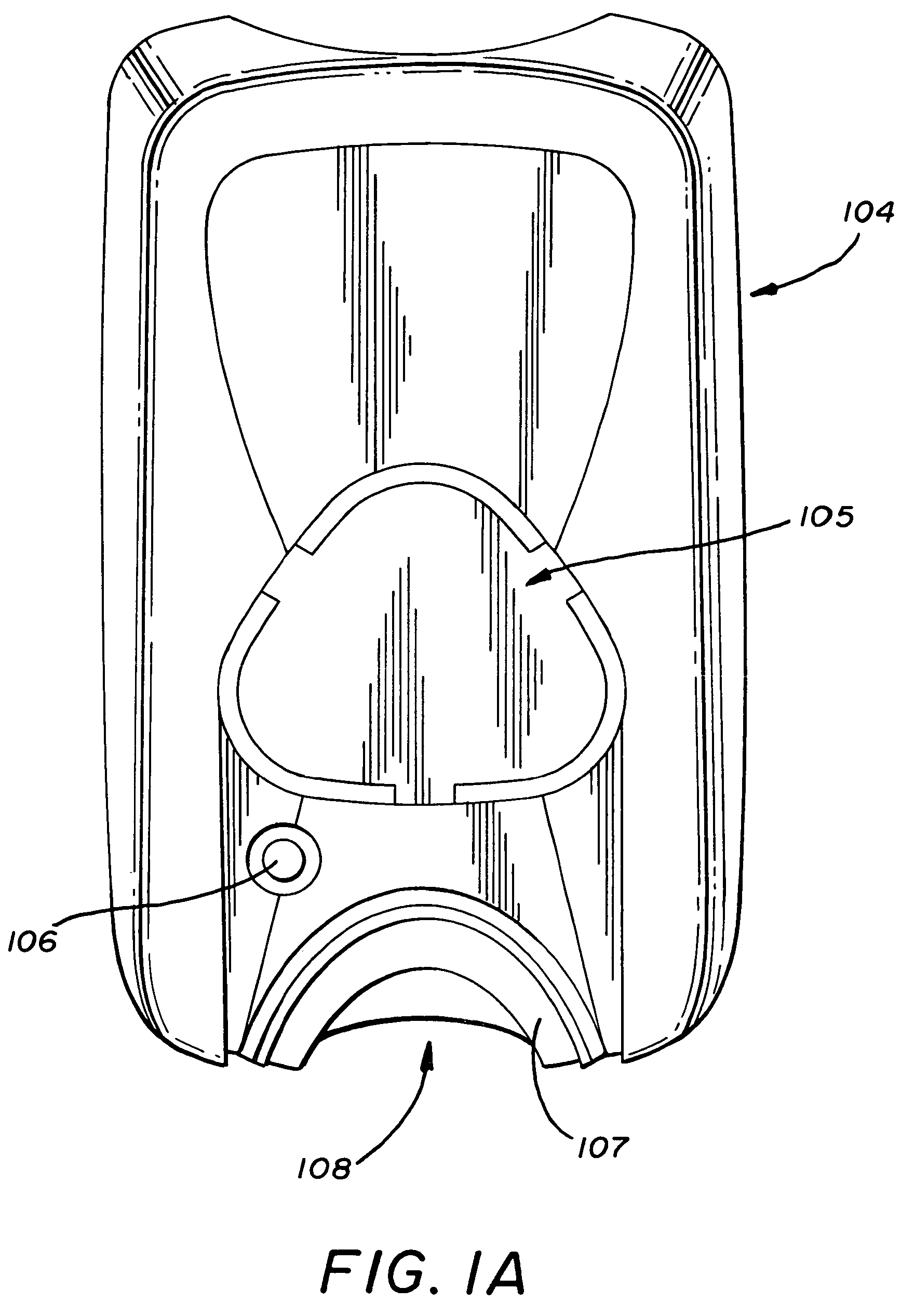

Drive system for an infusion pump

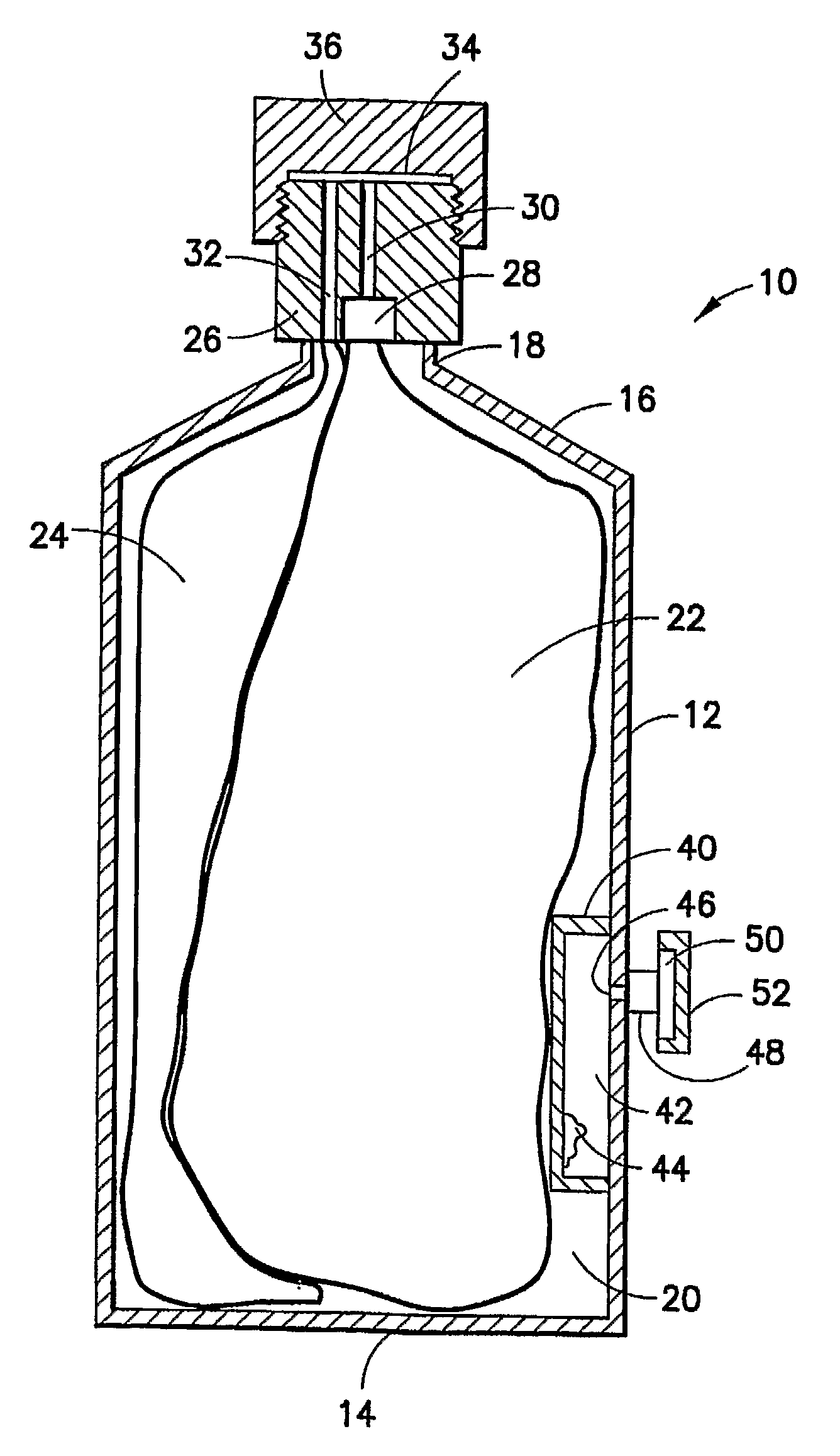

InactiveUS6854620B2Small sizeImprove portabilityClosure using stoppersLarge containersLinear motionProximity sensor

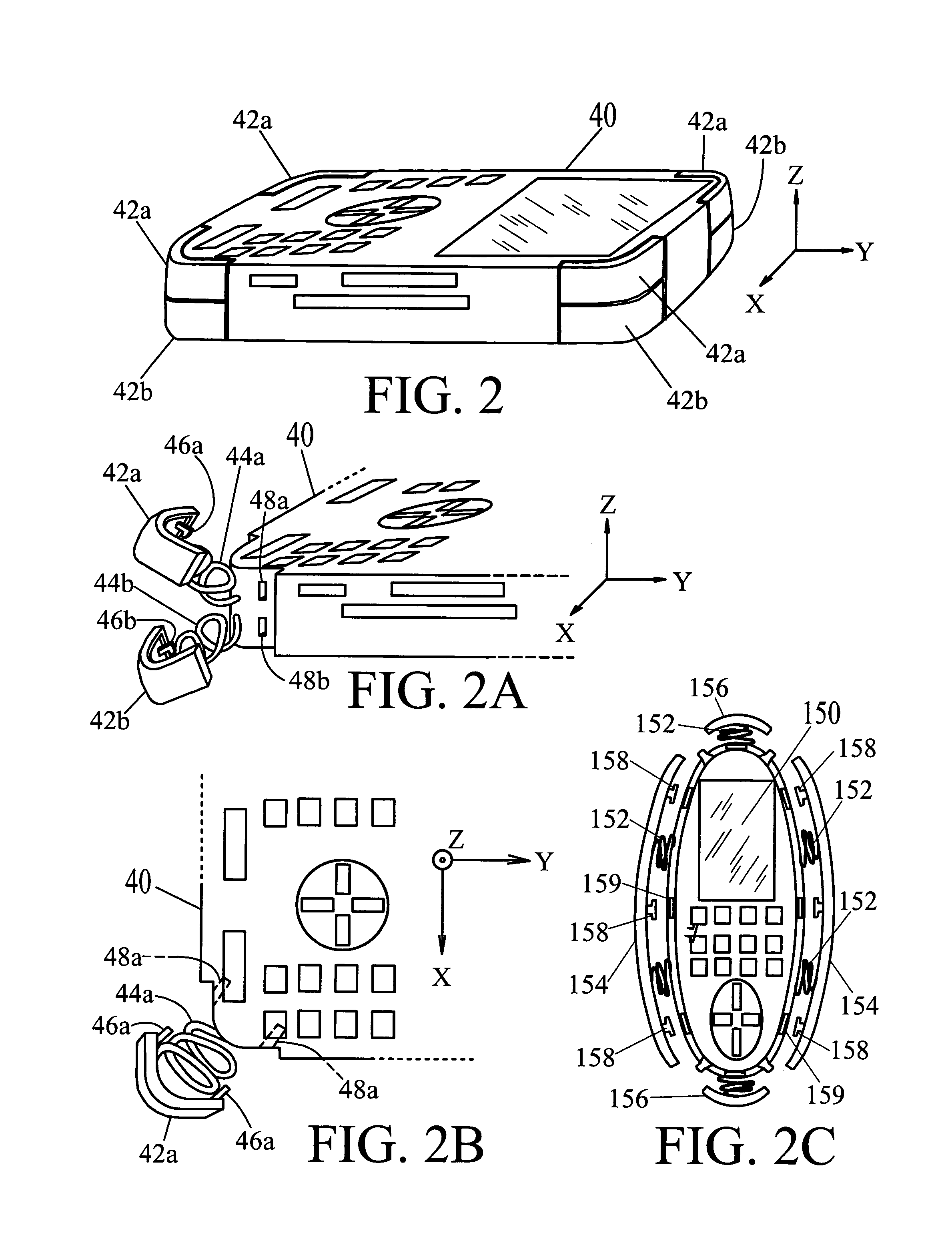

A pump system for an infusion system includes a linear drive (36, 36′) which minimizes the space occupied by the pump components in a portable housing (10, 10′). A motor (34) and a motor drive shaft (42) are arranged in parallel with, and adjacent to a syringe (14, 14′) and lead screw (94, 94′). A gear box (54) connects the drive shaft and lead screw to transfer rotational movements between them. A piston driving member, such as a cone (116) or drive nut (116′) converts the rotational movement of the lead screw into linear motion of a syringe piston (24). Sensors (150, 152) detect when the piston or cone is in a “home” position and in an “end” position, respectively. Optionally, a proximity sensor (170) is used to ensure that the cone and the piston (24) are abutting during dispensing. Alternatively, a clamping member (350) selectively clamps the lead screw (94′) against linear motion in at least a dispensing direction.

Owner:TRIVIDIA HEALTHCARE SYST LLC

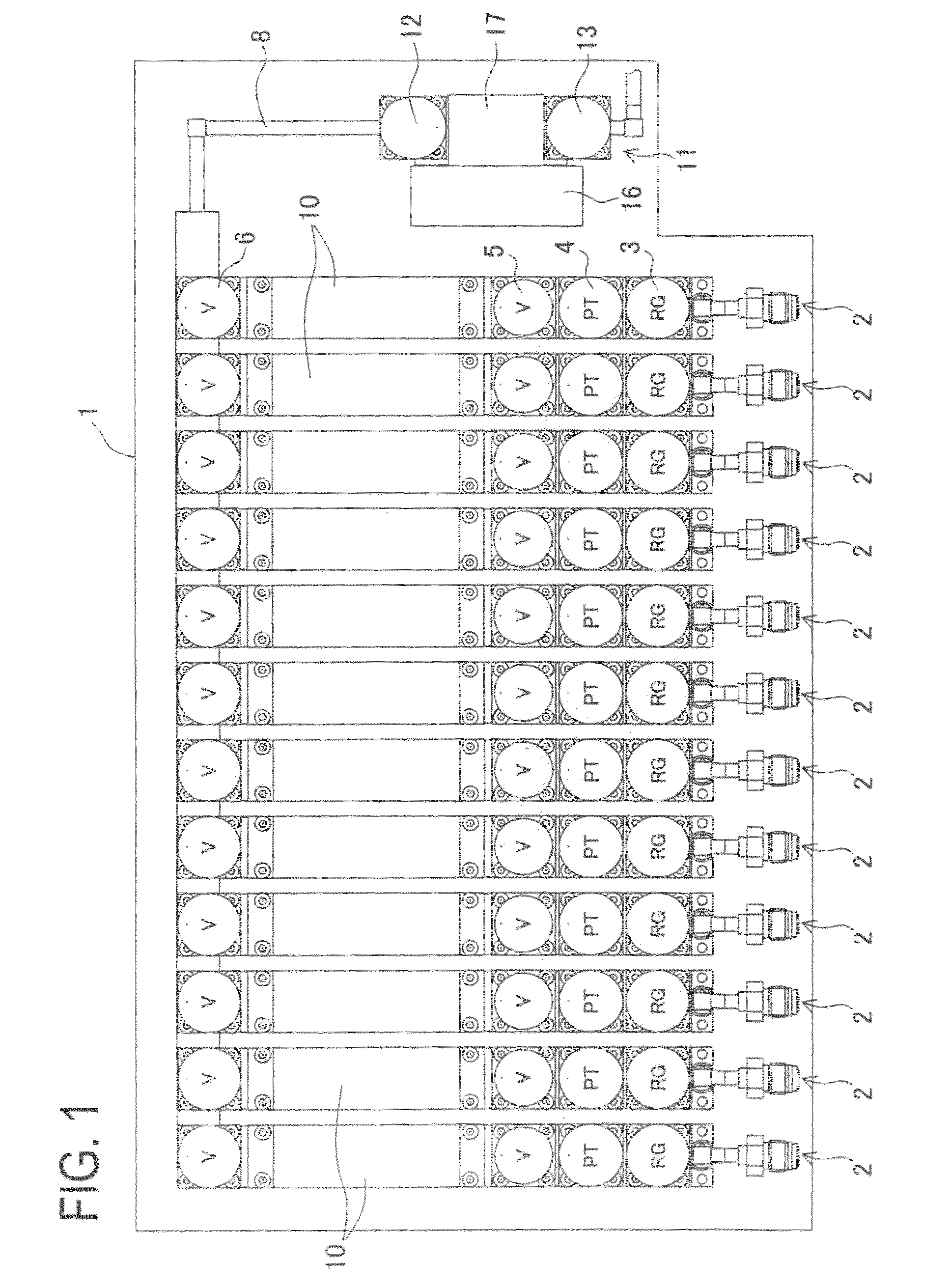

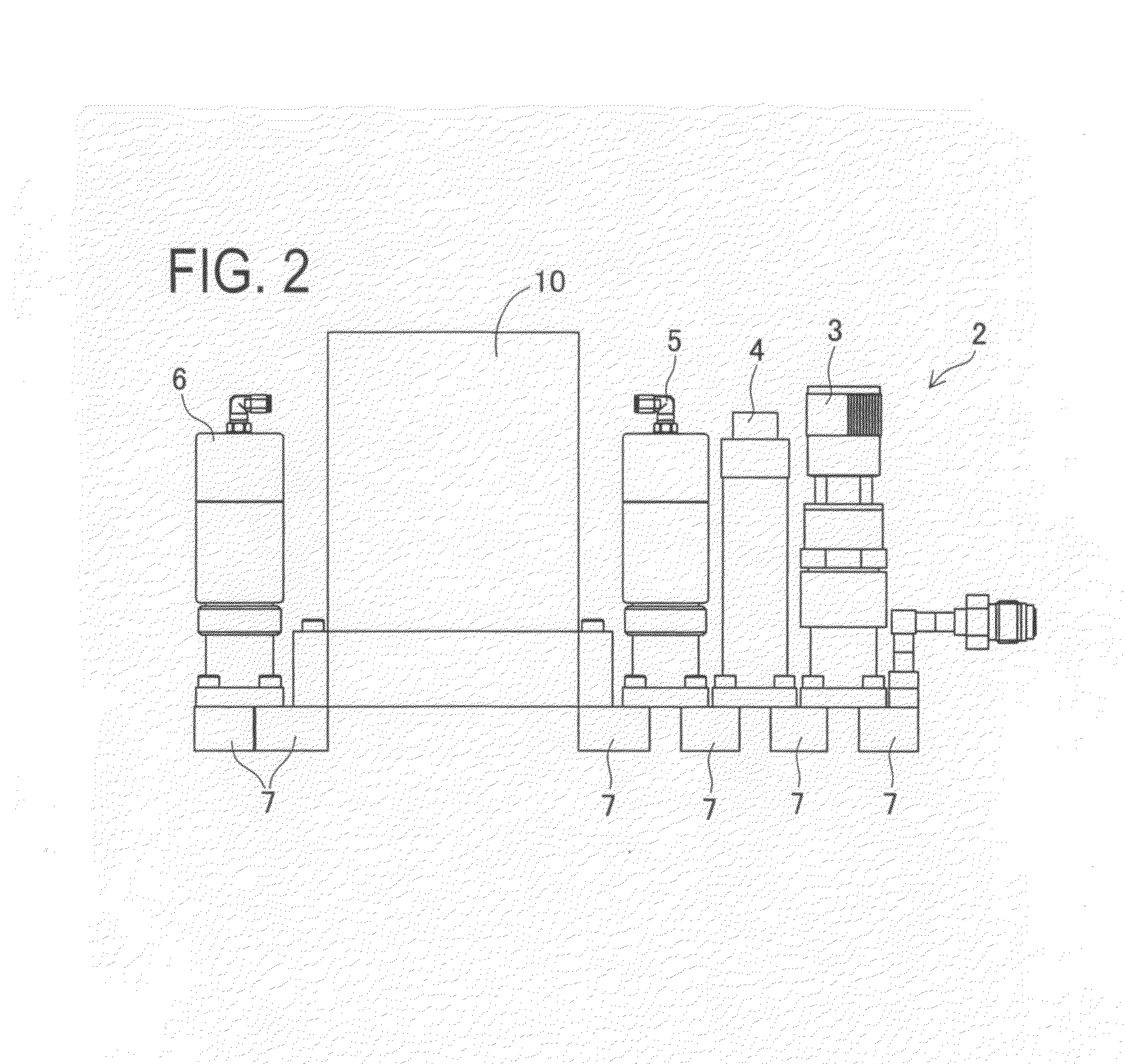

Gas flow rate verification unit

ActiveUS7716993B2Increase flow rateUniform pressureMultiple way valvesPipeline systemsEngineeringGas supply

A gas flow rate verification unit capable of enhancing reliability of gas flow rate verification. The gas flow rate verification unit has a first cutoff valve that is connected to a flow rate control device and to which gas is inputted, a second cutoff valve for discharging the gas, a communication member for allowing the first cutoff valve and the second cutoff valve to communicate with each other, a pressure sensor for detecting the pressure of the gas supplied between the first cutoff valve and the second cutoff valve, a temperature detector for detecting the temperature of the gas supplied between the first cutoff valve and the second cutoff valve, and a control means for verifying the flow of the gas flowing in the flow control device, the verification being performed by using both the result of the pressure detected by the pressure sensor and the result of the temperatures detected by the temperature detector. The volume (Vk) between the valve seat of the first cutoff valve and the valve seat of the second cutoff valve is equal to or less than the volume (Ve) between the outlet of the flow control device and the valve seat of the first cutoff valve.

Owner:CKD

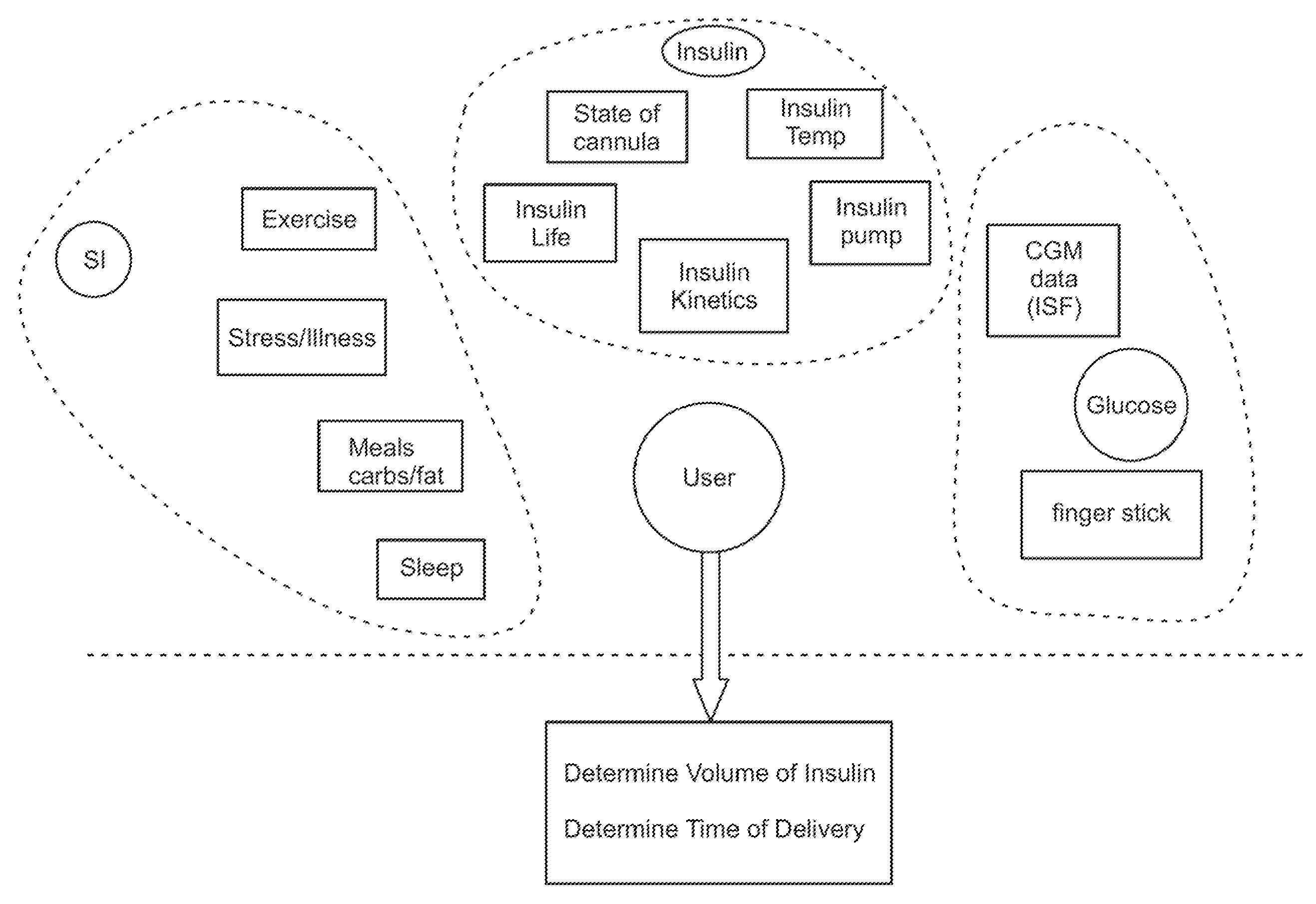

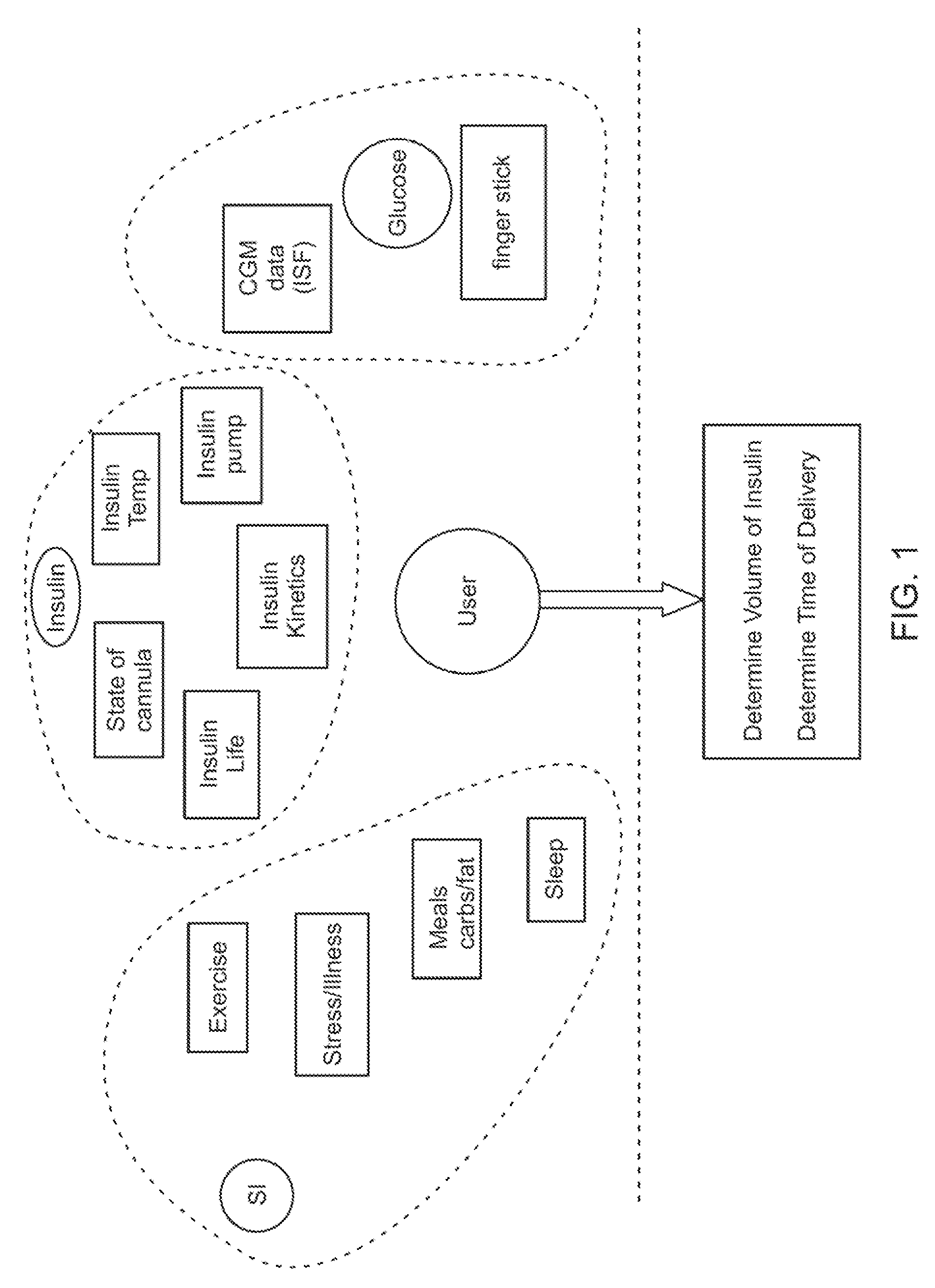

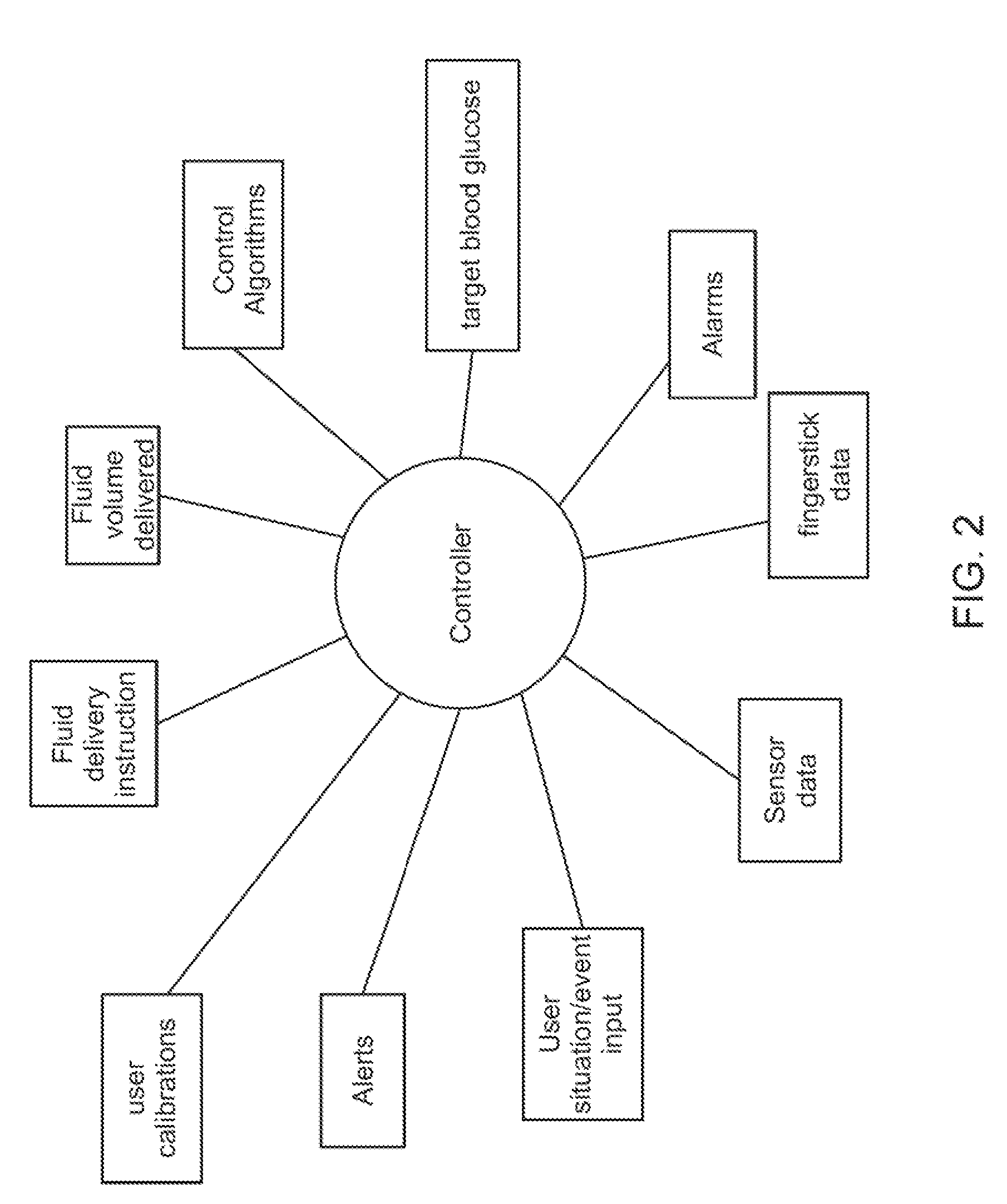

Systems and methods for fluid delivery

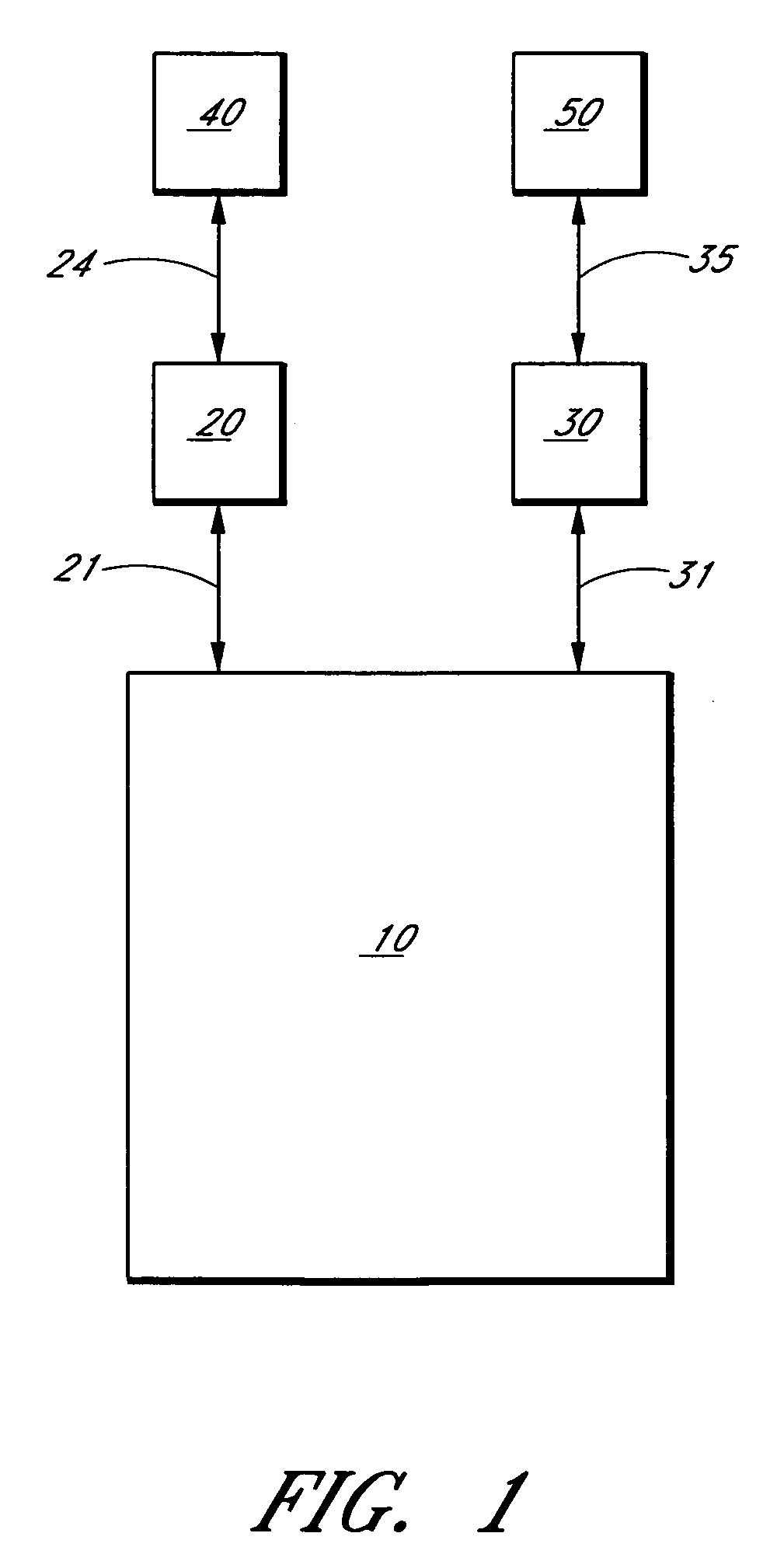

A system for at least partial closed-loop control of a medical condition is disclosed. The system includes at least one medical fluid pump. The medical fluid pump including a sensor for determining the volume of fluid pumped by the pump. Also, at least one continuous analyte monitor, and a controller. The controller is in communication with the medical fluid pump and the at least one continuous analyte monitor. The controller includes a processor. The processor includes instructions for delivery of medical fluid based at least on data received from the at least one continuous analyte monitor.

Owner:DEKA PROD LLP

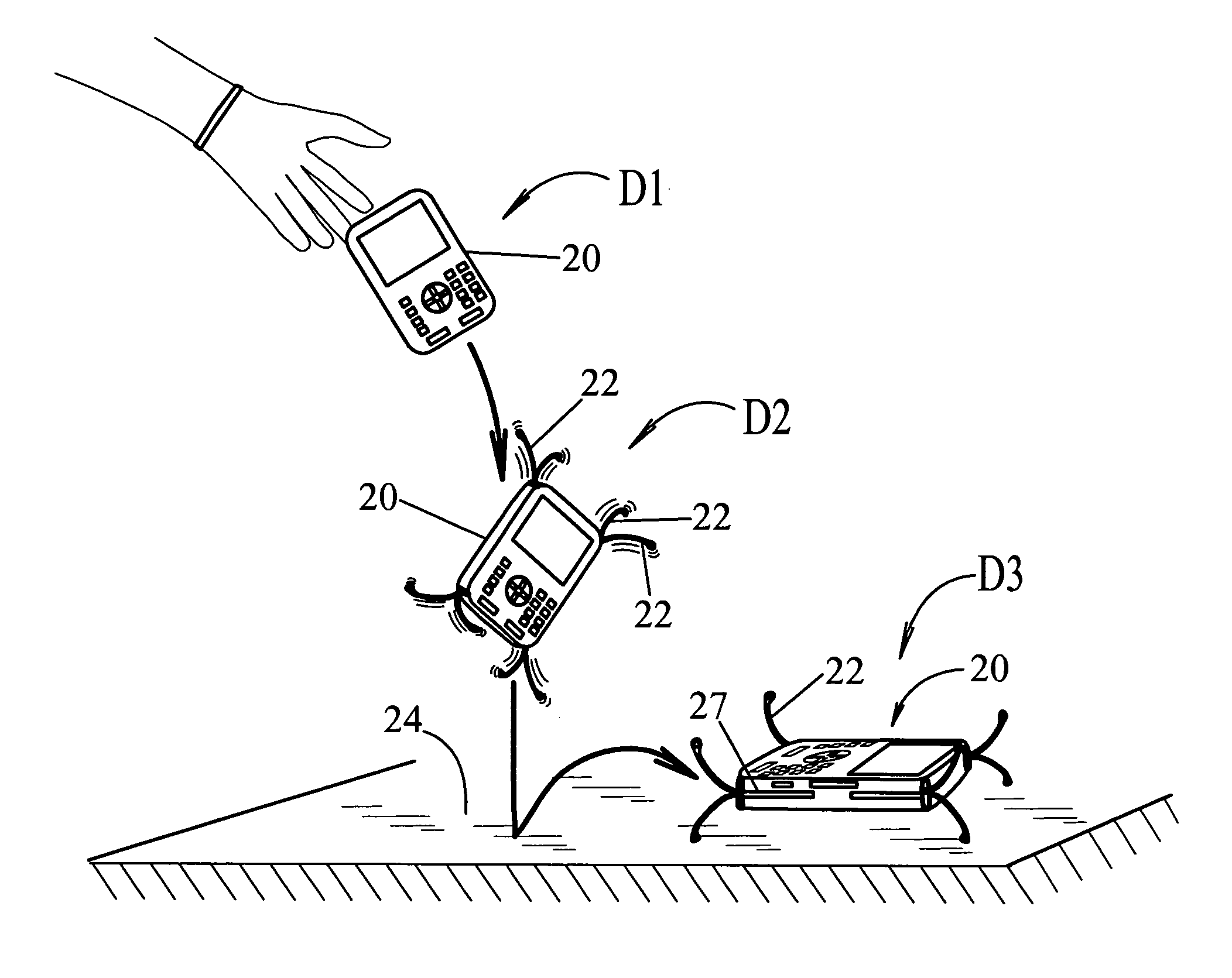

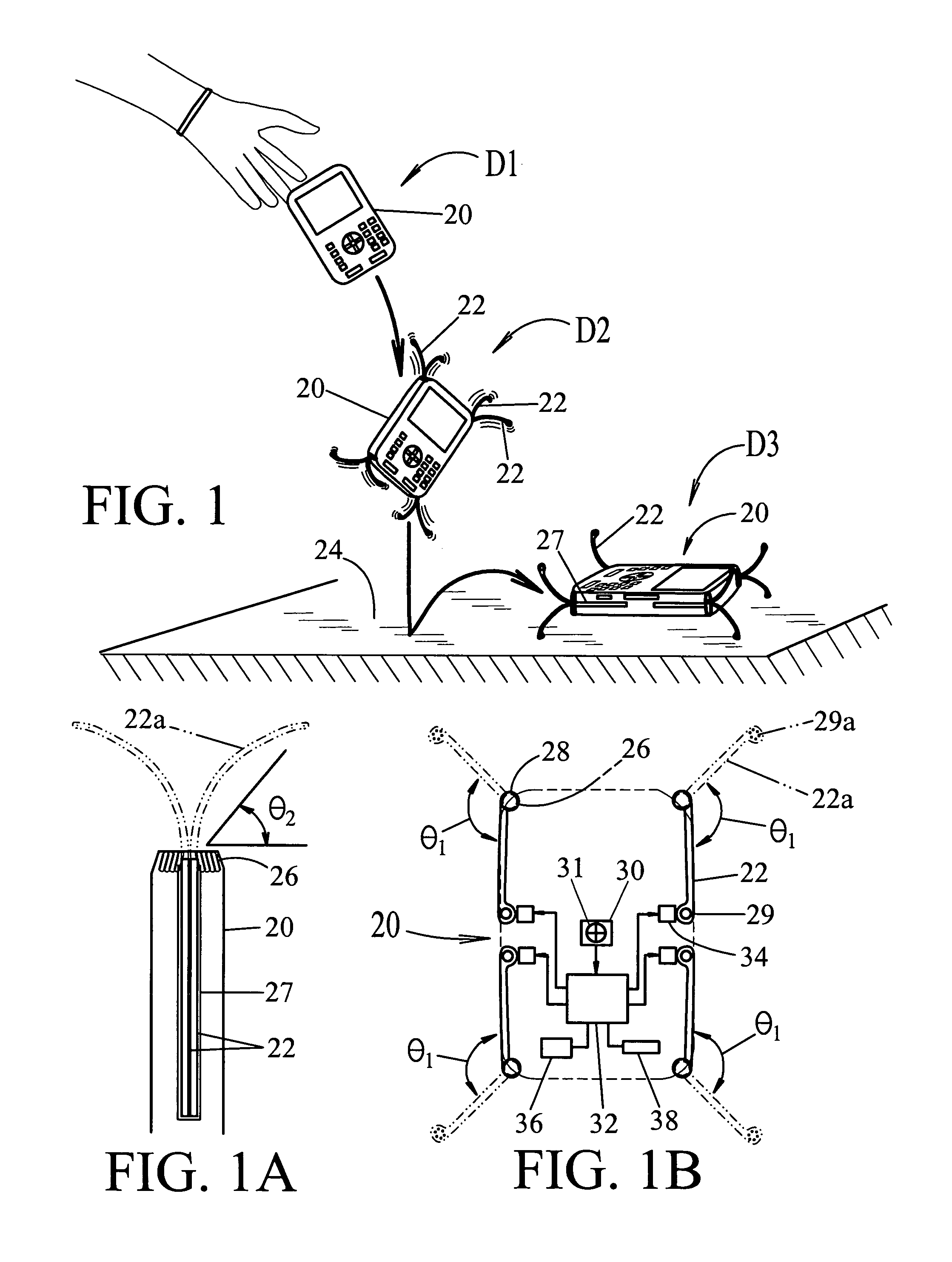

Active impact protection system

An impact protection system for a portable device, comprising a housing 20 with a plurality of impact absorbing arms 22 attached to housing 20 and having a retracted position and an extended position; an extension spring 26 connected to each arm provides forceful extension of the arms from their retracted position to their extended position; a free-fall detection sensor 30 defined within housing 20 for detecting dangerous free-fall conditions of the portable device and providing a signal to an activation controller 32 which is responsive to the free-fall detection sensor 30 and connected to the impact absorbing arms 22, whereby the arms are extended from their retracted position to their extended position upon detection of dangerous free-fall conditions to provide impact protection for the portable device.

Owner:RAGNER GARY DEAN

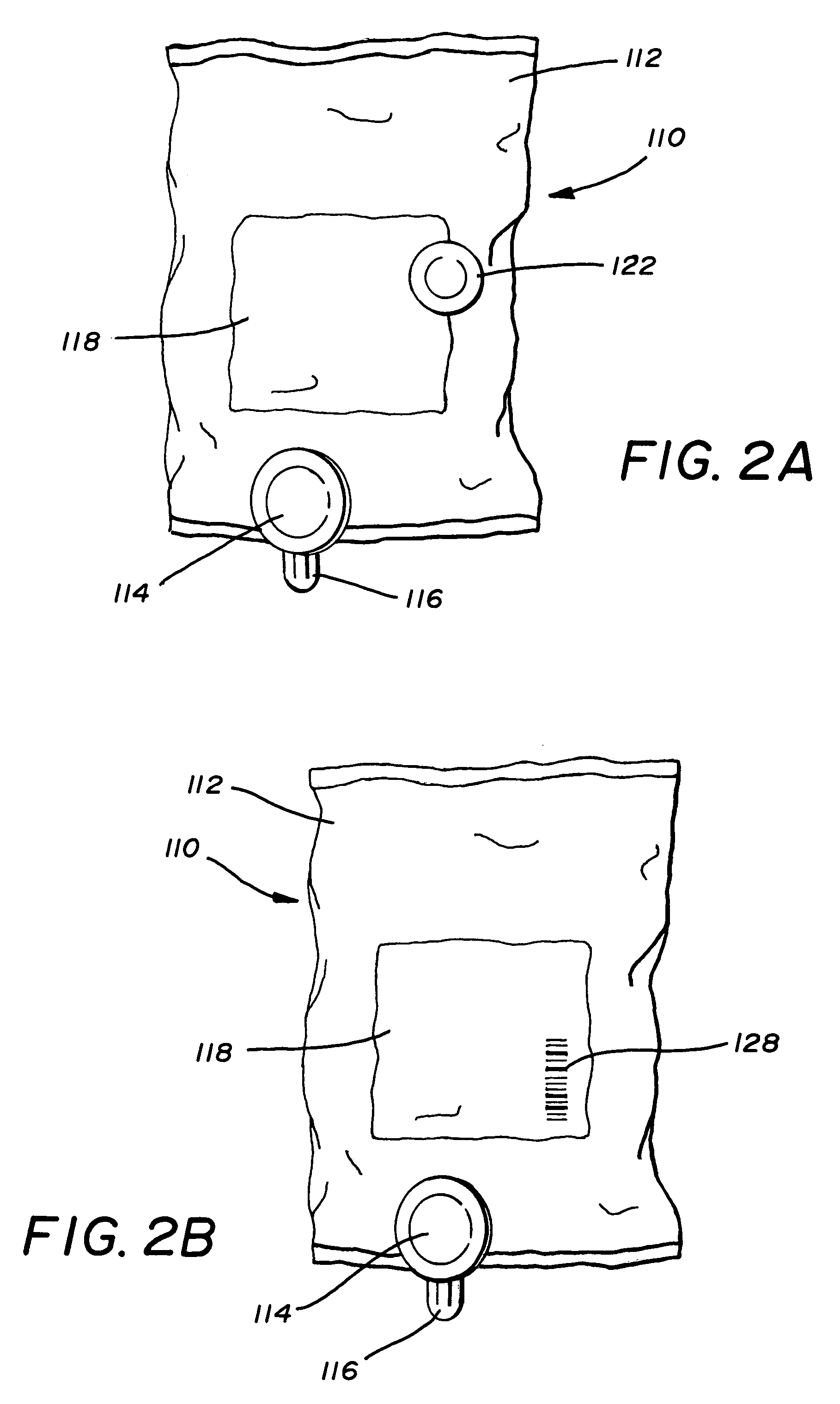

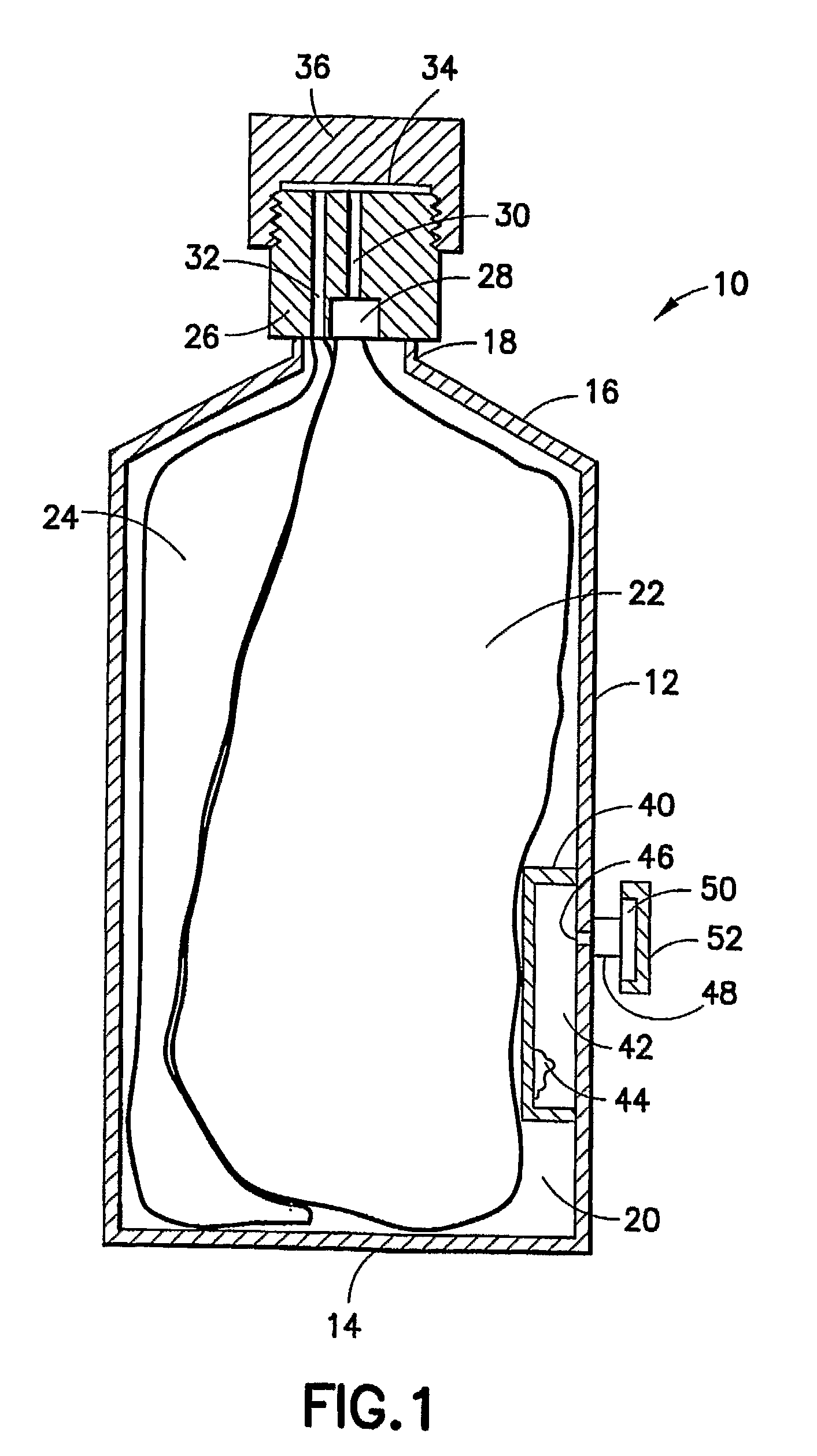

Vial adaptor for regulating pressure

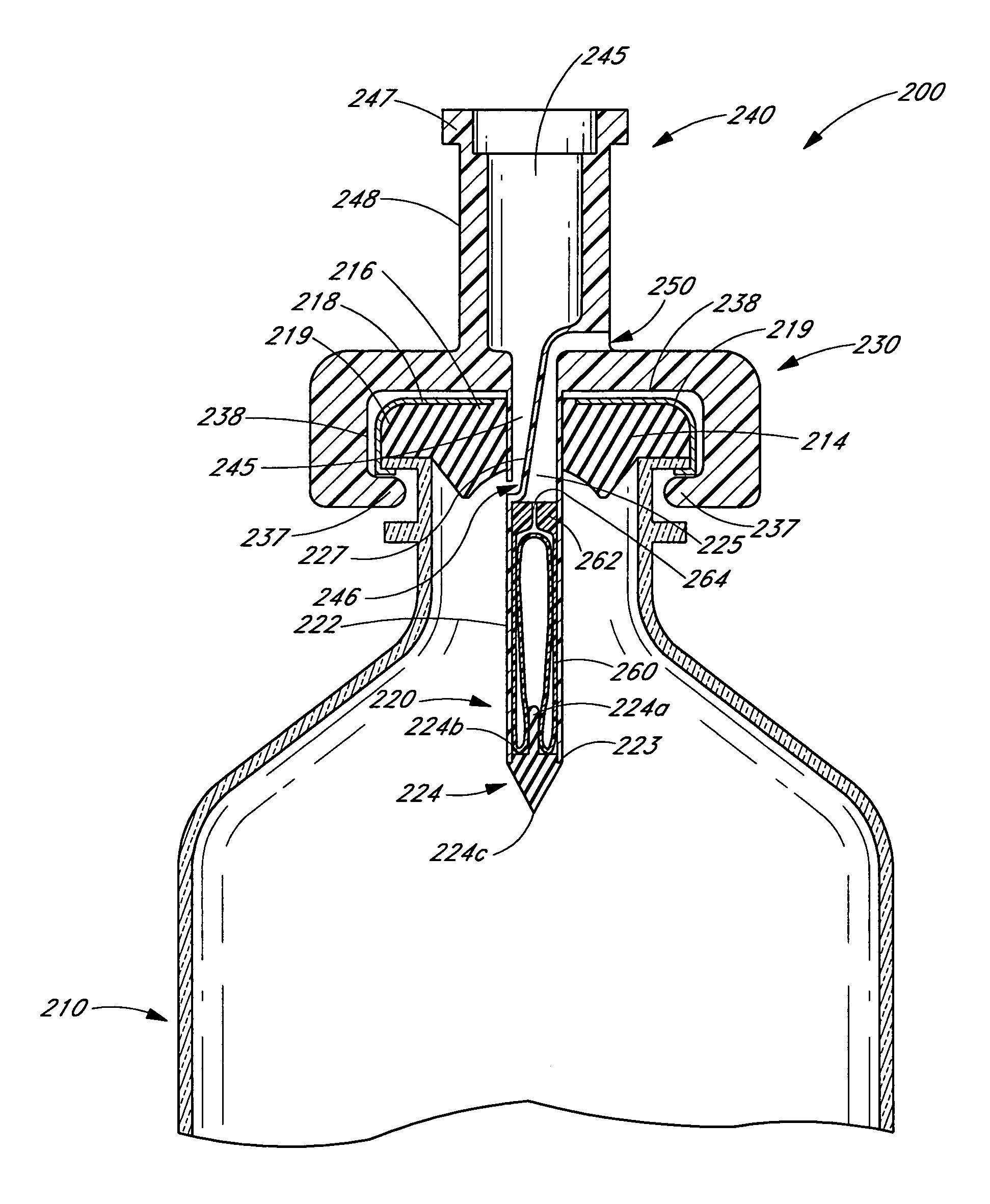

In certain embodiments, a vial adaptor for removing liquid contents from a vial includes a piercing member and a bag. The bag can be contained within the piercing member such that the bag is introduced to the vial when the vial adaptor is coupled with the vial. In some embodiments, the bag expands within the vial as liquid is removed from the vial via the adaptor, thereby regulating pressure within the vial. In other embodiments, a vial includes a bag for regulating pressure within the vial as liquid is removed therefrom. In some embodiments, a vial adaptor is coupled with the vial in order to remove the liquid. In some embodiments, as the liquid is removed from the vial via the adaptor, the bag expands within the vial, and in other embodiments, the bag contracts within the vial.

Owner:ICU MEDICAL INC

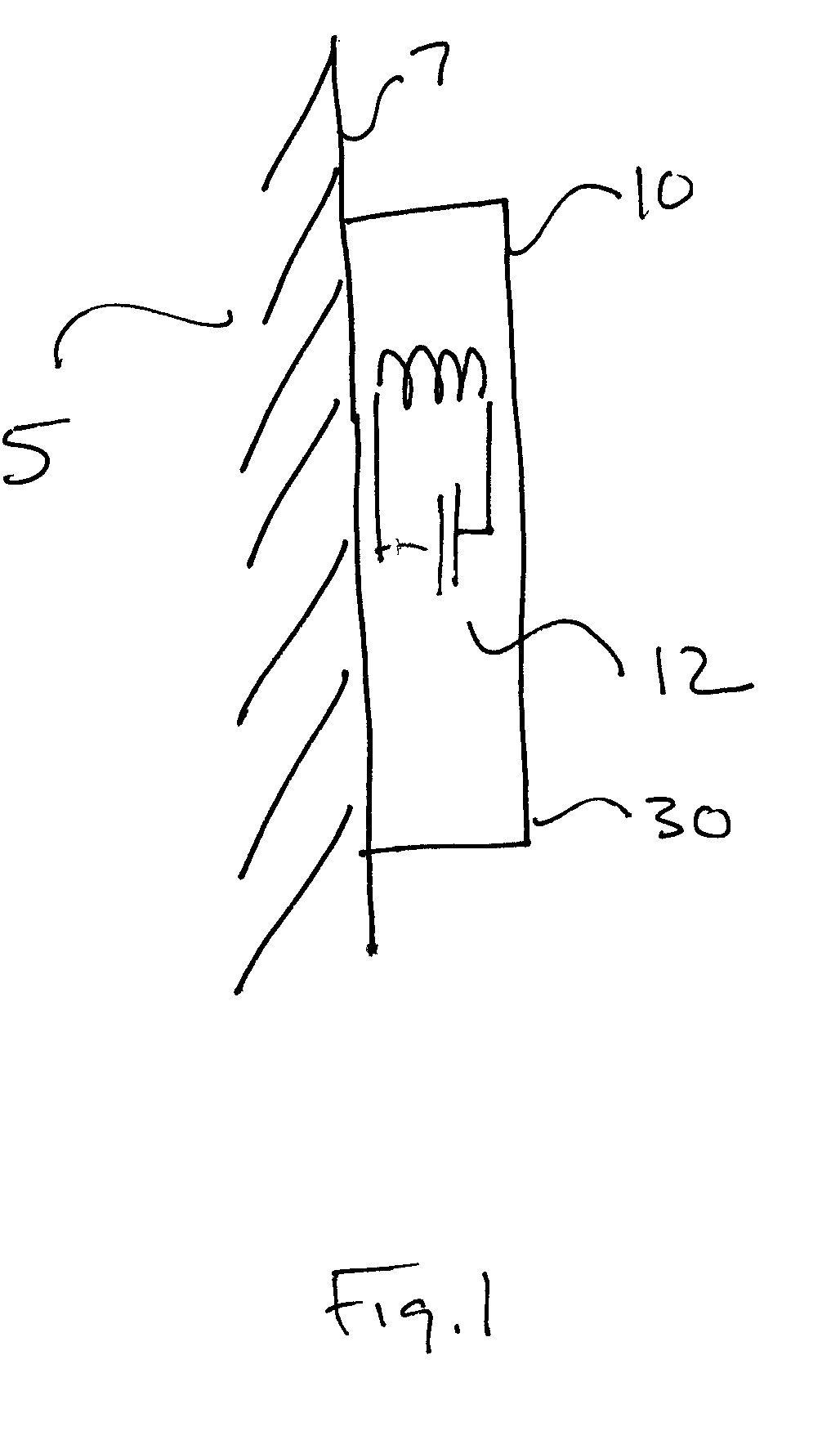

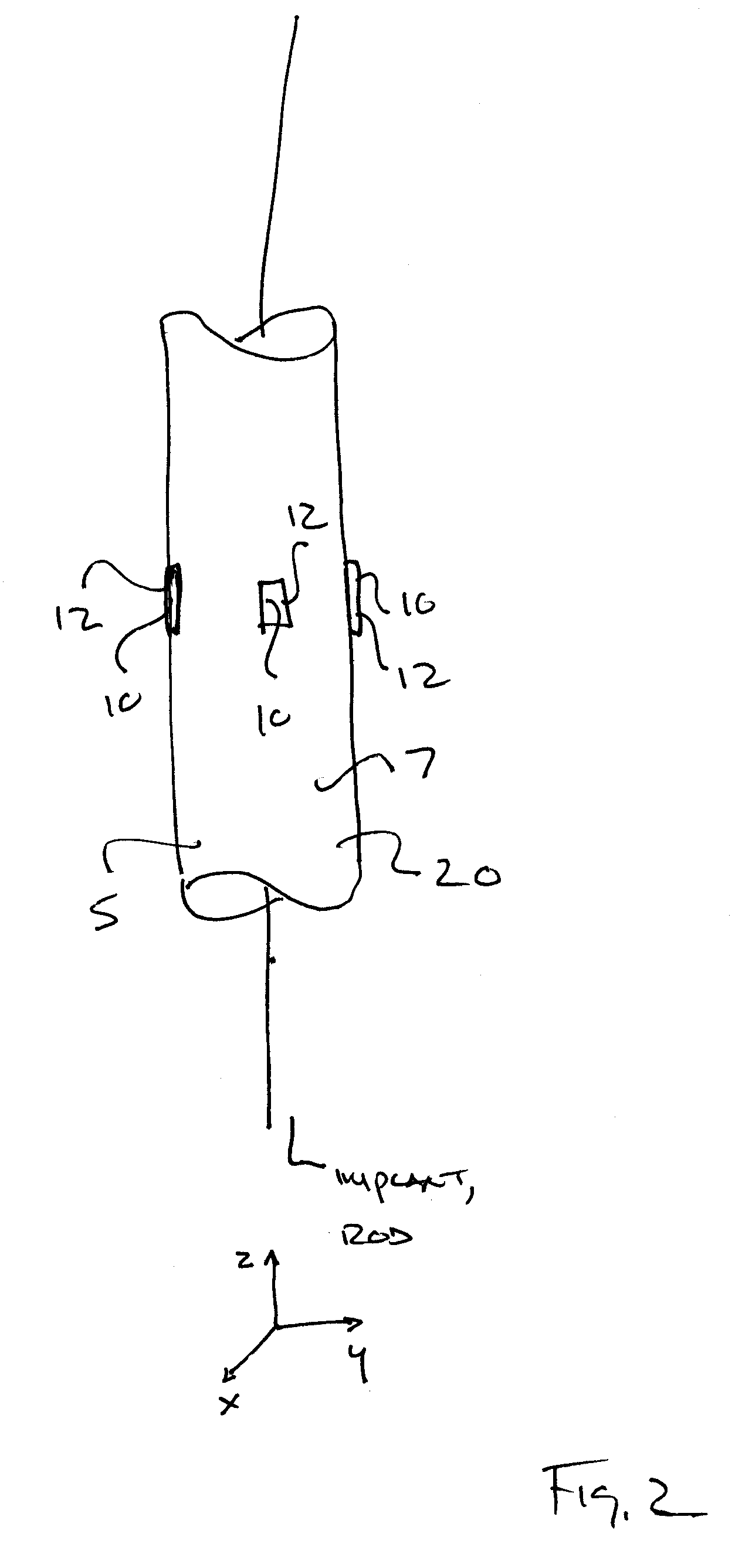

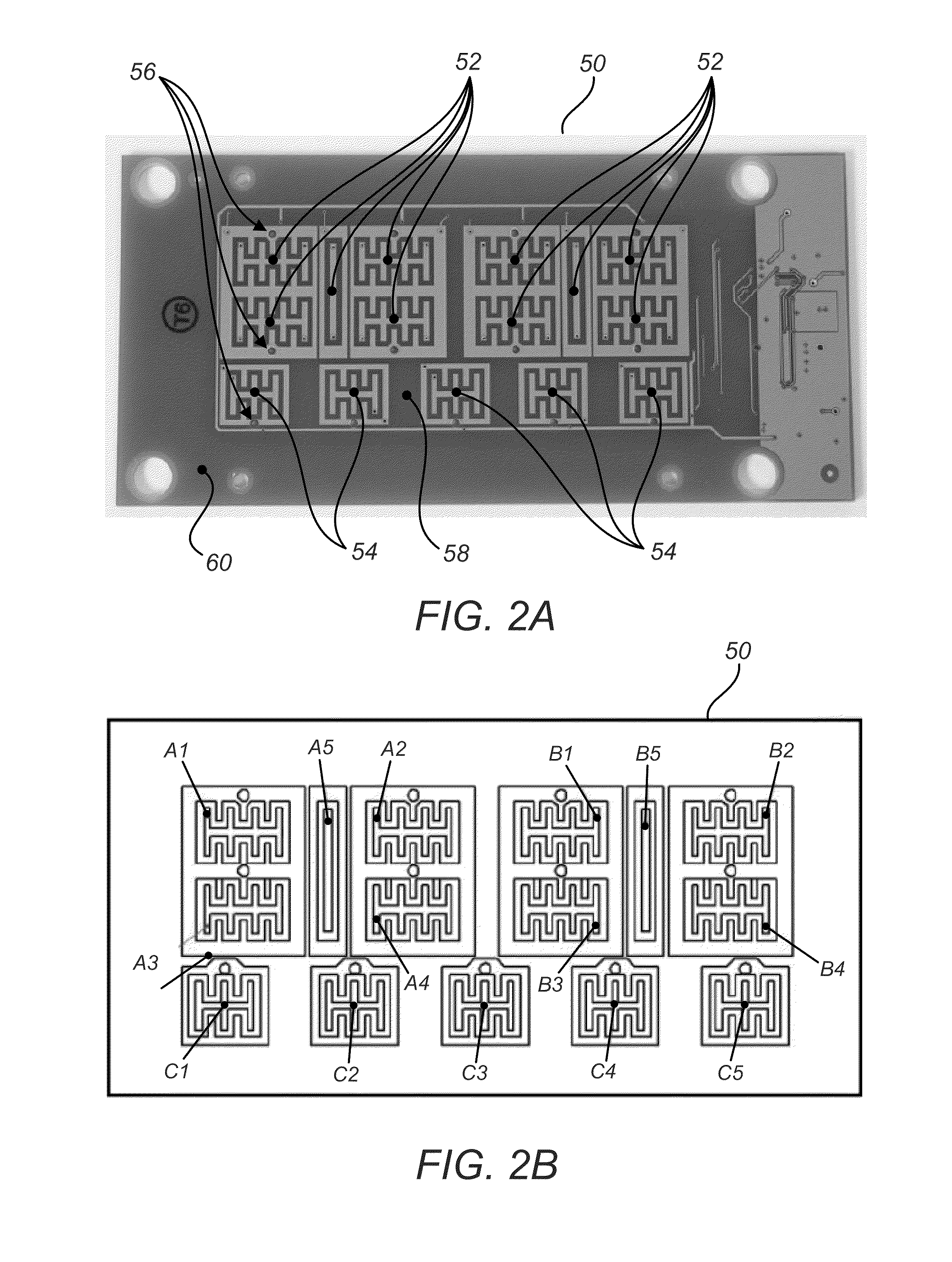

Strain monitoring system and apparatus

ActiveUS20090273353A1Internal osteosythesisResistance/reactance/impedenceElectromagnetic couplingBiological body

This application relates to an apparatus and system for sensing strain on a portion of an implant positioned in a living being. In one aspect, the apparatus has at least one sensor assembly that can be mountable thereon a portion of the implant and that has a passive electrical resonant circuit that can be configured to be selectively electromagnetically coupled to an ex-vivo source of RF energy. Each sensor assembly, in response to the electromagnetic coupling, can be configured to generate an output signal characterized by a frequency that is dependent upon urged movement of a portion of the passive electrical resonant circuit and is indicative of strain applied thereon a portion of the respective sensor assembly.

Owner:ST JUDE MEDICAL LUXEMBOURG HLDG II S A R L SJM LUX II

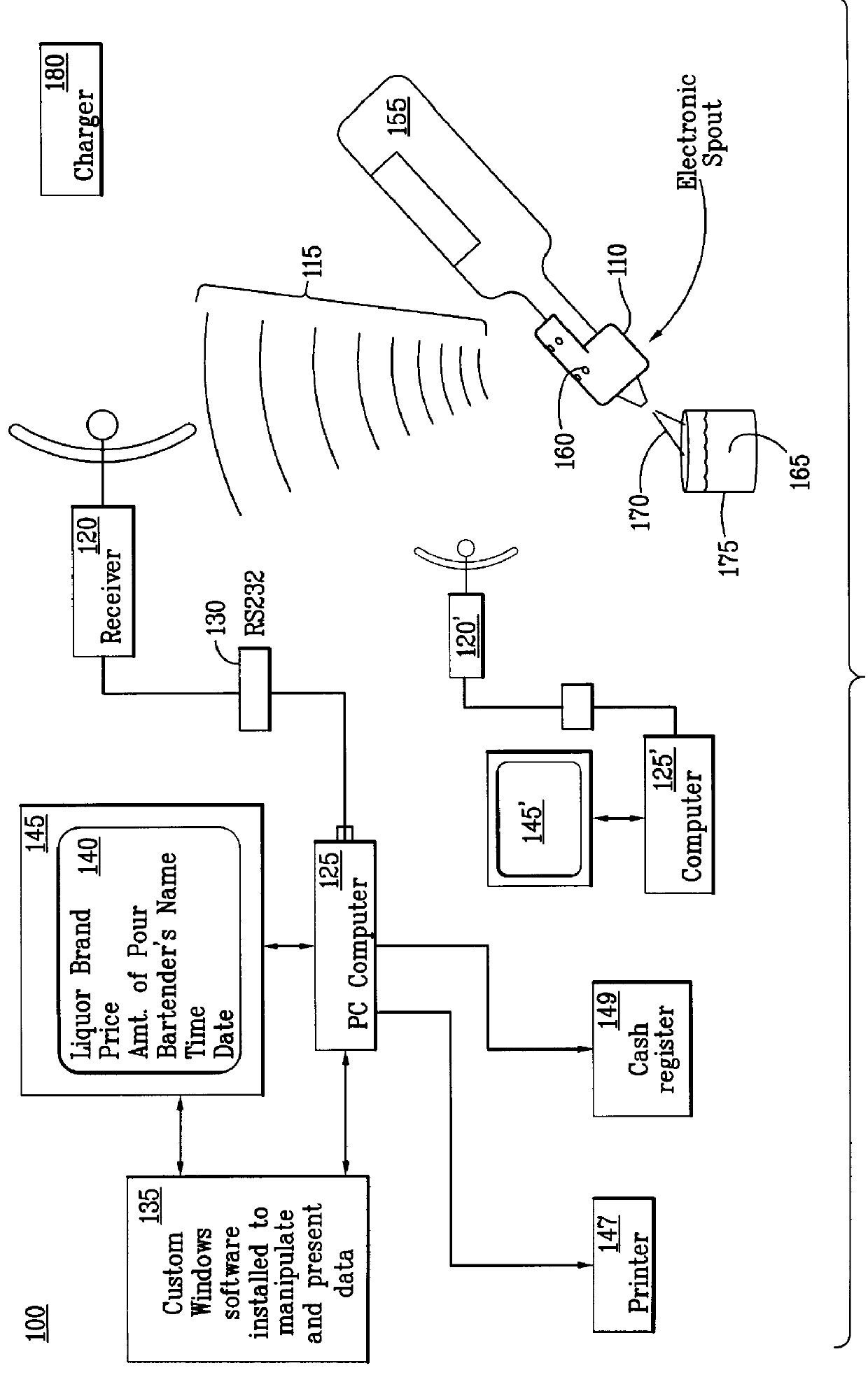

Wireless liquid portion and inventory control system

A system for controlling an amount of liquid poured from a liquid container includes a spout configured for attachment to an opening of a liquid container and for controlling a desired amount of liquid poured from the liquid container. The spout is further configured to emit signals containing activity information. A receiver is configured to receive the signals, and a computer is coupled to the receiver, for processing the signals into text for viewing. The present invention further provides a method of controlling liquid flow from a liquid container, including the steps of: (a) determining an amount of liquid which is to be poured from a liquid container; (b) transmitting activity information signal corresponding to a predetermined activity; (c) remotely receiving the activity information signal of step (b); and (d) processing the activity information signal of step (c) into readable form.

Owner:MOGADAM MASOUD M

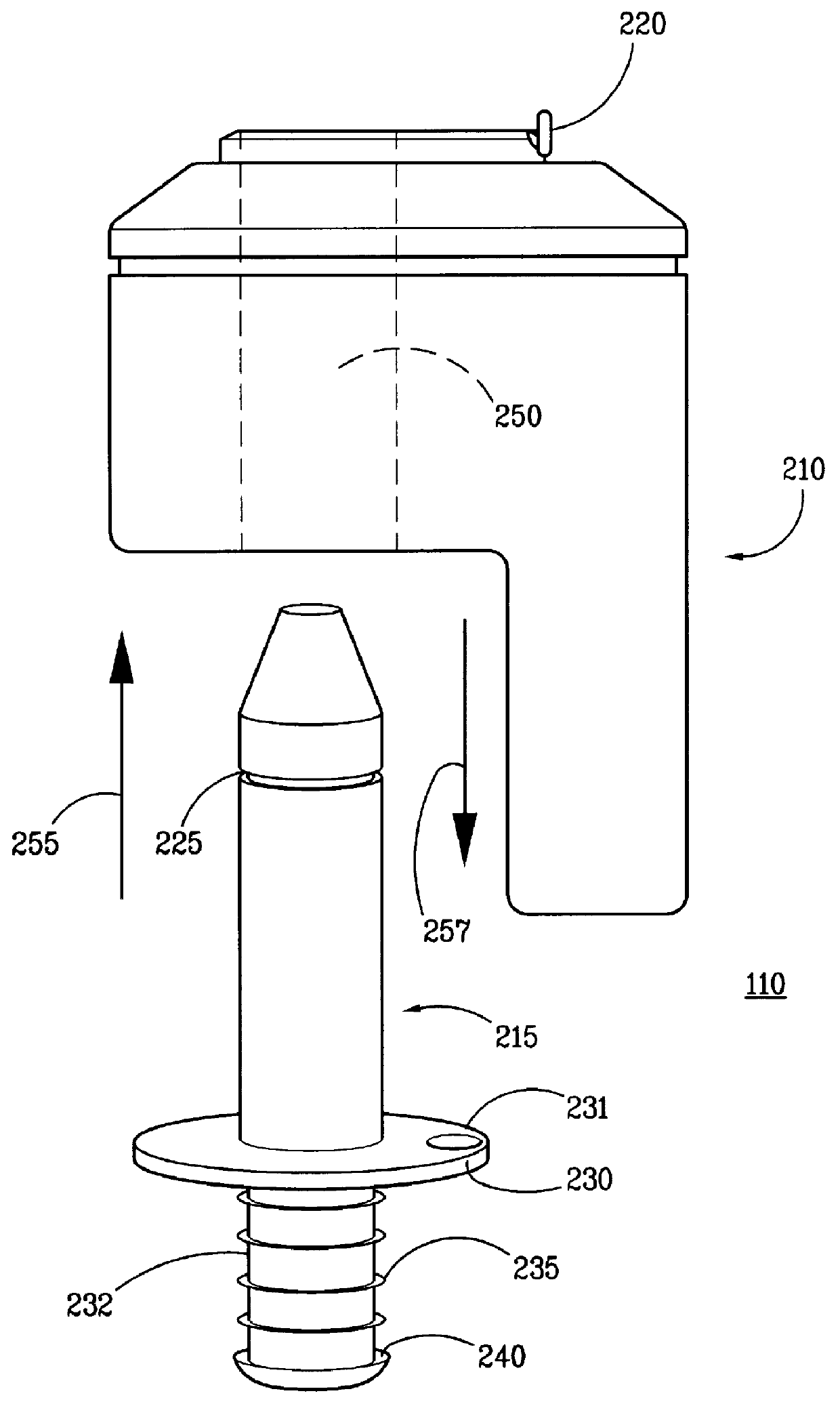

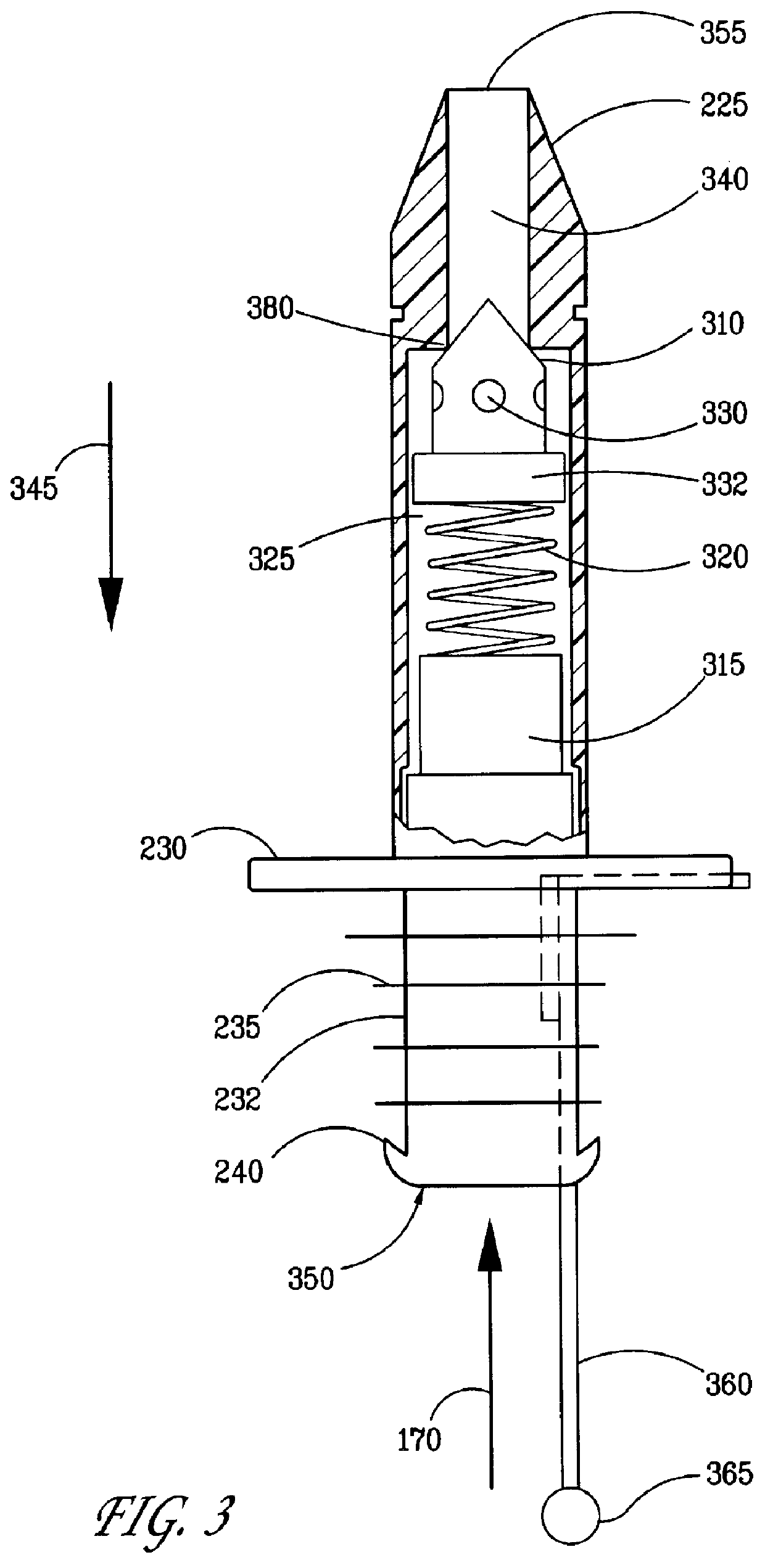

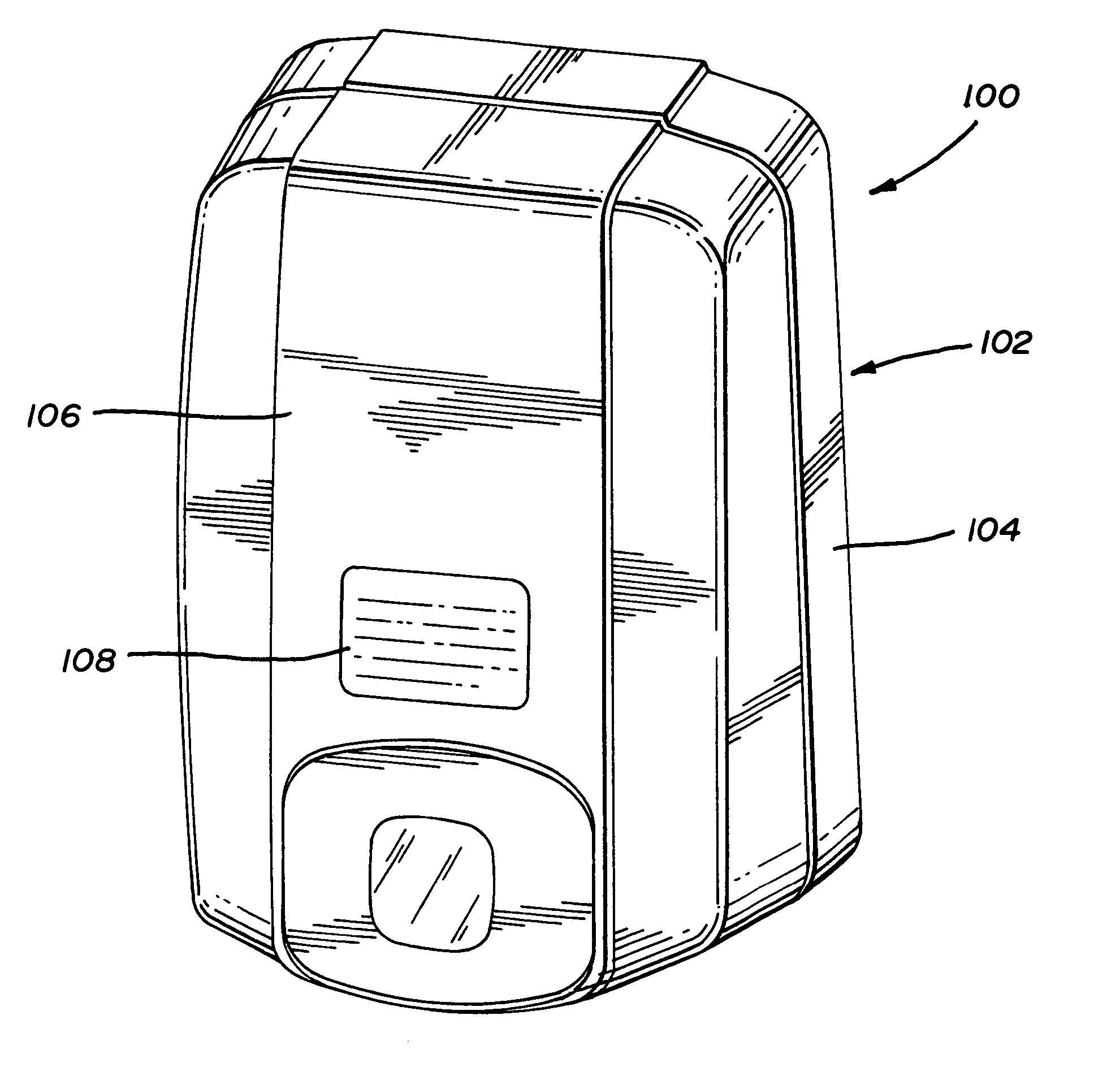

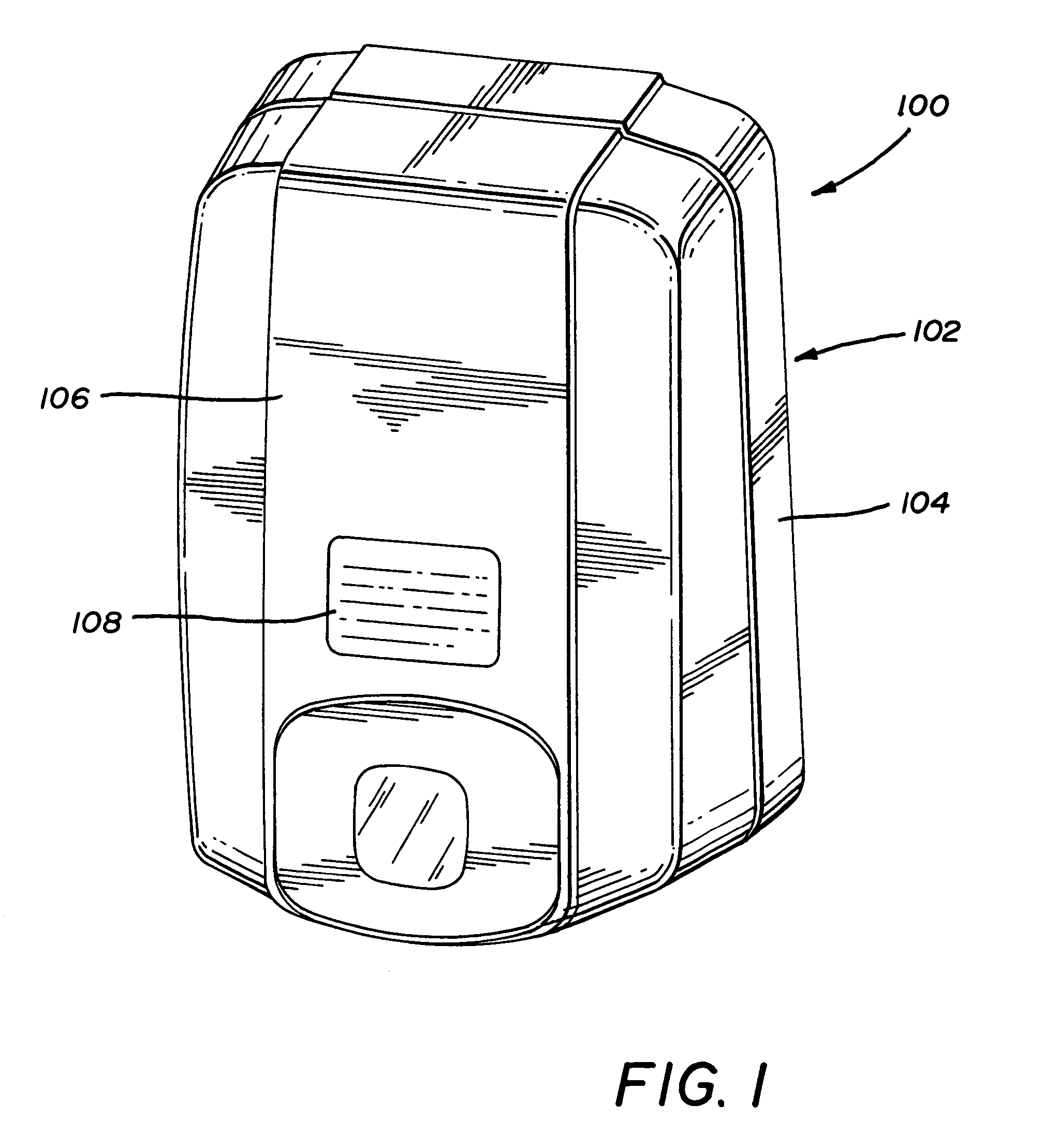

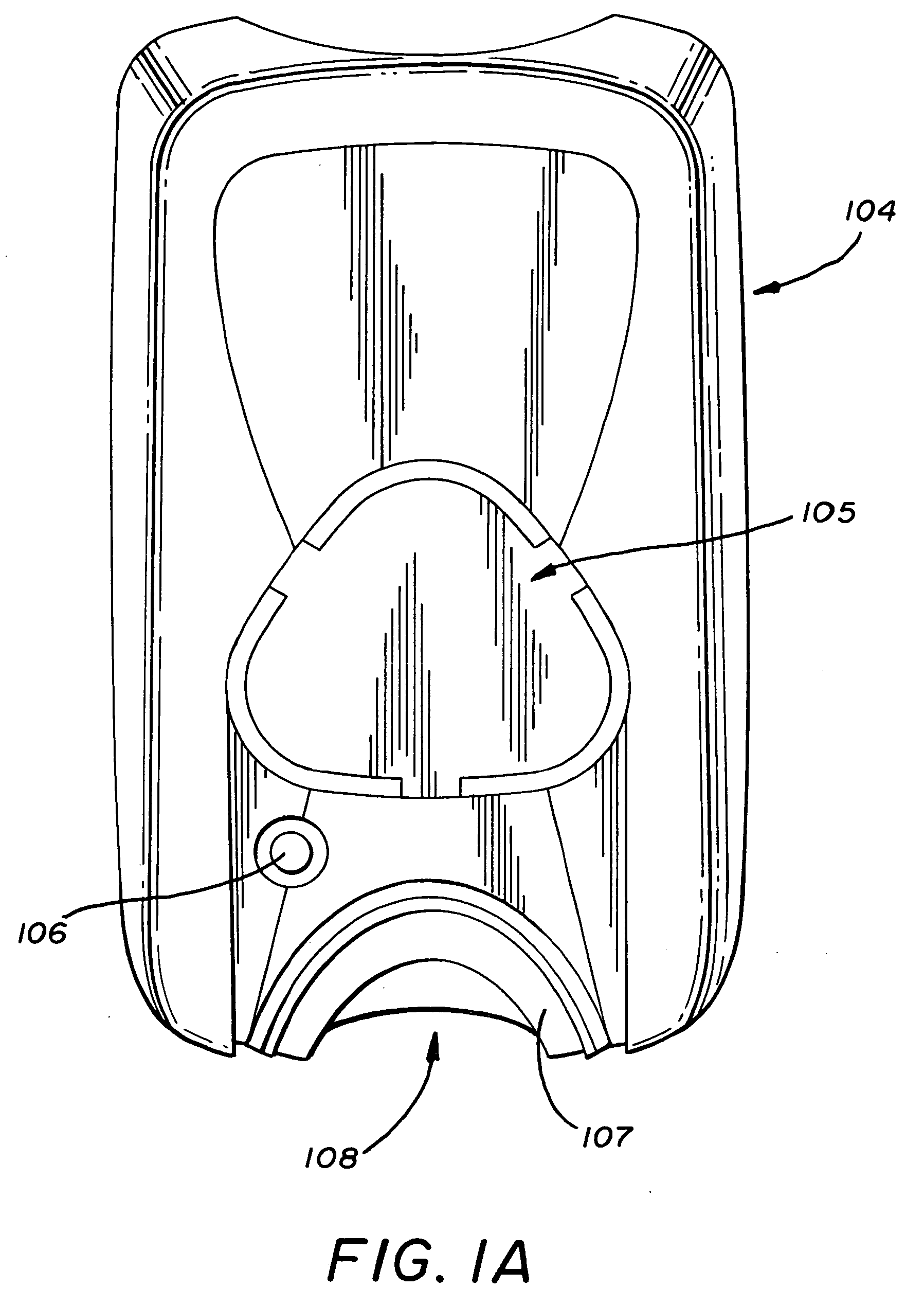

Electronically keyed dispensing systems and related methods of installation and use

Dispensing systems are disclosed which utilize electronically powered key devices and / or identification codes associated with a refill container to preclude the need for mechanical keys. A first embodiment of the device utilizes a matching code stored in a radio frequency identification tag or bar code associated with a fluid refill container and an identification code associated with the dispenser housing. Matching of the codes by a controller allows for continued use of the dispenser via some type of operational mechanism. Another embodiment employs a key which carries the matching code wherein matching of the codes allows for actuation of a motor actuated pumping device. Yet another embodiment employs a blocking mechanism to prevent use of a dispenser's push bar if a key and dispenser housing do not have matching codes. And yet another embodiment requires the use of a key that has a matching code that matches the dispenser's identification code in order to permit initial access to the dispenser housing.

Owner:JOSEPH S KANFER

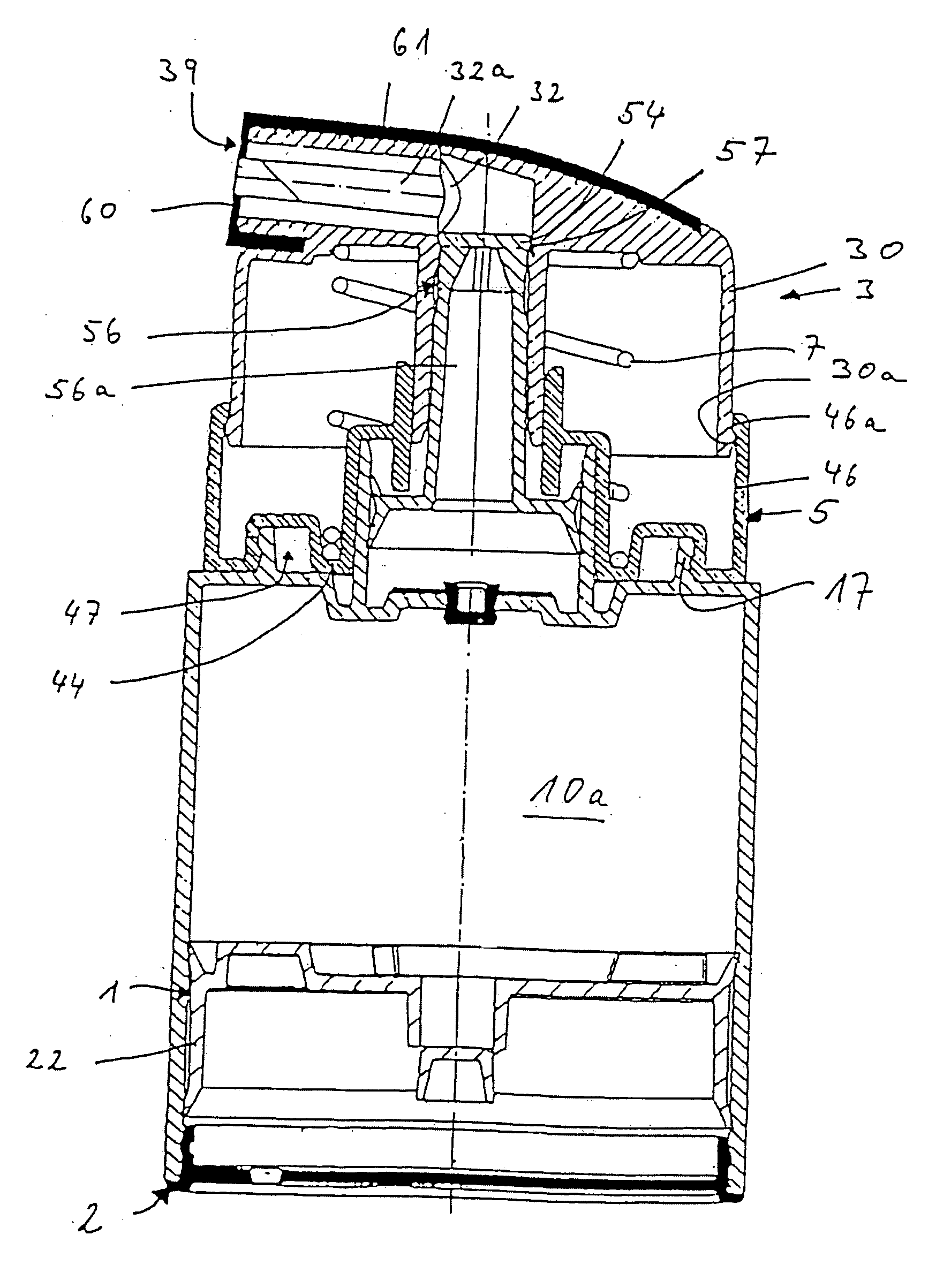

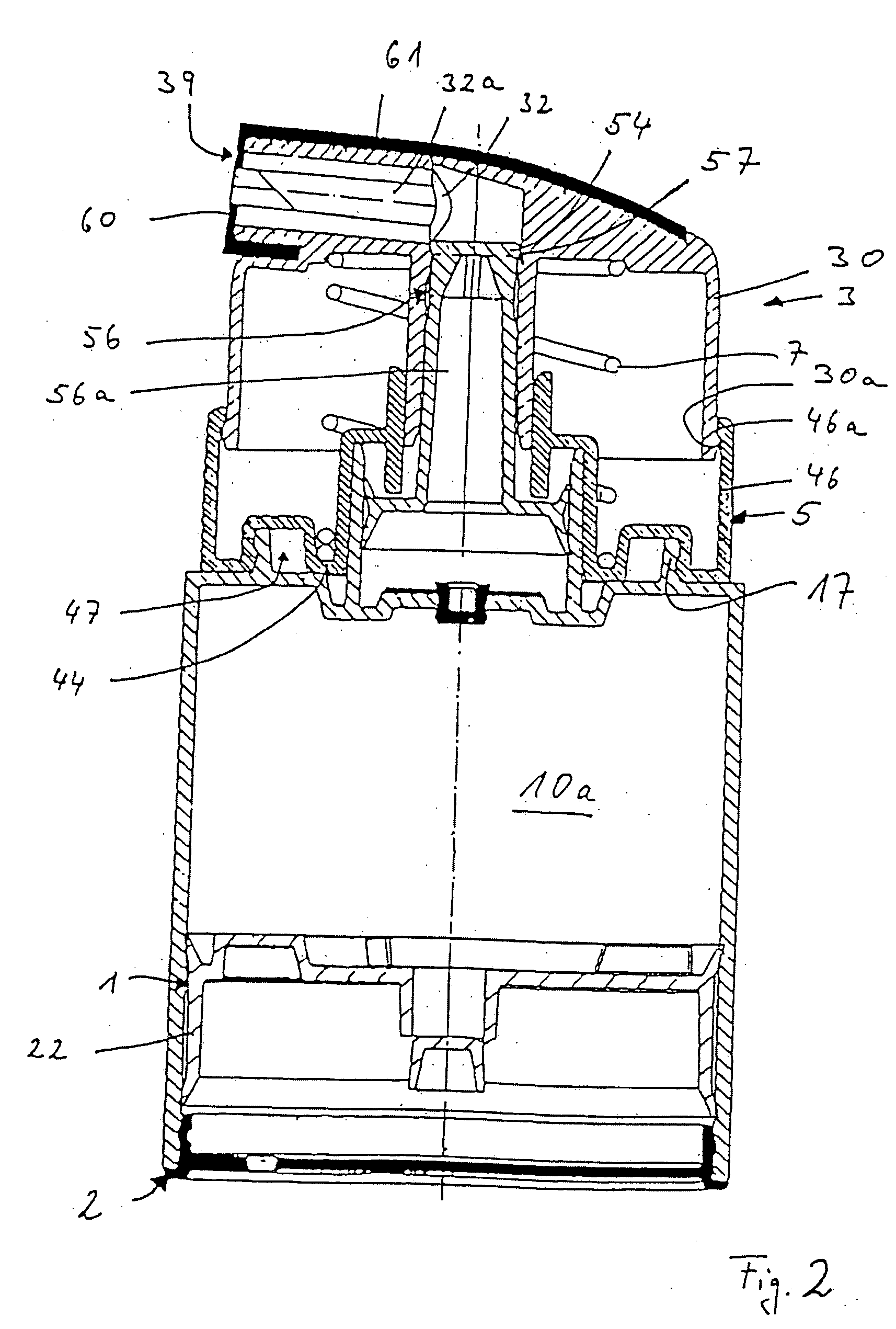

Vertebroplasty injection device and bone cement therefor

InactiveUS20020156483A1Small sizeIncrease pressurePowder deliveryShaking/oscillating/vibrating mixersInjectable biomaterialVertebroplasty procedure

This invention relates to a mixing and delivery device suitable for delivering injectable biomaterials, and to preferred bone cement formulations.

Owner:DEPUY ACROMED INC

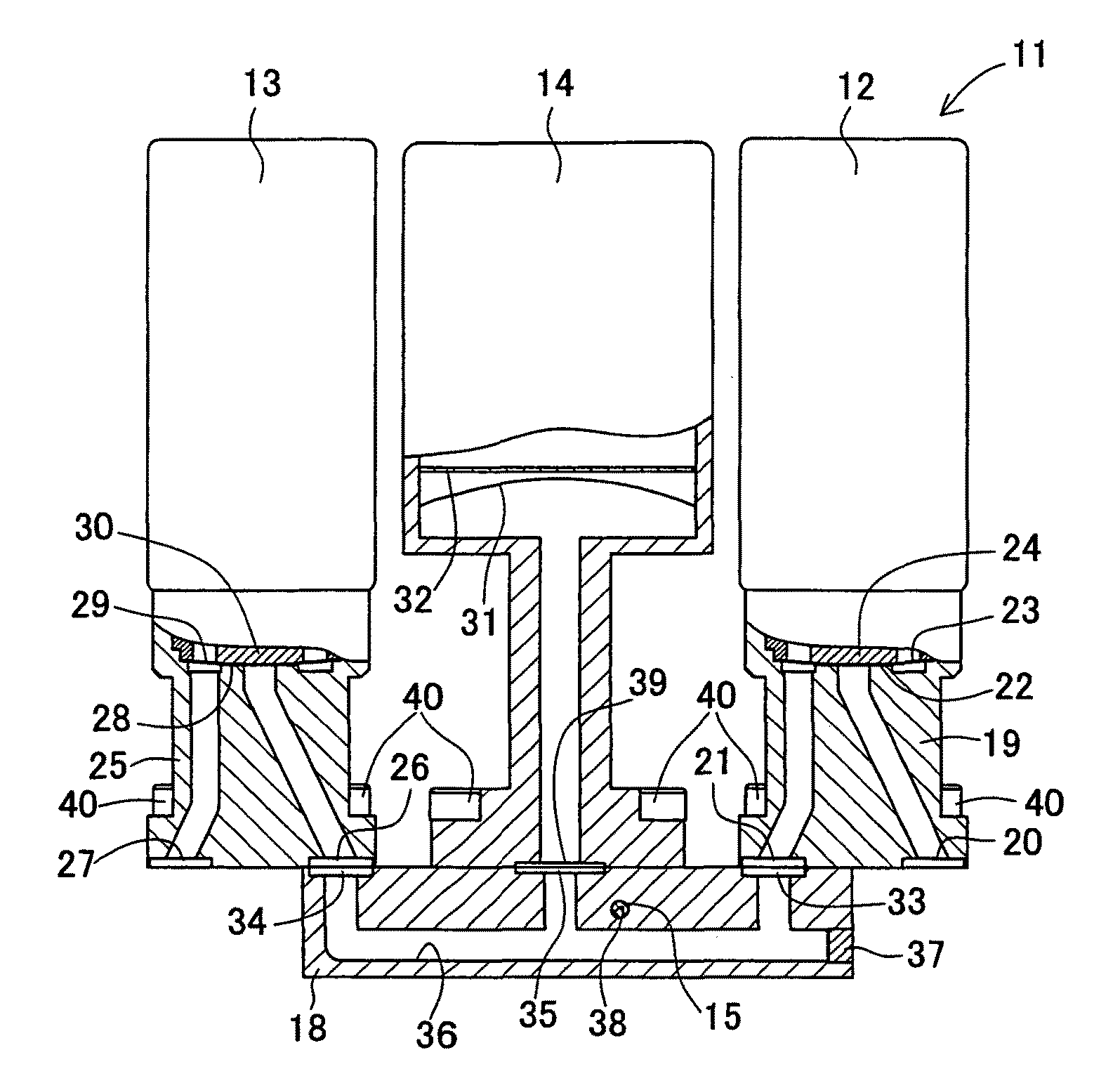

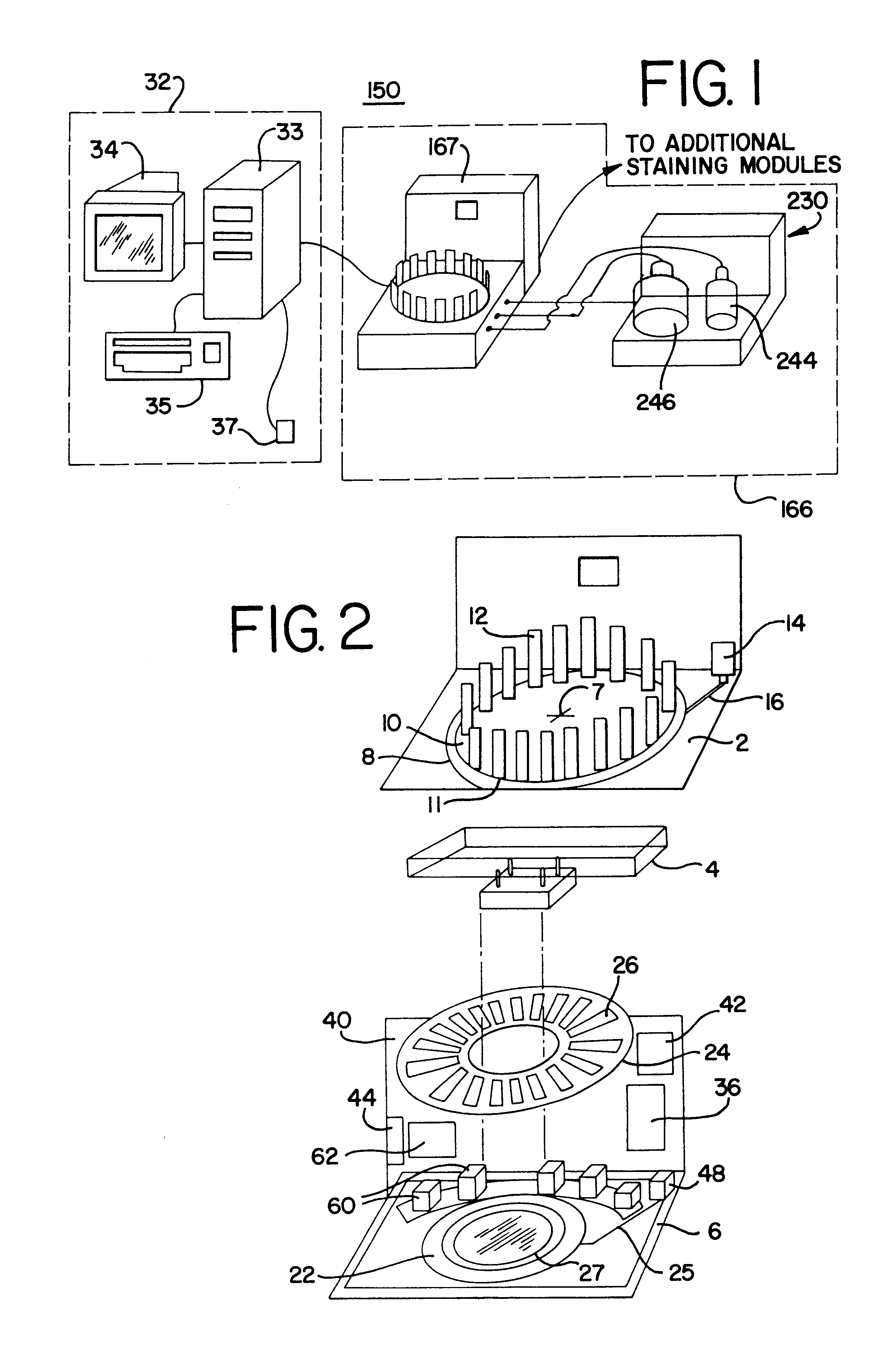

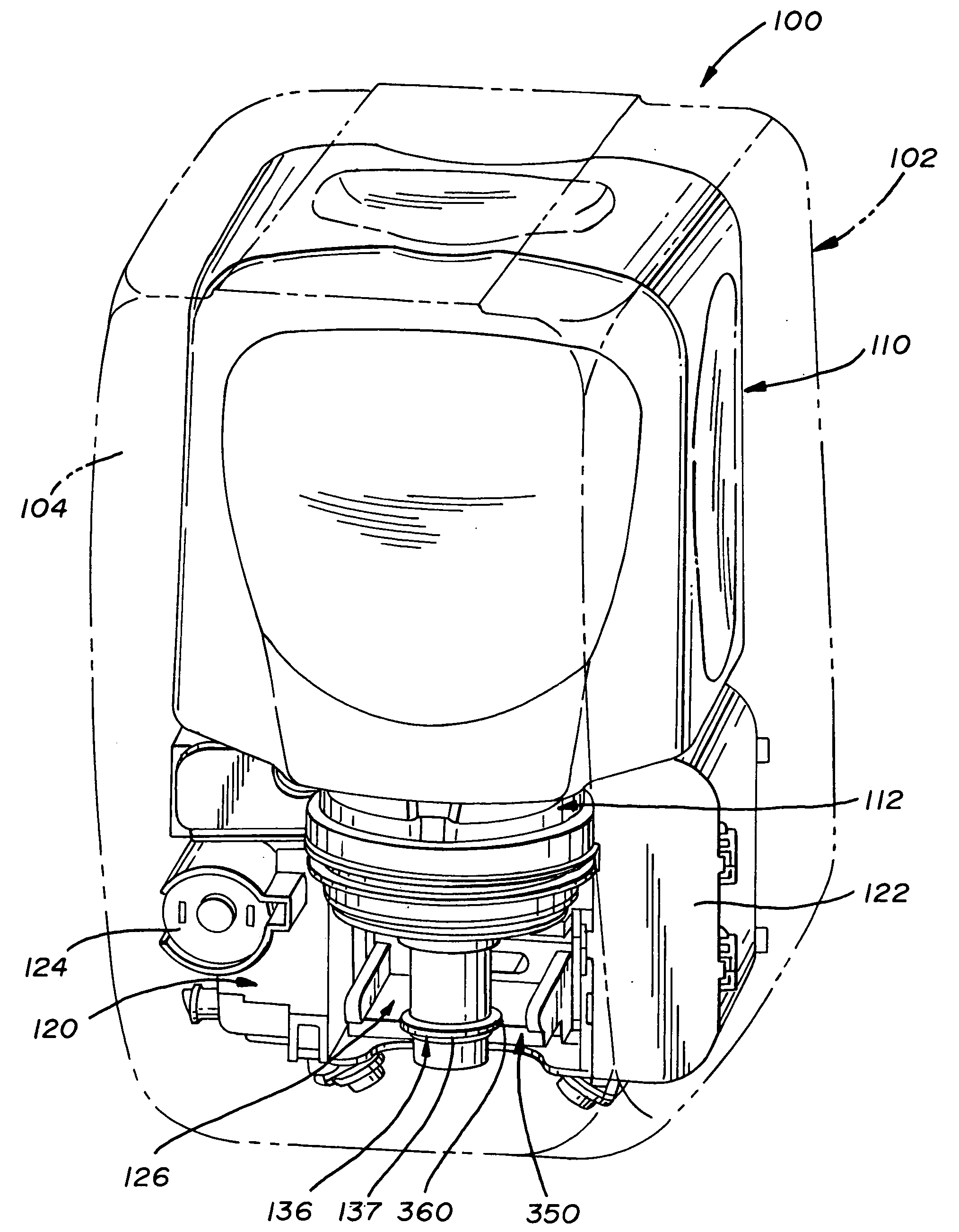

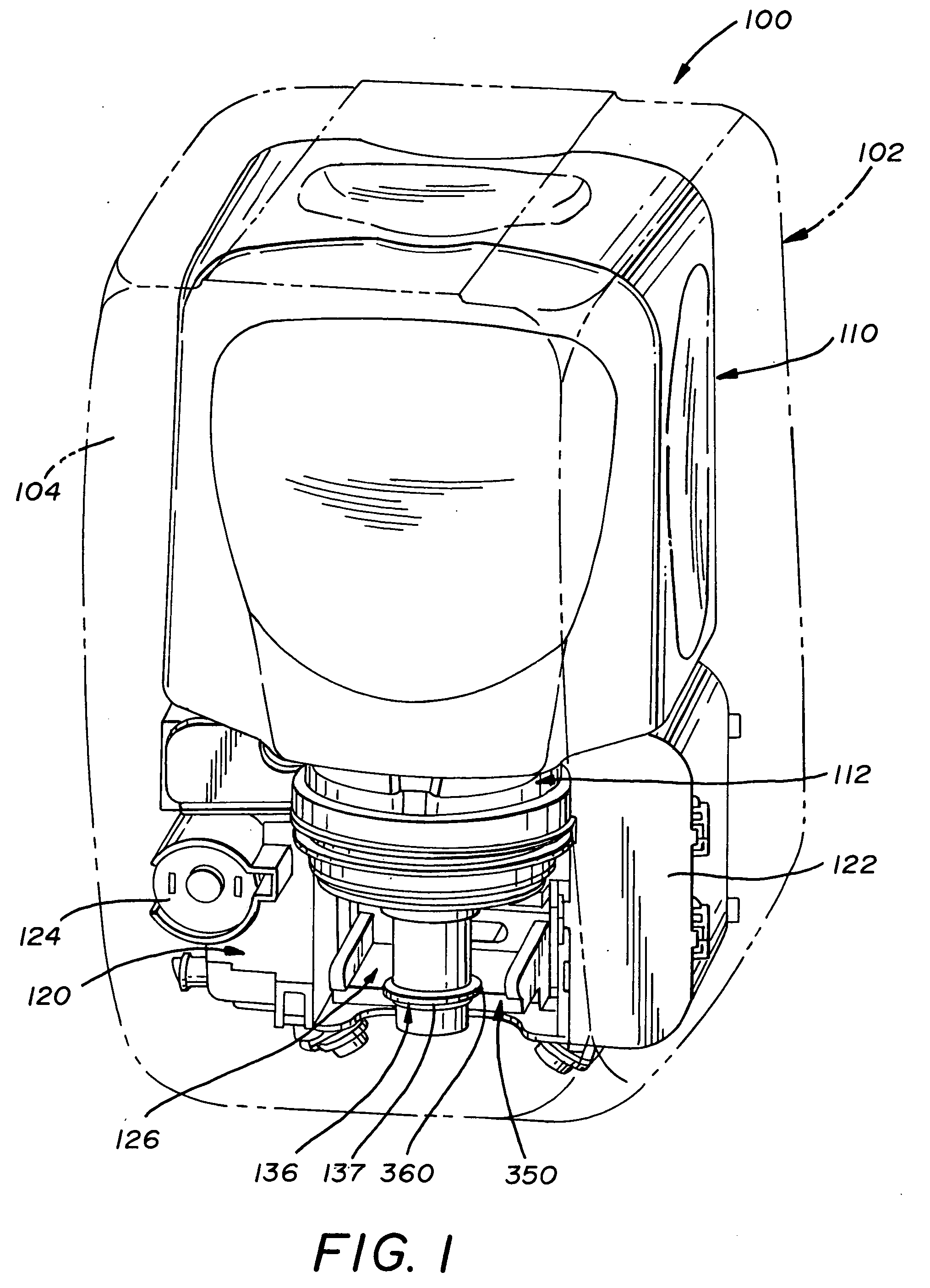

Fluid dispenser

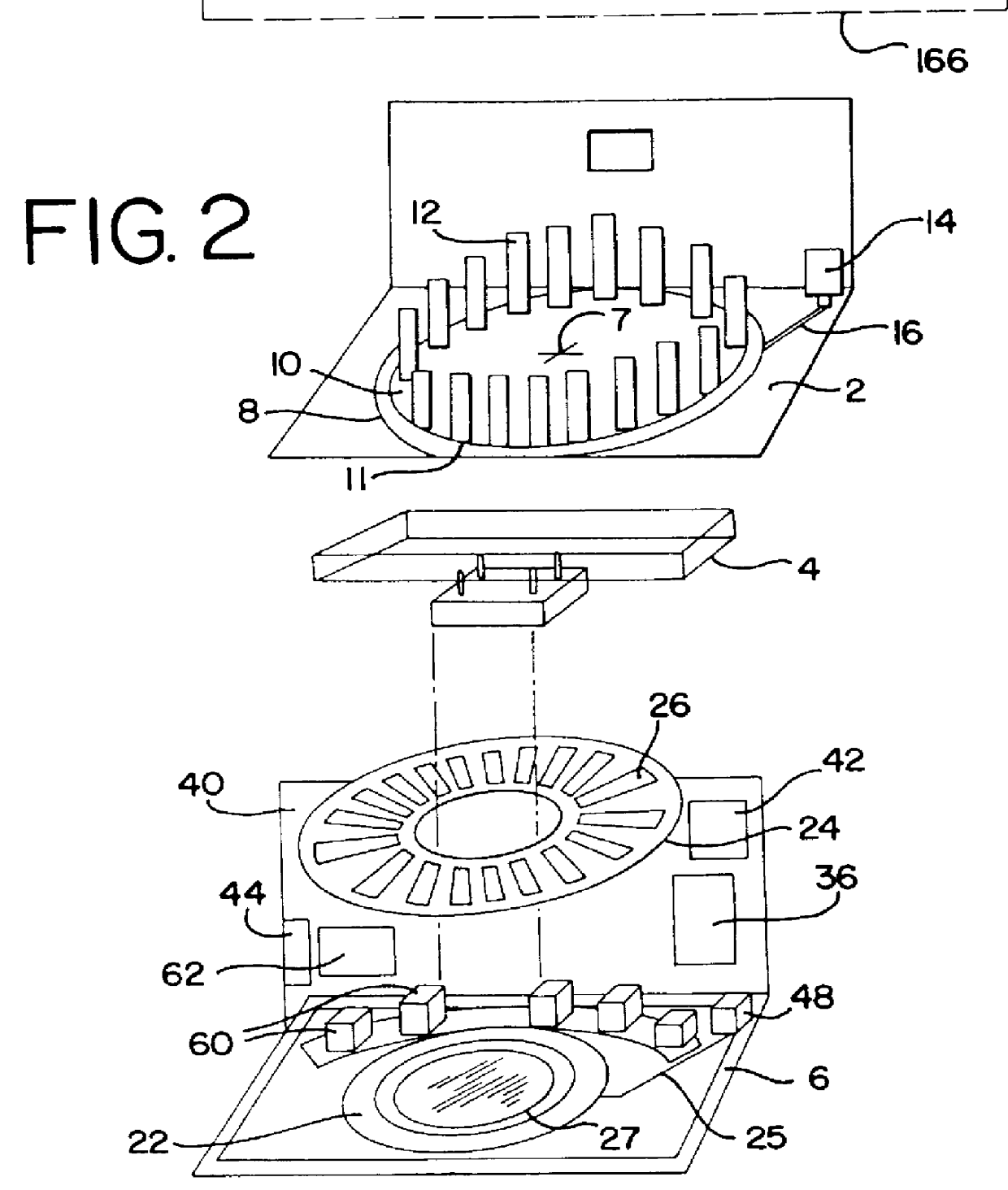

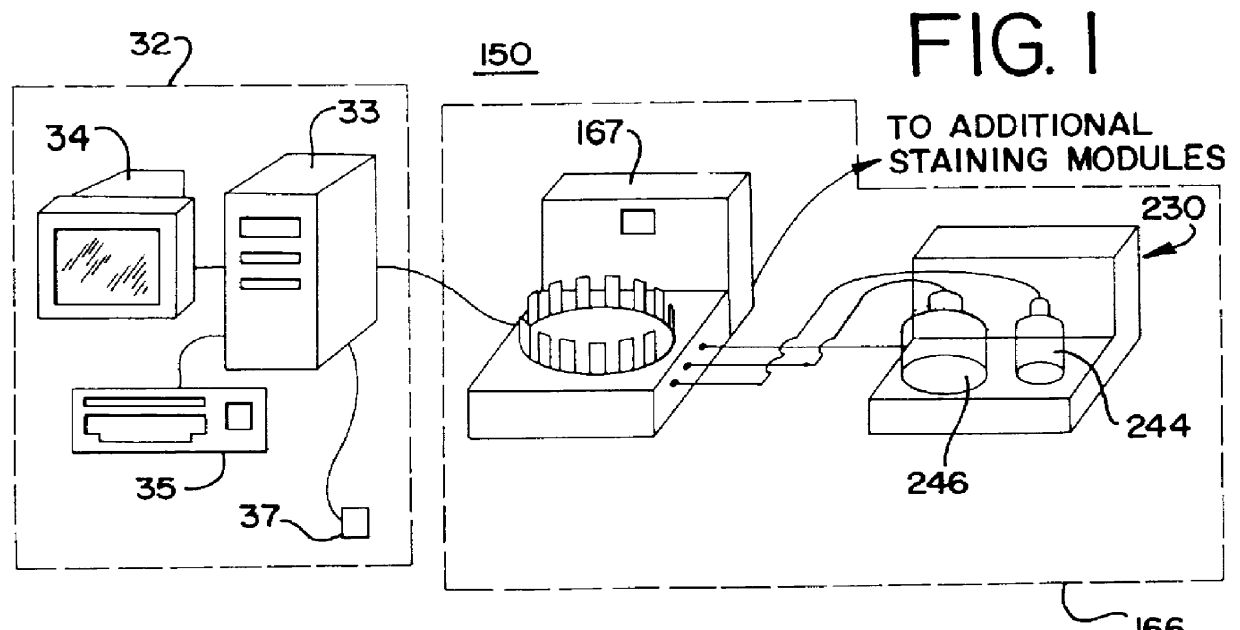

InactiveUS6045759AEfficient and reliableEasy to manufactureCheck valvesLarge containersModularityReactive system

A method and apparatus for an automated biological reaction system is provided. In the processing of a biological reaction system, there is a need for consistently placing an amount of fluid on a slide. In order to accomplish this, several methods are used including a consistency pulse and a volume adjust means. Moreover, in order to reliably operate an automated biological reaction system, the dispenser must be reliable, easy to assemble and accurate. Among other things, in order to accomplish this, the dispense chamber is substantially in line with the reservoir chamber, the reservoir chamber piston is removed, and the flow of fluid through the dispenser is simplified. Further, in order to operate the automated biological reaction system more reliably, the system is designed in modular pieces with higher functions performed by a host device and the execution of the staining operations performed by remote devices. Also, to reliably catalog data which is used by the automated biological reaction system, data is loaded to a memory device, which in turn is used by the operator to update the operator's databases. The generation of the sequence of steps for the automated biological reaction device based on data loaded by the operator, including checks to determine the ability to complete the run, is provided.

Owner:VENTANA MEDICAL SYST INC

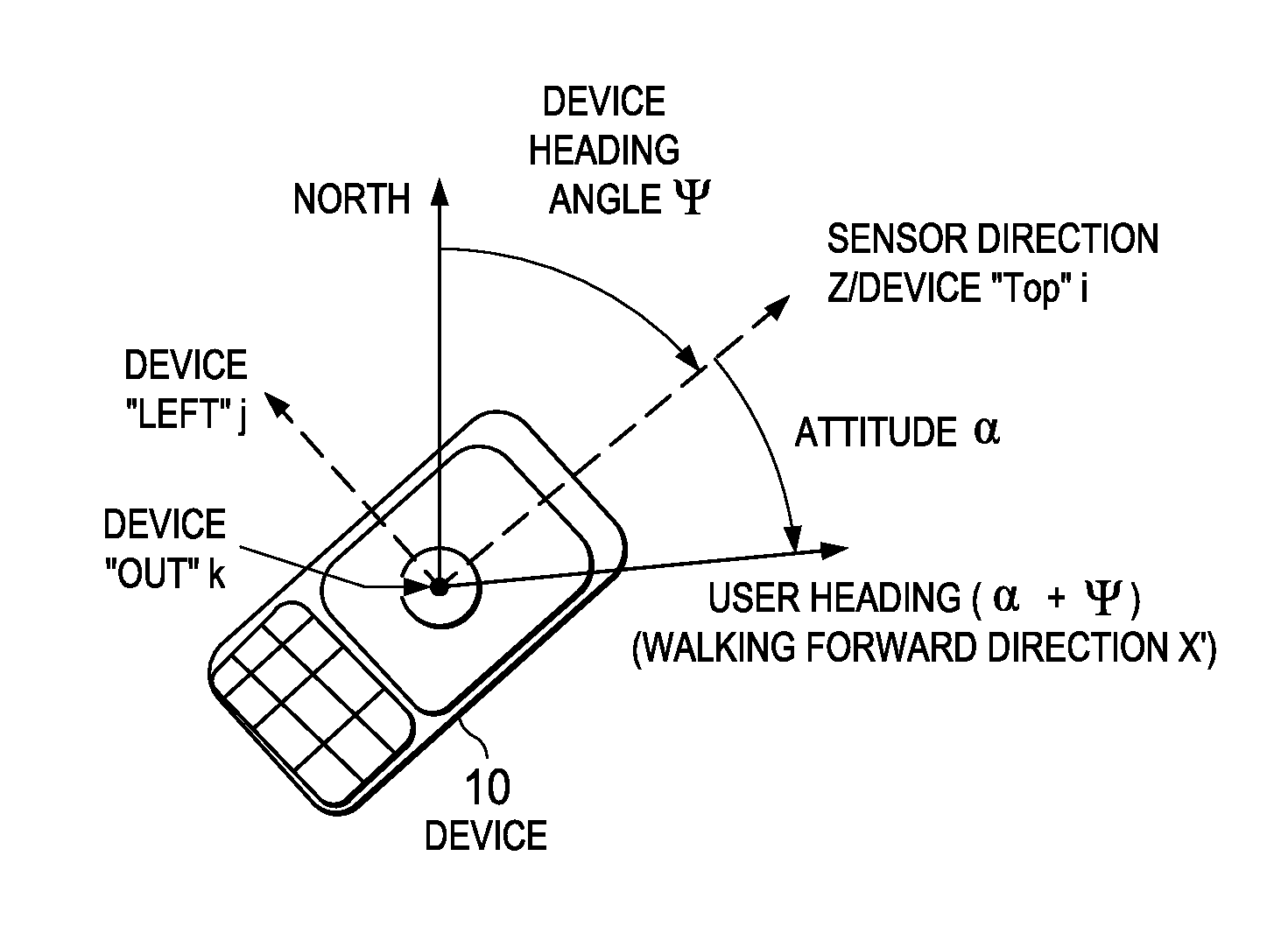

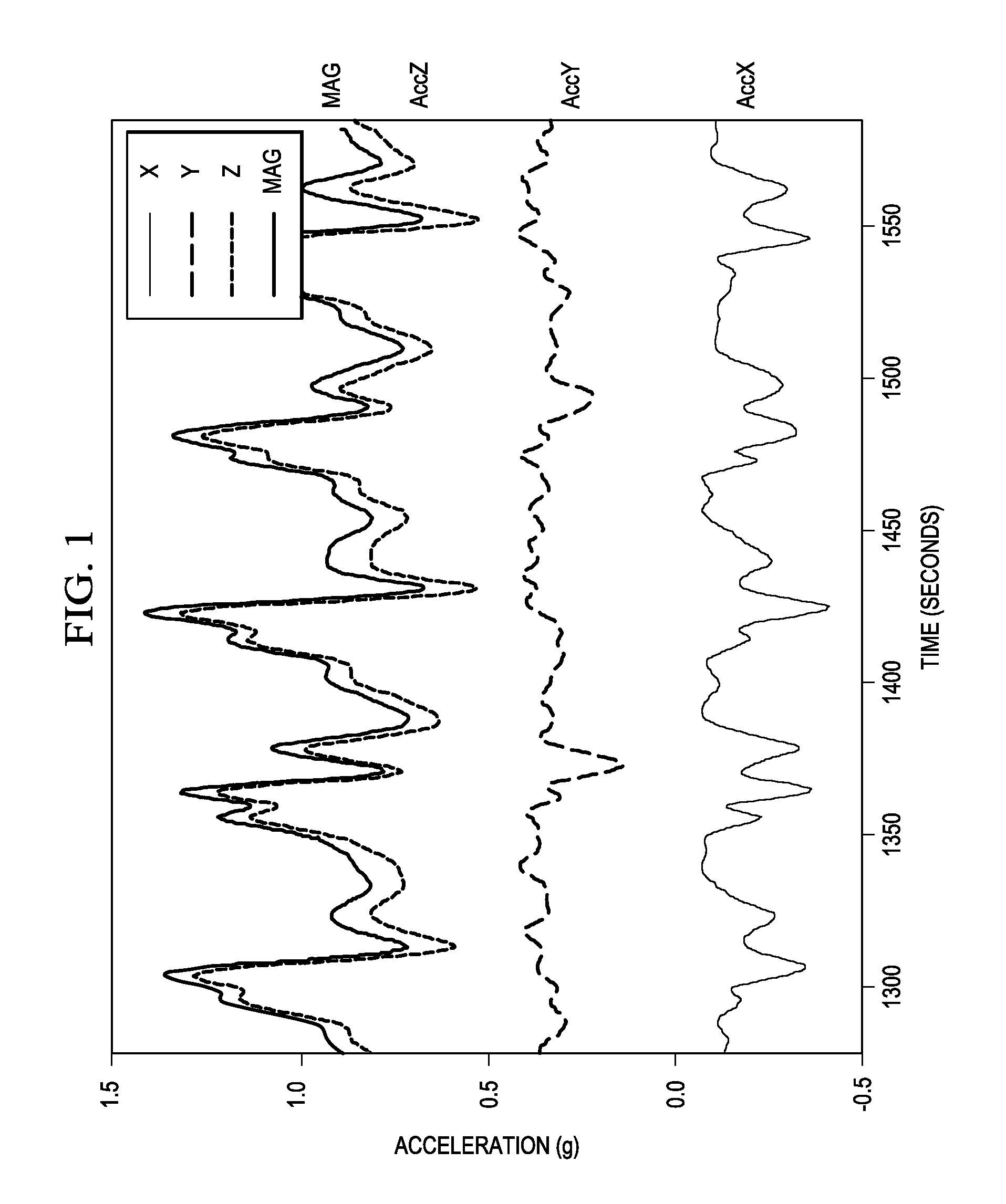

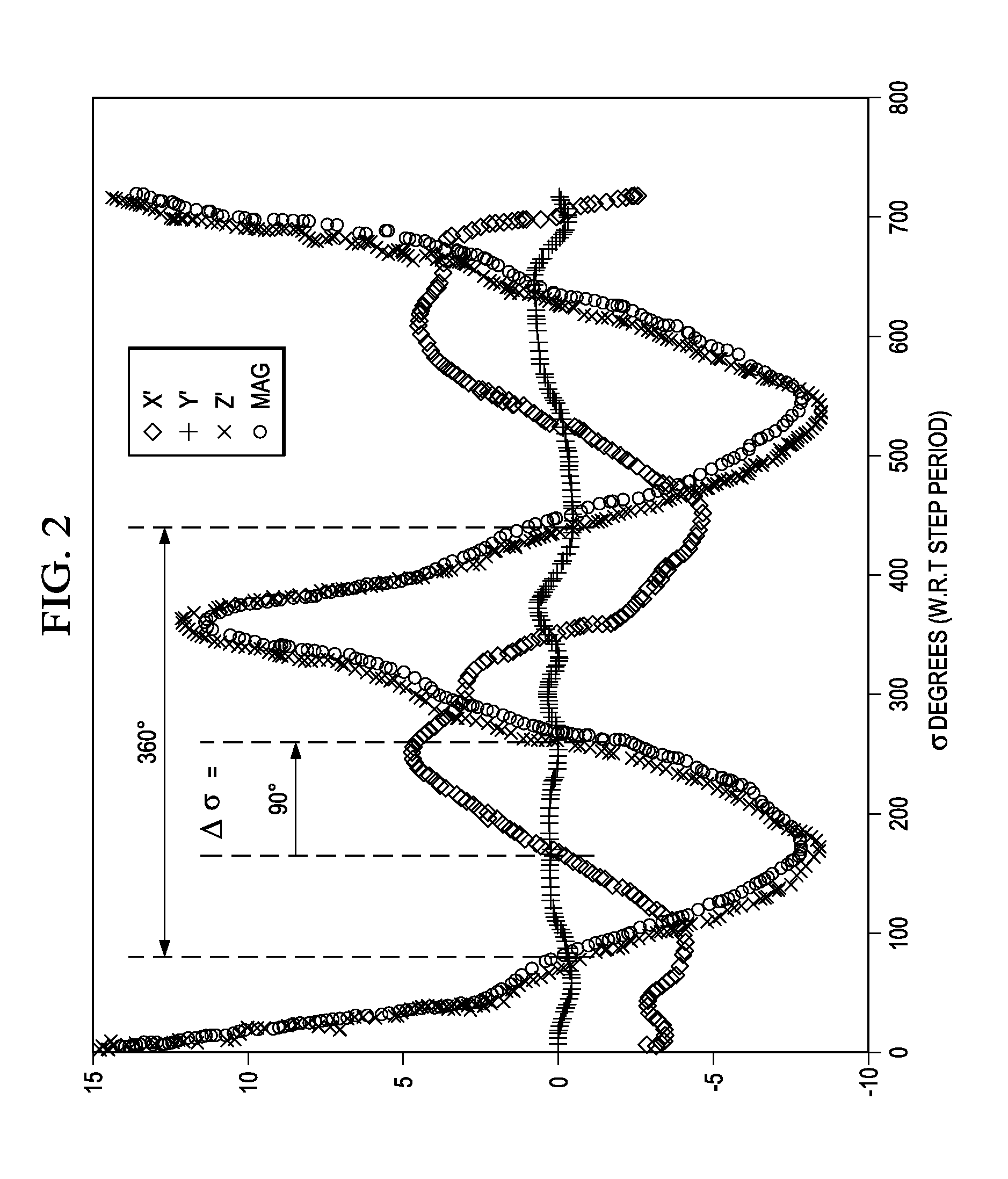

Robust step detection using low cost MEMS accelerometer in mobile applications, and processing methods, apparatus and systems

ActiveUS20130090881A1Testing/calibration apparatusNavigation by speed/acceleration measurementsAccelerometerSlide window

A system (10) for pedestrian use includes an accelerometer (110) having multiple electronic sensors; an electronic circuit (100) operable to generate a signal stream representing magnitude of overall acceleration sensed by the accelerometer (110), and to electronically correlate a sliding window (520) of the signal stream with itself to produce peaks at least some of which represent walking steps, and further operable to electronically execute a periodicity check (540) to compare different step periods for similarity, and if sufficiently similar then to update (560) a portion of the circuit substantially representing a walking-step count; and an electronic display (190) responsive to the electronic circuit (100) to display information at least in part based on the step count. Other systems, electronic circuits and processes are disclosed.

Owner:TEXAS INSTR INC

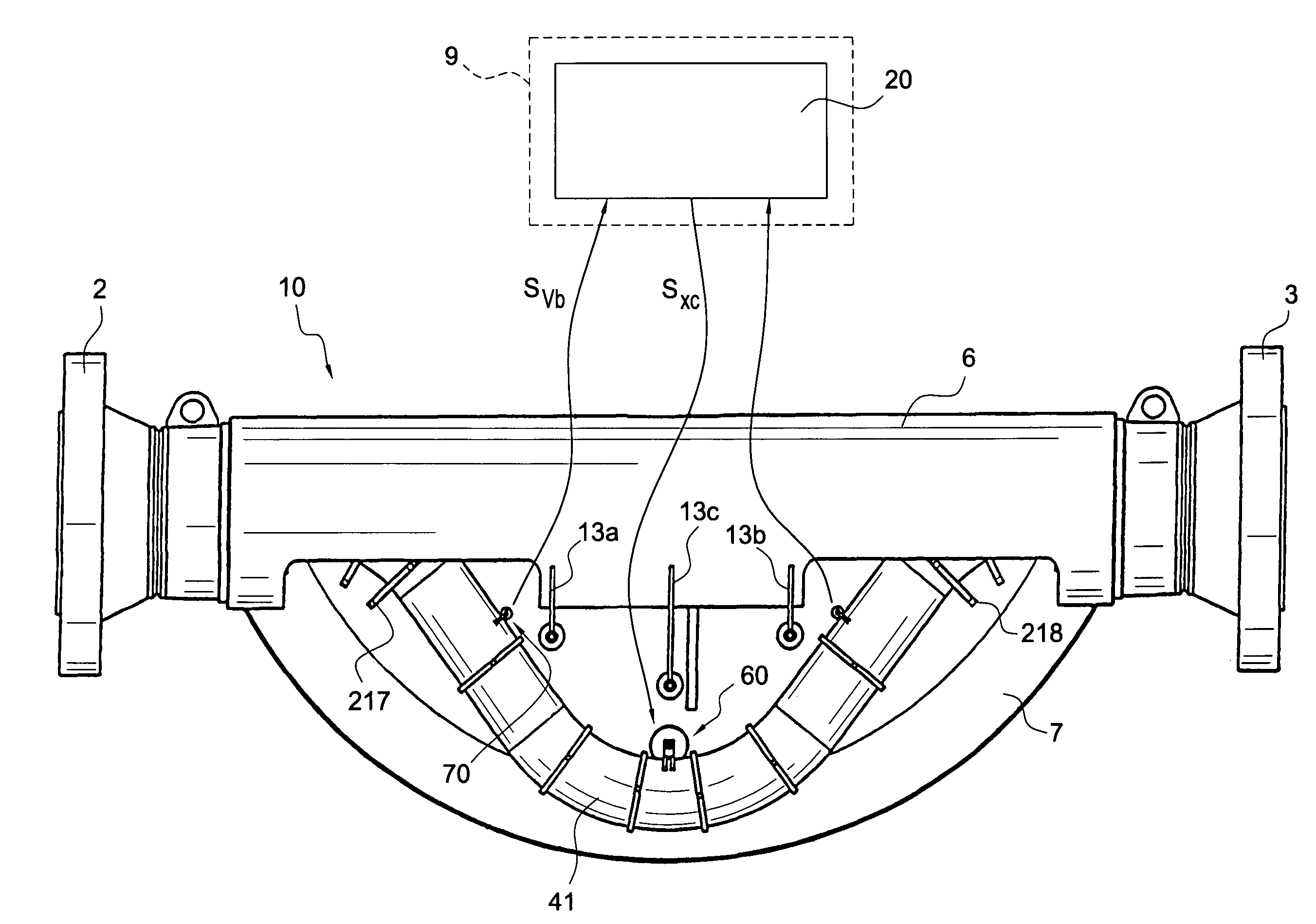

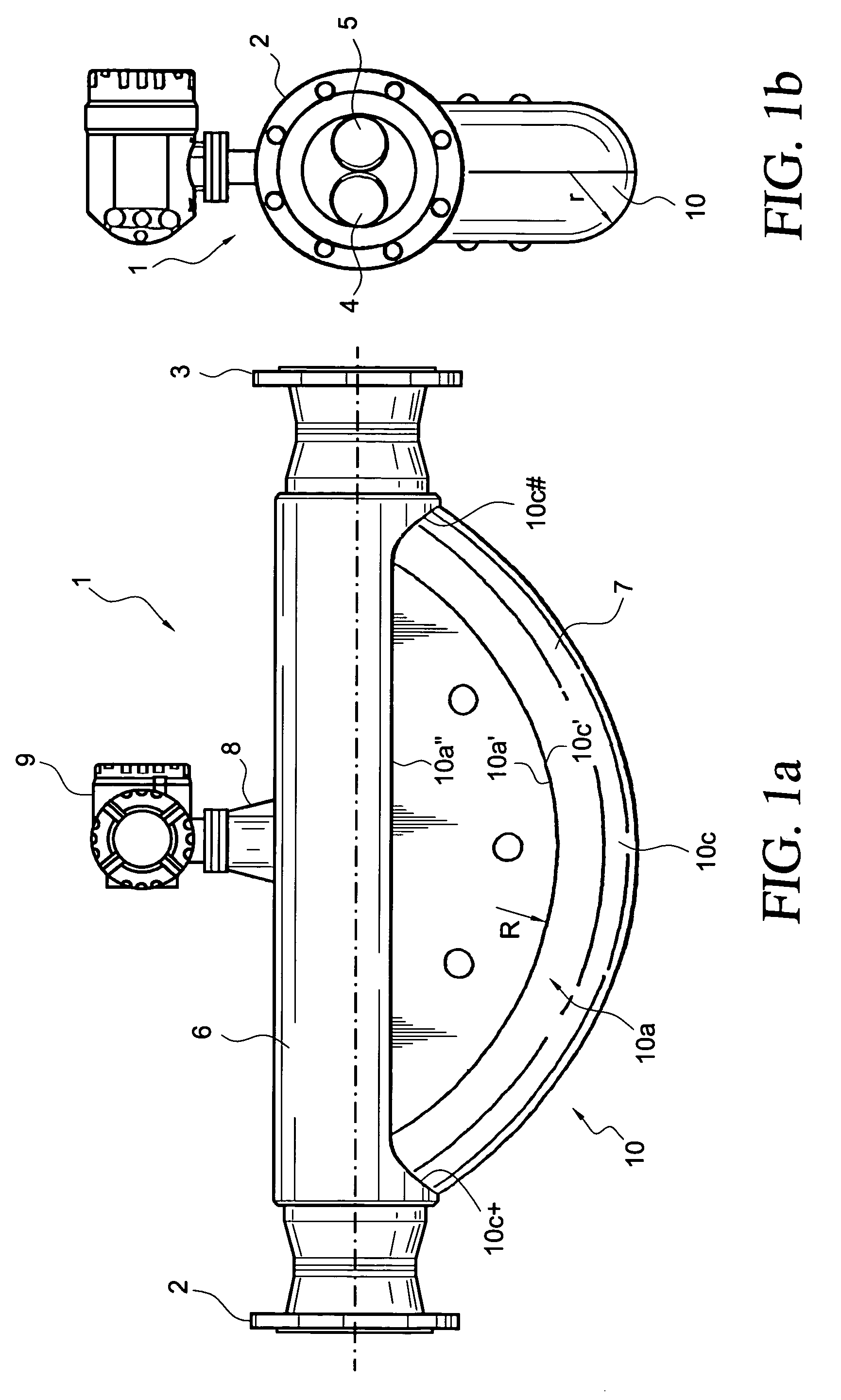

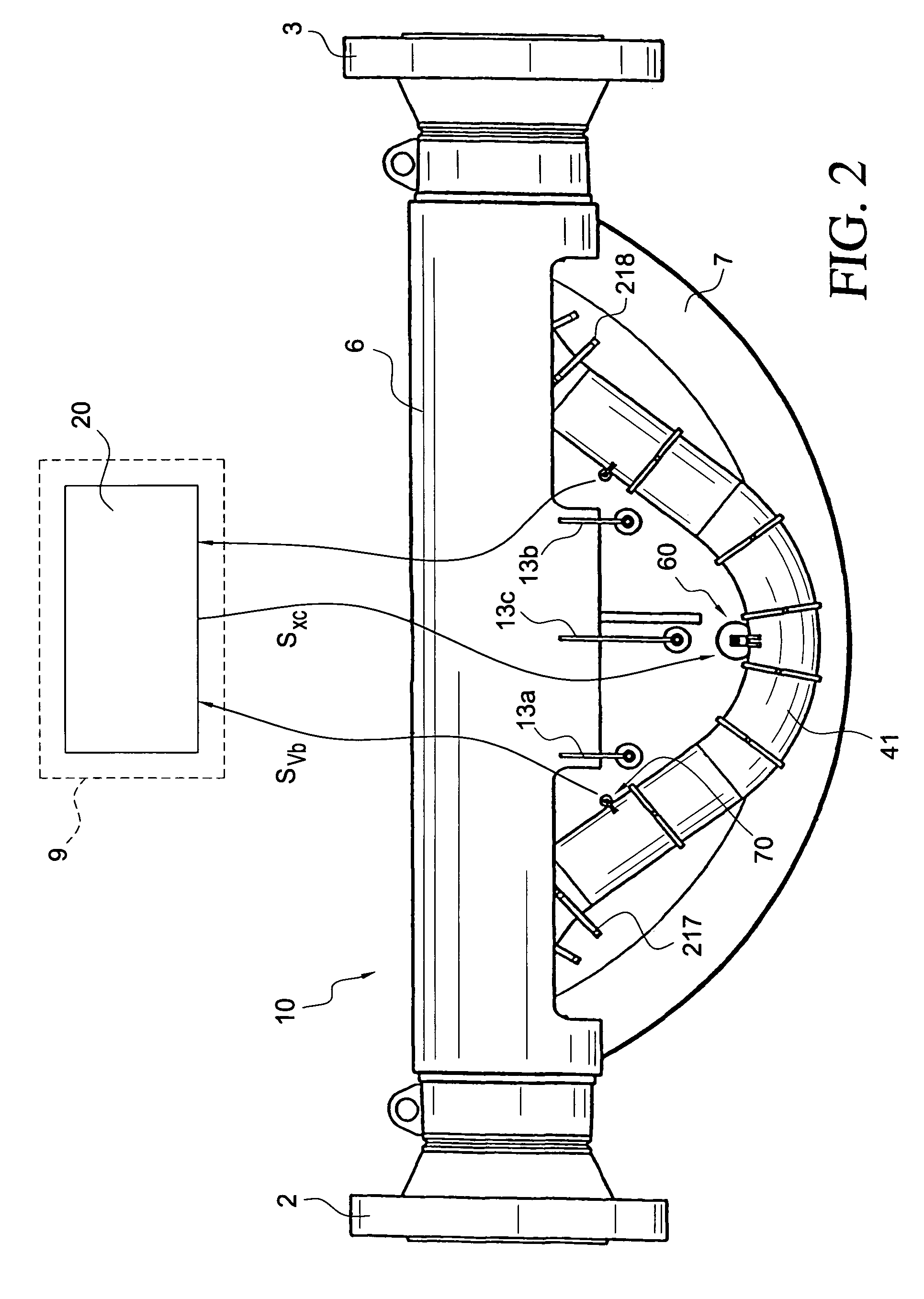

Inline measuring device with a vibration-type measurement pickup

An inline measuring device serves for measuring a medium, especially a gaseous and / or liquid medium, in a pipeline. It includes, a vibration-type measurement pickup and a measuring device electronics electrically coupled with the measurement pickup. The measurement pickup has at least one measuring tube vibrating during operation and communicating with the pipeline, an electromechanical, especially electrodynamic, exciter mechanism acting on the at least one measuring tube for producing and maintaining mechanical oscillations of the measuring tube, a sensor arrangement for producing at least one oscillation measurement signal representing oscillations of the measuring tube and having at least one oscillation sensor arranged on the measuring tube or in its vicinity, and a measurement pickup housing. In an inline measuring device of the invention, it is additionally provided that the measuring device electronics monitors a static internal pressure within the measurement pickup housing and / or a hermeticity of the at least one measuring tube.

Owner:ENDRESS HAUSER FLOWTEC AG

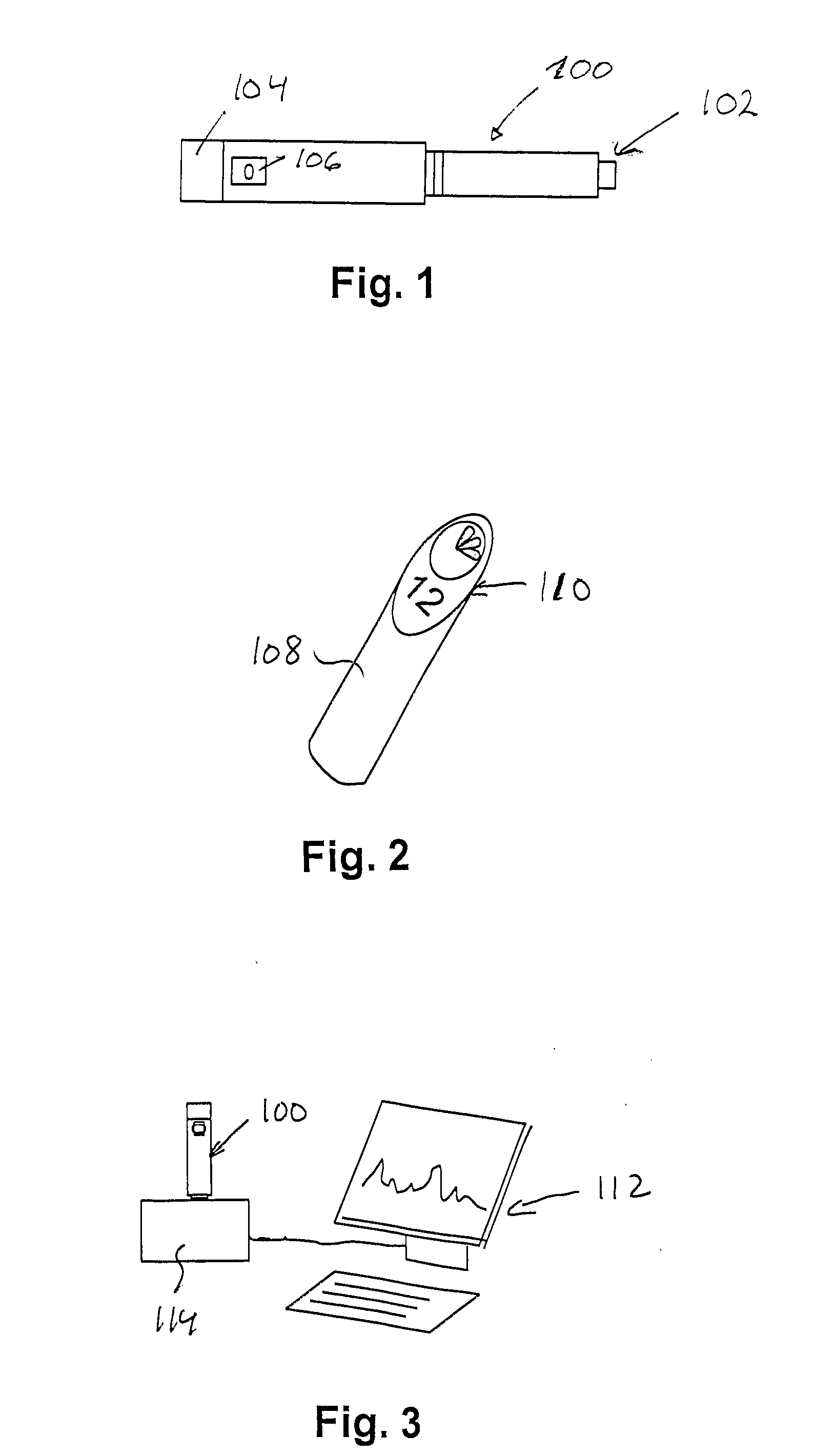

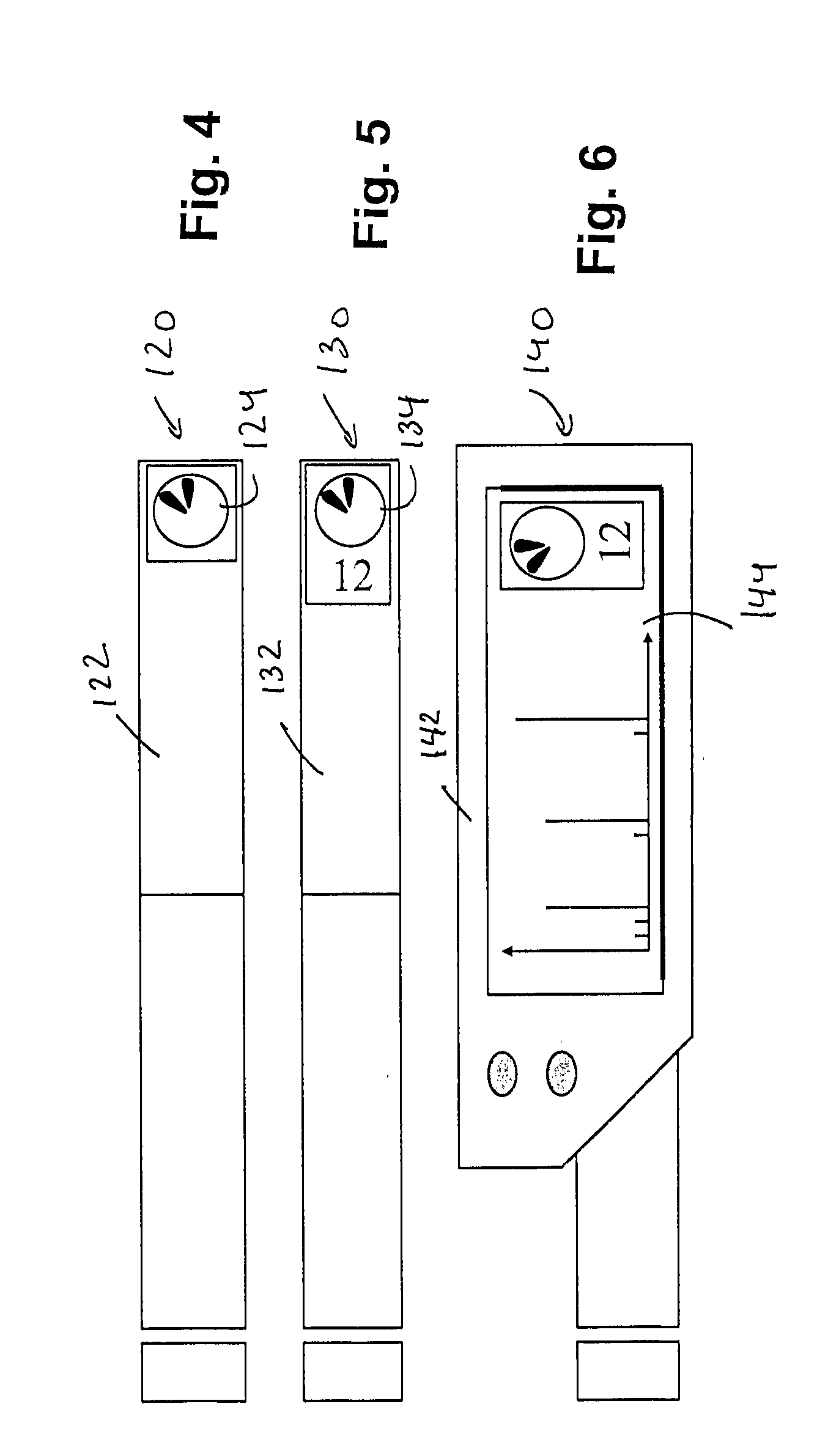

Injection Device with a Processor for Collecting Ejection Information

InactiveUS20080188813A1Improve patient safetyHigh dexterityAmpoule syringesAutomatic syringesBiomedical engineeringInjection device

A medication delivery device comprises an injection device having a reservoir comprising a medicament to be ejected, and a sensor arranged to detect an ejection of the medicament from the injection device, the sensor being arranged to output a signal comprising ejecting information, and a processor for collecting and storing the ejection information.

Owner:NOVO NORDISK AS

Hazardous material handling system and method

A method and system for handling hazardous materials contained in a vial includes an isolation enclosure having an opening selectively sealable about the vial, a bag body portion, and a cap portion. A latching extraction element is attached to the cap portion and has a preceding engaging member to secure the vial to the isolation enclosure, an extraction member to be inserted into the vial and remove material therefrom, and a primary engaging member to secure the vial to the extraction member. A valve is mounted outside the isolation enclosure and controls the flow of fluid from the vial. An adaptor having a reseal member permits flow when coupled to the valve and restricts flow when uncoupled from the valve. Once uncoupled, the adaptor is removably associated with a second valve located remotely from the isolation enclosure, allowing fluid to pass into the second valve.

Owner:HOSPIRA

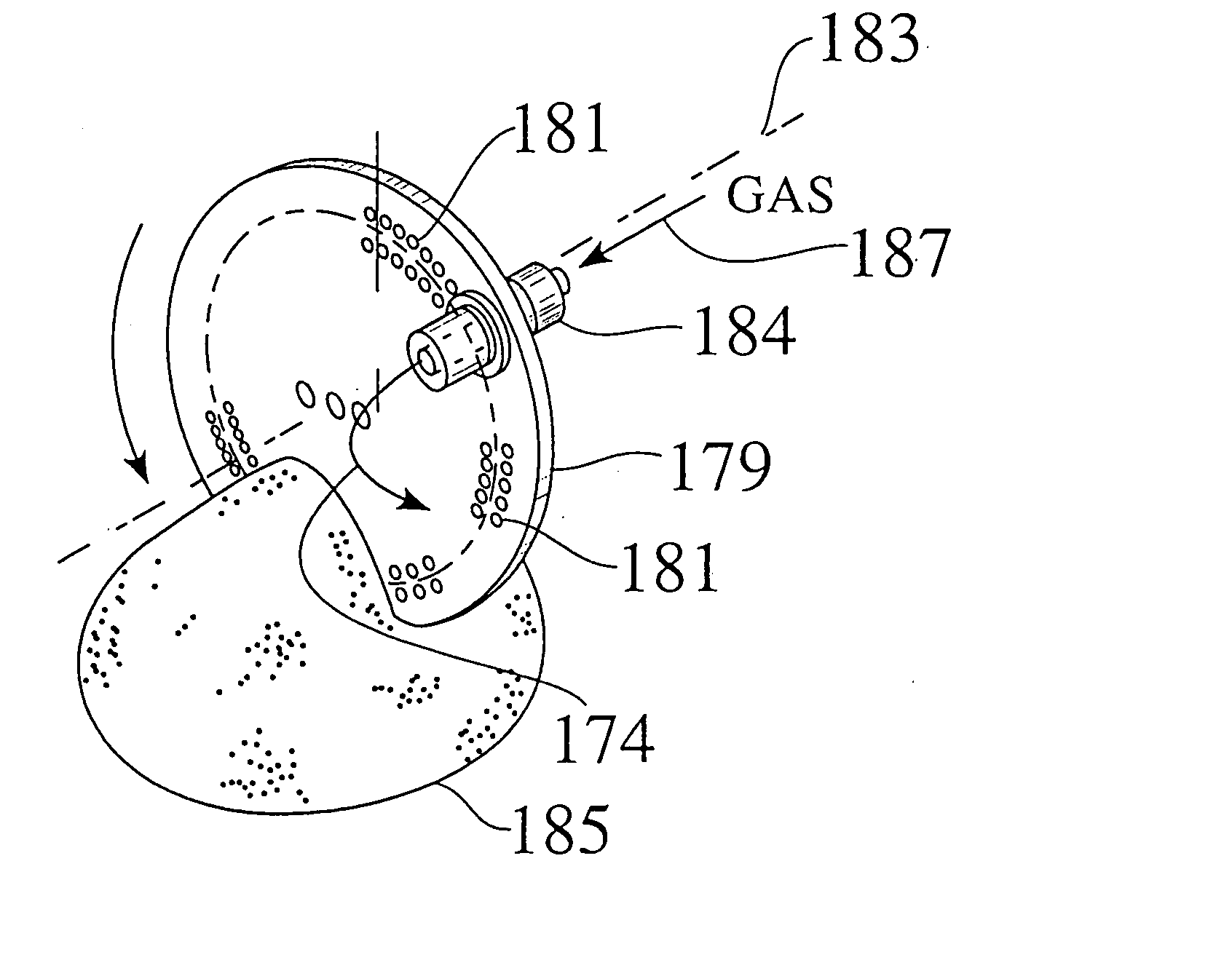

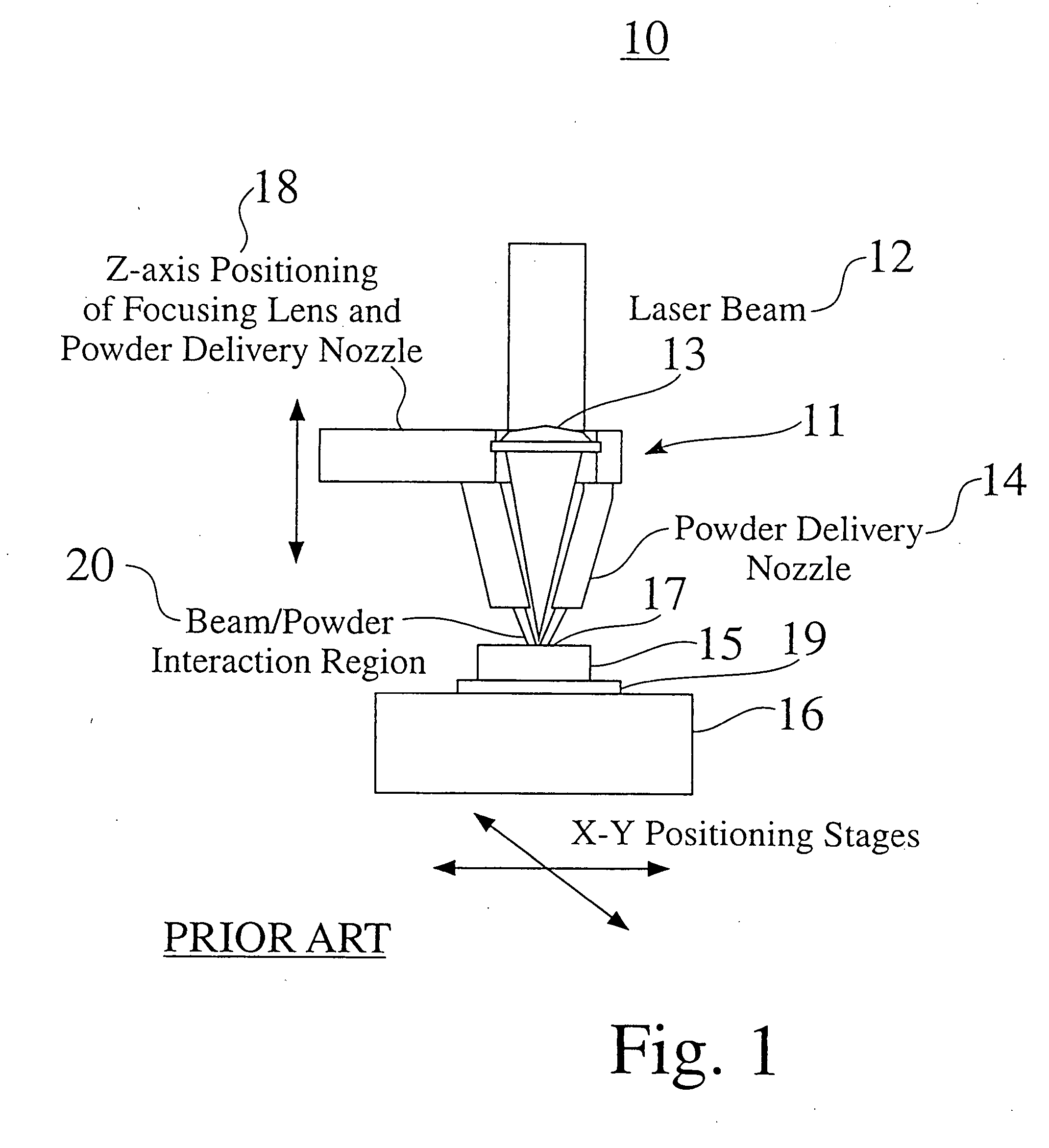

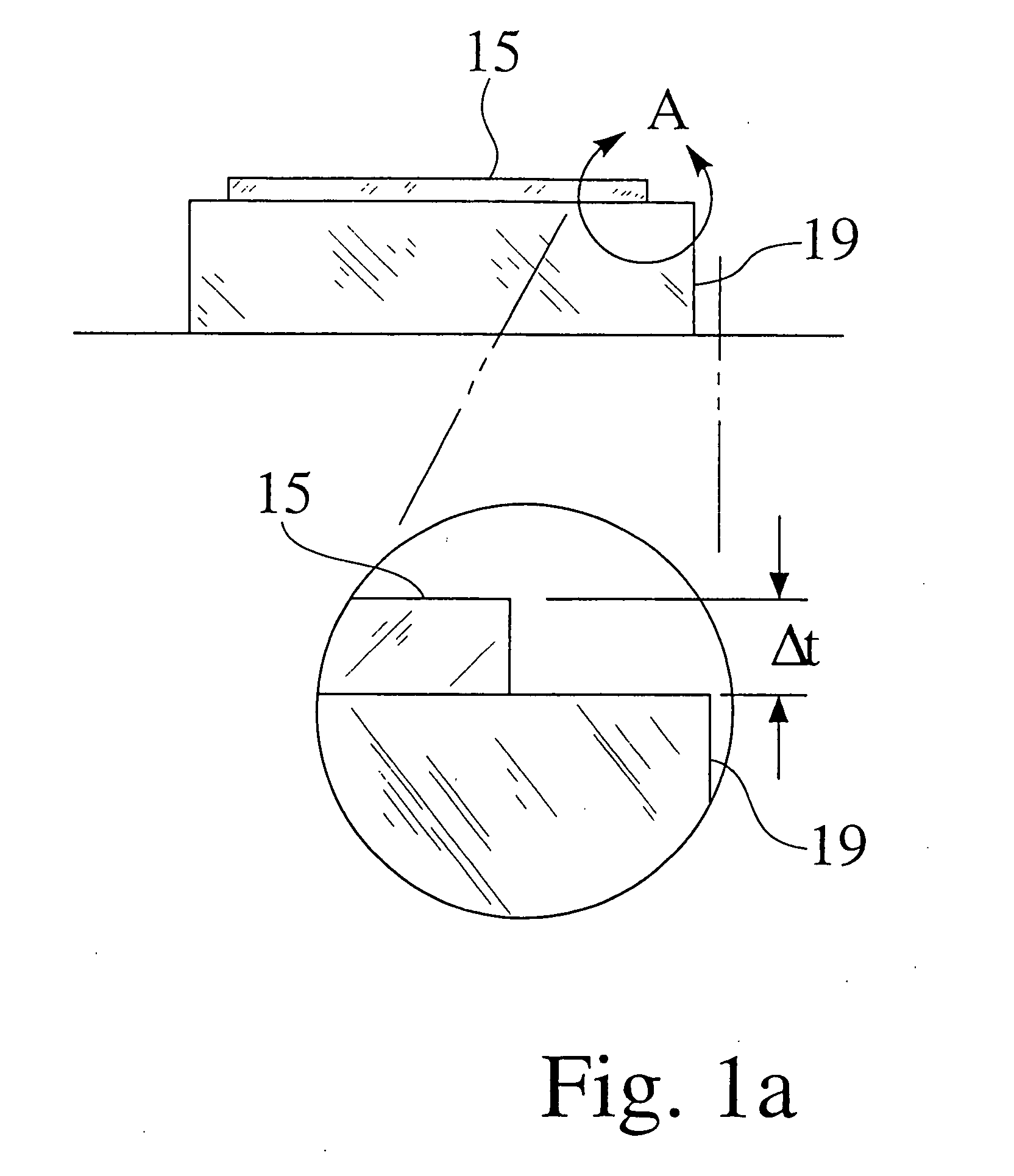

Powder feeder for material deposition systems

InactiveUS20050133527A1Small sizeEliminate warpingPower operated devices3D object support structuresSolid componentCoolant flow

A method and apparatus for embedding features and controlling material composition in a three-dimensional structure (130) is disclosed. The invention enables the control of material characteristics, within a structure (130) made from a plurality of materials, directly from computer renderings of solid models of the components. The method uses stereolithography and solid model computer file formats to control a multi-axis head (480) in a directed material deposition process (123). Material feedstock (126, 127) is deposited onto a pre-heated substrate (19). Depositions (15) in a layer-by-layer pattern, defined by solid models (141, 146), create a three-dimensional article having complex geometric details. Thermal management of finished solid articles (250-302), not available through conventional processing techniques, is enabled by embedded voids (152) and / or composite materials (126, 127), which include dissimilar metals (210, 216). Finished articles control pressure drop and produce uniform coolant flow and pressure characteristics. High-efficiency heat transfer is engineered within a solid structure by incorporating other solid materials with diverse indexes. Embedding multi-material structures (132, 134) within a normally solid component (141) produces articles with diverse mechanical properties. Laser and powder delivery systems (420, 170) are integrated in a multi-axis deposition head (480) having a focused particle beam (502) to reduce material waste.

Owner:OPTOMEC DESIGN CO

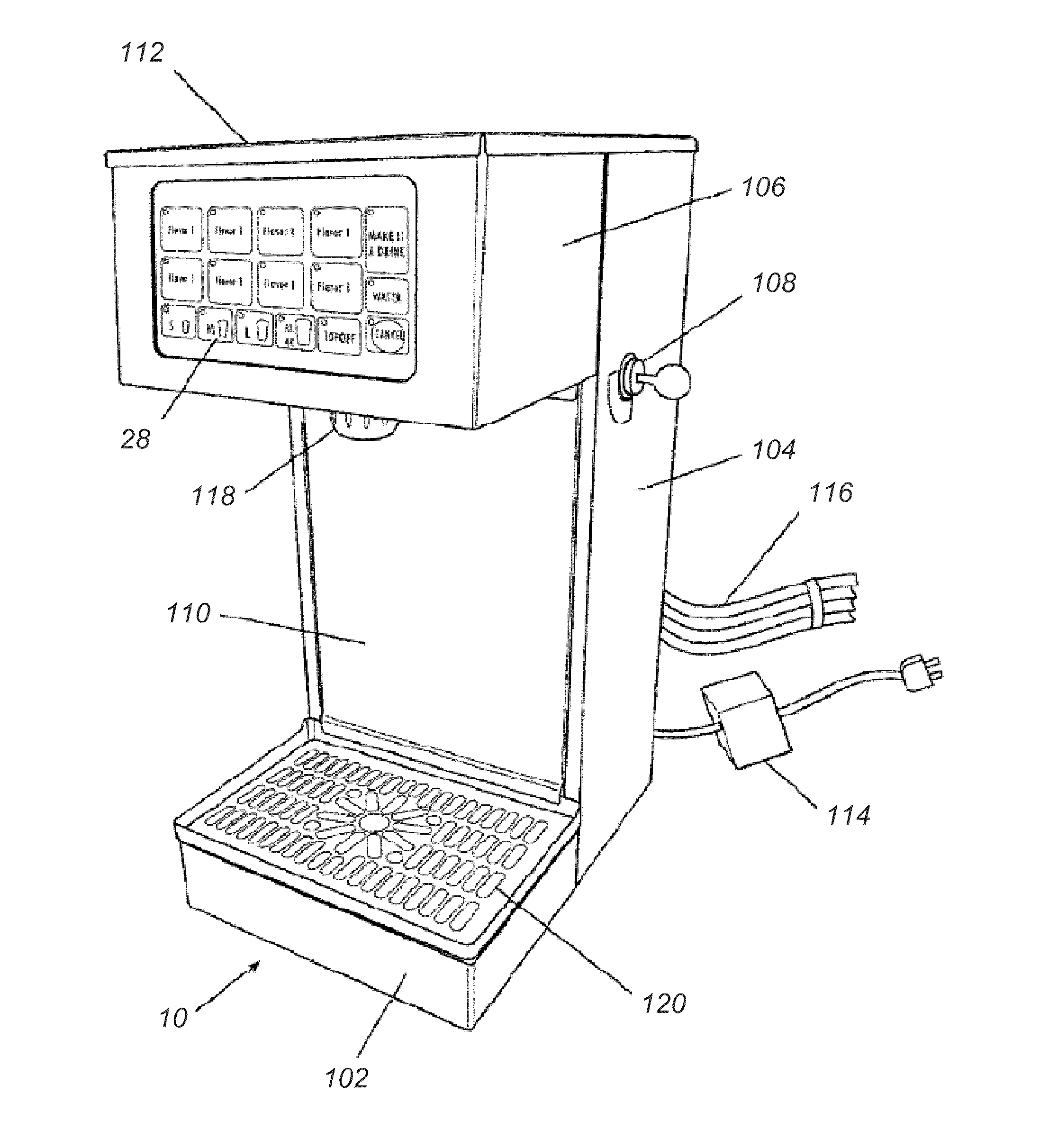

Touch Screen Interface for a Beverage Dispensing Machine

ActiveUS20110315711A1Increase flexibilityAvoid cross contaminationOpening closed containersBottle/container closureEngineeringTouchscreen

A beverage dispensing system including a control unit and a touch screen. Inputs are made to the touch screen to dispense beverages and apply system adjustments. The control unit controls a plurality of beverage dispensing valves according to inputs made to the touch screen.

Owner:AUTOMATIC BAR CONTROLS

Fluid dispenser

InactiveUS6192945B1Efficient and reliableEasy to manufacturePreparing sample for investigationLiquid flow controllersModularityReactive system

A method and apparatus for an automated biological reaction system is provided. In the processing of a biological reaction system, there is a need for consistently placing an amount of fluid on a slide. In order to accomplish this, several methods are used including a consistency pulse and a volume adjust means. Moreover, in order to reliably operate an automated biological reaction system, the dispenser must be reliable, easy to assemble and accurate. Among other things, in order to accomplish this, the dispense chamber is substantially in line with the reservoir chamber, the reservoir chamber piston is removed, and the flow of fluid through the dispenser is simplified. Further, in order to operate the automated biological reaction system more reliably, the system is designed in modular pieces with higher functions performed by a host device and the execution of the staining operations performed by remote devices. Also, to reliably catalog data which is used by the automated biological reaction system, data is loaded to a memory device, which in turn is used by the operator to update the operator's databases. The generation of the sequence of steps for the automated biological reaction device based on data loaded by the operator, including checks to determine the ability to complete the run, is provided.

Owner:VENTANA MEDICAL SYST INC

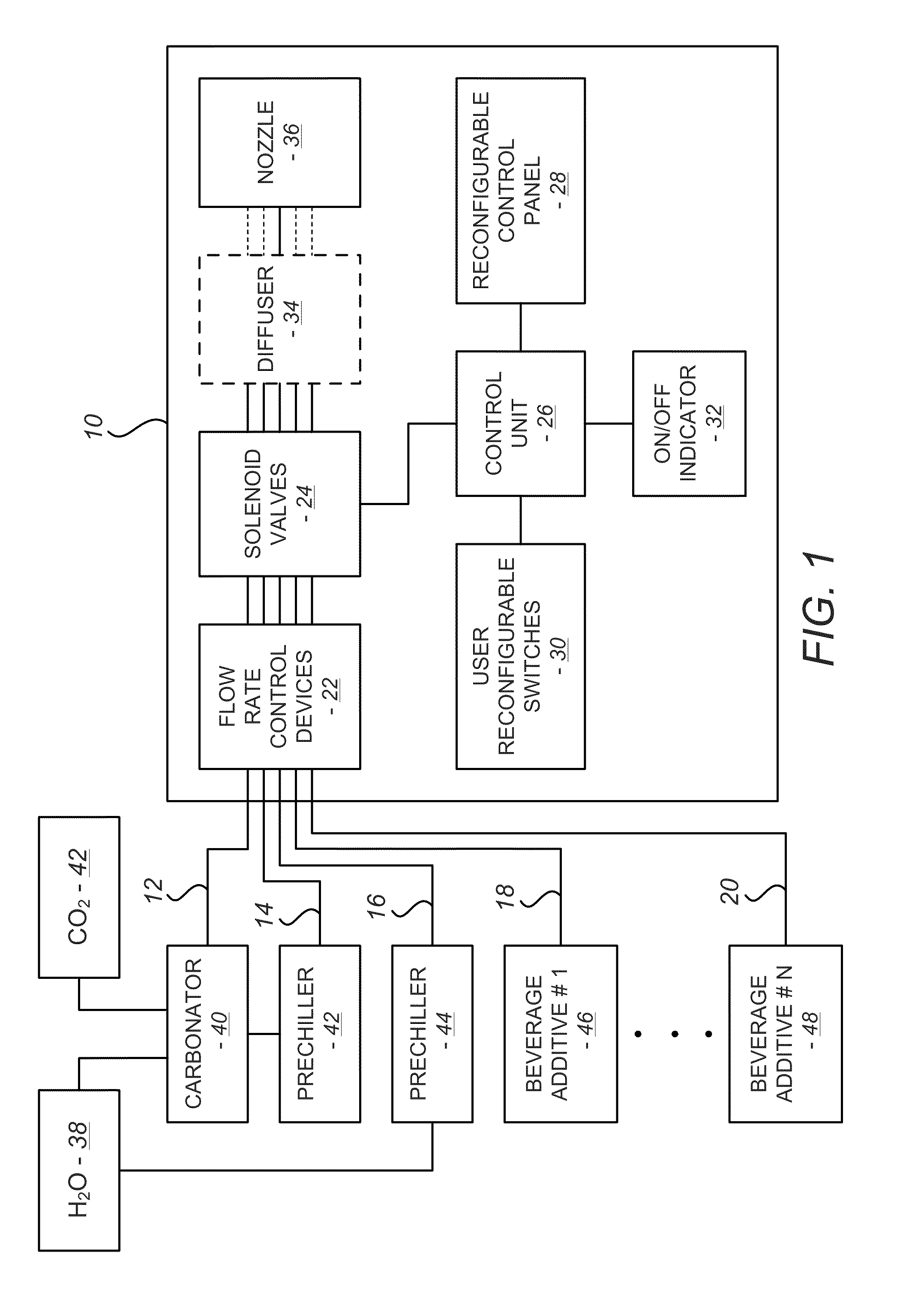

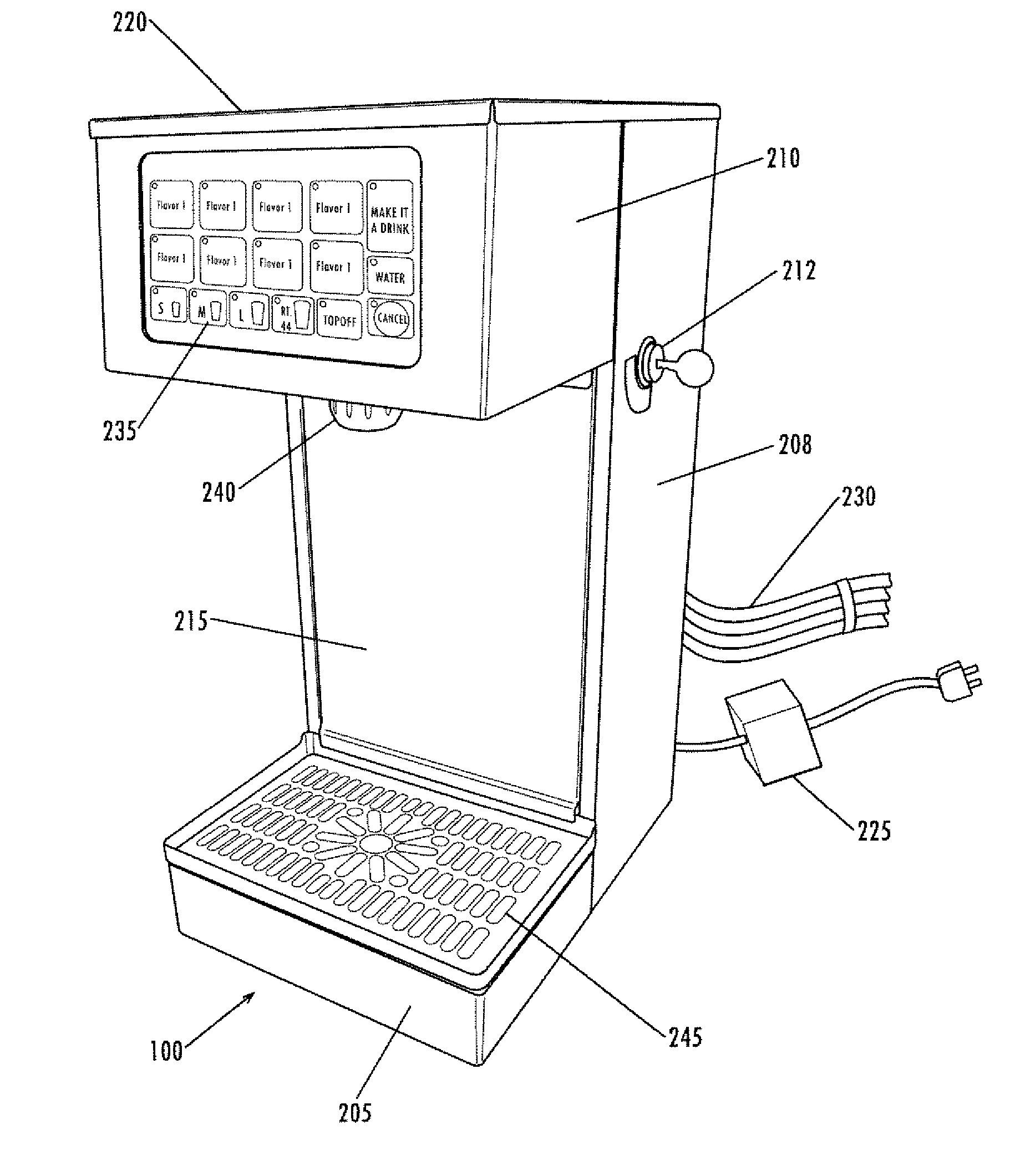

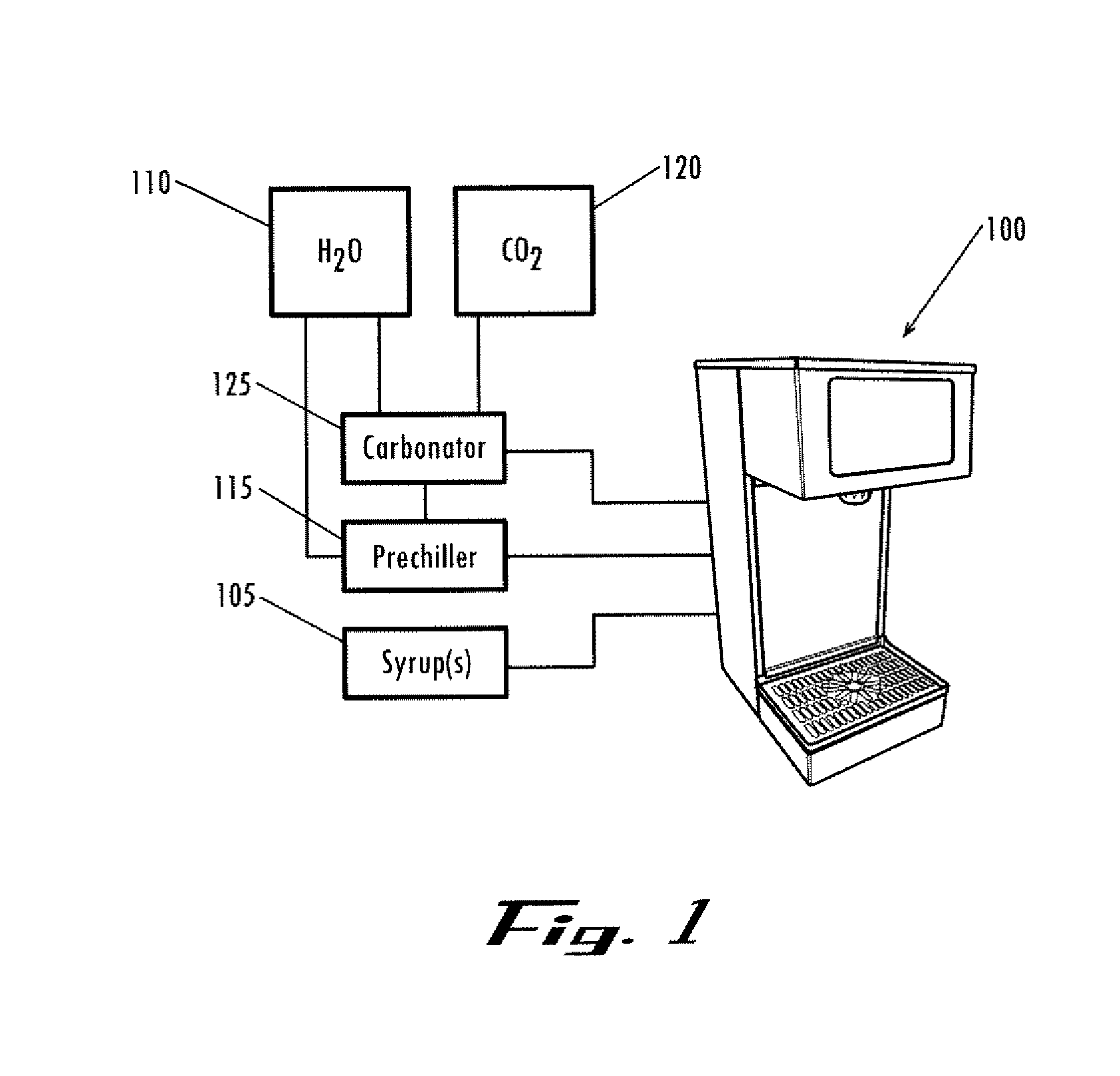

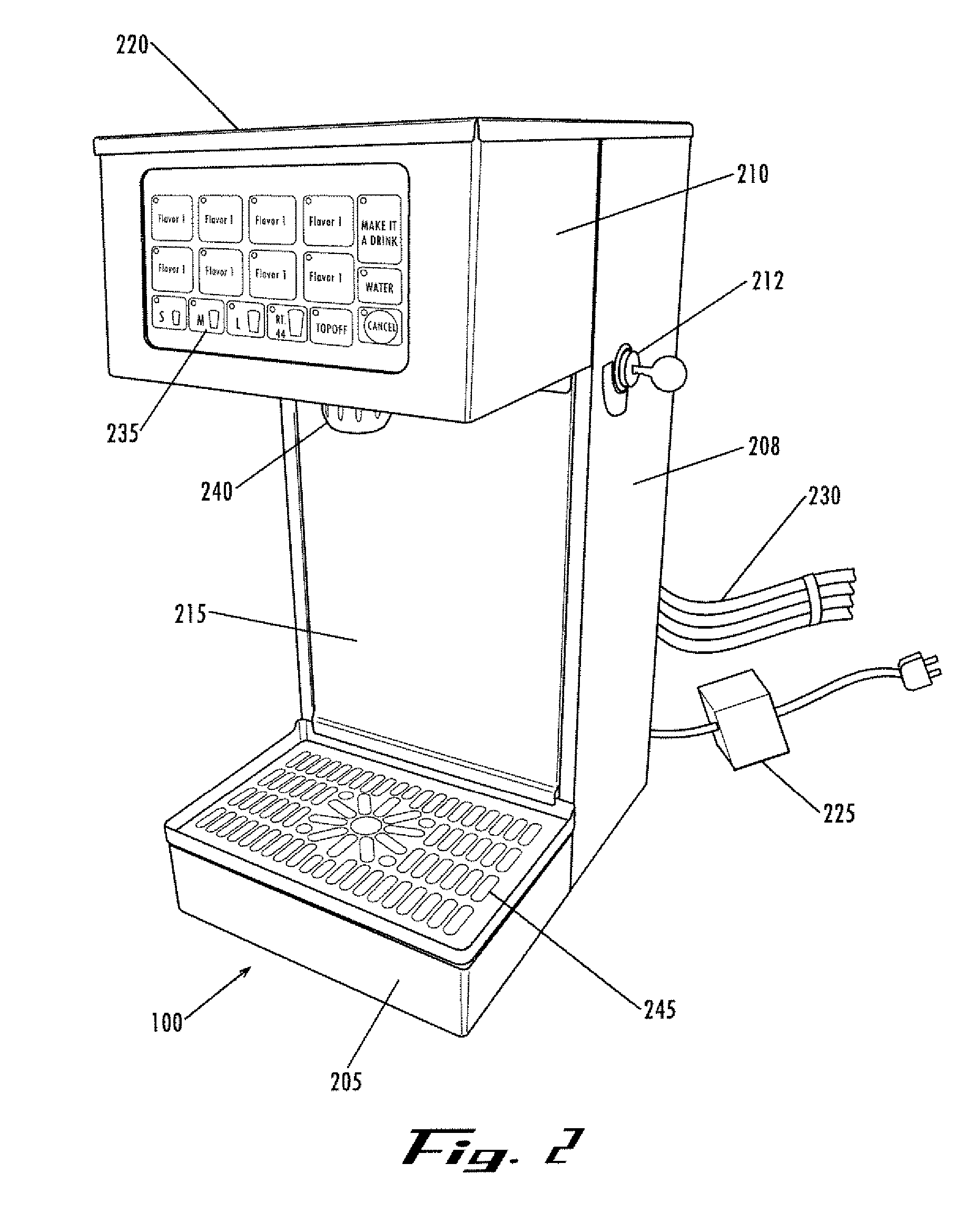

Systems and methods for dispensing flavor doses and blended beverages

ActiveUS20070114244A1Small footprintRich varietyOpening closed containersBottle/container closureUser inputFlavouring agent

Disclosed are systems and methods for dispensing flavor doses and beverages. A beverage tower may be provided that has a small footprint and that is capable of dispensing a wide variety of flavor doses and blended beverages. The beverage tower may include a flow control module that controls the flow rate of beverage additives and water through the beverage tower and a switch module that includes a plurality of switches that may be selectively opened and closed to control the flow of beverage additives and water through the beverage tower to a point of dispense. A flavor dose or blended beverage may be dispensed by the beverage tower in accordance with user input that is provided to the beverage tower via a control panel. The user input may specify a desired beverage additive, a desired cup size, and an indication of whether a flavor shot or a blended beverage is desired. Additionally, a user may define and program into the memory of the beverage tower the various flavor doses and blended beverages that are capable of being dispensed by the beverage tower.

Owner:THE COCA-COLA CO

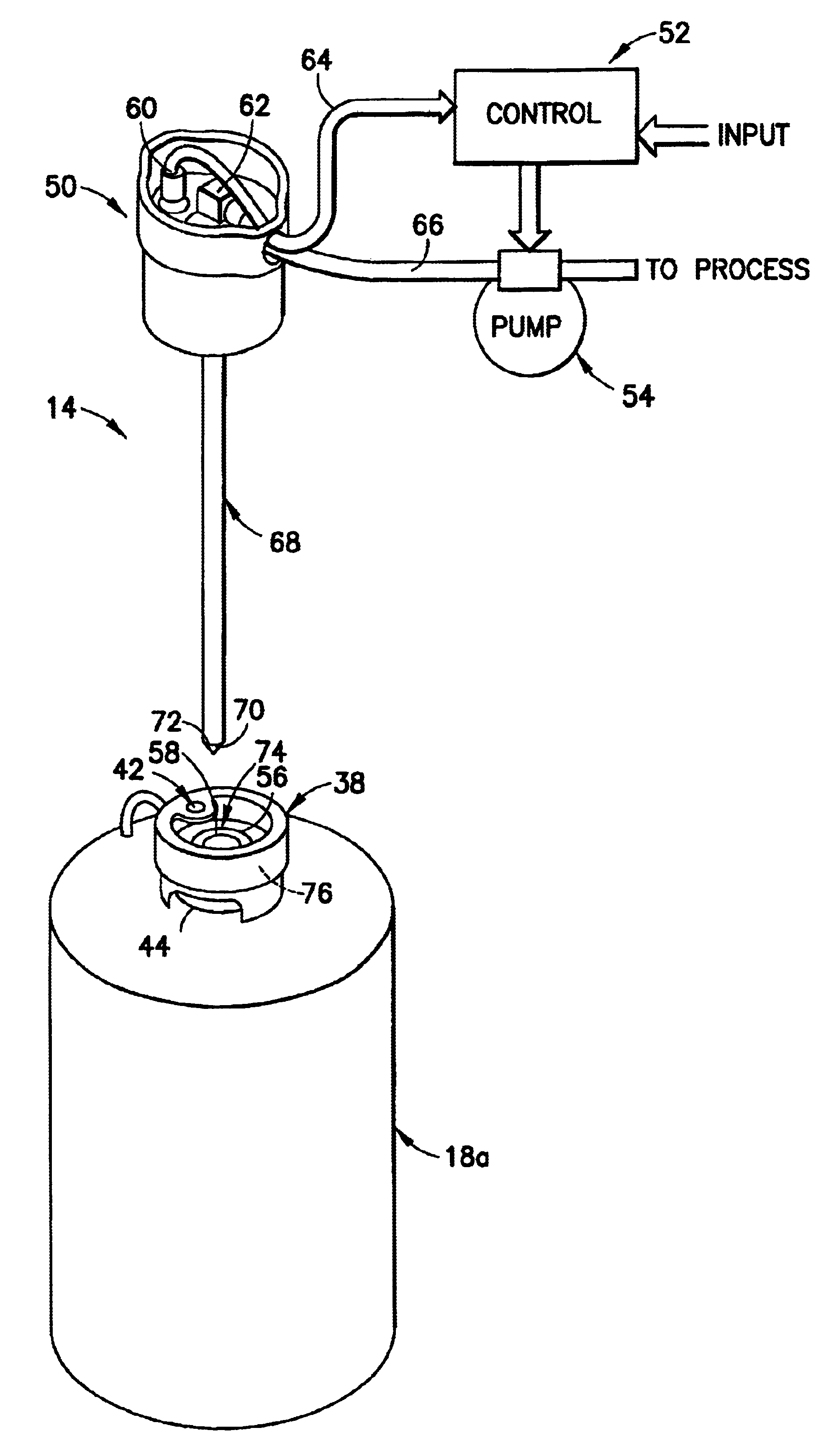

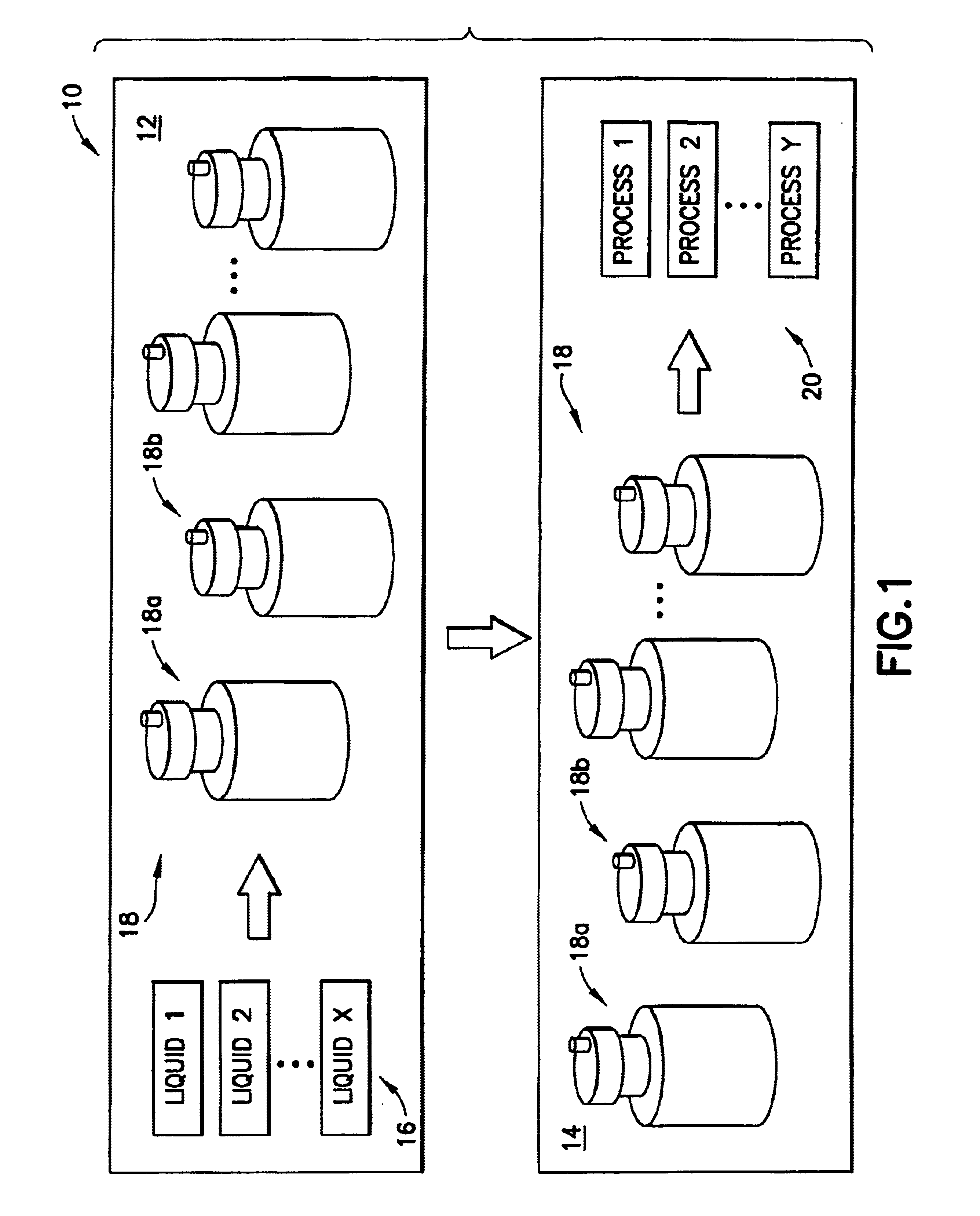

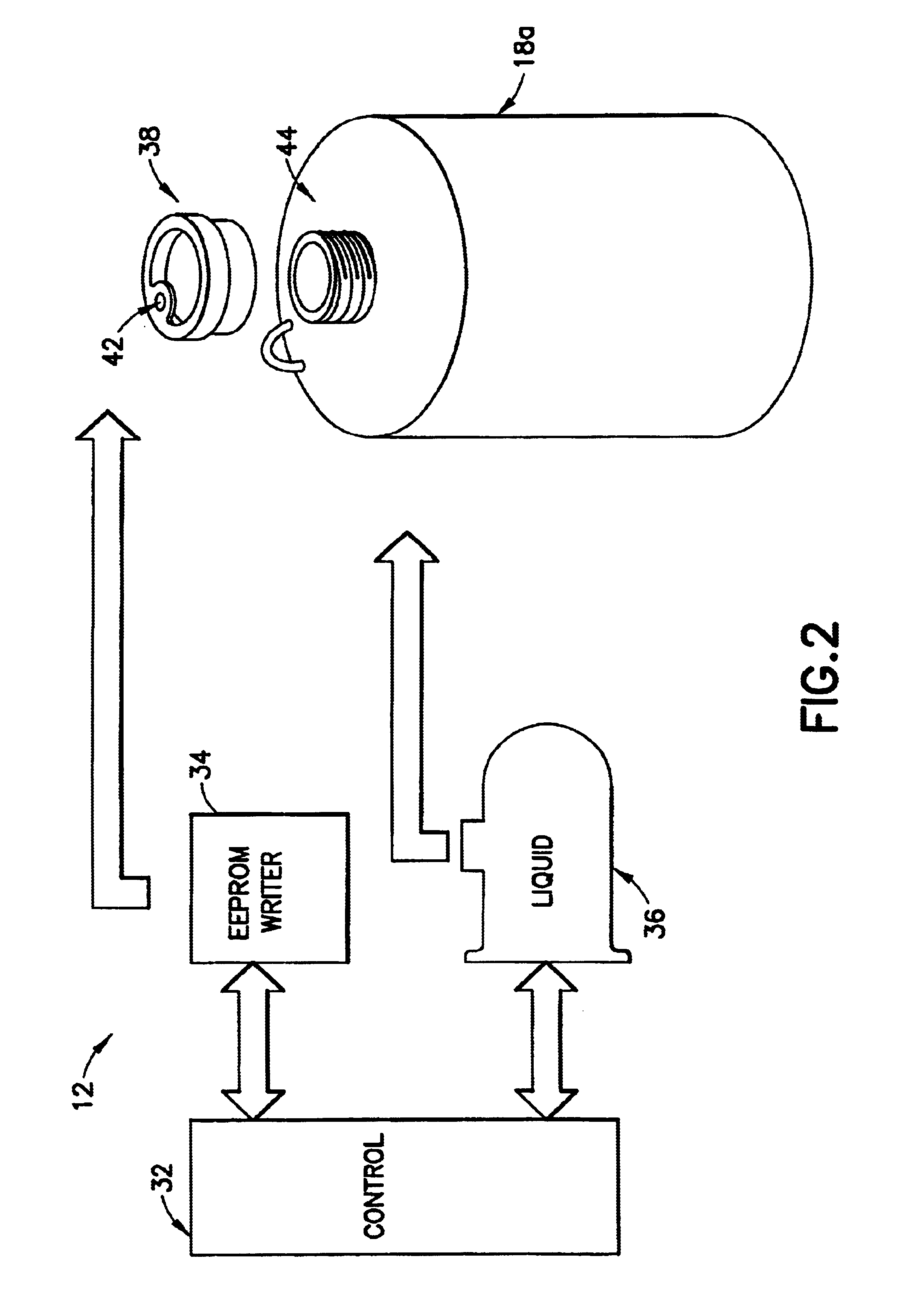

Liquid handling system with electronic information storage

The present invention is a system for handling liquid and a method for the same. The system has a container capable of holding a liquid. An electronic storage device is coupled with the container for electronically storing information relating to the liquid stored in the container. The system also has an antenna, for storing information to and reading information from the electronic storage device. Finally, the system has a microprocessor-based controller, coupled with the antenna, for controlling processing of the liquid based on information read from the electronic storage device by the antenna.

Owner:ENTEGRIS INC

Electronically keyed dispensing systems and related methods utilizing near field frequency response

ActiveUS20060124662A1Optimize quantityAcutation objectsIndication apparatusEngineeringMechanical engineering

A dispensing system is disclosed which utilizes an electronically powered key device and / or identification code associated with a refill container to preclude the need for mechanical keys. The system utilizes a near field frequency response to determine whether a refill container is compatible with a dispensing system. In particular, the refill container is provided with a coil terminated by one of a number of capacitors. The container is received in a housing that provides a pair of coils that are in a spatial relationship with the installed refill container's coil. By energizing one of the housing's coils, the other coil detects a unique electronic signature generated by the container's coil. If the signature is acceptable, the dispensing system is allowed to dispense a quantity of material. The system also provides a unique latching mechanism to retain the container and ensure positioning of all the coils.

Owner:KANFER JOSEPH

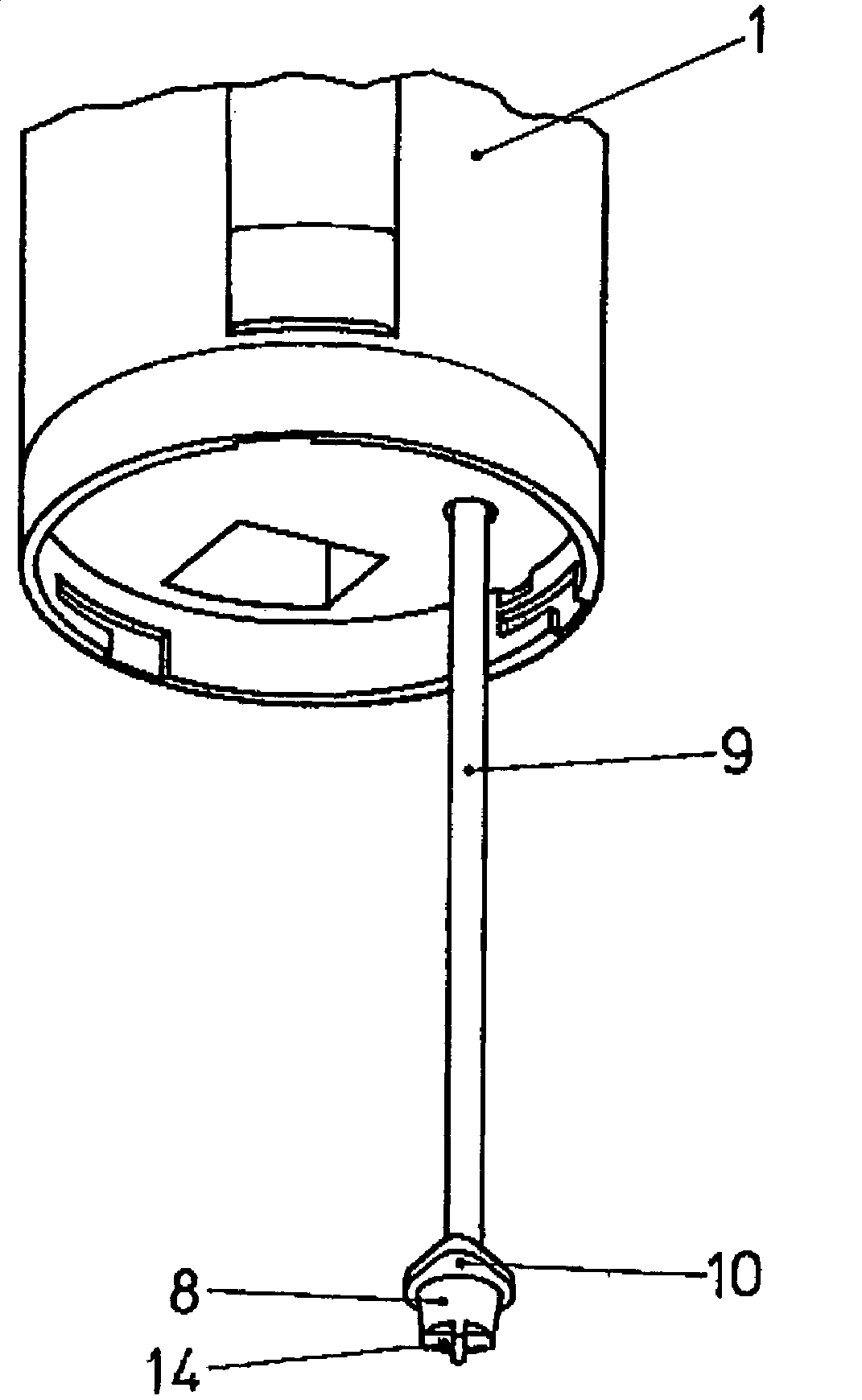

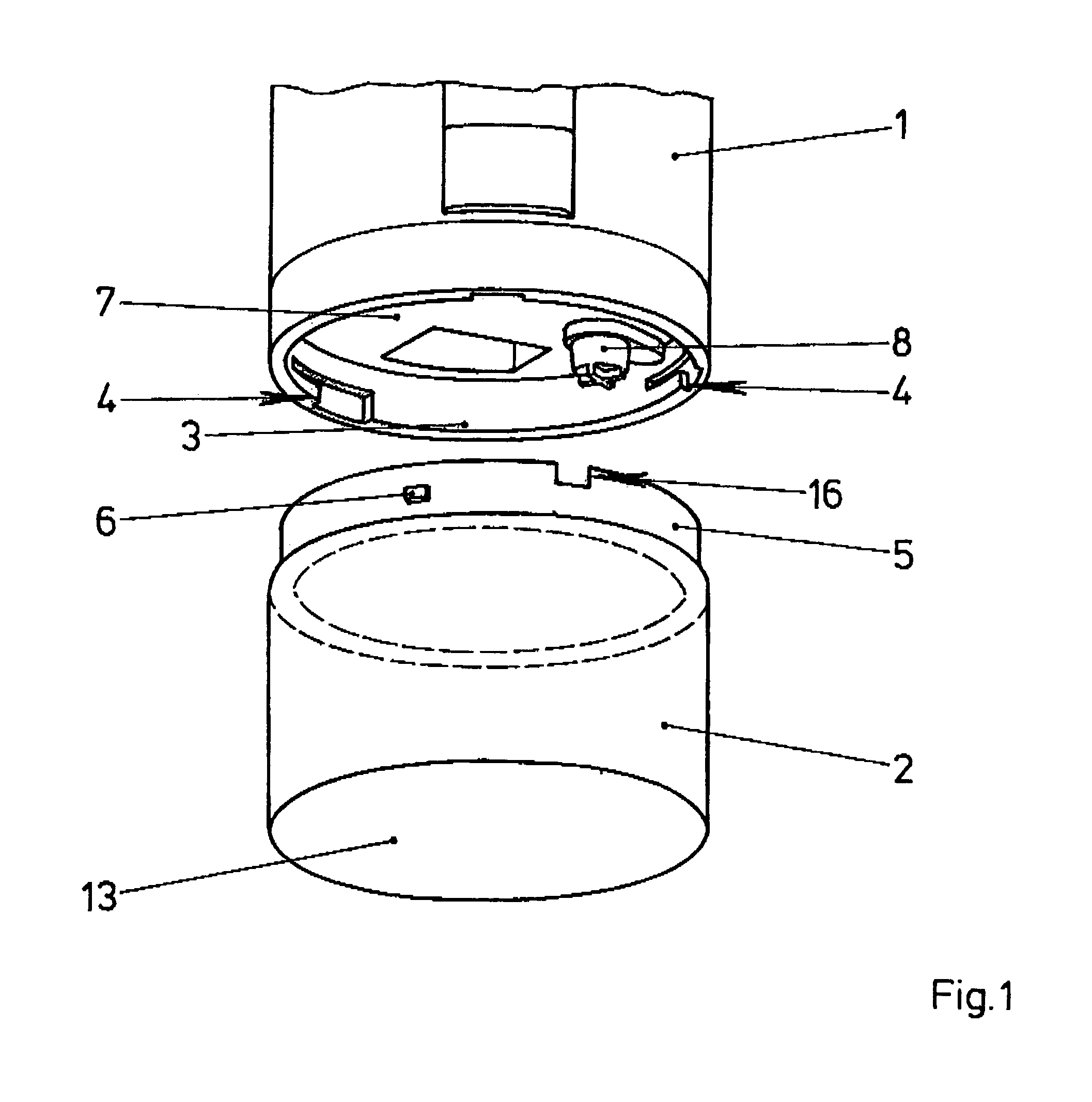

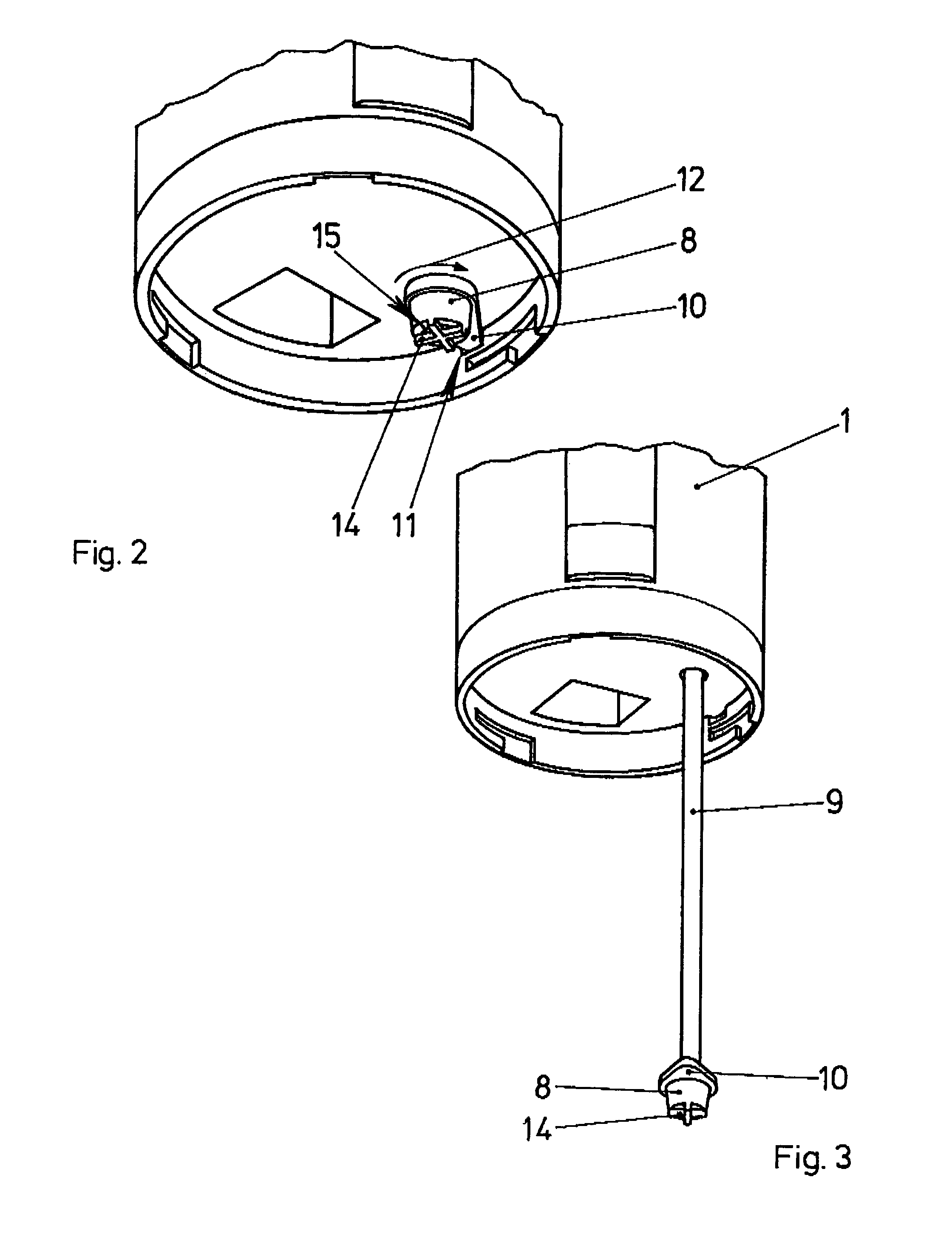

Mouth rinsing device having two detachably connectable housings

InactiveUS7500584B2Easy to holdEasy to masterBrush bodiesLarge containersEngineeringMechanical engineering

Owner:GIMELLI LAB

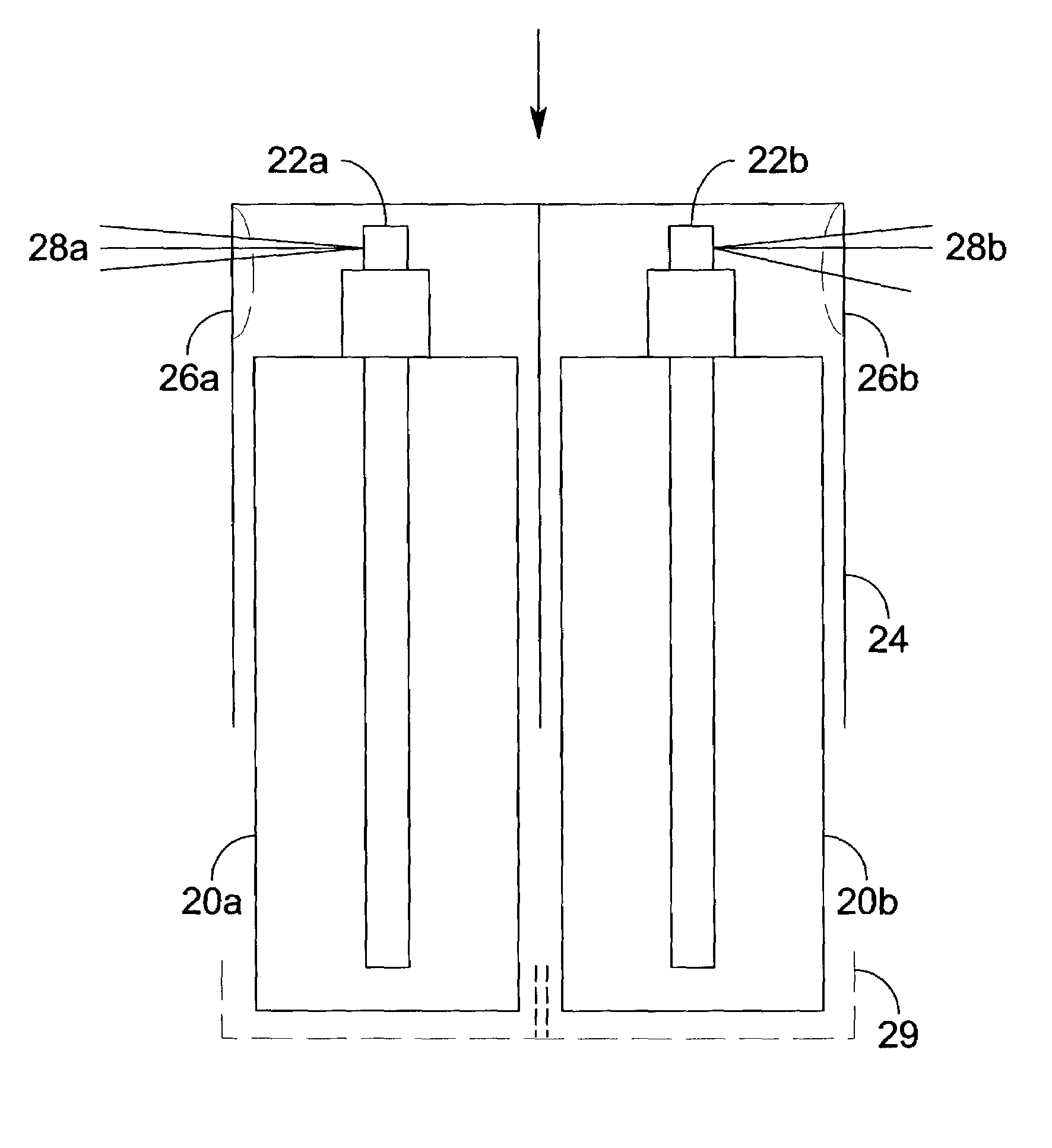

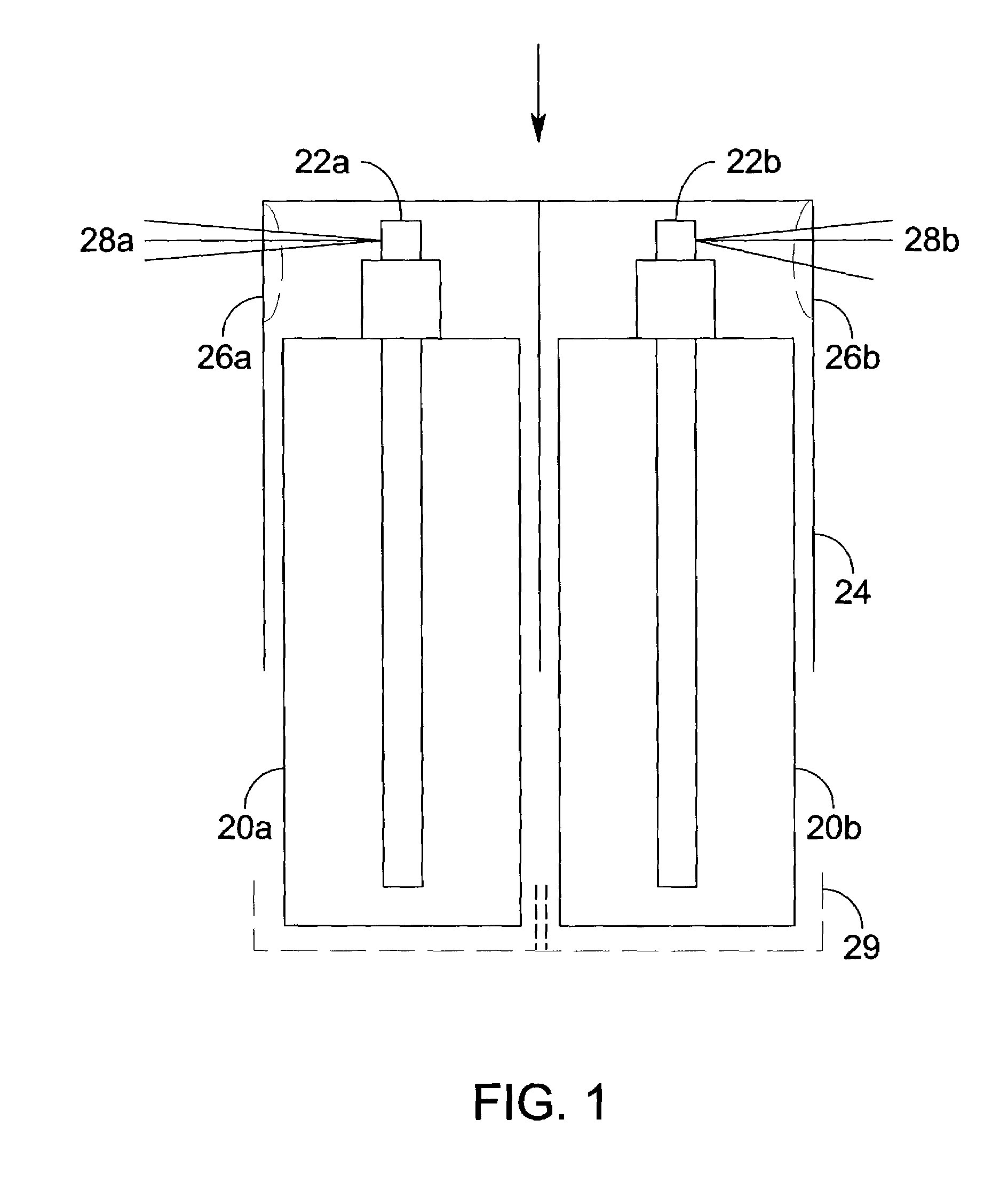

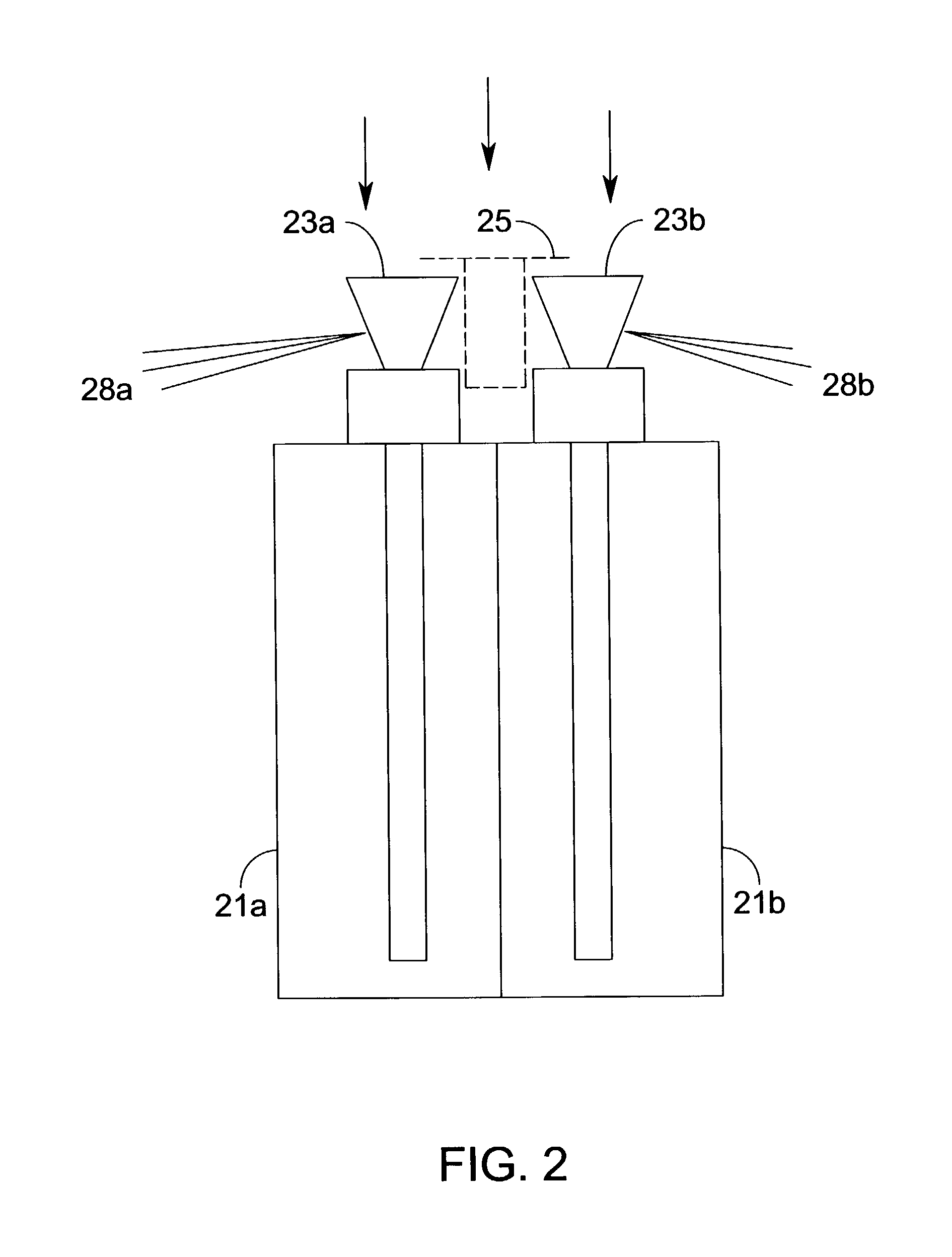

Multiple-mist dispenser

InactiveUS6968982B1The process is convenient and fastLarge containersLiquid transferring devicesBiochemical engineeringProcess engineering

One preferred embodiment of the present invention is directed to a convenient and efficient dispenser that includes at least one container and at least one nozzle for dispersing the contents of the container(s). In one preferred embodiment, first and second nozzles functionally associated with sterilization agent within the container are positioned to disperse the sterilization agent to first and second target points respectively, the first target point being distinct from the second target point. In another preferred embodiment of the present invention, a grid is positioned in front of the nozzle(s) so that a dispersement of sterilization agent from within the container(s) sterilizes the grid(s) when the nozzle(s) are activated. Yet another preferred embodiment of the present invention is directed to a multiple-mist dispenser that includes a dual chamber activation sleeve so that two nozzles are simultaneously actuable by depression of the dual chamber activation sleeve.

Owner:BURNS CALEB E S

Material storage and dispensing packages and methods

InactiveUS20090212071A1Solve the lack of spaceInhibit productionPower operated devicesShock-sensitive articlesEngineeringParticle generation

Packages and methods for storage and dispensing of materials, e.g., high purity liquid reagents and chemical mechanical polishing compositions used in the manufacture of microelectronic device products, including containment structures and methods adapted for pressure-dispensing of high-purity liquids. Liner packaging of liquid or liquid-containing media is described, in which zero or near-zero head space conformations are employed to minimize adverse effects of particle generation, formation of bubbles and degradation of contained material.

Owner:ADVANCED TECH MATERIALS INC

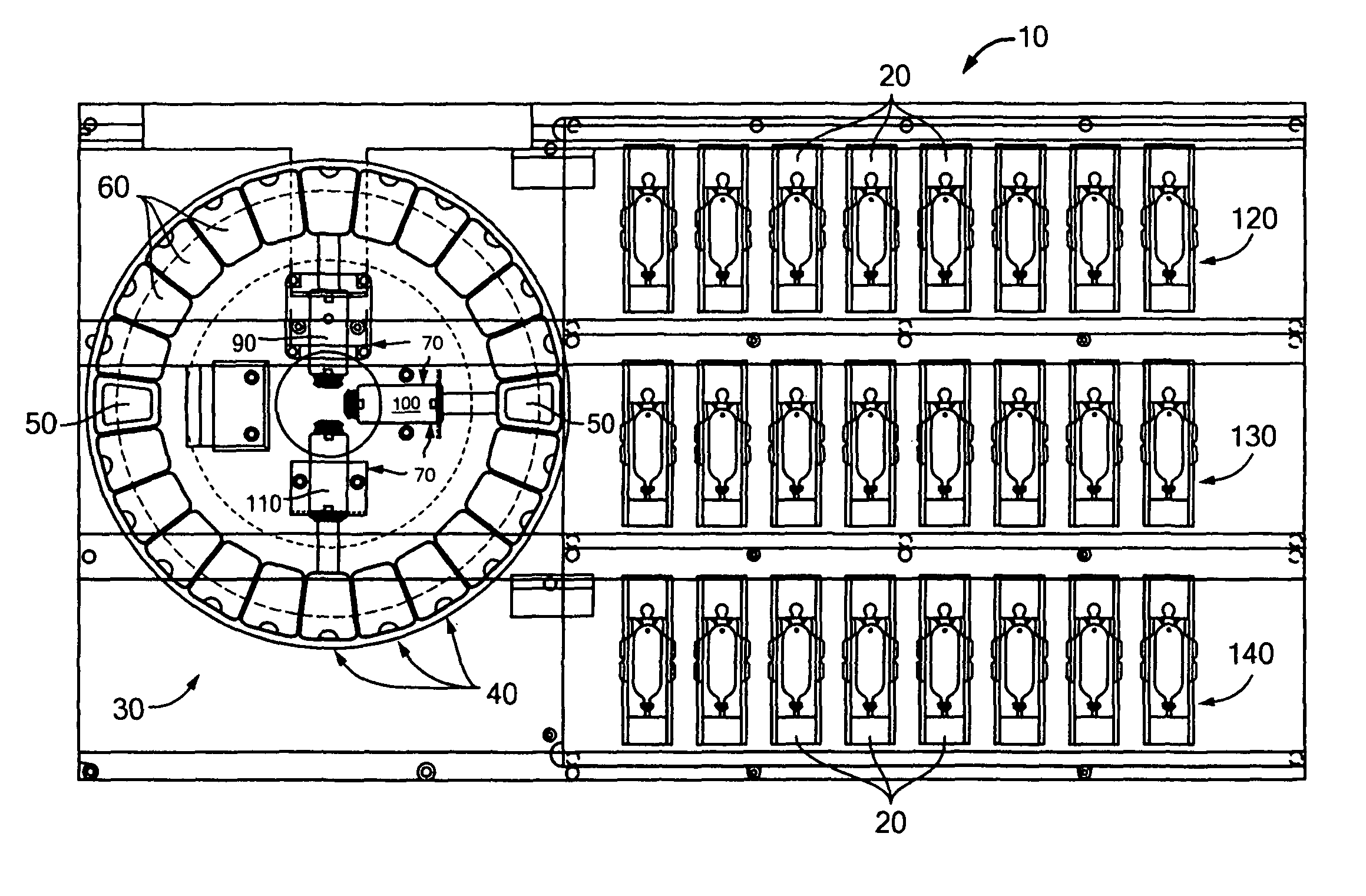

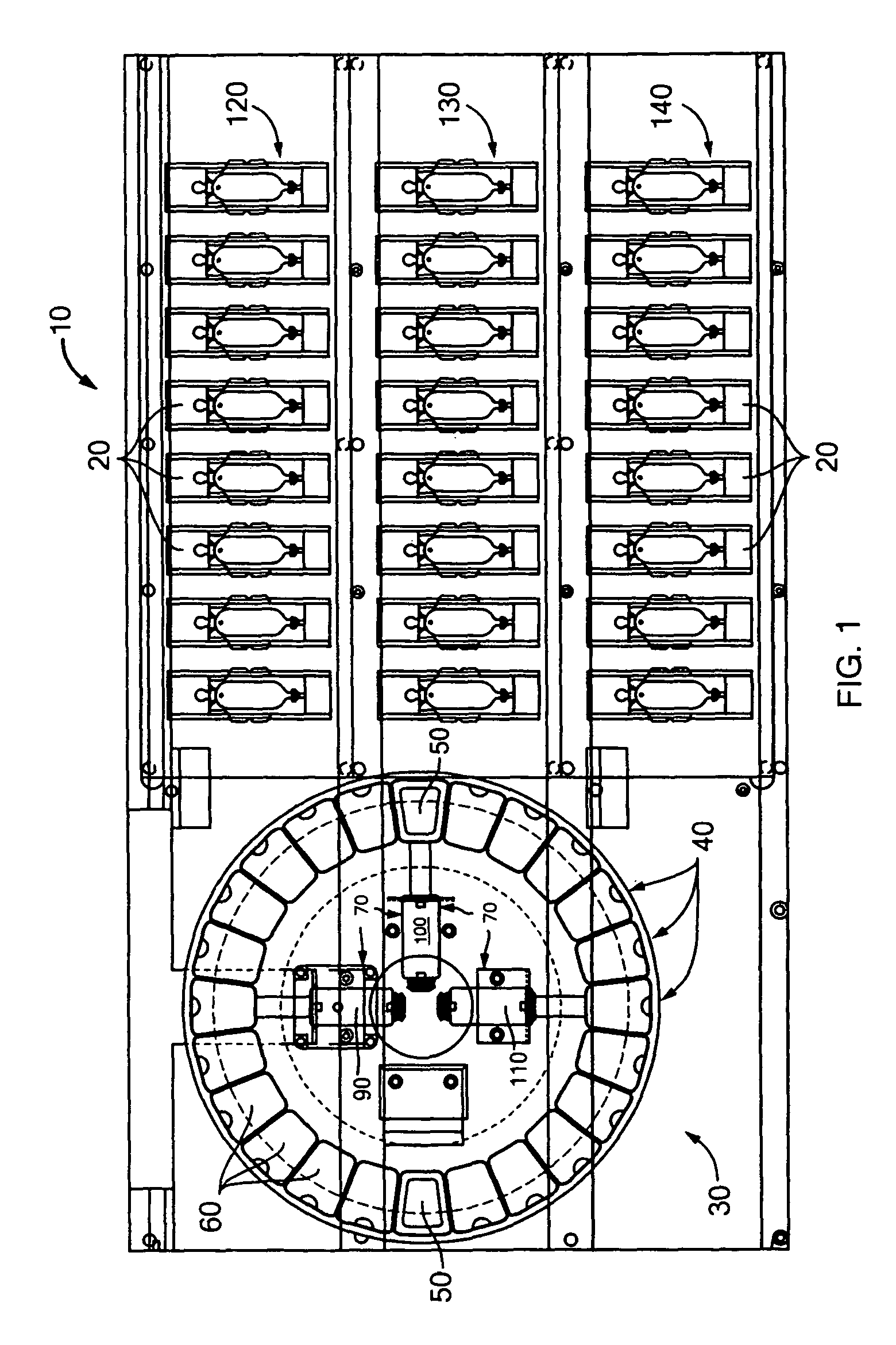

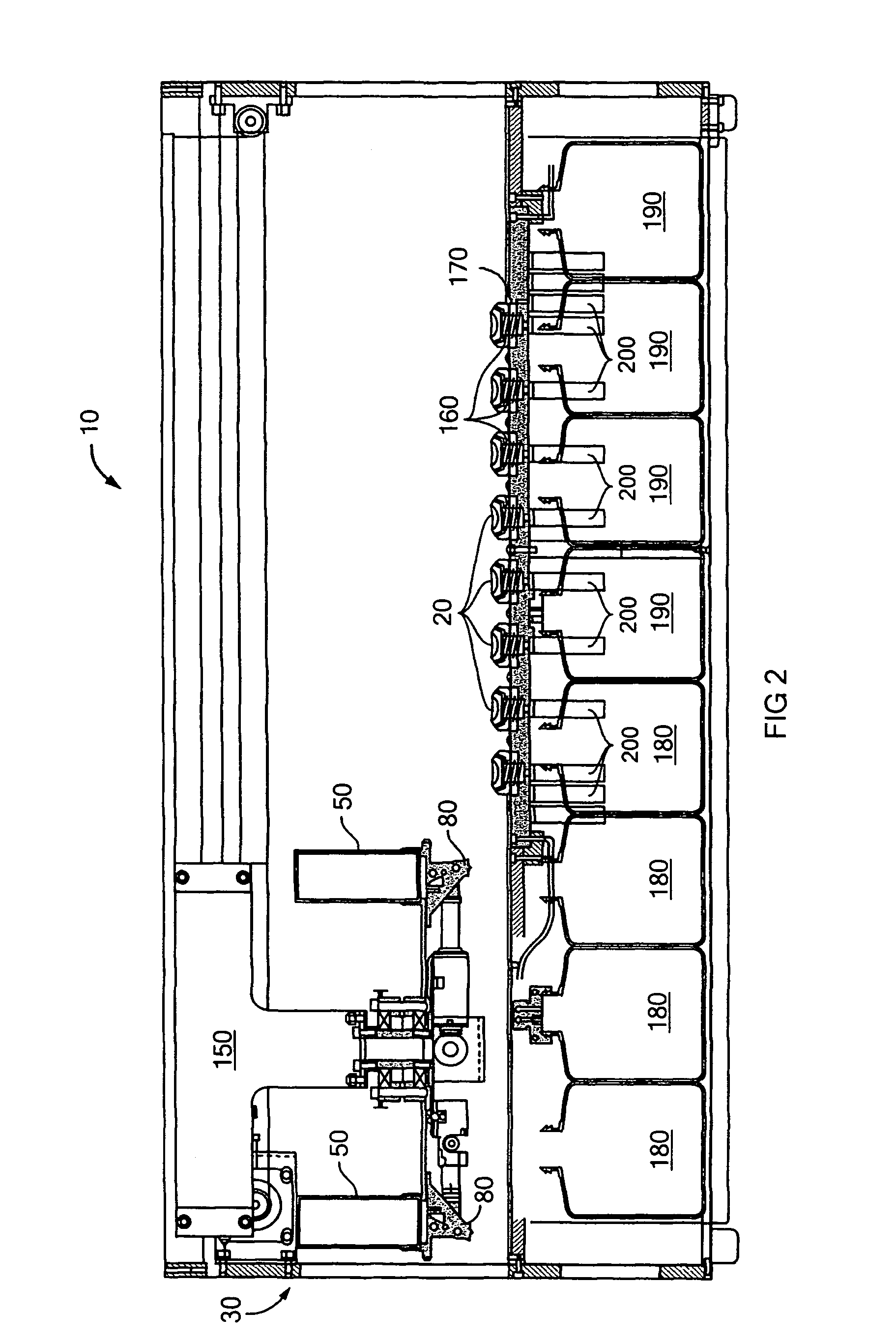

Manifold assembly

ActiveUS7744817B2Precise processReduce disadvantagesWithdrawing sample devicesLarge containersThermoelectric coolingBottle

A manifold assembly that directs fluid to and from individually selectable sample receiving trays of a tissue processing system includes a manifold, fluid conduits machined in the manifold, and valves that may be selectively configured to provide a direct fluid path to or from a particular tray. The valves are controlled by a controller that positions each valve such that a desired path is created. Pressure is created in supply and / or drain bottles to supply or drain fluid from the trays supported by the manifold assembly. Independently operated heaters are provided on the manifold assembly to heat the trays to desired temperatures. Thermoelectric cooling elements may also provided to cool the heaters and / or trays.

Owner:SAKURA FINETEK U S A

Electronically keyed dispensing systems and related methods utilizing near field frequency response

A dispensing system is disclosed which utilizes an electronically powered key device and / or identification code associated with a refill container to preclude the need for mechanical keys. The system utilizes a near field frequency response to determine whether a refill container is compatible with a dispensing system. In particular, the refill container is provided with a coil terminated by one of a number of capacitors. The container is received in a housing that provides a pair of coils that are in a spatial relationship with the installed refill container's coil. By energizing one of the housing's coils, the other coil detects a unique electronic signature generated by the container's coil. If the signature is acceptable, the dispensing system is allowed to dispense a quantity of material. The system also provides a unique latching mechanism to retain the container and ensure positioning of all the coils.

Owner:KANFER JOSEPH

Dispenser and cosmetic or dermatological preparation comprising an auxiliary for use with dispenser

InactiveUS20050189377A1Improves haptic propertyReduce forceCosmetic preparationsPower operated devicesPolyolSURFACTANT BLEND

The present invention is a cosmetic or dermatological preparation for use with a dispenser that includes an auxiliary to keep the dispenser operating smoothly. The auxiliary is selected from the group consisting of (i) polyols having 2 to 6 carbon atoms and 2 to 6 hydroxyl or alkoxy groups and (ii) surfactants that reduce the surface tension of the preparation to less than 30 mN / m. The preparation is particularly suitable with a dispenser comprising a container and an inner container wall for housing a cosmetic or dermatological preparation; a follow-up plunger on a base side of the dispenser, which is capable of being slidably displaced on the inner container wall under the pressure of the ambient atmosphere; a head section on a top end of the dispenser that can be slidably displaced in relation to the container and that comprises a dispensing channel, the dispensing channel capable of being connected in a communicating manner to the container; a manually actuable delivery device comprising a variable-volume delivery chamber, a delivery element that can be displaced longitudinally in relation to the container and the head section, comprising a delivery plunger that can be slidably displaced within the delivery chamber and a delivery stem connected to the delivery plunger, and a delivery channel circumferentially enclosed by the delivery stem and comprising a delivery-channel inlet opening communicating with the delivery chamber and a delivery-channel outlet opening. The delivery channel outlet opening is capable of being moved into an open position relative to the dispensing channel by displacing the delivery element.

Owner:BEIERSDORF AG

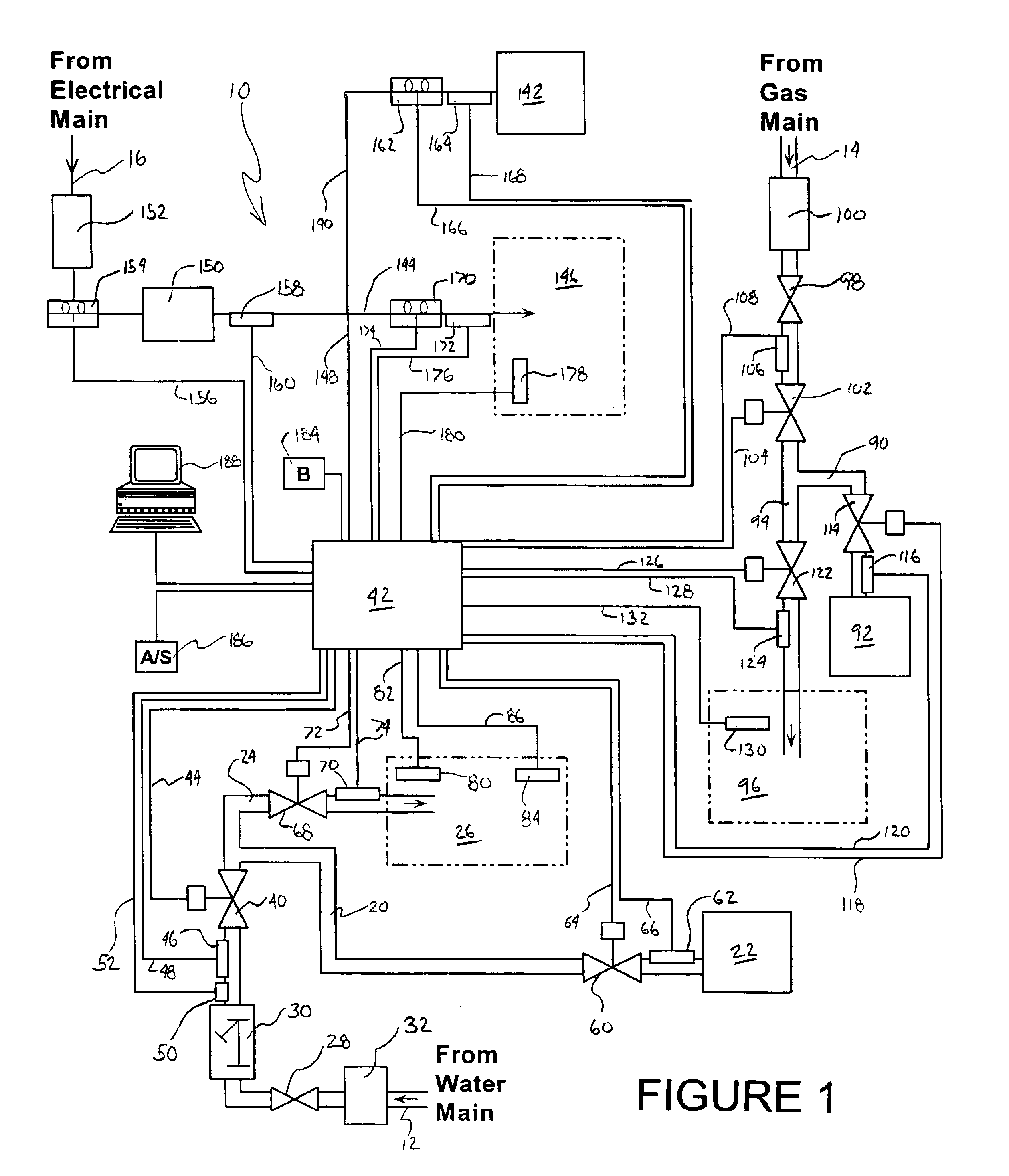

System and method for monitoring and controlling utility systems

A system for monitoring and controlling one or more utility systems includes a utility system main supply line for supplying a utility to at least one of a structure, an area and a building and a controlled shut-off device on the utility system main supply line. The controlled shut-off device is bias toward an open position and is movable toward a closed position upon receipt of an actuation signal wherein the utility is prevented from passing by the controlled shut-off device. A main utility sensor is on the utility system main supply line and a motion sensor that detects occupancy is in the building. A processor communicates with the controlled shut-off device, the main utility sensor and the motion sensor. The processor sends the actuation signal to the controlled shut-off device to move the controlled shut-off device toward the closed position when input from the main utility sensor and the motion sensor indicates occurrence of an abnormal event.

Owner:UHLER KENNETH J

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com