Patents

Literature

367results about How to "Accurate flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for wide range gas flow system with real time flow measurement and correction

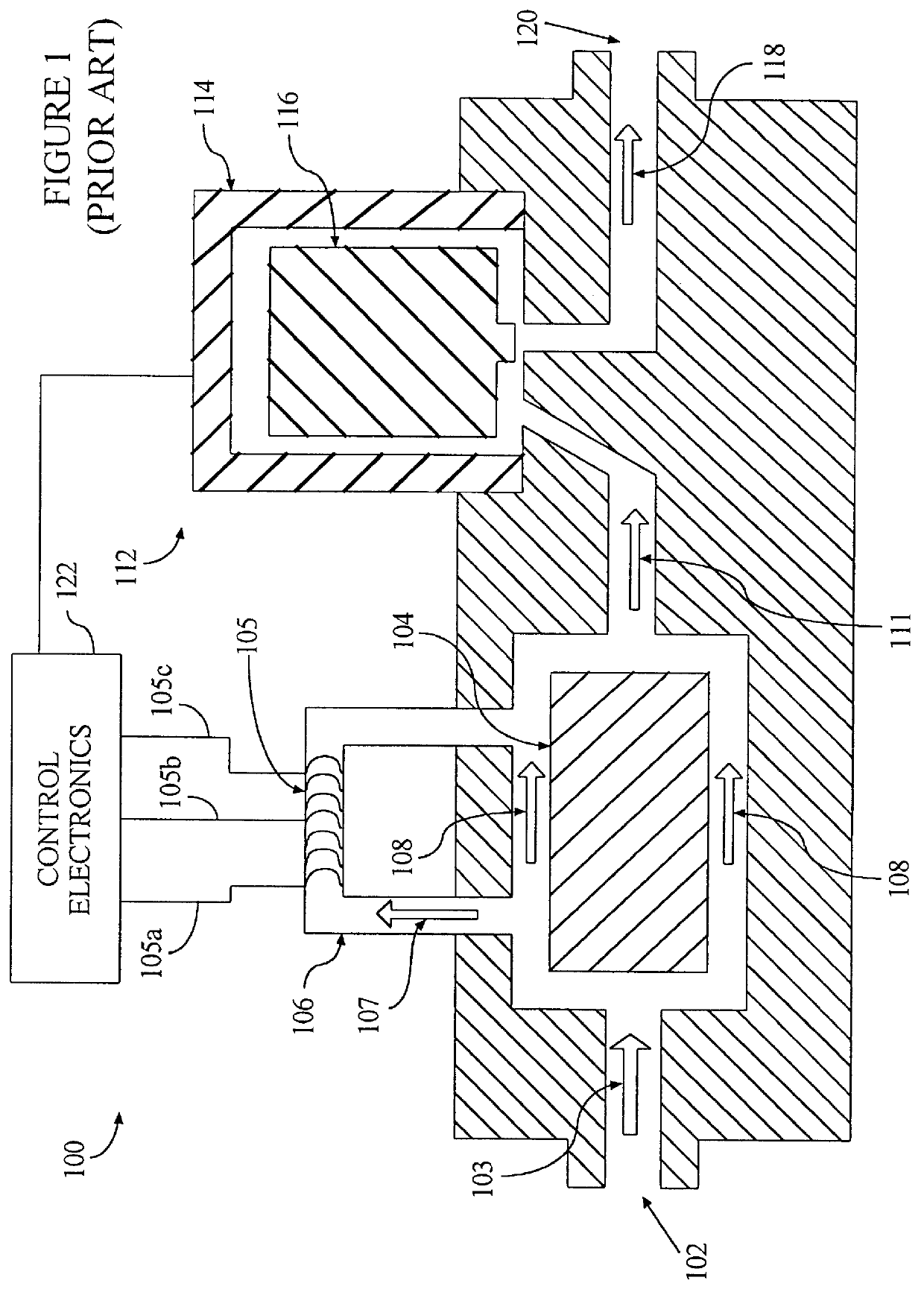

InactiveUS6119710AAccurate measurementAccurate flowOperating means/releasing devices for valvesVolume/mass flow by thermal effectsDifferential pressureInlet valve

A gas delivery system accurately measures and optionally regulates mass flow rate in real time. A fluid conduit connects an inlet valve, calibration volume, flow restrictor, and outlet valve in series. Pressure and temperature sensors are coupled to the calibration volume. One or more pressure sensors may be attached across the flow restrictor. Alternatively, an absolute pressure sensor may be attached upstream of the flow restrictor. One embodiment of differential pressure sensors comprises a floating reference differential pressure sensor, including a first transducer attached to the fluid conduit upstream of the flow restrictor and a second transducer attached to the conduit downstream of the flow restrictor. In this embodiment, each transducer receives a reference pressure from a reference source, and optionally, after the calibration volume is charged, the floating reference differential pressure transducers are calibrated. When gas flow is initiated, differential and / or absolute pressure measurements are repeatedly taken, and a measured mass flow rate calculated thereon. Gas flow is adjusted until the measured mass flow rate reaches a target mass flow. Using the temperature / pressure sensors at the calibration volume, repeated calculations of actual flow rate are made to uncover any discrepancy between actual and measured mass flow rates. Whenever a discrepancy is found, the manner of calculating measured mass flow is conditioned to account for the discrepancy; thus, the measured mass flow rate more accurately represents the actual mass flow rate thereby providing an actual mass flow rate more accurately achieving the target mass flow rate.

Owner:CYBER INSTR TECH LLC AN ARIZONA LIMITED LIABILITY +1

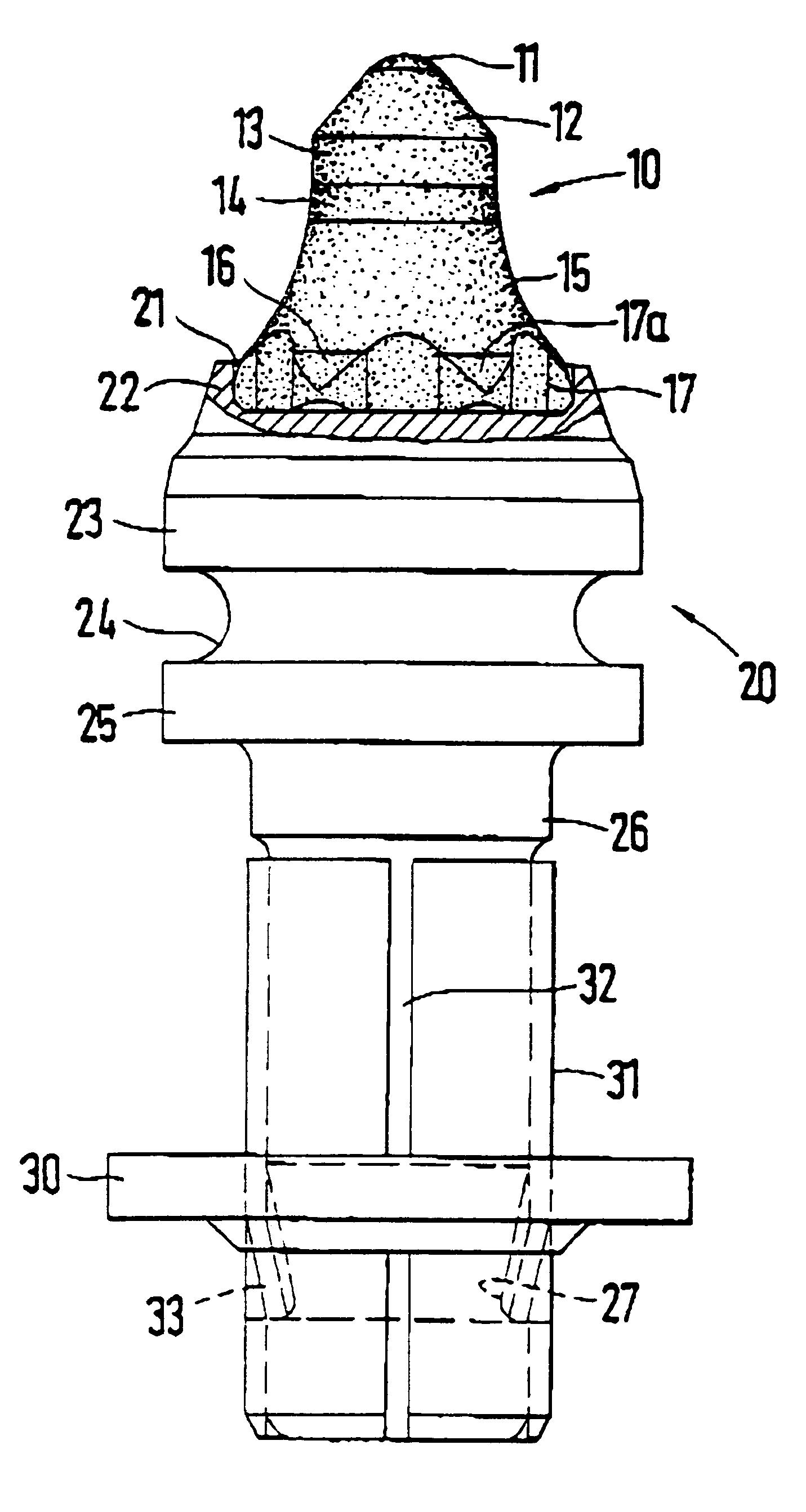

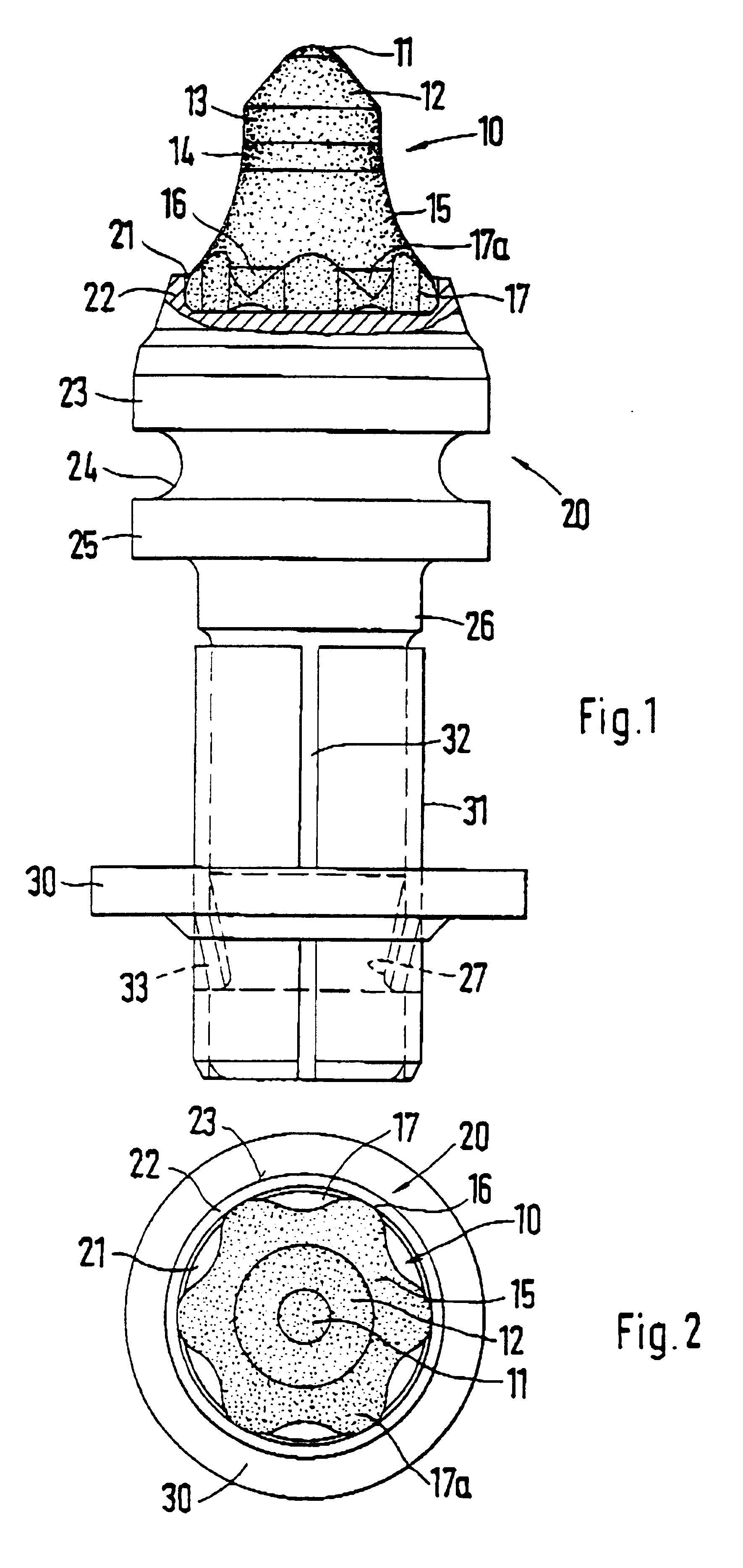

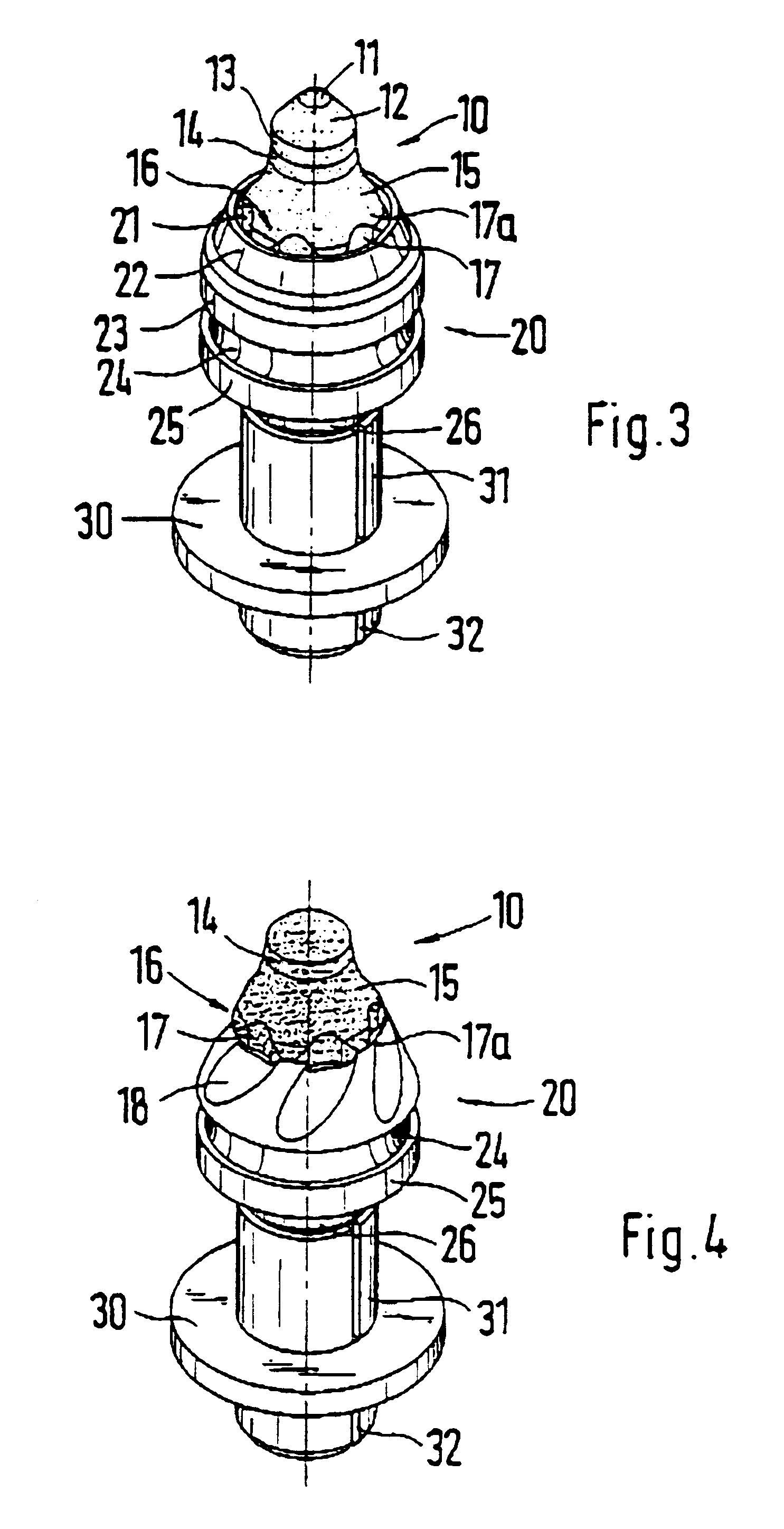

Round-shank bit for a coal cutting machine

InactiveUS6199956B1Sufficient supportLess stressPolishing machinesRevolution surface grinding machinesMaximum diameterEngineering

A round-shank bit for a coal cutting machine or the like, having a bit head and a bit shank, wherein the bit head has a bit tip, maintained by a base element in a receptacle of the bit head. Starting at the base element, the bit tip tapers in a direction toward the free end of the bit tip, wherein the base element forms a maximum diameter of the bit tip, and wherein the bit tip has recesses on its outer contour. In order to assure good rotational behavior over the entire length of the operating time, the base element has the recesses on an outer circumference forming the maximum diameter.

Owner:BETEK BERGBAU UND HARTMETALLTECHN KARL HEINZ SIMON

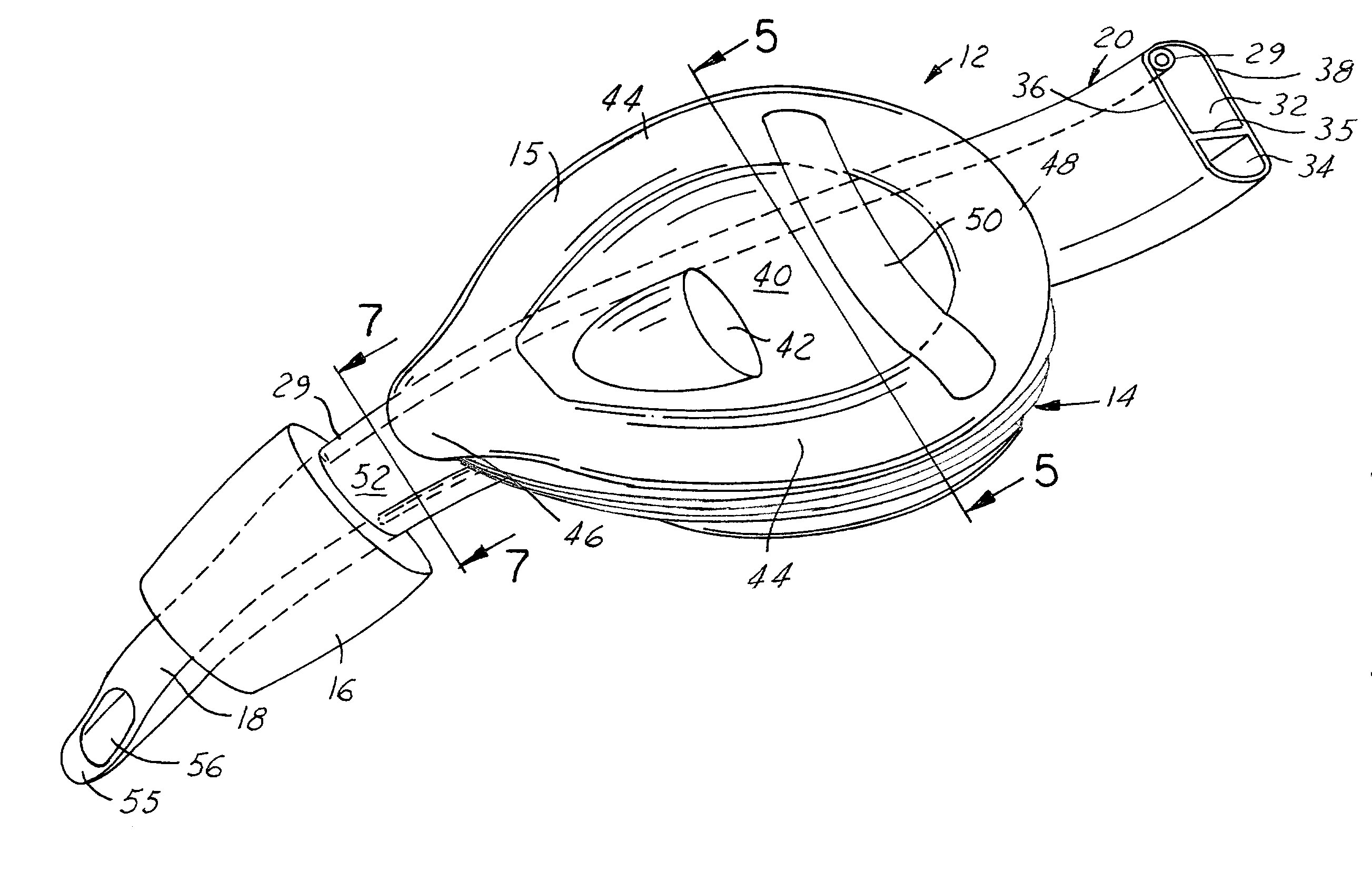

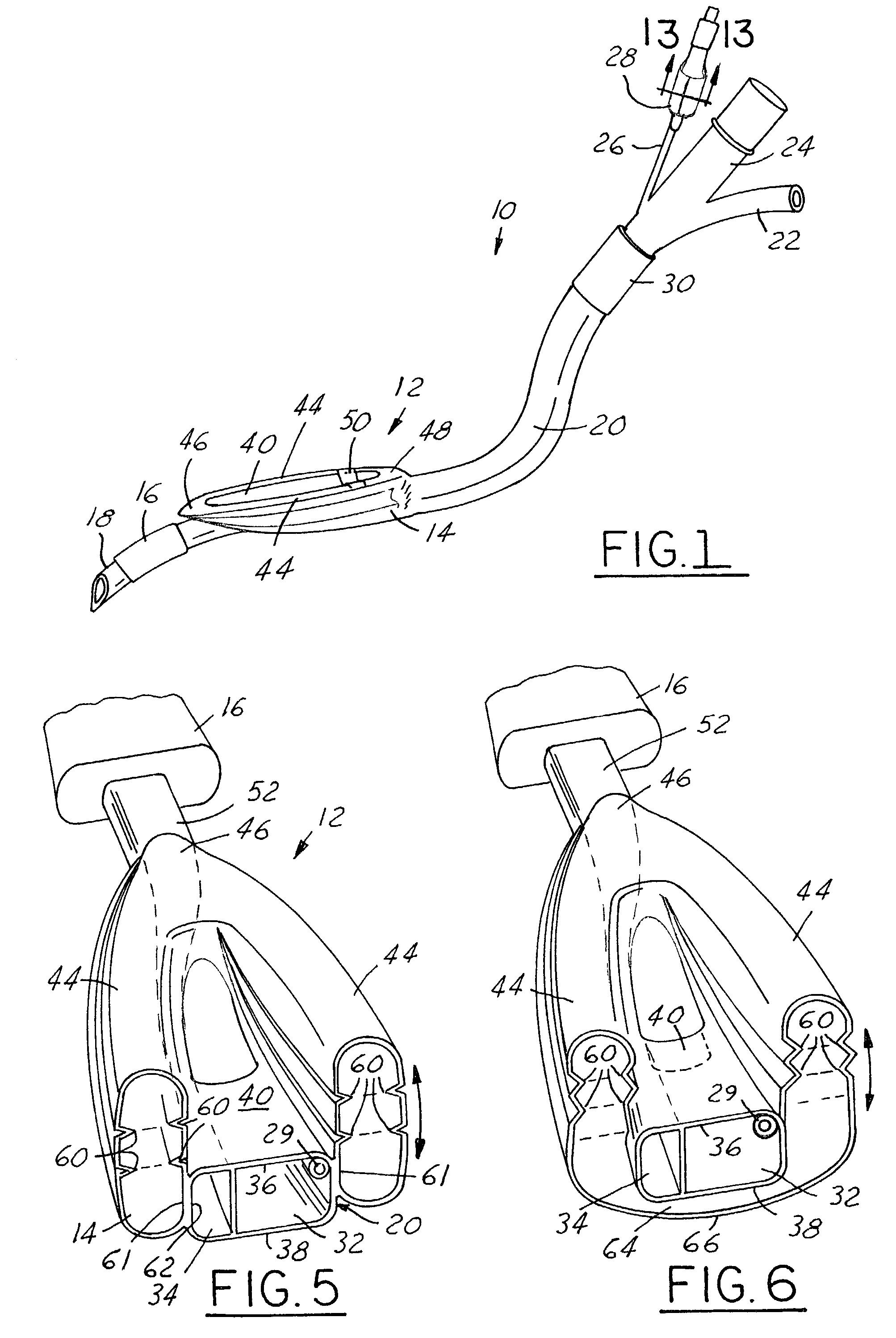

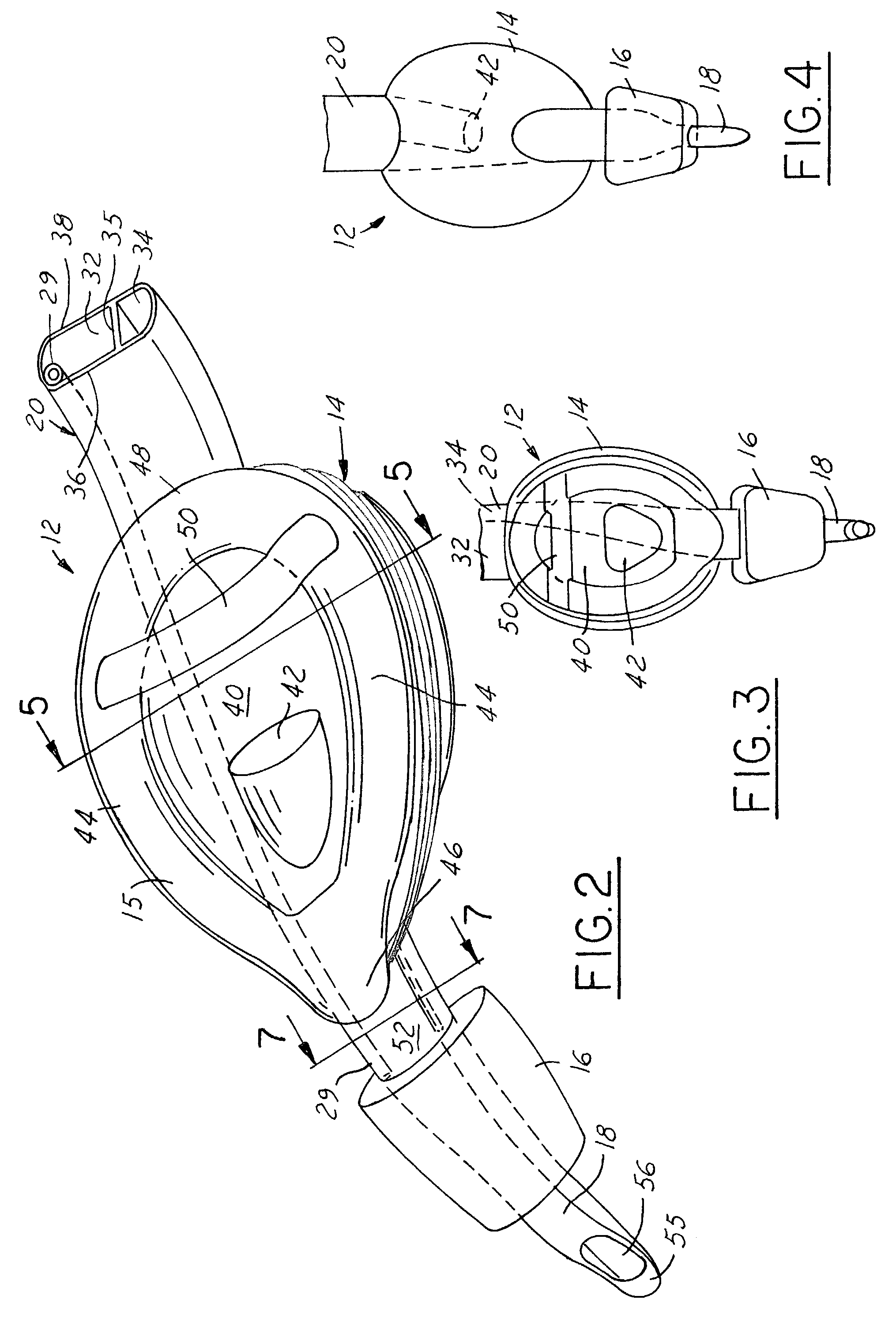

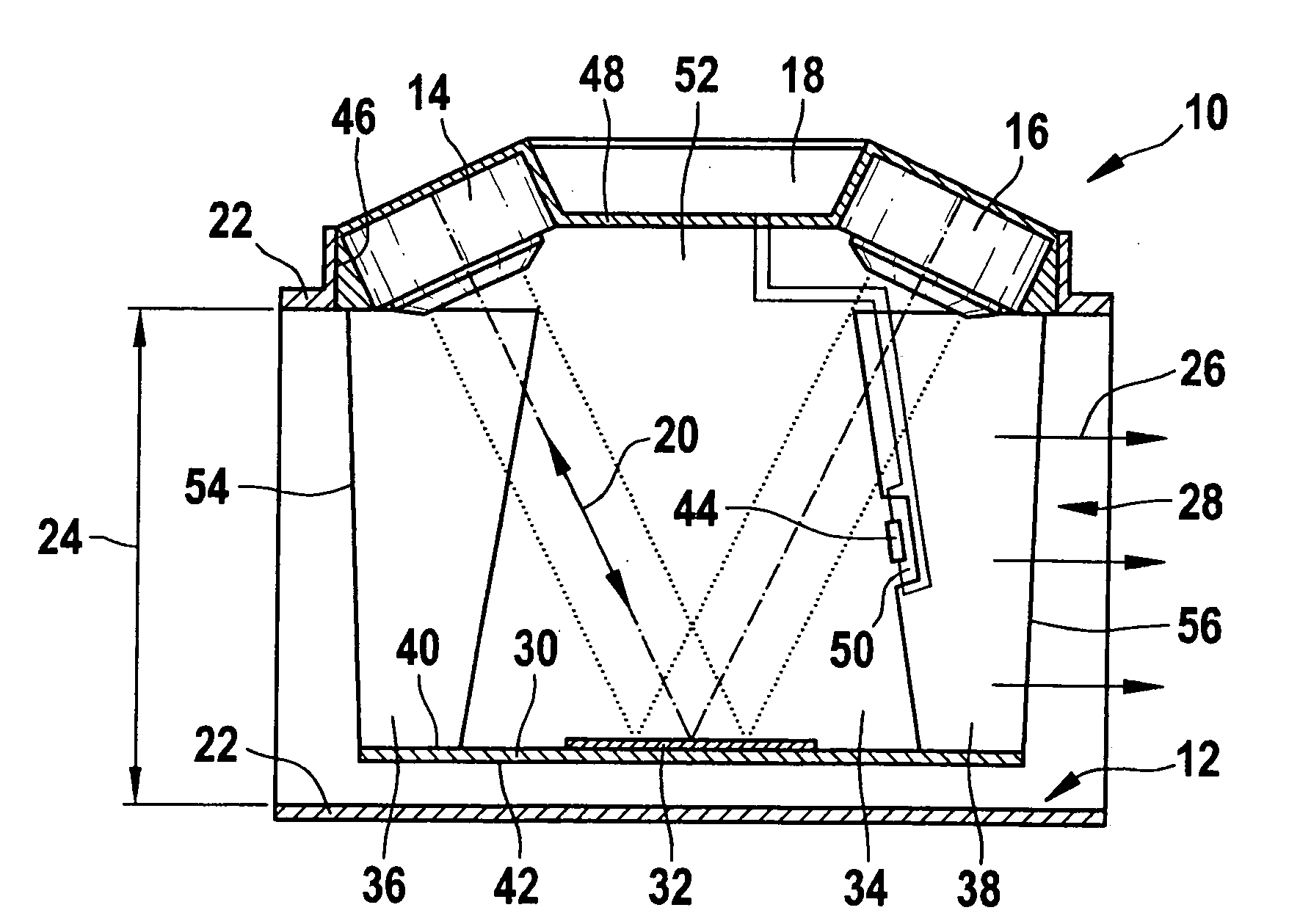

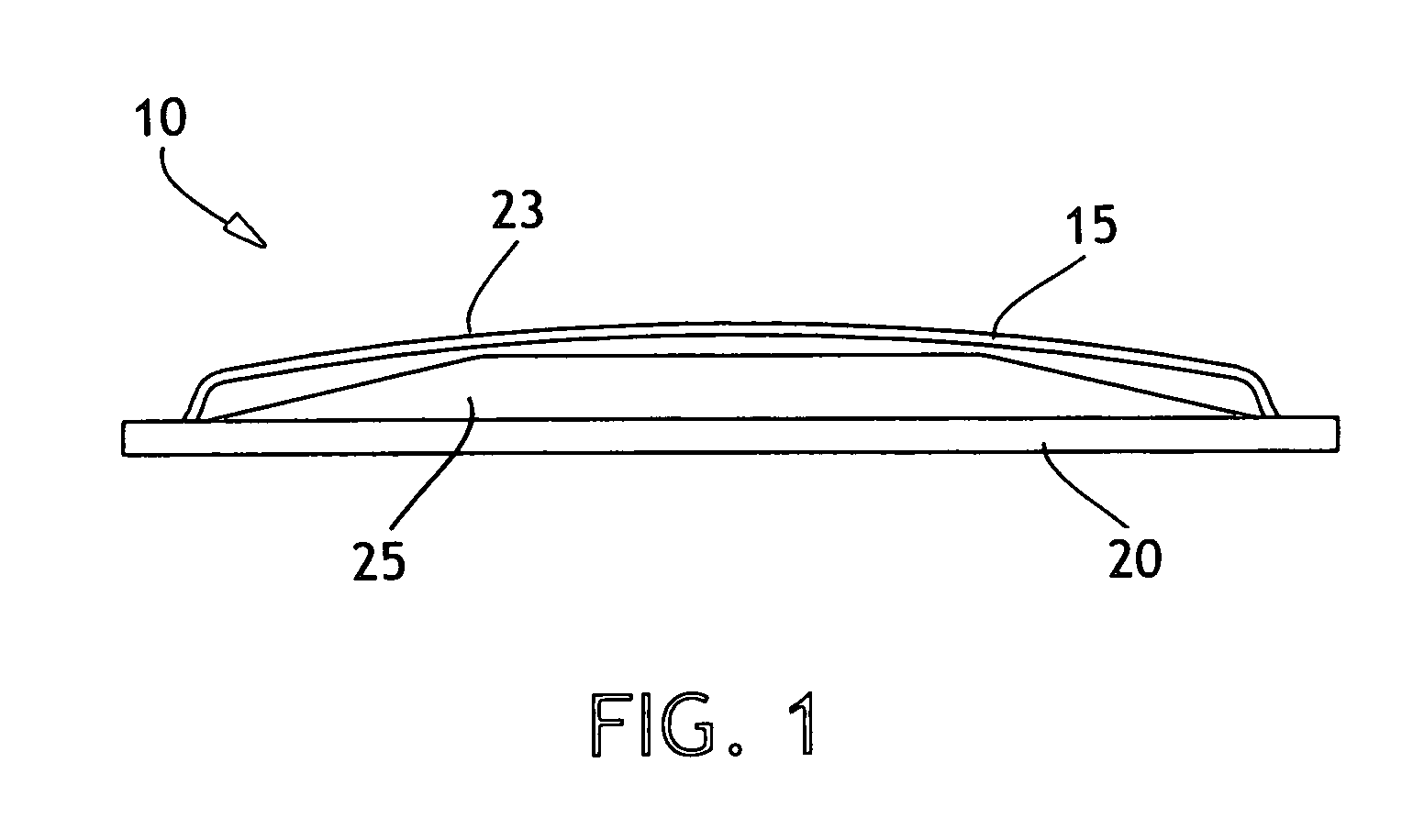

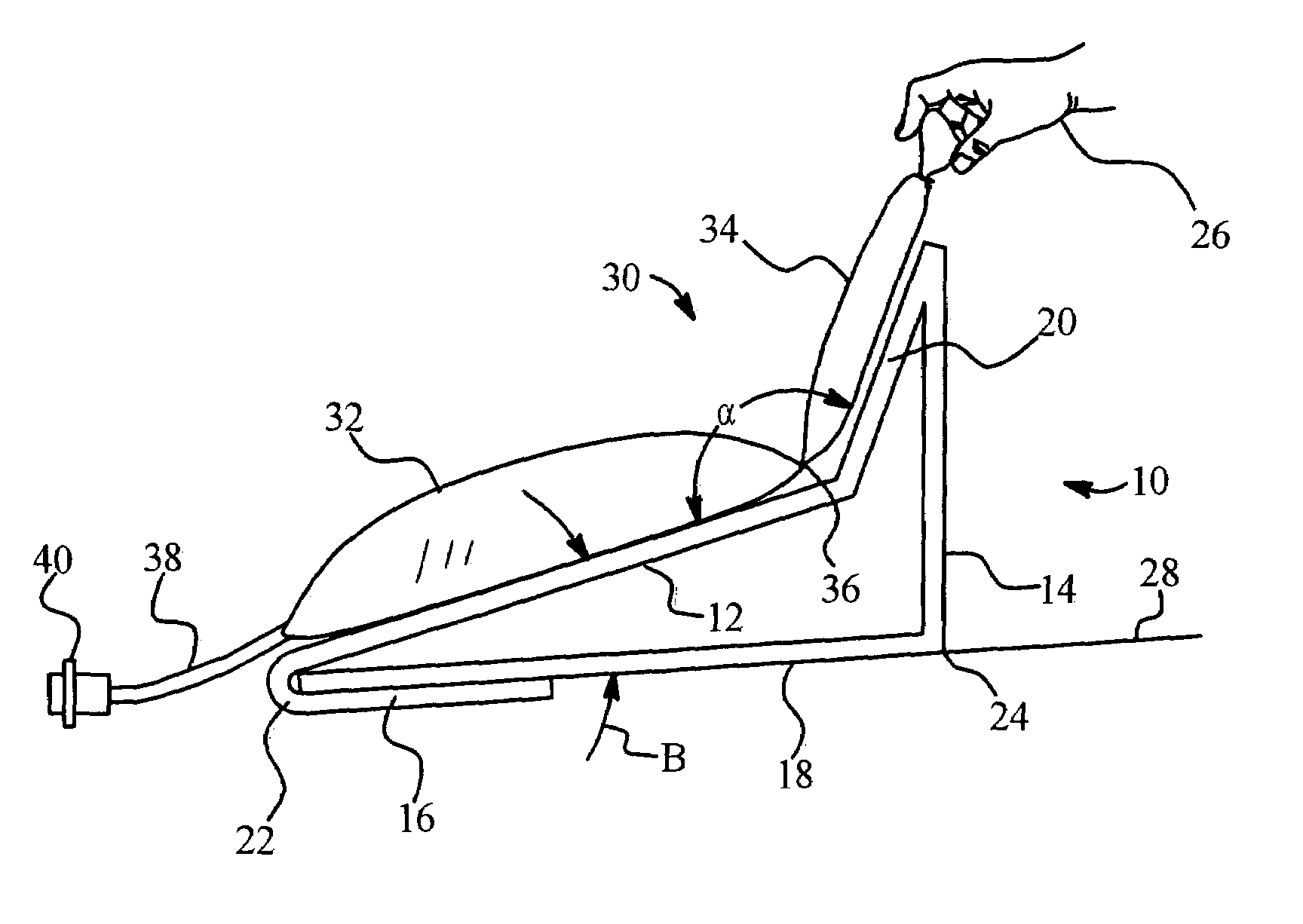

Combination artificial airway device and esophageal obturator

ActiveUS7040322B2Reduce chanceReduce thicknessTracheal tubesBreathing masksInternal pressureEsophageal obturator

A combination artificial airway device and esophageal obturator (10) includes a esophageal cuff (16) and supraglottic cuff (14) that are inflated in a sequence to provide quick isolation of the esophagus relative to the tracheal air passage. The supraglottic cuff is asymmetrical in shape with a wedge like or cone like shape that is ergonomically shaped for providing less trauma to the pharyngeal tissues. A pressure indicator (25) surrounds a pilot balloon (28) for continuous monitoring of the internal pressure within the cuffs (14&16).

Owner:FORTUNA ANIBAL DE OLIVEIRA

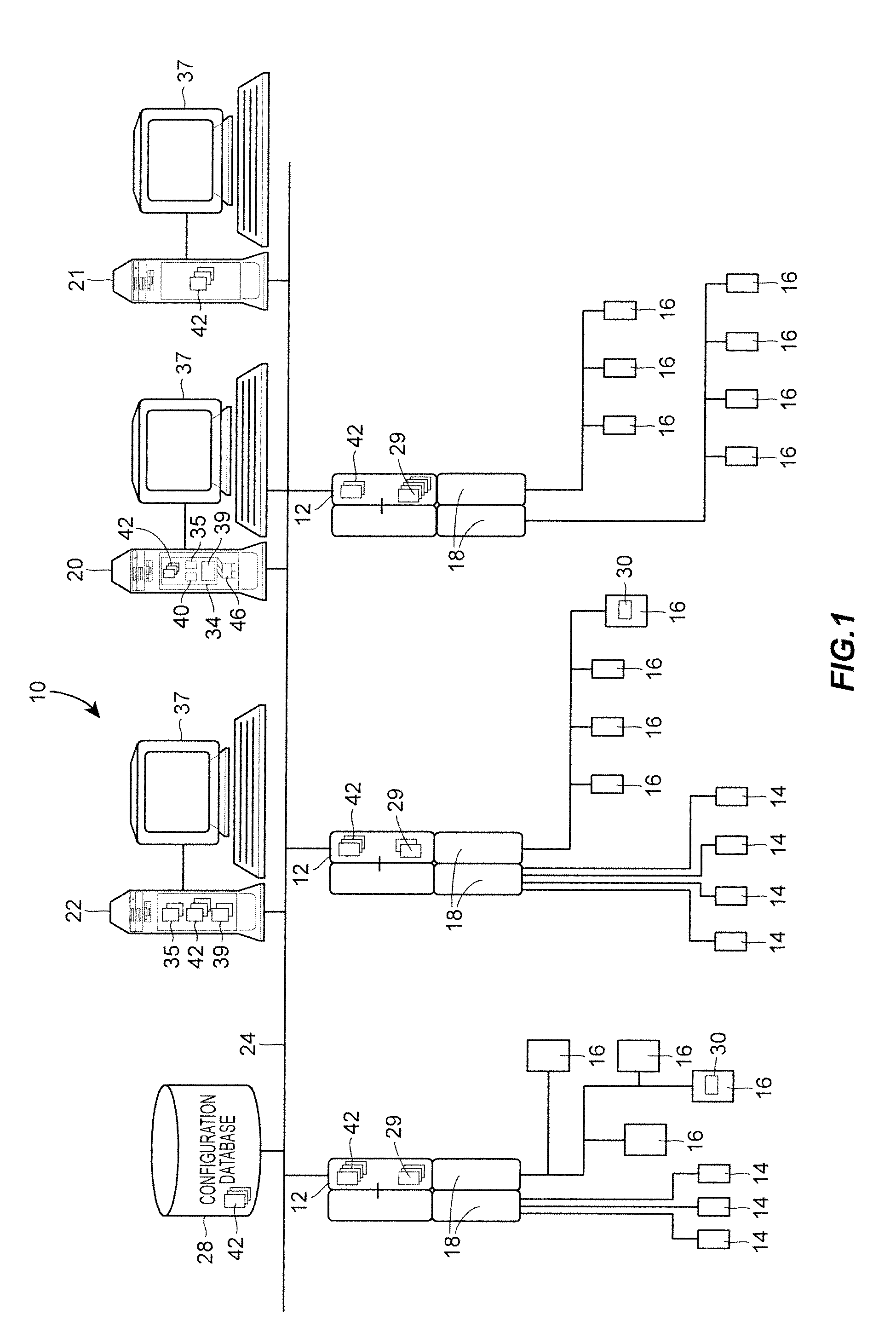

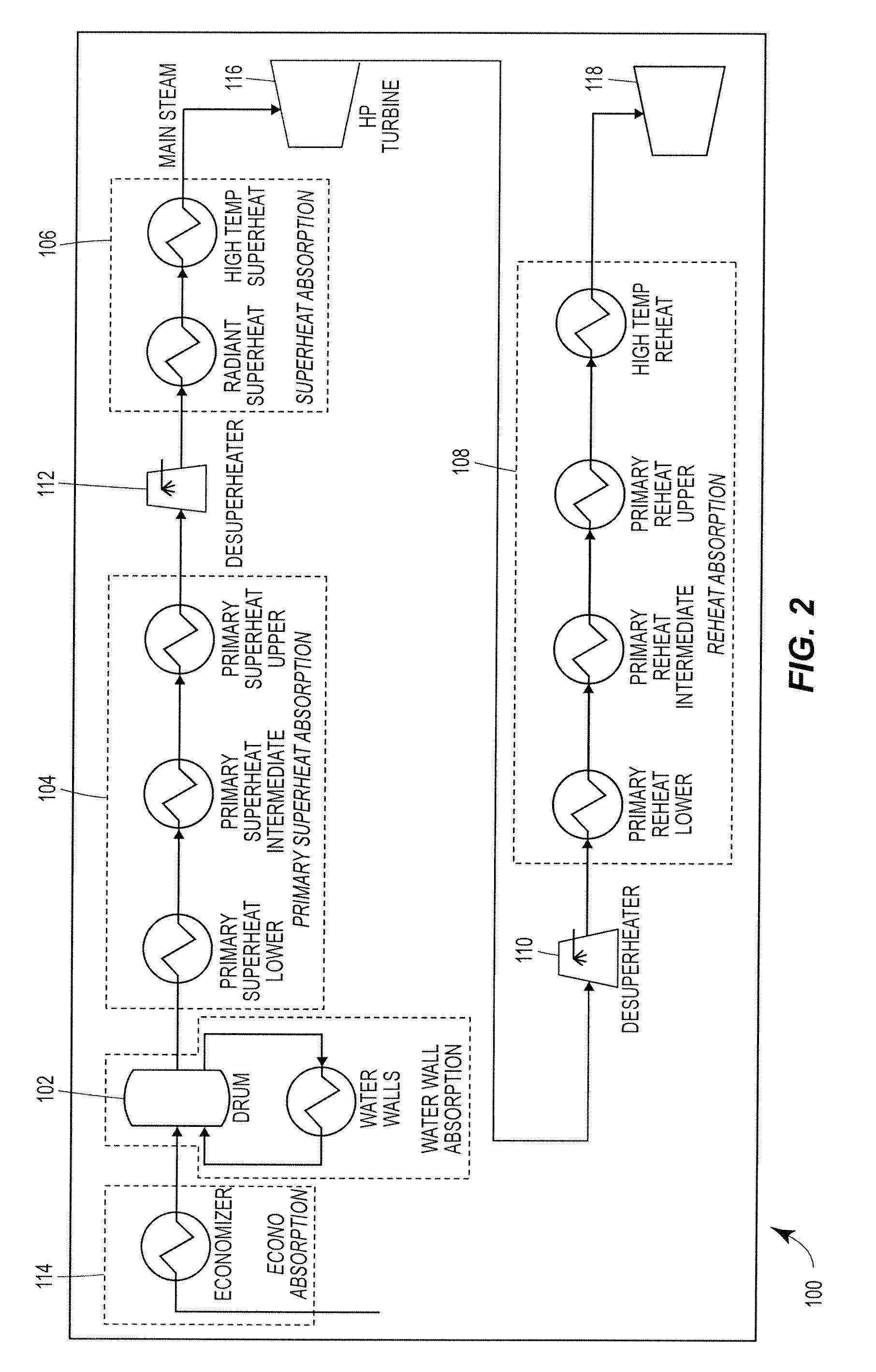

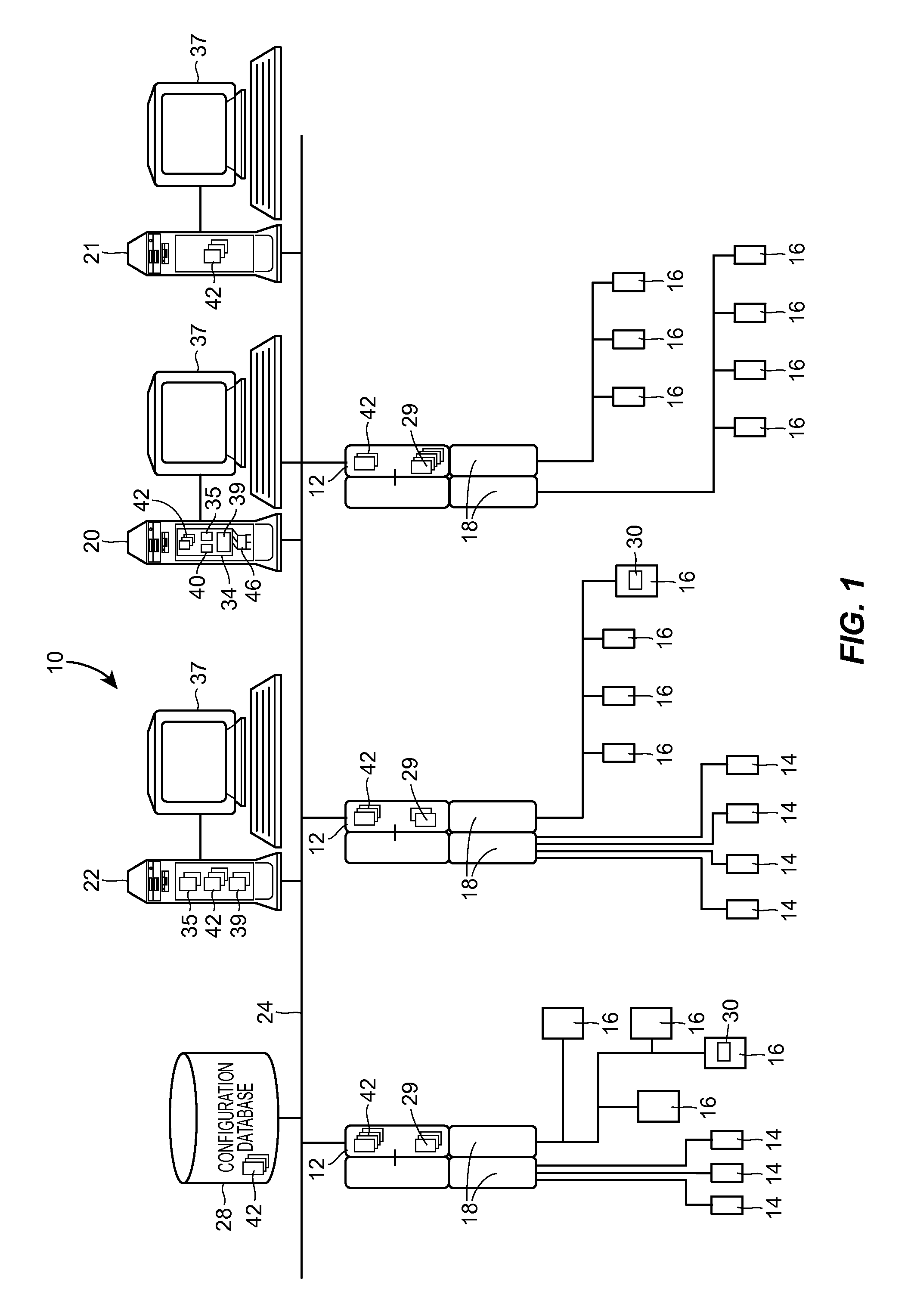

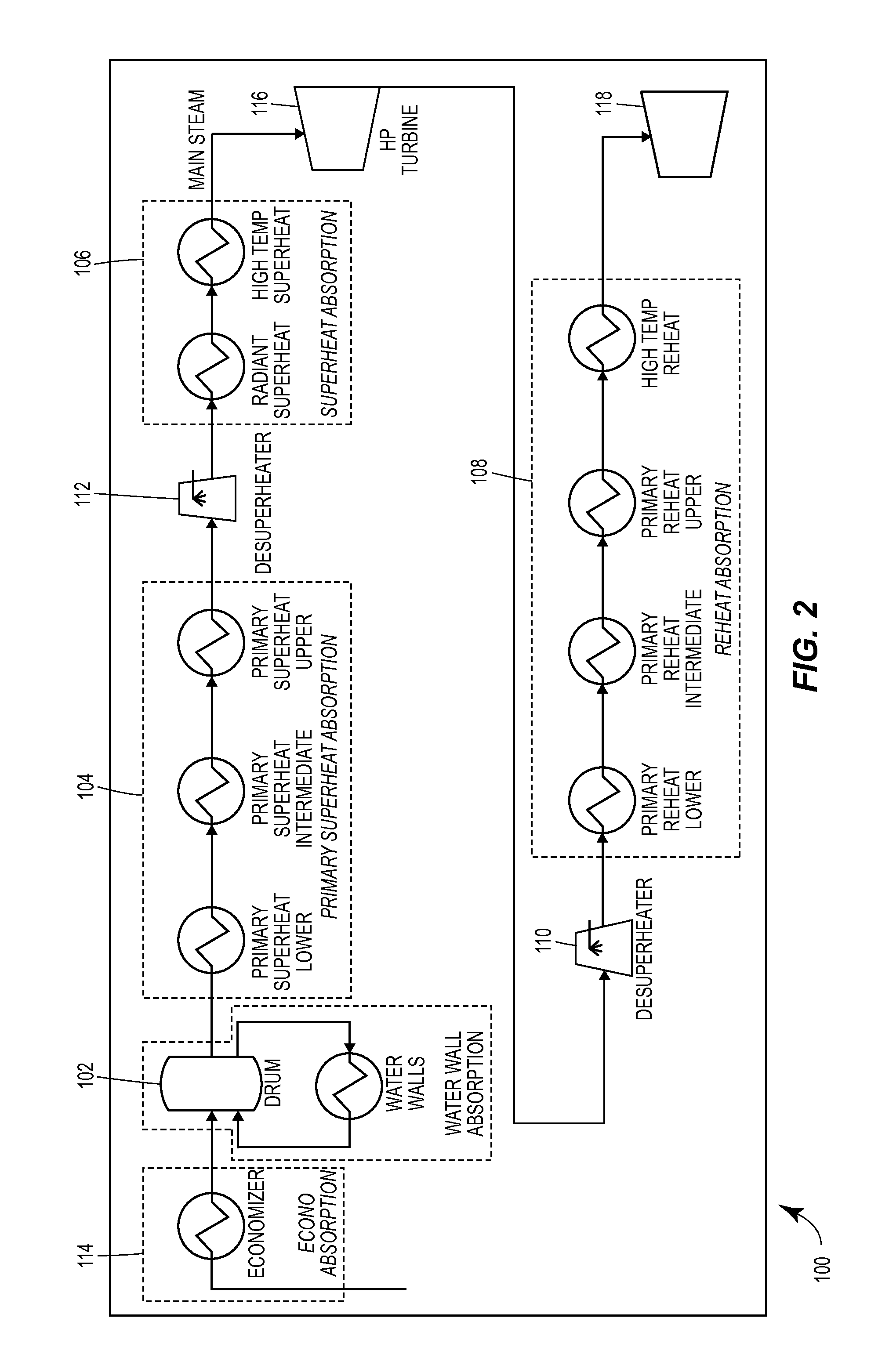

Decentralized industrial process simulation system

ActiveUS20110131017A1Accurately solves massAccurately flow balanceProgramme controlAnalogue computers for control systemsMass storageParallel computing

A high fidelity distributed plant simulation technique includes a plurality of separate simulation modules that may be stored and executed separately in different drops or computing devices. The simulation modules communicate directly with one another to perform accurate simulation of a plant, without requiring a centralized coordinator to coordinate the operation of the simulation system. In particular, numerous simulation modules are created, with each simulation module including a model of an associated plant element and these simulation modules are stored in different drops of a computer network to perform distributed simulation of a plant or a portion of a plant. At least some of the simulation modules, when executing, perform mass flow balances taking into account process variables associated with adjacent simulation modules to thereby assure pressure, temperature and flow balancing (i.e., conservation of mass flow) through the entire simulation system. In a dynamic situation, a transient mass storage relay technique is used to account for transient changes in mass flow through any non-storage devices being simulated by the simulation modules. Moreover, adjacent simulation modules located in different drops communicate directly with one another using a background processing task, which simplifies communications between adjacent simulation modules without the need for a central coordinator.

Owner:EMERSON PROCESS MANAGEMENT POWER & WATER SOLUTIONS

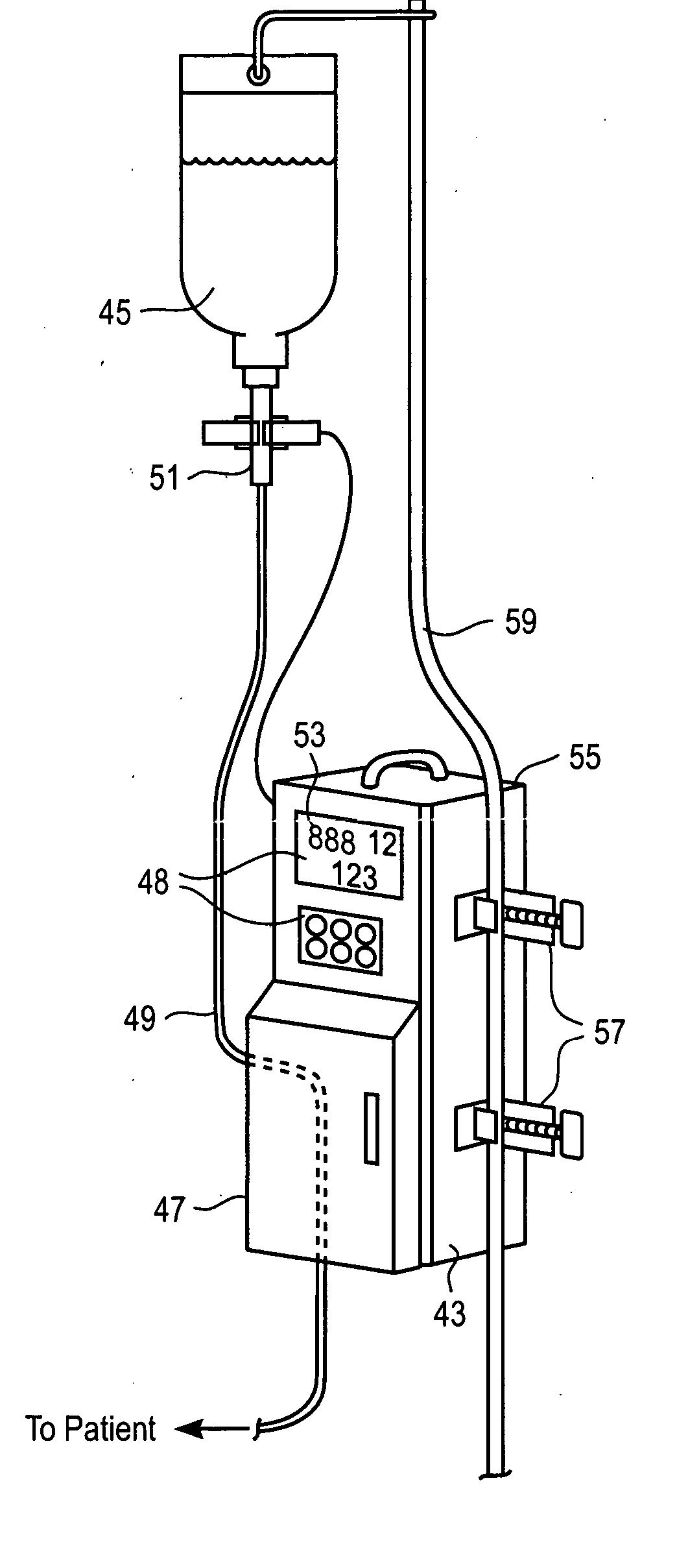

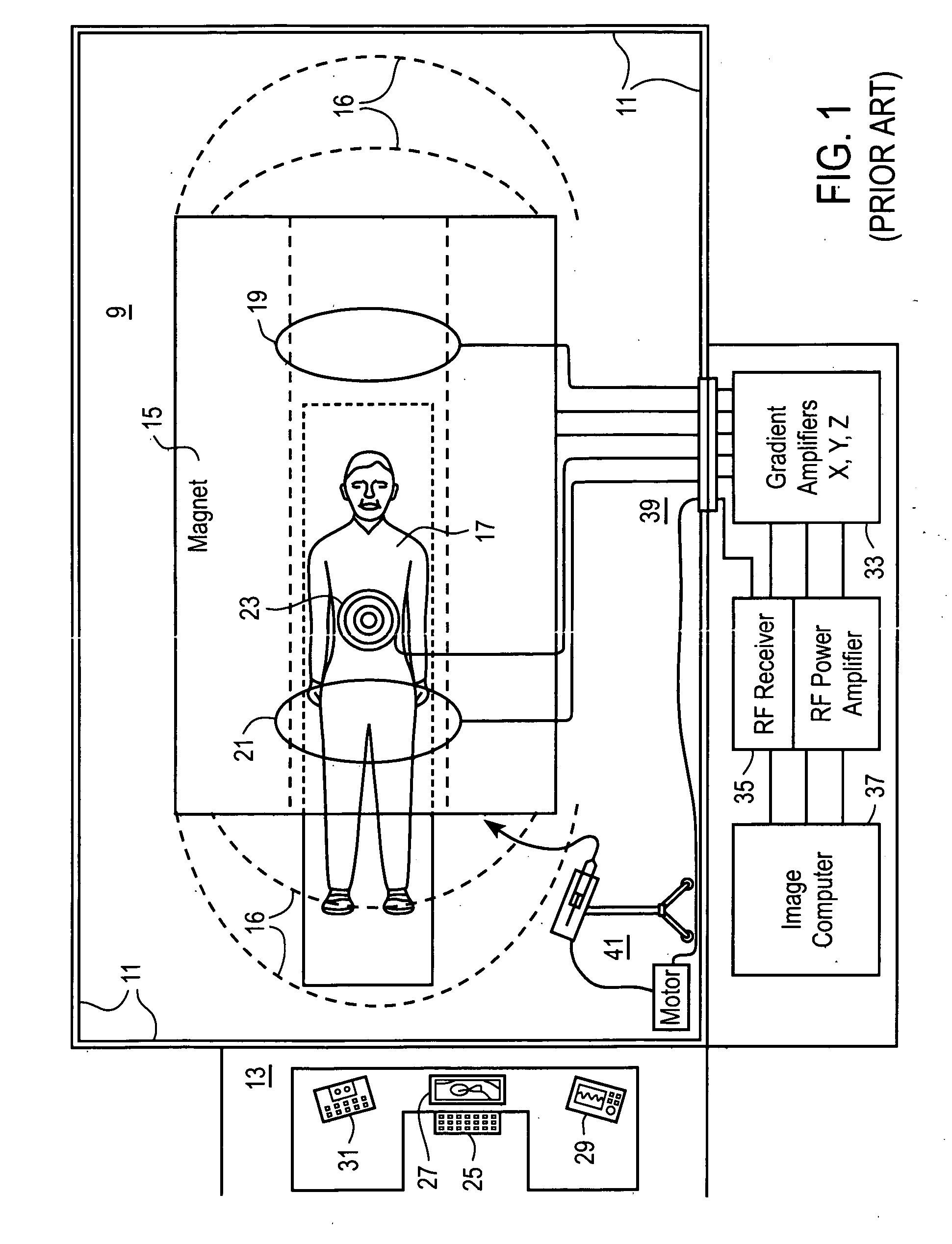

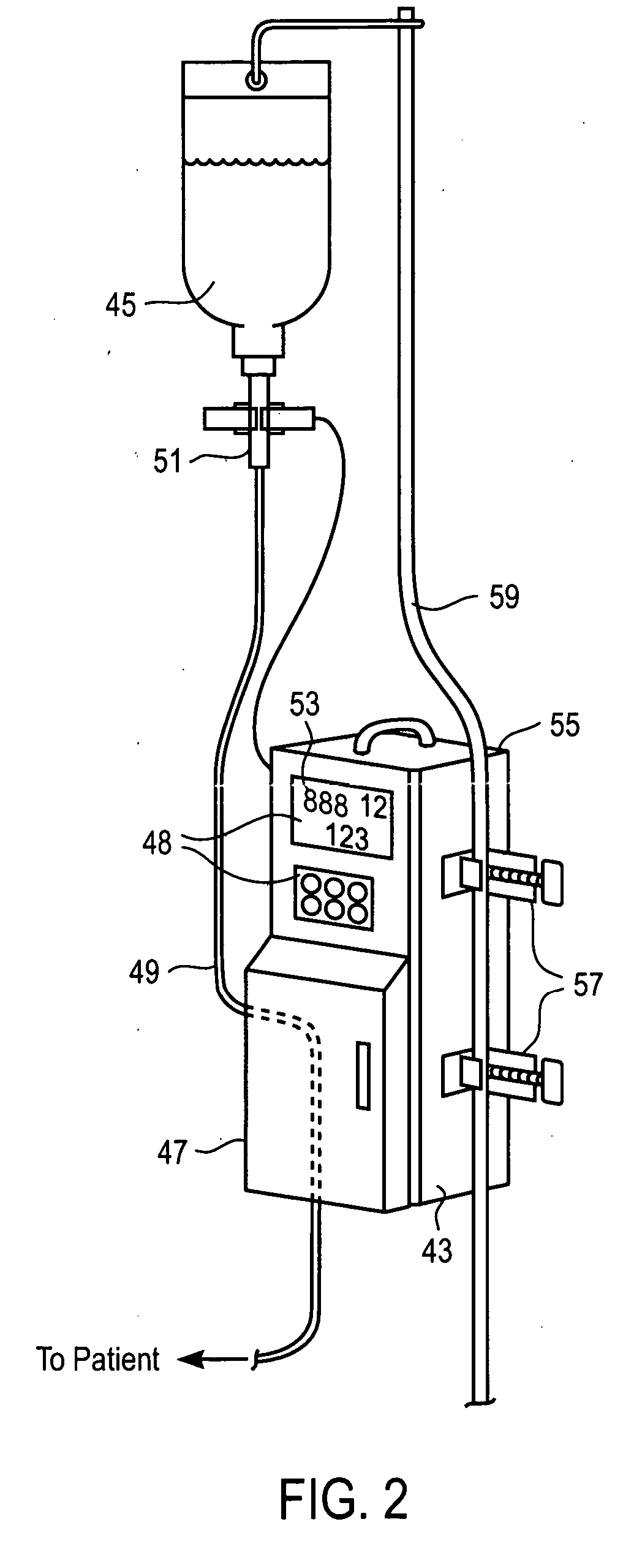

Liquid infusion apparatus

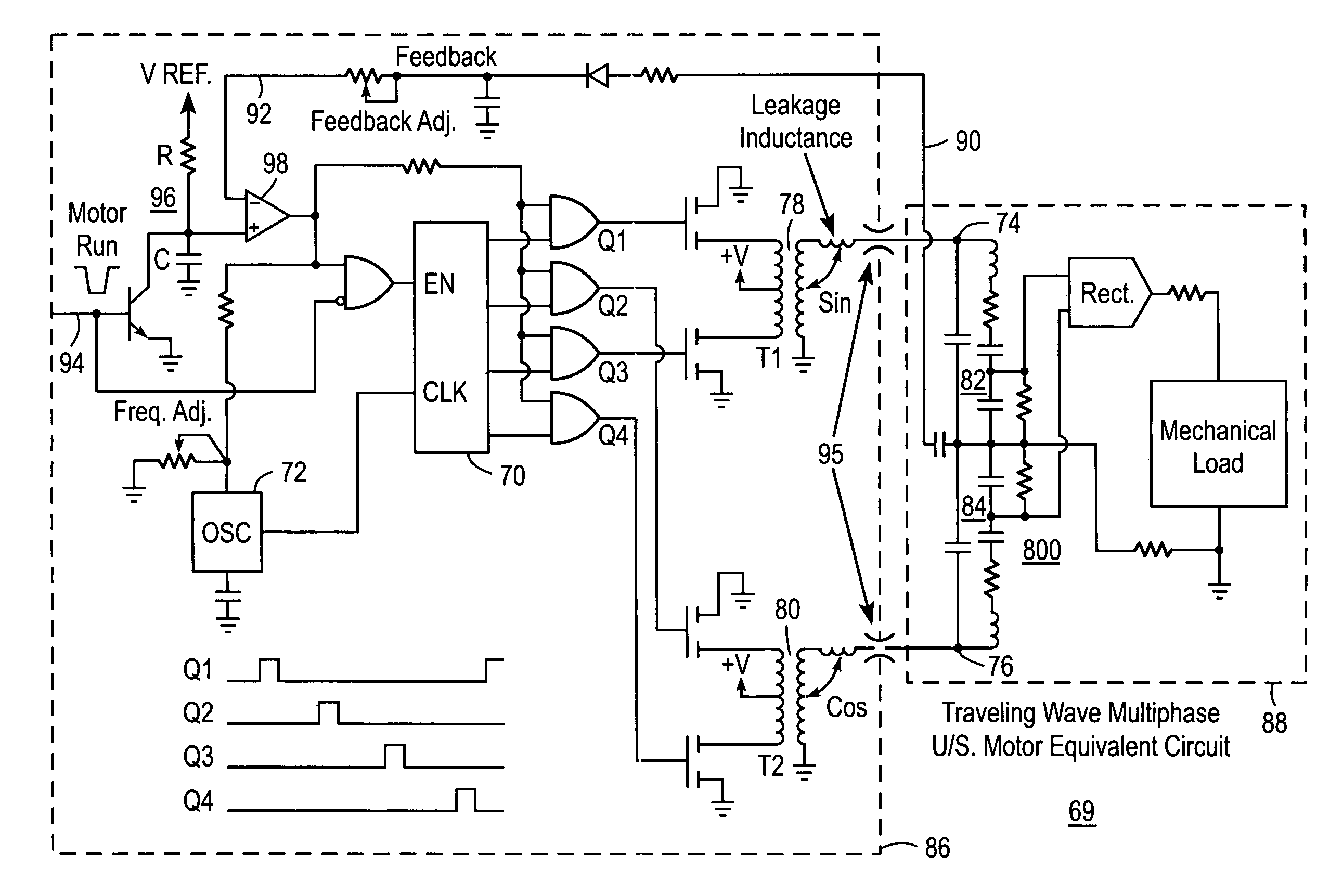

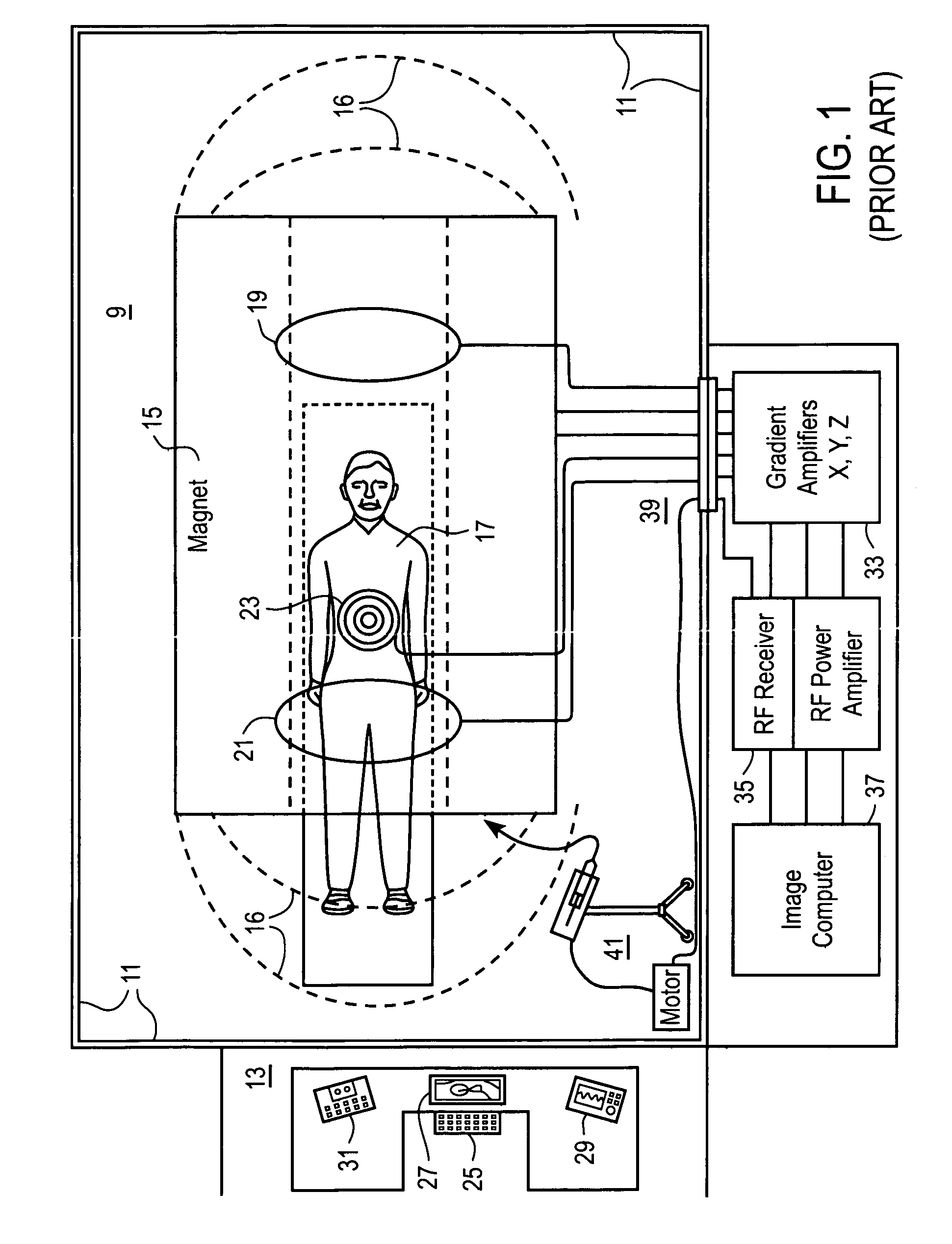

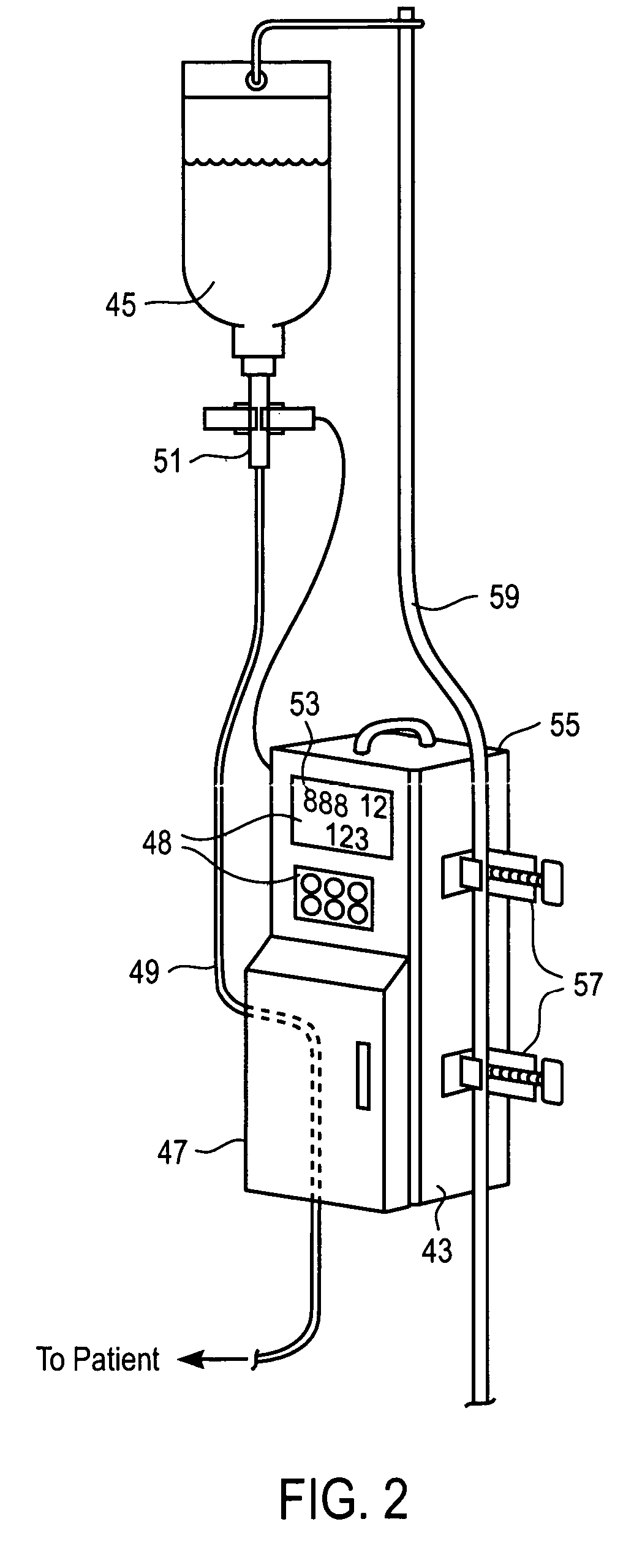

InactiveUS7553295B2Reduce materialEasy to controlDC motor speed/torque controlFlexible member pumpsPeristaltic pumpEngineering

Liquid infusion apparatus includes non-magnetic materials in a pumping structure and ultrasonic drive motor therefor, and in a controller that supplies drive signals to the motor to facilitate convenient operation in intense magnetic fields without distorting the magnetic fields and without radiating objectionable radio-frequency interference. A non-MRI-compatible liquid infusion apparatus is temporarily replaced with MRI-compatible, non-magnetic liquid infusion apparatus without disconnecting a patient from an installed intravenous infusion set to continue infusing liquid within the MRI environment. The pumping apparatus operates on a segment of a liquid conduit that is mounted in tension between a linear peristaltic pump and platen, with associated safety interlocks to assure proper operation of infusing liquid into a patient compatibly with conditions in an MRI environment. Drive circuitry generates low-harmonic signals for operating the ultrasonic motor at variable speeds to compensate for flow rate discontinuities through the peristaltic pumping cycles.

Owner:IRADIMED CORP

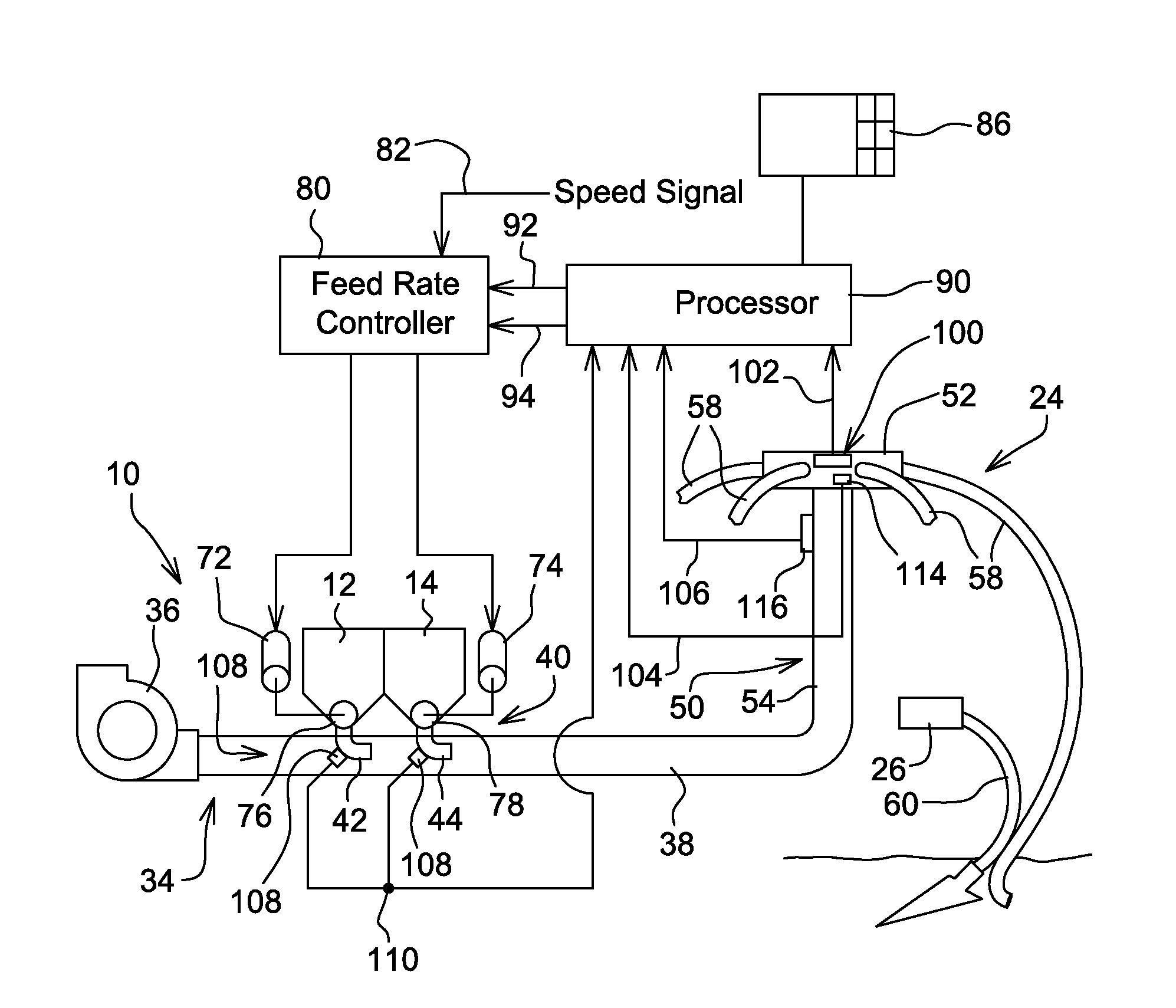

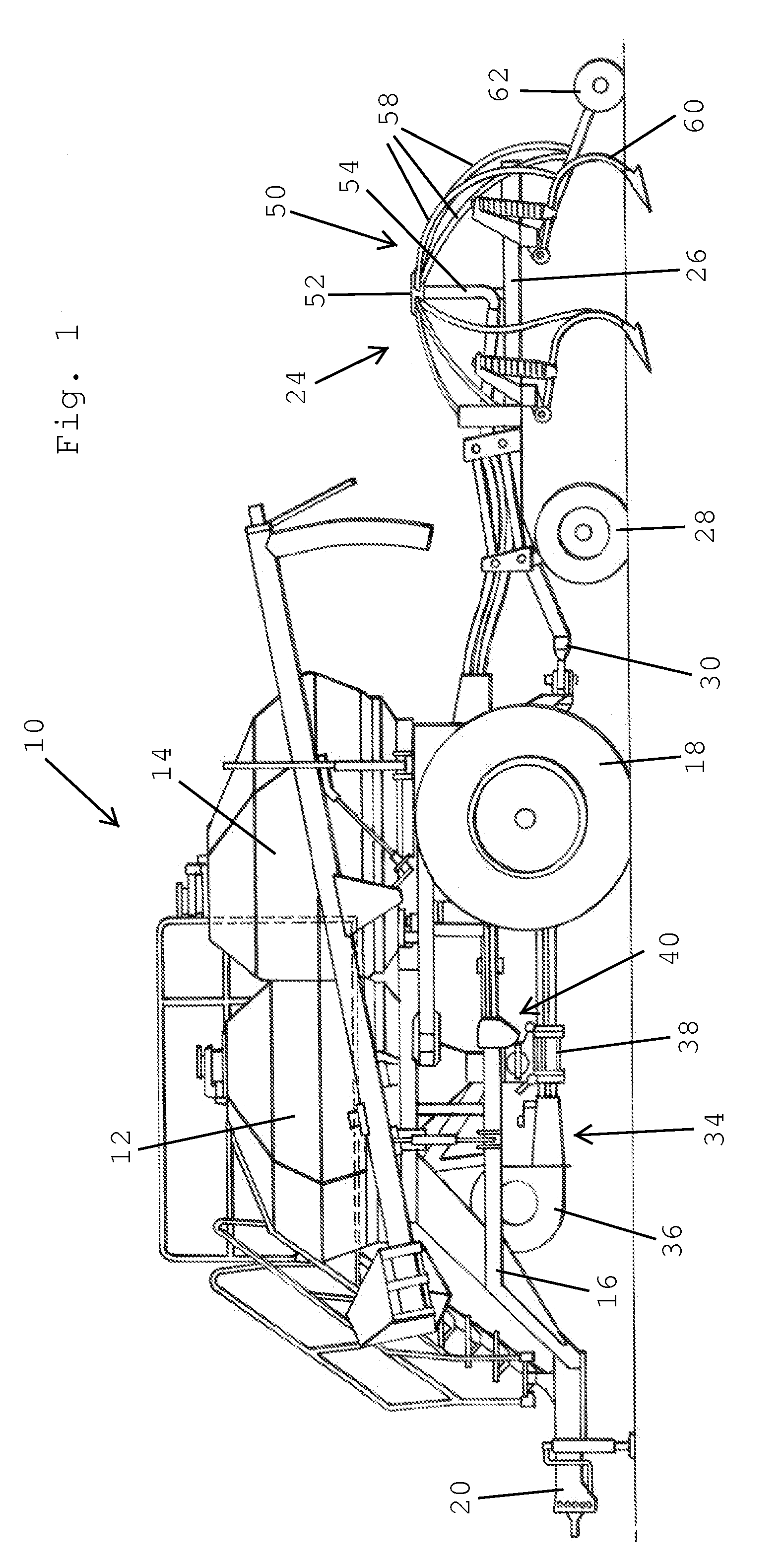

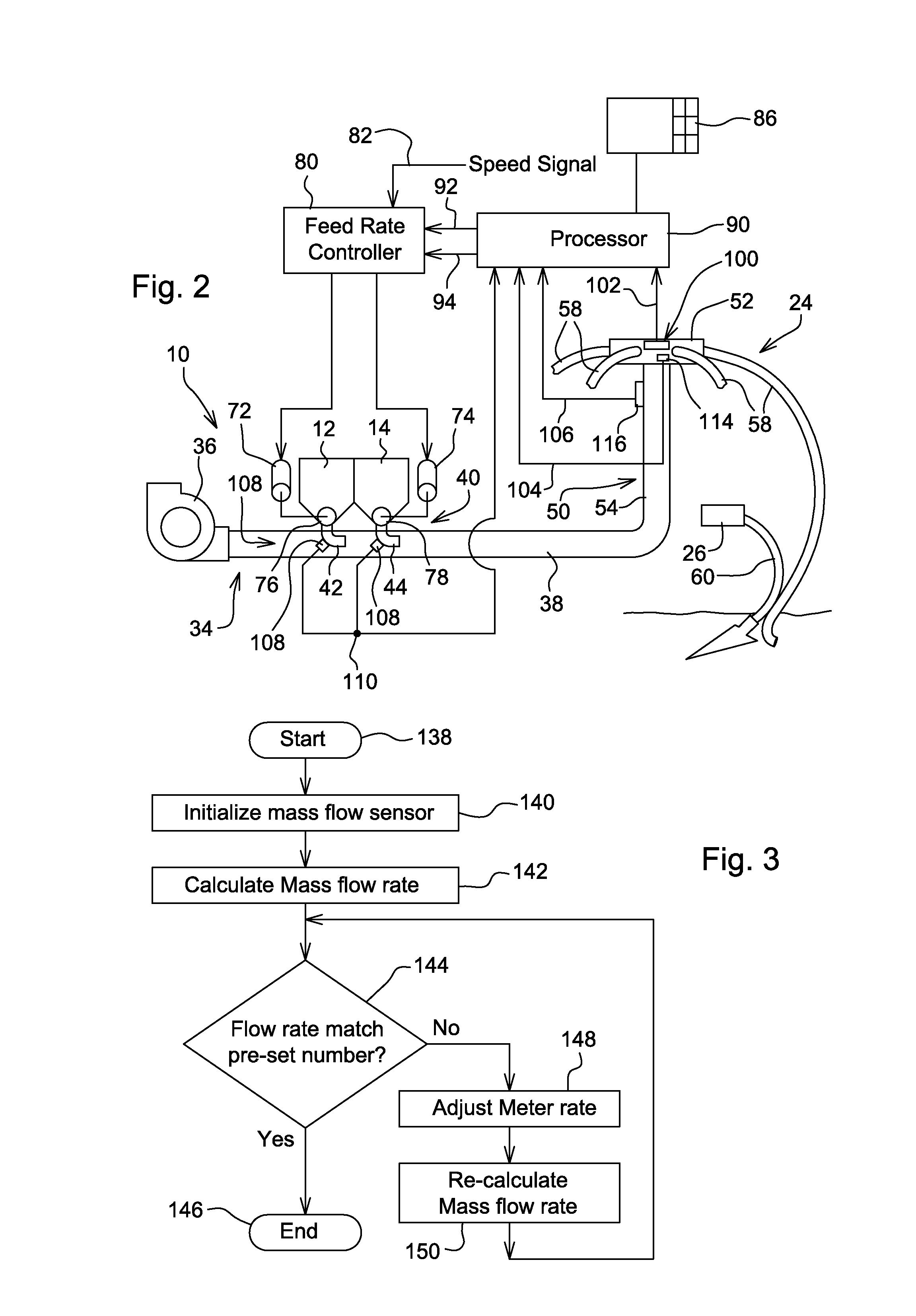

Particulate flow sensing for an agricultural implement

ActiveUS8504310B2Reduce delaysMore accurate seeding and fertilizing ratesFlow propertiesSowingAir velocityEngineering

Owner:DEERE & CO

Liquid infusion apparatus

InactiveUS20060173412A1Reduction of magnetic materialEliminate the problemDC motor speed/torque controlFlexible member pumpsPeristaltic pumpEngineering

Liquid infusion apparatus includes non-magnetic materials in a pumping structure and ultrasonic drive motor therefor, and in a controller that supplies drive signals to the motor to facilitate convenient operation in intense magnetic fields without distorting the magnetic fields and without radiating objectionable radio-frequency interference. A non-MRI-compatible liquid infusion apparatus is temporarily replaced with MRI-compatible, non-magnetic liquid infusion apparatus without disconnecting a patient from an installed intravenous infusion set to continue infusing liquid within the MRI environment. The pumping apparatus operates on a segment of a liquid conduit that is mounted in tension between a linear peristaltic pump and platen, with associated safety interlocks to assure proper operation of infusing liquid into a patient compatibly with conditions in an MRI environment. Drive circuitry generates low-harmonic signals for operating the ultrasonic motor at variable speeds to compensate for flow rate discontinuities through the peristaltic pumping cycles.

Owner:IRADIMED CORP

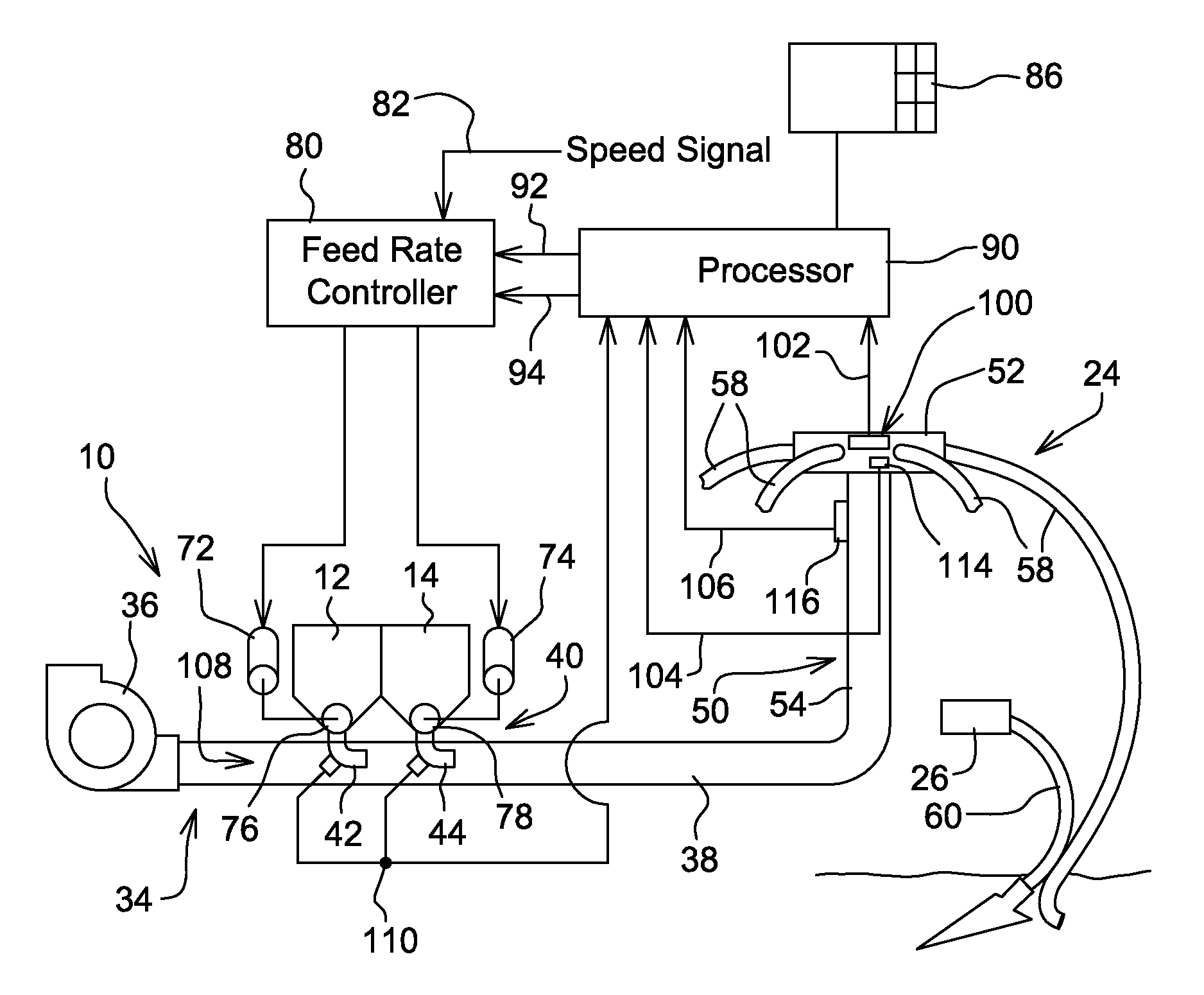

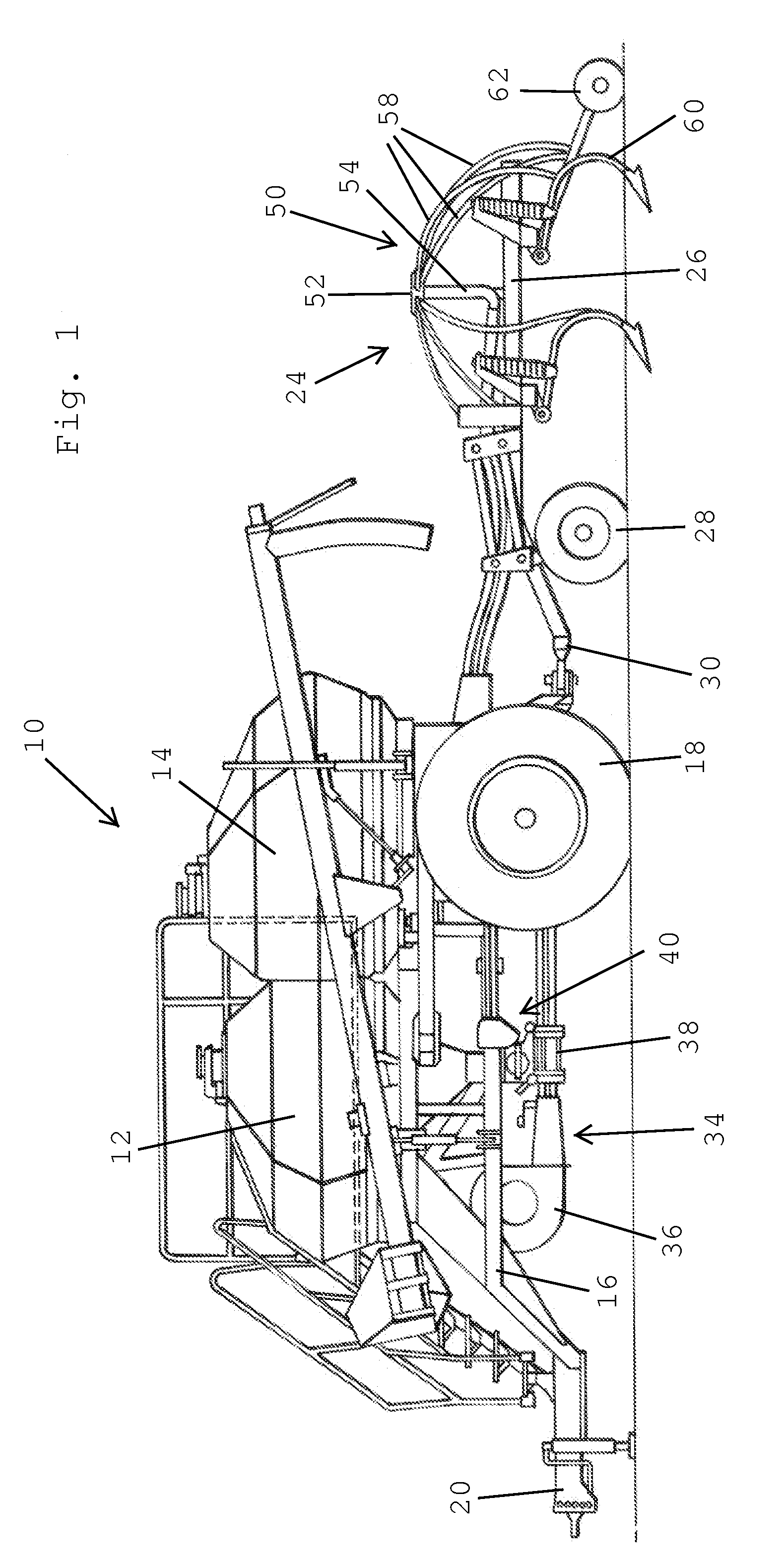

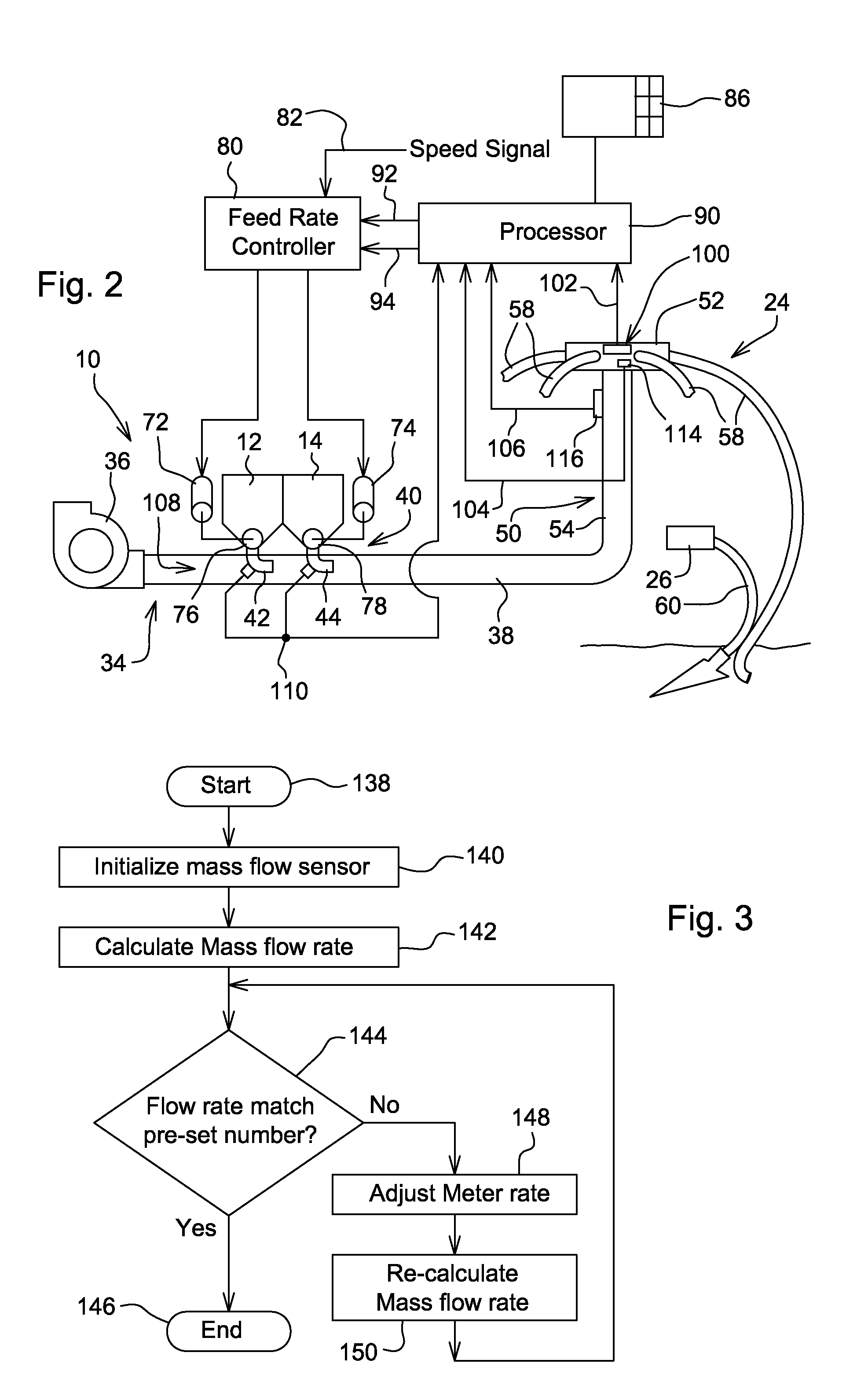

Particulate flow sensing for an agricultural implement

ActiveUS20110035163A1Reduce delaysMore accurate seeding and fertilizing ratesFlow propertiesSowingAir velocityEngineering

An impact sensor is located in a distribution tower which divides the seed and / or nutrient flow into individual rows, and a second sensor provides a compensation signal dependent upon one or more variables such as the velocity of the air in the conveying system, implement vibrations. As the seed / fertilizer bounces off of the impact sensor and flows into the individual row air streams, the impact sensor provides a force signal to a processor which calculates the total particulate mass flow rate from the force signal and the air velocity signal. To determine individual seed and fertilizer rates, a rate controller temporarily changes the metering rate of one of the materials, and the processor then calculates the desired information from the mass flow change and meter speed change. Another embodiment includes seed sensor structure at the meter output for achieving or confirming accuracy.

Owner:DEERE & CO

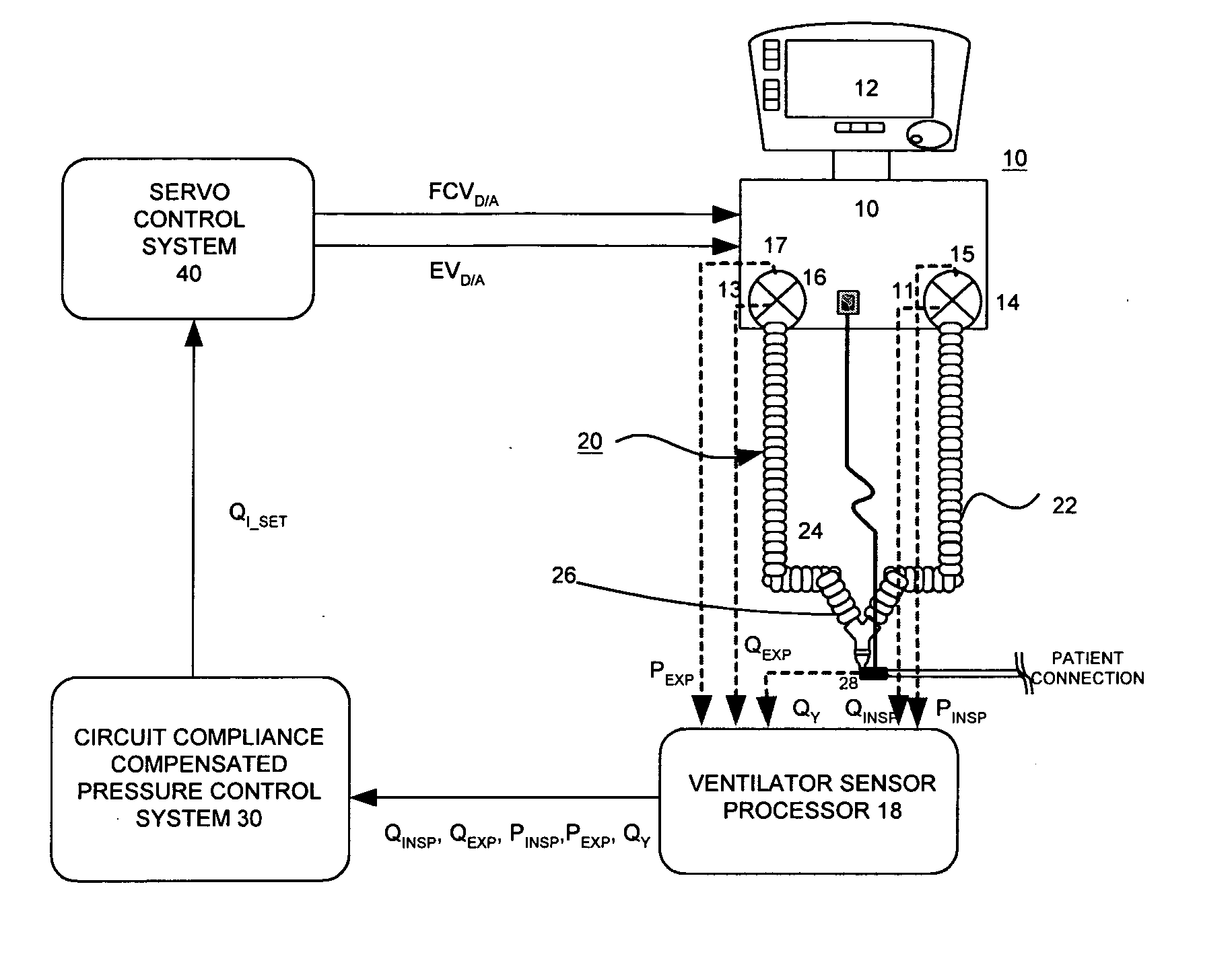

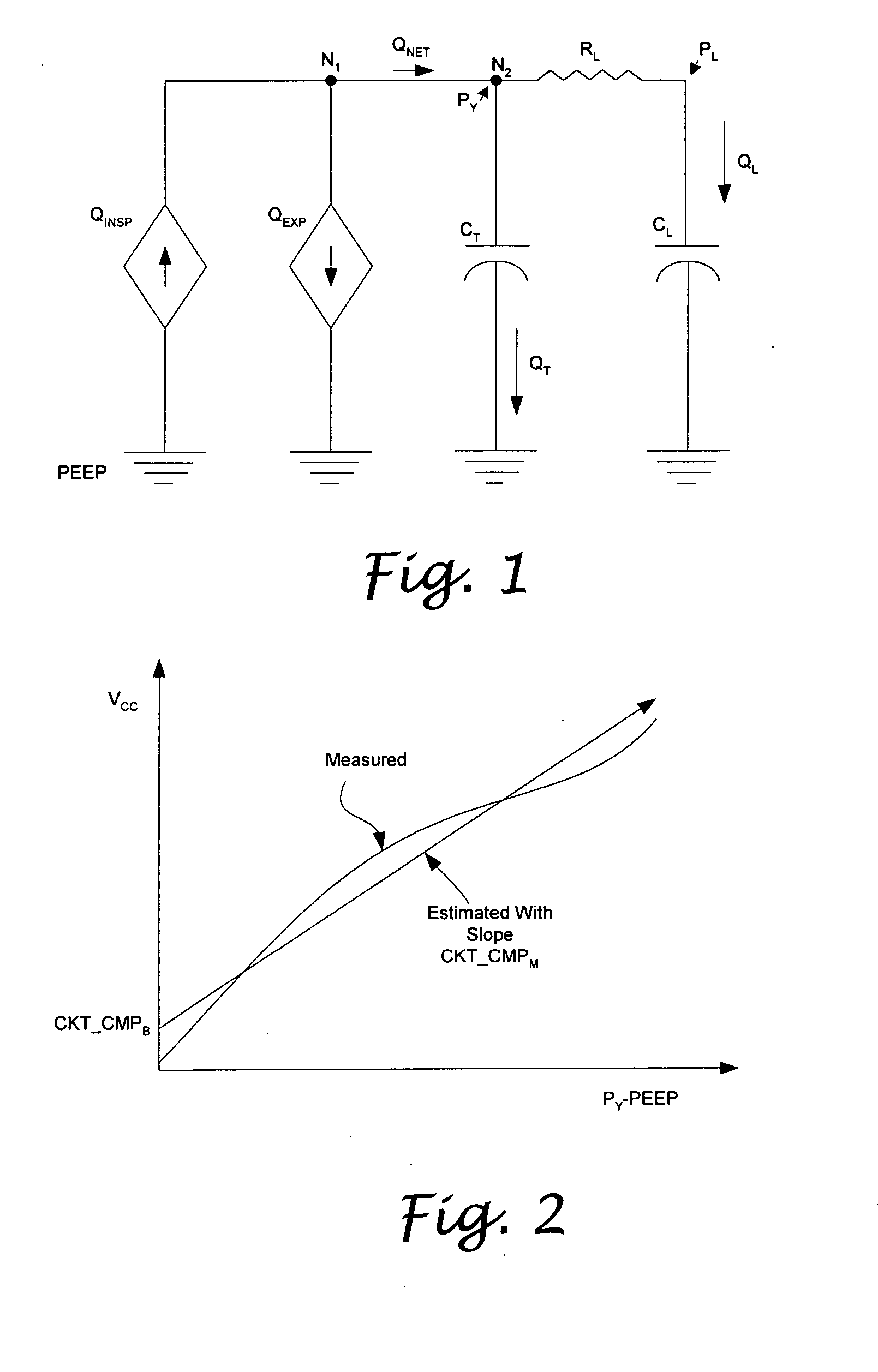

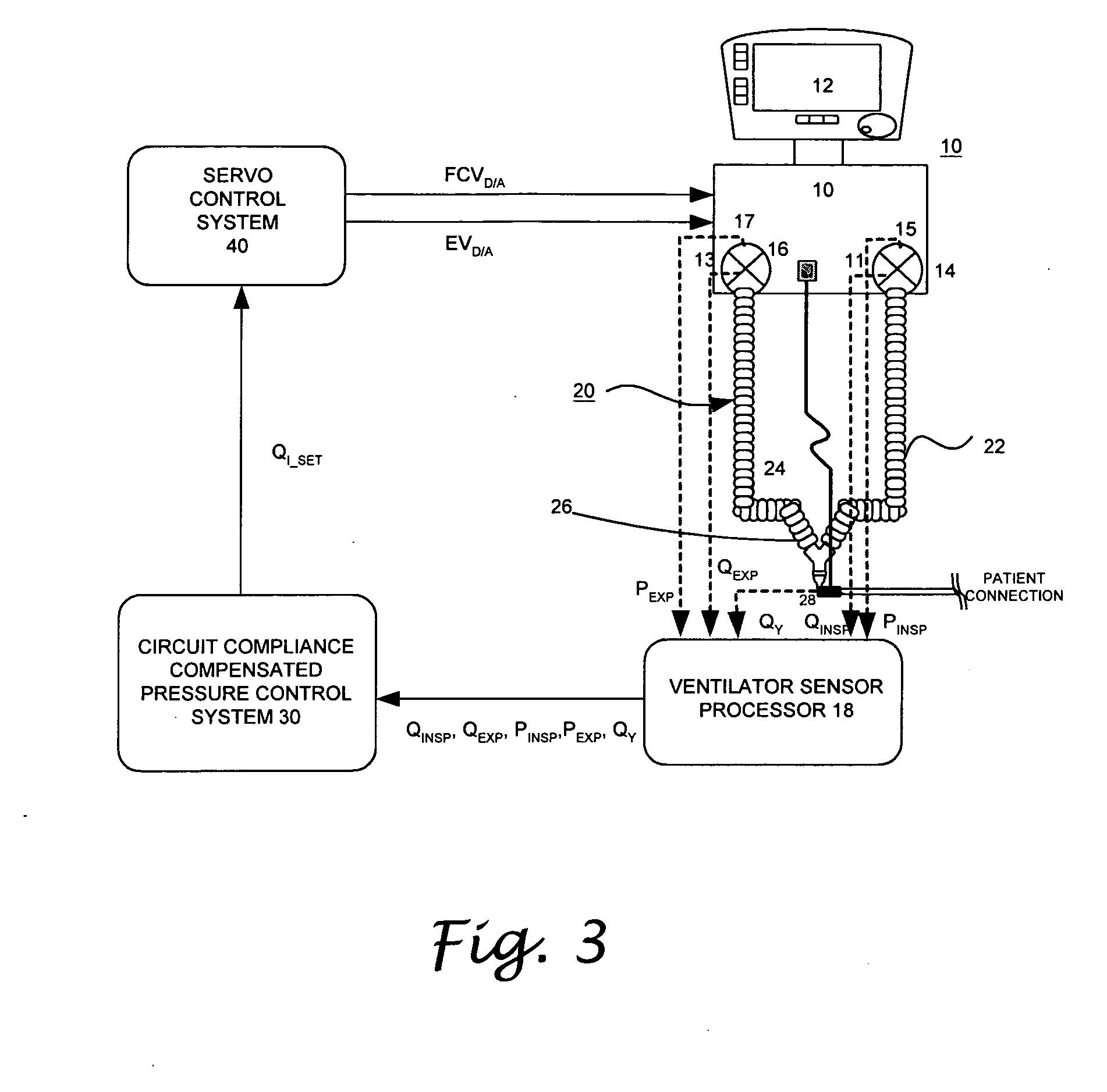

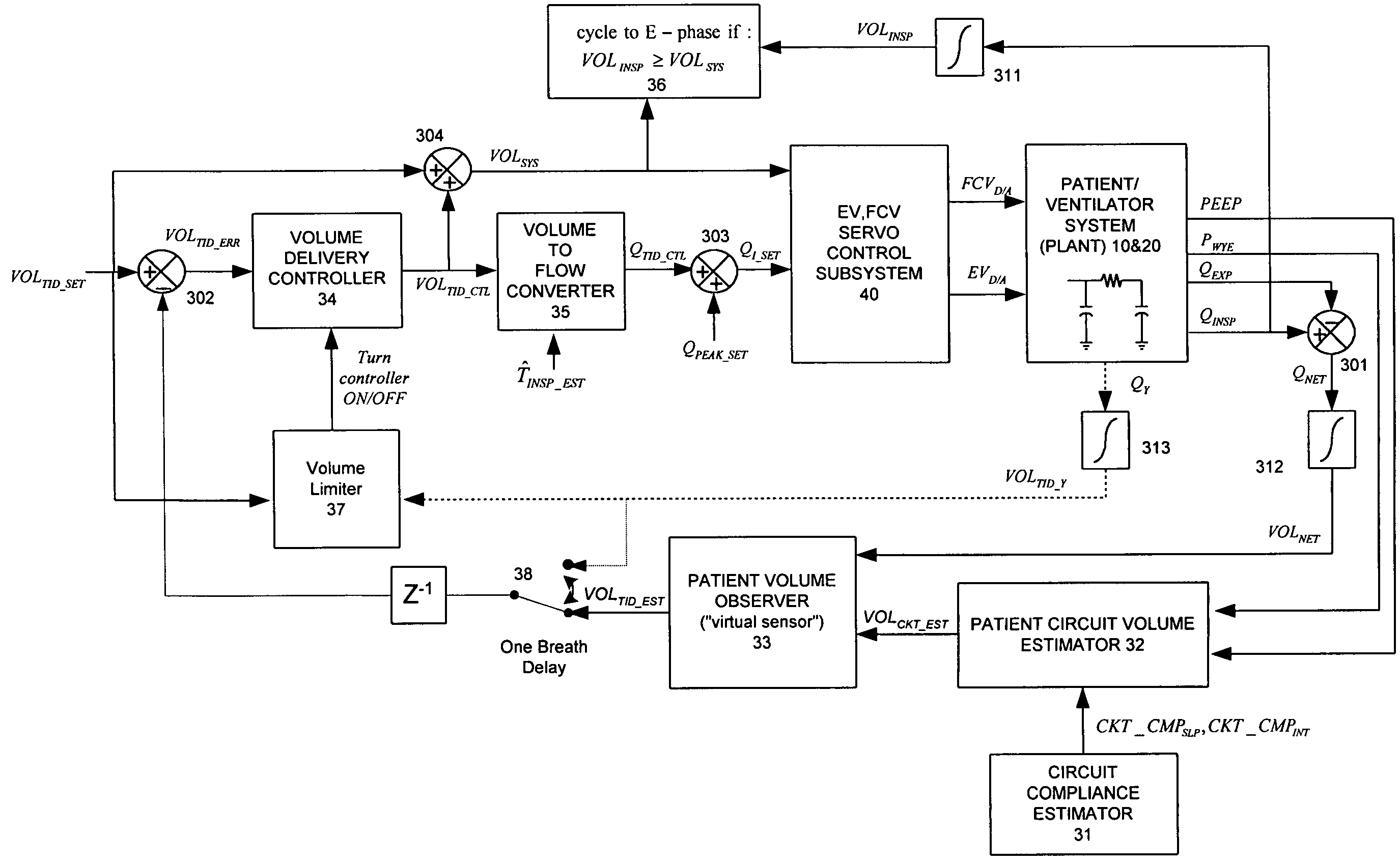

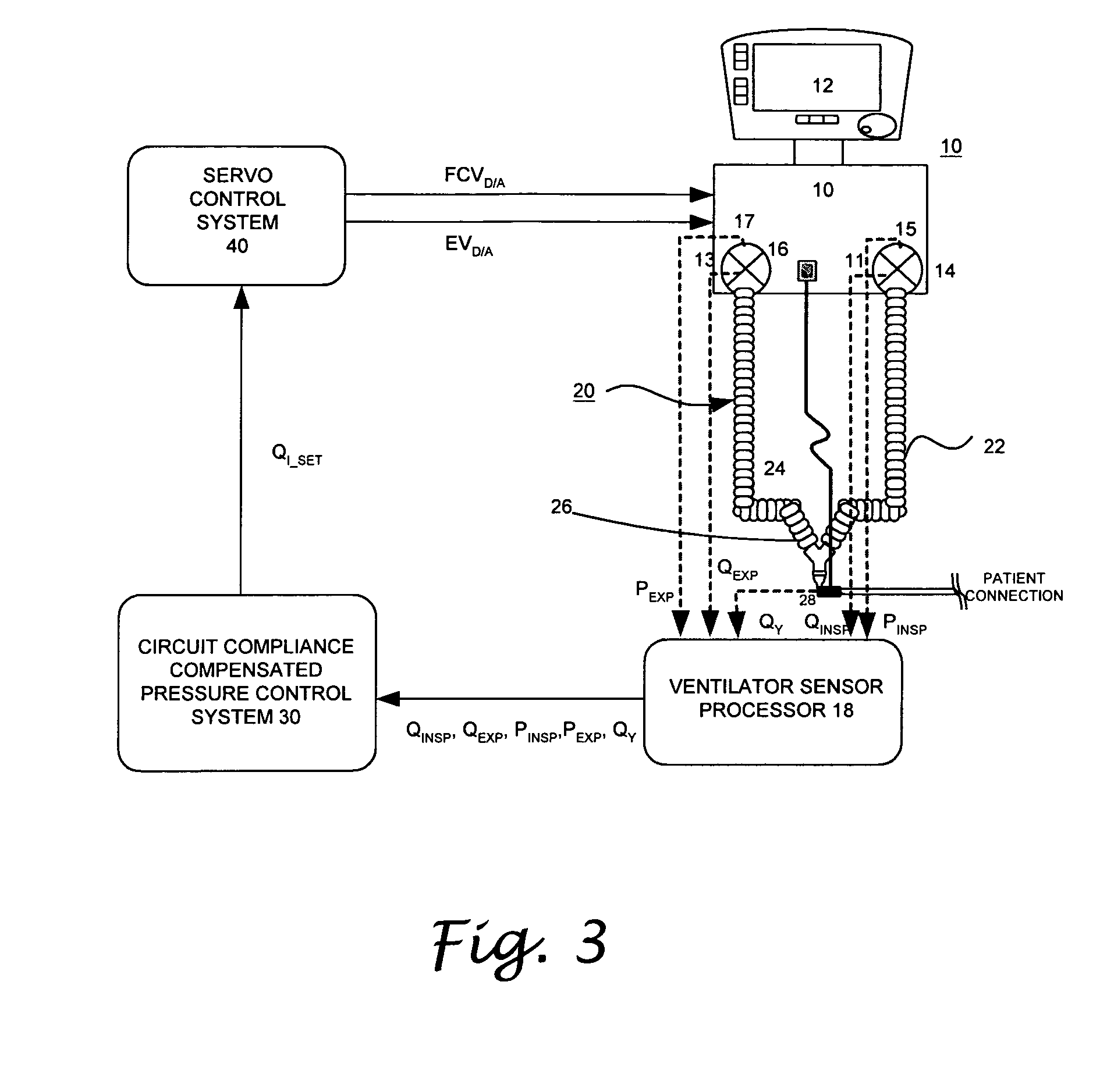

System and method for circuit compliance compensated volume control in a patient respiratory ventilator

ActiveUS20070089738A1Accurate flowGas trapping and auto PEEP is preventedLevel controlInflated body pressure measurementMedicinePeak inspiratory flow

A system and a method for circuit compliance compensated volume control in a patient respiratory ventilation system having a flow regulated feedback servo control loop, a volume delivery controller, and a patient volume observer. In the flow regulated feedback servo control loop, an estimate of patient volume is used for feedback control, such that a tidal volume is achieved upon servo regulation, and the peak inspiratory flow is modulated based on volume error between the set tidal volume and the estimated patient volume. Thereby, a constant inspiratory time and a constant I:E ratio can be maintained. In the volume delivery control, the feedback volume error is normalized to a volume error percentage, and the gain of the controller is dynamically changed based on the volume error percentage, such that the controller effort can be minimized when the volume target is approached. The patient volume observer is operative to estimate the patient delivered volume based on the estimated circuit volume and the measured net delivered volume, while the measured net delivered volume includes effects of leaks and valve dynamics and is synchronously captured with true patient breathing.

Owner:VYAIRE MEDICAL 211 INC

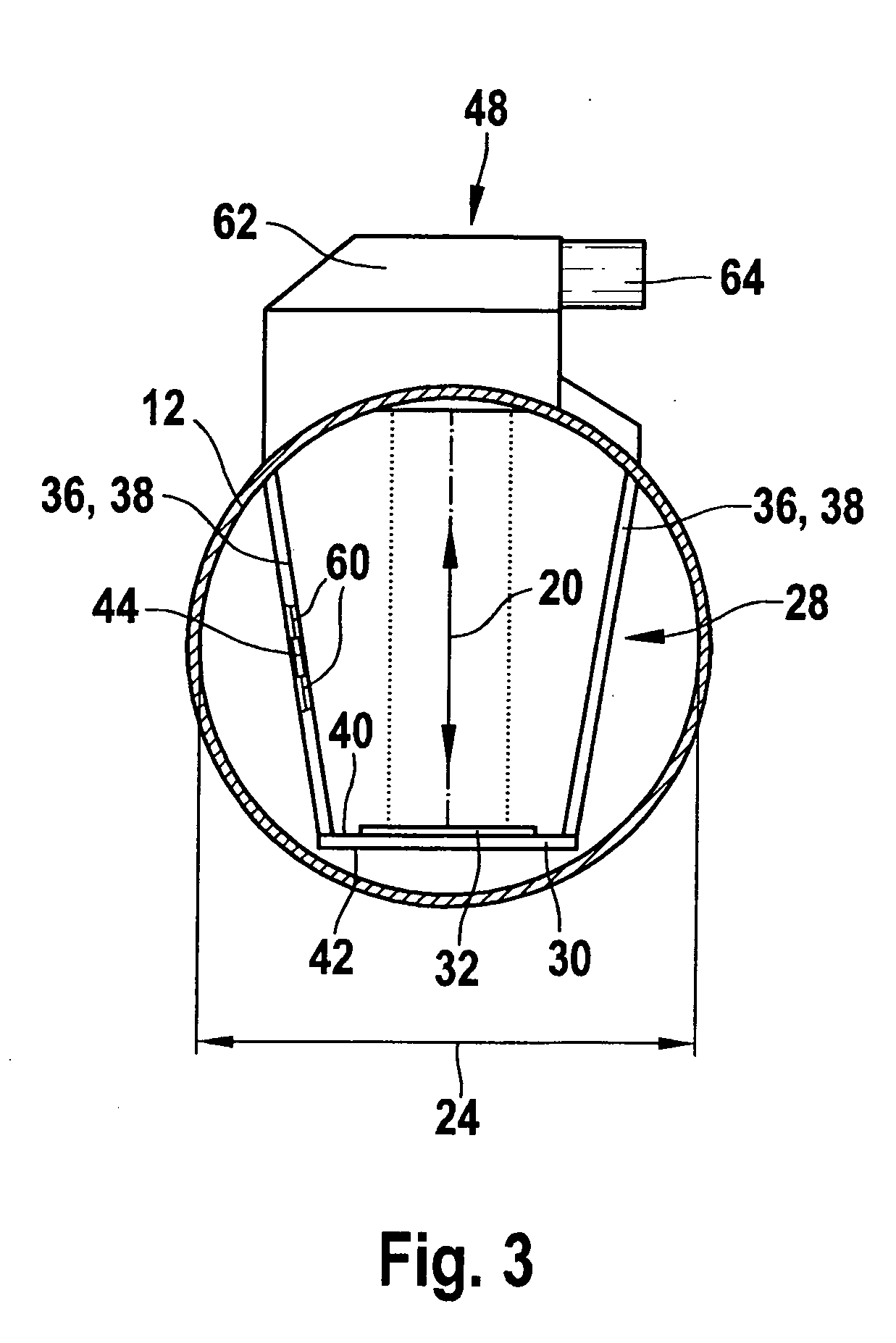

Ultrasonic Measuring Unit Having Integrated Humidity Analysis

InactiveUS20090178490A1Accurate detectionAccurate engine controlVolume/mass flow measurementVolume flow proportion measurementRunning timeElectron

An ultrasonic measuring unit and a method for detecting ultrasonic signal run-times, in which the ultrasonic measuring unit has two ultrasonic transducers for coupling ultrasonic signals into a flowing medium. Analysis electronics are provided to be accommodated on or in a flow tube, in which a gaseous medium such as circulating air flows. A probe unit is accommodated in the flow tube, the probe unit being assigned a temperature probe having a flow around it, whose measured value is used for correcting a temperature signal detected by ultrasound.

Owner:ROBERT BOSCH GMBH

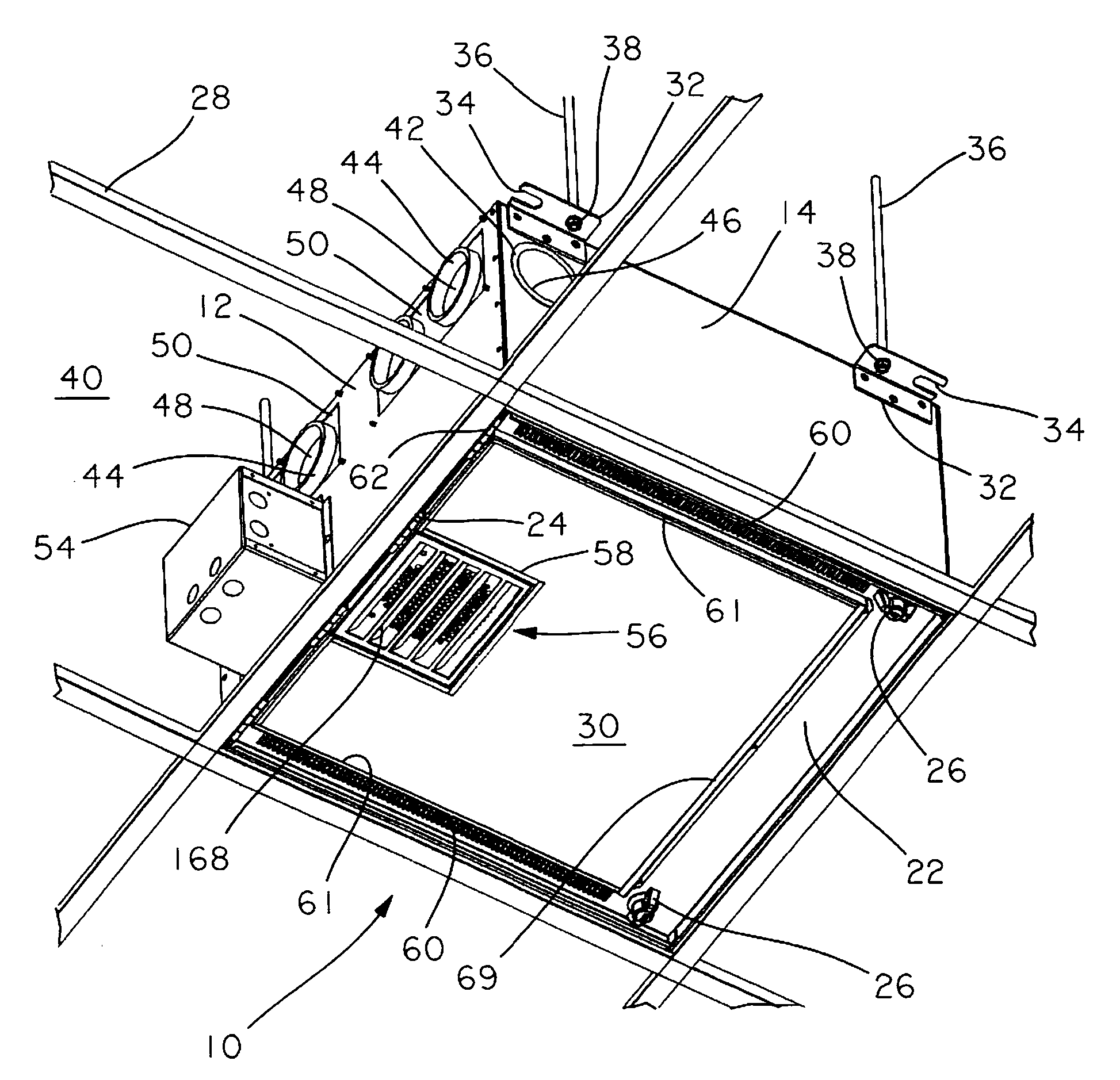

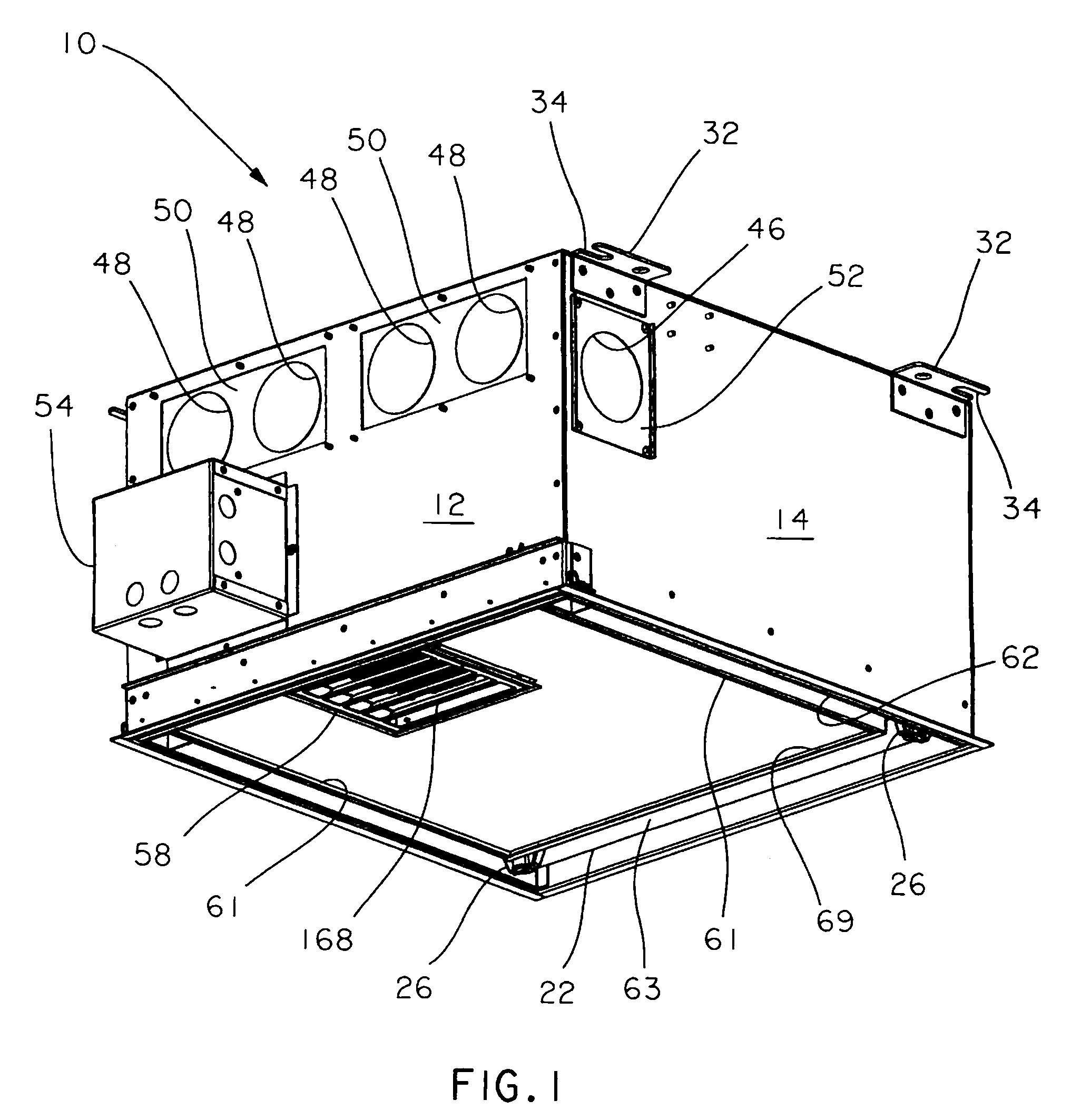

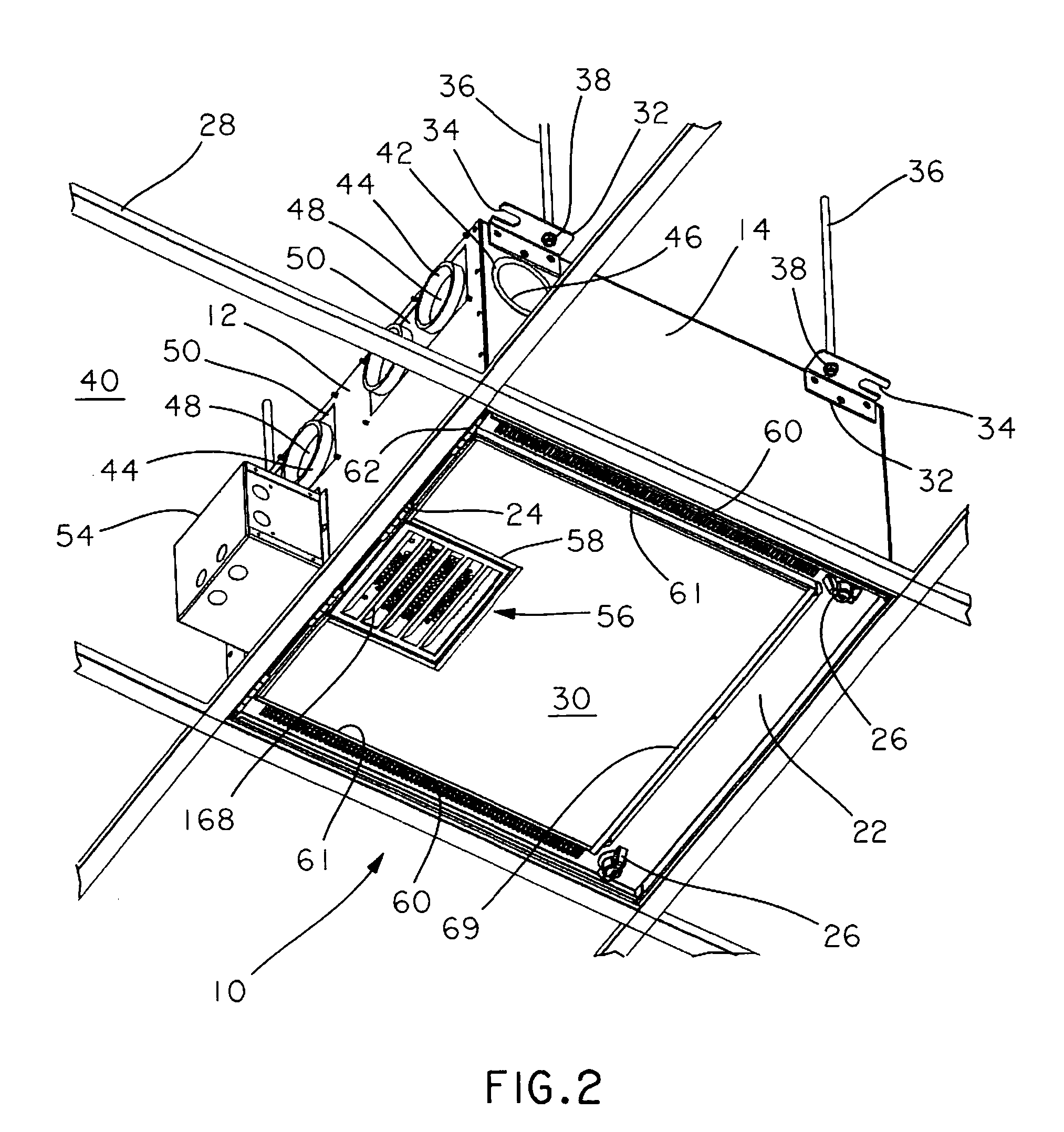

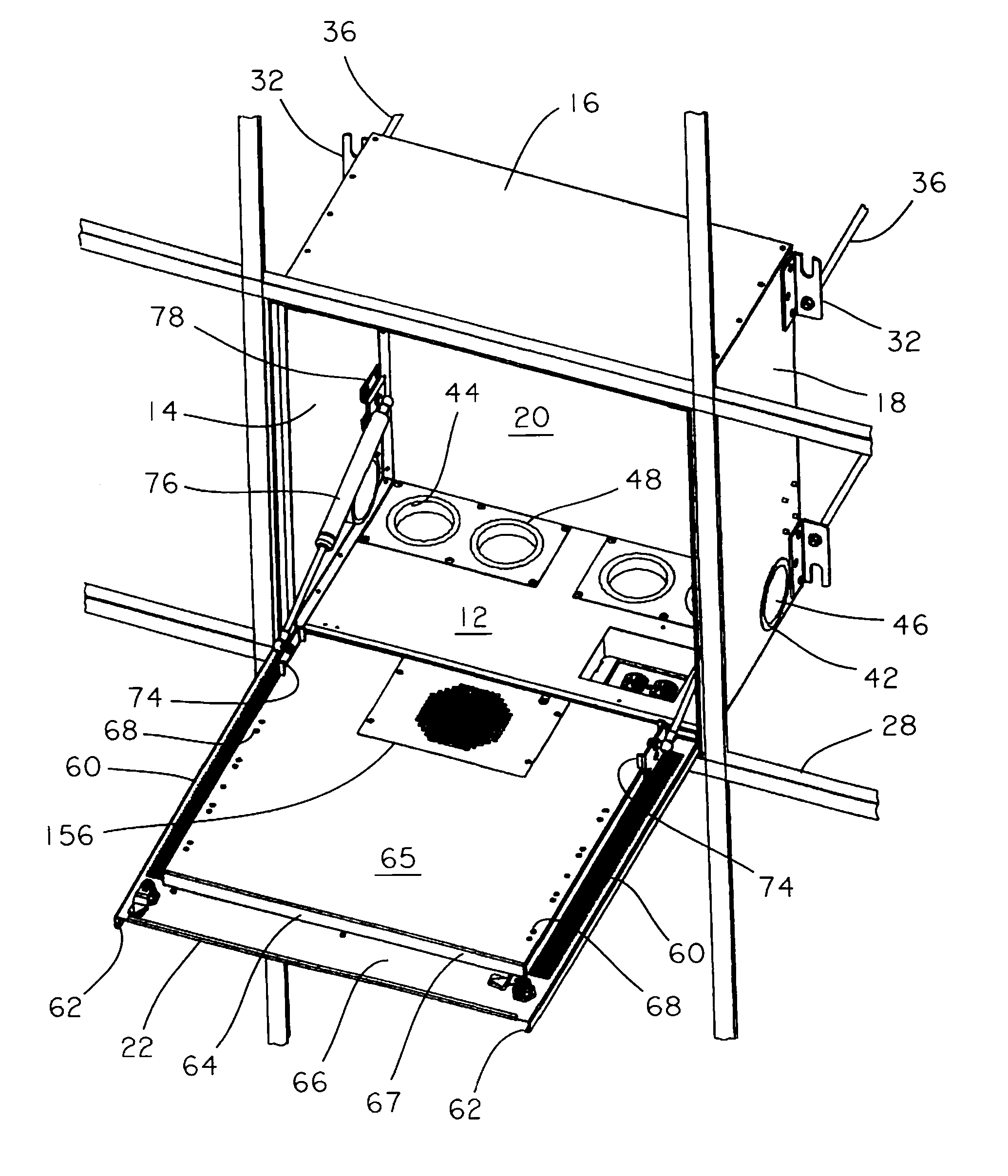

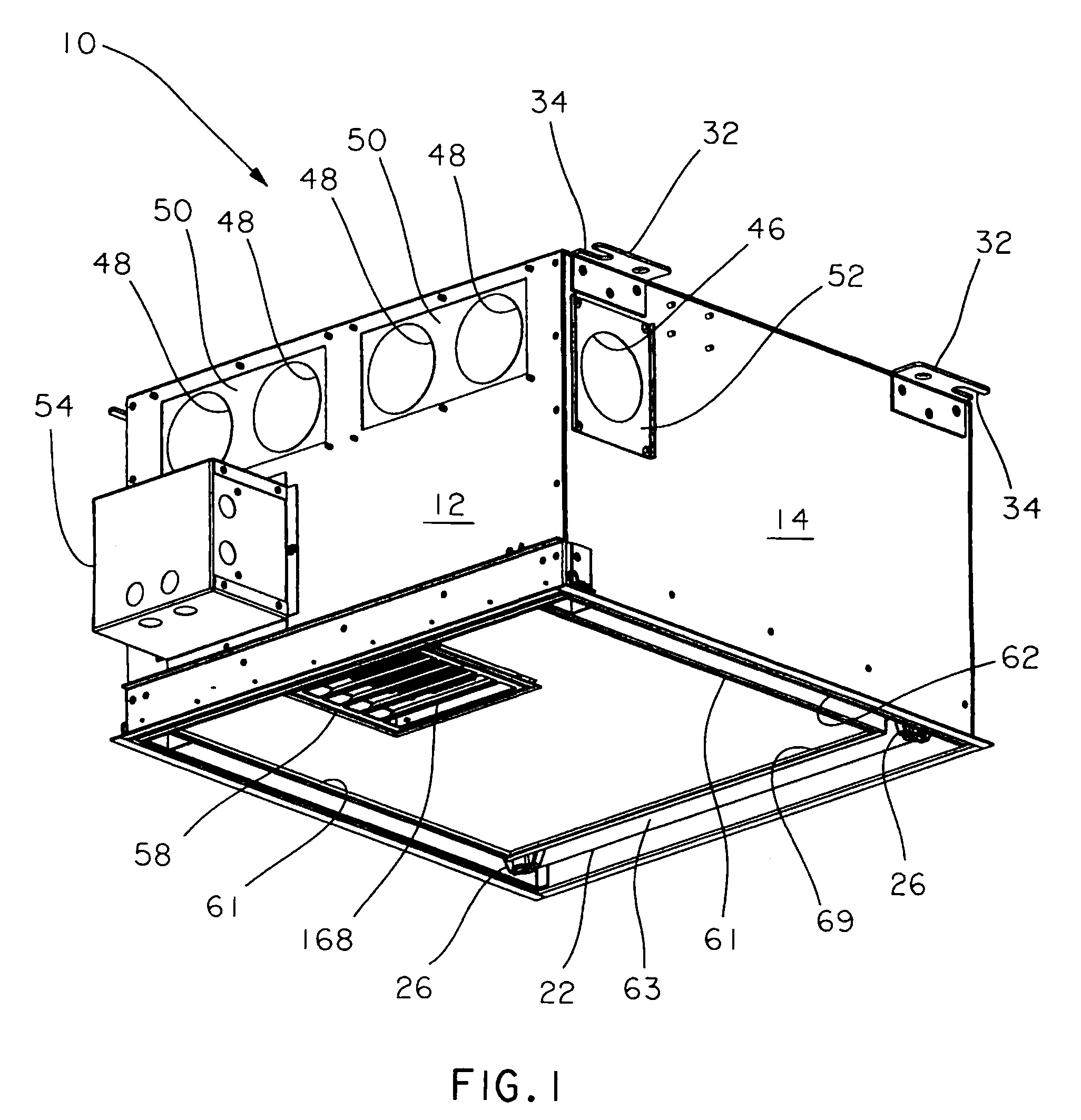

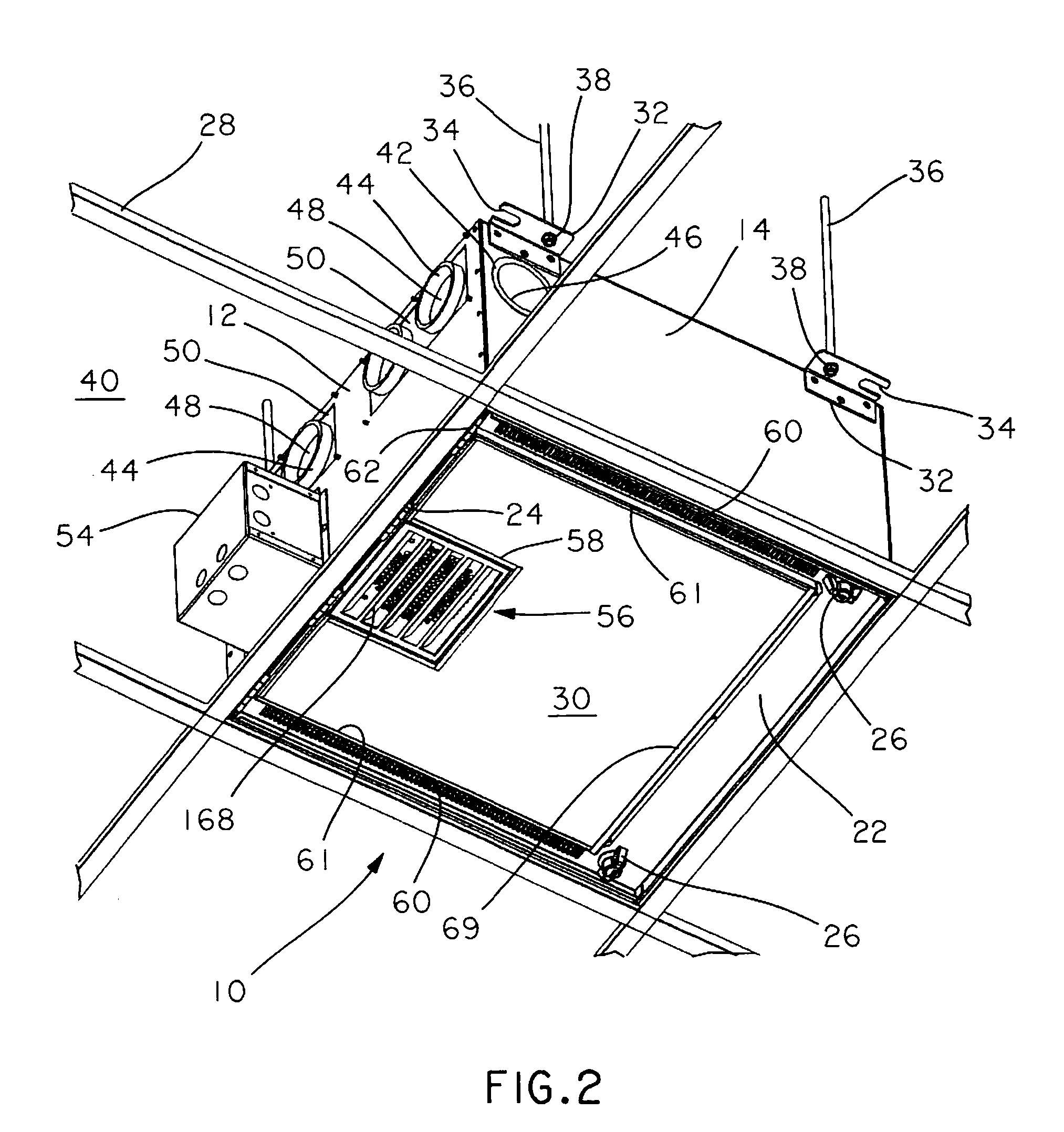

In-Ceiling Zone Cabling Enclosure

ActiveUS20100000758A1Proper air flowRobust structural designInstallation of lighting conductorsCouplings bases/casesDevices fixationEngineering

An in-ceiling cabling enclosure for supporting communications network equipment and cables interconnecting the network equipment including a front wall a rear wall and two side walls extending between the front wall and the rear wall creating a volume inside the enclosure. An access door assembly is pivotally connected to either the rear wall or the two side walls. The access door assembly pivots through an arc of ninety degrees between a first position opening the enclosure and a second position closing the enclosure. An equipment mount plate is attached to an interior portion of the access door assembly, and opposed equipment mount rails are removably attached to the equipment mount plate. The equipment mount rails are adapted to receive the network equipment and to secure the network equipment to the access door assembly. A cable slack management tray extends between the opposed equipment mount rails, and the slack management tray has a surface adapted to support and maintain the position and the contour of cable bundles located in the enclosure. A thermal management system is also disposed in the housing to provide efficient exhaust of hot air generated by active equipment in the enclosure to the space outside of the enclosure.

Owner:PANDUIT

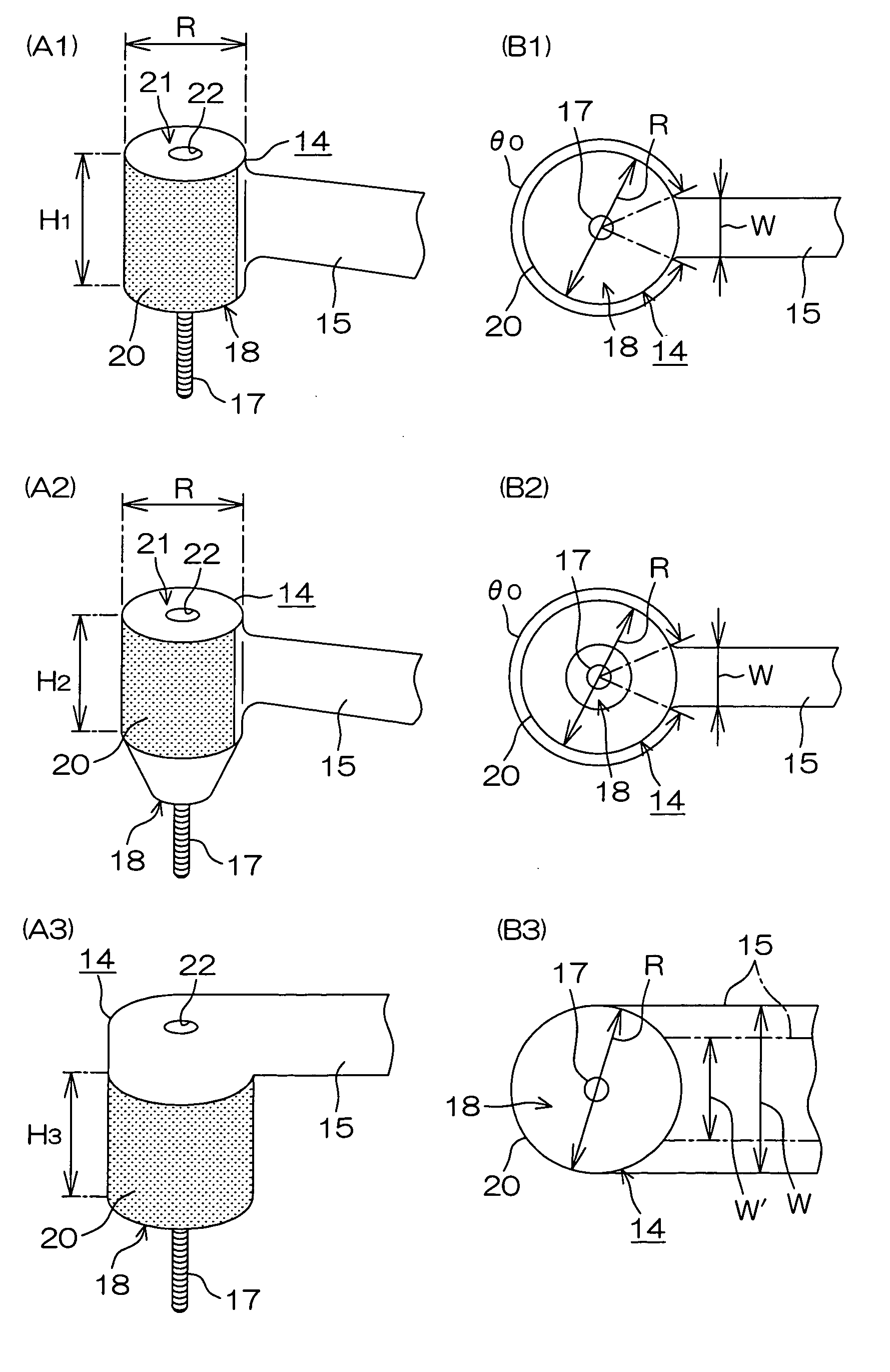

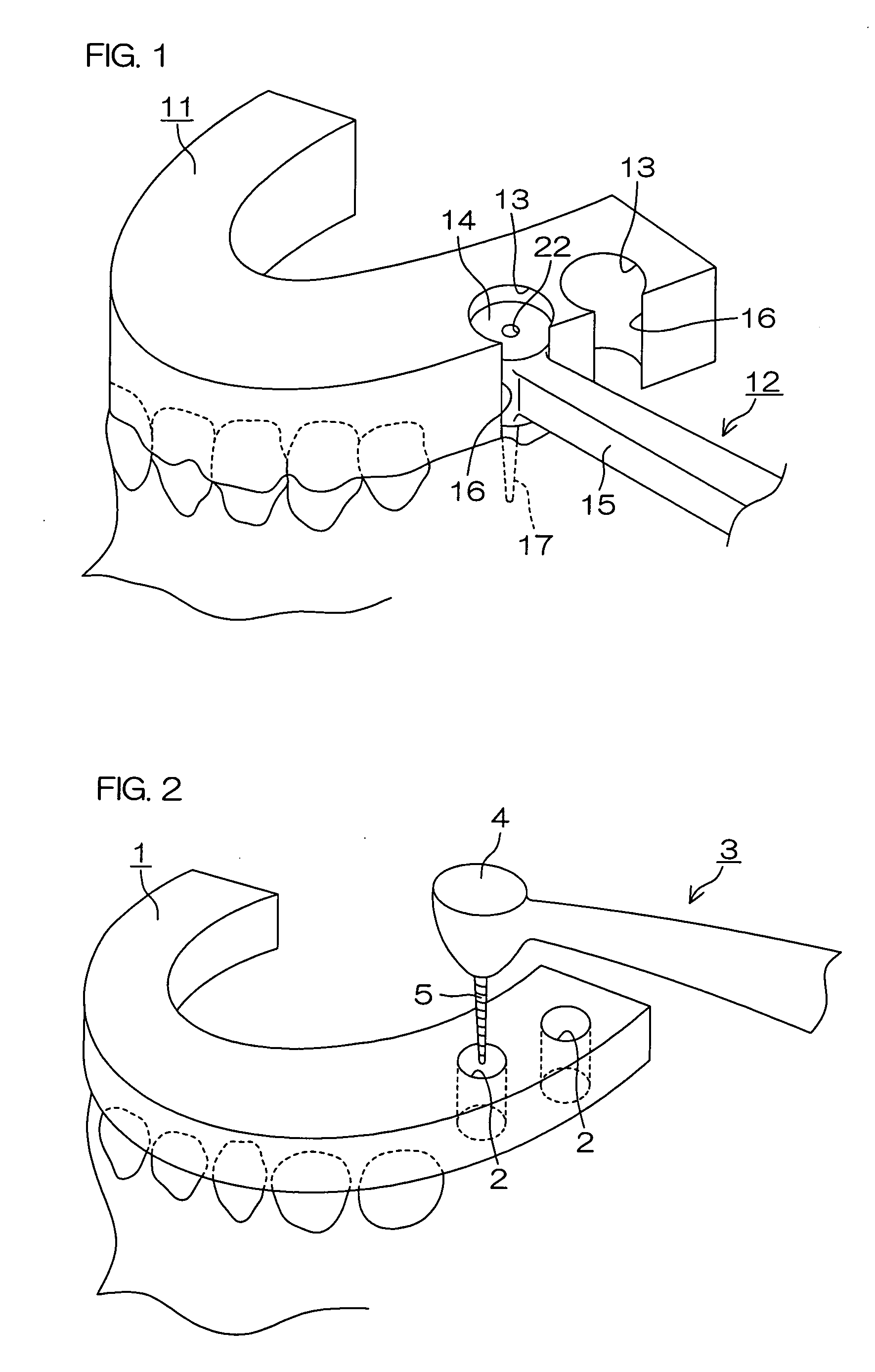

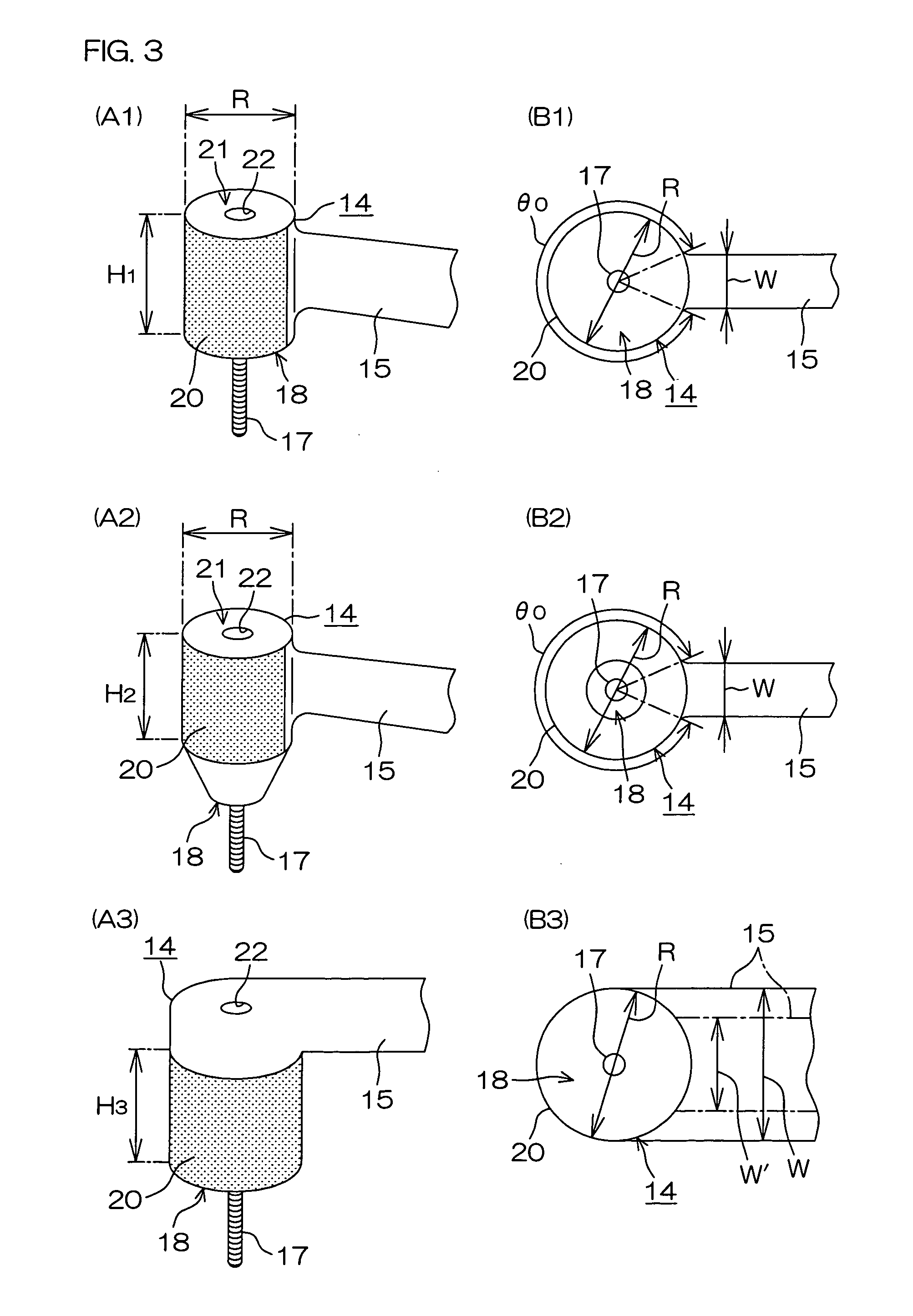

Implant erecting drill toll, hand-piece, adaptor for the hand-piece, and surgical guide

InactiveUS20100185201A1Precise drillingEnsure correct executionBoring toolsProsthesisBiomedical engineeringDrill bit

An inventive implant handpiece (12) includes a head (14) having a round outer peripheral surface (20) which is concentric with a center axis of a drill bur (17) and has a predetermined length (H1 to H3) as measured axially of the drill bur (17). A surgical guide (11) has a guide hole (13) having a round inner peripheral surface to be opposed to the round peripheral surface (20) of the head (14). Since a drilling operation is performed with the head (14) fitted in the guide hole (13), the head (14) can be reliably uniquely guided to form an implant implantation hole as desired. Thus, the present invention provides an implant handpiece capable of accurately drilling a hole for formation of an implant implantation hole, and a surgical guide capable of guiding this handpiece.

Owner:IMAGNOSIS

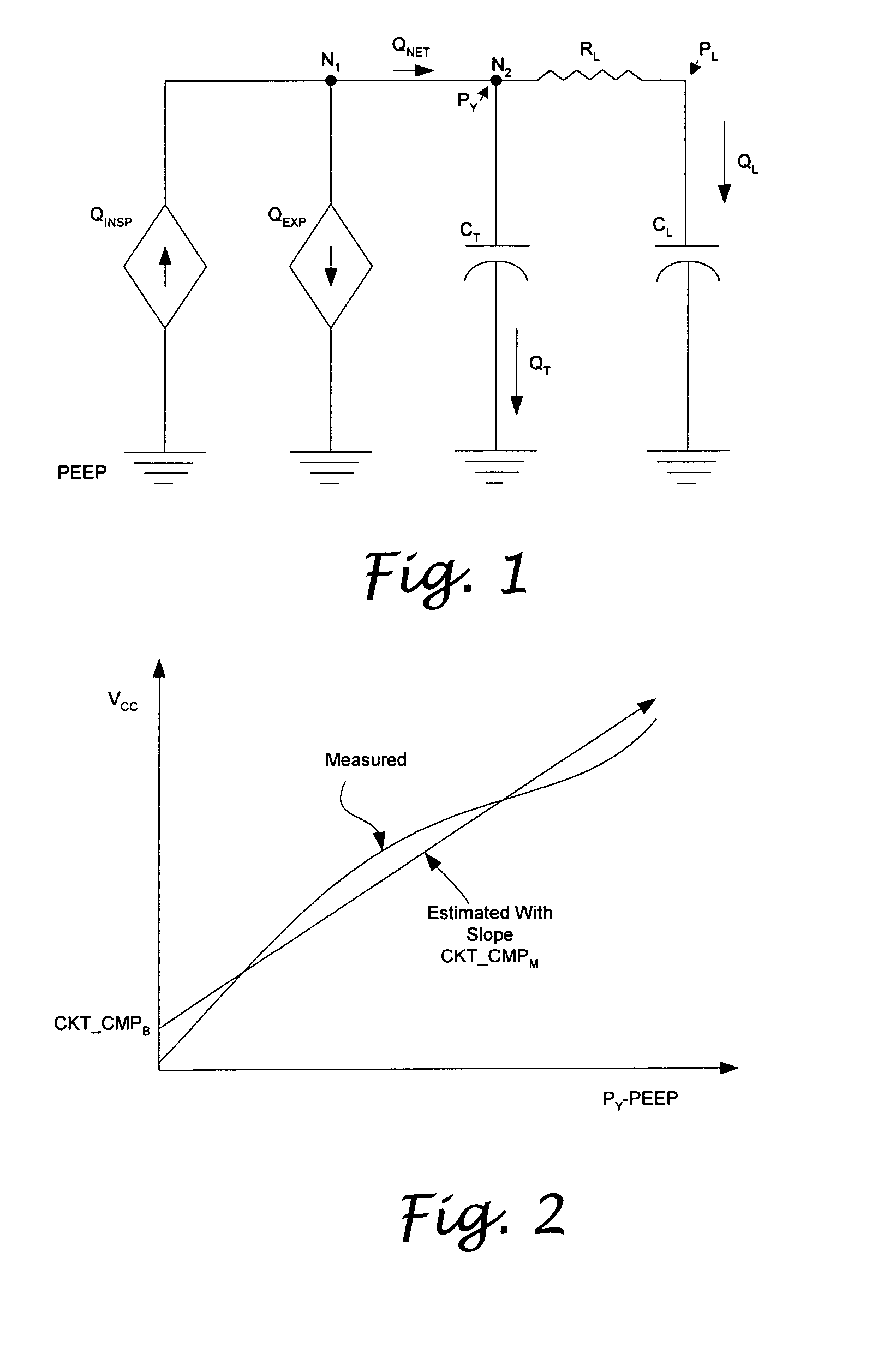

System and method for circuit compliance compensated volume control in a patient respiratory ventilator

ActiveUS7886739B2Accurate flowGas trapping and auto PEEP is preventedLevel controlInflated body pressure measurementDifferential pressureControl system

A circuit compliance compensated volume control system in a patient respiratory ventilation system and method, including: a circuit compliance estimator, to provide a relationship between a circuit volume and a differential pressure between a circuit pressure and a positive end-expiratory pressure (PEEP) of the respiratory circuit, a circuit volume estimator, operative to provide an estimated circuit volume based on the relationship between the circuit volume and the differential pressure, a patient volume observer, operative to provide an estimated patient volume by subtracting the estimated circuit volume from a measured machine delivered net volume, and a volume delivery controller, operative to update the machine delivered net volume based on the estimated patient volume and a set tidal volume.

Owner:VYAIRE MEDICAL 211 INC

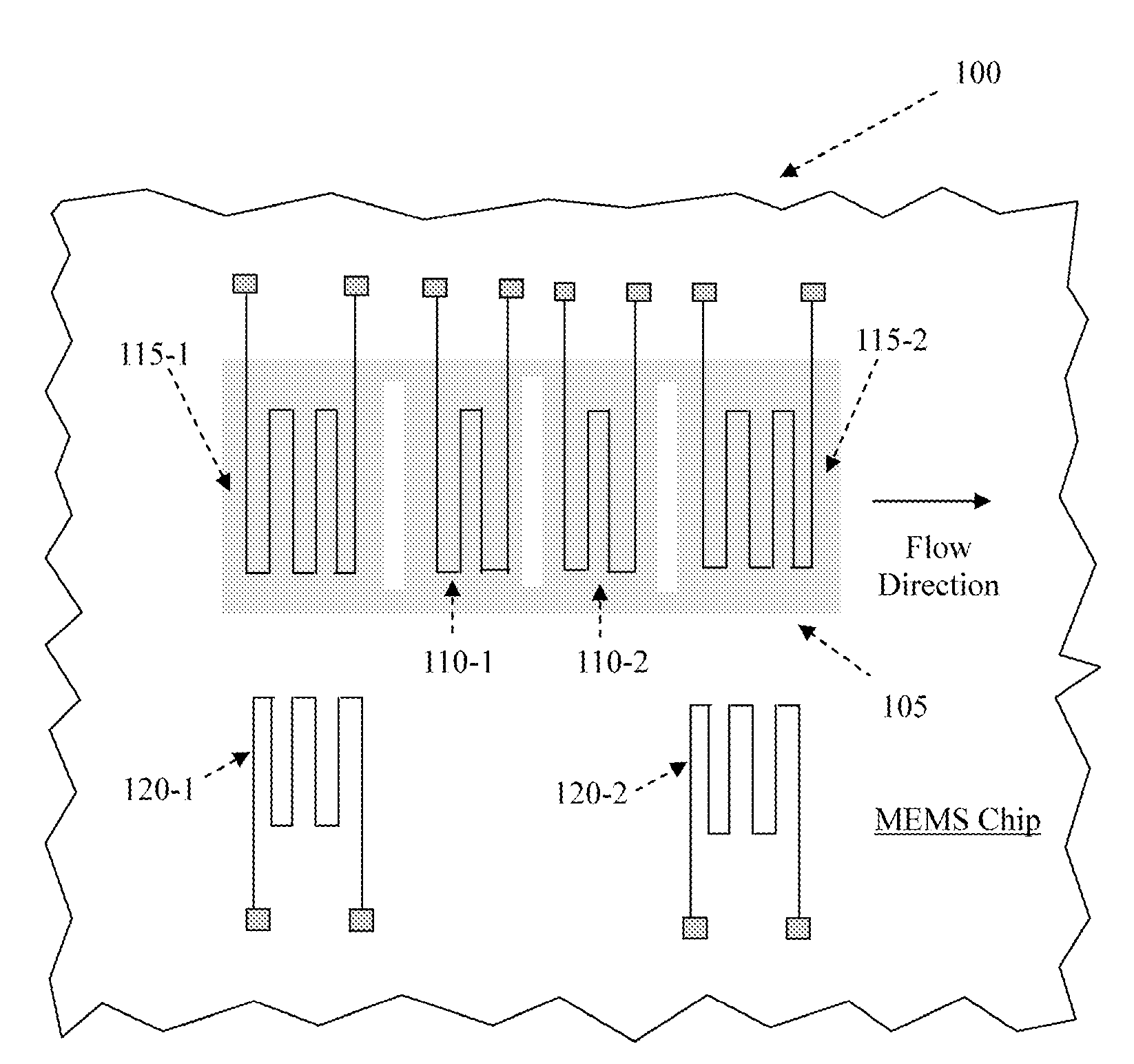

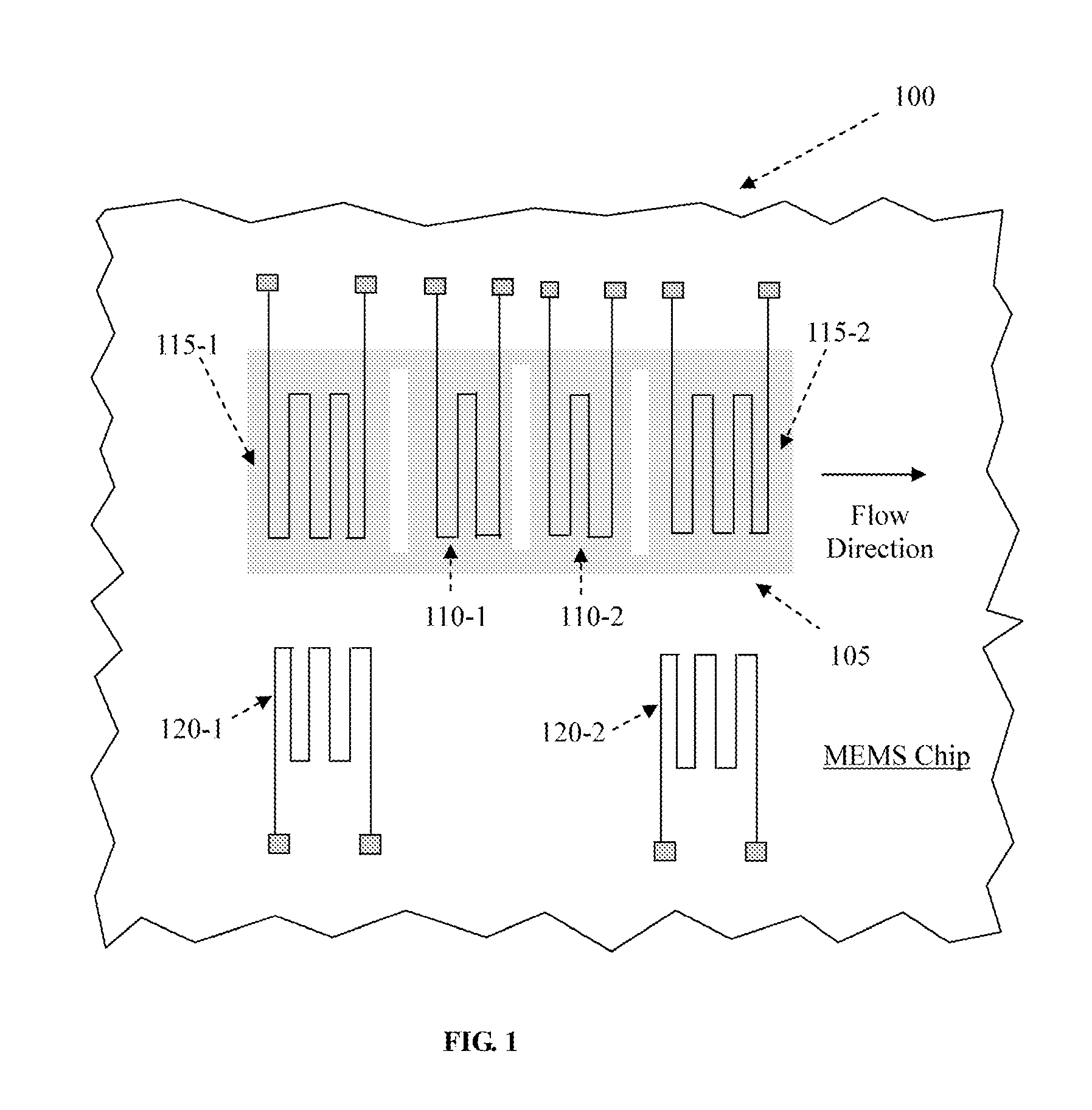

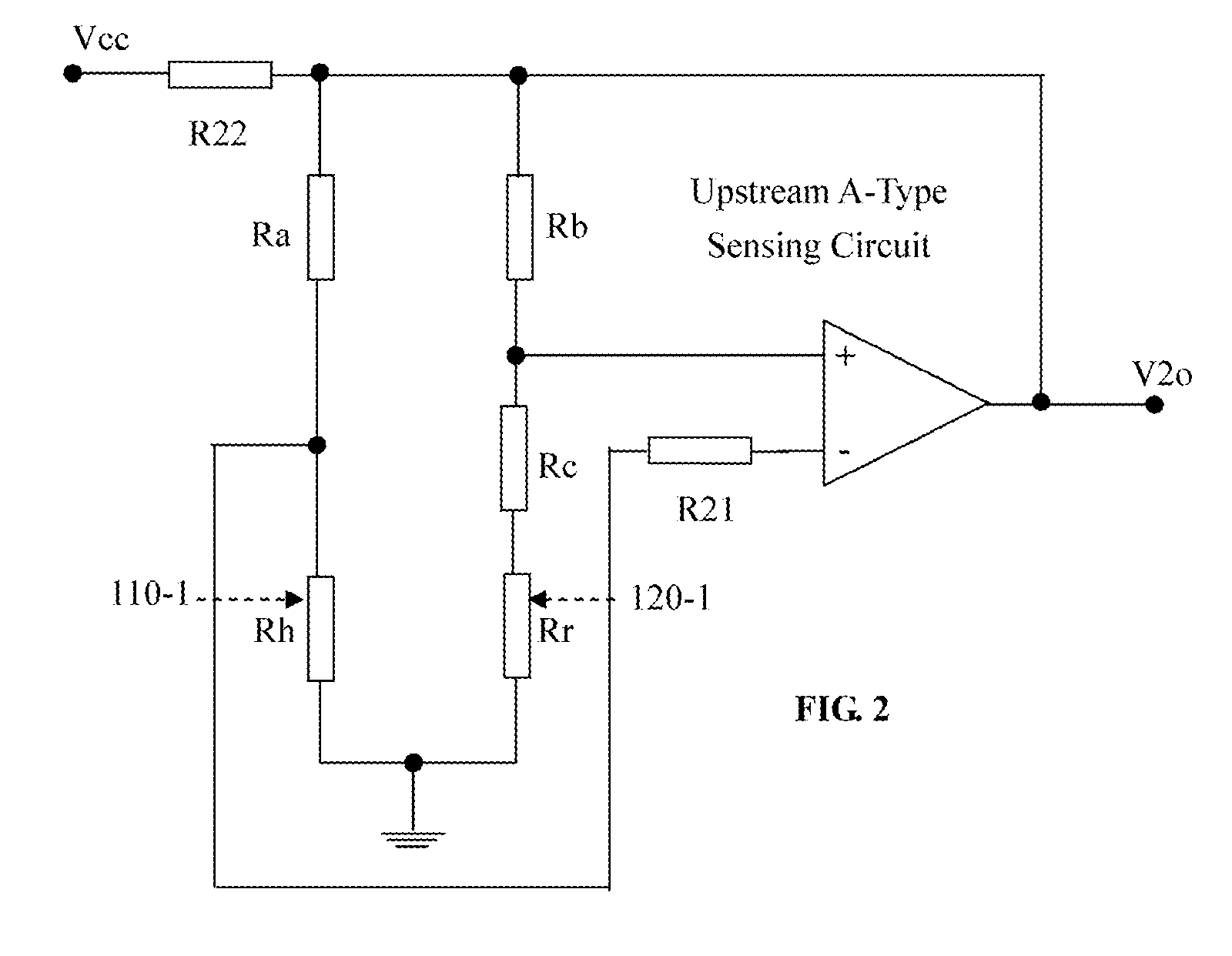

Integrated micromachined thermal mass flow sensor and methods of making the same

ActiveUS20090164163A1Accurate flowIncrease speedTesting/calibration apparatusVolume/mass flow by thermal effectsEngineeringP type silicon

An integrated mass flow sensor is manufactured by a process of carrying out a micro-machining process on an N or P-type silicon substrate with orientation <100>. This mass flow sensor comprises an upstream thin-film heater, an downstream thin-film heater, and a pair of thin-film heat sensing elements, and a thermally isolated membrane for supporting the heaters and the sensors out of contact with the substrate base. This mass flow sensor is operated with three sets of circuits, a first circuit for measuring a flow rate in a first range of flow rates, a second circuit for measuring a flow rate in a second range of flow rates, and a third circuit in a differential configuration for measuring a flow rate in said first range of flow rates or said second range of flow rates, to significantly increase range of flow rate measurements and provide an optional for concentration measurement, while maintains a high degree of measurement accuracy.

Owner:M TECH INSTR HLDG

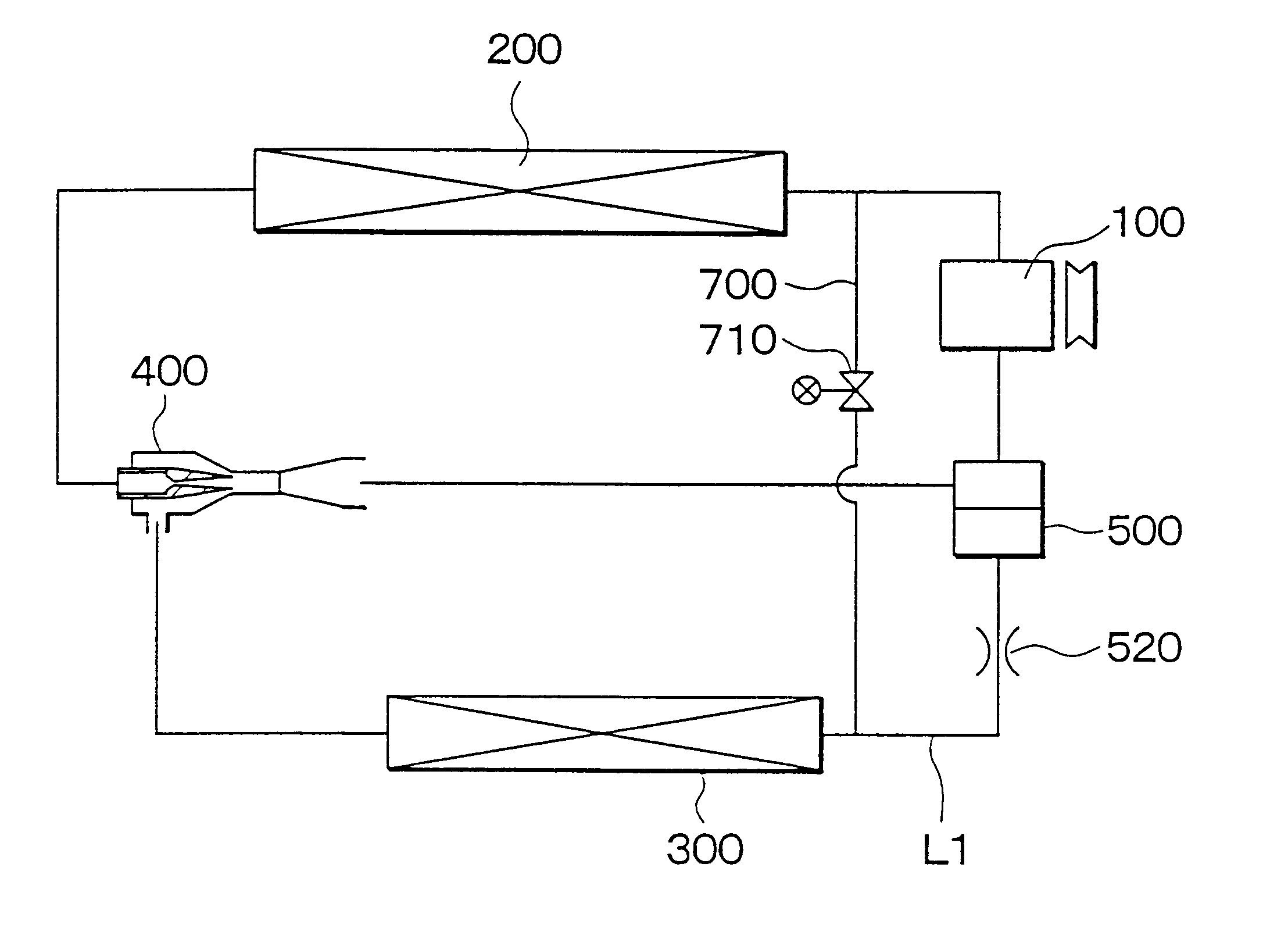

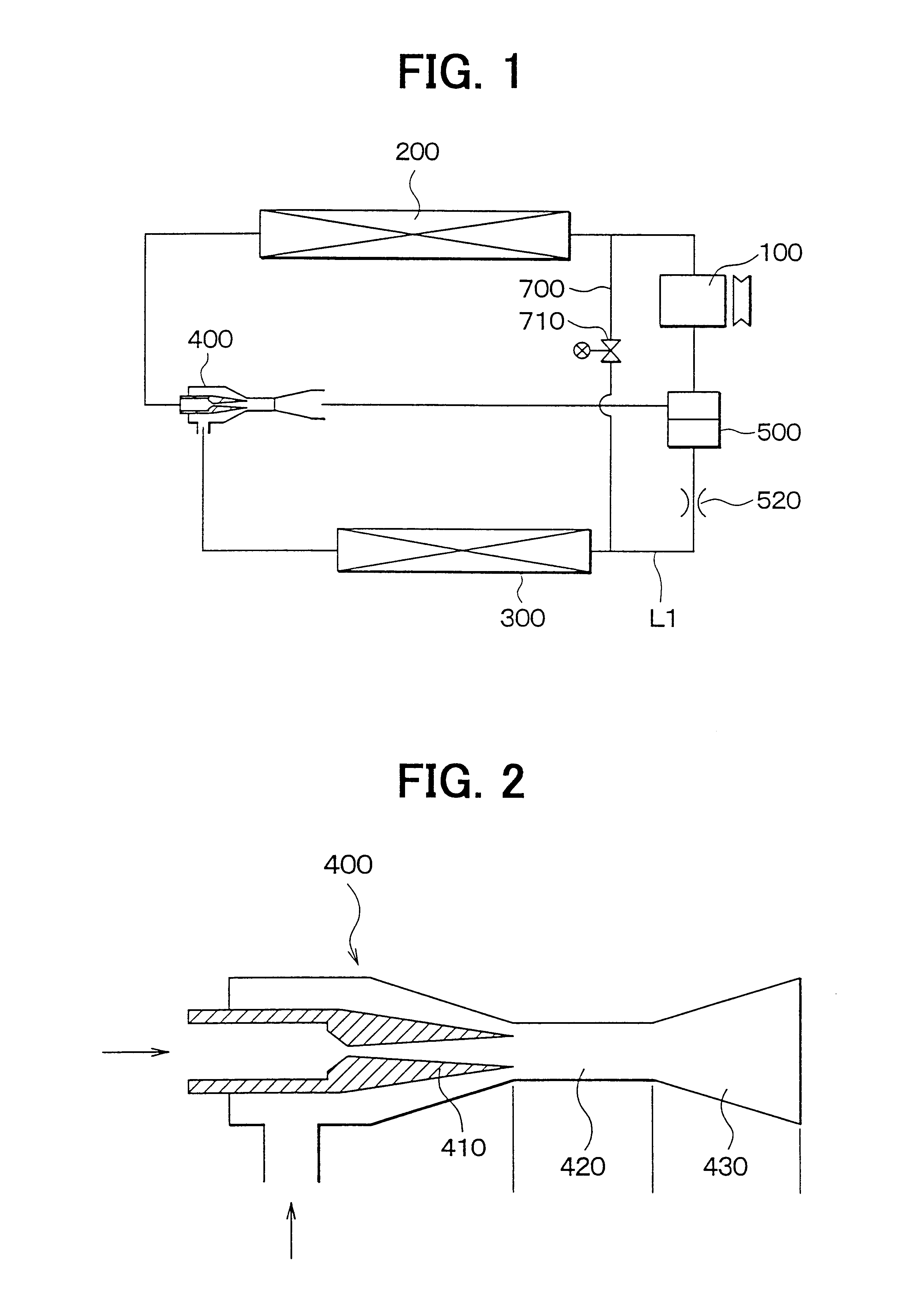

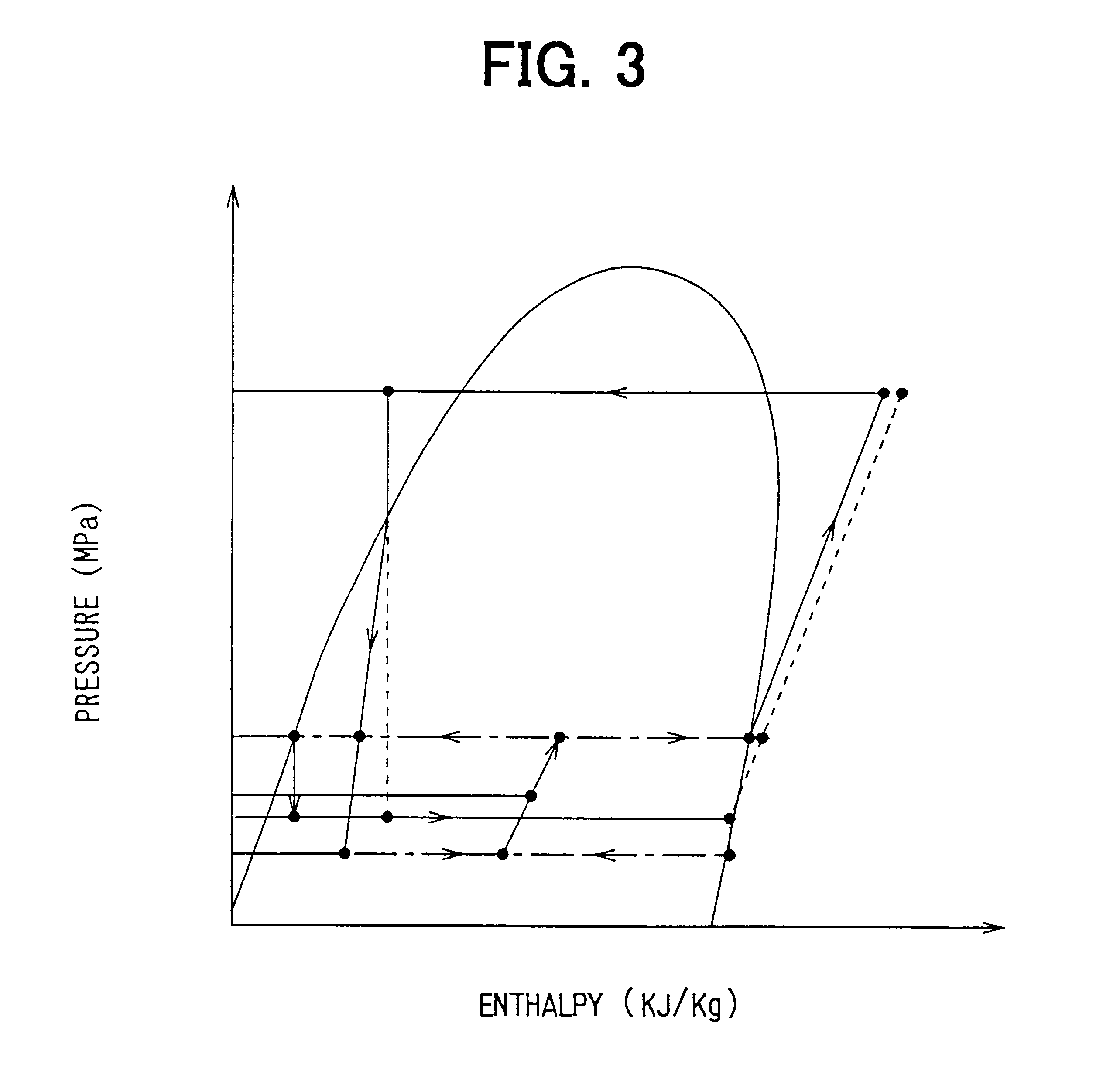

Ejector cycle system

InactiveUS6584794B2Shorten the time periodEasy to operateCompression machines with non-reversible cycleCorrosion preventionVapor–liquid separatorFrost

In an ejector cycle system, hot gas refrigerant discharged from a compressor is introduced into an evaporator through a bypass passage while bypassing an ejector and a gas-liquid separator in a defrosting operation for defrosting frost generated on the evaporator. In addition, a throttle or a check valve is provided in a refrigerant passage from the gas-liquid separator to a refrigerant inlet side of the evaporator. Accordingly, in the defrosting operation, the hot gas refrigerant from the compressor can be accurately introduced into the evaporator through the bypass passage without flowing toward the gas-liquid separator.

Owner:DENSO CORP

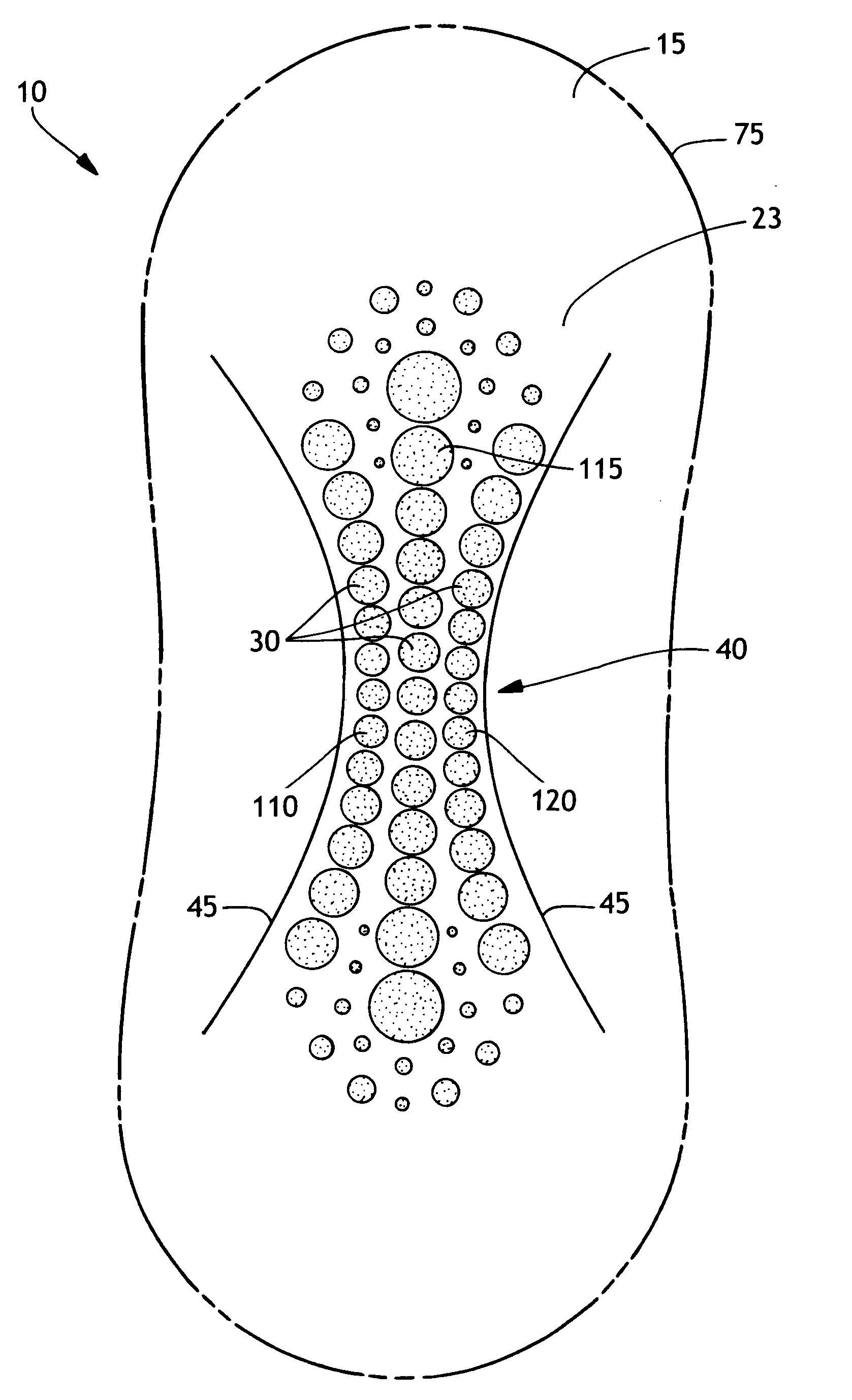

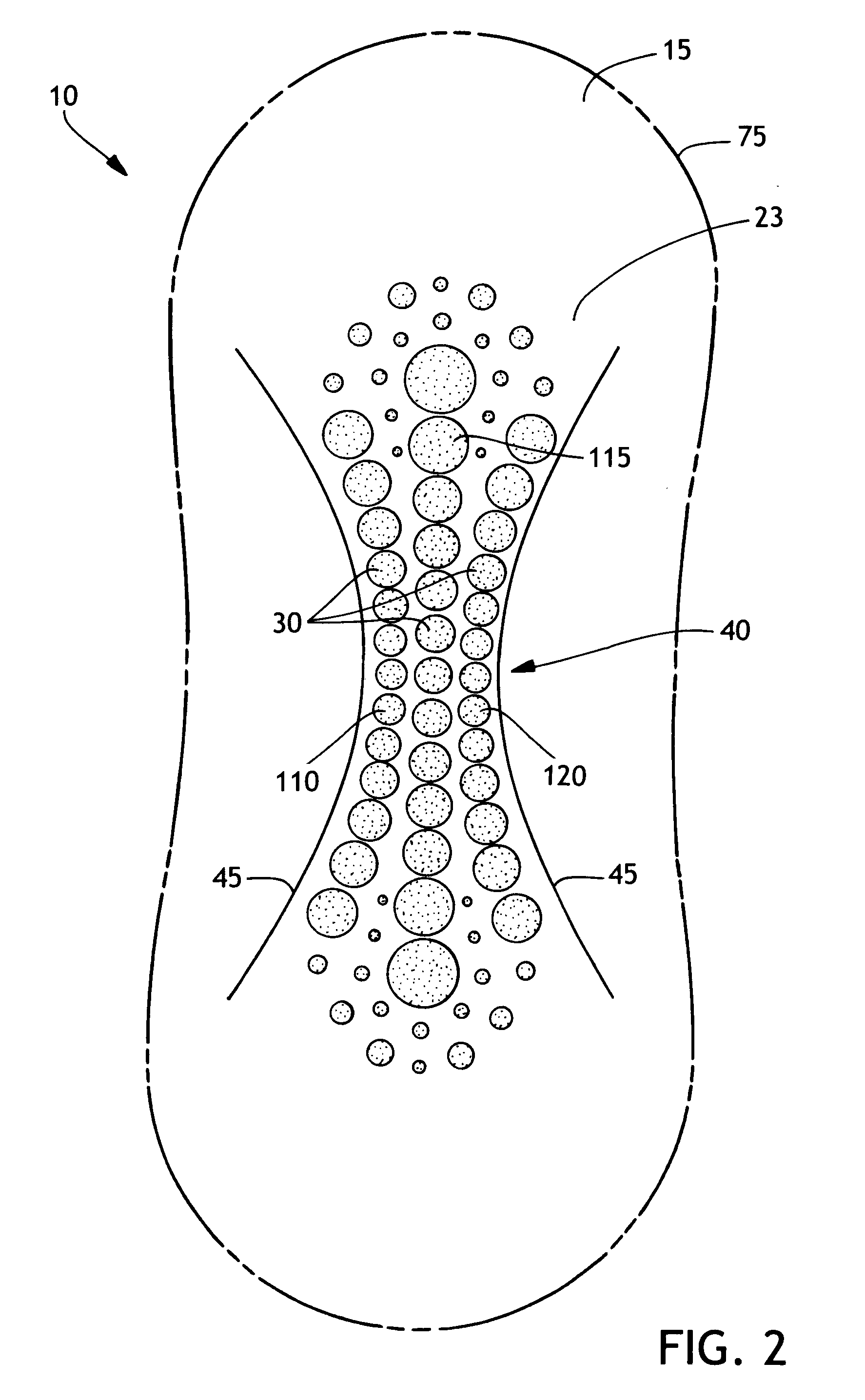

Articles with a series of graphical objects providing a functional cue

InactiveUS20100100067A1Facilitate cognitionEnhanced informationBaby linensTamponsPersonal careGraphics

The present disclosure provides an absorbent personal care article having a graphic which creates a visual perception of a functional aspect of the absorbent personal care article. For example, an absorbent personal care article has a personal care absorbent article having an absorbent core and a body-facing surface. A plurality of graphical objects are visible on the surface such that the graphical objects form a pattern illustrating at least one ordered sequence to create a functional cue. This functional cue conveys at least one functional aspect associated with as structural feature of the absorbent personal care article.

Owner:KIMBERLY-CLARK WORLDWIDE INC

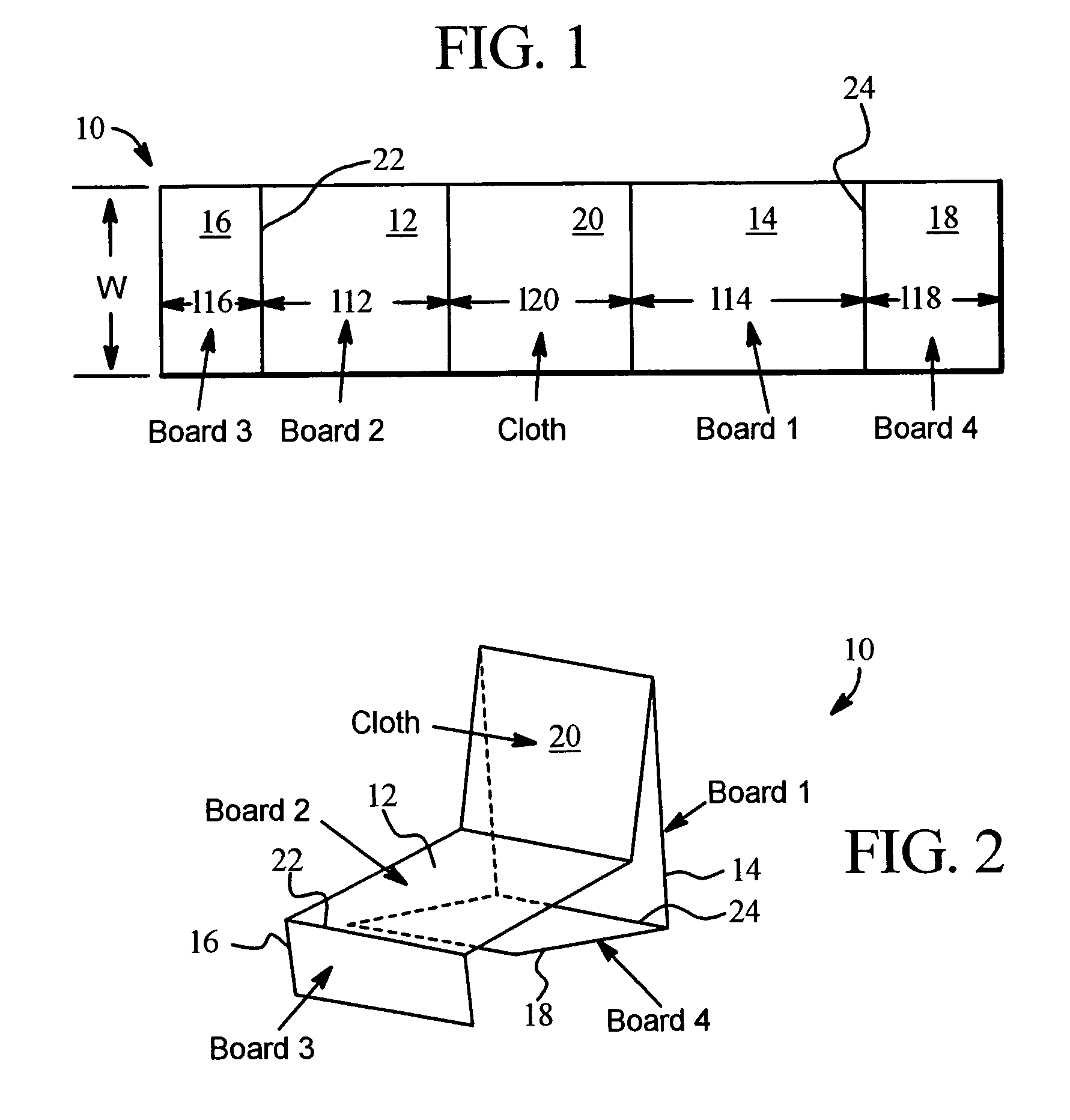

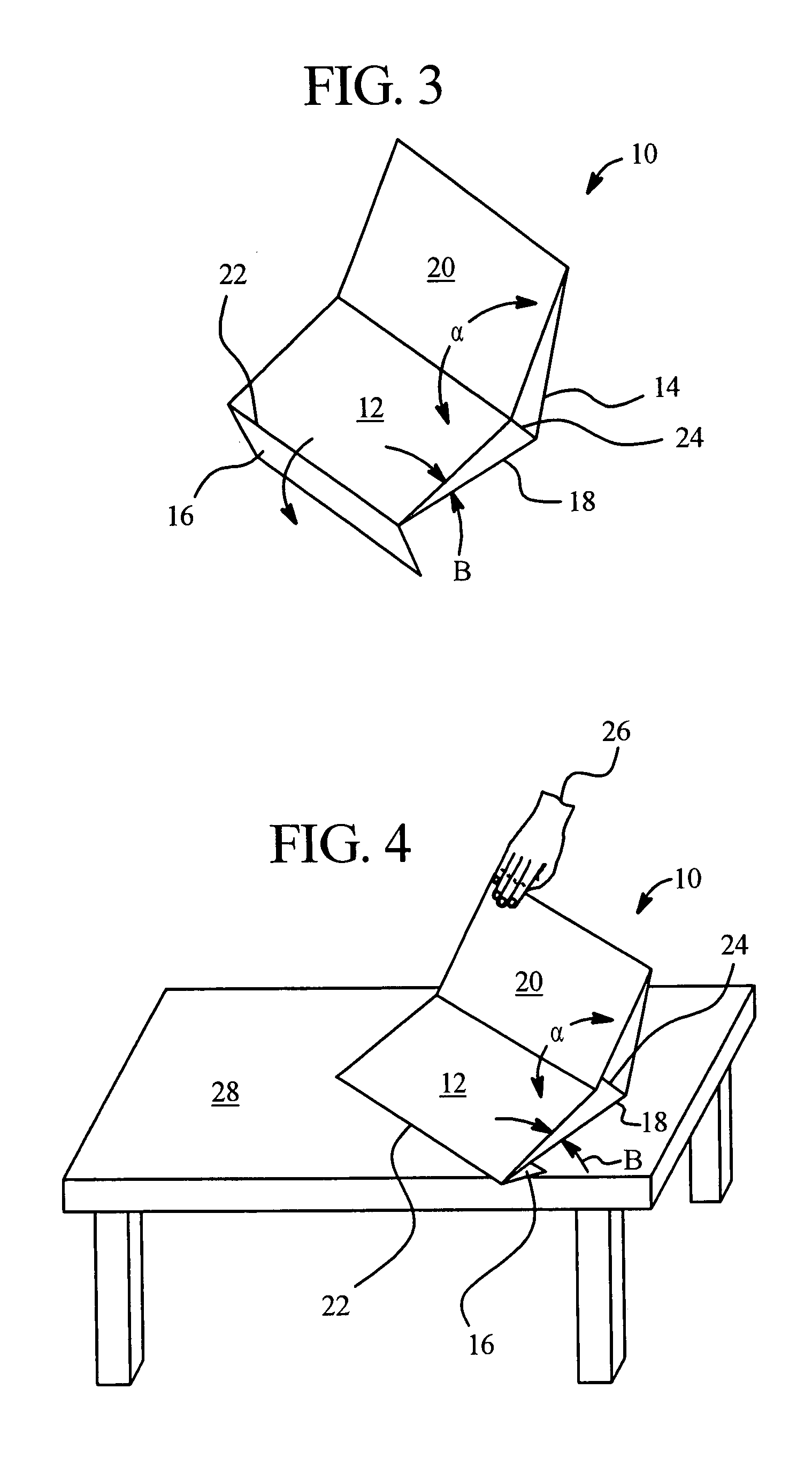

Dialysis solution bag stand

InactiveUS7243893B2Accurate flowTherapy failurePharmaceutical containersMedical devicesVisual perceptionMedical treatment

A stand for a medical fluid treatment, a system for supporting multi-chamber medical fluid bags and a method for testing whether the multi-chamber bags have been preset properly for therapy are provided. In one embodiment a multi-section stand is provided that is folded in a number of places to produce a structure upon which fluid from a properly preset solution bag flows readily to a patient, but upon which a dual-chamber bag that has not been modified properly for treatment collapses, folds or falls to a position providing visual indication that the chamber seal needs to be released or opened.

Owner:BAXTER INT INC +1

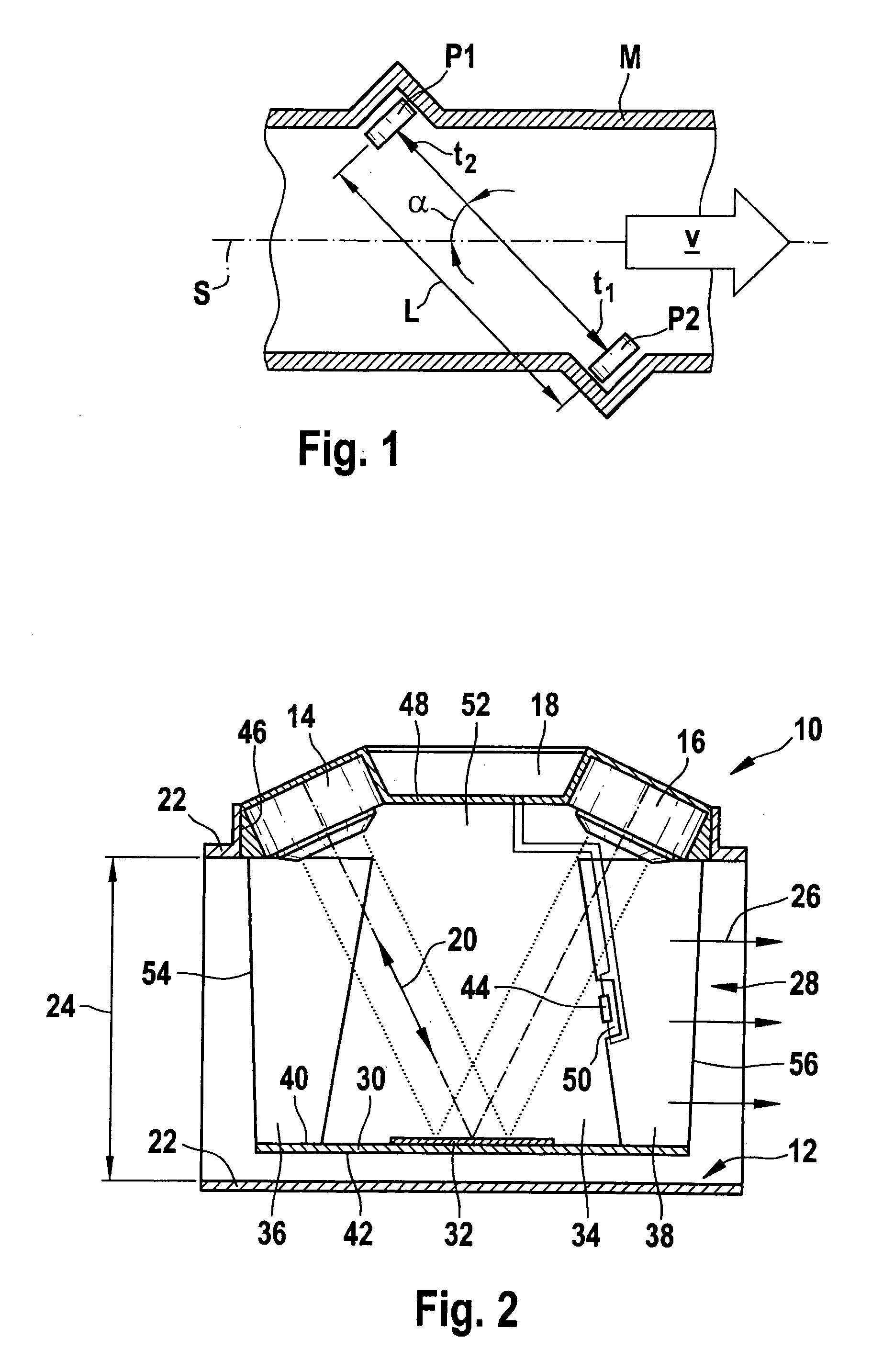

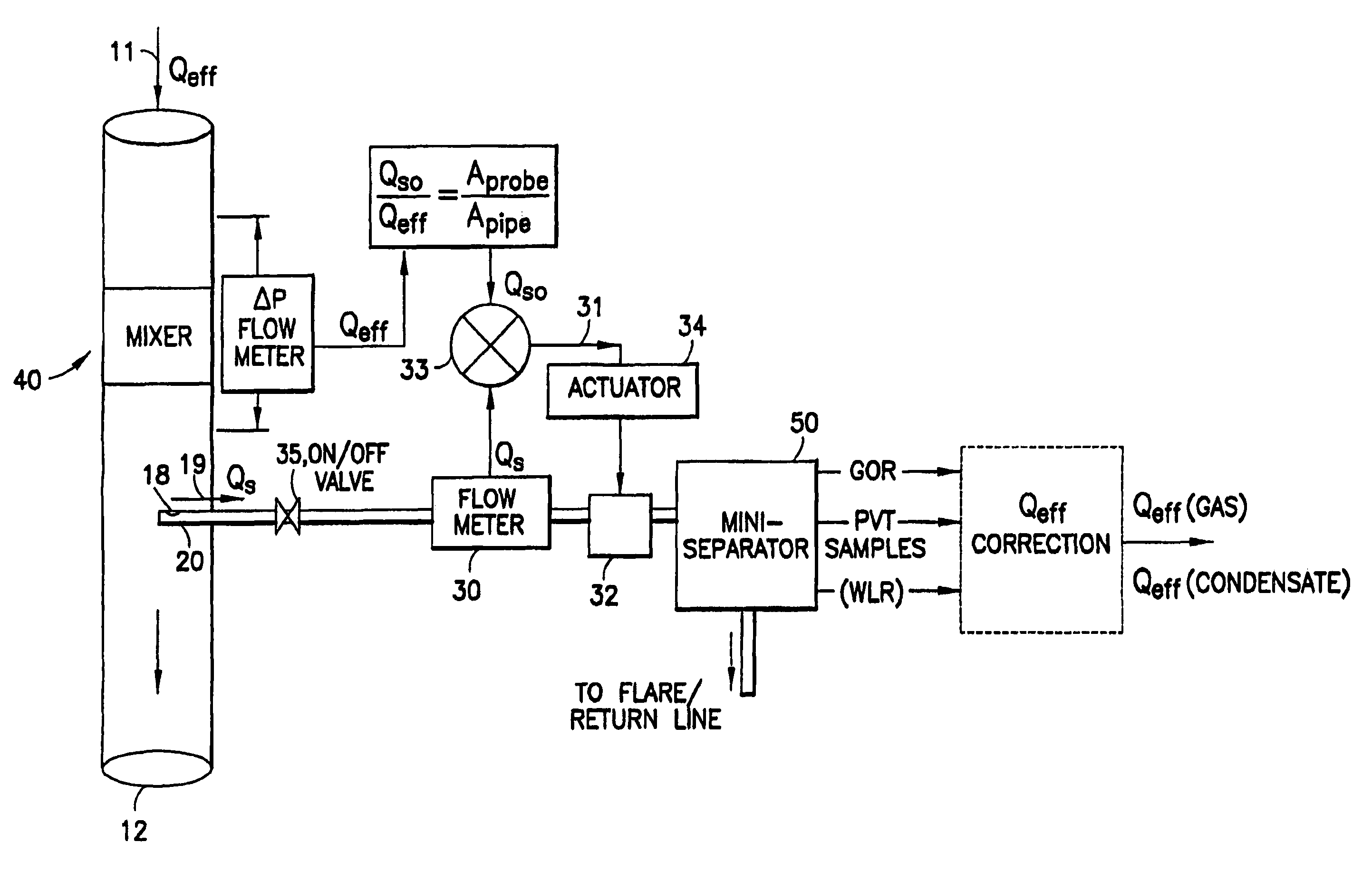

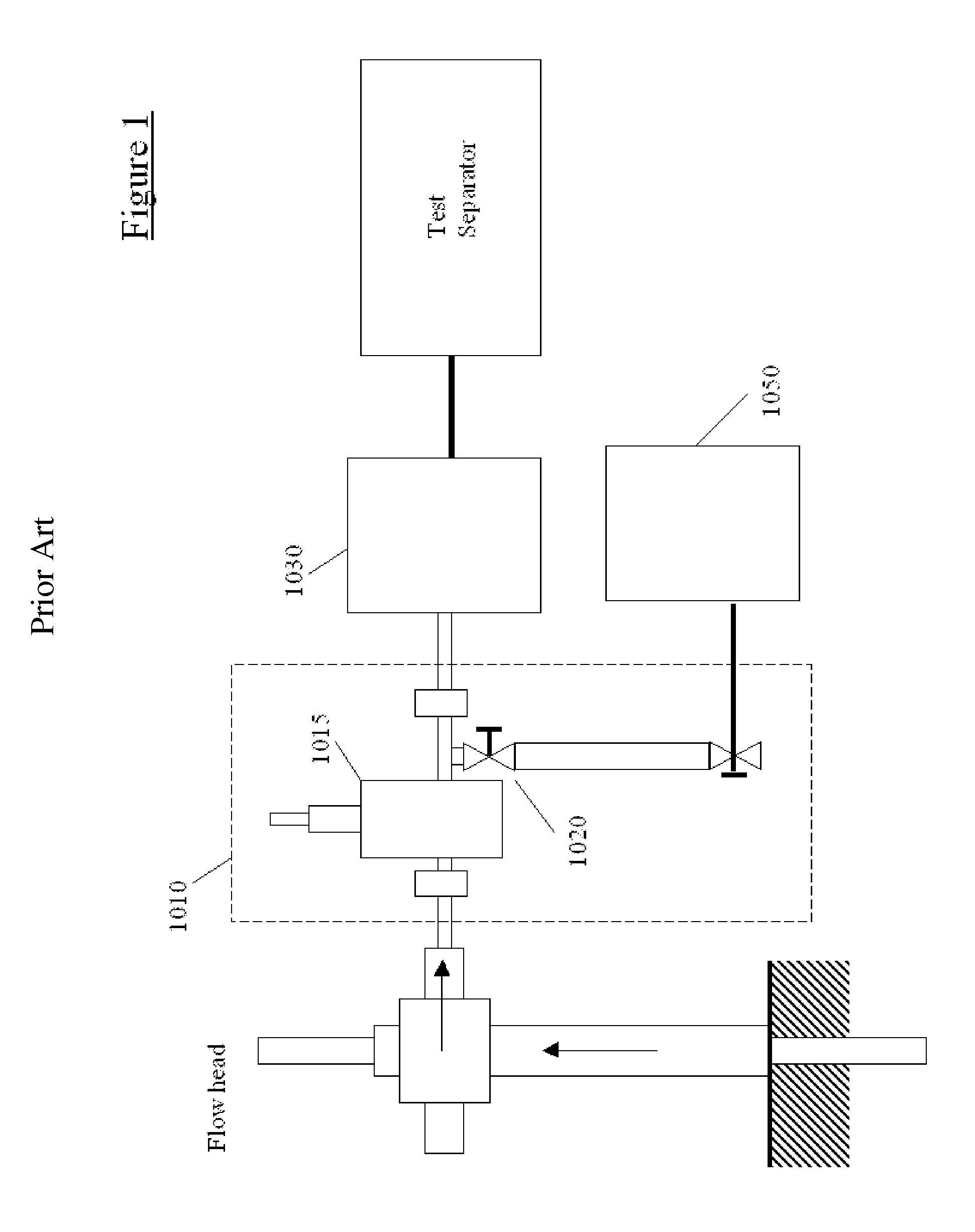

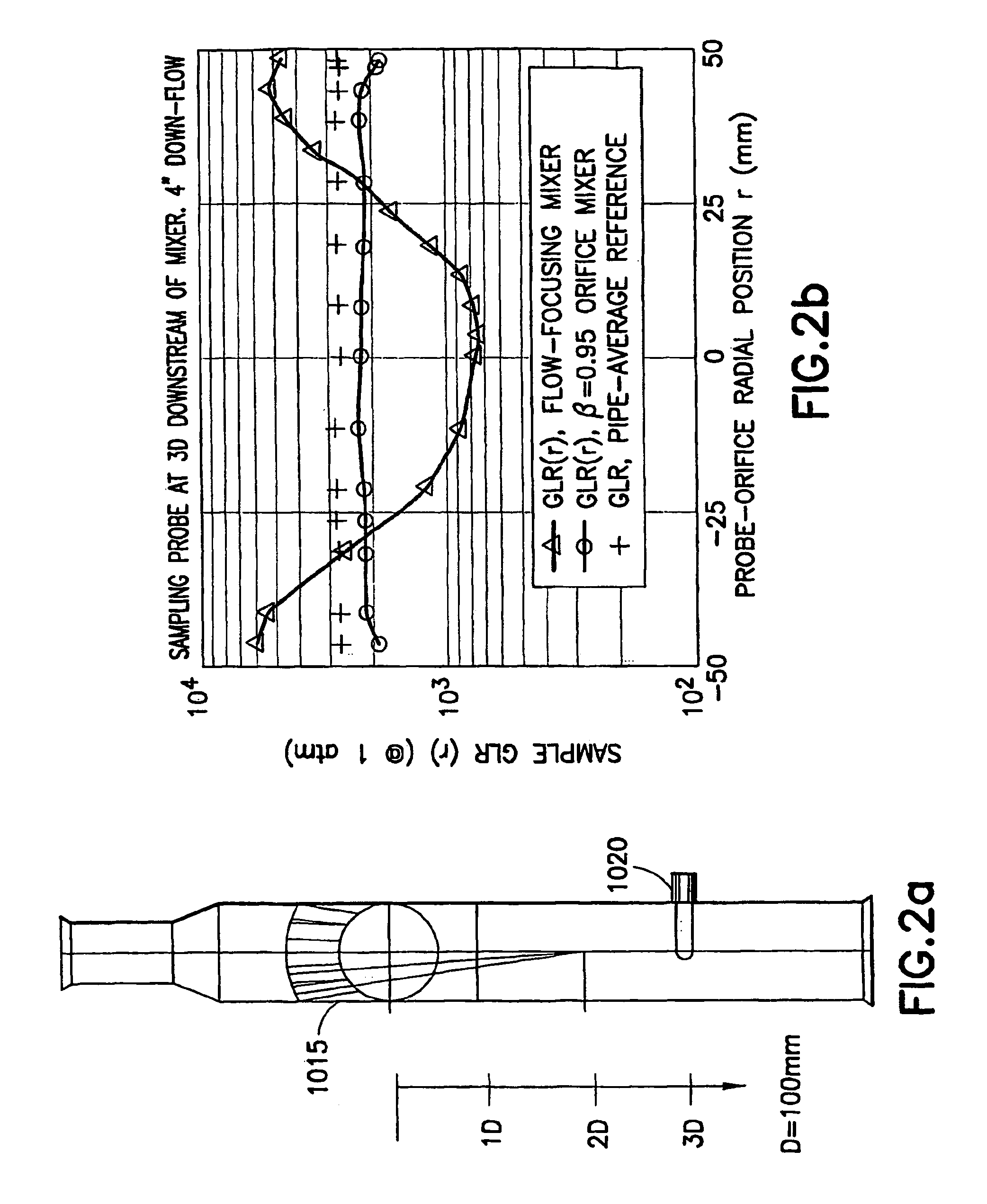

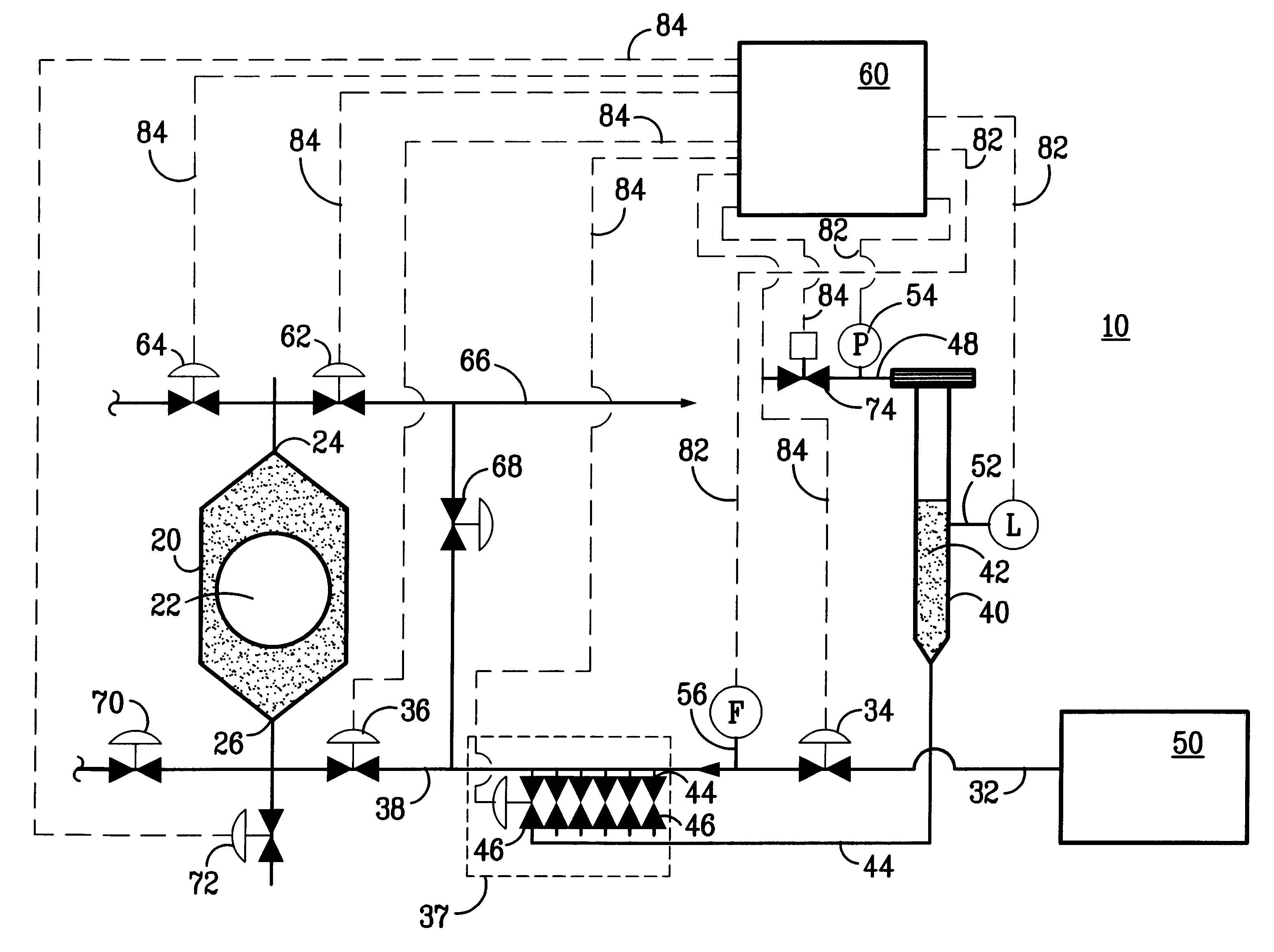

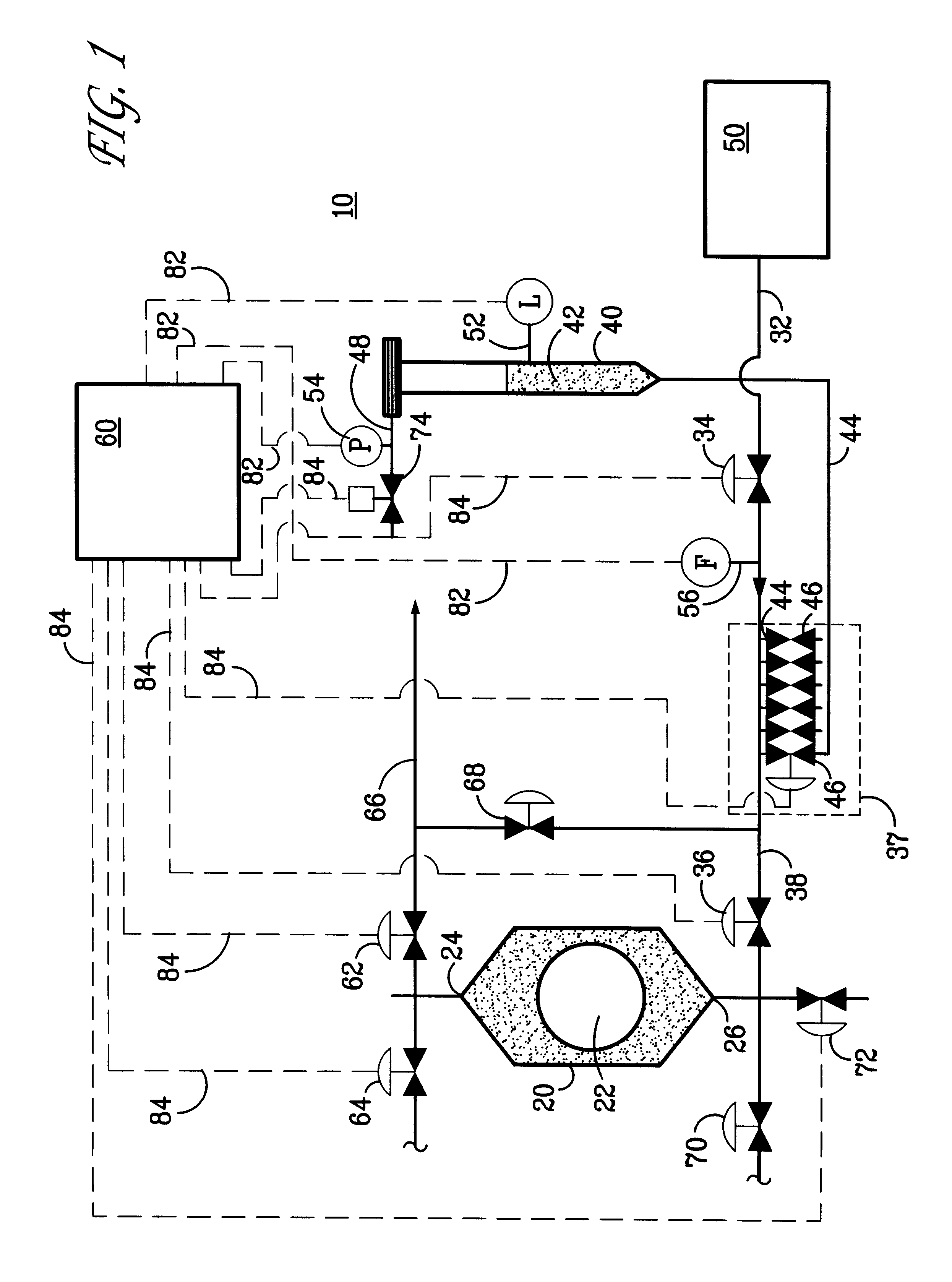

Isokinetic sampling

InactiveUS7717000B2Accurate measurementAccurate flowSurveyFlow mixersVena contracta diameterHigh rate

A method of sampling a multi-phase fluid stream is provided which comprises the steps of: sampling, with a sampling probe, a portion of the fluid stream; measuring the flow rate of said sampled portion; and measuring, independently of the sampling step, the total flow rate of the fluid stream, wherein the flow rate of the sampled portion is controlled according to the ratio of the flow rate of the sampled portion to the flow rate of the fluid stream, in order to obtain substantially isokinetic sampling of the fluid stream. The method may provide isokinetic sampling to an accuracy of 5% or less and preferably only samples a small portion of the fluid stream. The method has particular application for high rate condensate gas wells. A corresponding sampling system is provided which has particular application in the sampling of streams from well-heads. A flow conditioner for use with sampling methods and systems is also provided, the flow conditioner being a pipe section including: a swirl inducing section; a flow straightener; and an orifice plate.

Owner:SCHLUMBERGER TECH CORP

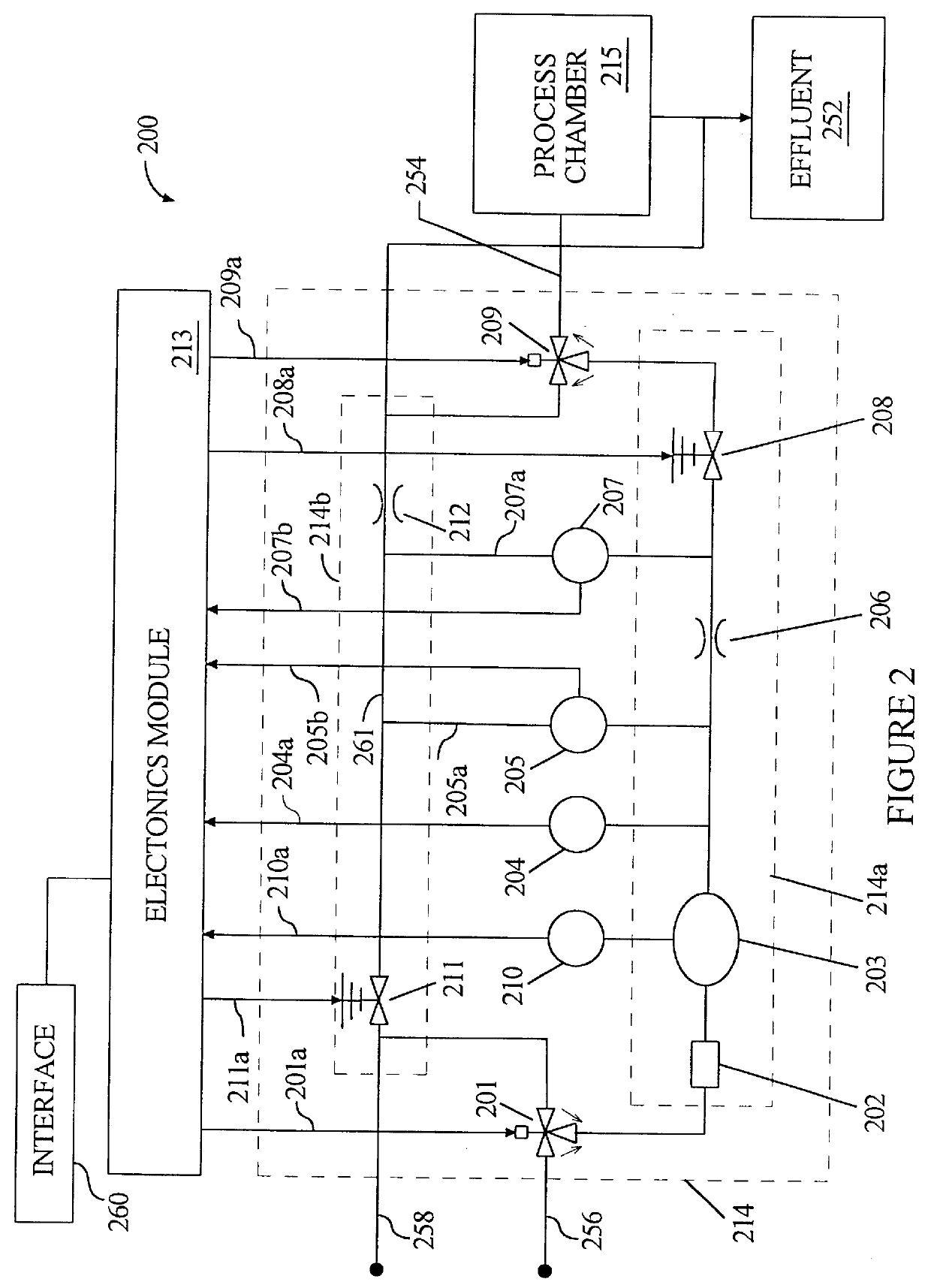

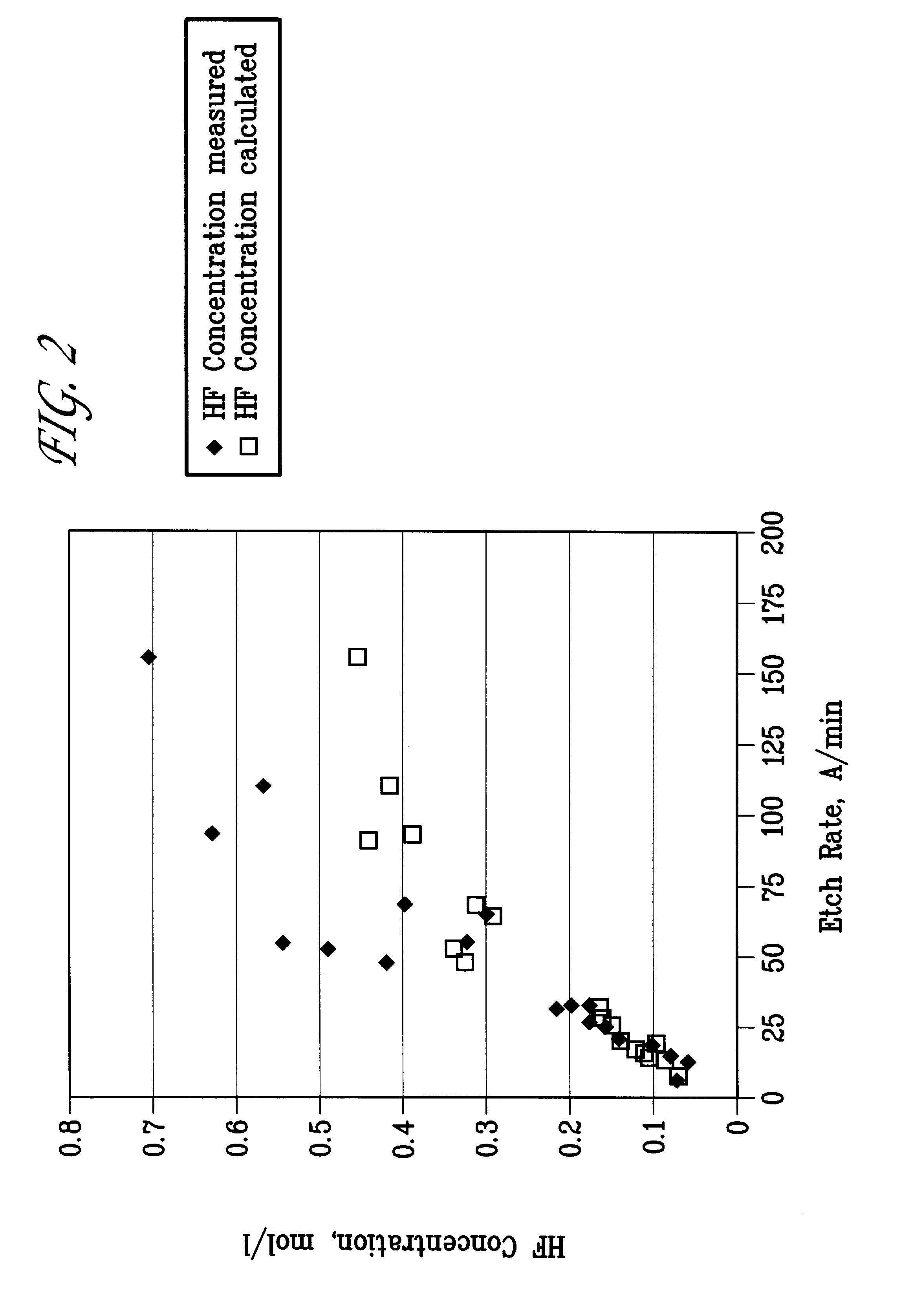

Methods and systems for determining chemical concentrations and controlling the processing of semiconductor substrates

InactiveUS6261845B1Eliminate needLow variabilitySemiconductor/solid-state device manufacturingBiological testingChemical concentrationEnvironmental chemistry

The present invention provides systems and methods of determining the concentration of chemicals in a wet processing stream where the wet processing stream is formed from two or more liquid streams having known chemical concentrations. The concentration of chemicals in the wet processing stream are monitored by measuring the flow rates of the liquid streams during combination to form the wet processing stream, and calculating the concentrations of chemicals in the wet processing stream based on the flow rates and known chemical concentrations of the liquid streams. The present invention also provides systems and methods for controlling the wet processing of semiconductor substrates using the calculated concentrations in the wet processing stream. The methods and systems of the present invention are particularly useful when the semiconductor substrates are contacted with the wet processing stream in a single pass.

Owner:CFMT +1

In-ceiling zone cabling enclosure

ActiveUS7795533B2Robust designEasy to convertInstallation of lighting conductorsCouplings bases/casesThermal management systemEngineering

An in-ceiling cabling enclosure for supporting communications network equipment and cables interconnecting the network equipment including a front wall, a rear wall, and two side walls extending between the front wall and the rear wall creating a volume inside the enclosure. An access door assembly is pivotally connected to either the rear wall or the two side walls. An equipment mount plate is attached to an interior portion of the access door assembly, and opposed equipment mount rails are removably attached to the equipment mount plate. A cable slack management tray extends between the opposed equipment mount rails, and the slack management tray has a surface adapted to support and maintain the position and the contour of cable bundles located in the enclosure. A thermal management system is also disposed in the housing to provide efficient exhaust of hot air generated by active equipment in the enclosure to the space outside of the enclosure.

Owner:PANDUIT

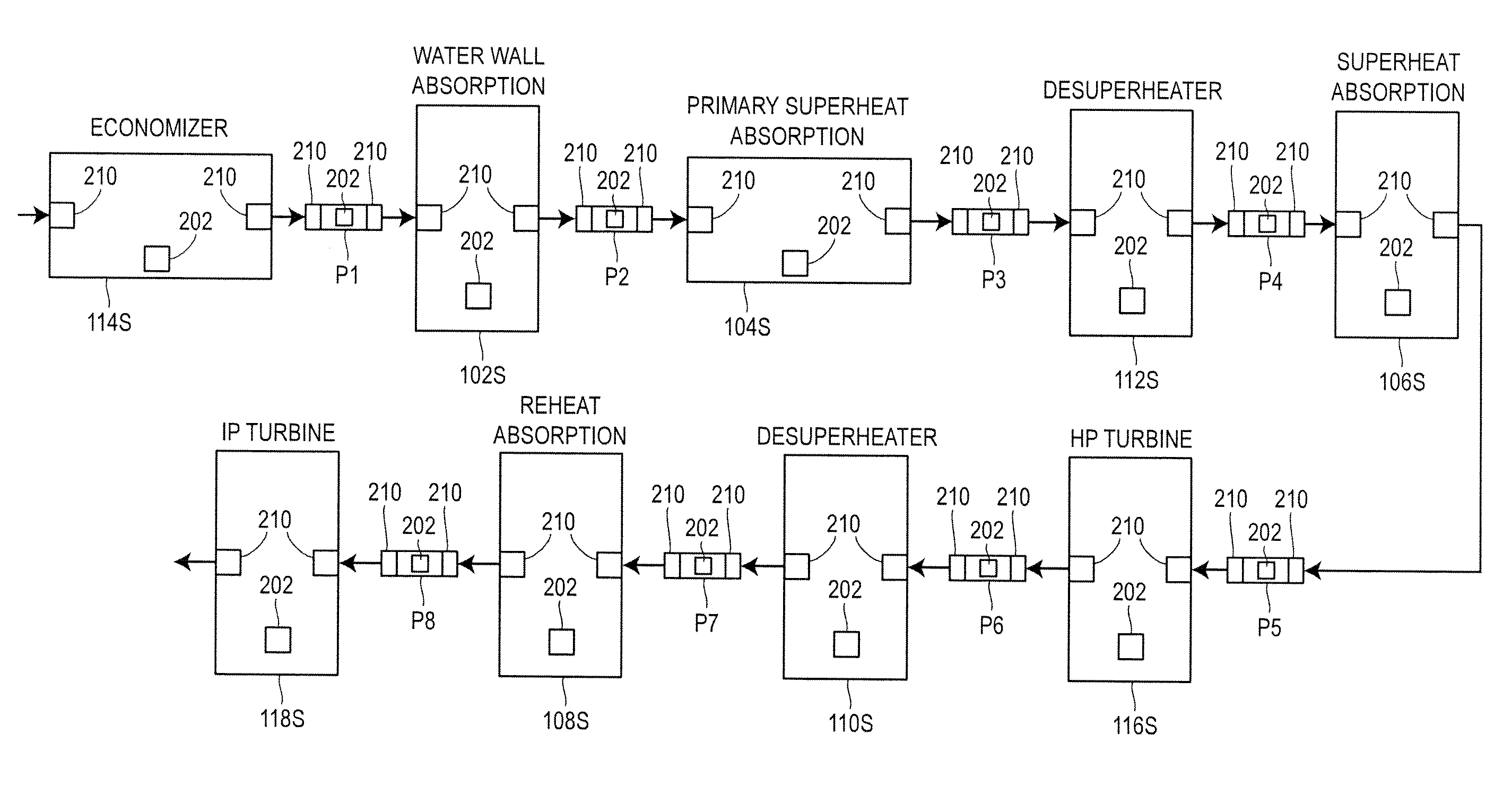

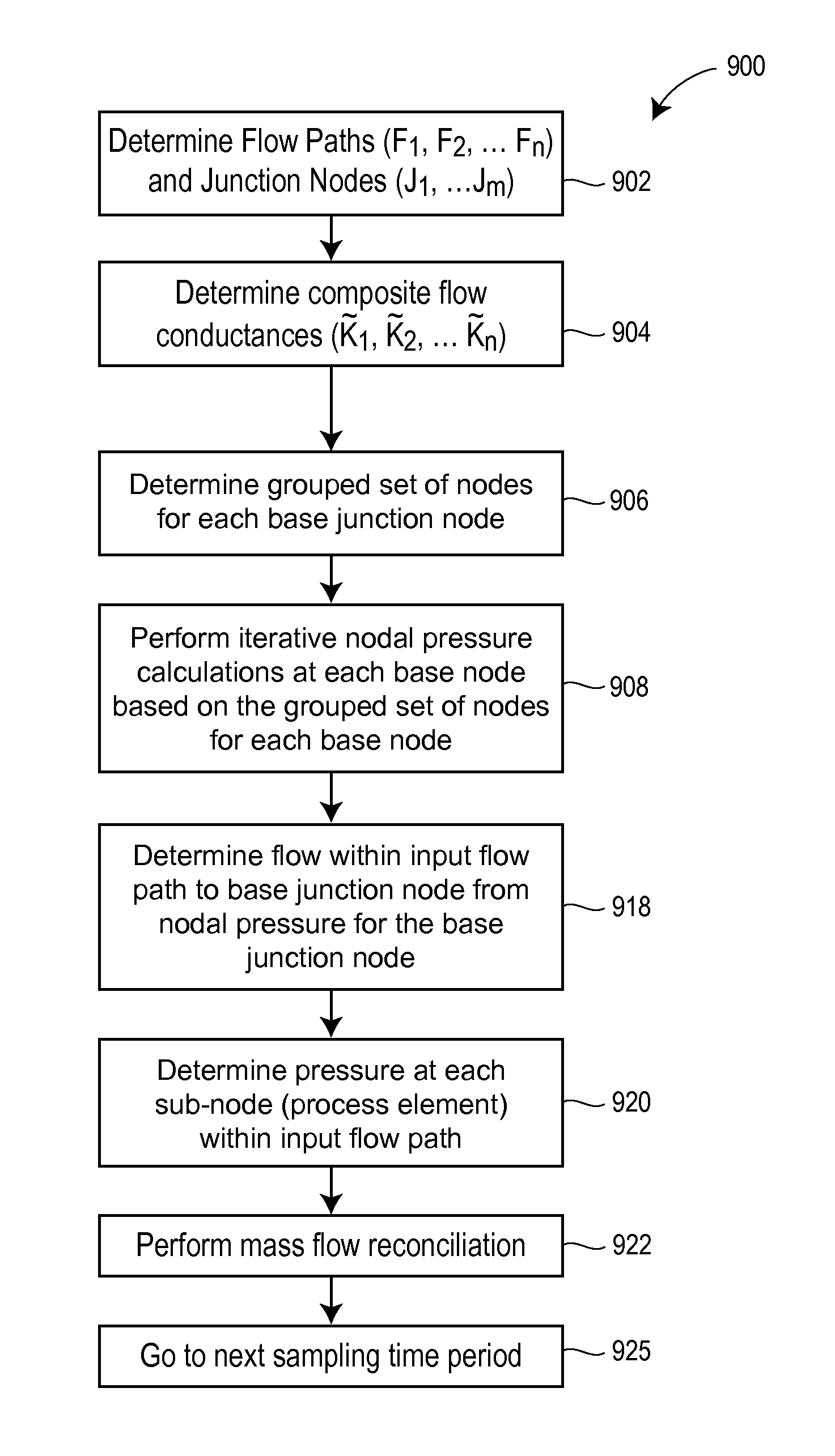

Enhanced sequential method for solving pressure/flow network parameters in a real-time distributed industrial process simulation system

ActiveUS20130204587A1Good and faster simulationImprove accuracyProgramme controlSimulator controlCalculation techniqueComputer engineering

A pressure and flow calculation technique can be used in a distributed process network simulation system that uses the sequential solving method to perform better or faster simulations of a process flow, especially with respect to process junction nodes at which flow either converges or diverges. The pressure and flow variable determination technique uses a grouped node identification technique that identifies a local set of nodes for each junction node of the process network to use when solving for the pressure at the junction node, a grouped node iteration technique that uses the grouped set of nodes at each junction node to perform iterative pressure calculations at the junction node, and a flow-based pressure calibration technique at each junction node to enable the system to perform highly accurate pressure and flow variable determination at each junction node in real-time.

Owner:EMERSON PROCESS MANAGEMENT POWER & WATER SOLUTIONS

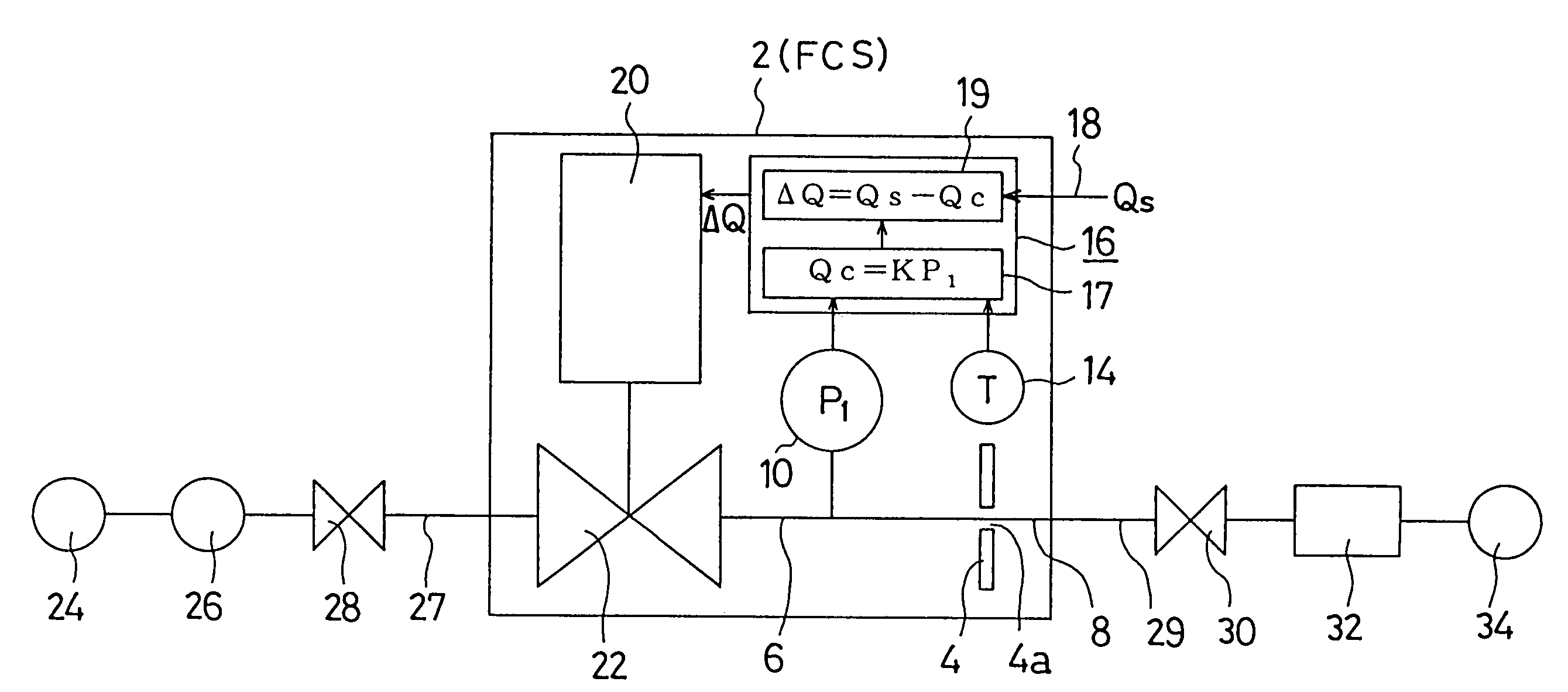

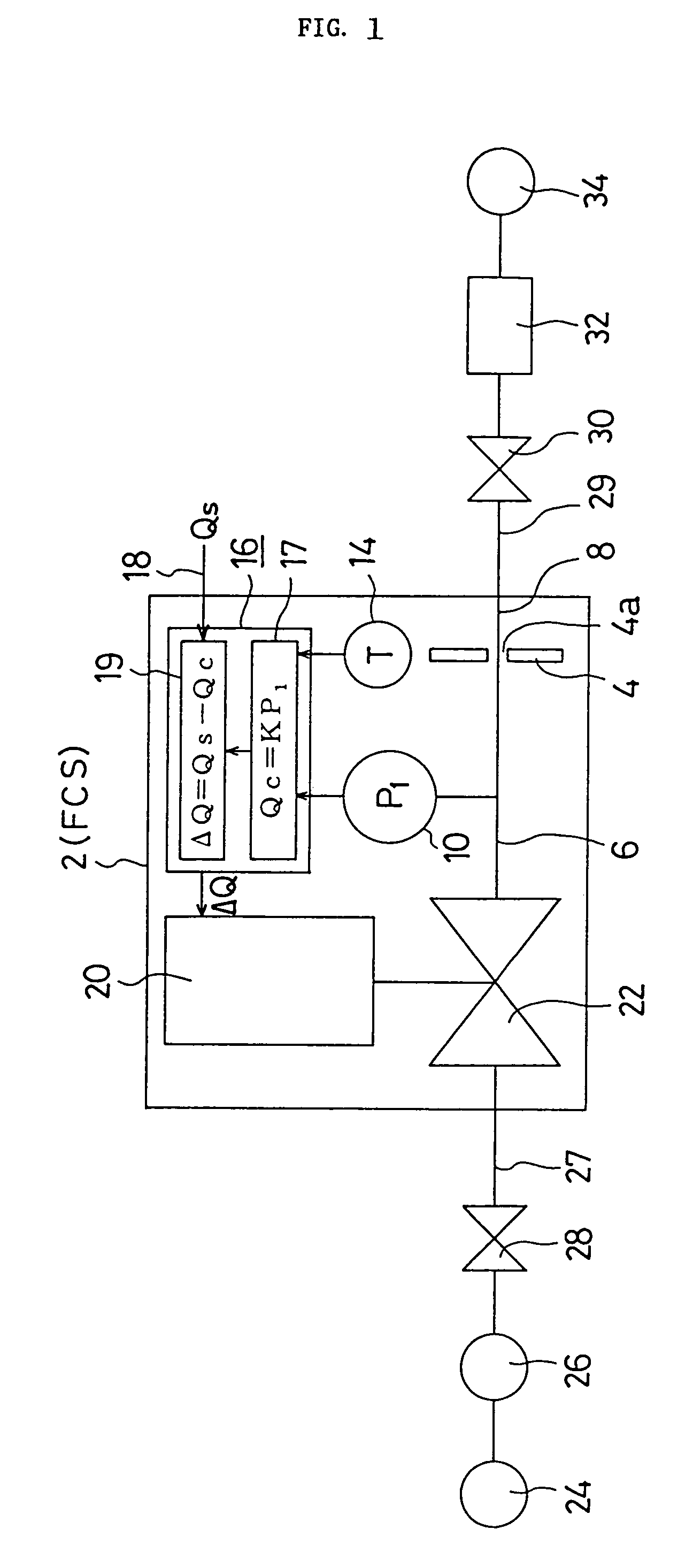

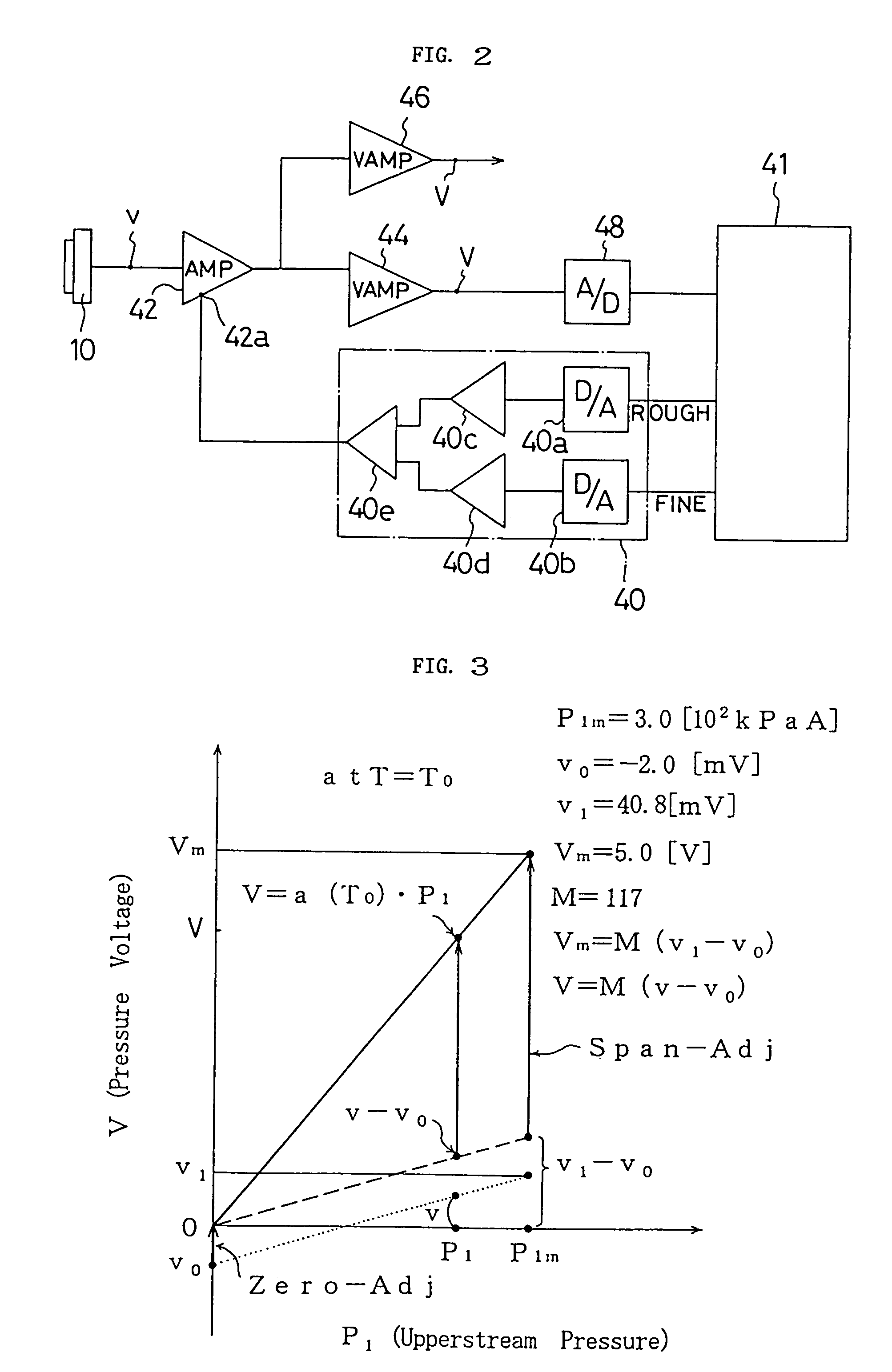

Apparatus for the correction of temperature drift for pressure sensor, pressure control apparatus and pressure-type flow rate control apparatus

ActiveUS7085628B2Accurately controlAccurately measureSampled-variable control systemsComputer controlEngineeringPressure sensor

A pressure sensor, a pressure control apparatus, and a flow rate control apparatus are provided to automatically correct temperature drift of the pressure sensor and accurately detect pressure despite changes in temperature. An embodiment includes an upstream side pressure sensor between an orifice and a control valve, to control flow rate through the orifice by a regulating control valve, while calculating the flow from the upstream side pressure. With a temperature sensor, a memory means, and a temperature drift correcting means which calculates drift of the upstream side pressure sensor from data in the memory means when the temperature of the fluid changes and offsets the output drift of the upstream side pressure sensor with the calculated amount of the output drift, temperature drift of the pressure sensor is automatically corrected, enabling accurate control of flow rate.

Owner:FUJIKIN INC +2

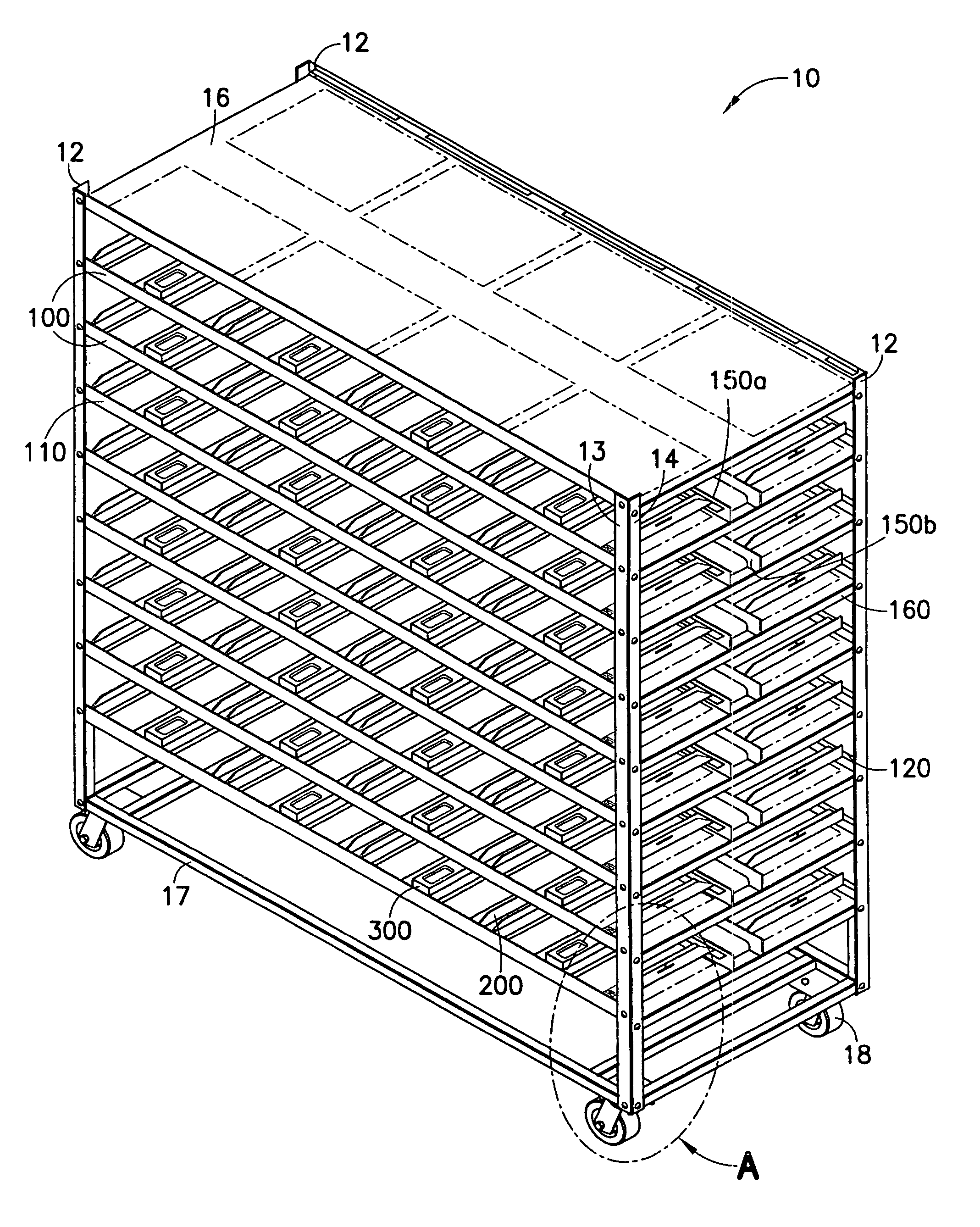

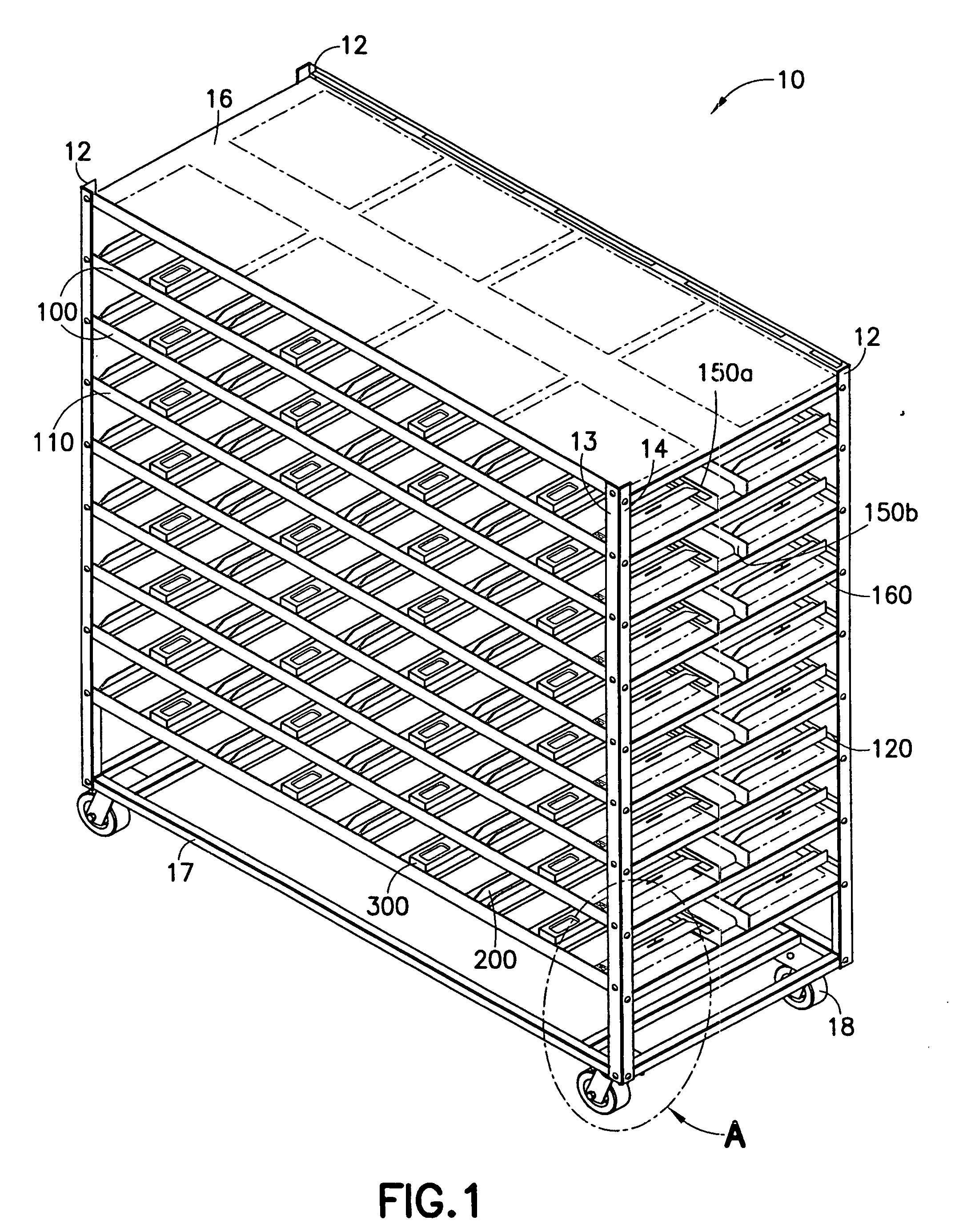

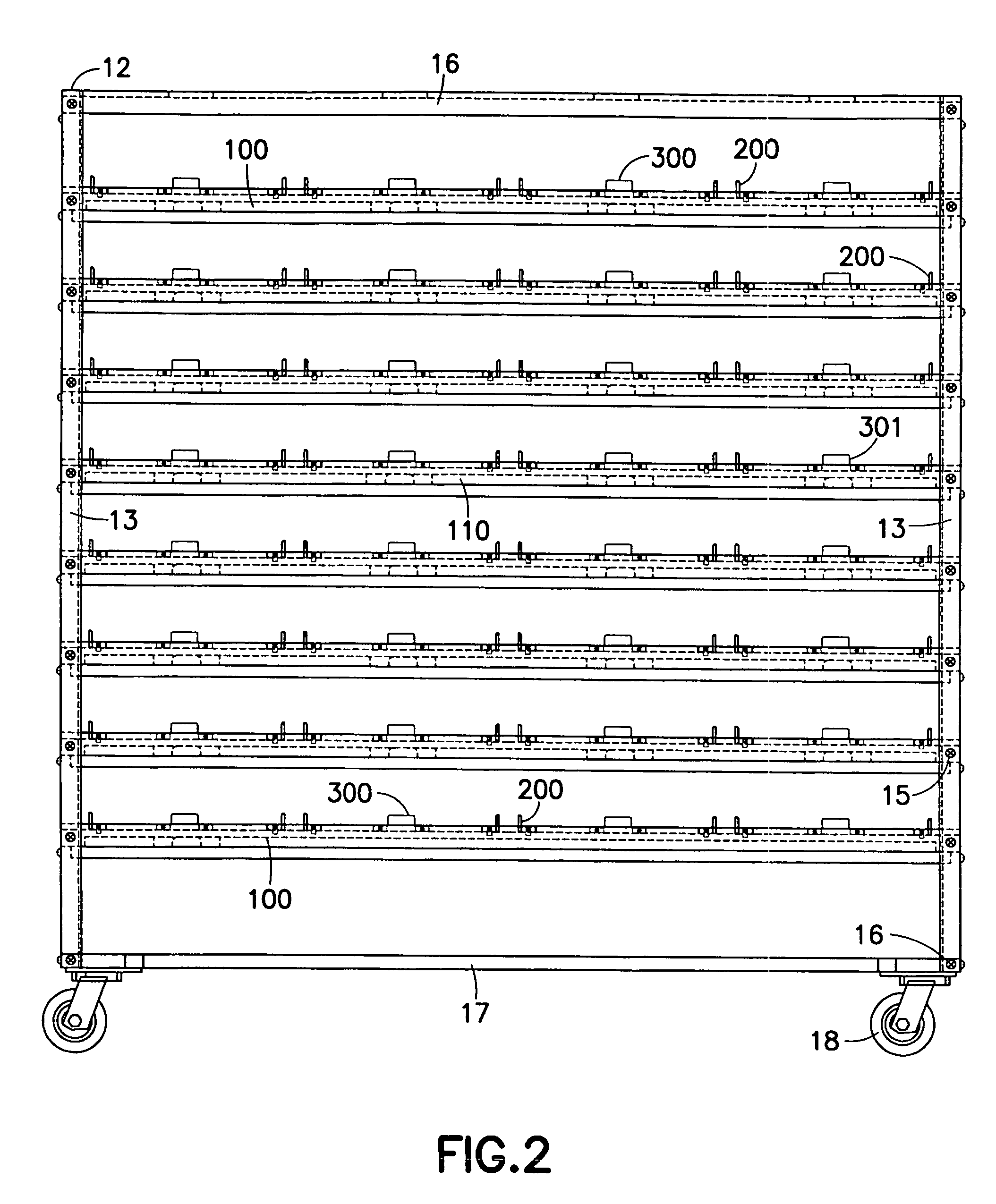

Rack system for housing animals in cages having different widths

ActiveUS20060236951A1Easy to installMaintaining proper air flowAnimal housingBird housingsElectrical and Electronics engineering

Embodiments of a rack assembly for housing cages comprise at least one shelf, the shelf having a shelf section comprising a runner capable of being positioned in a least a first position and a second position. The shelf section is constructed and arranged to accommodate two cages having a first and second widths when the runner is positioned in the first position. The shelf section is constructed and arranged to accommodate a single cage having a third width when the runner is in a second position, the first and second widths being less than the third width.

Owner:LAB PROD LLC

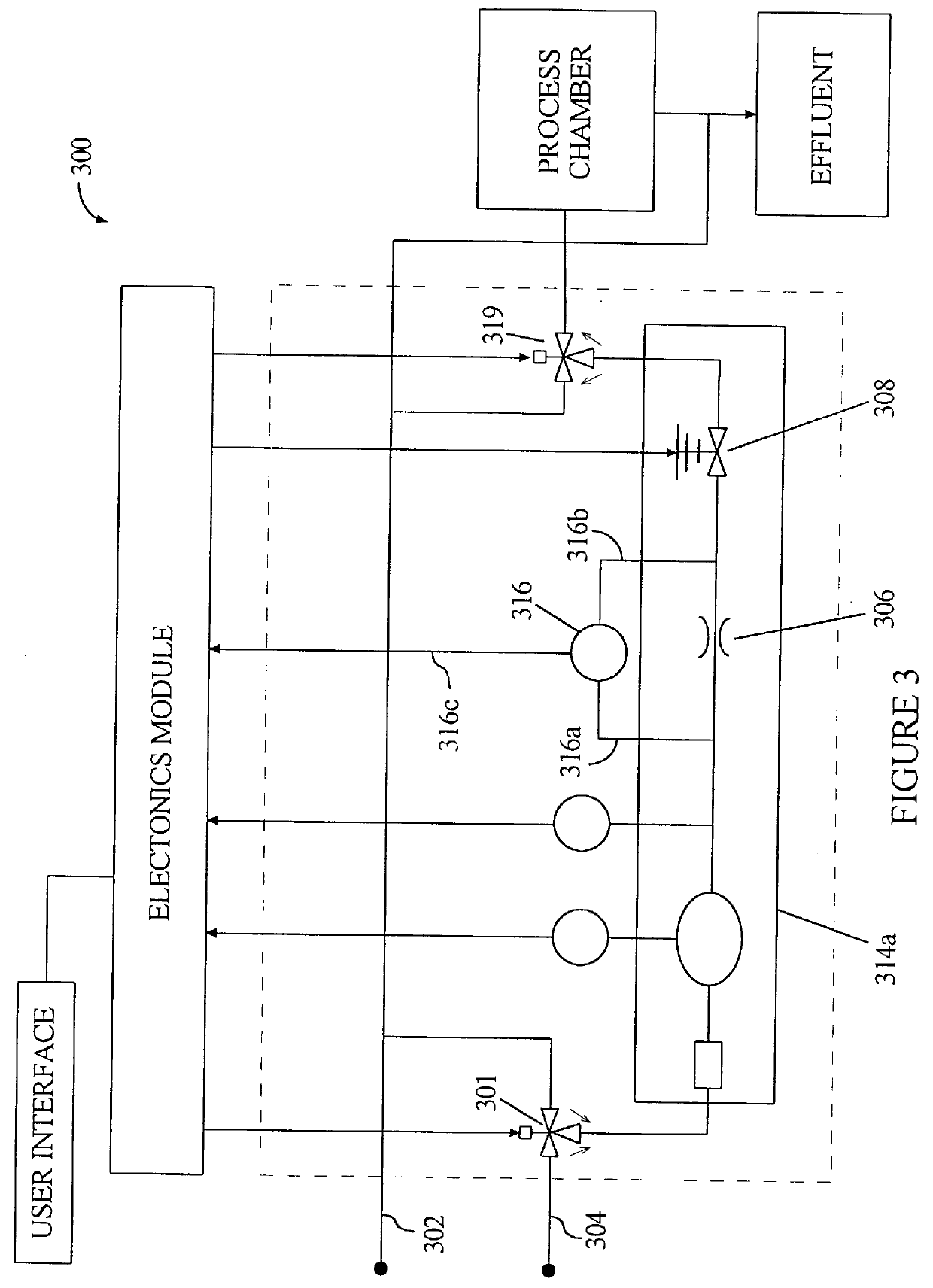

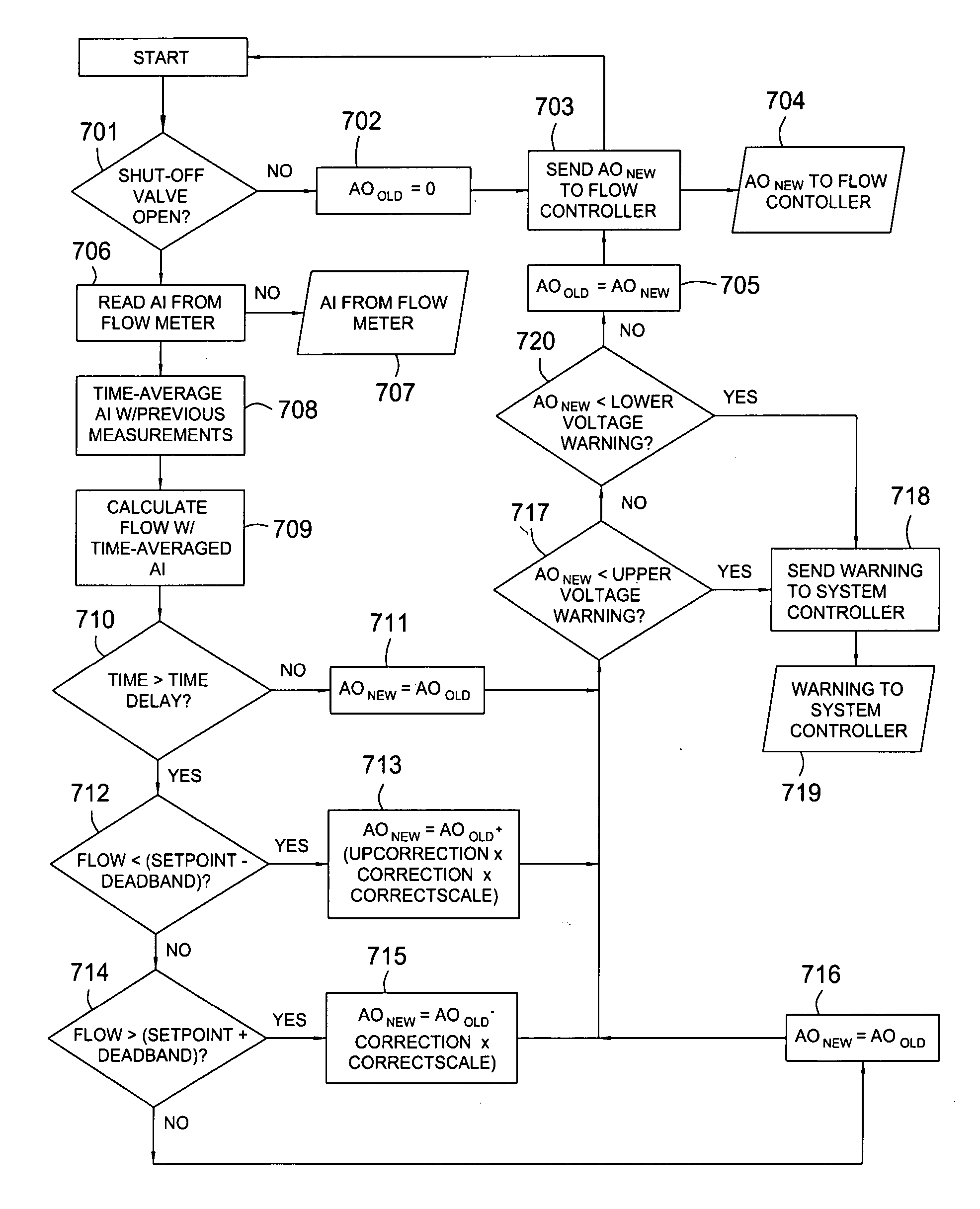

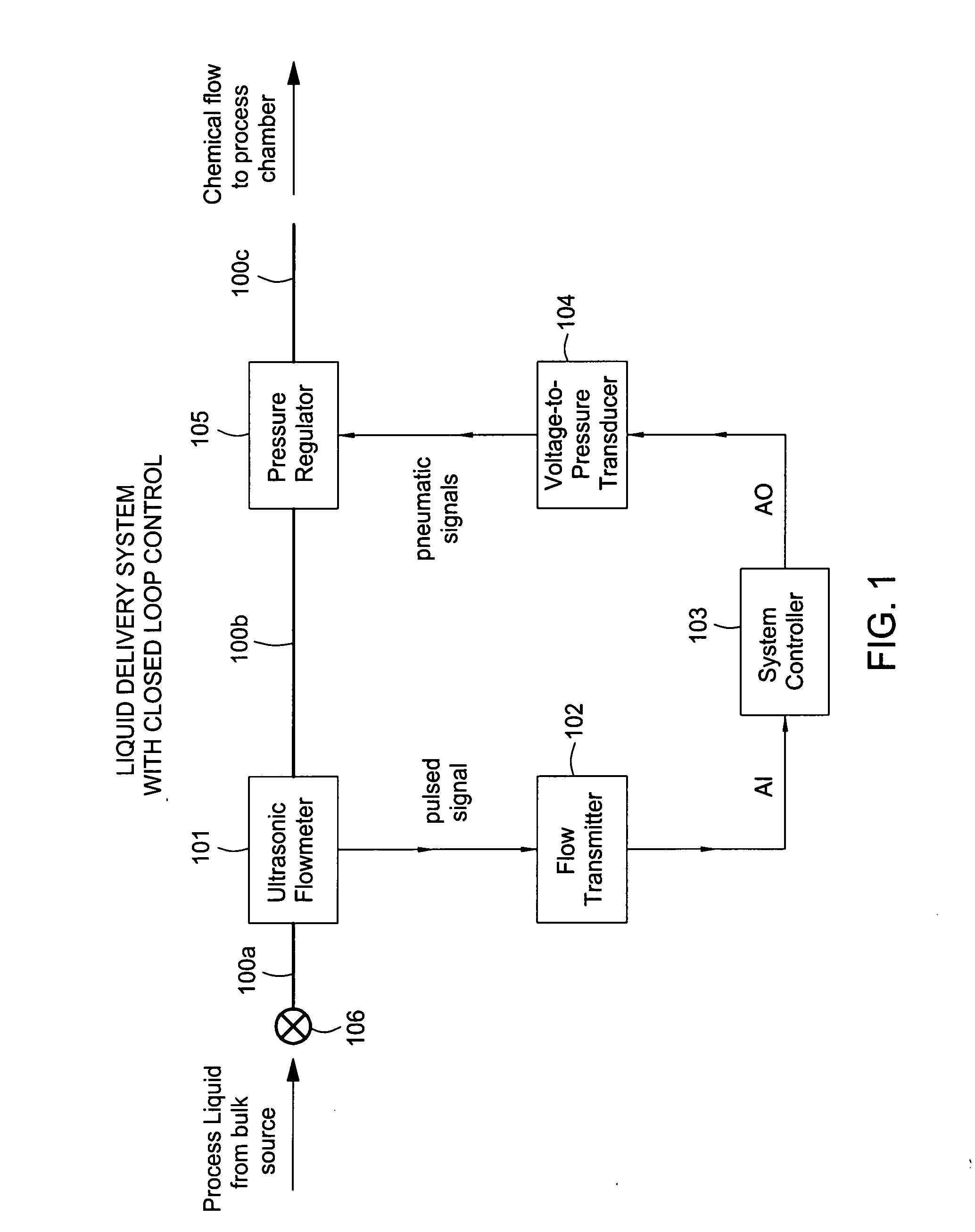

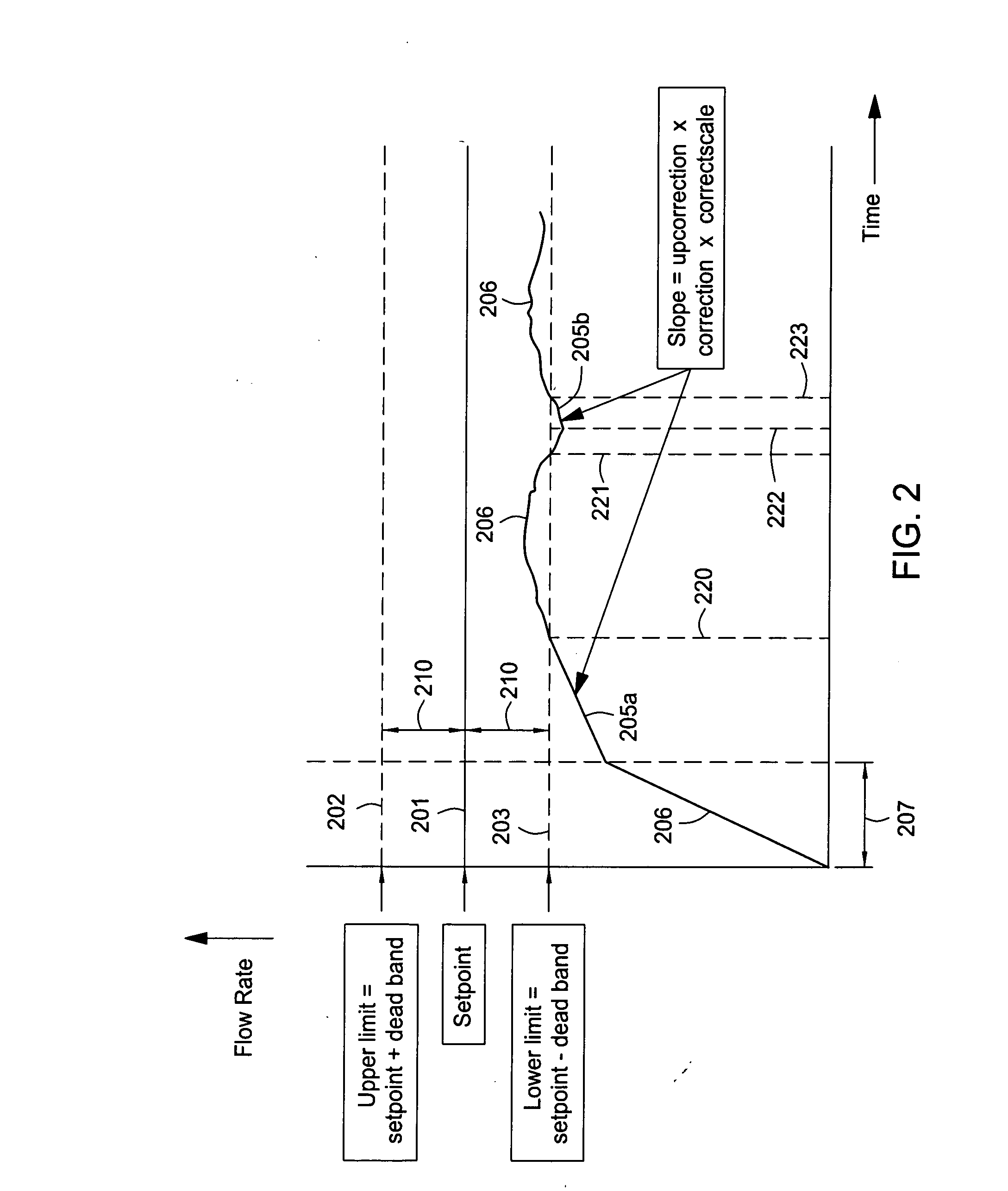

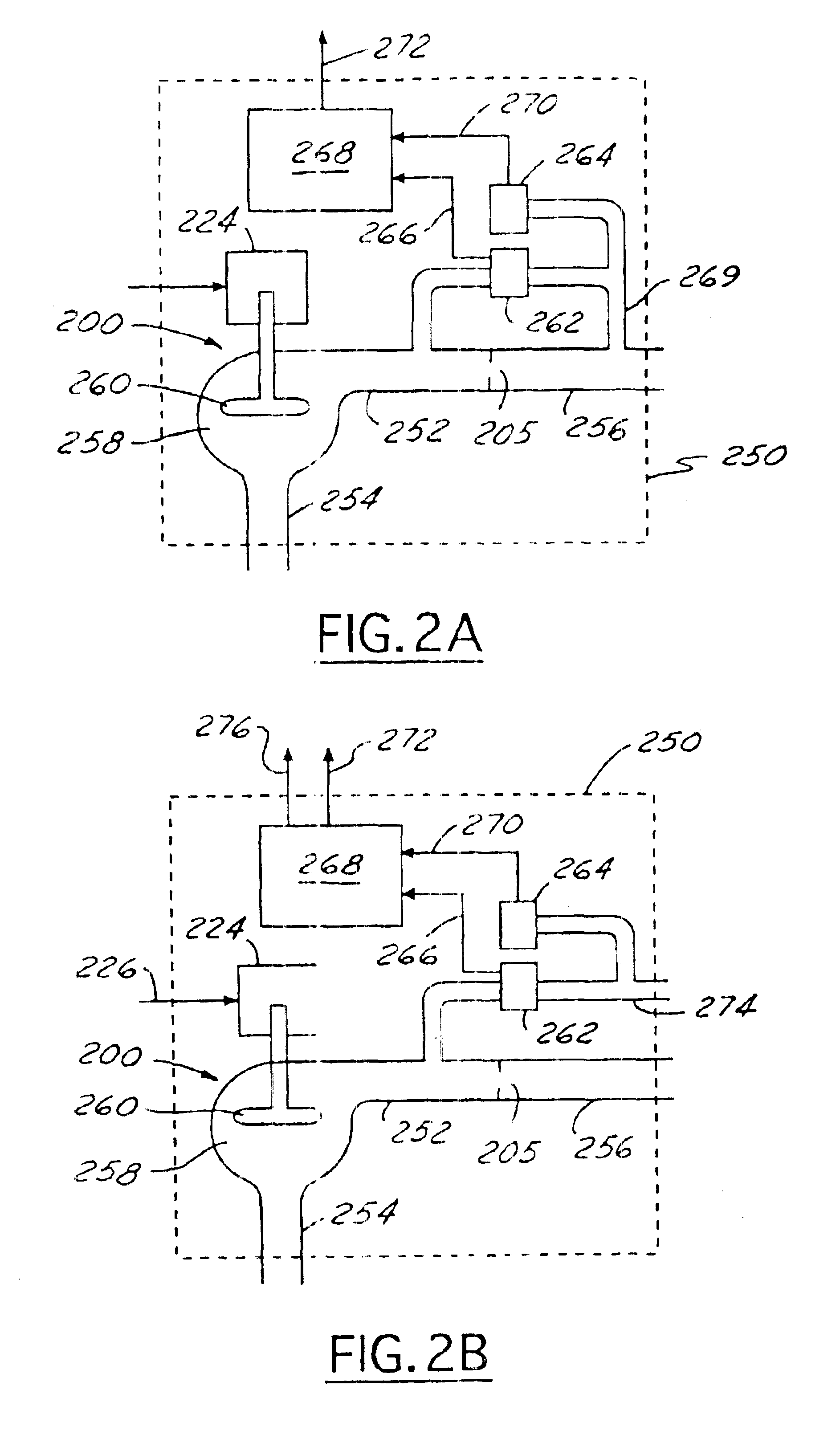

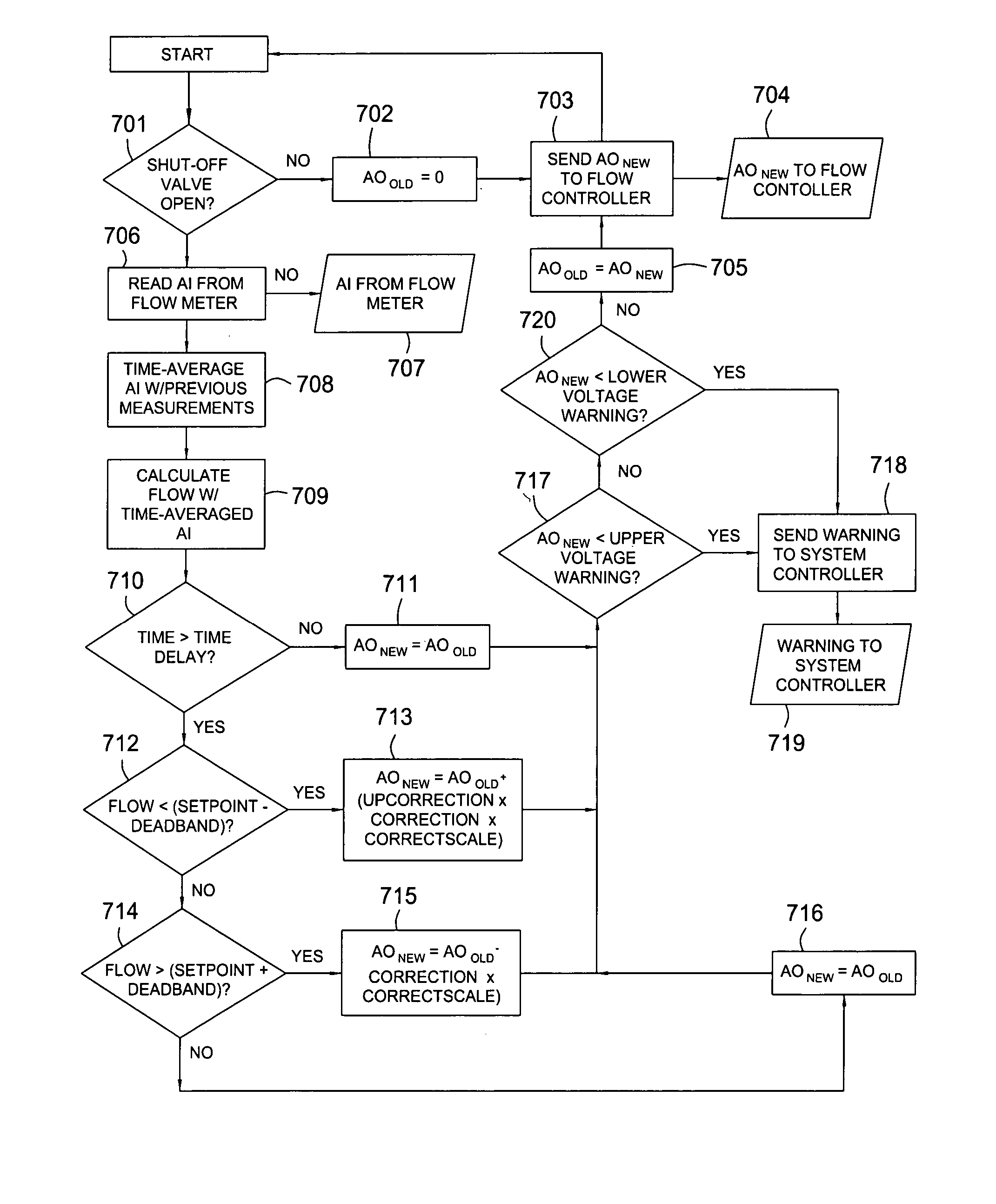

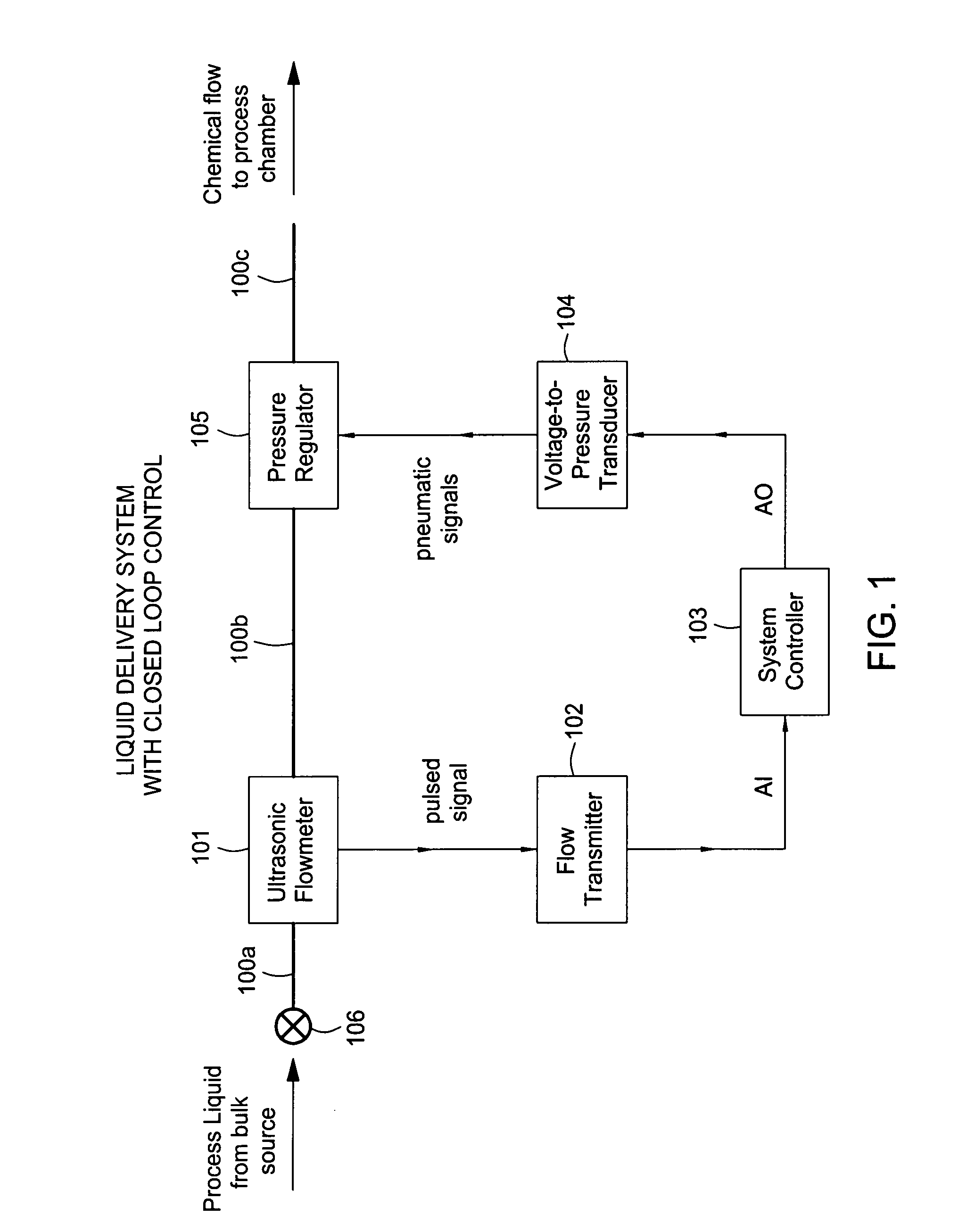

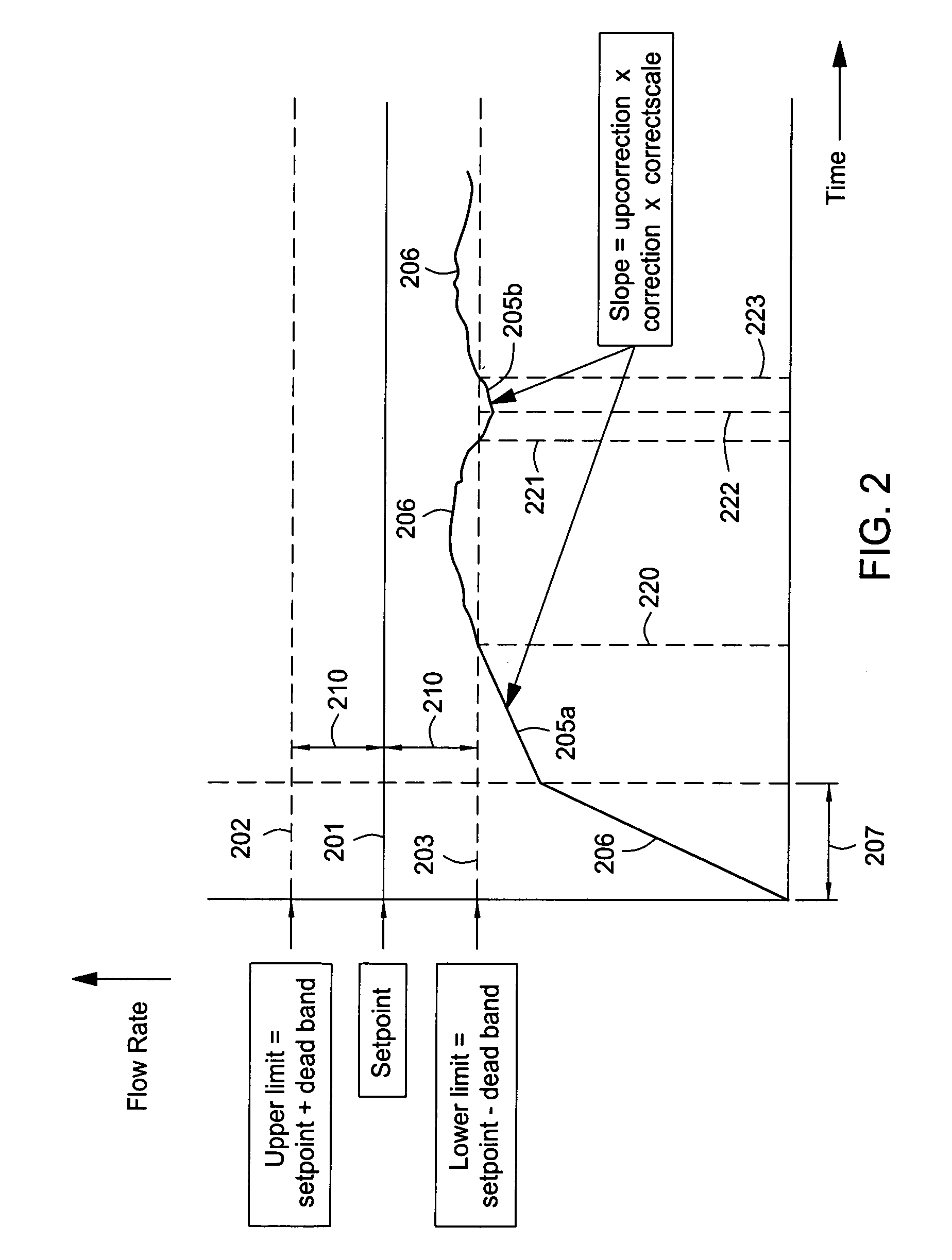

Closed loop control on liquid delivery system ECP slim cell

ActiveUS20060190099A1Accurate flowEasy to controlLevel controlTesting/calibration apparatusClosed loopEngineering

A method for controlling liquid delivery in a processing chamber. The method includes generating an analog input (AI) signal proportional to a process variable and calculating an analog output (AO) signal based on a setpoint and a deadband. The setpoint is a target value of the process variable and the deadband is an allowable tolerance around the setpoint that determines when the control logic is activated to control the process variable. The method further includes transmitting the AO signal to a control device and adjusting the process variable proportional to the value of the AO signal.

Owner:APPLIED MATERIALS INC

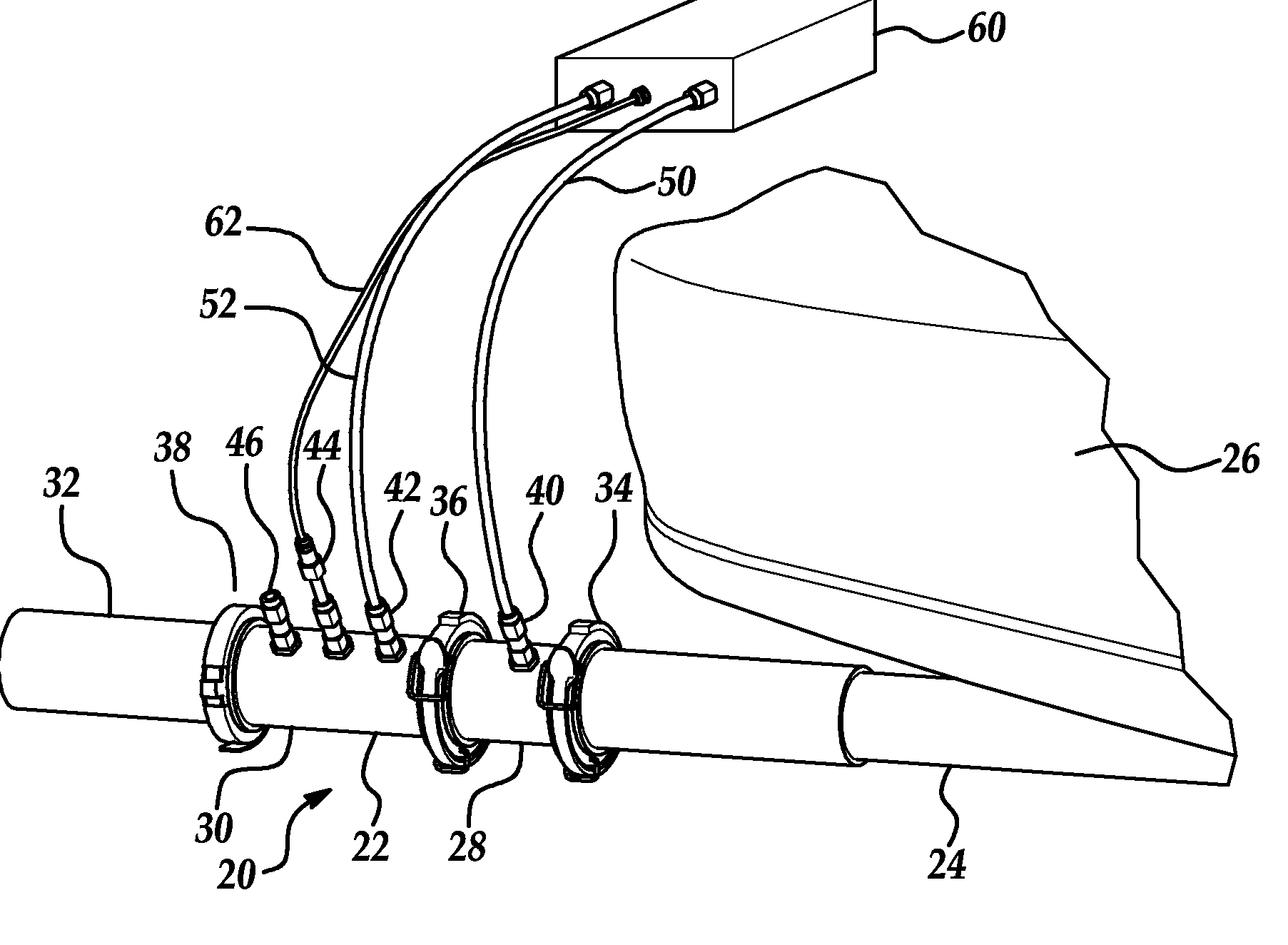

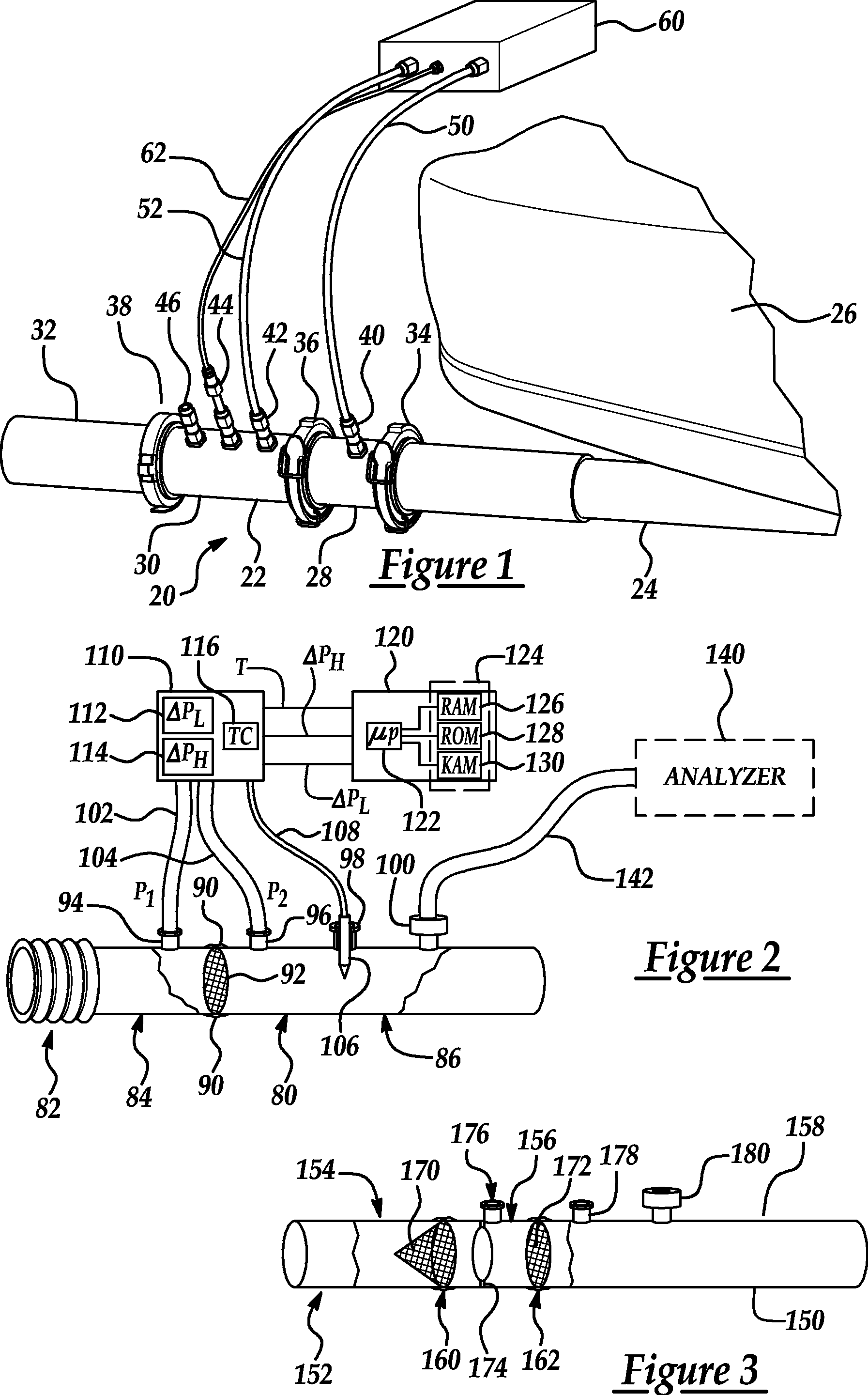

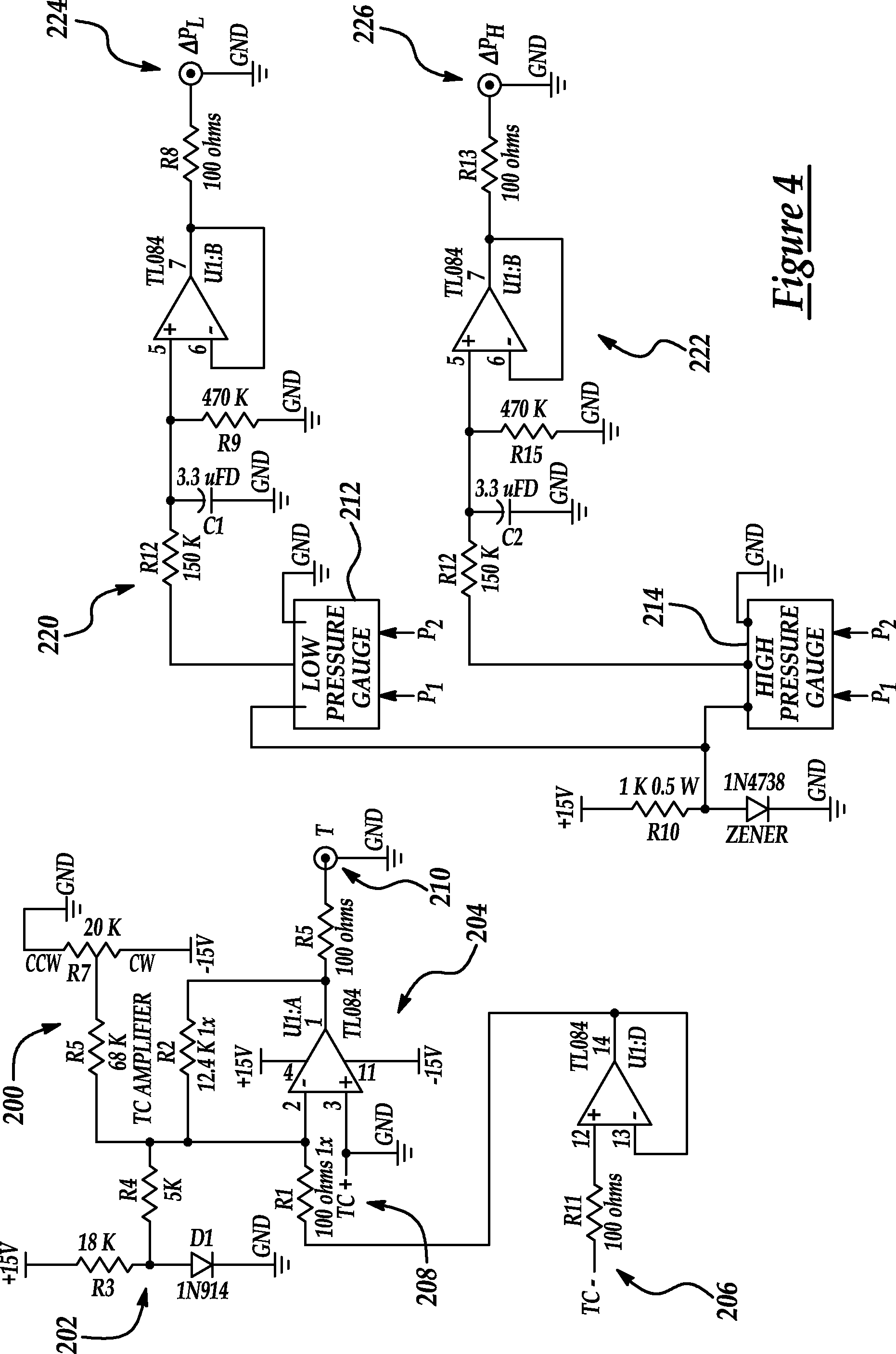

Portable vehicle exhaust flow sensor

InactiveUS20050257605A1Accurately determineAdditional back pressureExhaust apparatusEngine testingExhaust gasEngineering

A portable exhaust gas flow sensor includes a tube for coupling to an exhaust pipe of a vehicle. The tube includes a circular flow restricting element to induce a pressure drop based on the exhaust gas flow with an upstream port and a downstream port relative to the flow restricting element connected to a differential pressure transducer. A thermocouple extends through a temperature port to measure exhaust gas temperature flowing through the tube. A processor in communication with the thermocouple and the differential pressure transducer determines the exhaust gas flow based on the differential pressure and the temperature. The circular flow restricting element includes sufficient spaces to resist formation of condensation and minimize added back pressure while providing an accurately measurable pressure drop for flows ranging from idle to full throttle.

Owner:FORD GLOBAL TECH LLC

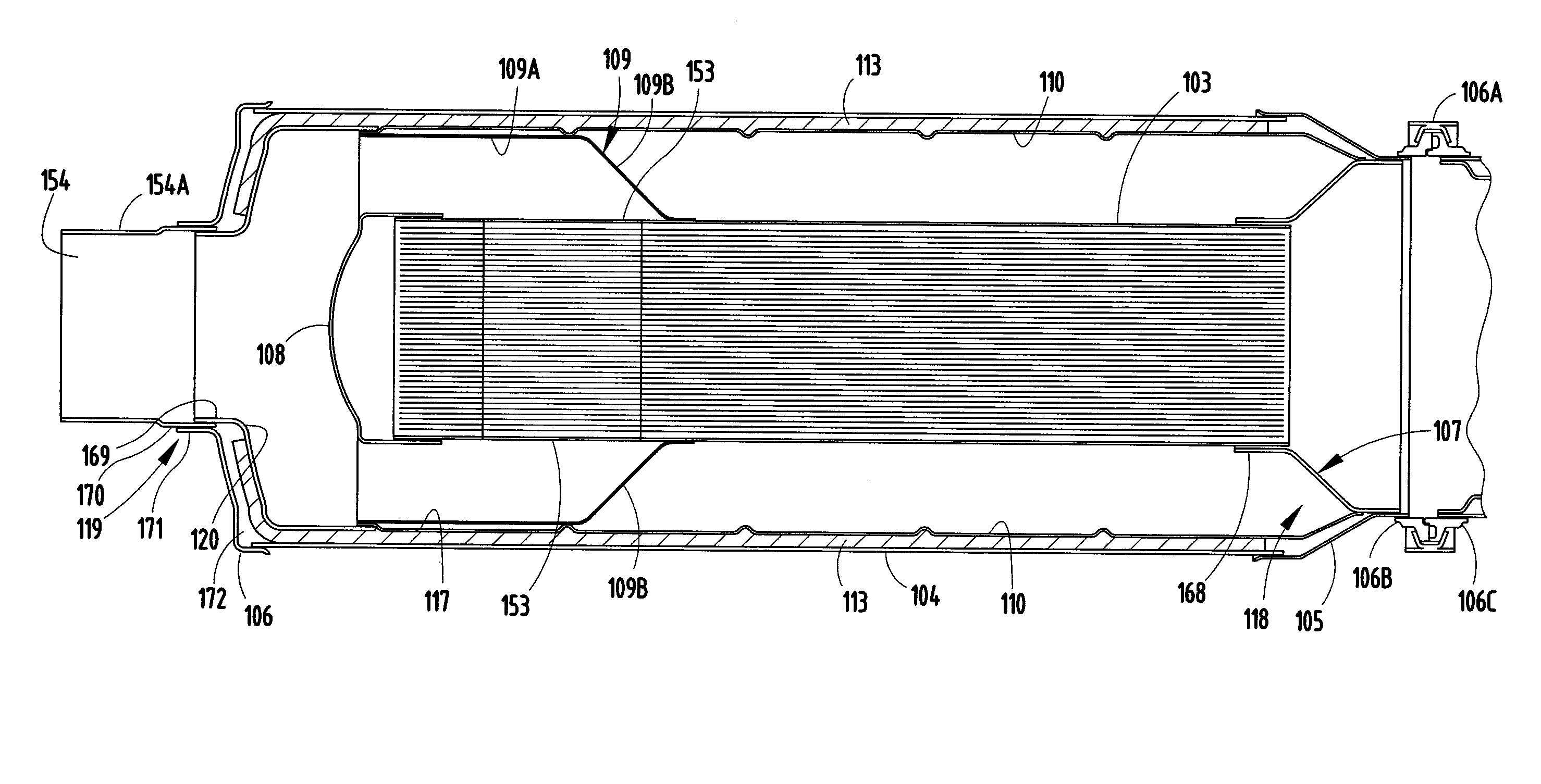

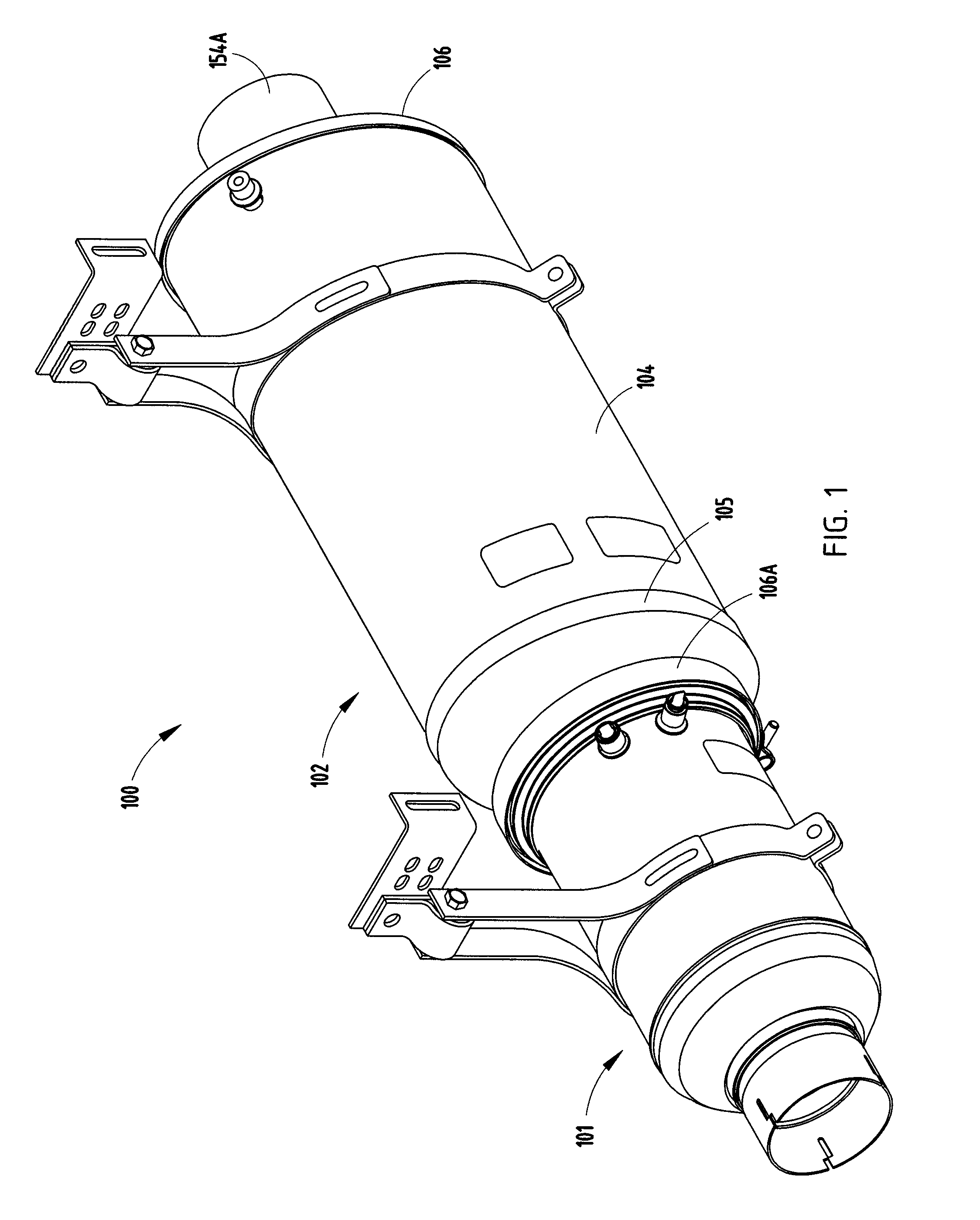

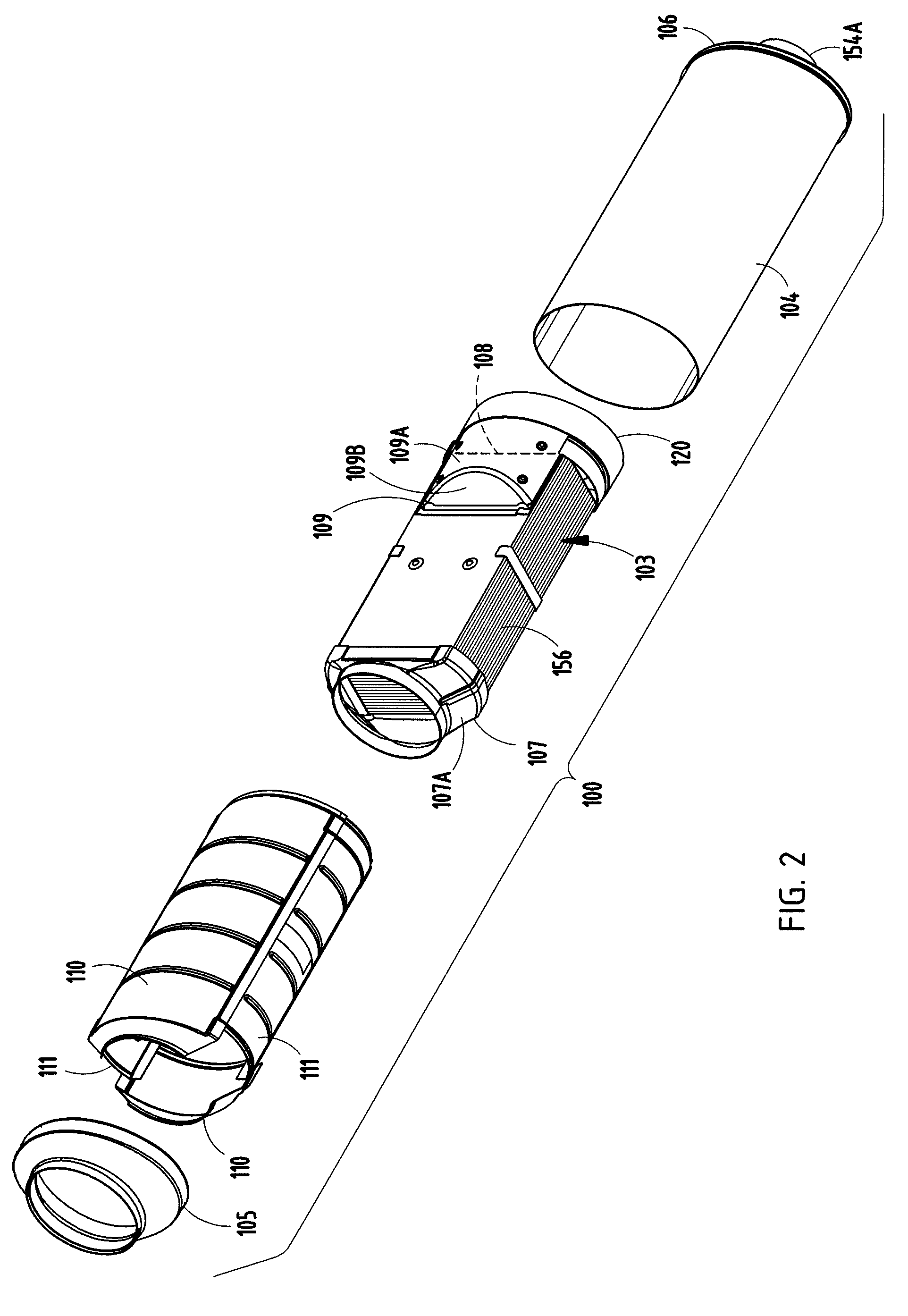

Diesel exhaust filter construction

InactiveUS7611561B2Reduce surface temperatureReduce in quantityCombination devicesInternal combustion piston enginesExhaust fumesThermal expansion

Owner:BENTELER AUTOMOTIVE CORP

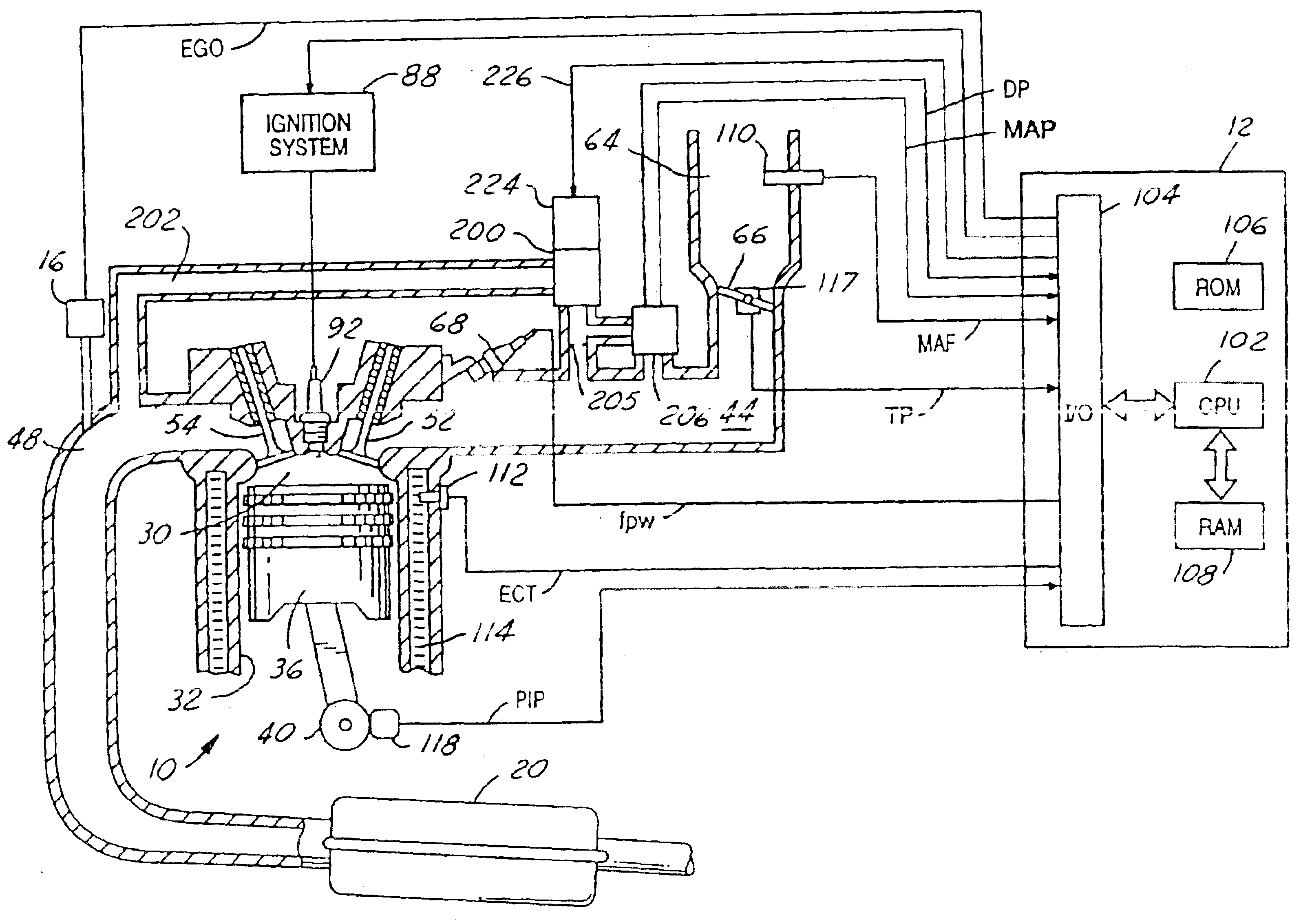

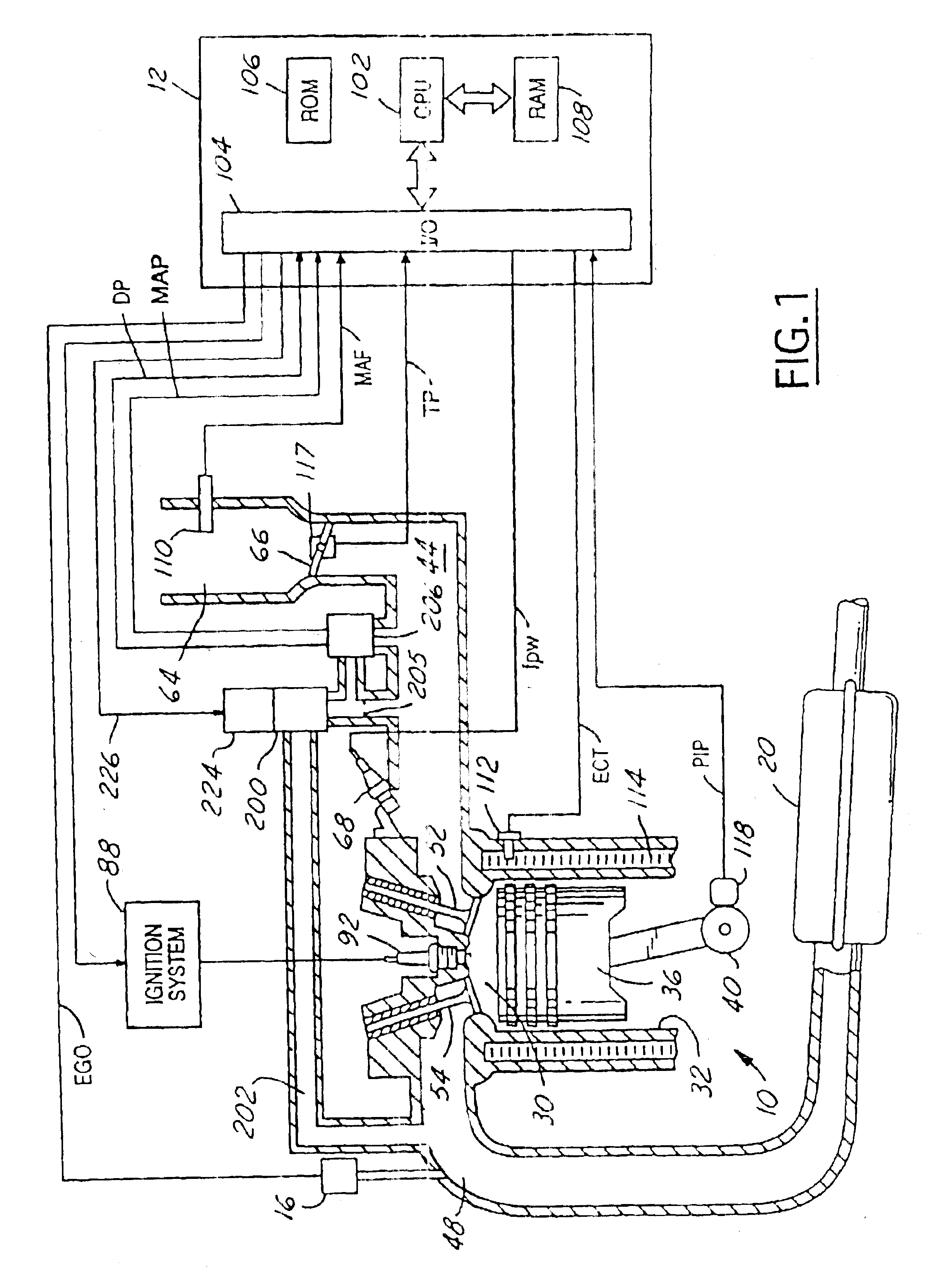

System and method for air flow and EGR flow estimation

InactiveUS6944530B2Improve accuracySimple structureElectrical controlInternal combustion piston enginesExhaust fumesExhaust gas recirculation

An exhaust gas recirculation system directs exhaust gasses from an exhaust manifold to an intake manifold of an internal combustion engine. The exhaust gasses travel from the exhaust manifold, first passing through a flow control valve and then through a measuring orifice before entering the intake manifold. Pressure upstream of the orifice is used, along with correction pressure downstream of the orifice, to measure and control exhaust gas flow. Further, manifold pressure is determined from downstream pressure and the used along with the measured exhaust gas flow to calculated a cylinder air charge amount.

Owner:FORD GLOBAL TECH LLC

Closed loop control on liquid delivery system ECP slim cell

ActiveUS7155319B2Easy to controlFast response timeLevel controlTesting/calibration apparatusClosed loopDeadband

A method for controlling liquid delivery in a processing chamber. The method includes generating an analog input (AI) signal proportional to a process variable and calculating an analog output (AO) signal based on a setpoint and a deadband. The setpoint is a target value of the process variable and the deadband is an allowable tolerance around the setpoint that determines when the control logic is activated to control the process variable. The method further includes transmitting the AO signal to a control device and adjusting the process variable proportional to the value of the AO signal.

Owner:APPLIED MATERIALS INC

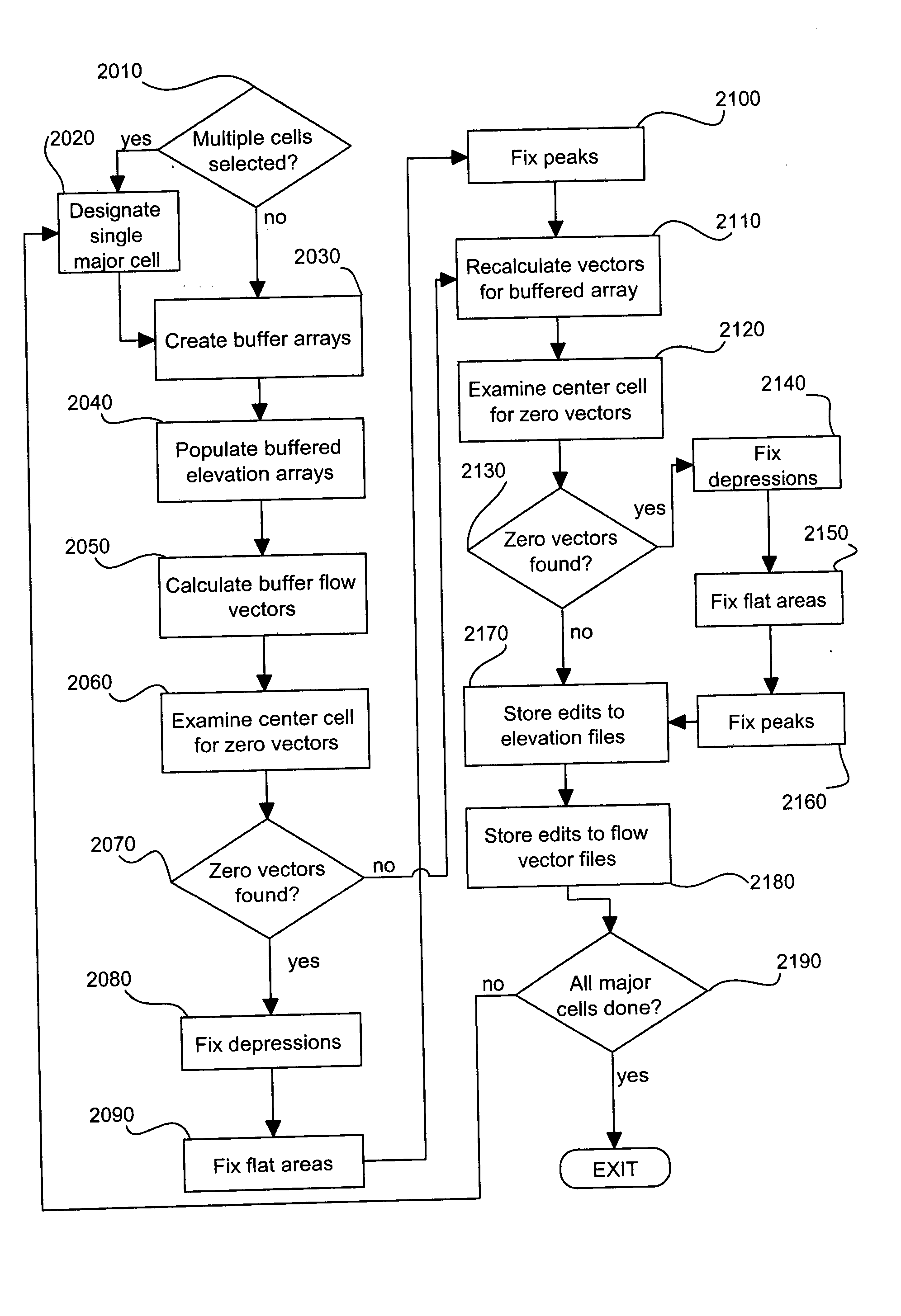

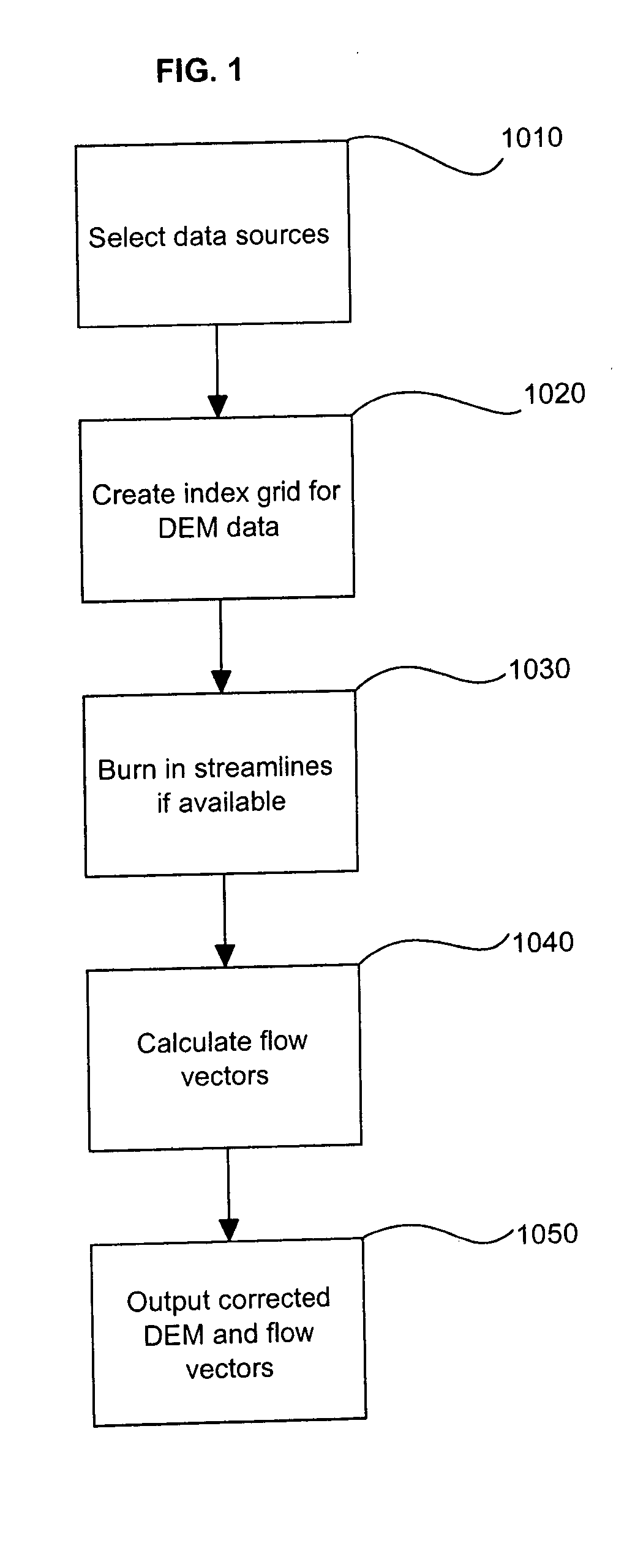

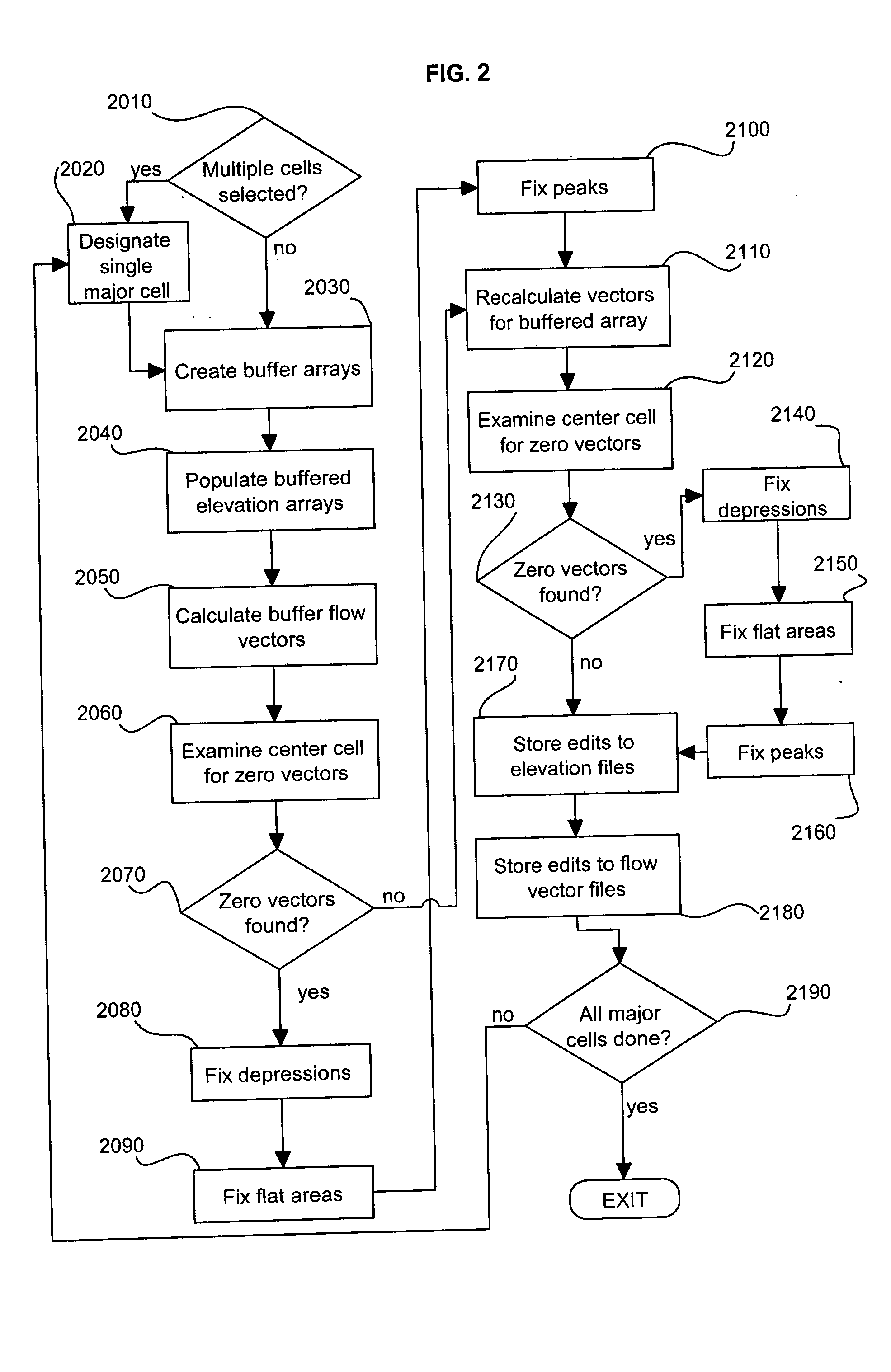

Method for flow analysis utilizing cell elevation topology

InactiveUS20050049802A1Accurate flowAccurate correctionVolume/mass flow measurementComputation using non-denominational number representationPeak valueElevation data

A method for generating hydrologically correct flow vectors based on elevation data in a watershed which includes any one or more of depressions, flat areas and peaks. The watershed is typically divided into a plurality of major cells each of which encompasses a plurality of minor cells, and a user selects one or more major cells for which flow vectors are desired. Flow vectors are then calculated pursuant to the D8 method and assigned to those minor cells in the selected major cell and in surrounding major cells for which an optimal D8 solution is possible. The remaining minor cells are designated as zero vector cells and include those cells located in the problem areas. The method then generates flow vectors for minor cells in all depressions, flat areas and peaks, in that order, which exist in the selected major cells.

Owner:HAYES SEAY MATTERN & MATTERN

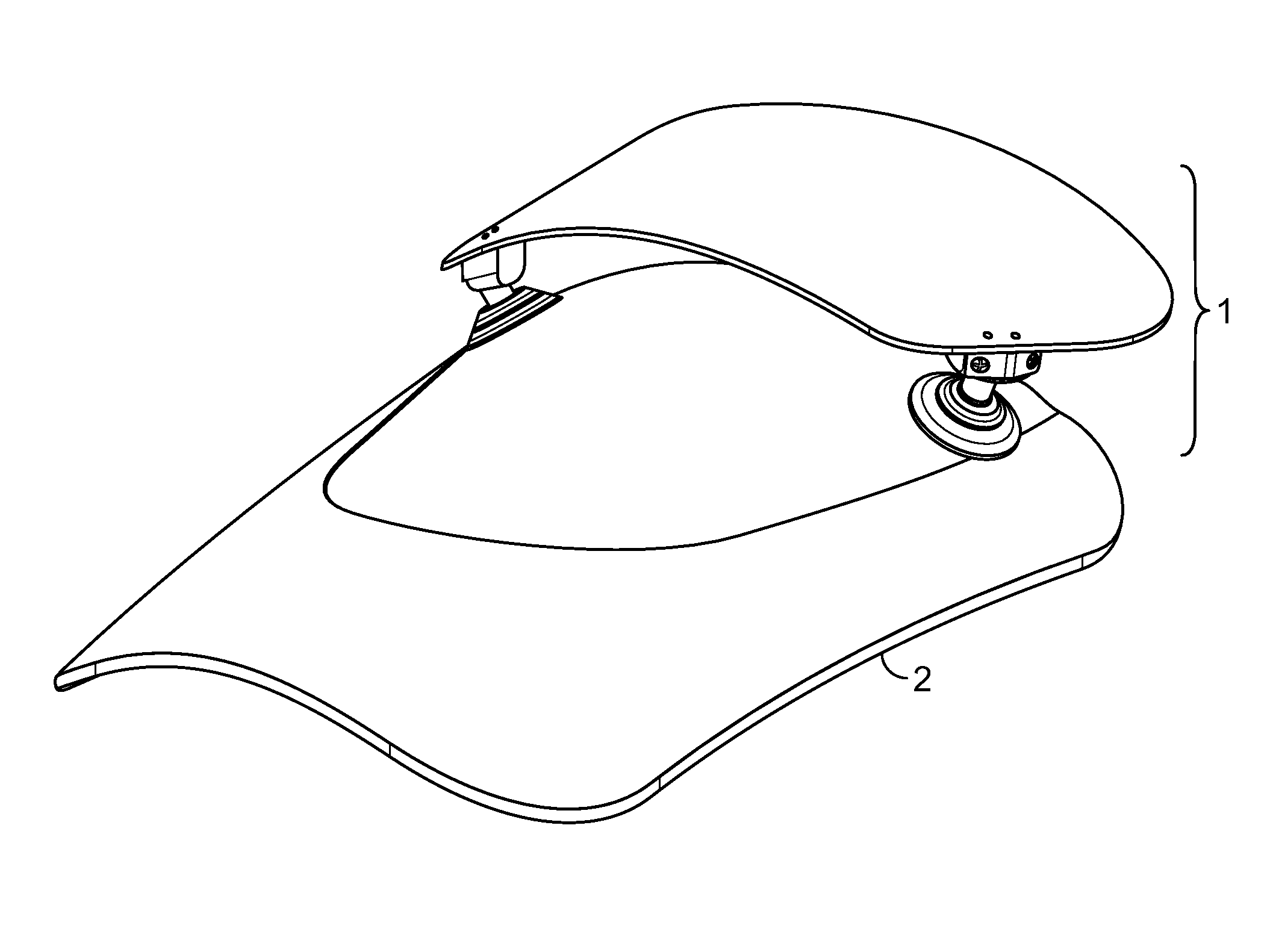

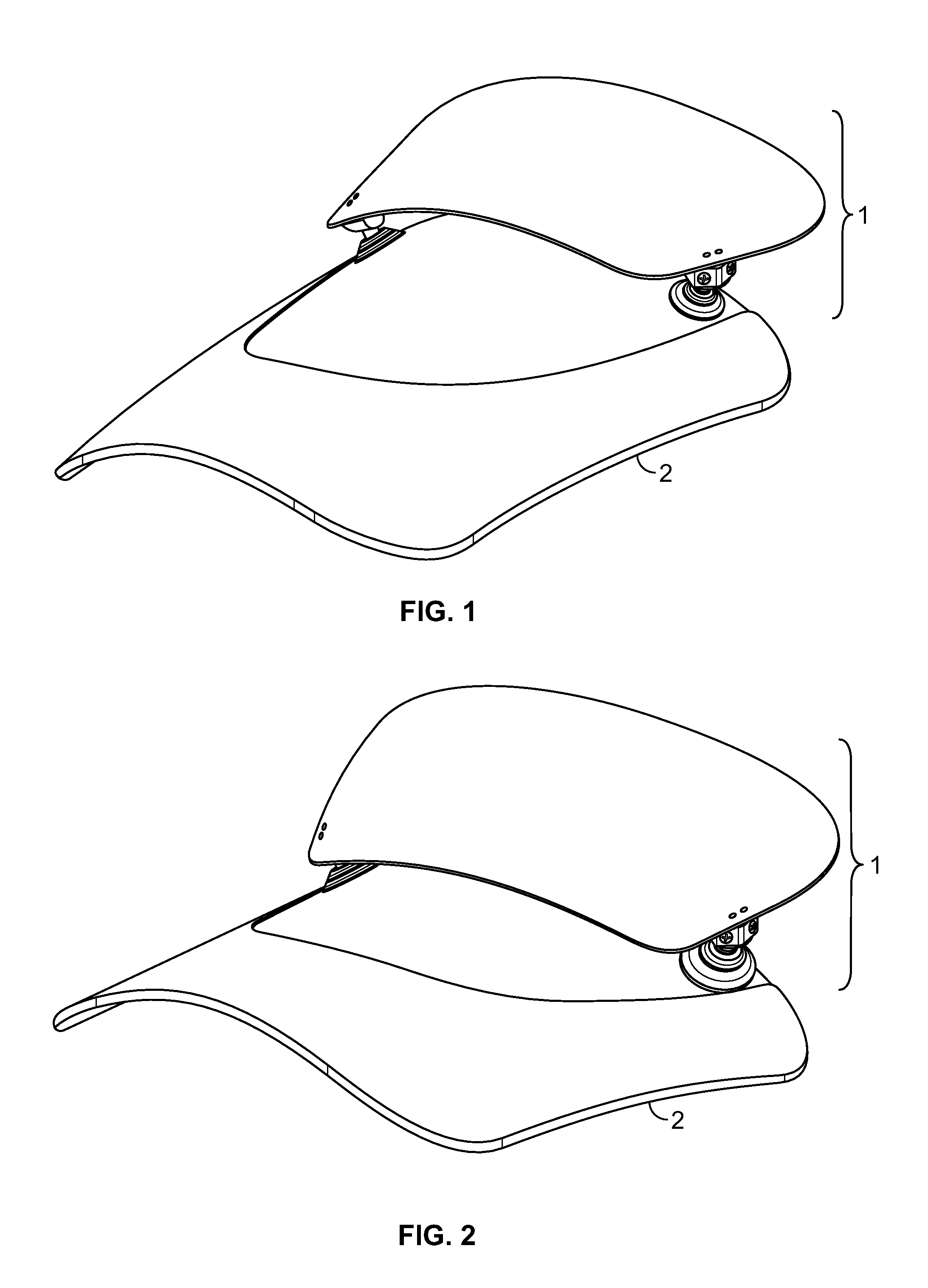

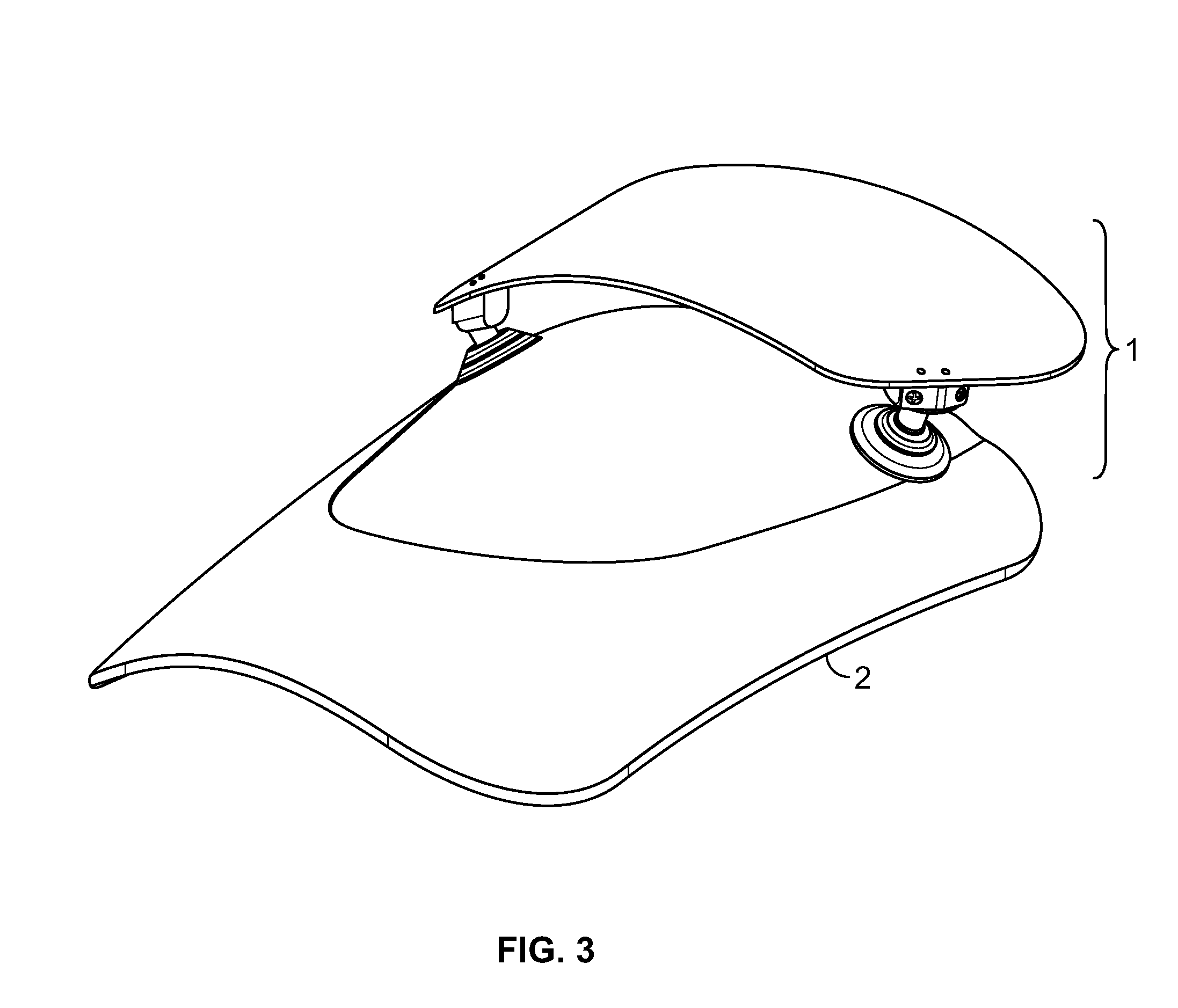

Exterior surface mounted adjustable wind deflector

A wind deflector assembly attachable to the exterior, front or side surface of a vehicle windshield or body, adaptable to be connected to differently shaped and contoured windshields and bodywork, tunable to obtain the desired wind deflection effect and, in some embodiments, removable and reattachable to the vehicle windshield or other aerodynamically desirable locations on the vehicle body. The exterior surface mounted adjustable wind deflector of the present invention comprises a transparent, flexible shield along with two integrated mounting assemblies in the preferred embodiment. The mounting assemblies employ a clamshell type connector adapted for adhesive attachment to the exterior front surface of a windshield without having to drill or otherwise alter the windshield. In other embodiments, the mounting assemblies may utilize a simple non-clamshell adhesive connector, a hook-and-loop connector, a magnetic connector, or similar connection methods to attach the wind deflector to an aerodynamically desirable location on the vehicle windshield or body. The mounting assemblies each comprise a peripherally-toothed post that is integrated into of one the leaves of the clamshell connector. The post is threadedly mated to one end of a stem extending along the central longitudinal axis of the post. The other end of the stem is threadedly mated to a ball. A platform connector element carries as a part thereof a jaw-forming socket sized to receive the ball and squeeze it so as to maintain an adjusted position when the jaws of the socket are tightened down thereagainst. The platform connector element further includes means to attach the shield to the mounting assemblies using screws and adhesive tape.

Owner:SAUNDERS CHARLES A

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com