Patents

Literature

1150results about How to "Reduce contact surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

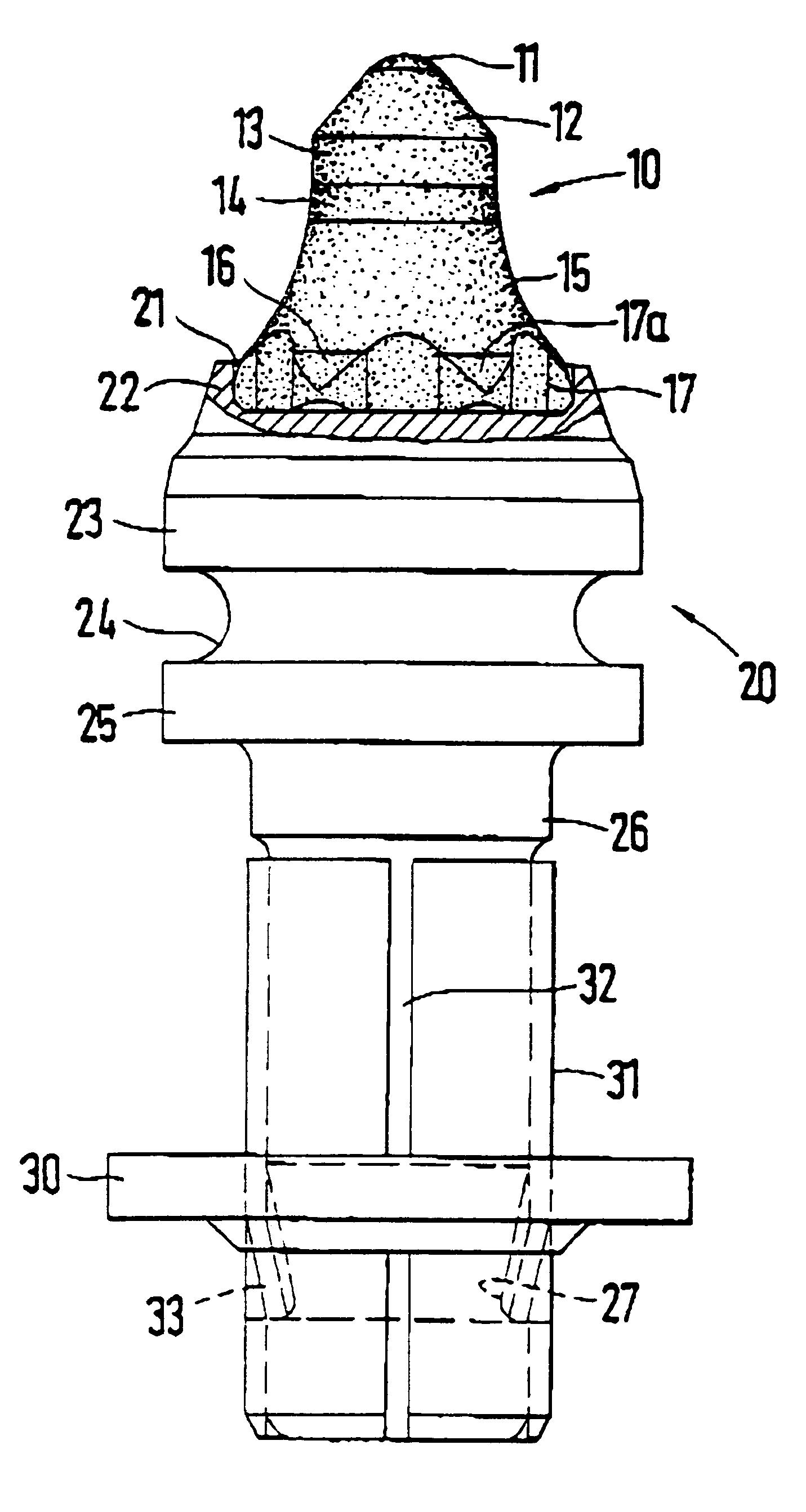

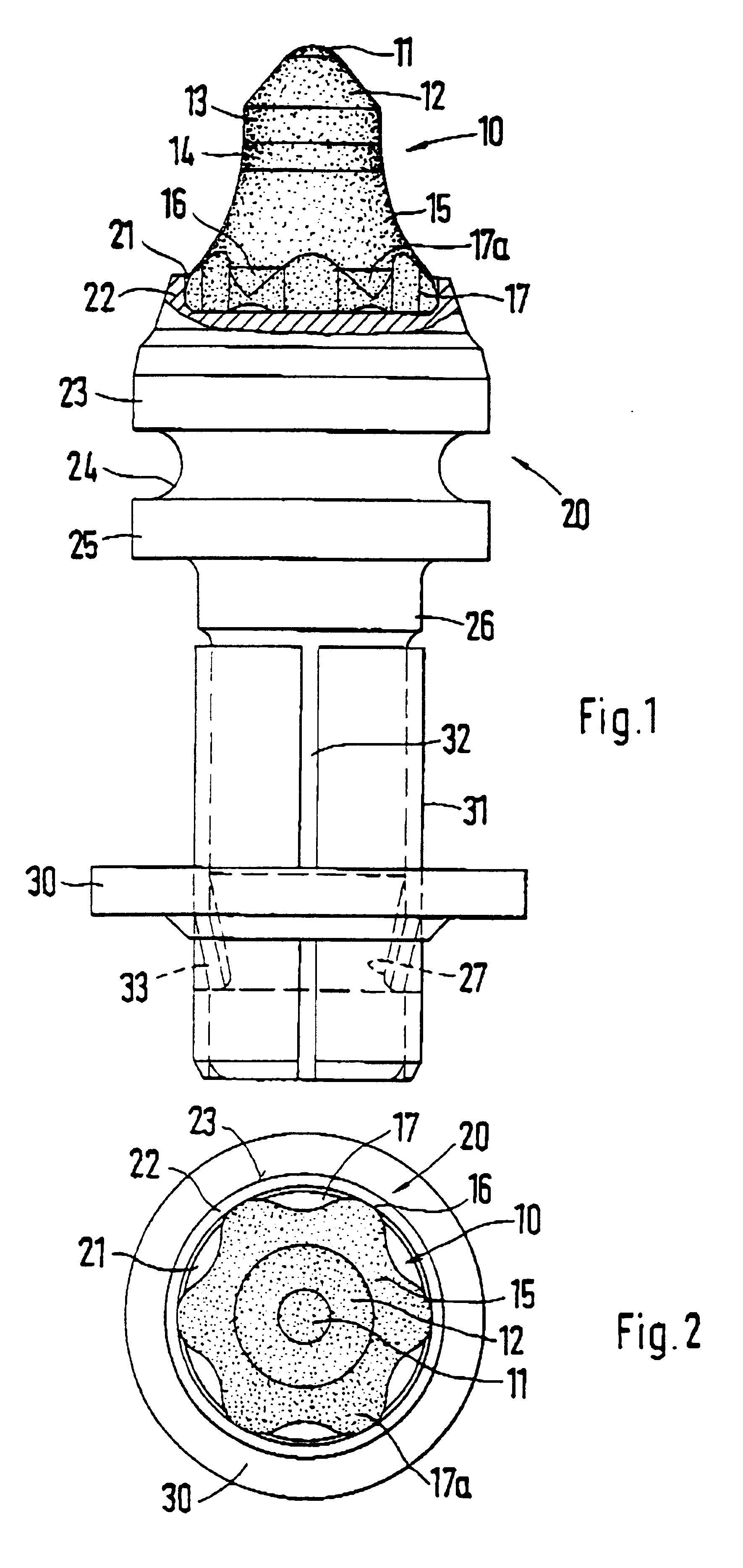

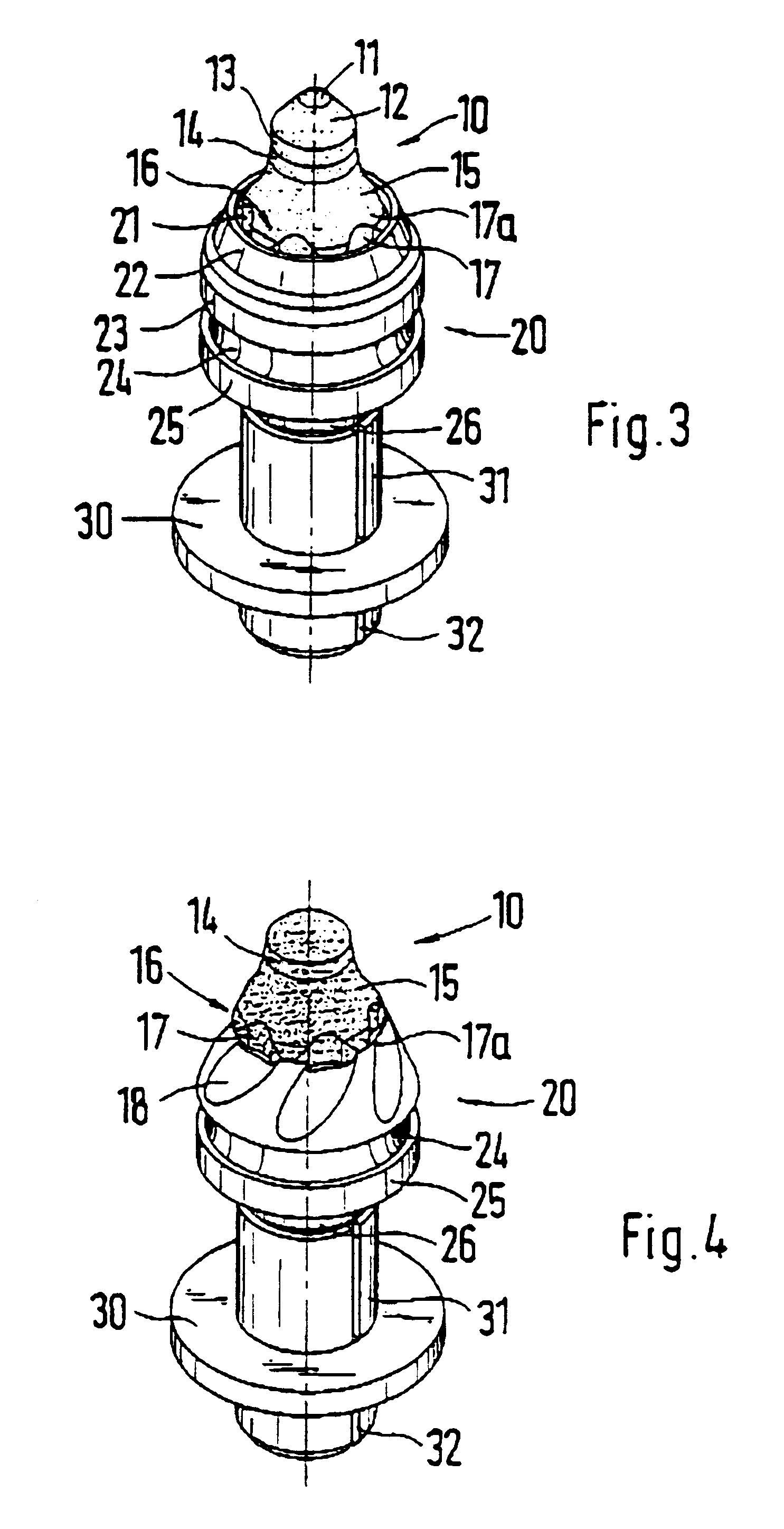

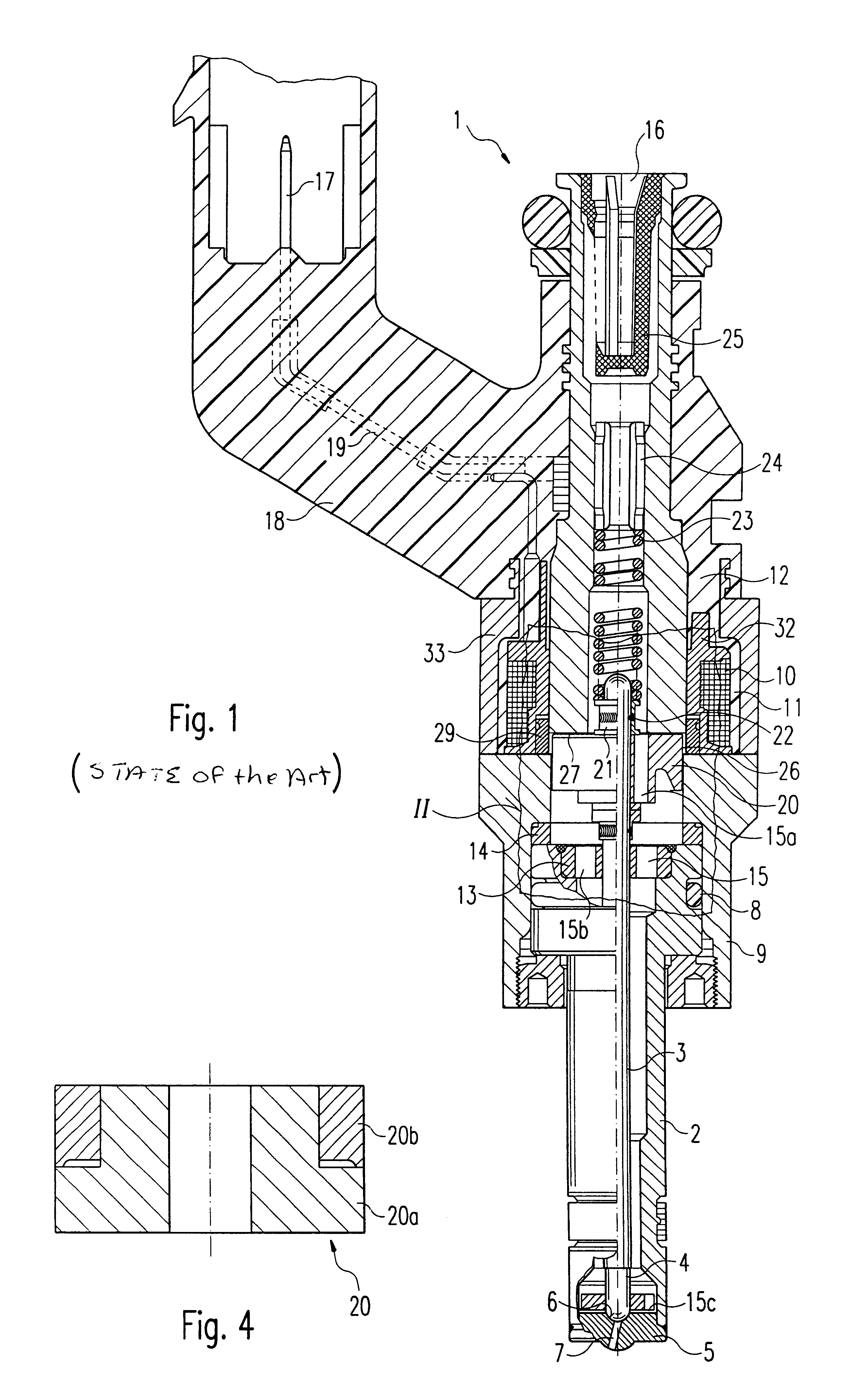

Round-shank bit for a coal cutting machine

InactiveUS6199956B1Sufficient supportLess stressPolishing machinesRevolution surface grinding machinesMaximum diameterEngineering

A round-shank bit for a coal cutting machine or the like, having a bit head and a bit shank, wherein the bit head has a bit tip, maintained by a base element in a receptacle of the bit head. Starting at the base element, the bit tip tapers in a direction toward the free end of the bit tip, wherein the base element forms a maximum diameter of the bit tip, and wherein the bit tip has recesses on its outer contour. In order to assure good rotational behavior over the entire length of the operating time, the base element has the recesses on an outer circumference forming the maximum diameter.

Owner:BETEK BERGBAU UND HARTMETALLTECHN KARL HEINZ SIMON

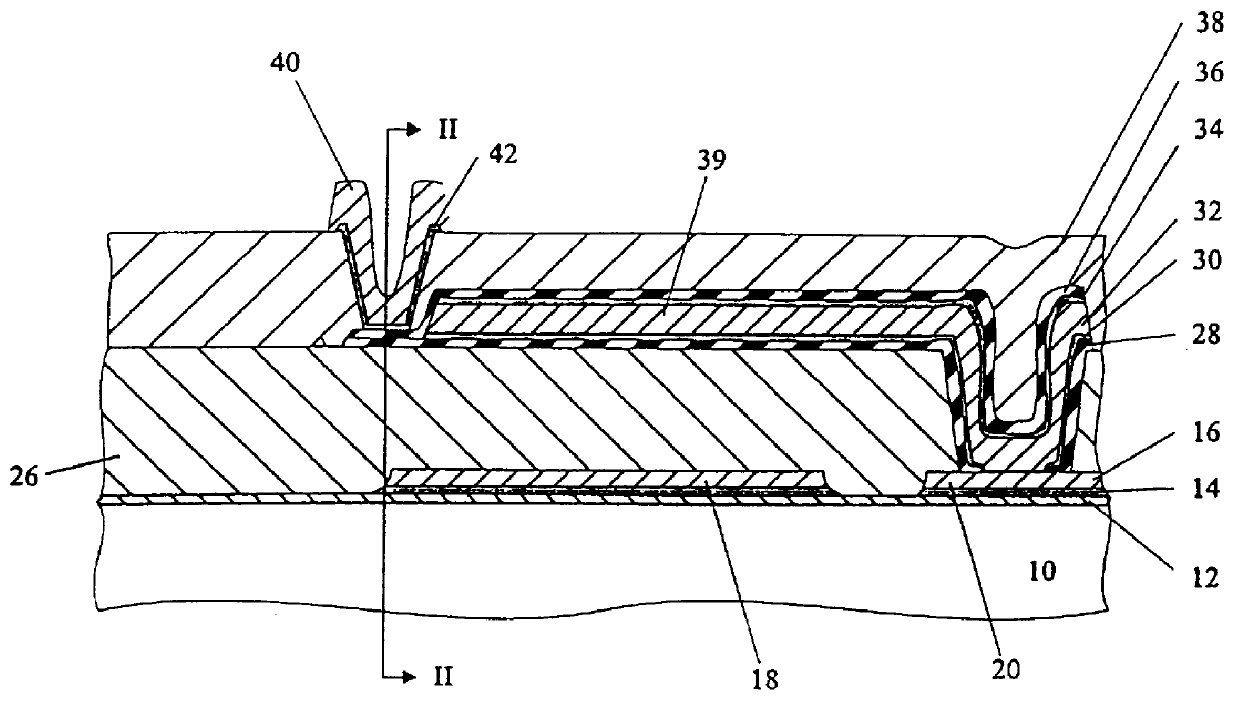

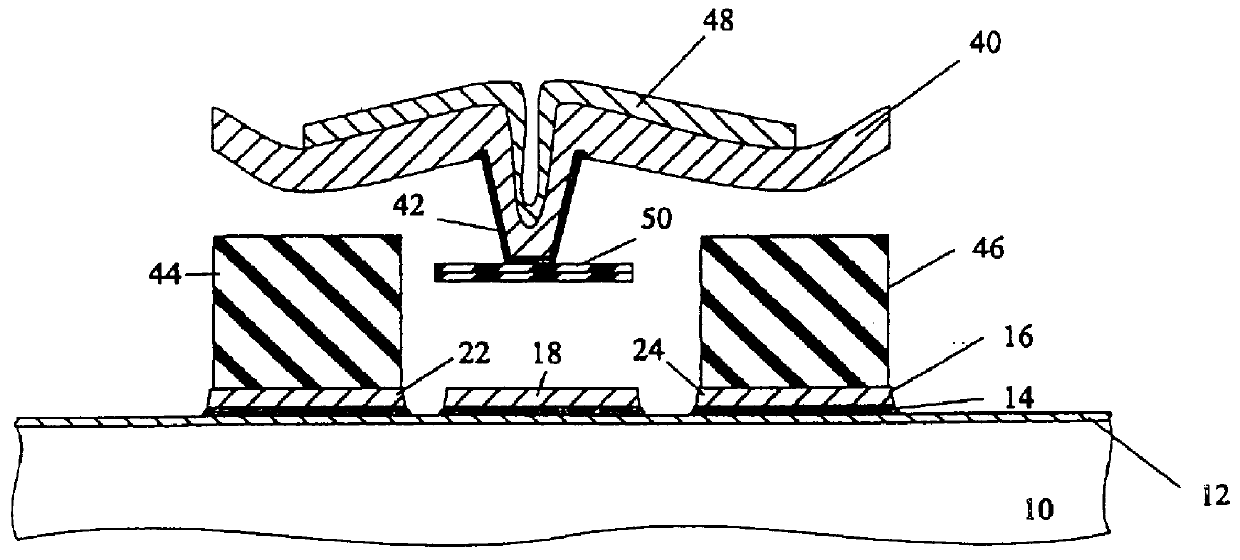

Method for manufacturing a micromechanical relay

InactiveUS6162657ASmall productSmall sizeElectrostatic/electro-adhesion relaysDecorative surface effectsEtchingEngineering

PCT No. PCT / EP97 / 06174 Sec. 371 Date May 11, 1999 Sec. 102(e) Date May 11, 1999 PCT Filed Nov. 6, 1997 PCT Pub. No. WO98 / 21734 PCT Pub. Date May 22, 1998A method of producing a micromechanical relay comprises the steps of providing a substrate including a conductive fixed electrode in or on said substrate. A sacrificial layer and a conductive layer are applied and the conductive layer is structured so as to define a beam structure as a movable counterelectrode opposite said fixed electrode. A contact area is applied, the conductive layer extending between an anchoring region and the contact area and being insulated from said contact area. Subsequently, the sacrificial layer is removed by means of etching so as to produce the beam structure comprising a movable area and an area secured to the anchoring region on the substrate. The beam structure is defined such that etch access openings in said beam structure are structured such that the size of the area covered by the etch access openings used for etching the sacrificial layer increases from the area of the beam structure secured to the substrate to the movable area of the beam structure so that the etching of the sacrificial layer is controlled in such a way that the portion of the sacrificial layer arranged below the movable area of the beam structure is etched faster than the portion of the sacrificial layer arranged in the area of the anchoring region.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

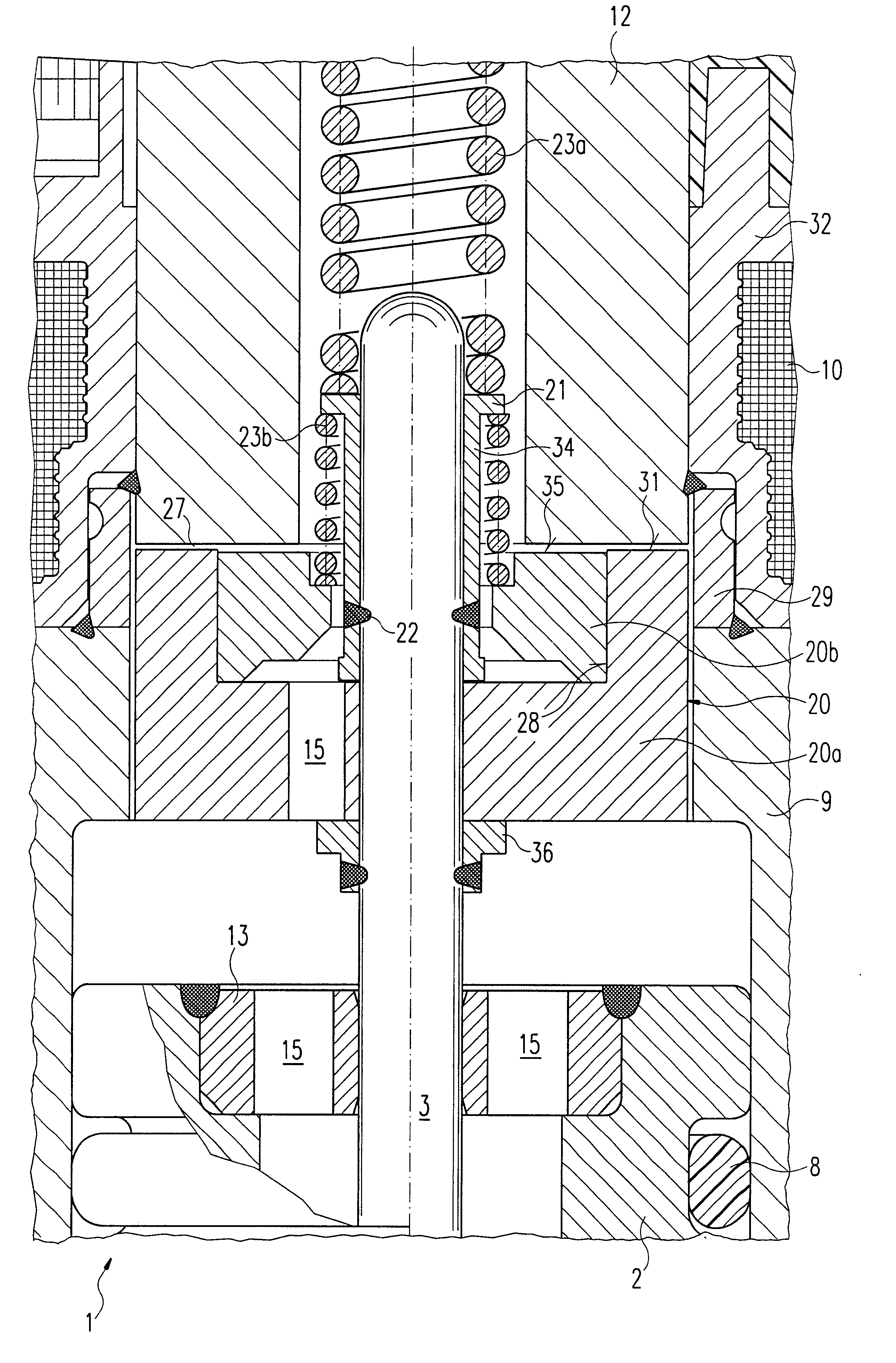

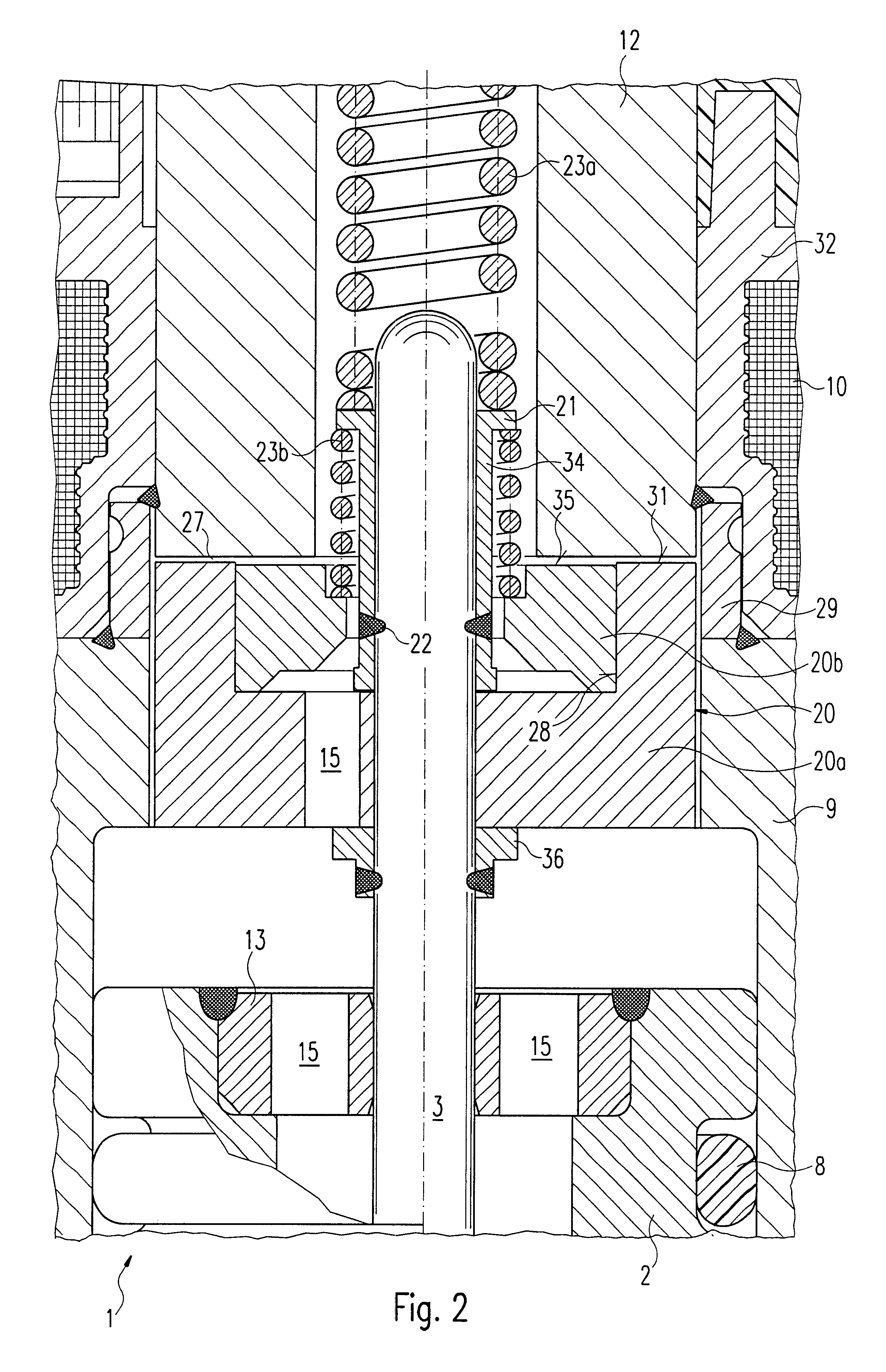

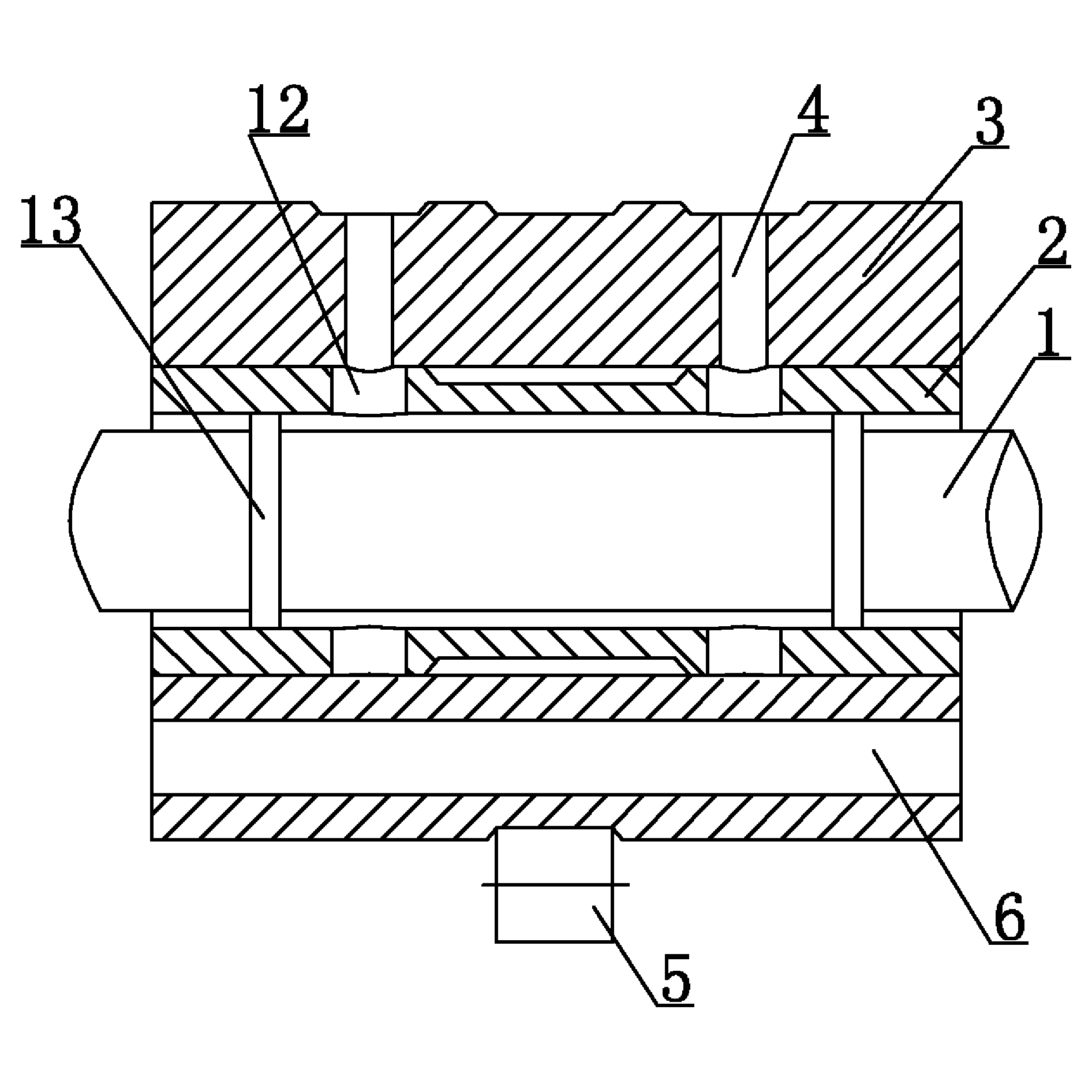

Fuel injection valve

InactiveUS6510841B1Great metering precisionGreat massOperating means/releasing devices for valvesSpray nozzlesExternal combustion engineEngineering

A fuel injector (1) for fuel injection systems of internal combustion engines is specially designed for the direct injection of fuel into the combustion chamber of an internal combustion engine. It is provided with a solenoid coil (10), a two-part armature (20a, 20b) that is acted upon through the solenoid coil (10) in a closing direction by a first resetting spring (23a), and a valve needle (3) that is connected to the larger armature part (20a) in a force-locking manner, for actuating a valve-closure member (4) which together with a valve seat surface (6) forms a sealing seat. The first armature part (20a) is acted upon in the closing direction by the first resetting spring (23a), and the second armature part (20b) is acted upon in the closing direction by the second resetting spring (23b), the spring constants of the resetting springs (23a, 23b) being different.

Owner:ROBERT BOSCH GMBH

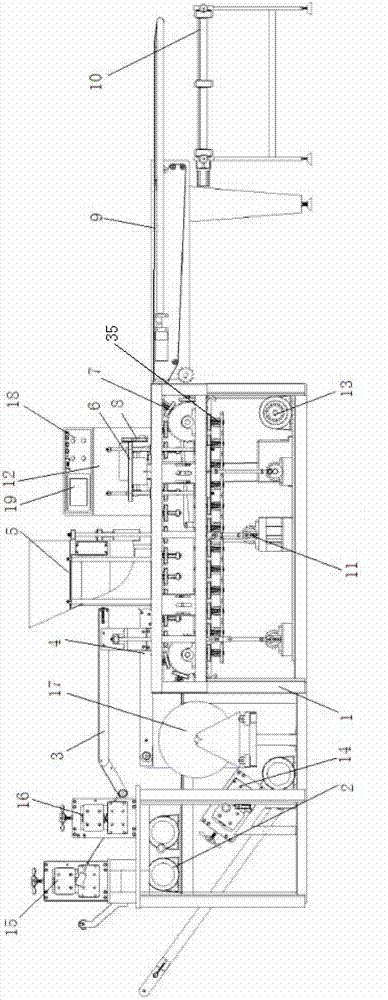

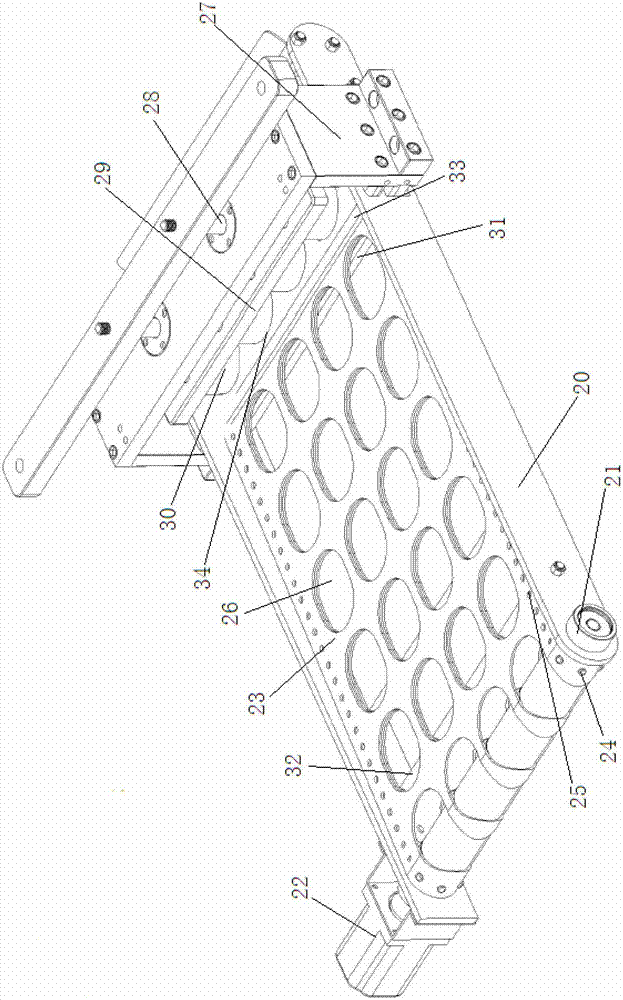

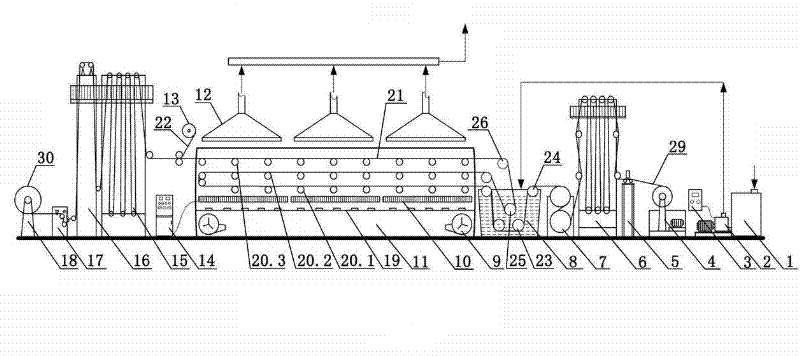

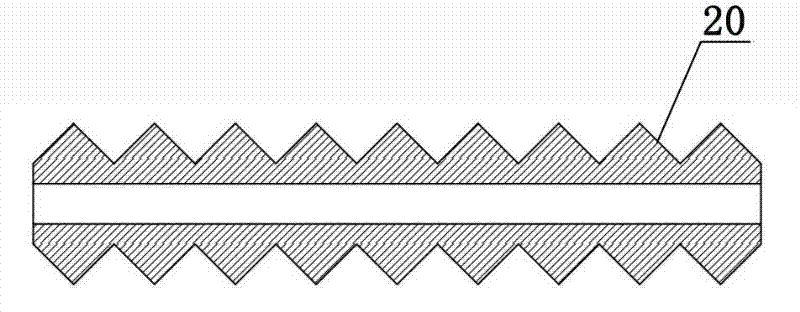

Multifunctional automatic dumpling machine

InactiveCN102726671AGood synchronizationSimple designFood shapingFood preparationSkin rollingBiomedical engineering

The invention discloses a multifunctional automatic dumpling machine, comprising a rack, a skin rolling mechanism, a skin conveyer belt, a punching skin conveying mechanism, a stuffing filling unit, a die closing unit, an encircling intermittent movement dumpling forming template, a disk conveying mechanism, a placement mechanism, an intermittent driving unit and a stepping motor, wherein the punching skin conveying mechanism structurally has a structure that blanking holes on upper and lower side synchronous belts are vertically alignment, the stuffing filling unit realizes multi-hole quantification and synchronization stuffing filling; the contact surface between the skin and the template is reduced by 90% by using the structure of a movable template on the encircling intermittent movement dumpling forming template; protrusion ribs have certain gradients, thus the skins do not adhere to the template and can smoothly enter the forming die; and die assembly can be complete by the projection and concave cavity, thus the produced dumpling has beautiful appearance, and the advantages of firm bonding and low cost are achieved.

Owner:朱景超

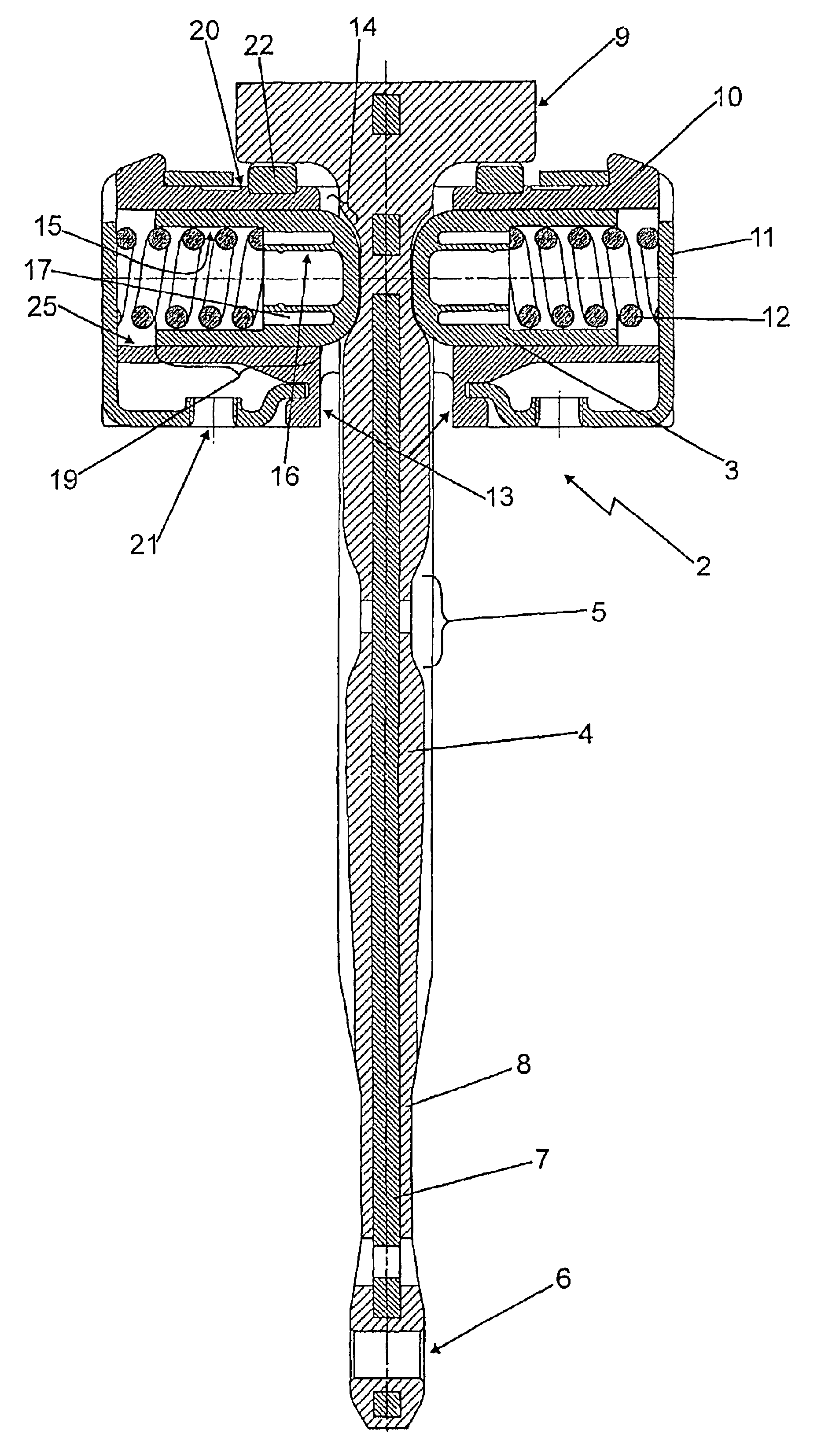

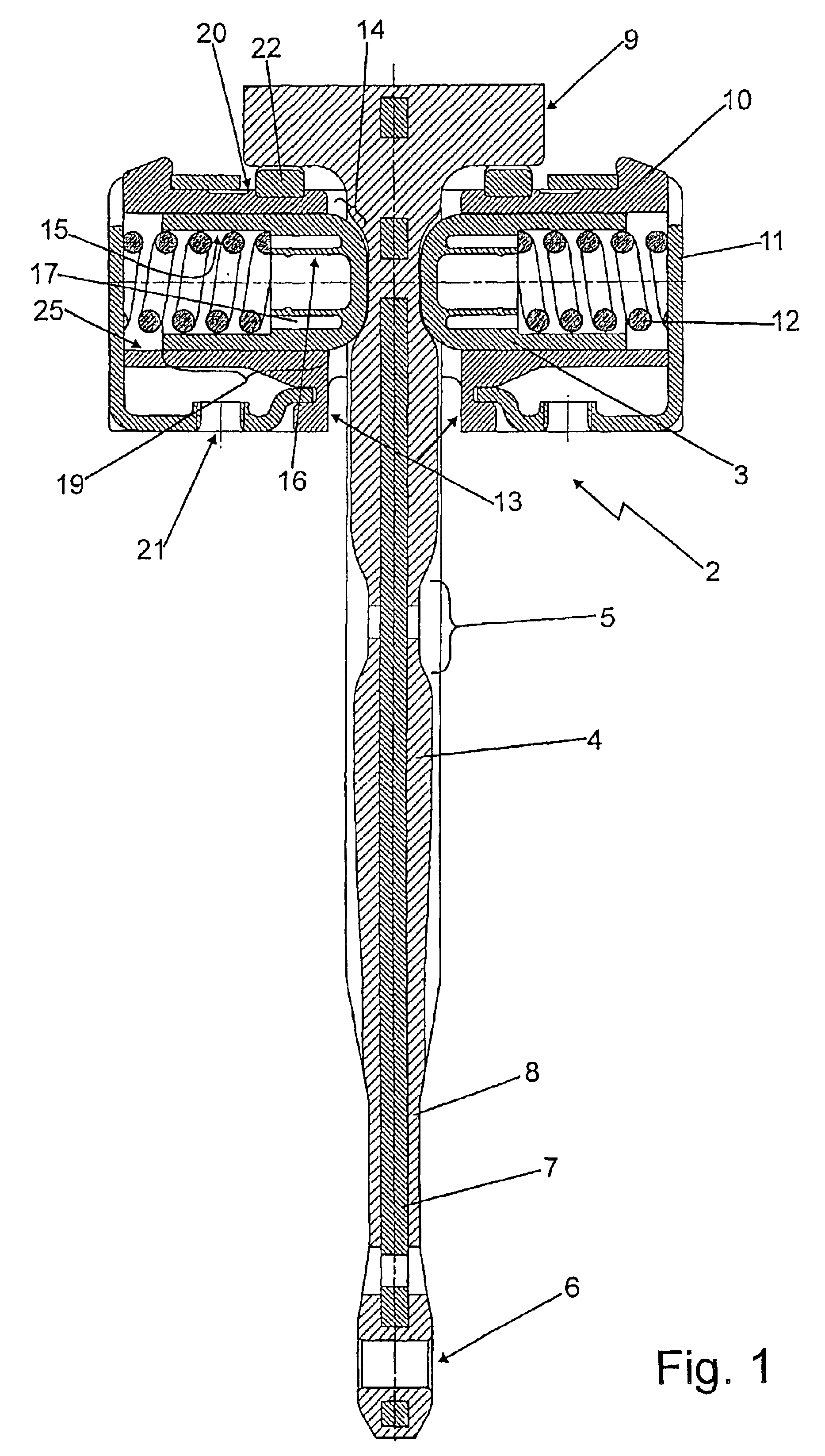

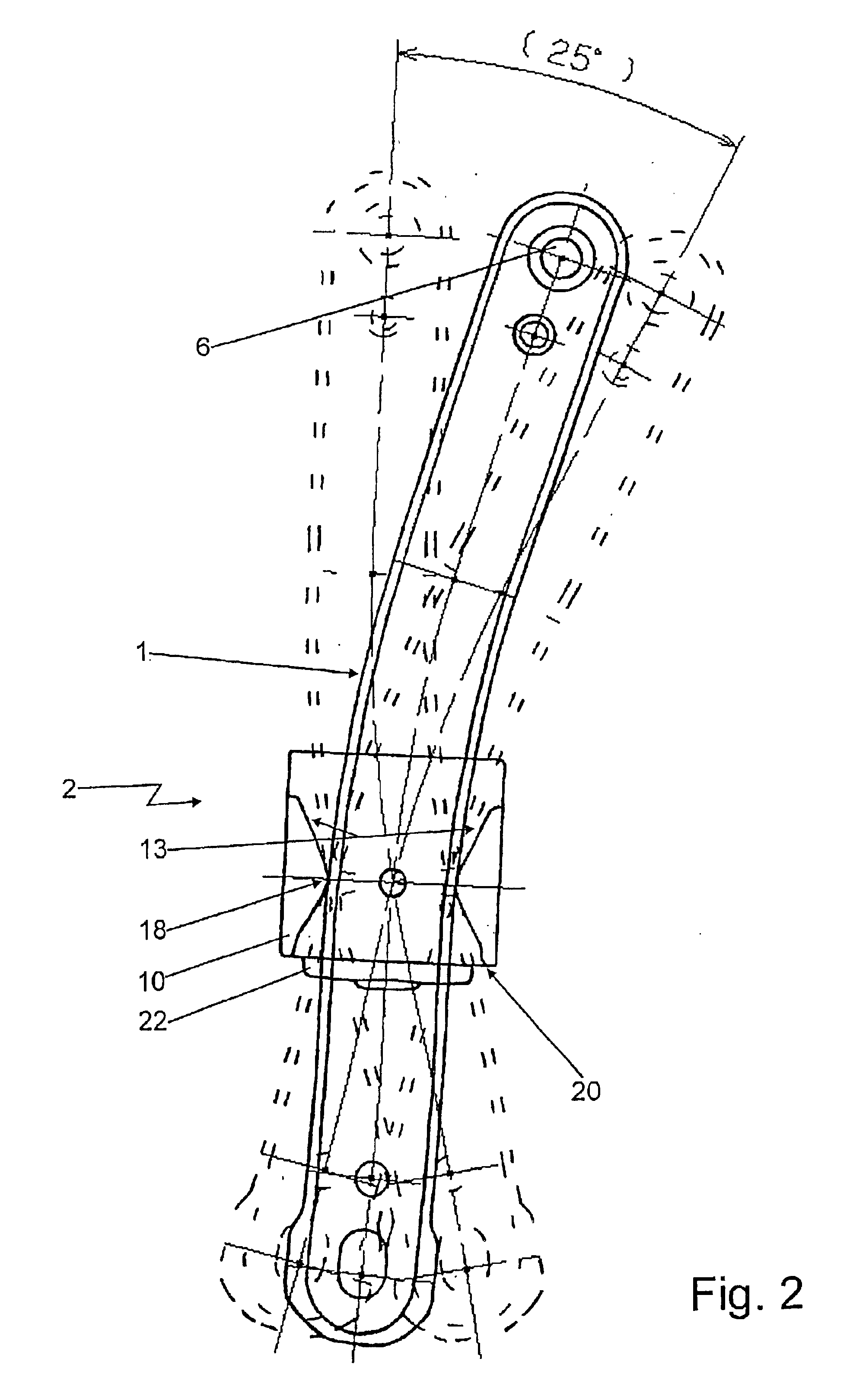

Pressure-ball sliding doorstop

InactiveUS6842943B2Precise constructionHigh stop forceBuilding braking devicesWing fastenersEngineeringMechanical engineering

A doorstop that includes a retainer piece disposed on one of a door and a door support, the retainer piece including a plastic housing with a main opening and a guide opening arranged perpendicular to the main opening and parallel to a pivot axis of the door. The doorstop also includes a door retaining rod articulated on the other of the door and the door support. The door retaining rod passes through the main opening of the retainer piece housing and includes a brake ramp and a catch depression on a side of the door retaining rod. The doorstop also includes a catch device configured to determine specific door opening positions. The catch device includes a brake body and a spring. The catch device connects the retainer piece and the door retaining rod to each other in a moveable manner. The brake body includes a hollow cylinder having a semi-spherical closed end and an open end and is slidingly disposed in the guide opening of the retainer piece. The open end accommodates the spring so that the closed end is pre-tensioned by the spring relative to the brake ramp and catch depression and is guided in the guide opening free of tilt.

Owner:EDSCHA ENG GMBH

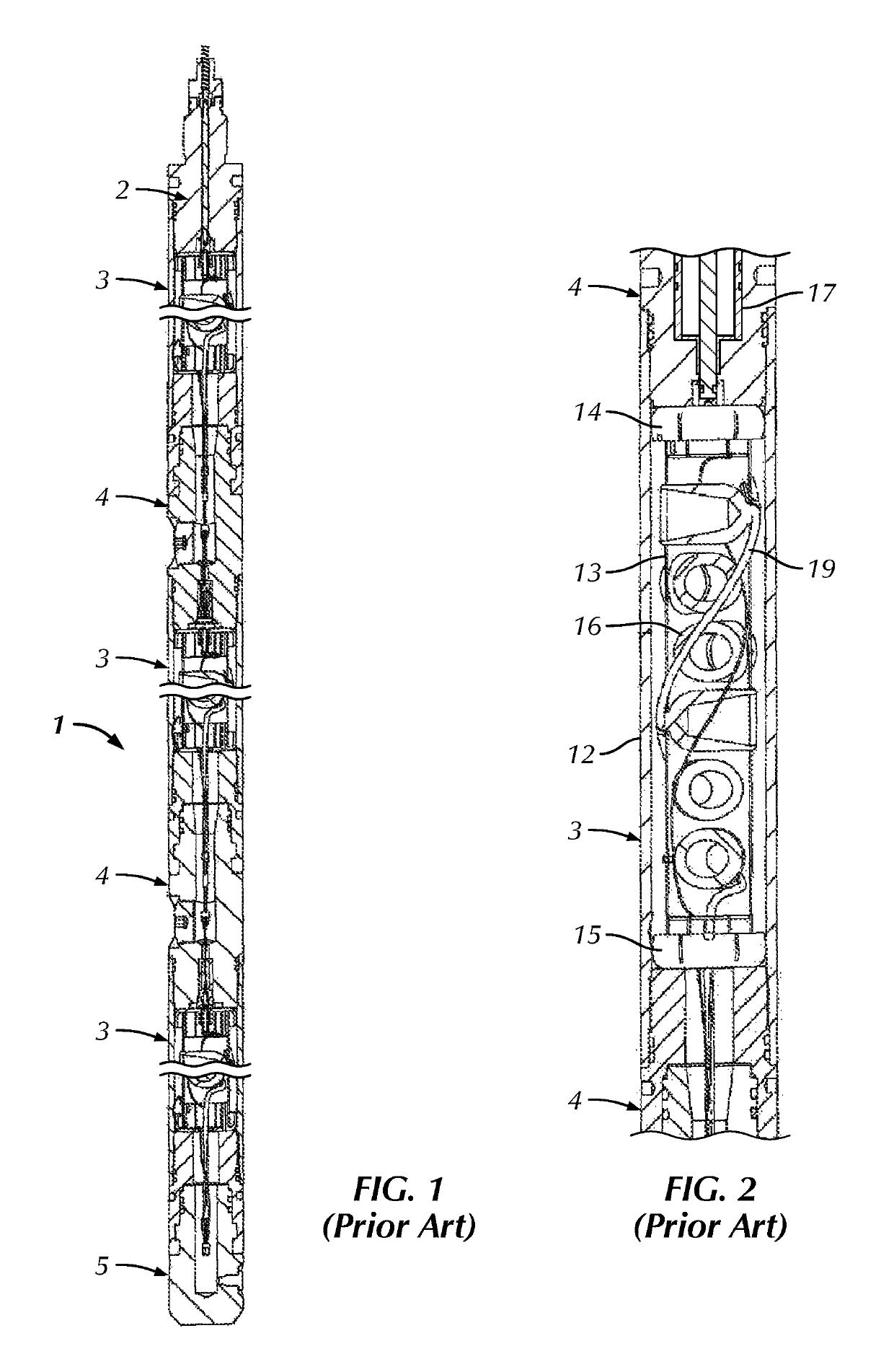

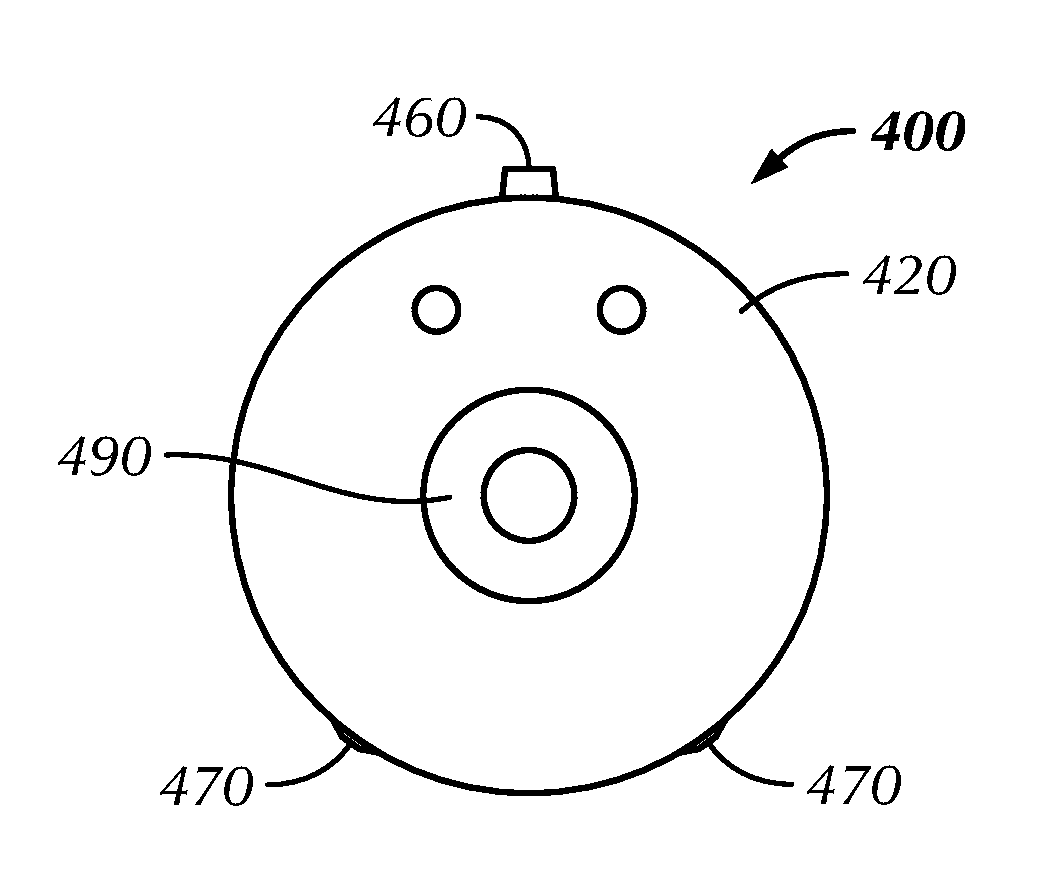

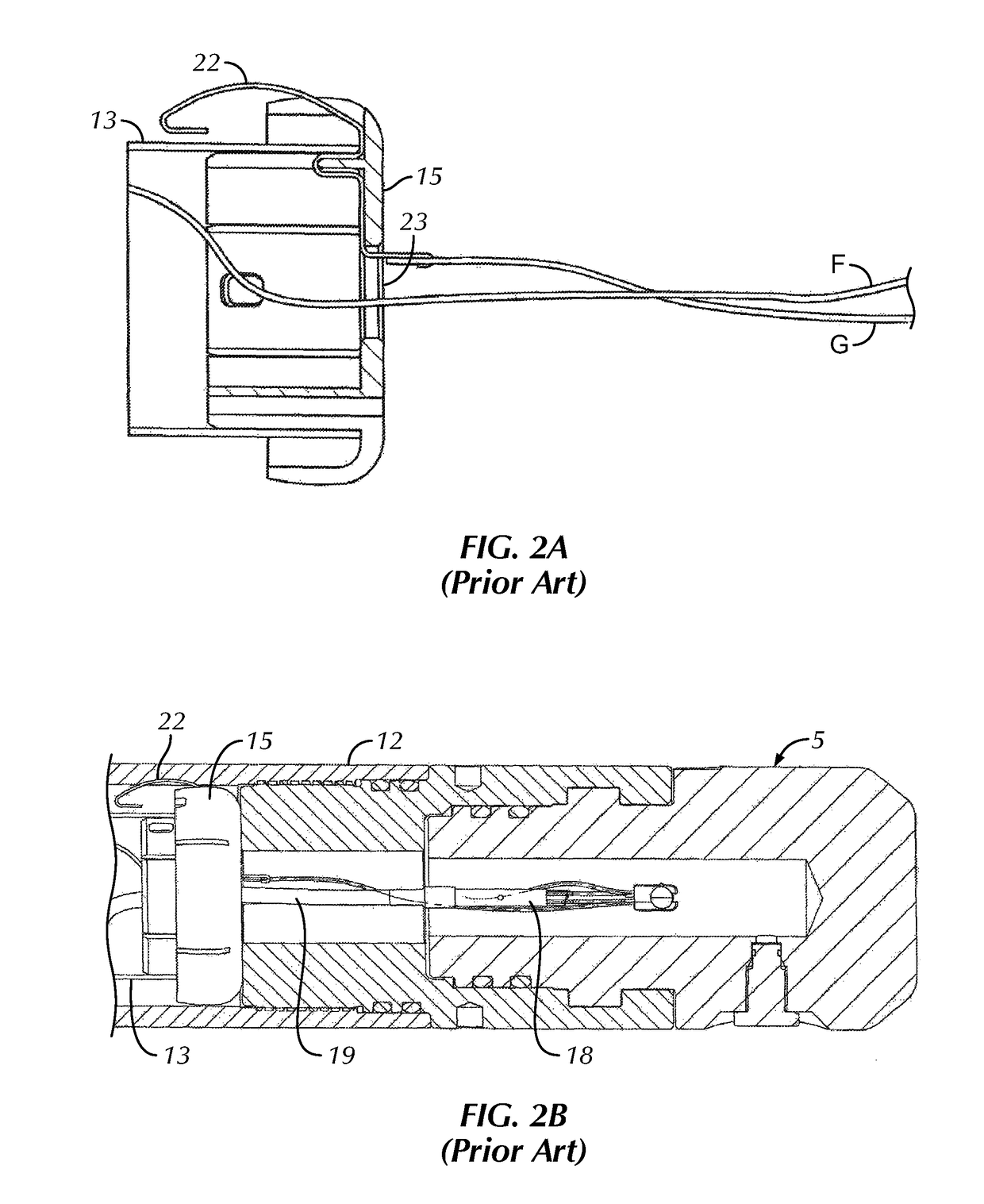

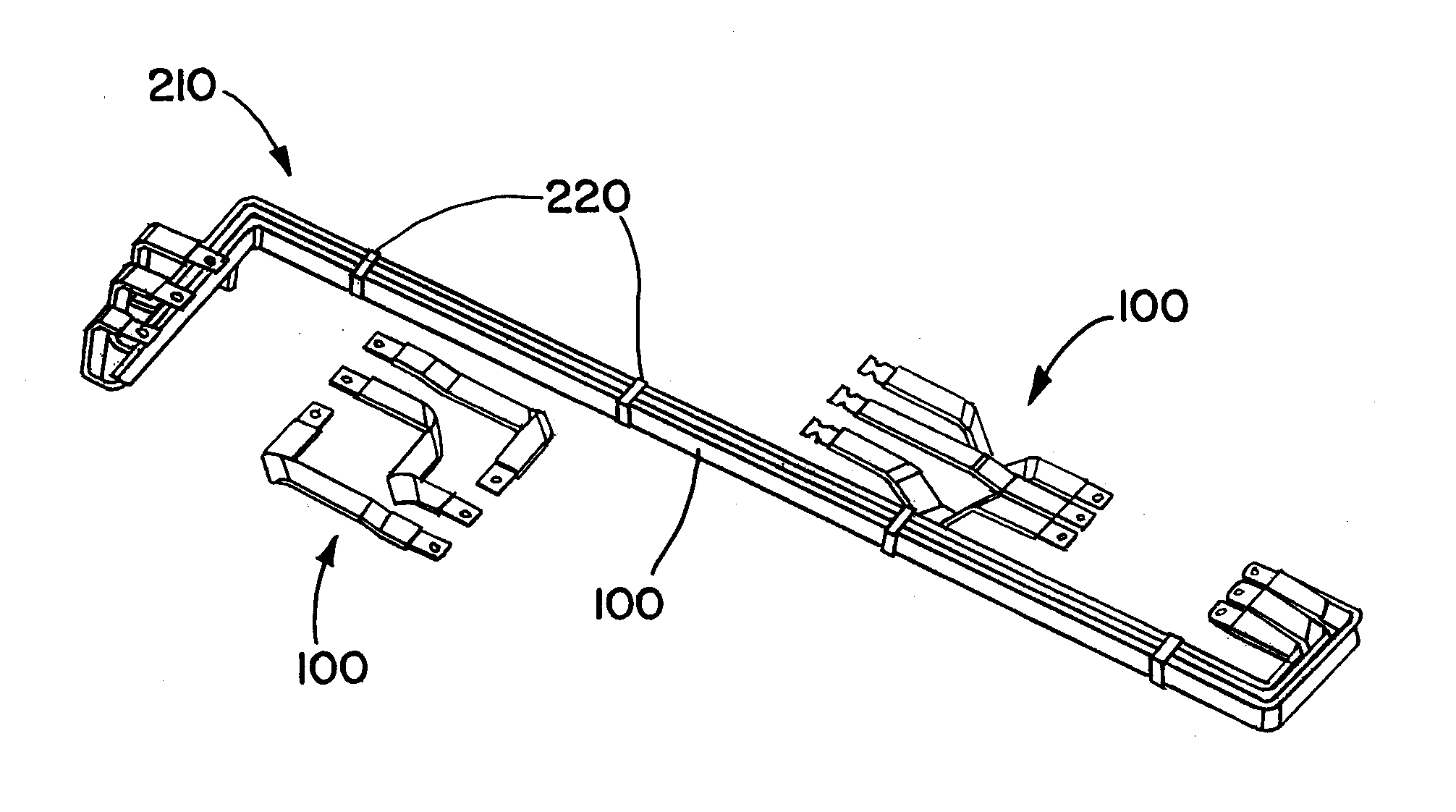

Apparatus for electromechanically connecting a plurality of guns for well perforation

InactiveUS10352136B2Protection from damageReduce frictionExplosive chargesFluid removalElectrical connectionMaterial Perforation

A gun assembly for perforating wells comprising a plurality of guns with shape charges aligned centrically by end caps having insulated connector pins for conducting electrical signals and pressure through the end caps while preventing debris from the blast of one gun from entering and damaging the electrical connections and components of the next gun. The end caps being interconnected physically and electrically by specialized intermediate subs.

Owner:NEXUS PERFORATING LLC

Preparation method of high porosity metal porous carrier materials

InactiveCN101007347AIncreased porosity and through-porosityGood performanceCoatingsPorous metalCarrier material

A high void rate metal porous carrier material preparation method relates to the preparation method of metal porous body with high void rate, small aperture for adsorbing and storing special material, accelerant carrier in the field of astronavigation and environmental protection. It is characterized by: the preparation process coats the metal powder with pore-creating agent to preparing coating powder, then prepares porous metal carrier material after pressing, shaping and sintering. The method of the invention mixes the metal powder and pore-creating agent uniformly to forming the coating powder, then prepares metal porous carrier material after pressing, shaping and multi-stage insulation sintering. It reaches the aims of high porosity, small aperture and high via hole rate through adding pore-creating agent and reducing the contact face between powder and particles, prepares metal porous carrier material with excellent property which porosity>60%, aperture<35 mum and via hole rate >=95%.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

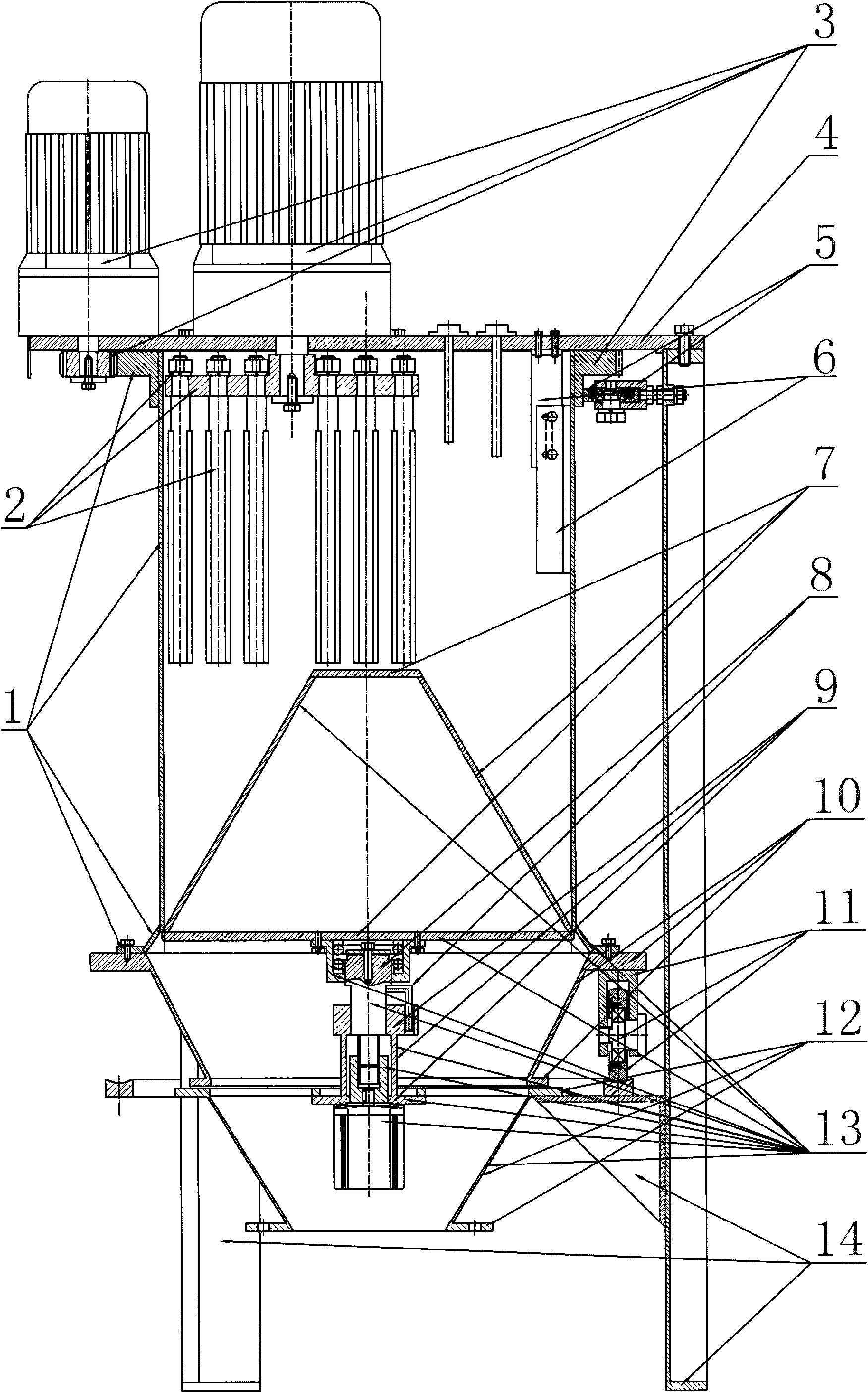

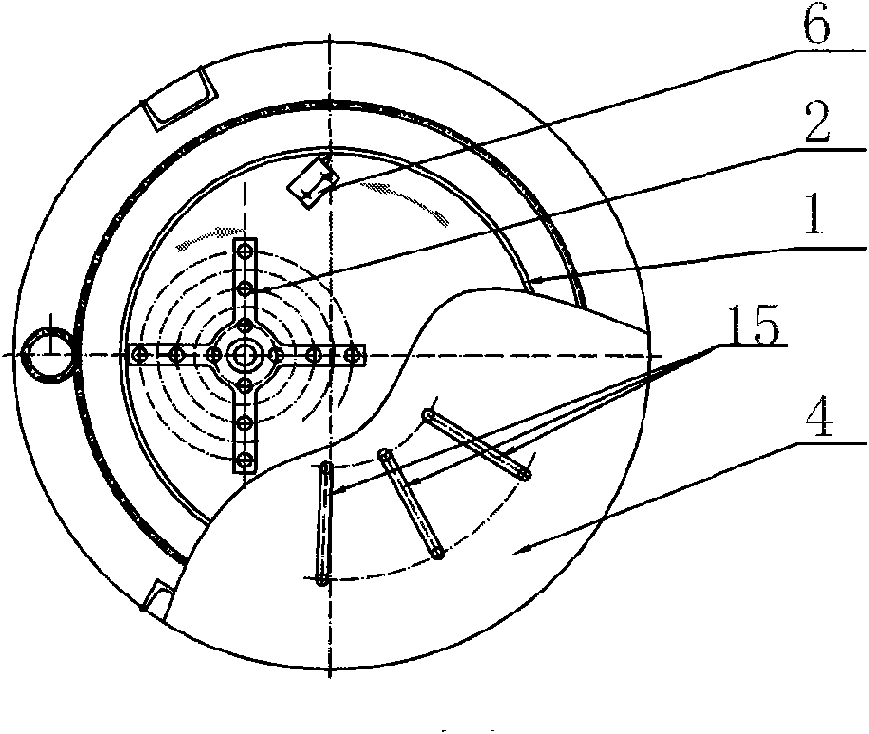

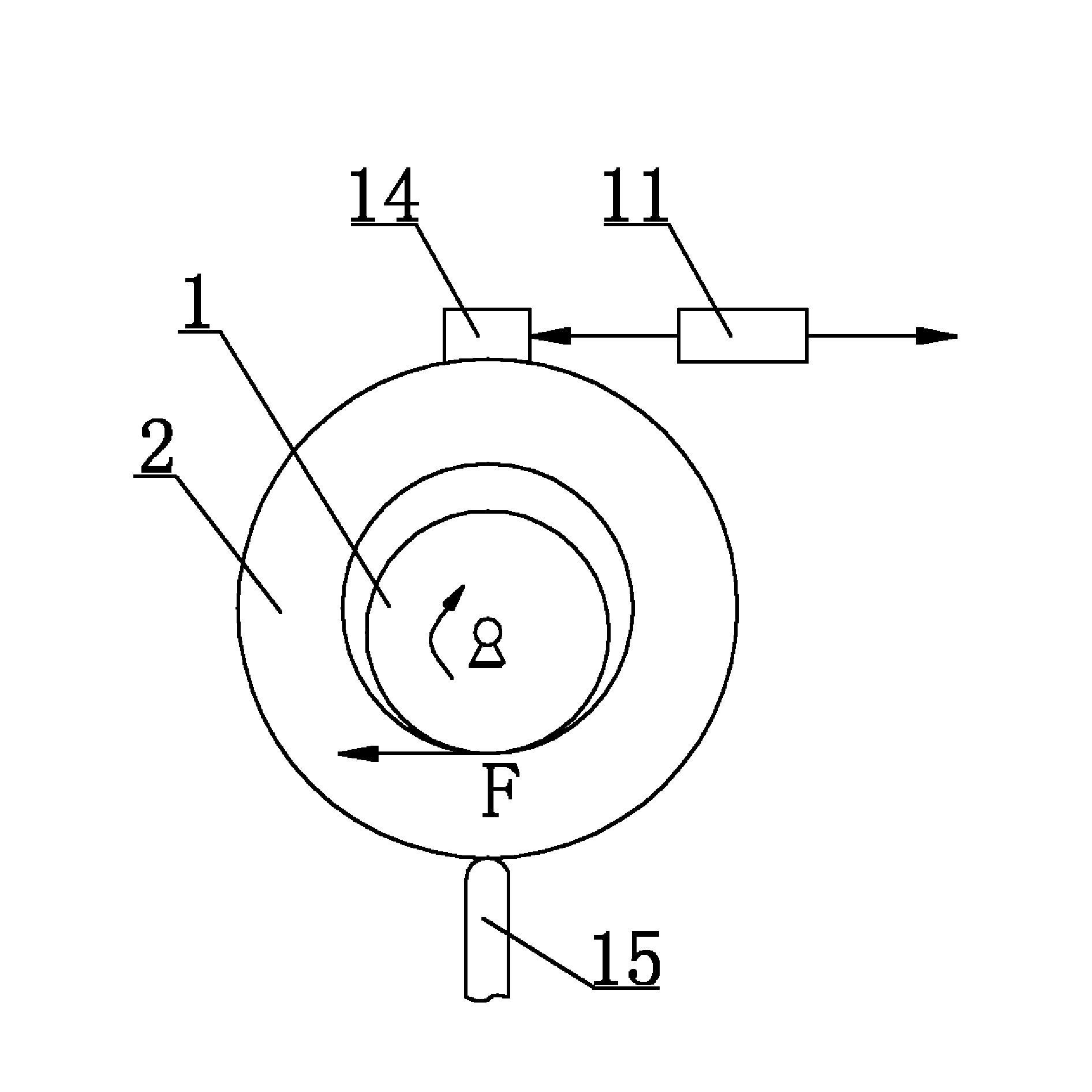

Multifunctional stirring machine

InactiveCN101658771AImprove work efficiencyImprove the quality of workRotating receptacle mixersTransportation and packagingAutomatic controlPulp and paper industry

The invention relates to a multifunctional stirring machine which consists of a rotatable vertical cylindrical container and a stirrer capable of rotating in reverse direction in the container. The structural design that a rotating shaft center of the container and the rotating shaft center of the stirrer are eccentric and a scraper mechanism which is specially arranged can ensure that the multifunctional stirring machine has no stirring dead angles during the work, and an electrical material level automatic control device can ensure the discharge flow of materials by relying on the self-gravity and simultaneously maintain the stable material level in the container. The multifunctional stirring machine can have a plurality of functions of mixing, peeling, clearing, polishing, dampening andthe like by being matched with stirring rods with different structures. When the multifunctional stirring machine is used as a mixing machine, the multifunctional stirring machine has the advantagesof simple structure, low cost, fast mixing speed, high mixing uniformity, small segregation tendency, low energy consumption, simple use and maintenance, long service life and the like. When the multifunctional stirring machine is used as a peeling machine, a clearing machine or a polishing machine, the multifunctional stirring machine has the advantages of high peeling efficiency or good clearingeffect, no production of crushed particles, low energy consumption and the like. When the multifunctional stirring machine is used as a dampening machine, the multifunctional stirring machine has theadvantages of uniform dampening, low energy consumption and the like.

Owner:王洪福

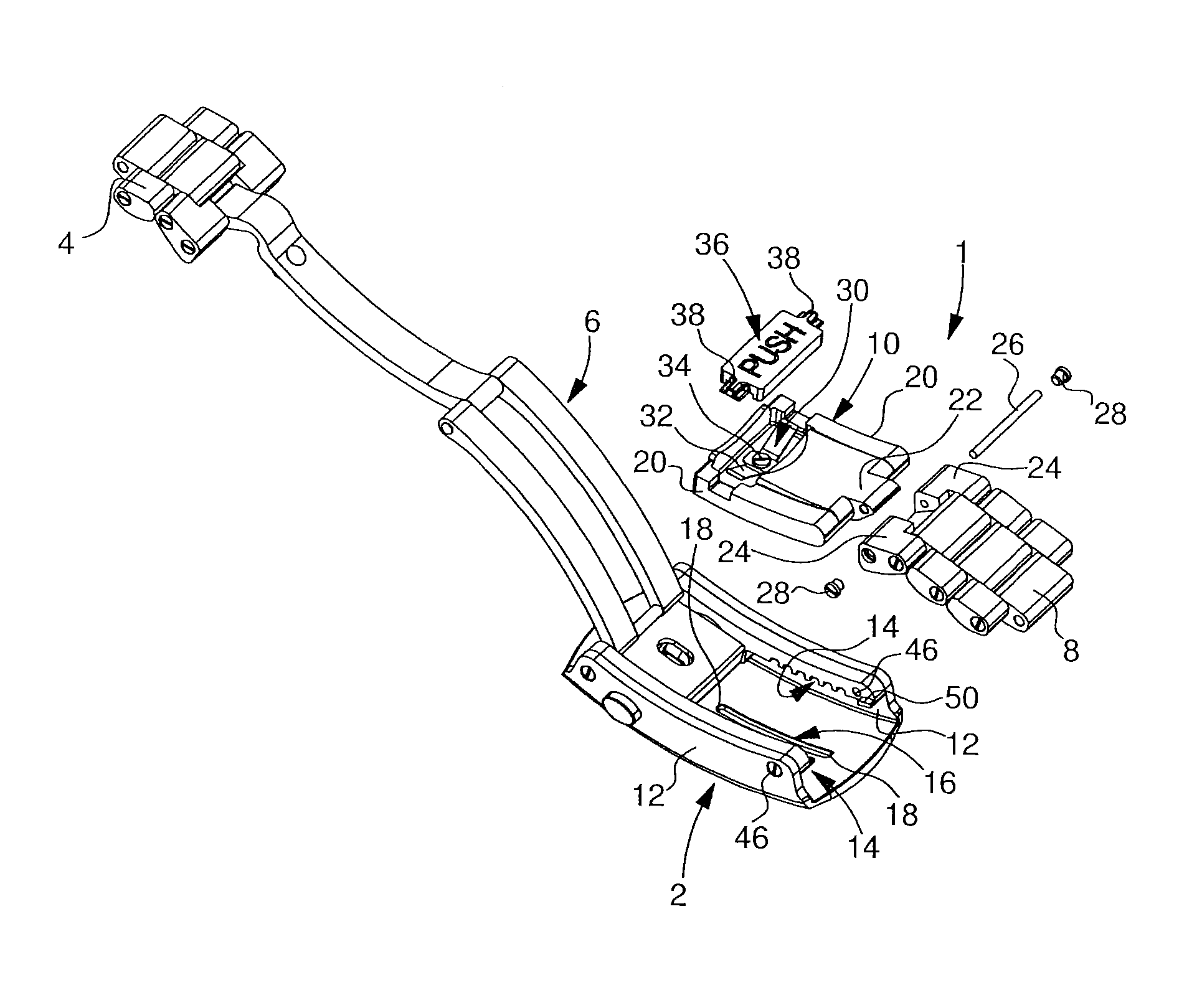

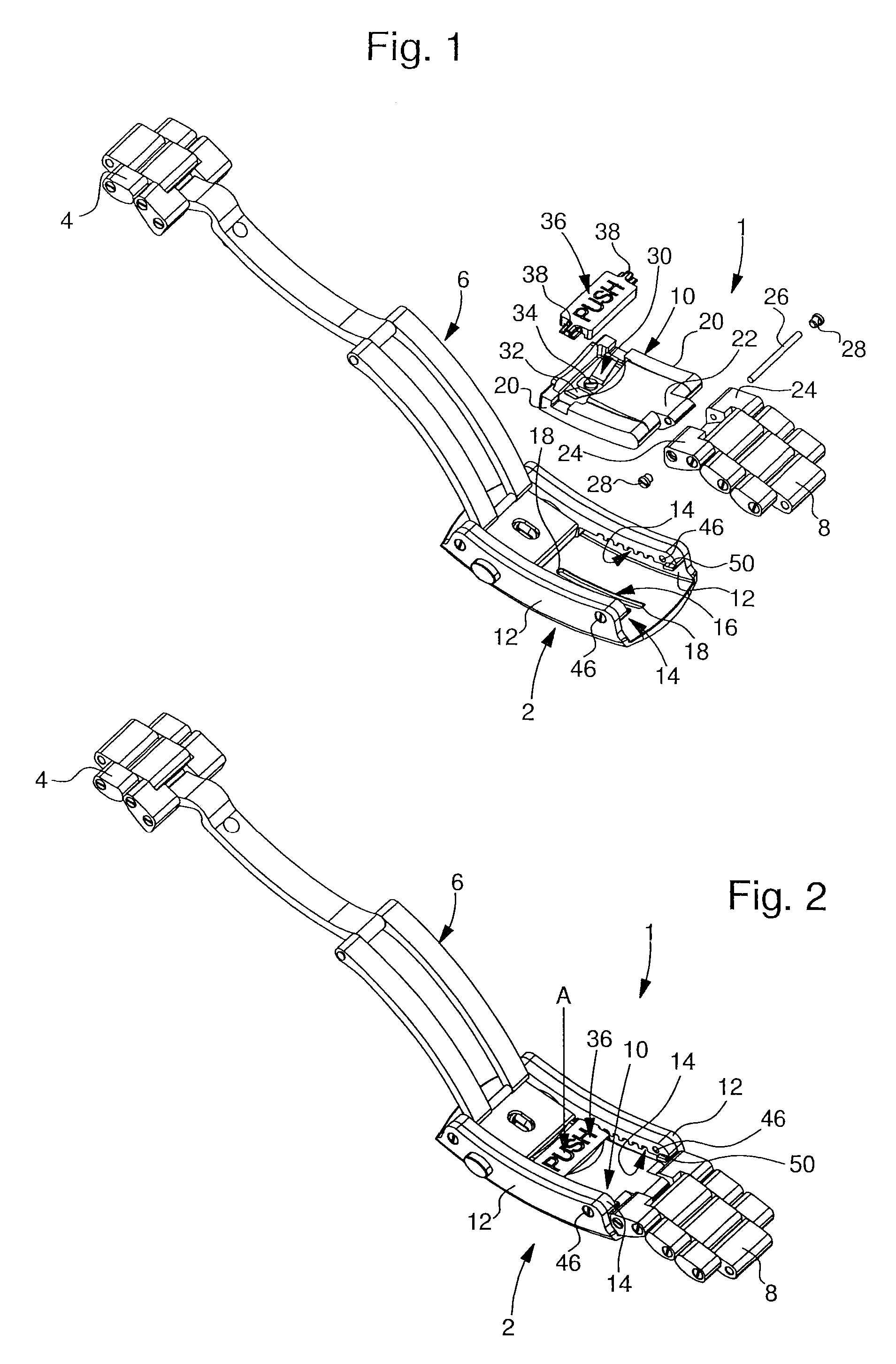

Clasp for a watch bracelet

ActiveUS9003611B2Simple mechanical structureGuaranteed uptimeBraceletsWrist-watch strapsPush-buttonEngineering

Owner:OMEGA SA

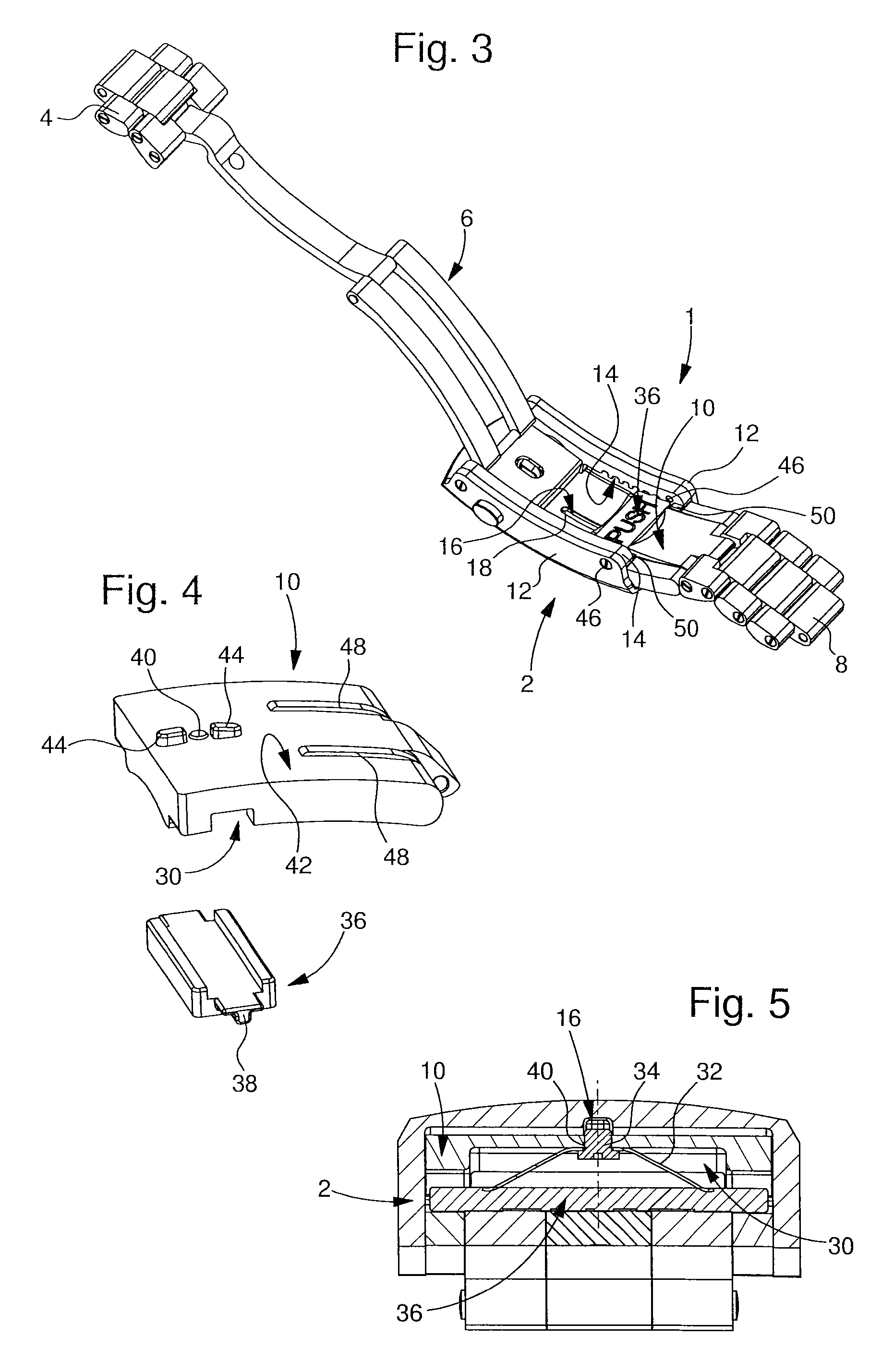

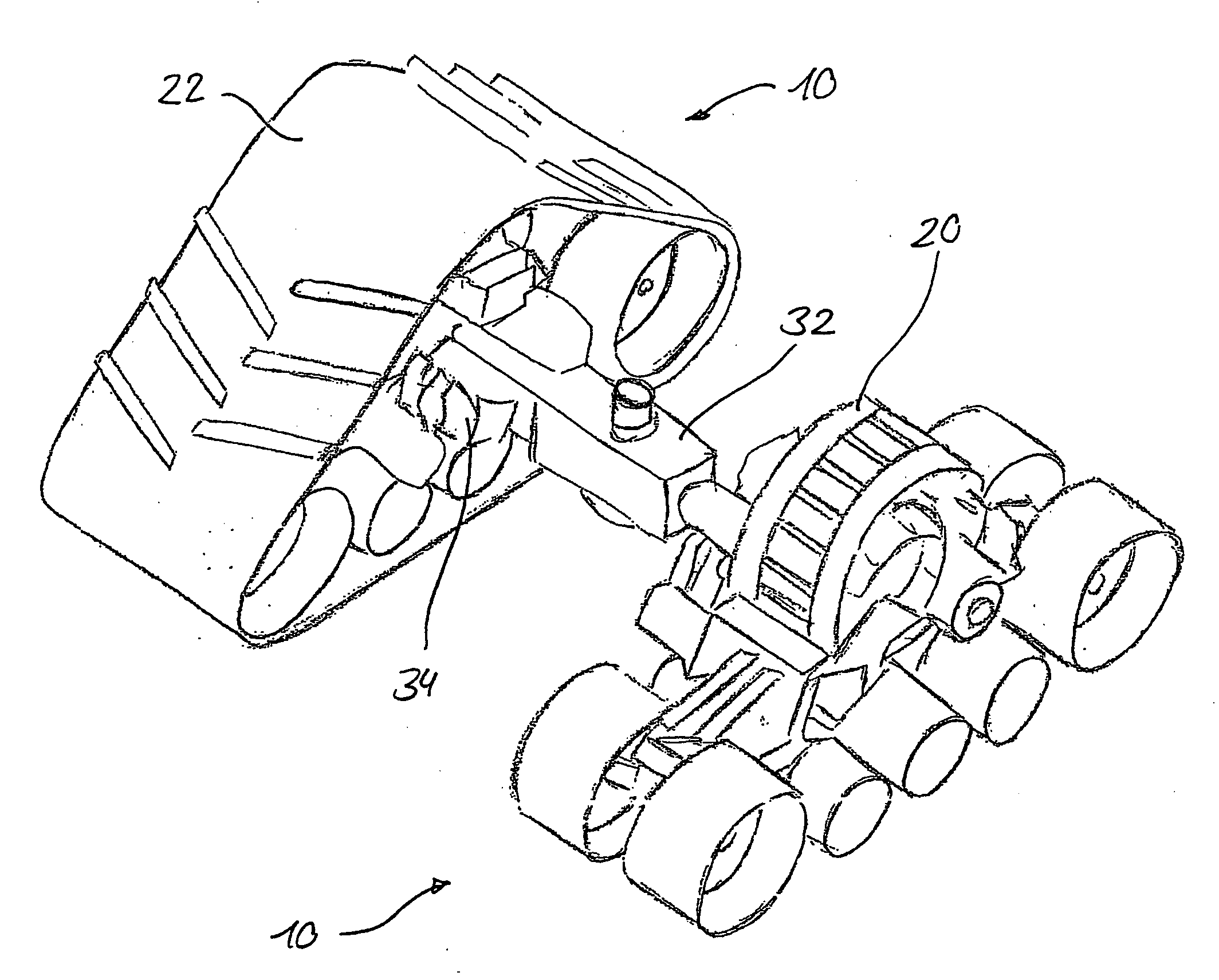

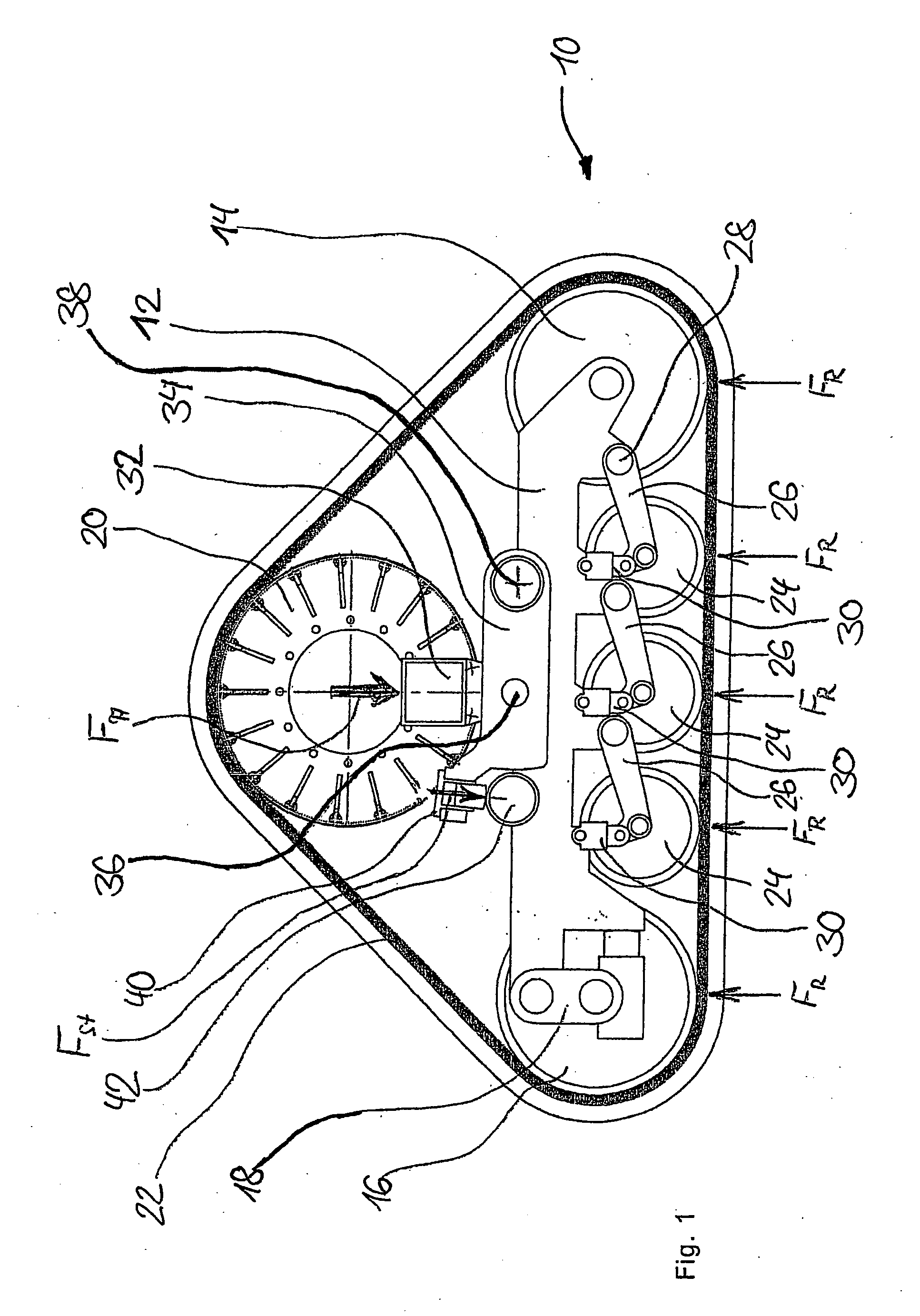

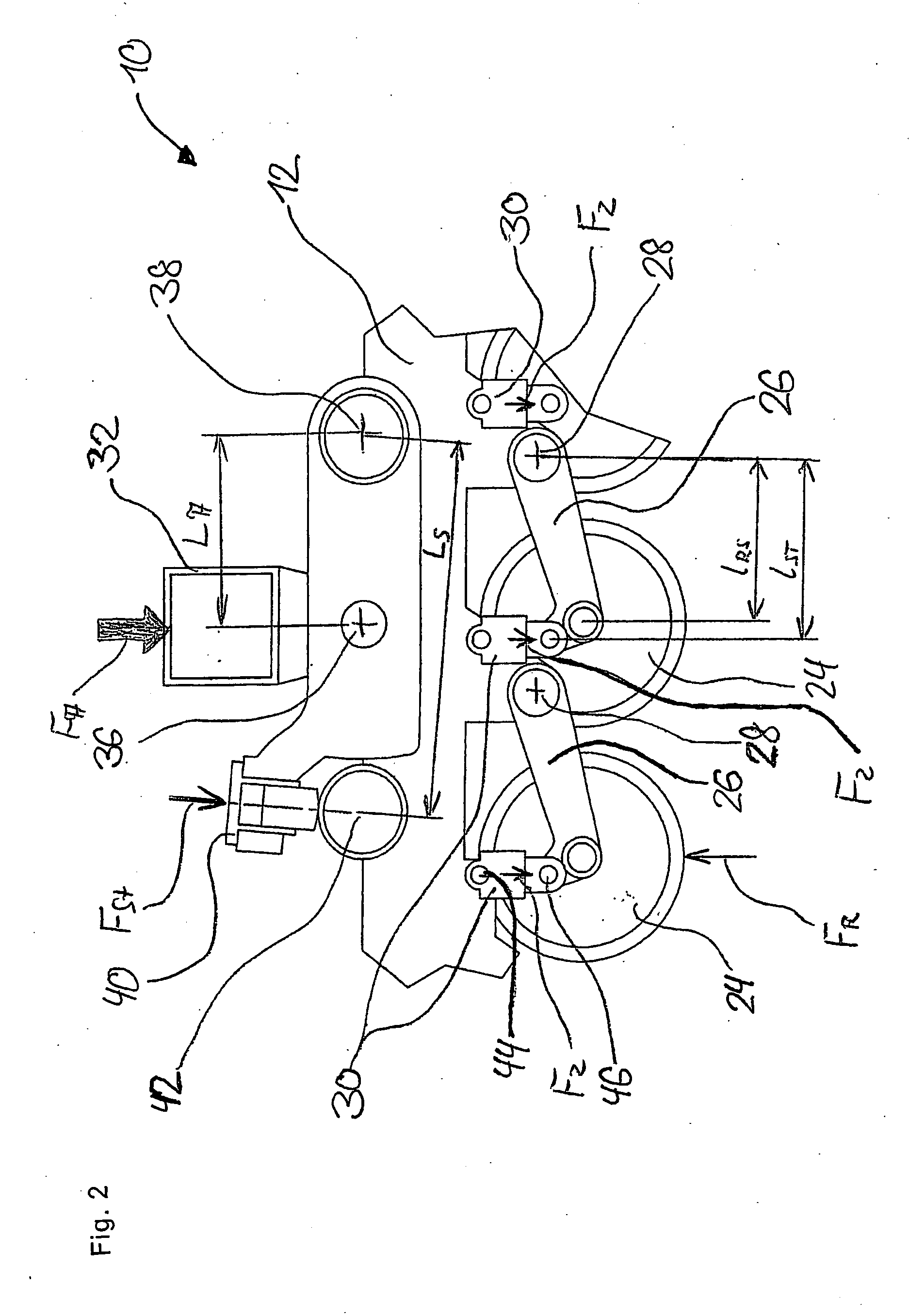

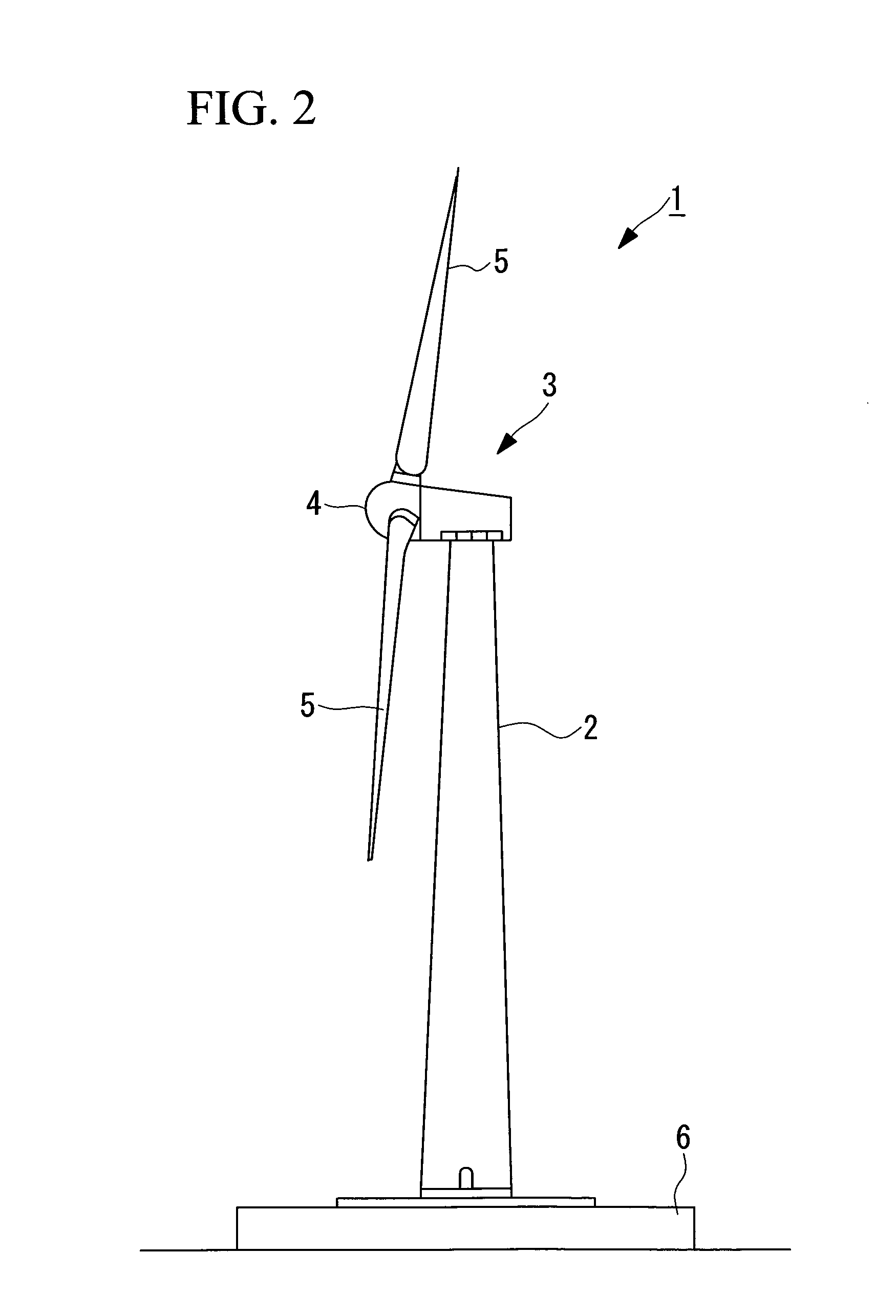

Traveling Mechanism for Agricultural Machines and Off-Road Vehicles Having an Endless Belt -Band Traveling Gear and a Corresponding Belt-Band Traveling Gear

InactiveUS20080084111A1Improve tilt resistanceGreat tractionSuspensionsEndless track vehiclesBogieVehicle frame

The invention relates to a spring-suspended, bearing force-optimized belt-band traveling gear (10) for ground vehicles, particularly for self-propelled agricultural machines and other off-road vehicles, comprising at least two outer deflection rollers (14, 15, 16, 17) over whose periphery an endless belt-band (22) rolls off, and at least one supporting roller (24) for supporting the belt-band section, which is in contact with the ground, between both deflection rollers (14, 15, 16, 17). A bogie truck (12, 13), in which the at least two deflection rollers (14, 15, 16, 17) are mounted in a manner that enables them to rotate, is supported against a body frame of the vehicle by means of a first fluidic suspension unit and / or damping unit. The at least one supporting roller (24) is supported on the bogie truck (12, 13) by means of a second fluidic suspension unit and / or damping unit. A fluidic coupling of the suspension units and / or damping units of the bogie truck (12, 13) is provided against the vehicle frame and the at least one supporting roller (24) mounted on the bogie truck (12, 13).

Owner:DEERE & CO

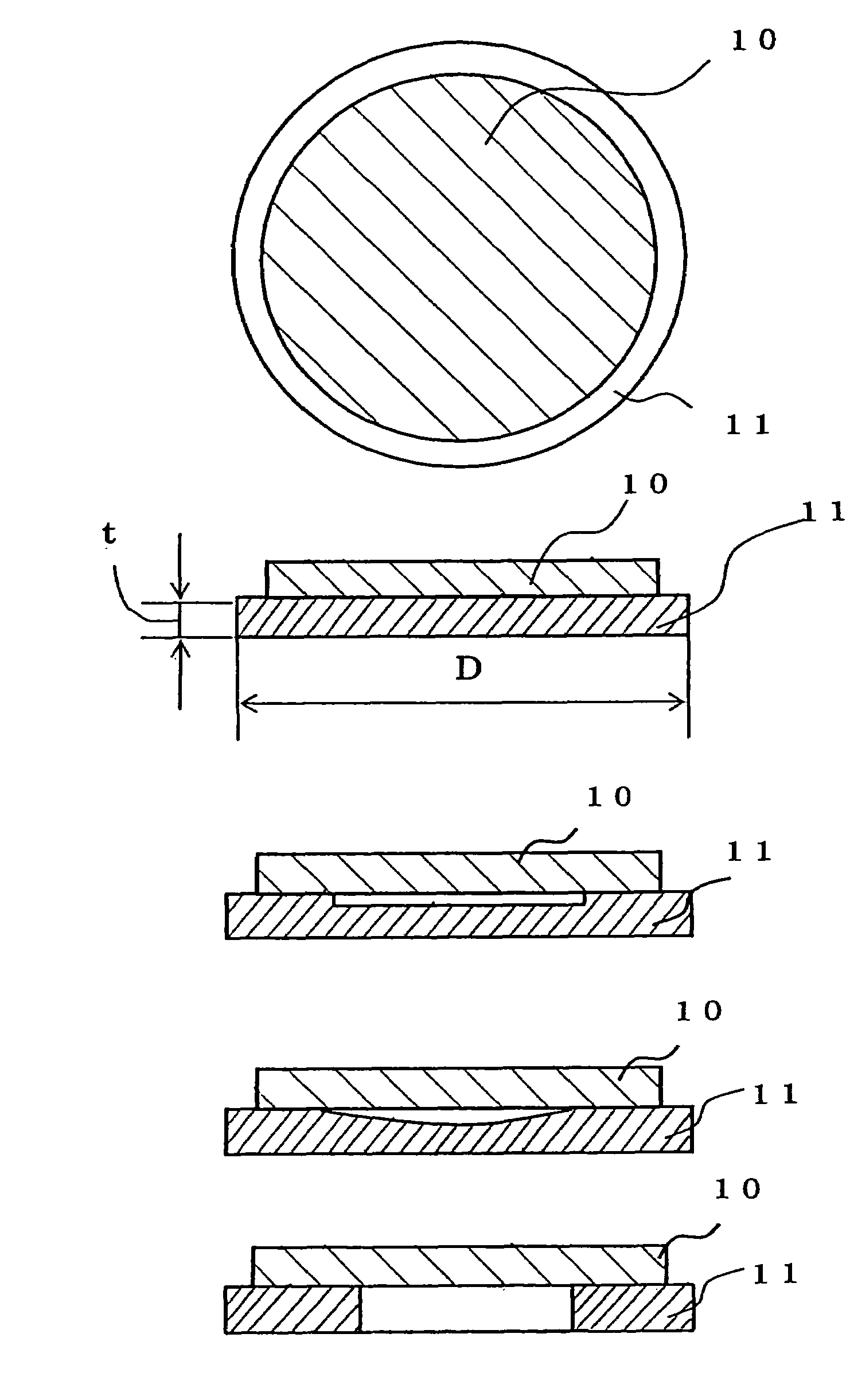

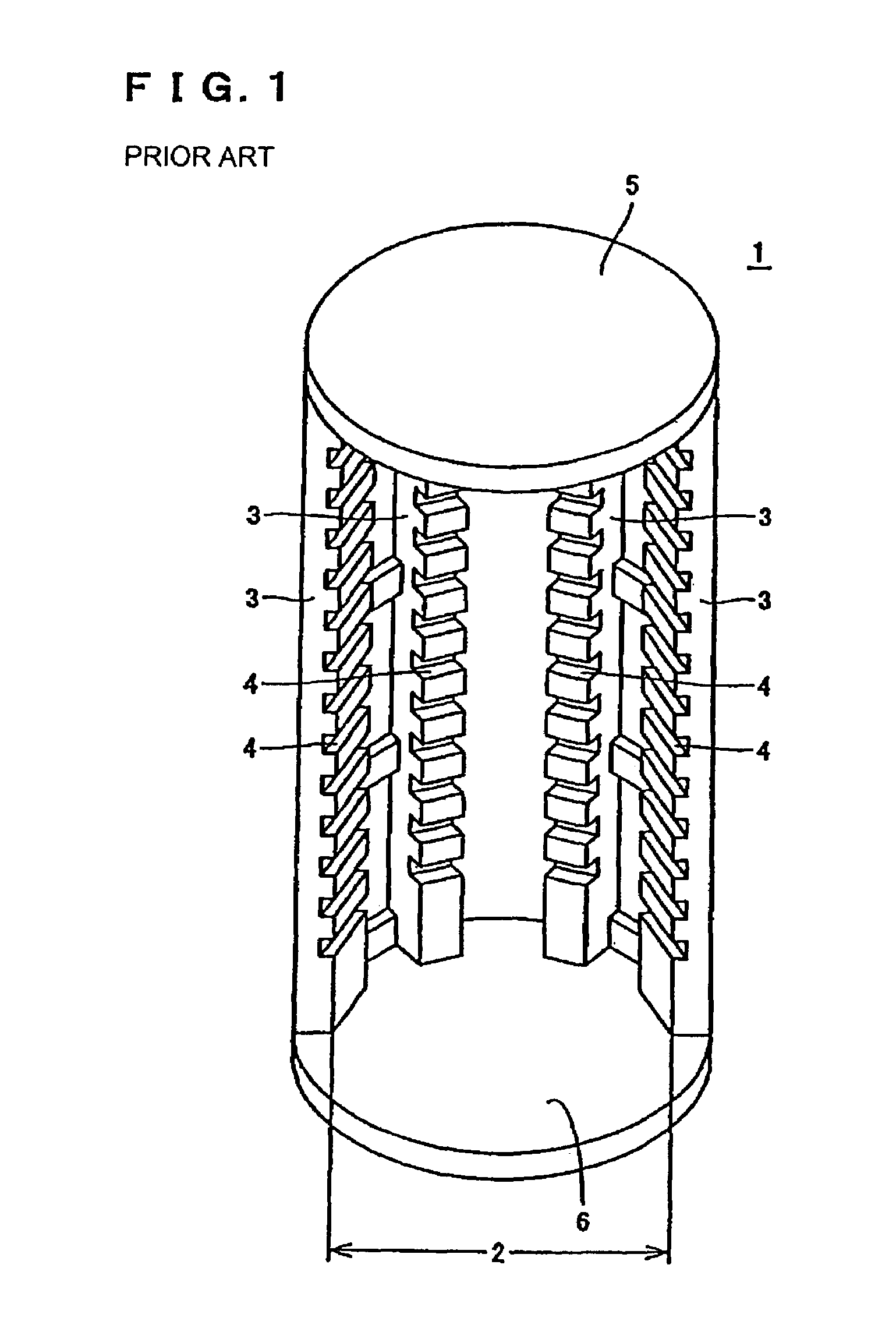

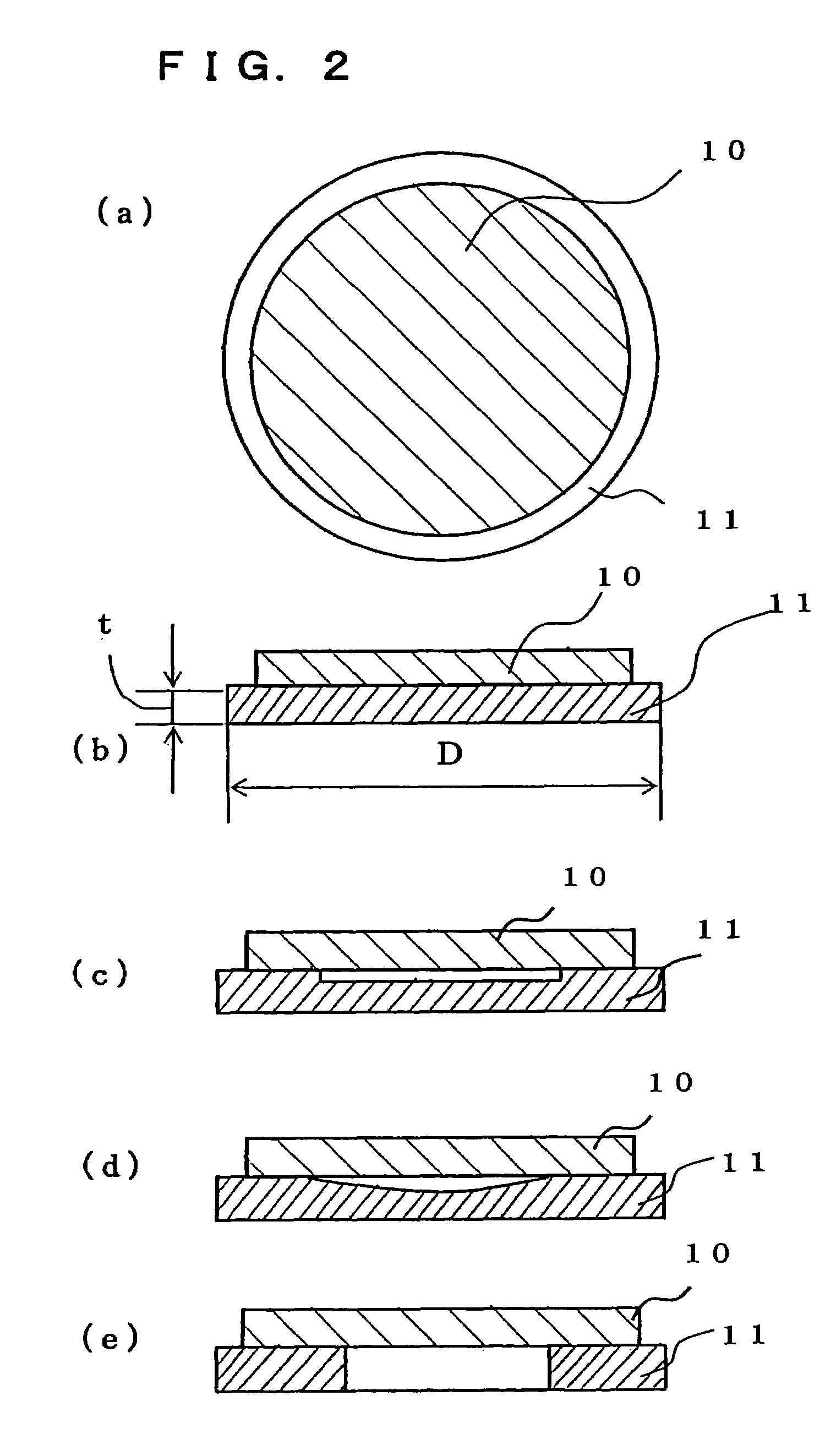

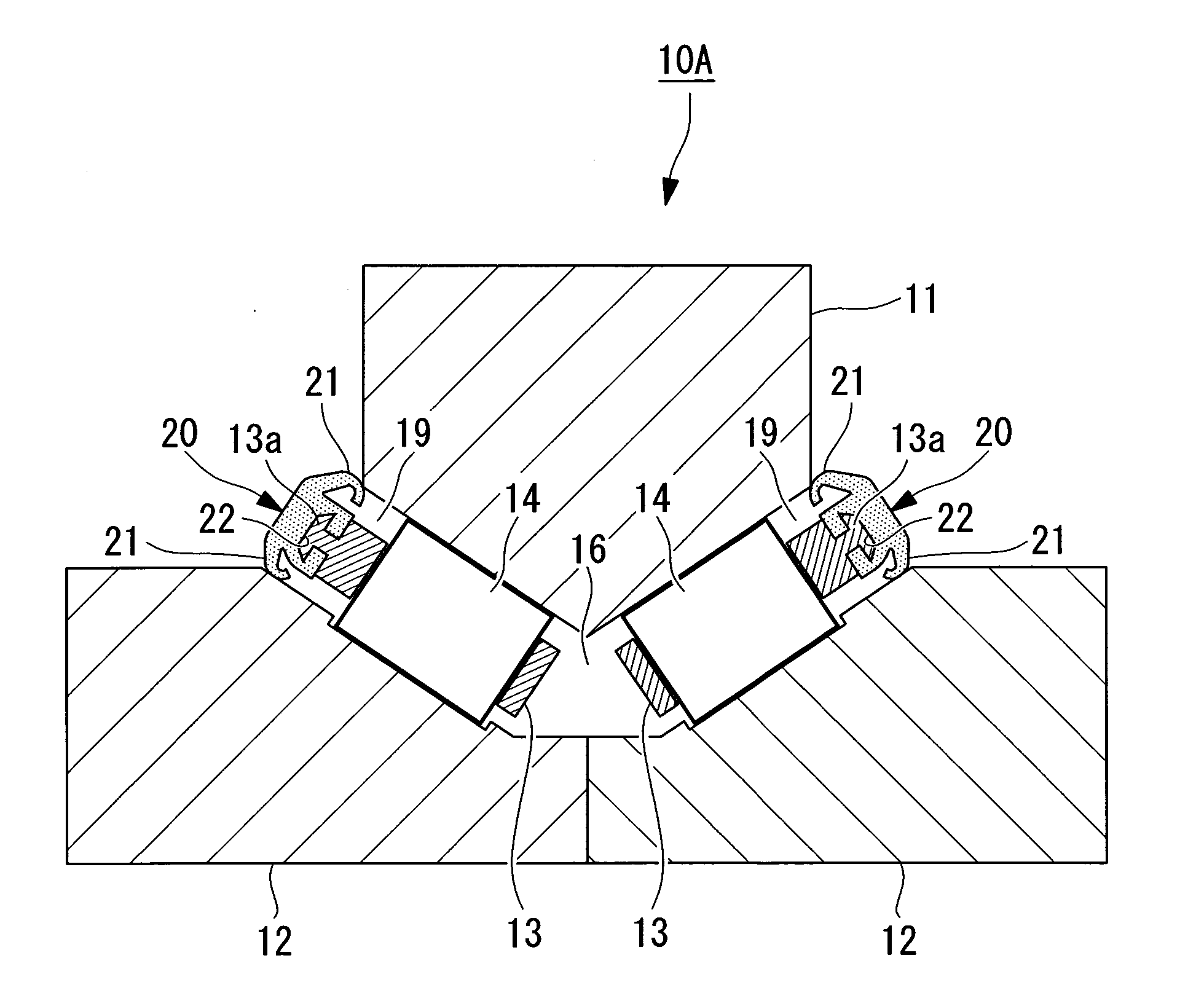

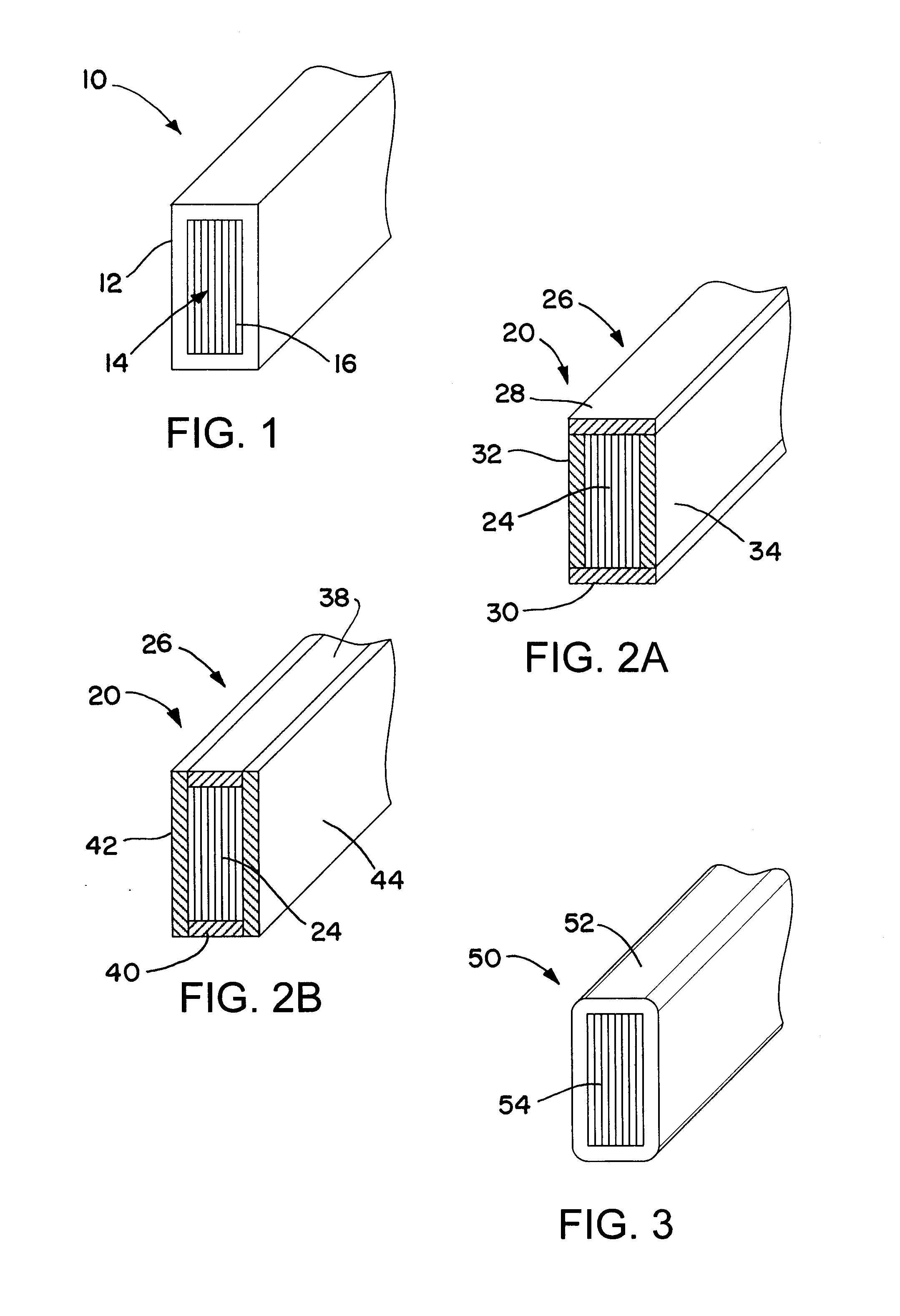

Heat treatment jig for semiconductor wafer

ActiveUS7331780B2Suppress generationSurface planarity and roughnessCharge supportsSemiconductor/solid-state device manufacturingSurface roughnessSemiconductor

A heat treatment jig by the invention comprising: the diameter of a disk-type structure being 60% or more of that of loaded semiconductor wafers; the thickness being 1.0 mm or more but 10 mm or less; the surface roughness Ra of 0.1 μm or more but 100 μm or less at a contacting surface with the wafers; and the surface planarity being specifically controlled in the concentric direction as well as in the diametrical direction, otherwise in place of above planarity, comprising a controlled maximum height in such a way that the maximum height is obtained by the flatness measurement at the multiple positions and the difference between said maximum height and the hypothetical-average-height-plane thus set is 50 μm or less, can reduce the slip generation due to the close adhesion of the wafers and the jig. Owing to this, even if the wafers having large tare weight should be heat-treated, the slip generation can be effectively prevented, thus enabling the jig to be widely used as the reliable heat treatment jig for semiconductor substrates.

Owner:SUMCO CORP

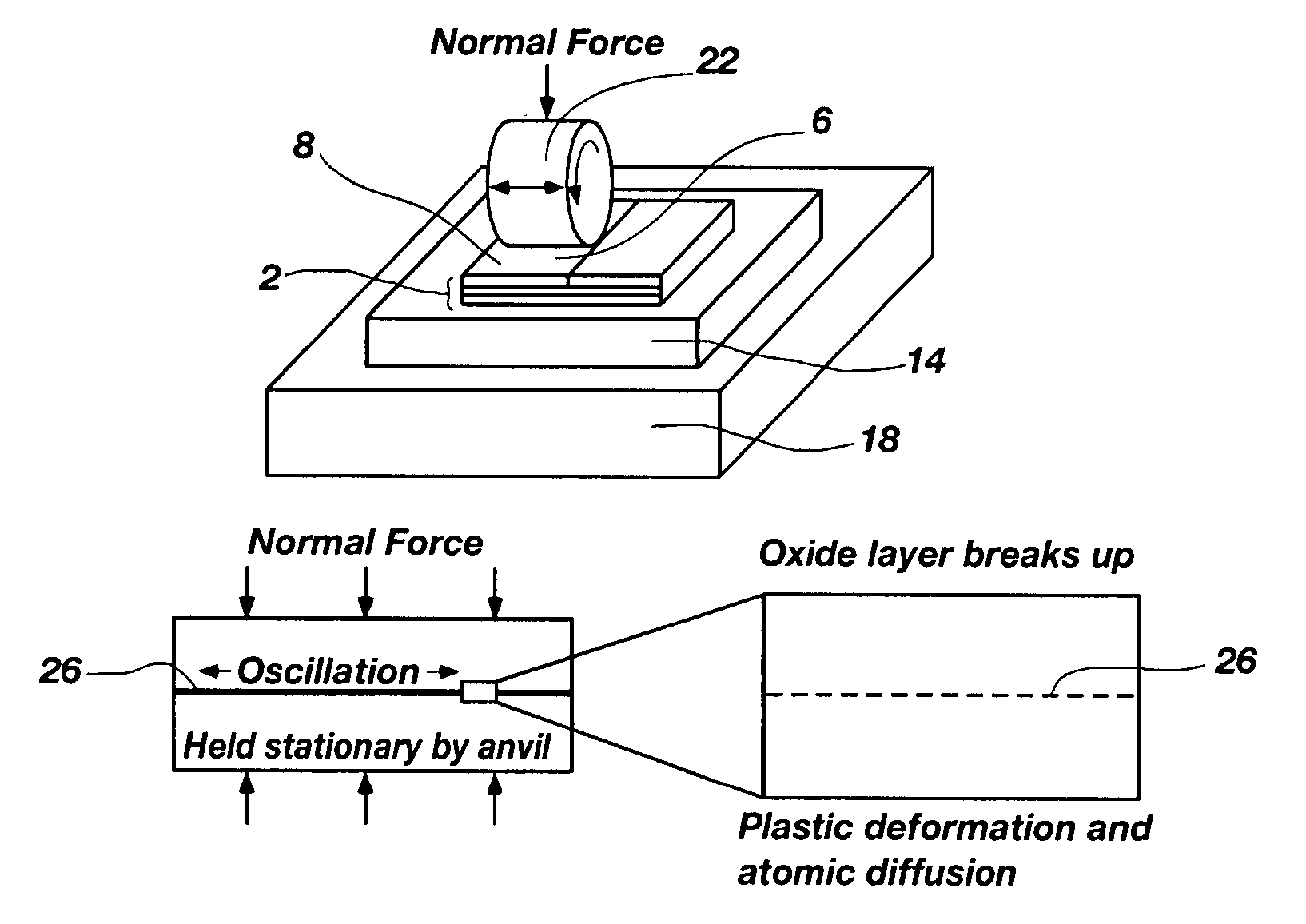

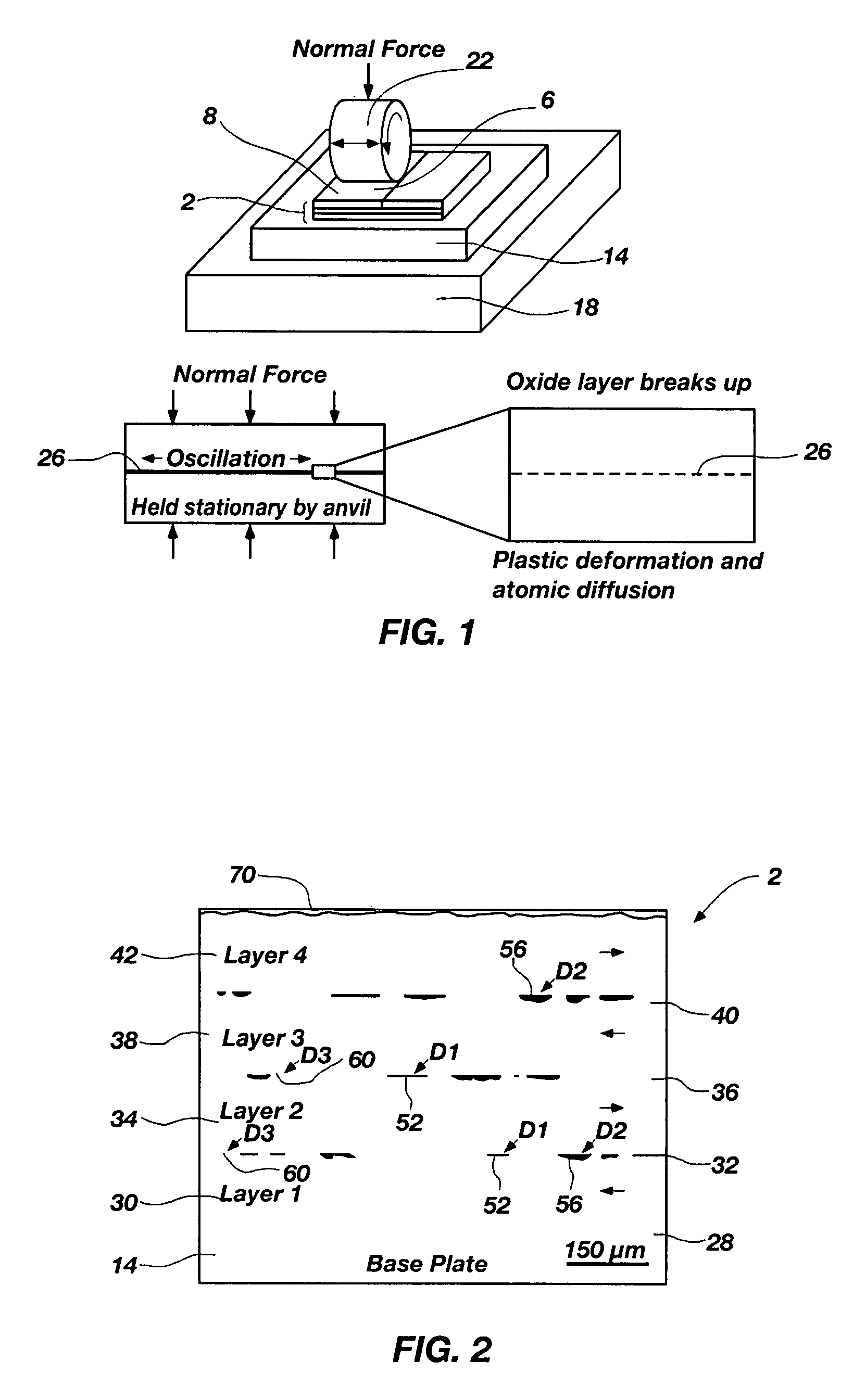

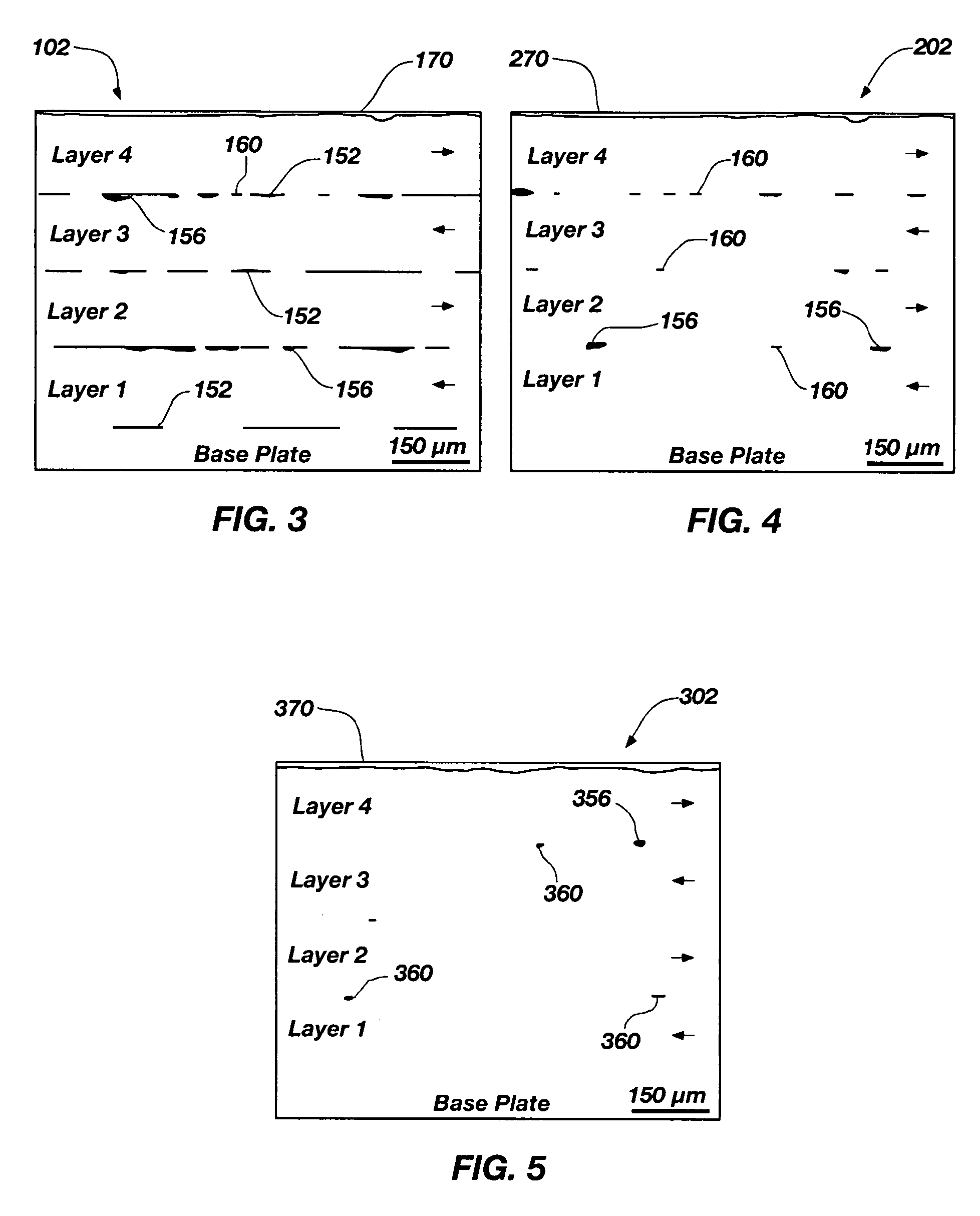

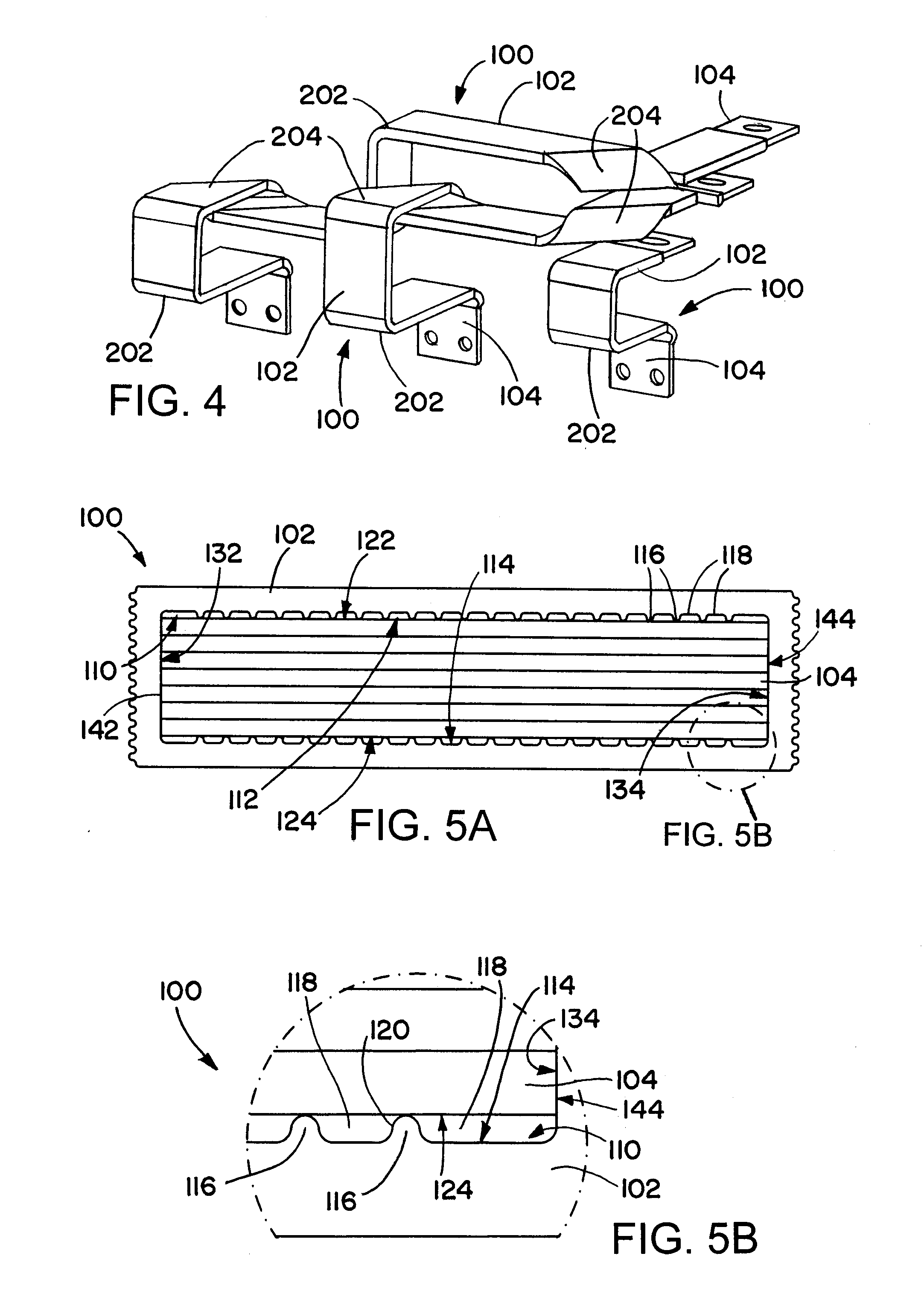

Surface roughness reduction for improving bonding in ultrasonic consolidation rapid manufacturing

InactiveUS20070295440A1Efficient manufacturingReduce contact surfaceAdditive manufacturing apparatusLaminationMetallurgySurface roughness

A method for enhancing the bonding and linear weld density along the interface of material layers deposited in accordance with an ultrasonic consolidation manufacturing process, the method comprising: initiating an ultrasonic consolidation manufacturing process; depositing a first material layer having a contact surface; reducing surface roughness of the contact surface to prepare the contact surface to receive a subsequent material layer, the step of reducing facilitating an increased percentage and quality of material contact between the first and subsequent material layers; and bonding a subsequent material layer to the contact surface of the first material layer, as prepared.

Owner:UTAH STATE UNIVERSITY

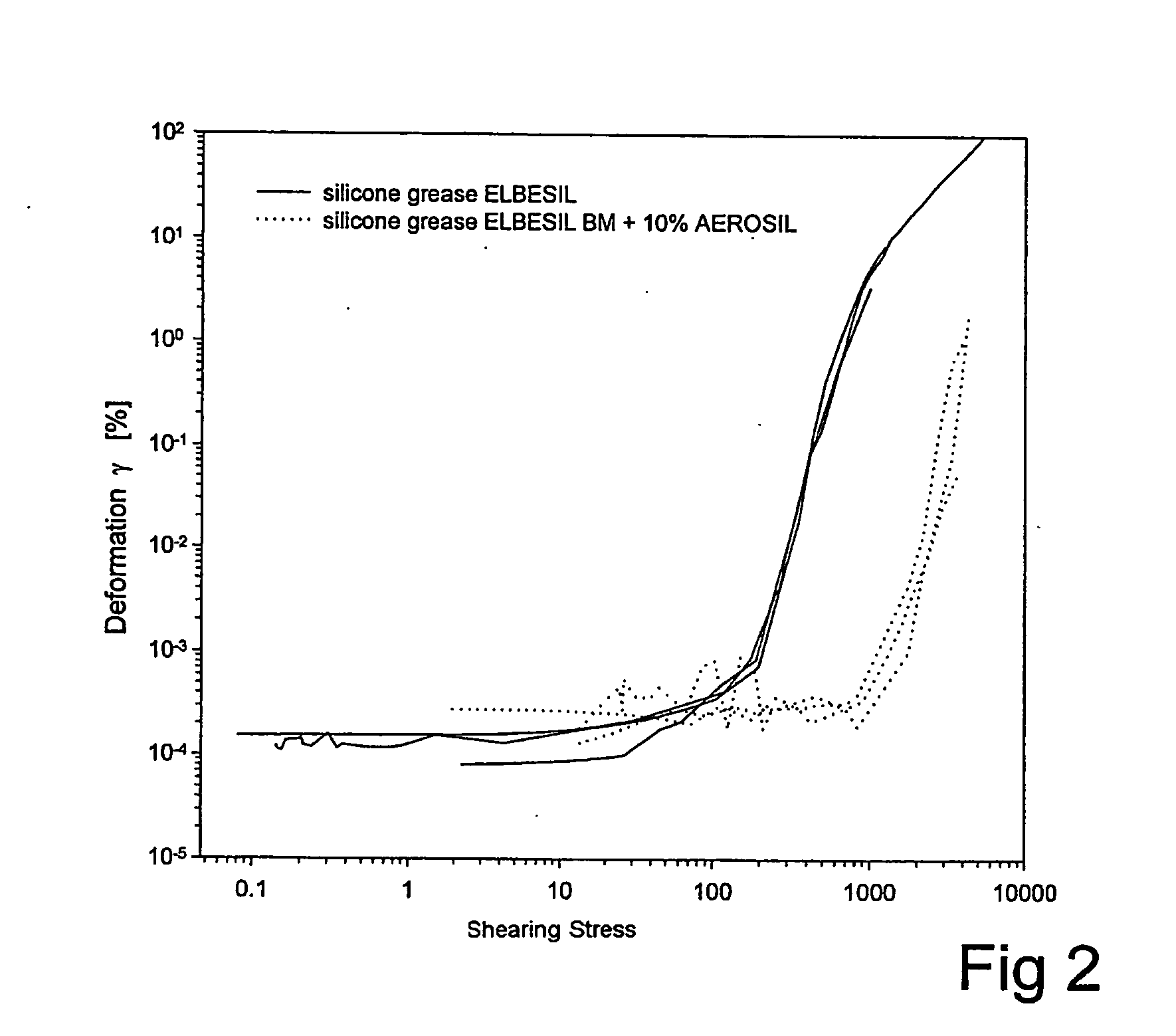

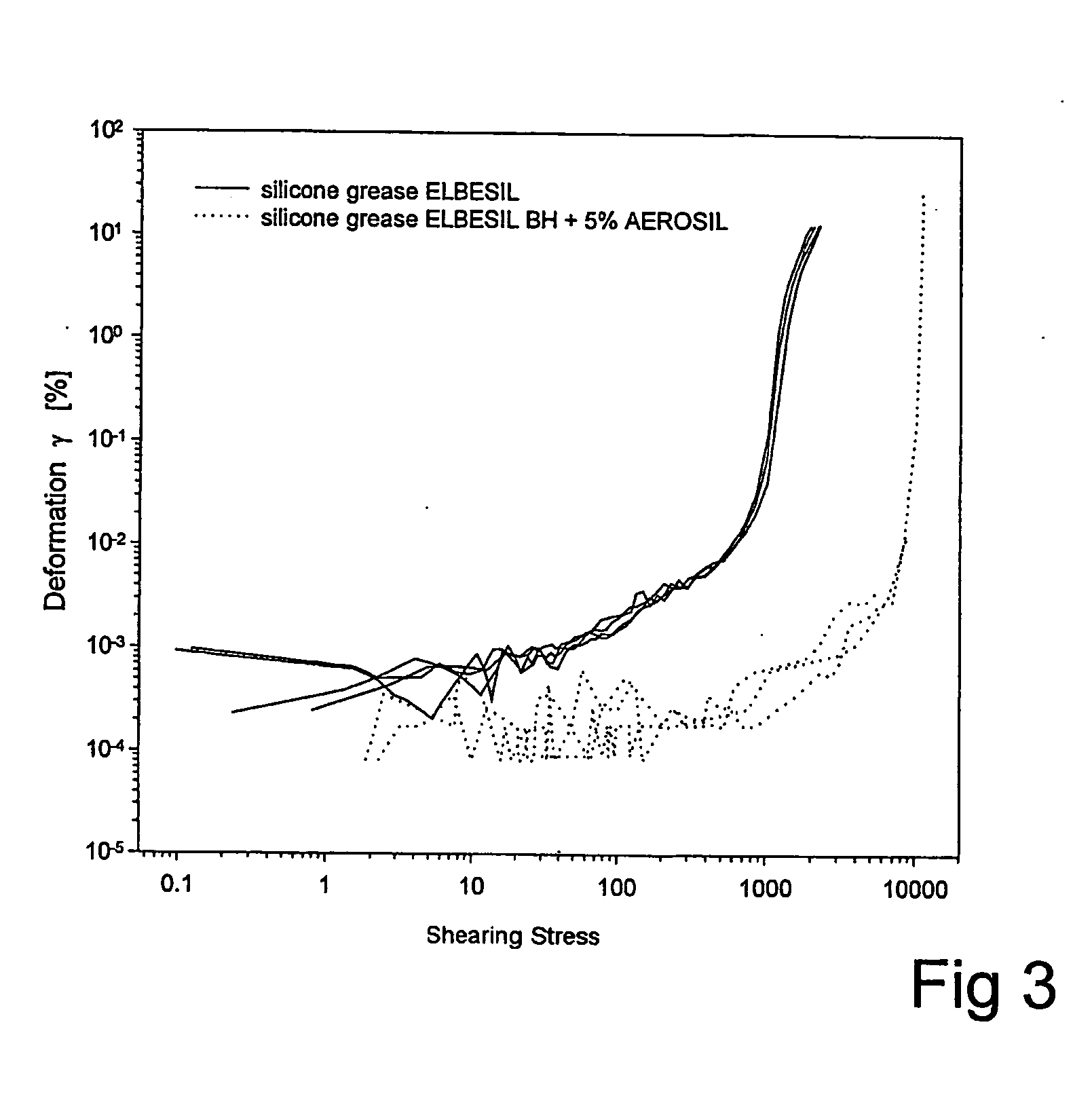

Viscoelastic coating paste for protecting against macrofouling and method for producing a coating

InactiveUS20060144286A1Improve antifouling performanceConvenient coatingFireproof paintsAntifouling/underwater paintsWall shearMacroscopic scale

A non-toxic anti-fouling coating paste having a rheologic switching behavior based on a flow point, which can be set to the hydrodynamic and biological environmental conditions of a submarine component to be protected and which is between 5 Pa and 2,000 Pa above the wall shearing stress of the unfouled component to form a substrate which prevents colonization by marine fouling organisms.

Owner:CGGVERITAS SERVICES HLDG U S +1

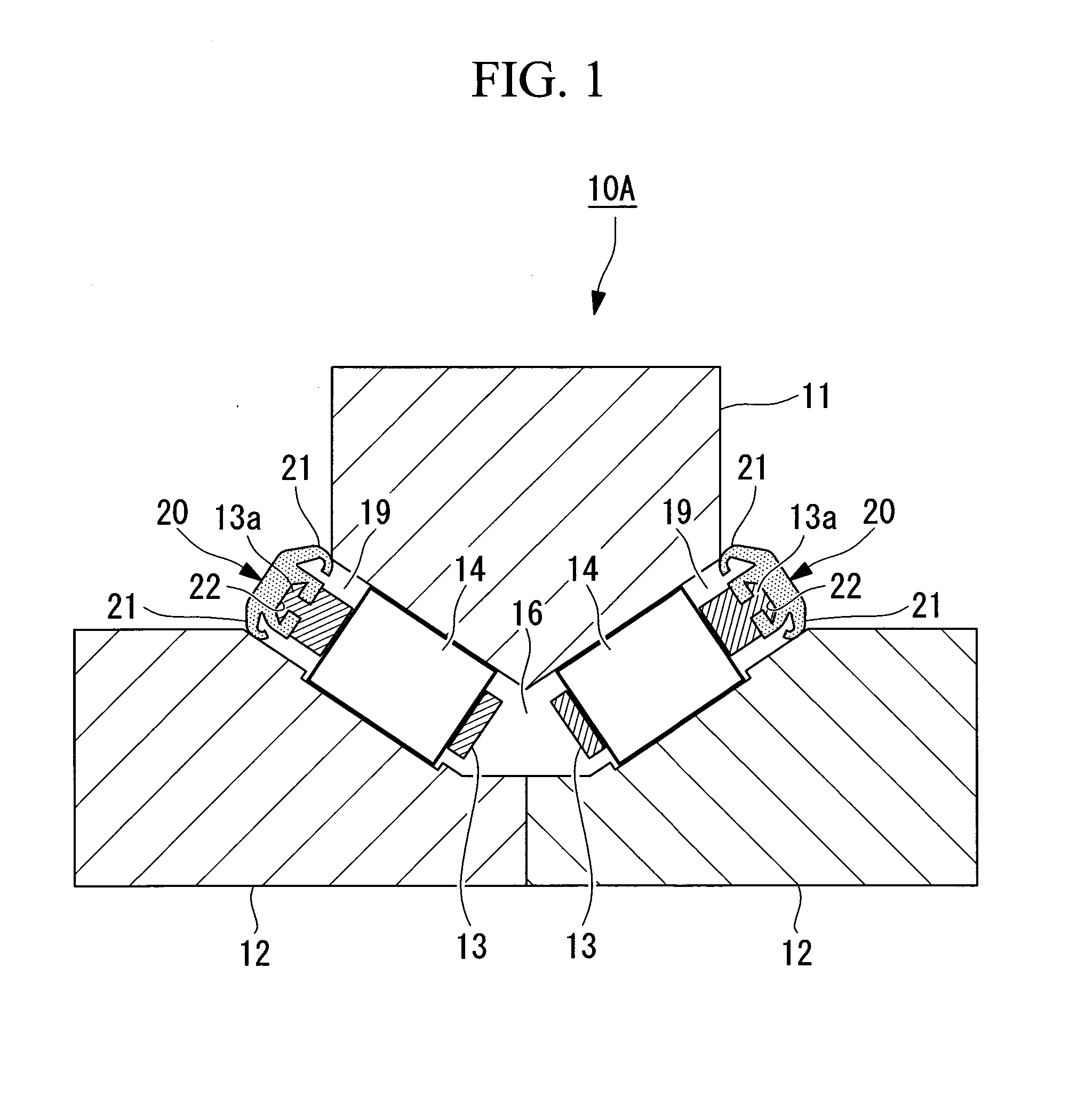

Bearing structure and wind turbine generator

InactiveUS20100308594A1Sliding surface is reducedDeformation to temperature differenceRoller bearingsBearing assemblyTemperature differenceEngineering

A bearing structure that reduces the relative sliding speed of a sealing ring and a contact surface and suppresses relative deformation due to a temperature difference of inner and outer rings is provided. A rolling member is disposed inside a space formed between an outer ring and an inner ring, the outer ring or the inner ring rotating relatively via the rolling element, wherein a sliding section of the surface of the rolling member and the inner surface of the space is lubricated with a lubricant supplied into the space, and a sealing ring attached to a supporter supporting the rolling element seals an opening of the space at an end section in the axial direction.

Owner:MITSUBISHI HEAVY IND LTD

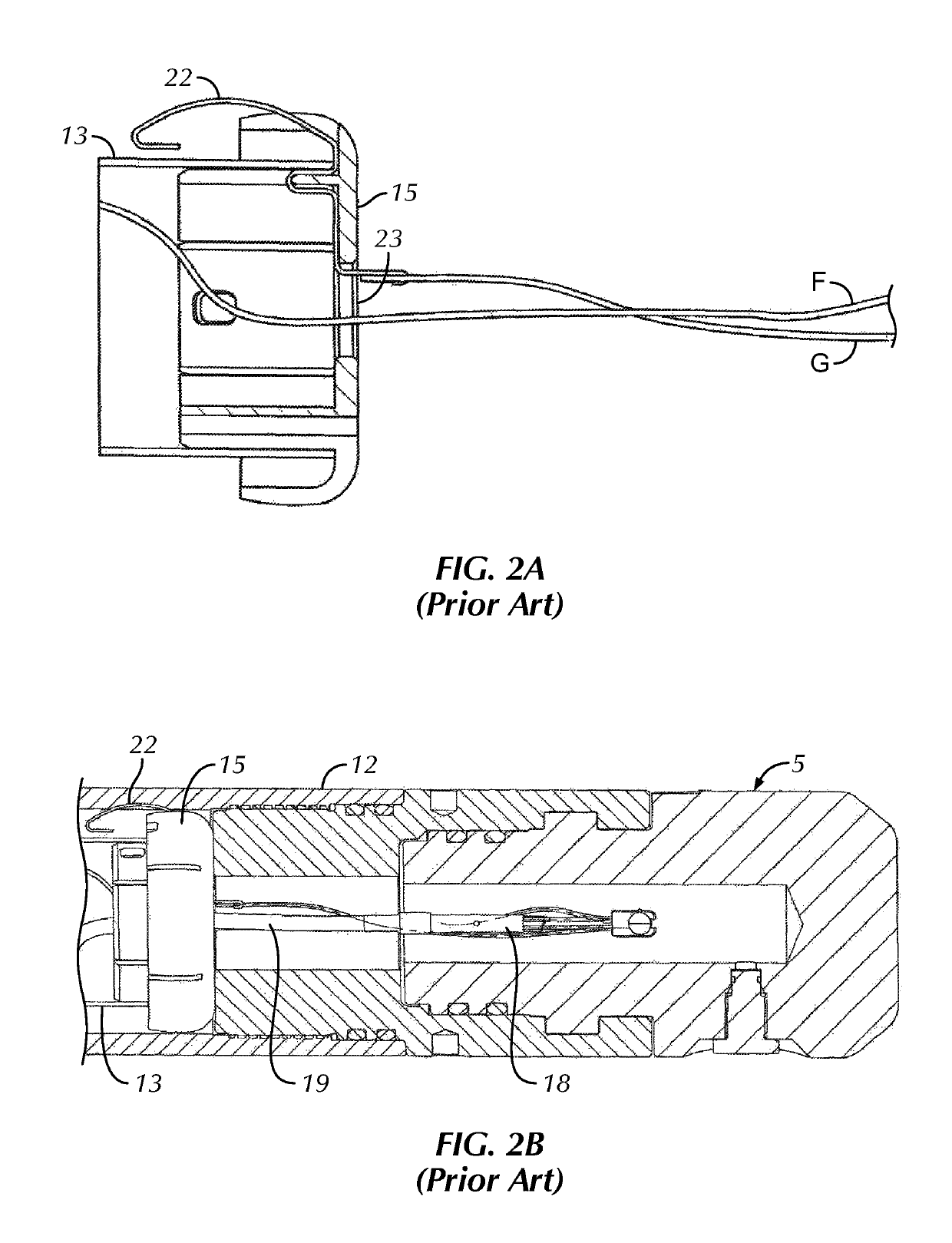

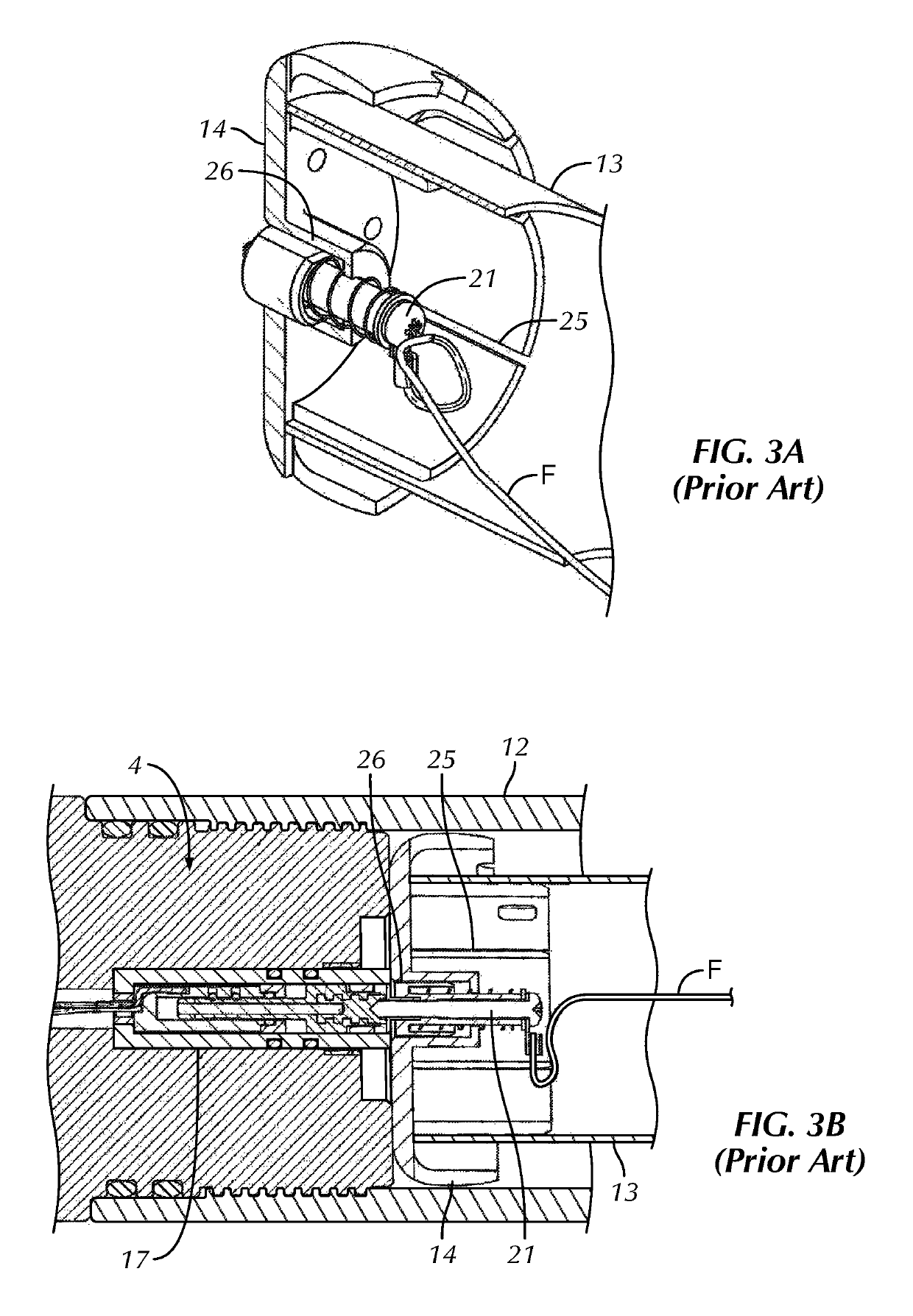

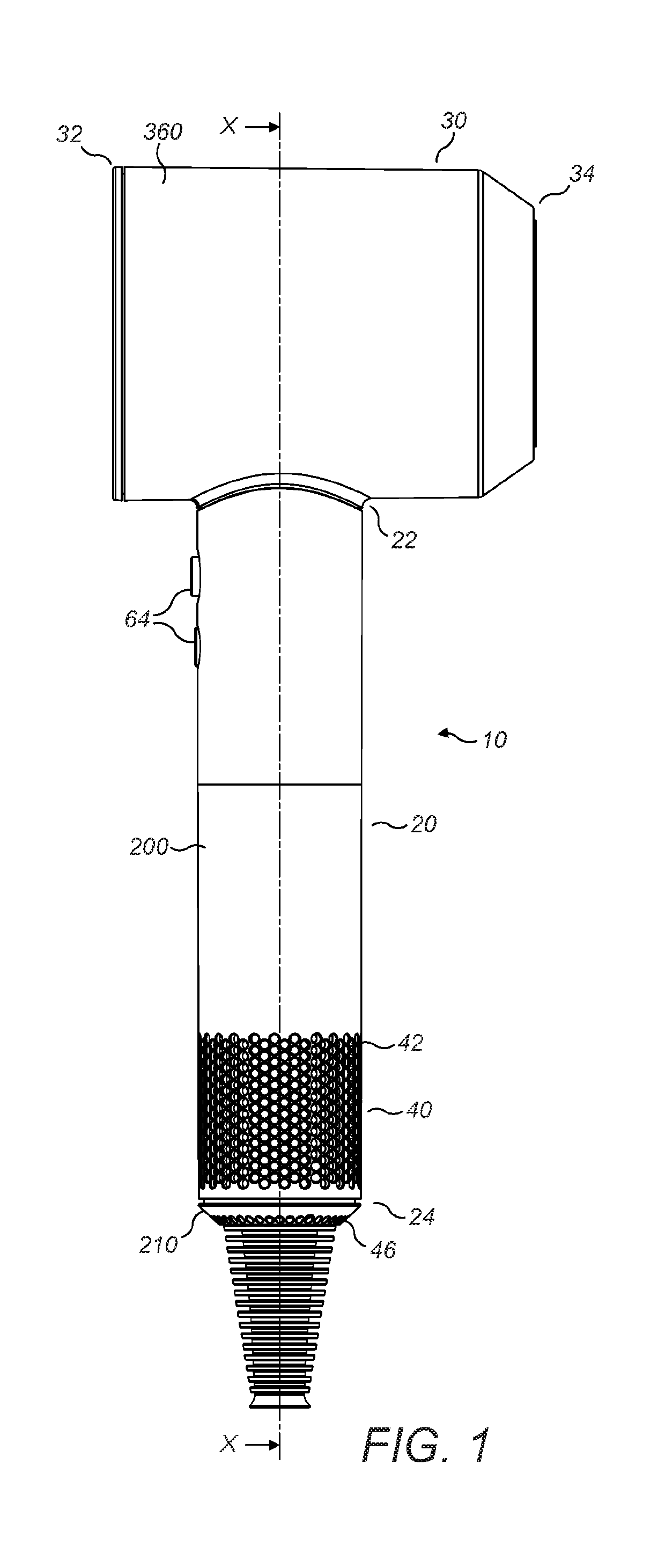

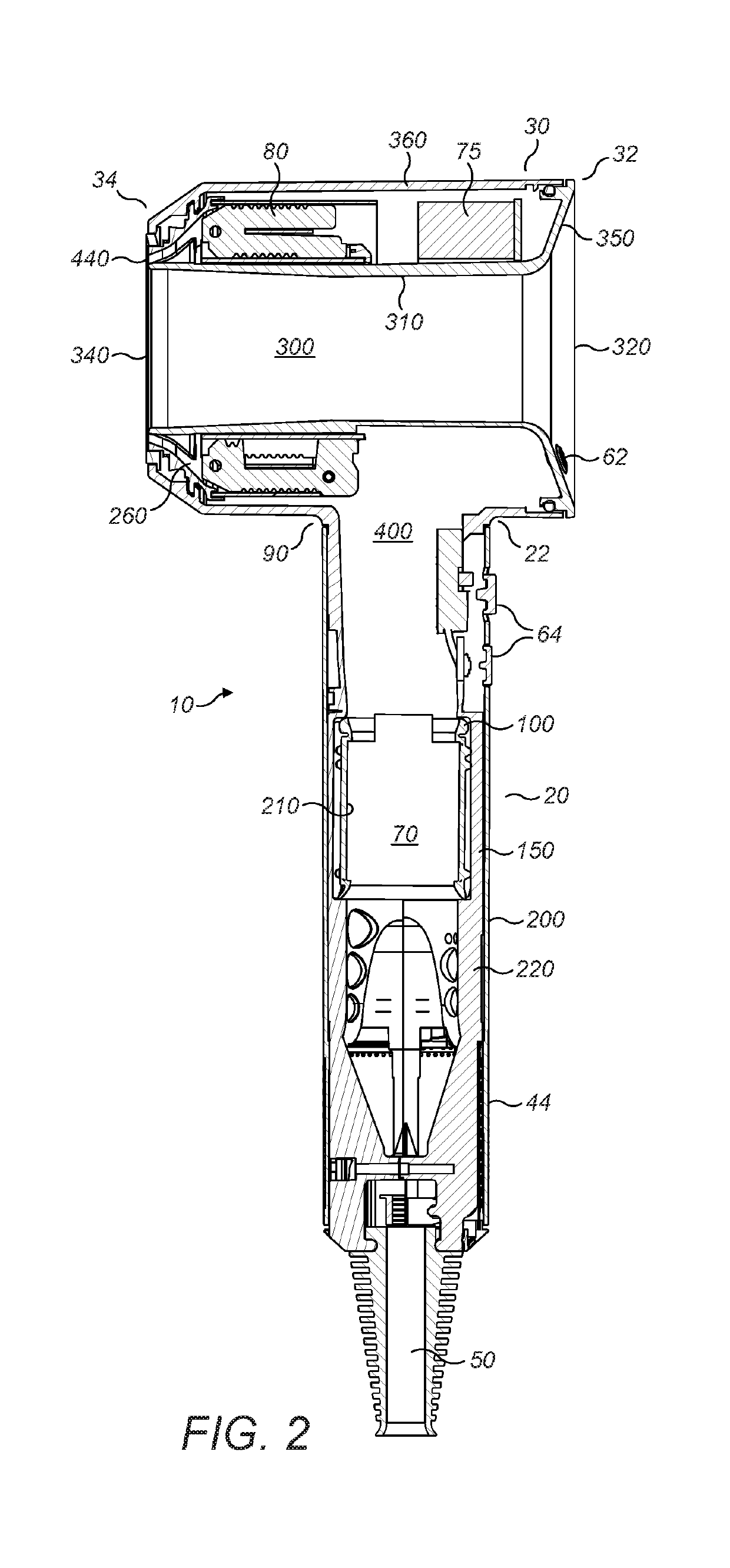

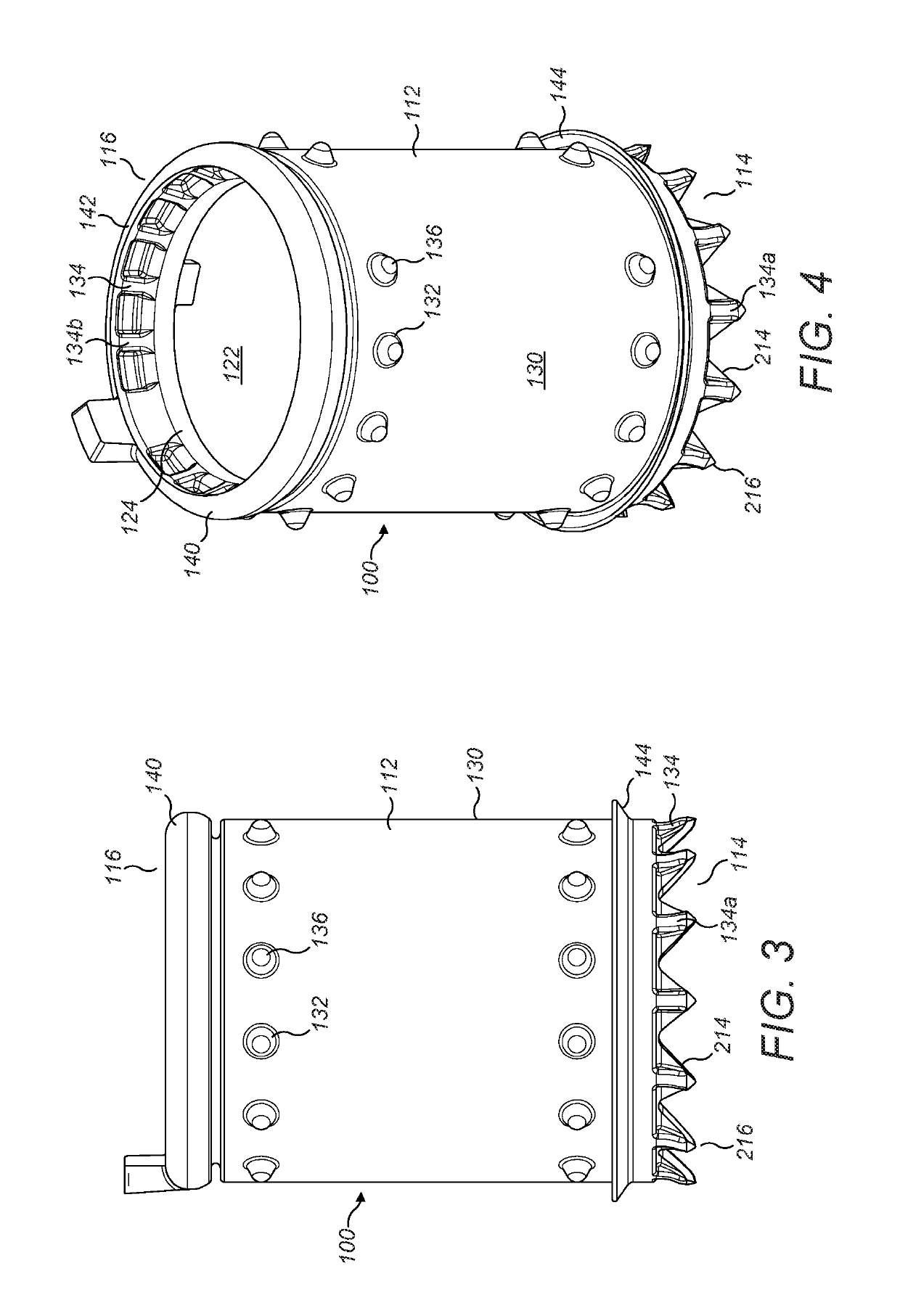

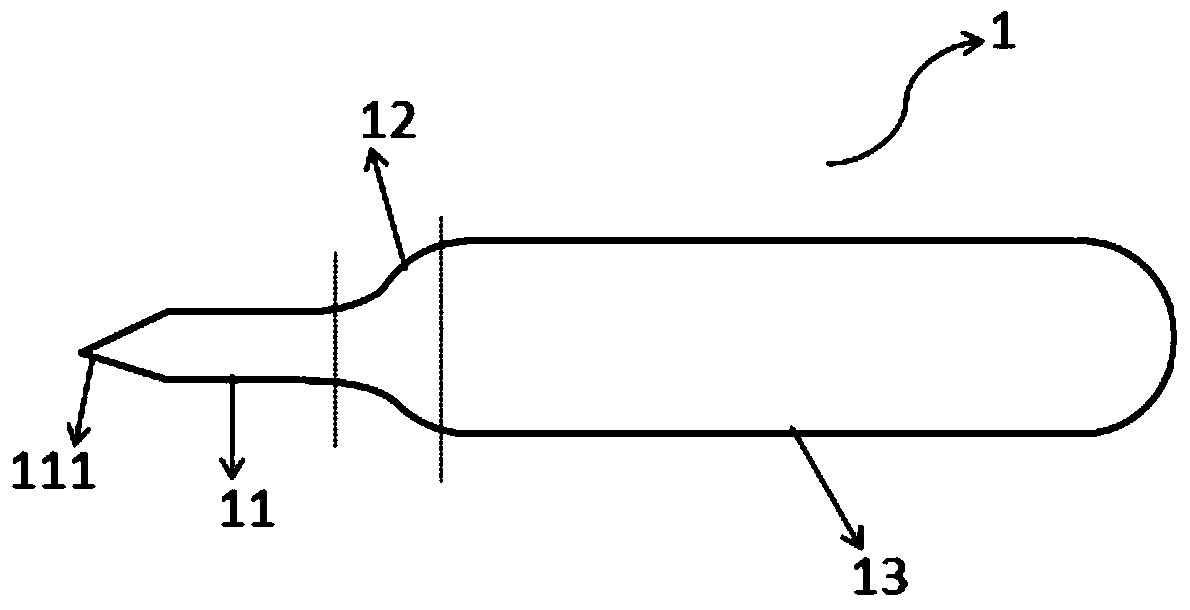

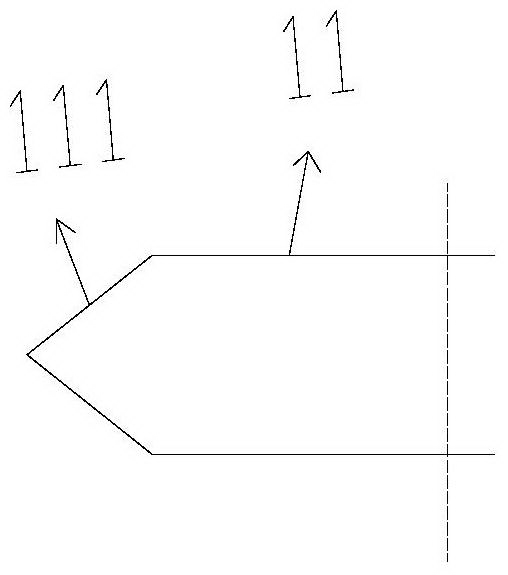

Hand held appliance

InactiveUS10441050B2Reduce transmissionReduce contact surfaceMotor fan assembly mountingAir heatersConstant frequencyHand held

A mount for an electric motor, the mount comprising a sleeve for receiving a motor, the sleeve having a longitudinal axis extending between a first end and a second end, wherein the first end comprises a plurality of plurality of projections and the plurality of projections extend along the longitudinal axis. The sleeve may receive the motor via the first end or the second end. The plurality of projections may be spaced around a circumference of the sleeve. The plurality of projections may comprise a pattern of substantially constant frequency around the sleeve. The plurality of projections may be substantially V-shaped with the point extending along the longitudinal axis from the first end of the sleeve.

Owner:DYSON TECH LTD

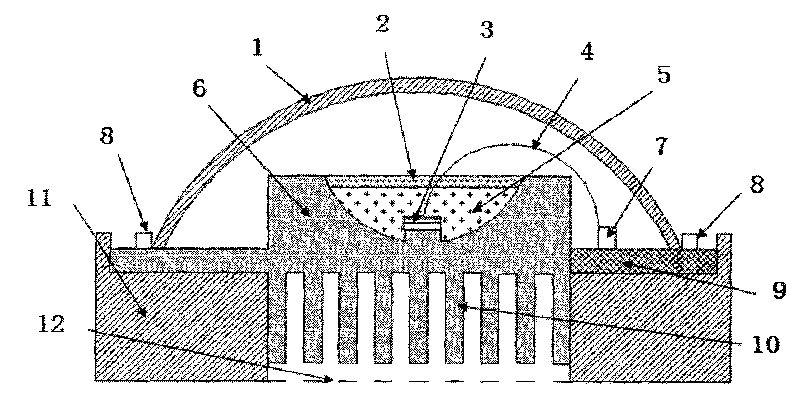

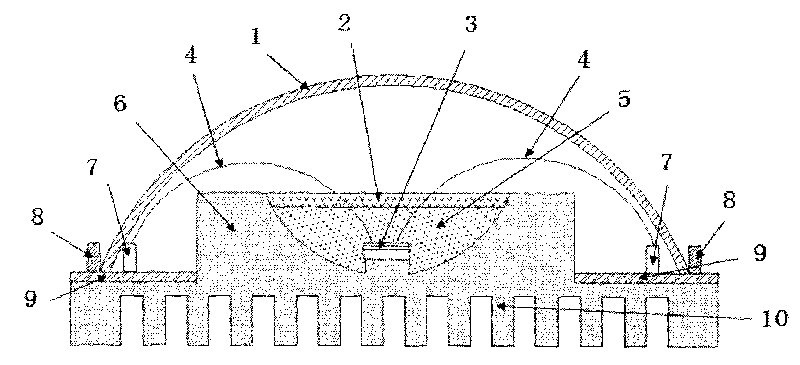

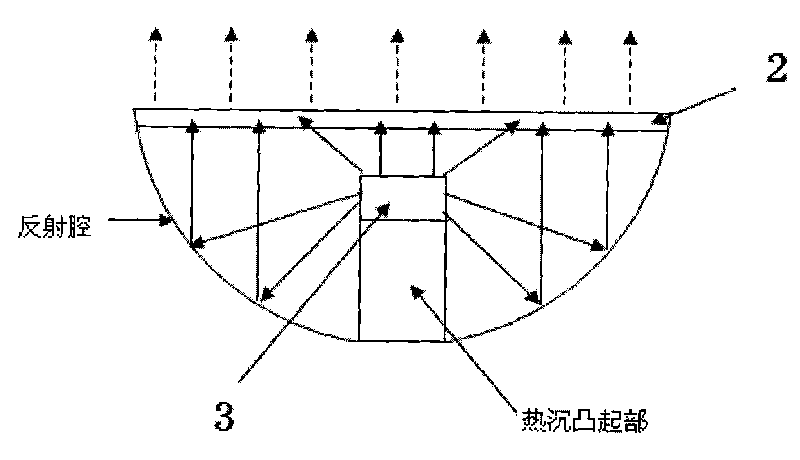

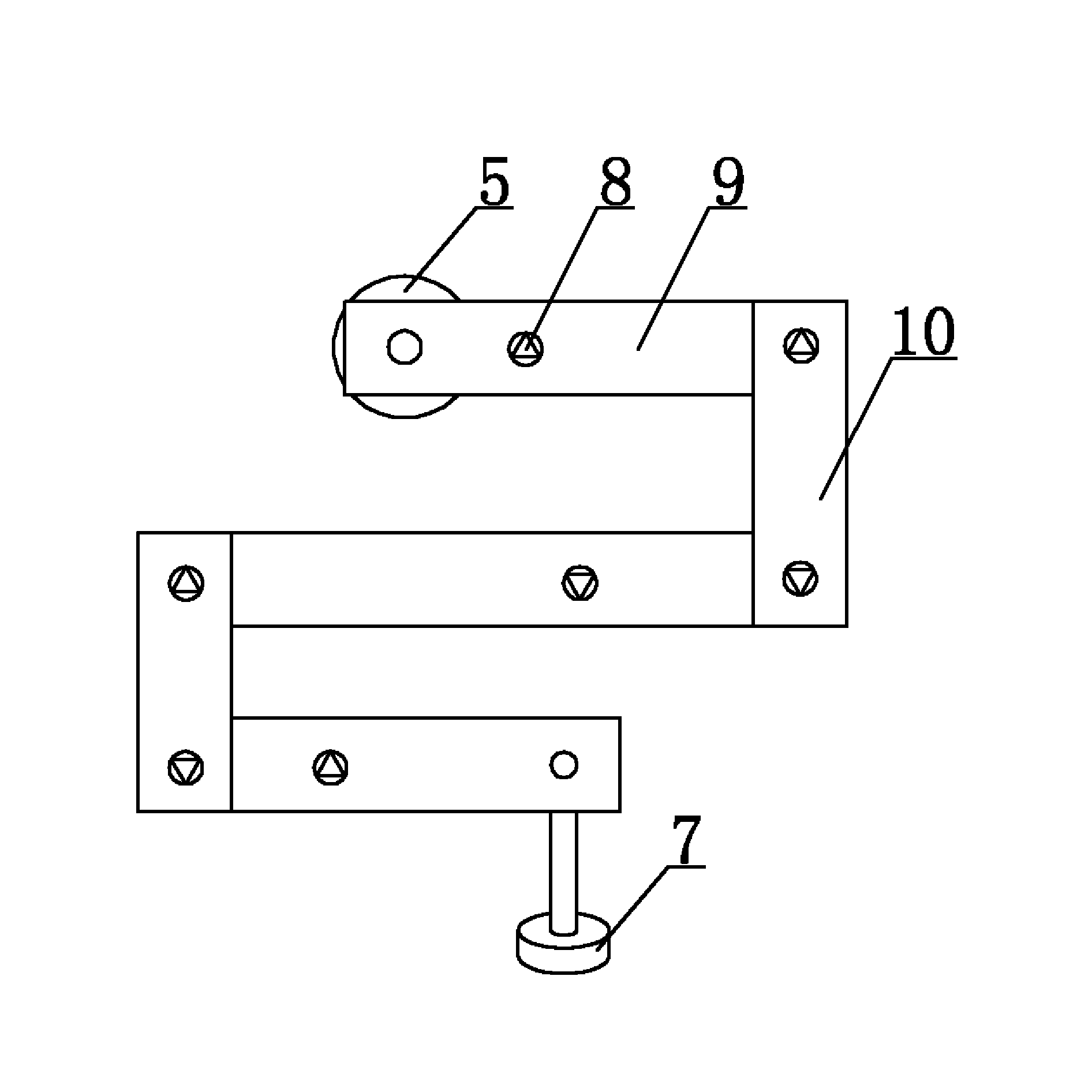

High-power LED heat-dissipation packaging structure

InactiveCN101696790AAvoid thermal quenchingImprove external quantum efficiencyPoint-like light sourceLighting heating/cooling arrangementsFluorescenceInverted t

The invention relates to a high-power LED packaging structure. The packaging structure is characterized in that an aluminum heat sink (6) is in the structure of an inverted T; a scalelike heat-dissipation plate (10) integrated with the aluminum heat sink (6) extends under the aluminum heat sink; an extending arm of the aluminum heat sink (6) is connected with a printed circuit board (9), the center of the aluminum heat sink (6) is provided with a semi-spherical surface concave cavity; a chip (3) is adhered to a lug boss on the inner bottom surface of the semi-spherical surface concave cavity; flexible silica gel (5) is packaged inside the semi-spherical surface concave cavity comprising the chip (3); and the top surface of the flexible silica gel (5) is coated with a fluorescent powder layer (2). The high-power LED packaging structure ensures that the heat of an LED can be dissipated quickly, thereby increasing the light-emitting stability and service life of high-power LEDs.

Owner:IRICO

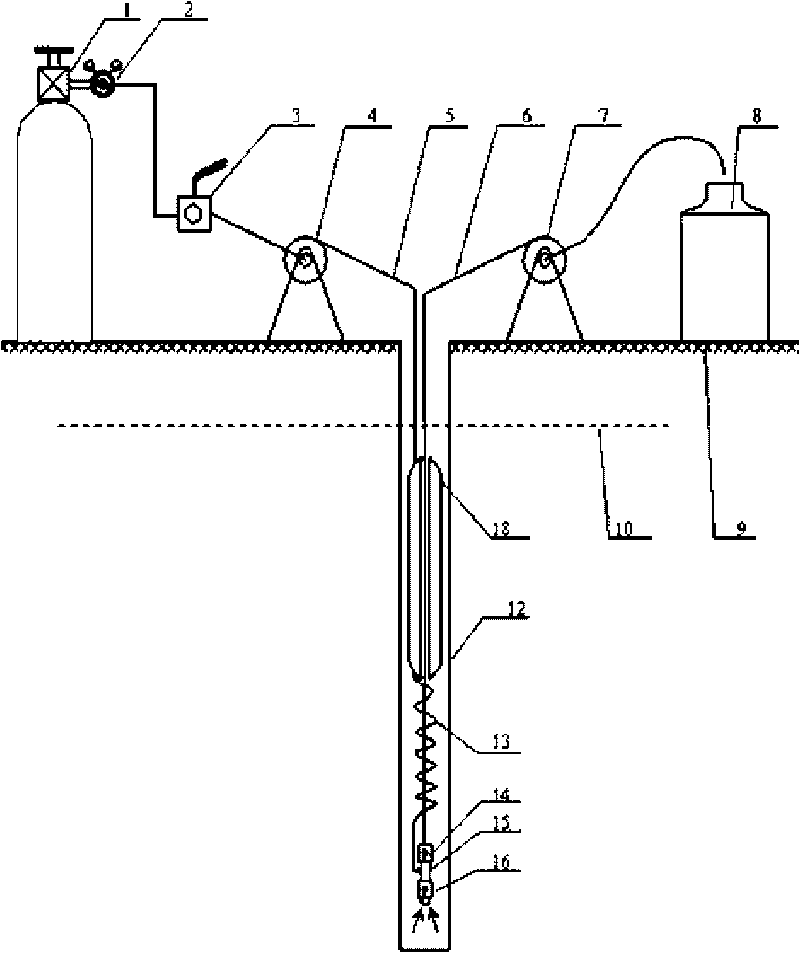

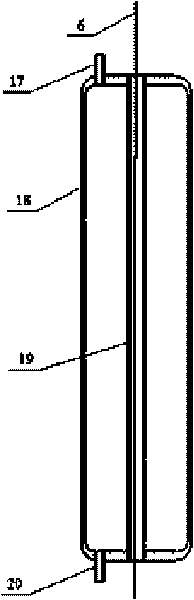

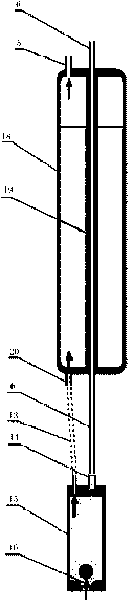

Split type gas displacement type underground water sampler

InactiveCN101718640AImprove sampling efficiencyRelieve pressureWithdrawing sample devicesLine tubingEngineering

The invention relates to a split type gas displacement type underground water sampler which comprises a sample containing pipe, an inflation and deflation unit and a water acquirement pipeline; the inflation and deflation unit comprises an air source, an air pipe and an air pressure controller, the upper end of the sample containing pipe is communicated with the inflation and deflation unit, and the water acquirement pipeline comprises a water outlet pipe. The underground water sampler also comprises a sampling unit, wherein the sampling unit comprises a water outlet non-return valve, a tee and a water inlet non-return valve which are sequentially communicated from top to bottom; the water acquirement pipeline also comprises a hose which is communicated with the lower end of the sample containing pipe and a middle outlet of the tee, and the water outlet non-return valve is communicated with the water outlet pipe. The invention solves the technical problems of large disturbance of underground water, existence of a gas spilling phenomenon and the like during sampling. The invention realizes the sampling of the underground water under the conditions of low air pressure and small gas quantity and has the advantage of high sampling efficiency.

Owner:NORTHWEST INST OF NUCLEAR TECH

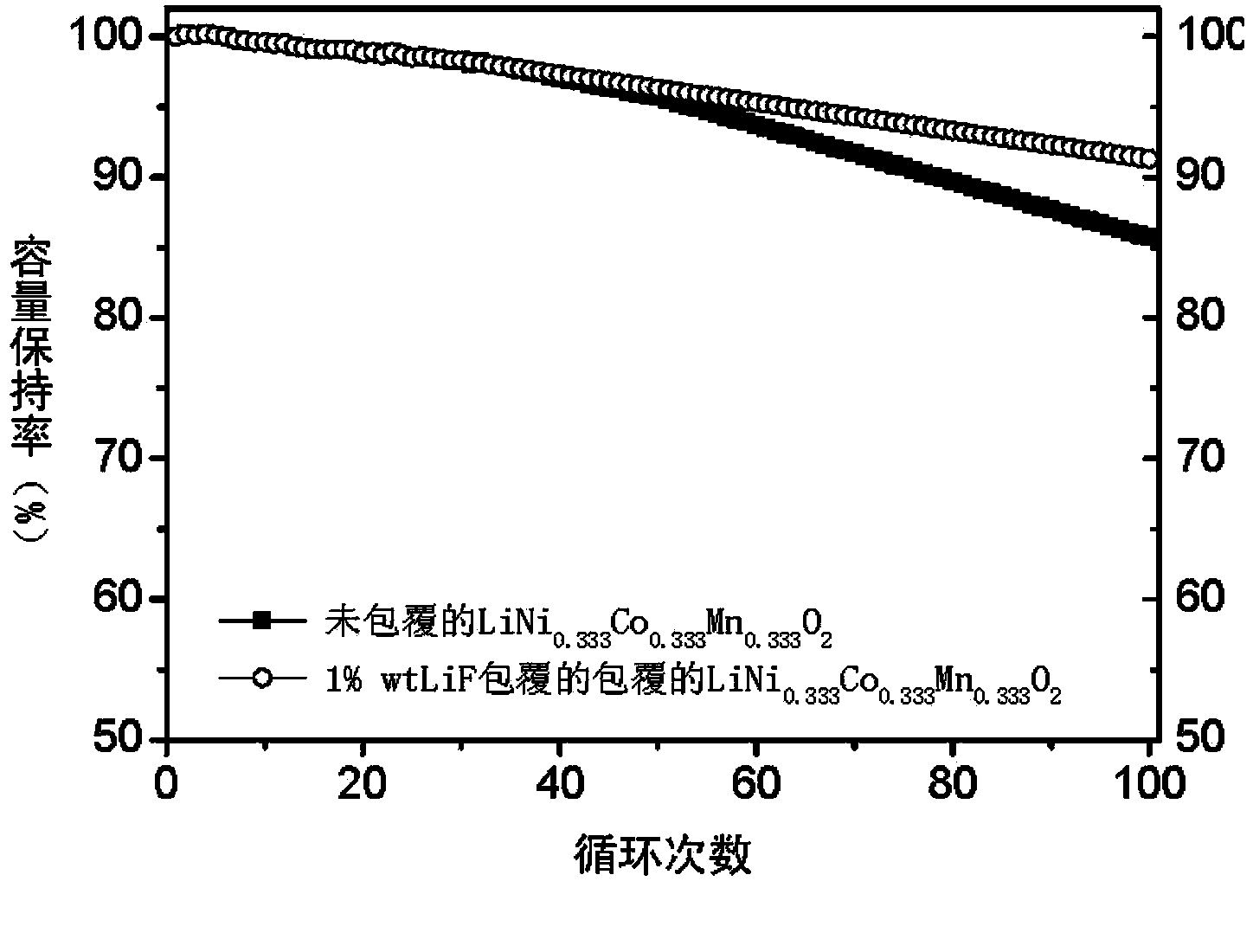

Surface coating method for ternary positive material of lithium ion battery

ActiveCN104112851AReduce contact surfaceImprove electrochemical performanceCell electrodesSecondary cellsCapacitanceMass ratio

The invention discloses a surface coating method for a ternary positive material of a lithium ion battery. The surface coating method comprises the following steps: 1, mixing lithium fluoride with a strong polar solvent in the mass ratio of (0.1-100) to 100, and stirring to form a homogeneous solution A; 2, transferring the ternary material into the solution A in the mass ratio of lithium fluoride to the ternary material of (0.05-10) to 100 and continuously stirring to form a turbid liquid B; 3, adding a poor solvent to the turbid liquid B which is stirred in the mass ratio of the turbid liquid B to the poor solvent of (0.1-100) to 1, thereby forming a turbid liquid C, and aging for 0.5-48 hours; 4, filtering the turbid liquid C, washing a filter cake by use of a volatile lithium fluoride poor solvent and drying the filter cake at 50-100 DEG C; and 5, calcining the filter cake, thereby obtaining the lithium fluoride coated ternary positive material. The surface coating method is capable of realizing relatively even coating, effectively inhibiting side reactions of an electrode, prolonging the cycle life of the electrode, lowering the safety risk of the battery and reducing the capacitance loss of the battery.

Owner:厦门太和动力电源科技有限公司

Pig feed and preparation method thereof

The invention provides a pig feed and a preparation method of the pig feed, and belongs to the feed field. The pig feed comprises the following raw materials in parts by weight: 650-720 parts of corns for pigs, 25-40 parts of oil bran, 200-250 parts of high-temperature bean pulp, 5-10 parts of mountain flour, 6-10 parts of calcium hydrophosphate, 1-5 parts of table salt, 0.5-3 parts of baking soda, 0.5-2 parts of choline chloride, 1-3 parts of a mildew preventive, 0.1-0.5 part of an antioxidant and 25-35 parts of a core material. The pig feed is reasonable in formulation and complete in nutrition; due to the reasonable combination of energy substances, vitamins, mineral substances and Chinese herbal medicines and the optimization for the preparation method, the metaboilic level of the pigs can be improved, and the digestibility of the feed can be increased; and therefore, the utilization rate of the feed is greatly increased, the shelf life of the feed is prolonged, the loss of the feed is reduced, and the feed cost is lowered.

Owner:广西康佳龙农牧集团有限公司

Nice and cool purified cotton yarn dyed fabric manufacturing process

InactiveCN103526391ARaw materials are natural and greenReduce contact surfaceWoven fabricsPulp and paper industryMoisture absorption

The invention relates to a nice and cool purified cotton yarn dyed fabric manufacturing process. The structure of a nice and cool purified cotton yarn dyed fabric comprises 1 / 1 plain weave, 1 / 1 plain back plus through holes, 1 / 1 plain back plus 3 / 1 twill weave or 2 / 2 basket weave, and the specification of the nice and cool purified cotton yarn dyed fabric comprises that yarn counts range from 35s to 70s, warp density ranges from 110 to 190 per inch, and weft density ranges from 58 to 110 per inch. The nice and cool purified cotton yarn dyed fabric manufacturing process is characterized by sequentially comprising the following processing steps of spinning, yarn setting, yarn dyeing, warping, slashing, weaving, singeing, desizing, mercerizing, liquid ammonium processing, noniron finishing, tentering, preshrinking and finished product obtaining, or spinning, yarn setting, yarn dyeing, warping, slashing, weaving, singeing, desizing, mercerizing, liquid ammonium processing, tentering, preshrinking and finished product obtaining. A finished product fabric processed through the nice and cool purified cotton yarn dyed fabric manufacturing process has a soft hand feel, no special auxiliary which feels cool is added in the production process, the contact area between yarn and the skin is reduced, gaps between the yarn are enlarged, the superficial area for moisture and heat dissipation is enlarged, moisture absorption and air permeability are more than doubled, and therefore a wearer can feel quite cool in summer.

Owner:LUTAI TEXTILE

Apparatus for Electromechanically Connecting a Plurality of Guns for Well Perforation

ActiveUS20180119529A1Eliminate needProtection from damageExplosive chargesFluid removalElectrical connectionEngineering

A gun assembly for perforating wells comprising a plurality of guns with shape charges aligned centrically by end caps having insulated connector pins for conducting electrical signals and pressure through the end caps while preventing debris from the blast of one gun from entering and damaging the electrical connections and components of the next gun. The end caps being interconnected physically and electrically by specialized intermediate subs.

Owner:NEXUS PERFORATING LLC

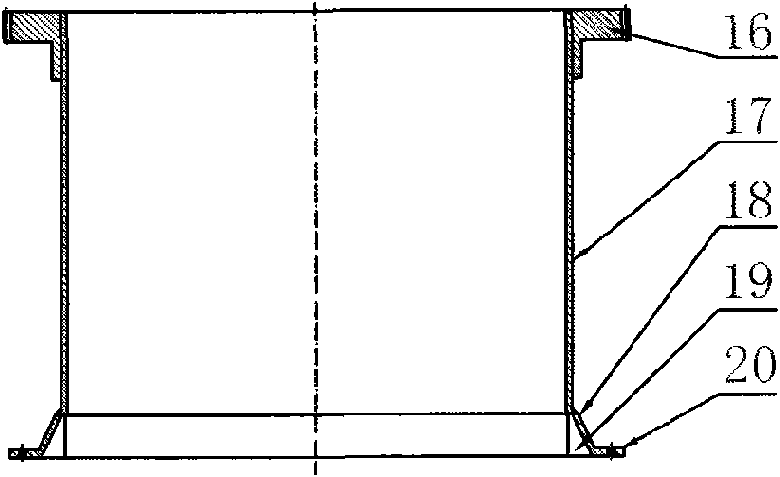

Horizontal growth device and growth method of phosphorus silicon cadmium mono-crystal

ActiveCN104047047AConducive to spontaneous nucleationLow costPolycrystalline material growthFrom frozen solutionsSpontaneous nucleationCrystal orientation

The invention discloses a horizontal growth device and growth method of a phosphorus silicon cadmium mono-crystal, belonging to the technical field of phosphorus silicon cadmium mono-crystal preparation. The device comprises an outer layer quartz tube, an inner layer quartz tube sleeved in the outer layer quartz tube, and a PBN boat-shaped crucible sleeved in the inner layer quartz tube, wherein the PBN boat-shaped crucible comprises a crystal nucleus growth section, a transition section and a mono-crystal growth section which are connected with one another in sequence; a first end part of the crystal nucleus growth section is set to be spire-shaped so as to improve the uniformity of crystal orientation in spontaneous nucleation. By virtue of the design of a double-layer quartz tube, inert gas is introduced between the quartz tubes, so that the problems of tube explosion extremely easily generated in the crystal growth process can be solved, and the stability of a thermal field and the durability of the growth device can be improved. The method is used for preparing the phosphorus silicon cadmium mono-crystal on a horizontal crystal growth furnace with the growth device by using a horizontal gradient freezing method so as to ensure a more stable crystallization process and reduce the defects of parasitic nucleation; the method is beneficial for obtaining a CSP mono-crystal with good mono-crystal performance and complete crystal lattice, and is simple in operation, easy in control and low in cost.

Owner:北京雷生强式科技有限责任公司 +1

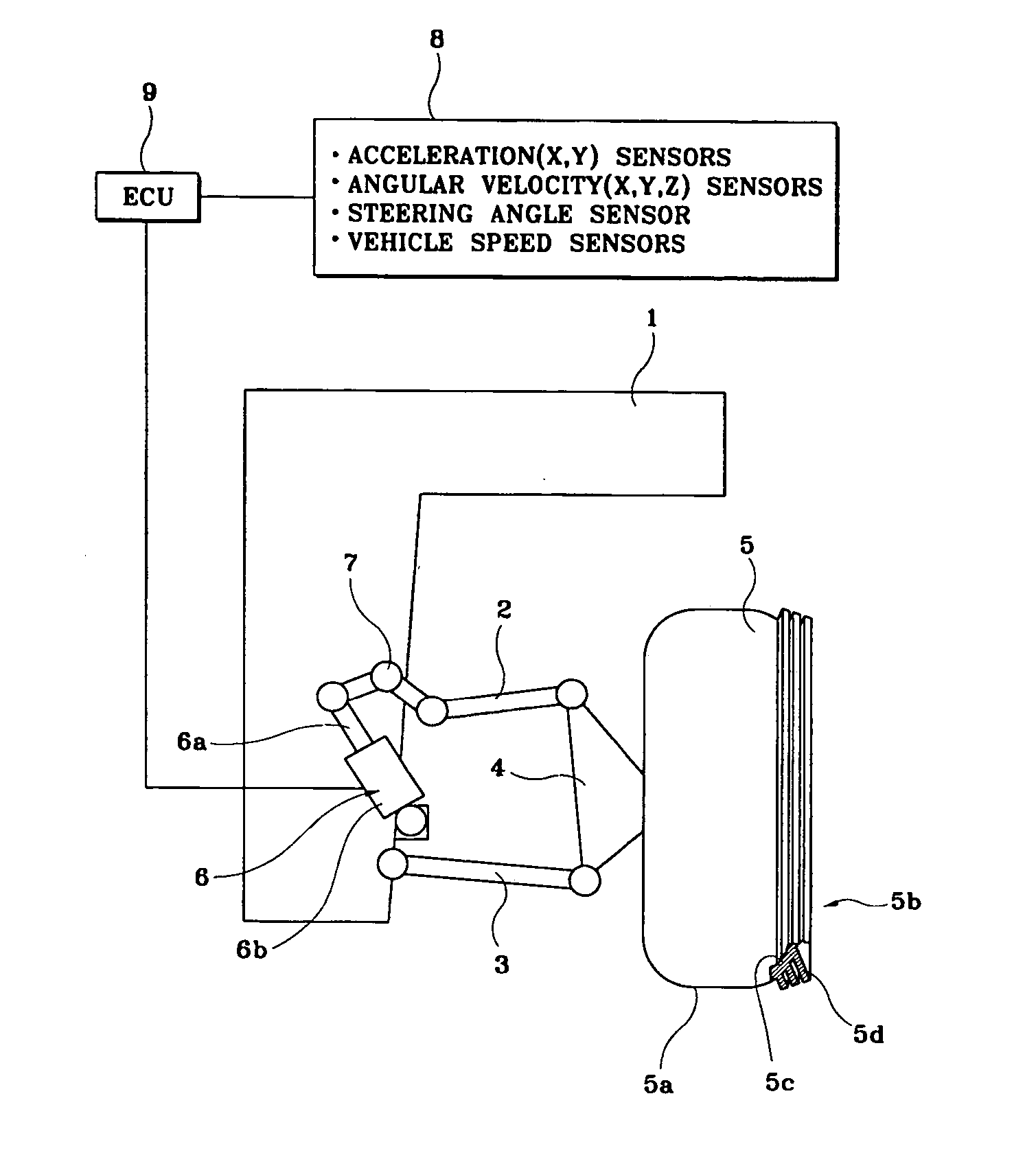

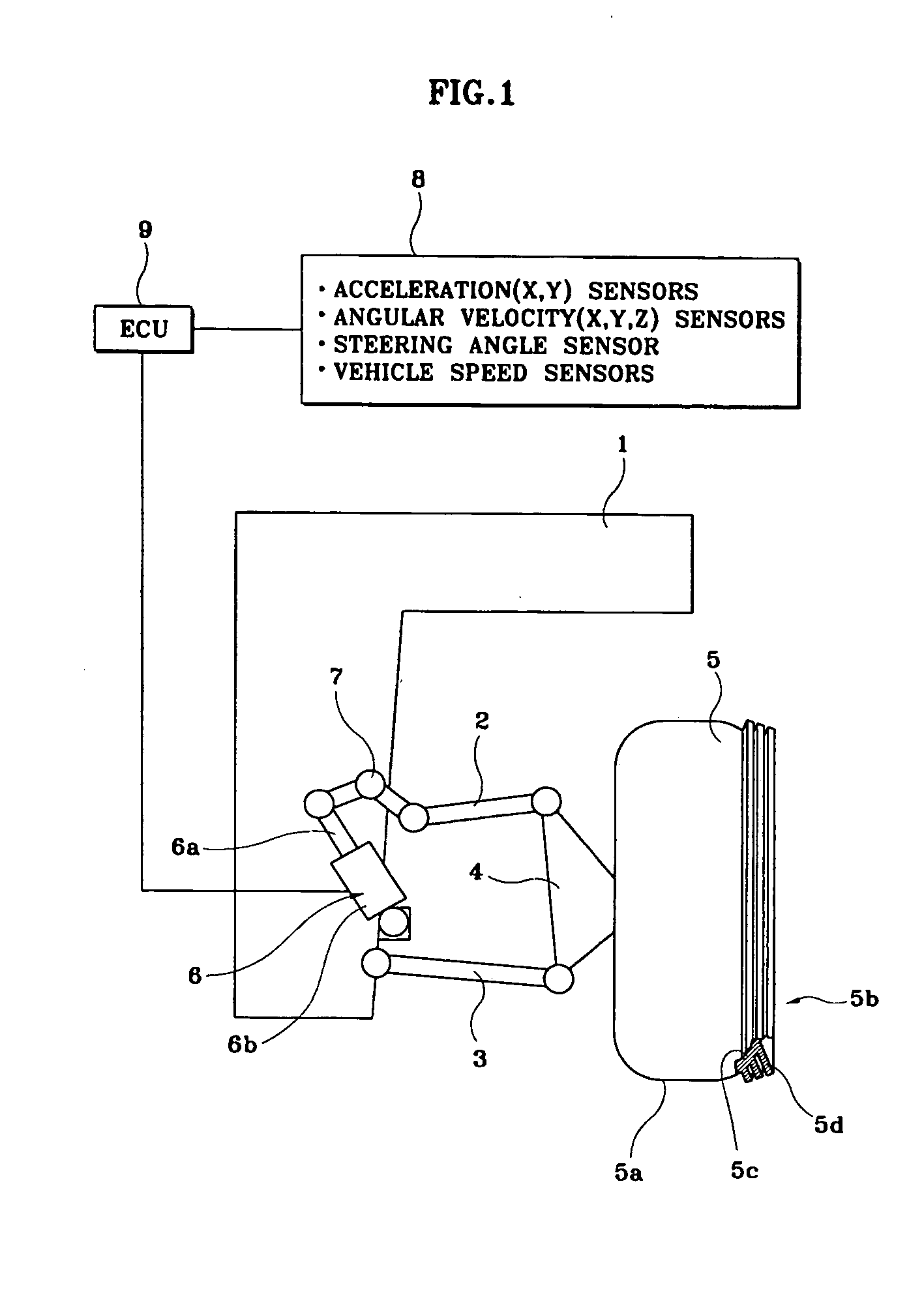

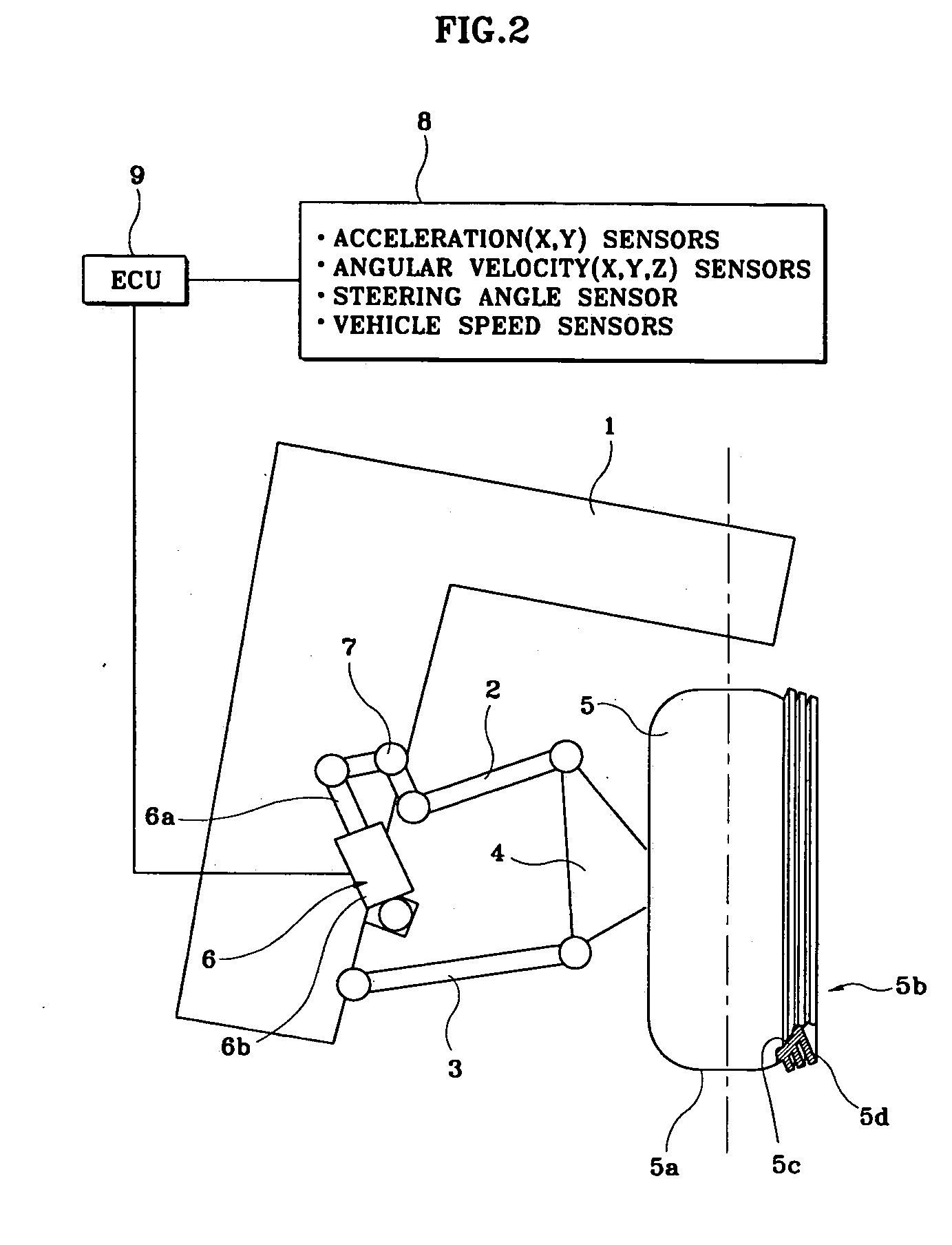

Rollover protecting system for vehicle

InactiveUS20050006166A1Improve steering stabilityReduce contact surfacePedestrian/occupant safety arrangementInterconnection systemsRolloverRoad surface

A rollover protecting system for a vehicle comprising an actuator for pushing out an upper arm to an external direction of the vehicle by pivoting a pivot arm such that a tire produces a positive camber in relation to the road surface. Protruding ends are formed on a shoulder part of the tire for reducing a contact surface of the tire to the road, thereby reducing the lateral force applied to the tire and preventing an occurrence of rollover.

Owner:HYUNDAI MOTOR CO LTD

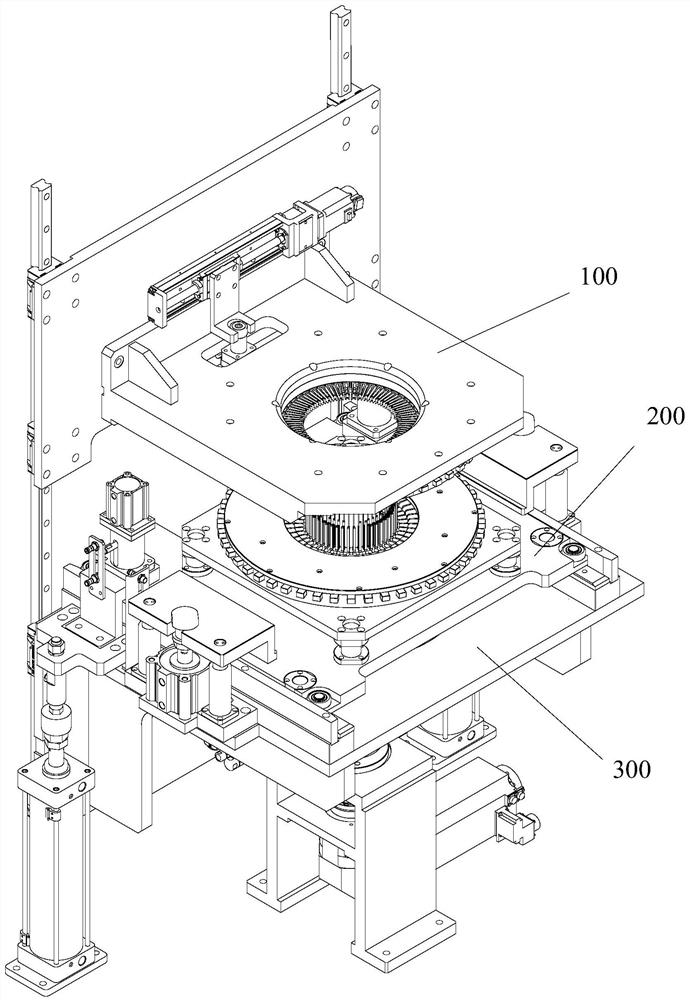

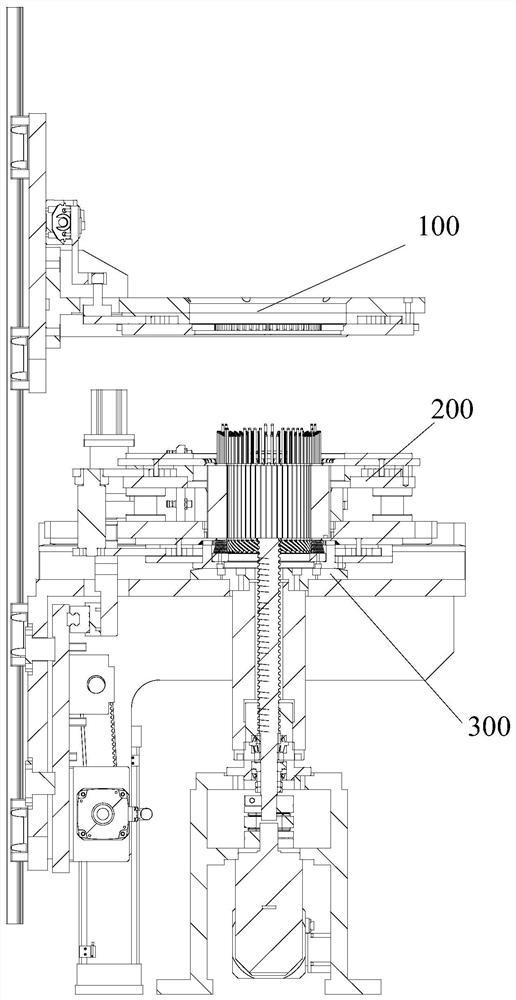

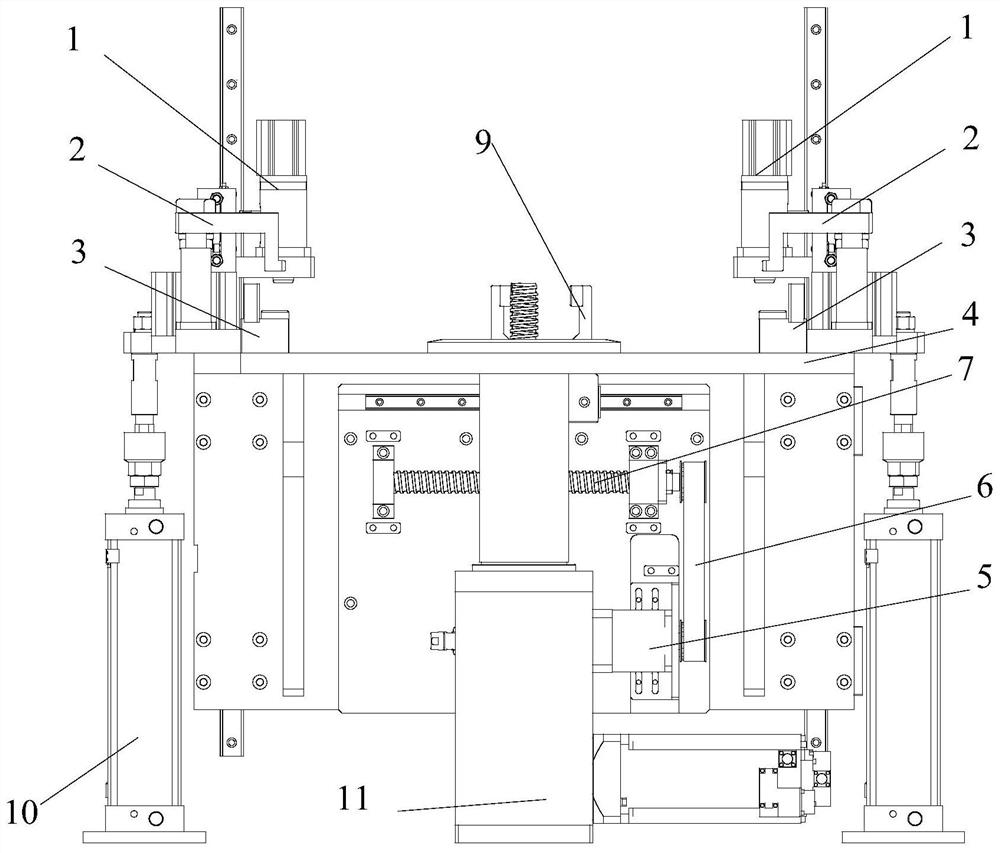

Device and method for twisting end part of stator of flat-wire motor

ActiveCN112039298ASave human effortImprove flaring efficiencyManufacturing stator/rotor bodiesElectrical and Electronics engineeringMechanical engineering

The invention discloses a device for twisting the end part of a stator of a flat-wire motor. The device comprises: a clamp positioning mechanism used for positioning and transporting the stator; a flaring mechanism used for enabling the end part of a stator coil to move along the radial direction of a stator iron core; an end twisting mechanism used for twisting a flared flat wire; and a base usedfor mounting the end twisting mechanism and the flaring mechanism. The invention further provides a method for twisting the end part of the stator of the flat-wire motor. The method comprises the steps of positioning, primary twisting and secondary twisting. The invention also discloses a method for layered flaring of the end part of the stator of the flat-wire motor. The method comprises the steps of positioning, primary flaring, secondary flaring and the like. By arranging the flaring mechanism, a contact surface of a flaring part and a flat wire is small, so it is guaranteed that each wirecan be inserted into an end twisting die, the accuracy of wire insertion is guaranteed, and the percent of pass of twisted ends is increased; and full-automatic flaring is achieved, so manpower is saved, flaring efficiency is improved, the accuracy of wire insertion can be guaranteed, and the percent of pass of twisting ends is increased.

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

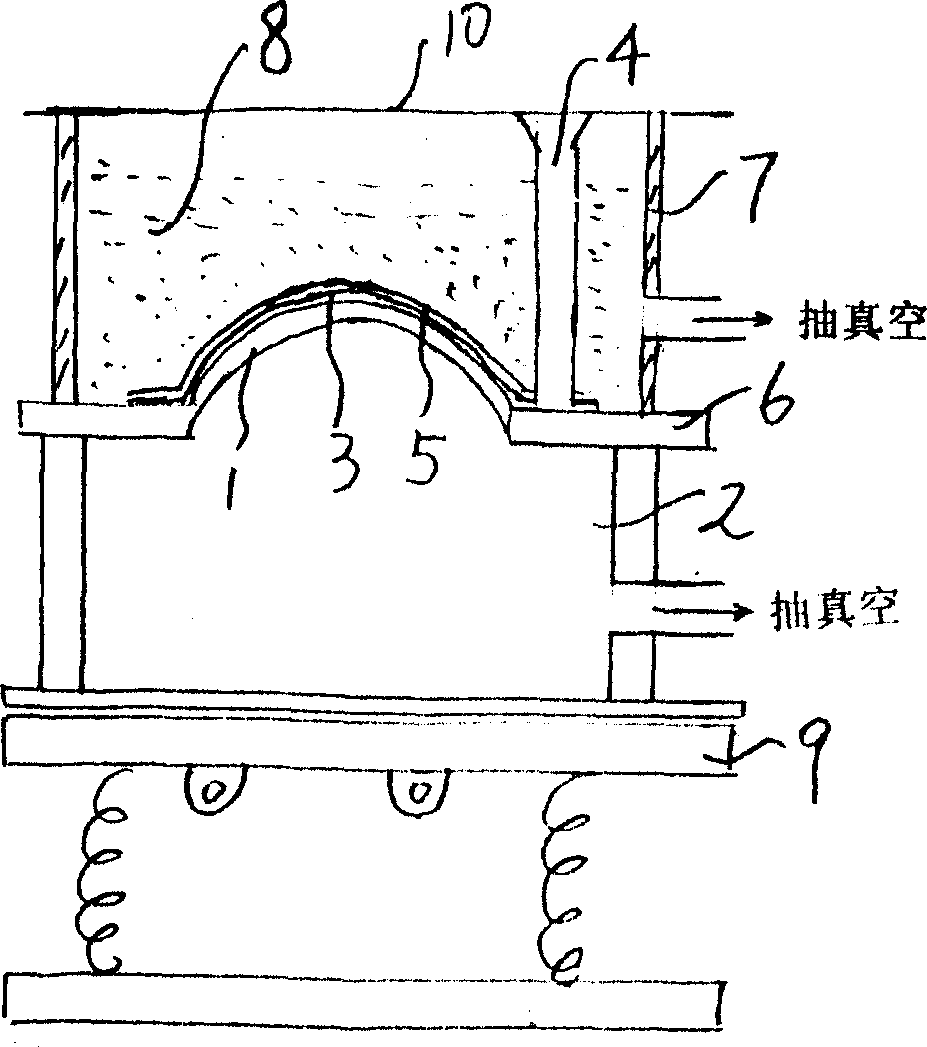

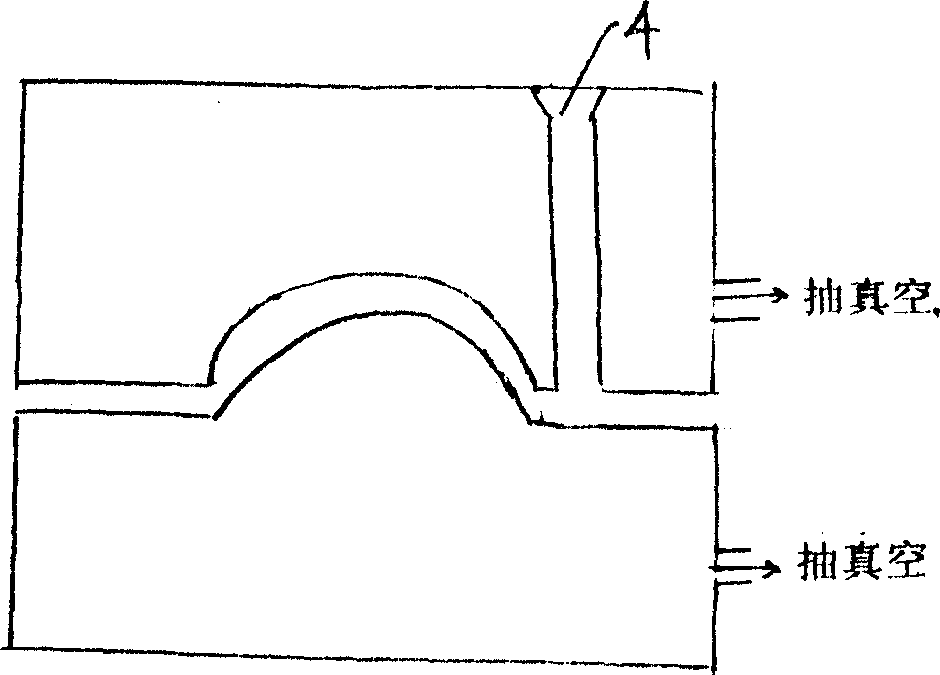

Vacuum negative pressure casting process of foam die casting piece

InactiveCN1701874AImprove compactnessReduce oxidationFoundry mouldsFoundry coresPressure castingSpray coating

The invention discloses vacuum negative-pressure casting method for sop plastic mould cast, which comprises steps: fix the mould on pull box, heat and cover the plastic membrane on the mould, spray coating layer on membrane surface, put casting box covered with seal membrane, take vacuum treatment for casting box to harden its surface; then, draw mould, obtain and combine upper-down cavity, cast on the casting gate, demould to get the cast. This technique is simple, easy to operate; the product has high intensity, high precision size and easy to demould.

Owner:如皋市超达模具配套有限公司

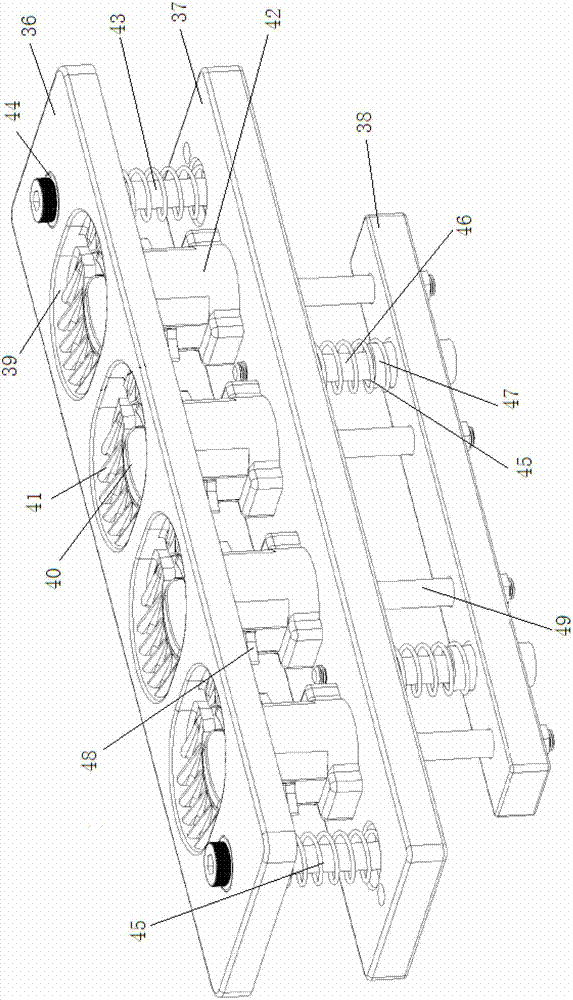

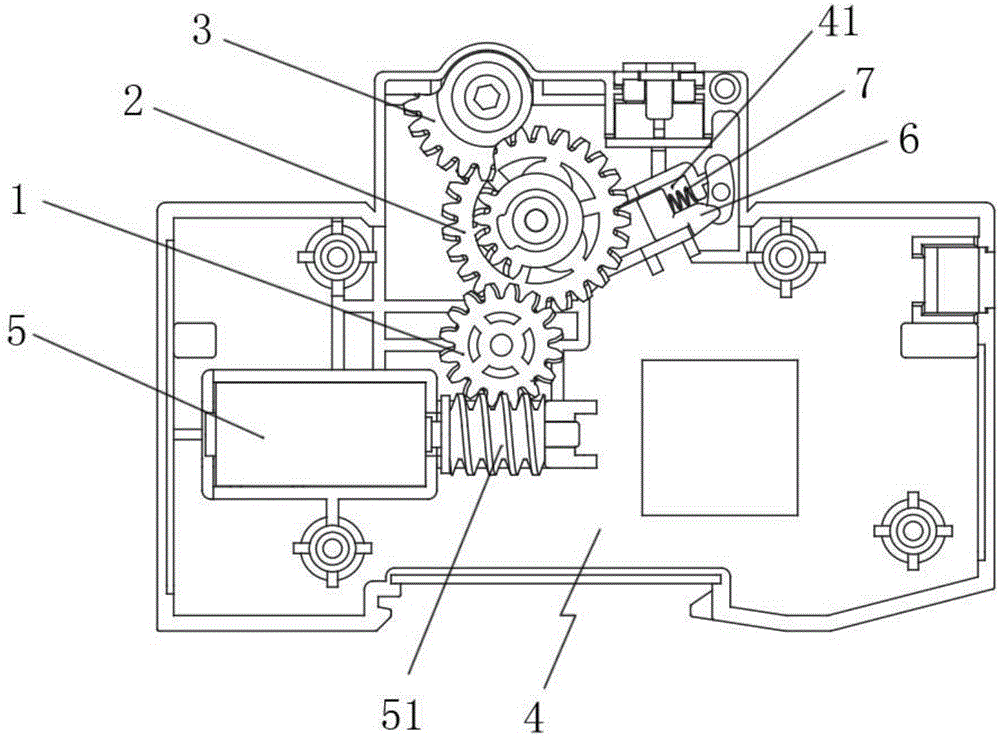

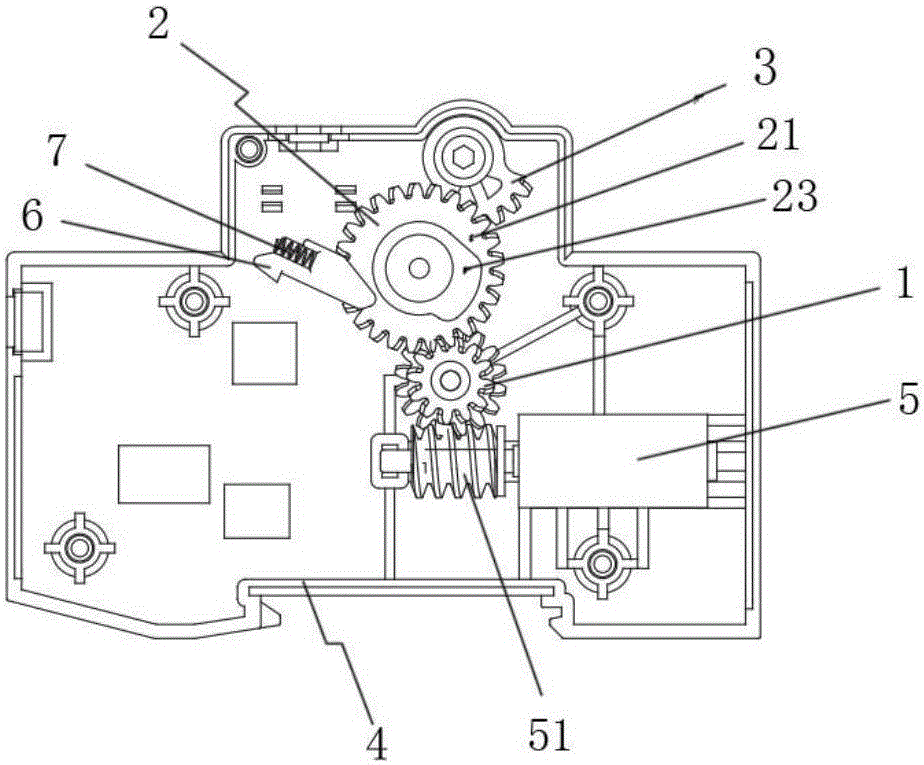

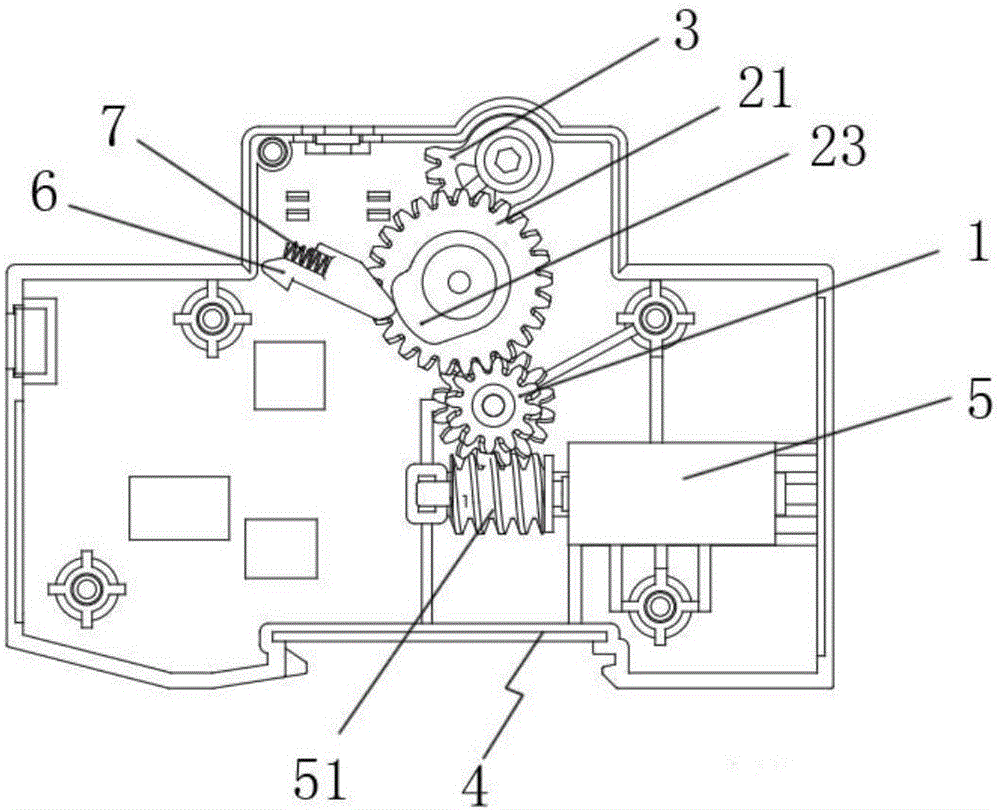

Automatic reclosing lock device of breaker

ActiveCN106356263ANo shakingSolve the unstable transmissionProtective switch operating/release mechanismsDrive motorEngineering

The invention provides an automatic reclosing lock device of a breaker. The automatic reclosing lock device comprises a drive motor, a linkage tripping mechanism, a transmission gear mechanism and a breaker handle mechanism, wherein the transmission gear mechanism comprises a first transmission gear, a second transmission gear and a third transmission gear which are adjacently meshed with one other, a cam portion of the second transmission gear can drive a push rod to shift a tripping rod, so as to quickly separate the breaker, the second transmission gear can drive an incomplete gear to rotate continuously, and the incomplete gear and the third transmission gear are in mesh transmission to drive a handle to switch on automatically through a linkage rotation shaft. The automatic reclosing lock device has the advantages of being reliable in transmission, strong in stability and capable of enabling the second transmission gear not to be prone to shaking or rising; thus, the automatic reclosing lock device can avoid the problem of tripping clamping stagnation or tripping slide when being matched with a linkage tripping part, the use performance of a product is favorably improved, and the service life of the product is favorably prolonged.

Owner:ZHEJIANG ZHONGFU ELECTRIC

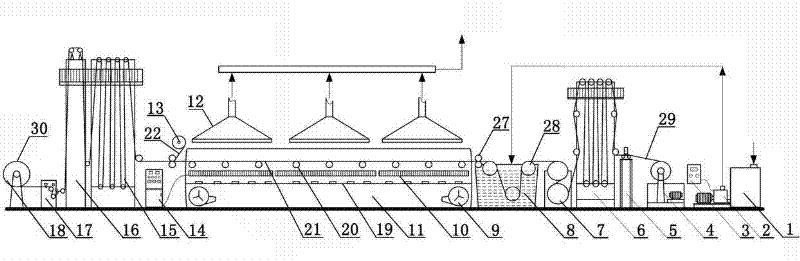

Production equipment and method of self-adhesive layer band

InactiveCN102350852AGuaranteed bondingControl UniformityLamination ancillary operationsFilm/foil adhesivesEngineeringError correcting

Production equipment and a method of a self-adhesive layer band. A base material is treated by a base material unfolding machine, a head-tail-overlapping machine, a base material buffering adjusting bracket and a base material dryer successively, enters into a gluing pool for gluing, then enters a dryer for drying; the dried base material is rolled with an isolated film on a surface thereof by a mulch applicator, cooled by a self-adhesive layer buffering adjusting bracket and adjusted by an automatic error correcting controller; then the base material can be packaged by a product winder and finally cut into dimensions required by production specifications by a cutting machine. After gluing, the base material is dried and returns to the gluing pool for a second gluing; and base material enters into the dryer again for drying after the second gluing, so as to increase peeling intensity of a self-adhesive waterproof coiled material and bonding strength of the material with a base, accelerate drying speed and increase product quality. According to the invention, base material treatment, gluing, drying, coating, cooling, rolling and packaging can be finished in a line, so as to realizeflexible operation, high degree of automation and good product quality.

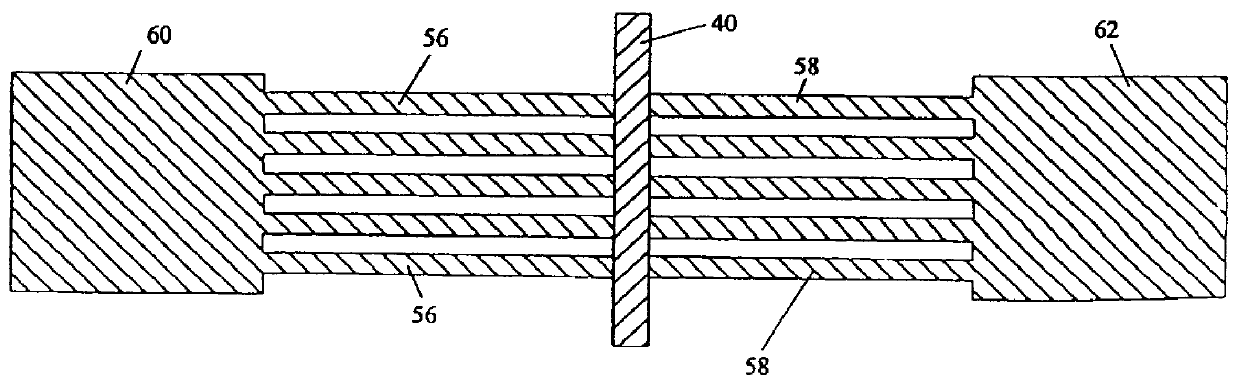

Flexible busbar

ActiveUS20130068495A1Easy to slideIncrease flexibilityCoupling device connectionsLine/current collector detailsElectrical conductorBusbar

A flexible busbar includes a central conductor (generally of rectangular cross section comprising multiple layers of thin aluminum, copper or other alloys with good electrical properties (conductivity)) and a sleeve having a shape on the internal surface to reduce the adhesion between the two conductors and the sleeve when the flexible busbar is bent, folded, or twisted. This increases the flexibility of the flexible busbar.

Owner:ERICO INT

Test device of frictional characteristic of sliding bearing under middle and heavy radial load

InactiveCN101995310AReduce contact surfaceSmall sizeMachine bearings testingWork measurementRolling-element bearingEngineering

The invention relates to a test device of a frictional characteristic of a sliding bearing under a middle and heavy radial load, comprising a simulative sliding bearing, wherein the simulative sliding bearing comprises a shaft and a shaft sleeve, a radial loading device is arranged on the outer peripheral surface of the shaft sleeve, and two raised ring surfaces which have the same structure and are matched with the inner peripheral surface of the shaft sleeve in a sliding mode are symmetrically arranged on the outer peripheral surfaces of shafts arranged on both sides of loading points supported by the loading end and the outer peripheral surface of the shaft sleeve. In the invention, two raised ring surfaces are arranged on the outer peripheral surface of the shaft along an axial direction at intervals, the inner peripheral surface of the shaft sleeve is in contact with two ring projections, thus, the contact surface of the shaft sleeve and the shaft is smaller, the dimensions of related parts can be reduced in the same proportion, the working state of the sliding bearing can be simulated in reality, the internal friction force of the sliding bearing can be accurately measured in an experiment condition, and meanwhile, the two raised ring surfaces are symmetrically arranged corresponding to the loading points to ensure two even contact loads.

Owner:HENAN UNIV OF SCI & TECH

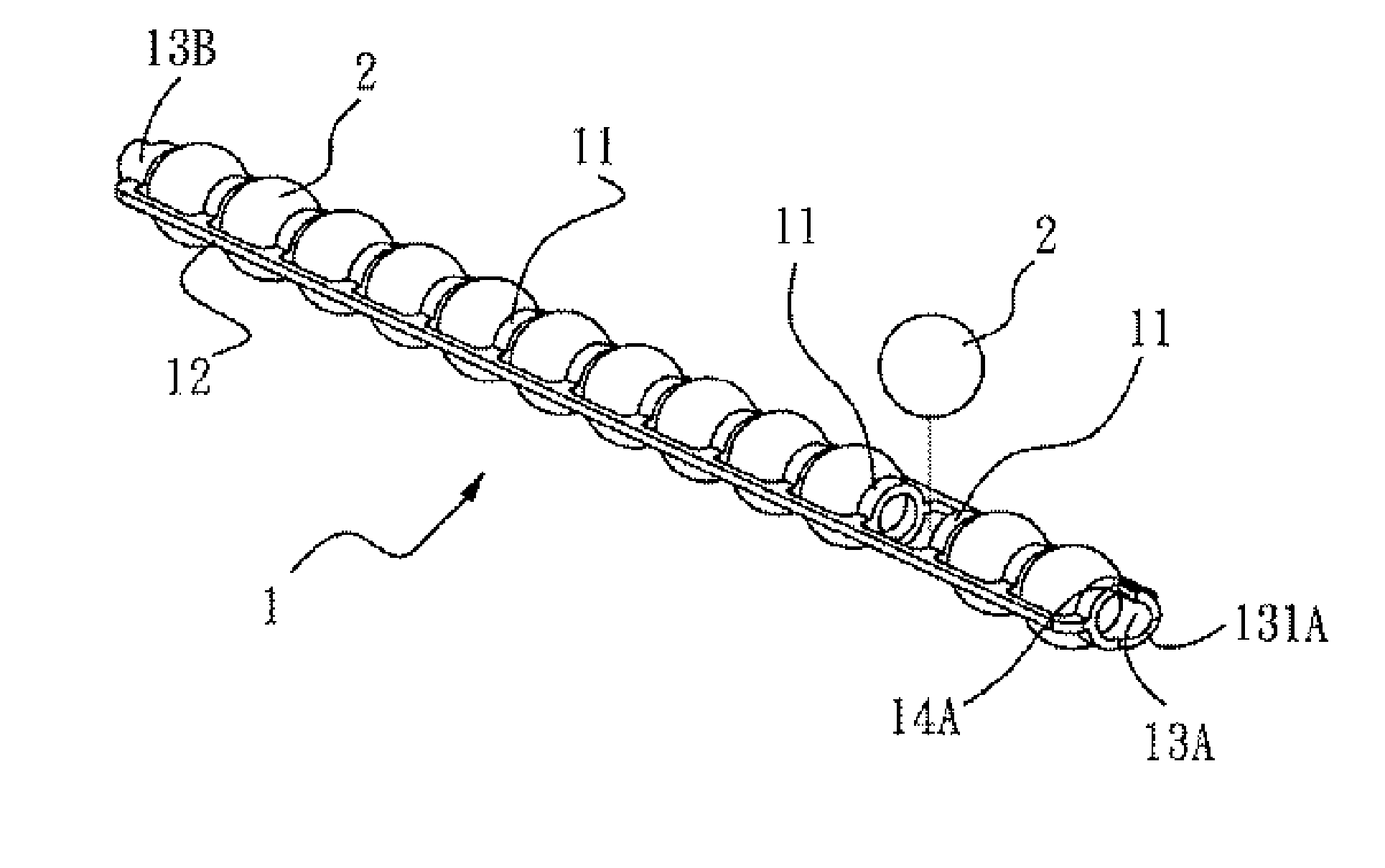

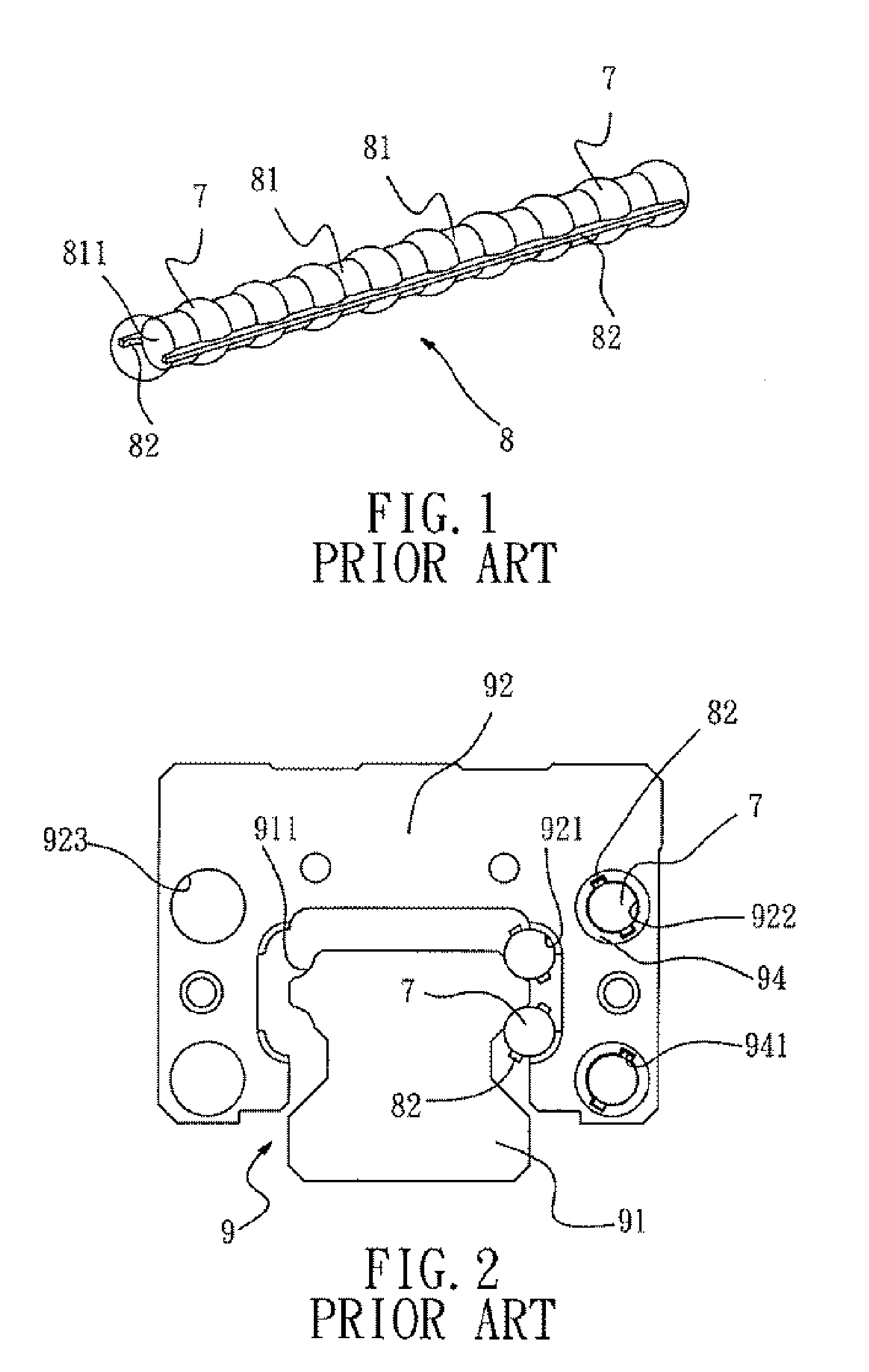

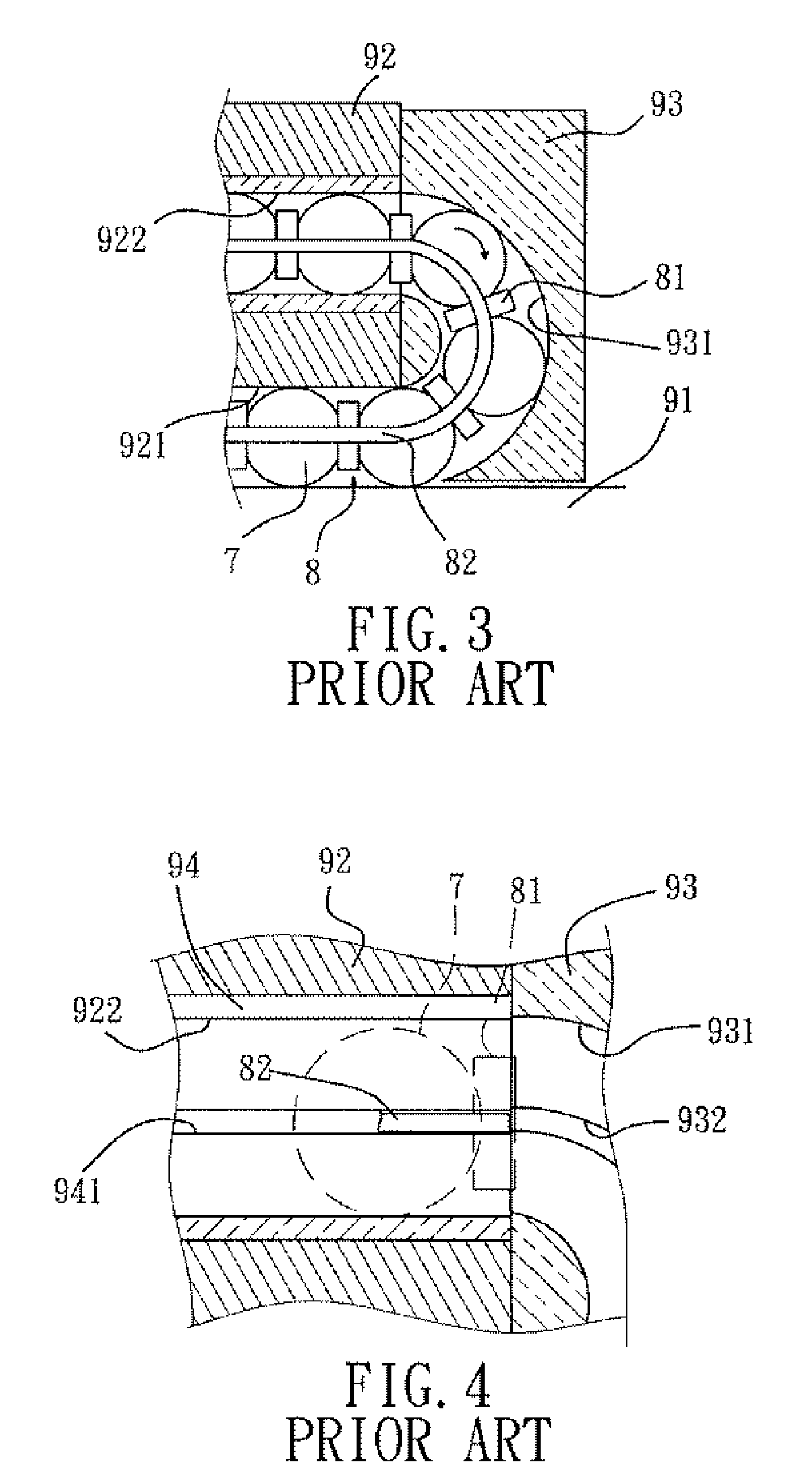

Ball Chain

ActiveUS20070160313A1Suppress axial distortionImprove operational fluencyRolling contact bearingsLinear bearingsEngineeringMechanical engineering

A ball chain used in a linear guideway, at either end of the chain is formed a protruded connecting block, the connecting blocks each has an abutting surface that is parallel to a radial direction of a center of the radius of curvature of the ball chain, the abutting surfaces of the connecting blocks of the spacers at both ends of the chain are mated with each other for limiting axial rotation of the ball chain. Due to the two connecting blocks at the end of the ball chain that has entered the return path protrude out of the groove, the end of the chain within the return path will use the abutting surface to limit the end of the chain that has not entered the return path and to guide the end of the chain, which has not entered the return path, into the return path smoothly, thus improving the operating smoothness of the chain.

Owner:HIWIN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com