Test device of frictional characteristic of sliding bearing under middle and heavy radial load

A radial load, sliding bearing technology, used in mechanical bearing testing, measuring devices, power metering, etc., can solve the problems of difficult sliding bearing internal friction, huge load capacity of sliding bearing, inability to accurately measure, etc., to achieve load stability , Simple structure, small loading impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

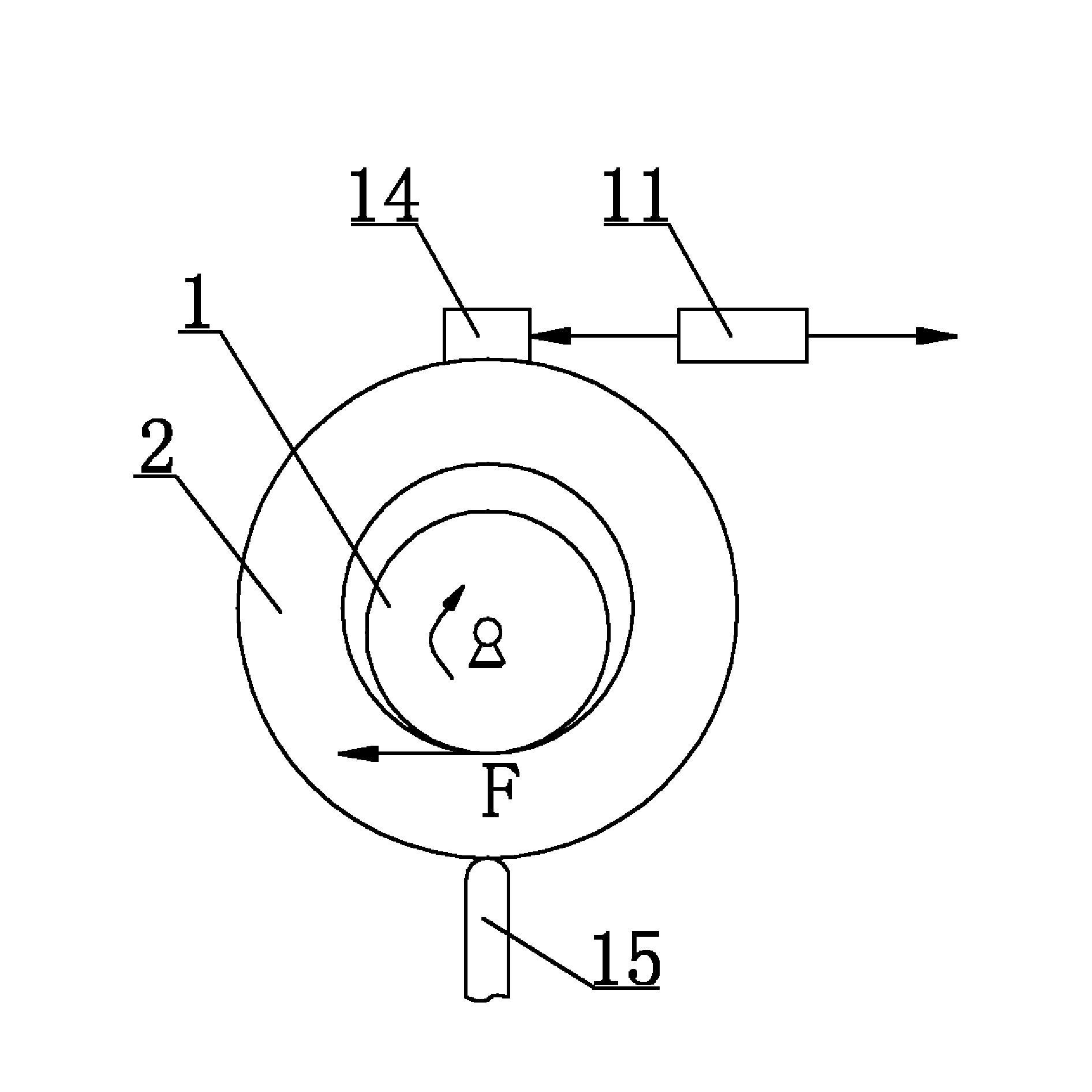

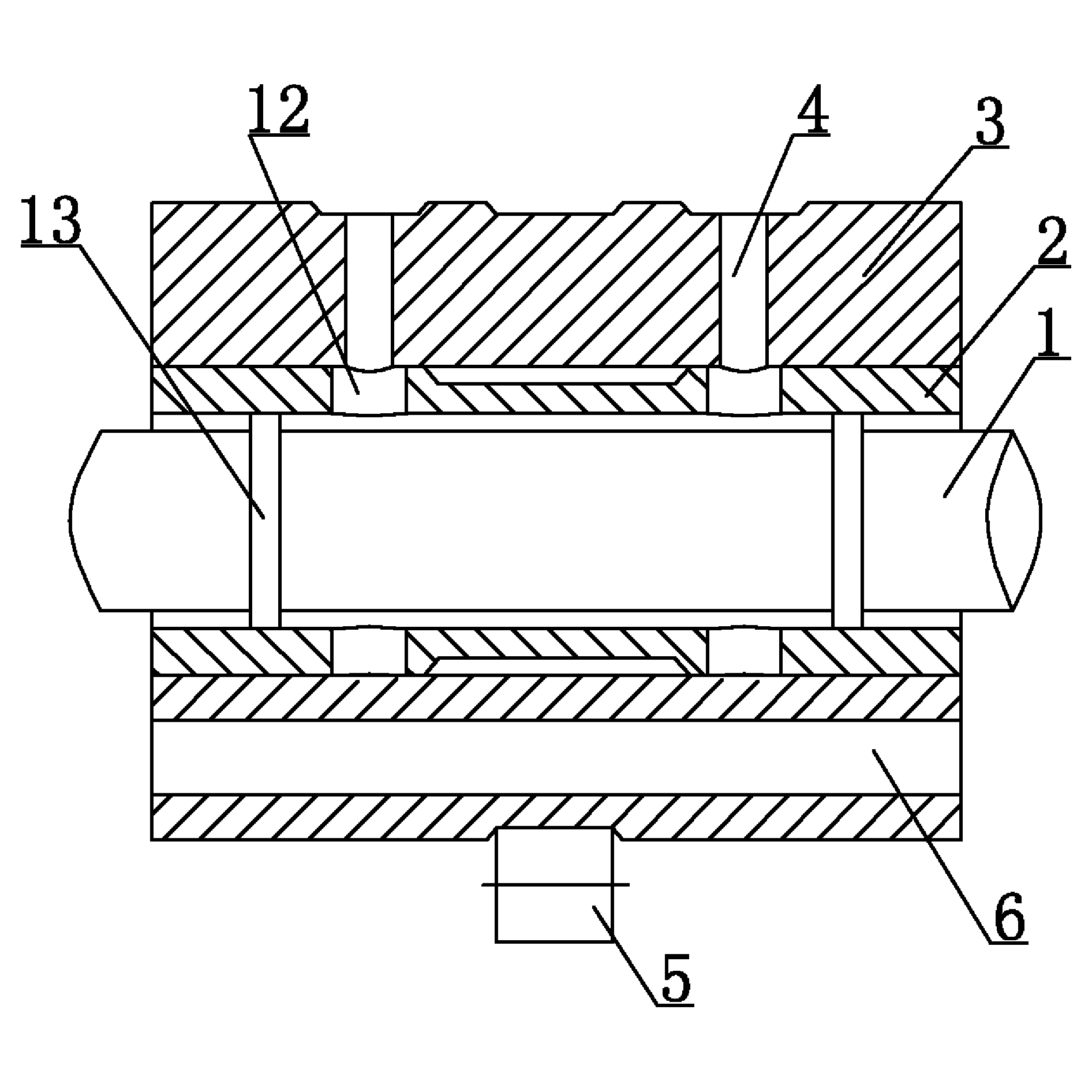

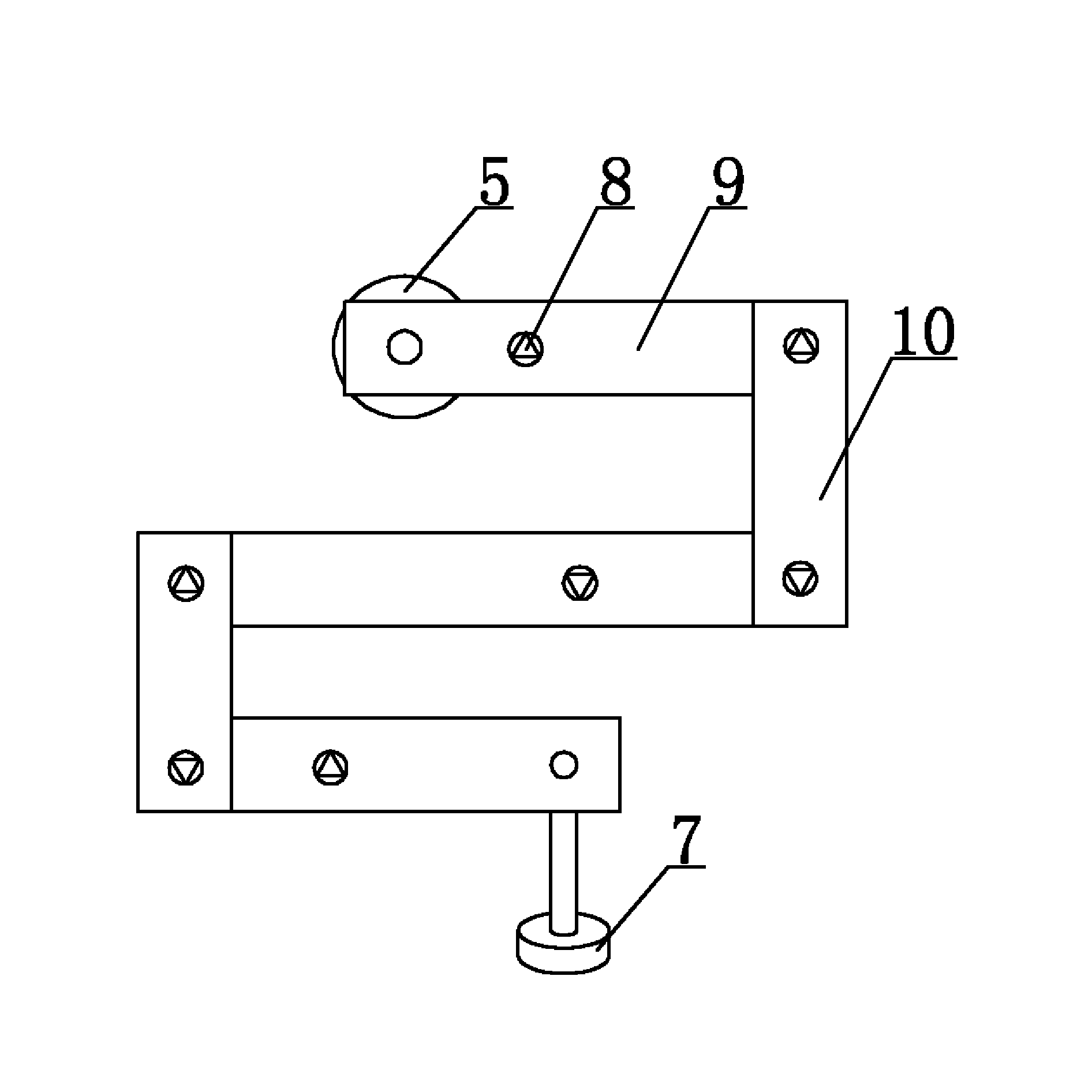

[0022] An embodiment of a testing device for the friction characteristics of sliding bearings under medium and heavy radial loads. figure 2 , image 3 The test device includes a shaft 1, a shaft sleeve 2 is freely sleeved on the shaft 1, and the shaft 1 and the shaft sleeve 2 form a simulated sliding bearing. The outer peripheral surface of the shaft 1 is provided with two convex annular surfaces 13 with the same structure. , The two convex annular surfaces 13 are arranged at intervals along the axial direction of the shaft 1, the inner peripheral surface of the sleeve 2 is in sliding fit with the two convex annular surfaces 13, and the two convex annular surfaces 13 are shafts relative to the radial loading device The loading points of the sleeve 2 are arranged symmetrically, that is to say, the distance between the loading point of the shaft sleeve 2 and the two convex annular surfaces 13 by the radial loading device is equal.

[0023] As an improvement of the above technical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com