Production equipment and method of self-adhesive layer band

A production equipment and self-adhesive layer technology, applied in the field of self-adhesive layer strip production equipment, can solve the problems of difficulty in guaranteeing product quality and production capacity, no special equipment for self-adhesive waterproof coils, and difficulty in refitting the production line, etc., to achieve Avoid the waste of glue, speed up the drying speed, and improve the effect of peeling strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

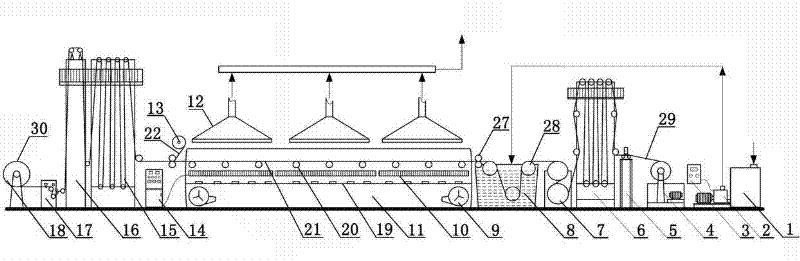

[0046] Embodiment one sees figure 1 As shown, the production equipment of this self-adhesive layer tape is suitable for one-time gluing of the substrate. , including substrate pretreatment system, gluing system, dryer, ventilation system, laminating machine and finished product winding system;

[0047] The base material pretreatment system is composed of a base material unfolding machine 4, a head-to-tail joining machine 5, a base material buffer adjustment frame 6 and a base material dryer 7 arranged in sequence;

[0048] The gluing system is composed of a gluing pool 8, an adhesive storage tank 1, a delivery pump 2 and an automatic flow controller 3; the entrance of the gluing pool 8 is adjacent to the outlet of the substrate dryer 7, and the gluing pool 8 can adopt the thick stainless steel plate of 5mm to make, and is square, and the section is trapezoidal with big top and small bottom. There is a group of rubber rollers 28 in the glue coating pool 8, which can be compo...

Embodiment 2

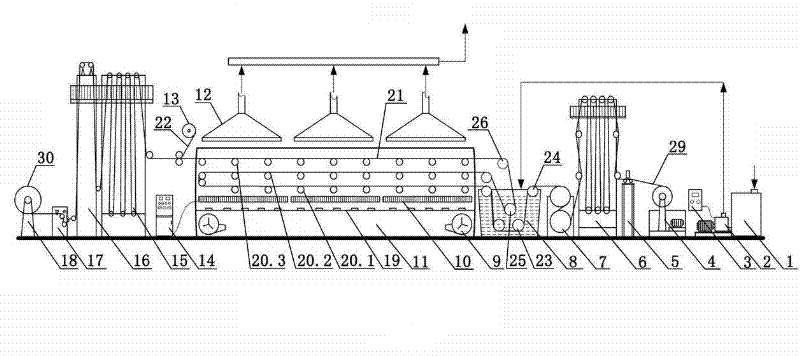

[0056] Embodiment two see figure 2 As shown, the production equipment of this self-adhesive layer tape is suitable for the secondary coating of the substrate. Two sets of rubber rollers are arranged in the gluing pool 8, wherein one group is a primary rubber roller, and the other group is a secondary rubber roller; the primary rubber roller consists of two lower rubber rollers I23 and two The upper rubber roller I24, which is placed at the entrance and exit of the gluing pool, is combined. The secondary rubber roller is composed of a lower rubber roller II25 and two upper rubber rollers II26. The lower rubber roller II25 is located at the gluing Above the two lower rubber rollers I23 in the pool, two upper rubber rollers II26 are located above the glue coating pool.

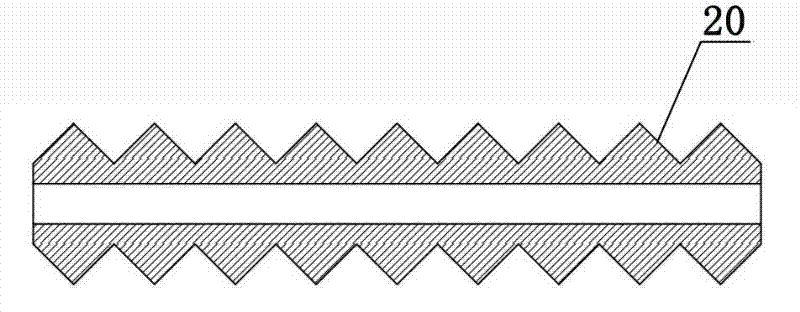

[0057] There are upper, middle and lower layers of support rollers in the dryer 11, among which the lower support roller 20.1 used for drying the base material after one-time gluing is matched with the first-ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com