Patents

Literature

5323results about How to "Fast drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

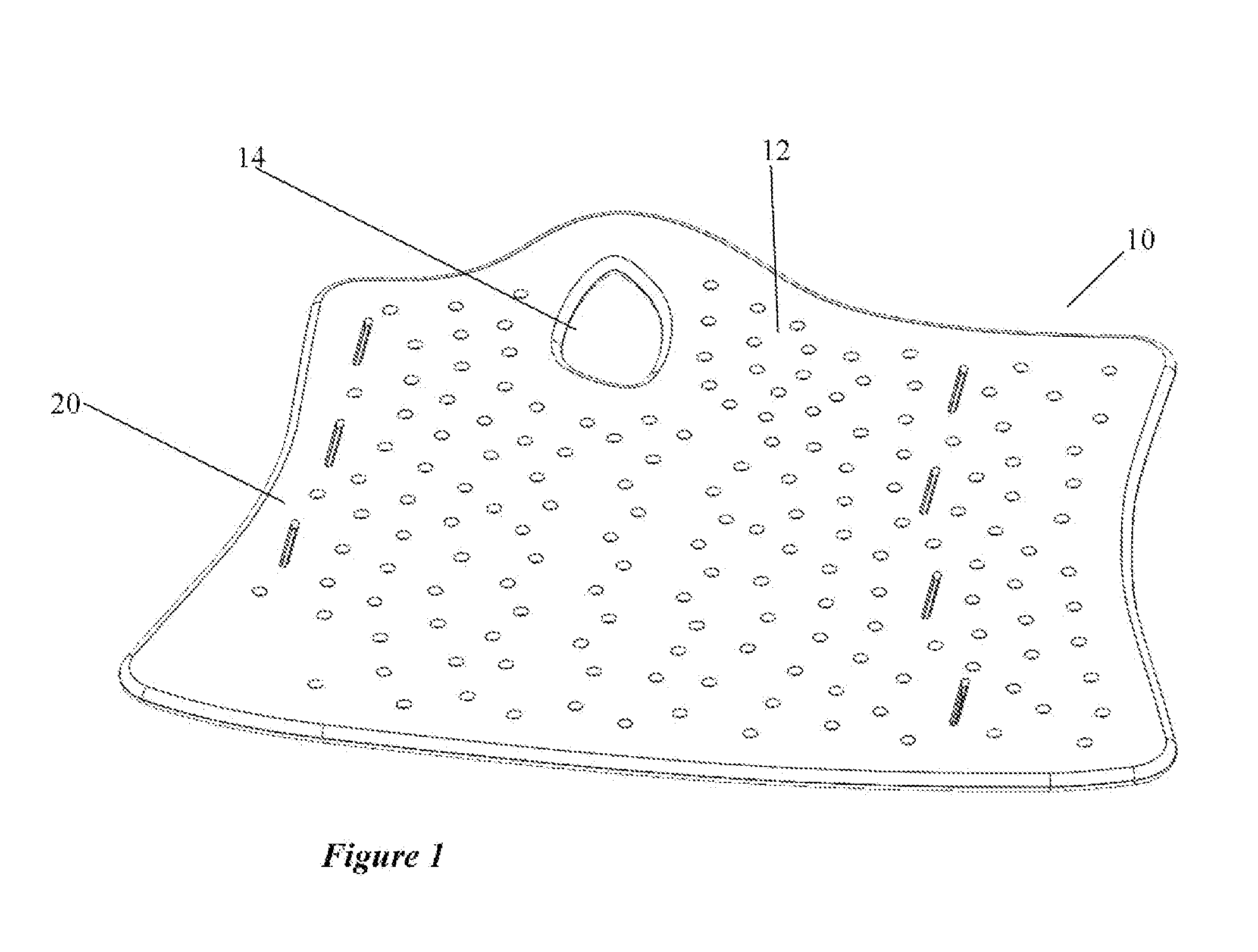

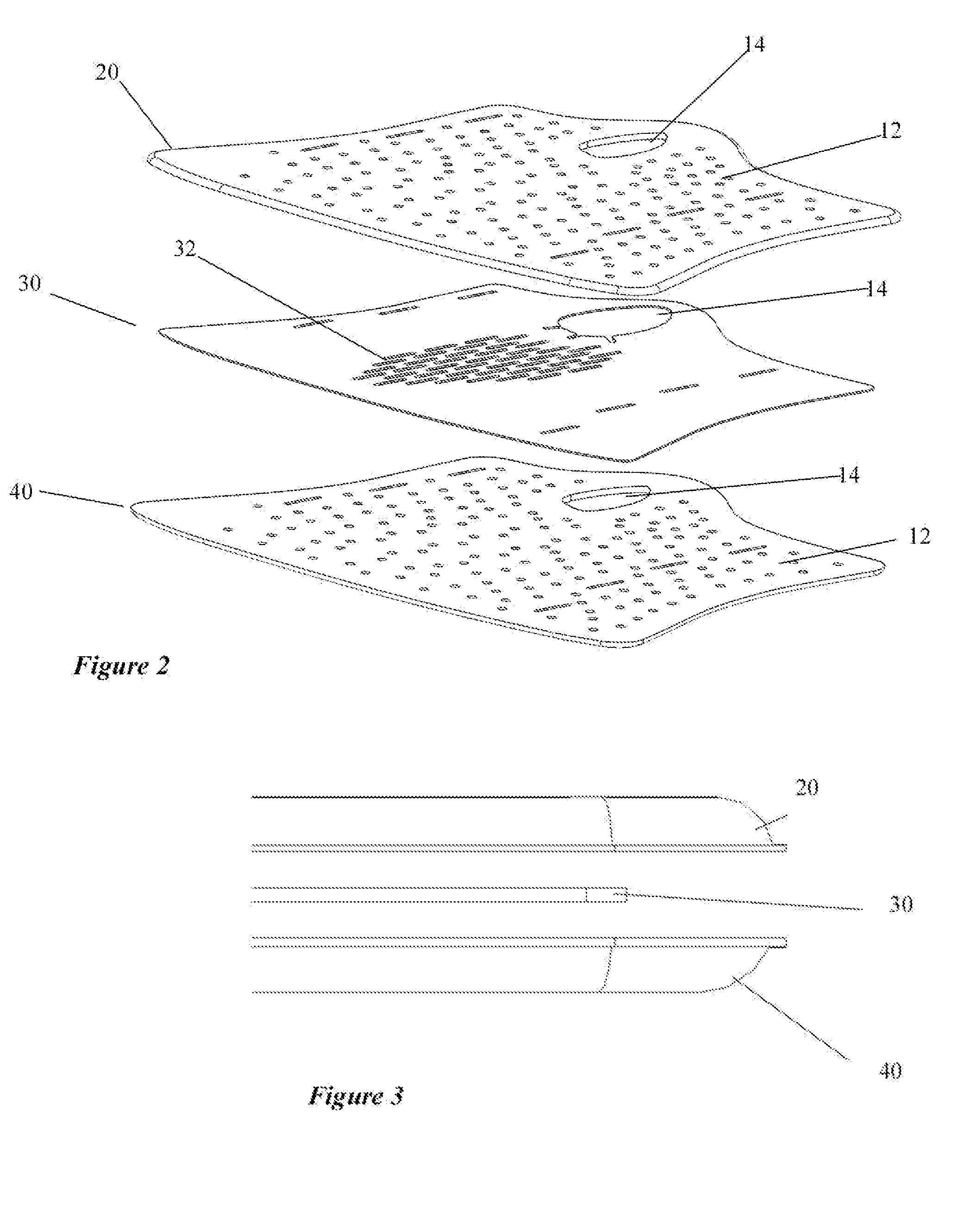

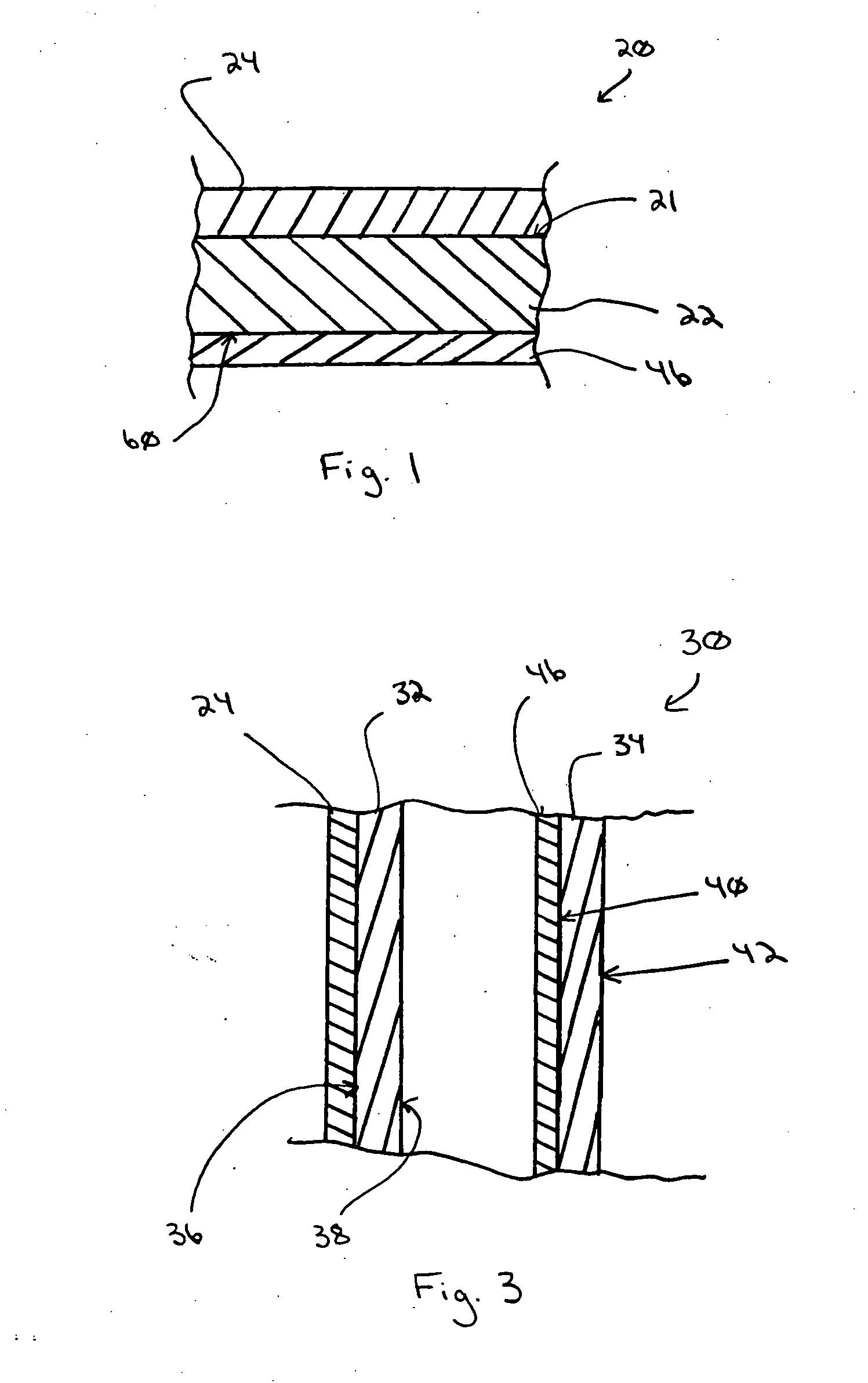

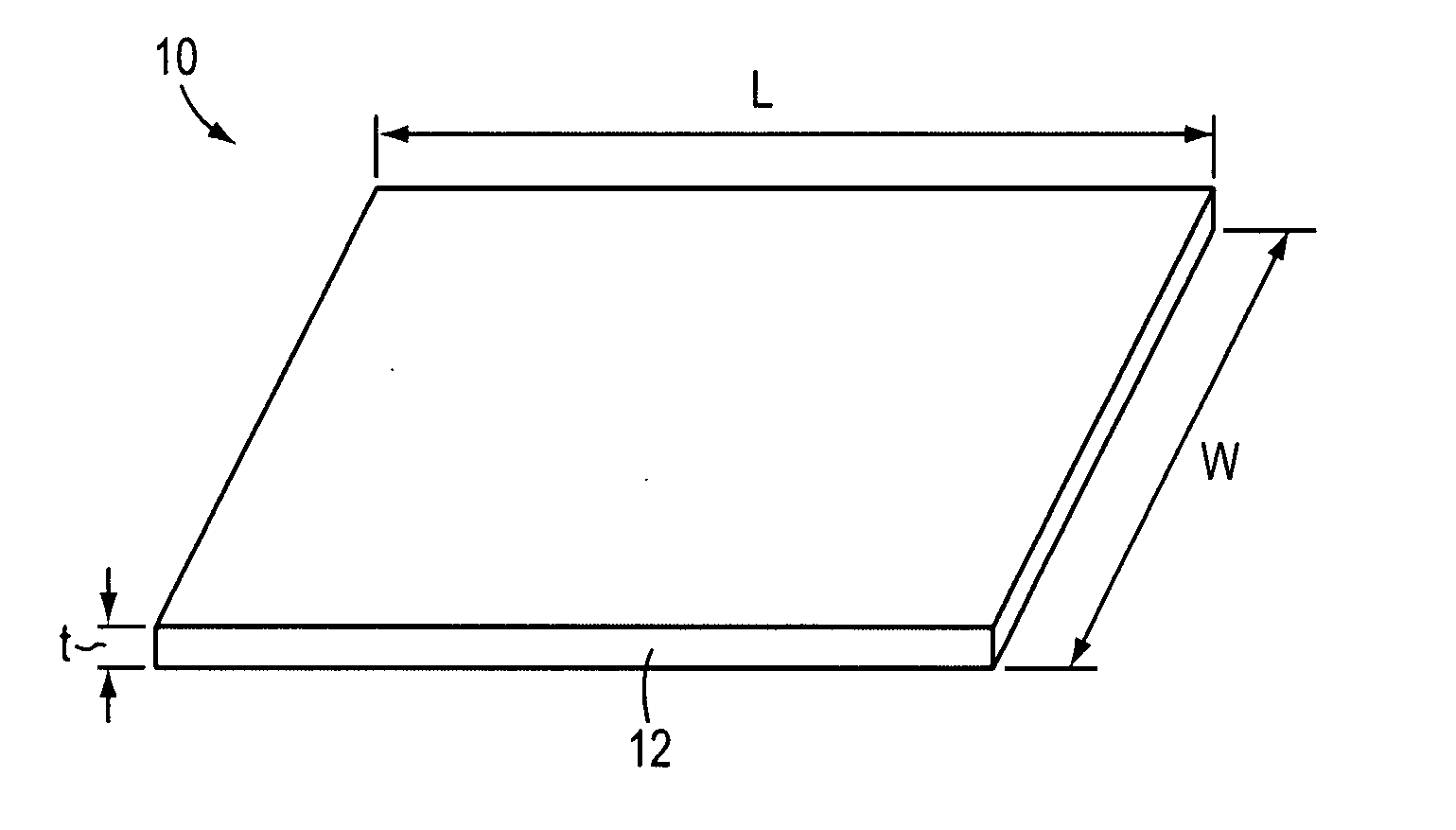

Orthopedic System for Immobilizing and Supporting Body Parts

ActiveUS20080319362A1Little timeLittle manipulationChemical protectionHeat protectionEngineeringStructural material

A unitized cast system for immobilizing and supporting a body part. The unitized casting system includes a first inner layer for padding and dissipating heat against the patient's skin. A second layer is formed from a thermoformable structural material such as perforated plastic. A protective third outer layer is provided to provide insulation for the second layer. These three layers are formed together to form a unitized cast system that is easily formed and applied to the patient.

Owner:DJO

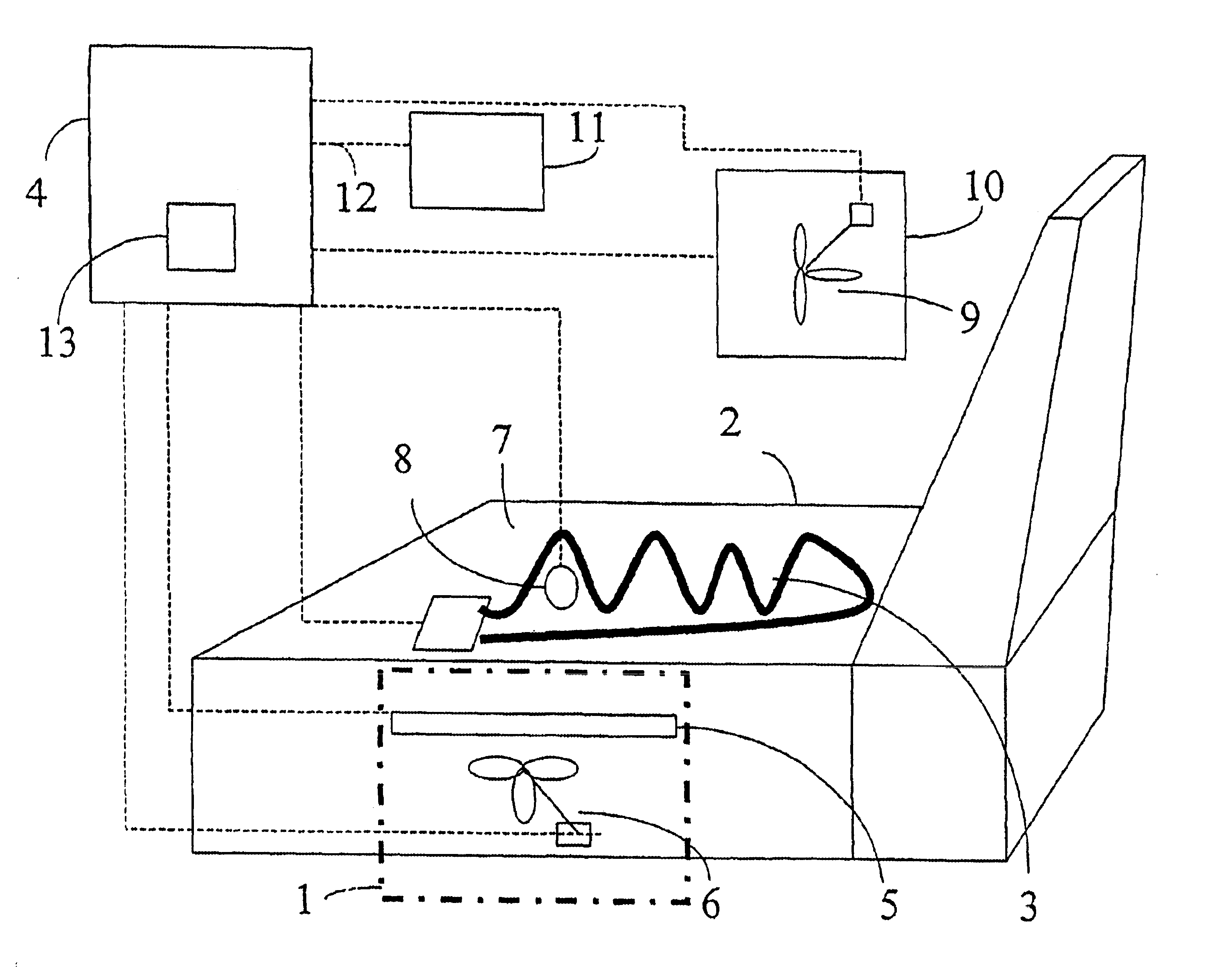

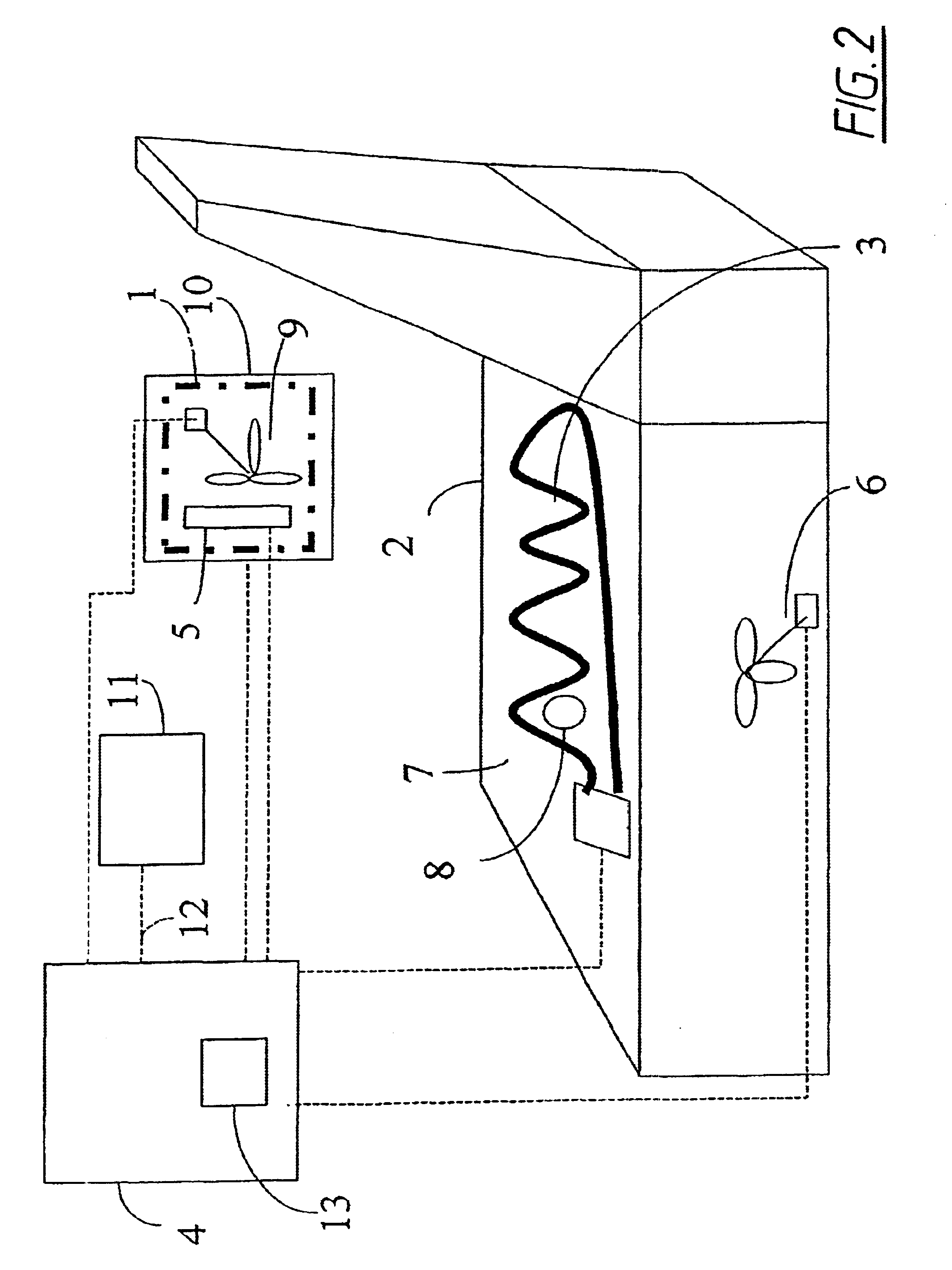

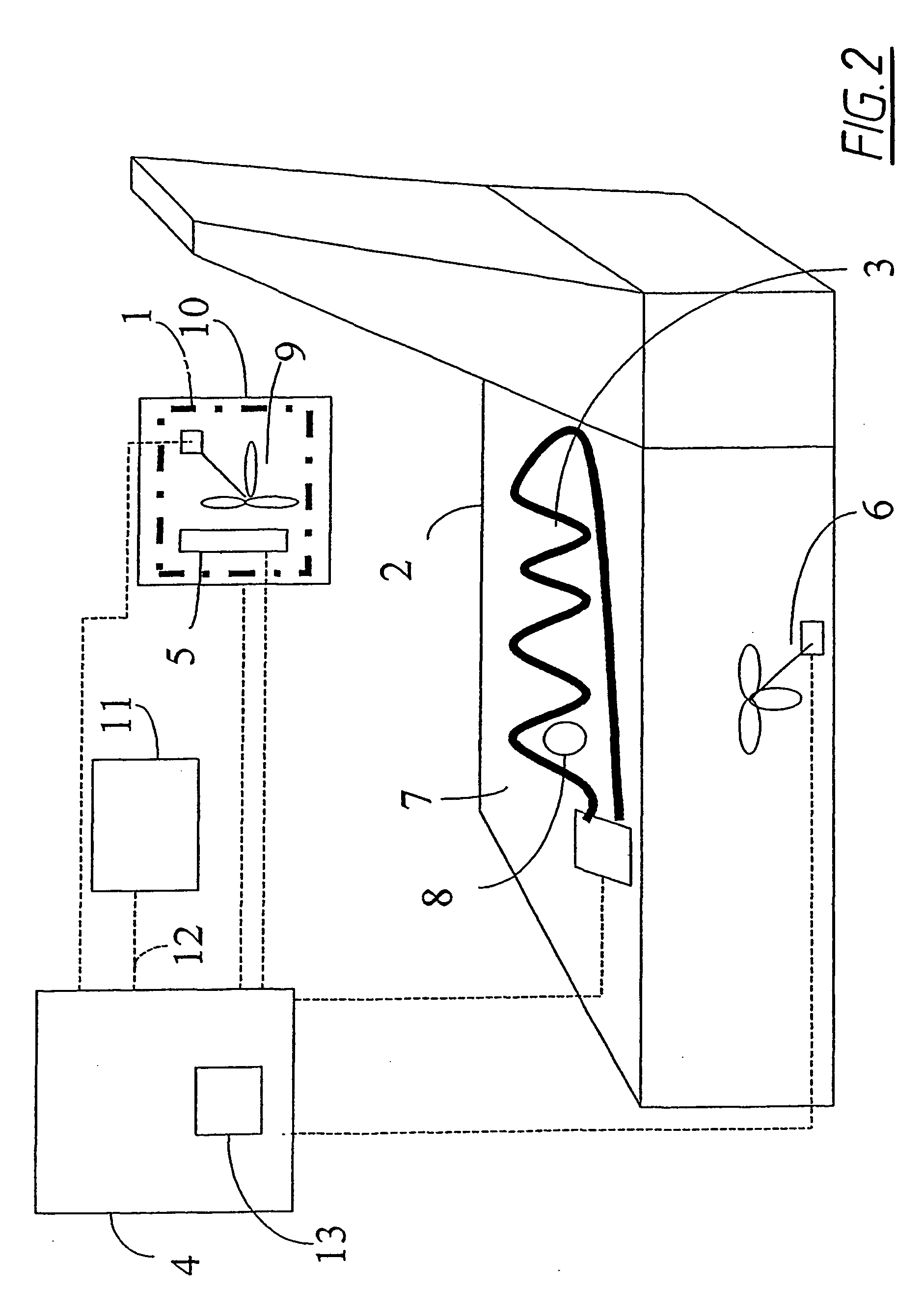

Seat with temperature control and ventilation and safety system for a vehicle

InactiveUS6892807B2Shorten drying timeReduce the negative local chillingDomestic cooling apparatusPower to electric heating circuitsTemperature controlEngineering

Methods and apparatus for controlling the temperature of a seat such as a vehicle seat are disclosed. The apparatus includes an electrical heater disposed in the seat, a cooling unit such as a cooling element and a fan, a detector for detecting the temperature associated with the electrical heater, and a controller for controlling the electrical heater and the cooler based upon the detected temperature and upon the humidity algorithm comprising a predetermined set of calculations of the humidity of air at different temperatures.

Owner:LEAR CORP

Ink jet ink containing polyurethane dispersant

InactiveUS6136890AImprove resistanceRapid dryingDuplicating/marking methodsInksPolymer chemistryPigment

Described are pigmented inks comprising a liquid medium, a pigment, and a polyurethane dispersant, the pigment being stabilized by the polyurethane dispersant, and the ink being suitable for use in an ink jet printer.

Owner:3M INNOVATIVE PROPERTIES CO

Automatic cleaning and recycling device for glass bottles

InactiveUS20200130032A1Low costReduce inputSolid waste disposalHollow article cleaningProcess engineeringBottle

The invention discloses an automatic cleaning and recycling device for glass bottles, which includes a fuselage. A central cavity is opened in the fuselage. A first conveyor belt is provided near the bottom of the central cavity on the left side of the first conveyor belt. A cleaning mechanism is provided. The storage chamber is provided with a first slider, a right side of the storage chamber is provided with a fan chamber, the fan chamber is provided with a drying mechanism. The device is fixed by a cleaning mechanism and The inner wall of the glass bottle is cleaned, the outer wall of the glass bottle is cleaned by a first brush, the glass bottle is conveyed by a conveyor mechanism, the inner wall of the glass bottle is rinsed by squeezing the disinfectant and water through the first slider, and the glass bottle is quickly dried by the drying mechanism.

Owner:LIN SHICHANG

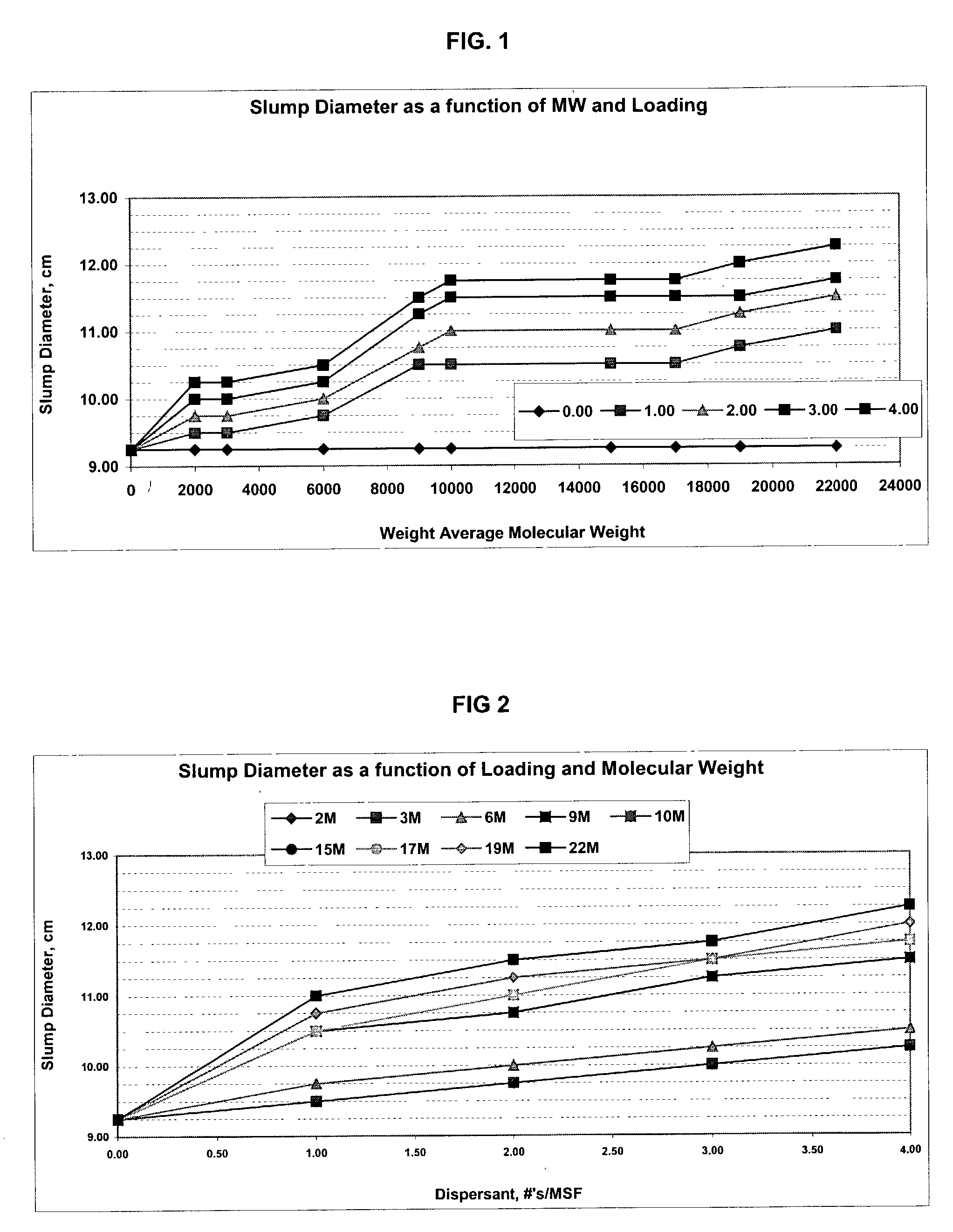

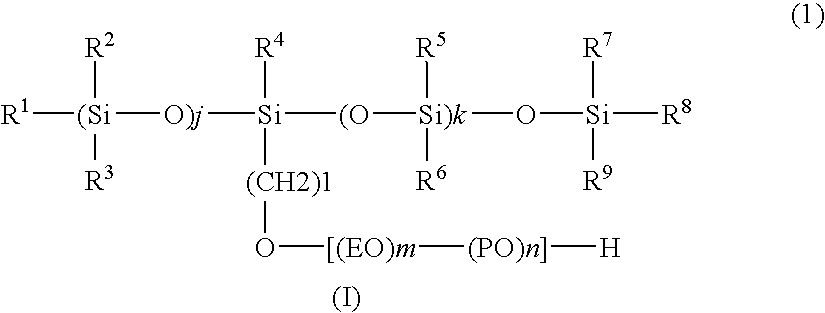

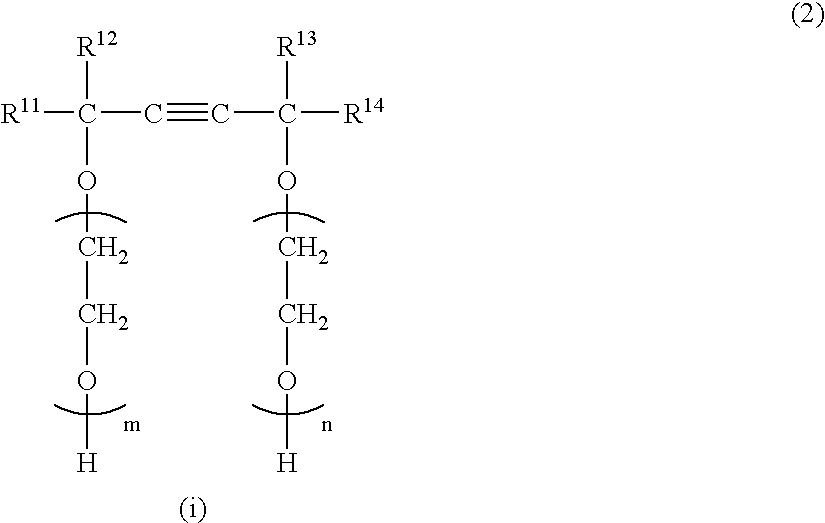

Dispersant and foaming agent combination

InactiveUS20040028956A1Low densityReduce weightConstruction materialOther chemical processesAlkaline earth metalAir entrainment

The present invention provides a dispersant and foaming agent combination that is useful in the production of gypsum wallboard and other aqueous cementitious products, a method of forming a gypsum wallboard and a gypsum wallboard. The dispersant in the combination according to the invention is a naphthalene sulfonate-aldehyde condensate alkali salt polymer having a weight average molecular weight of from about 17,000 to about 47,000. The alkali is preferably an alkali metal and / or an alkaline earth metal. The aldehyde is preferably formaldehyde. The foaming agent used in the combination according to the invention is a soap, preferably an alkali salt of an alkyl ether sulfate and / or an alkyl sulfate. The combination of a high molecular weight dispersant and a foaming agent produces a gypsum wallboard core effect that more efficiently entrains air (i.e., creates void space), thereby lowering overall board weight without detrimentally affecting strength. A gypsum wallboard formed using the dispersant and foaming agent combination according to the invention exhibits a higher nail pull value than gypsum wallboard formed using a conventional dispersant and a foaming agent at the same solids loading ratio.

Owner:GEO SPECIALTY CHEM

Photo-induced hydrophilic article and method of making same

InactiveUS20070218265A1Easy to cleanEasy to wipeSynthetic resin layered productsVacuum evaporation coatingHydrophilic coatingSpray pyrolysis

Methods and articles are disclosed in which a substrate is provided with a photo-induced hydrophilic surface by forming a photo-induced hydrophilic coating on the substrate by spray pyrolysis, chemical vapor deposition, or magnetron sputter vacuum deposition. The coating can have a thickness of 50 Å to 500 Å, a root mean square roughness of less than 5, preferably less than 2, and photocatalytic activity of less than 3.0×10−3 cm−1 min−1±2.0×10−3 cm−1 min−1. The substrate includes glass substrates, including glass sheets and continuous float glass ribbons.

Owner:VITRO FLAT GLASS LLC

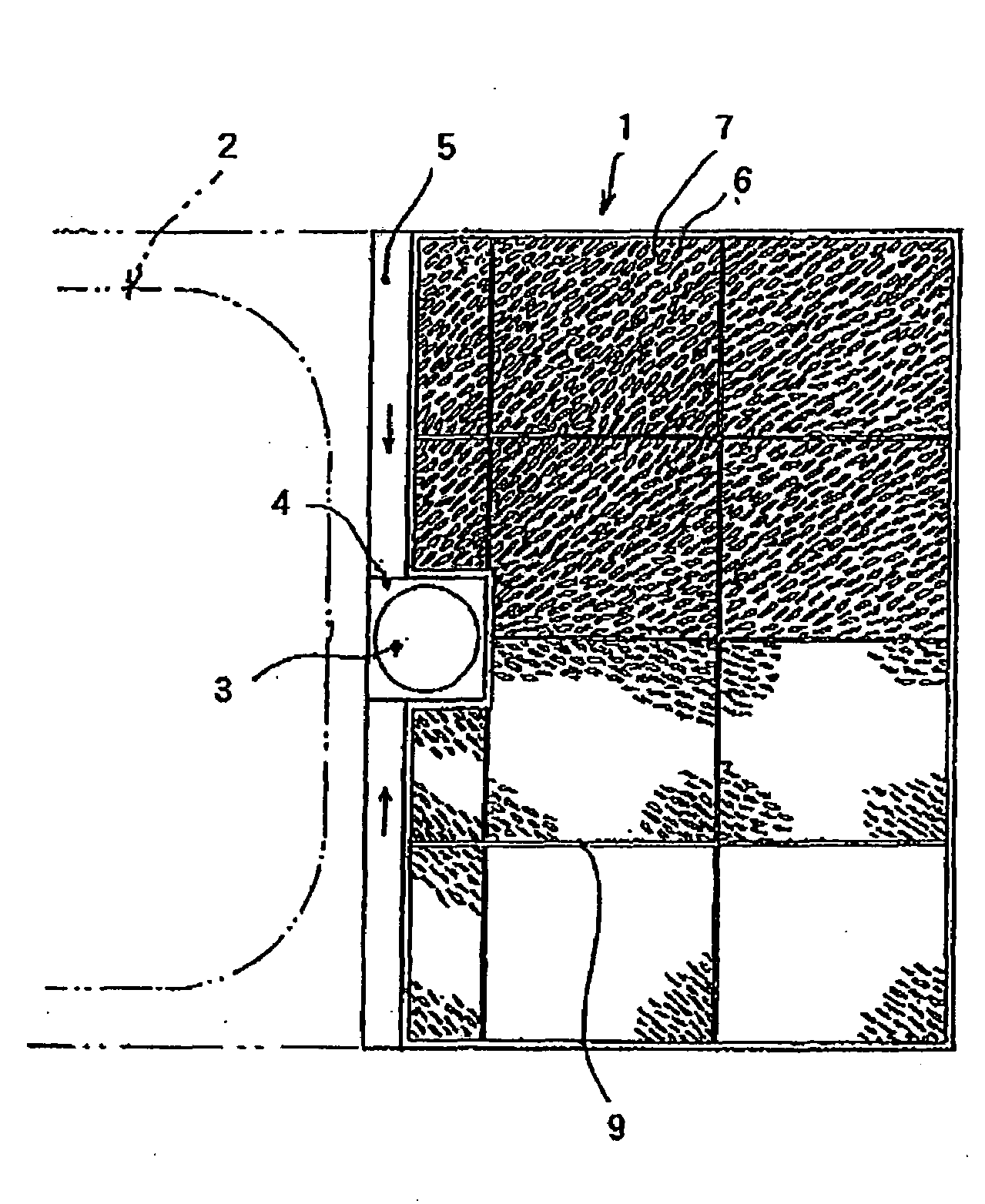

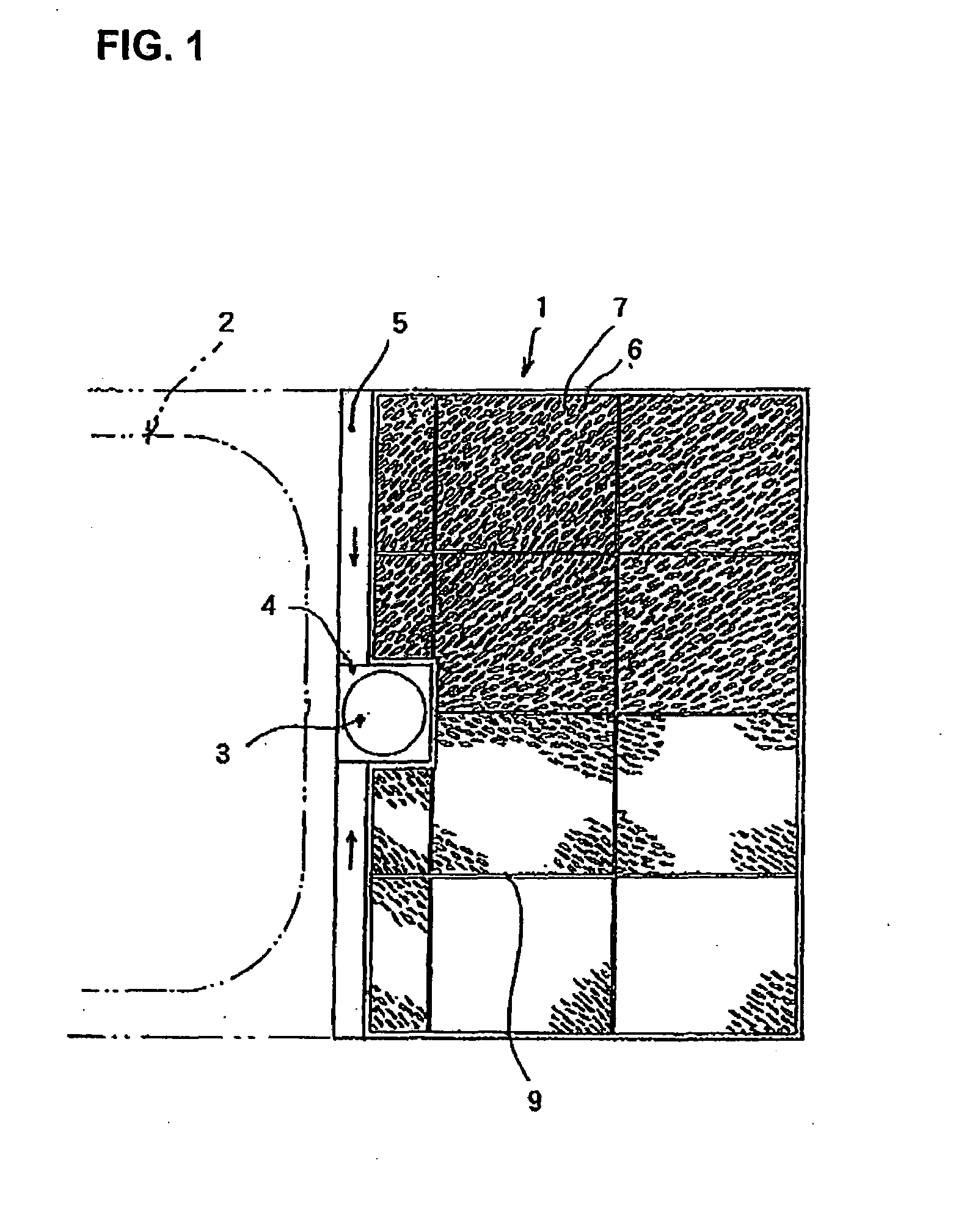

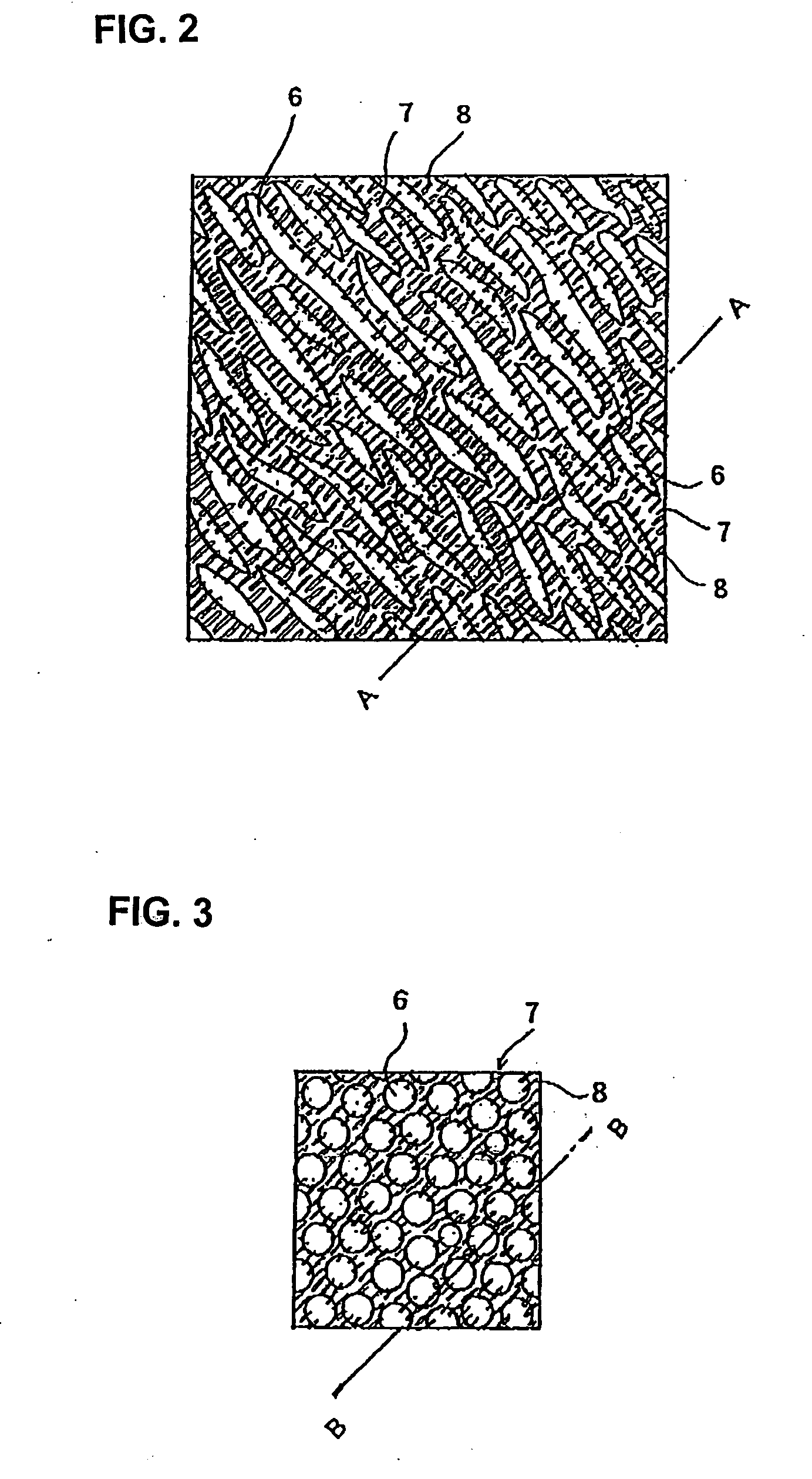

Bathroom floor panel

InactiveUS20080190048A1Prevent slippingReduce the average velocityTreadsFlooringWater flowEngineering

A bathroom floor panel for use in an airtight and water tight space is configured to be efficiently dried in a few hours under ambient conditions. When water drops onto the floor panel, the surface tension of the water is broken by irregular-shaped portions and the water spreads without forming waterdrops. Also, the irregular-shaped portions reduce the flow velocity of the water due to a gradient of the panel, so as to prevent the water flowing in channels to a drain from being discontinued. With this, although the drain velocity of the water is low, substantially no water remains as isolated drops. Further, even if some water remain on the irregular-shaped portions after the water flows out the channels to the drain, any amount of water remaining in the channels is evaporated in a relatively short period of time because the amount of the remaining water is very small.

Owner:TOTO LTD

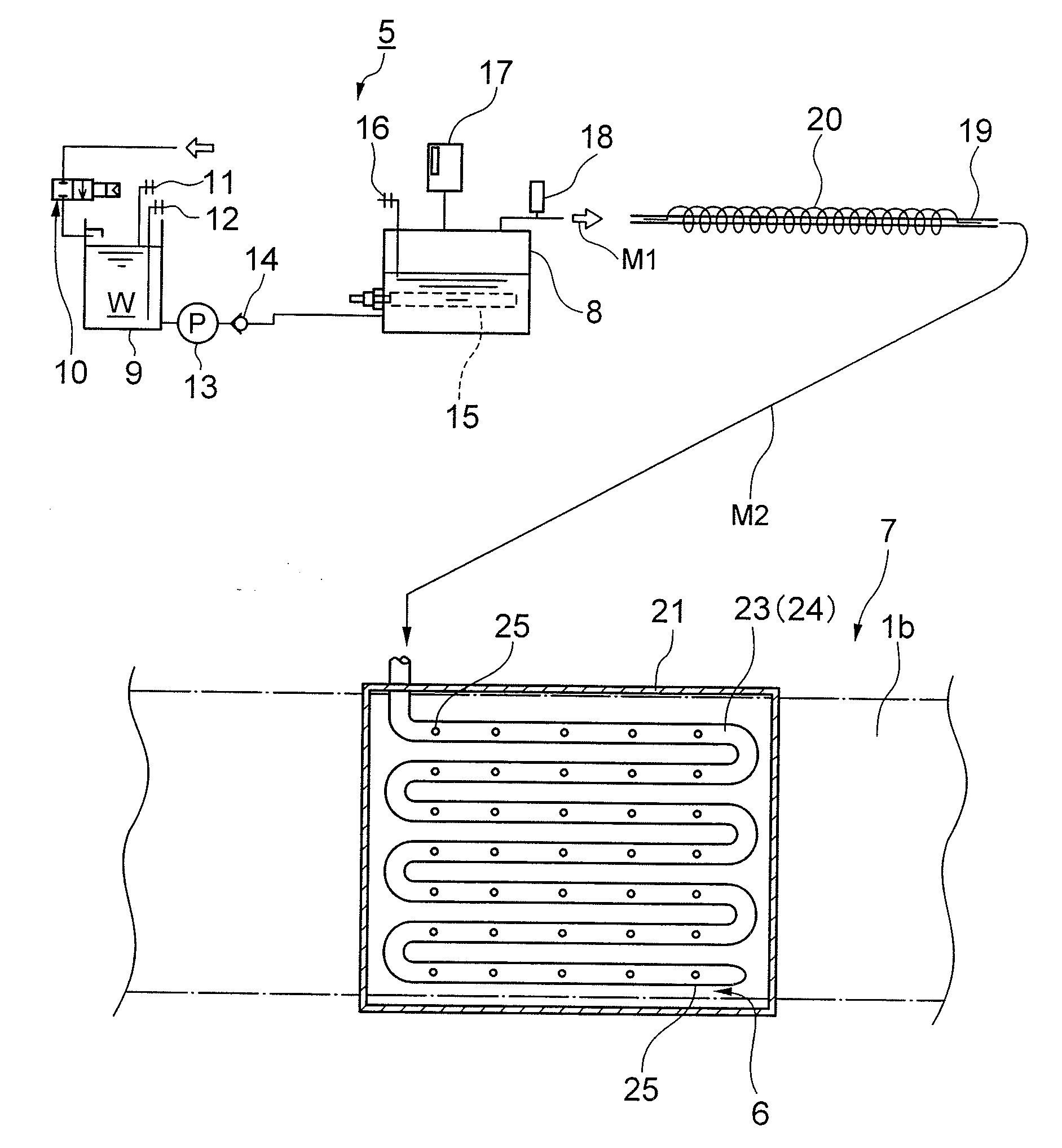

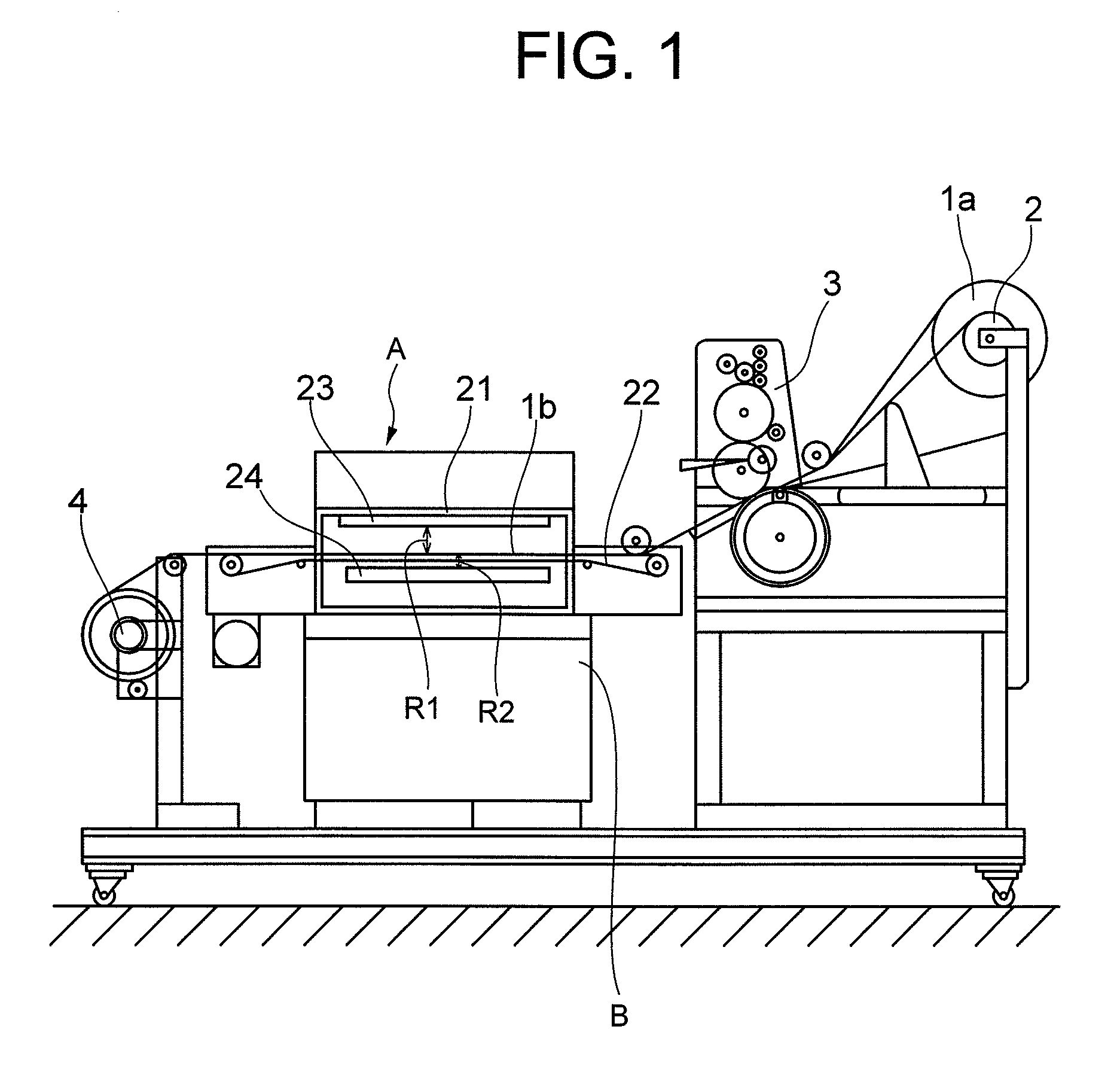

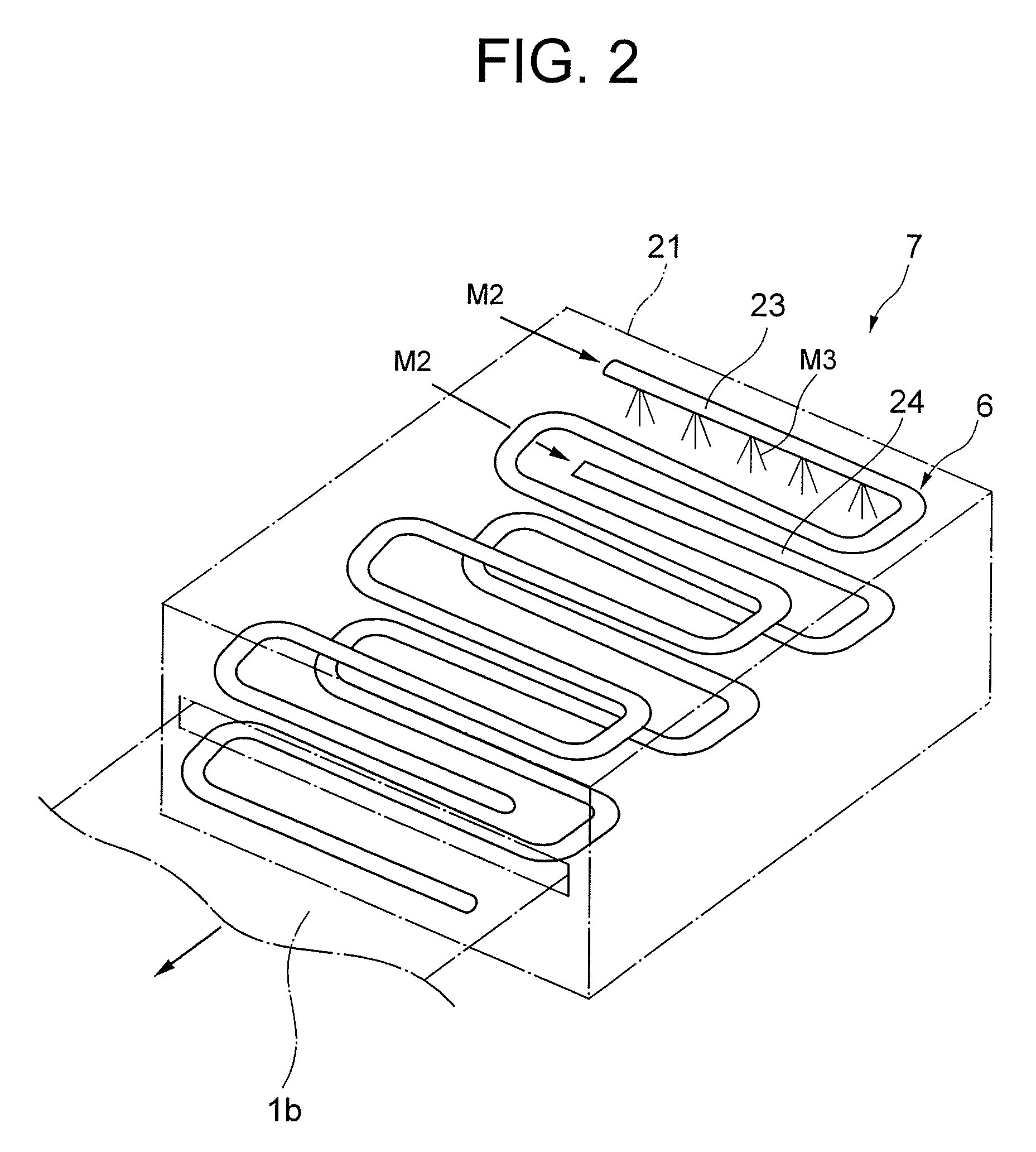

Method of drying printed material and apparatus therefor

InactiveUS20100192402A1Avoid stickingFast dryingDrying solid materials with heatDrying gas arrangementsFiberNano size

To carry out drying of printing ink with the use of Nano sized high-temperature dryness steam. Nano sized high-temperature dryness steam being clustered on Nano oder is generated and jetted to the print side of printed material so that the Nano sized high-temperature dryness steam imparts intramolecular vibrational energy to ink of the print side. Consequently, the Nano sized high-temperature dryness steam being clustered on Nano oder not only passes through fiber pores in the printed material but also collides with the ink of the print side. The Nano sized high-temperature dryness steam having collided with the ink of the print side imparts thermally excited energy as intramolecular vibrational energy to the ink containing polar molecules. The ink is dried by the intramolecular energy.

Owner:DAIDO SANGYO

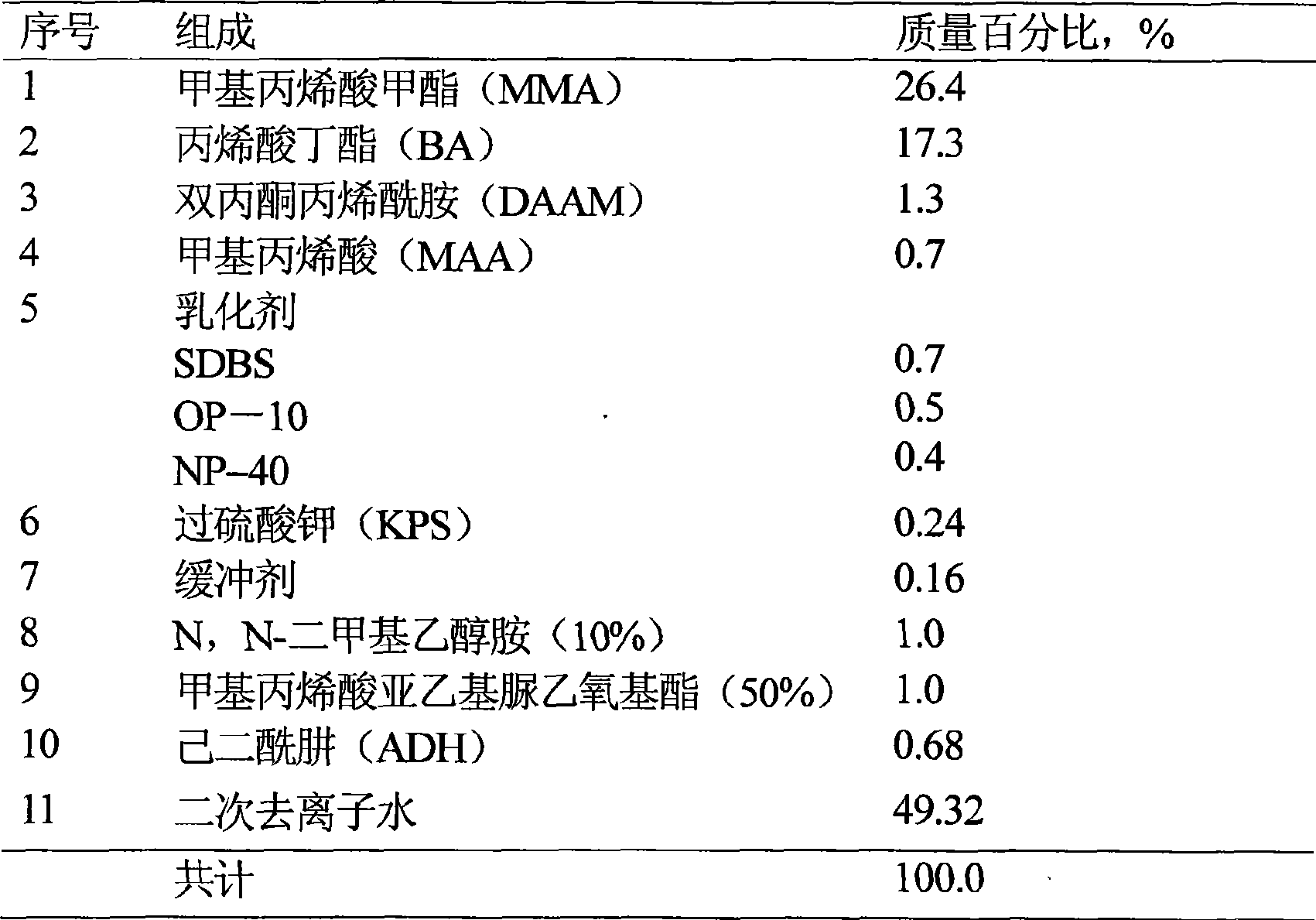

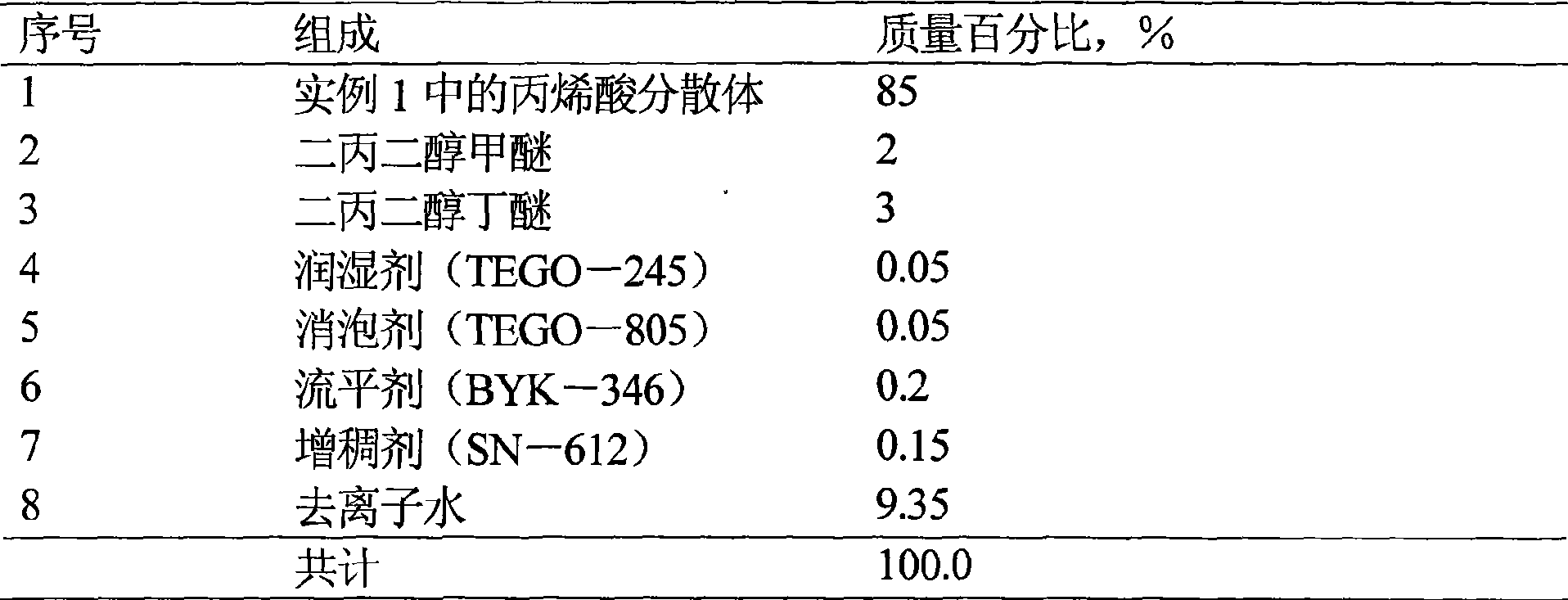

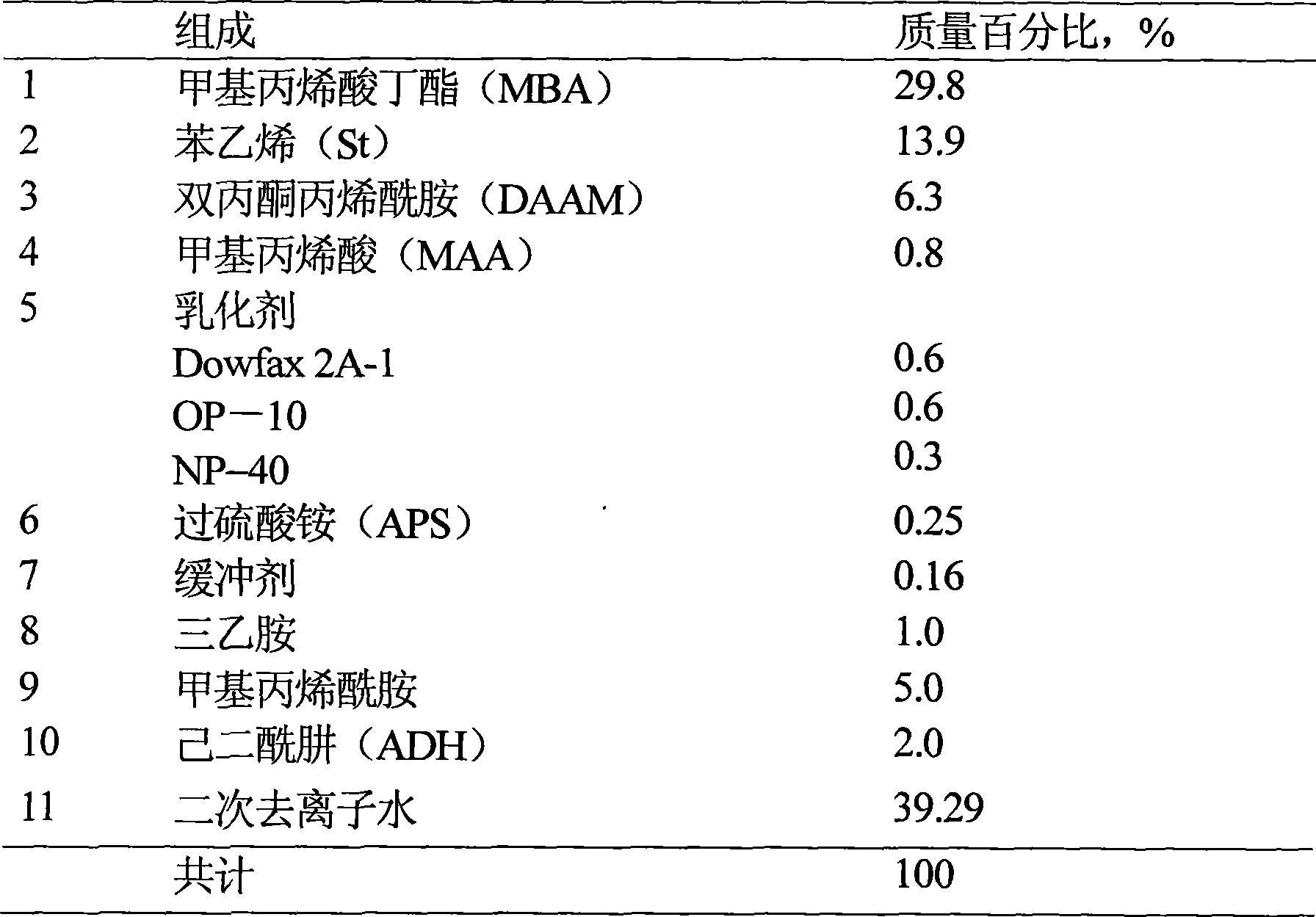

Preparation of high closeness polyacrylacid ester dispersion

The invention relates to a high-sealing polyacrylic ester dispersoid and a preparation method thereof; a multi-element emulsifier system which consists of an anionic emulsifier and a compound non-ionic emulsifier is adopted for controlling the charging process and components of the emulsifier in different polymerization periods, and the room-temperature self-crosslinking high-sealing polyacrylic ester dispersoid is prepared by a semi-continuous seeding emulsion polymerization process. The dispersoid has small particle size, good electrolyte-resistance (calcium ion) stability and high tolerance to various film forming accessory ingredients (various organic solvents with high boiling point). The dispersoid is used as seal coat of water-based wood coating and has good sealing performance to various woods; harmful volatile organic compounds (VOC) such as formaldehyde, and the like sealed against escaping from plates to pollute indoor environment, and the colored compounds such as turpentine, pine oil and tannin and the like are sealed against dissolving out of the plates to pollute pure top coating and white top coating of a water-based wooden ware; and in addition, the dispersoid can be used in water-based leather finishing agents.

Owner:SOUTH CHINA UNIV OF TECH

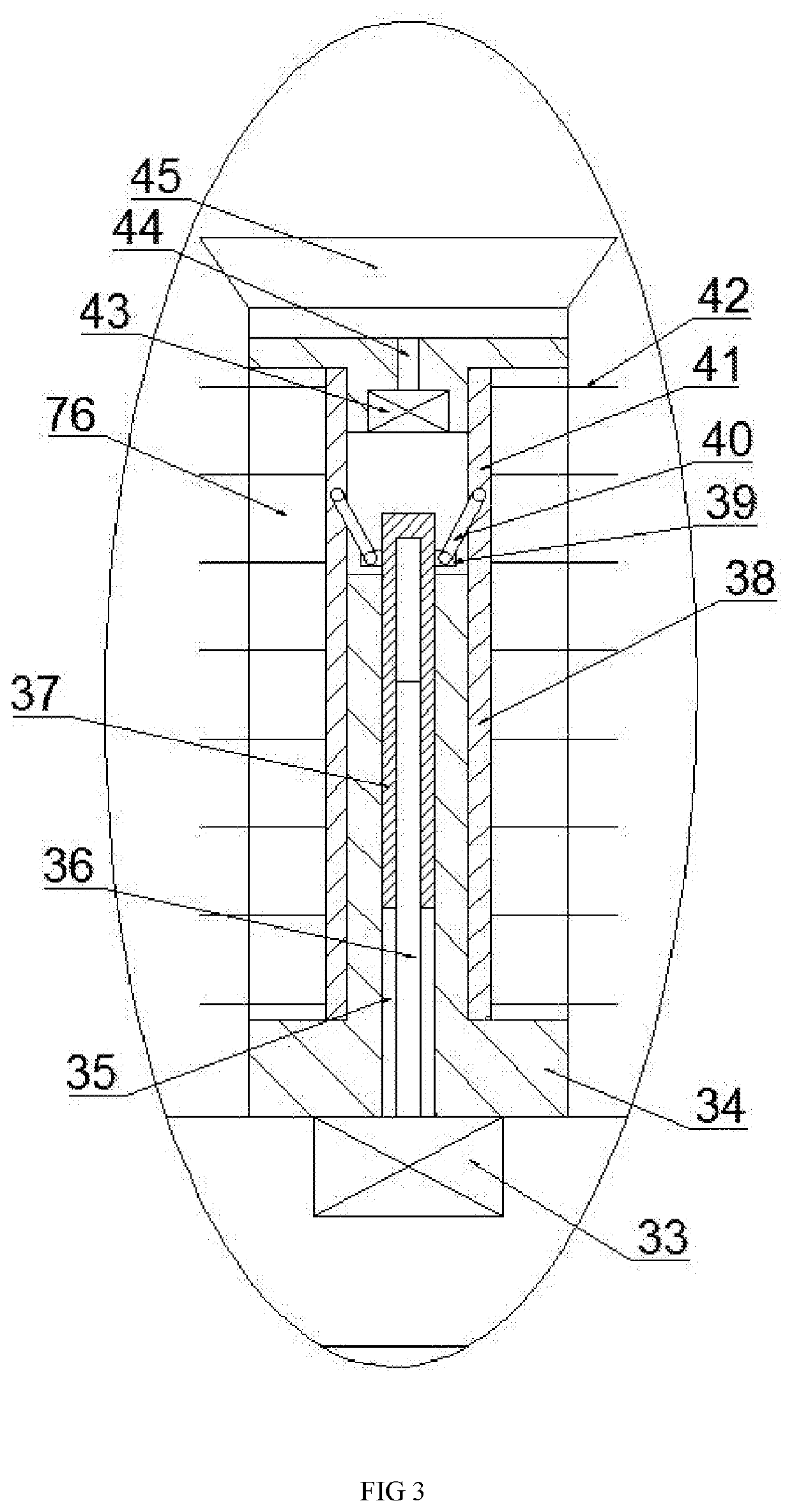

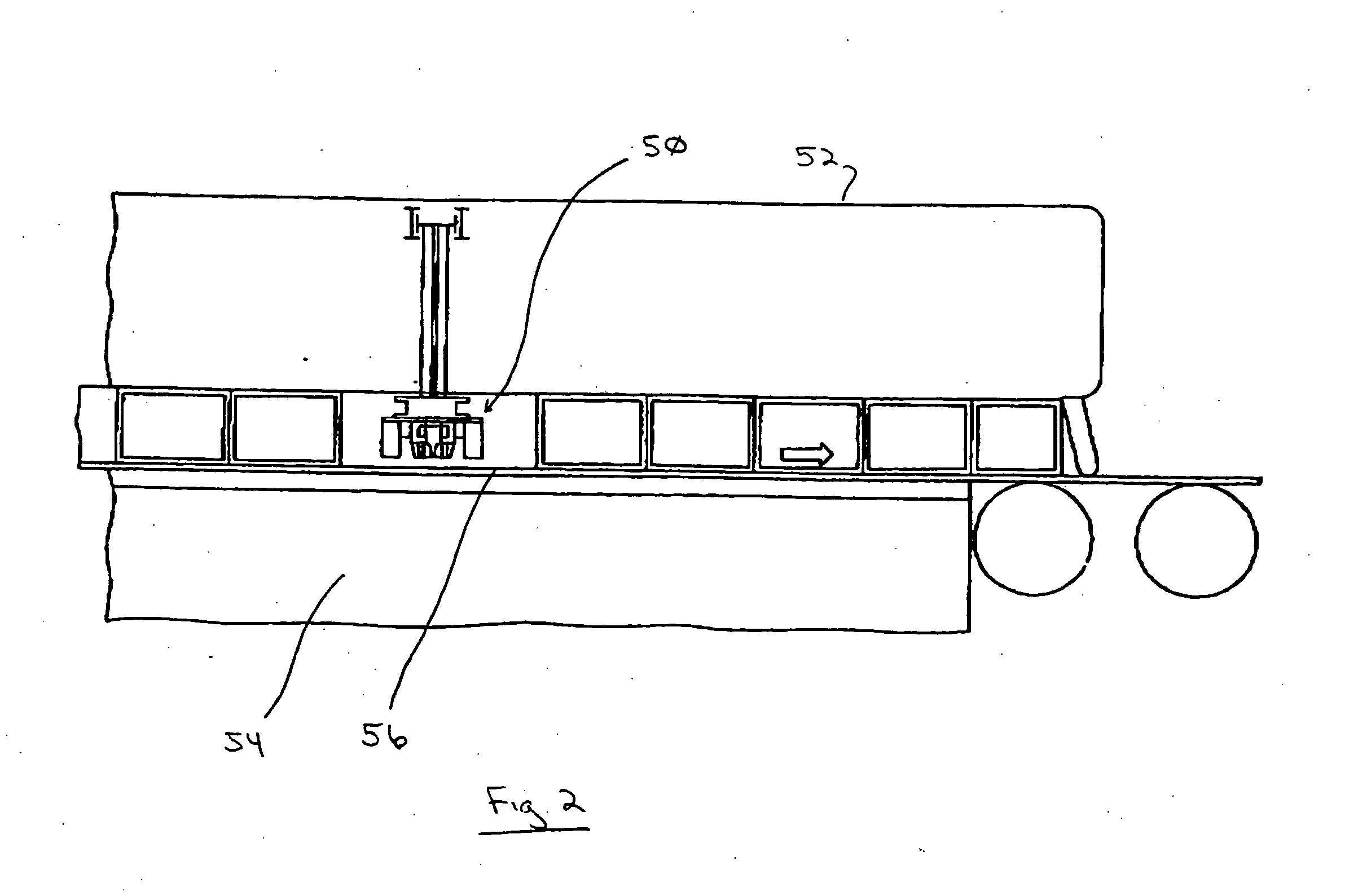

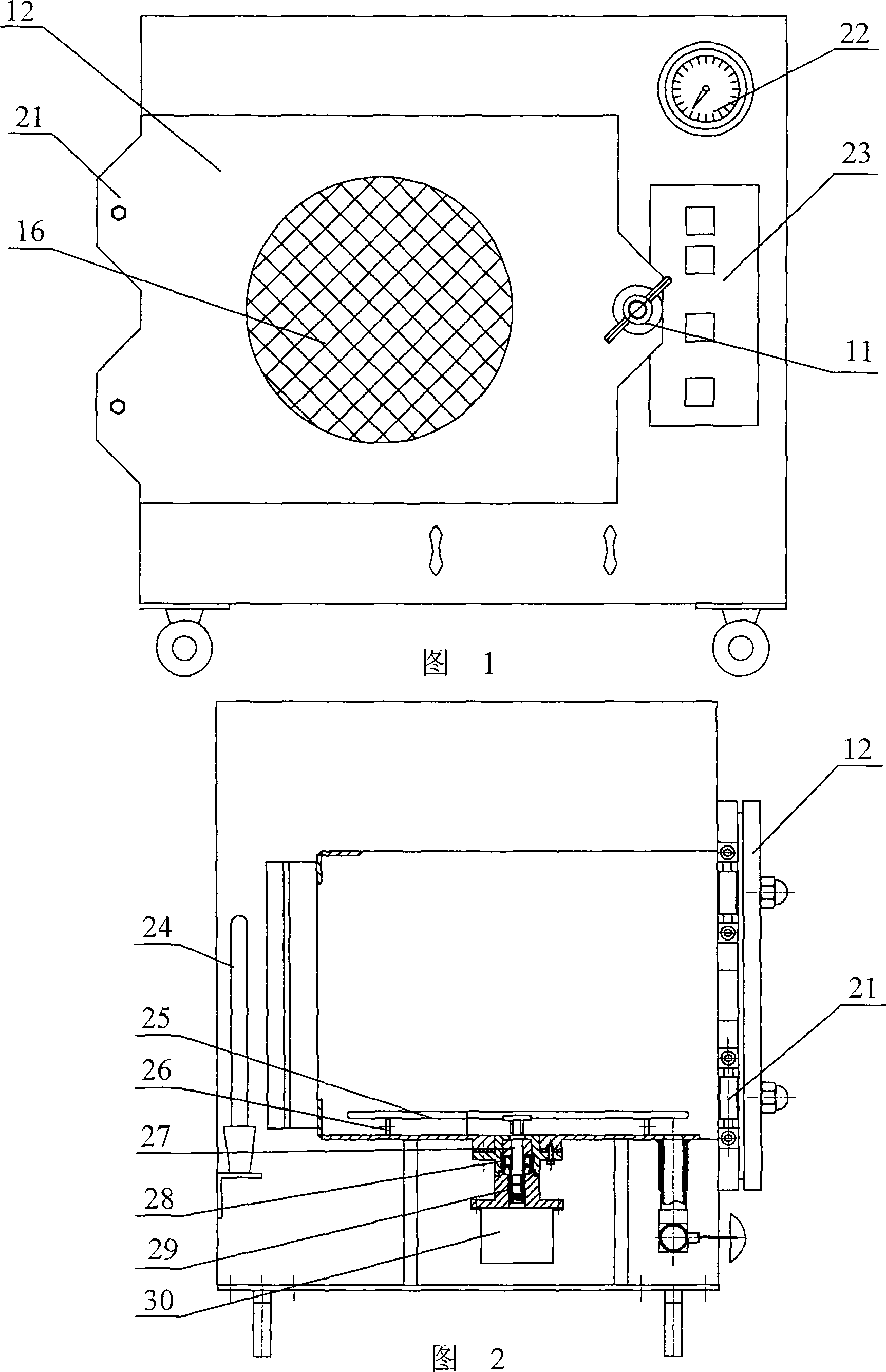

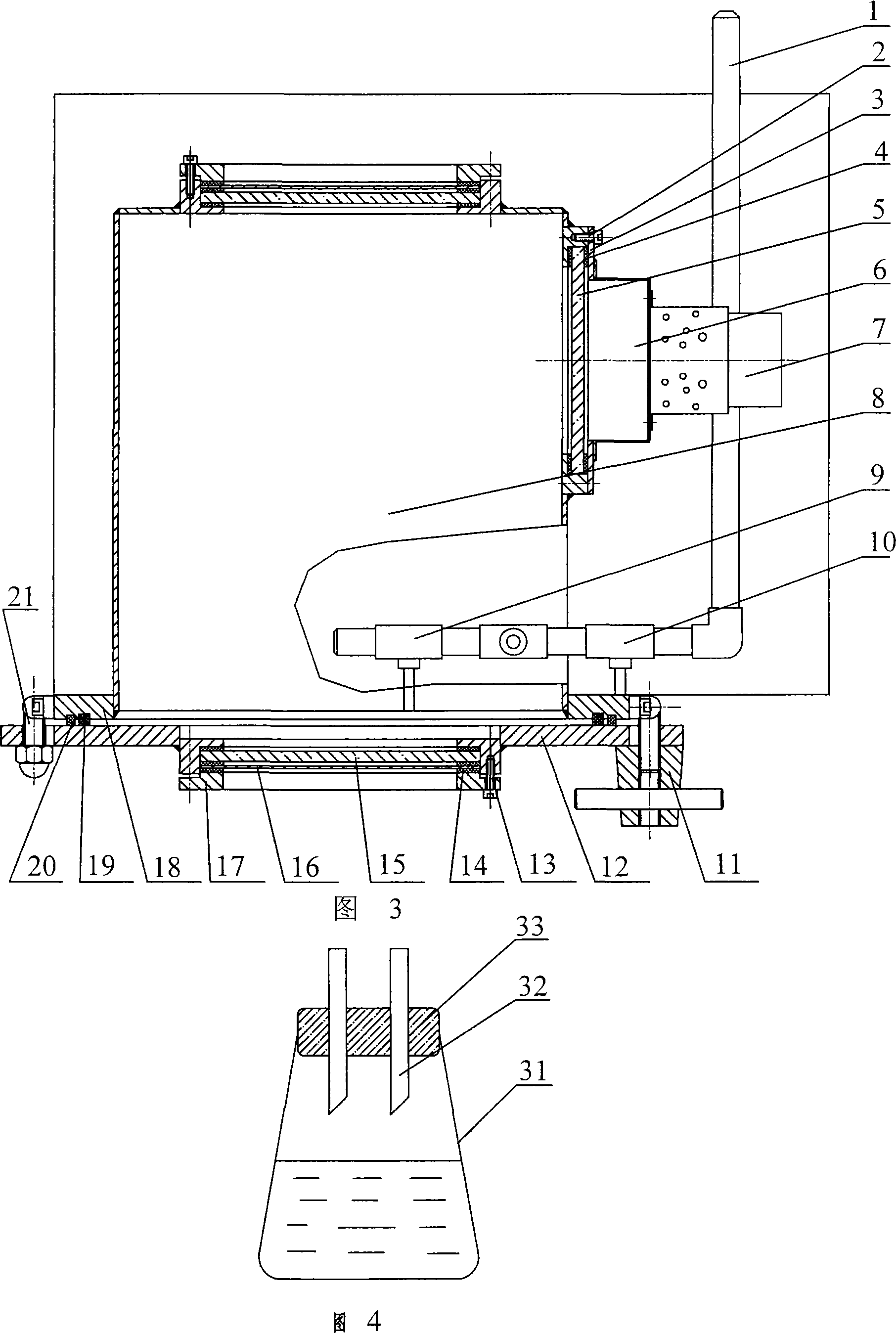

Micro-wave vacuum equipment

InactiveCN101082464AFast dryingFast concentrationDrying solid materials with heatDrying chambers/containersVacuum pumpingMicrowave

This invention relates to a sort of integral dry and dewatering set of the microwave and vacuum system, it consists of a hothouse of hermetic estate which is used to pose the materiel, the on-off door body which is propitious to gain and put materiel is fitted on the wall of the hothouse, the microwave produced by the microwave generator can cross the wall of the hothouse and it use the microwave to heat the materiel of the hothouse, there has the vacuum connector tub which is extended to the hothouse on the wall of the hothouse, the vacuum connector tub connects with the vacuum-pumping set. Because thin invention makes the microwave heating system connects with the vacuum system in the organic way, the speed of its dryness and condensation is fast, the temperature is low (25 to 45 deg. C), It very fit to the use of the lab, and fit to desiccate and condense the multifarious hydrous, and specially fit to food materiel of the heat sensitivity, and so on, and it is widely used to desiccate and condense the multifarious hydrous in the way of small-scale in the lab, such as the food, the medication, the chemical production.

Owner:JIANGNAN UNIV

Method for preparing modified aqueous adhesion agent of polyurethane

InactiveCN101003715AIncrease the degree of cross-linkingImprove cohesive strengthPolyureas/polyurethane adhesivesEpoxyPolyester

This invention discloses a method for preparing modified aqueous polyurethane adhesive. The method comprises: (1) modifying epoxy resin with modifier to obtain modified epoxy resin; (2) reacting polyisocyanate with polyester or polyol polyether, and adding chain extender to obtain polyurethane with prepolymer; (3) modifying polyurethane prepolymer with modified epoxy resin to obtain modified polyurethane prepolymer; (4) adding water, dispersing by a high-speed disperser, and adding neutralizer and crosslinking agent to obtain modified aqueous polyurethane adhesive. This invention introduces epoxy resin into the modification of aqueous polyurethane adhesive, thus combines high modulus, high strength and good chemical resistance of epoxy resin with the advantages of polyurethane resin. The modified aqueous polyurethane adhesive can meet the needs of automobile inner decoration materials. The method has such advantages as simple process, and low cost.

Owner:SOUTH CHINA UNIV OF TECH

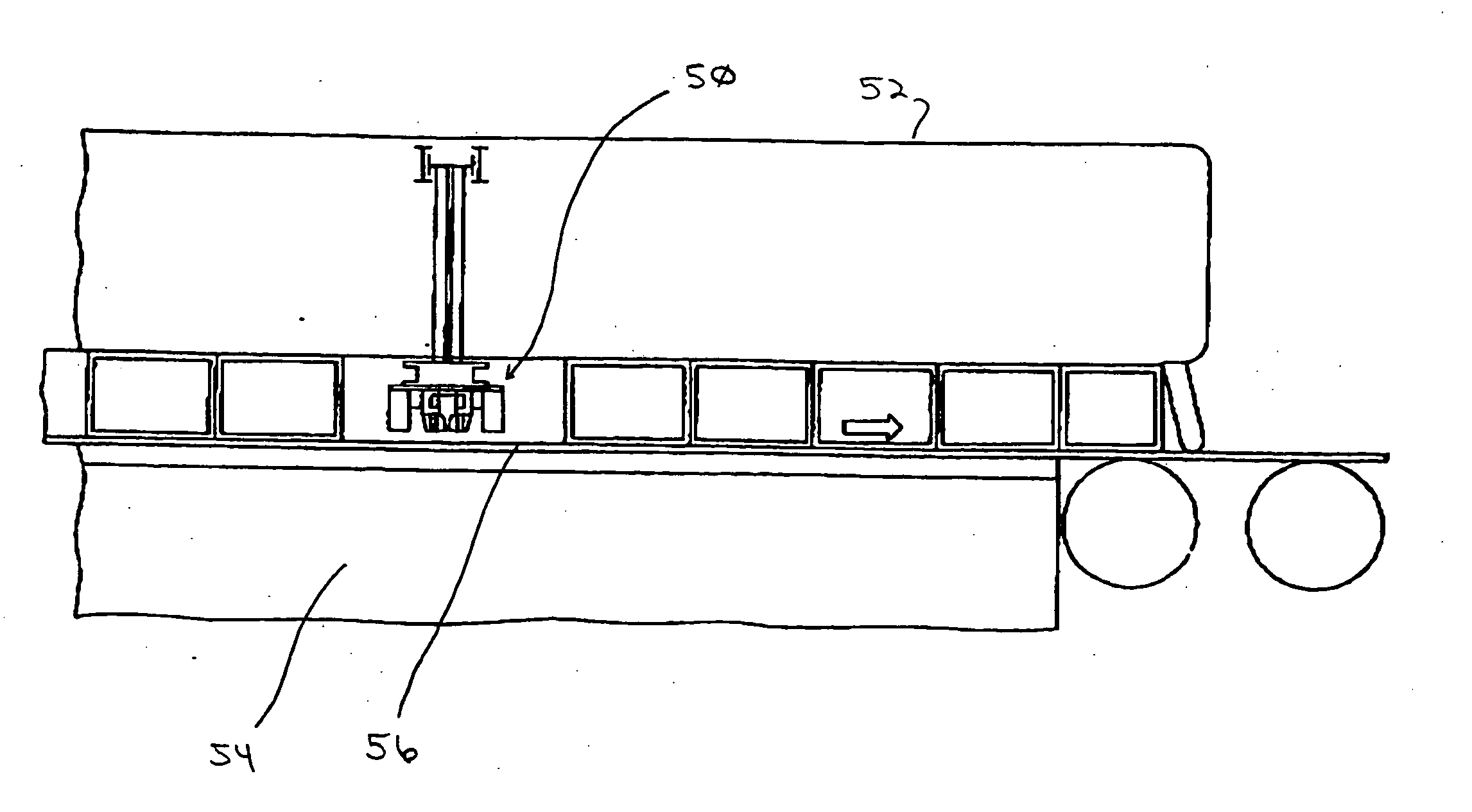

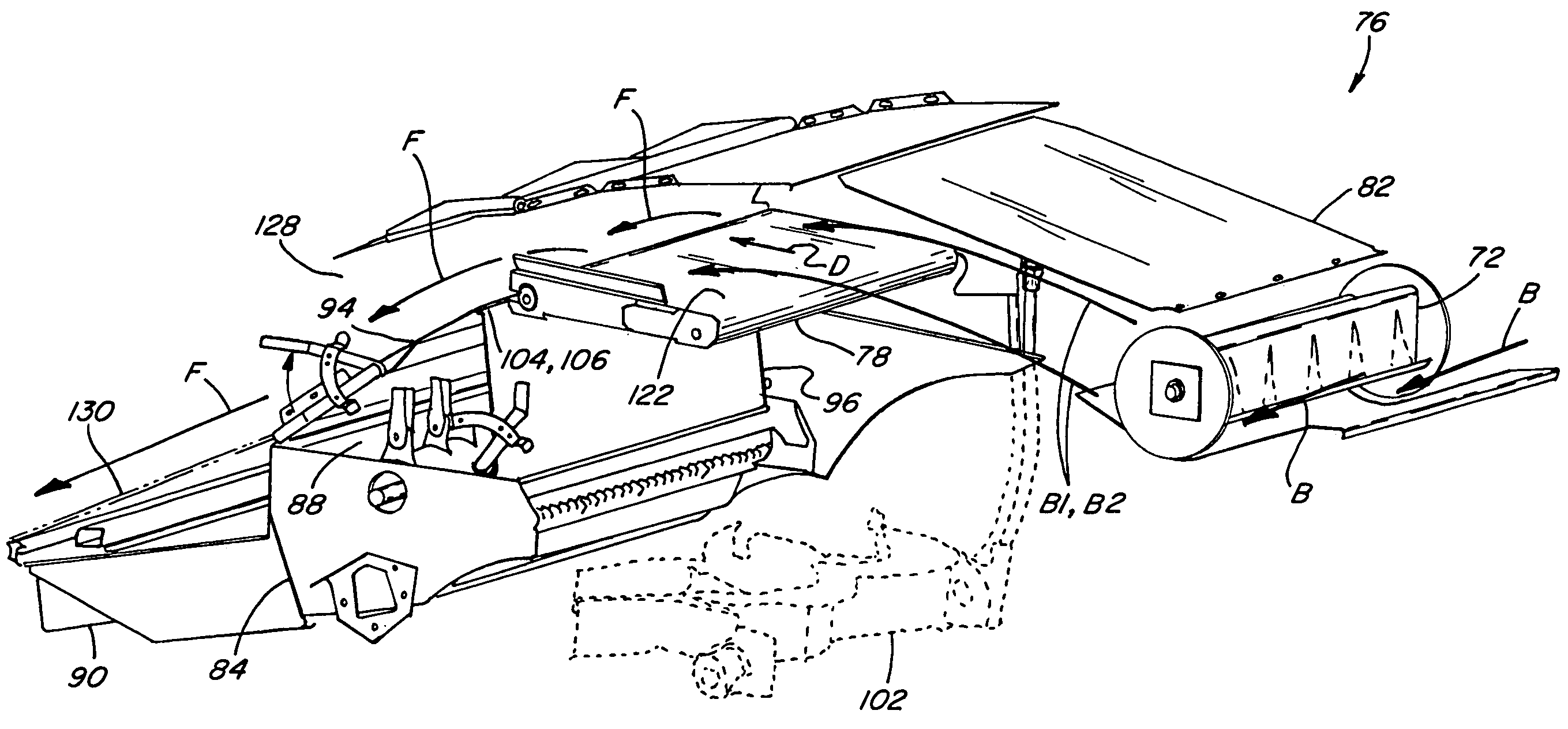

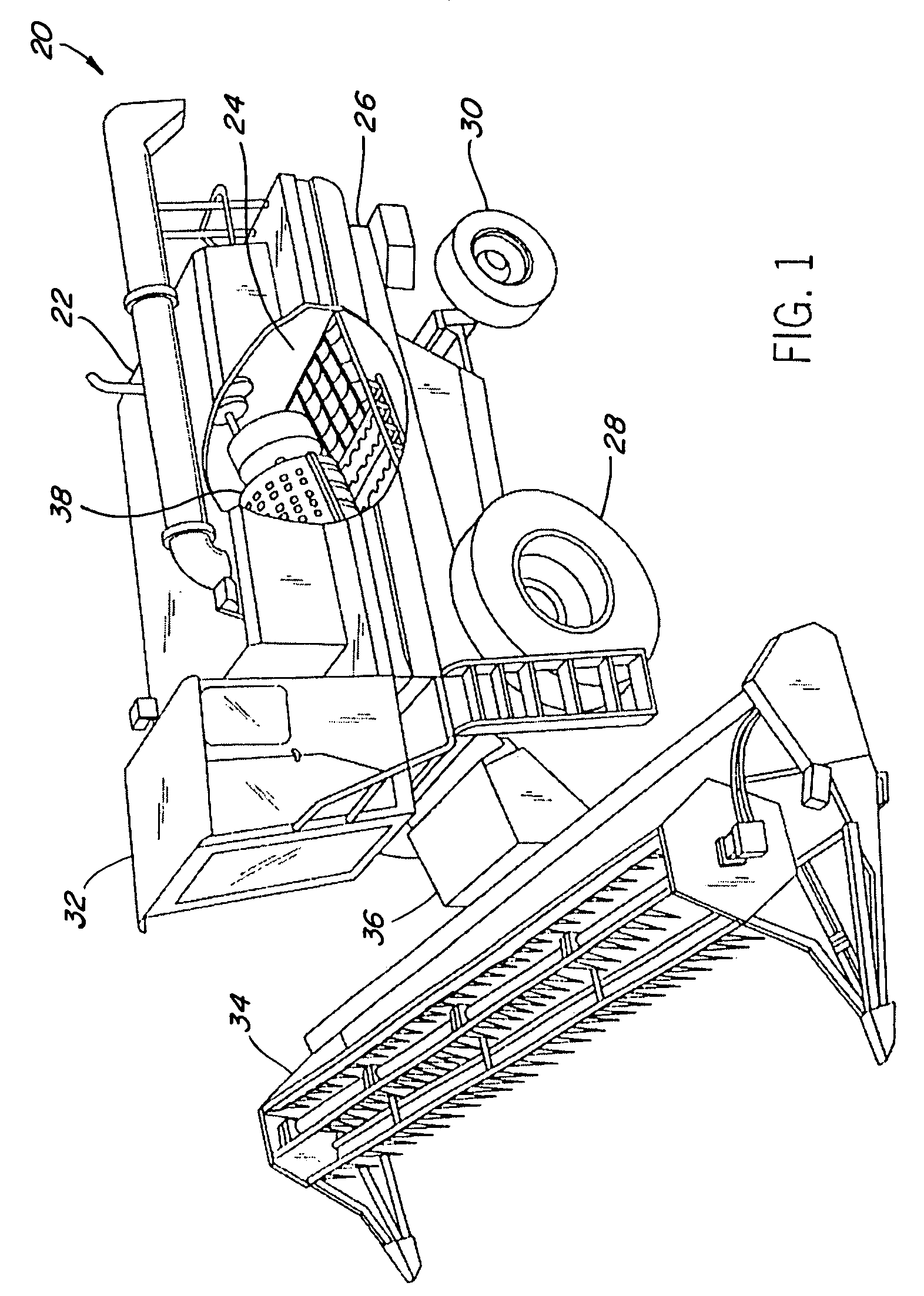

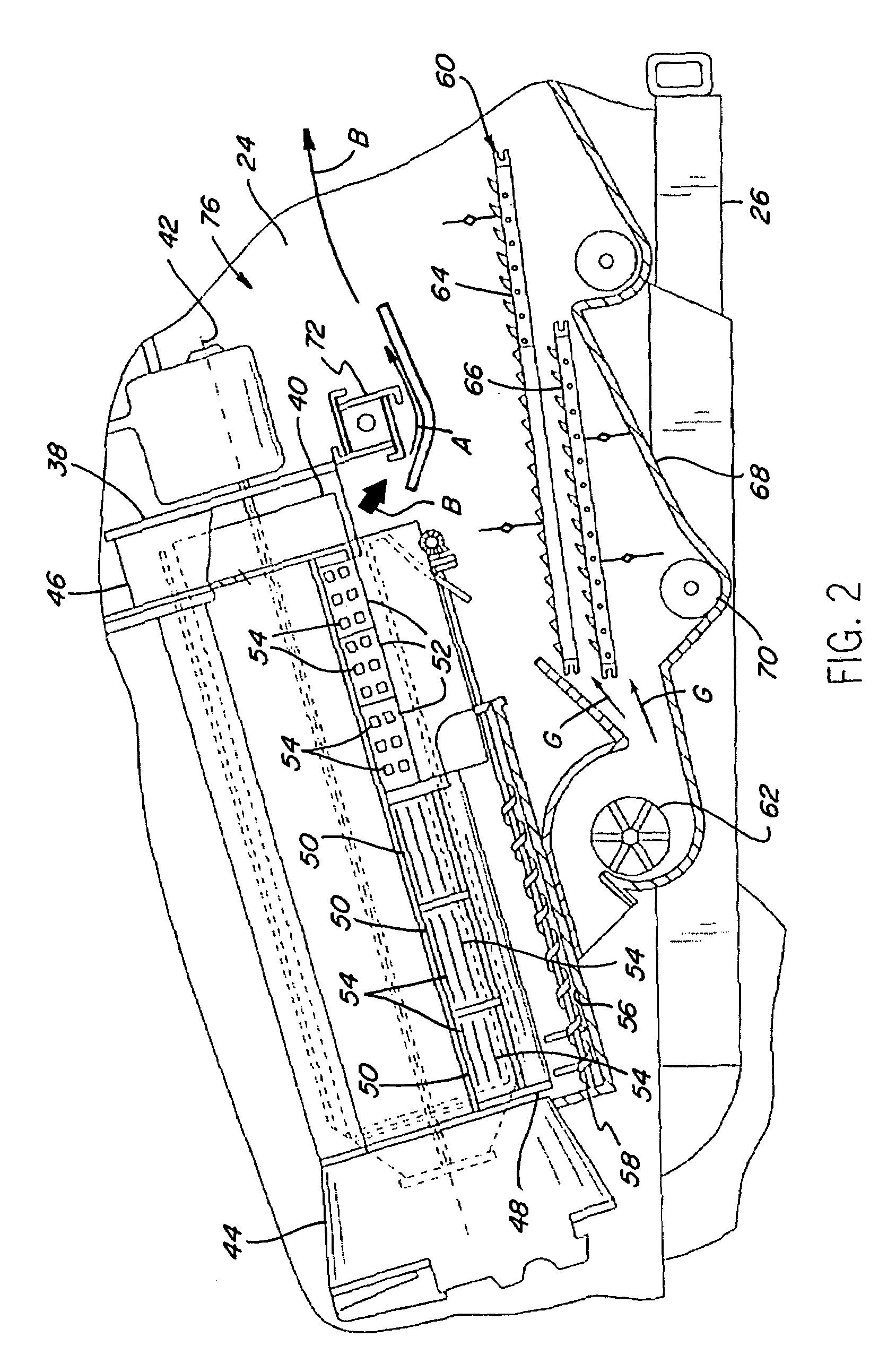

System and method for positively discharging crop residue from a combine

ActiveUS7066810B2Precise, efficient, and consistent crop residue dischargeDifferent typeMowersThreshersChaffEngineering

A system and method for positively discharging crop residue from a combine for precisely and consistently delivering crop residue from the threshing and separating area of a combine to the combine's residue handling system or outwardly from the rear of the combine and onto the harvested field below as a windrow. The present invention can include, or operate in cooperation with, a discharge mechanism, such as a conventional discharge beater, which delivers at least some of the crop residue to a conveying mechanism of the system. The system also includes a guide mechanism including a door arrangement configurable in several alternative configurations for receiving and merging and regulating crop residue flow from the discharge mechanism and the conveying mechanism, and directing the merged flow to a desired processing mechanism, such as, but not limited to, a chaff spreader, a straw chopper and / or spreader, etc.

Owner:BLUE LEAF I P INC

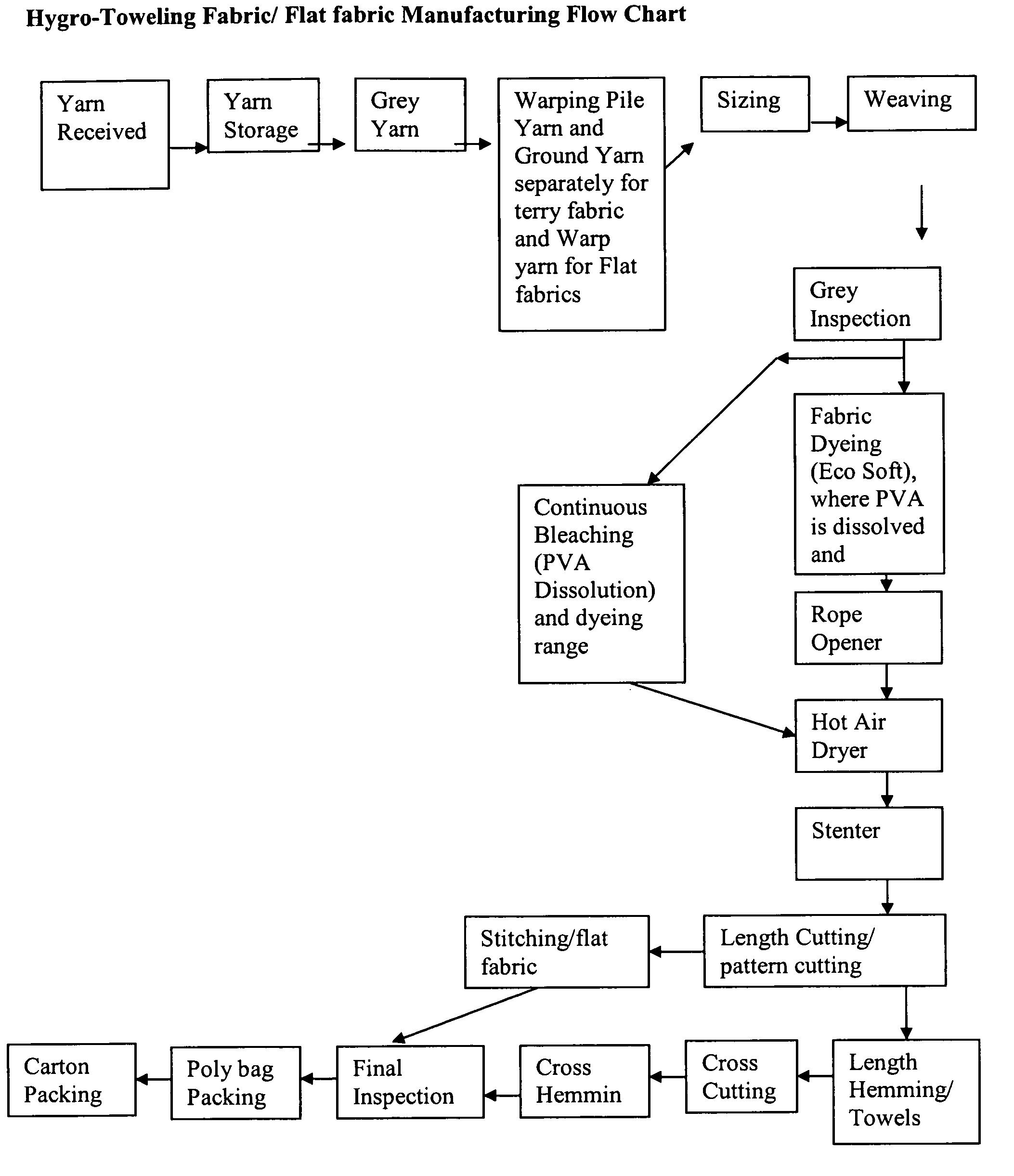

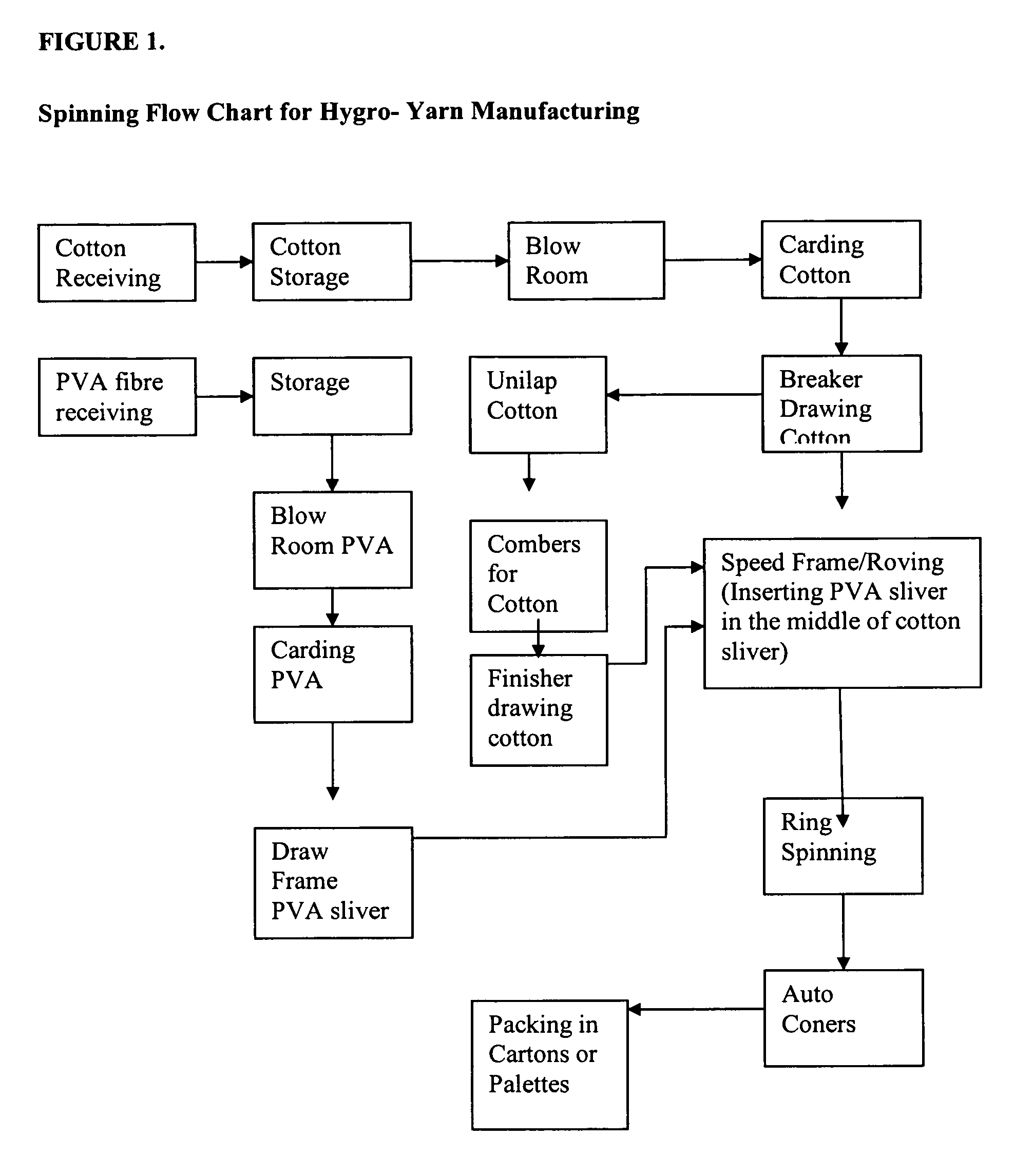

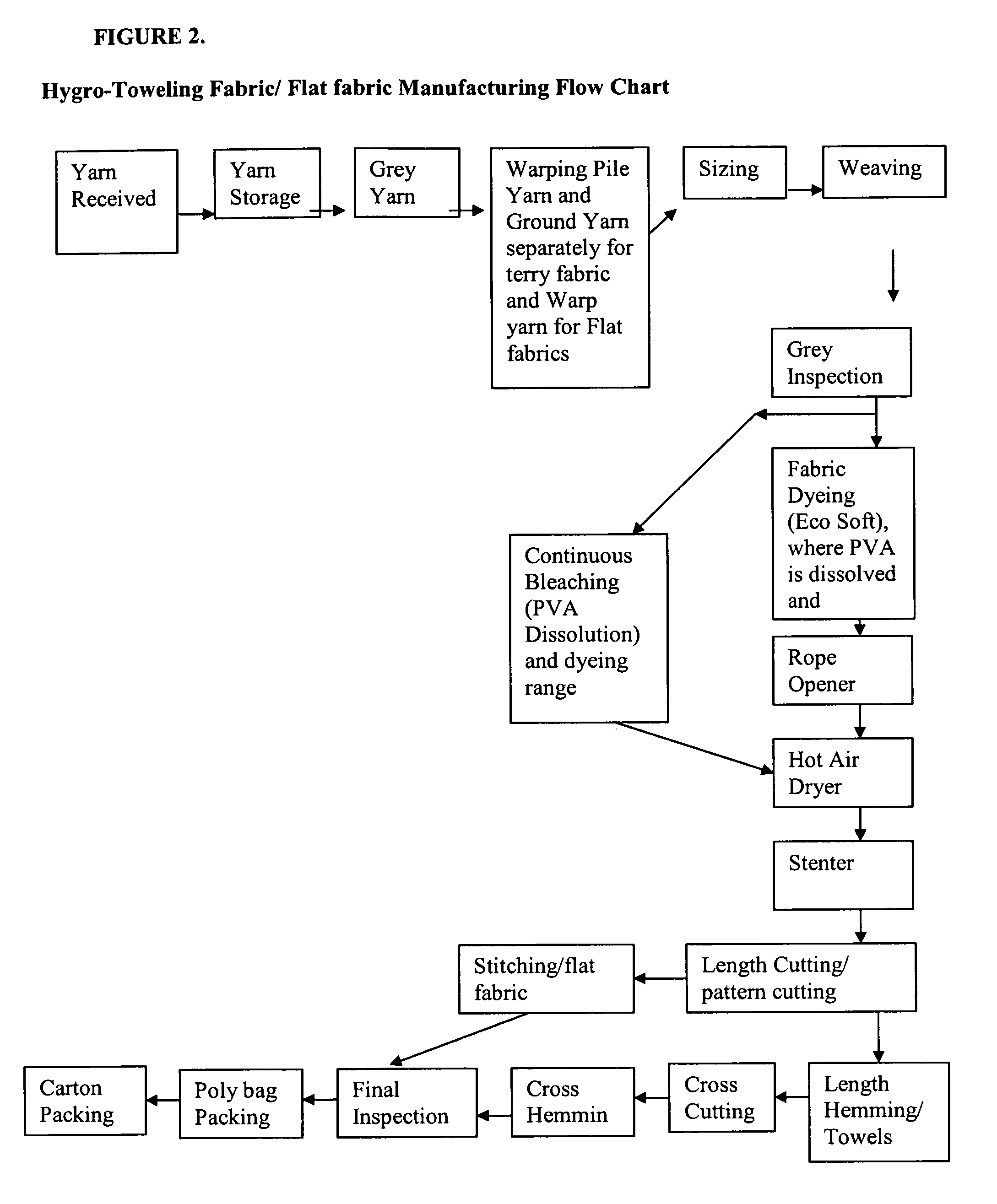

Hygro materials for use in making yarns and fabrics

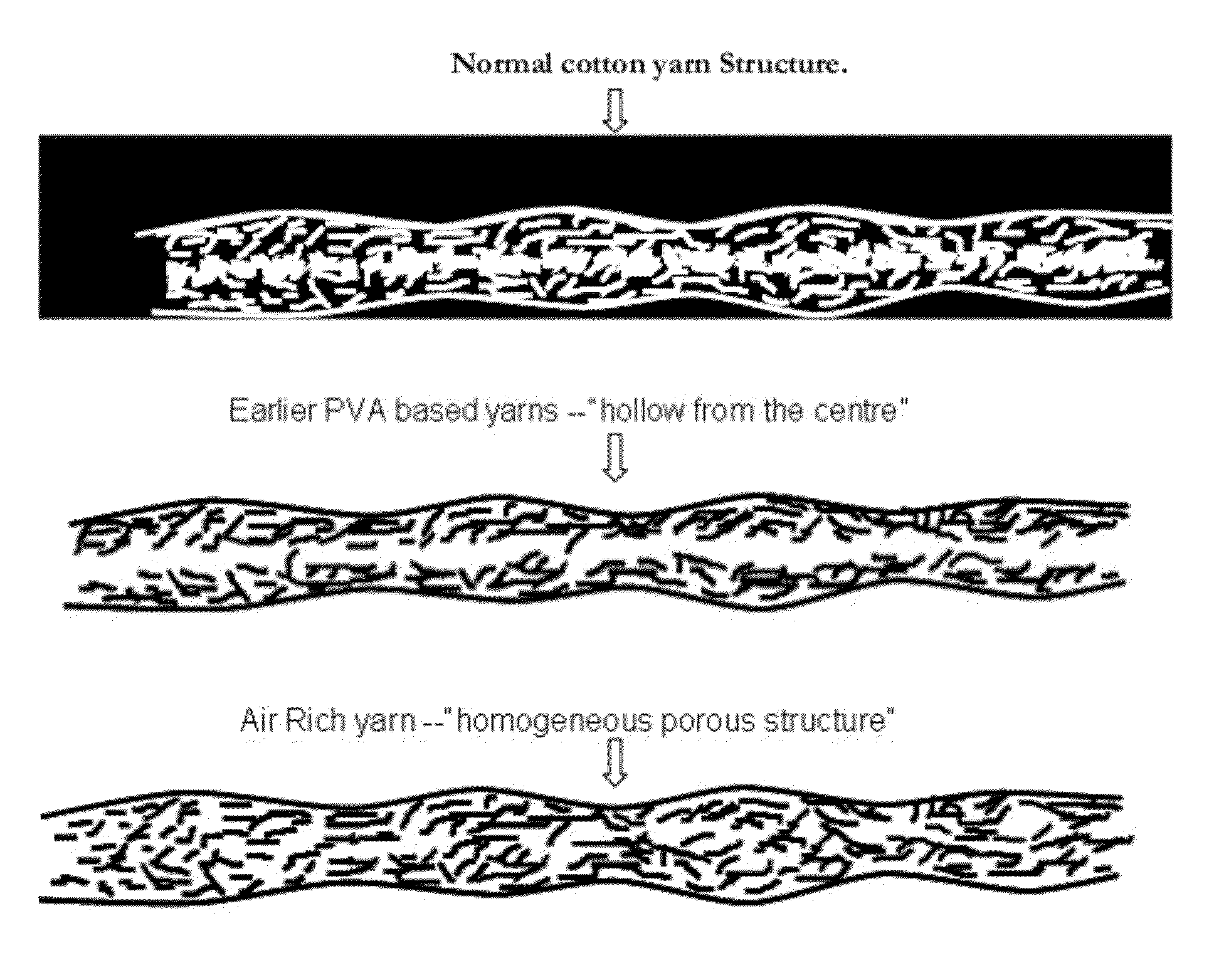

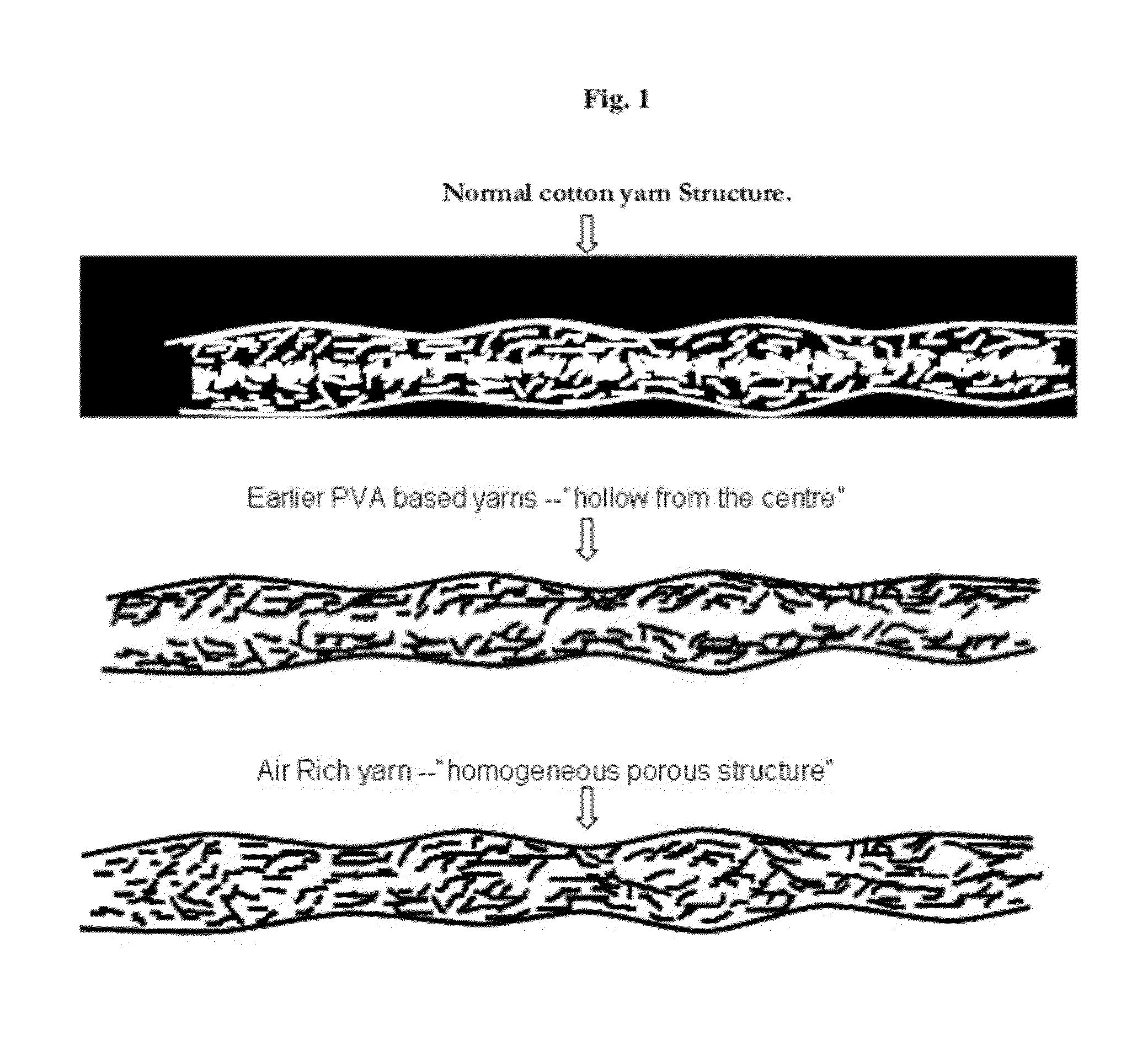

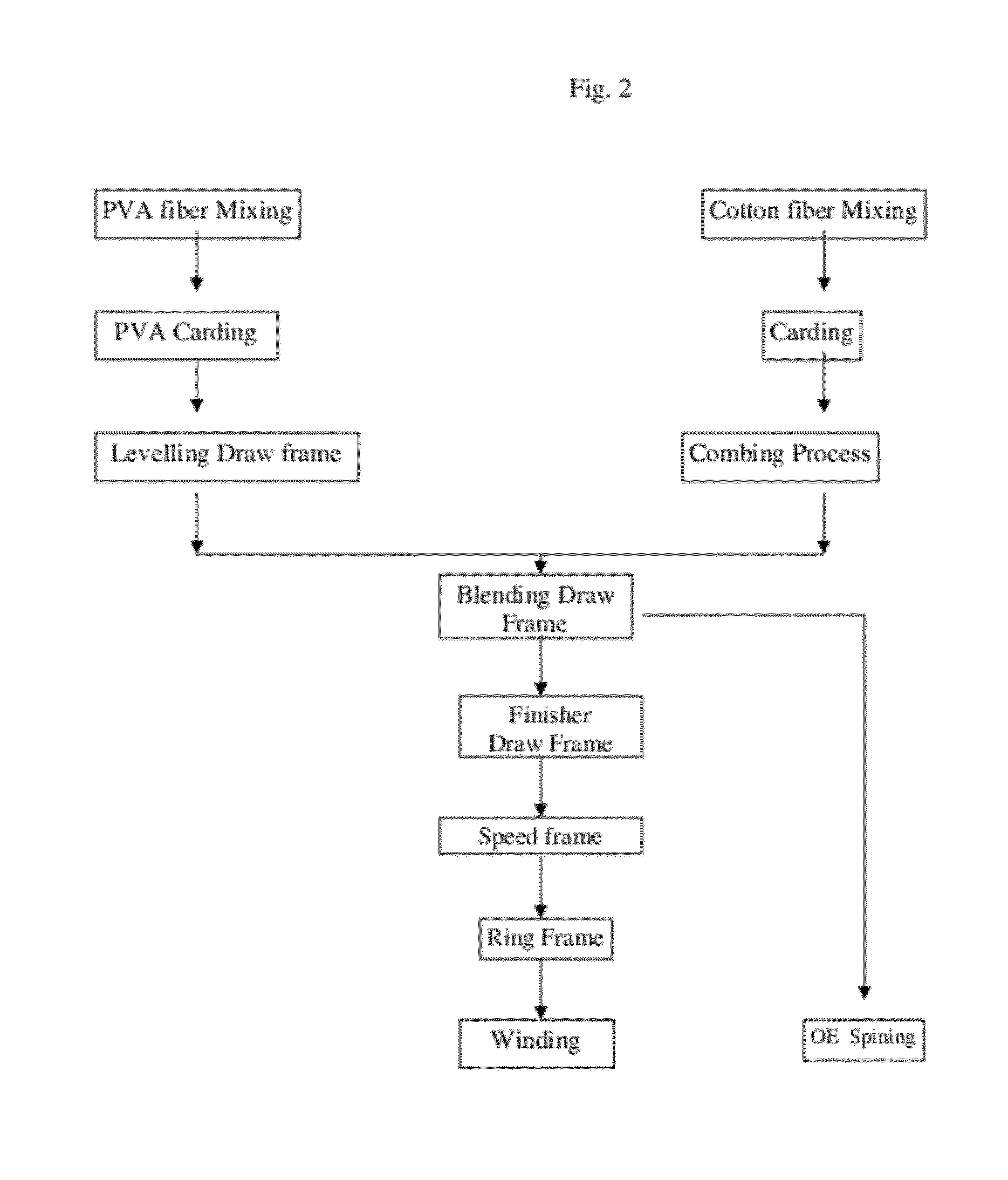

ActiveUS20070087162A1Fast dryingIncrease in sizeFabric breaking/softeningLayered productsFiberWarm water

A process is described wherein pile yarn is woven with cotton weft and warp yarns to produce terry fabrics, such as towels. The fabric is then washed in warm water to dissolve the PVA fibers. The amount of fibers dissolved, depends upon the count of the yarn or yarns used. By dissolving the PVA fibers, a hollow air space is produced throughout the pile yarn, corresponding to an increase in the air space in the pile yarn. By increasing the air space in the pile yarn, the resulting towels are softer and bulkier than standard cotton towels. The present invention further relates to pile yarn in terry woven fabric (warp yarn), or weft yarn, in the case of flat fabrics.

Owner:WELSPUN INDIA LTD

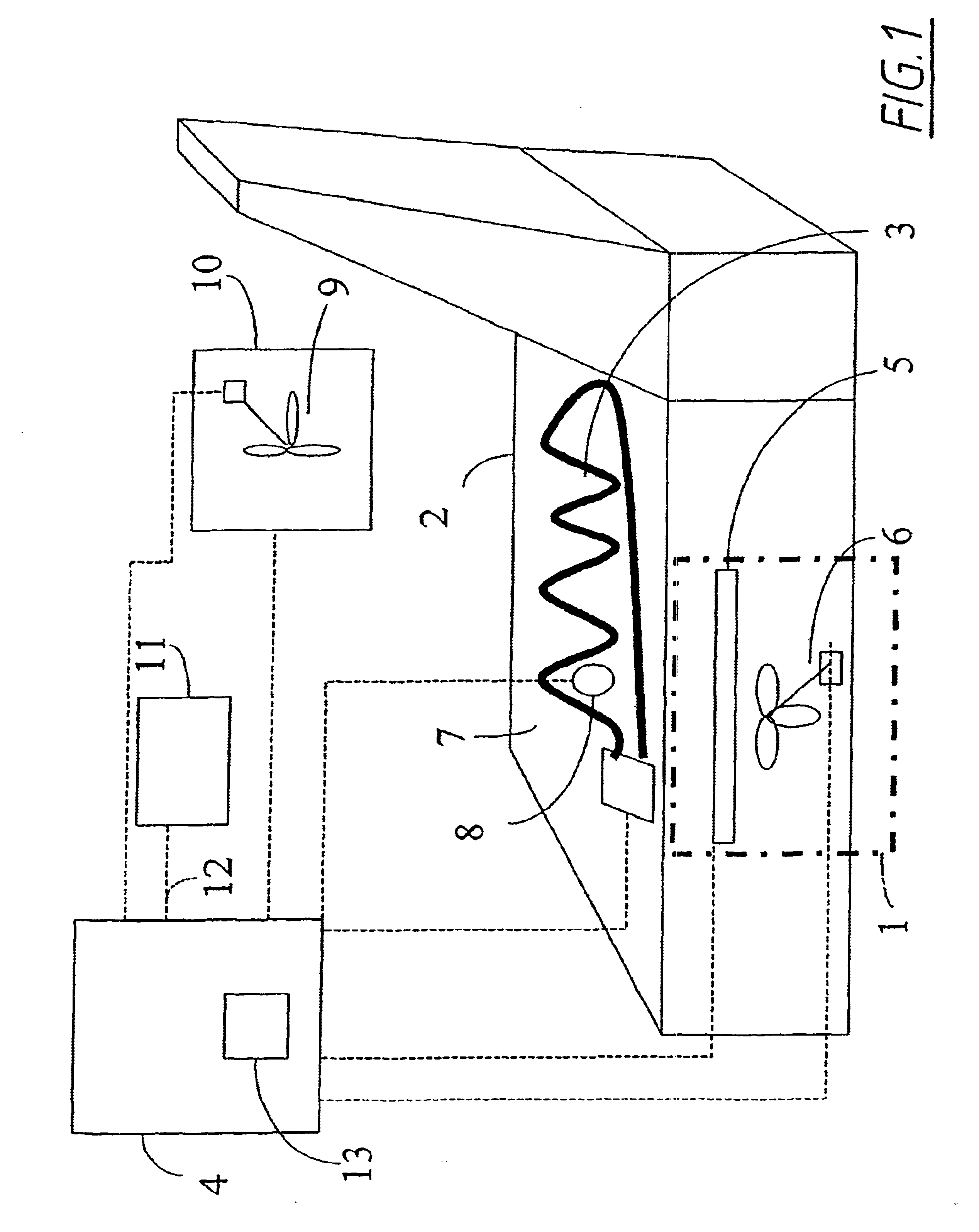

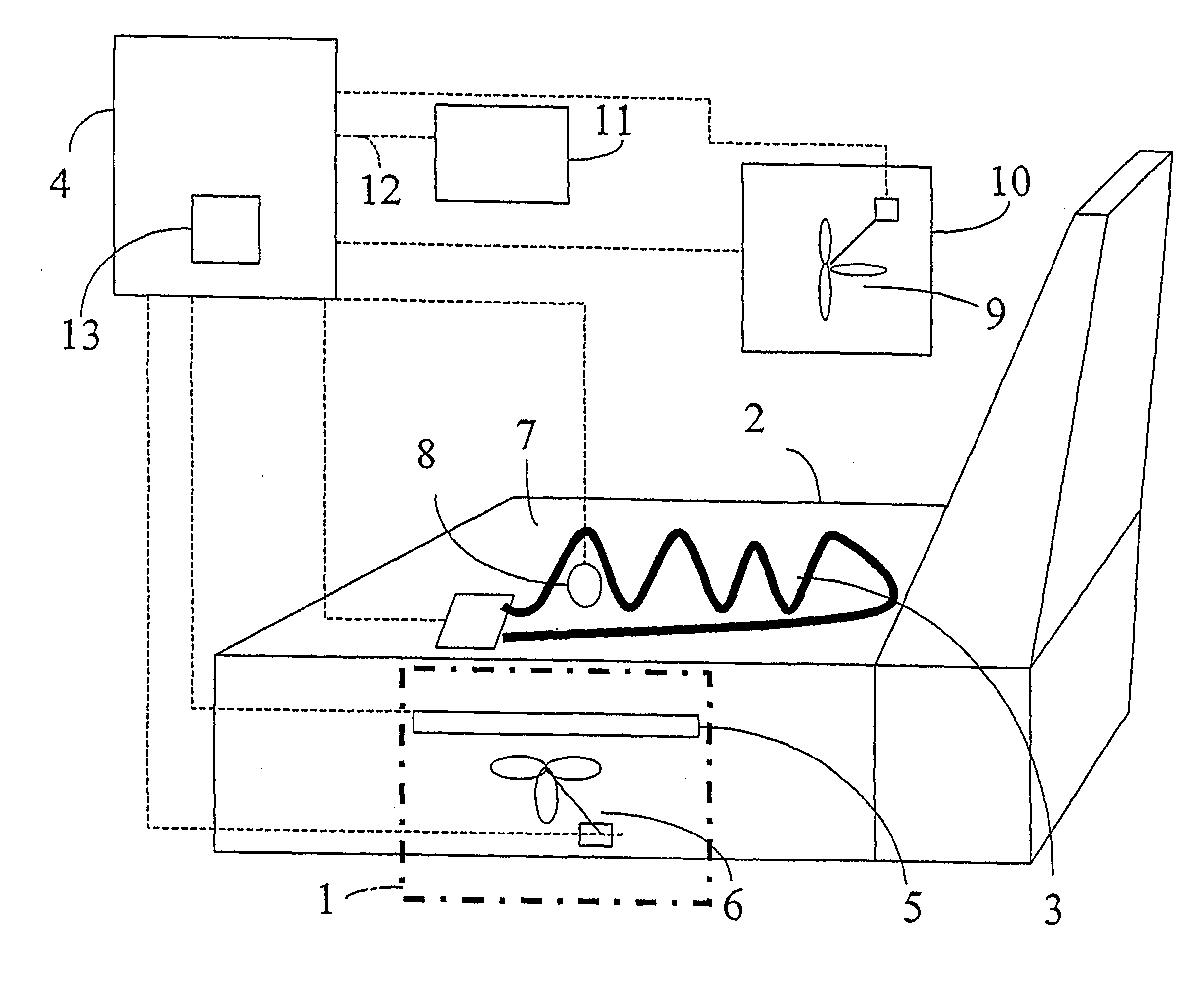

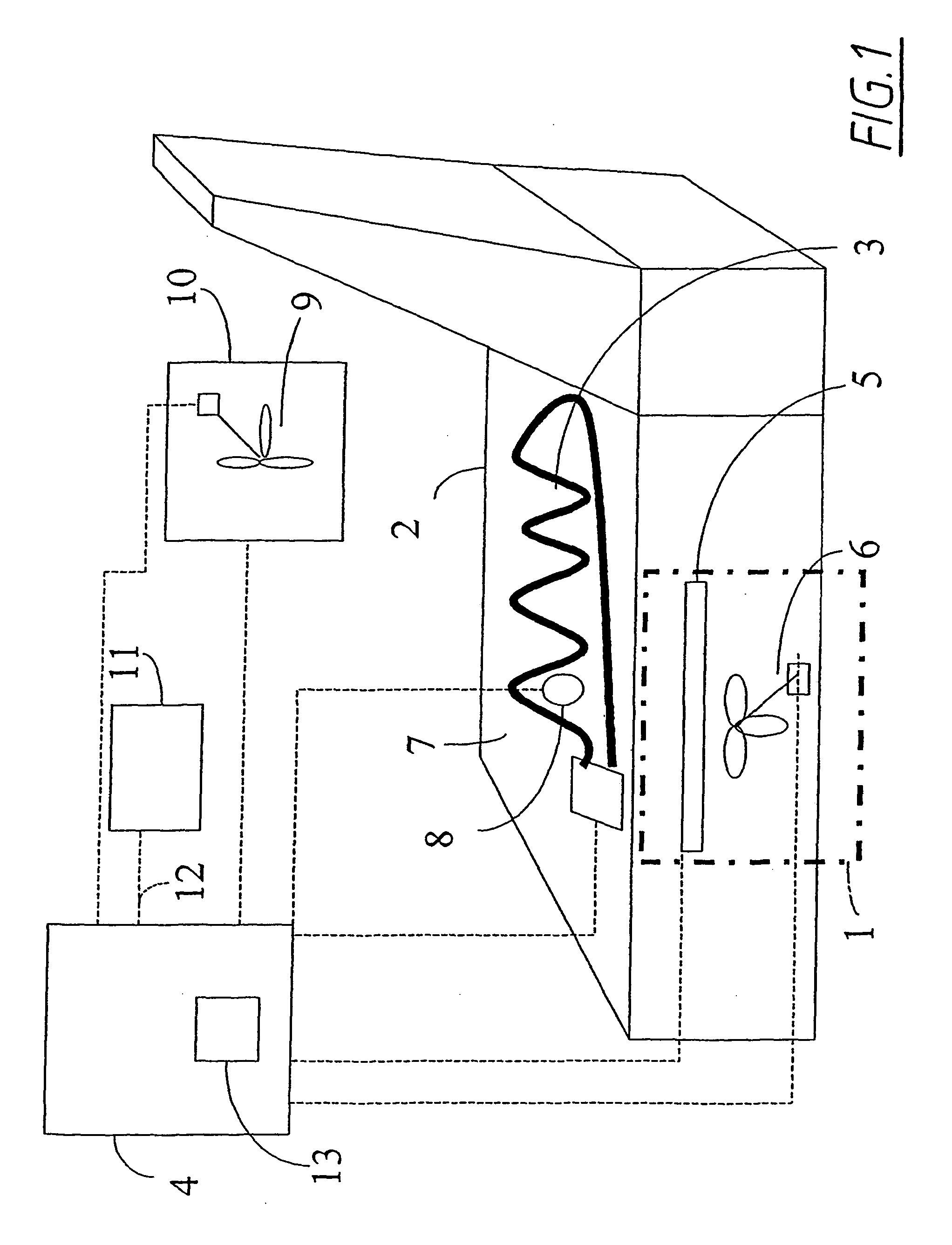

Seat with temparature control and ventilation and safety system for a vehicle

InactiveUS20040118555A1Improve cooling effectAccelerated dryingDomestic cooling apparatusPower to electric heating circuitsTemperature controlEngineering

Methods and apparatus for controlling the temperature of a seat such as a vehicle seat are disclosed. The apparatus includes an electrical heater disposed in the seat, a cooling unit such as a cooling element and a fan, a detector for detecting the temperature associated with the electrical heater, and a controller for controlling the electrical heater and the cooler based upon the detected temperature and upon the humidity algorithm comprising a predetermined set of calculations of the humidity of air at different temperatures.

Owner:LEAR CORP

Quick-drying cosmetic emulsions for roll-on application

InactiveUS20090047226A1Improve shelf stabilityExtend shelf stabilityCosmetic preparationsToilet preparationsOil in waterPolymer chemistry

Cosmetic oil-in-water emulsions that are suitable in particular for application with a roll-on applicator and that exhibit high shelf stability, a non-greasy skin feel, and particularly quick drying characteristics, the emulsions containing a low concentration of oil phase or fat phase as well as at least one polysaccharide.

Owner:HENKEL KGAA

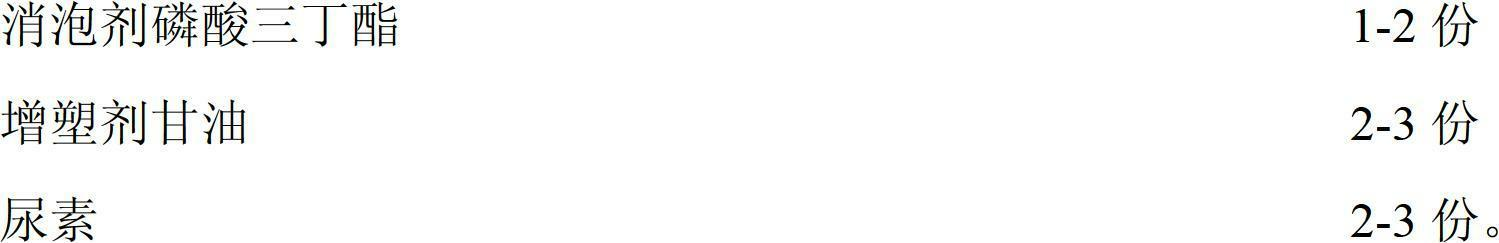

Method for preparing starch glue for lumber

InactiveCN1687279AHigh bonding strengthImprove water resistanceStarch derivtive adhesivesAdjuvantPlasticizer

The present invention relates to a preparation method of starch glue for wood. Said invention uses starch as main raw material, and adopts the following steps: firstly, making starch undergo the processes of acidolysis, oxidation and graft copolymerization, etc., then adding modifying agent and complexing agent to make cross-linking modification, then heating and gelatinizing, cooling and successively adding the adjuvants of diluent, plasticizer and defoaming agent so as to obtain a starch glue with excellent performance for wood.

Owner:JIANGNAN UNIV

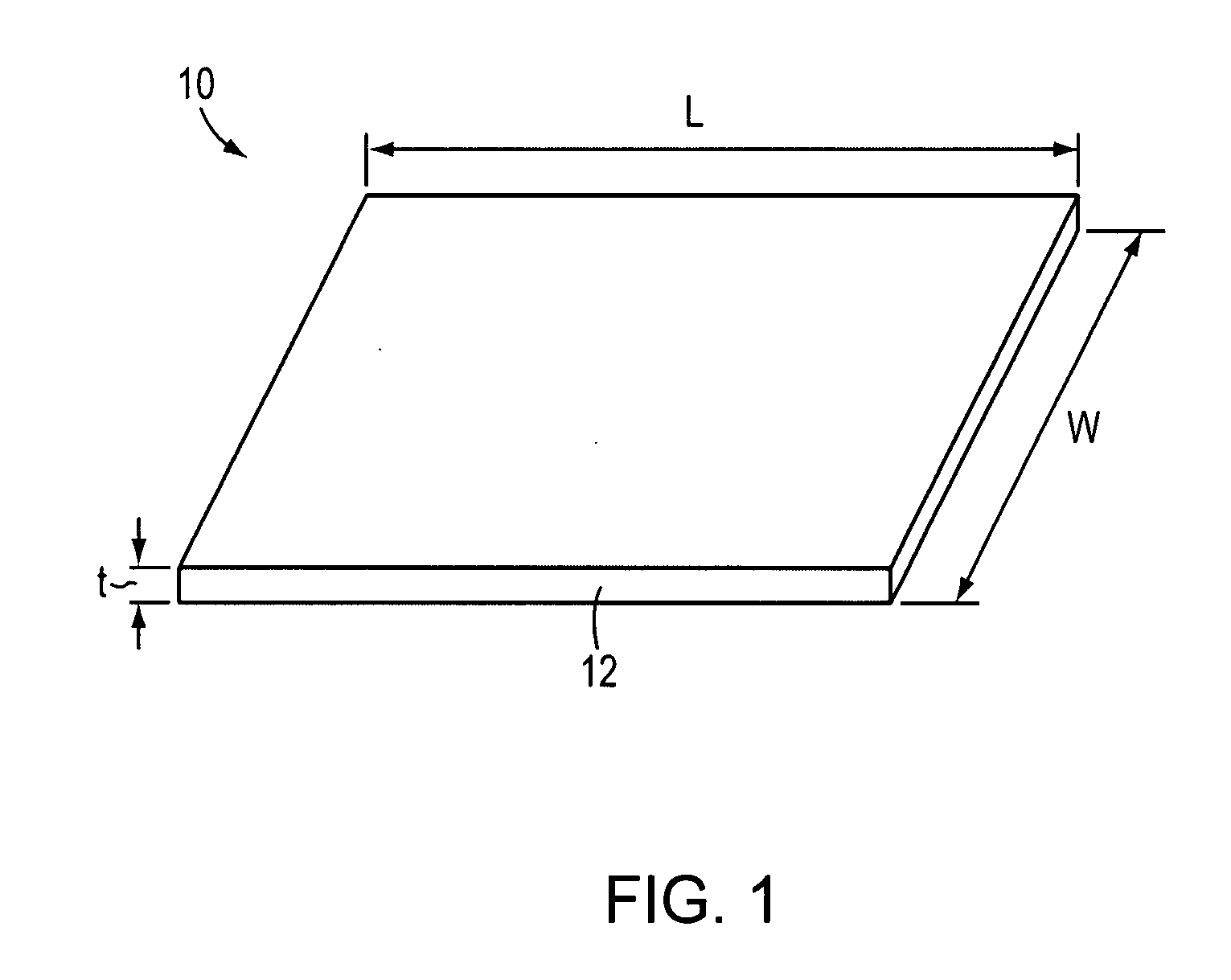

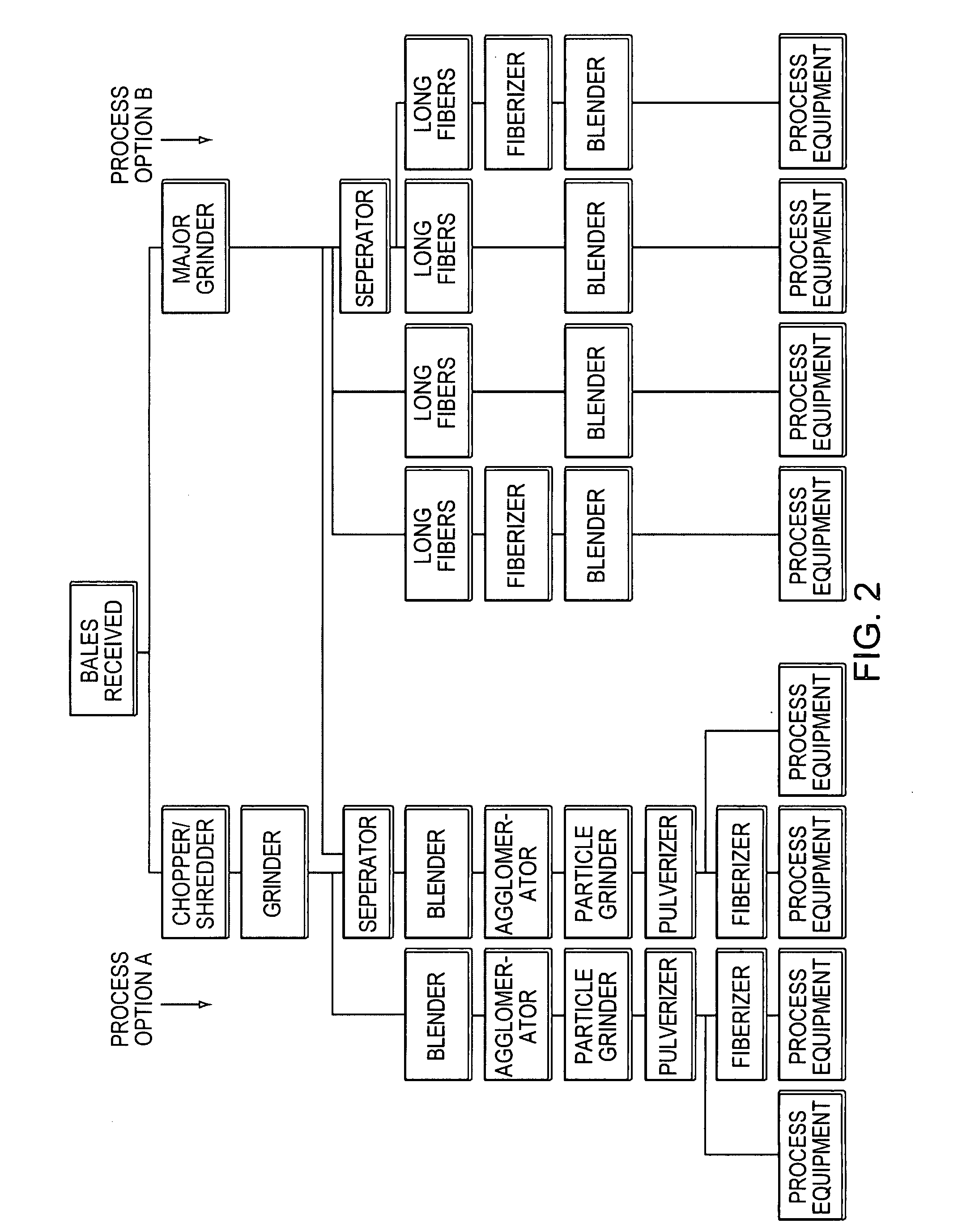

Carpet Waste Composite

A composite material is produced from carpet waste and a binding agent, in intimate association, and may also include wood fiber or chips and / or other additives. A method of manufacturing a composite material includes shredding carpet waste, coating the carpet waste with a binding agent, and subjecting the shredded, coated carpet waste to elevated heat and pressure. As an additional step, the composite material may be actively cooled to prevent deformation of the material.

Owner:MATERIAL INNOVATIONS LLC

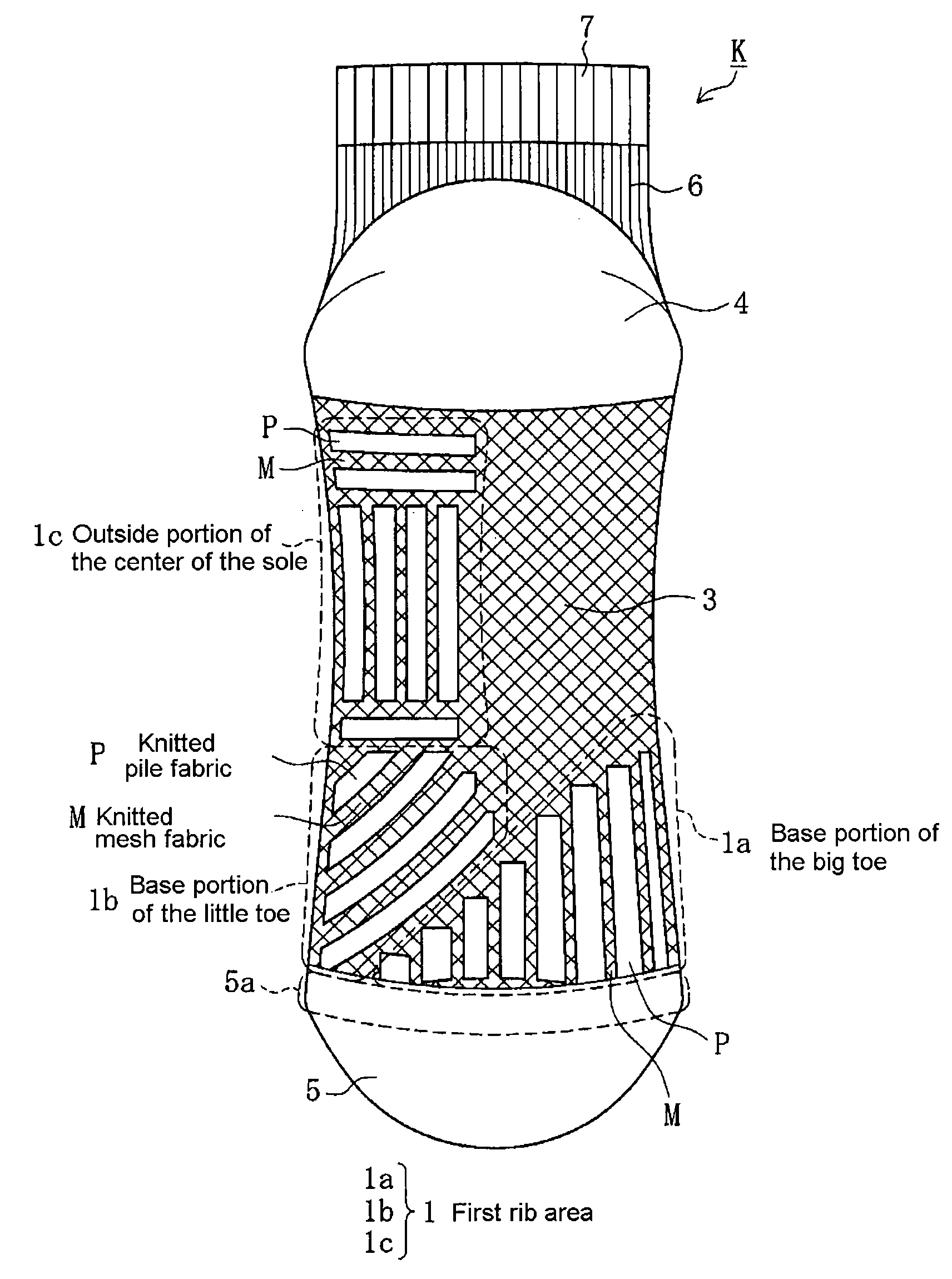

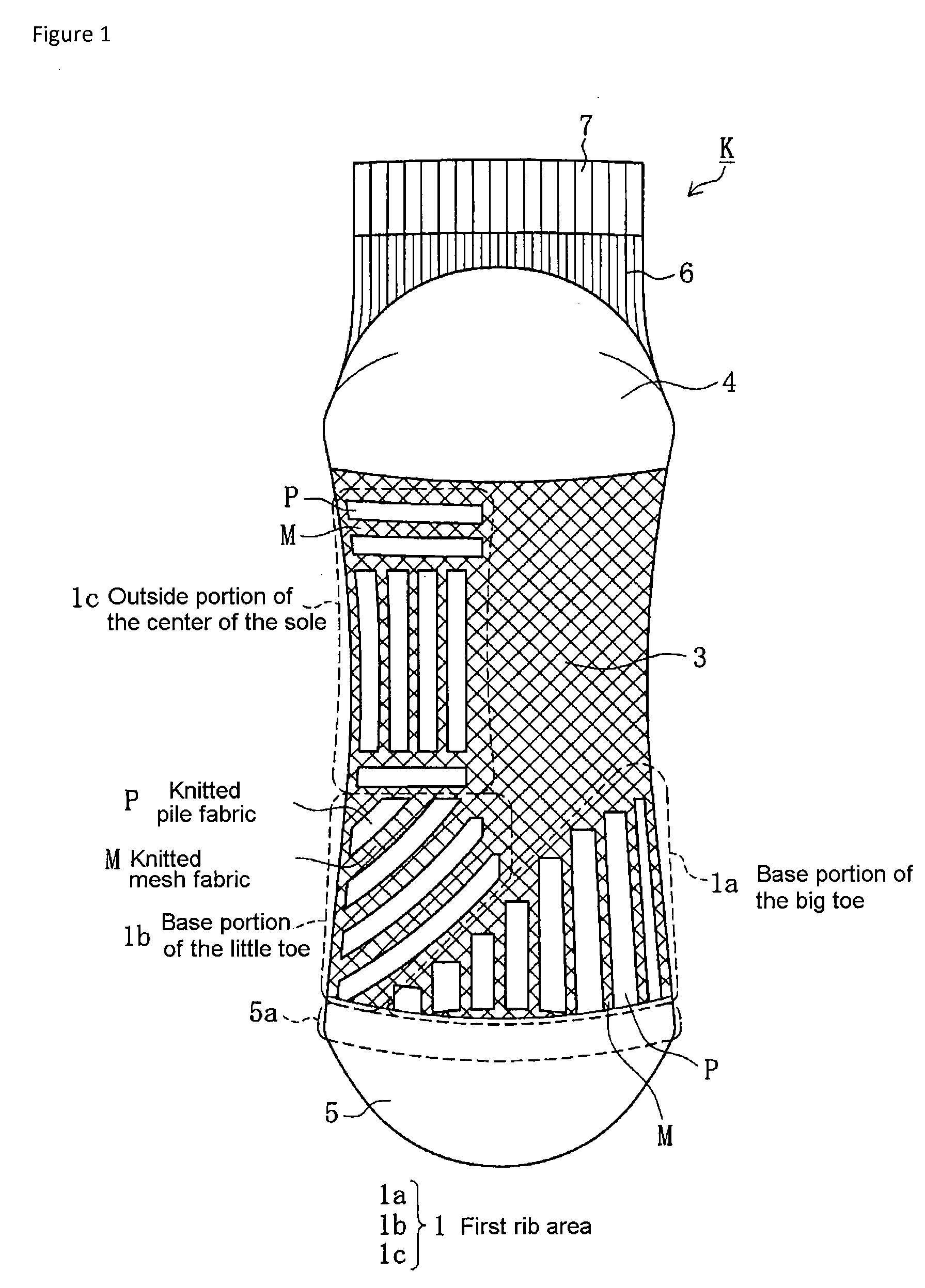

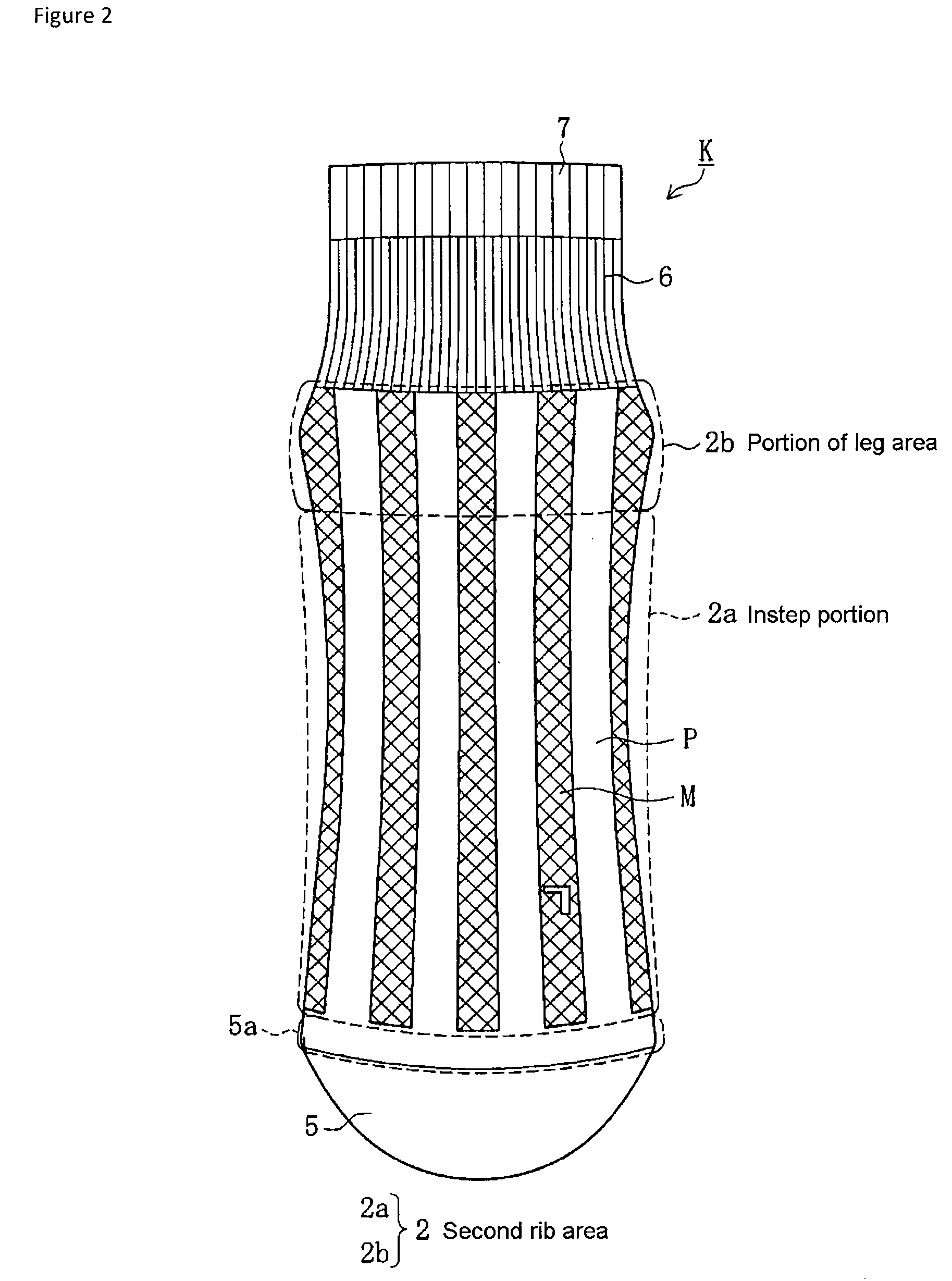

Sock

A sock includes an air escape route that allows humid air to be expelled to the outside of a shoe. The sock may include a first rib area provided in a ground-touching area of a sole portion of the sock, the ribs being formed in a desired direction. A second rib area, in which ribs are formed in a wale direction, may also be provided in an instep portion of the sock. The ribs of the first and second rib areas may be knitted with alternating knitted pile and knitted mesh fabric. Humid air collecting in areas that do not touch the ground passes through the concave portions of the ribs of the first rib area, and is impelled toward the instep side. Air flowing to the instep side of the sock via the first rib area is expelled to the outside of the shoe via the second rib area.

Owner:OKAMOTO INDS

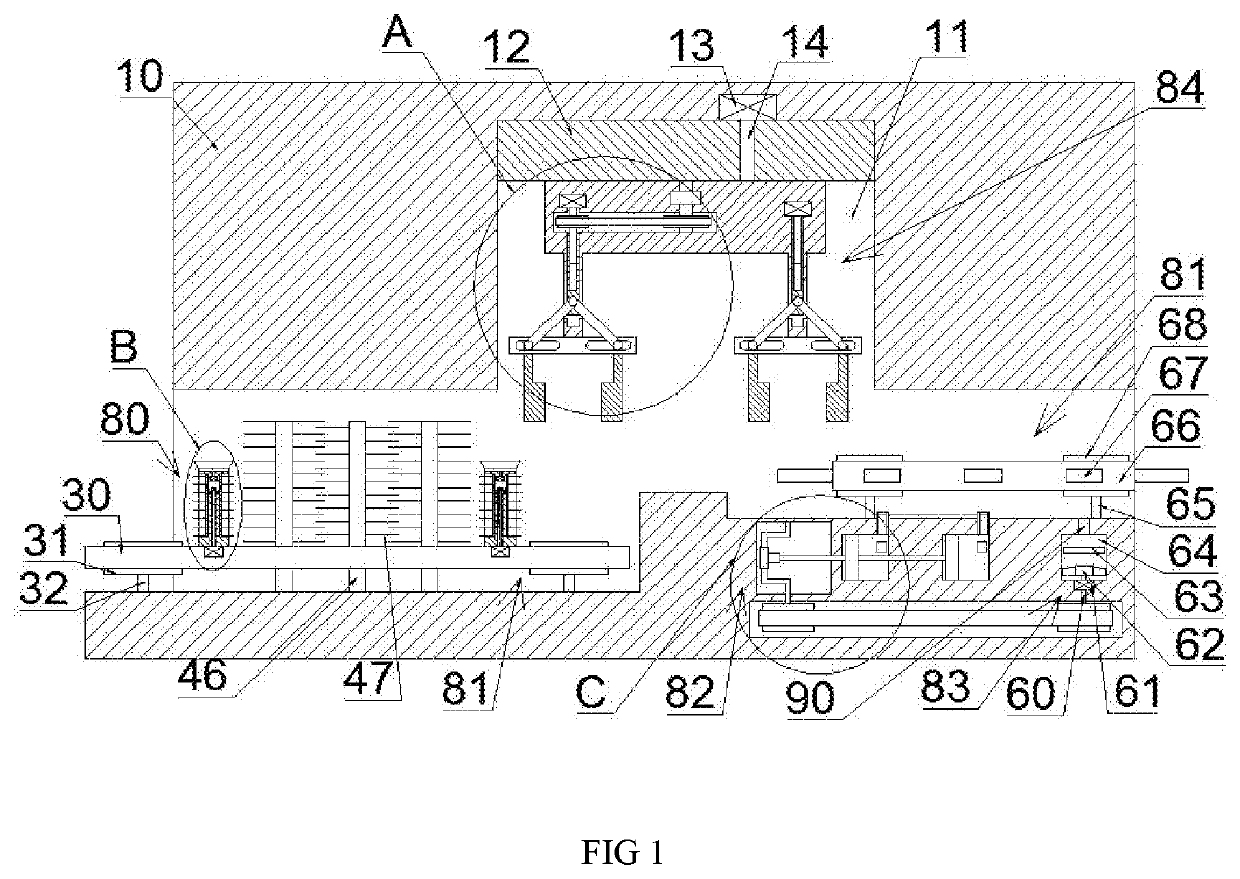

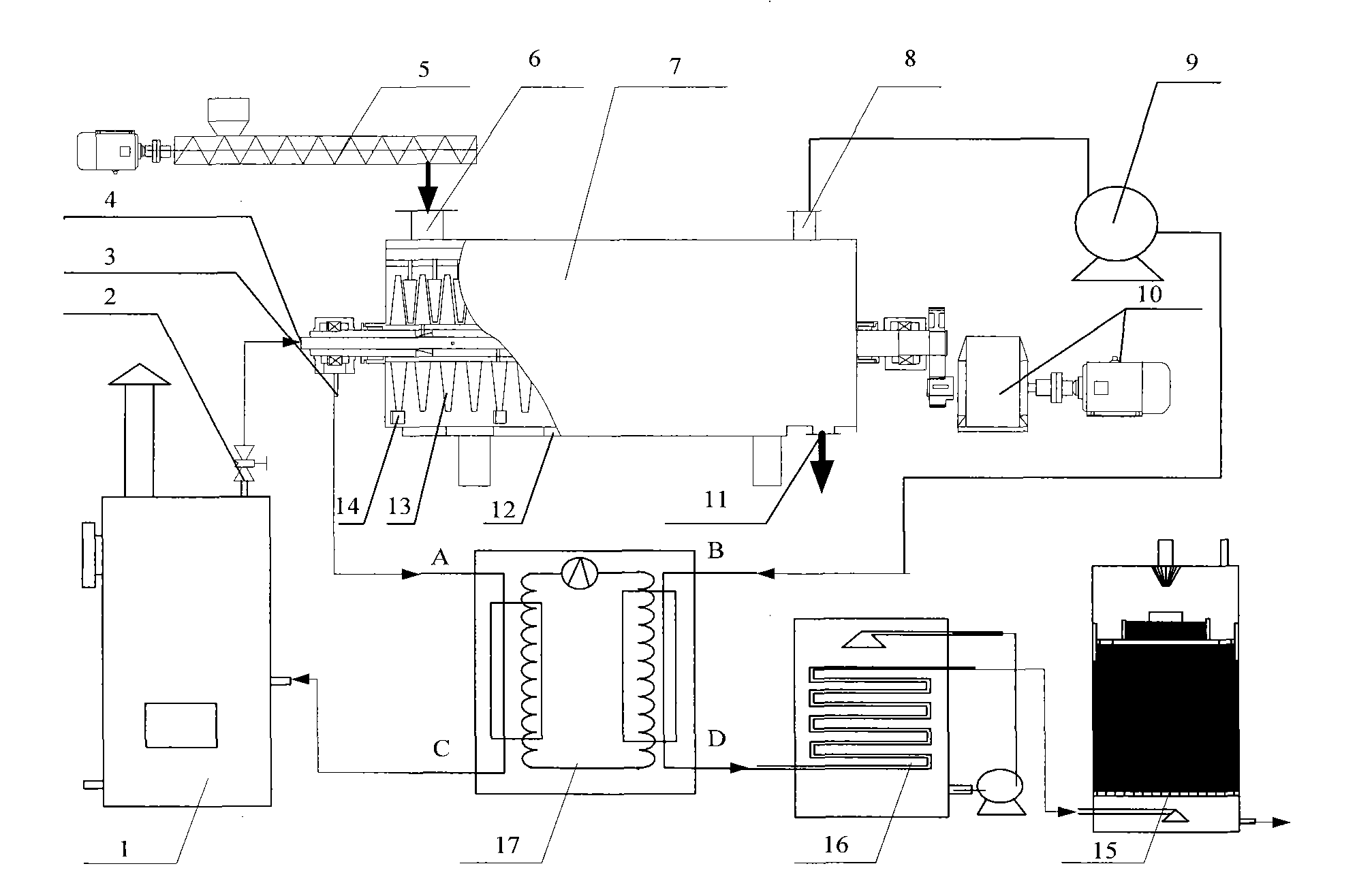

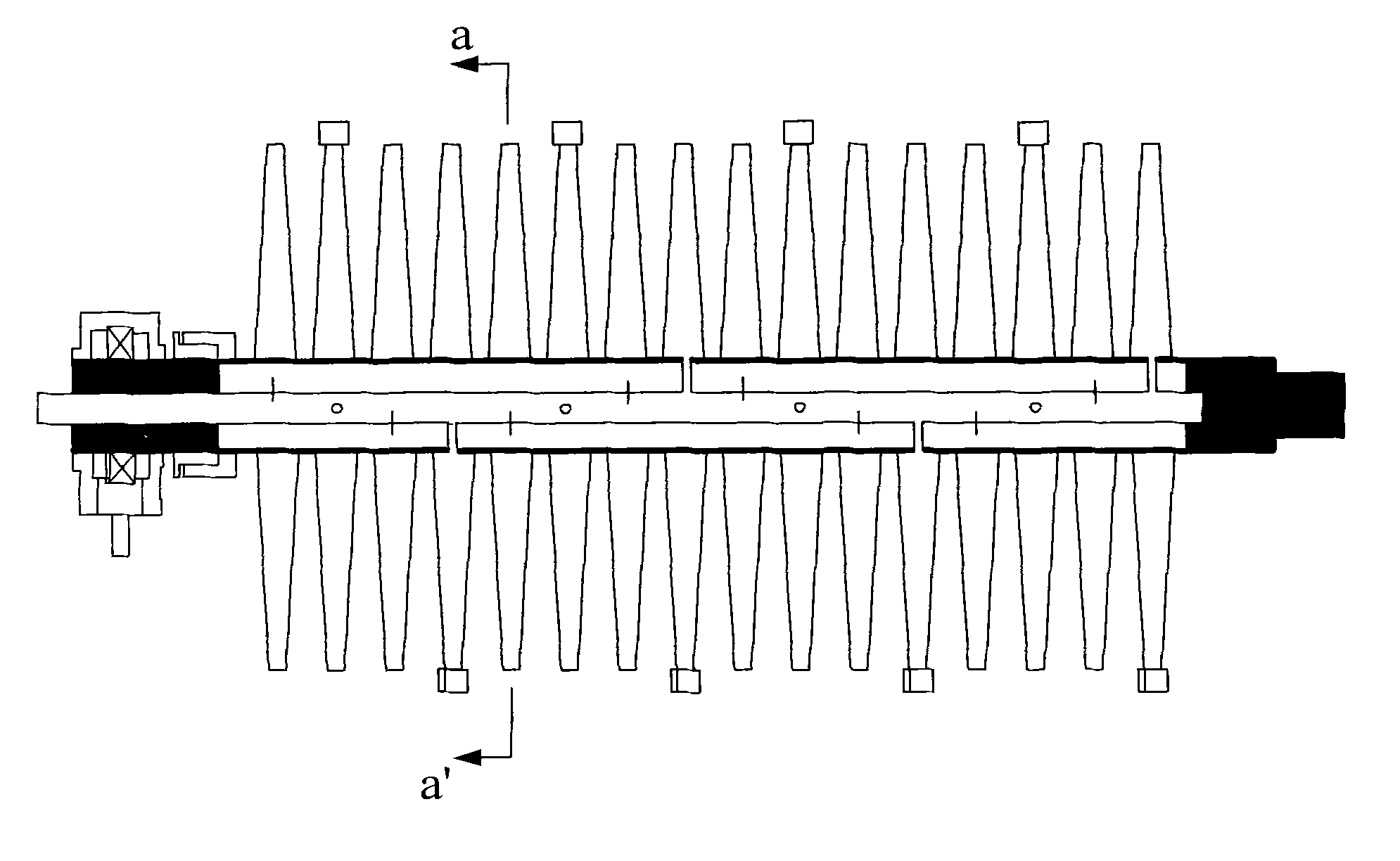

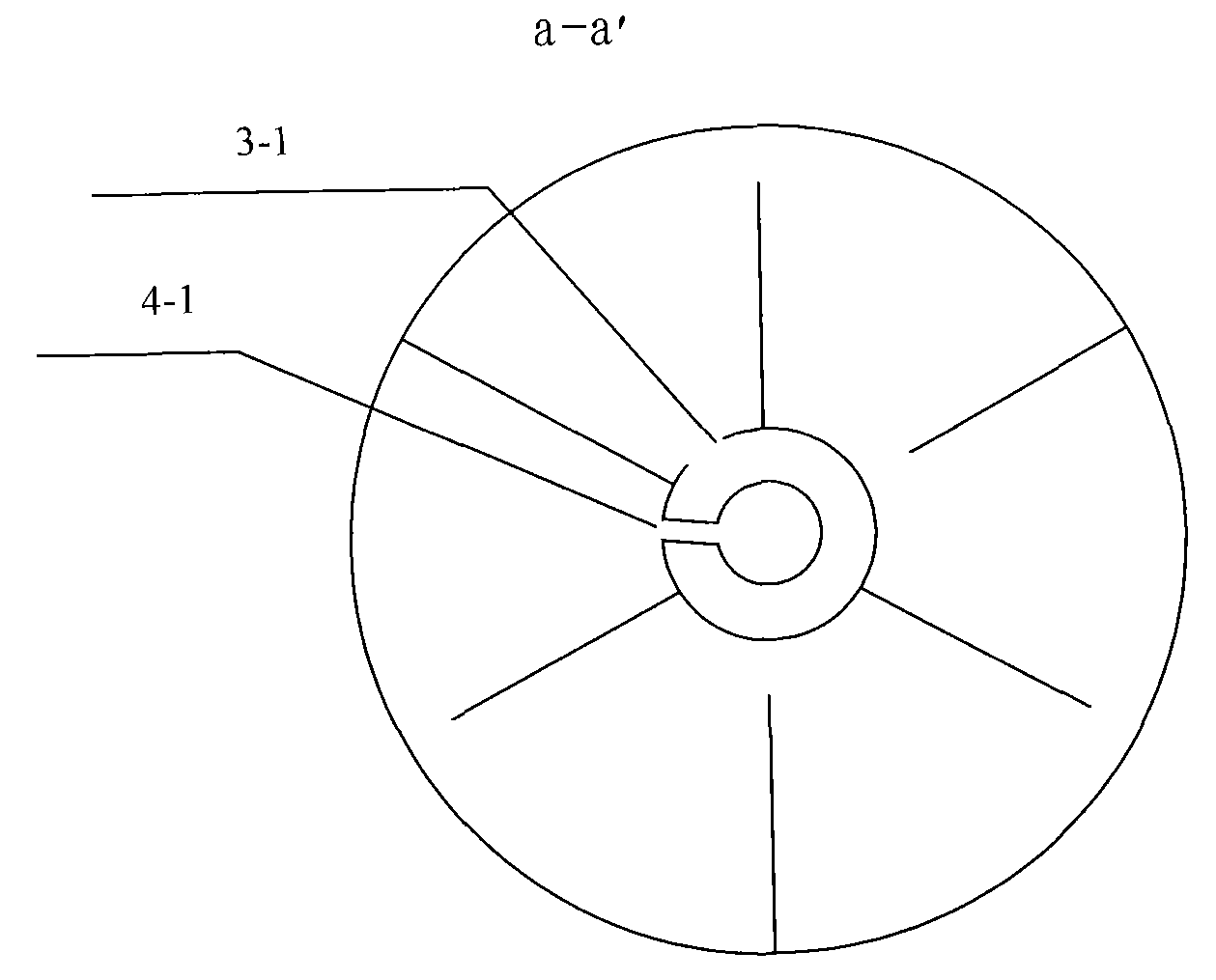

Latent heat recoverable multi-phase change sludge drying method and device

ActiveCN101774743AReduce drying costsEnergy balanceSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningThermal energyBrick

The invention discloses a latent heat recoverable multi-phase change sludge drying method and a latent heat recoverable multi-phase change sludge drying device, which are designed for solving the technical problems that the energy consumption is high, the latent heat of the sludge vapor cannot be recovered and reused, the dried tail gas pollutes the environment, the operating cost is high and the like in the conventional sludge drying technology. Due to the combination of a low-temperature vapor turntable dryer, a sludge waste vapor latent heat recover heat pump and a tail gas purification device, and the use of indirect phase change heat exchange for low-temperature vapor, the heat exchange is improved, and the loss of organic components of the sludge is low. The latent heat of the sludge drying tail gas is recovered by using the latent heat recover heat pump, and the recovered heat energy is reused for sludge drying. Therefore, the heat efficiency is improved, the operating cost is reduced, and the problems that the heat utilization ratio is low, the operating cost is high and the like in the sludge drying process are better solved. The dried products meet the requirement of baking light and energy-saving bricks and producing cement laminated products, and over 90 percent of heat value of the original sludge is maintained. Therefore, the resource utilization value of the sludge is maximized.

Owner:SHENYANG INST OF AERONAUTICAL ENG

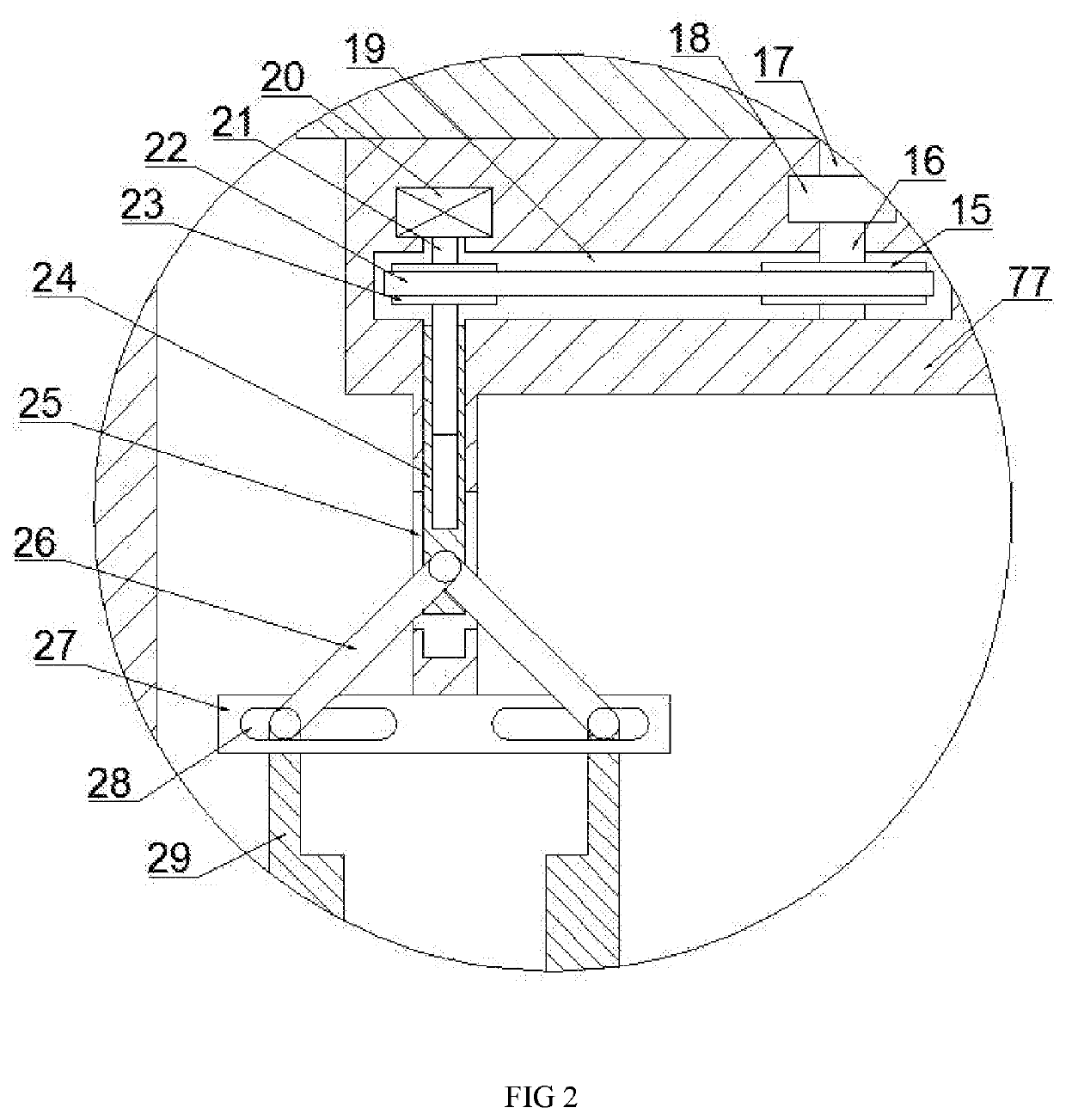

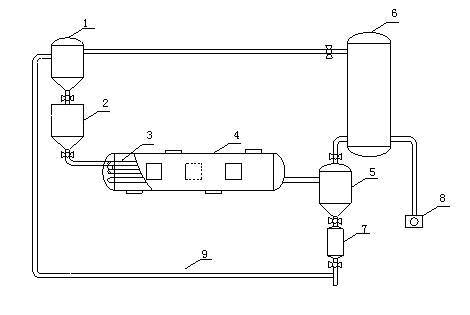

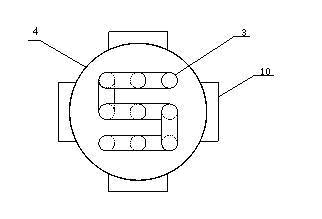

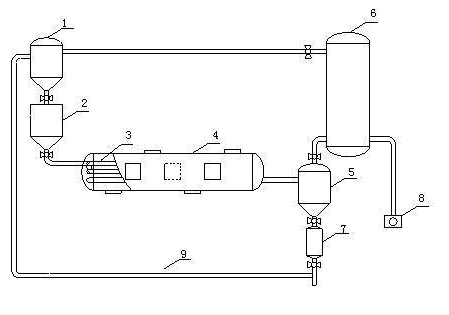

Negative-pressure microwave uniform spraying and drying device and application

ActiveCN102062525ADry evenlyAvoid uneven heatingDrying using combination processesDrying machinesMicrowaveDrying time

The invention discloses a negative-pressure microwave uniform spraying and drying device and application, belonging to the technical field of uniform drying devices. The negative-pressure microwave uniform spraying and drying device comprises a circulating material storage device, a feeder, a negative-pressure spraying pipe, a microwave heating cavity, a cyclone separator, a vacuum storage tank, a discharger, a water ring vacuum pump, a circulating pipe and microwave sources. The circulating material storage device is used for storing materials dried circularly, the feeder is used for feeding dry materials to the negative-pressure spraying pipe which is a channel for drying and circulating the materials, and the microwave sources are uniformly distributed inside the microwave heating cavity, two ends of which are sealed. The cyclone separator is connected with an outlet of the negative-pressure spraying pipe inside the microwave heating cavity and is connected with the vacuum storage tank and the discharger through a channel. The discharger is connected with the circulating material storage device through the circulating pipe. Because the materials can be sprayed under negative pressure, the device can be used for spraying, rotating and circulating the materials under a microwave vacuum drying condition so as to achieve the purpose of drying the materials efficiently and uniformly, meanwhile, is favorable for shortening the drying time by above 40% and reducing the cost of large-scale production.

Owner:JIANGNAN UNIV

Nano composite photocatalytic coating

InactiveUS20070000407A1Good anti-aging performanceNot perishableBiocideSolid waste managementAir cycleFungal microorganisms

A photocatalytic coating composition and method of coating articles, the composition containing solvents for rapid evaporation at room temperature, polyalkylphenylsiloxane, xylene, nano densified hydrophilic fumed silica, nanostructured composite photocatalyst powder and nano inorganic anti-bacteria powder. The coating may be applied by conventional coating methods to organic or inorganic structured surfaces where photocatalytic activity is desired, such as in a forced air-circulating environment. Once applied, the coating quickly dries to leave an adherent, flexible, durable, and long-lasting photocatalytic coating having a large surface area and exhibiting high surface activity against pathogens and pollutants such as bacteria, viruses, mold, fungi, and volatile organic compounds.

Owner:YORK INT CORP

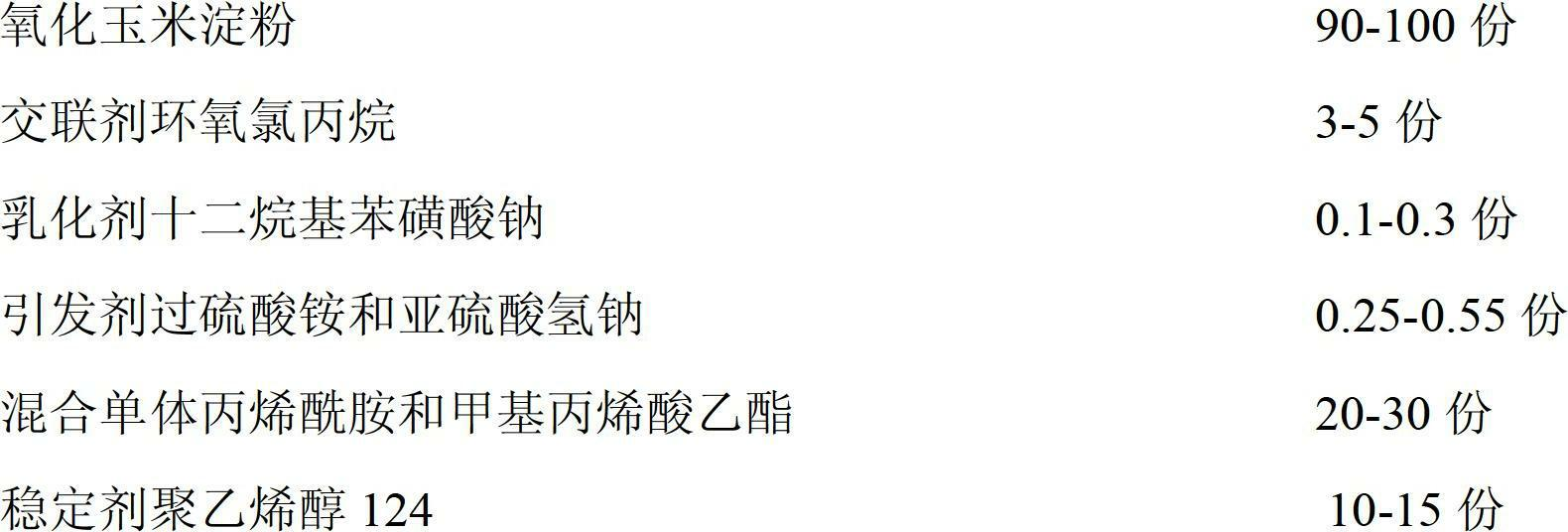

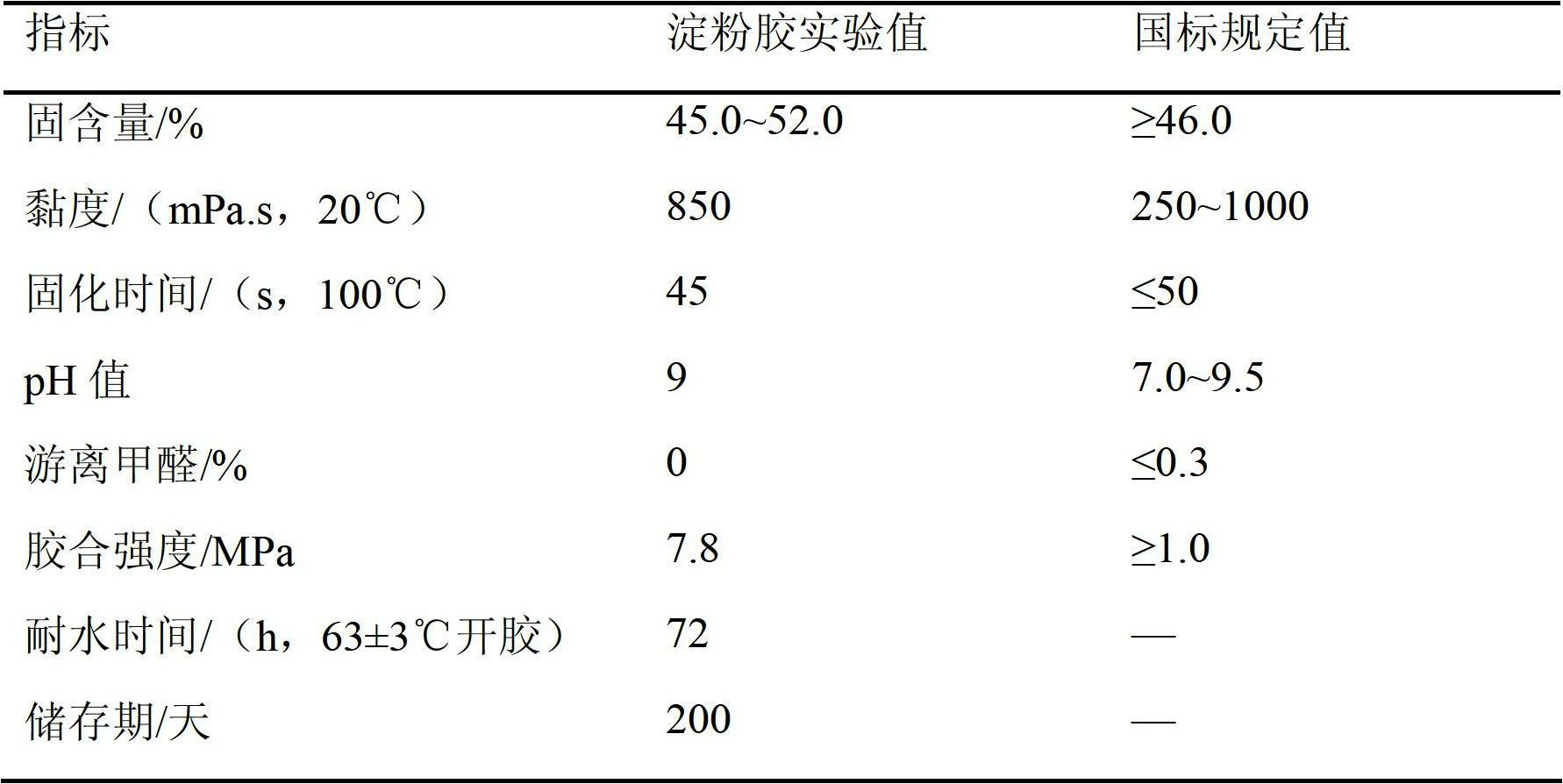

Modified-starch-based wood adhesive and preparation method thereof

InactiveCN102676098AReduce dependenceStrong water resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesCelluloseCross-link

The invention discloses a modified-starch-based wood adhesive and a preparation method thereof. The preparation method comprises the steps that oxidized corn starch is used as a main raw material, a cross-linking agent is added into the oxidized corn starch to conduct crosslinking modification, and then an initiating agent and a high molecular monomer are added to the oxidized corn starch to conduct graft modification, so as to obtain a modified starch emulsion in a complex net structure; and after the modified starch emulsion is warmed up and pasted, modifying agents comprising a stabilizing agent, a defoaming agent, a plasticizing agent and the like are added into the modified starch emulsion, and the high-performance green environment-friendly adhesive is manufactured. Each performance of the adhesive disclosed by the invention can reach or exceed requirements of a GB / T9846-2004 standard, the adhesive has the characteristics of high bonding strength, good water resistance, long storage time, high solid content, low cost, greenness, environment friendliness and wide use range, and can be widely applied to the bonding and the use of wood materials such as artificial boards, plywood and cellulose boards.

Owner:HEFEI UNIV OF TECH

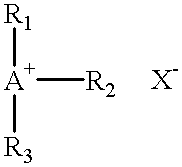

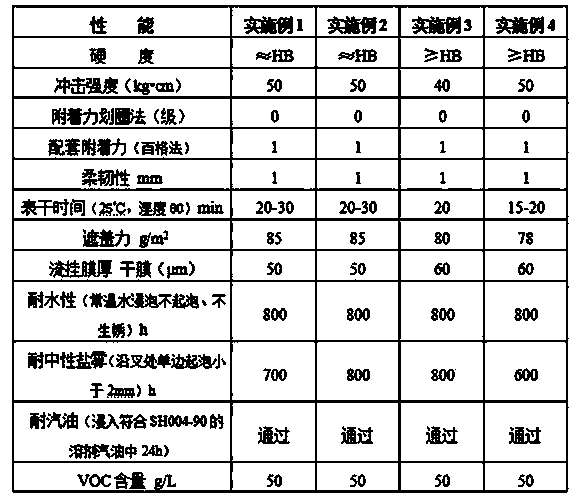

Water-based epoxy intermediate paint

The invention relates to a water-based epoxy intermediate coating, consisting of two components of A and B, wherein component A is produced by grinding, dispersing and other process after the base material of water-based epoxy curing agent is mixed with pigment, filler, additives, co-solvents and water and component B is produced by stirring, filtering and other processes after the base material of water-based epoxy emulsion is mixed with water. The water-based epoxy intermediate coating has no pollution to the environment and is harmless to the workers, secure and convenient in application. Suitable for high-pressure airless spraying, the water-based epoxy intermediate coating is provided with high operation efficiency and 40-200um thickness of a single coating layer. The coating has advantages of fast drying, high mechanical strength and good anticorrosion performance. The water-based coating can be used as intermediate coating for container, as well as inner top finish. Additionally the coating is widely used in the antirust for the iron and steel parts of transportation means like automobiles, trains and ships; of structures like bridges, towers, doors and windows; and of facilities like tanks and pipes.

Owner:V ABC PAINTS MFG JIANGXI CO LTD

Ink jet recording method

ActiveUS20080152877A1Inhibit coloringAvoid non-uniformityLiquid surface applicatorsMeasurement apparatus componentsWater basedPlastic film

A recording method for printing on a plastic film surface of a print medium by ejecting droplets of a water-based ink composition onto the plastic film surface includes applying a water-based ink composition on the plastic film surface, and heating the water-based ink composition on the plastic film surface to a temperature of 40° C. or more. The water-based ink composition contains a coloring agent, 0.1% to 1.5% by weight of a silicone surfactant, an acetylene glycol surfactant, a pyrrolidone derivative, a thermoplastic resin, and water.

Owner:SEIKO EPSON CORP

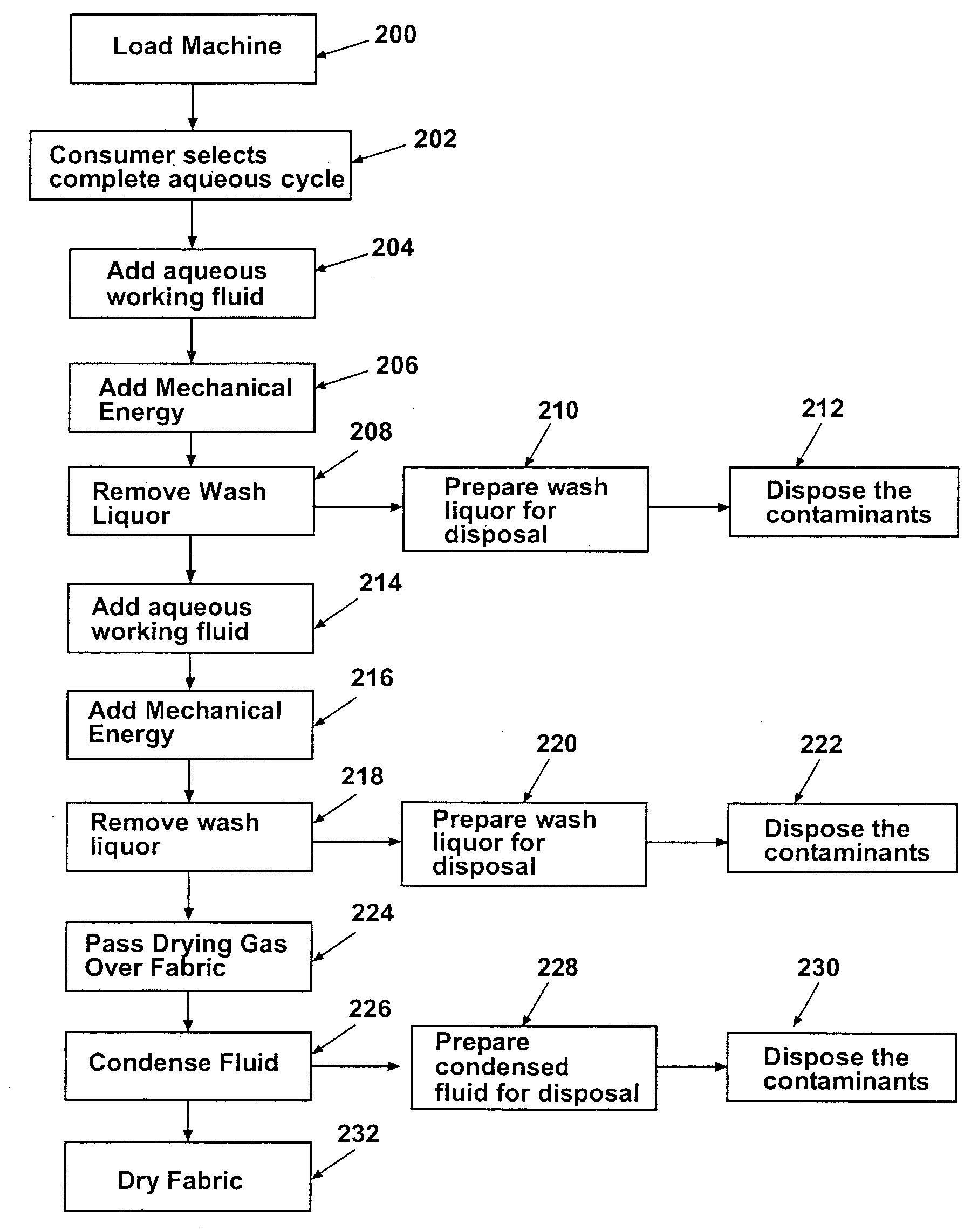

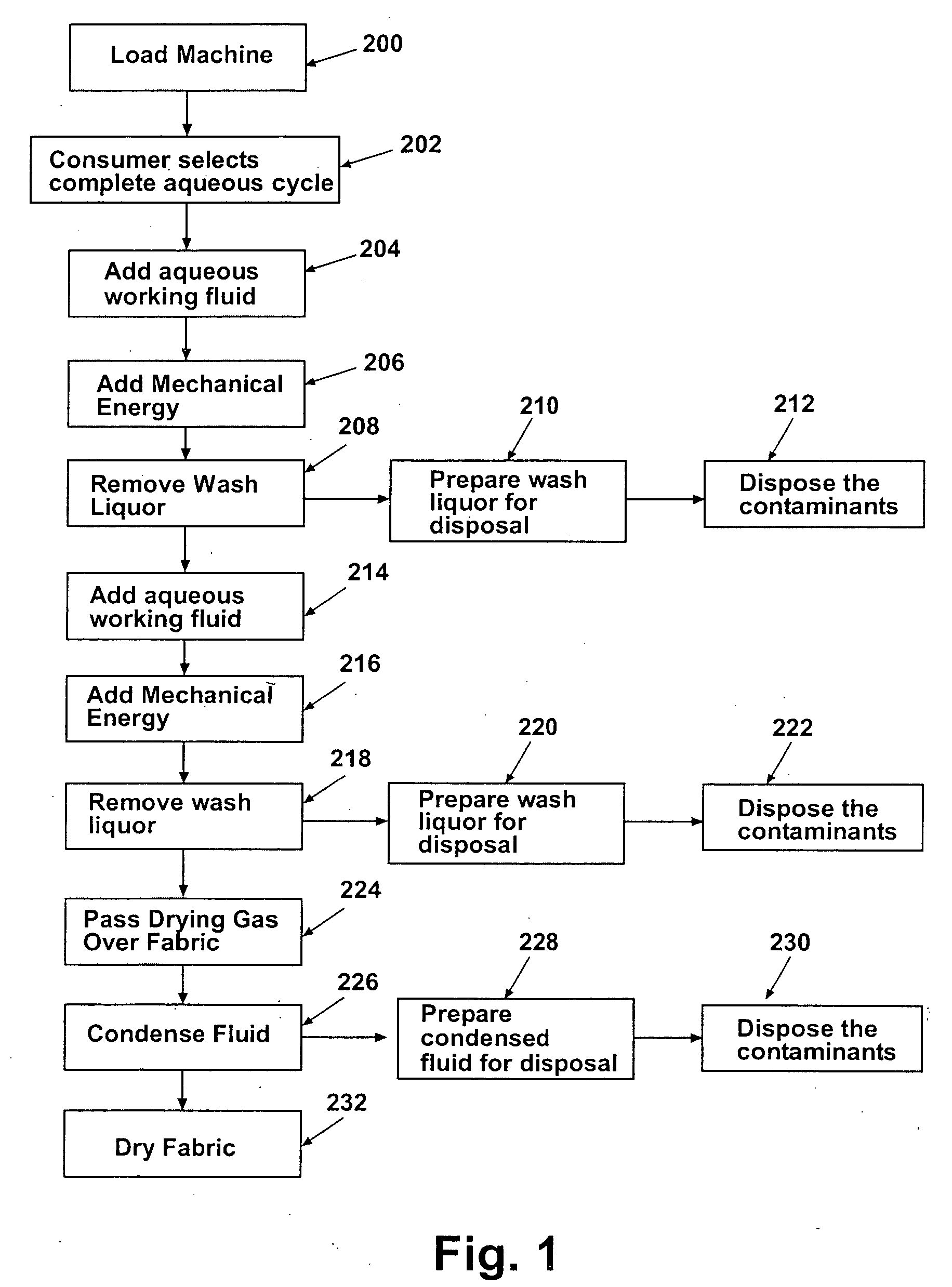

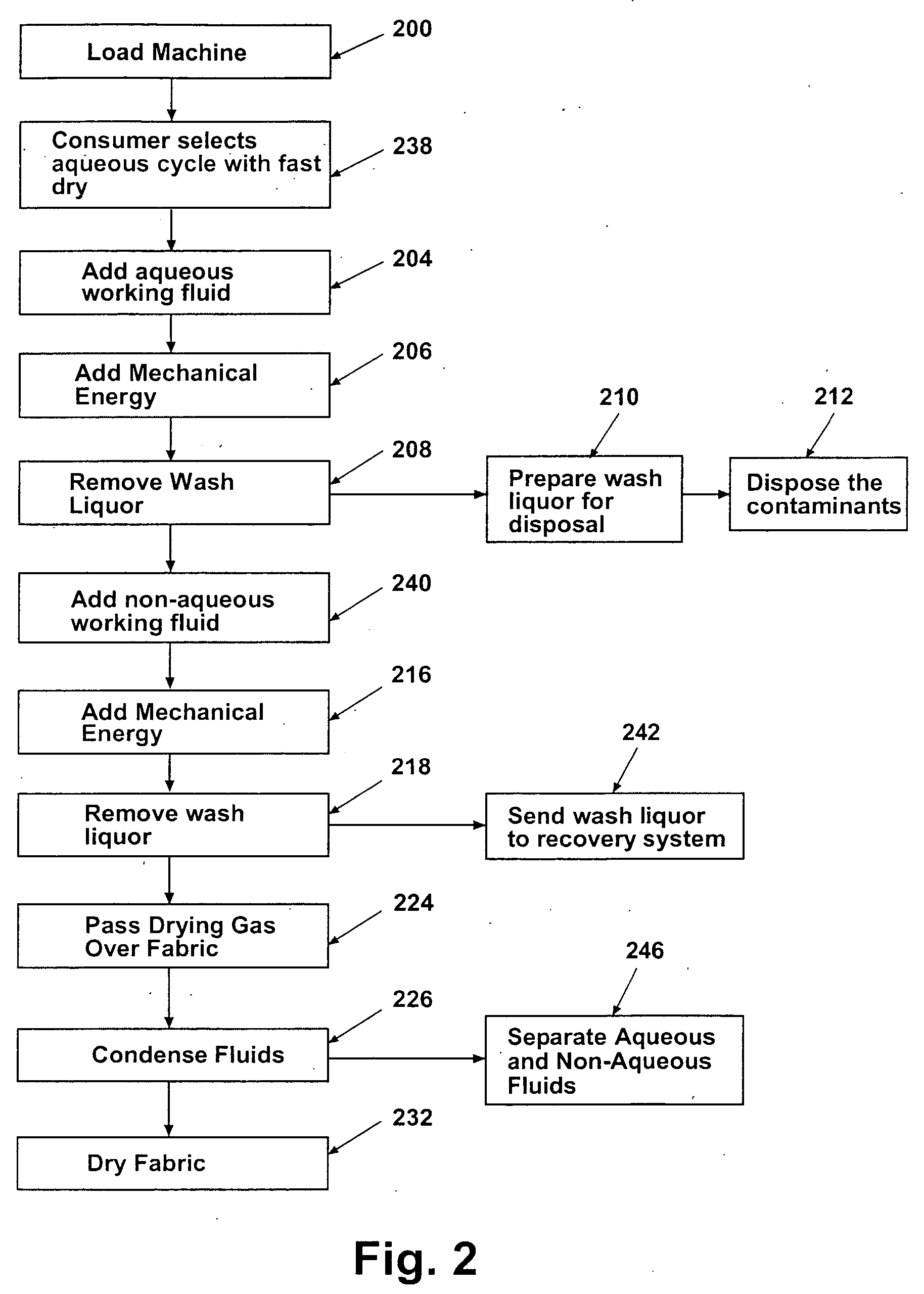

Multifunctioning machine and method utilizing a two phase non-aqueous extraction process

InactiveUS20050257812A1Shorten drying timeFast dryingDry-cleaning apparatusOther washing machinesWorking fluidEngineering

A method and apparatus of laundering a fabric load is disclosed including the steps of processing a fabric load in an aqueous-based working fluid, substantially replacing the aqueous-based working fluid with a non-aqueous working fluid of the type which extracts some of the aqueous-based working fluid from the fabric load.

Owner:WHIRLPOOL CORP

Ink jet recording element

InactiveUS6228475B1Fast dryingEliminates bleedingLayered productsDuplicating/marking methodsColloidal silicaPolyolefin

An ink jet recording element comprising a support having thereon the following layers in the order recited:I) a solvent-absorbing layer of a porous, polyolefin material, andII) an image-recording layer comprising a polymeric binder and colloidal silica having an attached silane coupling agent.

Owner:EASTMAN KODAK CO

Ink-jet printing system for improved print quality

InactiveUS6247808B1Improve print qualityReduce bleedingMeasurement apparatus componentsDuplicating/marking methodsInkjet printingColoring agents

An ink-jet printing system is disclosed comprising a set of ink-jet inks comprising a first anionic ink comprising an aqueous vehicle, at least one first colorant, and at least one first anionic polymer; a second anionic ink comprising an aqueous vehicle; at least one second colorant, at least one second anionic polymer, and an acid additive having a pKa up to the pKa of the at least first polymer of the first ink; a third cationic ink comprising an aqueous vehicle, at least one third colorant, at least one third cationic polymer, and a pH in the range from about 2 to about 5; and a fourth anionic ink comprising an aqueous vehicle, at least one fourth anionic dye, and a precipitating agent. The printing system provides improved print quality, specifically, reduced bleed; improved edge-acuity, uniform area fills, and color quality; while maximizing lightfastness without sacrificing printing reliability.

Owner:HEWLETT PACKARD DEV CO LP

Room-temperature-curable aqueous anticorrosion primer used for coating external surface of construction crane and preparation method of primer

ActiveCN103436136AIntensity rises fastShort construction intervalAnti-corrosive paintsPolyurea/polyurethane coatingsAntifoam agentCorrosion resistant

The invention discloses a room-temperature-curable aqueous anticorrosion primer used for coating the external surface of a construction crane. The primer comprises the following components by weight: 35-45% of an aqueous resin, 5-8% of a curing agent, 1-3% of a dispersant, 5-12% of an antirust pigment, 20-35% of a pigment filling material, 1-2% of an anti-settling agent, 0.5-1% of a wetting agent, 0.5-1% of a thixotropic agent, 0.5-1% of an antifoaming agent, 0.1-0.8% of a flash etching inhibitor, 0.1-0.8% of a mildew inhibitor, 1-3% of a film-forming auxiliary agent and 10-20% of deionized water. The invention also discloses a preparation method of the aqueous anticorrosion primer. The aqueous anticorrosion primer has a room-temperature-curable paint film, is energy-saving and environment friendly, and can satisfy safe production requirements of enterprises; the primer is high in solidity, low in viscosity, convenient for construction; and the coating of the primer has good corrosion resistance and water proofness, and the comprehensive properties of the coating reach performance indexes of same-type oiliness products.

Owner:GUANGZHOU KINTE IND +1

Air rich yarn and fabric and its method of manufacturing

The present invention relates to air rich yarn and fabric with pores throughout the cross-section. Air rich yarn and fabric have high wettability, easy dryability, quick absorbency and increased thickness. When air rich yarn is used to make terry fabric it makes thicker fabric with increased capacity to absorb water and also release moisture faster while drying.

Owner:TRIDENT

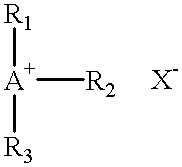

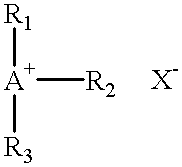

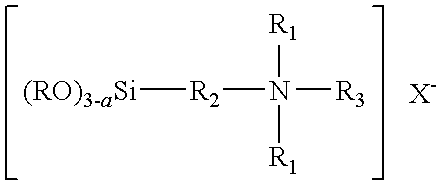

Stable aqueous solutions of silane quat ammonium compounds

InactiveUS20100028462A1Stable and long lifeEfficient use ofBiocideInorganic active ingredientsAmmonium compoundsSilanes

Stable aqueous compositions of silane quaternary ammonium compounds are provided by diluting an alkanol solution of the silane quaternary ammonium compound in water with at least one nonionic surfactant. The weight ratio of the silane quaternary ammonium compound and nonionic surfactant is provided to yield a composition which can remain stable in dilute aqueous compositions, can be applied to any surface and dry quickly to provide an anti-microbial film. The addition of an alkali metal bicarbonate salt to the composition improves the anti-microbial properties as well as the drying time of the composition.

Owner:CHURCH & DWIGHT CO INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com