Patents

Literature

717 results about "Lightfastness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lightfastness is a property of a colourant such as dye or pigment that describes how resistant to fading it is when exposed to light. Dyes and pigments are used for example for dyeing of fabrics, plastics or other materials and manufacturing paints or printing inks.

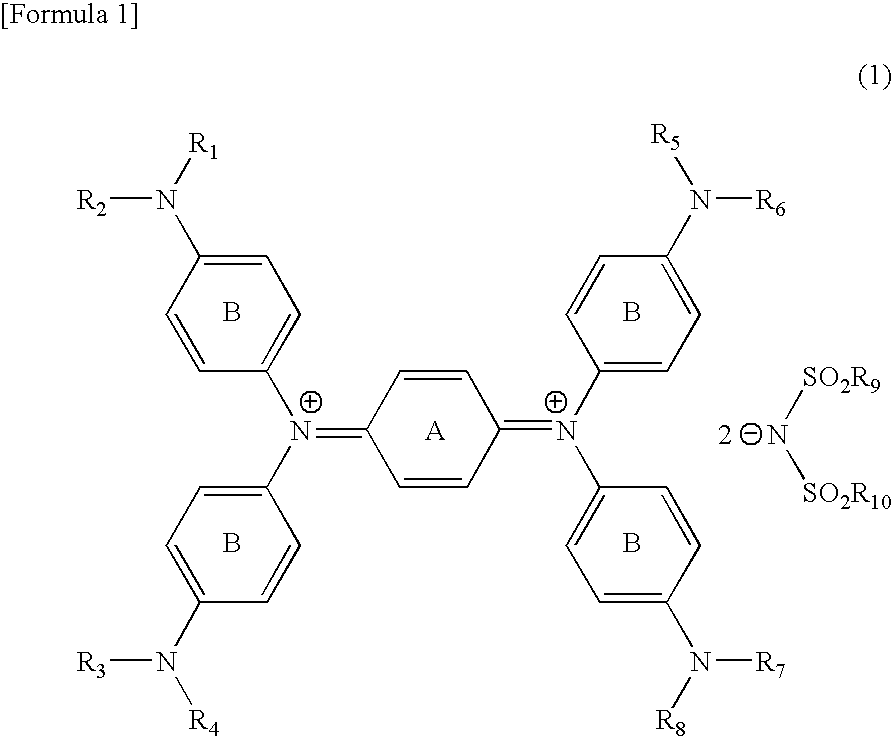

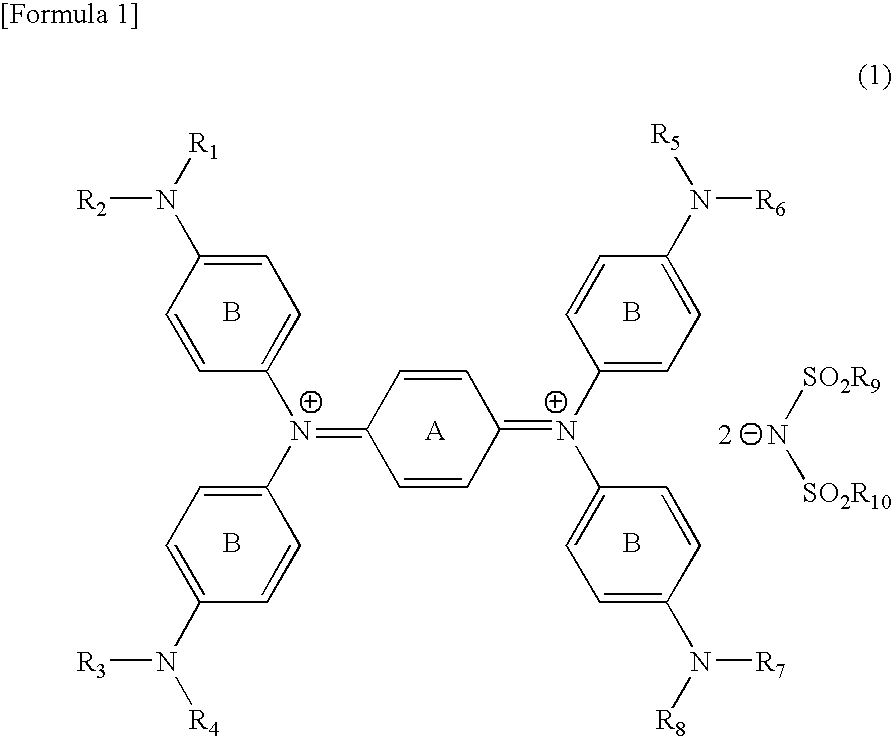

Diimmonium compound and use thereof

InactiveUS20050148786A1High visible light transmittanceHigh light transmittanceOrganic chemistryPhotomechanical apparatusInfraredAmmonium compounds

To provide a near-IR absorption compound free from antimony or arsenic and excellent in stability, especially, in heat resistance, light fastness, and moisture-and-heat resistance and also an IR absorption filter, an optical information recording medium, and a resin composition excellent in durability by using the near-IR absorption compound. The near-IR absorption compound is a diimmonium compound having the following structure and the resin composition contains the diimmonium compound: (wherein R1 to R8 independently denote hydrogen atom or an optionally substituted aliphatic hydrocarbon group; R9 and R10 independently denote an aliphatic hydrocarbon group optionally containing a halogen atom; and rings A and B may further have substituent groups.).

Owner:NIPPON KAYAKU CO LTD

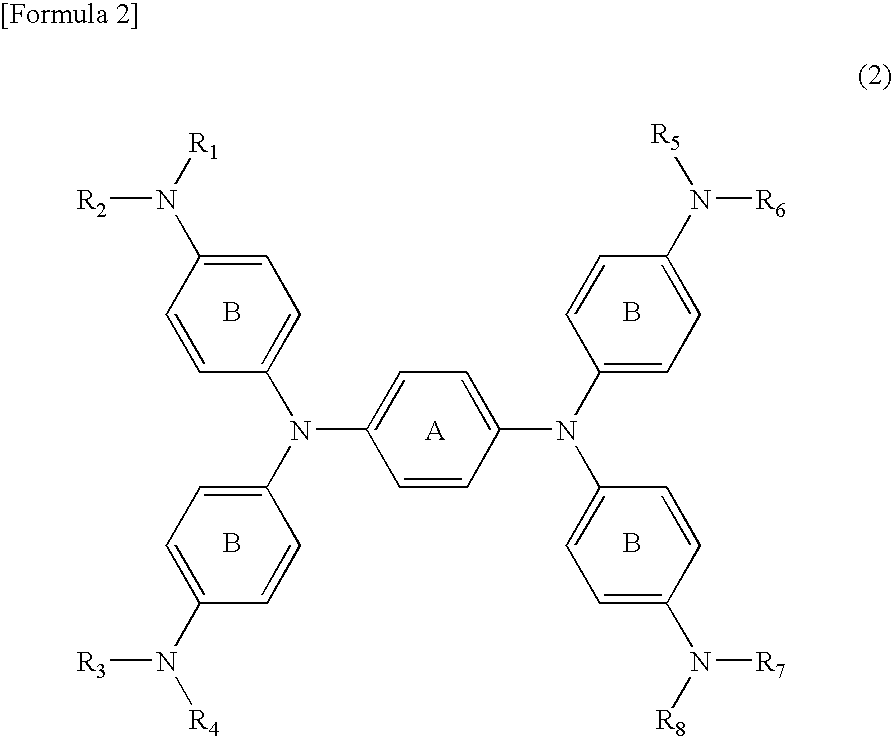

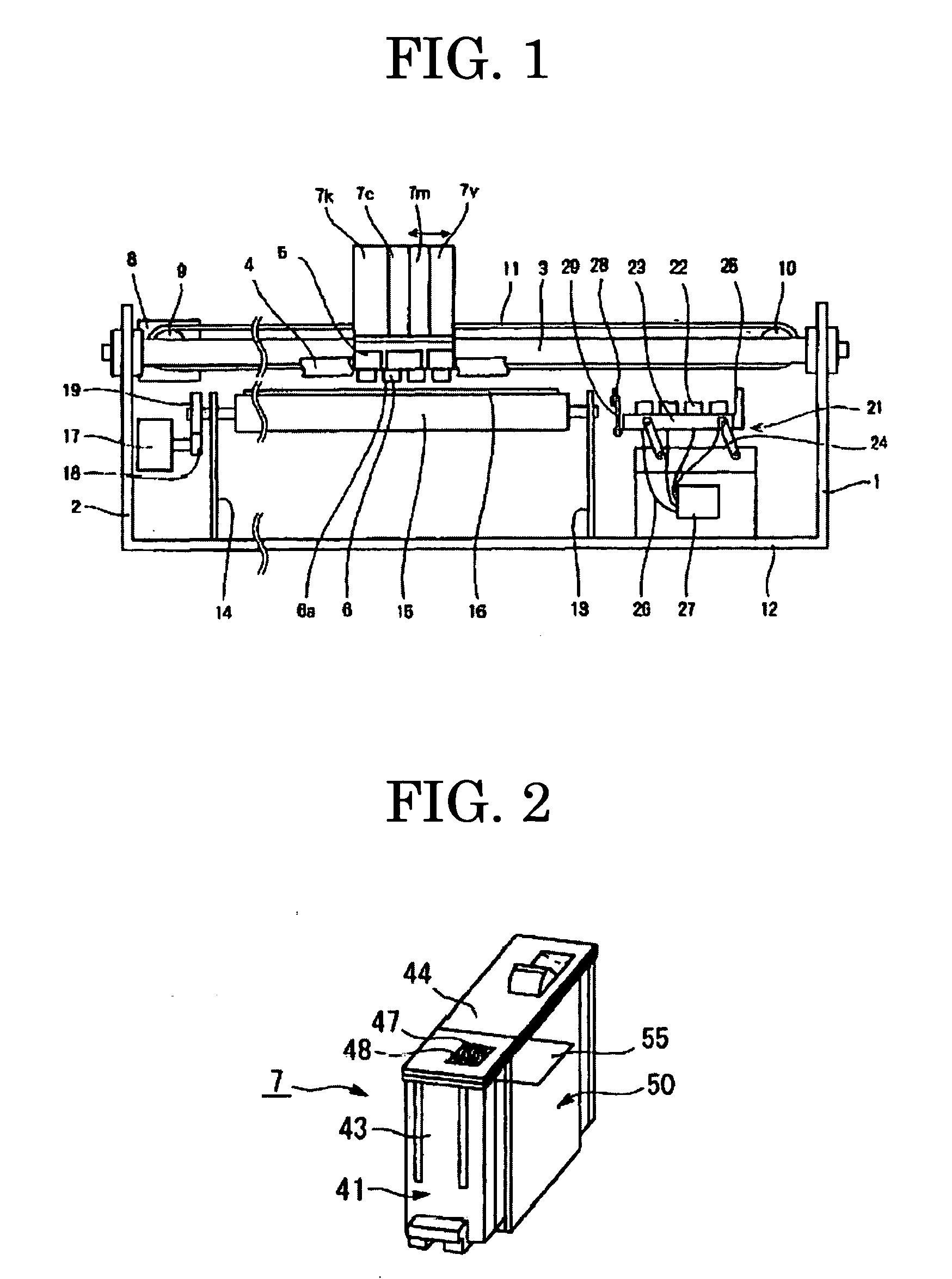

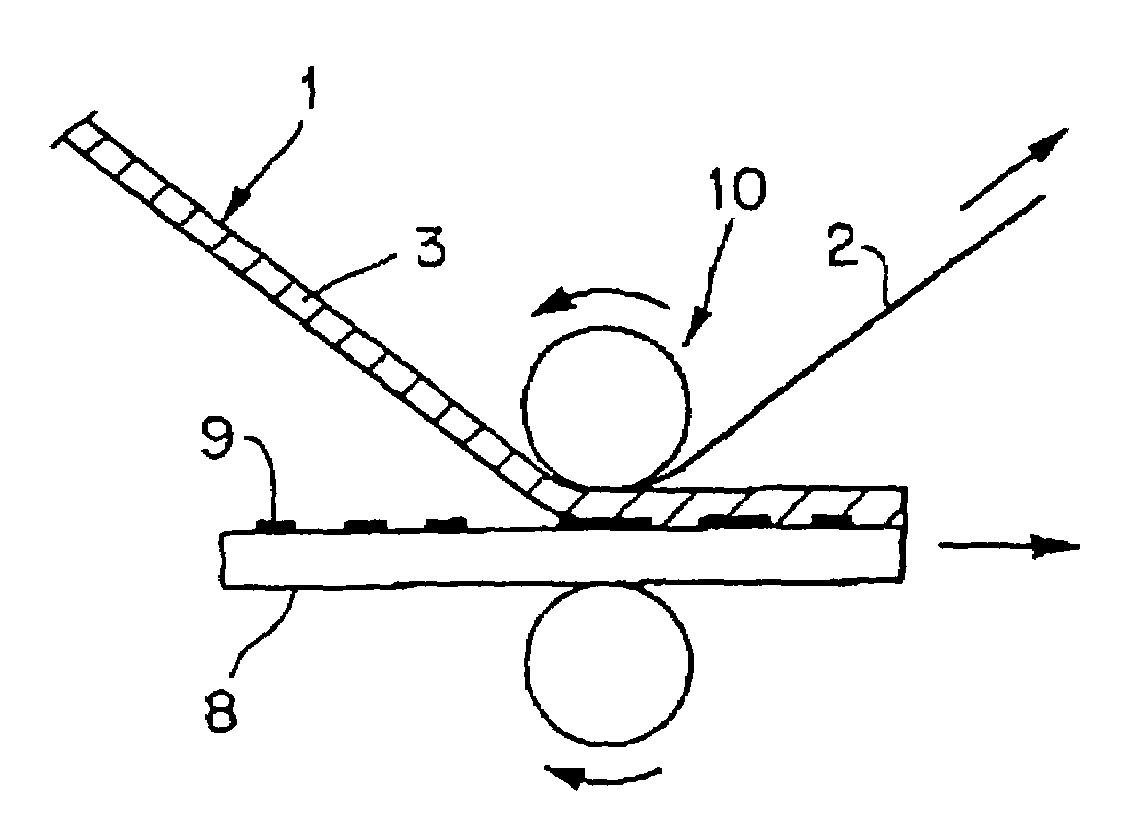

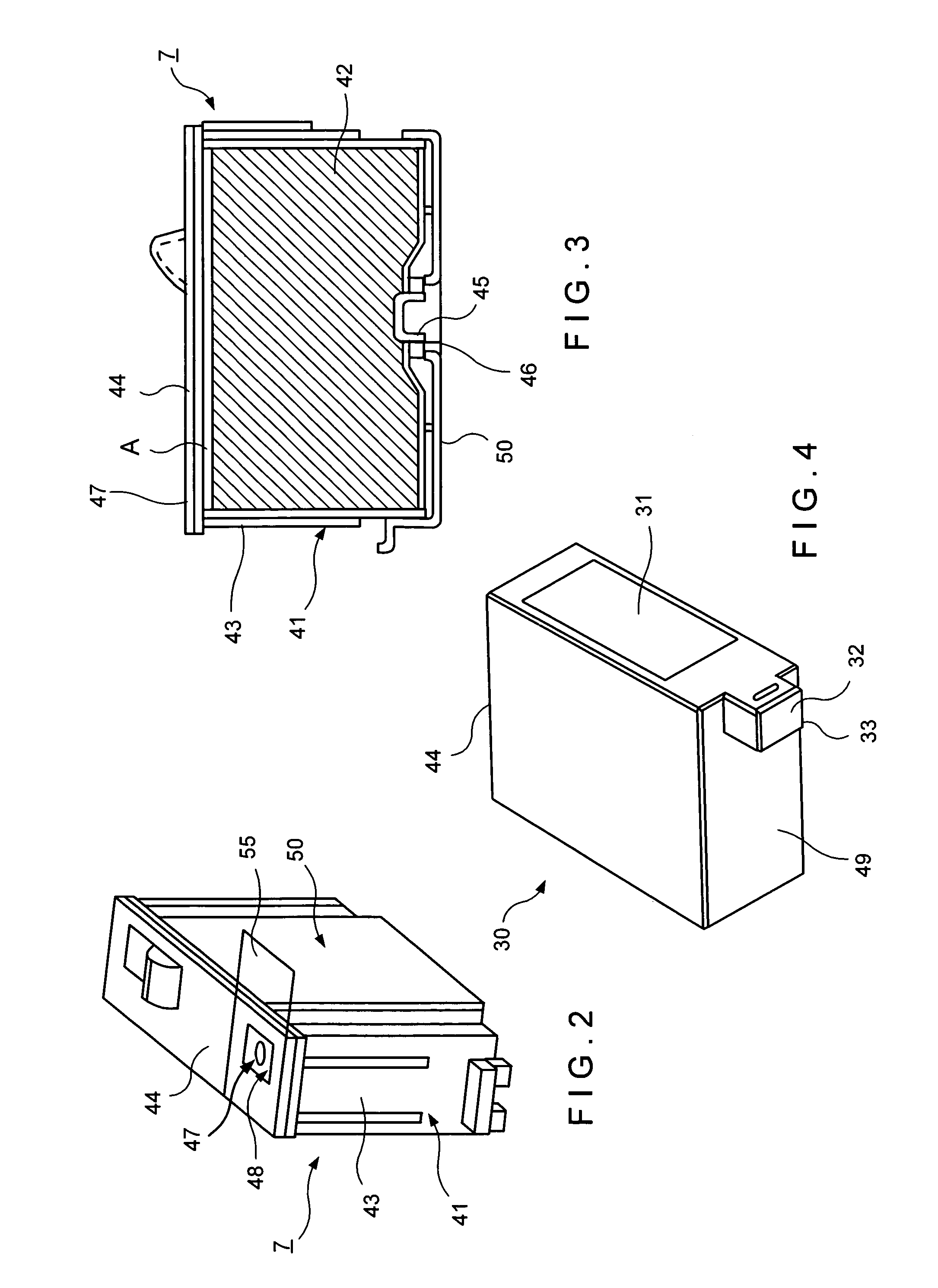

Ink-jet recording ink, ink-jet recording ink set, ink cartridge, ink-jet printer, and ink-jet printing method

An ink and ink set characterized in that both a combination of a specific wetting agent, penetrating agent, and water-soluble organic solvent and use of surfactant, particularly fluorine surfactant are enabled by using water dispersion in which polymer fine particles contain coloring material. Even when plain paper is printed at high speed by ink-jet recording by using this ink and ink set, the ink and ink set can realize a pigment ink for ink-jet recording, an ink set, an ink-jet recording method, ink cartridge, and recorder which have an excellent ejection stability and excellent preservability, and provide (1) good color tone, (2) high image density, (3) recorded image free of unsharpness near character or image and feathering and high in sharpness, (4) less boundary color bleedings between different colors, (5) image adaptable to both-side printing and causing less strike-throughs, and (6) image fastness such as water resistance and light resistance.

Owner:RICOH KK

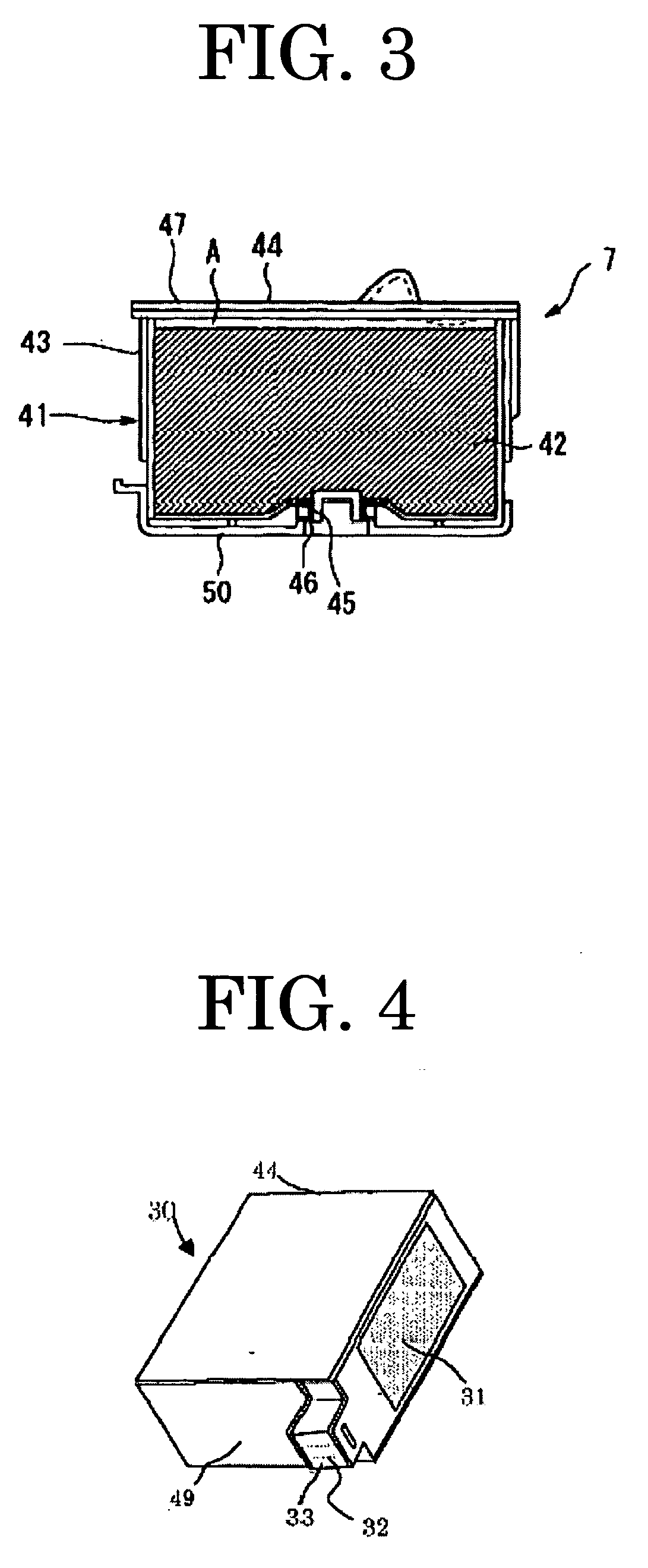

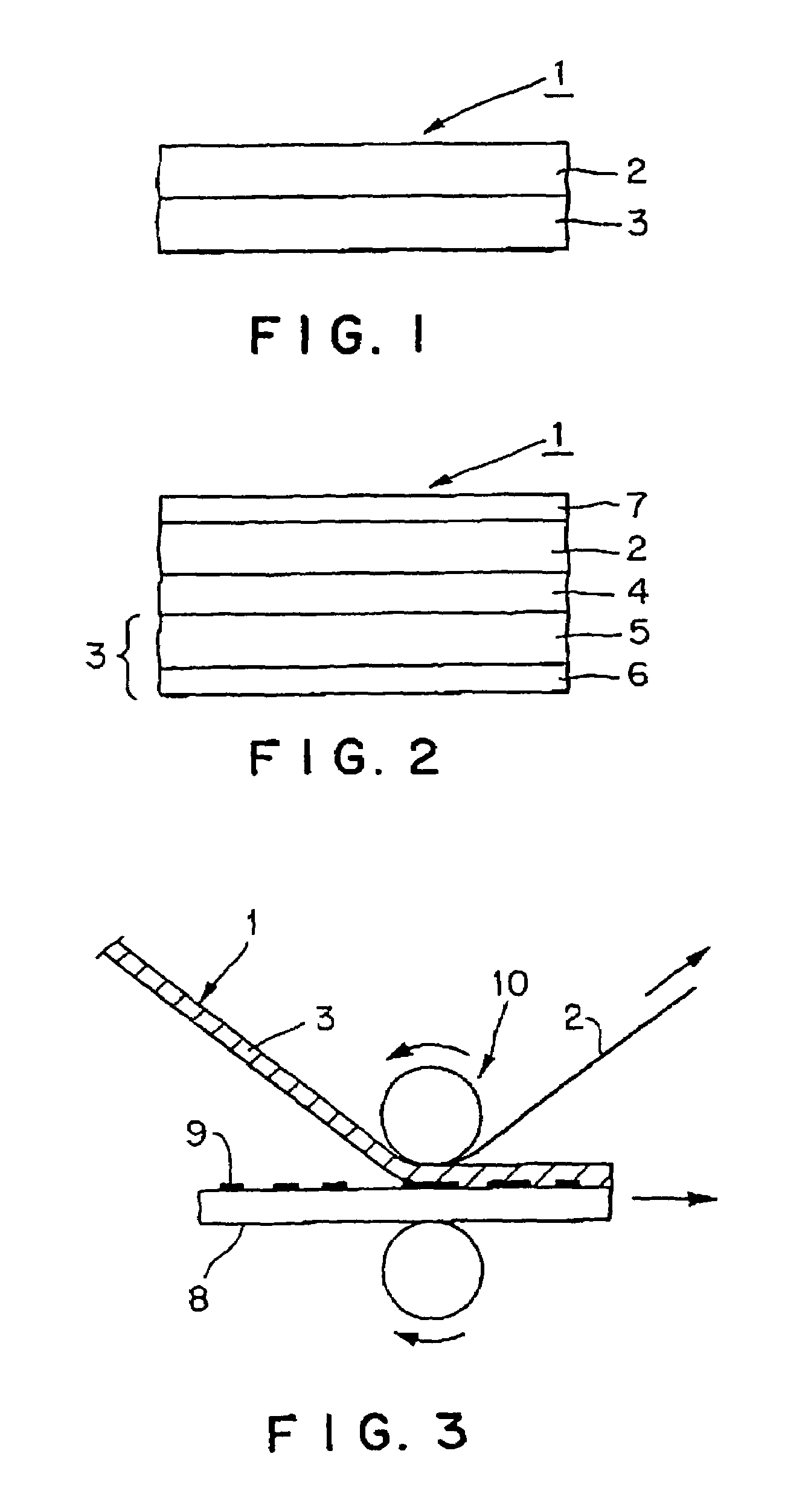

Thermally transferable image protective sheet, method for protective layer formation, and record produced by said method

InactiveUS7169546B2High fastnessIncrease resistancePhotography auxillary processesRadiation applicationsAngle of incidenceLightfastness

Disclosed are a thermally transferable image protective sheet and a method for protective layer formation that can provide a protective layer which can protect an image of a record produced by a nonsilver photographic color hard copy recording method, can impart lightfastness and other properties to the record, and can realize a record having a glossy impression comparable to silver salt photographs. The thermally transferable image protective sheet comprises a support and a thermally transferable resin layer having a single-layer or multilayer structure stacked on the support so as to be separable from the support. The thermally transferable image protective sheet has been constructed so that, when the thermally transferable image protective sheet is put on top of a print so as for the thermally transferable resin layer to be brought into contact with an image portion in the print and the thermally transferable resin layer is thermally transferred to cover at least the image portion of the print followed by the separation of the support from the thermally transferable image protective sheet to form a thermally transferred resin layer on the surface of the print, the surface of the thermally transferred resin layer on the print has a specular glossiness of not less than 60% as measured at an angle of incidence of 20 degrees according to JIS (Japanese Industrial Standards) Z 8741.

Owner:DAI NIPPON PRINTING CO LTD

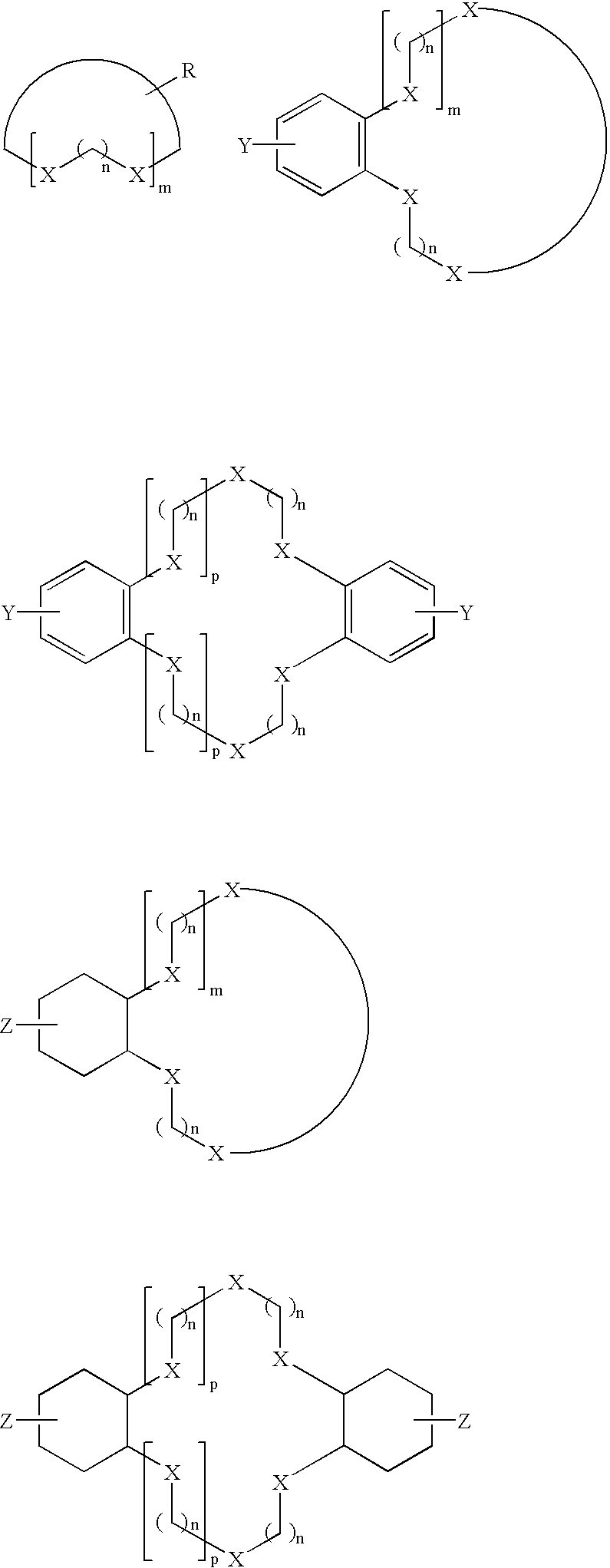

Thermoplastic fibers exhibiting durable high color strength characteristics

InactiveUS6849330B1Reduce extractionQuick and efficient changeoverFireproof paintsSynthetic resin layered productsYarnPolymer science

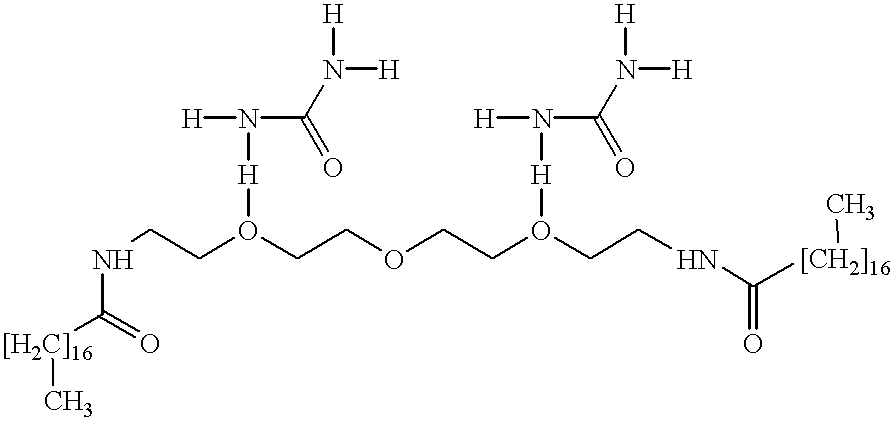

Improvements in permitting brighter colorations within polypropylene fibers and / or yarns while simultaneously providing more efficient production methods of manufacturing of such colored fibers as well are provided. Generally, such fibers and / or yarns have been colored with pigments, which exhibit dulled results, or dyes, which exhibit high degrees of extraction and low levels of lightfastness. Such dull appearances, high extraction levels, and less than stellar lightfastness properties negatively impact the provision of such desirable colored polypropylene fibers and / or yarns which, in turn, prevents the widespread utilization of such fibers and yarns in various end-use applications. Thus, it has surprisingly been determined that brighter colorations, excellent extraction, and more-than-acceptable lightfastness characteristics can be provided, preferably, through manufacture with certain polymeric colorants that include poly(oxyalkylene) groups thereon. Fabric articles comprising such novel fibers and / or yarns are also encompassed within this invention.

Owner:MILLIKEN & CO

Ink compositions

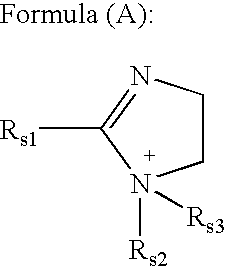

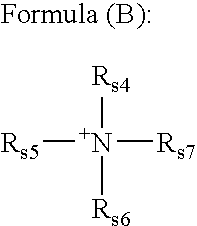

An aqueous ink composition comprised of (1) a quaternary compound selected from the group consisting of (a) imidazolinium quaternary salts, (b) phosphonium quaternary salts, and (c) an ammonium quaternary salt; (2) a liquid ink vehicle; (3) a paper-curl reducing compound; (4) a lightfastness component; (5) a lightfastness antioxidant; (6) a substantially water soluble organic salt or a substantially water soluble inorganic salt; (7) a biocide; and (8) a colorant.

Owner:XEROX CORP

White color reflecting material and process for production thereof

ActiveUS20120138997A1Improve heat resistanceImprove light resistanceDiffusing elementsSolid-state devicesUltravioletRutile

A general-use white color reflecting material, and a process for production thereof are provided. The white color reflecting material, without troublesome surface treatment such as formation of a reflective layer by plating, is capable of reflecting a near-ultraviolet ray of a wavelength region of 380 nm or longer or a near-infrared ray sufficiently without light leakage; does not become yellow even when exposed to near-ultraviolet rays; has excellent lightfastness, heat resistance, and weatherability; has high mechanical strength and chemical stability; is capable of maintaining a high degree of whiteness; and is easily moldable at a low cost. Further a white color reflecting material used as an ink composition for producing the white color reflecting material in a film shape is also provided. The white color reflecting material comprises; a silicone resin or silicone rubber formed from titanium oxide-containing silicone composition, in which anatase-type or rutile-type titanium oxide particles are dispersed.

Owner:ASAHI RUBBER

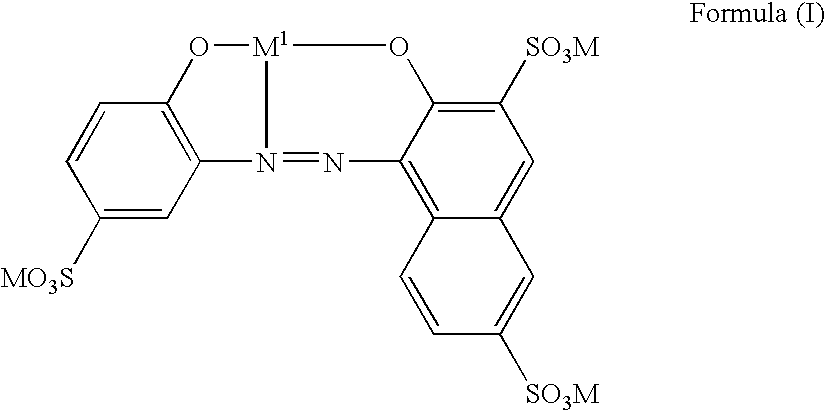

Inkjet ink, dye set, ink set, and method of use thereof

InactiveUS6843838B2Excellent photo-realistic print qualityImprove the level ofMeasurement apparatus componentsInksYELLOW DYEXanthene dye

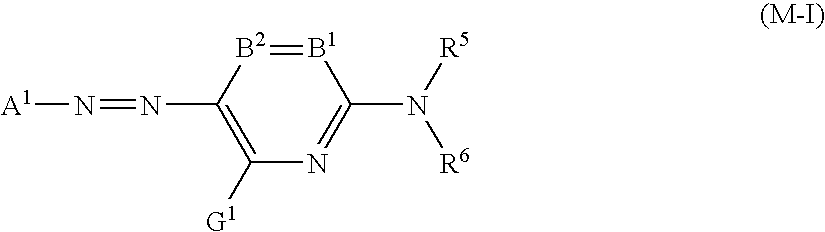

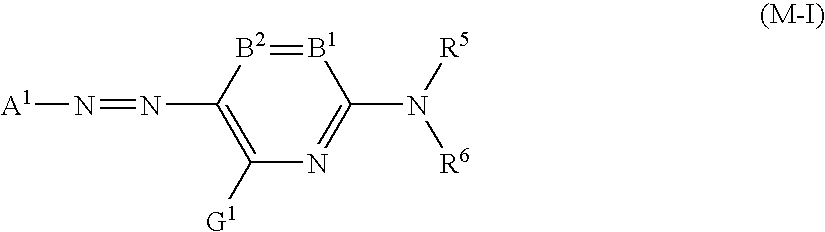

The present invention provides inkjet inks, dye sets, and inkjet ink sets for use in inkjet printing methods. The inkjet inks and inkjet ink sets of the present invention can provide excellent photo-realistic print quality while achieving a high level of lightfastness. The inkjet ink comprises: a xanthene dye, and a metallized azo dye having the Formula (I). The inkjet ink set comprises: a magenta dye set comprising a xanthene dye, and a metallized azo dye having the Formula (I), at least one yellow ink comprising at least one yellow dye, and at least one cyan ink comprising at least one cyan dye. The present invention also provides a method of printing using the inkjet ink set of the present invention.

Owner:BRADY JOHN A +1

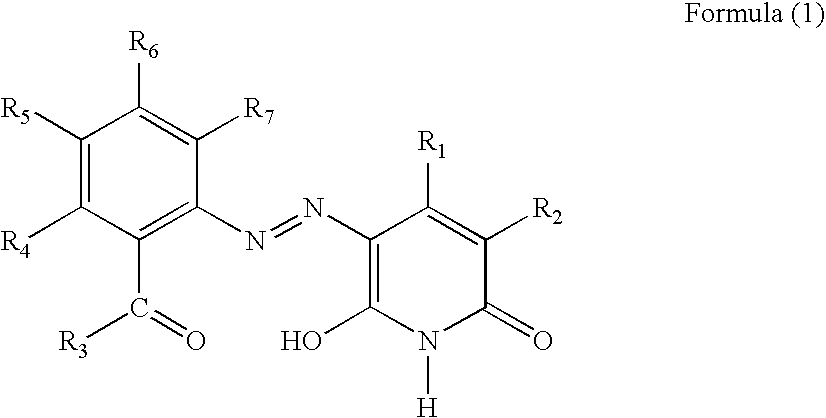

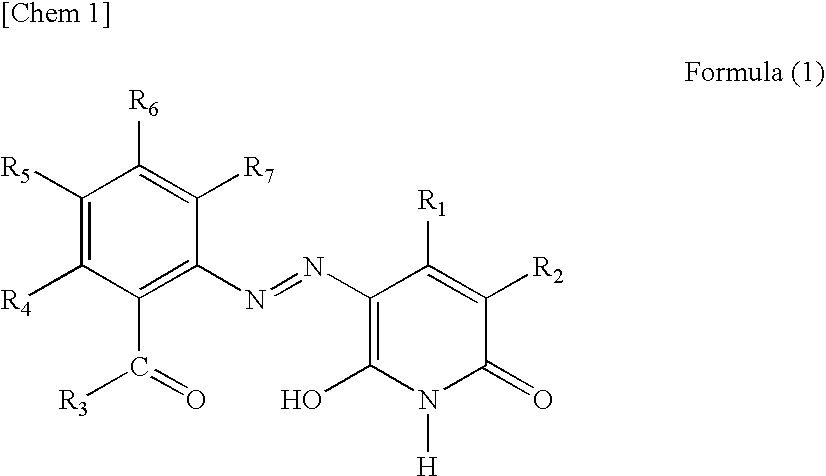

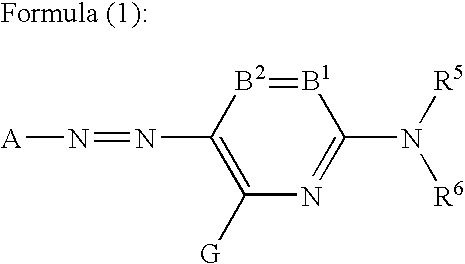

Coloring compound and yellow toner containing the coloring compound

Provided are a coloring compound for color toner which satisfies all of solubility in an organic solvent, a color tone, and lightfastness, and does not inhibit the polymerization of a polymerizable monomer when used in a polymerized toner, and a yellow toner using the coloring compound and achieving compatibility between a good color tone and excellent lightfastness, in which, the coloring compound has a structure represented by the following formula (1).

Owner:CANON KK

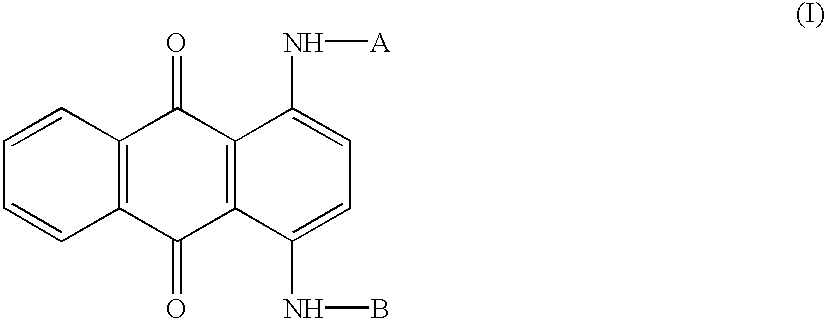

Articles comprising novel polymeric blue anthraquinone-derivative colorants

A blue colorant comprising a chromophore having at least one poly(oxyalkylene) chain attached, through aromatic amino group (or groups), to the 1-position, the 4-position, or both, of an anthraquinone backbone is provided. Such colorants exhibit excellent amine / base stability and thermal stability, effective colorations, excellent low extraction rates, and high lightfastness levels, particularly when incorporated within certain media and / or on the surface of certain substrates, particularly polyesters, polyolefins, and polyurethanes. The poly(oxyalkylene) chain or chains can be conveniently tailored to increase the solubility or compatibility in different solvents or resins thereby permitting the introduction of such excellent coloring chromophores within diverse media and / or or diverse substrates as well as provides a liquid colorant which facilitates handling. Compositions and articles comprising such colorants are provided as well as methods for producing such inventive colorants.

Owner:MILLIKEN & CO

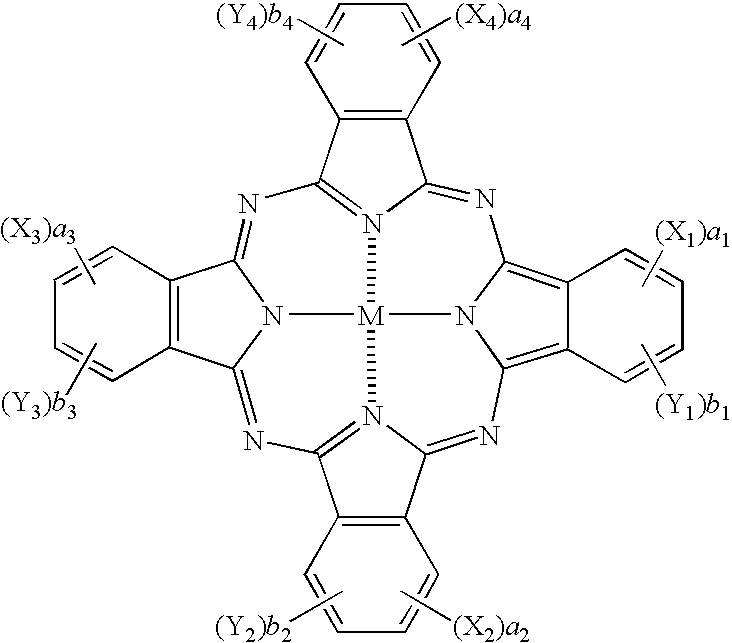

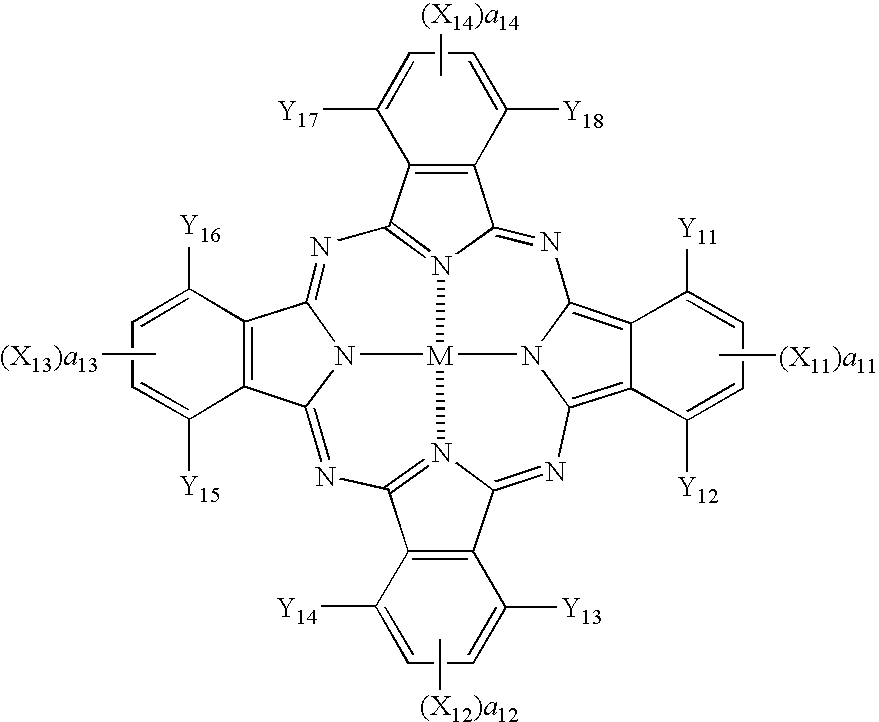

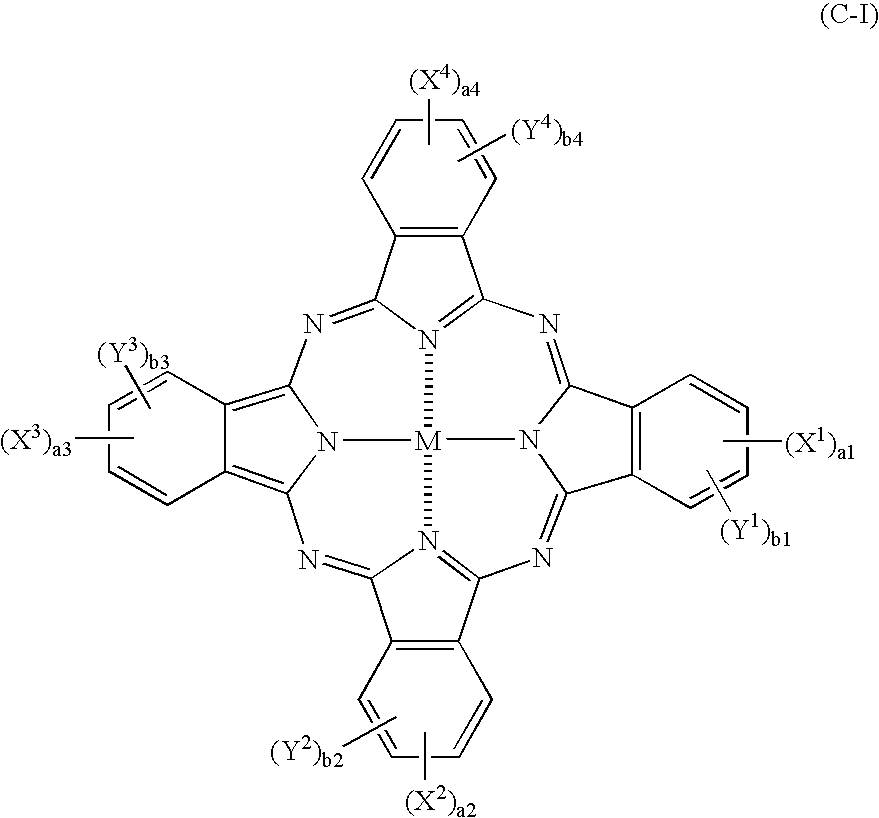

Phthalocyanine compound, ink, inkjet recording ink, ink-jet recording method and method for improving ozone gas resistance of color image material

InactiveUS7087107B2Excellent toneHigh fastnessLiquid surface applicatorsMeasurement apparatus componentsColor imagePhthalocyanine

According to the present invention, a novel phthalocyanine compound having a specific structure is provided, and an ink, an inkjet recording ink, an inkjet recording method and a method for improving preservability of a formed image, each using the compound, are also provided. The novel phthalocyanine compound of the present invention has a sufficiently high fastness to light, heat, humidity and active gases in the environment and by using an ink, particularly inkjet recording ink, containing the phthalocyanine compound, an image having high fastness to light and ozone gas in the environment can be formed.

Owner:FUJIFILM CORP

Ink set for ink jet recording and method for ink jet recording

InactiveUS20090169834A1Enhance the imageExcellent in lightfastnessMeasurement apparatus componentsDecorative surface effectsHueLightfastness

Disclosed is a five-color ink set for ink jet recording, which can realize good images excellent in lightfastness and waterfastness, as well as particularly in hue. The five-color ink set for ink jet recording comprises a cyan ink composition, a magenta ink composition, a yellow ink composition, a green ink composition and an orange ink composition, wherein the cyan ink composition comprises C.I. Pigment Blue 15: 3 or C.I. Pigment Blue 15: 4, the magenta ink composition comprises C.I. Pigment Red 122, C.I. Pigment Red 202, C.I. Pigment Red 209 or C.I. Pigment Violet 19, the yellow ink composition comprises C.I. Pigment Yellow 213, the green ink composition comprises C.I. Pigment Green 7 or C.I. Pigment Green 36, and the orange ink composition comprises C.I. Pigment Orange 64, C.I. Pigment Orange 43 or C.I. Pigment Orange 71.

Owner:SEIKO EPSON CORP

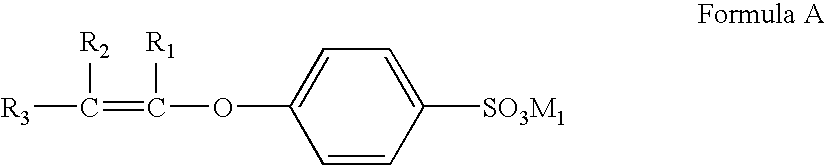

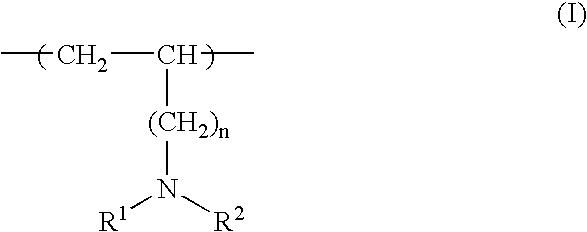

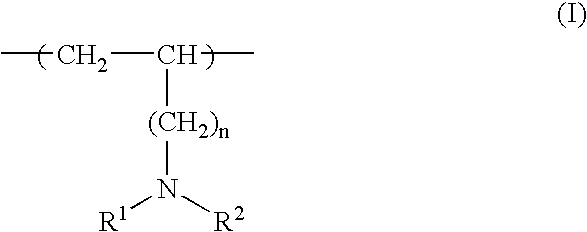

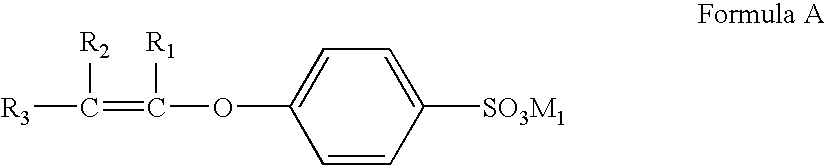

Ink composition comprising cationic, water-soluble resin

A composition, for ink jet recording, containing a cationic, water-soluble resin comprising a repeating unit represented by the following formula (I) can realize an image possessing excellent waterproofness and lightfastness and having no significant feathering or bleeding, especially no significant color-to-color bleeding:wherein R<1 >and R<2 >which may be the same or different represent a hydrogen atom or a C1-5 alkyl group, provided that R<1 >and R<2 >do not simultaneously represent a hydrogen atom; and n is 0, 1, or 2.

Owner:SEIKO EPSON CORP

Ink compositions

An ink composition containing (1) a complex mixture of a urea compound and an alkylene oxide containing oxyalkylene compound wherein the conductive mixture optionally possesses a melting point of from about 60 to about 120° C.; (2) a polymeric binder with an optional melting point of from about 60 to about 115° C.; (3) a lightfastness component; (4) a lightfast antioxidant, and (5) a colorant.

Owner:XEROX CORP

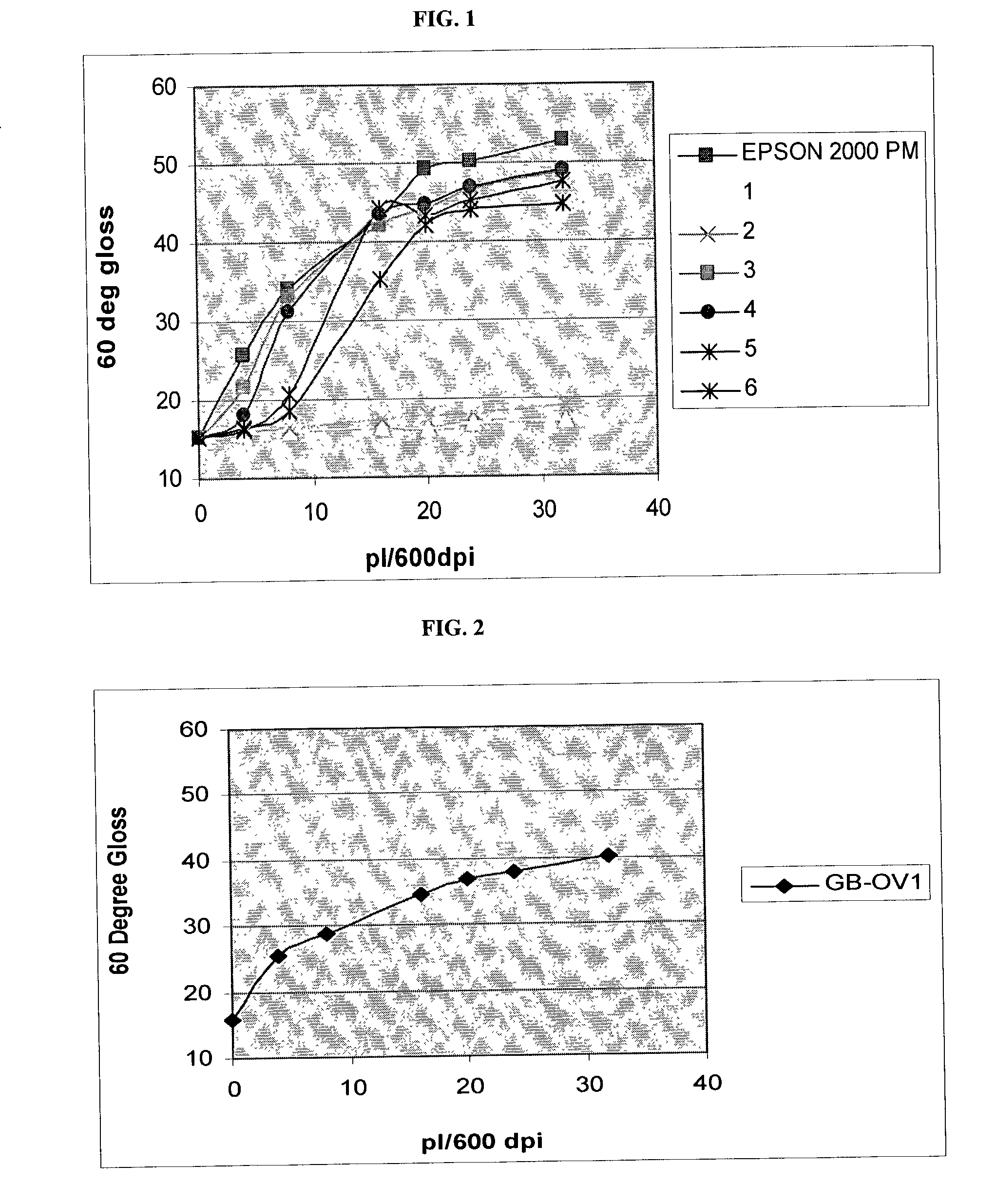

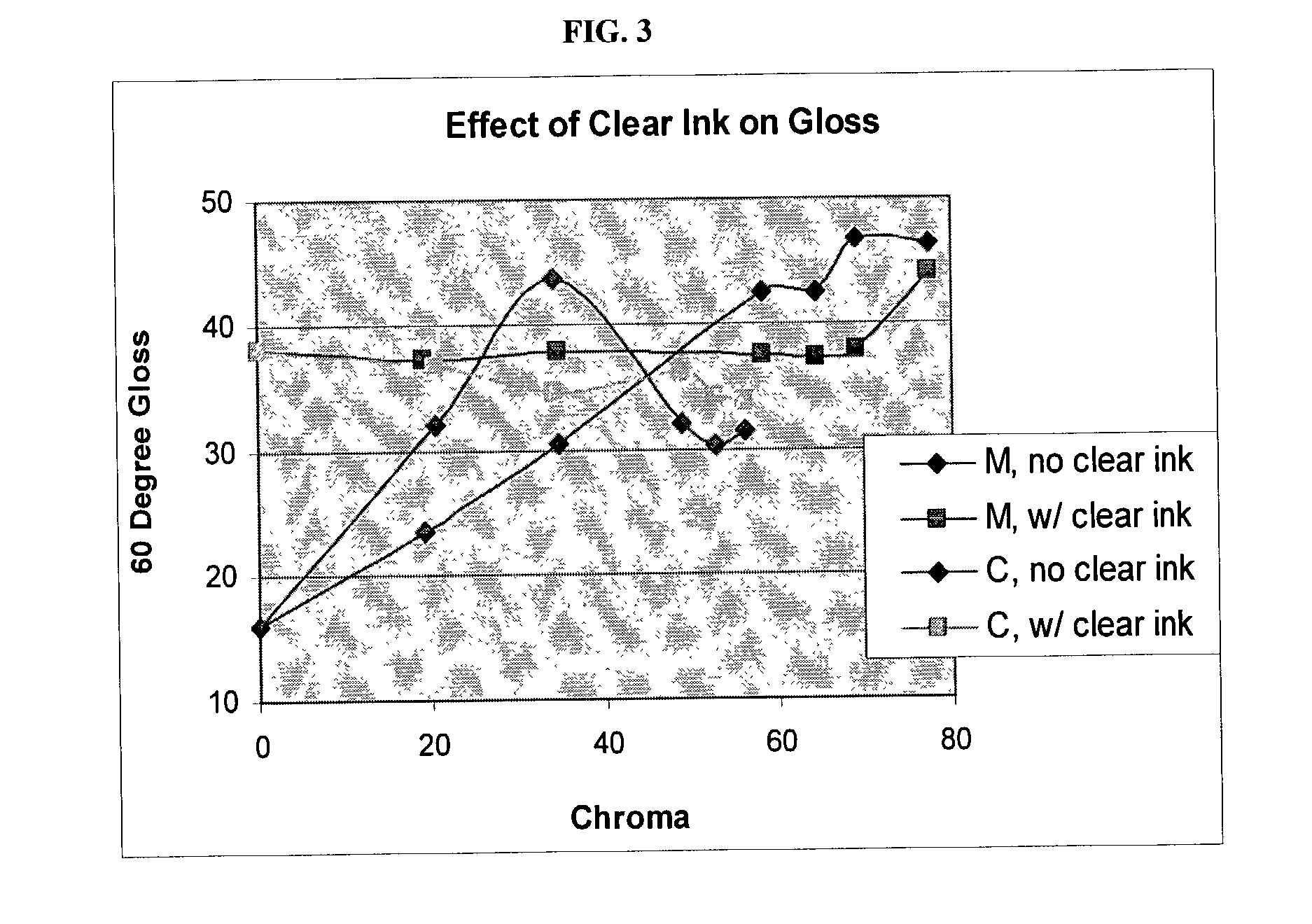

Colorless inkjet ink compositions for improved image quality

InactiveUS20040030001A1Fast ink dryingMaintaining light fastness fastnessMeasurement apparatus componentsDuplicating/marking methodsPolymer scienceImaging quality

A colorless ink jet ink composition is provided for printers for printing on both porous and hybrid glossy or semi-glossy media. The ink composition comprises a water soluble polymer or dispersed latex. The ink formulation provides substantially air fast, stain resistant, and light fastness to the printed image. Further, the ink formulation evidences improved overall image quality.

Owner:HEWLETT PACKARD DEV CO LP

Ink, recording method, recording unit, ink cartridge, ink set, and recording apparatus

InactiveUS6843839B2Excellent toneIncreased durabilityMonoazo dyesOrganic chemistryWater basedImage density

Magenta ink exhibiting excellent coloration on various recording materials is provided according to the present invention. The magenta ink can realize high image densities and can produce images having superior light resistance. The magenta ink contains first and second coloring materials represented by the following general formulae 1 and 2, respectively, and a water-based medium

Owner:CANON KK

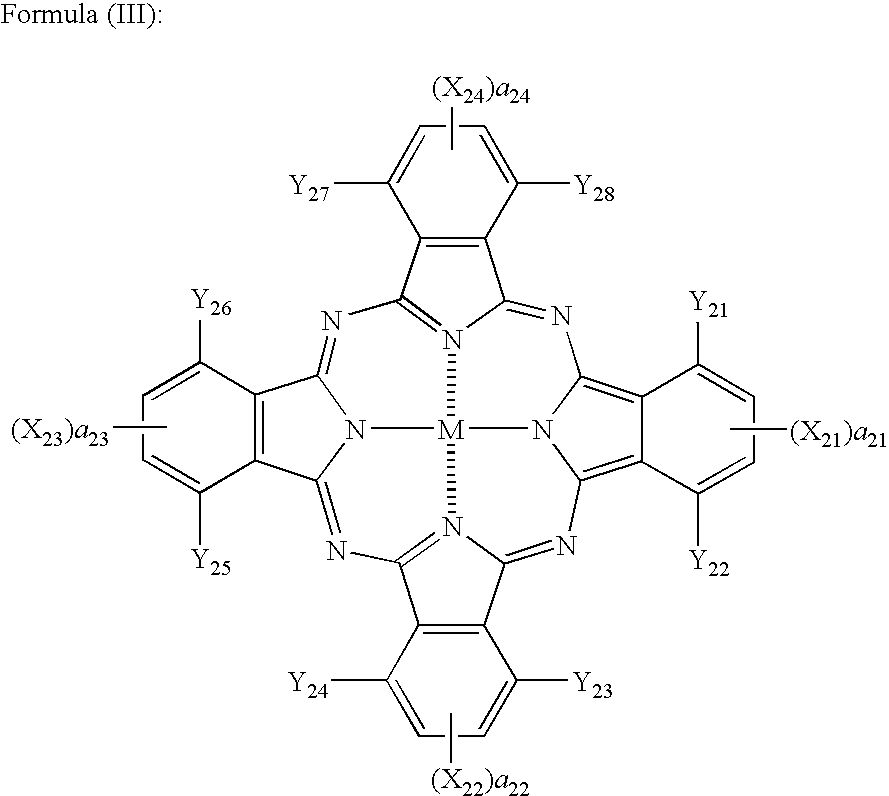

Ink jet ink, ink jet recording method, ink cartridge, recording unit and ink jet recording apparatus

InactiveCN101298526AExcellent toneGood light fastnessDuplicating/marking methodsInksLightfastnessMagenta

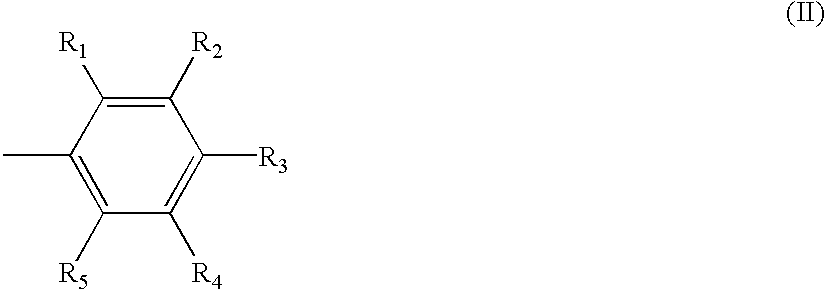

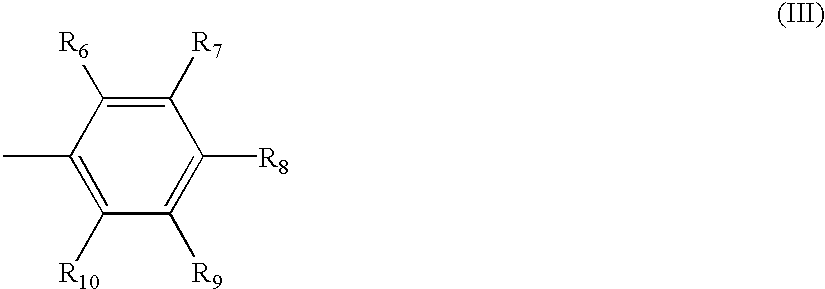

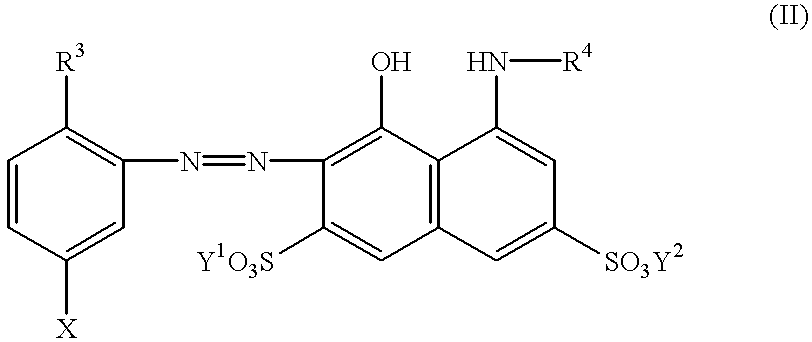

The present invention provides an ink jet ink having a magenta color which gives an image excellent in magenta color tone and also excellent in image fastness (lightfastness and gas resistance). The ink jet ink includes a first coloring material that is an anthrapyridone compound having a structure represented by general formula (I) and / or general formula (II) and a second coloring material that is an azo compound having a structure represented by general formula (III), wherein the mass ratio of the content of the first coloring material to the content of the second coloring material is from 2.5 or more to 10.0 or less.

Owner:CANON KK

Ink jet ink, ink jet recording method, ink cartridge, recording unit and ink jet recording apparatus

ActiveUS7618484B2Good colorExcellent in lightfastnessMonoazo dyesMeasurement apparatus componentsMagentaLightfastness

The present invention provides an ink jet ink having a magenta color which gives an image excellent in magenta color tone and also excellent in image fastness (lightfastness and gas resistance). The ink jet ink includes a first coloring material that is an anthrapyridone compound having a structure represented by general formula (I) and / or general formula (II) and a second coloring material that is an azo compound having a structure represented by general formula (III), wherein the mass ratio of the content of the first coloring material to the content of the second coloring material is from 2.5 or more to 10.0 or less.

Owner:CANON KK

Dye set for improved color quality for ink-jet printers

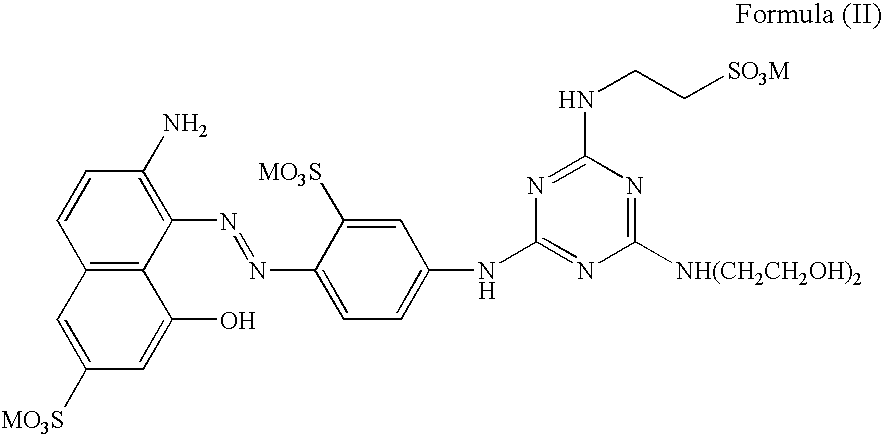

In accordance with the invention inks suitable for use in ink-jet printers and method for using the same are provided. More particularly, inks comprising the present dye set exhibits excellent color performance and lightfastness across a range of media. Furthermore, the dye set enables good reliability in an environment having a relatively high concentration of precipitating agents. This reliability enables the use of precipitation bleed control mechanisms. More specifically, a specific dye set for formulating the yellow, magenta, and cyan inks is disclosed, comprising Acid Yellow 17 and a yellow dye according to Formula I; Acid Red 52 and a magenta dye according to Formula II; and Direct Blue 199 and Acid Blue 9; respectively.

Owner:HEWLETT PACKARD CO

Ink-jet recording ink, ink-jet recording ink set, ink cartridge, ink-jet printer, and ink-jet printing method

Owner:RICOH KK

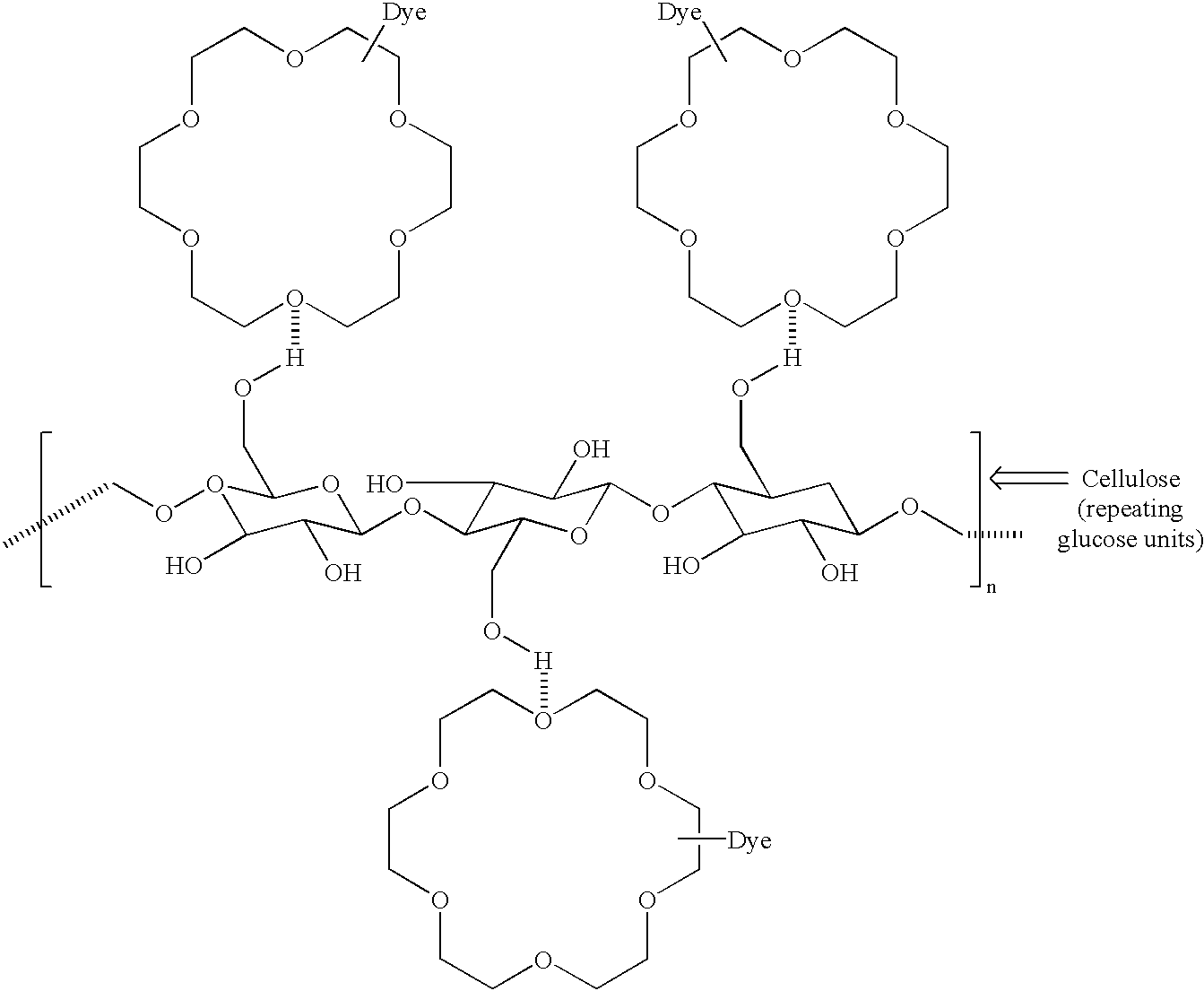

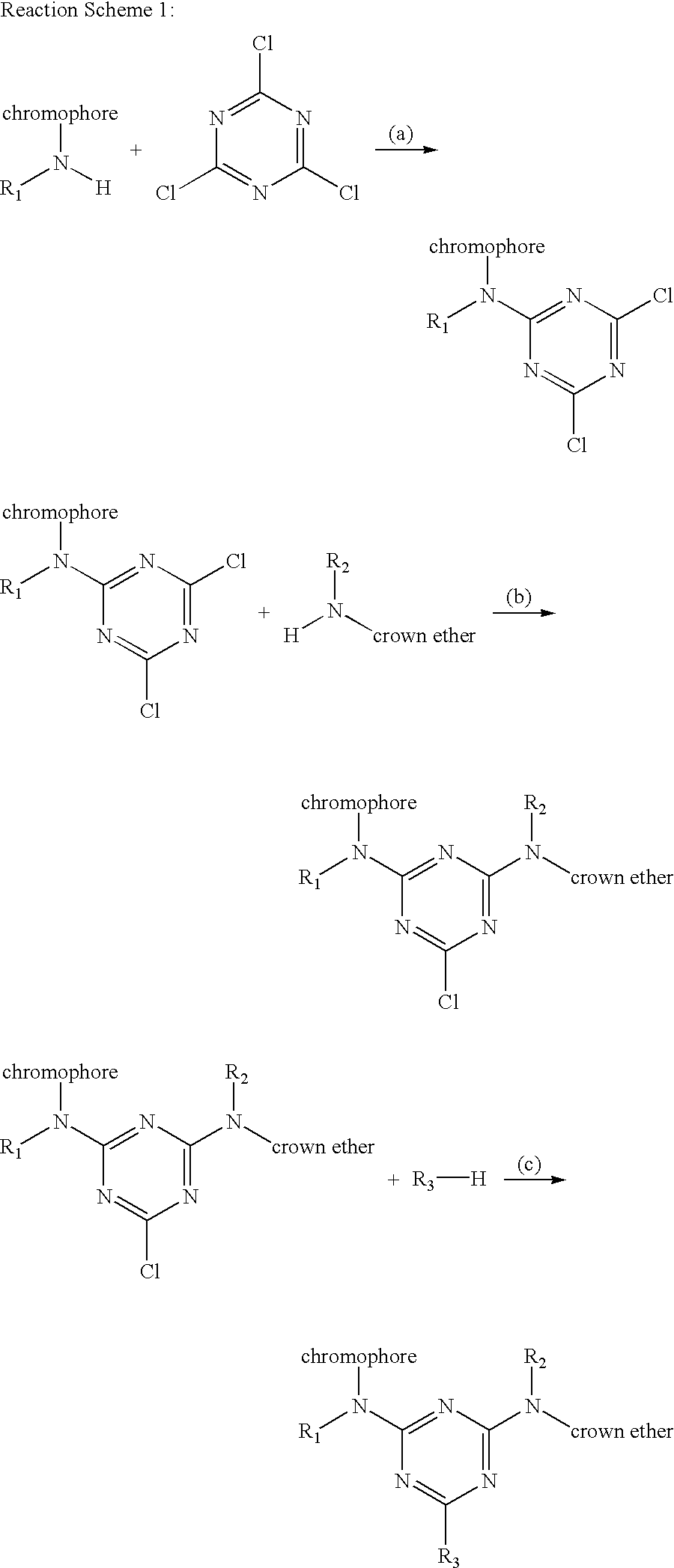

Derivatization of dyes/pigments with crown ethers and inkjet printing fluids containing the same

InactiveUS20020144626A1Improved lightfastnessImproved smearfastnessInksOrganic dyesDisperse dyeOrganic solvent

An inkjet ink is provided that employs one or more water-soluble colorants or water-insoluble colorants, such as solvent dyes, disperse dyes, or pigments. The colorant, whether water-soluble or water-insoluble, is derivatized with one or more crown ethers to render the water-insoluble colorants soluble in water and in water-miscible organic solvents commonly employed in inkjet printing, particularly thermal inkjet printing, and to impart improved properties to the colorants, such as lightfastness, smearfastness, and waterfastness. The inkjet ink comprises a vehicle and at least one crown ether derivatized colorant. The resulting inkjet ink evidences improved print quality properties, compared to inkjet inks containing colorants that are not so derivatized.

Owner:HEWLETT PACKARD DEV CO LP

Encapsulating composition for LED

An organopolysiloxane composition which cures to a resinous solid has high strength, transparency, and resistance to thermal- and photo-degradation, and is especially suited for encapsulating LEDs. The composition contains specific addition curable organopolysiloxanes having D, T, and Q units, and a proportion of silicon-bonded aromatic groups.

Owner:WACKER CHEM GMBH

Ink and ink set for ink jet printing and method of ink jet printing

InactiveUS20050178288A1Improve spraying effectFastness to light and heatInksPorphines/azaporphinesCyanineHeat resistance

An inkjet recording ink composition comprising an aqueous medium having dissolved and / or dispersed therein at least one dye, wherein at least one betaine-type surfactant is contained in the ink composition. The dye used is preferably a magenta dye having a specific azo structure or a cyanine dye having a specific phthalocyanine structure. By virtue of such a constitution, an inkjet recording ink composition excellent in ejection property, light fastness, heat fastness and oxidation resistance and causing less dye bleeding can be provided.

Owner:FUJIFILM HLDG CORP +1

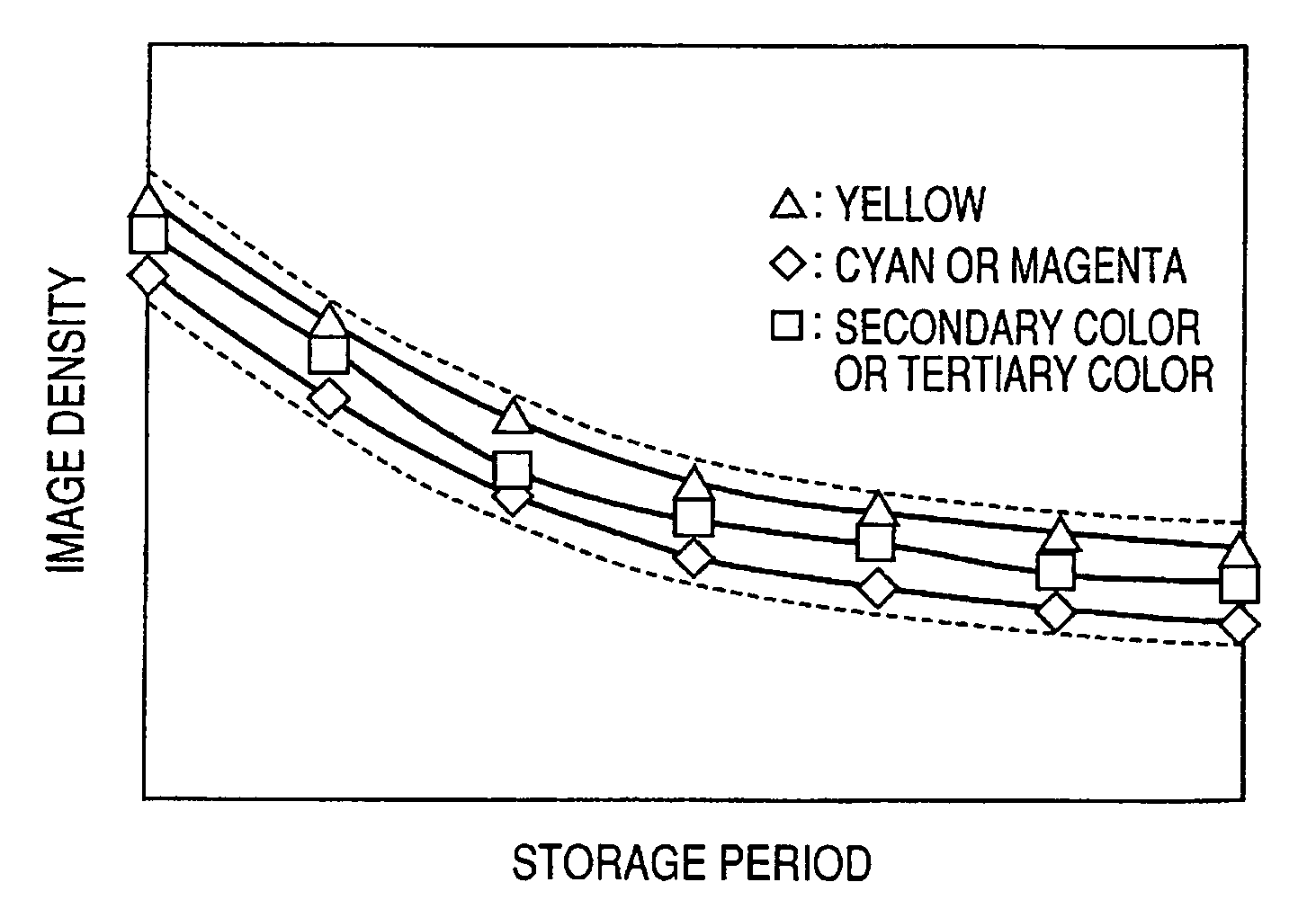

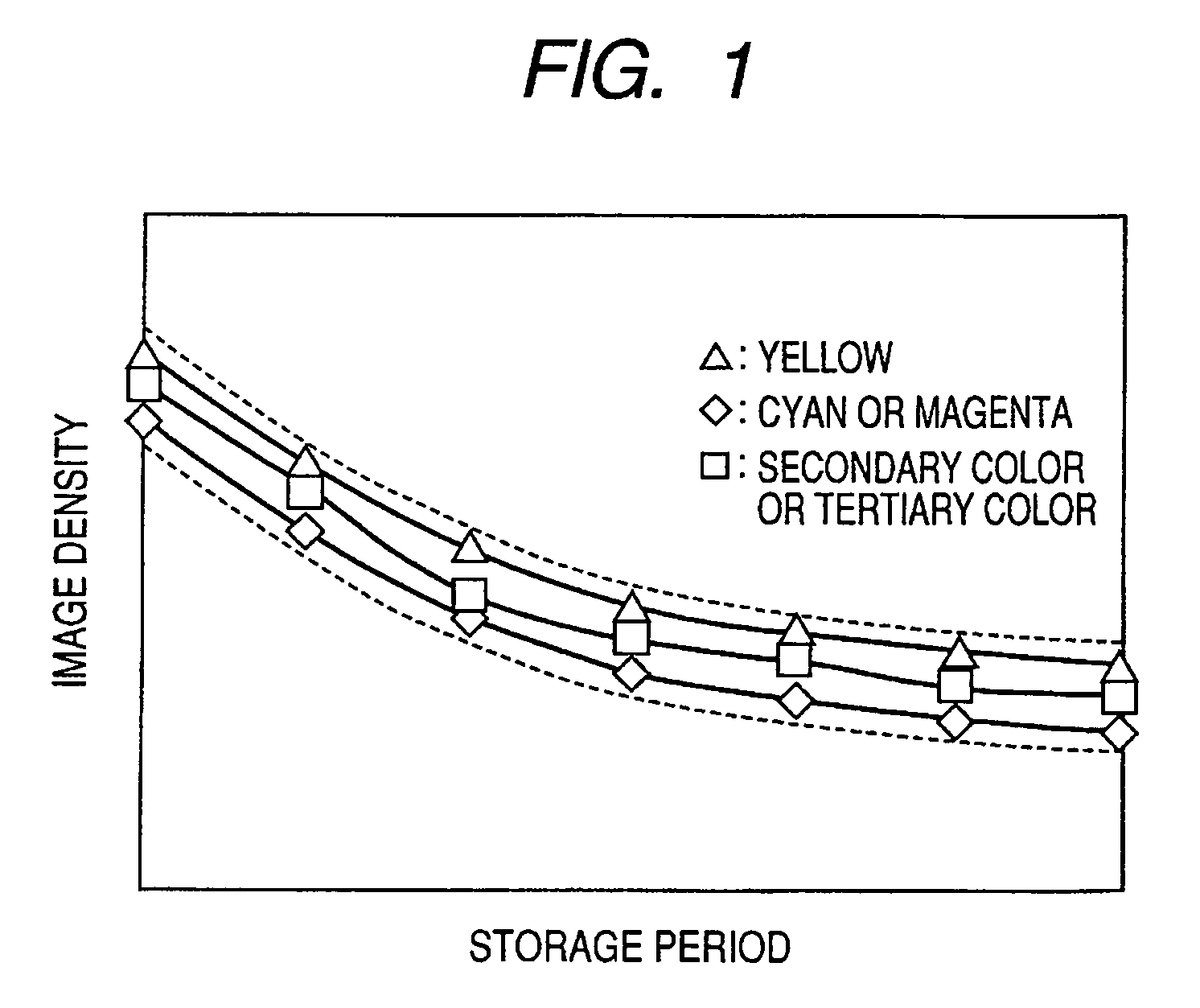

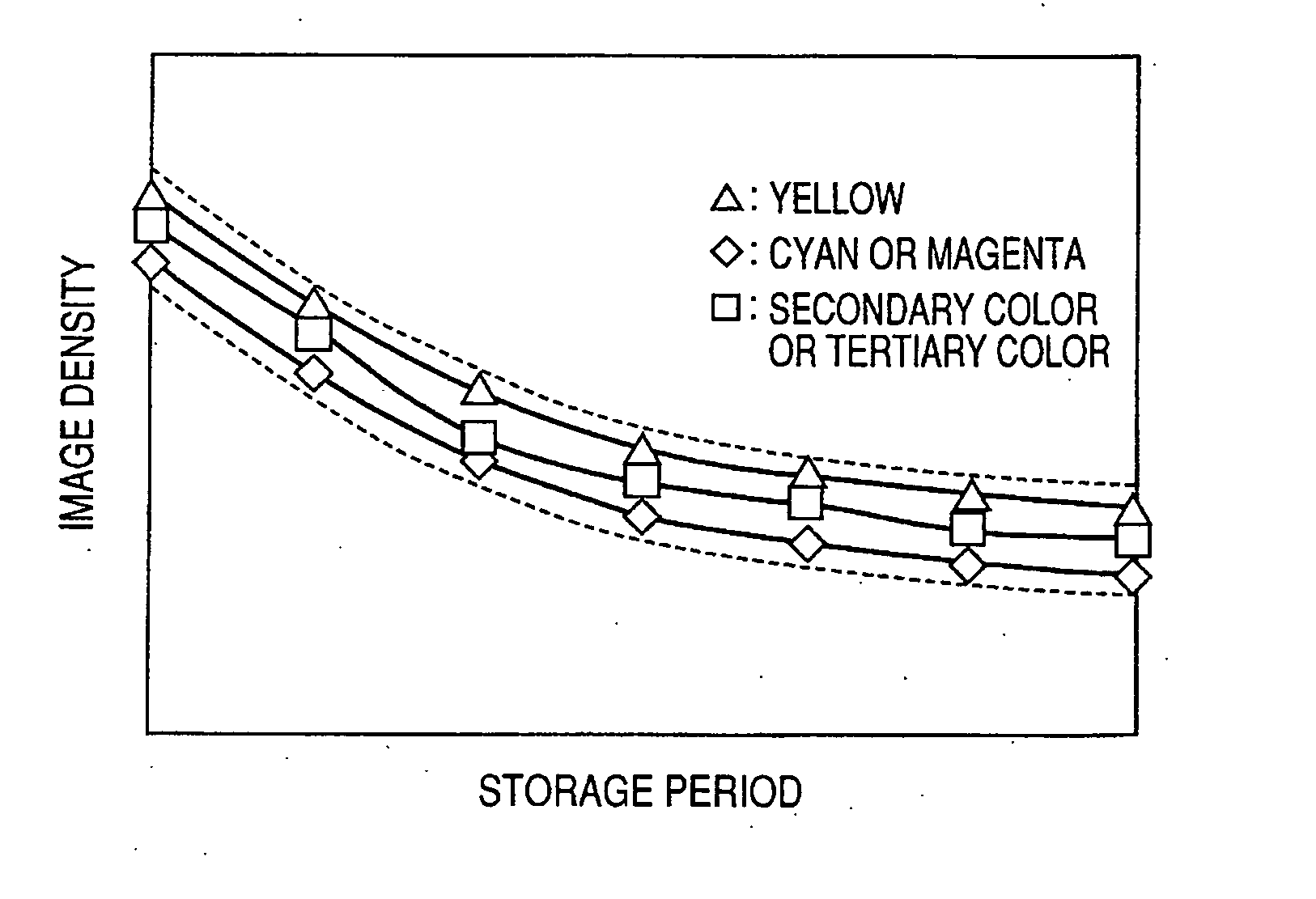

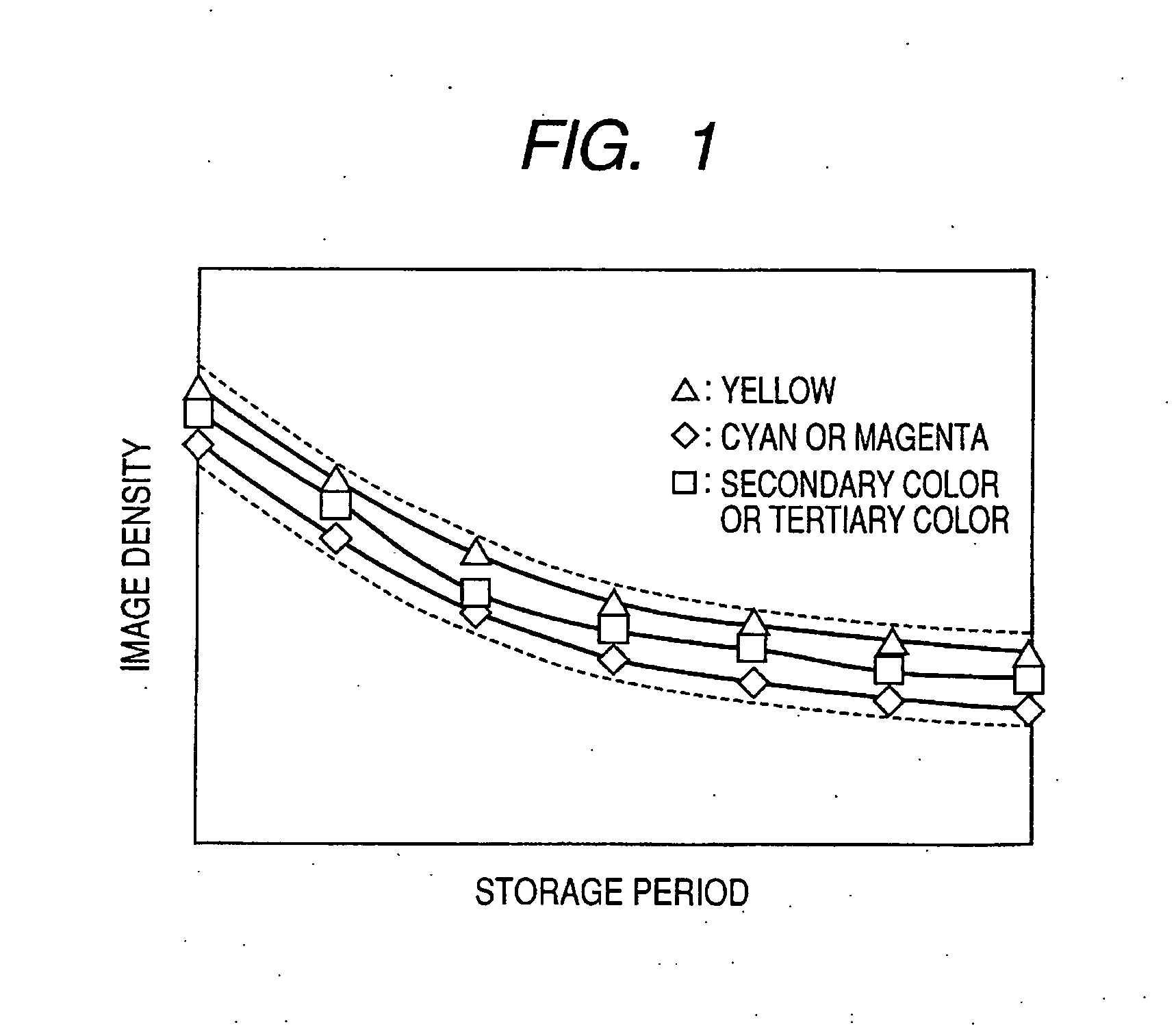

Ink jet yellow ink, ink set, ink jet recording method, ink cartridge, recording unit, and ink jet recording apparatus

InactiveUS7241332B2Good storage stabilityStable storageDuplicating/marking methodsInksLightfastnessDirect yellow

To provide an ink jet yellow ink to be used in combination with ink excellent in light resistance and environmental gas resistance with a color fading balance with respect to light and an environmental gas between the inks uniformized. The ink jet yellow ink is an ink jet yellow ink to be used for forming an image together with a cyan ink comprising a compound represented by a general formula (1) or a compound represented by a general formula (2) as a coloring material, the ink jet yellow ink comprising: at least one kind of coloring material selected from the following A group; and at least one kind of coloring material selected from the following B group.A group: C.I. Direct Yellow 132 and C.I. Direct Yellow 173B group: C.I. Direct Yellow 142, C.I. Direct Yellow 86, and a compound represented by a general formula (3).

Owner:CANON KK

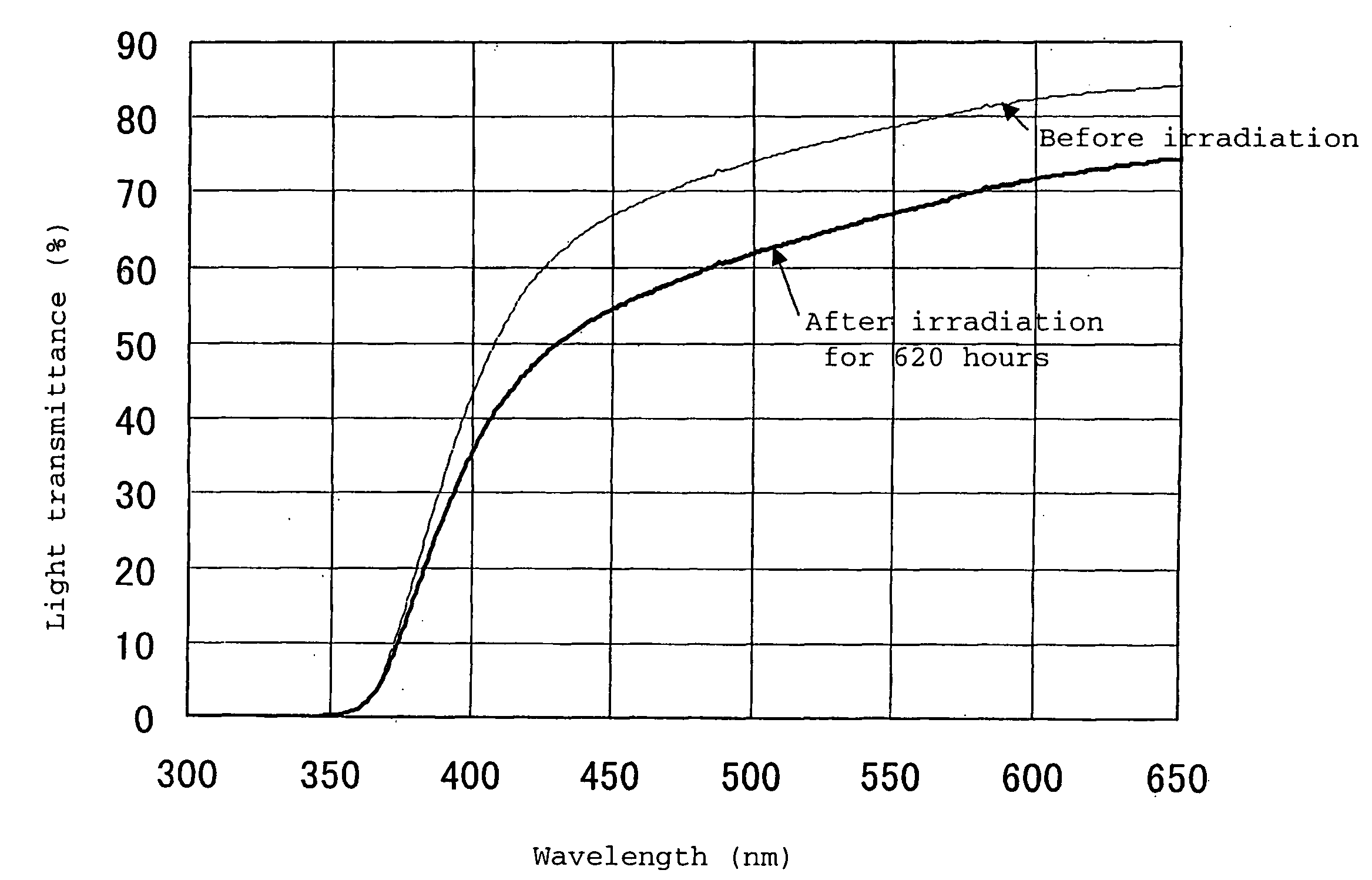

Thermoplastic resin composition and molded product employing it

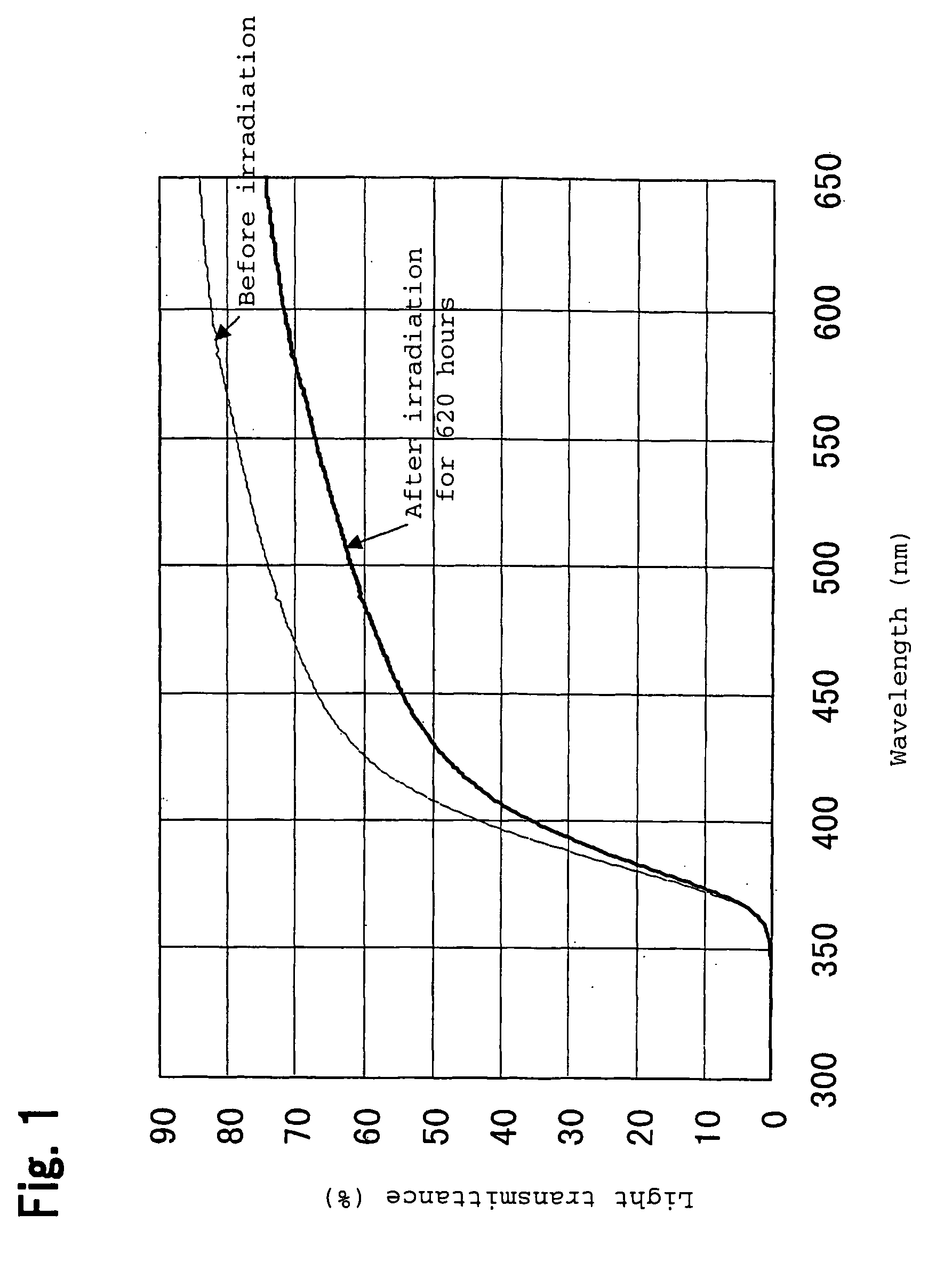

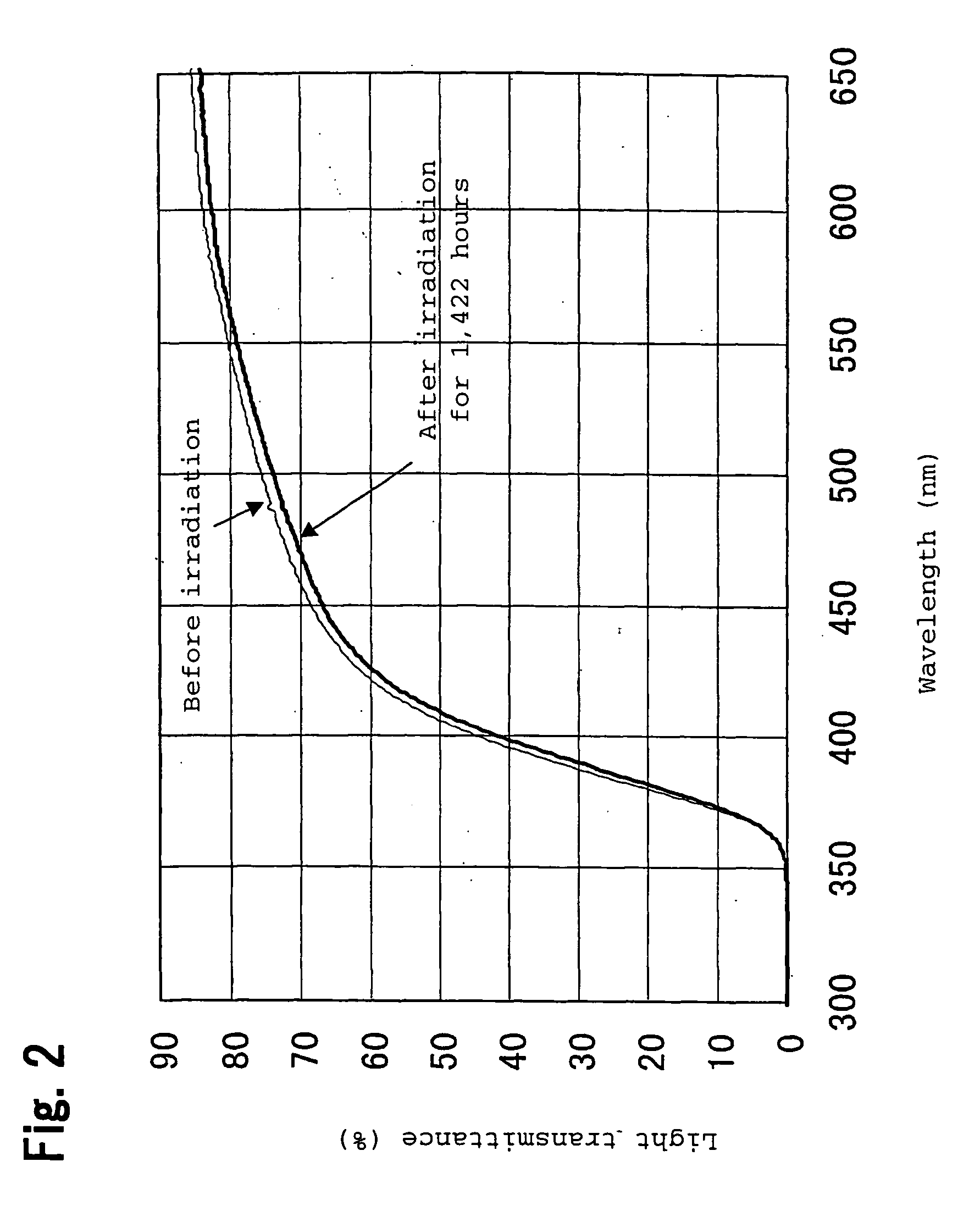

InactiveUS20050170180A1Ultraviolet resistance improvedHigh light transmittanceSynthetic resin layered productsCellulosic plastic layered productsUltra high pressurePath length

A thermoplastic resin composition and a molded product, having excellent transparency, ultraviolet absorptivity and light resistance, are provided. A thermoplastic resin composition comprising from 0.001 to 10 wt %, based on the total resin composition, of a glass filler whose glass formulation consists mainly of a silicon oxide composition and exhibiting light transmittances at wavelengths of 340 nm and 400 nm of from 0 to 0.5% and from 30 to 99%, respectively, per mm of light path length. A molded product which is a molded product of a thermoplastic resin composition, characterized in that in a case where (1) an ultra-high pressure mercury lamp which does not substantially emit ultraviolet light having a wavelength of at most 250 nm, is used at such a distance that the intensity of ultraviolet light having a wavelength of 350 nm generated by the lamp would be 0.1 W / cm2 on the surface of the molded product, and (2) the molded product is irradiated for 72 hours in the air at the surface temperature thereof being 60° C., the light transmittance at a wavelength of 650 nm after the irradiation, is at least 70% per mm of light path length.

Owner:MITSUBISHI CHEM CORP

Ink set for ink jet recording and method for ink jet recording

InactiveUS7867327B2Enhance the imageParticularly hueMeasurement apparatus componentsDecorative surface effectsEngineeringHue

There is provided an ink set for ink jet recording, which can realize lightfastness and waterfastness and, at the same time, can realize good images, especially images having a good hue. The ink set for ink jet recording comprises a cyan ink composition, a magenta ink composition, and a yellow ink composition, wherein the cyan ink composition comprises as a colorant at least one pigment selected from the group consisting of C.I. Pigment Blue 15:3 and C.I. Pigment Blue 15:4, the magenta ink composition comprises as a colorant at least one pigment selected from group consisting of C.I. Pigment Red 122, C.I. Pigment Red 202, C.I. Pigment Red 209, and C.I. Pigment Violet 19, and the yellow ink composition comprises as a colorant C.I. Pigment Yellow 213.

Owner:SEIKO EPSON CORP

Ink jet yellow ink, ink set, ink jet recording method, ink cartridge, recording unit, and ink jet recording apparatus

InactiveUS20060119683A1Enhance the imageStable storageMeasurement apparatus componentsDuplicating/marking methodsPolymer scienceEngineering

To provide an ink jet yellow ink to be used in combination with ink excellent in light resistance and environmental gas resistance with a color fading balance with respect to light and an environmental gas between the inks uniformized. The ink jet yellow ink is an ink jet yellow ink to be used for forming an image together with a cyan ink comprising a compound represented by a general formula (1) or a compound represented by a general formula (2) as a coloring material, the ink jet yellow ink comprising: at least one kind of coloring material selected from the following A group; and at least one kind of coloring material selected from the following B group. A group: C.I. Direct Yellow 132 and C.I. Direct Yellow 173 B group: C.I. Direct Yellow 142, C.I. Direct Yellow 86, and a compound represented by a general formula (3).

Owner:CANON KK

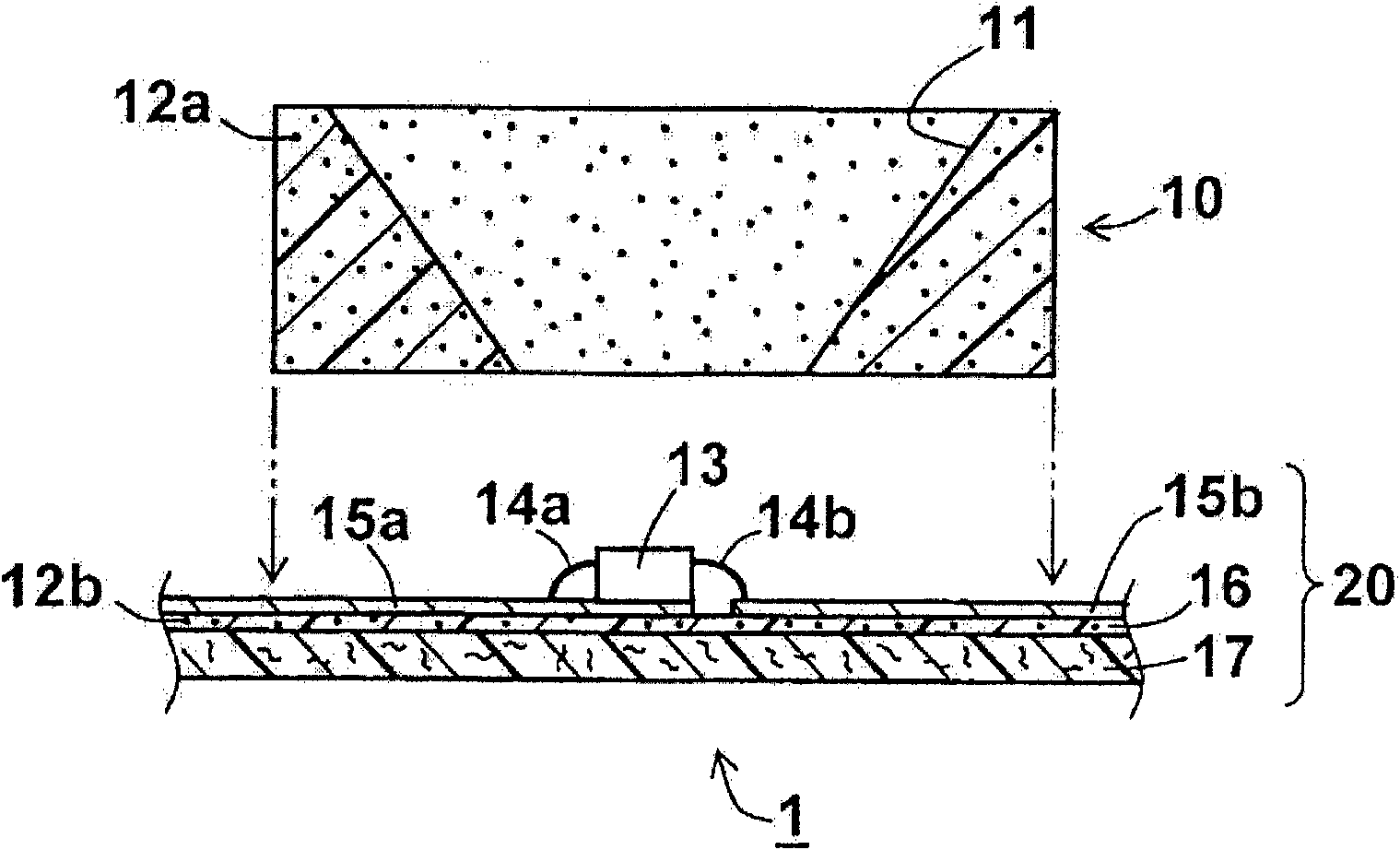

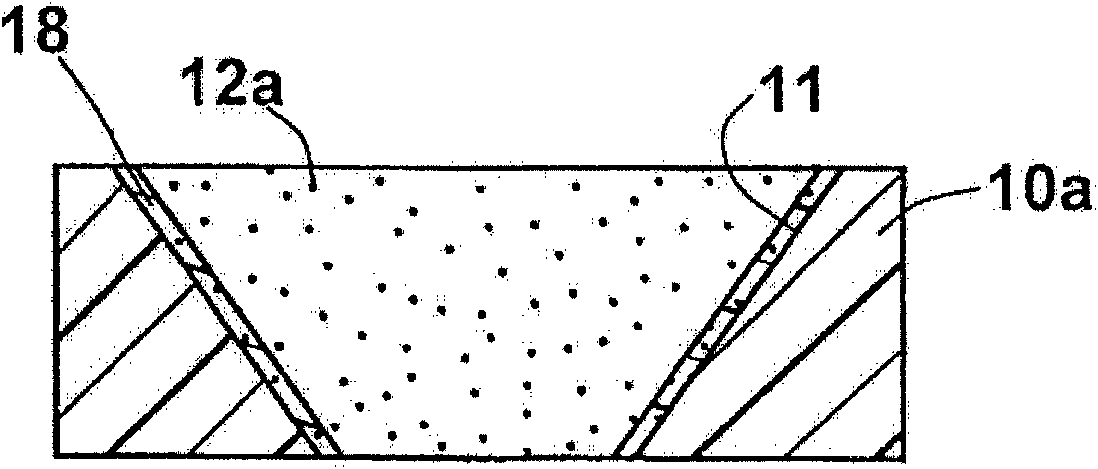

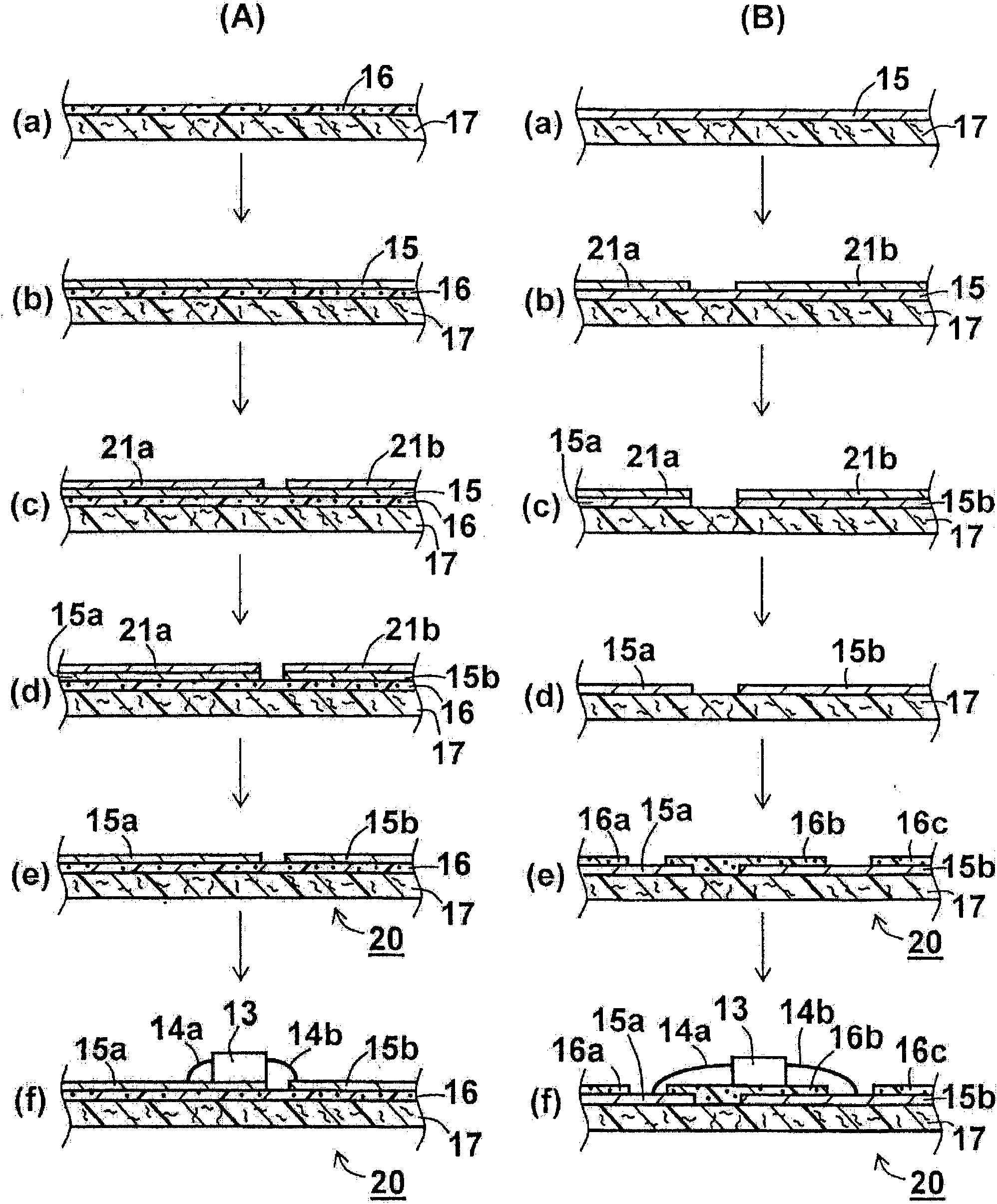

White color reflecting material and process for production thereof

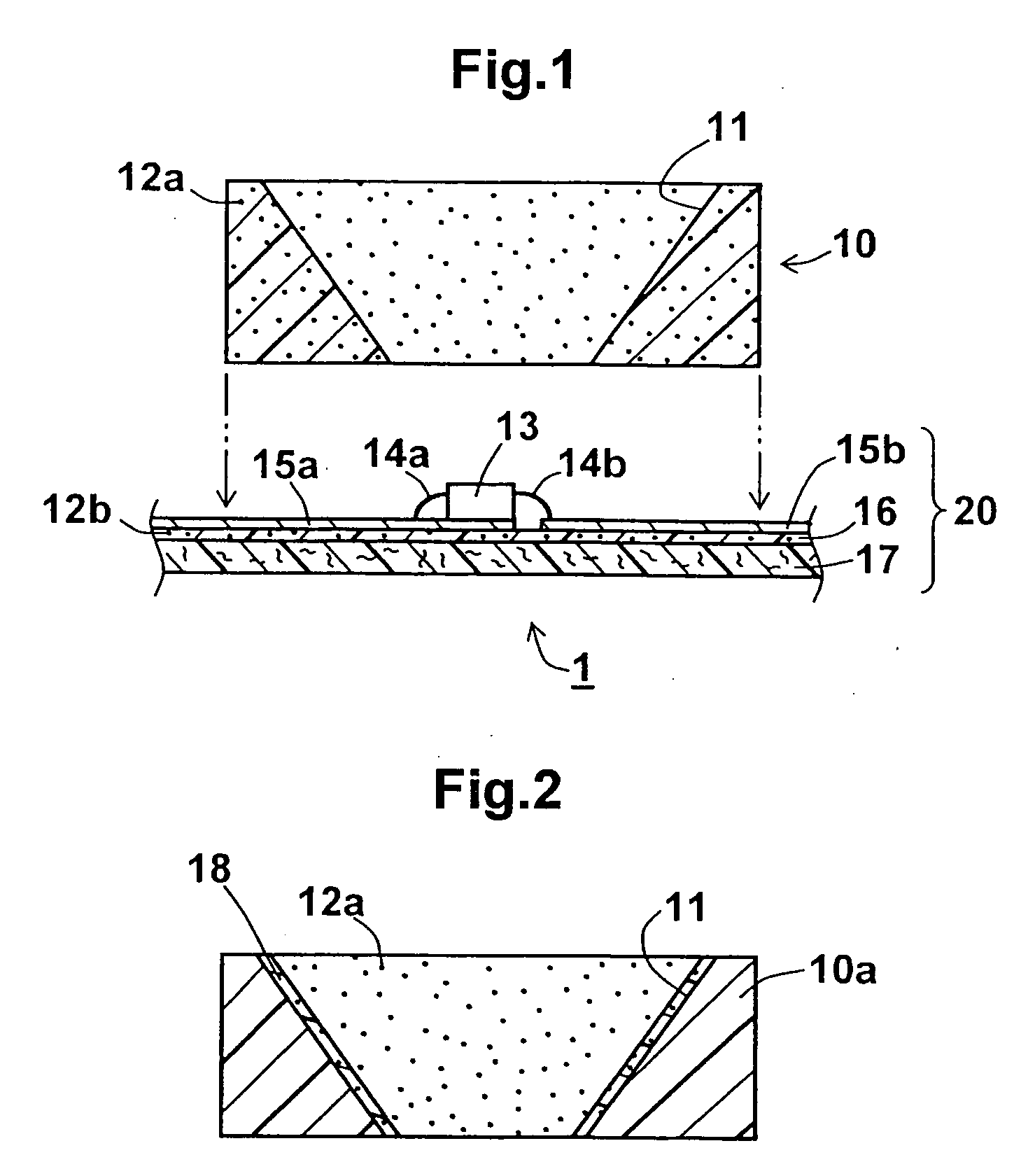

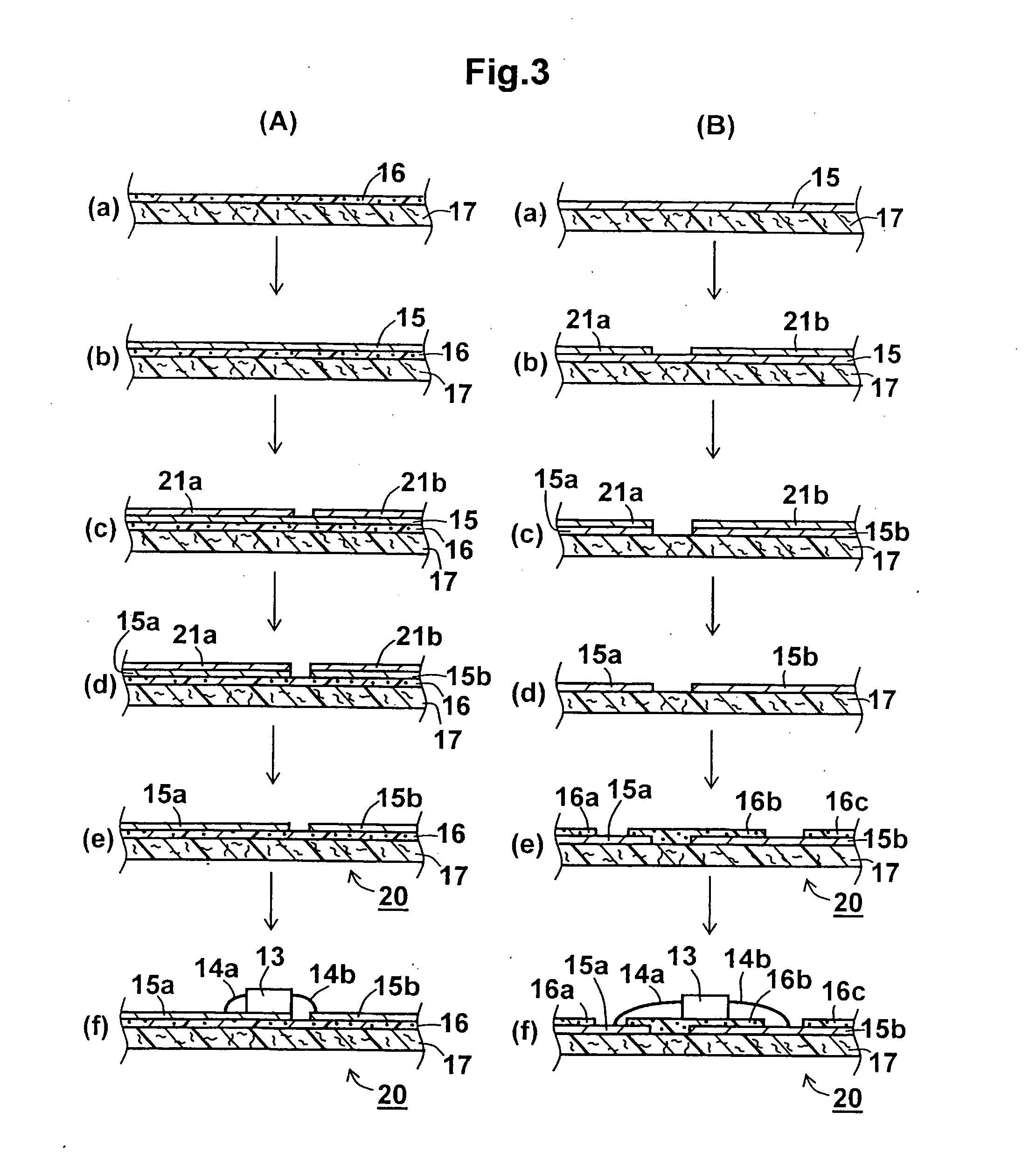

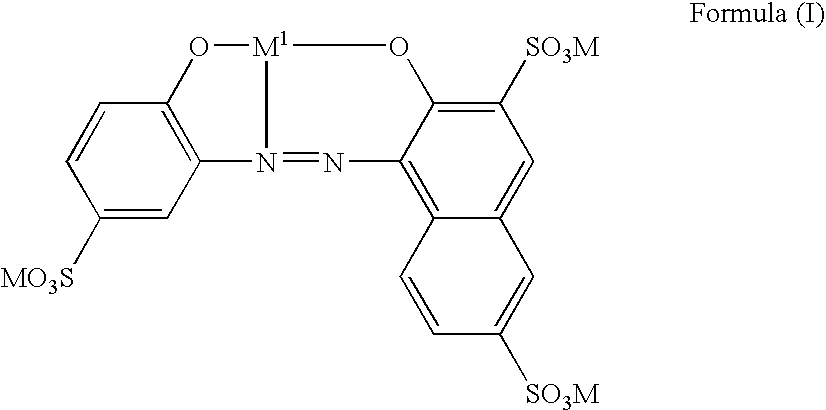

A general-use white color reflecting material, and a process for production thereof are provided. The white color reflecting material, without troublesome surface treatment such as formation of a reflective layer by metallization, is capable of reflecting a near-ultraviolet ray of a wavelength region of 380 nm or longer or a near-infrared ray sufficiently without light leakage; does not become yellow even when exposed to near-ultraviolet rays; has excellent lightfastness, heat resistance, and weatherability; has high mechanical strength and chemical stability; is capable of maintaining a high degree of whiteness; and is easily moldable at a low cost. Further a white color reflecting material used as an ink composition for producing the white color reflection material in a film-shape is also provided. The white-color reflecting material (10. 16) is molded as a dispersion of particles (12a. 12b) of anatase-type or rutile-type of titanium oxide in a silicone resin or silicone rubber, and comprises a titanium oxide-containing silicone composition.

Owner:ASAHI RUBBER

Ink set for ink jet recording and method for ink jet recording

InactiveUS20090142555A1Enhance the imageParticularly hueMeasurement apparatus componentsDecorative surface effectsHueEngineering

There is provided an ink set for ink jet recording, which can realize lightfastness and waterfastness and, at the same time, can realize good images, especially images having a good hue. The ink set for ink jet recording comprises a cyan ink composition, a magenta ink composition, and a yellow ink composition, wherein the cyan ink composition comprises as a colorant at least one pigment selected from the group consisting of C.I. Pigment Blue 15:3 and C.I. Pigment Blue 15:4, the magenta ink composition comprises as a colorant at least one pigment selected from group consisting of C.I. Pigment Red 122, C.I. Pigment Red 202, C.I. Pigment Red 209, and C.I. Pigment Violet 19, and the yellow ink composition comprises as a colorant C.I. Pigment Yellow 213.

Owner:SEIKO EPSON CORP

Ink set, ink cartridge, ink jet printer and recording method

ActiveUS20040050291A1Excellent in handleabilityExcellent in odorMonoazo dyesMeasurement apparatus componentsComputer printingImage recording

The ink set of the present invention provides a high ejection stability, gives an image having an excellent hue, light-resistance and waterproofness and improves the image preservability under severe conditions in ink jet recording, in which the ink set comprising a plurality of inks different in hues, wherein the plurality of inks includes a yellow ink containing a coloring agent that is a dye having: a lambdamax of from 390 nm to 470 nm; an I(lambdamax+70 nm) / I(lambdamax) ratio of not greater than 0.4, in which I(lambdamax) is the absorbance at lambdamax and I(lambdamax+70 nm) is the absorbance at (lambdamax+70 nm); and a forced fading rate constant of not greater than 5.0x10<-2 >[hour<-1>], an ink cartridge having the ink set received therein, an ink jet printer comprising the ink cartridge mounted therein and an image recording method.

Owner:FUJIFILM HLDG CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com