Patents

Literature

3277results about How to "Improve spraying effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

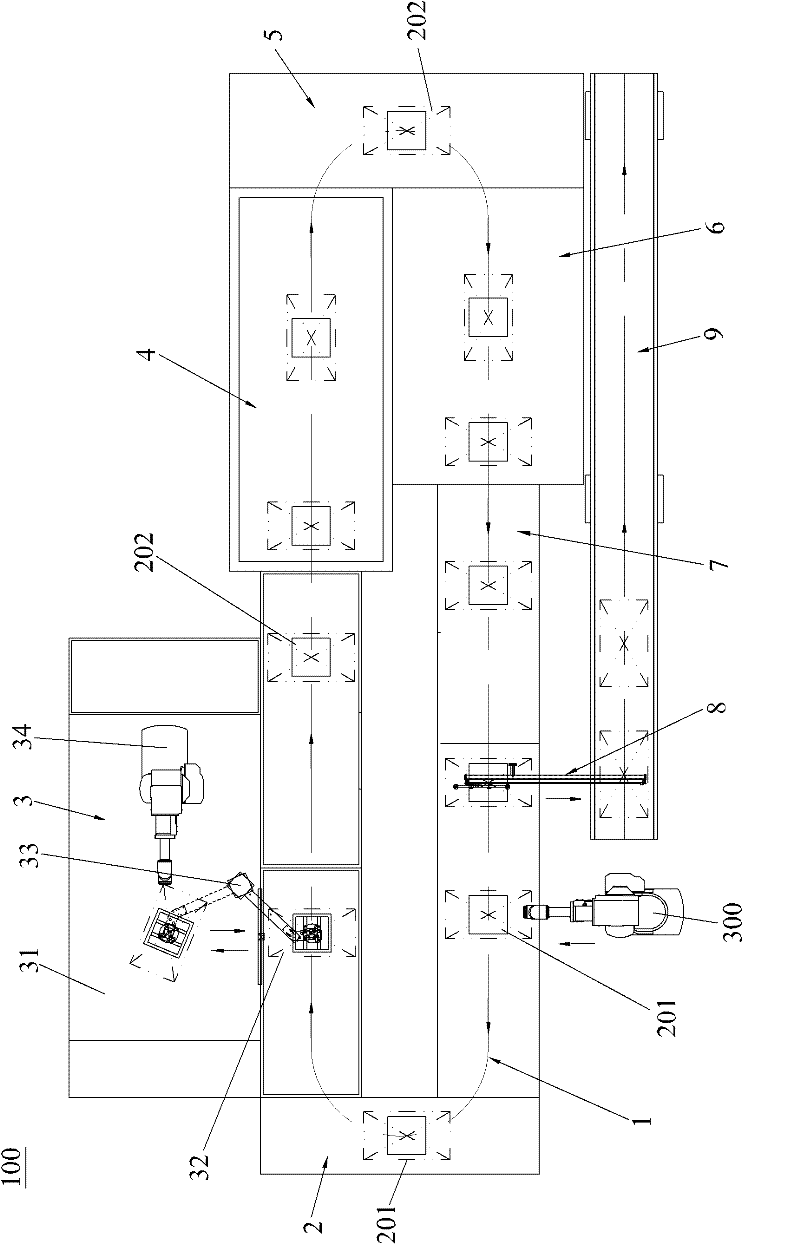

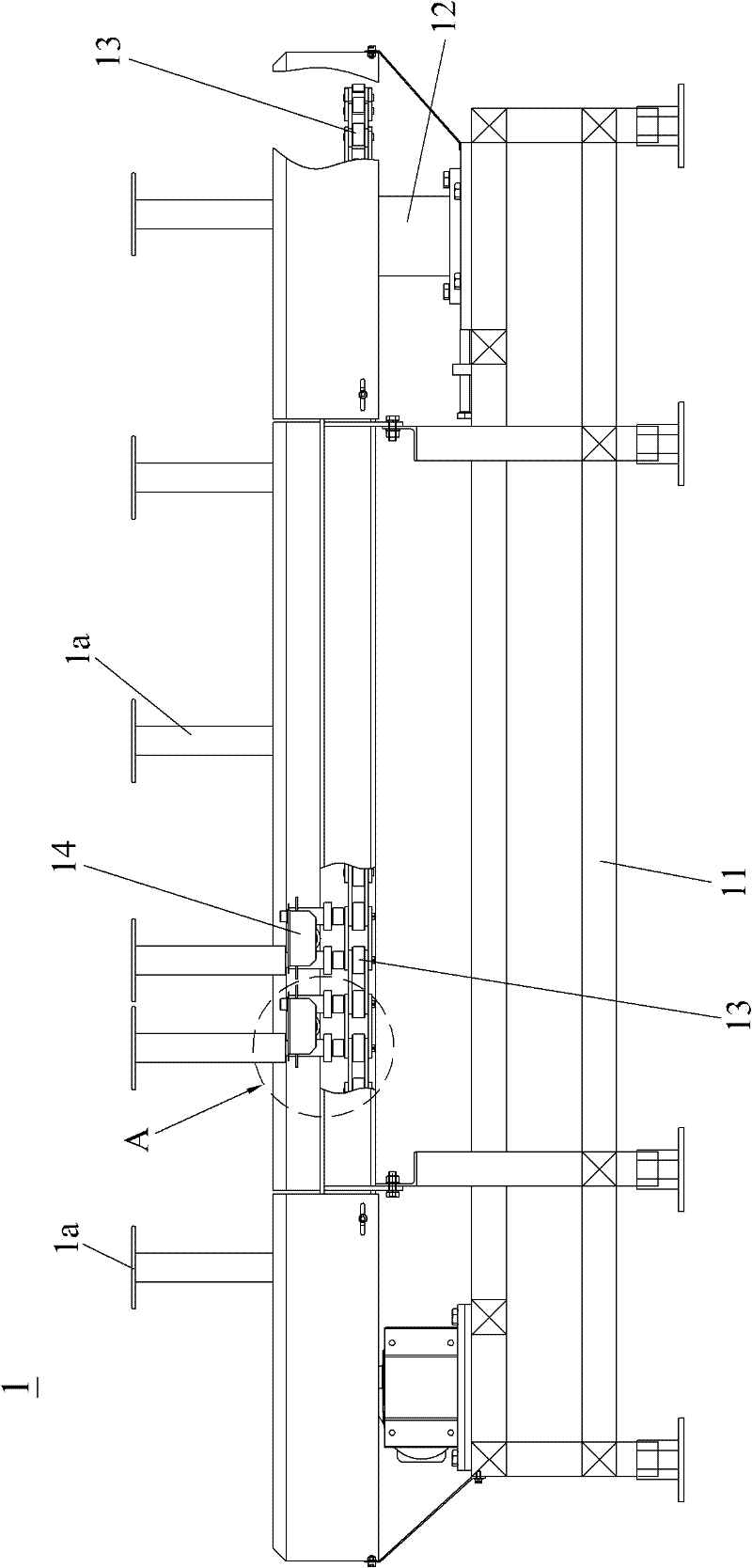

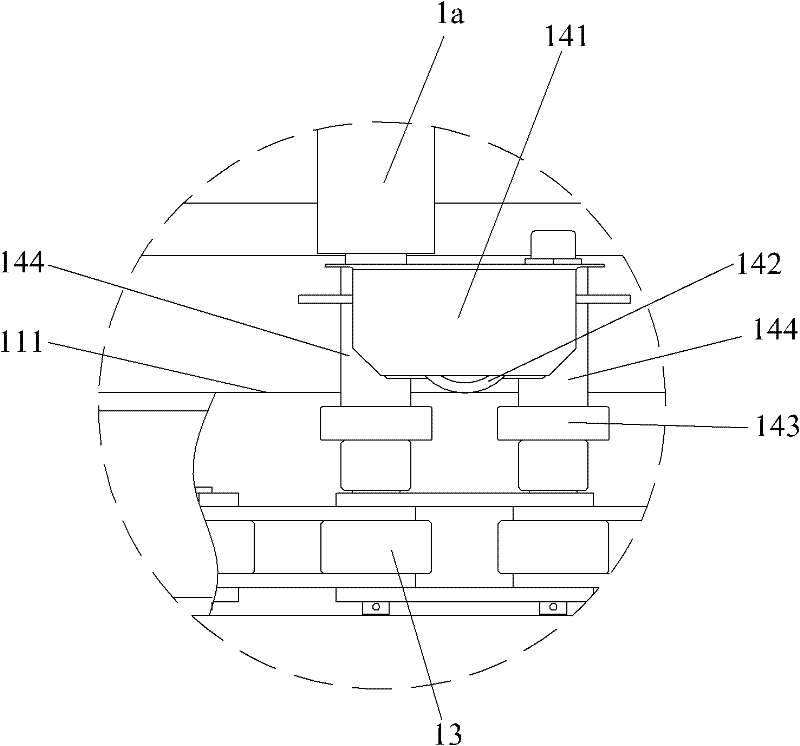

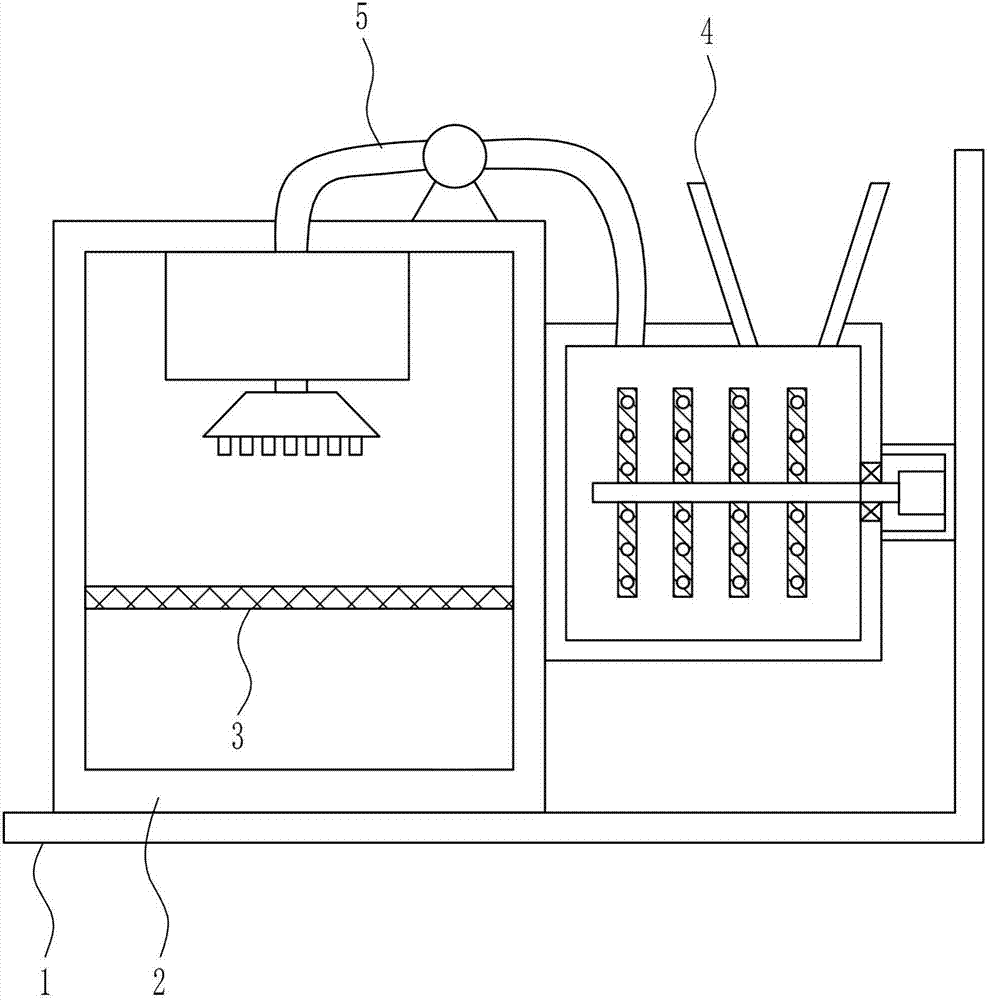

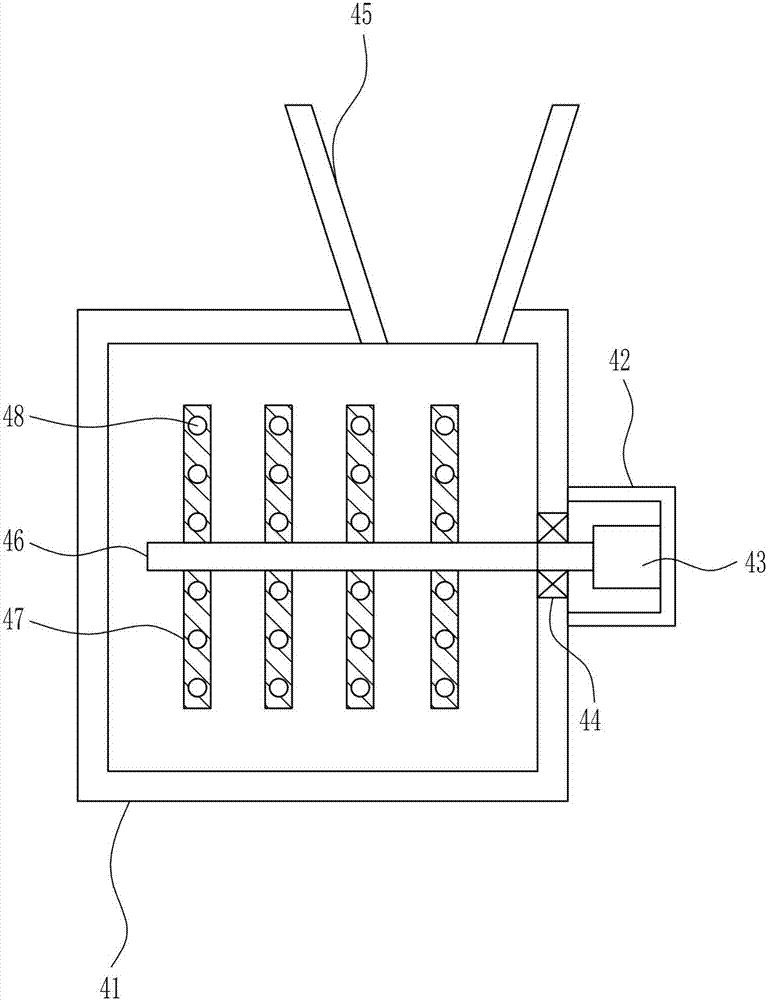

Automatic spraying equipment

InactiveCN102259071AAffect the spraying qualityReduce manual operationsSpraying apparatusPretreated surfacesElectricityControl system

The invention discloses fully-automatic spray coating equipment, which comprises a ground track type conveying chain, a cooling and dedusting device, a spray coating system, an infrared curing furnace, a cooling furnace, an ultraviolet curing furnace, an automatic discharging mechanical arm, an air supply and exhaust system and a control system. The ground track type conveying chain winds along awaist-like line and conducts closed circulating conveying of workpieces; the cooling and dedusting equipment cools and dedusts the workpieces; the spray coating system performs spray coating on the workpieces; the infrared curing furnace performs the infrared curing of the spray-coated workpieces; the cooling furnace is used for cooling the workpieces; the ultraviolet curing furnace is used for ultraviolet curing of the workpieces; the automatic discharging mechanical arm catches and unloads the workpieces; the air supply and exhaust system is arranged above the ground track type conveying chain and is used for supplying air to and exhausting all equipment; and the control system is electrically connected with all components and controls the operation of the components. The high automation degree of the fully-automatic spray coating equipment is high, the spraying effect of the fully-automatic spray coating equipment is desirable, and when the fully-automatic spray coating equipment is used, production space can be saved greatly.

Owner:东莞丰裕电机有限公司

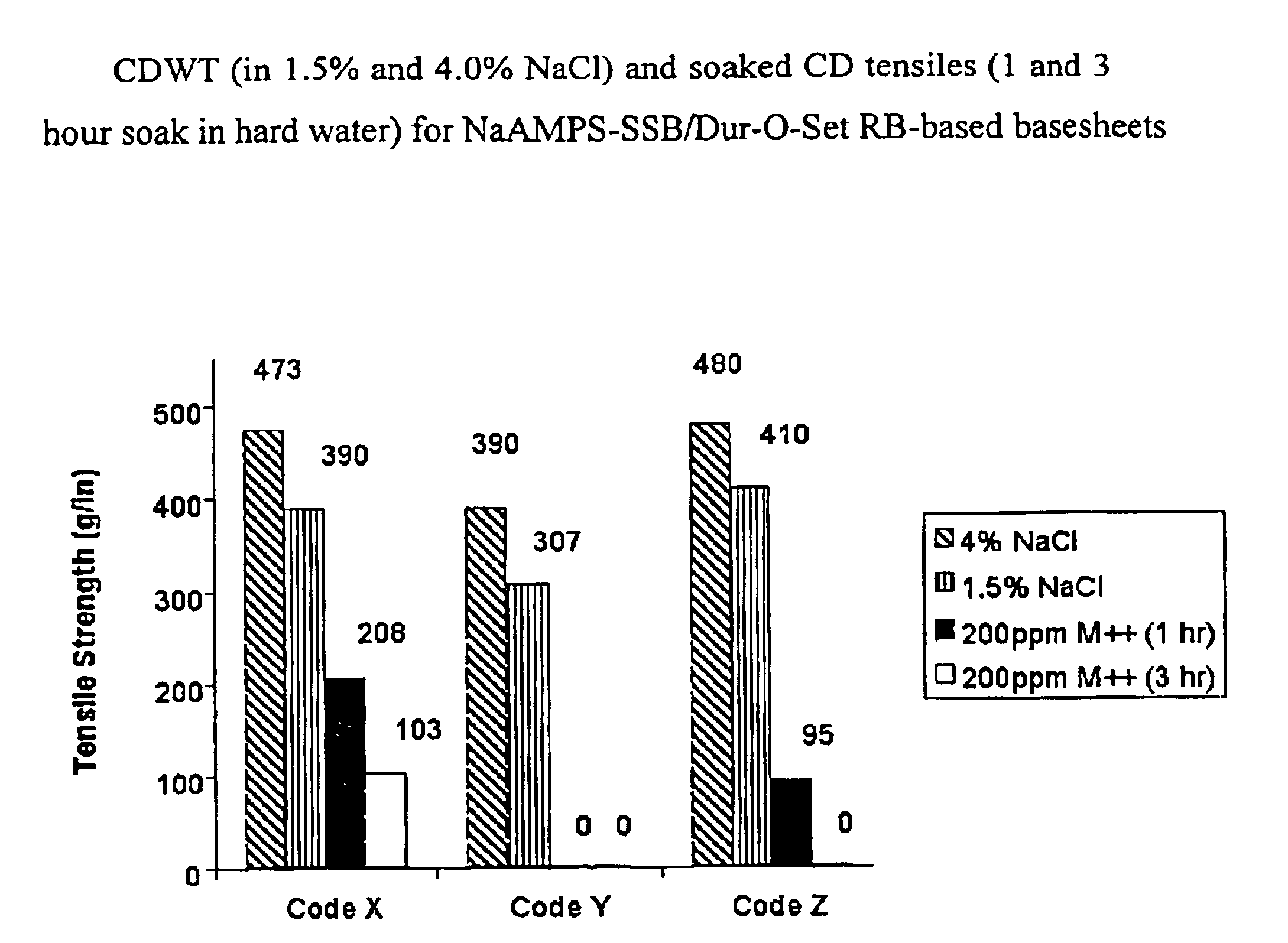

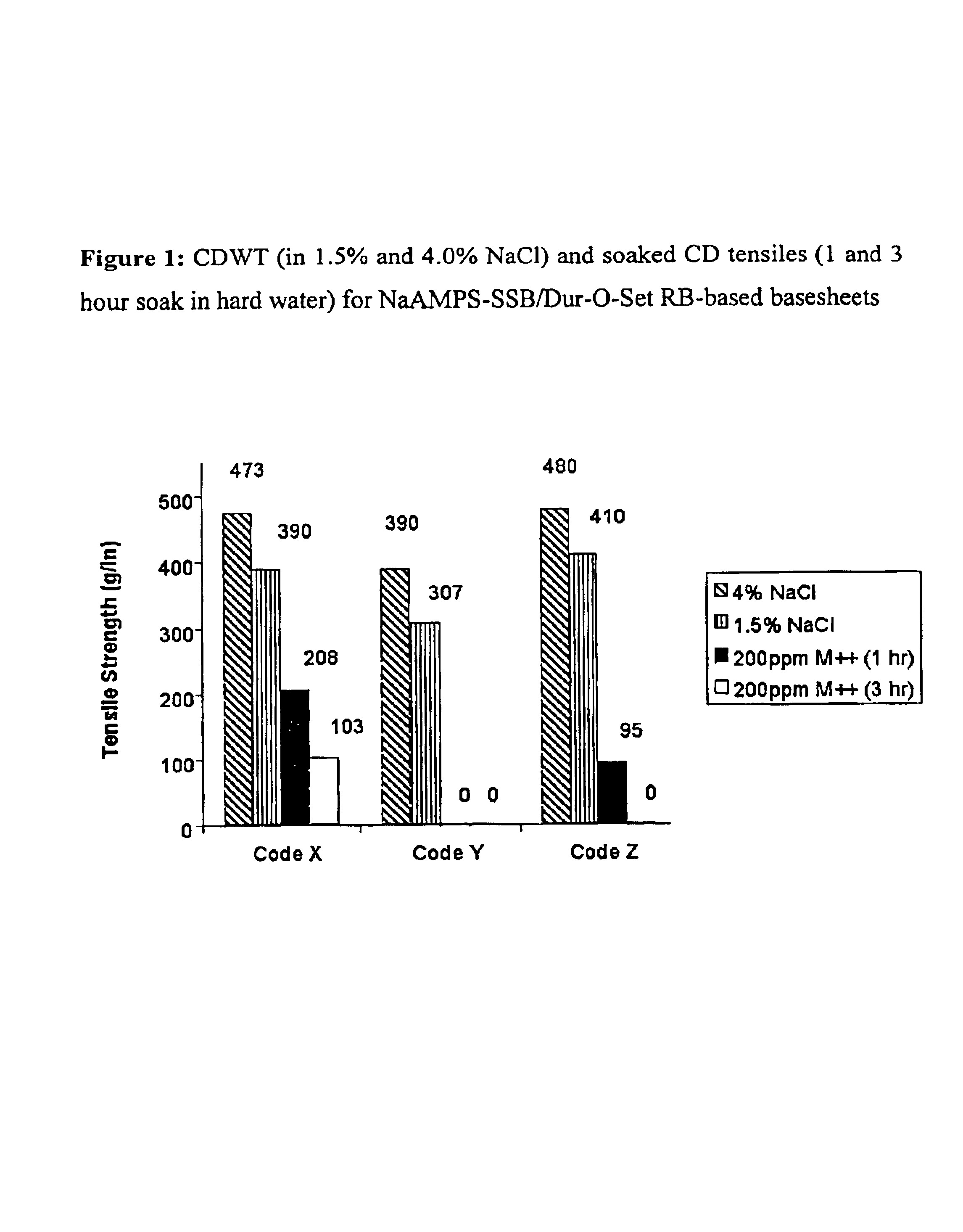

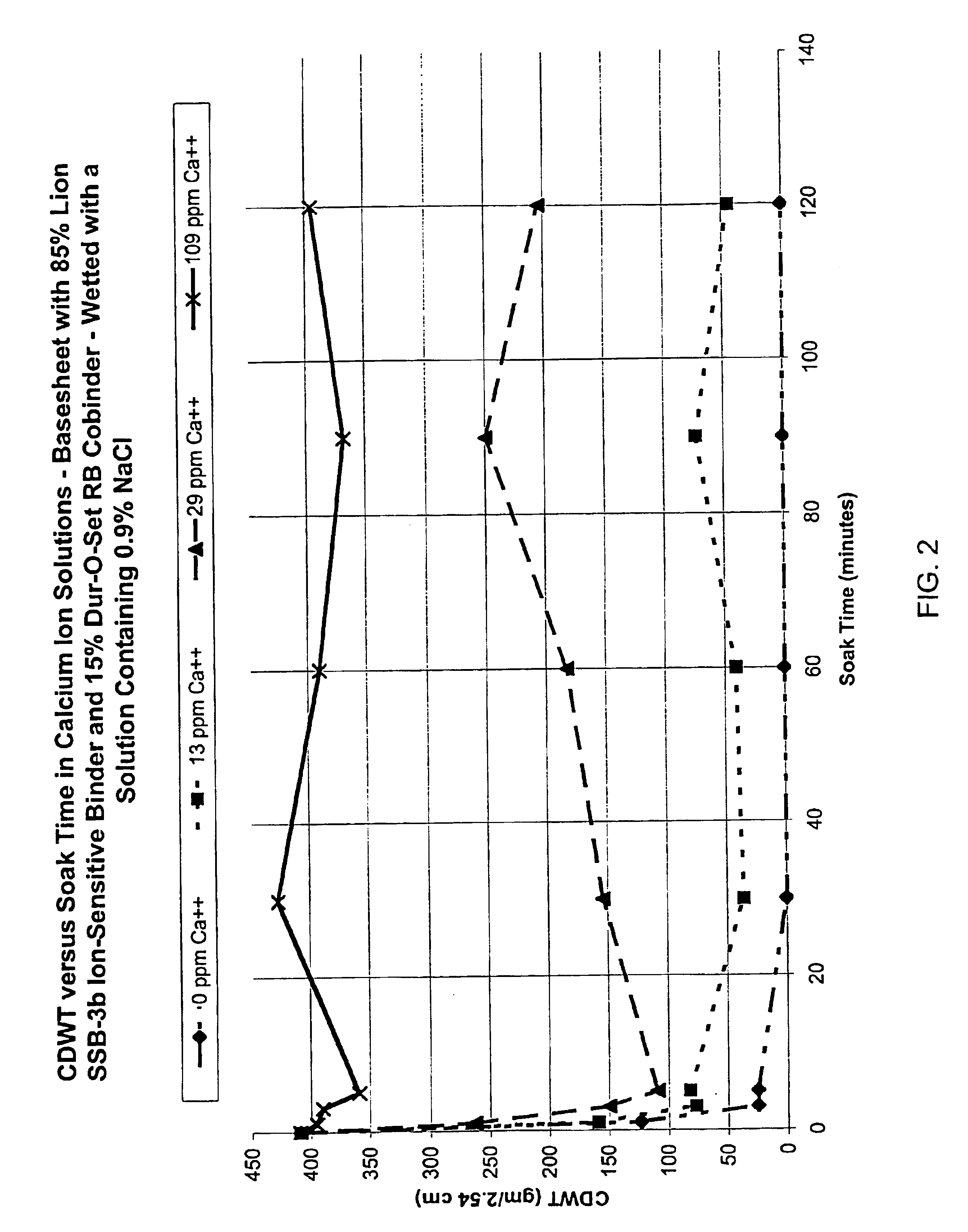

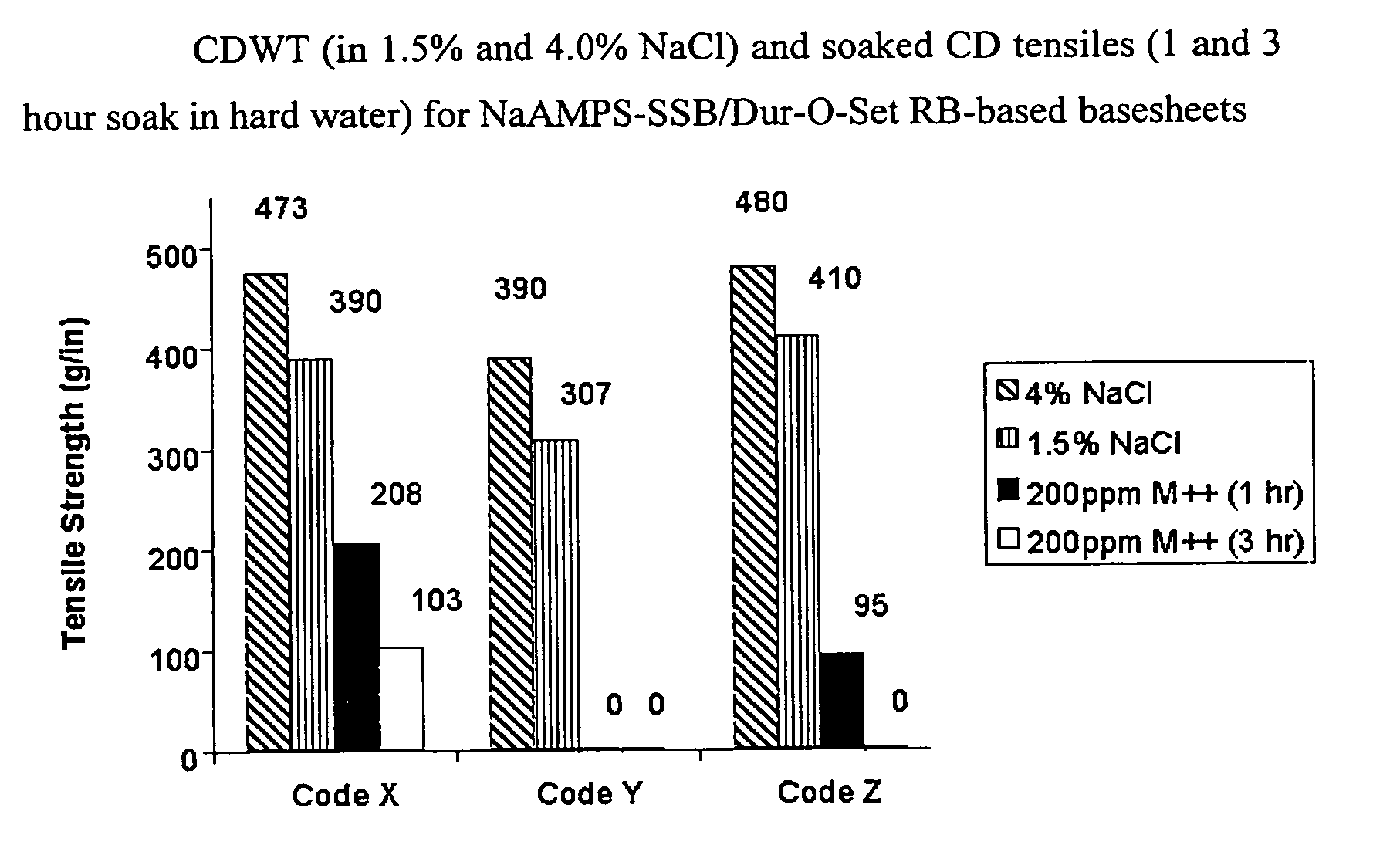

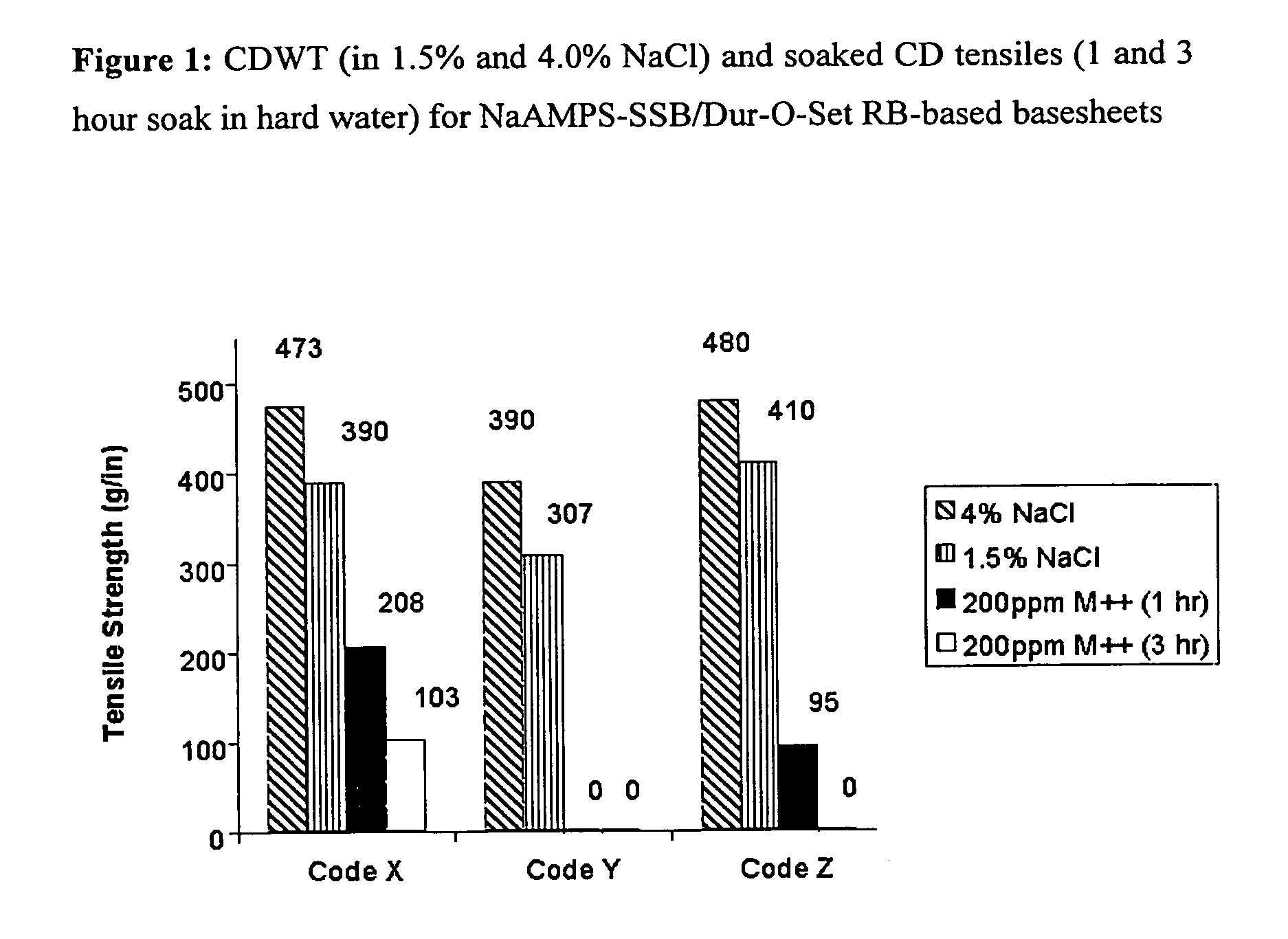

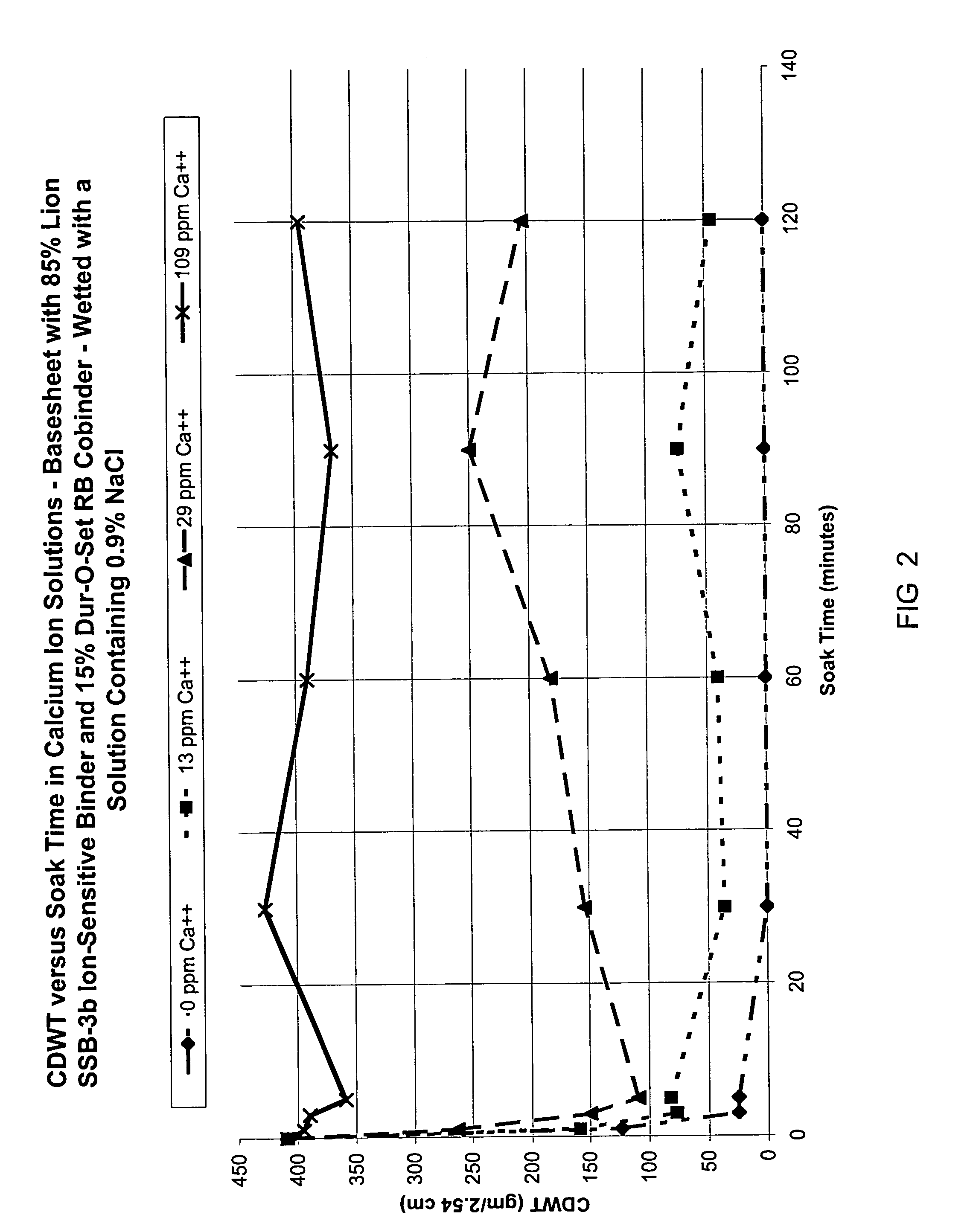

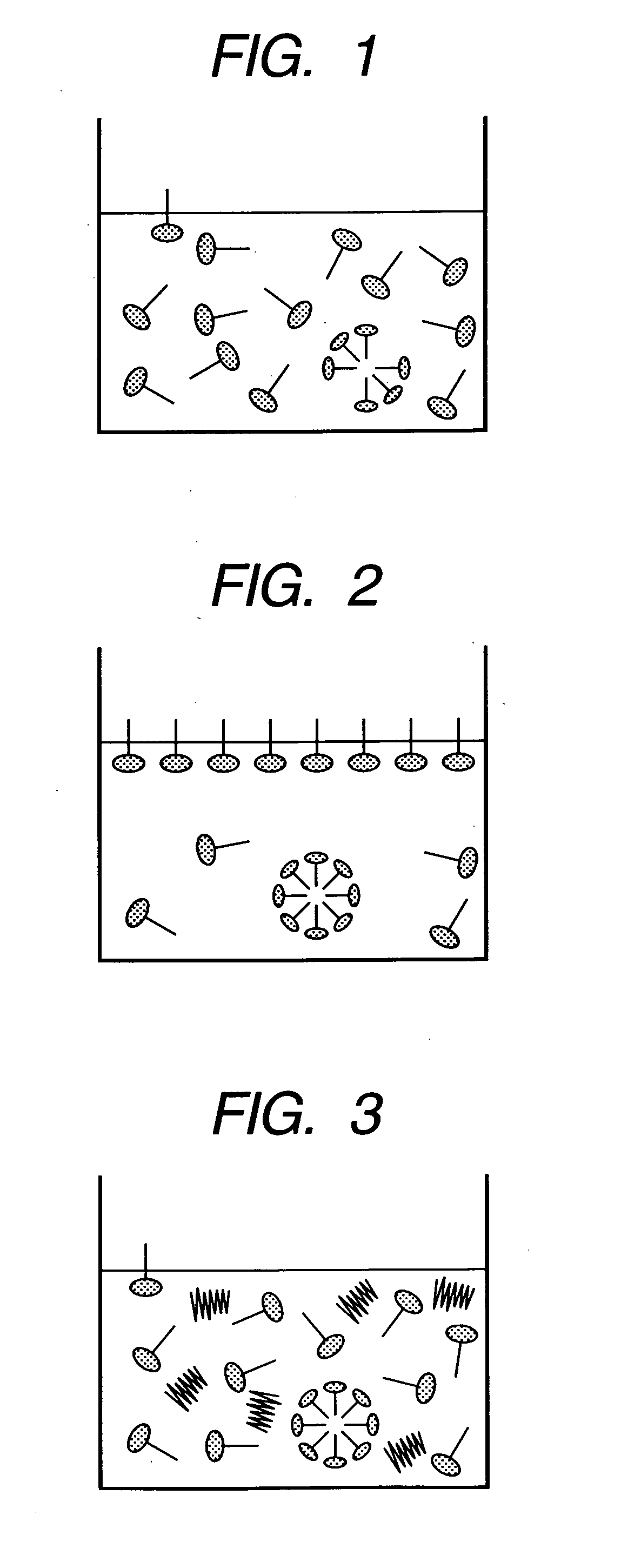

Pre-moistened wipe product

InactiveUS7101612B2Improve propertiesReduced high-shear viscosityInorganic/elemental detergent compounding agentsCosmetic preparationsFiberWater dispersible

The present invention provides ion-sensitive, water-dispersible polymers. The present invention also provides a method of making ion-sensitive, water-dispersible polymers and their applicability as binder compositions. The present invention further provides fiber-containing fabrics and webs comprising ion-sensitive, water-dispersible binder compositions and their applicability in water-dispersible personal care products.

Owner:KIMBERLY-CLARK WORLDWIDE INC

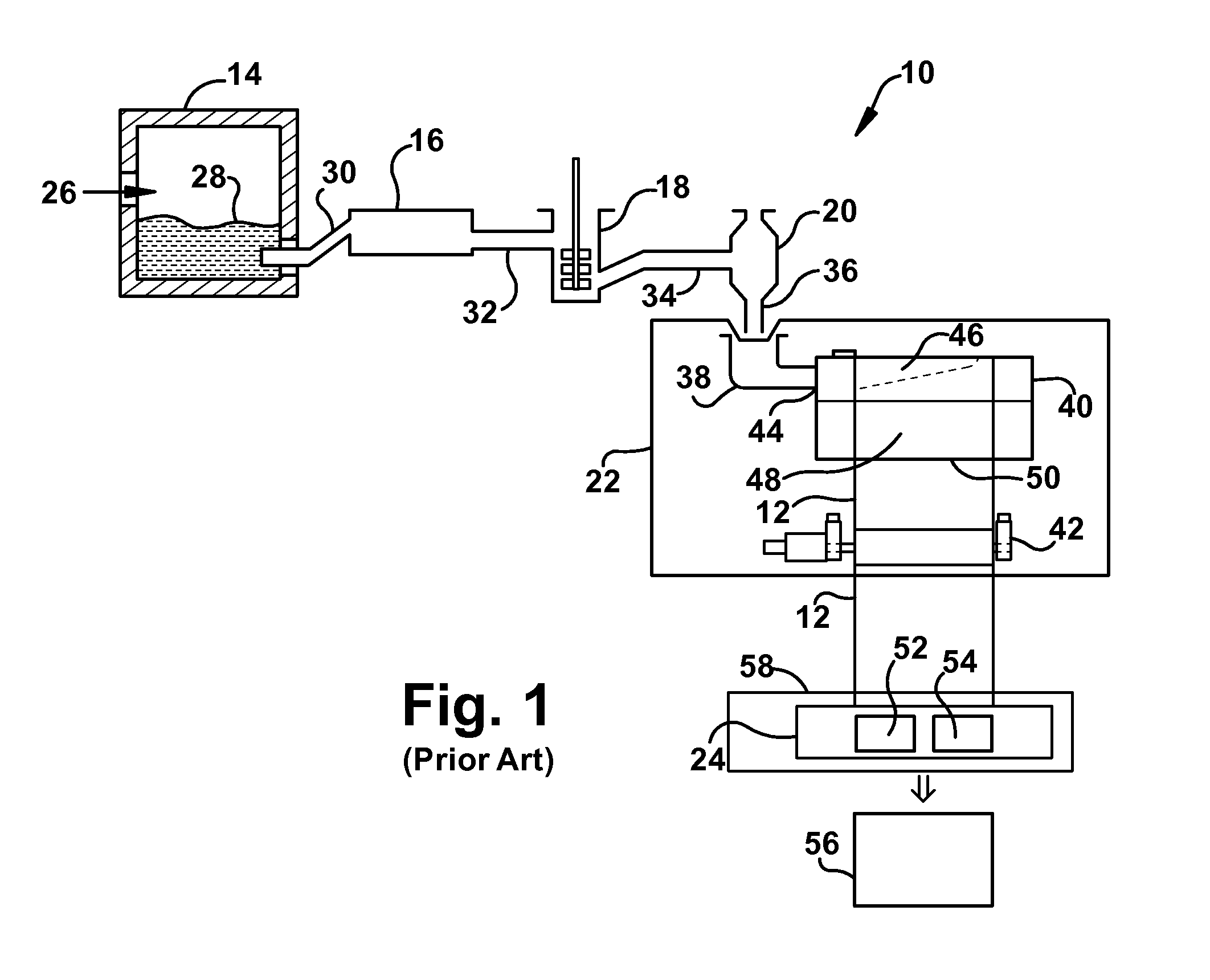

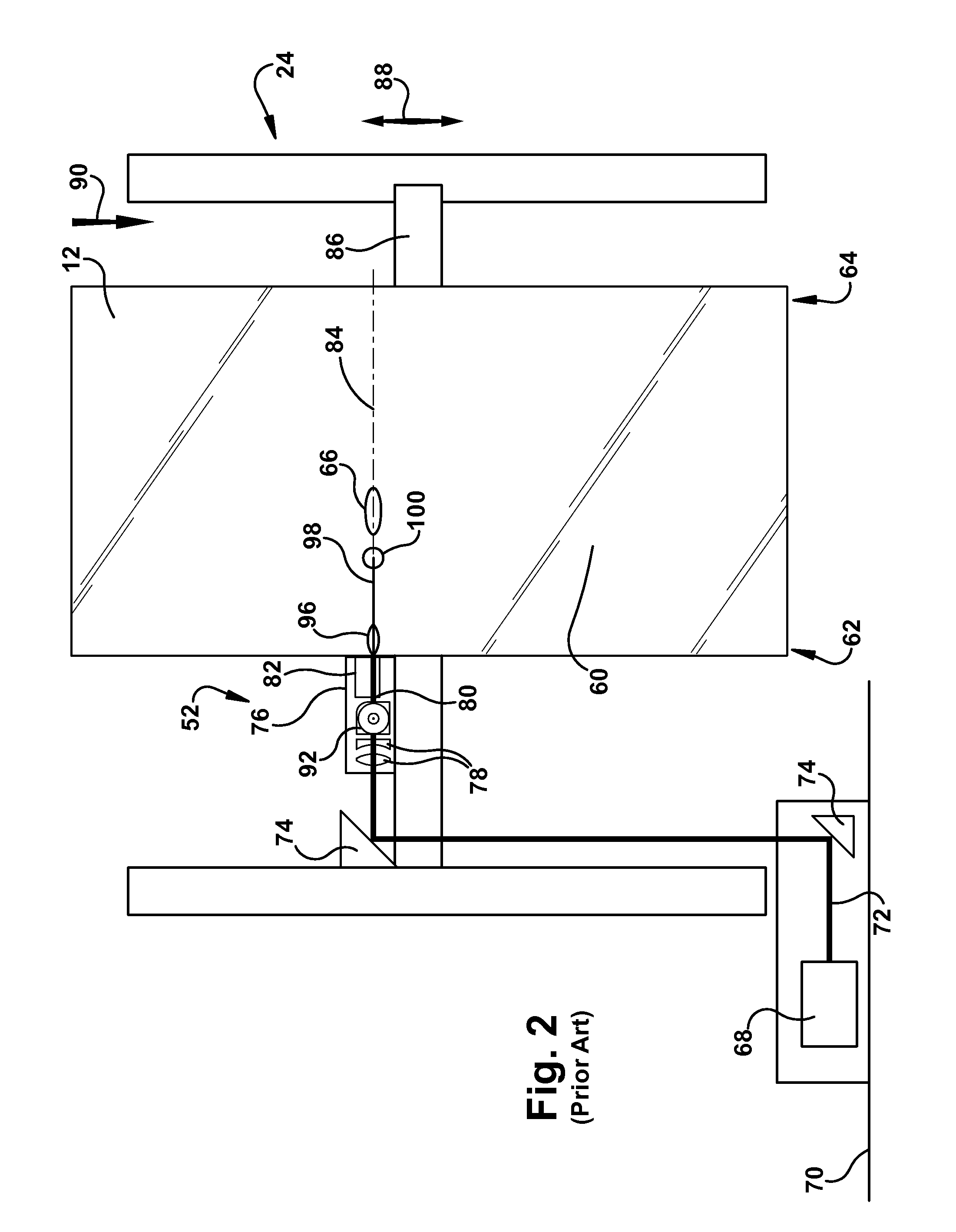

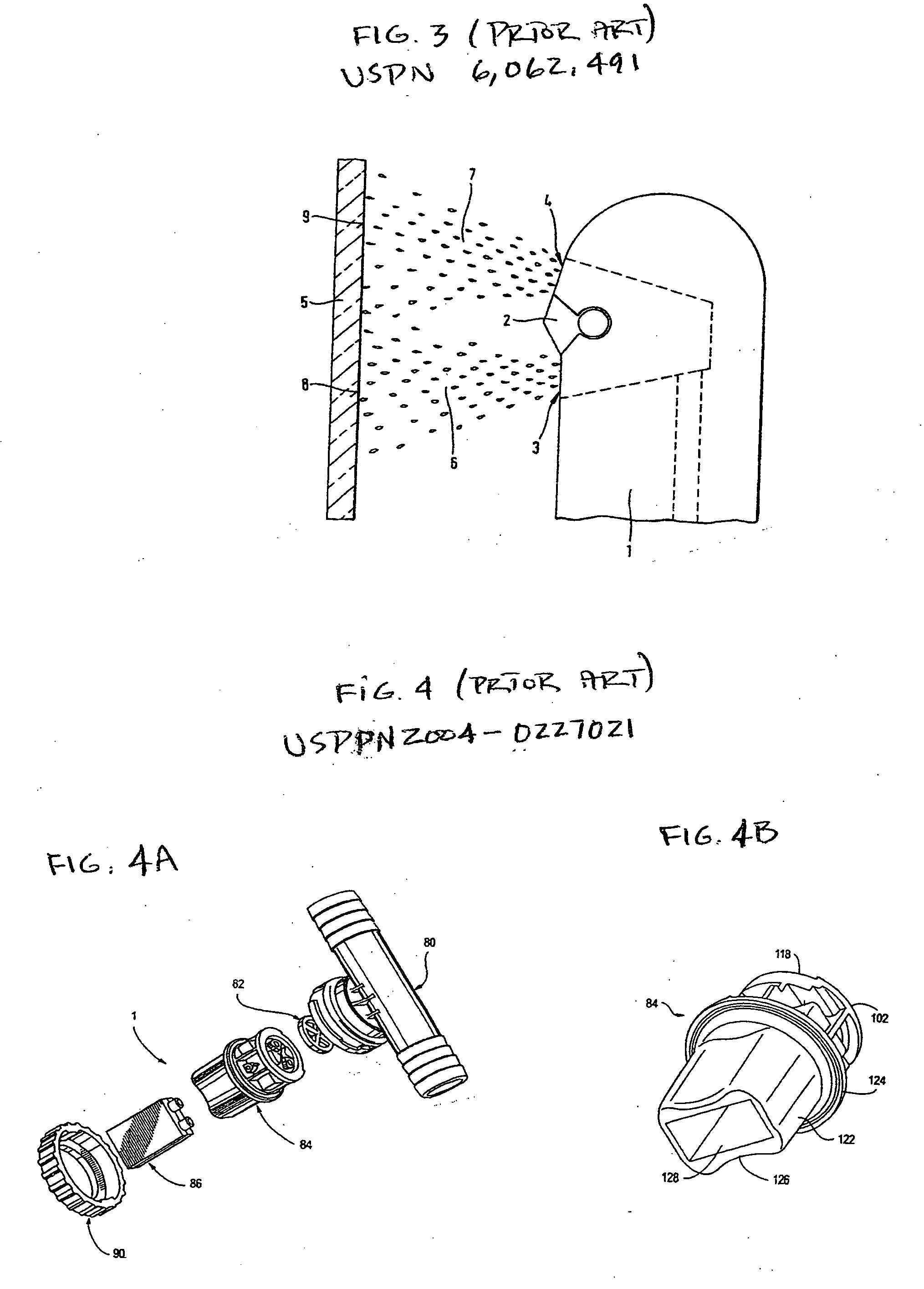

Preventing gas from occupying a spray nozzle used in a process of scoring a hot glass sheet

ActiveUS20100287991A1Improve spraying effectImprove performanceGlass drawing apparatusGlass forming apparatusSolubilityHigh energy

A spray nozzle is used in a process of quenching a hot glass sheet during a laser scoring process or other high energy glass heating process. The scoring is conducted by a high energy means such as a laser. The nozzle is located in proximity to the glass sheet, creating gas in liquid used to quench the glass located in the nozzle (e.g., water). The gas (e.g., air bubbles) is removed from the quenching liquid. Then, the spray nozzle is used to spray the quenching liquid onto the sheet at a location trailing laser scoring of the sheet, such as using a traveling anvil machine at the bottom of the draw. The spray nozzle (purge nozzle) has a purge opening and tubing leading to a discharge location. The purge nozzle can have a sloped passageway that pre-stages gas bubbles near the purge opening in the nozzle. The spray nozzle can include a cooling coil passing around the nozzle passageway that enables a coolant to travel along the coil. This cools the quenching liquid passing through the nozzle, and increases the solubility of bubbles in the quenching liquid in the nozzle. A gas filter can receive gas-rich quenching liquid from the pressurized quenching liquid source, remove gas from the liquid, and send gas-depleted quenching liquid to the spray nozzle.

Owner:CORNING INC

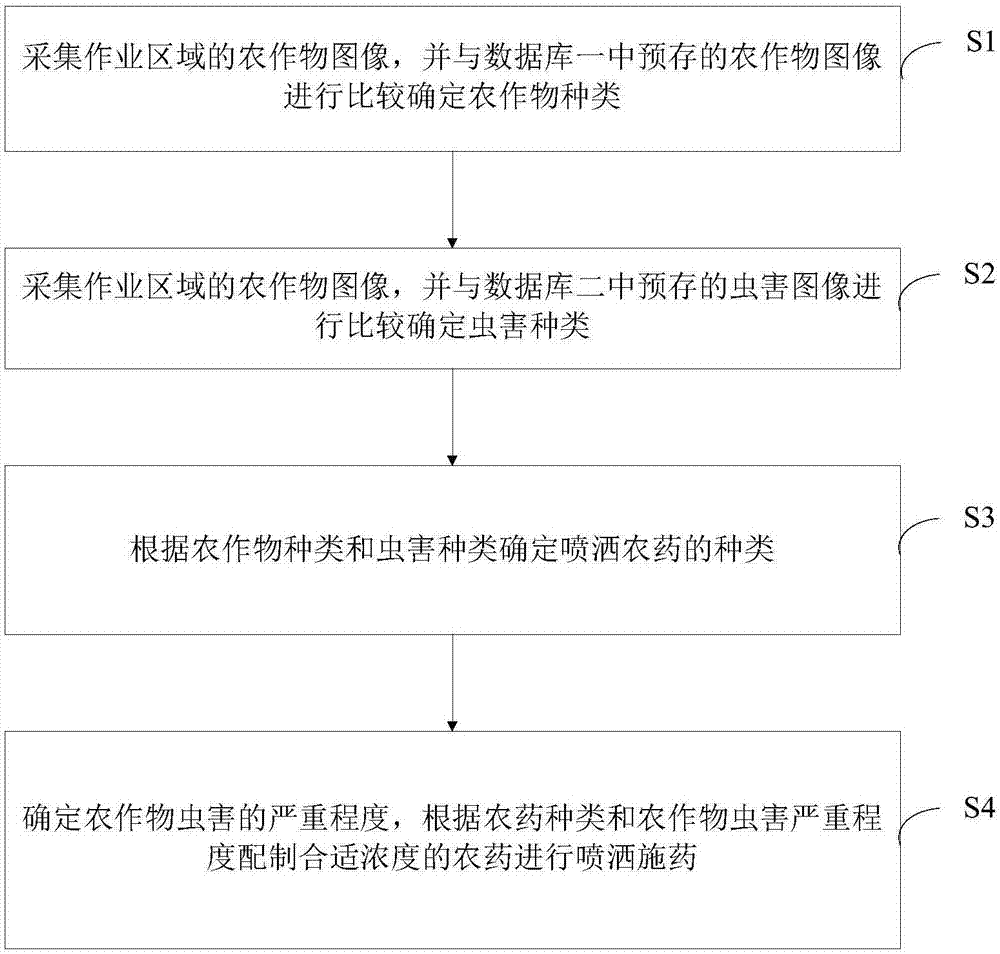

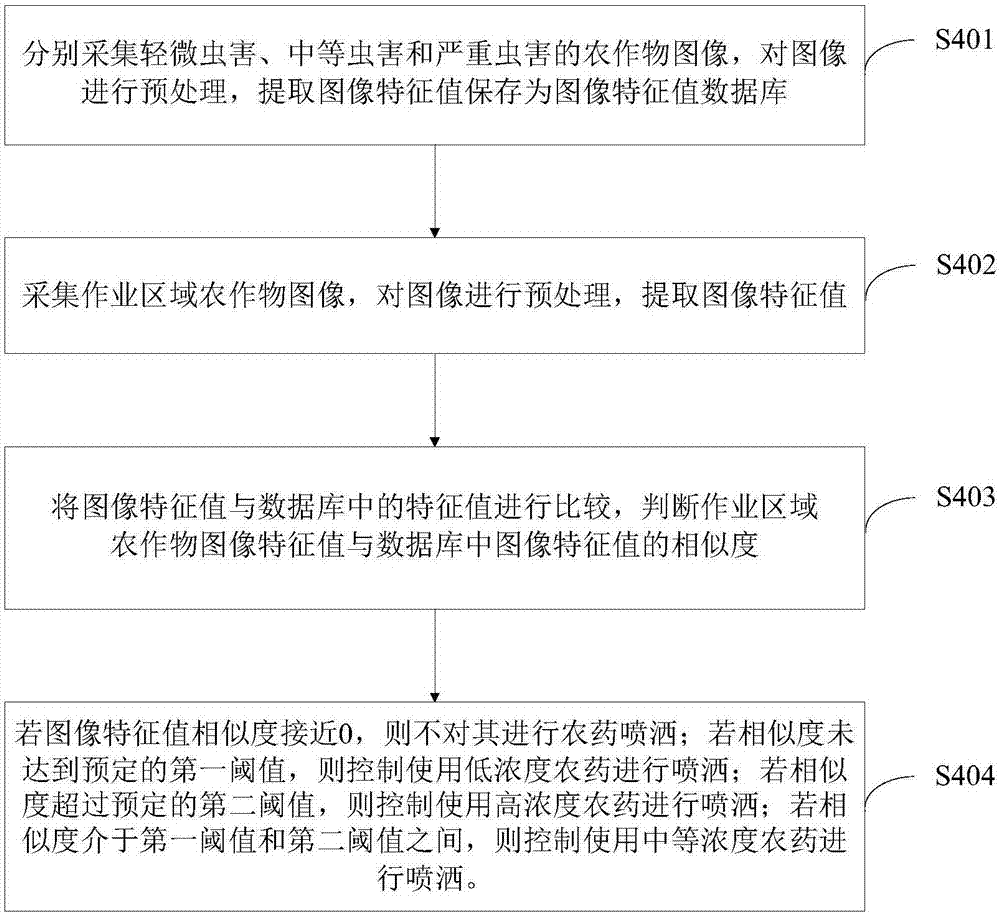

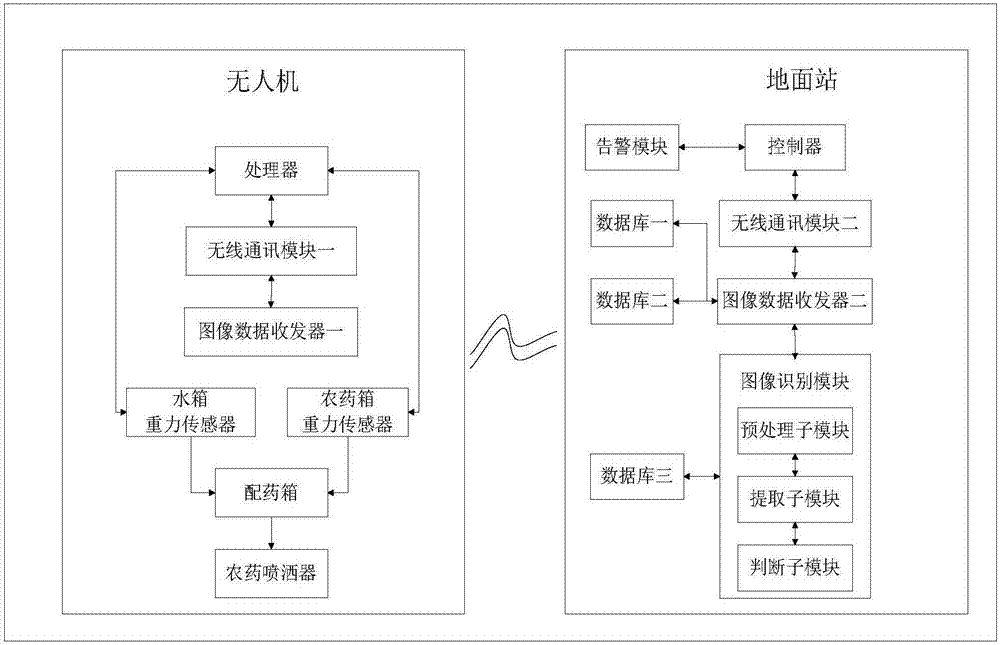

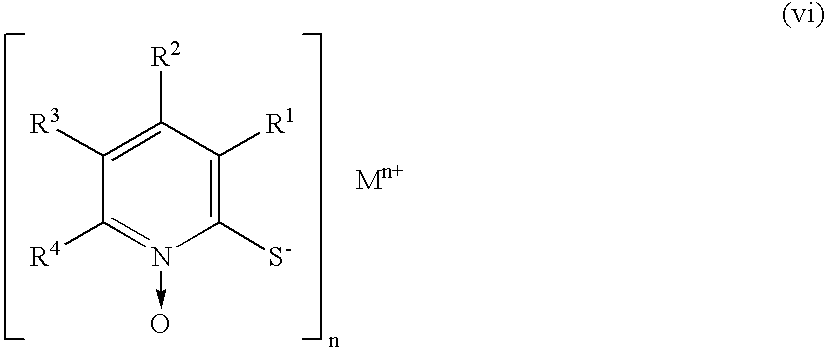

Unmanned aerial vehicle pesticide spraying method and system

InactiveCN106956778AIncrease profitAvoid wastingAircraft componentsTransmission systemsUncrewed vehicleComputer science

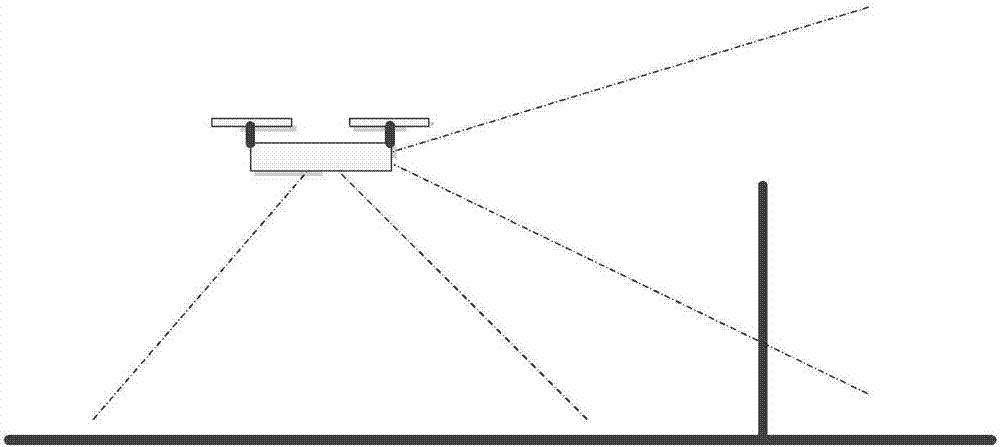

The invention relates to the technical field of unmanned aerial vehicles, and provides an unmanned aerial vehicle pesticide spraying method and system. The unmanned aerial vehicle pesticide spraying method comprises the following steps: (1) acquiring crop images of a working area, and comparing the crop images with crop images stored in a databank I in advance so as to confirm types of crops; (2) acquiring crop images of the working area, and comparing the crop images with insect images stored in a databank II in advance so as to confirm types of insects; (3) confirming types of insecticides to be sprayed according to the types of the crops and the types of the insects; (4) confirming the serious degree of crop insects, preparing insecticides of proper concentration according to the types of the insecticides and the serious degree of the crop insects, and spraying the insecticides. As the insecticides are automatically specifically sprayed according to the types of the crops and the crop insects, the insecticide spraying effects and the utilization rates of the insecticides can be improved, insecticide waste can be avoided, the cost can be reduced, and the intelligence and automation levels of the insecticide spraying process are increased.

Owner:GUANGDONG RONGQE INTELLIGENT TECH CO LTD

Curable composition, coating composition, paint, antifouling paint, cured product thereof and method of rendering base material antifouling

InactiveUS20020197490A1Shorten the running cycleExcellent in uniformity of coating film surfaceAntifouling/underwater paintsLayered productsHydrophobic silicaHardness

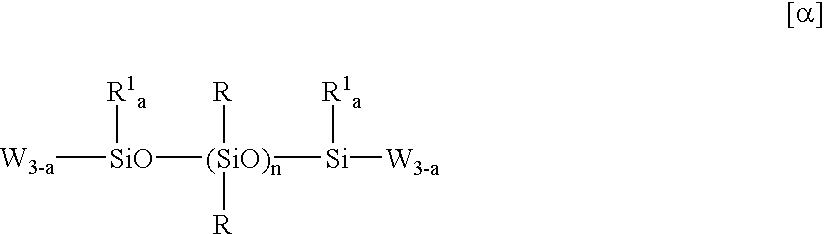

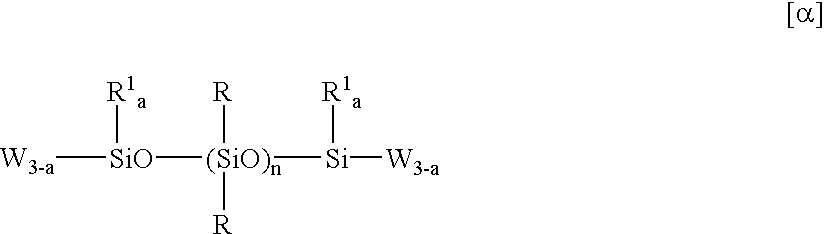

A curable composition comprising (A) an organopolysiloxane having functional groups capable of condensation reaction at both molecular terminals thereof and (B-1) a hydrophobic silica and a hydrophilic silica. A curable composition comprising (A) an organopolysiloxane having functional groups capable of condensation reaction at both molecular terminals thereof and (B-2) a hydrophobic silica, wherein the hydrophobic silica (B-2) is thermally treated together with the organopolysiloxane (A). The organopolysiloxane (A) is preferably represented by the formula: W3-a(R1a)Si(R2)O-(Si(R2)O)n-Si(R1a)W3-a [alpha] (wherein W represents a hydroxyl group or a hydrolyzable group; each of R1 and R independently represents an unsubstituted or substituted monovalent hydrocarbon group having 1 to 12 carbon atoms, provided that the hydrocarbon groups R1 as well as the hydrocarbon groups R may be identical with or different from each other; n is an integer of 5 or greater; and a is 0, 1 or 2). When, in the formula [alpha], W represents a hydroxyl group and a is 2, the curable composition preferably comprises, in addition to the components (A) and either (B-1) or (B-2), (C) an organosilane represented by the formula: R1bSiX4-b [I] (wherein R1 represents an unsubstituted or substituted monovalent hydrocarbon group having 1 to 8 carbon atoms; X represents a hydrolyzable group; and b is 0 or 1), or a partial hydrolyzate of the organosilane. Thus, a curable composition, especially a curable paint composition and an antifouling paint composition, and an antifouling coating film of the following characteristics can be provided. The curable composition, in particular when used as a coating material or a paint, is excellent in sprayability and enables forming a thick coating film by one-time application. The curable composition enables shortening the operating period for coating, and a coating film of uniform thickness can be obtained by the application thereof. The obtained coating film is excellent in film strength and film hardness and, when used for antifouling purposes, exerts excellent antifouling capability for a prolonged period of time. Further, the curable composition ensures excellent storage stability before application thereof.

Owner:CHUGOKU MARINE PAINTS +1

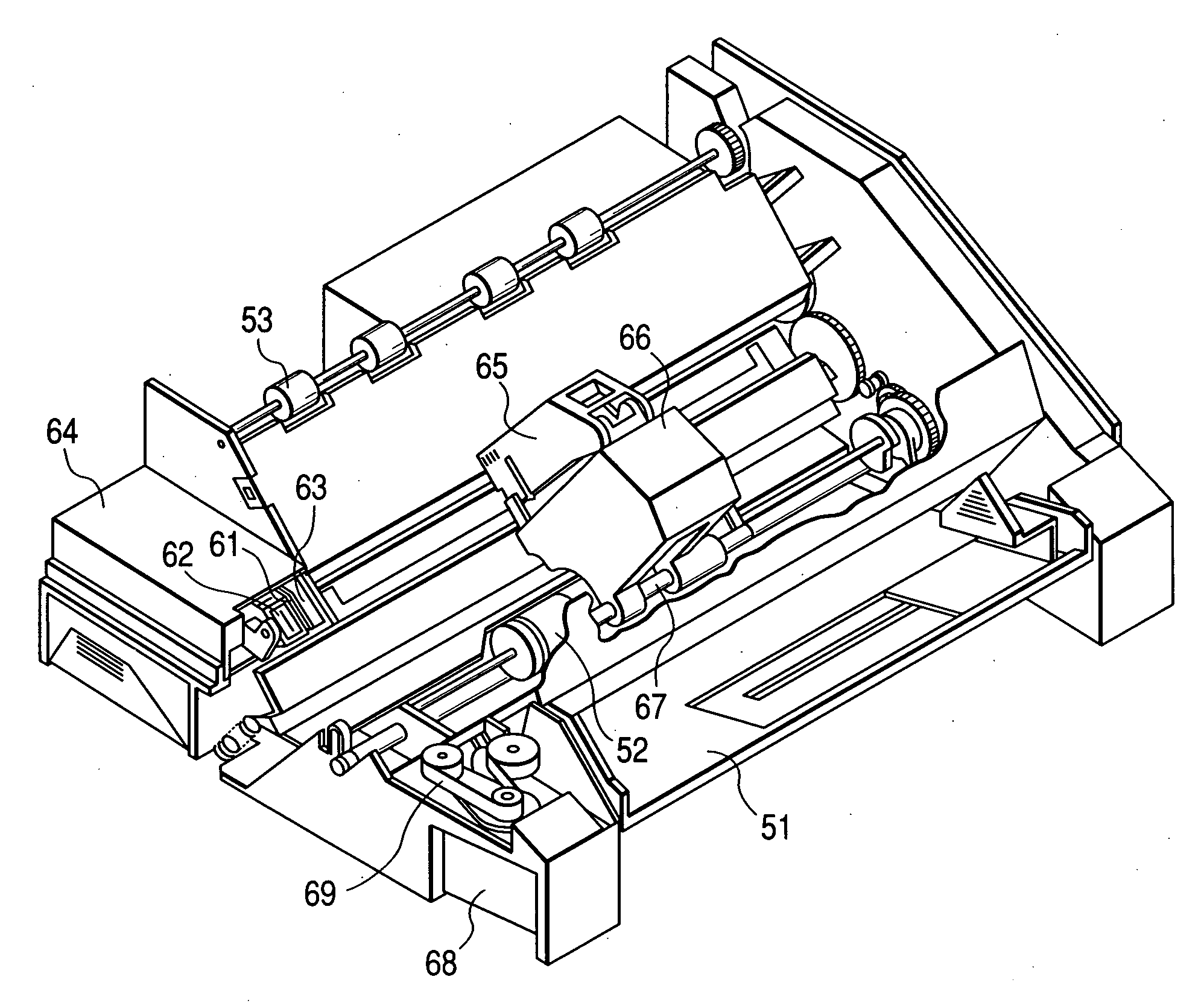

Spraying system having a liquid flow and rotating speed feedback

ActiveUS20170129605A1Less driftSpray effect be improveAircraft componentsUnmanned aerial vehiclesTraffic volumeRotation velocity

Systems and methods can determine a liquid flow in a spraying system. An amount of liquid that is output from the spraying system during a pump cycle is determined. A number of pump cycles that occur within a given amount of time are measured. The number of pump cycles are measured using an electronic speed controller (ESC). Additionally, the ESC indicates the number of pump cycles within a given amount of time within a threshold of precision. The amount of liquid flow in the spraying system is calculated based on the measured number of pump cycles and the determined amount of liquid that is output from the spraying system.

Owner:SZ DJI TECH CO LTD

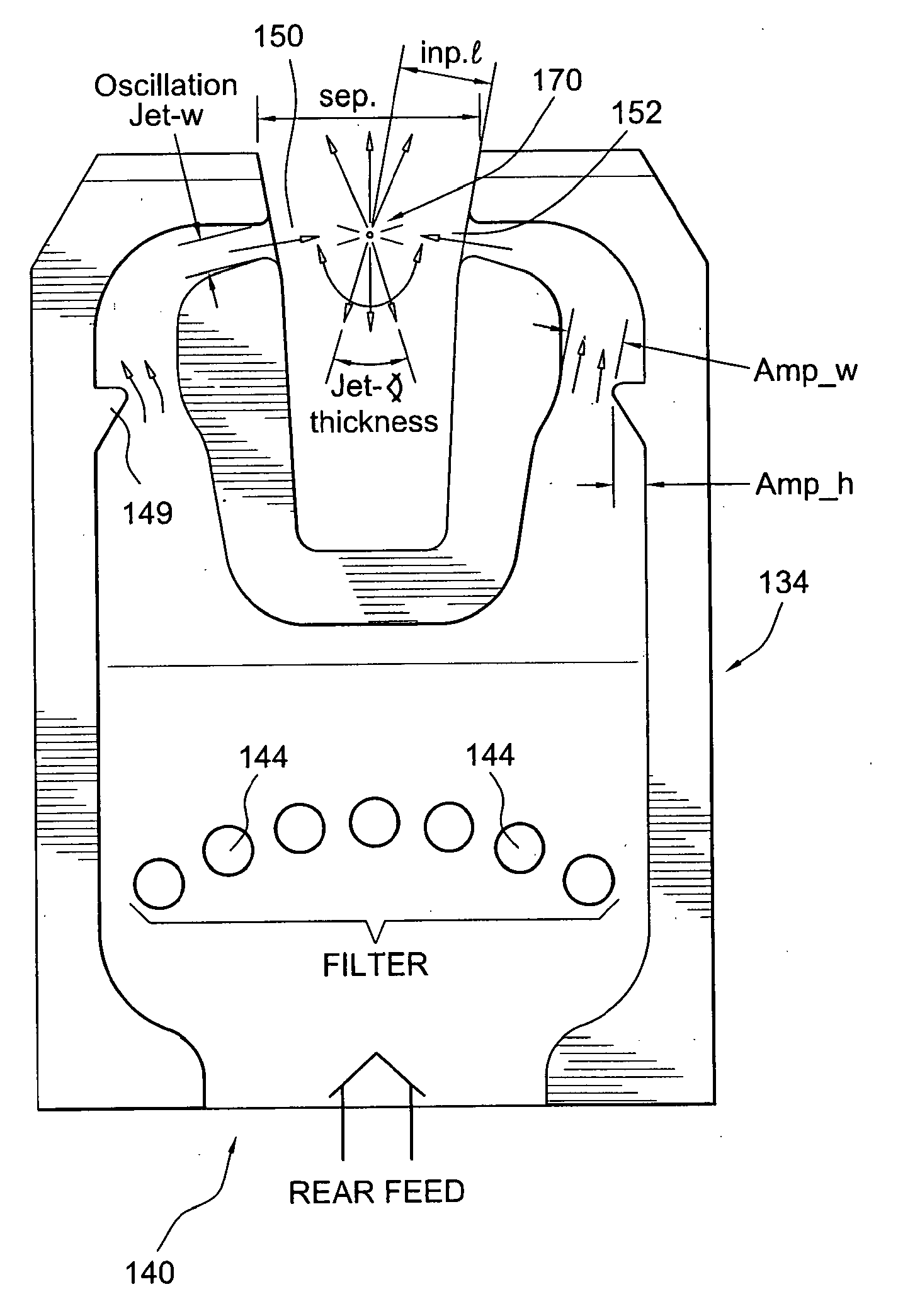

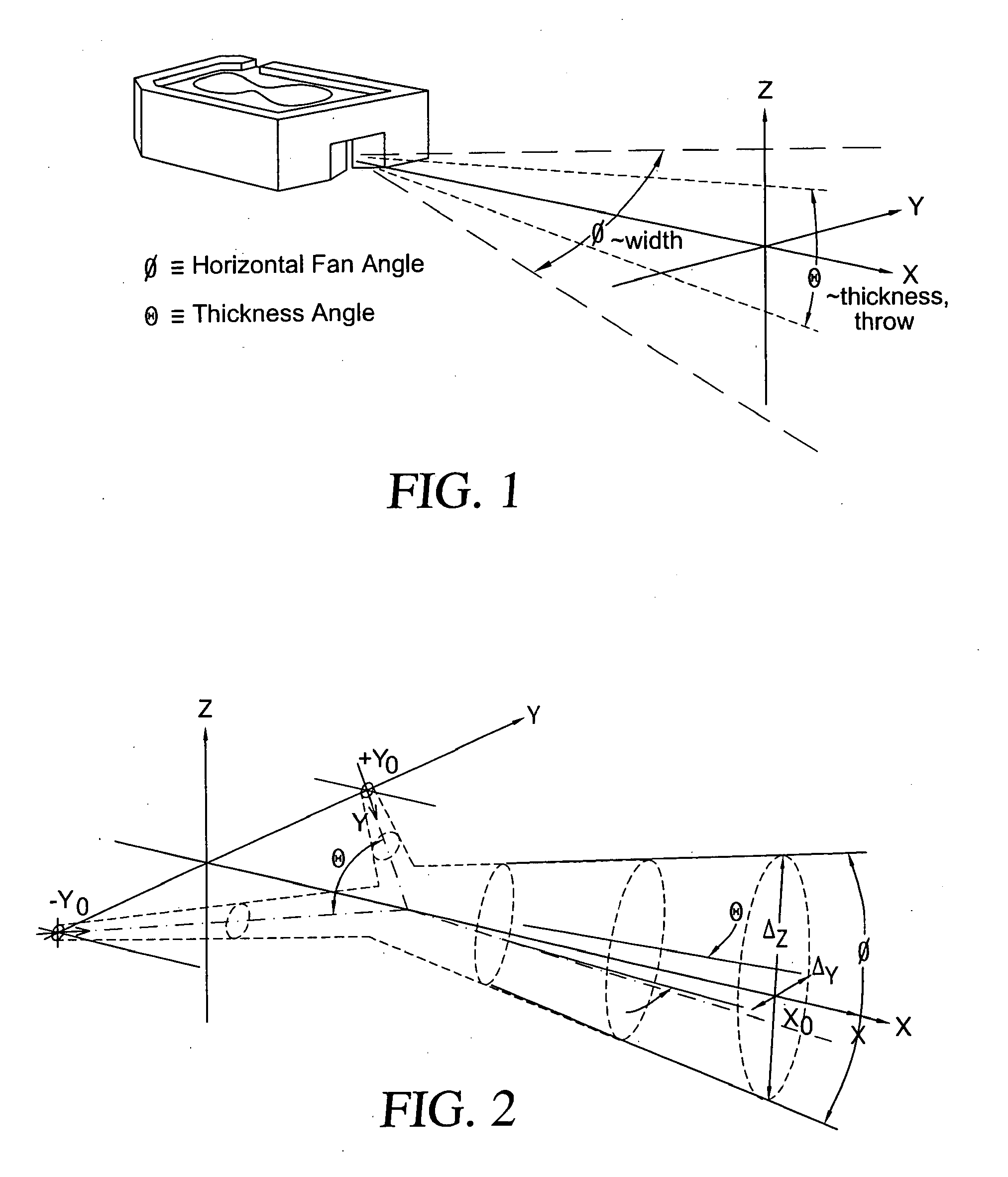

Full coverage fluidic oscillator with automated cleaning system and method

InactiveUS20110061692A1Increase heightImprove spraying effectUrinalsWater closetsAudio power amplifierFluidic oscillator

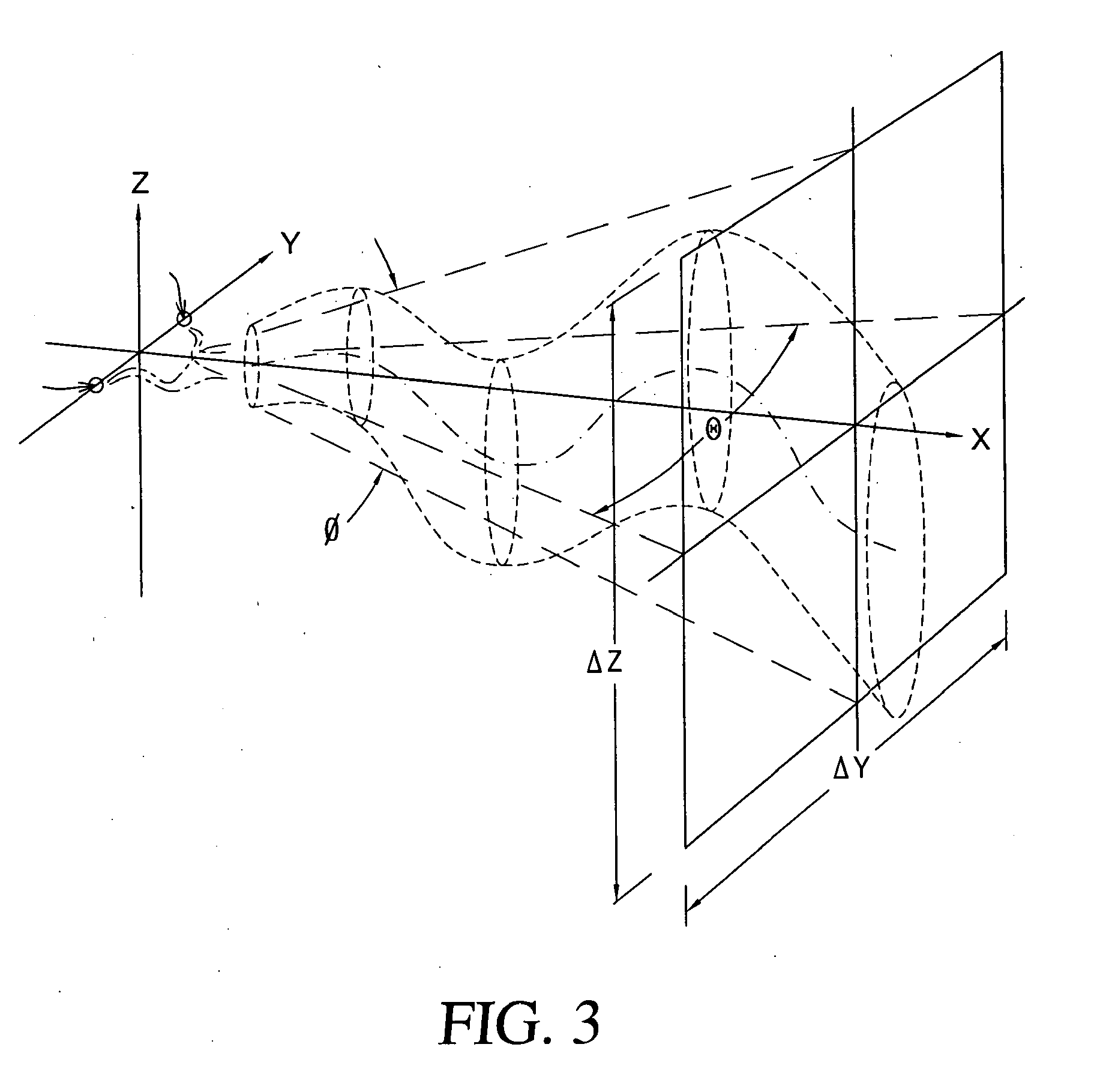

A full coverage fluidic oscillator (2) includes a fluidic circuit member preferably having an oscillation inducing internal chamber, at least one inlet (8) or source of fluid under pressure, at least a pair of output nozzles (14, 16) connected to the source of fluid for projecting at least first and second impinging fluid jets into free space, where the first and second impinging jets collide or impinge upon one another at a selected jet angle to generate a substantially omni-directional sheet jet having selected thickness. The first and second jets are aimed at a pre-selected intersection point in free space where impingement is to occur. The sheet jet's thickness Δy is determined by the time-varying path or oscillation of each of the first and second impinging jets. The first and second impinging jets can be made to oscillate or pulsate by use of vortex generating amplifier structures (68, 70, 72, 149) within the internal chamber's fluid flow paths.

Owner:DLHBOWLES INC

Heat-Managing Composite Structures

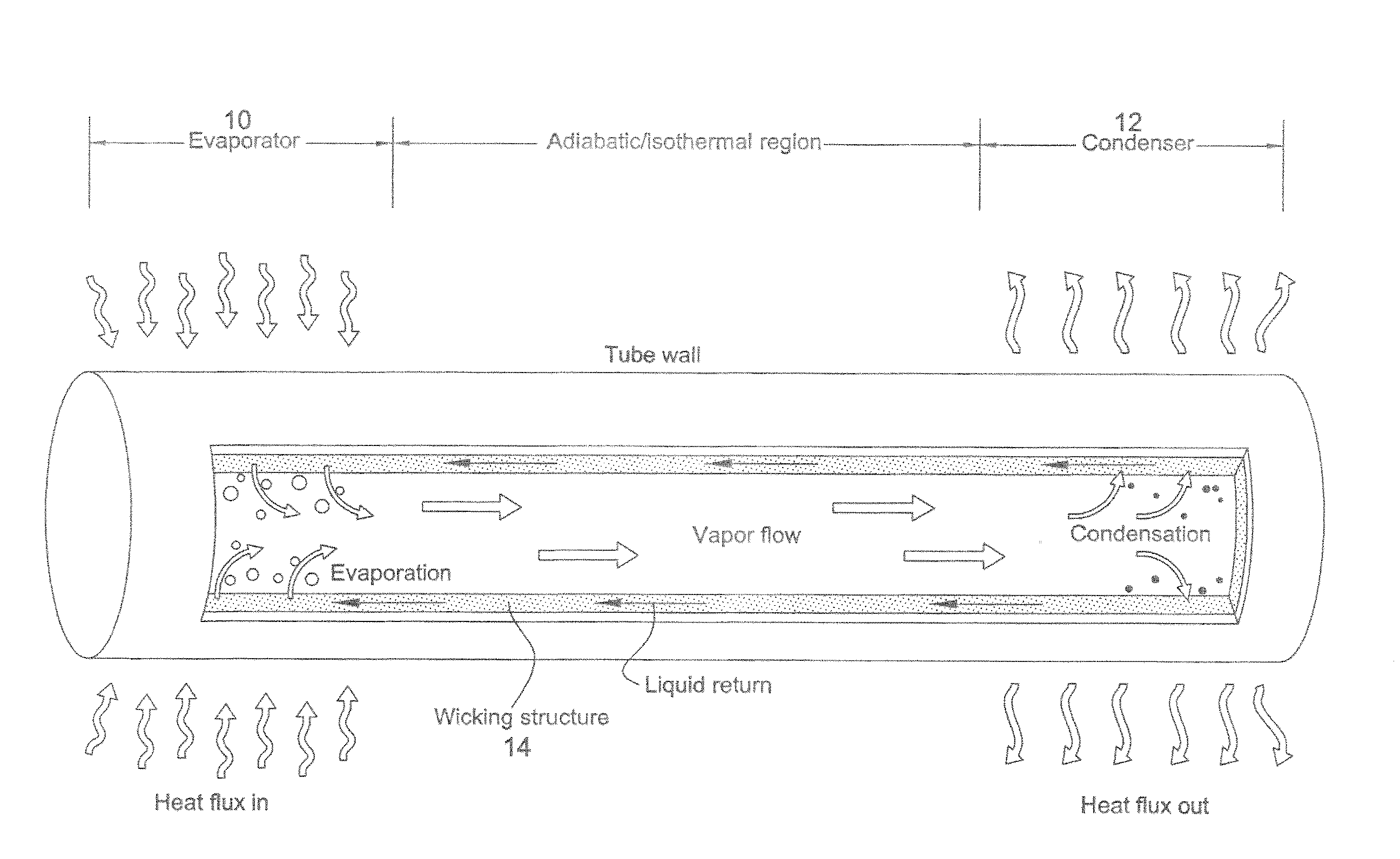

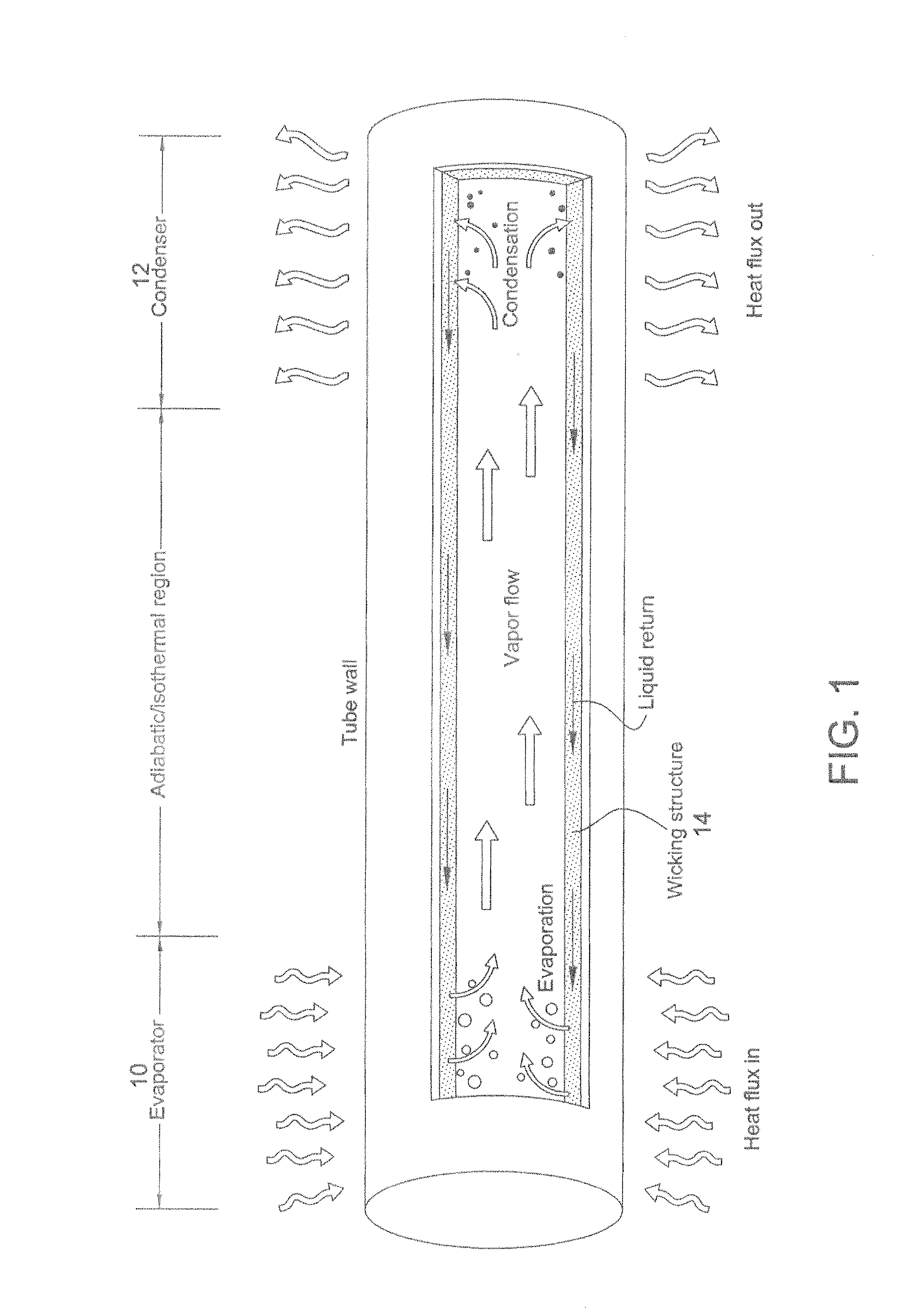

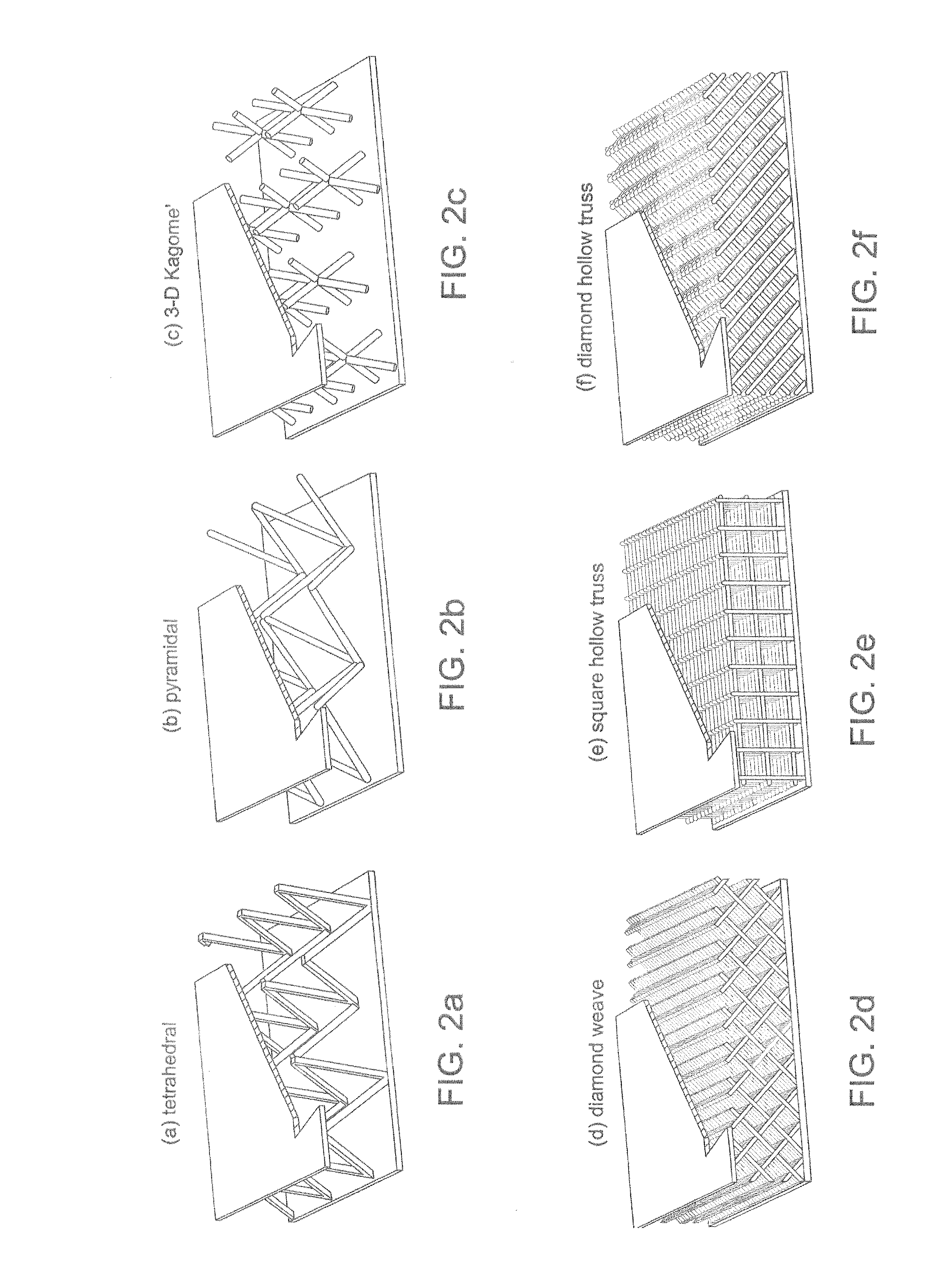

ActiveUS20100236759A1Improve spraying effectHigh dynamic strengthCorrosion preventionBuilding componentsHigh stressRocket

Light-weight, heat-managing structures feature open-cell lattice, honeycomb, and / or corrugated (prismatic) arrangements in their substructures, combined with heat pipe / heat plate arrangements for managing heat to which the structures are subjected. The structures are well suited to aerospace applications and may be employed in the leading edge of wings or other airfoil-shaped components; gas turbine engine components; rocket nozzles; and other high-heat, high-stress environments.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

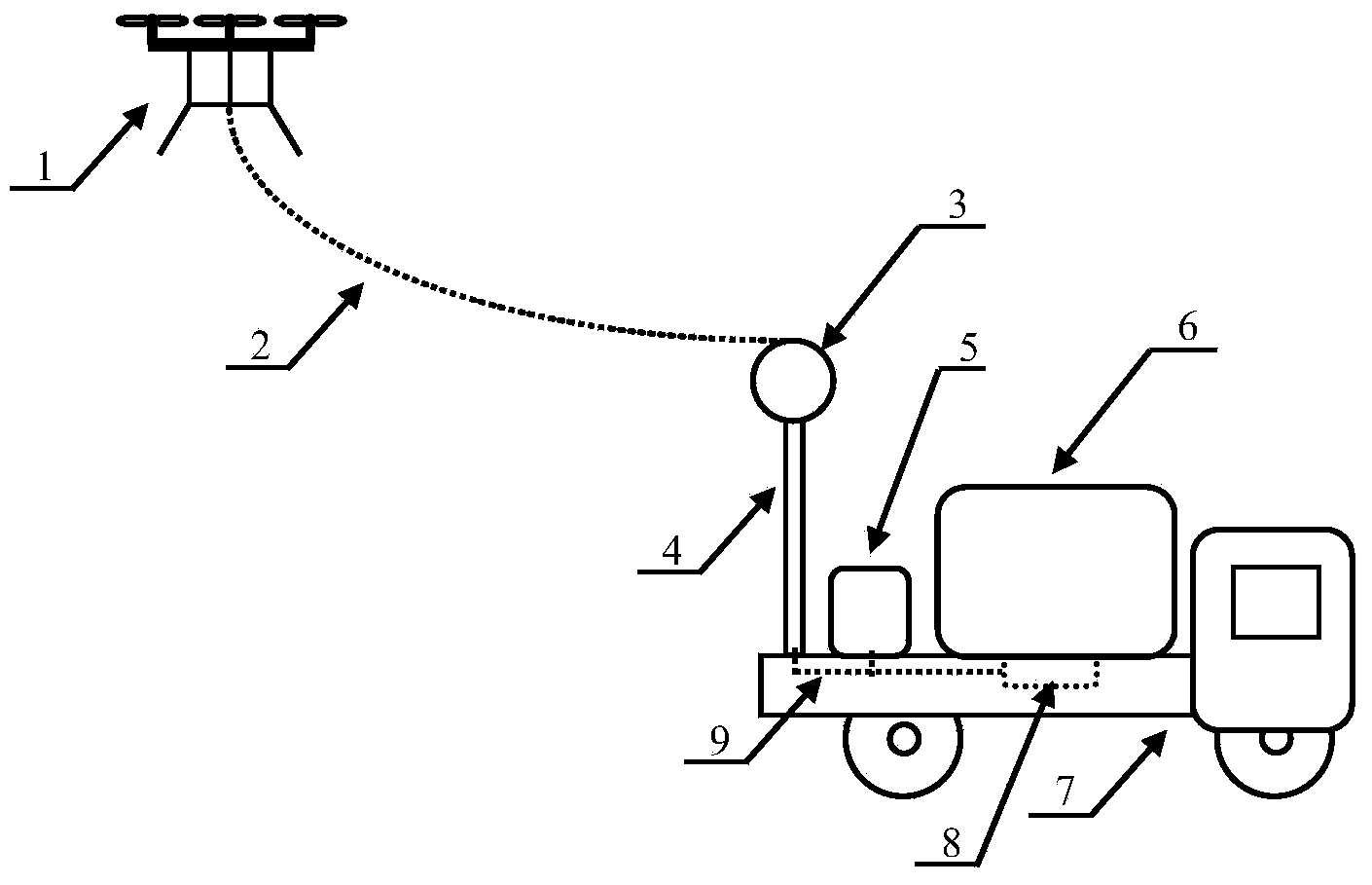

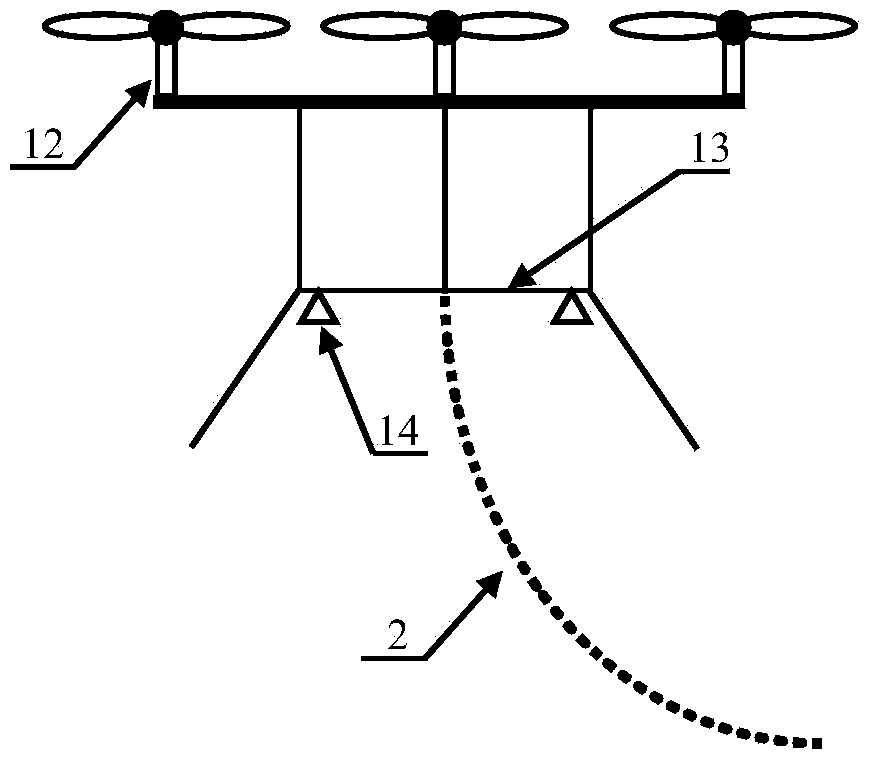

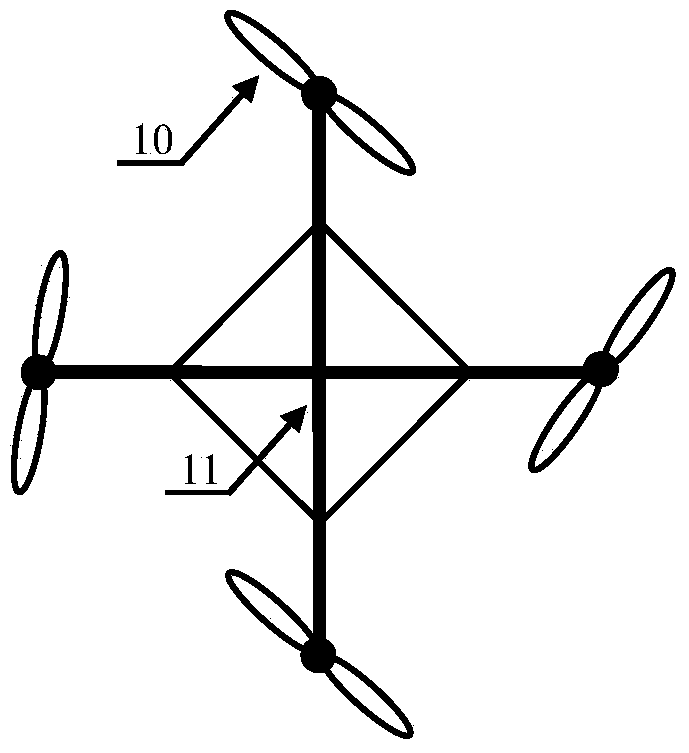

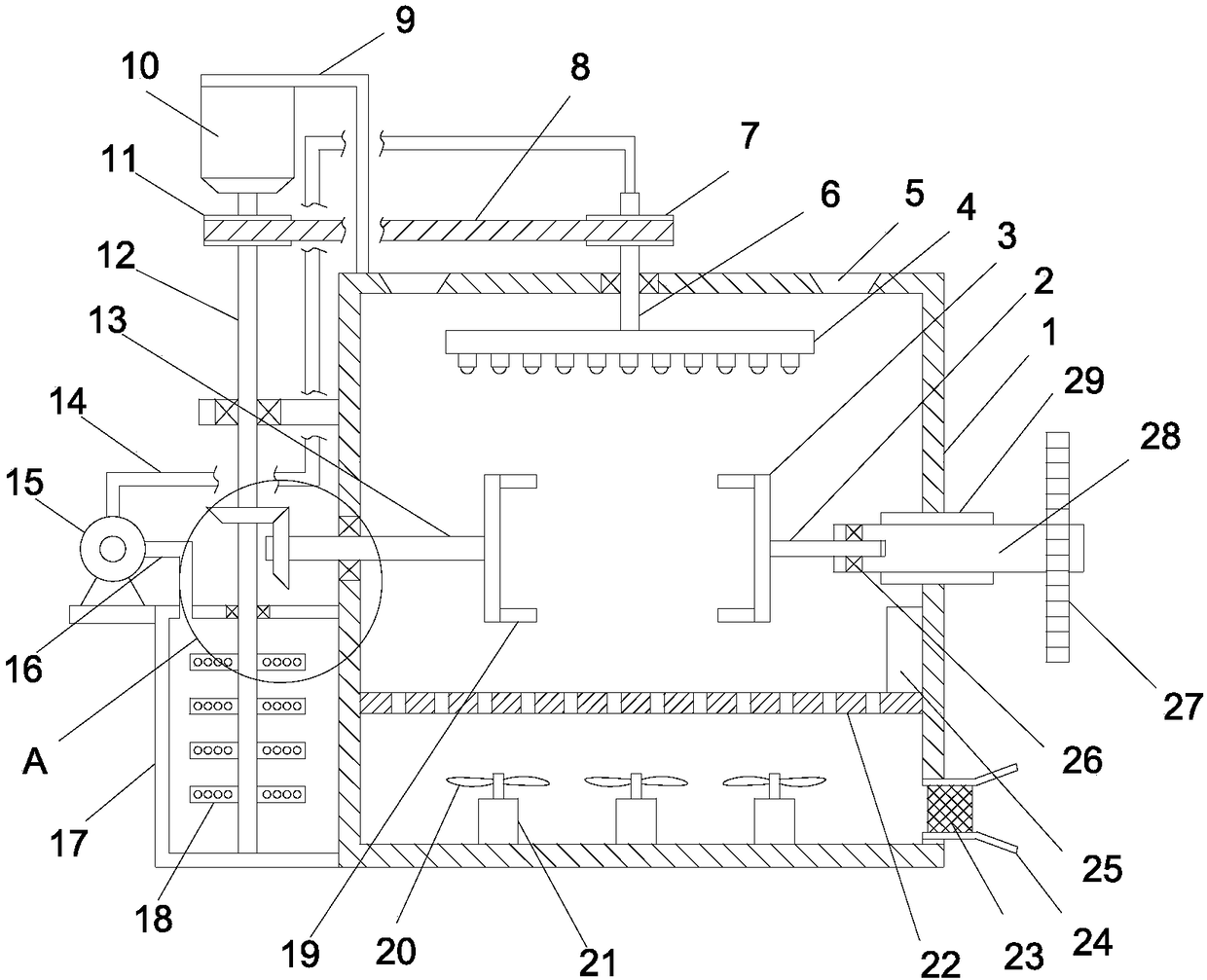

Air-ground combined agricultural spraying device and application thereof

InactiveCN103754368ASolve the problem of long-distance ground transportationOptimize joint operation effectAircraft componentsInsect catchers and killersAgricultural engineeringPropeller

The invention discloses an air-ground combined agricultural spraying device and application of the air-ground combined agricultural spraying device. The air-ground combined agricultural spraying device comprises an aircraft, connecting pipelines, a winch mechanism, a winch mechanism supporting rod, a power system, a liquid pesticide storage tank, a transport vehicle, a pressure pump, an inner passage, a propeller, a propeller beam, a propeller drive motor, an aircraft bracket and spray heads. According to the air-ground combined agricultural spraying device, the large-size heavy liquid pesticide tank, the pressure pump and the power system are installed on the transport vehicle, a spraying mechanism is installed on the small unmanned rotorcraft, and an air device and a ground device are connected through hoses and wires. In this way, aerial spraying in a limited area within ultra-long auto-hover time is achieved, and meanwhile long-distance ground transportation of an aircraft is achieved.

Owner:SOUTH CHINA AGRI UNIV

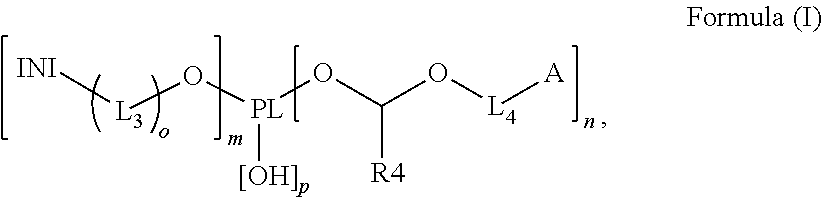

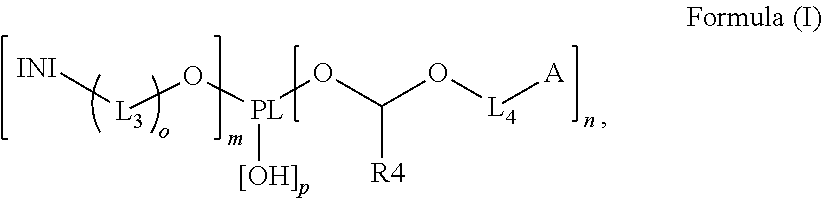

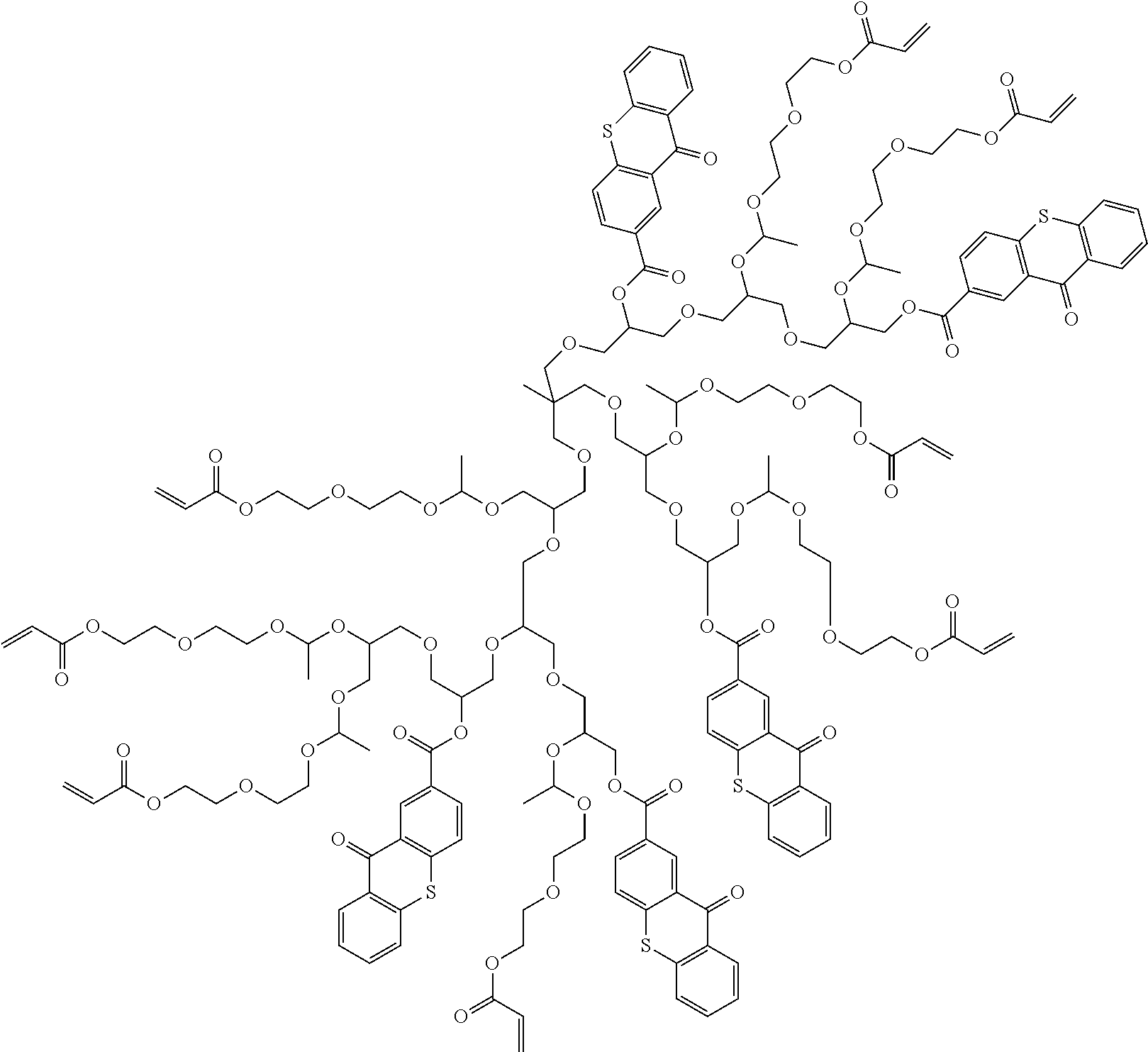

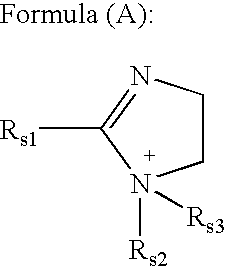

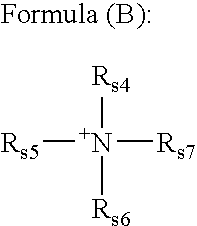

Polymerizable polymeric photoinitiators and radiation curable compositions

InactiveUS20120046376A1Simple and cost efficient procedureAvoiding unecological removal of solventInksVinyl etherPhosphine oxide

A polymerizable polymeric photoinitiator according to Formula (I):wherein:PL represents an n+m+p-functional polymeric core;n and m independently represent an integer from 1 to 30;p represents an integer from 0 to 10;o is 0 or 1;INI represents a group selected from the group consisting of a benzophenone, a thioxanthone, a carbazole, a anthraquinone, a camphor quinone, an α-hydroxyalkylphenone, an α-aminoalkylphenone, an acylphosphine oxide, a bisacyl phosphine oxide, an acylphosphine sulfide, a phenyl glyoxalate, a benzoin ether, a benzyl ketal, an α-dialkoxyacetophenone, a carbazolyl-O-acyl-oxime, an α-haloarylketone and an α-haloaryl sulfone;L3 and L4 represent a substituted or unsubstituted divalent linking group comprising 1 to 14 carbon atoms;A represents a radically polymerizable functional group selected from the group consisting of an acrylate, a methacrylate, a styrene, an acryl amide, a methacryl amide, a maleate, a fumarate, an itaconate, an vinyl ether, an allyl ether, an allyl ester, a maleimide, a vinyl nitrile and a vinyl ester; andR4 represents a substituted or unsubstituted alkyl group.Radiation curable compositions containing the polymerizable polymeric photoinitiator and methods for preparing the polymerizable polymeric photoinitiator are also disclosed.

Owner:AGFA NV

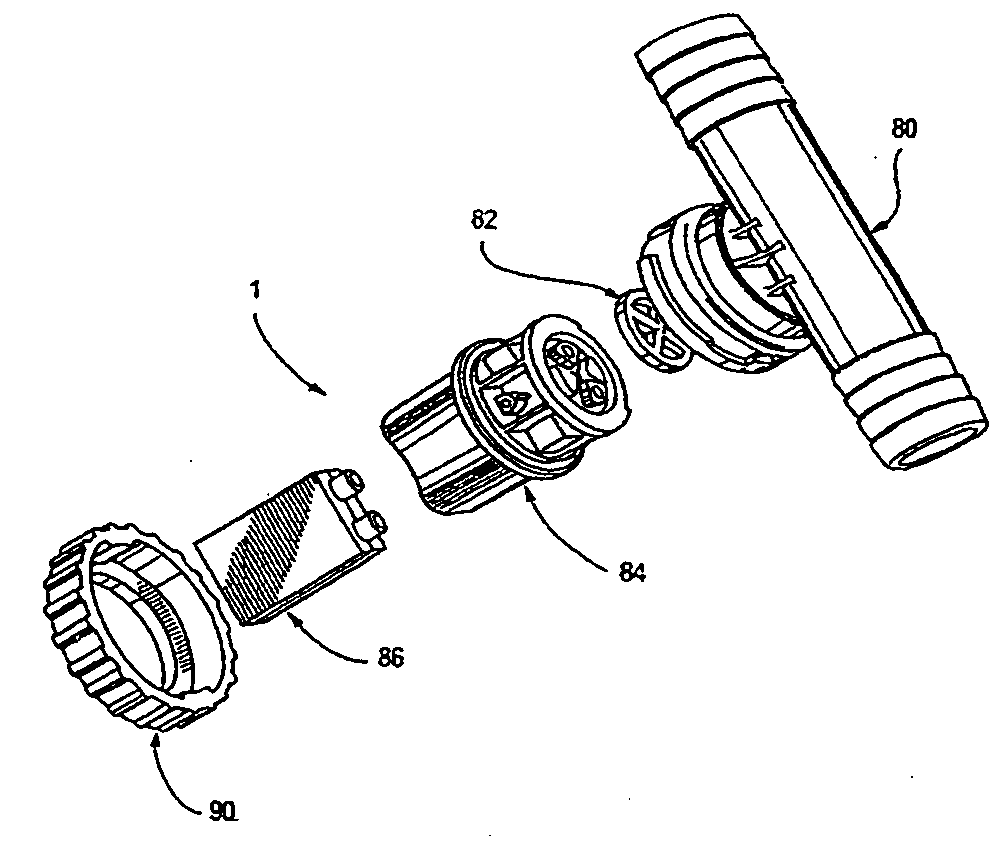

Enclosures for fluidic oscillators

ActiveUS20060108442A1Improve spraying effectIncrease surface areaCircuit elementsMovable spraying apparatusFluidic oscillatorEngineering

For those spray applications that use a fluidic oscillator of the type that generates a spray by having a pressurized liquid flow through the oscillator and exhaust into a surrounding environment, and where such an oscillator has a boundary surface which has fabricated into it a channel in the form of what is referred to herein as fluidic circuit, an improved enclosure for this oscillator includes: a body having an interior and an exterior surface, wherein a portion of this interior surface is configured to attach to the oscillator boundary surface so as to form with the oscillator's channel an enclosed pathway through which the to-be-sprayed liquid may flow, and wherein a segment of this interior surface is configured so as to yield specified properties of the resulting spray.

Owner:DLHBOWLES INC

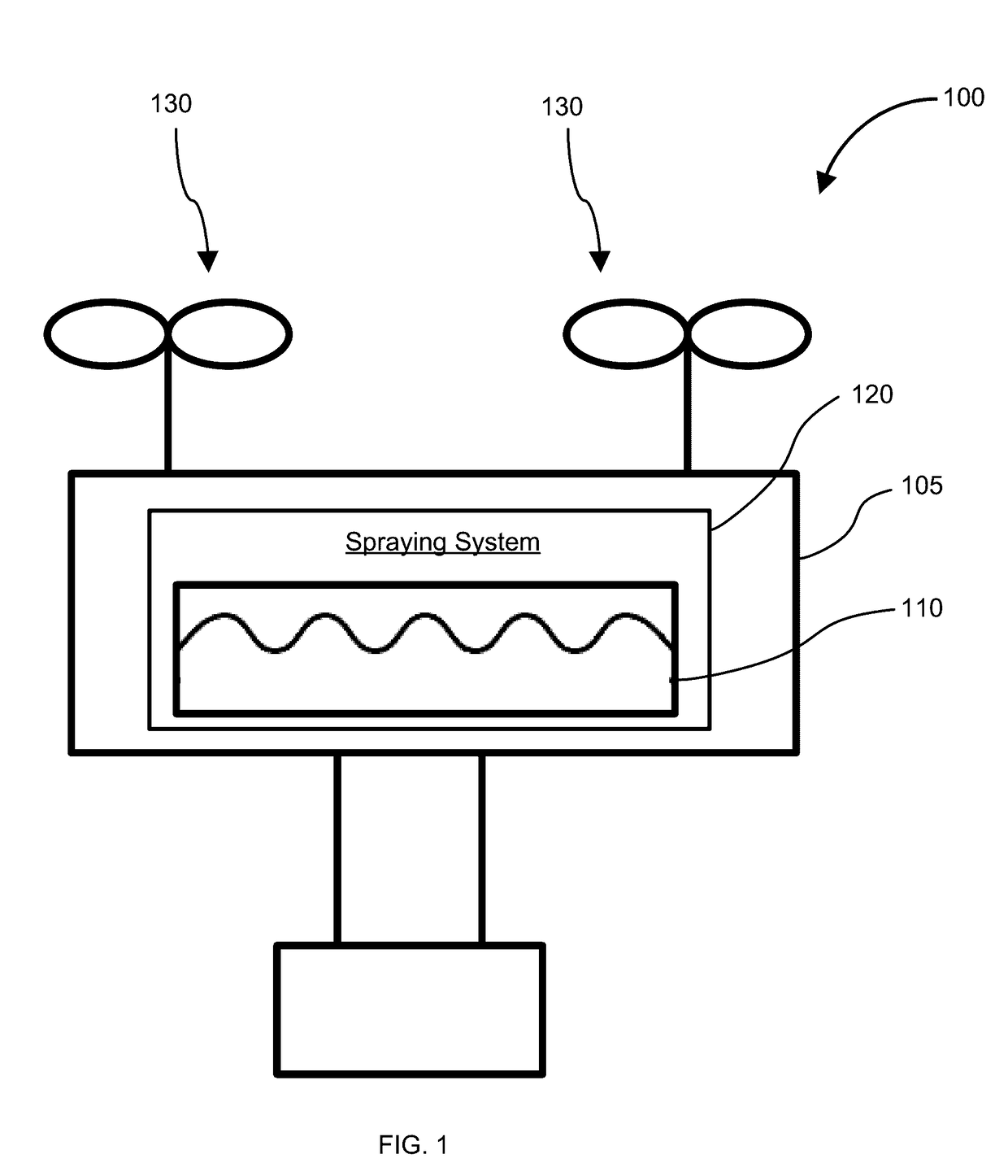

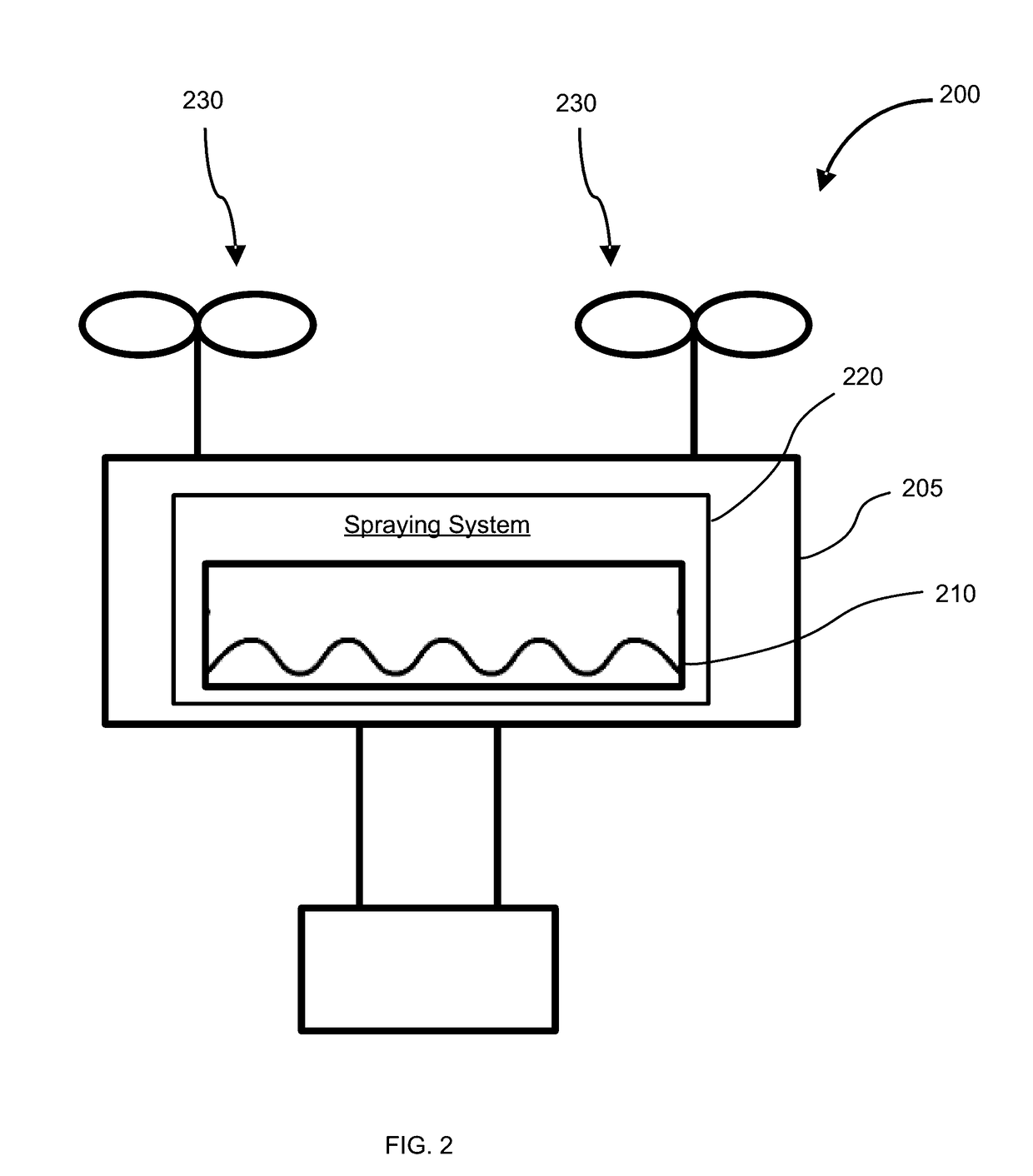

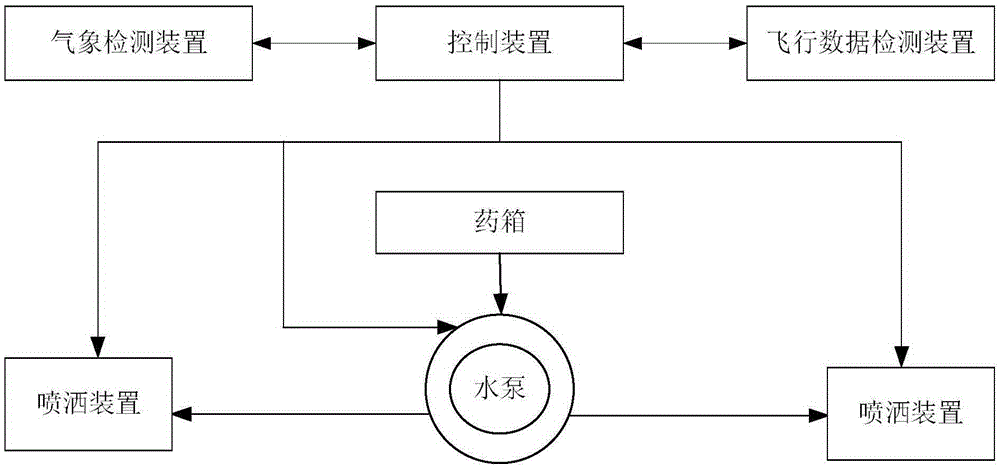

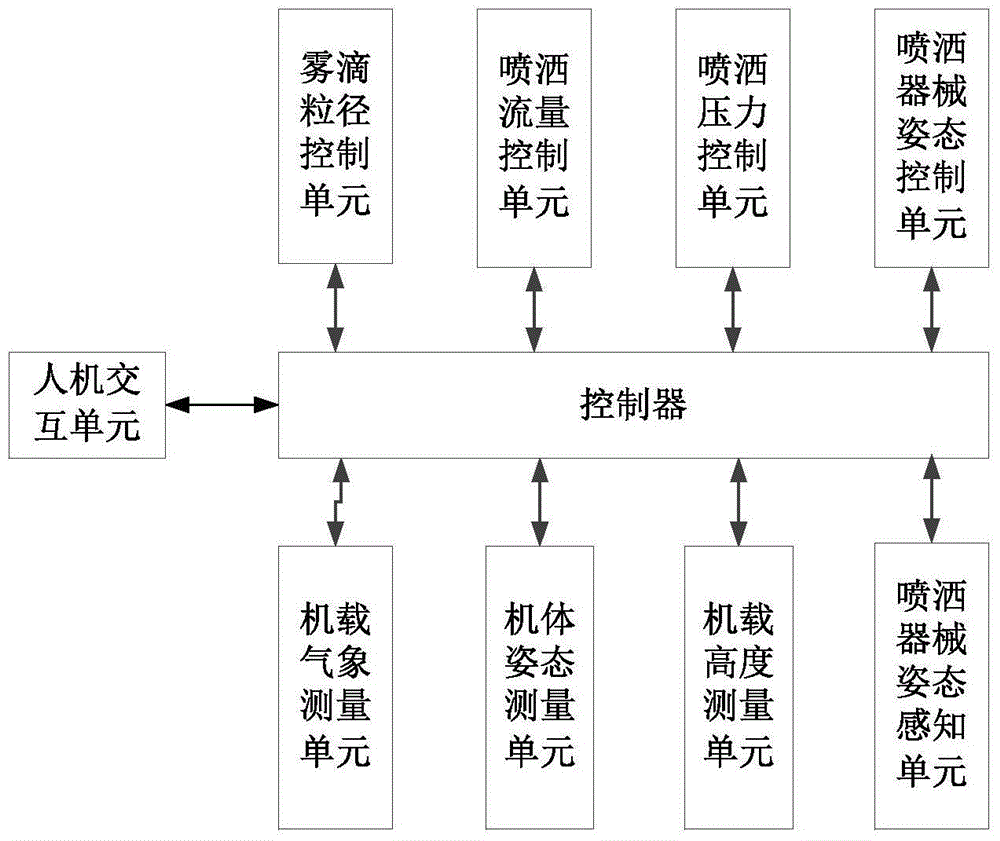

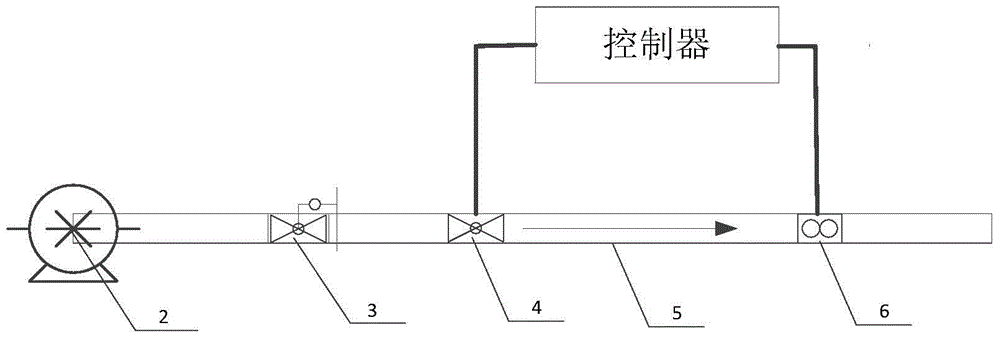

Multi-rotor unmanned aerial vehicle sprinkling system and sprinkling control method

ActiveCN105292480AImprove spraying effectAircraft componentsLaunching weaponsFlight dataAerospace engineering

The invention discloses a multi-rotor unmanned aerial vehicle sprinkling system and a sprinkling control method. A control device is used for coordinately controlling a weather detection device, a flight data detection device and a sprinkling device to execute respective functions, sprinkling of the sprinkling device is adaptively adjusted according to weather information and flight parameters, the influences of the flight parameters of an unmanned aerial vehicle, the weather information and the size of sprinkling fog drops on the sprinkling radiation range are fully considered, the problem that drifting or miss sprinkling of sprinkling liquid is easily caused by unmanned aerial vehicle sprinkling in the prior art is solved, and accurate control over sprinkling is achieved.

Owner:南京衡创天伟无人机技术有限公司

Construction site dust removing device used for preventing fog and haze

InactiveCN106522144AEasy to operateSprinkle water evenlyRoad cleaningCircular discArchitectural engineering

The invention relates to a construction site dust removing device, in particular to a construction site dust removing device used for preventing fog and haze. The construction site dust removing device used for preventing fog and haze is easy to operate, uniform in spraying and small in work amount, and comprises a flat belt, a circular disc, a first bearing pedestal, a small belt pulley, a connecting rod, a lifting rod, a piston, a cylinder block, a first fixed pulley, a first one-way valve, a first flexible pipe and the like. Wheels are symmetrically arranged at the bottom of a bottom plate. A big belt pulley is arranged on the front side of each right wheel. A push handle is welded to the left end of the top of the bottom plate. A water tank is connected to the left side of the top of the bottom plate in a bolt connection mode. By adoption of the construction site dust removing device used for preventing fog and haze, the effects of easy operation, uniform water spraying and small work amount are achieved, and the construction site dust removing device plays an important role in being good in spraying effect and high in safety and improving the working efficiency.

Owner:朱雪梅

Ion-sensitive, water-dispersible polymers, a method of making same and items using same

InactiveUS7276459B1Improve propertyReduce high shear viscosityInorganic/elemental detergent compounding agentsBiocideIonWater dispersible

The present invention is directed to ion-sensitive, water-dispersible polymers. The present invention is also directed to a method of making ion-sensitive, water-dispersible polymers and their applicability as binder compositions. The present invention is further directed to fiber-containing fabrics and webs comprising ion-sensitive, water-dispersible binder compositions and their applicability in water-dispersible personal care products.

Owner:KIMBERLY-CLARK WORLDWIDE INC

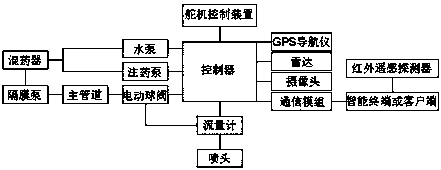

Agricultural chemical application monitoring and accurate flow rate control device and method

InactiveCN108605923APrecision medicineExpand the injection volumeControlling ratio of multiple fluid flowsFlow control using electric meansDiseaseInfrared remote sensing

The invention relates to an agricultural chemical application monitoring and accurate flow rate control device and method. The device comprises a chemical mixing device, a flow rate meter, a nozzle, acontroller and an infrared remote sensing detector, on-spot preparing and using of agricultural chemical is achieved by the chemical mixing device, the agricultural chemical is sprayed by passing through a primary pipeline to reach the nozzle, remote sensing images of a field are detected by the infrared remote sensing detector, and a corresponding application prescription map and an applicationstrategy are generated after data analysis processing is conducted; agricultural chemical spraying is controlled by the controller according to the application prescription map and the application strategy, the application concentration is adjusted by controlling a water pump and a chemical filling pump, application situation is monitored in real time according to signals transmitted by a camera,an ultrasound radar, the flow meter and a velocity sensor to adjust the application concentration and the flow rate, and therefore accurate application and flow rate control can be achieved. Accordingto the device, computation of the concentration and amount of the chemical can be conducted according to disease and pest situation of the field, feedback is conducted in real time, accurate application is conducted to improve the utilization rate of the agricultural chemical, and agricultural residue and waste caused by blindly application are prevented.

Owner:HENAN UNIV OF SCI & TECH

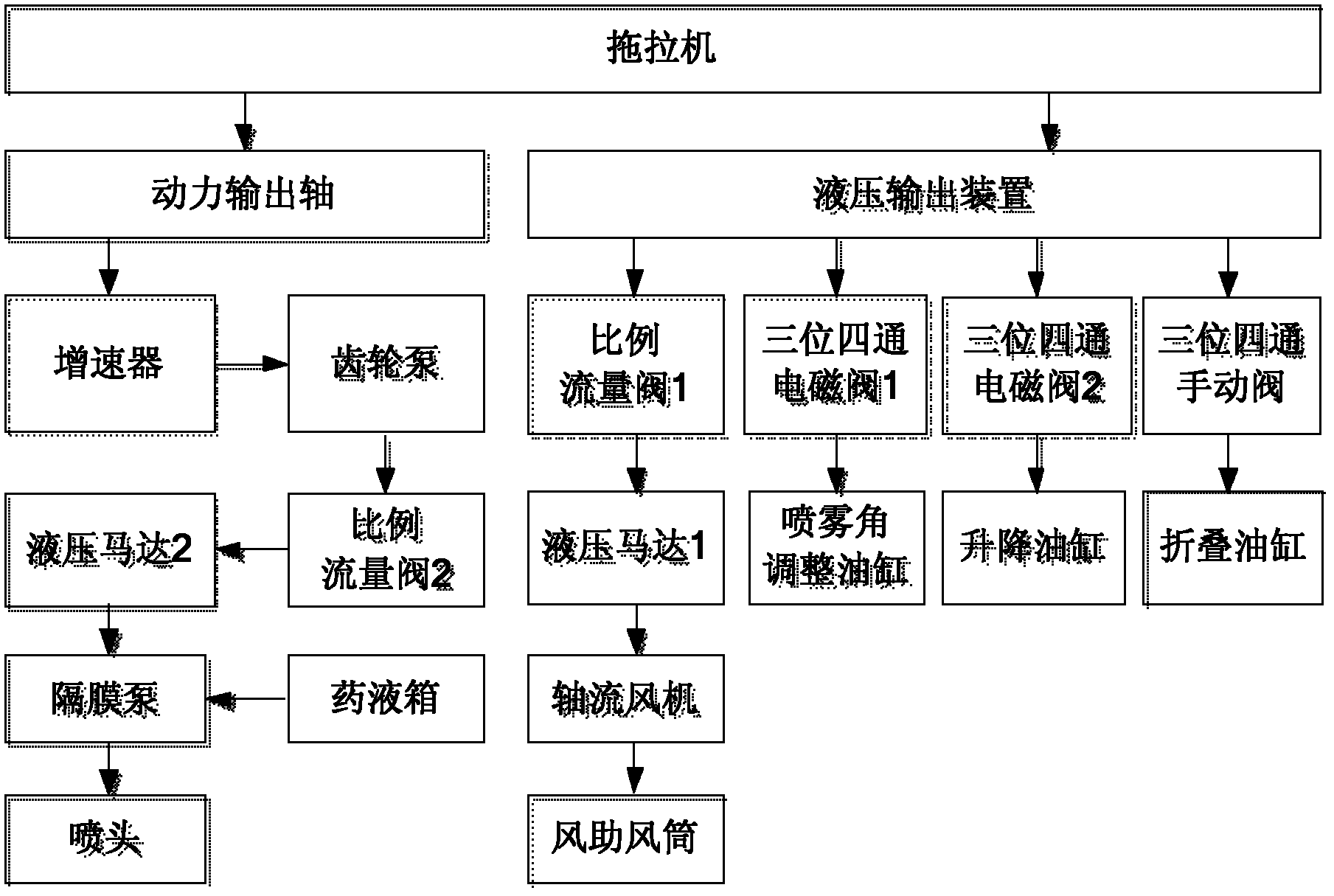

Control system for boom sprayer and spraying compensation control method

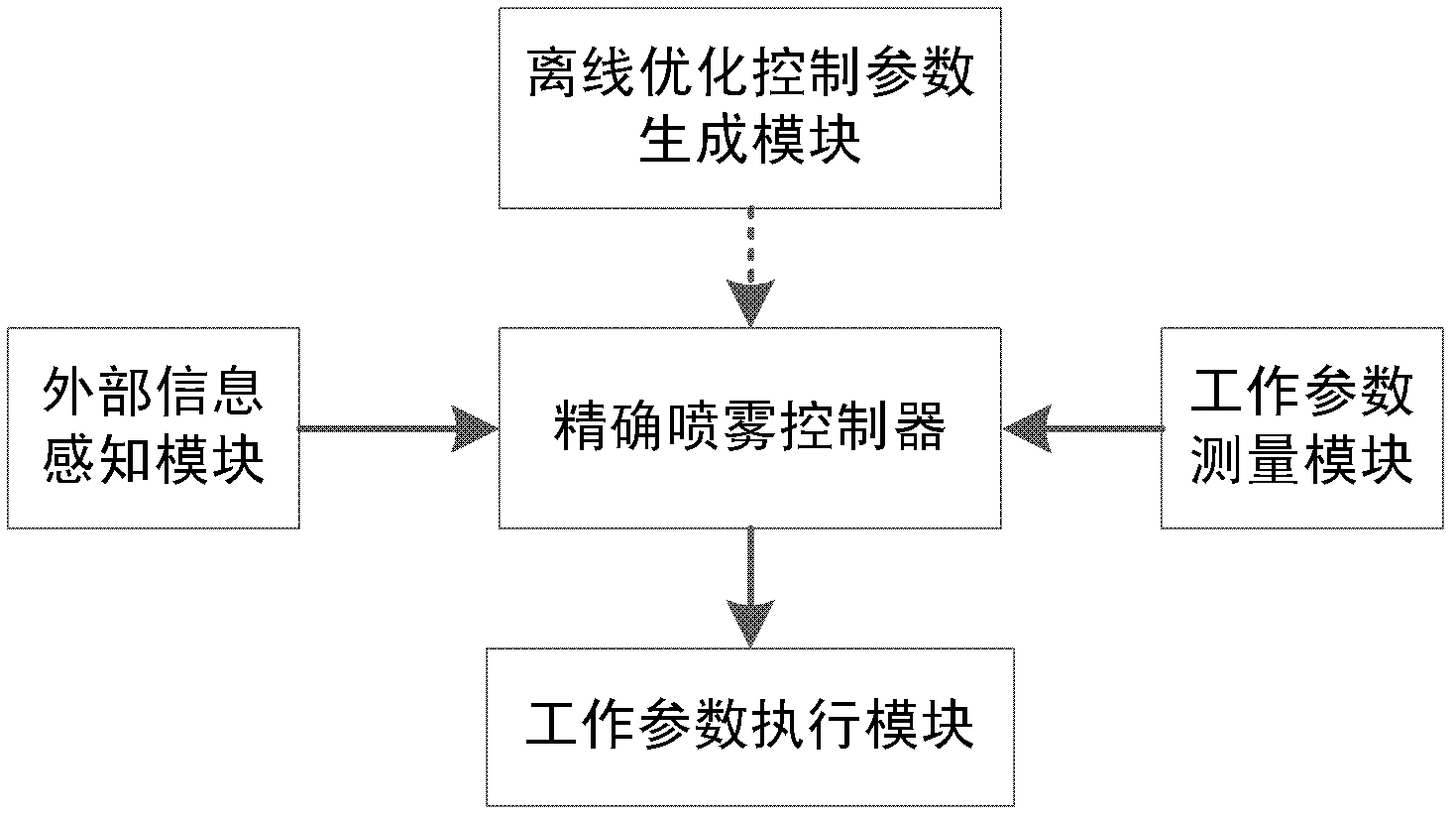

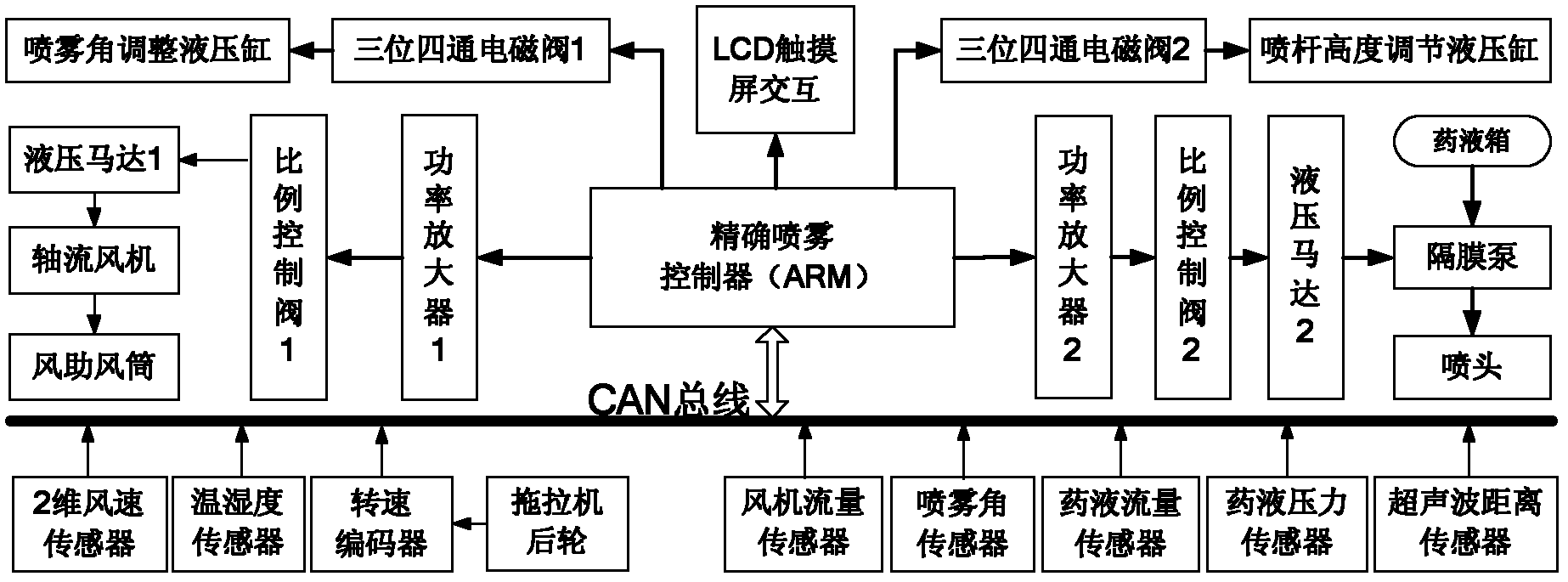

InactiveCN102613161AReal-time control of working parametersPenetratingInsect catchers and killersSolenoid valveOptimal control

The invention relates to a control system for a boom sprayer and a spraying compensation control method. The control system comprises a hydraulic and mechanical driving part and an electric control part, wherein the hydraulic and mechanical driving part provides a proportional flow valve and a three-position four-way solenoid valve to control working parameters of the sprayer, such as the liquid pesticide pressure, fan delivery, spraying angle and distance from a spraying head to a crop canopy; the electric control part searches parameters in an optimal control index parameter table to work out the best spraying control parameters in the state according to acquired external information such as two-dimensional natural wind speed, environmental humiture and tool traveling speed; and then PID (Proportion, Integration and Differentiation) feedback control is performed on each parameter; further, an intelligent control method for the optimal control index is provided; a support vector machine is used for nonlinear characteristic modeling of spraying under a dynamic environment, and the optimal control parameter index table is established by using multi-objective optimization and storedin an SD (Secure Digital) card for reading by a spraying master control system; with the adoption of the above spraying control considering the dynamic variation of the natural environment and based on the optimal control parameter index table, the stability of a spraying system is effectively improved, and the spraying effect is ensured.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Ink and ink set for ink jet printing and method of ink jet printing

InactiveUS20050178288A1Improve spraying effectFastness to light and heatInksPorphines/azaporphinesCyanineHeat resistance

An inkjet recording ink composition comprising an aqueous medium having dissolved and / or dispersed therein at least one dye, wherein at least one betaine-type surfactant is contained in the ink composition. The dye used is preferably a magenta dye having a specific azo structure or a cyanine dye having a specific phthalocyanine structure. By virtue of such a constitution, an inkjet recording ink composition excellent in ejection property, light fastness, heat fastness and oxidation resistance and causing less dye bleeding can be provided.

Owner:FUJIFILM HLDG CORP +1

Directly sprayed polypropylene material and preparation method thereof

The invention relates to a directly sprayed polypropylene material and a preparation method thereof. The polypropylene material is prepared with the following materials: polypropylene, second component high polymer material, compatilizer, filler, lubricating agent and antioxidant. The preparation method includes the following steps: (1) the materials are weighed according to a ratio, and are uniformly mixed in a high-speed mixer at a high speed for 5 to 10 minutes; (2) the mixed material is added in a double-screw extruder, melted, extruded and granulated. The polypropylene material has high rigidity and good sprayability, cannot be easily scratched and chipped and cannot easily leave traces, and moreover, the preparation method has the advantages of simple technique, convenient operationand low cost.

Owner:SHENZHEN KEJU NEW MATERIAL

Autonomous path planning method for plant protection unmanned aerial vehicle

InactiveCN107992078AImprove the effect of prevention and controlSave human effortPosition/course control in three dimensionsUncrewed vehiclePlanning approach

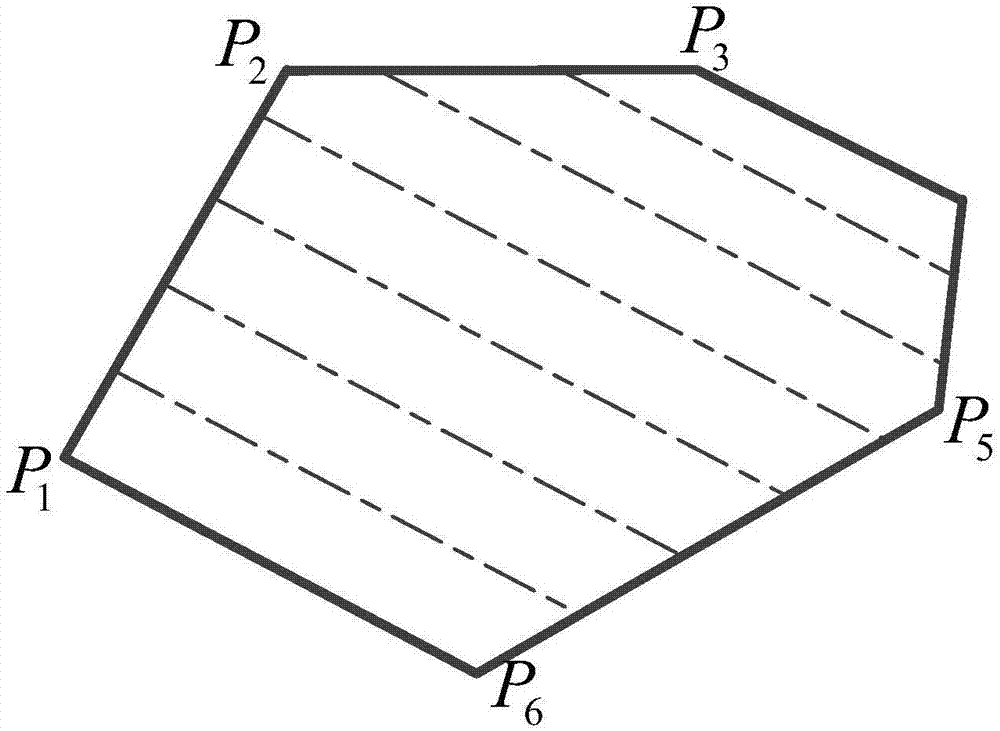

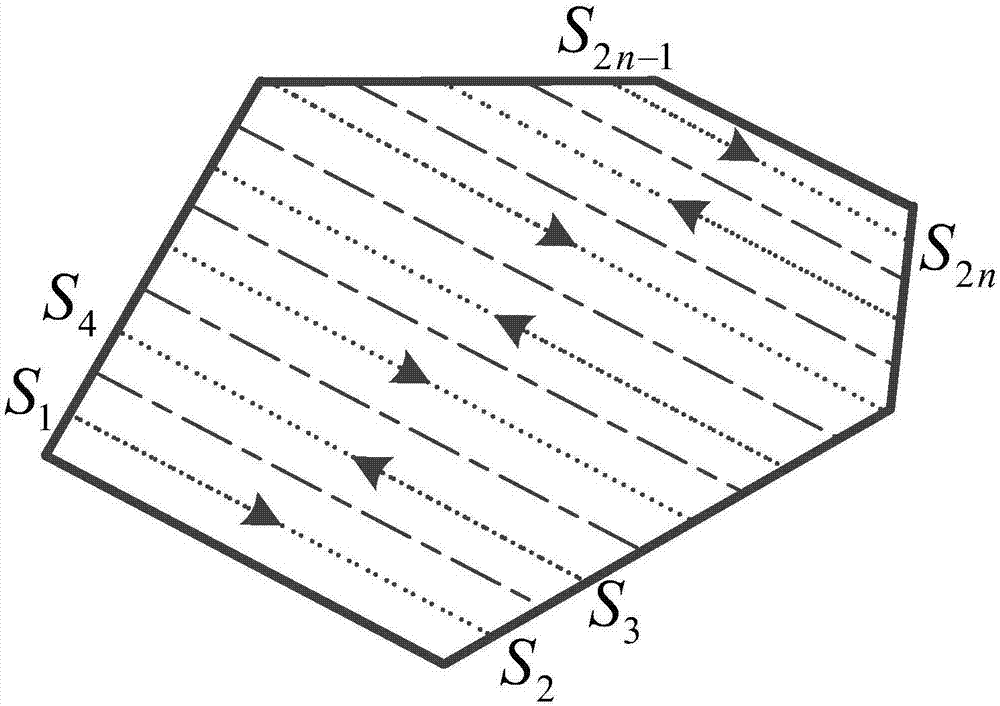

The invention discloses an autonomous path planning method for a plant protection unmanned aerial vehicle. A spraying area of the unmanned aerial vehicle is given. After the unmanned aerial vehicle receives a spraying task, a to-be-sprayed area is divided into strip-shaped areas, a spraying path is planned, the unmanned aerial vehicle tracks the spraying path to carry out a spraying mission, complex earlier-stage preparatory work is not required before the unmanned aerial vehicle works, spraying work is performed according to the pre-planned path, overspray and missing spray and the like are avoided, pesticides are saved, the pest control effect is improved, and manpower is saved.

Owner:XIAN TANVEN INTELLIGENT TECH CO LTD

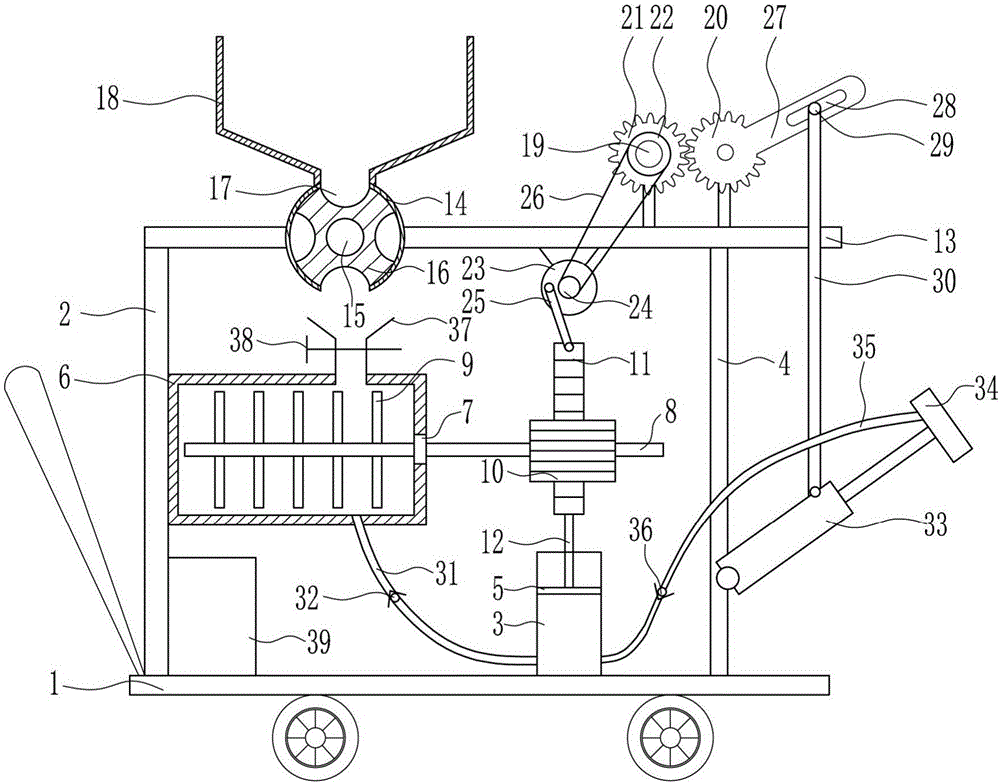

Automatic high-efficiency pesticide spray device

InactiveCN107173373AImprove work efficiencyMention the scope of sprayingInsect catchers and killersEngineeringBevel gear

The invention discloses an automatic high-efficiency pesticide spray device. The device comprises a mobile frame, and a spray tank arranged on the top of the left side of the mobile frame, wherein a pesticide storage cavity is formed in the spray tank, and a stirring mechanism is connected in the pesticide storage cavity in a matched connection manner; a first transmission cavity is formed in the mobile frame at the bottom of the pesticide spray tank; a second transmission cavity is formed in the mobile frame on the right side of the first transmission cavity and extends forward; a guide groove is formed in the mobile frame on the right side of the front extending section of the second transmission cavity, and the top of the guide groove runs through the end face of the top part of the mobile frame; a first rotating shaft is connected into the wall body of the mobile frame between the first transmission cavity and the second transmission cavity in a matched connection manner, and extends toward left and right sides; the left end of the first rotating shaft extends into the first transmission cavity, and a first bevel gear is fixedly arranged at the tail end of the left end of the first rotating shaft; and the right extending section of the first rotating shaft extends into the first transmission cavity, and a second bevel gear is fixedly arranged at the tail end of the right extending section of the first rotating shaft. The automatic high-efficiency pesticide spray device has a simple structure, and can meet the requirement of uniformly spraying crops having different plant heights, so that the spraying efficiency can be improved, and automatic stirring operation can be realized.

Owner:付天龙

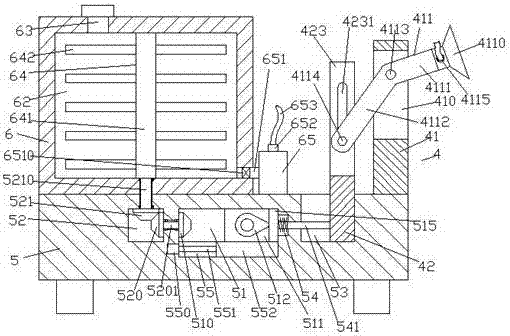

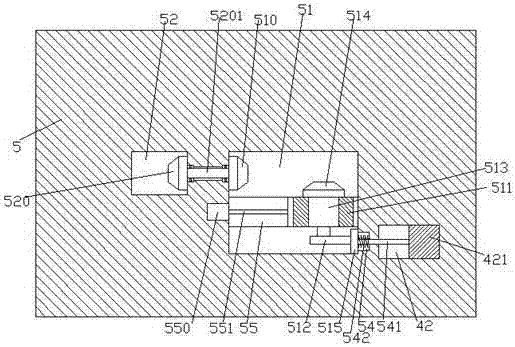

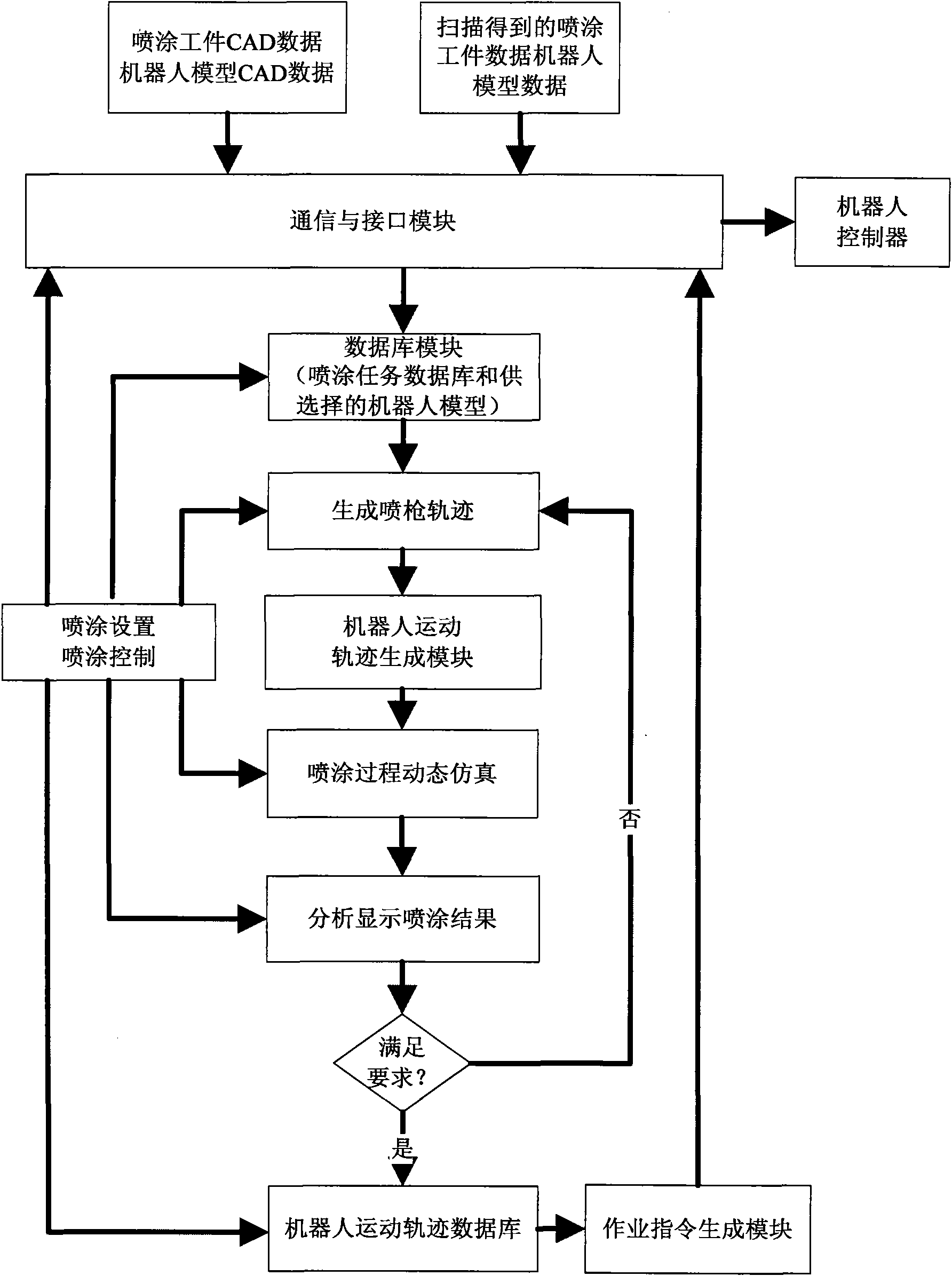

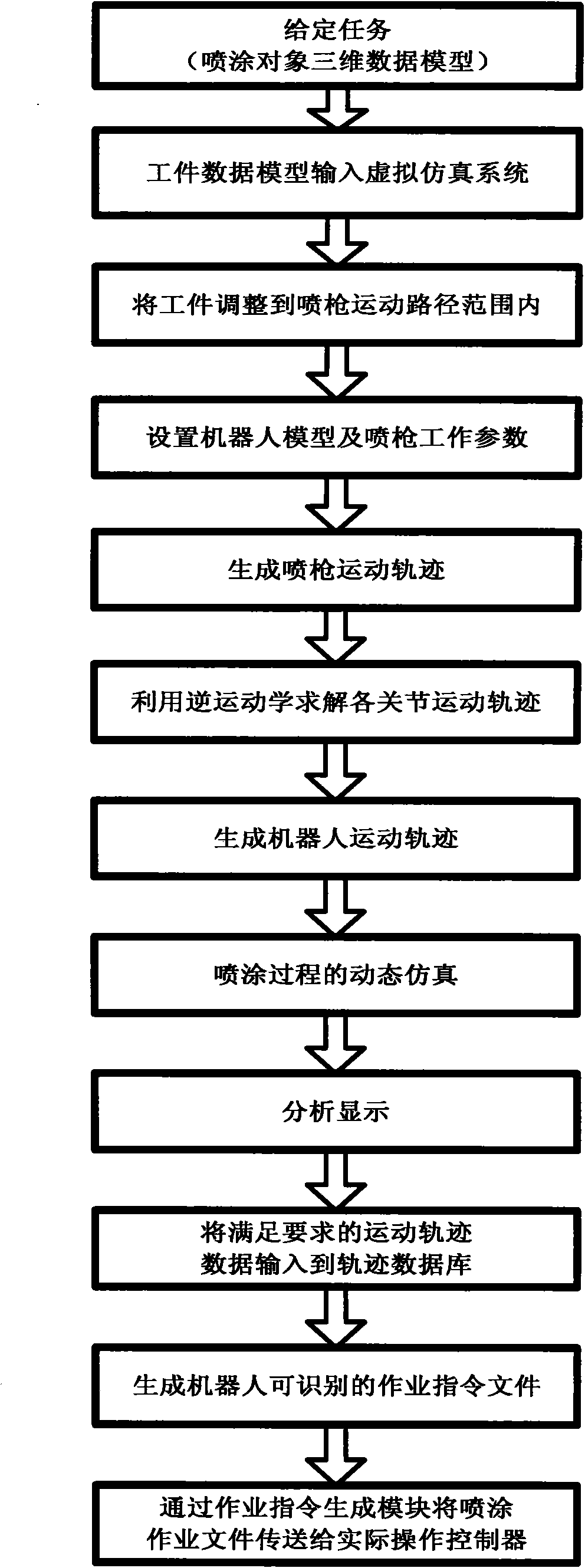

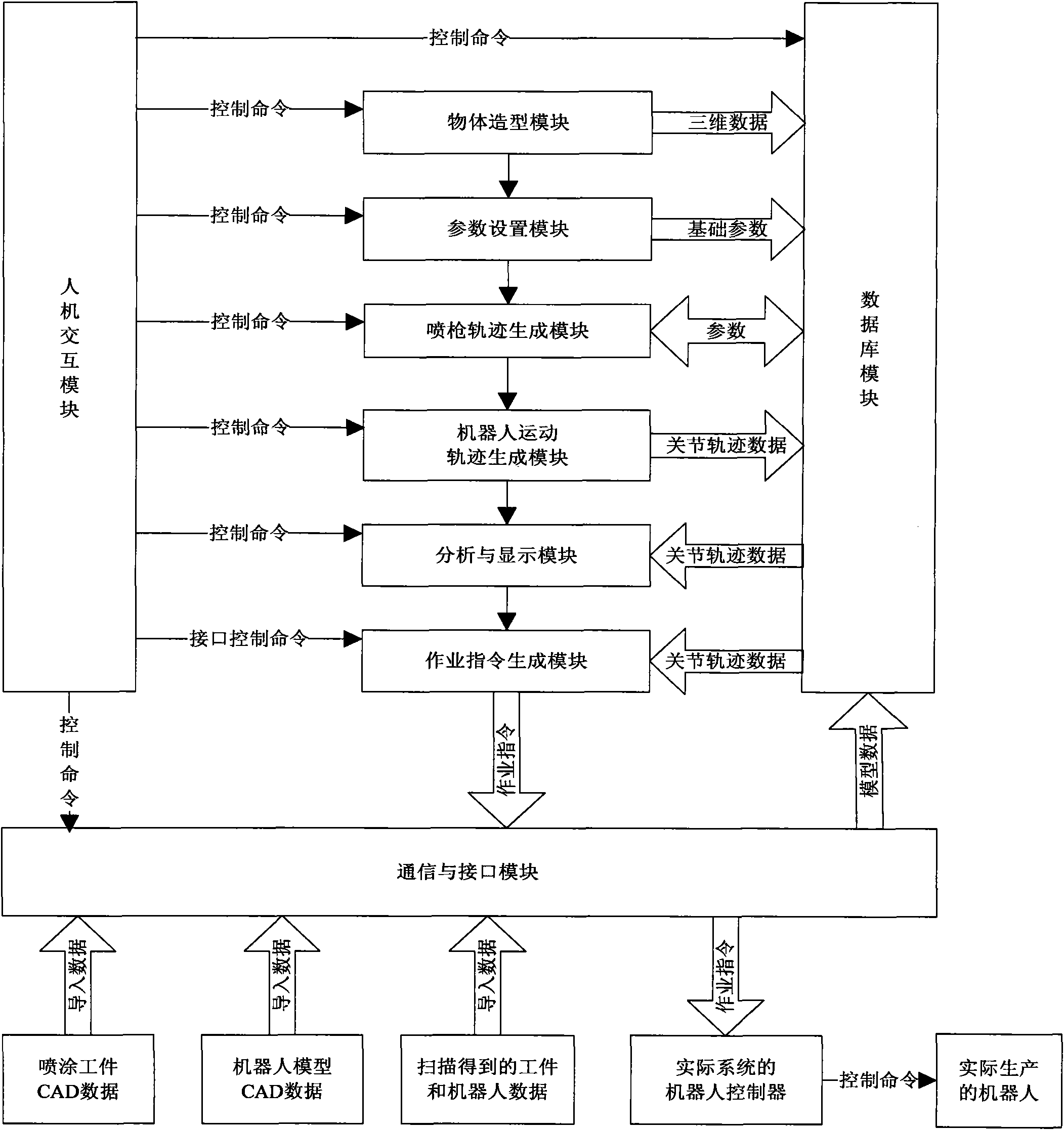

Industrial robot comprehensive control platform and control method thereof

InactiveCN101850552AReduce in-circuit debugging timeDoes not take up working timeManipulatorProduction ratePath generation

The invention relates to an industrial robot comprehensive control platform and a control method thereof. The industrial robot comprehensive control platform comprises an object modeling module, a parameter setting module, a database module, a spray gun path generation module, a robot motion path generation module, a man-machine interaction module, an analysis and display module, an operation command generation module and a communication and interface module. The invention has the advantages that the functions are complete, the commonality is high, the robot program development cycle is shortened, the painting accuracy of the system is improved, the production cost is reduced, the production efficiency is improved, the requirements on the technical capability of operators are reduced, the economic benefit is high and the platform can be easily accepted by users.

Owner:GUANGDONG UNIV OF TECH

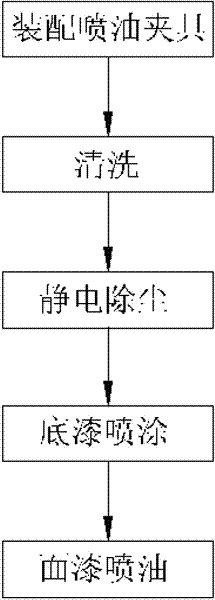

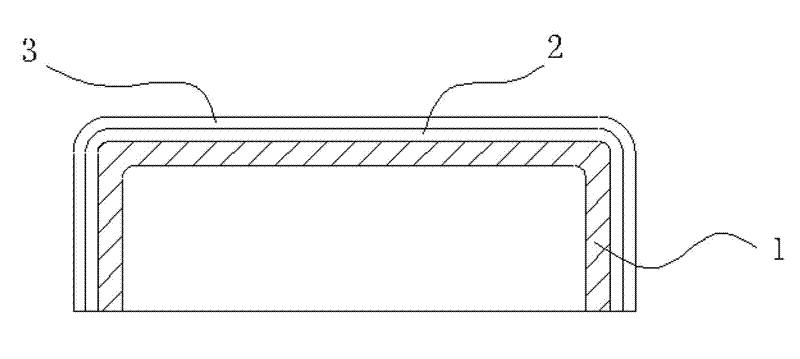

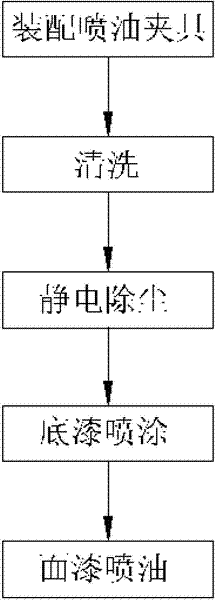

Process for spraying plastic parts of mobile phone and mobile phone shell made by adopting process

InactiveCN102671844AReduce consumptionImprove drop resistancePretreated surfacesCoatingsColor effectEngineering

The invention discloses a process for spraying plastic parts of a mobile phone. The process comprises the following steps of (1) assembly of an oil injection clamp; (2) cleaning; (3) electrostatic dust collection; (4) spraying of primer; and (5) oil injection on finishing paint. The invention also discloses a mobile phone shell made by adopting the process. The process is easy to operate, the primer of a corresponding color is selected according to the required color effect, the spraying frequency is lowered, the consumption of the pigments is reduced, and the production efficiency is improved, the production cost is lowered; and due to the adoption of the steps of cleaning and electrostatic dust collection, the adhesive force of the primer and the finishing paint is improved, the spraying effect is effectively improved, and the product quality is guaranteed. The mobile phone shell has a reasonable structure; due to the combination of the primer and the finishing paint, the primer is used for showing the required color effect, the finishing paint is used for improving the crash resistance and the wear resistance of the mobile phone shell, and the service life is prolonged. The spraying process is simple, low in cost and convenient to produce, and large-area popularization and application are facilitated.

Owner:DONGGUAN XUTONGDA MOLD PLASTIC +2

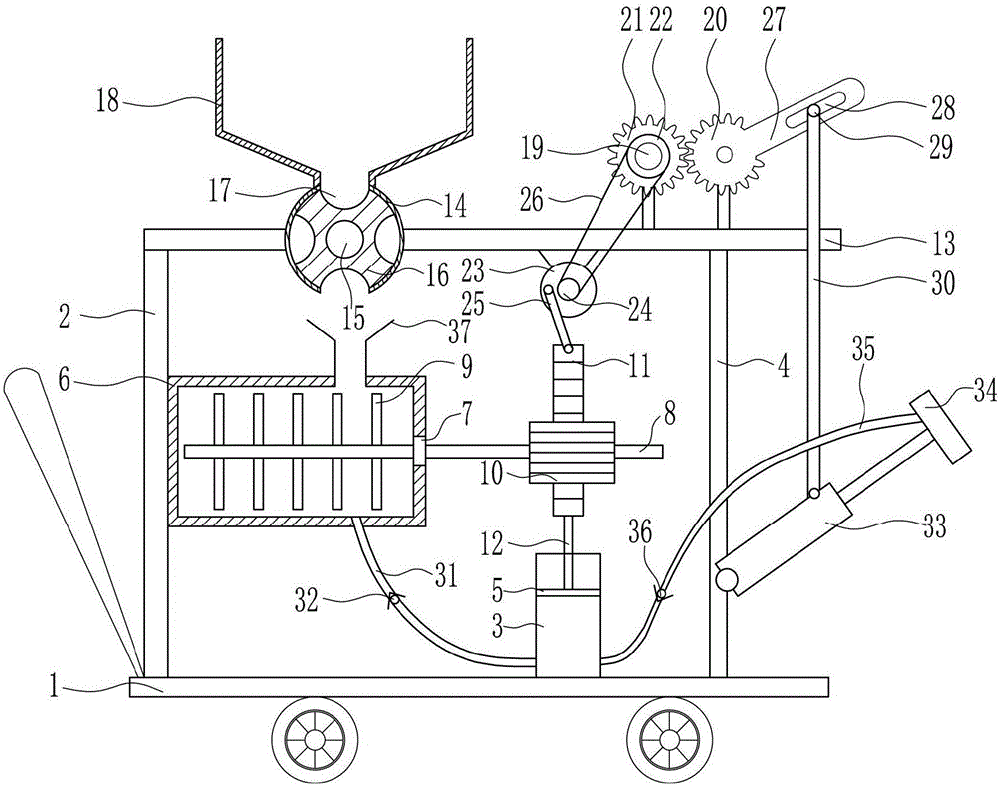

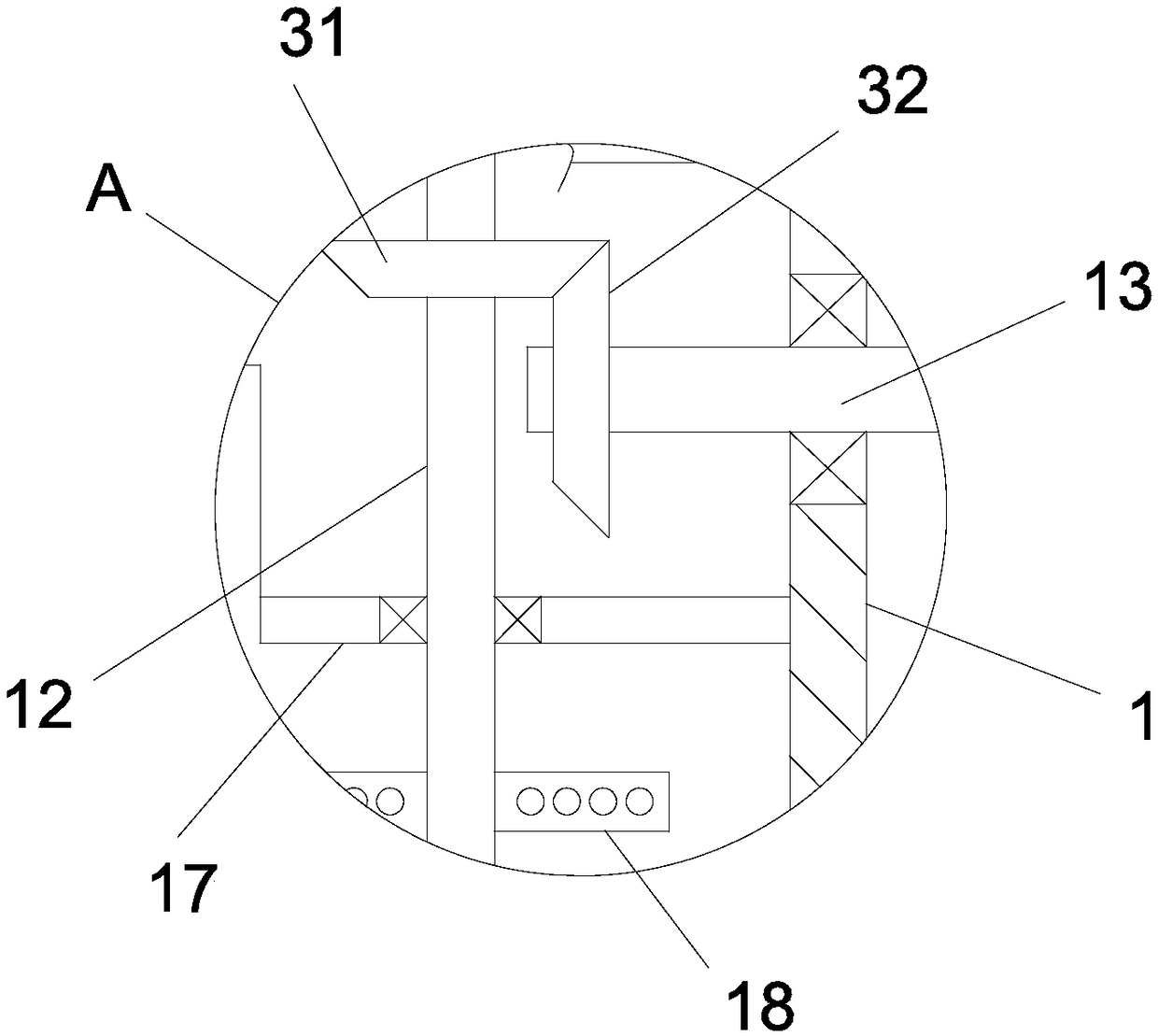

Coating spraying device for parts of agricultural machinery

InactiveCN107225065AStir wellImprove spraying effectLiquid surface applicatorsLiquid spraying apparatusAgricultural engineeringAgricultural machinery

The invention relates to a spraying device, in particular to a paint spraying device for parts and components of agricultural machinery. The technical problem to be solved by the present invention is to provide a paint spraying device for parts of agricultural machinery with high efficiency and good spraying effect. In order to solve the above-mentioned technical problems, the present invention provides such a paint spraying device for parts and components of agricultural machinery, including a bracket, etc.; The middle part of the side is connected with a stirring mechanism, the right side of the stirring mechanism is connected with the left wall of the bracket, the upper part of the spraying box is provided with a spraying mechanism, and the left side of the front part of the spraying box is connected with a box door through a hinge connection. The invention designs a paint spraying device for parts of agricultural machinery, which is provided with a stirring mechanism, which can stir the paint more fully, so that the spraying effect of the parts is better, and is provided with a spraying mechanism.

Owner:刘万忠

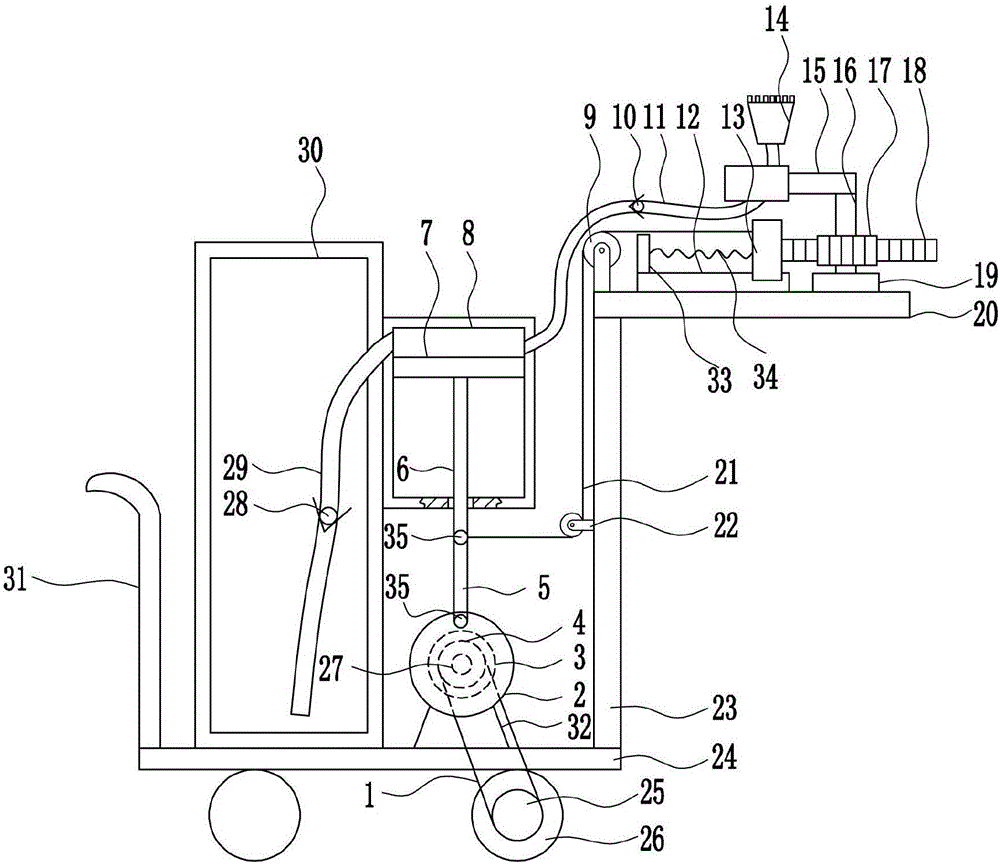

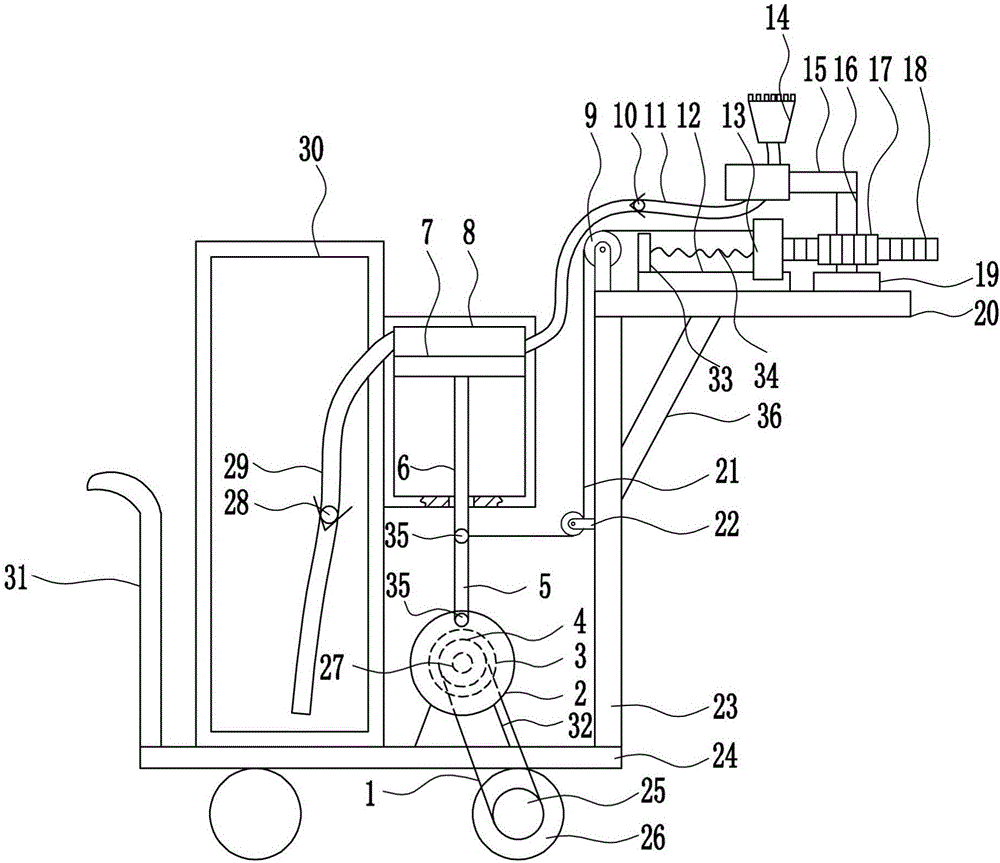

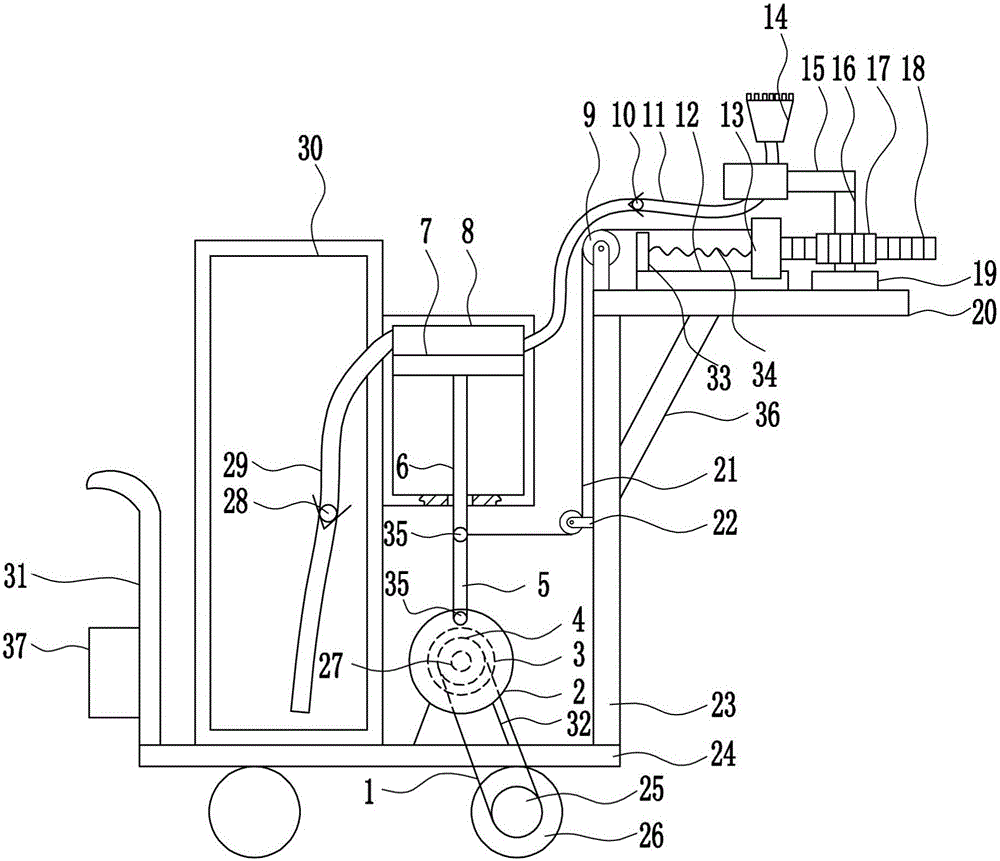

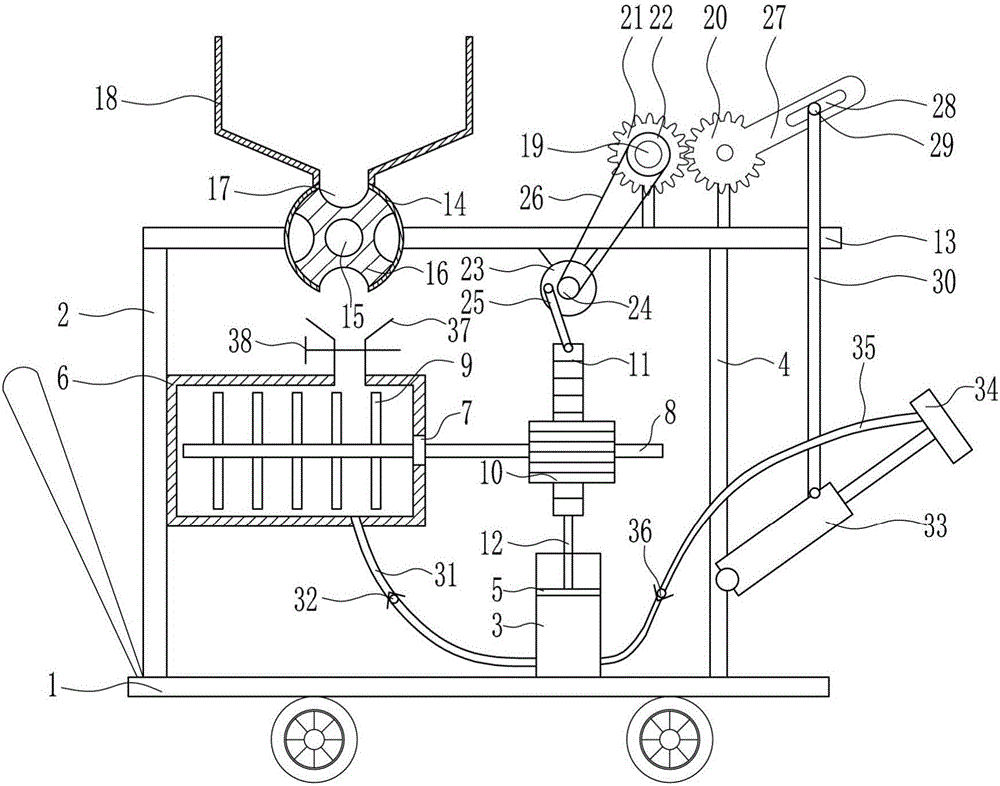

Experimental pesticide spraying device for transgenic plants

InactiveCN106577613ANot easy to rustSave human effortInsect catchers and killersUltimate tensile strengthBiology

The invention belongs to the technical field of genetic engineering, and particularly relates to an experimental pesticide spraying device for transgenic plants. The invention aims to solve the technical problem of providing an experimental pesticide spraying device for the transgenic plants, which can save labor, is high in working efficiency and can reduce labor strength. In order to solve the technical problem, the invention provides the experimental pesticide spraying device for the transgenic plants, which comprises a cart, a left side plate, a compression cylinder, a right side plate, a piston, a stirring tank, a bearing seat, a rotating rod, stirring blades, a first gear, a rack, a push rod, a top plate and the like. The left side plate, the compression cylinder and the right side plate are sequentially arranged at the top of the cart from left to right; and the left side plate and the right side plate are connected with the top of the cart in a welding mode. The experimental pesticide spraying device for the transgenic plants, which is provided by the invention, is manually pushed to spray a pesticide, so that labor can be saved and labor intensity can be reduced.

Owner:杜海燕

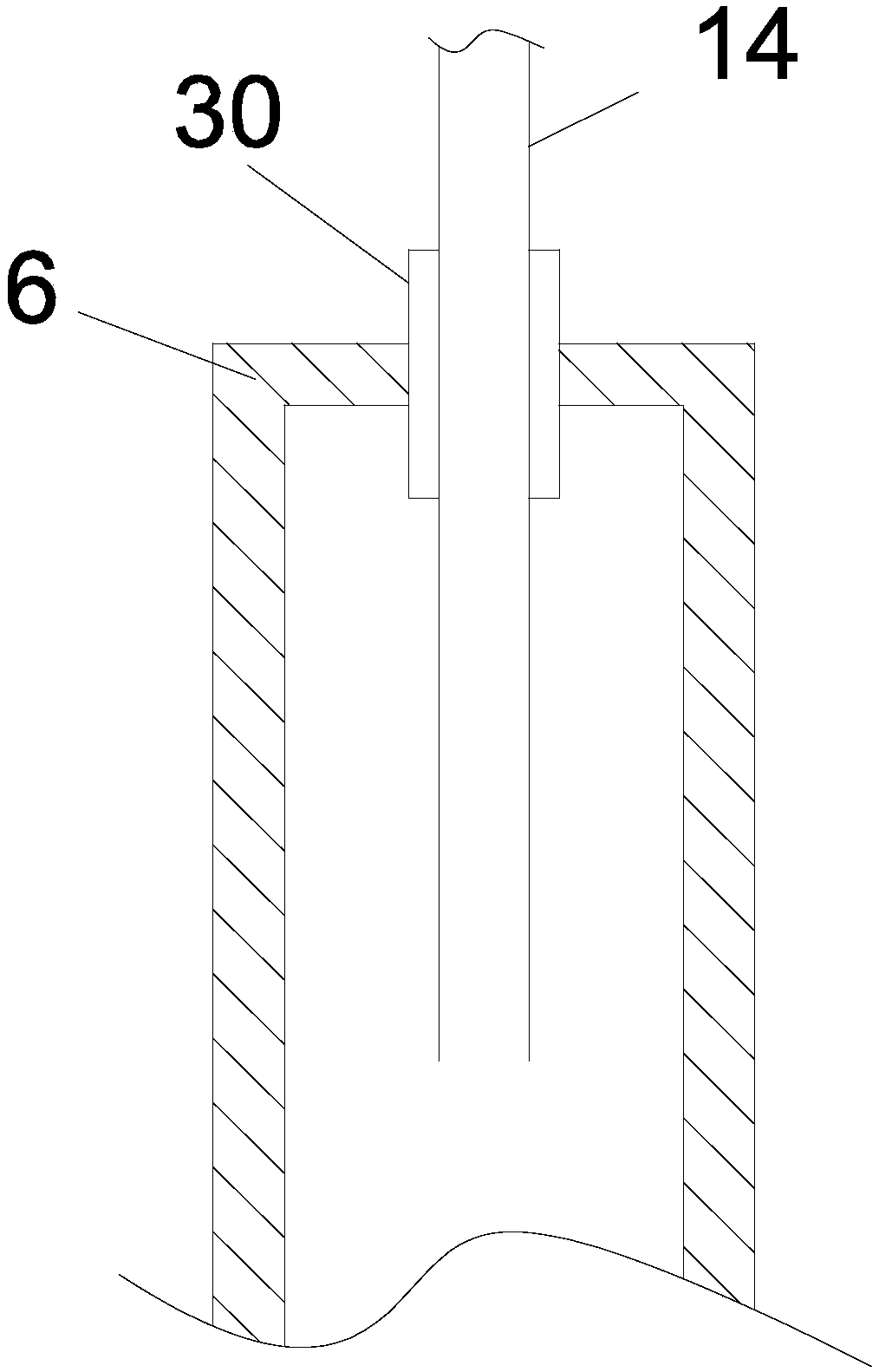

Motor shell paint spraying device with drying function

InactiveCN108339702AImprove spraying effectImprove spraying efficiencySpray boothsDrive shaftEngineering

The invention discloses a motor shell paint spraying device with a drying function. The device comprises an operating box, wherein an oil pant box is fixedly mounted on the left side wall of the operating box; a motor supporting rack is fixedly mounted on the top of the operating box; a reducing motor is fixedly mounted on the motor supporting rack; a plurality of rotating motors are fixedly mounted in the bottom of the operating box; and a plurality of fan blades are fixedly mounted on an output shaft of each rotating motor. The device disclosed by the invention sprays the oil paint uniformlyby means of rotary paint spray of a paint spray disc and attaches the oil paint uniformly to the surface of the motor shell by clamping and rotating the motor shell by means of a first clamp and a second clamp, so that the oil paint spraying effect and efficiency are improved; the oil paint in the oil paint box is uniformly stirred as the stirring blades rotate along with a driving shaft, so thatthe uniform degree of the oil paint is improved effectively, agglomeration of the oil paint is avoided, and the oil paint spraying quality is improved. The device also has a very good oil paint drying function, accelerates quick drying of the oil paint on the surface of the motor shell, and improves the work efficiency.

Owner:ZHEJIANG OUDAO AUTOMATION EQUIP CO LTD

Ink jet ink, ink jet recording method, ink cartridge, recording unit and ink jet recording apparatus

ActiveUS20090258145A1Improve spraying effectImprove scratch resistanceDuplicating/marking methodsInksAcid valueSURFACTANT BLEND

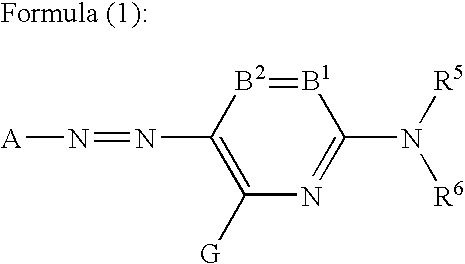

The invention provides provide an ink jet ink exhibiting such an excellent ejection property that when an ink containing a polymer capable of improving the scratch resistance of a recorded article is used, the deviation of the ink-droplet impact point on a recording medium is prevented. The ink jet ink contains a polymer and a surfactant, wherein the acid value of the polymer is from 100 mg KOH / g or more to 220 mg KOH / g or less, the weight-average molecular weight of the polymer is from 3,000 or more to 10,000 or less, and the surfactant has a structure represented by the following formula (1)wherein n is a numerical value of from 3 or more to 27 or less, and m is a numerical value of from 16 or more to 31 or less.

Owner:CANON KK

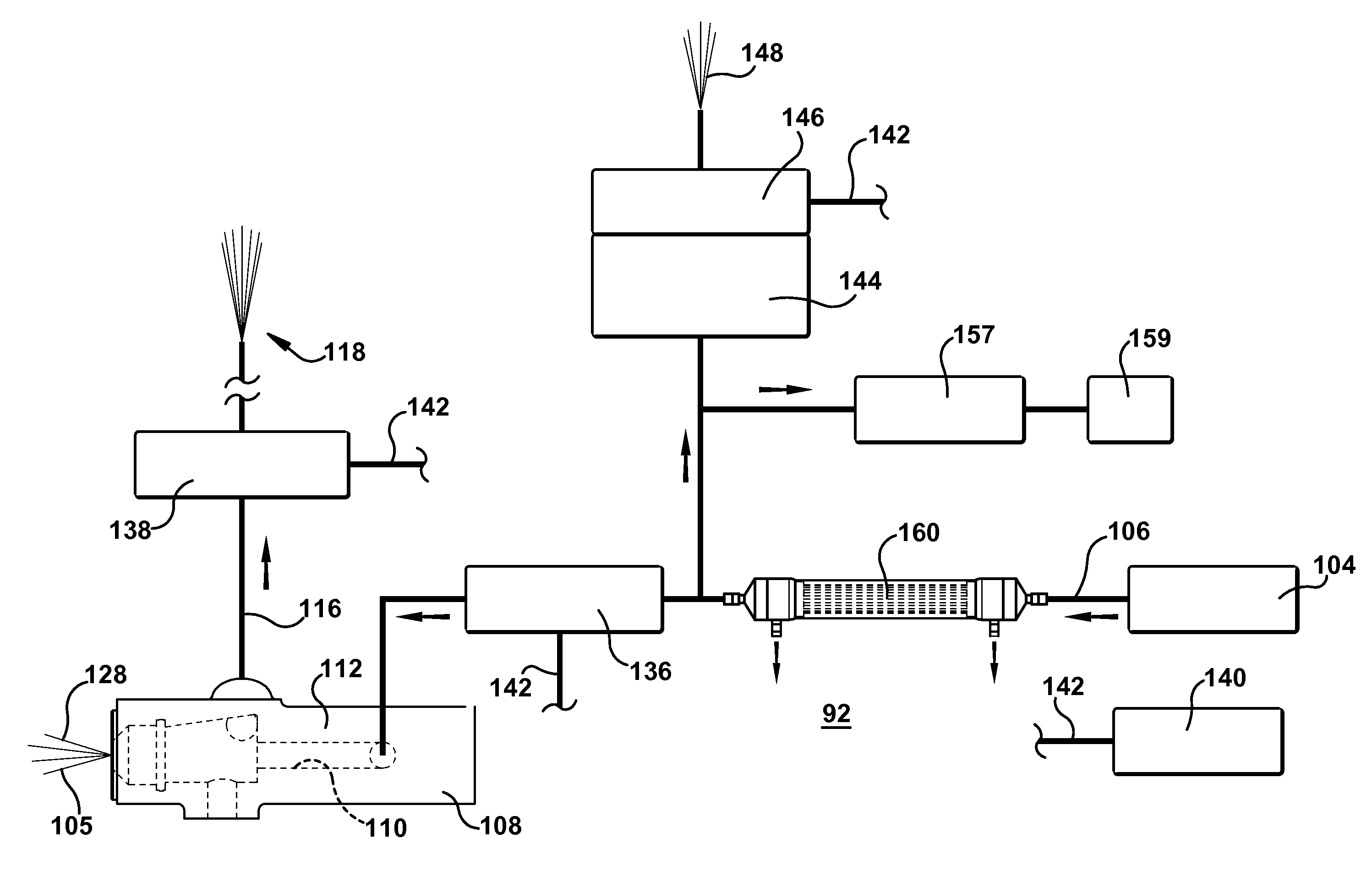

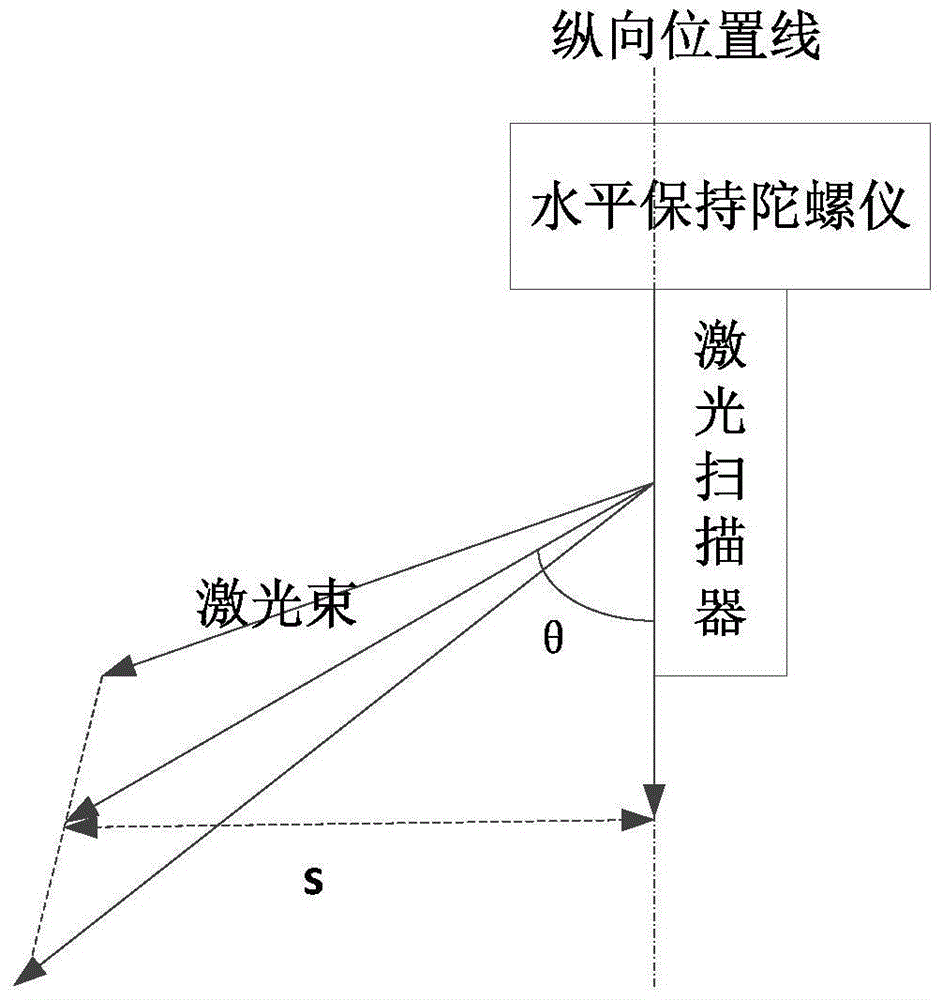

Accurate aerial spraying control system and method for aircraft

ActiveCN105707040AImprove spraying effectImprove the deposition effectInsect catchers and killersAviationFlight vehicle

The invention relates to an accurate aerial spraying control system and method for an aircraft.The accurate aerial spraying control system for the aircraft comprises a controller, a droplet particle size control unit, an airborne weather measurement unit and an airborne altitude measurement unit.The controller is connected with the droplet particle size control unit, the airborne weather measurement unit and the airborne altitude measurement unit.The airborne weather measurement unit is used for acquiring information of the environment where the aircraft is located.The airborne altitude measurement unit is used for acquiring information of the altitude of the aircraft relative to ground.The controller is used for calculating a target value of the particle size of sprayed droplets according to the information of the environment and the information of the altitude and sending a control instruction to the droplet particle size control unit according to the target value.The droplet particle size control unit is used for adjusting the particle size of droplets according to the control instruction.By means of the accurate aerial spraying control system and method for the aircraft, accurate control over a droplet depositing area is achieved, and the particle size of droplets can be accurately regulated and controlled according to environmental requirements, so that the ground depositing effect of droplets is optimized, influences of attitude changes of the aircraft on spraying are overcome, and the aerial spraying effect is improved.

Owner:BEIJING RES CENT OF INTELLIGENT EQUIP FOR AGRI

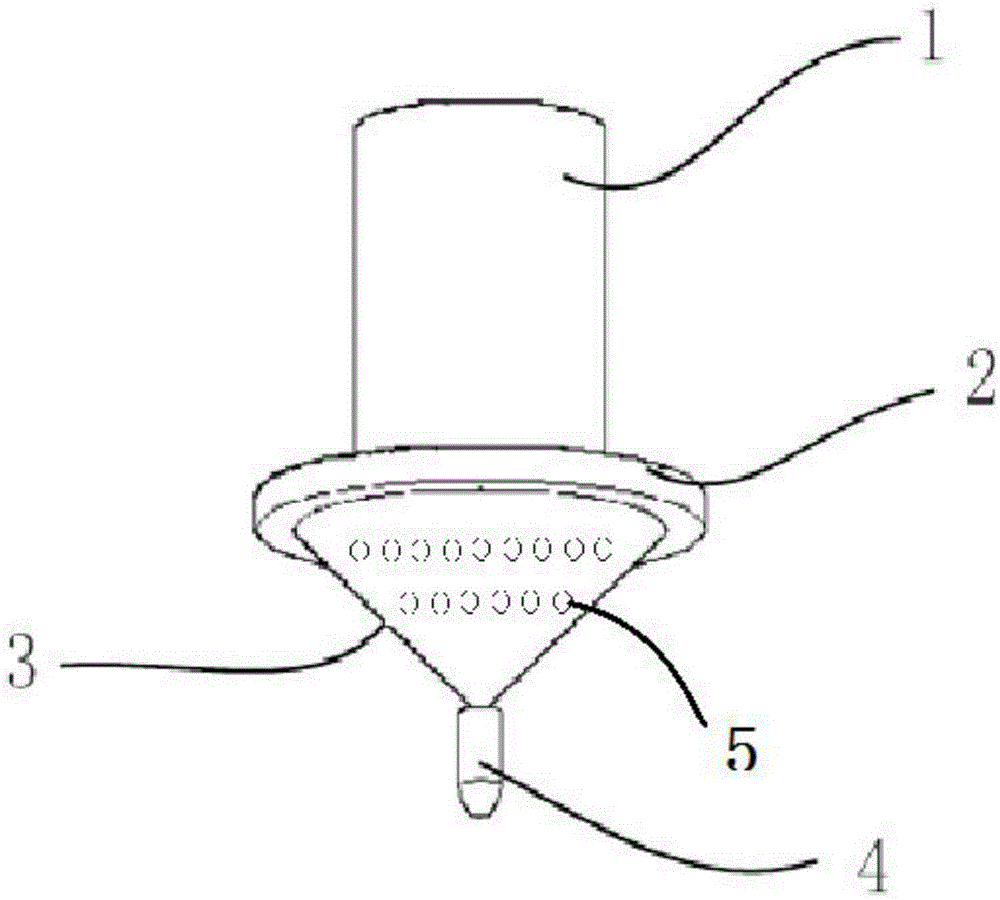

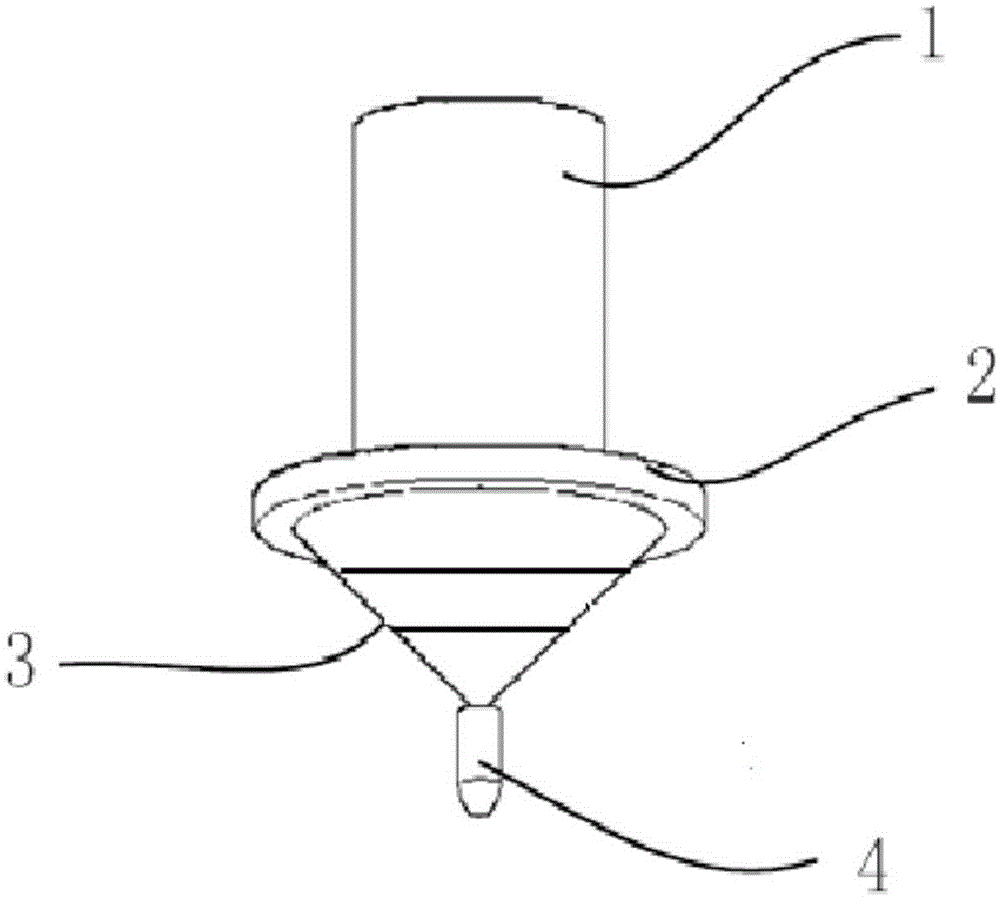

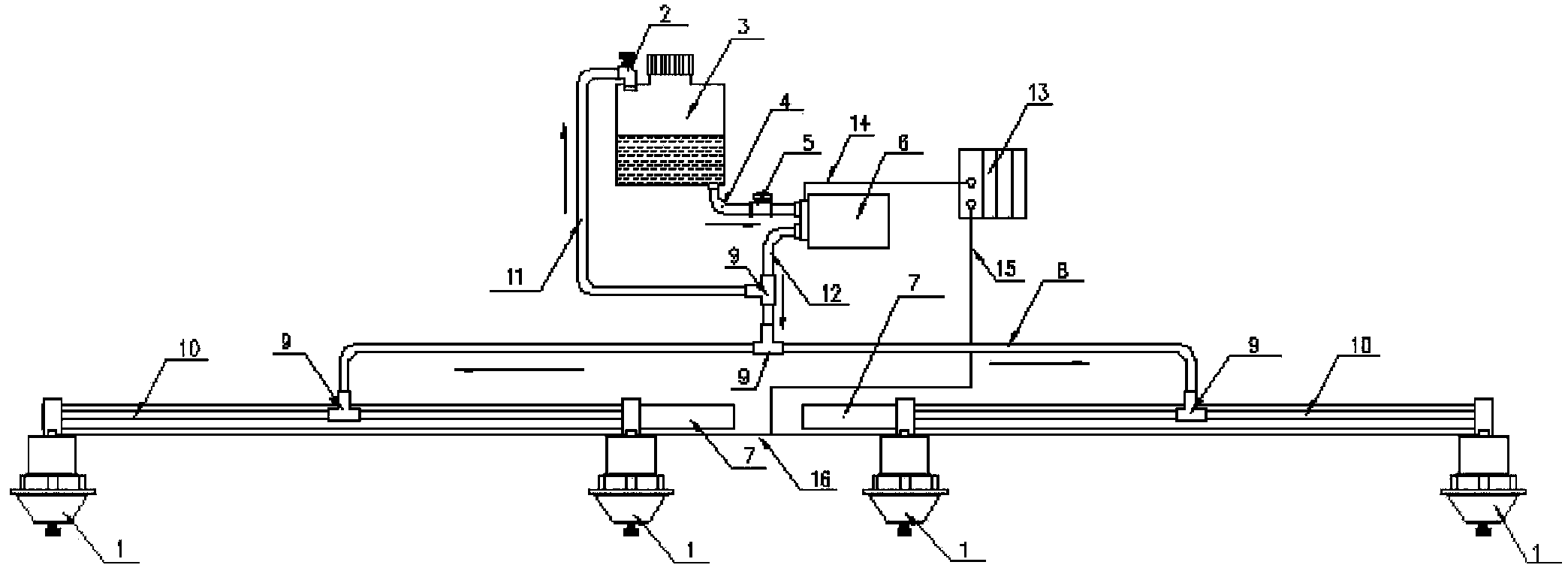

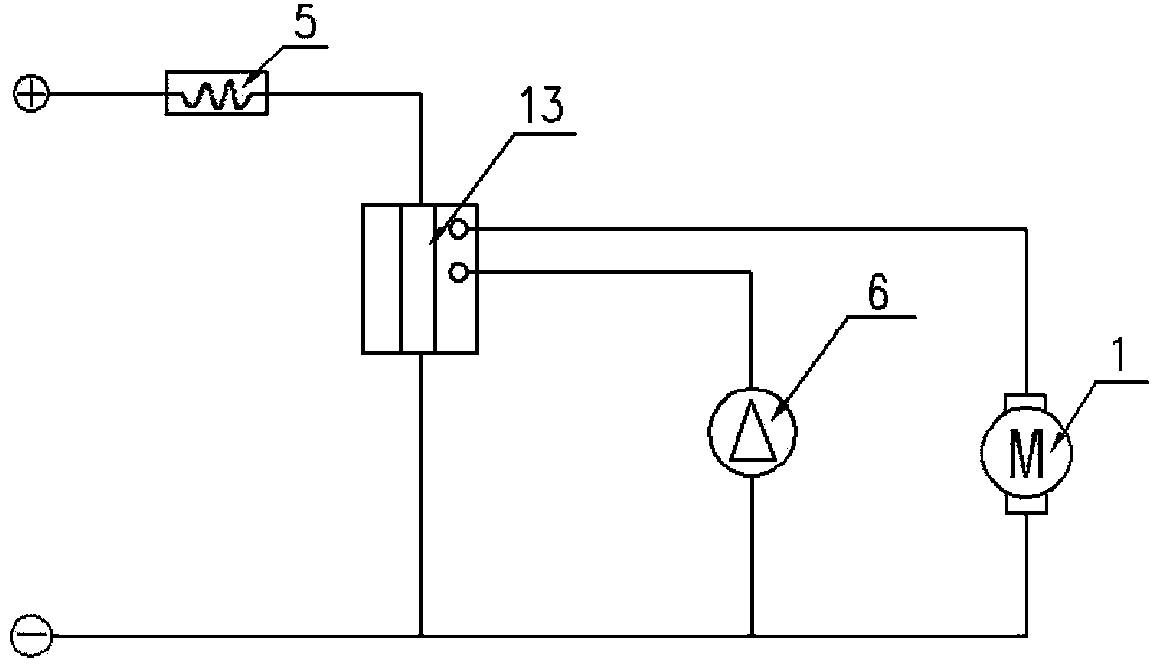

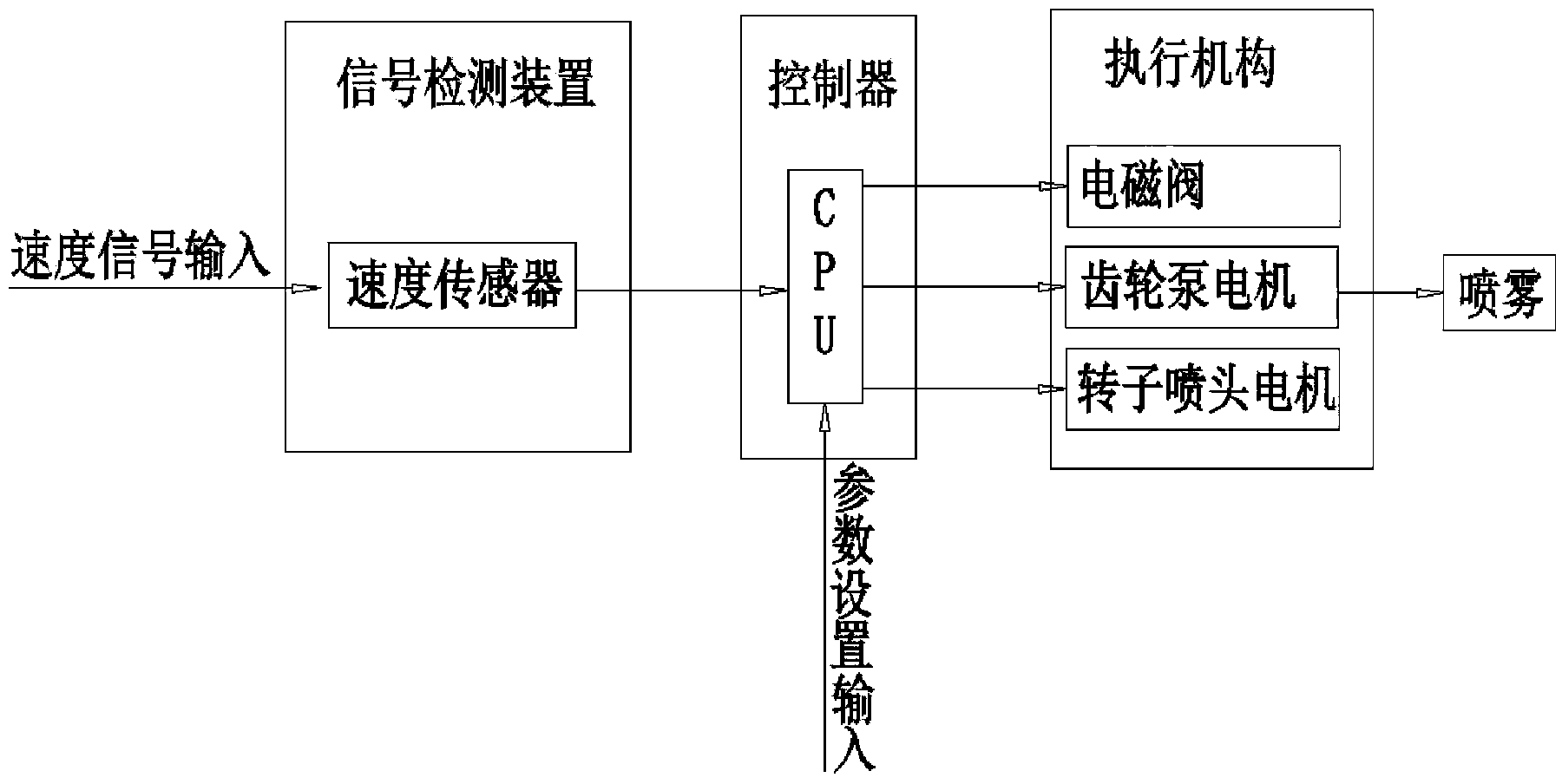

Pesticide spraying and applying device for unmanned aerial vehicle

ActiveCN103723275AFlexibleGood mist coverageAircraft componentsLaunching weaponsAgricultural engineeringAgricultural science

The invention discloses a pesticide spraying and applying device for an unmanned aerial vehicle. The device comprises a spraying device and a control system. The spraying device comprises a liquid storage system, a liquid pesticide conveying system, a spraying system and a backflow system. The liquid storage system is connected with the spraying system through the liquid pesticide conveying system. The liquid storage system is connected with the backflow system through a pipeline. The control system is connected with the liquid pesticide conveying system and the spraying system. By means of the pesticide applying device, the pesticide applying efficiency is high, the prevention and treatment effects are good, crops are not damaged, the labor intensity is low, and the defects that according a traditional pesticide applying machine, the pesticide utilizing ratio is low, the labor intensity is high, the crops are prone to damage, the pesticide residue exceeds the standard, the environment is polluted and an operator is poisoned are overcome.

Owner:GAUNGXI TIANYUAN BIOCHEM

Inkjet ink

This invention pertains to an ink for inkjet printing, in particular to an aqueous ink comprising a self-dispersing pigment colorant and certain soluble polymers which enhance print quality without compromising jetting performance.

Owner:EI DU PONT DE NEMOURS & CO

Ammonium phosphate ultra-fine dry powder extinguishing agent and preparation thereof

The present invention provides a ammonium phosphate salt superfine dry powder extinguishing agent and its preparing method. The proportioning by weight of material is common ammonium phosphate salt powder 600-850kg, active carclazyte 15-80kg, silicified white carbon black 40-100kg, mica 25-100kg, calcium carbonate 10-300kg, silicon oil 8-15kg; alternatively, wet-process monoammonium phosphate 700-900kg, active carclazyte 15-80kg, silicified white carbon black 40-100kg, mica 25-100kg, calcium carbonate 10-300kg, silicon oil 8-15kg; the granularity of the product is below 20 mu m. The fire extingushing method has a better effect and wide range. Type A solid matter fire, type B liquid matter fire, type C gas matter fire and type E appliance fire are all put out under the state of closing and semi-closing, since extinguishing agent has a small grain diameter, specific surface is doubled, particulates can not gather after being silicified, extinguishing agent has a better liquidity, improved jet performance, quick pervasion, and the wet-process monoammonium phosphate contains sulfur and ammonium, generating N by heating, greatly enhances the extinguishing effect, about 6-10 times of the common powder extinguishing agent. The extinguishing agent also energy conservation and has a lower cost.

Owner:KUNMING TAIKANG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com