Patents

Literature

1347results about How to "Not easy to rust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

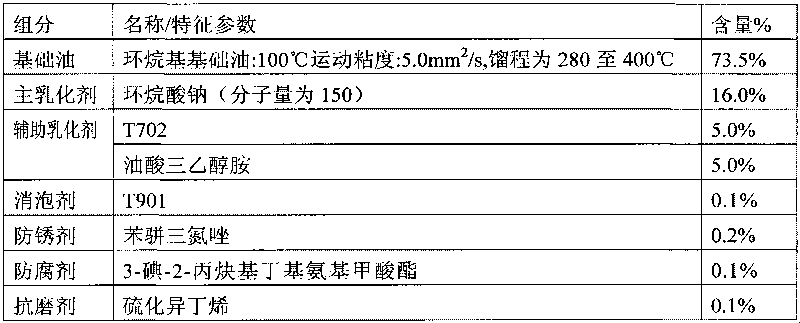

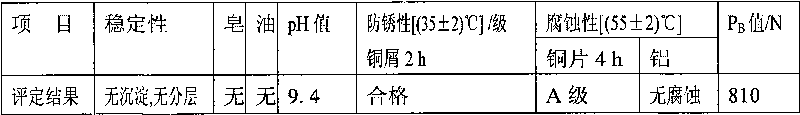

Water-based copper and aluminum wiredrawing oil composite and preparation method thereof

The invention relates to an oil-based lubricating composite and a preparation method thereof, in particular to a water-based copper and aluminum wiredrawing oil composite and a preparation method thereof. The water-based copper and aluminum wiredrawing oil composite comprises base oil, an emulsifier, an auxiliary emulsifier, a defoaming agent, a rust-proof agent, an antiseptic and an antiwear agent. The preparation method comprises the following steps of: configuring the water-based copper and aluminum wiredrawing oil composite into 3 percent to 45 percent water-based emulsion according to weight percentage; and spraying the water-based emulsion into a wiredrawing die cavity in the copper and aluminum wiredrawing process. The water-based copper and aluminum wiredrawing oil composite has the advantages of excellent lubricating property, great optimal light stability and storage stability, low cost, good cooling effect, fast heat transfer, little temperature increase in the using process, difficult combustion and easy cleaning and ensures the safety of the service environment; and in addition, a copper wire and an aluminum wire drawn by the method have the advantages of uniform wireshape, bright surfaces, difficult corrosion, good ultraviolet and storage stability and good stability.

Owner:PETROCHINA KARAMAY PETROCHEMICAL CO LTD

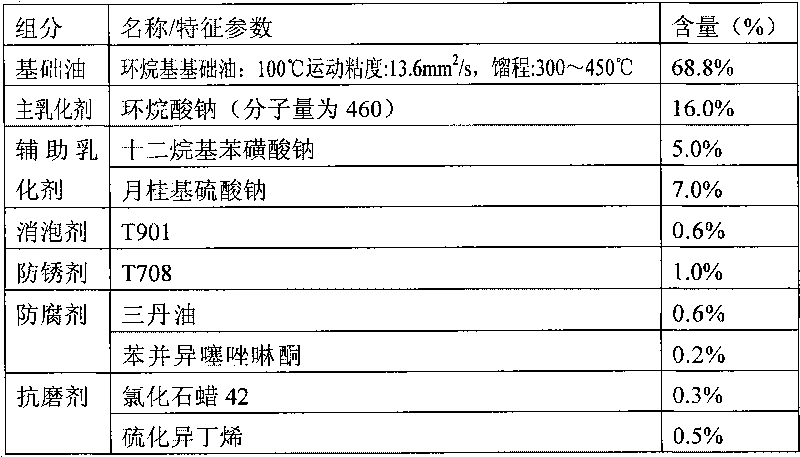

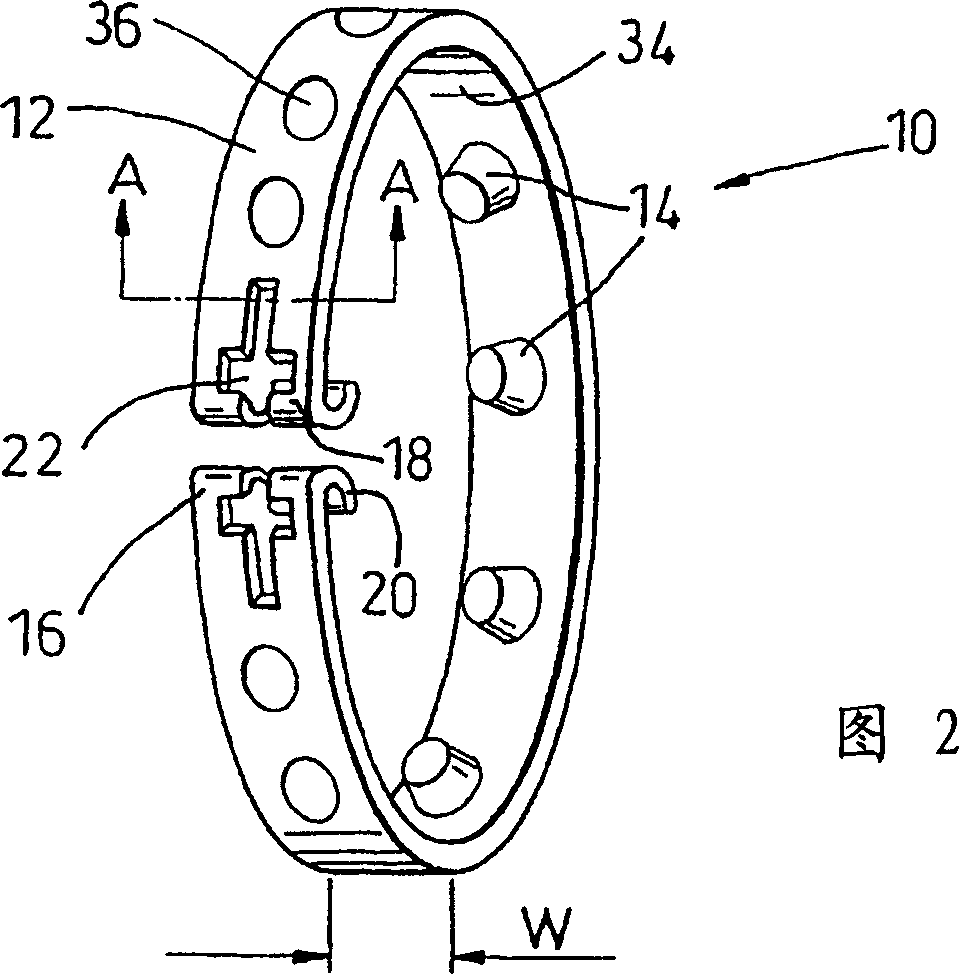

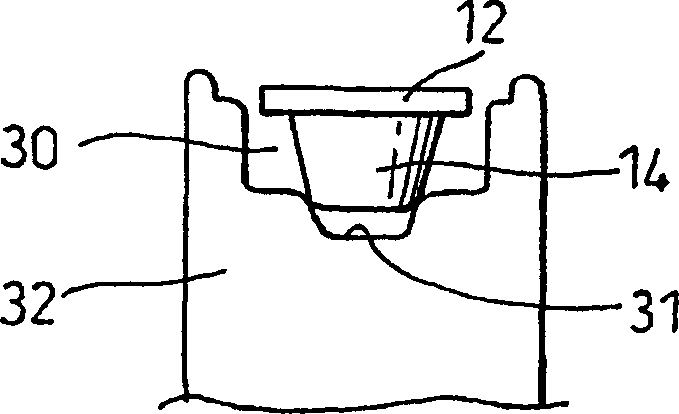

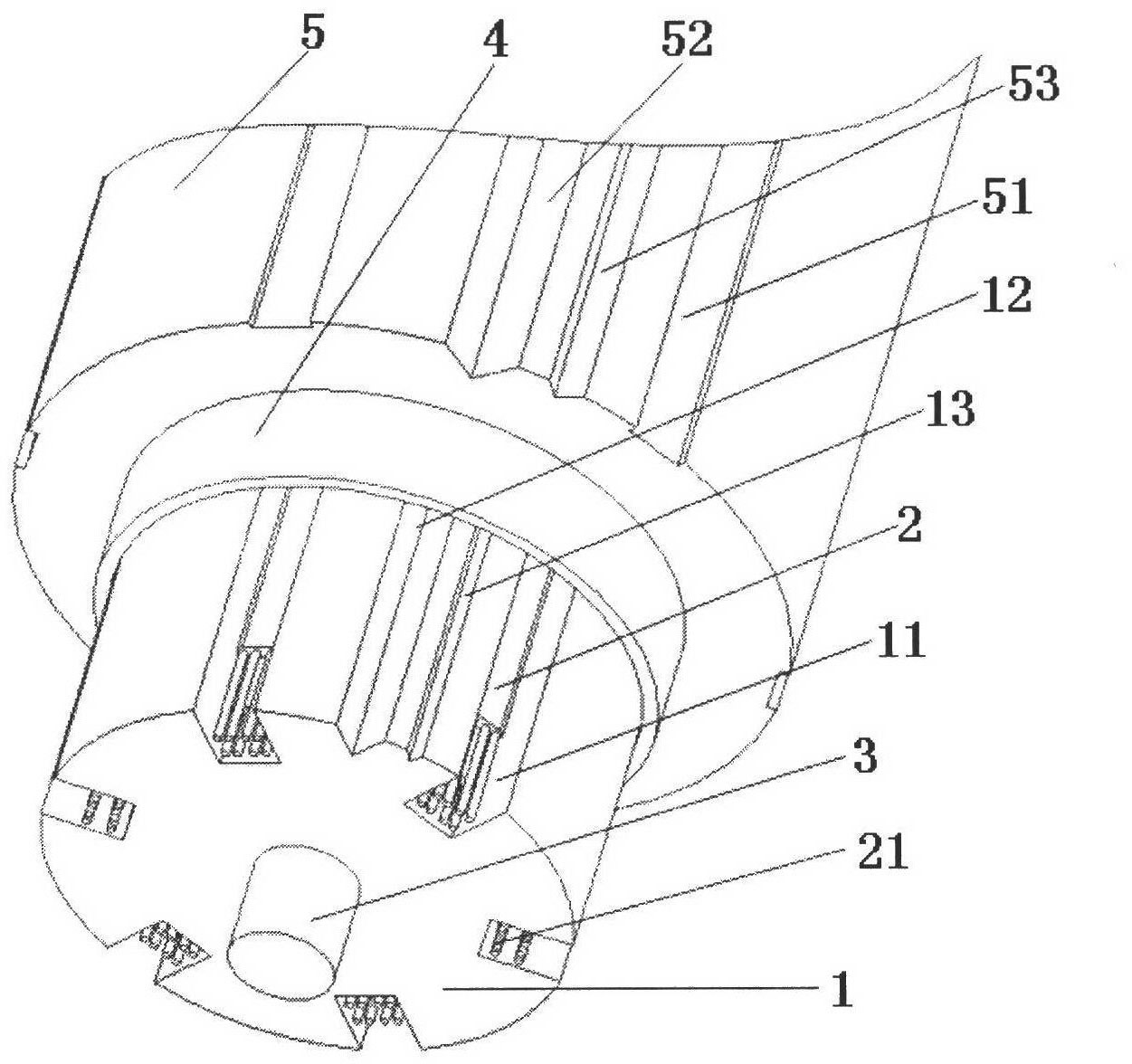

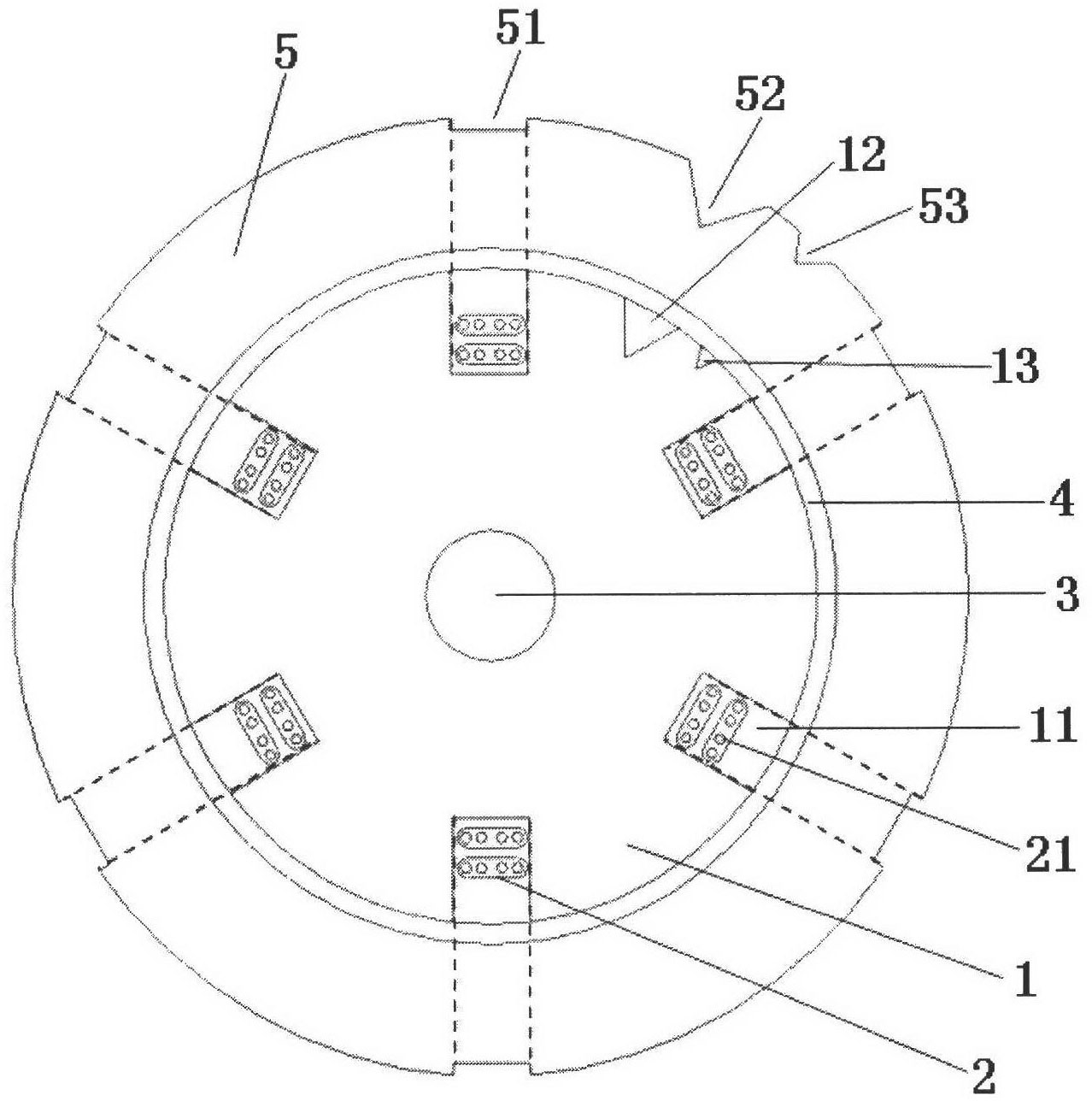

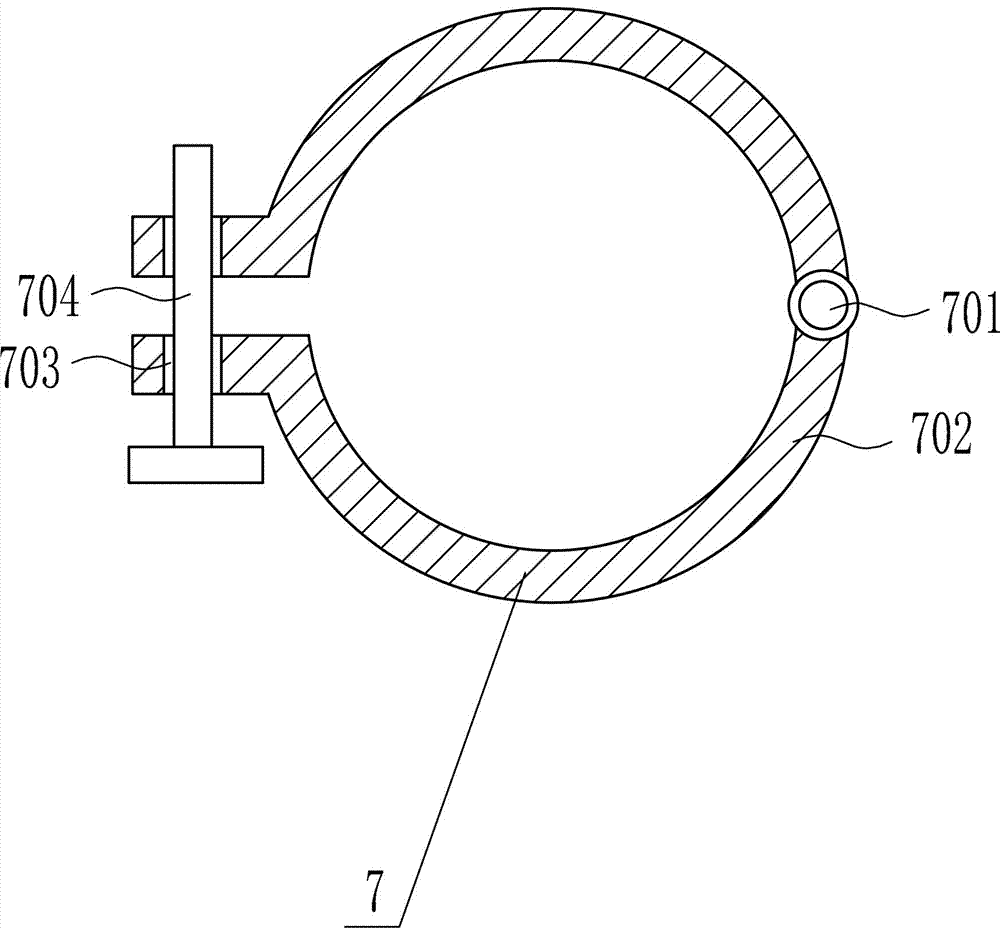

Band device for a wheel rim

An assembly ( 10 ) for location around a wheel rim ( 32 ) includes an annular support band ( 12 ) being formed of a relatively inextensible material. The support band ( 12 ) is split at at least one circumferential location to define a pair of opposed ends ( 16, 18 ). Adjustment bolt ( 24 ) is operably connected to the opposed ends ( 16, 18 ) for enabling adjustment of the diameter of the support band ( 12 ), and feet ( 14 ) depend from the radially inner face ( 34 ) of the support band ( 12 ). The feet ( 14 ) are formed from a relatively non-compressible material and, in use, are seated upon the wheel rim ( 32 ) to maintain the support band ( 12 ) in a spaced apart relationship with the wheel rim ( 32 ). The assembly may be adapted for use as a runflat assembly or as a beadlock assembly.

Owner:蒂龙爆胎保护有限公司

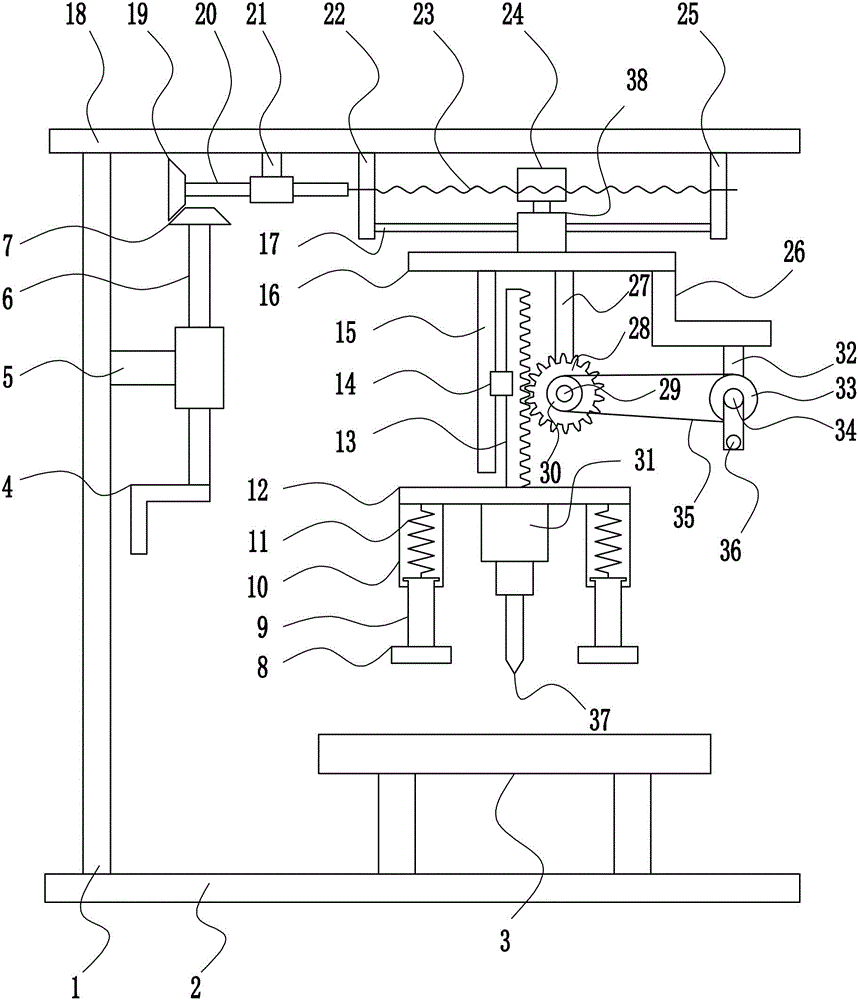

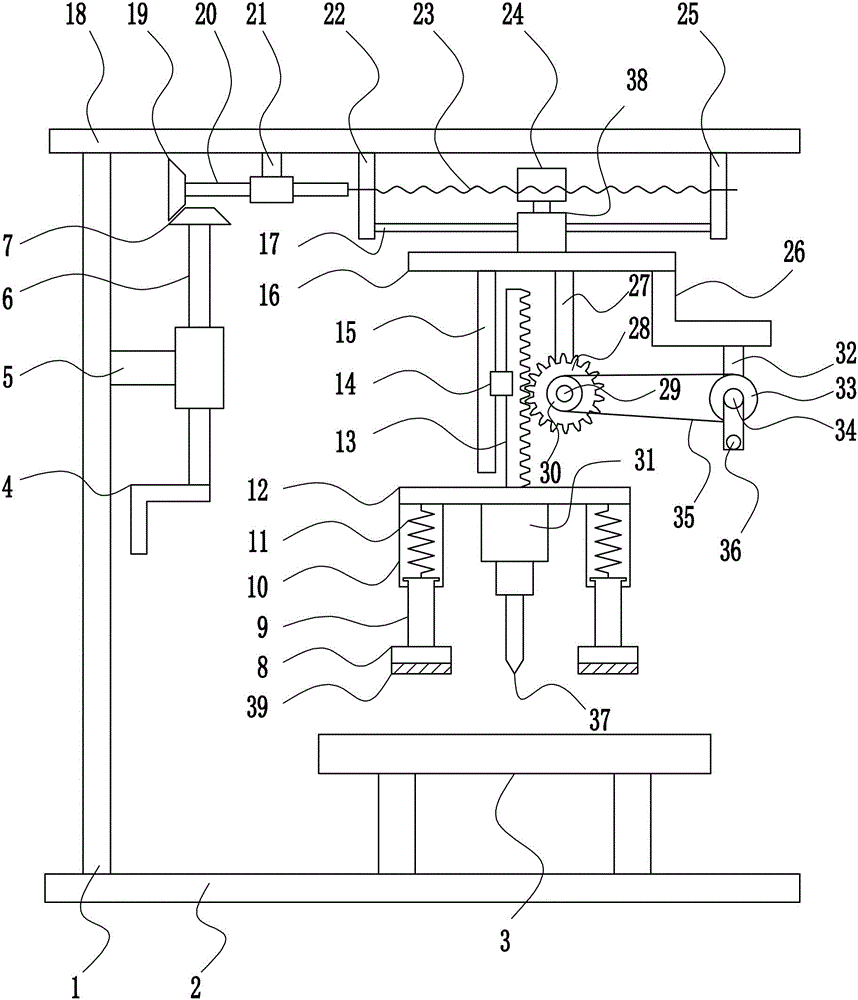

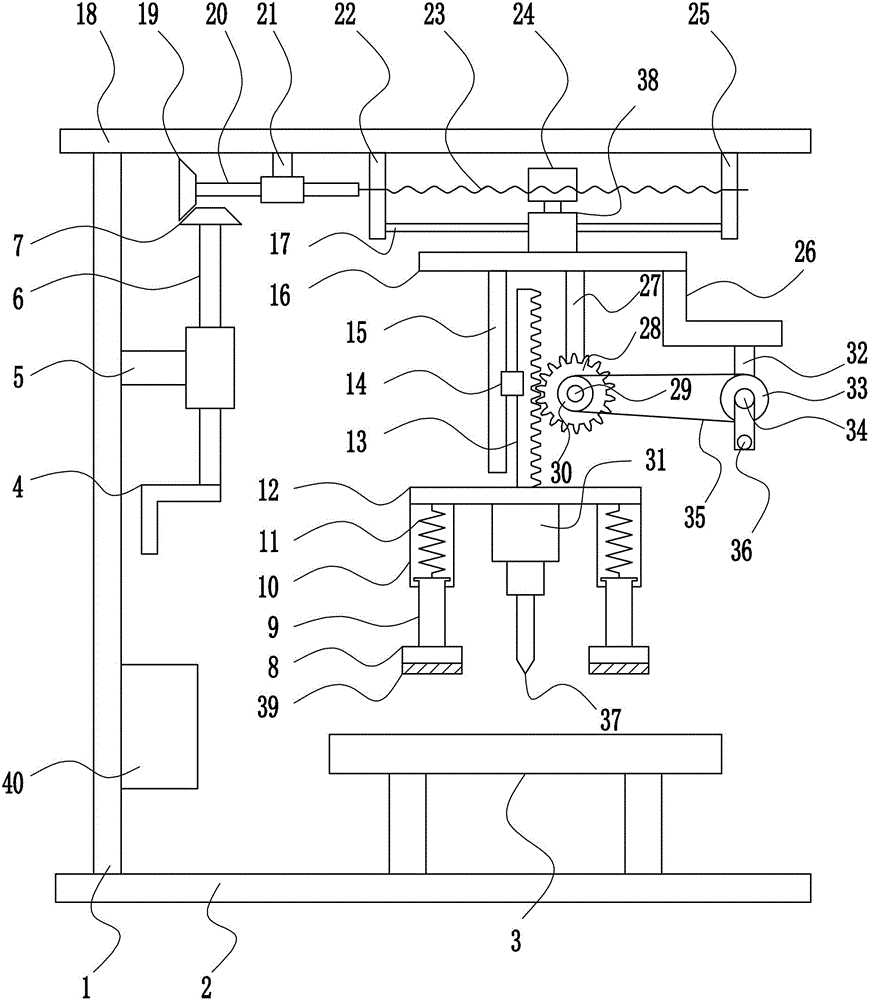

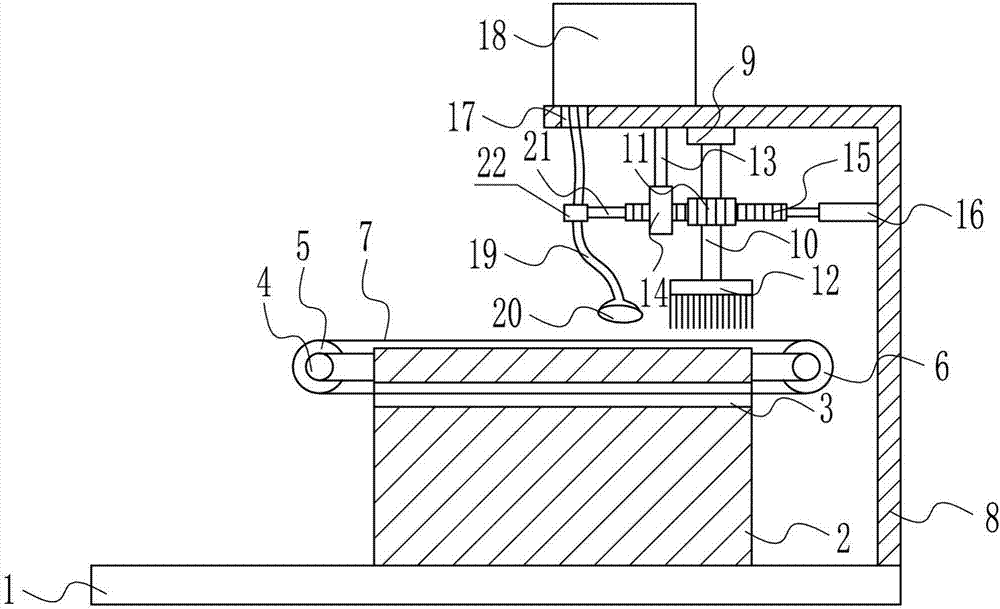

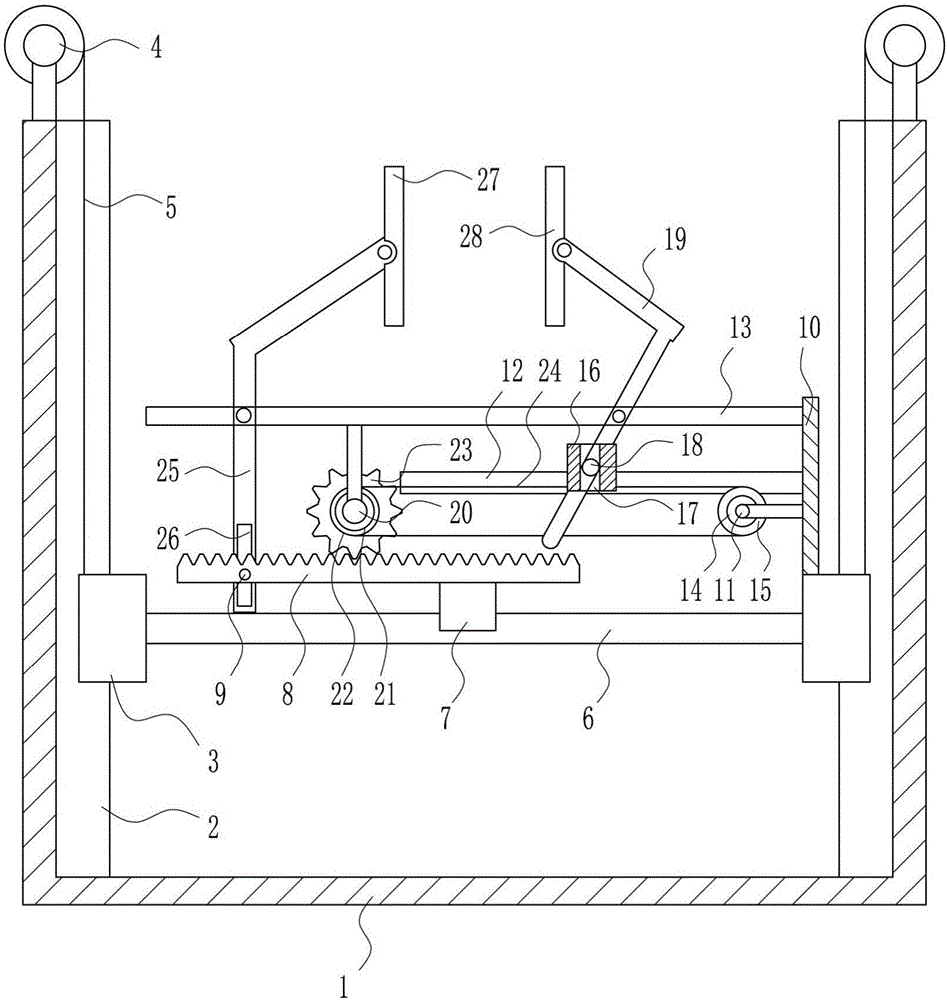

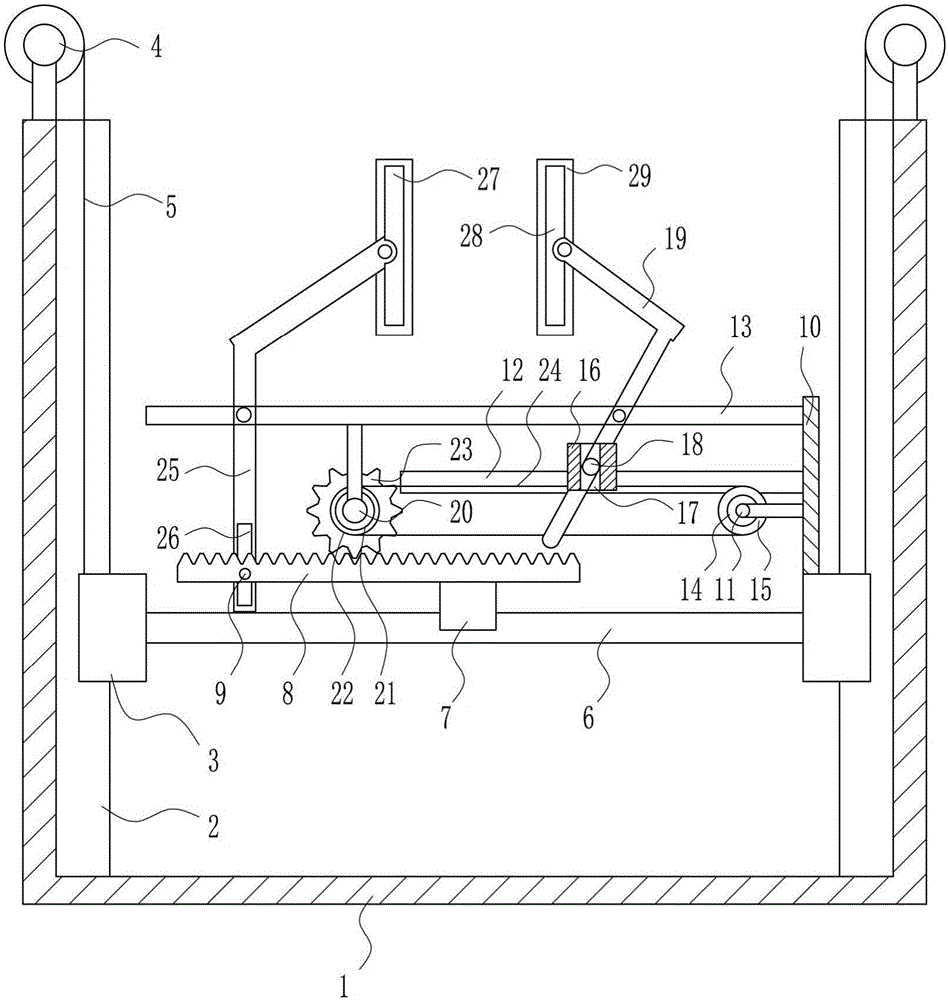

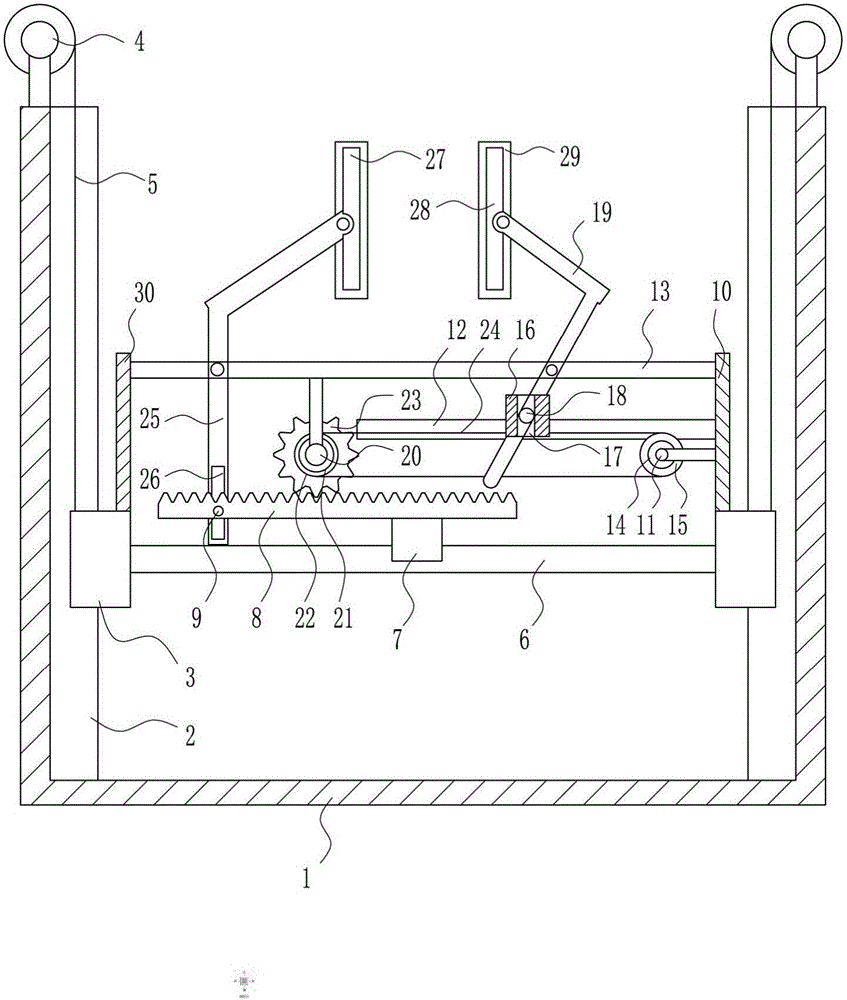

Novel drilling machine for carbon fiber composite plate

The invention relates to a drilling machine and particularly relates to a novel drilling machine for a carbon fiber composite plate. The technical problem to be solved by the invention is to provide the novel drilling machine for the carbon fiber composite plate, which is low in energy consumption, convenient to operate and high in drilling precision. In order to solve the technical problem, the invention provides such novel drilling machine for the carbon fiber composite plate, comprising a left frame, a bottom plate, a placing platform, a first rocking handle, a first bearing block, a first rotating shaft, a first bevel gear, a pressing block, a moving rod, a sleeve, an elastic element, a first fixed plate and the like; the left side of the top of the bottom plate is welded with the left frame; the middle of the top of the bottom plate is welded with the placing platform; and the upper end of the right side of the left frame is connected with the first bearing block in a bolt connection way. According to the novel drilling machine for the carbon fiber composite plate, the horizontal movement of a drill bit and the drilling operation for any position on the carbon fiber composite plate can be realized through rotating the first rocking handle, and the vertical movement of the drill bit can be realized through rotating a second rocking handle.

Owner:江苏吉神环卫设备有限公司

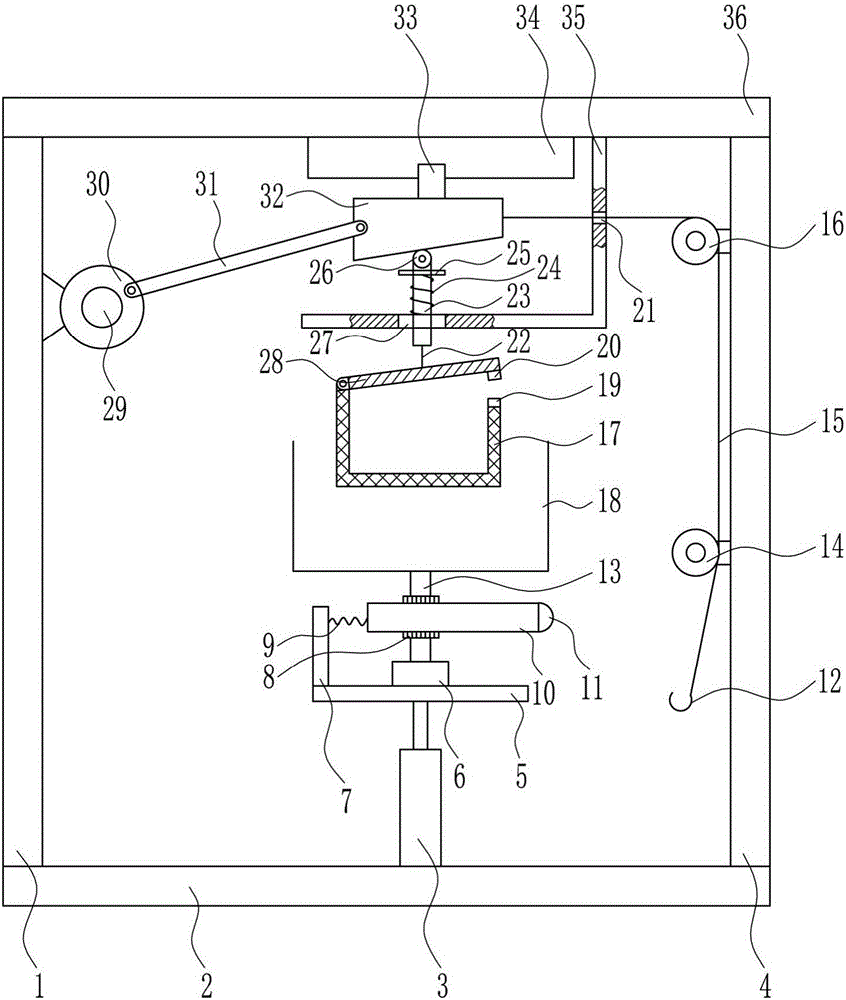

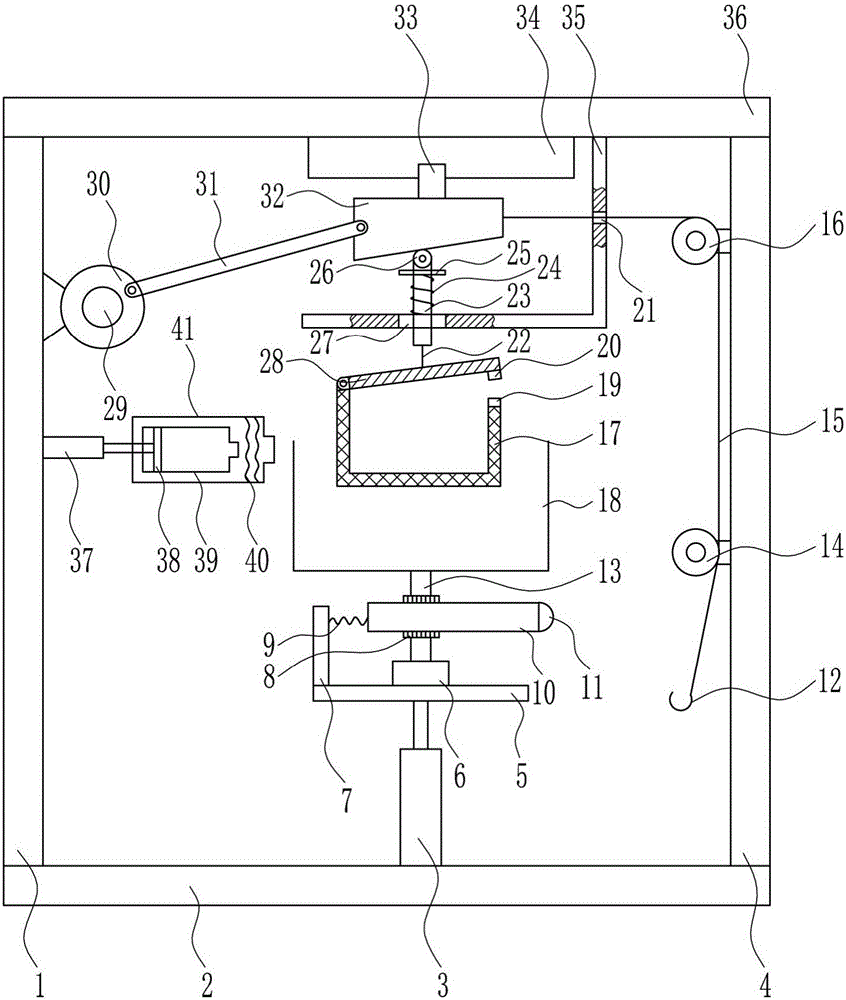

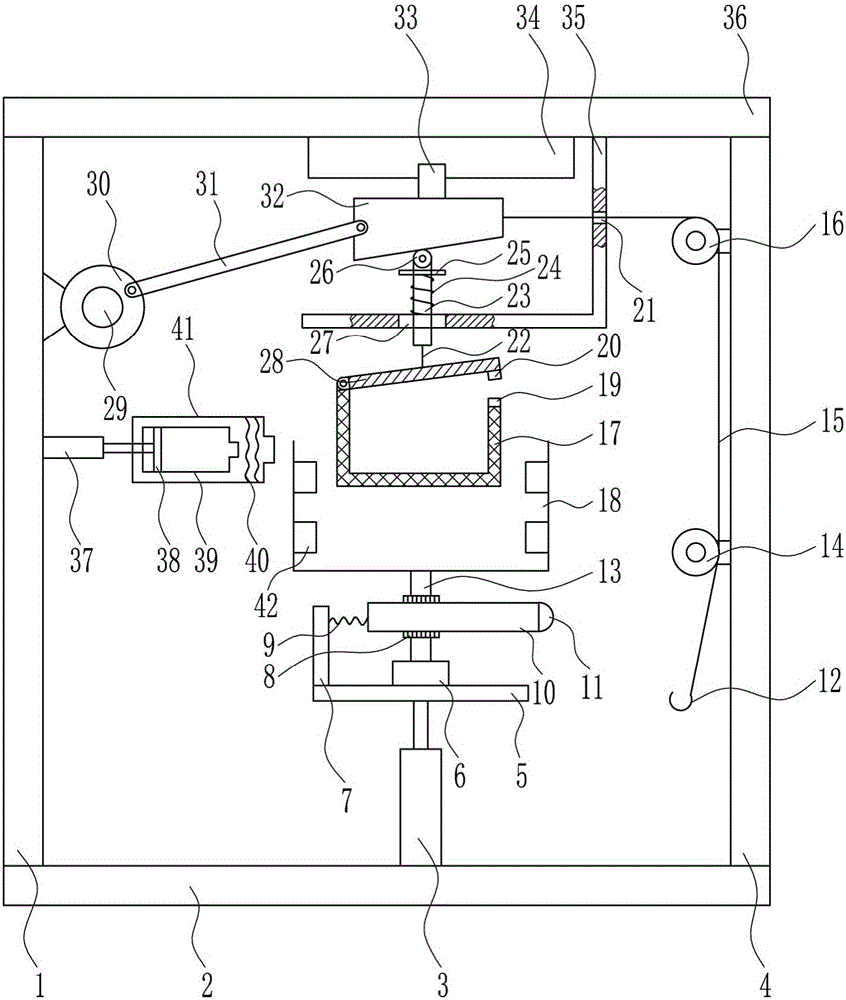

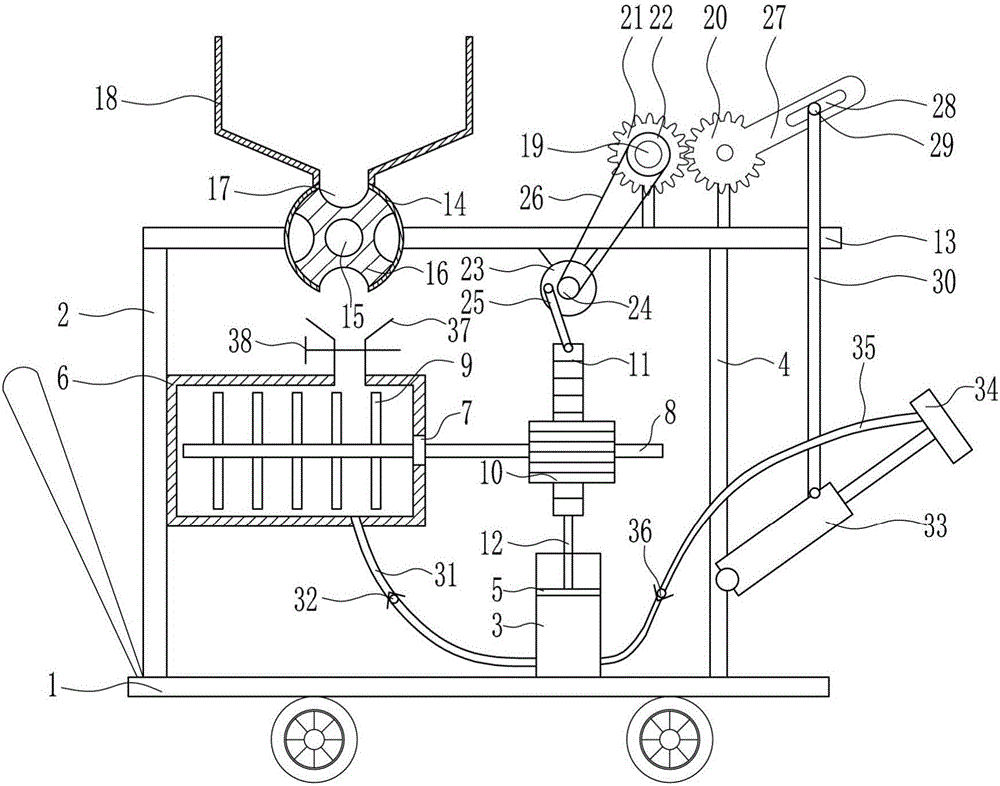

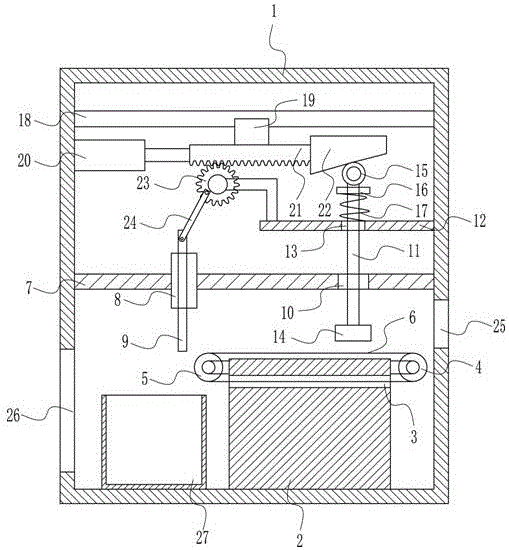

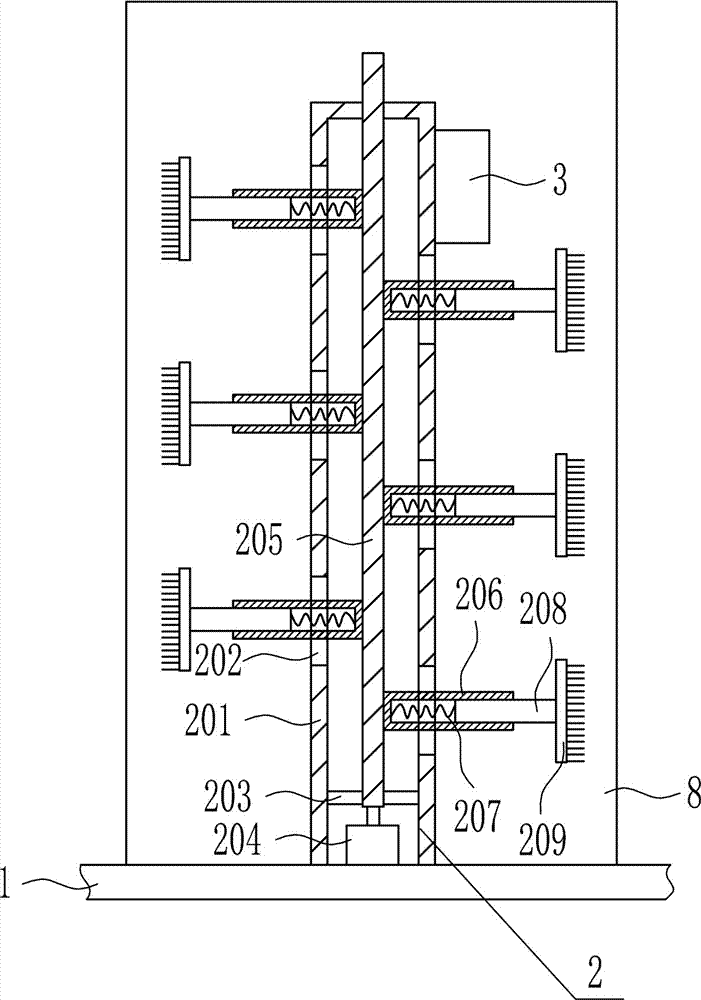

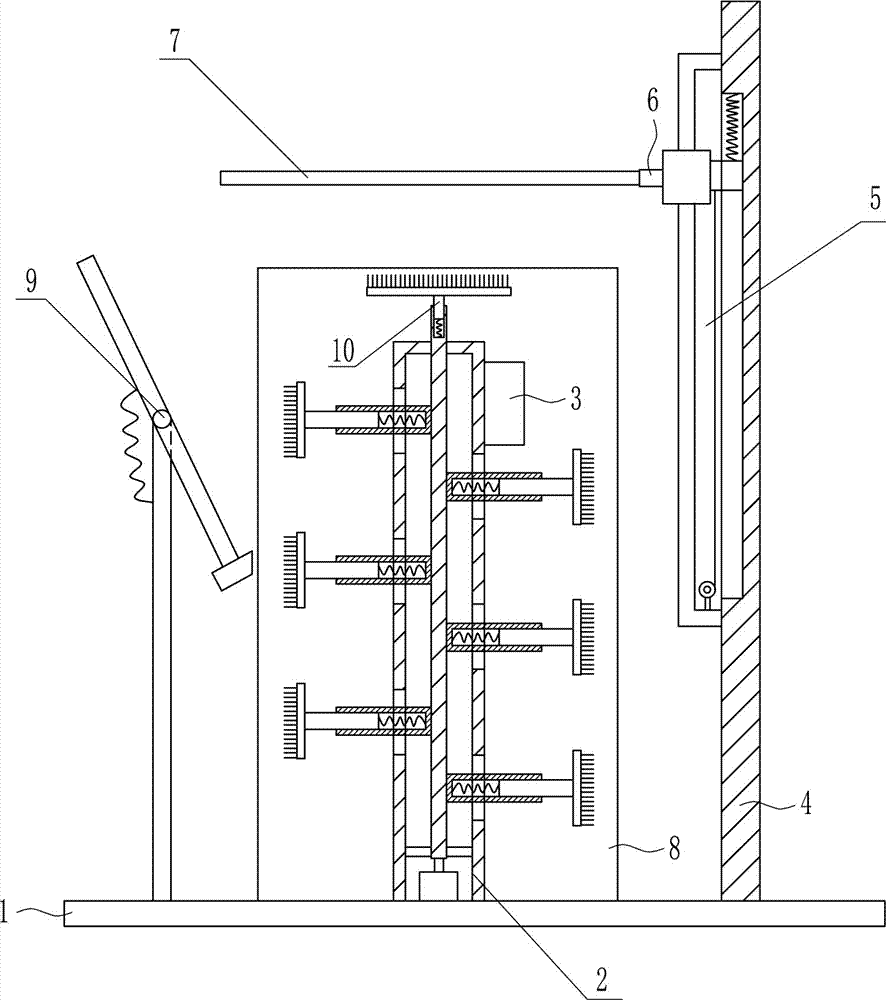

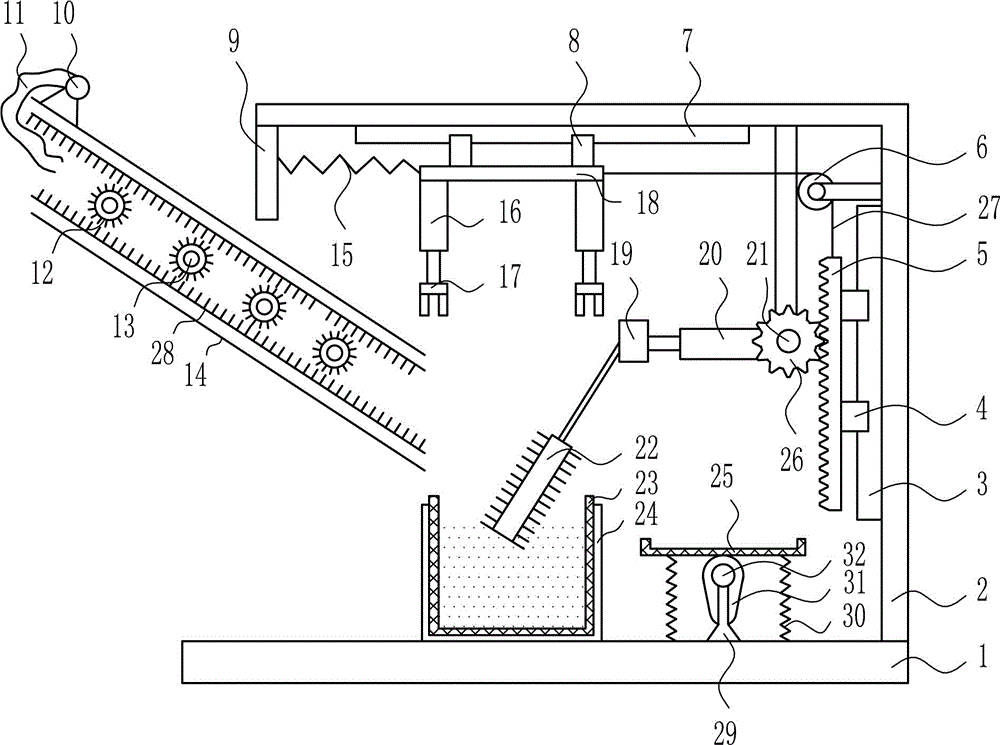

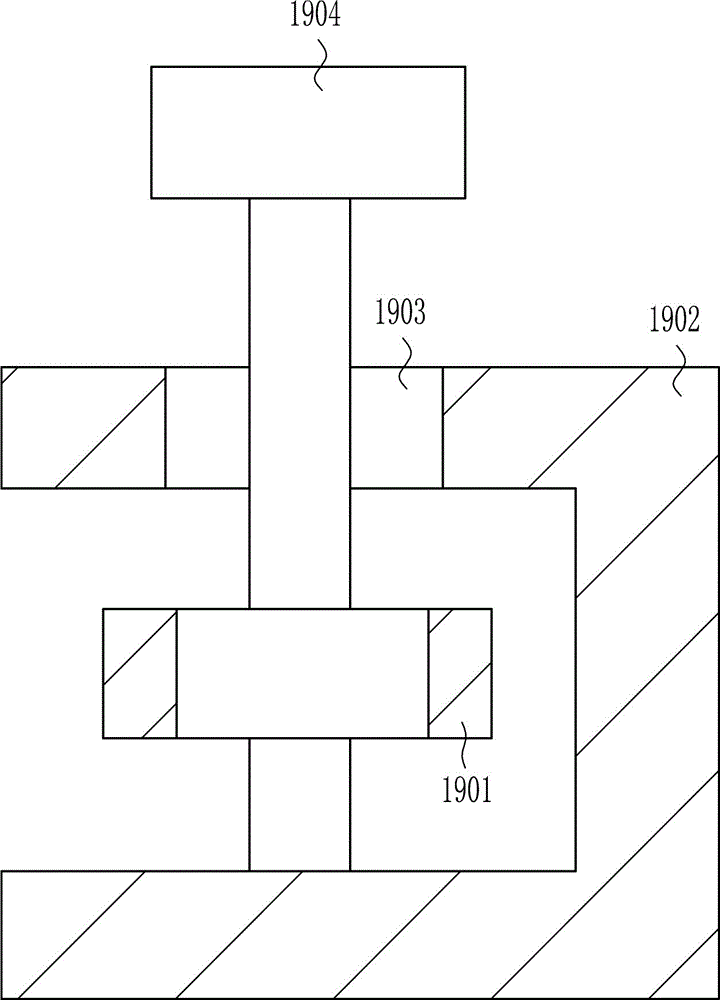

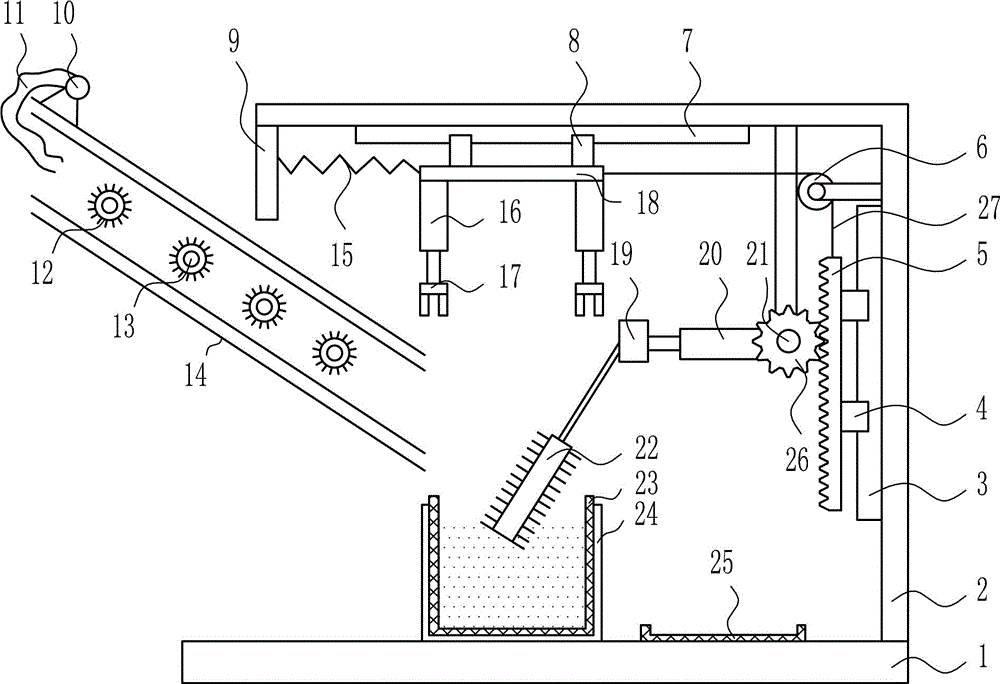

Medical traditional Chinese medicinal material efficient cleaning device

ActiveCN106391556AFast dryingExtended service lifeDrying gas arrangementsCleaning using liquidsWater resourcesTraditional medicine

The invention relates to a traditional Chinese medicinal material cleaning device, in particular relates to a medical traditional Chinese medicinal material efficient cleaning device, and aims to provide the medical traditional Chinese medicinal material efficient cleaning device which is high in cleaning speed and high in cleaning efficiency and can save water resources. In order to solve the technical problem, the medical traditional Chinese medicinal material efficient cleaning device comprises a left side plate, a bottom plate, a first cylinder, a right side plate, a fixed plate, a bearing pedestal, a fixed baffle, a gear, a spring, a rack, a hanging ring, a hook, a rotating shaft, a first pulley, a pull rope, a screen frame, a cleaning barrel, an iron block, a pull wire, a lifting rod, a contact roller, a first baffle, a motor, a disk, a connection rod, a wedge-shaped block, a sliding block, a sliding rail, a top plate, an L-shaped supporting plate and the like. According to the medical traditional Chinese medicinal material efficient cleaning device provided by the invention, by the adoption of a cleaning mode that the screen frame and the cleaning barrel are matched, the traditional Chinese medicinal material cleaning speed can be increased, and the cleaning effect can be enhanced.

Owner:宁夏仙草汇中药材科技有限公司

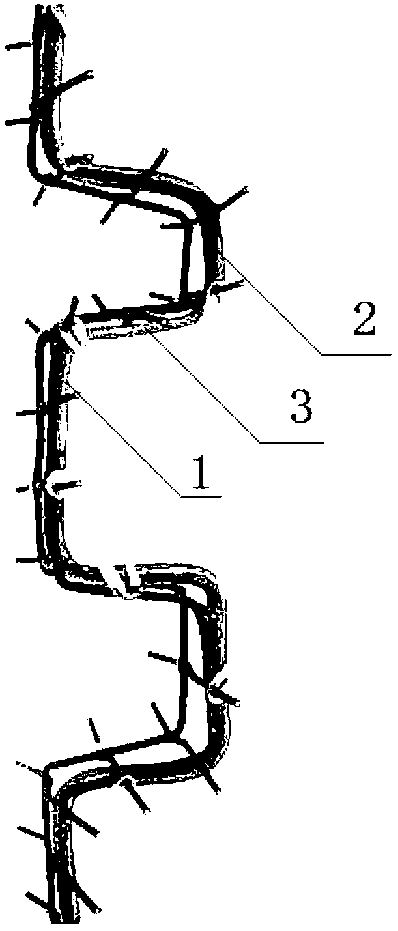

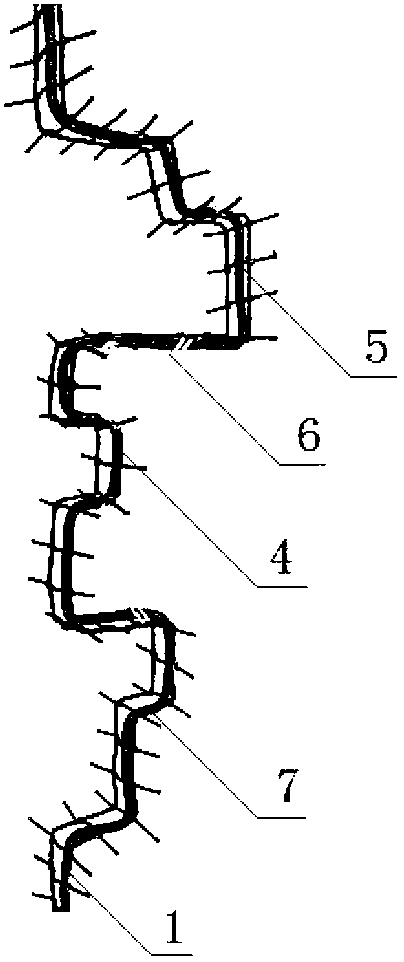

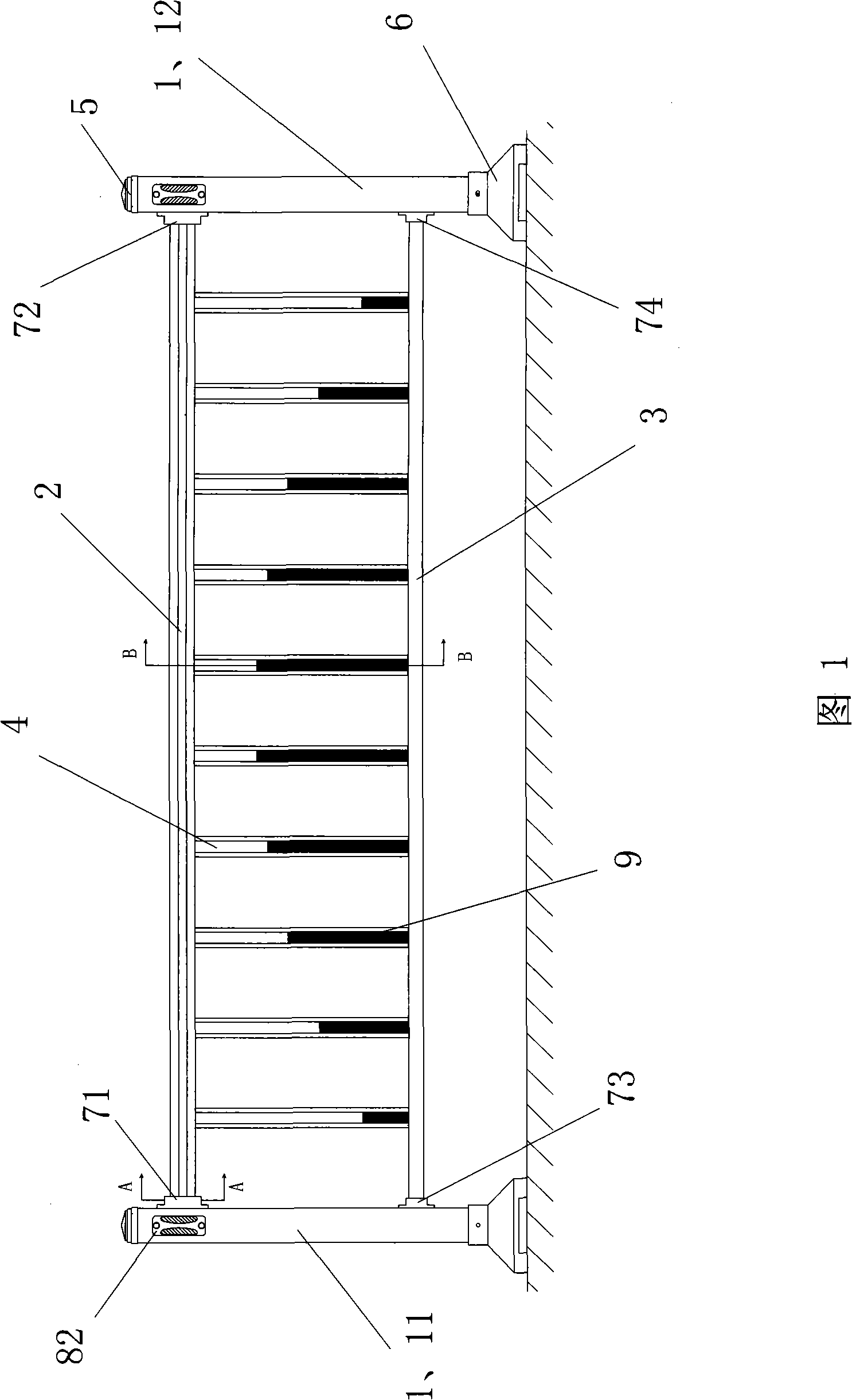

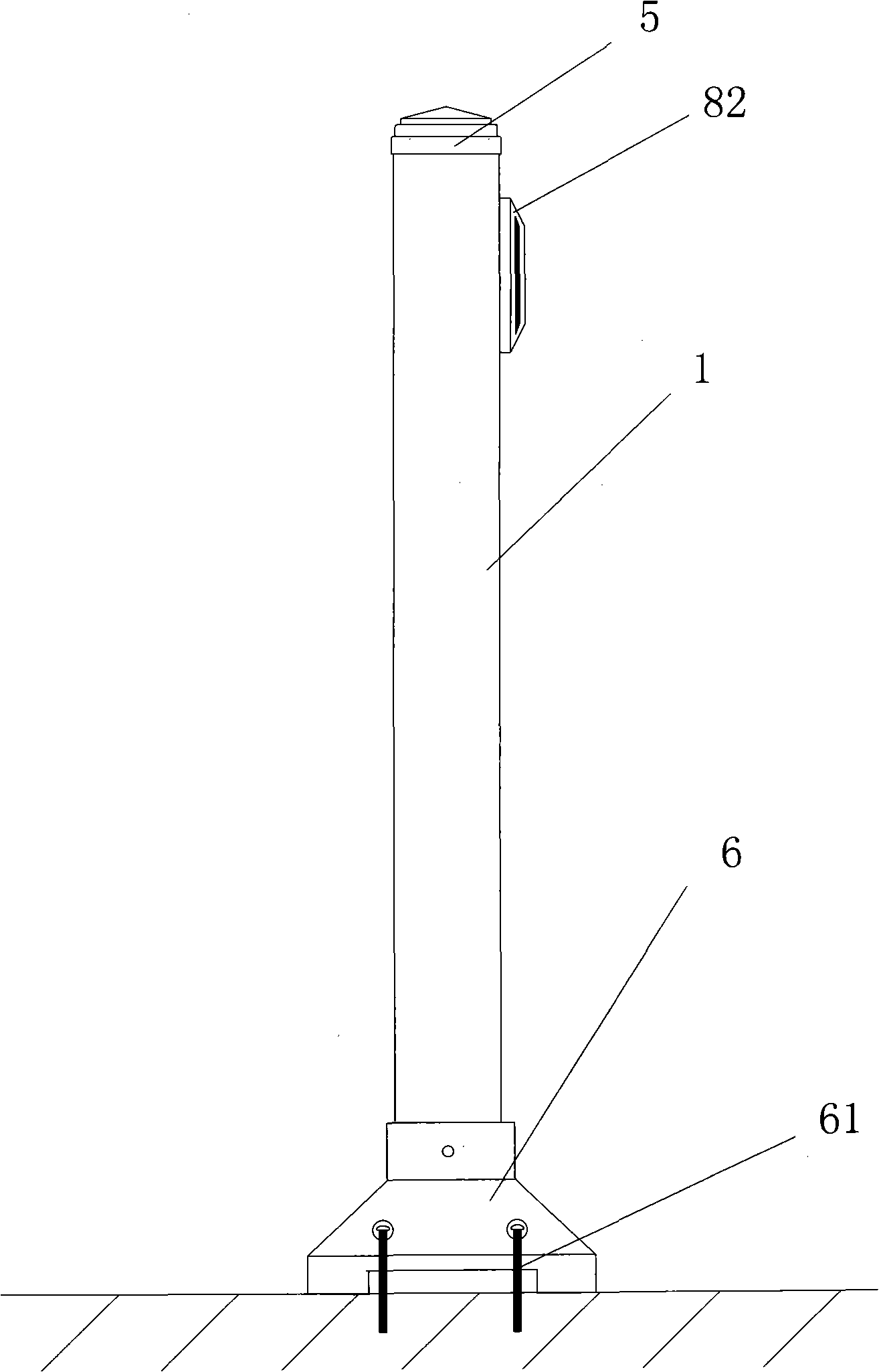

Bow-type cultivation trunk molding method of lythraceae lagerstroemia trunks

The invention discloses a bow-type cultivation trunk molding method of lythraceae lagerstroemia trunks. The method mainly includes the following steps: (1) designing trunk molds, deconstructing the molds into single-plant technical atlases, and selecting a planting bed for cultivating nursery-grown plants; (2) manufacturing and installing a supporting net frame in the planting bed; (3) manufacturing and installing a bow-shaped cultivation trunk molding ladder frame on the supporting frame; (4) carrying out bud fixing and bud picking on the nursery-grown plants; (5) binding and fixing twigs on the bow-shaped cultivation trunk molding ladder frame; (6) unbinding and exchanging binding objects which are not beneficial for trunk growth; (7) carrying out multi-point nurse grafts on the bow-shaped trunks according to molding design; and (8) cultivating in a healing mode, constructing crowns, the trunks and branches, and forming the target molds. The bow-type cultivation trunk molding method of the lythraceae lagerstroemia trunks is creative. Moreover, the nurse grafts can be carried out on single plants of the certain number to obtain the molded trunks, molding time is shortened, and characters, patterns or three-dimensional bodies can also be molded on planes or curved surfaces of the trunks.

Owner:TONGREN MANTANGHONG AGRI TECH

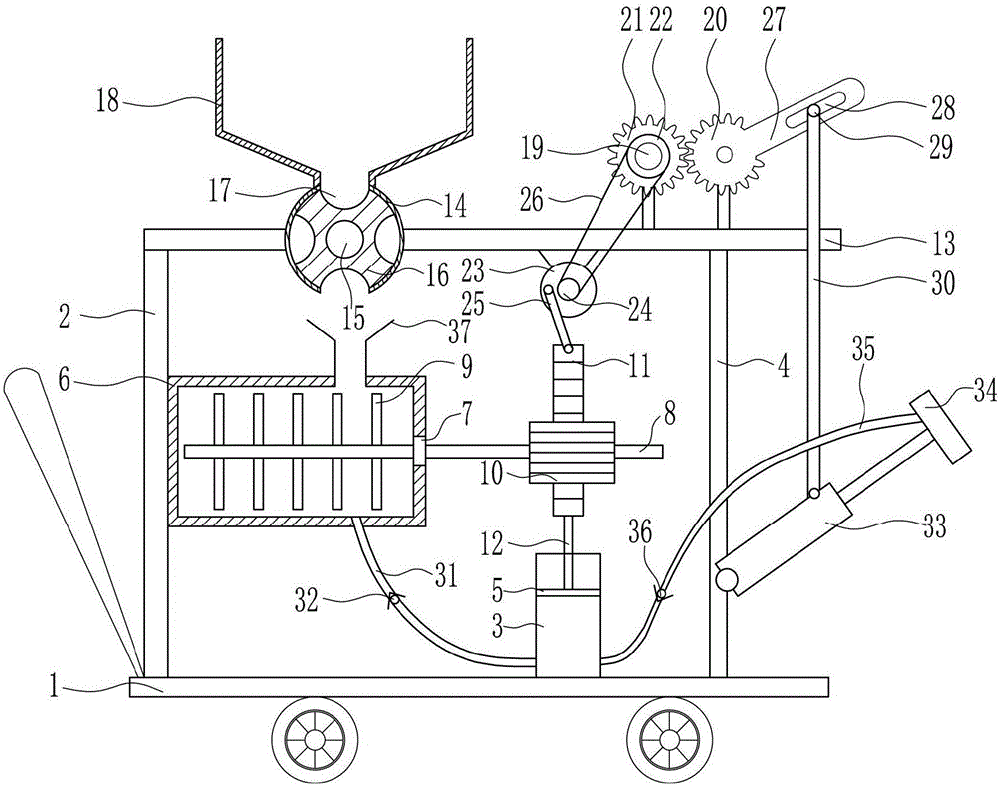

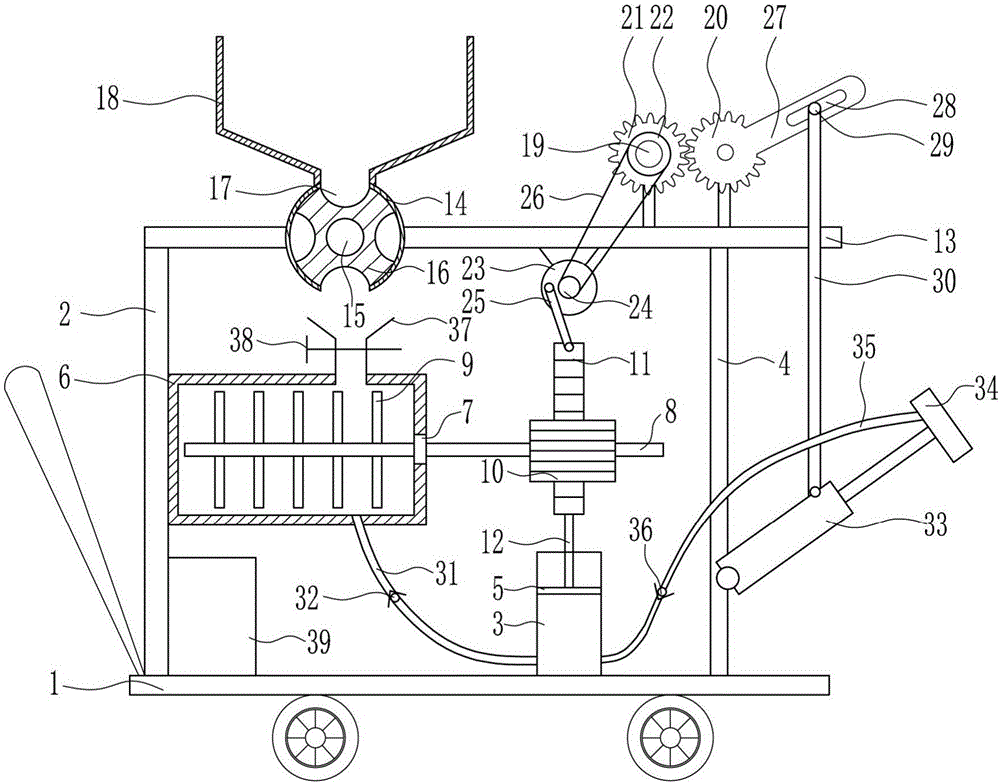

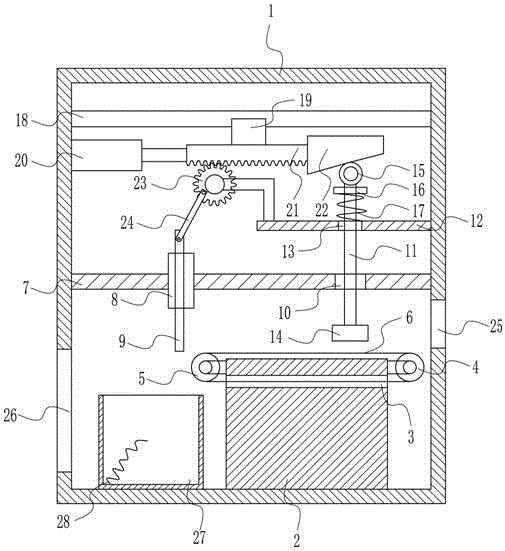

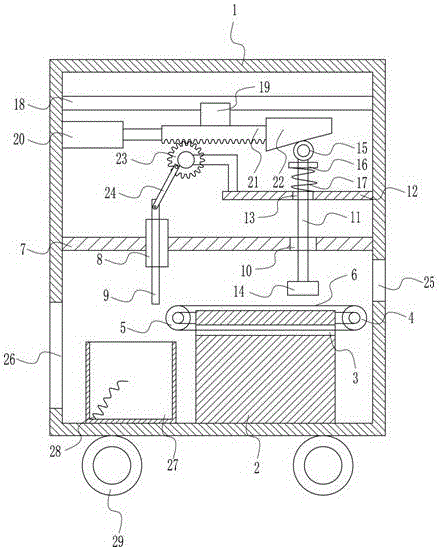

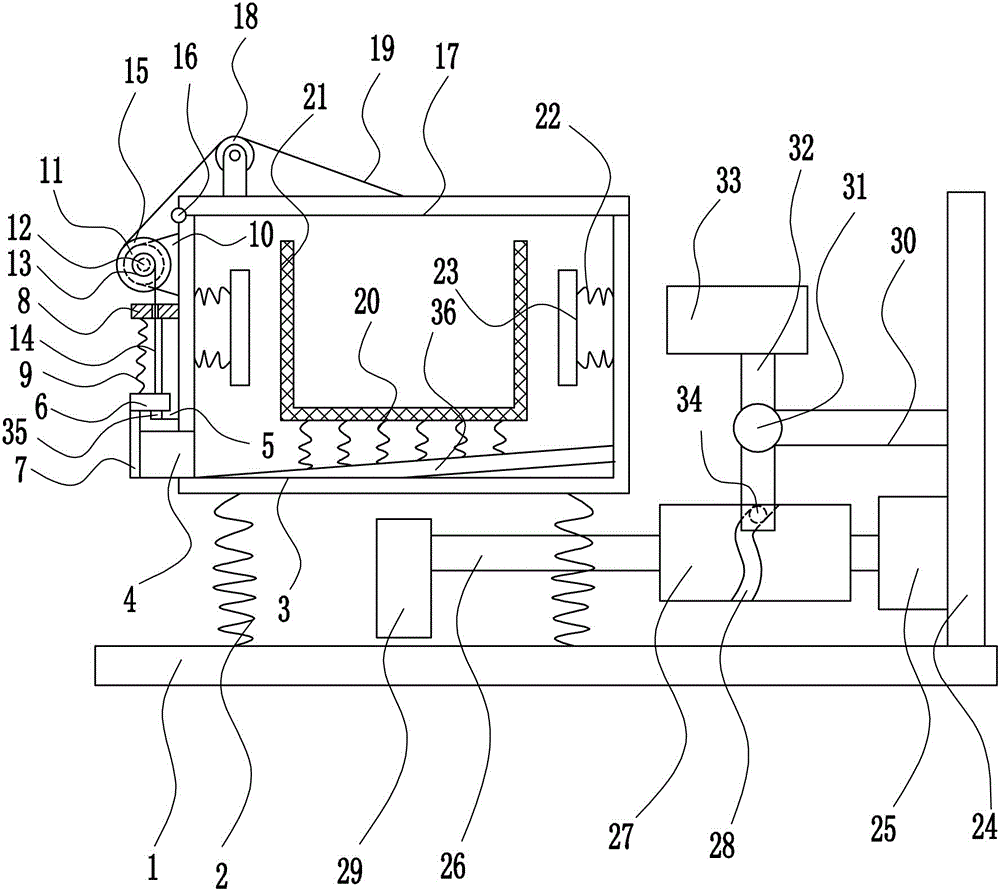

Experimental pesticide spraying device for transgenic plants

InactiveCN106577613ANot easy to rustSave human effortInsect catchers and killersUltimate tensile strengthBiology

The invention belongs to the technical field of genetic engineering, and particularly relates to an experimental pesticide spraying device for transgenic plants. The invention aims to solve the technical problem of providing an experimental pesticide spraying device for the transgenic plants, which can save labor, is high in working efficiency and can reduce labor strength. In order to solve the technical problem, the invention provides the experimental pesticide spraying device for the transgenic plants, which comprises a cart, a left side plate, a compression cylinder, a right side plate, a piston, a stirring tank, a bearing seat, a rotating rod, stirring blades, a first gear, a rack, a push rod, a top plate and the like. The left side plate, the compression cylinder and the right side plate are sequentially arranged at the top of the cart from left to right; and the left side plate and the right side plate are connected with the top of the cart in a welding mode. The experimental pesticide spraying device for the transgenic plants, which is provided by the invention, is manually pushed to spray a pesticide, so that labor can be saved and labor intensity can be reduced.

Owner:杜海燕

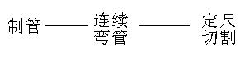

Production process and production line for continuous stainless steel coil

ActiveCN101797602ABeautiful appearanceUniform and bright colorProduction lineUltimate tensile strength

The invention relates to the machining for a stainless steel coil of a heat exchanging pipe. A production process for a continuous stainless steel coil comprises a pipe making step, a pipe bending step and a cutting step which adopt continuous on-line machining, wherein the first pipe making step comprises the following step: using a steel band as a raw material to perform on-line continuous pipe making; the second pipe bending step comprises the following steps: conveying an obtained steel pipe into a pipe bending machine; conveying a bent pipe to a second pipe bending position to bend the bent pipe for a second time; continuously bending the pipe in turn until the steel pipe is bent and assumes a single continuous bent pipe; and the third cutting step comprises the following step: sizing the single continuous bent pipe and cutting pipe end excess materials to obtain a single coil single pipe with a length of between 15 and 133 meters without a radial weld joint. The production process has the advantages of low cost, continuous pipe making and pipe bending and convenient machining, assembling and transportation. The obtained stainless steel coil has few or no radial welding spot, strong corrosion resistance without stress corrosion or corrosive pitting phenomenon, stable mechanical strength and relatively better heat exchanging efficiency.

Owner:BAC DALIAN

Skeleton type cable

ActiveCN102590968ANot easy to rustEffective protectionFibre mechanical structuresEngineeringBuilding construction

The invention relates to a skeleton type cable, belonging to the technical field of cables. The cable comprises a skeleton, a reinforcement, an internal skeleton slot, a cable core, a protective layer and a sheath, and is characterized in that a first groove and a second groove are formed on the internal skeleton; an external skeleton slot is arranged on the external edge of the sheath; the position of the internal skeleton slot corresponds to the position of the external skeleton slot; a third groove and a fourth groove are formed on the external edge of the sheath; and the positions of the first and third grooves correspond to the positions of the second and fourth grooves; the bottom surfaces of the internal and external skeleton slots are planes and the bottom surfaces at the corresponding positions are parallel; on the cross section of the cable, the area of the first groove is larger than the area of the second groove; the area of the third groove is larger than the area of the fourth groove; and on the projection of the bottom surface of any of the internal skeleton slot, the bottom of the external skeleton slot at the corresponding position is located in the bottom surface of the internal skeleton slot or has the size the same as that of the bottom surface of the internal skeleton slot. The cable provided by the invention mainly has the following beneficial effects that the manufacturing is simple, the mass production is easy, the construction is convenient, and the protection to cables is more effective.

Owner:JIANGSU NANFANG COMM TECH

Cutting device for foam plastic plate

The invention relates to a foam plastic plate device, in particular to a cutting device for a foam plastic plate and aims at achieving the technical purpose of providing the cutting device for the foam plastic plate, wherein the cutting device can save time and labor, reduce the labor intensity of workers, improve the foam plastic plate cutting efficiency and protect workers. To achieve the above technical purpose, the cutting device for the foam plastic plate is provided and comprises a box, a base table, an electric wheel, a driven wheel, a belt, a transverse plate, a hollow guiding sleeve, a sliding rod, a lifting rod, a guide rod, a blade, a contact wheel, a fixing stop block and the like. The bottom of the right side in the box is provided with the base table in a welding connecting manner, and an opening is horizontally formed in the upper portion of the base table. According to the cutting device, through left-right movement of a wedge block, the lifting rod moves up and down, the lifting rod moves up and down to drive the blade to move up and down to cut the foam plastic plate, and time and labor can be saved.

Owner:广州鼎实建筑环保材料有限公司

Cleaning device for water bucket for sewage treatment

The invention relates to a cleaning device for a water bucket, in particular to a cleaning device for a water bucket for sewage treatment, and aims to provide the cleaning device which is used for the water bucket for sewage treatment, can save the time and the labor, can improve the cleaning efficiency and is convenient to use. The cleaning device comprises a bottom plate and the like; a first cleaning device is arranged in the middle of the top of the bottom plate; a water spraying device is arranged on the first cleaning device; a supporting plate is vertically connected at the top of the bottom plate on the right side of the first cleaning device; a vertical moving mechanism is arranged at the upper part of the left side surface of the supporting plate; a first connecting rod is connected onto a moving component of the vertical moving mechanism; and a first fixing device is arranged on the first connecting rod. With the cleaning device, the water bucket is fixed through the first fixing device and a second fixing device and then is cleaned through rotation of a first brush and a second brush, so that the time and the labor can be saved.

Owner:李良

Jet printing type steel guard rail

ActiveCN101265694AImprove structural strengthAvoid deformationTraffic signalsRoad signsVertical barEngineering

The invention discloses a spraying type steel barrier, which comprises columns, upper cross bars, lower cross bars and vertical bars. The main bodies of the columns, the upper cross bars, the lower cross bars and the vertical bars are all integrated style steel works. The columns are made from the galvanized steel strip, made into steel pipe of a certain shape and sprayed with plastic or paint; the upper cross bars, the lower cross bars and the vertical bars are integrated parts which the upper cross bars, the lower cross bars and the vertical bars are respectively made from the galvanized steel strip, steel pipes of a certain shape are made through extrusion forming of the steel pipe stock mould, seam welding of the high frequency induction welder and extrusion forming of the steel pipe shaping mould and the integrated parts are formed by placing the vertical bars between the upper cross bars and the lower cross bars, welding and fixing, and at last spraying plastic or paint on the exterior surface of the integrated parts. The spraying type steel barrier has the advantages of high structural strength, deformation resistance, beautiful and clean barrier surface, rustiness resistance, easy cleaning, greatly reduced maintenance cost, both the beautiful appearance of the PVC plastic steel barrier and the high strength of the assembly type barrier.

Owner:JIANGSU AIKEQING IND

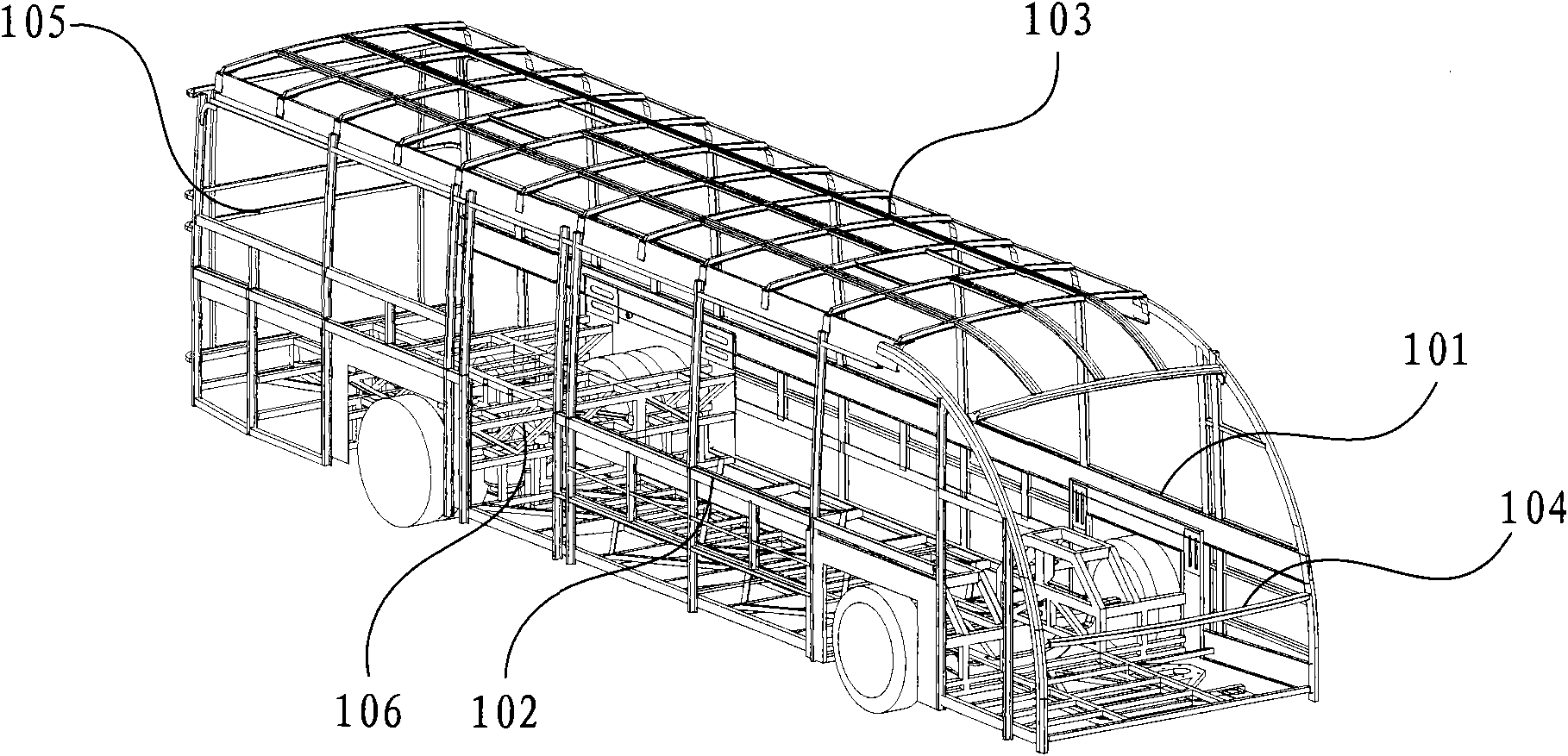

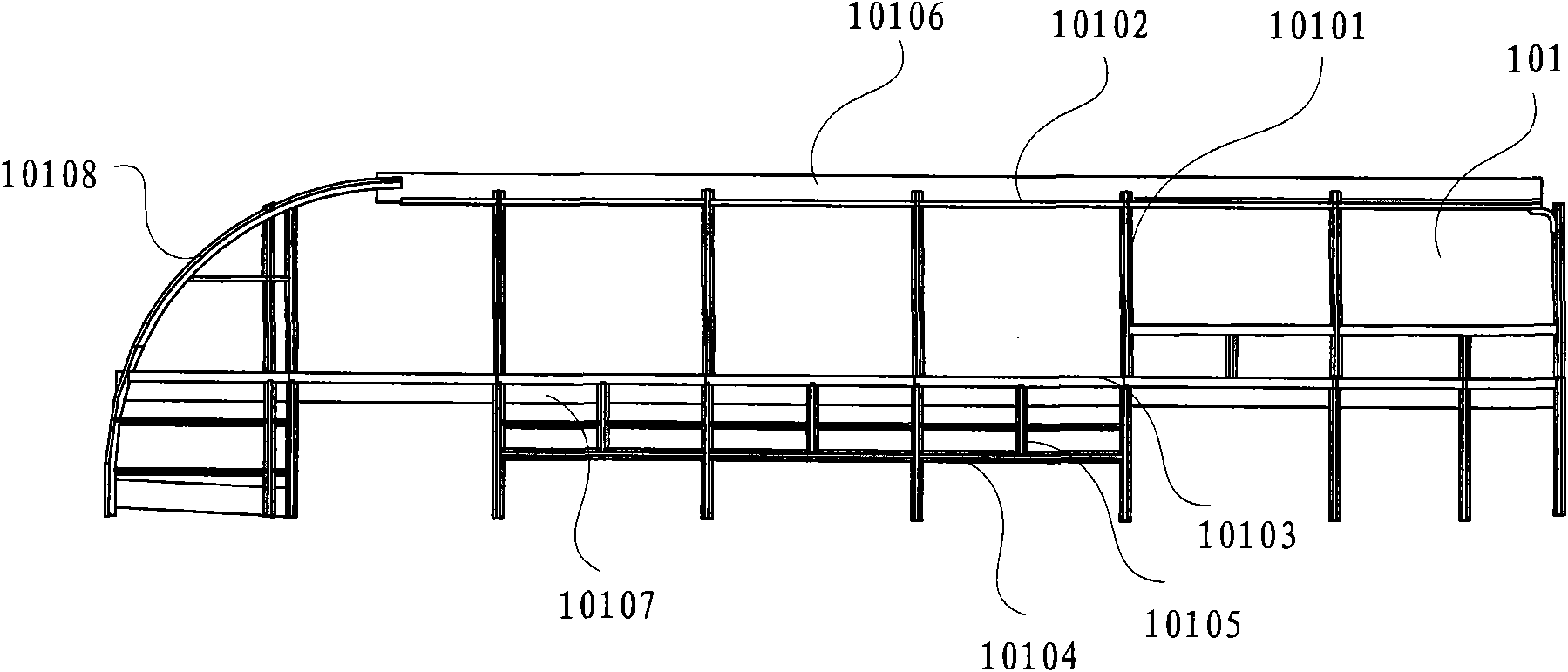

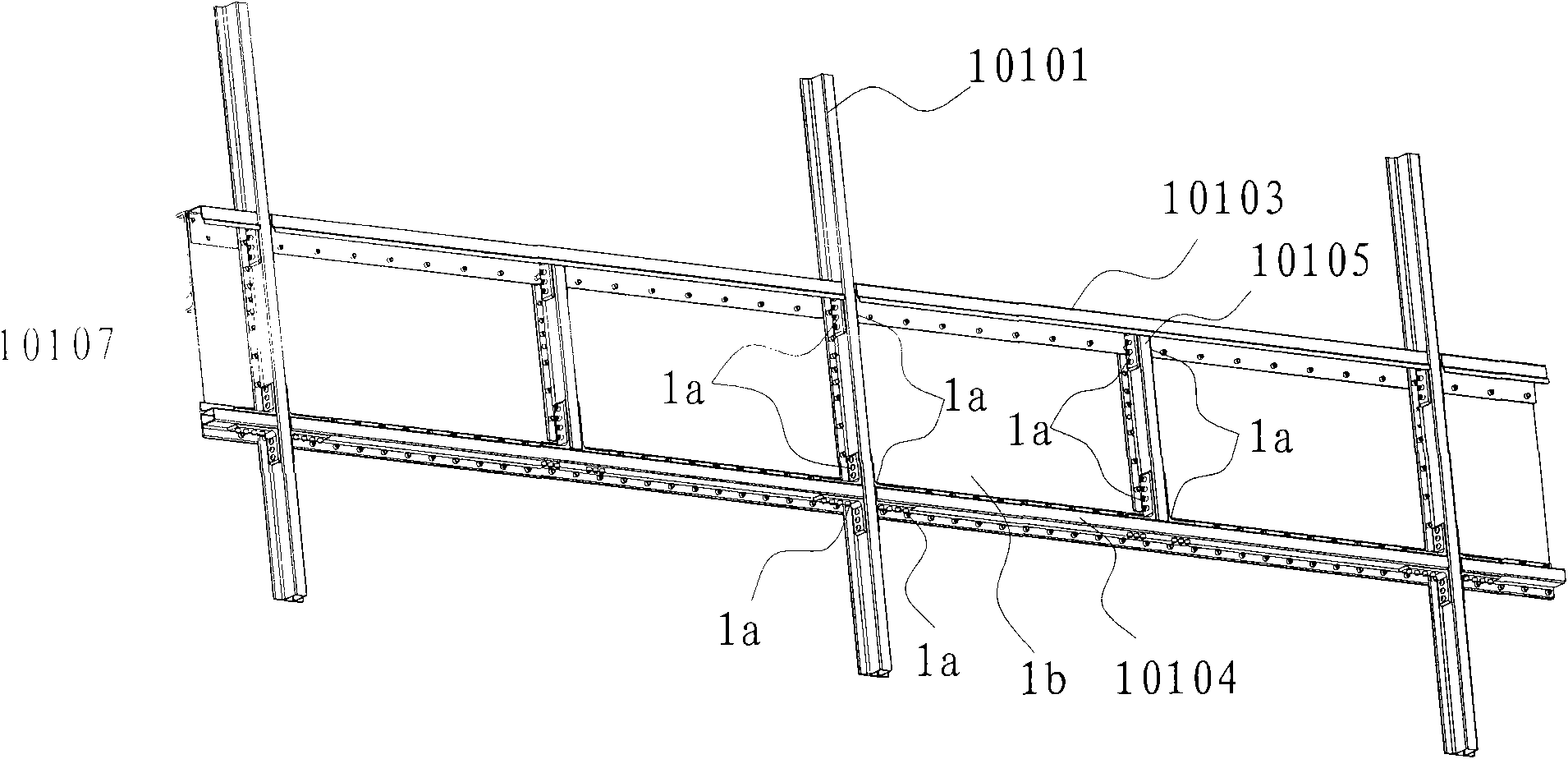

Lightweight total-bearing body frame structure

ActiveCN101863290AReduce weightExtended service lifeSuperstructure connectionsPassenger vehicle superstructuresSteel frameUltimate tensile strength

The invention relates to a lightweight total-bearing body frame structure, which comprises a side wall frame, a roof frame, a front wall frame, a rear wall frame and an interlayer frame. The lightweight total-bearing body frame structure is made of an aluminum alloy or magnesium alloy material, and is riveted with lockbolts so as to ensure that the weight of the body frame is greatly reduced while the whole strength of the body is not lower than the conventional steel body frame. The parts forming the body frame has a unique design, so that well balance between weight reduction and strength maintenance can be achieved. The lightweight total-bearing body frame structure saves more energy than the conventional steel frame.

Owner:北京绿程锦绣能源科技有限公司

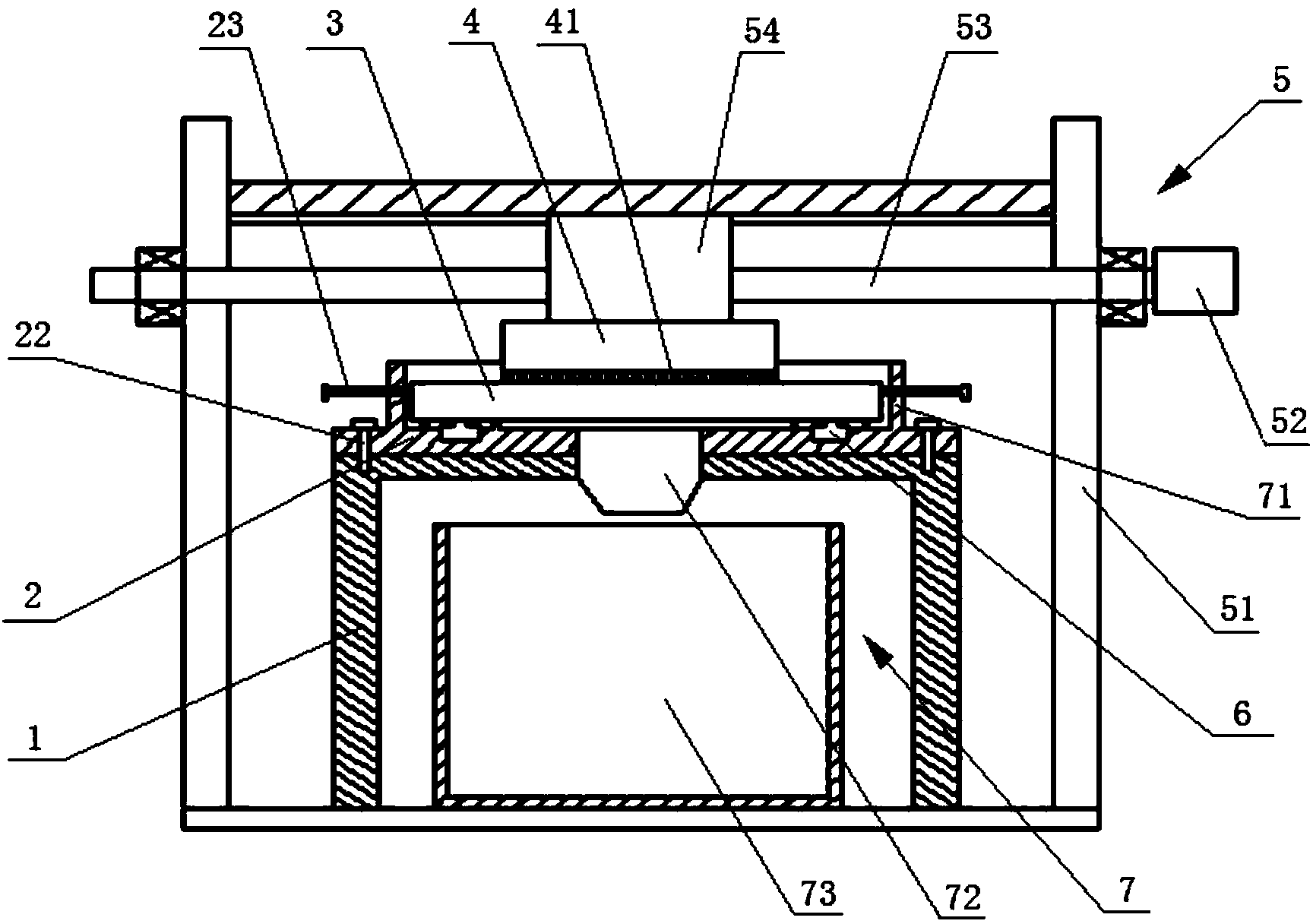

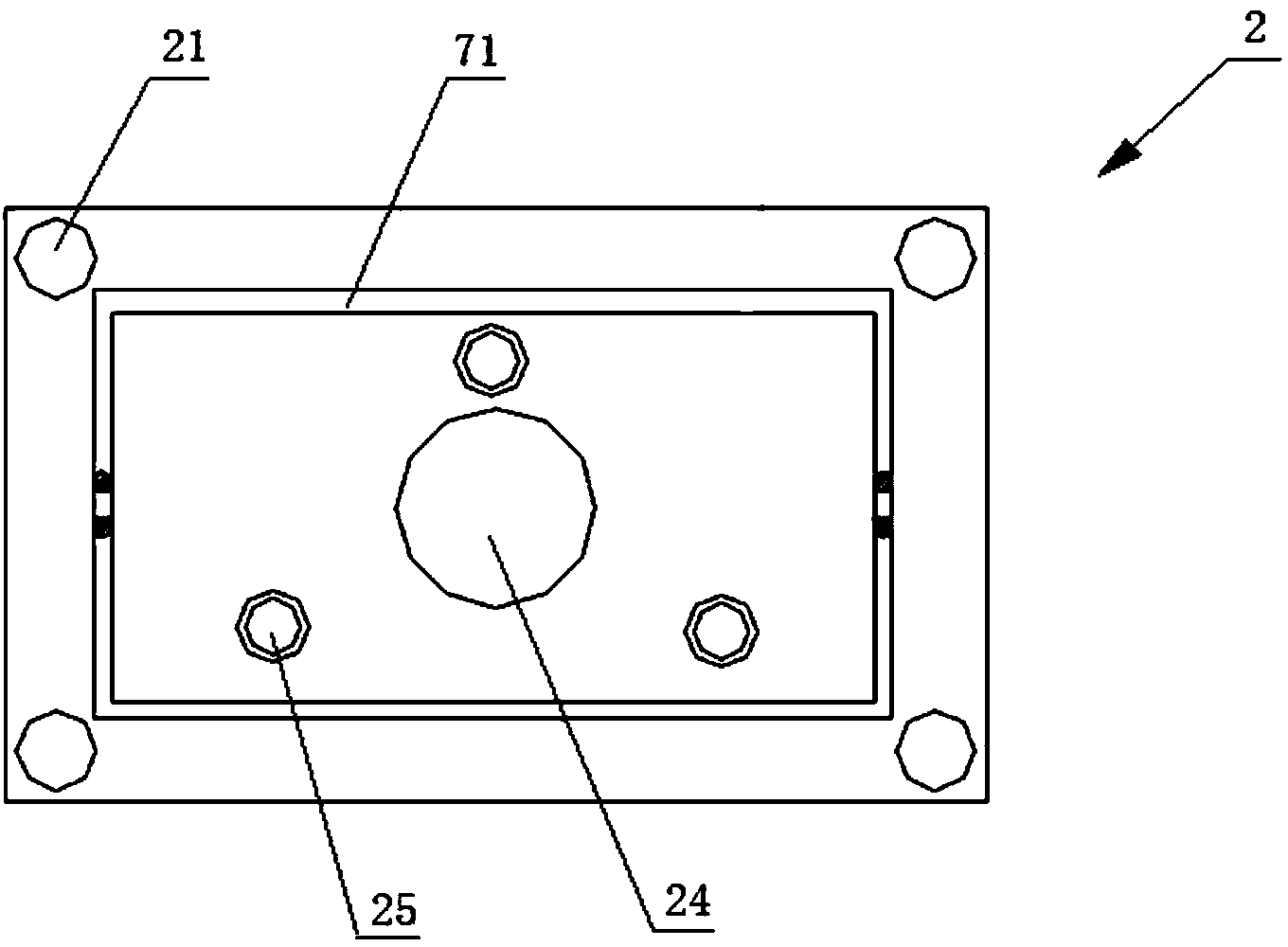

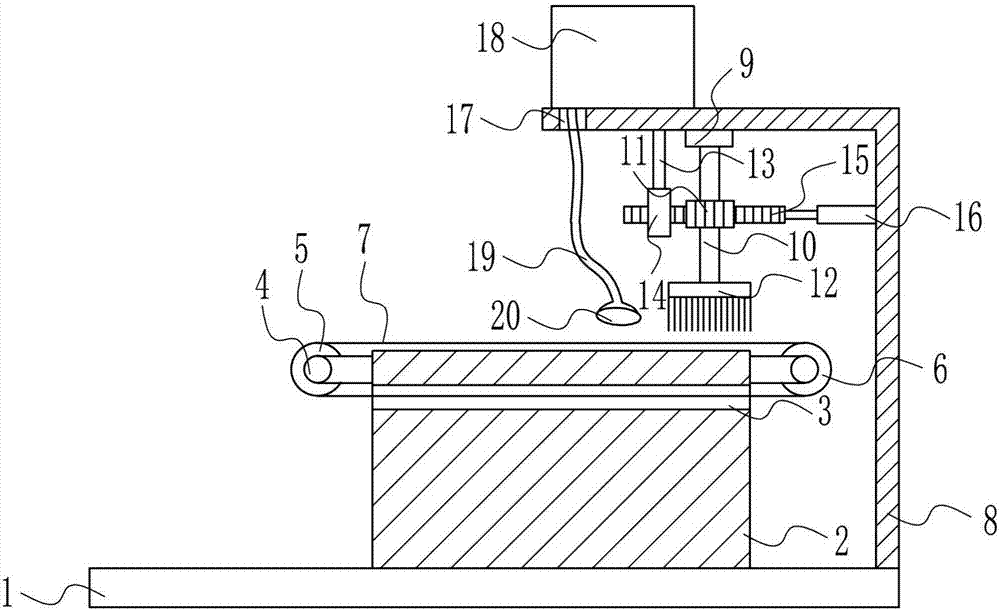

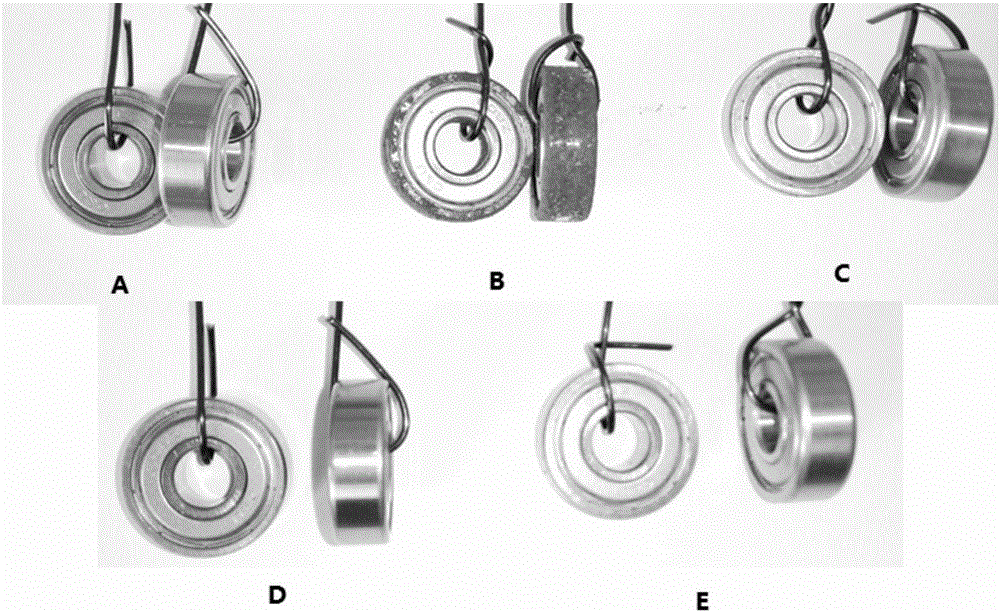

Brushing electroplating experimental platform

The invention discloses a brushing electroplating experimental platform which comprises a lifting platform, a clamping table, a plating pen anode, a plating solution conveying device, and further comprises a plating solution recovery device, wherein the clamping table is arranged at the upper end of the lifting table, and can be driven to move up and down through the lifting platform, and the clamping table is provided with a pressure testing device corresponding to a workpiece clamped by the clamping table; the plating pen anode is arranged above the clamping table through a driving mechanism, and corresponds to the workpiece, and a wrapping layer is distributed at the lower end of the plating pen anode; the plating solution conveying device is used for conveying a plating solution to the plating pen anode; the pressure detecting device comprises a plurality of pressure sensors; the wrapping layer comprises a plurality of pieces fixedly arranged at the lower end of the plating pen anode. According to the invention, brushing electroplating is automatically performed through adjusting and controlling the speed, the pressure, the voltage and the plating solution flow during a brushing electroplating process, and an optimal parameter range during the brushing electroplating to different materials can be obtained through experiments to plate blocks made of different materials.

Owner:GUANGXI UNIV

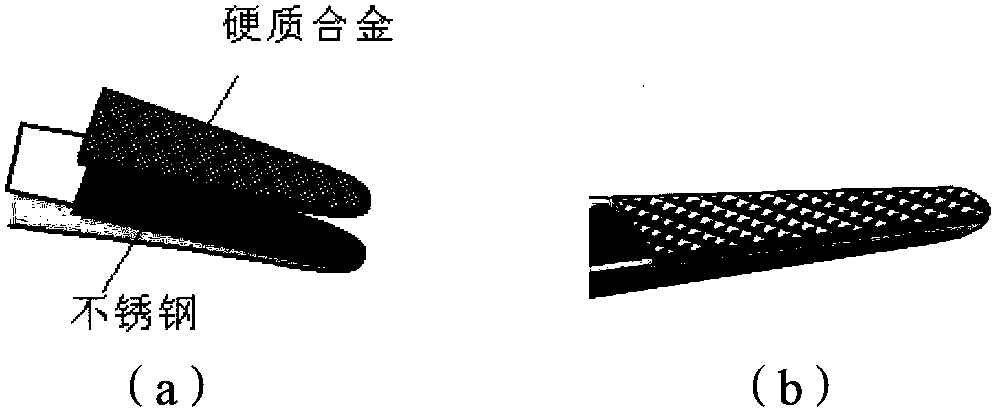

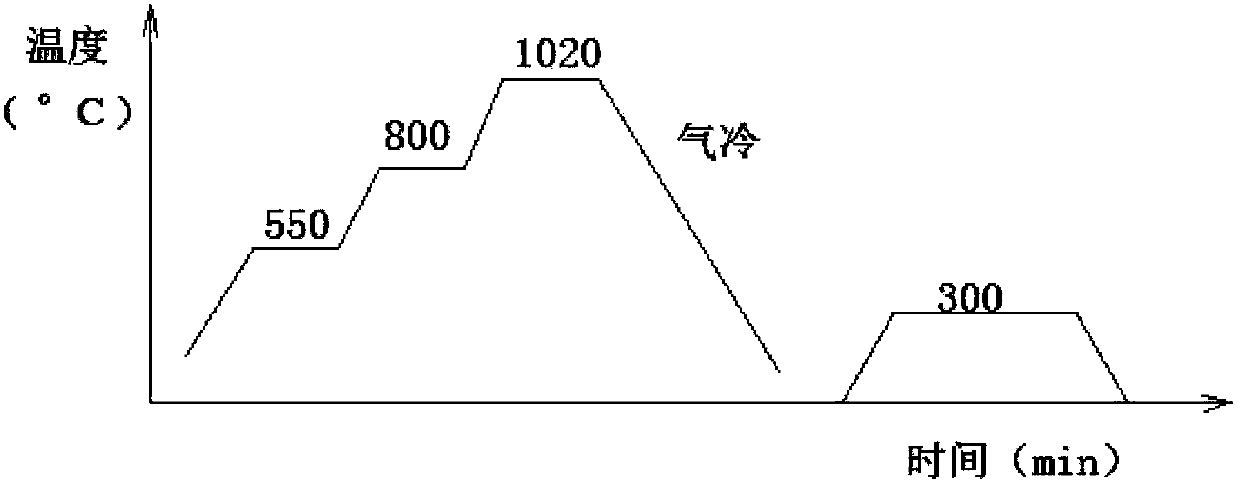

Vacuum brazing and thermal treatment composite process for stainless steel surgical instrument and application of process

InactiveCN103386525AImprove anti-corrosion performanceNot easy to rustSoldering apparatusCemented carbideProduction rate

The invention relates to a vacuum brazing and thermal treatment composite process for a stainless steel surgical instrument and the application of the process. An embedding method is adopted for embedding cemented carbide in the working end of the stainless steel surgical instrument, vacuum brazing and vacuum thermal treatment are adopted for synchronous treatment, the two processes are combined into one process, and on the basis of controlling the vacuum degree, the heating speed, the heating temperature, the brazing temperature, the brazing opportunity and the cooling method, the stainless steel surgical instrument with the working end embedded with the brazed cemented carbide is obtained. The stainless steel surgical instrument has excellent abrasive resistance, anti-slip performance, anti-corrosive performance and the like, the product quality is high, the energy consumption is low, the production rate is high and the operation environment is improved, and quality defects of the original process are overcome. The composite process has great significance in the process of treating stainless steel surgical instruments.

Owner:上海医疗器械(集团)有限公司

Rare earth alloy iron pan and production method thereof

InactiveCN103239139AImprove mechanical propertiesHigh burst resistanceCooking-vessel materialsSocial benefitsVegetable oil

A rare earth alloy iron pan production method includes: (1) smelting cast iron by an intermediate frequency furnace, and heating the iron molten iron till the temperature is higher than 1400 DEG C; (2) smashing rare earth ferrosilicon alloy till the size ranges from 2mm to 6mm, and preheating till the temperature reaches 60 DEG C; (3) placing the rare earth ferrosilicon alloy block with a quantity of weight ratio ranging from 0.3% to 1.8% in a ladle and then pouring the molten iron, and mixing and drossing; (4) casting after the molten iron is cleared, preheating a casting mold and injecting the molten iron to the mold, and pressing an upper pan mold down to form an iron pan; (5) taking out the iron pan after the iron pan is chilled in the mold, and clearing in a mechanical fine grinding and buffing manner; (6) feeding the iron pan into an electric furnace, heating till temperature ranges from 270 DEG C to 330 DEG C, painting edible vegetable oil on the pan body to form an oil film, and allowing oil molecules to penetrate in the pan body; and (7) taking out the iron pan and detecting. The rare earth alloy iron pan production method has good social benefit and economic benefit, and is adaptable to the field of iron pans.

Owner:SANSUI HONGLI KITCHEN UTENSILS CO LTD

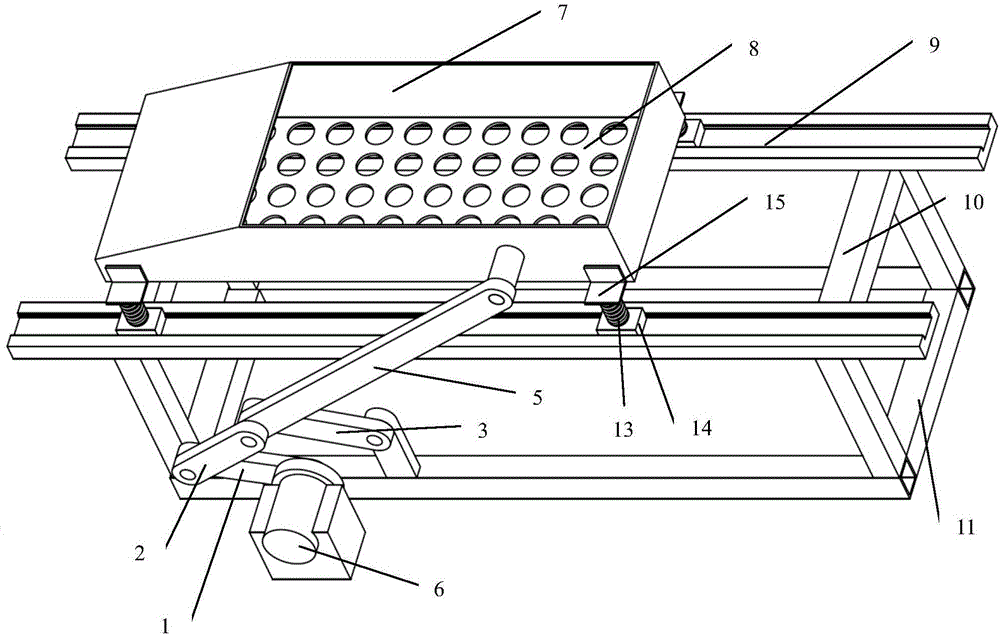

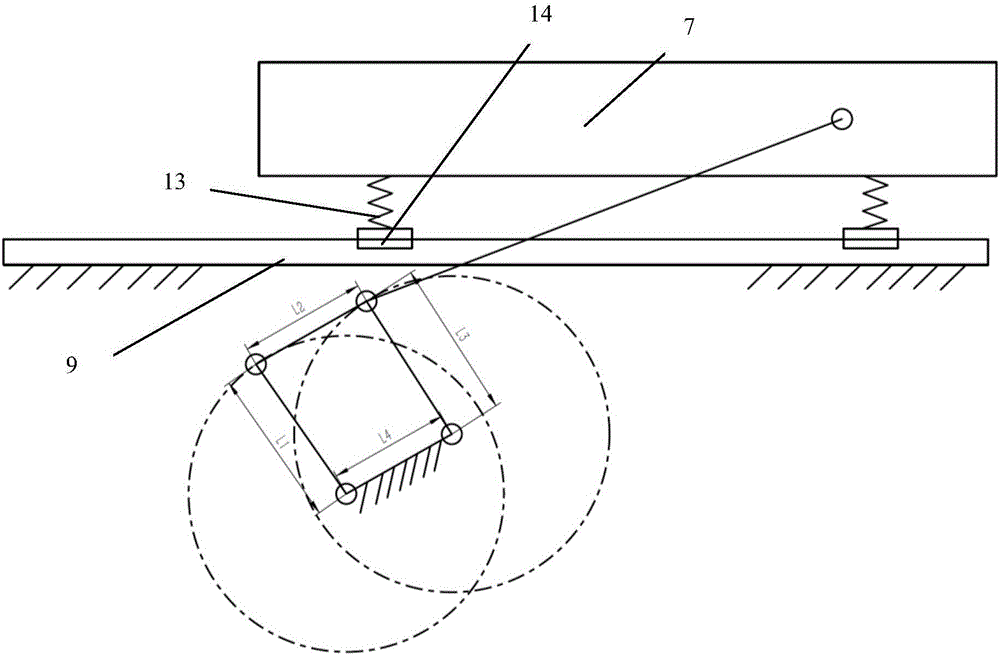

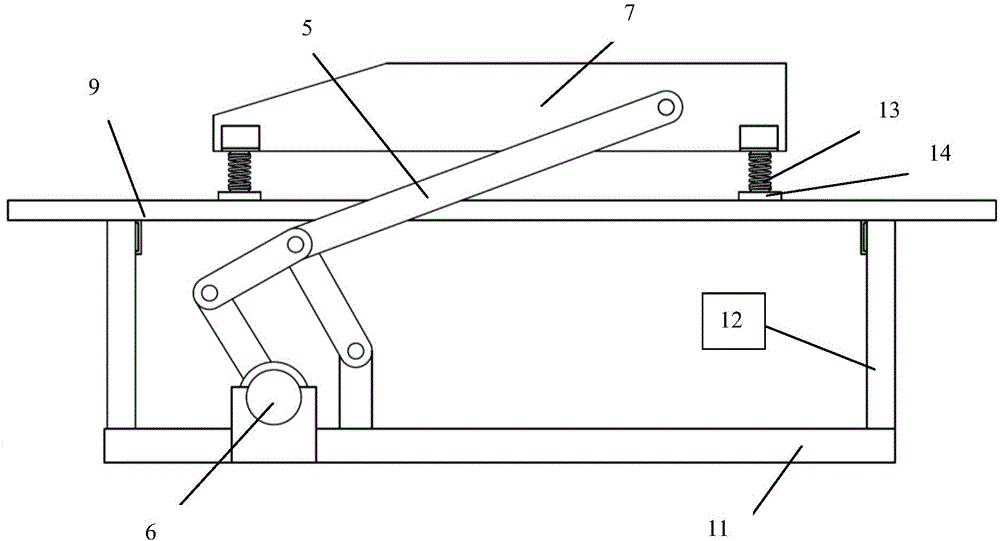

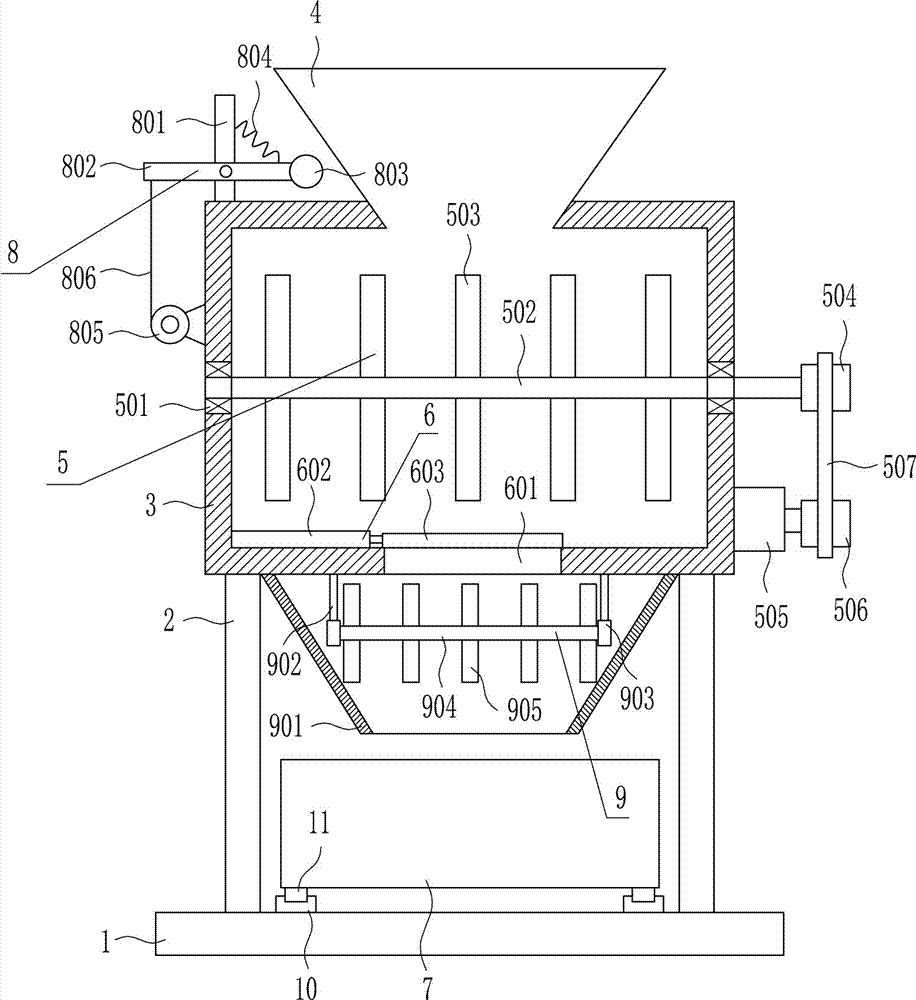

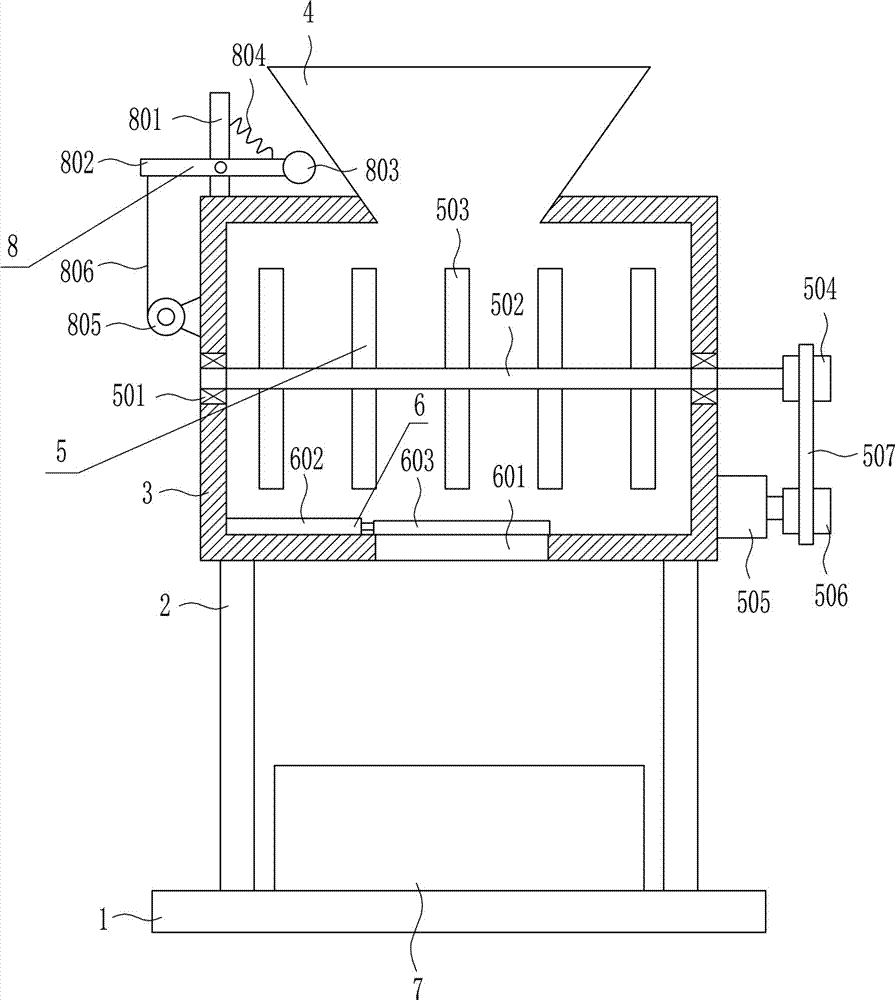

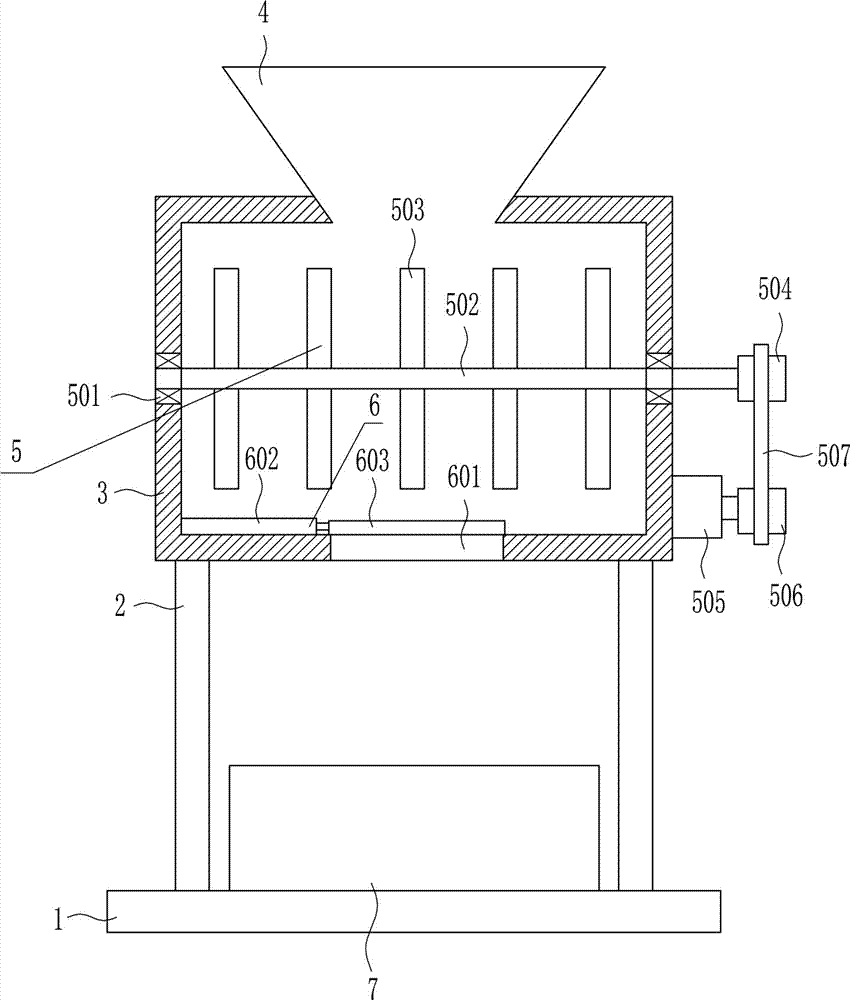

Inertial vibrating screen mechanism

InactiveCN106311596ASimple structureAssembly facilitationSievingScreeningMechanical engineeringTranslational motion

The invention discloses an inertial vibrating screen mechanism and belongs to the field of vibration screening. The mechanism comprises a rack, a screen body, a motor, springs and a connection rod mechanism; the motor is a power source and drives the connection rod mechanism to move; the connection rod mechanism is a five-rod mechanism and comprises two cranks and two connection rods, wherein the first crank and the second crank are both connected with a rack rotating pair, the two ends of the first connection rod are connected with a first crank rotating pair and a second crank rotating pair correspondingly, one end of the second connection rod, the second crank and the first connection rod are jointly connected through a rotating pair, and the other end of the second connection rod is connected with a screen body rotating pair; the screen body comprises a screen frame, a screen net and supporting frames; the two ends of each supporting frame are connected with the screen frame and the springs through bolts; the screen body is pushed by a double-crank mechanism to make reciprocating translational motion; the other ends of the springs are fixedly connected with sliders on a guiding rail; the rack comprises a base, stand columns and a cross beam; the lower ends of the stand columns are fixedly connected with the base; the upper ends of the stand columns are fixedly connected with the cross beam; and by means of vibration of a machine, classification, desliming and separation according to mass or particle diameter on materials are achieved.

Owner:JIANGSU UNIV

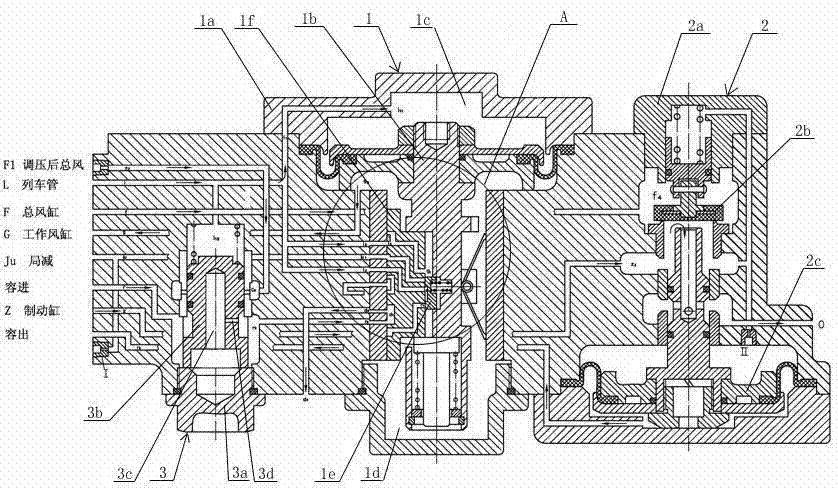

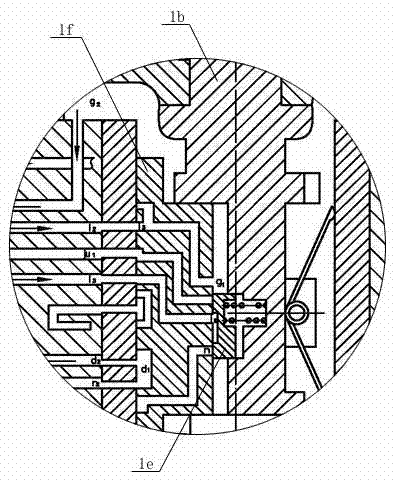

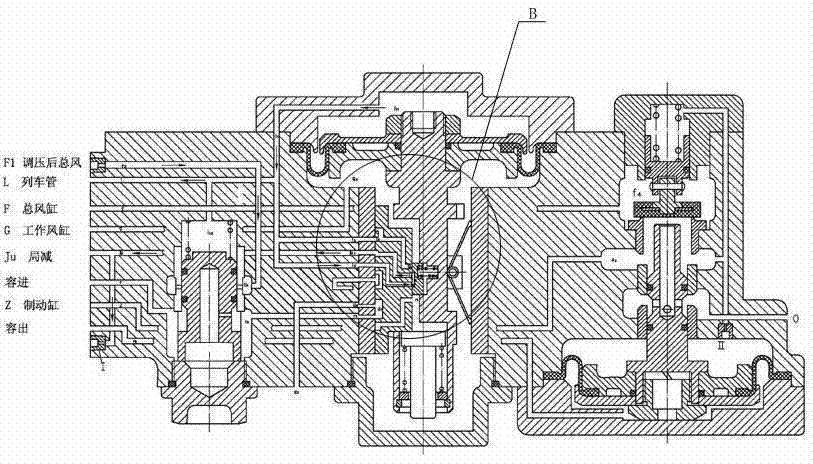

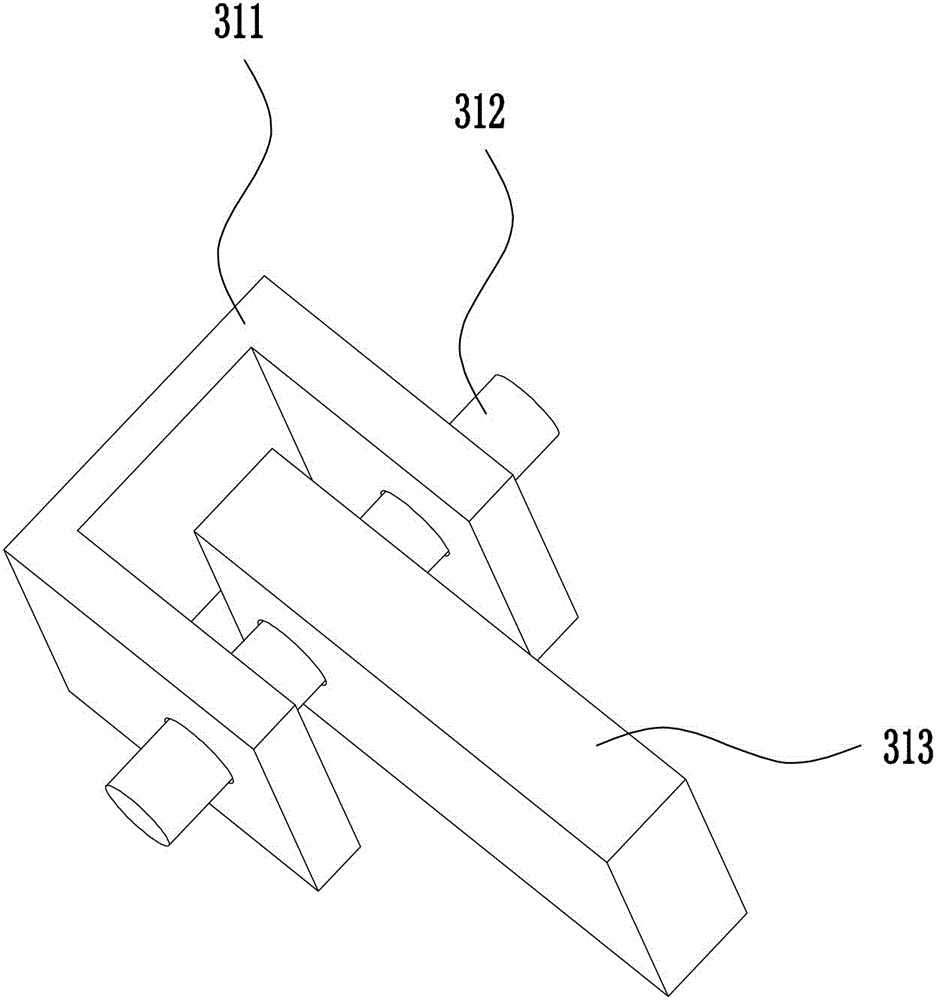

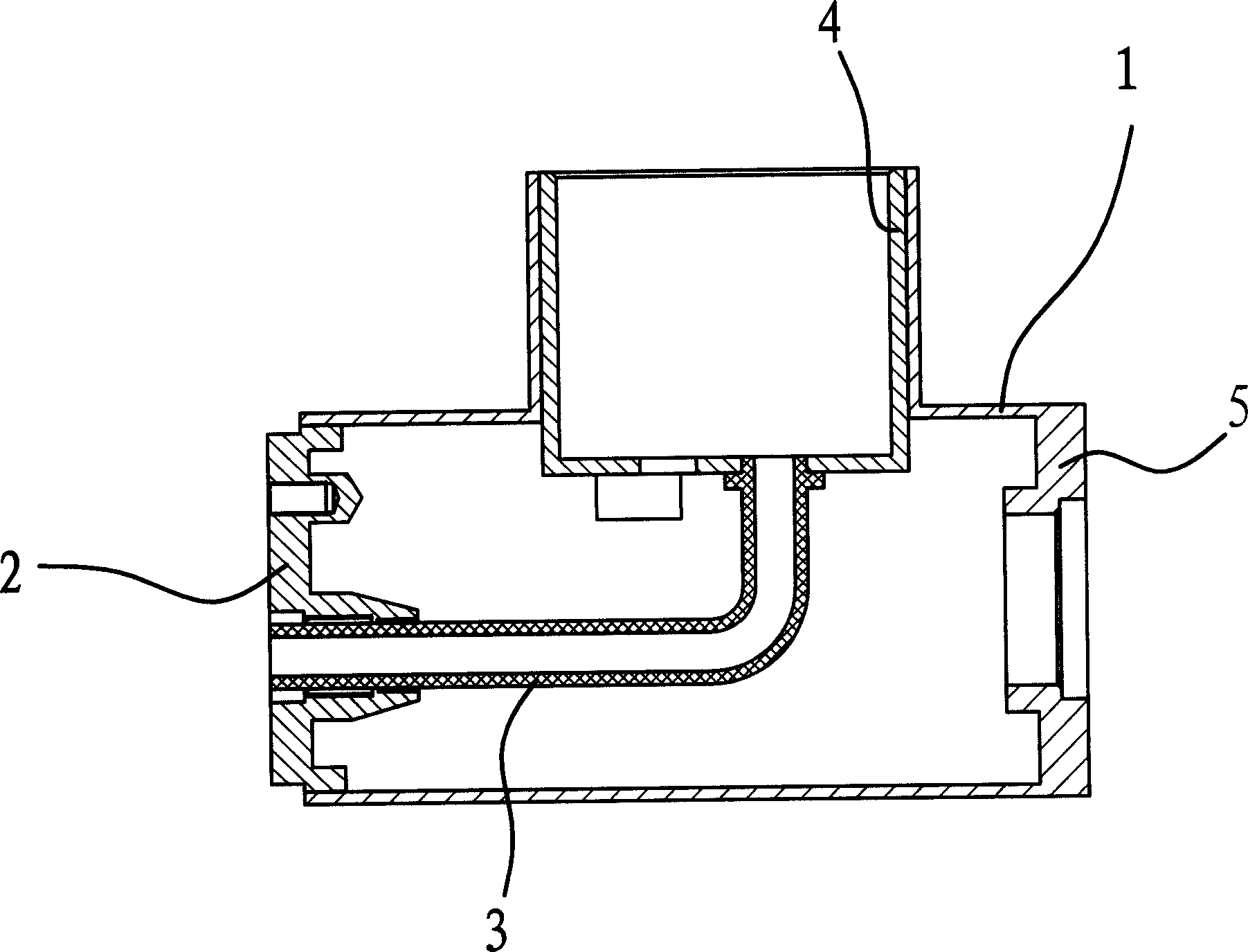

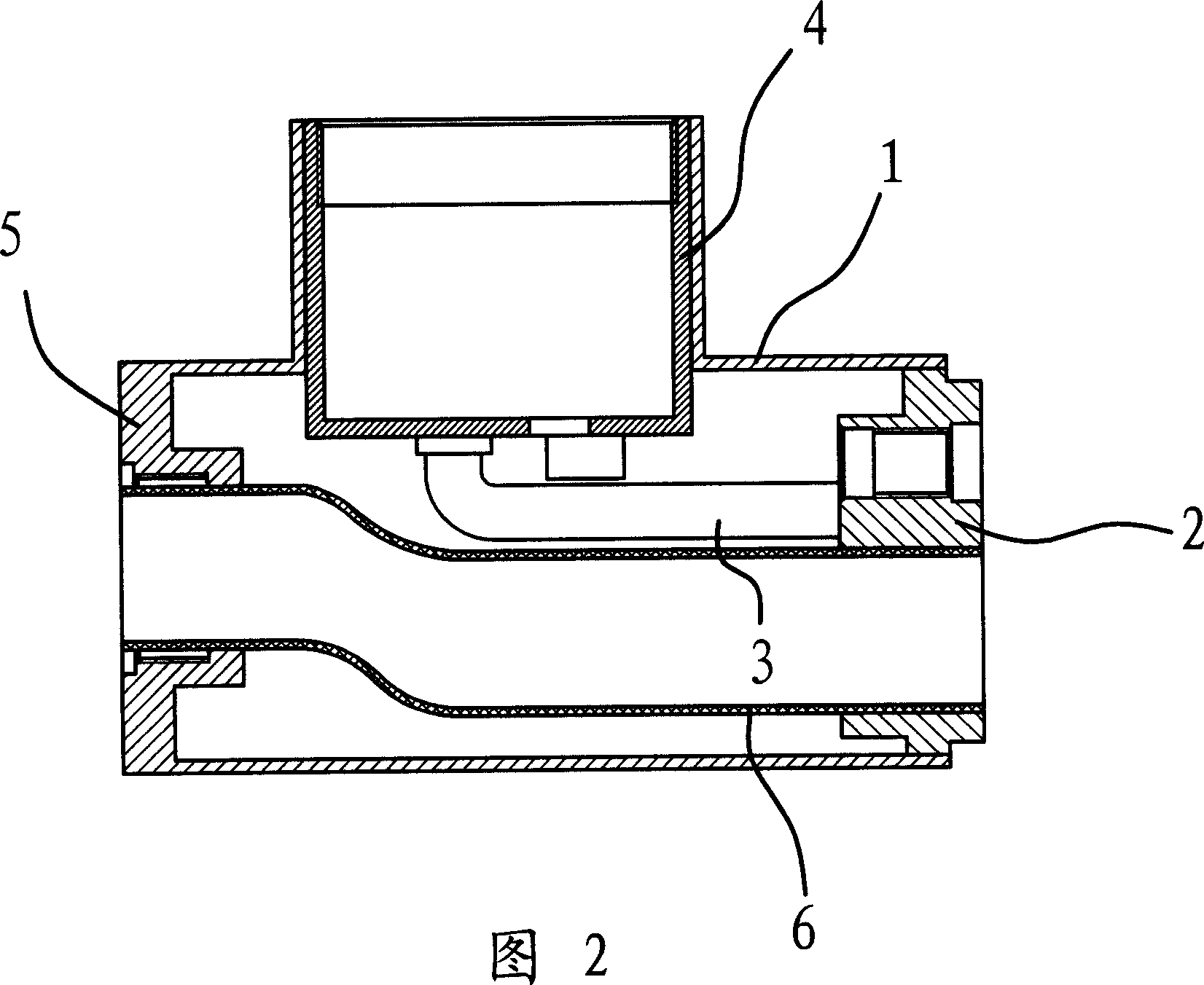

Locomotive distribution valve and working method thereof

ActiveCN102923118AReduce frequency of useNot easy to rustApplication and release valvesAlloyEngineering

The invention discloses a locomotive aluminum-alloy distribution valve applicable for an electrically-controlled brake of a locomotive, and a working method of the locomotive aluminum-alloy distribution valve. The distribution valve consists of an operating valve, a balance valve and an emergency pressure-increasing valve, wherein the operating valve, the balance valve and the emergency pressure-increasing valve are communicated with one another by a gas circuit connecting board arranged on the emergency pressure-increasing valve. The operating valve, the balance valve and the emergency pressure-increasing valve are combined together and then are arranged on a gas circuit board used for the existing locomotive; a brake cylinder of the locomotive is inflated and exhausted according to the pressure change movement of a train pipe, so that the locomotive is braked, pressurized and relieved. In the common brake, the emergency pressure-increasing valve is closed; when a train is in an emergency brake, the emergency pressure-increasing valve is opened, and pressure-regulated main air flows into a volume room through an opened valve port, so as to exert the effect of pressurization of the volume room; and the brake cylinder can obtain the controllable pressure larger than the common braking pressure due to the action of the balance valve, so as to guarantee the driving safety of the train.

Owner:MEISHAN CRRC BRAKE SCI & TECH CO LTD

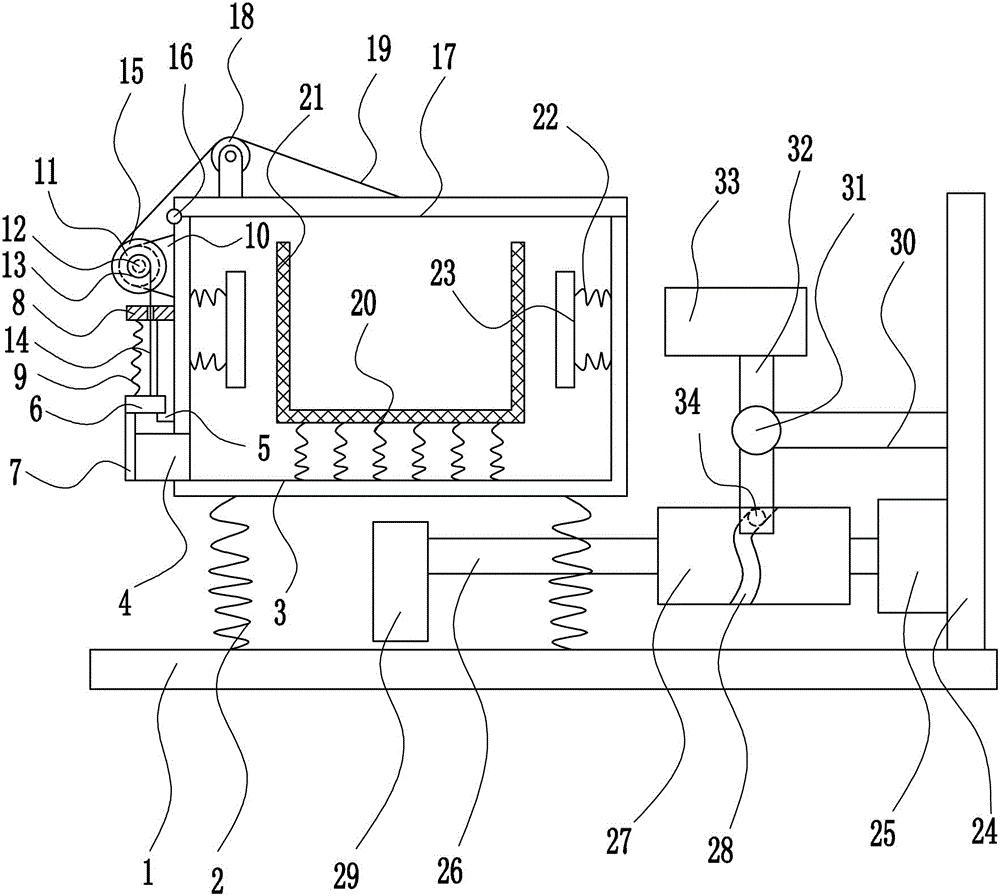

Shakeout machine for sand casting of automobile engine part

The invention belongs to the field of automobile engine part manufacturing, and particularly relates to a shakeout machine for sand casting of an automobile engine part. The technical effect that the shakeout machine for sand casting of the automobile engine part which is good in shakeout effect, rapid in shakeout rapid and convenient to operate is provided is achieved. In order to achieve the technical effect, the provided shakeout machine for sand casting of the automobile engine part comprises a bottom plate, first springs, a vibrating case, a sand outlet, a sliding rail, a sliding block, a baffle, a fixing plate, a second spring, a mounting base, a first motor, a first rotary shaft and the like. The first springs are symmetrically connected with the left side of the top of the bottom plate in a hook connecting mode. The top ends of the first springs are connected with the vibrating case in a hook connecting mode. The shakeout machine achieves the effects of good shakeout effect, high shakeout speed and convenient operation, labor intensity of workers is relieved, the shakeout treatment speed is increased, the operation efficiency is improved, and the shakeout effect is good.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

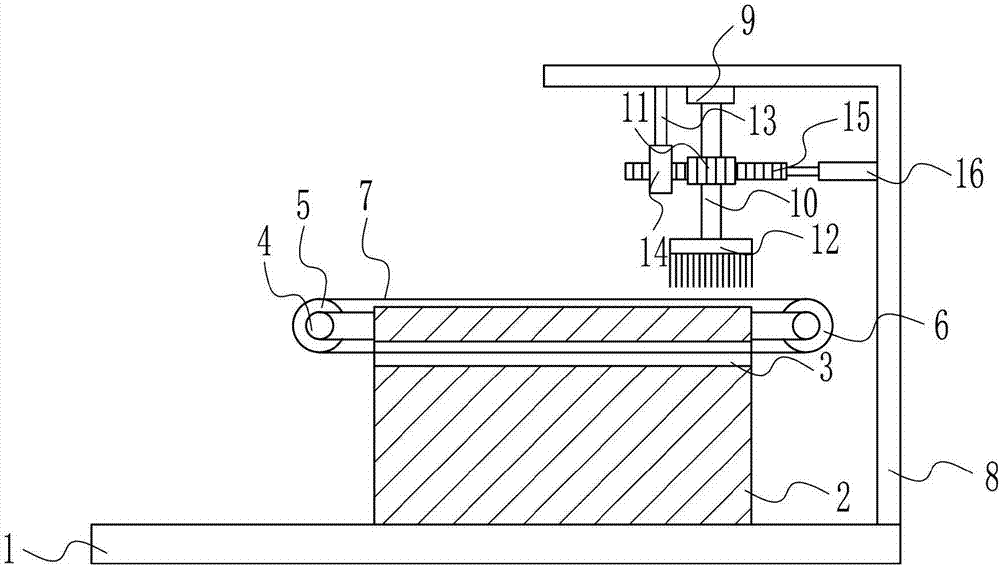

Main board impurity removing device for computer hardware production

InactiveCN106944386AAvoid driftingAvoid inhalationDirt cleaningCleaning using toolsVertical barImpurity

The invention relates to a device for computer hardware production, in particular to a main board impurity removing device for computer hardware production. The technical problem to be solved by the invention is to provide the main board impurity removing device for computer hardware production capable of removing impurities of a main board, improving the quality of the main board and improving the quality of a computer. In order to solve the technical problem, the invention provides the main board impurity removing device for computer hardware production. The device comprises a baseplate, a worktable, a first motor, a first belt wheel, a second belt wheel, a flat belt, a support plate, a bearing base, a rotating shaft, a gear, a brush, a vertical rod and the like; the worktable is arranged at the top of the baseplate; an opening is horizontally formed in the upper part of the worktable; and the first motor is arranged on the left side surface of the worktable. The device enables the brush to alternately rotate forwards and reversely to brush away fine impurities on the main board moving to the left side, and uses a dust sucker for sucking the fine impurities brushed from the main board into through holes by an air sucking pipe and a sucking nozzle.

Owner:汪国栋

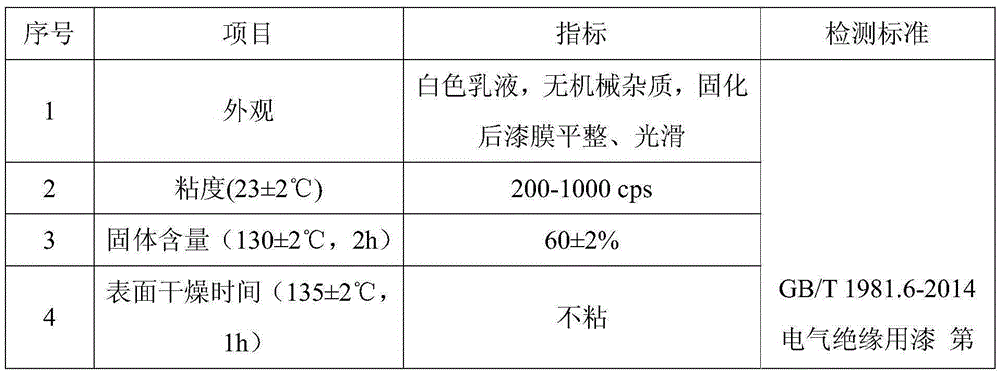

Waterborne epoxy impregnating insulating varnish and preparation method thereof

The invention discloses waterborne epoxy impregnating insulating varnish and a preparation method thereof. The waterborne epoxy impregnating insulating varnish is water-borne epoxy latex formed by epoxy resin, water, latent curing agents, accelerant, epoxy emulsifier, a polyvinyl alcohol water solution, other auxiliaries and the like, and the water-borne epoxy latex is free of VOC, good in stability, low in curing temperature and high in speed. The waterborne epoxy impregnating insulating varnish is simple in preparation method and low in cost and meets industrial production and application requirements.

Owner:湖南沃特邦恩新材料有限公司

Self-protection flux-cored wire for underwater wet-method welding

ActiveCN104057214AEasy arc startGood mechanical propertiesWelding/cutting media/materialsSoldering mediaSlagFerrosilicon

The invention provides a self-protection flux-cored wire for underwater wet-method welding. The self-protection flux-cored wire is characterized in that a N6 nickel band is used as a metal covering of the wire, an alkaline calcium fluoride-aluminum oxide slag system is used as a flux-cored basic slag system, the internal flux core consists of calcium fluoride, aluminum powder, iron powder, magnesium oxide, silicon iron, lithium fluoride, manganese powder and metal chromium, and the weight percent of each component is as follows: 40 to 55 percent of calcium fluoride, 8 to 13 percent of aluminum powder, 5 to 9 percent of iron powder, 0.5 to 5 percent of magnesium oxide, 3 to 7 percent of silicon iron, 3 to 9 percent of lithium fluoride, 6 to 11 percent of manganese powder and 4 to 10 percent of metal chromium. When the flux-cored wire is used for the underwater wet-method welding, arc is likely to start, the electric arc is stable in combustion, the restarting arc is good in performance, the forming property of the weld seam is good, the tensile strength of the weld metal after being welded is not lower than 460MPa, and the underwater welding of the medium-low carbon steel and low-alloy high-strength steel structure of ordinary strength requirement can be satisfied.

Owner:HARBIN INST OF TECH AT WEIHAI

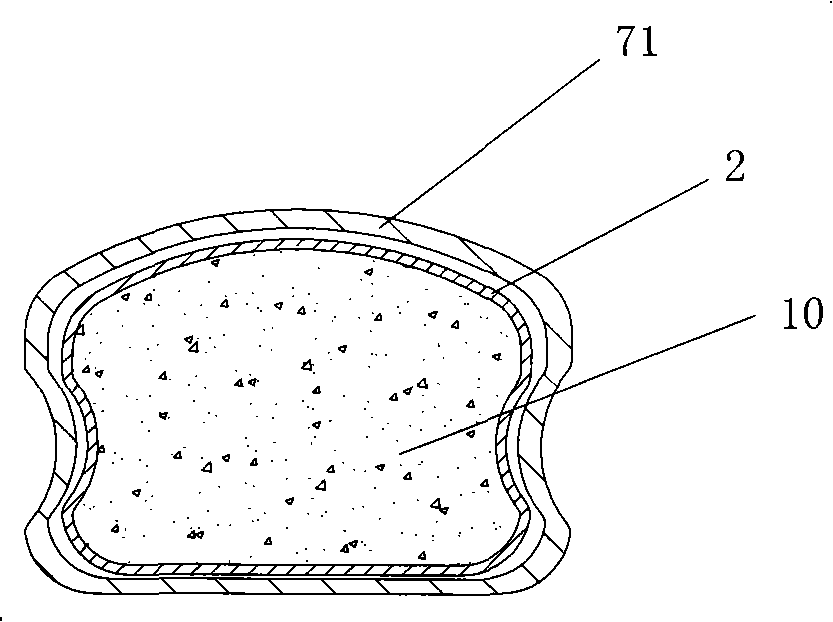

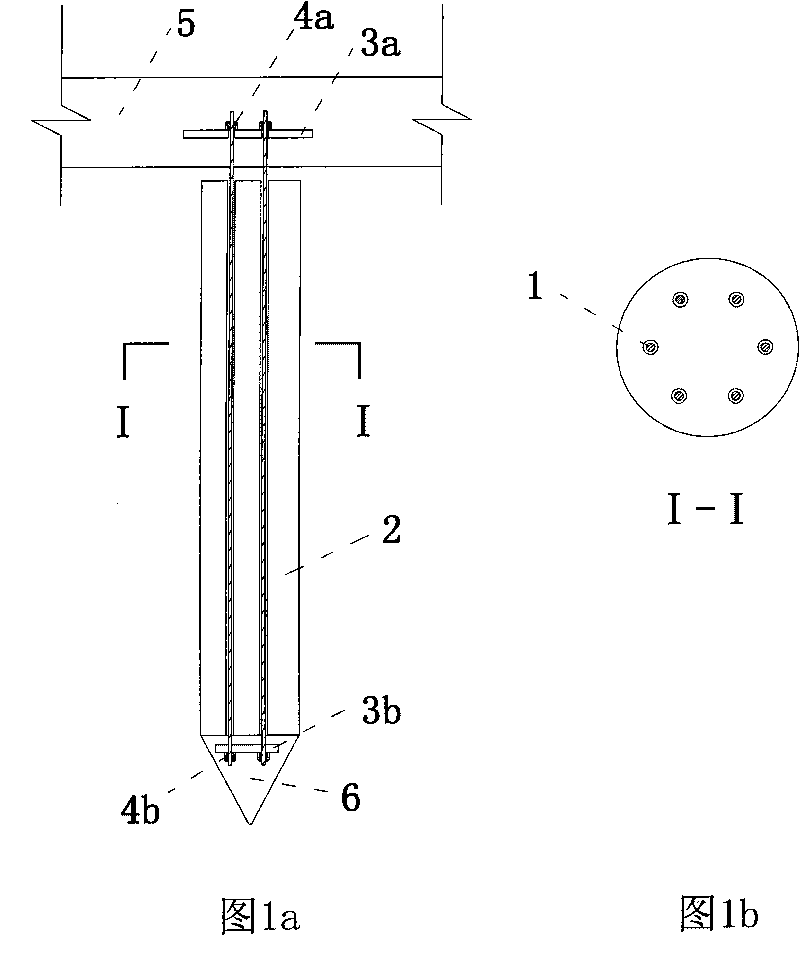

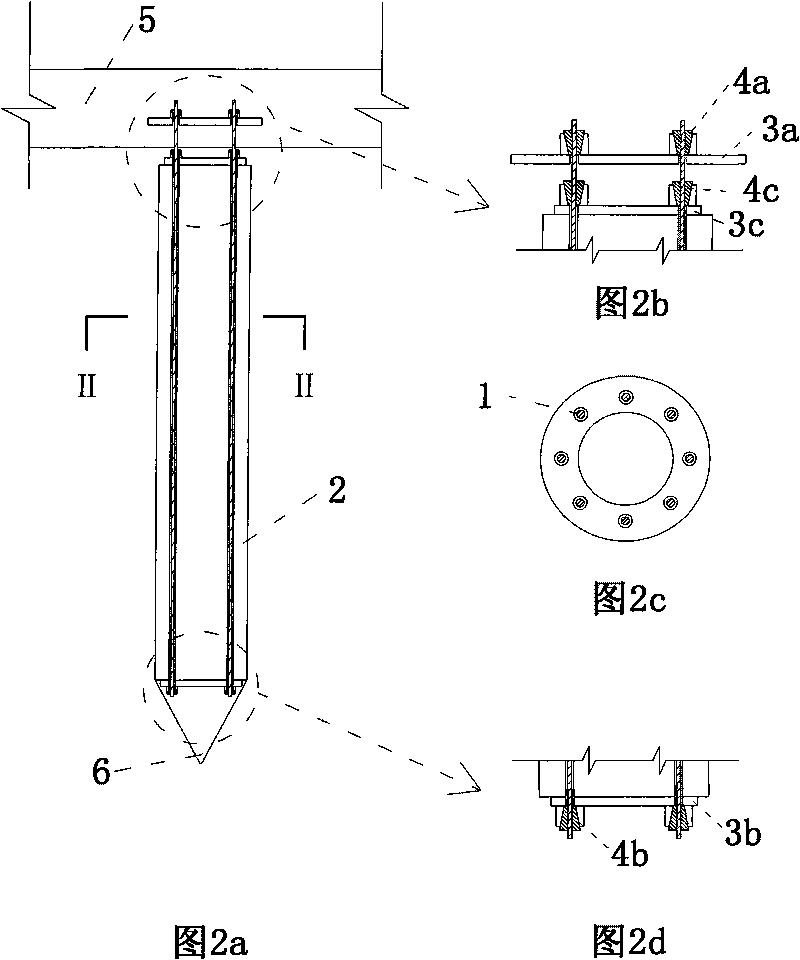

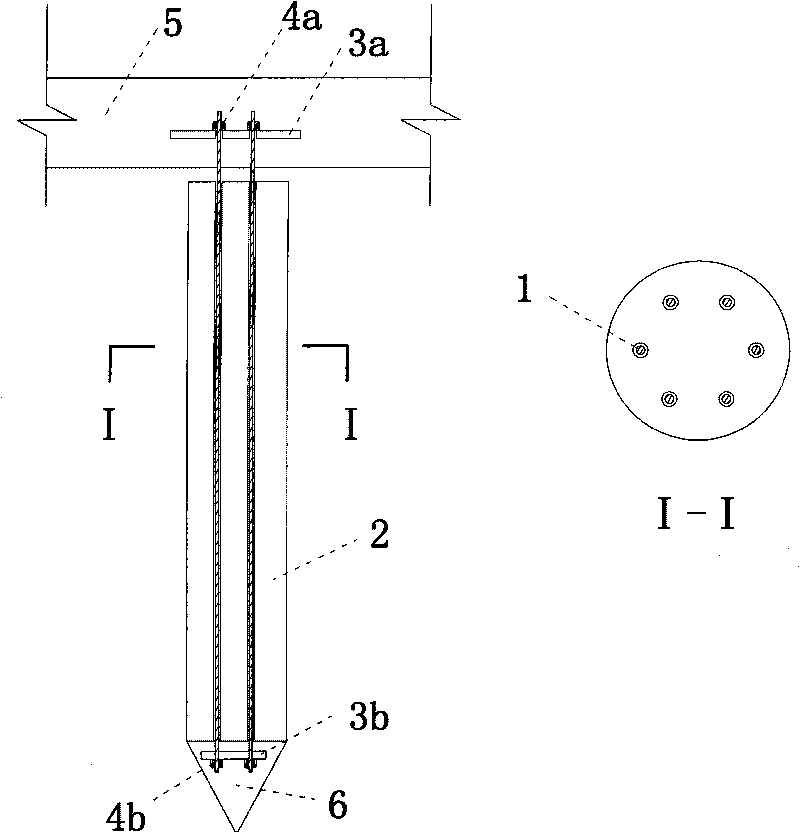

Fiber reinforced concrete uplift pile

InactiveCN101761089AInhibition of upward movementNo tensile cracksBulkheads/pilesPre stressFiber-reinforced concrete

The invention relates to a fiber reinforced concrete uplift pile which comprises a concrete pile body. A pile head is arranged at one end part of the concrete pile body; a FRP fiber reinforcement externally sleeved by a sleeve is arranged in the concrete pile body, one end thereof extends into the pile head, and the other end thereof reversely extends out of the concrete pile body; a second supporting plate is arranged in the pile head; one end of the FRP fiber reinforcement positioned in the pile head is fixed on a second supporting plate by a second anchorage device; a first supporting plate is sleeved at the other end of the FRP fiber reinforcement, and the other end of the FRP fiber reinforcement is fixed on the first supporting plate by a first anchorage device. Prestressing force is not applied to the FRP fiber reinforcement, the sleeve is enwrapped on the periphery of the FRP fiber reinforcement and is not bonded with concrete; and relative slide can be generated between the sleeve and the concrete. The lower end of the FRP fiber reinforcement is tensioned by the supporting plates at the bottom part of the pile and the anchorage devices, and the upper end of the RP fiber reinforcement is fixed in a bearing platform by the supporting plates in the bearing platform and the anchorage devices; and the bearing platform is completely separated with the concrete of the pile body.

Owner:NANCHANG CONSTR ENG GROUP

Feed mixing device for raising livestock

InactiveCN107149894AStir quicklyReduce labor intensityFeeding-stuffRotary stirring mixersEngineeringFodder

The invention relates to a mixing device for raising livestock, in particular to a feed mixing device for raising the livestock. The invention is to provide the feed mixing device for raising the livestock capable of reducing the labor intensity of a worker, improving the stirring efficiency, and being easy to use and simple in operation. In order to solve the technical problem, the invention provides the feed mixing device for raising the livestock, comprising a bottom plate, support plates, a mixing box, a first laying-off hopper, a first mixing device, and the like; the left and right sides of the top of the bottom plate are vertically connected with the support plates through bolts, the mixing box is arranged between the tops of the two support plates, the first laying-off hopper is arranged on the top of the mixing box, the first mixing device is arranged in the mixing box, a laying-off device is arranged in the bottom of the mixing box, the top of the bottom plate, right below the laying-off device, is connected with a collecting frame through the bolts. The feed mixing device for raising the livestock achieves the effects of reducing the labor intensity of the worker, improving the stirring efficiency, and being easy to use and simple in operation.

Owner:赖文辉

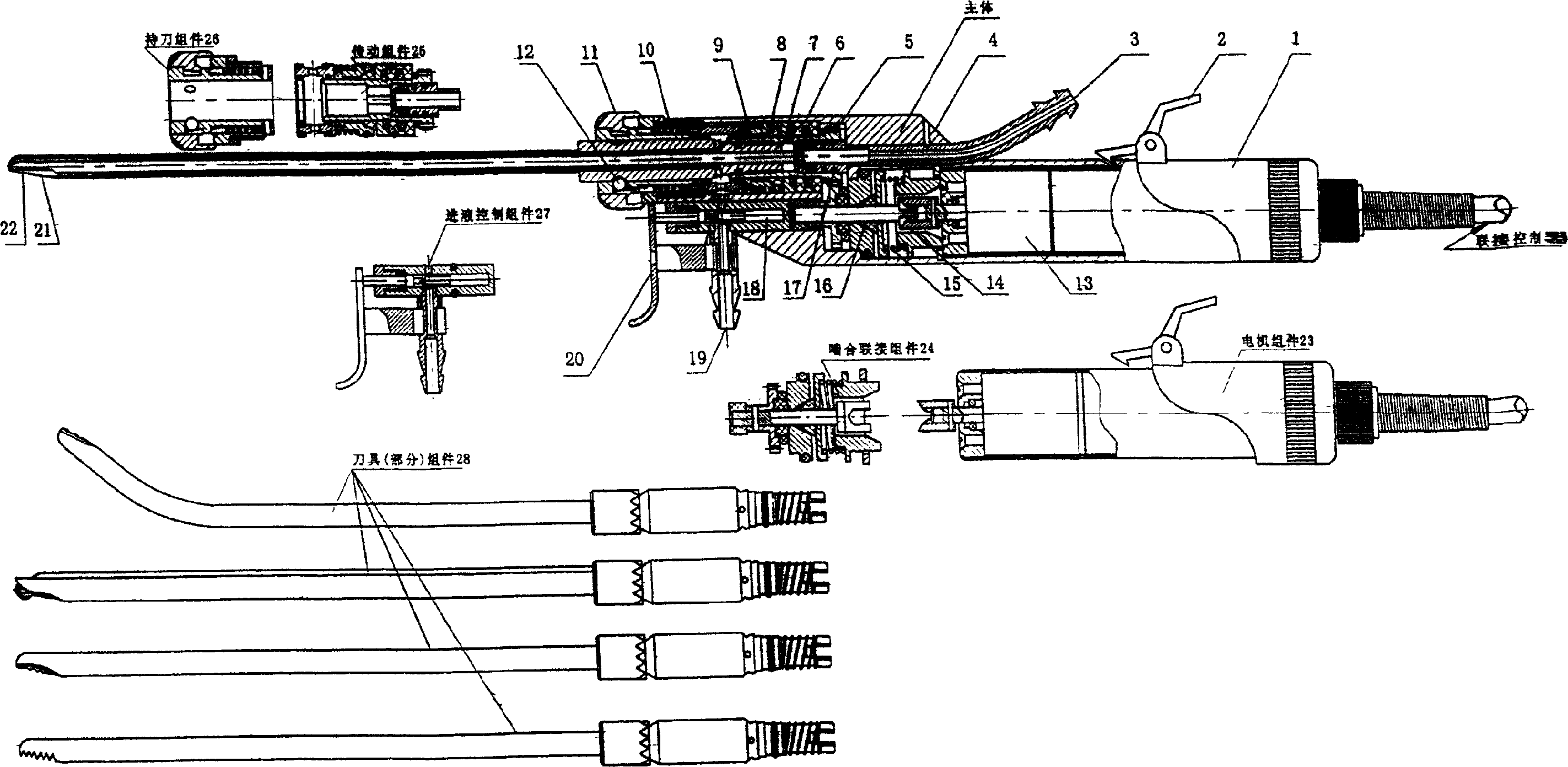

Medical operation suction cutter

ActiveCN101053527AIncrease speedNot easy to rustSuture equipmentsInternal osteosythesisReduction driveSewage

The invention relates to a medical operation attracting cutter used for cutting the polyp and the vegetation in the department of otorhinolaryngology. The present medical operation attracting cutter: 1. the reducer and the motor connected thereof are directly fixed on the main body, which is a one-piece structure, the motor and the reducer after being sterilized are easy to rust and erode; 2. the pipe is the same to suck the physiological saline and discharge the sewage conduit, which is easy to arouse the cross infection of germ. The invention includes a main body, a motor module which can be inserted into the main body and a cutter module assembled on the main body, characterized in that, the motor and the reducer are assembled in the motor module, and the reducer is meshed with a telescopic engage switch sleeve. The motor module and the main body in the invention is a fission type structure, which can be detached to avoid the motor and the reducer from being eroded, and prolongs the service life; the pipe to suck the physiological saline and the pipe to discharge the sew is separated, which avoids the germ cross infection, ensures the safety of the patients.

Owner:HANGZHOU OPTACLA MEDICAL INSTR

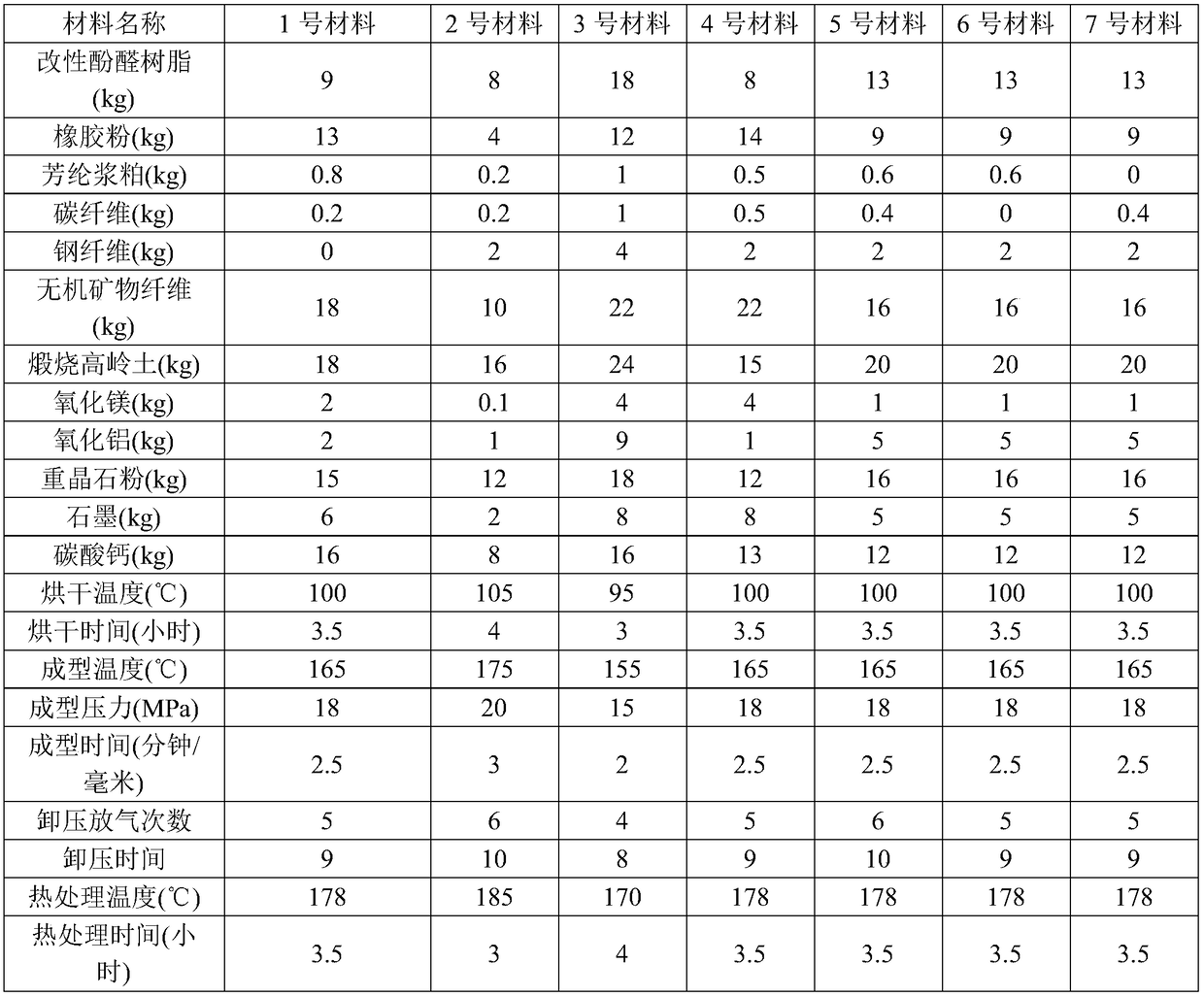

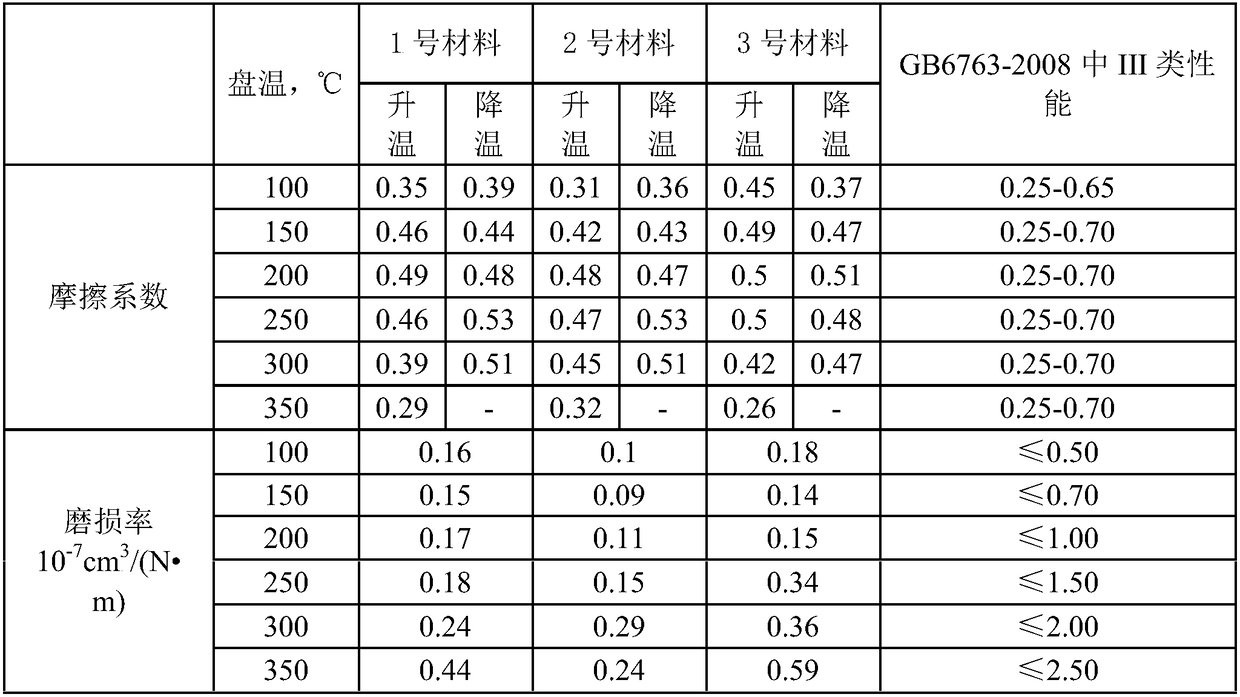

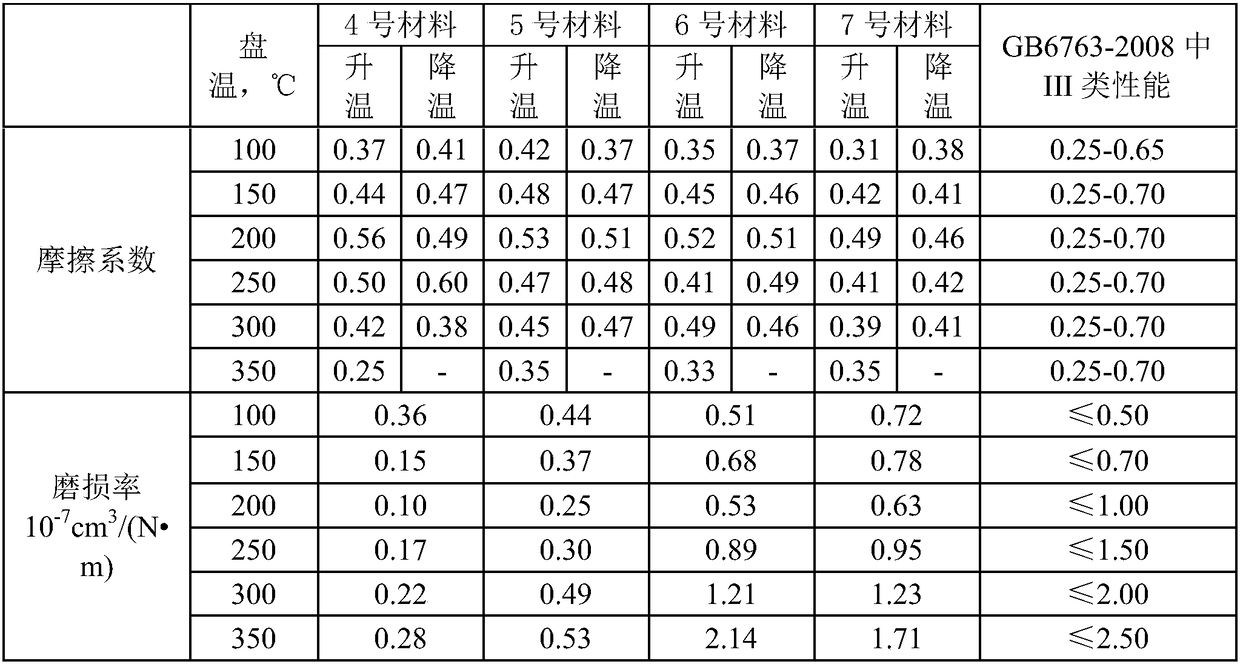

Environmental protection type friction material with less metal used for automobile brake block and preparation method thereof

ActiveCN108728041AAvoid damageModerate coefficient of frictionOther chemical processesFriction liningFiberLow noise

An environmental protection type friction material with less metal used for automobile brake block is prepared with the following raw materials in parts by weight: 8-18 parts of modified phenolic resin, 4-14 parts of rubber powder, 0.2-1 part of PPTA-pulp, 0.2-1 part of carbon fiber, 0-4 parts of steel fiber, 10-22 parts of mineral fiber, 16-24 parts of calcined kaolin, 0.1-4 parts of magnesium oxide, 1-9 parts of aluminum oxide, 12-18 parts of barite powder, 2-8 parts of graphite, and 8-16 parts of calcium carbonate, the invention adopts the above technology and has the following advantages:1, the environmental protection friction material with less metal used for the automobile brake block has no asbestos, no sulfide, no copper and no other harmful heavy metal components, which is environmentally friendly; 2. with the co-action of each component, the invention has appropriate friction coefficient, high heat-resistance, low wear rate, low noise, less damage to coupled parts, rust resistance and other performances; 3, the preparation technology provided by the invention is simple, which is applicable for industrial production and has significant economic and social benefits.

Owner:QILU UNIV OF TECH

Display screen fixing and adjusting device for big data

ActiveCN106647938AEasy to fixImprove stabilityDigital data processing detailsEngineeringHuman health

The invention relates to the technical field of big data, in particular to a display screen fixing and adjusting device for the big data. In order to achieve the technical purpose that the height of the display screen can be adjusted without affecting the use of the display screen and no influence on the human health is caused, the display screen fixing and adjusting device for the big data is provided and comprises a U-shaped bracket, first sliding rails, first sliding blocks, electric wire wrapping wheels, pull ropes, a second sliding rail, a second sliding block, a rack, a first roller, a first supporting rod and the like. The first sliding rails are connected with the left side and the right side of the top in the U-shaped bracket respectively through bolts. The display screen is fixed through a left clamping plate and a right clamping plate so that the display screen is stabilized, and meanwhile, the lifting function of the display screen is achieved by means of the electric wire wrapping wheels on the two sides so that the height of the display screen is adjusted.

Owner:GUANGZHOU ZHONGCHANG KANGDA INFORMATION TECH

Fast cleaning device for sport tennis balls

InactiveCN106180031AIncrease the speed of drippingFast dryingCleaning using toolsGear wheelMaterial resources

The invention relates to a cleaning device, in particular to a fast cleaning device for sport tennis balls. The fast cleaning device for the sport tennis balls is thorough in cleaning, capable of protecting fluff on the surfaces of the tennis balls, and high in working efficiency. In order to achieve the technical purposes, the fast cleaning device for the sport tennis balls comprises a base plate, a right support, a first slide rail, first slide blocks, a rack, a guide wheel, second slide blocks, a support rod, a water pump, a flexible pipe, first hairbrushes, first motors, a transfer passage, a first spring, first electric push rods, thumb cylinders, a movable plate, a connecting device, a filter case, a cleaning case, a storing case, a gear, a stay cord and the like; and the cleaning case, the filter case and the storing case are sequentially arranged on the base plate from left to right. By utilization of the fast cleaning device for the sport tennis balls, the effects that cleaning is thorough, the fluff on the surfaces of the tennis balls can be protected, and the working efficiency is high are achieved, manpower and material resources are saved, time for cleaning the tennis balls is reduced, and the tennis balls are clean.

Owner:叶明

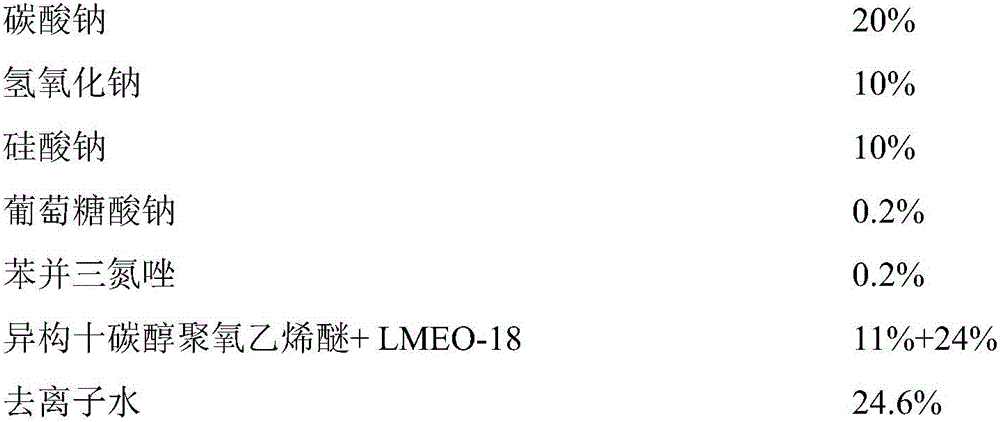

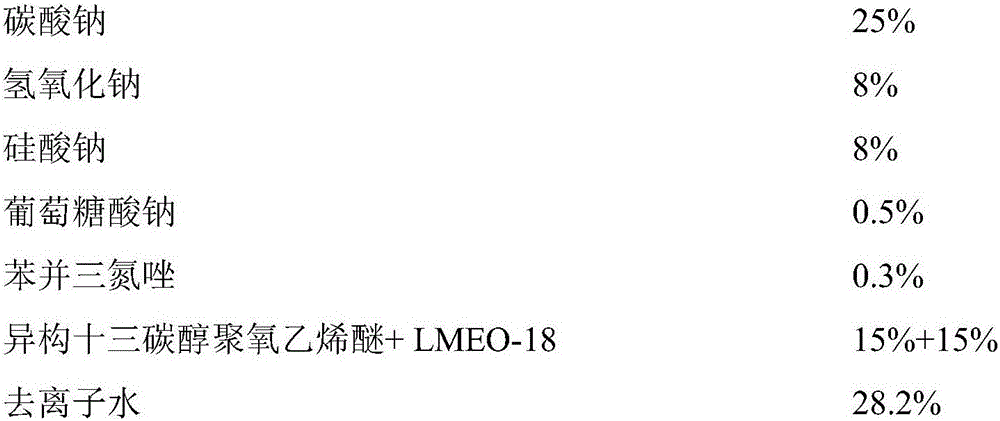

Environmentally friendly industrial heavy oil cleaning agent

The invention discloses an environmentally friendly industrial heavy oil cleaning agent. The environmentally friendly industrial heavy oil cleaning agent mainly comprises the following raw materials of 20-35% of sodium carbonate, 5-10% of sodium hydroxide, 5-10% of sodium silicate, 0.2-1% of sodium gluconate, 0.2-0.5% of benzotriazole, 15-35% of a composite surface active agent and the balance water. The composite surface active agent is at least one of alcohol alkoxylate, LMEO-18 and a low-foam type emulgator. The heavy oil cleaning agent is excellent in cleaning effect, capable of cleaning up heavy oil on various surfaces of machining equipment, machine tools, steel materials and the like, low in use amount and high in oil removal efficiency, and the cleaning rate for oil stains is up to 99% or above.

Owner:GUANGDONG UNIV OF TECH

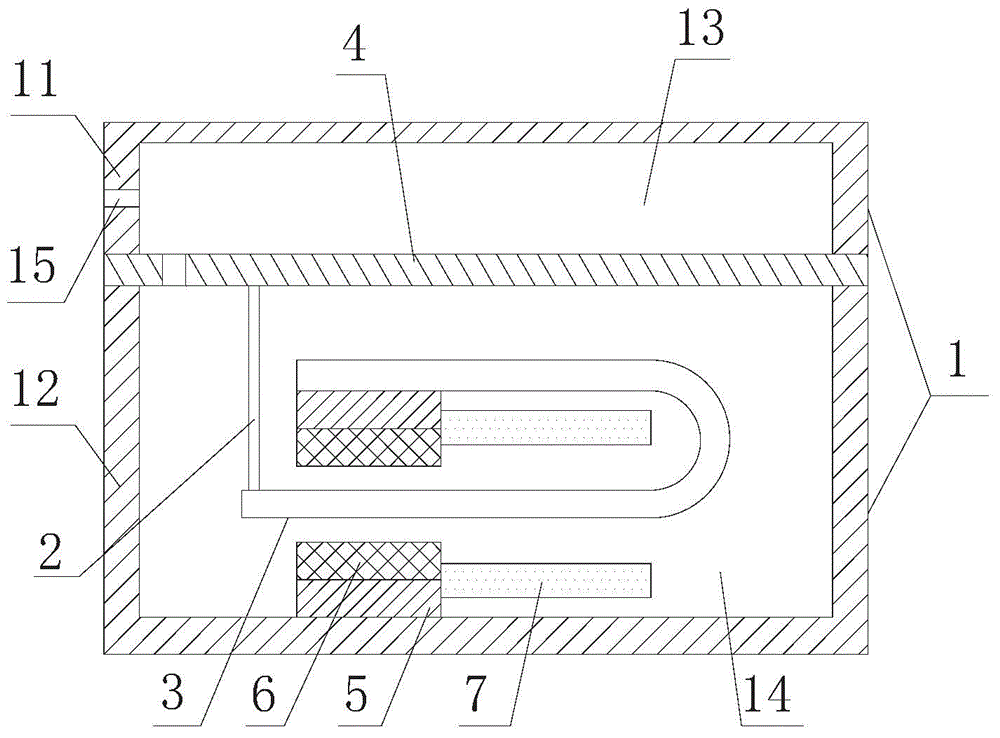

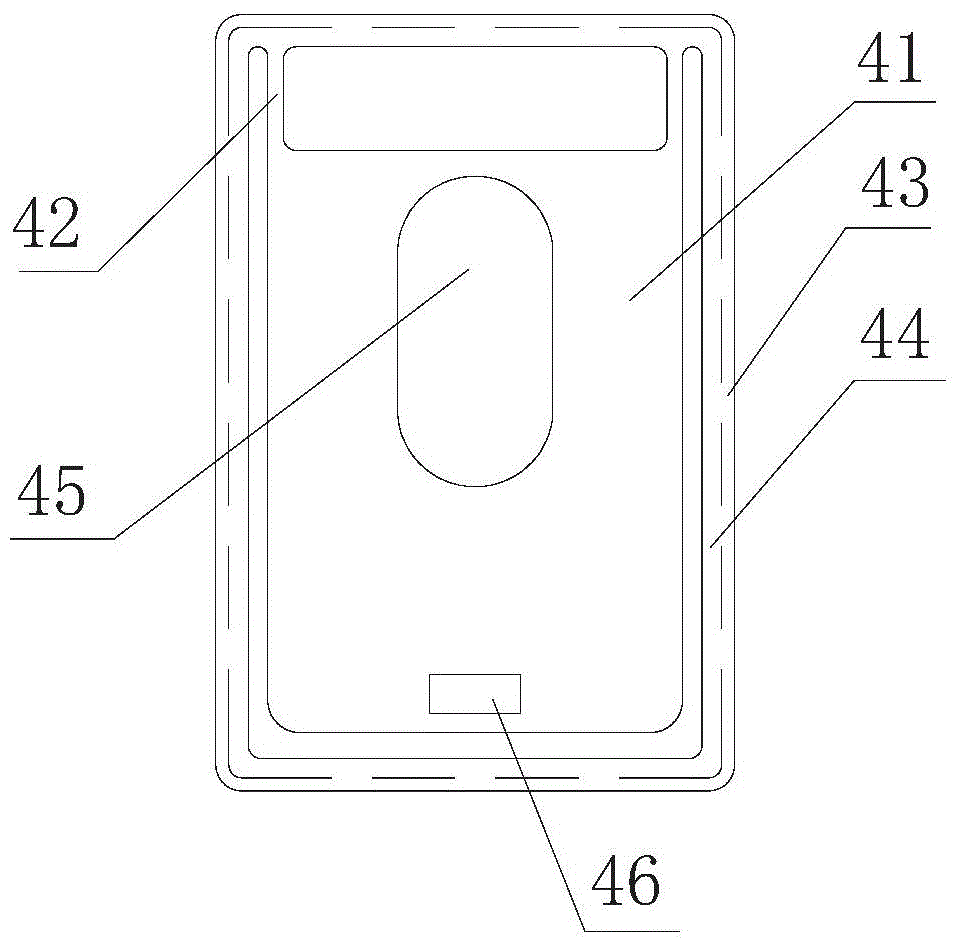

Telephone receiver provided with improved structure

InactiveCN104581580ANot easy to rustImprove resilienceElectrical transducersManufacturing technologyEngineering

The invention discloses a telephone receiver provided with an improved structure. The telephone receiver comprises a shielding shell, a moving iron unit, a conduction rod, an armature and a vibrating film, wherein the moving iron unit, the conduction rod, the armature and the vibrating film are arranged in the shielding shell. The two ends of the conduction rod are connected with the armature and the vibrating film respectively, the moving iron unit drives the armature to vibrate up and down and accordingly the conduction rod is driven to drive the vibrating film to vibrate up and down; the shielding shell comprises a shell cover and a shell body in the vibration direction of the vibrating film, and the edge of the front side and the edge of the back side of the vibrating film are connected with the shell cover and the outer wall of the shell body respectively. The telephone receiver provided with the improved structure is simple in manufacturing technology, reduces production cost, and is large in sound loudness.

Owner:SUZHOU YICHUAN TECH CO LTD

Manufacturing method of tap valve body

The invention provides a method for manufacturing hydro-valve body, comprising the steps of: a. part machining; b. welding; and c. fine machining. And it moulds case, water inlet base, inner water pipe, valve core seat, and water outlet base and weld them together. And it compromises the advantages of hot forging and casting processes, saving large number of materials, reducing manufacturing cost and easy to control.

Owner:李仁波 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com