Cutting device for foam plastic plate

A foamed plastic board, cutting device technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

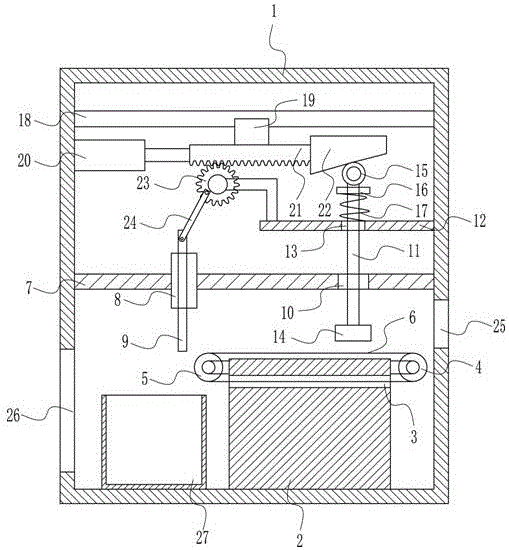

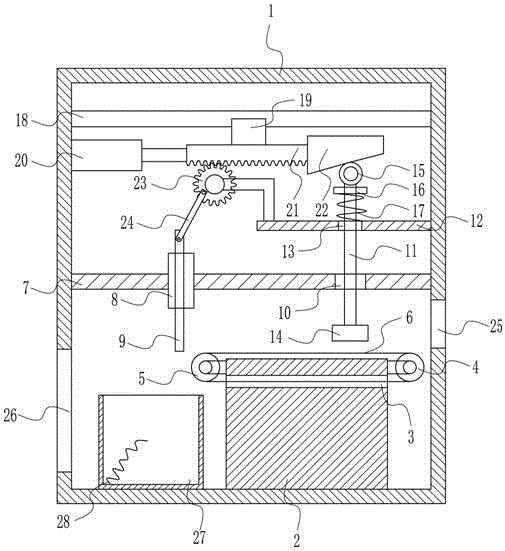

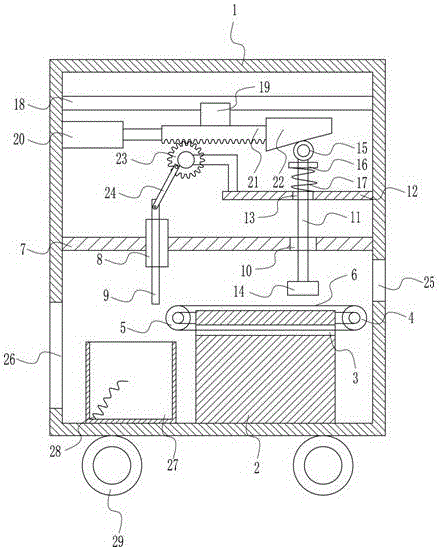

[0025] A cutting device for foam plastic panels, such as Figure 1-3 As shown, it includes box 1, abutment 2, electric wheel 4, driven wheel 5, belt 6, horizontal plate 7, hollow guide sleeve 8, sliding rod 9, lifting rod 11, guide rod 12, blade 14, contact wheel 15. Fixed block 16, elastic member 17, slide rail 18, slide block 19, cylinder 20, rack 21, wedge block 22, gear 23, pole 24 and placement frame 27, the right bottom of the box body 1 passes through The abutment 2 is installed in the way of welding connection, the upper part of the abutment 2 is horizontally opened with an opening 3, the right side of the upper part of the abutment 2 is connected with a motorized wheel 4 by means of bolt connection, and the left side of the upper part of the abutment 2 is connected by a bolt A driven wheel 5 is installed in the way of connection, a belt 6 is provided between the electric wheel 4 and the driven wheel 5, the belt 6 passes through the opening 3, the upper part of the bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com