Patents

Literature

49results about How to "Optimize energy distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Optimization of microgrid energy use and distribution

ActiveUS20100179704A1Optimize energy distributionOptimize energy useBatteries circuit arrangementsLevel controlPersonalizationMicrogrid

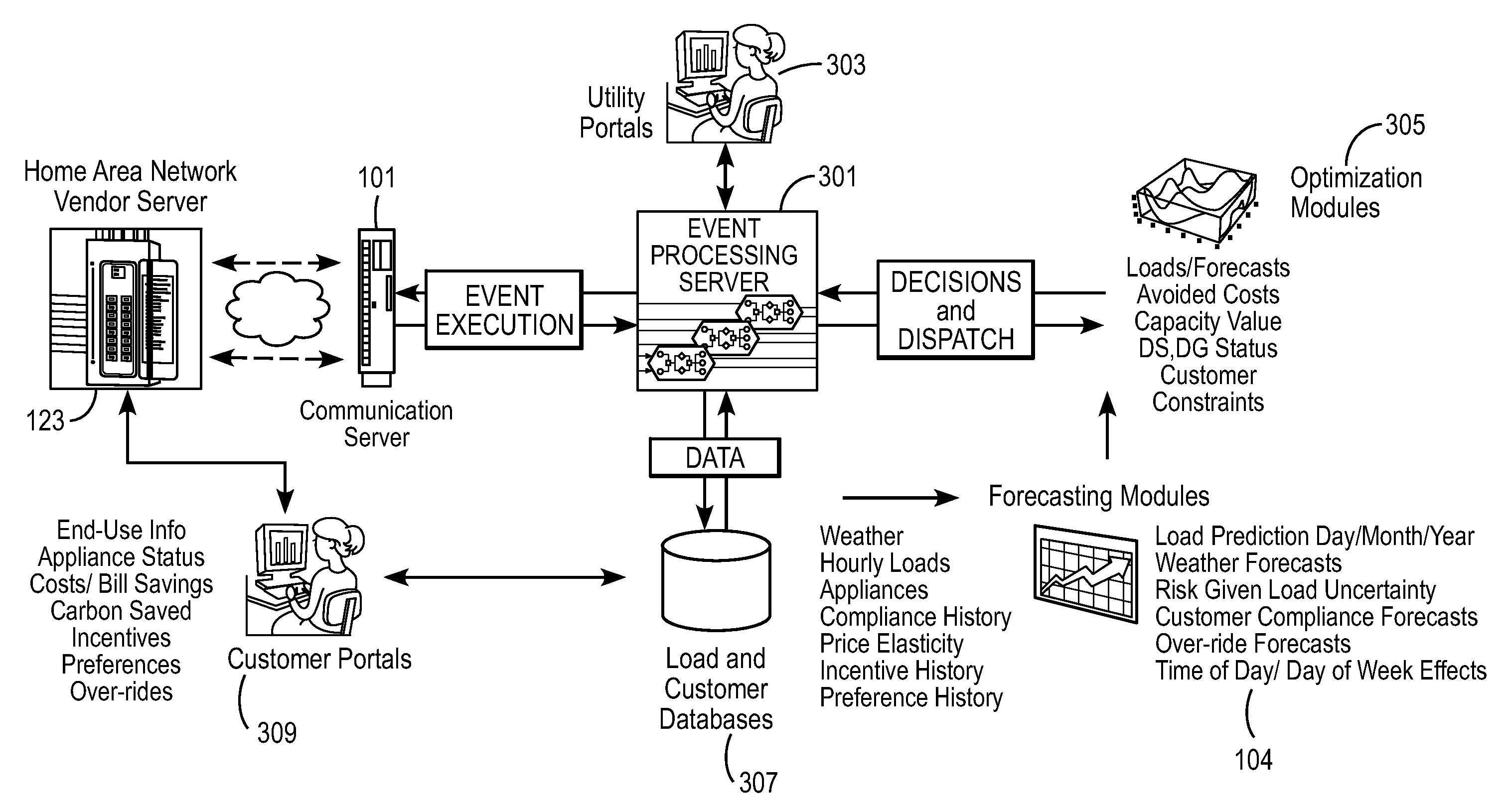

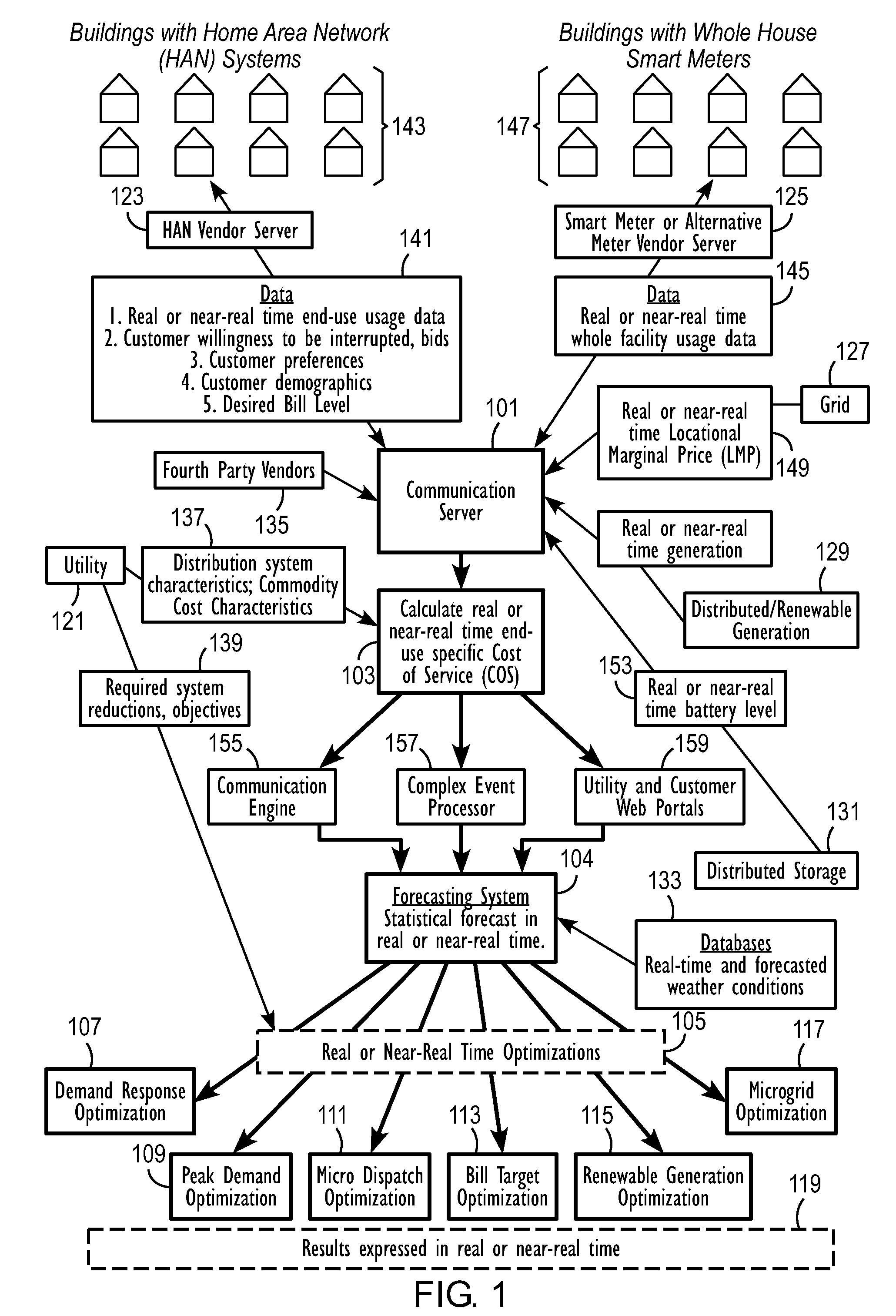

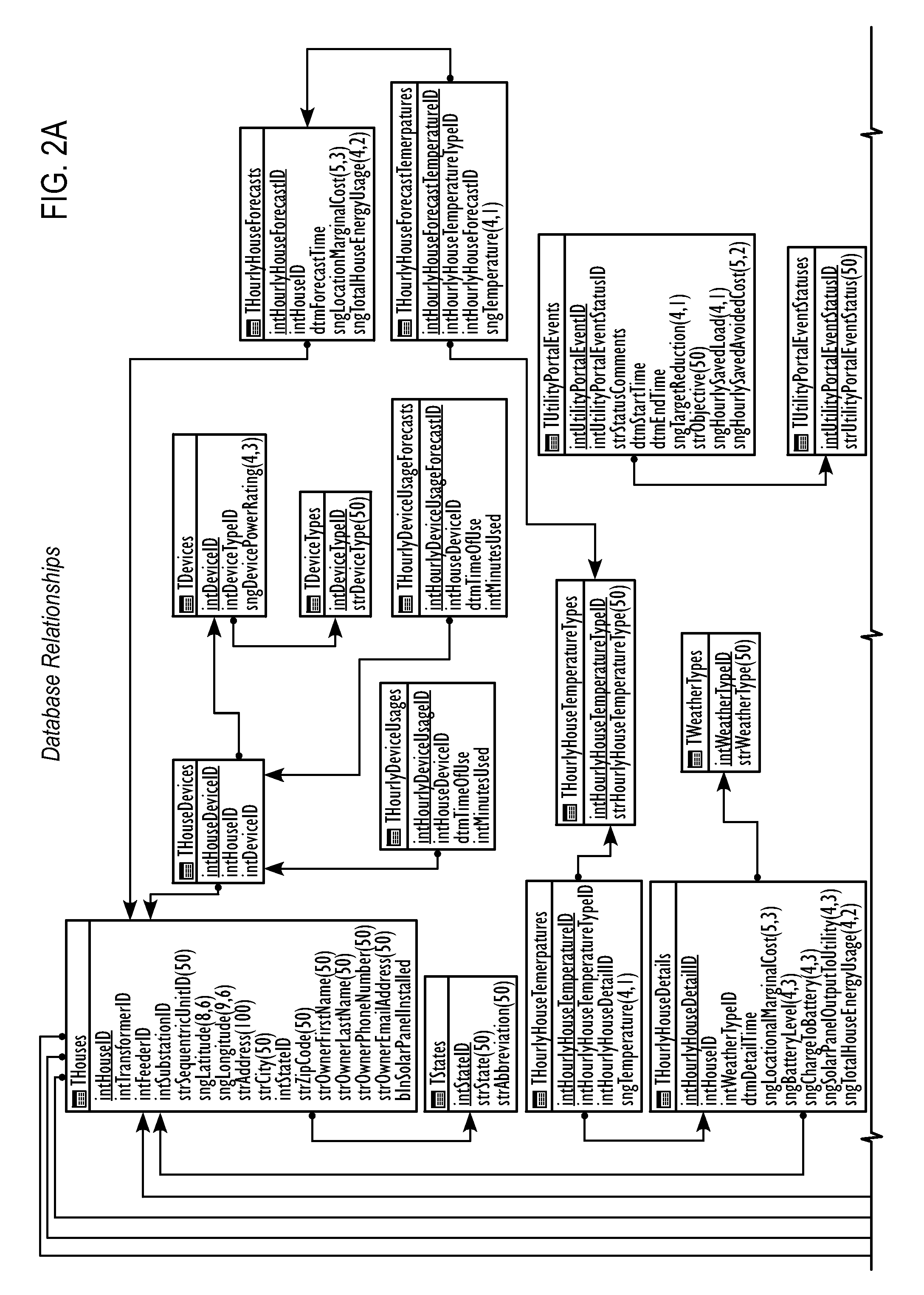

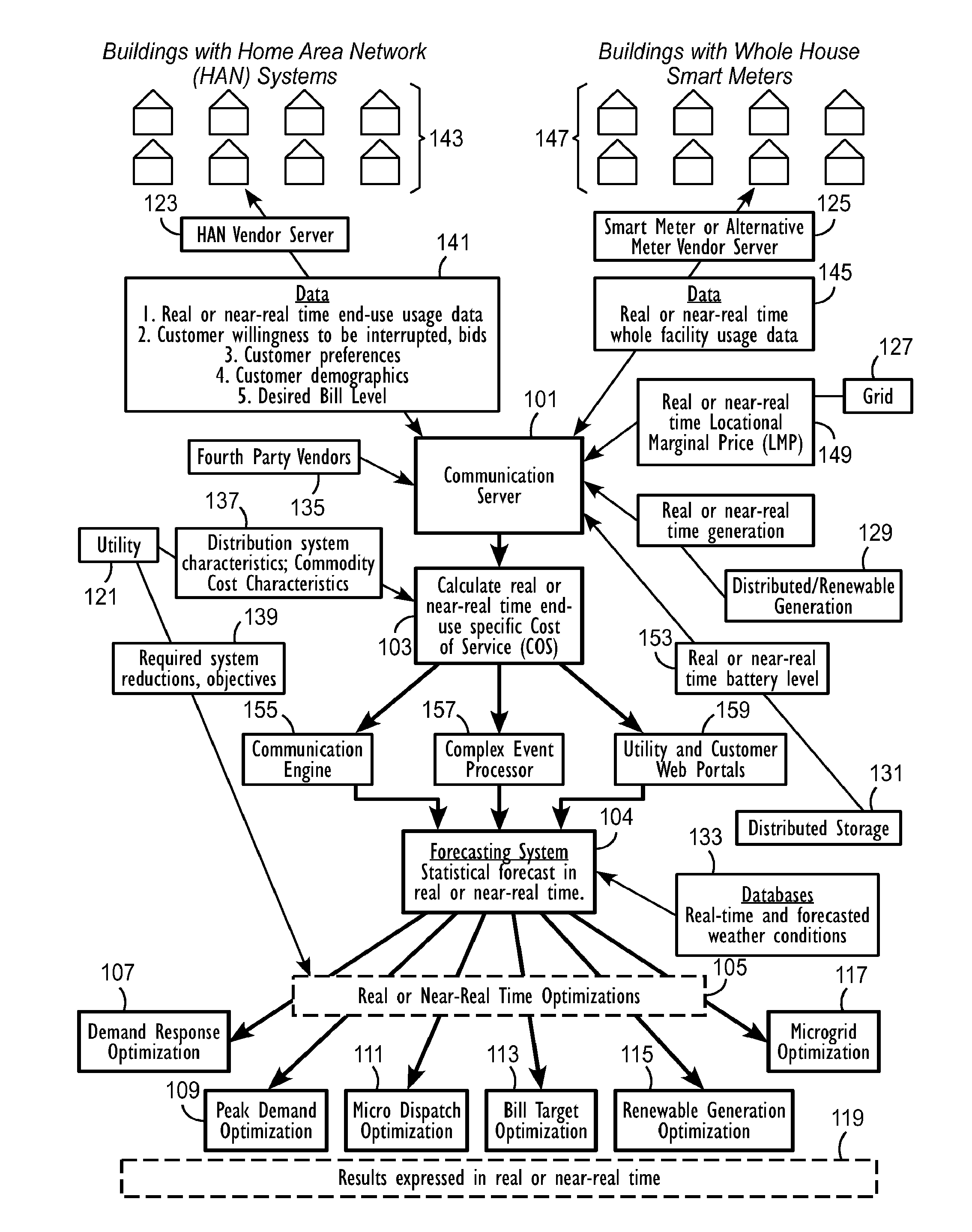

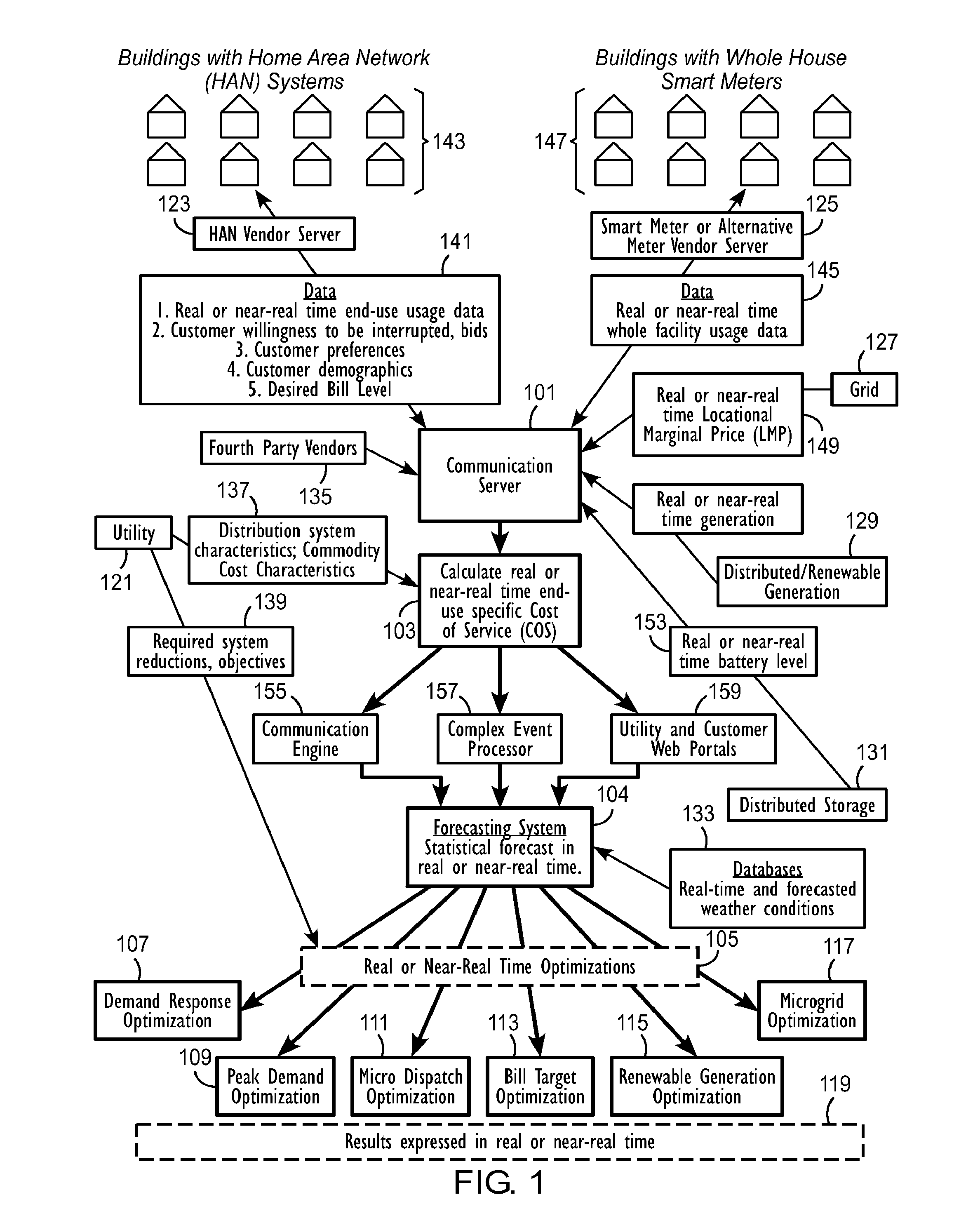

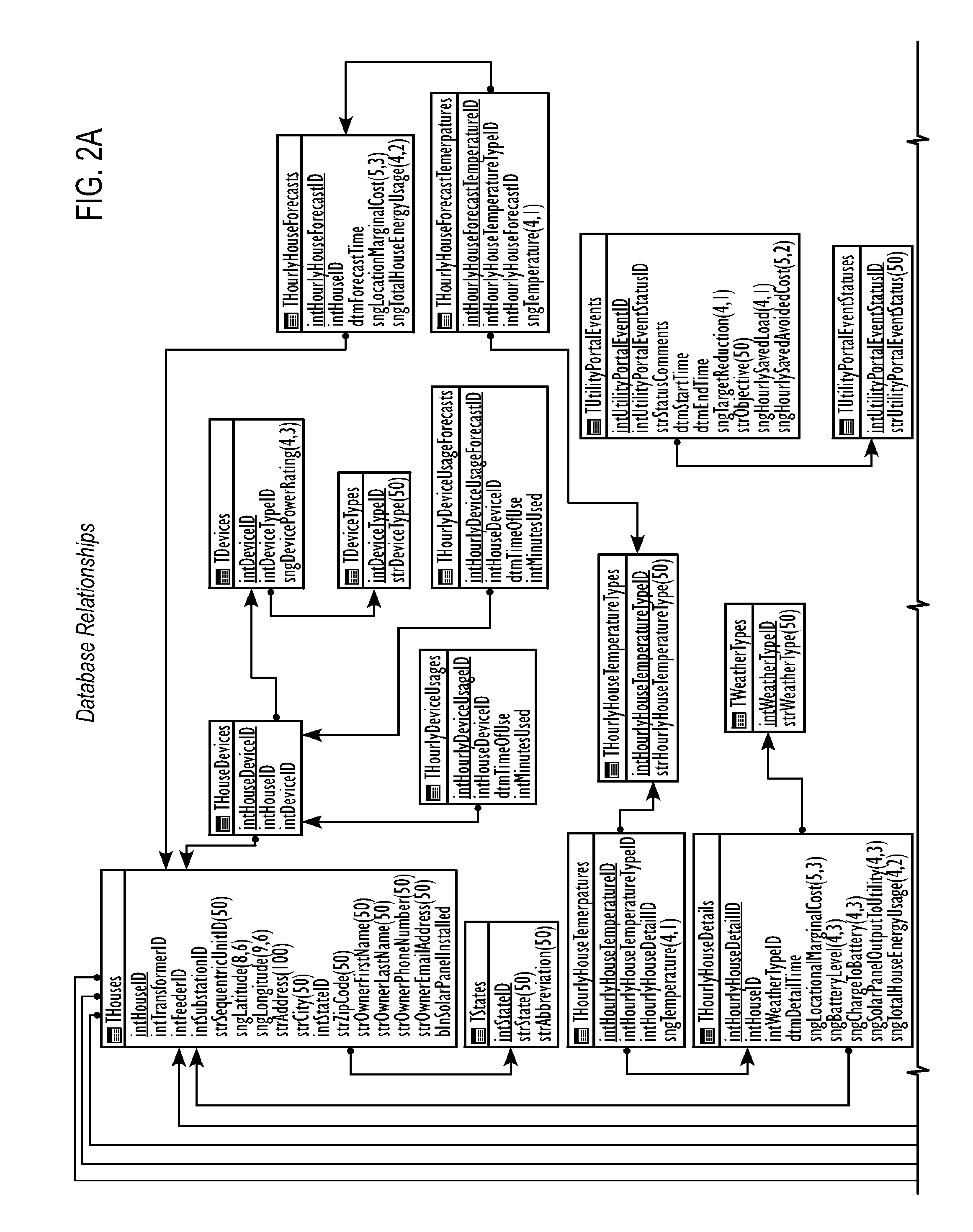

An energy distribution may include a server and one or more databases. The system may communicate with an energy provider to receive energy provider data, at least one information collector to receive information collector data such as individualized energy usage data, customer preferences, and customer or location characteristics, and the one or more databases for receiving data for optimization. The system may calculate a cost of service or avoided cost using at least one of the individualized energy usage data and a system generation cost at a nearest bus. The system may also forecast individualized demand by end-use, individualized demand by location, energy prices, or energy costs. The system may optimize energy distribution, energy use, cost of service, or avoided cost using the forecasted individualized demand by end-use, the forecasted individualized demand by location, the forecasted energy prices, and the forecasted energy costs.

Owner:INTEGRAL ANALYTICS

Optimization of microgrid energy use and distribution

InactiveUS20110231028A1Optimize energy distributionOptimize energy useLevel controlLoad forecast in ac networkPersonalizationMicrogrid

Systems and methods for energy optimization may receive receiving energy provider data, near-real time individualized energy usage data for each of a plurality of end-uses or near-real time individualized whole premise energy usage data, customer preferences, and near-real time and forecasted weather information. The systems and methods may forecast, for a selected time period, individualized energy usage for each of the plurality of end-uses or individualized whole premise energy usage data for a customer location using: (1) the energy provider data, (2) the near-real time individualized energy usage data, (3) the customer preferences, and (4) the near-real time and forecasted weather information. The systems and methods may optimize, for the selected time period, energy usage at the customer location using (1) the individualized energy usage, (2) the energy provider data, and (3) the customer preferences.

Owner:INTEGRAL ANALYTICS

Fuel cell vehicle, control method and control system thereof

ActiveCN104827922AOptimize energy distributionSimple control algorithmSpeed controllerElectric machinesPower batteryFuel cells

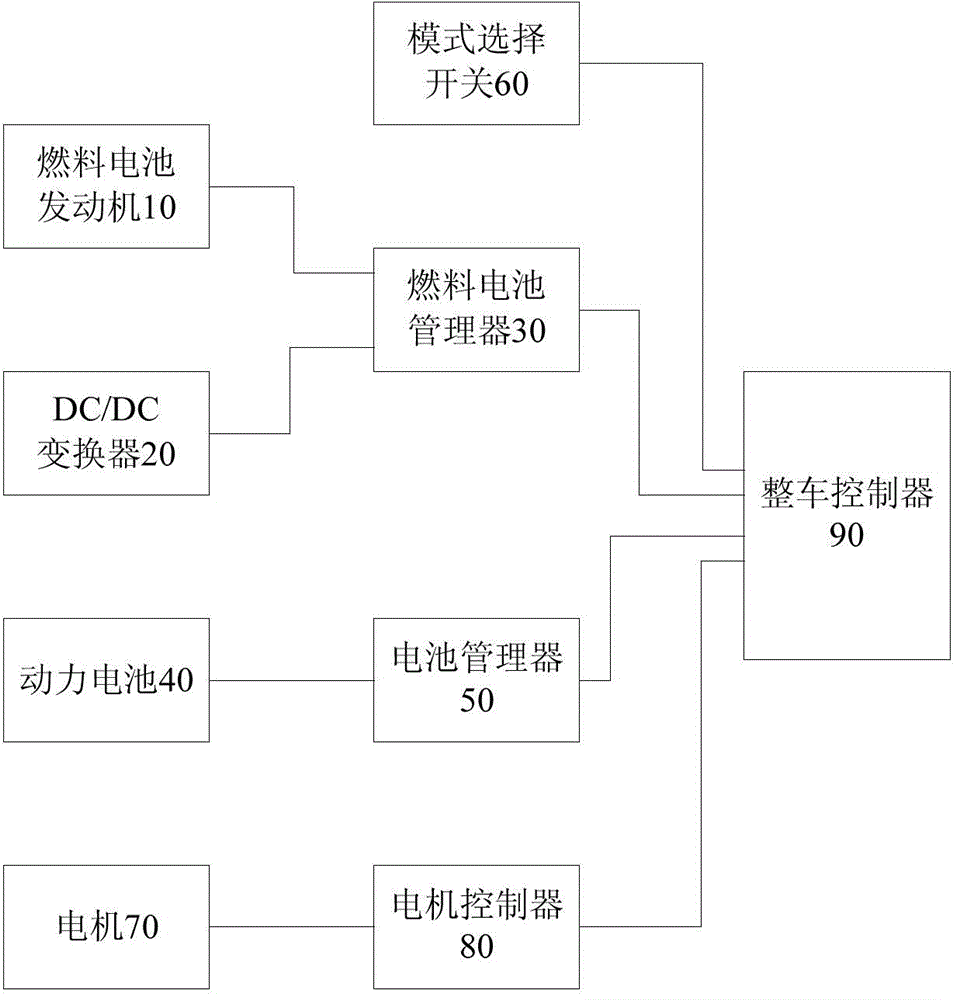

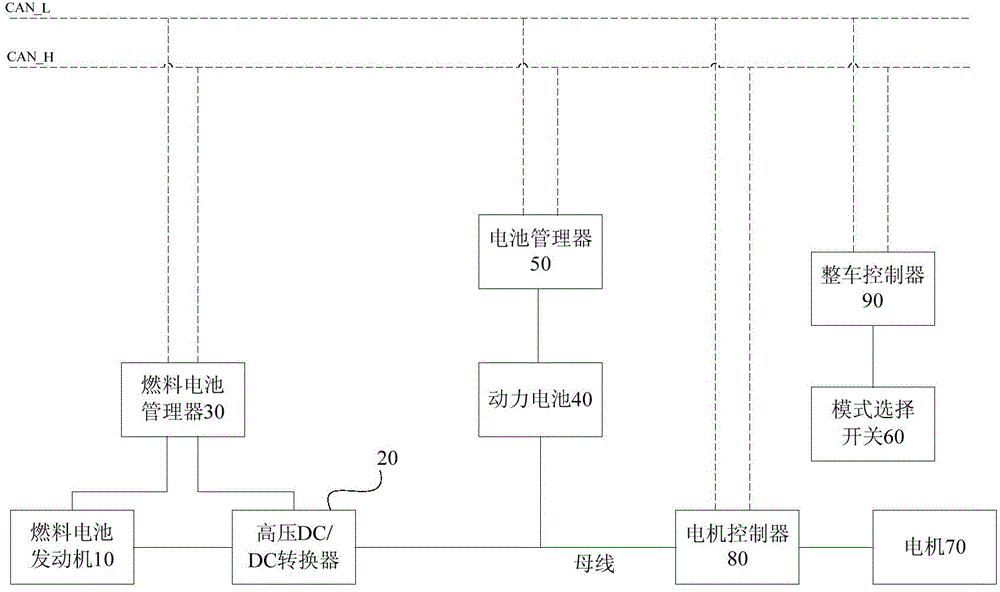

The invention discloses a control system of a fuel cell vehicle. The control system includes a fuel cell engine, a DC / DC converter, a fuel cell manager for controlling the fuel cell engine and the DC / DC converter, a power battery, a battery manager for controlling the power battery, a mode selection switch, a motor and a motor controller; a vehicle controller is connected with the fuel cell manager, the battery manager and the motor controller respectively; the vehicle controller determines the working mode of the fuel cell engine according to the fault state of the fuel cell vehicle, the charge value of the power battery and the state of the mode selection switch, and controls the fuel cell manager according to the working mode. With the control system of the fuel cell vehicle of the invention adopted, vehicle energy distribution can be optimized, and the efficiency of a fuel cell system and the power battery can be improved, and the fuel cell system can be effectively protected, and a vehicle control algorithm can be simplified, and the control algorithm is reliable and effective. The invention also discloses a fuel cell vehicle and a control method of the fuel cell vehicle.

Owner:BEIQI FOTON MOTOR CO LTD

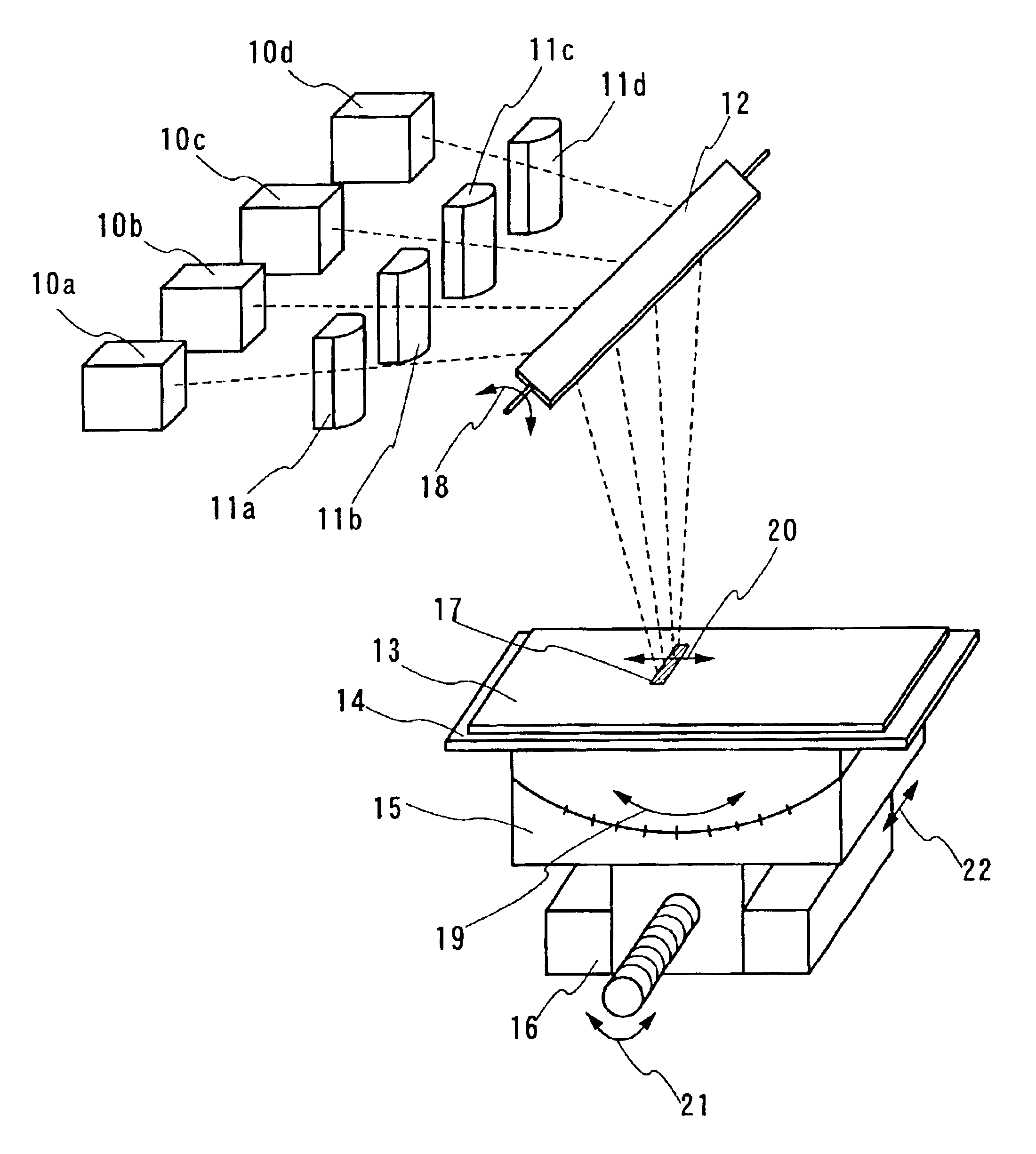

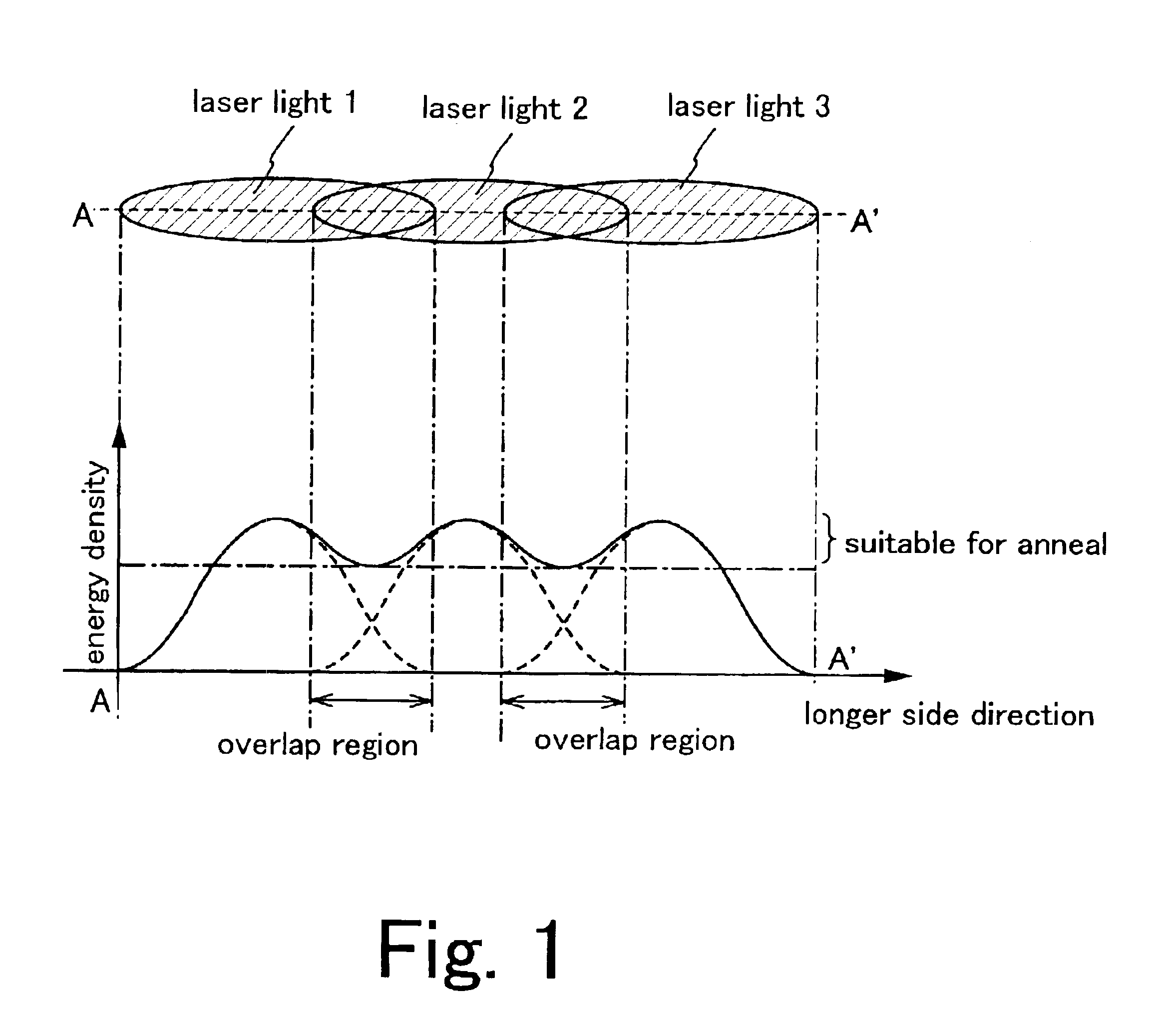

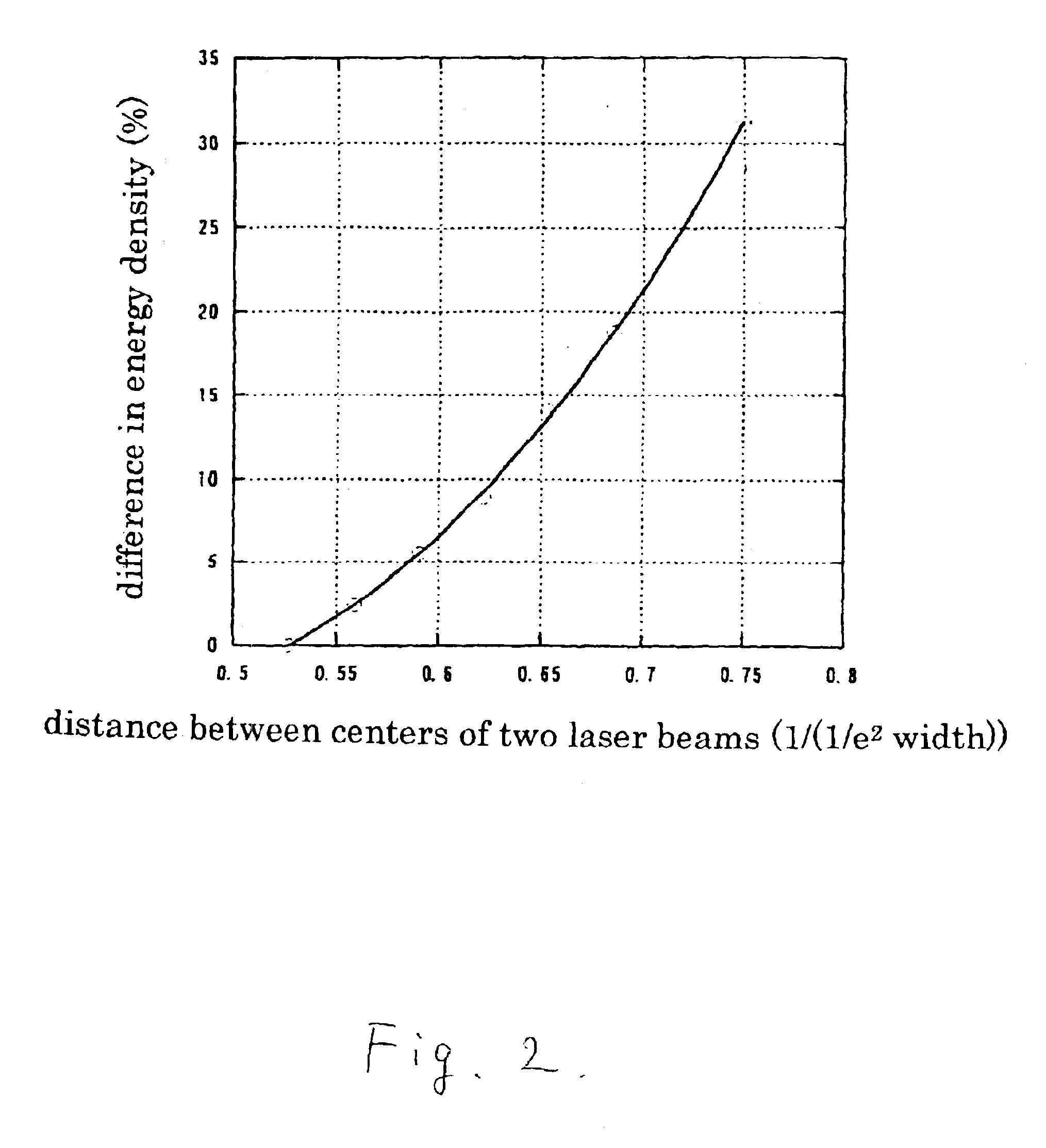

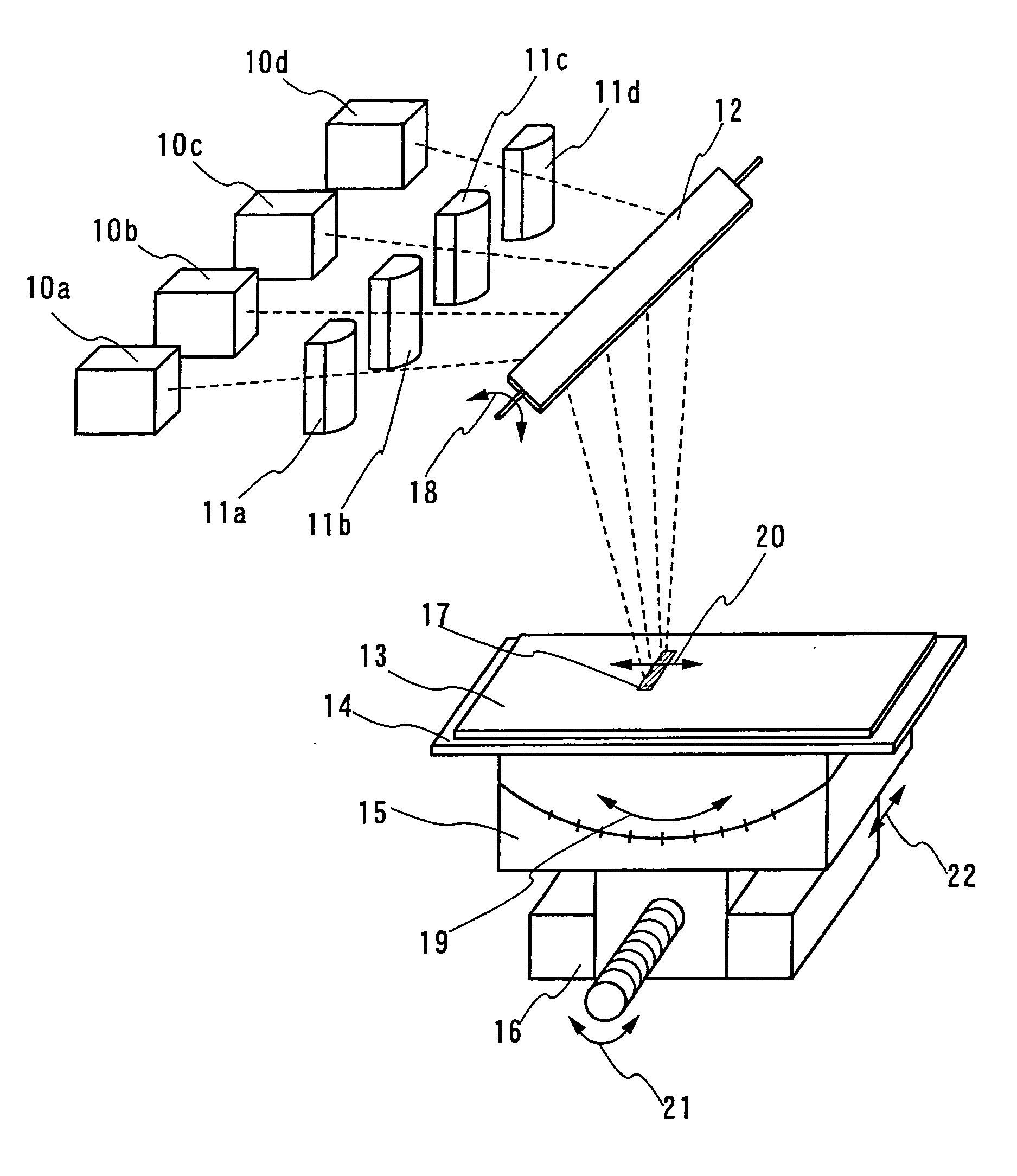

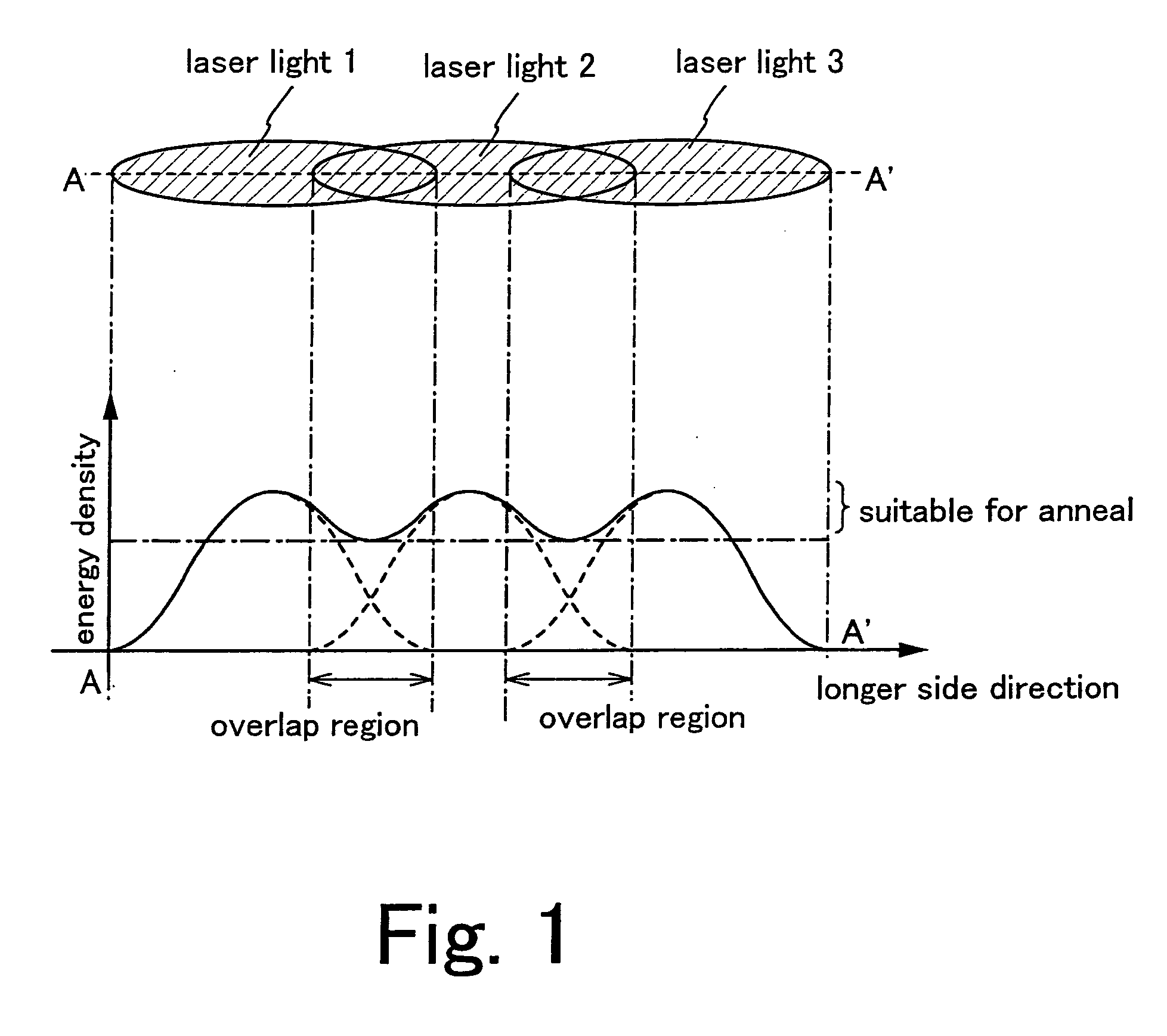

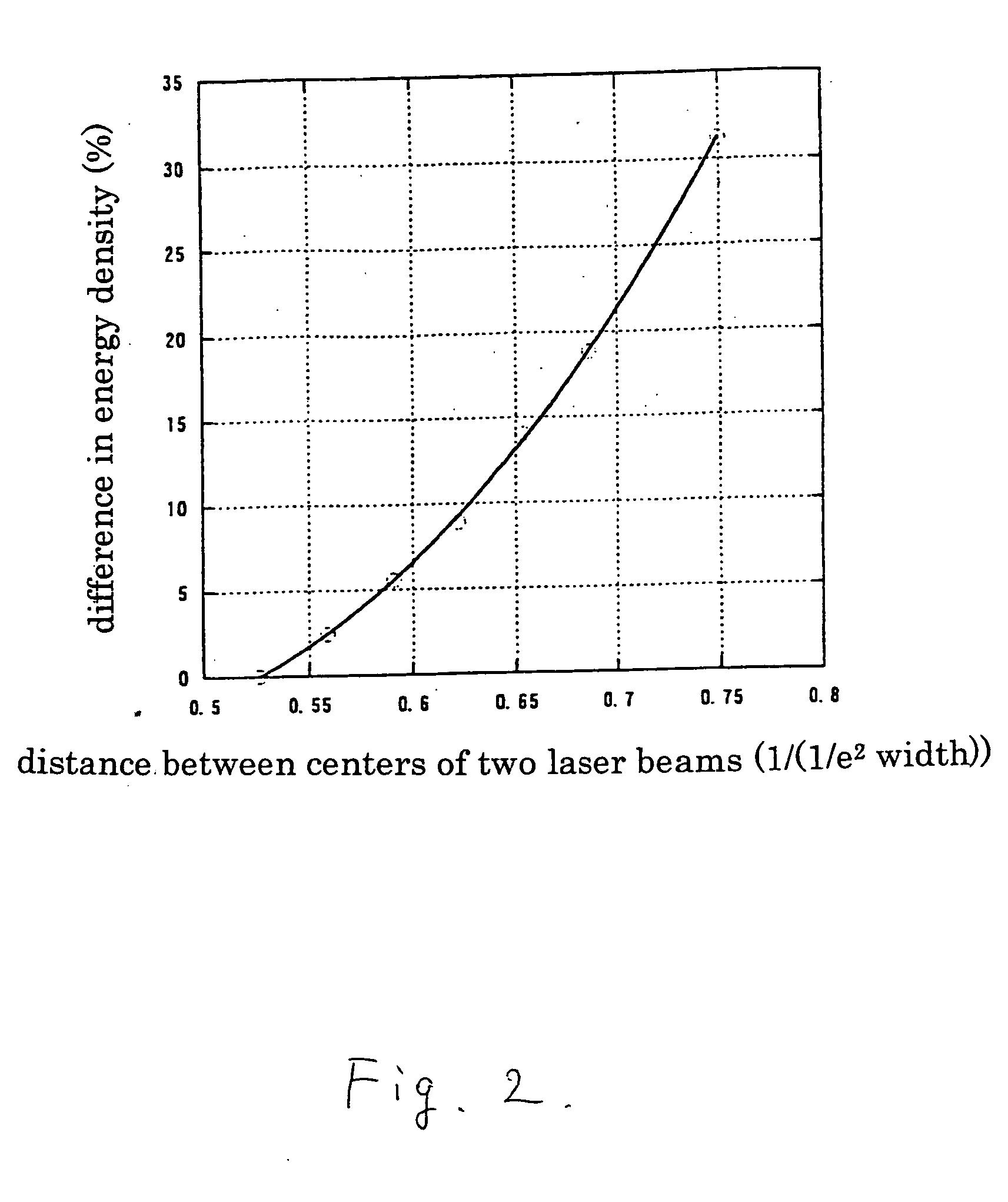

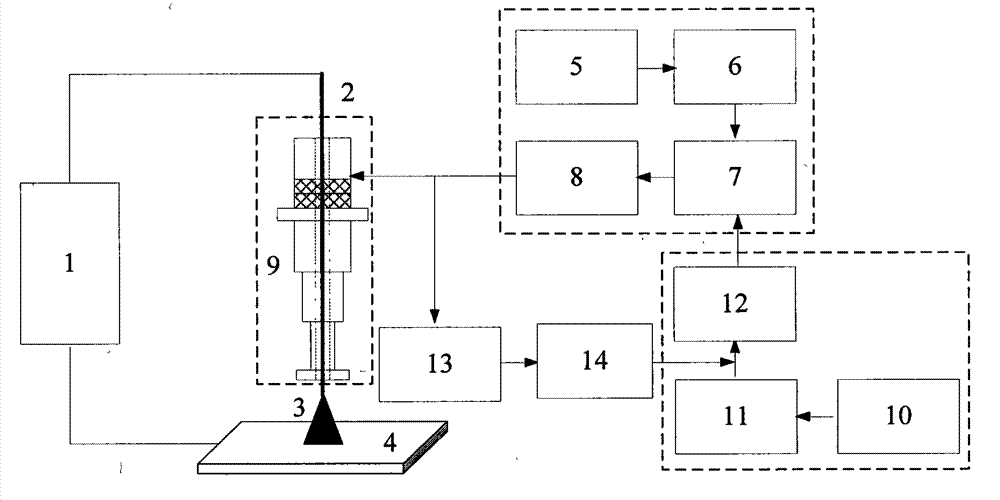

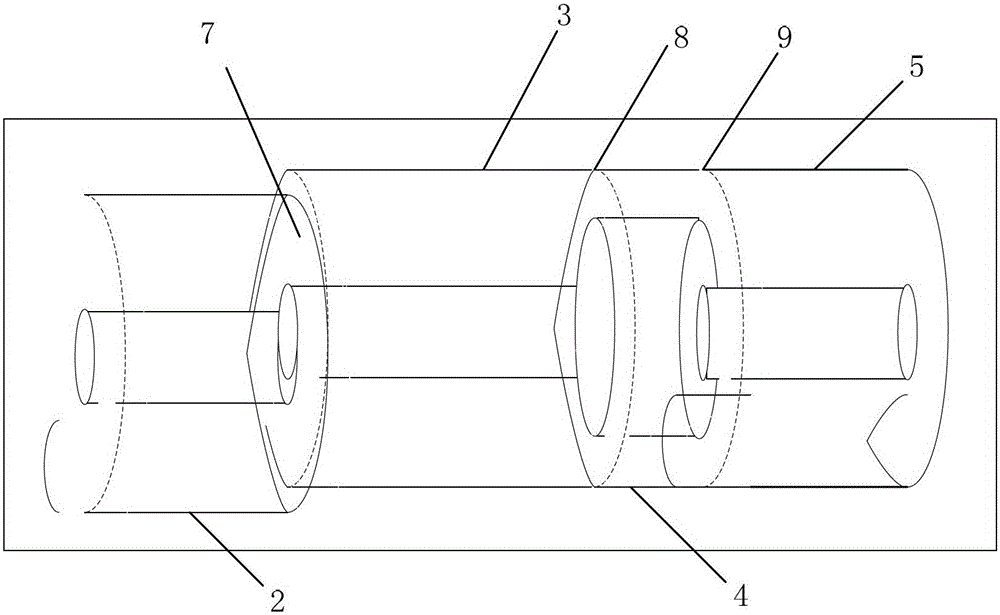

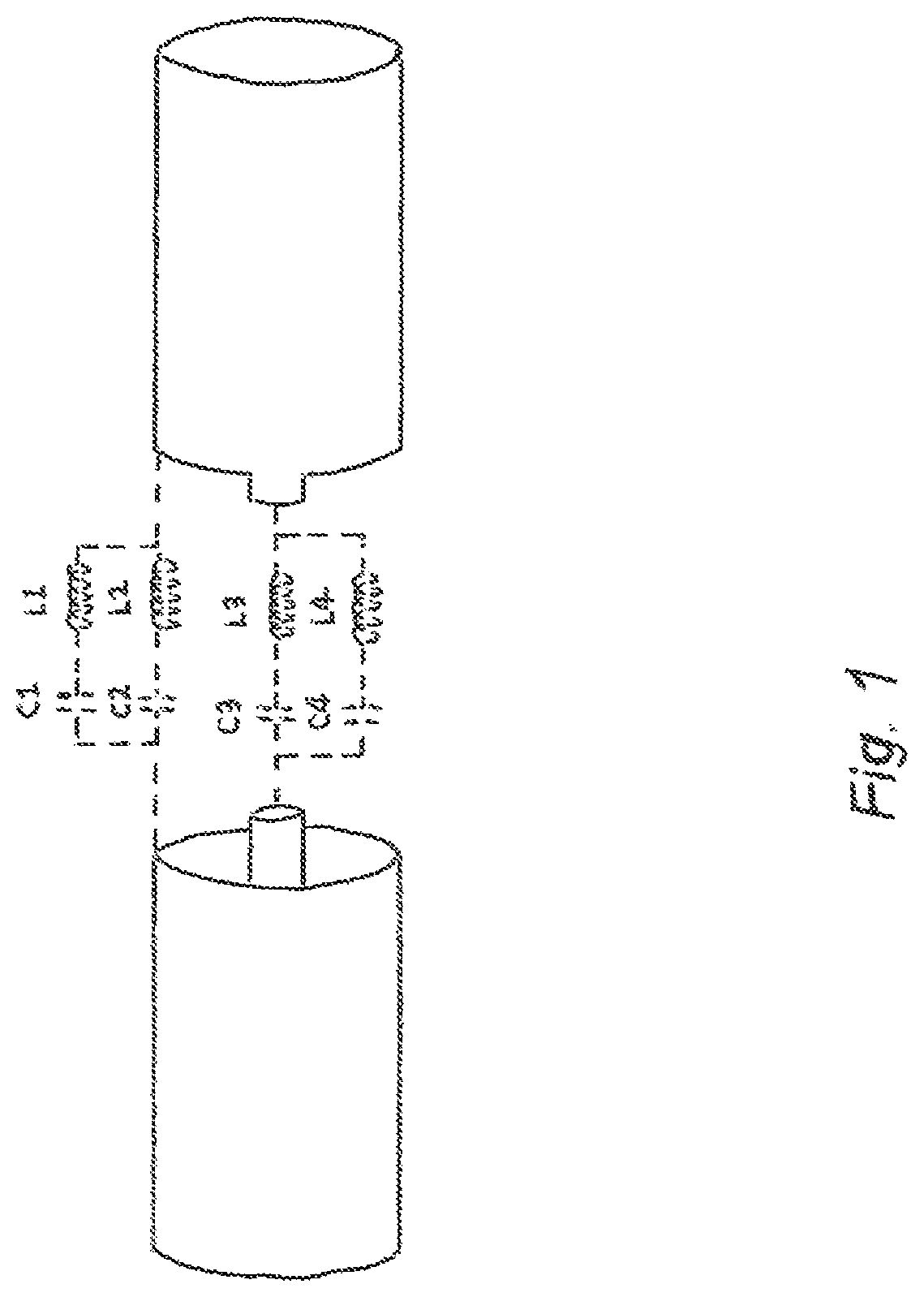

Laser beam irradiating apparatus, laser beam irradiating method, and method of manufacturing a semiconductor device

InactiveUS6897889B2Reduce weightIncreased durabilityTransistorInking apparatusLight beamIrradiation laser

A laser beam irradiating apparatus capable of achieving uniform annealing efficiently by employing a simple optical system using laser beams having attenuated regions is disclosed. It is possible to provide a method of irradiating a laser beam using the laser beam irradiating apparatus, and to provide a method of manufacturing a semiconductor device including the laser beam irradiating method in the fabrication sequence thereof.

Owner:SEMICON ENERGY LAB CO LTD

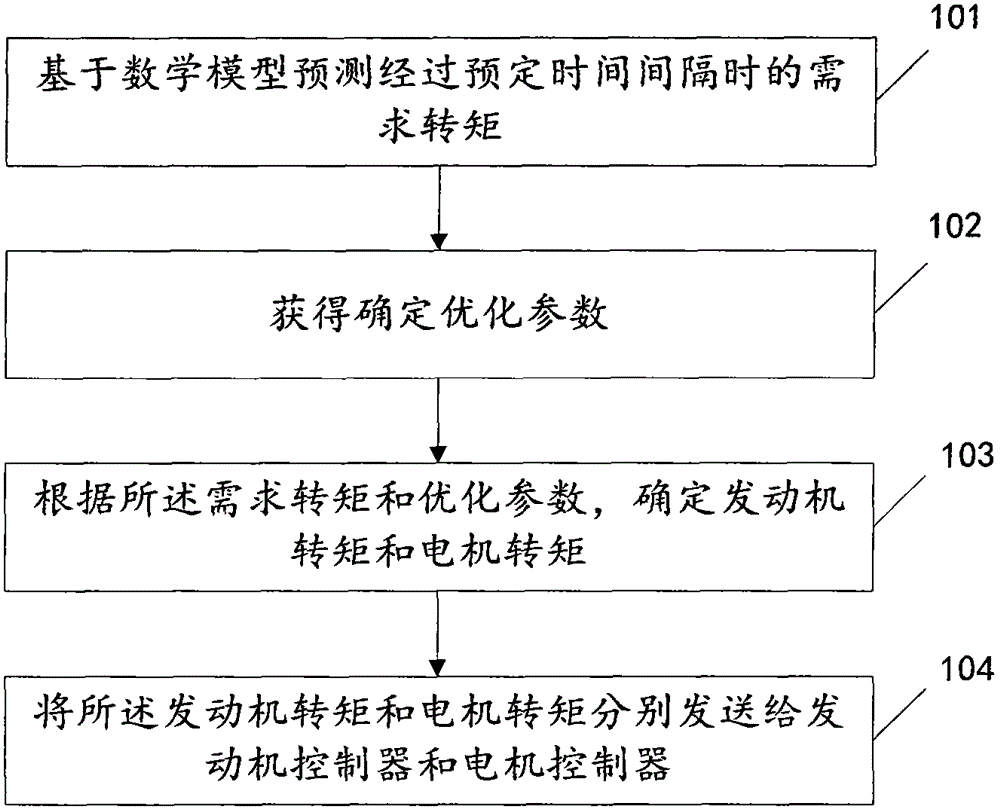

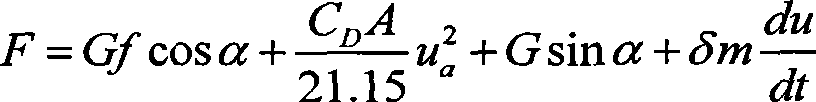

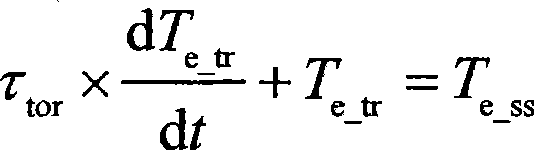

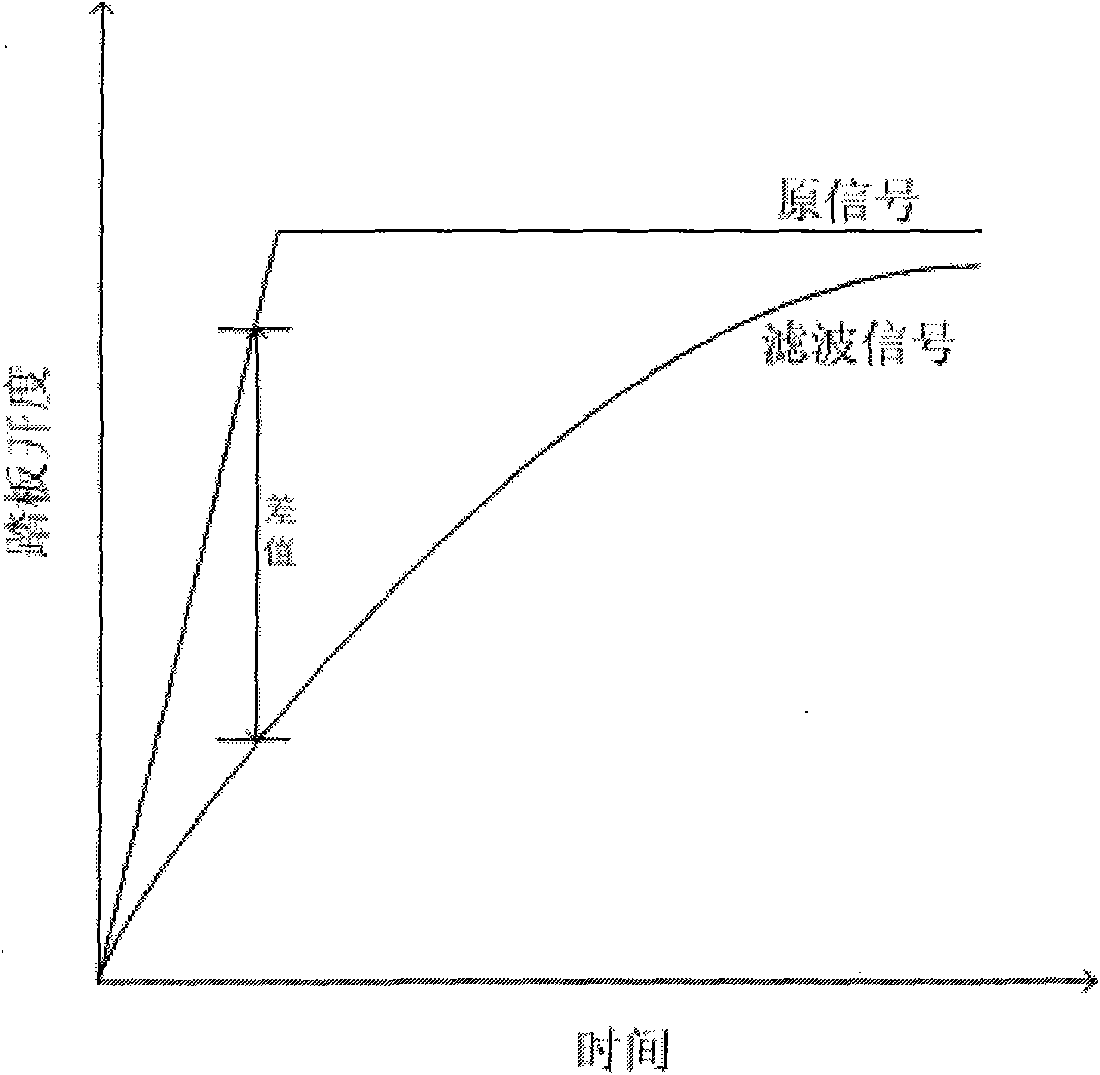

Hybrid electric vehicle control method based on model prediction control

InactiveCN102975713AOptimize energy distributionHybrid vehiclesInternal combustion piston enginesDriver/operatorElectric machine

The invention provides a hybrid electric vehicle control method based on model prediction control. The control method comprises the following steps: predicating a required torque at a preset time internal on the basis of a mathematic model; obtaining optimization parameters; determining an engine torque and a motor torque according to the required torque and the optimization parameters; and respectively transmitting the engine torque and the motor torque to an engine controller and a motor controller. According to the method provided by the invention, the condition that a driver operates an accelerator pedal is predicated, and the acquired predication information is used for carrying out real-time optimization on energy distribution of a hybrid electric vehicle, so that the hybrid electric vehicle is more oil-saving.

Owner:TSINGHUA UNIV

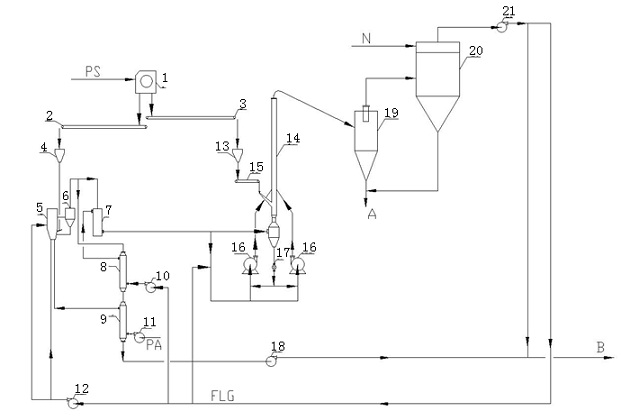

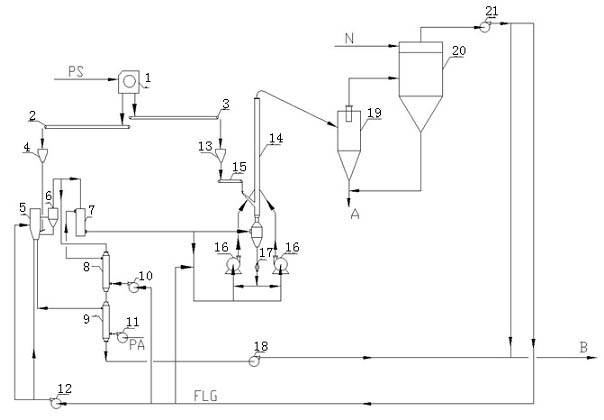

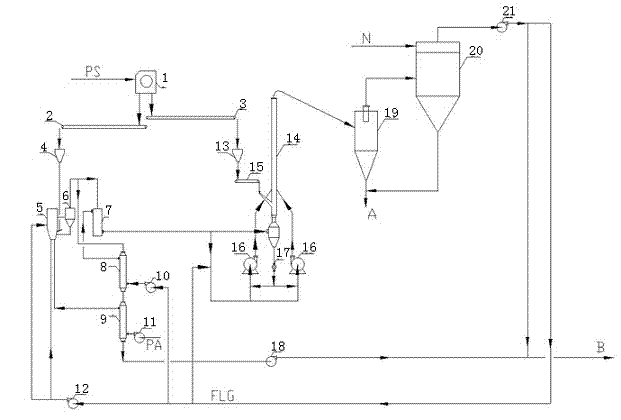

Process for carrying out strengthening circulation, stage grinding and quality improvement on lignite by utilizing superheated steam and system thereof

ActiveCN101870897AOptimize energy distributionMaximize energy utilizationCombination devicesDrying solid materials with heatFlue gasProcess engineering

The invention relates to a process for carrying out strengthening circulation, stage grinding and quality improvement on lignite by utilizing superheated steam and a system thereof. The method comprises the following steps: (1) carrying out grinding on the raw material lignite; (2) burning one part of coal blocks / powder to produce high-temperature flue gas serving as a heat source and carrying out air separation and dring on the other part of coal blocks / powder requiring to be subjected to quality improvement; (3) in the process of air separation, adopting the high-temperature flue gas from the step (2), carrying out drying, separation and dust removal on the qualified coal blocks / powder conforming to the standard grain diameter after air separation, collecting the qualified coal blocks / powder, sending the qualified coal blocks / powder to the forming process, making the unqualified coal blocks / powder drop in a grinding ventilating device to carry out grinding and drying, then continuously completing deep drying by air separation and repeating the steps, wherein the oxygen content in the flue gas is less than 8 percent; and (4) sending one path of waste gas subjected to air separation and drying to the washing process and returning the other path of waste gas serving as a return tail gas part to the step (2) so as to prepare the high-temperature flue gas and carry out air separation. The process has the advantages of safety, energy saving, environment protection, high efficiency, stability and the like.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

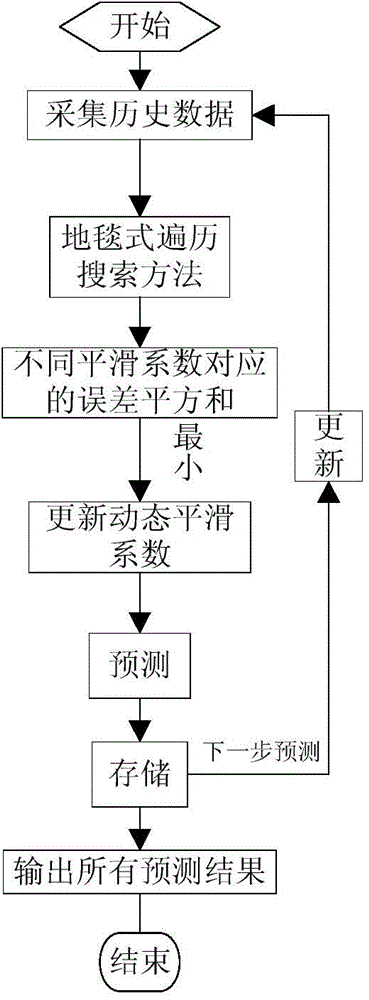

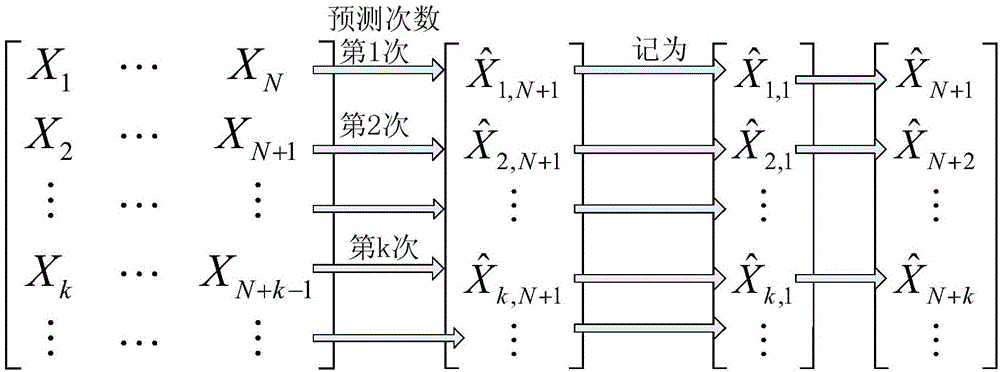

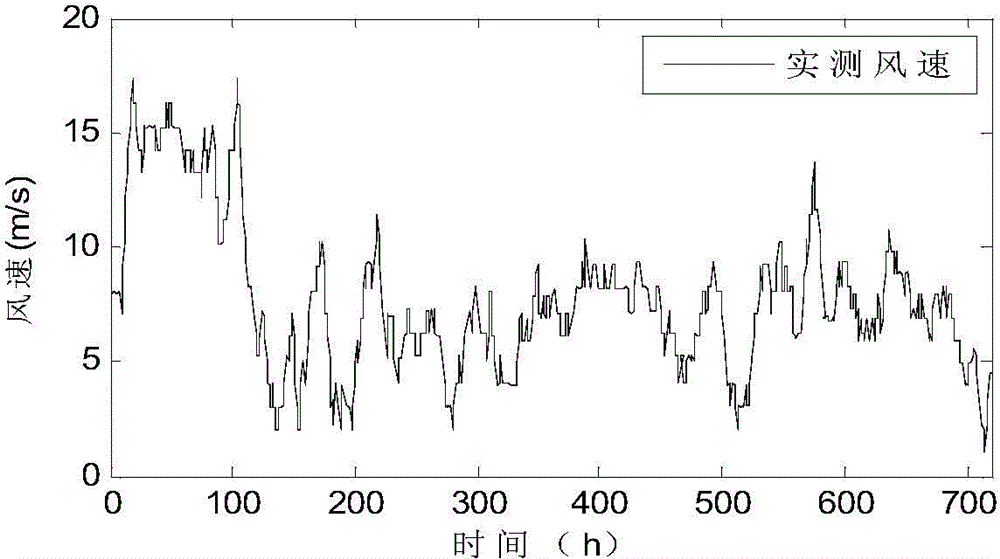

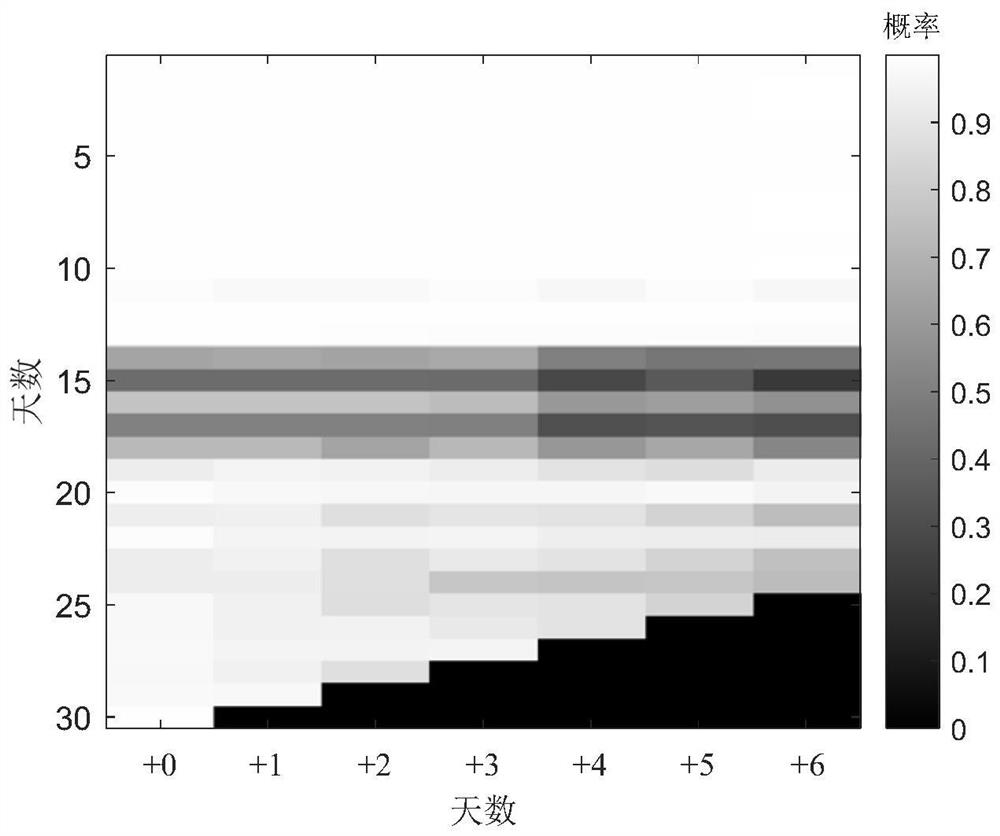

Method for predicting wind speed of wind power plant at short term

InactiveCN103559563AReduce randomnessStrong engineering application valueForecastingShort termsErrors and residuals

The invention discloses a method for predicting the wind speed of a wind power plant at a short term. The method includes the following steps that wind speed data in a period of time are acquired and reduced into a time sequence for analytical prediction; a carpet traversal search method is adopted, and based on a dynamic cubic exponential smoothing prediction method, dynamic smoothing coefficients are determined according to the criterion of the minimum error sum of squares; the determined dynamic smoothing coefficients and the dynamic cubic exponential smoothing method are utilized to conduct one-step or multi-step prediction; the rest is conducted in the same way, new historical data are acquired, the smoothing coefficients are updated, and the later wind speed prediction continues to be conducted. According to the method for predicting the wind speed of the wind power plant at the short term, the characteristics of local historical wind speed are comprehensively considered, and the prediction effect is good.

Owner:STATE GRID CORP OF CHINA +1

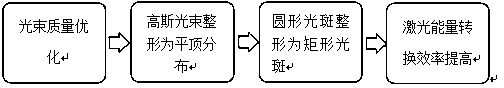

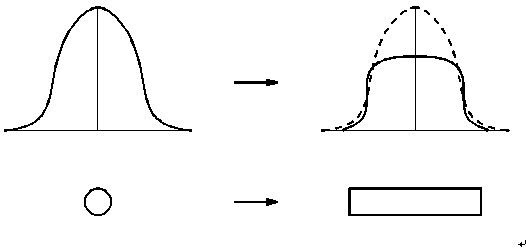

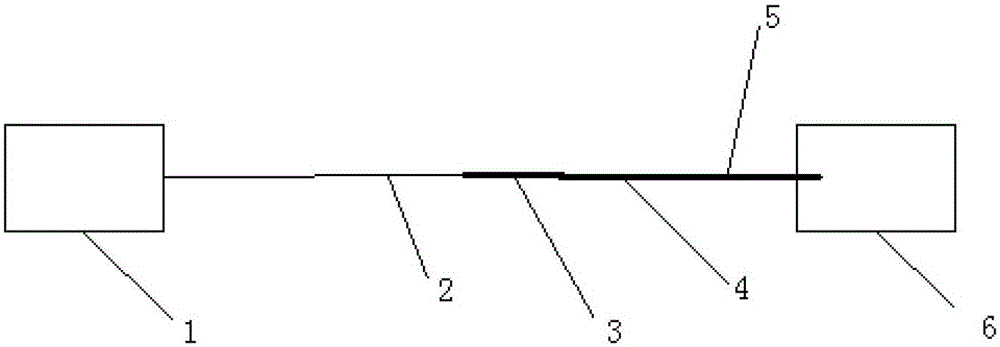

Method of improving laser processing efficiency by optimizing light beam quality

InactiveCN103513426AOptimize energy distributionEven energy distributionOptical elementsLaser processingLight beam

The invention discloses a method of improving laser processing efficiency by optimizing light beam quality, and relates to the technology application field of optical systems and laser processing systems. The method is characterized in that light beams of an Nd: YAG laser device are optimized and shaped from two aspects, wherein a step A is that a shaping system of a Galileo-type aspherical mirror set is used for optimizing and shaping round laser spots in a Gaussian distribution pattern into round laser spots in an ultra Gaussian flat-topped distribution pattern; a step B is that the round laser spots in the ultra Gaussian flat-topped distribution pattern in the step A pass through a spot conversion device and are converted into linear spots in the ultra Gaussian flat-topped distribution pattern under the action of the spot conversion device. Laser beams obtained through the method are uniform in energy distribution and optimized in quality, and energy conversion efficiency of laser is improved. The method has the advantages that the technique is simple, and since two sets of devices are both composed of various lenses, cost and power consumption are low, and the method is easy to implement.

Owner:JIANGSU UNIV

Laser beam irradiating apparatus, laser beam irradiating method, and method of manufacturing a semiconductor device

InactiveUS20050181550A1Increased durabilityReduce weightTransistorSolid-state devicesDevice materialLight beam

A laser beam irradiating apparatus comprising, a plurality of lasers, member for synthesizing a plurality of laser beams emitted respectively from the plurality of lasers into a single laser beam on a stage, and member for moving the synthesized laser beam on the stage while keeping a specific shape thereof. A semiconductor film can be crystallized or an impurity element doped therein can be activated by irradiating a laser beam to the semiconductor film from the laser beam irradiating apparatus arranged as above. Consequently, it is possible to provide a laser beam irradiating apparatus capable of achieving uniform annealing efficiently by employing an optical system simpler than a conventional one and using laser beams having attenuated regions. Also, it is possible to provide a method of irradiating a laser beam using the laser beam irradiating apparatus, and to provide a method of manufacturing a semiconductor device including the laser beam irradiating method in the fabrication sequence thereof.

Owner:SEMICON ENERGY LAB CO LTD

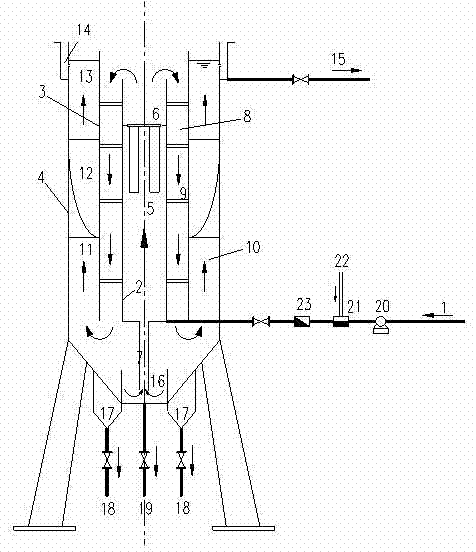

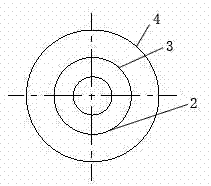

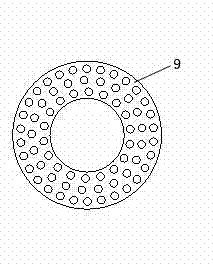

Tubular/cylindrical mud residue internal reflux mud-water high-efficiency separation device

InactiveCN102218234AIncreased hydroflocculation zoneReduce back flowSettling tanks feed/dischargeSedimentation settling tanksRefluxFlocculation

The invention relates to a small high-efficiency mud-water separation device used for supplying water to villages and small towns. The device comprises a mechanical flocculation area and a hydraulic flocculation area, a sedimentation area, an active mud residue concentration area, an active mud residue internal reflux tube / cylinder, an impeller lifting device, a water inlet and outlet system, a mud discharge system and the like. The main body of the device mainly comprises three layers of concentric cylinders; an inner cylinder is the mechanical flocculation area, the middle is provided with the impeller lifting device, and active mud residue at the bottom of a concentration chamber is lifted to the mechanical flocculation area by the internal reflux tube / cylinder arranged in the center of the bottom; the hydraulic flocculation area is formed between the inner cylinder and a middle cylinder, and is provided with a pore plate; the sedimentation area is formed between the middle cylinder and an outer cylinder, and is provided with a single-blade single-curve rotary sloping plate; and the bottom of the equipment is provided with a mud residue concentration chamber. The device has theadvantages of compact structure, high space utilization rate, small occupied area, mechanical flocculation area, easily controlled reflux quantity, low energy consumption, good effluent quality and the like, and has great promotion value.

Owner:CHONGQING UNIV

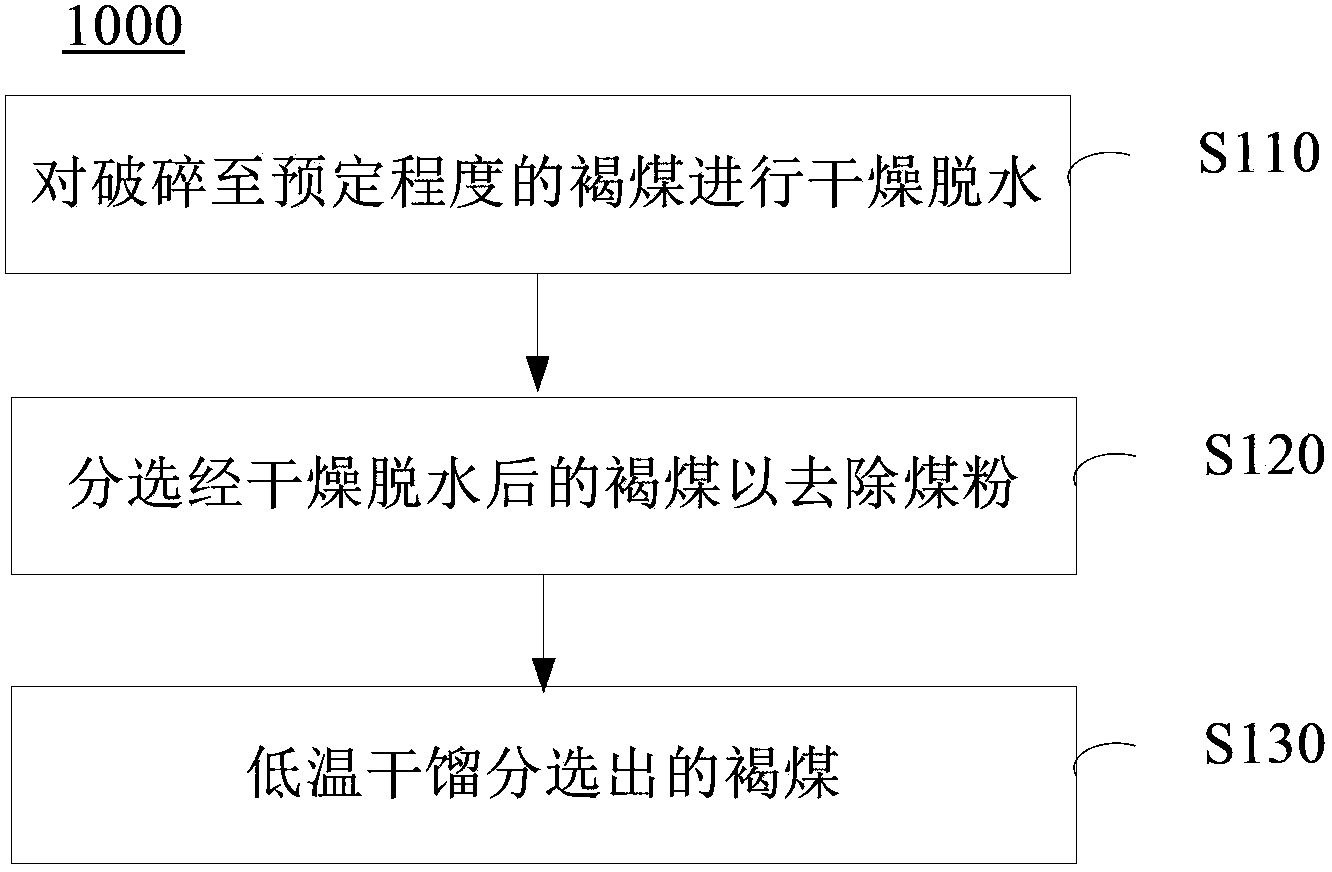

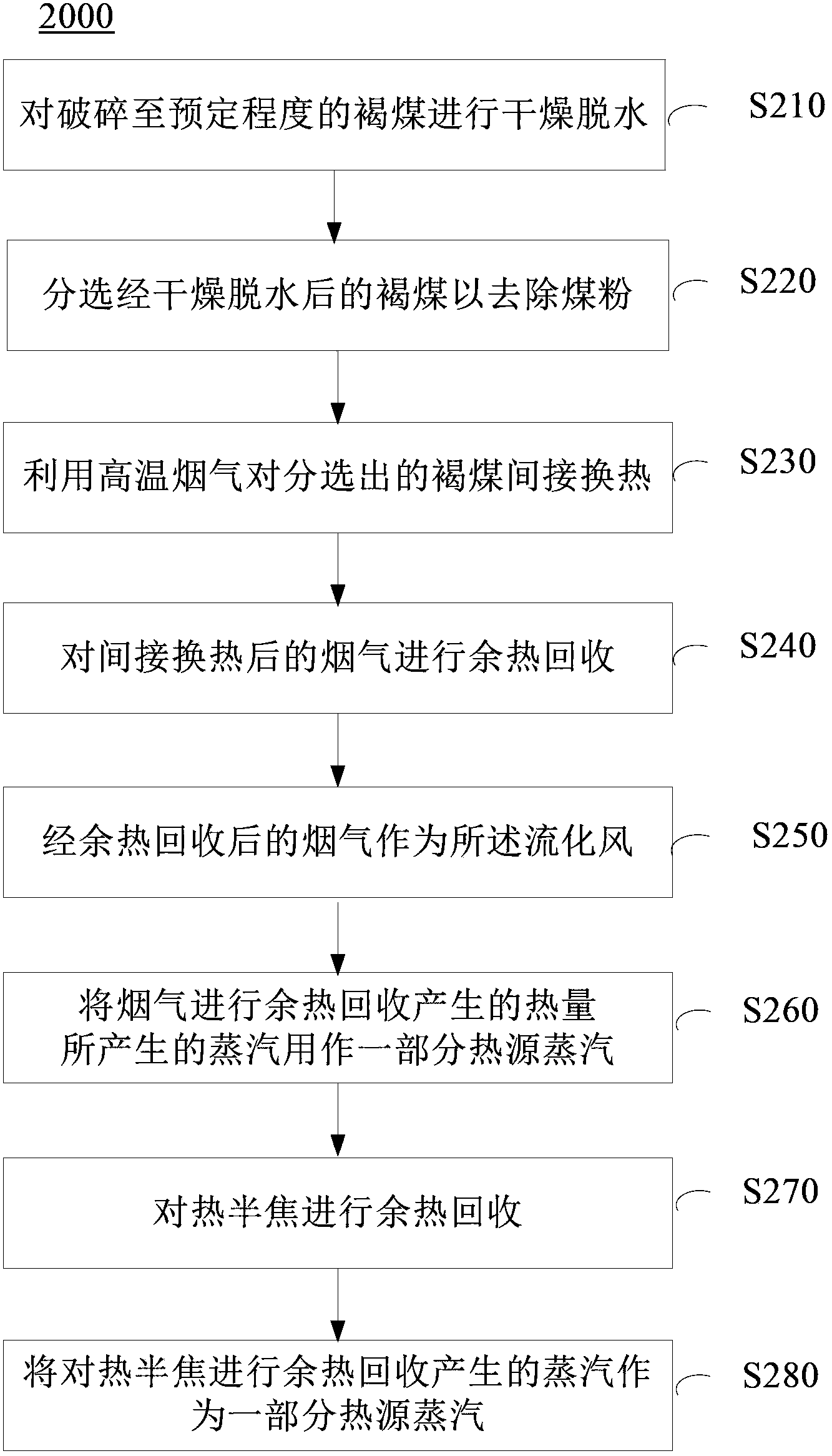

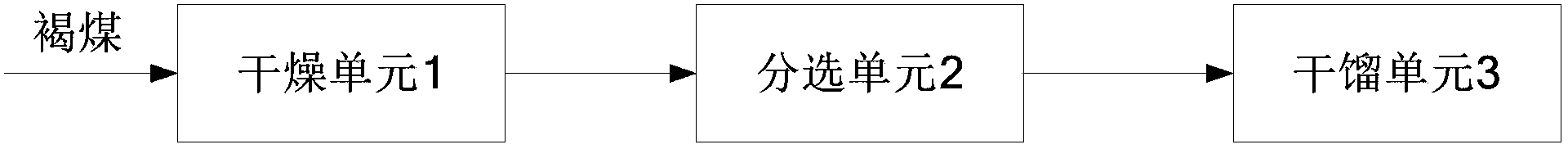

Method and system for improving quality of low-rank coal

ActiveCN103421525AFlexible combinationImprove qualitySpecial form destructive distillationSpontaneous combustionGranularity

The application discloses a method and system for improving the quality of low-rank coal. The method comprises the following steps: drying to remove water in lignite which is crushed into a preset degree; sorting the dried lignite to remove pulverized coal; conducting destructive distillation on the sorted lignite at a low temperature. According to the application, the adjustability of the whole process is enhanced, and the energy distribution of the system is optimized, so that the adverse impact of pulverized lignite on low-temperature destructive distillation is reduced to the maximum extent, the quality of tar is improved, and the granularity range of quality-improving feed coal is broadened; as severe screening of the feed coal is not required, equipment investment is reduced, and potential accidents of dust pollution and spontaneous combustion are reduced.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP +1

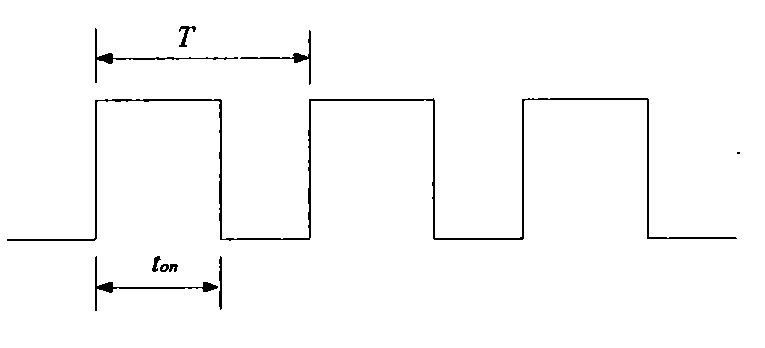

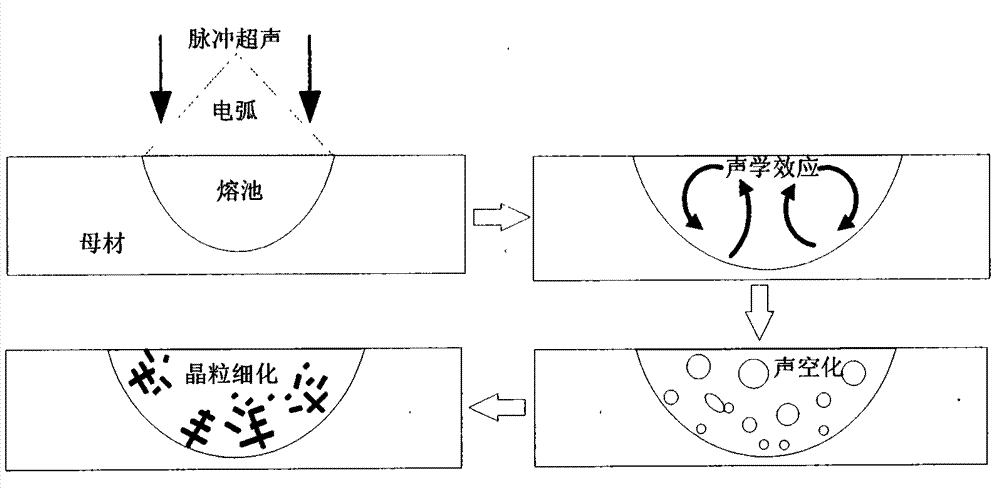

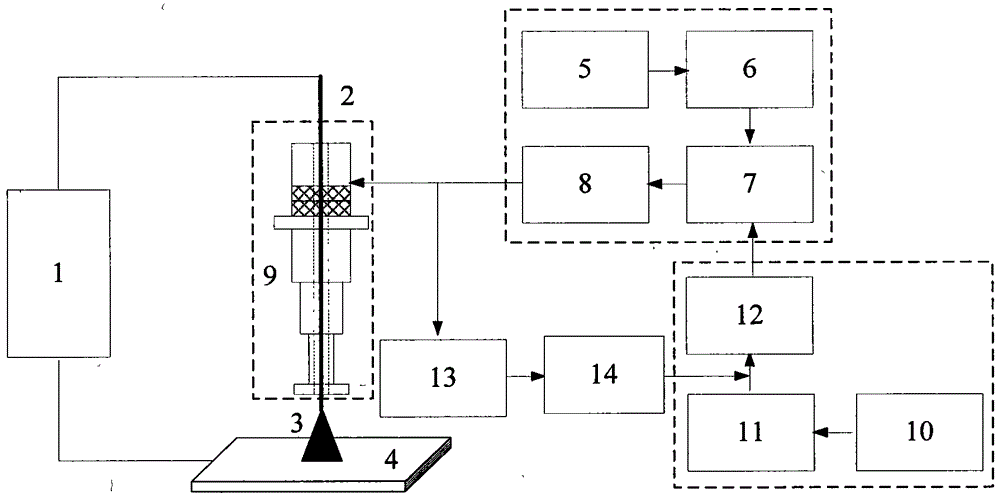

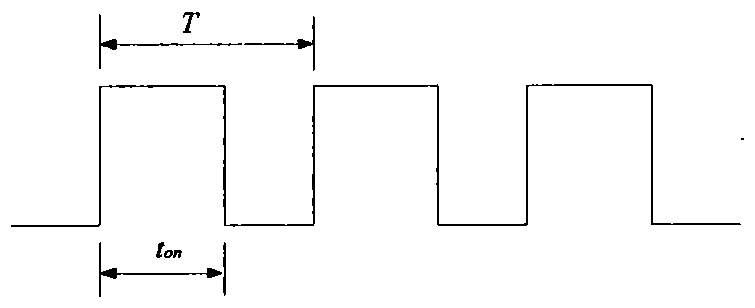

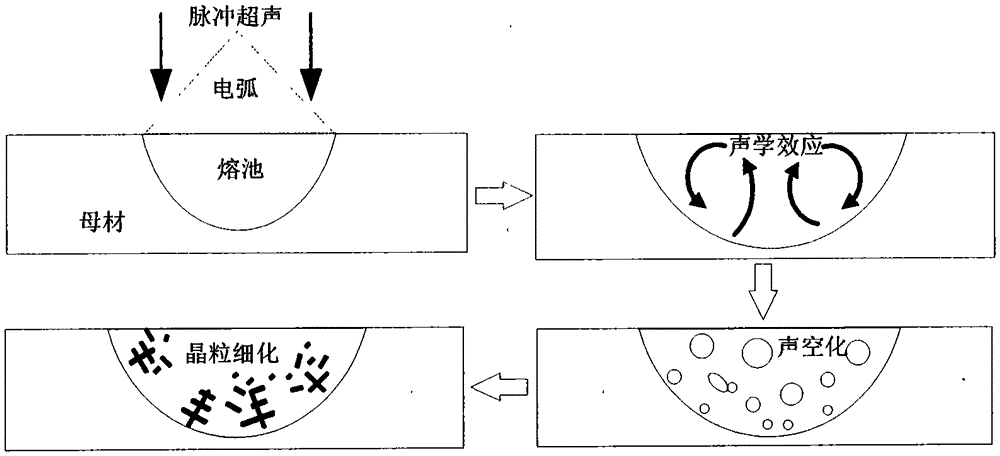

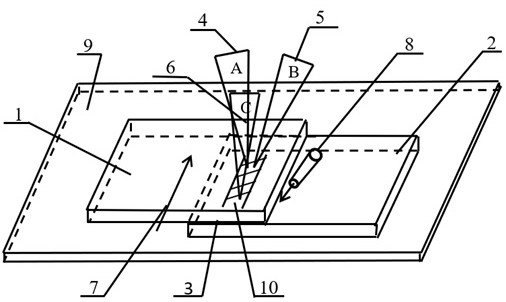

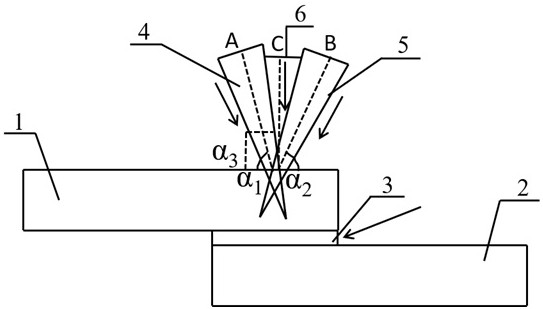

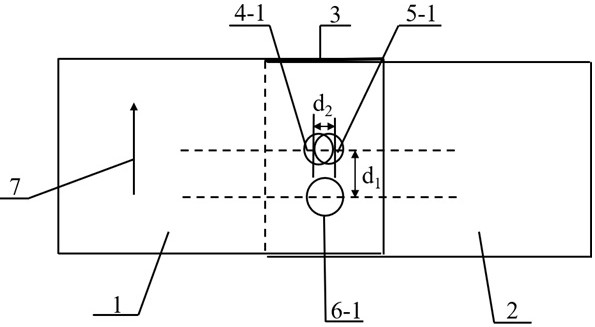

Aluminum alloy pulse ultrasound and electric arc composite welding device and method

InactiveCN104741805AImprove uniformityStrong penetrating powerWelding/soldering/cutting articlesWelding apparatusFull bridgeEngineering

The invention discloses an aluminum alloy pulse ultrasound and electric arc composite welding device and method. Based on ultrasound and electric arc composite welding, the device further comprises a current and voltage detection circuit, a DSP, a single chip microcomputer, a triode switch circuit and a drive circuit. The current and voltage detection circuit is connected with the output end of a matching circuit of an ultrasound generation system. The current and voltage detection circuit is connected with the DSP. The DSP is connected with the drive circuit. The single chip microcomputer is connected with the triode switch circuit. The triode switch circuit is connected with the drive circuit. The drive circuit is connected with a DC / AC full-bridge inversion circuit of the ultrasound generation system. According to the welding method, ultrasound is applied to conduct pulsing processing, and aluminum alloy pulse ultrasound and electric arc composite welding is achieved. The aluminum alloy pulse ultrasound and electric arc composite welding device and method have the advantages of ordinary ultrasound and electric arc composite welding, the electric arc stiffness can be improved, weld penetration is increased, grains are refined, the size of molten drops is reduced, transition frequency is increased, splashing is reduced, high-quality welding under a common welding environment is achieved, aluminum alloy welding pores, welding cracks and the like can be reduced effectively, the microstructure of weld metal is optimized, and the mechanical property of welding connectors is improved remarkably.

Owner:HARBIN INST OF TECH

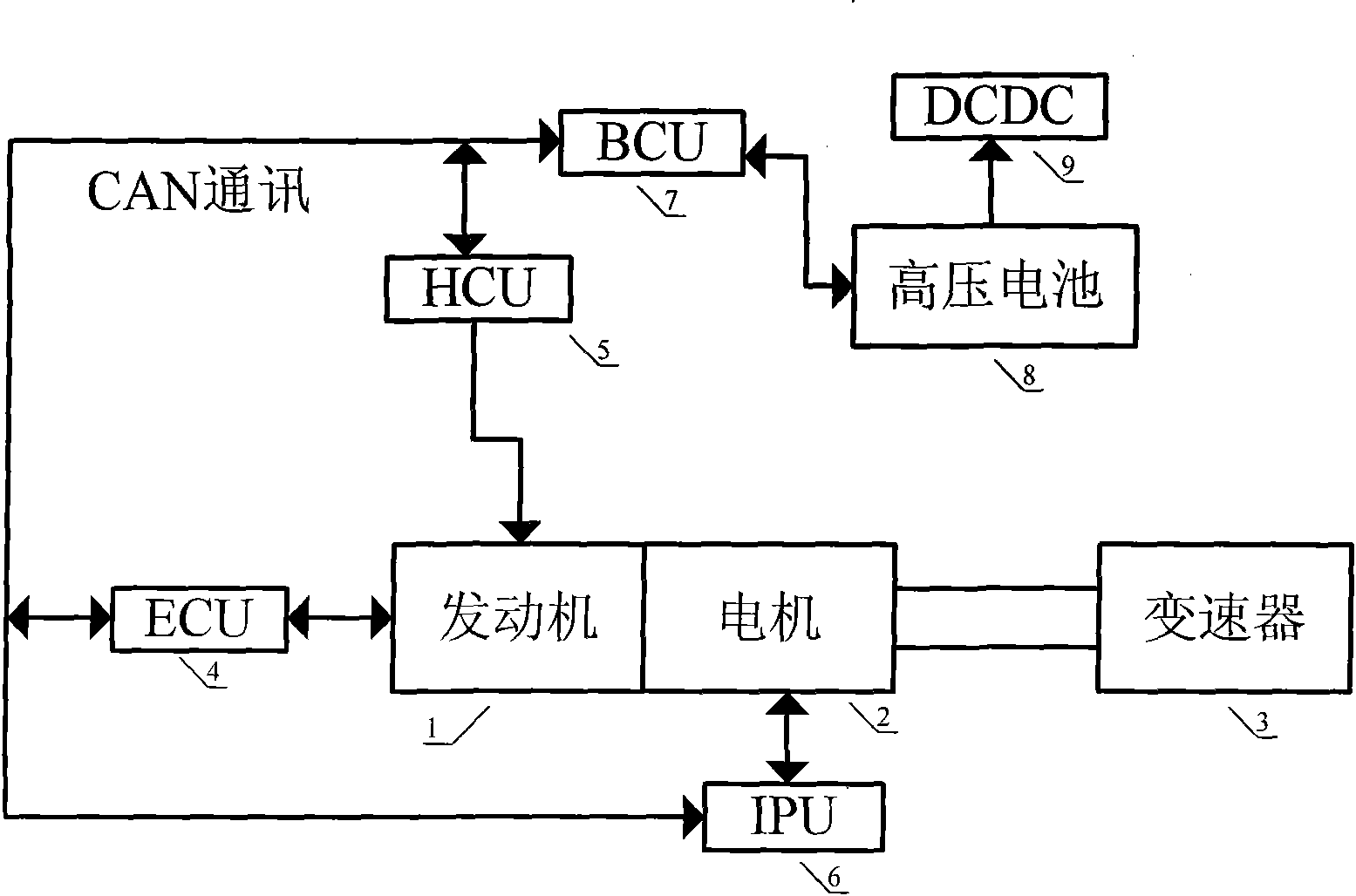

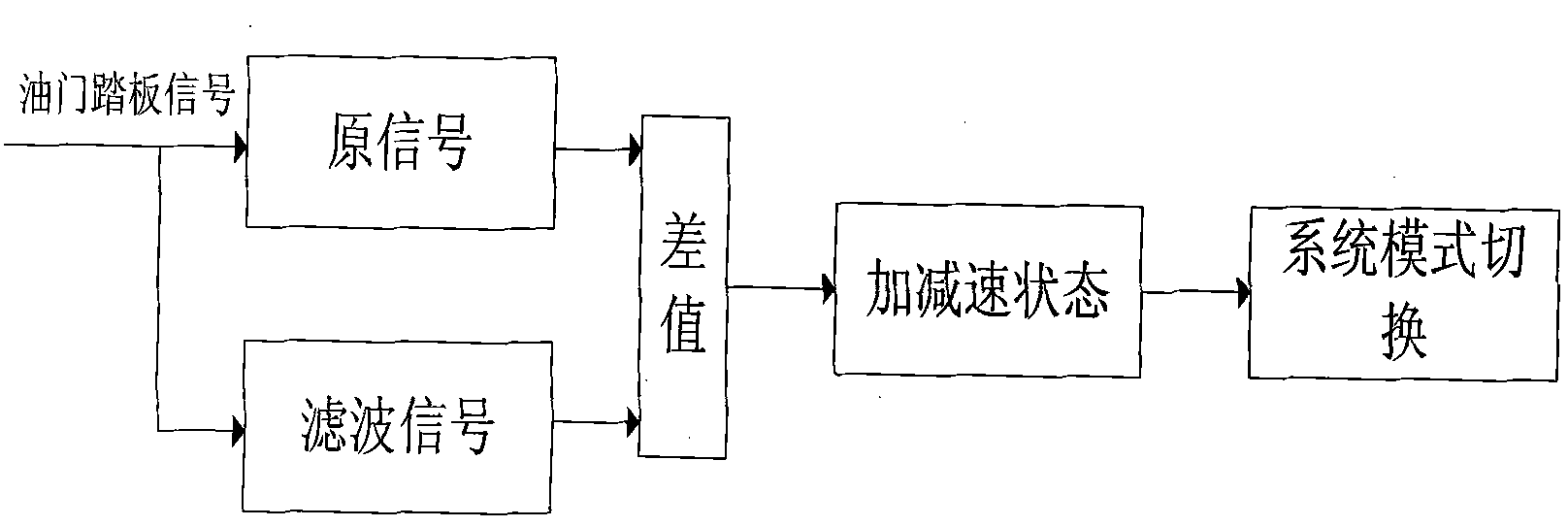

System and method for judging intentions to accelerate and decelerate hybrid electric vehicle

ActiveCN101857027AOptimize energy distributionReduce fuel consumptionHybrid vehiclesData transmissionAutomotive engineering

The invention provides a system for judging the intentions to accelerate and decelerate a hybrid electric vehicle. The system comprises an HCU (hybrid vehicle control unit), an ECU (engine control unit), an IPU (motor control unit) and a BCU (battery control unit), wherein the data transmission is carried out among the HCU, the IPU, the ECU and the BCU through CAN (controller area network) communication; the ECU and the BCU are controlled by the HCU; the ECU is used for acquiring the opening signal of an accelerator pedal according to the requirement of a driver for the accelerator pedal and transmitting the opening signal to the HCU through the CAN communication; and the HCU is used for judging the intentions of acceleration and deceleration according to the current status of the hybrid electric vehicle, switching among the state modes and acquiring the required torque of an engine and a motor, so that the motor can be used for power-assisting in an accelerating state and charged in a decelerating state.

Owner:江西鼎盛新材料科技有限公司

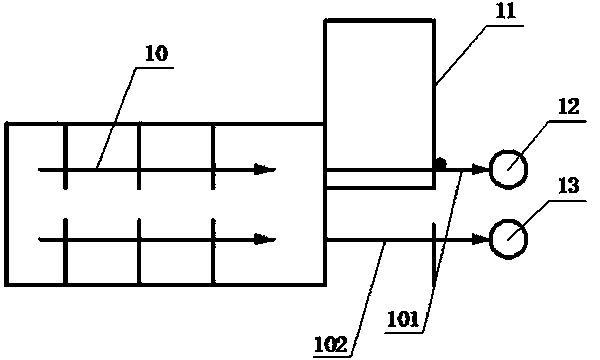

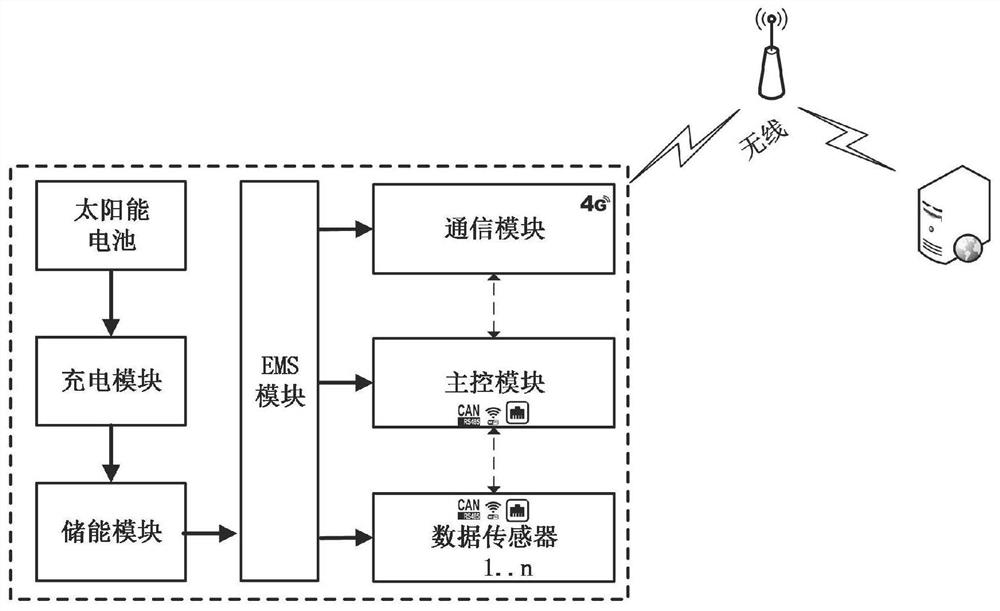

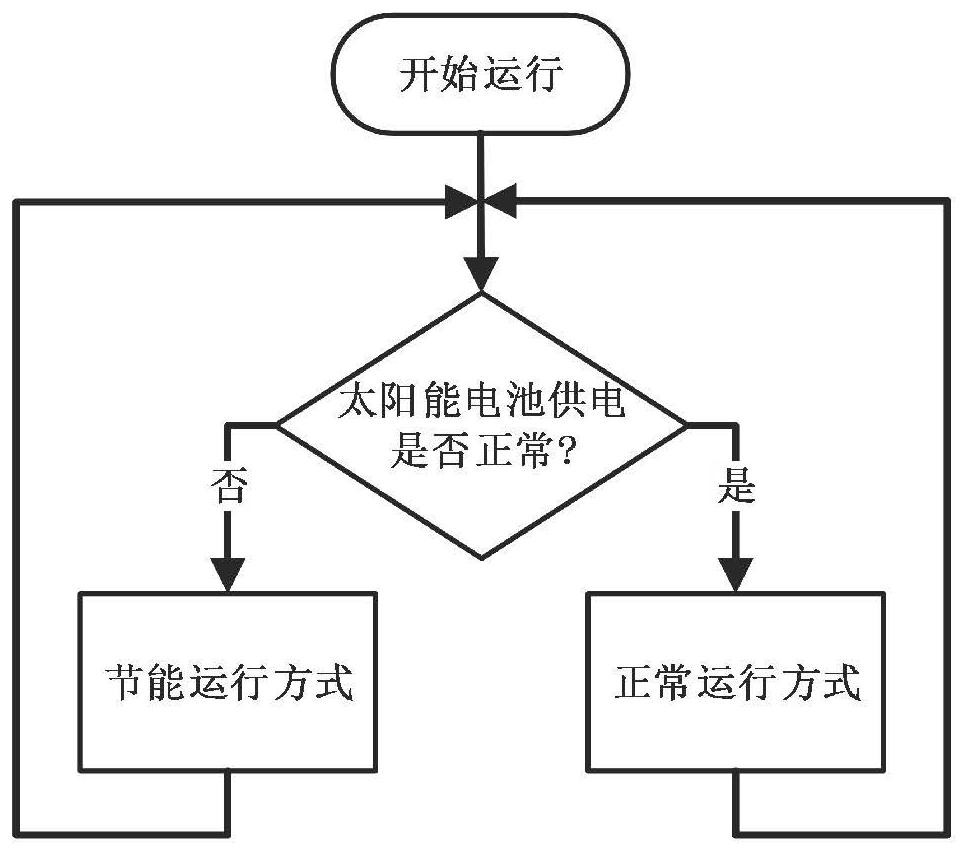

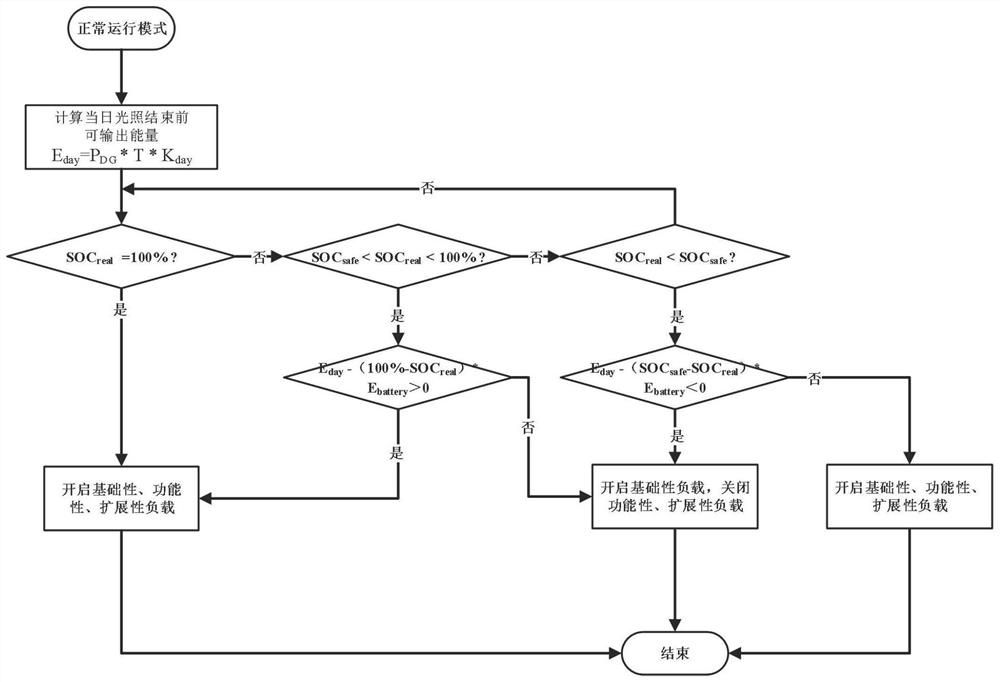

Power transmission line multi-source data fusion device with load priority control and control method thereof

PendingCN111864910AOptimize energy distributionSmart on-demand flowBatteries circuit arrangementsResource allocationElectrical batterySource data

The invention belongs to the technical field of power transmission line on-line monitoring. The invention especially relates to a power transmission line multi-source data fusion device with load priority control and a control method thereof. The device comprises a solar cell, a charging module, an energy storage module, an EMS module, a main control module, a communication module and n data sensors, wherein n in the n data sensors is a positive integer. According to the power transmission line multi-source data fusion device with load priority control and the control method thereof, the powertransmission line multi-source data fusion device can collect data of various data sensors, the collected data are collected and subjected to fusion summarization and intelligent analysis, an analysis result can be transmitted to a server side through 4G wireless communication, solar energy is matched with an energy storage battery for power supply, all functional modules in the device are powered in a load priority management mode, load energy distribution is optimized, and electric energy is intelligently controlled to flow as required.

Owner:ANHUI NANRUI JIYUAN POWER GRID TECH CO LTD

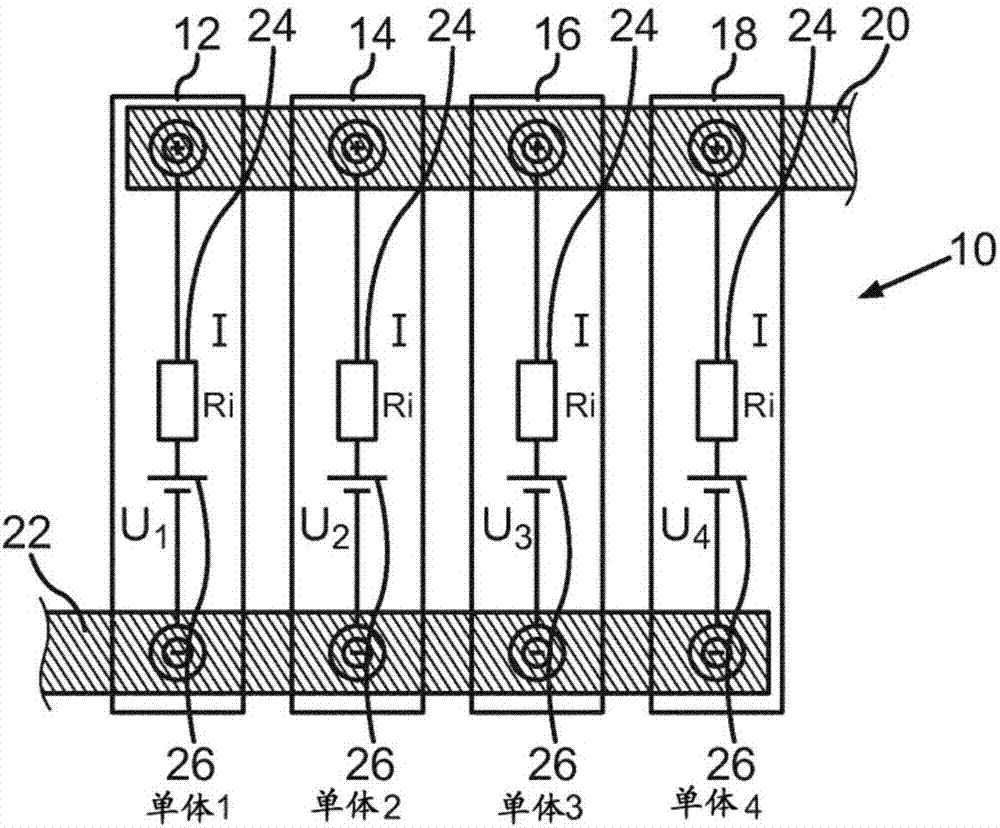

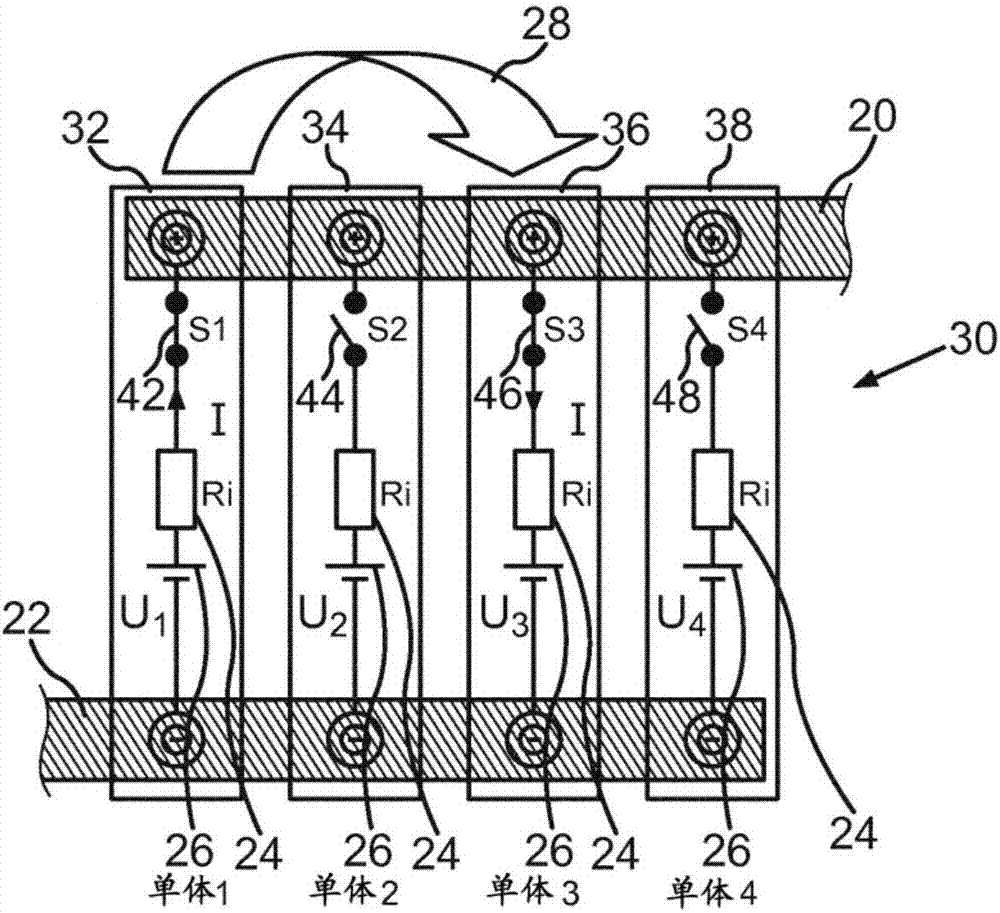

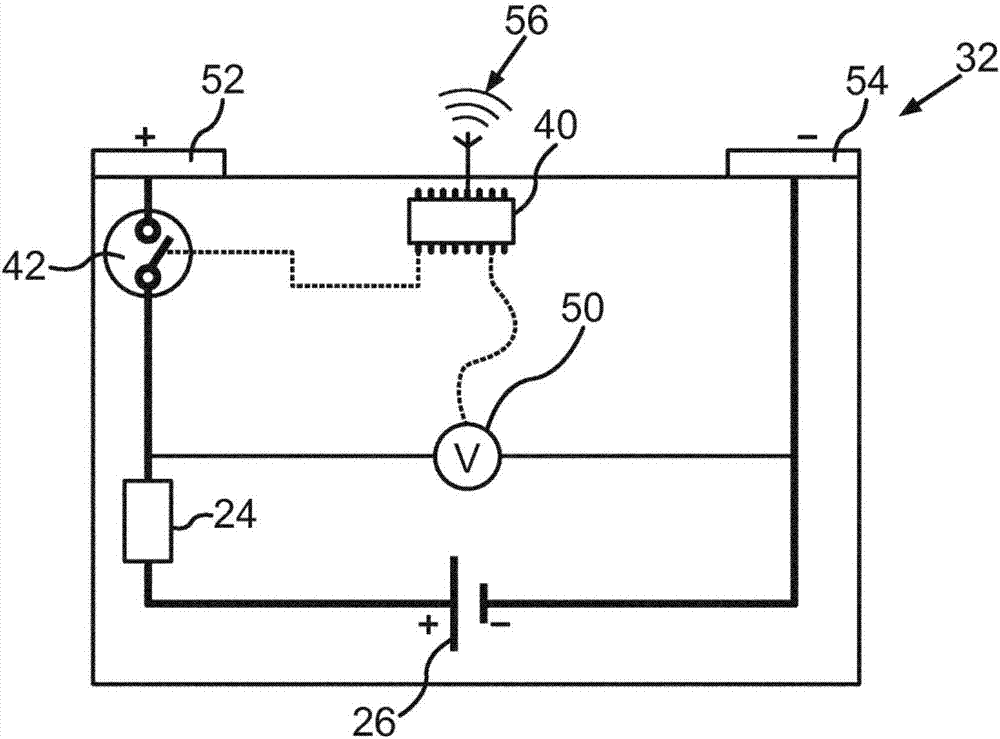

Adjustment of states of charge of battery cells

ActiveCN107258033AOptimize energy distributionImprove charge balanceParallel/serial switchingSecondary cells charging/dischargingState of chargeEngineering

The invention relates to a method for adjusting states of charge of battery cells which are electrically operated in a manner connected in parallel, having the following steps of: - determining the states of charge of the battery cells, - selecting those battery cells whose states of charge are intended to be adjusted according to a predefinable selection rule, - activating those battery cells which are adjusted using a semiconductor switch of the battery cells in each case, and deactivating the remaining battery cells using the semiconductor switches of the respective remaining battery cells, - adjusting the states of charge and monitoring the states of charge, and - ending the adjustment of the states of charge if a predefined state of charge is reached by the activated battery cells.

Owner:AUDI AG

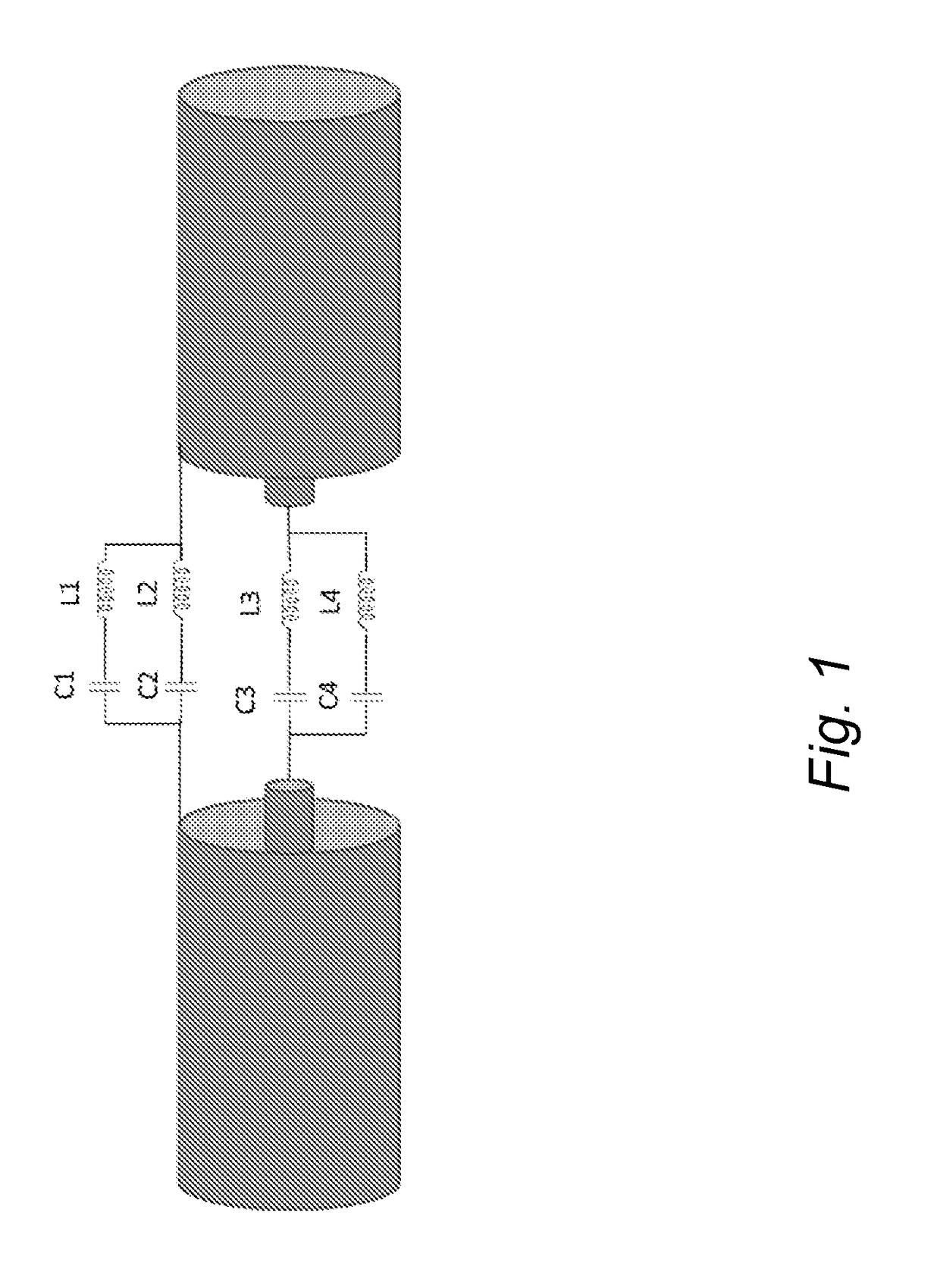

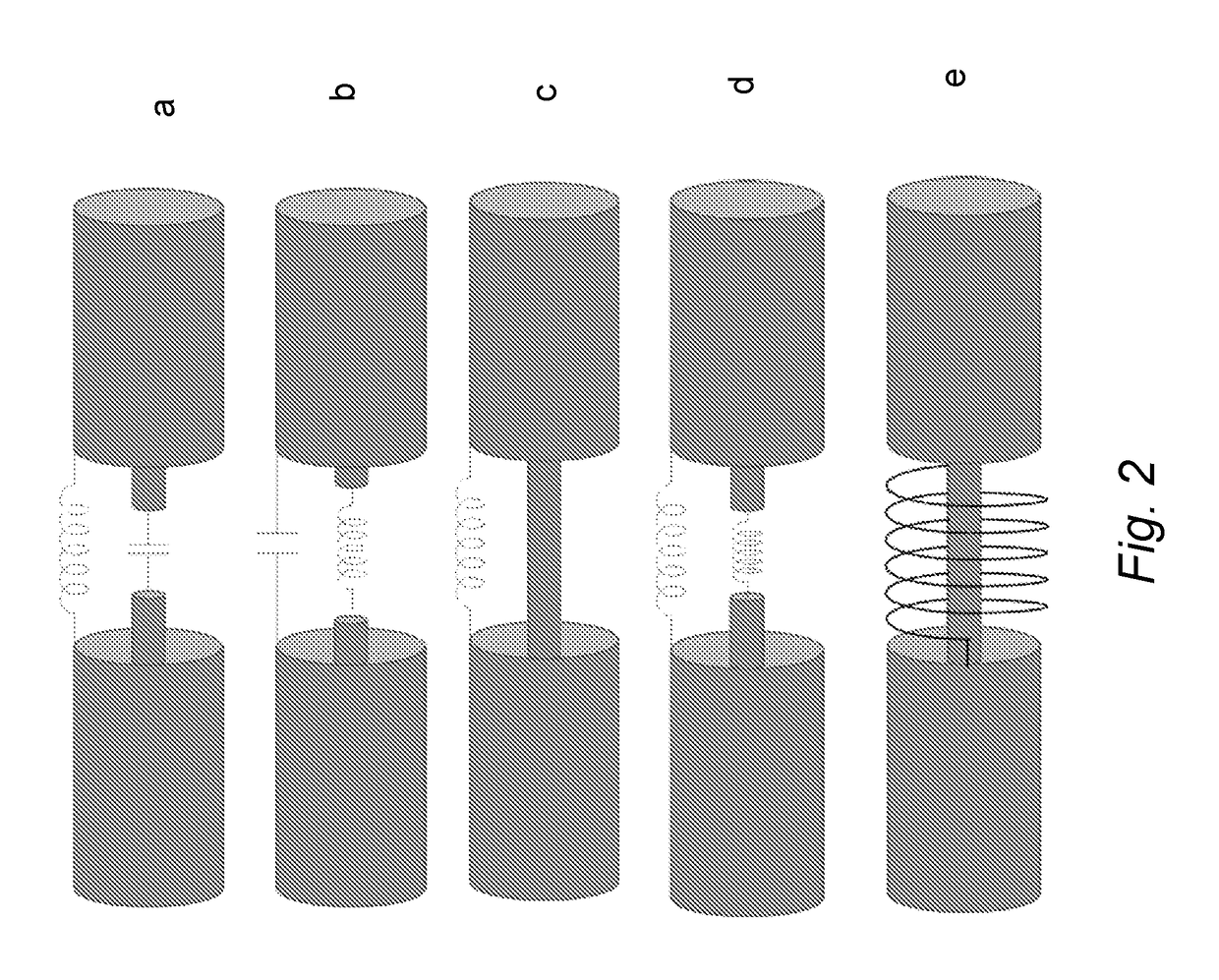

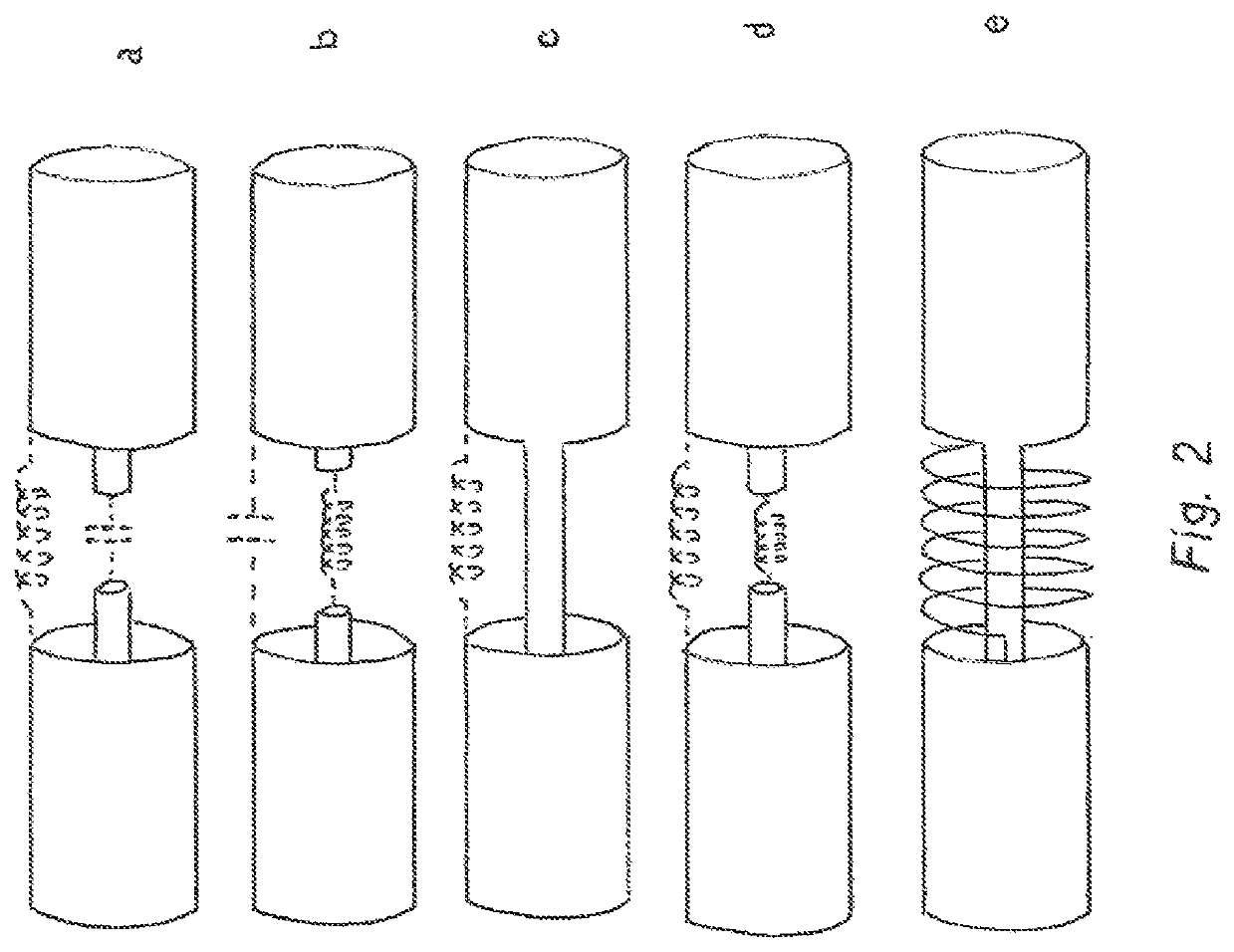

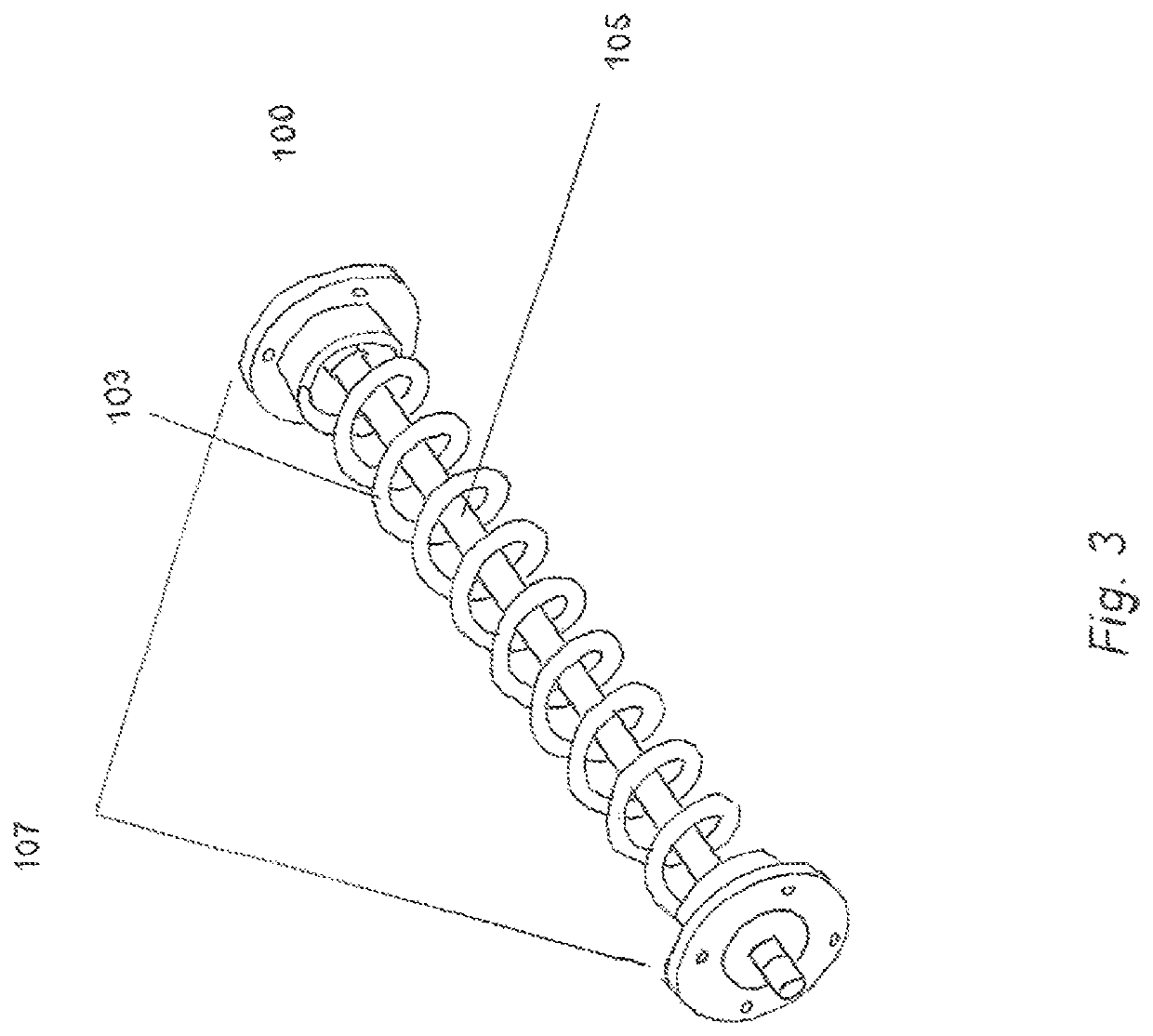

Coaxially Arranged Mode Converters

ActiveUS20170237145A1Bulk is limitedPossible to applyBaseband system detailsInsulationCoaxial transmission lineVIT signals

The present invention relates to a device for generating a disturbance in the differential mode of propagation of an RF signal transmitted along a coaxial transmission line.

Owner:ENI SPA

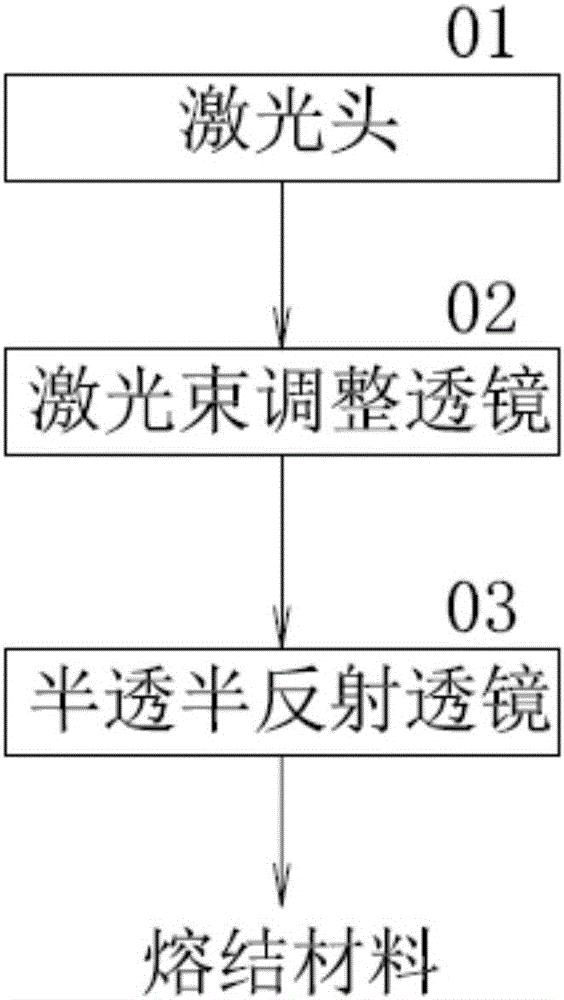

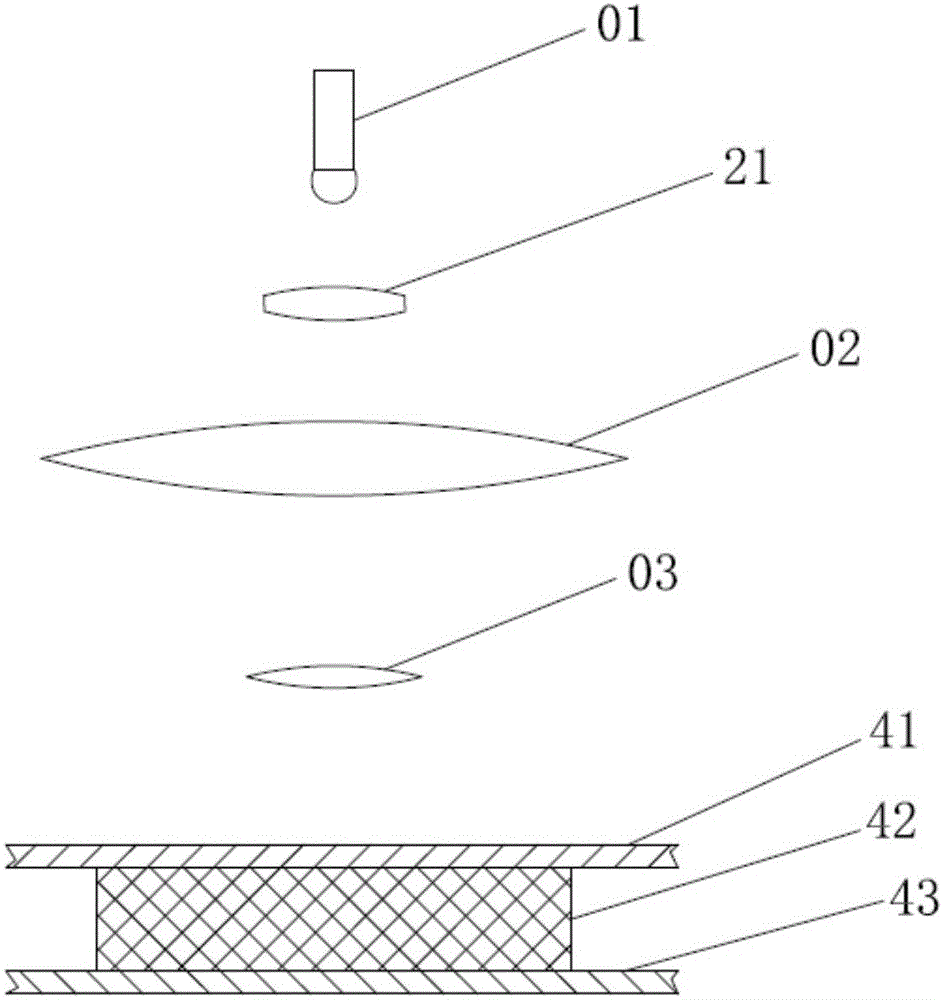

Adjusting structure for reducing bubbles in fritting sealing process

InactiveCN106125313AOptimize energy distributionGood energy uniformitySemiconductor/solid-state device manufacturingOptical elementsOptical axisFrit

The invention provides an adjusting structure for reducing bubbles in a fritting sealing process. A laser beam adjusting lens and a semi-transparent semi-reflective lens are sequentially arranged between a laser head and a fritting material along a principal optic axis of the laser head. The fritting process is completed by irradiating the fritting material with a laser spot. The adjusting structure for reducing the bubbles in the fritting sealing process provided by an embodiment of the invention utilizes the semi-transparent performance of a light transmitting film to improve energy distribution of the laser beam, so that the energy uniformity of the laser beam is improved. Furthermore, combination of the lens and the light transmitting film enables the energy distribution and the spot shape to be well matched, so that requirements for the fritting dimension of the Frit packaging technology can be flexibly met.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

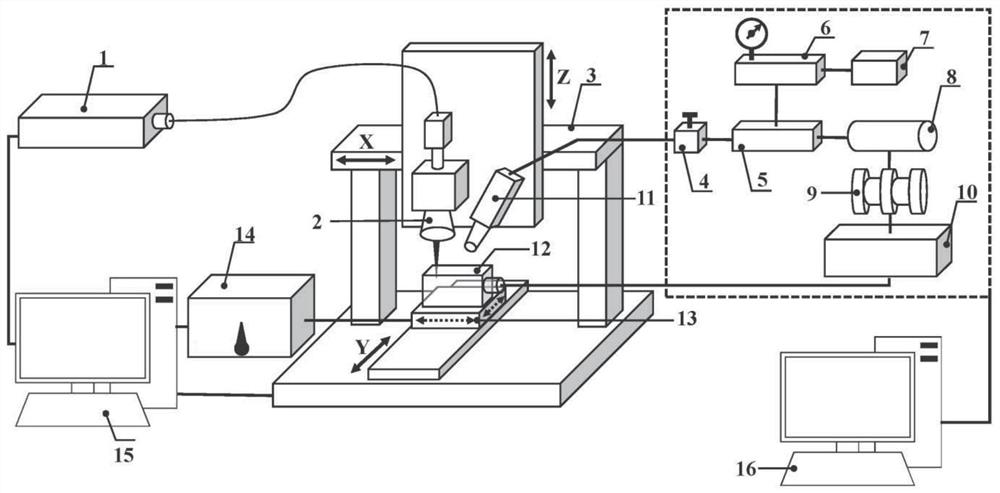

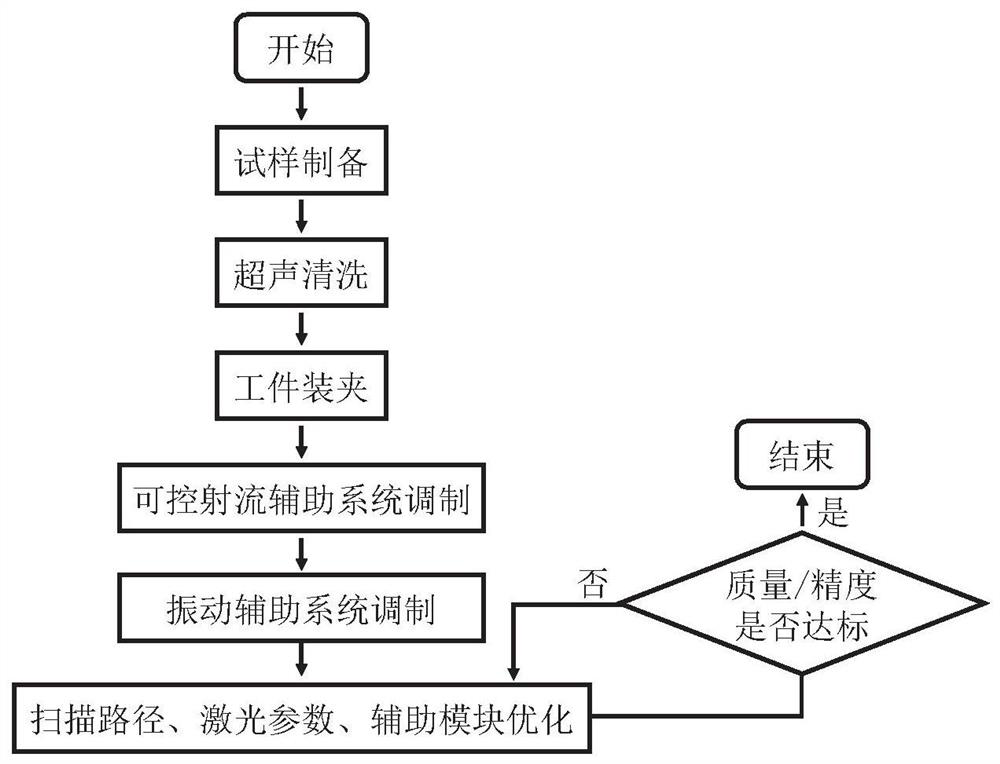

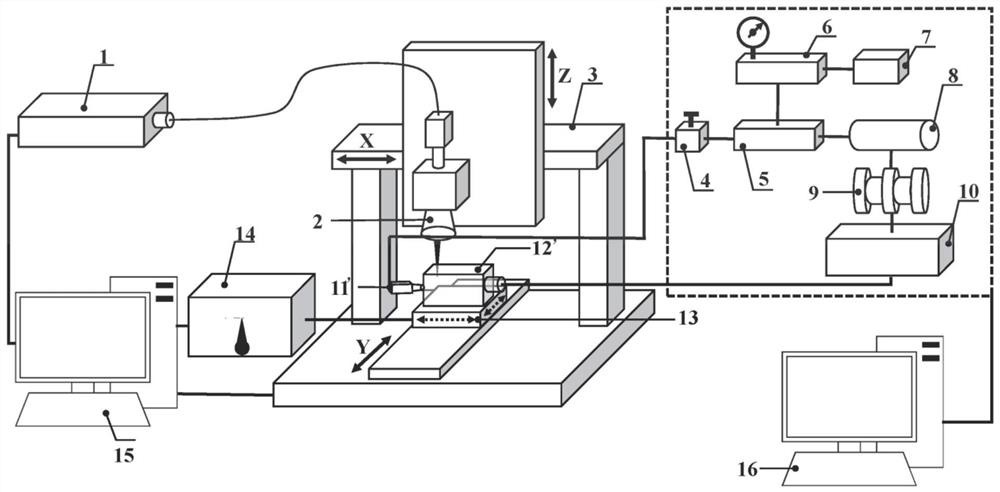

Controllable liquid flow-vibration coupling auxiliary laser milling and polishing machining method and system

ActiveCN113732515AImprove removal efficiencyOptimize energy distributionLaser beam welding apparatusMachining vibrationsLaser processing

The invention discloses a controllable liquid flow-vibration coupling auxiliary laser milling and polishing machining method and system. The machining system comprises a laser machining unit used for conducting laser machining on a workpiece; a liquid flow auxiliary unit used for providing liquid flow to be in contact with the workpiece; a vibration auxiliary unit used for applying vibration to the workpiece; and a control unit used for regulating and controlling the working states of the laser machining unit, the liquid flow auxiliary unit and the vibration auxiliary unit so as to realize controllable coupling of laser machining, vibration and liquid flow. By controllable coupling of laser, vibration, liquid flow and the like, superiority of each process / energy field can be exerted, coupling complementation is realized, macro-micro-scale energy distribution characteristics of a machining area are effectively regulated and controlled, heat influence is reduced, micro-cracks are avoided, laser milling and polishing chip removal characteristics and machining quality are remarkably improved, workpiece quality is greatly improved, and the material removal efficiency is effectively improved. The machining system of the invention is particularly suitable for precision machining of metal materials, hard and brittle materials and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

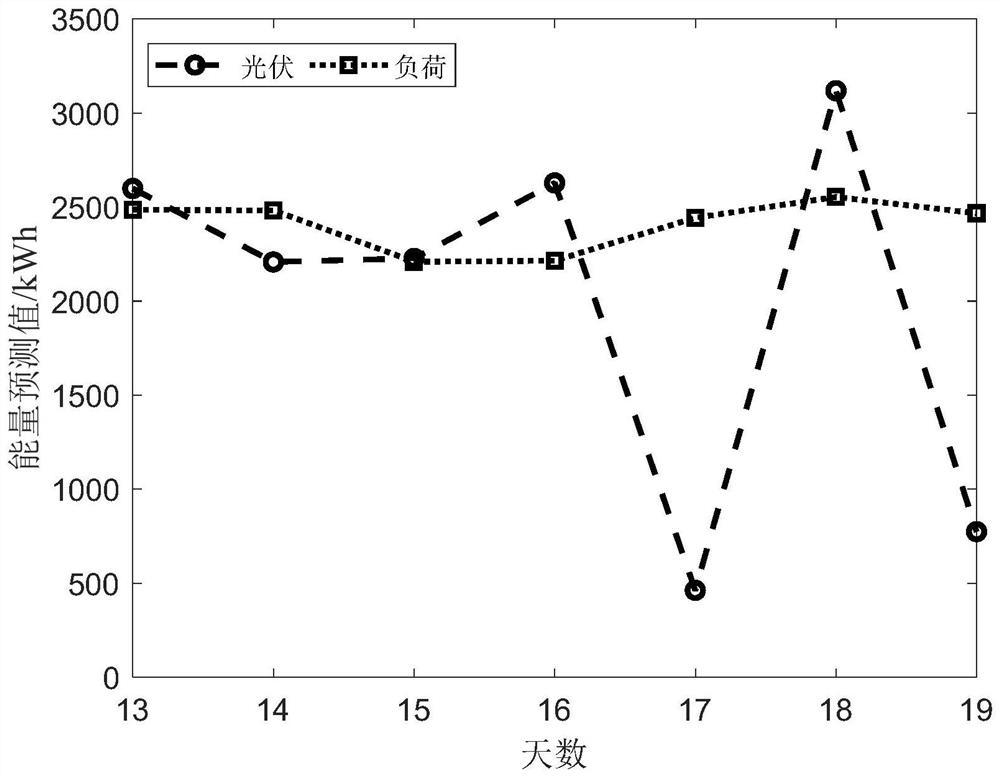

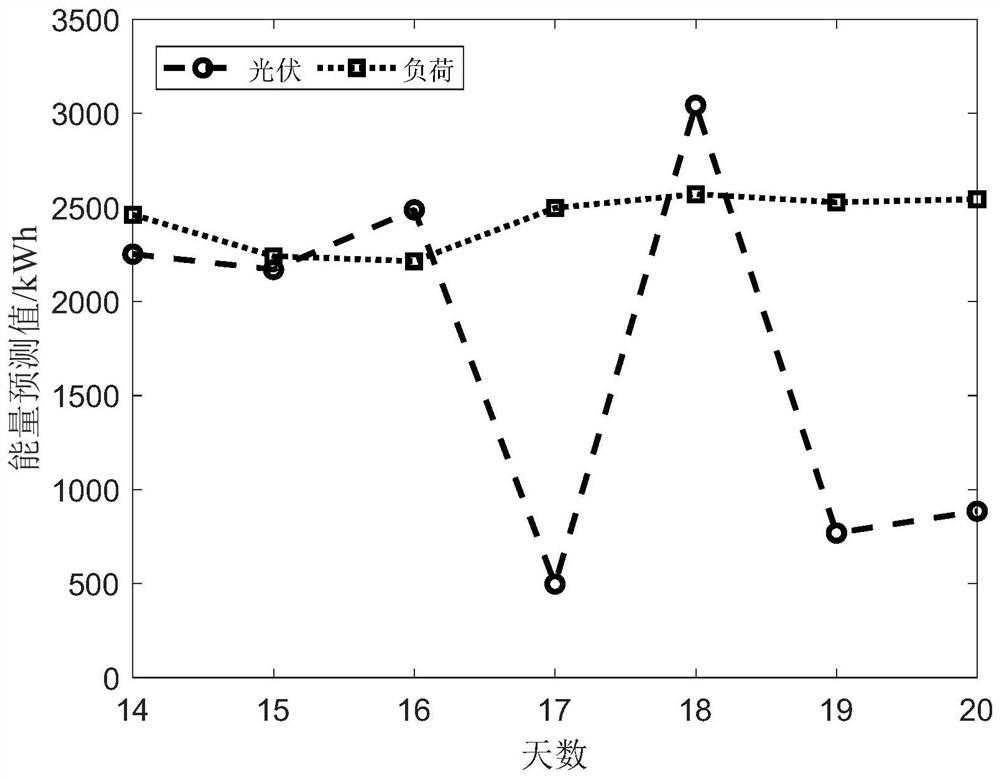

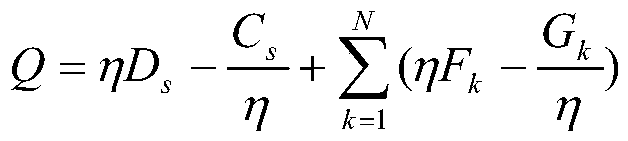

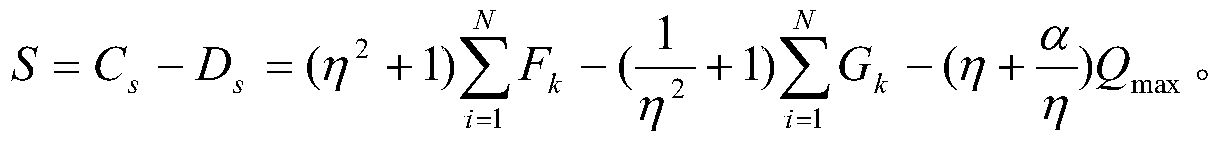

Independent micro-grid dynamic optimization scheduling method

PendingCN114336599AImprove power supply reliabilityIncrease profitSingle network parallel feeding arrangementsTechnology managementPower balancingElectric consumption

The invention discloses an independent micro-grid dynamic optimization scheduling method, which comprises the following steps of: 1, establishing a long-period energy matching evaluation and optimization model for an independent micro-grid system, and formulating a diesel oil consumption plan, an energy storage system energy storage plan and a load transfer plan within expectation; comprising the following steps: establishing objective functions about reliable power supply probability, diesel consumption and load transfer amount; setting constraint conditions of an energy storage system, diesel oil consumption and load energy transfer; 2, establishing a day-ahead stochastic optimization model based on scene analysis, and making a micro-grid hourly scheduling plan in the next day; the photovoltaic and load uncertainty is processed through a multi-scene technology, and meanwhile, the scheduling risk cost caused by the photovoltaic and load uncertainty is measured by using the conditional value-at-risk CVaR; the load transfer scheme and the standby electricity demand in the long-period energy matching evaluation and optimization stage are considered; an objective function in the day-ahead stochastic optimization model is to minimize comprehensive scheduling cost, and the comprehensive scheduling cost comprises scheduling cost and risk cost; the constraint conditions comprise a power balance constraint, an energy storage operation constraint, a diesel generator operation constraint, a load transfer constraint and a standby electricity demand constraint.

Owner:TIANJIN UNIV

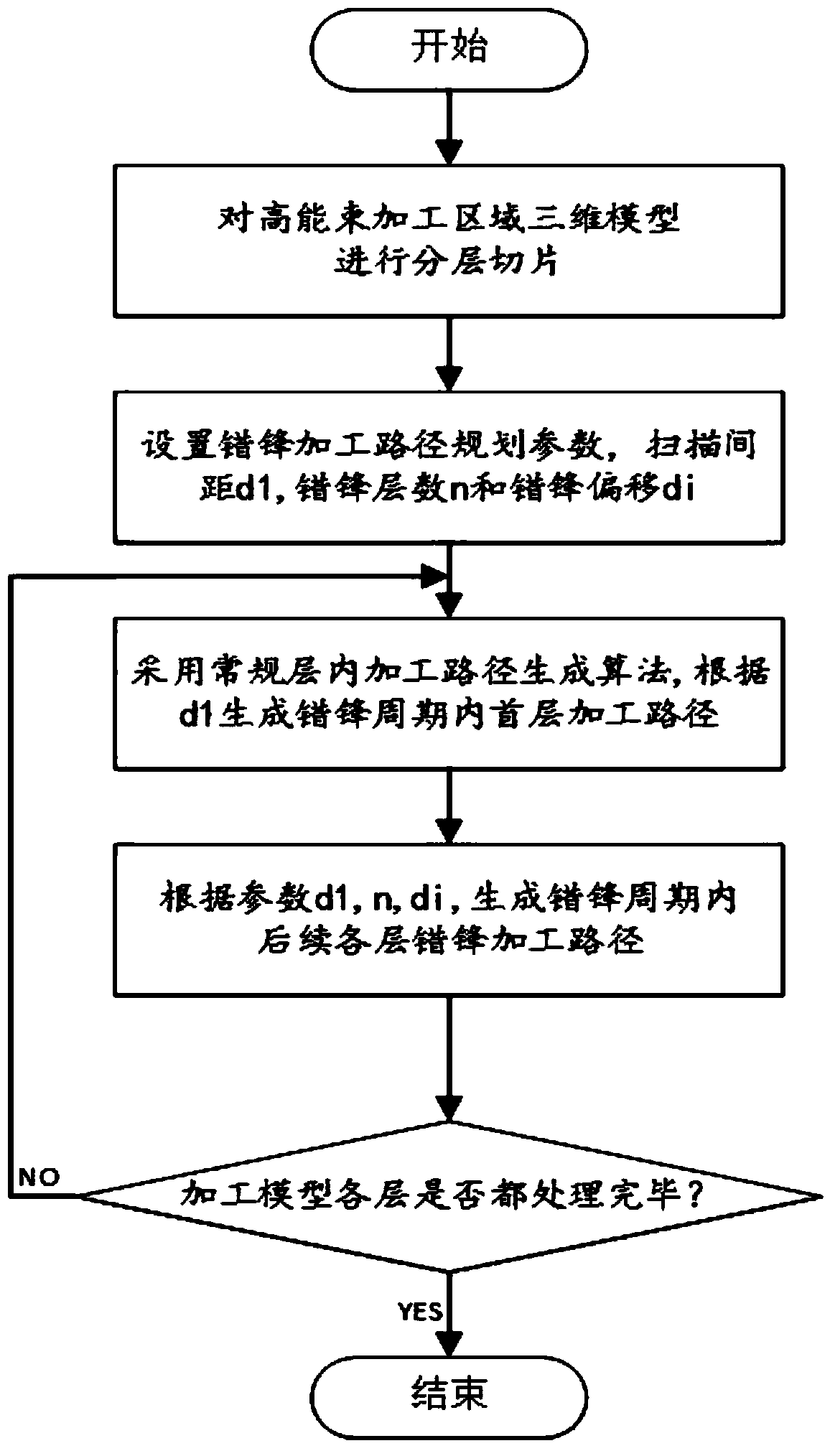

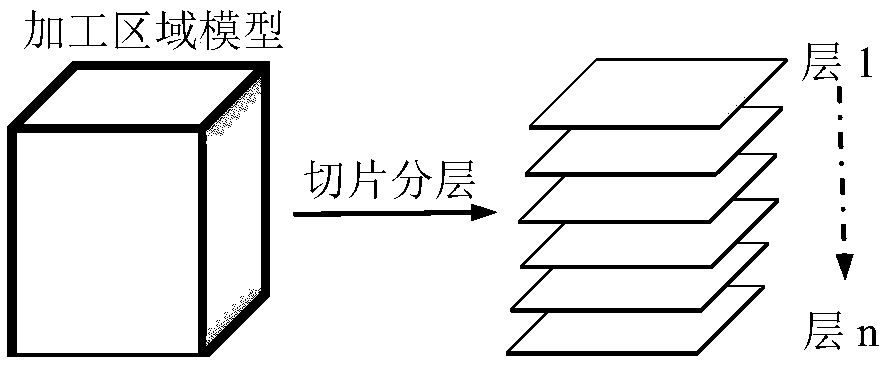

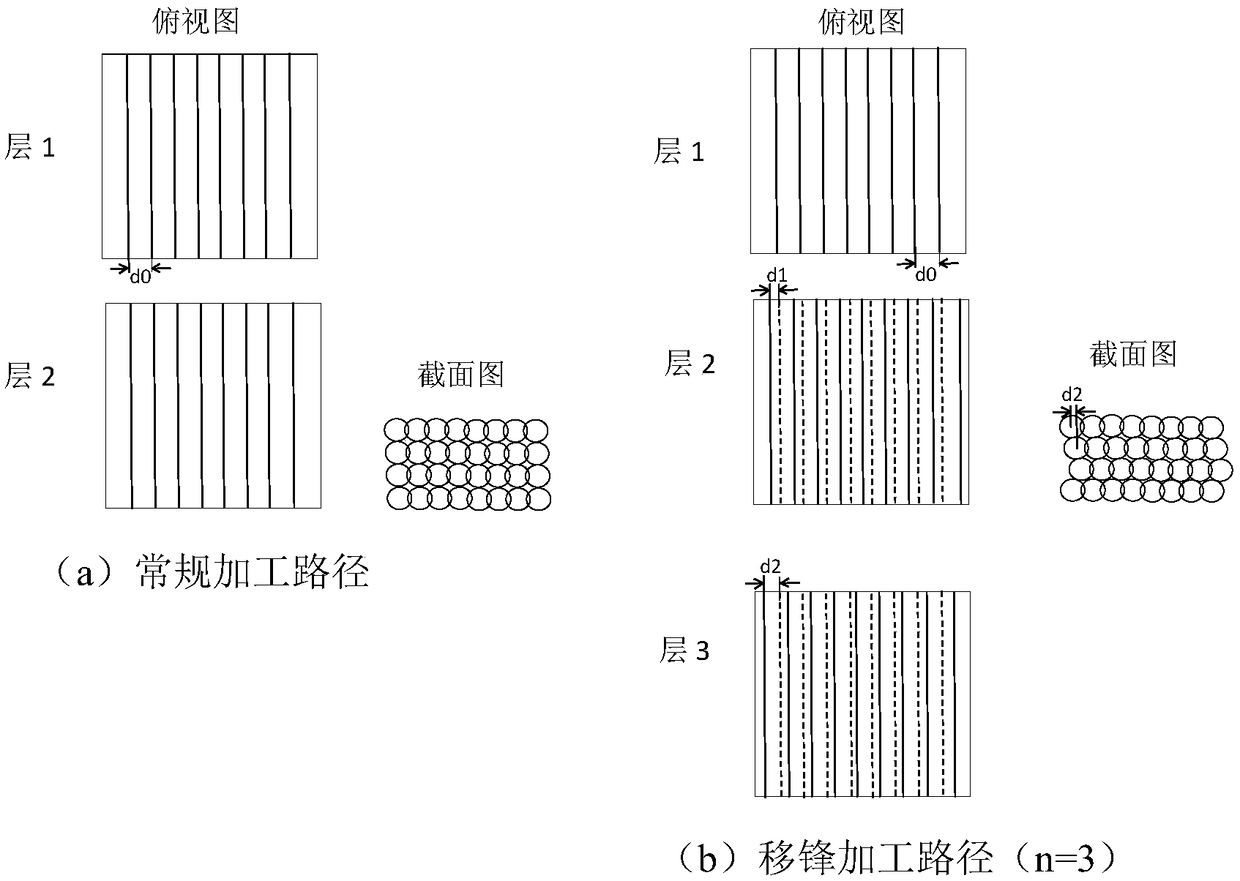

High-energy beam peak moving processing path planning method

ActiveCN108705224AImprove energy distribution uniformityOptimize energy distributionWelding/cutting auxillary devicesAuxillary welding devicesPhysicsEnergy density

The invention discloses a high-energy beam peak moving processing path planning method and belongs to the technical field of high-energy beam manufacturing. According to the high-energy beam peak moving processing path planning method, when filling scanning paths of various to-be-processed layers are generated, between the adjacent various layers, positions, highest in power, in the high-energy beam scanning paths mutually deviate by set amounts, and therefore energy distribution in the processing process is improved, and then the processing quality and precision in the additive manufacturingor subtractive manufacturing process are improved; the method includes the following steps that firstly, a processing model is subjected to layering; secondly, peak moving processing path planning parameters are set; thirdly, a processing path of a first layer in the peak moving period is generated; fourthly, processing paths of subsequent various layers in the peak moving period are generated; and fifthly, the step (3) and the step (4) are repeated till the processing paths of all the layers are generated. According to the method, by adjusting the center position deviation of the high-energybeam scanning paths of the adjacent processing layers, that is, a pointed peak is moved away, peak moving for short, energy density homogenization of processing of the plurality of layers is achieved,and the processing quality and precision are improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Interferometric optical fiber sensor based on eccentric structure and manufacturing method thereof

ActiveCN103344263BHigh extinction ratioEasy to packPhase-affecting property measurementsThermometers using physical/chemical changesSensing dataSpectrograph

Owner:HUAZHONG UNIV OF SCI & TECH

An aluminum alloy pulsed ultrasonic arc hybrid welding device and welding method thereof

InactiveCN104741805BImprove uniformityStrong penetrating powerWelding/soldering/cutting articlesWelding apparatusFull bridgeEngineering

The invention discloses an aluminum alloy pulse ultrasound and electric arc composite welding device and method. Based on ultrasound and electric arc composite welding, the device further comprises a current and voltage detection circuit, a DSP, a single chip microcomputer, a triode switch circuit and a drive circuit. The current and voltage detection circuit is connected with the output end of a matching circuit of an ultrasound generation system. The current and voltage detection circuit is connected with the DSP. The DSP is connected with the drive circuit. The single chip microcomputer is connected with the triode switch circuit. The triode switch circuit is connected with the drive circuit. The drive circuit is connected with a DC / AC full-bridge inversion circuit of the ultrasound generation system. According to the welding method, ultrasound is applied to conduct pulsing processing, and aluminum alloy pulse ultrasound and electric arc composite welding is achieved. The aluminum alloy pulse ultrasound and electric arc composite welding device and method have the advantages of ordinary ultrasound and electric arc composite welding, the electric arc stiffness can be improved, weld penetration is increased, grains are refined, the size of molten drops is reduced, transition frequency is increased, splashing is reduced, high-quality welding under a common welding environment is achieved, aluminum alloy welding pores, welding cracks and the like can be reduced effectively, the microstructure of weld metal is optimized, and the mechanical property of welding connectors is improved remarkably.

Owner:HARBIN INST OF TECH

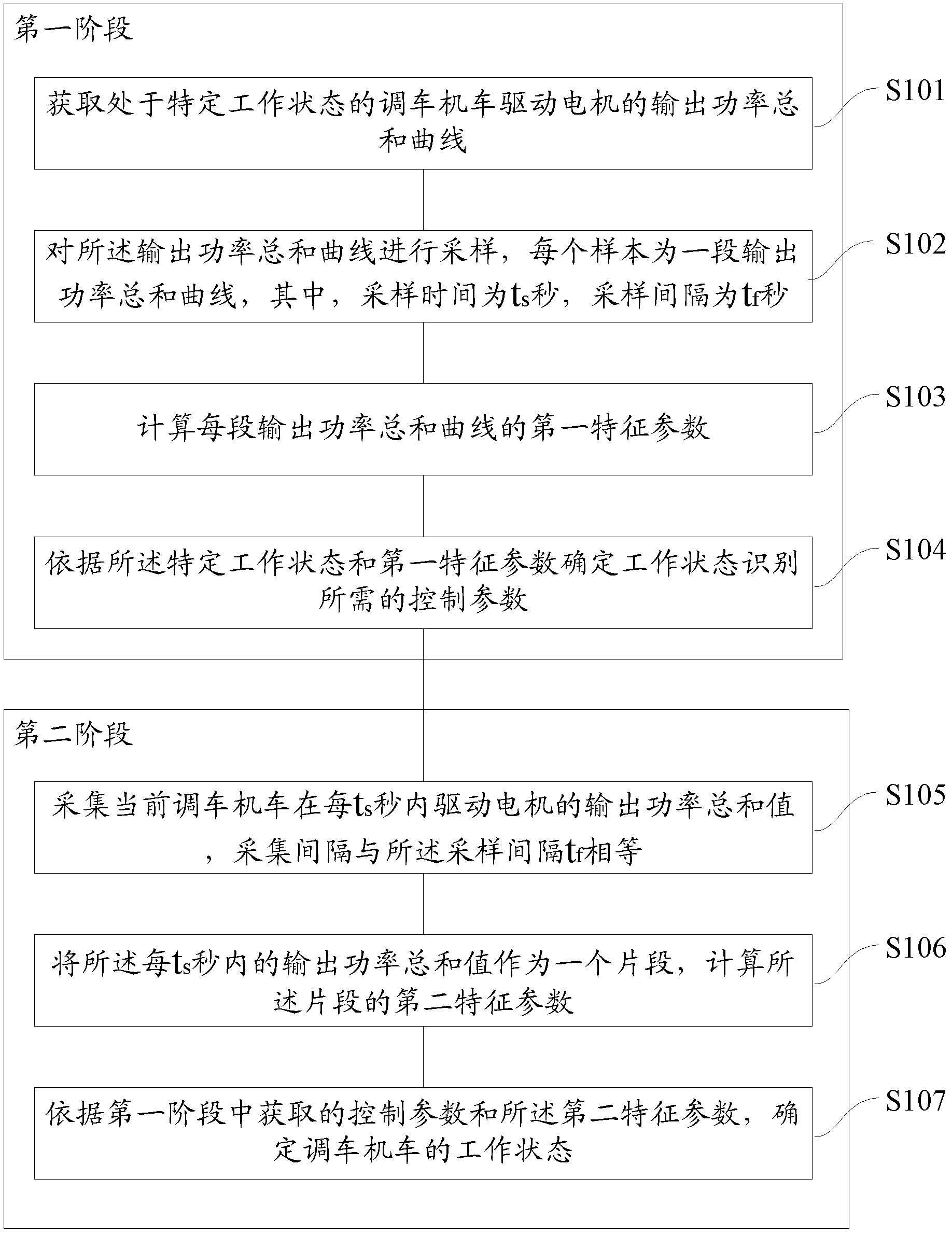

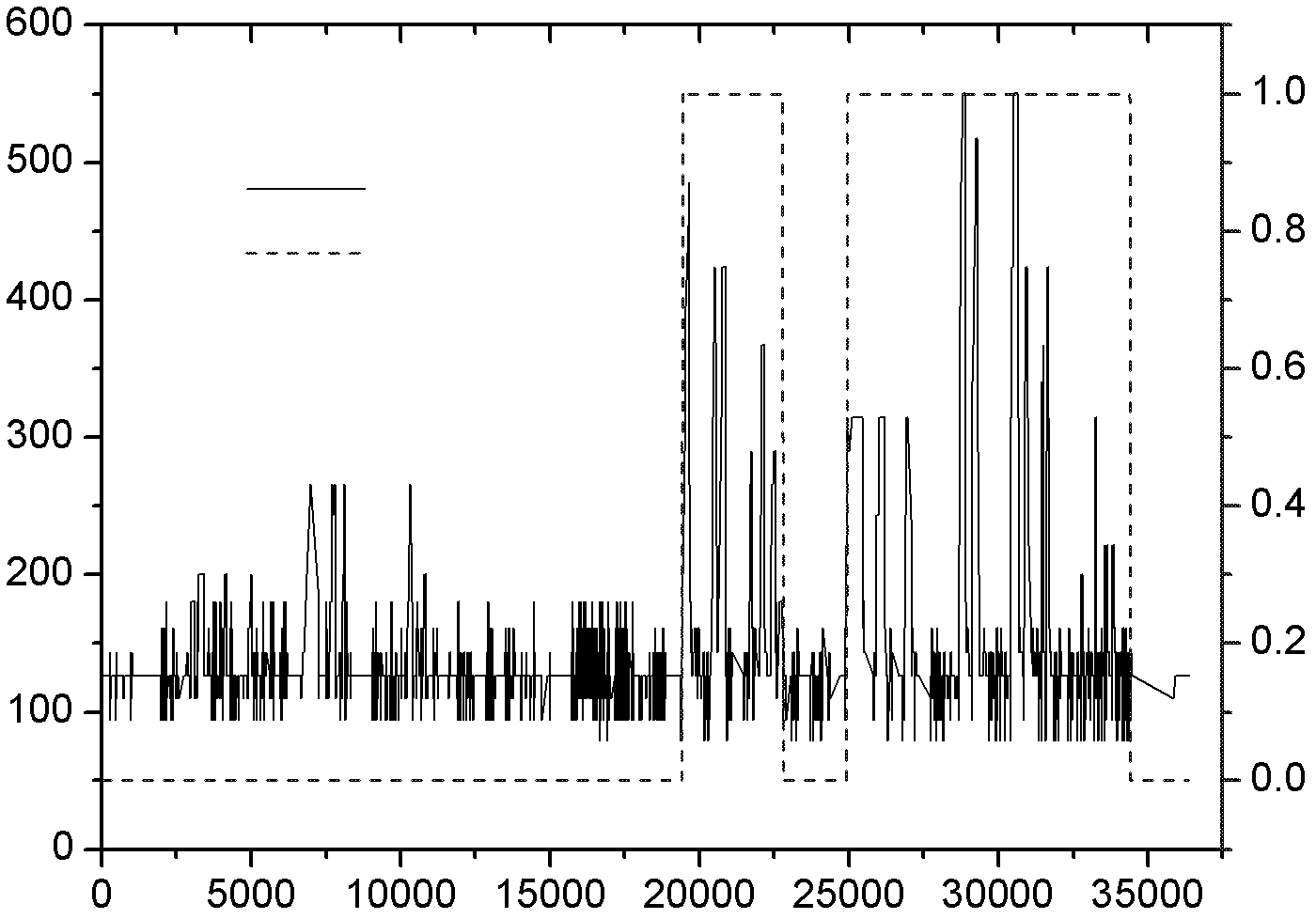

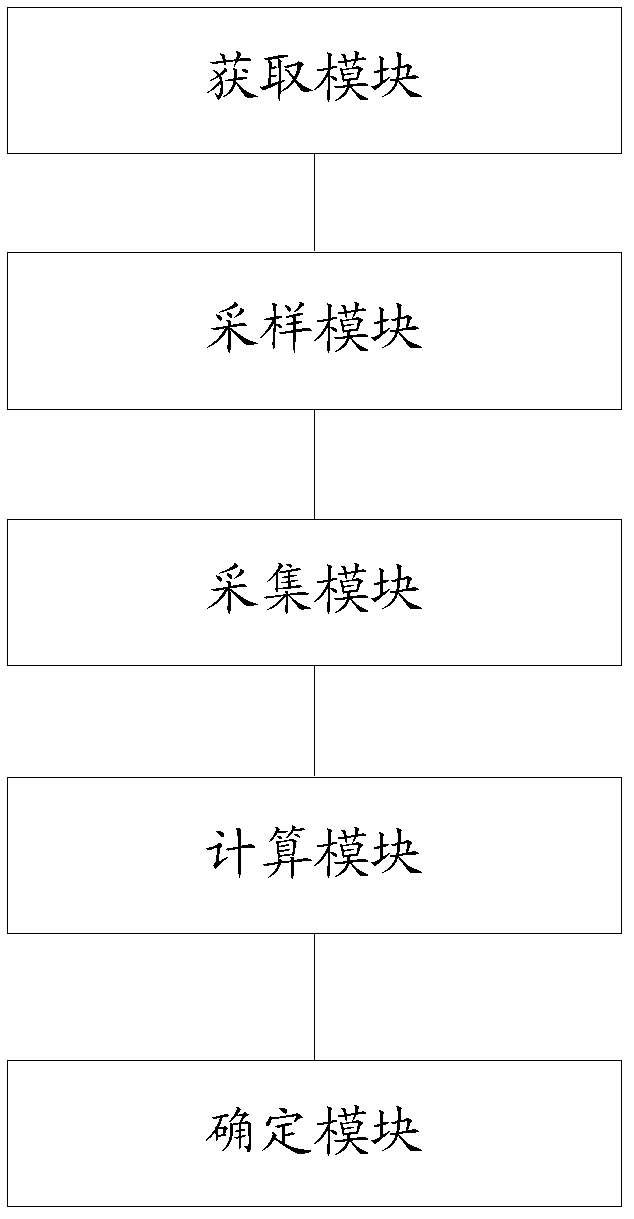

Method and system for recognizing working conditions of hybrid-power shunting engine

InactiveCN102556083AOptimize energy distributionImprove fuel economyHybrid vehiclesLocomotivesElectric machineDrive motor

The invention provides a method and a system for recognizing working conditions of a hybrid-power shunting engine. The recognizing method includes: a first stage: obtaining an output power sum curve of the shunting engine in a specific working state; sampling the output power sum curve, wherein each sample is a section of output power sum curve, sampling time is ts seconds, and sampling interval is tf seconds; calculating a first characteristic parameter of each section of output power sum curve; and confirming control parameters required by working state recognition according to the specific working state and the first characteristic parameter; and a second stage: collecting output power sum value of a driving motor in each ts second of the current shunting engine, wherein collecting gap is equal to the sampling interval tf; enabling the output power sum value in each ts second to be a segment, and calculating a second characteristic parameter of the segment; and confirming working state of the shunting engine according to the control parameter acquired in the first stage and the second characteristic parameter.

Owner:BEIJING JIAOTONG UNIV

Steel-aluminum alloy laser welding method adopting nickel-based high-entropy alloy intermediate layer

PendingCN114406469AReduce thicknessReduce interdiffusionWelding/soldering/cutting articlesLaser beam welding apparatusMolten stateMetal foil

The invention relates to a steel-aluminum alloy laser welding method adopting a nickel-based high-entropy alloy intermediate layer, and belongs to the technical field of dissimilar material welding. And a nickel-based high-entropy alloy metal foil is used as a middle layer material. The high entropy effect and the high thermal resistance effect of the nickel-based high-entropy alloy metal foil control that no intermetallic compound is generated in a weld fusion area, and the intermetallic compound is only generated at the interface of the fusion area and the aluminum alloy. And by adding the nickel element and the silicon element, generation of Fe-Al intermetallic compounds at the interface is reduced, a Ni-Al-Si phase with better toughness is generated, the metallurgical reaction at the interface is improved, and then the mechanical property of the joint is improved. Laser beams A, B and C are adopted for simultaneous welding, the connecting area of the interface of the steel plate and the aluminum alloy plate is increased, and it is ensured that aluminum in the molten state fully wets and spreads the interface. The anti-shearing strength of a lap joint is improved; and meanwhile, the defects such as cracks and air holes are avoided.

Owner:JILIN UNIV

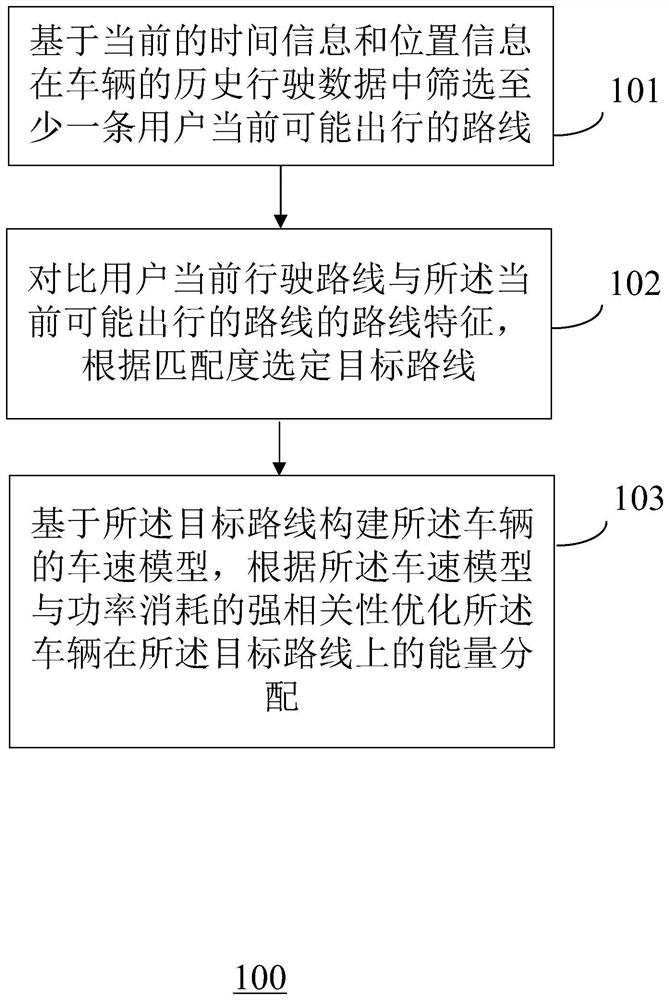

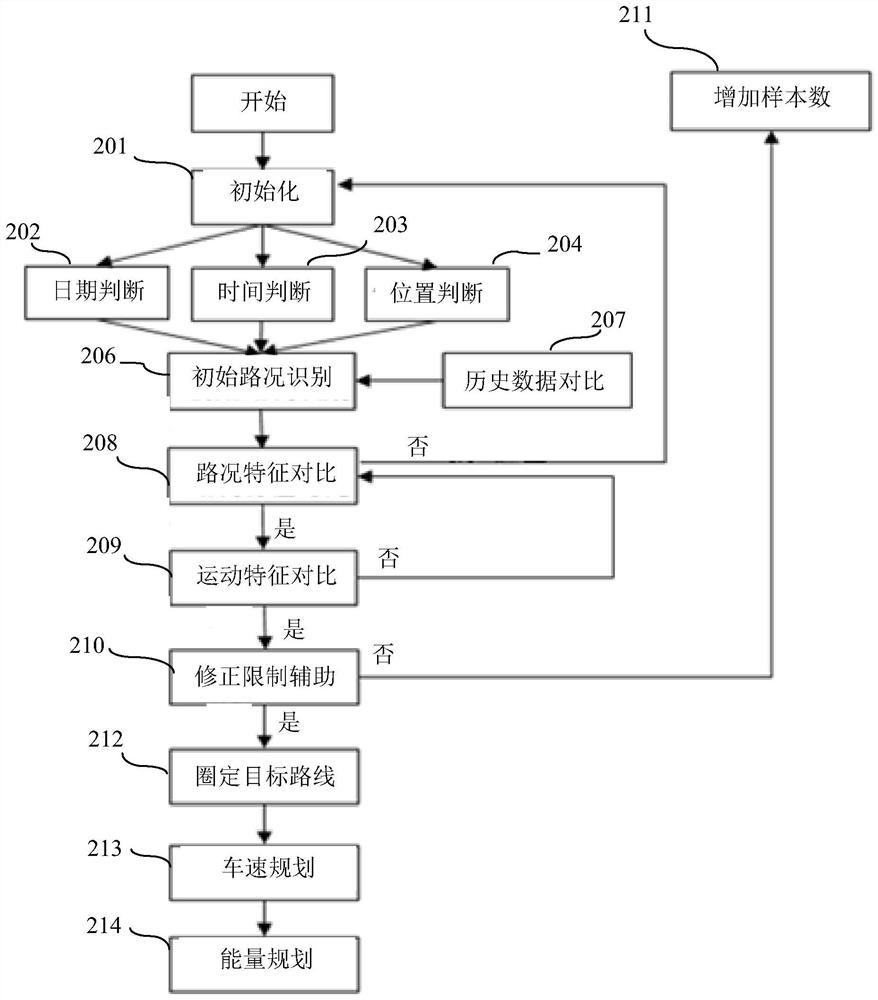

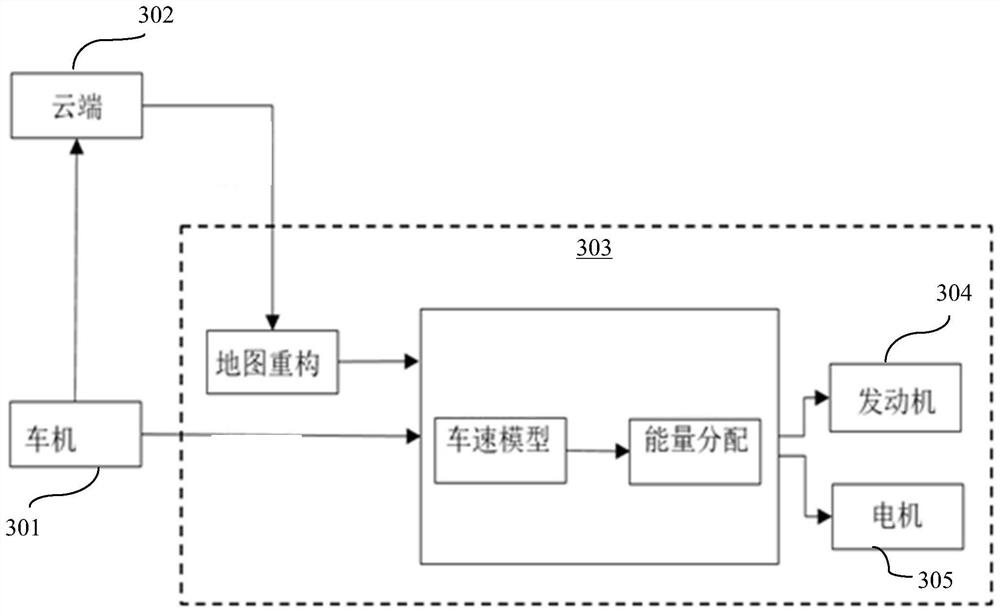

Vehicle energy management method and device

PendingCN114701479AOptimize energy distributionHybrid vehiclesExternal condition input parametersTime informationComputer science

The invention provides a vehicle energy management method and device. The method comprises the following steps: screening at least one current possible travel route of a user from historical driving data of a vehicle based on current time information and position information; comparing the current driving route of the user with the route characteristics of the current possible travel route, and selecting a target route according to the matching degree; and constructing a vehicle speed model of the vehicle based on the target route, and optimizing the energy distribution of the vehicle on the target route according to the strong correlation between the vehicle speed model and the power consumption.

Owner:HOZON NEW ENERGY AUTOMOBILE CO LTD

Coaxially arranged mode converters

ActiveUS10662747B2Improve productivityReduce dependenceInsulationFluid removalConvertersSoftware engineering

The present invention relates to a device for generating a disturbance in the differential mode of propagation of an RF signal transmitted along a coaxial transmission line.

Owner:ENI SPA

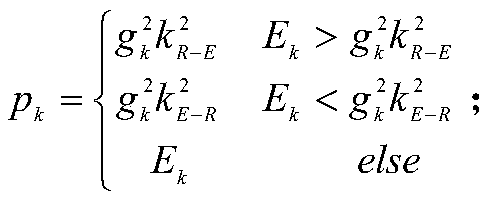

Dynamic power distribution method of EH distributed base station system

ActiveCN110677913AContributes to homeostasisOptimize energy distributionHigh level techniquesWireless communicationDistribution methodPower grid

The invention discloses a dynamic power distribution method based on an EH distributed base station system. The purpose of the invention is to ensure that the energy collected by the EH remote antennaunit can be used by itself. Redundant energy can be conveyed to the energy sharing pool; and the energy sharing pool is shared by other EH remote antenna units, and whether the energy sharing pool transactions with the intelligent power grid is determined according to the amount of energy in the energy sharing pool, so that dynamic change of an energy transmission rate threshold value between theEH remote antenna units and the energy sharing pool and dynamic distribution of power are realized. According to the invention, dynamic balance of energy utilization is facilitated, and the performance of the system is improved.

Owner:GUANGXI NORMAL UNIV

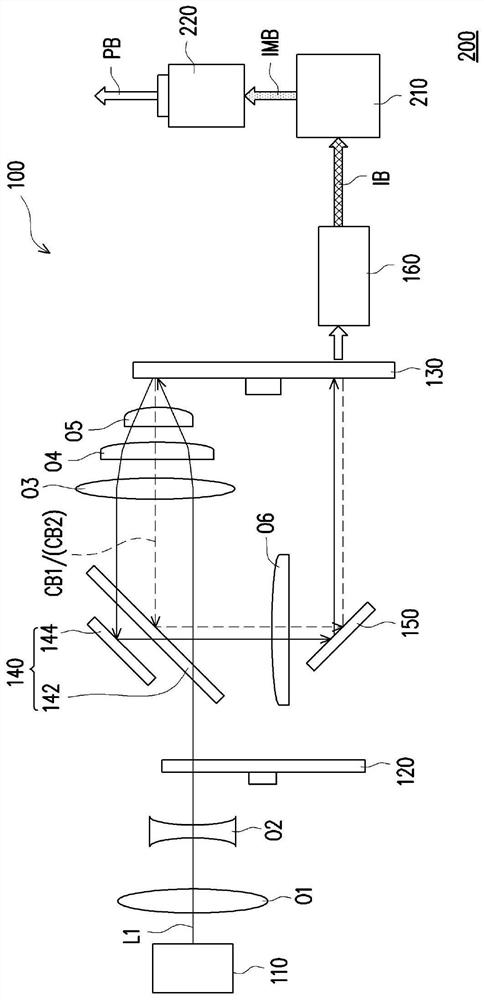

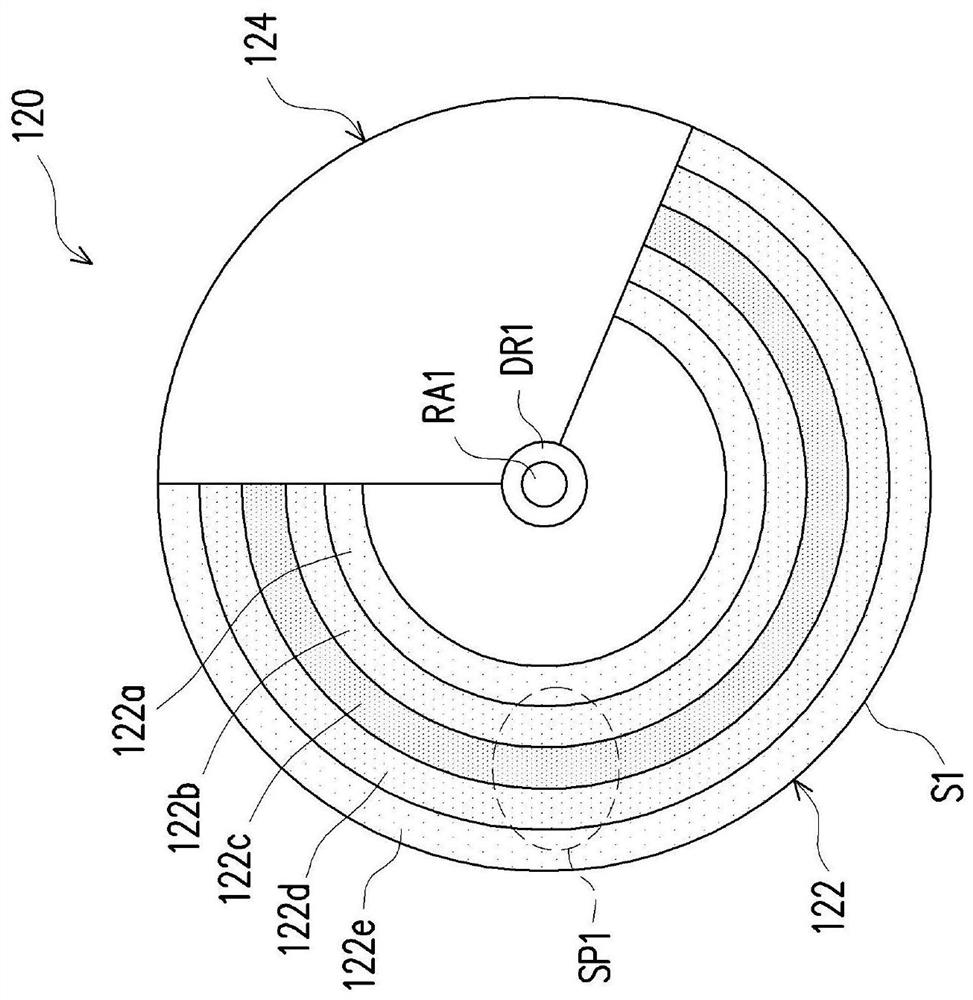

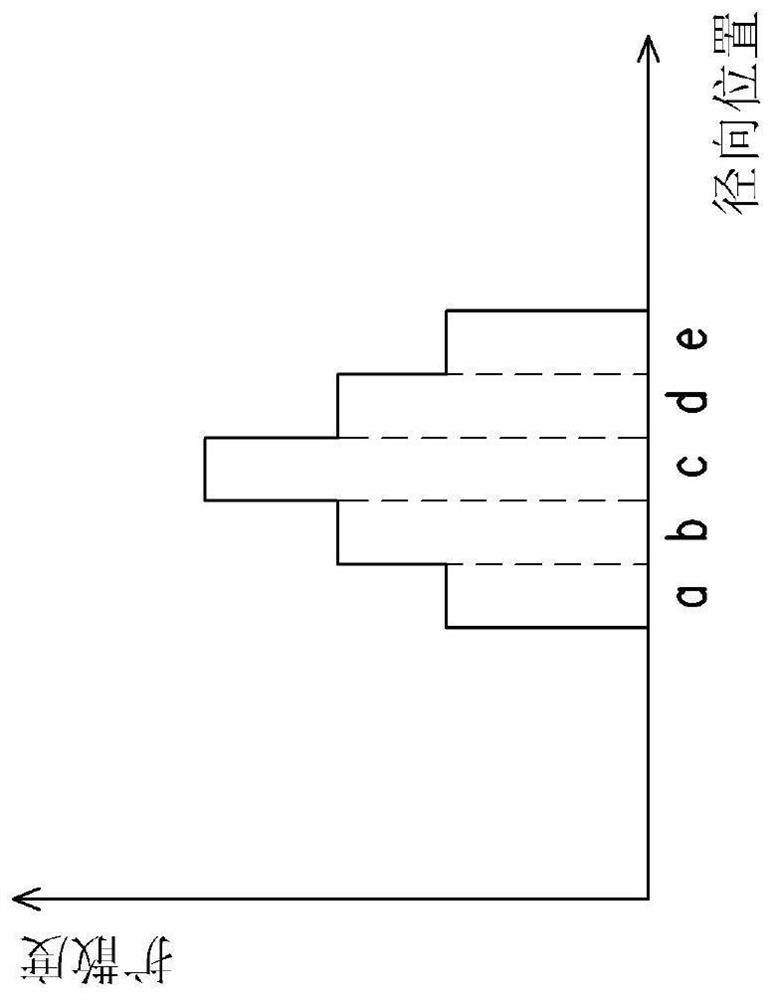

Diffusion rotating device and projection device

PendingCN112241101AOptimize energy distributionImprove optical efficiencyProjectorsOptical elementsLight beamFirst light

The invention discloses a diffusion rotating device which is arranged on a transmission path of a light beam. The diffusion rotating device comprises a substrate, a rotating shaft and a driving element. The rotating shaft is connected to substrate. The driving element is connected to the rotating shaft and used for driving the rotating shaft to rotate. The substrate comprises a first diffusion region and an optical region which are adjacently arranged, the first diffusion region is provided with a plurality of first diffusion sub-regions, and each first diffusion sub-region extends along the circumferential direction of the substrate and the plurality of first diffusion sub-regions are concentrically arranged along the radial direction of the substrate; when the first diffusion region cutsinto a transmission path of a light beam, the light beam forms a first light spot on the first diffusion region of the substrate; in the radial direction of the substrate, the diffusivity of the first diffusion sub-region corresponding to the central part of the first light spot in the plurality of first diffusion sub-regions is greater than the diffusivity of the first diffusion sub-region corresponding to the edge part of the first light spot. A projection device is also provided. Therefore, the projection device applying the diffusion rotating device has good optical efficiency.

Owner:CORETRONIC

Process for carrying out strengthening circulation, stage grinding and quality improvement on lignite by utilizing superheated steam and system thereof

ActiveCN101870897BOptimize energy distributionMaximize energy utilizationCombination devicesDrying solid materials with heatFlue gasProcess engineering

The invention relates to a process for carrying out strengthening circulation, stage grinding and quality improvement on lignite by utilizing superheated steam and a system thereof. The method comprises the following steps: (1) carrying out grinding on the raw material lignite; (2) burning one part of coal blocks / powder to produce high-temperature flue gas serving as a heat source and carrying out air separation and dring on the other part of coal blocks / powder requiring to be subjected to quality improvement; (3) in the process of air separation, adopting the high-temperature flue gas from the step (2), carrying out drying, separation and dust removal on the qualified coal blocks / powder conforming to the standard grain diameter after air separation, collecting the qualified coal blocks / powder, sending the qualified coal blocks / powder to the forming process, making the unqualified coal blocks / powder drop in a grinding ventilating device to carry out grinding and drying, then continuously completing deep drying by air separation and repeating the steps, wherein the oxygen content in the flue gas is less than 8 percent; and (4) sending one path of waste gas subjected to air separation and drying to the washing process and returning the other path of waste gas serving as a return tail gas part to the step (2) so as to prepare the high-temperature flue gas and carry out air separation. The process has the advantages of safety, energy saving, environment protection, high efficiency, stability and the like.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

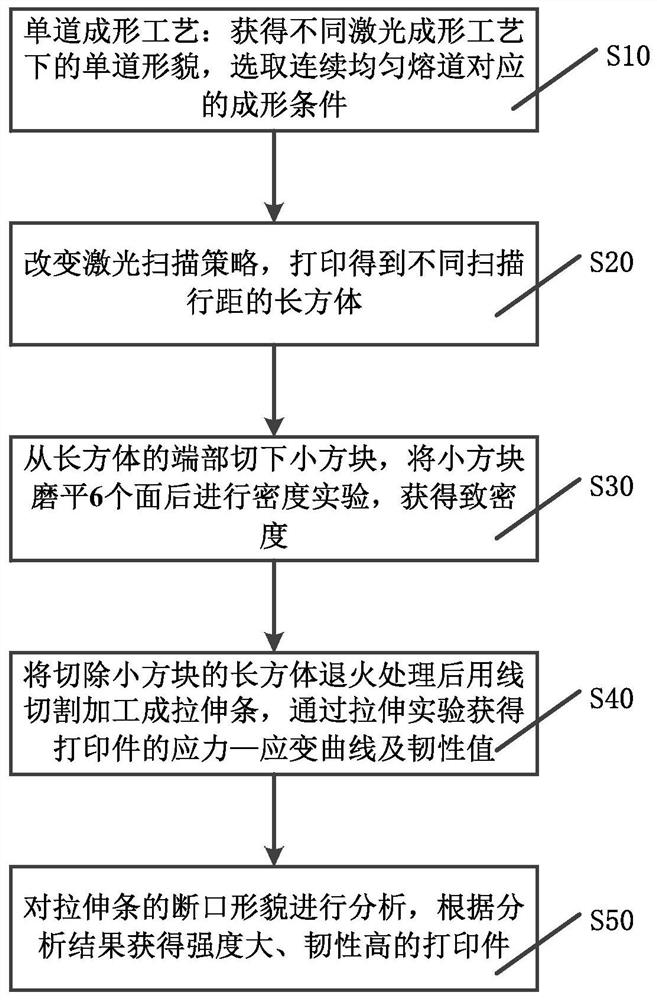

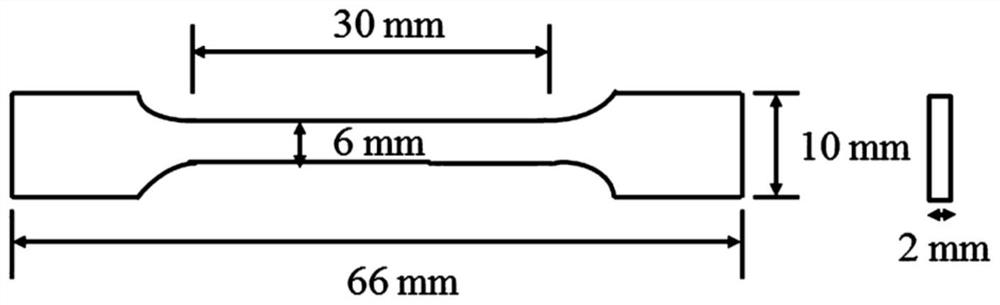

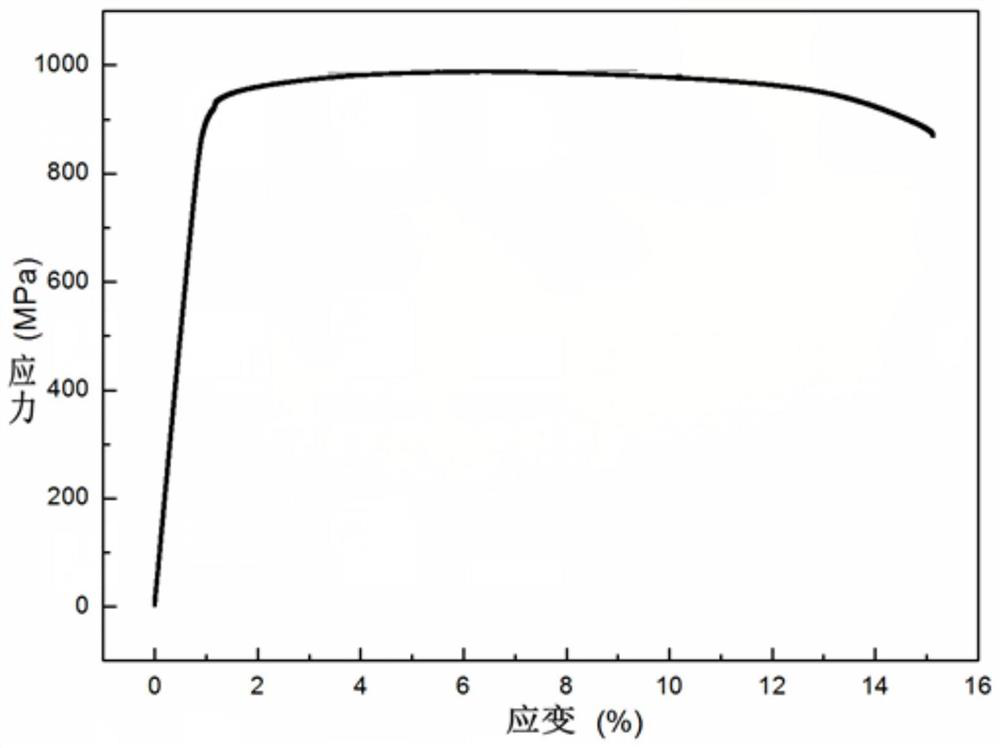

A method for improving the toughness of additively manufactured prototypes

ActiveCN111185598BImprove toughnessImprove surface accuracyAdditive manufacturing apparatusIncreasing energy efficiencyLaser scanningWire cutting

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com