Patents

Literature

1887 results about "Weld metal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Weld metal. noun. : the part of the metal of a welded joint that has been fused in its formation.

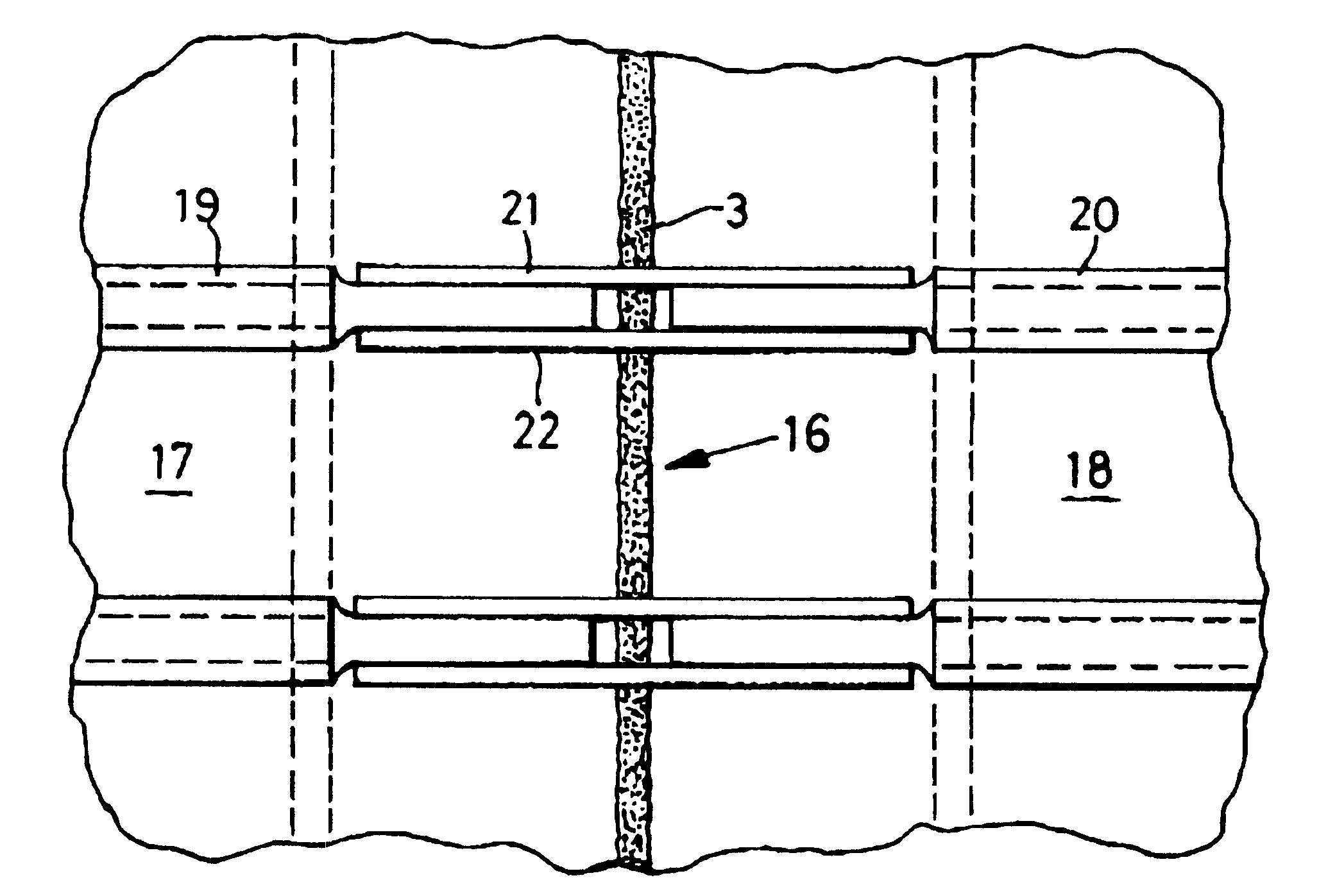

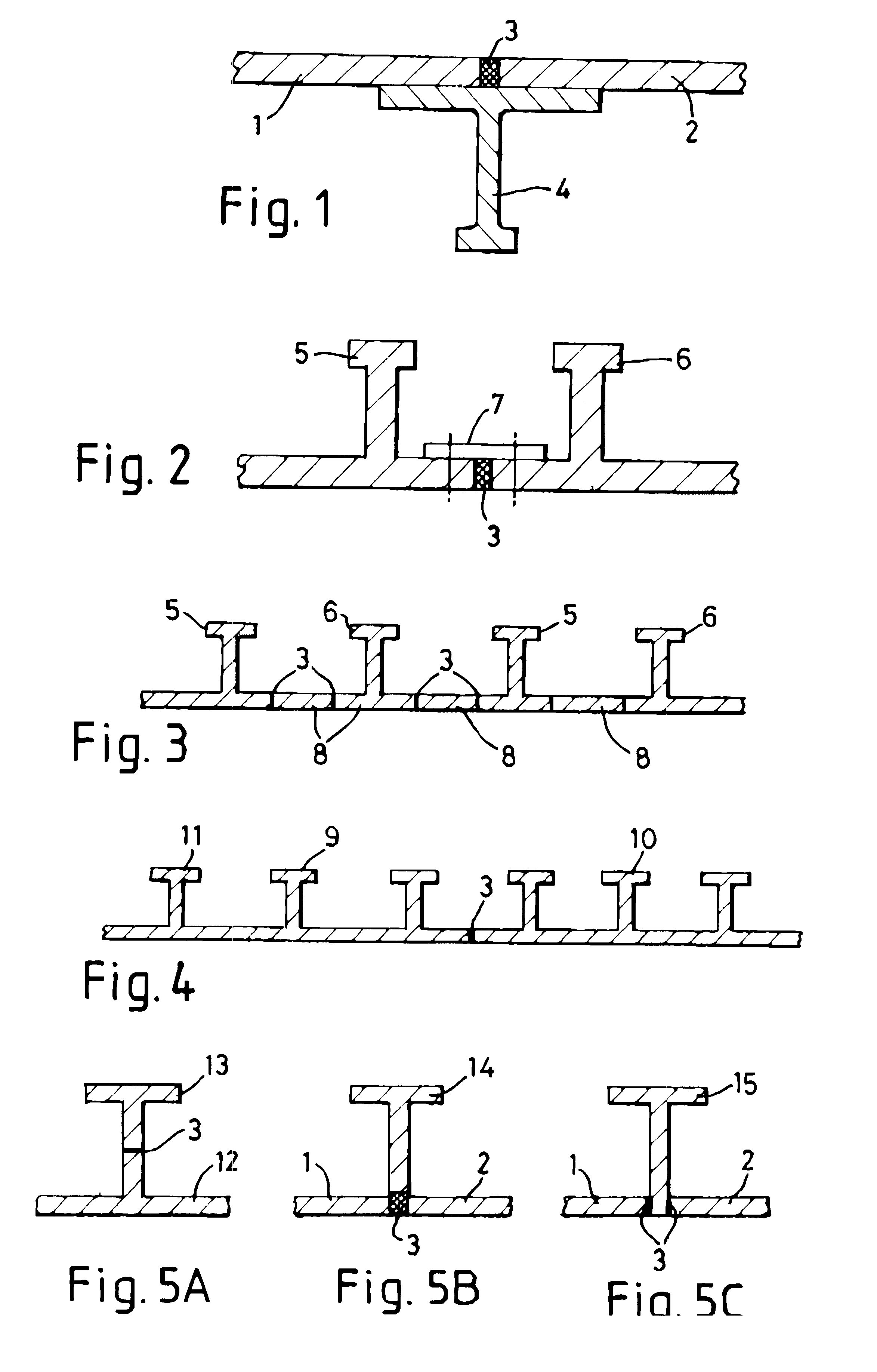

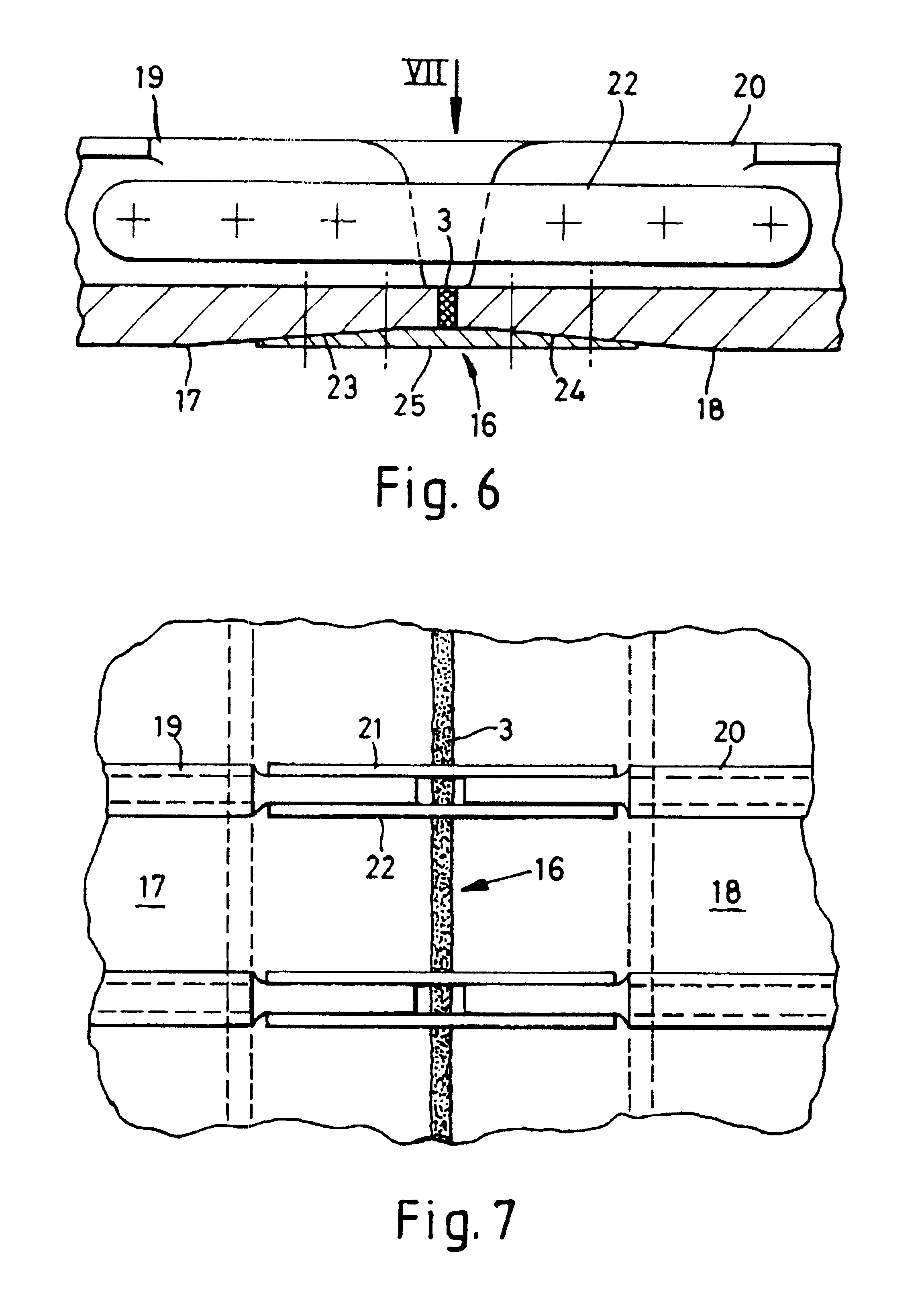

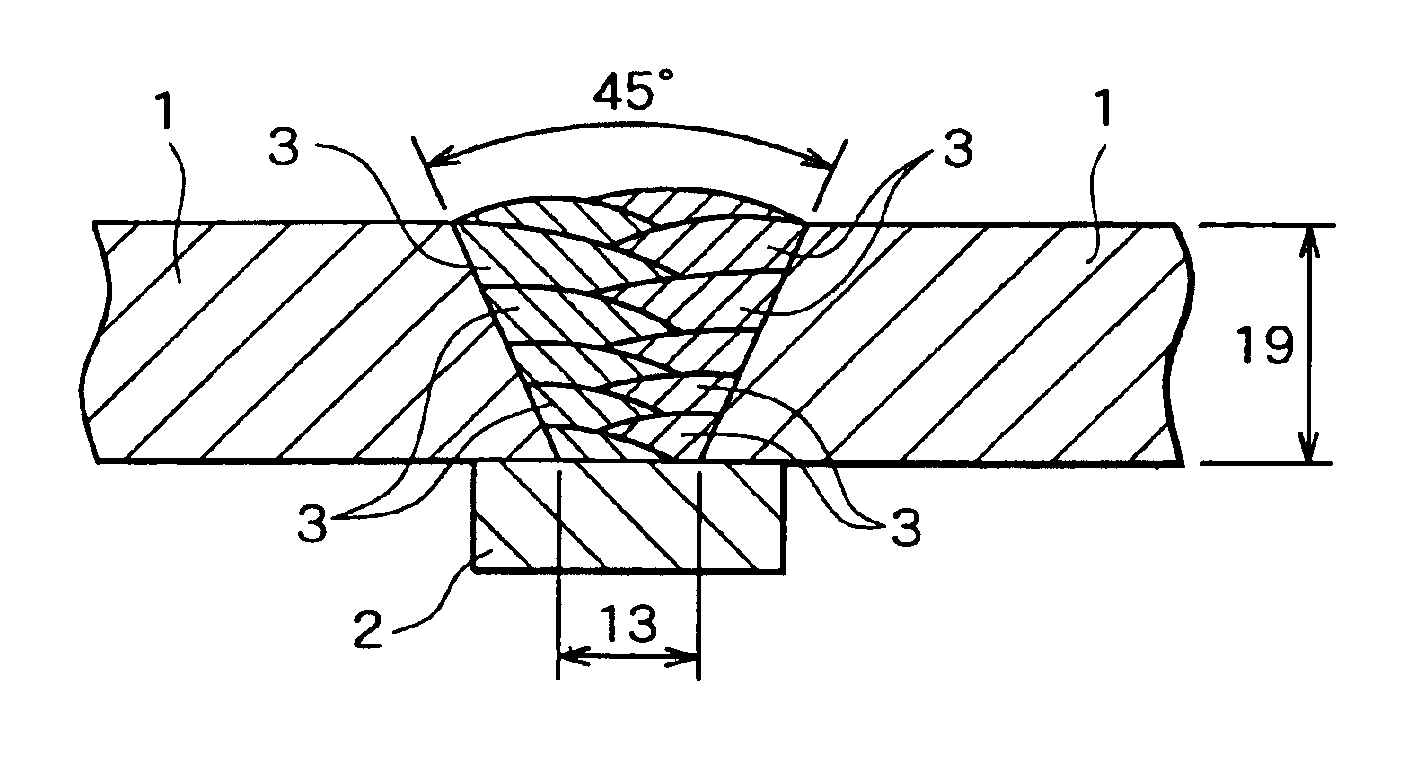

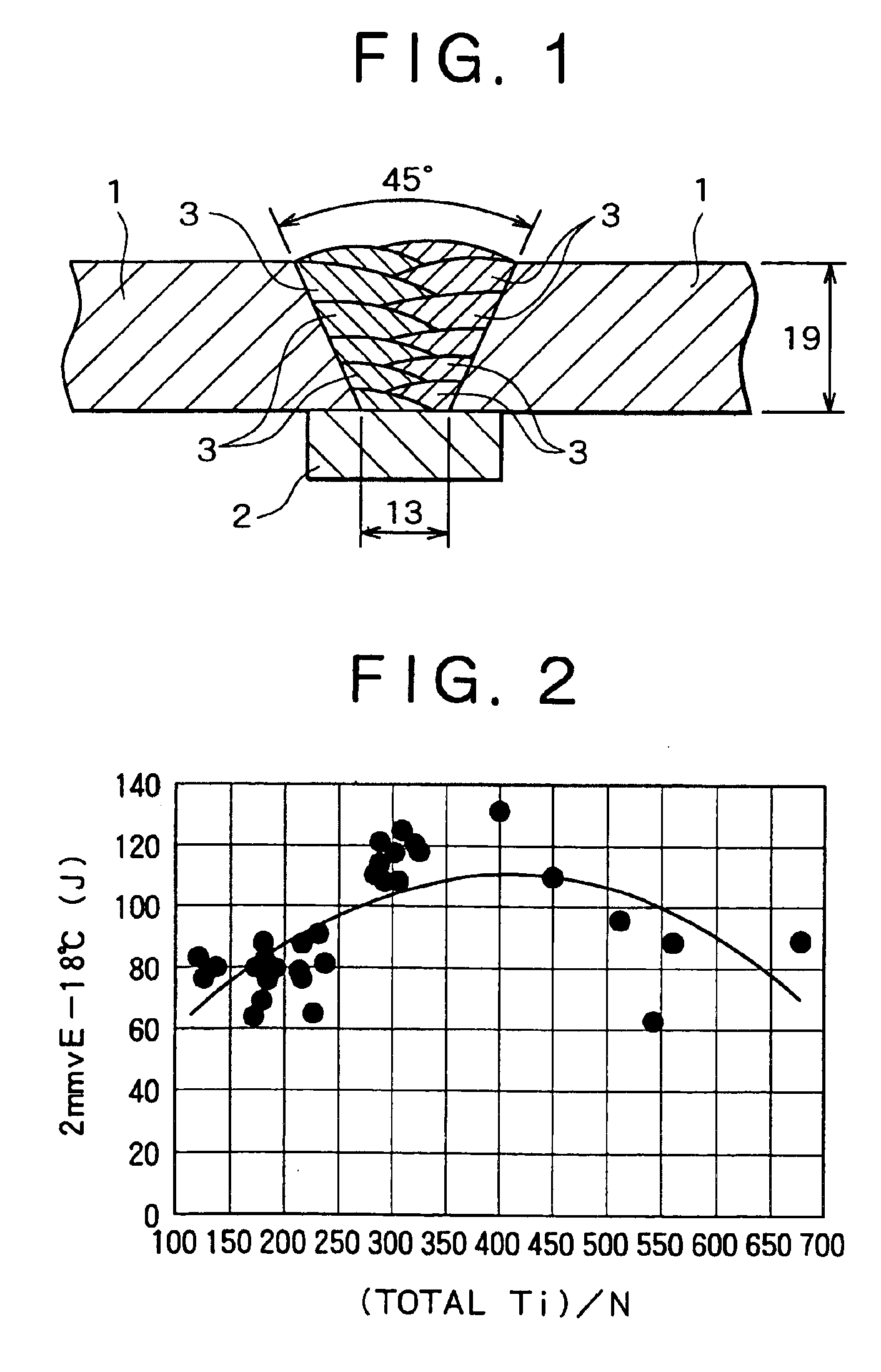

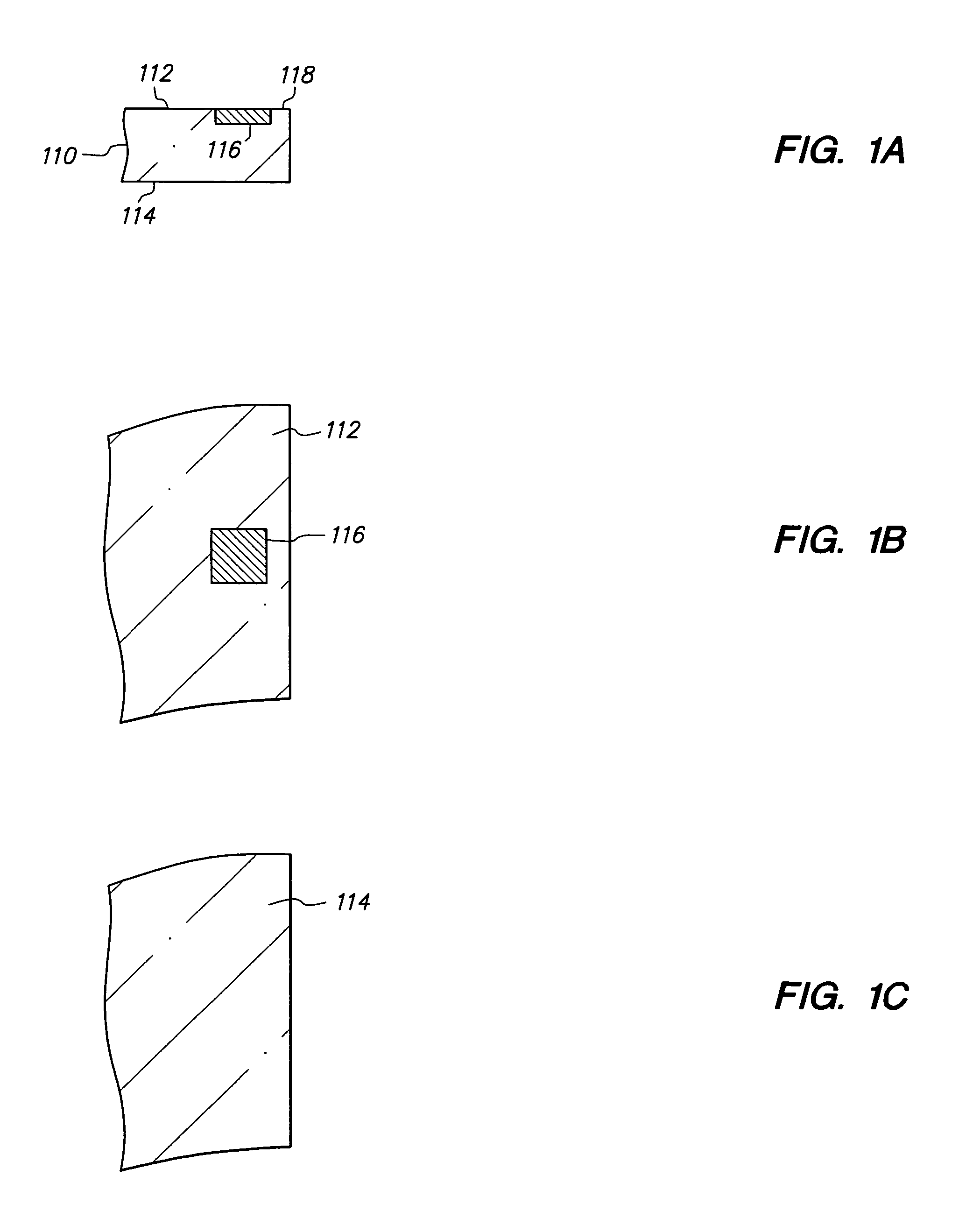

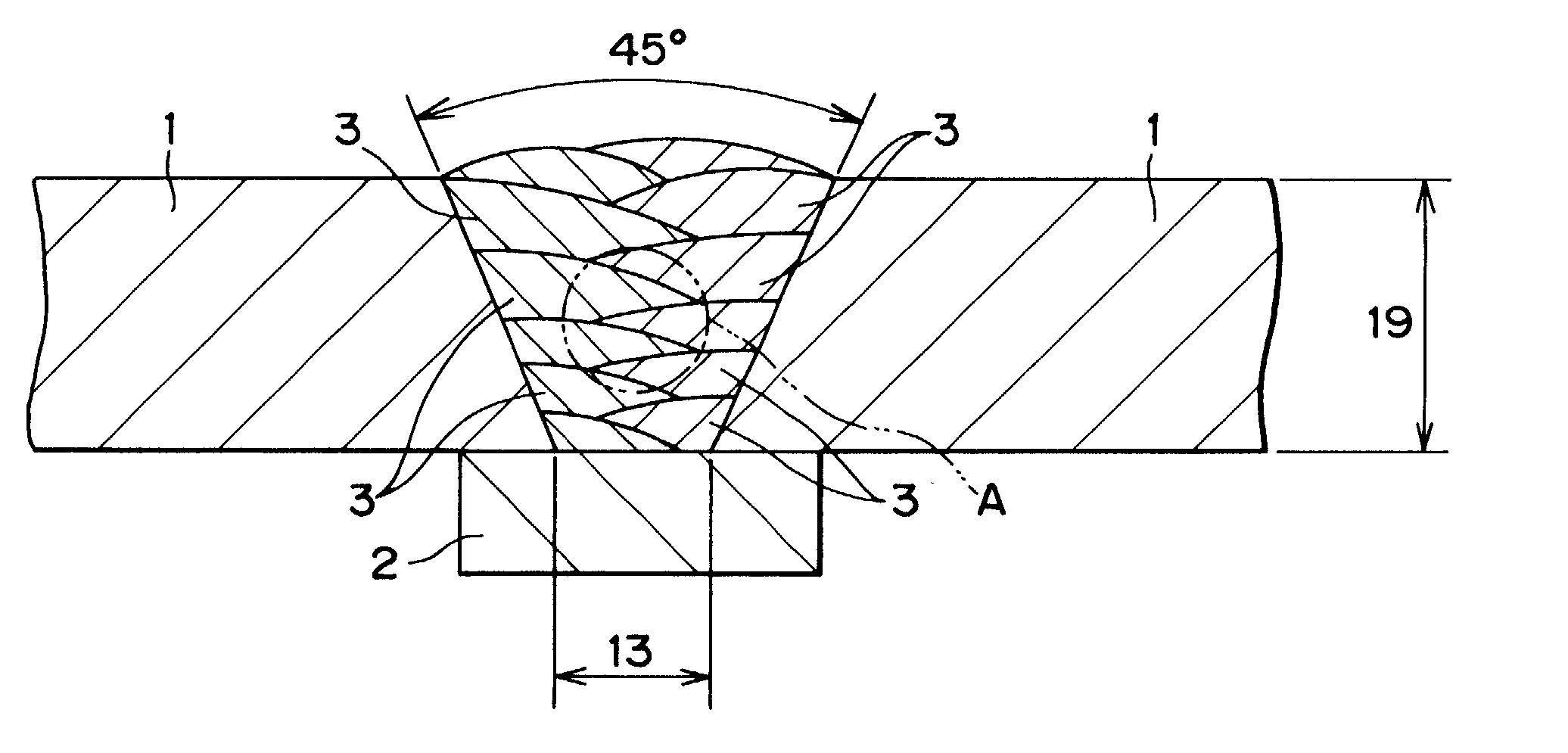

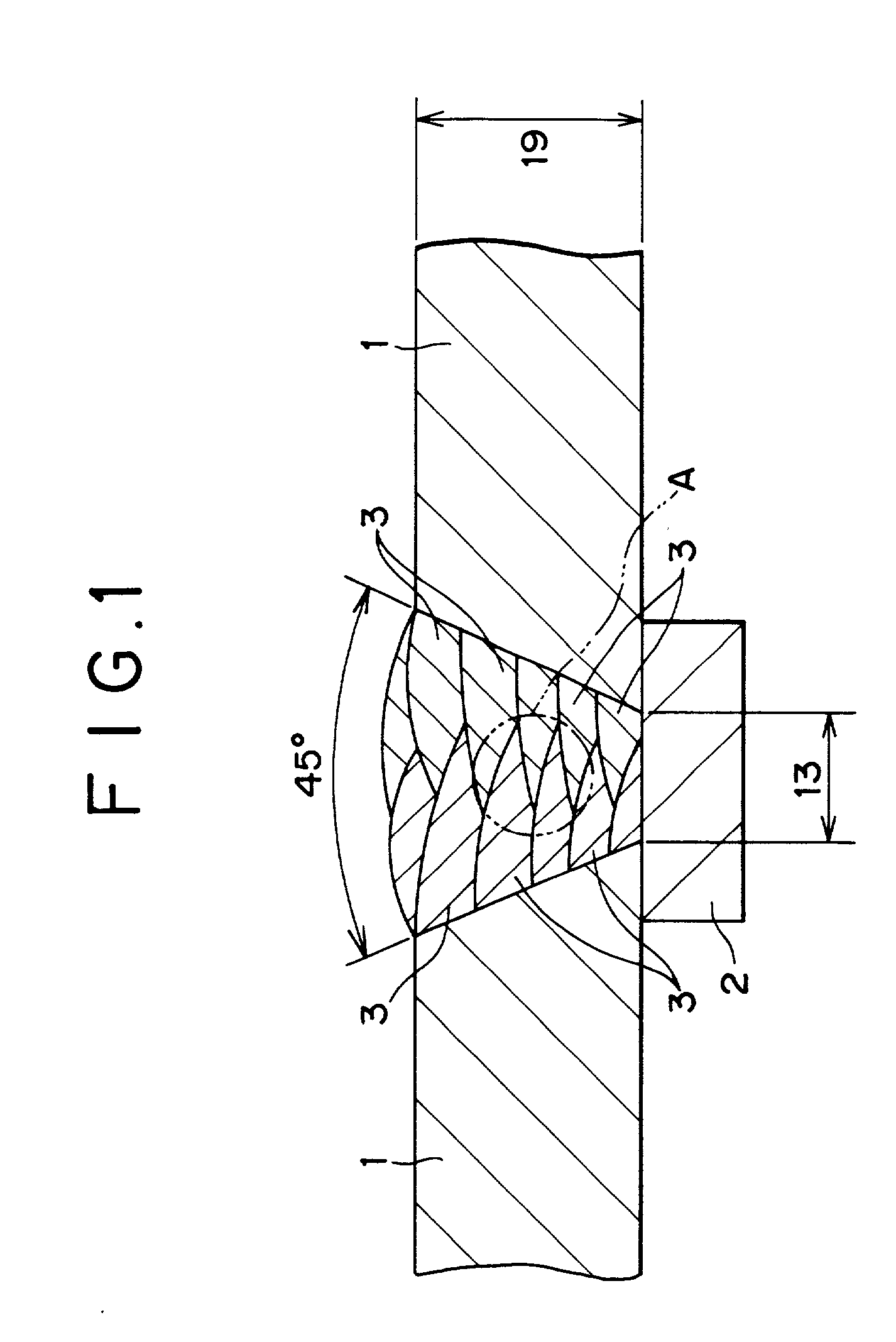

Friction welding metal components

InactiveUS6328261B1Additions can be avoidedPrevent skinFuselage framesWingsFriction weldingButt welding

A method of forming a structural airframe component for an aircraft and an airframe structural component The method includes placing at least two components (1,2) in abutting relationship with each other and joining them together by friction stir butt welding (3), and the structural airframe component comprises a component manufactured according to the method of the invention.

Owner:AIRBUS OPERATIONS LTD

Process for welding

InactiveUS7170032B2Long electrode lifeEvacuating shieldingWelding/cutting media/materialsElastomerShielding gas

A welding process for non-stainless steel workpieces using GTAW equipment and hydrogen containing shield gas on a first root pass is improved by using a shield gas delivery system comprising hoses or conduits made of elastomeric material having a moisture permeability coefficient of less that 275, preferably less than 100, and using a tungsten electrode composition comprising at least tungsten and lanthanum oxide, and preferably tungsten, lanthanum oxide, yttrium oxide and zirconium oxide. Preventing moisture permeation through the elastomeric hoses delivering hydrogen containing shield gas eliminates expulsion of fused weld metal during second pass filler welding over the root pass weld. Electrode life is enhanced using the tungsten compounds.

Owner:JV IND CO LLC

Process for welding

InactiveUS20050109735A1Long electrode lifeEvacuating shieldingWelding/cutting media/materialsElastomerShielding gas

A welding process for non-stainless steel workpieces using GTAW equipment and hydrogen containing shield gas on a first root pass is improved by using a shield gas delivery system comprising hoses or conduits made of elastomeric material having a moisture permeability coefficient of less that 275, preferably less than 100, and using a tungsten electrode composition comprising at least tungsten and lanthanum oxide, and preferably tungsten, lanthanum oxide, yttrium oxide and zirconium oxide. Preventing moisture permeation through the elastomeric hoses delivering hydrogen containing shield gas eliminates expulsion of fused weld metal during second pass filler welding over the root pass weld. Electrode life is enhanced using the tungsten compounds.

Owner:JV IND CO LLC

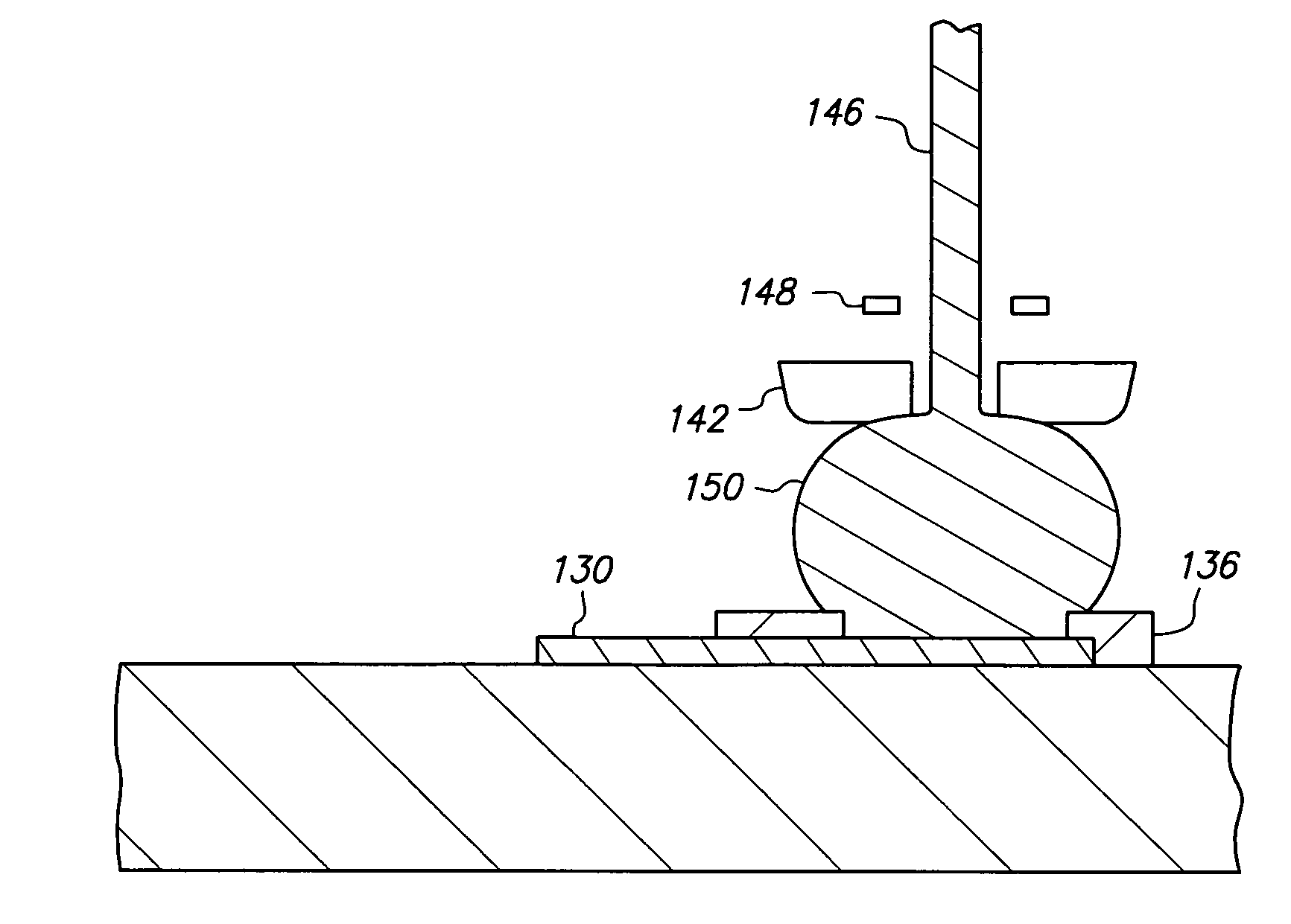

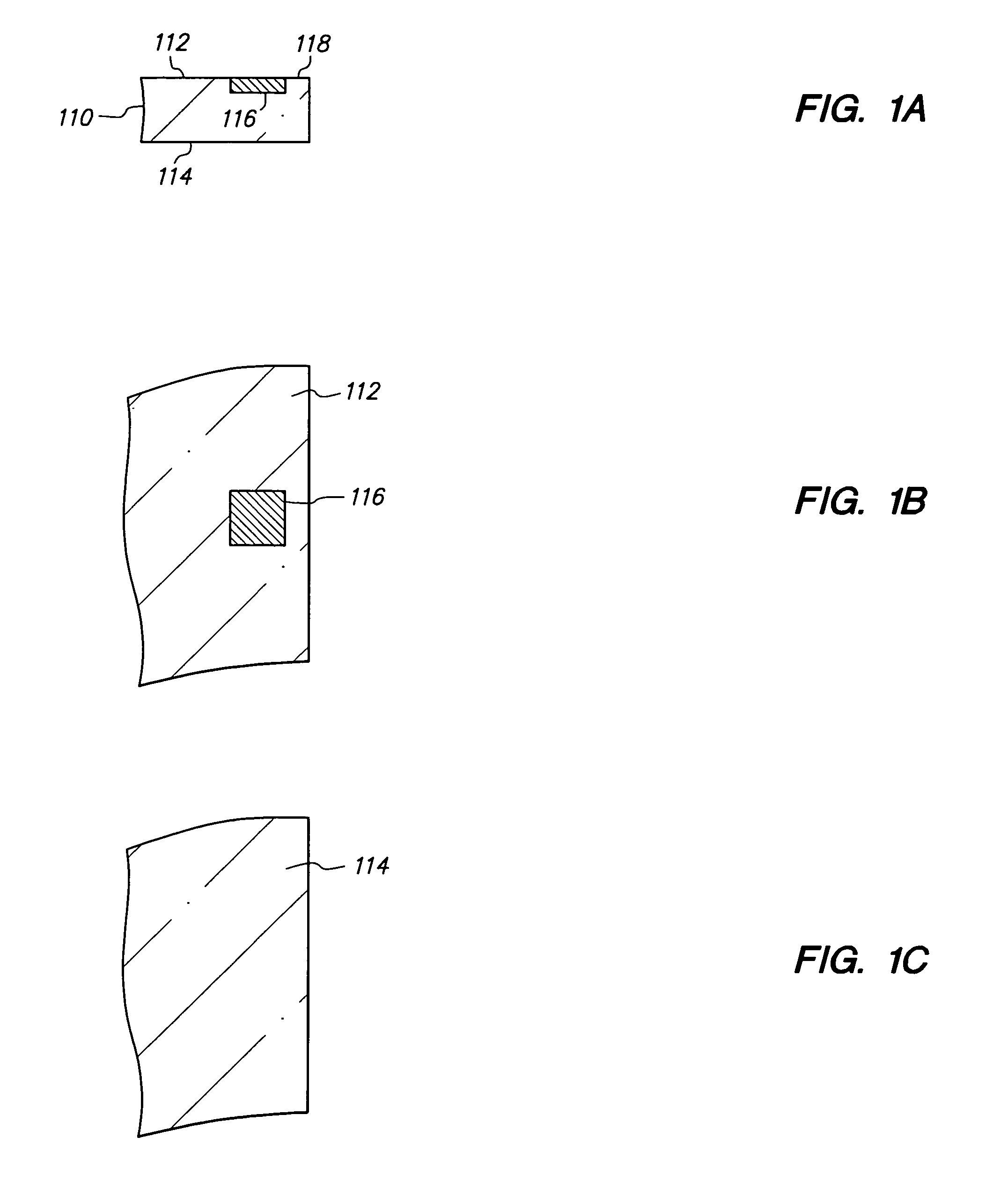

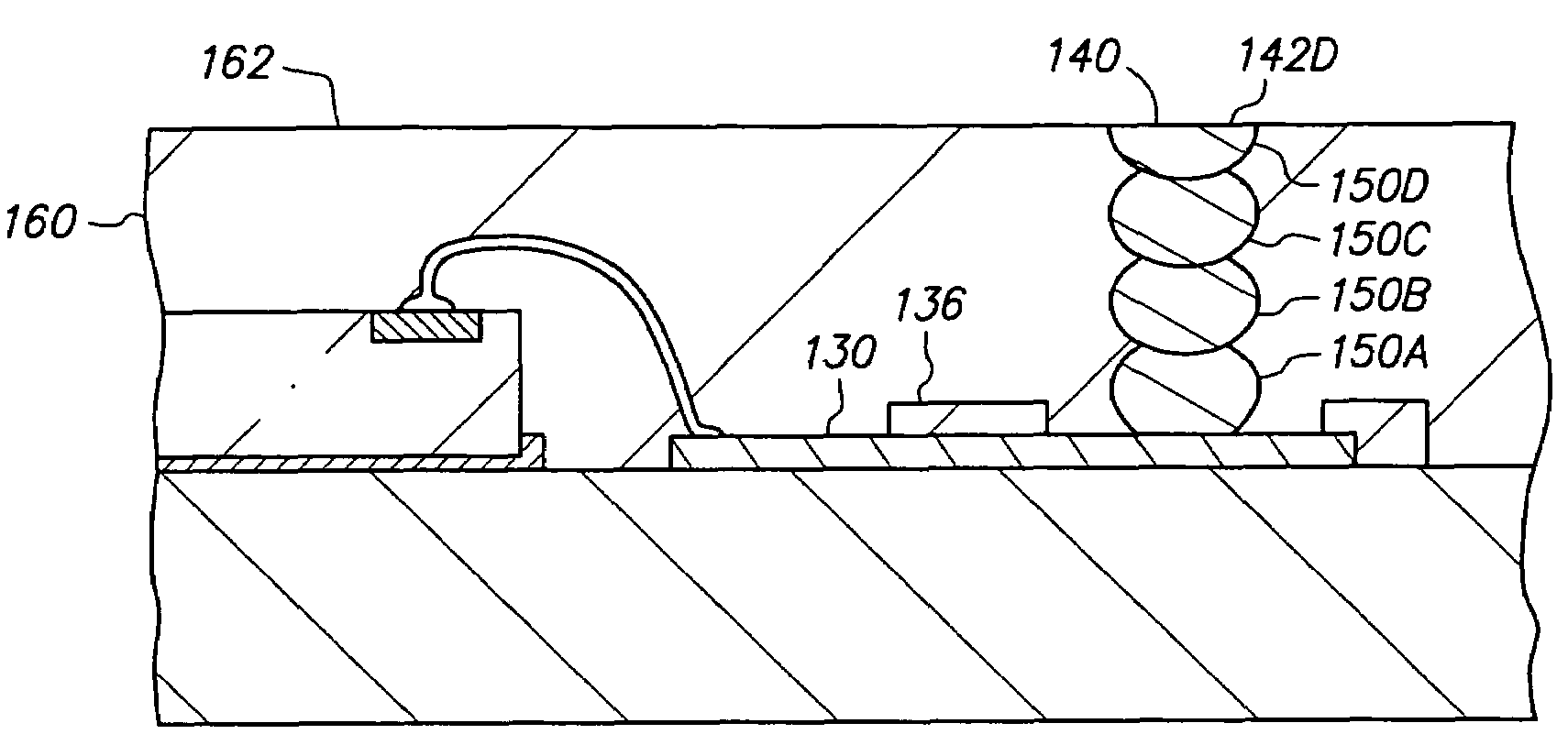

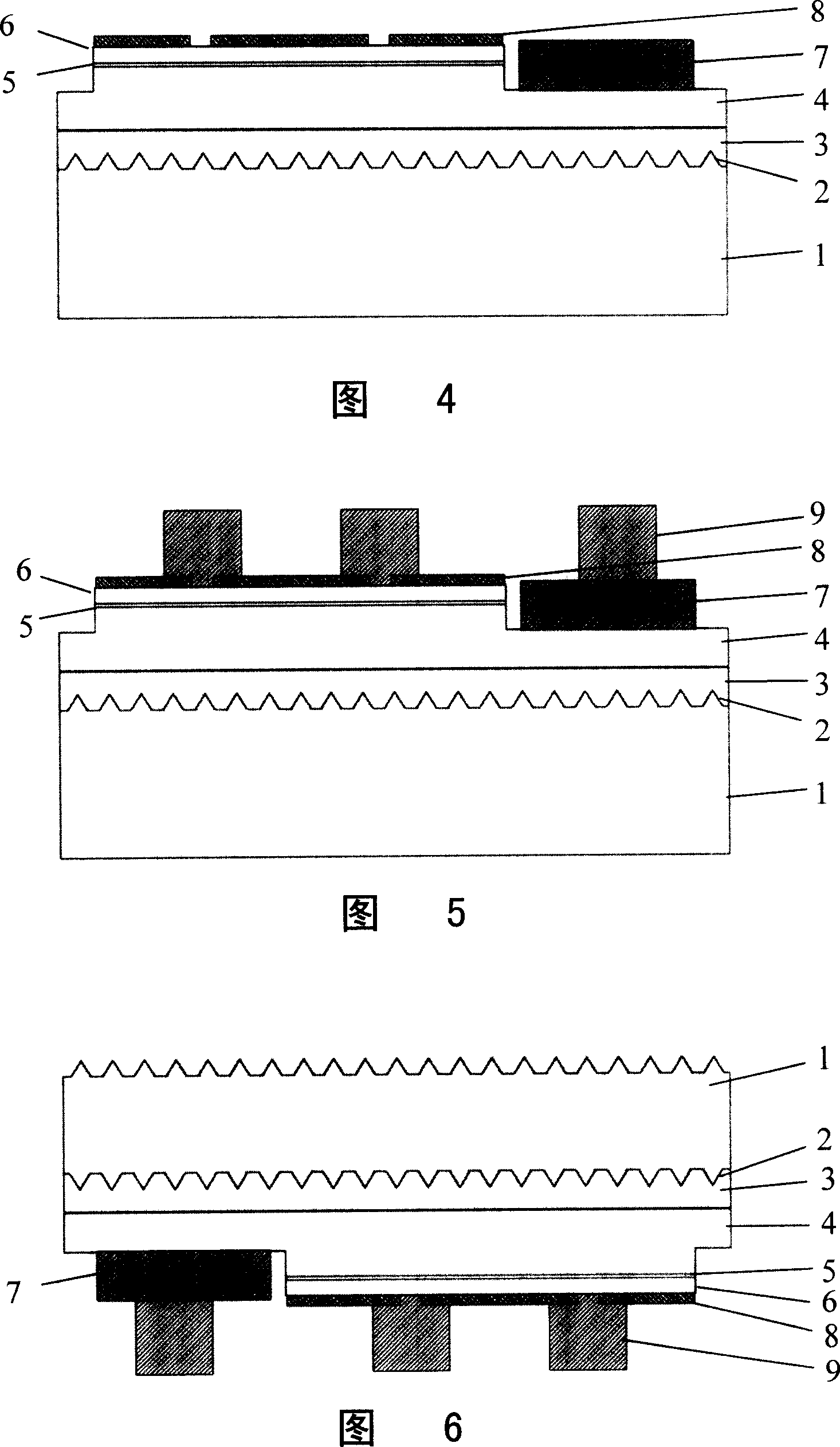

Semiconductor chip assembly with welded metal pillar that includes enlarged ball bond

InactiveUS7268421B1Enhancing mechanical supportImprove protectionThyristorSemiconductor/solid-state device detailsSemiconductor chipSealant

A semiconductor chip assembly includes a semiconductor chip that includes a conductive pad, a conductive trace that includes a routing line and a metal pillar, a connection joint that electrically connects the routing line and the pad, and an encapsulant. The chip and the metal pillar are embedded in the encapsulant, the routing line extends laterally beyond the metal pillar towards the chip, and the metal pillar is welded to the routing line.

Owner:BRIDGE SEMICON

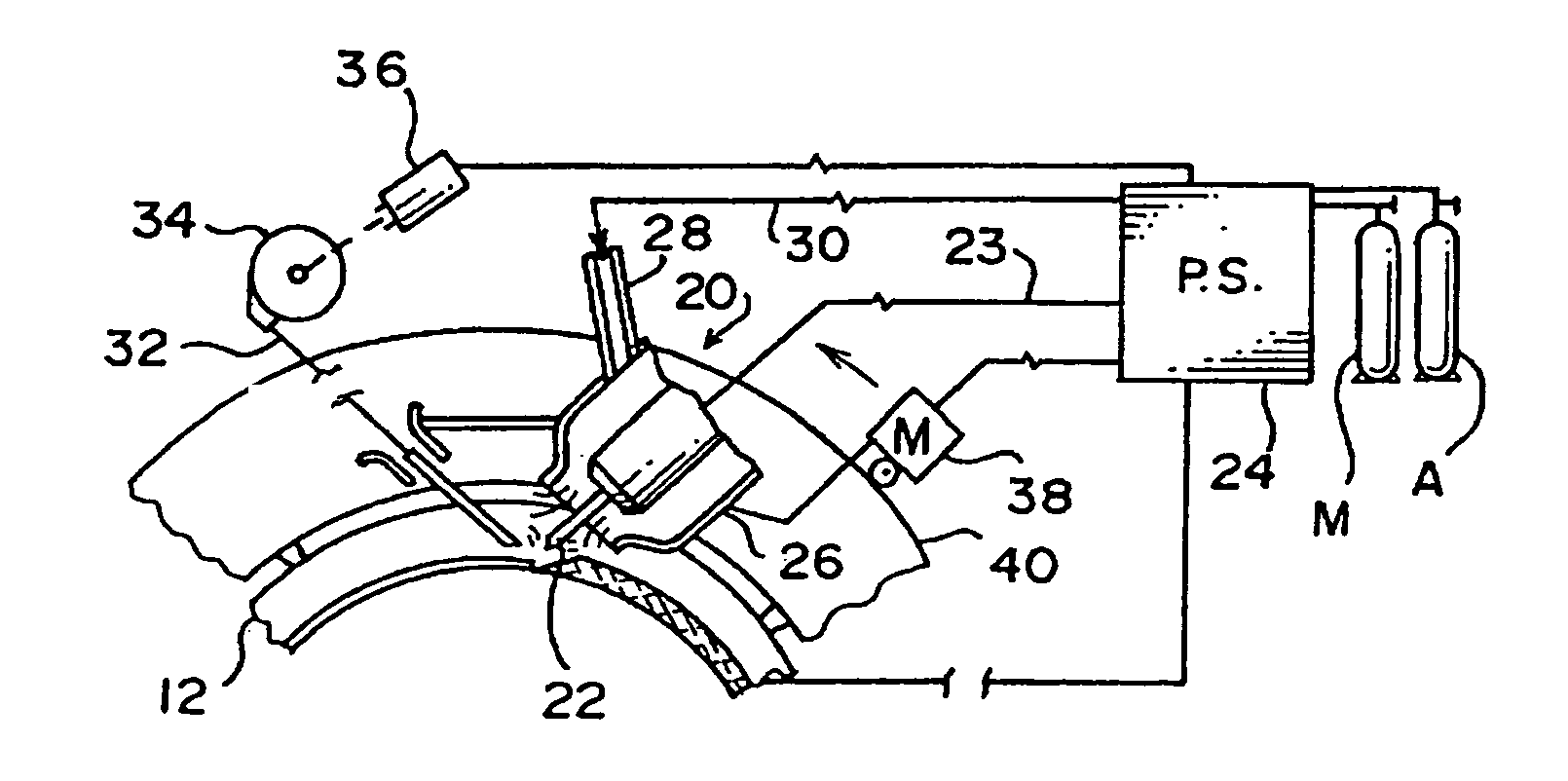

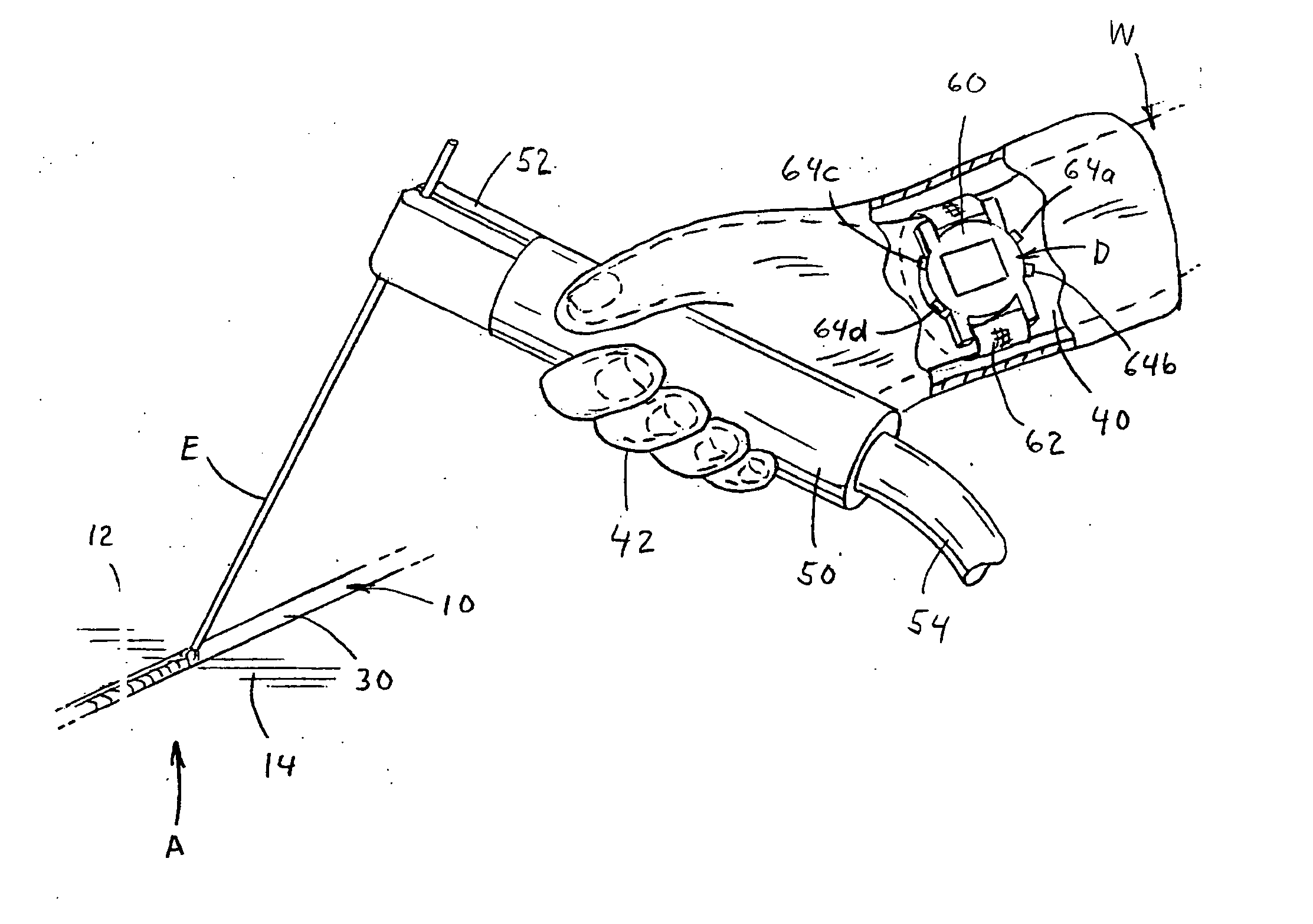

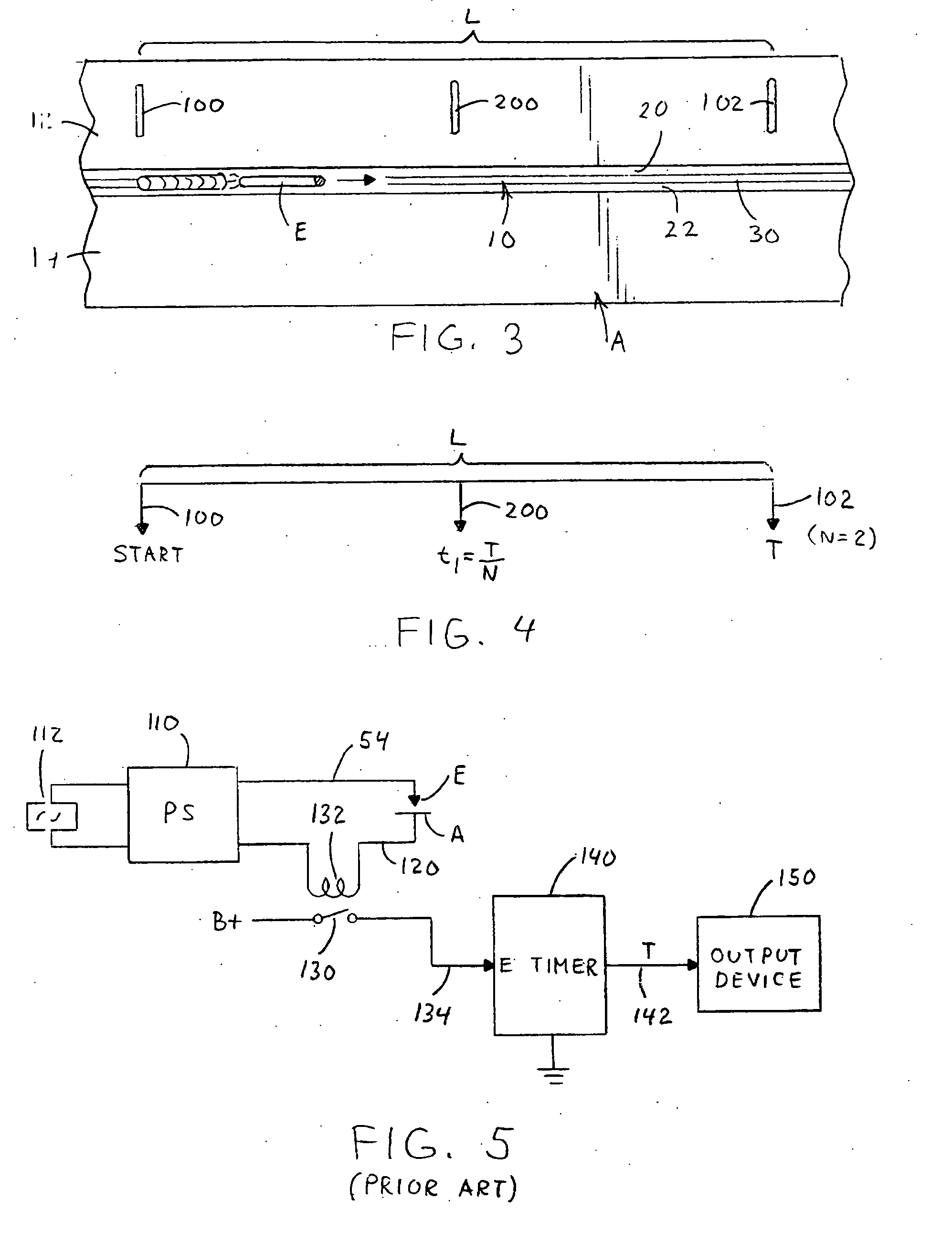

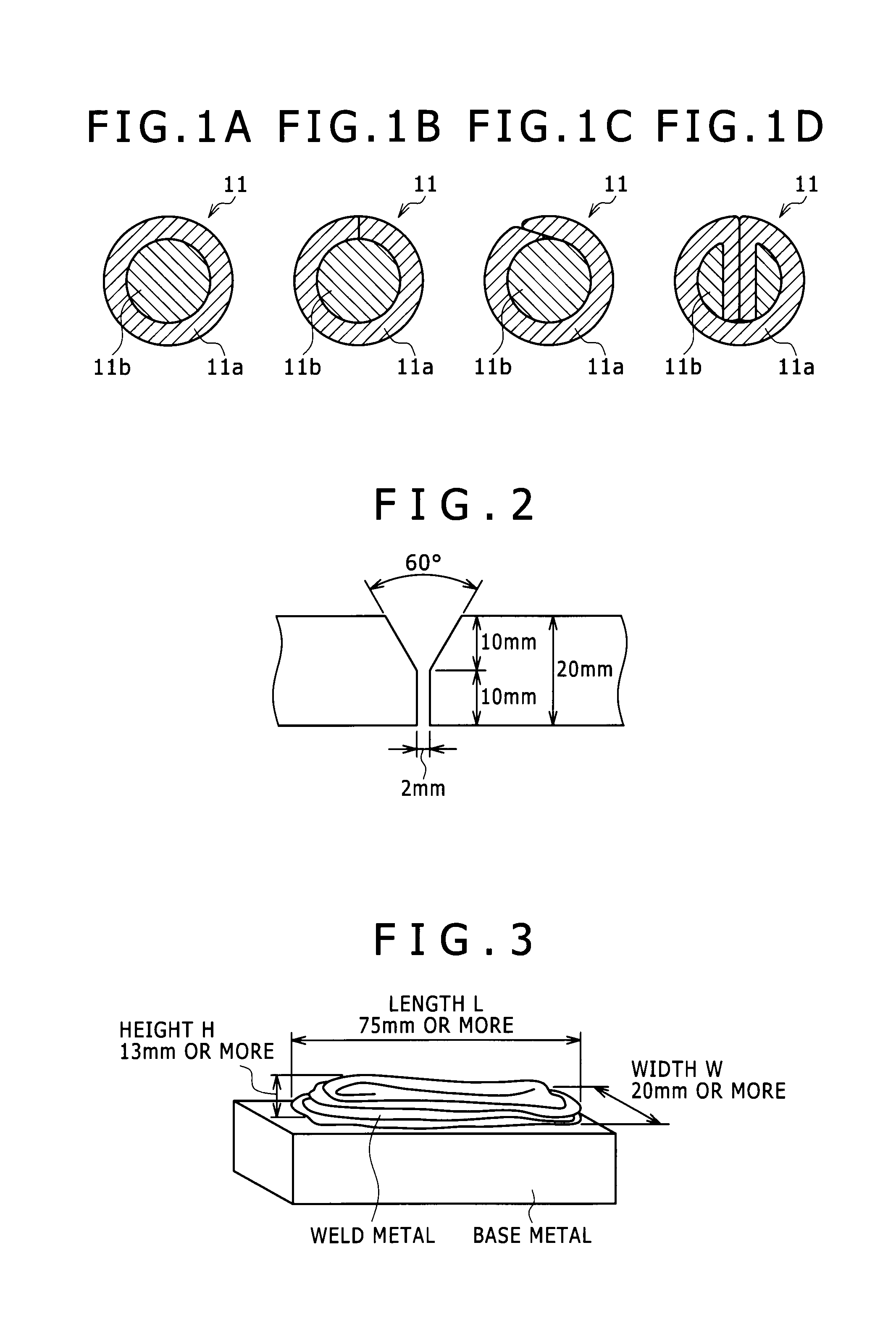

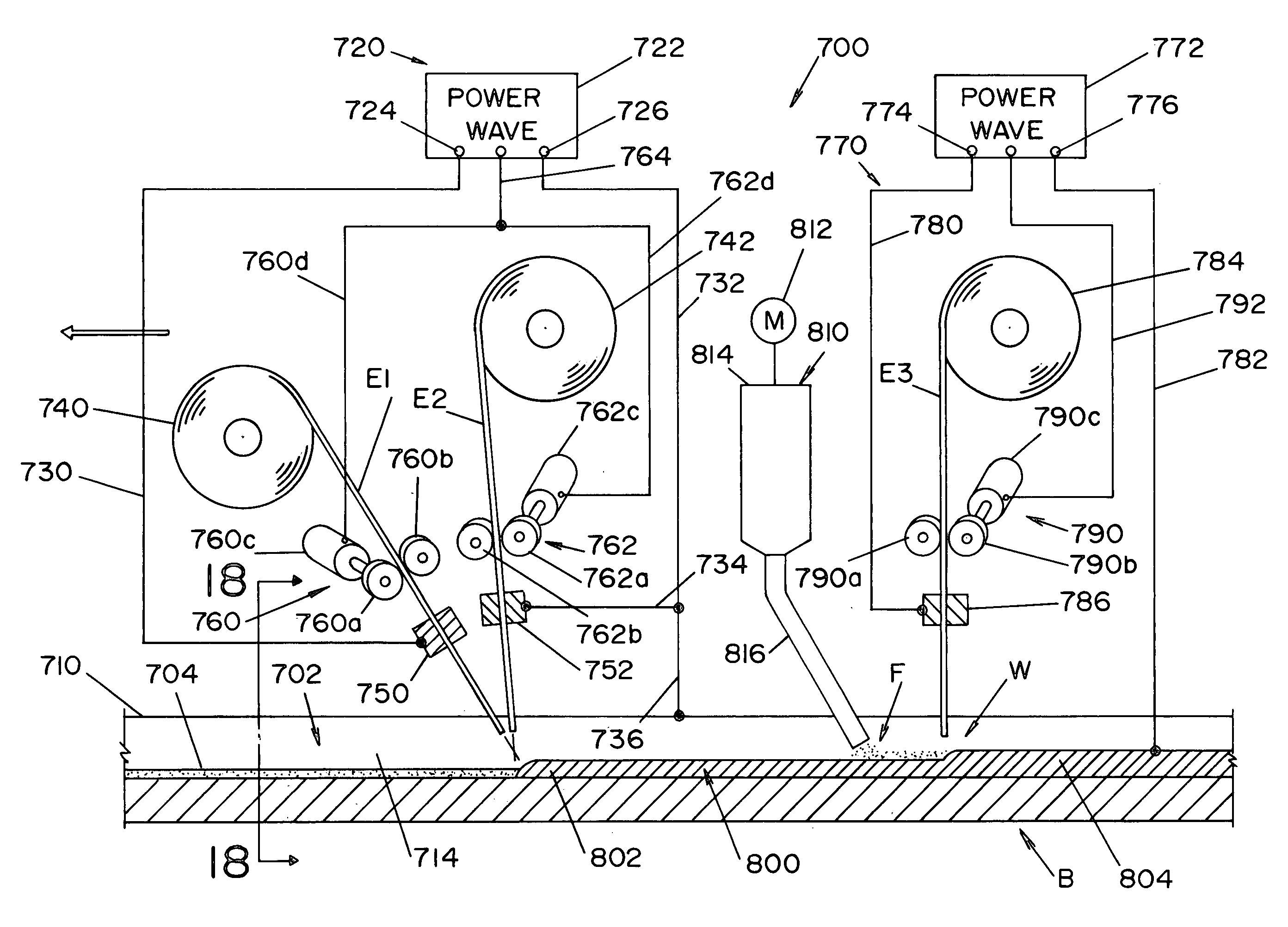

Method of pacing travel speed

InactiveUS20070114215A1Arc welding apparatusWelding/cutting media/materialsEngineeringElectrical current

A method of pacing a desired travel speed of a manual arc welding process performed by a welder for depositing weld metal on a workpiece and along a test groove with a given test length defined by a visible start location and a visual end location using a specified amount of energy distributed generally uniformly in the groove between the locations. The method comprises providing a power source with output leads and an arc current and an arc voltage; setting the output welding power of the power source; providing a consumable welding wire; connecting the output leads across the welding wire and the workpiece; determining the time T for the wire to traverse the test length to consume the specific amount of energy; marking the groove with a visible indicia spaced from the start location a given distance; associating a programmable haptic device with an exposed body part of the welder where the device has a tactile alarm activated after a programmed time t from start of the haptic device, which time t is coordinated with the given distance to give the desired travel speed; starting the haptic device when the operator commences welding at the start location and employs a manual rate of travel; and, changing the manual rate of travel according to the relationship of the wire to the indicia when the tactile alarm is activated.

Owner:LINCOLN GLOBAL INC

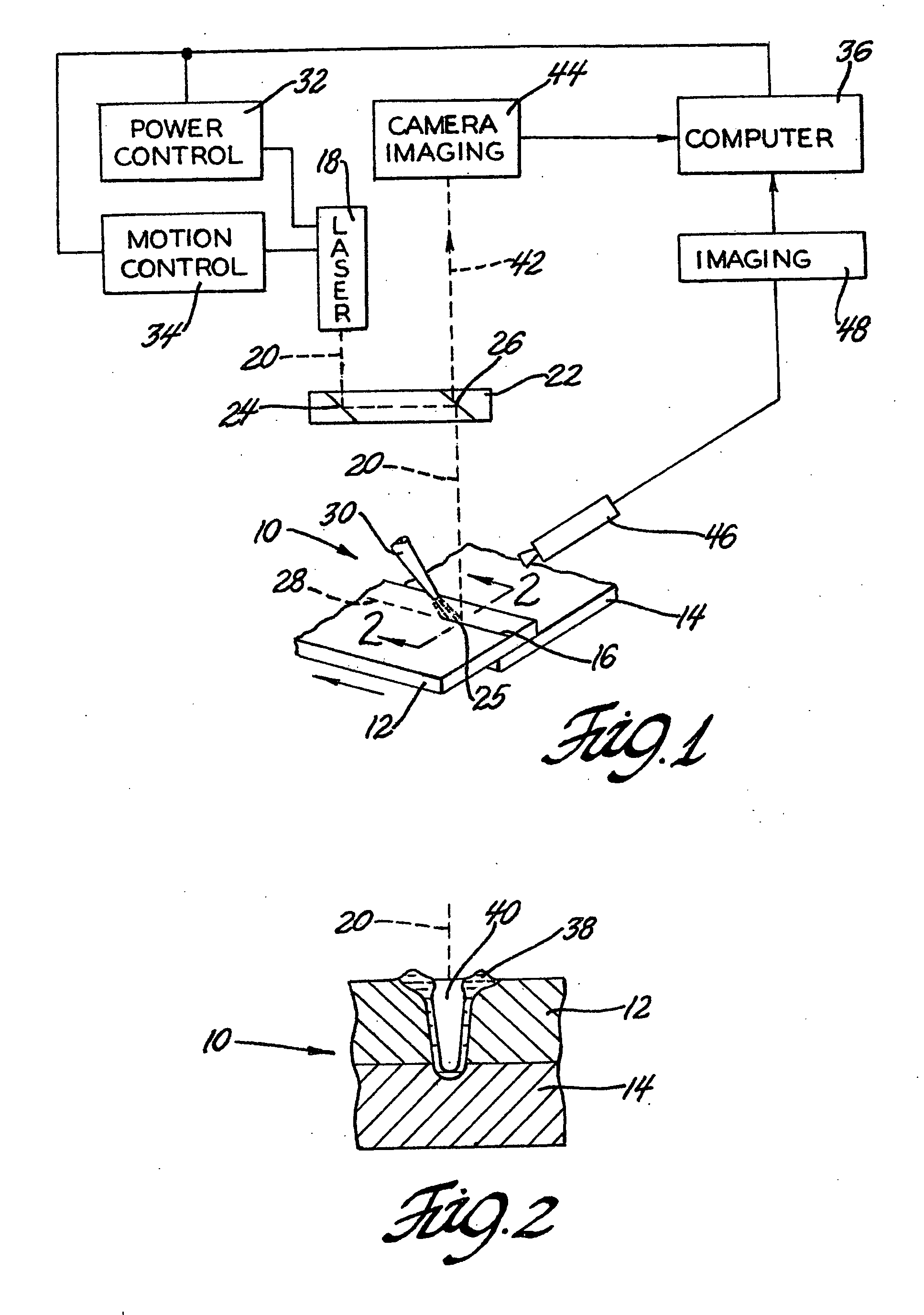

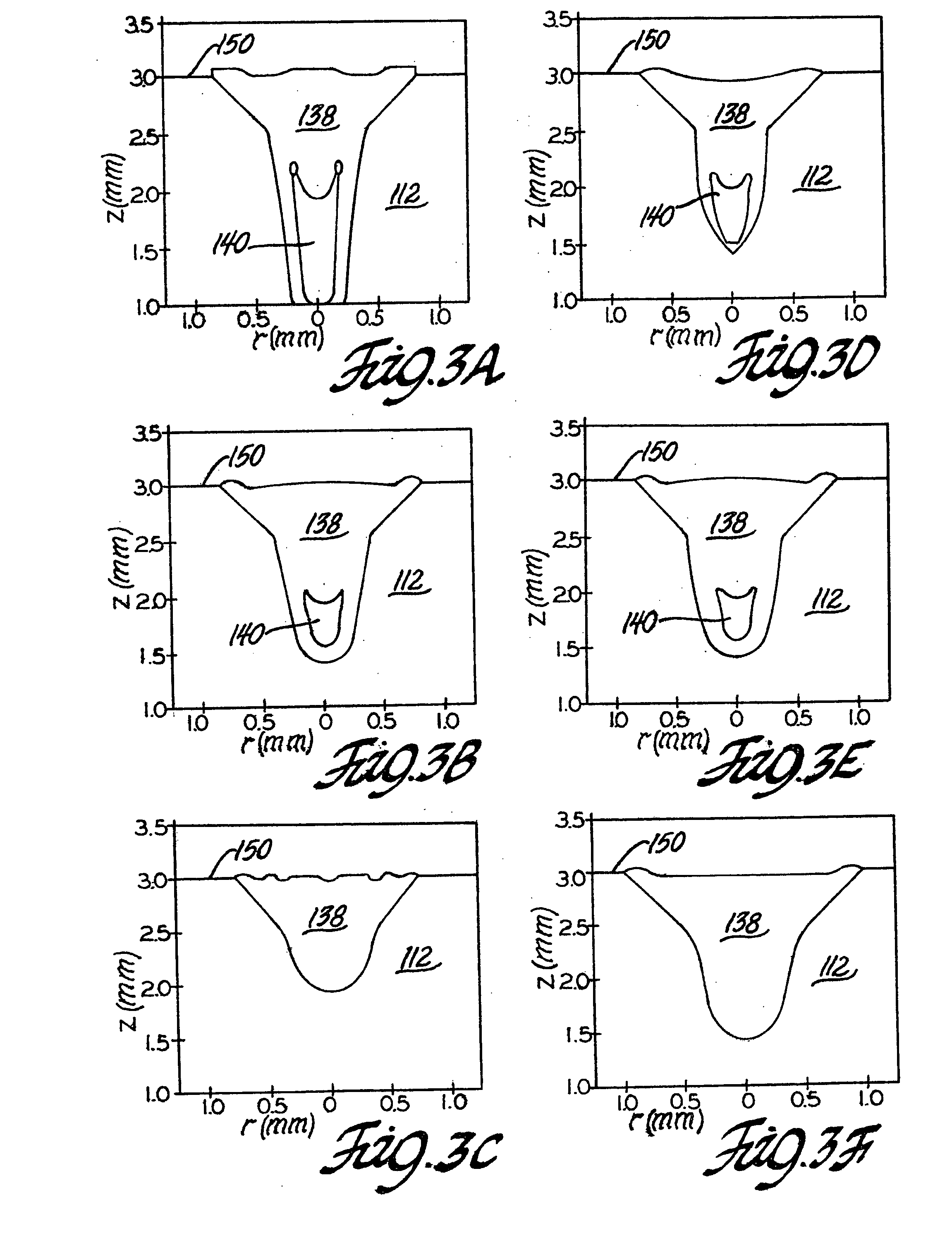

Laser welding control

In laser welding of metallic workpieces, the energetic beam is moved over the workpiece surface to form a pool of molten weld metal that quickly solidifies behind the advance of the laser into a weld nugget. The laser beam produces a keyhole of plasma-containing vapor within the molten pool. Weld nugget porosity, due to entrapment of the vapor, is minimized by continually sensing radiation from the molten metal pool to determine pool depth and width and then controlling laser power and speed to continually produce a weld metal pool wide enough for the liquid to fully expel the vapor and solidify into a pore free nugget.

Owner:GENERAL MOTORS COMPANY

Ni-base heat resistant alloy and welded joint thereof

InactiveUS20030005981A1Improve carburization resistanceImprove solubilityWelding/cutting media/materialsSoldering mediaUltimate tensile strengthEthylene

A Ni-base heat resistant alloy excellent in weldability and strength at elevated temperatures and suited for use in manufacturing cracking furnace tubes and reformer furnace tubes to be used in ethylene plants as well as a welded joint therefor is provided. The alloy of the invention is a Ni-base heat-resistant alloy, which comprises C: not more than 0.1%, Si: not more than 2%, Mn: not more than 2%, P: not more than 0.025%, S: not more than 0.005%, N: not more than 0.04%, Cr: 10 to 30%, Al: 2.1 to less than 4.5%, and Mo: 2.5 to 15% or W: 2.5 to 9% or Mo and W: 2.5 to 15% in total, and satisfies the relation (1) given below:<paragraph lvl="0"><in-line-formula>(104Si+1980P+1980S+9Al+15Ti+11Nb+1.8W+11600B)<={1.1(240-20000S-1900P-30Al-10Ti-9W+17000B) (1)< / in-line-formula>In the welded joint of the invention, both of the base metal and weld metal are made of the alloy having the above composition, and the ST value of the weld metal as calculated according to the following formula (2) or (3) is larger by not less than 3 than the ST value of the base metal:<paragraph lvl="0"><in-line-formula>in the case of Ti<=4C; ST-Mo+1.5W+100Ti (2)< / in-line-formula><paragraph lvl="0"><in-line-formula>in the case of Ti>4C; ST=Mo+1.5W+400C (3).< / in-line-formula>

Owner:NIPPON STEEL CORP

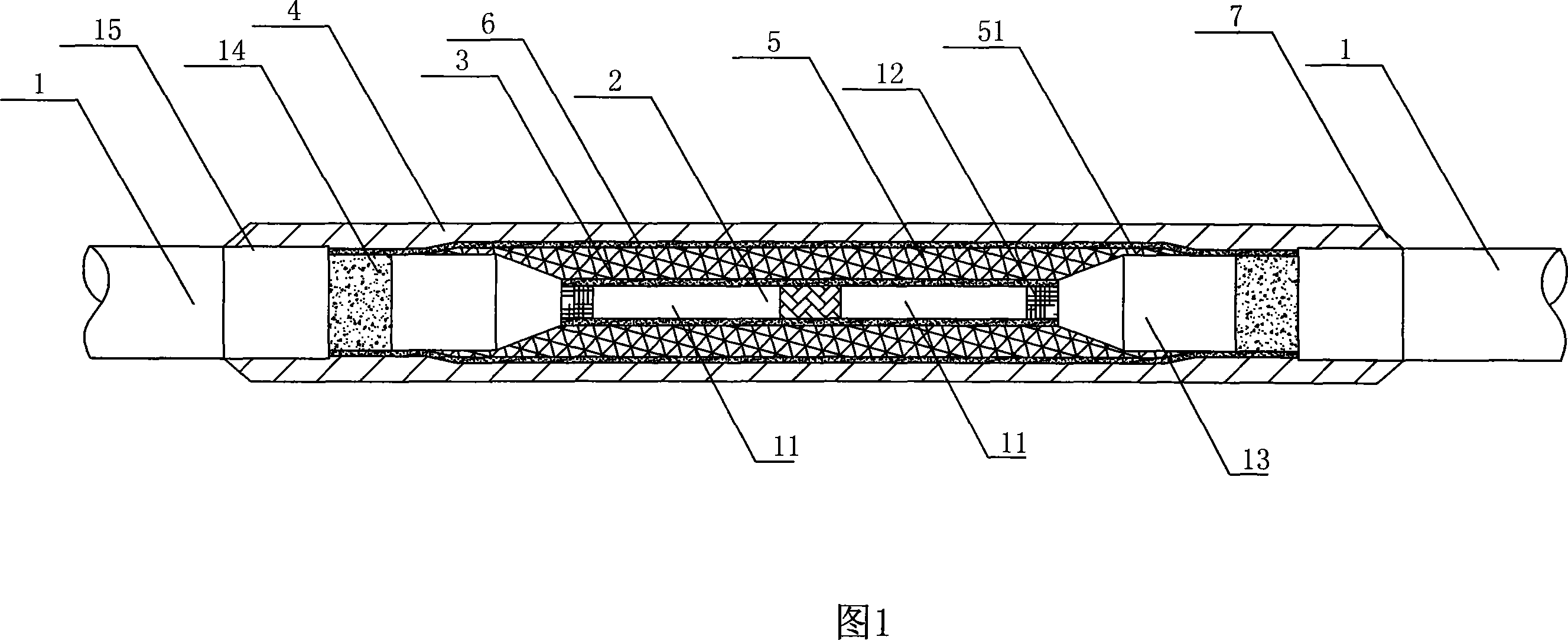

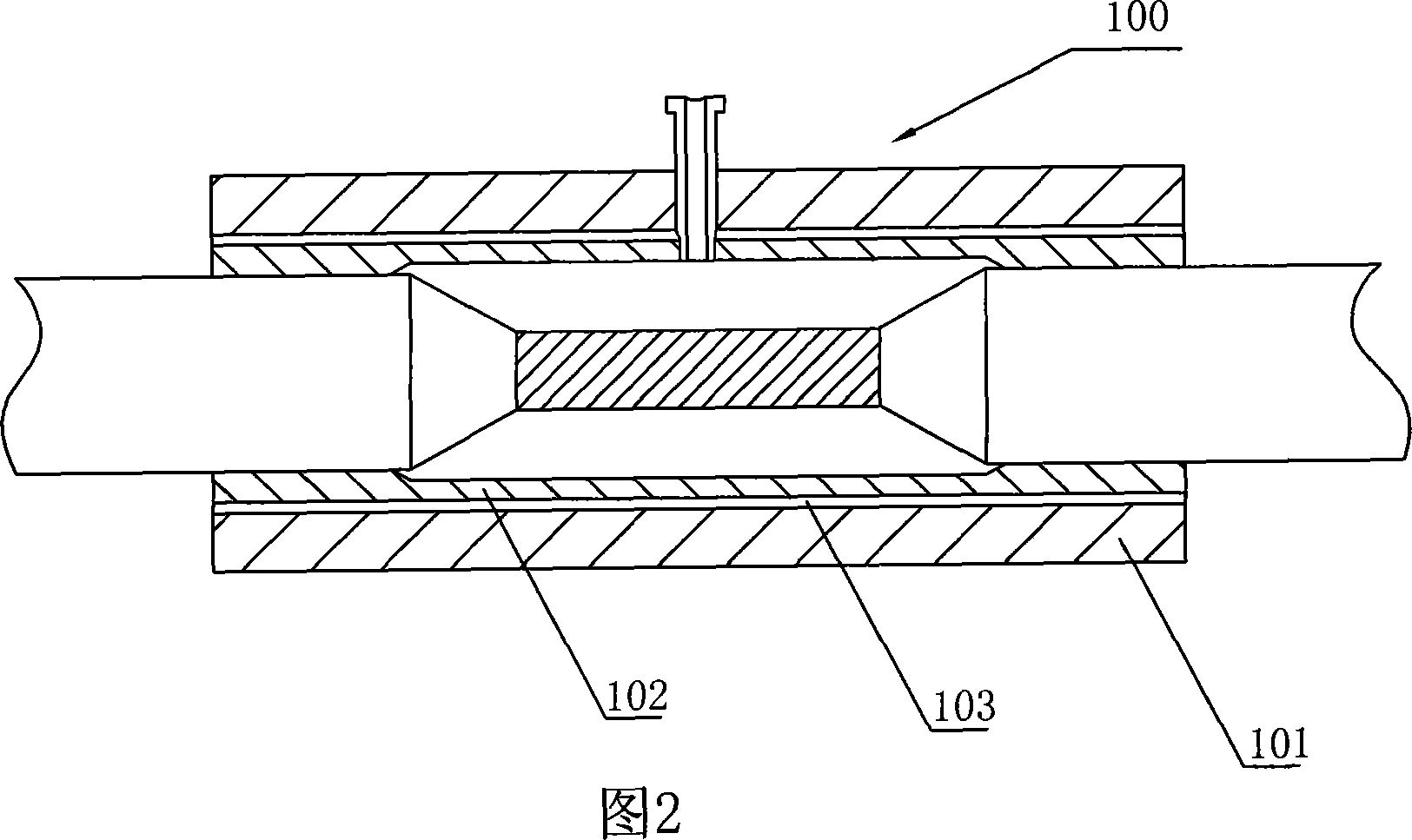

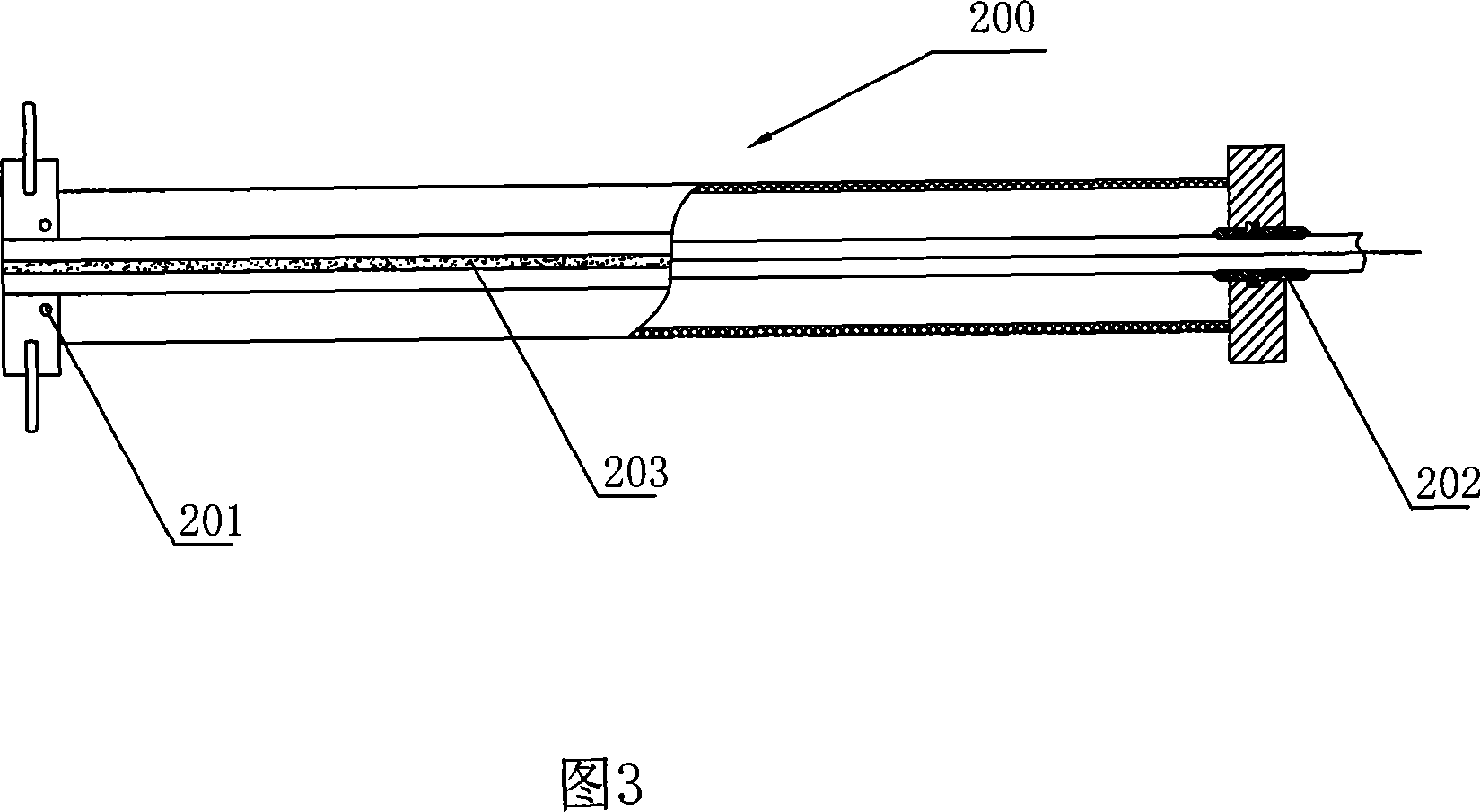

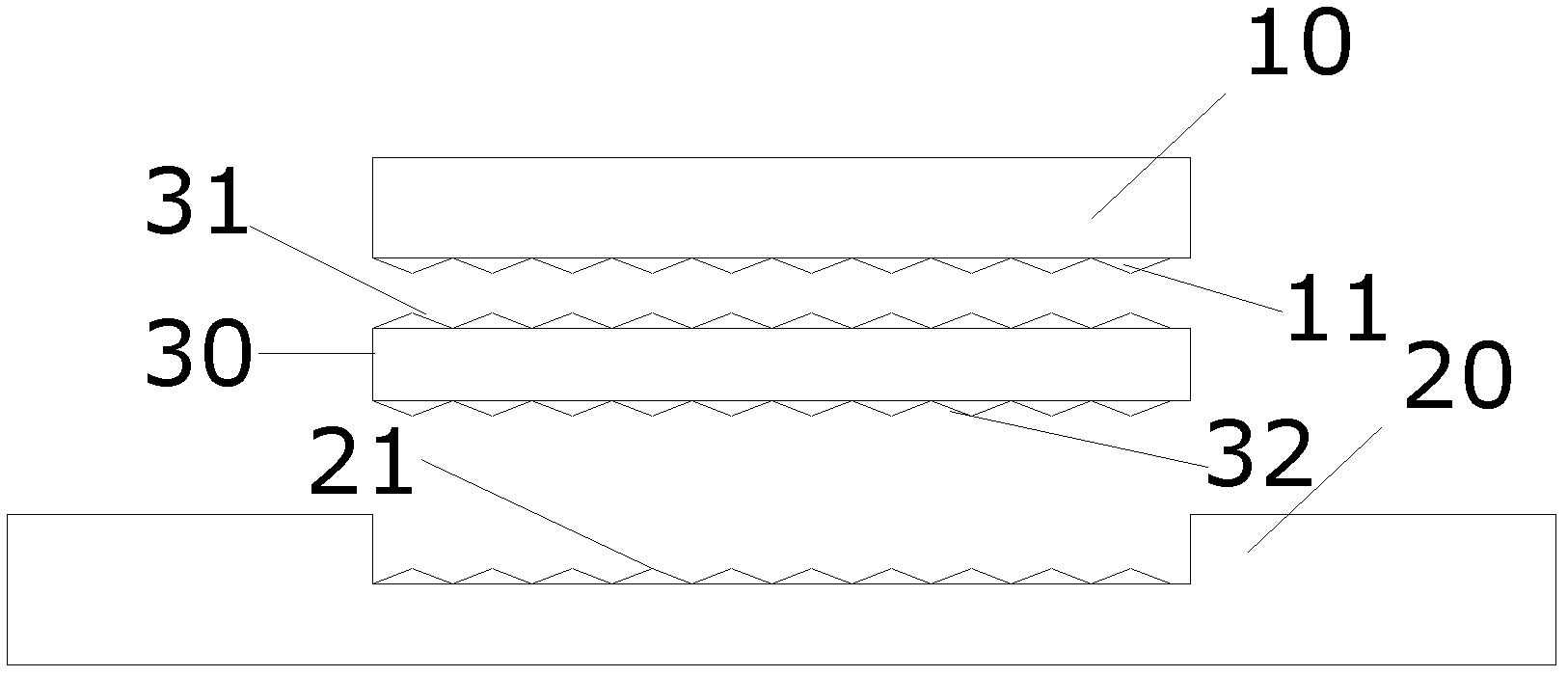

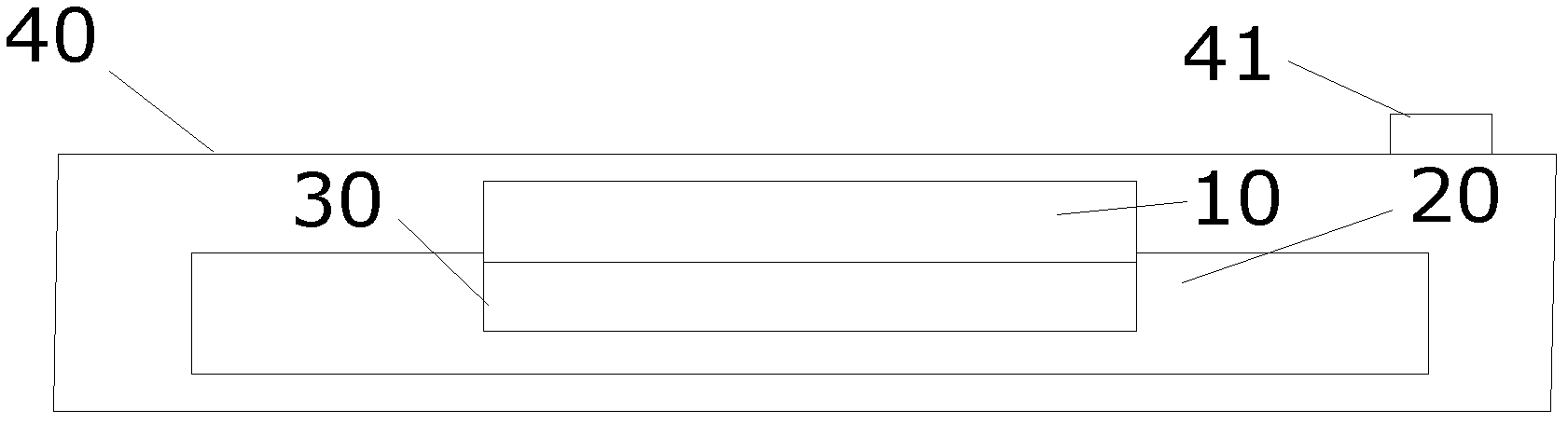

Soft joint for cross-linked polyethylene cable and producing method thereof

ActiveCN101068075AElectrical performance improvements and enhancementsEliminate void defectsCable junctionsApparatus for joining/termination cablesInsulation layerEngineering

This invention discloses a soft joint of a cross-linked polythene cable including an inner semiconductive layer and metal jacket sleeves, in which, two core leads between two cables are welded to form a core connection part, the inner semiconductive layer is combined with a preserved section of the inner screen layer of the cable characterizing in setting a polythene filled vulcanized insulation layer out of the inner semiconductive layer to be fused with the polythene insulation layer of the cable, and wrapping the polythene insulation of the cable with a transition connection section and an outer semiconductive layer combining with the preserved section of the outer screen of the cable is set out of the polythene filled vulcanized insulation layer, two ends of the metal jacket sleeve are welded with the out surfaces of lead protection pipe of the cable and set with slope connection sections.

Owner:宁波东方电缆股份有限公司

Flux-cored wire for gas-shielded arc welding

InactiveUS6940042B2Improve toughnessWelding/cutting media/materialsSoldering mediaToughnessFlux-cored arc welding

A flux-cored wire for gas-shielded arc welding comprises a steel sheath, and a flux filled in the steel sheath. The flux-cored wire has a C content of 0.20% by mass or below, a Si content in the range of 0.06 to 1.10% by mass, a Mn content in the range of 0.55 to 1.60% by mass, a Cr content of 2.60% by mass or below, a Mo content in the range of 0.30 to 1.50% by mass, a Mg content in the range of 0.20 to 1.50% by mass, a N content in the range of 0.005 to 0.035% by mass and a B content in the range of 0.001 to 0.020% by mass on the basis of the total mass of the flux-cored wire. The flux has a TiO2 content in the range of 4.2 to 8.2% by mass and a fluorine compound content in terms of F content in the range of 0.025 to 0.55% by mass on the basis of the total mass of the flux-cored wire, and the flux-cored wire has an Al content of 0.50% by mass or below, a Nb content of 0.015% by mass or below, and a V content of 0.015% by mass or below on the basis of the total mass of the flux-cored wire. The flux-cored wire forms a weld metal that is resistant to ferrite band maintains proper tensile strength and excellent toughness even if the weld metal is processed at high temperatures for a long time for PWHT. The flux-cored wire has satisfactory usability

Owner:KOBE STEEL LTD

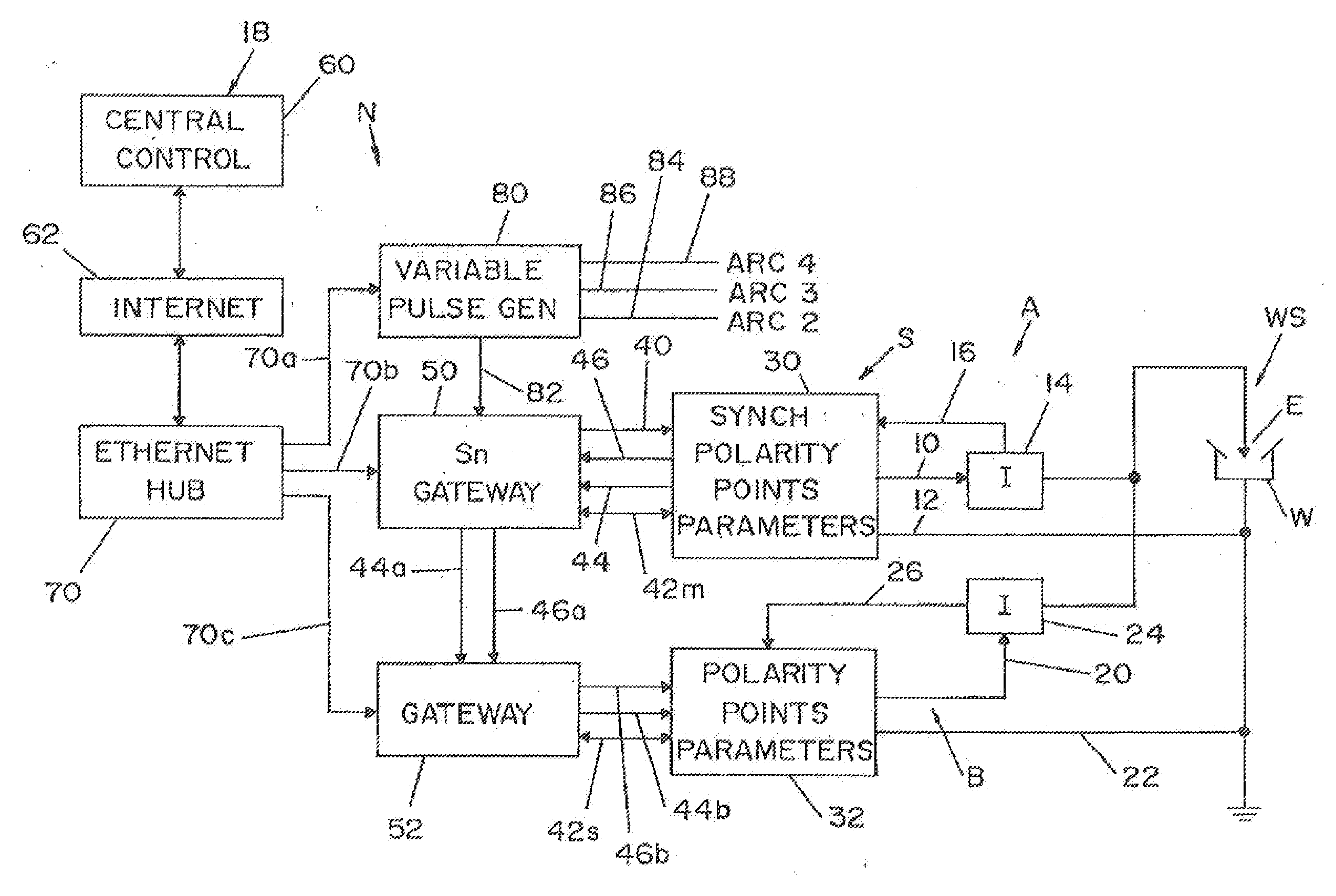

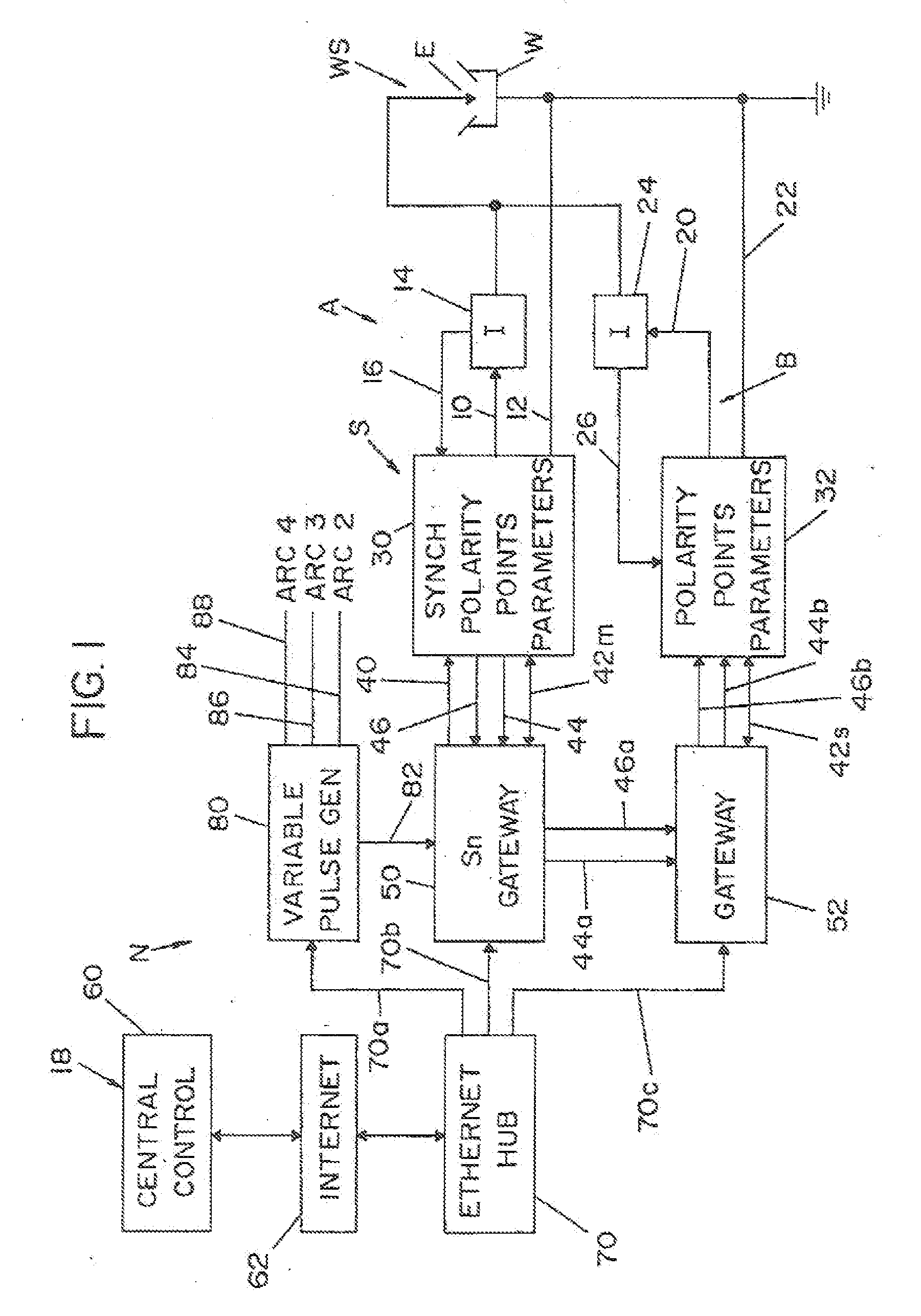

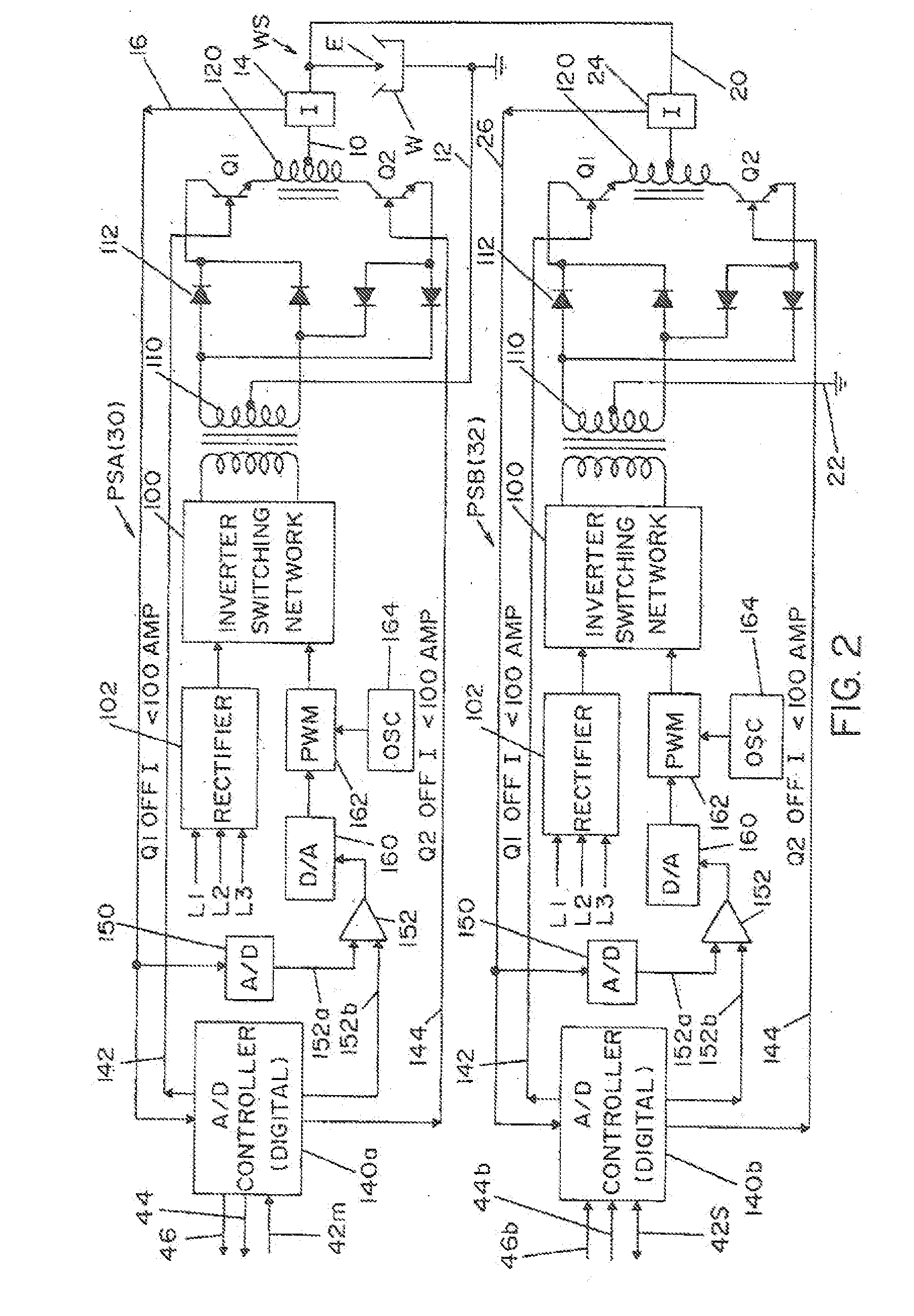

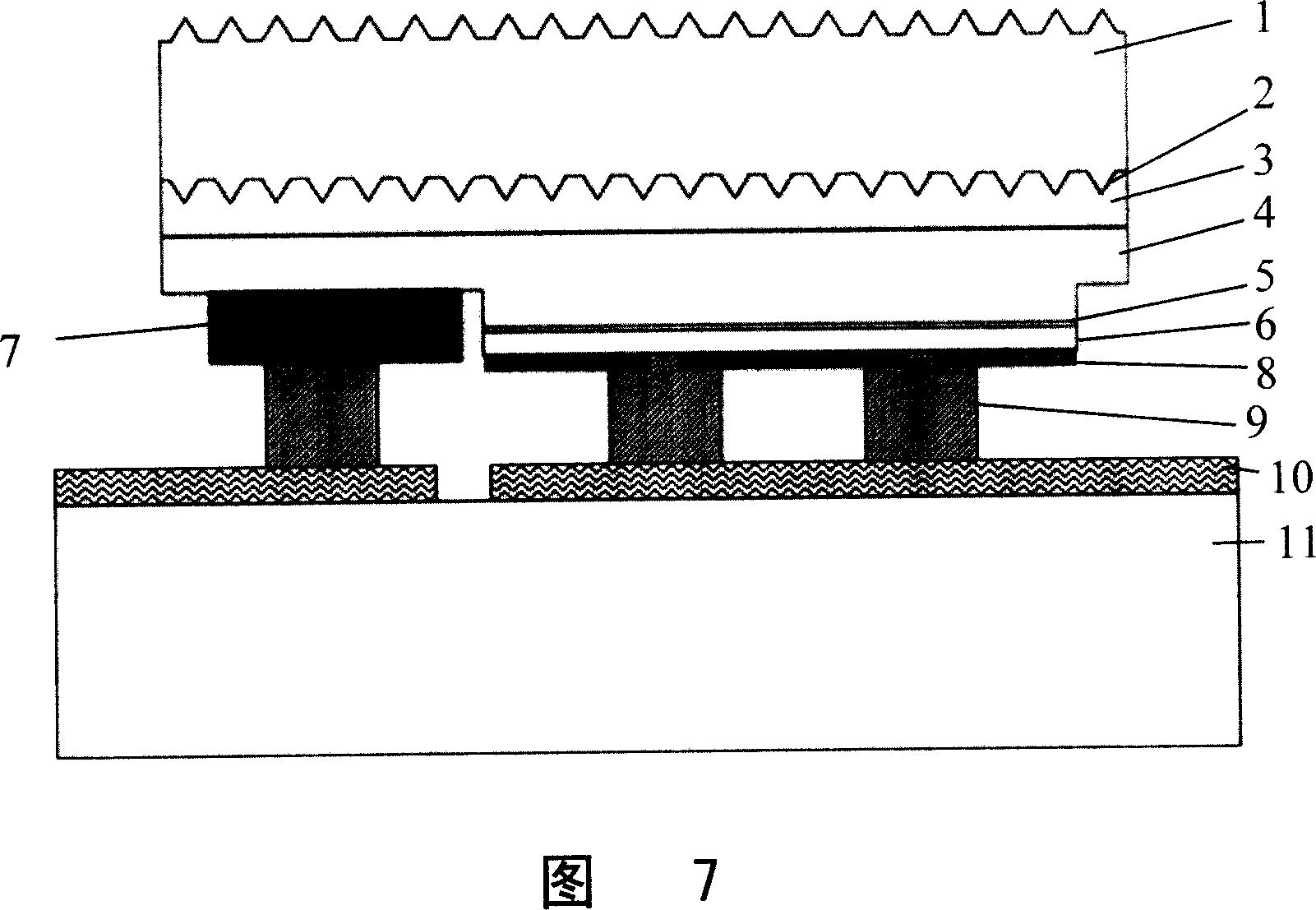

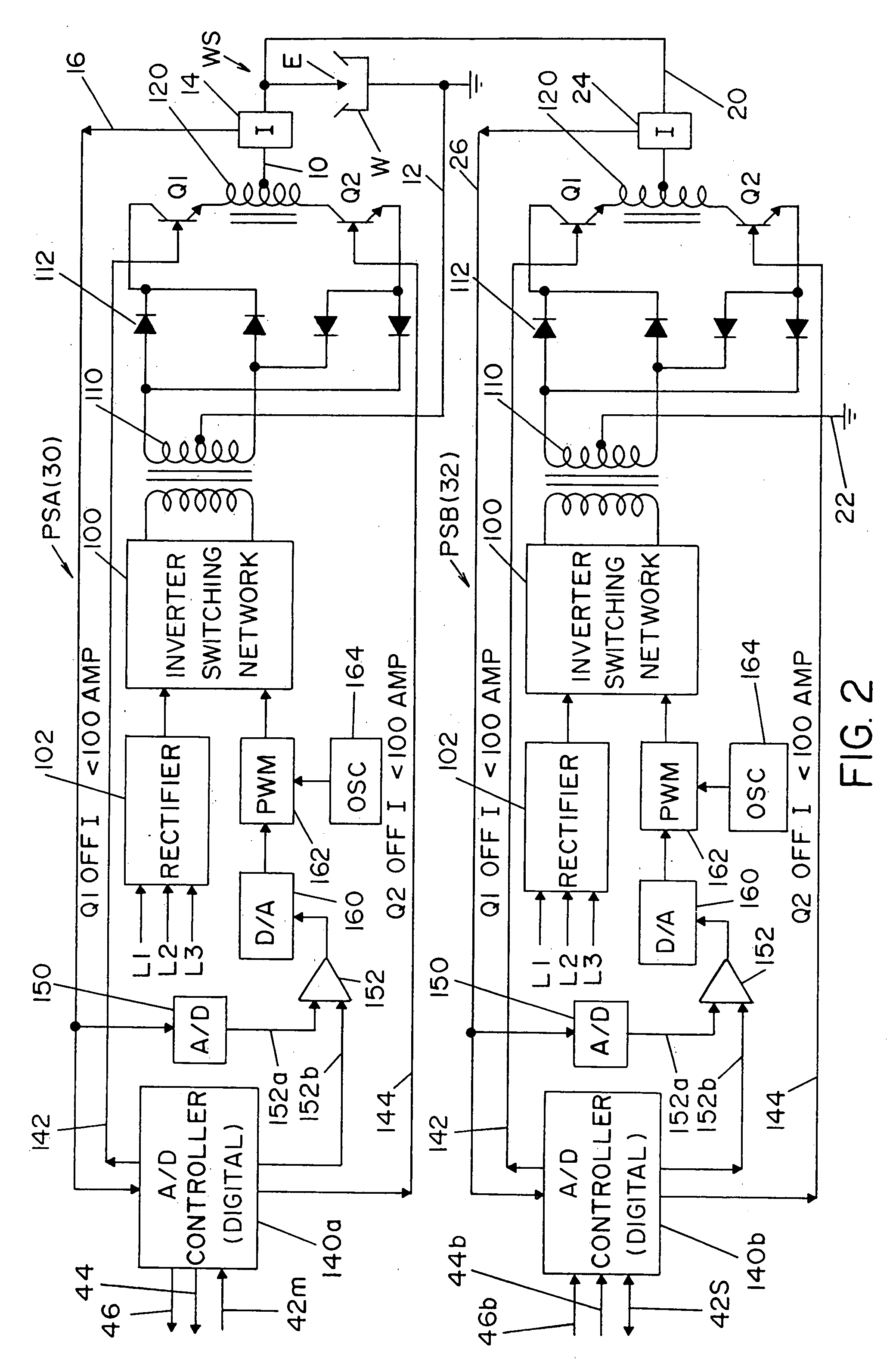

Modified series arc welding and improved control of one sided series arc welding

An electric arc welding system for depositing weld metal along a groove between two edges of a metal workpiece where the system contains a first power supply and a second power supply, each providing a welding waveform to respective welding electrodes. The positive output terminals of both power supplies are coupled to the same contact tip and the negative output terminal of one of the power supplies is not coupled to the workpiece.

Owner:LINCOLN GLOBAL INC

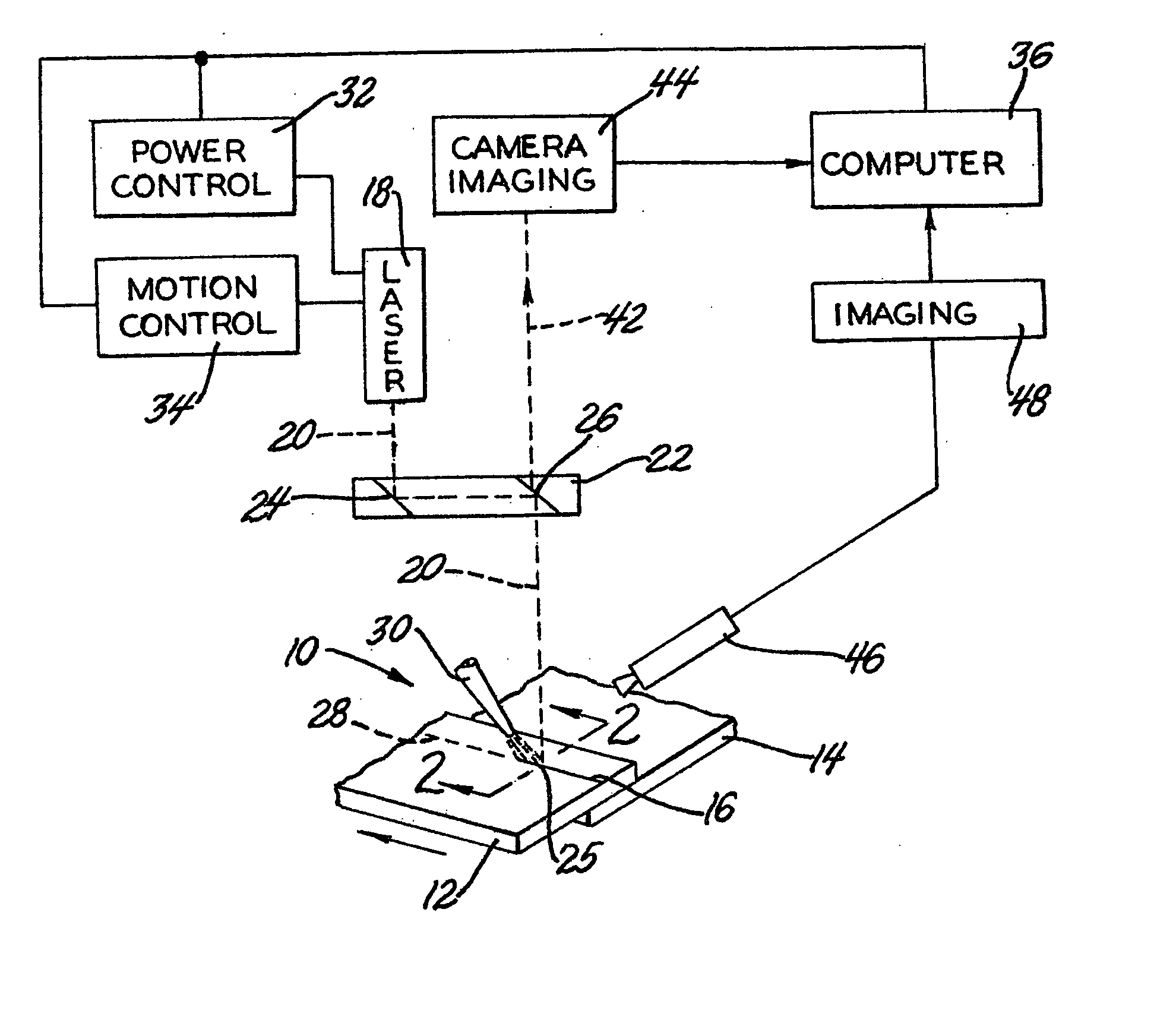

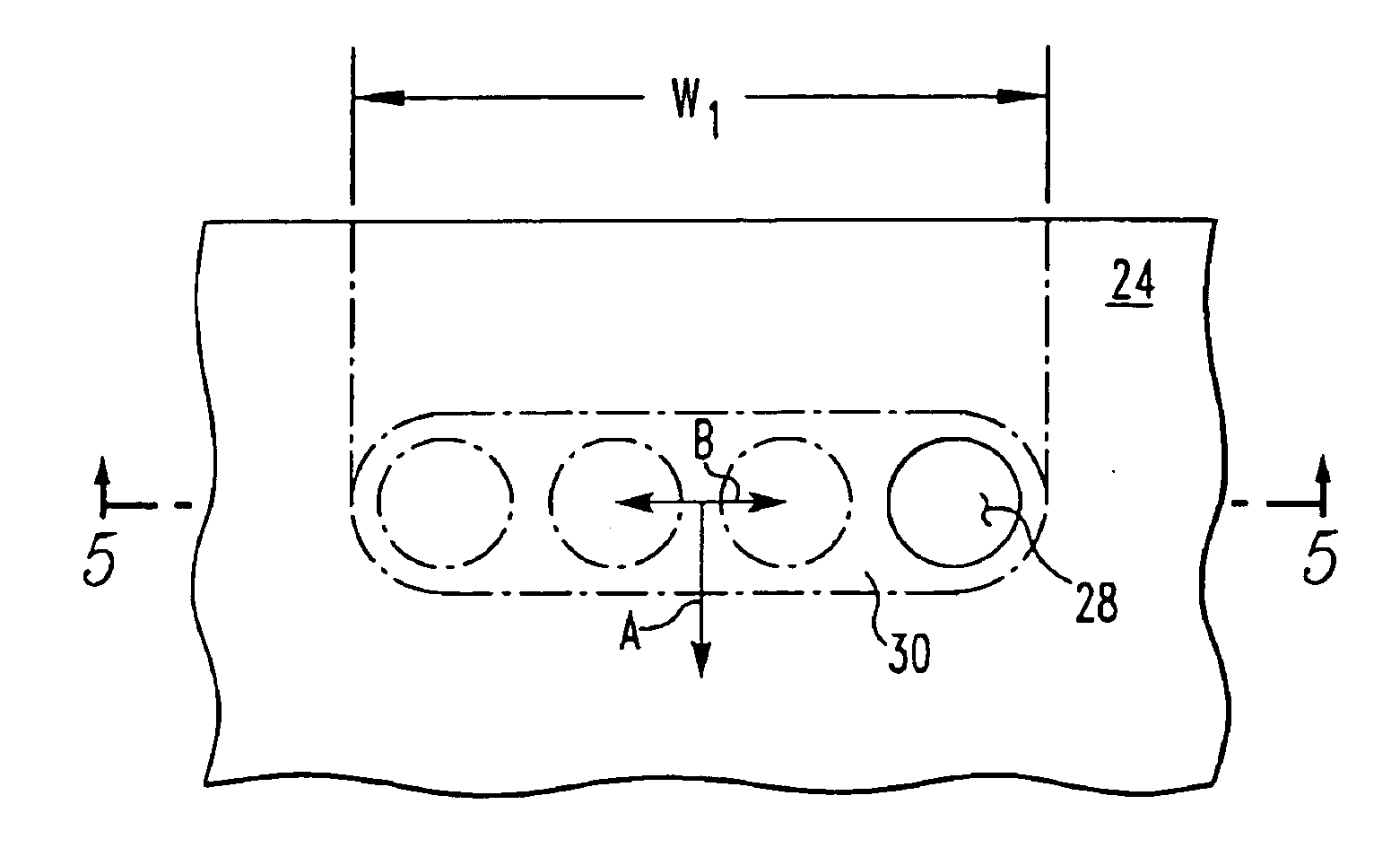

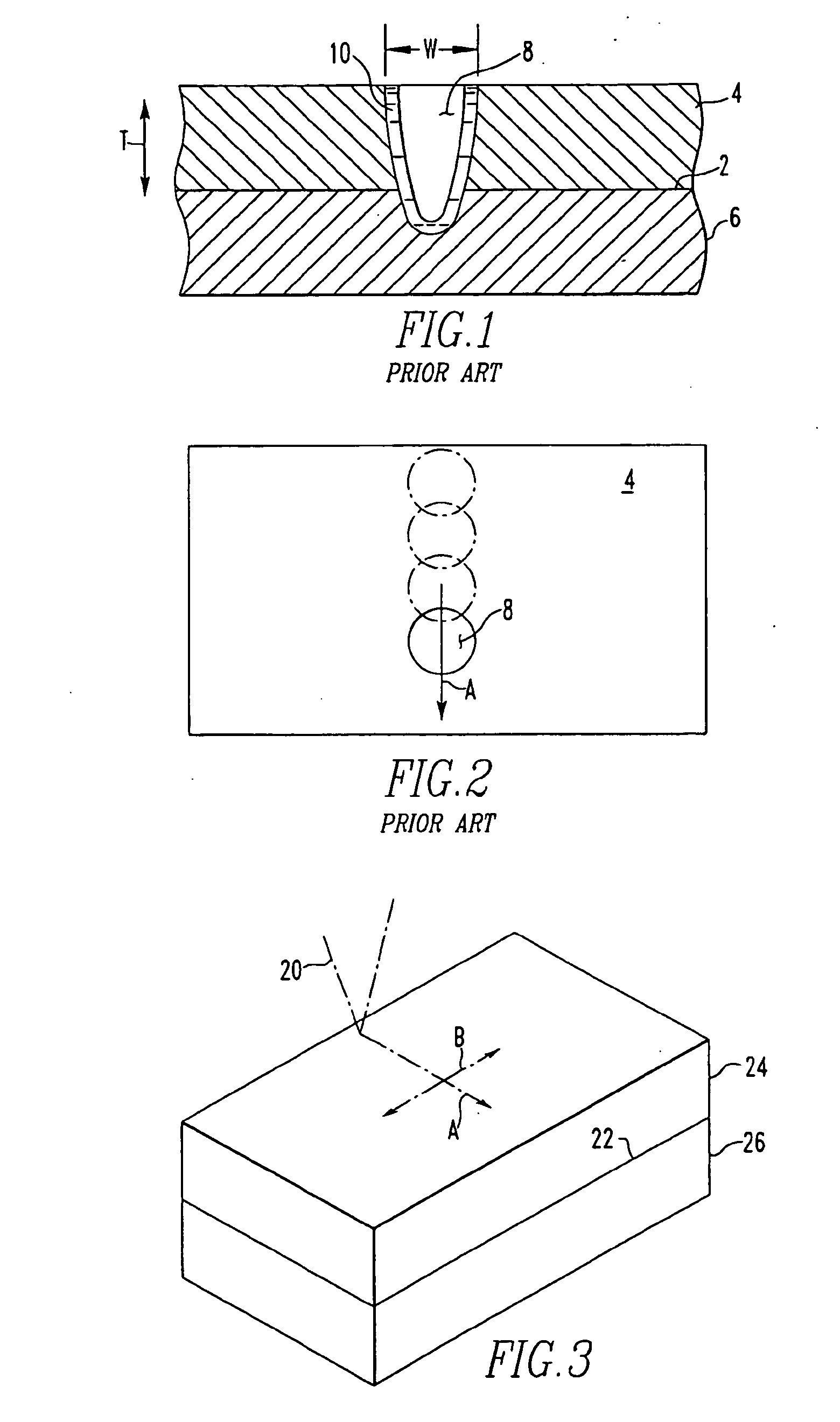

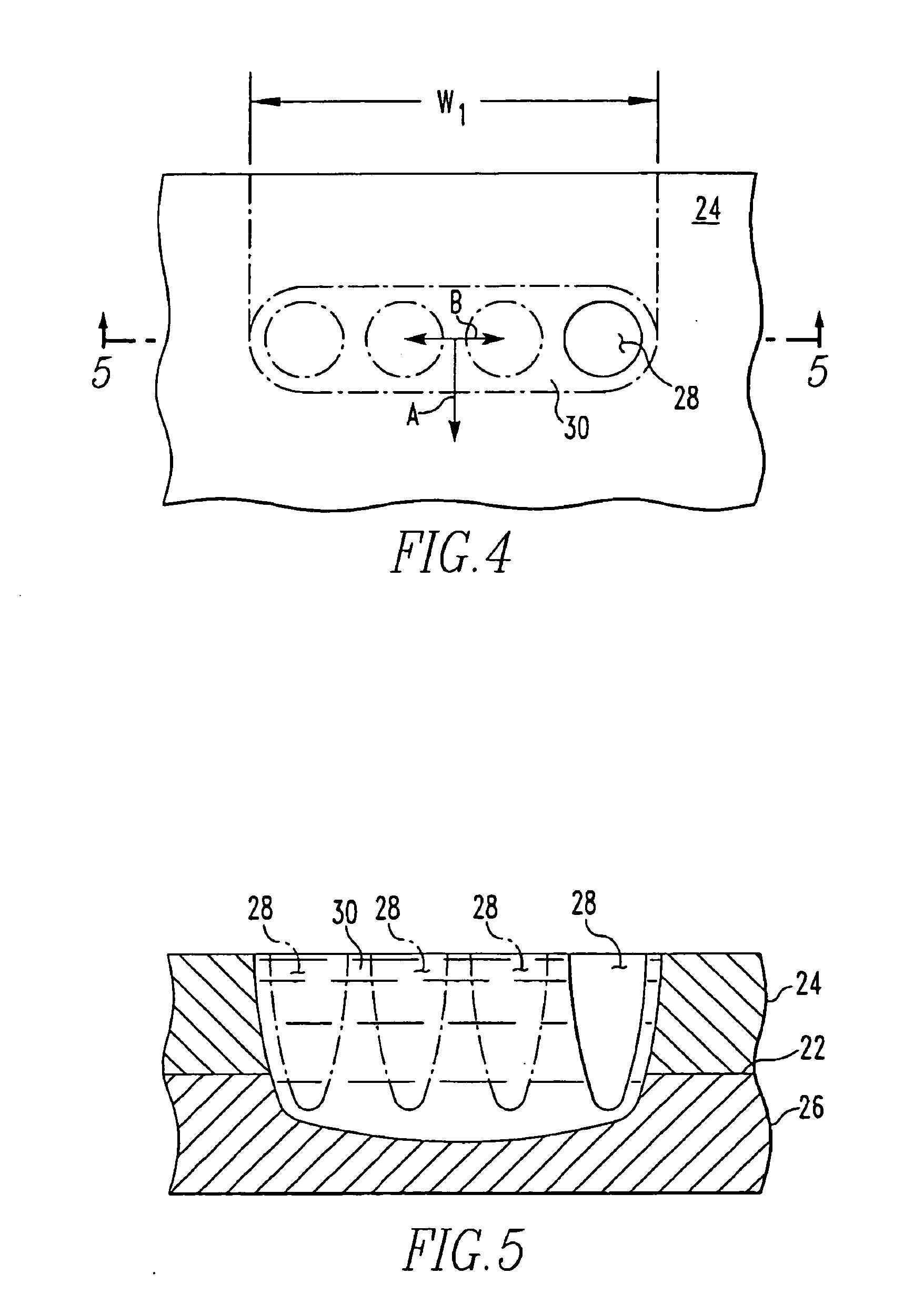

Apparatus and methods for conducting laser stir welding

InactiveUS20060255019A1Welding/soldering/cutting articlesLaser beam welding apparatusLight beamOptoelectronics

A method of welding metal components together including moving a laser beam in a first direction along an interface between a pair of metal components such that in the vicinity of the focused beam, metal from each component is vaporized to produce a keyhole in a pool of molten metal. The laser beam is oscillated in a direction different from (e.g., transverse to) the first direction such that the keyhole oscillates through the pool of molten metal and molten metal fills into the keyhole as the position of the keyhole changes. A laser welding apparatus achieves oscillation of the laser beam using optical elements in the path of the laser beam, for example trepanning optics located within an expanded portion of the laser beam.

Owner:PENN STATE RES FOUND

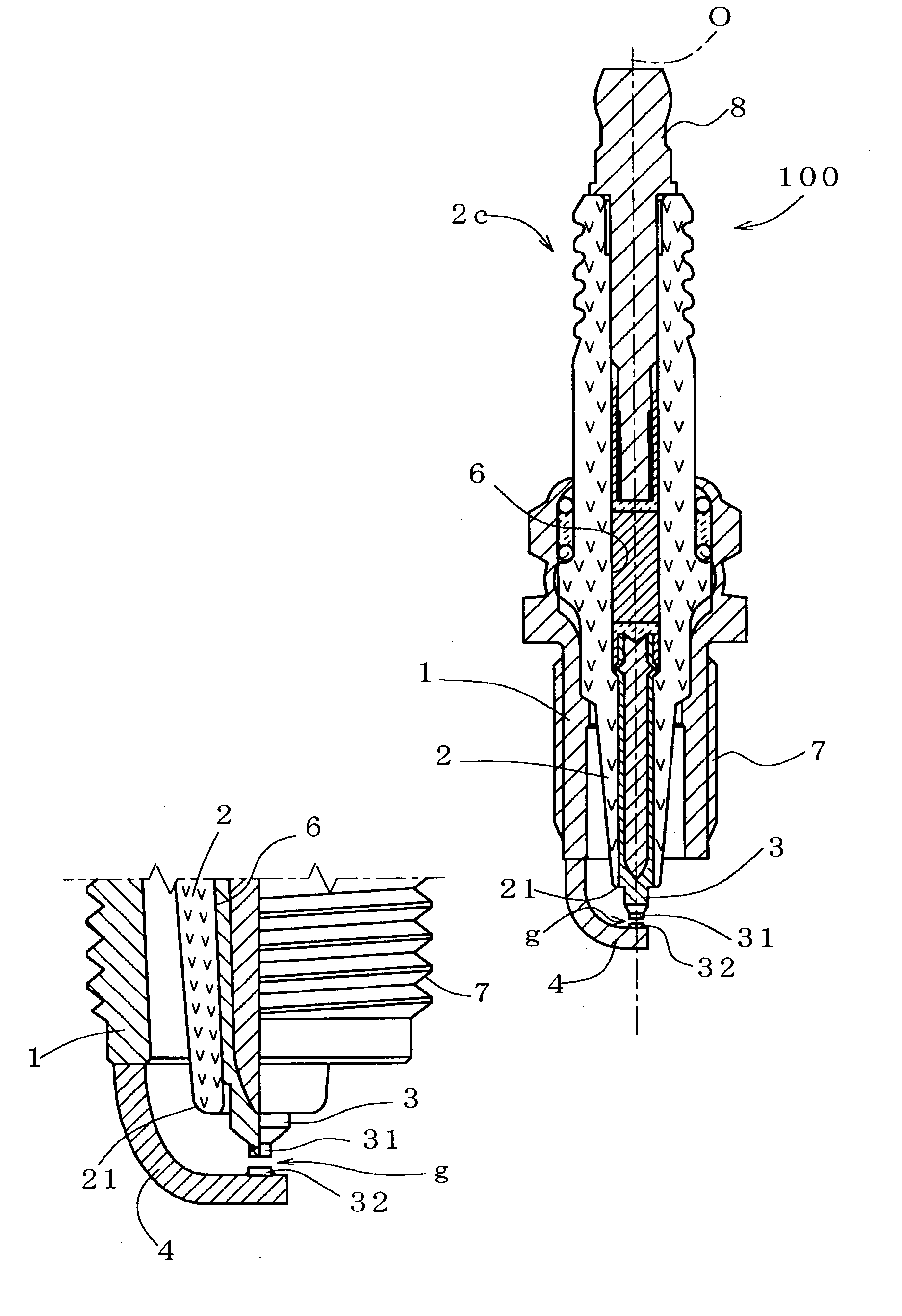

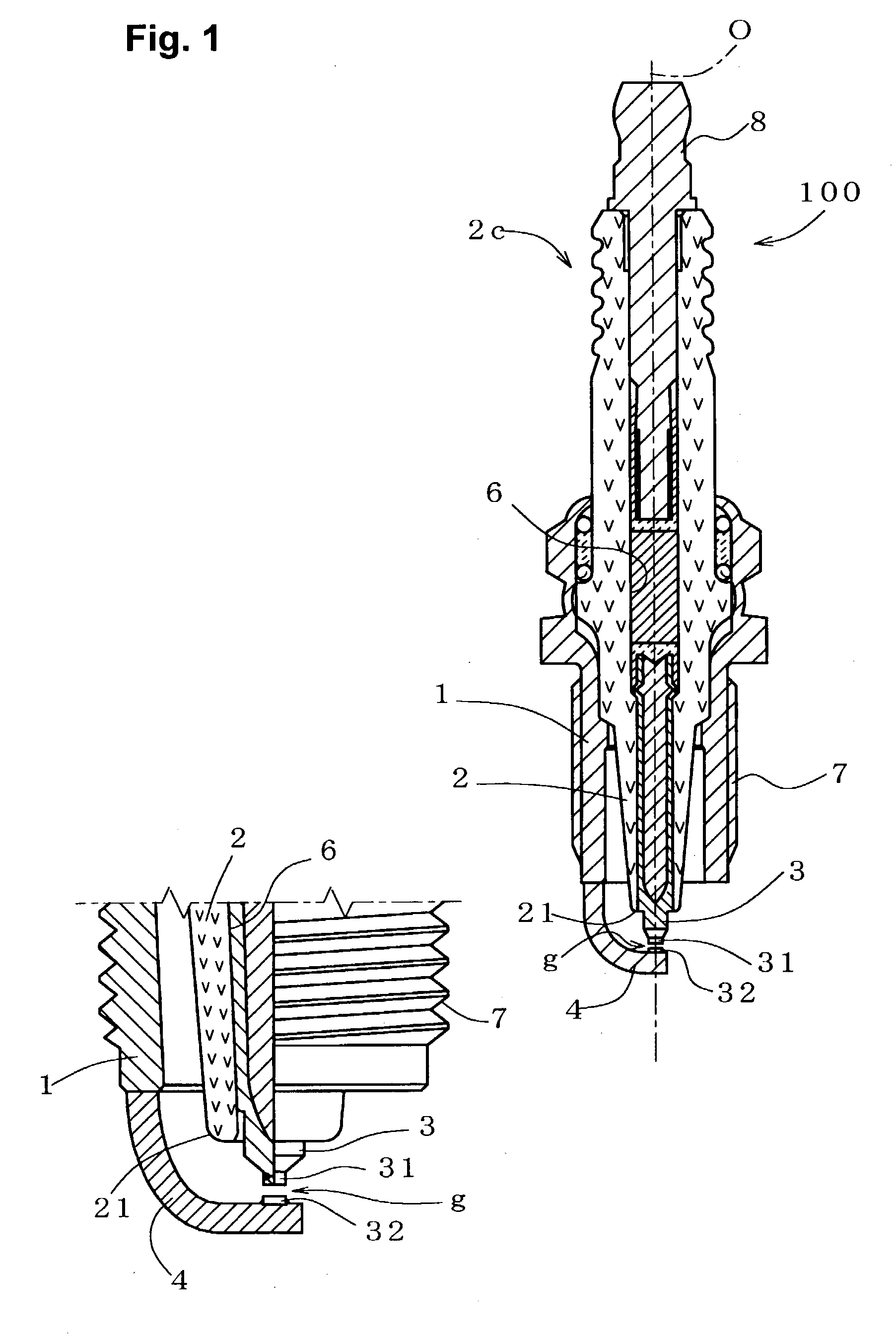

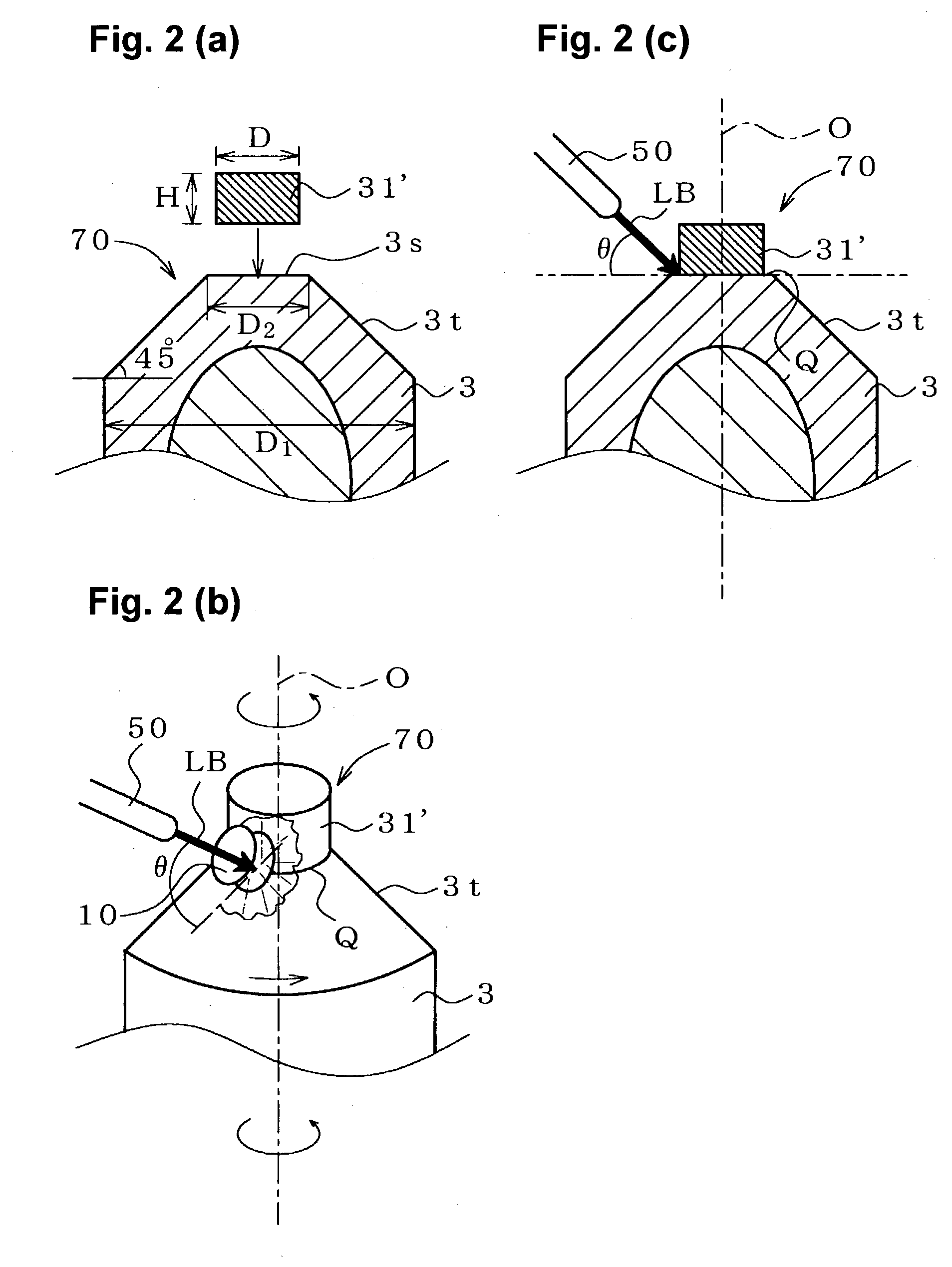

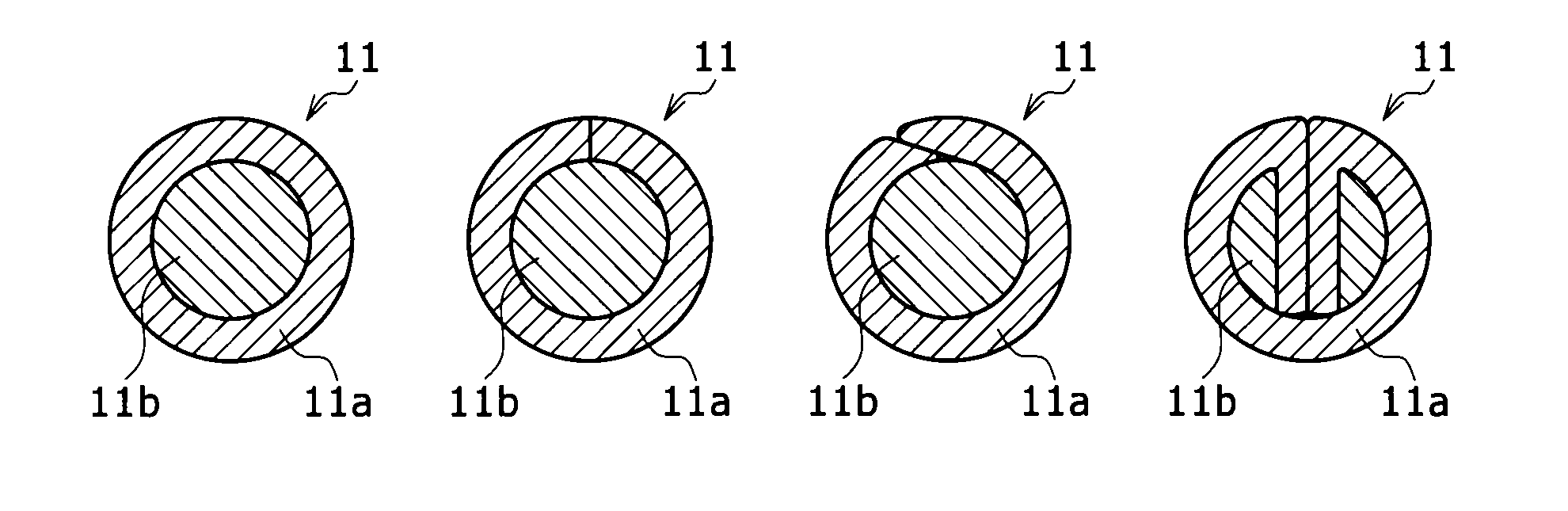

Method for manufacturing a spark plug, and spark plug

A method for manufacturing a spark plug which reduces the generation of spatters and the possibility of insufficient weld strength resulting from penetration depth insufficiency of a weld metal portion is disclosed. In accordance with the method, a chip joint face formation portion of a center electrode is formed from a heat-resistant alloy predominantly containing Fe or Ni. A noble metal chip is attached to a chip joint face of the chip joint face formation portion to thereby form a chip-attached assembly. A full-circled laser-beam weld metal portion is formed on the chip-attached assembly in such a manner as to intrude into the noble metal chip and into the chip joint face formation portion. A graded-index-type fiber optic cable is used as an optical transmission path extending between a laser beam generator and an optical emission section. A laser beam which is transmitted from the laser beam generator through the cable irradiates the chip-attached assembly while being condensed.

Owner:NGK SPARK PLUG CO LTD

Flux-cored nickel-based alloy wire

InactiveUS20110171485A1Improve solderabilityImprove pitting resistanceWelding/cutting media/materialsThin material handlingPotassiumLithium compound

A flux-cored nickel-based alloy wire contains, based on the total mass of the wire, 3 to 11 percent by mass of TiO2, 0.2 to 1.3 percent by mass of SiO2, 1 to 3 percent by mass of ZrO2, and 0.3 to 1.0 percent by mass of manganese oxides in terms of MnO2, contains of a total of 0.2 to 1.0 percent by mass in terms of Na, K and Li of sodium compounds, potassium compounds, and lithium compounds. The flux has a ratio (([TiO2]+[ZrO2]) / [SiO2]) of the total of the TiO2 and ZrO2 contents to the SiO2 content of 5.0 to 14.5, in which [TiO2], [SiO2] and [ZrO2] represent TiO2, SiO2 and ZrO2 contents. The wire shows excellent weldability in welding of all positions typically on 9% nickel steels and nickel-based alloy steels and gives a weld metal having good pitting resistance, bead appearance, and resistance to hot cracking.

Owner:KOBE STEEL LTD

Semiconductor chip assembly with welded metal pillar of stacked metal balls

InactiveUS7446419B1Improve protectionStable supportSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

A semiconductor chip assembly includes a semiconductor chip that includes a conductive pad, a conductive trace that includes a routing line and a metal pillar, a connection joint that electrically connects the routing line and the pad, and an encapsulant. The chip and the metal pillar are embedded in the encapsulant, the routing line extends laterally beyond the metal pillar towards the chip, and the metal pillar is welded to the routing line and includes stacked metal balls that are welded together.

Owner:BRIDGE SEMICON

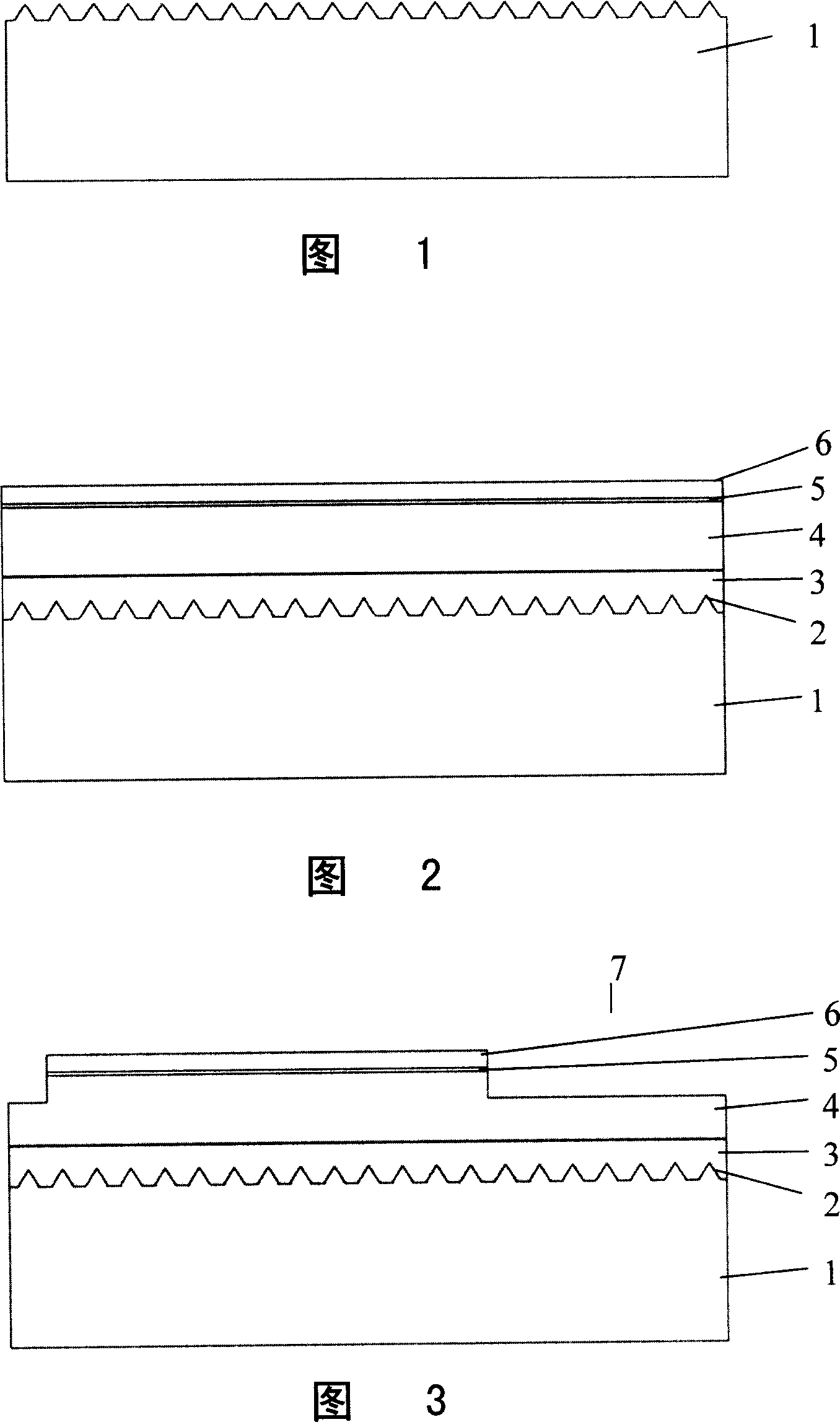

Coarse sapphire bushing LED and its making method

The invention discloses a production method of sapphire underlay granulated LBD that comprises providing a upside-down charging jointing plate and a sapphire underlay which includes a frontispiece and rear, and the first granulation surface which is corrupted to the frontispiece of the sapphire underlay by damp; the III-group nitride semiconductor multi film grows on the granulated underlay to form the LED chip, GaN crystal layer, GaN 2-D flat layer, n type GaN layer, lightening layer and p type GaN layer grows form the frontispiece of the underlay sequentially; the p type GaN layer of the LED chip is corroded partly to n type GaN layer; the p,n electrode are deposited to the LED chip; several press welding metal protruding points are deposited to the p, n electrode; step 6, the second granulation surface is formed on the back of the underlay; the LED chip is welded with upside-down charging jointing plate via upside-down metal protruding points. The sapphire underlay rear of invention is produced by damp. The craft is easy, the efficient is high. It can improve the efficiency remarkably.

Owner:HANGZHOU SILAN AZURE

900MPa high-strength steel preheating-free combined welding method

The invention discloses a 900MPa high-strength steel preheating-free combined welding method. 700-800 MPa low-hydrogen type high-tenacity shielded metal arc welding is adopted for backing welding, then a 900MPa high-tenacity solid wire is matched with Ar+CO2 mixed gas shielded welding for implementing filling welding, and a 800MPa flux-cored wire is matched with CO2 gas shielded welding for cosmetic welding. A crack-free welding joint can be obtained by welding 900MPa high-strength steel through adopting a preheating-free and postweld heat treatment free combined welding process, and a joint region is smooth and clean, and can meet operating requirements on a high-strength steel welding structure for higher bearing capacity because the room temperature tensile strength of weld metal is more than 860MPa and the damping power of a V-shaped notch of the weld metal with the test temperature of 0 DEG C is more than 90J; and meanwhile, the method has welding cost reduced by about 25 percent, simple and convenient operation and easy popularization.

Owner:SHANDONG UNIV

Electric arc welder

An electric arc welder for depositing weld metal along a groove between two edges of a metal workpiece where the welder comprises a first electrode driven by a first wire feeder toward a point in said groove, a second electrode driven by a second wire feeder toward the point and a main power source with a first output terminal connected to the first electrode and a second output terminal connected both to the second electrode and directly or indirectly to the metal workpiece to create a second electrode path and a workpiece path. The power source includes a high speed switching output stage for creating current with a selected AC waveform between the first and second output terminals where the waveform of the main power source is generated by a waveform generator controlling a pulse width modulator circuit to determine the current operation of the output stage.

Owner:LINCOLN GLOBAL INC

Weld joint and weld material thereof

InactiveCN1993488AIncreased durabilityImprove securityArc welding apparatusWelding/cutting media/materialsChemical compositionImpurity

A weld joint, characterized in that both of a base material and a weld metal have a chemical composition that C: 0.01 to 0.45%, Si: more than 1 % and not more than 4 %, Mn: 0.01 to 2 %, P: 0.05 % or less, S: 0.01 % or less, Cr: 15 to 35 %, Ni: 40 to 78 %, Al: 0.005 to 2 %, N: 0.001 to 0.2 % and Cu: 0.015 to 5.5 %, Ti: a content satisfying the following formula (1): {(Si - 0.01) / 30} + 0.01Cu <= Ti <= 5 (1) wherein an element symbol in the formula (1) means the content (mass %) of the element, and the balance: Fe and impurities. The base material and the weld metal may further contain one or more of Co, Mo, Ta, W, V, Zr, Nb, Hf, B, Ca, Mg and REM.

Owner:SUMITOMO METAL IND LTD

High-entropy alloy brazing filler metal for welding TA2 and 0Cr18Ni9Ti and preparation method thereof

InactiveCN101590574AHigh strengthImprove toughnessWelding/cutting media/materialsSoldering mediaElectric arc furnaceHigh entropy alloys

The invention discloses a high-entropy alloy brazing filler metal for welding TA2 and 0Cr18Ni9Ti. The brazing filler metal comprises the following compositions according to atomic percentage: 20 to 25 percent of Ti, 25 to 30 percent of Cu, 20 to 25 percent of Ni, 15 to 20 percent of Fe, 10 to 13 percent of Cr, 0.5 to 5 percent of Sn, 0.01 to 2 percent of In, and 0.01 to 2 percent of Ga. The invention also discloses a method for preparing a high-entropy alloy brazing filler metal foil, which comprises the following steps: smelting the compositions to obtain high-entropy master alloy in steps by a super-high vacuum arc furnace; and controlling the linear speed of a roller at 5 to 40m / s by a single roller rapid setting device to obtain the high-entropy alloy brazing filler metal foil. The high-entropy alloy brazing filler metal has good flexibility, and is convenient for processing and assembling; and in welding, the high-entropy alloy brazing filler metal has good matching property with welded metal and alloy, brazing seams have excellent corrosion resistance and are single-phase fcc solid solution tissues, and joints have high comprehensive mechanical performance.

Owner:XIAN UNIV OF TECH

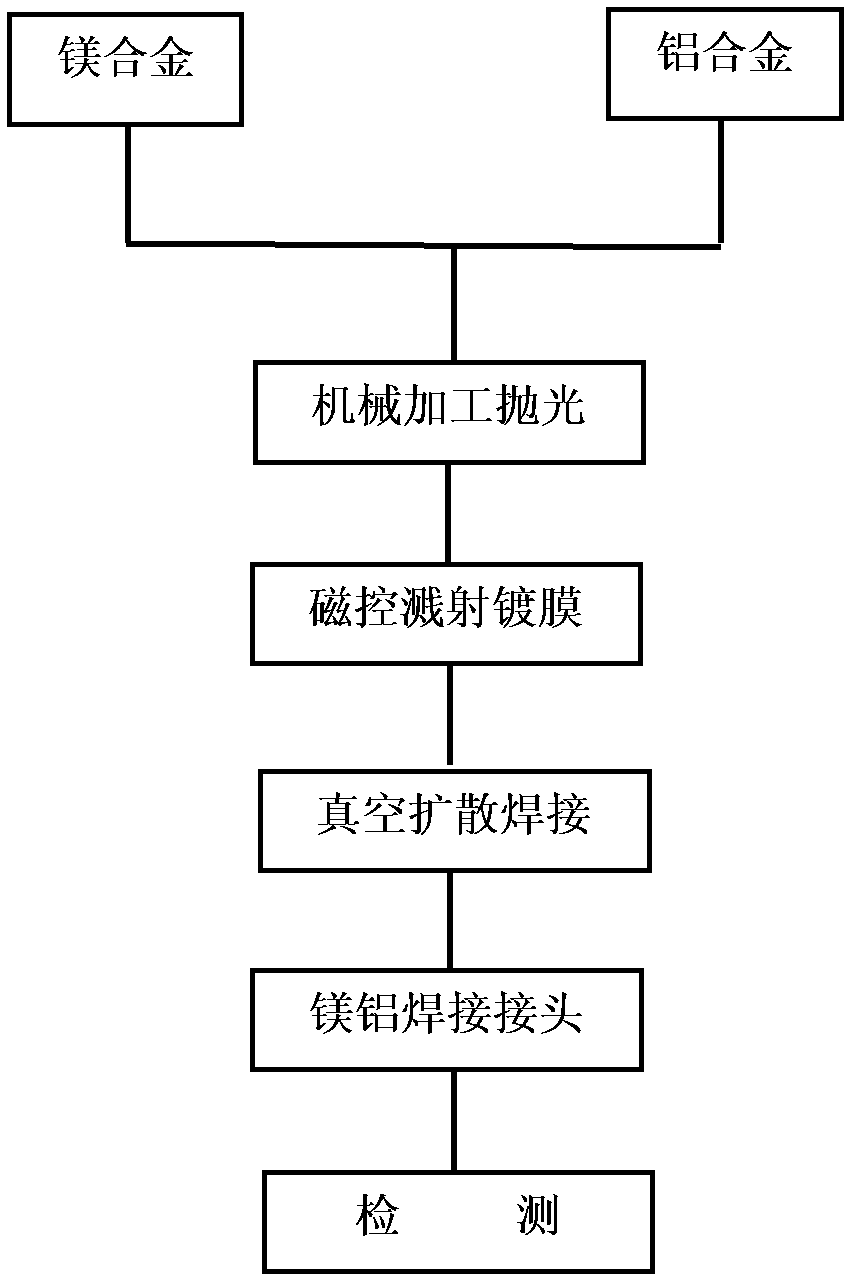

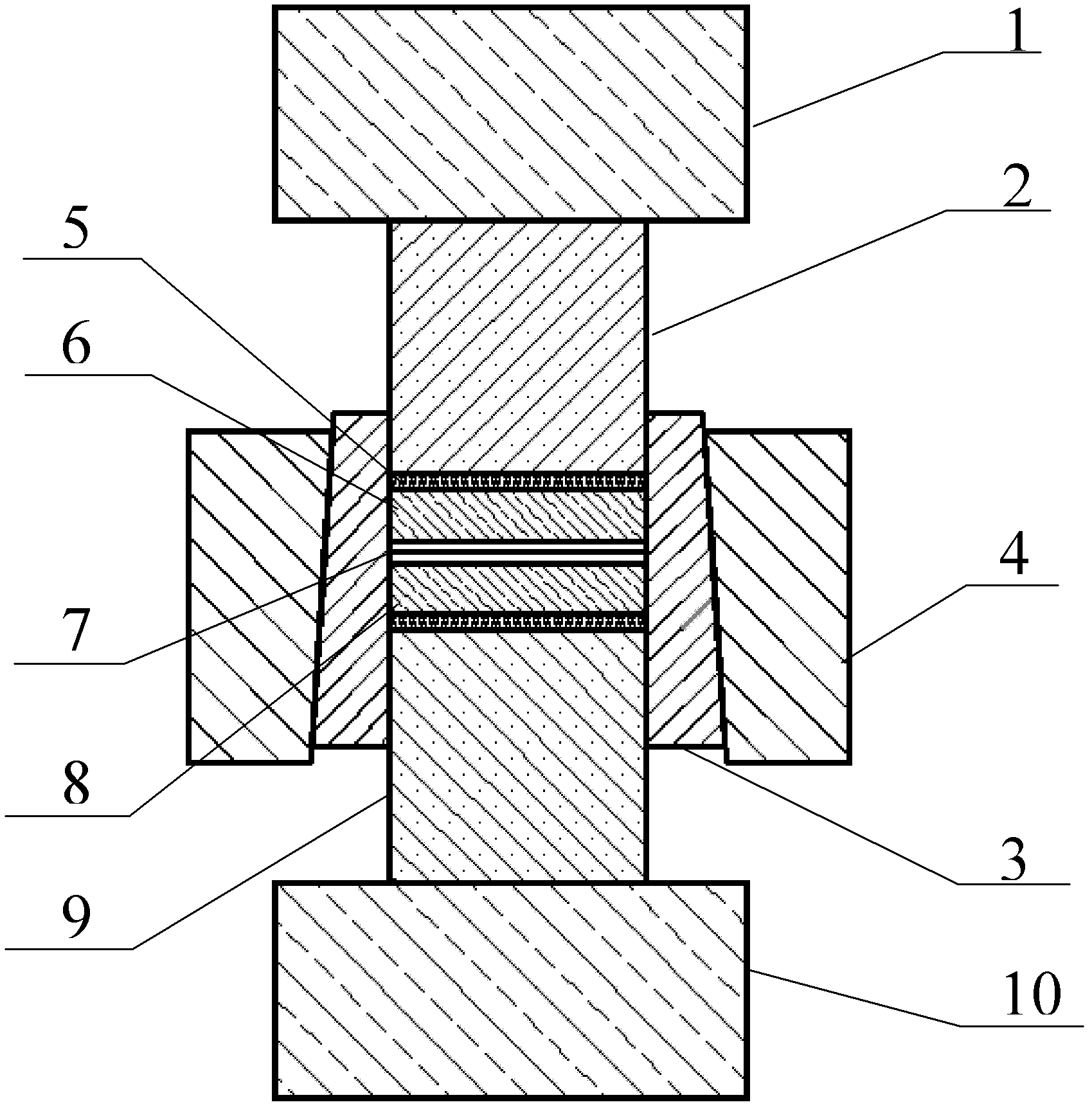

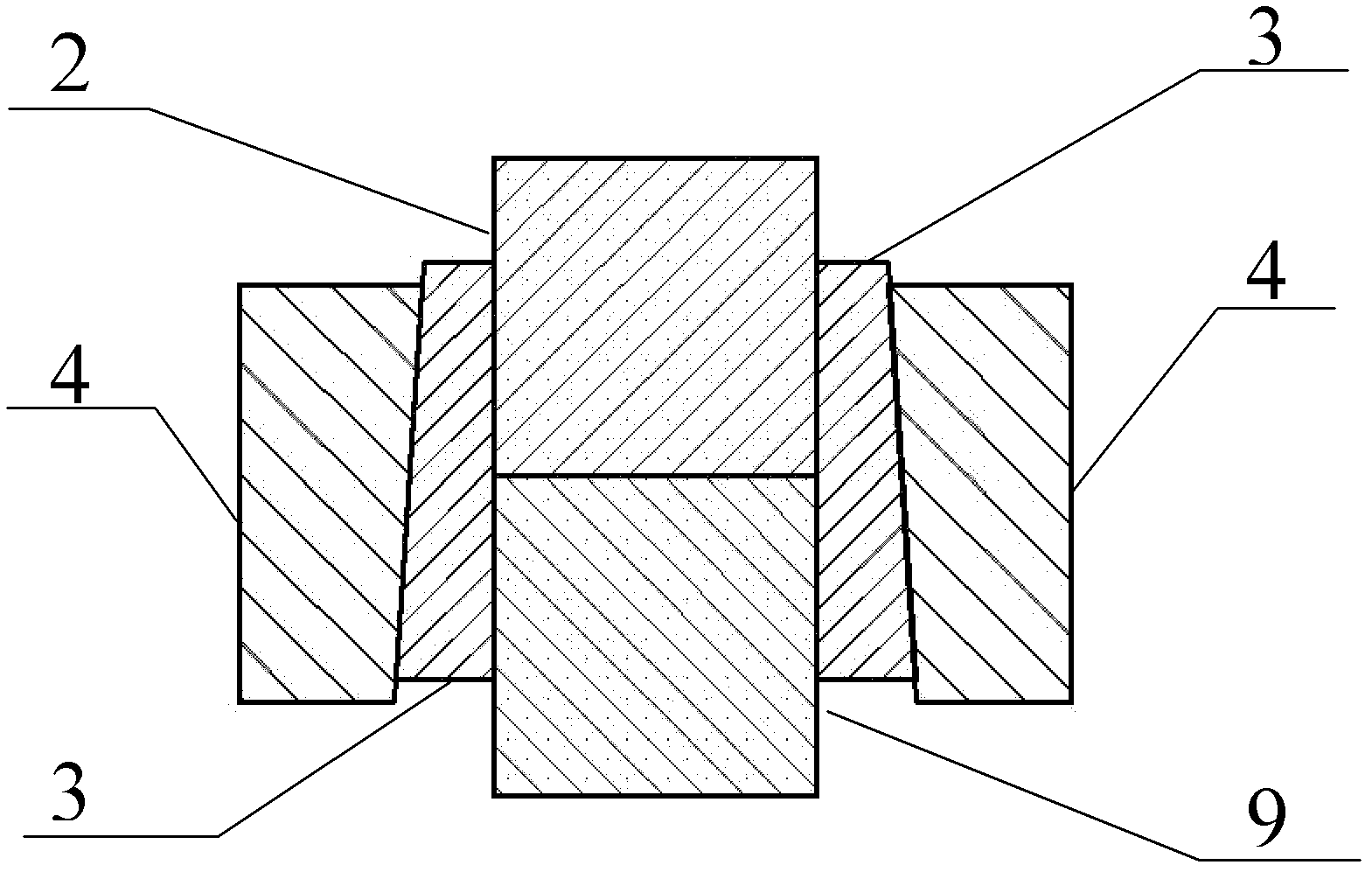

Magnesium alloy and aluminum alloy interlayer diffusion welding method

InactiveCN102248278AClosely connectedImprove parallelismVacuum evaporation coatingSputtering coatingCu elementMaterials science

The invention relates to a magnesium alloy and aluminum alloy interlayer diffusion welding method. The method mainly comprises the following steps of: (1) machining a welding metal base, namely processing, abrading, polishing and ultrasonically washing magnesium alloy and aluminum alloy; (2) depositing Cu films on the magnesium alloy and the aluminum alloy by controlling process parameters by using magnetron sputtering coating equipment; and (3) assembling the coated metal base by using a die, placing the die into a vacuum hot-pressing furnace, and controlling welding temperature, heat-preserving time and pressure to obtain a welding joint. The method has the advantages that: (1) the Cu film can protect the surface of the welding metal base better and reduce generation of inert metal oxide layers; (2) the Cu element improves phase constitution and the microstructure of a welding interface and inhibits generation of brittle intermetallic compounds in the midlayer of the welding joint; and (3) the welding joint has high strength, the tensile strength can reach 10 to 20 MPa, small deformation occurs in the welding joint, and the residual stress is small.

Owner:WUHAN UNIV OF TECH

High-strength and high-tenacity gas shielded welding wire

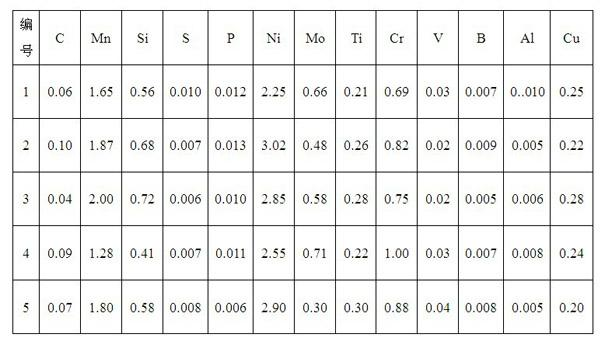

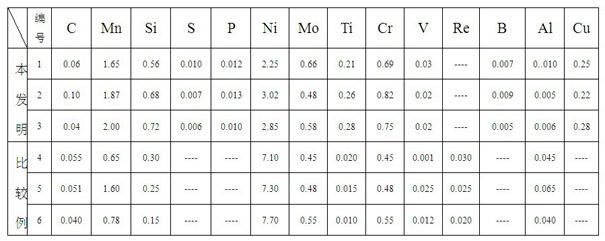

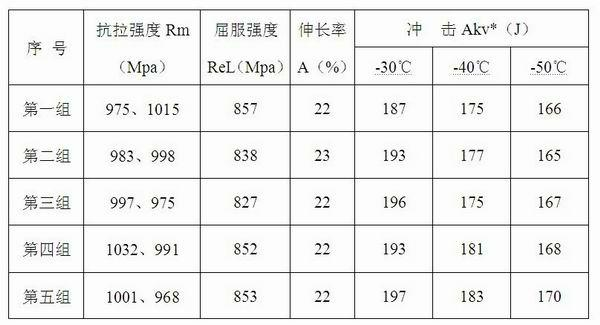

ActiveCN101992365AThe smelting process is stableEasy to implementWelding/cutting media/materialsSoldering mediaManganeseMixed gas

The invention discloses a high-strength and high-tenacity gas shielded welding wire. The welding wire comprises the following chemical composition in percentage by mass: 0.02 to 0.12 percent of carbon (C), 1.20 to 2.10 percent of manganese (Mn), 0.20 to 1.00 percent of silicon (Si), less than or equal to 0.010 percent of sulfur (S), less than or equal to 0.015 percent of phosphorus (P), 2.00 to 3.50 percent of nickel (Ni), 0.20 to 0.80 percent of molybdenum (Mo), 0.20 to 0.30 percent of titanium (Ti), 0.60 to 1.20 percent of chromium (Cr), less than or equal to 0.05 percent of vanadium (V), 0.005 to 0.010 percent of boron (B), less than or equal to 0.015 percent of aluminum (Al), less than or equal to 0.35 percent of copper (Cu) and the balance of iron (Fe). The welding wire is used for welding steels of a strength grade of between 850 and 950MPa; and under the protection of a mixed gas (80 percent of argon (Ar) and 20 percent of carbon dioxide (CO2)), the weld metal tensile strength of the welding wire is more than or equal to 850MPa, the yield strength is more than or equal to 720MPa, the elongation is more than or equal to 22 percent, and the low-temperature impact toughness Akv is more than or equal to 181J at the temperature of -30 DEG C, or more than or equal to 175J at the temperature of -40 DEG C, or more than or equal to 162J at the temperature of -50 DEG C.

Owner:CHENGDU XINDAYANG WELDING MATERIAL

Flux-cored wire for gas-shielded Arc welding of heat resisting steel

InactiveUS20020003135A1Improve mobilityImprove mechanical propertiesArc welding apparatusWelding/cutting media/materialsSlagFluoride

A flux-cored wire for gas-shielded arc welding of heat-resisting steel in the form of a steel tube filled with a flux, which is characterized in that the content of slag-forming agent is 6.10-9.90 mass % (based on the total mass of the wire), said steel tube and said flux all together contain less than 0.20 mass % C, 0.06-1.40 mass % Si, 0.55-1.60 mass % Mn, 0.004-0.090 mass % Cu, 0.004-0.090 mass % Ni, less than 2.60 mass % Cr, and 0.3-1.20 mass % Mo (based on the total mass of the wire), and said flux contains 4.2-8.2 mass % TiO2, 0.025-0.25 mass % of metal fluoride (in terms of fluorine), and 0.20-1.50 mass % Mg. The flux-cored wire has both good welding maneuverability and ability to give weld metal with good mechanical properties, such as strength and toughness.

Owner:KOBE STEEL LTD

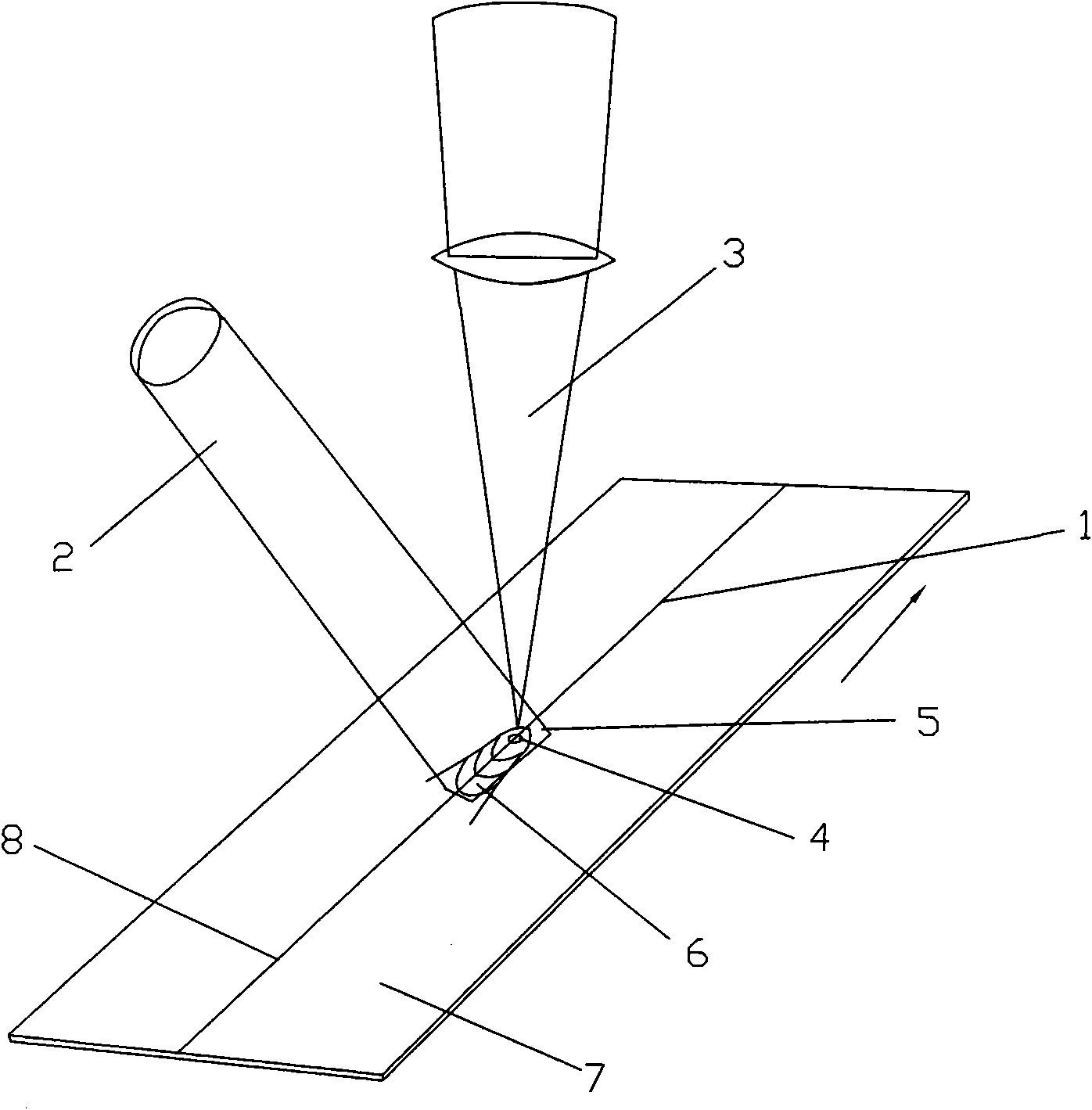

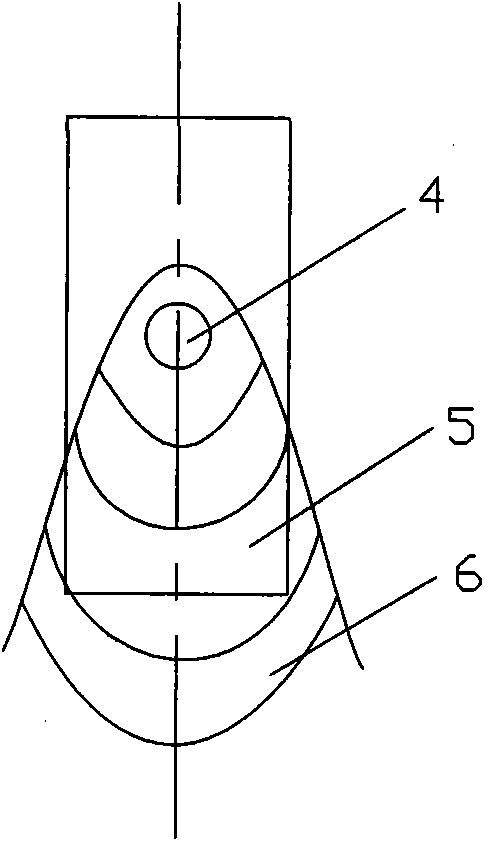

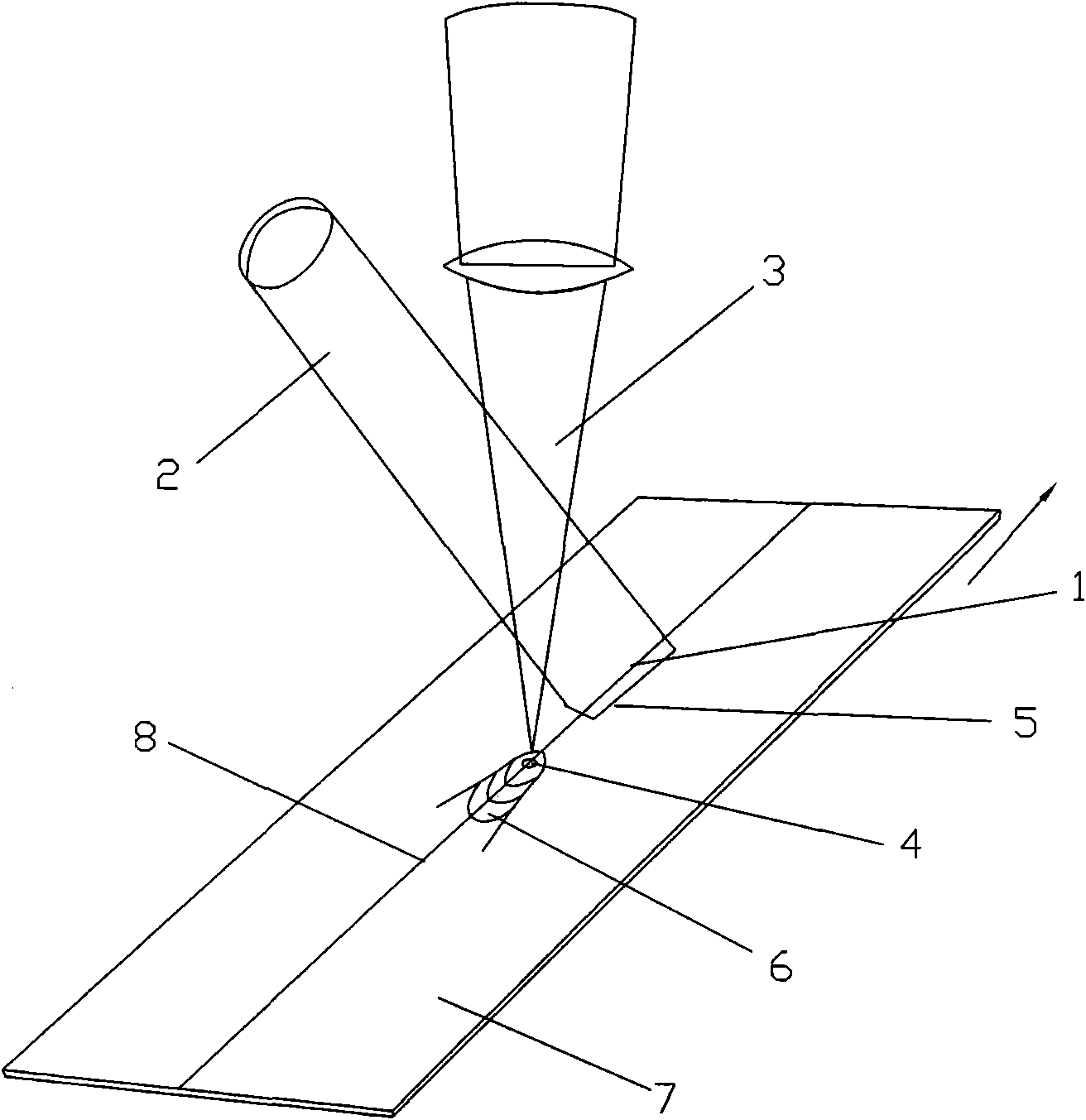

Compound welding method by using semiconductor laser and CO2 laser

InactiveCN101564799AFast preheating and homogenizationReduce temperature gradientLaser beam welding apparatusThermal treatmentCo2 laser

A compound welding method by using semiconductor laser and CO2 laser comprises the steps: using a semiconductor laser and a CO2 laser to be positioned on one side of a welding line of welded metals in a certain angle, adjusting a focusing position of the CO2 laser to cause a light spot of the CO2 laser to be positioned in the light spot of the semiconductor laser so that the welding direction is consistent with the slow axis direction of the semiconductor laser; using the semiconductor laser to pre-heat the welded metals, heating the part to be welded entering into the light spot of the semiconductor laser to 200-400 DEG C, using the CO2 laser to weld, and performing a post-welding thermal treatment to the welded metals by using the semiconductor laser for the welded parts of the welded metals welded by the welding of the CO2 laser. Due to synchronous pre-heating and post-heating treatments to the welding process, the invention can effectively solve the problem of cold cracking in high-strength steel welding and improve the quality of high-strength steel laser welding.

Owner:BAOSHAN IRON & STEEL CO LTD

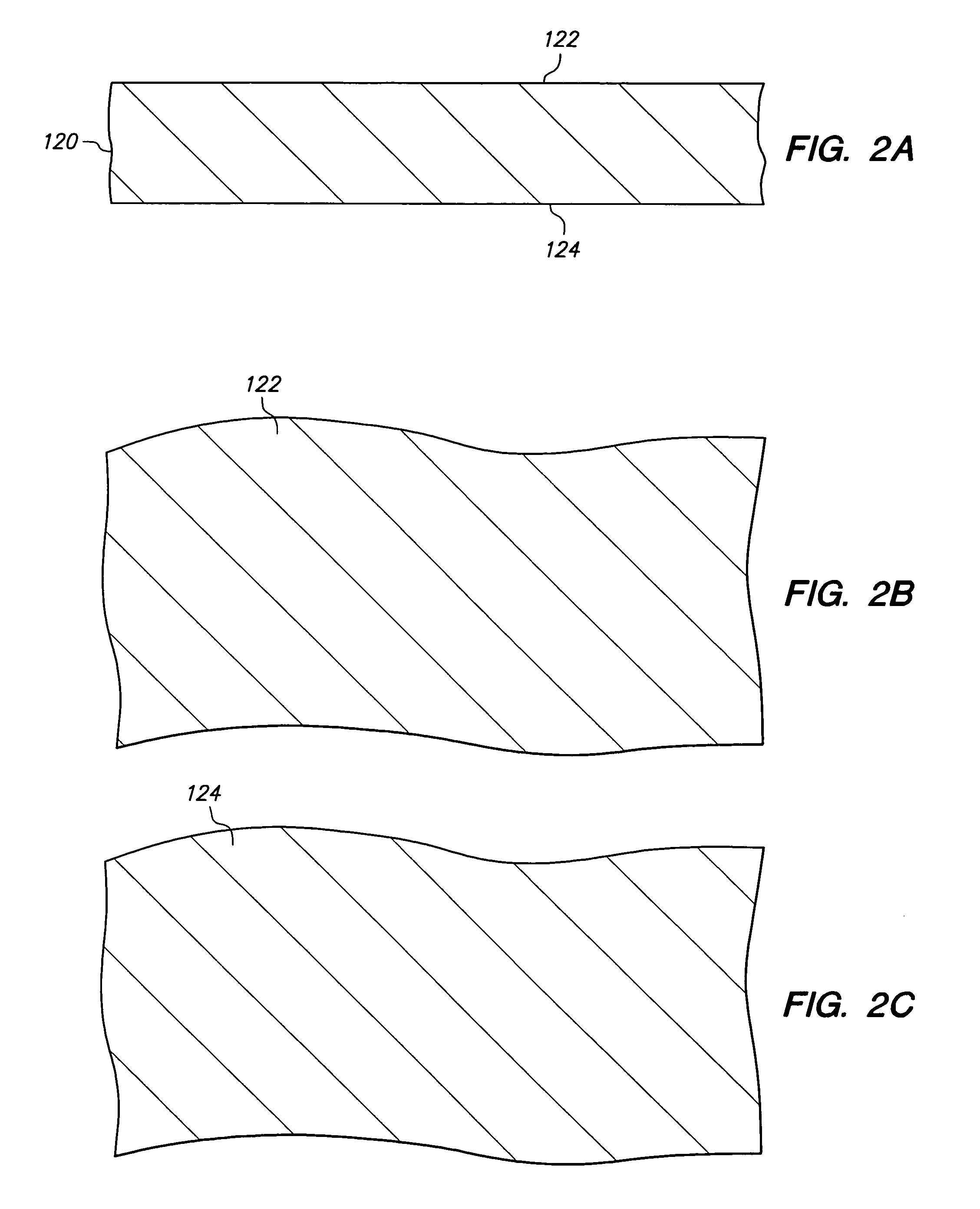

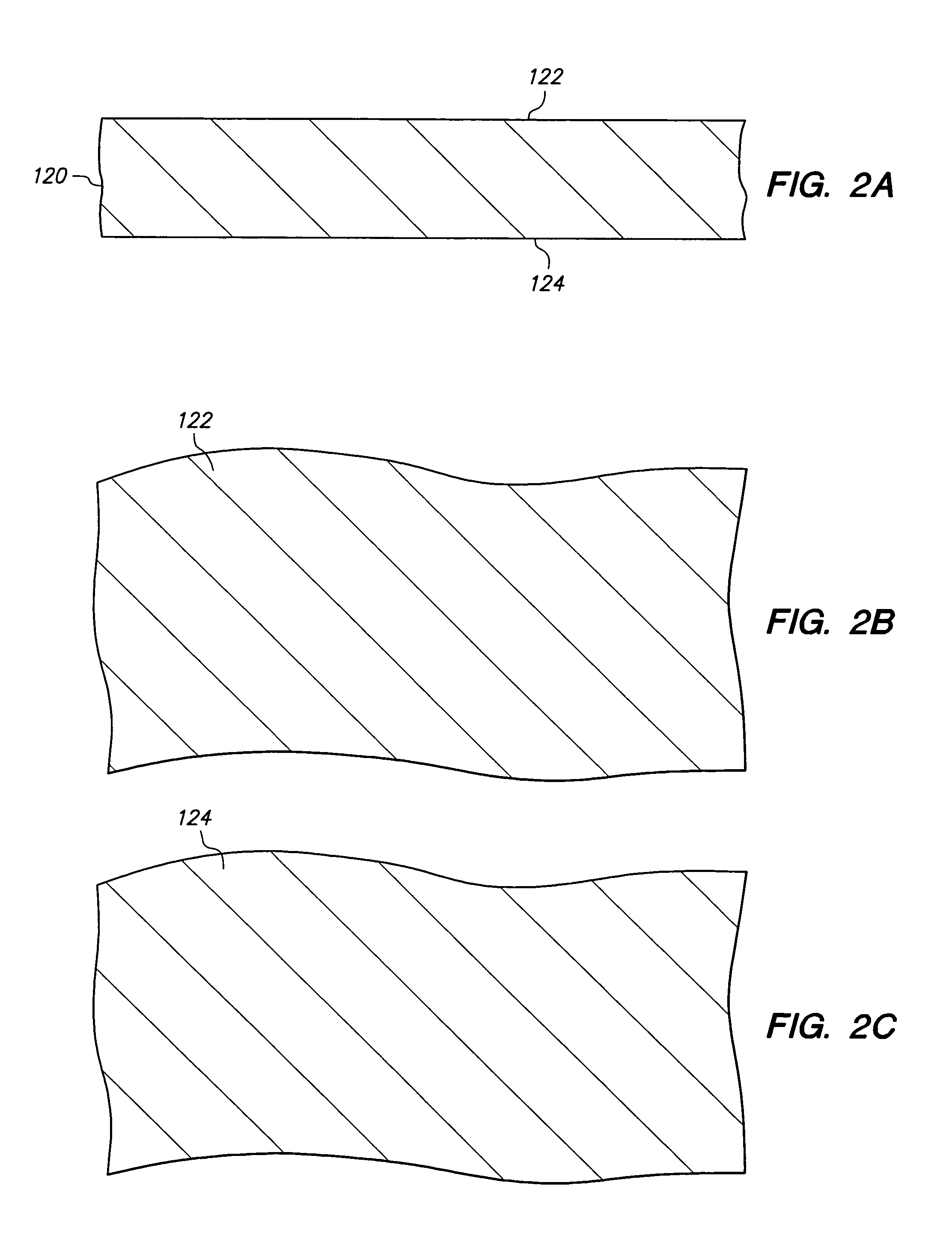

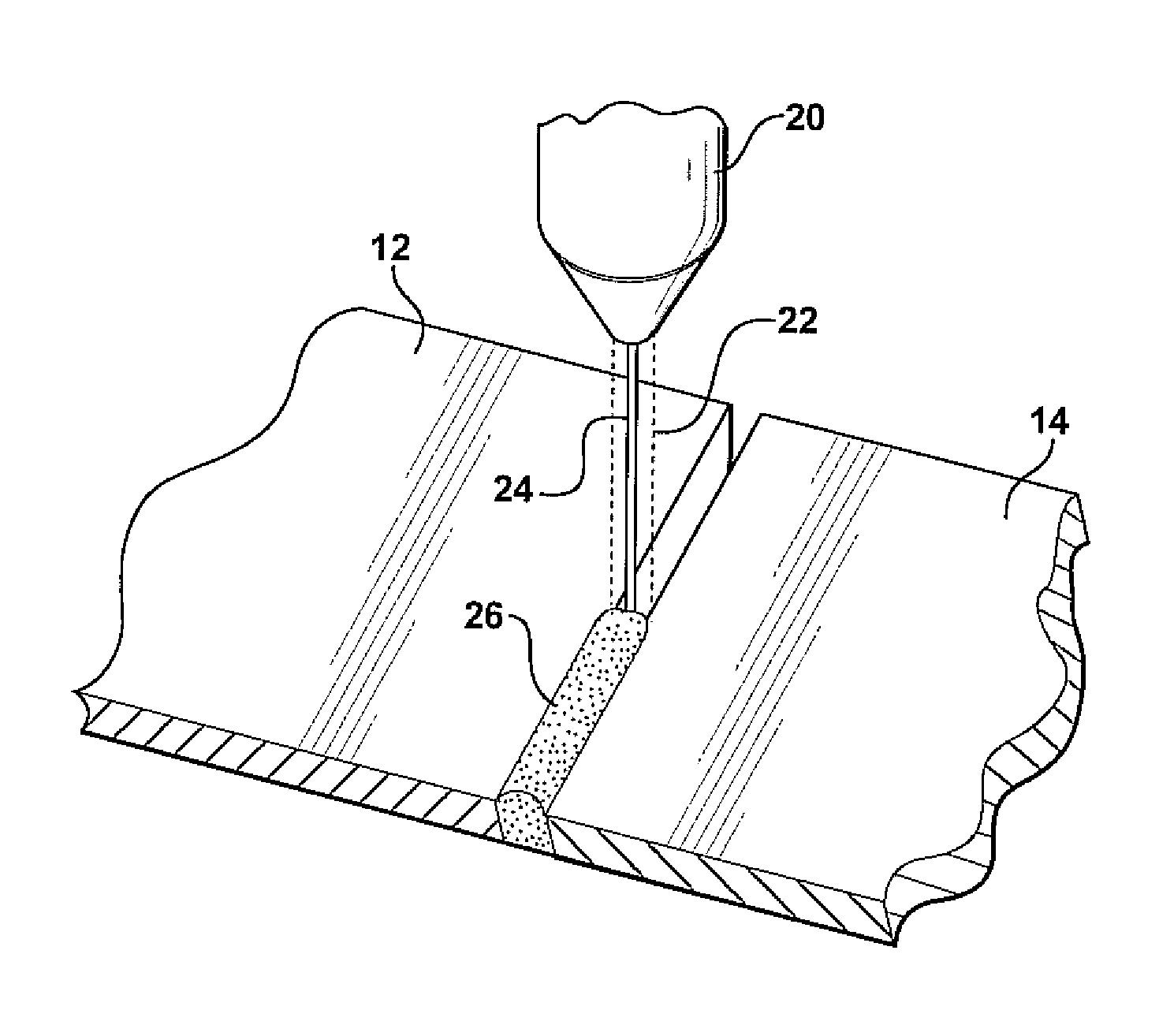

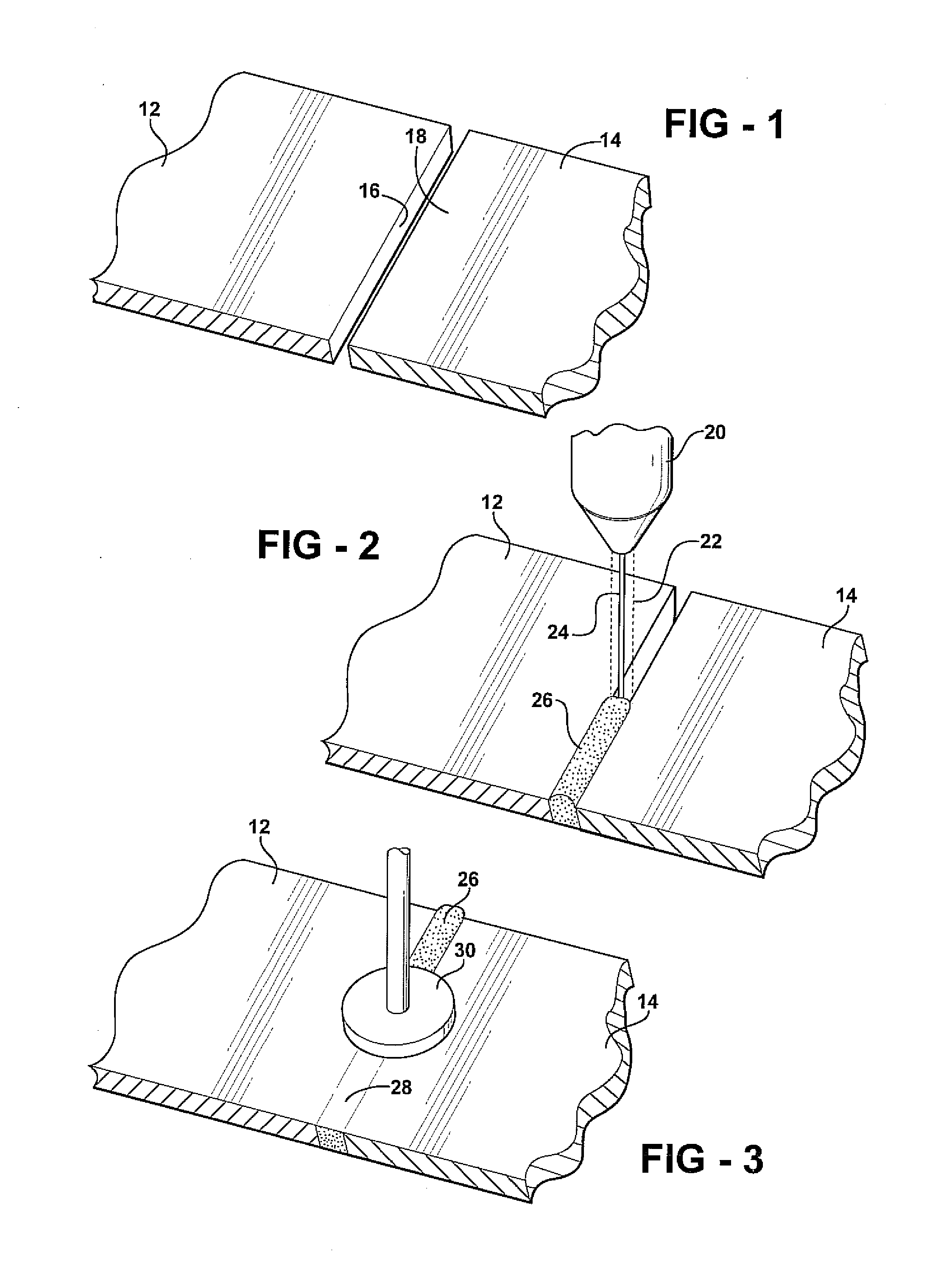

Method of manufacturing a welded metal panel having a high quality surface finish

InactiveUS20080128053A1Improve surface qualityReduce hardnessFurnace typesWelding/soldering/cutting articlesSurface finishWeld seam

In a method for preparing a welded metal panel having a high surface quality a first metal blank and a second metal blank are disposed so that edge portions of the blanks are in an abutting relationship. The blanks are laser welded together utilizing a powdered metal filler so as to produce a weld seam which is convex. A portion of the seam is removed to produce a flush weld seam between the blanks. The hardness of the weld seam is determined, and if the hardness of the weld seam is more than the hardness of the remainder of the panel, the weld seam is tempered so as to reduce its hardness. The thus produced welded metal panel may be subjected to a further shaping operation such as stamping, bending or the like. After shaping, the article may be plated, painted or otherwise finished.

Owner:NOBLE ADVANCED TECH

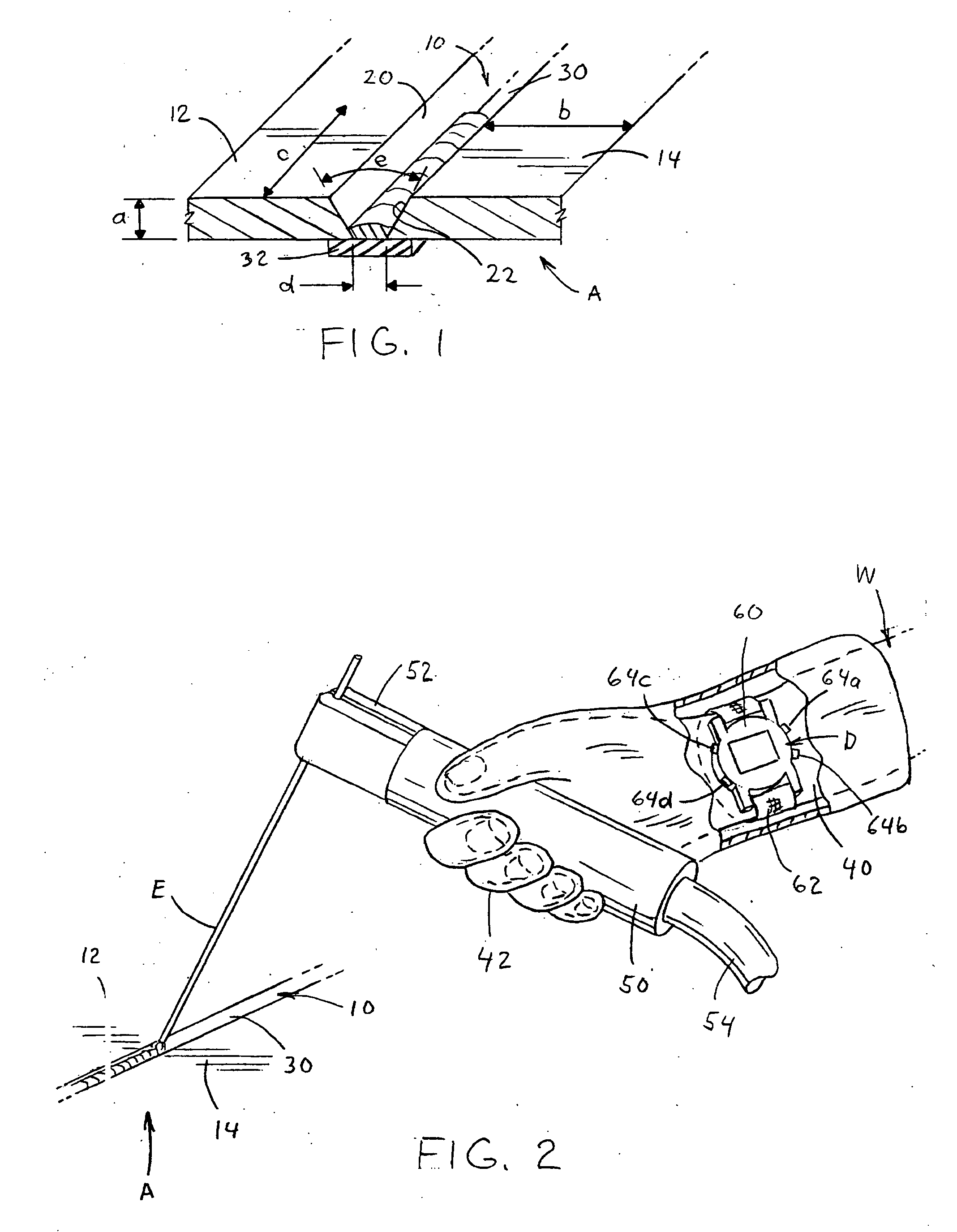

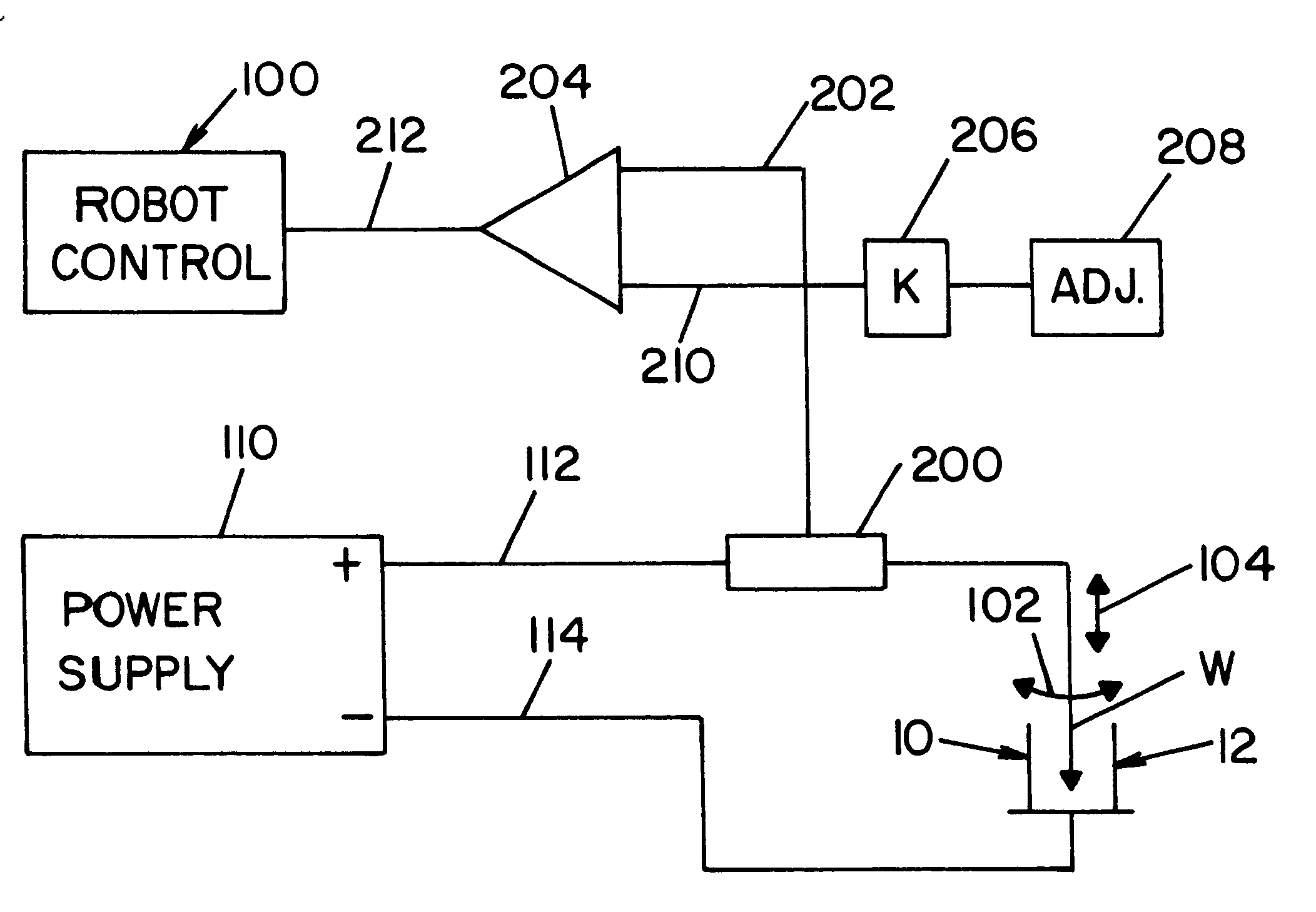

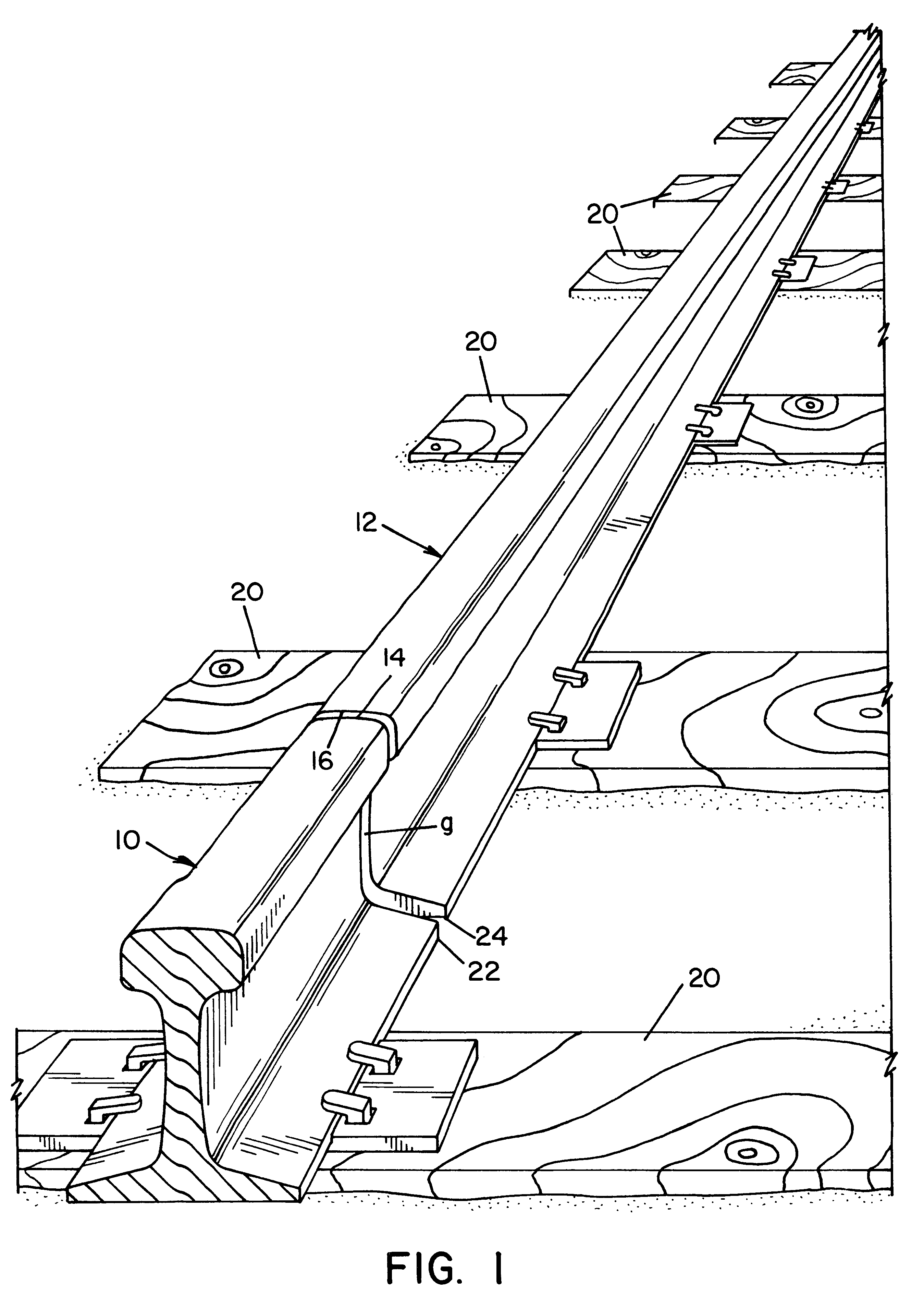

Method and system for welding railroad rails

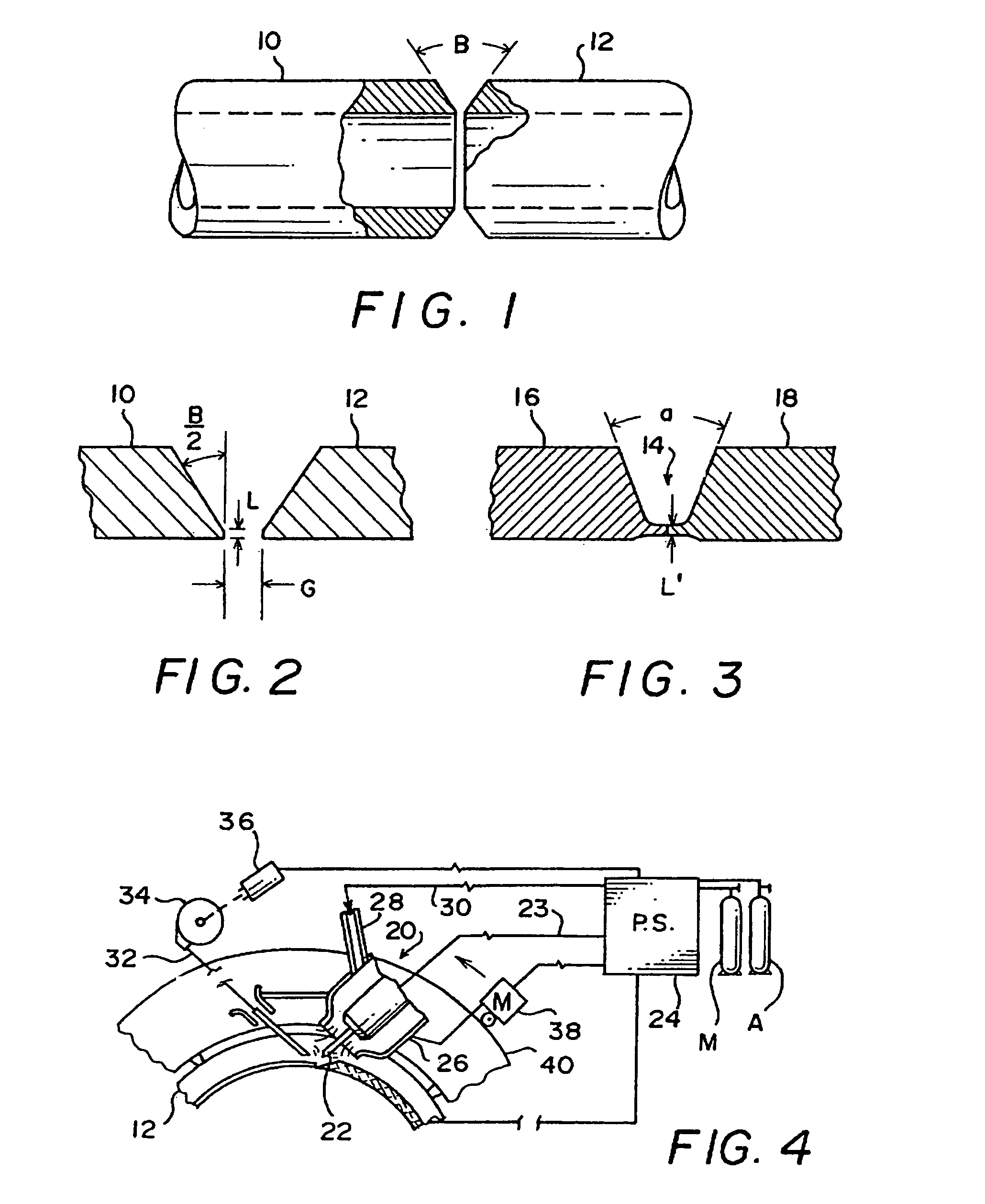

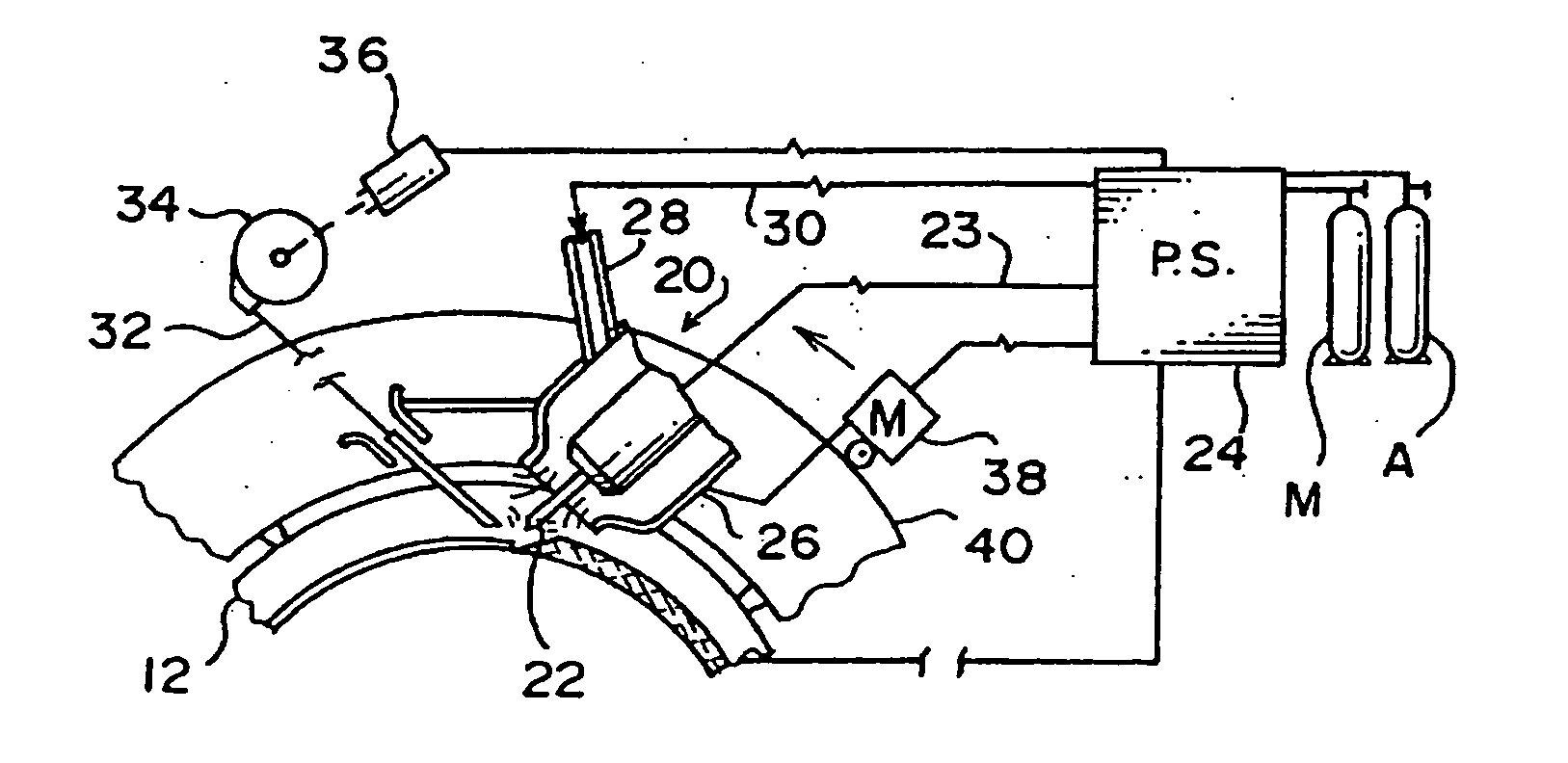

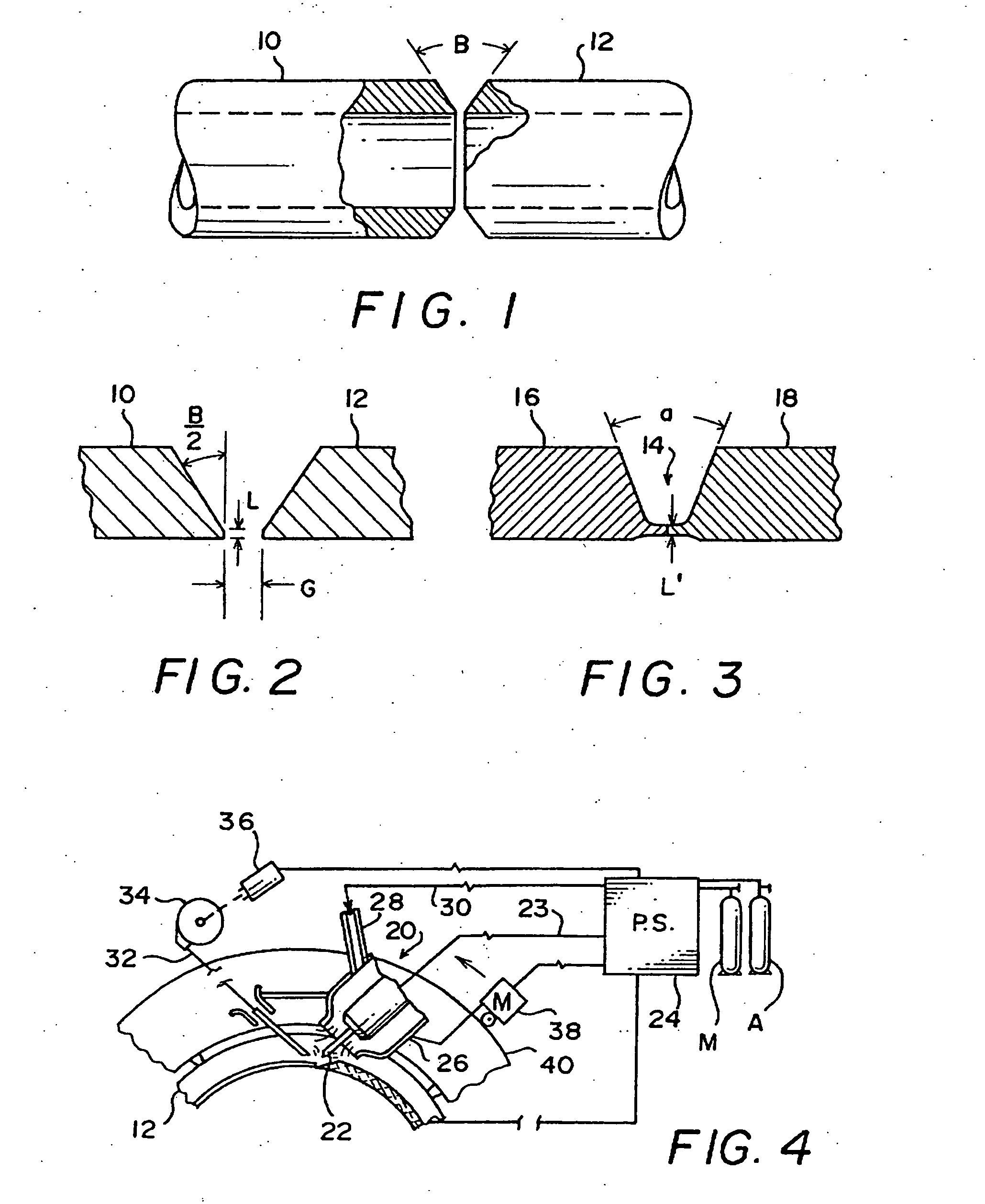

InactiveUS6201216B1Easy to implementReduce voltageRailsWelding/cutting auxillary devicesShortest distanceEngineering

A method and system of depositing molten metal from an advancing welding wire to form a root pass of weld metal in the bottom of a gap between first and second metal members having generally flat base elements joined by a metal backing plate extending between said base elements, which method and system includes passing welding current between the welding wire and the metal members from a power supply to create a heat generating welding arc, moving the welding wire in a given direction along selected path over the backing plate, sensing a blow through of the backing plate by the welding arc, reversing said given direction of said welding wire for a short distance when a blow through has been sensed and then, resuming movement of said welding wire in said given direction along the selected path.

Owner:LINCOLN GLOBAL INC

Ni-base heat resistant alloy and welded joint thereof

InactiveUS6702906B2Improve the immunityHigh strengthWelding/cutting media/materialsSoldering mediaEthyleneMetal

Owner:NIPPON STEEL CORP

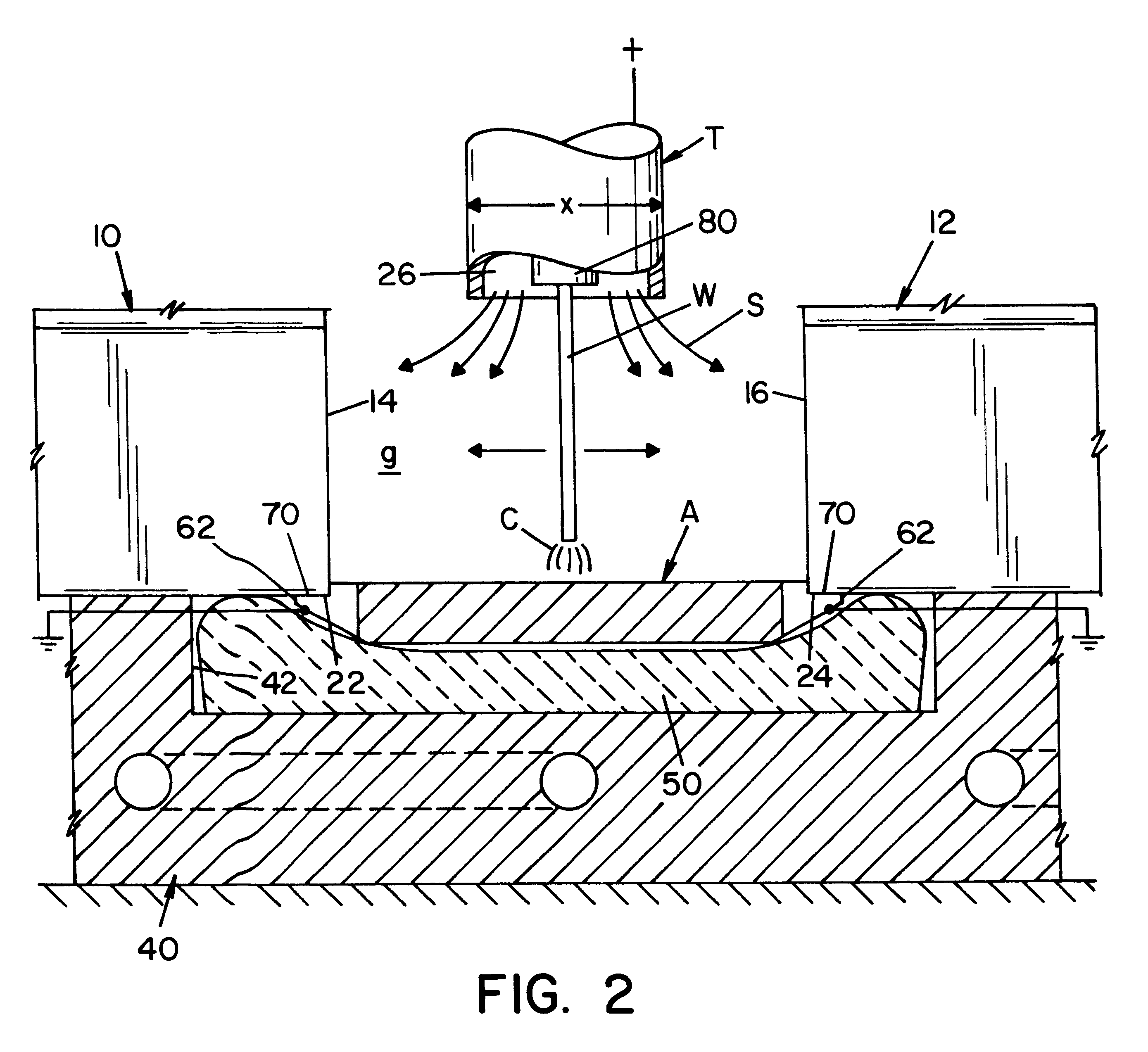

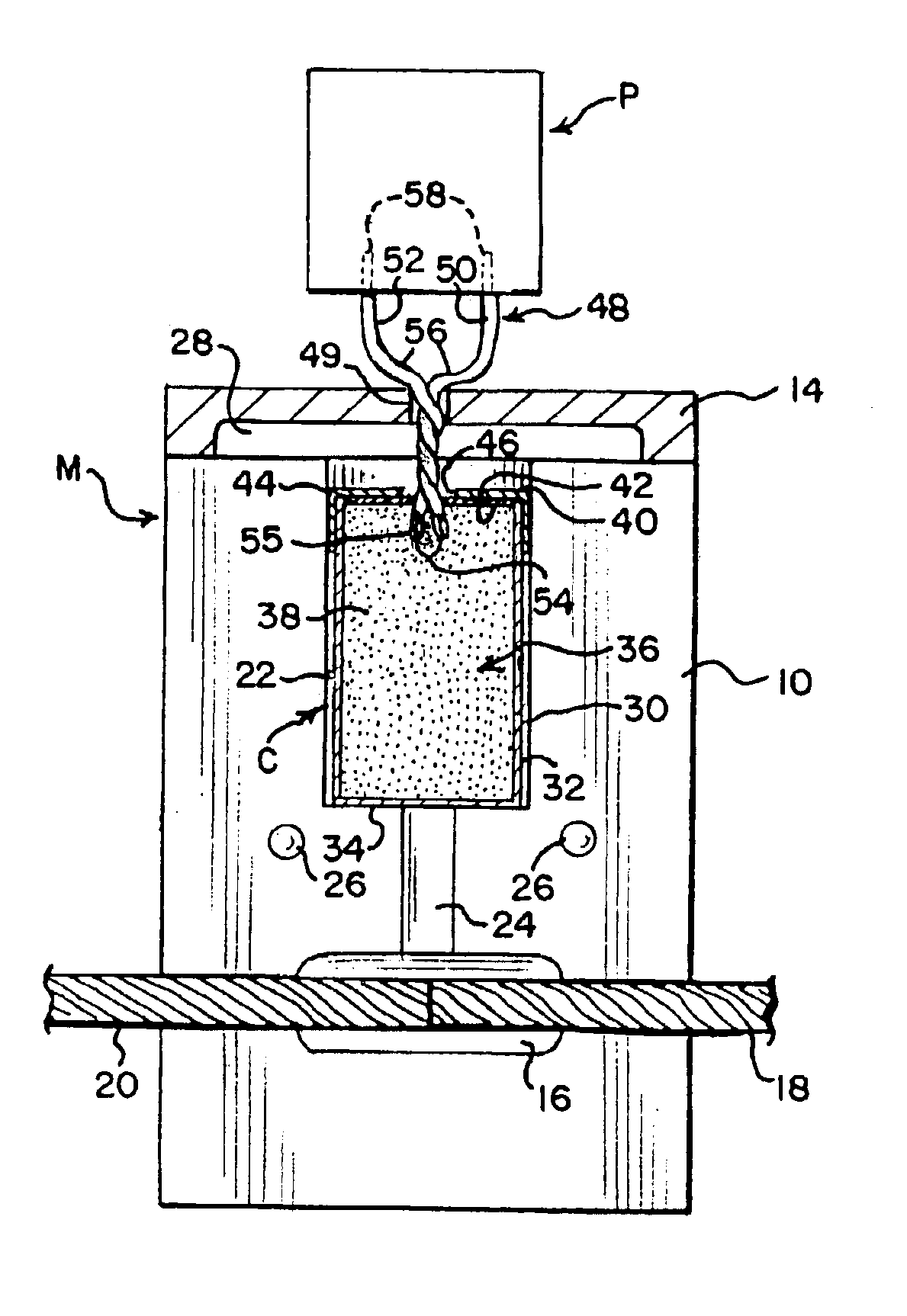

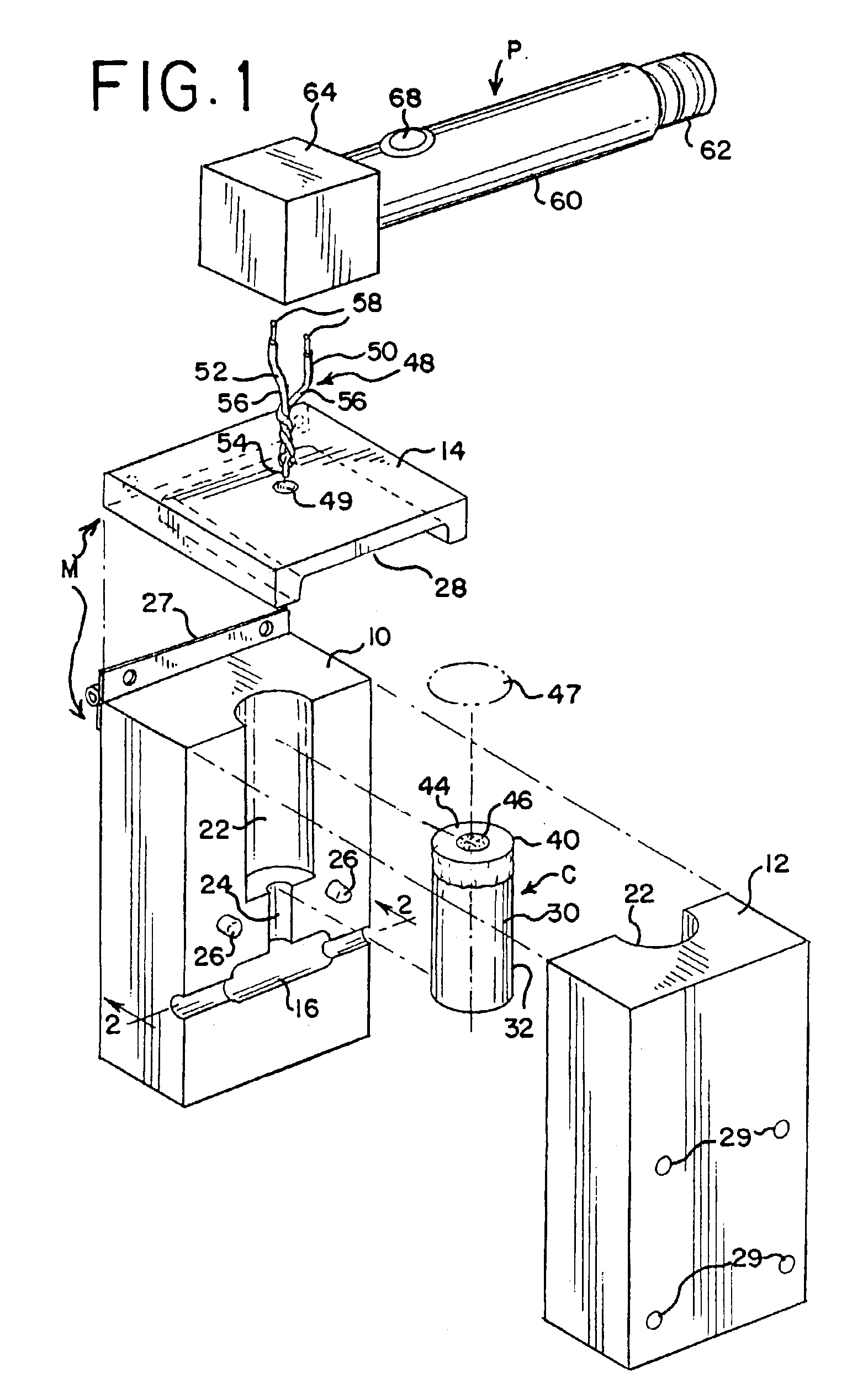

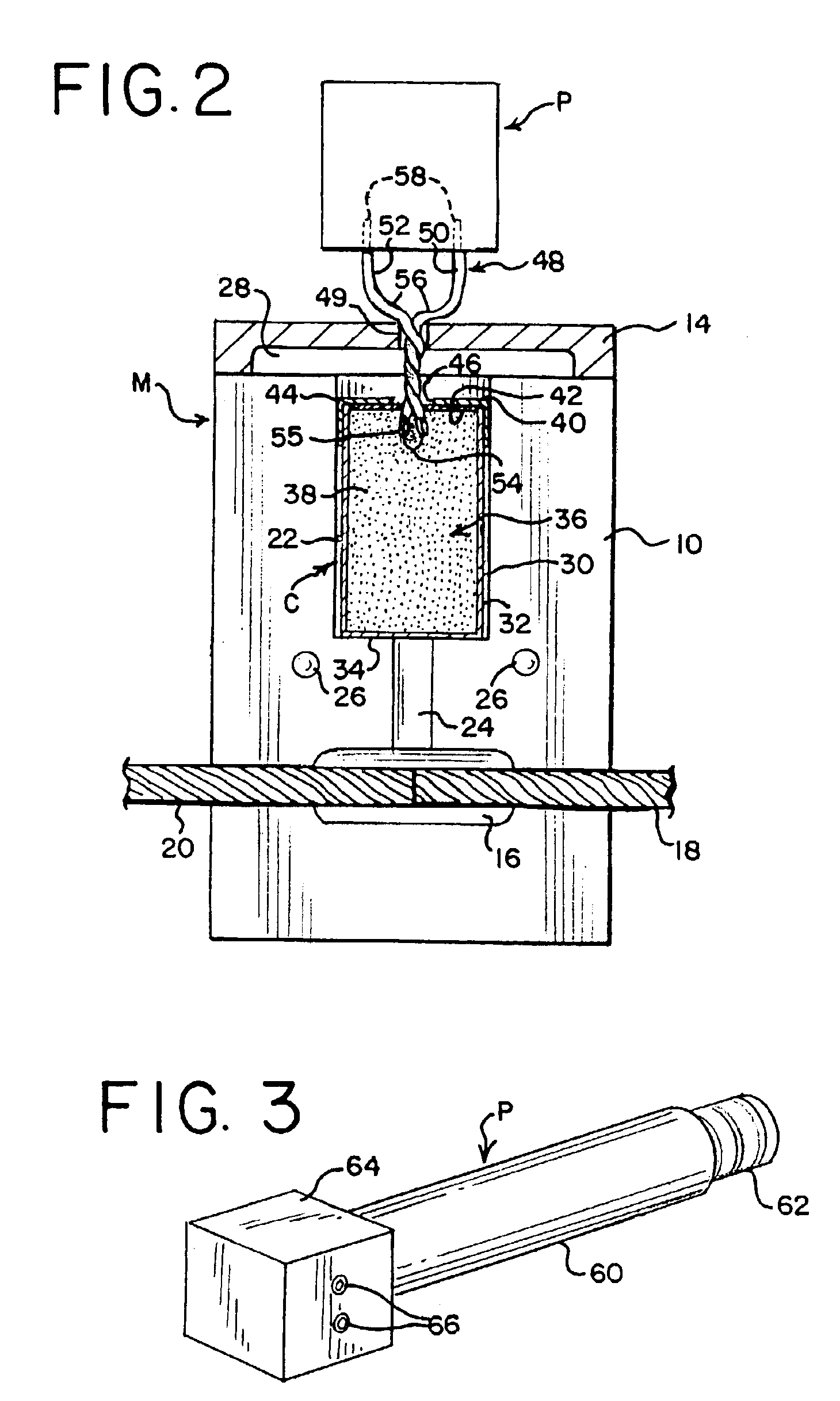

Exothermic welding

ActiveUS6994244B2Eliminate needImprove the immunityWelding/soldering/cutting articlesMetal working apparatusExothermic weldingEngineering

An assembly and method are disclosed for exothermic welding including a mold which is formed of a material which withstands exothermic welding temperatures, and includes a weld cavity therein for positioning at least two members which are to be exothermically welded together adjacent to each other, and an ignition cavity communicating with the first cavity. The members which are to be exothermically welded together are positioned adjacent to each other using the weld cavity, and a weld metal cartridge is positioned in the ignition cavity. The cartridge comprises a container having copper walls which define a chamber therein, and a particulate weld metal in the chamber. The tip of an electrical igniter is positioned into the chamber of the container and particulate weld material therein, the igniter is electrically fired while the container is in the ignition cavity of the mold to melt the particulate weld material, and the contents of the ignition cavity are passed after melting the particulate weld metal to the weld cavity to weld the members together.

Owner:HARGER

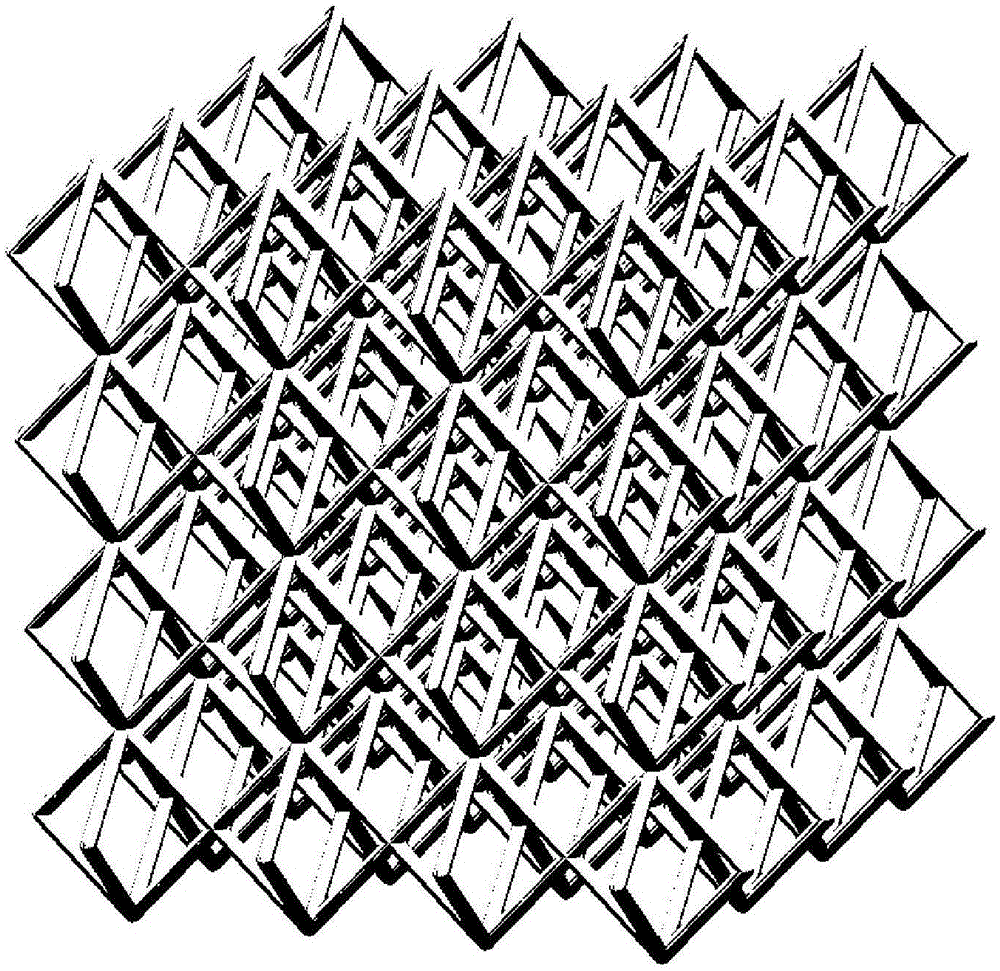

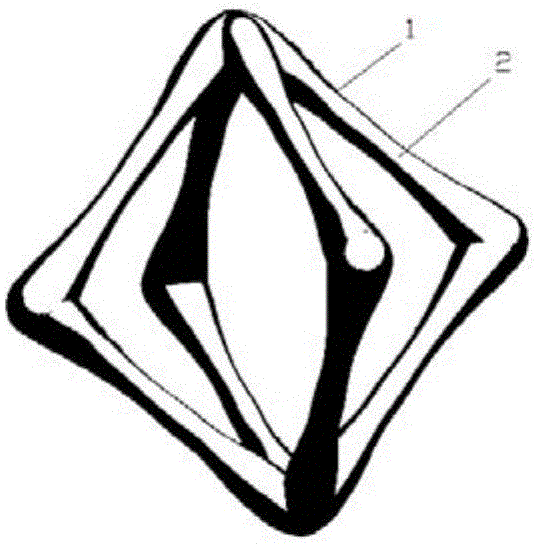

Section-variable metal lattice structure and machining method thereof

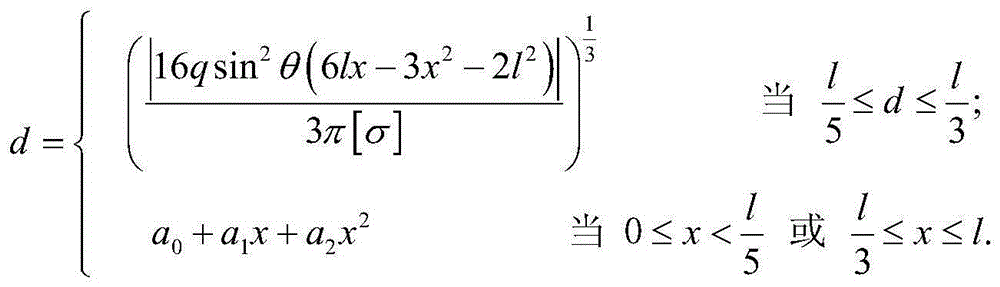

The invention discloses a section-variable metal lattice structure and a machining method thereof. The section-variable metal lattice structure comprises a plurality of section-variable lattice units arranged in the space. Each section-variable lattice unit is formed by connecting a plurality of section-variable rod pieces. The section-variable metal lattice structure is formed by conducting sintering layer by layer through a laser melting technology. A working bin of a metal powder sintering machine is kept sealed before machining with nitrogen being protection gas. For the internal force characteristics of all parts of the rod pieces, the rod pieces of the metal lattice units are optimized. Compared with an even lattice structure formed by weaving and welding metal wires, the section diameter of the section-variable rod pieces in the section-variable lattice structure is accurately determined by the internal force condition needing to be met under the load condition, materials forming the section-variable rod pieces are increased or decreased according to the stress gradient in the section-variable rod pieces, powder materials are saved, and the light characteristic is improved.

Owner:CHONGQING UNIV

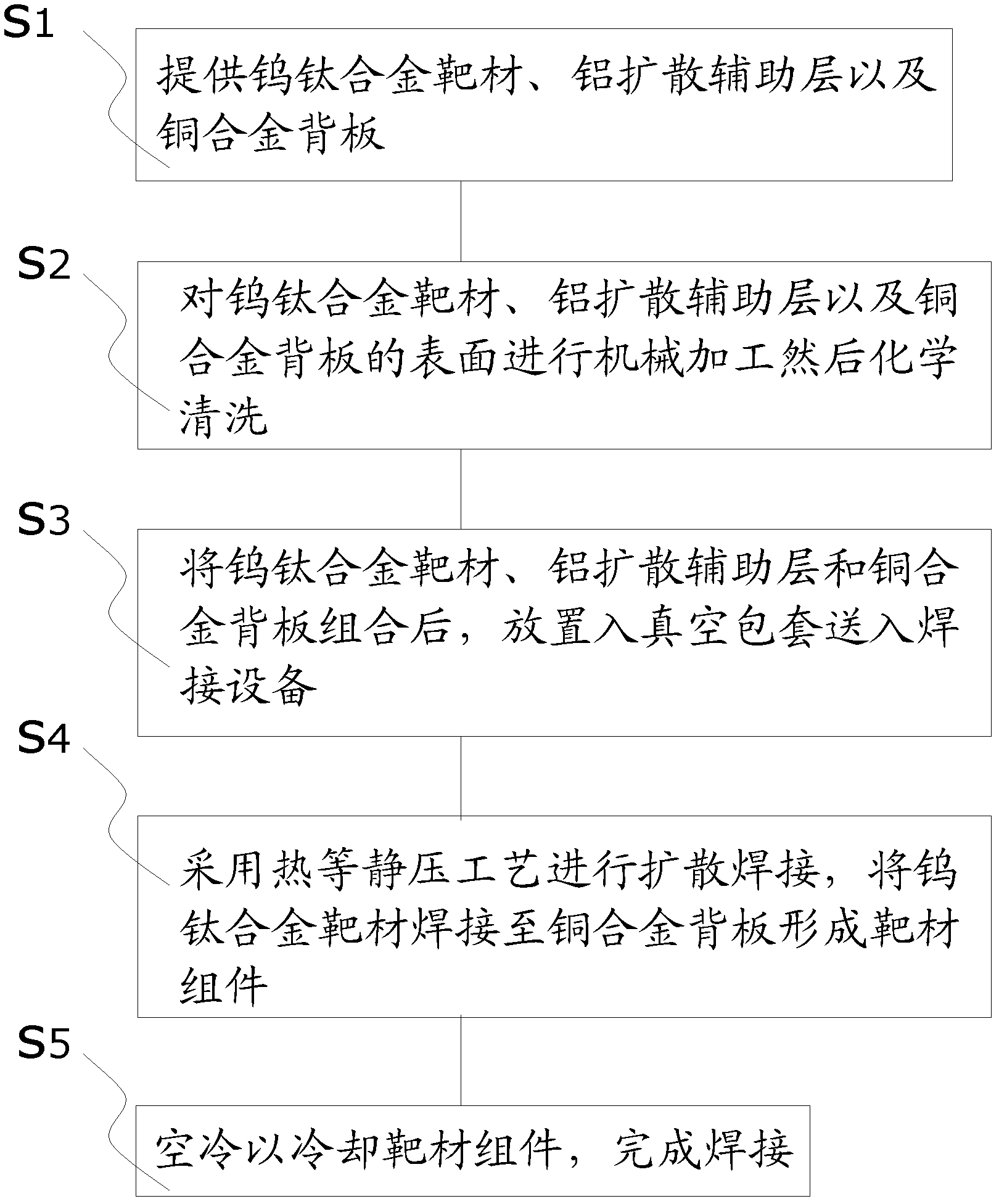

Diffusion welding method for tungsten-titanium alloy target and copper alloy back plate

ActiveCN102554455APrevent oxidationLow costNon-electric welding apparatusThermal deformationTitanium alloy

Disclosed is a diffusion welding method for a tungsten-titanium alloy target and a copper alloy back plate. An aluminum diffusion auxiliary layer is arranged between the tungsten-titanium alloy target and the copper alloy back plate, diffusion welding of the tungsten-titanium alloy target, the aluminum diffusion auxiliary layer and the copper alloy back plate is realized by the aid of high-strength atomic diffusivity between the tungsten-titanium alloy target and the aluminum diffusion auxiliary layer and between the aluminum diffusion auxiliary layer and the copper alloy back plate, and finally, welding quality of the tungsten-titanium alloy target and the copper alloy back plate is improved. Diffusion welding of the tungsten-titanium alloy target and the copper alloy back plate is implemented by a hot isostatic pressing process. As diffusion welding is performed in a vacuum sheath and air is isolated, the contact surface of welded metal can be effectively prevented from being oxidized, the bonding strength of the tungsten-titanium alloy target, the aluminum diffusion auxiliary layer and the copper alloy back plate is enhanced, the target is prevented from being separated from the back plate during sputtering, and sputtering coating is normally performed. A target assembly formed by the diffusion welding method has the advantages of high bonding compactness, high thermal deformation resistance and the like.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Al and Al alloy soft braze welding metal displaced type unleaded welding soldering flux

InactiveCN101204762AWith corrosion protectionImprove matchWelding/cutting media/materialsSoldering mediaSurface-active agentsSolder paste

The invention discloses a soldering metal replacement no lead welding scaling powder for aluminum and aluminum alloy, which is composed of the following weight proportions: 5 to 50 percent of metal salt that can be reduced by the aluminum, 10 to 15 percent of stripper, 3 to 40 percent of wetting agent, 3 to 20 percent of activating agent, 1 to 15 percent of surface active agent, 2 to 20 percent of inhibiter and a carrier with the rest percent. The invention has an extremely excellent matching effect with a lead-free solder in the welding temperature and is suitable for being made into a welding stick or a welding paste with the lead-free solder. After welding, the invention has a high welding intensity and a good expansion rate, belongs to an environment protection scaling powder, and has the function of inhibition protection on the aluminum and aluminum alloy as well as a simple and practical preparing method. Undoubtedly, the embodiment can also be used for the no lead soldering on the materials like stainless steel, galvanized iron, copper and copper alloy, etc., and bear the same effects as well.

Owner:昆山成利焊锡制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com