Patents

Literature

10522results about "Fuel injection apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

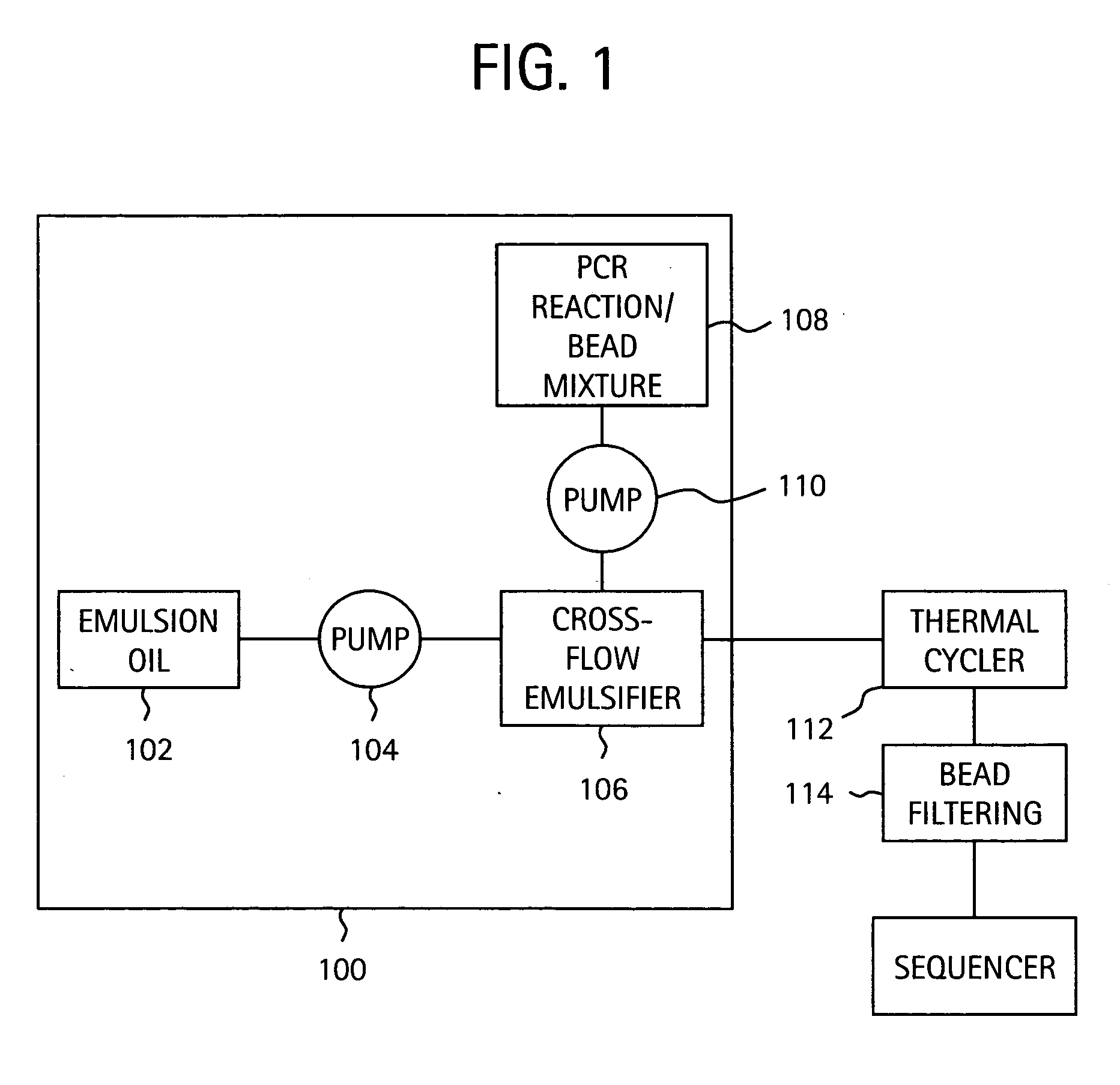

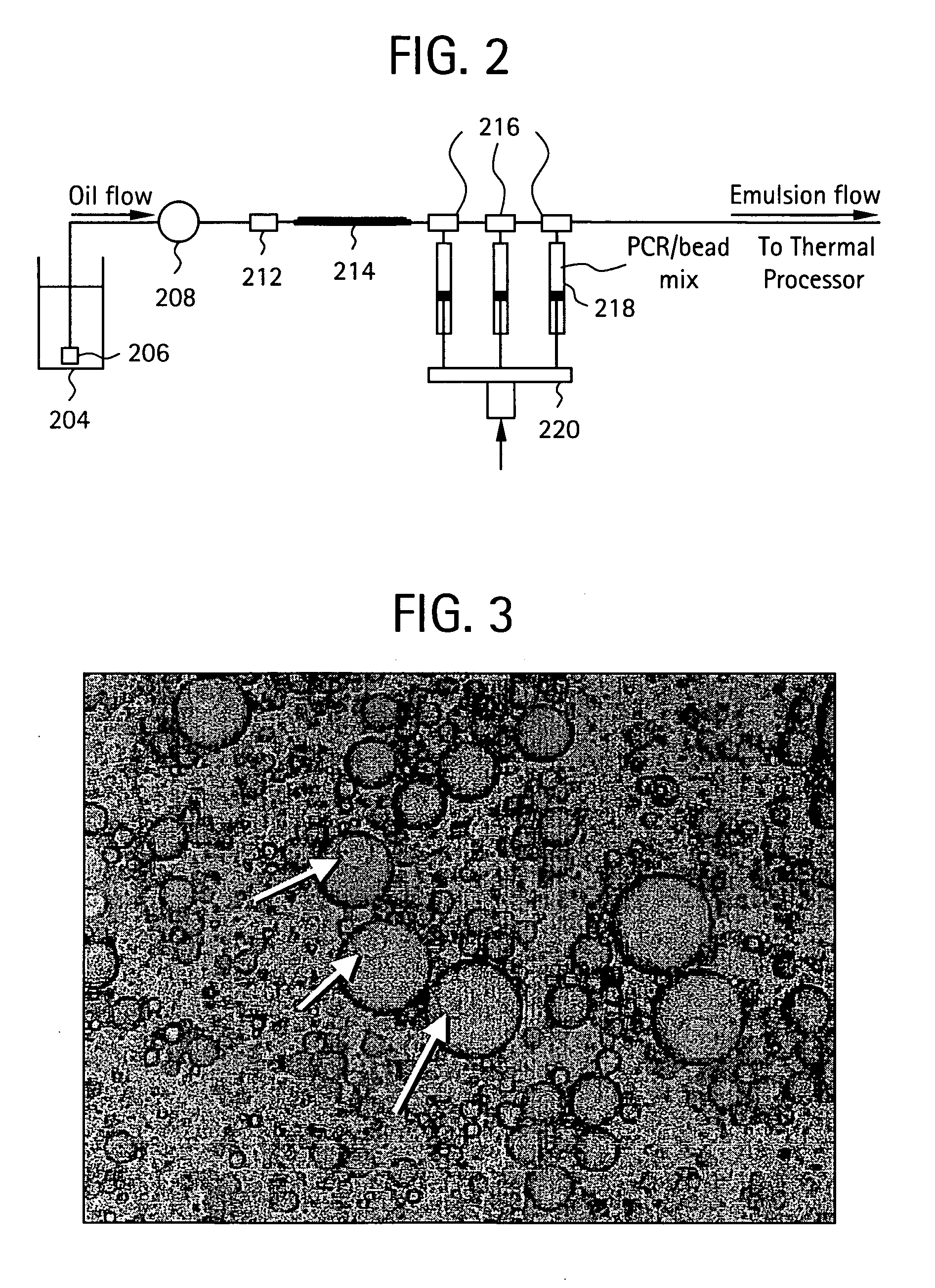

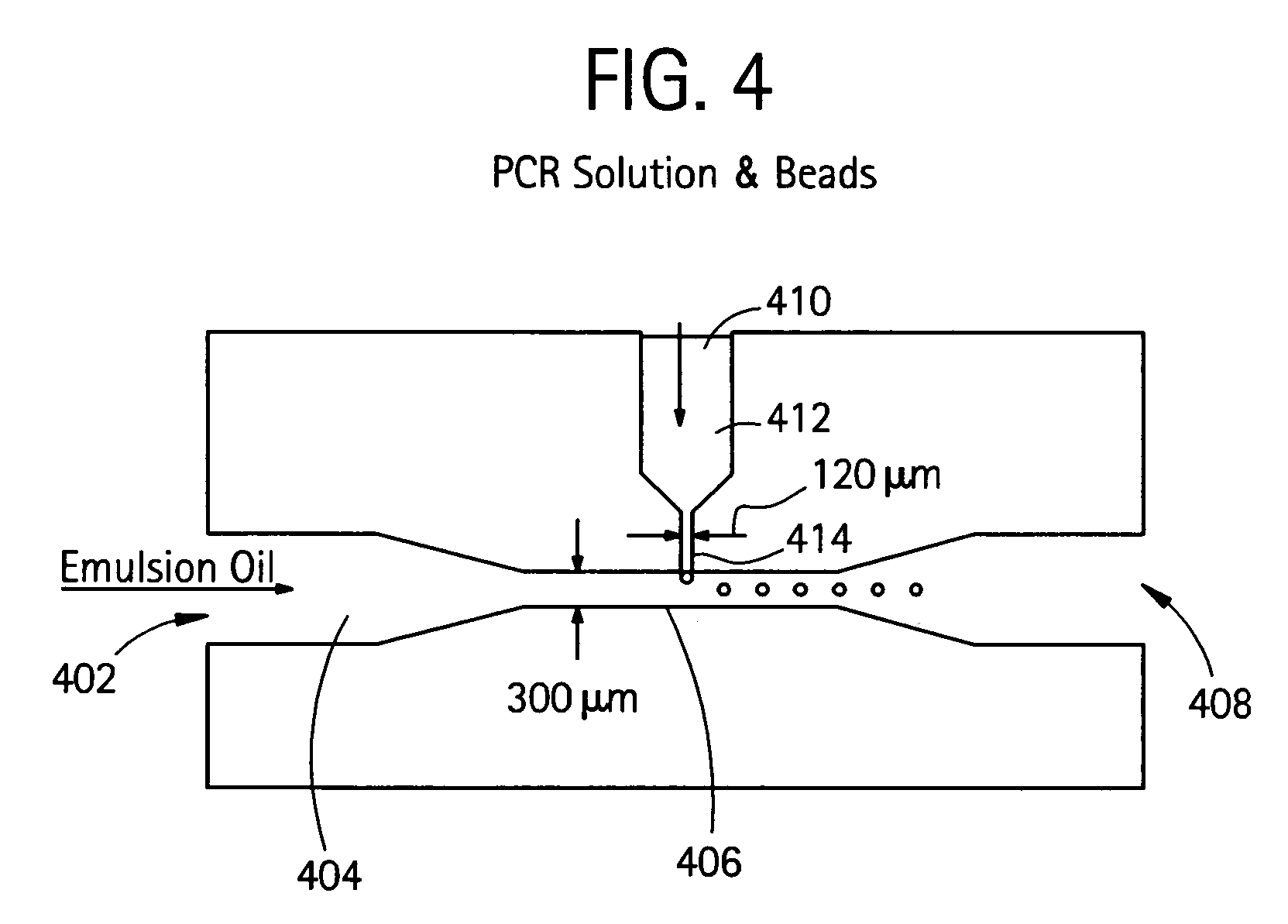

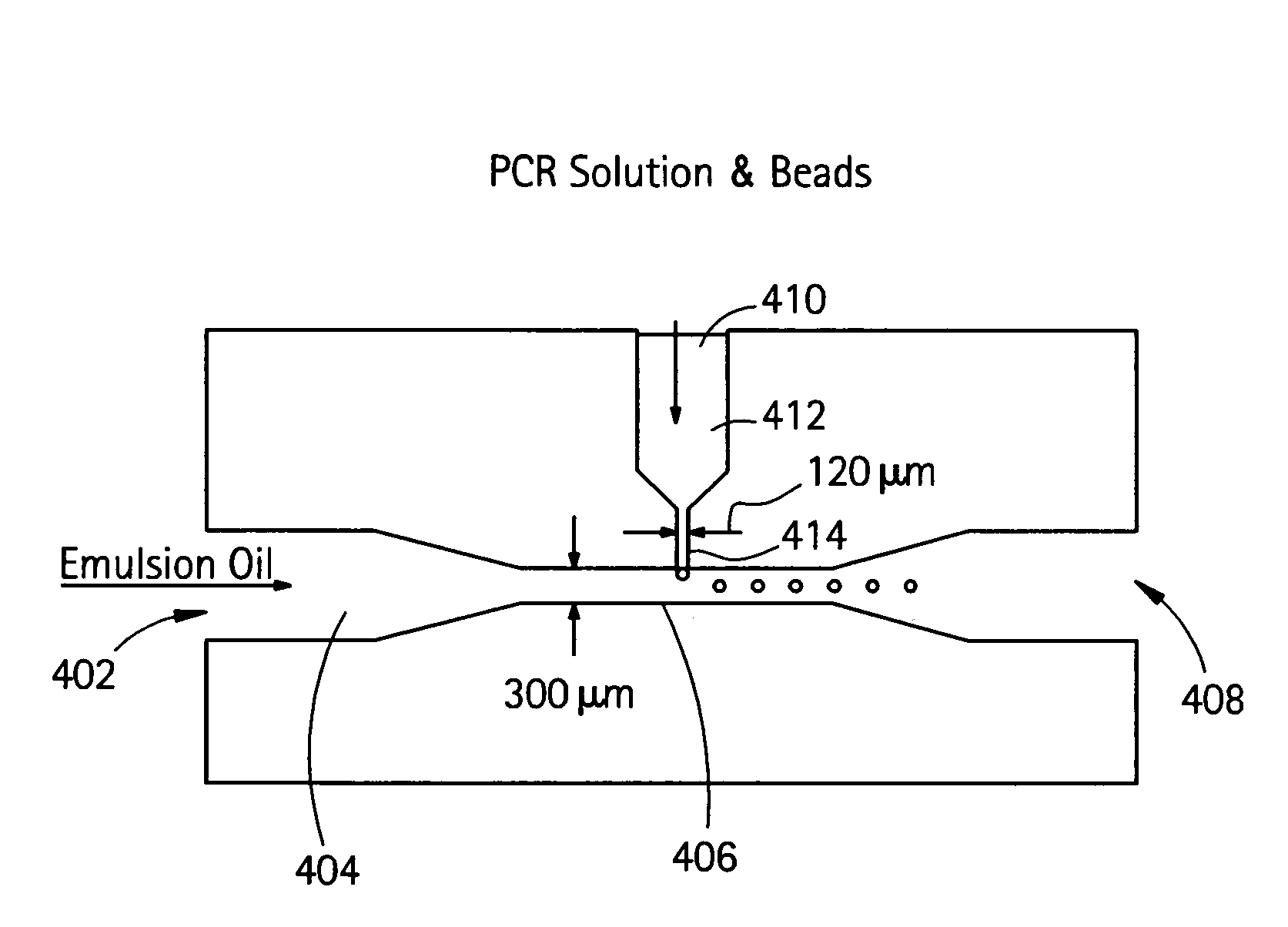

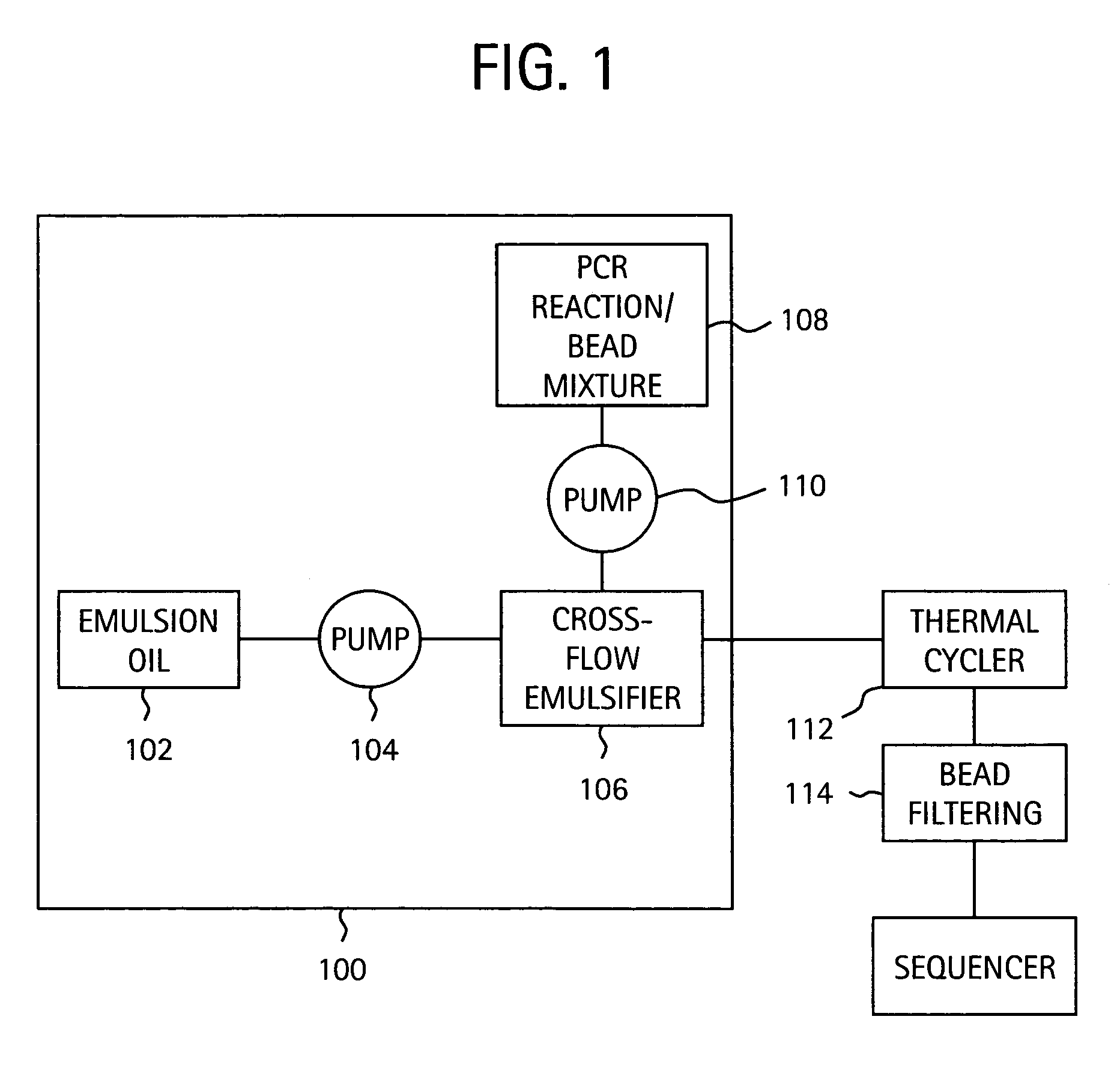

Nucleic acid amplification with continuous flow emulsion

InactiveUS20050227264A1Rapid and economical mannerReduce nozzle cloggingHeating or cooling apparatusFlow mixersMicroreactorGenetic Materials

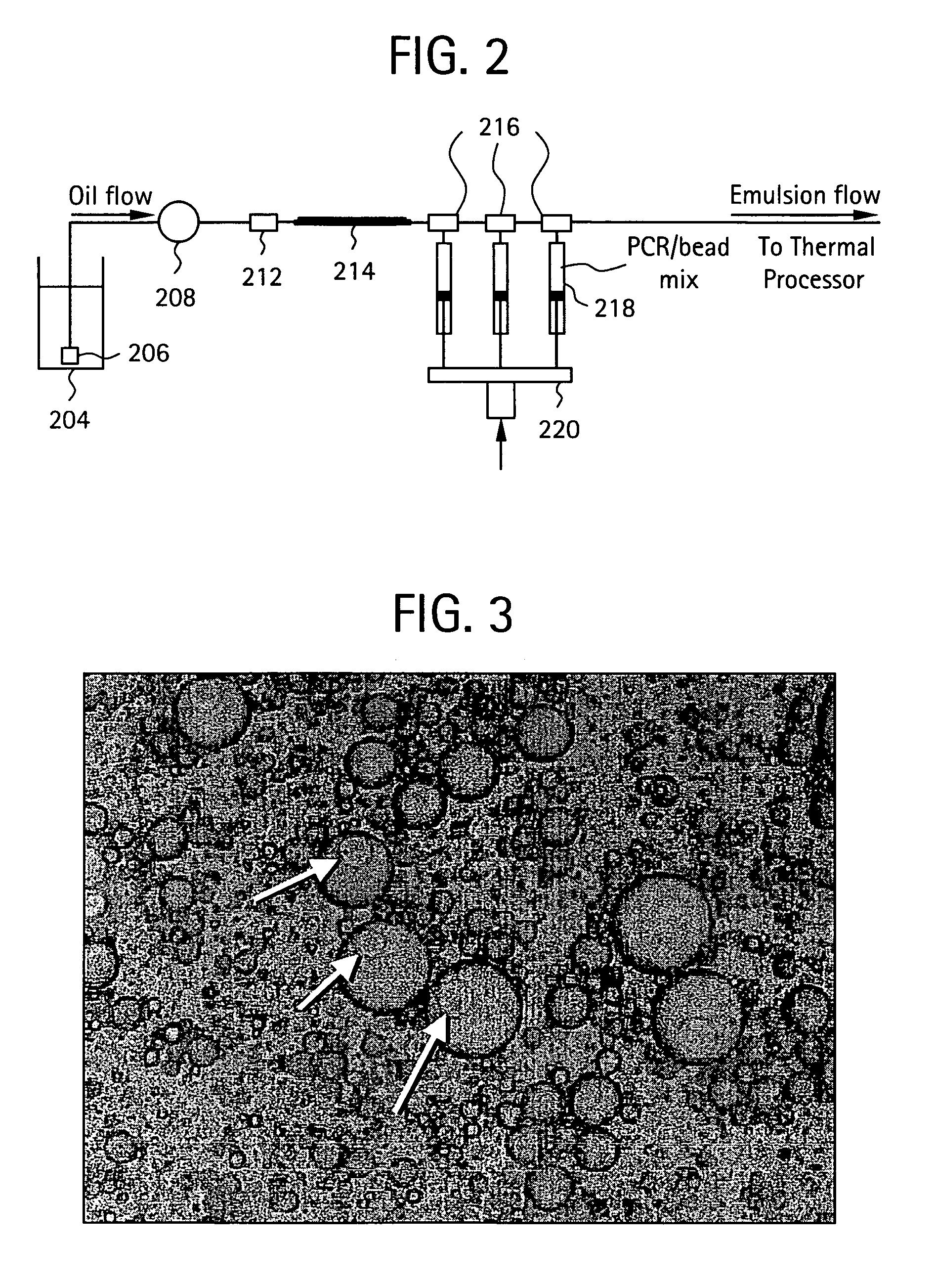

Embodiments of the present invention are directed to methods and devices / systems for amplifying genetic material and may include providing a water-in-oil emulsion in a continuous flow. The emulsion may include a plurality of water droplets comprising microreactors. Each of the plurality of microreactors may include a single bead capable of capturing a nucleic acid template, a single species nucleic acid template and sufficient reagents to amplify the copy number of the nucleic acid template. The method also includes flowing the emulsion across a first temperature zone and a second lower temperature zone to thermally process the microreactors to amplify the nucleic acid template by polymerase chain reaction.

Owner:454 LIFE SCIENCES CORP

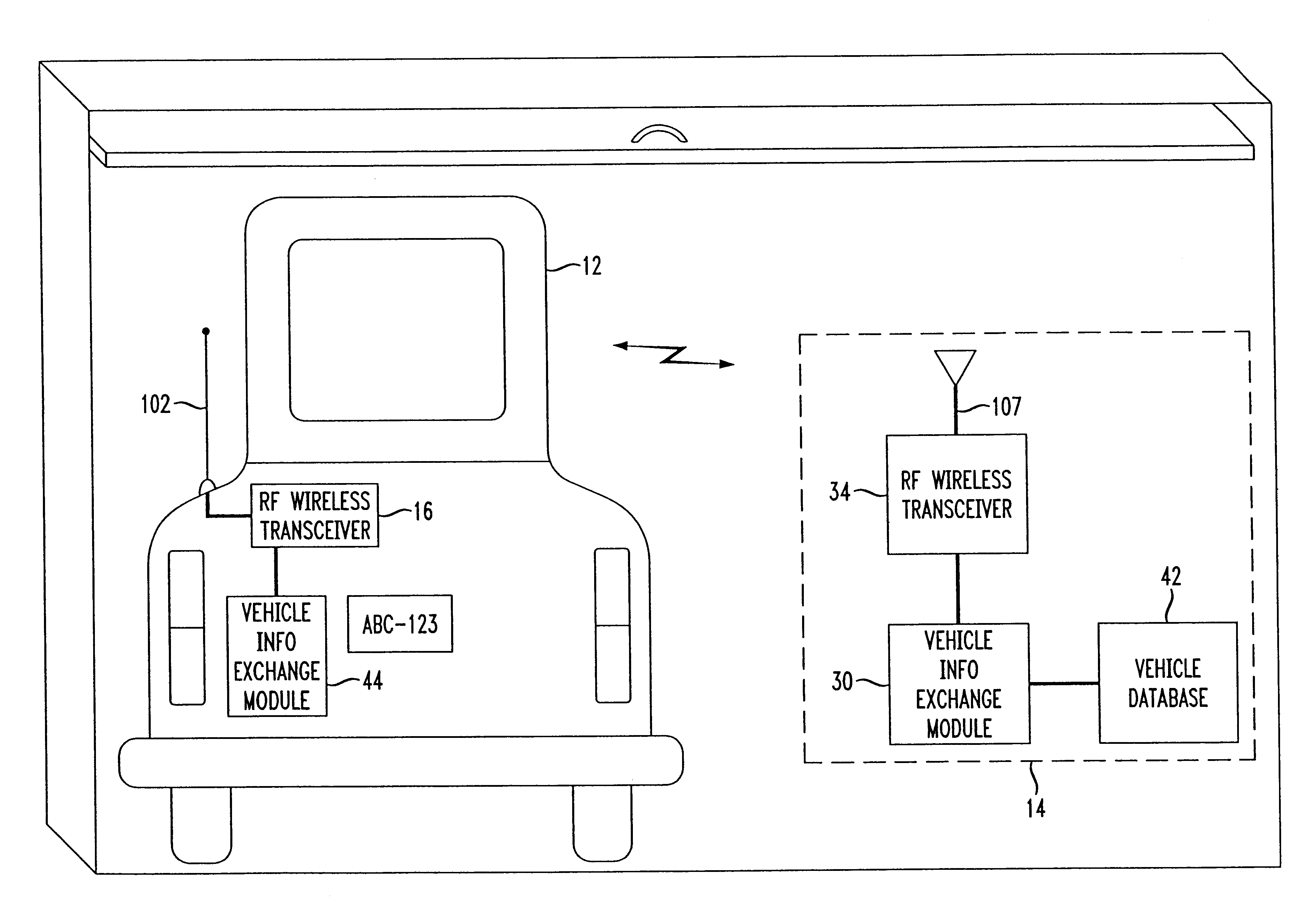

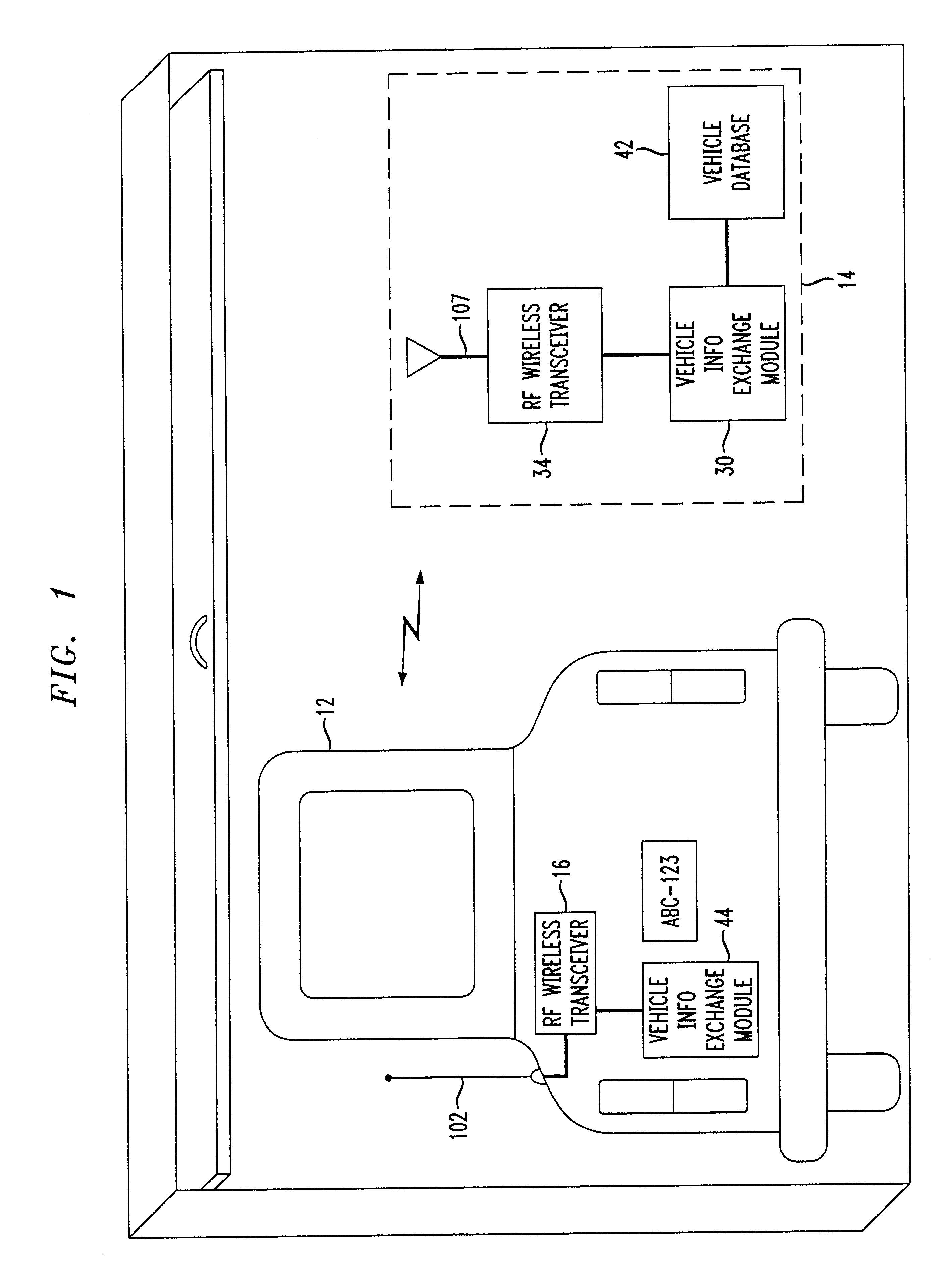

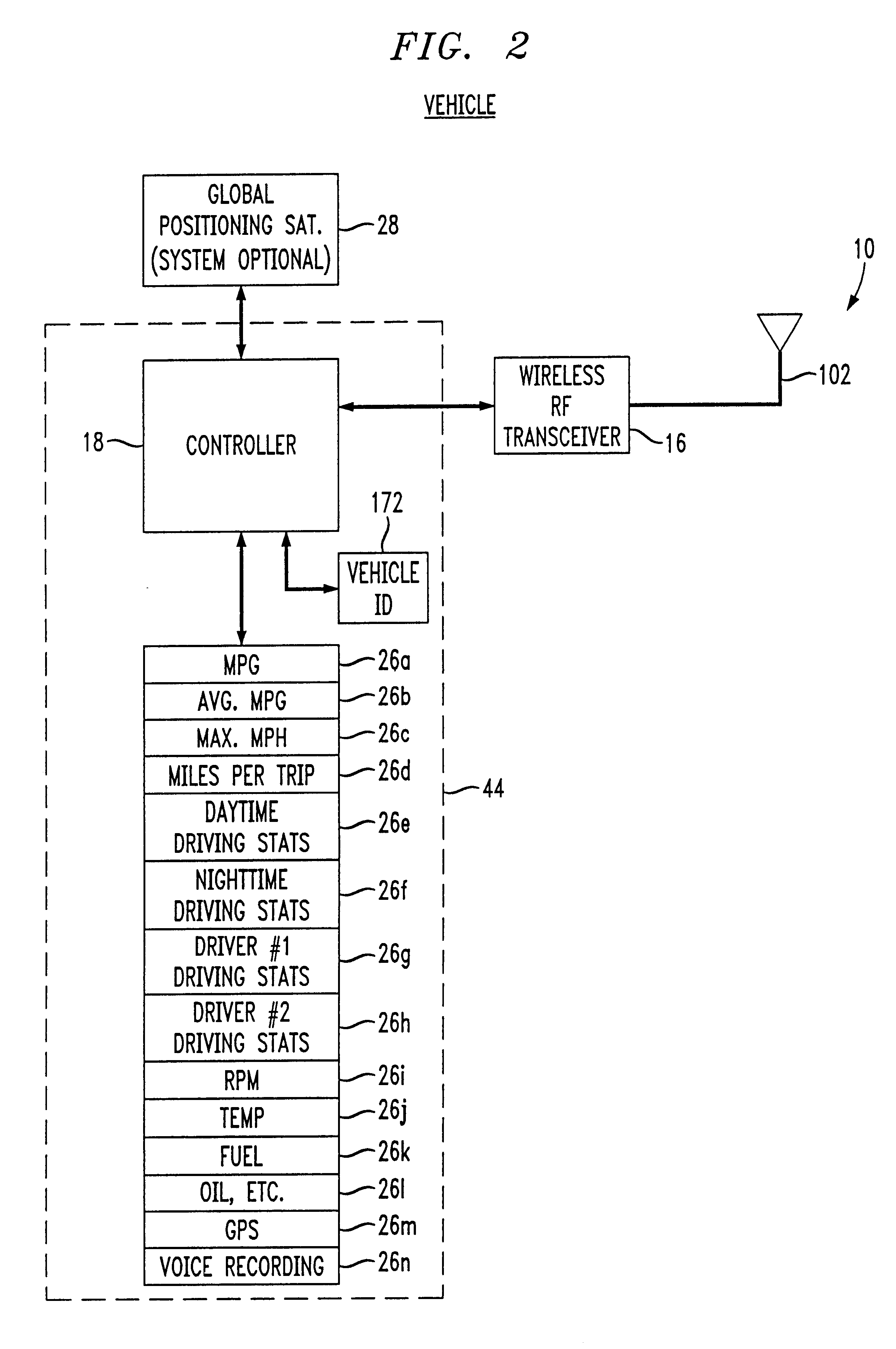

Wireless piconet access to vehicle operational statistics

InactiveUS6408232B1Vehicle testingArrangements for variable traffic instructionsTransceiverDriver/operator

A wireless piconet transceiver is mounted in a vehicle, and a complementary fixed wireless piconet transceiver is mounted in a garage, service station, police squad car, etc., for communication with the vehicle when parked adjacent thereto. The vehicle establishes a temporary piconet network with the user's home piconet. Vehicle operational statistics are tracked and maintained in a centralized vehicle computer database. This database can be manipulated to store the data desired by the vehicle owner. Via a wireless piconet connection, this database can transmitted to another piconet device such as the owner's computer. This computer system can be part of a wireless piconet, such as Bluetooth, This provides the computer with the ability to communicate with external wireless devices such as a cell phone, PDA, computer, or a cordless telephone. This invention allows for the configuration, or selection of desired vehicle data to be tracked. This configuration can take place on the owner's home computer (or laptop) and consequently transmitted to the vehicle computer using a wireless piconet protocol, e.g., the Bluetooth protocol. Additionally, this configuration can be manipulated by a direct interface to the vehicle provided by the manufacturer. Exemplary vehicle statistics which may be tracked include, but are not limited to, miles per gallon, average miles per hour, maximum MPH, miles driven per trip, driving statistics based on time of day and / or on identified driver, rotations of the engine per minute (RPM), temperature of engine, fuel gauge level, oil pressure, tires, brakes, engine coolant, wiper fluid, global positioning satellite (GPS) system, and / or even compressed voice from inside car cockpit during operation of vehicle.

Owner:CARRUM TECH LLC

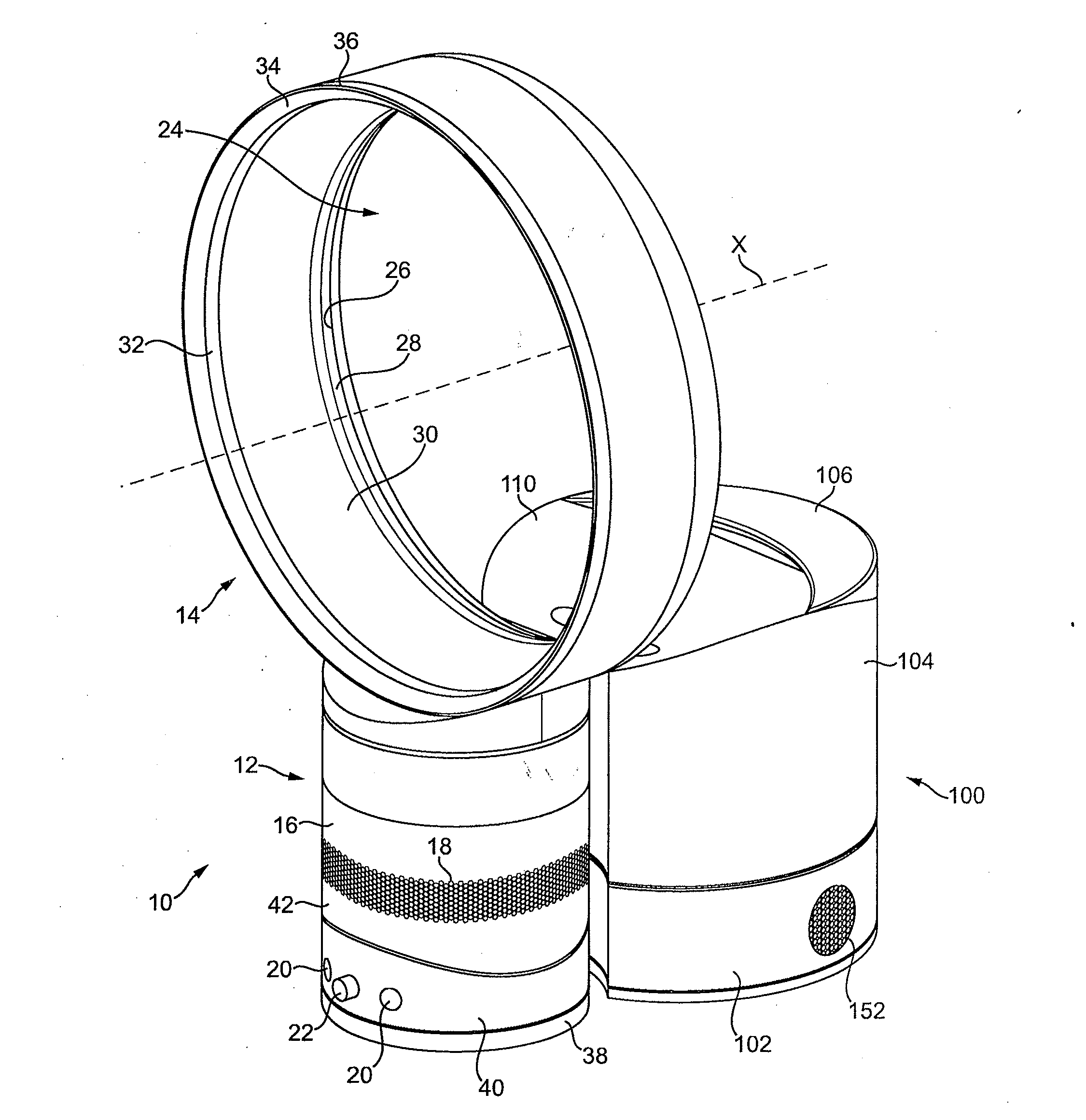

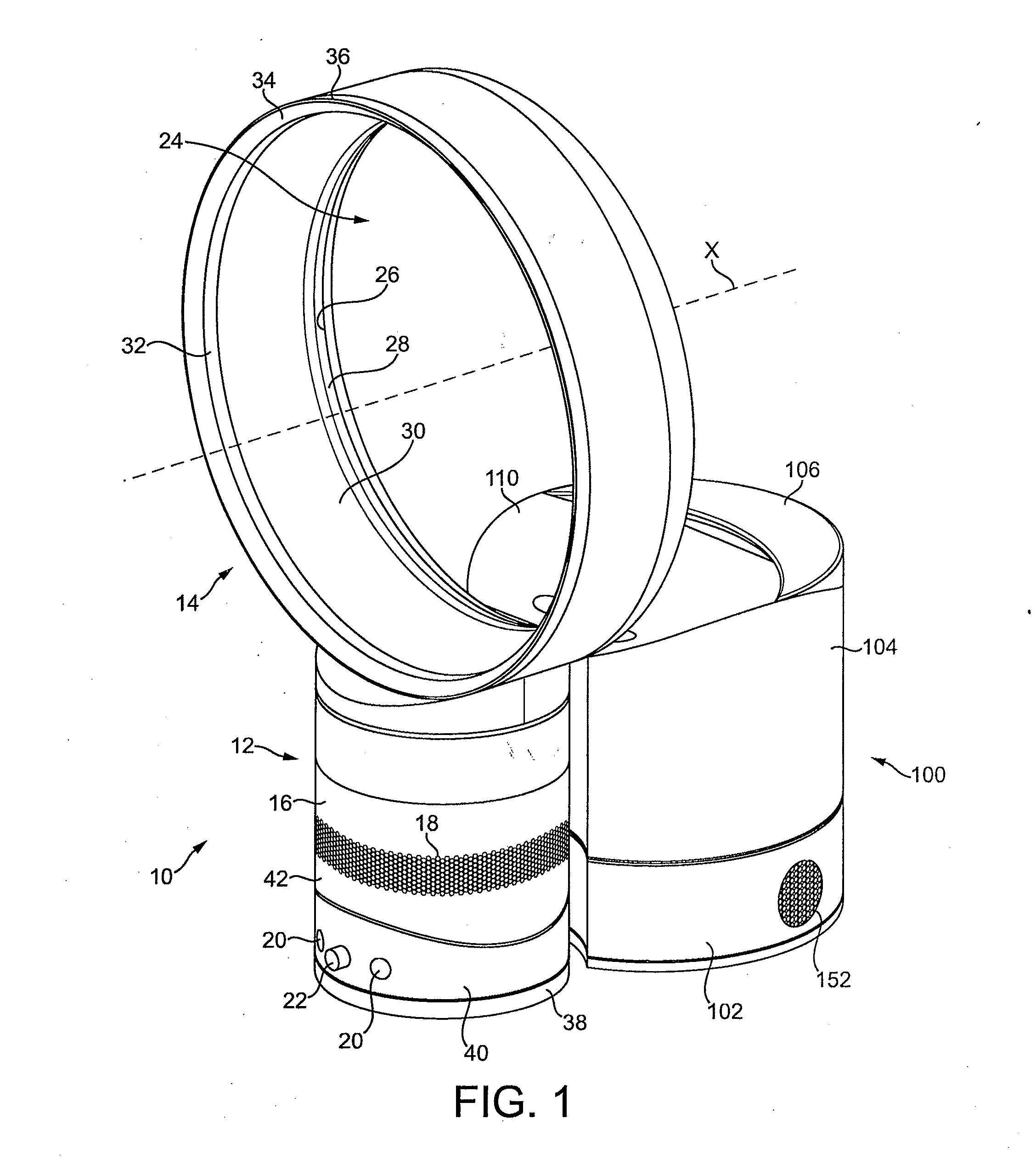

Humidifying apparatus

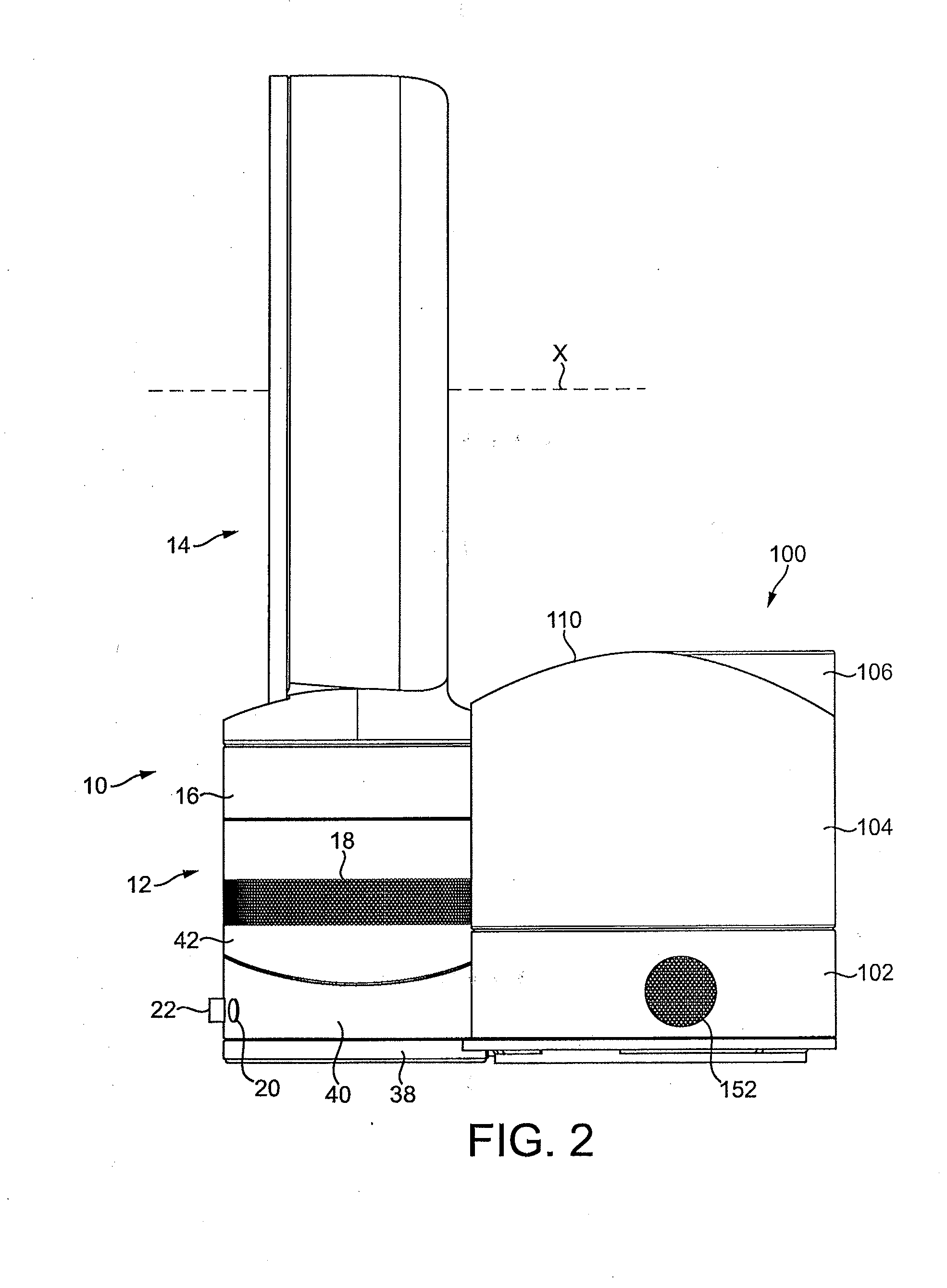

InactiveUS20100225012A1Rapid rise in relative humidityReduce the amount requiredFlow mixersSpace heating and ventilationEngineeringAirflow

Humidifying apparatus includes a humidifier for emitting moist air into an external environment, and a fan assembly for generating an air current within the external environment for conveying the emitted moist air away from the humidifier. The fan assembly includes a device for creating an air flow and a nozzle comprising an interior passage for receiving the air flow and a mouth for emitting the air flow. The humidifier is located behind nozzle, the nozzle extending about and defining an opening through which both air from outside the nozzle and the moist air emitted from the humidifier are drawn by the air flow emitted from the mouth.

Owner:DYSON TECH LTD

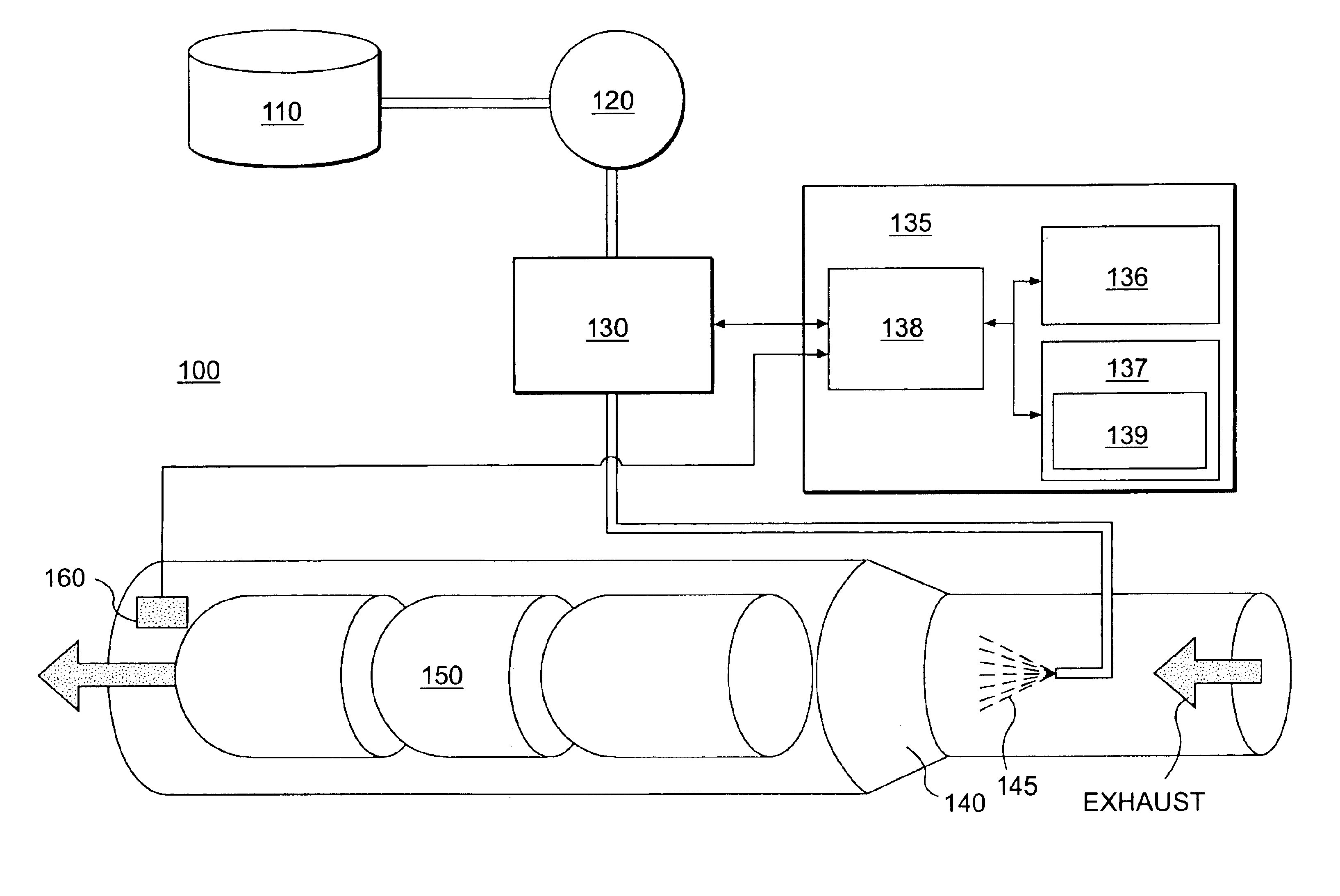

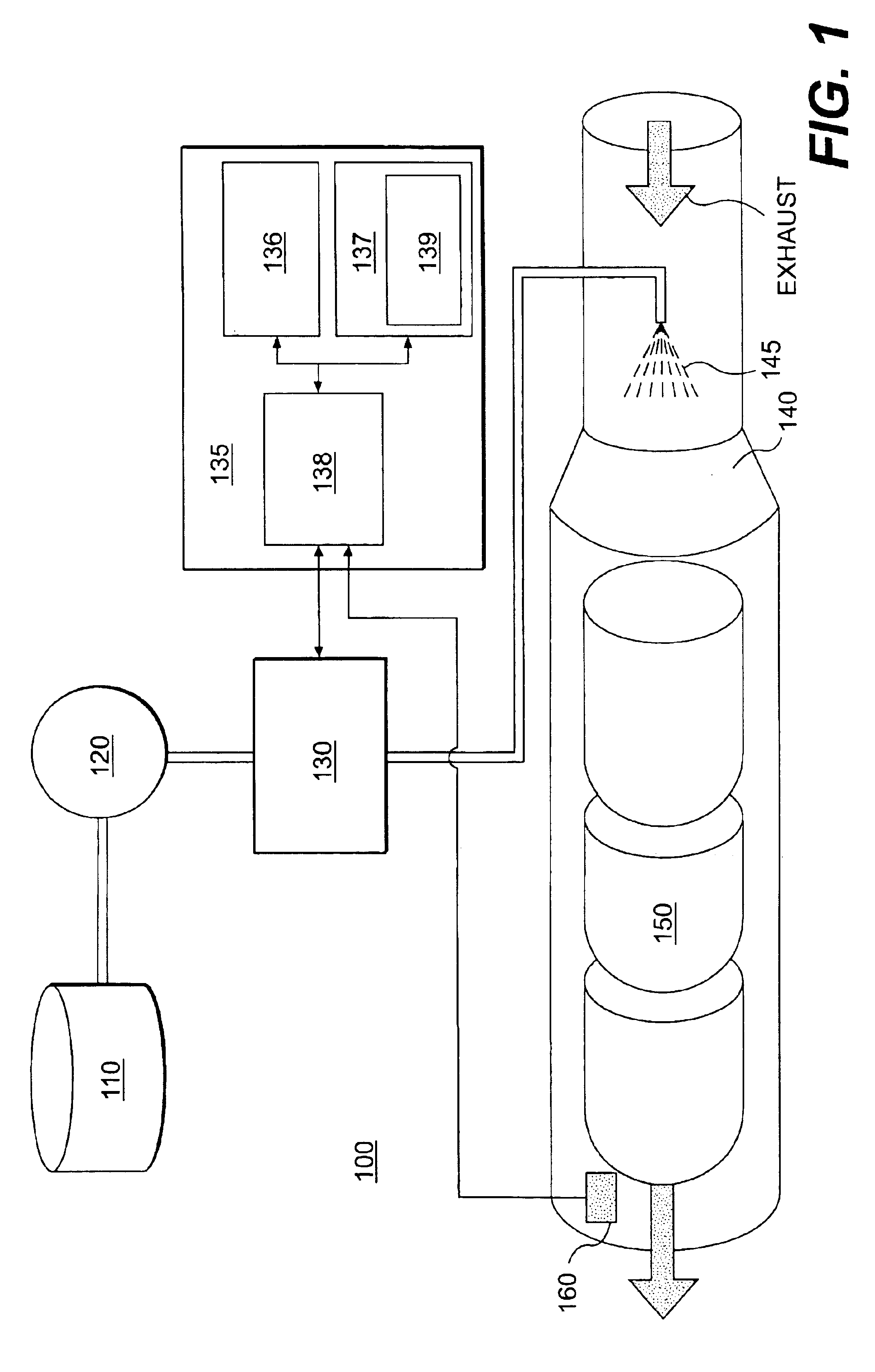

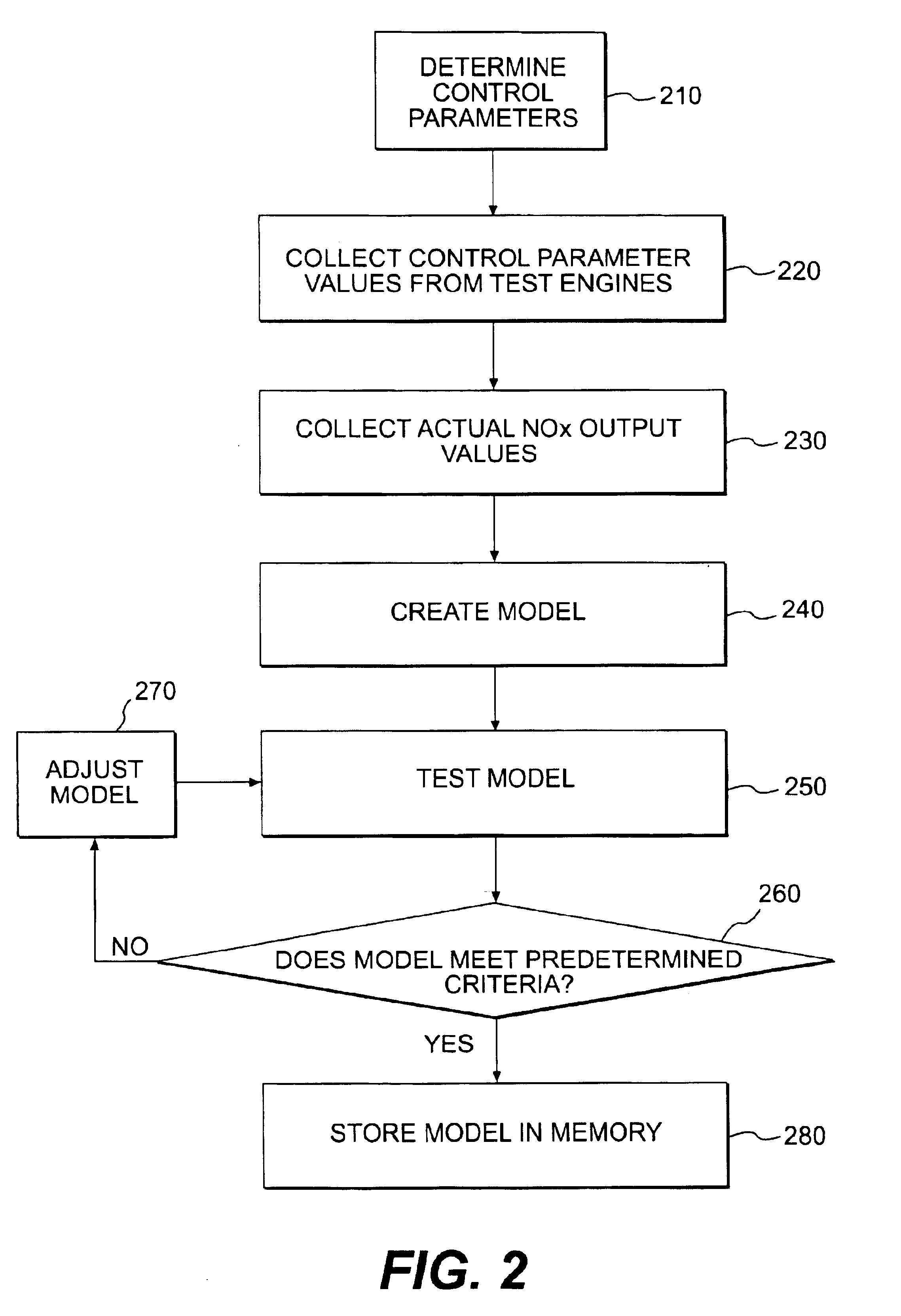

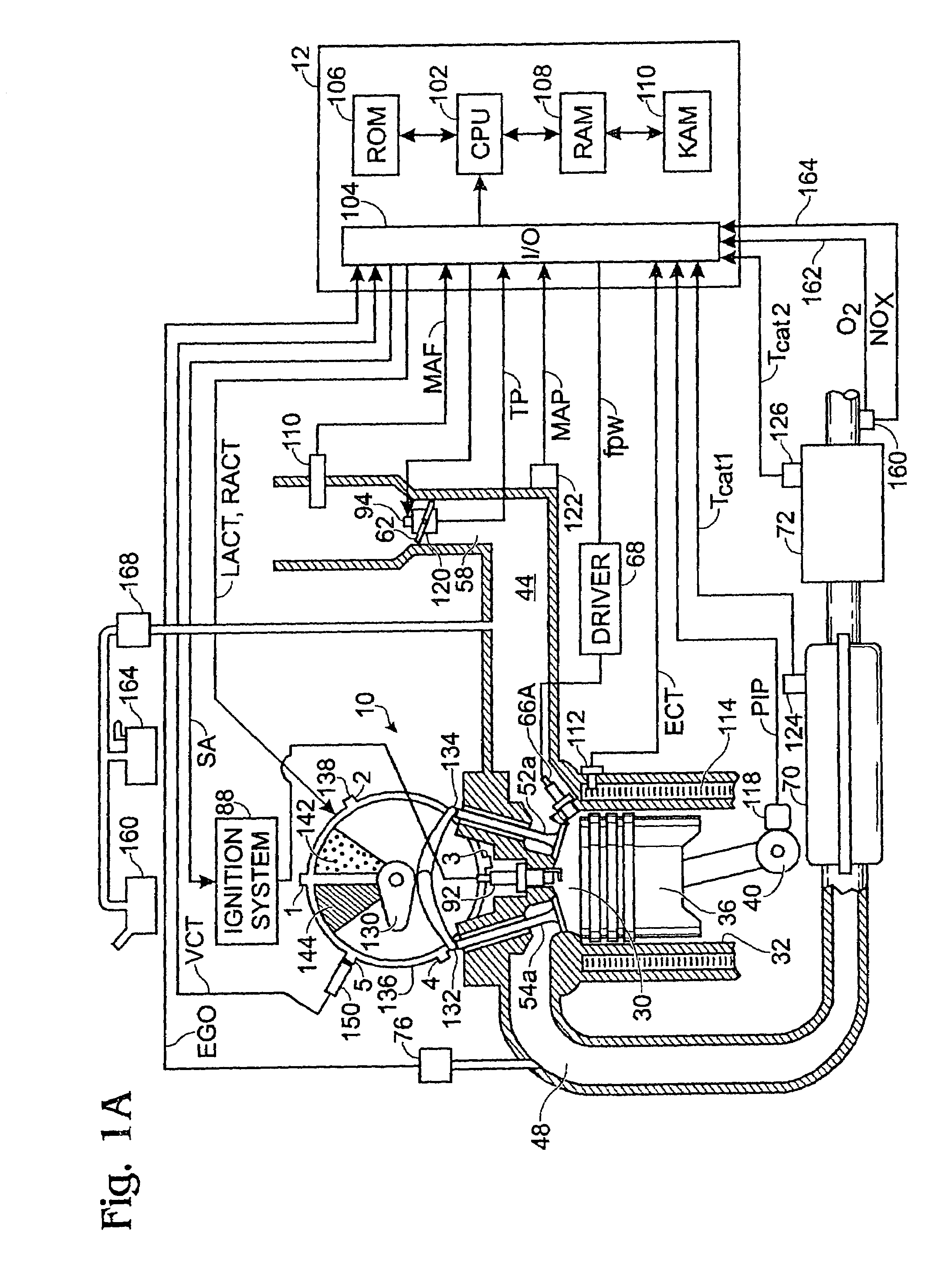

NOx emission-control system using a virtual sensor

InactiveUS6882929B2Reduce nitrogen oxide emissionsInternal combustion piston enginesDigital data processing detailsAmbient humidityControl system

A method and system may be provided to perform a process for controlling NOx emissions of an target engine. In one embodiment of the invention, the process may include determining predicted NOx values based on a model reflecting a predetermined relationship between control parameters and NOx emissions, wherein the control parameters include ambient humidity, manifold pressure, manifold temperature, fuel rate, and engine speed associated with the engine. Further, the process may include adjusting the model based on a determination of whether the predicted NOx values meet a predetermined criteria associated with actual NOx values. The adjusted model may be stored in a memory associated with the engine whereby NOx emissions exhausted from the engine may be reduced based on virtual NOx emission values determined from the adjusted model.

Owner:CATERPILLAR INC

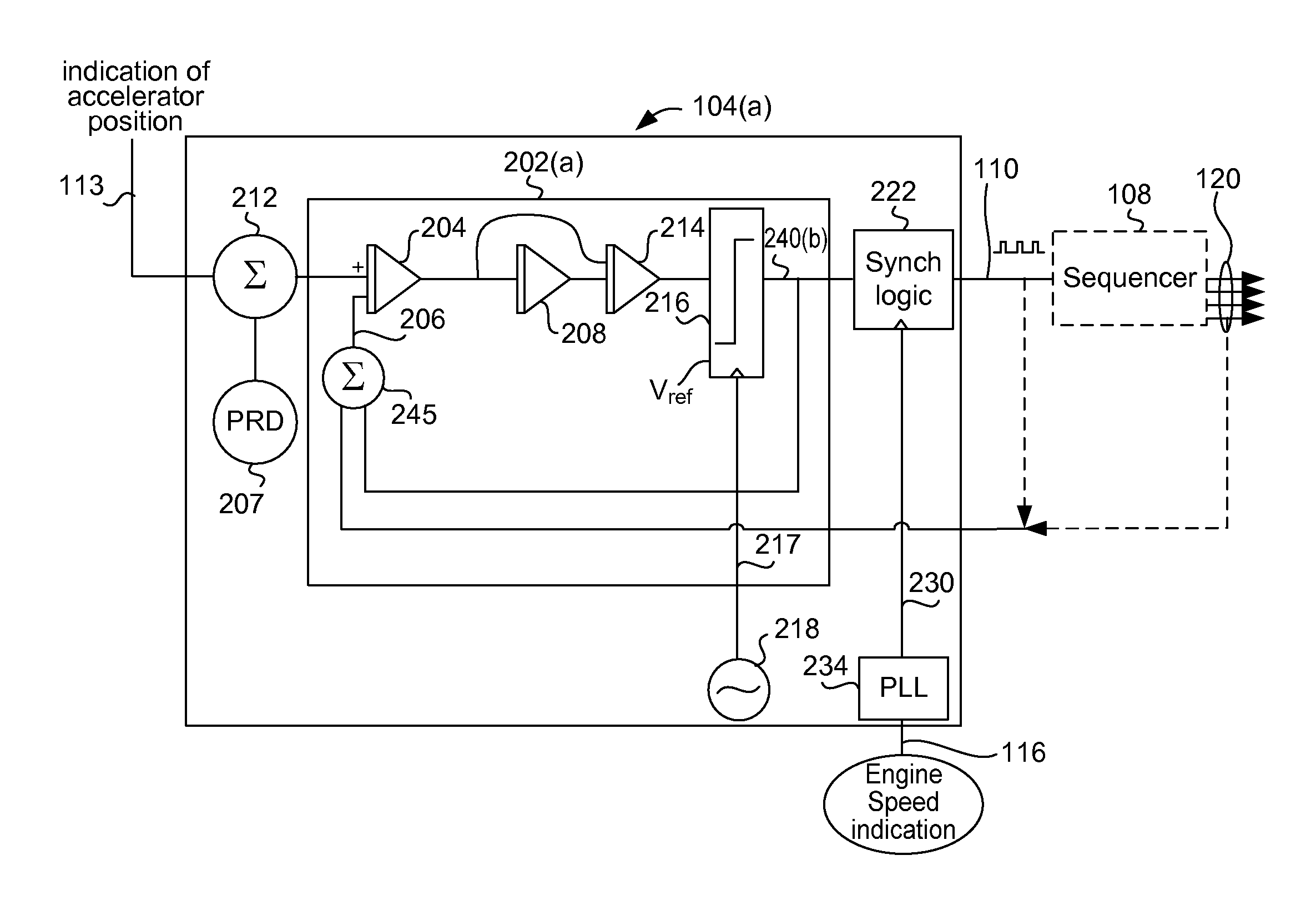

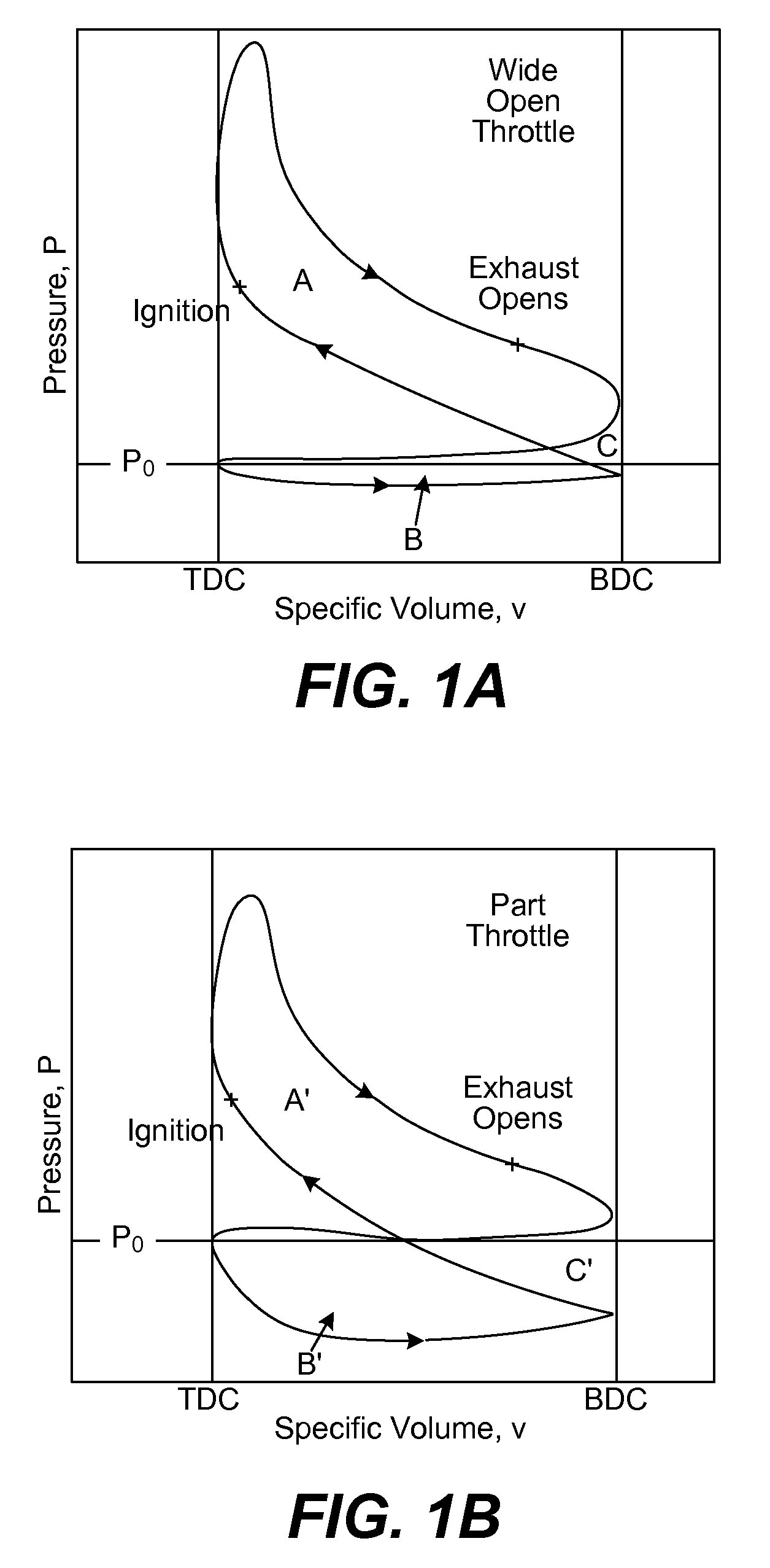

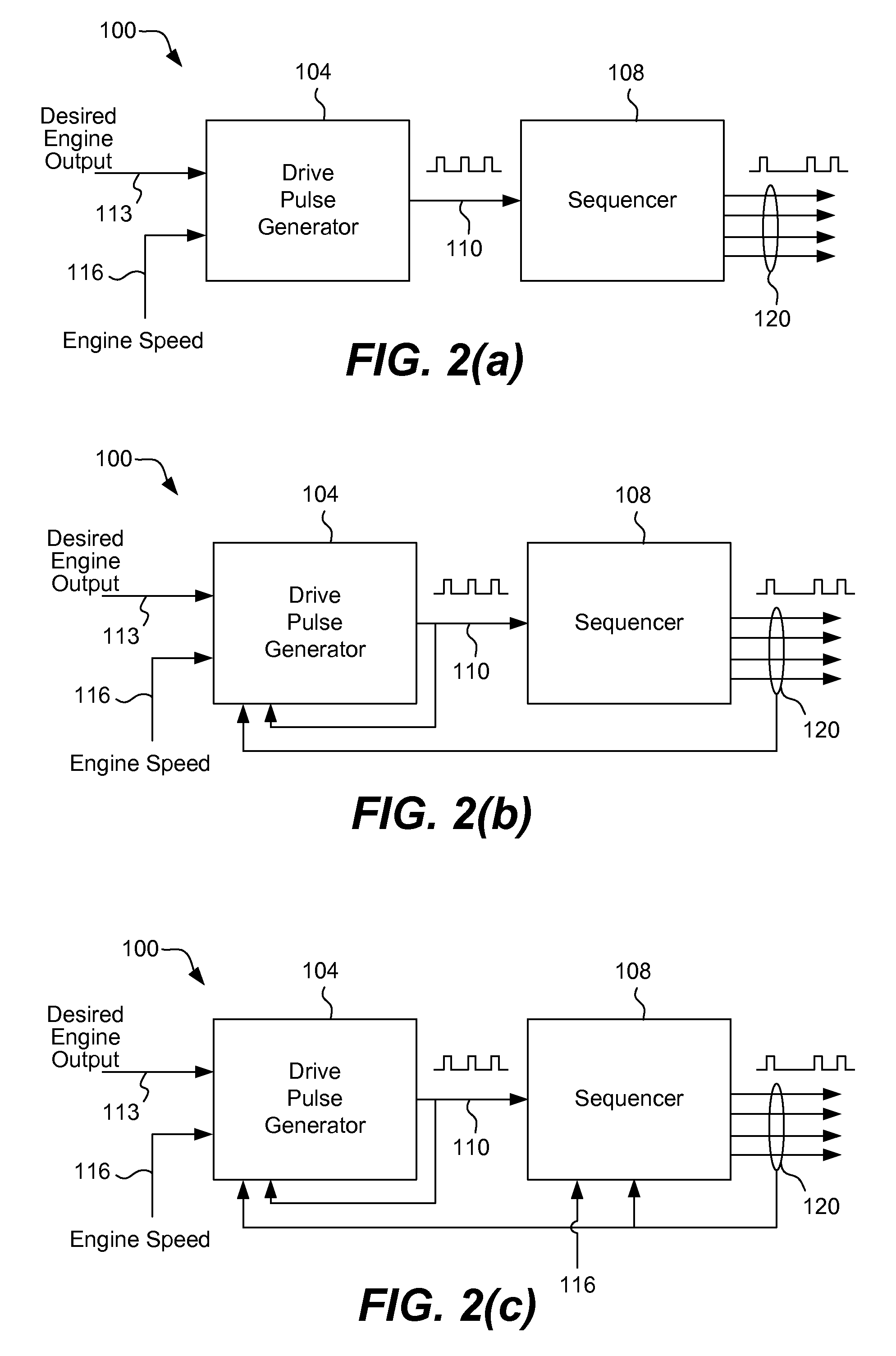

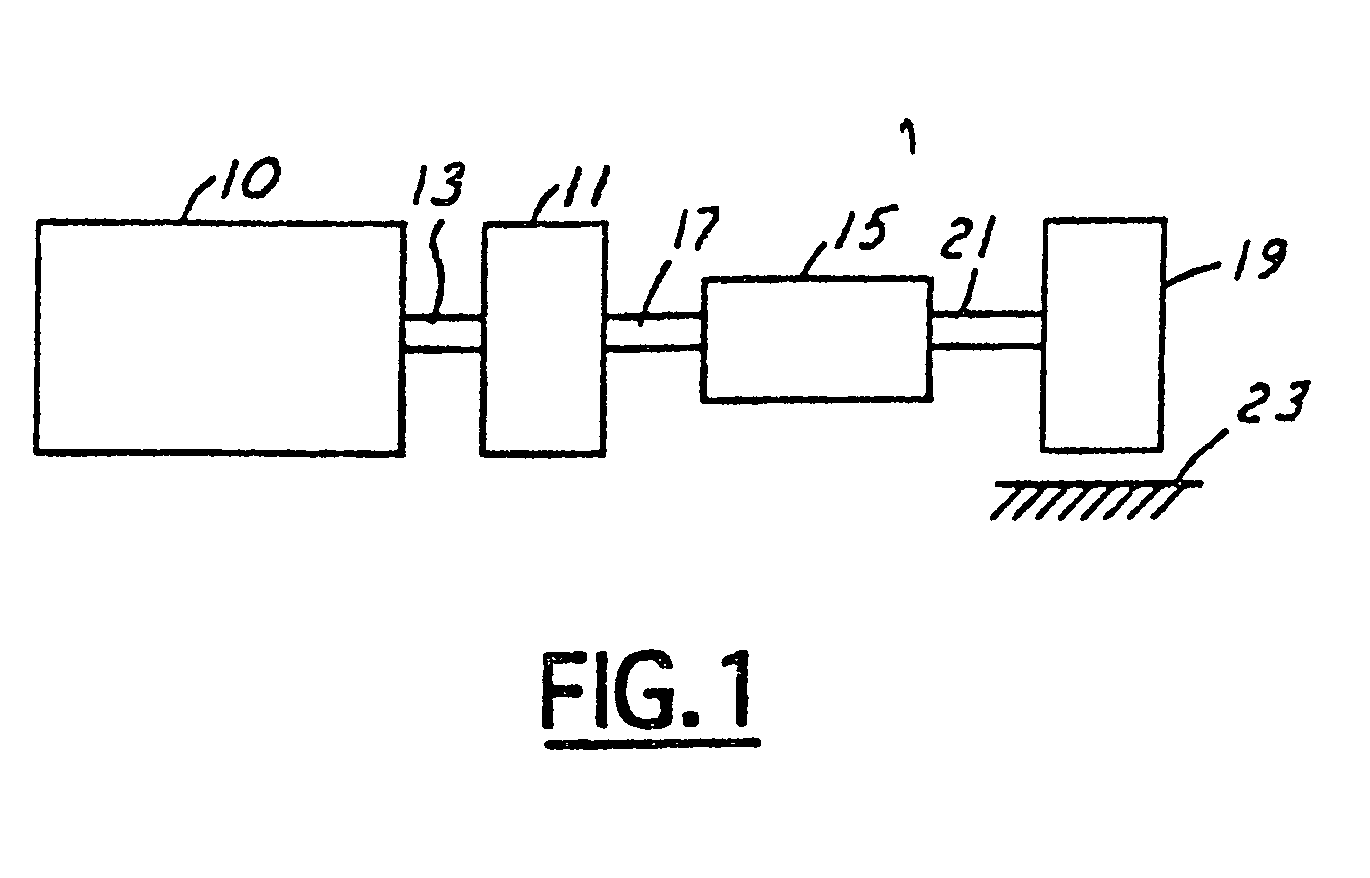

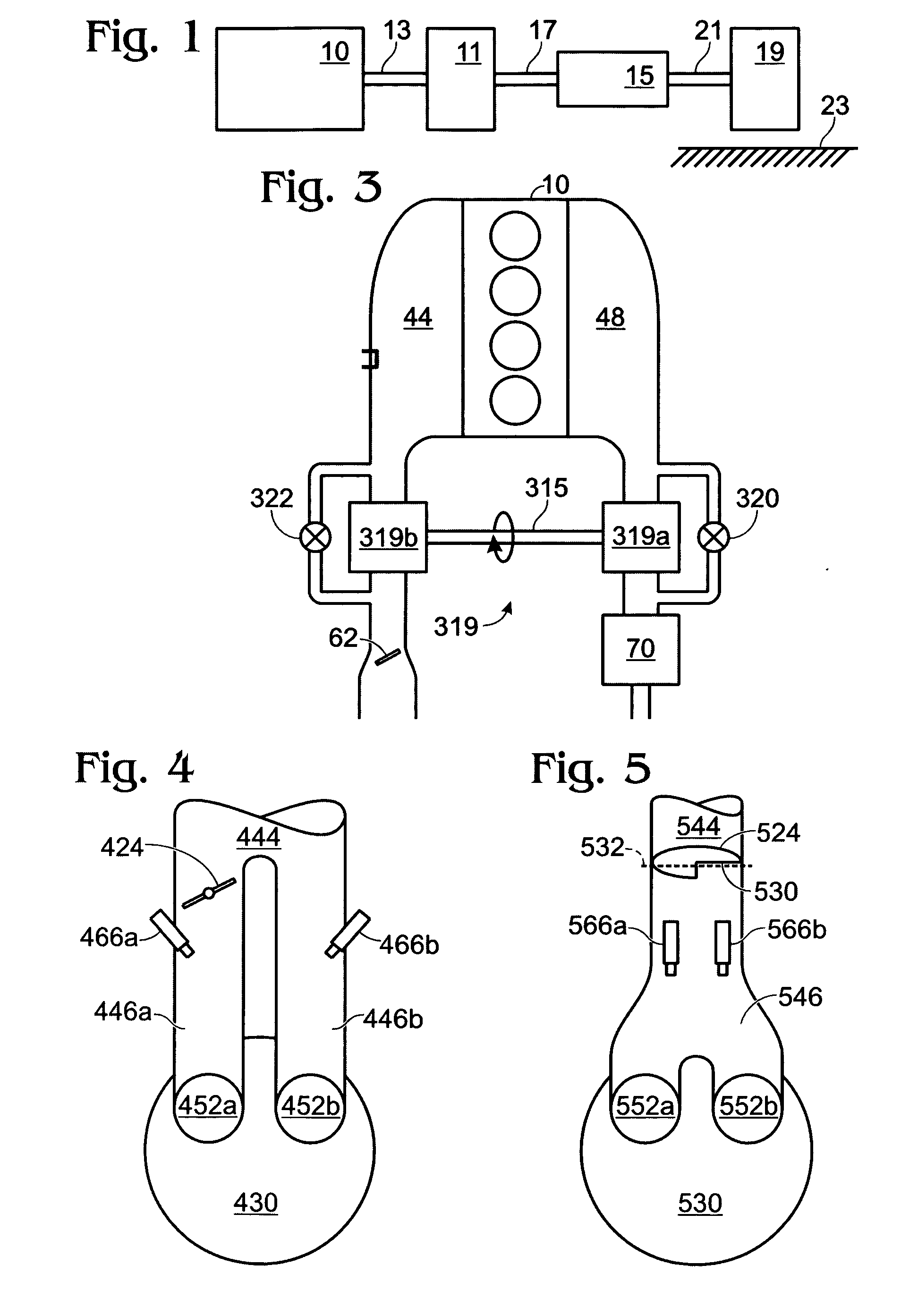

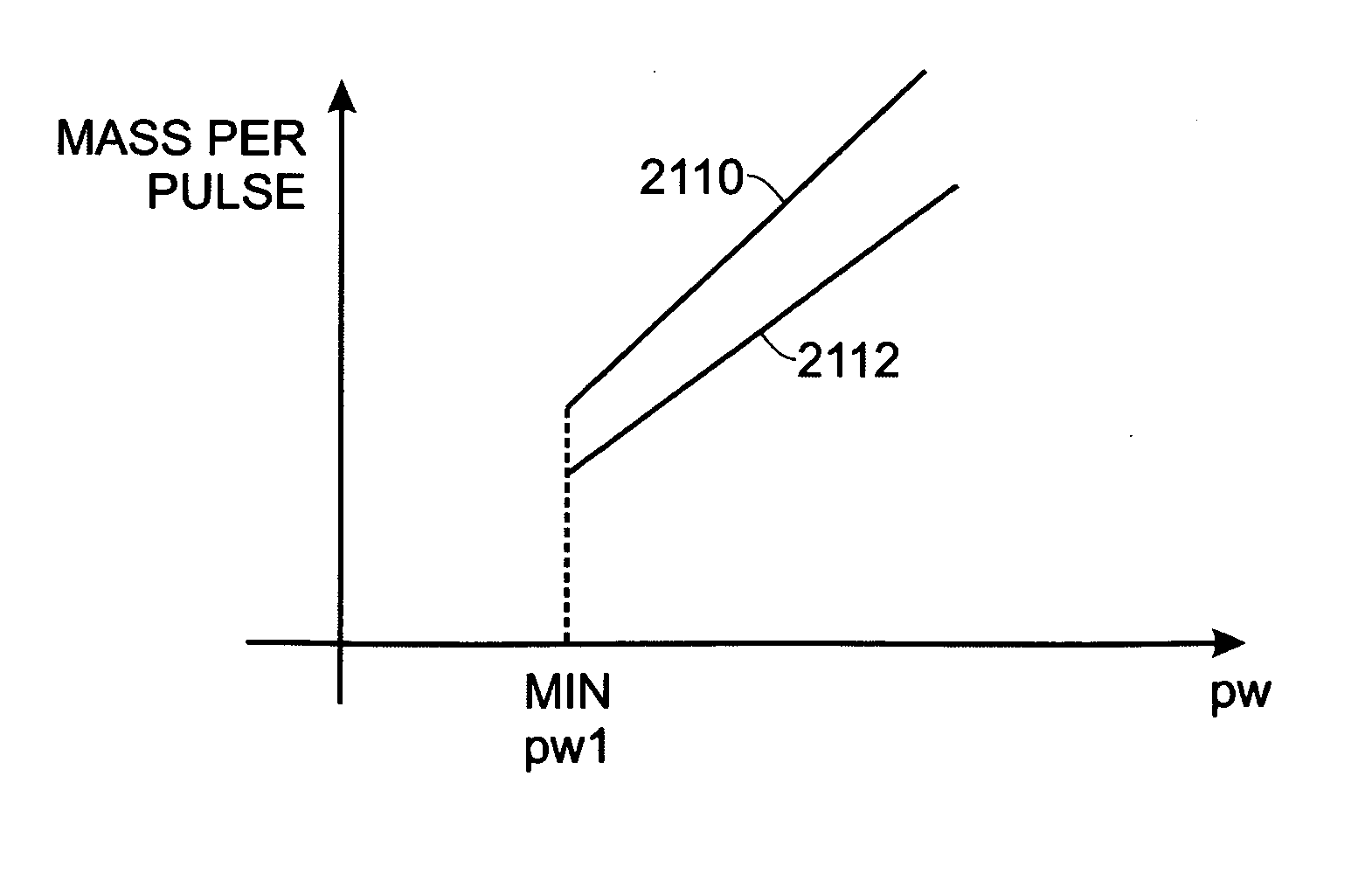

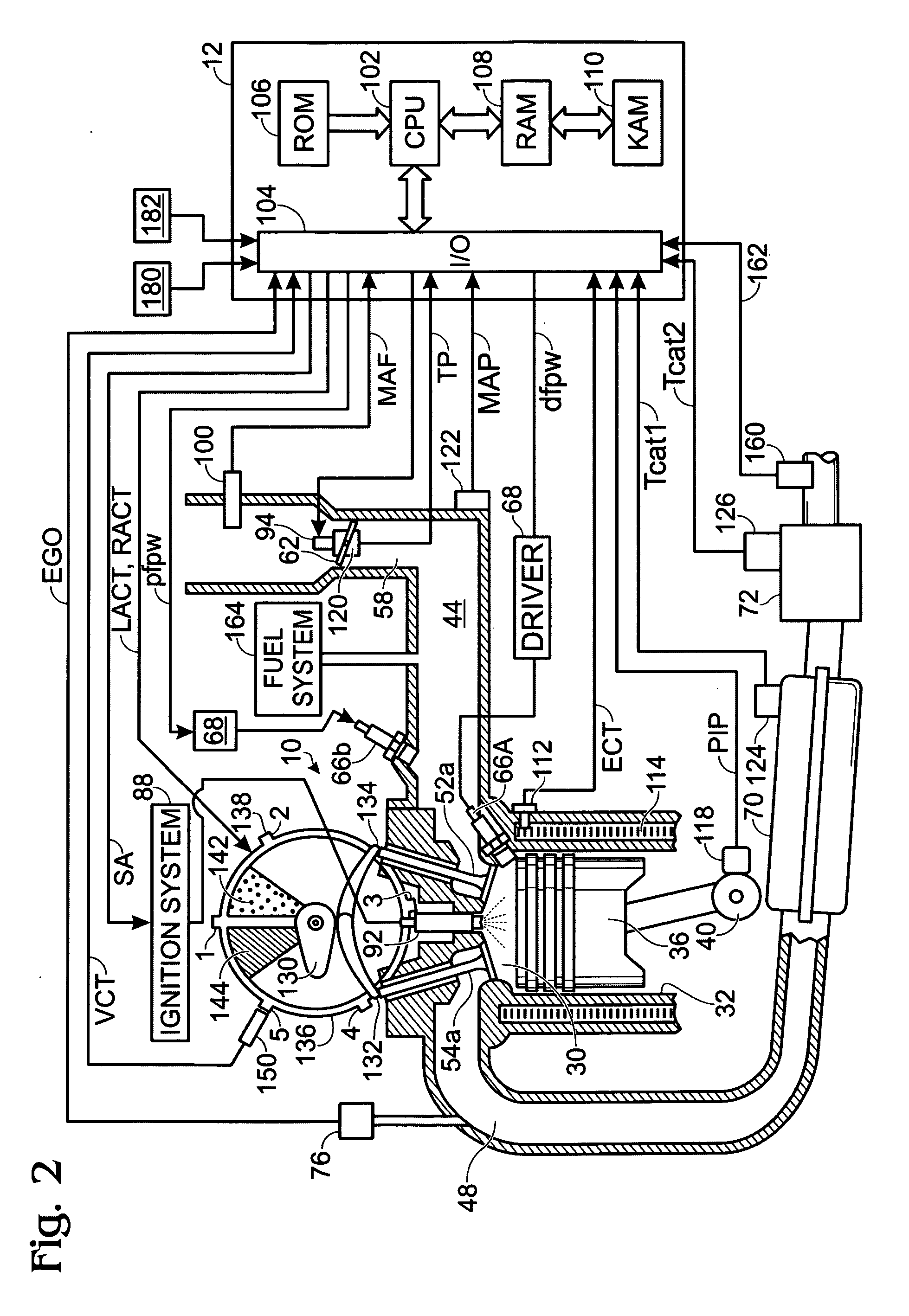

Internal combustion engine control for improved fuel efficiency

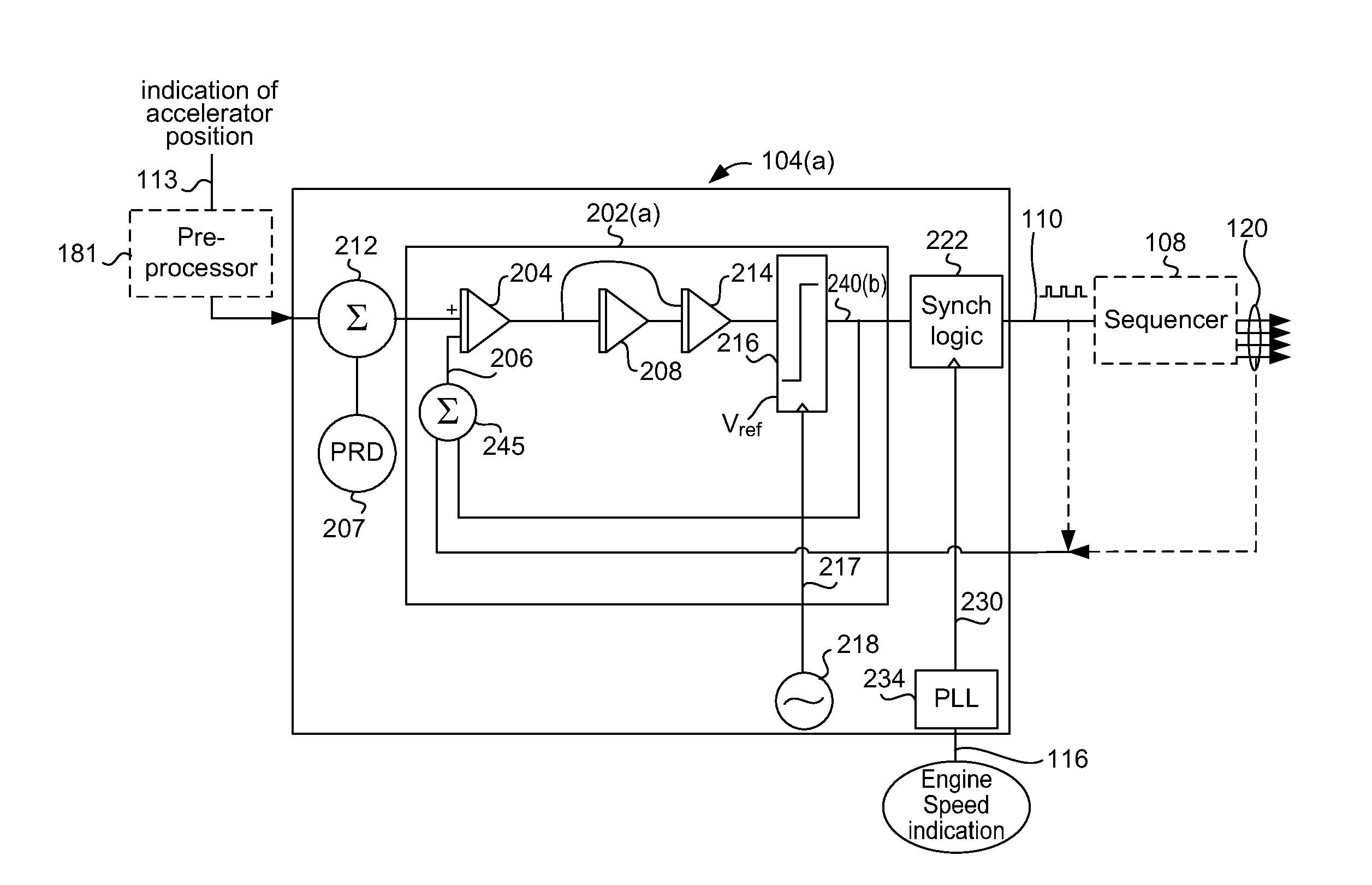

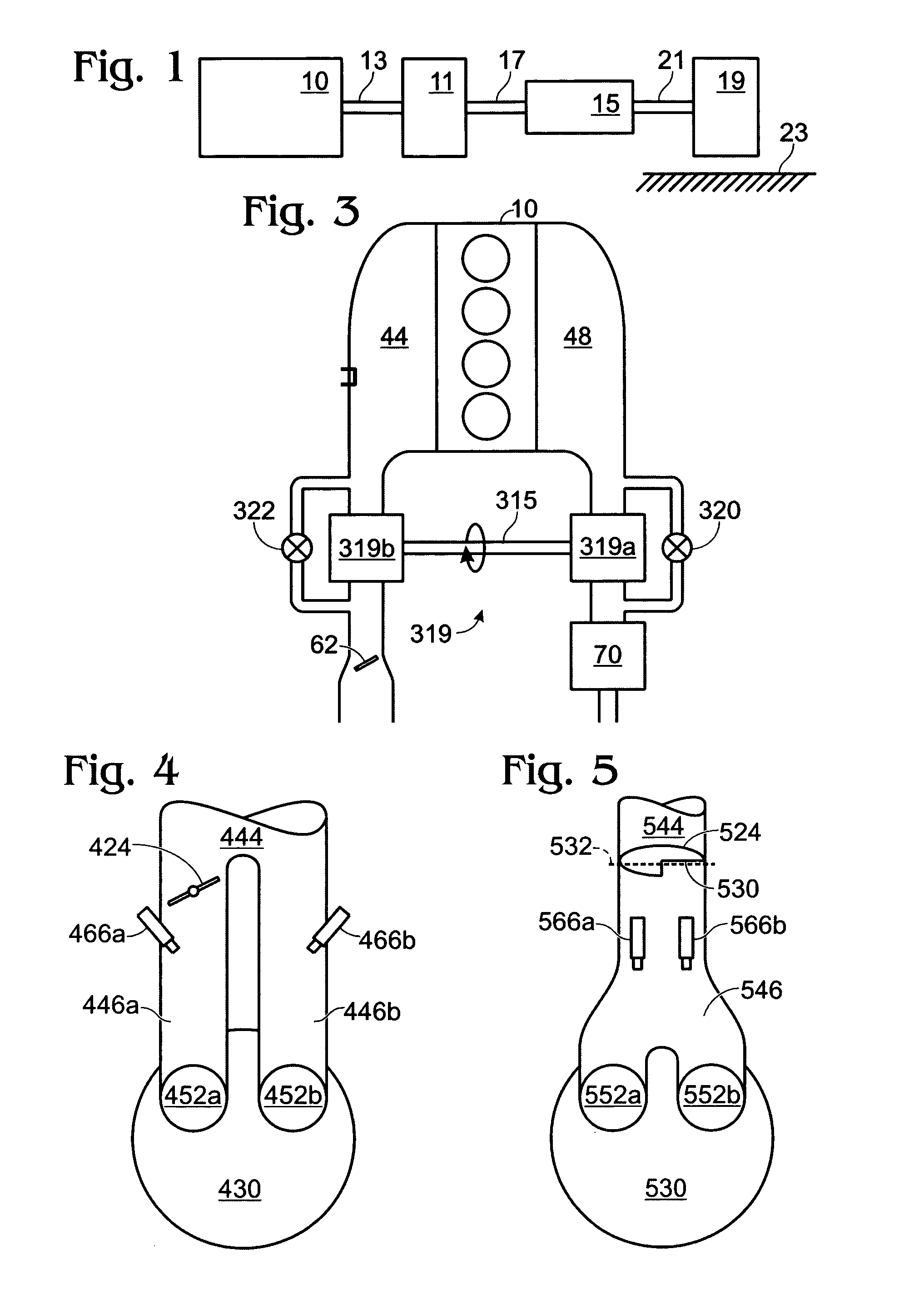

ActiveUS8131447B2Undesirable vibration reductionConvenient amountElectrical controlInternal combustion piston enginesCombustion chamberWork cycle

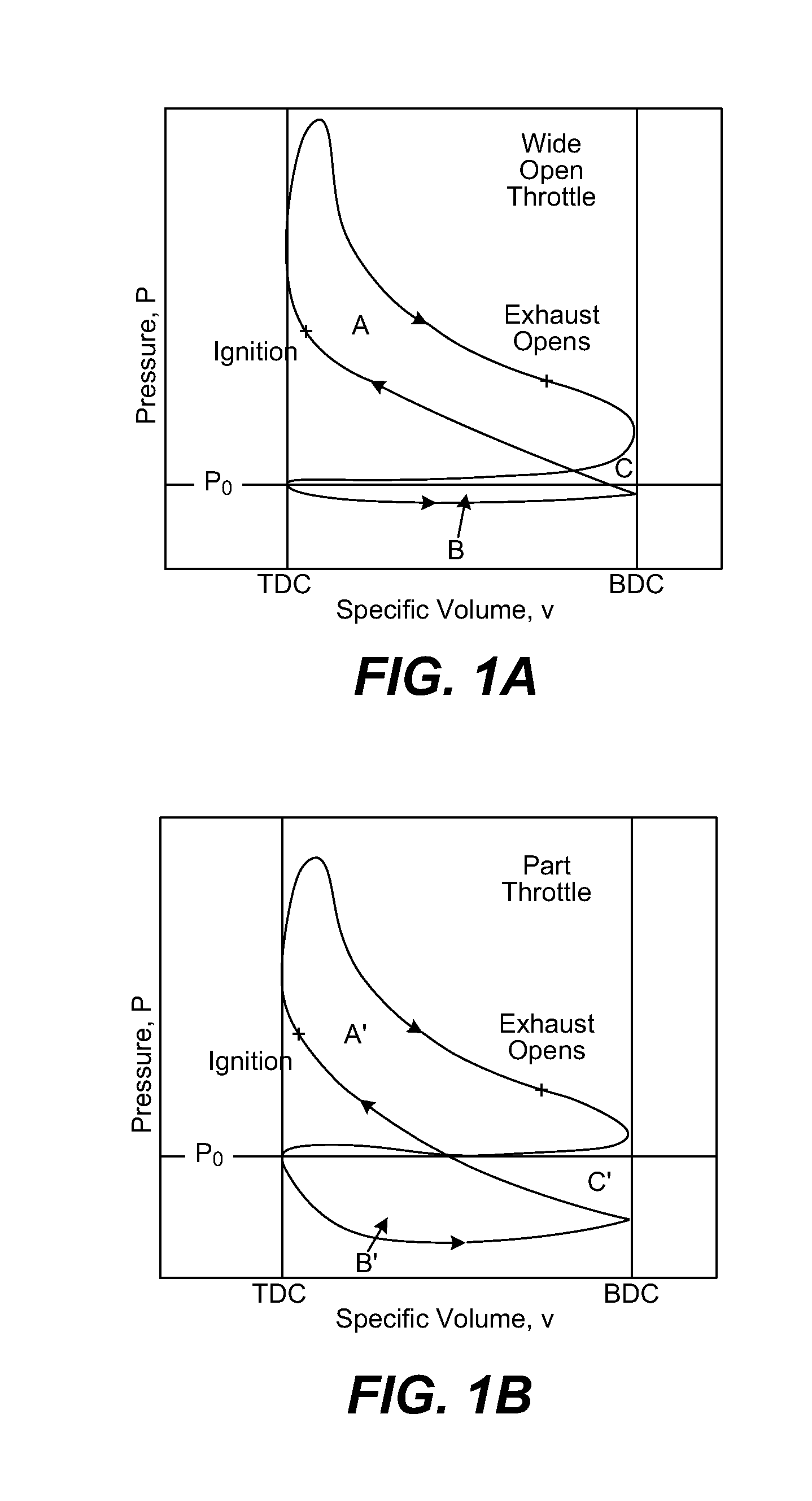

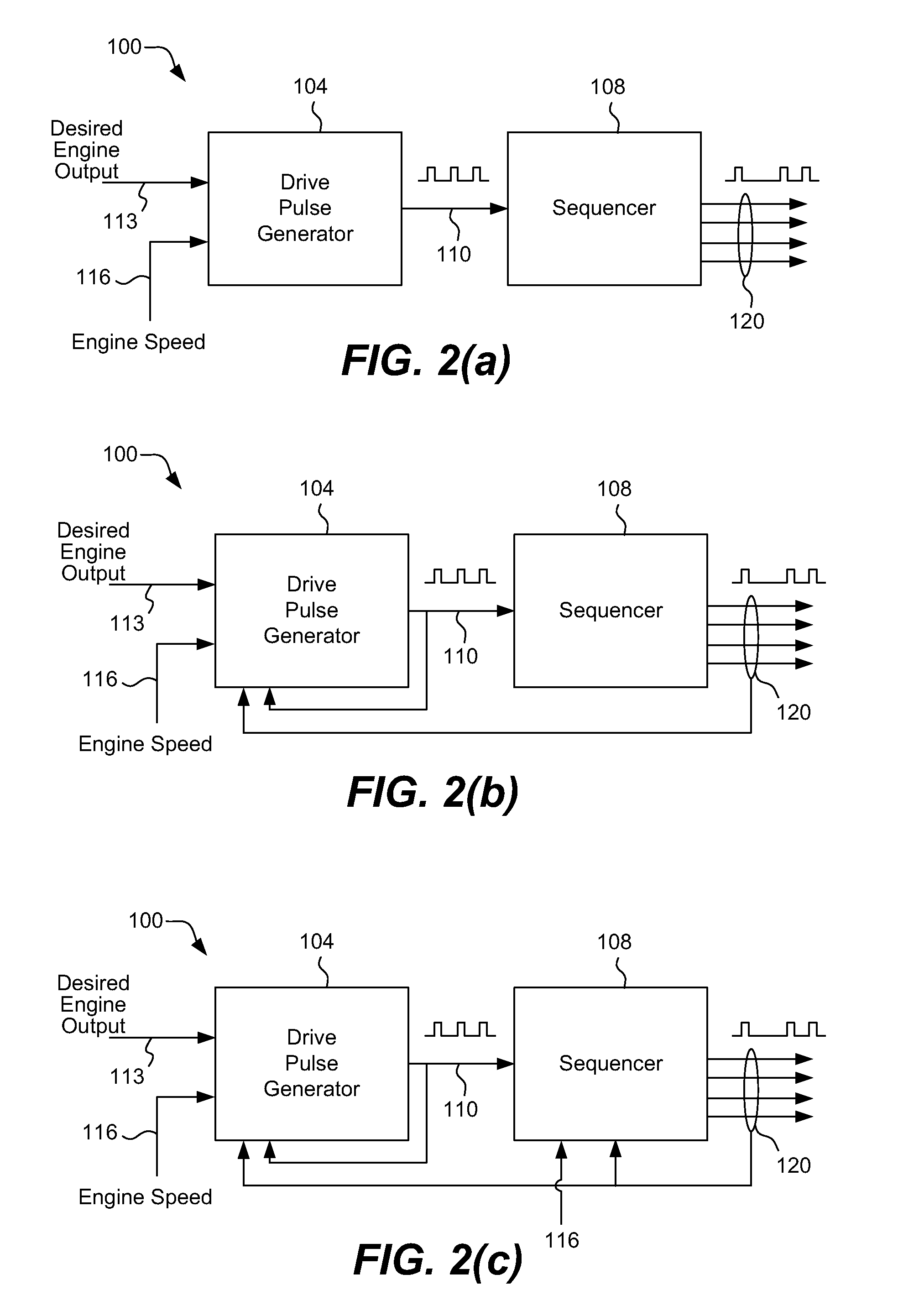

A variety of methods and arrangements for improving the fuel efficiency of internal combustion engines are described. Generally, selected combustion events are skipped during operation of the internal combustion engine so that other working cycles can operate at a better thermodynamic efficiency. In one aspect of the invention, an engine is controlled to operate in a variable displacement mode. In the variable displacement mode, fuel is not delivered to the working chambers (e.g. cylinders) during selected “skipped” working cycles. During active (“non-skipped”) working cycles, a maximum (e.g., unthrottled) amount of air and an optimized amount of fuel is delivered to the relevant working chambers so that the fired working chambers can operate at efficiencies closer to their optimal efficiency. A controller is used to dynamically determine the chamber firings required to provide the engine torque based on the engine's current operational state and conditions. The chamber firings may be sequenced in real time or in near real time in a manner that helps reduce undesirable vibrations of the engine.

Owner:TULA TECH INC

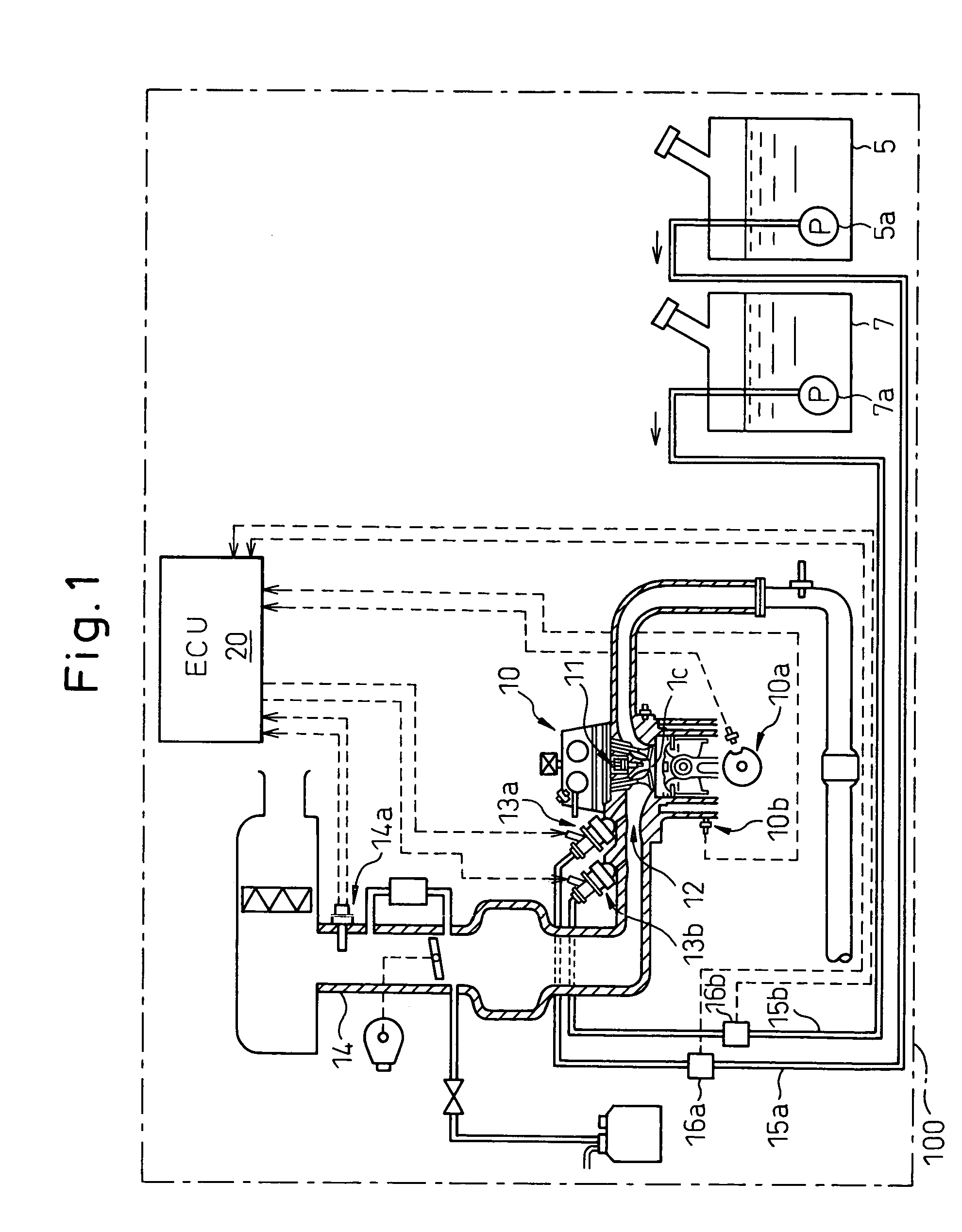

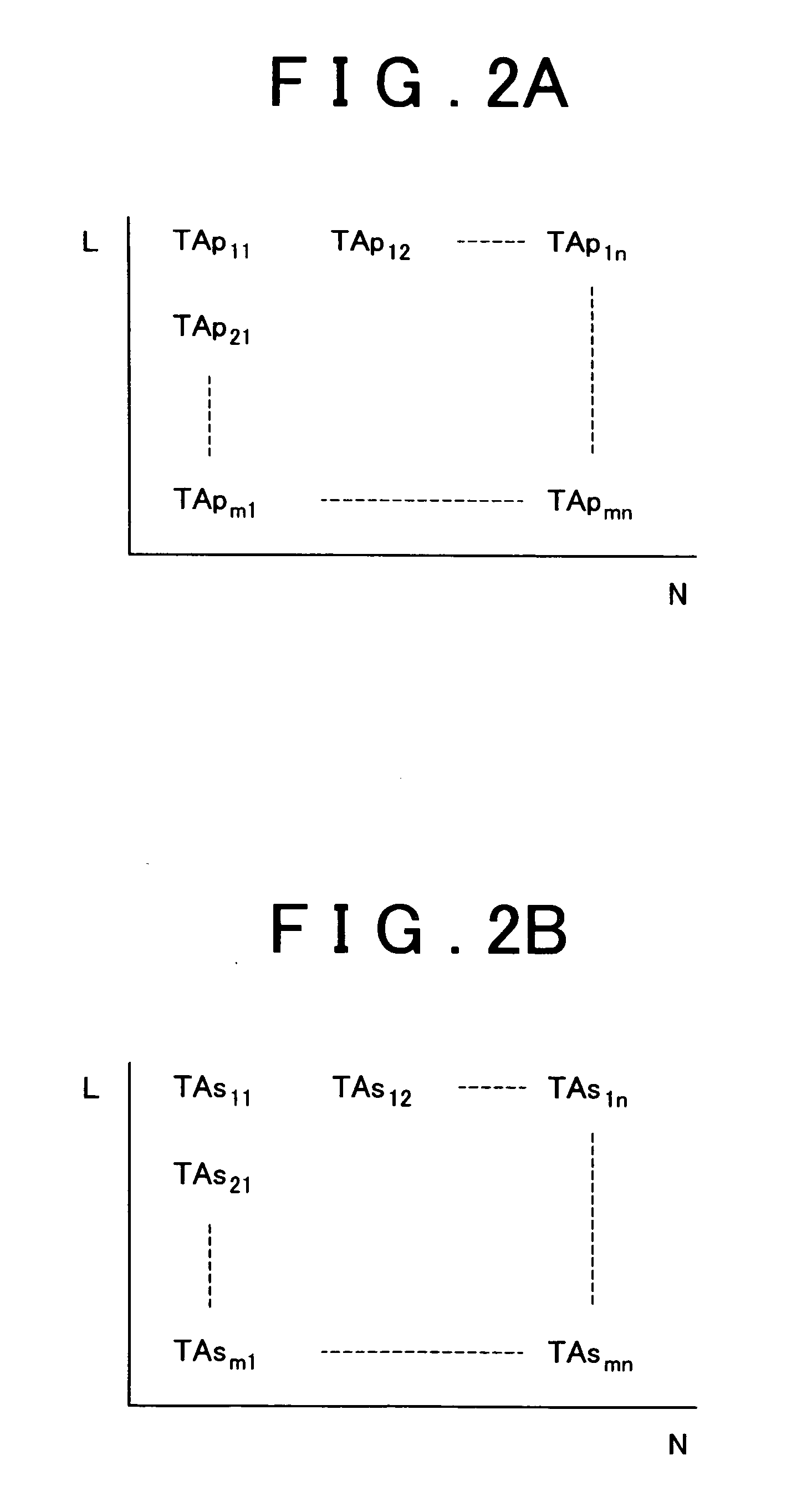

Internal combustion engine

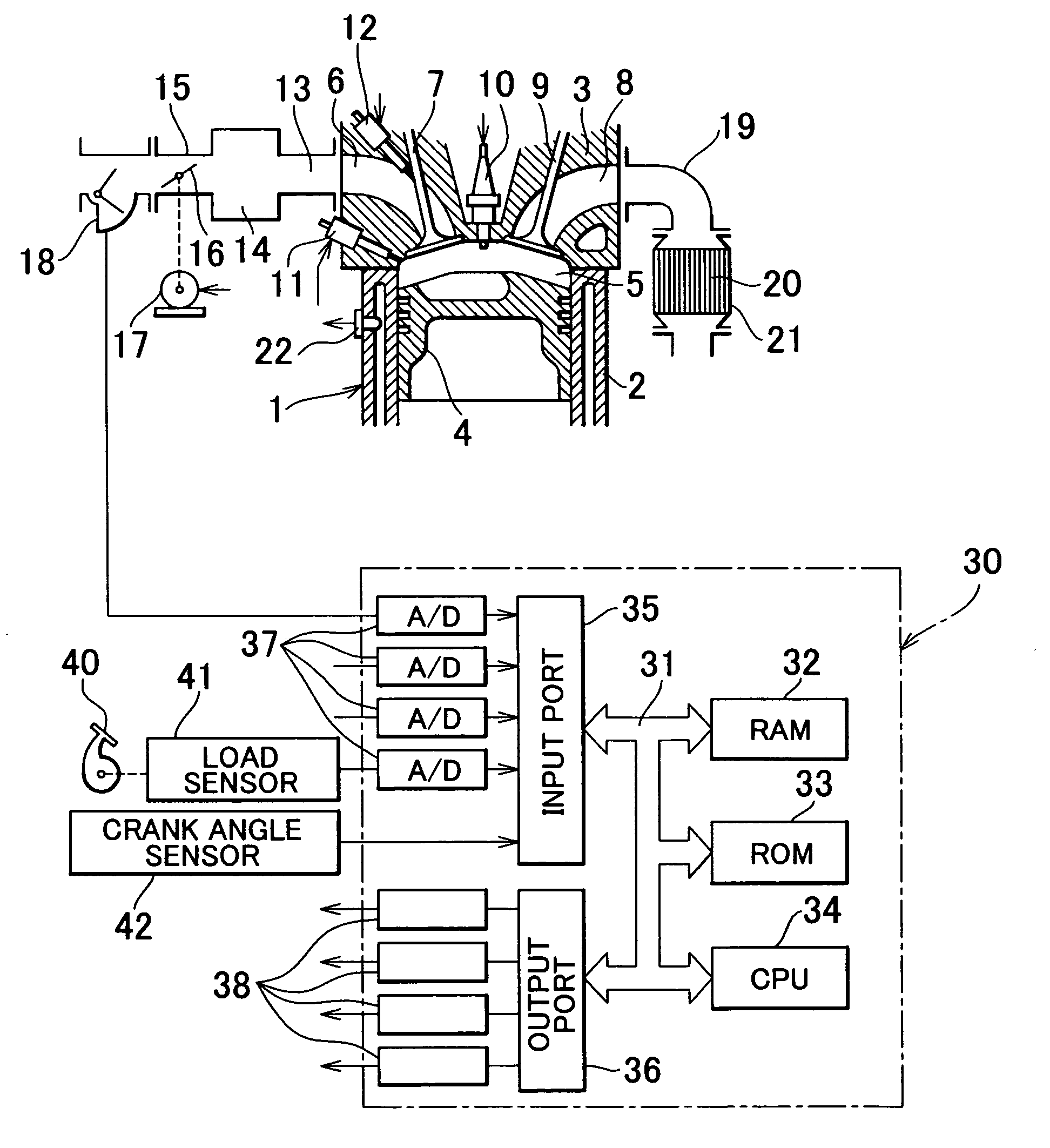

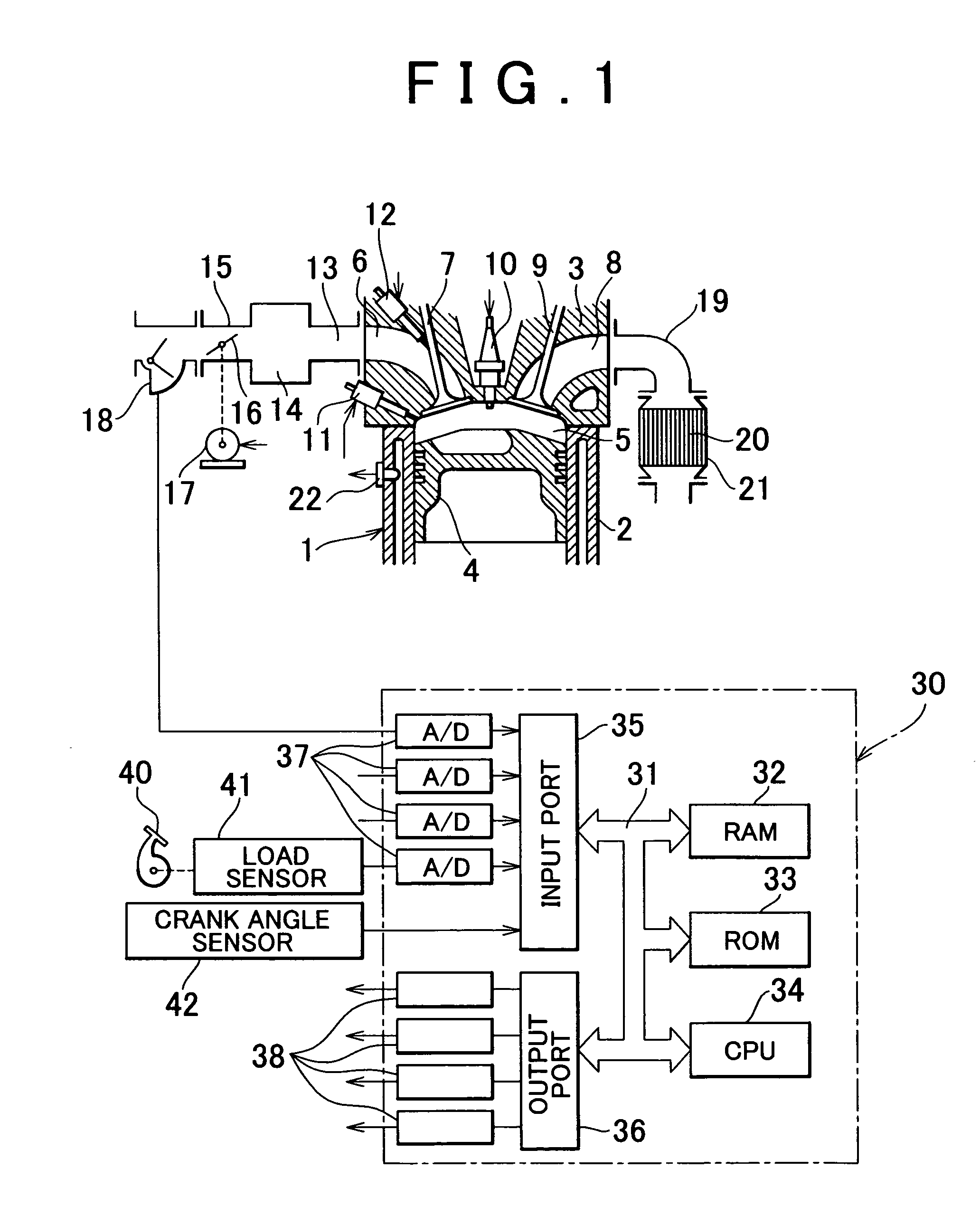

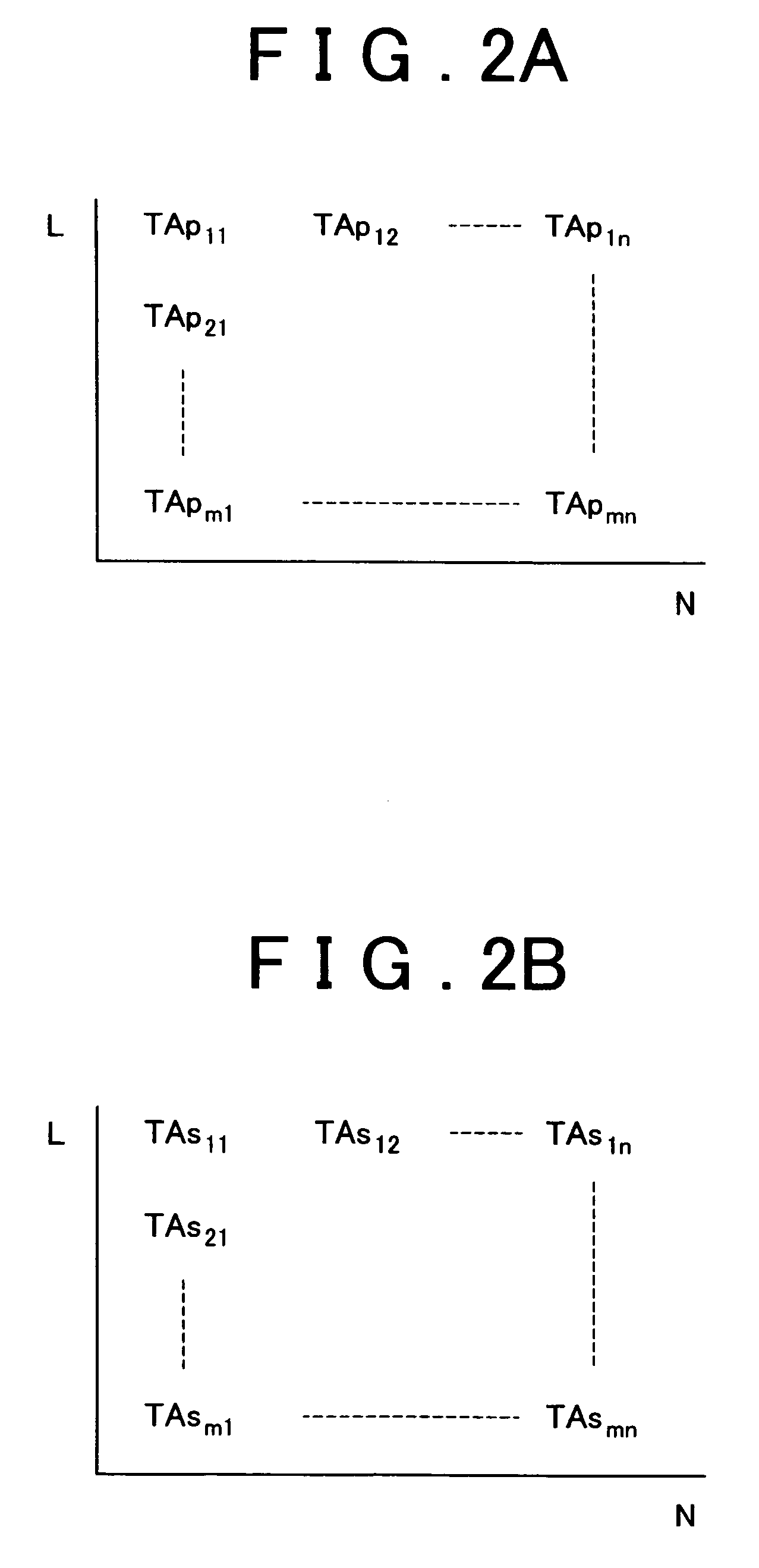

ActiveUS6990956B2Accurate calculationElectrical controlInternal combustion piston enginesMultifuelEngineering

An internal combustion engine, in which multiple kinds of fuels are fed to a cylinder from multiple fuel injectors each corresponding to each of multiple kinds of fuels at a target mixing ratio determined according to a running condition, includes an actual fuel mixing ratio calculator calculating an actual fuel mixing ratio of fuel fed to cylinder. The actual fuel mixing ratio calculator at first calculates actual fuel injection quantity of each fuel injection by adding or subtracting predetermined stuck-on-wall fuel to or from each quantity of fuel injected from each fuel injector, and then calculates an actual fuel mixing ratio of fuel fed to cylinder on the basis of the calculated actual fuel injection quantity of each fuel injector.

Owner:TOYOTA JIDOSHA KK

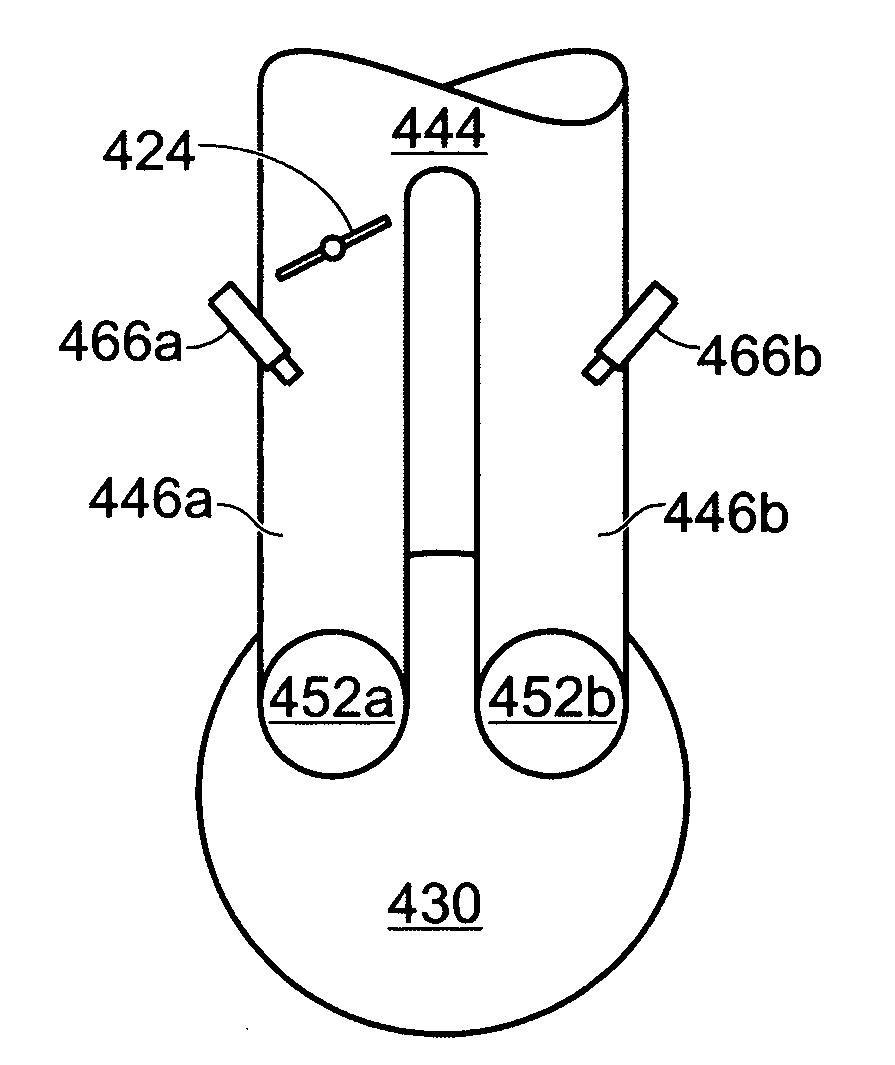

Nucleic acid amplification with continuous flow emulsion

InactiveUS7927797B2Rapid and economical mannerReduce nozzle cloggingHeating or cooling apparatusFlow mixersMicroreactorGenetic Materials

Embodiments of the present invention are directed to methods and devices / systems for amplifying genetic material and may include providing a water-in-oil emulsion in a continuous flow. The emulsion may include a plurality of water droplets comprising microreactors. Each of the plurality of microreactors may include a single bead capable of capturing a nucleic acid template, a single species nucleic acid template and sufficient reagents to amplify the copy number of the nucleic acid template. The method also includes flowing the emulsion across a first temperature zone and a second lower temperature zone to thermally process the microreactors to amplify the nucleic acid template by polymerase chain reaction.

Owner:454 LIFE SCIENCES CORP

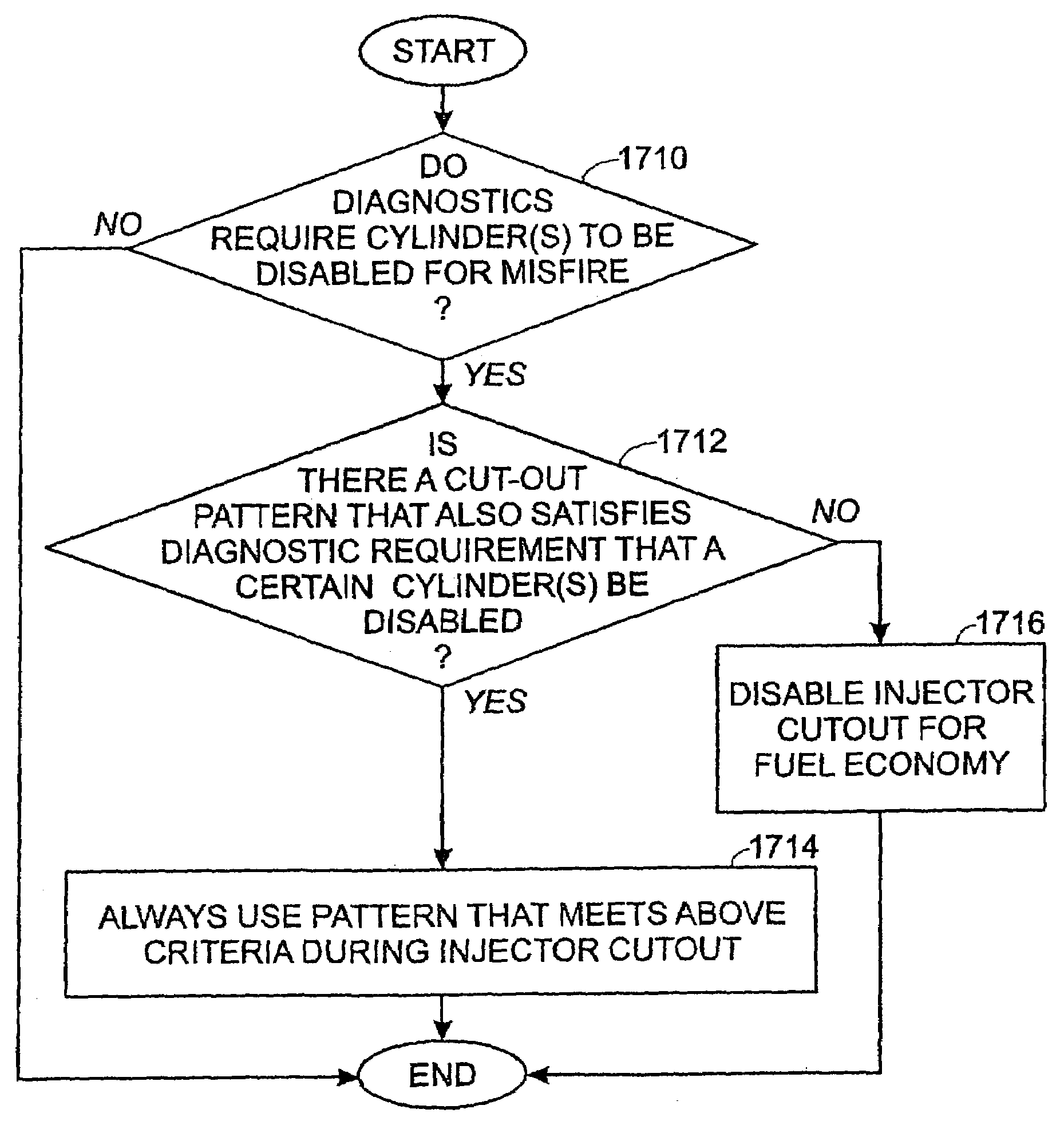

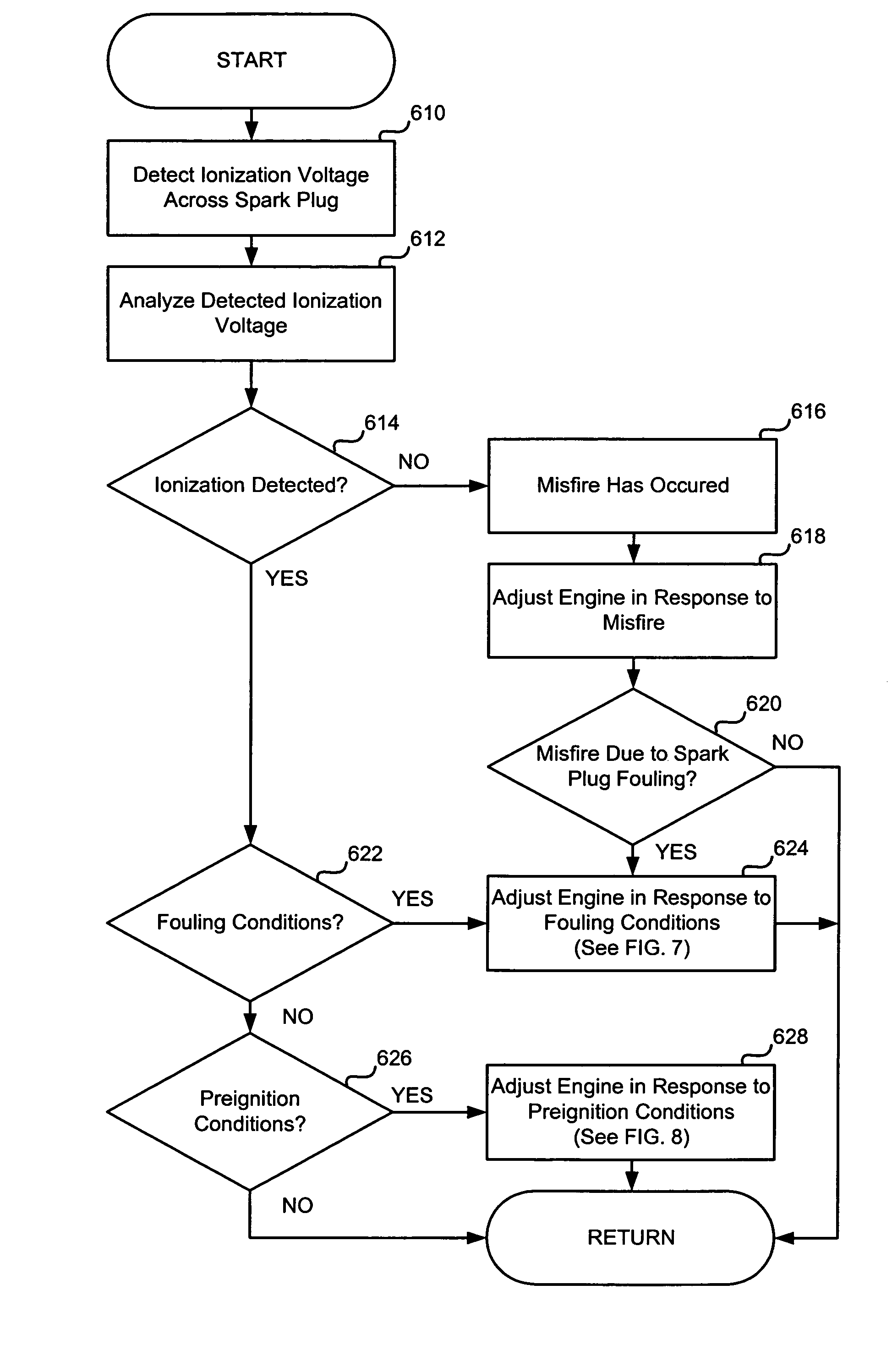

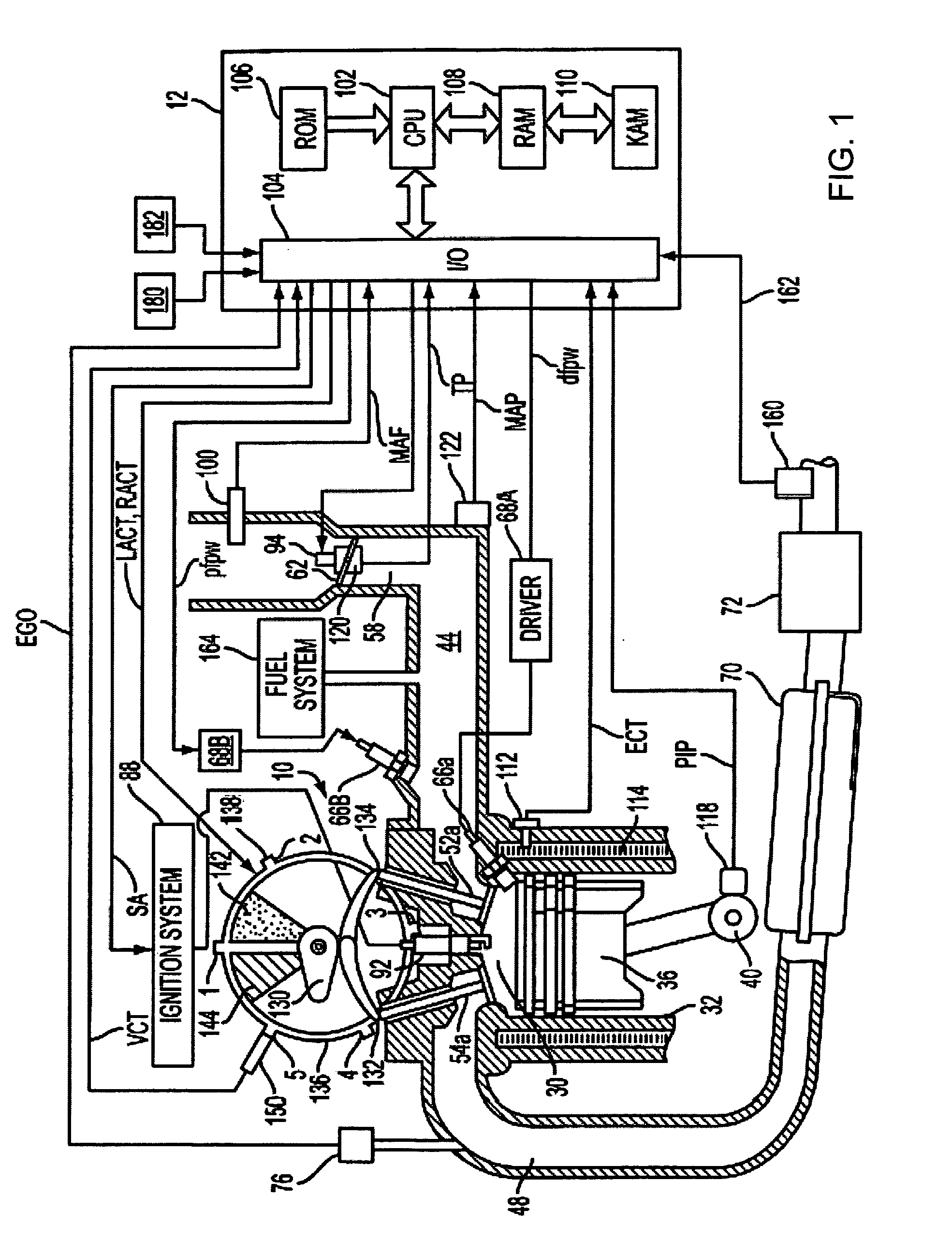

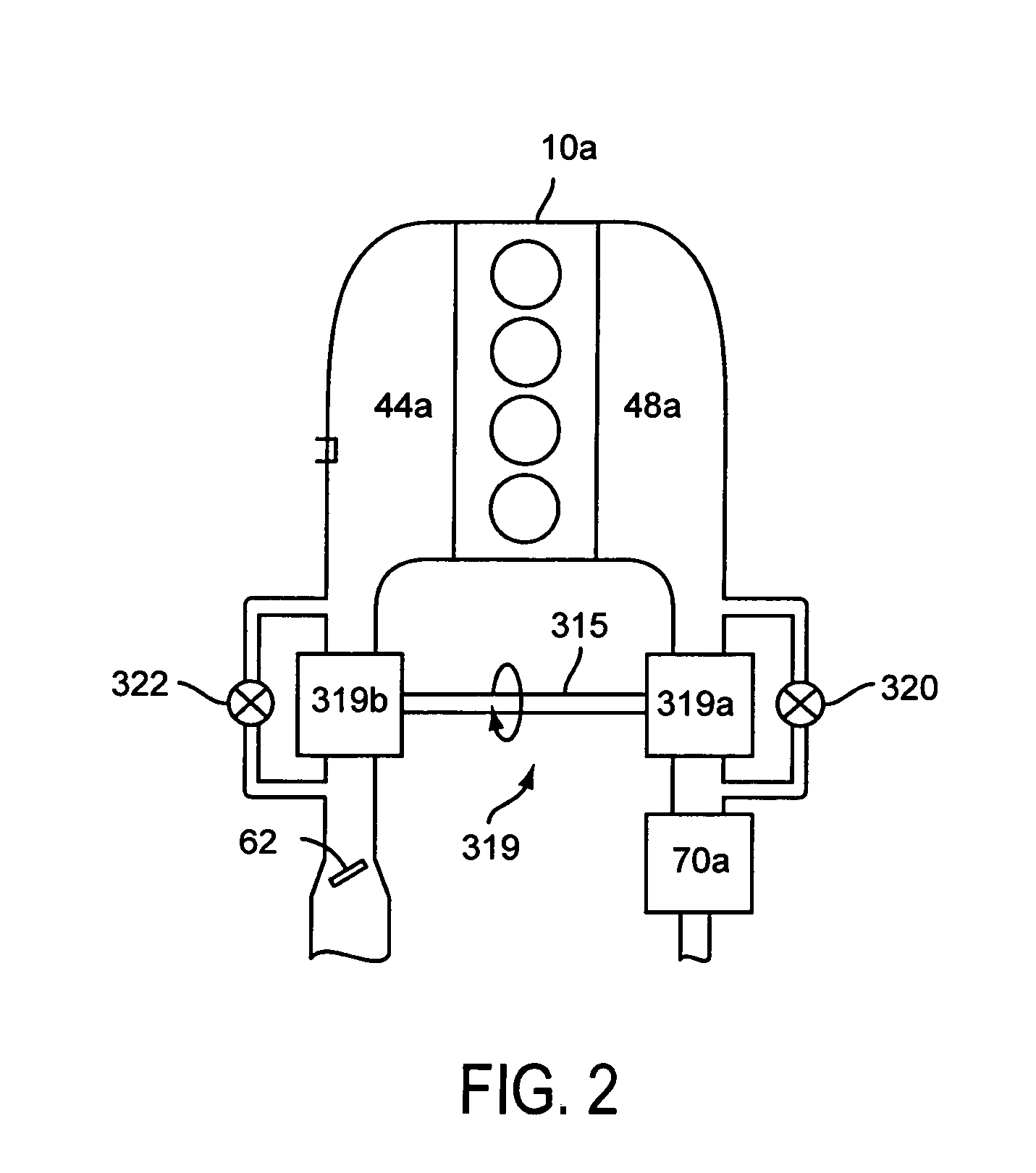

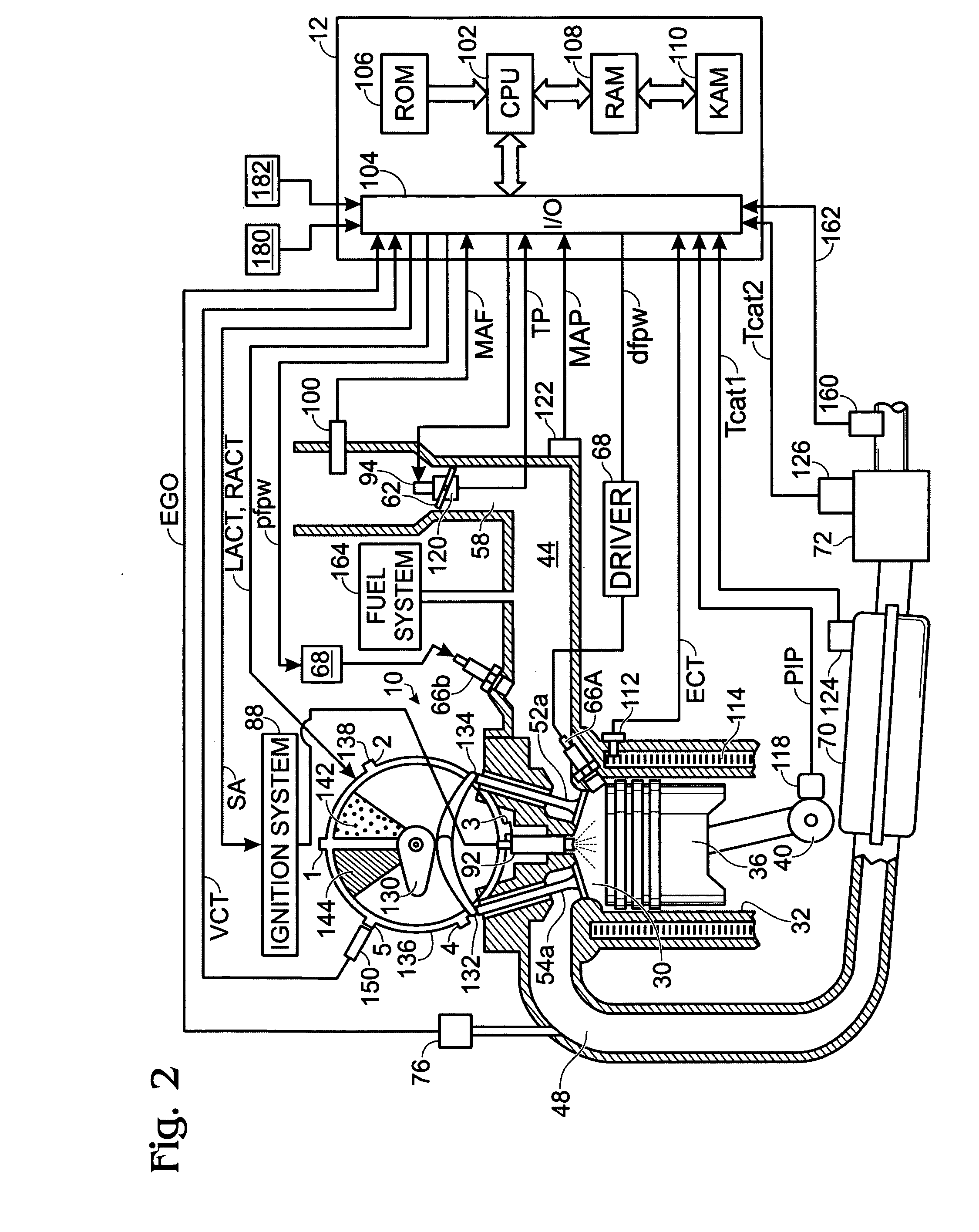

Engine system and method accounting for engine misfire

ActiveUS7086386B2Reducing engine pumping lossesMore efficientCombustion enginesOutput powerSystems designFuel vapor

Various systems and methods are disclosed for carrying out combustion in a fuel-cut operation in some or all of the engine cylinders of a vehicle. Further, various subsystems are considered, such as fuel vapor purging, air-fuel ratio control, engine torque control, catalyst design, and exhaust system design.

Owner:FORD GLOBAL TECH LLC

Fuel injection system and method

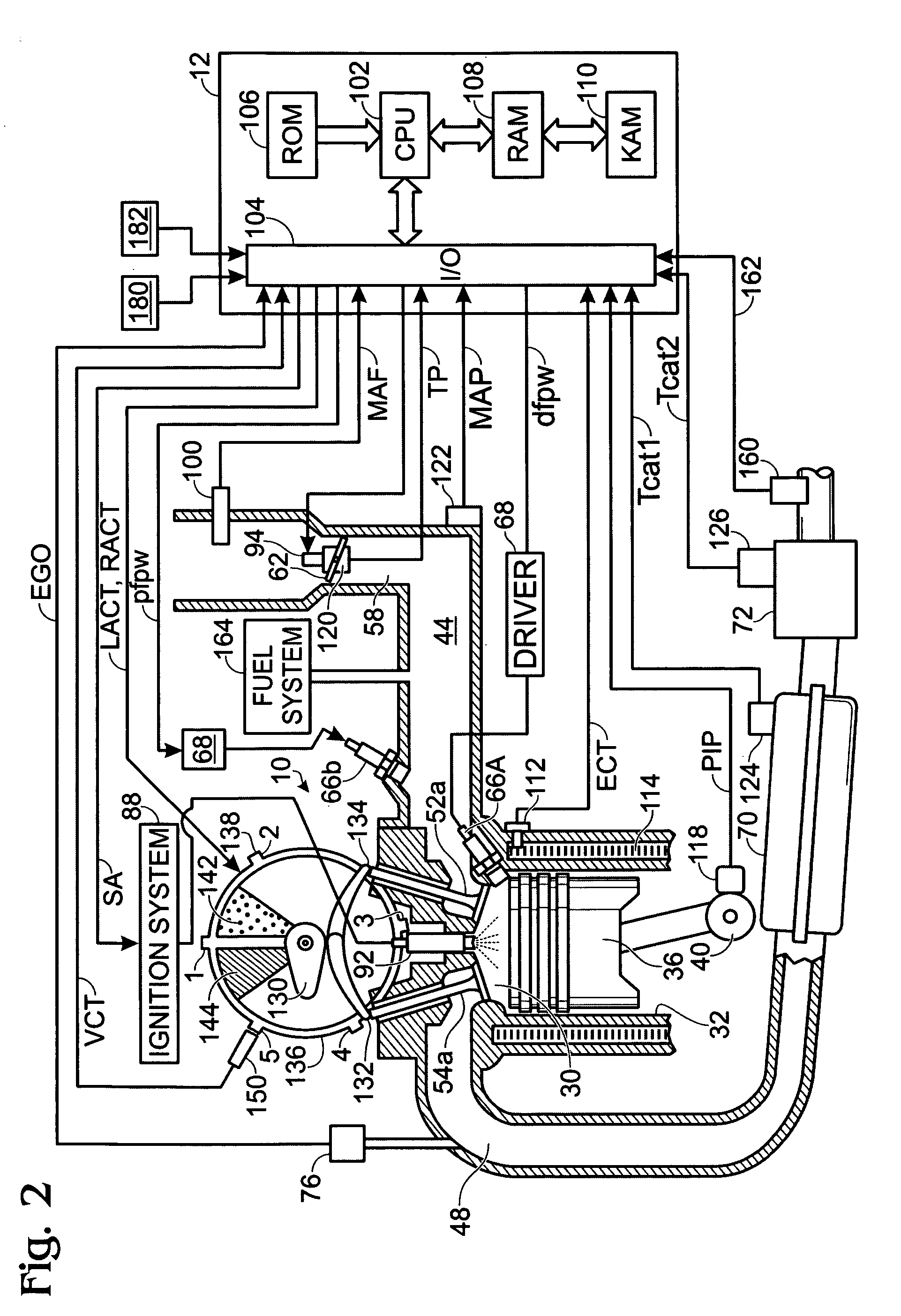

InactiveUS6959693B2Electrical controlCoolant flow controlCombustion chamberInternal combustion engine

A fuel injection system includes a first fuel injector that injects a lower-octane fuel into a combustion chamber of an internal combustion engine, and a second fuel injector that injects a higher-octane fuel into an intake passage of the engine. When the engine temperature is equal to or lower than a predetermined temperature during a start-up period of the internal combustion engine, fuel having the lower octane is injected via the first injector while prohibiting injection of the higher octane fuel via the second fuel injector.

Owner:TOYOTA JIDOSHA KK

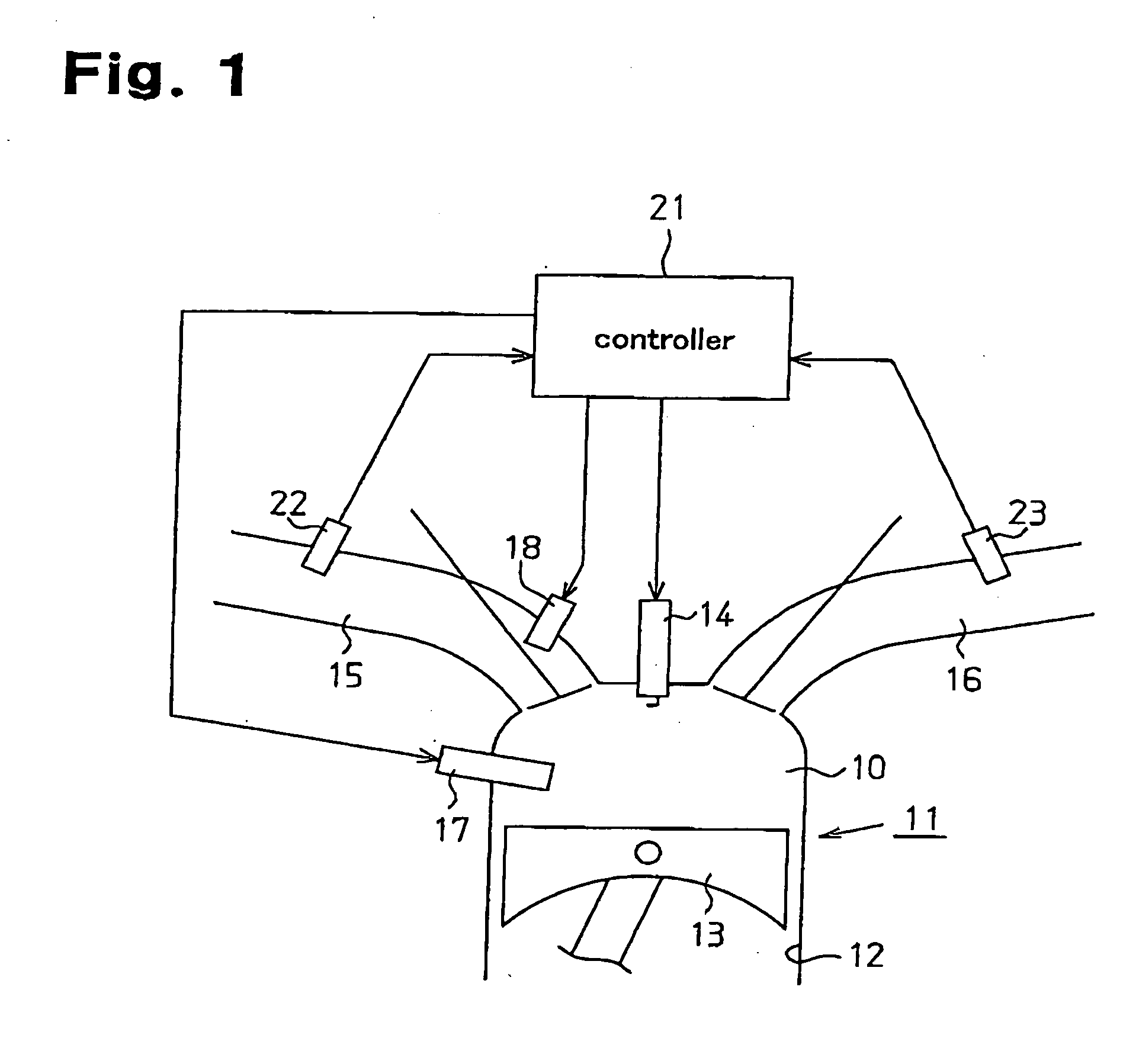

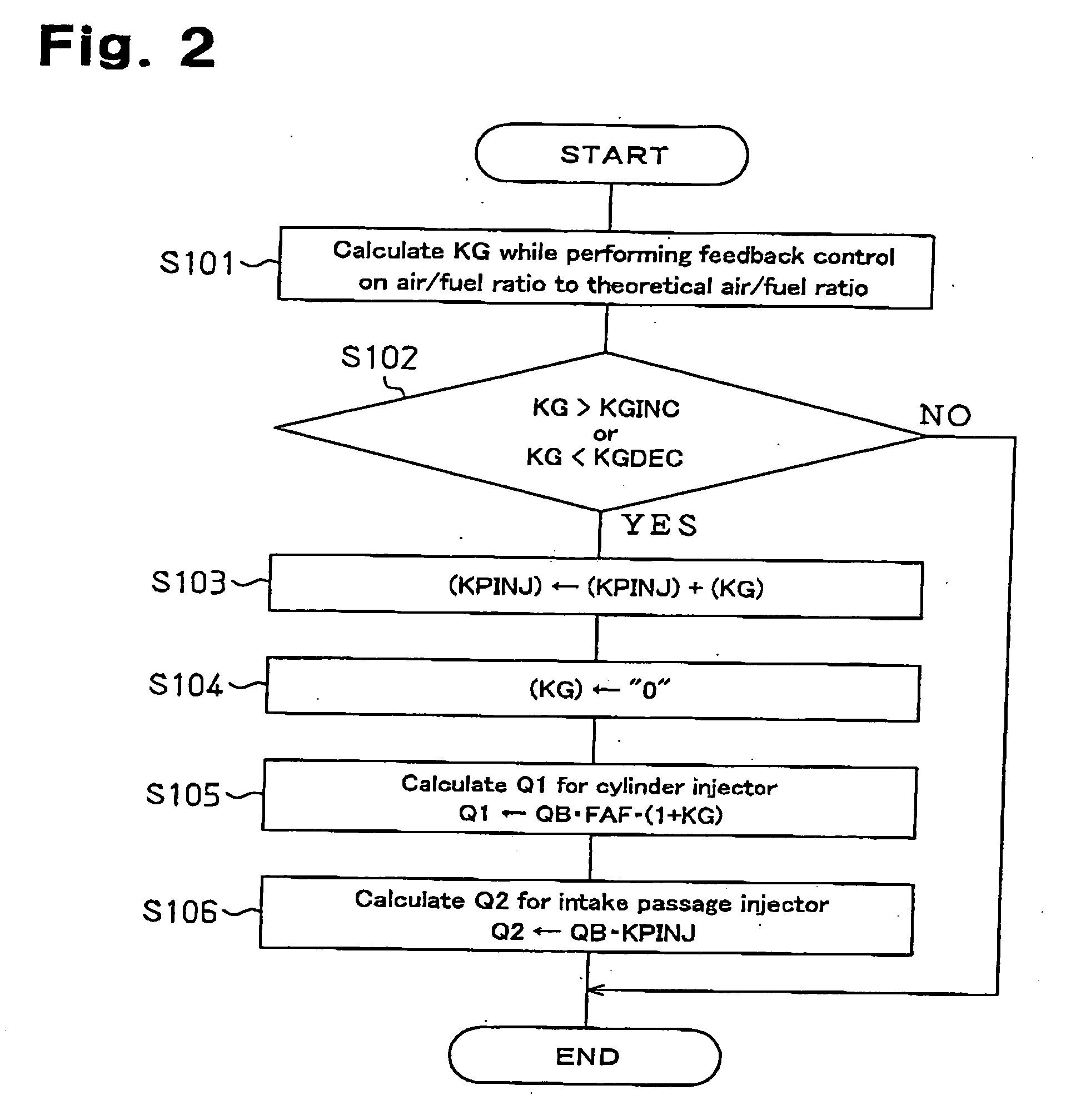

Engine fuel injection control system

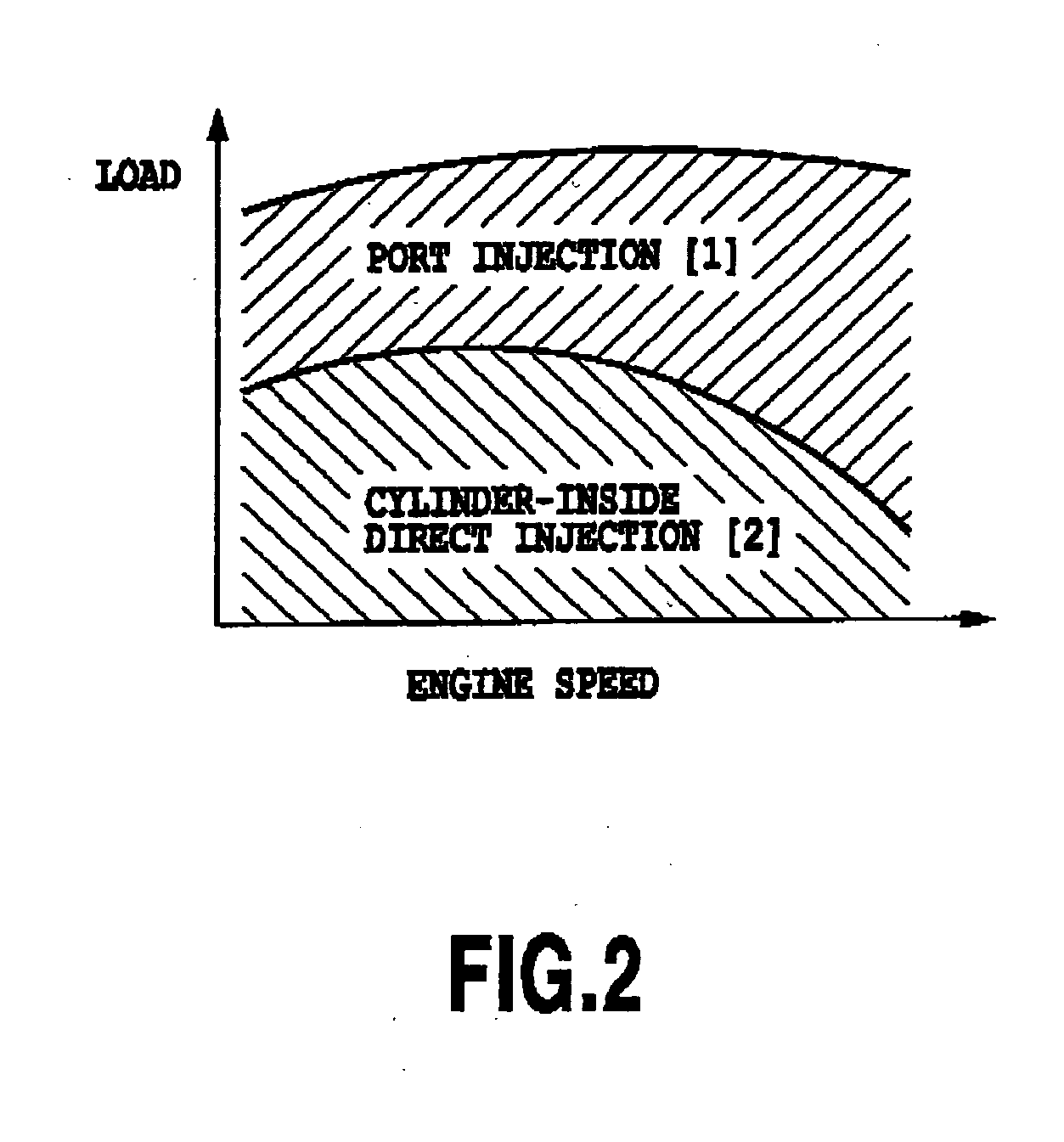

InactiveUS20050178360A1Inhibit deteriorationImprove suction efficiencyElectrical controlInternal combustion piston enginesCombustion chamberControl system

A system for controlling fuel injection in an engine. The engine includes an intake passage, an intake passage injector, a cylinder having a combustion chamber, and a cylinder injector for injecting a target amount of fuel into the combustion chamber. The system includes a controller for controlling the intake passage and cylinder injectors to permit fuel injection, each with an injection ratio, while said engine operates in a condition in which said engine permits fuel injection from said cylinder injector, a sensor for sensing the amount of fuel injected from the cylinder injector, a detector for detecting the difference between the target injection amount and the amount of fuel injected and an adjustor for adjusting the injection ratio based on the result of the detection by the detector so that the intake passage injector performs fuel injection together with the fuel injection performed by the cylinder injector.

Owner:TOYOTA JIDOSHA KK

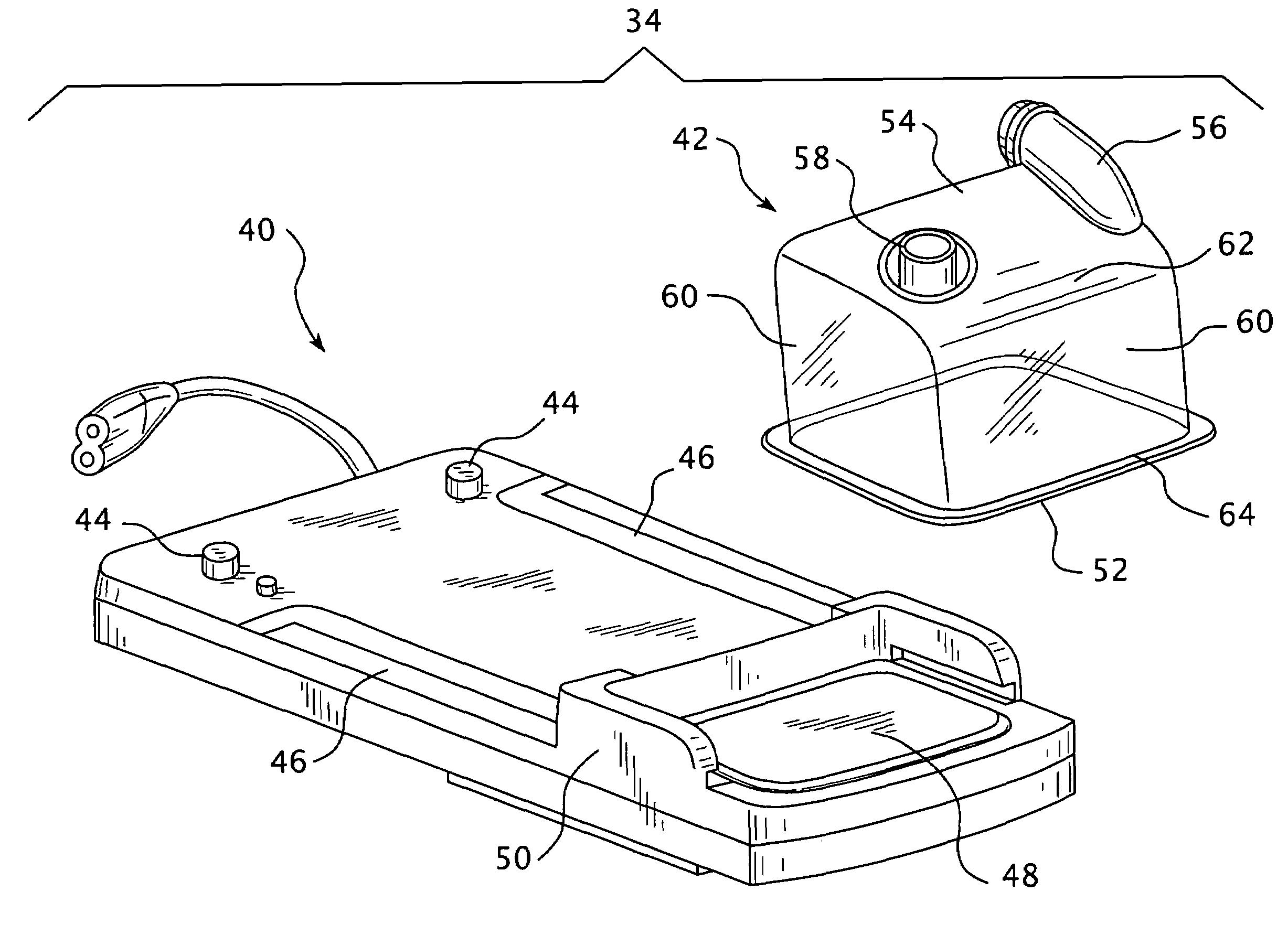

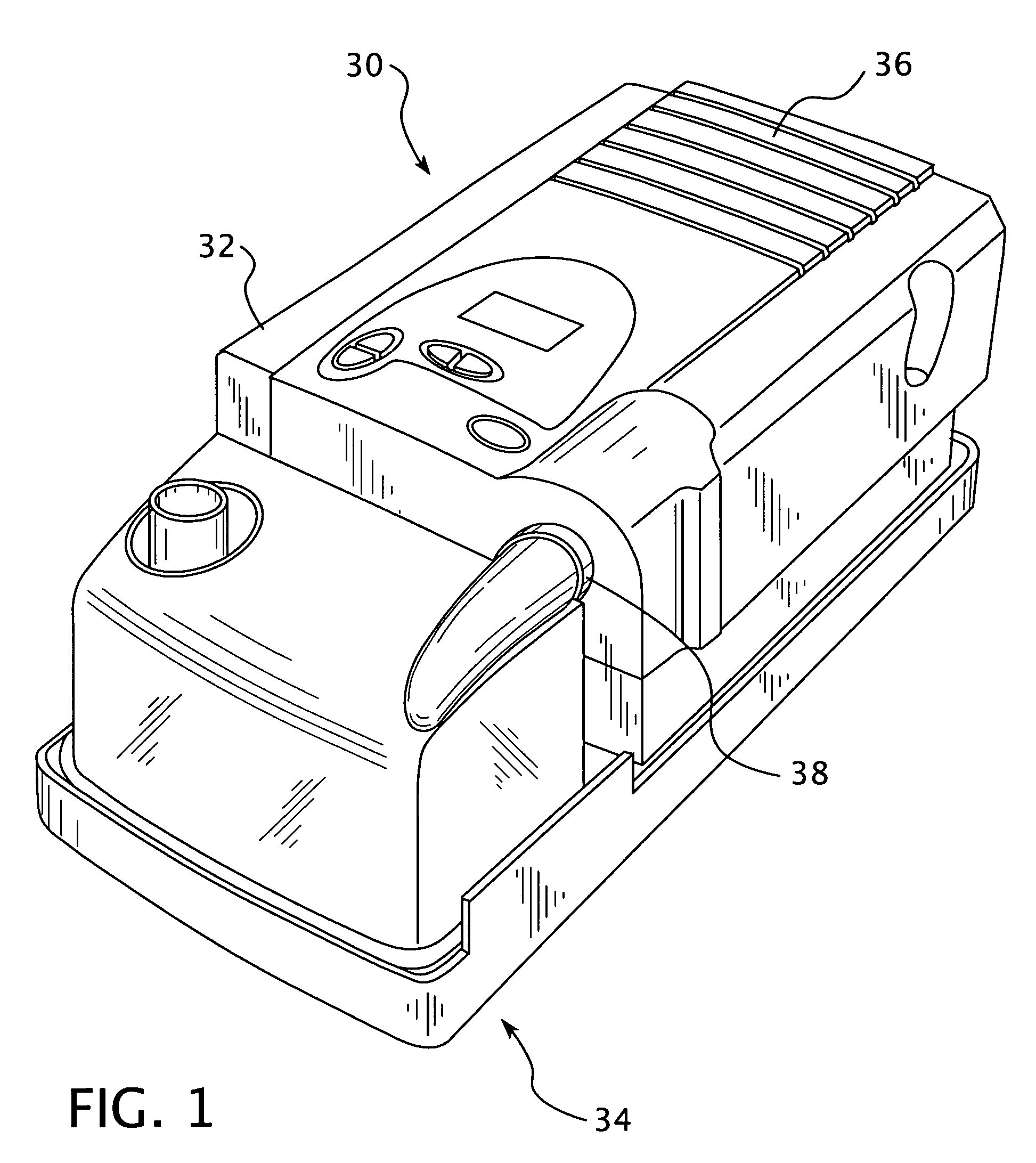

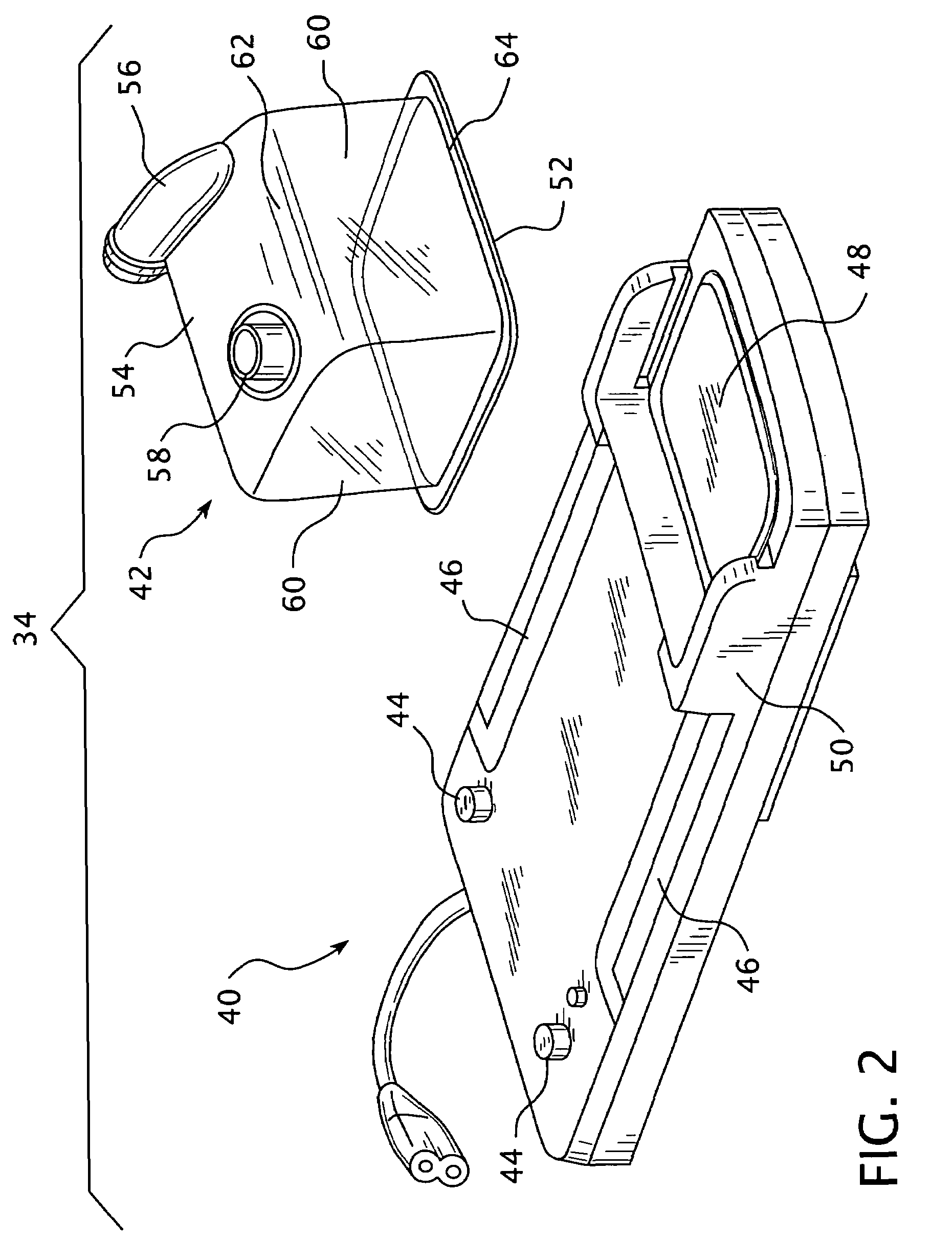

Molded water chamber base plate for use in a humidifier and ventilator assembly

A molded base plate for use in a humidifier and ventilation assembly is disclosed. The base plate is connected to a cover which forms the water chamber of the humidifier. A thermally conductive material is used in the molding process of the base plate so that heat applied to the base plate is conducted into the water.

Owner:RIC INVESTMENTS LLC

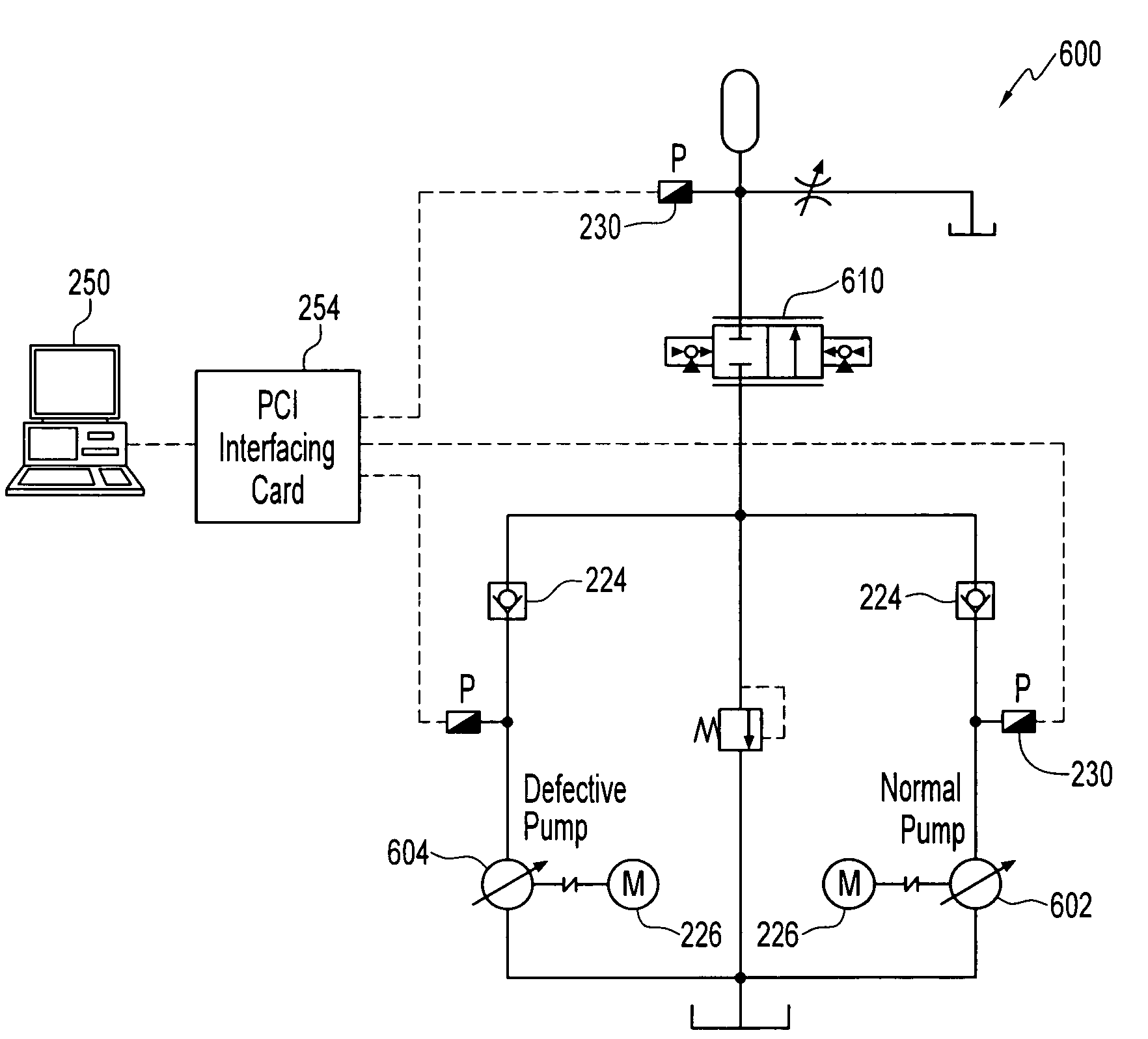

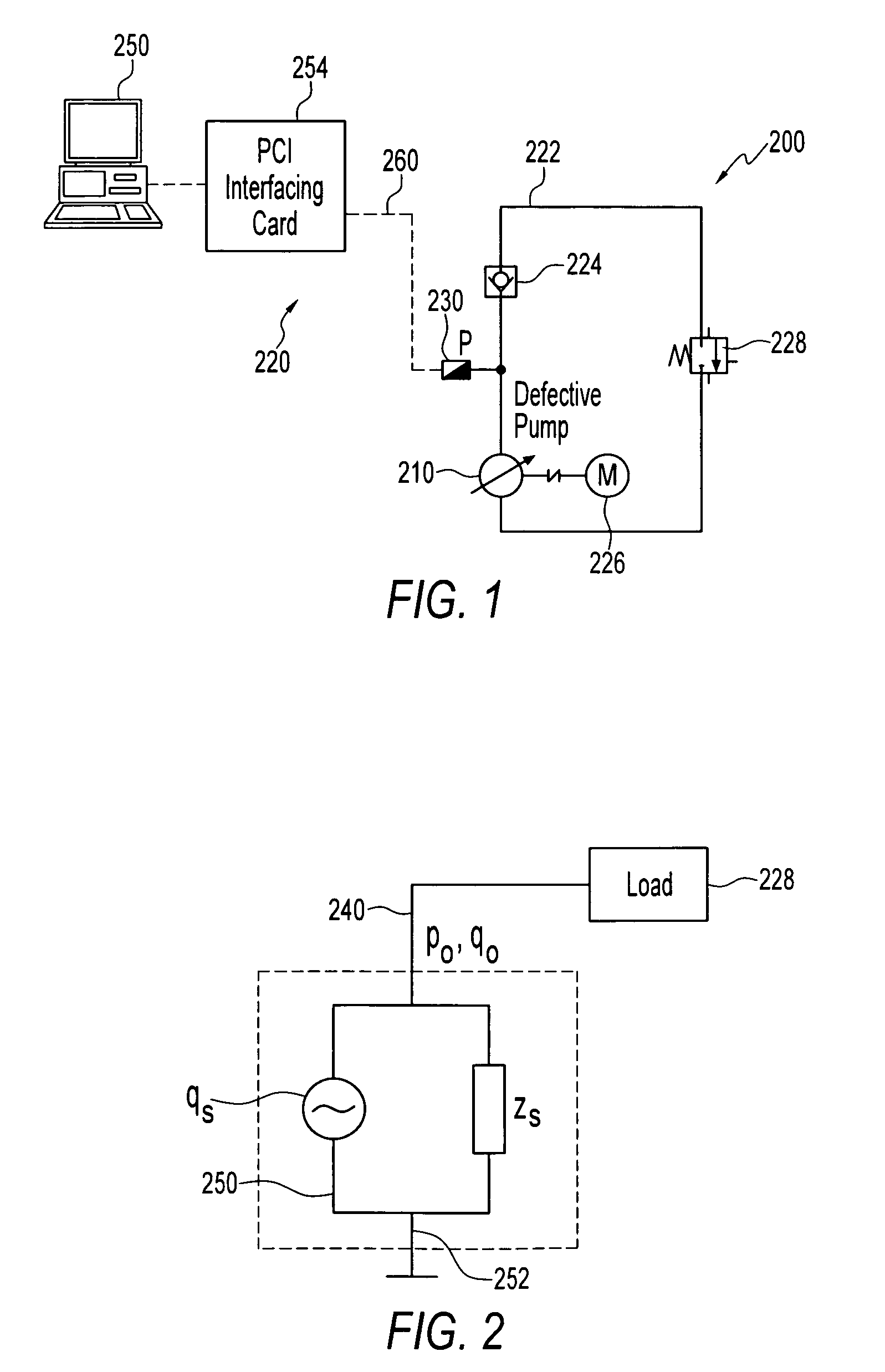

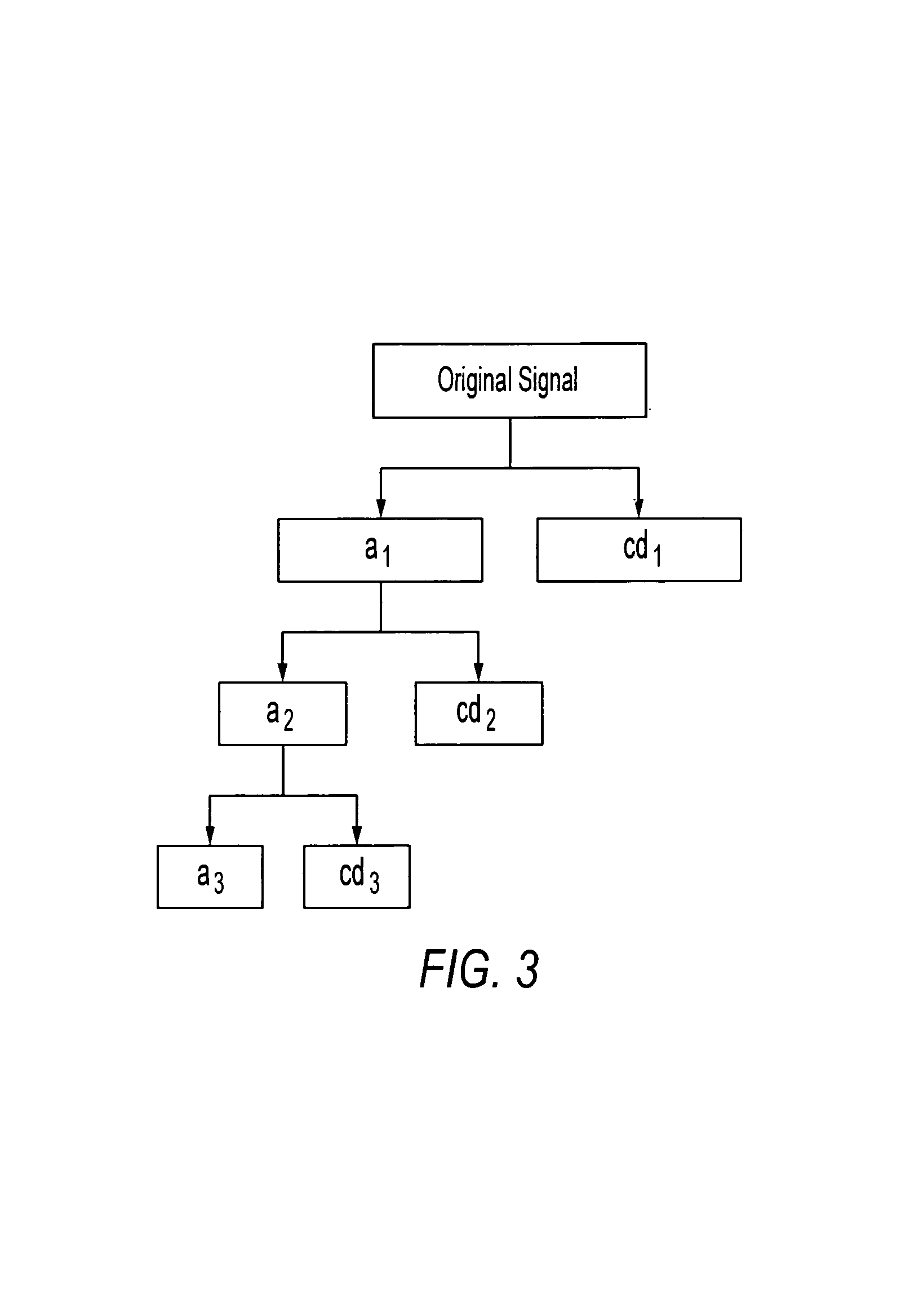

Method and apparatus for analyzing performance of a hydraulic pump

A method and apparatus for analyzing a hydraulic pump in real-time. A pressure signal is provided representing a discharge pressure of the hydraulic pump, and the pressure signal is decomposed into a plurality of levels. Each of the plurality of levels has at least one frequency band. A feature pressure signal is located in at least one of the frequency bands and compared to a reference wavelet to determine if a fault exists in the hydraulic pump and / or a type of defect in the hydraulic pump.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

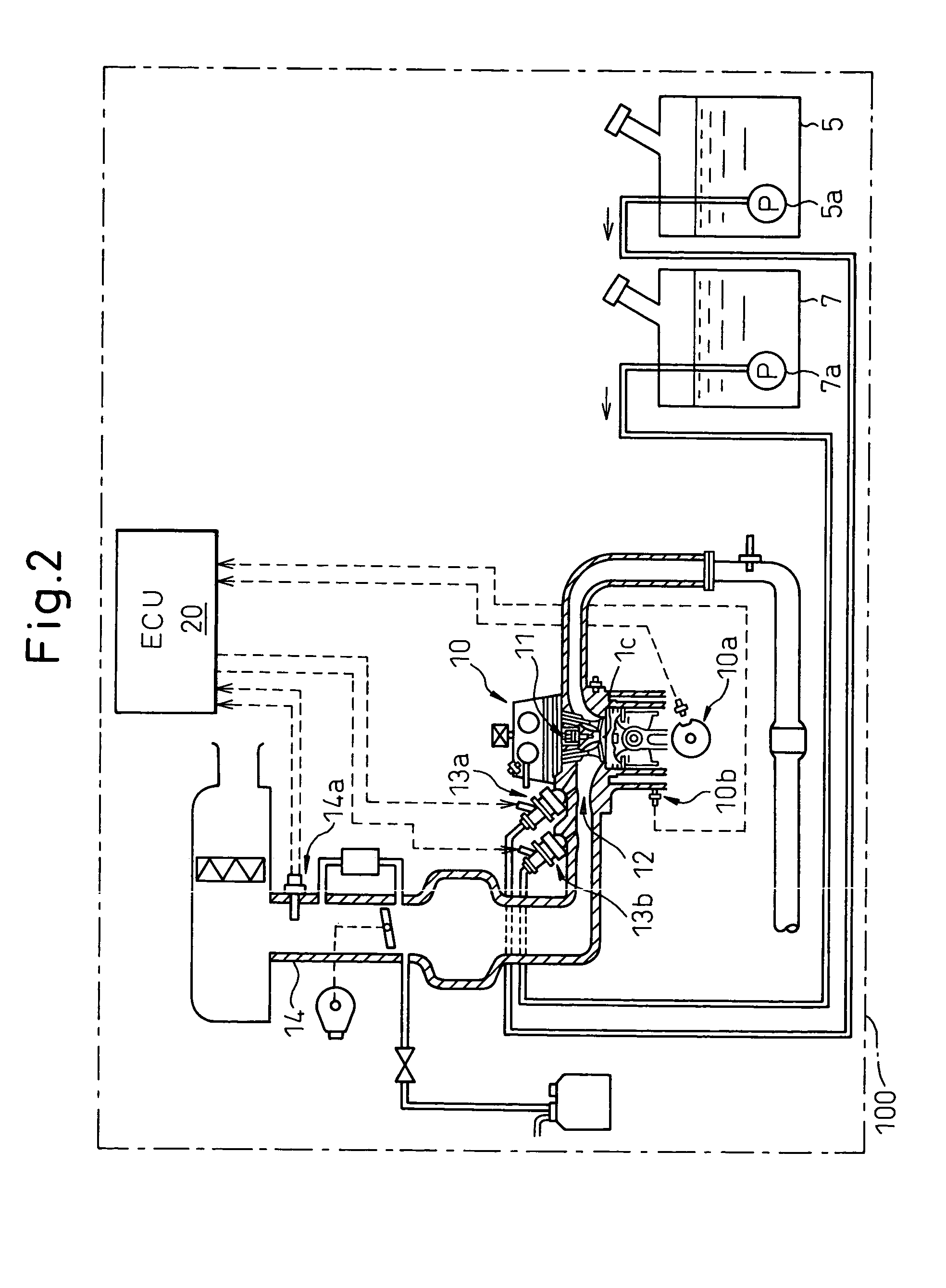

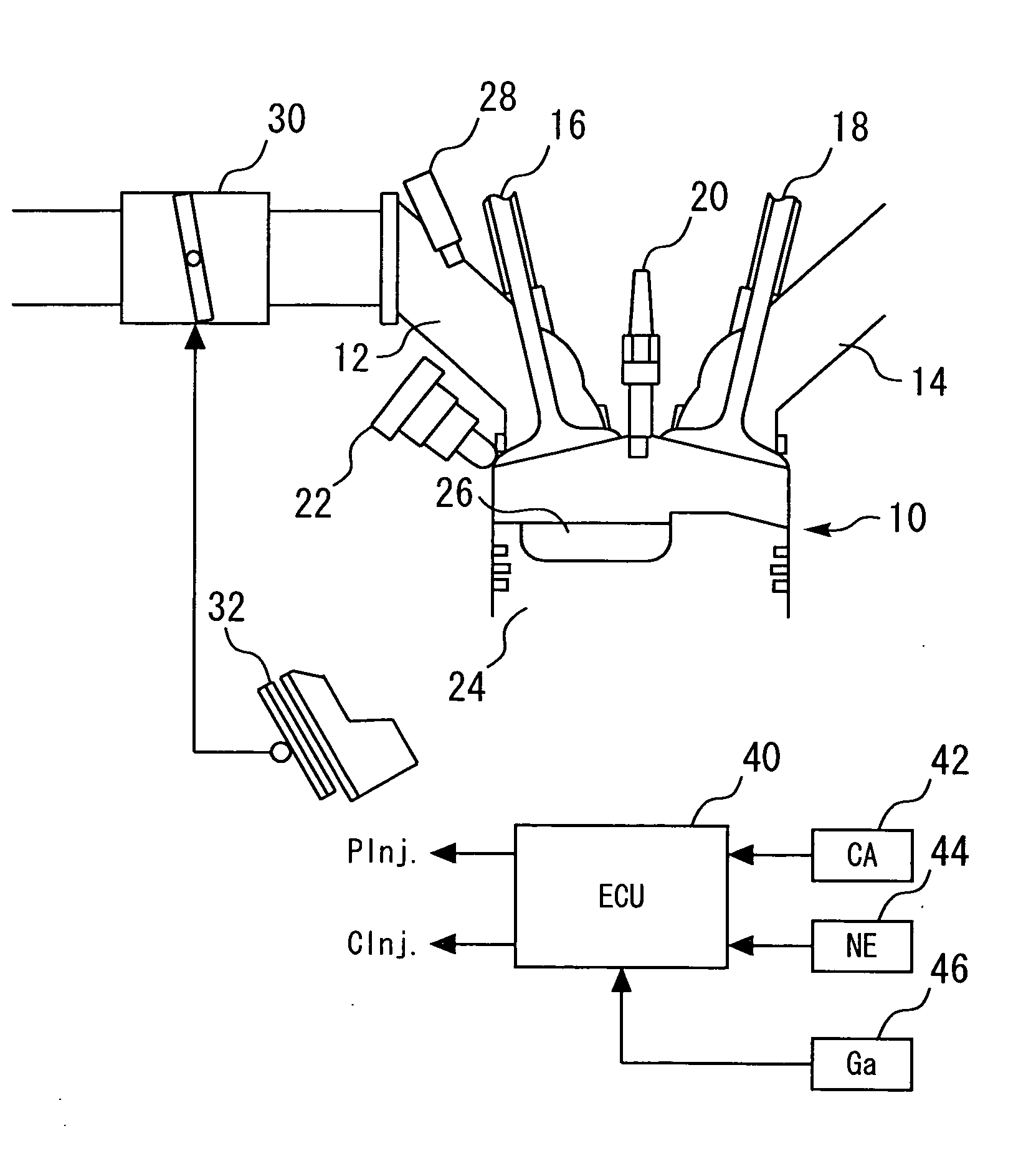

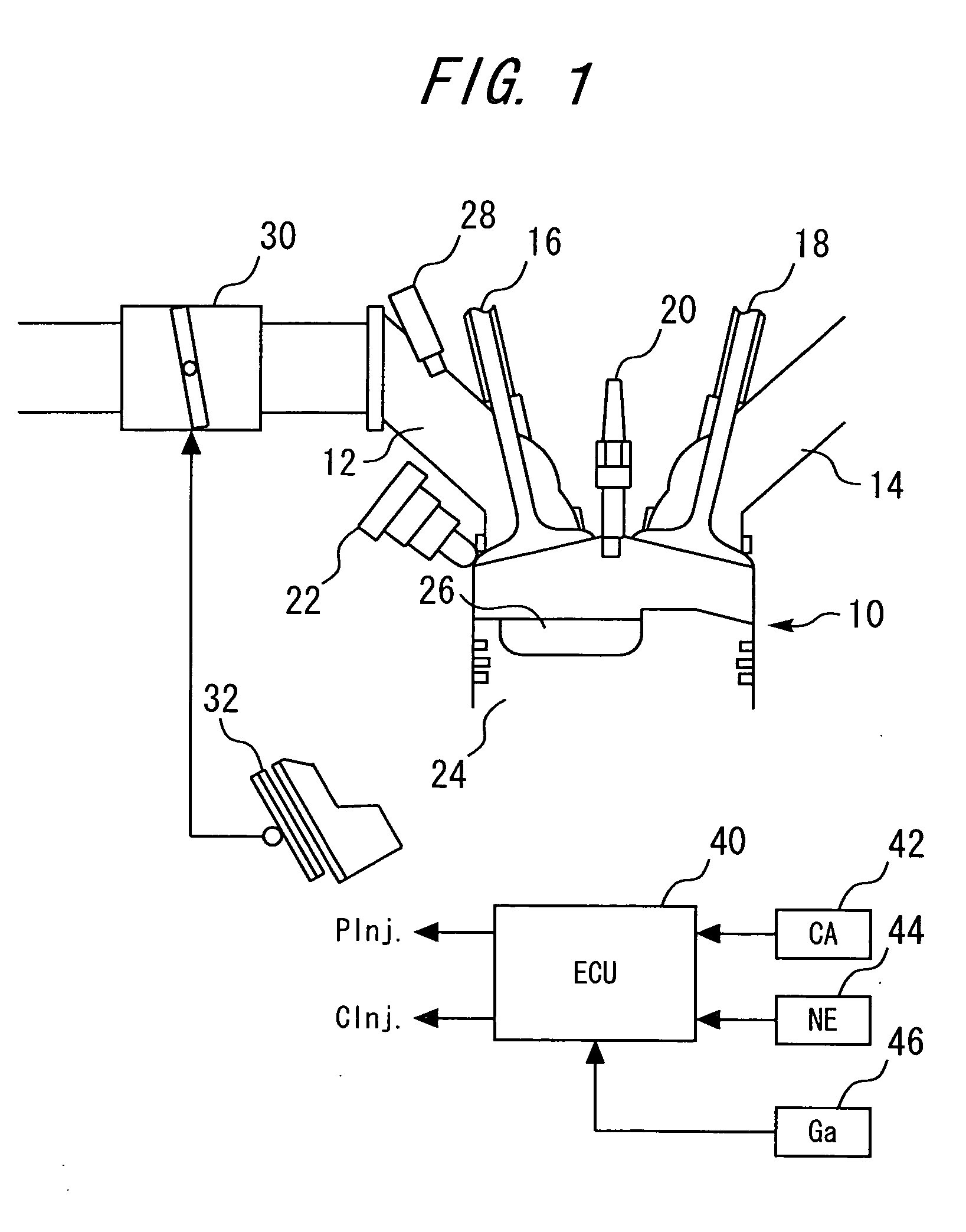

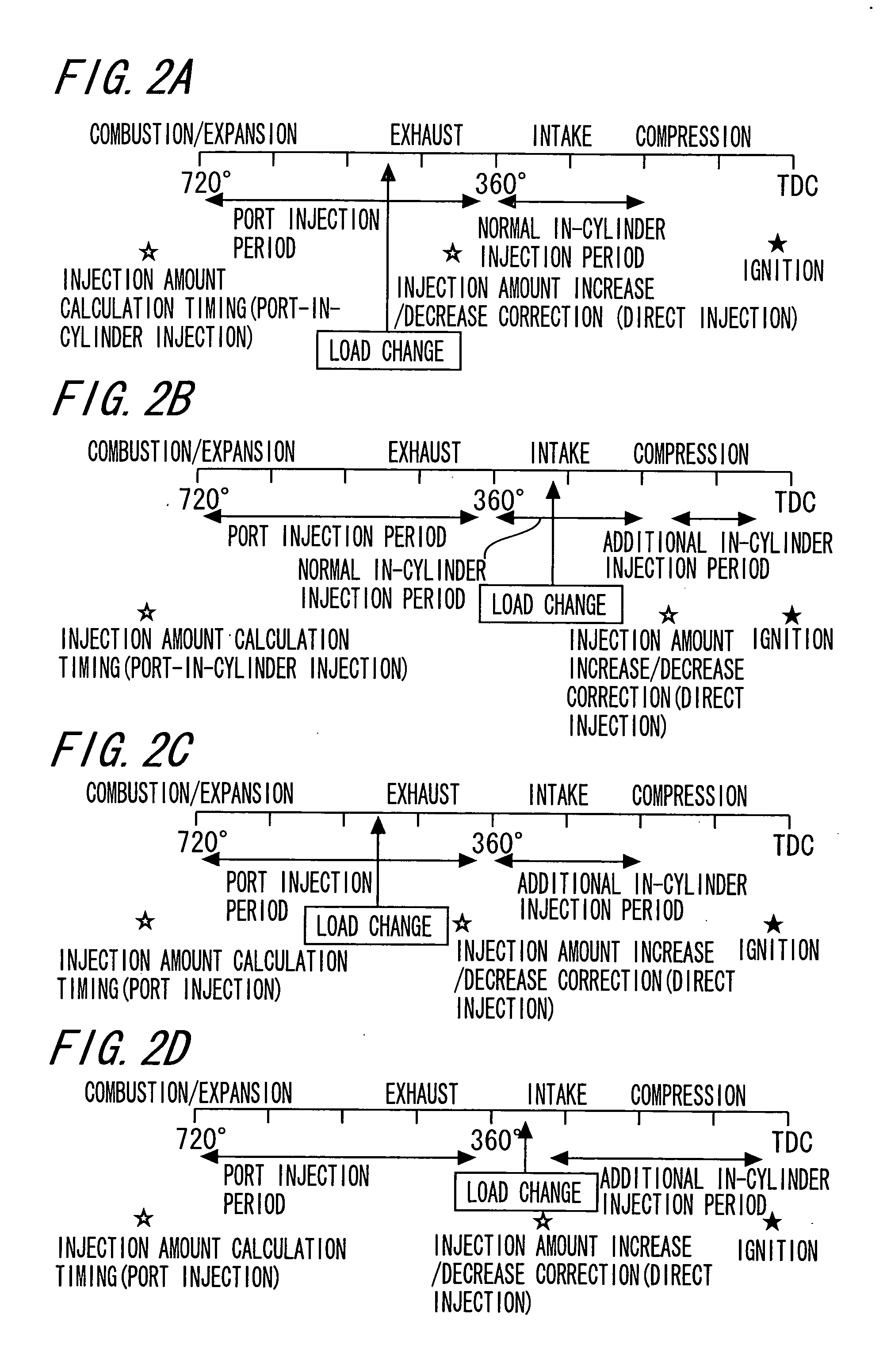

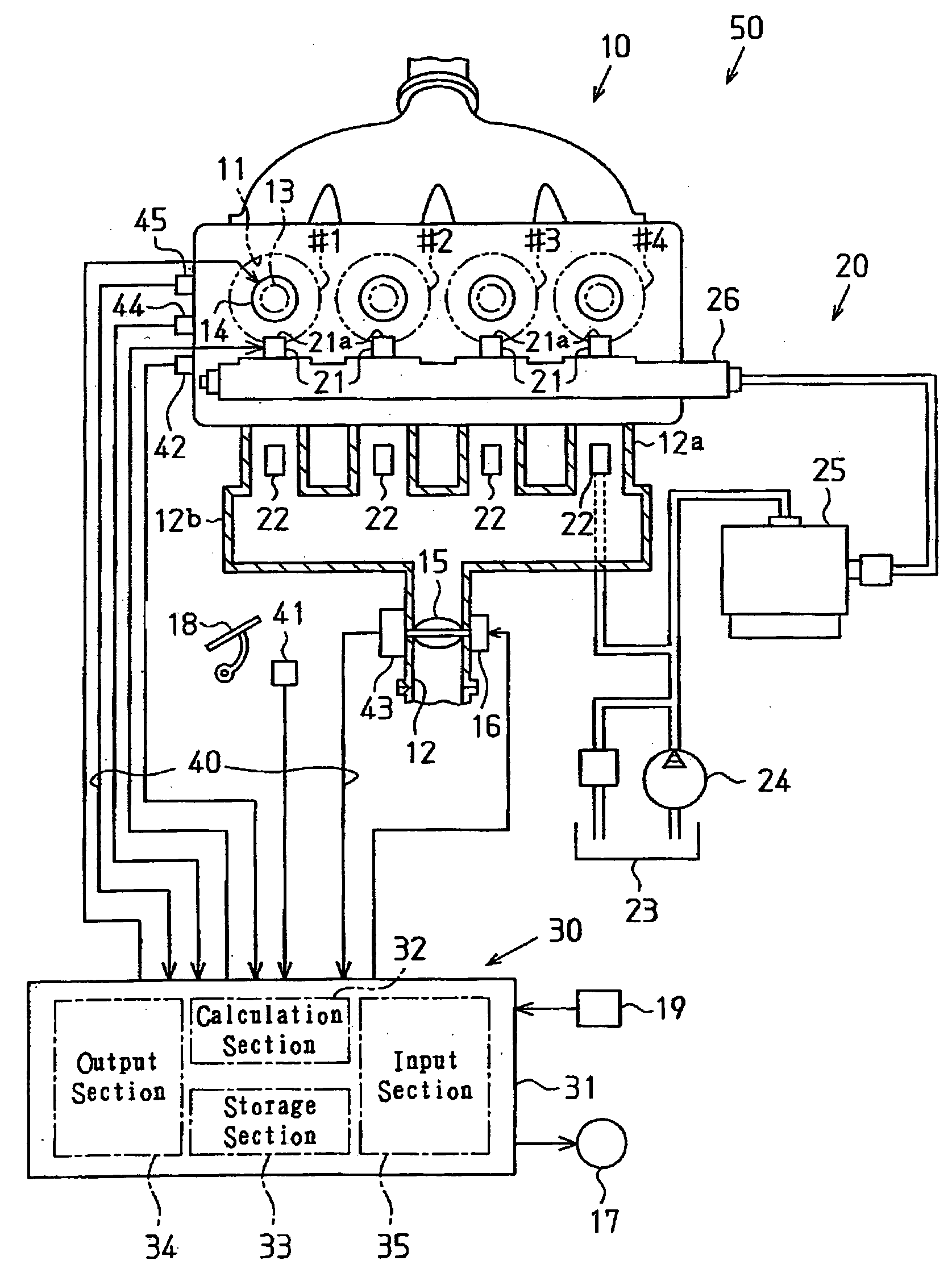

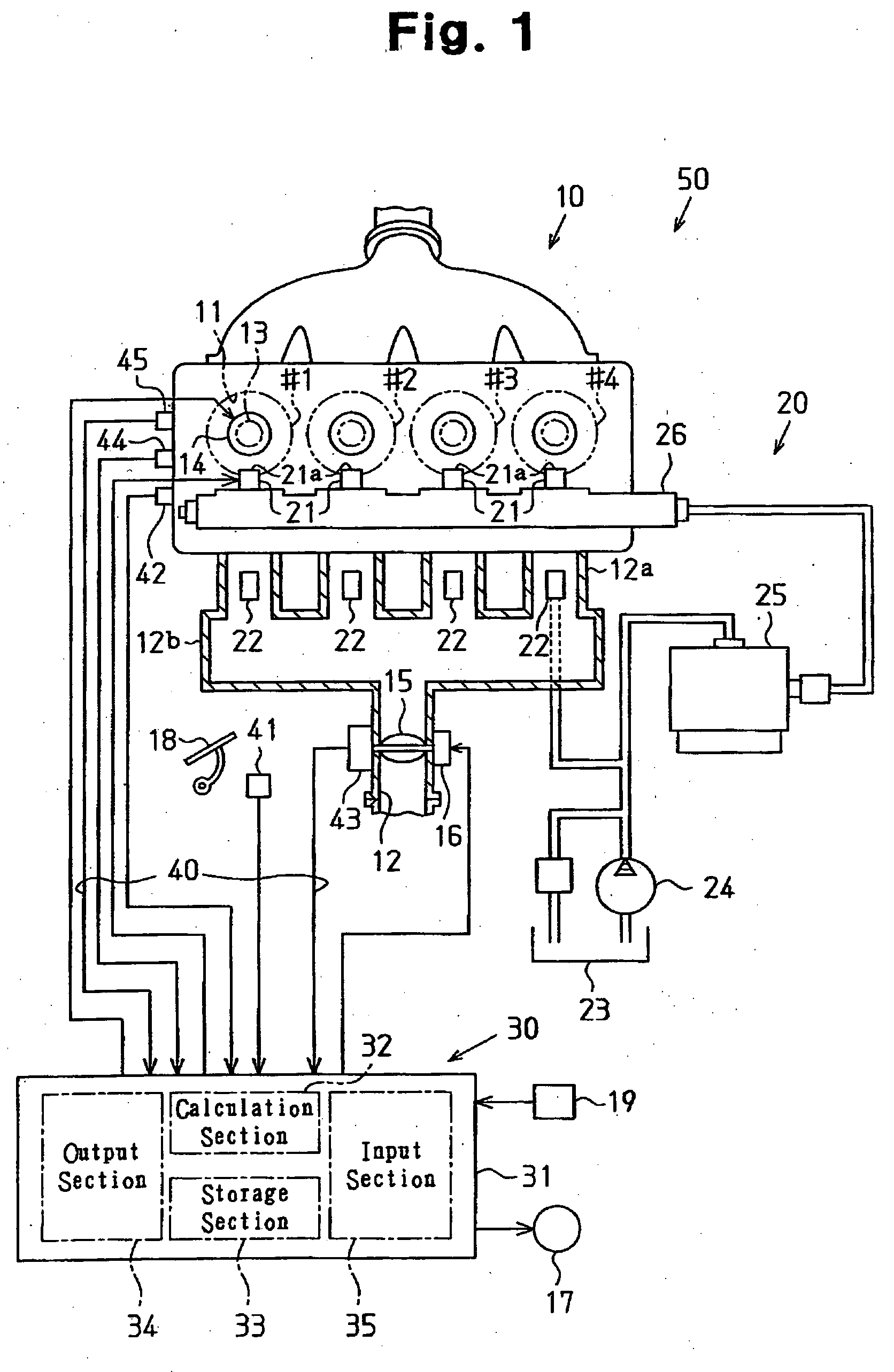

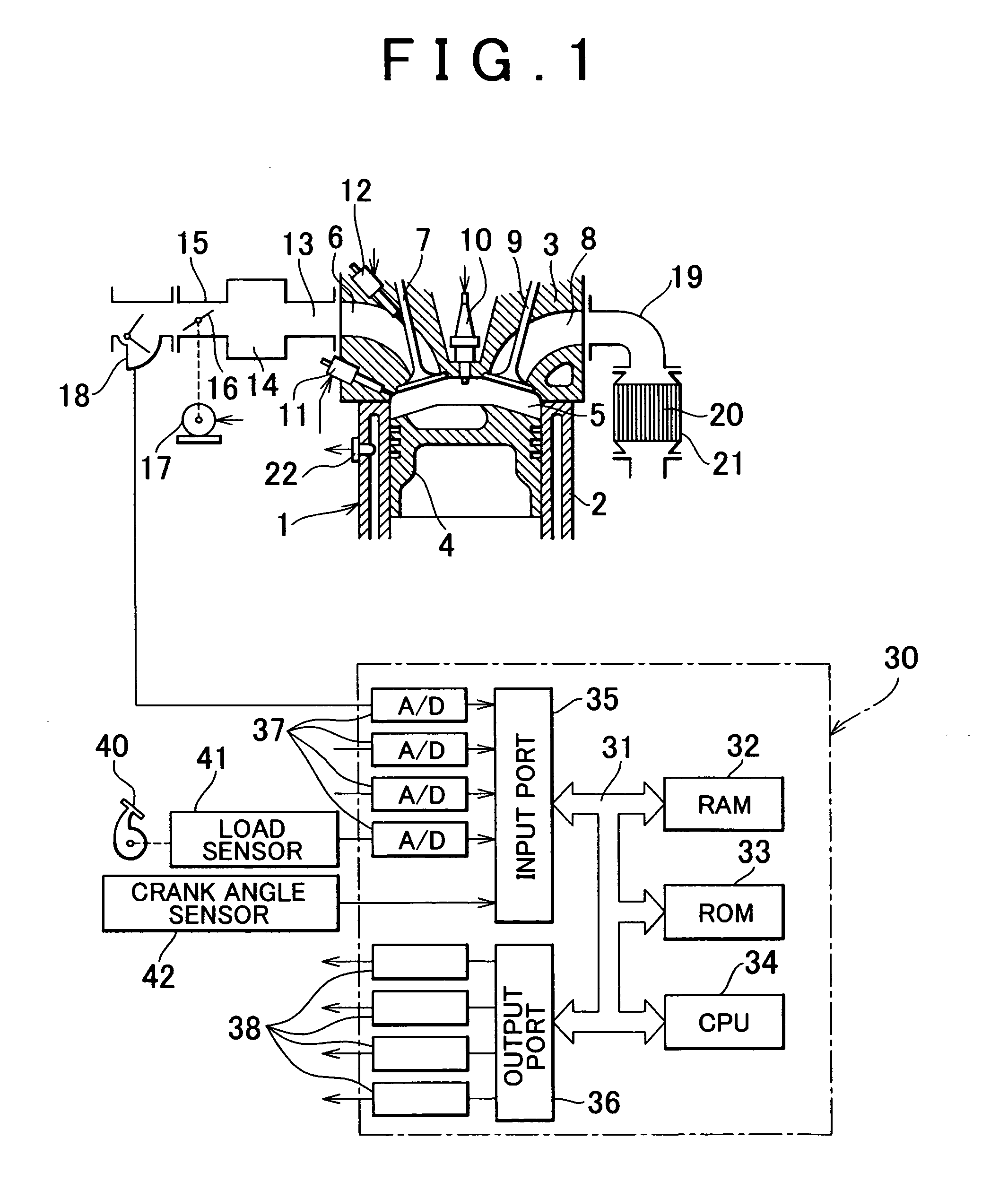

Fuel injection control device for internal combustion engine

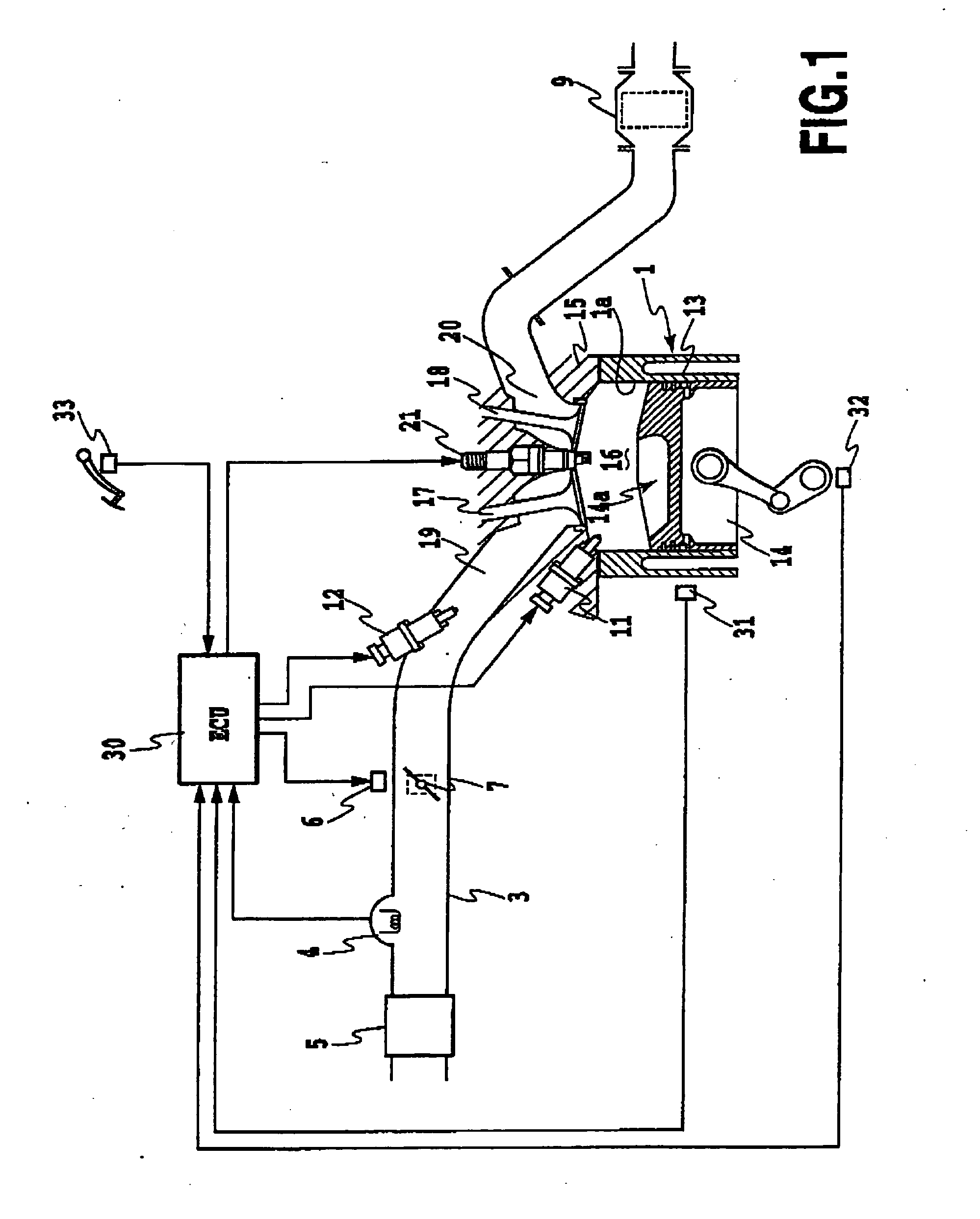

InactiveUS20050155578A1Good load changeElectrical controlInternal combustion piston enginesFuel injectionInjector

An internal combustion engine (10) is provided with a port injector (28) and an in-cylinder injector (22). Before a port injection is started, the total amount of fuel to be injected is calculated (at an injection amount calculation timing). The port injection fuel amount and the in-cylinder injection fuel amount are calculated by appropriately dividing the total amount between them. If a change of the operating load on the internal combustion engine (10) is detected after the injection amount calculation timing, the load change is reflected in the amount of fuel to be injected in the current engine cycle by increasing or decreasing the in-cylinder injection fuel amount.

Owner:TOYOTA JIDOSHA KK

Internal combustion engine control for improved fuel efficiency

ActiveUS20110208405A1Improve fuel efficiencyUndesirable vibration reductionAnalogue computers for vehiclesElectrical controlCombustionExternal combustion engine

Owner:TULA TECH INC

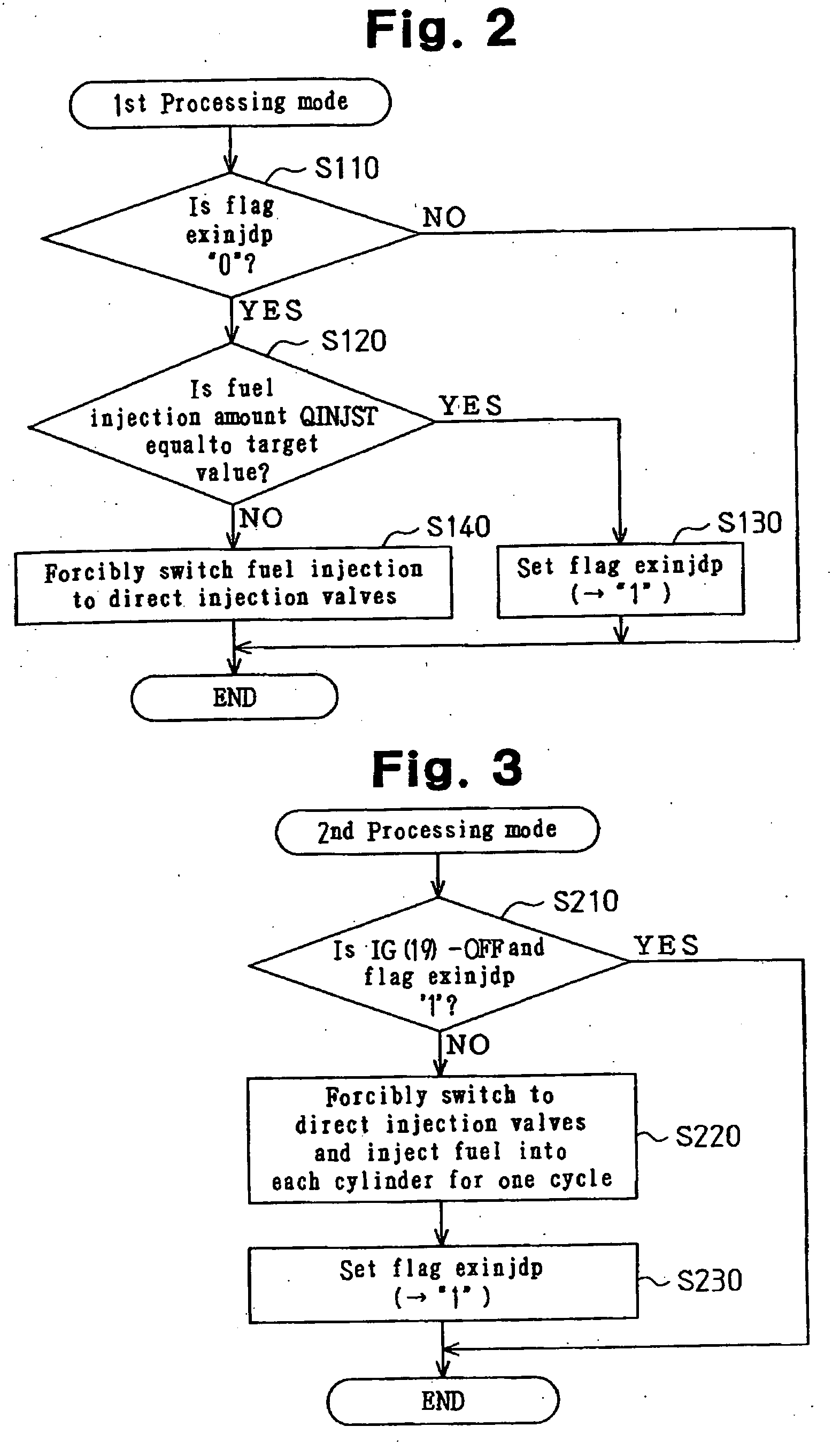

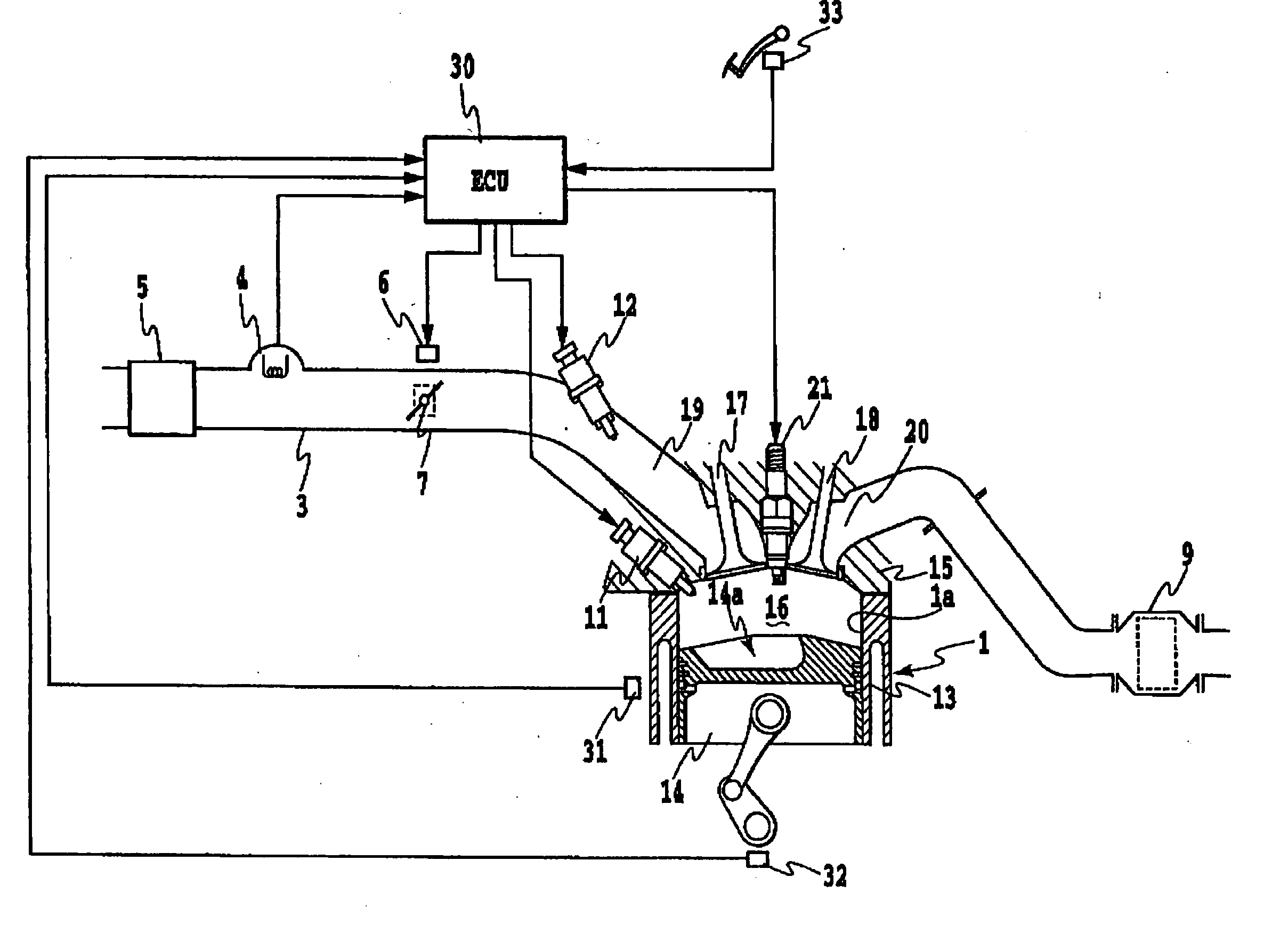

Injection controller for internal combustion engine

ActiveUS20050166896A1Avoid accumulationSuppresses accumulation of depositElectrical controlInternal combustion piston enginesInternal combustion engineVALVE PORT

An injection controller for an internal combustion engine that suppresses the accumulation of deposits on a nozzle hole of a direct injection valve. The injection controller includes the direct injection valve, which injects fuel into a cylinder, and an intake passage injection valve, which injects fuel into an intake passage. An ECU, which is connected to the direct injection and intake passage injection valves, executes a first fuel injection mode for injecting fuel with the direct injection valve and a second fuel injection mode for injecting fuel with the intake passage injection valve. The ECU switches fuel injection modes from the second fuel injection mode to the first fuel injection mode for a predetermined period when fuel is to be injected in the second fuel injection mode.

Owner:TOYOTA JIDOSHA KK

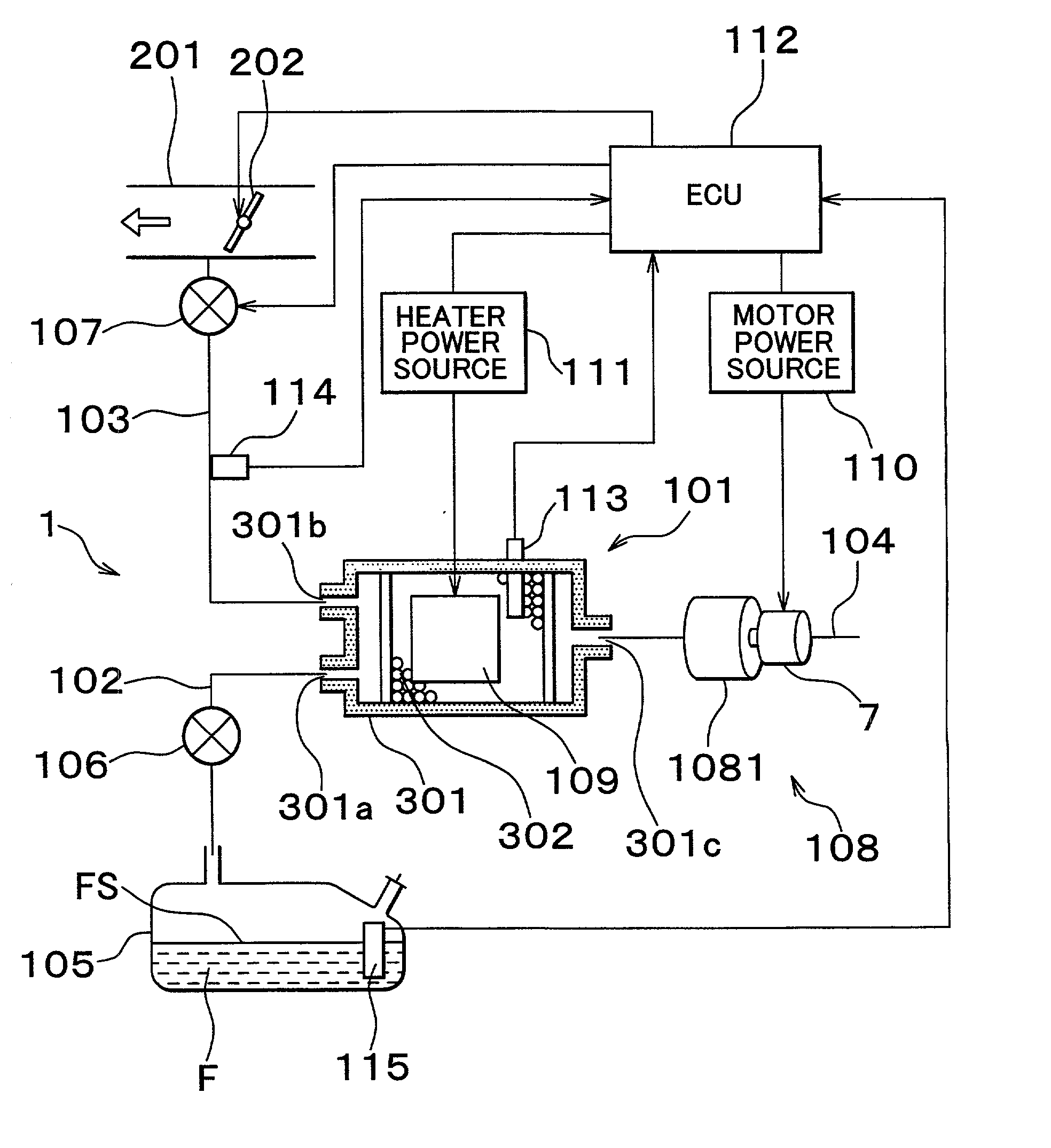

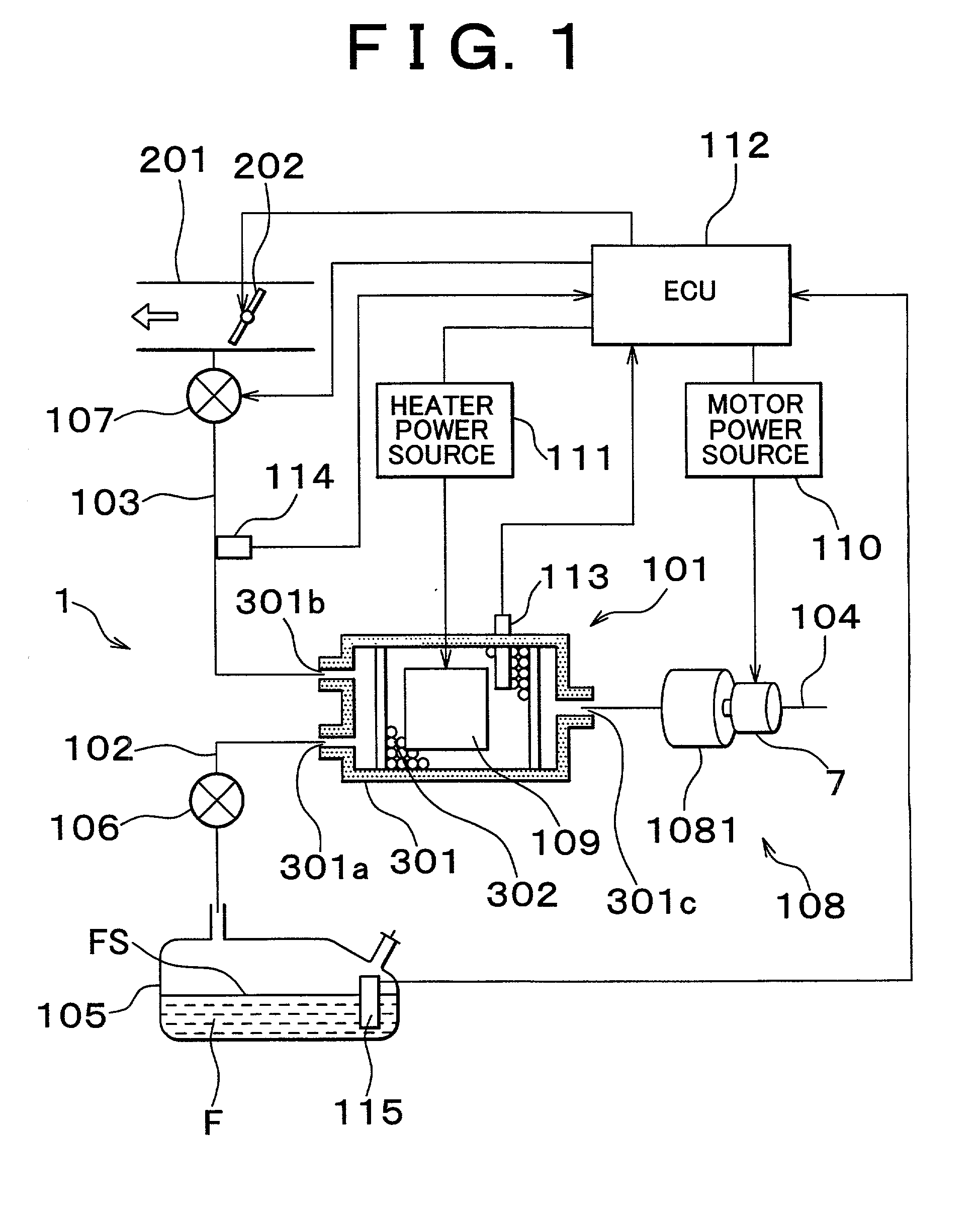

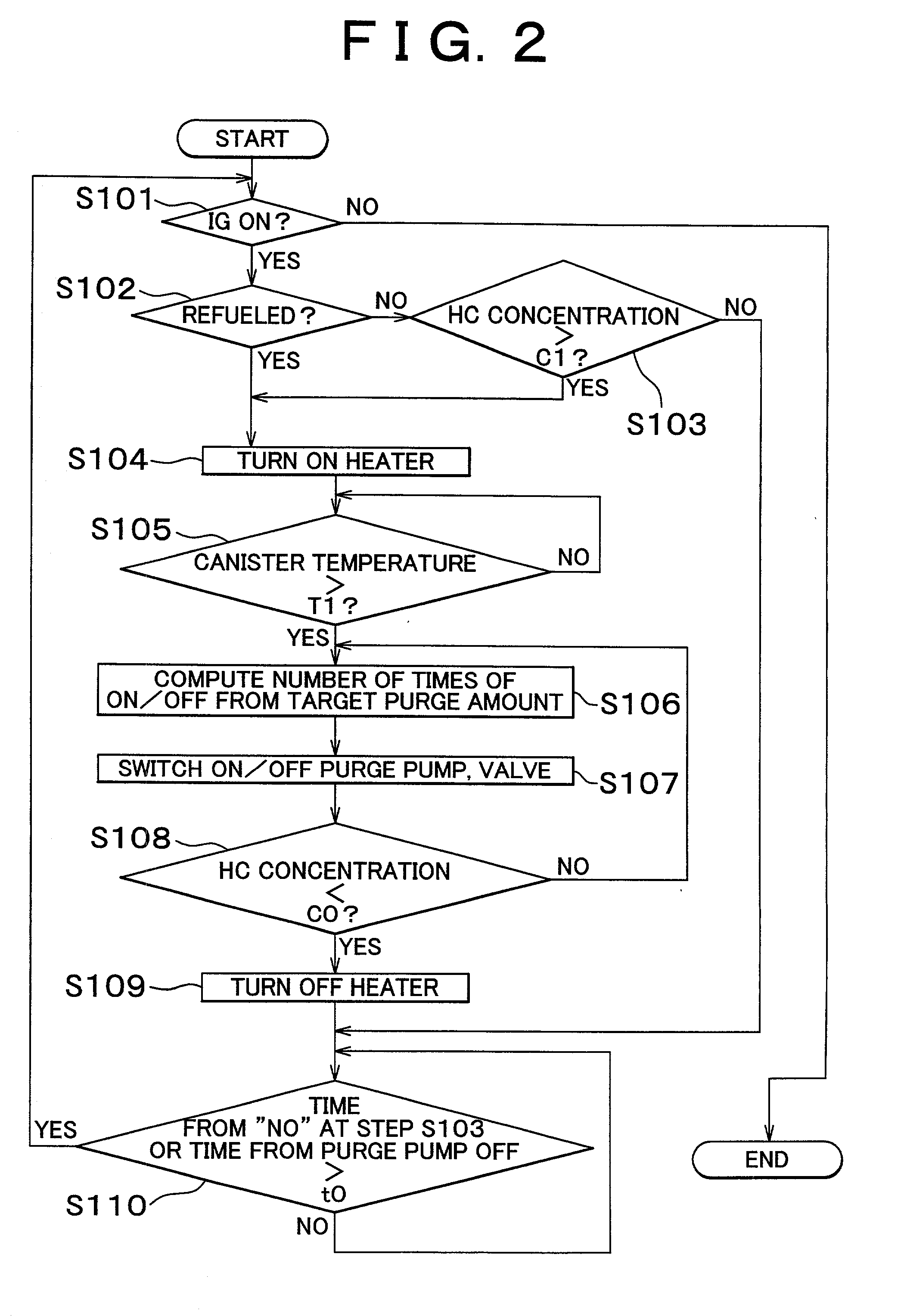

Fuel vapor handling apparatus and diagnostic apparatus thereof

InactiveUS20020162457A1Desorption of fuel is facilitatedFuel can be purged efficientlyNon-fuel substance addition to fuelFuel injection apparatusDesorptionVaporization

A fuel vapor handling apparatus supplies a purging air to a canister by using a purge pump and purges fuel desorbed from the canister into an intake pipe. A controller intermittently operates the purge so that the canister internal temperature recovers from a reduced level caused by the latent heat of vaporization of fuel during an operating period of the purge pump. Therefore, desorption of fuel from the canister during an operating period is facilitated. Since the actual operating time of the purge pump is reduced, the life of a motor that is a power unit of the purge pump becomes longer.

Owner:TOYOTA JIDOSHA KK +1

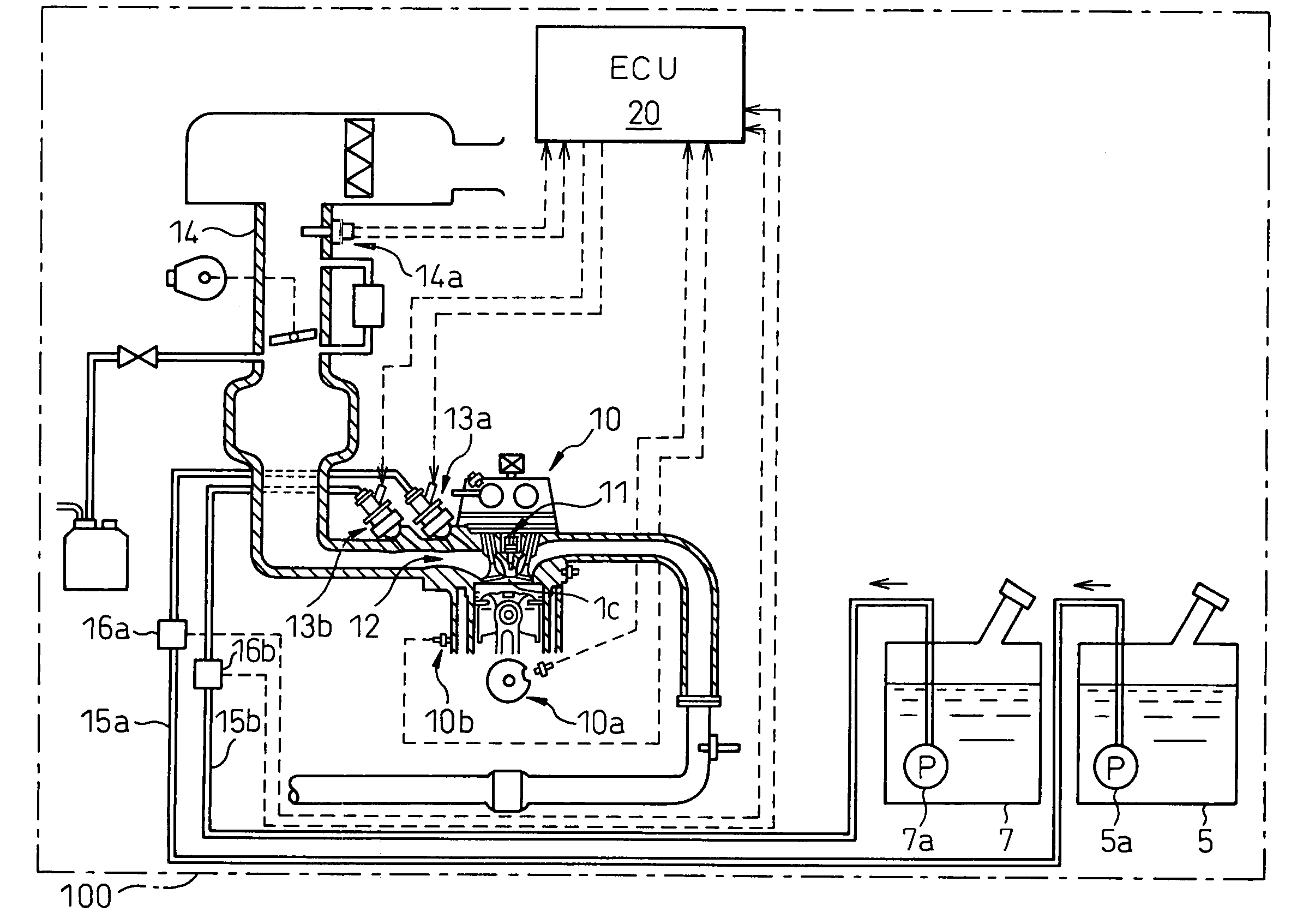

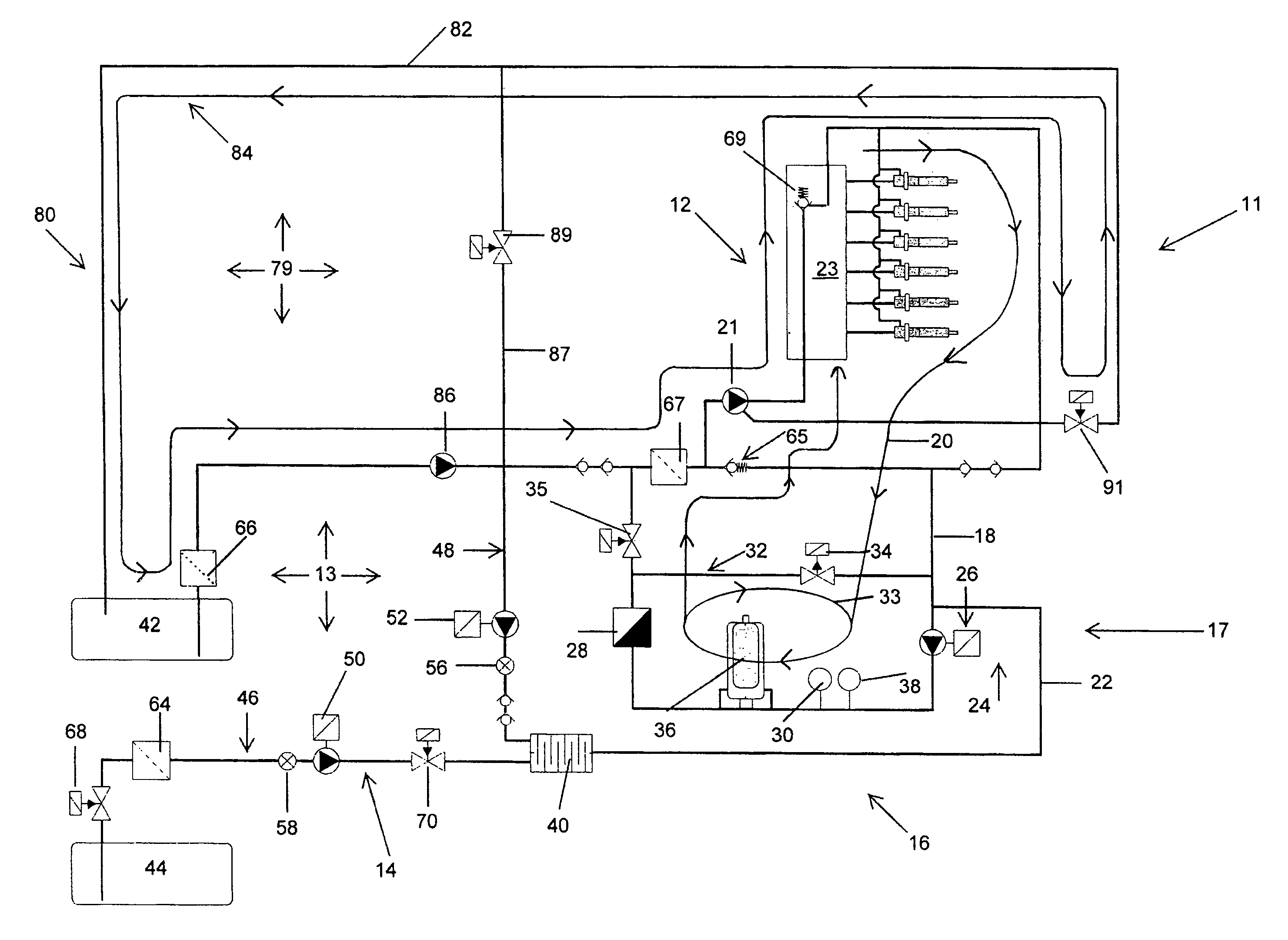

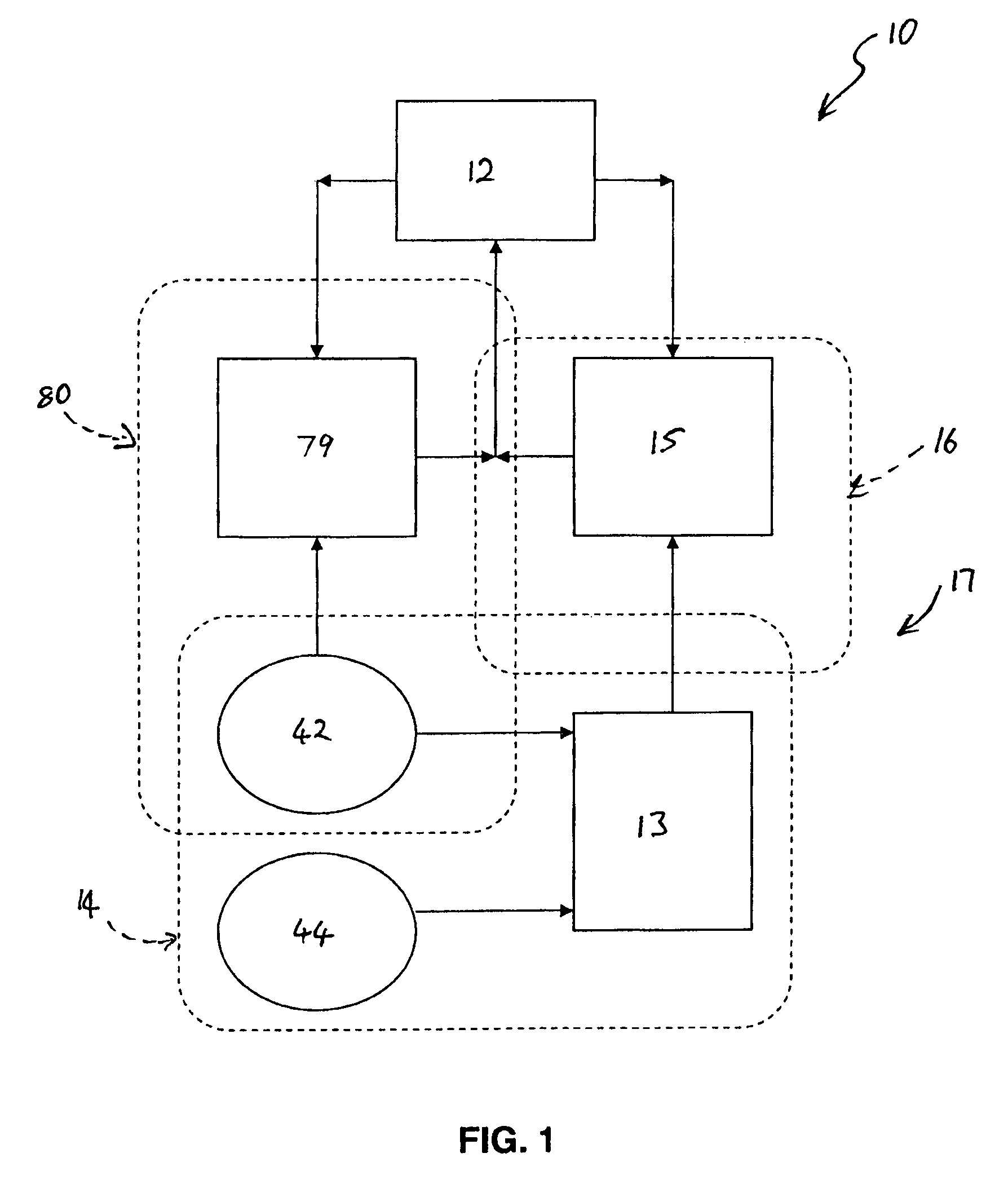

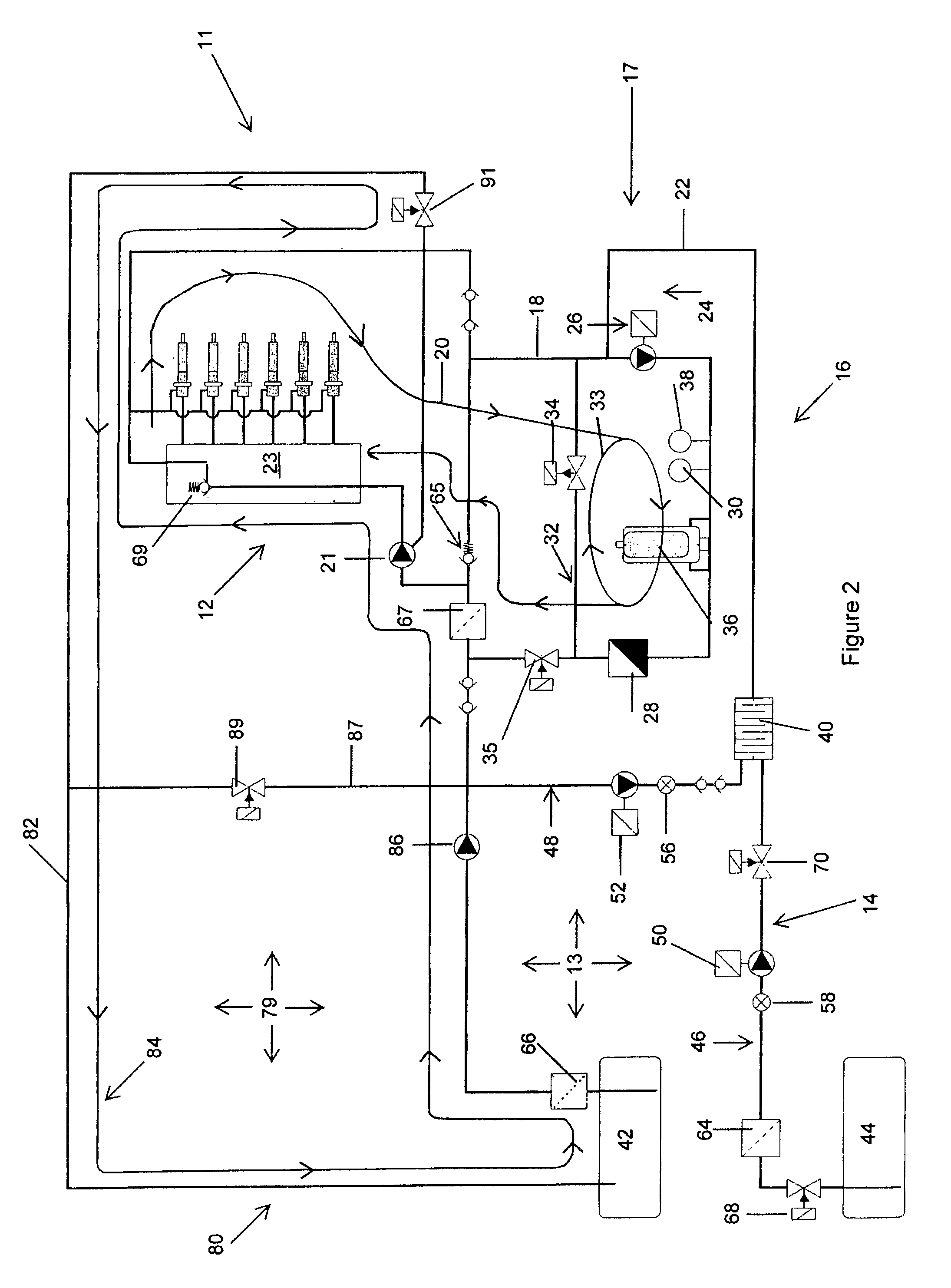

Dual fuel supply system for a direct-injection system of a diesel engine with on-board mixing

InactiveUS8973560B2Non-fuel substance addition to fuelInternal combustion piston enginesOn boardEngineering

The present invention is directed to a dual fuel supply system for supplying fuel to a direct-injection system of a diesel engine. The dual fuel supply system includes a diesel supply system to supply diesel to the direct-injection system; and a mixed fuel supply system that is operatively able to supply a liquid fuel premixture of diesel and liquefied gaseous fuel to the direct-injection system at a supply pressure within a fuel demand pressure range of the direct-injection system and at a corresponding temperature range that retains the fuel premixture below its vapor temperature as it flows through the fuel path of the direct-injection system and the diesel engine. The dual fuel supply system is configured to permit selective change over between the diesel supply system and the mixed fuel system to supply the direct-injection system selectively with either diesel or liquid fuel premixture respectively.

Owner:DGC IND

System and method for tip-in knock compensation

ActiveUS20070119425A1Improve the heating effectTrend downElectrical controlInternal combustion piston enginesHeat capacityOperant conditioning

A method of controlling an engine, the method comprising of providing fuel having a blend to a cylinder of the engine, actively varying said fuel blend in response to at least an operating condition, and where during a transient operating condition, said blend is adjusted to increase a heat capacity of said fuel to reduce a tendency for knock.

Owner:FORD GLOBAL TECH LLC

Control system for internal combustion engine

InactiveUS20050172931A1Suppresses torque fluctuationsRapid torque fluctuation is preventedElectrical controlInternal combustion piston enginesControl systemEngineering

In an internal combustion engine equipped with an injector for oylinder-inside injection to inject fuel into a cylinder and an injector for intake port injection to inject fuel into an intake port, both the injectors being switched for use depending upon operating conditions, wherein when an operating condition range using either one of the first or the second injector is switched to an operating condition range using the other one thereof, the amount of fuel to be injected by the either one of the first or the second injector is gradually decreased and the amount of fuel to be injected by the other one is gradually increased over a predetermined period during the switching. Further, at the time of the switching, at least one of ignition timing and throttle opening angle is gradually varied.

Owner:TOYOTA JIDOSHA KK

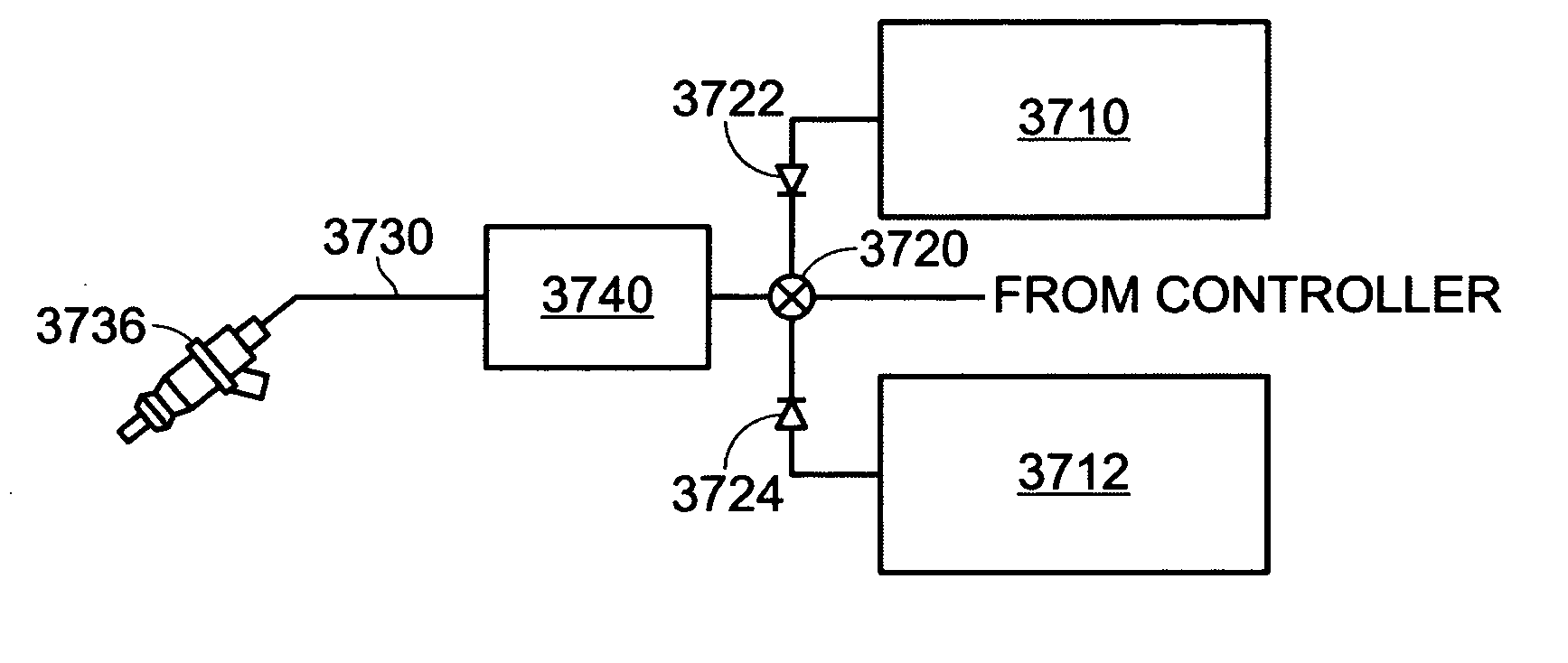

Spark control for improved engine operation

InactiveUS20070215130A1Low costImprove charge cooling effectElectrical controlInternal combustion piston enginesCombustion chamberControl system

A system for an engine of a vehicle, comprising of at least one combustion chamber located in the engine, a delivery system configured to deliver a fuel and a substance to the combustion chamber, an ignition system including a spark plug configured to ignite the fuel within the combustion chamber, and a control system configured to vary a number of sparks performed by the spark plug in relation to a combustion event of the combustion chamber responsive to a condition of the ignition system.

Owner:FORD GLOBAL TECH LLC

System for fuel vapor purging

InactiveUS20070119416A1Internal combustion piston enginesNon-fuel substance addition to fuelGasolineEngineering

A system for an engine, comprising of an injector coupled to the engine and configured to inject fuel to a cylinder of the engine; a first reservoir holding a first fluid containing at least a fraction of gasoline; a second reservoir holding a second fluid containing at least a fraction of ethanol; and a mixing device having an inlet portion coupled to both said first and second reservoir, said mixing device further having an outlet portion coupled to said injector.

Owner:FORD GLOBAL TECH LLC

Engine output control system and method

ActiveUS20070119422A1Accurate air-fuel ratio controlElectrical controlInternal combustion piston enginesControl systemChemical measurement

A system for an engine, comprising of a cylinder located in the engine; a first injector for injecting a first fuel into said cylinder; a second injector for injecting a second fuel into said cylinder; and a controller configured to vary an amount of said first and second fuel injection during engine operation based on operating conditions, where amounts of variation of said first and second fuels are set to maintain desired engine output and provide a substantially stoichiometric mixture.

Owner:FORD GLOBAL TECH LLC

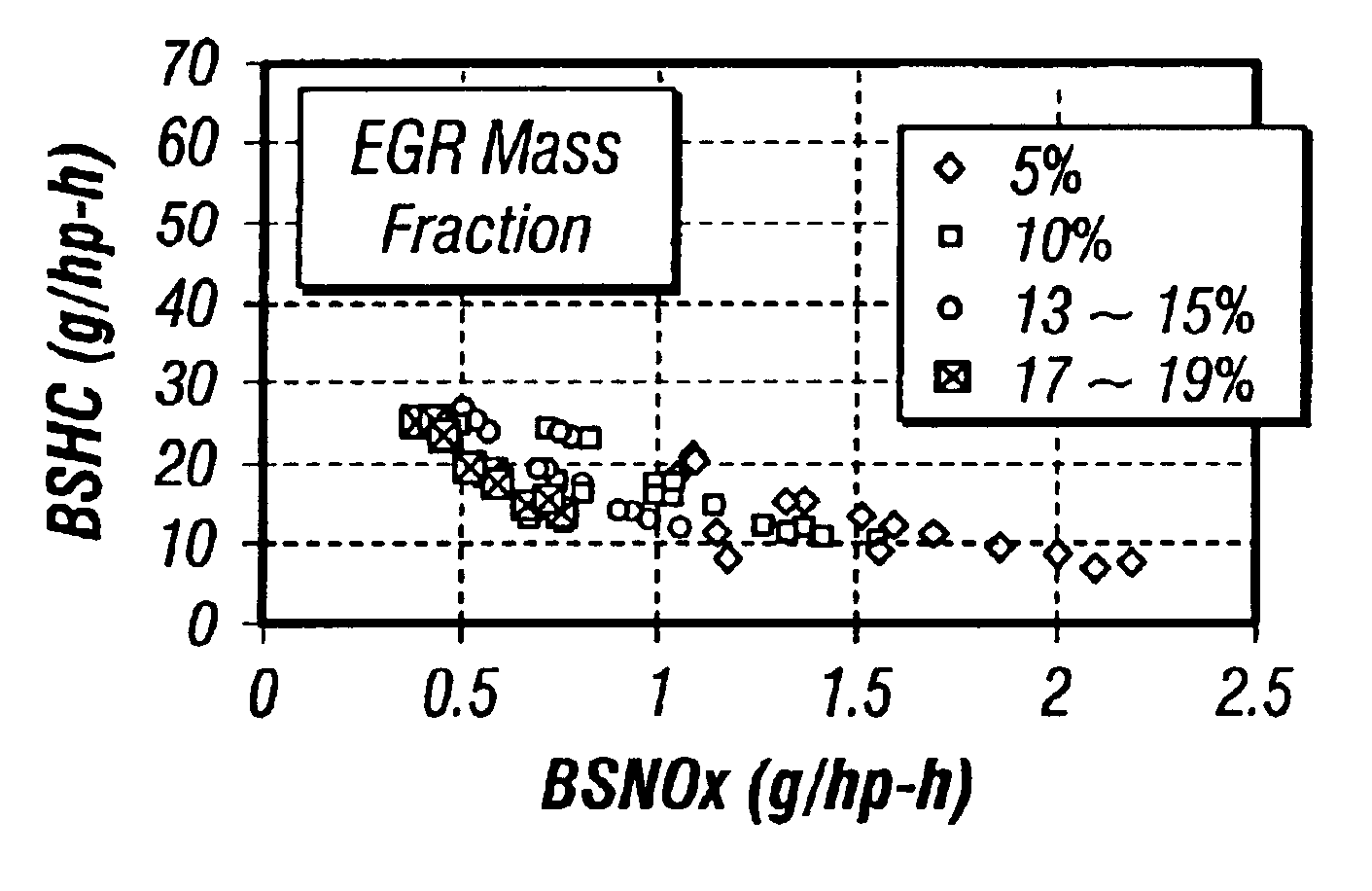

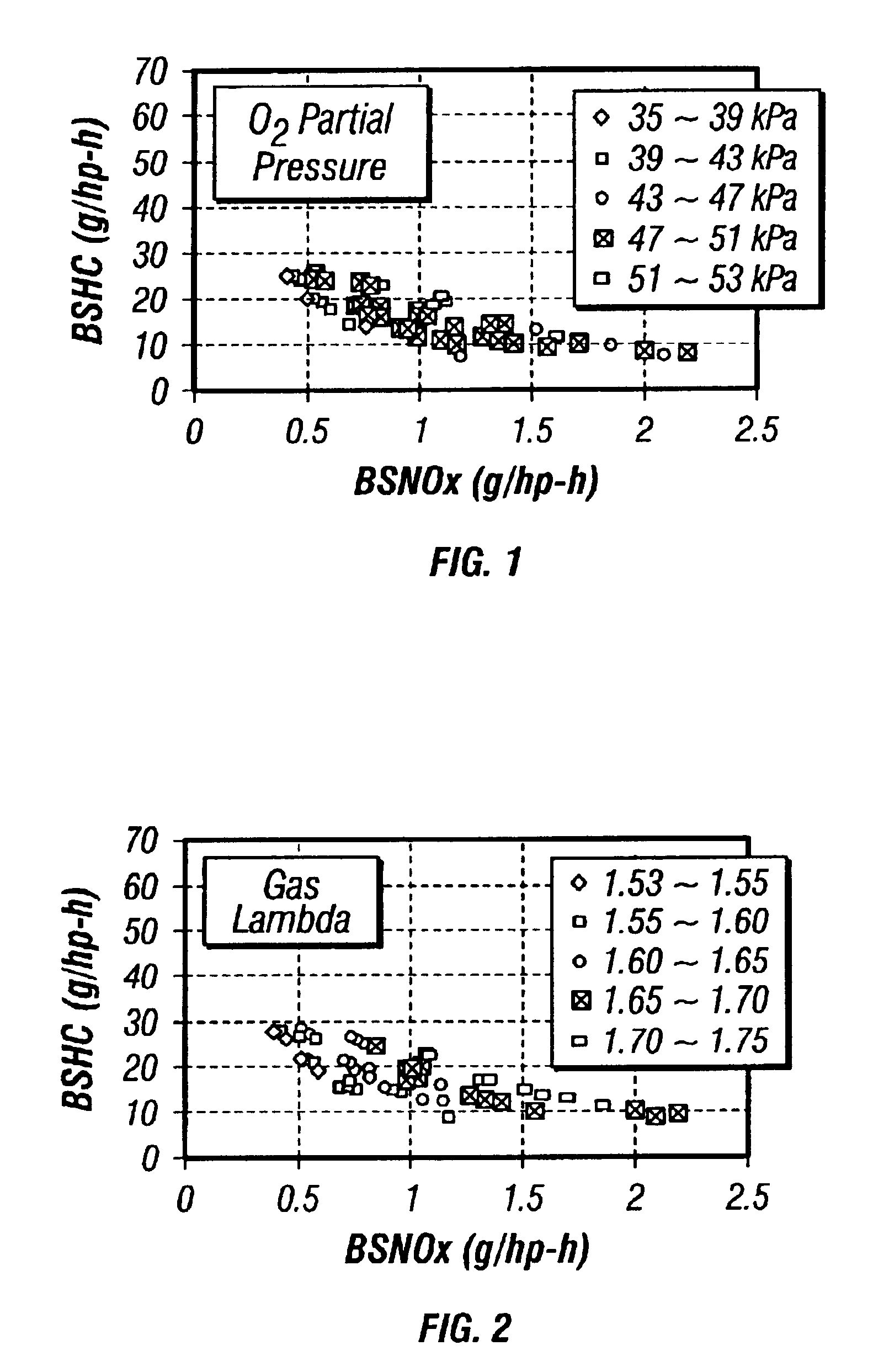

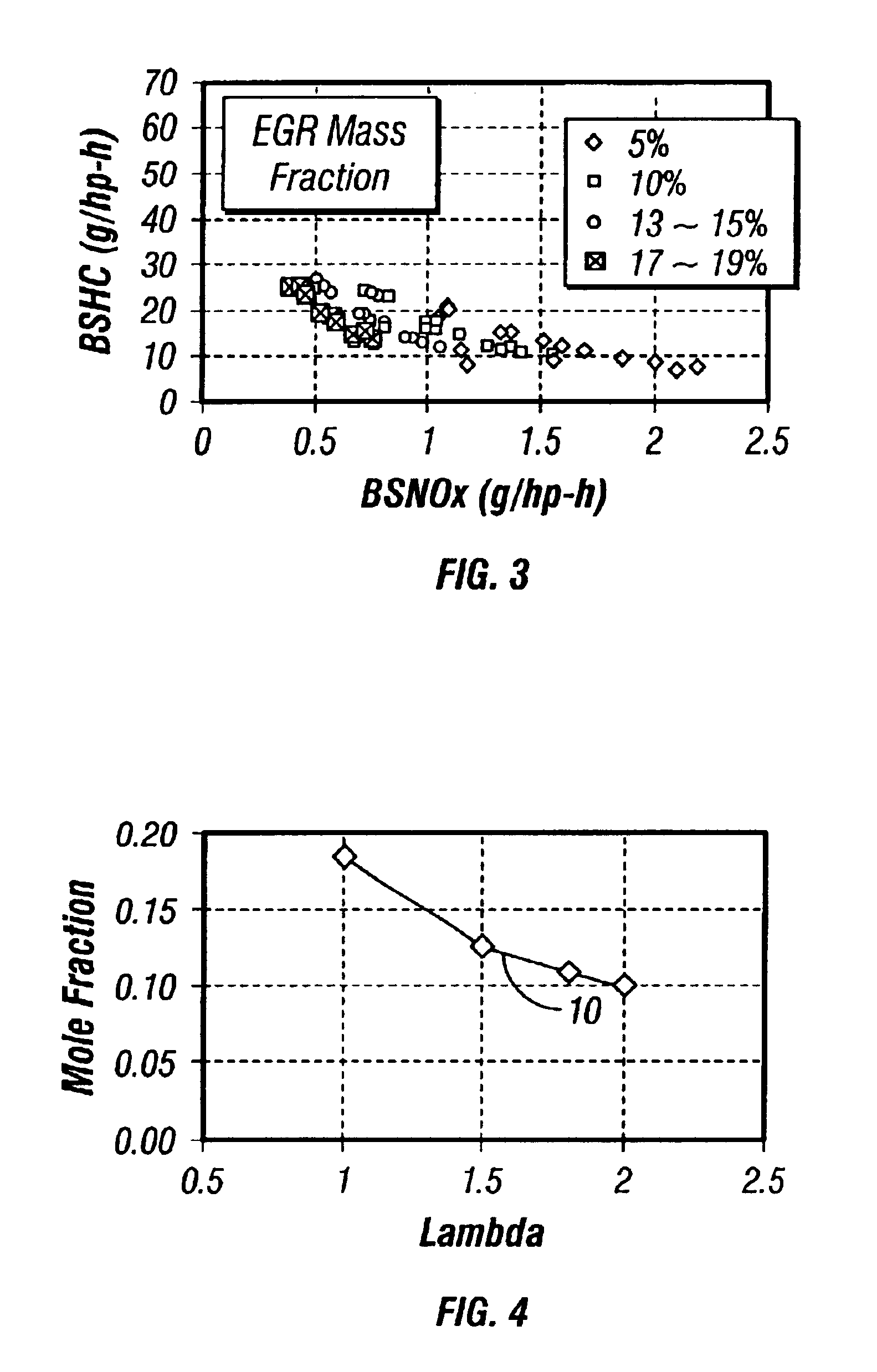

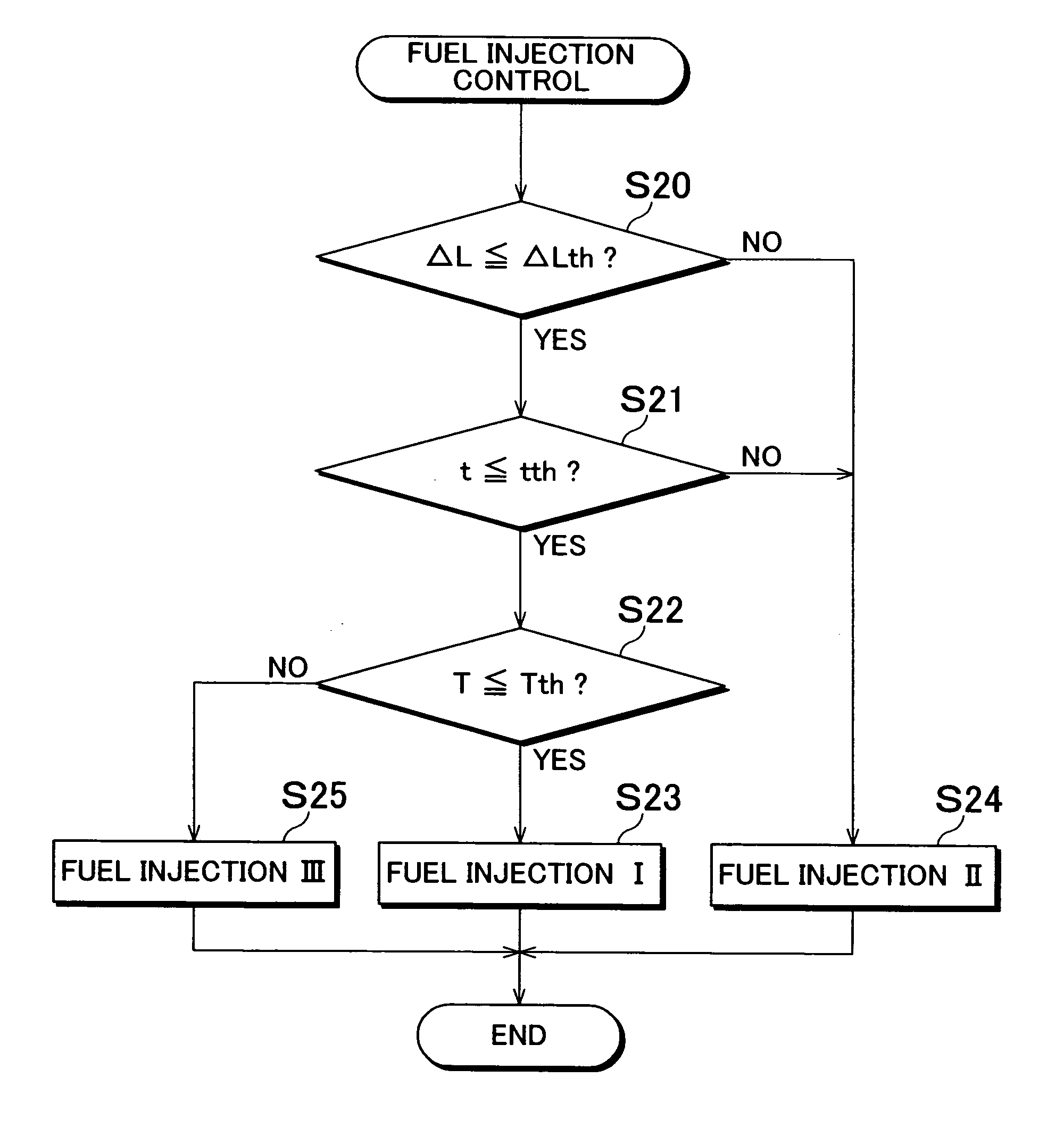

Optimized combustion control of an internal combustion engine equipped with exhaust gas recirculation

InactiveUS6948475B1Avoid condensationImprove concentrationElectrical controlNon-fuel substance addition to fuelExhaust fumesExhaust gas recirculation

An EGR equipped internal combustion engine is controlled to maximize the beneficial effects and minimize the detrimental effects of EGR on engine operation. Specifically, at least one parameter indicative of the O2 concentration in the intake mixture and / or at least one parameter indicative of the H2O concentration in the intake mixture is monitored, and the monitored parameter is relied on to control one or more aspects of engine operation by open loop adjustment of other control strategies and / or by a separate closed loop control strategy. These controls are applicable to virtually any engine, and are particularly beneficial to lean burn engines such as diesel (compression ignition) engines, spark ignited natural gas engines, and dual fuel or other compression ignited natural gas engines. The engine may be equipped with either actively controllable EGR or passive and uncontrolled EGR.

Owner:CLEAN AIR POWER

Fuel injection system and method

InactiveUS20050109319A1Sufficient engine startabilityReduce smoke emissionsElectrical controlCoolant flow controlCombustion chamberEngineering

A fuel injection system includes a first fuel injector that injects a lower-octane fuel into a combustion chamber of an internal combustion engine, and a second fuel injector that injects a higher-octane fuel into an intake passage of the engine. When the engine temperature is equal to or lower than a predetermined temperature during a start-up period of the internal combustion engine, fuel having the lower octane is injected via the first injector while prohibiting injection of the higher octane fuel via the second fuel injector.

Owner:TOYOTA JIDOSHA KK

Warm up strategy for ethanol direct injection plus gasoline port fuel injection

InactiveUS20070119414A1Reduce the impactReduced engine temperatureElectrical controlInternal combustion piston enginesPort fuel injectionEthanol

A system for an engine, comprising of a cylinder of the engine; a first injector configured to inject a first substance to said cylinder; a second injector configured to inject a second substance to said cylinder; and a controller configured to commence combustion in the engine by injecting fuel into said cylinder, where said fuel is injected by only one of said first and second injectors during said start and / or warm-up.

Owner:FORD GLOBAL TECH LLC

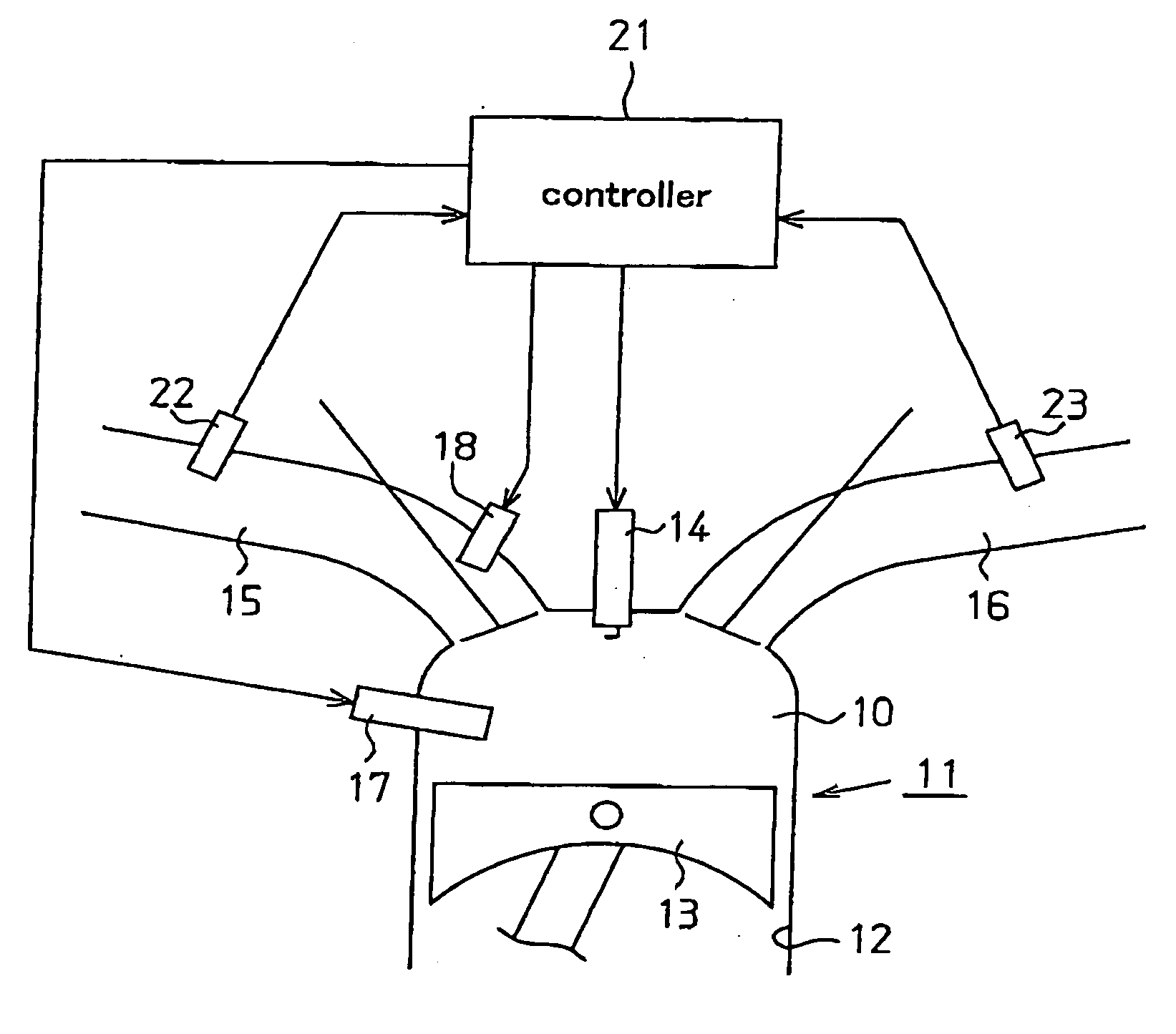

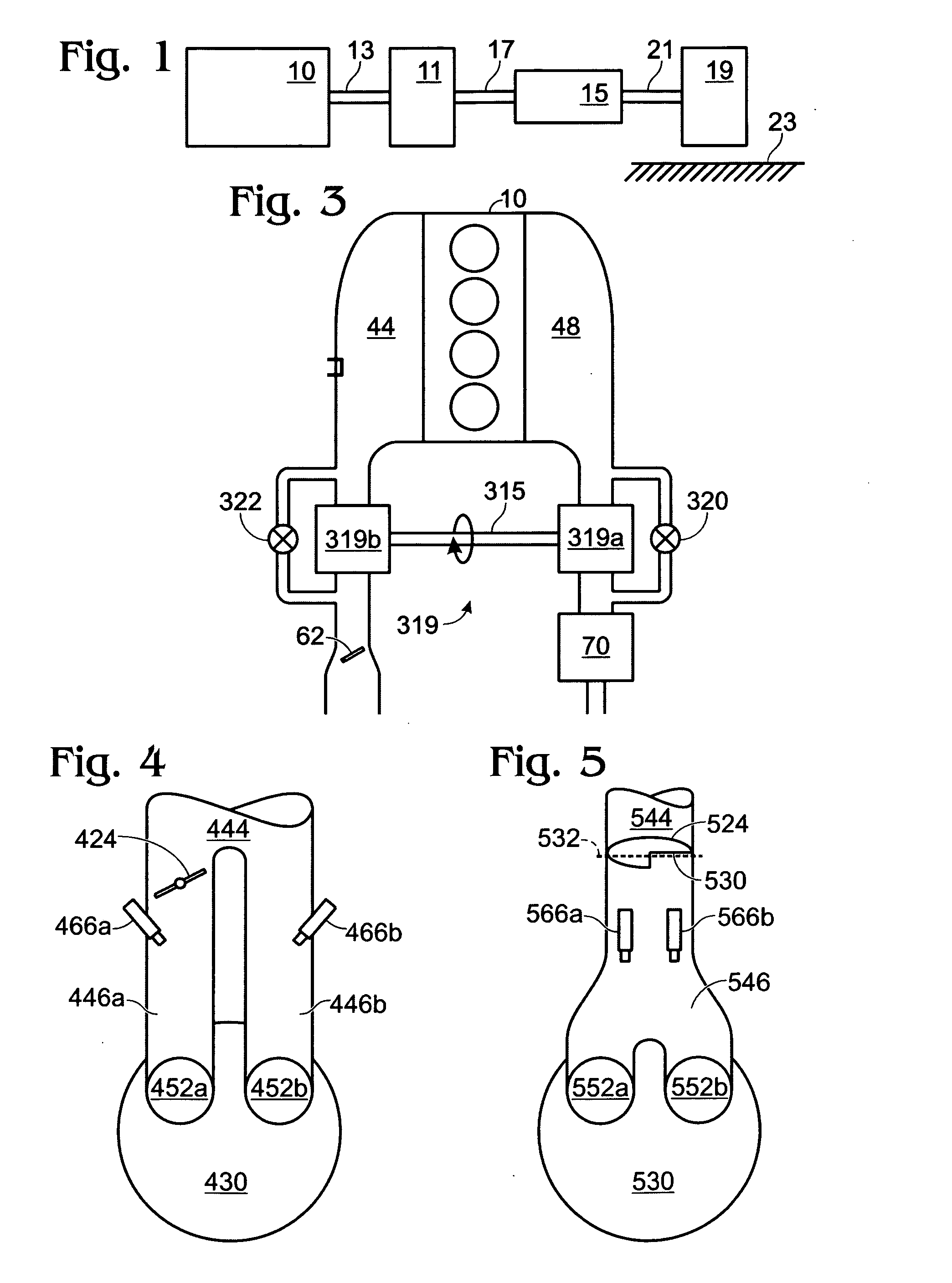

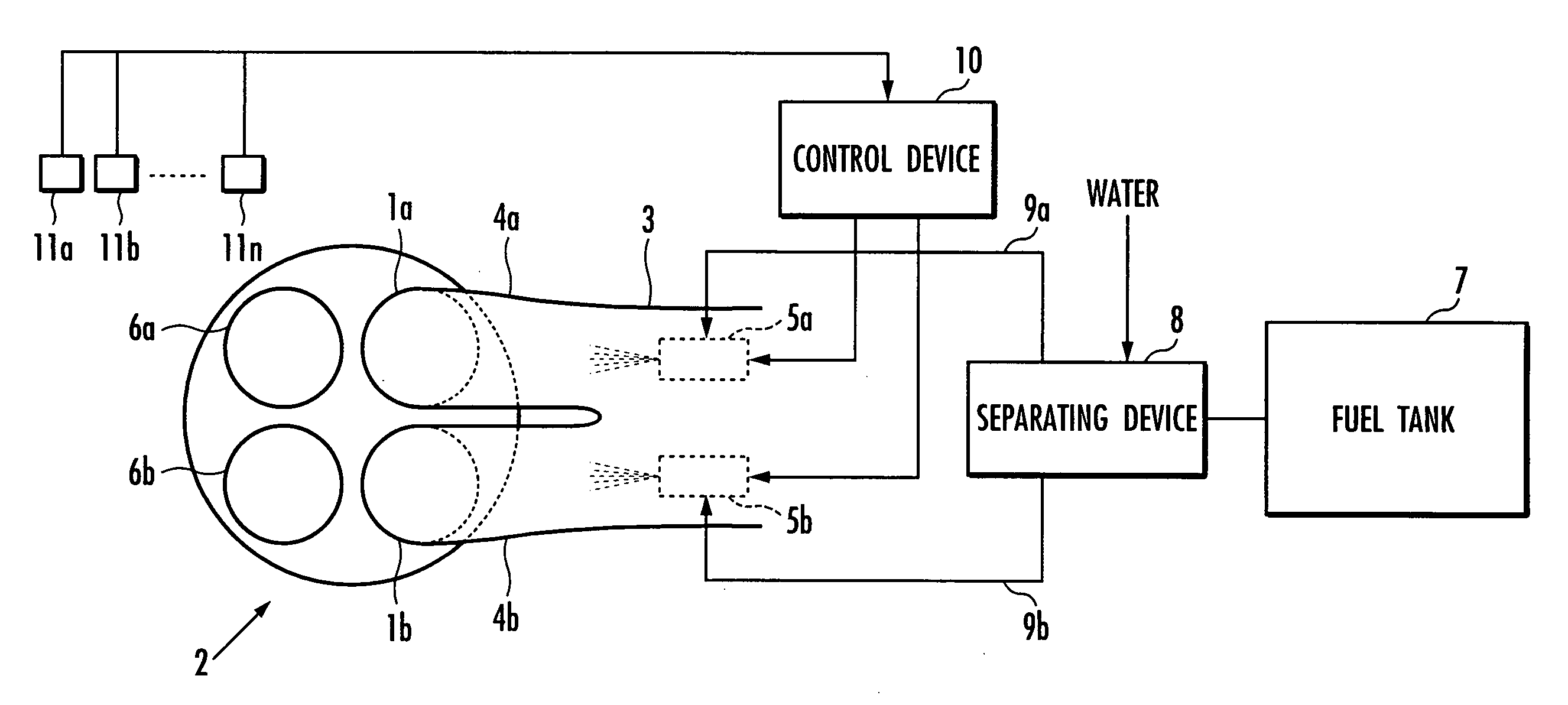

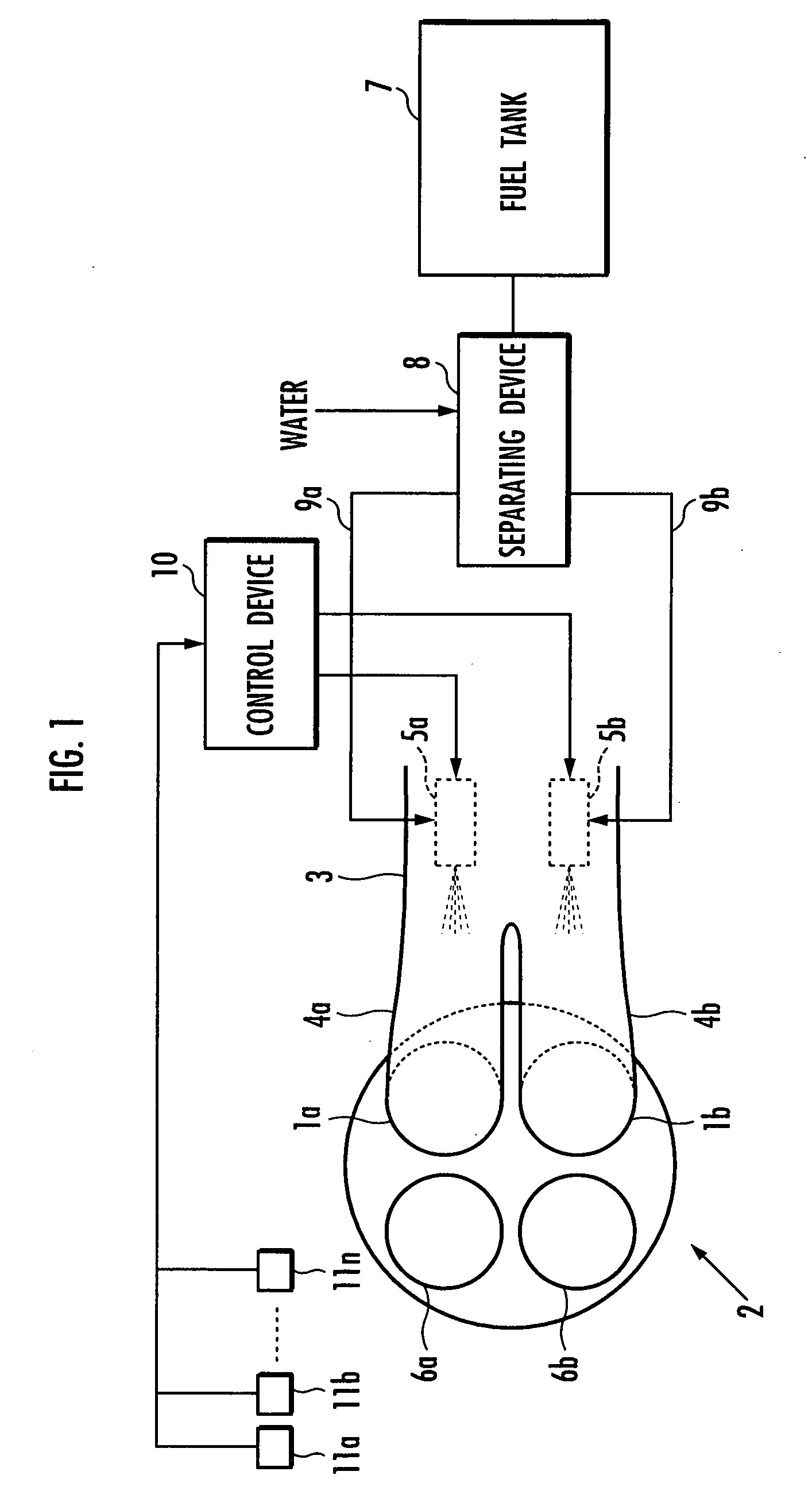

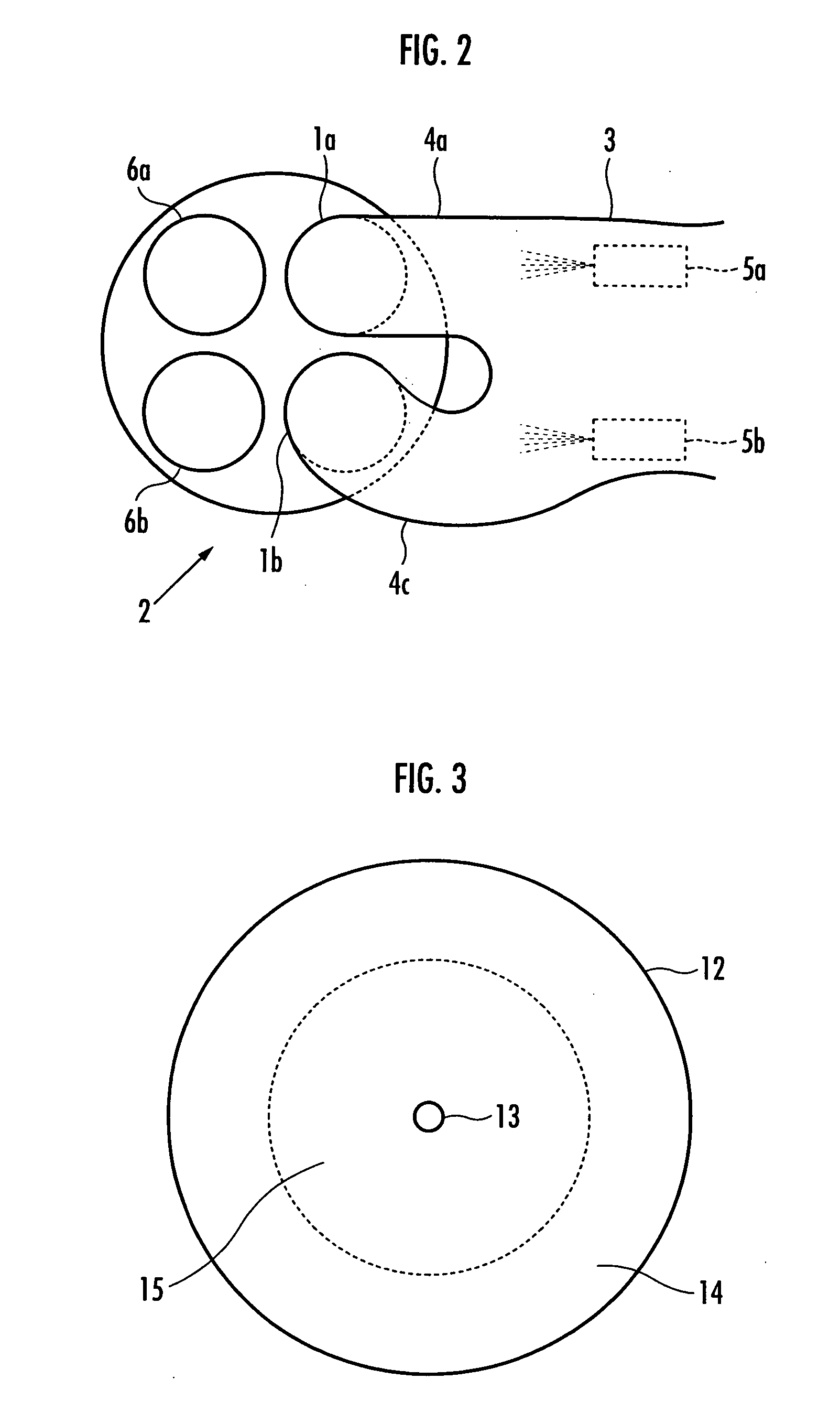

Internal combustion engine

InactiveUS20070034192A1Proportionally largeEasy to getInternal combustion piston enginesNon-fuel substance addition to fuelCombustion chamberAlcohol

There is provided an internal combustion engine that uses a blended fuel consisting of hydrocarbon and alcohol, and can efficiently operate relative to a wide range of required load. The internal combustion engine includes: intake ports 4a and 4b and two injectors 5a and 5b. The injectors include a first injector 5a that injects a hydrocarbon fuel and a second injector 5b that injects an alcohol fuel. An optimum combustion mode is selected according to an operation state, and the ratio of the alcohol is properly adjusted according to the combustion mode. The intake ports includes a first intake port 4a that guides the hydrocarbon fuel to an inner peripheral portion of a combustion chamber, and a second intake port 4c that guides the alcohol fuel to an outer peripheral portion of the combustion chamber to control octane number distribution in a cylinder. The internal combustion engine further includes separating means 8 for adding water to a blended fuel consisting of alcohol and hydrocarbon to separate into the alcohol fuel consisting of the alcohol and the water and the hydrocarbon fuel.

Owner:HONDA MOTOR CO LTD

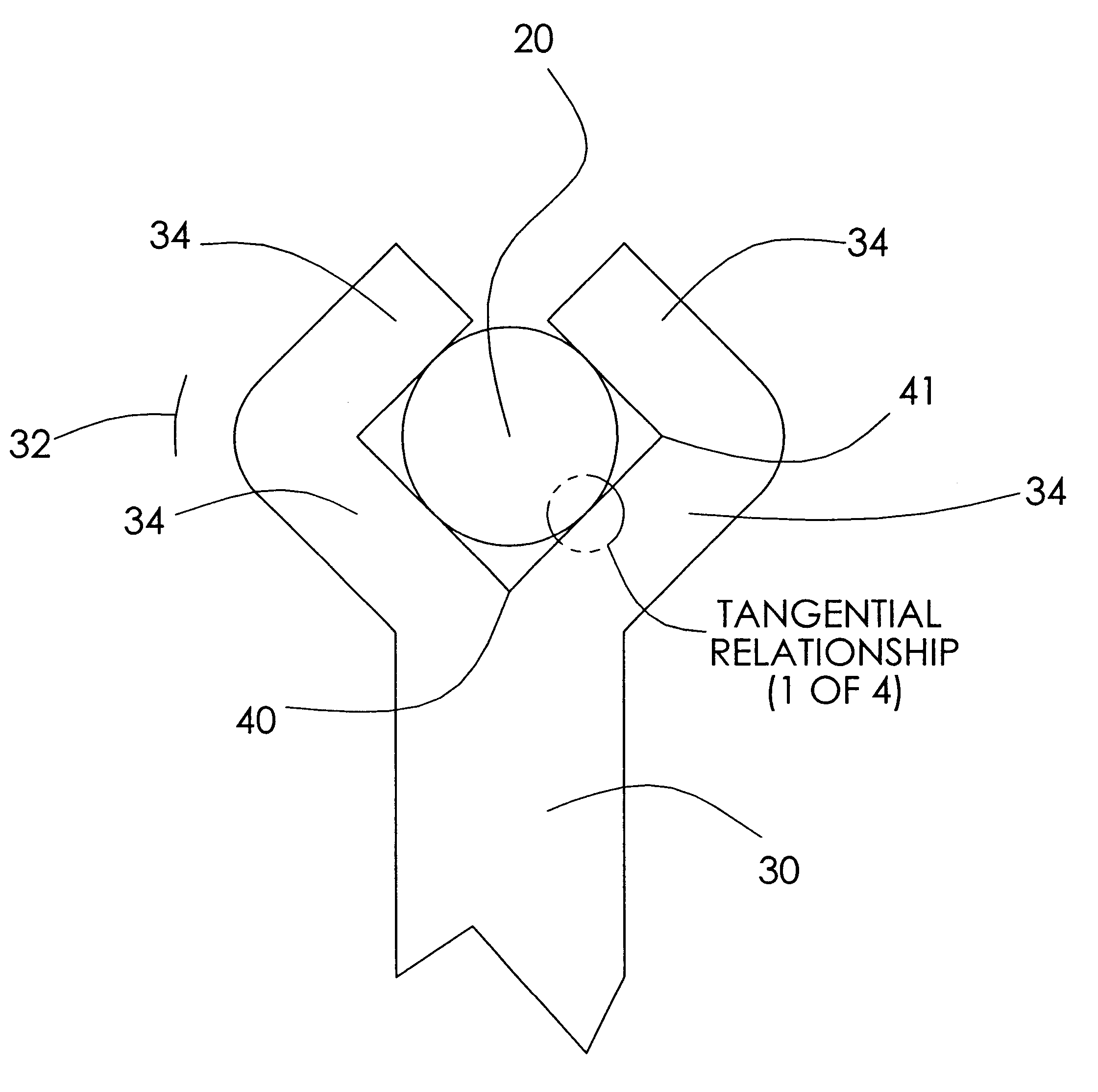

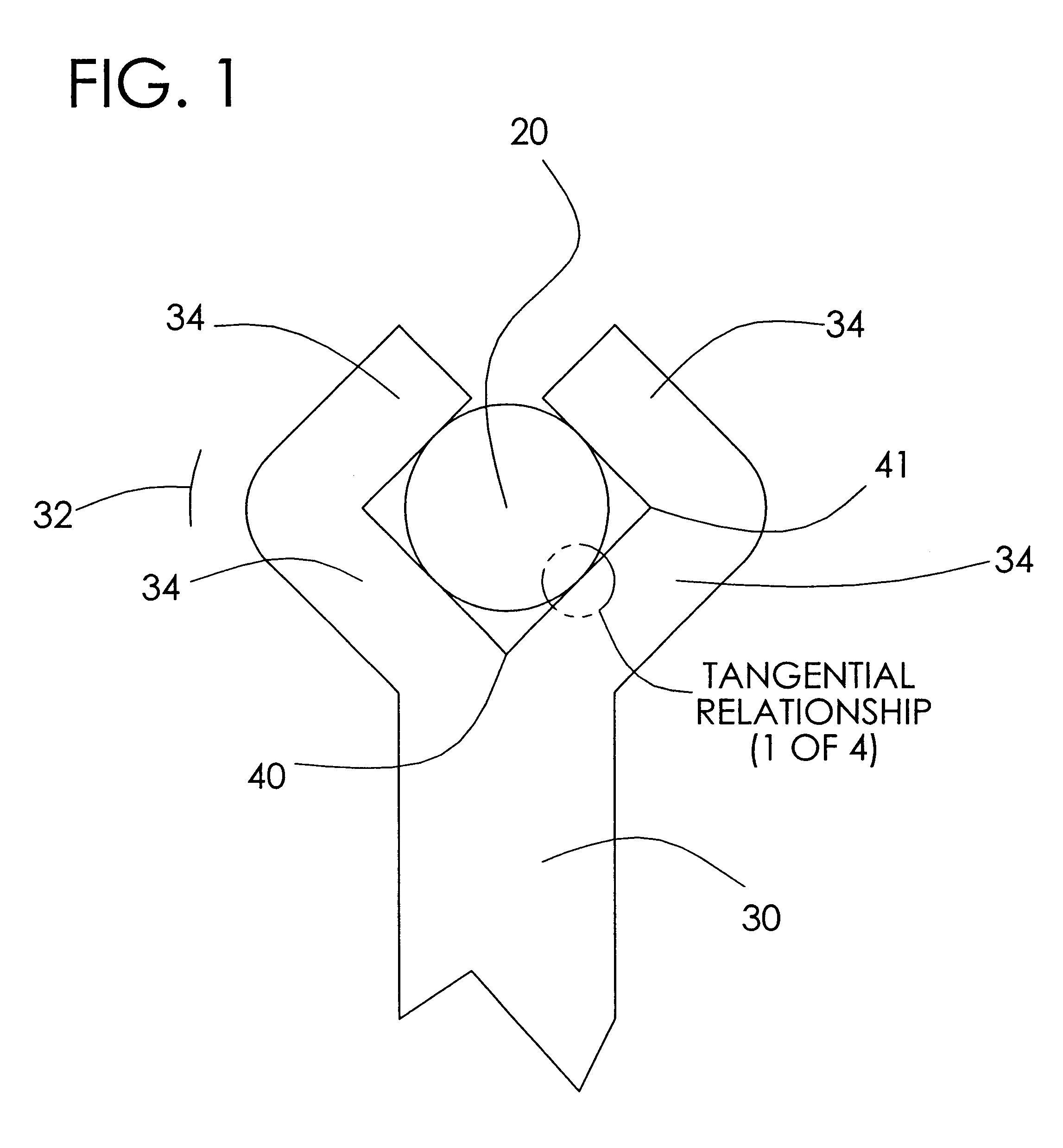

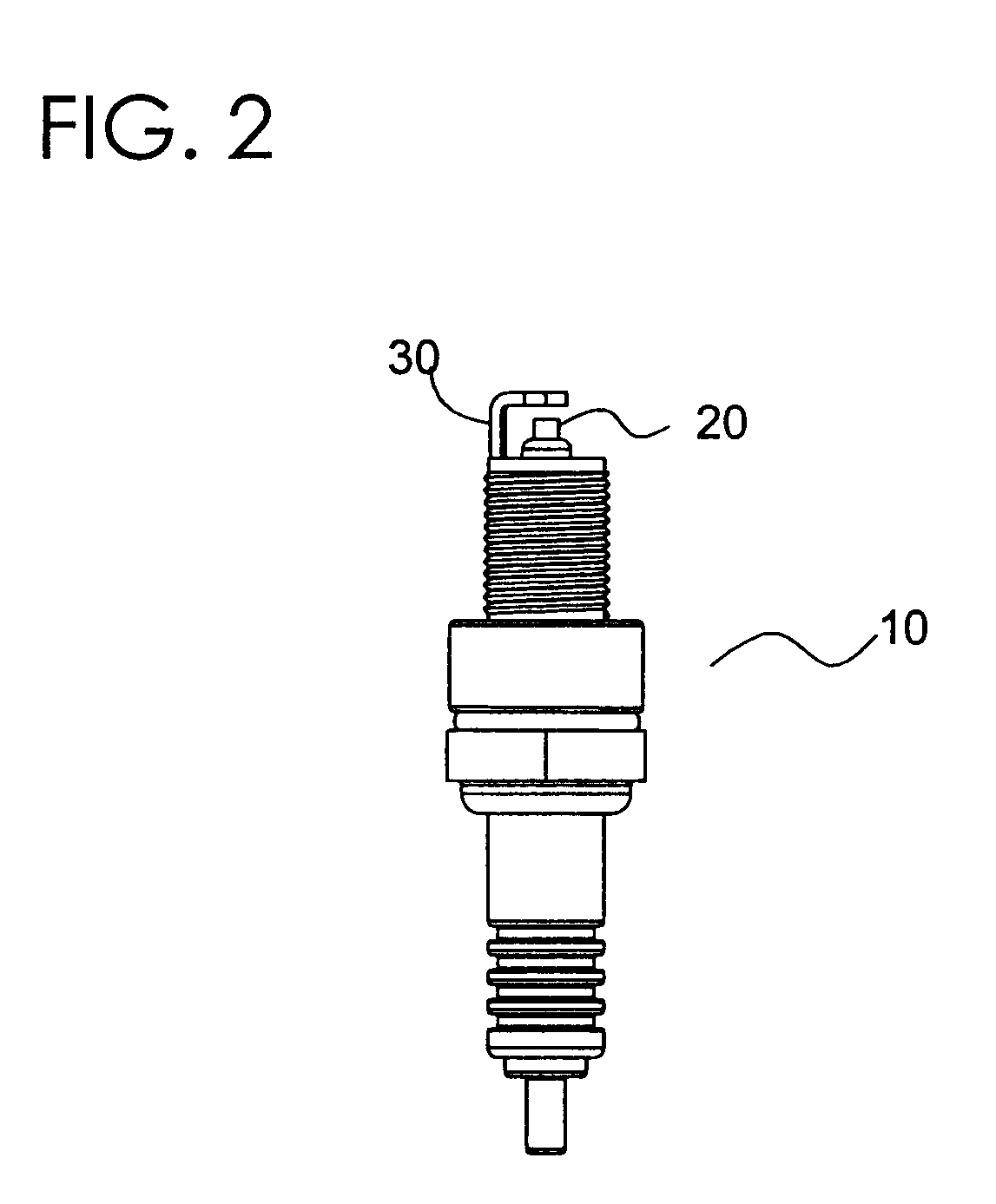

Spark plug

InactiveUS6495948B1Improve fuel efficiencyIncrease combustion pressureSparking plugsFuel injection apparatusInternal combustion engineSpark plug

The present invention relates to improved spark plugs for igniting a fuel charge in an internal combustion engine, and is particularly concerned with an improved spark plug construction which improves combustion pressure and fuel mileage and diminishes exhaust pollution. The spark plug includes a center electrode and a ground electrode. In one embodiment, the ground electrode has an elongate edge that extends past the major dimension of the center electrode. The elongate edge can either be positioned substantially tangentially to or within a "zone" outside of the center electrode's periphery. Preferably, the edge of the center electrode and the lower interior edge of the ground electrode will be presented towards one another such that the edges are or are among the closest portions within the sparking region.

Owner:PYROTEK E3 LLC

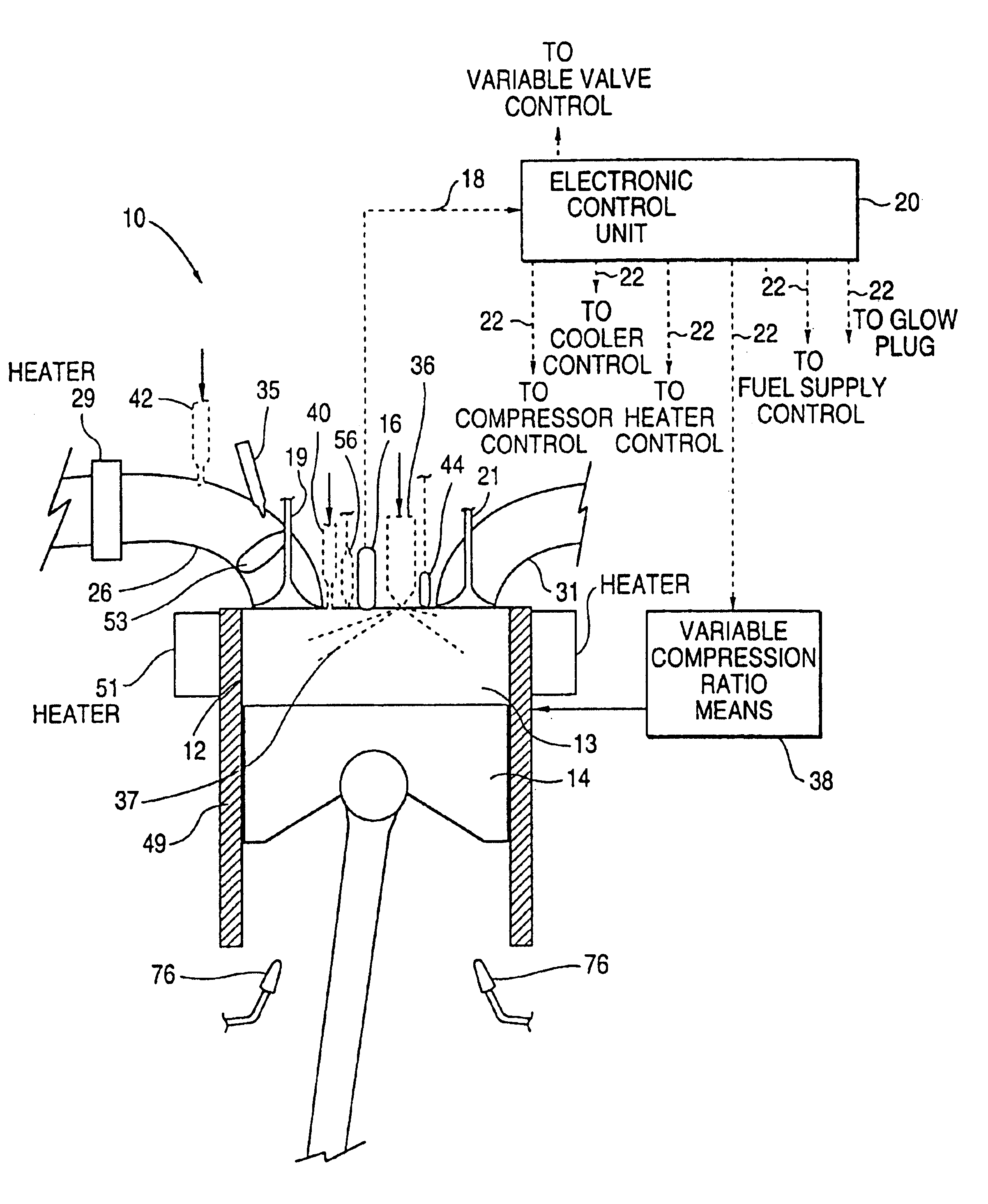

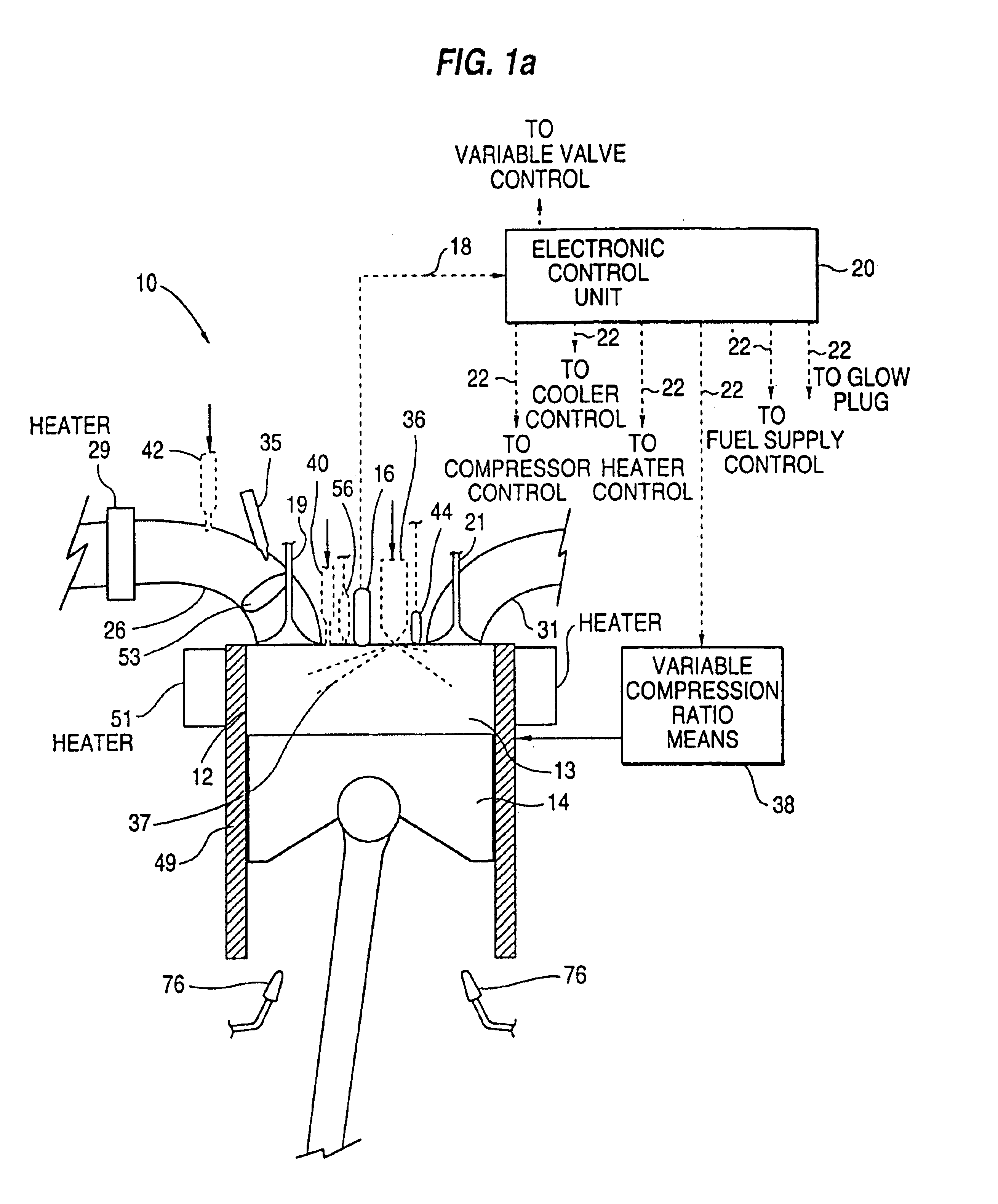

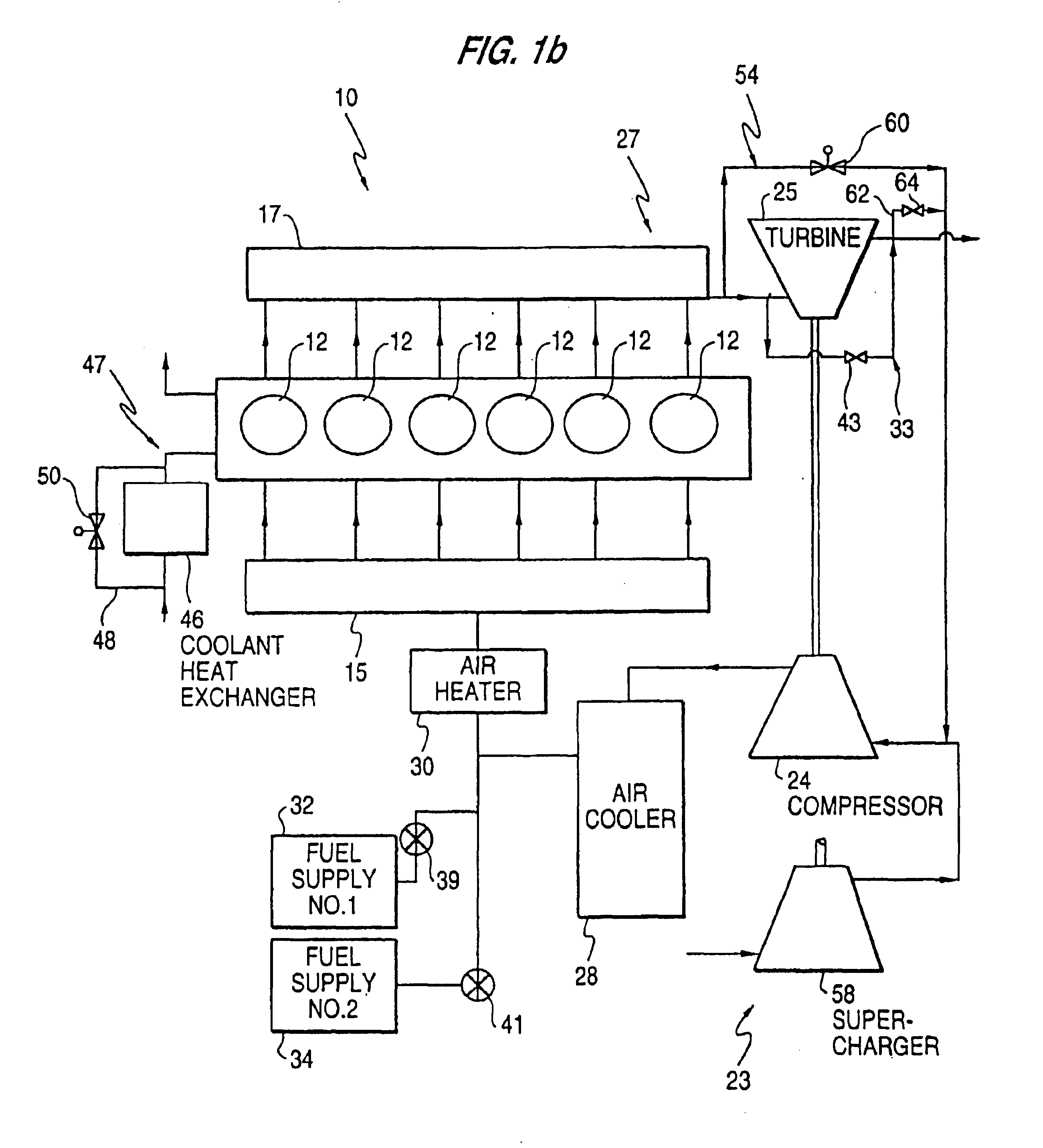

Premixed charge compression ignition engine with optimal combustion control

InactiveUS6915776B2Operate efficiently and effectivelyOvercome deficienciesElectrical controlNon-fuel substance addition to fuelCombustion noiseControl signal

A premixed charge compression ignition engine, and a control system, is provided which effectively initiates combustion by compression ignition and maintains stable combustion while achieving extremely low nitrous oxide emissions, good overall efficiency and acceptable combustion noise and cylinder pressures. The present engine and control system effectively controls the combustion history, that is, the time at which combustion occurs, the rate of combustion, the duration of combustion and / or the completeness of combustion, by controlling the operation of certain control variables providing temperature control, pressure control, control of the mixture's autoignition properties and equivalence ratio control. The combustion control system provides active feedback control of the combustion event and includes a sensor, e.g. pressure sensor, for detecting an engine operating condition indicative of the combustion history, e.g. the start of combustion, and generating an associated engine operating condition signal. A processor receives the signal and generates control signals based on the engine operating condition signal for controlling various engine components to control the temperature, pressure, equivalence ratio and / or autoignition properties so as to variably control the combustion history of future combustion events to achieve stable, low emission combustion in each cylinder and combustion balancing between the cylinders.

Owner:CUMMINS INC

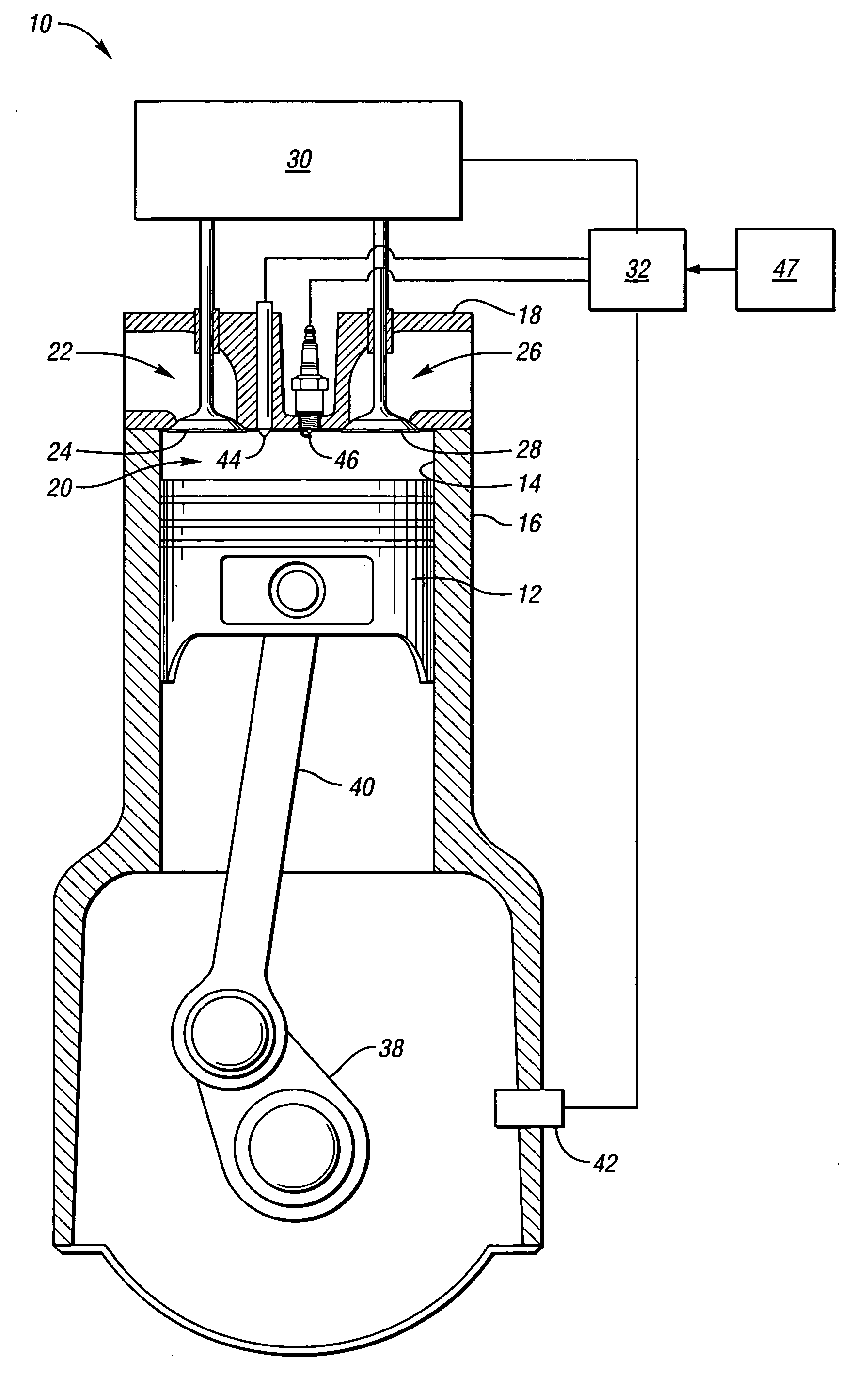

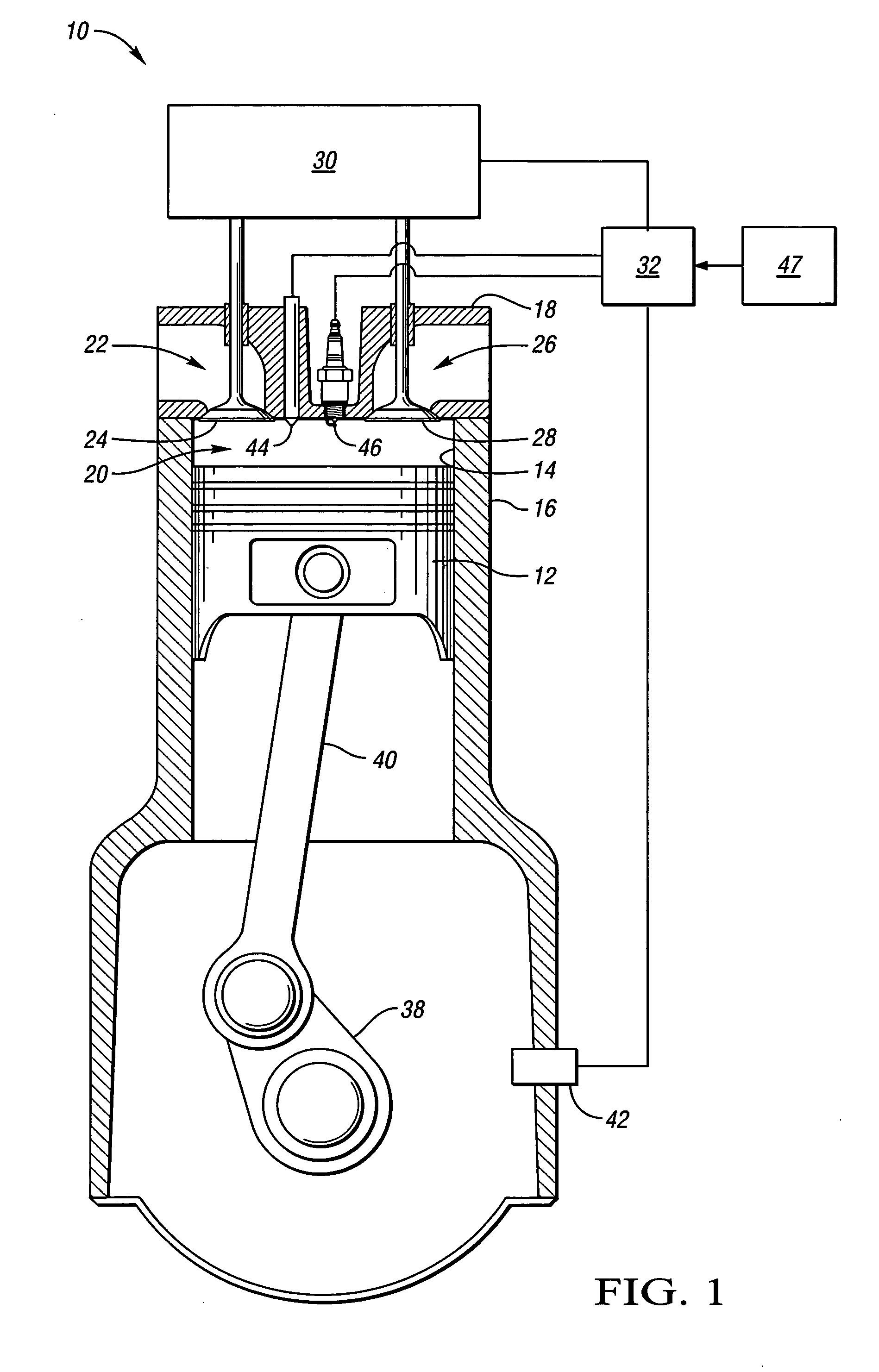

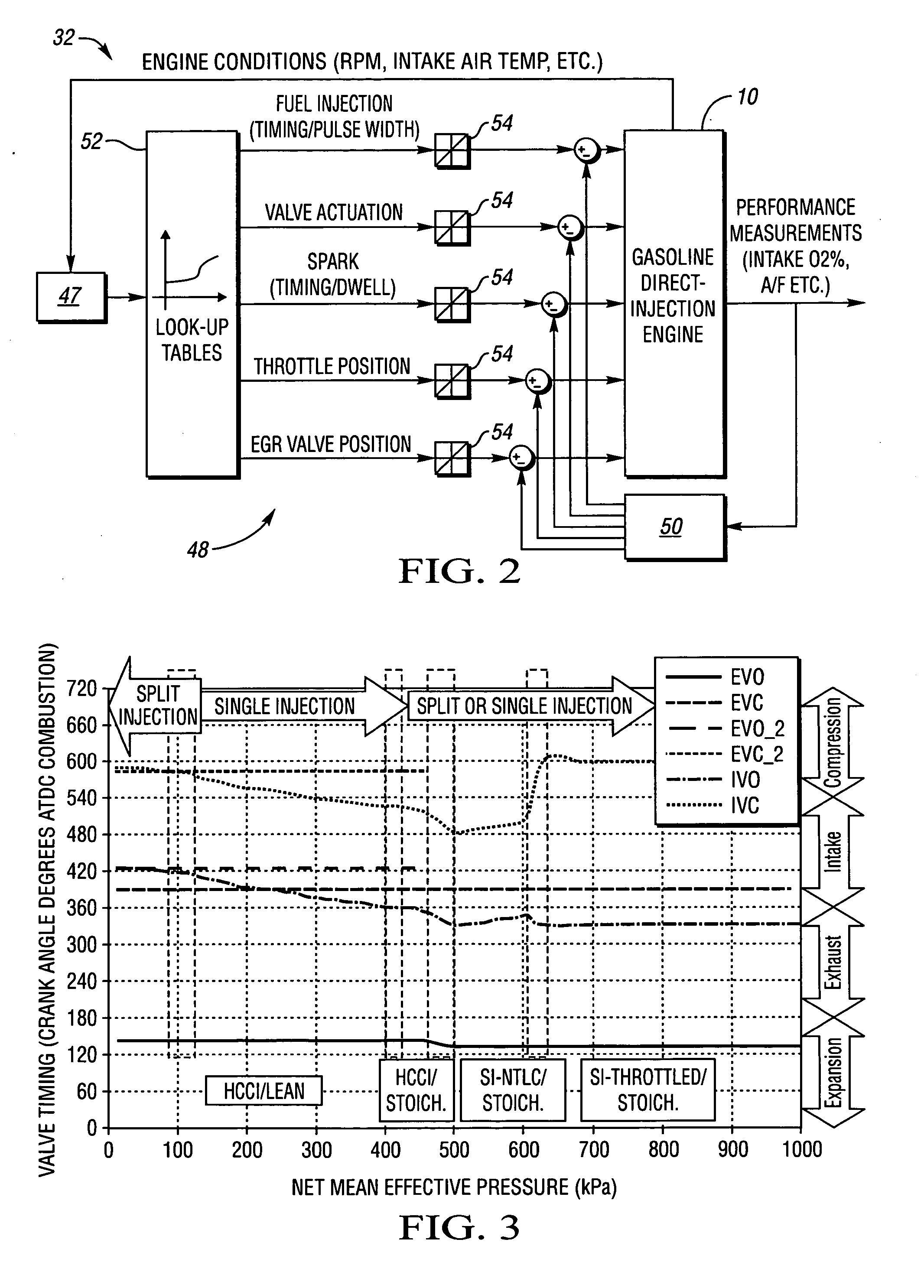

Method of HCCI and SI combustion control for a direct injection internal combustion engine

InactiveUS20060243241A1Improve fuel economyRobust controlValve arrangementsElectrical controlHomogeneous charge compression ignitionGasoline direct injection

The present invention relates to methods for robust controlled auto-ignition and spark ignited combustion controls in gasoline direct-injection engines, including transients, using either exhaust re-breathing or a combination of exhaust re-compression and re-breathing valve strategy. These methods are capable of enabling engine operation with either lean of stoichiometric or stoichiometric air / fuel ratio for oxides of nitrogen (NOx) control, with varying exhaust gas recirculation (EGR) rates and throttle valve positions for knock control, and with a combination of homogeneous charge compression ignition (HCCI) and spark ignition (SI) combustion modes to optimize fuel economy over a wide range of engine operating conditions.

Owner:GM GLOBAL TECH OPERATIONS LLC

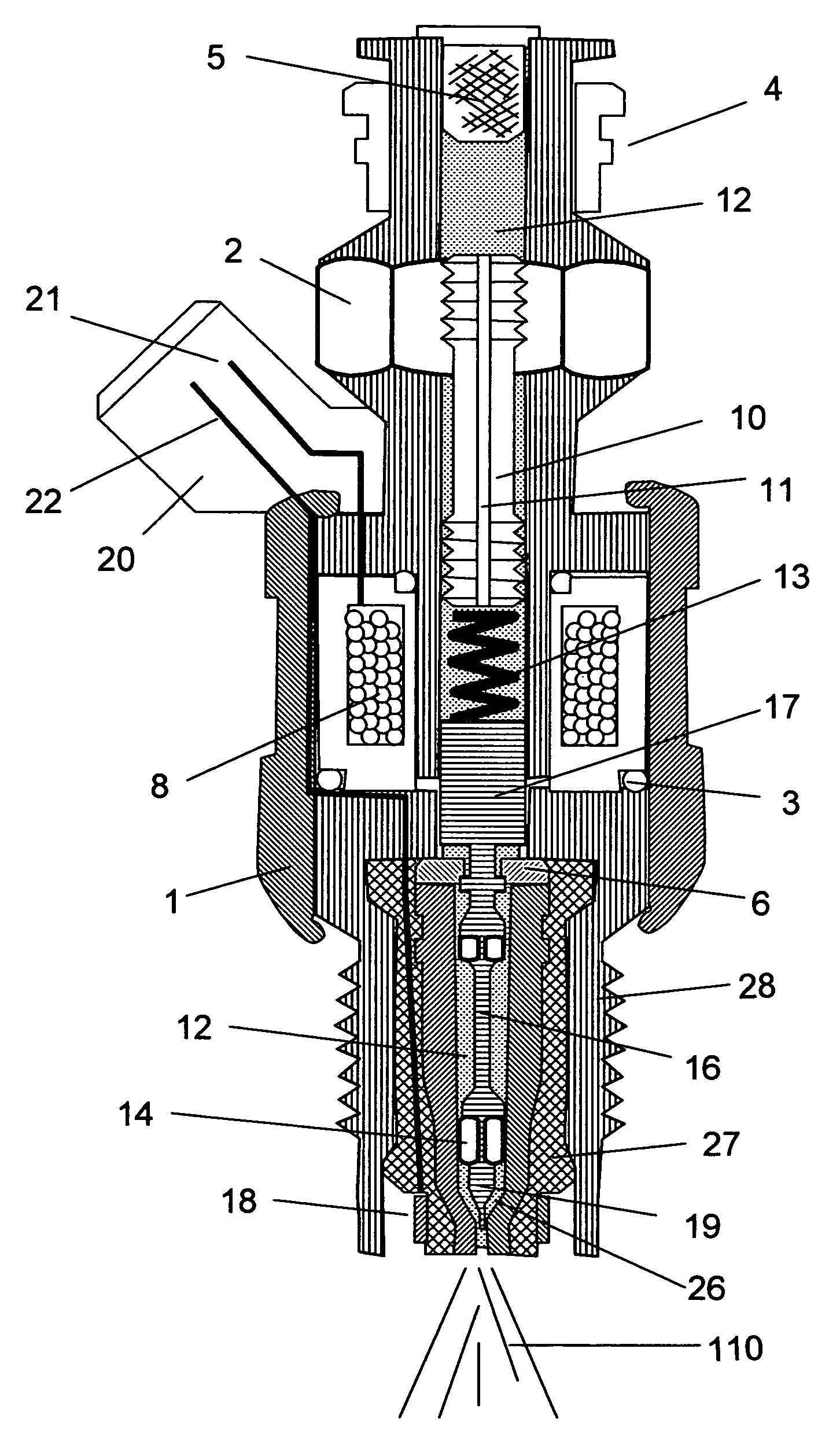

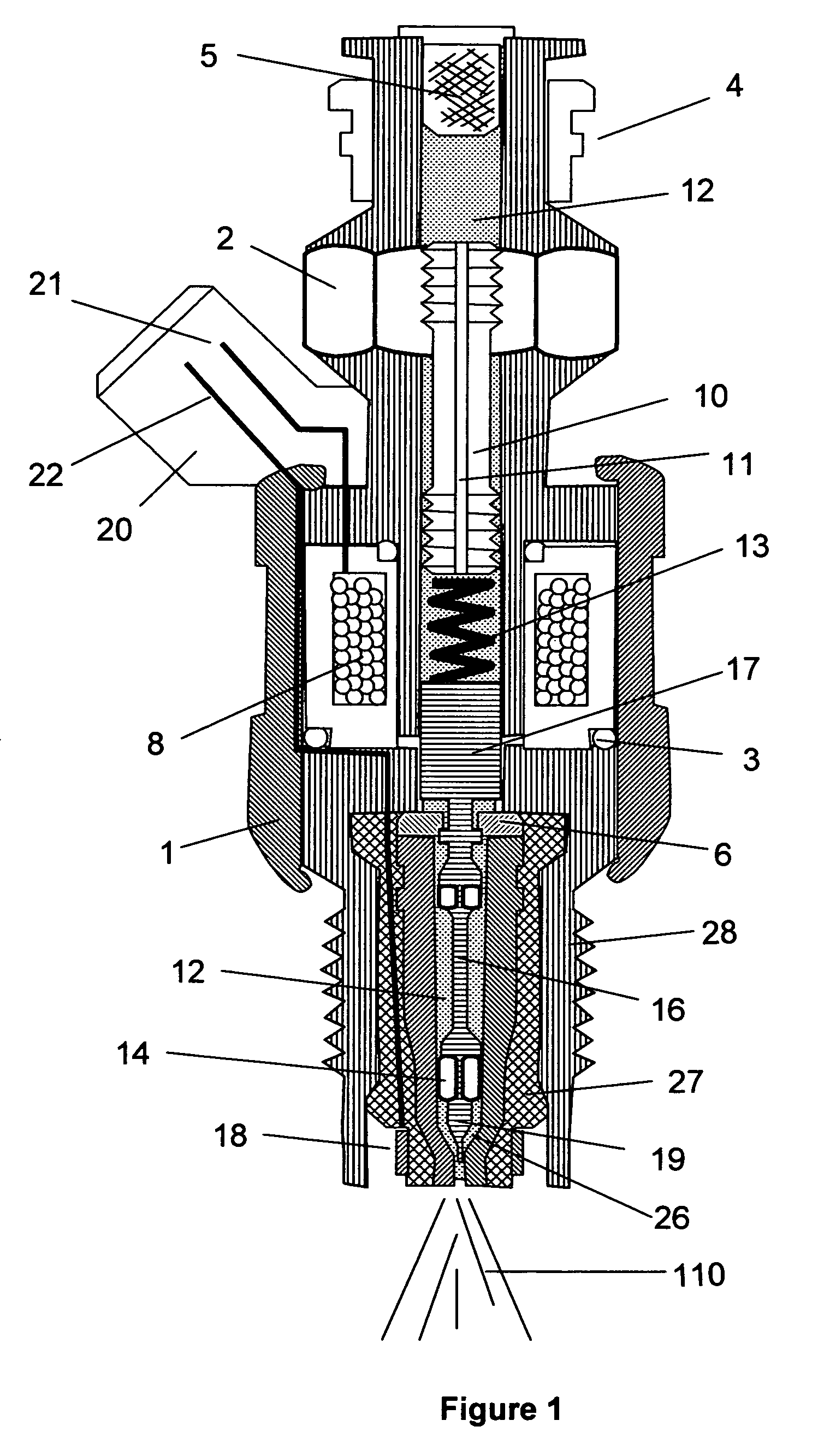

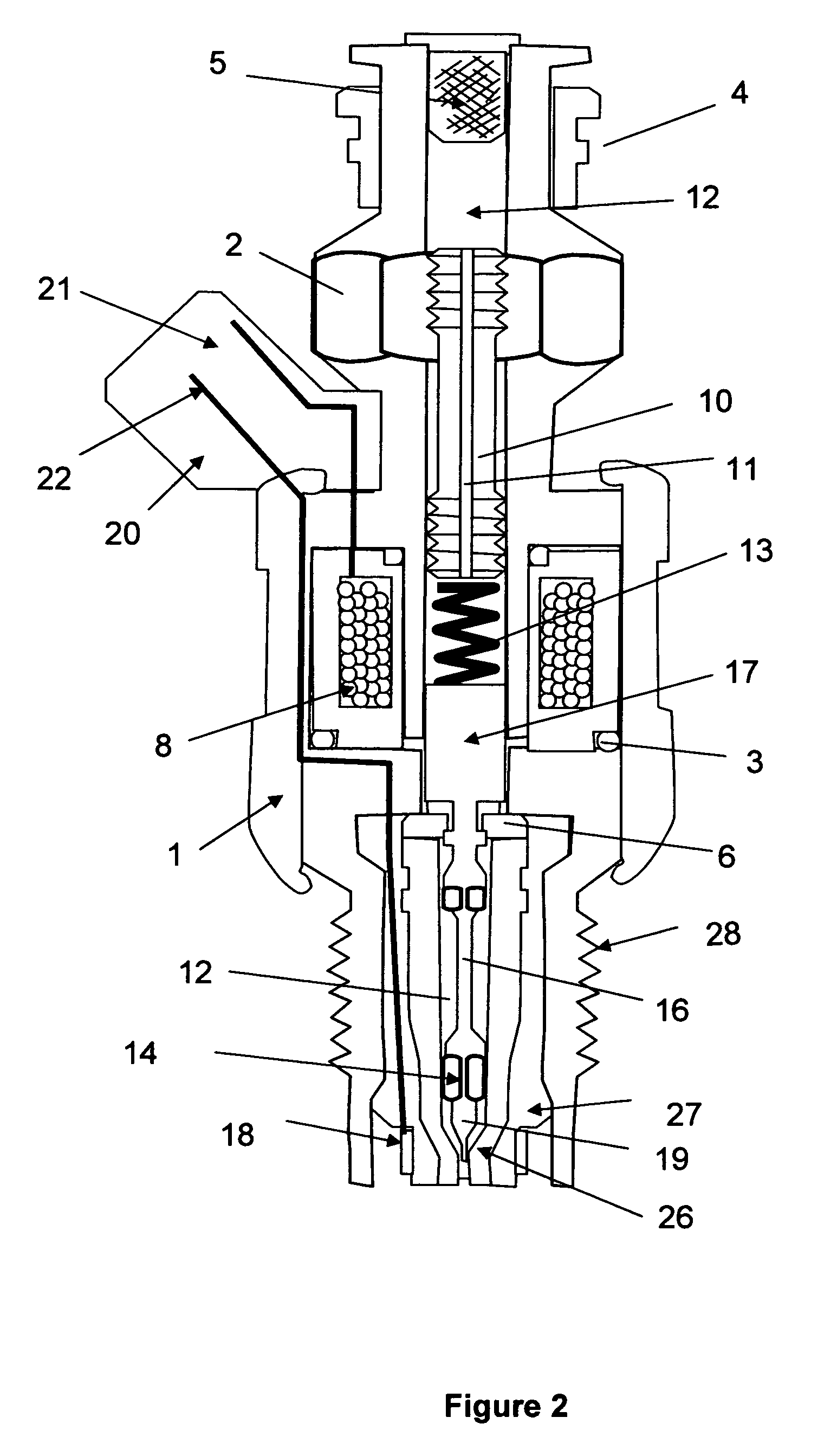

Fuel injector spark plug

InactiveUS6955154B1Eliminates excess fuel useRemove heatSparking plugsFuel injection apparatusCombustionEngineering

A spark plug and fuel injector combination. The spark plug has a central channel that funnels fuel into the lower portion of the spark plug, where it is superheated. A solenoid system causes a needle valve to rise up to allow a measured quantity of fuel to be injected into a cylinder through a nozzle, where it vaporizes upon exiting the spark plug. A spring releases the needle valve to close the nozzle. The spark plug also has an ignition ring on the base. The ignition ring produces an encompassing spark, which produces complete combustion of the vaporized fuel. This produces more power and better fuel economy.

Owner:DOUGLAS DENIS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com