Patents

Literature

115results about How to "Reduce smoke emissions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

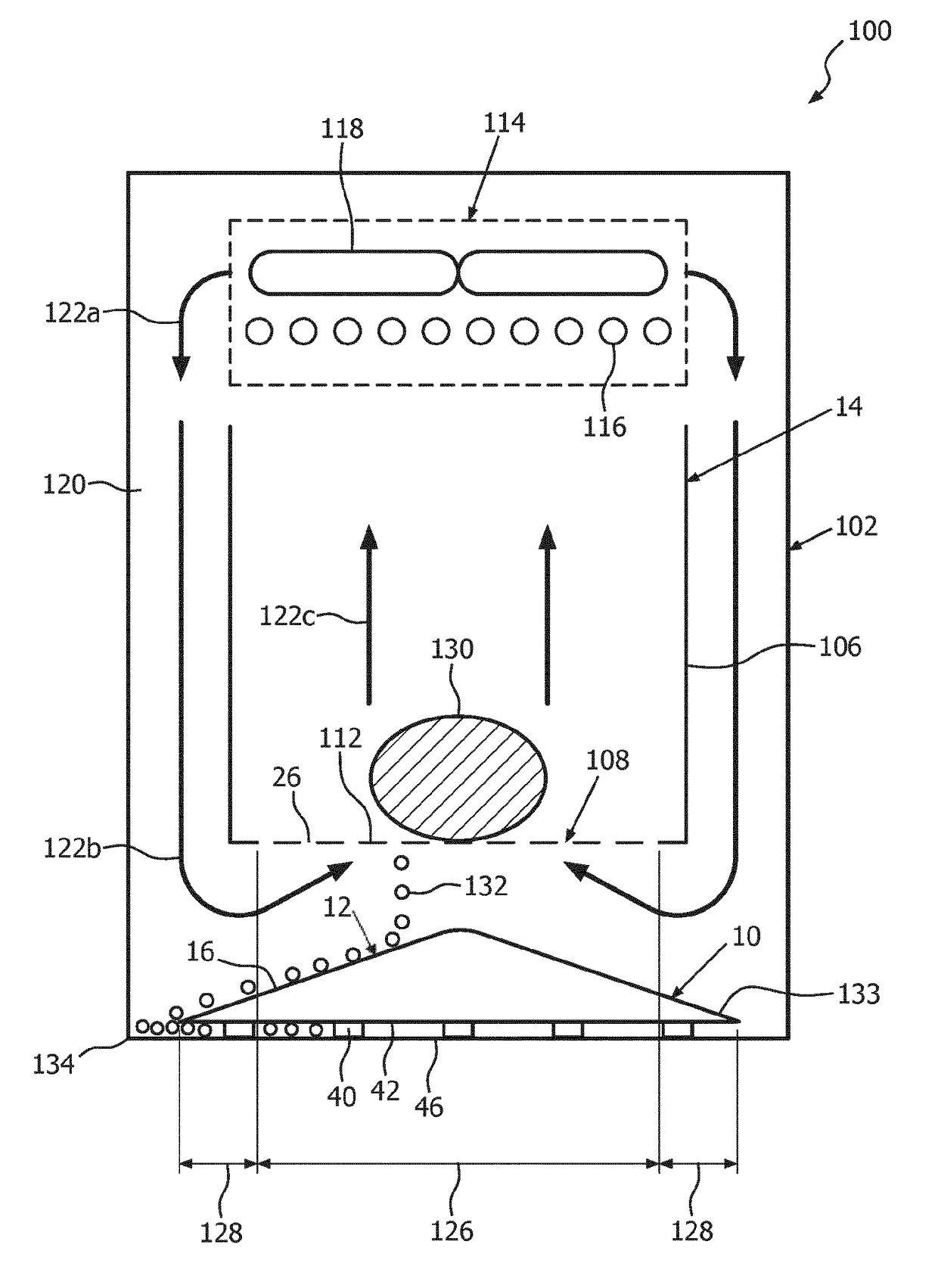

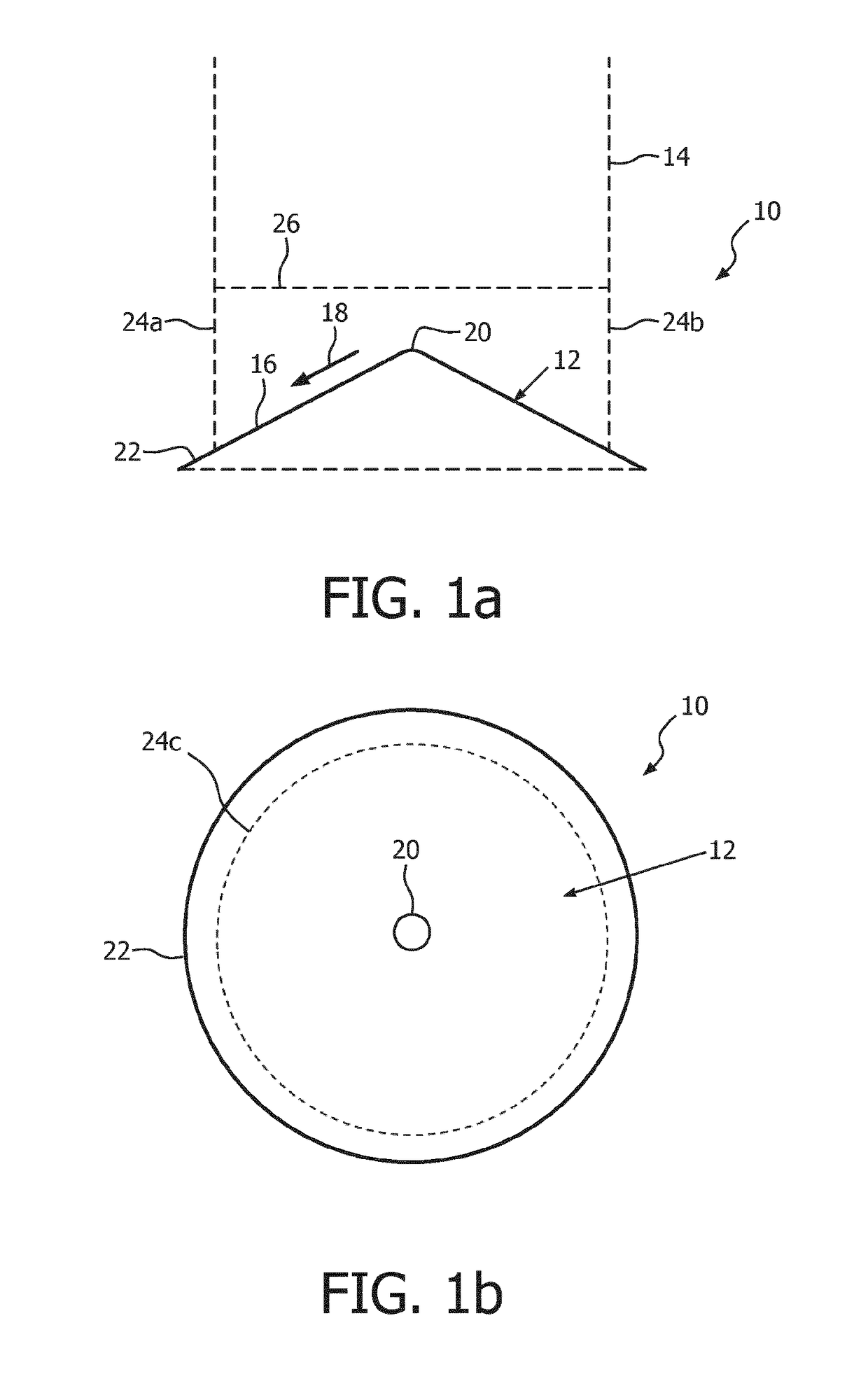

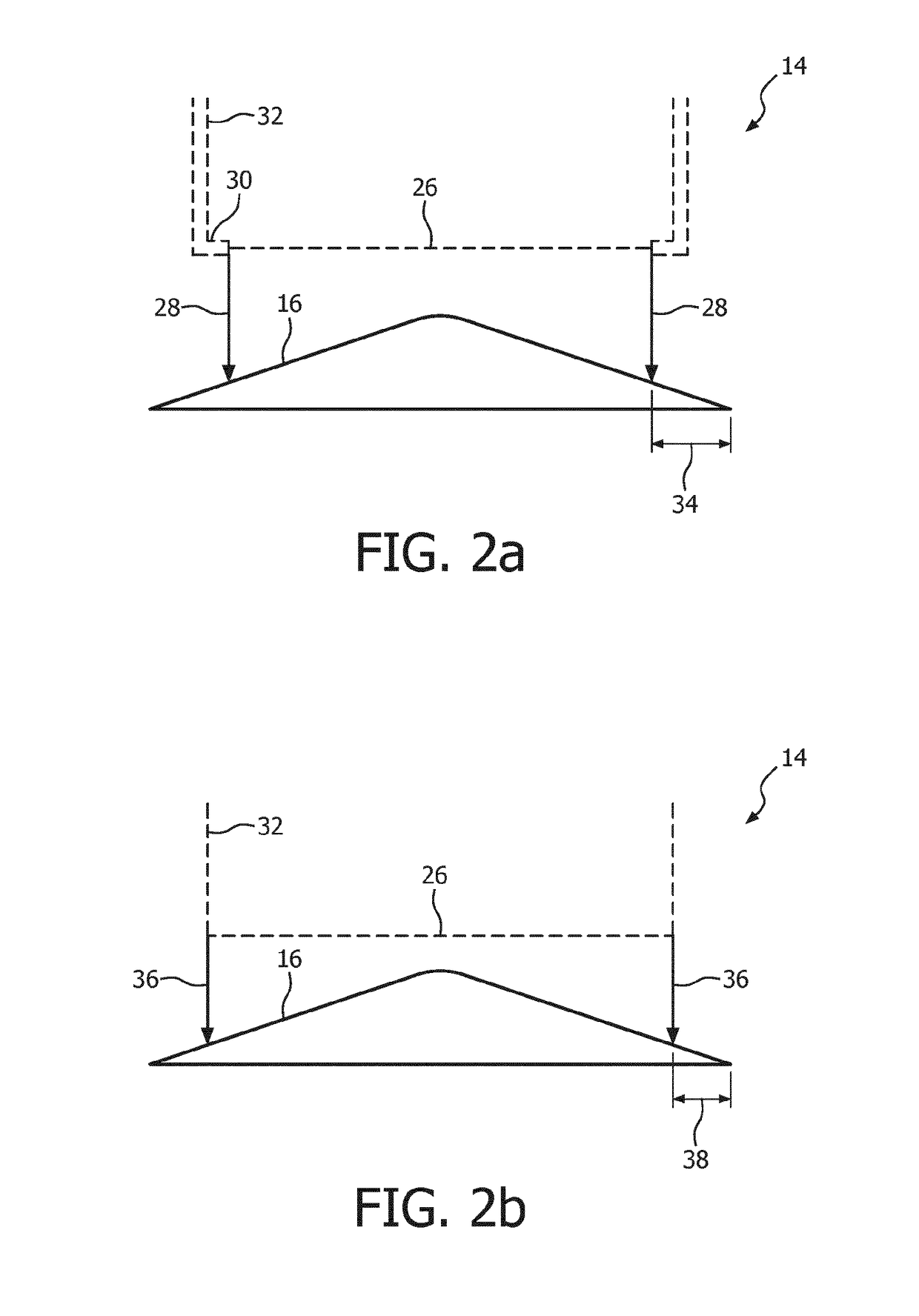

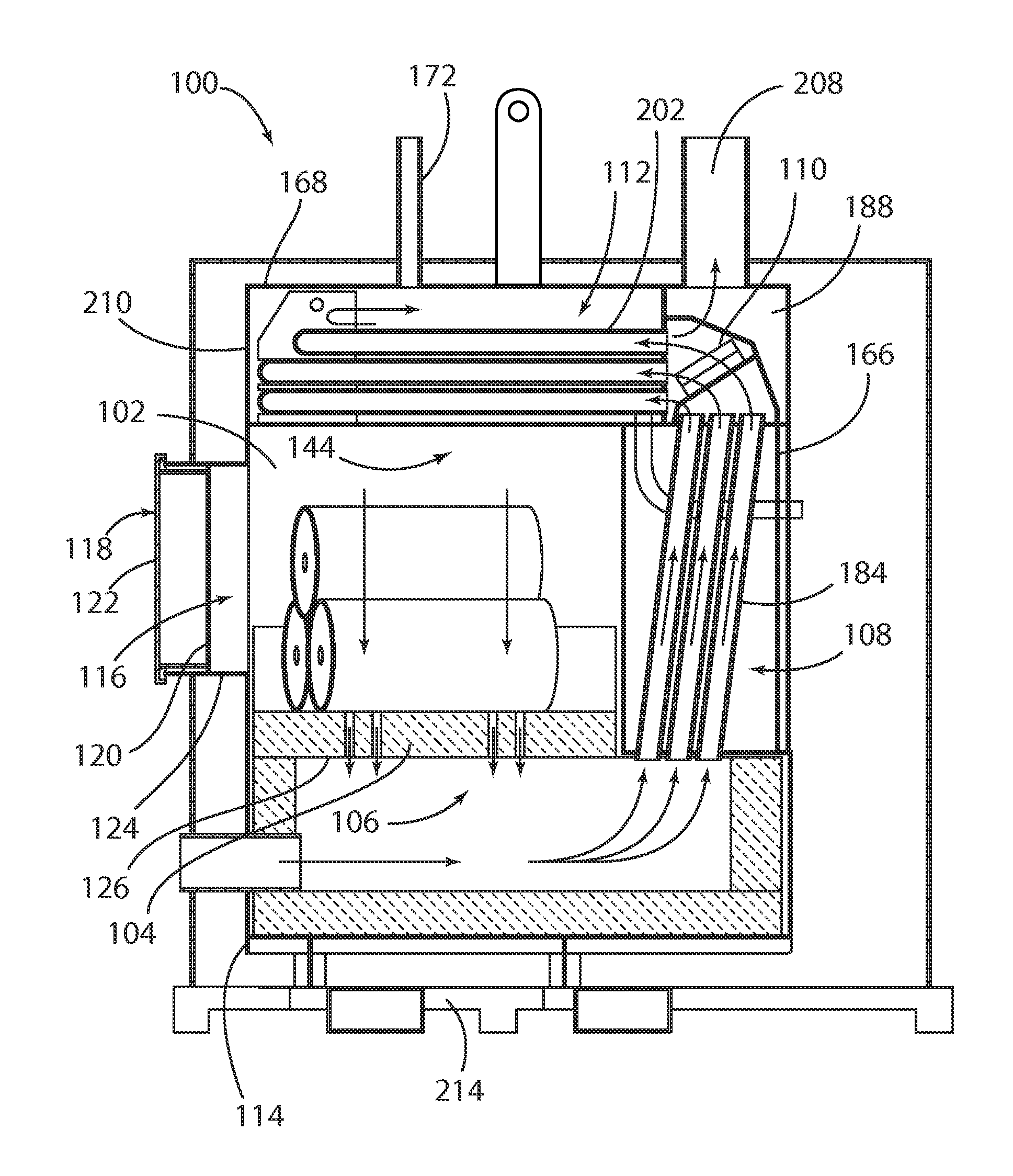

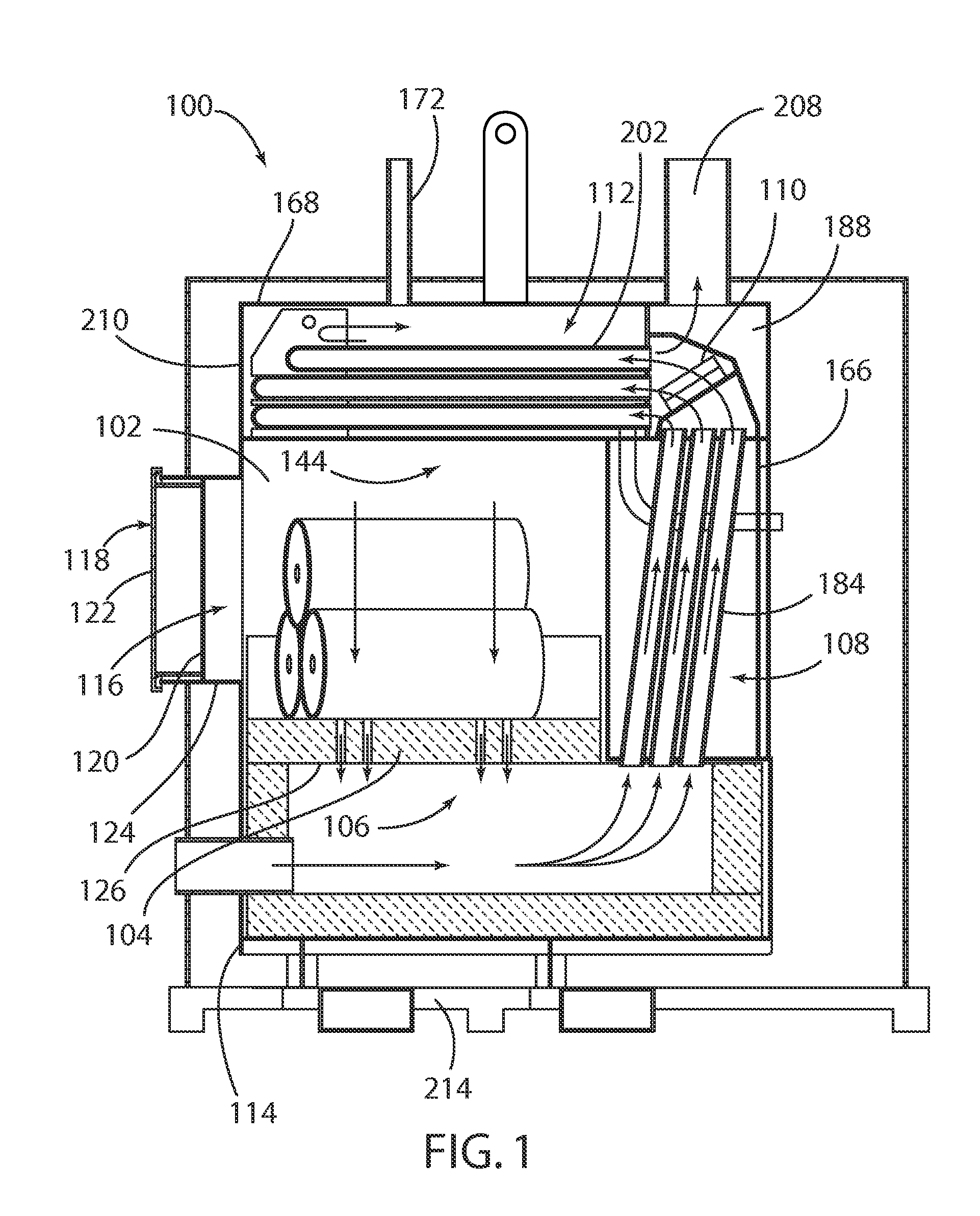

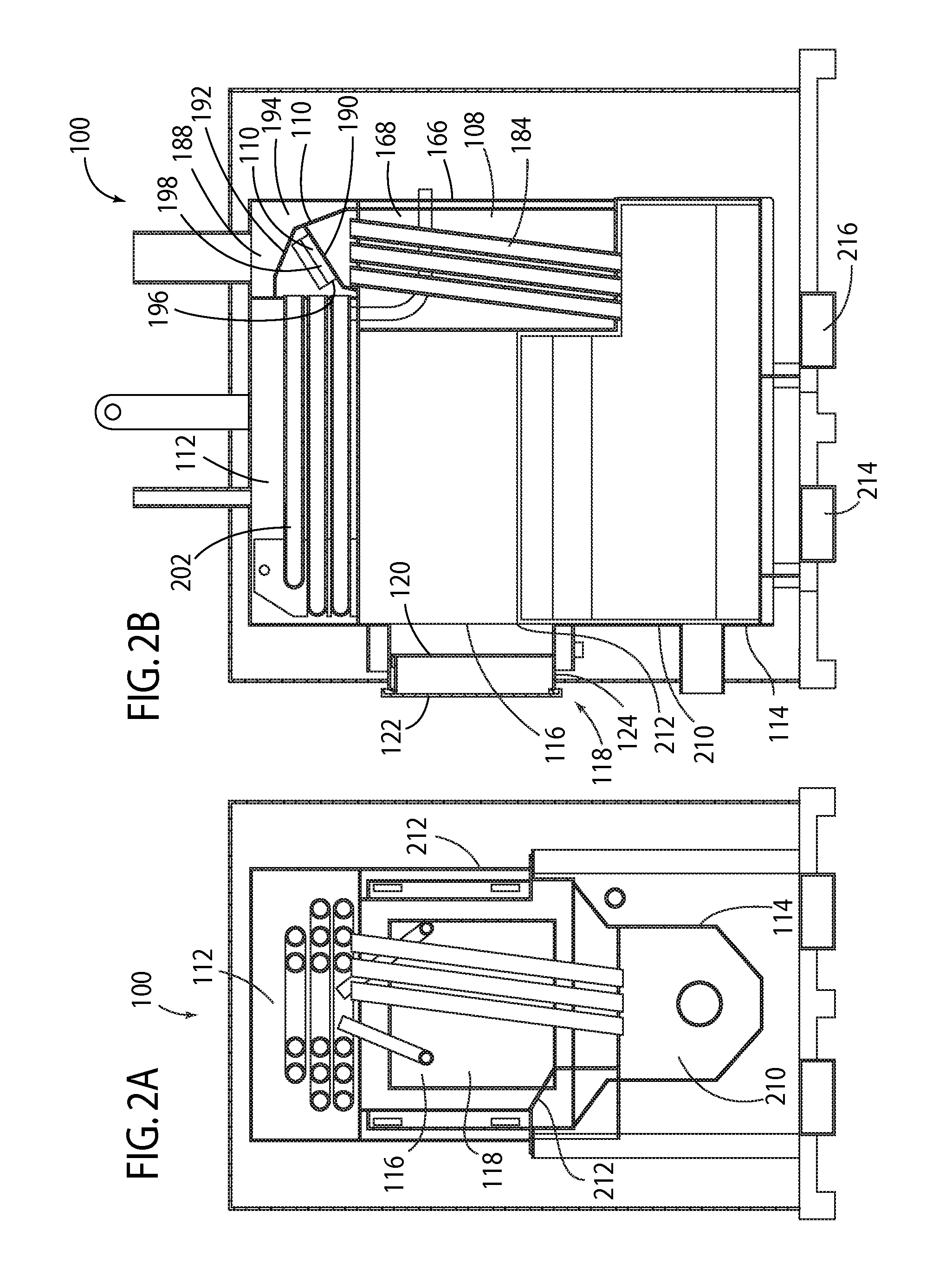

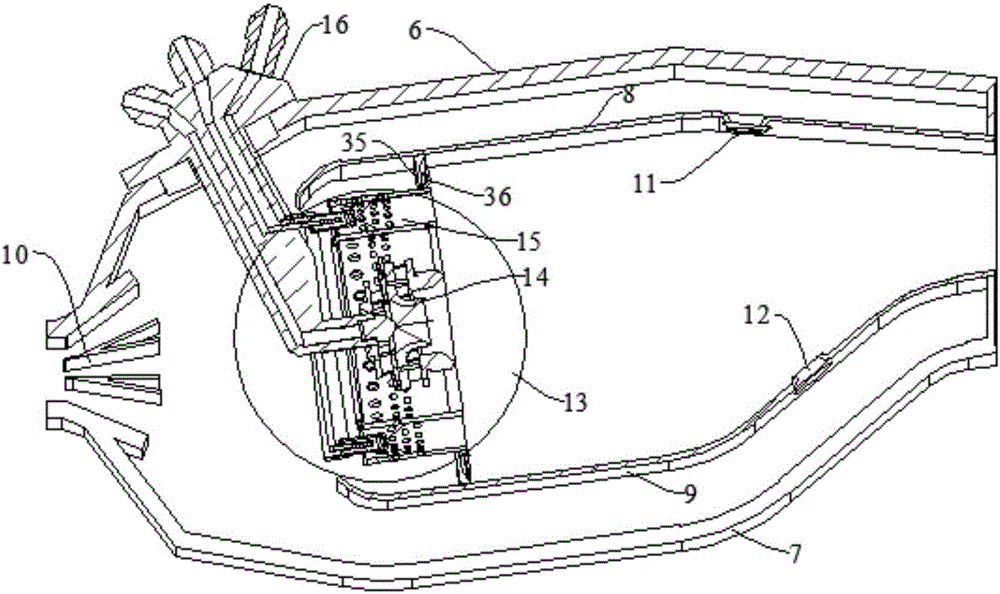

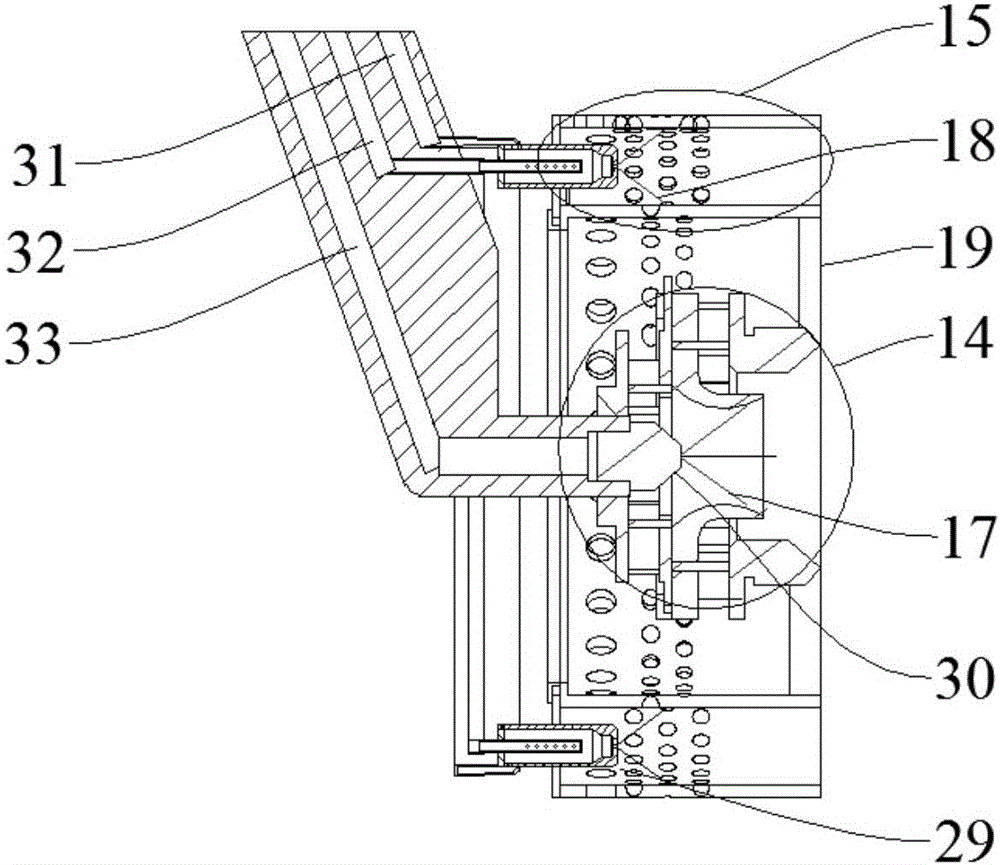

Insert for an air-based fryer, apparatus comprising such insert

ActiveUS20170303740A1Generation of fume can be reducedReduce generationRoasters/grillsVertical projectionEngineering

The invention relates to an insert (10) for an apparatus (100) for preparing food by circulation of a flow of hot air in a food basket (14) placed inside a food preparation chamber and having a bottom part (108) with a lower opening area (26) for the circulation of the flow of hot air. The insert comprises an upper surface (12) intended to be arranged below the food basket. The upper surface (12) defines an inclined surface (16) having a downward inclination extending outwards from a middle zone towards a perimeter of the insert. The inclined surface (16) is provided such that the inclination extends at least beyond a vertical projection of the lower opening area (26). The insert further comprises spacers (40) provided on a lower side (42) of the insert to create a clearance gap (44) between the lower side (42) and a bottom surface (46) of the food preparation chamber. This invention allows improving food preparation while minimizing the emission of cooking oil fumes.

Owner:VERSUNI HLDG BV

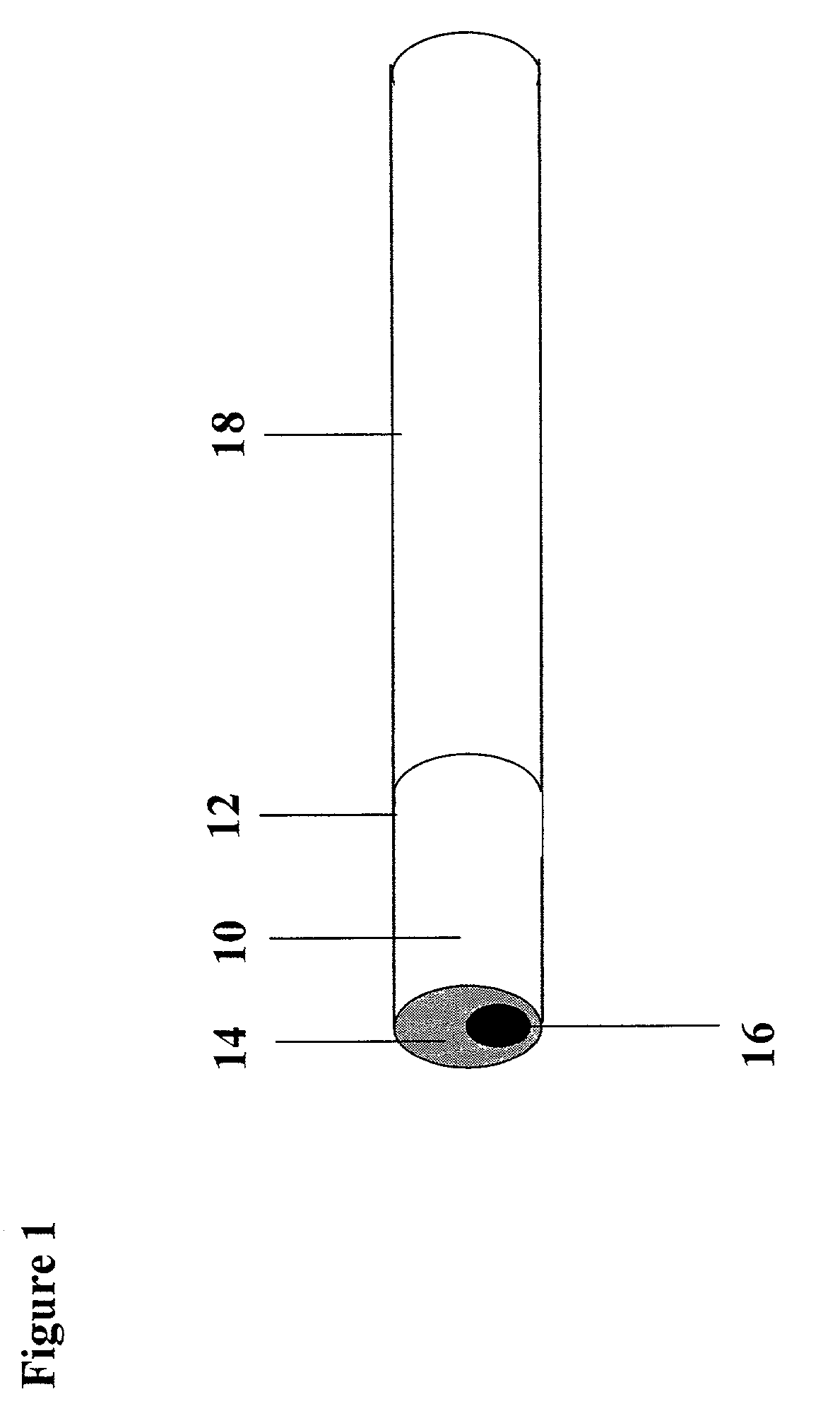

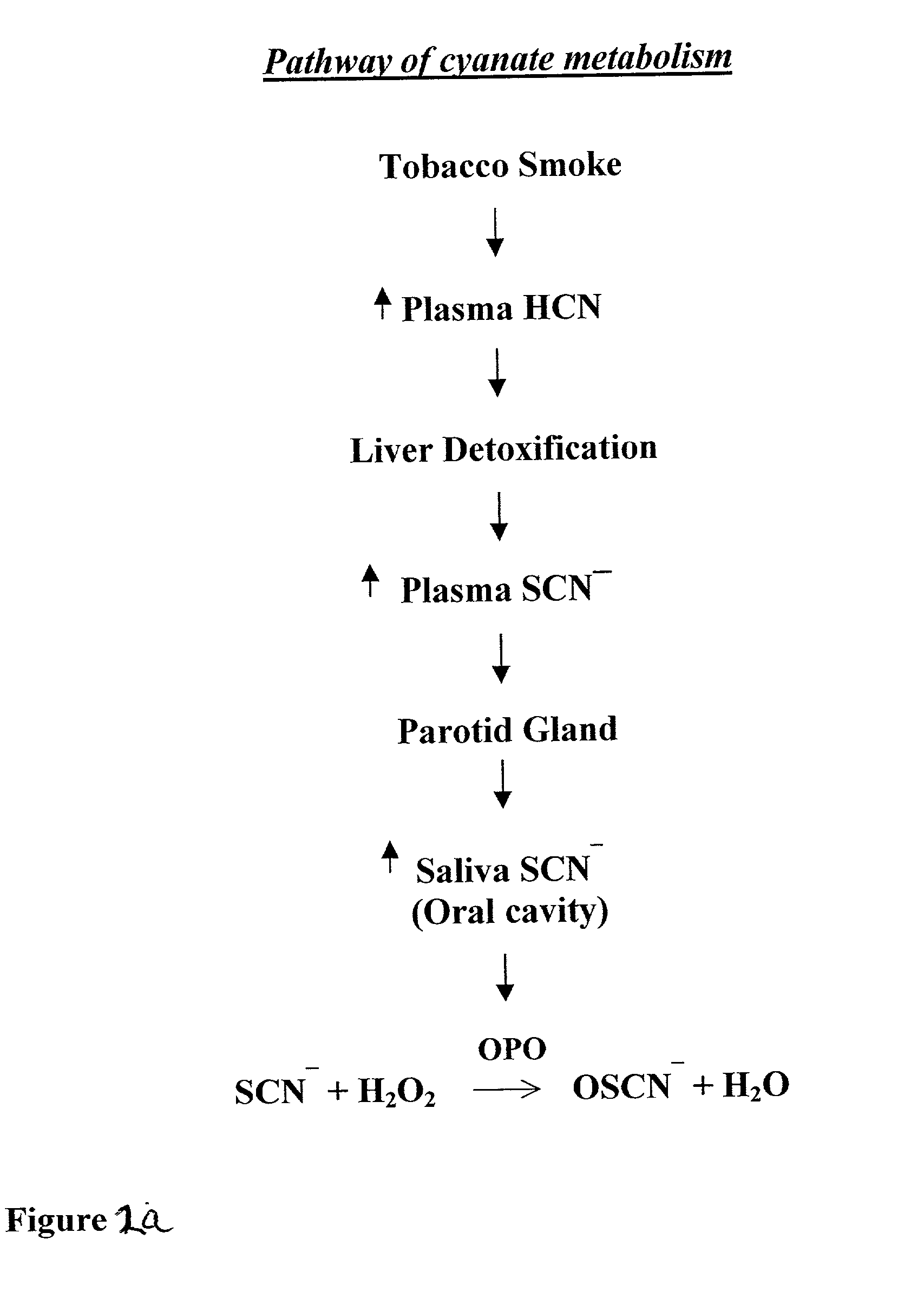

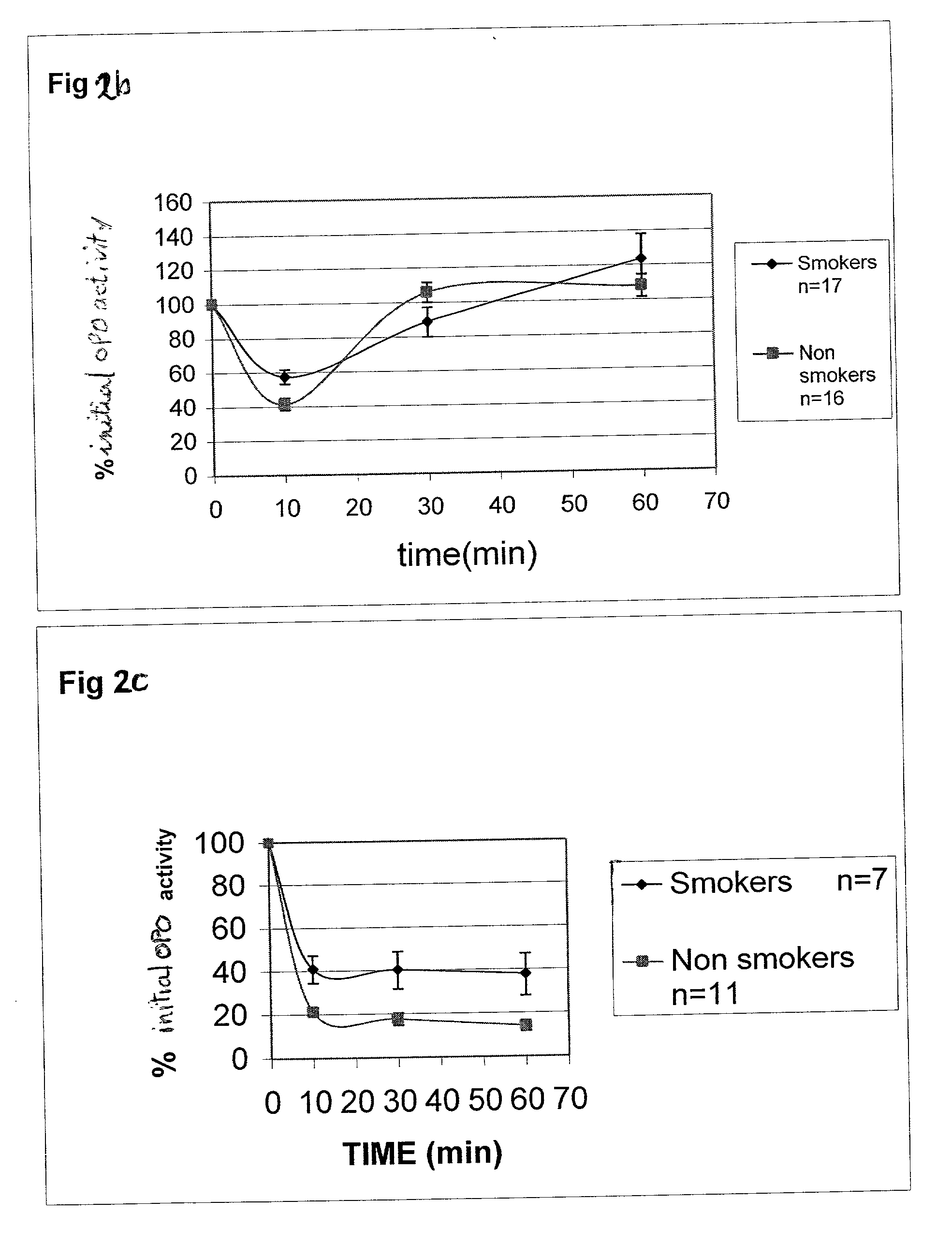

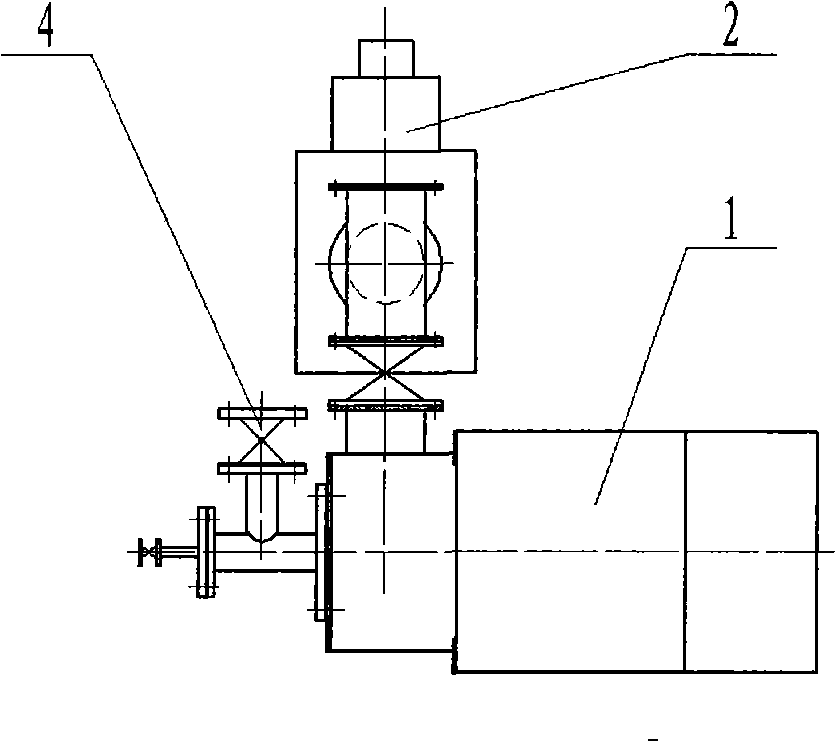

Methods, pharmaceutical compositions, oral compositions,filters and tobacco products for preventing or reducing tobacco smoke-associated injury in the aerodigestive tract of a subject

InactiveUS20030031630A1Improve responseReduce smoke emissionsBiocideTobacco treatmentAssociated injuryTobacco product

A method of preventing or reducing tobacco smoke-associated injury in the aerodigestive tract of a subject is disclosed. The method comprises administering a therapeutically effective amount of an antioxidant agent capable of preventing or reducing tobacco smoke-associated injury in the aerodigestive tract of a subject

Owner:TECHNION RES & DEV FOUND LTD

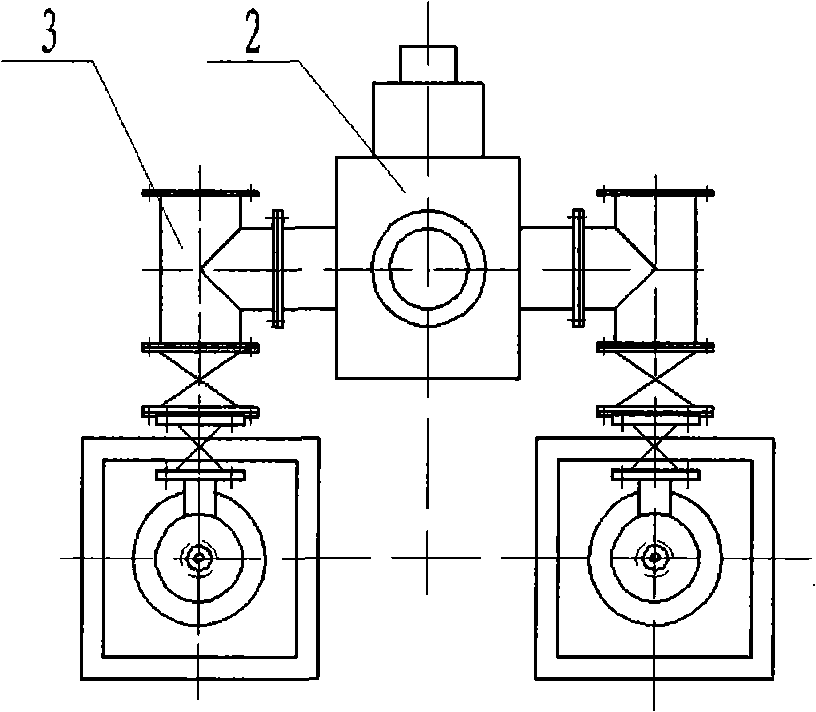

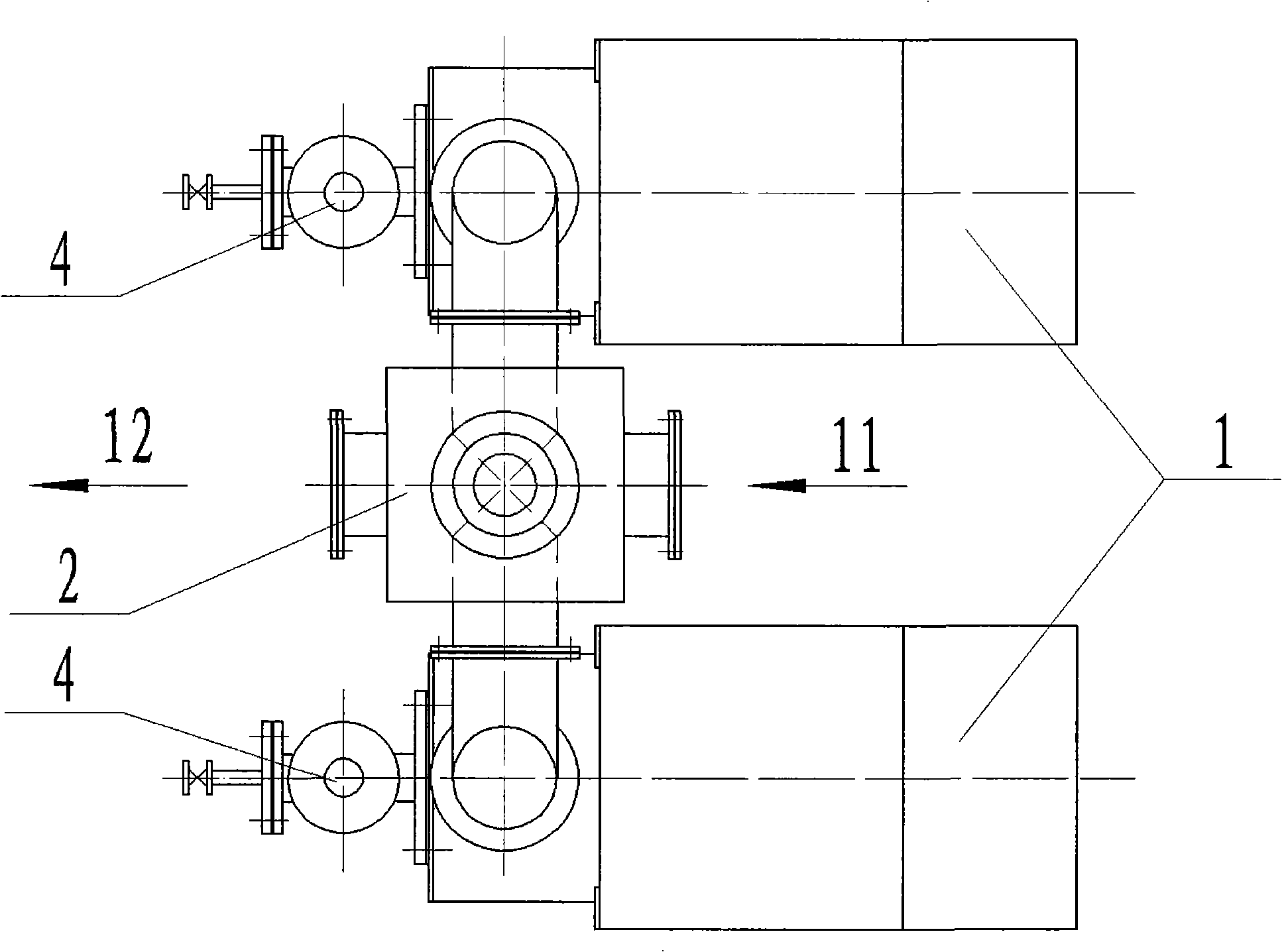

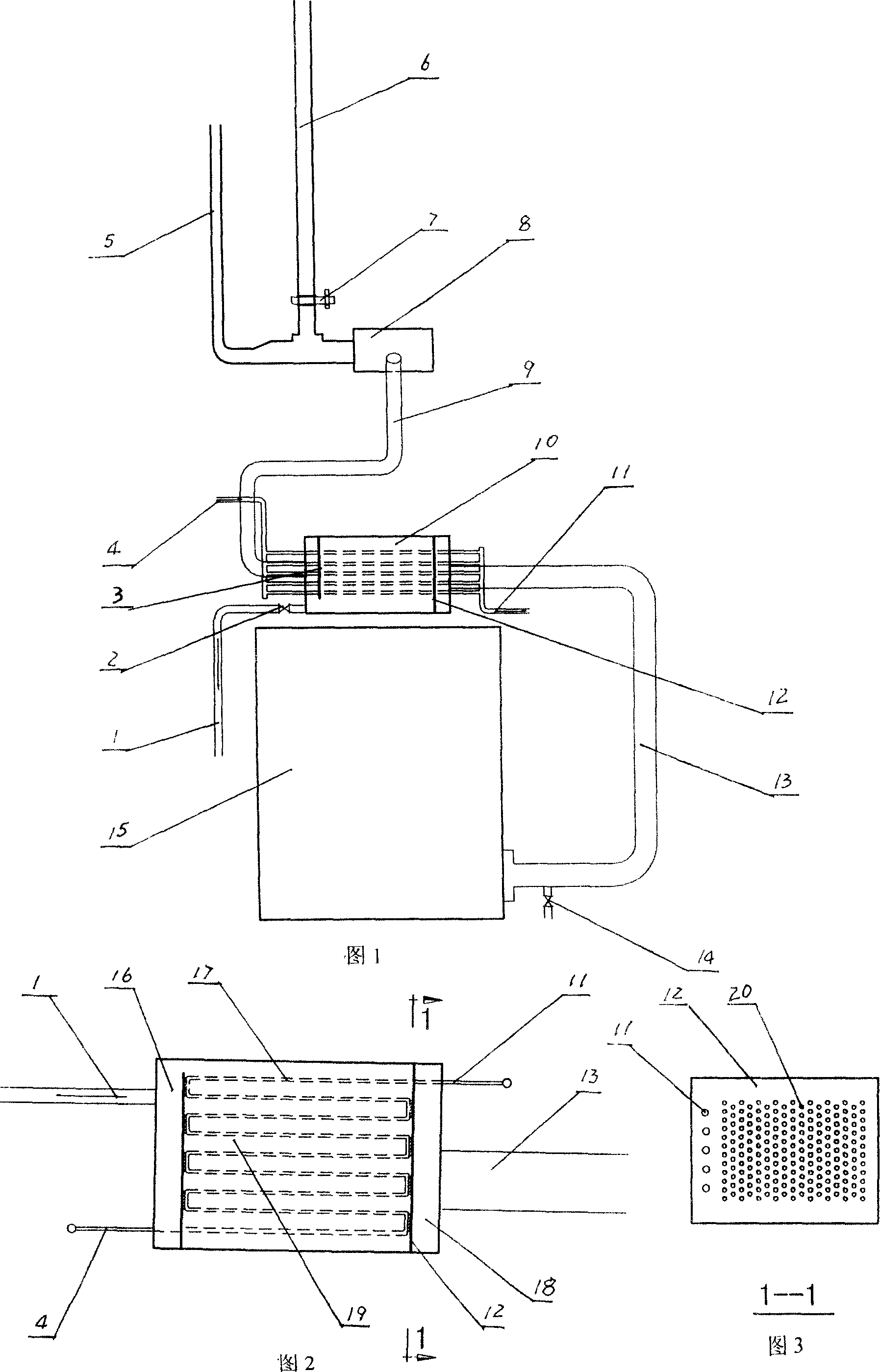

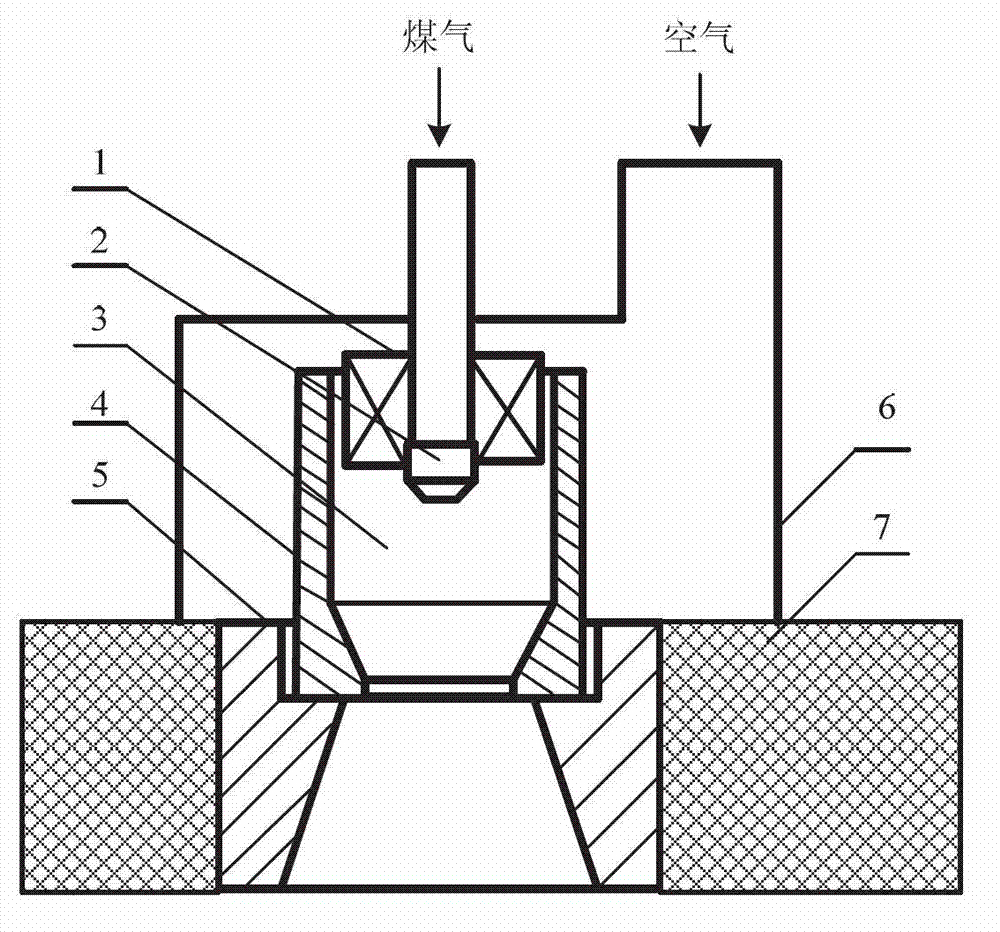

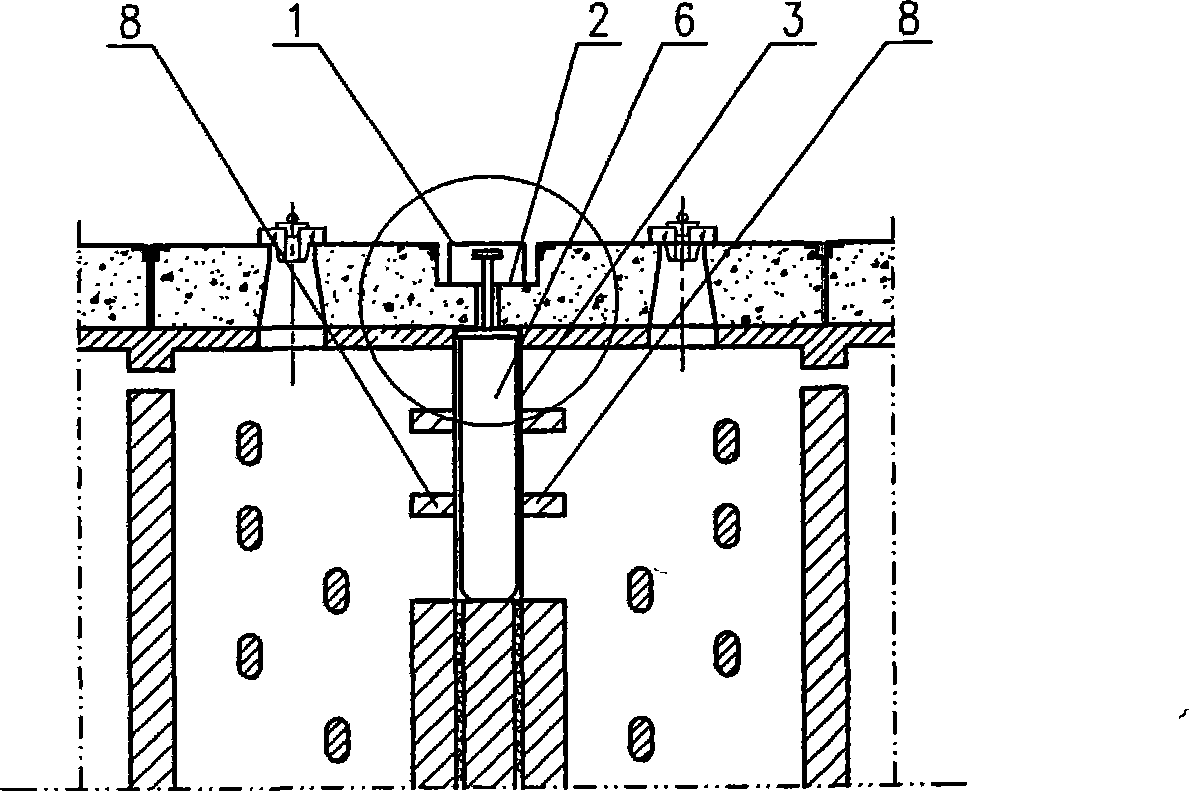

Thermal storage type oxygen-enriched combusting method and device

InactiveCN101280916AEasy to replaceCompact structureCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelFour-way valveEngineering

The invention discloses a heat accumulation type oxygen-enriched combustion method and apparatus, gas and oxygen or other gases are intensively mixed at oxygen mixing showerhead of the heat accumulation type oxygen-enriched combustor, and are sprayed into a mix gas duct arranged at center of a heat accumulation chamber, the intensively mixed gas is mixed again with combustion air pre-heated to 900-1000 DEG C at the showerhead of the combustor to combust; according to the invention, the heat accumulation type oxygen-enriched combustion apparatus comprises two heat accumulation type oxygen-enriched combustors, each of which comprises a heat accumulation chamber, a heat storage, mixture gas duct and a combustor showerhead, the heat accumulation chamber communicates with an air chamber, the air chamber communicates with a four-way valve, the oxygen mixing showerheads are separately arranged on ends of gas duct and oxygen duct. The method and device, employing the invention, have compact conformation, energy conservation, also can use low-calorie fuels as combustion air, can remarkably reduce exhaust smoke level and reduce smoke discharging temperature.

Owner:TIANJIN SAIYANG INDAL FURNACE

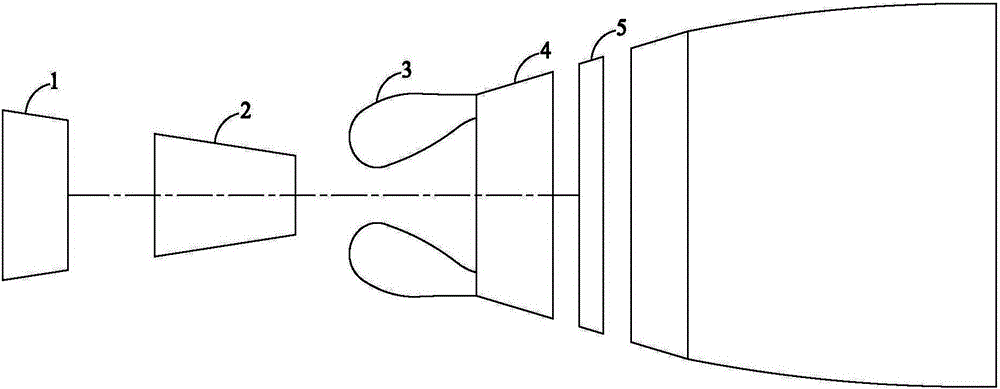

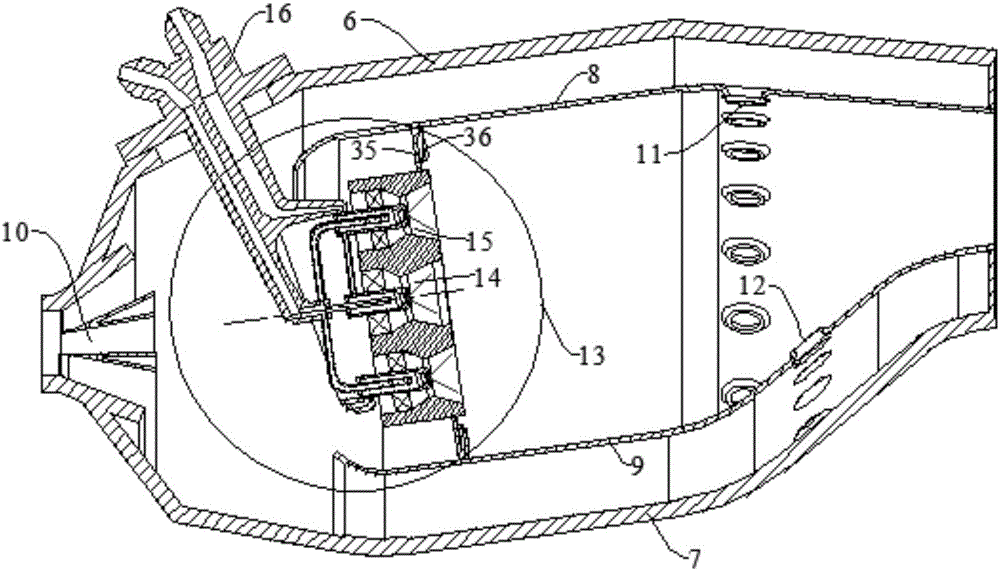

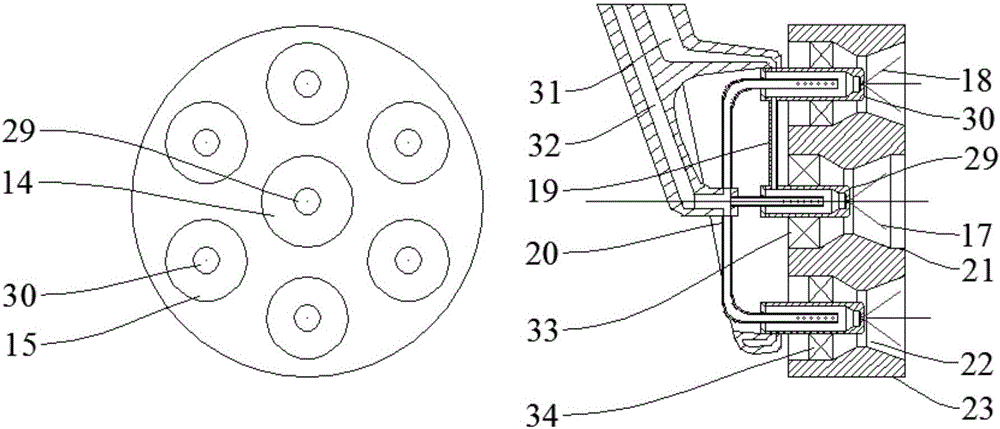

Lean direct injection low-emission combustor adopting effervescent atomizers

ActiveCN105716119AReduced risk of cokingImprove uniformityContinuous combustion chamberCombustion chamberCombustor

The invention discloses a lean direct injection low-emission combustor adopting effervescent atomizers. A single-ring cavity structure is adopted in the combustor. The lean direct injection low-emission combustor comprises a diffuser, a combustor outer case, a combustor inner case, a flame tube outer wall, a flame tube inner wall and combustor heads. Fuel oil is atomized into liquid mist which is extremely thin and extremely uniform through the multiple effervescent atomizers, and the liquid mist is directly injected into the combustor for combustion. A staged combustion structure is adopted in the combustor. A sinking design is adopted in a center precombustion stage, and the flame stabilizing function is played; and the flame is stabilized depending on the precombustion stage for primary combustion stages of the periphery of the precombustion stage, and the primary combustion stages start to work according to the needs of the working conditions. The lean direct injection technology is adopted in the low-emission combustor, the fuel oil is injected into the combustor through the multiple effervescent atomizers, and the spatial distribution uniformity of the fuel oil is increased; and the fuel oil is injected through the special effervescent atomizers, and therefore the fuel oil has the good atomizing quality, fuel oil atomizing and mixing are facilitated, distribution uniformity of the fuel oil is further increased, and the combustor has the great potential in reducing pollution emission.

Owner:BEIHANG UNIV

Process for comprehensive utilization of plant discarded matter

InactiveCN100999673AQuality assuranceHigh recovery rateBiofuelsLiquid hydrocarbon mixture productionTarEngineering

The process of comprehensively utilizing plant fibrous waste includes the following steps: depurating plant fibrous waste as material, cutting, drying, burning in a charring furnace at 200-400 deg.c, recovering the plant vinegar liquid with one recovering device connected to the charring furnace, recovering tar, discharging charred plant waste, cooling and recovering and treating the plant char. The present invention has reduced air pollution, high plant vinegar liquid recovering rate, and high plant char yield. The plant char may be used as soil improving agent and fertilizer and pesticide applying assistant.

Owner:孟知云 +1

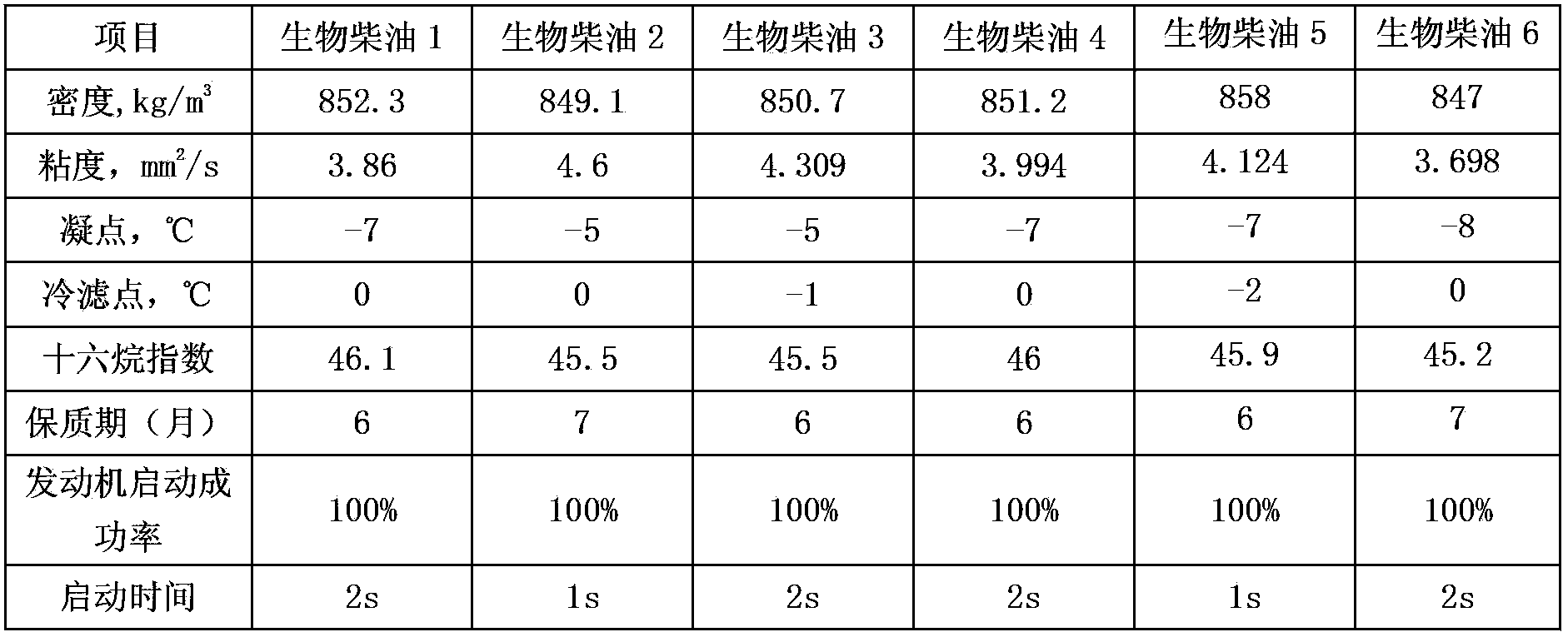

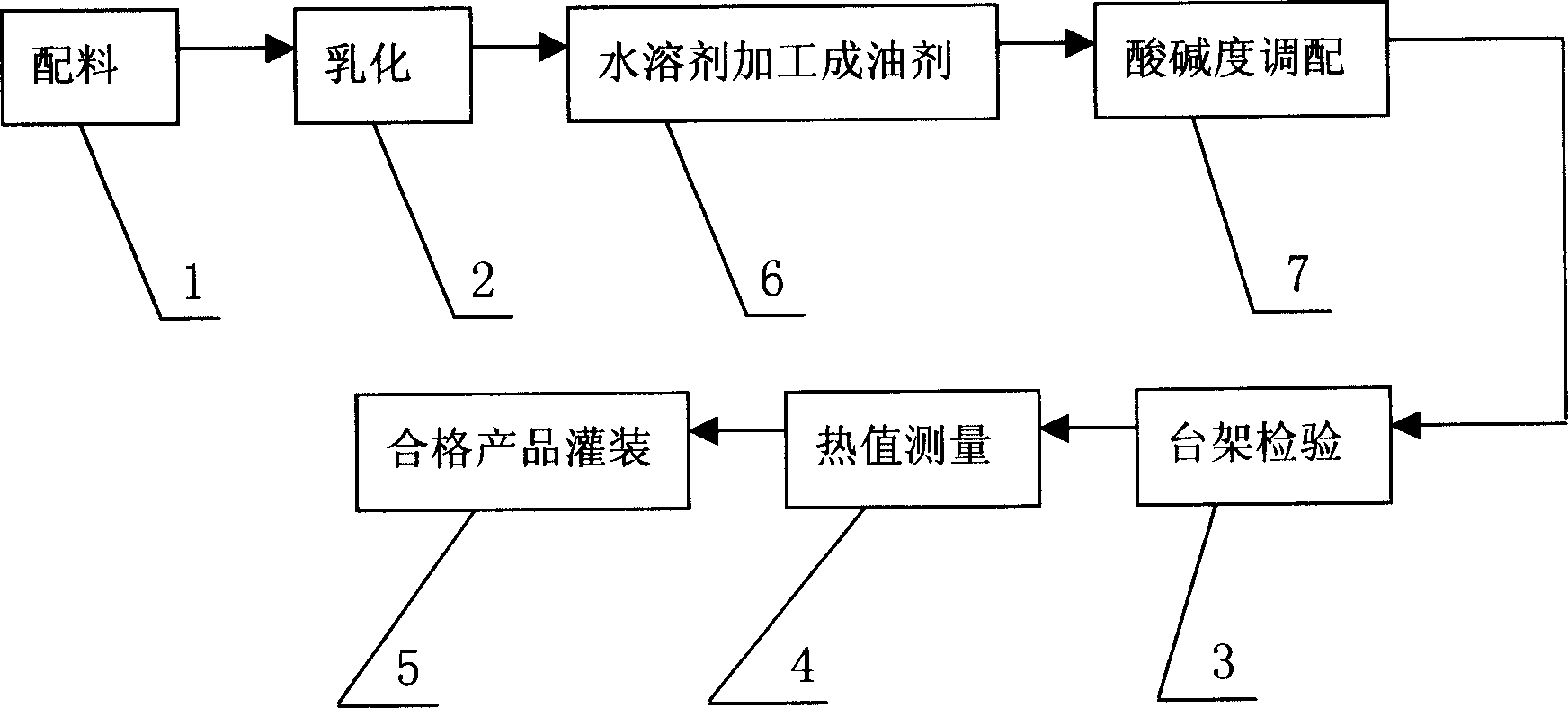

Biodiesel and preparation method thereof

InactiveCN103509611APowerfulHigh calorific valueBiofuelsLiquid carbonaceous fuelsIsobutanolAntioxidant

The invention discloses a biodiesel and a preparation method thereof. The biodiesel comprises a methanol-based fuel, an additive, and common fossil diesel. The additive is prepared from a pH value buffering pair composed of sodium petroleum sulfonate and barium petroleum sulfonate, isobutanol, tricresyl phosphate, dimethyl carbonate, an organic solvent, isooctyl nitrate, co-emulsifying dispersing agent and an antioxidant according to a certain process method. The biodiesel prepared with the method provided by the invention has the advantages of high cetane number, high flash point, low corrosion, low emission, and low cost. The biodiesel can be used for replacing common diesel in the fields such as boilers, vehicles and vessels. The biodiesel has substantial energy-saving and emission-reducing effects.

Owner:东莞恒量新能源科技有限公司 +1

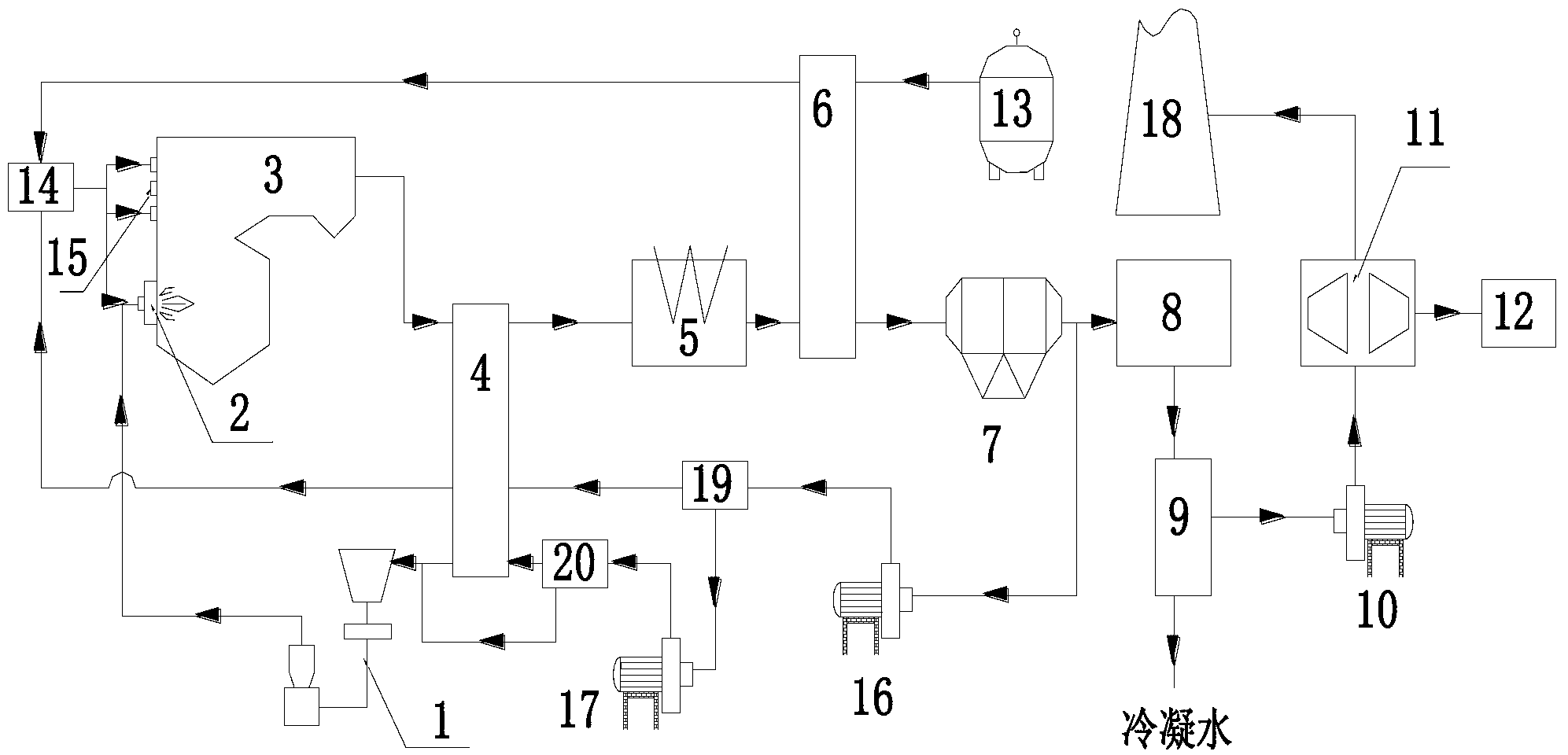

Superfine coal dust oxygen-enriched combustion technology and system

InactiveCN103234198AIncrease burnoutAlleviate the problem of slagging on the heating surfaceCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelTrappingFlue gas

The invention discloses a superfine coal dust oxygen-enriched combustion technology and system in the technical field of energy conservation and emission reduction. The technology comprises the following steps of: preparing superfine coal dust with an average particle size of less than 20 microns, and burning in an oxygen-enriched environment with overall concentration kept at 27-35% (v / v); extracting part of the hot flue gas in a flue at the rear part of a deduster; and circularly preparing superfine coal dust by taking the extracted flue gas and oxygen as combustion-supporting mediums again. According to the technology and system disclosed by the invention, the superfine coal dust is applied to the oxygen-enriched combustion technology, and the advantages of the two are effectively combined to realize an effect of using advantages and bypassing disadvantages; and the superfine coal dust oxygen-enriched combustion technology finishes efficient trapping of CO2 and is a new coal dust combustion technology with good combustion property and better pollutant discharge performance, and surely becomes an emerging technology for pollutant cooperative removal deserving vigorous promotion.

Owner:SHANGHAI JIAO TONG UNIV

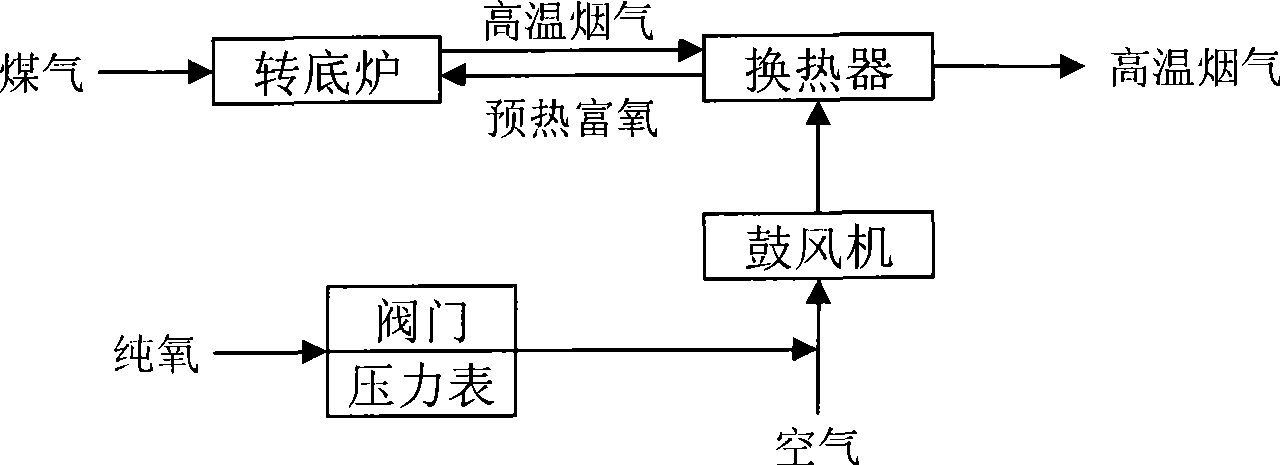

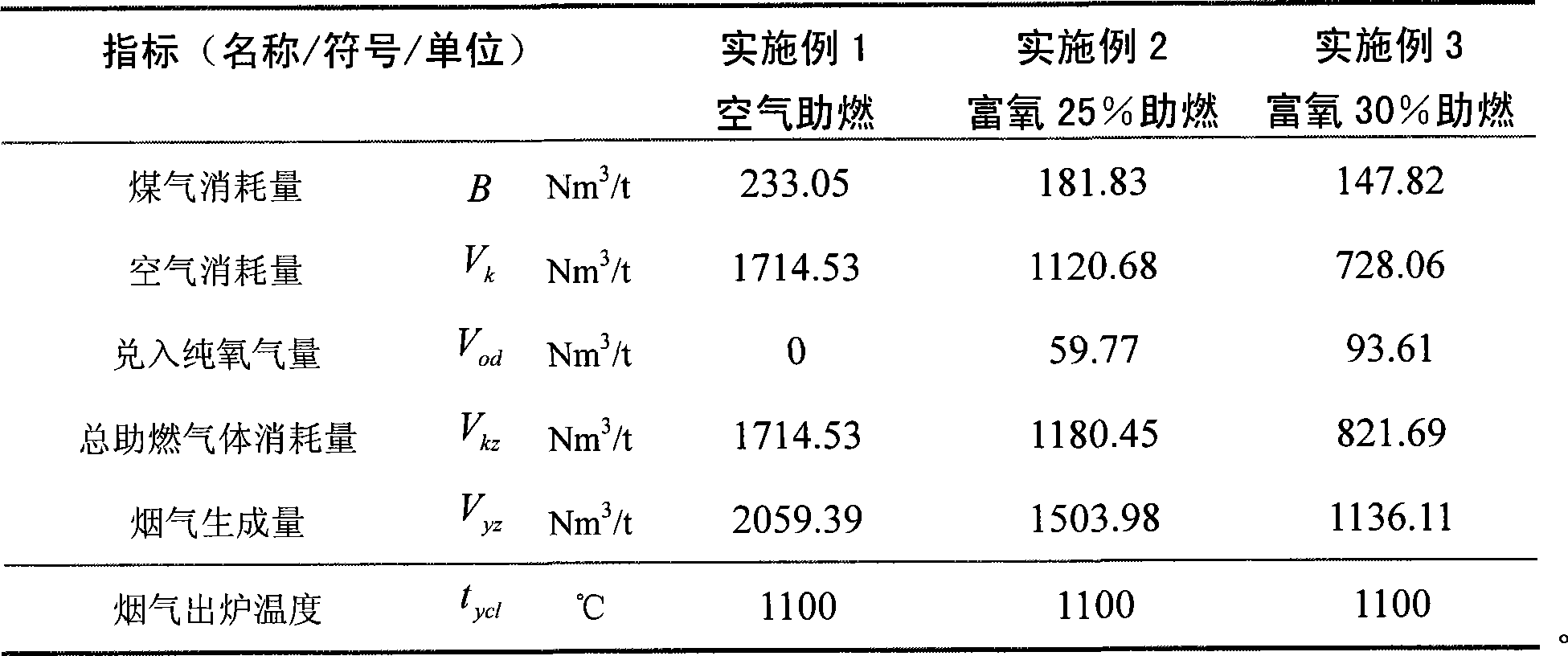

Method for manufacturing metallic pellets by direct reduction of oxygen-enriched combustion in rotary furnace

InactiveCN101445869AReduce consumptionReach the remarkable effect of saving energy and reducing consumptionProcess efficiency improvementAir blowerRotary furnace

The invention provides a method for manufacturing metallic pellets by direct reduction of oxygen-enriched combustion in a rotary furnace, which belongs to the technical field of steel industry for manufacturing metallic pellets (or direct reduction iron). The method is characterized in that oxygen enriched air is adopted as an auxiliary fuel gas; the oxygen enriched air enters a heat exchanger through a blower; and after the heat exchange between the oxygen enriched air and high temperature flue gas is performed, the temperature rises to 400 DEG C to 600 DEG C, and then the oxygen enriched air enters the rotary furnace. The invention breaks through the limitation of the prior air taking as a combustion medium and fixing the oxygen content, realizes the actual demand that the oxygen content in the combustion medium is controllable, further enhances the heat efficiency of the rotary furnace, reduces over 35% of air consumption amount, reduces over 31% of total consumption amount of the auxiliary fuel gas; and the coal gas consumption, the flue gas discharge capacity and the investment cost are reduced, and conforms to the national policy requirements of energy conservation, emission reduction and circulation economy.

Owner:LAIWU IRON & STEEL GRP

Low emission, wood fueled hydronic heater

InactiveUS20130186313A1Improve combustion efficiencyImproves resulting combustion productDamper arrangementSolid fuel combustionCombustion chamberEngineering

A wood burning hydronic heater comprises a primary firebox into which the wood is loaded and wherein initial combustion occurs. The heater also includes a secondary combustion chamber below the primary firebox into which the combustible gases from the primary firebox are forced and into which a fresh air stream is passed to burn the gases. A primary heat exchanger downstream of the secondary combustion chamber is adapted to reduce the temperature of the exhaust exiting from the secondary combustion chamber. A catalytic combustor, located in a chamber downstream of the secondary combustion chamber and primary heat exchanger, completes combustion and reduces emissions.

Owner:HAWKEN ENERGY

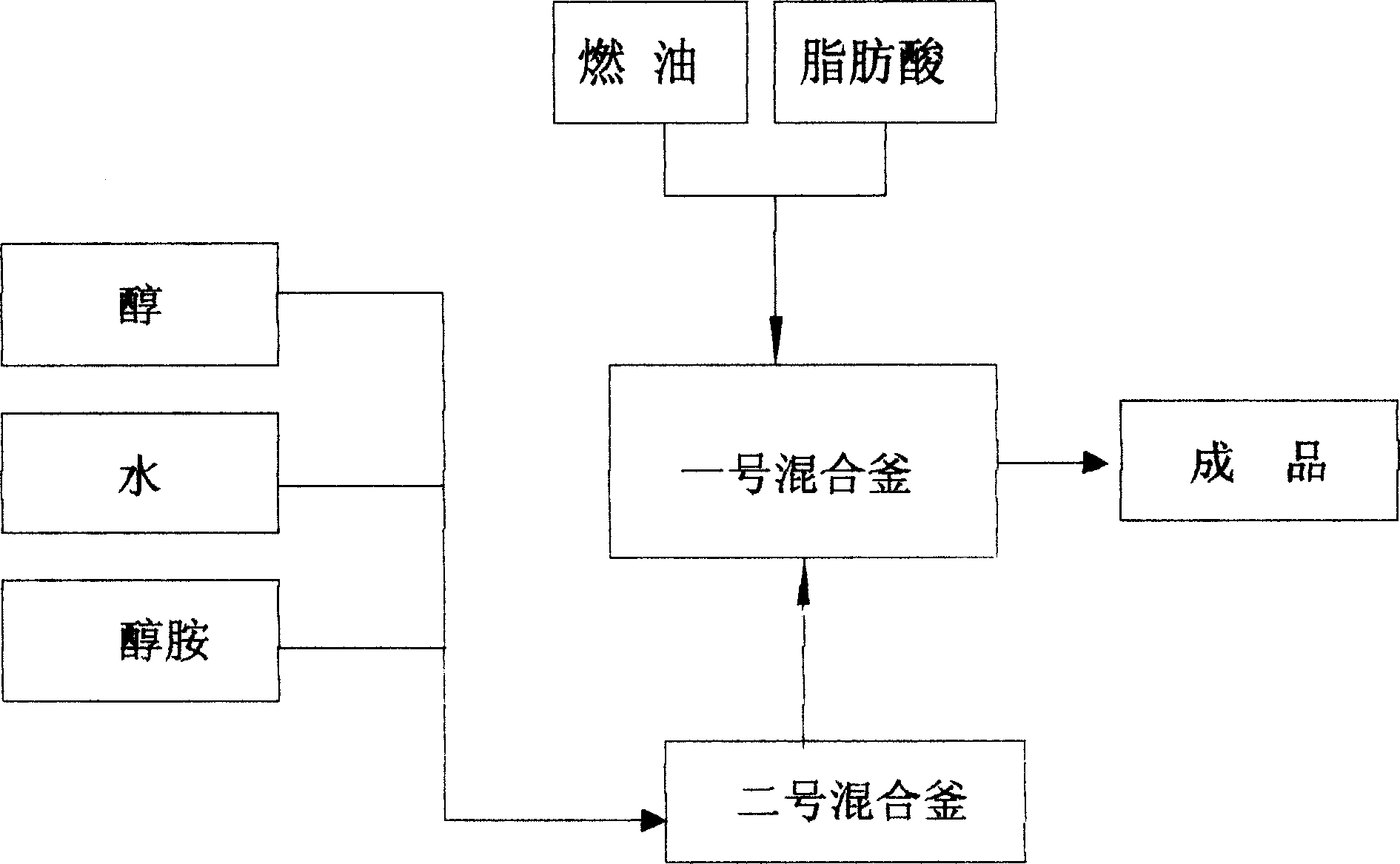

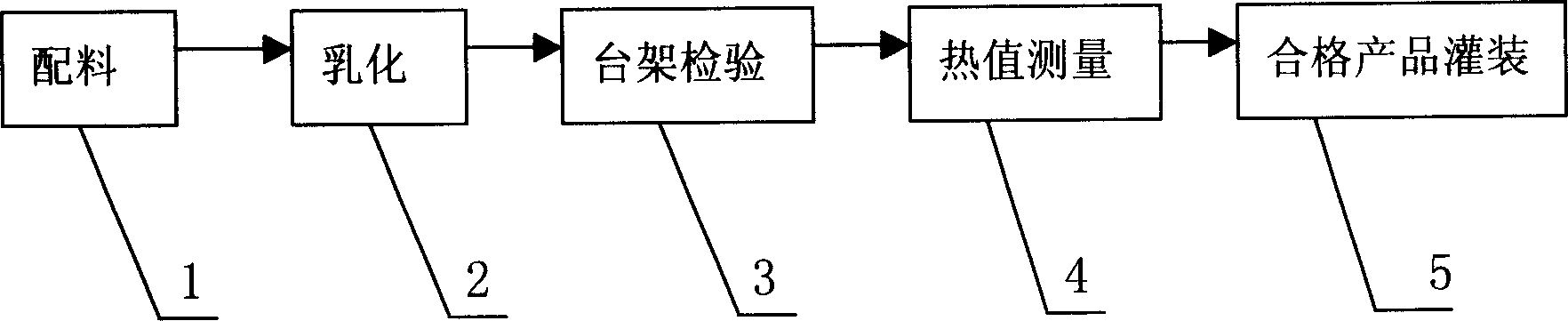

Method for producing microemulsified fuel oil

InactiveCN1632067AWide variety of sourcesLower operating temperatureRefining by water treatmentSocial benefitsAlcohol

The invention belongs to fuel oil field, especially a method for producing micro emulsive fuel oil, include the following steps: mix fatty acid and duel oil in general temperature and pressure by a certain ratio, which is mixing water alcohol and alcohol amine in general temperature and pressure by a certain ratio, then stir the mixture to be transparent brown liquid the micro emulsive fuel oil; fatty acid can be waste produced to be by squeezing of oil of soybean, peanut, rape seed or cotton seed. It has simple technique and equipment, heat value of 9000-9300 cal, cost decreased by 15-20%, smoke drainage decreased by 60%, harmful gas decreased by 50%, compared with the general one, making good used of waste produced by squeezing of oil of soybean, peanut, rape seed or cotton seed, it has remarkably high economic benefit as well as social benefit.

Owner:季忠

Diesel oil additive and its preparation method

InactiveCN103911191AReduce displacementCO reductionLiquid carbonaceous fuelsOil additiveSurface-active agents

The invention provides a multiple-component combined diesel oil additive and its preparing method, the diesel oil additive includes, on the basis of 100 parts by weight, 5 to 78 parts by weight of oleic acid; 5 to 88 parts by weight of methanol or ethanol or a mixture thereof; 1 to 31 parts by weight of a surface active agent; 1 to 42 parts by weight of a modified additive and 0 to 73 parts by weight of industrial water which is added according to the concrete application. New a multiple-component biodiesel can be obtained by adding of the additive into conventional fossil diesel, a methanol modified complex or their mixture, and the biodiesel has the advantages of high cetane number, high flash point, low condensation point, low cold filter plugging point, low corrosion, low emission and low cost.

Owner:US ENERGY INC

Fuel oil blending additive and preparation method thereof

InactiveCN103509615APowerfulHigh calorific valueLiquid carbonaceous fuelsFuel additivesFuel oilCold filter plugging point

The invention provides an additive for blending fuel oil. The additive comprises an emulsifier formed by complexing a Span-series emulsifier and a Tween-series (or OP-10) emulsifier, a pH value buffering pair formed by combination of sodium petroleum sulfonate and barium petroleum sulfonate, tricresyl phosphate, isooctyl nitrate, a co-emulsifying dispersing agent, an antioxidant, isobutyl alcohol and an organic solvent. The additive is prepared according to certain content and a certain preparation method. The additive can be used for blending methanol, methanol-oleic acid mixture, and other methanol modified complex into a biological fuel oil, and can be used for further blending biodiesel. The blended biological fuel oil and the biodiesel have the advantages of high cetane number, high flash point, low pour point, low cold filter plugging point, low corrosivity, low emission, and low cost.

Owner:刘粤荣 +1

Low-carbon fuel oil and preparation method thereof

InactiveCN103484172APowerfulHigh calorific valueBiofuelsLiquid carbonaceous fuelsIsobutanolAntioxidant

The invention discloses a low-carbon fuel oil and a preparation method thereof. The low-carbon fuel oil comprises methanol or a modified complex thereof, and an additive, and the additive is prepared through a certain process of an oleic acid-Span series-Tween series (or OP-10) compounded three-in-one emulsifier, a sodium petroleum sulfonate and barium petroleum sulfonate combined pH buffer pair, isobutanol, tritolyl phosphate, an organic solvent, isooctyl nitrate, an emulsification dispersion aid and an antioxidant. The low-carbon fuel oil prepared through the method has the advantages of high cetane number, high flash point, low corrosivity, low emission and low cost, can be compounded with or dissolved in routine diesel oil for use, can be used in the fields of boilers, cars and boats by substituting the routine diesel oil, and has substantial energy saving and emission reduction effects.

Owner:东莞恒量新能源科技有限公司 +1

Physical generating apparatus for fuel-oil additive

InactiveCN101070487ALow viscosityReduce surface tensionHydrocarbon oils refiningSupersonic wavesPhysical chemistry

The invention relates to a multiple physical technical disposal device which coul provide activated material and energy to fuel. It adopts four physical techniques which includes magnetization, fluctuation, supersonic wave and far infrared ray to deal with fuel, and makes physical oil adjunct. After dealed, put it with oil together, resonate with oil molecule, decrease the condensation, and the oil molecule crystalline constitution metamorphosis, then the oil viscidity and surface tension decline. The mixed mass of fuel and air increases, the air factor decreases, the burning velocity of oil, the temperature of burning area, and the viscidity of complete burning increase, ehile on the other hand, disposed fume decreases, the coking of spray nozzle is eliminated. Thus, the flow ability, flammability, cleaning ability are improved.

Owner:姜国常

Liquid combustion adjuvant for coal

The present invention discloses combustion promoter, and is especially one kind of liquid coal combustion promoter. The liquid coal combustion promoter is constituted with loosening agent, catalyst, oxidant, sulfur fixing agent, reinforcer, etc; and is prepared through dissolving sodium chloride, potassium nitrate, potassium permanganate, calcium chloride, sodium carbonate and cerium nitrate in water. It is suitable for bituminous coal, lignite, old coal, etc. and can reach one 20-30 % raised heat effect, coal saving effect and pollution reducing effect.

Owner:李德本

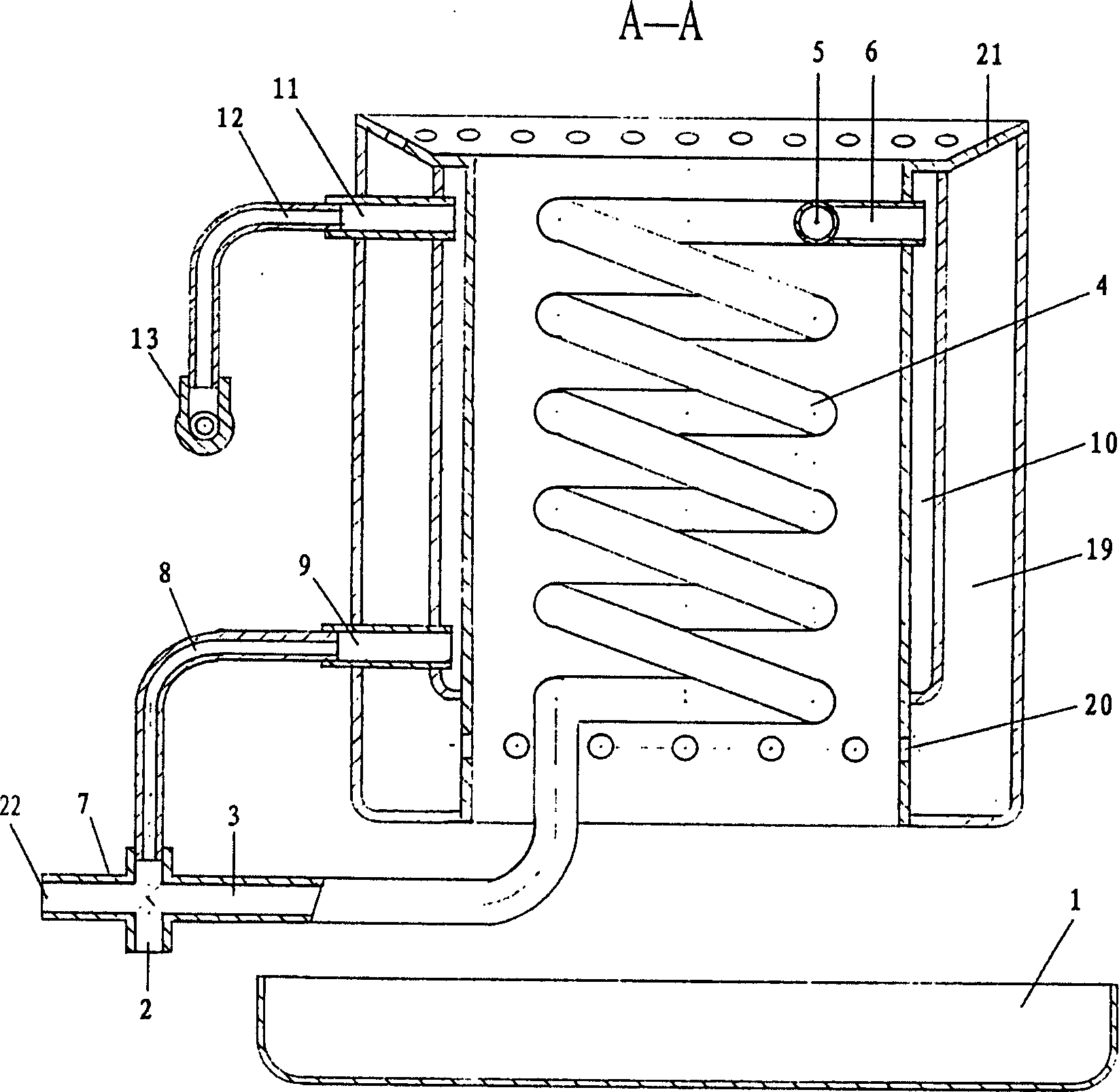

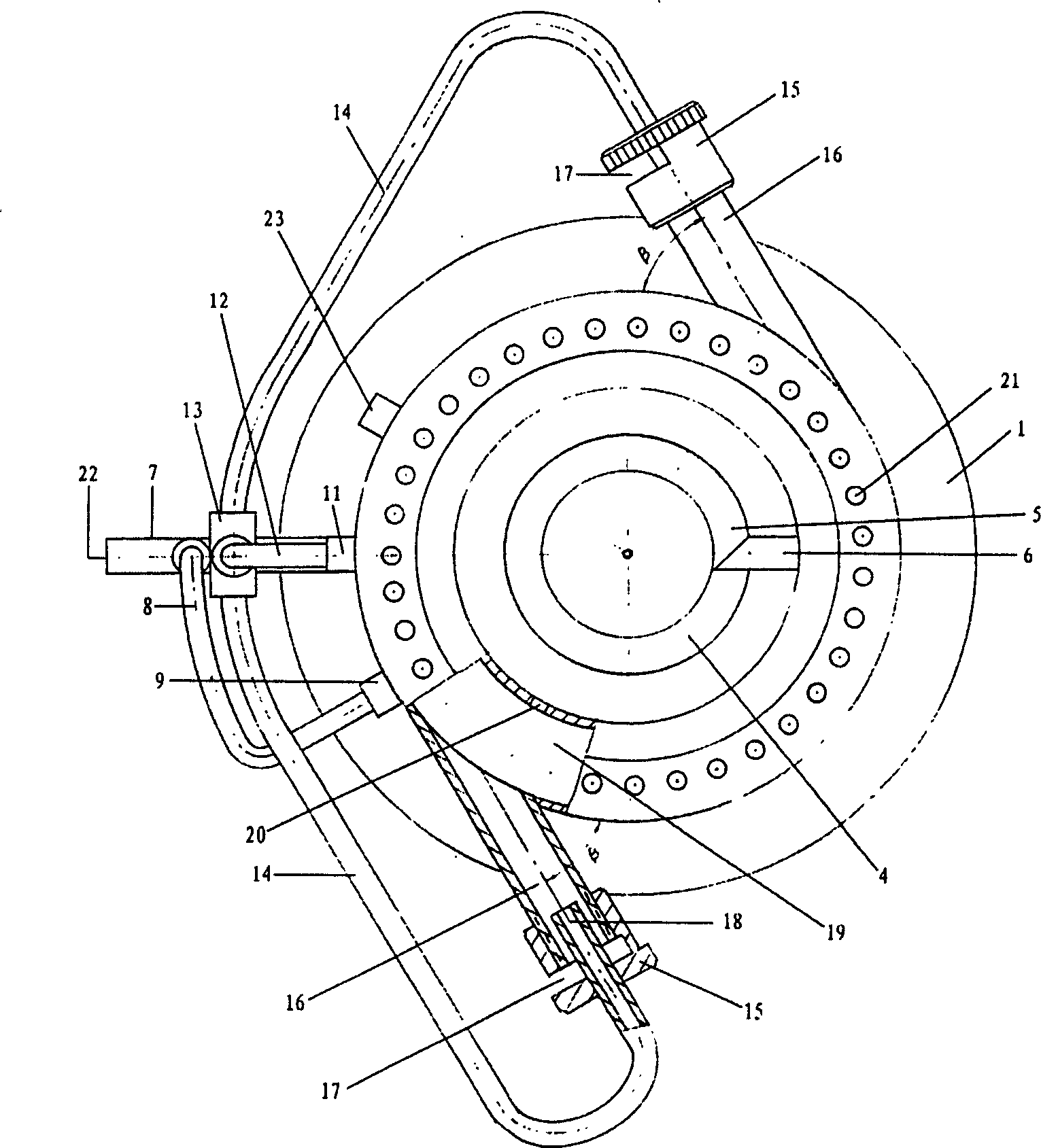

Liquid fuel evaporation and combustion furnace head

InactiveCN1594984AReduce noiseReduce smoke emissionsBurnersDomestic stoves or rangesEngineeringCooling fluid

This invention discloses a vaporizing furnace head using liquid fuel, including the inlet of liquid fuel, the preheating spiral pipe, the upper inlet of the vaporizing chamber, the vaporizing chamber, the outlet of the vaporizing chamber, the spout of burning gas, the regulating cap of air inlet, the air absorbing pipe, the allocating chamber of swirl flow and mixture air, the cooling fluid pipe, the lower inlet of the vaporizing chamber. Its characteristics are: the vaporizing chamber has the upper and the lower inlets, the vaporizing chamber connects with the spout through the outlet and the guiding pipe, the spout crosses the center hole of the regulating cap and inserts into one end of the air absorbing pipe, the other end of the absorbing pipe connects with the outer wall of the allocating chamber. This invention does not need the exterior wind machinery, and realizes more than 50 kw burning power under the working conditions of low noise, low exhaust and non splash. It is suitable for the kitchen ranges of the hotel, the minitype kitchen range, and other burning equipment.

Owner:郭建忠

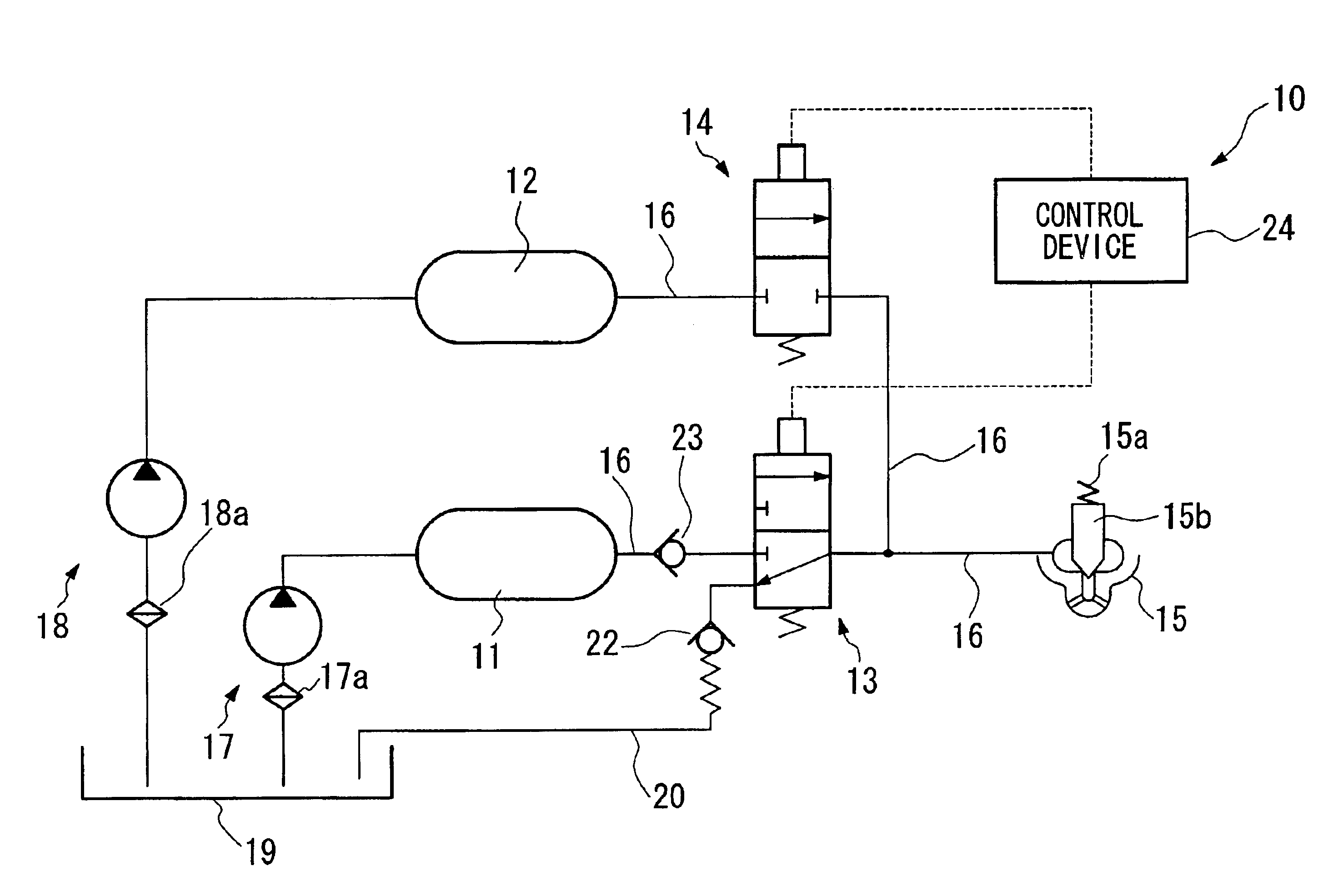

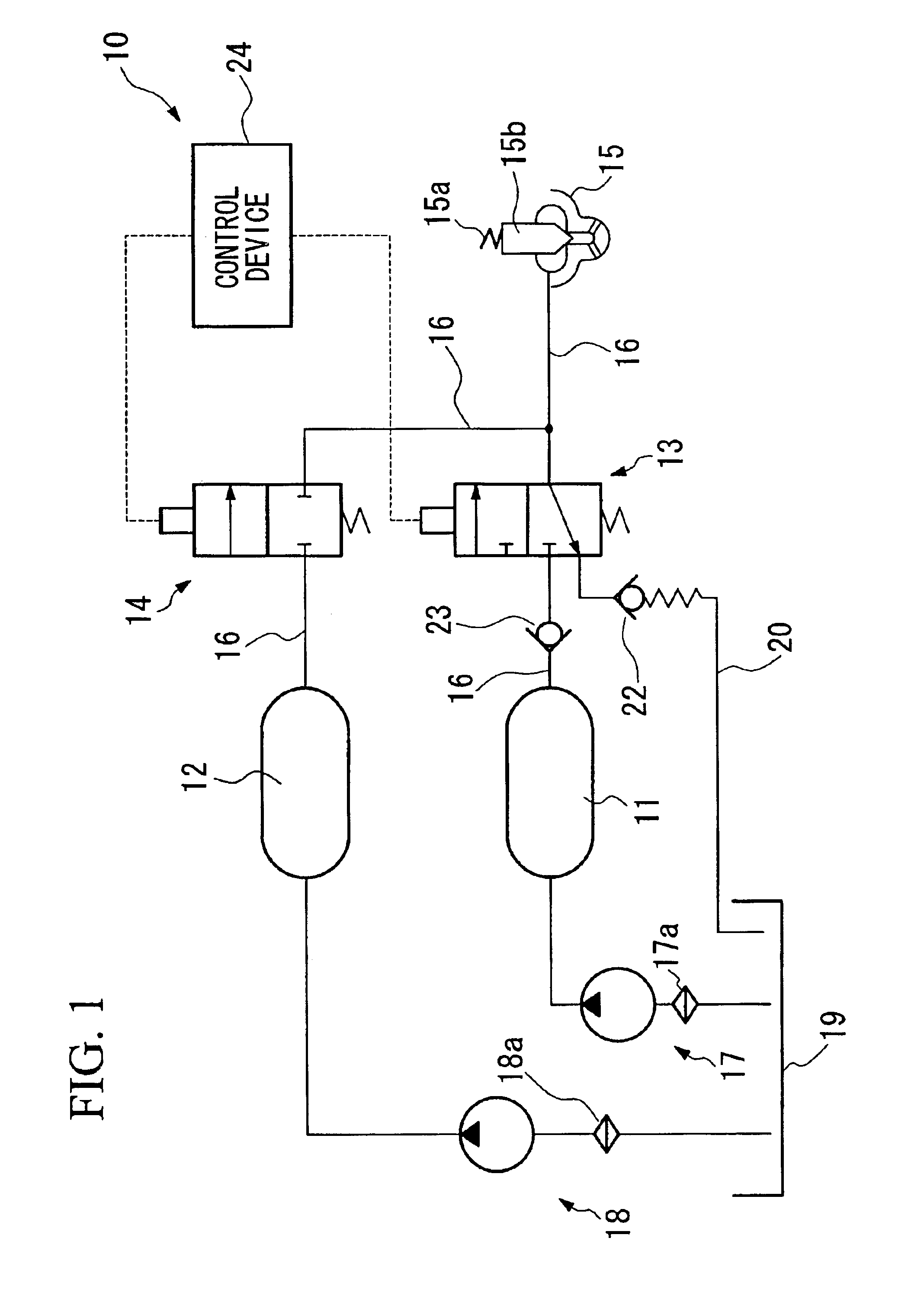

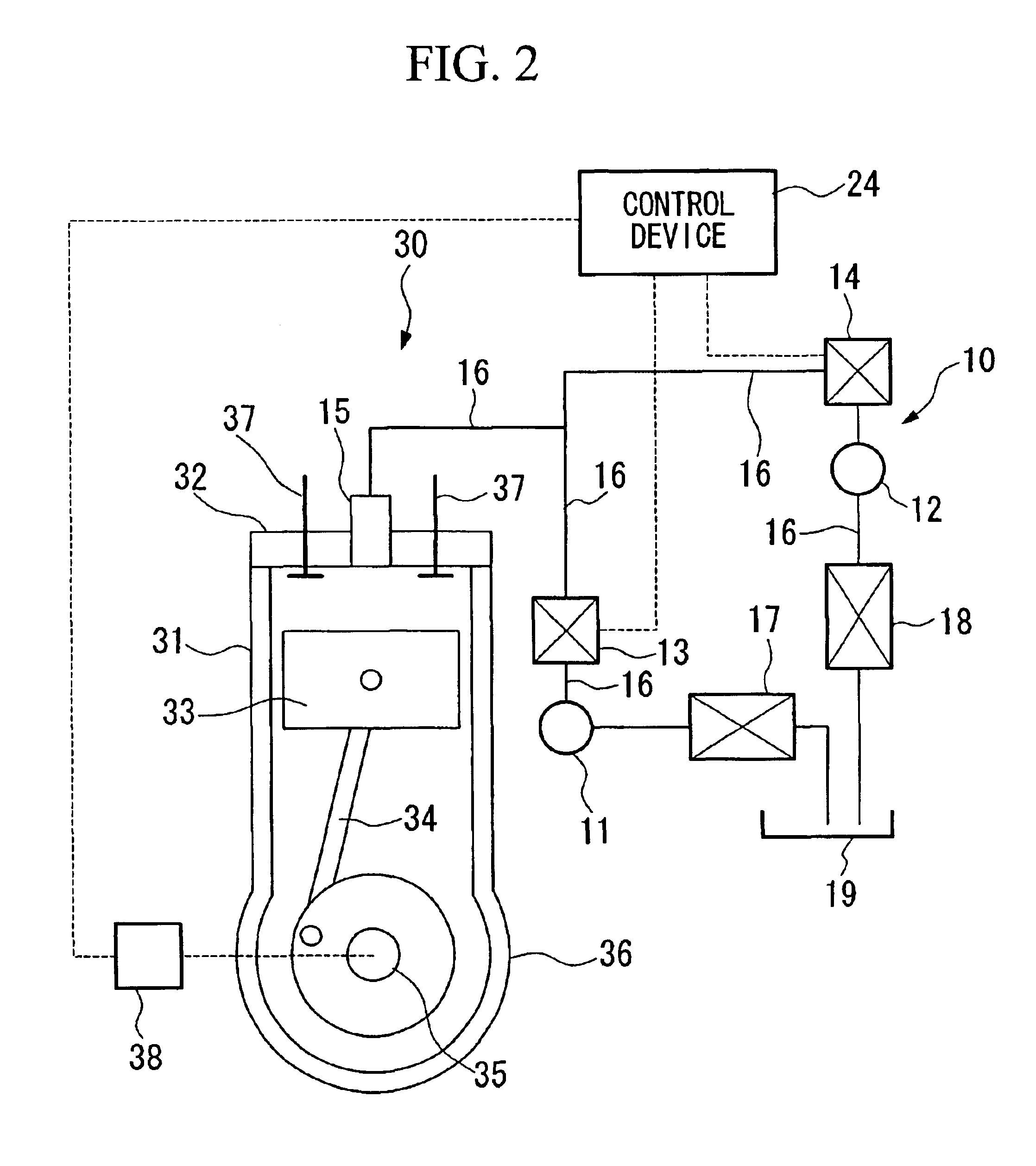

Fuel injector and diesel engine comprising the same

InactiveUS6895937B2Reduce smoke emissionsDecrease of NOxMachines/enginesFuel injection with fuel accumulatorsLow loadEngineering

A fuel injector can reduce the smoke emissions generated during low load and decrease NOx during high load. The fuel injector comprises a first accumulator for accumulating a pressurized fuel, a second accumulator for accumulating a fuel having a higher pressure than the pressure of the fuel in the first accumulator, fuel injection valves to which the fuel from the first and second accumulators is supplied and thereby the fuel injection valves are opened, and the fuel is injected, fuel feeding pipes for feeding the fuel accumulated in the first and second accumulators to the fuel injection valves; a first valve mechanism which is provided at the fuel feeding pipe and which opens and allows the flow of the fuel in the first accumulator to the fuel injection valves, a second valve mechanism which is provided at the fuel feeding pipe and which opens and allows the flow of the fuel in the second accumulator to the fuel injection valves, and a control device for controlling the first and second valve mechanisms. The first accumulator and the first valve mechanism, and the second accumulator and the second valve mechanism, are provided in parallel to each other to the fuel feeding pipe. In a normal injection mode, the control device makes the first and second valve mechanisms open at the same time. In an injection rate control mode, the control device makes an open timing of the first valve mechanism earlier than an open timing in the normal injection mode.

Owner:MITSUBISHI HEAVY IND ENGINE & TURBOCHARGER LTD

Clear synthetic binder

InactiveUS20110257318A1Reduce smoke emissionModerate viscosityIn situ pavingsOil/fat/wax adhesivesPolymer chemistryPetroleum

The disclosure relates to a clear synthetic binder comprising at least one oil of plant origin, at least one resin of petroleum origin and at least one polymer, the amount of oil of plant origin in the binder is greater than or equal to 10% by weight and the amount of polymer in the binder is less than or equal to 15% by weight. The clear synthetic binder according to the disclosure has a good consistency, a reduced viscosity, and suitable behaviour at low temperature and elastic properties. The disclosure also relates to a bituminous mix prepared from said clear synthetic binder, this bituminous mix is prepared at temperatures between 100° C. and 160° C., preferably between 120° C. and 140° C. and has suitable rutting resistance and water resistance.

Owner:TOTAL RAFFINAGE MARKETING

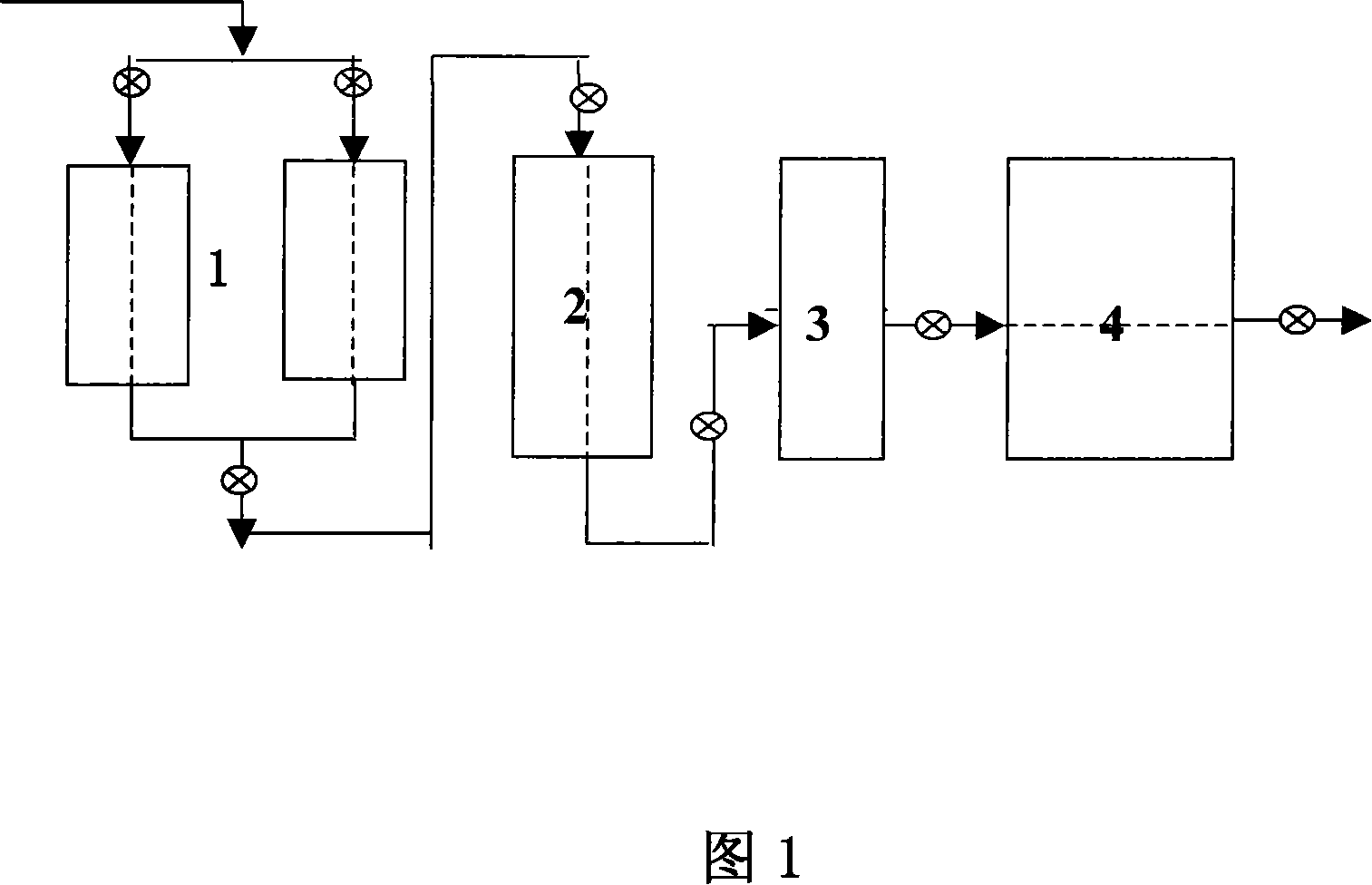

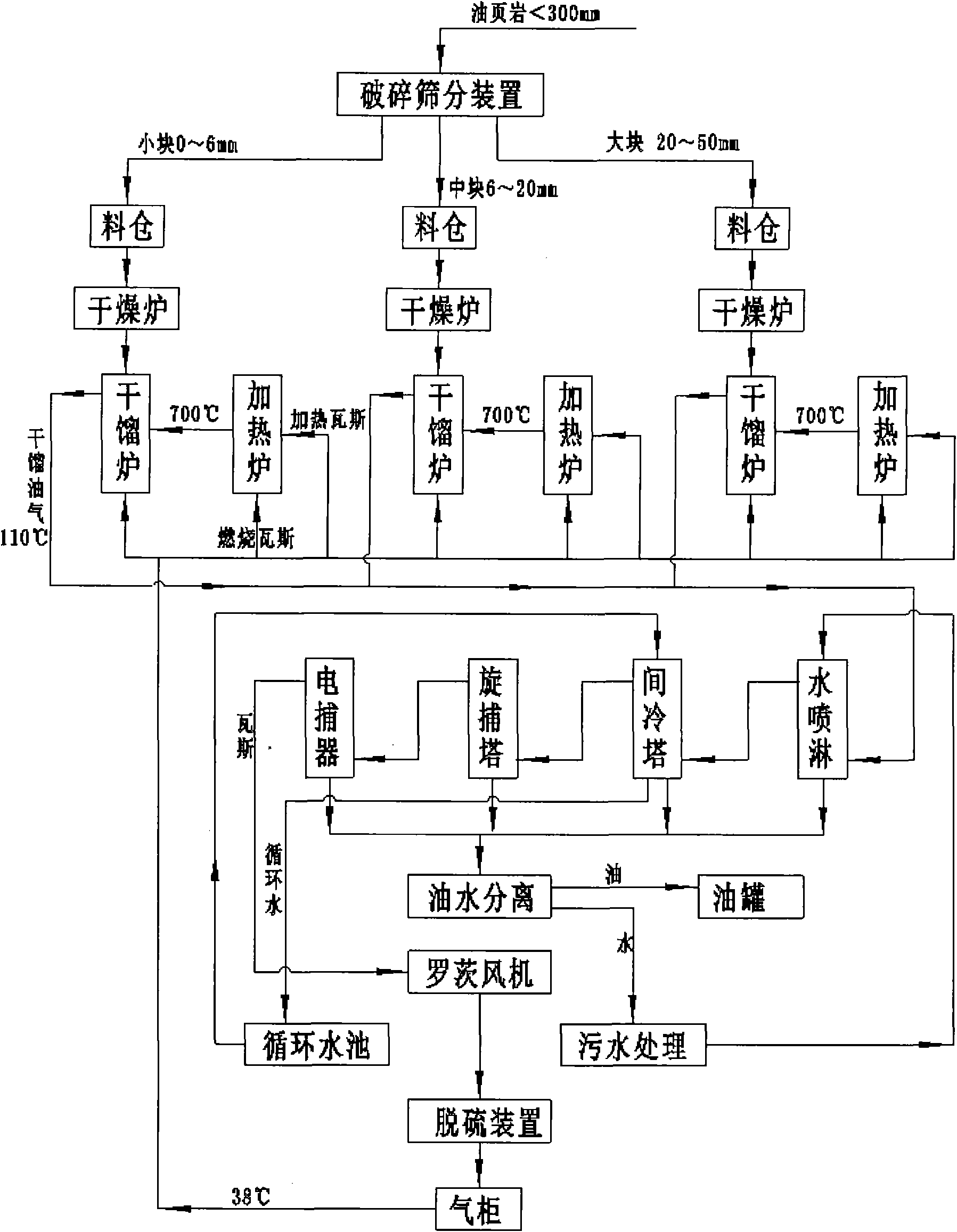

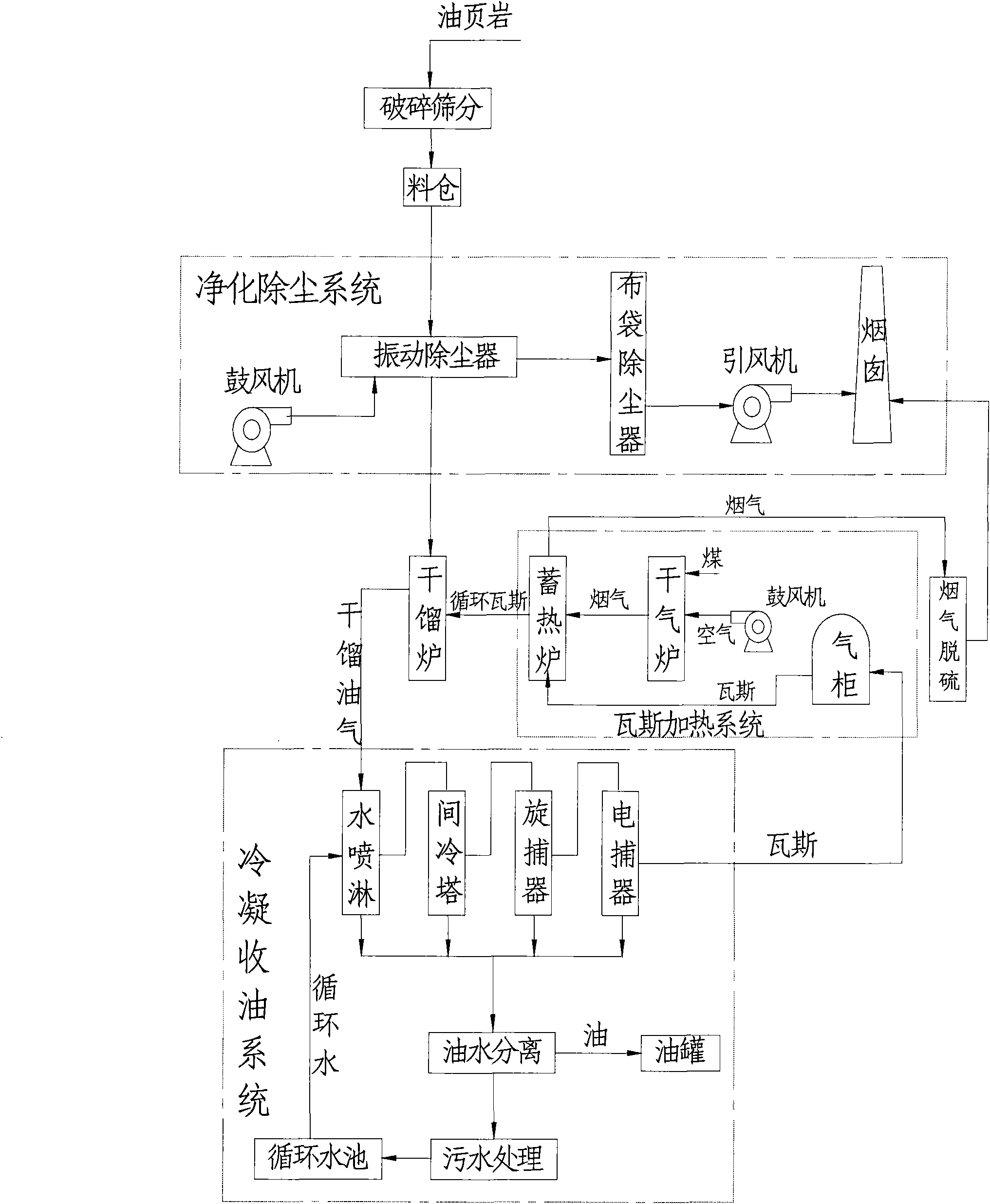

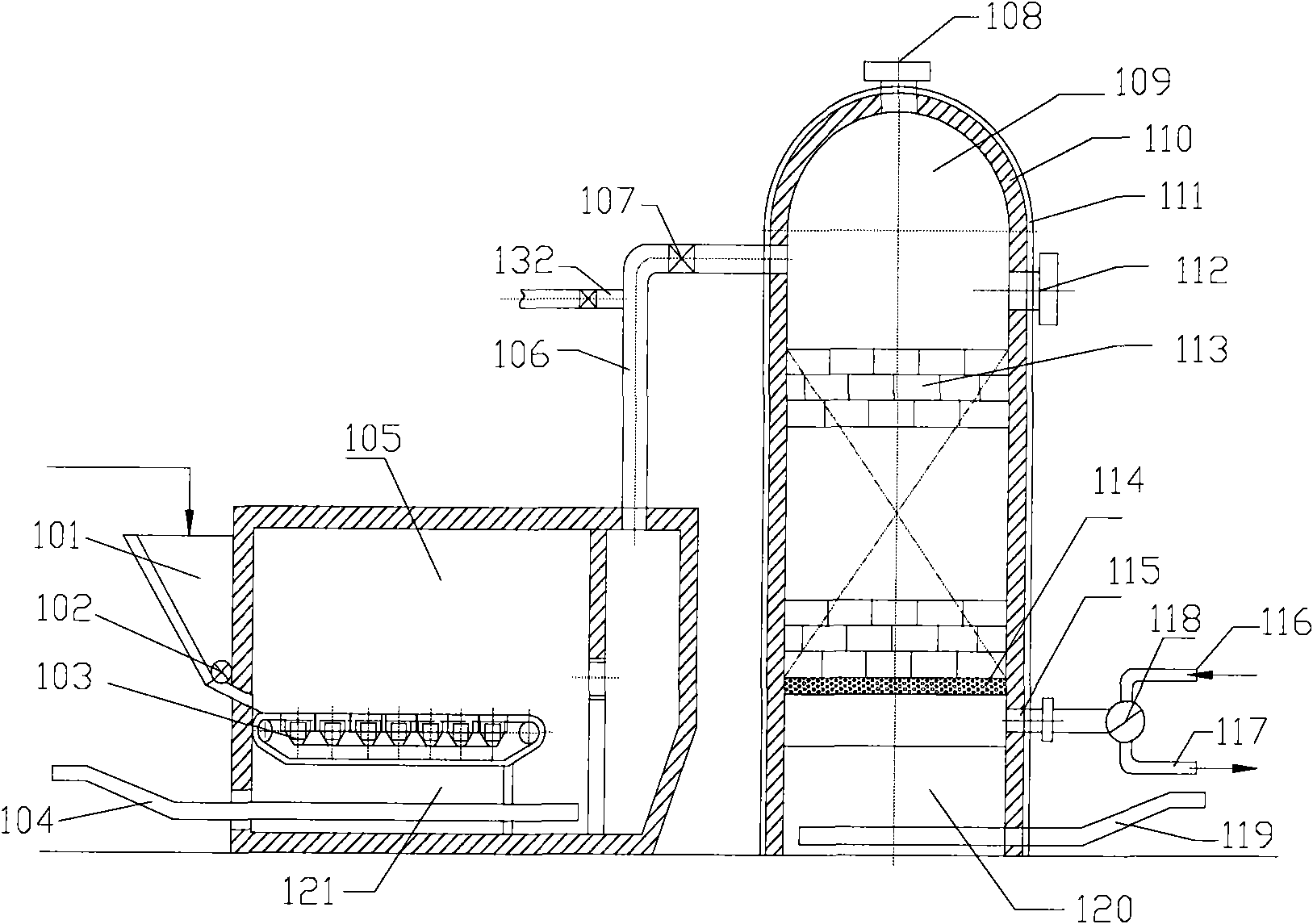

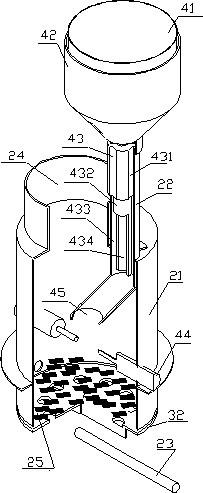

Process and device for dry distillation of oil shale with low gas content

InactiveCN102134498ALow recovery rateGuaranteed normal operationDirect heating destructive distillationSpecial form destructive distillationHeat carrierFlue gas

The invention discloses a process and a device for dry distillation refining of oil shale with low gas content, low fixed carbon content and low water content. The invention is characterized in that: tiny dust in the oil shale is removed by a vibration deduster; gas generated through dry distillation serves as a heat carrier for dry distillation refining of the oil shale; and the gas is heated and cycled by an external combustion regenerative heating furnace. The process flow comprises the following steps of: crushing and screening; grading and warehousing; purifying and dedusting; performing dry distillation refining; condensing and collecting oil; heating the gas; and desulfurizing flue gas. The device for dry distillation refining is an optimized combination of general equipment and proprietary equipment, and the oil recovery rate is over 85 percent.

Owner:吴启成

High-cleaning aged fuel

ActiveCN102373101APowerfulHigh calorific valueLiquid carbonaceous fuelsFuel additivesTert butylHeptane

The invention discloses a high-cleaning aged fuel, comprising 65-70 wt% of industrial methanol, 28-32 wt% of naphtha, and the balance consisting of an Al mixed additive, wherein, the Al mixed additive comprises burning accelerant(0.04-0.01 weight portions of ferrocene and 0.6-1.5 weight portions of methanol), lytic agent(0.1-0.4 weight portions of benzene, 0.1-0.4 weight portions of acetone, and 0.1-0.5 weight portions of n-heptane), anti-oxidant stabilizer(0.1-0.15 weight portions of 2,6-di-tert-Butyl- p-Cresol), and regulator( 0.1-0.2 weight portions of isopentane). The fuel has the advantages of strong dynamic property, little discharge capacity, lowered filter point, good universality, long reserve maintenance period and the like, and overcomes the defects that alcohol and petroleum fuels are not stable and immiscible, and the thermal efficiency of alcohol and petroleum fuels is low in the prior art.

Owner:白玉林

Low smoke rocket motor liner compositions

InactiveUS6051087AReduce smoke emissionsLow smokeNon-explosive/non-thermic compositionsPressure gas generationOxygenPolymer

A formulation is provided which is capable of performing as a liner layer between a rocket motor casing and the propellant grain disposed within the interior of the rocket motor casing. The composition produces relatively little smoke during the operation of the rocket motor and is capable of securely bonding a wide range of conventional propellants to a wide range of conventional casings. In one preferred formulation, the liner consists of from from about 50% to about 75% oxygen containing polymer; from about 3% to about 15% curing agent; from about 5% to about 50% filler and from about 0.01% to about 0.5% cure catalyst.

Owner:ORBITAL ATK INC

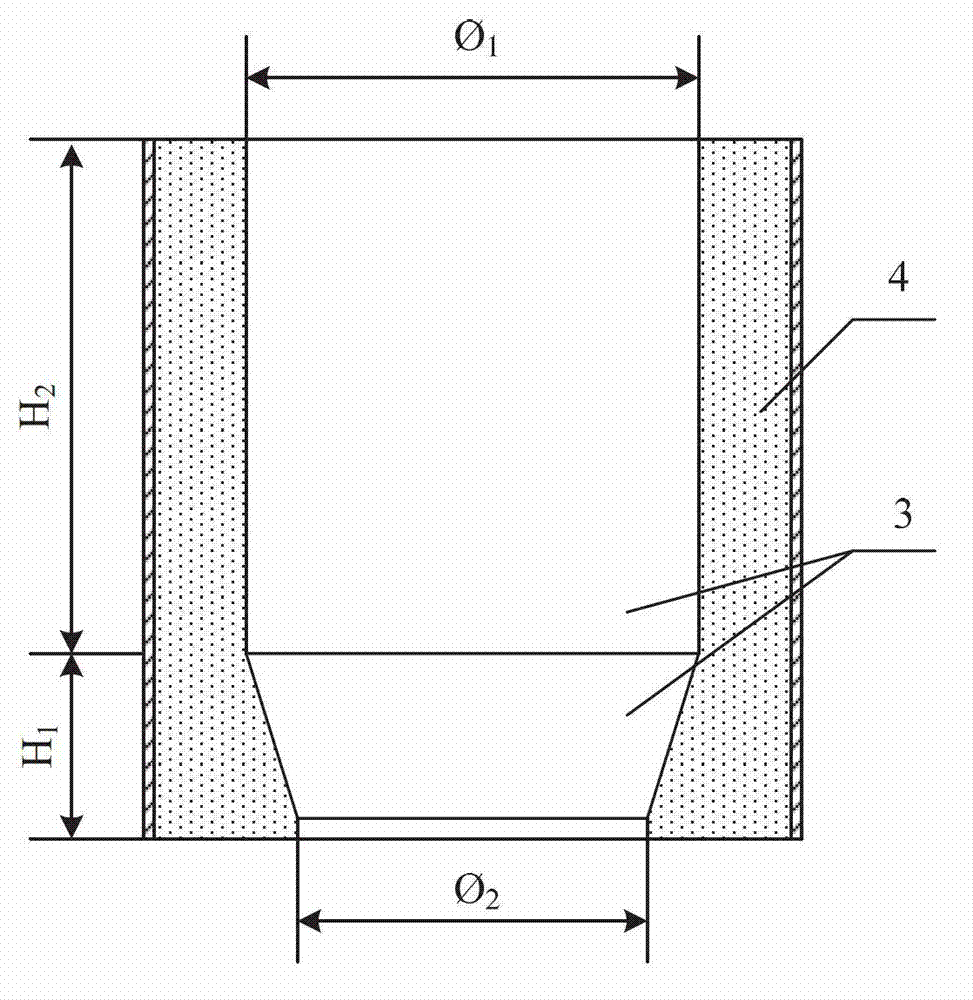

Swirling flow premixing type burner

The invention discloses a swirling flow premixing type burner. The swirling flow premixing type burner comprises a first burner brick, a second burner brick, a burning-supporting air chamber, an air swirler and a fuel gas nozzle, wherein a central hole is formed in the first burner brick; an upper section of the central hole is matched with the shape of the exterior outline and the dimension of the second burner brick; a lower section of the central hole is a cone-shaped hole with a large upper end aperture and small lower end aperture; a premixing chamber is arranged in a central part of the second burner brick; the fuel gas nozzle is a swirling flow nozzle and consists of a nozzle body and a gas inlet pipe which is connected with the nozzle body; the first burner brick is arranged on a furnace body; the second burner brick is arranged in the first burner brick; the air swirler is positioned at the inlet of the premixing chamber arranged in the second burner brick; the fuel gas nozzle is combined with the air swirler; the nozzle body of the fuel gas nozzle is positioned below the air swirler; and the burning-supporting air chamber is arranged on the furnace body.

Owner:SICHUAN UNIV

Mould-proof environmentally-friendly smokeless mosquito coil and production process thereof

InactiveCN108184830ALow VOC contentGood killing and suppression abilityBiocidePest repellentsChemical industryChemistry

The invention relates to the technical field of chemical industry, and in particular relates to a mould-proof environmentally-friendly smokeless mosquito coil and a production process thereof. The mosquito coil comprises the following the components in parts by weight: 50-60 parts of sticky powder, 20-30 parts of corn flour, 10-20 parts of starch, 20-35 parts of lignite, 20-30 parts of light calcium carbonate powder, 2-8 parts of potassium nitrate, 0.2-0.9 part of a toner, 2-5 parts of copper sulfate, and 70-80 parts of water. Compared with a traditional smokeless mosquito coil, the smokelessmosquito coil provided by the invention has a plurality of advantages that carbon powder is not added, and gases including CO which are unfavorable to human health are not generated during use; the smokeless mosquito coil provided by the invention is prepared by refining of pure natural materials, and does not pollute the environment; the copper sulfate is used as a mould inhibitor, and the coppersulfate is non-toxic and long-acting, has a low VOC content, thermal stability, and very good killing and inhibiting ability against fungi, bacteria, mould and enzymes; the lignite subjected to desulfurization and denitrification can greatly reduce the smoke discharging amount and reduce pollution to the environment; the potassium nitrate is used as a combustion improver, and can prevent the smokeless mosquito coil from being suffocated in the ignition process; and after a mosquito coil blank is subjected to compression molding and drying, secondary drying is performed, so that the smokelessmosquito coil can be effectively prevented from being cracked because heating is rapid in the drying process.

Owner:FUJIAN QUANZHOU FUDUODUO INCENSE

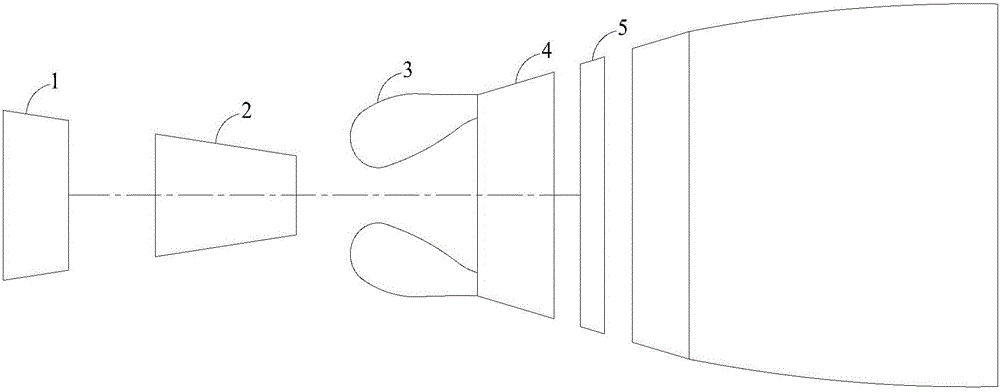

Low-pollution combustor with main combustion grade adopting effervescent atomizer

ActiveCN105823087ASimple structureImprove atomization qualityContinuous combustion chamberCombustorCombustion chamber

The invention discloses a low-pollution combustor with a main combustion grade adopting an effervescent atomizer. A single annular cavity structure is adopted. The low-pollution combustor comprises a diffuser, an outer combustor case, an inner combustor case, a flame tube outer wall, a flame tube inner wall and a combustor head. A graded combustion scheme is adopted for the combustor. The combustor head is divided into a precombustion grade and the main combustion grade. A diffusive combustion mode with stable rotational flow is adopted for the precombustion grade, and the precombustion grade serves as a stable combustion source of the combustor. A premixing and pre-evaporation combustion mode is adopted for the main combustion grade, and even combustion is facilitated. A center grading structure is adopted for the low-pollution combustor, and the precombustion grade is simple in structure; the unique effervescent atomizer is adopted for the main combustion grade for fuel oil injection, so that fuel oil has high atomization quality, fuel oil atomization and mixing are facilitated, the distribution evenness of the fuel oil is further improved, and thus pollutant discharging of whole landing and take-off (LTO) circulation of the combustor of an aero-engine is further lowered.

Owner:BEIHANG UNIV

Steel pipe as fuel injection pipe

ActiveUS20090078341A1Reduce black smoke emissionReduce carbon dioxide emissionsFurnace typesMachines/enginesInternal pressureNon-metallic inclusions

To provide a steel pipe as a fuel injection pipe with high material strength, high internal pressure limit free from fatigue failure, prolonged fatigue life, and high reliability. A steel pipe as a fuel injection pipe of 500 N / mm2 or higher tensile strength comprising, by mass, C: 0.12 to 0.27%, Si: 0.05 to 0.40%, and Mn: 0.8 to 2.0%, and the balance being Fe and impurities, the contents of Ca, P, and S in the impurities being Ca: 0.001% or less, P: 0.02% or less, and S: 0.01% or less, respectively, characterized in that the maximum diameter of nonmetallic inclusions present in at least in a region extending from the inner surface of the steel pipe to a depth of 20 μm is 20 μm or less. Further, this steel pipe may contain, in place of a portion of Fe, at least one selected from among Cr: 1% or less, Mo: 1% or less, Ti: 0.04% or less, Nb: 0.04% or less, and V: 0.1% or less.

Owner:NIPPON STEEL CORP +1

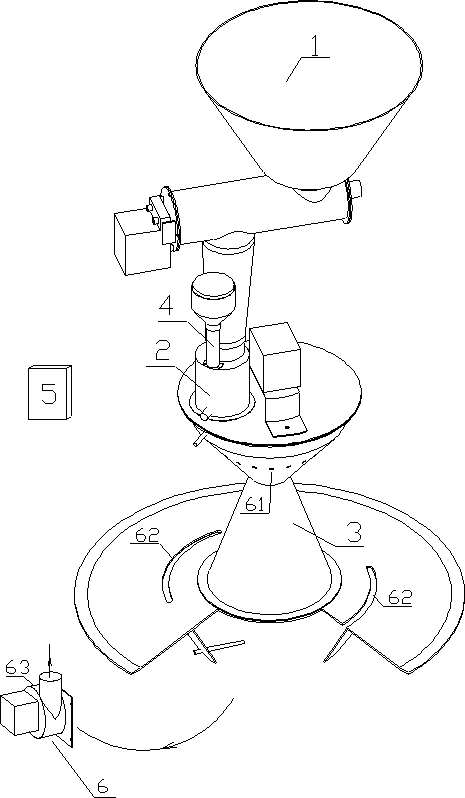

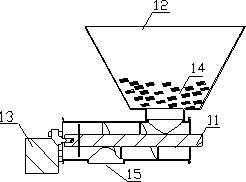

Automatic fire-leading igniting device and igniting method for biomass briquette

ActiveCN104266224ALess molding materialReduce air volumeIncandescent ignitionAutomotive engineeringBiomass briquettes

The invention discloses an automatic fire-leading igniting device and an igniting method for biomass briquette. The automatic fire-leading igniting device comprises an ignition chamber, and is characterized in that a feeding device and an ignition device are arranged above the ignition chamber, a main combustion device is disposed below the ignition chamber, and a smoke discharge device is mounted on one side of the main combustion device. According to the automatic fire-leading igniting device and the igniting method for the biomass briquette, ignition of the biomass briquette is divided into ignition of leading fire and ignition of main fire, a fire-leading material is ignited and then a main material is ignited, forming materials are few during ignition of leading fire, the passing air amount is small, reliably rapid ignition can be achieved, ignition energy consumption is reduced, and smoke discharge amount and dust content are reduced.

Owner:济南长城空调公司

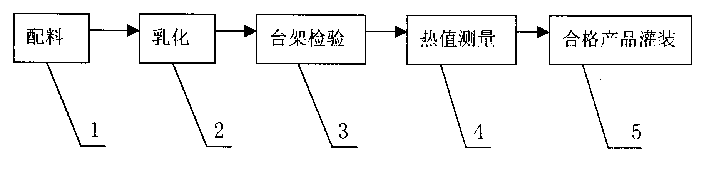

Liquid cleaning environmental-protection diesel fuel and preparation method thereof

ActiveCN103627448AAvoid discharge pollutionQuality improvementLiquid carbonaceous fuelsLiquid fuelEnvironmental engineering

The present invention relates to an efficient environmental-protection liquid fuel, particularly to a liquid cleaning environmental-protection diesel fuel and a preparation method thereof. The liquid cleaning environmental-protection diesel fuel is prepared from the following raw materials according to a certain weight ratio, wherein the optimal weight ratio of oleic acid to methanol to methylal to water to ammonia water to n-butanol to dimethyl carbonate is 40%:20%:10%:8%:8%:6.5%:7.5%. The preparation steps comprise: 1, selecting methanol, methylal and water, pouring into oleic acid to mix, and then adding ammonia water; 2, completely mixing the components in the step 1, and carrying out a static reaction for 5 min to spare; 3, selecting n-butanol and dimethyl carbonate, and carrying out a mixing reaction to spare; 4, adding the mixture obtained in the step 2 to the mixture obtained in the step 3, carrying out slight stirring for 10-20 min, taking 50% of the obtained solution to spare; and 5, mixing any one material selected from 0# international diesel fuel, -10# international diesel fuel and -20# international diesel fuel and the solution, and carrying out slight stirring for 10-20 min to obtain the liquid cleaning environmental-protection diesel fuel. The liquid cleaning environmental-protection diesel fuel has characteristics of strong power, low emission, wide application range and long shelf life.

Owner:杨戈坪

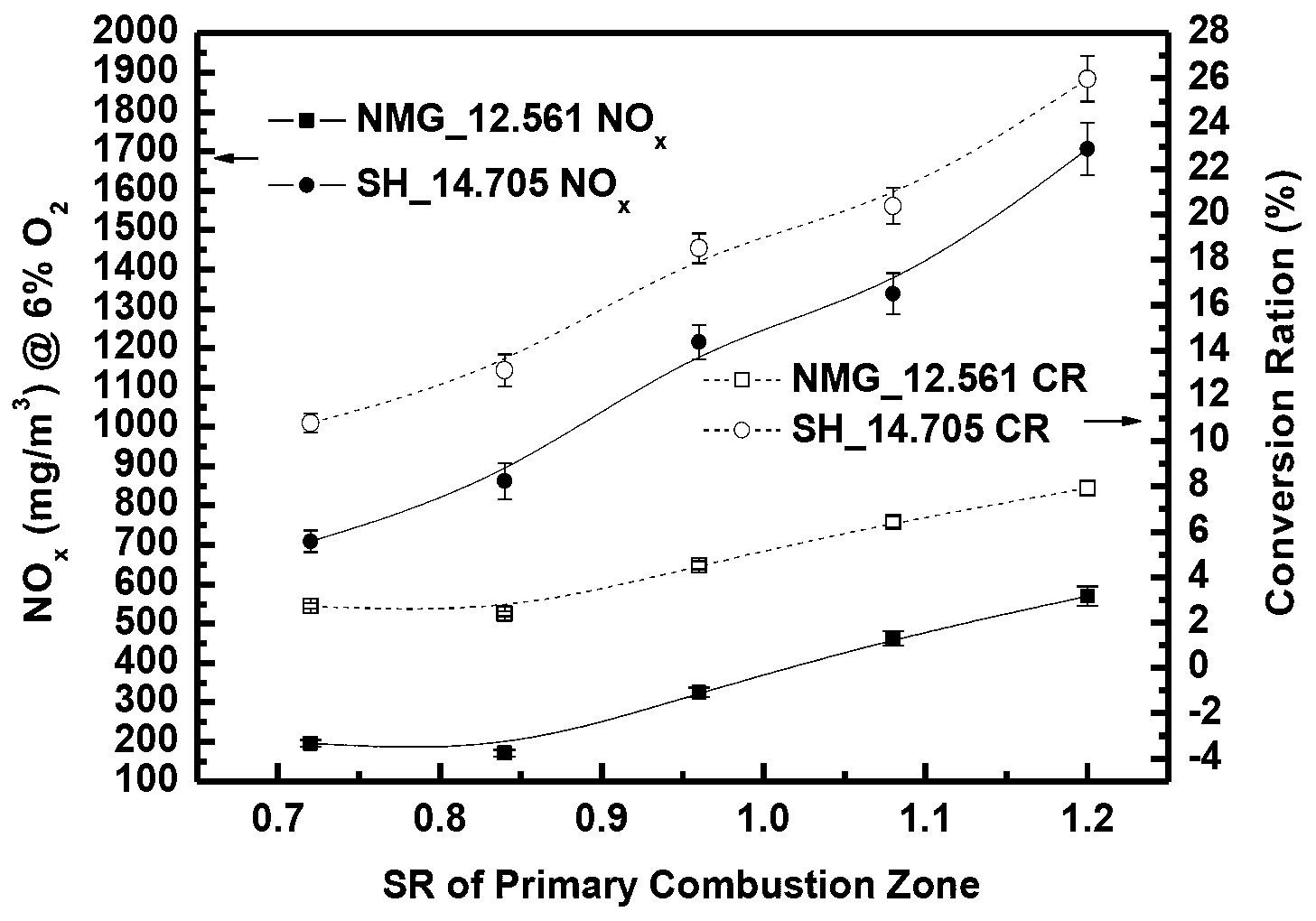

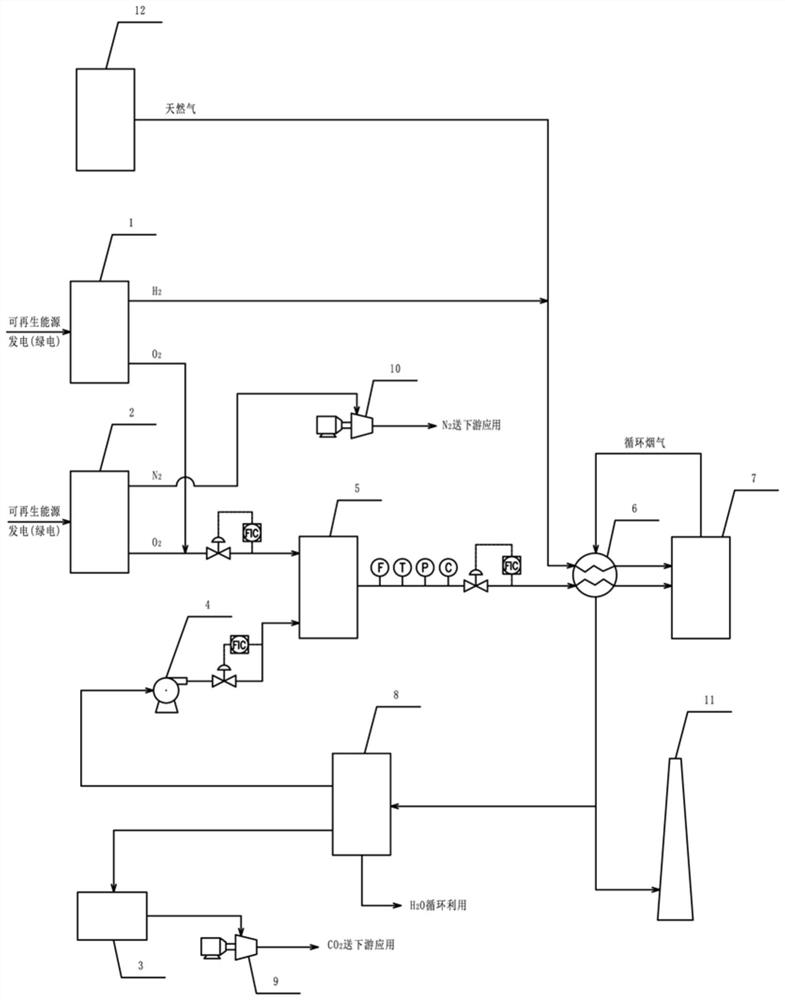

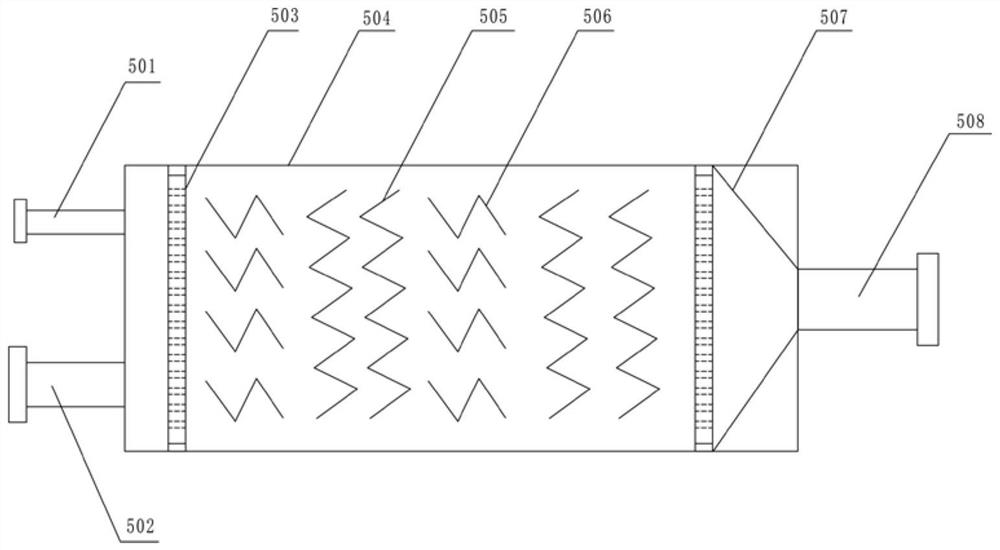

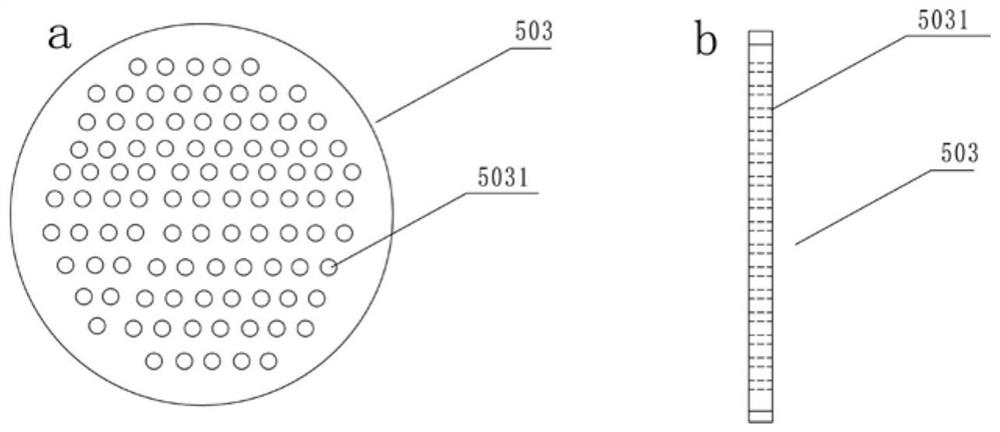

Nitrogen-insulating combustion and CO2 capture and utilization process for gas-fired boiler

The invention discloses a gas-fired boiler nitrogen-insulating combustion and CO2 capture and utilization process. A system required by the process comprises a natural gas supply device, a water electrolysis hydrogen production device, an oxygen preparation device, a nitrogen compressor, a carbon-based nitrogen-insulating gas mixer, a gas heat exchanger, a gas-fired boiler, a chimney, a flue gas dehydration device, an air blower, a CO2 recovery device and a CO2 compressor. The method has excellent performance in the aspects of yield increase, energy conservation and emission reduction, the unit consumption of per ton of steam and natural gas can be reduced by 10% or above, the yield can be improved by 10% or above, the flue gas emission is reduced, and ultralow emission of NOx is achieved.

Owner:SHANGHAI YUANHAN ENERGY&CHEM TECH CO LTD +1

Abstergent of saving oil, gas and coal

InactiveCN1519299AIncrease contact surfaceThoroughly remove carbon depositsLiquid carbonaceous fuelsCombustionHydrogen

A cleaning agent for saving oil, gas or coal features that it can suck the oxygen from air into water, where it reacts on the hydrogen and oxygen in water to become atomic hydrogen and atomic oxygen, and when the fuel is burning, the high-temp atomic hydrogen and atomic oxygen is exploded to break the carbon chains in fuel. Its advantages are full combustion and high heat value of fuel, no carbon deposit, and less exhausted smoke.

Owner:李天山

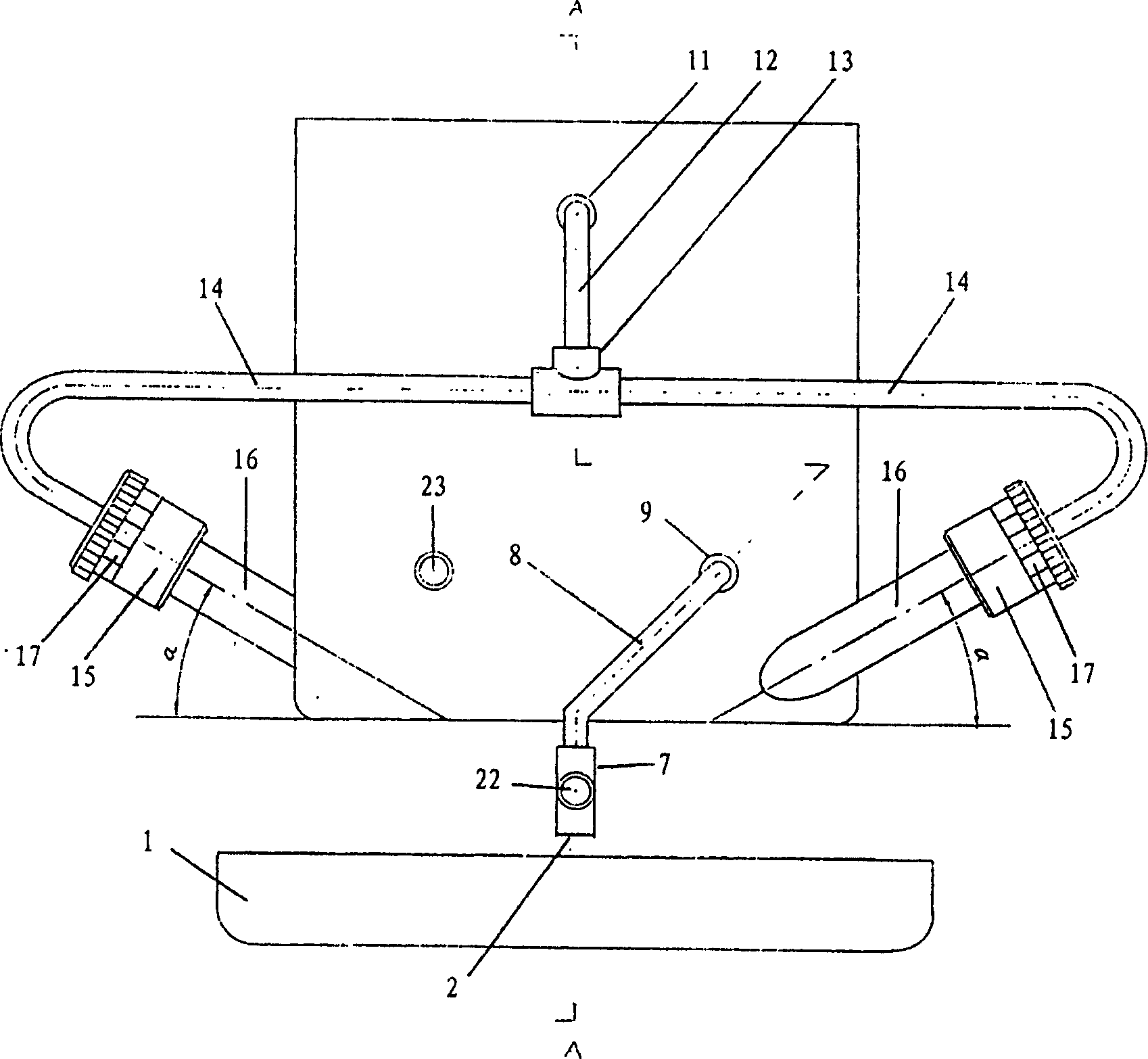

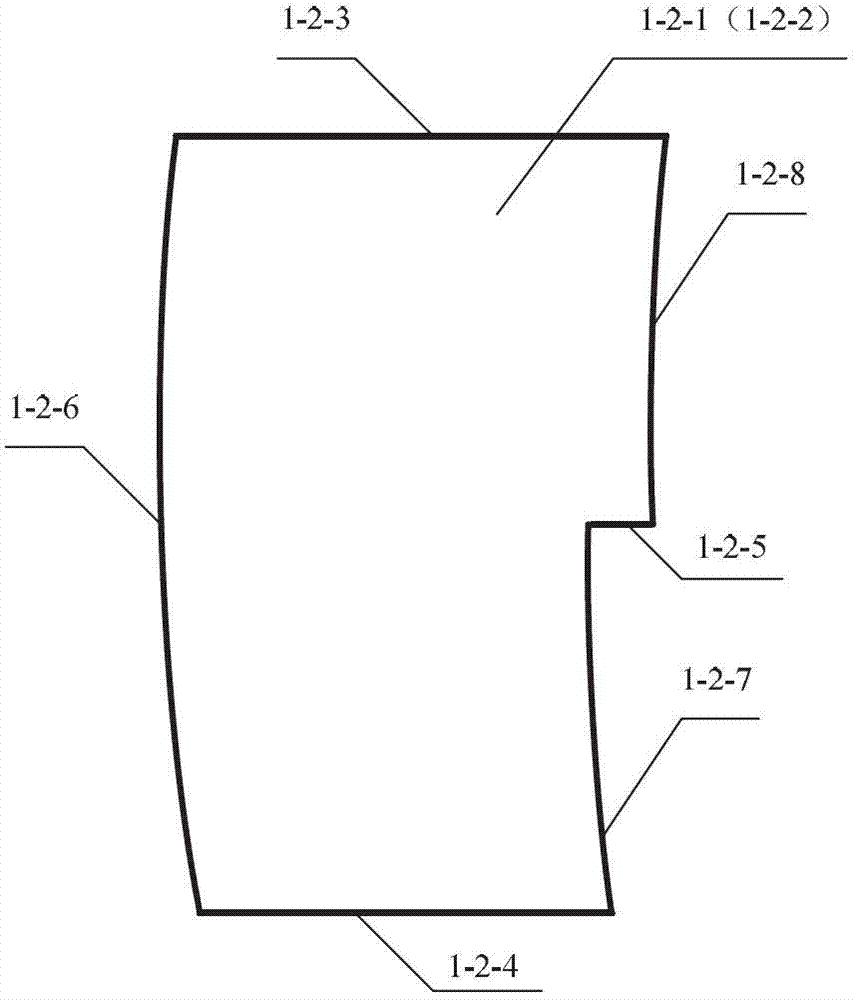

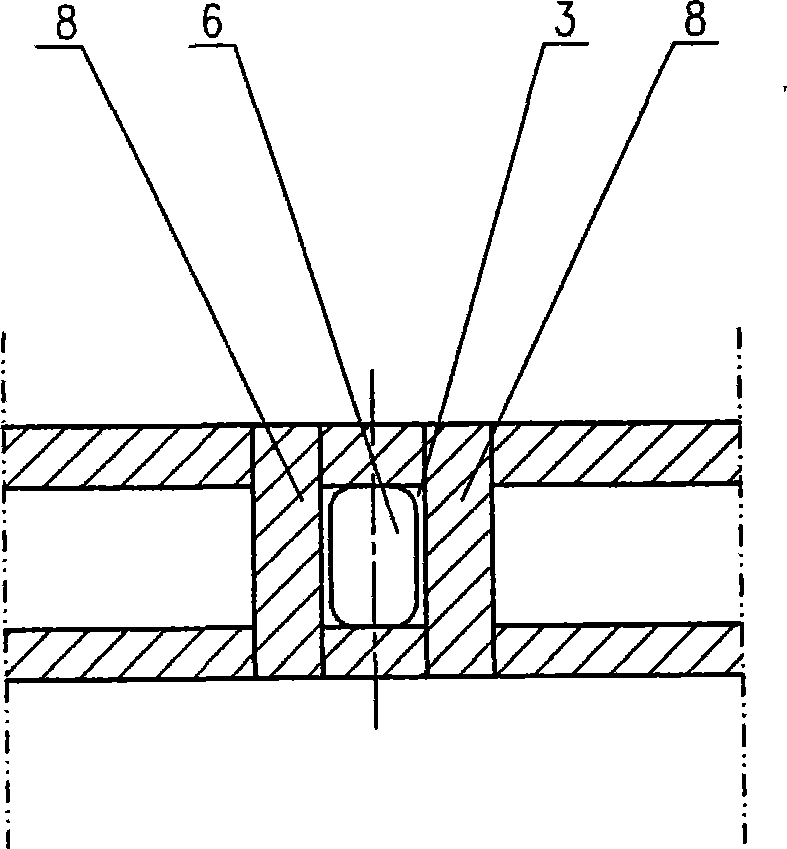

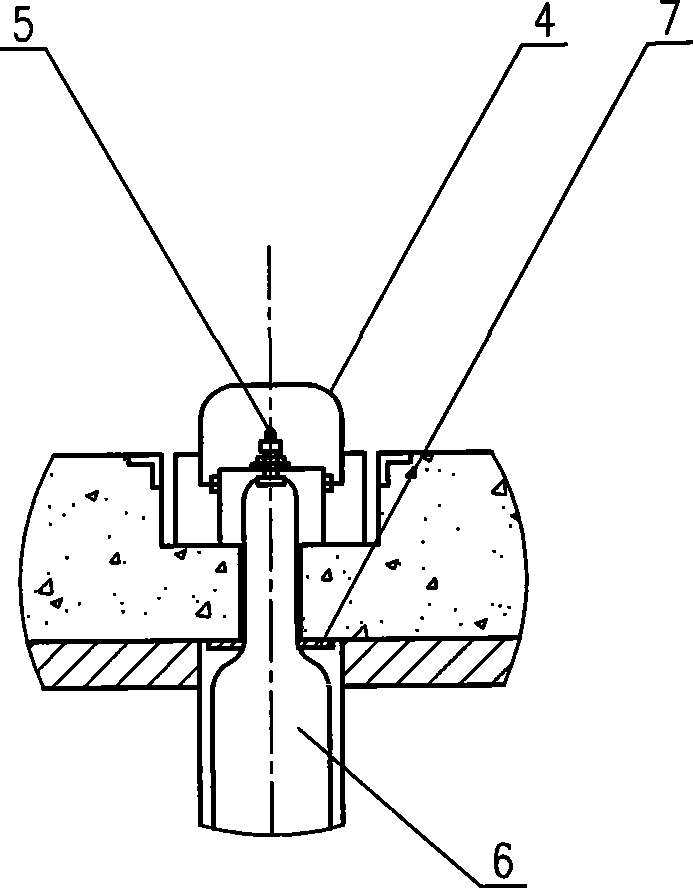

Fire channel separating apparatus of anode baking stove

InactiveCN101498551ASimple structureReduce weightMechanical apparatusFurnace componentsBrickMaterials science

The invention discloses an anode roasting furnace belonging to the production field of carbon used for aluminum, in particular to a flame path partition device of an anode roasting furnace. The structure of the flame path partition device of the anode roasting furnace is as flows: a plurality of furnace face function holes are arranged on the channels of the intersection of cross walls and flame paths among a plurality of furnace chambers and between the two rows of location pulling bricks; isolation positions are arranged on the channels among the furnace chambers underneath the furnace face function holes; a plurality of pressure bladders are arranged in the isolation positions; and the pressure bladders are communicated with a plurality of charging connectors arranged in the function holes. The invention has the advantages of simple structure, less weight, easy operation when being installed and discharged, low operation cost, high product quality, energy saving and good sealability even if the isolation positions are distorted at the high temperature.

Owner:山东平阴丰源炭素有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com