Thermal storage type oxygen-enriched combusting method and device

An oxygen-enriched combustion and regenerative technology, which is applied in the direction of combustion method, combustion type, combustion equipment, etc., can solve the problems of high emission concentration and high exhaust temperature, and achieve lower exhaust temperature, simple system, and reduced exhaust volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

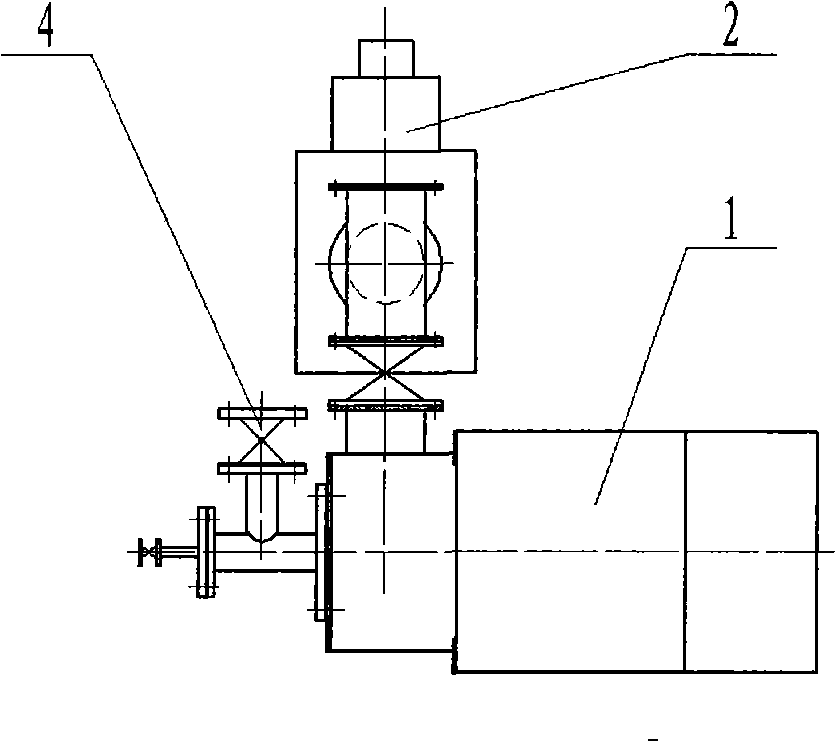

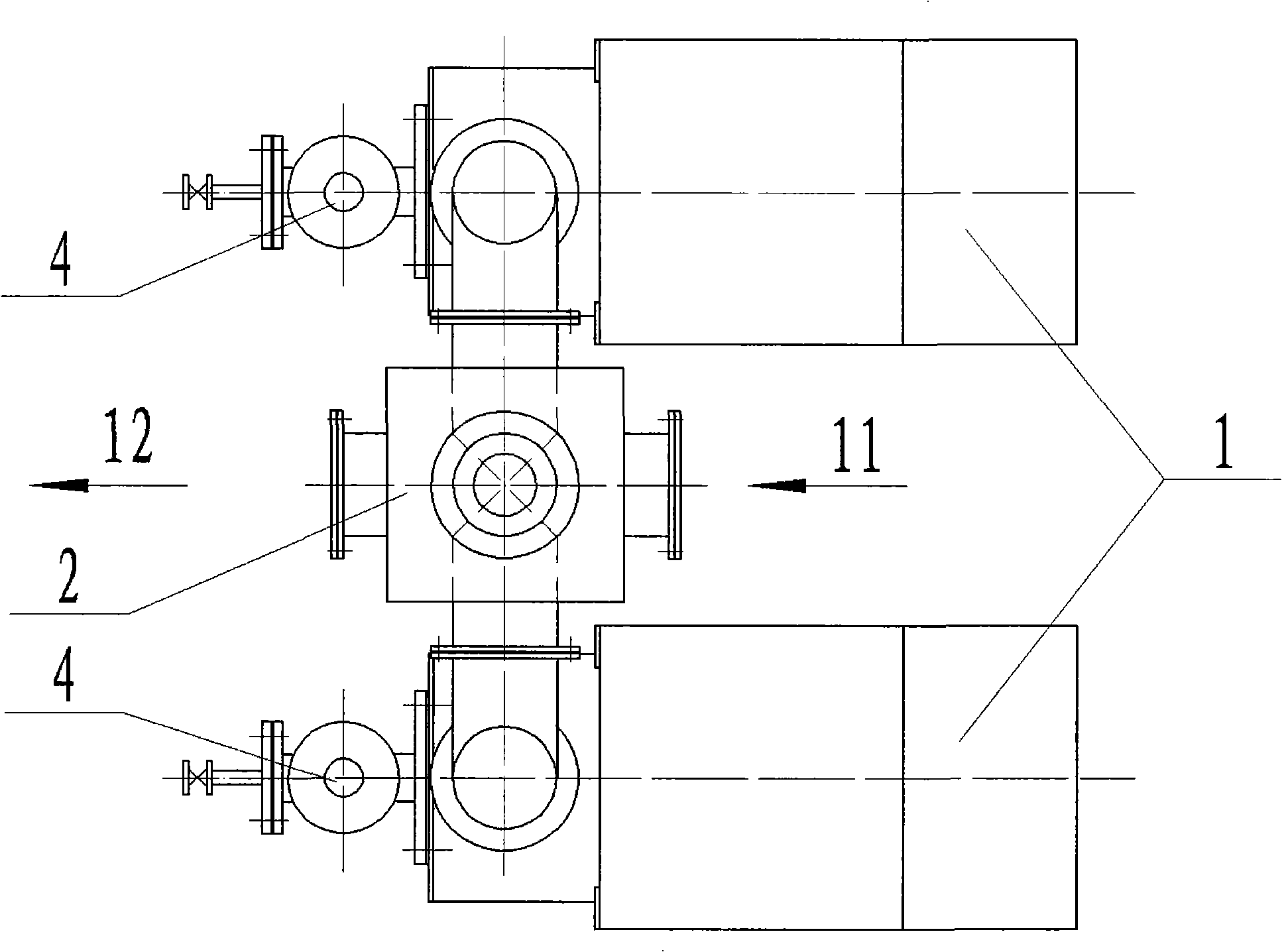

Embodiment 1

[0025] 16.5Nm respectively 3 / h flow into oxygen, at 150Nm 3 / h flow into the producer gas and fully mix the producer gas and oxygen at the oxygen mixing nozzle of a regenerative oxygen-enriched burner, and spray them into the mixed gas conduit set in the center of the regenerator; The fully mixed producer gas and oxygen gas are mixed again with the combustion air preheated to 900°C at the nozzle of the burner and burned, and the combustion temperature reaches above 1400°C; the combustion air preheated to 900°C is The room temperature air blown through the four-way reversing valve passes through the heat exchange chamber in a regenerative oxygen-enriched burner, and the room temperature air exchanges heat with the high-temperature regenerator, absorbing the heat of the regenerator and being preheated. At the same time, another regenerative oxygen-enriched burner inhales high-temperature flue gas with a temperature of 1000°C from the furnace through a plurality of through hole...

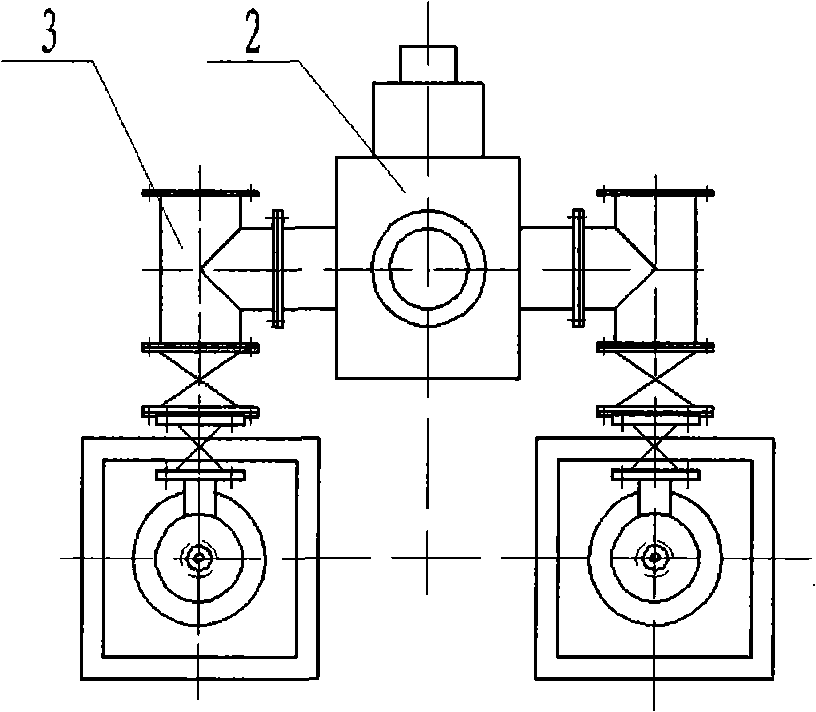

Embodiment 2

[0027] 33Nm 3 / h flow into oxygen, at 300Nm 3 / h flow into the producer gas and fully mix the producer gas and oxygen at the oxygen mixing nozzle of a regenerative oxygen-enriched burner, and spray them into the mixed gas conduit set in the center of the regenerator; The fully mixed producer gas and oxygen gas are mixed again with the combustion air preheated to 950°C at the nozzle of the burner and burned, and the combustion temperature reaches above 1400°C; the combustion air preheated to 950°C is The room temperature air blown through the four-way reversing valve passes through the heat exchange chamber in a regenerative oxygen-enriched burner, and the room temperature air exchanges heat with the high-temperature regenerator, absorbing the heat of the regenerator and being preheated. At the same time, another regenerative oxygen-enriched burner inhales high-temperature flue gas with a temperature of 1050°C from the furnace through a plurality of through holes arranged alon...

Embodiment 3

[0029] 7Nm 3 / h flow into liquefied gas, with 300Nm 3The / h flow is passed into the producer gas and the above two gases are fully mixed at the oxygen mixing nozzle of a regenerative burner, and injected into the mixed gas conduit arranged in the center of the regenerator; the fully mixed The two gases and the combustion-supporting air preheated to 980°C are mixed again at the burner nozzle and burned, and the combustion temperature reaches 1400°C; the combustion-supporting air preheated to 980°C is produced by the The blown room temperature air passes through a heat exchange chamber in a regenerative burner, the room temperature air exchanges heat with a high temperature heat storage body, and absorbs the heat of the heat storage body to be preheated; at the same time, another heat storage body The high-temperature flue gas with a temperature of 1100°C is sucked in by the burner from the furnace through a plurality of through holes arranged along the circumference of the bur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com