Patents

Literature

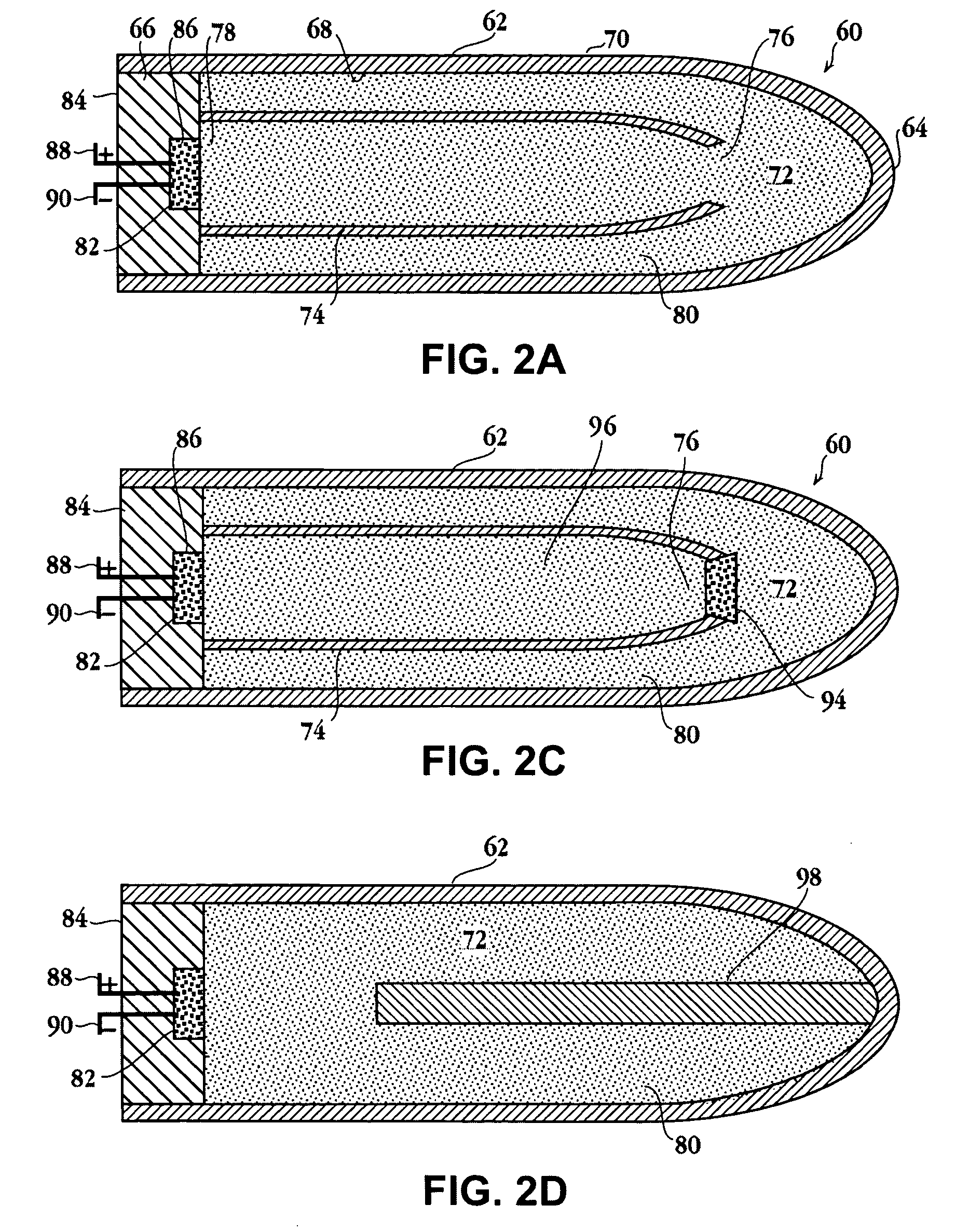

4090results about "Combustion apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

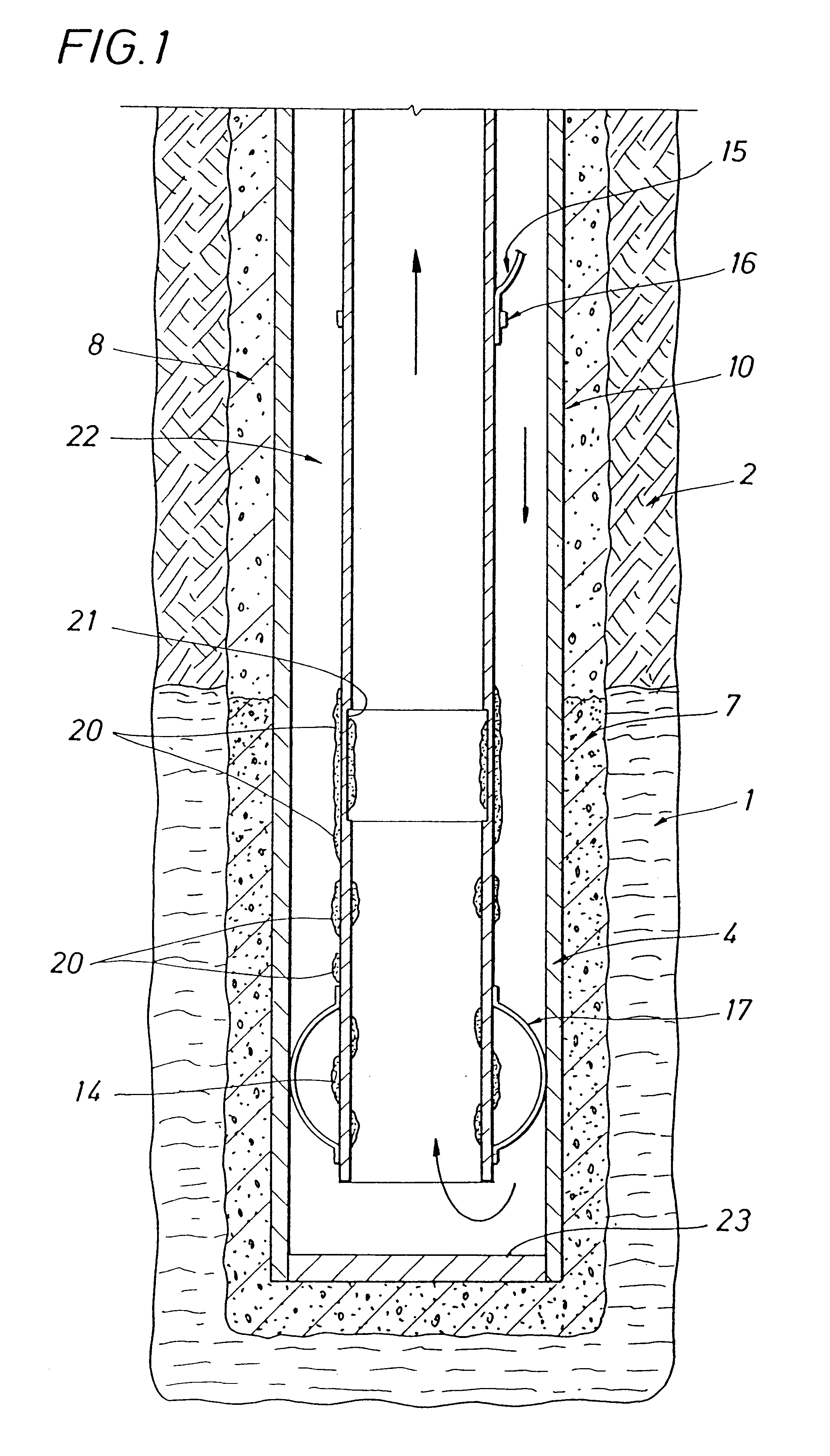

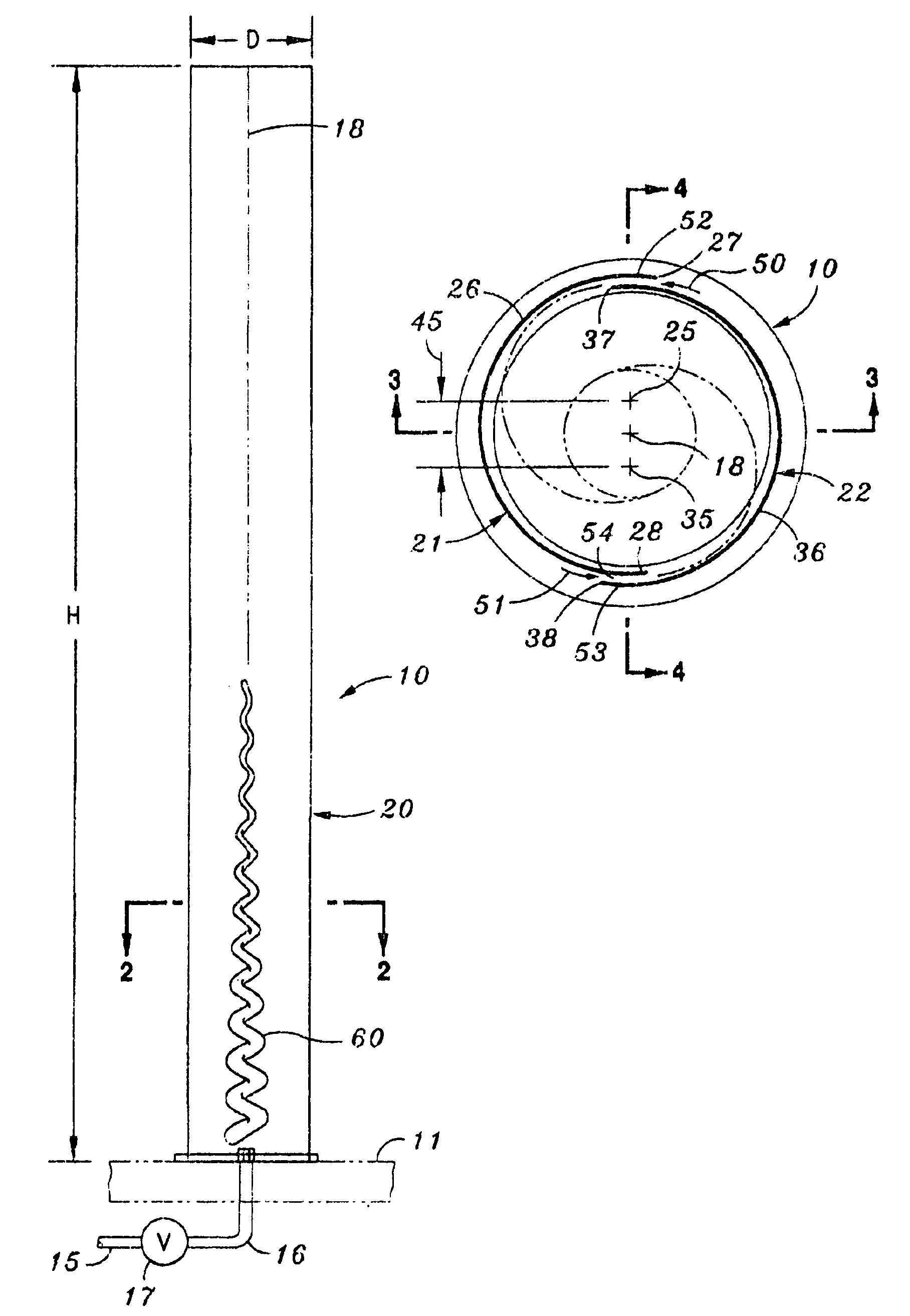

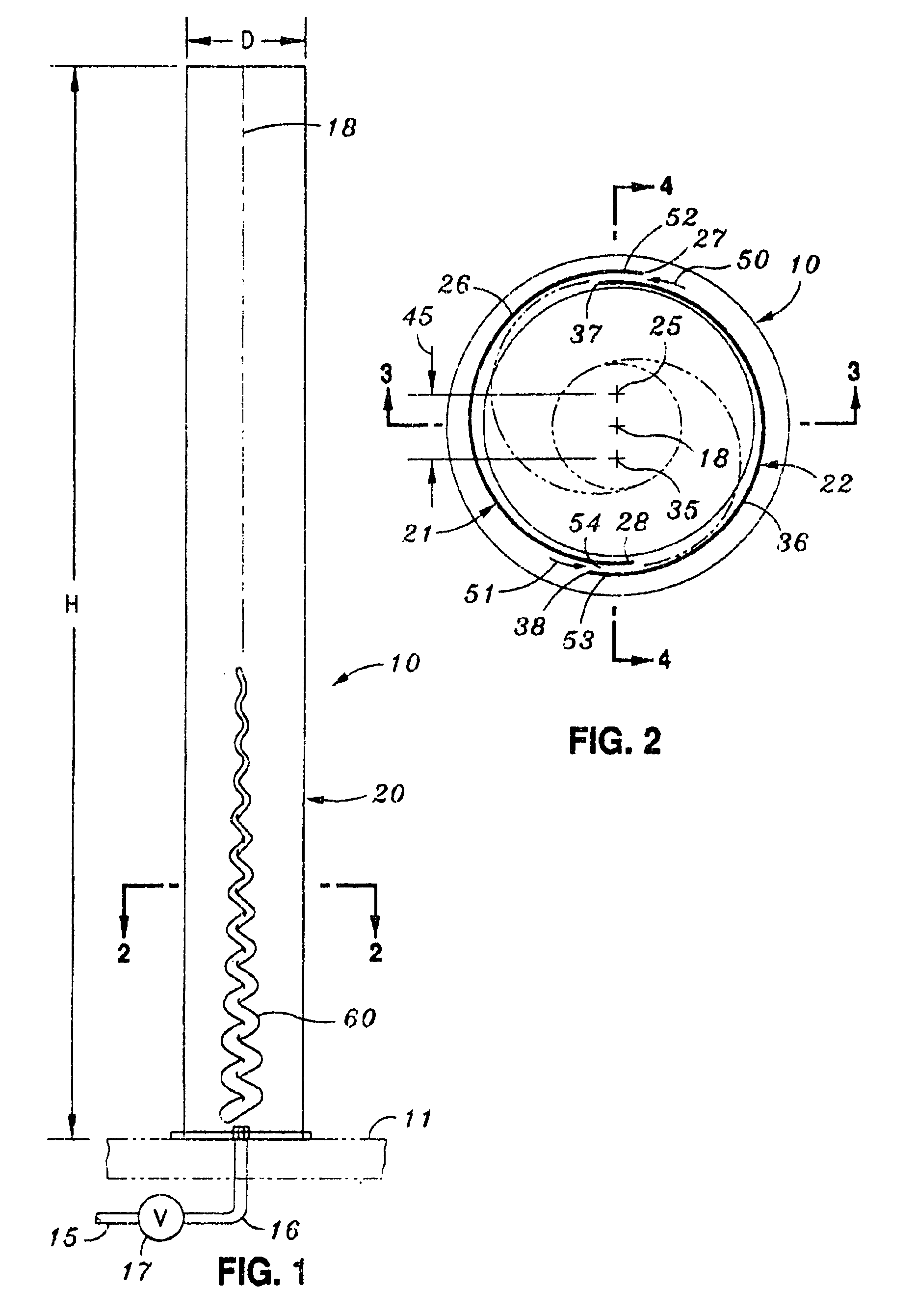

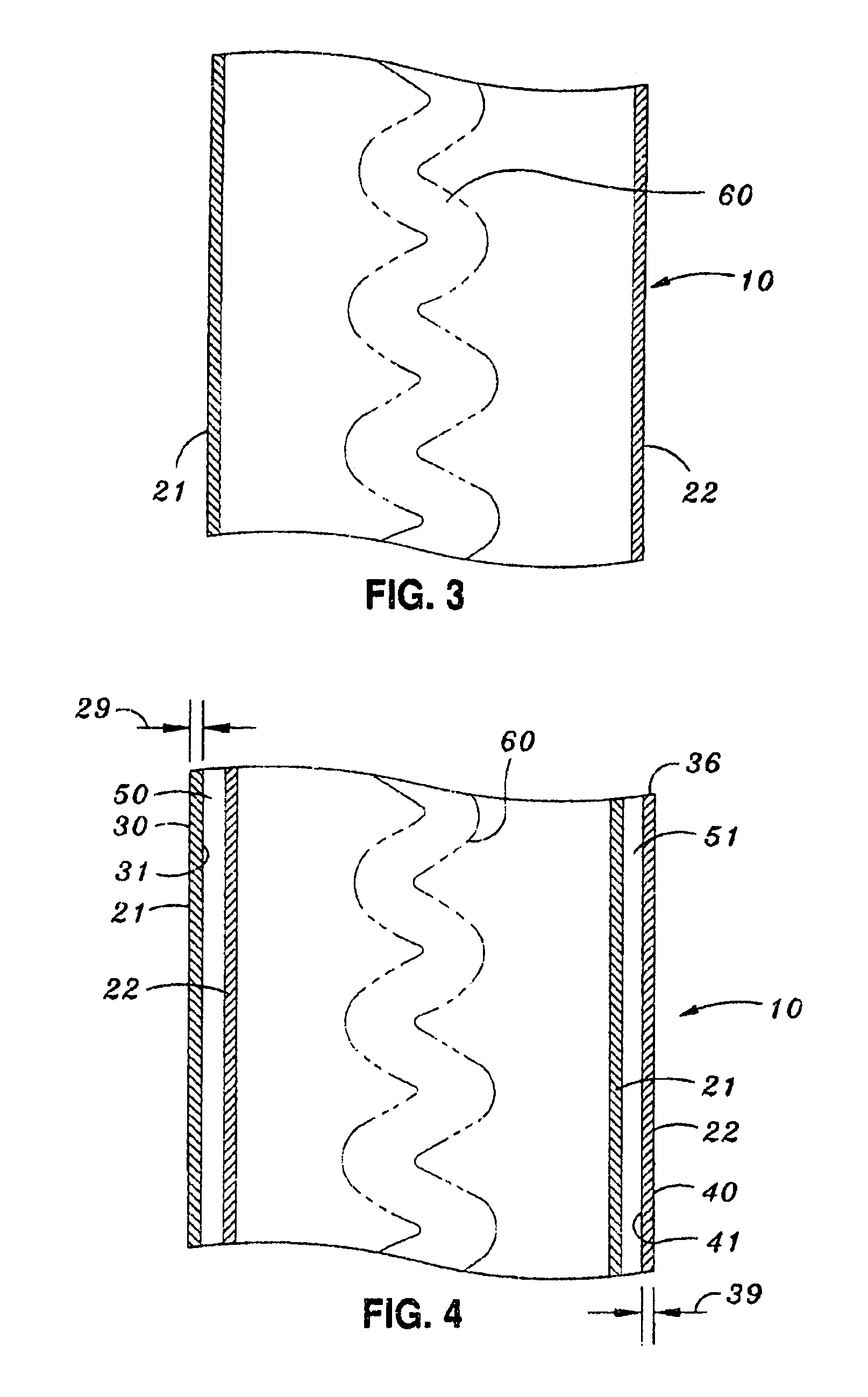

Flameless combustor

InactiveUS6019172AEasy to igniteImprove the level ofApparel holdersInsulationCombustorCombustion chamber

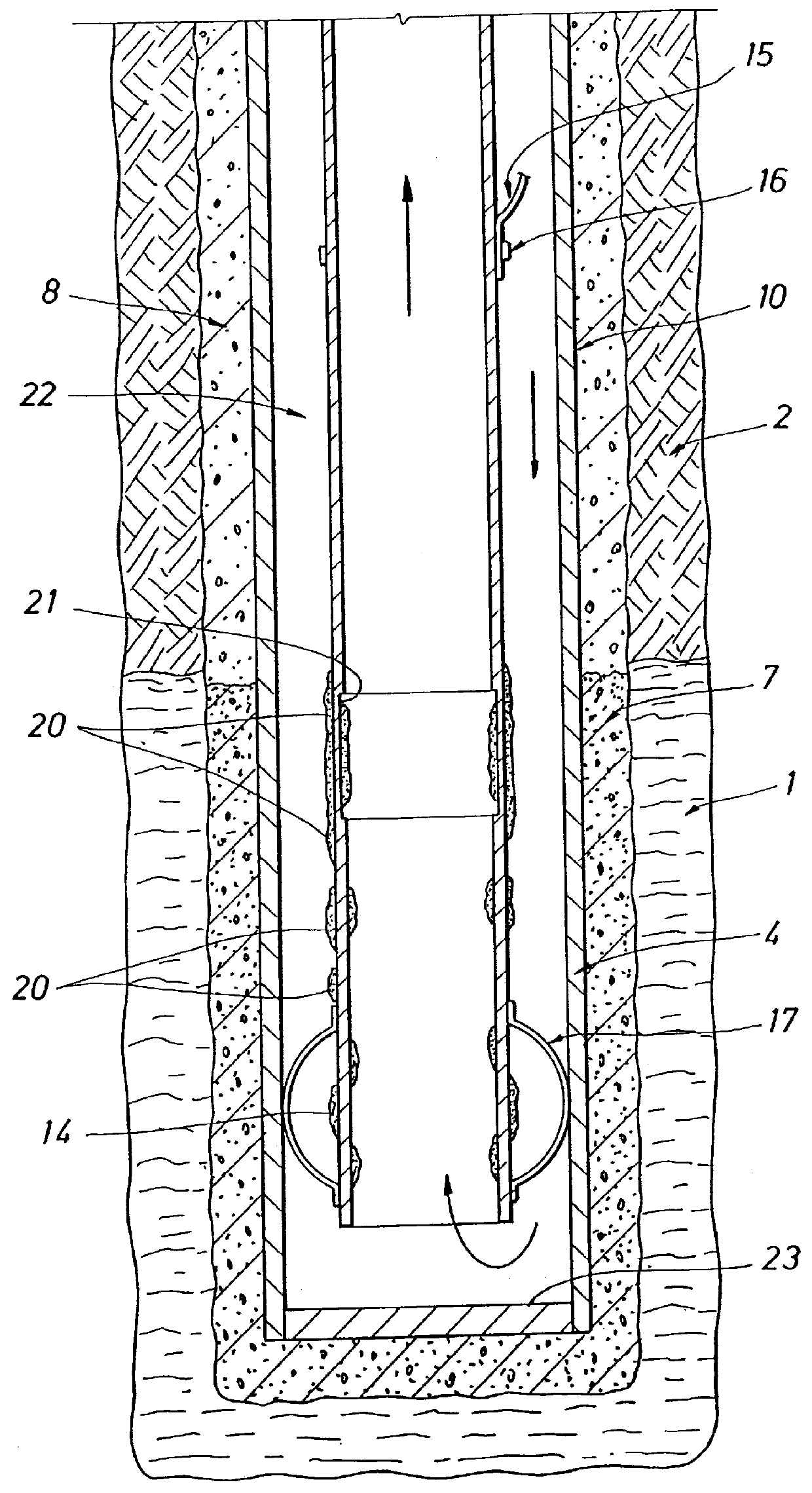

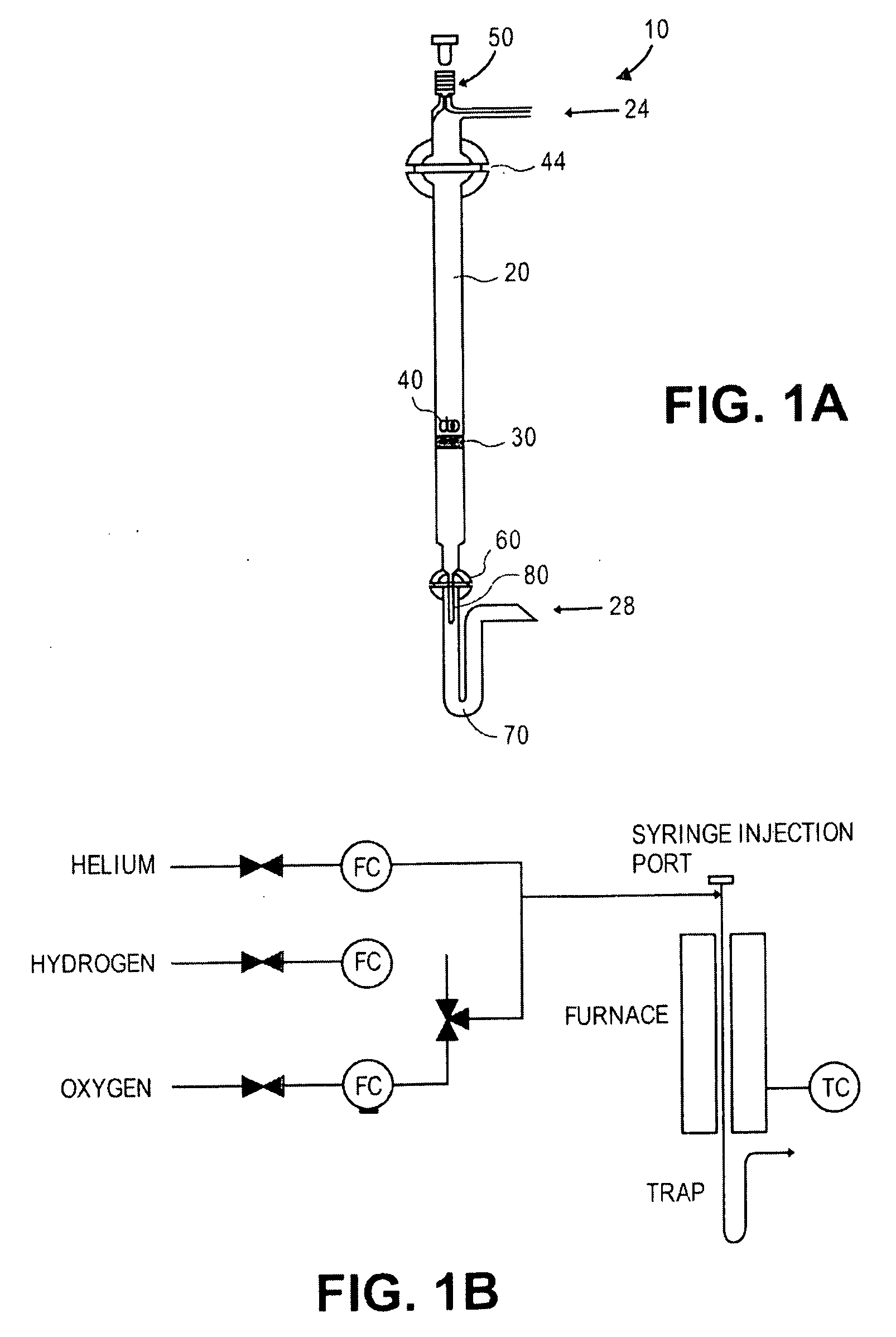

A combustor method and apparatus is provided. The method utilizes flameless combustion with one or more of three improvements to enhance ignition of the flameless combustor. A catalytic surface can be provided within a combustion chamber to provide flameless combustion at least in the vicinity of the catalytic surface at a temperature that is much lower than the autoignition temperature of fuel in air without the presence of the catalytic surface. Nitrous oxide or supplemental oxygen may also be used as an oxidant either instead of air or with air to reduce ignition temperatures. Further, electrical energy can be passed through the fuel conduit, raising the temperature of the conduit to a temperature above which the fuel will ignite when combined with the oxidant.

Owner:SHELL OIL CO

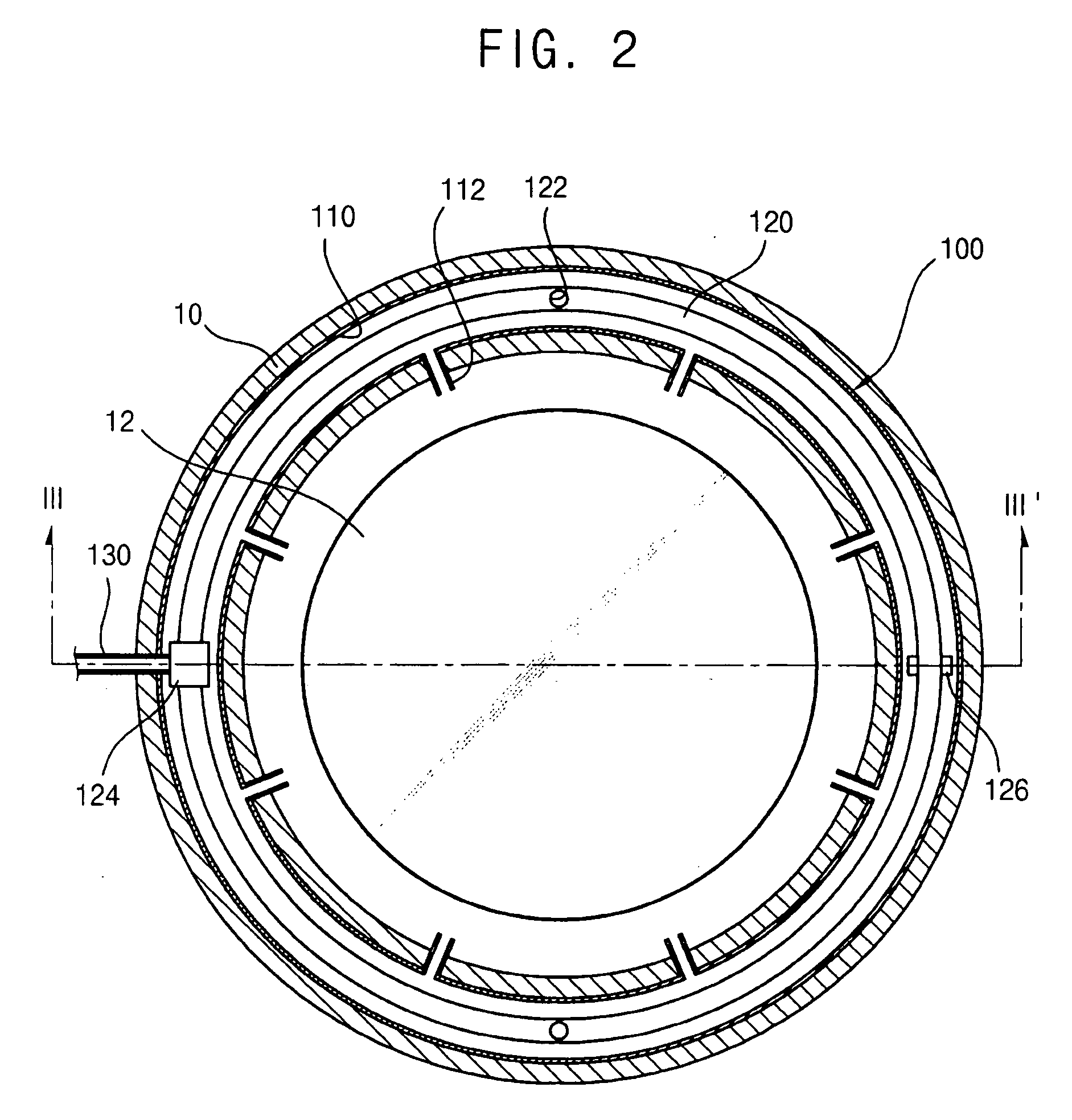

Gas supply device and apparatus for processing a substrate

InactiveUS20070087296A1Combustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelProcess engineeringGas supply

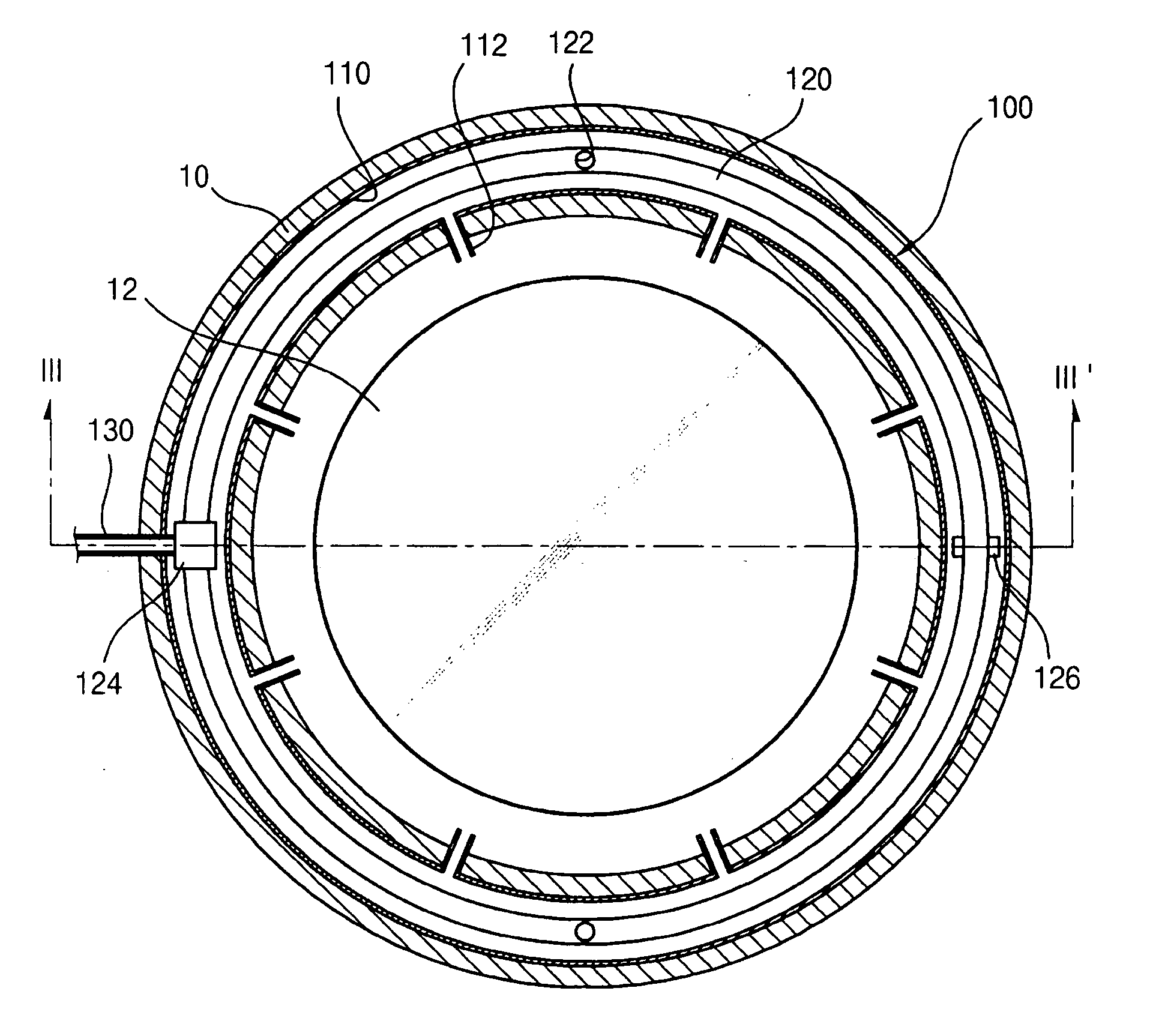

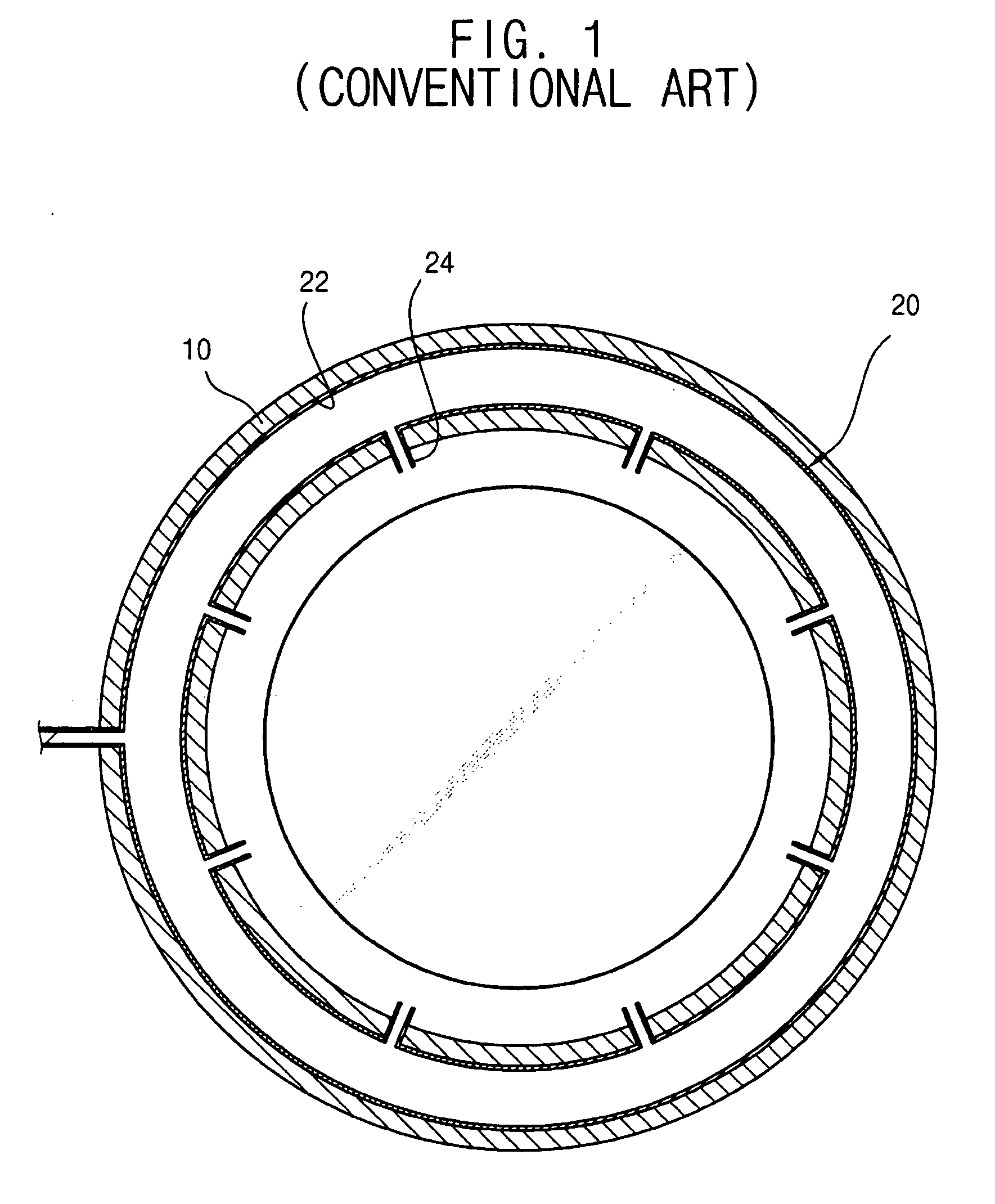

A gas supply device may include a first gas supply member that may be disposed in a chamber and around a substrate loaded in the chamber. The first gas supply member may include nozzles for providing a gas onto the substrate. A second gas supply member that may provide the gas supplied from at least one gas supply line to the first gas supply member.

Owner:SAMSUNG ELECTRONICS CO LTD

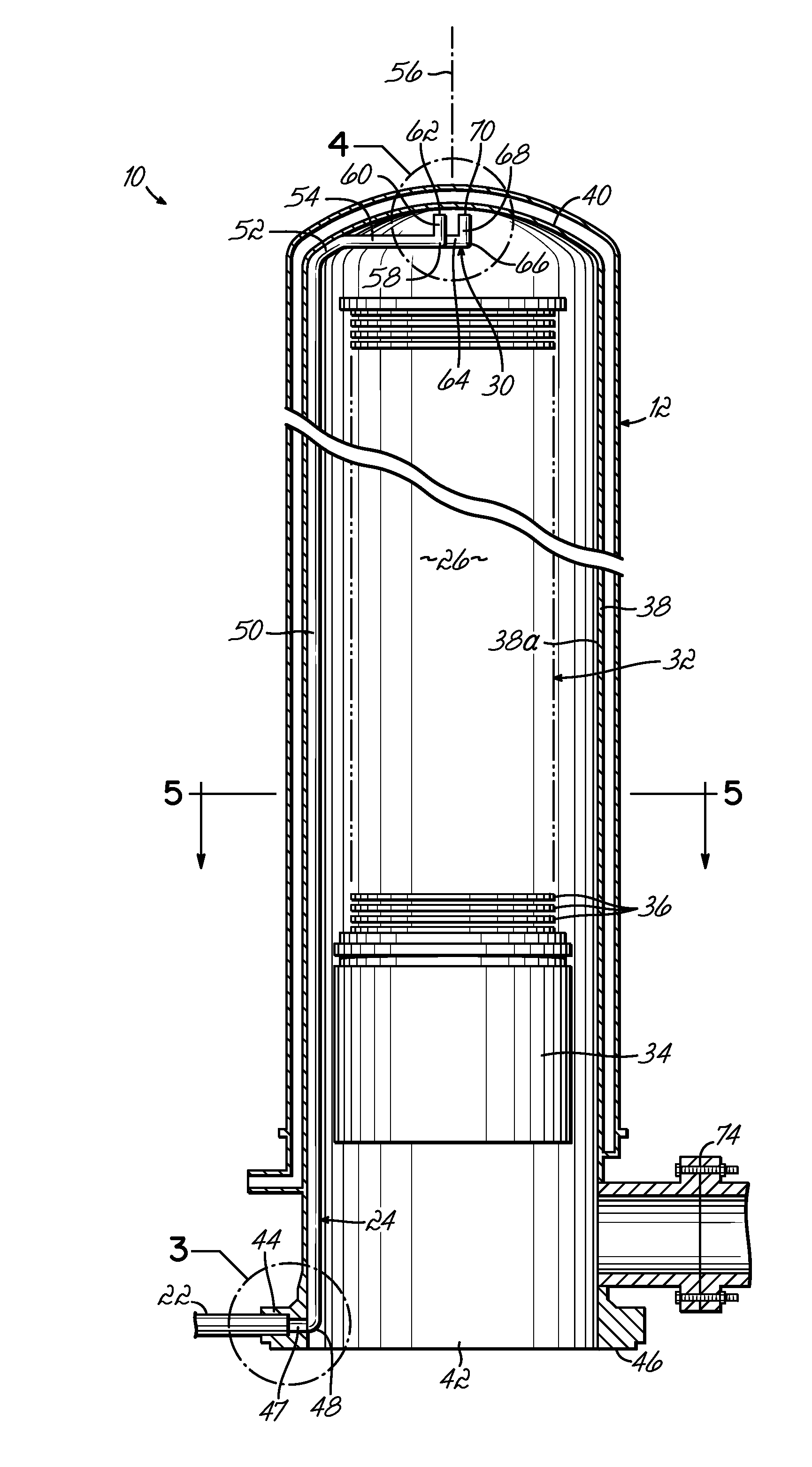

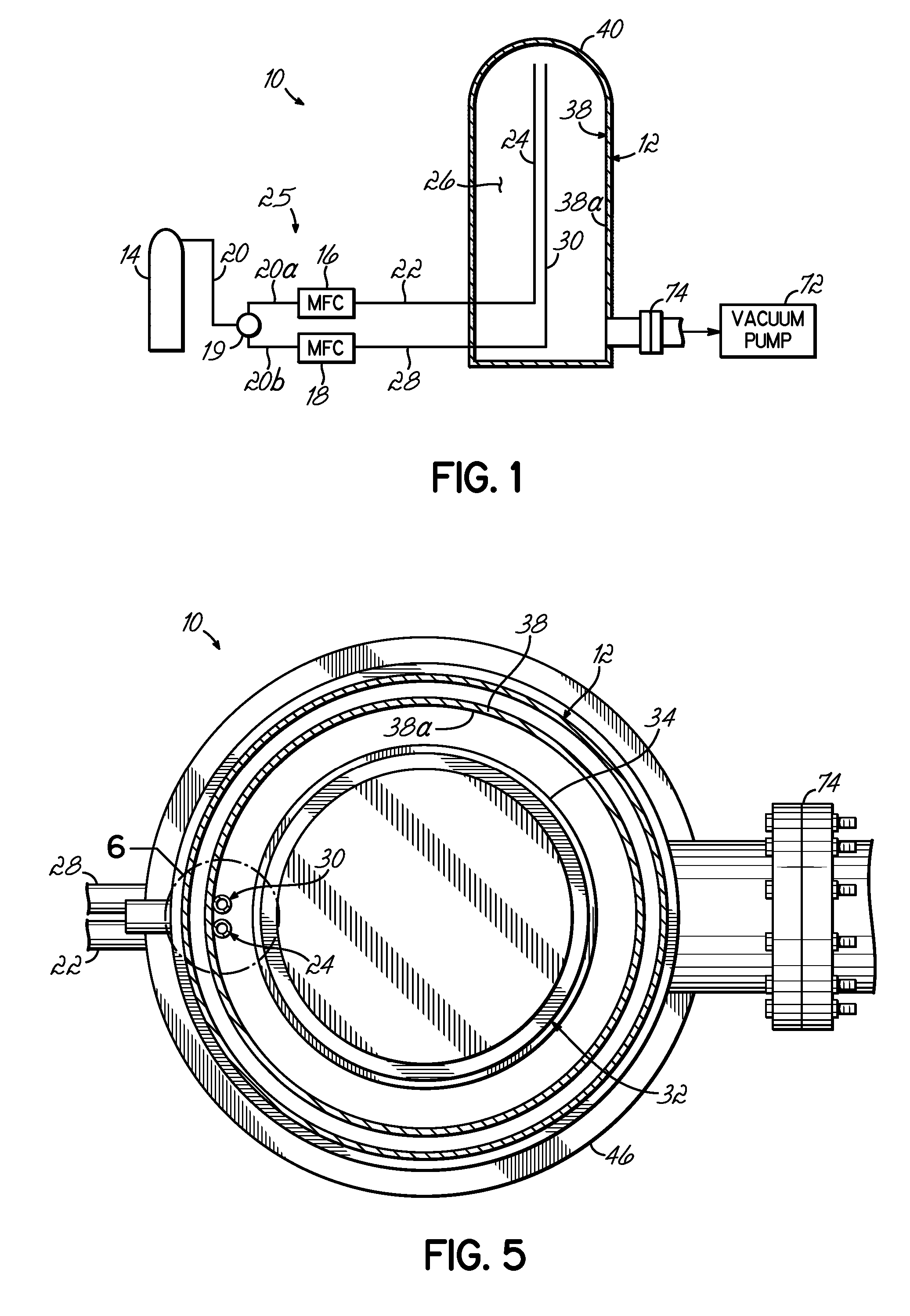

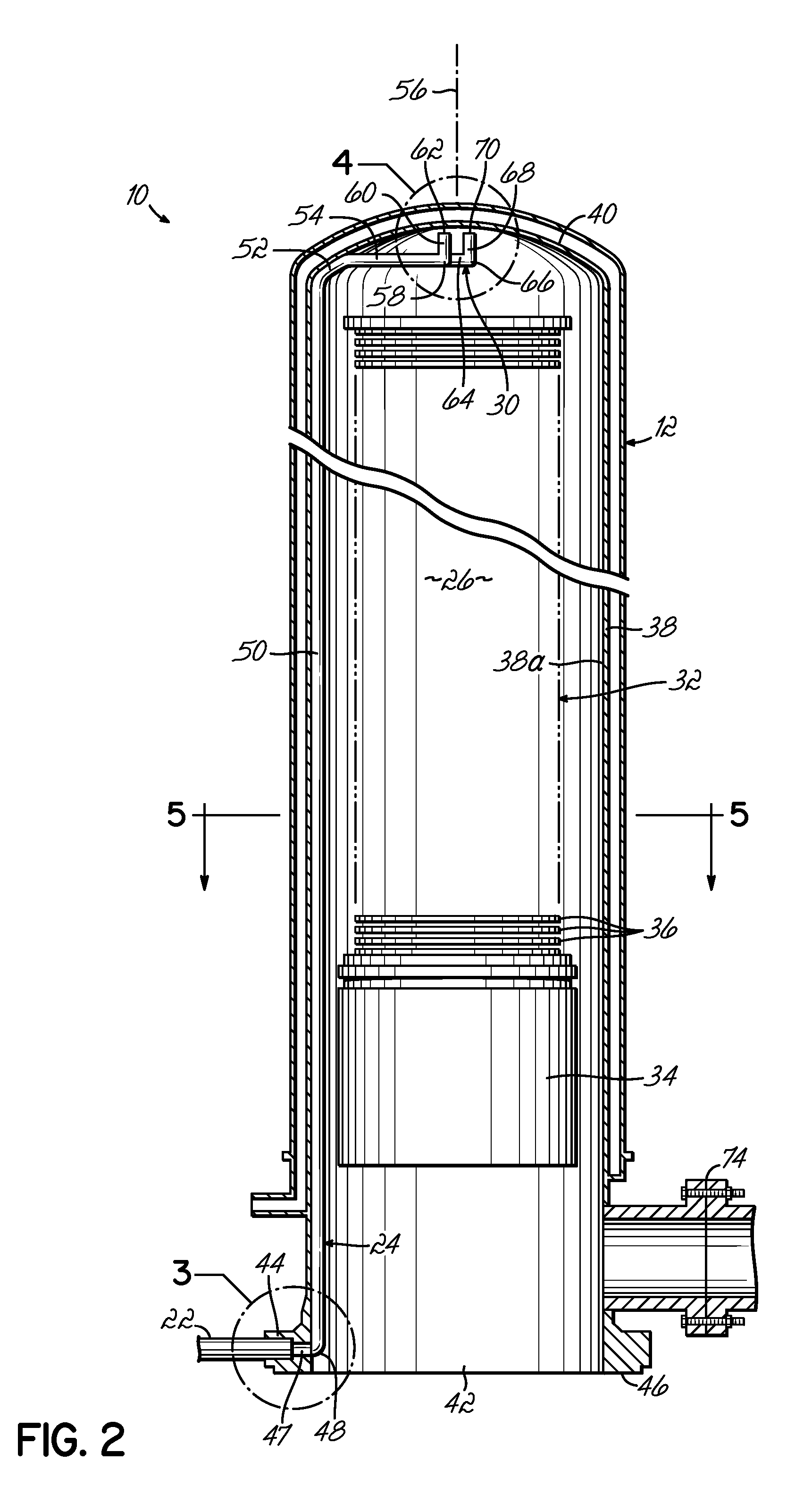

Thermal processing furnace, gas delivery system therefor, and methods for delivering a process gas thereto

InactiveUS7910494B2After-treatment apparatusCombustion using gaseous and pulverulent fuelProcess engineeringGas supply

A gas delivery system for supplying a process gas from a gas supply to a thermal processing furnace, a thermal processing furnace equipped with the gas delivery system, and methods for delivering process gas to a thermal processing furnace. The gas delivery system comprises a plurality of regulators, such as mass flow controllers, in a process gas manifold coupling a gas supply with a thermal processing furnace. The regulators establish a corresponding plurality of flows of a process gas at a plurality of flow rates communicated by the process gas manifold to the thermal processing furnace. The gas delivery system may be a component of the thermal processing furnace that further includes a liner that surrounds a processing space inside the thermal processing furnace.

Owner:TOKYO ELECTRON LTD

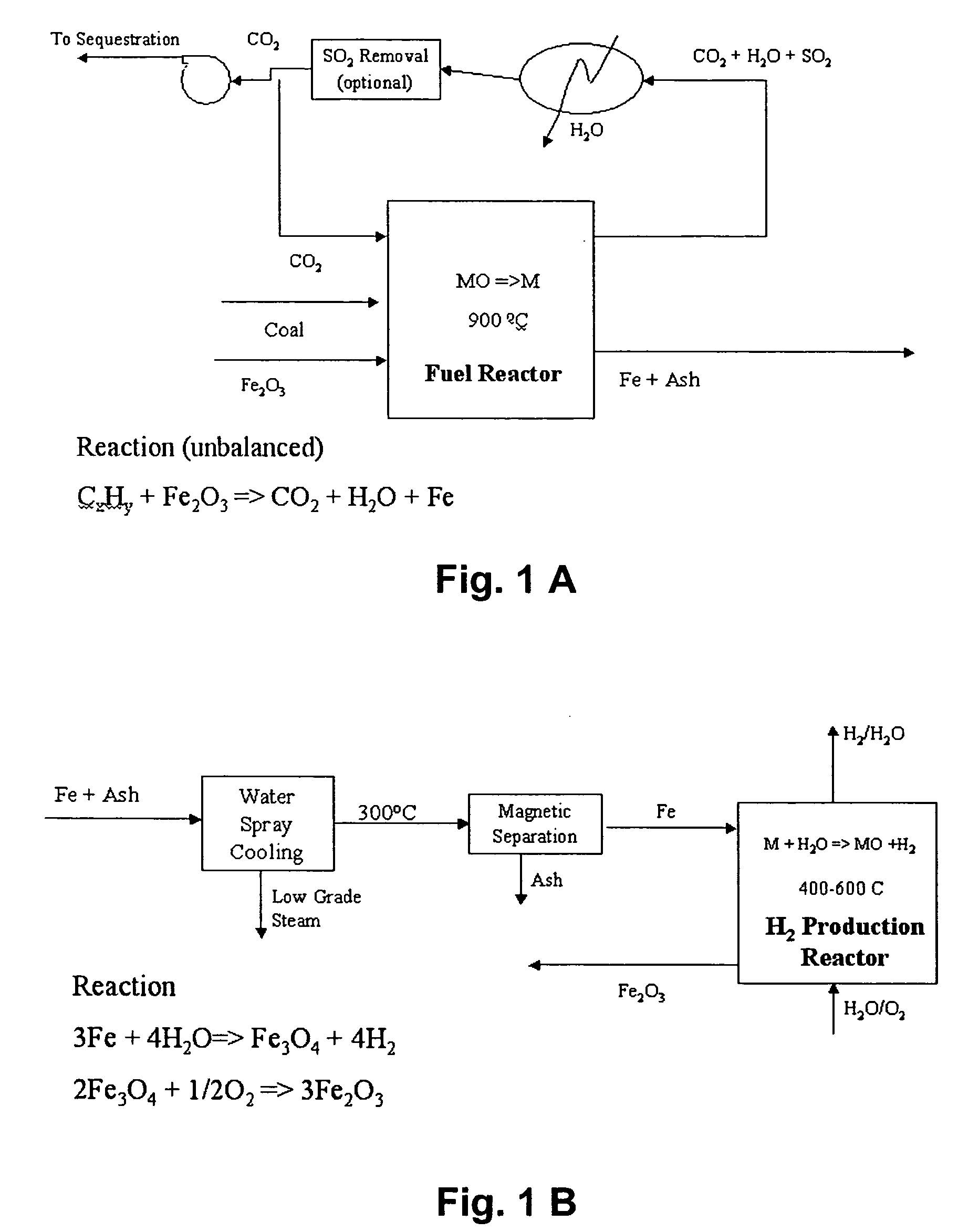

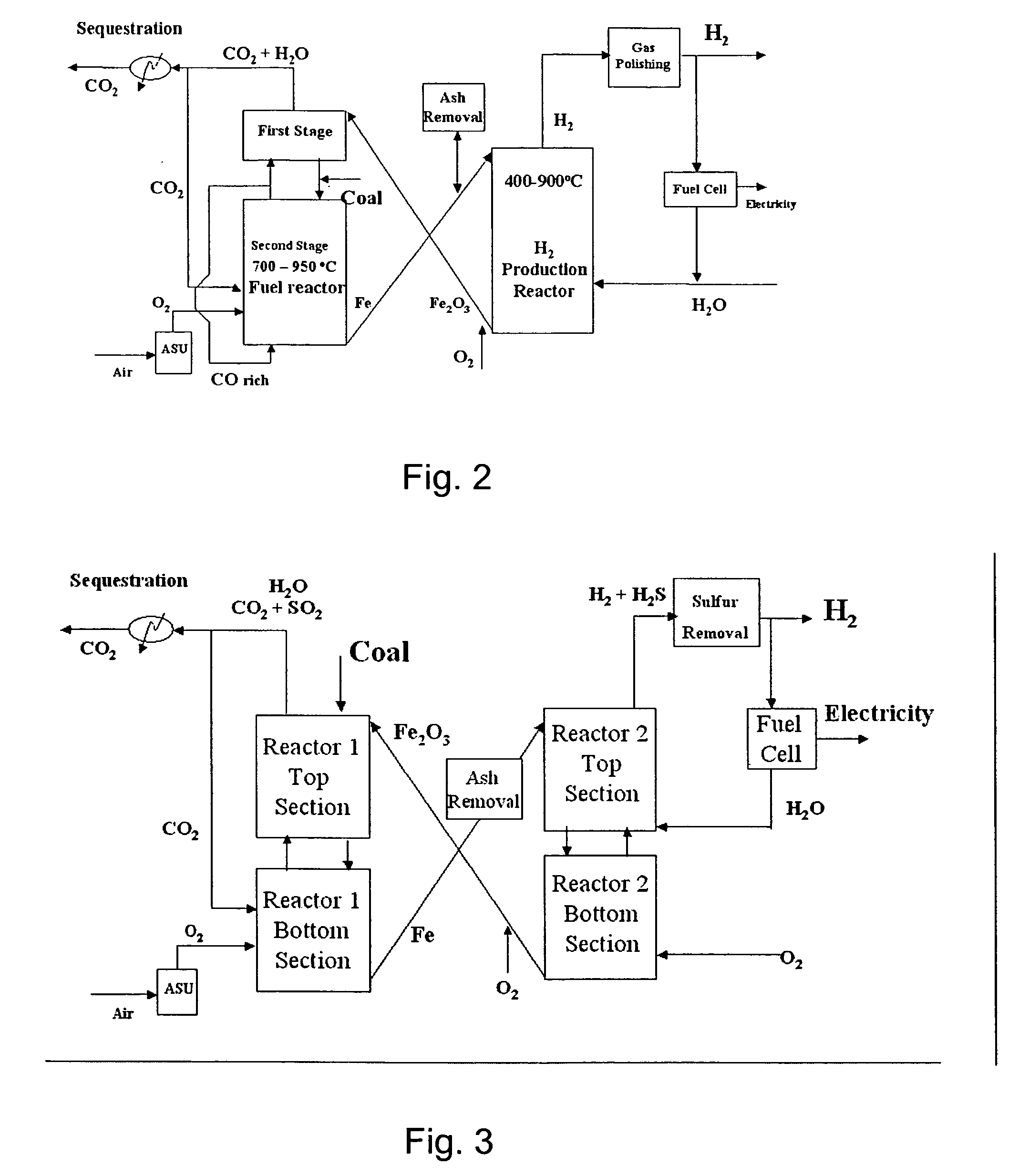

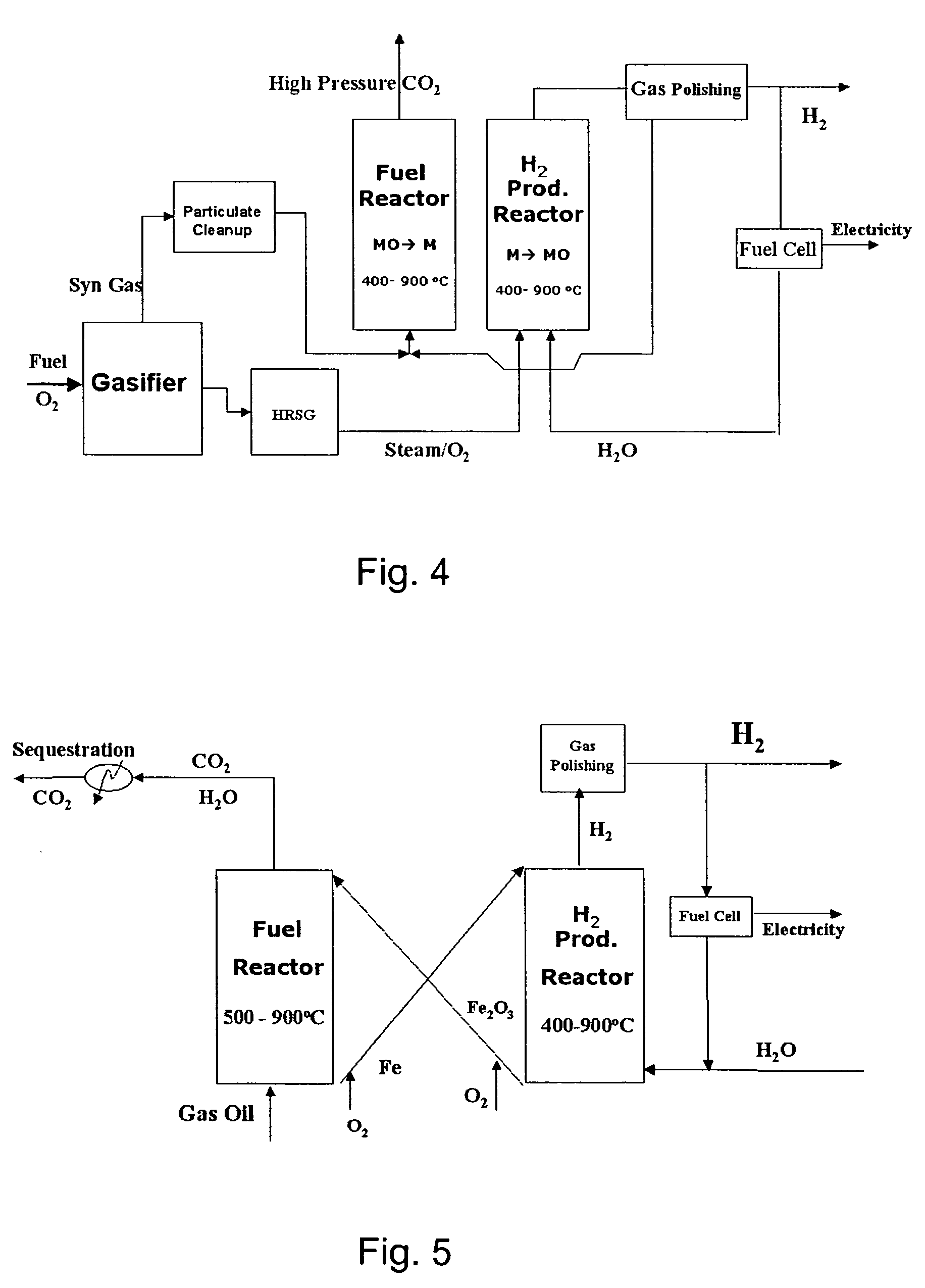

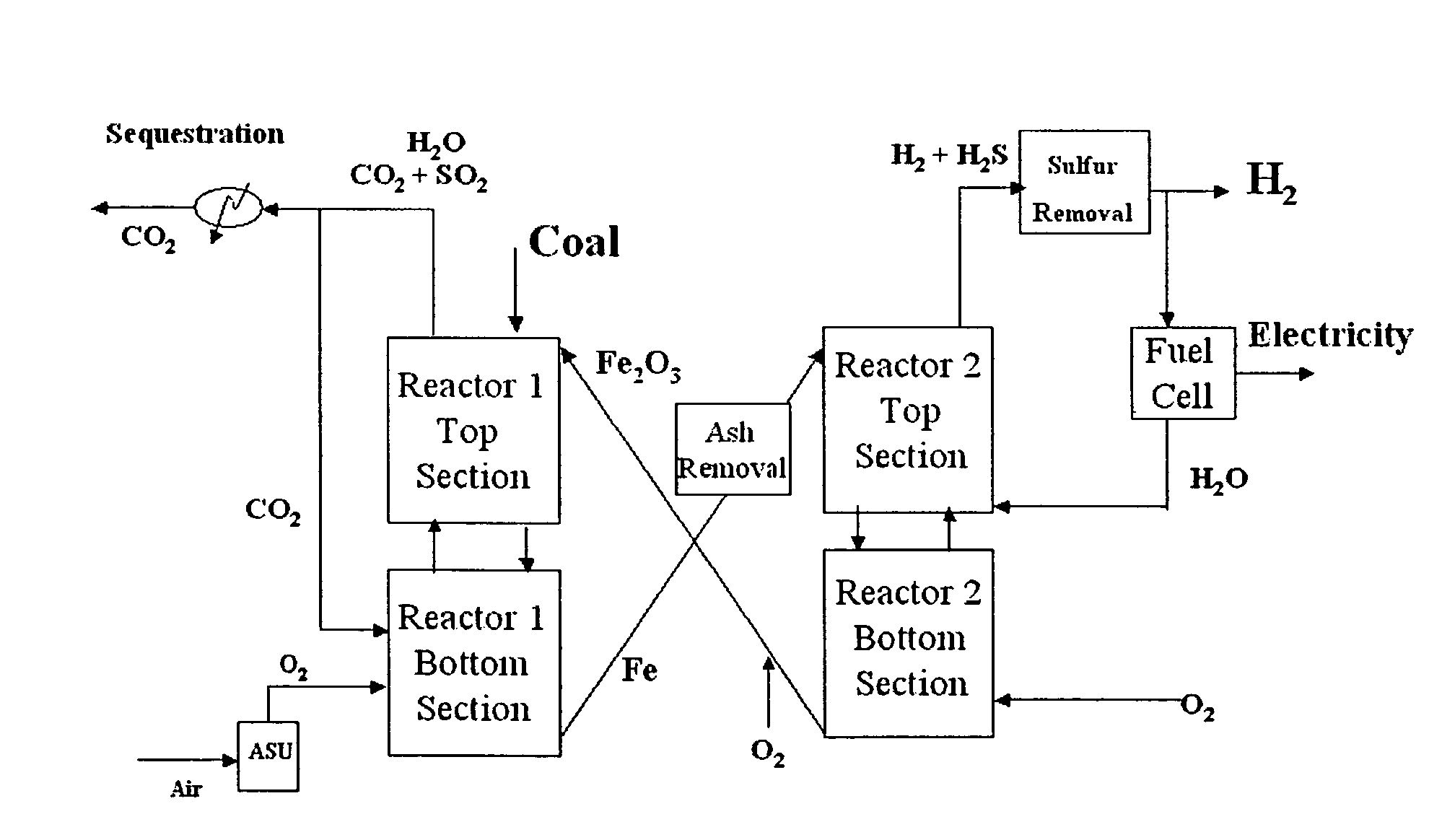

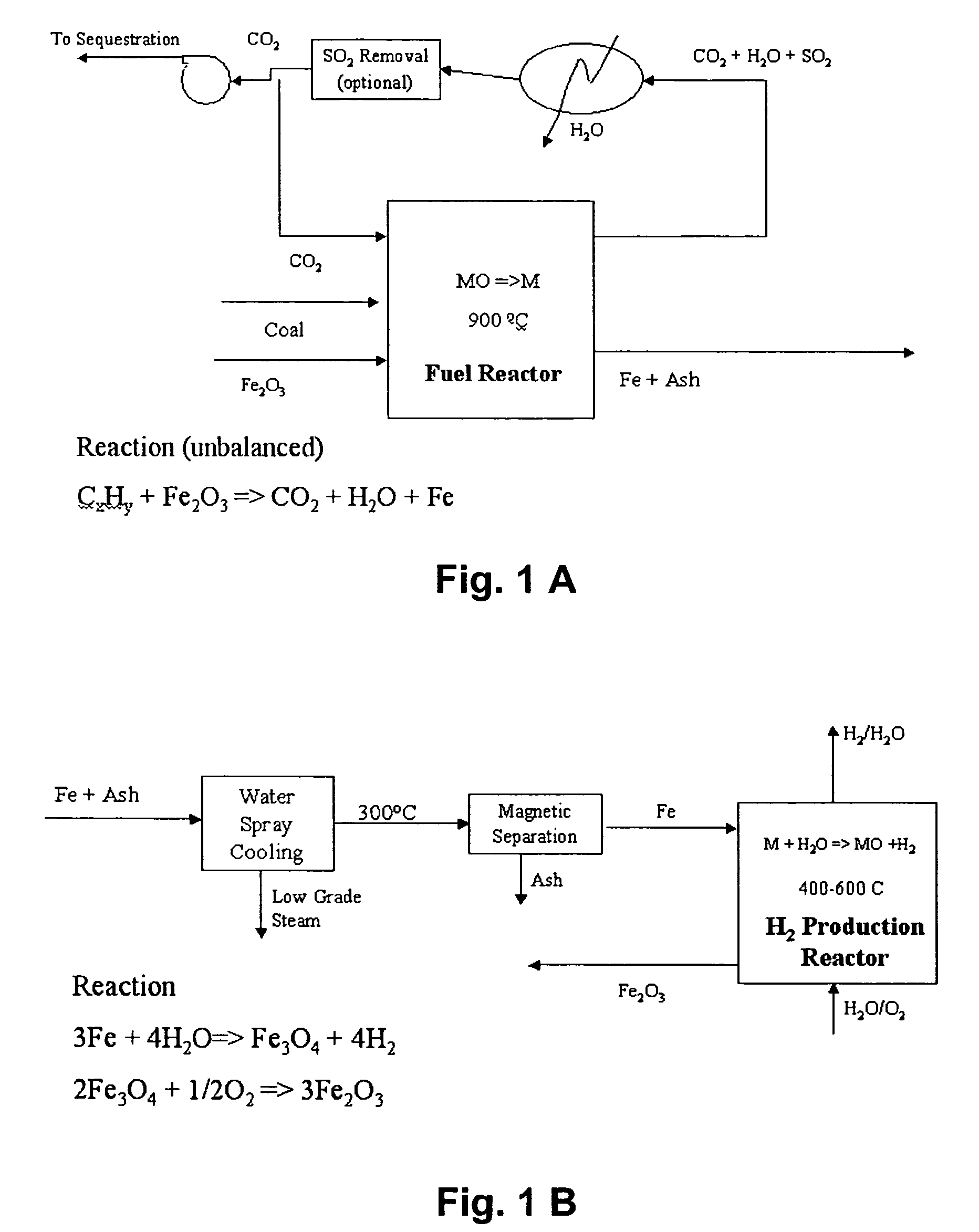

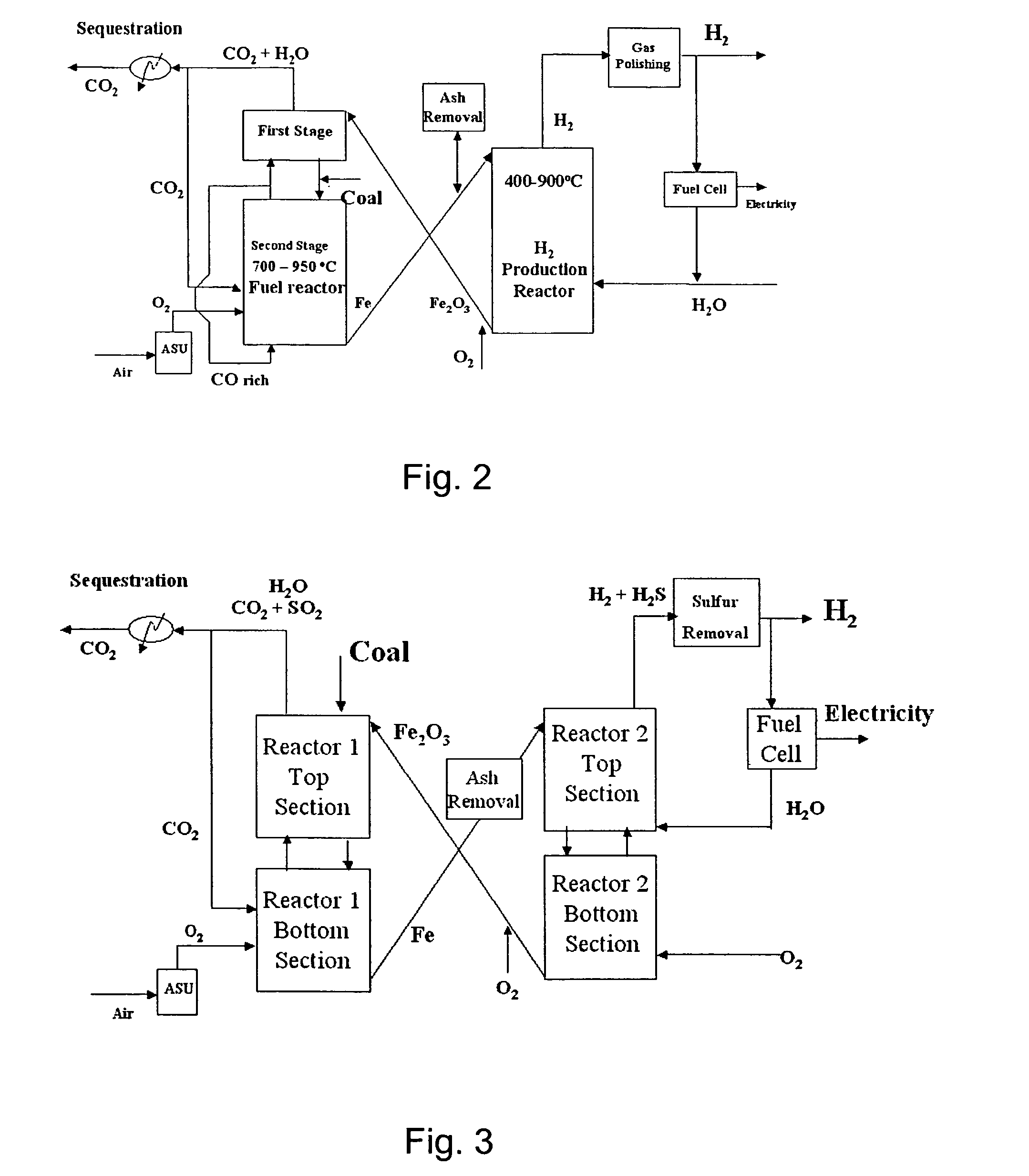

Combustion looping using composite oxygen carriers

ActiveUS20050175533A1Increase surface areaImprove energy conversion efficiencyHydrogen productionIndirect carbon-dioxide mitigationHydrogenCombustion

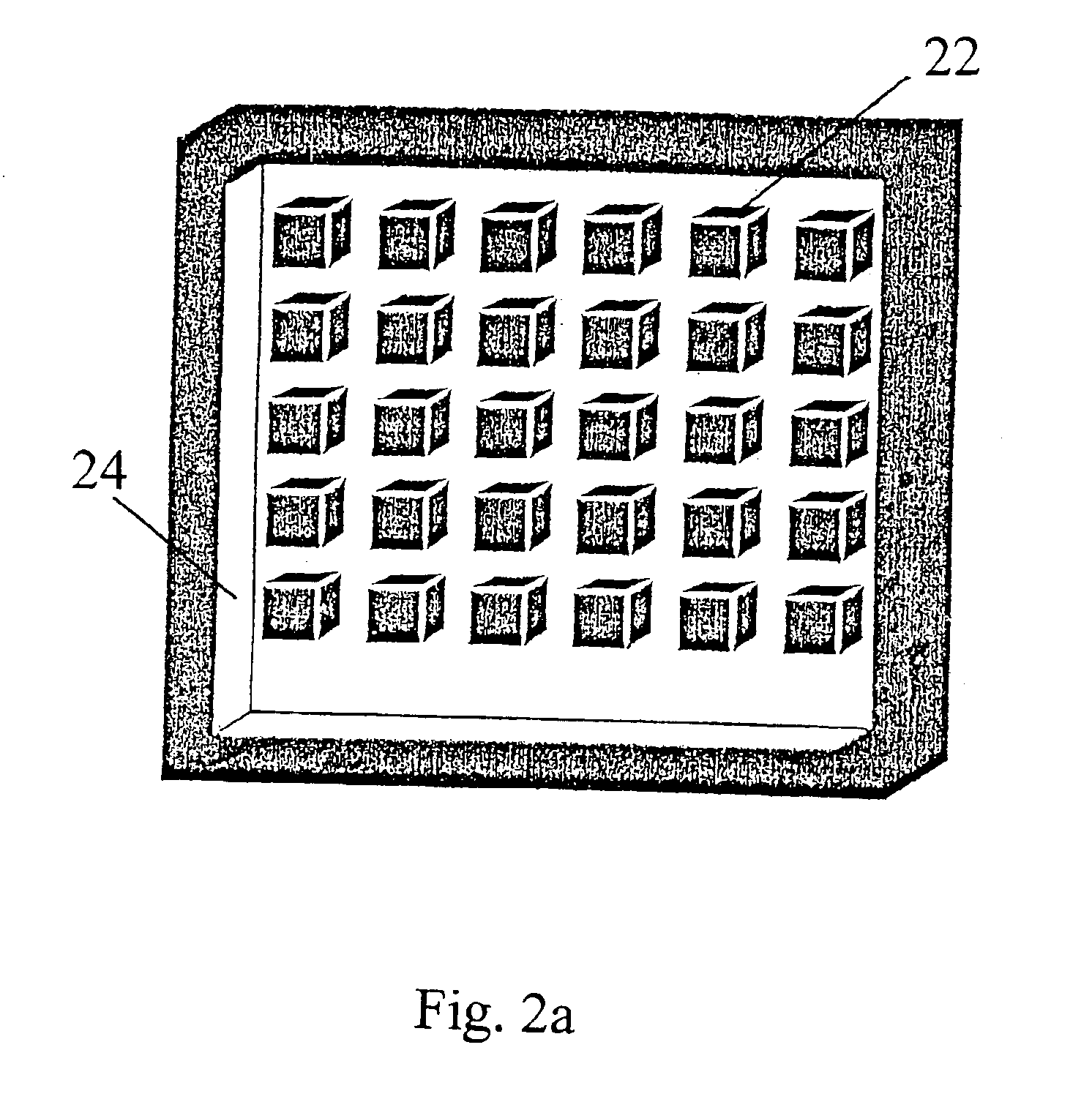

A method for producing hydrogen gas is provided and comprises reducing a metal oxide in a reduction reaction between a carbon-based fuel and a metal oxide to provide a reduced metal or metal oxide having a lower oxidation state, and oxidizing the reduced metal or metal oxide to produce hydrogen and a metal oxide having a higher oxidation state. The metal or metal oxide is provided in the form of a porous composite of a ceramic material containing the metal or metal oxide. The porous composite may comprise either a monolith, pellets, or particles.

Owner:OHIO STATE INNOVATION FOUND

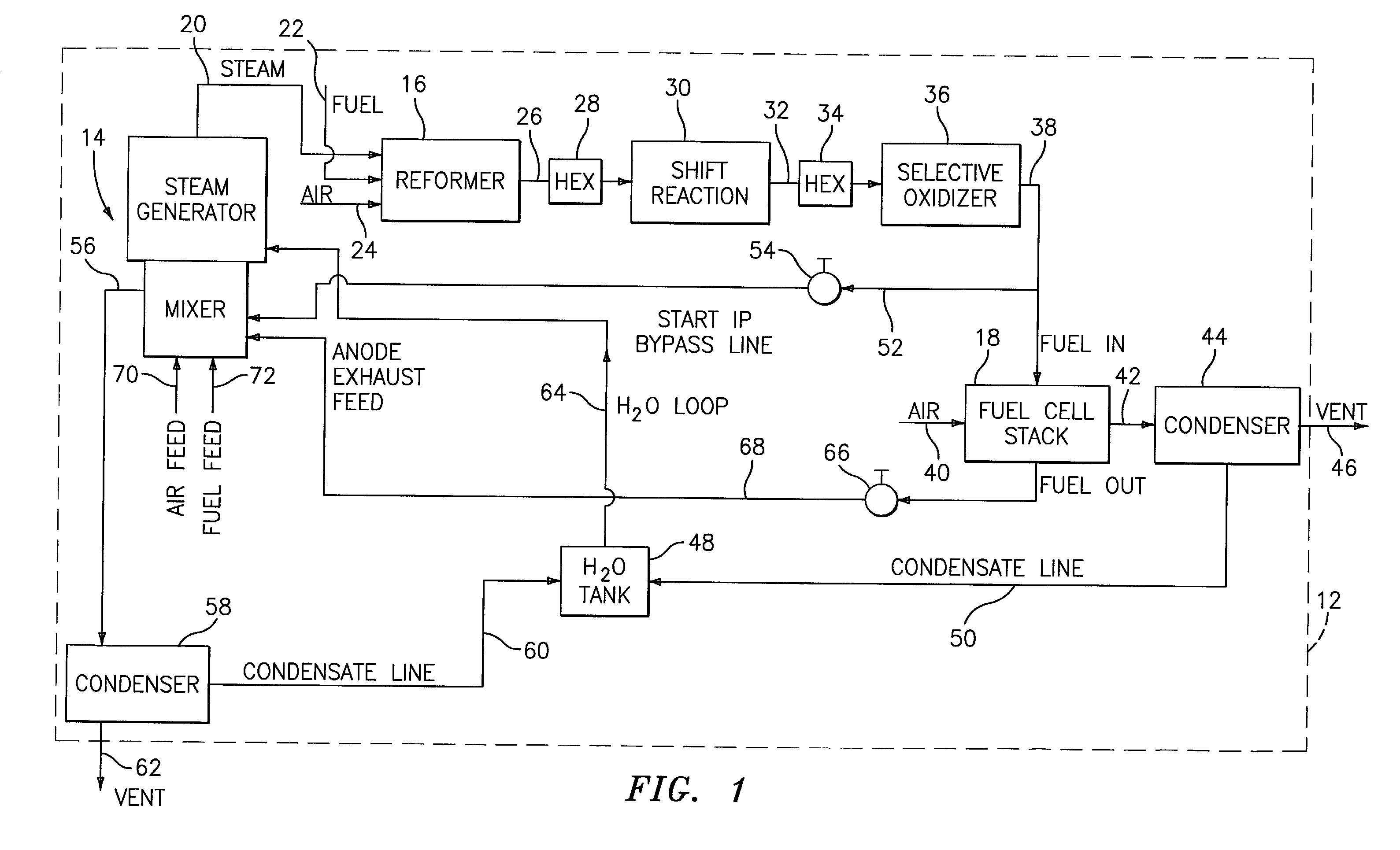

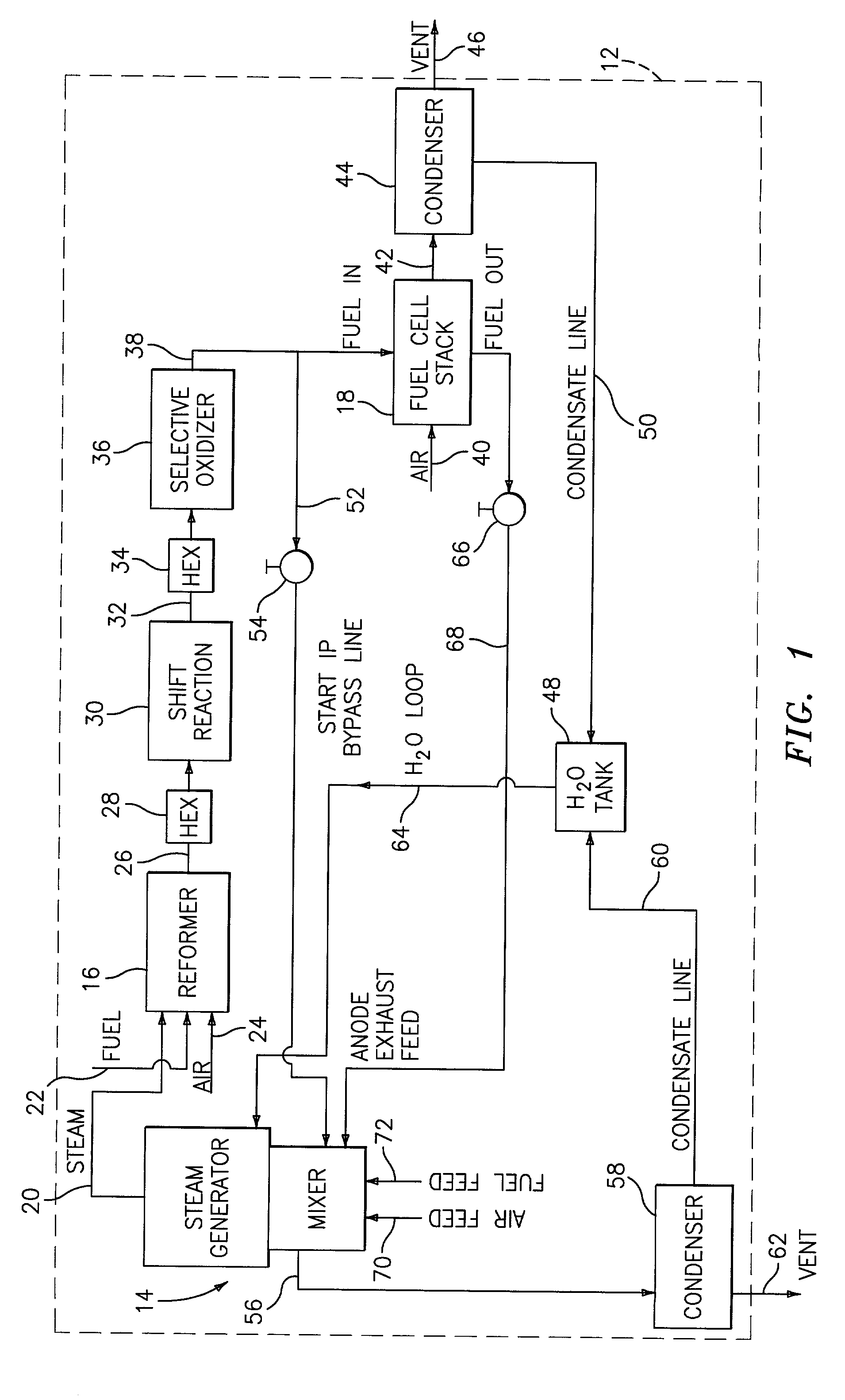

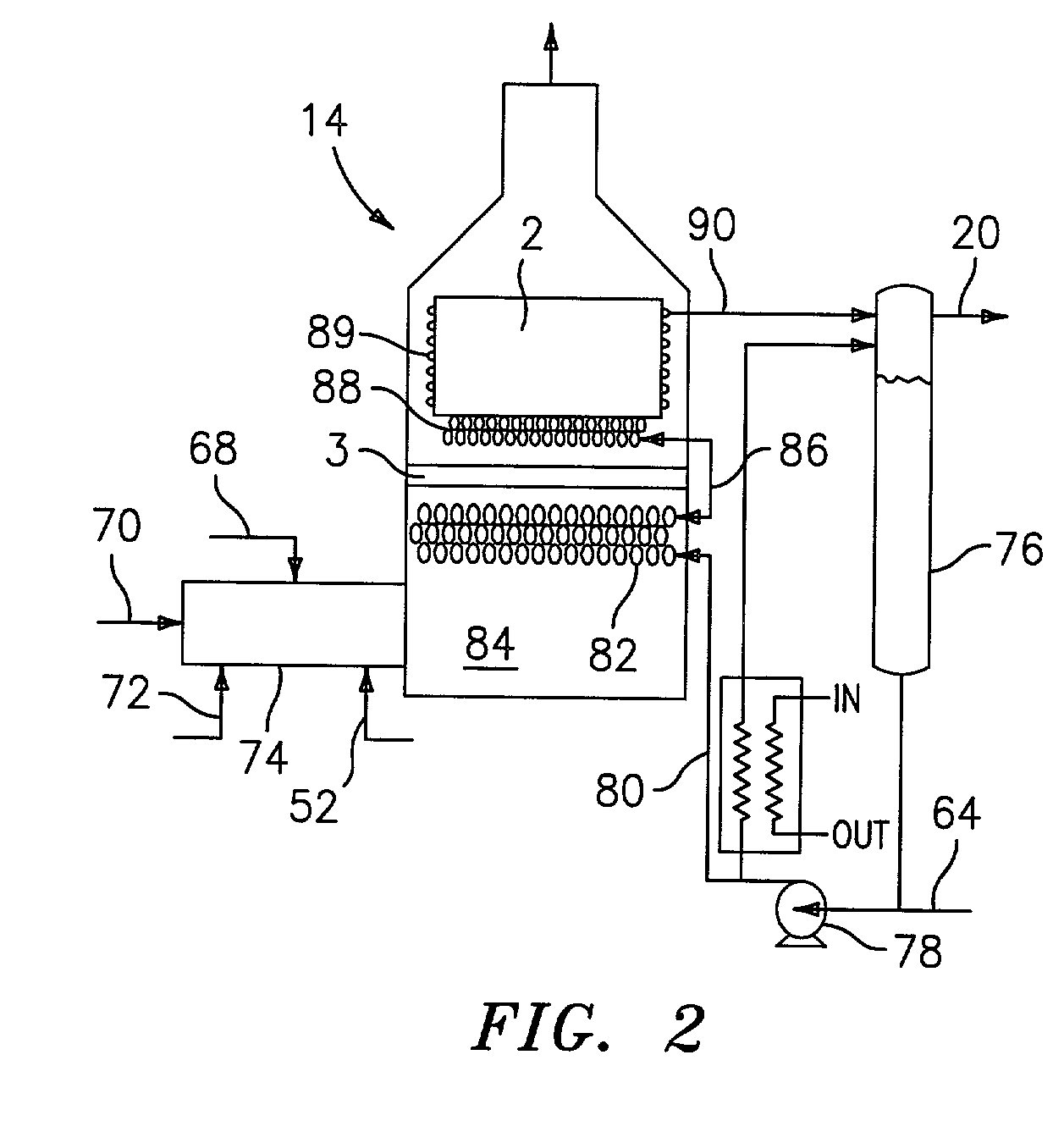

Steam generator for a PEM fuel cell power plant

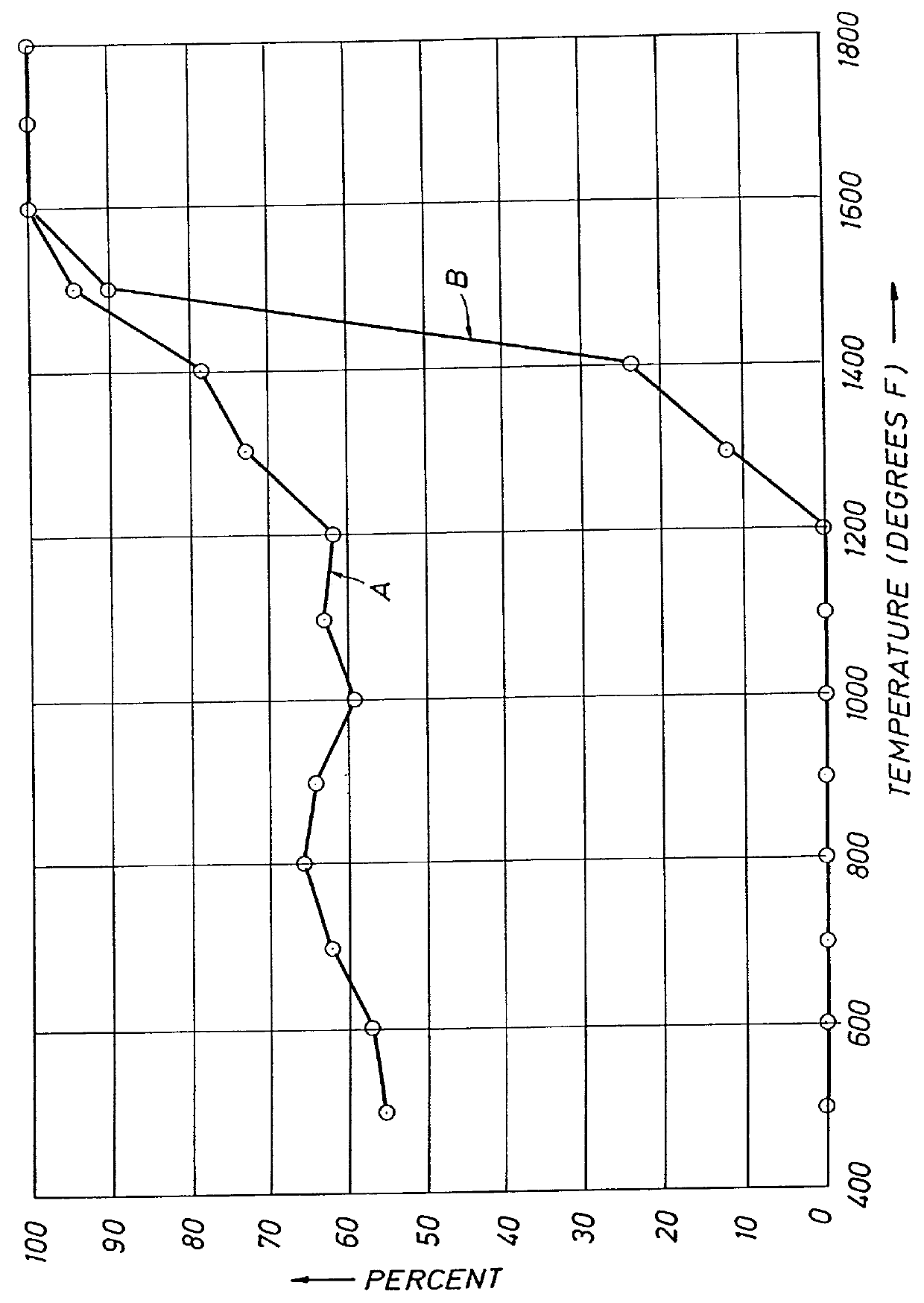

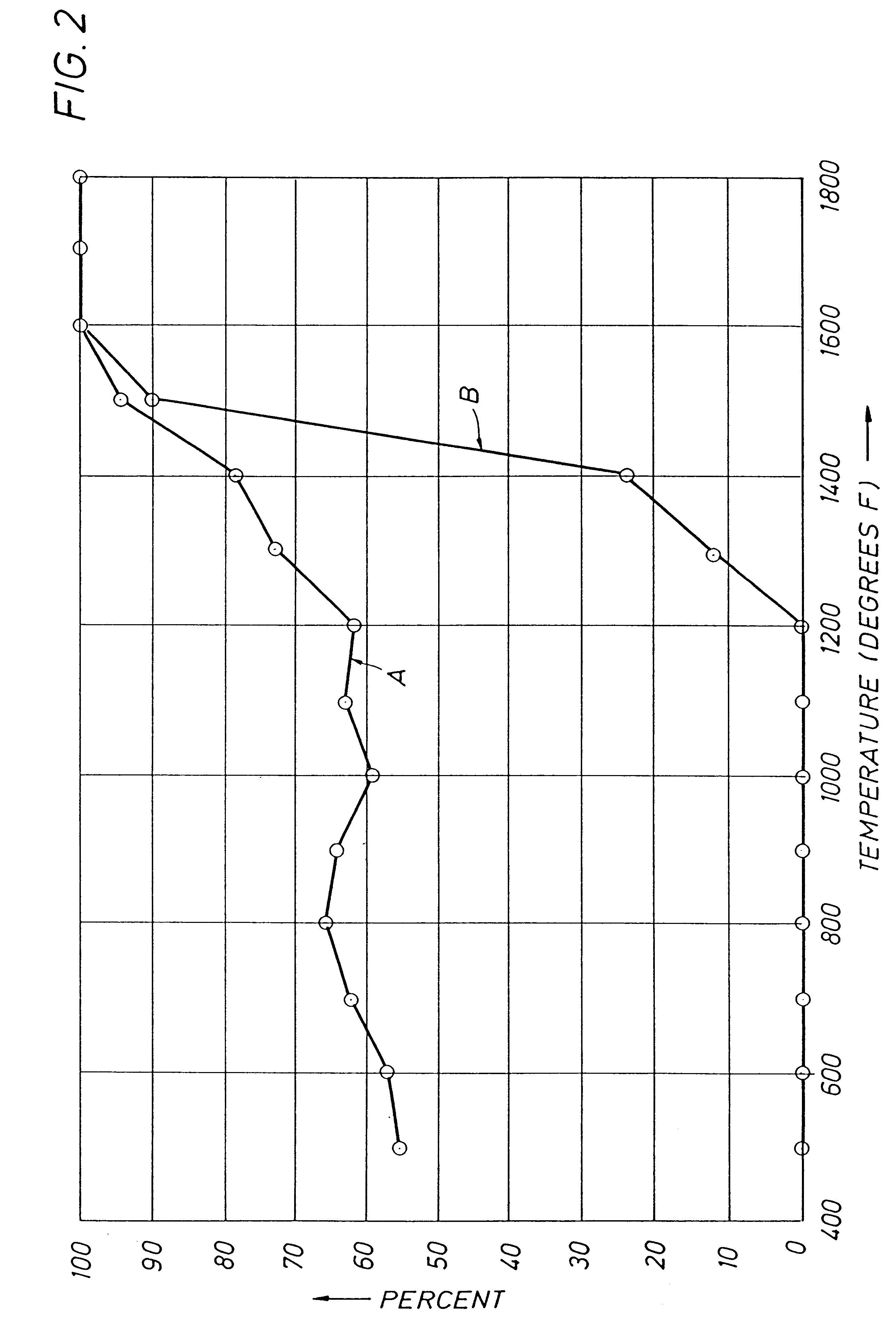

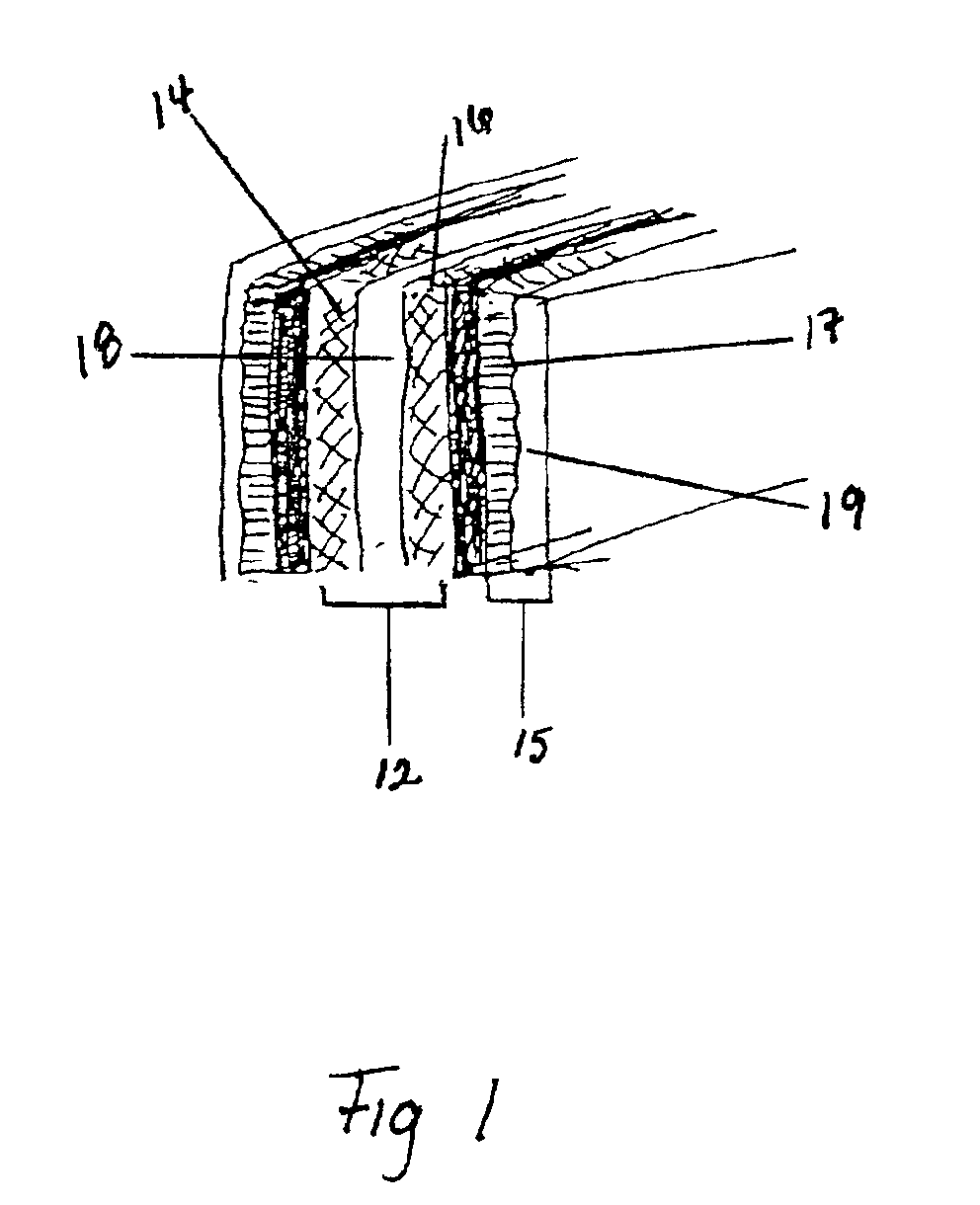

A burner assembly includes a catalyzed burner for combusting an anode exhaust stream from a polymer electrolyte membrane (PEM) fuel cell power plant. The catalysts coated onto the burner can be platinum, rhodium, or mixtures thereof. The burner includes open cells which are formed by a lattice, which cells communicate with each other throughout the entire catalyzed burner. Heat produced by combustion of hydrogen in the anode exhaust stream is used to produce steam for use in a steam reformer in the PEM fuel cell assembly. The catalyzed burner has a high surface area wherein about 70-90% of the volume of the burner is preferably open cells, and the burner has a low pressure drop of about two to three inches water from the anode exhaust stream inlet to the anode exhaust stream outlet . The burner assembly operates at essentially ambient pressure and at a temperature of up to about 1,700° F. (646° C.). The burner assembly can combust anode exhaust during normal operation of the fuel cell assembly. The burner assembly also includes an adjunct burner which can combust gasoline or anode bypass gas (the latter of which is a reformed fuel gas which is tapped off of the fuel cell stack fuel inlet line) during startup of the fuel cell power plant. Once start up of the fuel cell power plant is achieved, the burner assembly will need only combustion of the anode exhaust by the catalytic burner to produce steam for the reformer.

Owner:BALLARD POWER SYSTEMS

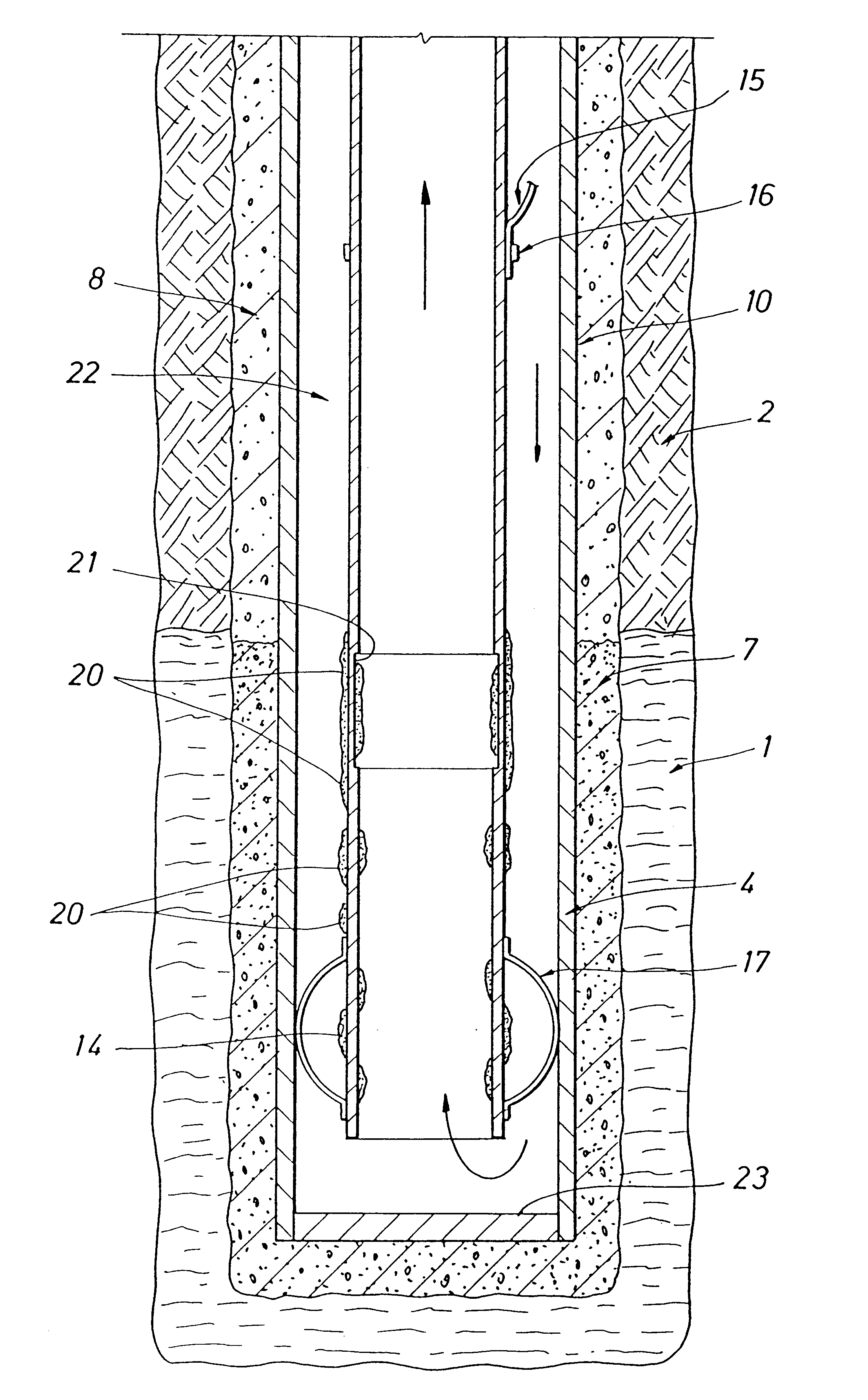

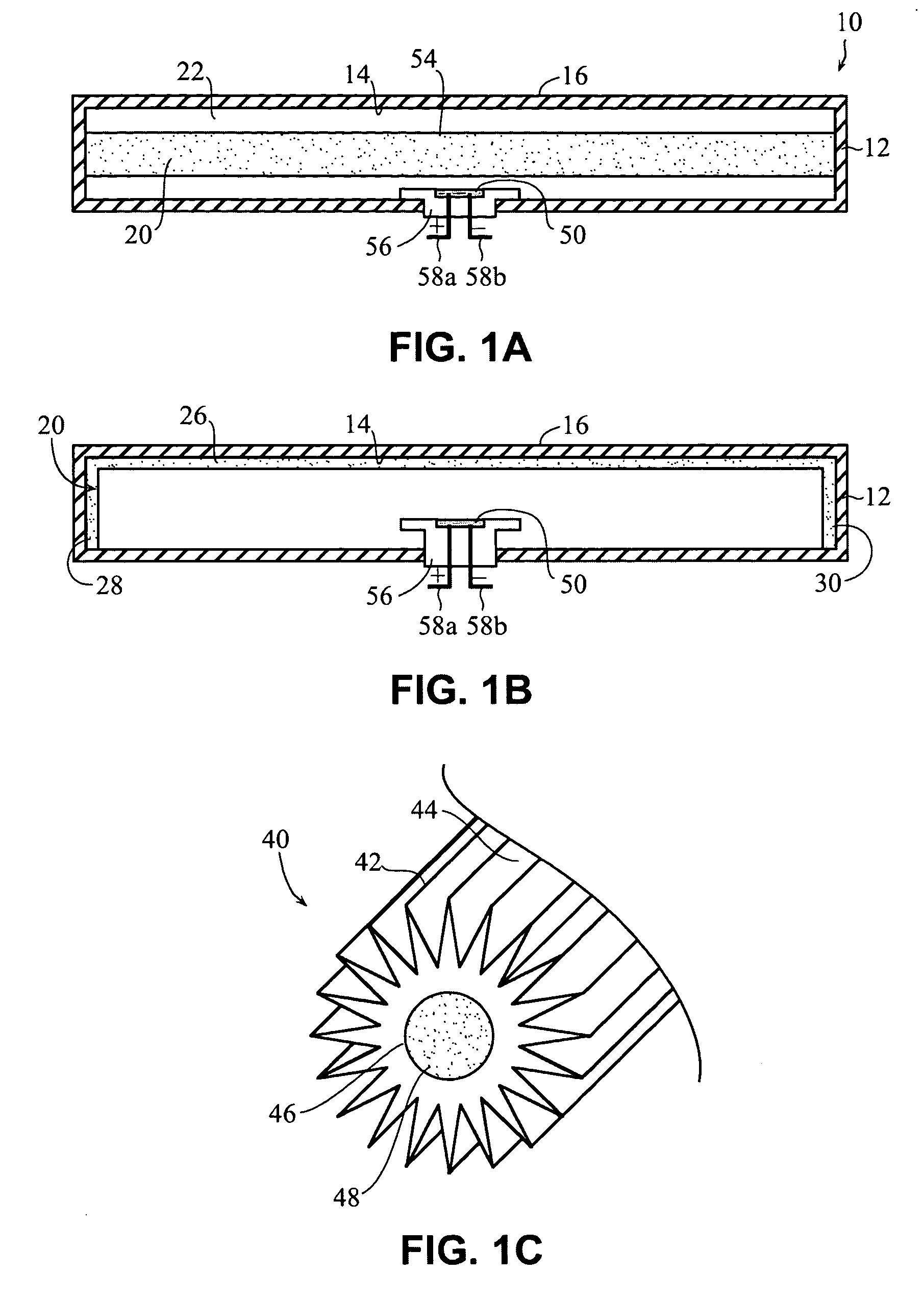

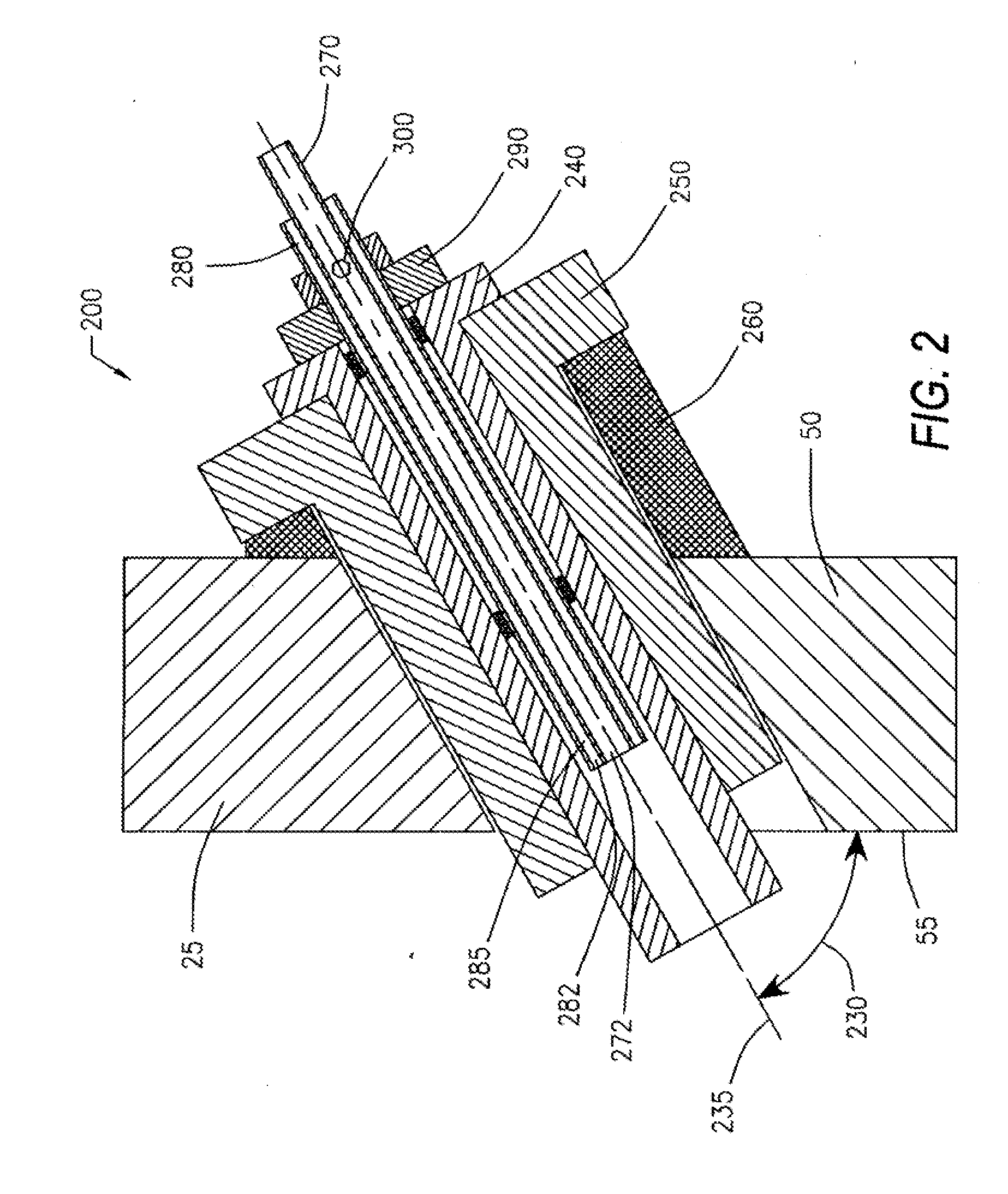

Method for ignition of flameless combustor

InactiveUS6269882B1Easy to igniteImprove the level ofApparel holdersIncandescent ignitionCombustorCombustion chamber

A combustor method and apparatus is provided. The method utilizes flameless combustion with one or more of three improvements to enhance ignition of the flameless combustor. A catalytic surface can be provided within a combustion chamber to provide flameless combustion at least in the vicinity of the catalytic surface at a temperature that is much lower than the autoignition temperature of fuel in air without the presence of the catalytic surface. Nitrous oxide or supplemental oxygen may also be used as an oxidant either instead of air or with air to reduce ignition temperatures. Further, electrical energy can be passed through the fuel conduit, raising the temperature of the conduit to a temperature above which the fuel will ignite when combined with the oxidant.

Owner:SHELL OIL CO

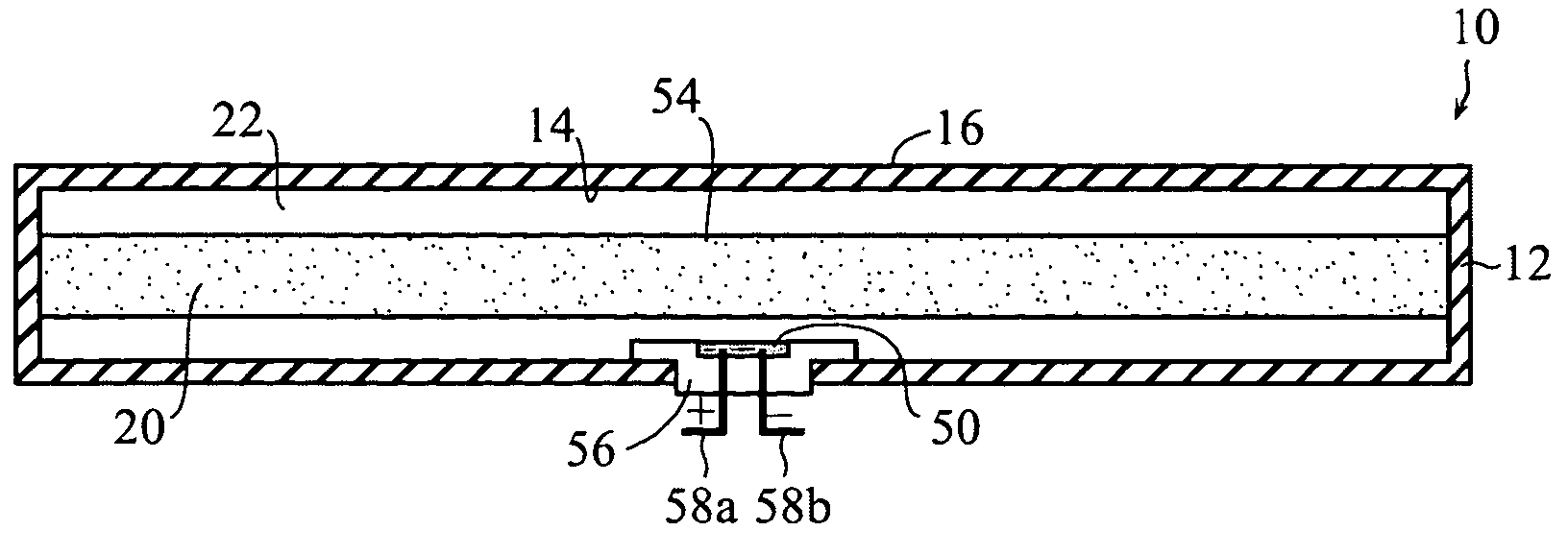

Self-contained heating unit and drug-supply unit employing same

InactiveUS20050079166A1Exothermal chemical reaction heat productionSemiconductor/solid-state device manufacturingSolid fuelEngineering

Heating units, drug supply units and drug delivery articles capable of rapid heating are disclosed. Heating units comprising a substrate and a solid fuel capable of undergoing an exothermic metal oxidation reaction disposed within the substrate are disclosed. Drug supply units and drug delivery articles wherein a solid fuel is configured to heat a substrate to a temperature sufficient to rapidly thermally vaporize a drug disposed thereon are also disclosed.

Owner:ALEXZA PHARMA INC

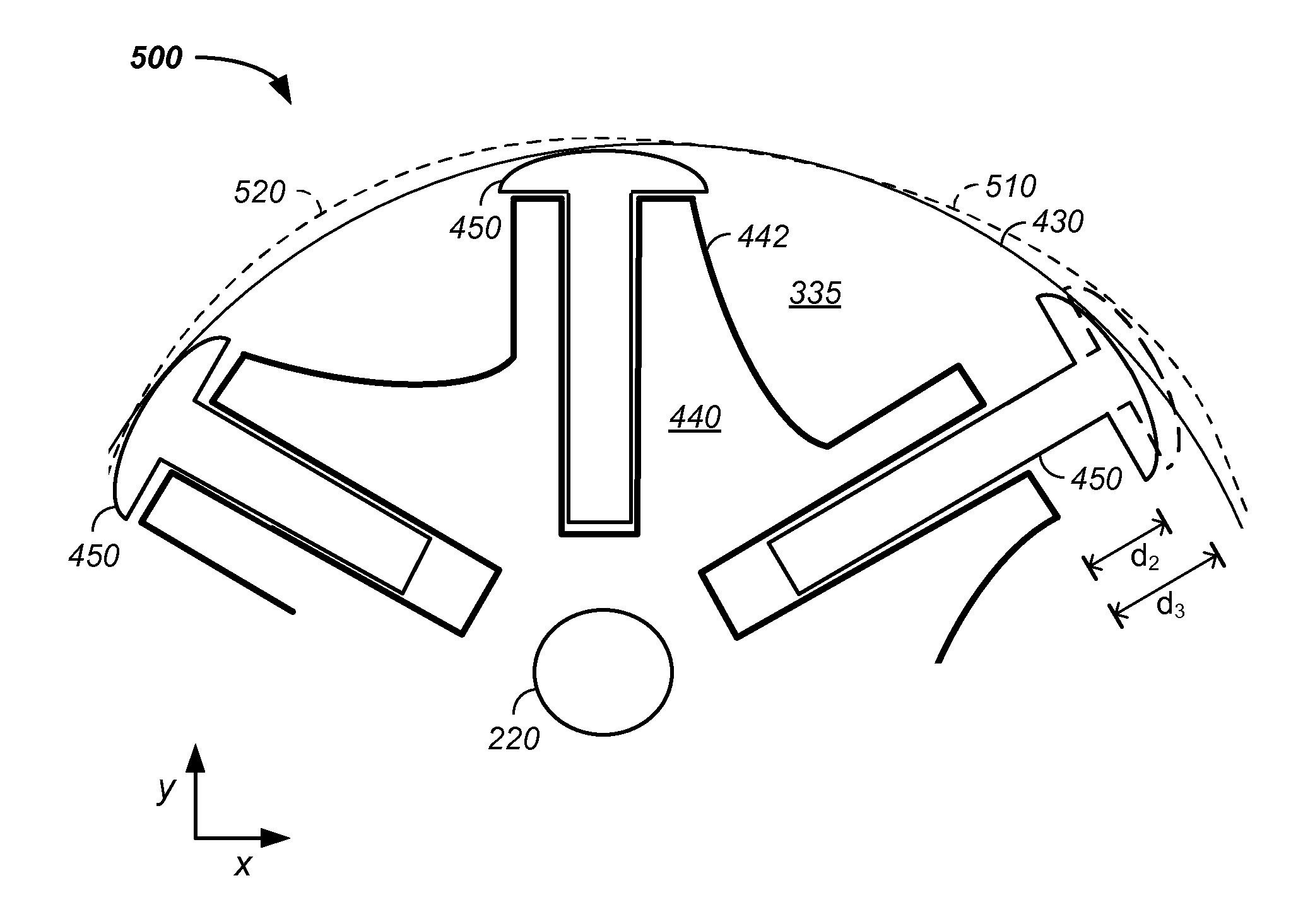

Rotary engine expansion chamber apparatus and method of operation therefor

ActiveUS8523547B2Internal combustion piston enginesOscillating piston enginesRotary engineExpansion chamber

Owner:PEKRUL MERTON W

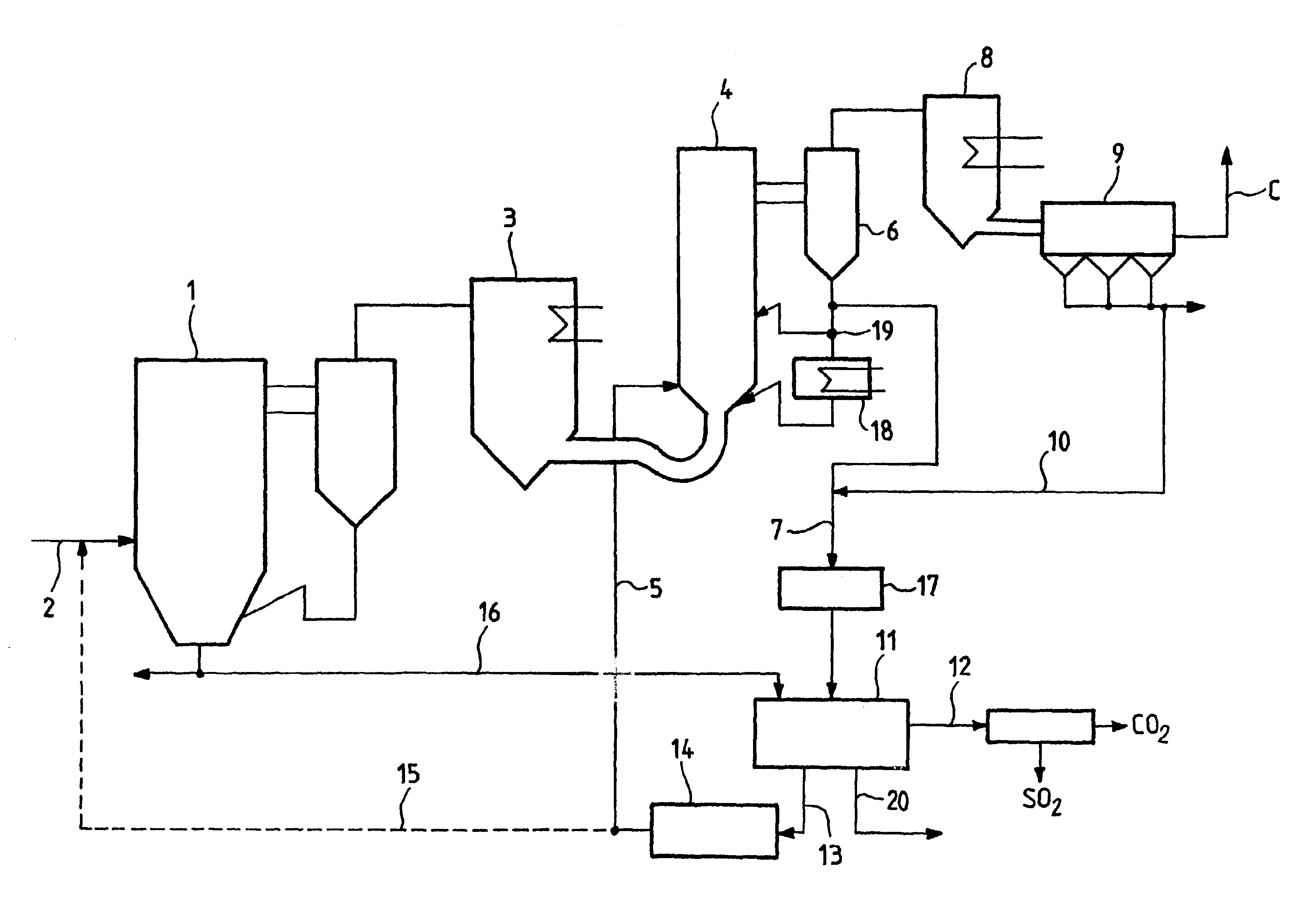

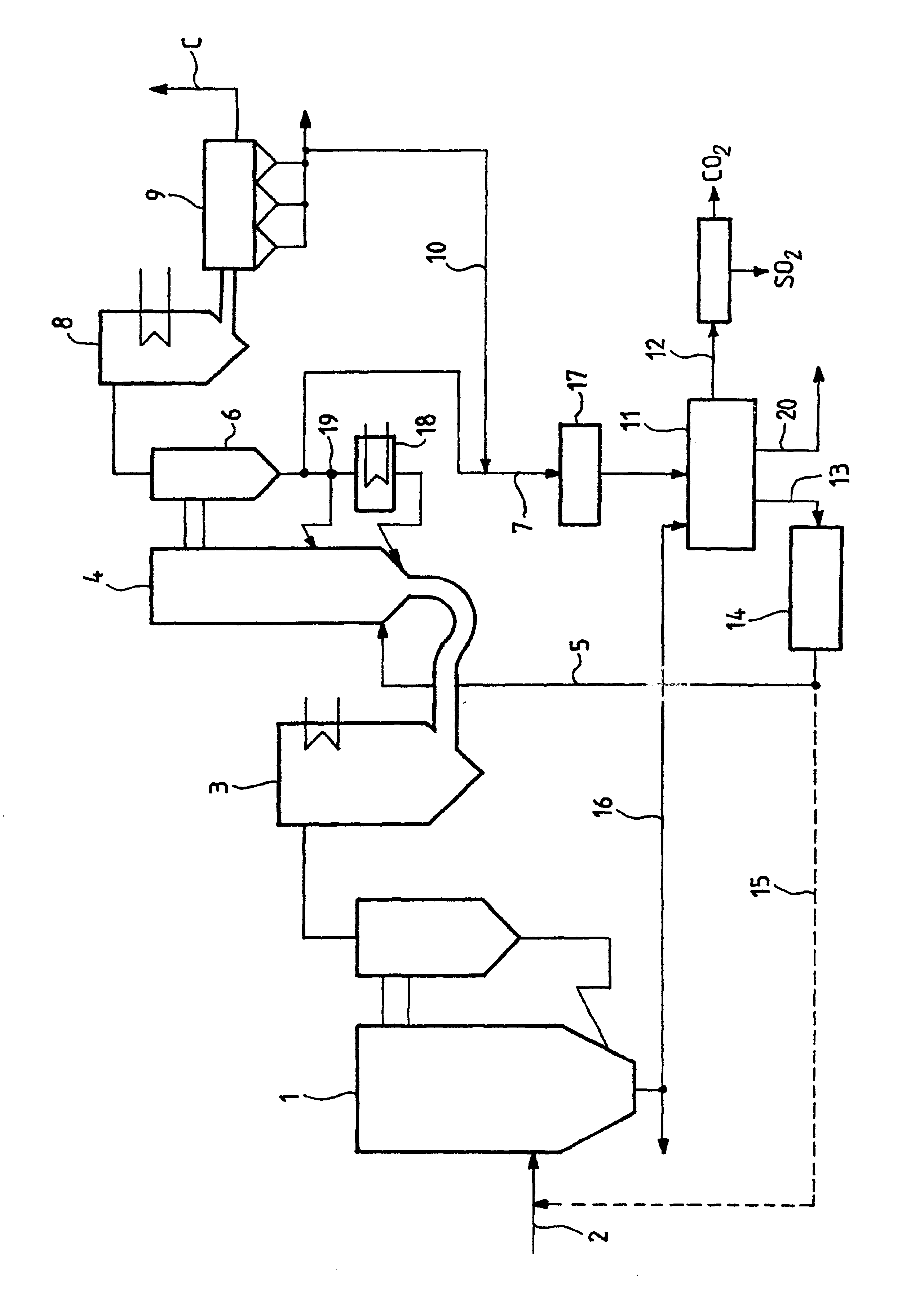

Method of simultaneously reducing CO2 and SO2 emissions in a combustion installation

InactiveUS6737031B2Reduce carbon dioxide emissionsFluidized bed combustionGas treatmentCombustionFlue gas

The method of simultaneously reducing carbon dioxide (CO2) emissions and sulfur dioxide (SO2) emissions produced by the combustion of carbon-containing matter in a hearth consists in injecting into the hearth a calcium-based agent, a fraction of which absorbs SO2 after decarbonization, and then, after the flue gases have been subjected to intermediate cooling, in causing them to transit via a first reactor and in putting them in contact therein with the other fraction of the absorbant that has not reacted with SO2 so as to capture CO2 from the flue gases by carbonization, then, in a separator, in extracting the solids contained in the flue gases output from the first reactor so as to subject them to heat treatment in a second reactor in order to extract CO2 therefrom by decarbonization and in order to recycle the resulting regenerated CO2 absorbant to the first reactor.

Owner:GENERAL ELECTRIC TECH GMBH

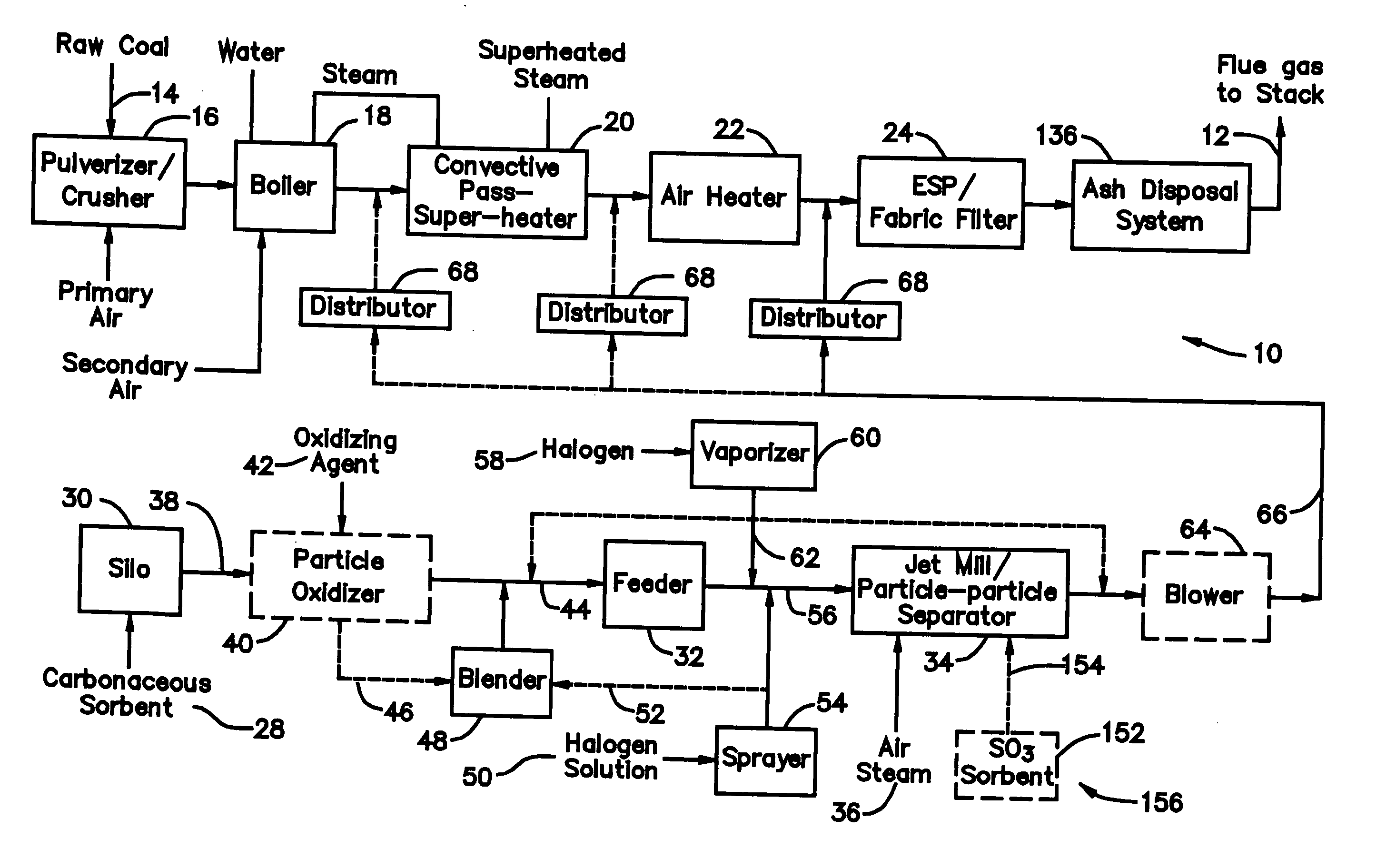

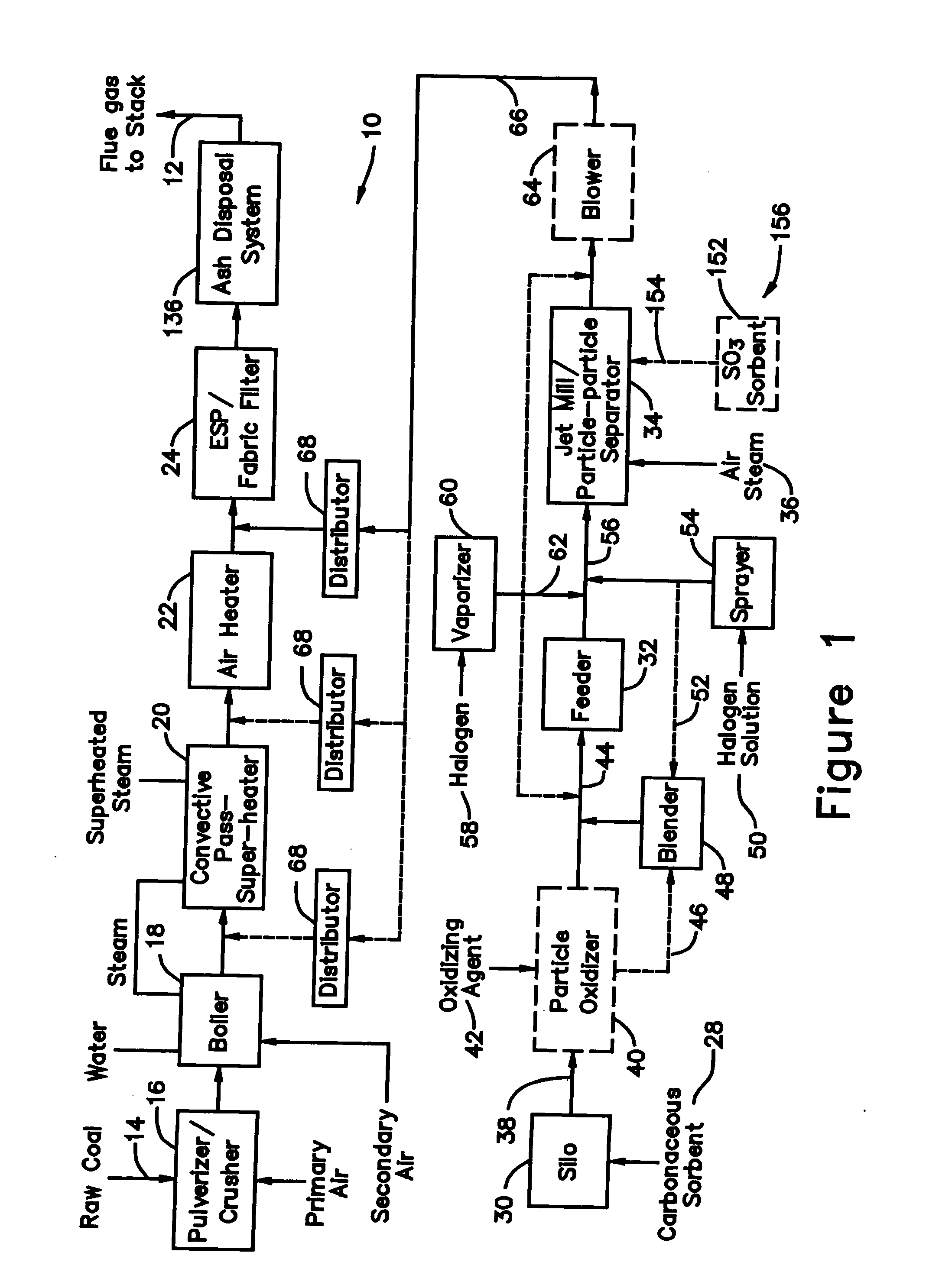

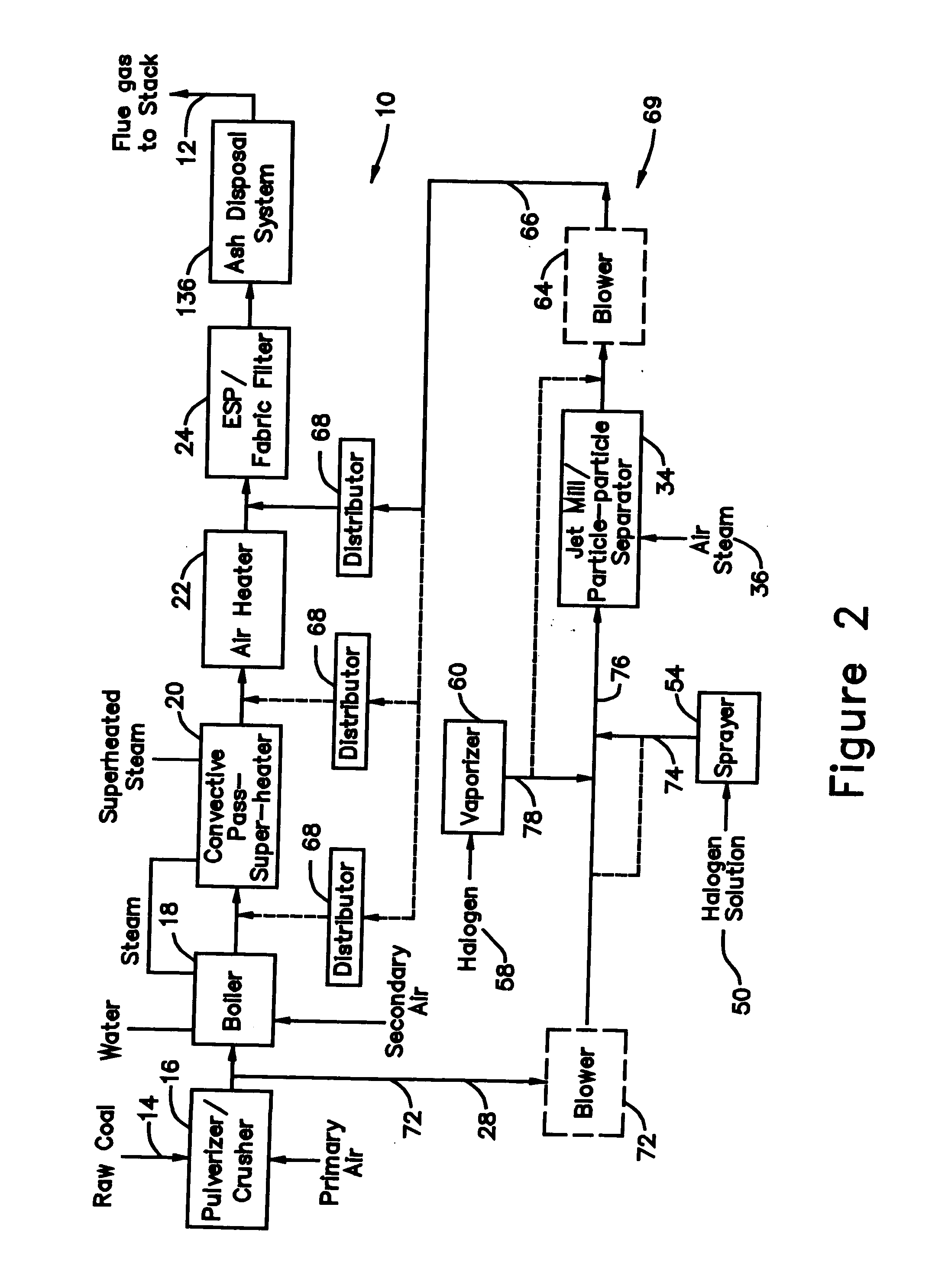

Control of mercury emissions from solid fuel combustion

ActiveUS20050039598A1Remove pollutantsEasy to captureGas treatmentEmission preventionSorbentSolid fuel

A system 26 for removing elemental mercury or mercury compounds handles carbonaceous sorbent 28 of a starter batch stored in a silo 30 in an agglomerated state. The sorbent 28 is fed by a feeder 32 to a separation device 34, which comminutes (if necessary) and de-agglomerates the sorbent particles 28 to their primary size distribution. This device 34 may be a particle-particle separator or a jet mill, where compressed air or high-pressure steam is the energy source. The de-agglomerated sorbent 28 of a contact batch created from the starter batch is conveyed by an airsteam for injection at a contact location 66 in a flue gas duct whereat carbonaceous sorbent of the contact batch adsorbs mercury from the flue gas.

Owner:GENERAL ELECTRIC TECH GMBH

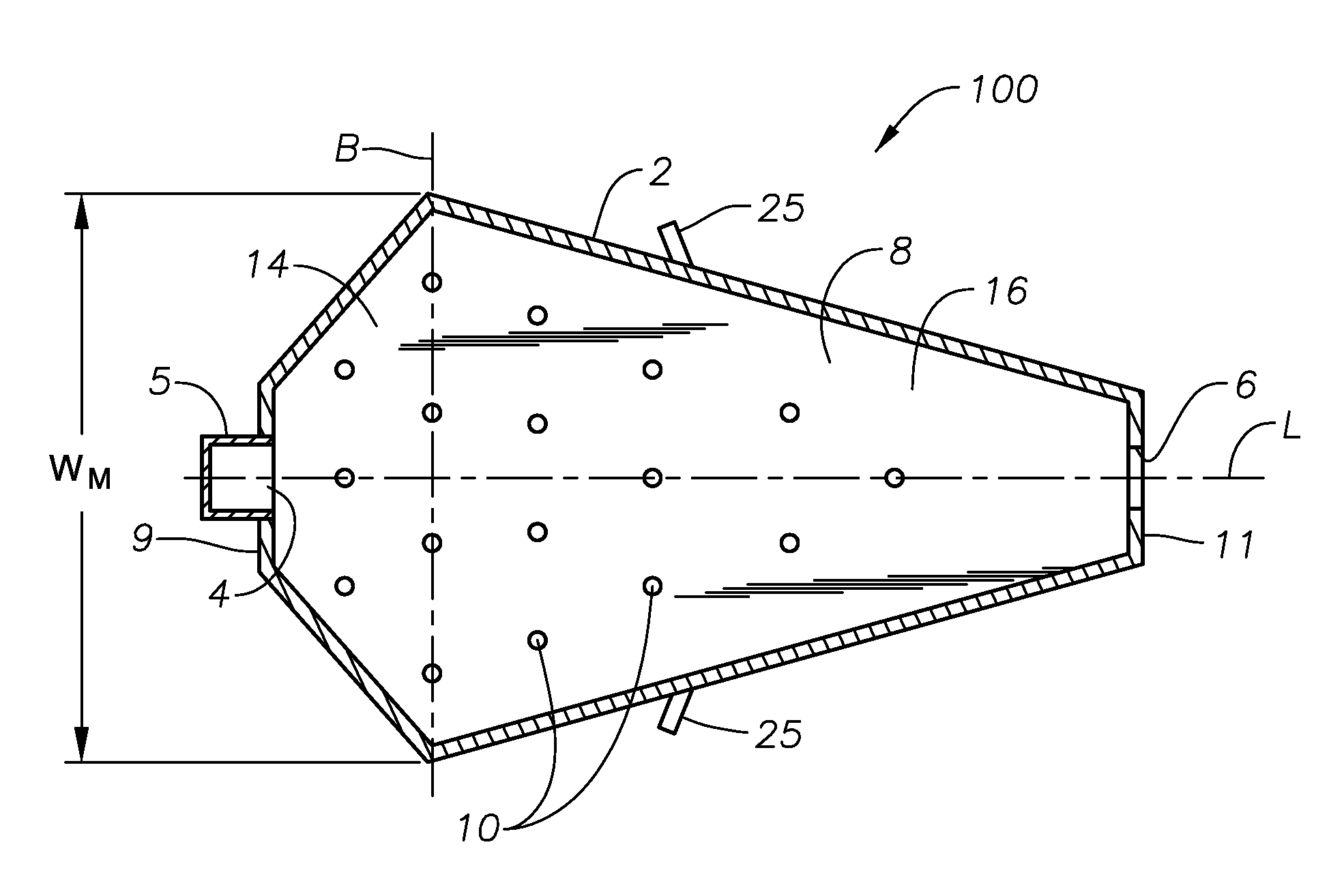

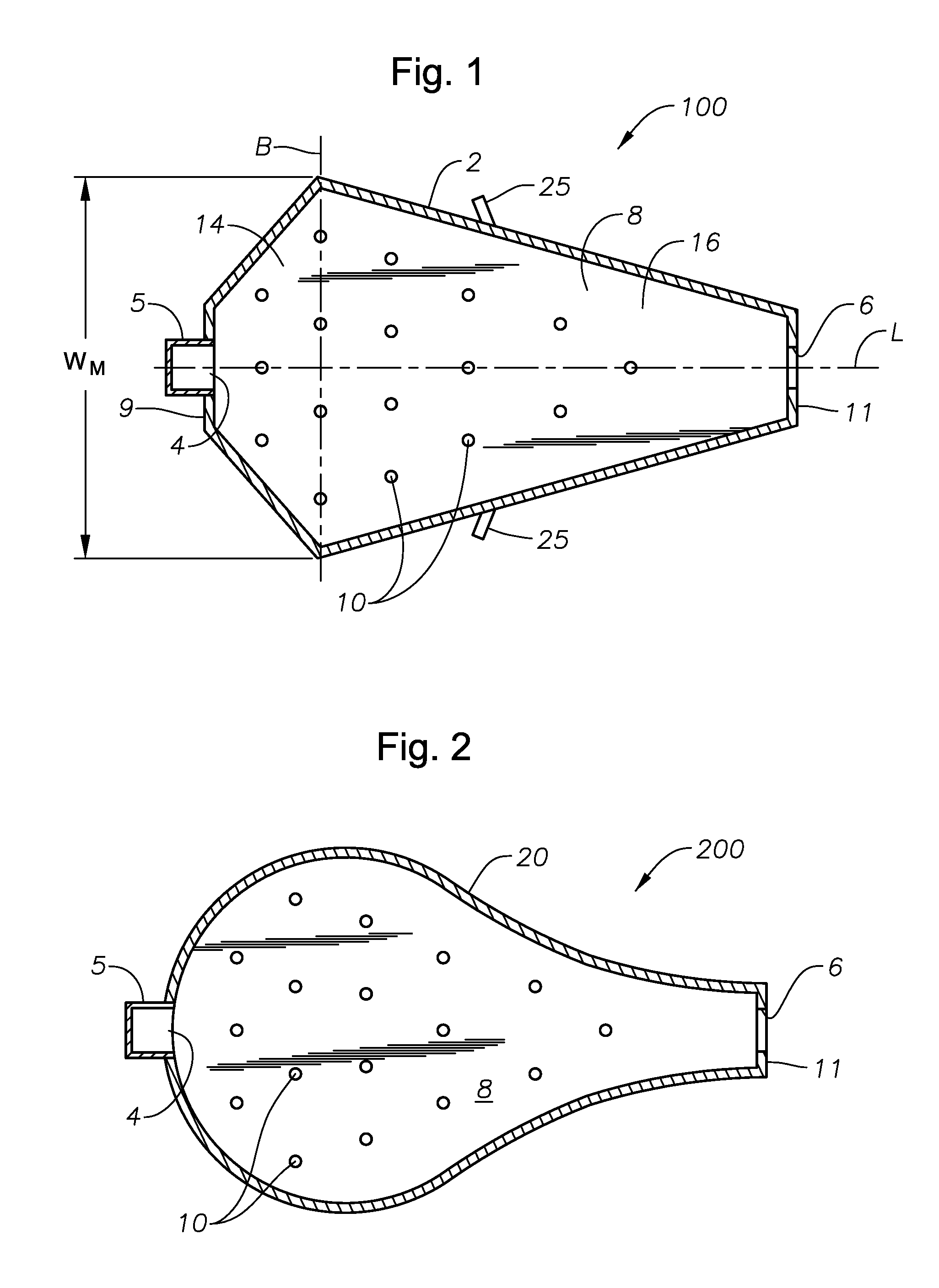

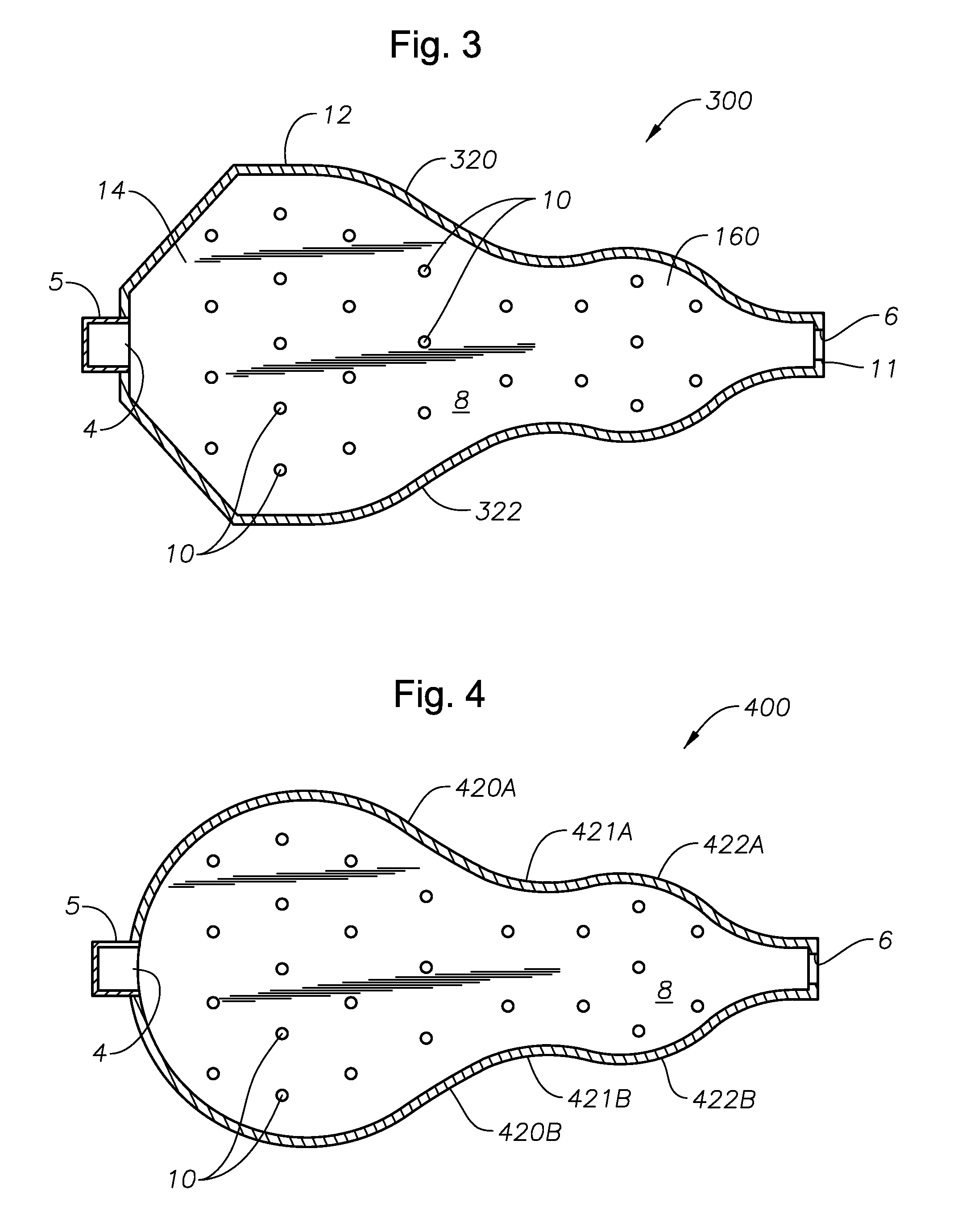

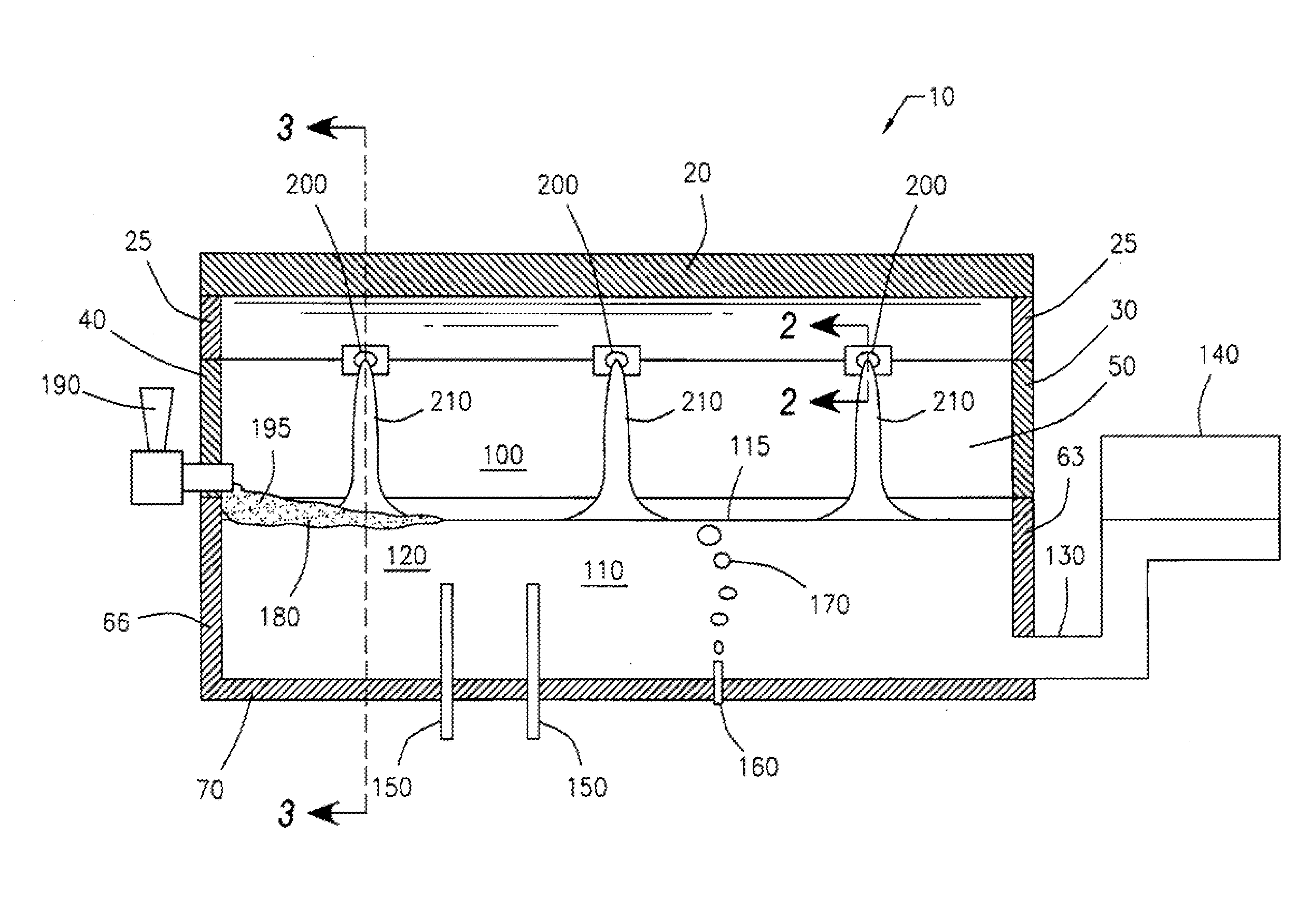

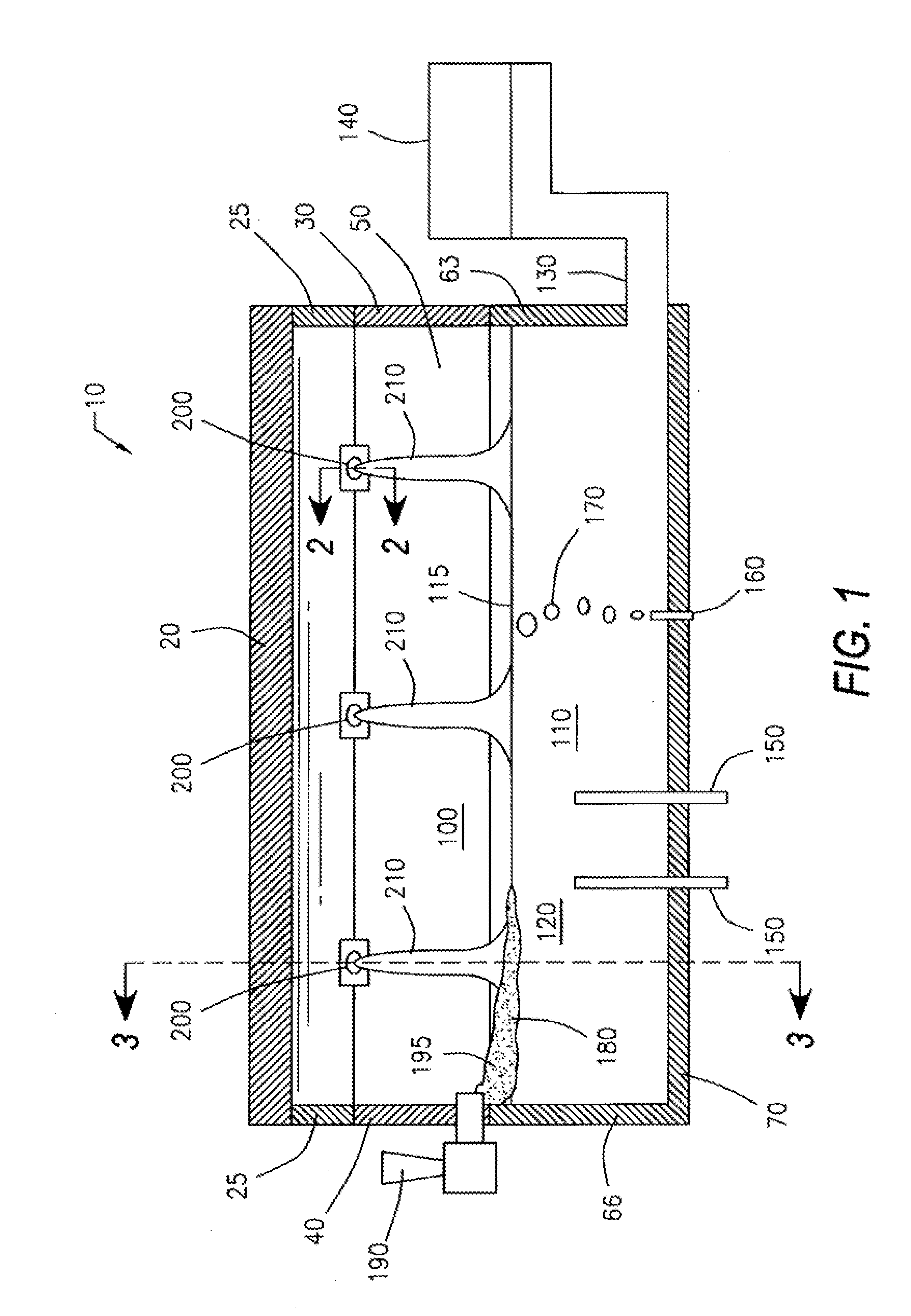

Panel-cooled submerged combustion melter geometry and methods of making molten glass

ActiveUS20110308280A1Reduce dead flow (stagnant) regionSmall sizePulsating combustionTank furnacesCombustorDirect combustion

A melter apparatus includes a floor, a ceiling, and a substantially vertical wall connecting the floor and ceiling at a perimeter of the floor and ceiling, a melting zone being defined by the floor, ceiling and wall, the melting zone having a feed inlet and a molten glass outlet positioned at opposing ends of the melting zone. The melting zone includes an expanding zone beginning at the inlet and extending to an intermediate location relative to the opposing ends, and a narrowing zone extending from the intermediate location to the outlet. One or more burners, at least some of which are positioned to direct combustion products into the melting zone under a level of molten glass in the zone, are also provided.

Owner:MANVILLE JOHNS

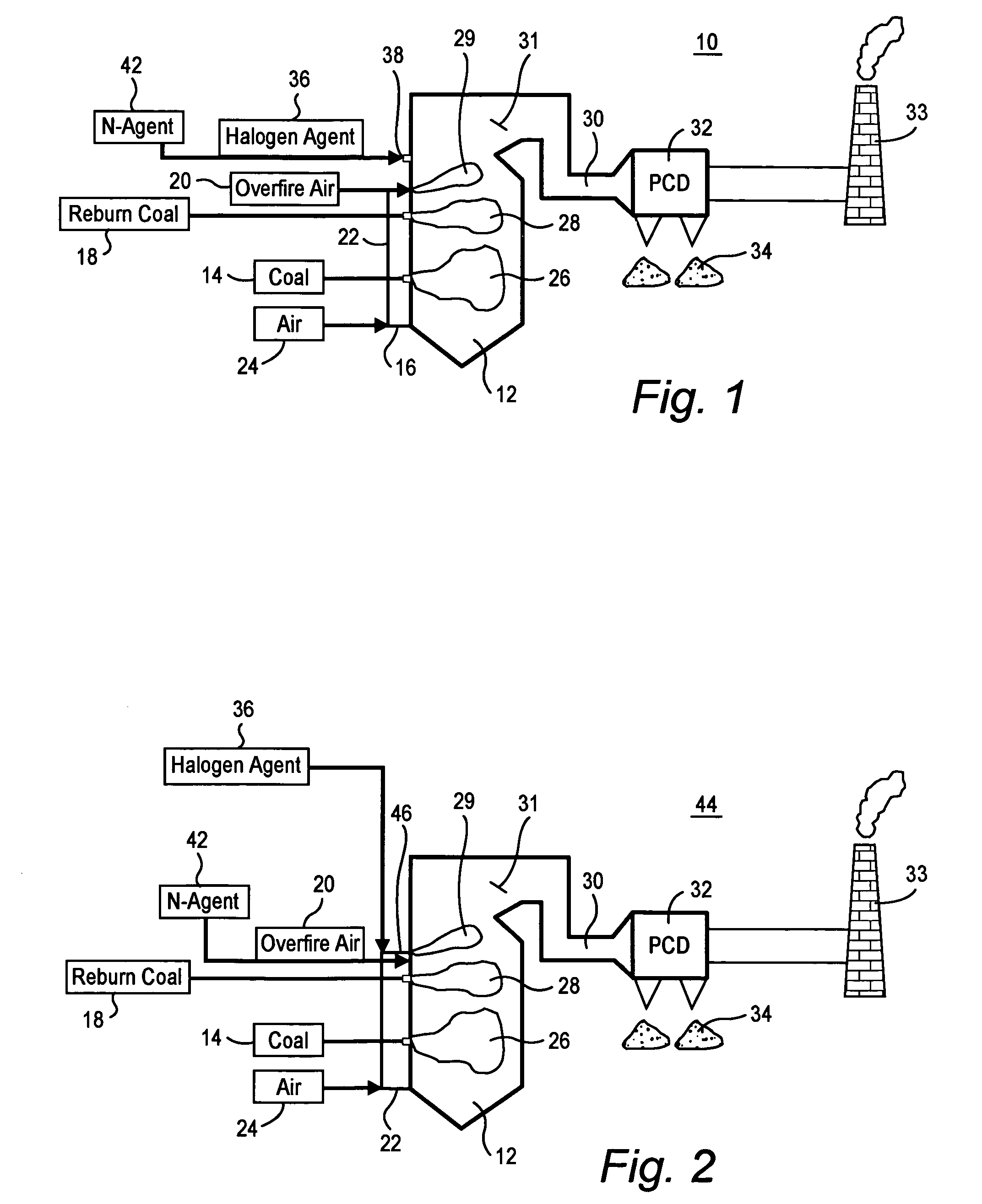

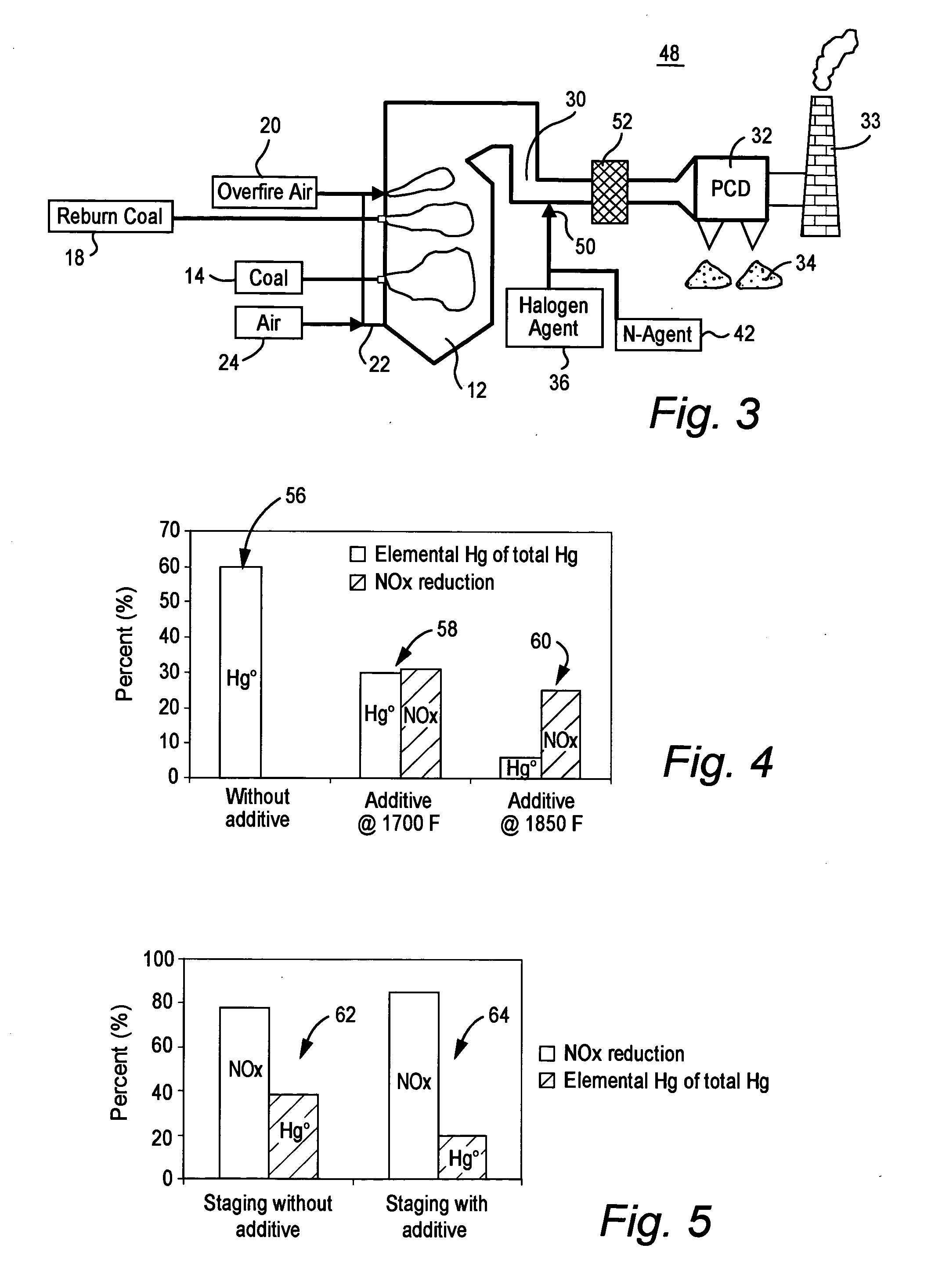

Method for removal of mercury emissions from coal combustion

A method to reduce emissions in flue gas due to combustion of coal in a combustion unit including the steps of: combusting coal in a primary combustion zone of the combustion unit; releasing elemental mercury from the combustion into the flue gas; injecting NH4Cl, NH4Br, or NH4I into the flue gas; oxidizing the elemental mercury with halogen from the additive; adsorbing the oxidized mercury generated by the combustion of the coal with an adsorbent in the flue gas, and collecting the adsorbent with the oxidized mercury in a combustion waste treatment system.

Owner:GENERAL ELECTRIC CO

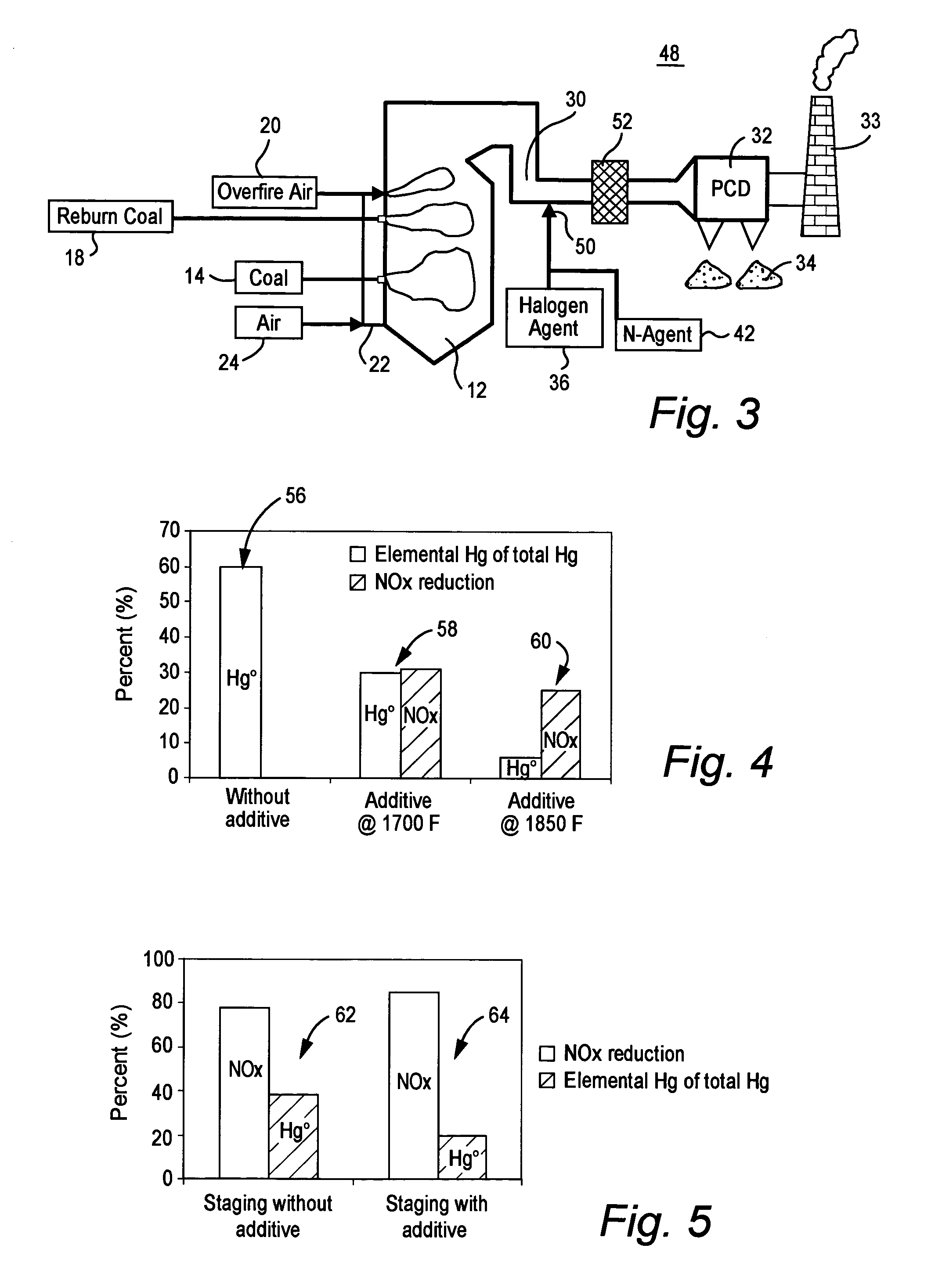

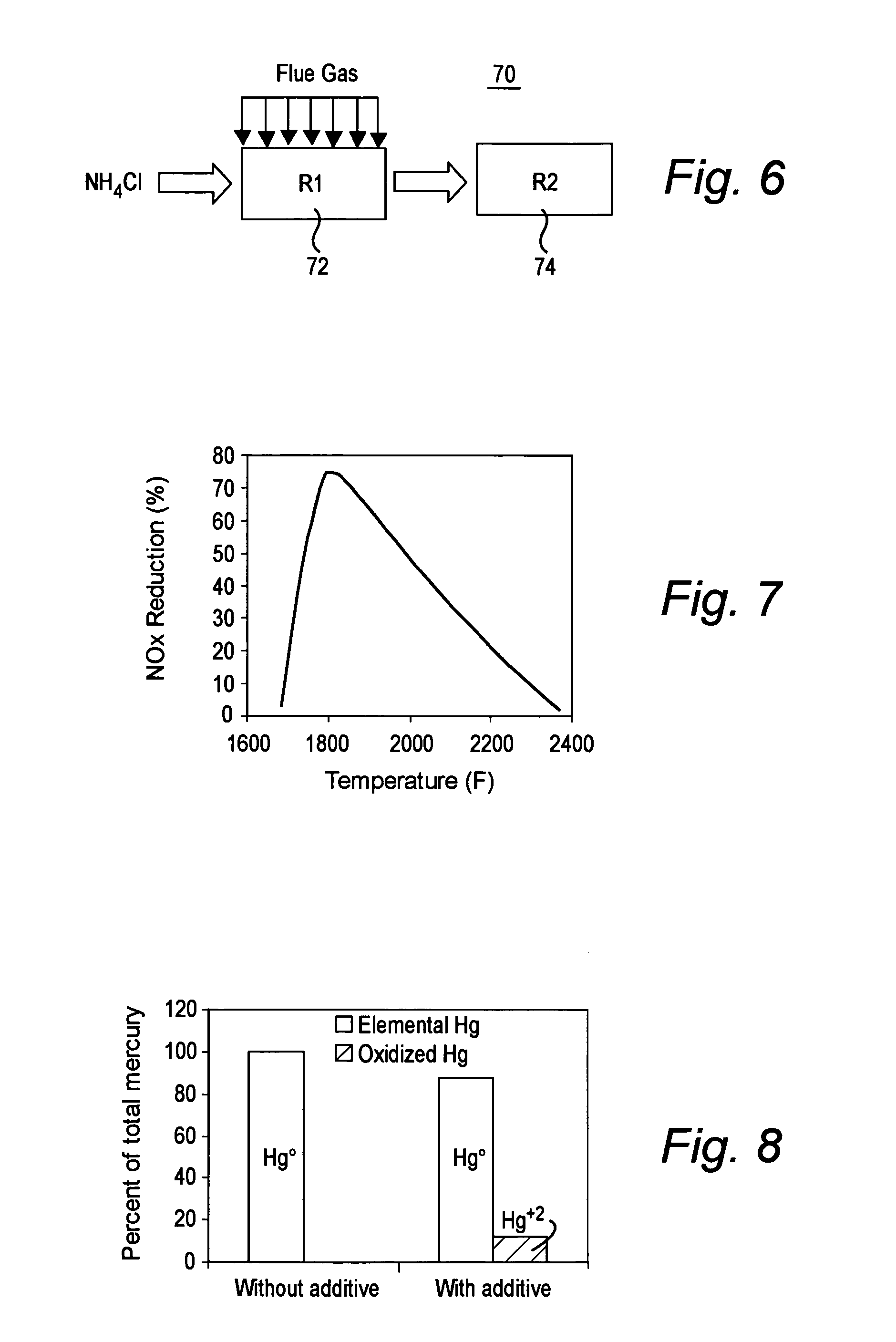

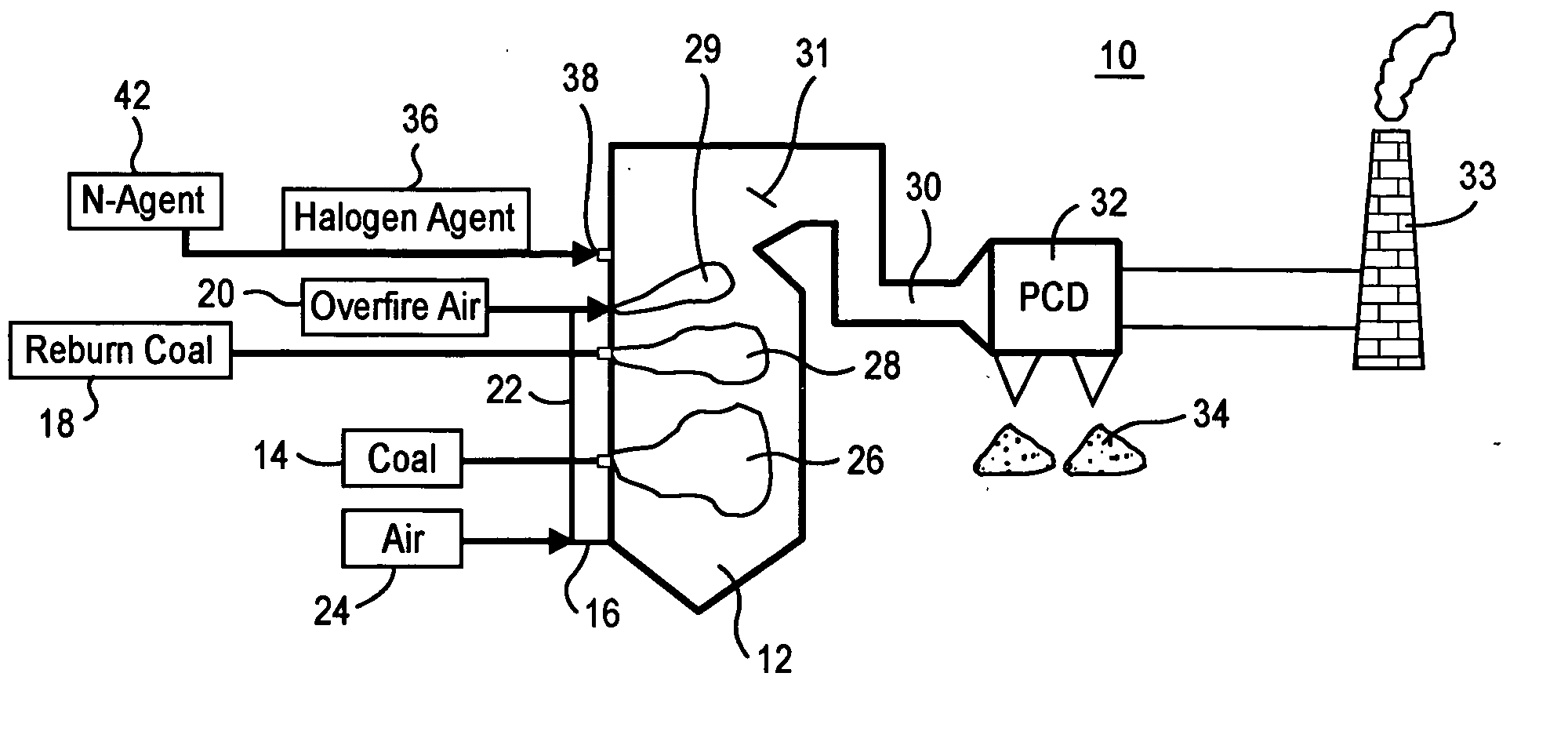

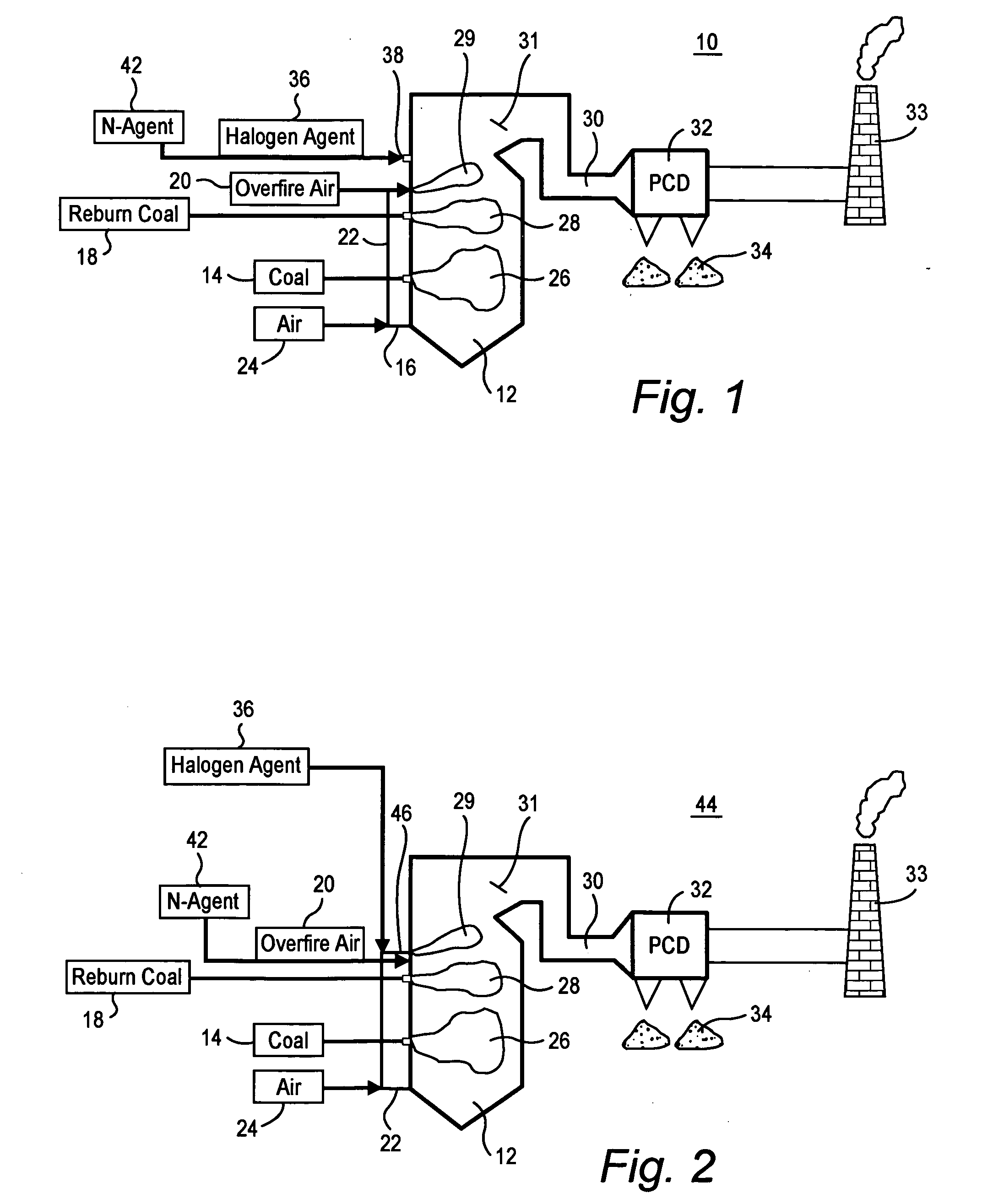

Method and system for removal of NOx and mercury emissions from coal combustion

InactiveUS20050147549A1Emission reductionReduce mercury in gas emissionCombination devicesGas treatmentHalogenSorbent

A method to reduce emissions in flue gas due to combustion of coal in a combustion unit including the steps of: combusting coal in a primary combustion zone of the combustion unit; releasing elemental mercury from the combustion into the flue gas; injecting NH4Cl, NH4Br, or NH4I into the flue gas; oxidizing the elemental mercury with halogen from the additive; adsorbing the oxidized mercury generated by the combustion of the coal with an adsorbent in the flue gas, and collecting the adsorbent with the oxidized mercury in a combustion waste treatment system.

Owner:GENERAL ELECTRIC CO

Production and use of biosolid granules

This invention relates to the production and use of encapsulated and / or concentrically-constructed fertilizer or bioremediation granules such as, for example, granules of 0.5 mm to 10 mm in diameter constructed so that there are at least two components to the granule including a core with a surrounding capsule or a core with one or more concentric layers that are distinguishable from the core with respect to nutrient content, density, hardness, solubility, composition, microbial content and permeability, as in permeability to odors or the permeability of nutrients that might volatize to the atmosphere or leach into the soil. The basic idea was to create a method for manufacturing and using fertilizer granules, which incorporate multiple concentric layers or a core plus an encapsulating outer layer.

Owner:UNIFIED ENVIRONMENTAL SERVICES GROUP

Combustion looping using composite oxygen carriers

ActiveUS7767191B2Increase surface areaImprove energy conversion efficiencyHydrogen productionIndirect carbon-dioxide mitigationHydrogenCombustion

A method for producing hydrogen gas is provided and comprises reducing a metal oxide in a reduction reaction between a carbon-based fuel and a metal oxide to provide a reduced metal or metal oxide having a lower oxidation state, and oxidizing the reduced metal or metal oxide to produce hydrogen and a metal oxide having a higher oxidation state. The metal or metal oxide is provided in the form of a porous composite of a ceramic material containing the metal or metal oxide. The porous composite may comprise either a monolith, pellets, or particles.

Owner:OHIO STATE INNOVATION FOUND

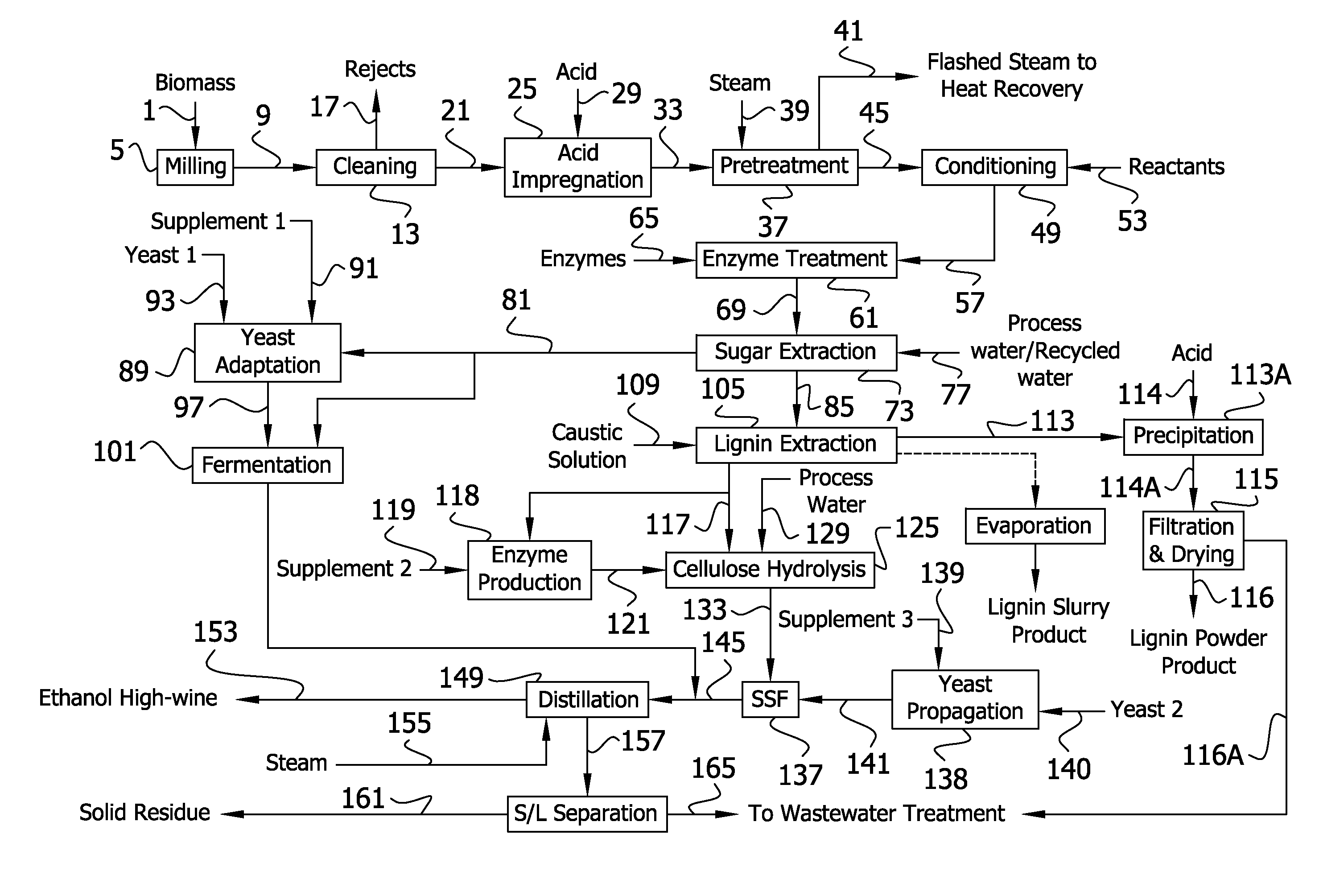

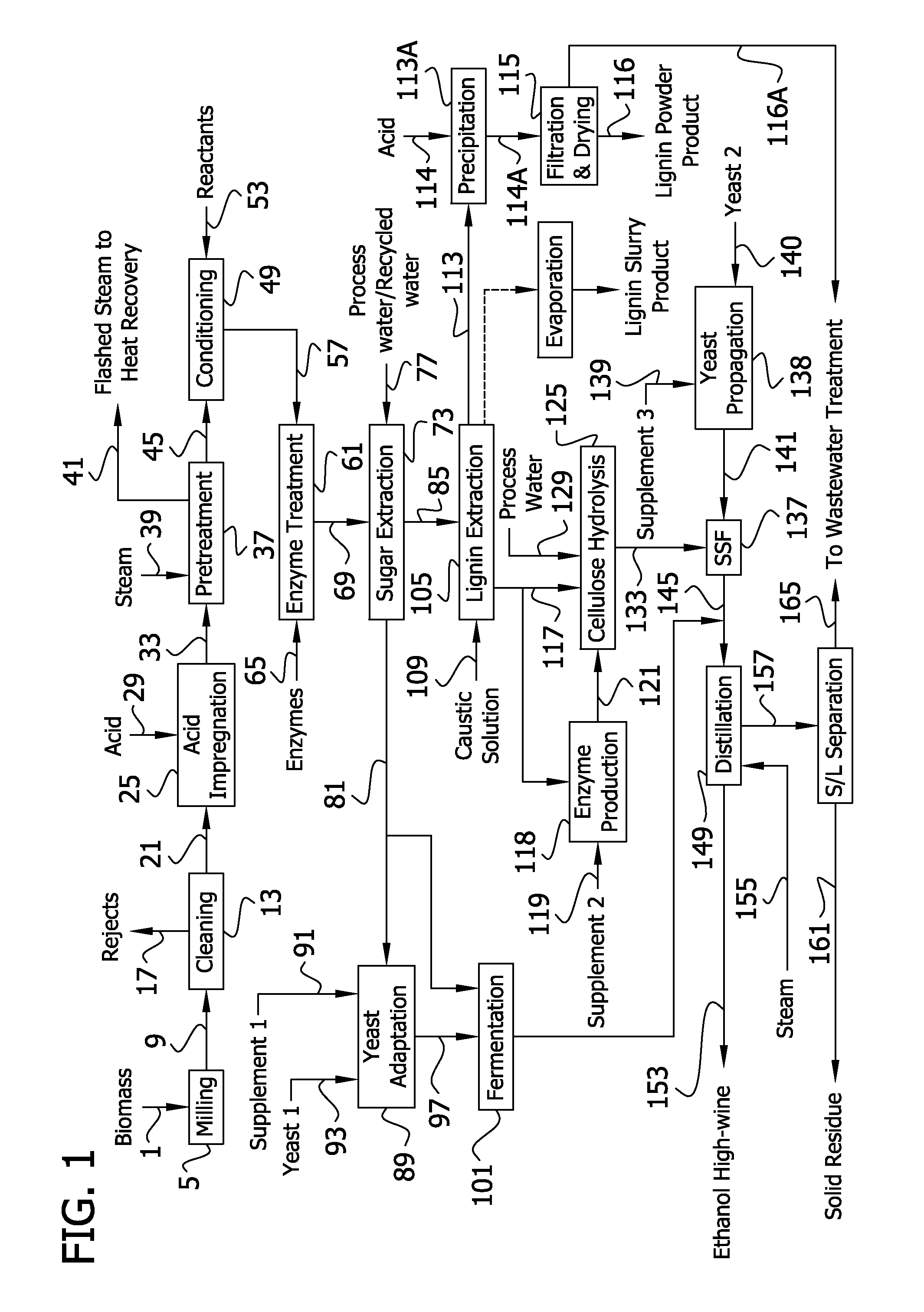

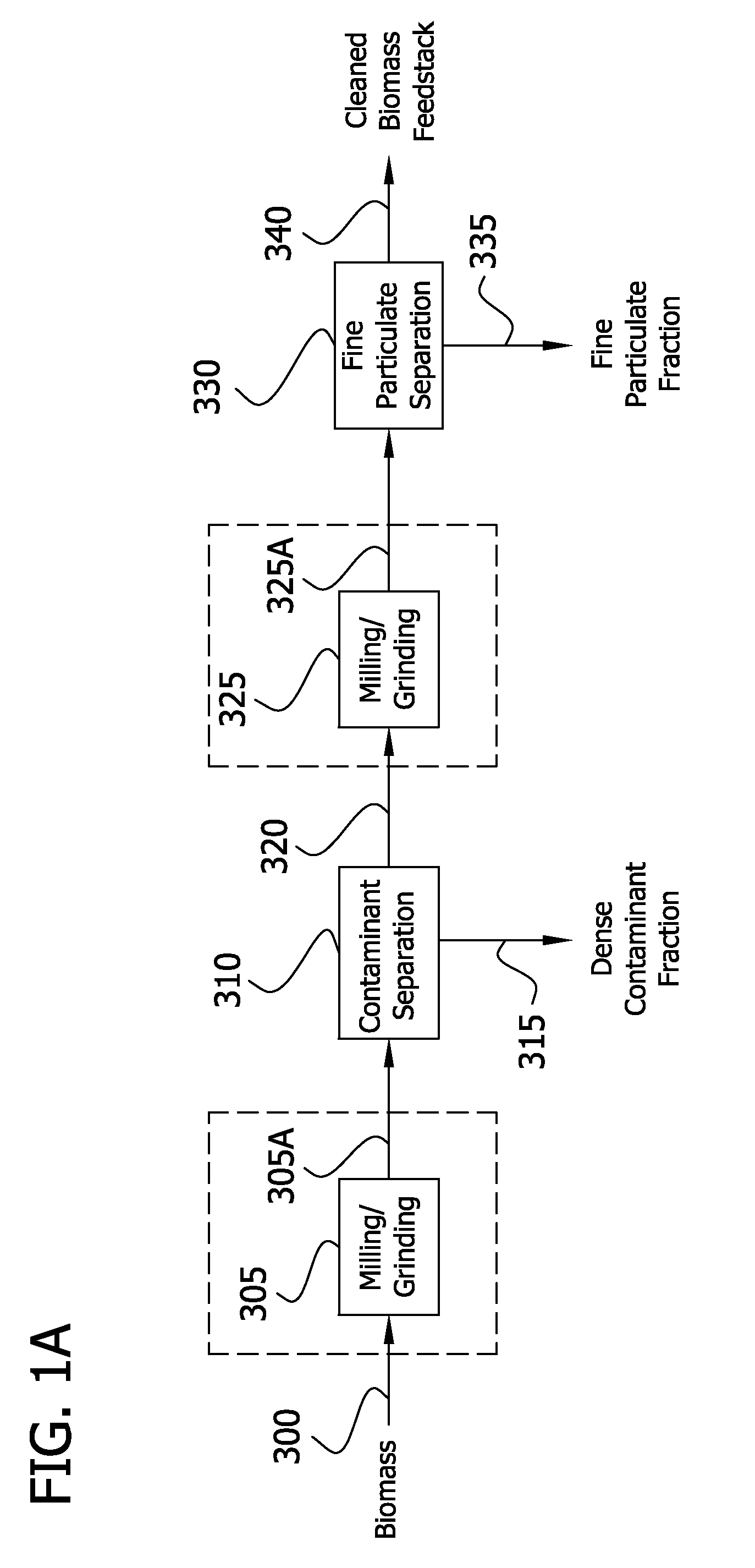

Method for producing ethanol and co-products from cellulosic biomass

InactiveUS20120006320A1Increased ethanol productionImproved co-productsFuel supply regulationPretreatment with acid reacting compoundsCelluloseLignocellulosic biomass

The present invention generally relates to processes for production of ethanol from cellulosic biomass. The present invention also relates to production of various co-products of preparation of ethanol from cellulosic biomass. The present invention further relates to improvements in one or more aspects of preparation of ethanol from cellulosic biomass including, for example, improved methods for cleaning biomass feedstocks, improved acid impregnation, and improved steam treatment, or “steam explosion.”

Owner:ABENGOA BIOENERGY NEW TECH

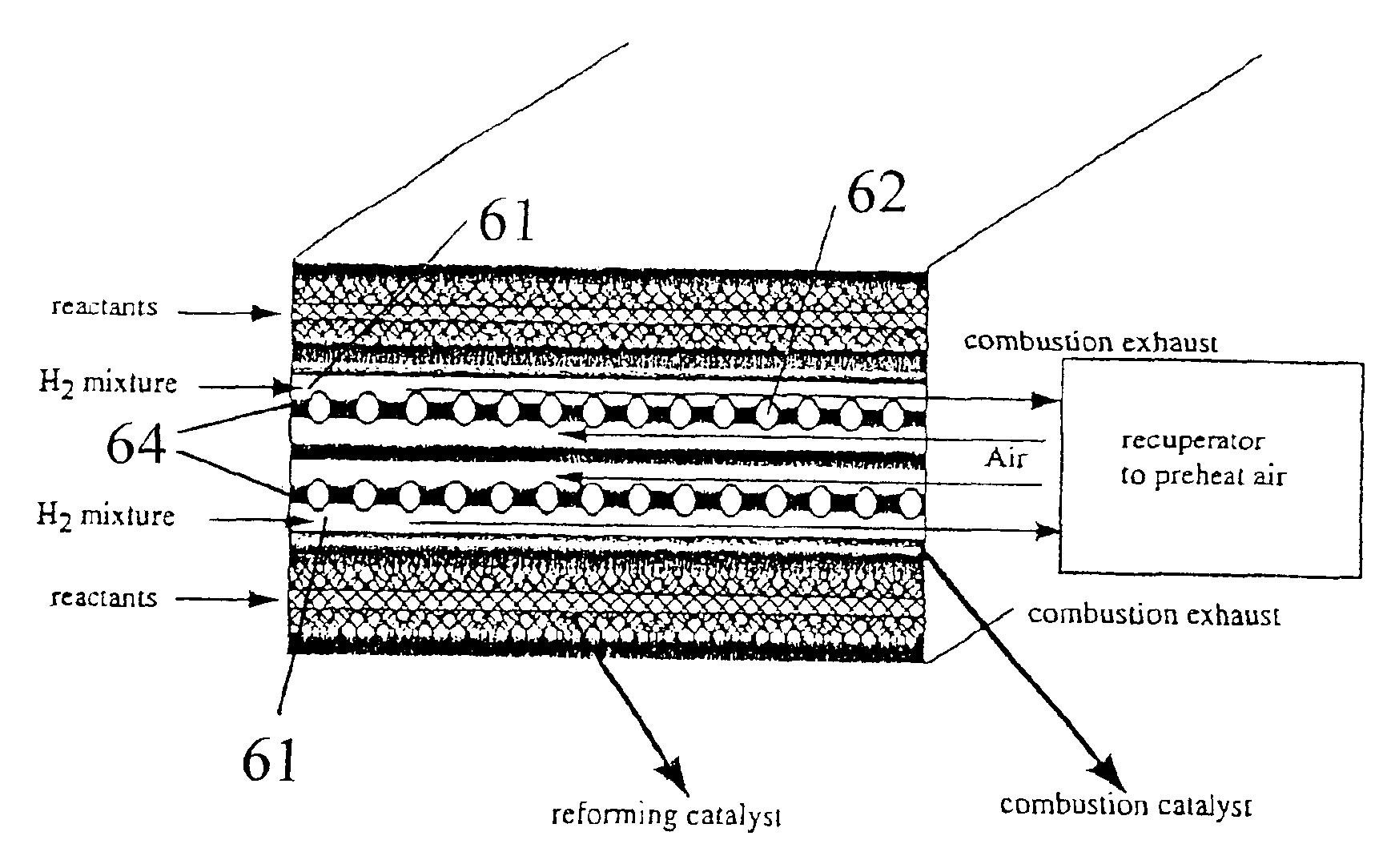

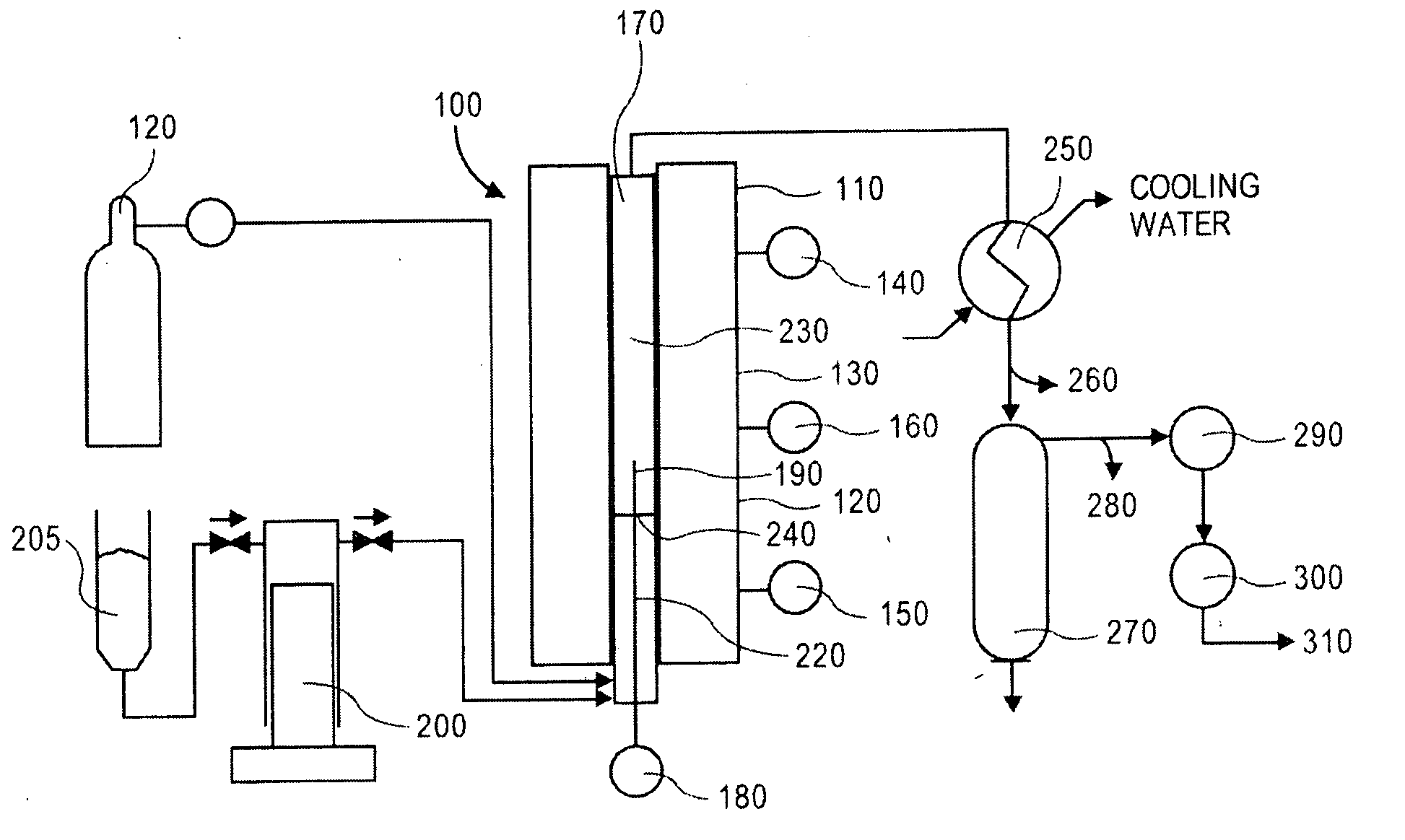

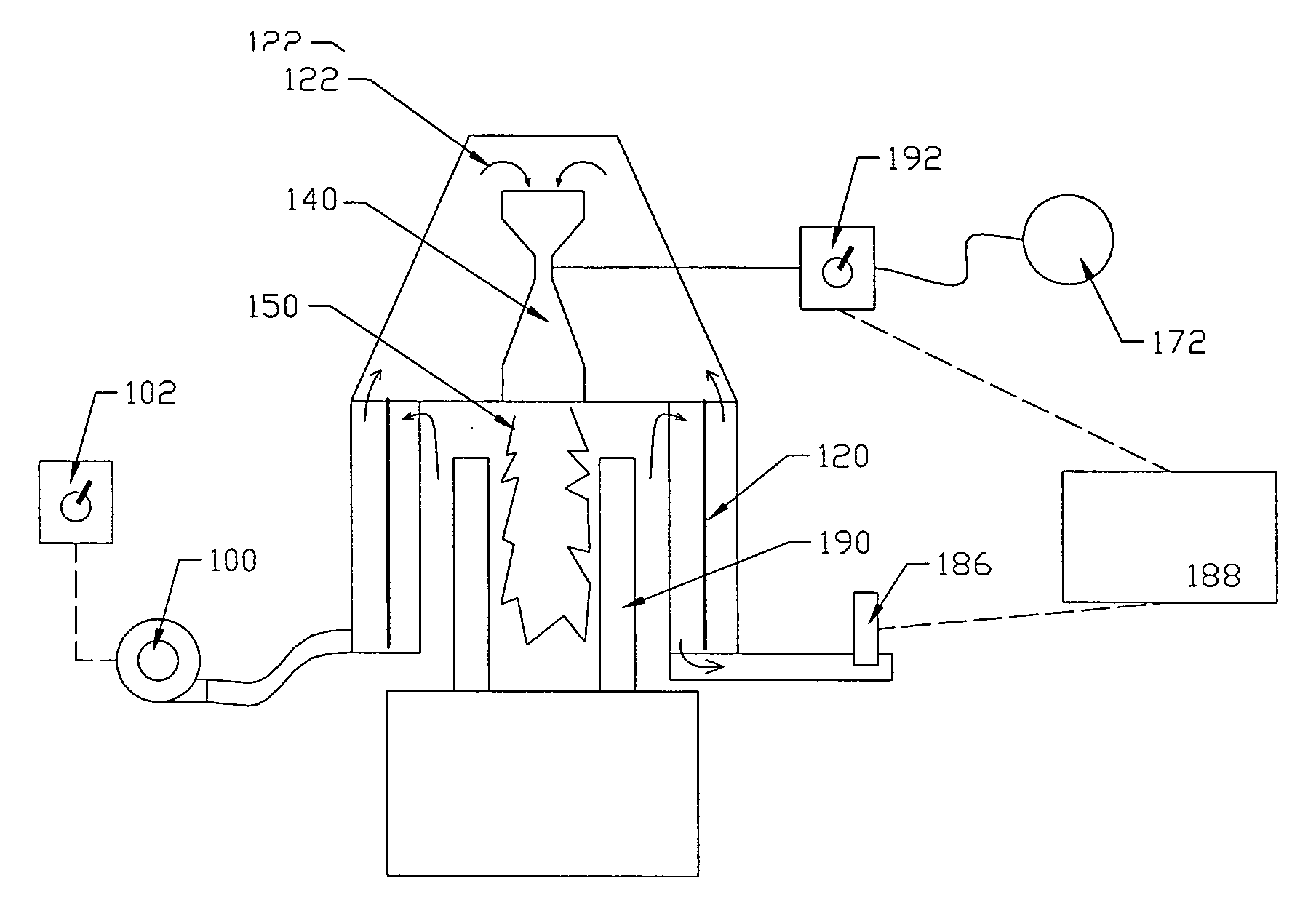

Methods of conducting simultaneous exothermic and endothermic reactions

InactiveUS6969506B2High yieldImprove performanceFinal product manufactureChemical/physical/physico-chemical microreactorsCombustion chamberEngineering

Integrated Combustion Reactors (ICRs) and methods of making ICRs are described in which combustion chambers (or channels) are in direct thermal contact to reaction chambers for an endothermic reaction. Superior results were achieved for combustion chambers which contained a gap for free flow through the chamber. Particular reactor designs are also described. Processes of conducting reactions in integrated combustion reactors are described and results presented. Some of these processes are characterized by unexpected and superior results.

Owner:BATTELLE MEMORIAL INST

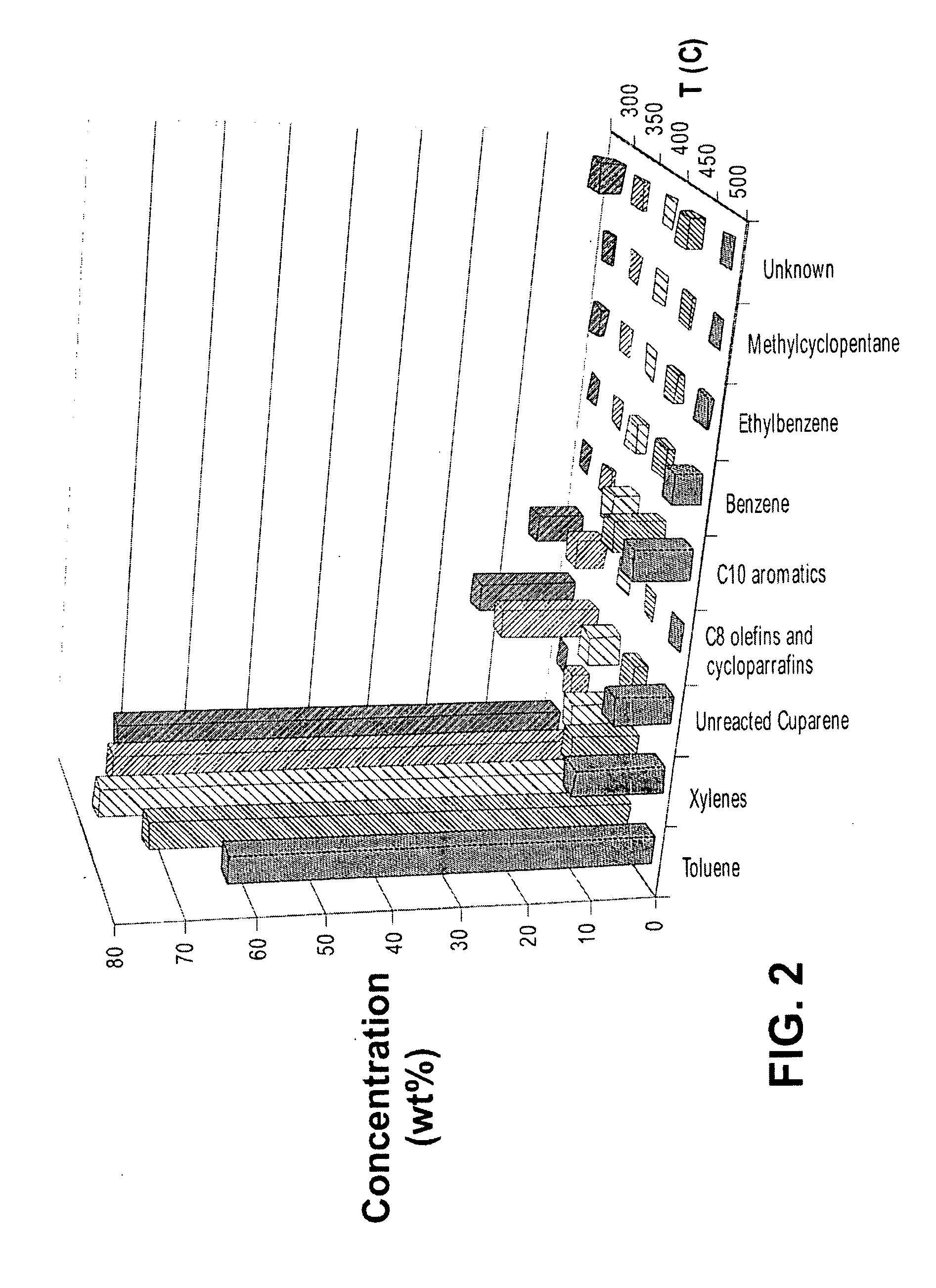

Methods of refining hydrocarbon feedstocks

Processes of converting to feedstocks comprising hydrocarbons to compositions comprising light hydrocarbon products are described herein. Also described are processes and methods of producing and refining compositions comprising terpenes from biomass that can be suitable as a fuel product.

Owner:RENEW BIOPHARMA INC +1

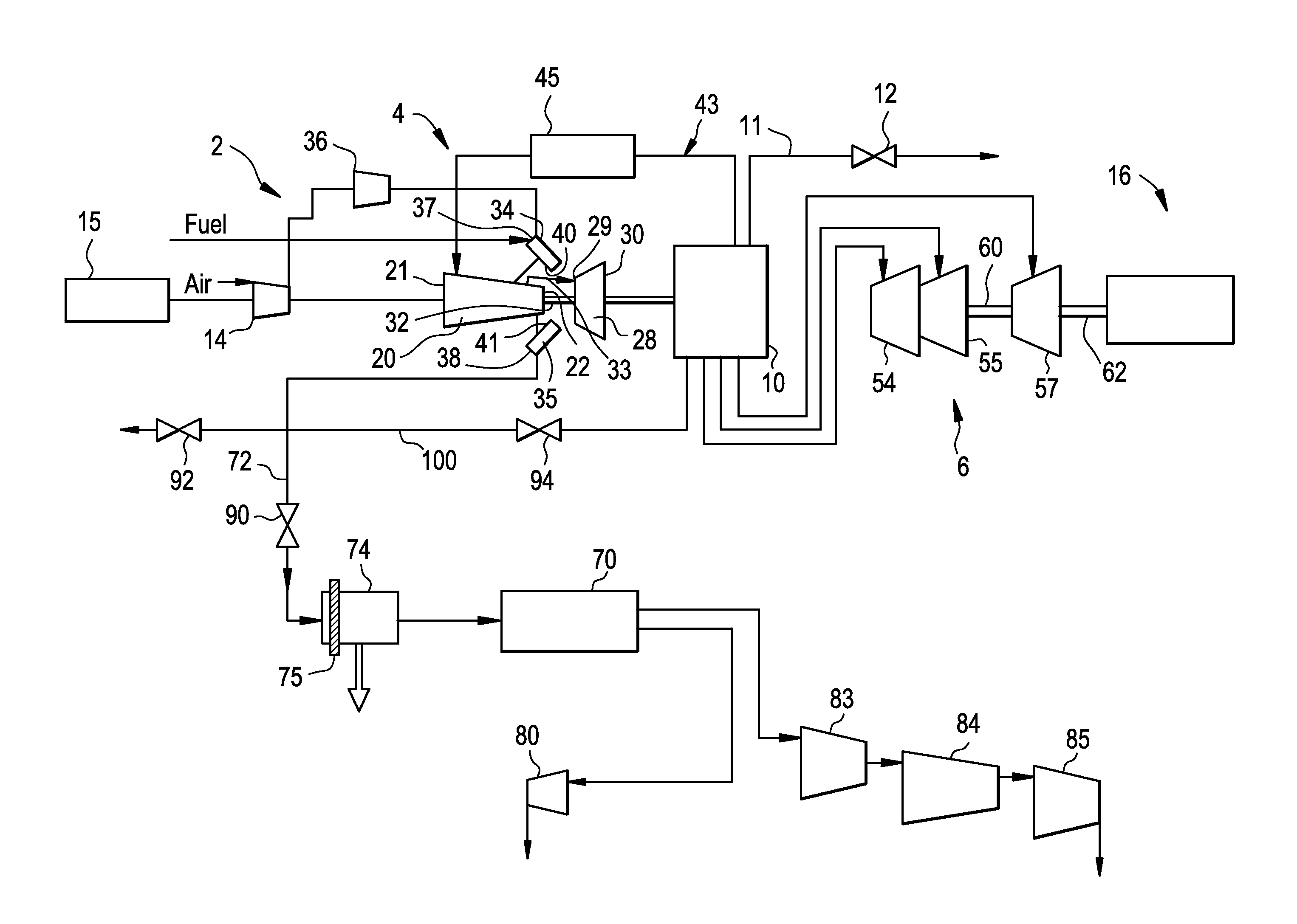

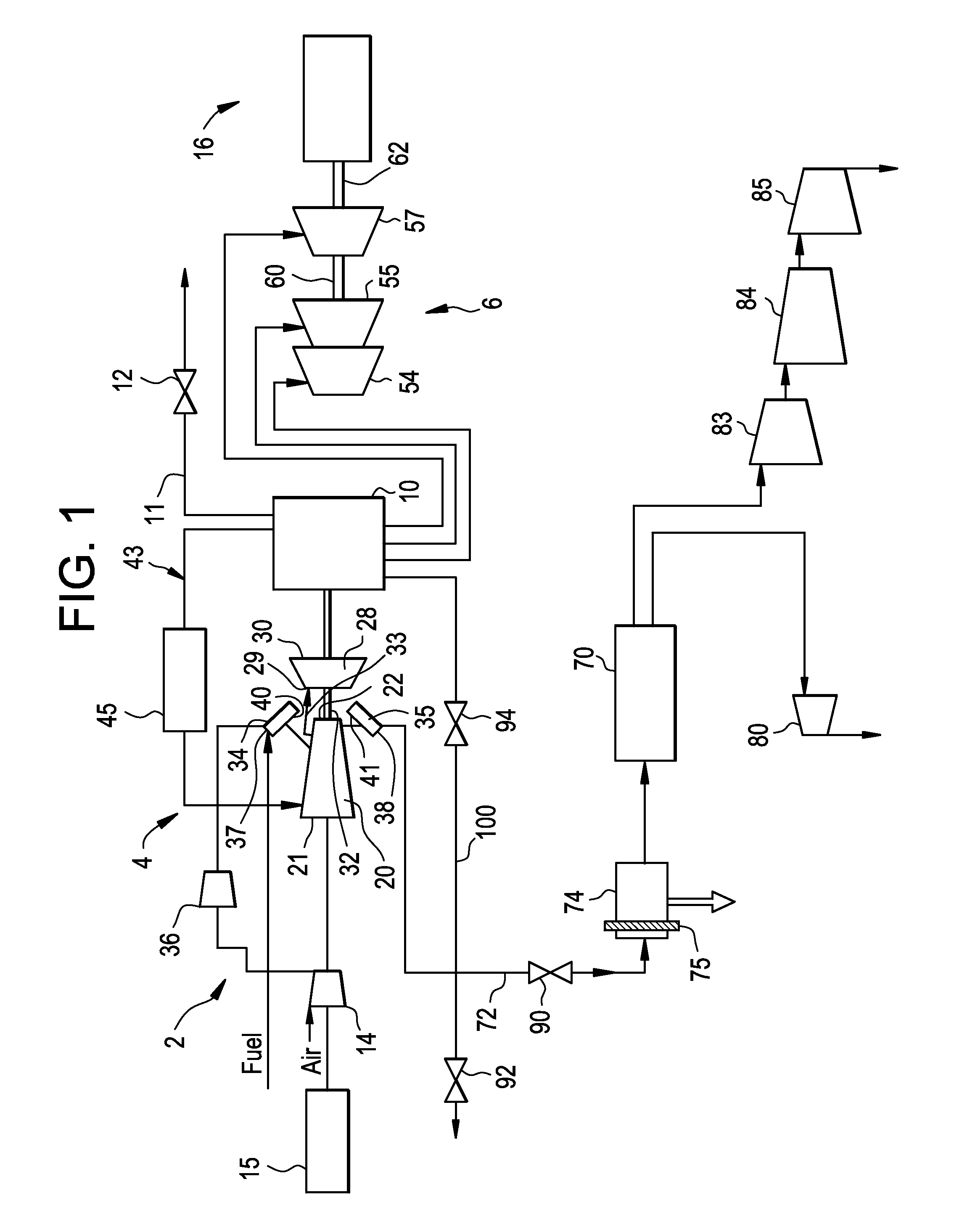

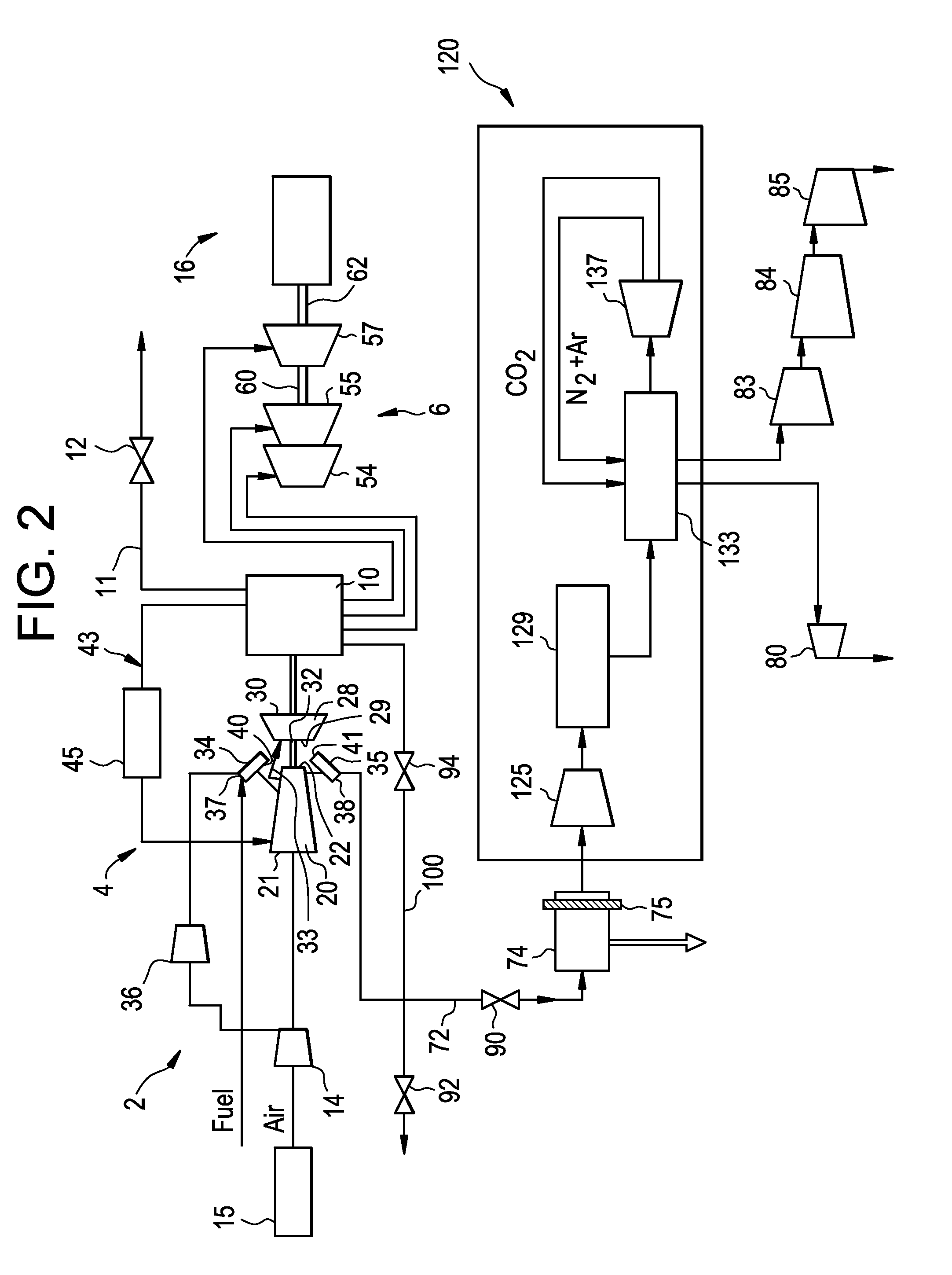

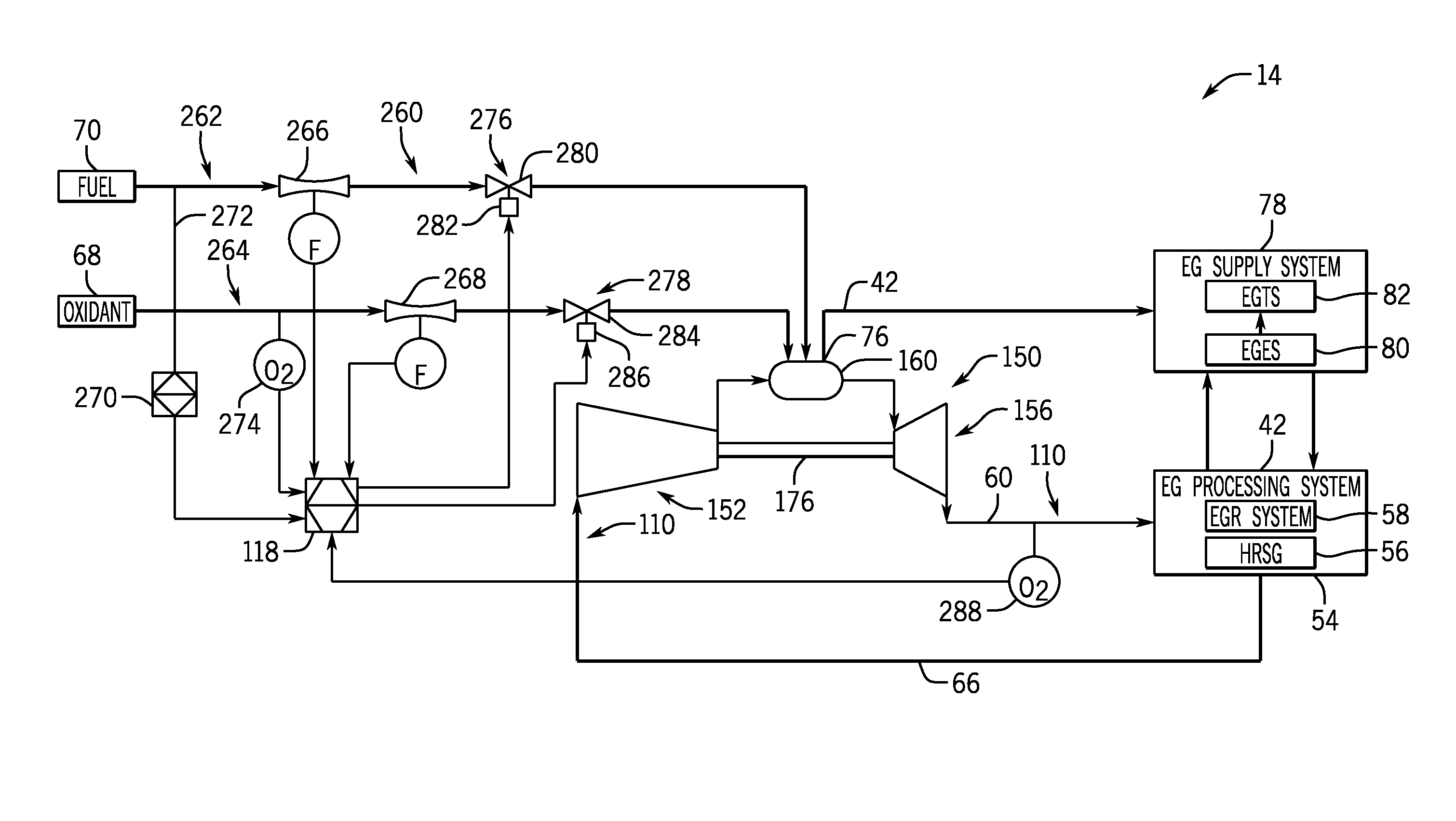

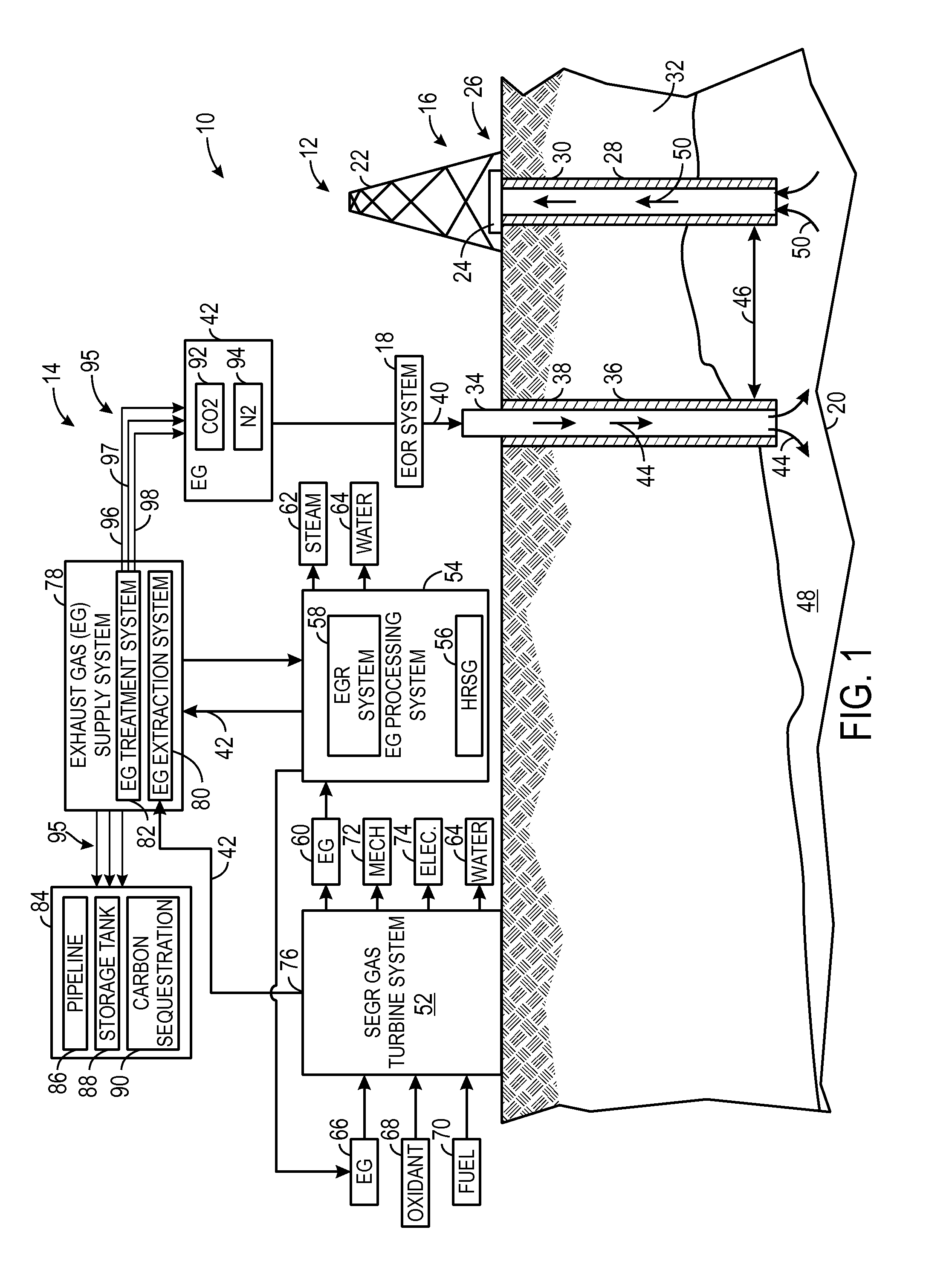

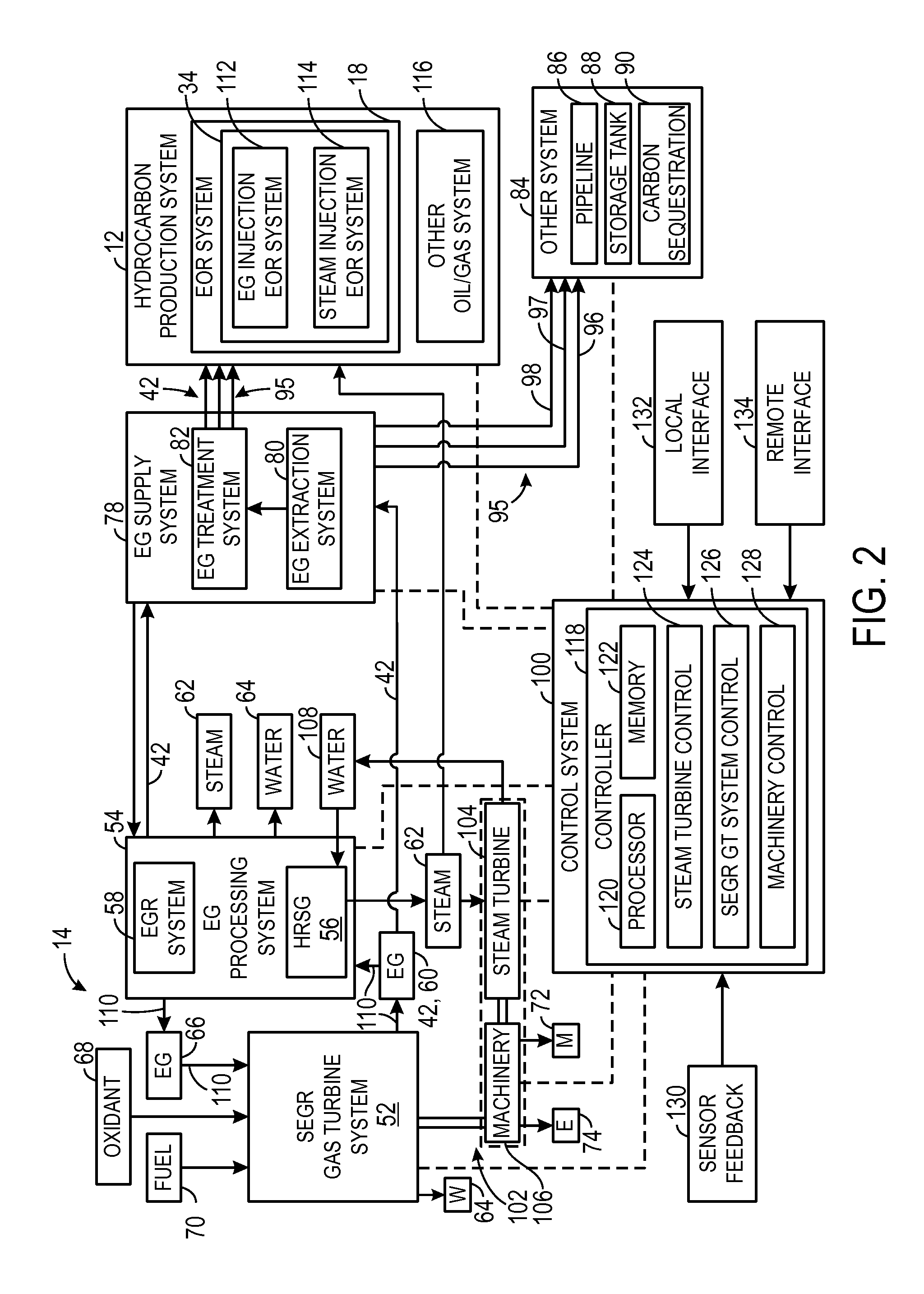

Combined cycle power plant including a carbon dioxide collection system

A combined cycle power plant includes a compressor section including a compressor inlet and a compressor outlet, and a turbine section operatively connected to the compressor section. The turbine section includes a turbine inlet and a turbine outlet. A heat recovery steam generator (HRSG) is fluidly connected to the turbine outlet. A combustor includes a head end and a combustor discharge. The head end is fluidly connected to the compressor outlet and the combustor discharge is fluidly connected to the turbine inlet. A carbon dioxide collection system is fluidly connected to one of the compressor outlet and the head end of the combustor. The carbon dioxide collection system is configured and disposed to extract a first fluid comprising carbon dioxide and a second fluid from a substantially oxygen free fluid flow passed from the one of the compressor outlet and the head end of the combustor.

Owner:GENERAL ELECTRIC CO

Gas turbine combustor control system

ActiveUS20140123624A1Fuel supply regulationEfficient propulsion technologiesCombustion chamberCombustor

In one embodiment, a gas turbine system includes a controller configured to receive fuel composition information related to a fuel used for combustion in a turbine combustor; receive oxidant composition information related to an oxidant used for combustion in the turbine combustor; receive oxidant flow information related to a flow of the oxidant to the turbine combustor; determine a stoichiometric fuel-to-oxidant ratio based at least on the fuel composition information and the oxidant composition information; and generate a control signal for input to a fuel flow control system configured to control a flow of the fuel to the turbine combustor based on the oxidant flow information, a target equivalence ratio, and the stoichiometric fuel-to-oxidant ratio to enable combustion at the target equivalence ratio in the presence of an exhaust diluent within the turbine combustor.

Owner:GENERAL ELECTRIC CO +1

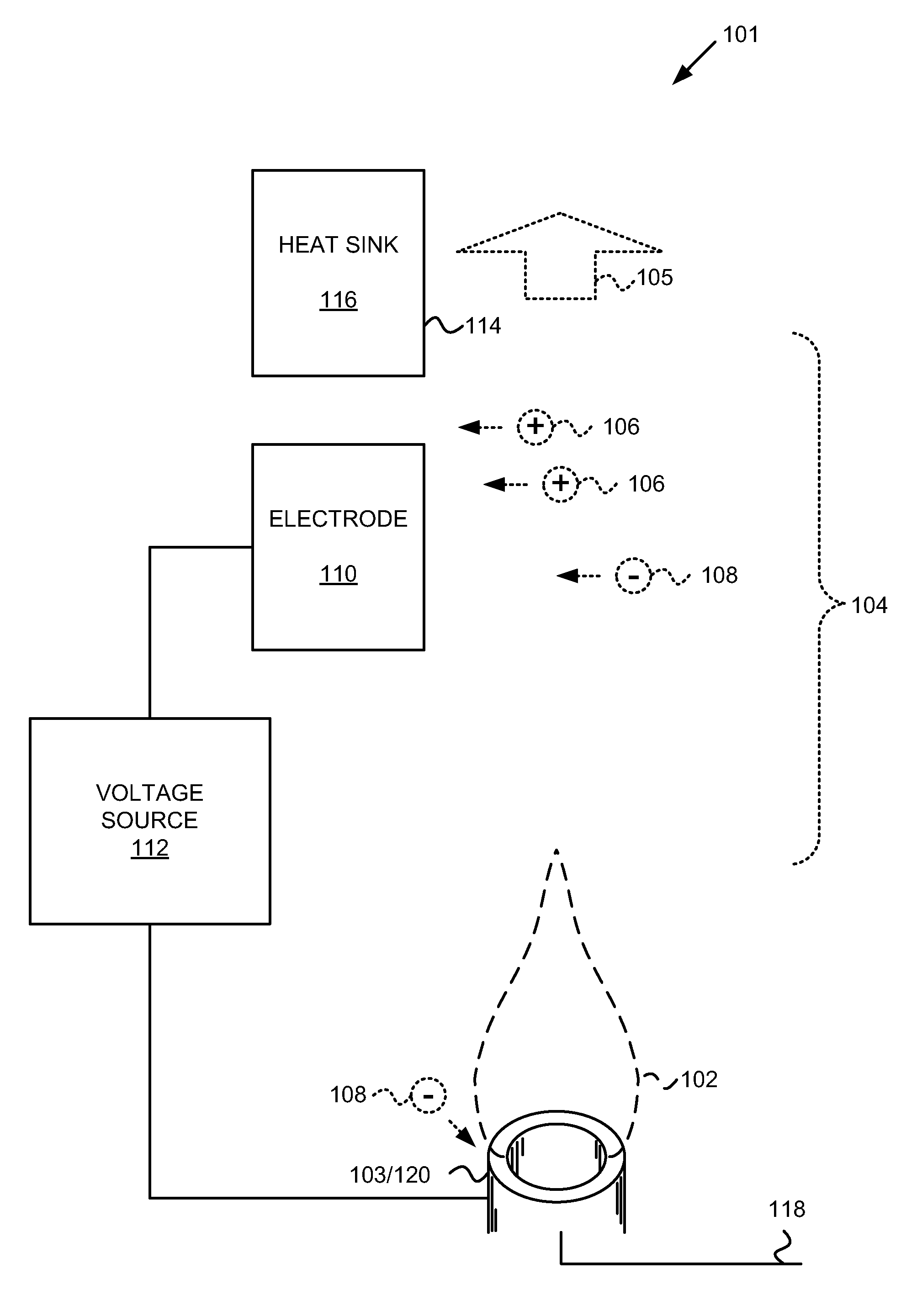

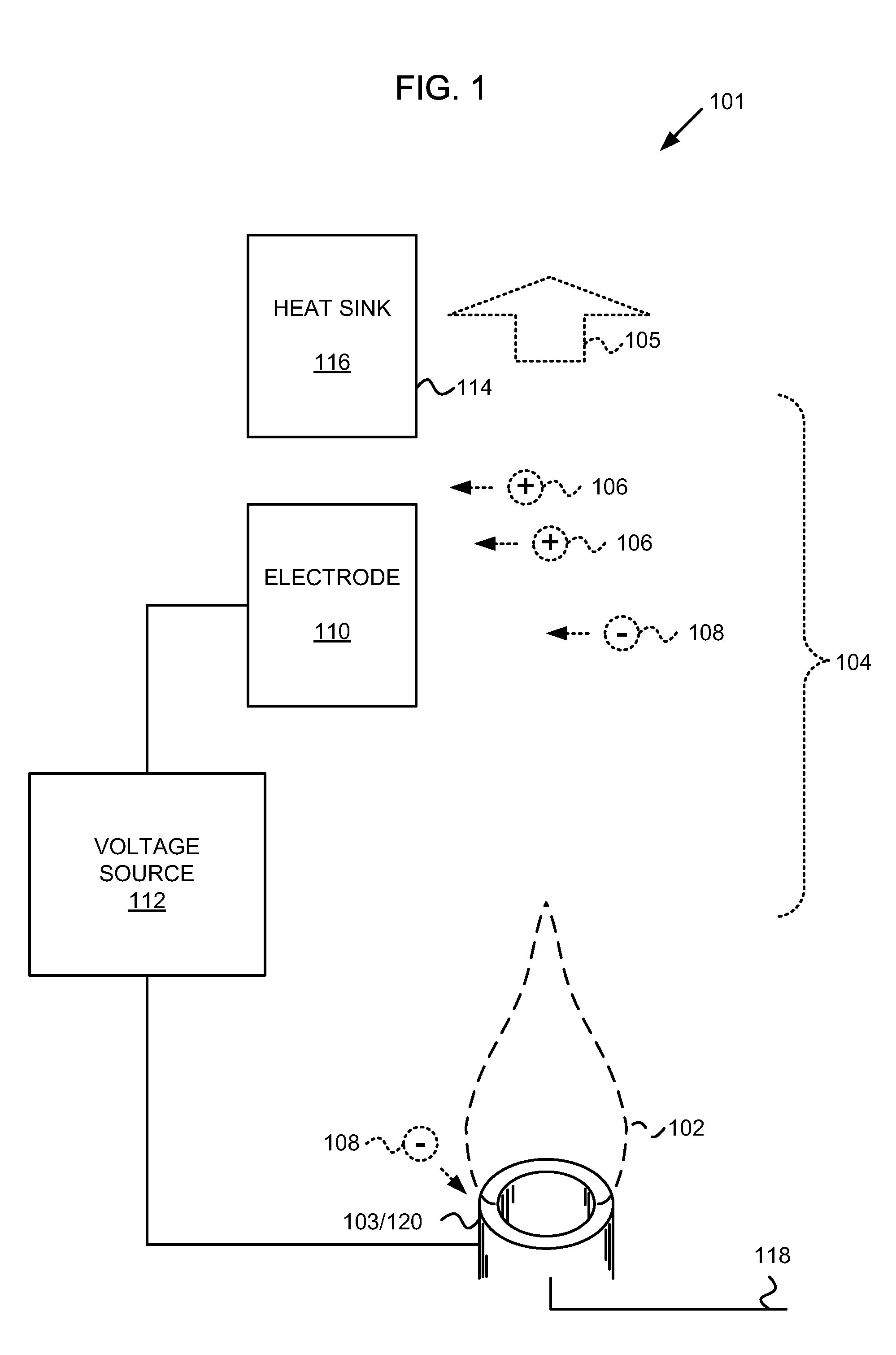

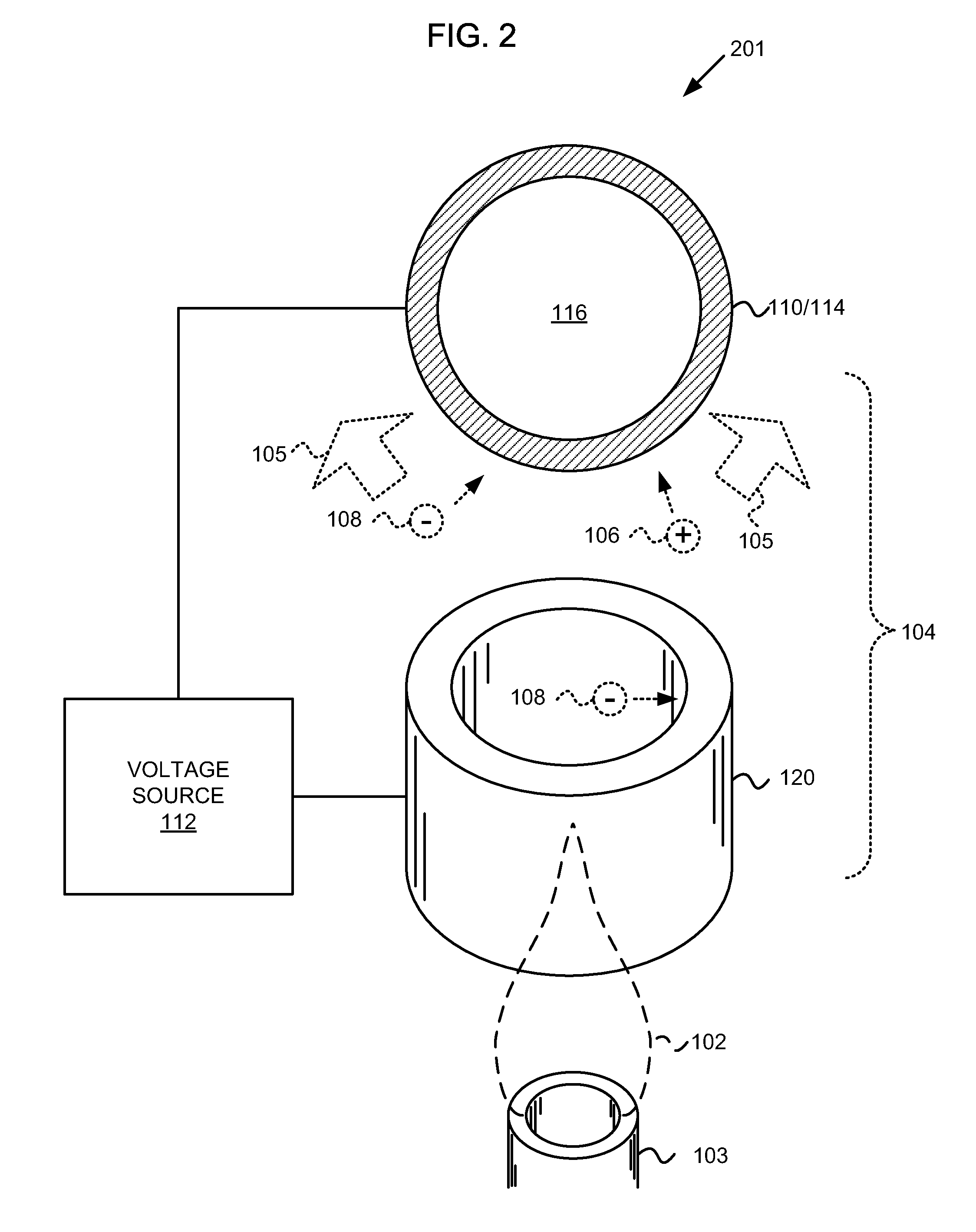

Method and apparatus for electrical control of heat transfer

A heat exchange system includes an electrode configured to electrostatically control a flow of a heated gas stream in the vicinity of a heat transfer surface and / or a heat-sensitive surface.

Owner:CLEARSIGN COMBUSTION CORP

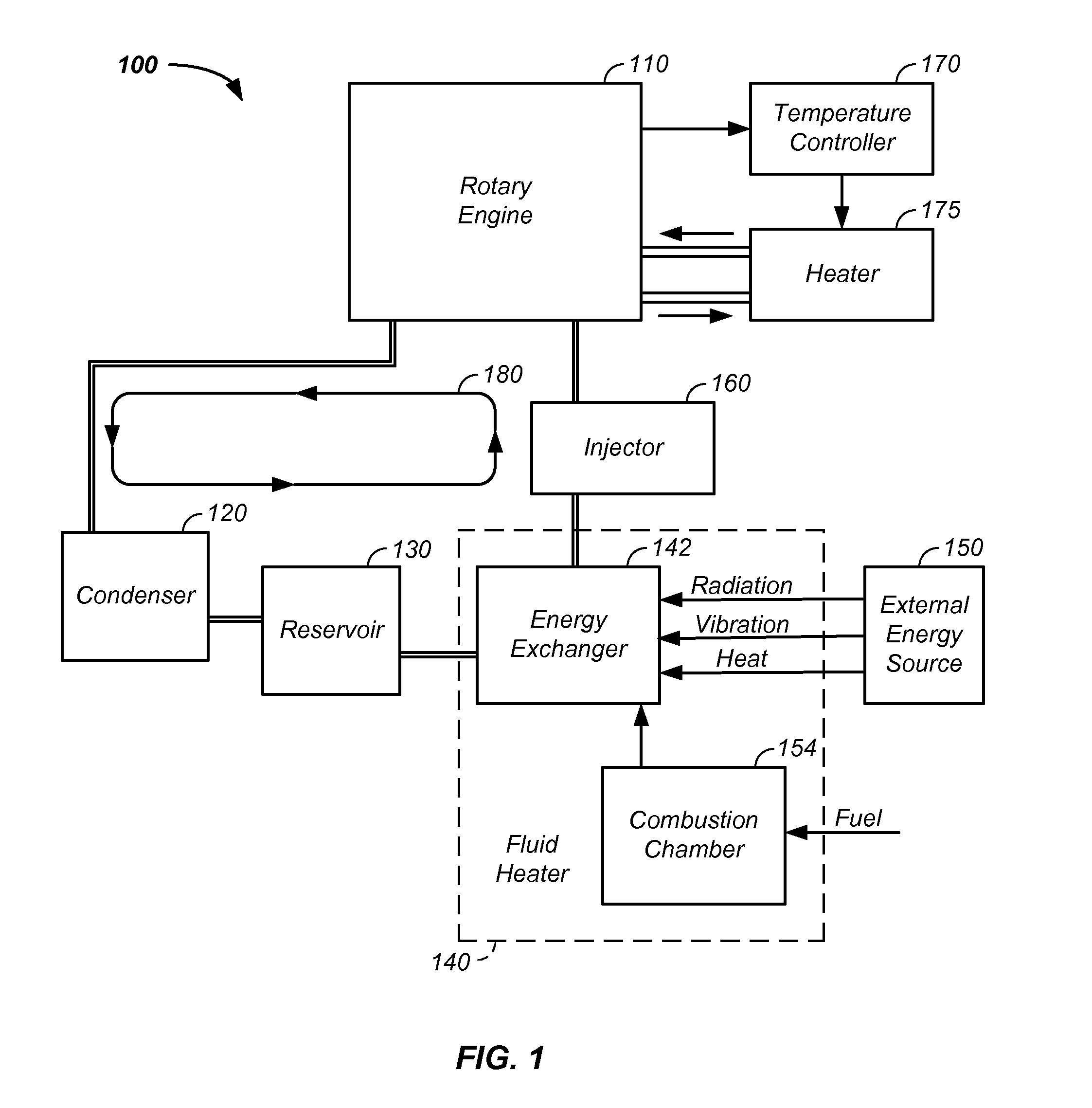

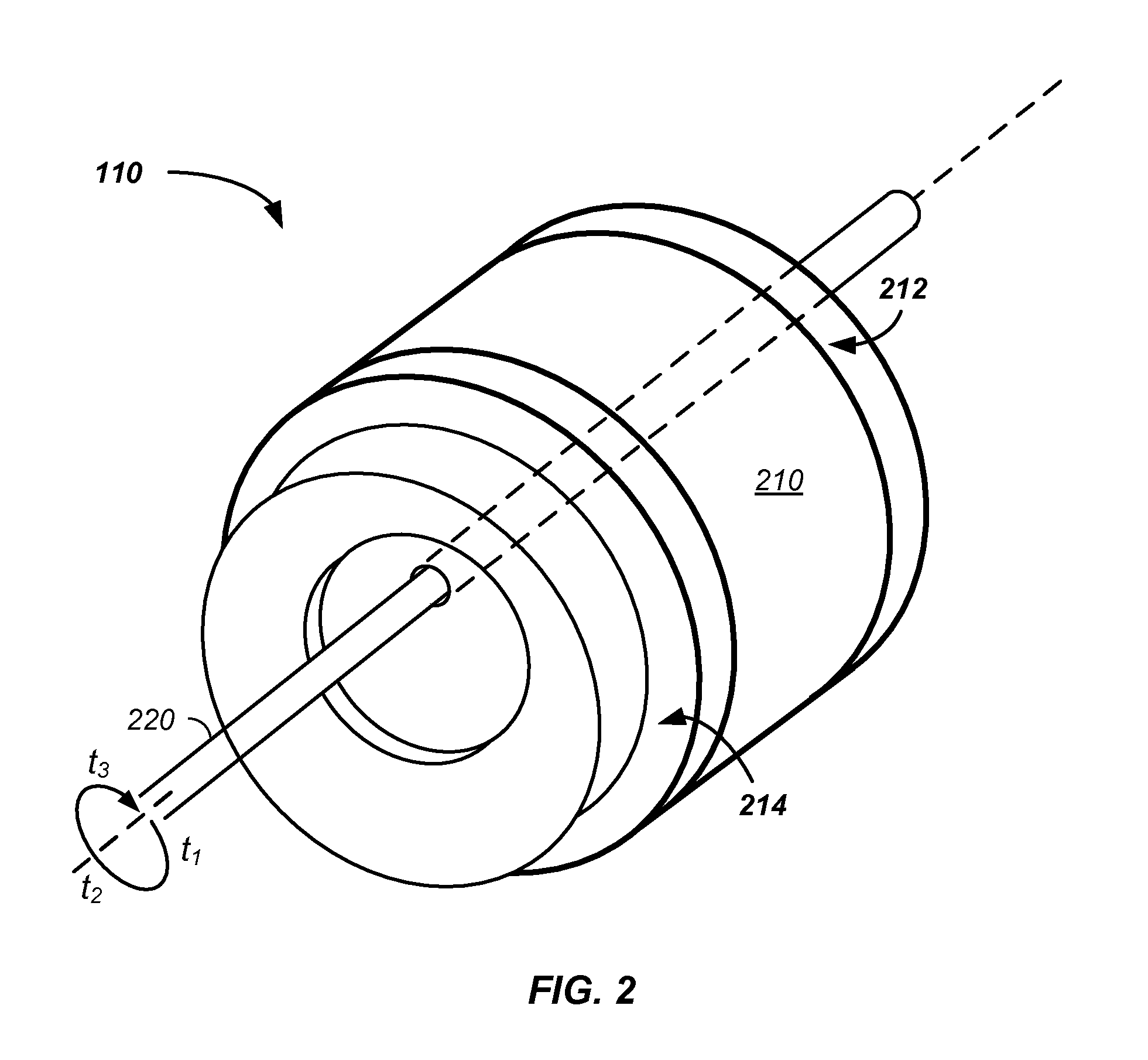

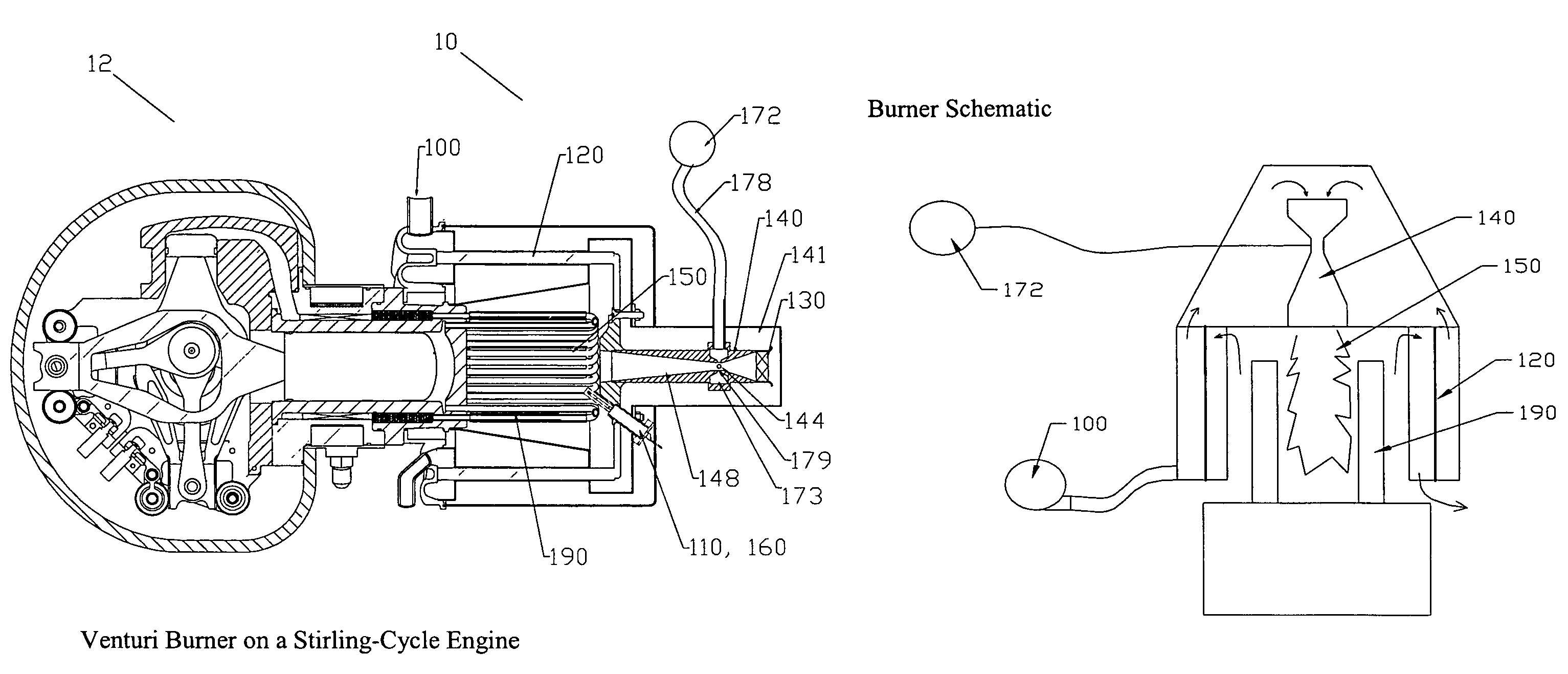

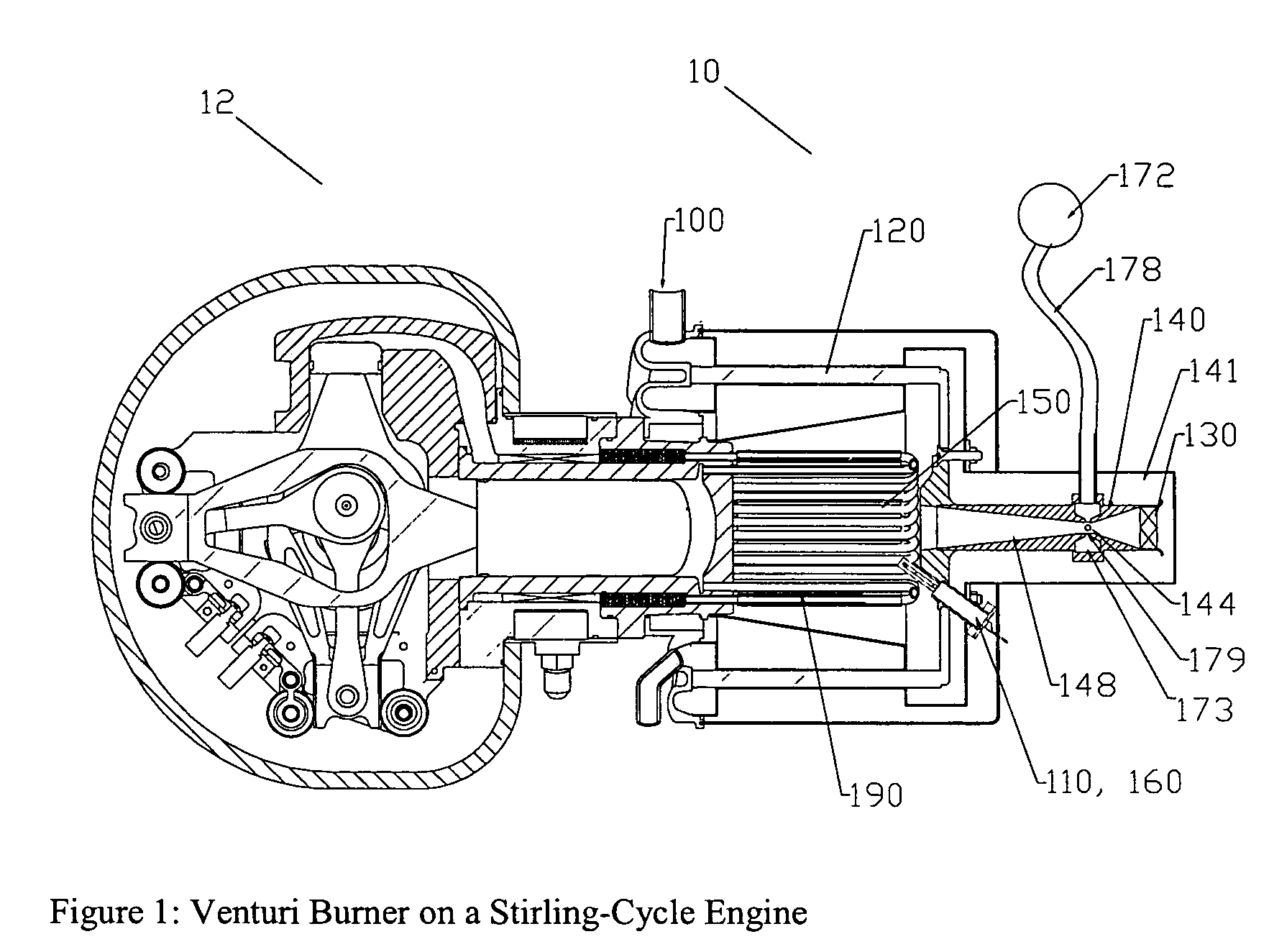

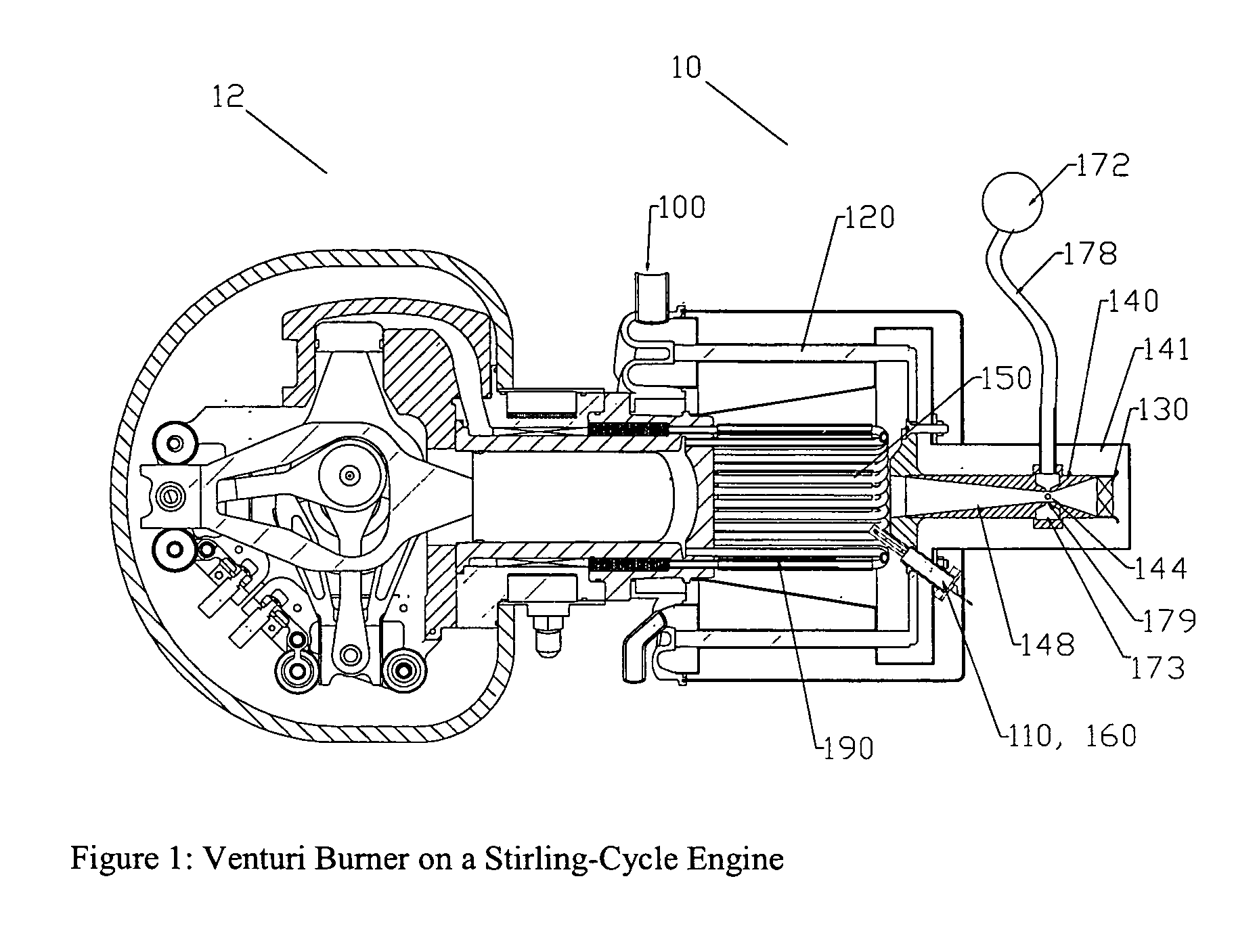

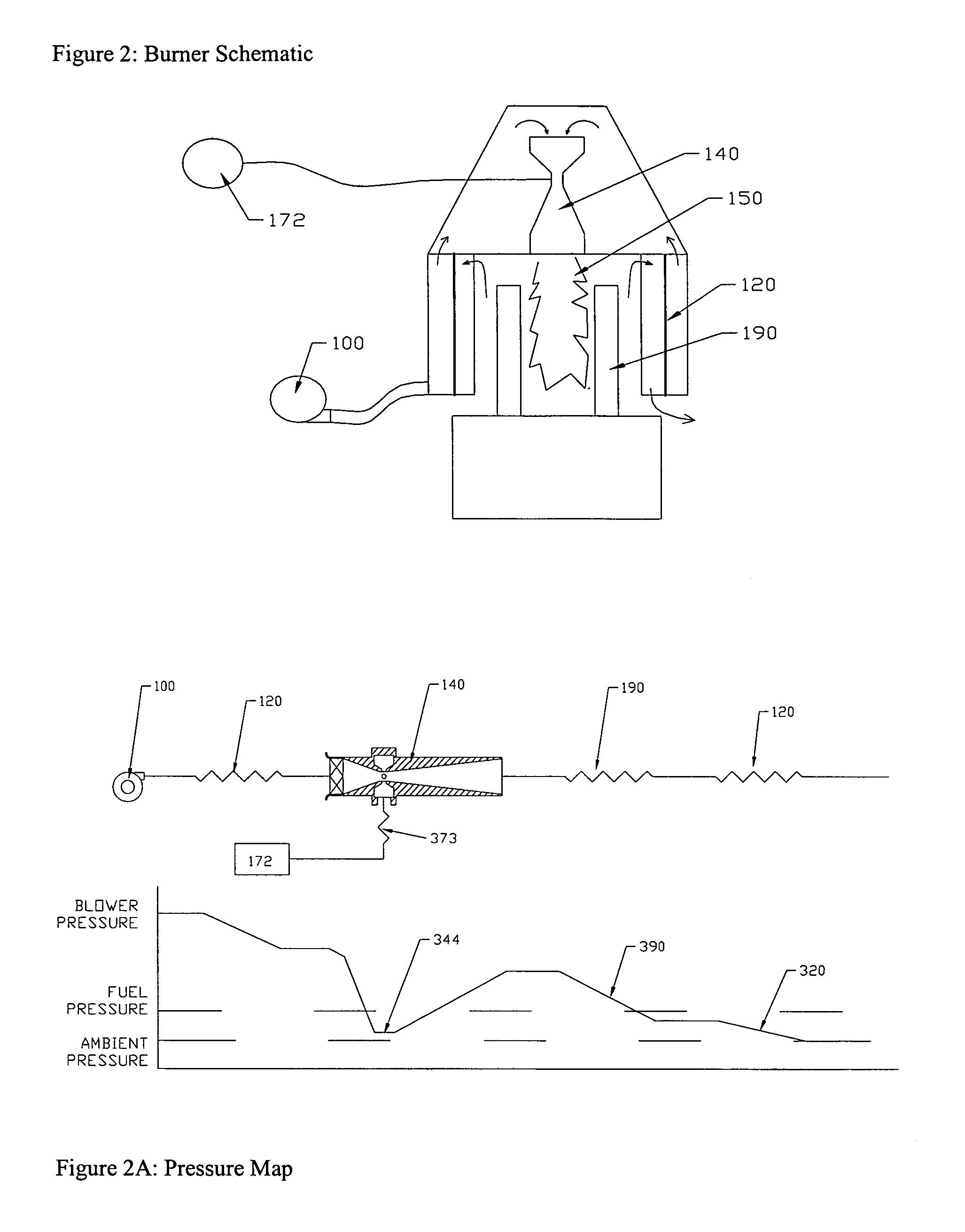

Gaseous fuel burner

ActiveUS7934926B2Address is challengeEliminate needFuel supply regulationAir supply regulationAir velocityAutomatic control

Owner:NEW POWER CONCEPTS

Intelligent emissions controller for substance injection in the post-primary combustion zone of fossil-fired boilers

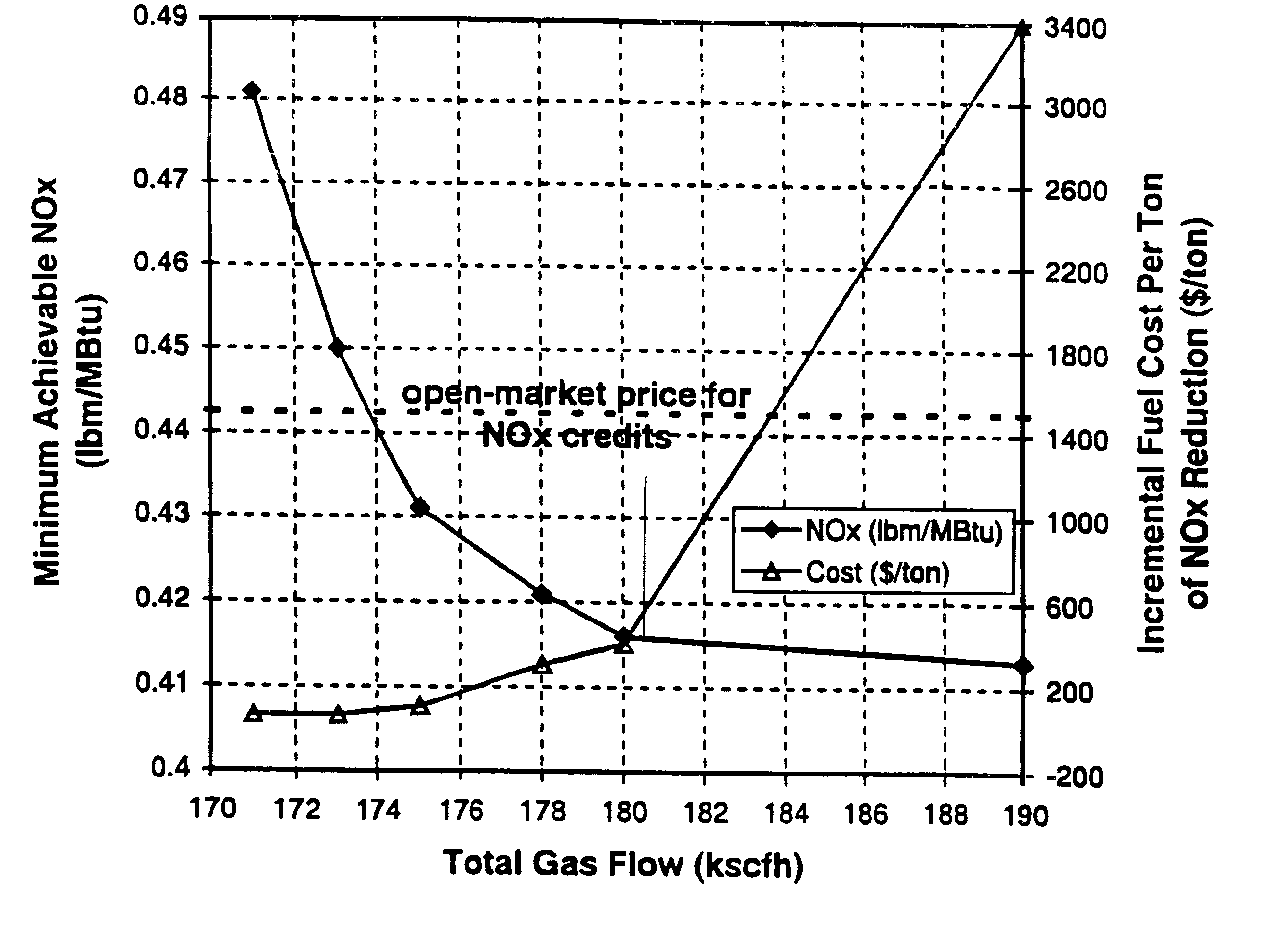

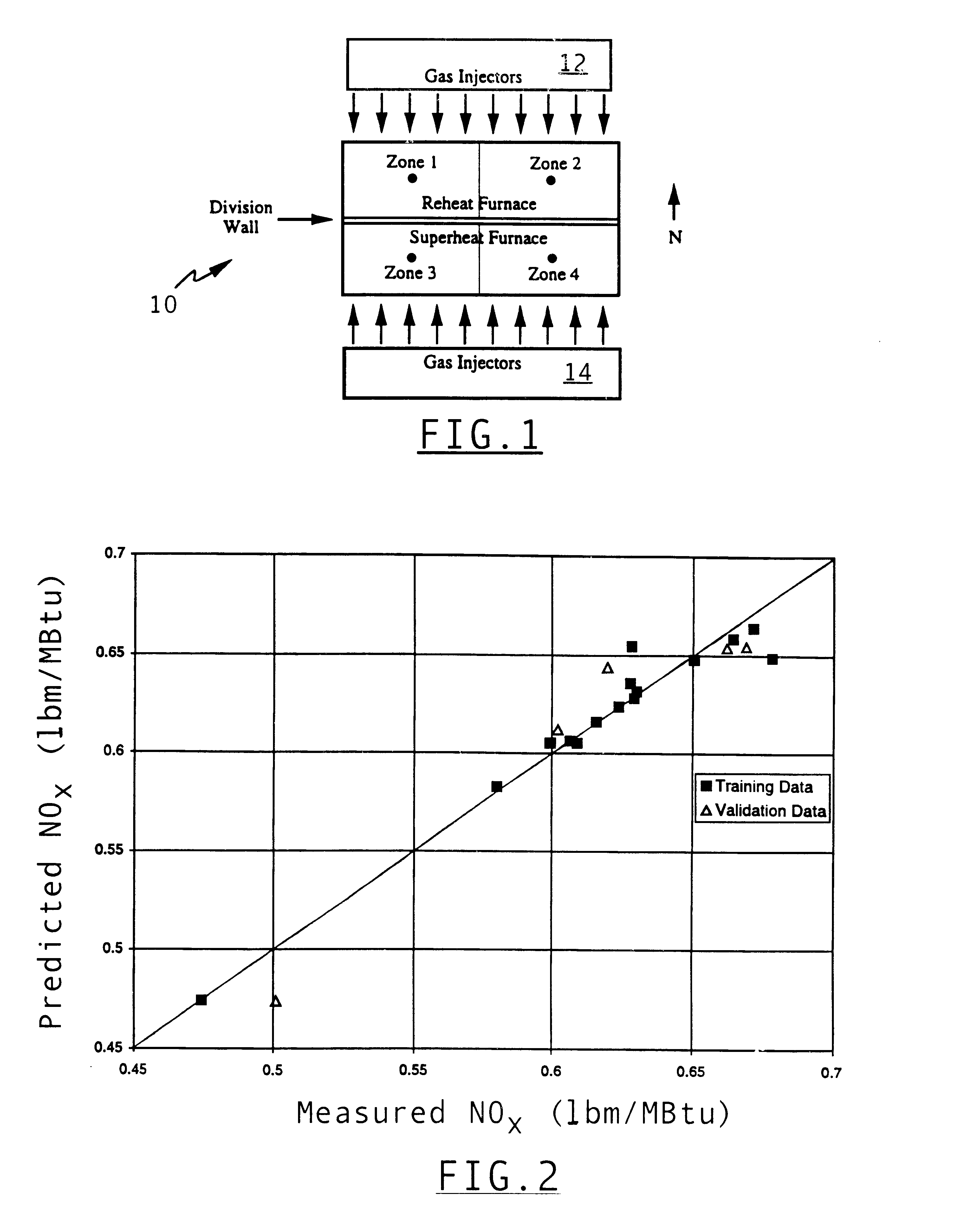

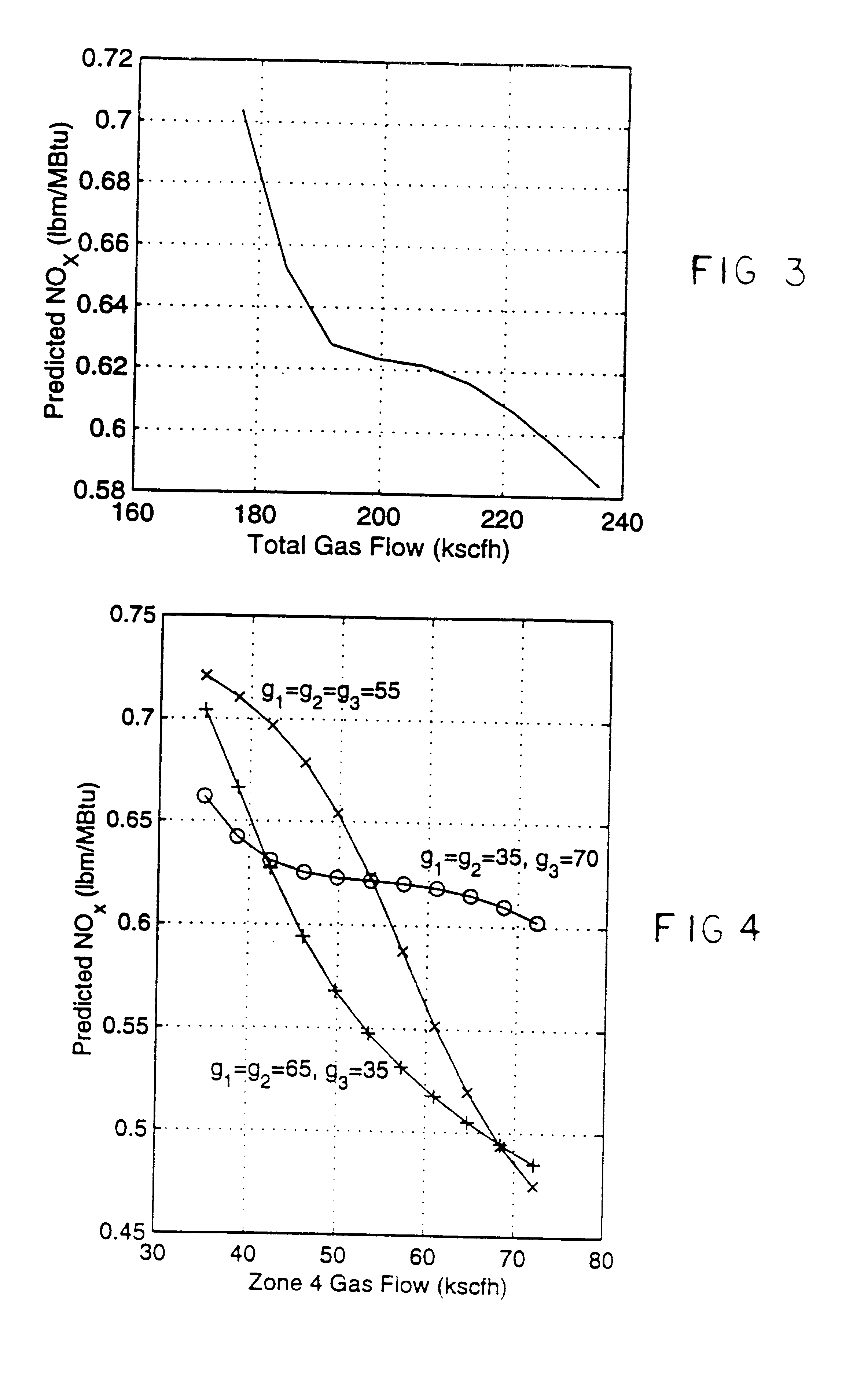

InactiveUS6507774B1Emission reductionReduce pollutant emissionsSampled-variable control systemsCombustion signal processingWater oil emulsionU s economy

The control of emissions from fossil-fired boilers wherein an injection of substances above the primary combustion zone employs multi-layer feedforward artificial neural networks for modeling static nonlinear relationships between the distribution of injected substances into the upper region of the furnace and the emissions exiting the furnace. Multivariable nonlinear constrained optimization algorithms use the mathematical expressions from the artificial neural networks to provide the optimal substance distribution that minimizes emission levels for a given total substance injection rate. Based upon the optimal operating conditions from the optimization algorithms, the incremental substance cost per unit of emissions reduction, and the open-market price per unit of emissions reduction, the intelligent emissions controller allows for the determination of whether it is more cost-effective to achieve additional increments in emission reduction through the injection of additional substance or through the purchase of emission credits on the open market. This is of particular interest to fossil-fired electrical power plant operators. The intelligent emission controller is particularly adapted for determining the economical control of such pollutants as oxides of nitrogen (NOx) and carbon monoxide (CO) emitted by fossil-fired boilers by the selective introduction of multiple inputs of substances (such as natural gas, ammonia, oil, water-oil emulsion, coal-water slurry and / or urea, and combinations of these substances) above the primary combustion zone of fossil-fired boilers.

Owner:ENERGY SYST ASSOCD +1

Gas turbine combustor diagnostic system and method

In an embodiment, a method includes performing a turbine combustor diagnostic routine including operating a first turbine combustor of a plurality of turbine combustors at a substantially steady state of combustion; adjusting an operational parameter of the first turbine combustor to cause a change in combustion products produced by the first turbine combustor; identifying a first sensor response of a first subset of a plurality of sensors disposed within or downstream from a turbine fluidly coupled to the turbine combustor, the first sensor response being indicative of the change in the combustion products, and wherein the first subset comprises one or more first sensors; correlating the first subset of sensors with the first turbine combustor; and diagnosing a condition of the first subset of the plurality of sensors, the first turbine combustor, or a combination thereof, based on the first sensor response.

Owner:GENERAL ELECTRIC CO +1

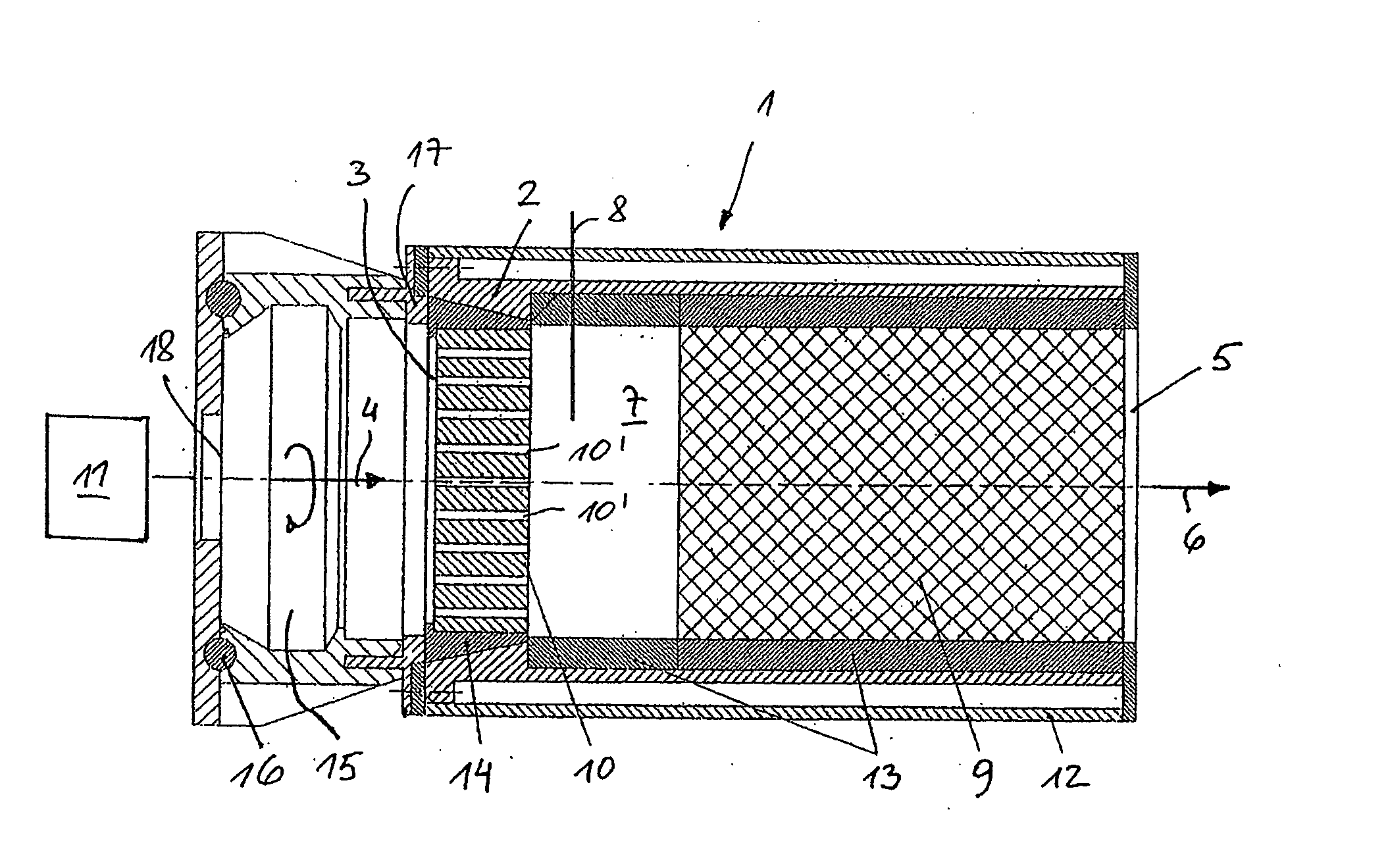

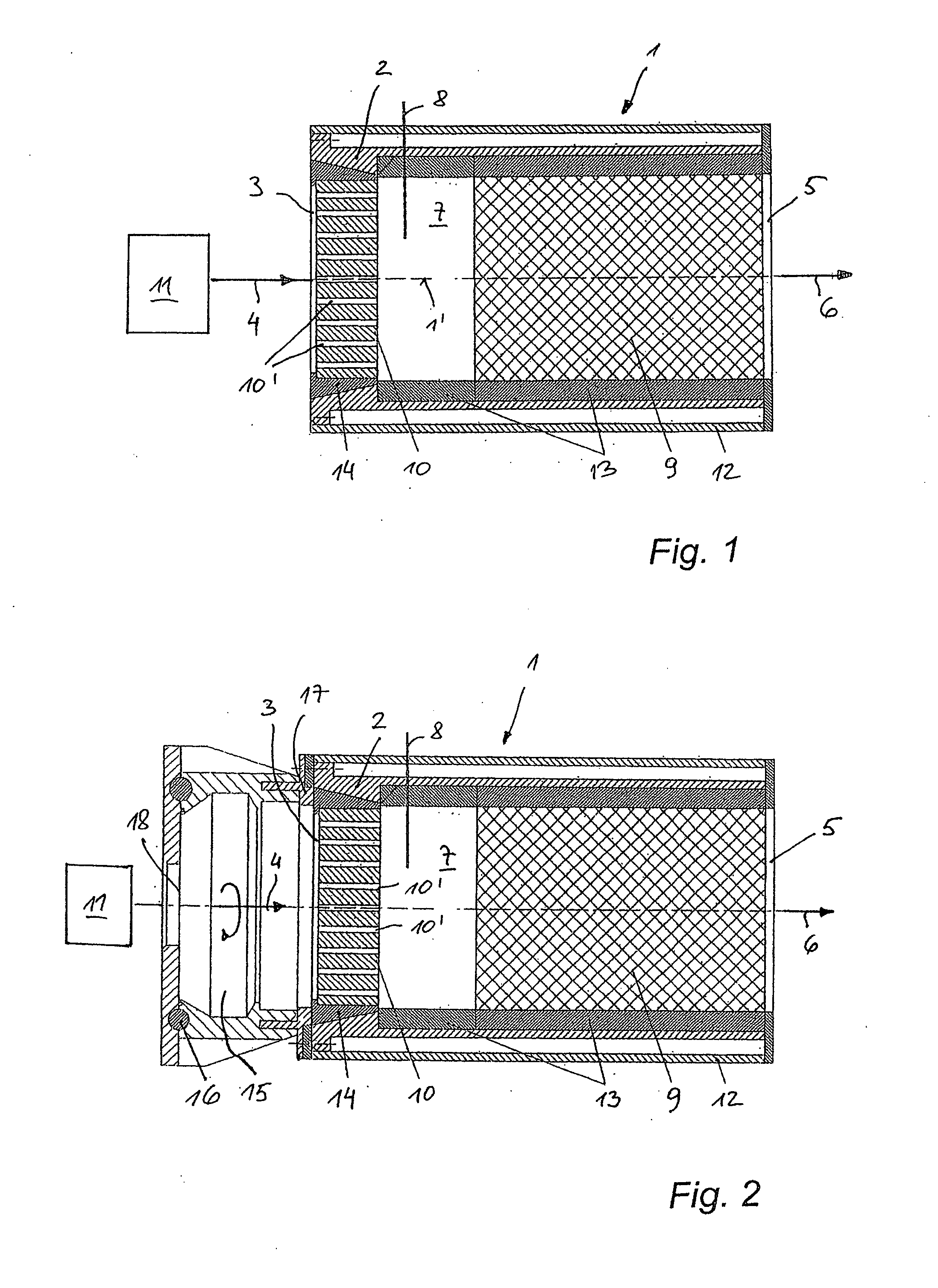

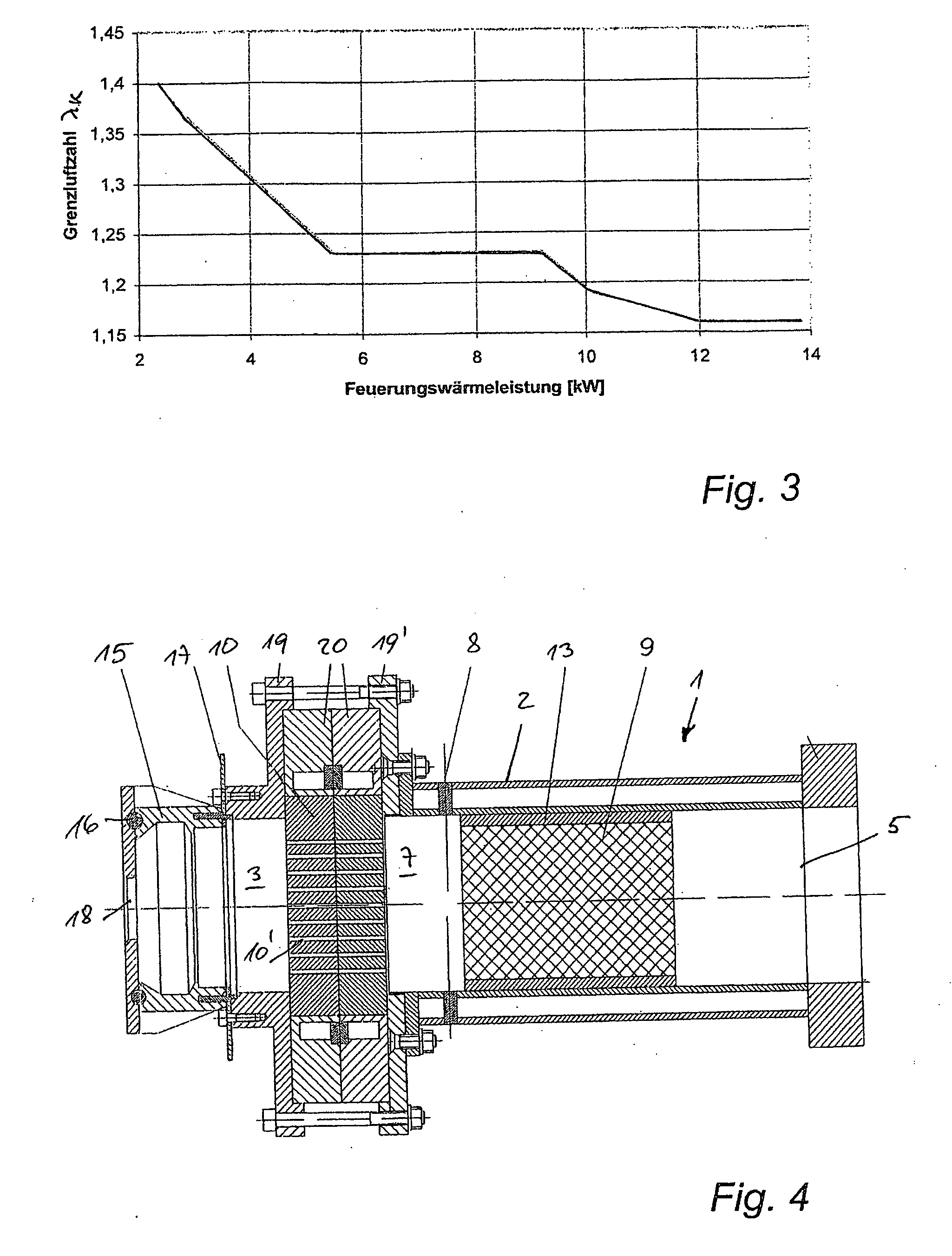

Porous burner as well as a method for operating a porous burner

The invention relates to a porous burner with a housing, which has an inlet for a fuel-air mixture and an outlet for the exhaust gas mixture generated in the burner, where in flow-direction of the fuel-air mixture the housing contains an ignition space with an ignition device and adjacent to this space a porous burner medium. On the inlet side the ignition space is provided with a stabilizing element, which reduces the inlet cross-section and directs the flow of the fuel-air mixture essentially perpendicular to the inlet cross-section of the porous medium. The porous burner is provided with a device for controlling the mass flow of the fuel-air mixture, which serves to shift the combustion zone from the ignition space into the porous medium.

Owner:WINDHAGER ZENTRALHEIZUNG TECHN

Downward Firing Oxygen-Fuel Burners for Glass Melting Furnaces

InactiveUS20100300153A1Maximize convective transferMaximize radiant heat transferCharging furnaceGlass furnace apparatusCombustorEngineering

This invention relates to a glass melting furnace with downward firing oxygen-fuel burners placed in the breast walls of the combustion space and adjacent to the skew block. The downward firing oxygen-fuel burner may be placed at an angle so that the oxygen-fuel flame from the downward firing oxygen-fuel burner impinges on the upper surface of the glass bath. The placement and angle of the downward firing oxygen-fuel burner may maximize the amount of heat transferred to the batch cover or the molten glass, ensure the formation of high quality glass products, and protect the integrity of the downward firing oxygen-fuel burners and the glass melting furnace.

Owner:ZHANG ZHIFA +1

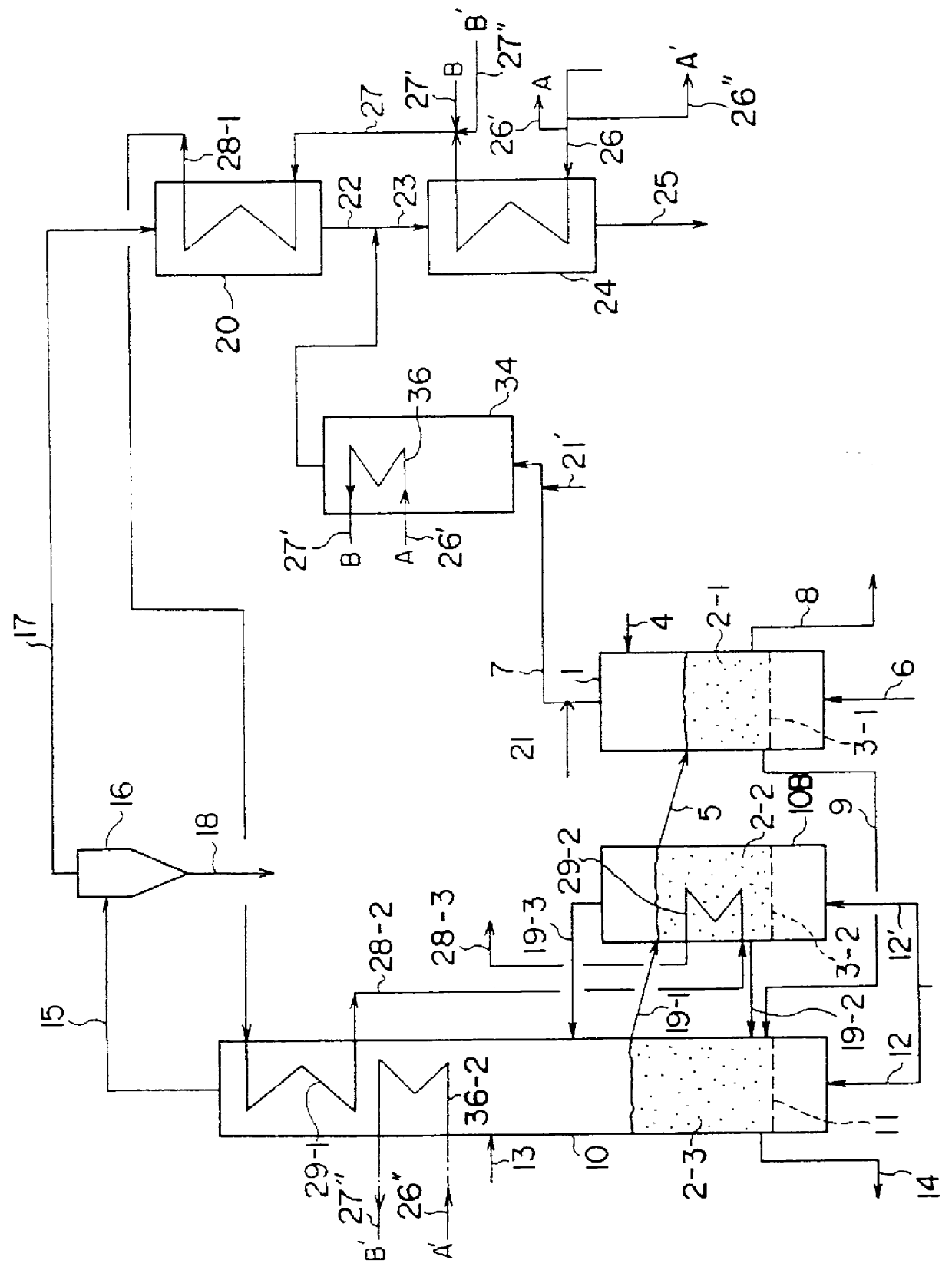

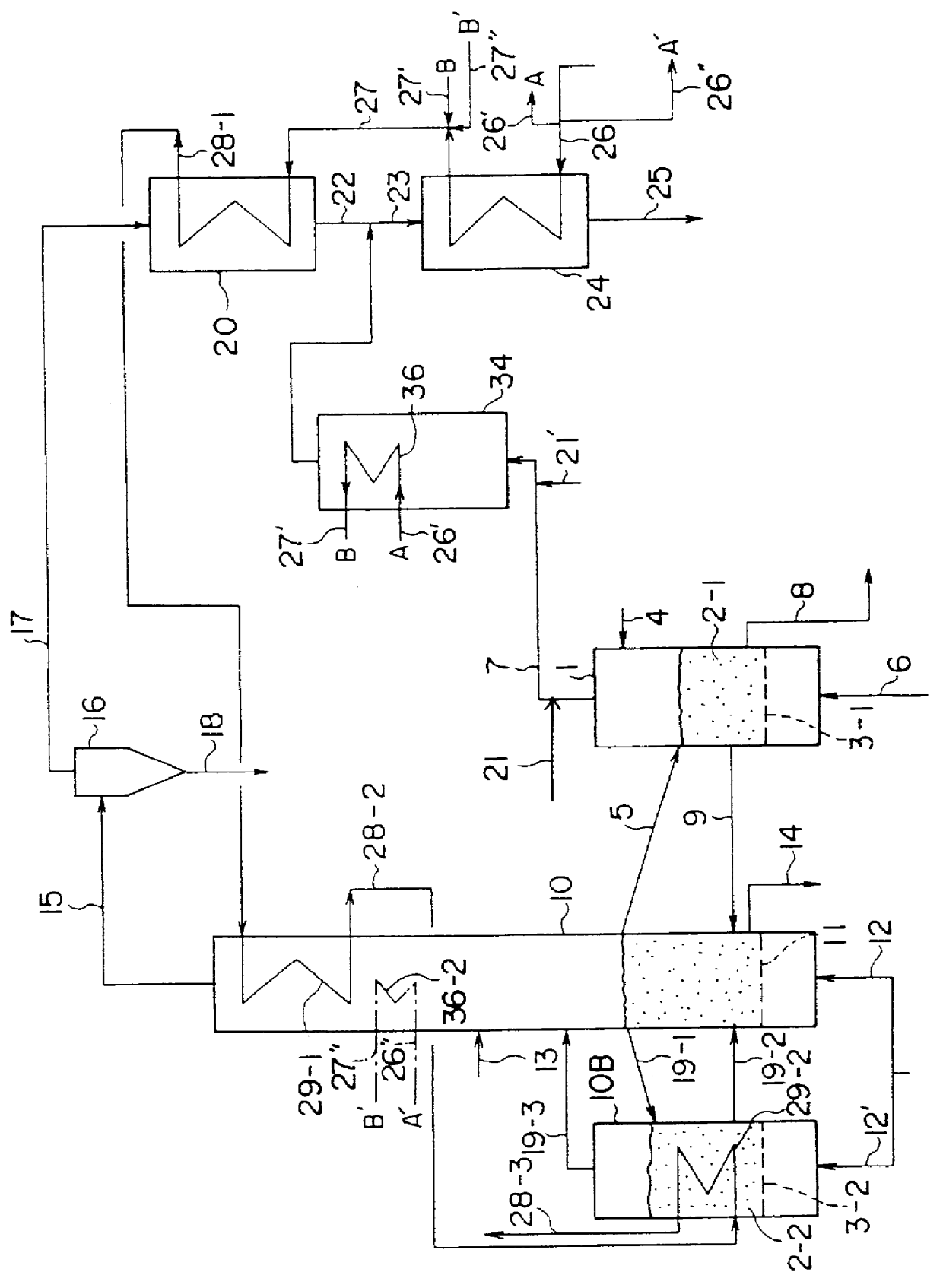

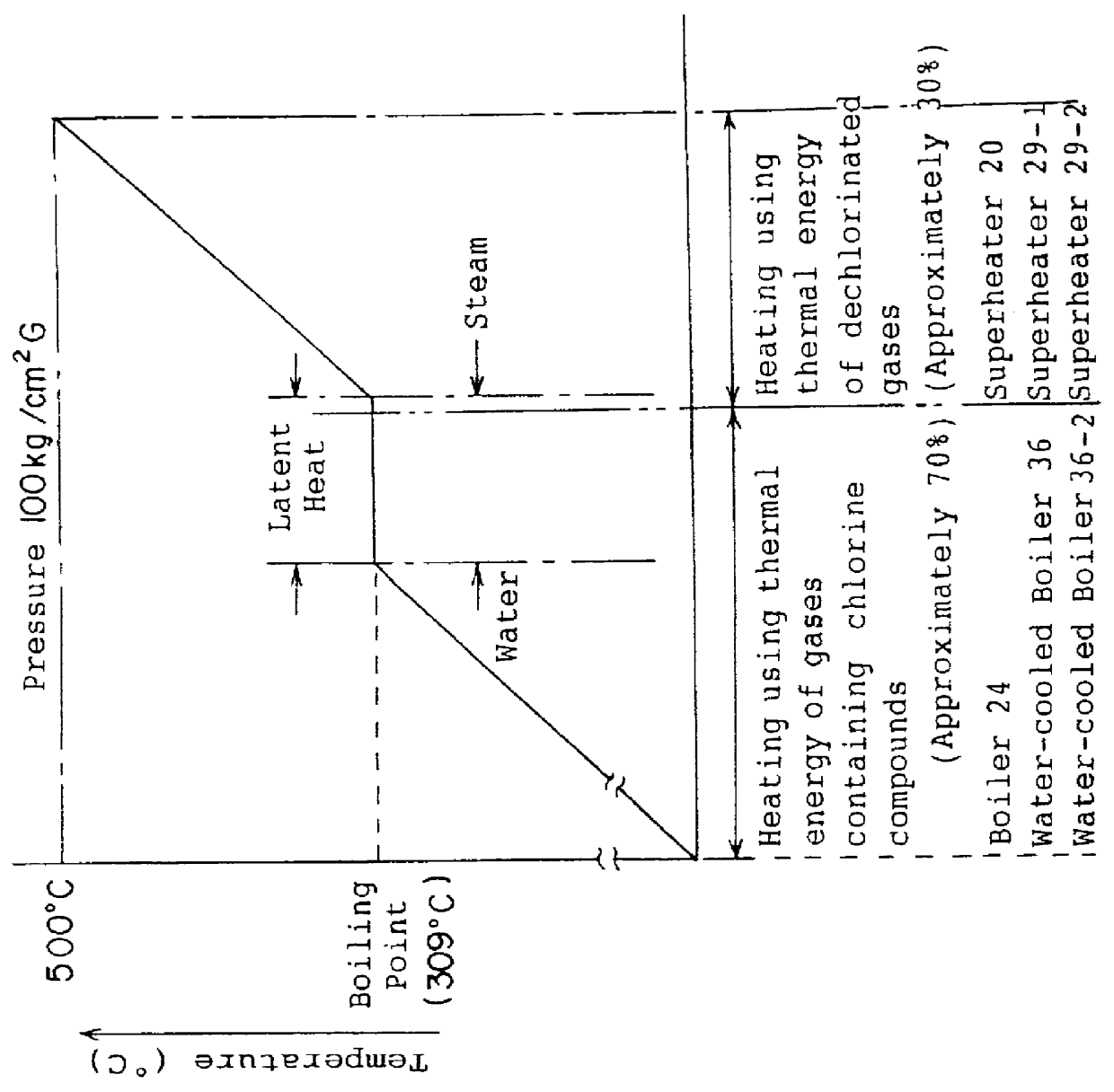

Method and apparatus for producing superheated steam using heat from the incineration of waste material

PCT No. PCT / JP97 / 00573 Sec. 371 Date Jan. 12, 1998 Sec. 102(e) Date Jan. 12, 1998 PCT Filed Feb. 27, 1997 PCT Pub. No. WO97 / 32161 PCT Pub. Date Sep. 4, 1997According to the present invention, boiler water is pressurized so that its boiling point is set at approximately 200 DEG C. to 320 DEG C. The boiler water is heated in at least two stages. Thermal energy of gases containing chlorine compounds is used to heat the water to its boiling point. Thermal energy of gases which do not contain chlorine compounds is used to heat the water from its boiling point until superheated steam of a given temperature is generated. The heating which uses the thermal energy of gases containing chlorine compounds is accomplished using the thermal energy from the combustion of pyrolysis gases obtained from a pyrolysis means in which waste material is supplied into a chamber containing a fluidized bed medium which has been heated to at least 300 DEG C., and a pyrolytic reaction is induced. The heating which uses the thermal energy of gases which do not contain chlorine compounds is accomplished using the thermal energy obtained from a char combustion means to combust char in which a char mixture consisting of unpyrolyzed residue and fluidized bed medium removed from the pyrolysis means is fluidized by a stream of air, and the unpyrolyzed residue is combusted.

Owner:MITSUBISHI HEAVY IND LTD

Production and use of biosolid granules

This invention relates to the production and use of encapsulated and / or concentrically-constructed fertilizer or bioremediation granules such as, for example, granules of 0.5 mm to 10 mm in diameter constructed so that there are at least two components to the granule including a core with a surrounding capsule or a core with one or more concentric layers that are distinguishable from the core with respect to nutrient content, density, hardness, solubility, composition, microbial content and permeability, as in permeability to odors or the permeability of nutrients that might volatize to the atmosphere or leach into the soil. The basic idea was to create a method for manufacturing and using fertilizer granules, which incorporate multiple concentric layers or a core plus an encapsulating outer layer.

Owner:UNIFIED ENVIRONMENTAL SERVICES GROUP

Vortex type gas lamp

A vortex type gas lamp comprising a base and an axially extending-transparent shield. Gas is supplied near the bottom end of the shield. The shield is formed of a plurality (preferably two) axial curved sections which overlap one another at their axial edges to form tangentially directed port. Combustion of the gas with atmospheric oxygen admitted through the ports results in an axial vortex of burning gas useful for illumination, decoration and heat.

Owner:CHESNEY PETER

Gaseous fuel burner

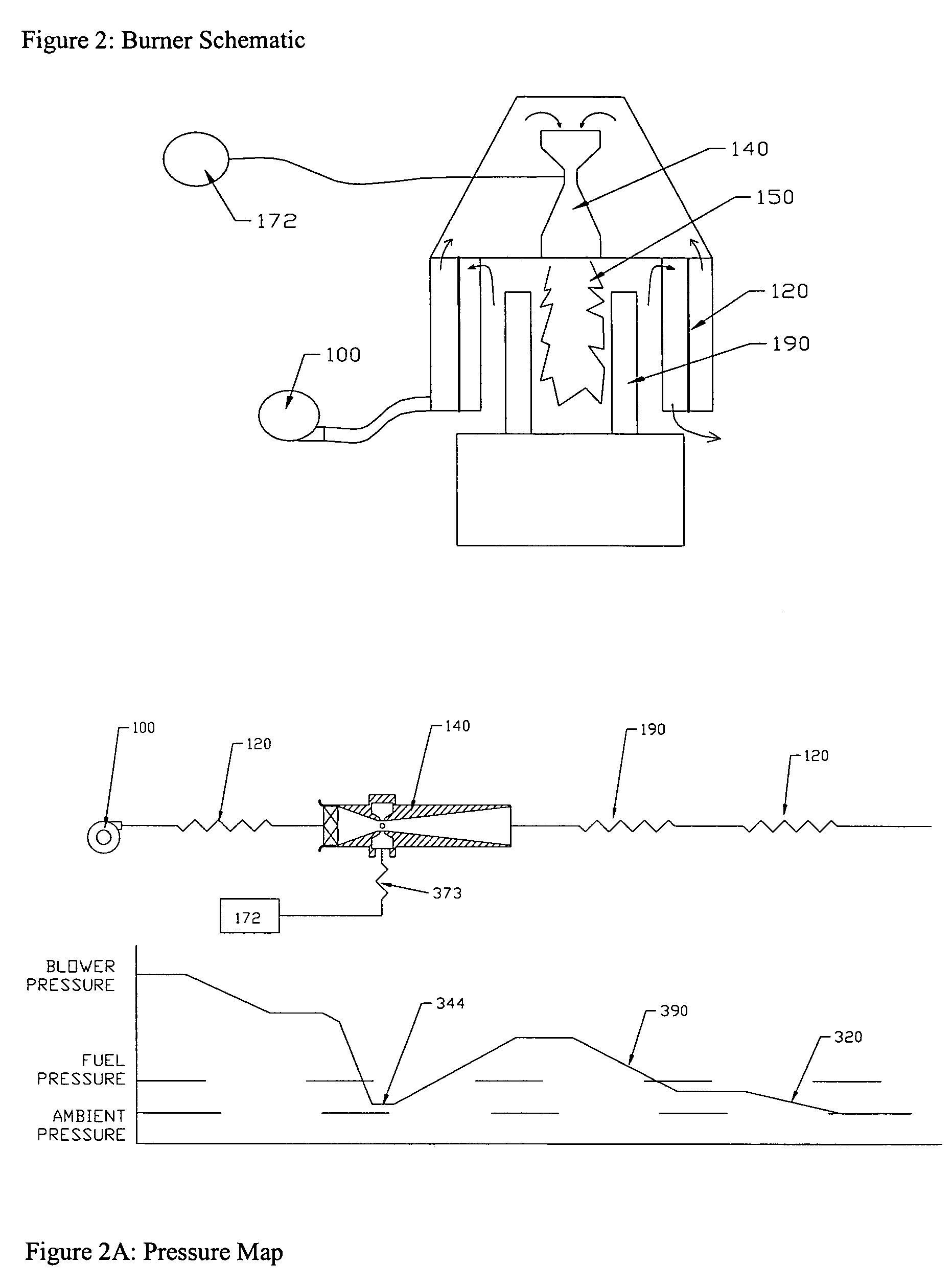

ActiveUS20050250062A1Address is challengeEliminate needFuel supply regulationAir supply regulationAir velocityAutomatic control

An ejector, such as a venturi, facilitates the delivery of gaseous fuel to the combustion chamber of a burner. A blower forces air through the ejector, and the air flow produces a suction that draws fuel from a fuel inlet to produce a fuel-air mixture. The amount of fuel drawn from the fuel inlet is a function of the air flow such that a substantially constant fuel-air ratio is obtained over a range of air flow rates and temperatures without the need for a separate high-pressure fuel pump. The fuel-air mixture may be provided to a combustion chamber for combustion. Air from the blower may be pre-heated prior to entering the ejector, for example, using a heat exchanger that recovers some of the heat from the combusted fuel-air mixture. Air flow through the ejector may be conditioned, for example, by a swirler, to produce a tangential air flow that can increase fuel flow by increasing air velocity across the fuel inlet and / or produce a swirl-stabilized flame in the combustion chamber. The combusted fuel-air mixture may be provided to a thermal load, such as an external combustion engine. Blower speed may be controlled manually or automatically to control power output. Fuel flow to the ejector can be controlled manually or automatically to control fuel-air ratio. The burner can be configured to operate with multiple fuel types, for example, using a fuel selector with fixed or variable restrictors.

Owner:NEW POWER CONCEPTS

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com