Patents

Literature

1201results about How to "Easy to ignite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

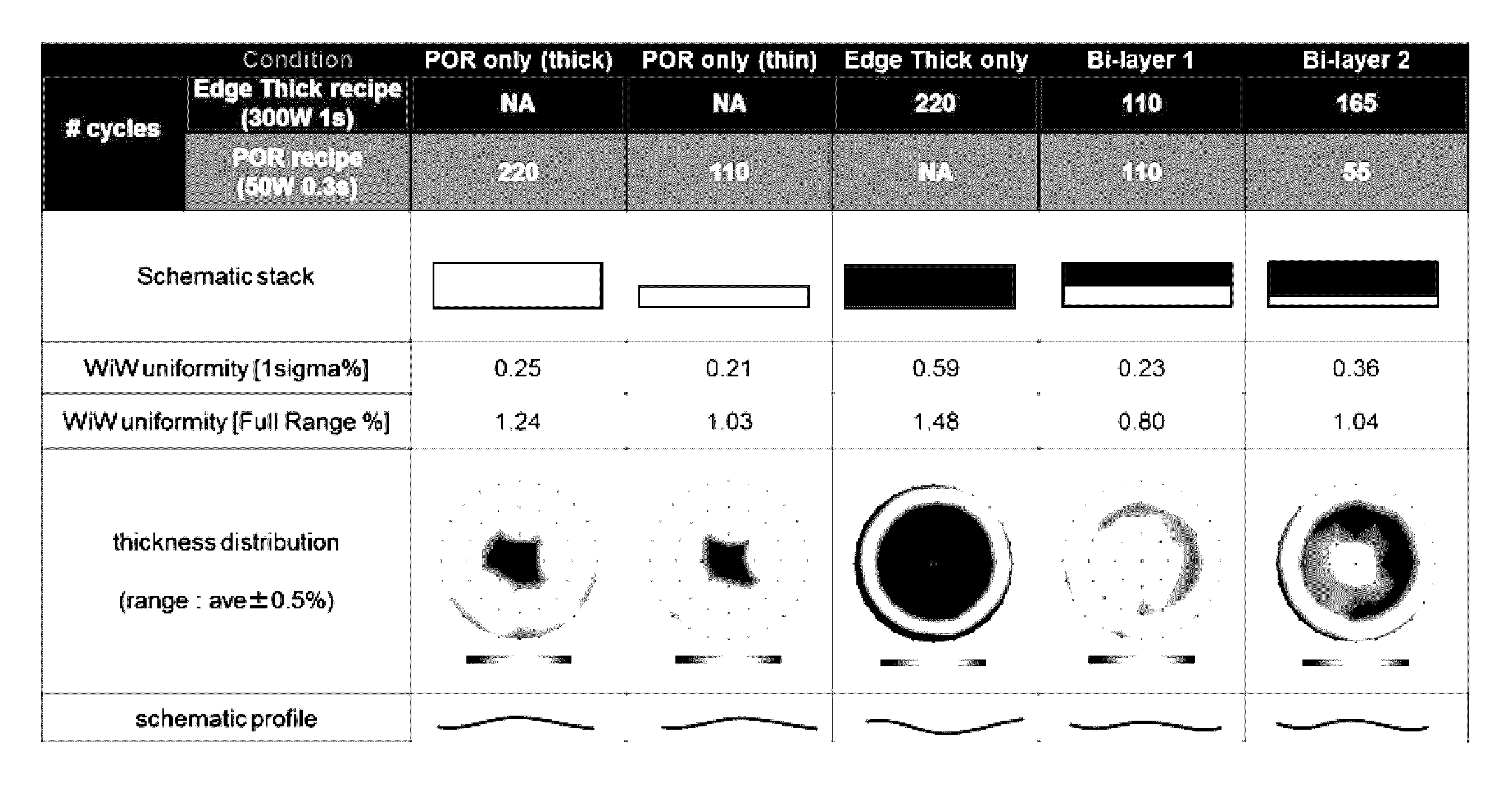

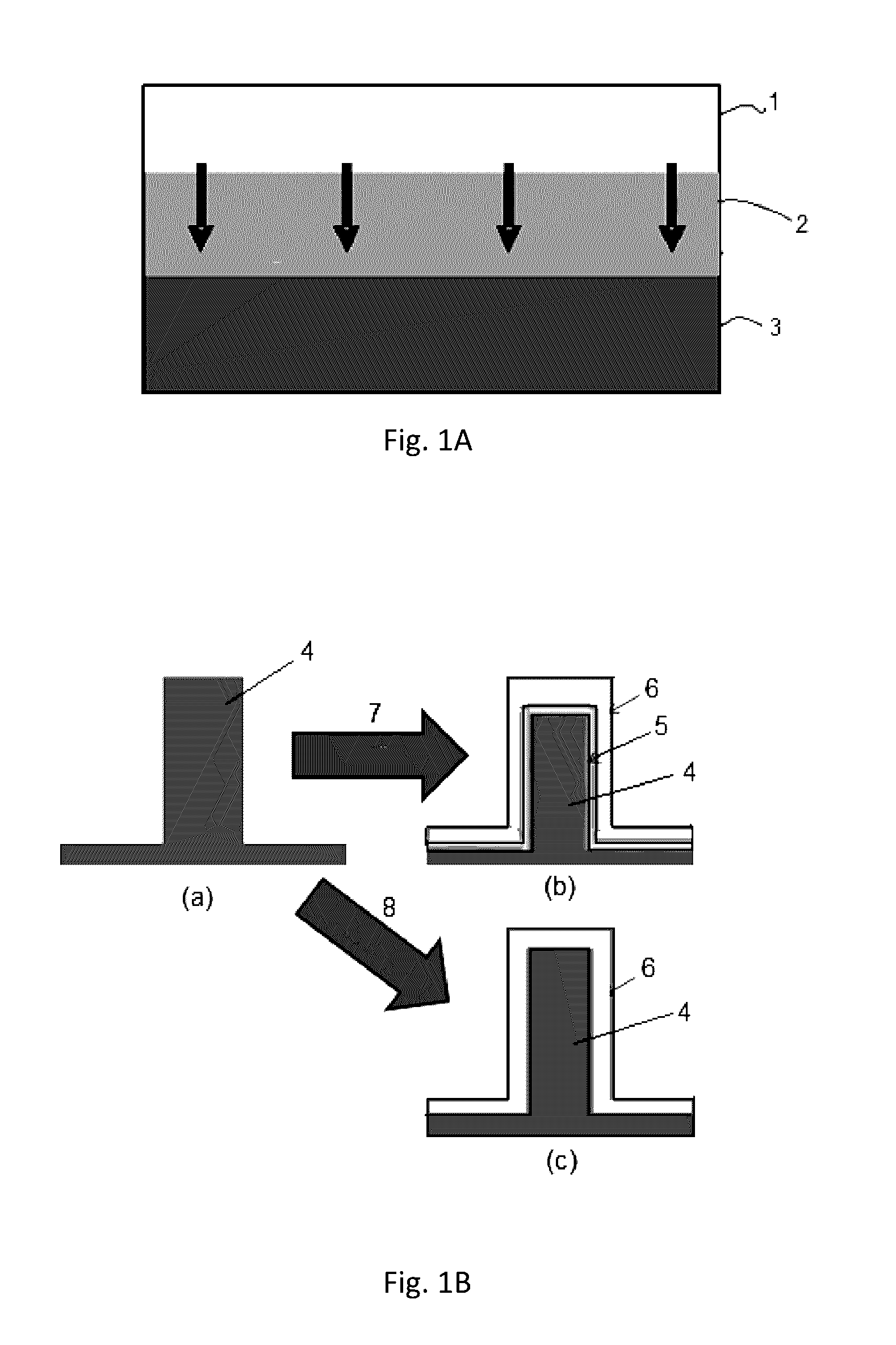

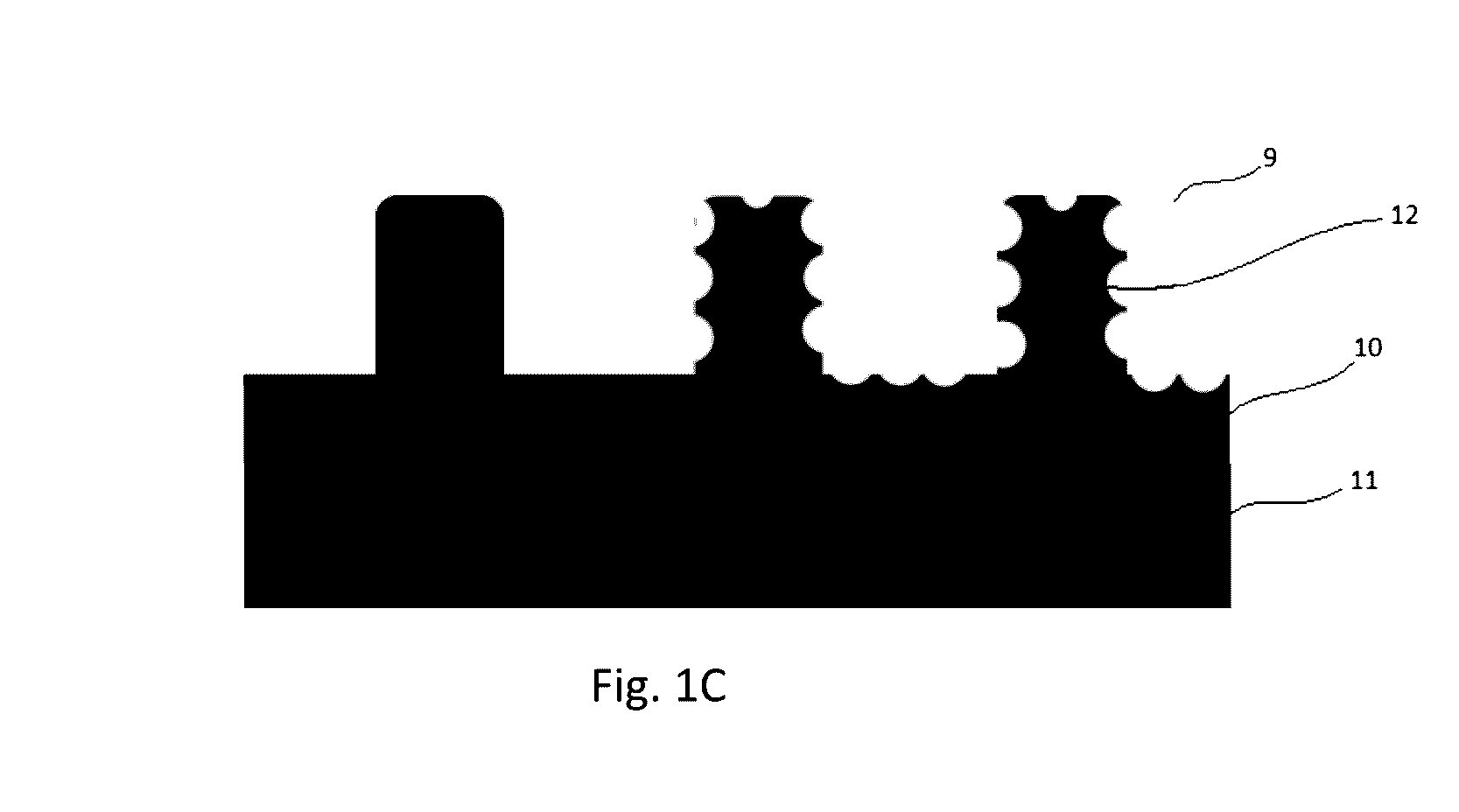

Low-Oxidation Plasma-Assisted Process

ActiveUS20150315704A1Improve film qualitySuppressing of layerElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringOxide

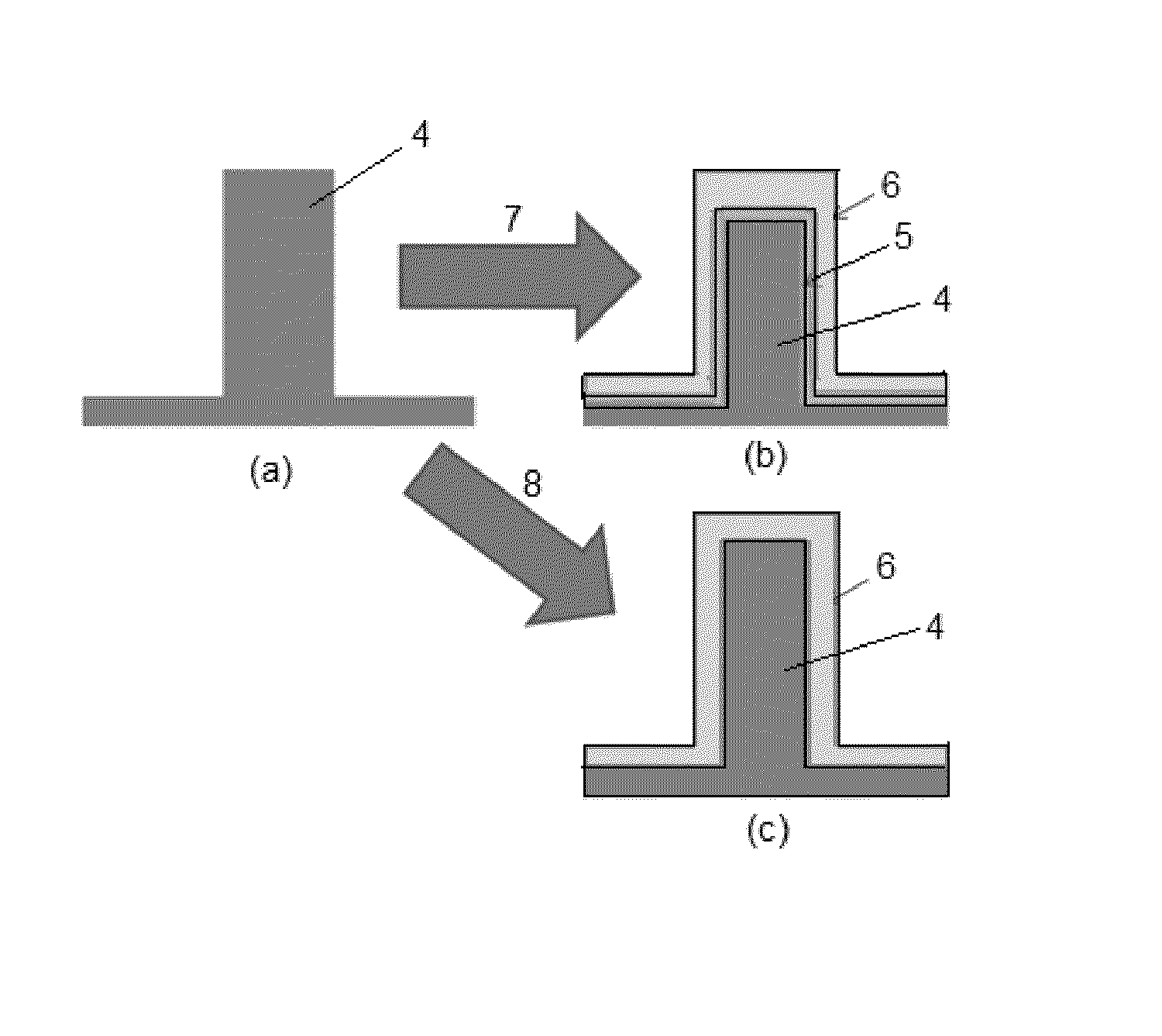

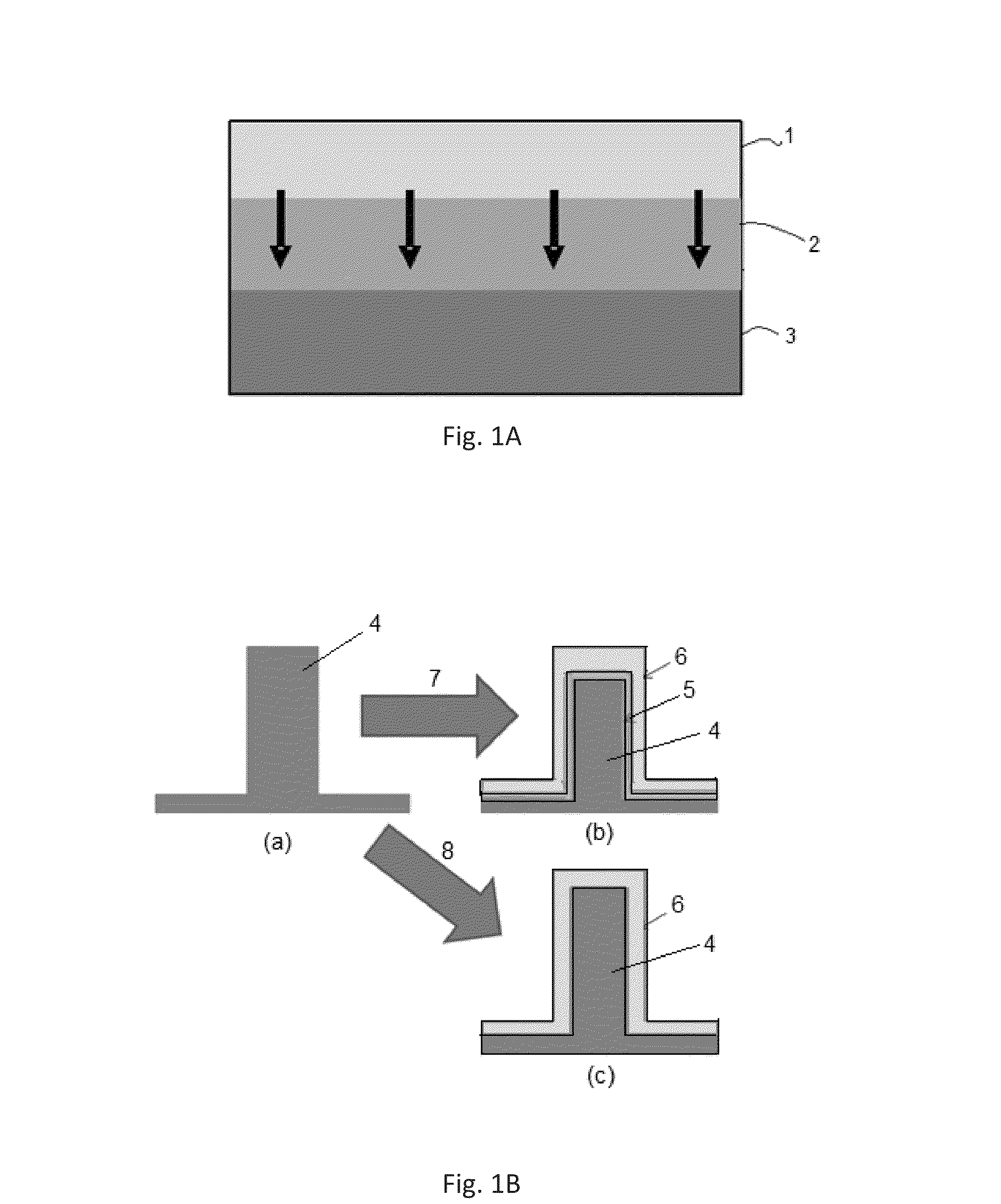

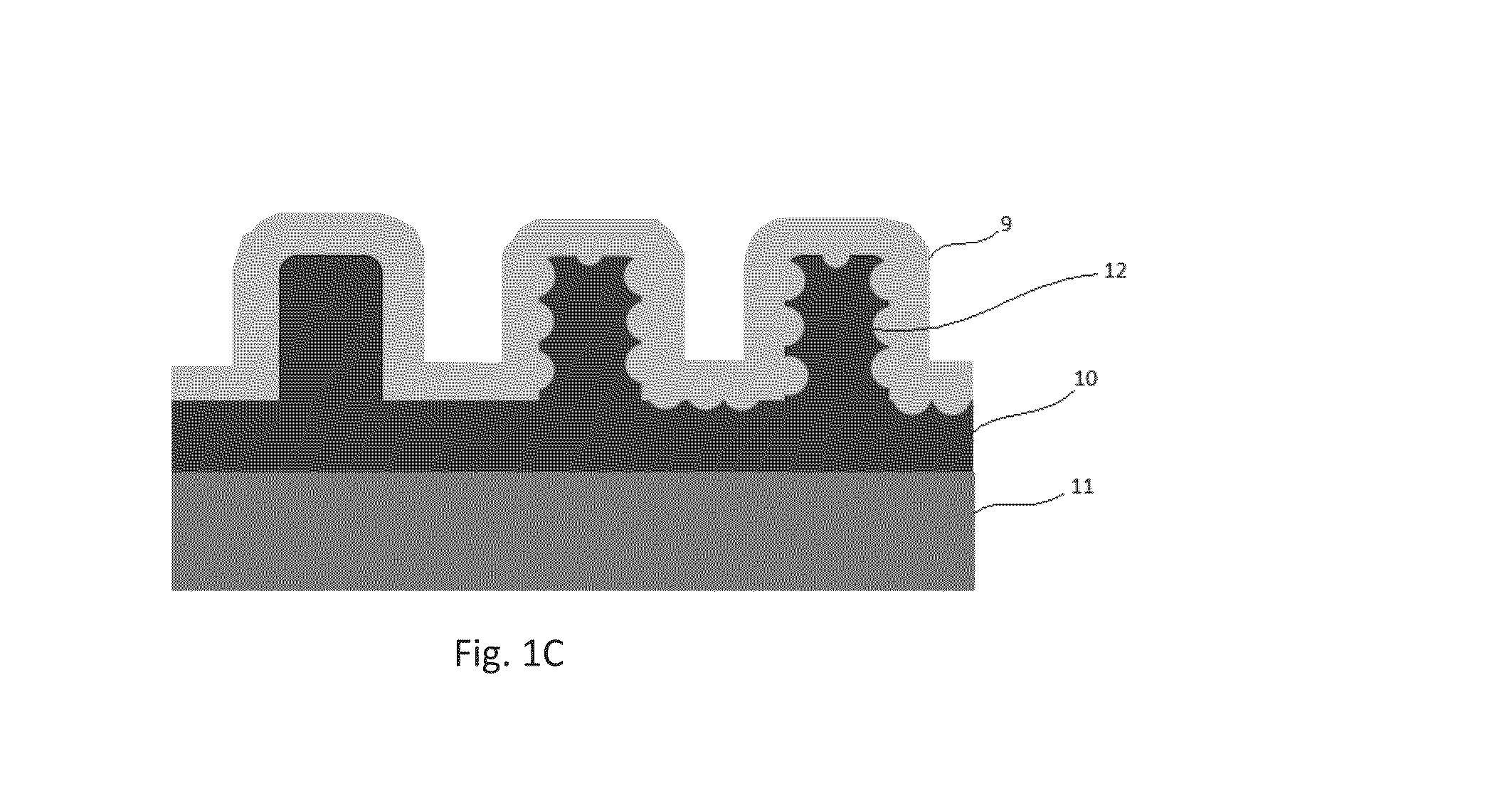

A method for forming an oxide film by plasma-assisted cyclic processing, includes: (i) supplying a precursor to a reaction space wherein a substrate is placed; (ii) applying a first RF power to the reaction space for a first period of time without supplying a precursor; and (iii) applying a second RF power to the reaction space for a second period of time without supplying the precursor, wherein the first RF power is lower than the second RF power, and / or the first period of time is shorter than the second period of time.

Owner:ASM IP HLDG BV

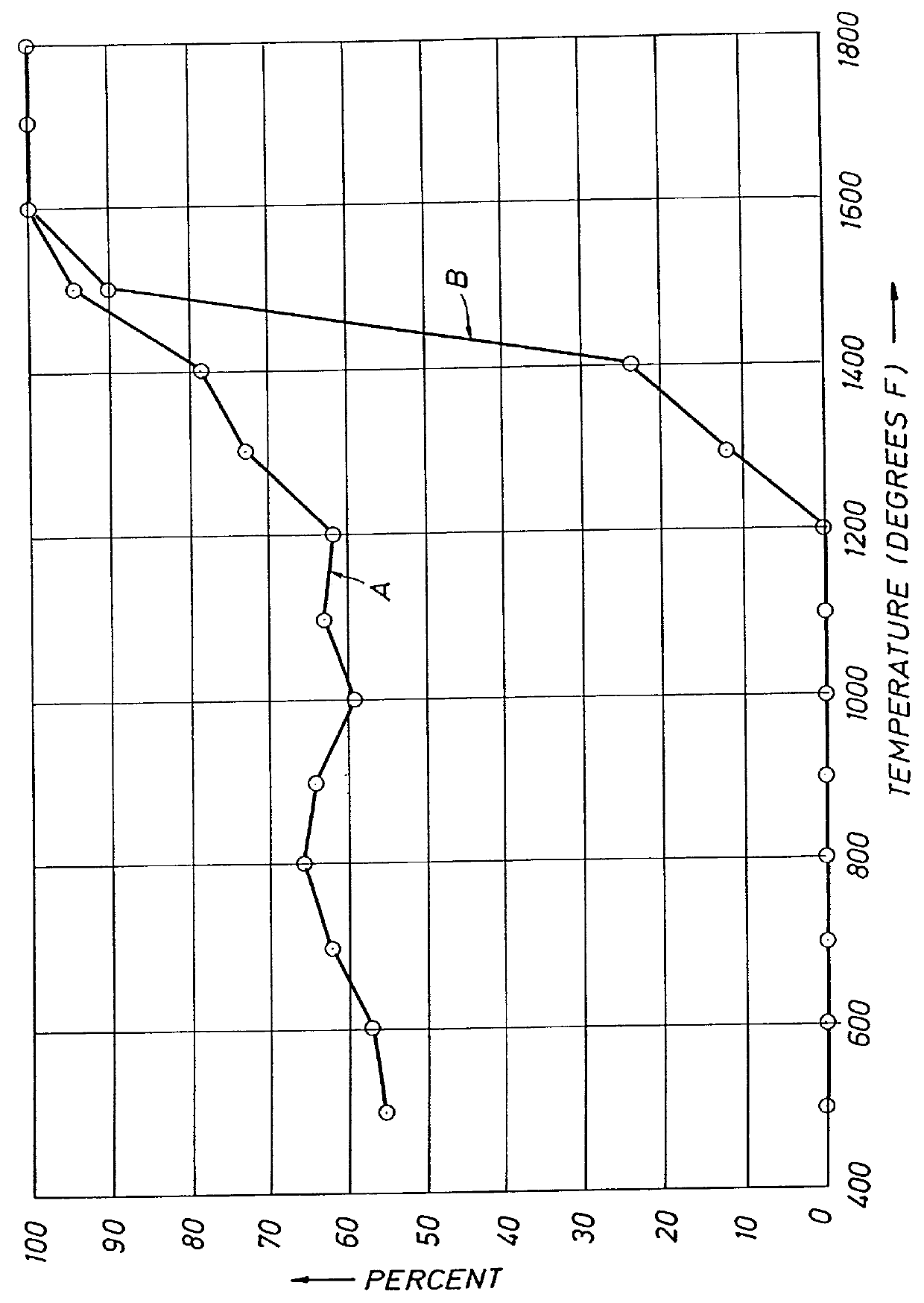

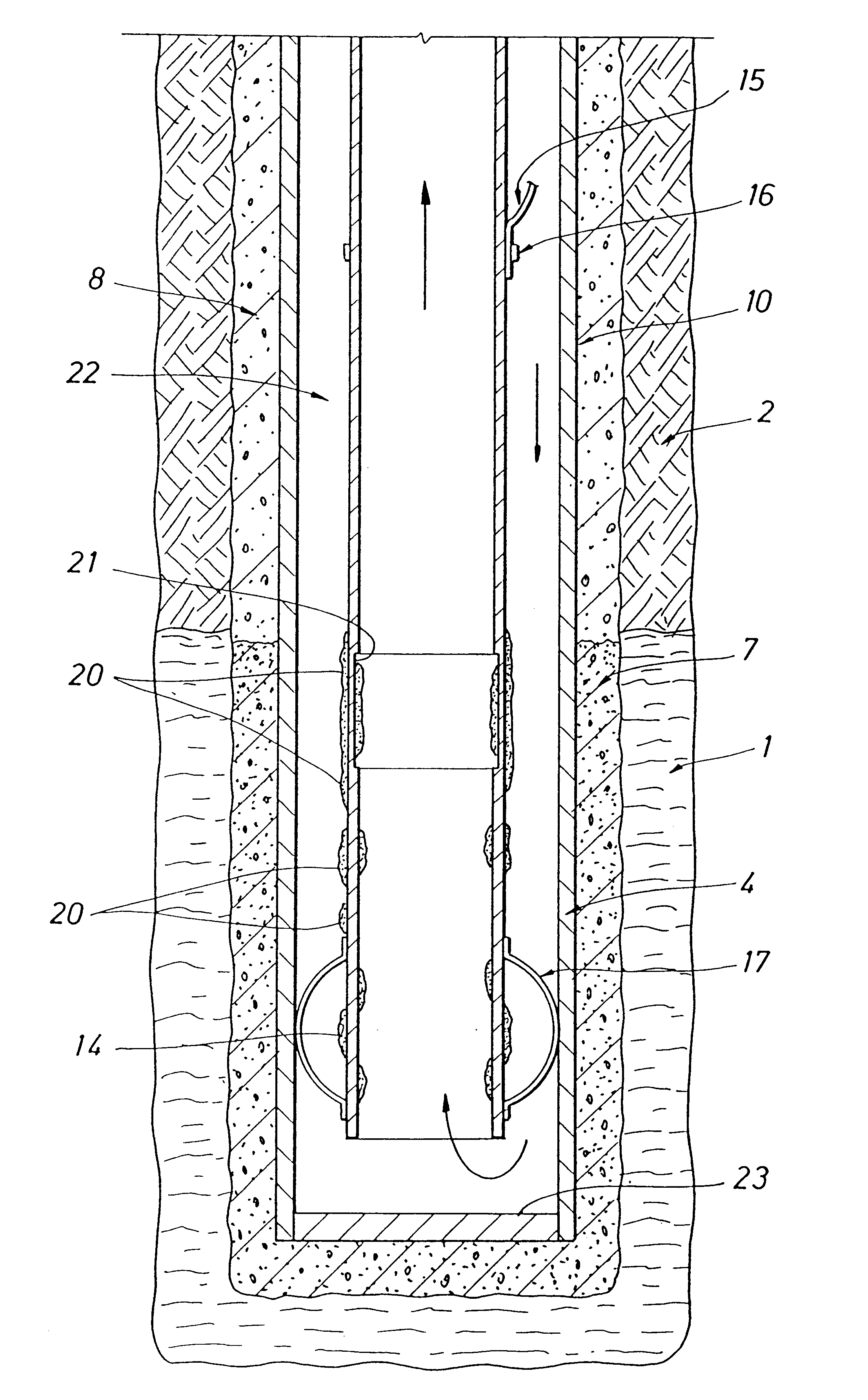

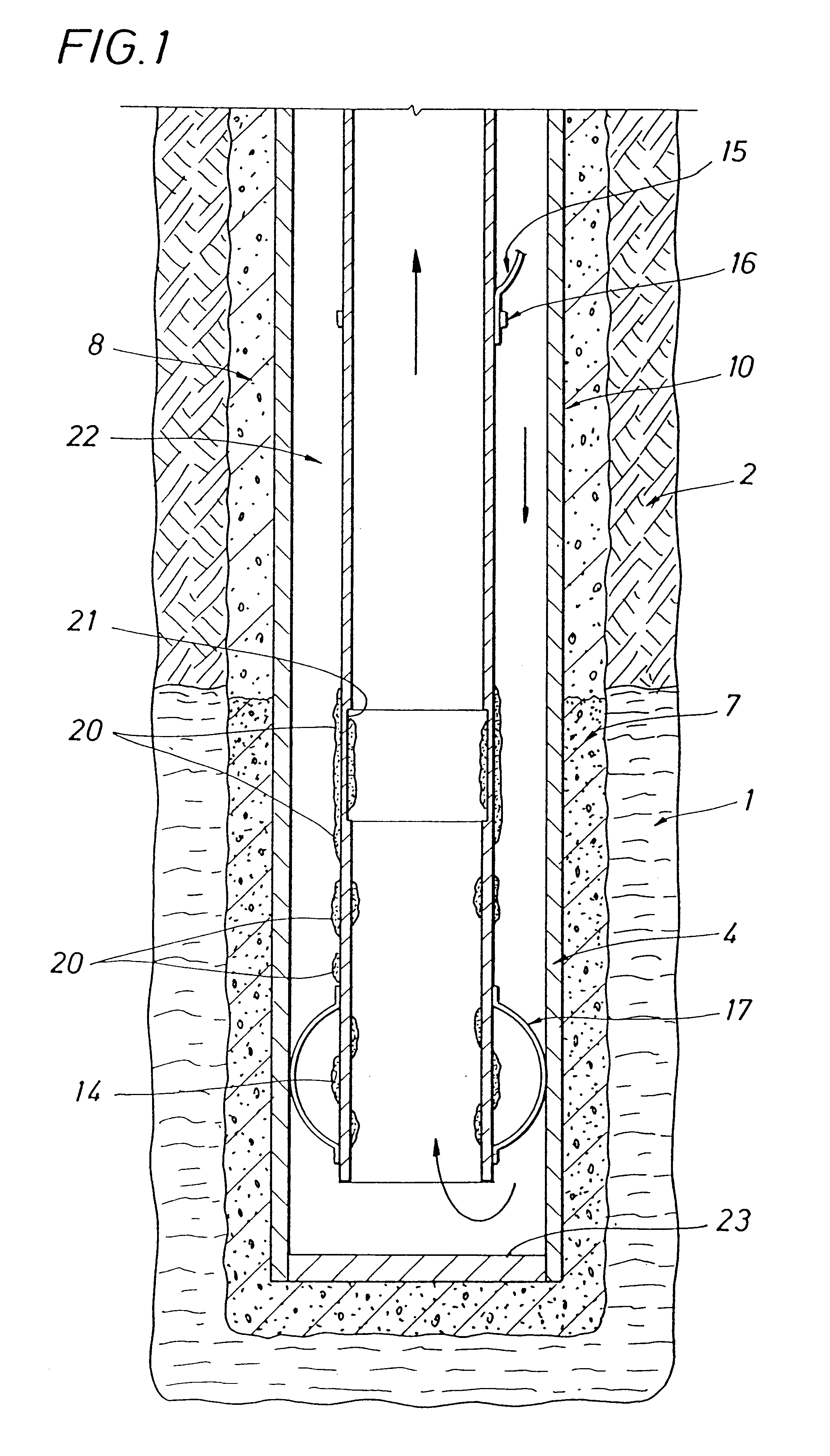

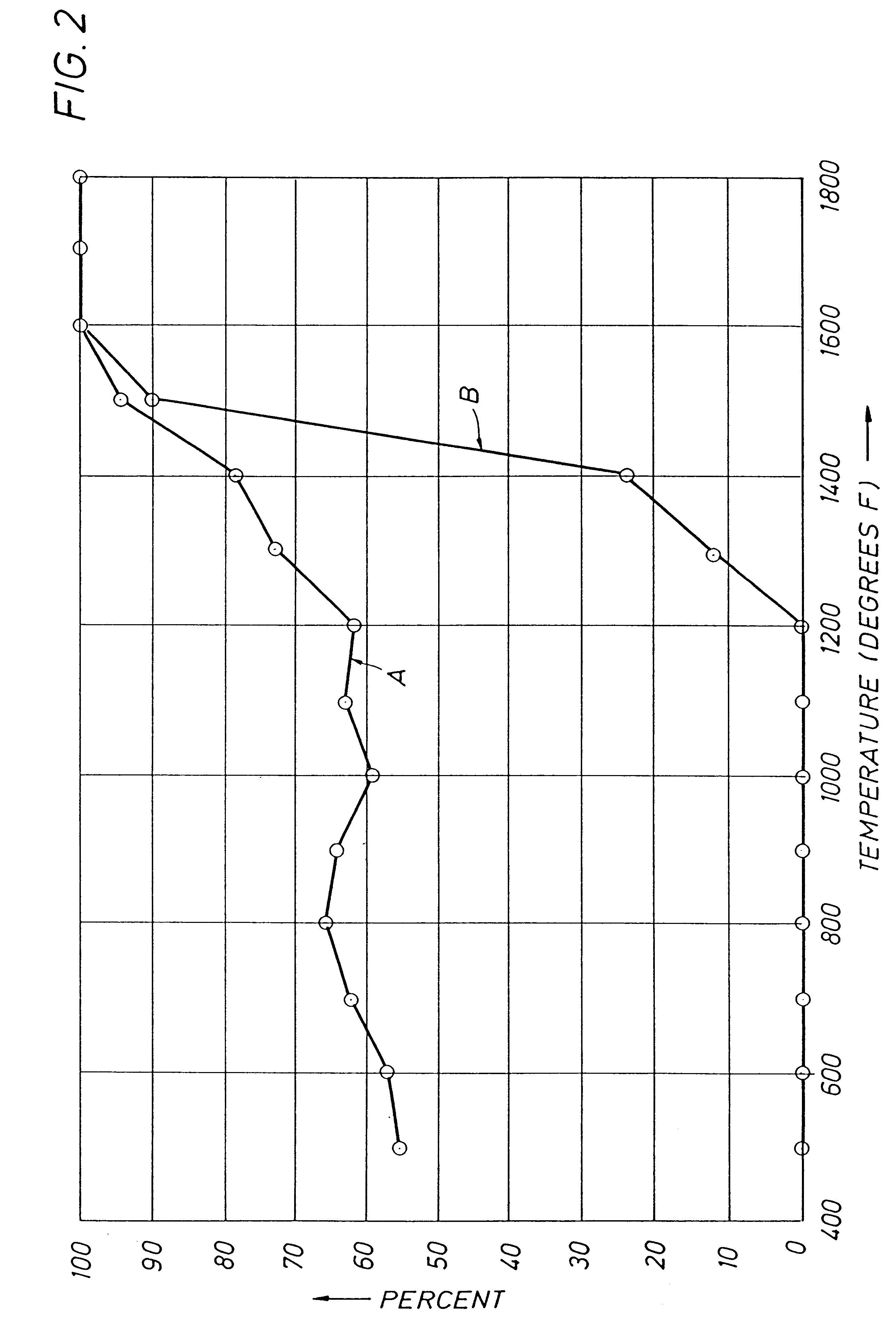

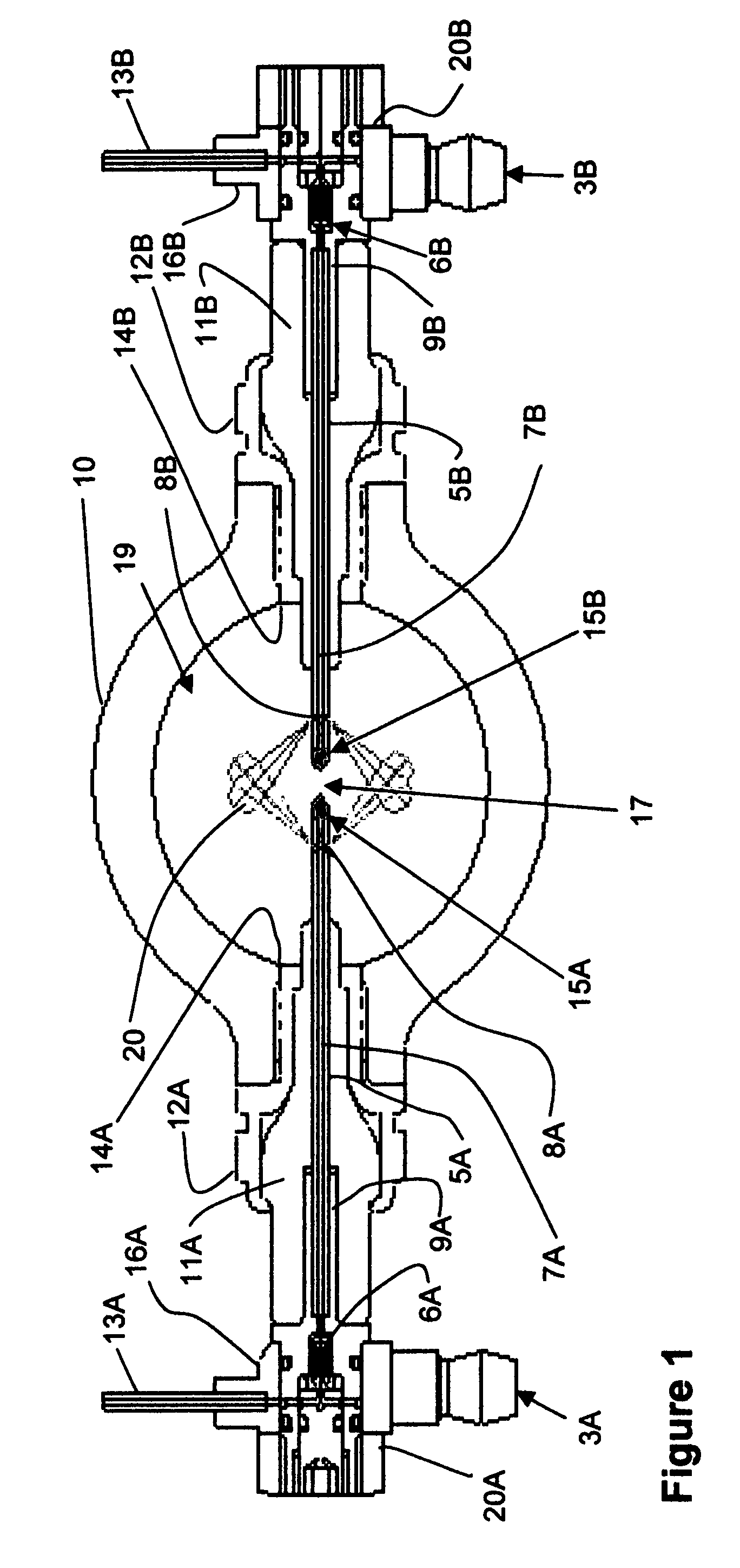

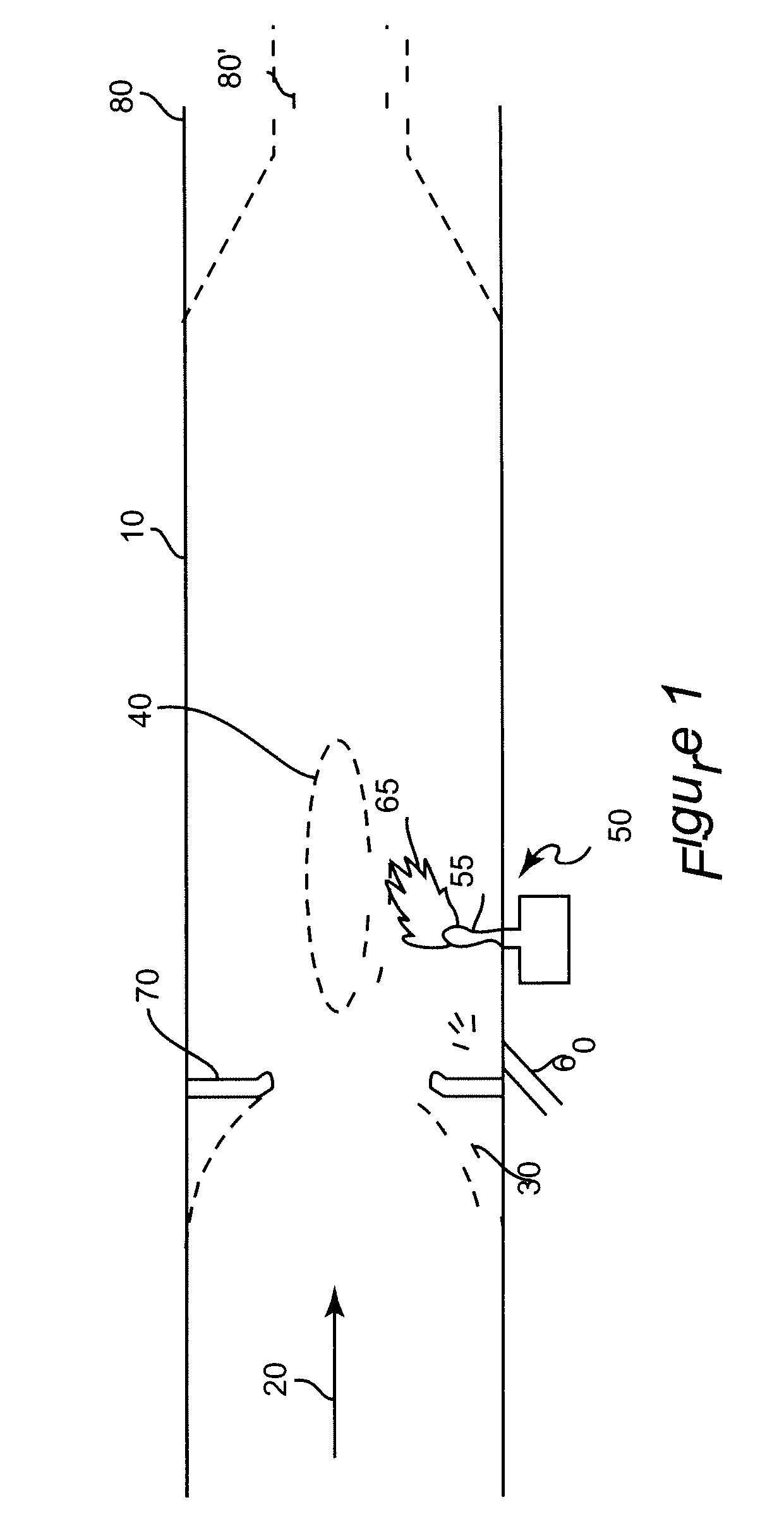

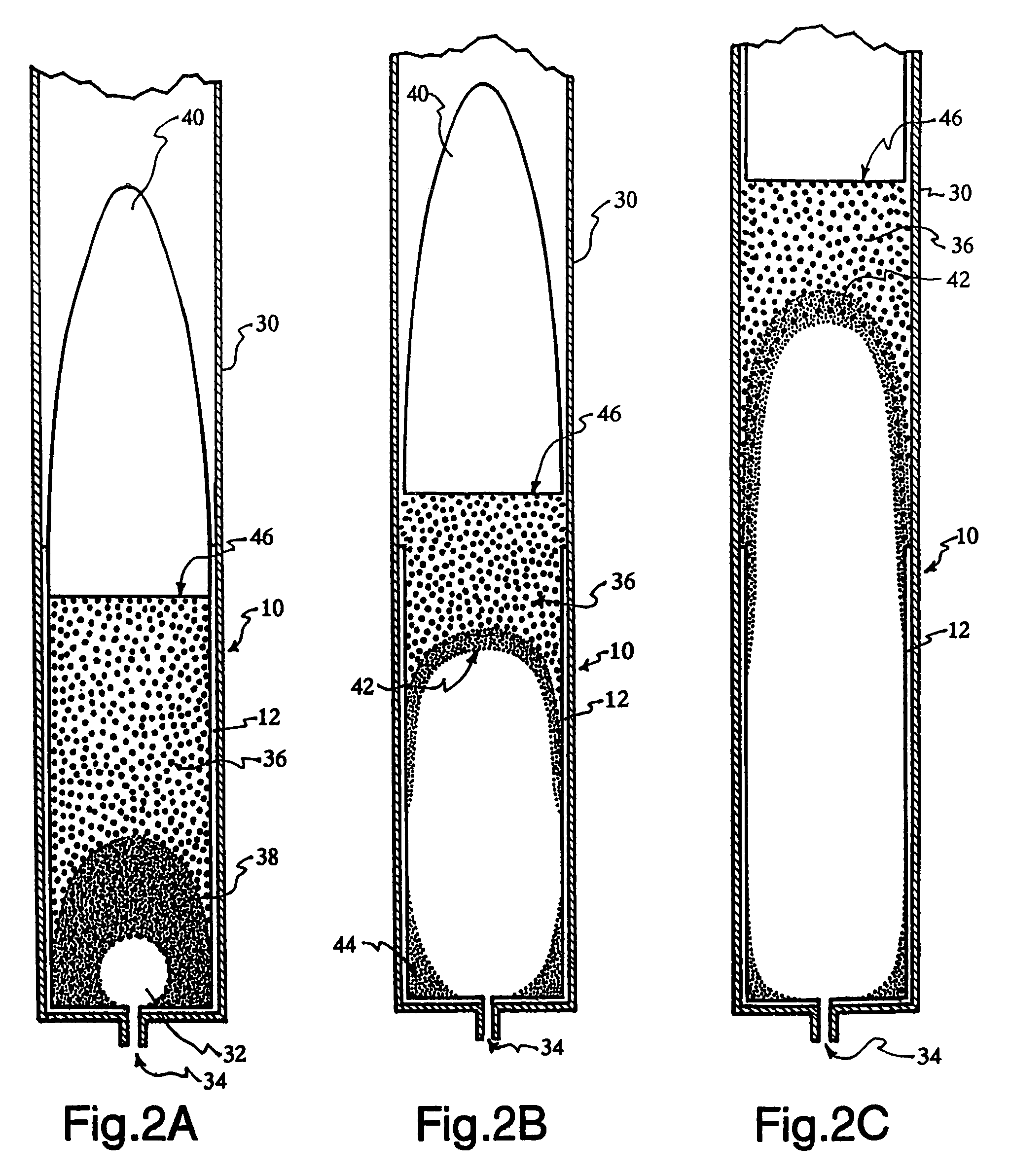

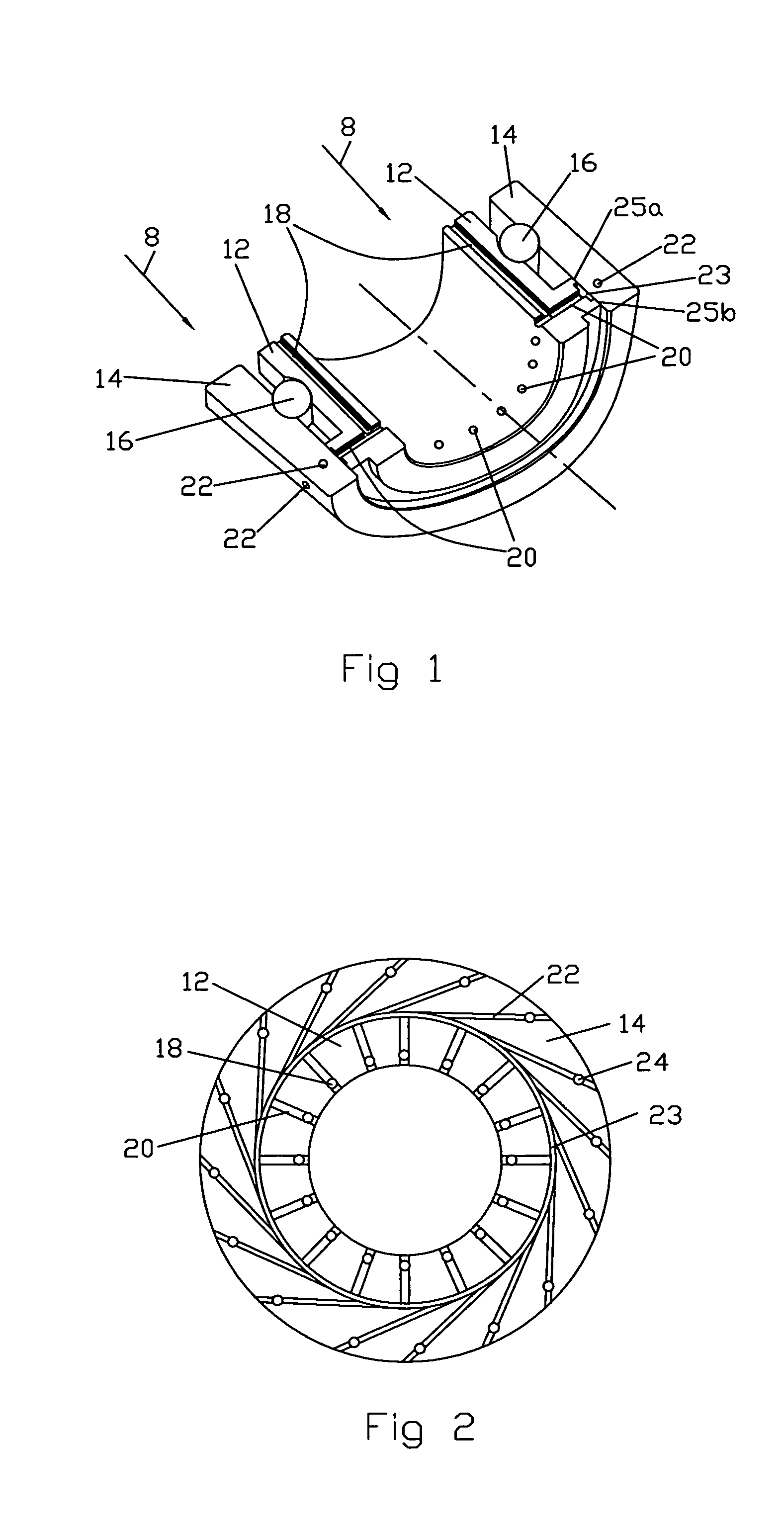

Flameless combustor

InactiveUS6019172AEasy to igniteImprove the level ofApparel holdersInsulationCombustorCombustion chamber

A combustor method and apparatus is provided. The method utilizes flameless combustion with one or more of three improvements to enhance ignition of the flameless combustor. A catalytic surface can be provided within a combustion chamber to provide flameless combustion at least in the vicinity of the catalytic surface at a temperature that is much lower than the autoignition temperature of fuel in air without the presence of the catalytic surface. Nitrous oxide or supplemental oxygen may also be used as an oxidant either instead of air or with air to reduce ignition temperatures. Further, electrical energy can be passed through the fuel conduit, raising the temperature of the conduit to a temperature above which the fuel will ignite when combined with the oxidant.

Owner:SHELL OIL CO

Low-oxidation plasma-assisted process

ActiveUS9464352B2Suppressing of layerImprove film qualityElectric discharge tubesSemiconductor/solid-state device manufacturingPhysical chemistryRadio frequency

A method for forming an oxide film by plasma-assisted cyclic processing, includes: (i) supplying a precursor to a reaction space wherein a substrate is placed; (ii) applying a first RF power to the reaction space for a first period of time without supplying a precursor; and (iii) applying a second RF power to the reaction space for a second period of time without supplying the precursor, wherein the first RF power is lower than the second RF power, and / or the first period of time is shorter than the second period of time.

Owner:ASM IP HLDG BV

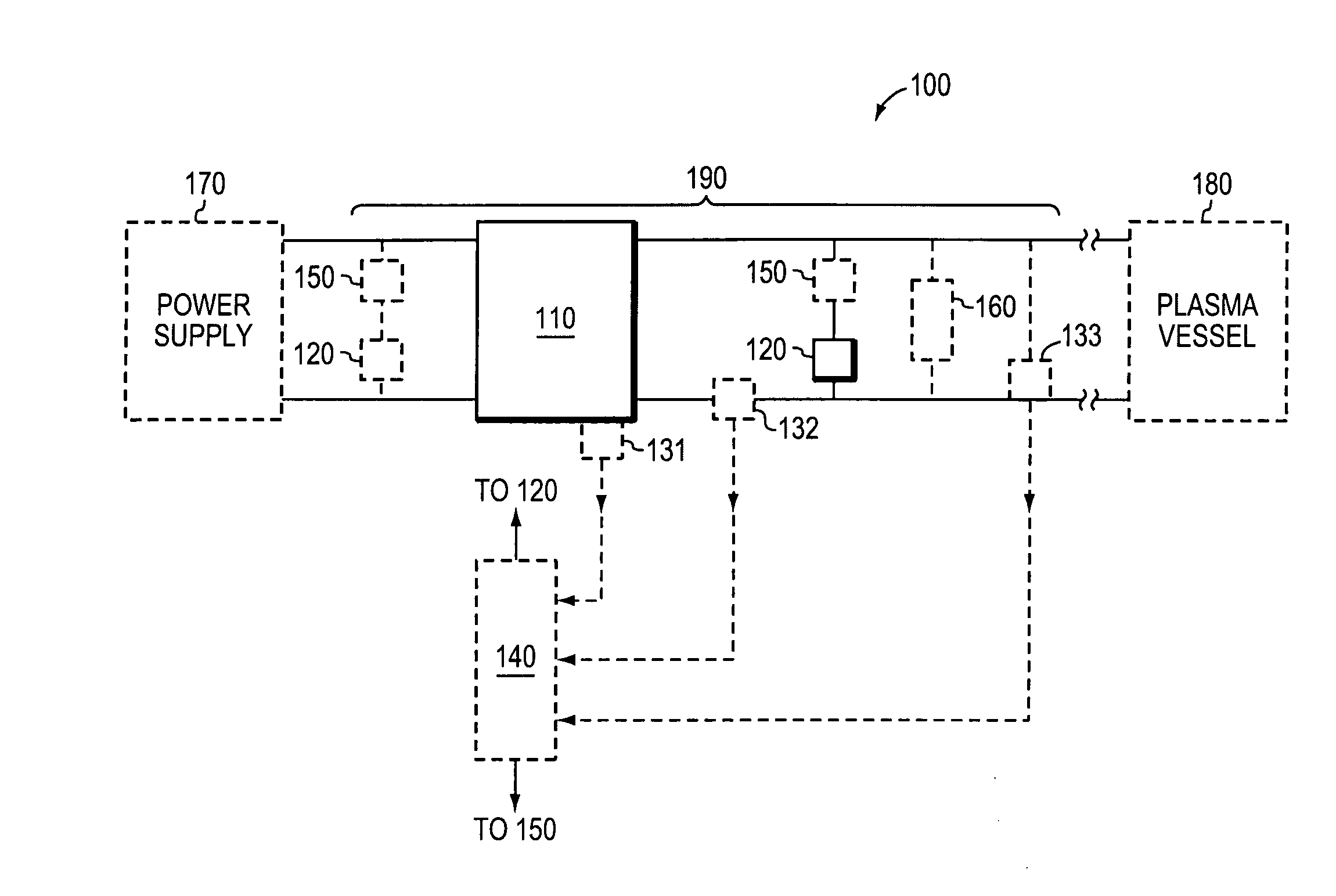

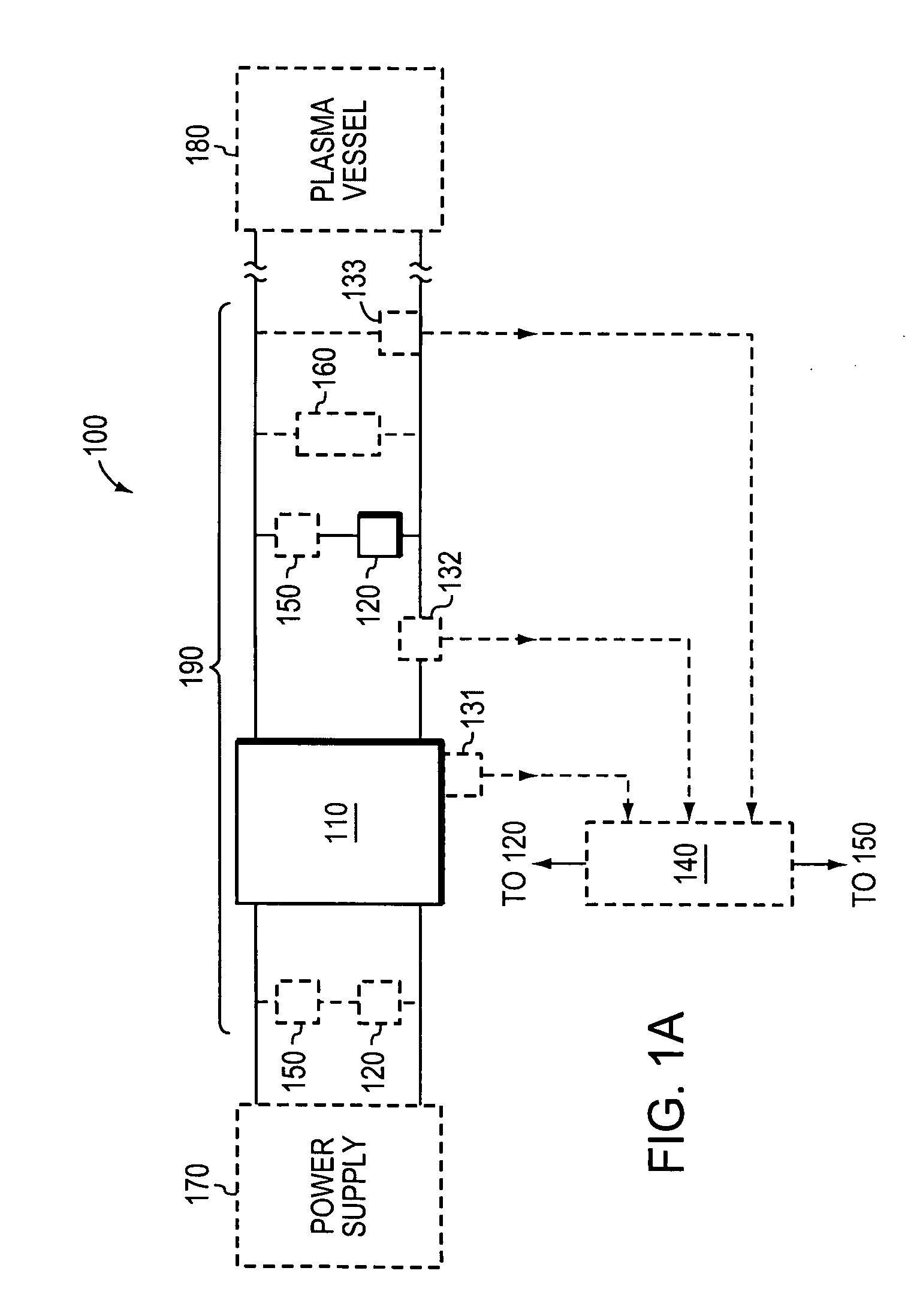

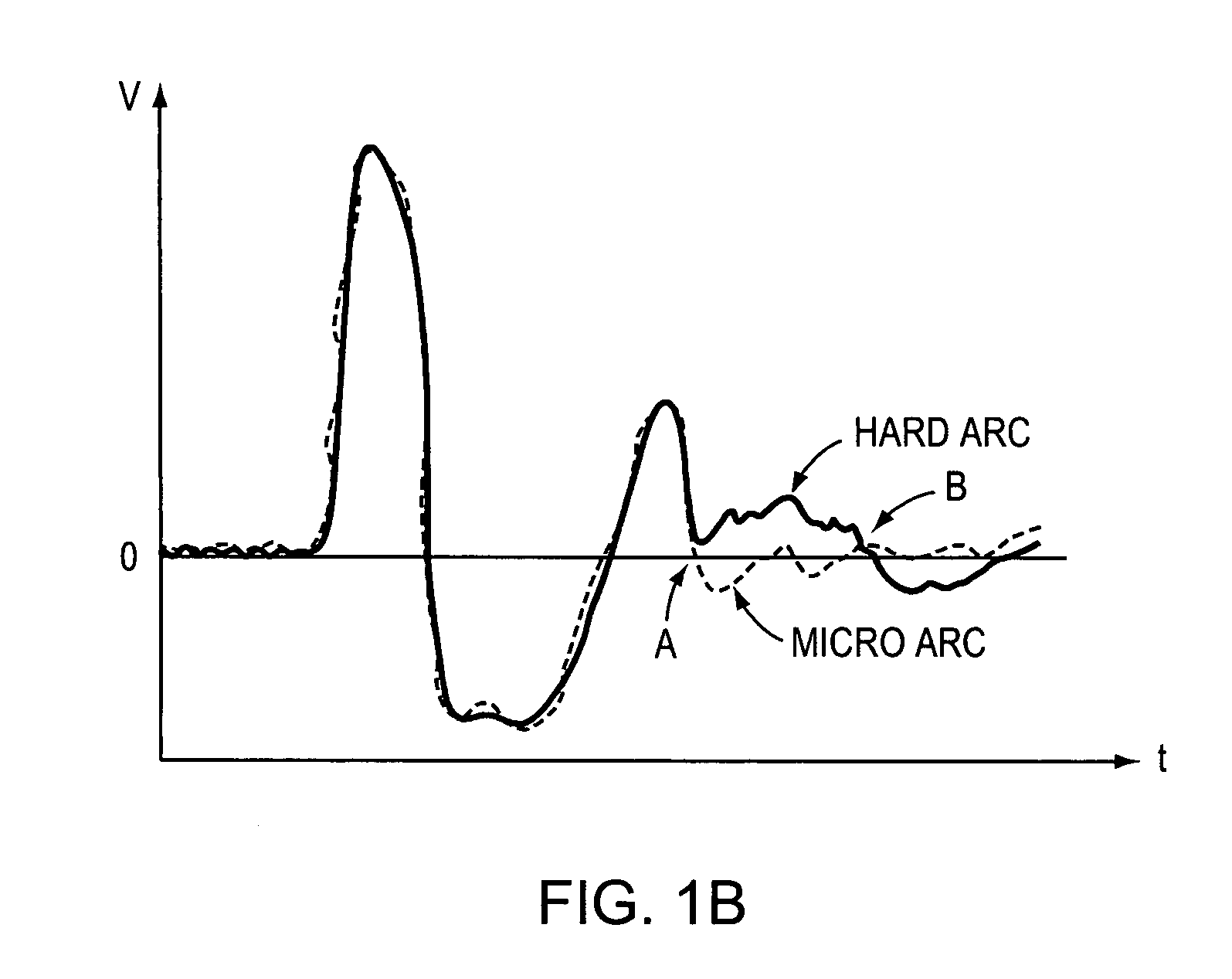

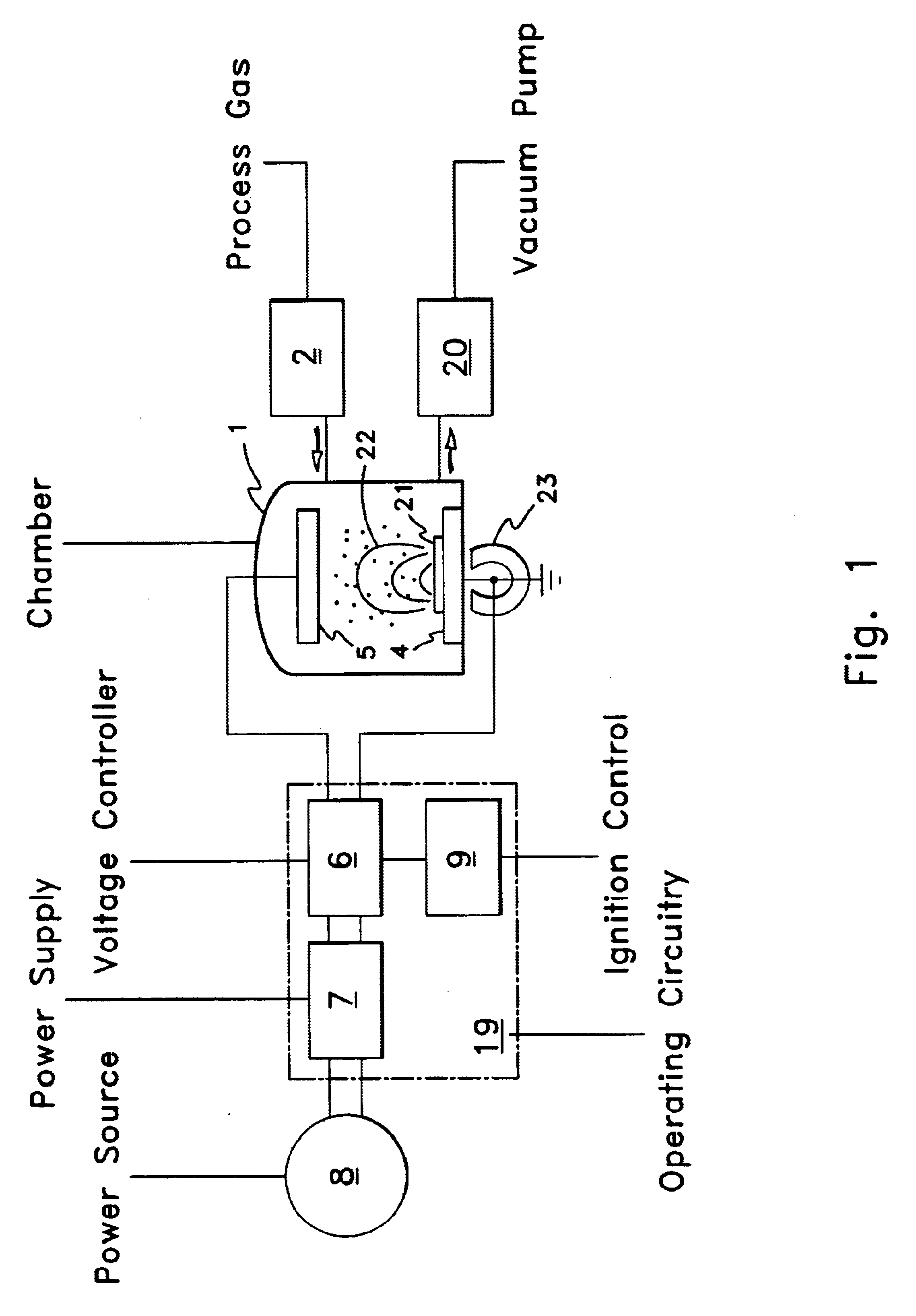

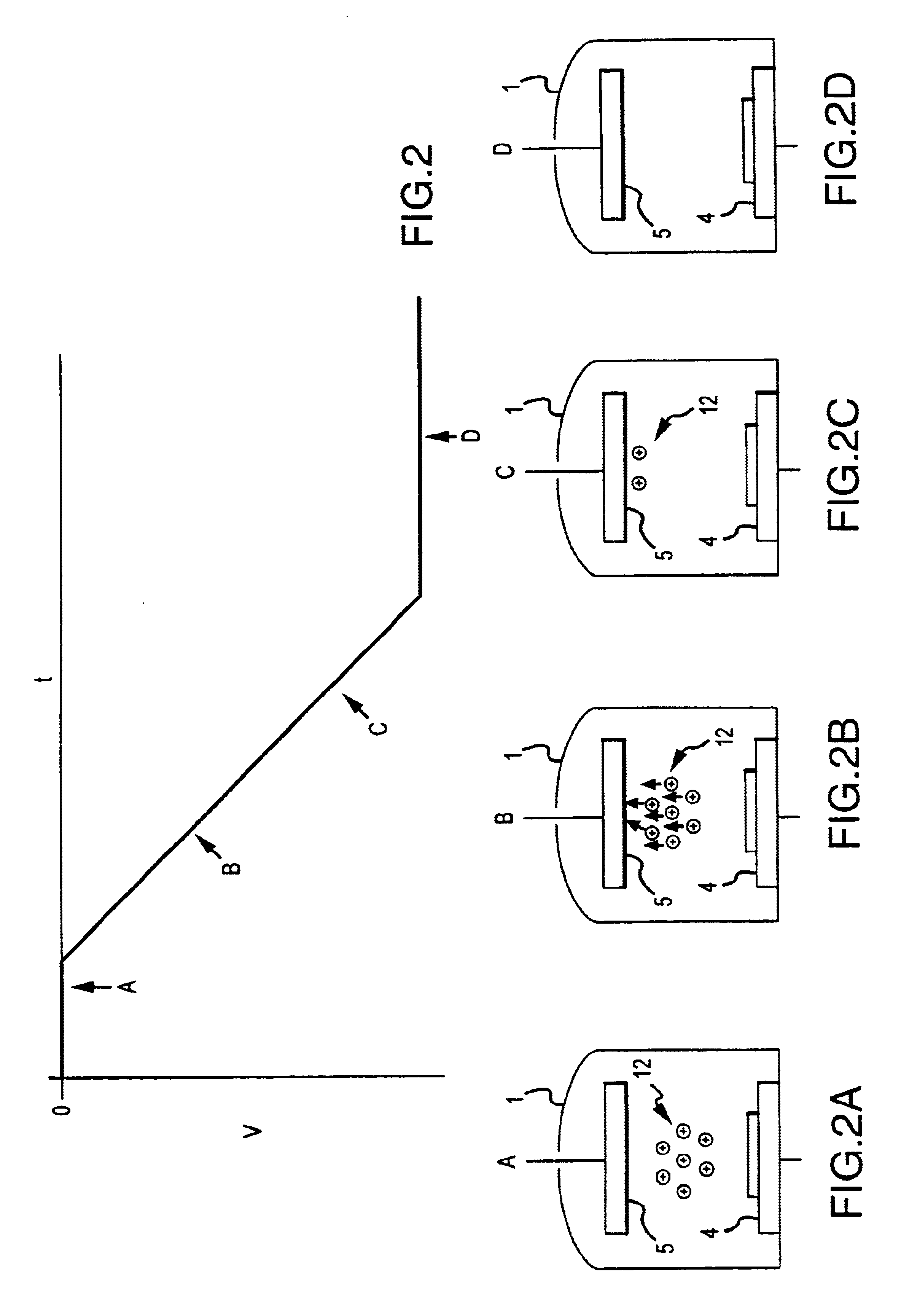

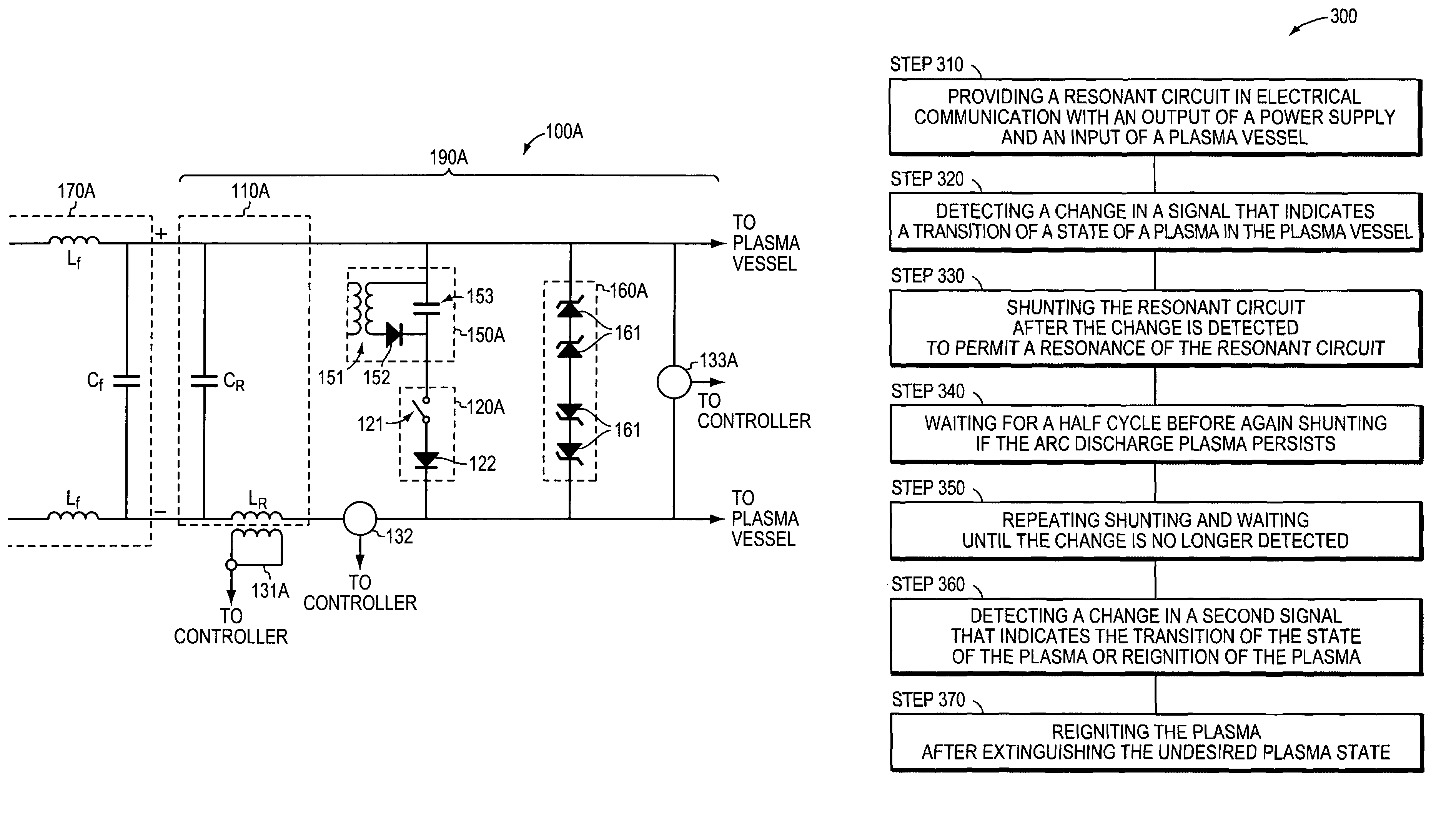

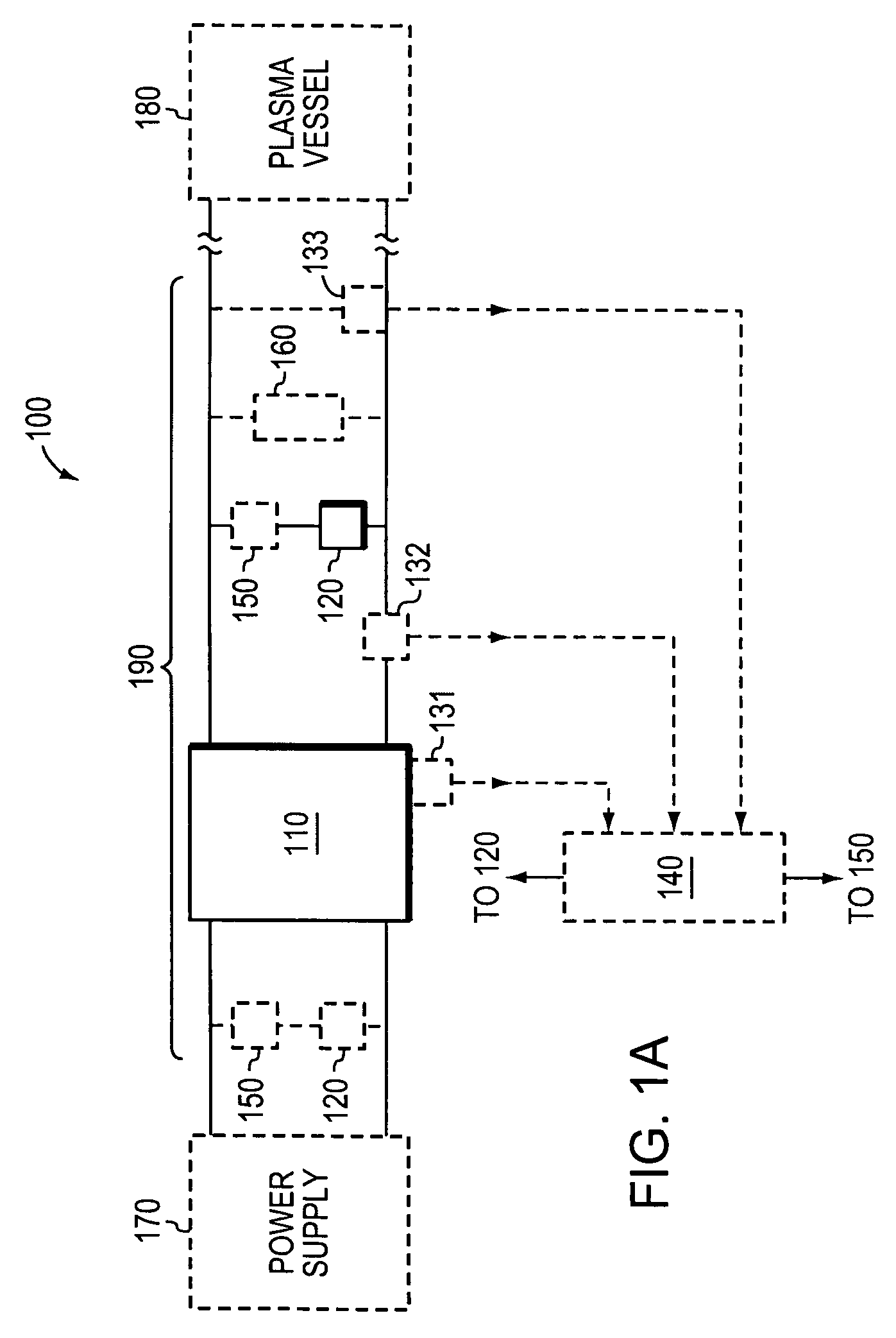

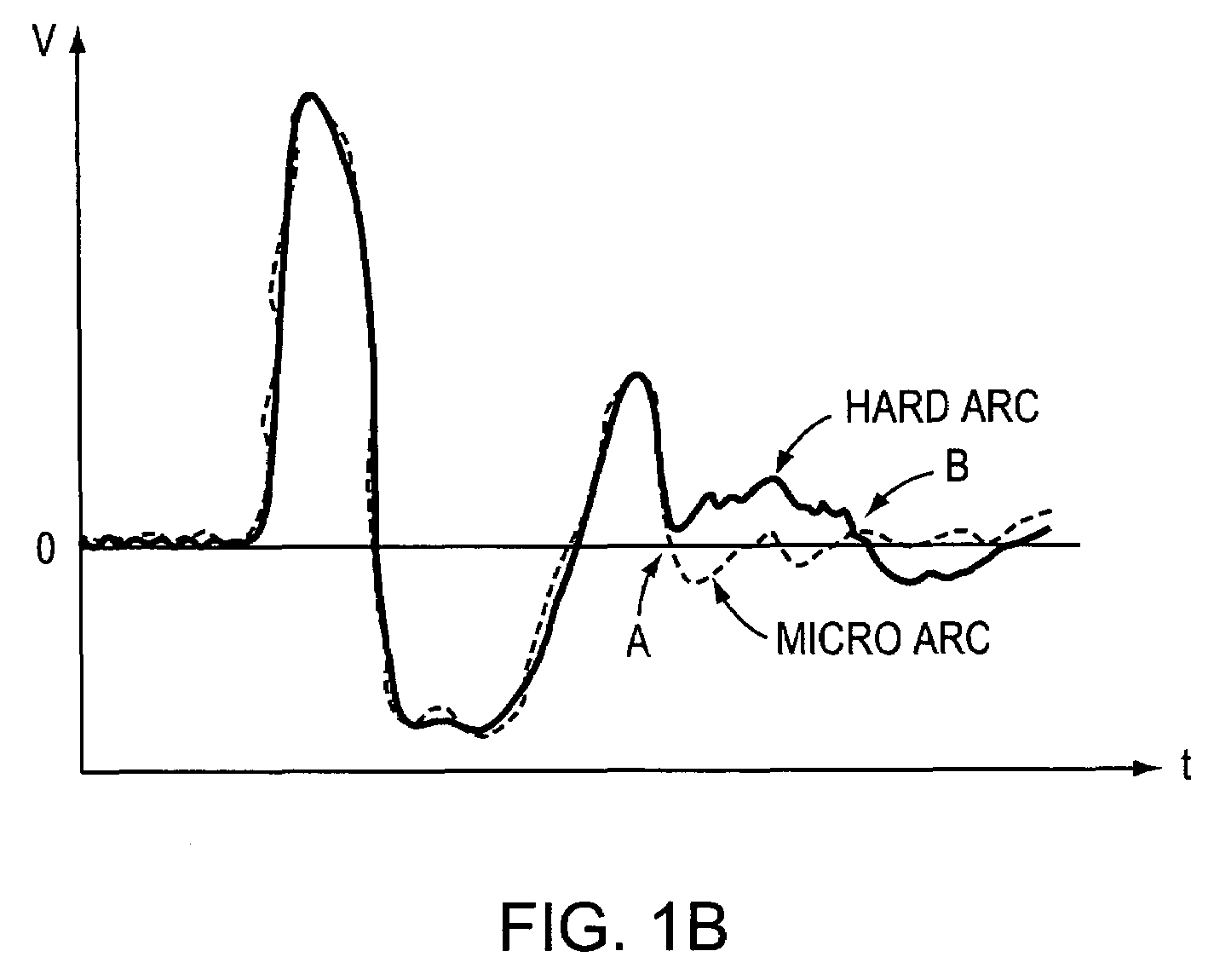

Control of plasma transitions in sputter processing systems

ActiveUS20050040144A1Improve ignition of plasmaImprove ignitionElectric discharge tubesVacuum evaporation coatingEngineeringMaterials processing

Methods and apparatus for controlling a plasma used for materials processing feature cooperative action of a resonant circuit and a switch unit coupled to a plasma vessel and a power supply. A sensor for acquiring a signal associated with a state of a plasma in the plasma vessel supports closed-loop control of the switch unit. Undesirable plasma states detected by the sensor can be eliminated by closing the switch unit to shunt the resonant circuit.

Owner:MKS INSTR INC

Method for ignition of flameless combustor

InactiveUS6269882B1Easy to igniteImprove the level ofApparel holdersIncandescent ignitionCombustorCombustion chamber

A combustor method and apparatus is provided. The method utilizes flameless combustion with one or more of three improvements to enhance ignition of the flameless combustor. A catalytic surface can be provided within a combustion chamber to provide flameless combustion at least in the vicinity of the catalytic surface at a temperature that is much lower than the autoignition temperature of fuel in air without the presence of the catalytic surface. Nitrous oxide or supplemental oxygen may also be used as an oxidant either instead of air or with air to reduce ignition temperatures. Further, electrical energy can be passed through the fuel conduit, raising the temperature of the conduit to a temperature above which the fuel will ignite when combined with the oxidant.

Owner:SHELL OIL CO

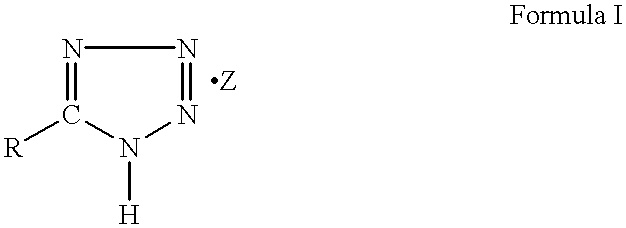

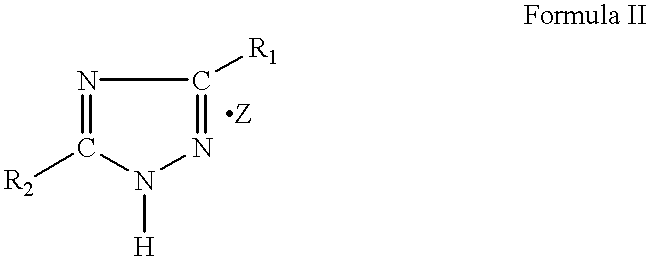

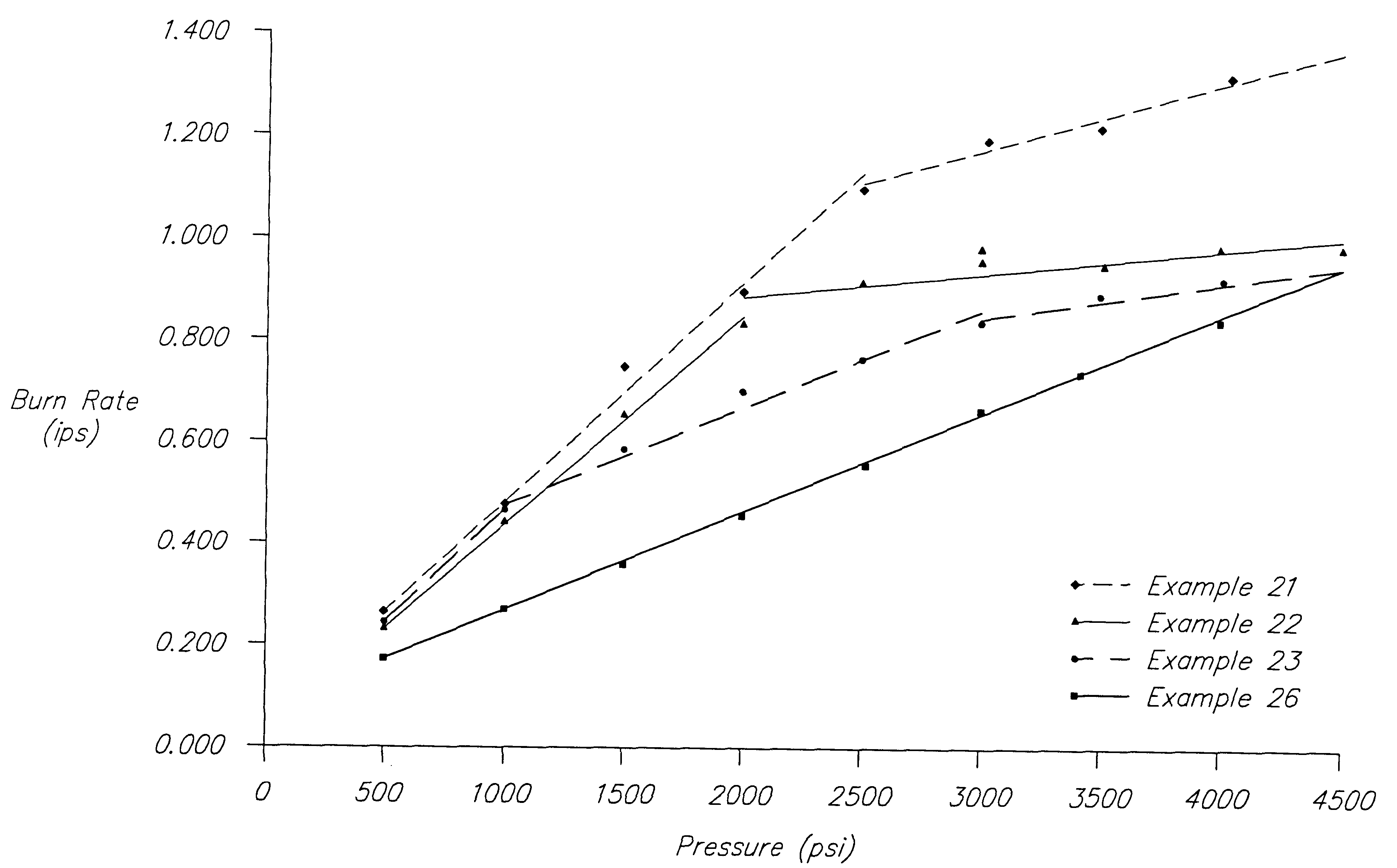

High gas yield non-azide gas generants

InactiveUS6210505B1Abundant nontoxic gasesMinimizes particulate formationLoomsPedestrian/occupant safety arrangementAzideBurn rate

High nitrogen nonazide gas compositions, useful in inflating passenger restraint gas inflator bags, comprise a nonmetal salt of triazole or tetrazole fuel, phase stabilized ammonium nitrate (PSAN) as a primary oxidizer, a metallic second oxidizer, and an inert component such as clay or mica. The combination of these constituents results in gas generants that are relatively more stable and less explosive, have improved ignitability and satisfactory burn rates, have sustained combustion throughout the various combustion pressures at the inflator level, and generate more gas and less solids than known gas generant compositions.

Owner:AUTOMOTIVE SYST LAB

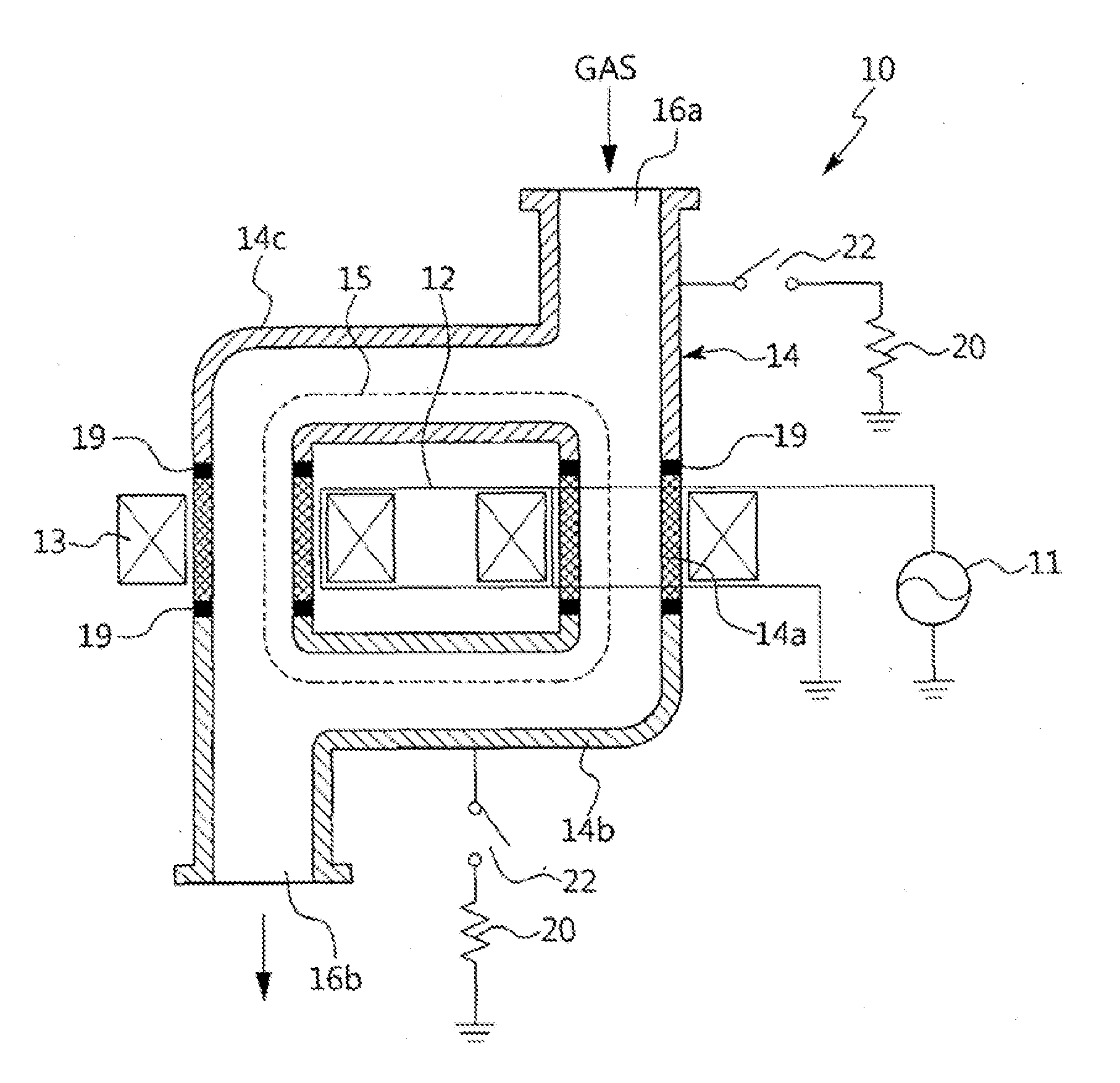

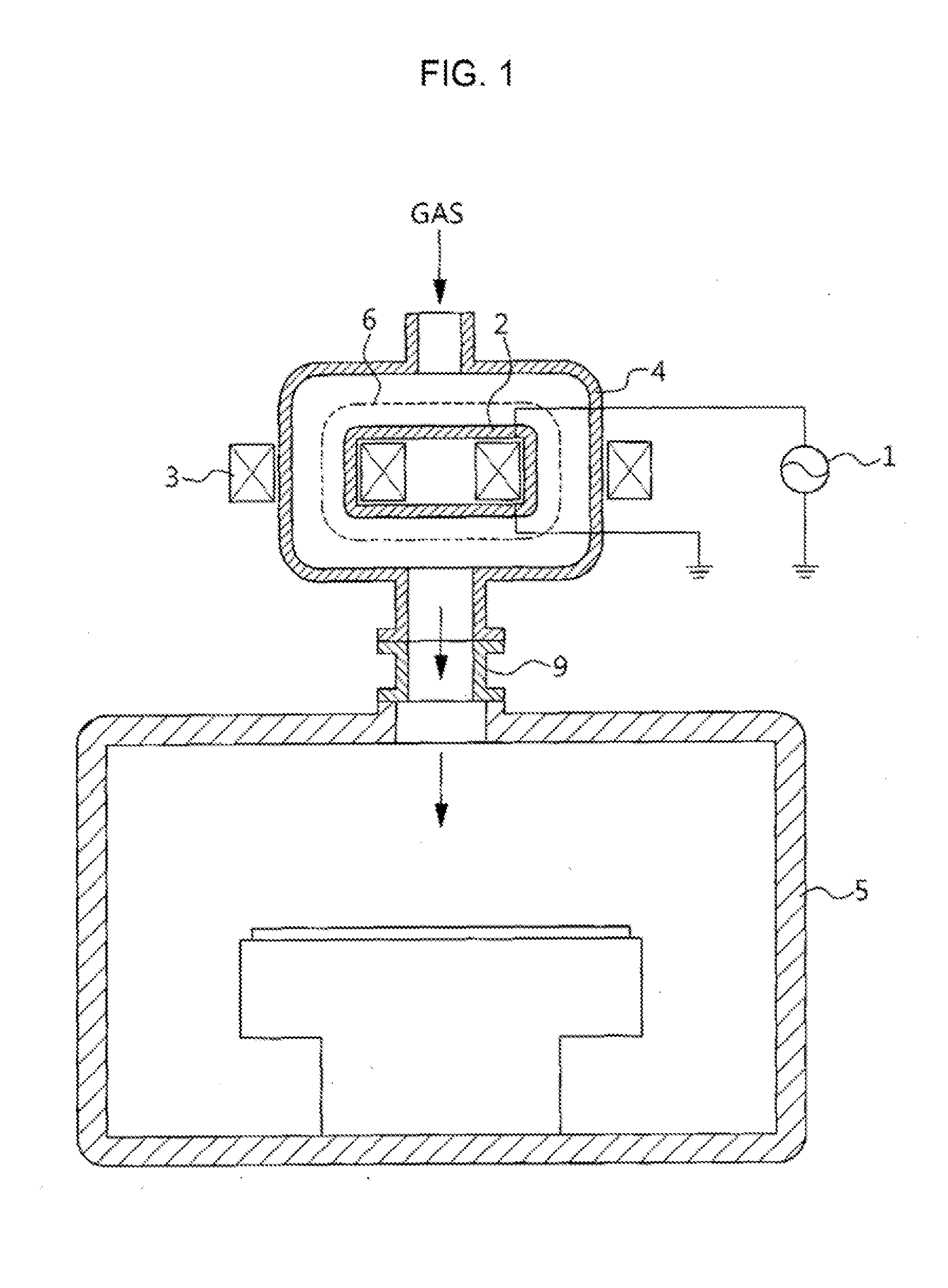

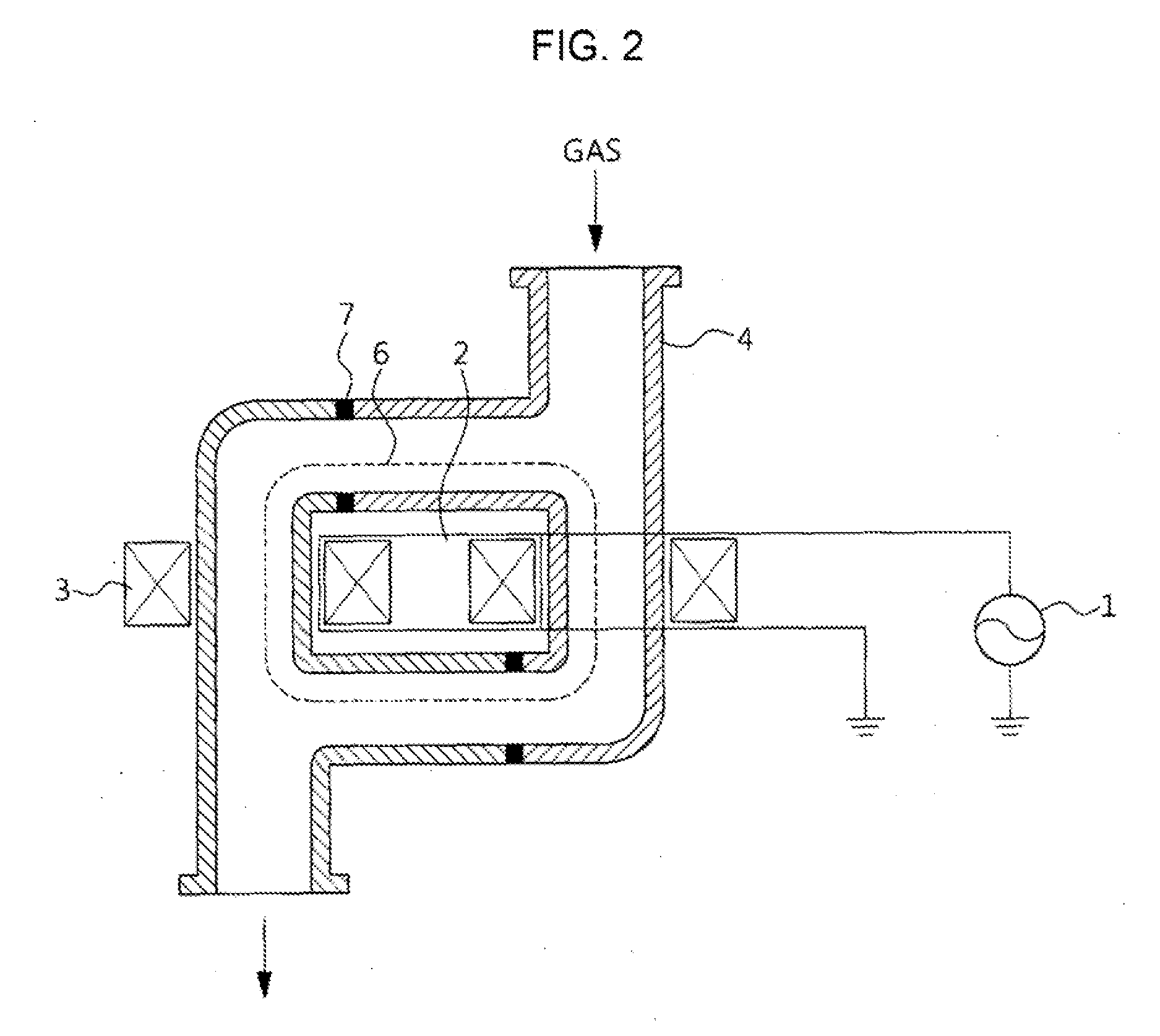

Plasma reactor and plasma ignition method using the same

InactiveUS20150303031A1Easy dischargeEasy maintenanceElectric discharge tubesElectric arc lampsTransformerEngineering

A plasma reactor and a plasma ignition method using the same are disclosed. The disclosed plasma reactor includes at least one magnetic core having a transformer primary winding wound thereon, an AC power supply for supplying AC power to the transformer primary winding wound on the magnetic core, at least one plasma chamber body, at which the magnetic core is installed, to directly induce a voltage in the plasma chamber body through the magnetic core, thereby inducing induced electromotive force in the plasma chamber body, and at least one floating chamber connected to the plasma chamber body via an insulating region, the induced electromotive force from the plasma chamber body being indirectly transferred to the floating chamber. Ignition of plasma is generated in accordance with a voltage difference generated between, the plasma chamber body and the floating chamber, and the ignited plasma is supplied to a process chamber.

Owner:NEW POWER PLASMA CO LTD

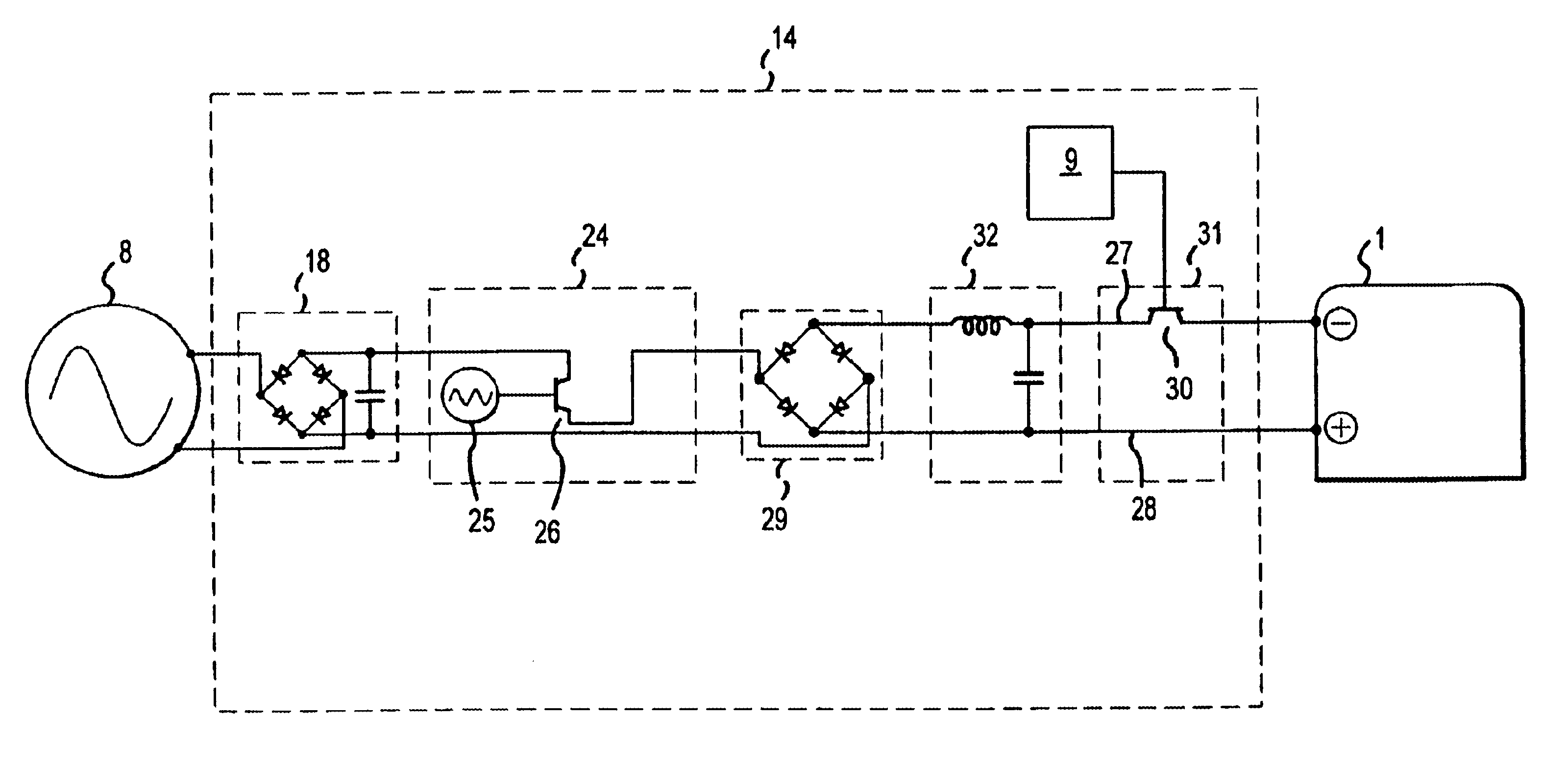

System for plasma ignition by fast voltage rise

InactiveUS6633017B1Increase probabilityIncrease variabilityElectric discharge tubesArc welding apparatusSecondary electronsEngineering

An improved system of igniting a plasma using a rapid voltage rise and thus causing ions that may be pre-existing to create secondary electron emission or the like is provided. In one embodiment, the voltage rise can be timed to be comparable to the transit time of the electrons across the plasma. It can also be arranged to achieve a voltage rise in less than 1000 microseconds, to result in a transition time that is less than one hundred times the transit time, to maximize the emission of secondary electrons, or even to merely result in collision energies ranging from 5 to 500 electron volts. The transition time can be controlled through an ignition control that may be programmable, may involve charging output storage devices, or may involve delayed switching to supply the increased voltage to the plasma after the storage elements have been more fully charged.< / PTEXT>

Owner:ADVANCED ENERGY IND INC

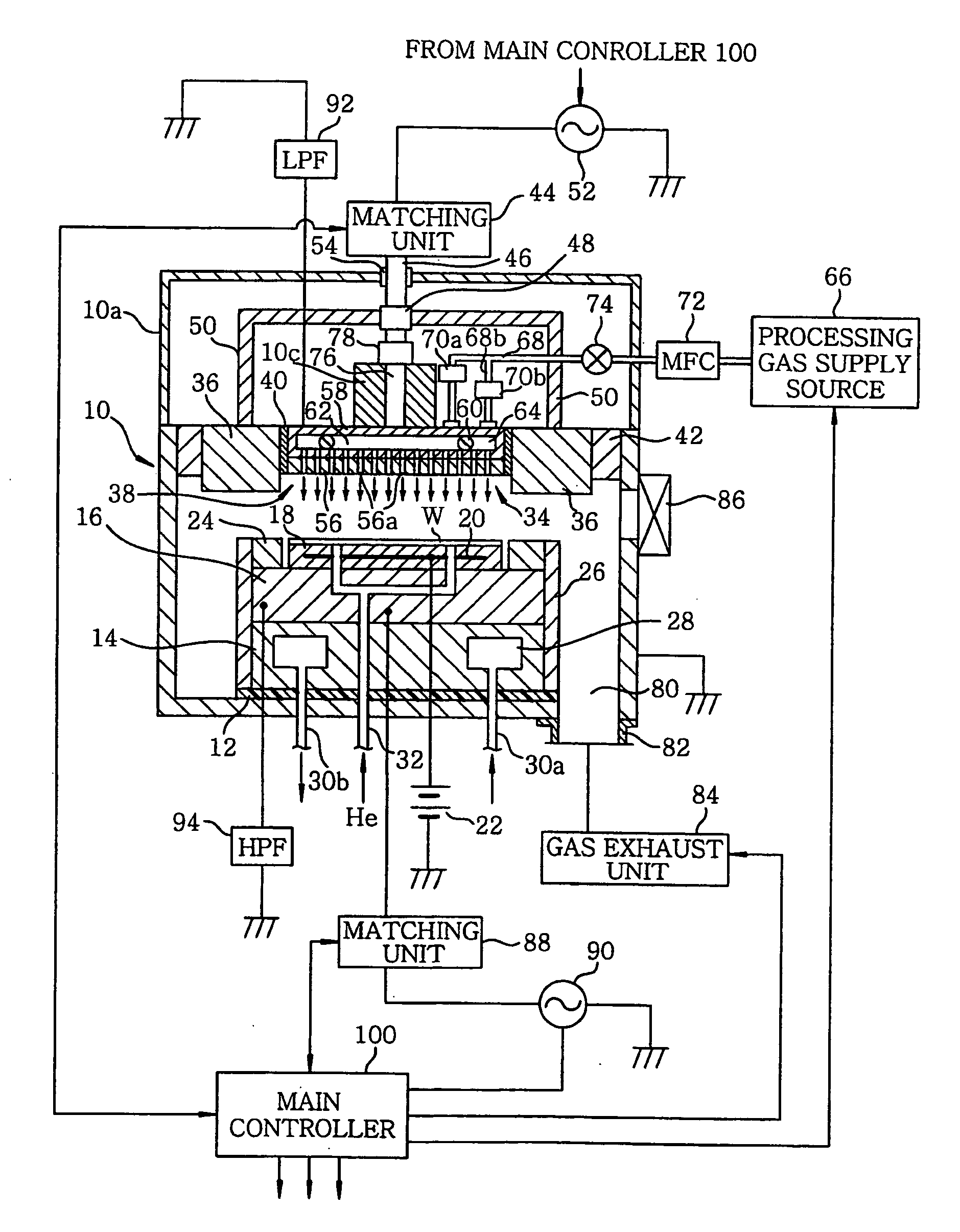

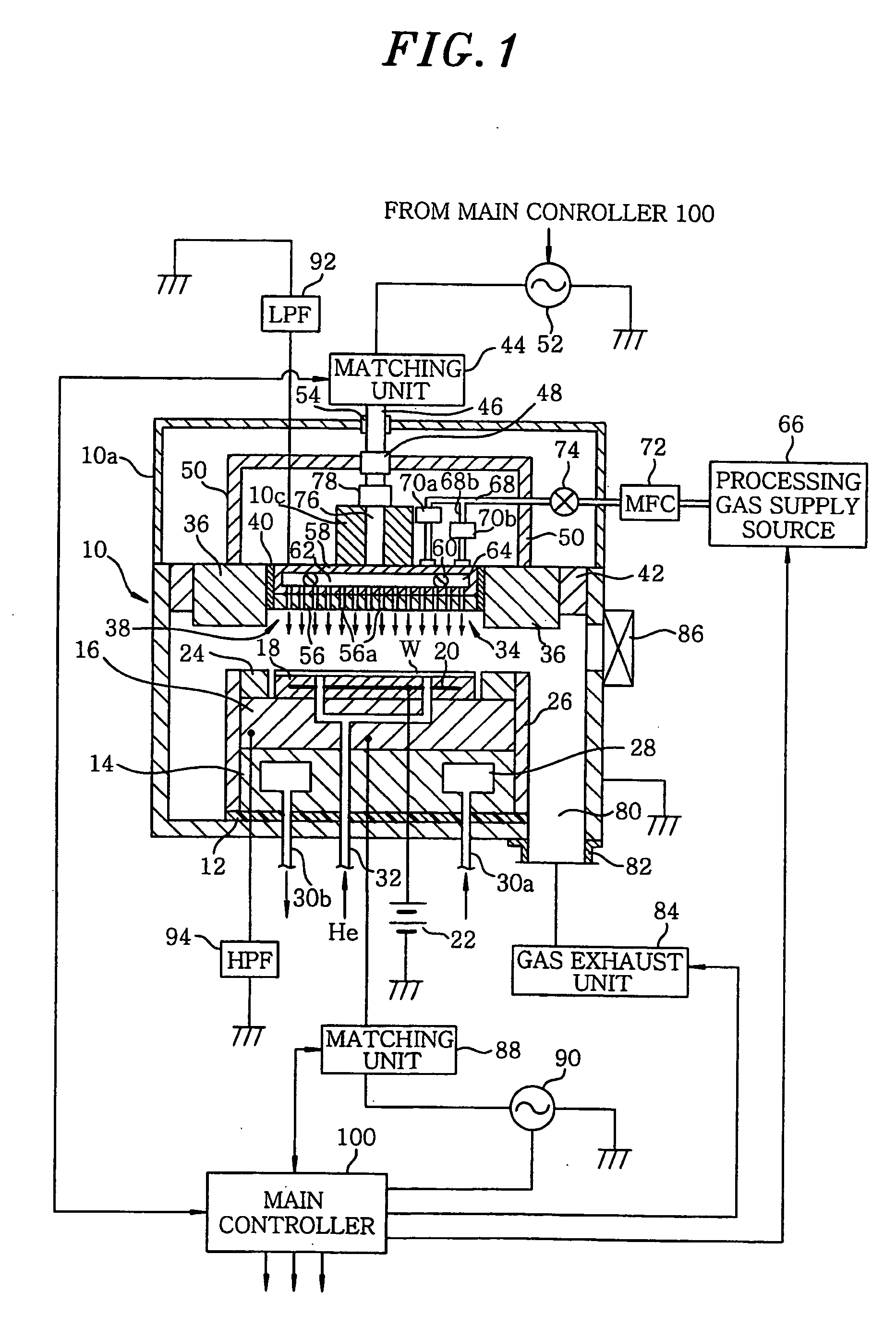

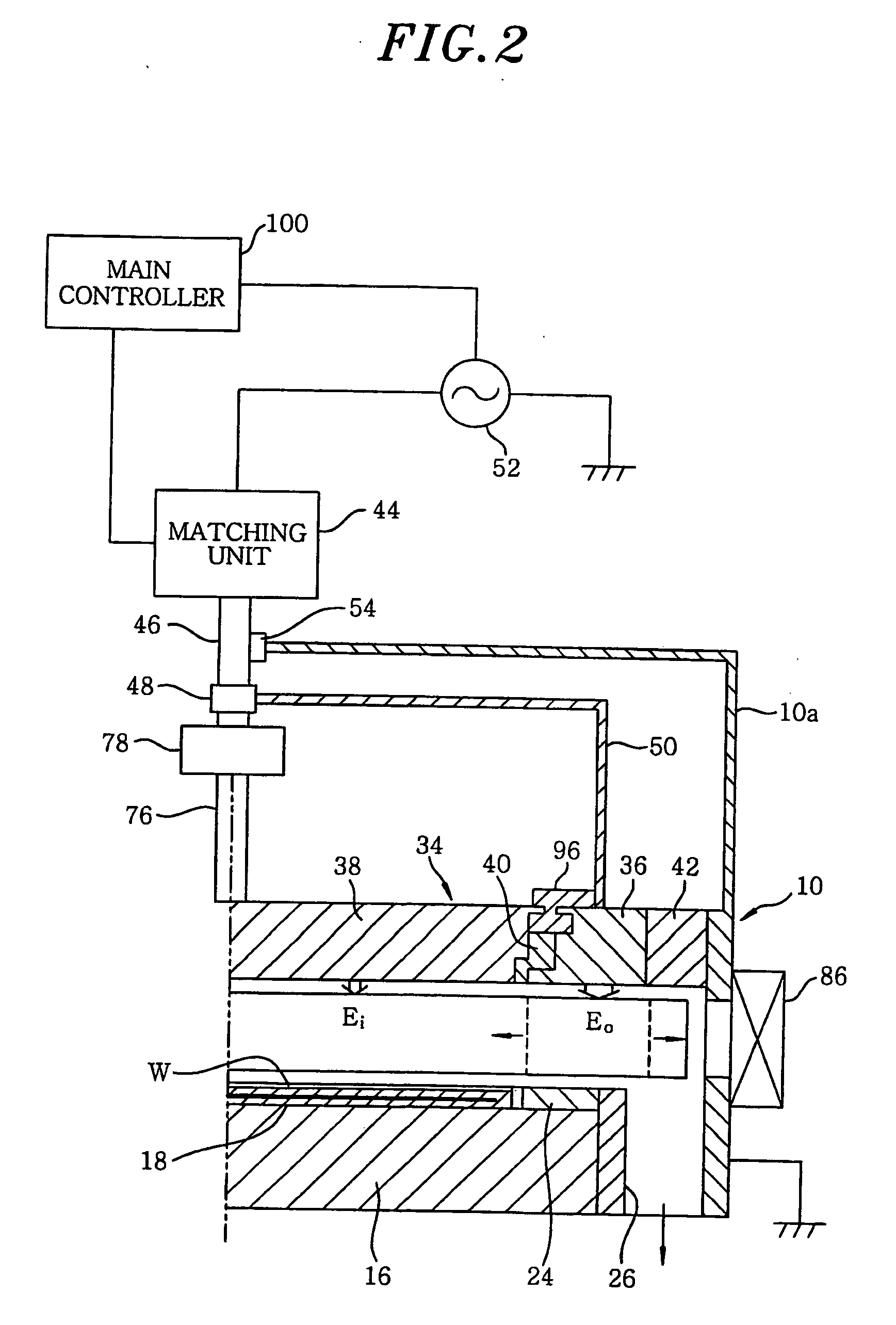

Plasma processing method and apparatus, and autorunning program for variable matching unit

ActiveUS20060220574A1Easy to igniteImprove reliabilityElectric discharge tubesVacuum gauge using ionisation effectsEngineeringPeak value

A plasma processing apparatus includes an upper matching unit 44 which is a variable matching unit whose impedance can be varied, and a main controller 100. The upper matching unit 44 includes a controller 104 for variably controlling the impedance positions of a variable reactance element of a matching circuit 102, a RF sensor for measuring a load impedance including the matching circuit 102, and a VPP measuring circuit 112 for measuring a peak value (peak-to-peak value) of a radio frequency voltage in a waveguide line at the output side of the upper matching unit 44. The main controller 100 executes and controls an autorunning of the matching units 44, 88 for optimizing an off preset of the impedance positions thereof. The plasma can be readily get ignited without requiring to set or change special processing conditions while influencing none of the processes.

Owner:TOKYO ELECTRON LTD

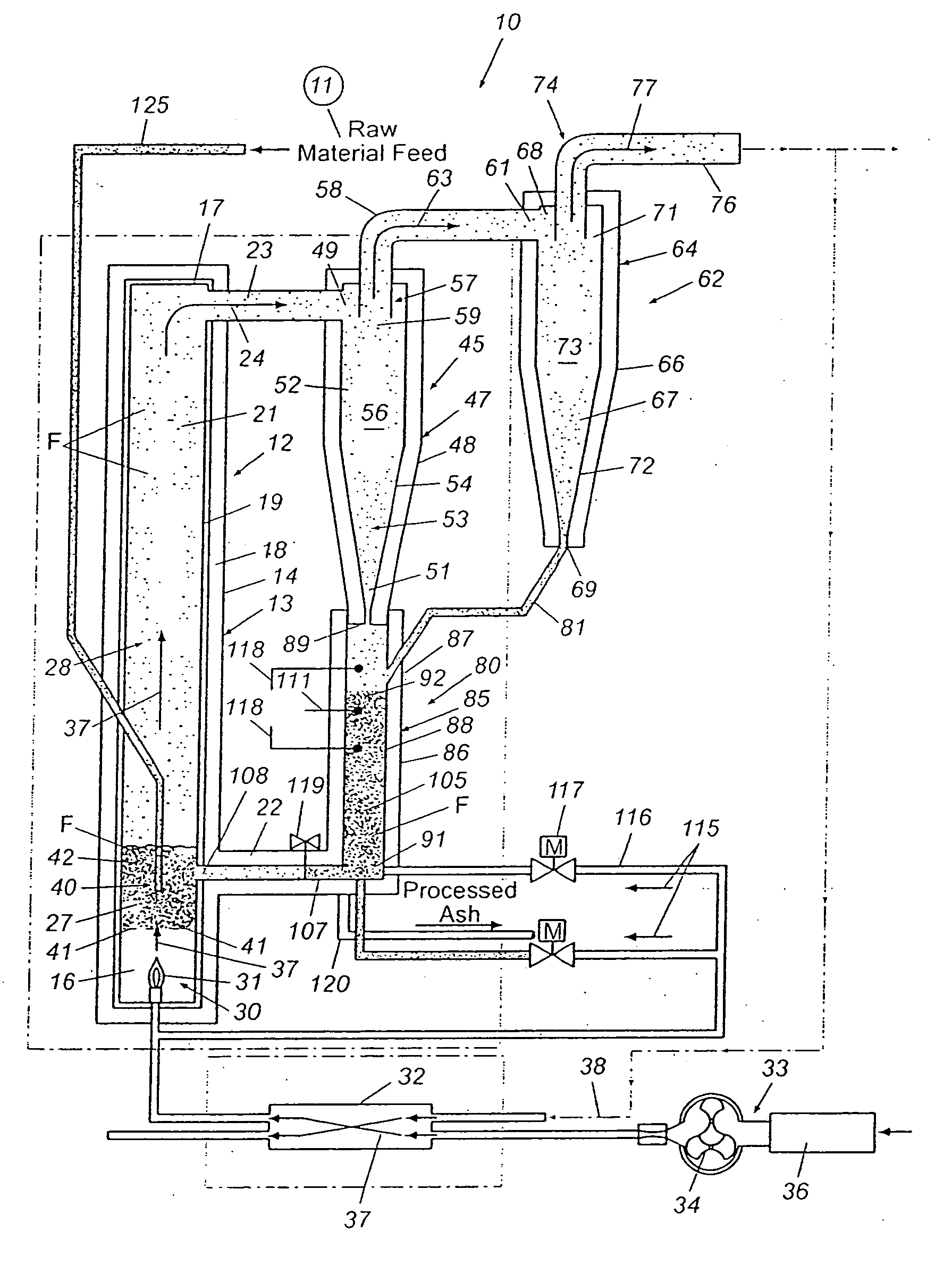

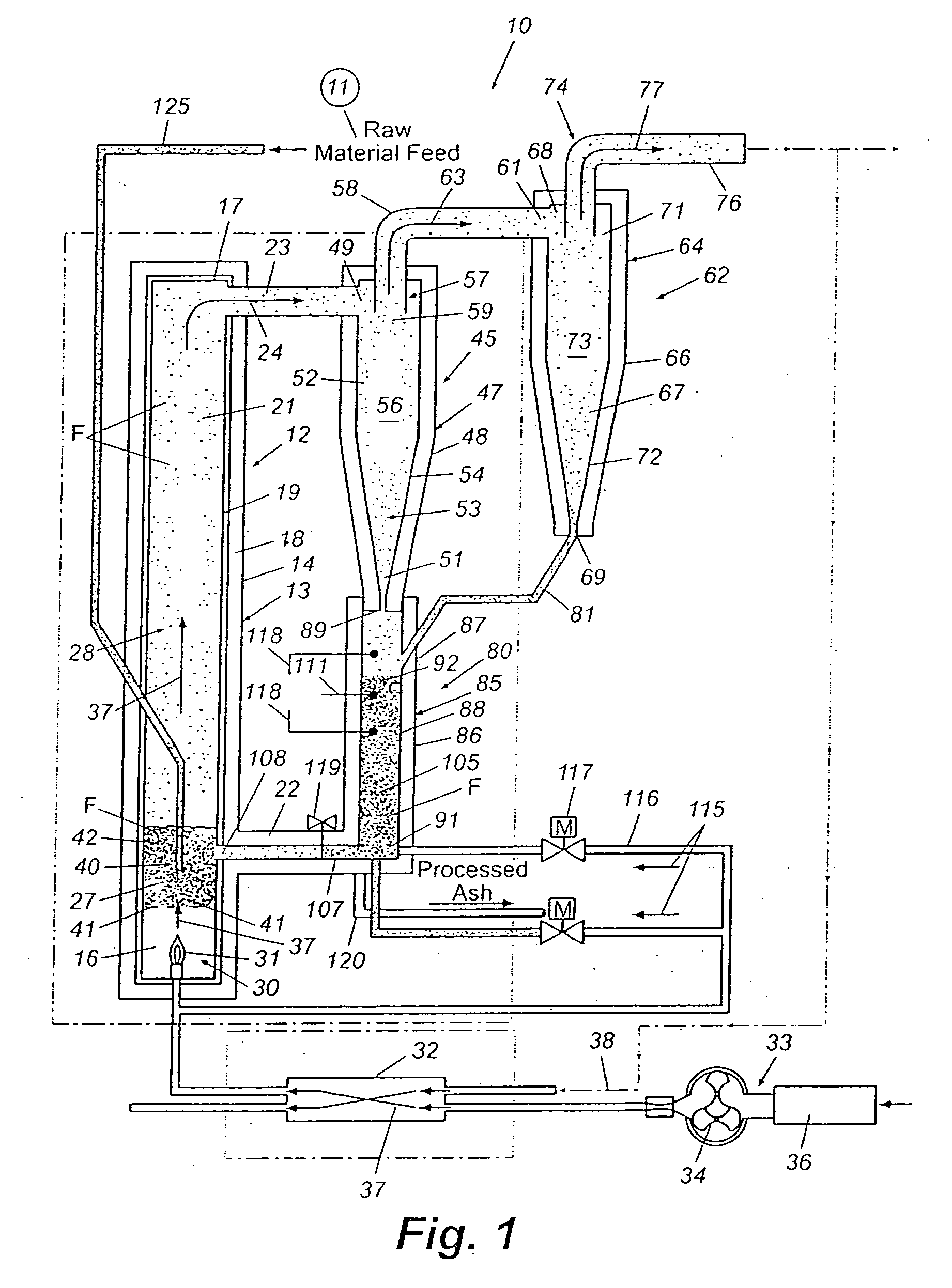

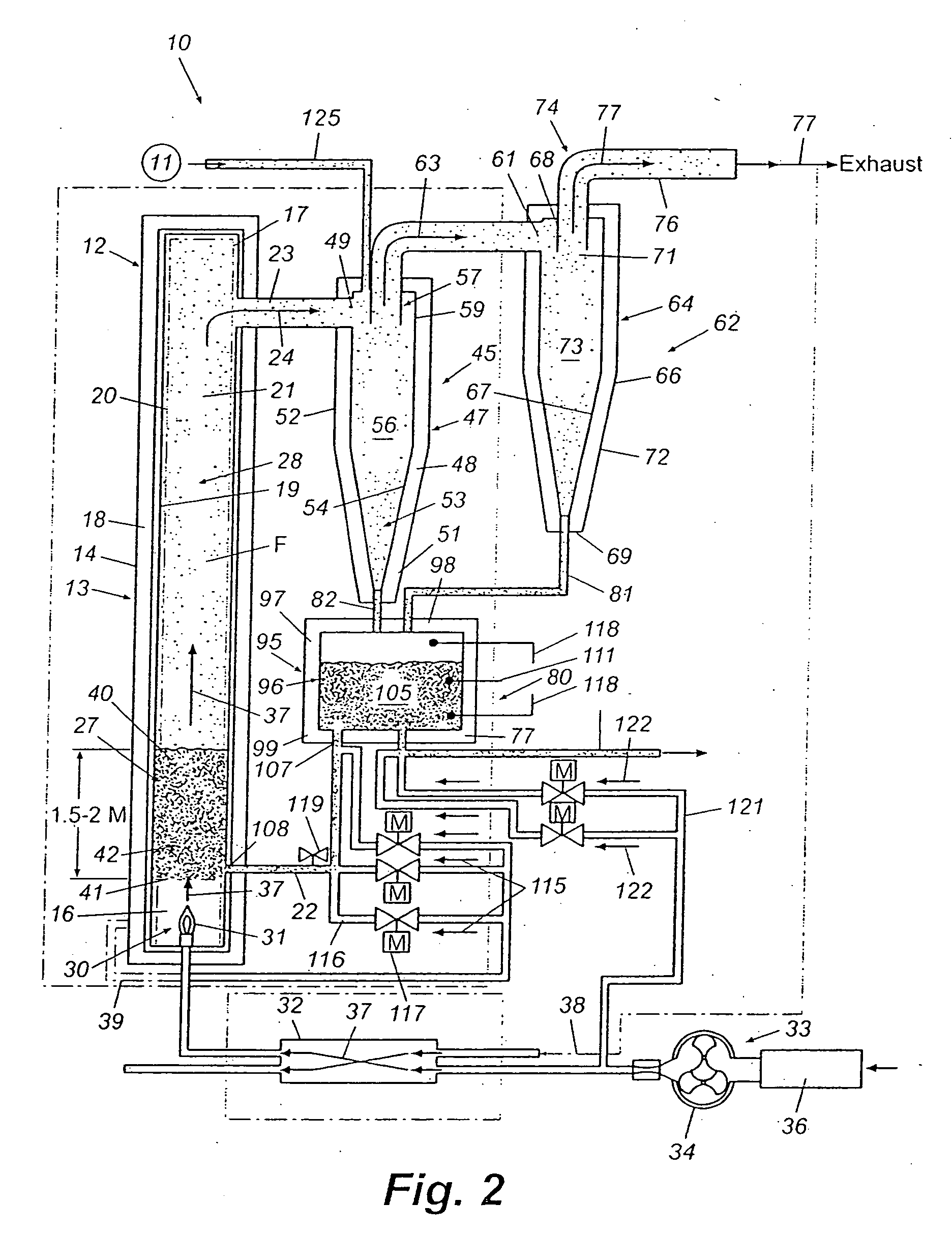

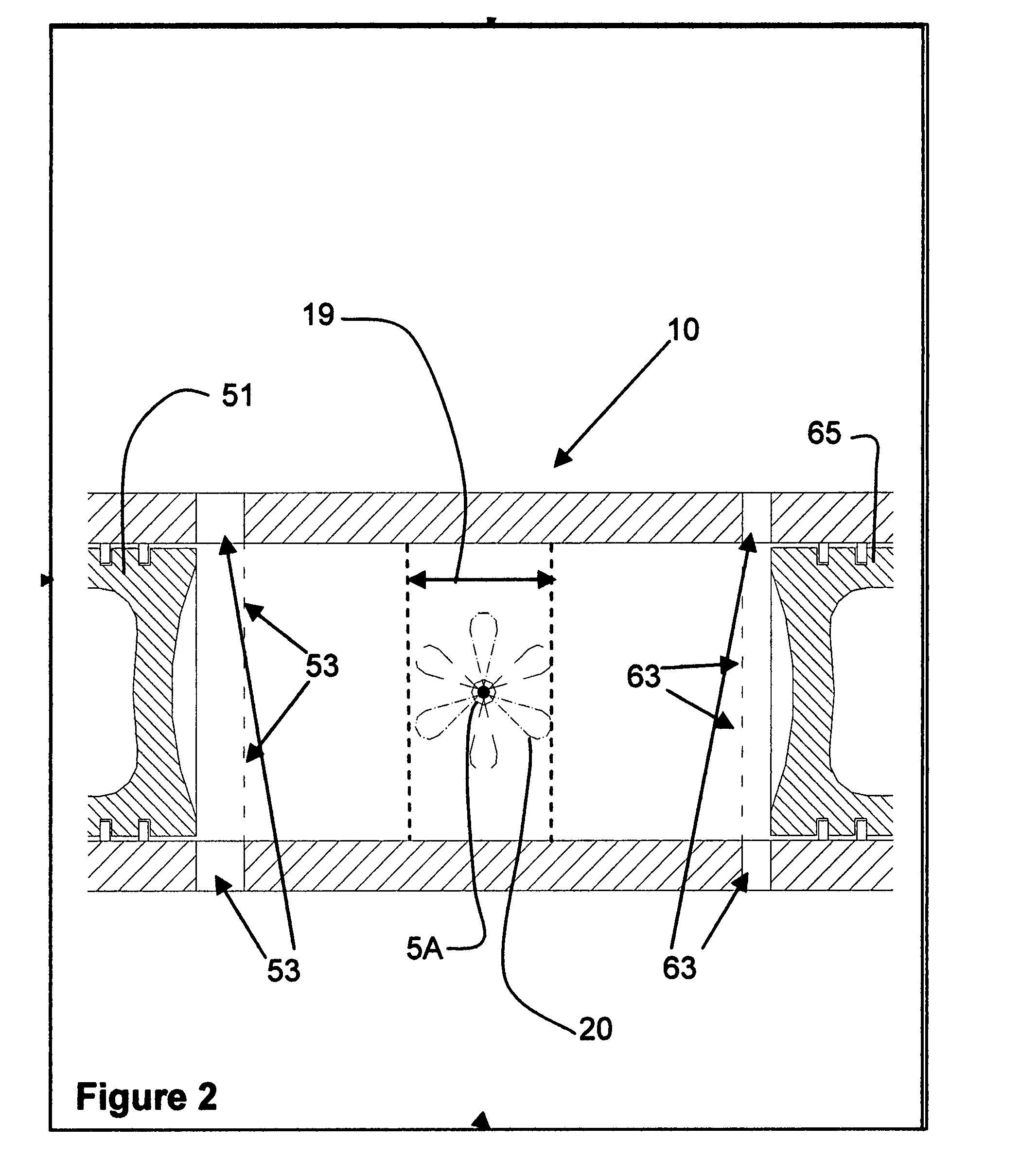

Method and apparatus for combustion of residual carbon in fly ash

InactiveUS20060180060A1Lower Level RequirementsDecrease in levelSolid fuel combustionIncinerator apparatusParticulatesCombustion

Owner:CONSOL ENG

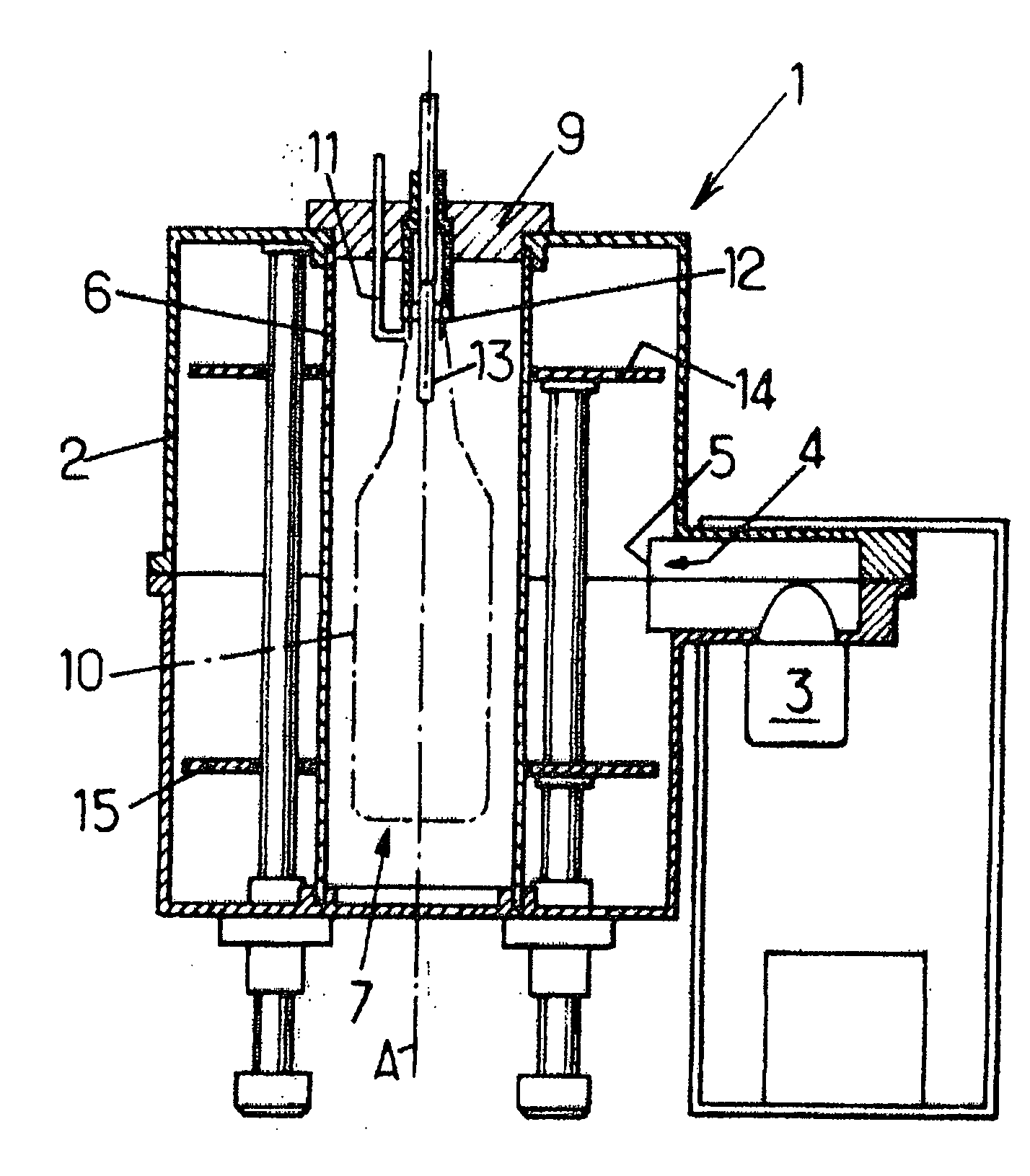

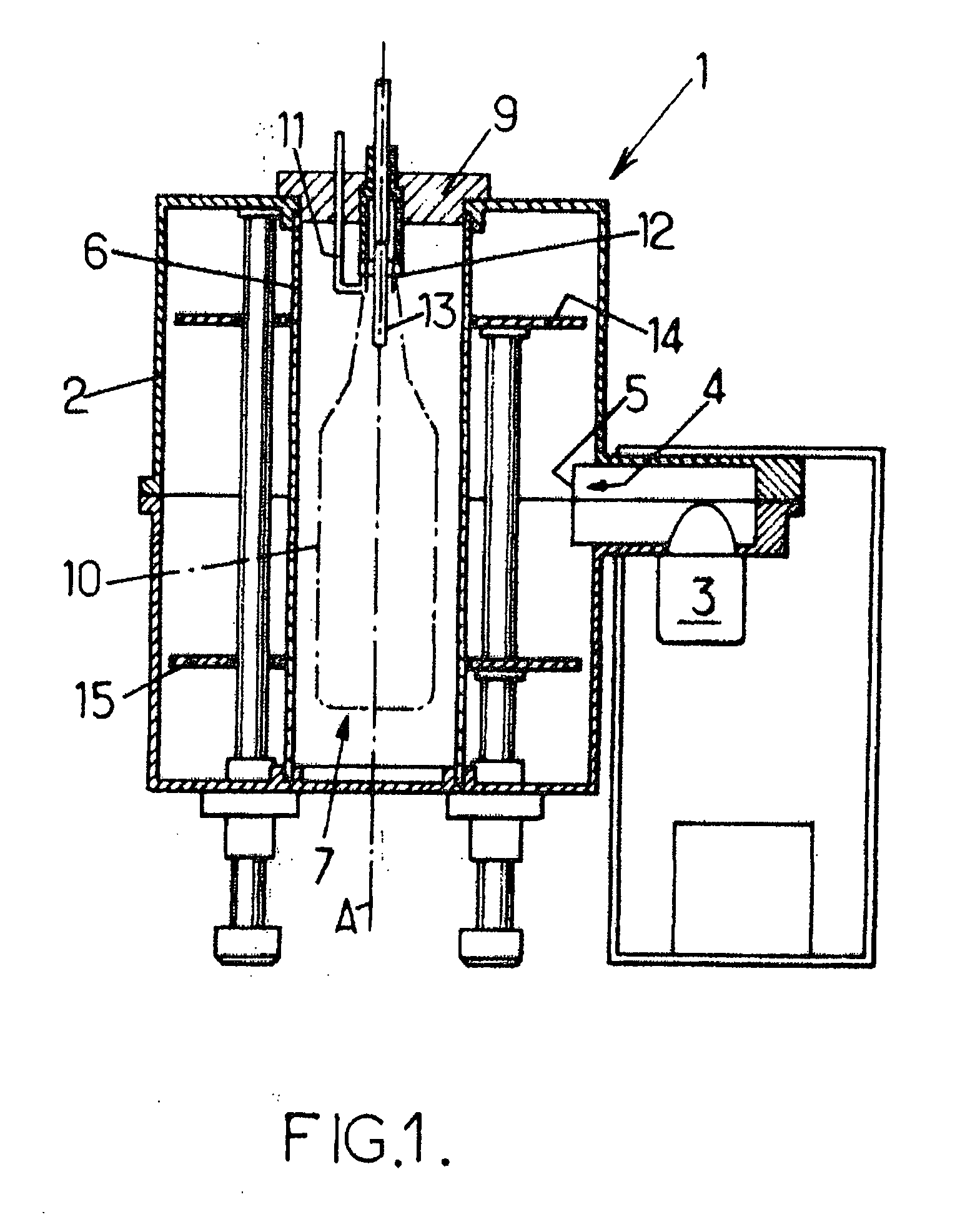

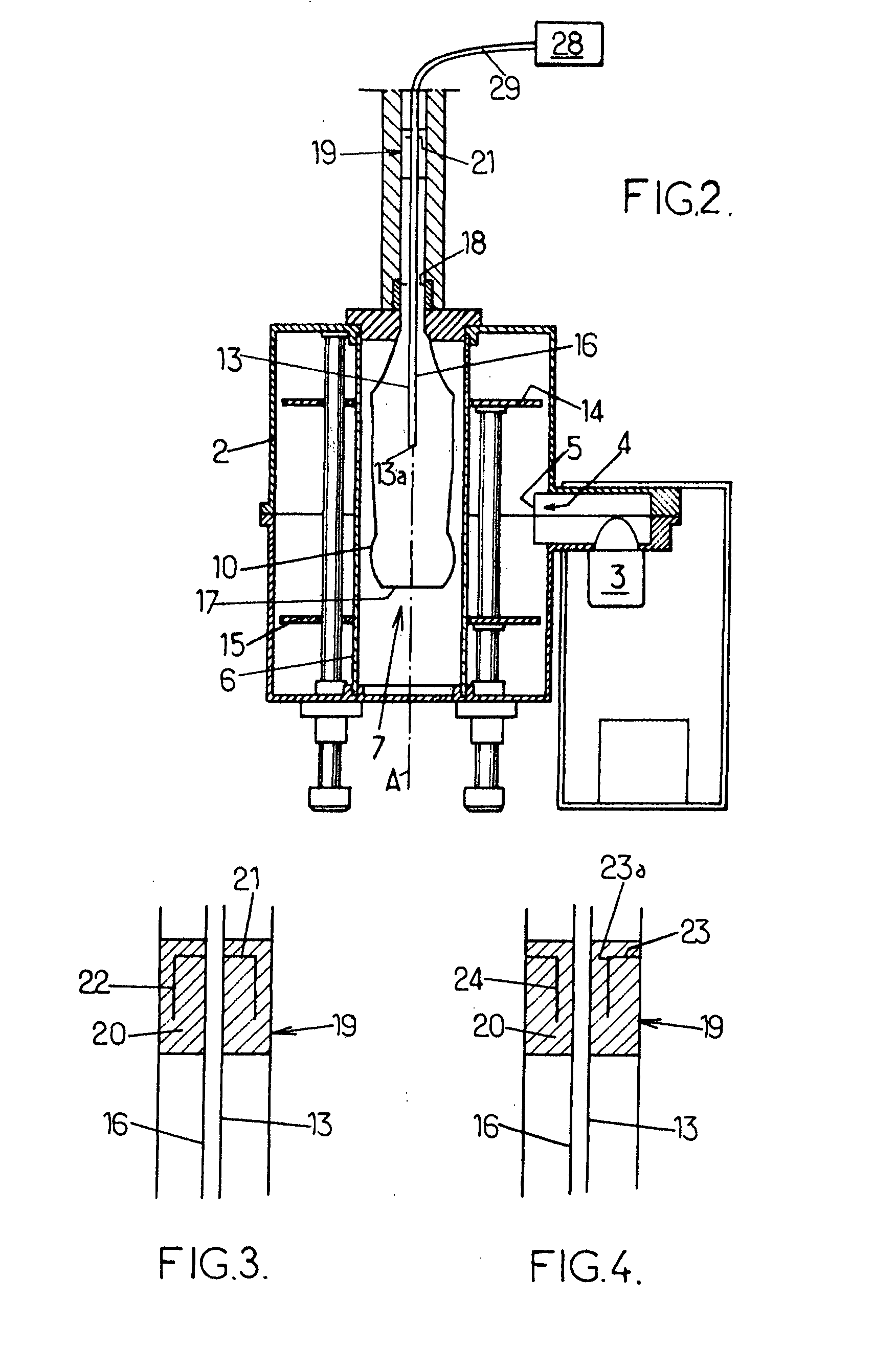

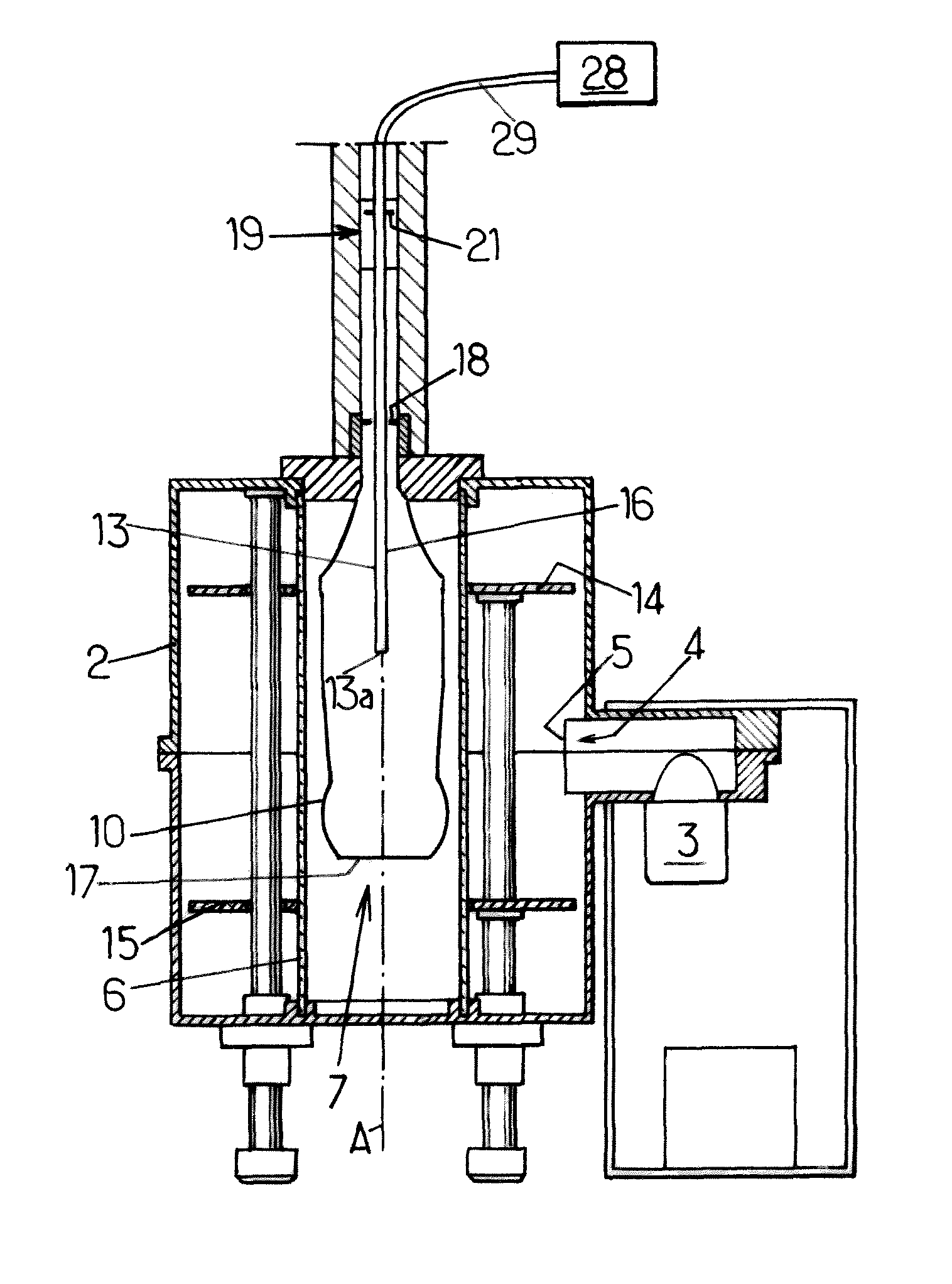

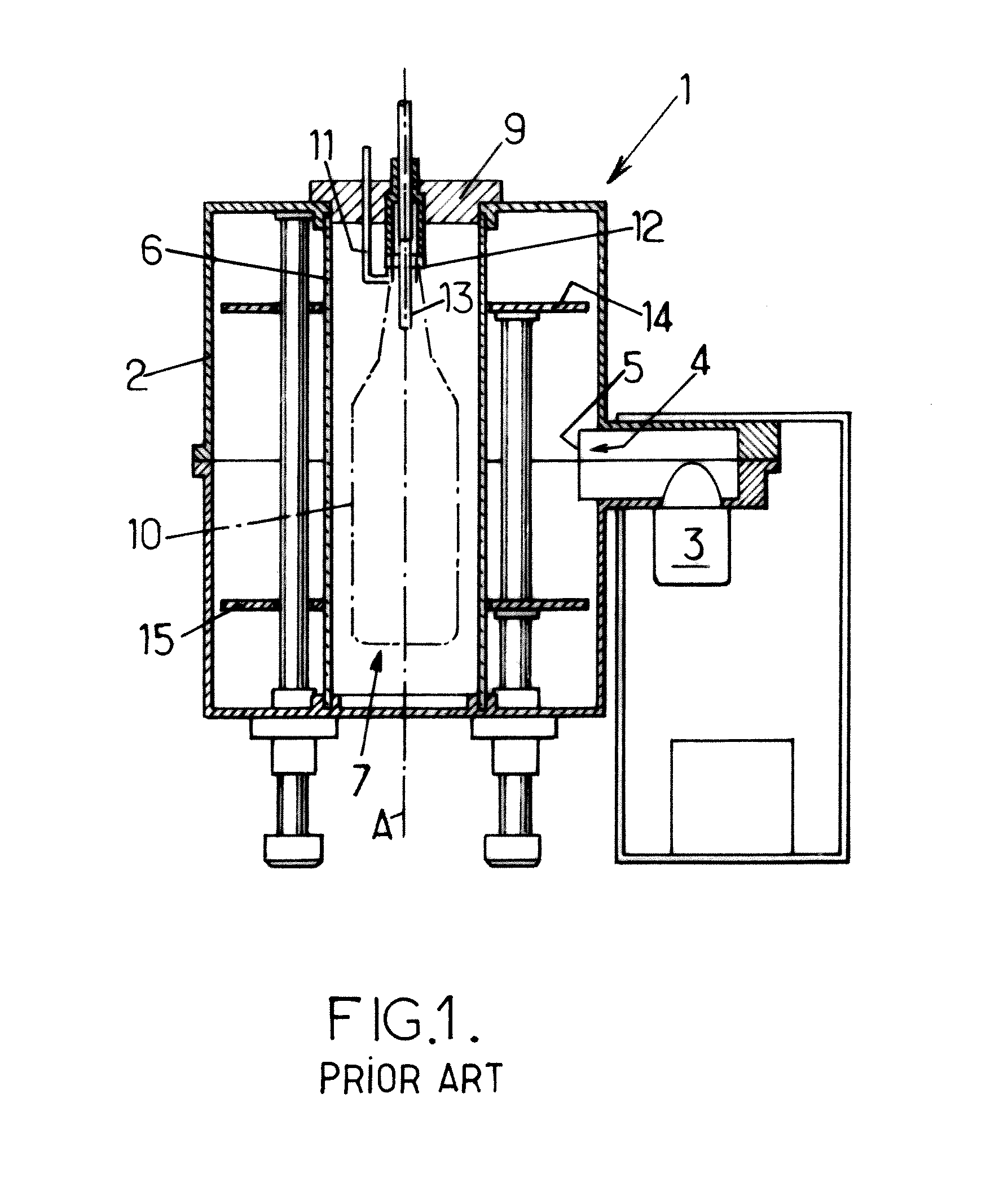

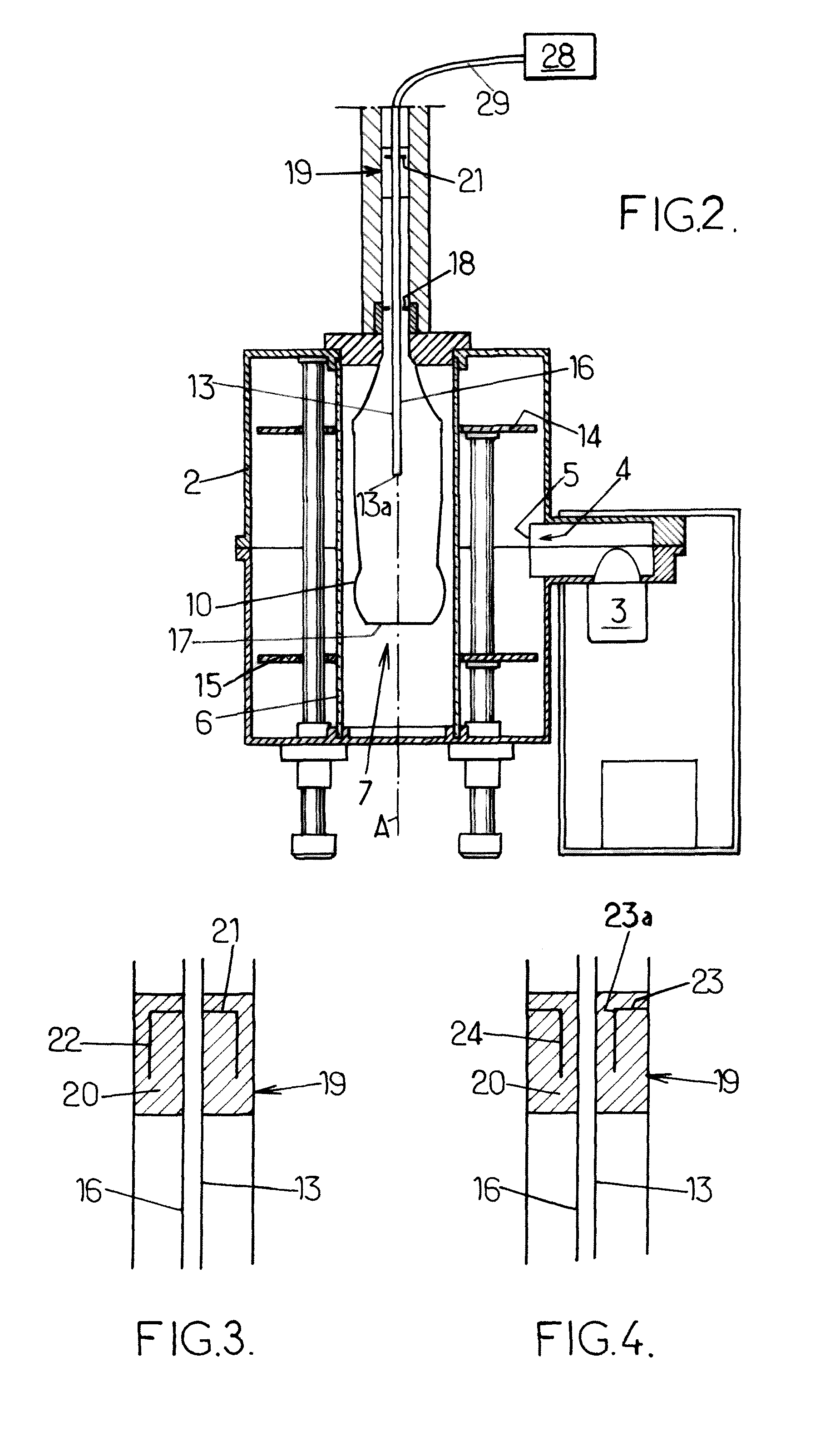

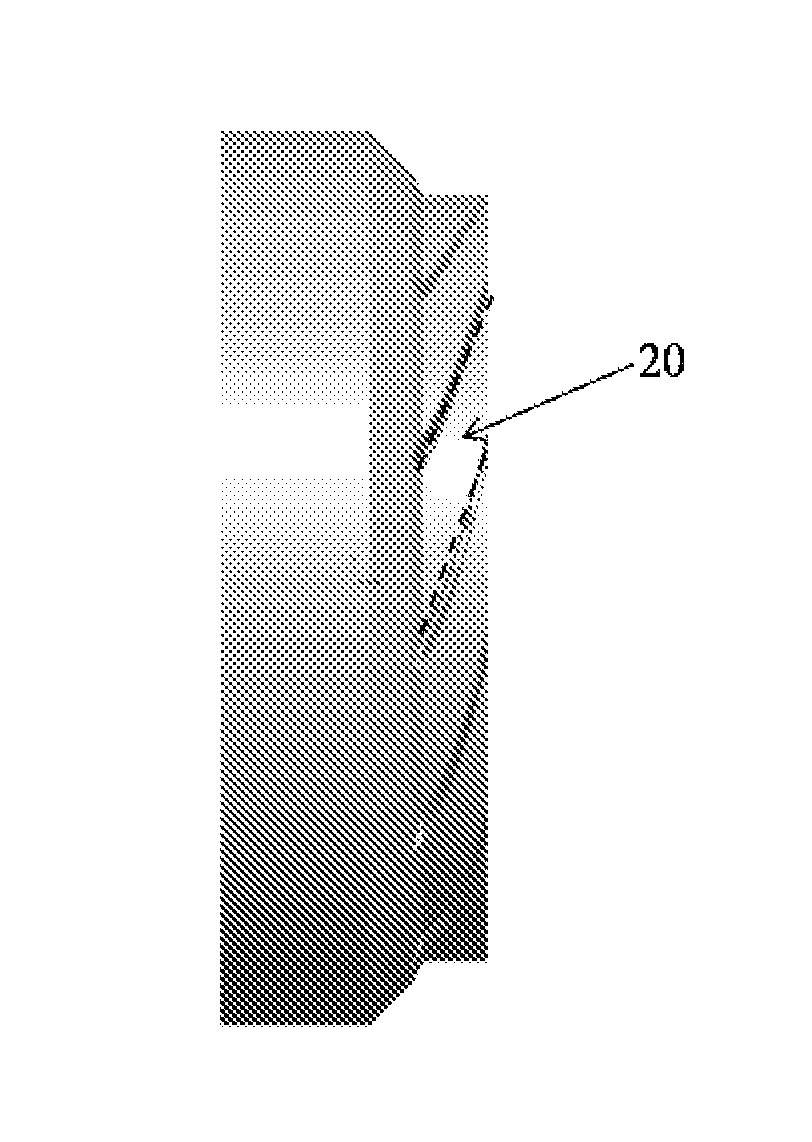

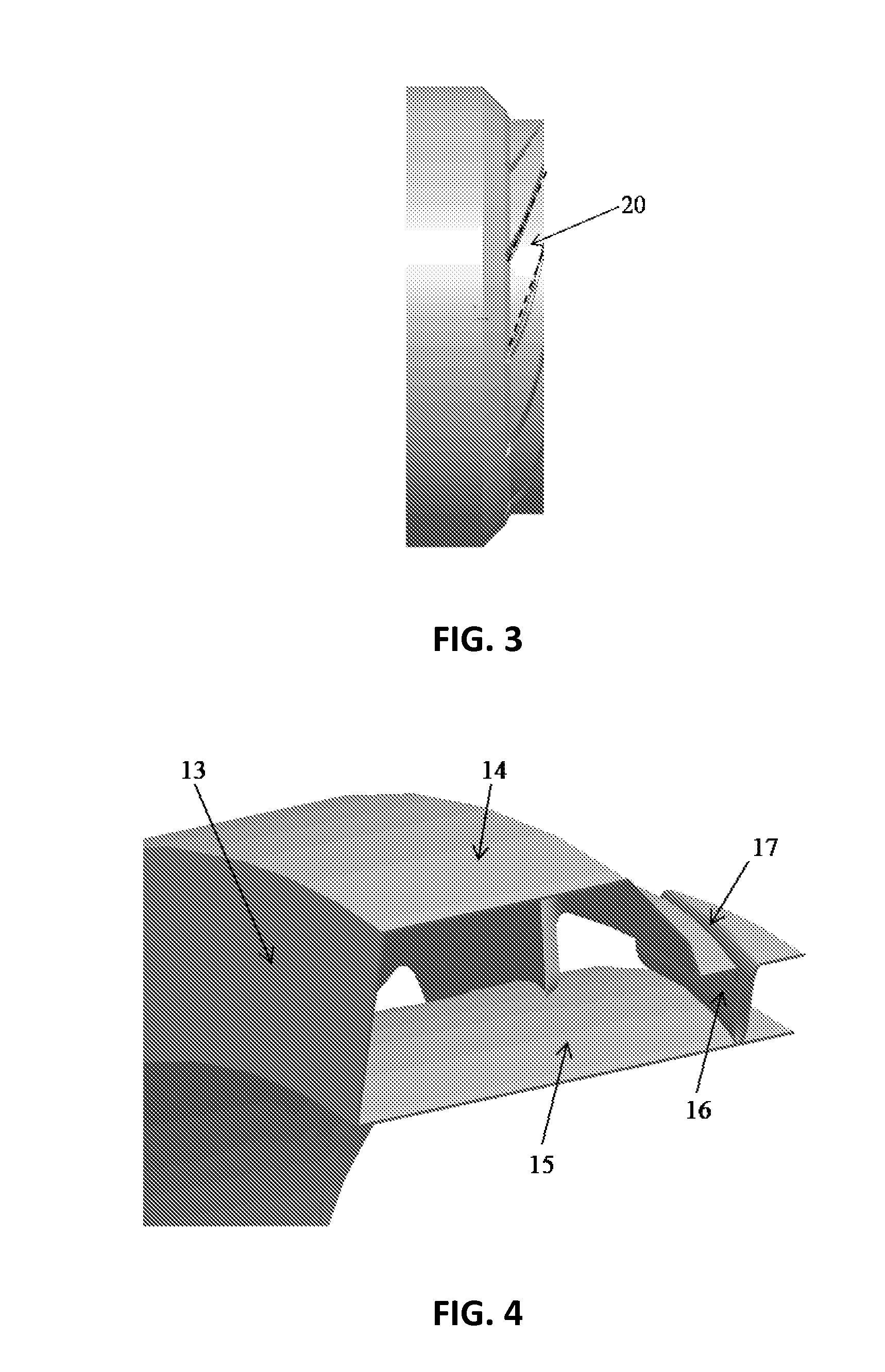

Device for depositing a coating on an internal surface of a container

InactiveUS20080011232A1Improve blockageReduce the amount requiredLiquid surface applicatorsElectric discharge tubesMicrowaveEngineering

Device for depositing a coating on an internal surface of a container (10), of the type in which the deposition is carried out by means of a low-pressure plasma created inside the container (10) by excitation of a precursor gas by microwave-type electromagnetic waves. An injection tube (13) is provided that dips into the container (10) to a length of between one quarter and one half of the total height of the container (10) in question, between the top (18) and the bottom (17) of the container (10), said length of the injection tube (13) constituting a longitudinal antenna (16) capable of picking up a UHF electromagnetic wave generated by said generator (3) and of propagating the HT ignition signal, a UHF short-circuit (19) in the form of a plate (21, 23, 25) being provided on the injection tube (13) in such a way that the face of said plate (21, 23, 25) on the cavity side defines a point of zero amplitude of the electromagnetic wave propagating along said injection tube (13), the length between said short-circuit (19) and the free end (13a) of said injection tube (13) corresponding to an odd number of quarter-wavelengths so as to obtain a maximum amplitude, that is to say an antinode, at the free end (13a) of the injection tube (13).

Owner:SIDEL PARTICIPATIONS SAS

Control of plasma transitions in sputter processing systems

InactiveUS6967305B2Improve responseEasy to igniteElectric discharge tubesVacuum evaporation coatingClosed loopEngineering

Methods and apparatus for controlling a plasma used for materials processing feature cooperative action of a resonant circuit and a switch unit coupled to a plasma vessel and a power supply. A sensor for acquiring a signal associated with a state of a plasma in the plasma vessel supports closed-loop control of the switch unit. Undesirable plasma states detected by the sensor can be eliminated by closing the switch unit to shunt the resonant circuit.

Owner:MKS INSTR INC

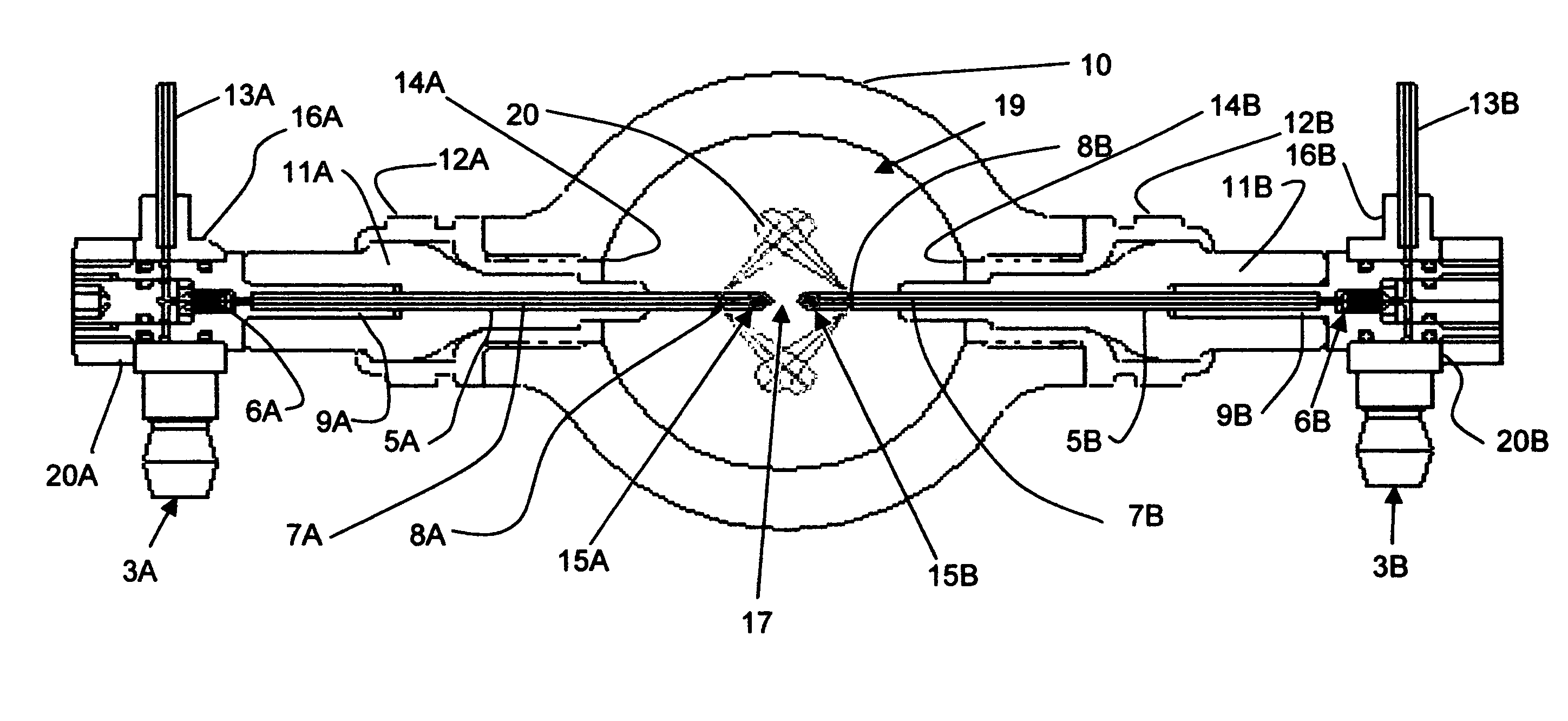

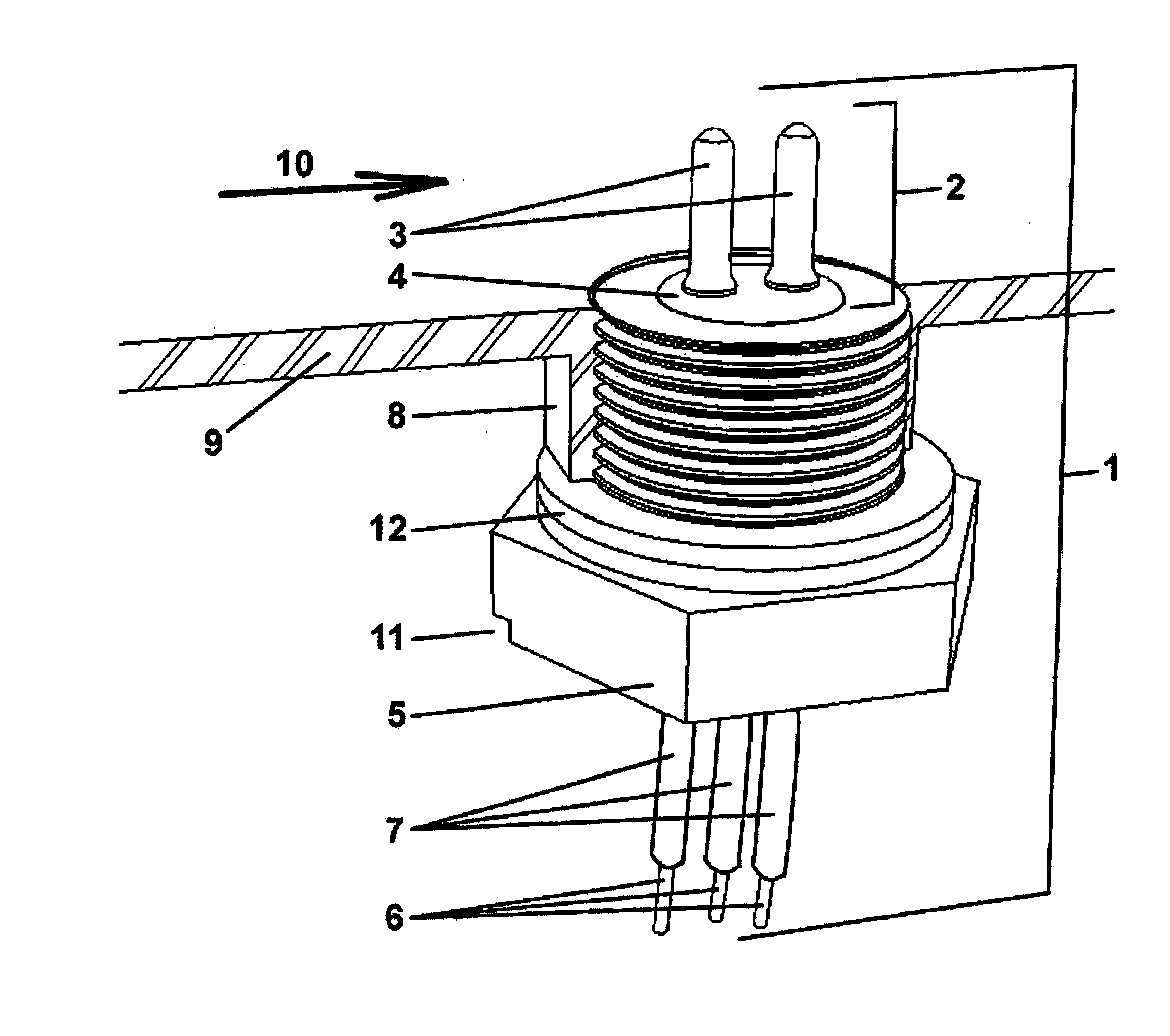

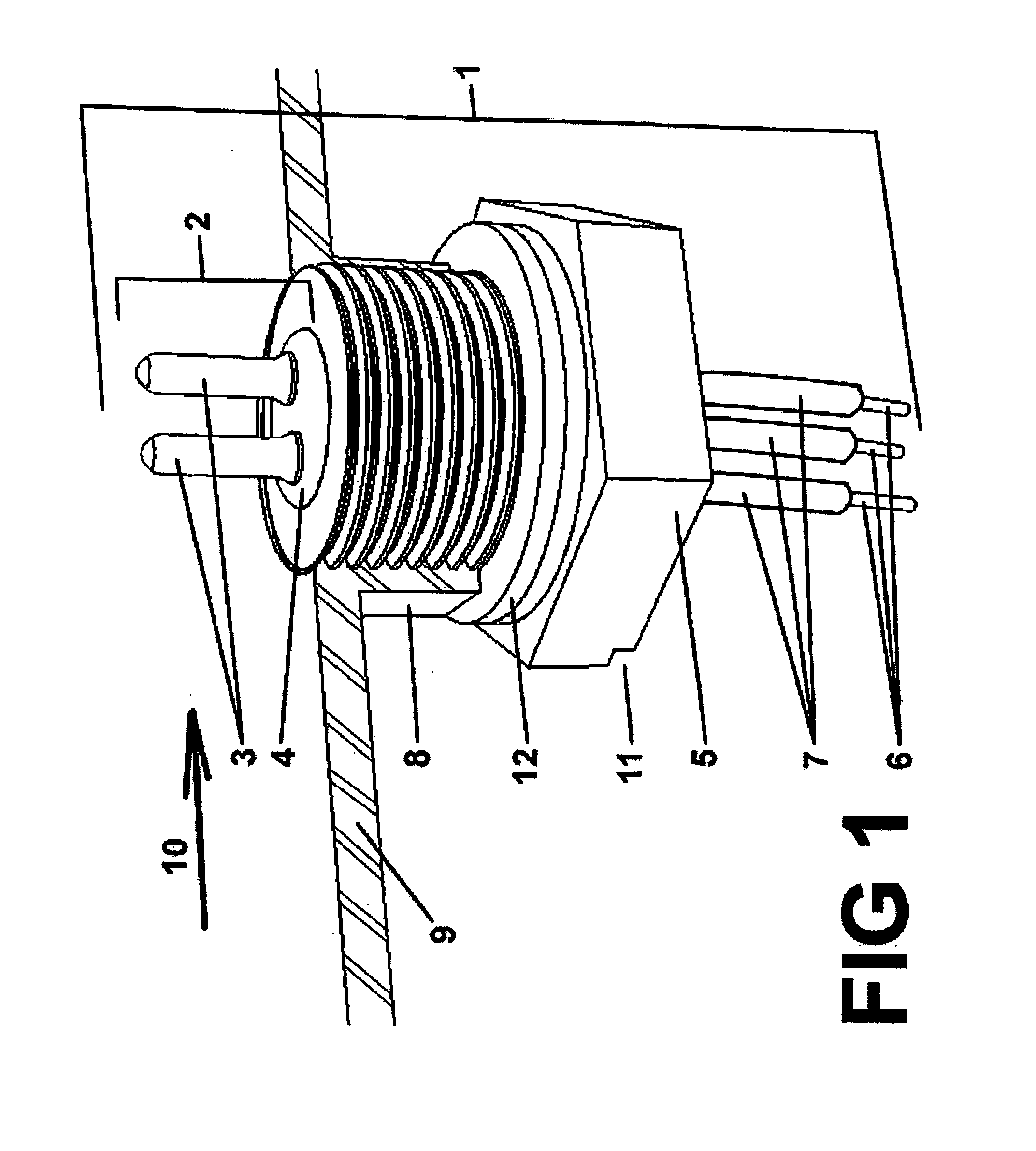

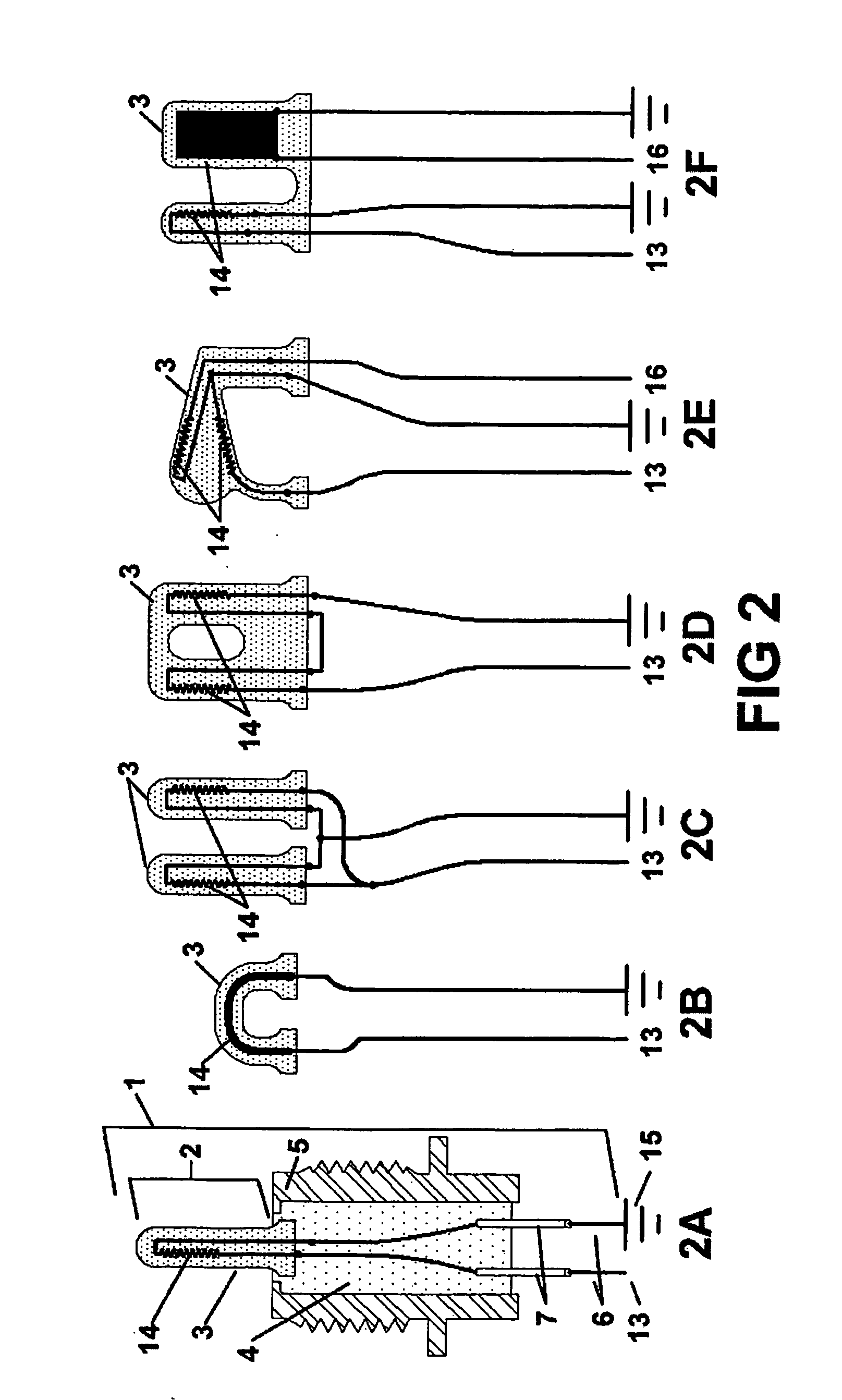

Spark ignition and fuel injector system for an internal combustion engine

InactiveUS7650873B2Avoid excessive heat buildupImprove engine efficiencyCombustion enginesFuel injection apparatusCombustion chamberCapillary channel

An improved spark ignition system for an internal combustion engine that includes a pair of electrodes disposed to extend from opposite sides and into a combustion chamber to form a spark gap between them that is central to the combustion chamber. Each electrode is integral with a conductive fuel delivery tube that contains a capillary passage and fuel outlet ports adjacent the electrode. The heat from combustion conducted into the electrodes and fuel delivery tubes is used to vaporize the fuel within the capillary passages before it exits the outlet ports as an atomized fog into the combustion chamber adjacent the spark gap. The vaporization of the fuel flowing in the capillary passages absorbs energy from the electrodes and thus performs a cooling effect on the electrodes. The spacing of the electrodes from opposite sides of the cylinder also allows a design that can utilize and increased spark gap to produce a larger spark across the gap.

Owner:ADVANCED PROPULSION TECH

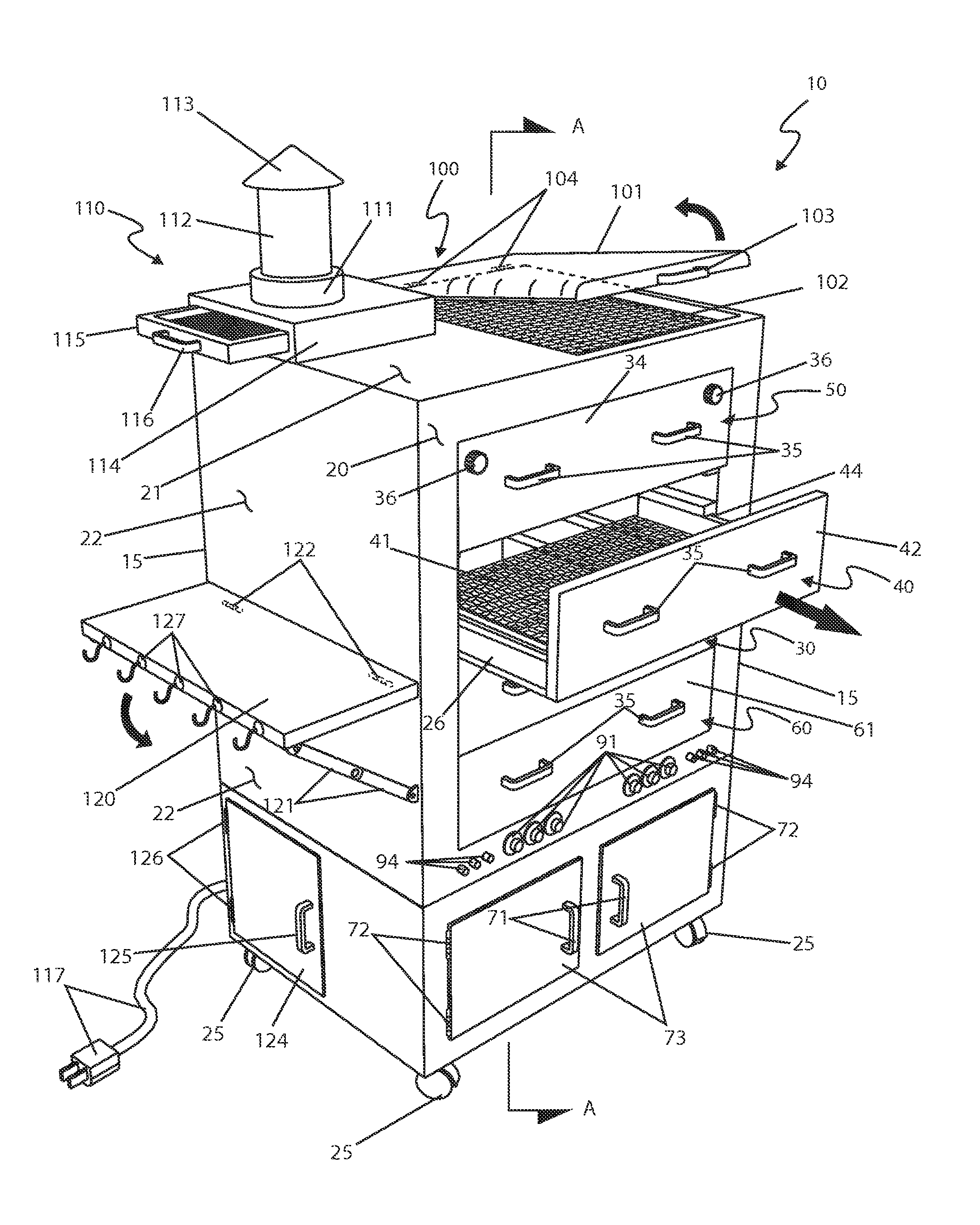

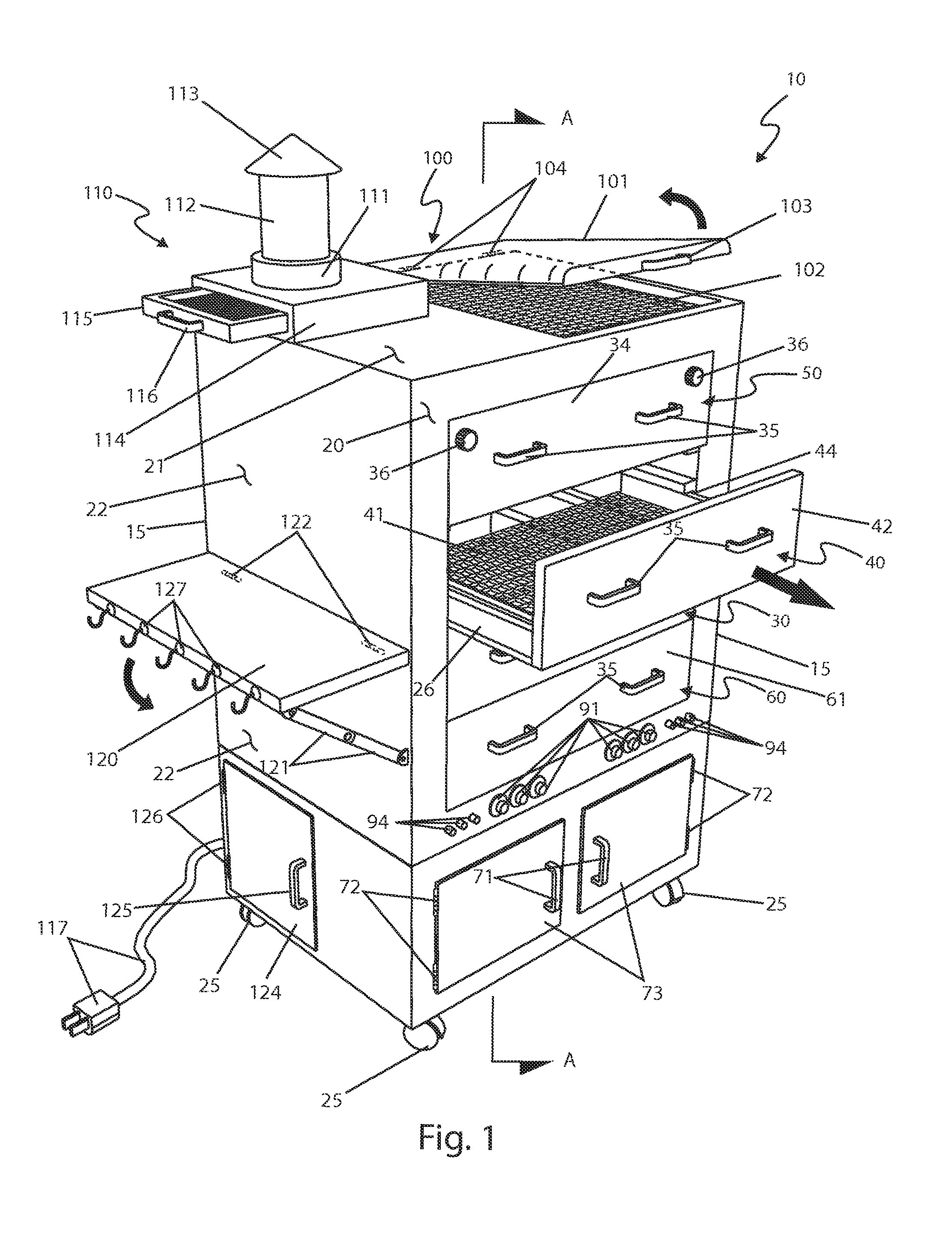

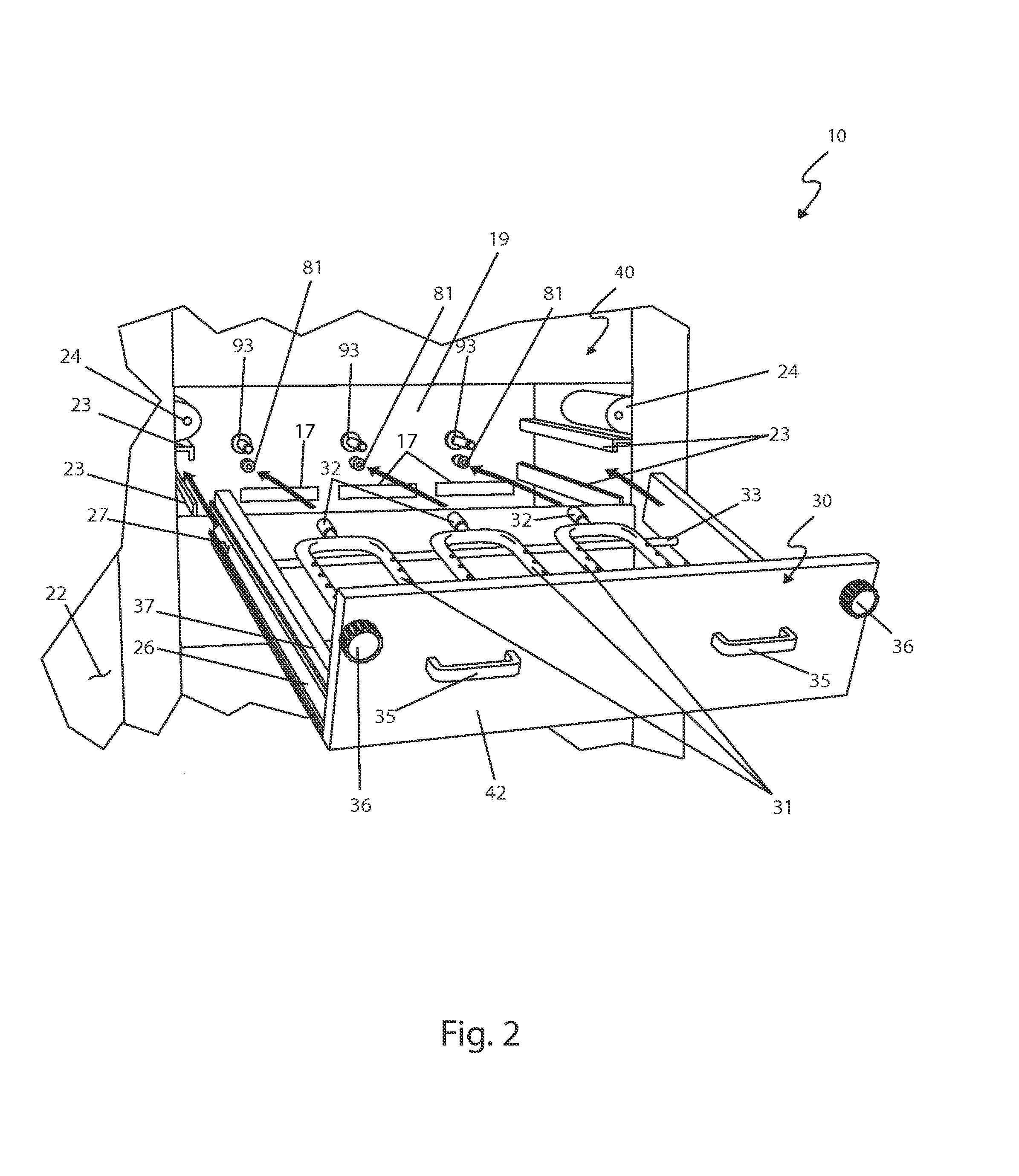

Residential flame broiler

InactiveUS8490614B1Avoid enteringEffective top and bottom cooking meanStoves/ranges foundationsLighting and heating apparatusCombustorBroiler chick

The invention discloses a gas grill with multiple enhancements to allow for easy grilling of foods, subsequent clean-up, and replacement of parts. In lieu of a top-opening lid, the apparatus provides a plurality of removable and insertable drawers, comprising a plurality of burner units, a plurality of grill trays, and a drip tray located in a vertical configuration therein a base unit. All drawers are interchangeable as desired. A storage compartment is located on the bottom directly below the drip tray and an exhaust assembly is located on the top for directing smoke away from the apparatus. The invention is adaptable to propane or natural gas. Additional drawers and burner assemblies are provided and may be used for charcoal or wood burning, bun or food warming, and water steaming. All drawers are easily removable on slides with a safety catch system for easy care and cleaning.

Owner:GREGORY MICHAEL S

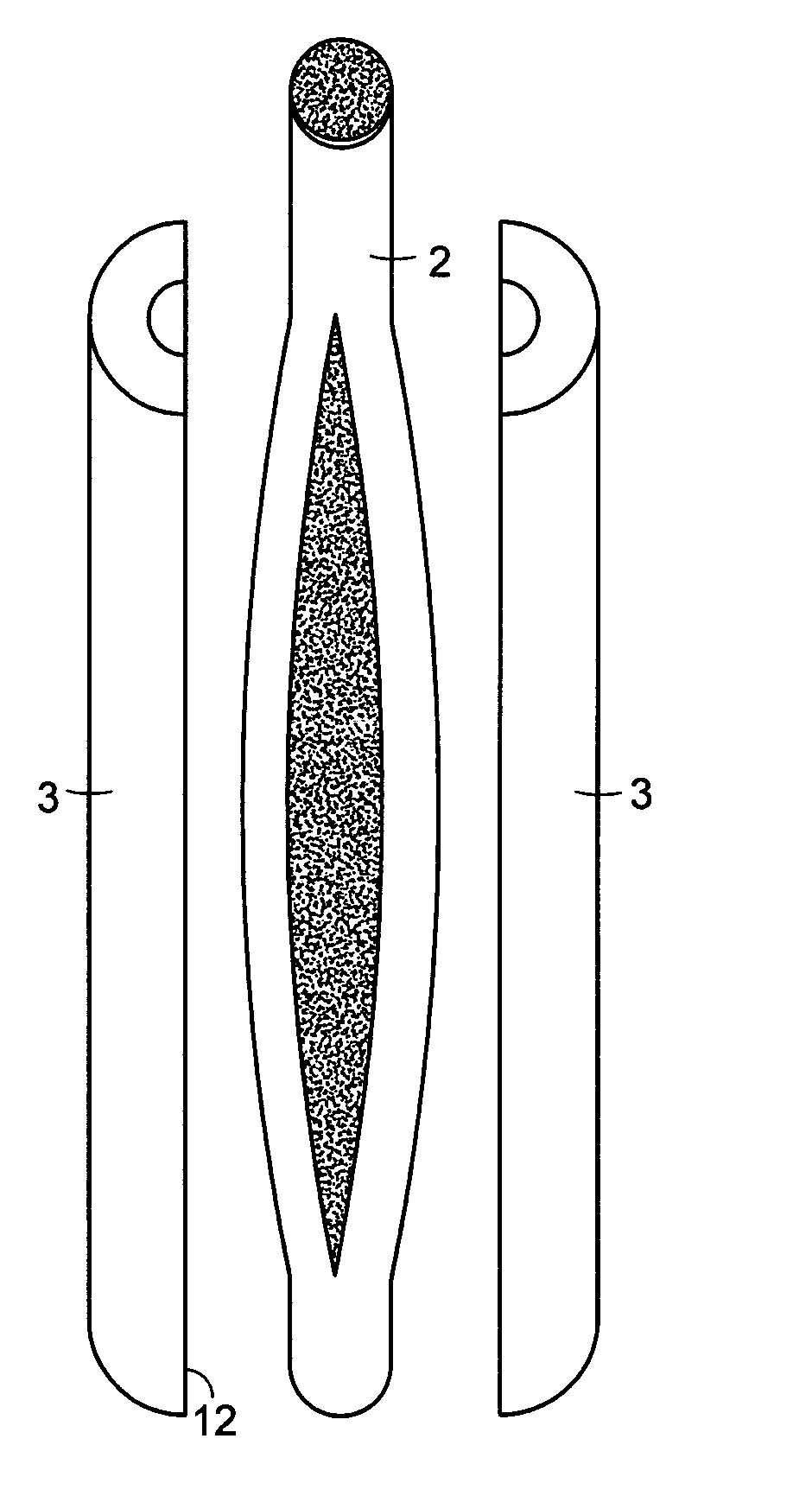

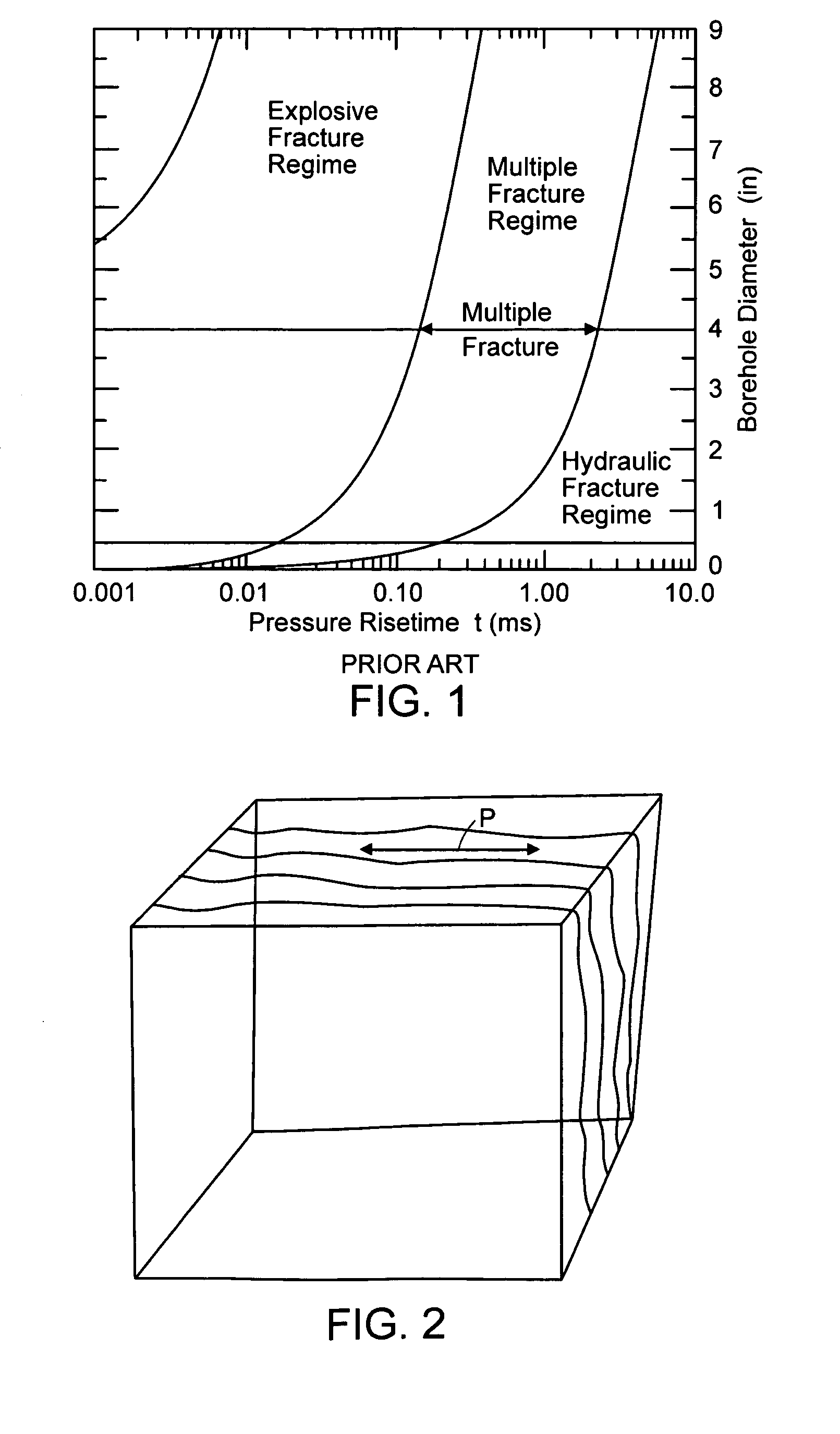

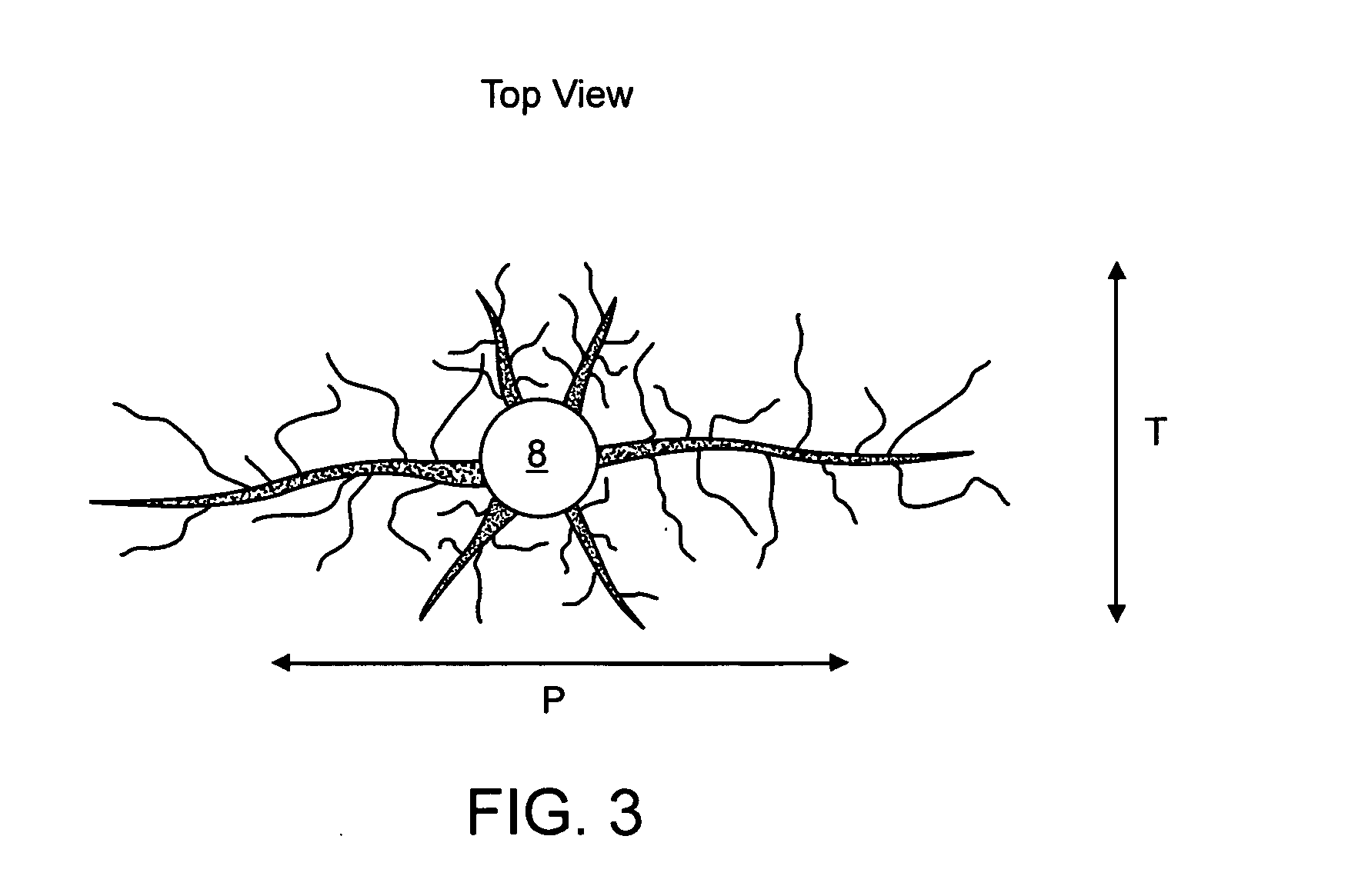

Method and apparatus for stimulating wells with propellants

ActiveUS20060185898A1Multiple fracture regimeExtend fractureBlasting cartridgesNuclear explosivesPorosityEngineering

The present invention relates to apparatus and methods to stimulate subterranean production and injection wells, such as oil and gas wells, utilizing rocket propellants. Rapid production of high-pressure gas from controlled combustion of a propellant, during initial ignition and subsequent combustion, together with proper positioning of the energy source in relation to geologic formations, can be used to establish and maintain increased formation porosity and flow conditions with respect to the pay zone.

Owner:SEEKFORD DALE B

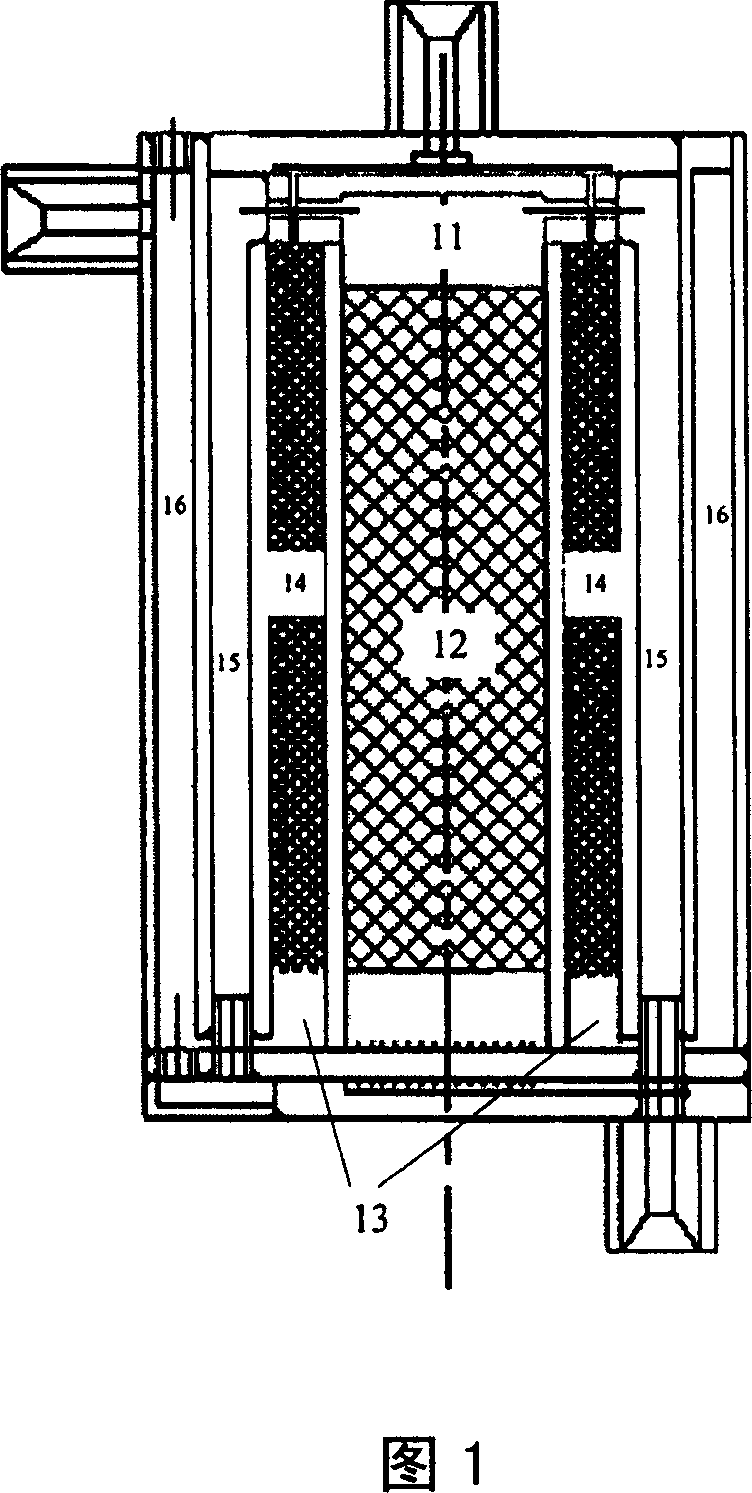

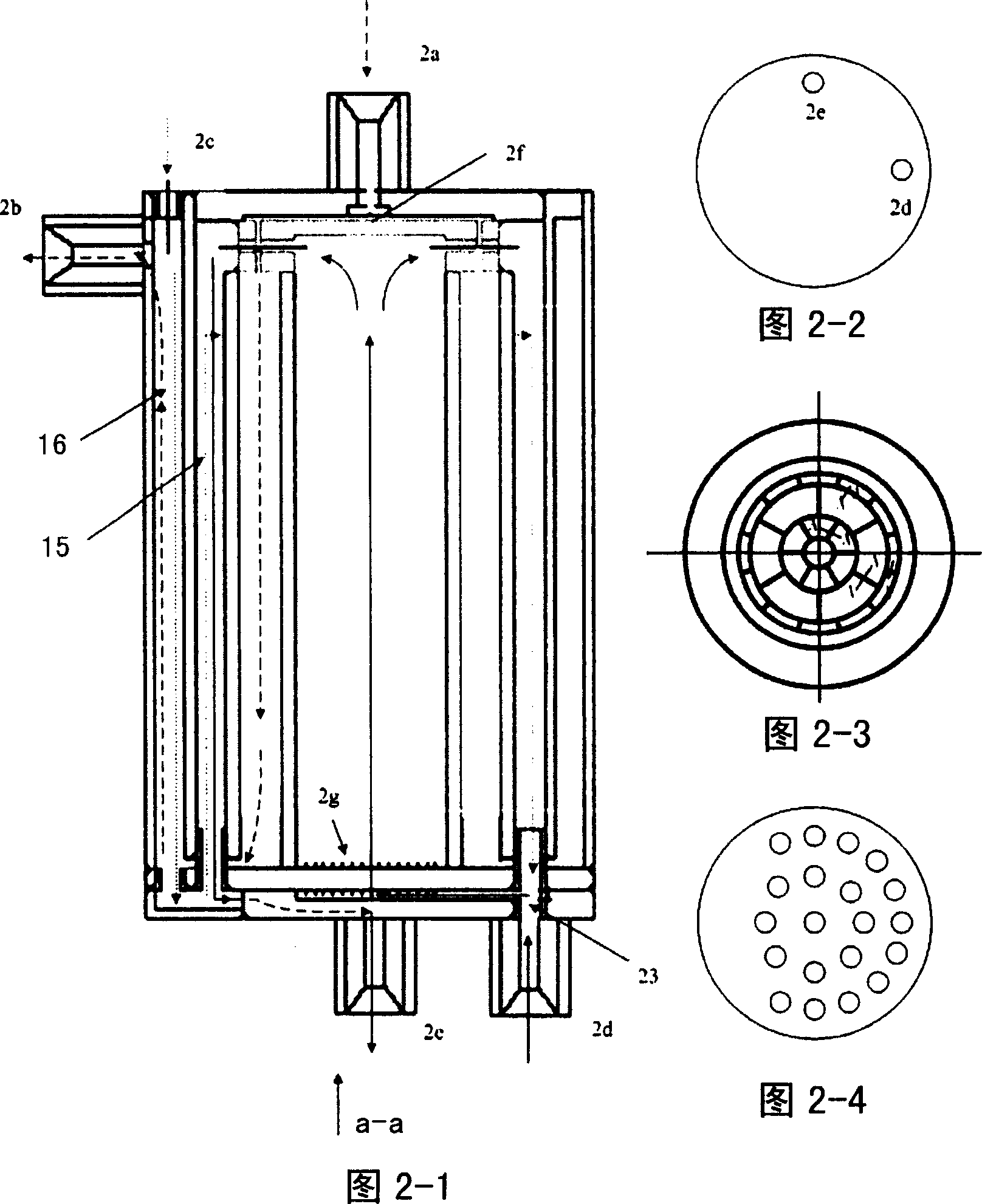

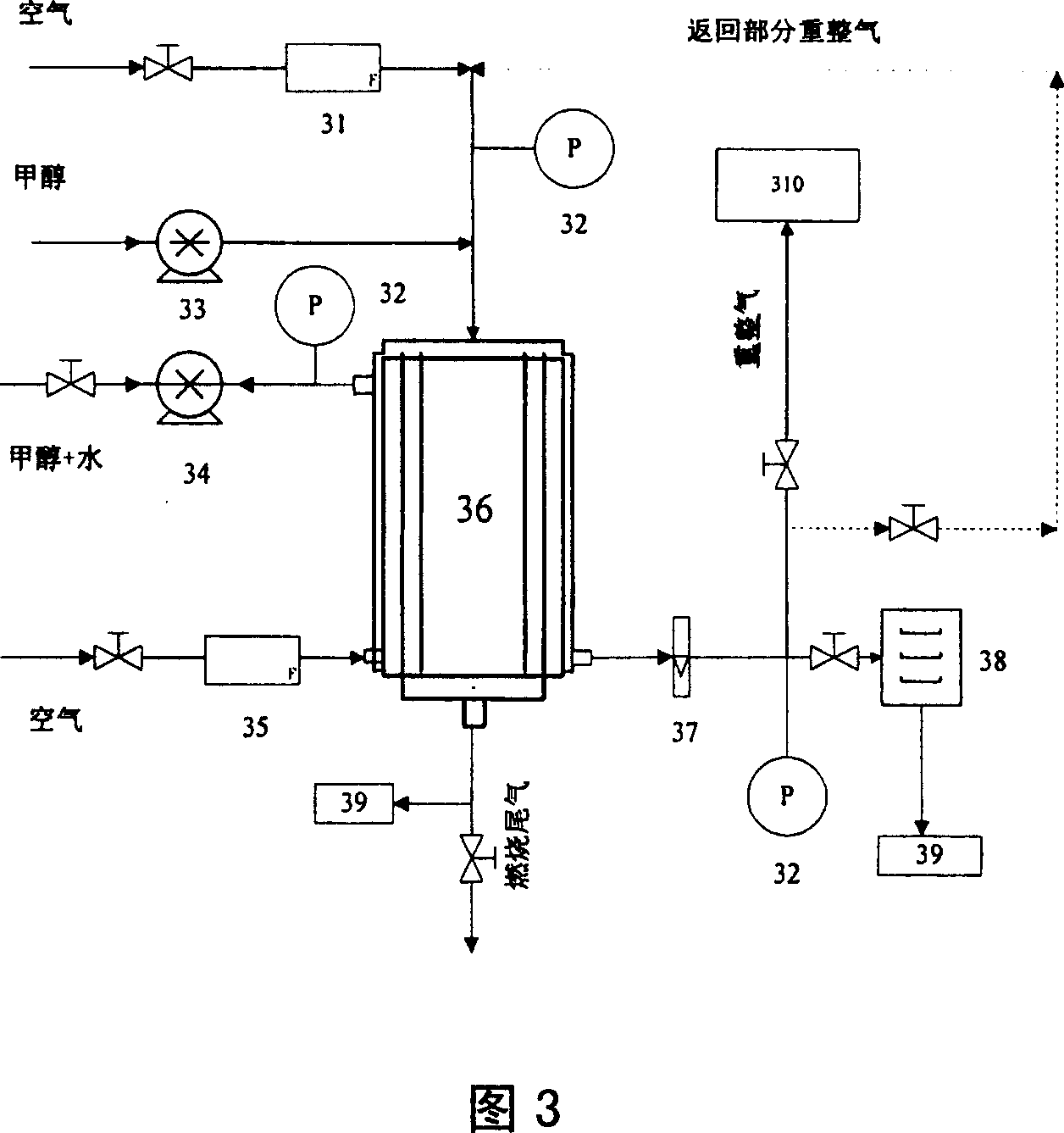

Mini reforming hydrogen-preparation reactor

InactiveCN101054160ARapid reforming hydrogen production reactionEven air distributionHydrogenHydrogenFuel cells

A minitype reactor for reforming hydrogen, which main part has telescopefeed structure, comprising a burning offgas heat exchange cavity, a reforming offgas heat exchange cavity, a burning cavity and a reforming cavity in sequence from outside; a fuel inlet is arranged communicating with the burning cavity; a reforming material inlet is arranged communicating with a built-in cavity of the burning offgas heat exchange cavity; reforming material liquid is preheated in the built-in cavity of the burning offgas heat exchange cavity then supplied into a built-in cavity of the reforming offgas heat exchange cavity; reforming material liquid flows in built-in cavities, burning offgas and reforming offgas exchange heat via tube wall of built-in cavities and flow oppose to reforming material liquid; a reforming air inlet is arranged, mixture gas of reforming air mixing with gas phase vaporized in the reforming offgas heat exchange cavity is supplied into the reforming cavity to process reforming hydrogen reaction. The catalytic burning reaction and reforming reaction of the invention has advantages of temperature easy to be control, stable running, easy operation; compact structure; the invention is suit for hydrogen source system of 10-500 W fuel cell minitype electrical source.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

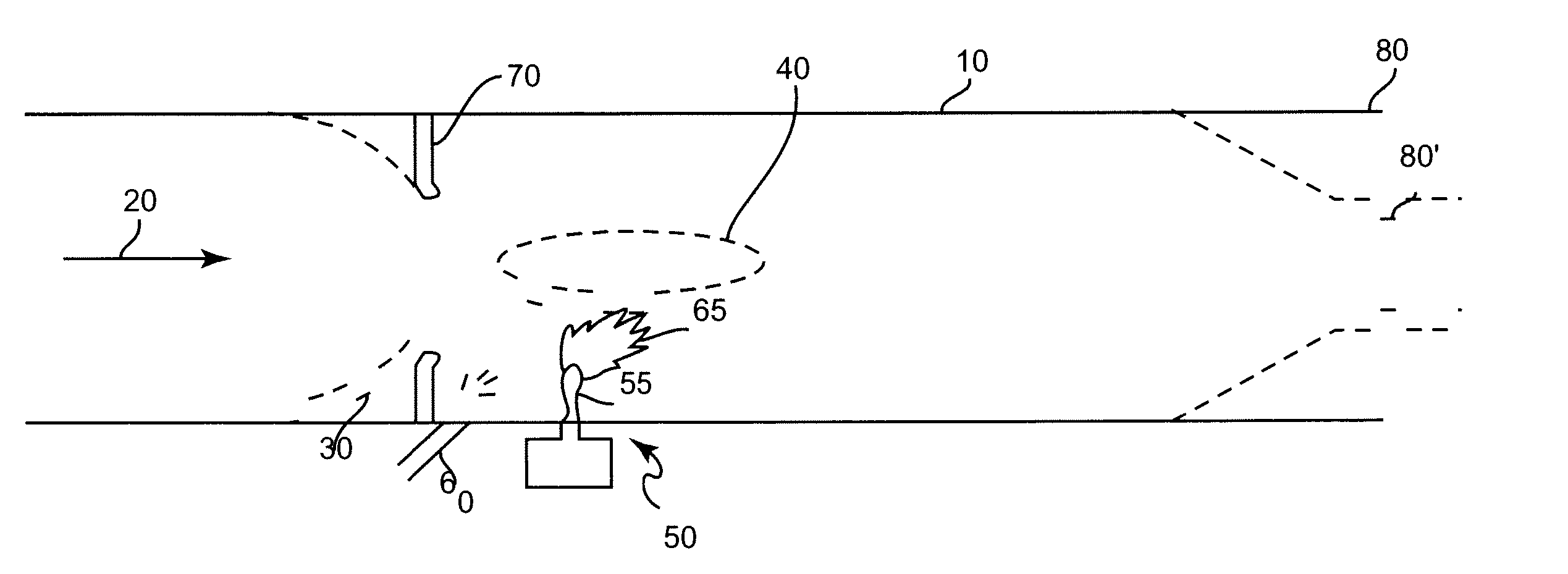

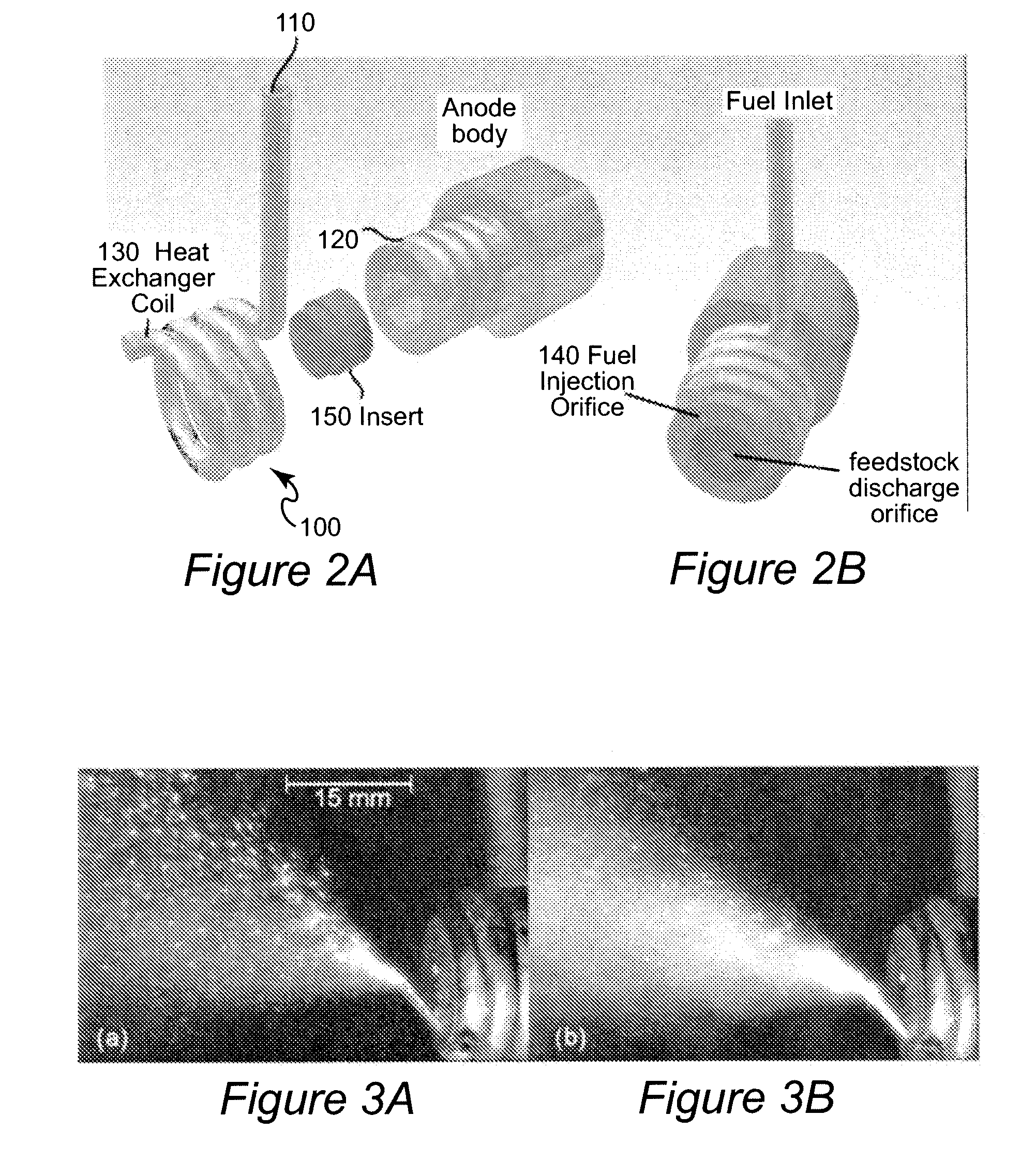

Improved Plasma Torch for Ignition, Flameholding and Enhancement of Combustion in High Speed Flows

InactiveUS20070044449A1Improves fuel mixingEnhances combustion reactionContinuous combustion chamberGas turbine plantsCombustionNitrogen

Preheating of fuel and injection into a plasma torch plume fro adjacent the plasma torch plume provides for only ignition with reduced delay but improved fuel-air mixing and fuel atomization as well as combustion reaction enhancement. Heat exchange also reduced erosion of the anode of the plasma torch. Fuel mixing atomization, fuel mixture distribution enhancement and combustion reaction enhancement are improved by unsteady plasma torch energization, integral formation of the heat exchanger, fuel injection nozzle and plasma torch anode in a more compact, low-profile arrangement which is not intrusive on a highspeed air flow with which the invention is particularly effective and further enhanced by use of nitrogen as a feedstock material and inclusion of high pressure gases in the fuel to cause effervescence during injection.

Owner:VIRGINIA TECH INTPROP INC

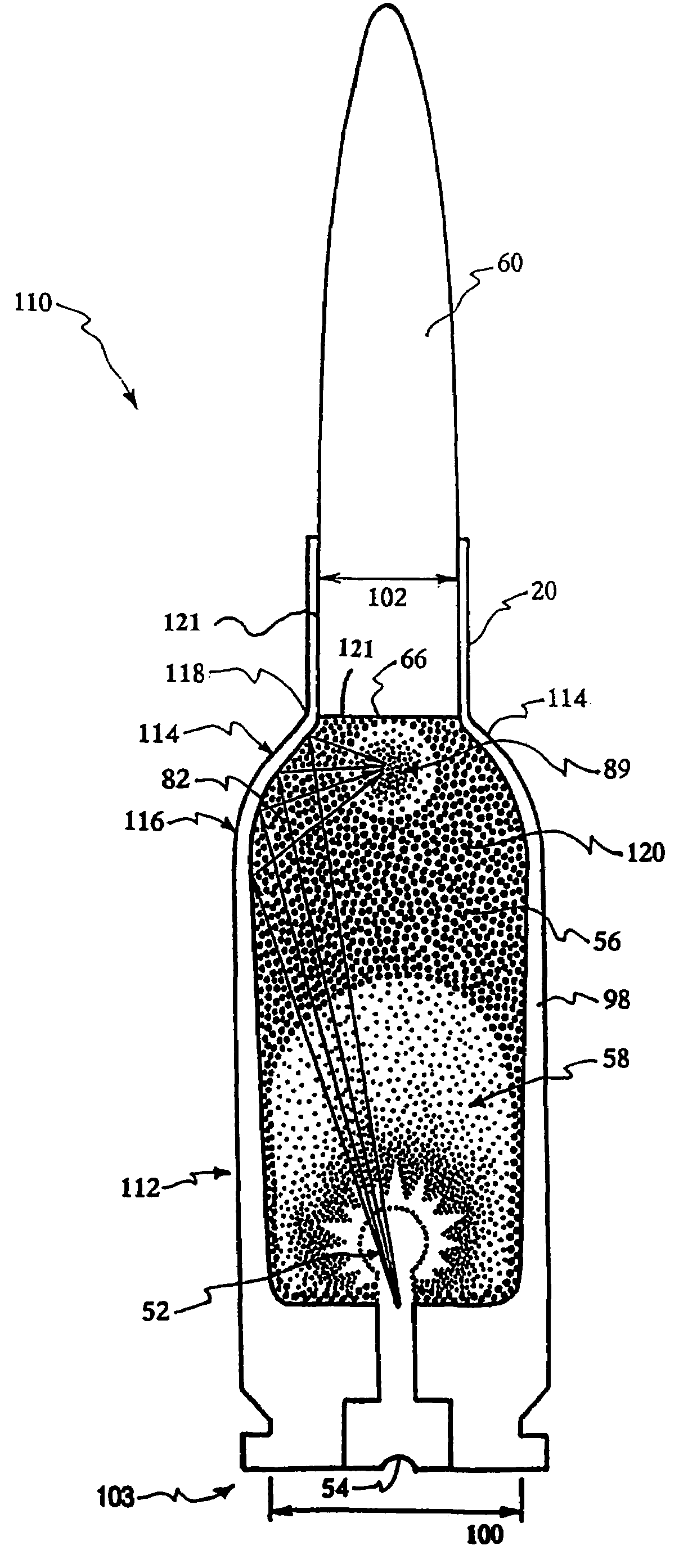

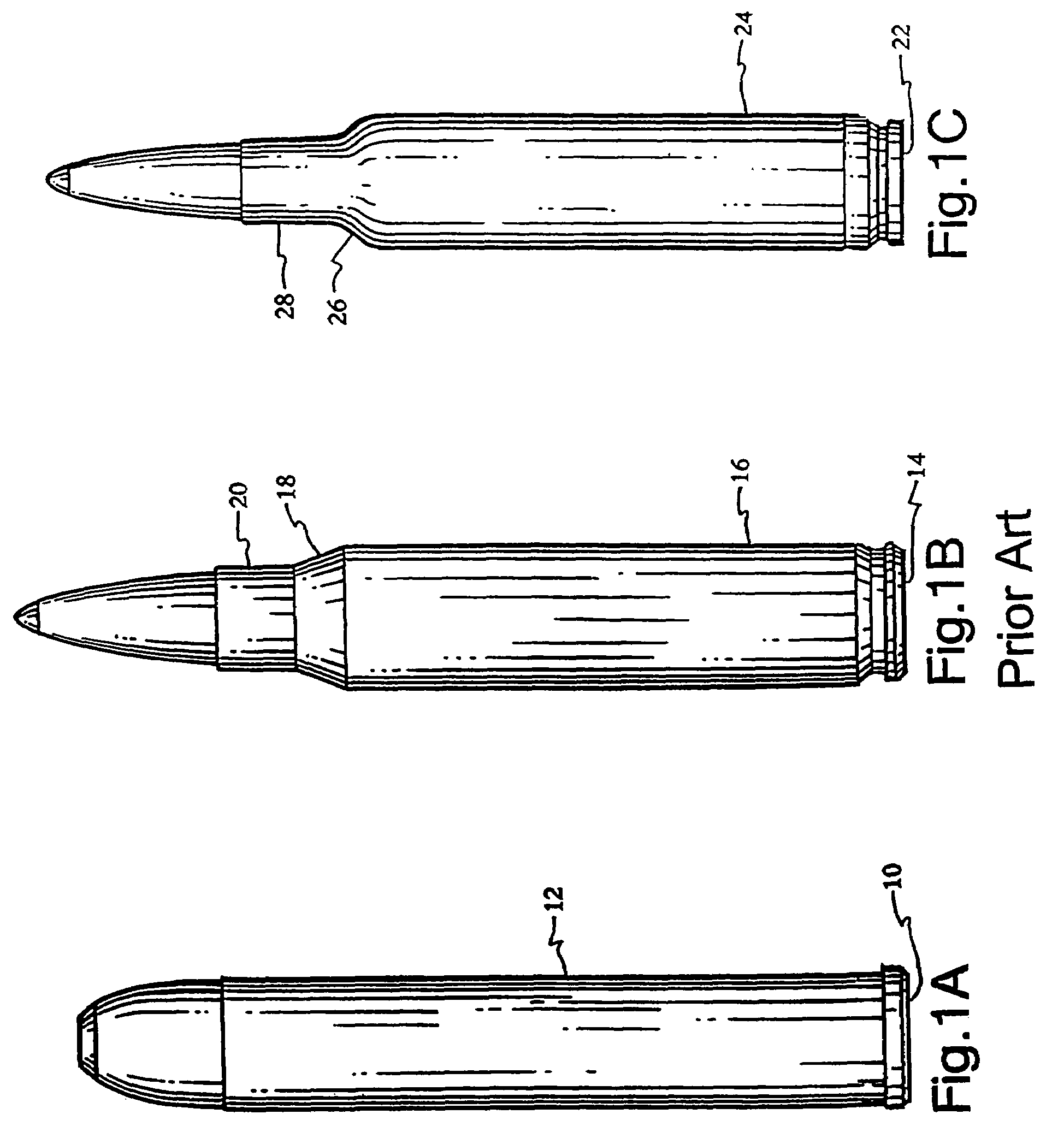

Firearm cartridge and case-less chamber

InactiveUS7086336B2Improve combustion efficiencyGreat primary ignition zoneAmmunition projectilesShotgun ammunitionCombustionDiameter ratio

A firearm cartridge has a case configured with a relatively straight-walled portion and a shoulder portion for housing a quantity of propellant. The case further includes a neck for retaining a bullet. The straight-walled portion defines a base cavity having an interior base diameter. The interior base diameter is approximately twice or more the neck diameter. The diameter ratios of the base and neck optimize combustion efficiency to reduce heat and acceleration losses. The cartridge body cavity is sized and configured to contain a sufficient quantity of propellant such that igniting the propellant causes formation of a propellant plug having a diameter that is approximately the diameter of the bullet, and wherein the propellant plug shears free from unburned propellant that is disposed adjacent the relatively straight-walled body portion.

Owner:SUPERIOR BALLISTICS

Device for depositing a coating on an internal surface of a container

InactiveUS7975646B2Stable ignitionEasy to igniteLiquid surface applicatorsElectric discharge tubesMicrowaveEngineering

Device for depositing a coating on an internal surface of a container, of the type in which the deposition is carried out by means of a low-pressure plasma created inside the container by excitation of a precursor gas by microwave-type electromagnetic waves. An injection tube is provided that dips into the container to a length of between one quarter and one half of the total height of the container in question, between the top and the bottom of the container said length of the injection tube constituting a longitudinal antenna capable of picking up a UHF electromagnetic wave generated by said generator and of propagating the HT ignition signal, a UHF short-circuit in the form of a plate being provided on the injection tube in such a way that the face of said plate on the cavity side defines a point of zero amplitude of the electromagnetic wave propagating along said injection tube, the length between said short-circuit and the free end of said injection tube corresponding to an odd number of quarter-wavelengths so as to obtain a maximum amplitude, that is to say an antinode, at the free end of the injection tube.

Owner:SIDEL PARTICIPATIONS SAS

Ceramic-encased hot surface igniter system for jet engines

InactiveUS20080141651A1Increased voltageIncreasing power flowBurnersIncandescent ignitionCeramicSilicon nitride

A ceramic-encased hot surface igniter system for jet engines is presented. The advanced ceramic-encased hot surface igniter system comprises at least one electrical resistance heated element encased in a durable, thermal and mechanical shock resistant, high temperature advanced ceramic compound such as silicon nitride. The one or more advanced ceramic-encased hot surface igniter elements are mounted proximally upstream or within a combustion chamber of a jet engine enclosure or within the afterburner section of a jet propulsion engine's exhaust. The surface temperature of each ignition element's encasement being of sufficient temperature to cause the ignition of a gaseous, atomized, or liquid fuel.

Owner:STATE OF FRANKLIN INNOVATIONS

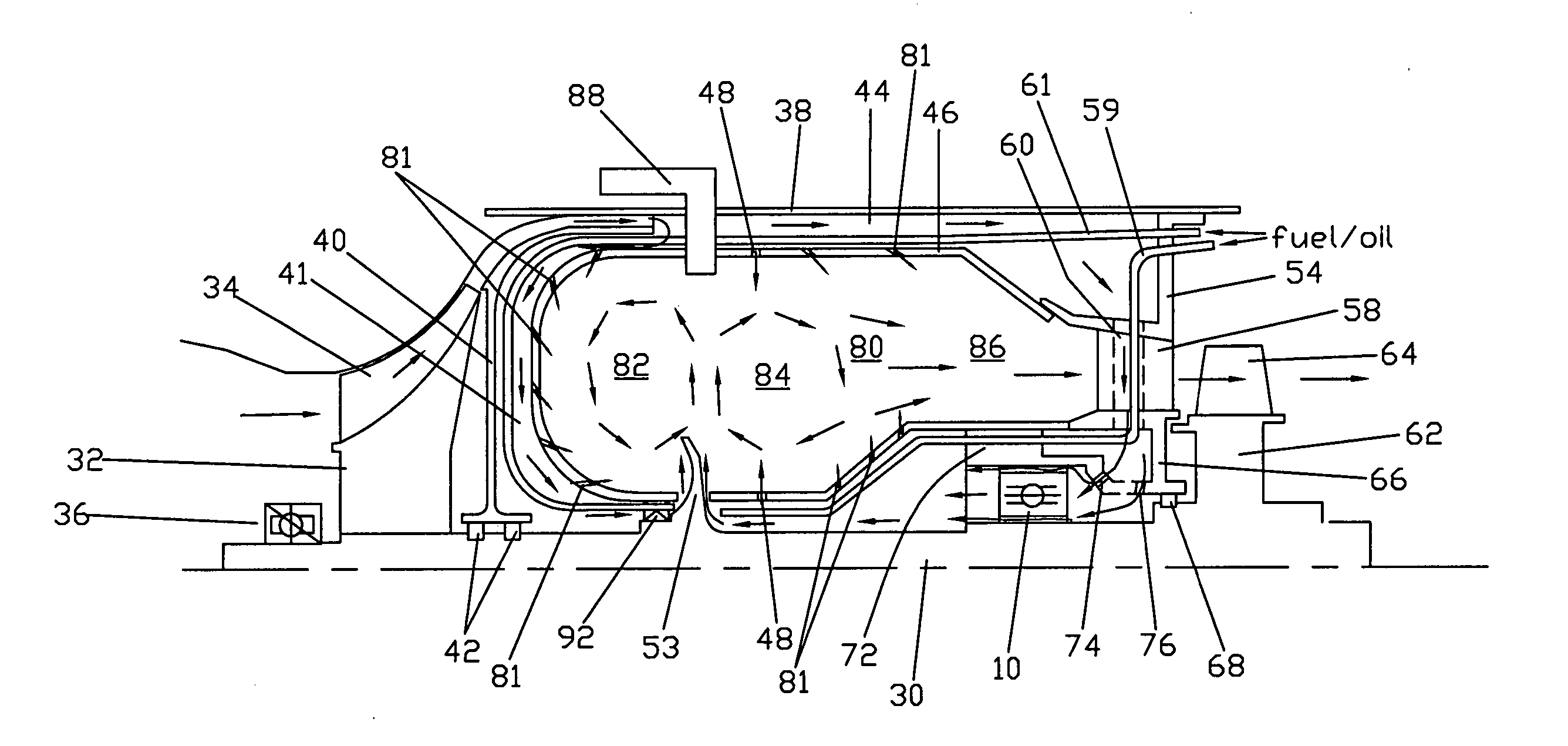

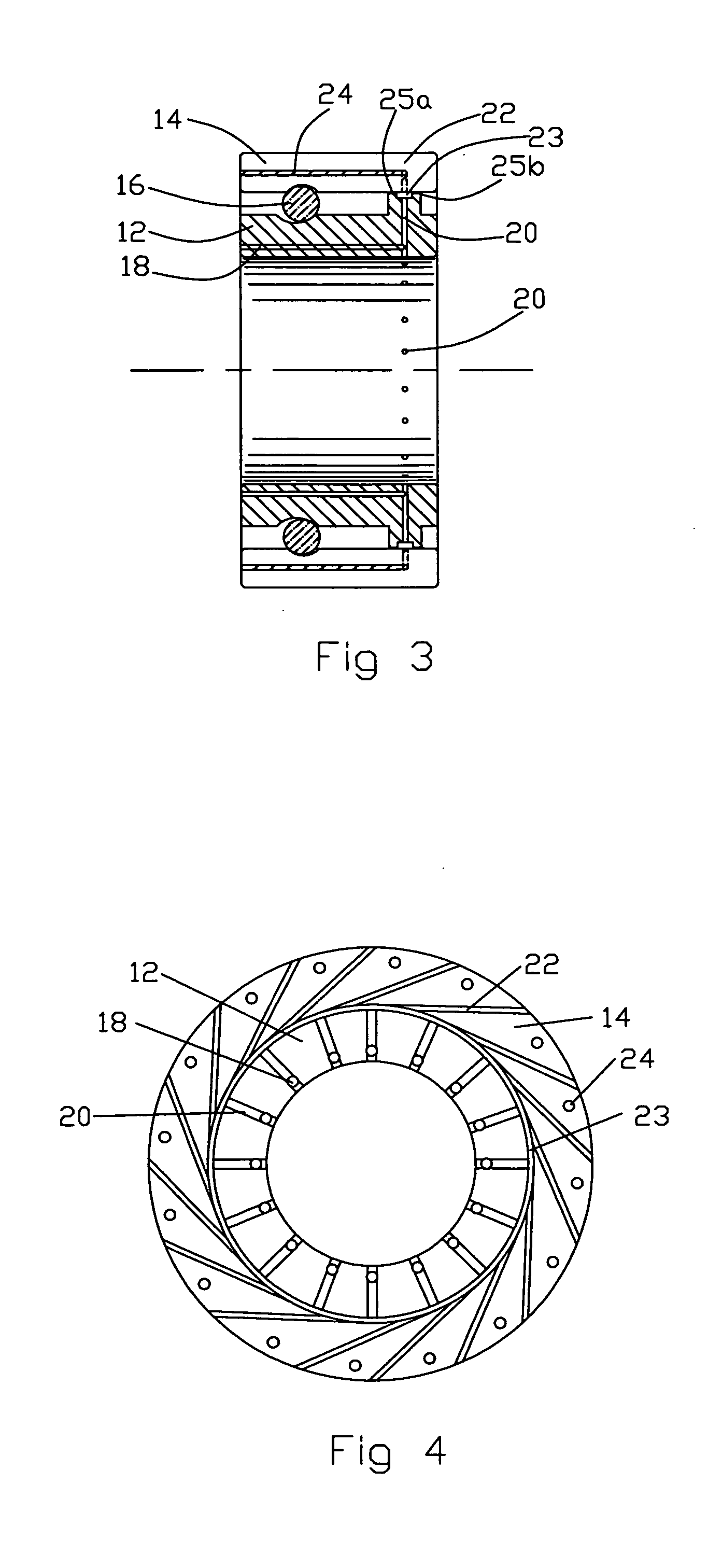

Small gas turbine engine with multiple burn zones

InactiveUS20070234733A1Most efficientImprove stabilityTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustorTurbine

A small gas turbine engine for use in an UAV such as a cruise missile, the gas turbine having a combustor forming a primary burn zone and a secondary burn zone, and in which fuel is injected into both the primary and the secondary burn zones by either a rotary cup injector or a plurality of fuel injector nozzles. The secondary burn zone with separate fuel injection allows for the diameter of the engine to be reduced in size but still allow for adequate power and efficiency to be reached for powering the vehicle. Air flow from the compressor is used to cool the combustor walls before being injected into the combustor, and to pass through and cool the guide nozzles and a main bearing located near the hot section of the combustor prior to being introduced into the combustor.

Owner:FLORIDA TURBINE TECH

Tangential combustor with vaneless turbine for use on gas turbine engines

ActiveUS20110209482A1Shorten the lengthReduce manufacturing costContinuous combustion chamberGas turbine plantsTurbine bladeStaged combustion

A combustion device used in gas turbine engines includes an annular combustor that contains the combustion process of air and fuel and then guides the hot gas products to a first stage turbine subsection of a gas turbine engine. The annular combustor has an inner / outer shell having corrugated surfaces that extend radially outward and inward across an entire hot gas stream inside the annular combustor. The corrugations twist about the engine centerline in a longitudinal direction of travel of the engine. The resulting flow path accelerates and turns the hot gas stream to conditions suitable for introduction into the first stage turbine blades, which eliminate the need for first stage turbine vanes. The annular combustor is configured with a system of fuel and air inlet passages and nozzles that results in a staged combustion of premixed fuel and air.

Owner:TOQAN MAJED +3

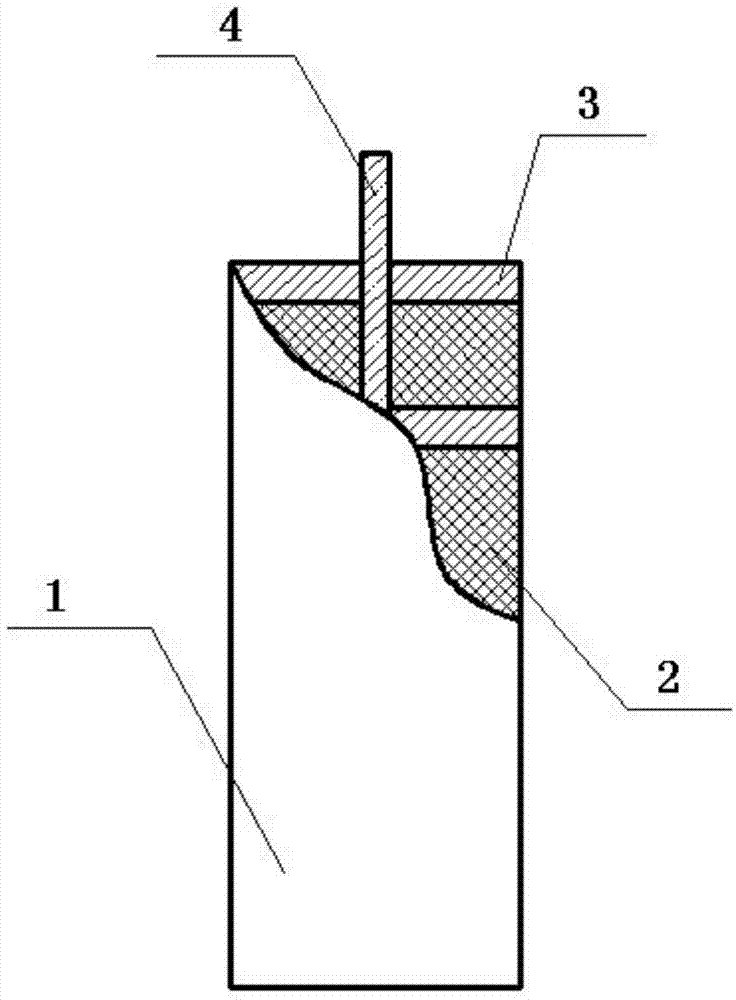

Moxa cone

InactiveCN104739638AEasy to igniteDevices for heating/cooling reflex pointsRolling paperPulp and paper industry

The invention relates to a moxa cone which comprises wrapping and rolling paper, a moxa cone body, an artemisia argyl oil layer and an ignition wick. The wrapping and rolling paper wraps the outer side face of the moxa cone body, the ignition wick penetrates through the moxa cone body, the ignition wick exceeds the top of the moxa cone body, and the artemisia argyl oil layer is arranged at the top of the moxa cone body. The moxa cone can be ignited easily, and can be ignited easily after the moxa cone is used for the first time and when the moxa cone is used next time.

Owner:金艳

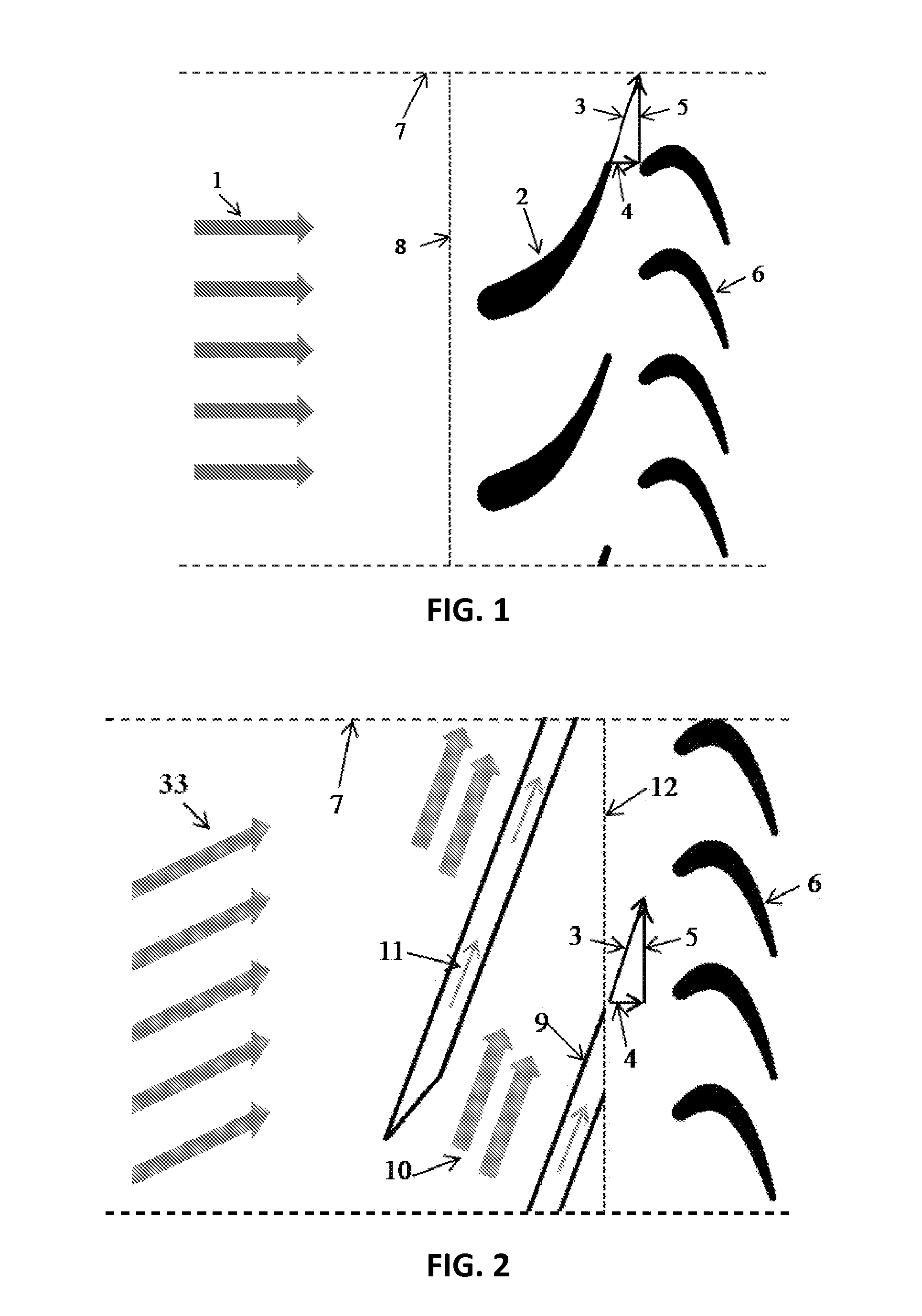

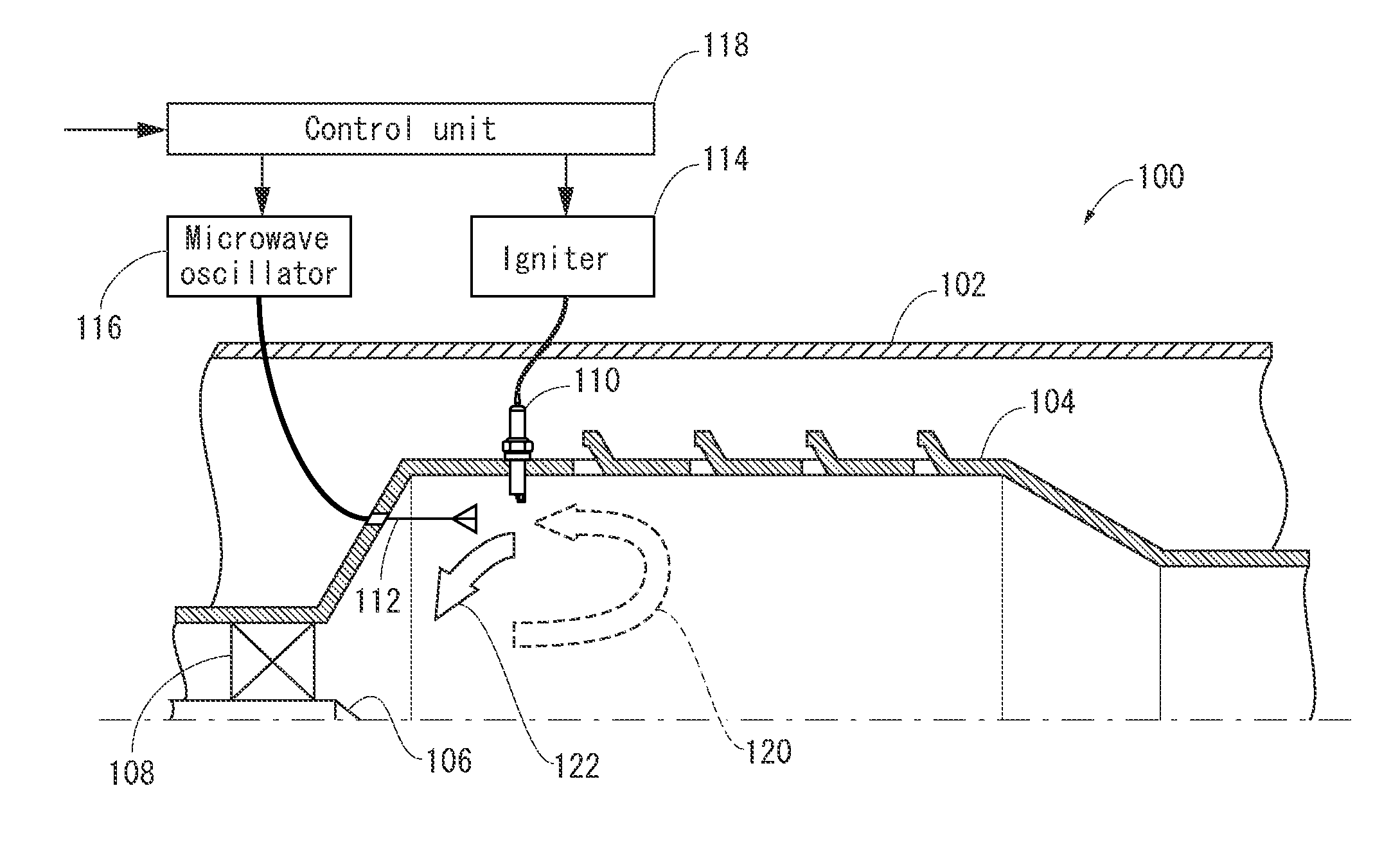

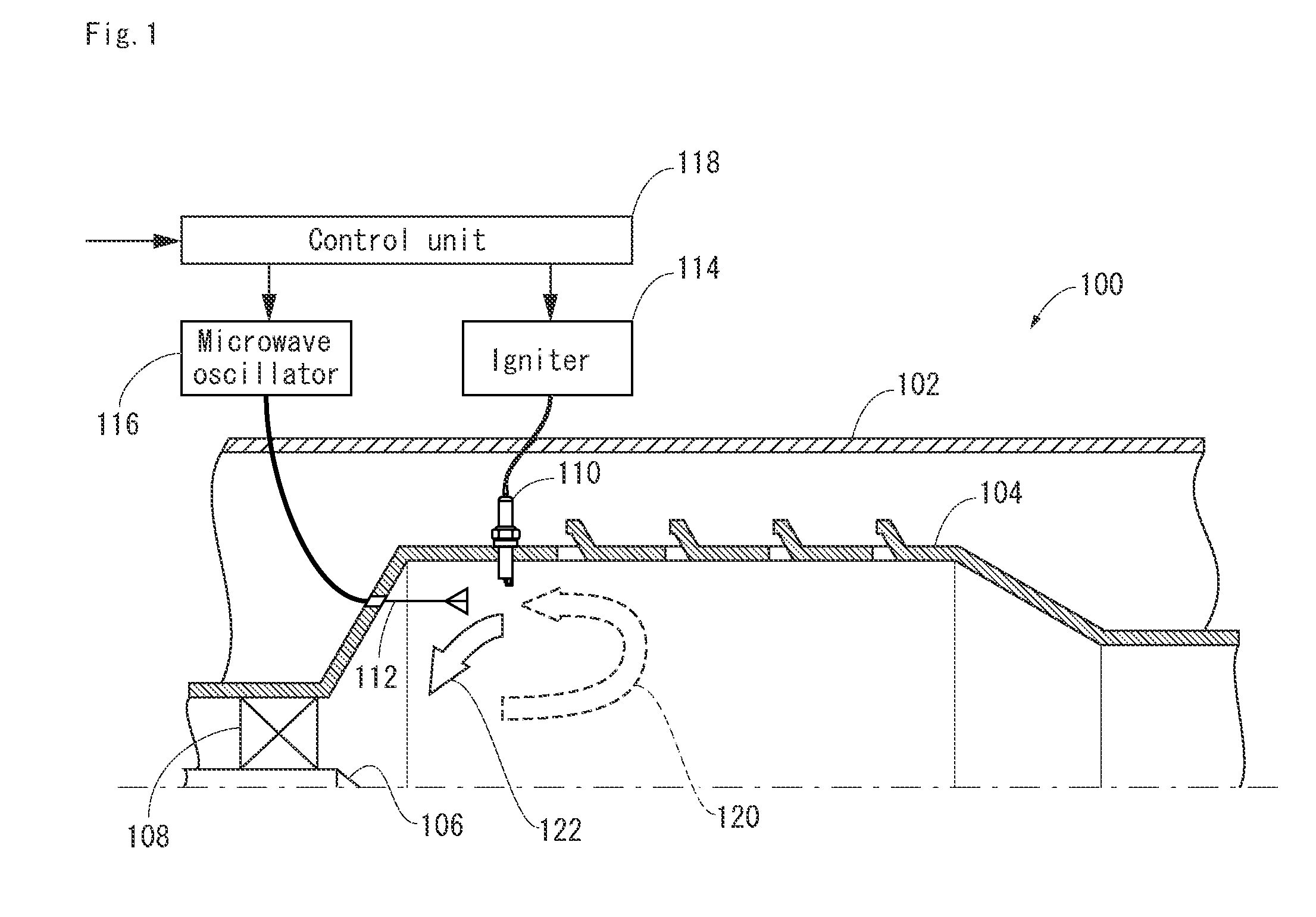

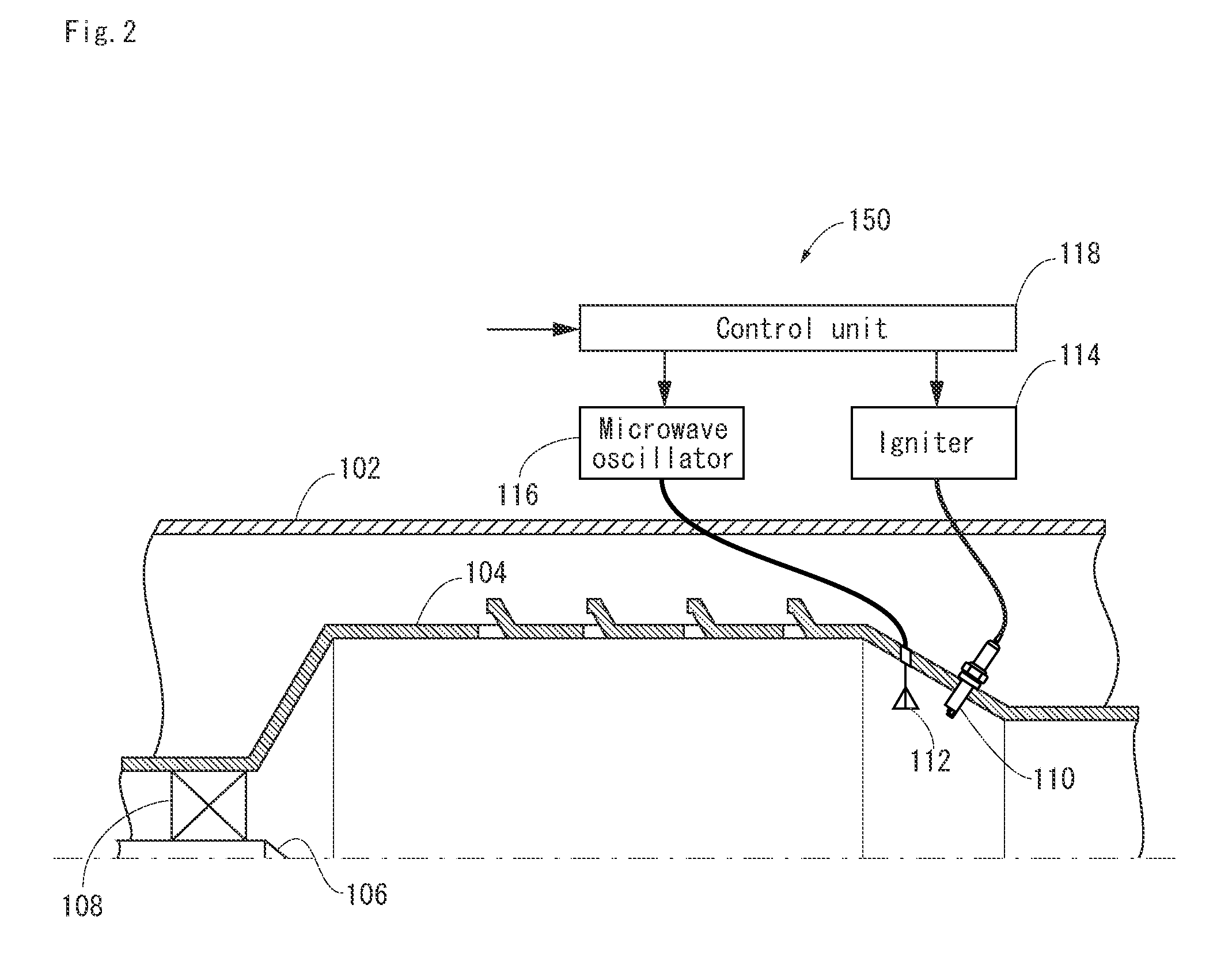

Ignition/ chemical reaction promotion/ flame holding device, speed-type internal combustion engine, and furnace

ActiveUS20100186368A1Easy to igniteEasy to spreadContinuous combustion chamberIncandescent ignitionWorking fluidChemical reaction

An ignition and chemical reaction accelerator and flame stabilizer and a high-performance speed-type internal combustion engine using this device are provided, whereby ignition and the spreading and holding of flames can be dramatically improved in a gas turbine, a ram machine, a rocket engine, or another speed-type internal combustion engine. An ignition and chemical reaction accelerator and flame stabilizer of a speed-type internal combustion engine comprises a spark plug (110) for preparing charged particles in a predetermined location in a combustor (104) of the speed-type internal combustion engine, and a microwave oscillator (116) and antenna (112) for inducing plasma with a working fluid in the combustor as a starter material by irradiating the charged particles and their surrounding vicinity with microwave pulses; wherein a region in which sufficient conditions for performing combustion are met is formed in the combustor by supplying an active chemical species produced from the working fluid by the effect of the plasma.

Owner:I LAB INC

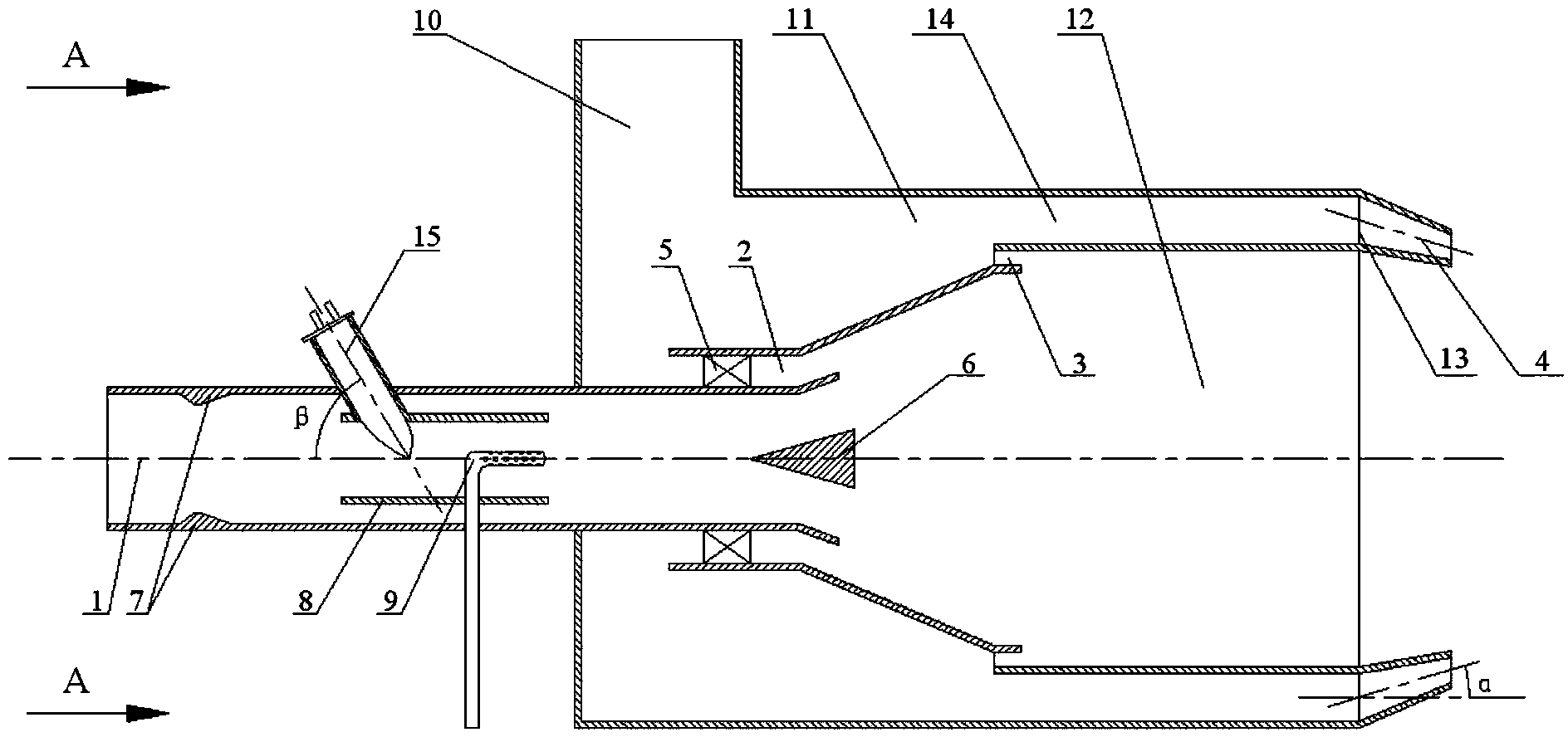

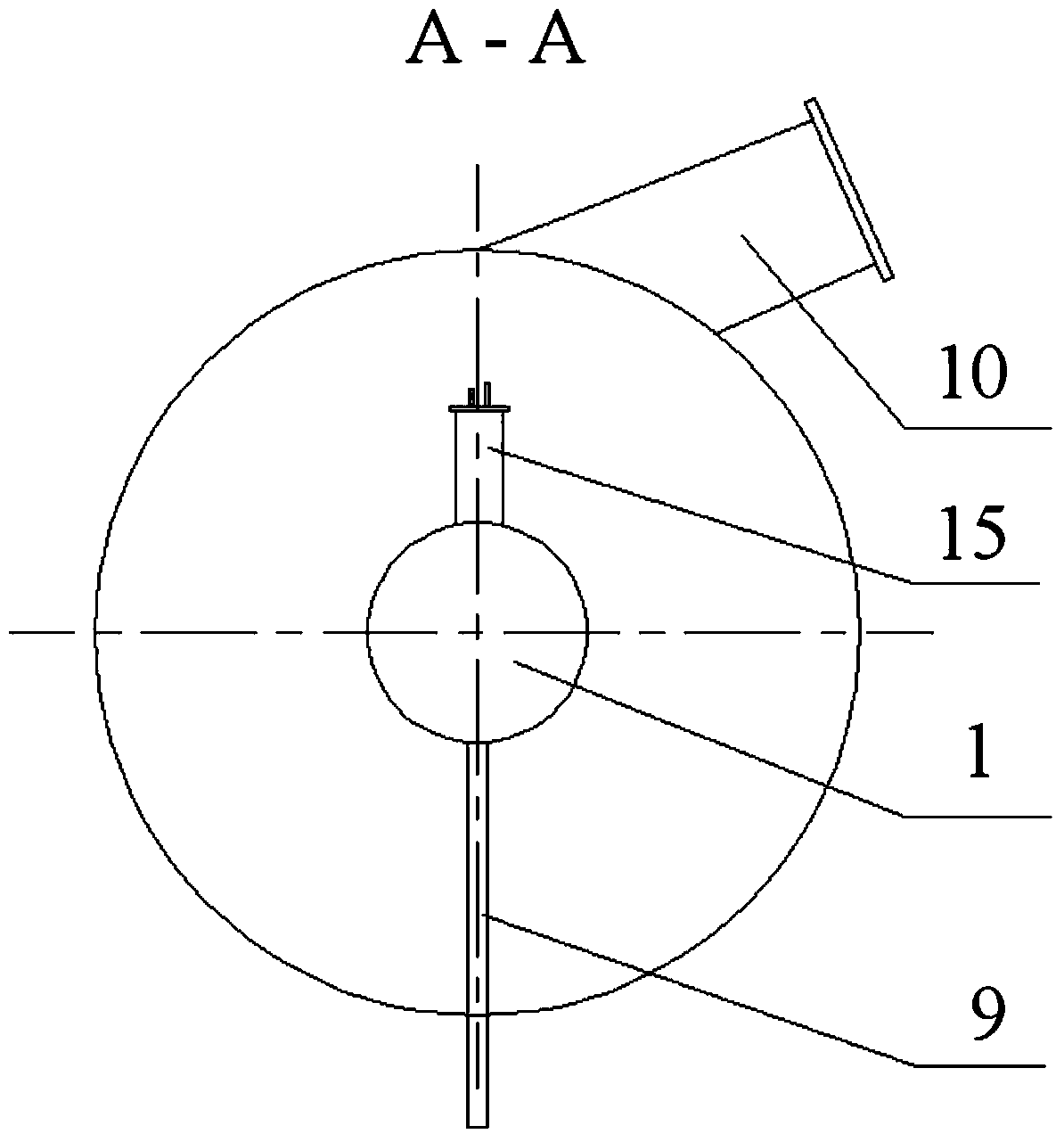

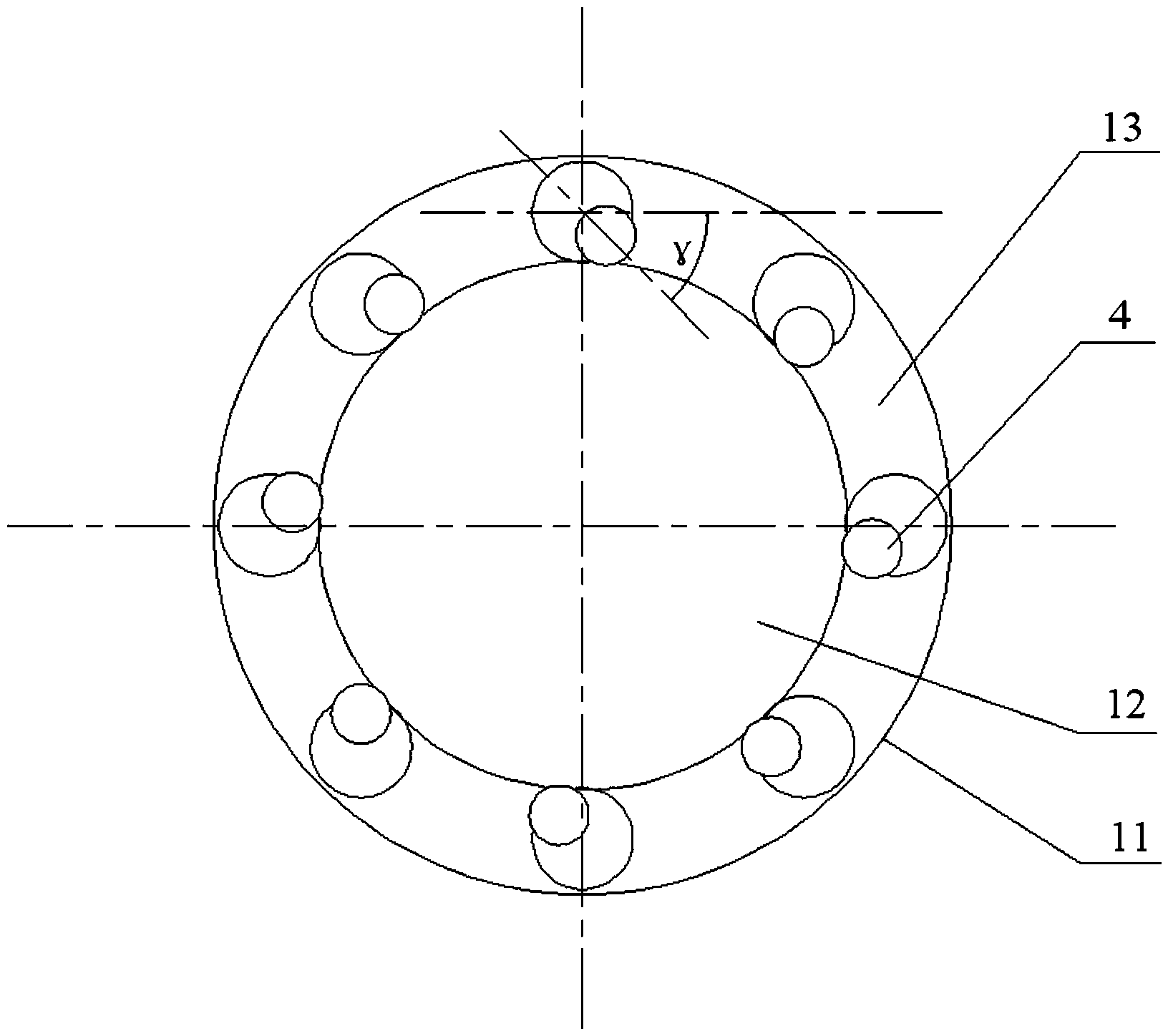

Novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor

ActiveCN103615717AWith low load stable combustion functionProvide in timePilot flame ignitersPulverulent fuel combustion burnersCombustion chamberCombustor

The invention discloses a novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor. The novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor comprises an oxygen enrichment guide pipe, a primary air pipe, a cylindrical oil-coal mixed combustion chamber, a secondary air pipe, a secondary air box and a pre-combustion chamber, wherein the central axes of the primary air pipe, the cylindrical oil-coal mixed combustion chamber, the secondary air pipe, the secondary air box and the pre-combustion chamber coincide. A secondary air inlet inclining in the circumferential direction is formed in the pipe wall of the secondary air box; the primary air pipe penetrates through the secondary air box in the axial direction, the oil-coal mixed combustion chamber is coaxially arranged in the primary air pipe, and a high-energy tiny-oil ignition oil gun and the oxygen enrichment guide pipe are arranged in the oil-coal mixed combustion chamber; the secondary air pipe with a rotational flow impeller is coaxially arranged outside the primary air pipe in a sleeved mode and an outlet end is provided with a bluff body; the pre-combustion chamber is arranged in the secondary air box, the inlet end of the pre-combustion chamber is provided with a graded air duct, and a plurality of disturbance air nozzles are installed in an outlet of the combustor. The ignition fuel saving ratio reaches over 90% and the novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor has the function of low load stable combustion and the function of ultralow load stable combustion; the technologies of oxygen enrichment, coal dust concentration, graded air feeding and the like are adopted, so that the novel oxygen enrichment tiny-oil ignition and ultralow load stable-combustion combustor has the advantages of being high in coal dust burn-off rate, low in NOx discharge and the like.

Owner:CHINA JILIANG UNIV

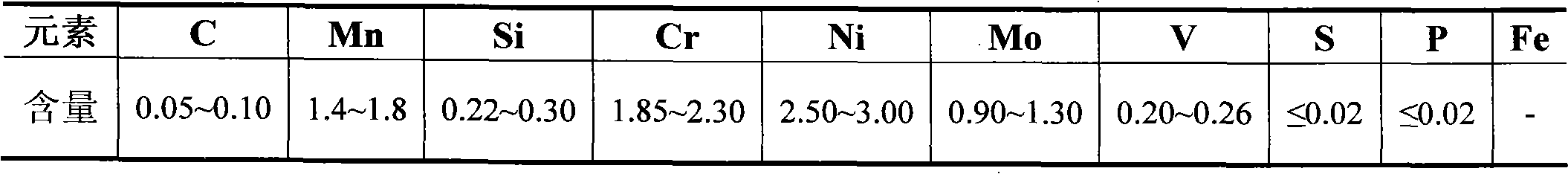

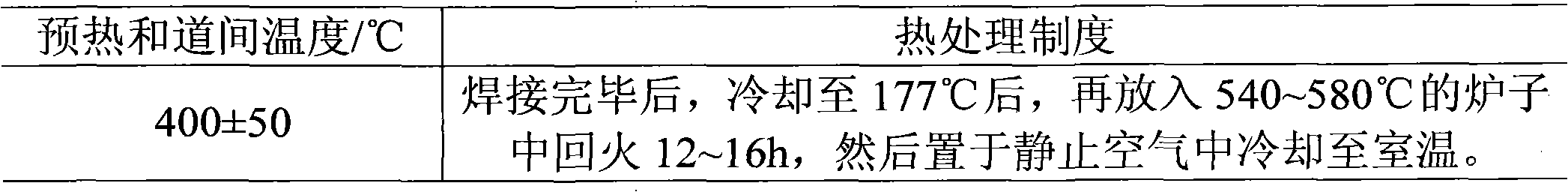

Surfacing electrode for repairing hot forged mould

InactiveCN101898284AExcellent welding performanceImprove yieldWelding/cutting media/materialsSoldering mediaSolid componentSlag

The invention discloses a surfacing electrode for repairing a hot forged mould, which uses a low-carbon steel H08A core wire conforming to the GB / T3429 requirement. The solid component quality content of coating is as follows: 30-40% of marble, 12-20% of fluorite, 1.5-3% of zircon sand, 0-2% of soda ash, 2-5% of silicon epitaxy material, 1-3% of titanium white, 0-3% of flogopite, 1-2% of rare earth fluoride, 3-7% of manganese metal, 2-5% of ferrosilicon, 4-6% of ferrotitanium, 4-8% of chromium metal, 4-8% of ferromolybdenum, 6-12% of metallic nickel and 1-2% of aluminium magnesium alloy. The invention has favorable welding rod performance, smooth welding rod surface, high yield and stable eccentricity; electric arc is easy to ignite and is stable to burn; coating is even to melt, a welding line is attractive in shape, and slag is easy to clean; and a deposition metal weld metal buildup has moderate welding state hardness which reaches the requirements of the hot forged mould, thus improving the service life cycle of the hot forged mould.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

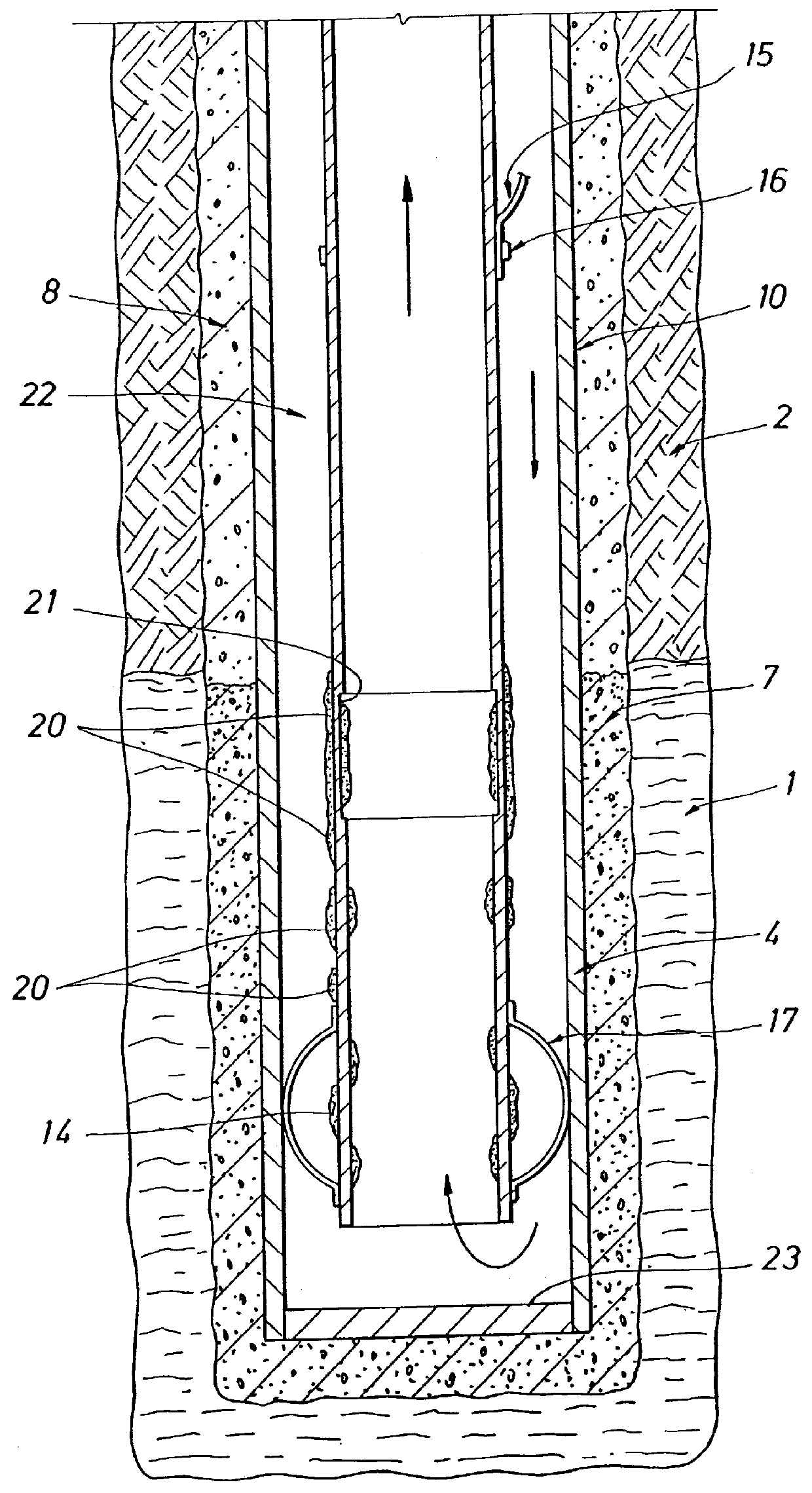

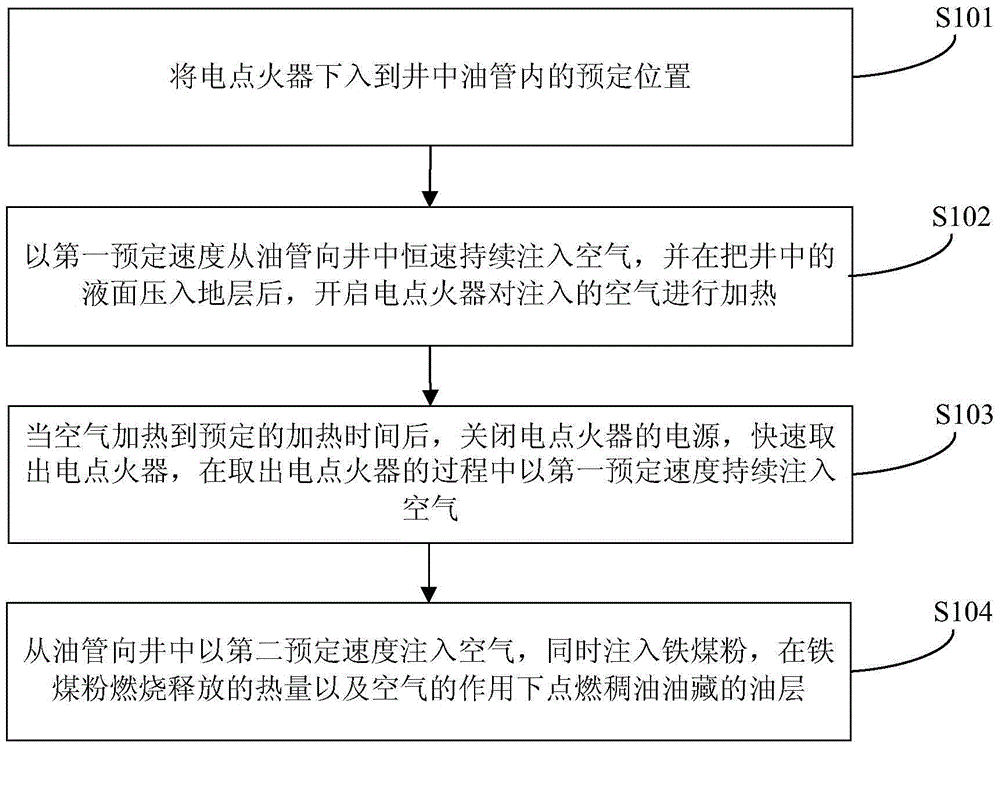

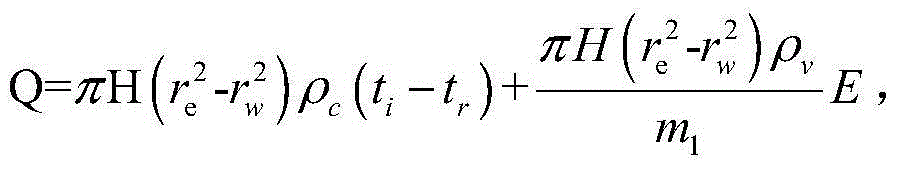

In-situ combustion combustion-supporting ignition method

ActiveCN104453817AReduce moisturePlay the role of profile control and channel sealingFluid removalElectricityHeating time

The invention discloses an in-situ combustion combustion-supporting ignition method. The method comprises the steps that an electric igniter is tripped in the preset position in an oil tube in a well; air is continuously injected into the well from the oil tube at a first preset speed, and after a liquid level in the well is pressed into a stratum, the electric igniter is started to heat the injected air; after the air is heated by the preset heating time, a power source of the electric igniter is turned off, the electric igniter is taken out, and the air is continuously injected at the first preset speed in the process of taking out the electric igniter; air is injected into the well from the oil tube at a second preset speed, meanwhile, iron pulverized coal is injected, and an oil layer of a heavy oil reservoir is ignited under the action of heat released by combustion of the iron pulverized coal and the air. Through the electric igniter, the oil layer is preheated, and water of near bore zones is reduced. The iron pulverized coal has the functions of profile correction and channeling blocking, combustion products are stored in holes, a gas entry profile continues to be adjusted, ignition is facilitated better, gas channeling is reduced, and meanwhile fast ignition is achieved.

Owner:PETROCHINA CO LTD

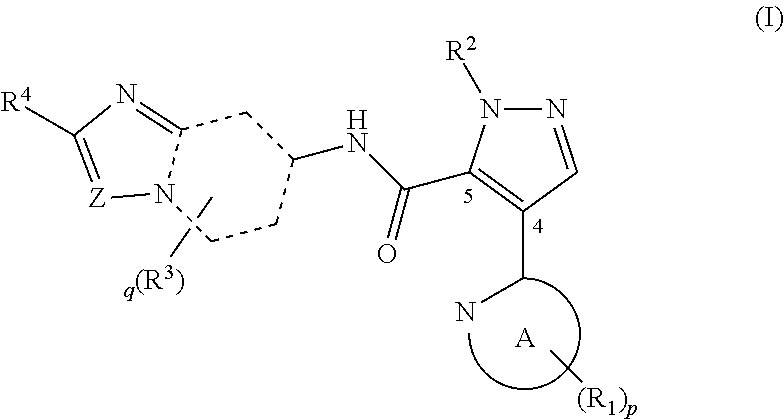

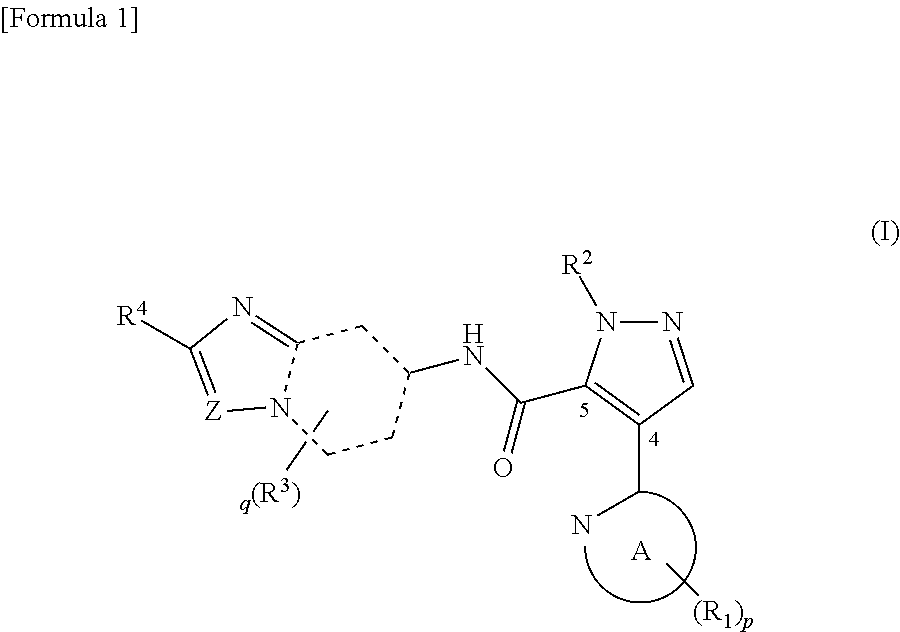

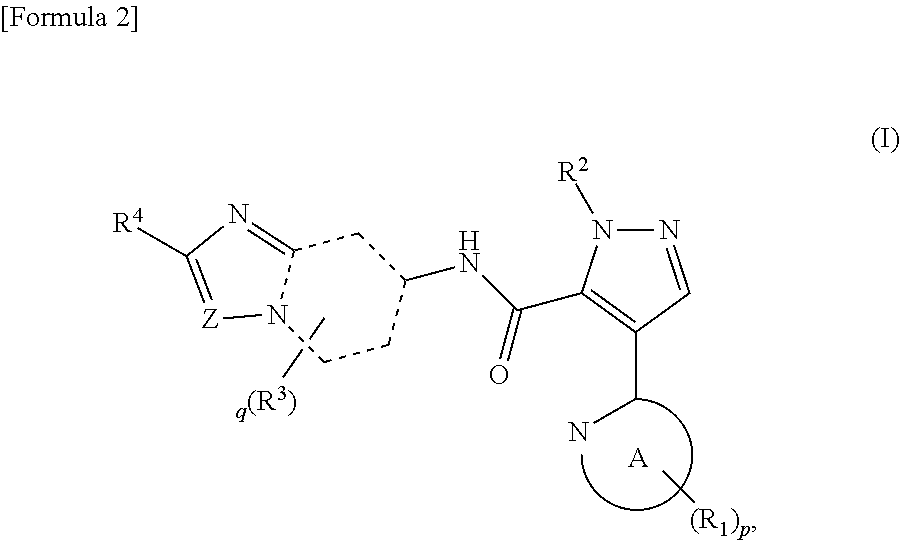

Novel pyrazole derivative

It has been desired to develop a pharmaceutical composition, which is used in agents for preventing and / or treating various diseases related to PDE10 (e.g. mental disorder and neurodegenerative disorder). The present invention provides: compounds having PDE10 inhibitory effect, in particular, compounds having a 4-heteroarylpyrazole-5-carboxylic acid amide structure represented by the following formula (I), or their pharmaceutically acceptable salts, or their solvates; pharmaceutical compositions comprising, as active ingredients, the compounds, or their pharmaceutically acceptable salts, or their solvates; and medical use of the compounds, or their pharmaceutically acceptable salts, or their solvates.

Owner:MOCHIDA PHARM CO LTD

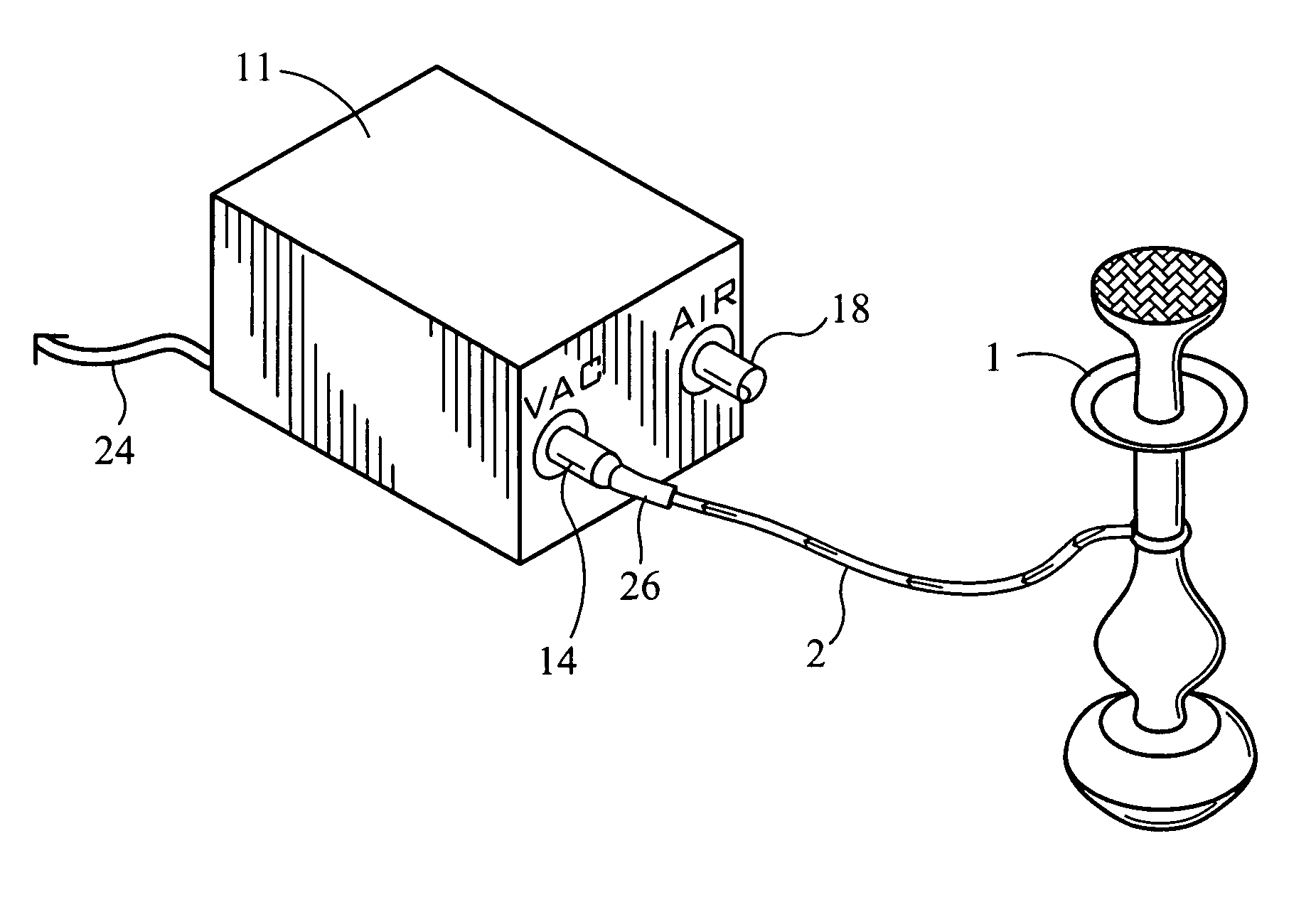

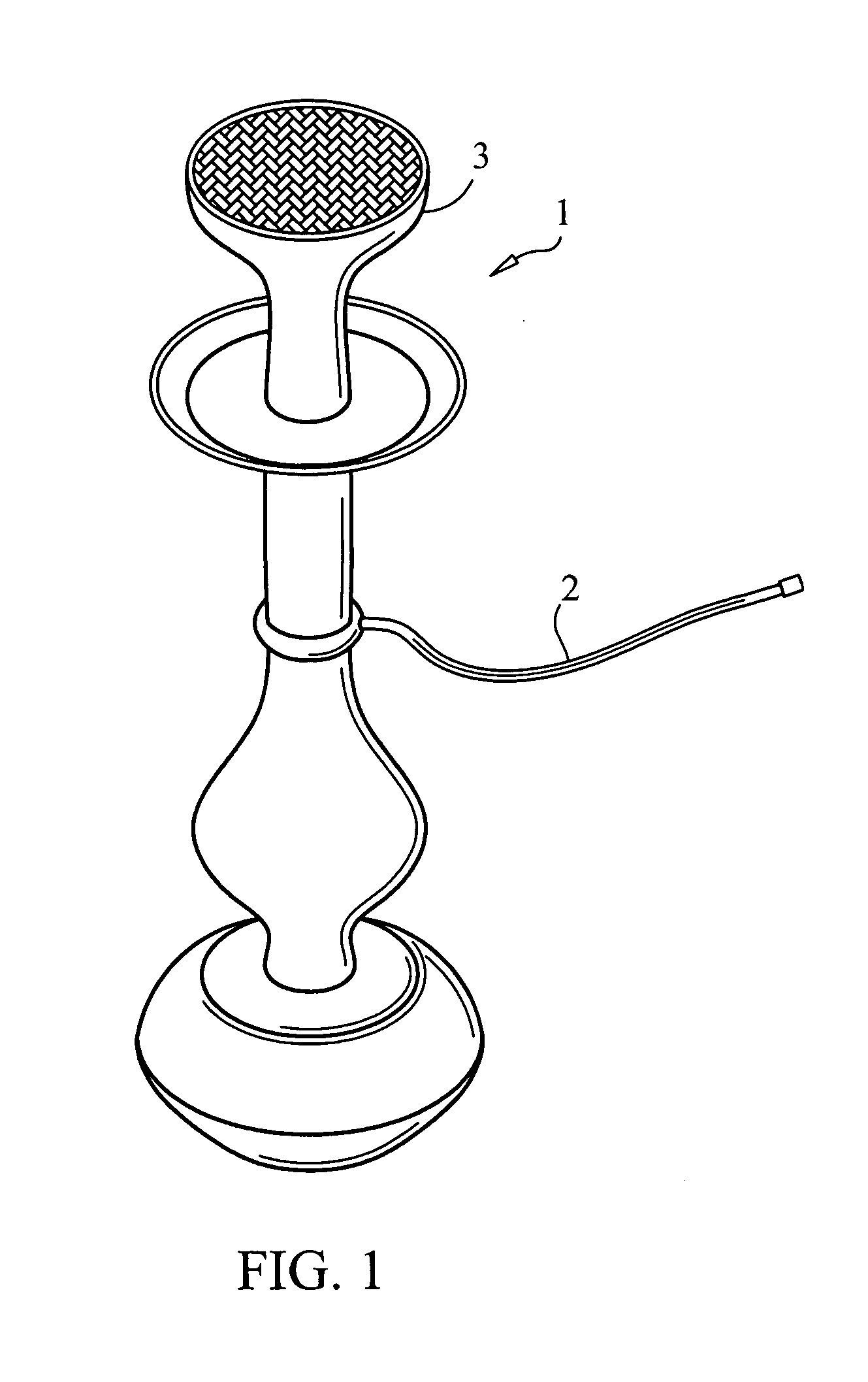

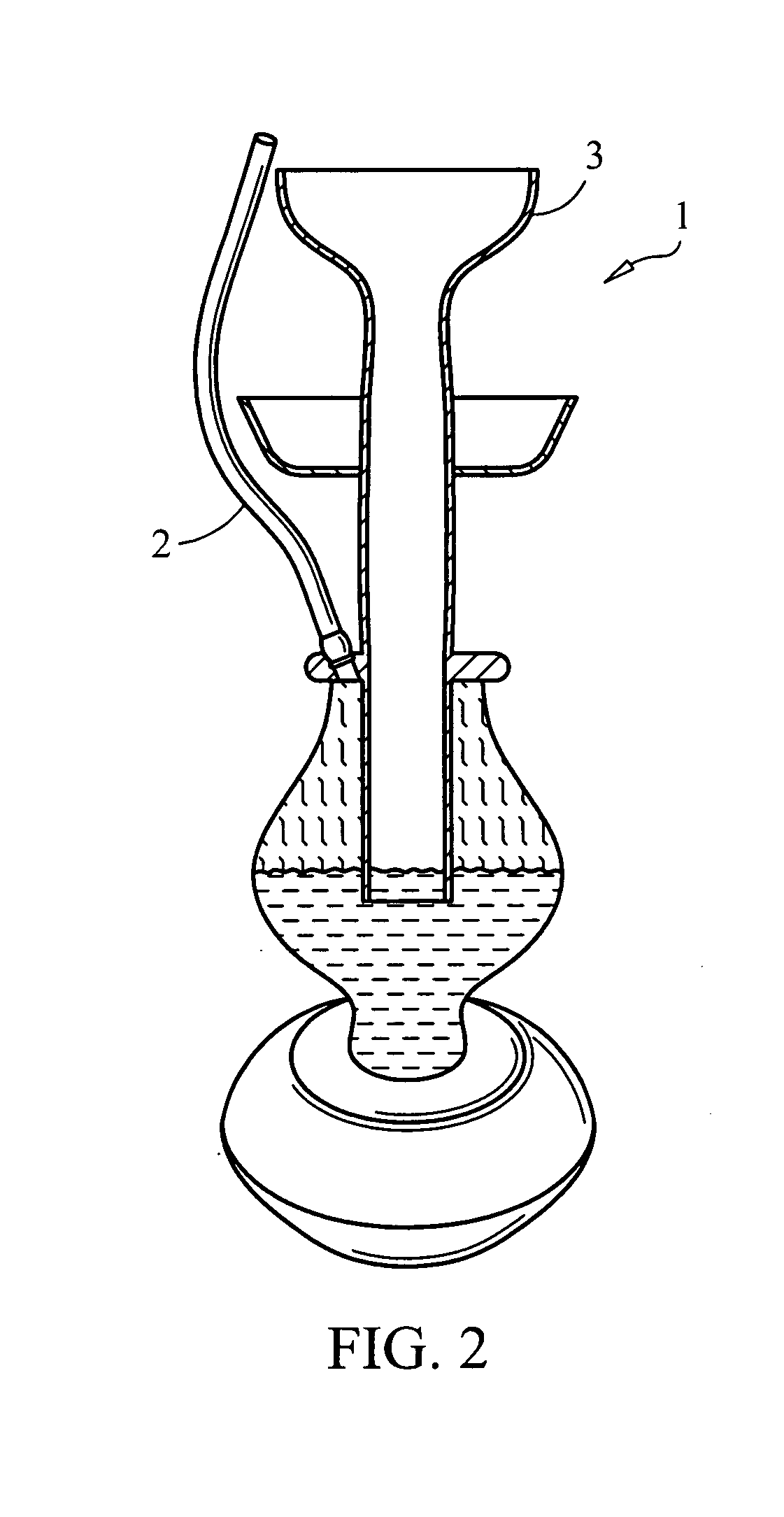

Water pipe starter and cleaning device

InactiveUS20070261194A1Accelerate ignitionEasy to igniteMechanical cleaningPressure cleaningFree spaceWater pipe

Owner:TANNOUS BISHARA

In situ self-spread welding repair method of aluminum mother plate

InactiveCN101474719AQuick Weld RepairUnique process methodAlumino-thermic welding apparatusFusible plugGraphite

The invention relates to a welding repairing method for aluminum parent metal, in particular to an in-situ self-propagting welding repairing method for aluminum parent metal. The method is characterized in that: self-propagting medical preparation is firstly prepared, and cleaning, oil removal, oxide film removal are carried out on parts to be welded of aluminum parent metal, then welding fluid is coated on a groove face; according to the shape and size of the groove, a mould with lower holes is made by graphite and is fixed on the upper part of the groove, and a graphite plate is clamped at the two sides of the groove by a clamping device and forms a melting chamber together with the mould, an automatic fusible plug is laid at the bottom part of the mould, then the self-propagting medical preparation is poured into the mould, pyrophoric powder is coated above the self-propagting medical preparation, after the parent metal is preheated to a certain temperature, the pyrophoric powders is lighted, thus realizing in-situ self-propagting welding repairing of the aluminum parent metal. By the method provided by the invention, intense magnetic field interference can be avoided, welding quality can be improved, labor intensity can be relieved, and the operation is easy and rapid.

Owner:QINGTONGXIA ALUMINUM IND GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com