Patents

Literature

33 results about "Neck diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The maximum allowed difference between the diameter of the case neck and the diameter of the chamber is 0.060 mm (2.4 mil).

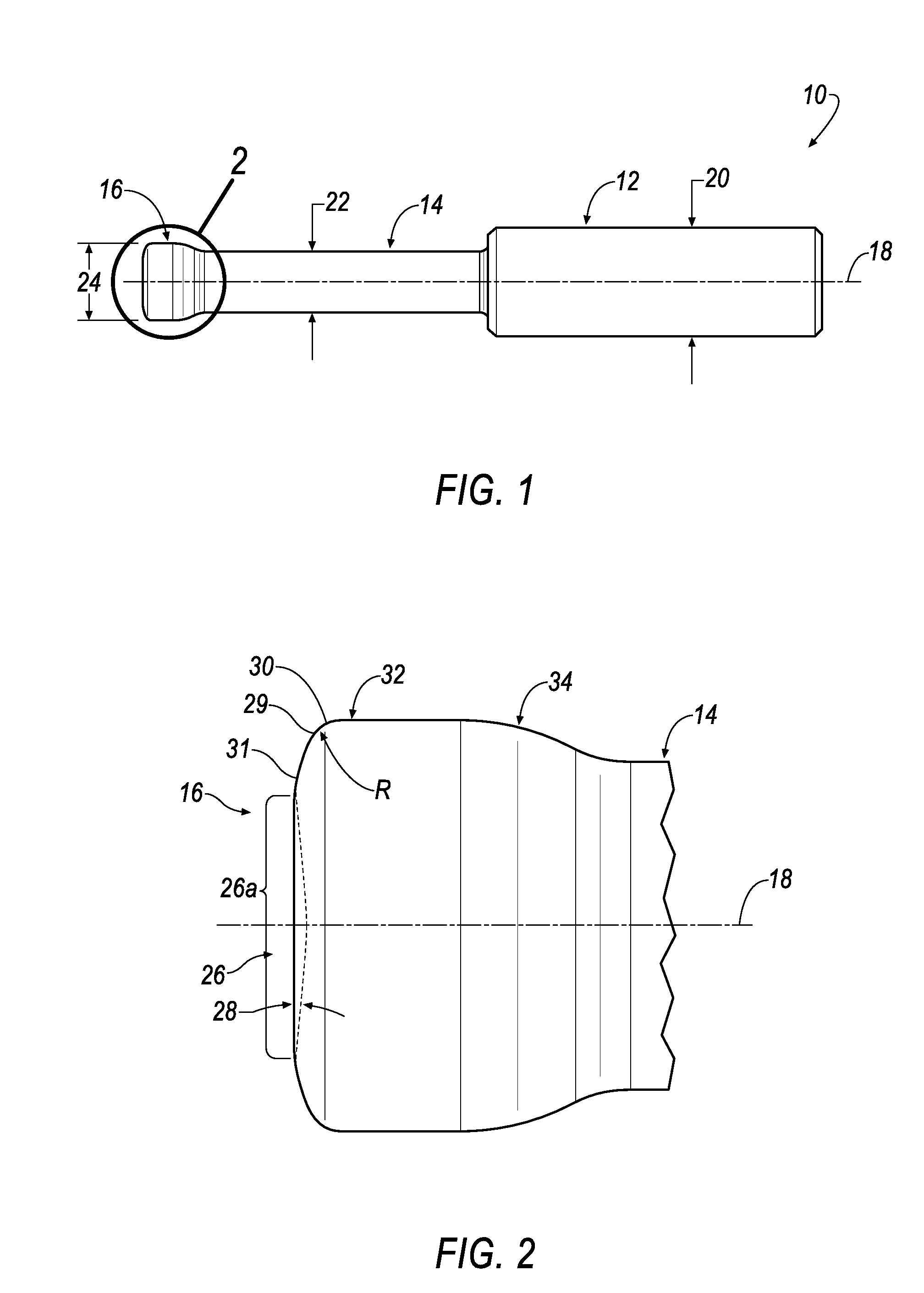

Firearm cartridge and case-less chamber

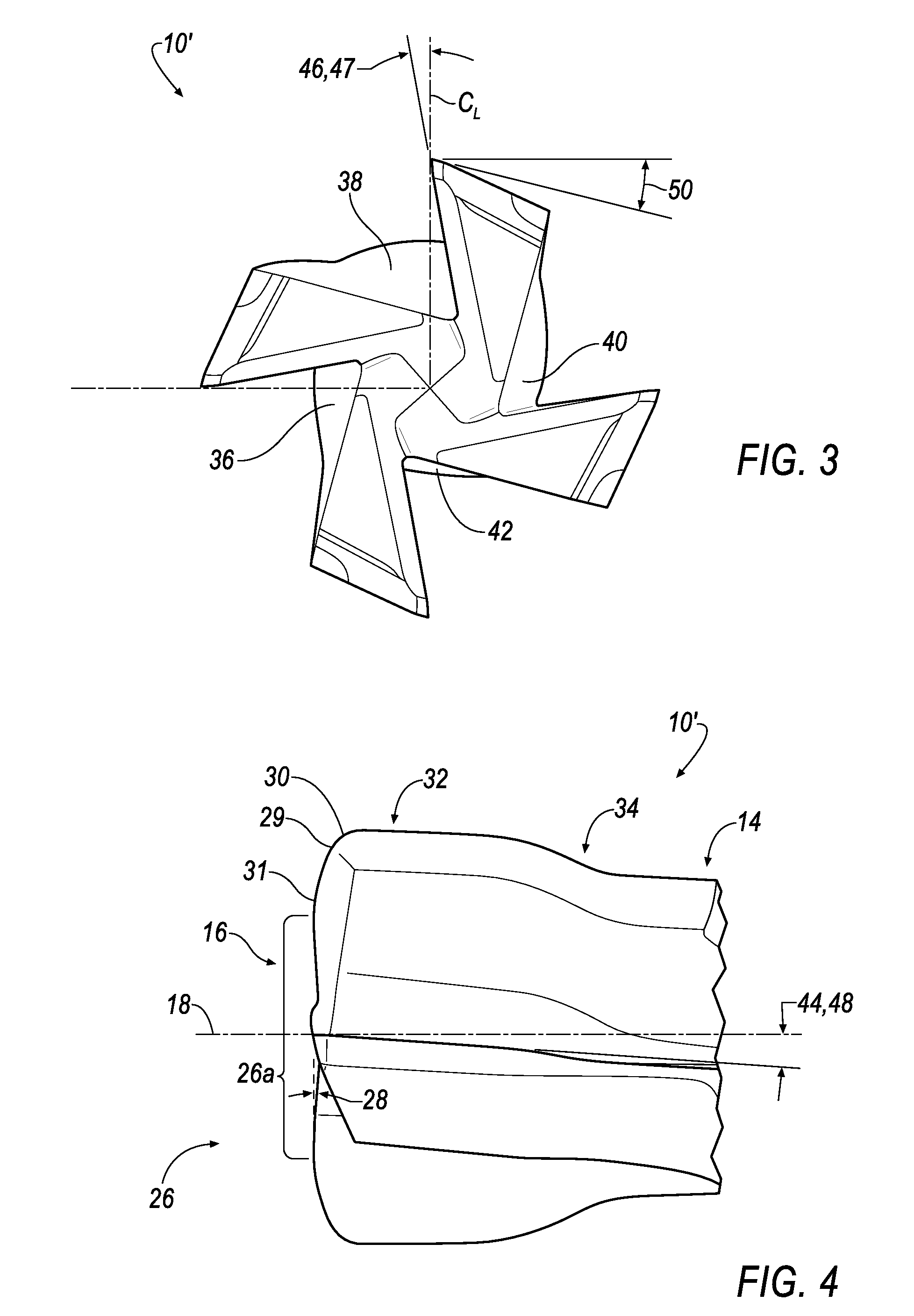

InactiveUS7086336B2Improve combustion efficiencyGreat primary ignition zoneAmmunition projectilesShotgun ammunitionCombustionDiameter ratio

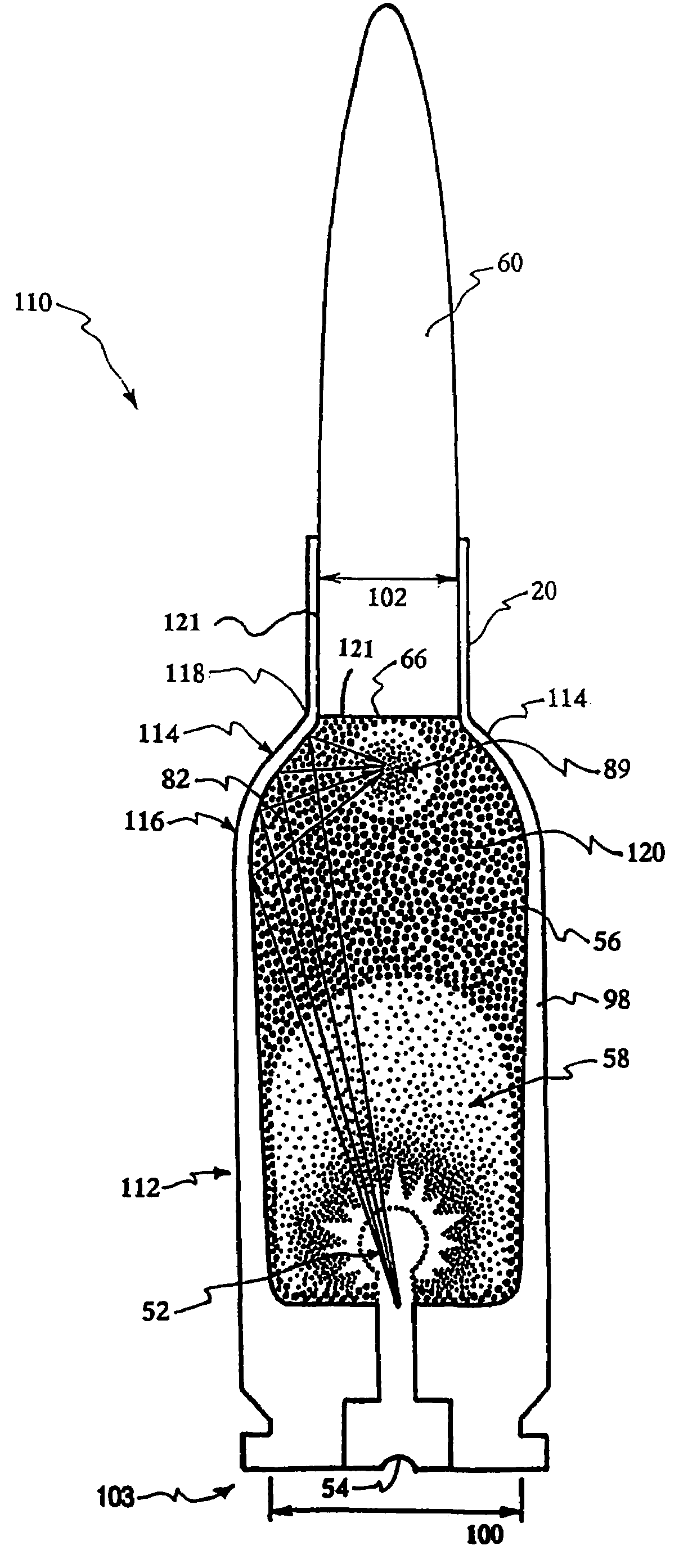

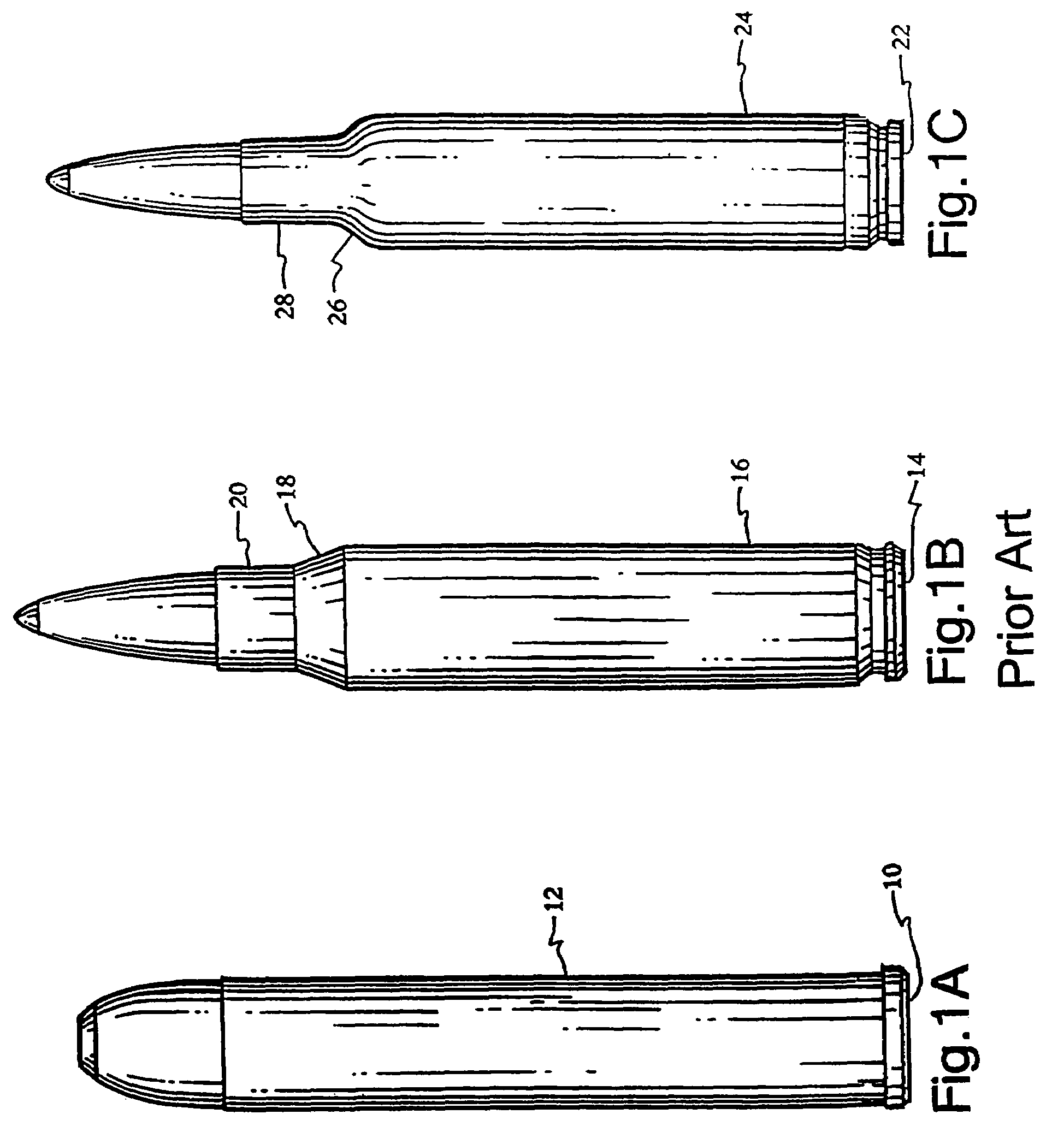

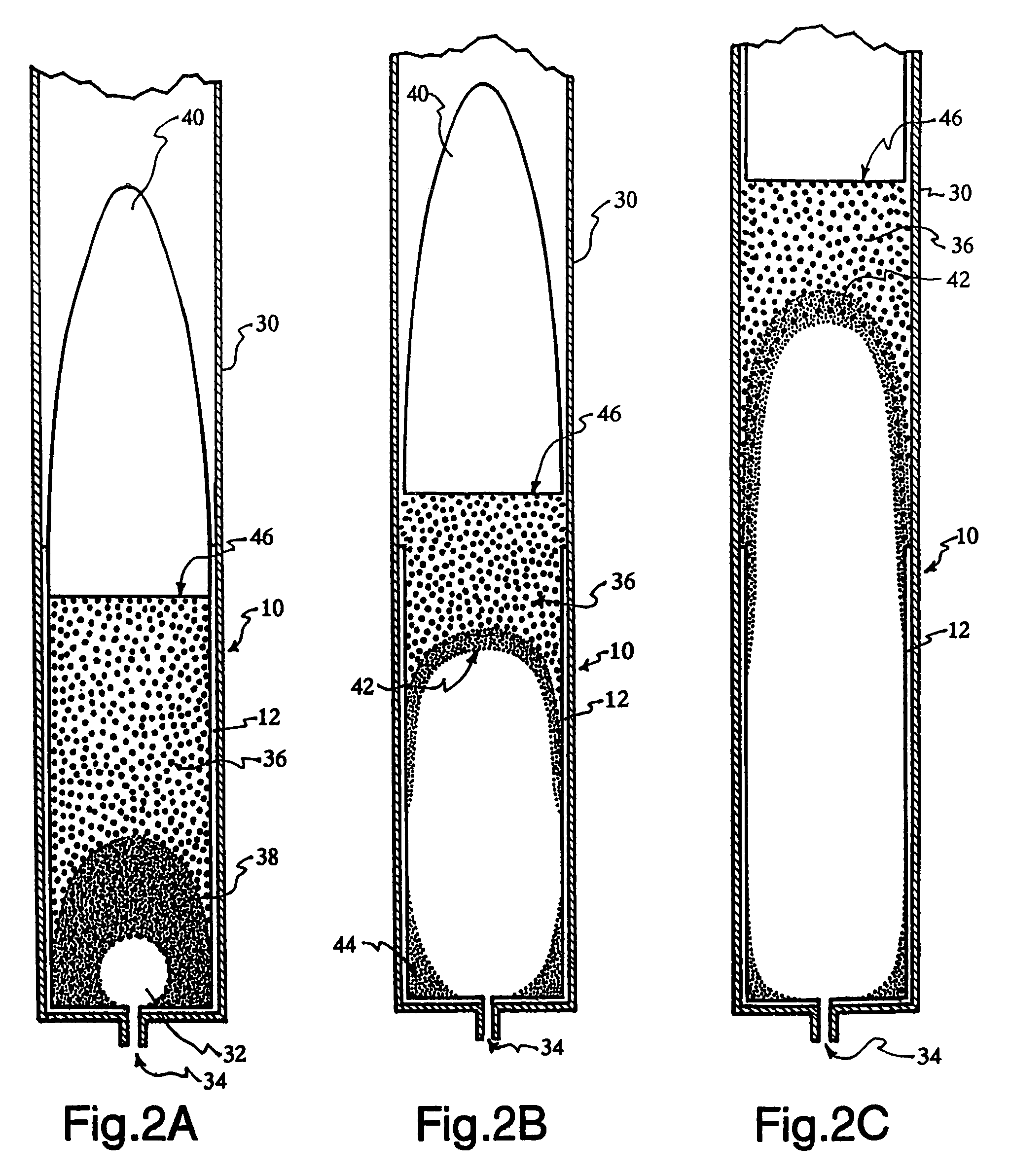

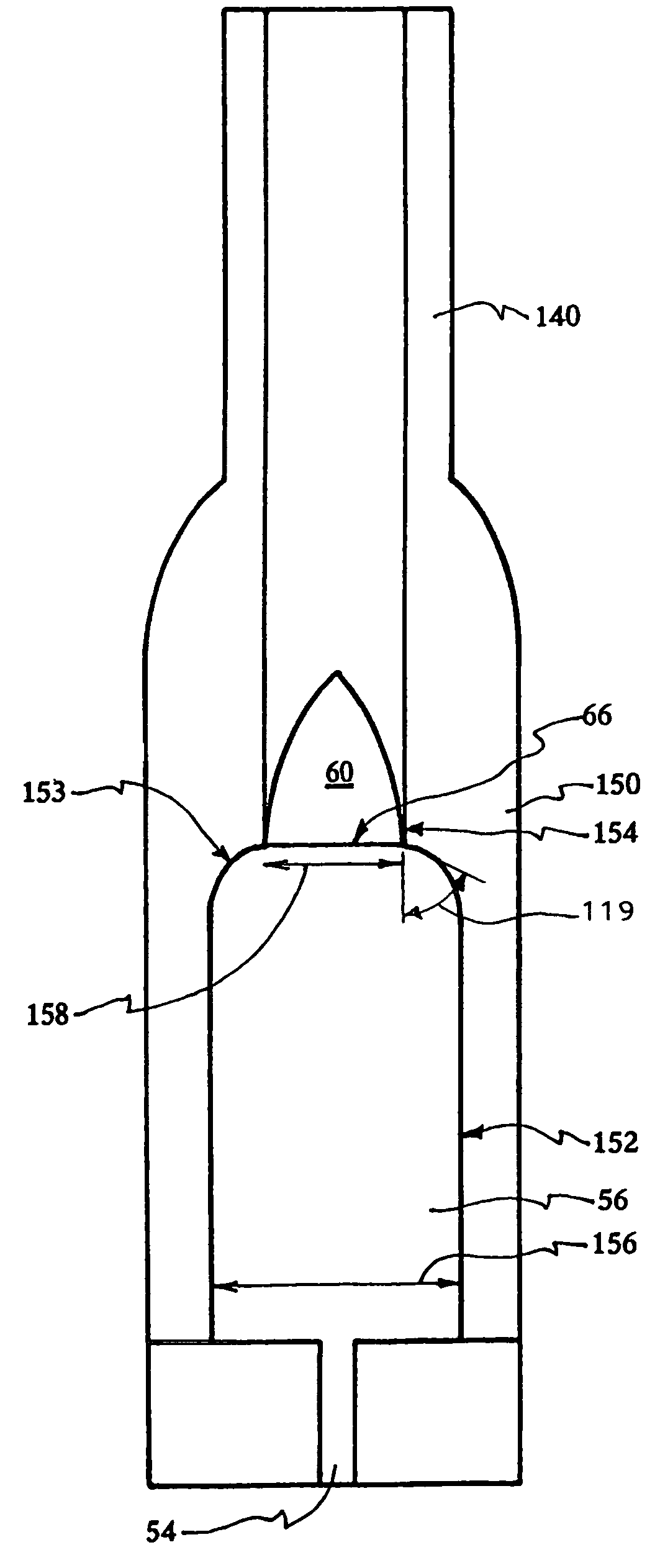

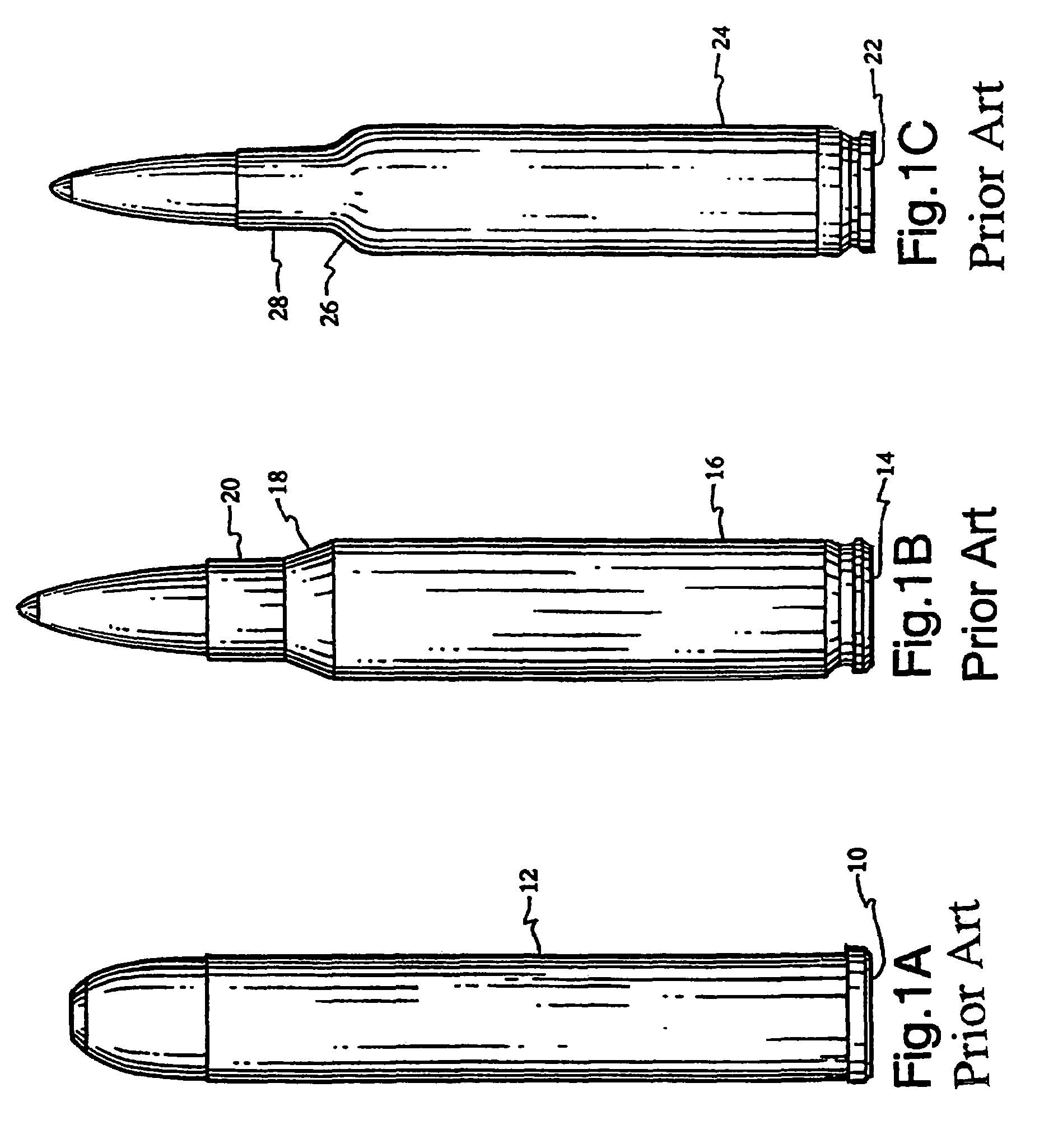

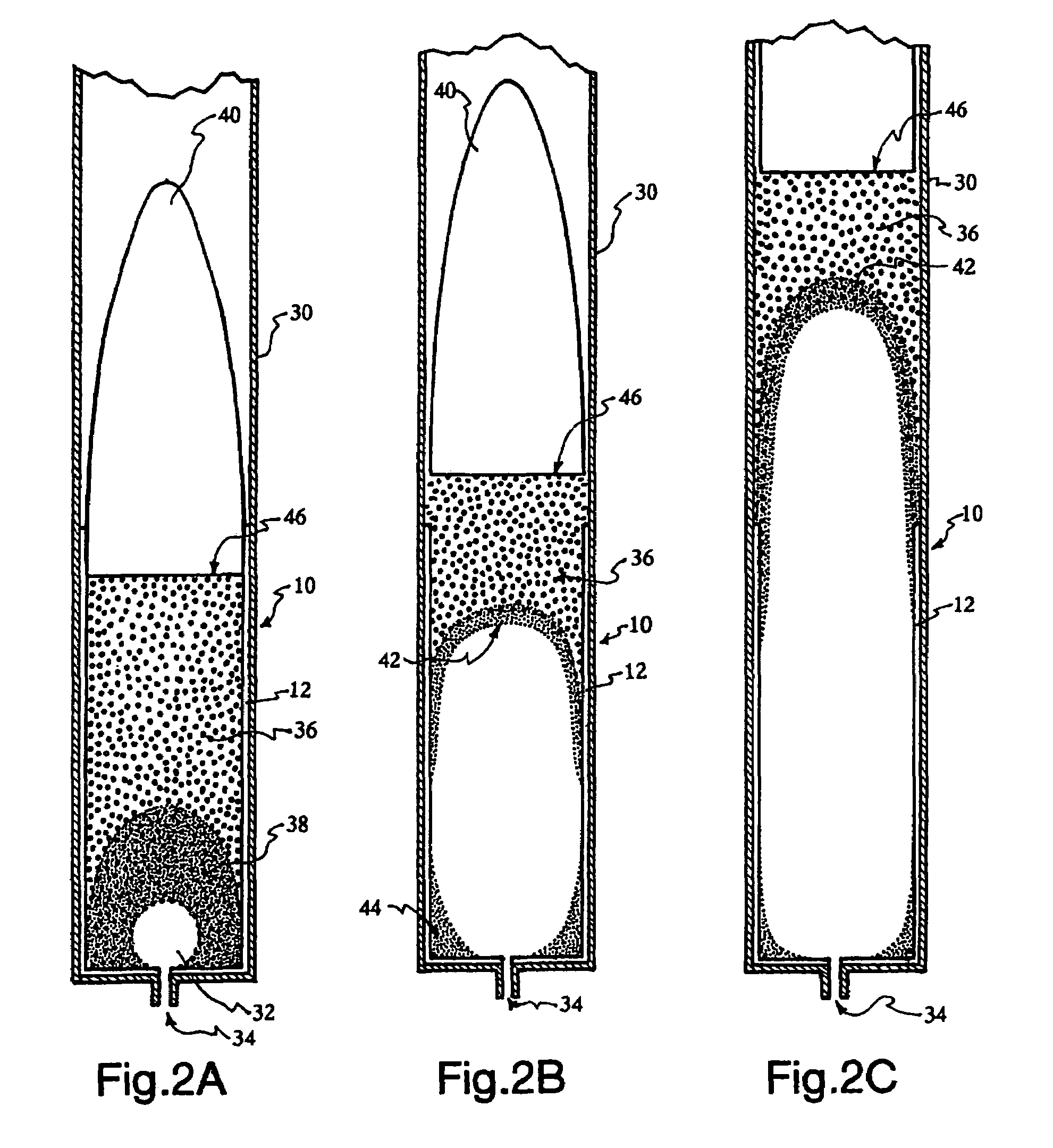

A firearm cartridge has a case configured with a relatively straight-walled portion and a shoulder portion for housing a quantity of propellant. The case further includes a neck for retaining a bullet. The straight-walled portion defines a base cavity having an interior base diameter. The interior base diameter is approximately twice or more the neck diameter. The diameter ratios of the base and neck optimize combustion efficiency to reduce heat and acceleration losses. The cartridge body cavity is sized and configured to contain a sufficient quantity of propellant such that igniting the propellant causes formation of a propellant plug having a diameter that is approximately the diameter of the bullet, and wherein the propellant plug shears free from unburned propellant that is disposed adjacent the relatively straight-walled body portion.

Owner:SUPERIOR BALLISTICS

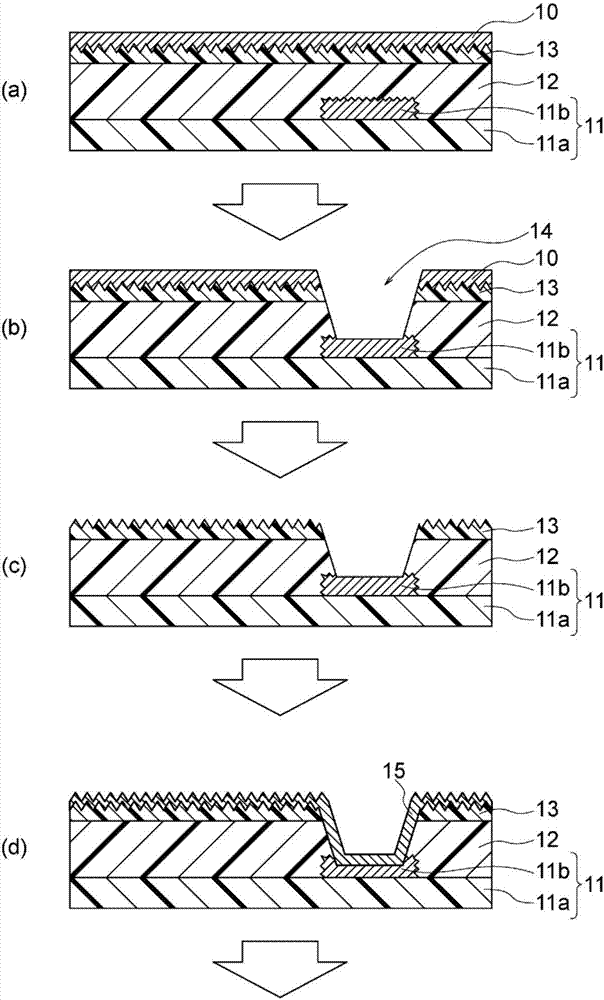

Methods and apparatus for manufacturing metal components with ceramic injection molding core structures

InactiveUS20120186681A1Conservation of manufacturing costIncrease expensesServomotor componentsFoundry mouldsBlow moldingMetal

Preforms for use in injection blow molding processes and such processes are described herein. The preforms can have both a body and a neck wherein the external body diameter of the preform is at most 95% of the external neck diameter. The body comprises internal and external diameters that together form a sidewall, the thickness of which can be greater than 2.0 mm. Also disclosed is a mold for the injection molding of the preform described above.

Owner:SUN DONALD +1

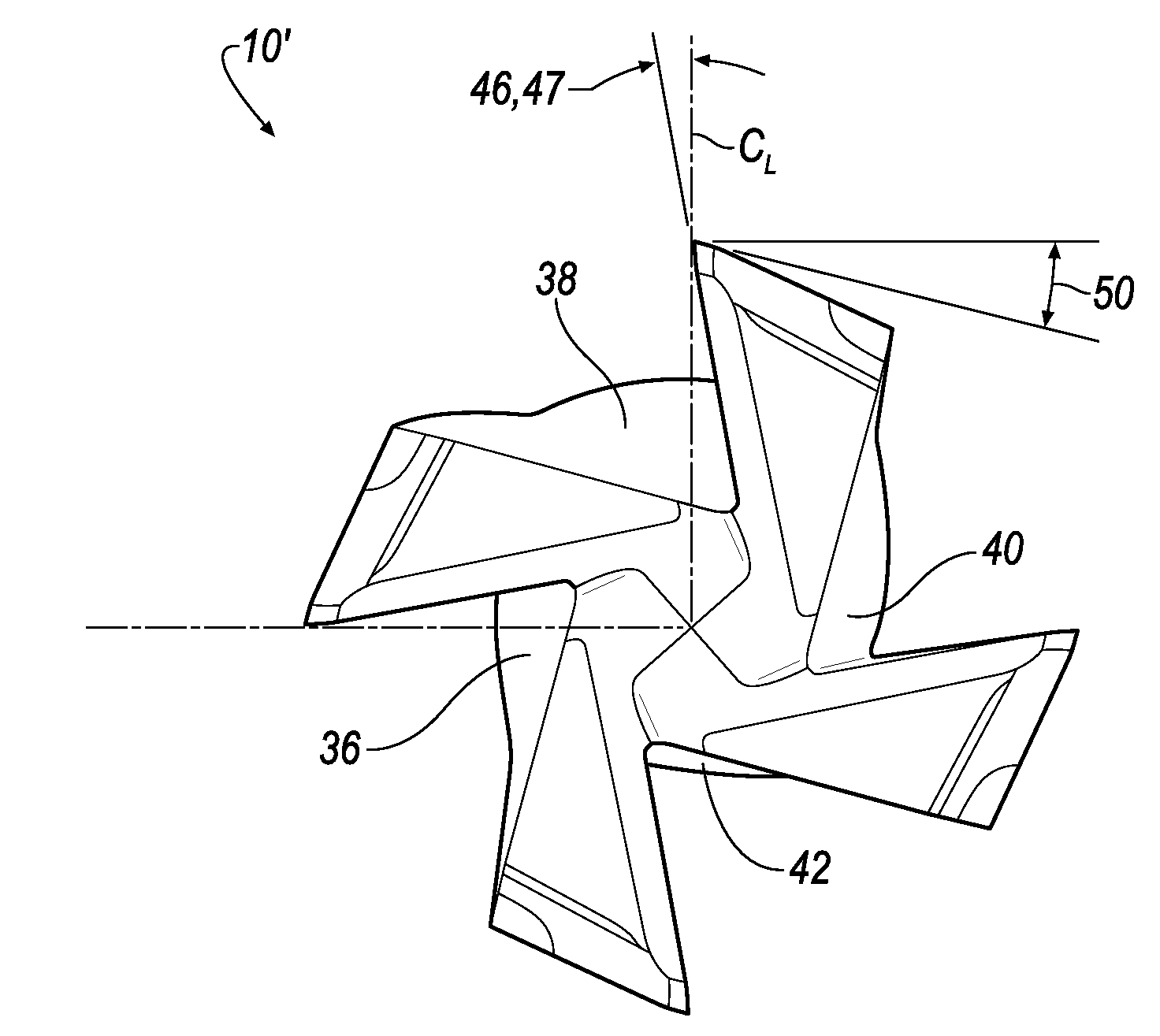

End mill for orbital drilling

A center or non-center cutting end mill for orbital drilling includes a shank having a shank diameter; a neck having a neck diameter; a cutting head having a cutting diameter; a corner radius; a dish angle; and a longitudinal axis, the cutting head including a forward cutting end having a convexly curved section located between the longitudinal axis and the corner radius, wherein the convexly curved section causes material removed from a workpiece to flow radially outward from an initial contact area toward the corner radius, thereby minimizing the accumulation of material in a central portion of the forward cutting end.

Owner:KENNAMETAL INC

Method for preparing (110) float zone silicon crystal

ActiveCN101974779AMeet the requirements for preparing silicon materials for high-efficiency solar cellsMeeting Silicon Material Requirements for High Efficiency Solar CellsPolycrystalline material growthBy zone-melting liquidsSingle crystalEngineering

The invention discloses a method for preparing a (110) float zone silicon crystal. The key point of the technical scheme is that: 1, in the seeding technology, by controlling and adjusting the descending speed of a lower shaft and adjusting the power, the seeding neck diameter is controlled in a range from 2 to 6 mm, wherein the seeding neck diameter is more than or equal to 1.5 times the diameter of a single crystal; 2, in the shouldering technology, by controlling and adjusting the descending speed and rotating speed of the lower shaft and the descending speed and rotating speed of an upper shaft and adjusting the power, the shouldering angle is 50+ / -5 degrees; and 3, in the ending technology, the ending length is more than 1.2 times the diameter of the single crystal, and the minimum tail diameter is less than or equal to 5mm. The method overcomes the defects that the (110) silicon single crystal prepared by the conventional direct pulling method has high impurity content and cannot meet the requirement on the silicon single crystal of a high-efficiency solar cell, and successfully prepares a low-impurity content and long-service life (110) dislocation-free float zone silicon crystal by a floating zone method, wherein the (110) float zone silicon crystal has the dislocation density of less than or equal to 500 units / cm<2> and the minority carrier lifetime of more than or equal to 300us, and meets the requirement of a silicon material for preparing the high-efficiency solar cell.

Owner:ZHONGHUAN ADVANCED SEMICON MATERIALS CO LTD +1

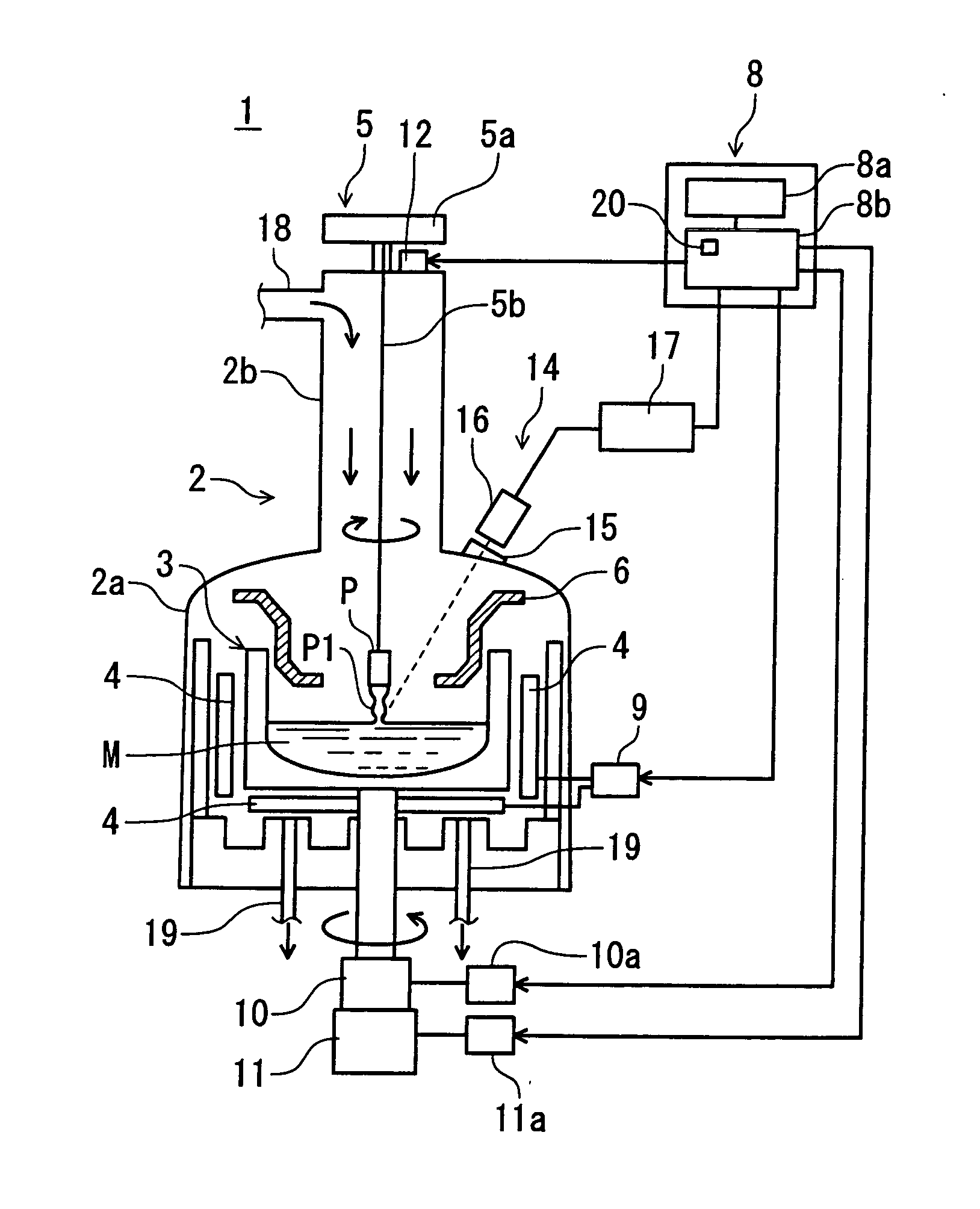

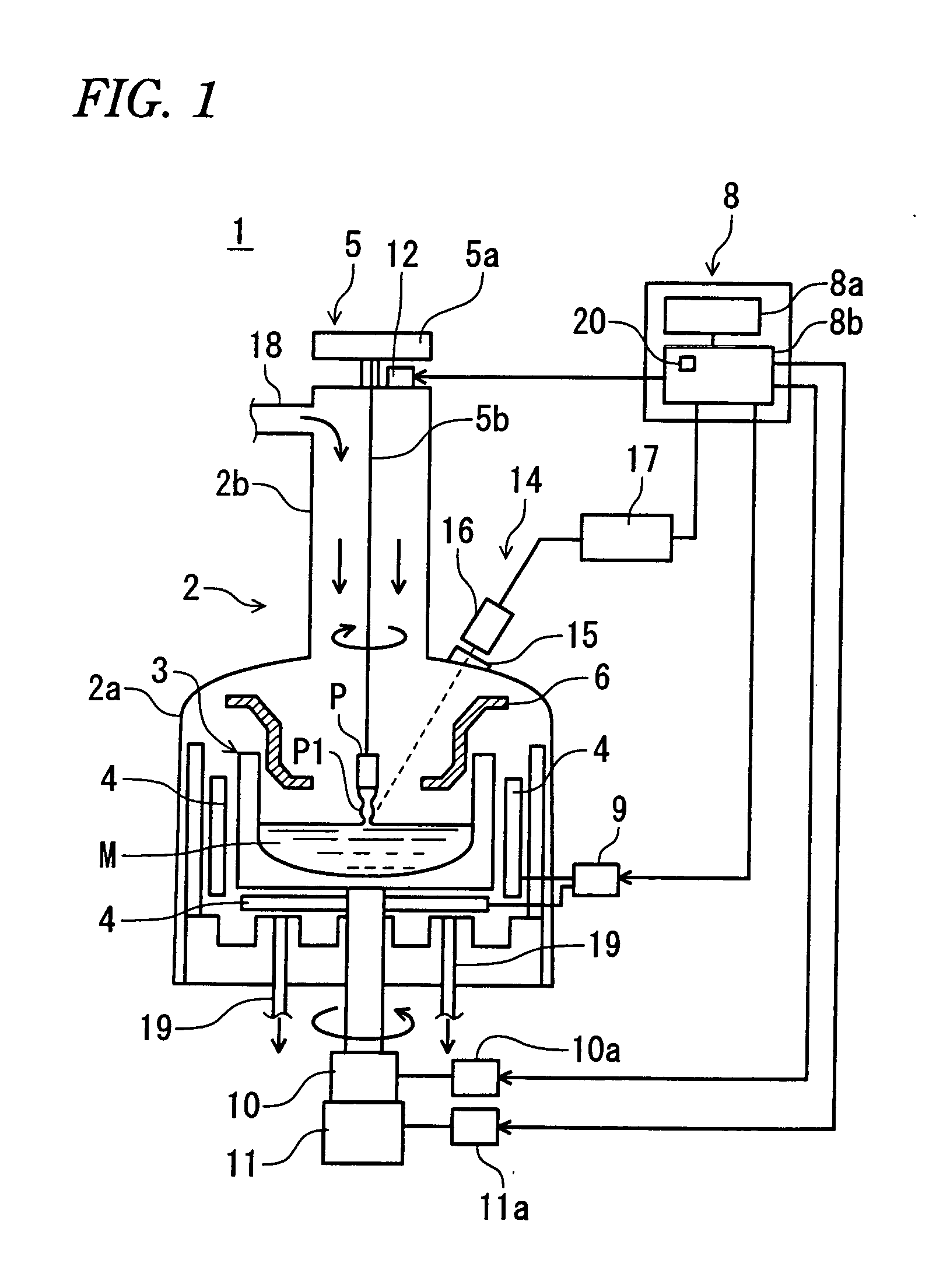

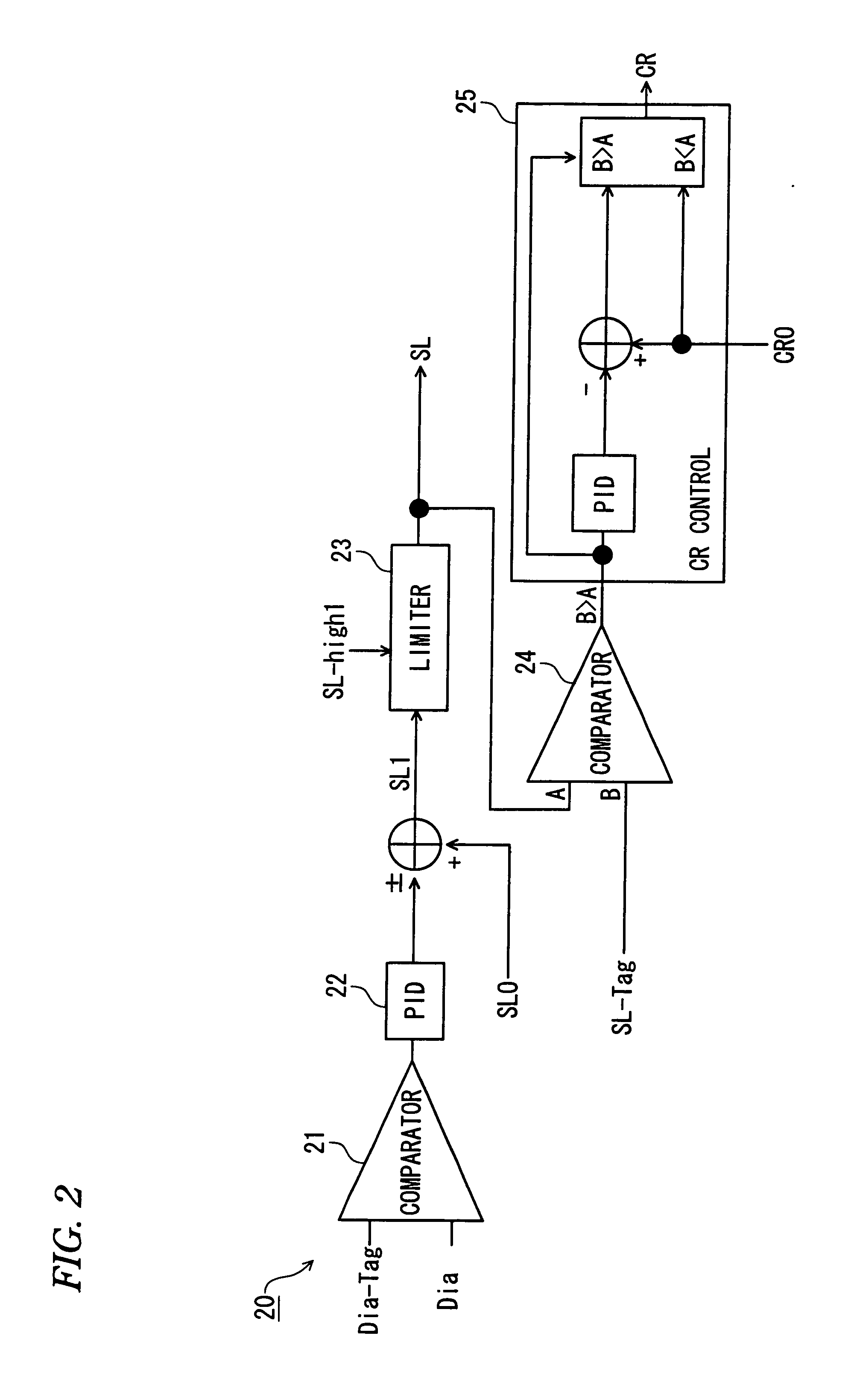

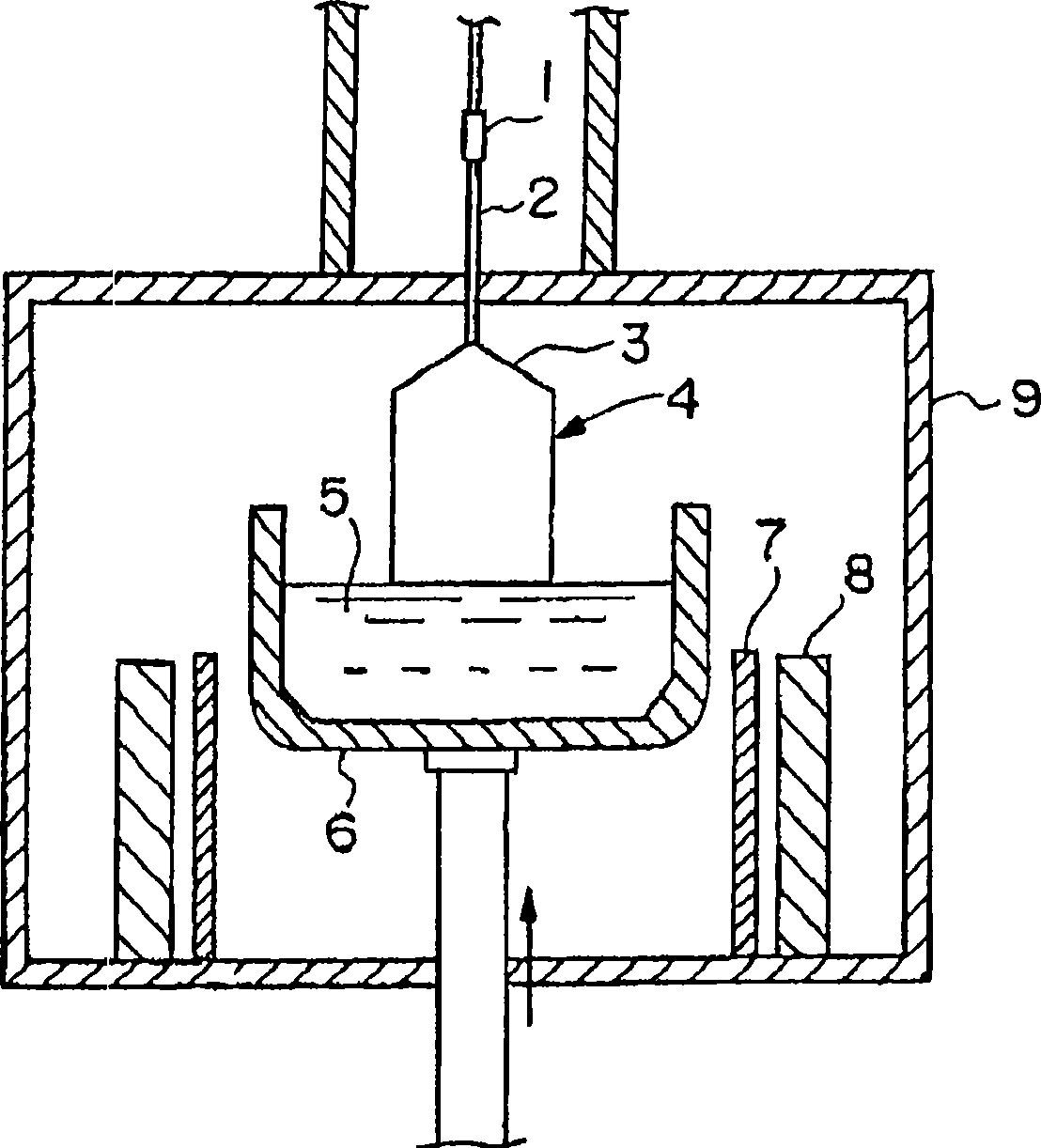

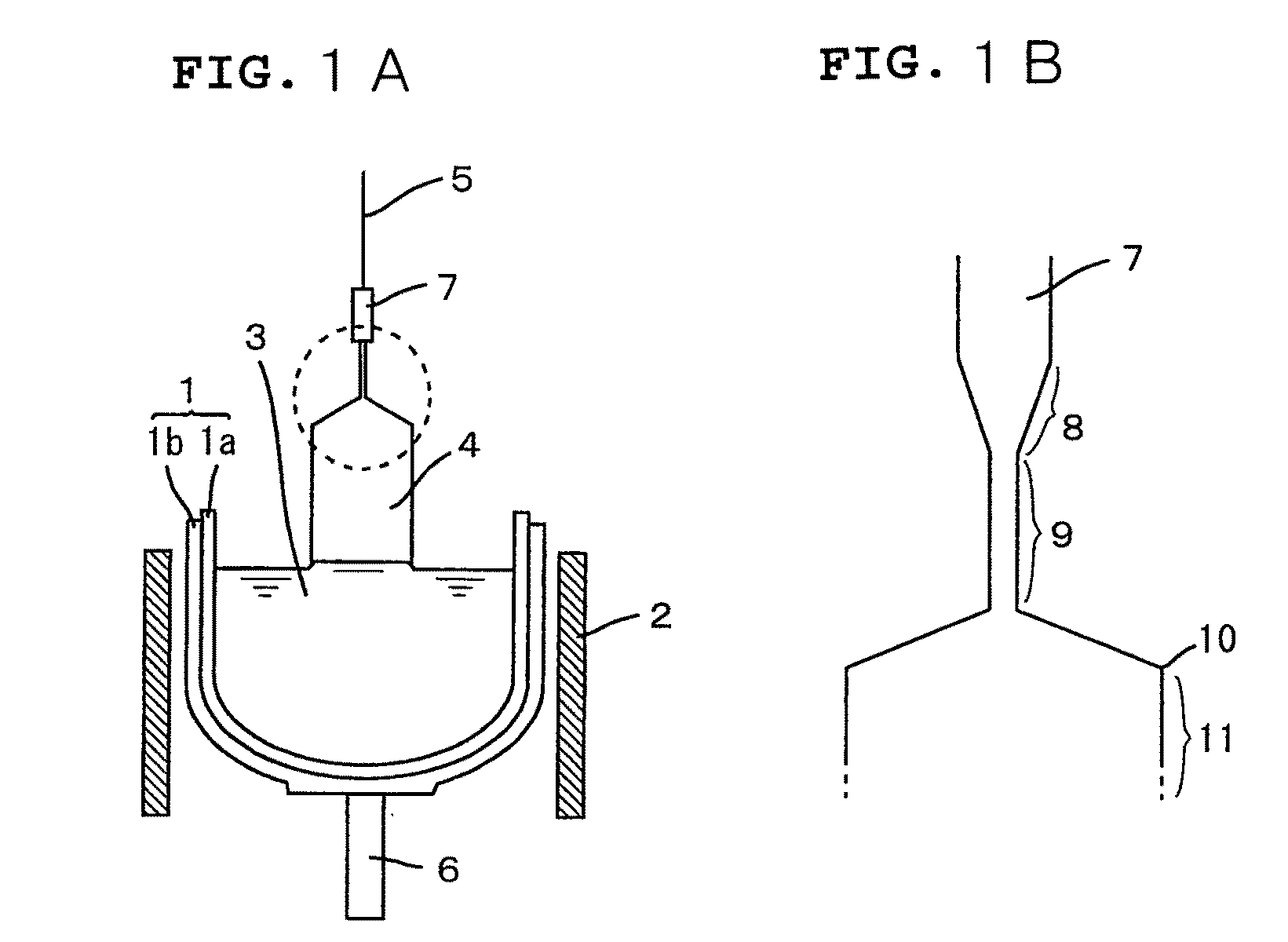

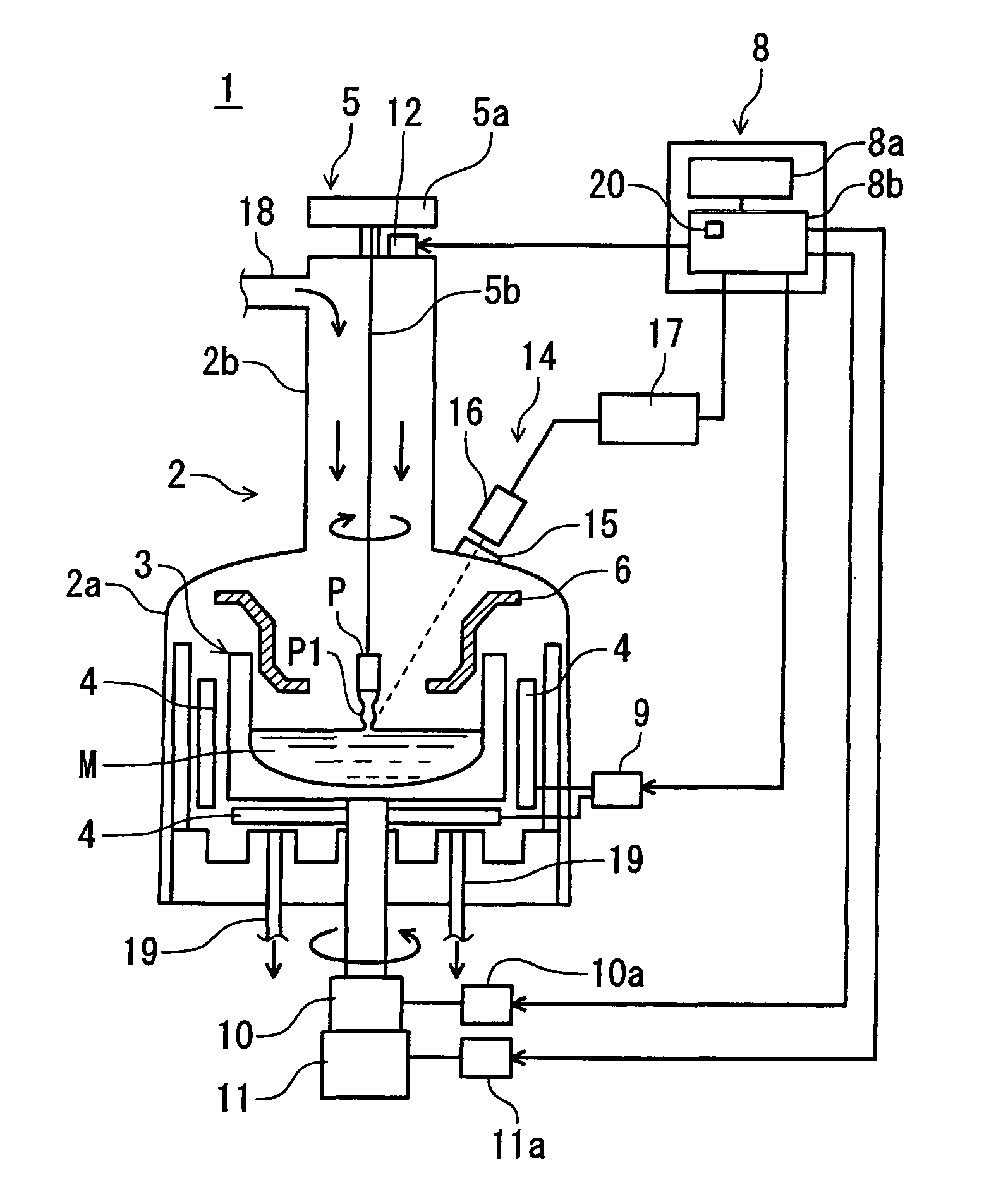

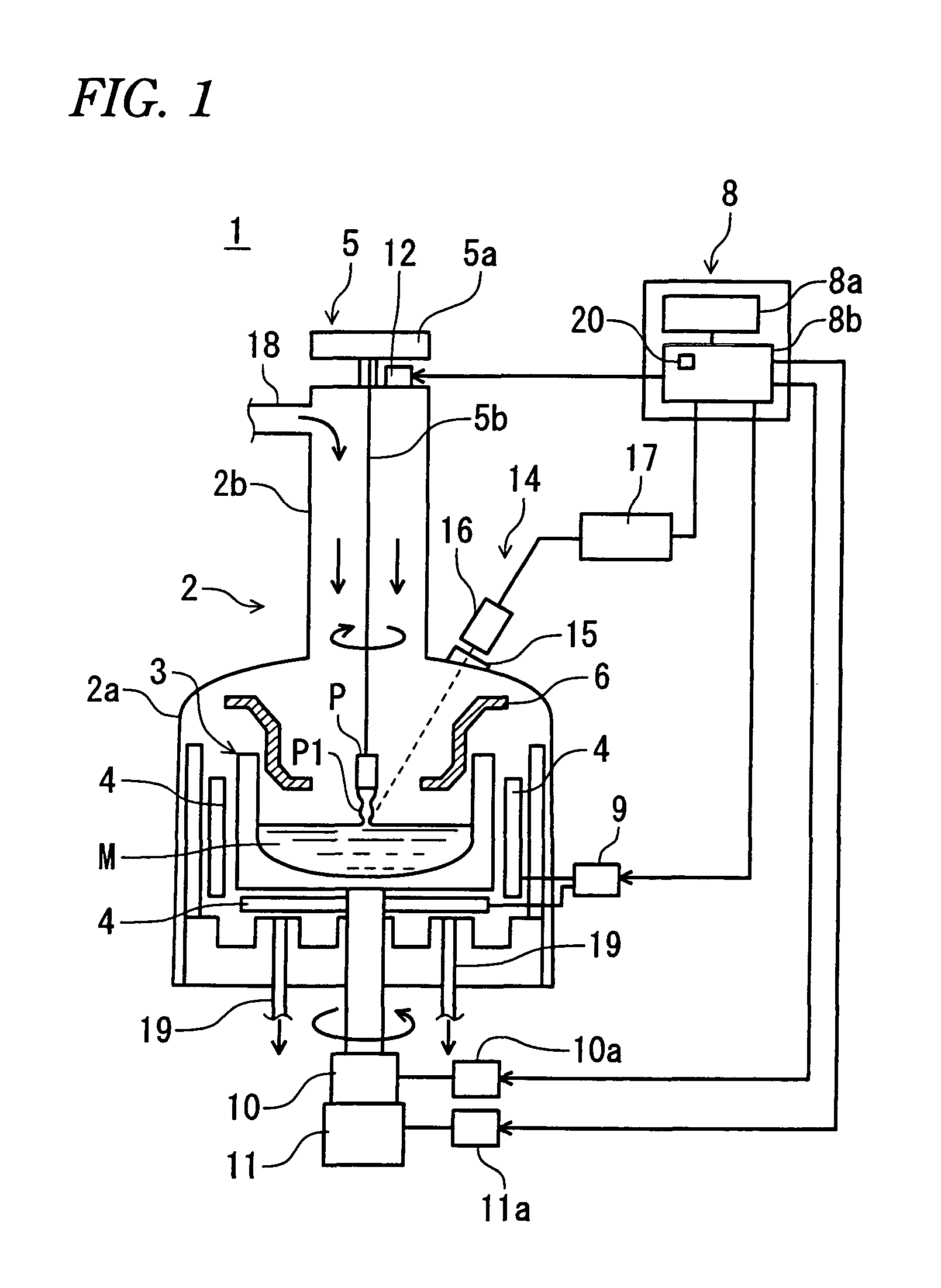

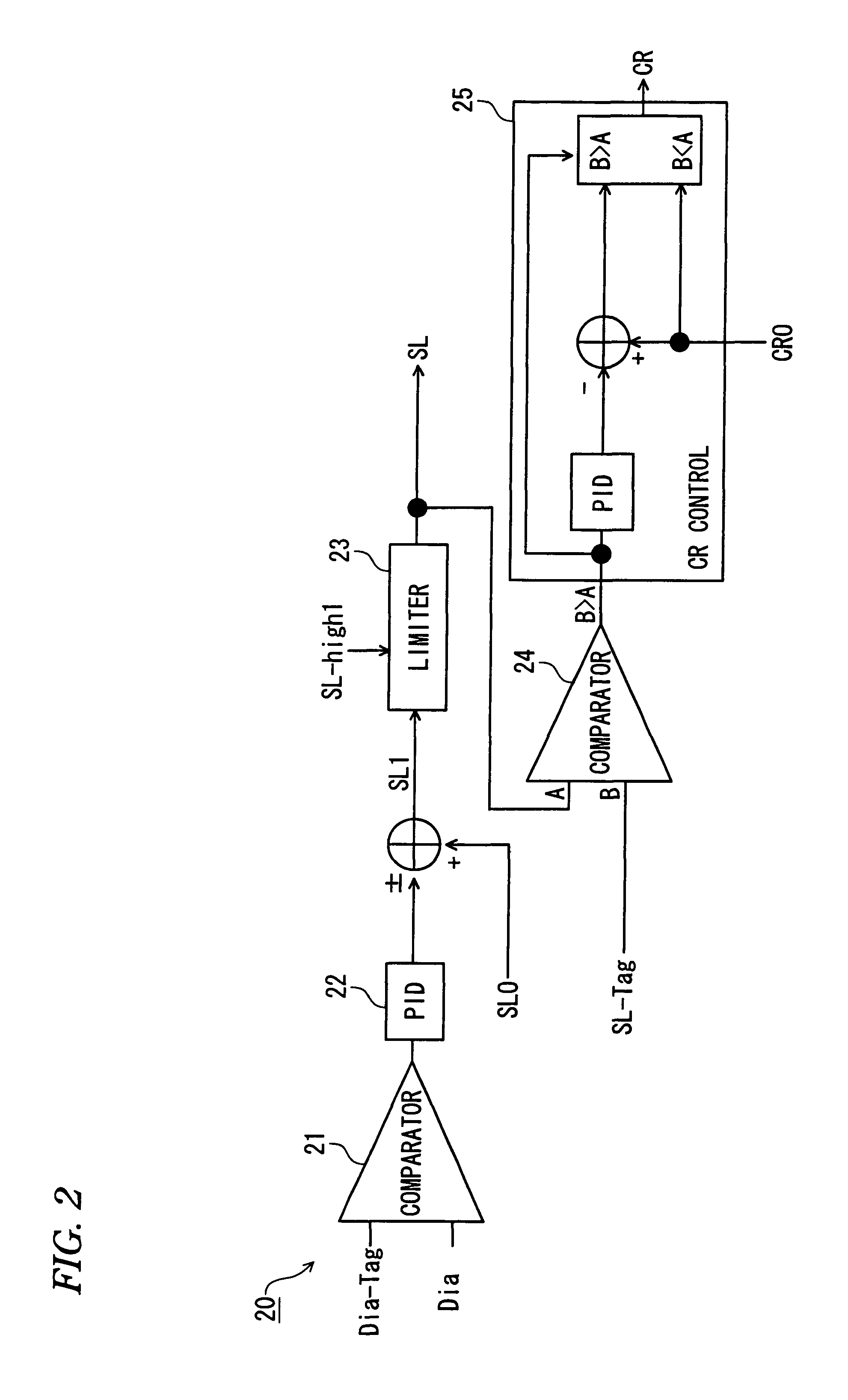

Single crystal pulling-up apparatus and single crystal pulling-up method

ActiveUS20120067272A1Quality improvementAvoid misalignmentPolycrystalline material growthBy zone-melting liquidsCrucibleCzochralski method

According to one exemplary embodiment, a single crystal pulling-up apparatus of pulling-up silicon single crystals by a Czochralski method, is provided with: a neck diameter measuring portion which measures a diameter of a grown neck portion; a first compensation portion which outputs a first compensated pulling-up speed for the seed crystals based on a difference between a measured value of the diameter of the neck portion and a target value of the neck portion diameter previously stored; a second compensation portion which outputs a second pulling-up speed while limiting an upper limit of the first pulling-up speed to a first limit value; and a crucible rotation number compensation portion which lowers the number of a rotation of a crucible at least in a period where the upper limit of the first pulling-up speed is limited to the first limit value.

Owner:GLOBALWAFERS JAPAN

Firearm cartridge and case-less chamber

InactiveUS7210260B1Improve combustion efficiencyGreat primary ignition zoneCartridge ammunitionCombustionDiameter ratio

A firearm cartridge has a case configured with a relatively straight-walled portion and a shoulder portion for housing a quantity of propellant. The case further includes a neck for retaining a bullet. The straight-walled portion defines a base cavity having an interior base diameter. The interior base diameter is approximately twice or more the neck diameter. The diameter ratios of the base and neck optimize combustion efficiency to reduce heat and acceleration losses. The cartridge body cavity is sized and configured to contain a sufficient quantity of propellant such that igniting the propellant causes formation of a propellant plug having a diameter that is approximately the diameter of the bullet, and wherein the propellant plug shears free from unburned propellant that is disposed adjacent the relatively straight-walled body portion.

Owner:SUPERIOR BALLISTICS

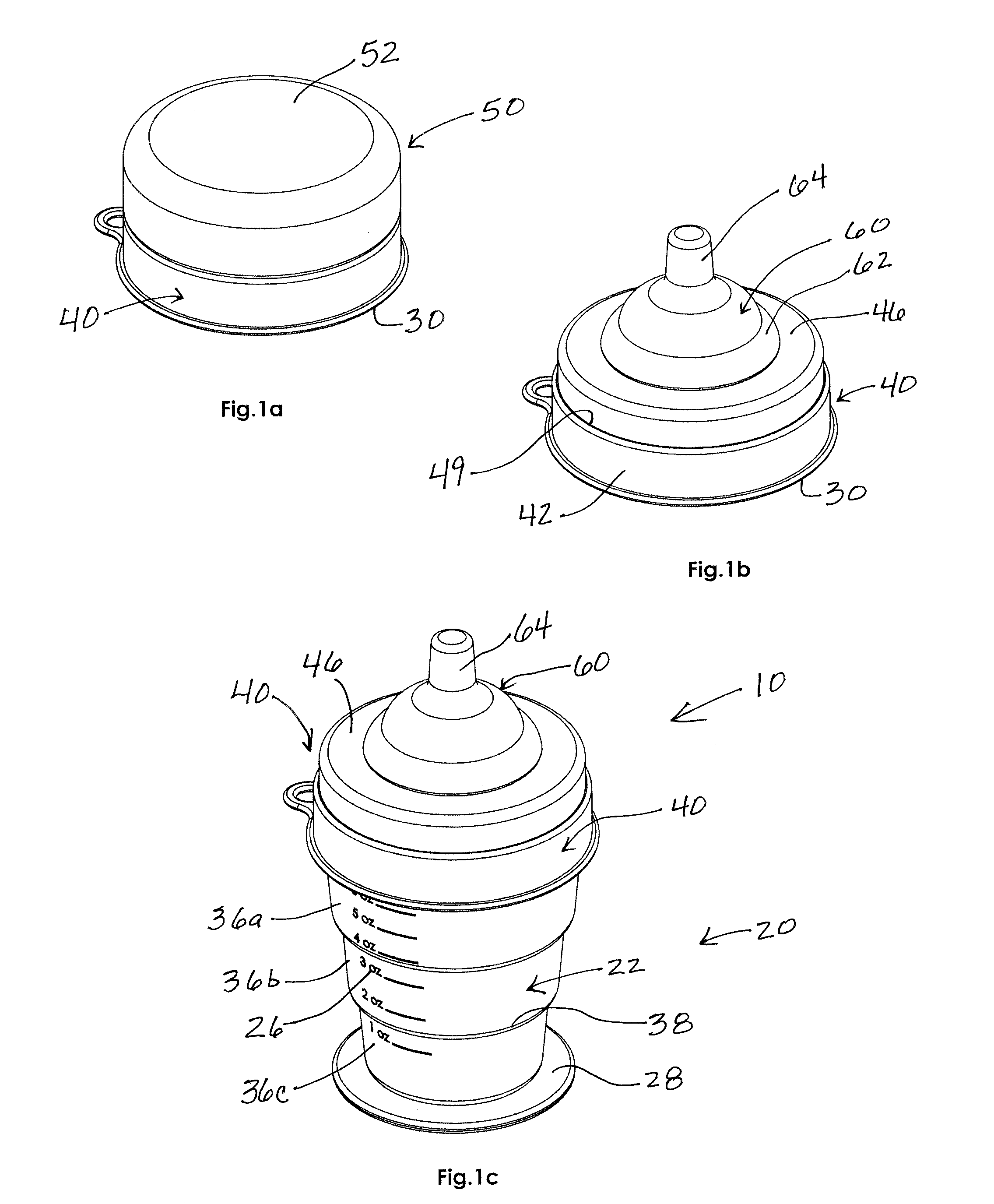

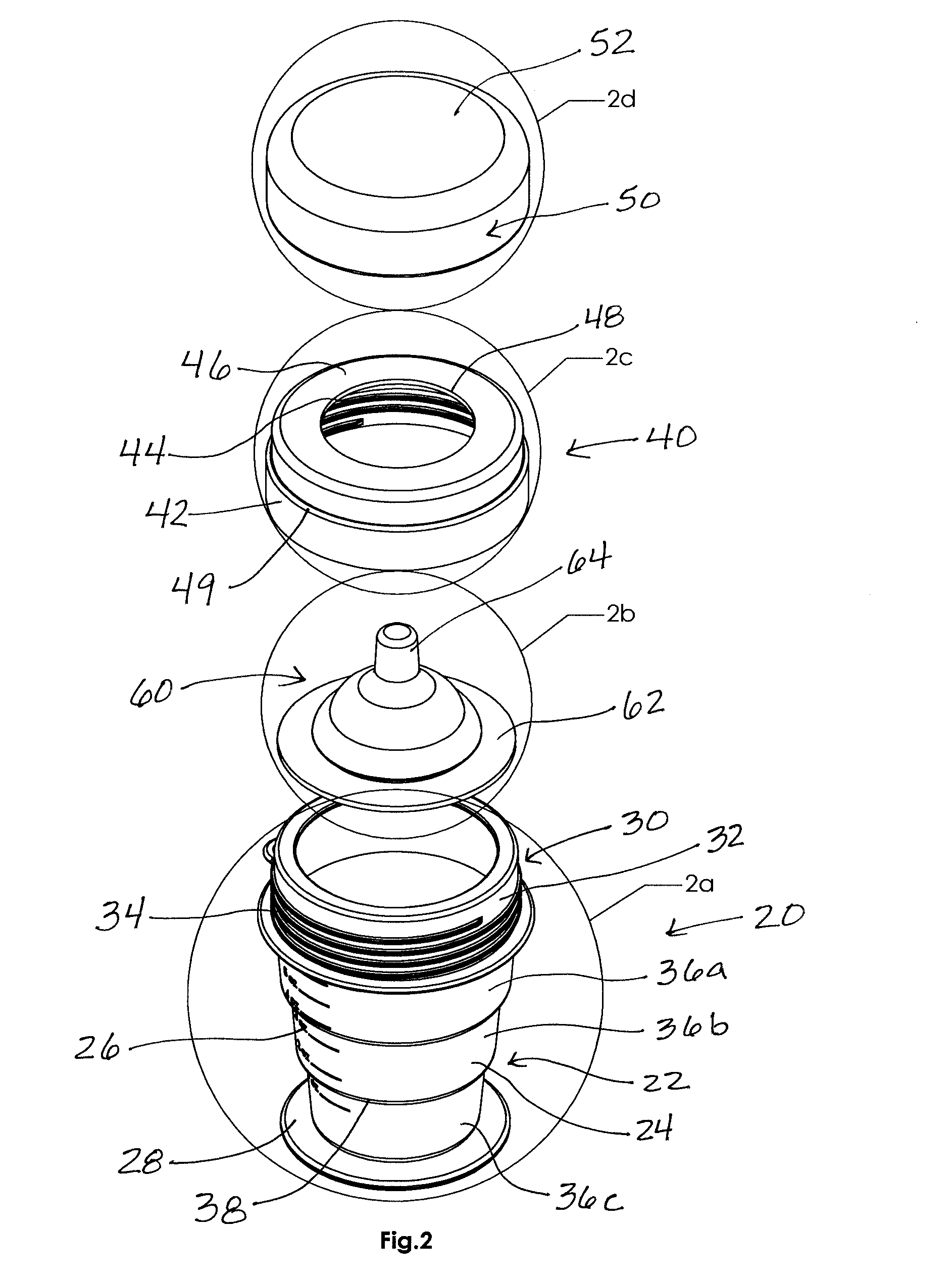

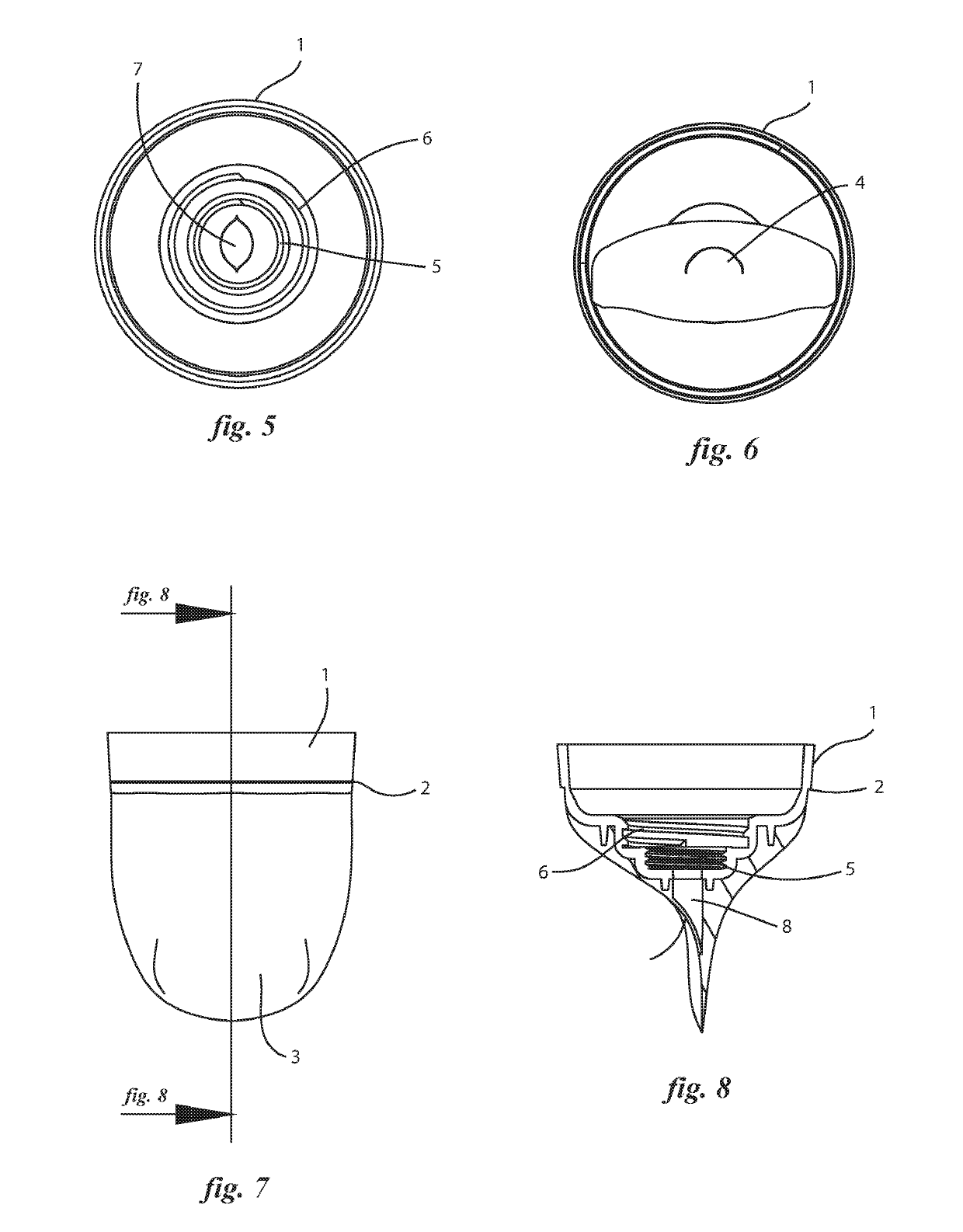

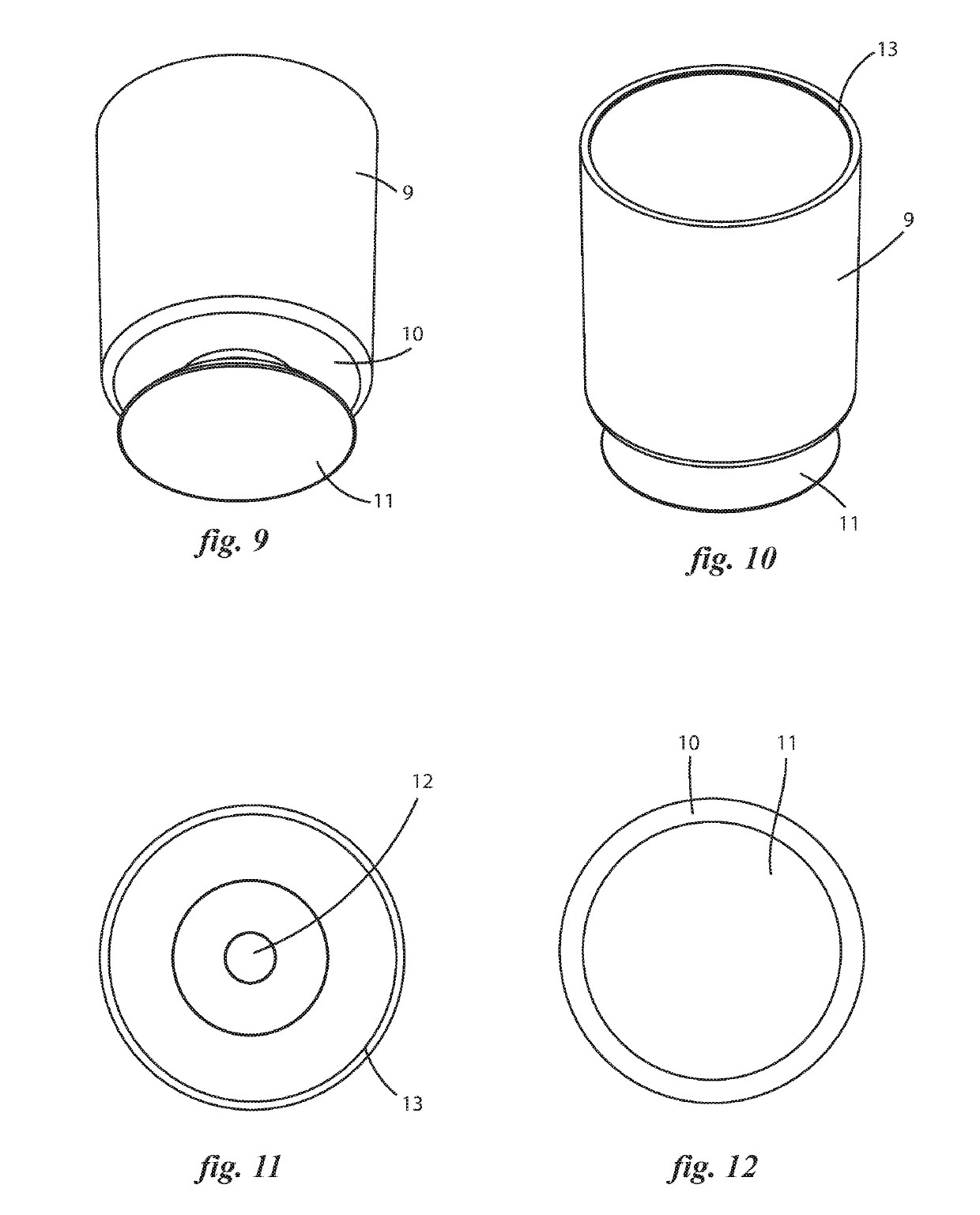

Collapsible Bottle Apparatus

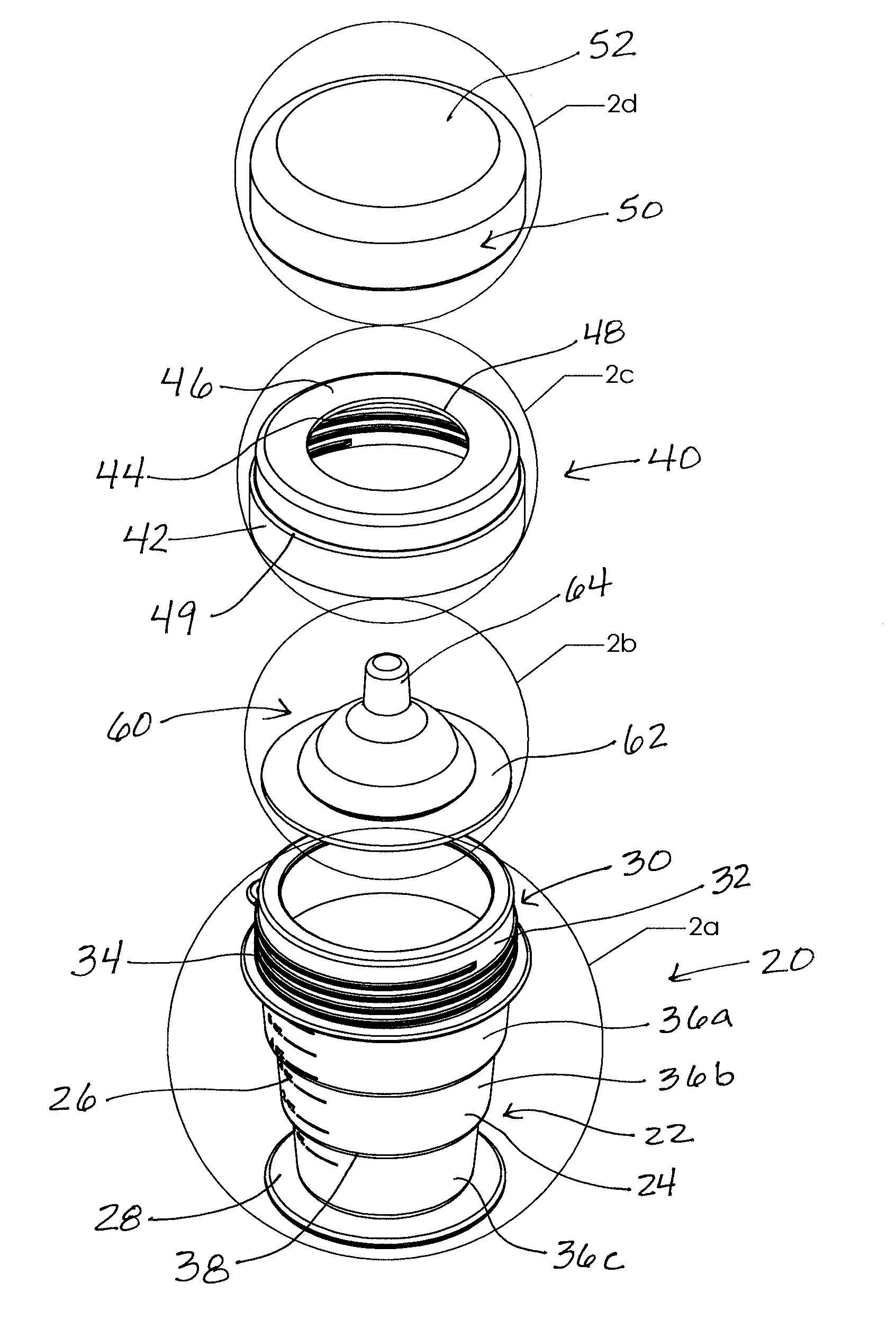

A collapsible bottle apparatus includes a body member having a flexible liquid reservoir, a base, and a primary thread adapter. The primary thread adapter defines an open interior space in communication with the reservoir. The body member is movable between an extended configuration and a collapsed configuration in which the reservoir is disposed in the interior space of the primary thread adapter. A retaining ring includes a top wall defining an aperture and a continuous side wall selectively coupled to the primary thread adapter. A primary dispensing member is selectively coupled to the retaining ring and includes a nipple extending upwardly through the aperture when the primary mounting section is coupled to the retaining ring. An auxiliary thread adapter enables an auxiliary dispensing member that includes a spout to be selectively coupled to either a water bottle or juice bottle having different neck diameters.

Owner:VELASQUEZ VERA ISIDRO

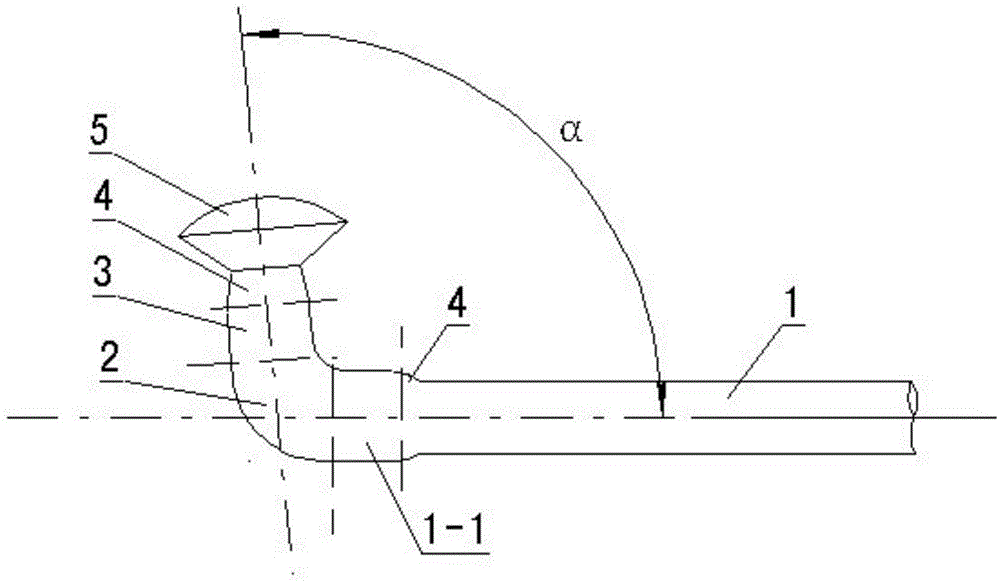

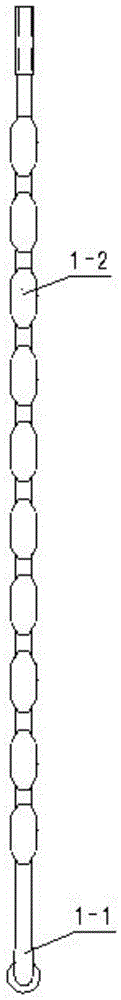

Method of pulling up silicon single crystal

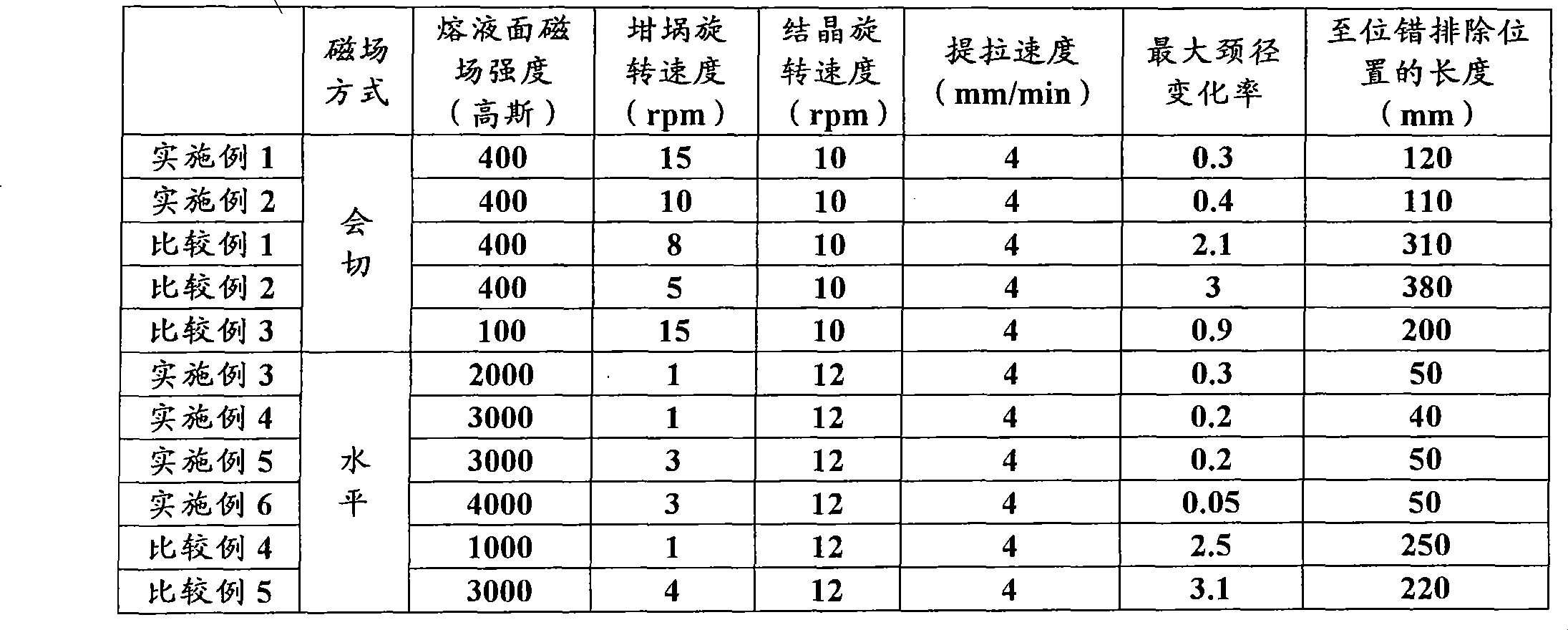

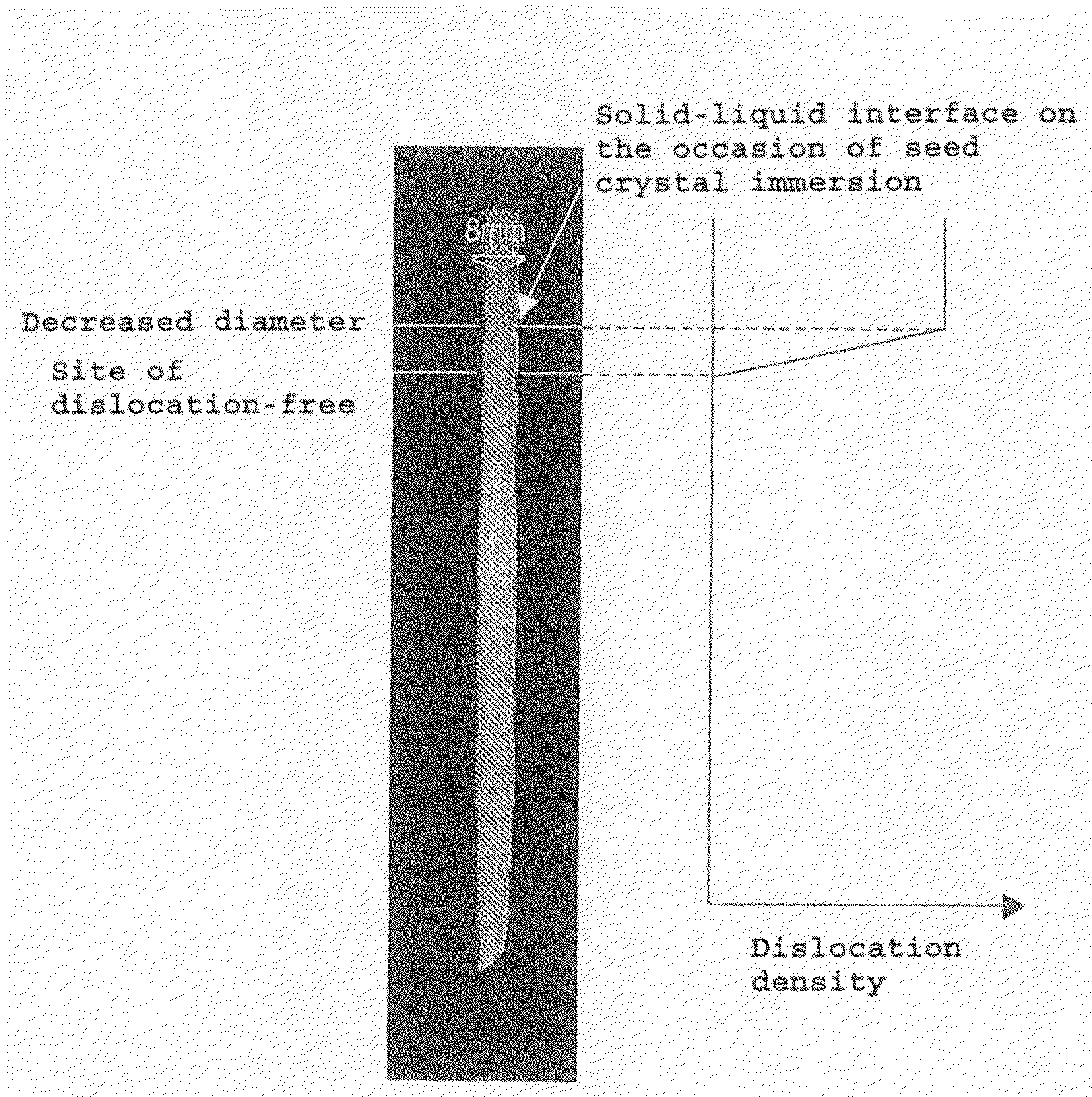

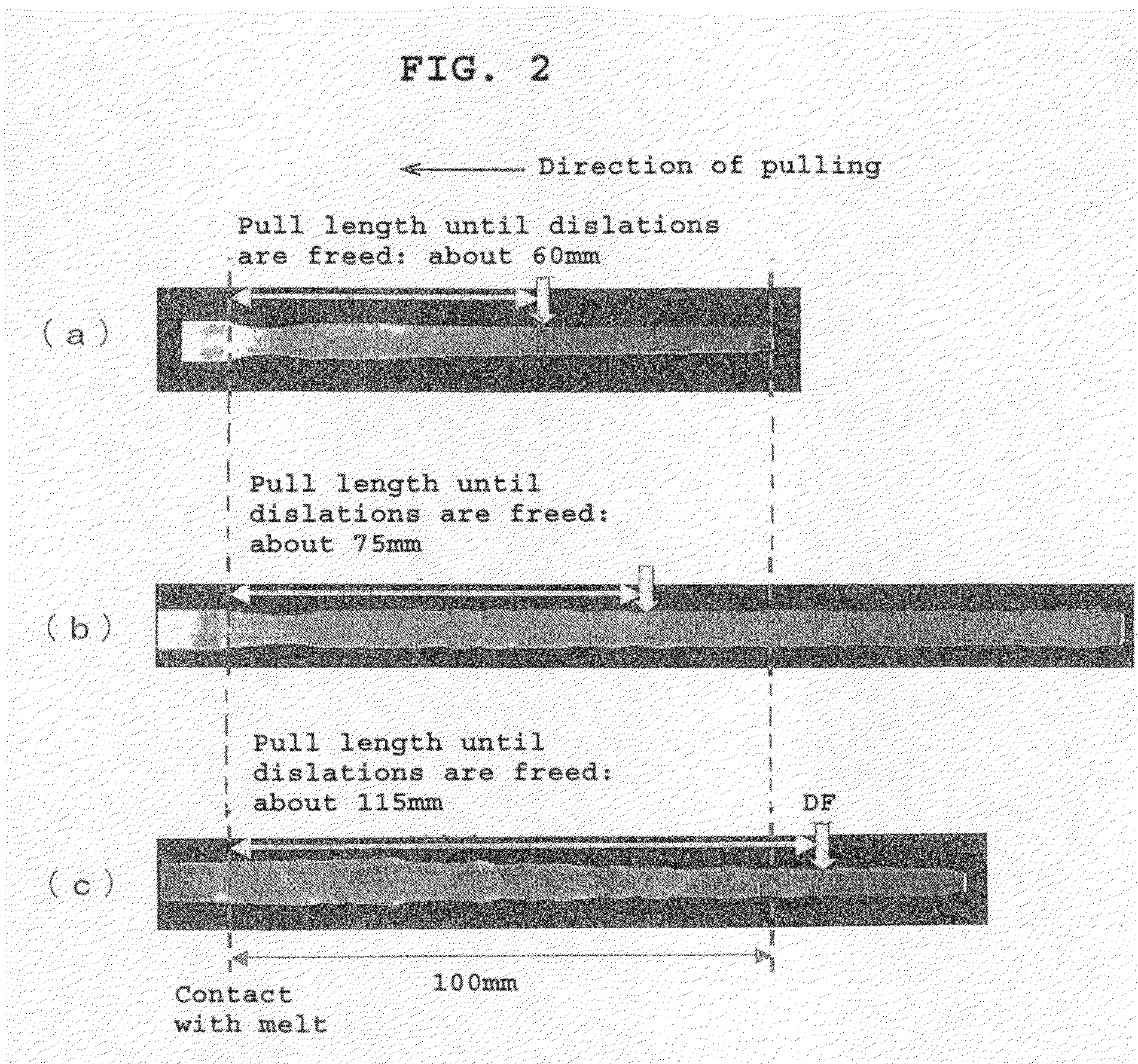

InactiveCN101363132AInhibition rate of changeEliminate dislocationsPolycrystalline material growthBy pulling from meltDislocationSeed crystal

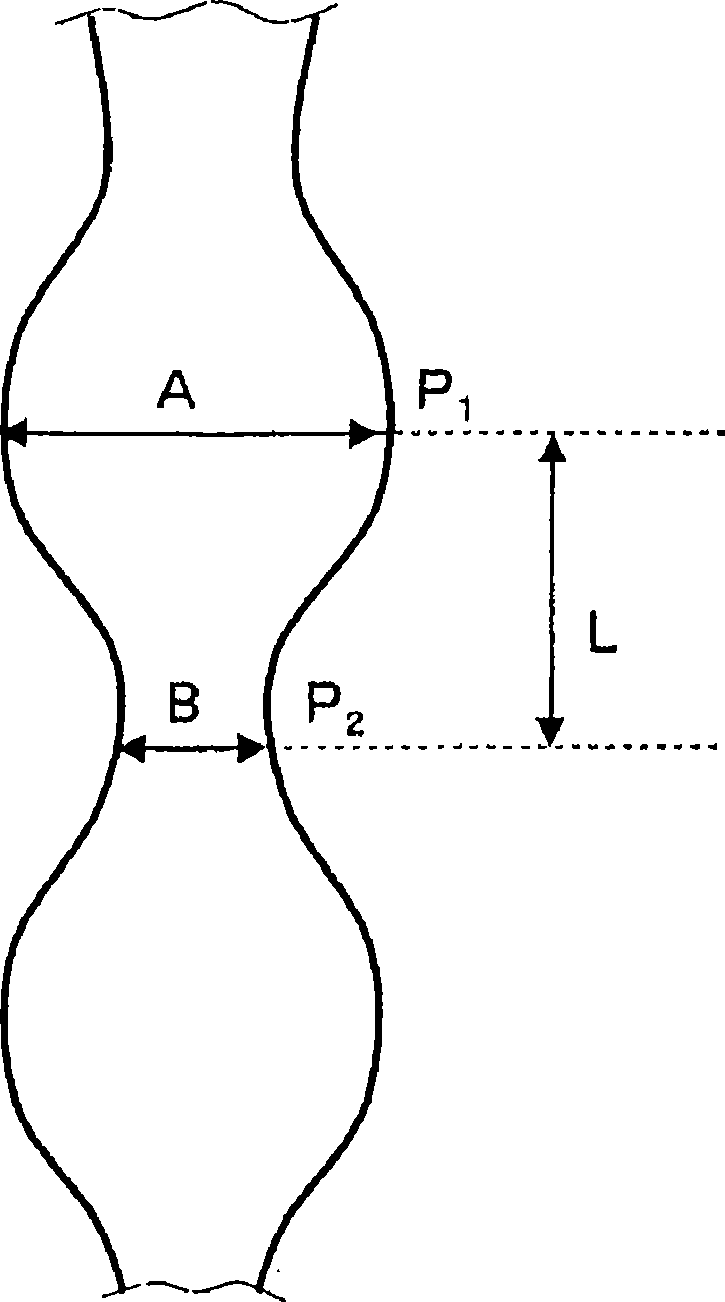

The invention provides a method of pulling up a silicon single crystal in which a variation rate of a neck diameter is controlled to be within a predetermined range, and a dislocation in a neck is eliminated. When pulling up the silicon single crystal, a single crystal with a predetermined crystal diameter is grown by bringing a seed crystal into contact with a material silicon melt, pulling up the seed crystal, growing the neck, and then increasing a diameter. The above-mentioned neck diameter is increased and decreased to grow the neck, during which a neck diameter variation rate is greater than or equal to 0.05 and less than 0.5, assuming that a value obtained in such a manner that a neck diameter difference (A-B) between adjoining inflection points is divided by a neck length L between the above-mentioned inflection points P1 and P2 is the neck diameter variation rate.

Owner:TOSHIBA CERAMICS CO

Method for growing silicon single crystal

InactiveUS20090260564A1Eliminate misalignmentEliminate the effects ofPolycrystalline material growthBy pulling from meltCrucibleDislocation

A method for growing silicon single crystal by the CZ method, namely by feeding silicon materials for crystal into a crucible to melt the materials, and growing a silicon single crystal on the lower end of the seed crystal, comprises: forming a narrowingly tapered portion with a gradually decreased seed crystal diameter by pulling up the seed crystal inserted in the melt; and providing increased or decreased neck diameter regions in the process of forming a neck in such a manner that each increased neck diameter is provided by increasing the neck diameter, followed by reverting the neck diameter to the original diameter, or alternatively, each decreased neck diameter region is provided by decreasing the neck diameter, followed by reverting the diameter to the original diameter, thereby enabling to reliably eliminate dislocations remaining in the central axial region of the neck in the step of necking. When the neck diameter is increased or decreased at the final stage in the process of forming the neck, dislocations can be eliminated more efficiently.

Owner:SUMCO CORP

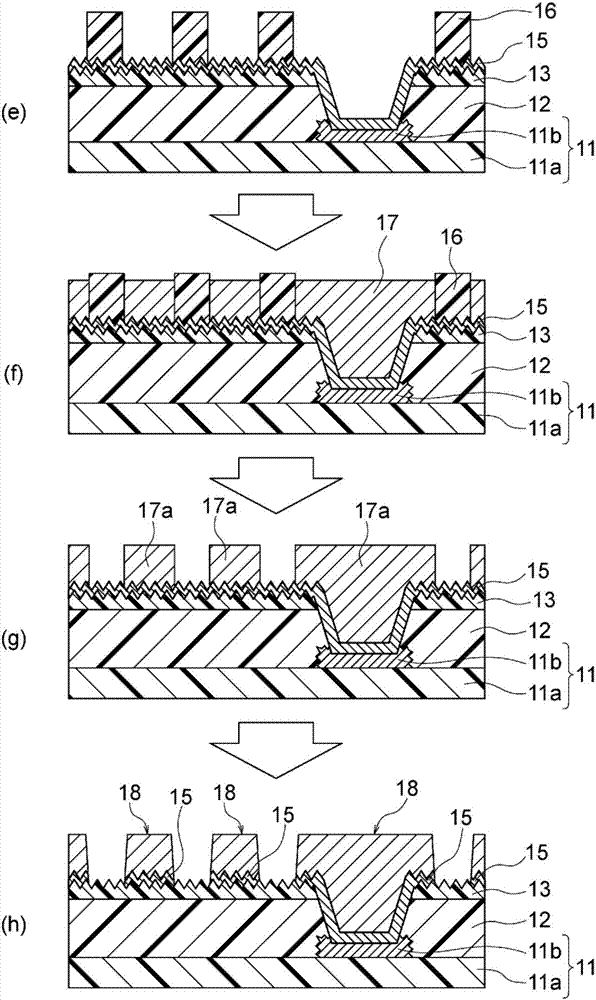

Roughened copper foil, copper foil provided with carrier, copper-clad laminated sheet, and printed wiring board

ActiveCN107429417AGood etchingExcellent dry film resolutionInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentCopper platingMaximum diameter

Provided is a roughened copper foil which, when used in the SAP method, can endow a laminate with a surface profile excellent not only in plated circuit adhesion but also in etching performance for electroless copper plating and dry film resolution. This roughened copper foil has a roughened surface on at least one side, wherein: the roughened surface is provided with a plurality of substantially spherical projections composed of copper particles; the mean height of the substantially spherical projections is 2.60 [mu]m or less; and the ratio bave / aave of the mean maximum diameter bave of the substantially spherical projections to the mean neck diameter aave of the substantially spherical projections is 1.2 or higher.

Owner:MITSUI MINING & SMELTING CO LTD

Methods and apparatus for manufacturing metal components with ceramic injection molding core structures

InactiveCN102481631AReduce manufacturing costFoundry mouldsDomestic plumbingBlow moldingMaterials science

Owner:哈维苏

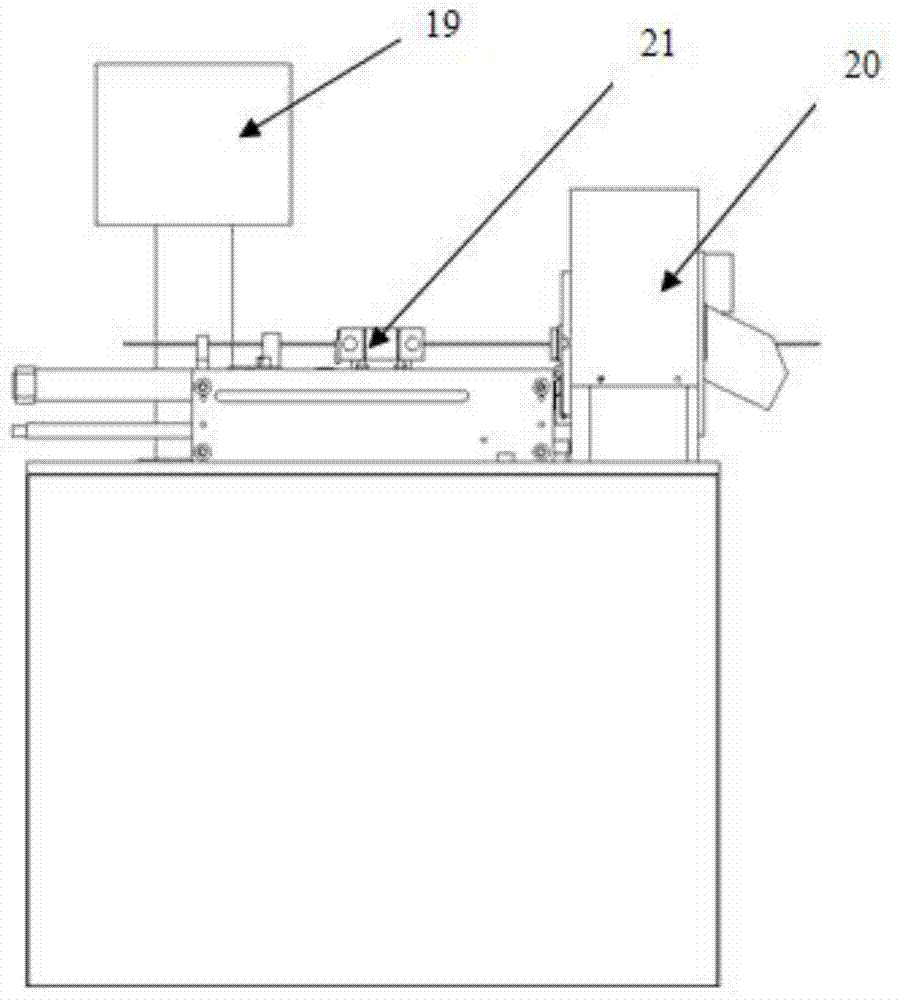

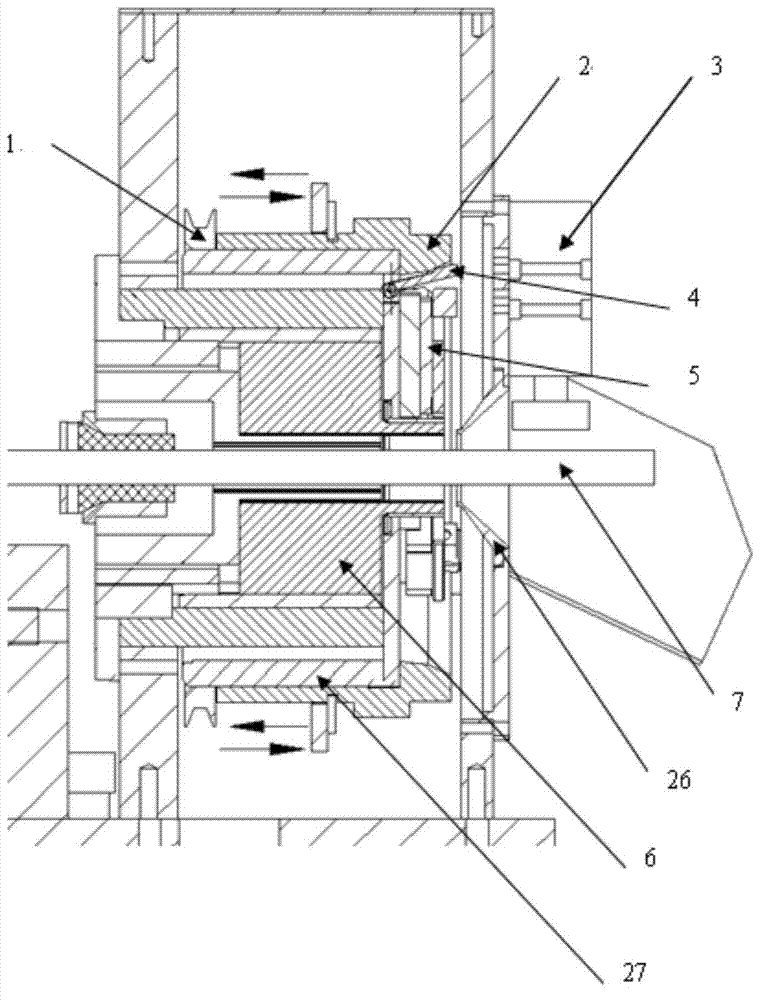

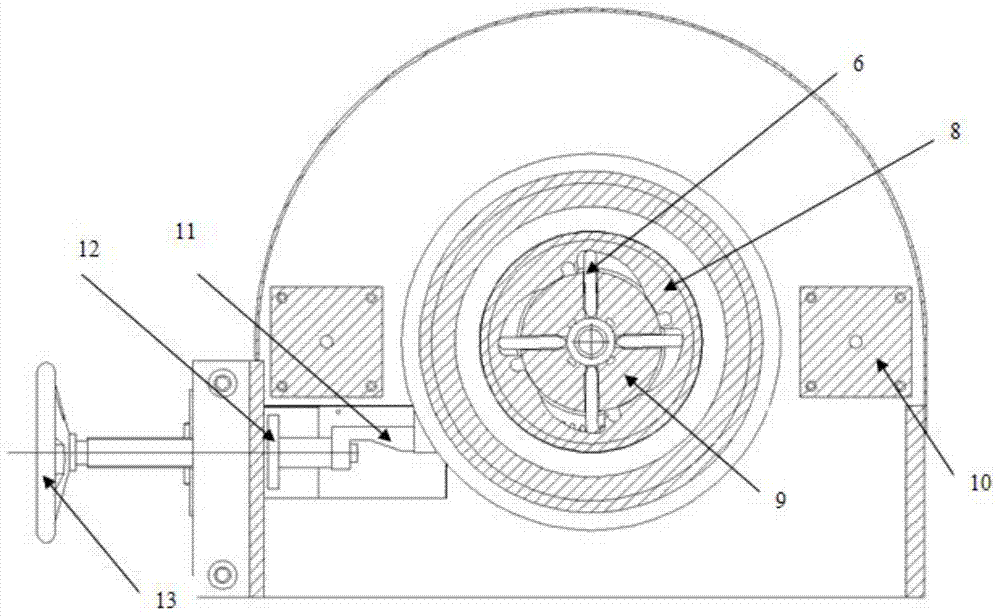

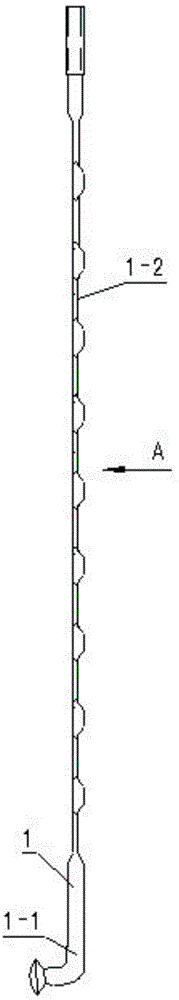

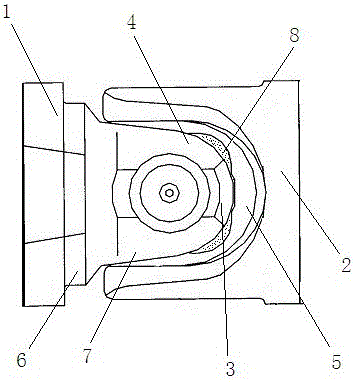

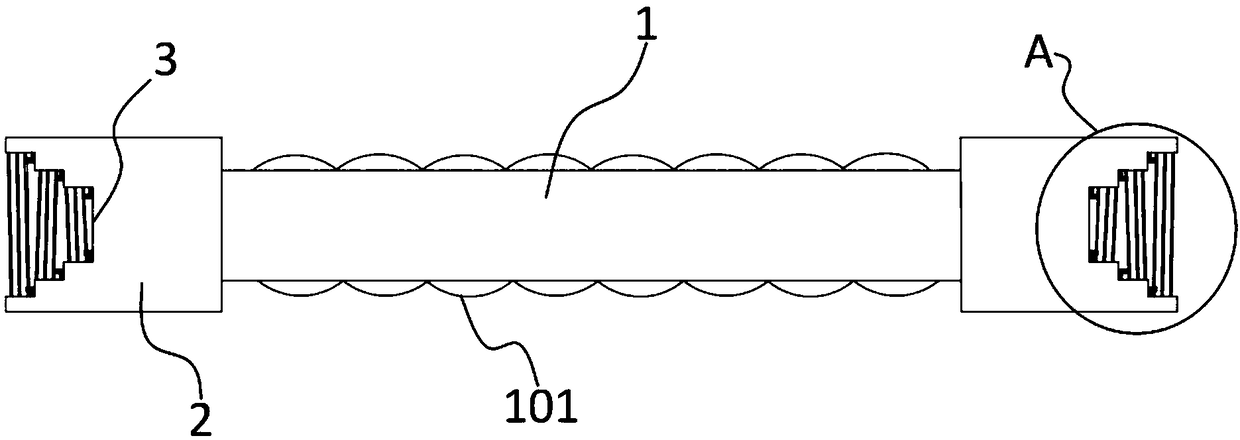

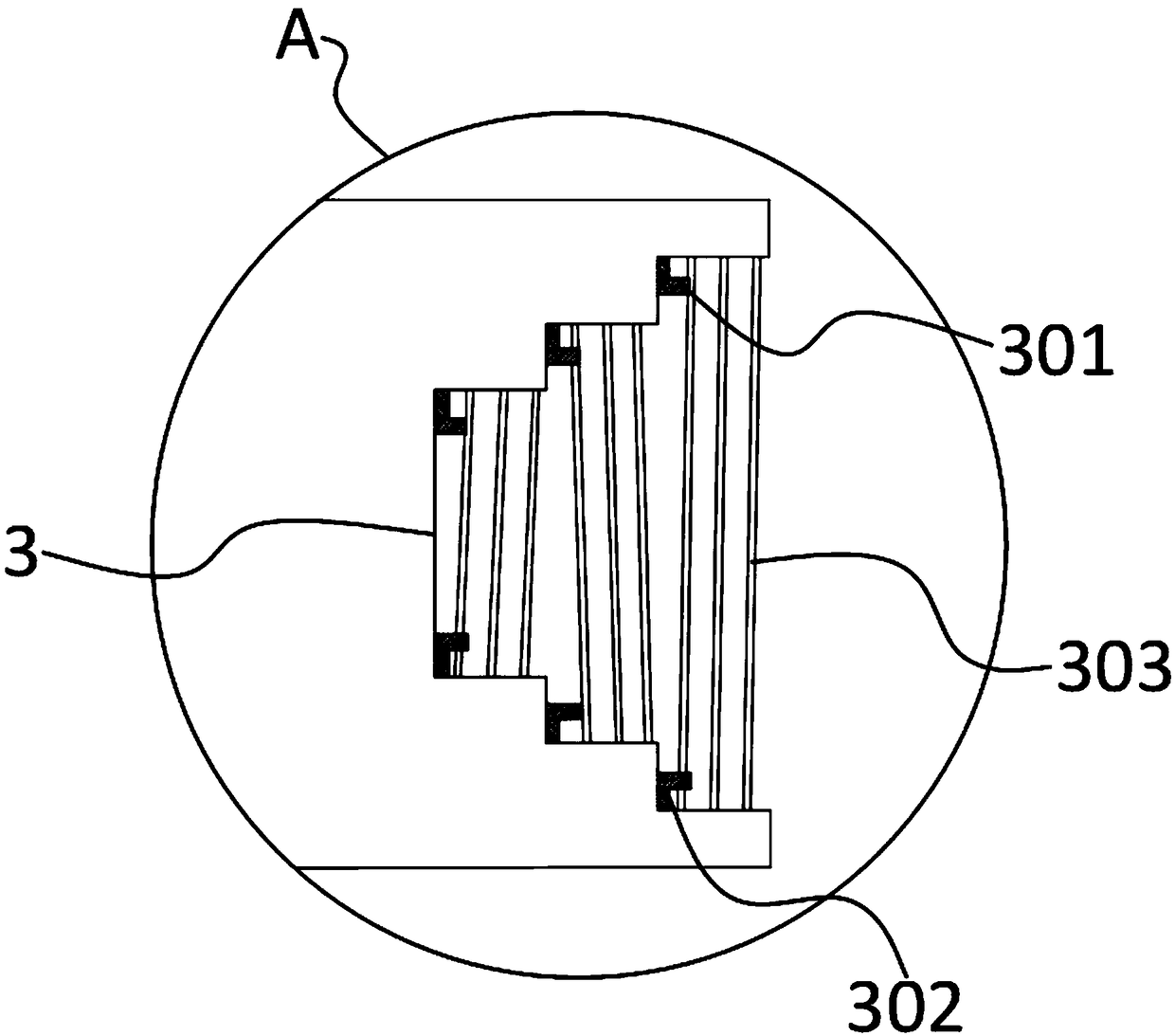

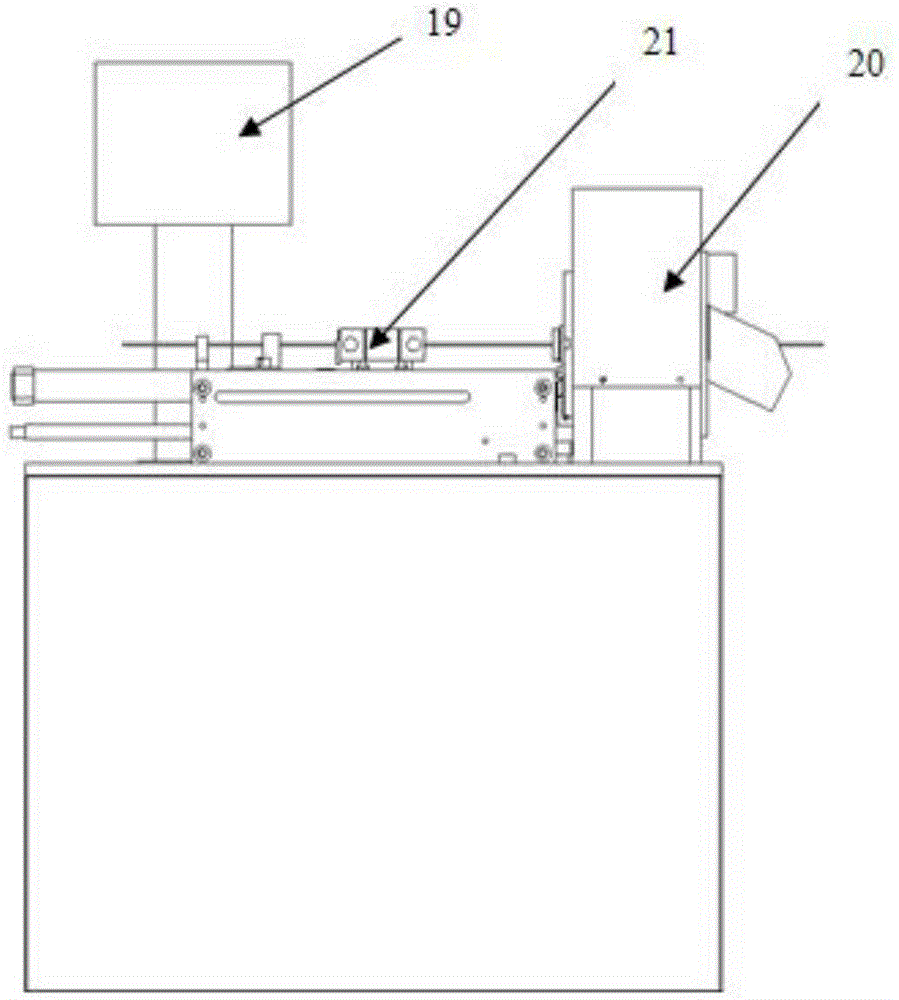

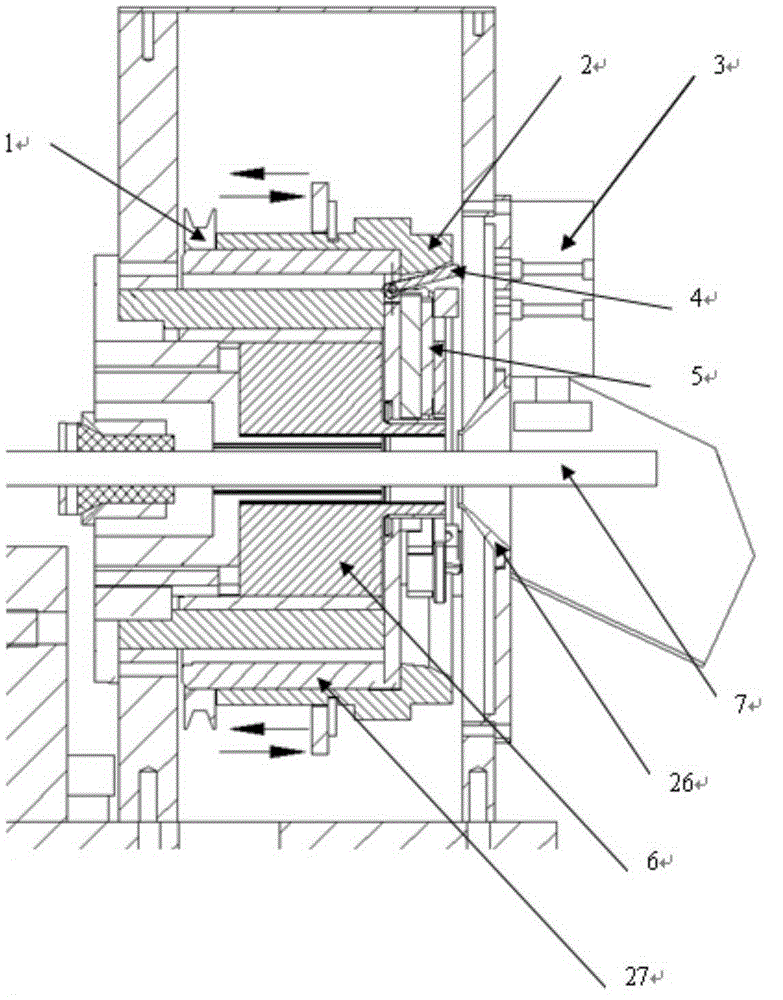

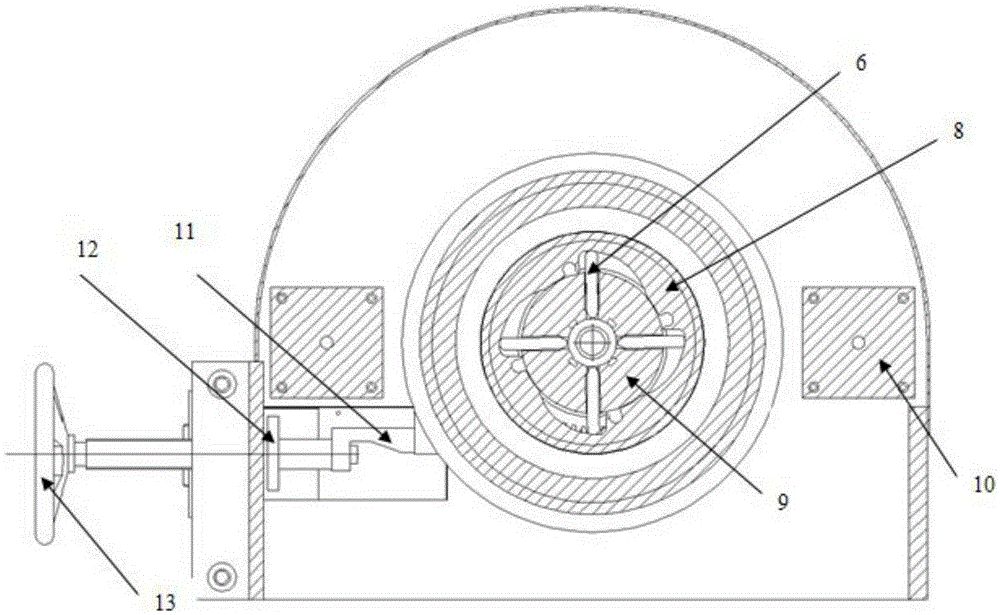

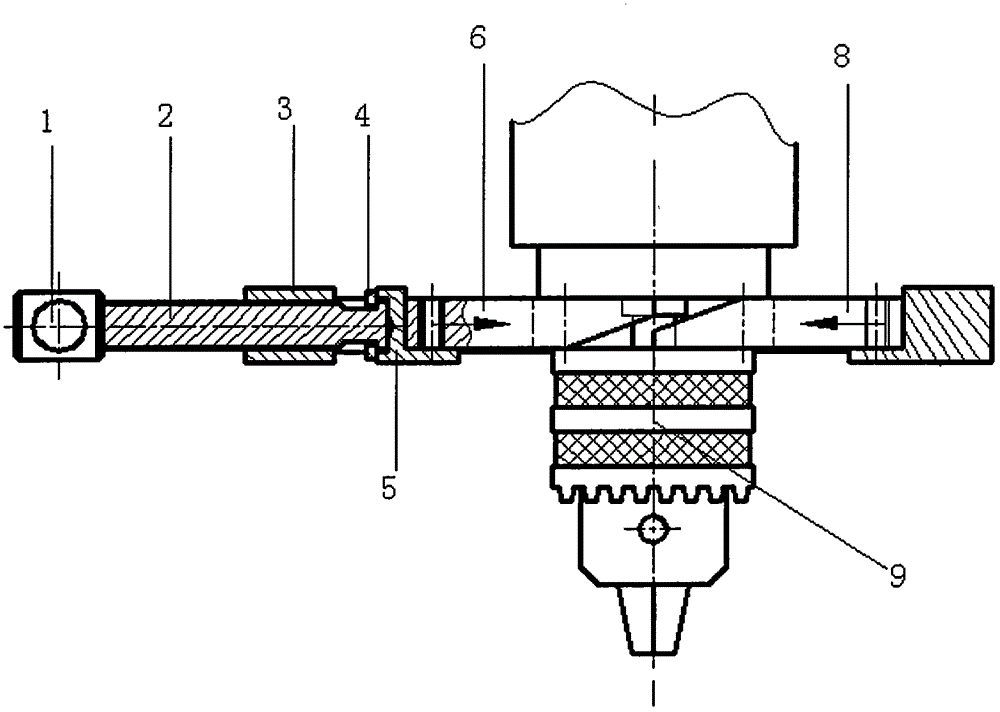

Concealed necking precision tubing ring cutting machine

ActiveCN103753621AReduce manufacturing costReduce machine set-up timeMetal working apparatusReciprocating motionGear wheel

A concealed necking precision tubing ring cutting machine comprises a machine frame body, wherein a control interface, a concealed necking ring cutting composite assembly and a feed mechanism assembly are arranged on the machine frame body, a feed mechanism is arranged at the rear of the concealed necking ring cutting composite assembly, a necking aperture adjustment hand wheel is arranged on a necking diameter adjustment screw, the front end of the adjustment screw is connected with a reciprocating motion power air cylinder, a cylinder rod of the reciprocating motion power air cylinder is connected with a straight rack, and the straight rack is arranged on a driving gear of a necking clamping cam. The concealed necking precision tubing ring cutting machine further comprises four or three necking plates, wherein the necking plates are installed on a necking plate guiding frame, the necking plate guiding frame is erected in the middle of the driving gear of the necking clamping cam, the necking plates, the necking clamping cam and the necking plate guiding frame are arranged in the middle of a main rotation shaft, a rotatable linear cam is arranged on the main rotation shaft, two rotatable linear cam reciprocating motion power air cylinders are respectively connected with two sides of a cutting feed mechanism, and the rotatable linear cam reciprocating motion power air cylinders are arranged on a ring cutting composite assembly seat.

Owner:SHENZHEN JINDIAN MACHINERY AUTOMATION CO LTD

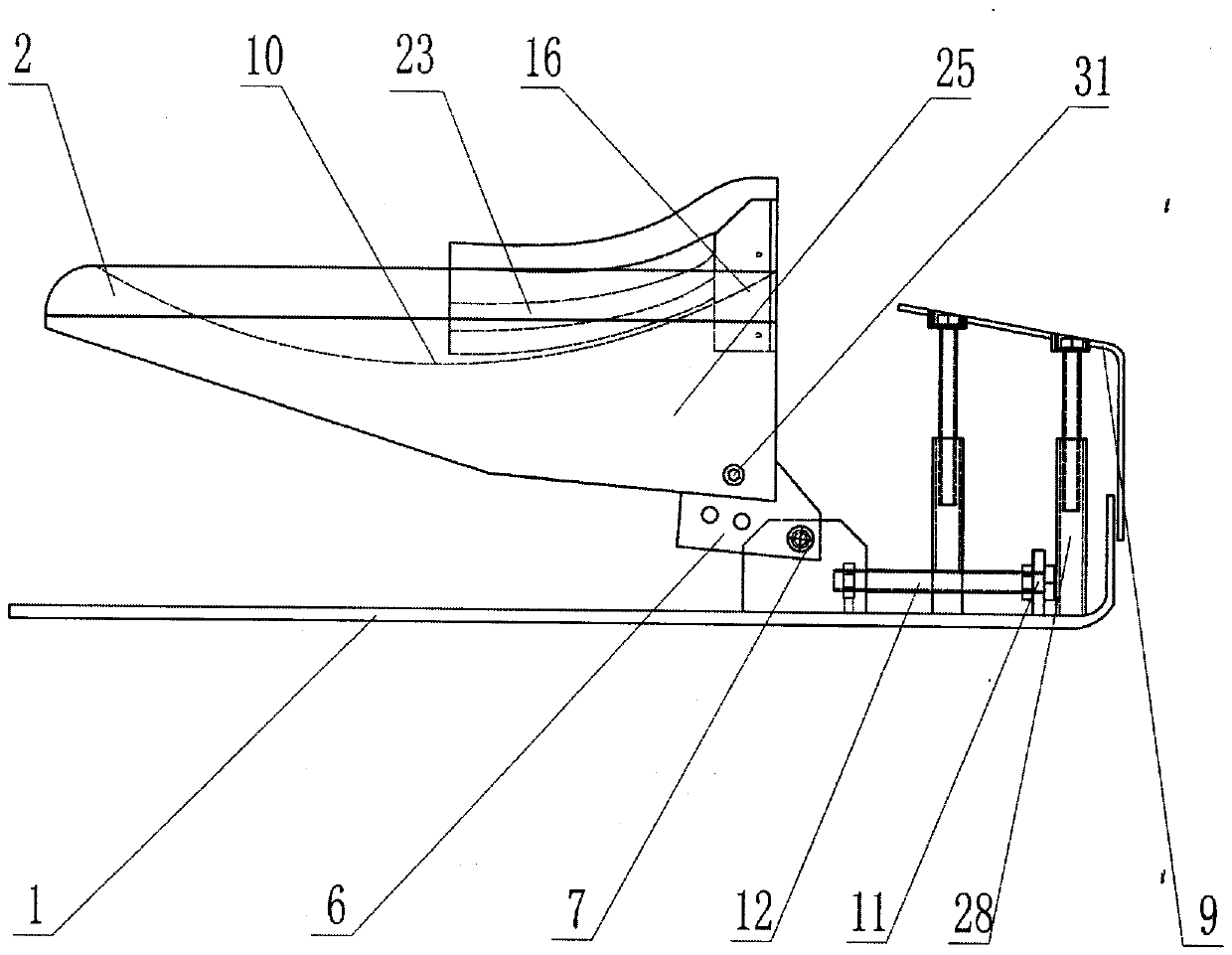

Cervical vertebra prone position traction device for cervical spondylosis traction treatment

A cervical vertebra prone position traction device for cervical spondylosis traction treatment comprises a base, an adjustable cervical vertebra curvature control board, a headrest and a neck diametercontrol clamping lock, wherein the two ends of the base are provided with symmetrical slideways, and each slideway is provided with an adjusting screw rod positioning base; a headrest fulcrum is arranged at the position, corresponding to a sliding fulcrum base, on the lower portion of the headrest; reset spring strength adjusting ratchet wheels are arranged on the two sides of the headrest, the adjustable cervical vertebra curvature control board is installed on the front side of the base, a concave arc-shaped pillow face is arranged on the headrest, the front portion of the headrest is provided with a softly connected movable joint strip-shaped connecting sheet composed of a plurality of clamping pieces through a connecting shaft, and the lower portion of each clamping piece straight section of the neck diameter control clamping lock is provided with a vertical ribbed connecting plate. The traction device is characterized in that the adjustable cervical vertebra curvature control board treats the neck and shoulders at the lower end of the cervical vertebra of a patient through traction, the occipital bone and mastoid at the upper end of the cervical vertebra are clamped and locked through the neck diameter control clamping lock, traction force directly acts at the upper and lower end of the cervical vertebra, and then the physiological curvature of the cervical vertebra is corrected and controlled. The patient feels relaxed and comfortable during traction treatment, and the patient does not suffer from pain caused when the lower jaw is tightened and compressed any more during traction.

Owner:董延巍

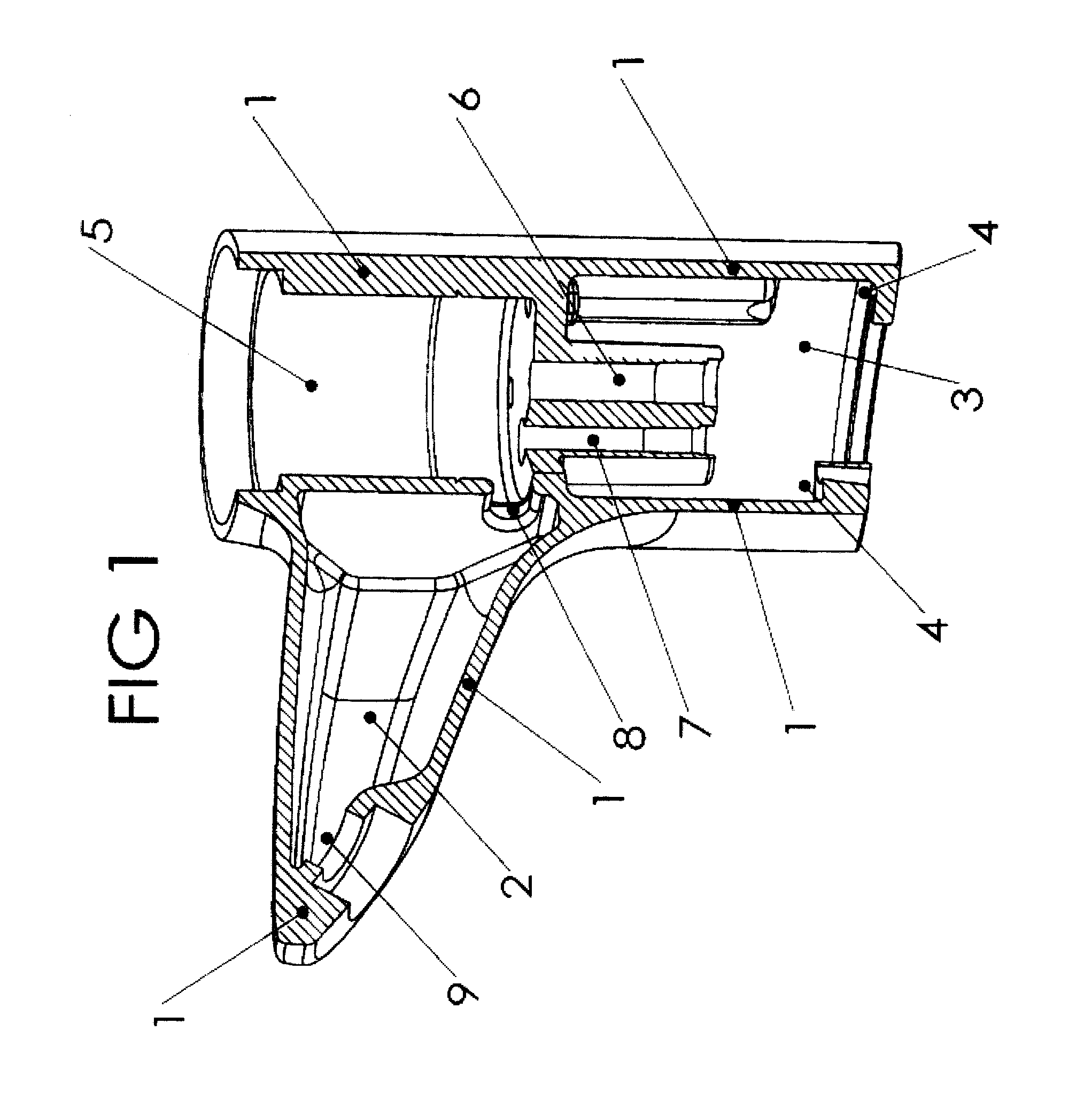

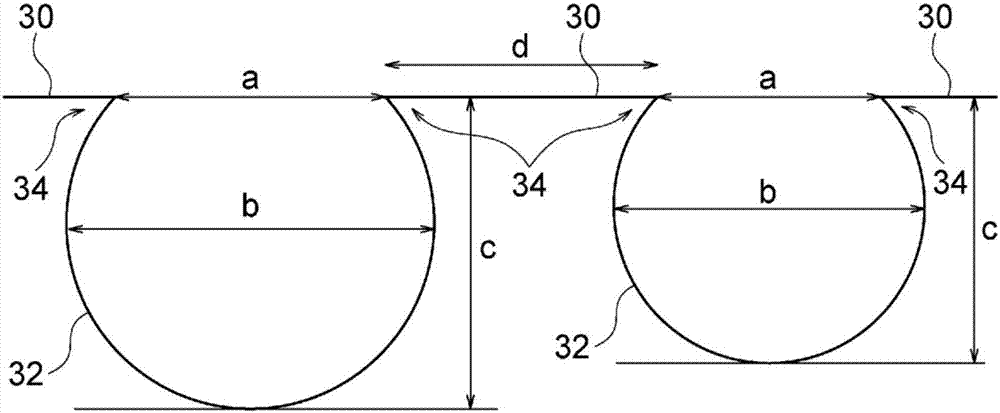

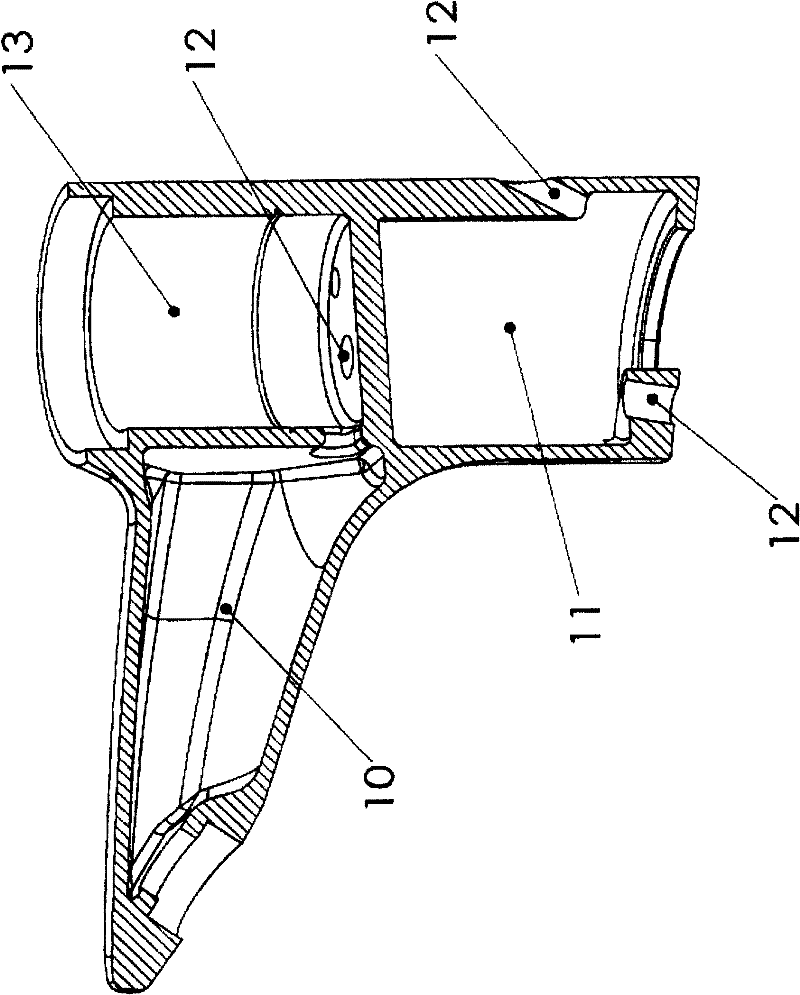

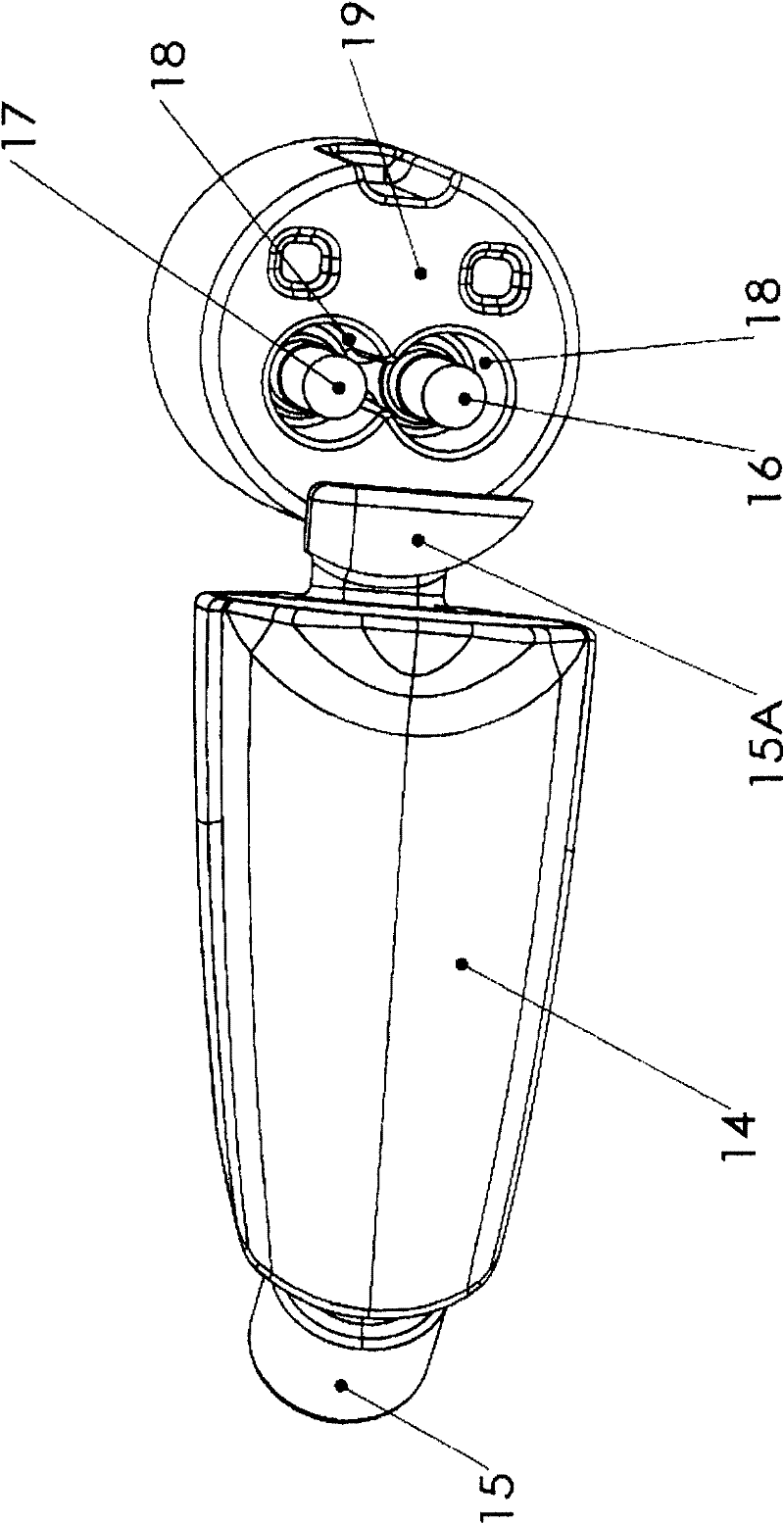

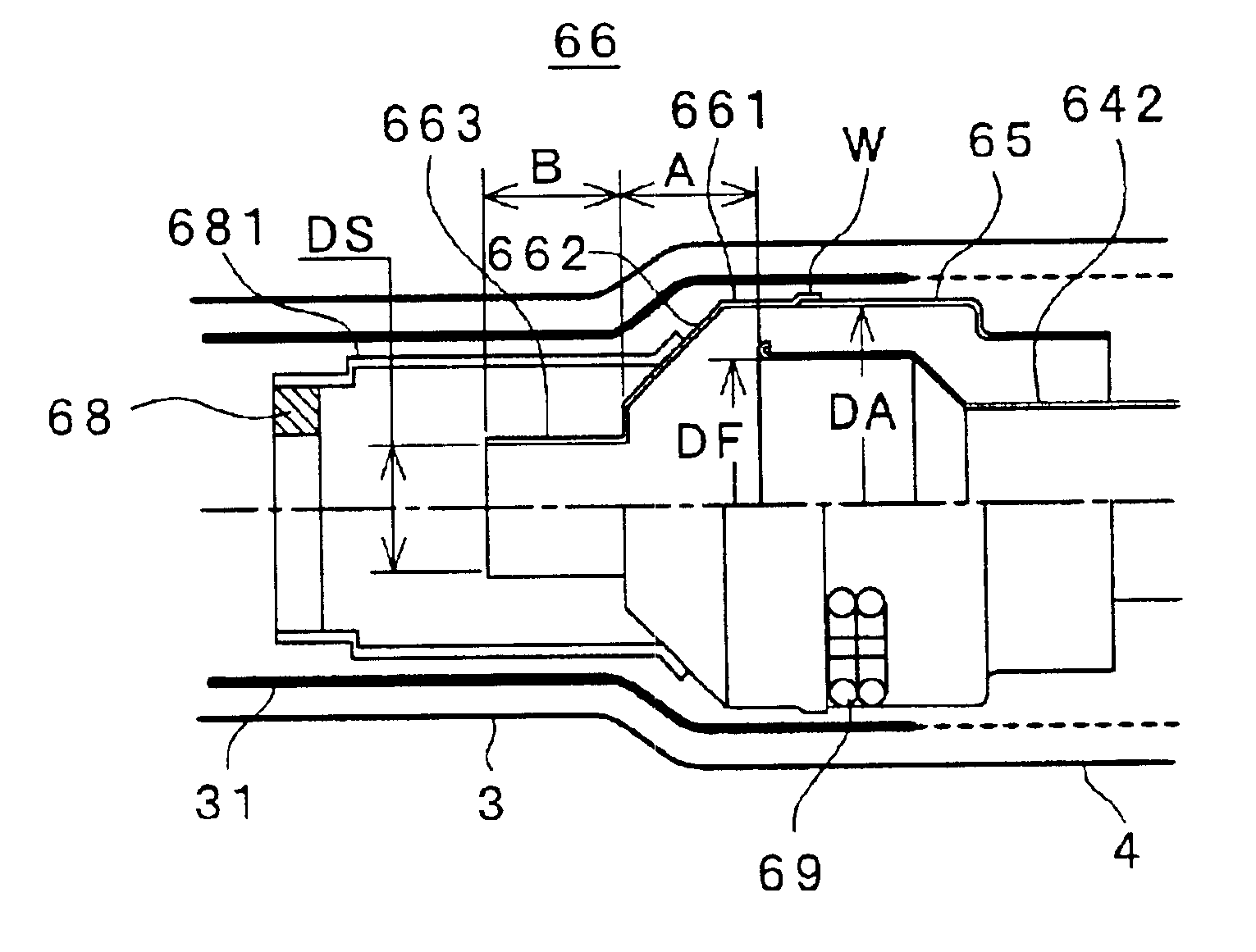

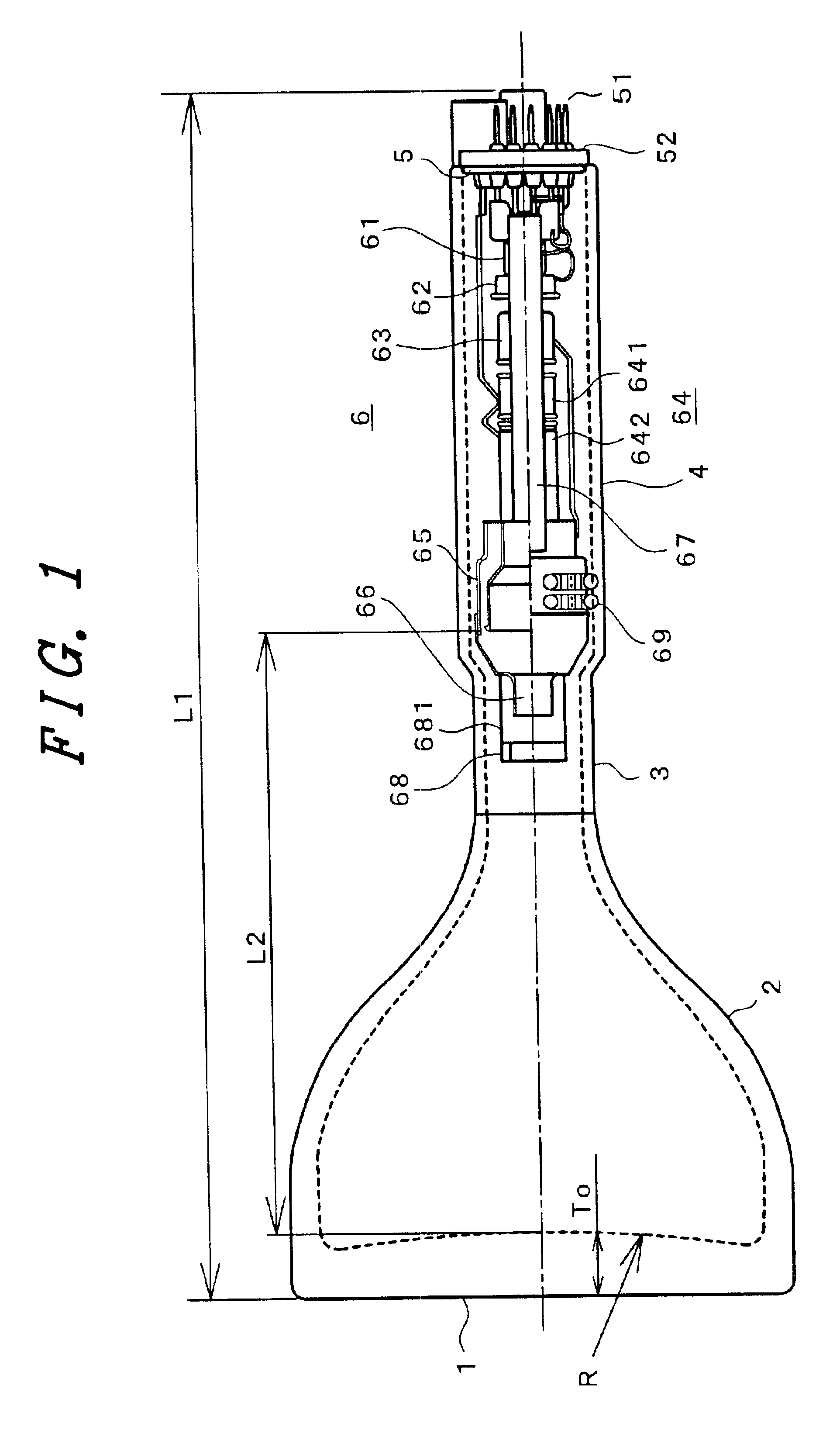

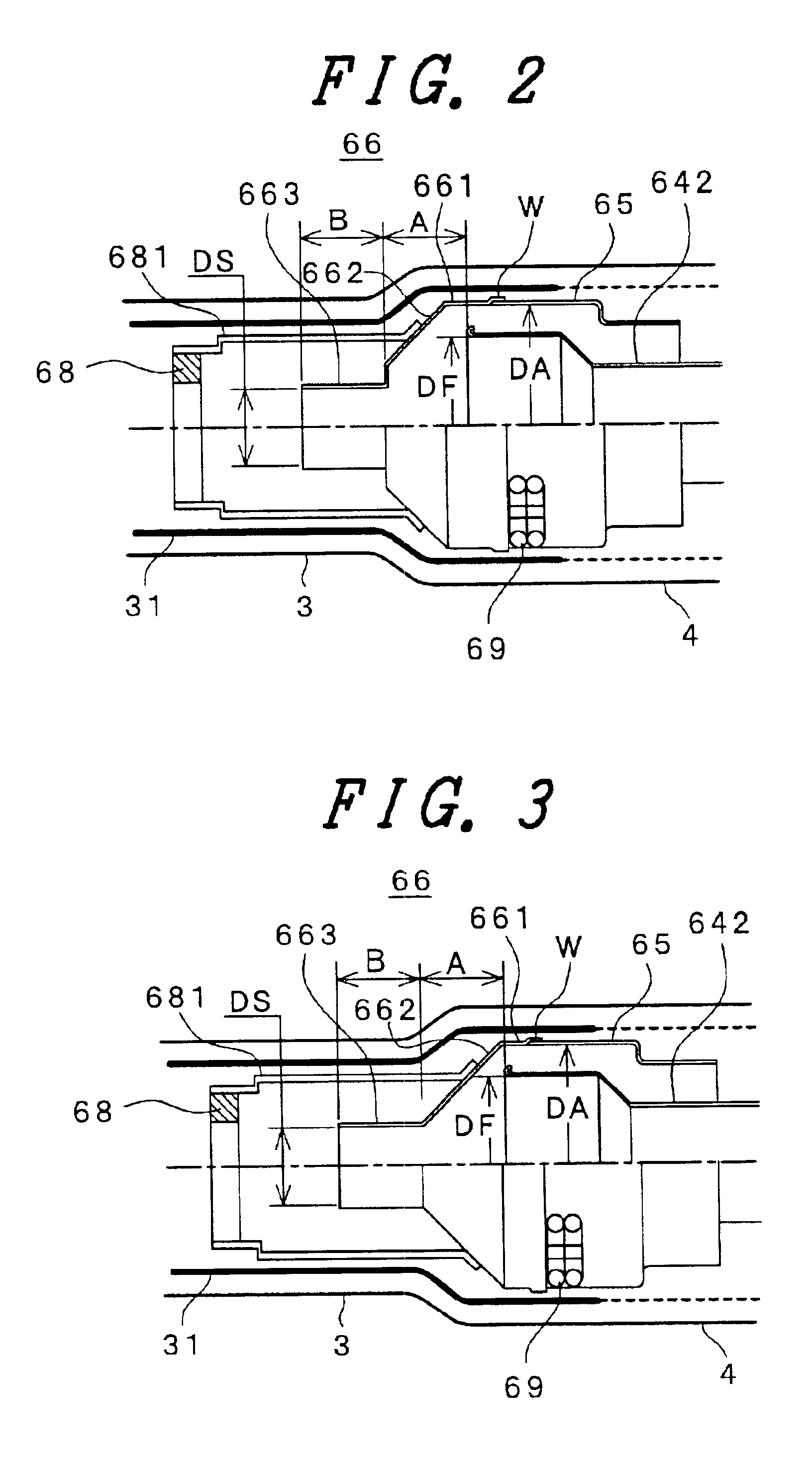

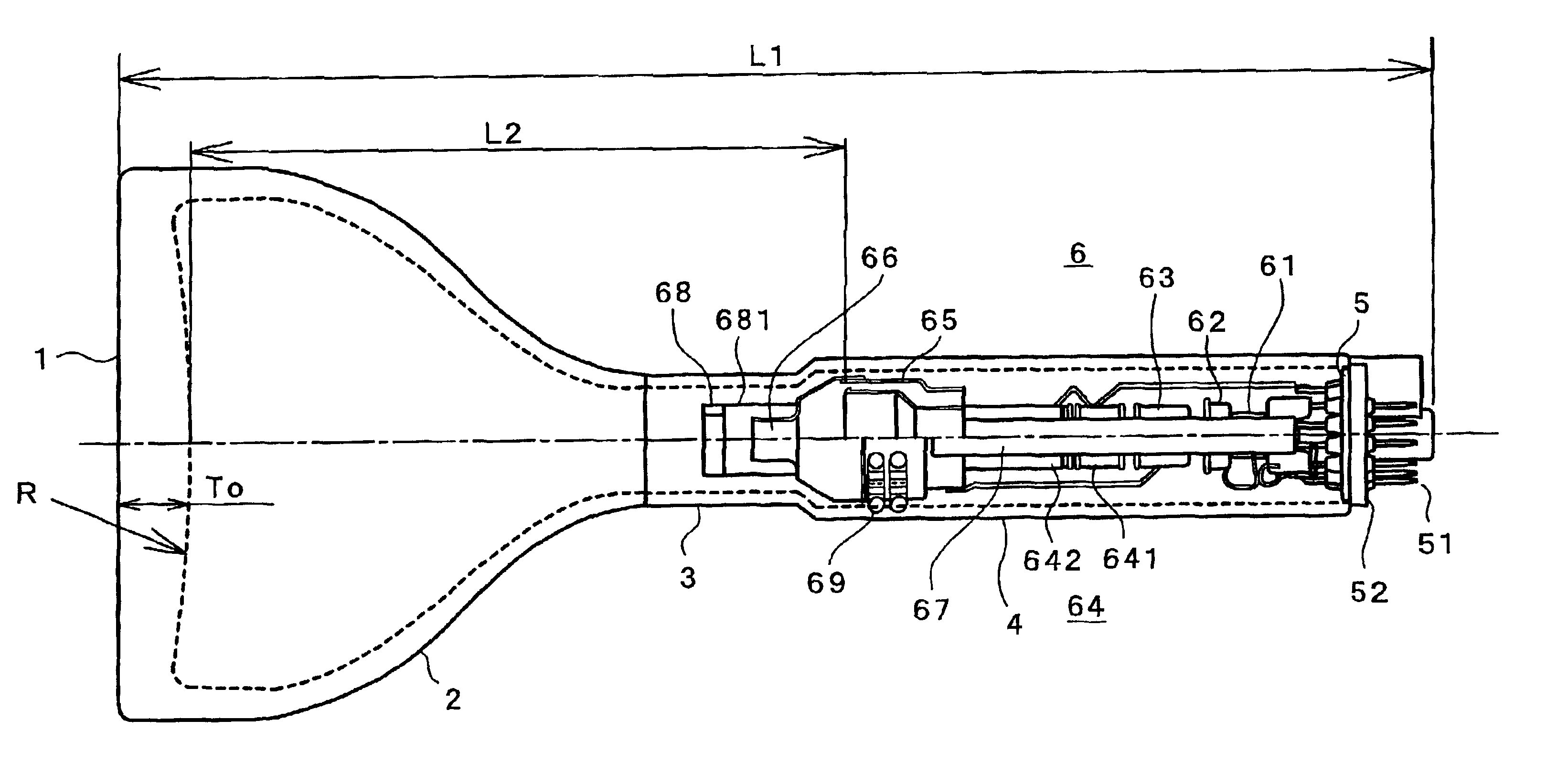

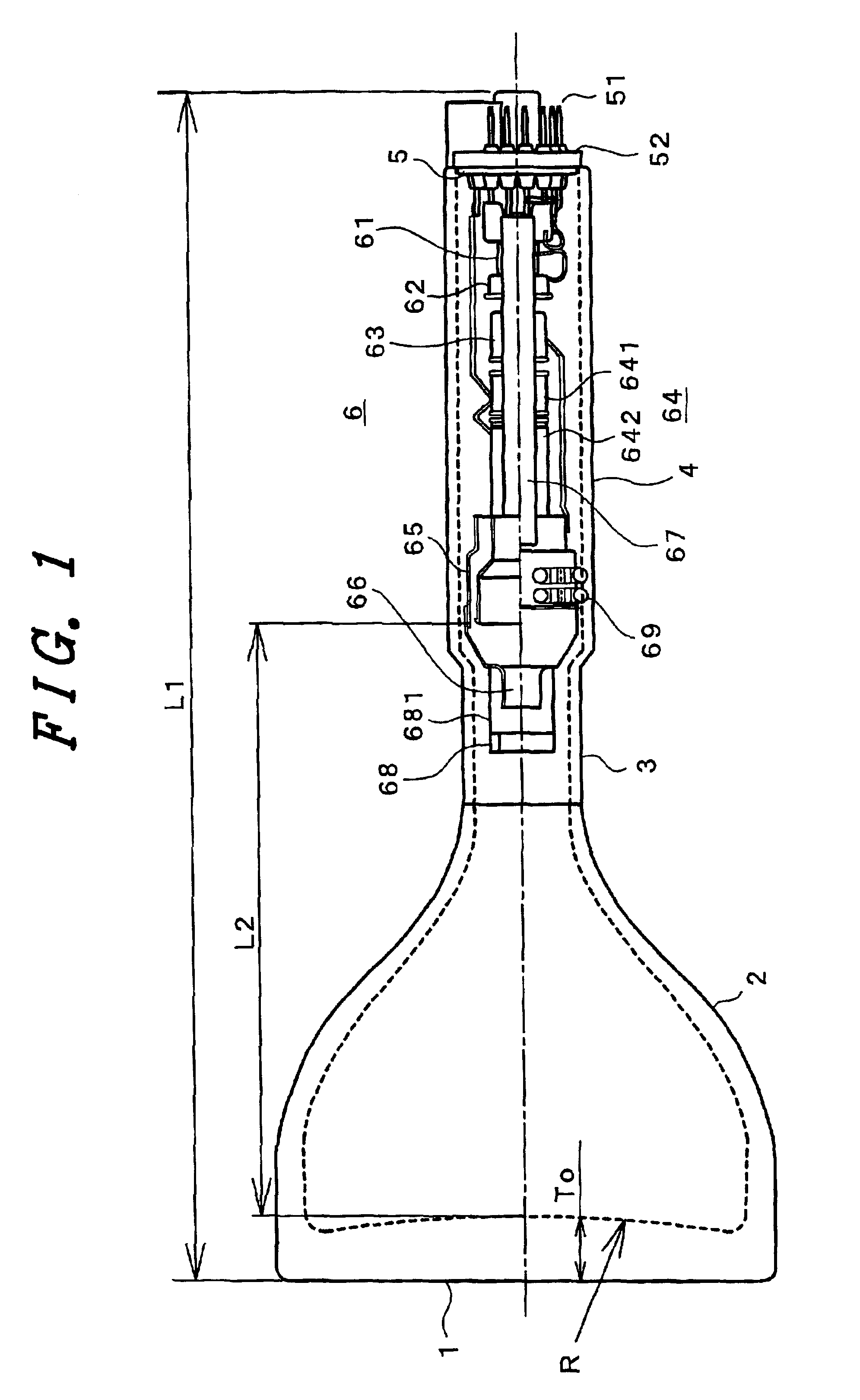

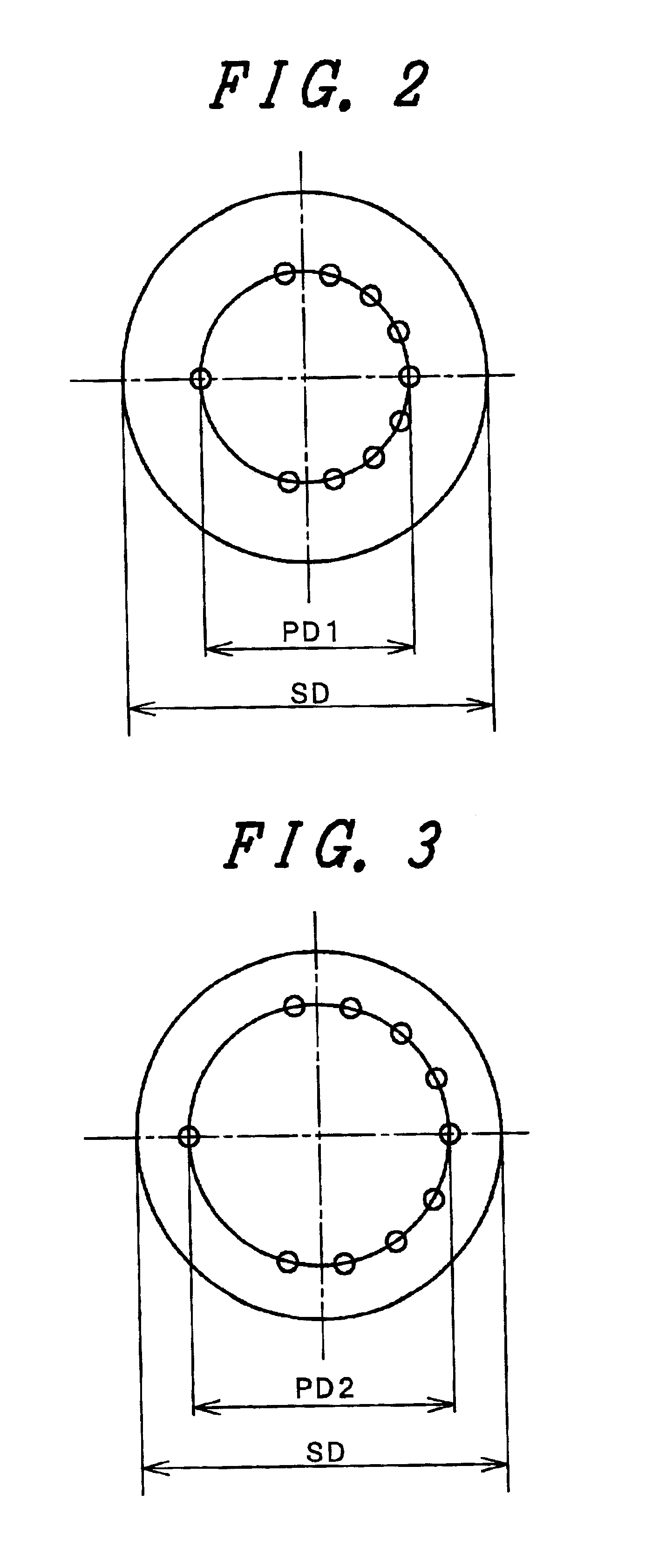

Projection tube having different neck diameters

InactiveUS6847159B2Avoid problemsReduce deflectionCathode-ray/electron-beam tube electrical connectionCathode-ray/electron-beam tube vessels/containersSingle electronAnode voltage

The present invention aims at maintaining the high focusing performance with a low deflection power in a projection tube which is used as a projection type TV receiver or a projector and is operated at a high voltage and with a single-electron-beam high current. A neck outer diameter of a portion on which a deflection yoke is mounted is made smaller than a neck outer diameter of a portion which accommodates an electron gun. A final electrode of the electron gun has a diameter thereof gradually decreased toward a phosphor screen. The maximum anode voltage of the projection tube is set to equal to or more than 25 KV and the maximum beam current is set to equal to or more than 4 mA.

Owner:HITACHI LTD +1

High-strength wheel spoke

The invention relates to a high-strength wheel spoke which comprises a bar, a threaded portion at one end of the bar, a bending portion at the other end of the bar, a diameter enlarging portion between a neck and a bar cap and a diameter enlarging portion between the neck and the bending portion. A bar diameter enlarging portion is arranged on the joint part of the bar and the bending portion, reducing joint portions are arranged between a neck diameter enlarging portion and a bar cap and between the bar diameter enlarging portion and the bar. According to the high-strength wheel spoke, the practical problem that the joint part of the bar and the bending portion is worn most obviously and is prone to being broken in the using process of the spoke, the diameter enlarging portion is arranged on the joint part and remarkably reduces the phenomenon that breaking is caused easily due to the fact that the part is worn most obviously, and the tension intensity of the high-strength wheel spoke is obviously better than common hard steel spokes of the same specification. The high-strength wheel spoke is obtained through a die stamping method, and the bar cap and all the diameter enlarging portions are formed at the same time through stamping of two sets of dies. The high-strength wheel spoke has the advantages that the intensity of the spoke is improved remarkably.

Owner:TIANJIN WANHUAVEHICLE COMPONENTS CO LTD

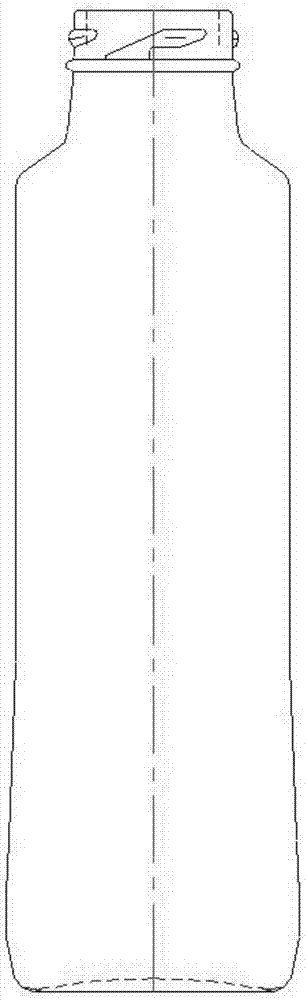

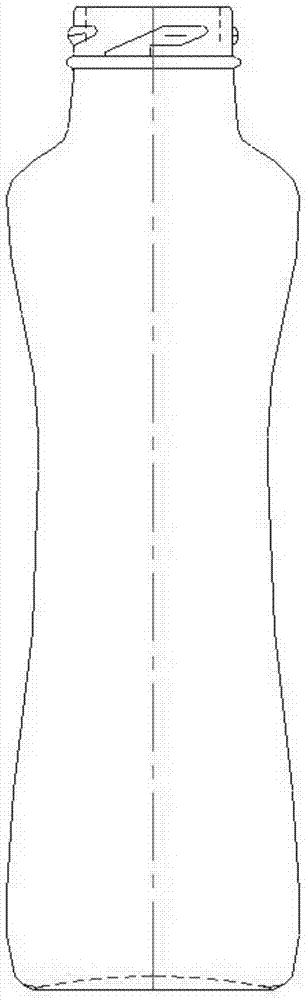

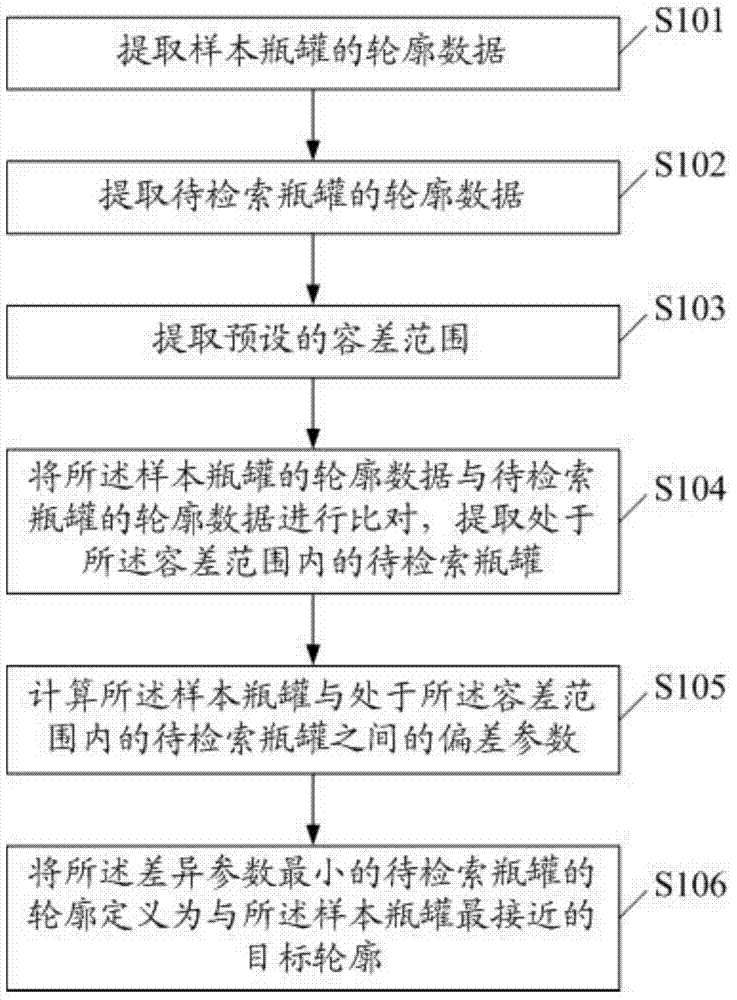

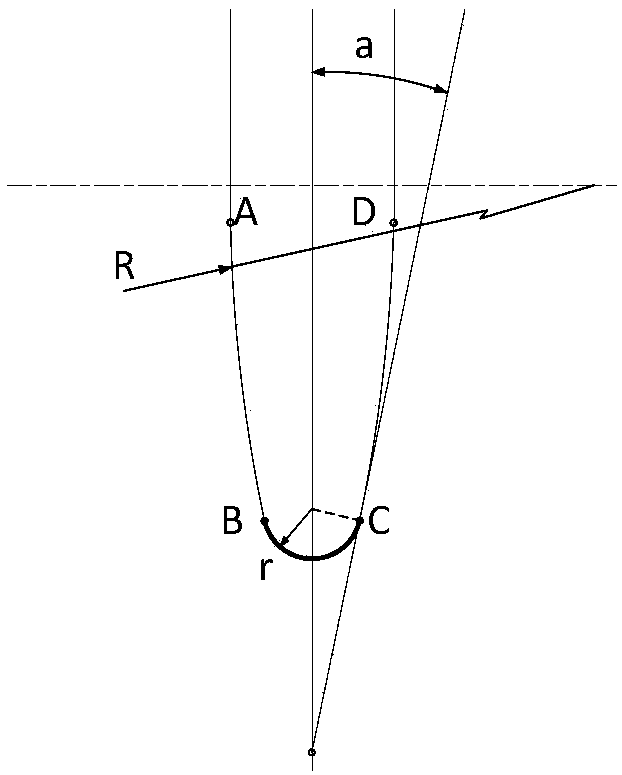

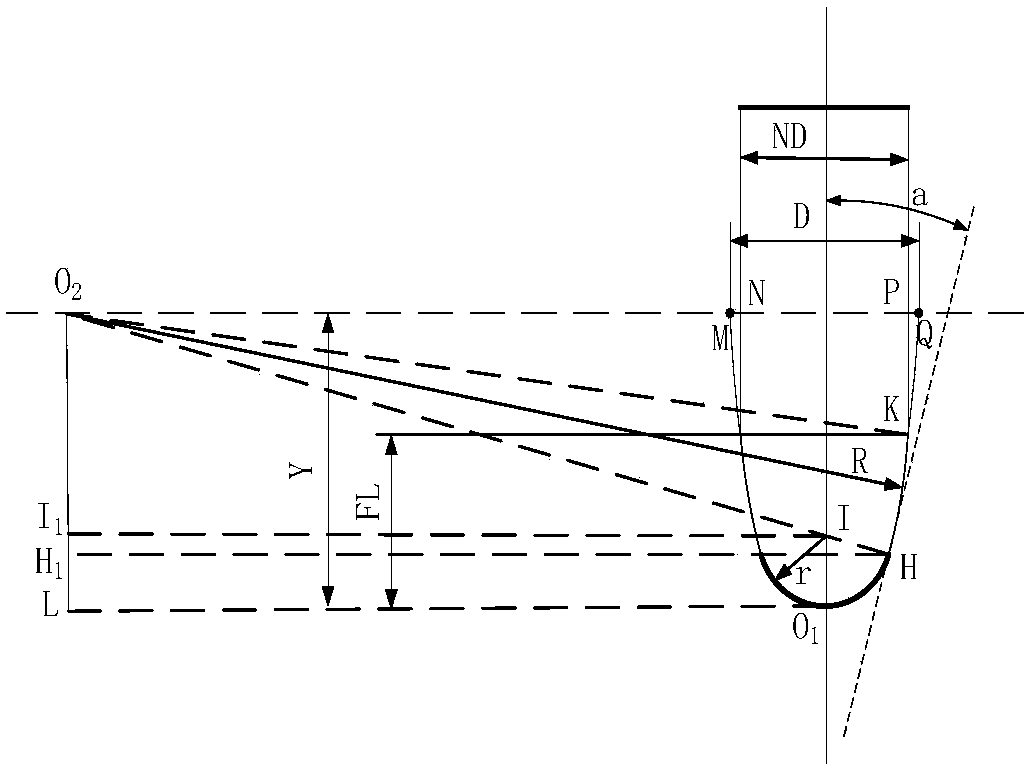

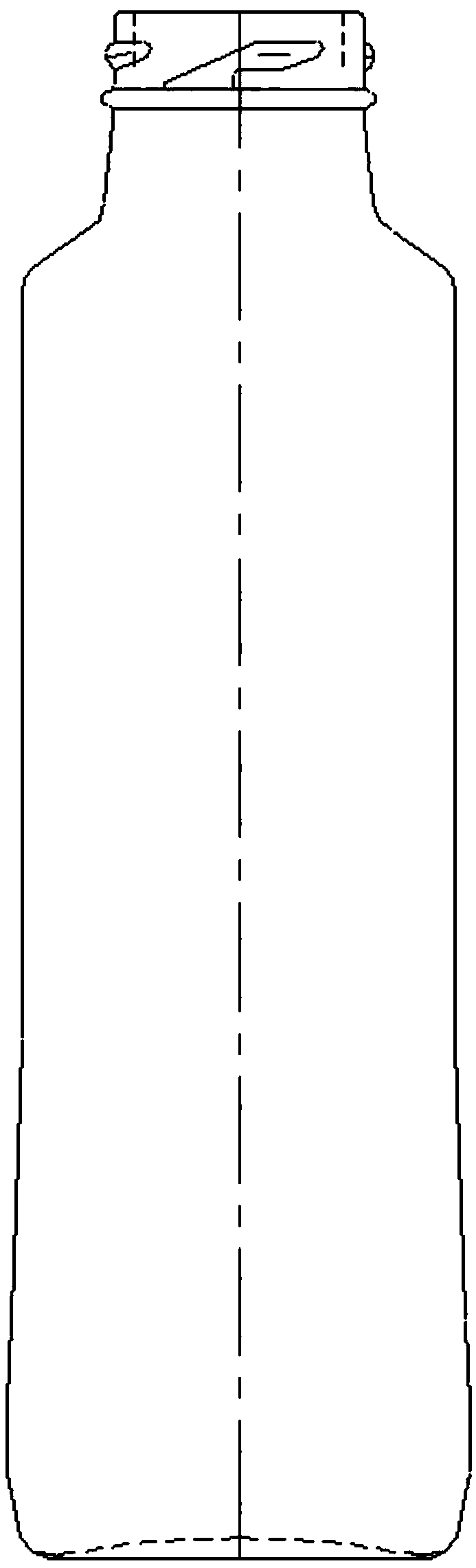

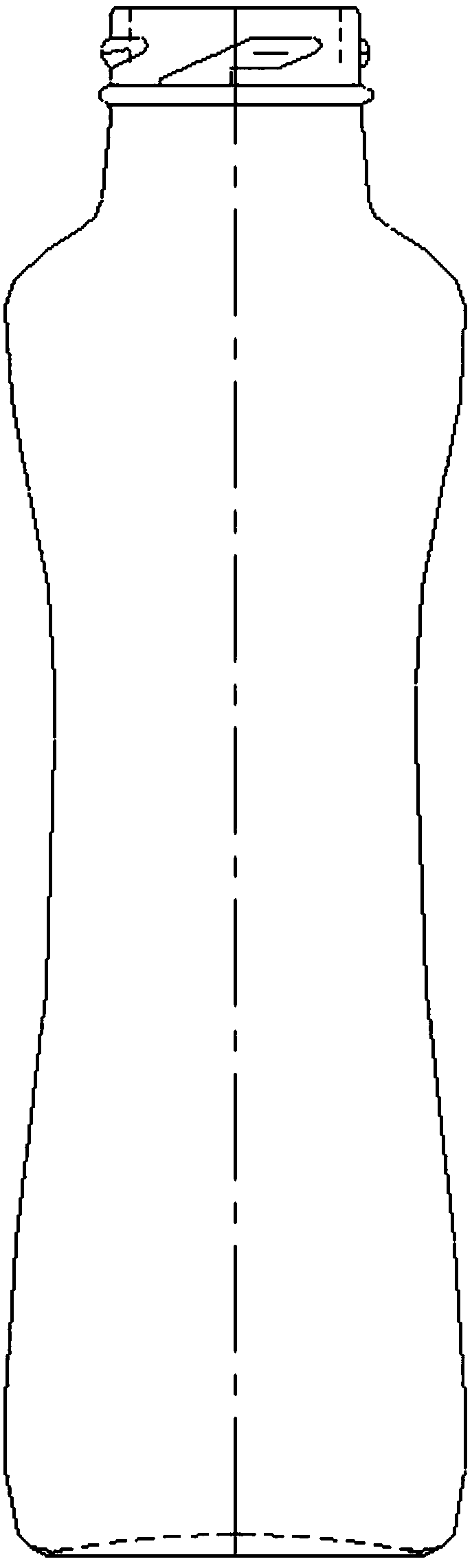

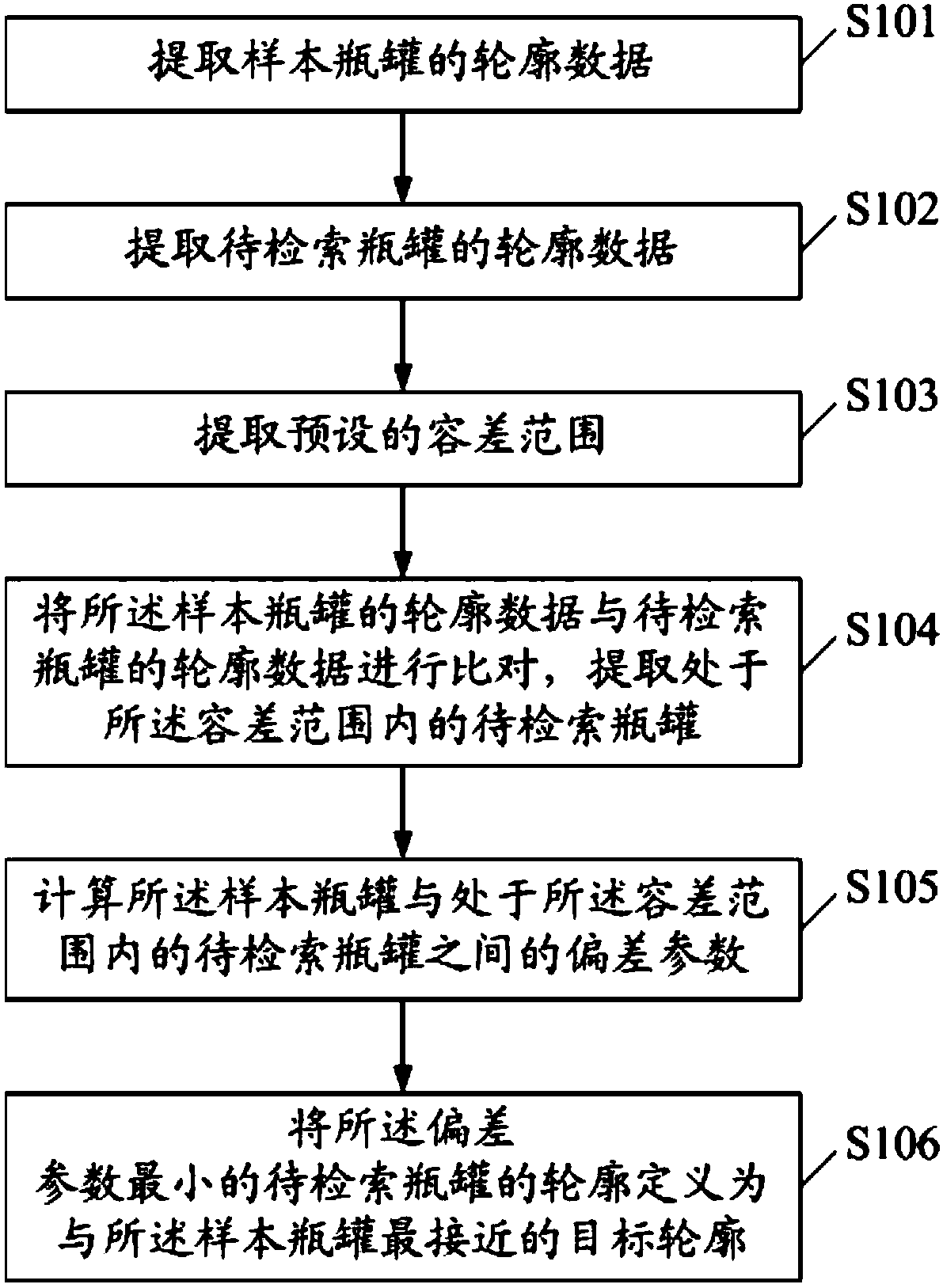

Round container contour similarity retrieving method

ActiveCN104299226AExact searchImage analysisSpecial data processing applicationsPattern recognitionComplete data

The invention discloses a round container contour similarity retrieving method which includes the steps that contour data of a sample container are extracted; contour data of a container to be retrieved are extracted; a preset tolerance range is extracted; the contour data of the sample container and the contour data of the container to be retrieved are compared, and the container to be retrieved in the tolerance range is extracted; the deviation parameter between the sample container and the container to be retrieved in the tolerance range is calculated; the contour of the container to be retrieved with the maximum difference parameter is defined as the target contour which is most similar to the sample container. By means of the round container contour similarity retrieving method, the contour data are automatically extracted, a container contour database with complete data is set up, and the method is more convenient and more accurate; meanwhile, the contour of the container to be retrieved with the minimum difference is defined as the target contour most similar to the sample container by analyzing the height tolerance, the neck diameter tolerance, the arithmetic mean deviation and the mean variance, and convenient and accurate searching of the round container with the similar contour is achieved.

Owner:DAYE HUAXING GLASS

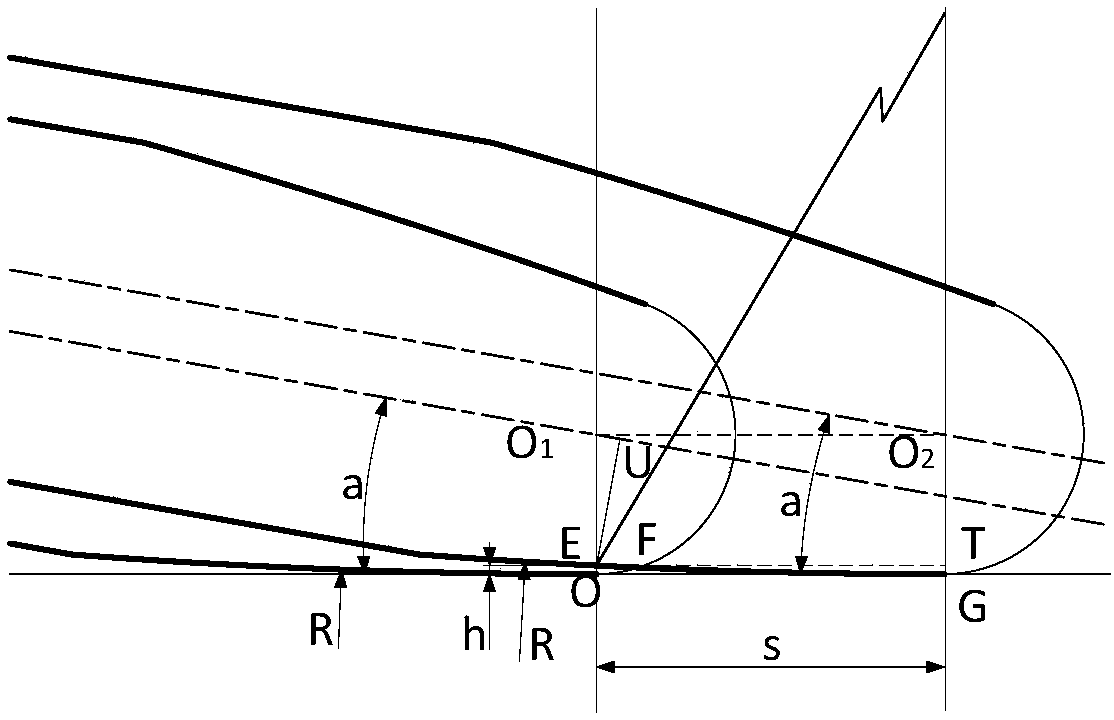

Customizing method of drum-taper-shaped ball-end milling cutter

ActiveCN108176887AGuarantee the quality of the machined surfaceImprove processing efficiencyGeometric CADMilling cuttersNumerical controlGeometric relations

The invention provides a customizing method of a drum-taper-shaped ball-end milling cutter, and belongs to the technical field of numerical control milling machining. The customizing method comprisesthe steps that relevant geometrical relationships of the drum-taper-shaped ball-end milling cutter are designed, and cutting parameters of the machining efficiency are taken into consideration, so that relevant geometrical drawings are obtained; then mathematical models are established according to the limitation and restriction relationship of the relevant geometrical relationships; when parameterized customization is conducted, known parameters are brought in the relevant mathematical models, and the barrel-shaped side blade radius range and the cutter bar neck diameter range are calculated;parameters within the barrel-shaped side blade radius range and the cutter bar neck diameter range are manually given, and integers are selected as the parameters; and the rest of parameter values are obtained, and a three-dimensional model of the drum-taper-shaped ball-end milling cutter is established in three-dimensional software UG. The customizing method of the drum-taper-shaped ball-end milling cutter has the advantages that the machining efficiency is improved threefold or severalfold on the basis that the quality of the machined surface is guaranteed, the phenomenon that due to cutterreplacement, cutter connecting marks and cutter replacement errors exist is avoided, systematized and parameterized customization conducted by engineering personnel is facilitated, and the customizing method is quite simple and convenient to use.

Owner:DALIAN UNIV OF TECH

Single crystal pulling-up apparatus of pulling-up silicon single crystal and single crystal pulling-up method of pulling-up silicon single crystal

ActiveUS8936679B2Quality improvementAvoid misalignmentAfter-treatment apparatusPolycrystalline material growthCrucibleCzochralski method

According to one exemplary embodiment, a single crystal pulling-up apparatus of pulling-up silicon single crystals by a Czochralski method, is provided with: a neck diameter measuring portion which measures a diameter of a grown neck portion; a first compensation portion which outputs a first compensated pulling-up speed for the seed crystals based on a difference between a measured value of the diameter of the neck portion and a target value of the neck portion diameter previously stored; a second compensation portion which outputs a second pulling-up speed while limiting an upper limit of the first pulling-up speed to a first limit value; and a crucible rotation number compensation portion which lowers the number of a rotation of a crucible at least in a period where the upper limit of the first pulling-up speed is limited to the first limit value.

Owner:GLOBALWAFERS JAPAN

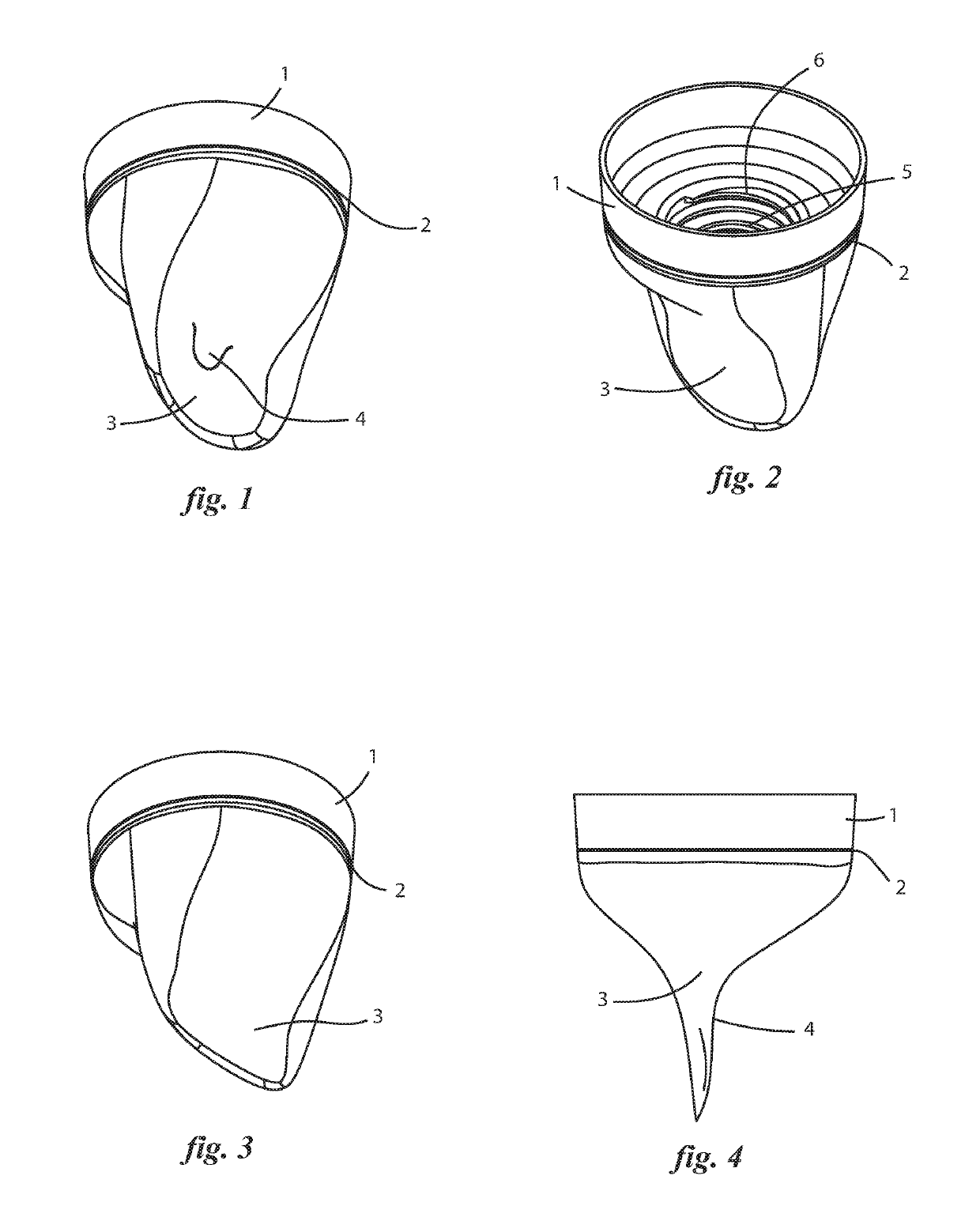

Diaper cream applicator with lid

ActiveUS20190104825A1Improved cream applicator apparatusTravelling carriersHoldersHermetic sealDiaper rash

This invention offers improvements over the diaper rash cream applicator that I described in U.S. Pat. No. 8,920,059. The earlier invention provided an applicator apparatus and lid to facilitate one-handed application of diaper rash cream or other therapeutic cream. The present invention comprises the same essential parts and provides three particular improvements. First, this version has two sets of female screw threads, which fit two common neck diameters for squeeze tubes. Second, the new version has an improved applicator apparatus with a nozzle and a soft, flexible tip with opening flap, providing smoother and more even application of cream than the previous embodiment. Third, the present invention adds a tongue to the lid's interior. When the tube is stored in the lid, the tongue presses the soft, flexible tip of the applicator apparatus firmly against the opening of the nozzle, creating a leakproof and airtight seal.

Owner:KRAVCHENKO ALINA

Projection tube having different neck diameters

InactiveUS6998767B2Improve focus performanceReduce total powerTelevision system detailsCathode-ray/electron-beam tube electrical connectionMedicineElectron gun

A projection tube having a high focusing performance at a low deflection power includes a funnel, a neck portion and a stem portion which seals the neck portion. The neck portion of the projection tube includes a first neck portion which is connected to the funnel and has a first neck outer diameter, and also includes a second neck portion which accommodates an electron gun and has a second neck outer diameter which is larger than the first neck outer diameter.

Owner:HITACHI LTD +1

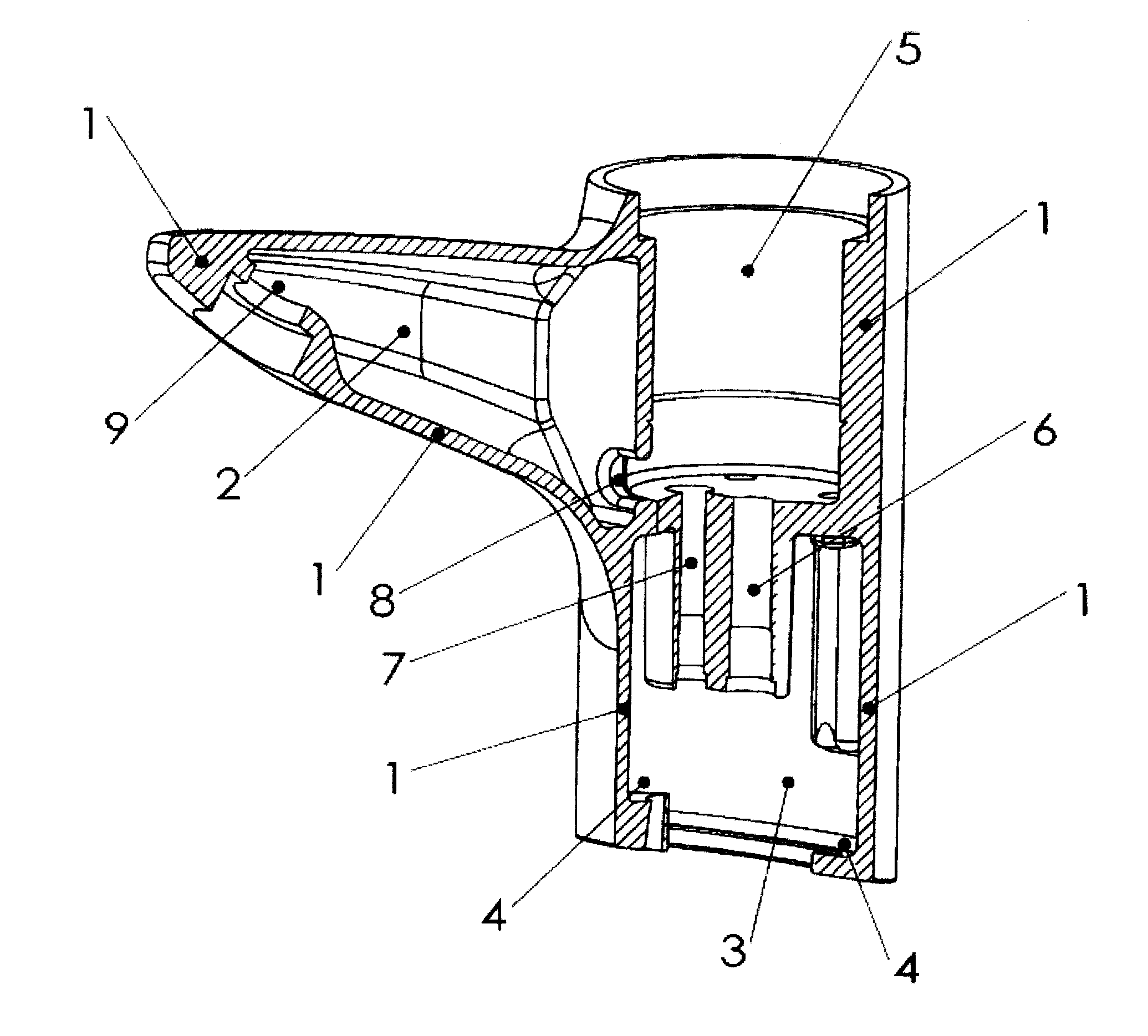

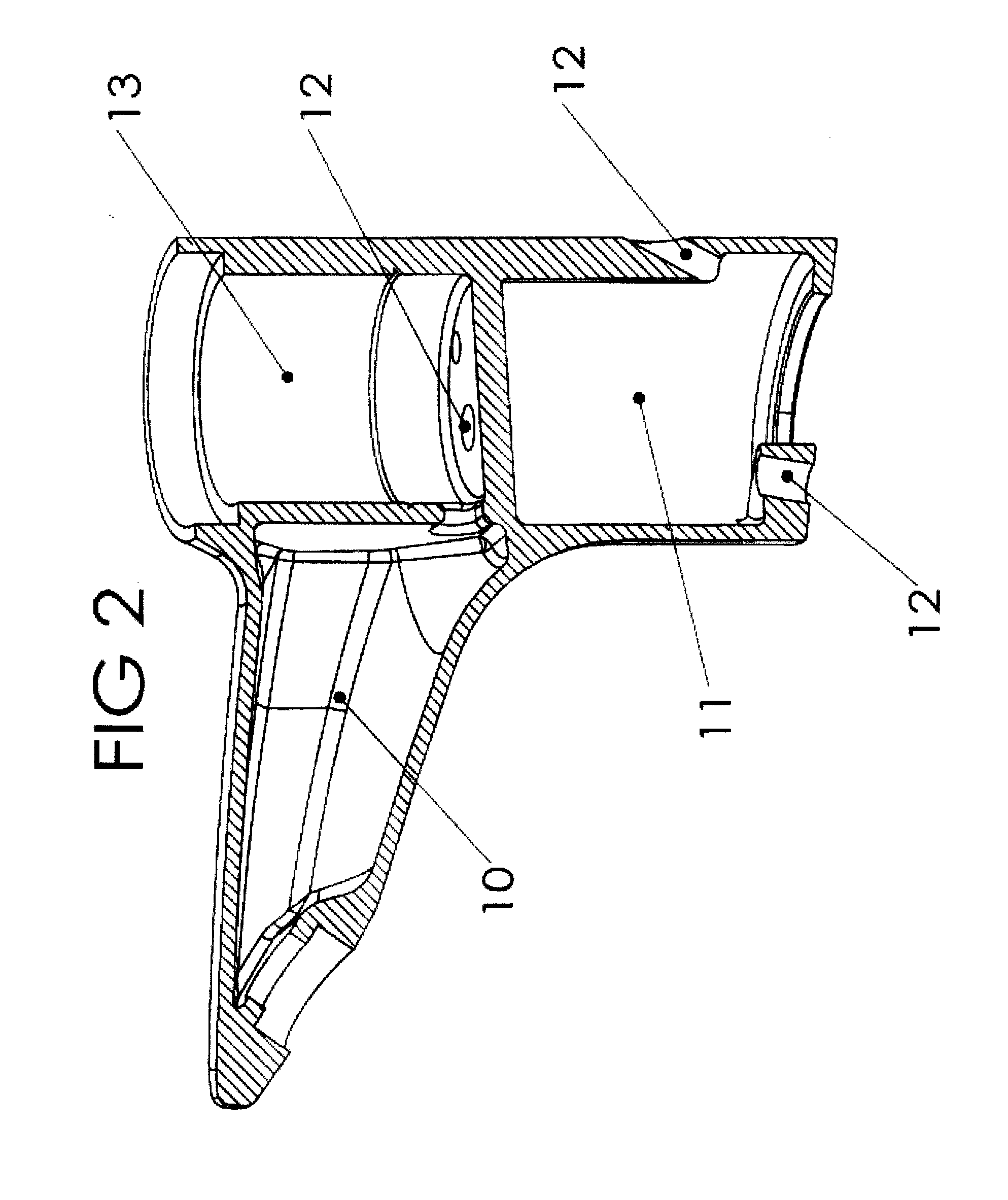

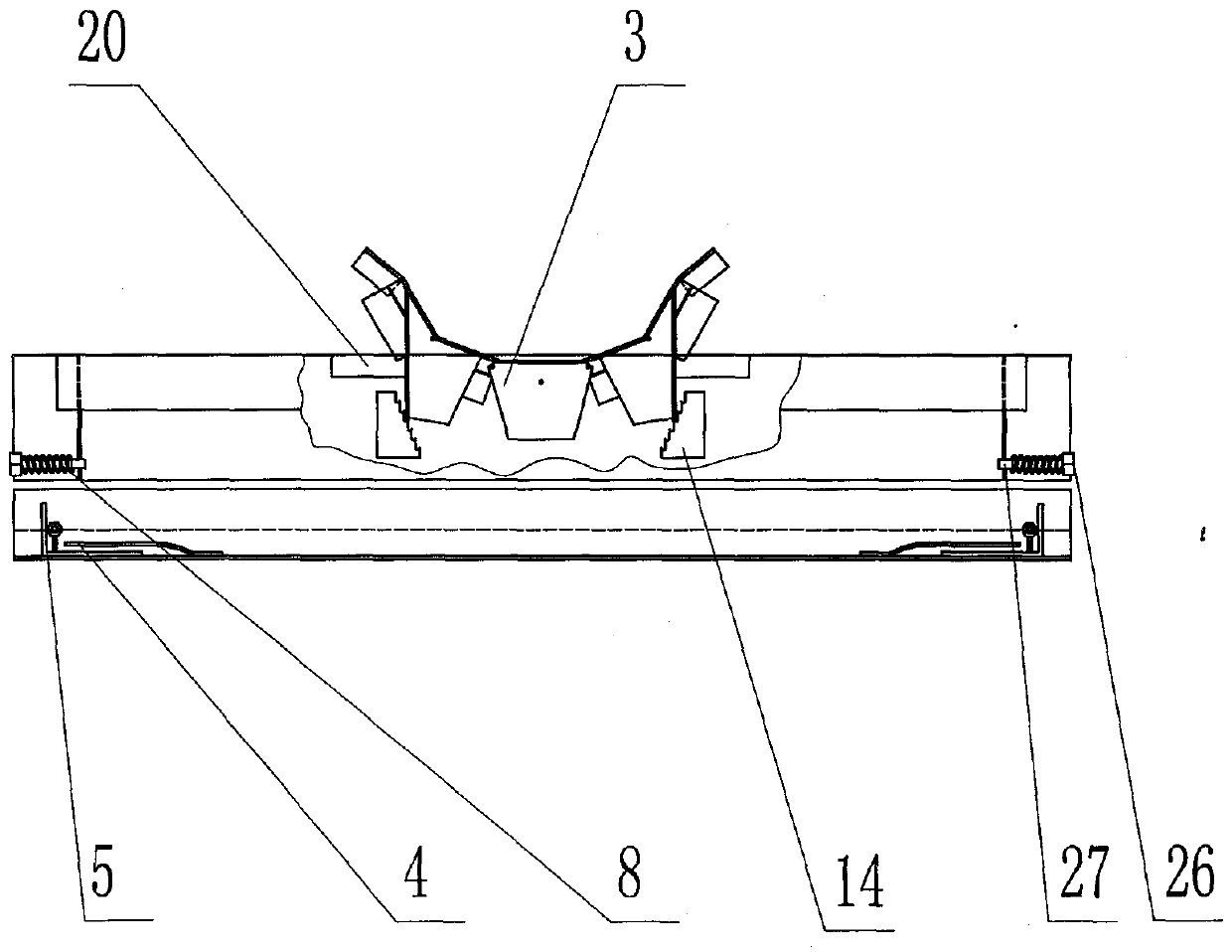

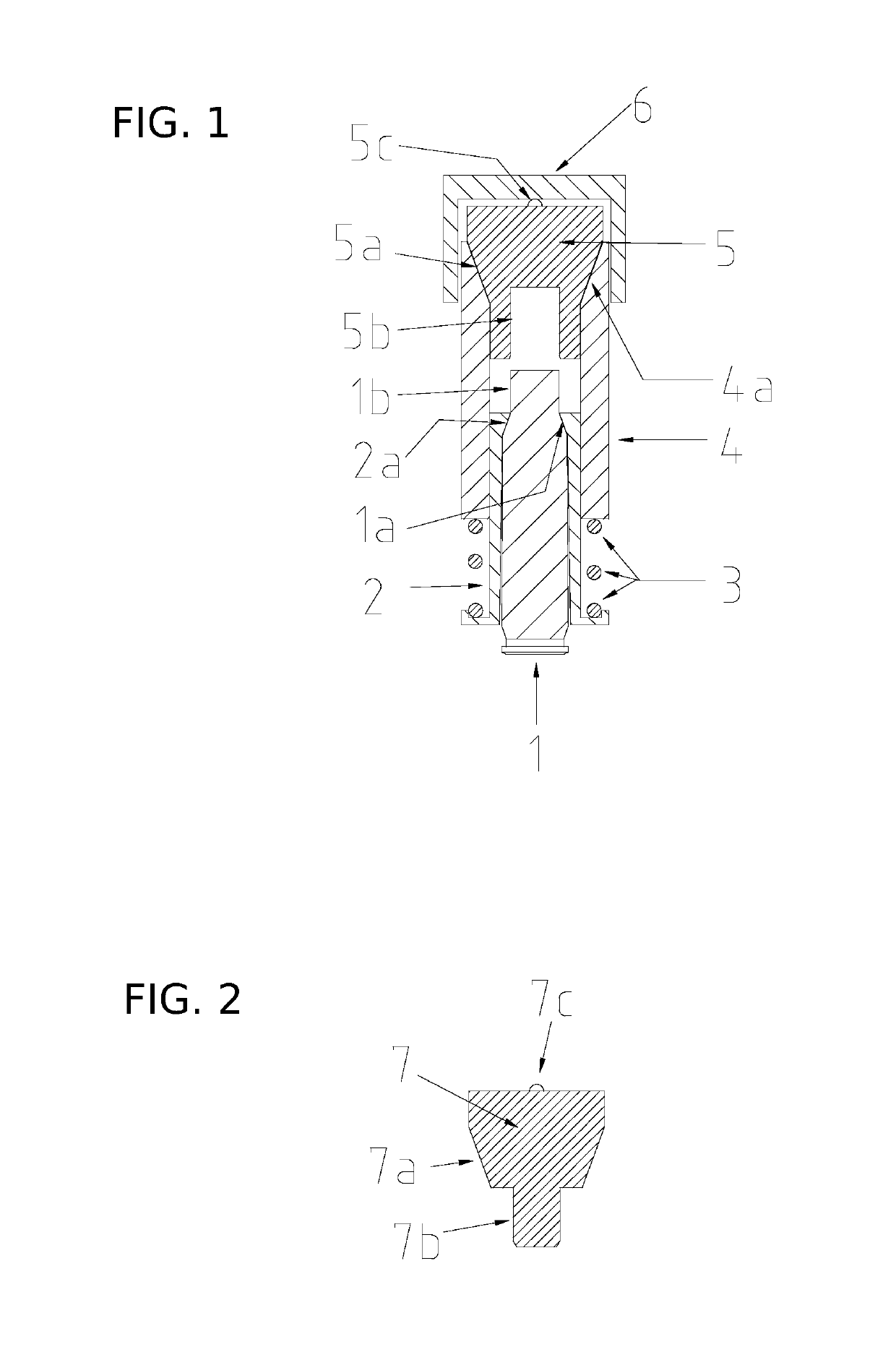

Necking sizing die for shoulder breeching rifle cartridges

ActiveUS10473444B1Easy to controlImprove accuracyAmmunition testingHollow articlesEngineeringTwo step

A neck sizing die for shoulder breeching ammunition cartridge cases that uses the shoulder to align the case, not the body. Alignment occurs before resizing. Resizing is done in a two-step process: a bushing is used to shrink the neck diameter and then an expansion button is used to increase it. Bushing and button diameters are highly selectable and easily changed. Cone-and-cup interfaces ensure concentricity of the case shoulder to the bushing or button. The unique alignment technique and two-step sizing method produces a case with a neck having an interior diameter of the user's choice with the interior wall of the neck aligned to the shoulder. This results in a case that will more reliably position the bullet concentric with the bore of the barrel than existing tools and methods.

Owner:GENT JEFFREY HOWARD

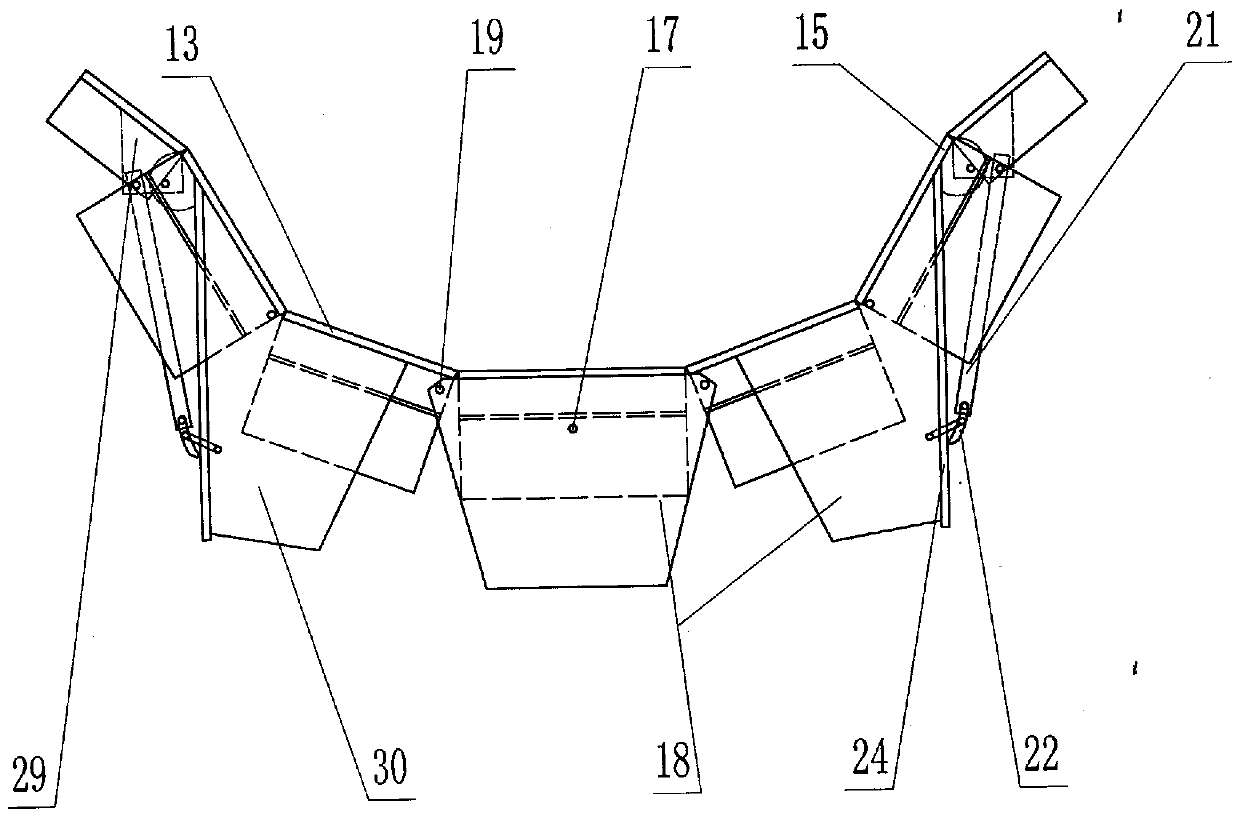

Design method of a slider-type cross cardan shaft used for high torque

ActiveCN102518688BImprove bearing capacityIncreased neck diameterYielding couplingEngine lubricationCarrying capacityUniversal joint

In order to improve the lubricity of the cross cardan shaft and reduce wear and bearing capacity, the present invention provides a design method for a slider-type cross cardan shaft used for high torque, which includes the first universal joint yoke and the second joint yoke connected to each other. Two universal joint yokes, the first universal joint yoke extends into the depression at the left end of the second universal joint yoke through the protrusion at the right end and connects with the bottom surface of the depression; and the second universal joint yoke is connected to the bottom surface of the depression; The neck diameter of a universal joint yoke is larger than the body diameter; a groove for placing lubricant is arranged on the bottom surface of the recessed part. In the present invention, lubricant is provided between the contact surfaces of the universal joint yokes, which reduces wear and improves the service life, and at the same time increases the diameter of the neck of the first universal joint yoke, so that the cross cardan shaft has High bearing capacity.

Owner:西安奥奈特固体润滑工程学研究有限公司

Method for preparing (110) float zone silicon crystal

ActiveCN101974779BMeeting Silicon Material Requirements for High Efficiency Solar CellsPolycrystalline material growthBy zone-melting liquidsEngineeringSingle crystal

The invention discloses a method for preparing a (110) float zone silicon crystal. The key point of the technical scheme is that: 1, in the seeding technology, by controlling and adjusting the descending speed of a lower shaft and adjusting the power, the seeding neck diameter is controlled in a range from 2 to 6 mm, wherein the seeding neck diameter is more than or equal to 1.5 times the diameter of a single crystal; 2, in the shouldering technology, by controlling and adjusting the descending speed and rotating speed of the lower shaft and the descending speed and rotating speed of an uppershaft and adjusting the power, the shouldering angle is 50+ / -5 degrees; and 3, in the ending technology, the ending length is more than 1.2 times the diameter of the single crystal, and the minimum tail diameter is less than or equal to 5mm. The method overcomes the defects that the (110) silicon single crystal prepared by the conventional direct pulling method has high impurity content and cannot meet the requirement on the silicon single crystal of a high-efficiency solar cell, and successfully prepares a low-impurity content and long-service life (110) dislocation-free float zone silicon crystal by a floating zone method, wherein the (110) float zone silicon crystal has the dislocation density of less than or equal to 500 units / cm<2> and the minority carrier lifetime of more than or equal to 300us, and meets the requirement of a silicon material for preparing the high-efficiency solar cell.

Owner:ZHONGHUAN ADVANCED SEMICON MATERIALS CO LTD +1

Dumbbell bar matched with various kinds of bottlenecks

Owner:安徽上造智能设备科技有限公司

A method for similarity retrieval of round bottle and can contours

ActiveCN104299226BExact searchImage analysisSpecial data processing applicationsComplete dataPattern recognition

The invention discloses a round container contour similarity retrieving method which includes the steps that contour data of a sample container are extracted; contour data of a container to be retrieved are extracted; a preset tolerance range is extracted; the contour data of the sample container and the contour data of the container to be retrieved are compared, and the container to be retrieved in the tolerance range is extracted; the deviation parameter between the sample container and the container to be retrieved in the tolerance range is calculated; the contour of the container to be retrieved with the maximum difference parameter is defined as the target contour which is most similar to the sample container. By means of the round container contour similarity retrieving method, the contour data are automatically extracted, a container contour database with complete data is set up, and the method is more convenient and more accurate; meanwhile, the contour of the container to be retrieved with the minimum difference is defined as the target contour most similar to the sample container by analyzing the height tolerance, the neck diameter tolerance, the arithmetic mean deviation and the mean variance, and convenient and accurate searching of the round container with the similar contour is achieved.

Owner:DAYE HUAXING GLASS

A Built-in Shrinking Nozzle Precision Tube Ring Cutting Machine

ActiveCN103753621BReduce manufacturing costReduce machine set-up timeMetal working apparatusReciprocating motionEngineering

Owner:SHENZHEN JINDIAN MACHINERY AUTOMATION CO LTD

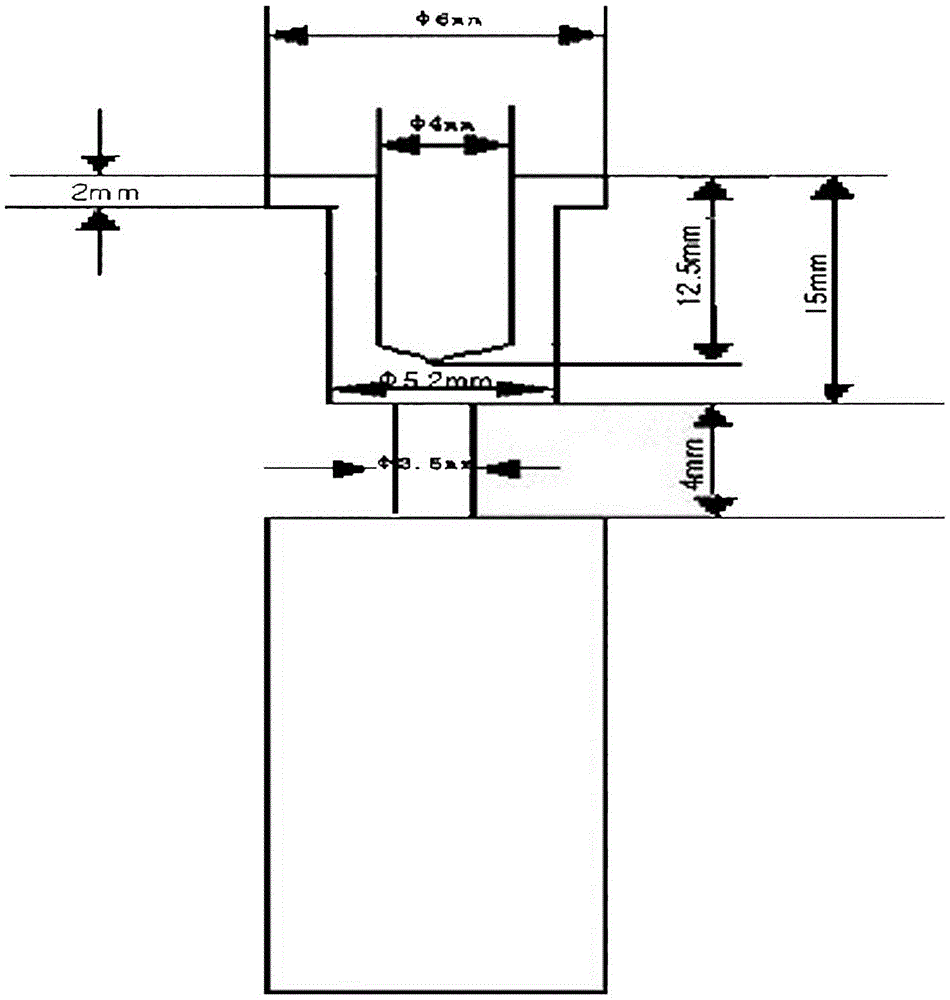

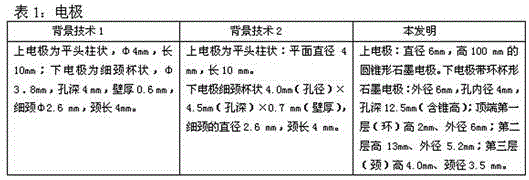

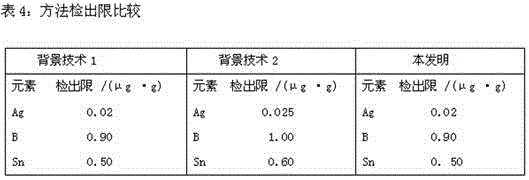

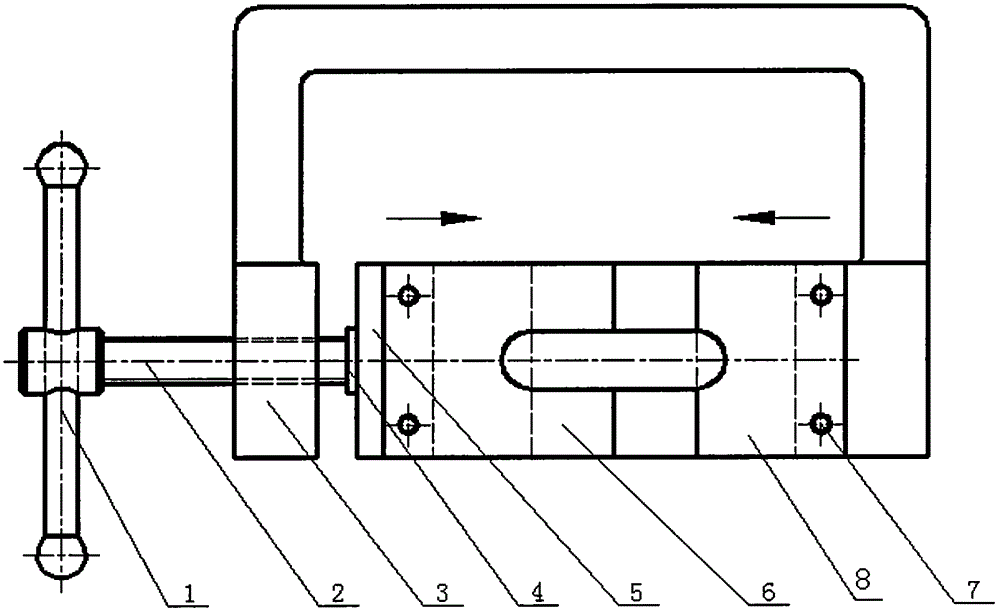

Method for Determination of Silver Boron Tin in Geochemical Exploration Samples

ActiveCN103983583BReliable Analytical QualityLess loadingColor/spectral properties measurementsSpectrographBuffering agent

The invention relates to a method for measuring silver, boron and tin in a geochemical exploration sample, for solving the problems of poor accuracy and precision while boron, tin and silver in soil are measured simultaneously in the original method; instruments, equipment and reagents are as follows: a grating spectrograph, an automatic photometer, an electrode, a spectrum sensitive plate, an agate mortar, a buffering agent and CdO, wherein the automatic photometer is connected to a computer; the electrode comprises an upper electrode and a lower electrode; the upper electrode is a conical graphite electrode; the lower electrode is 6 mm in outside diameter and is provided with a ring-shaped cup graphite electrode; the ring cup graphite electrode is 2 mm in ring height, 6 mm in ring outside diameter, 4 mm in hole inside diameter, 12.5 mm in hole depth, 13 mm in cup height, 5.2 mm in cup outside diameter, 4.0 mm in neck height and 3.5 mm in neck diameter; the mass percentage of the buffering agent is that mKI:mK2S207:mSiO2:mC:mZnO is 24:20:48:7:1; 0.015% of CdO is additionally added; a specimen is weighed; 0.0500 g of buffering agent is weighed and put into a crucible; after being stirred for one minute, the mixture is put into the electrode and subjected to pressing, spectrograph, development and photographic fixing; the automatic photometer translates a spectrum and analyzes internal standard line pairs as follows: Ag328.07 nm / Cd326.1 nm, B249.7 nm / Si249.4 nm, and Sn317.51 nm / Cd326.1 nm; a standard curve is automatically fit; the content of individual elements in a sample is automatically calculated.

Owner:四川省地质矿产勘查开发局成都综合岩矿测试中心

Simple taper shank puller

InactiveCN104669201AQuick changeEasy to manufactureMetal-working hand toolsArchitectural engineeringDrill

The invention relates to a simple taper shank puller. A screw is installed on the left part of a support frame, a mixing rod is fixed on the left end of the screw, a pressing plate is fixed on the right end of the screw, the pressing plate is connected with a support plate, a left wedge block is fixed on the support plate by cylindrical pins, and a right wedge block is fixed on the right part of the support frame by cylindrical pins. U-shaped grooves are formed in the left wedge block and the right wedge block, the cross sections of the left wedge block and the right wedge block are inclined surfaces, and the inclination is between 1:4 and 1:5. A drill chuck is arranged in the U-shaped grooves between the left wedge block and the right wedge block. When taper shanks of a milling chuck and the drill chuck are removed, screw transmission is utilized, and extrusion force is generated, so that equipment is difficult to damage. Additionally, different specifications of wedge blocks can be quickly replaced for removal according to different specifications of neck diameters of the taper shanks, so that the efficiency is high. Various specifications and dimensions of U-shaped groove wedge blocks can be processed according to different sizes of the neck diameters of the taper shanks by U-shaped groove holes in the wedge blocks, so as to be convenient to select and use. The wedge blocks of the simple taper shank puller can be manufactured by utilizing leftover materials, the manufacturing is convenient, and the cost is low.

Owner:富妍馨

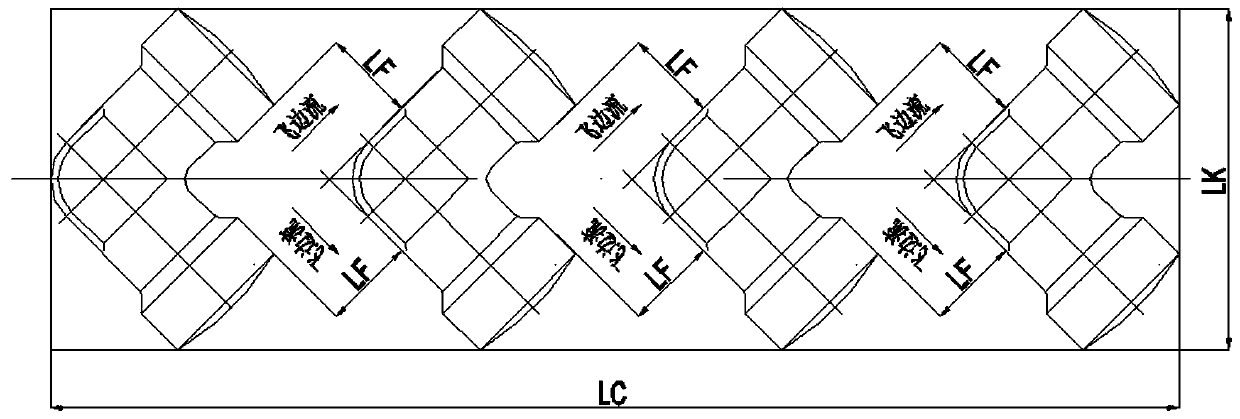

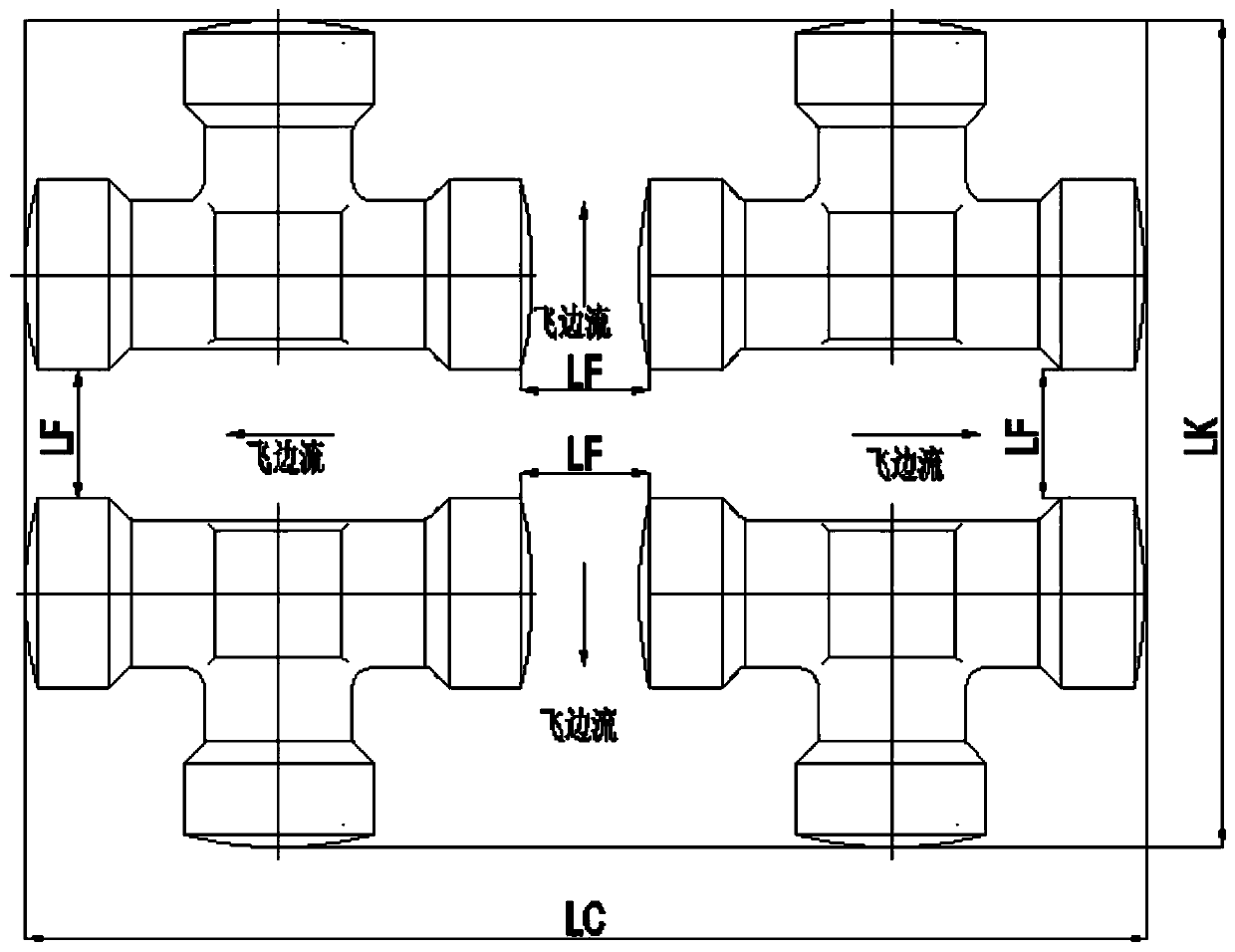

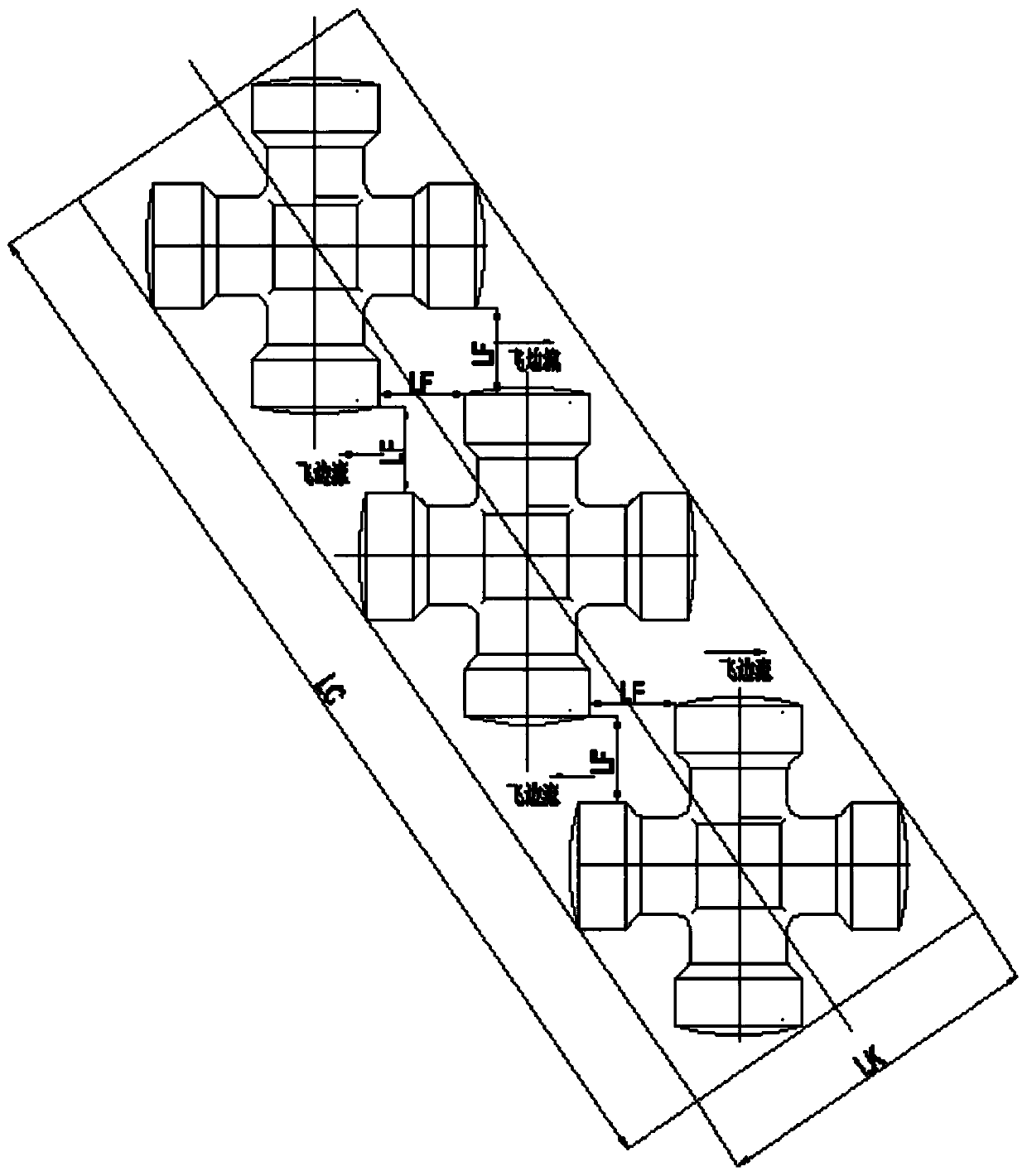

Hydraulic pneumatic pipe joint blank group die forging manufacturing method

ActiveCN110538954AIncrease production capacityReduce energy costsForging/hammering/pressing machinesEngine componentsManufacturing technologyCombined method

The invention provides a hydraulic pneumatic pipe joint blank group die forging manufacturing method. The die forging manufacturing method is based on a combined method of one-die multi- forge piecesto make pipe joint blanks. The form of each forge piece is consistent in the combined method of the one-die multi- forge pieces. The specific forms comprise that elbow combines with elbow, three-way combines with three-way and four-way combines with four-way; the die design of group die forging manufacturing method for fly edge flow direction is that the dimension calculation value of the fly edgeflow LF is LF = K (H + D1 + D2) / 3; when D1 = D2, LF = K (H + 2d2) / 3; wherein, the fly edge flow LF is the fly edge flow direction, H refers to the size of a joint body wrench, D1 refers to the head diameter length of a tube joint blank, D2 refers to the neck diameter length of the tube joint blank, and K ranges from 0.8 to 0.9. According to the characteristics that the volume and weight of the hydraulic pneumatic pipe joint blanks are less, the production capacity can be effectively increased, the energy consumption and the production cost can be effectively reduced through the group dieforging manufacturing technology and the combined method of the one-die multi- forge pieces.

Owner:海盐管件制造有限公司

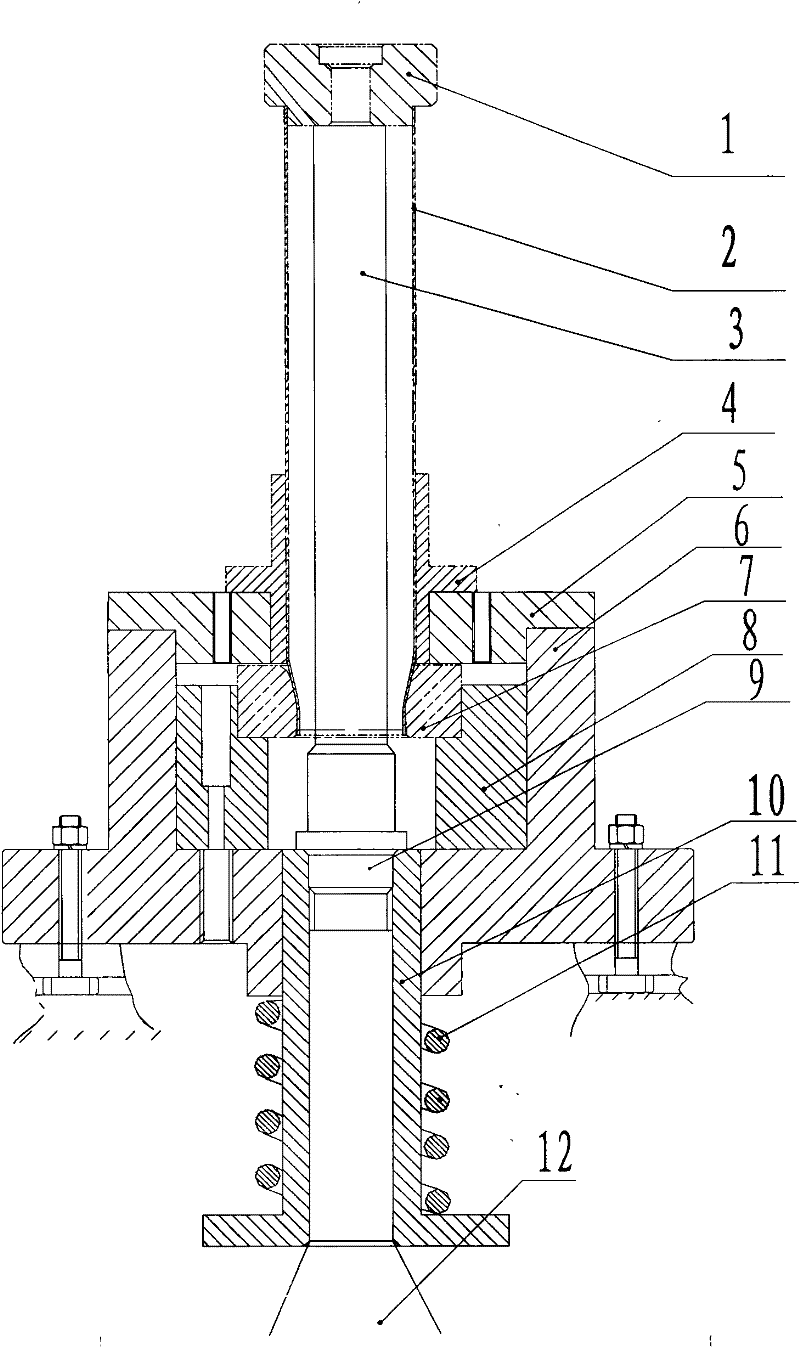

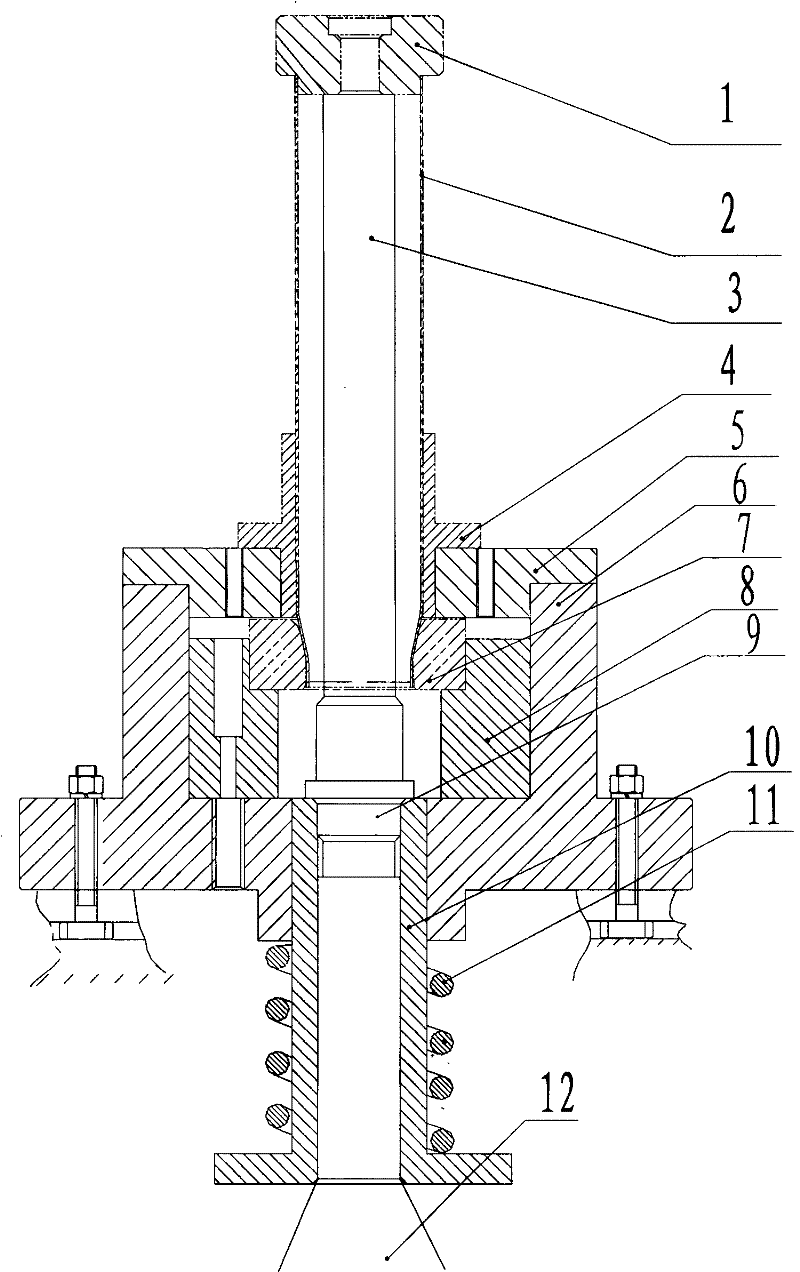

Combined necking die

InactiveCN101670400BTooling versatility is goodLow costShaping toolsEjection devicesEngineeringPush out

The invention relates to a necking die of a cylinder material, which mainly solves the problems that the current inner and outer supporting necking dies are hard to be changed when being partially damaged and the surface thereof is easy to be scratched when the cylinder material is taken out. The lower die holder (6) of the necking die of a cylinder material is fixed on a pressure device; a die sleeve (8), a cavity (7), a locating plate (5), a guide block (10), a spring (11) and a material returning block (9) are arranged in the lower die holder (6) to form a material returning mechanism; a mandrel (3) is closely fastened with a pressing sleeve (1); the inner diameter of the guide sleeve (4) is the same as the outer diameter of the cylinder material (2); and the shape and size of the cavity (7) are the same as the shape and size of the necking diameter. After the mode is adopted, corresponding parts can be changed when the cavity or other parts are damaged, thus reducing the cost; andwhen returning materials, the cylinder material and the mandrel can be pushed out simultaneously, thus reducing the surface scuffing.

Owner:LEACREE CHENGDU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com