Patents

Literature

89results about How to "Reduce machine set-up time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

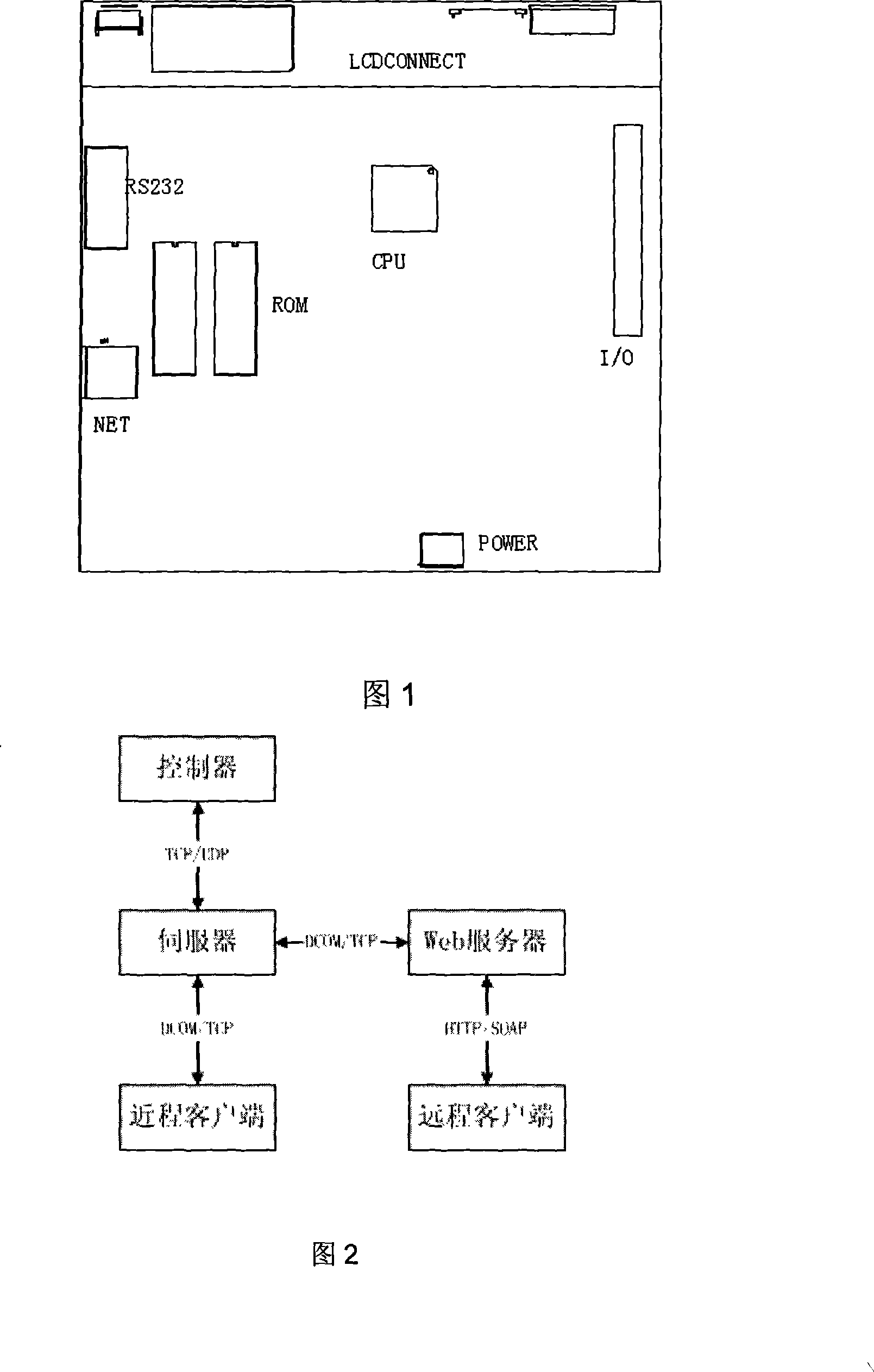

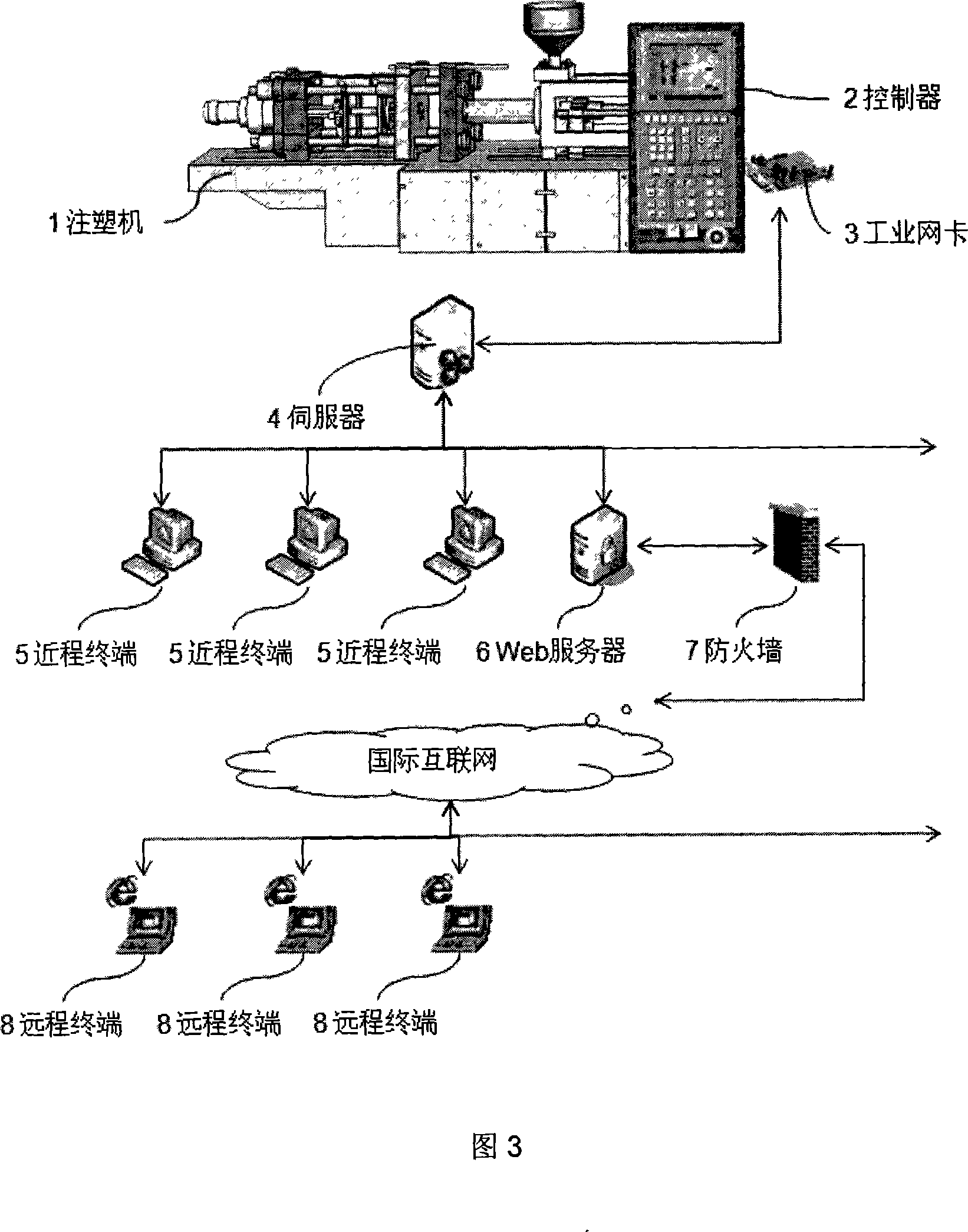

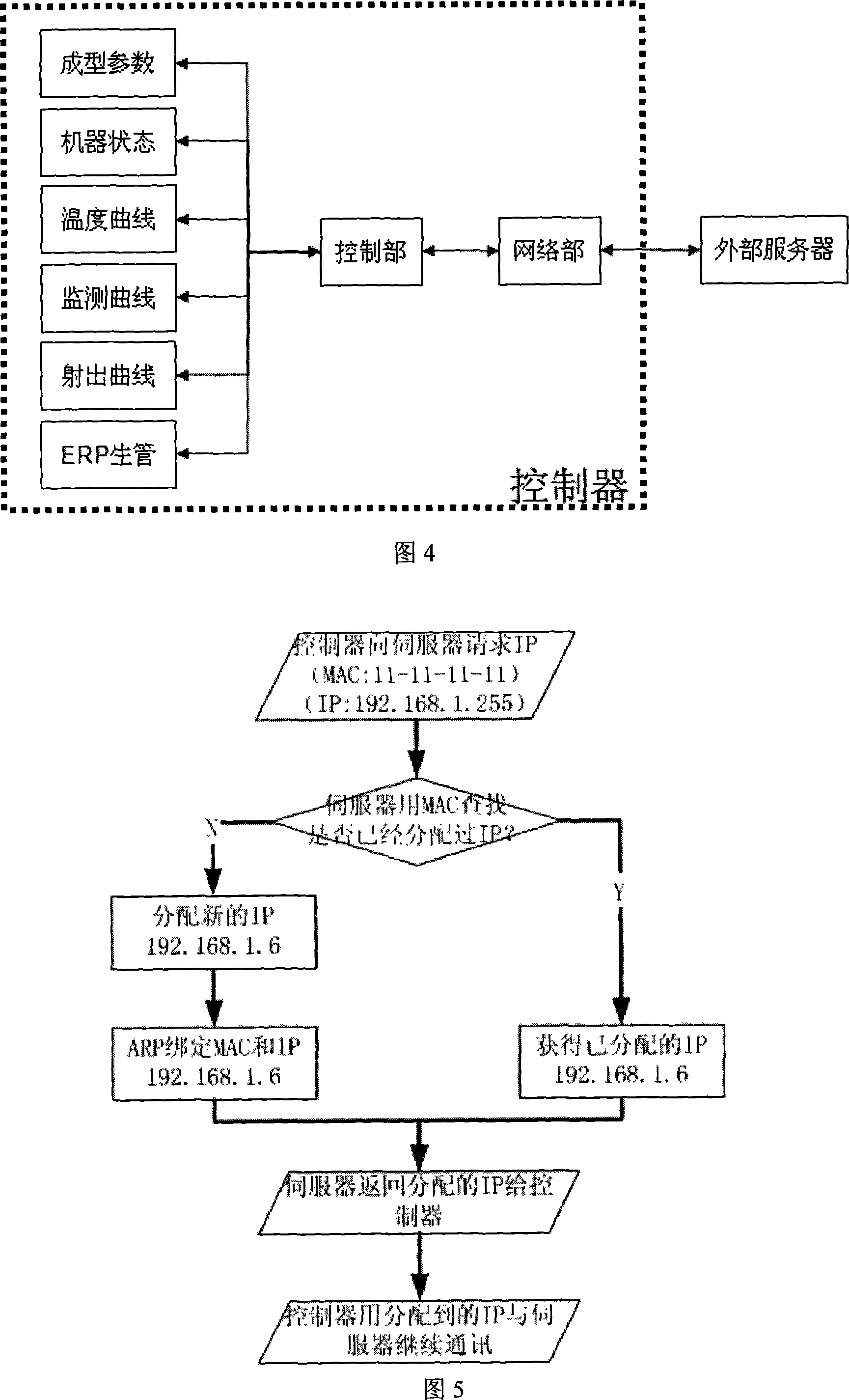

Networking system and method for injection forming machine

InactiveCN101201615AComprehensive collectionImprove efficiencyTotal factory controlProgramme total factory controlIndustrial EthernetInjection molding machine

The invention relates to a networking system and a method for an injection moulding machine. The controller of the injection moulding machine comprises a control device which controls the shaping motion of an injection machine and a network device which sends data in the injection machine to an external servo deriver and receives the control order of the external servo deriver. The interface of the network device adopts a standard industrial Ethernet card which can be both compositive and independent. The standard industrial Ethernet card of the network device is cut over the Ethernet card with the external servo deriver through a twisted pair line and is two-way communicated with the external servo deriver based on transmission control protocol TCP / user datagram protocol UDP communication protocol. The data collection of the invention reaches a second level, that is to say, the data collection of all on-line machines can be finished within a second. With the invention, factories can real-time monitor production process, predict the production process, increase the accuracy of production plan schedule and monitor and manage the progress of orders at any moment.

Owner:NINGBO TECHMATION

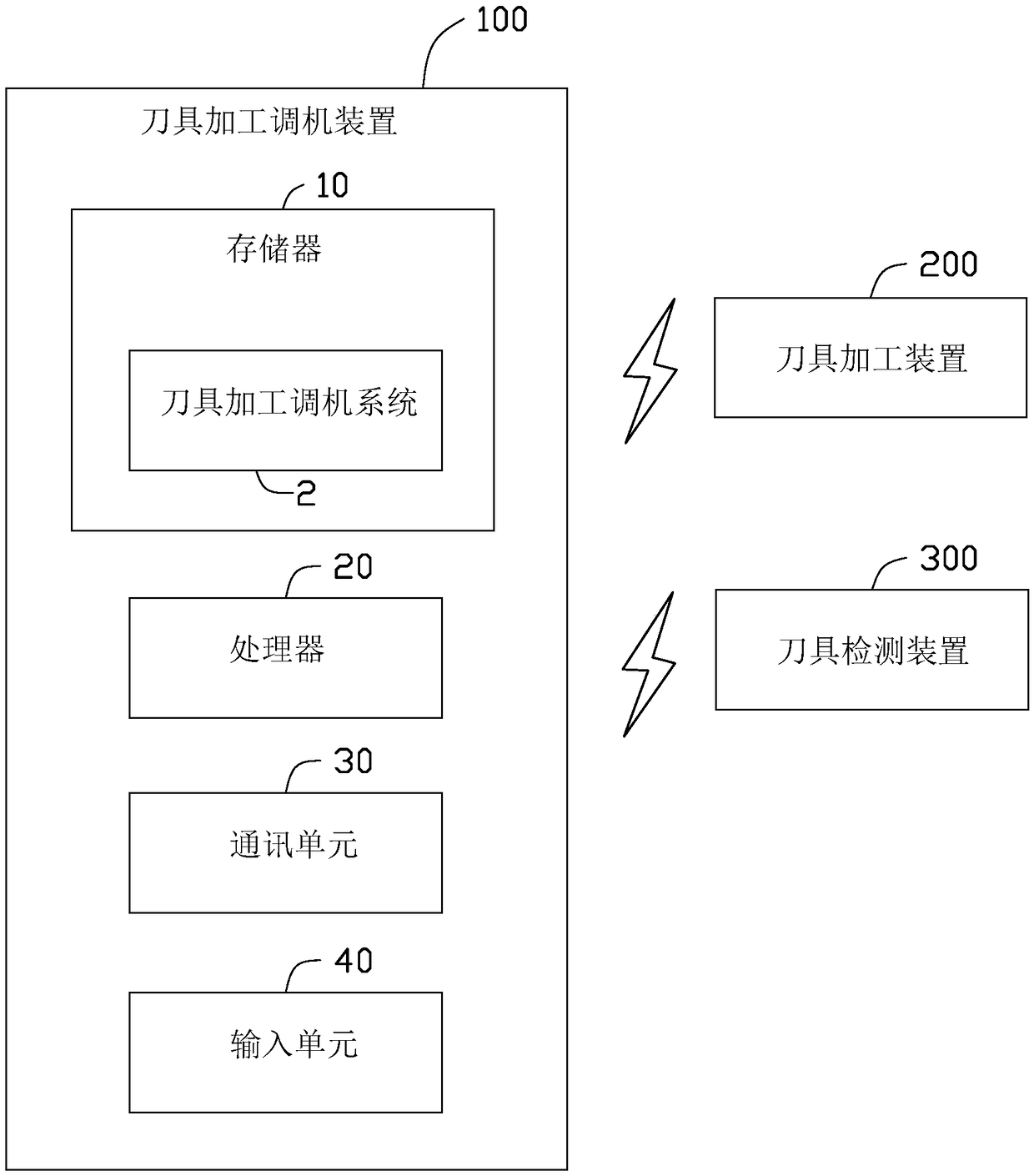

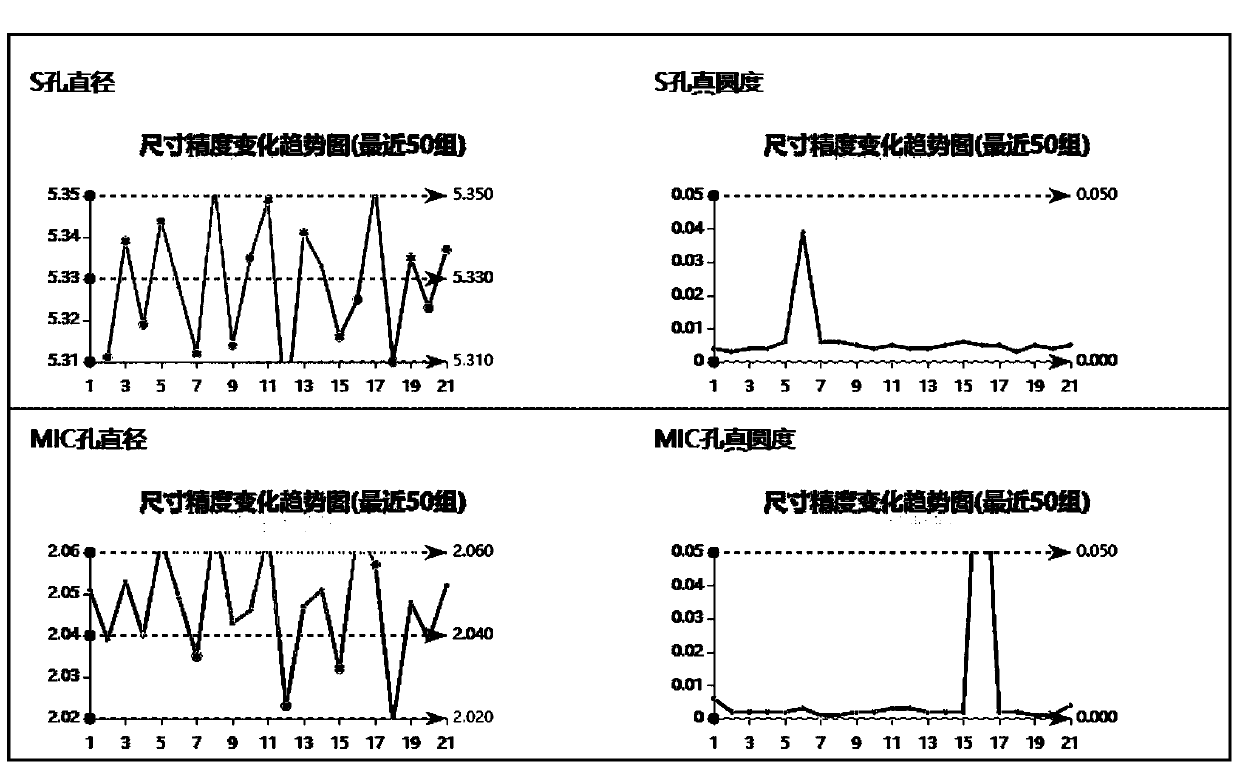

Machine adjusting device and method for tool machining

ActiveCN109176168AImprove the efficiency of processing and adjustment machinesReduce machine set-up timeOther manufacturing equipments/toolsAutomatic grinding controlSize measurementComputer science

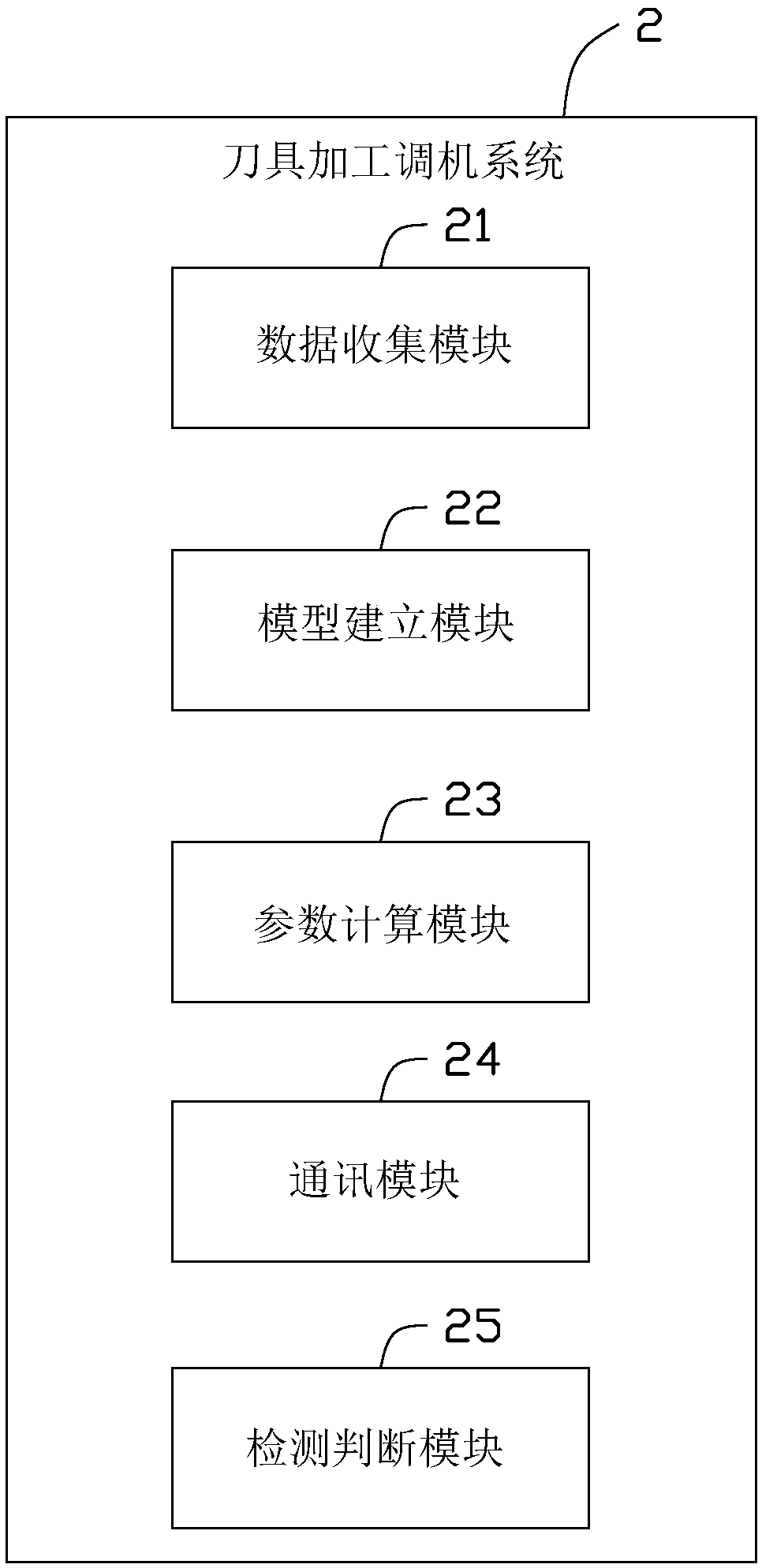

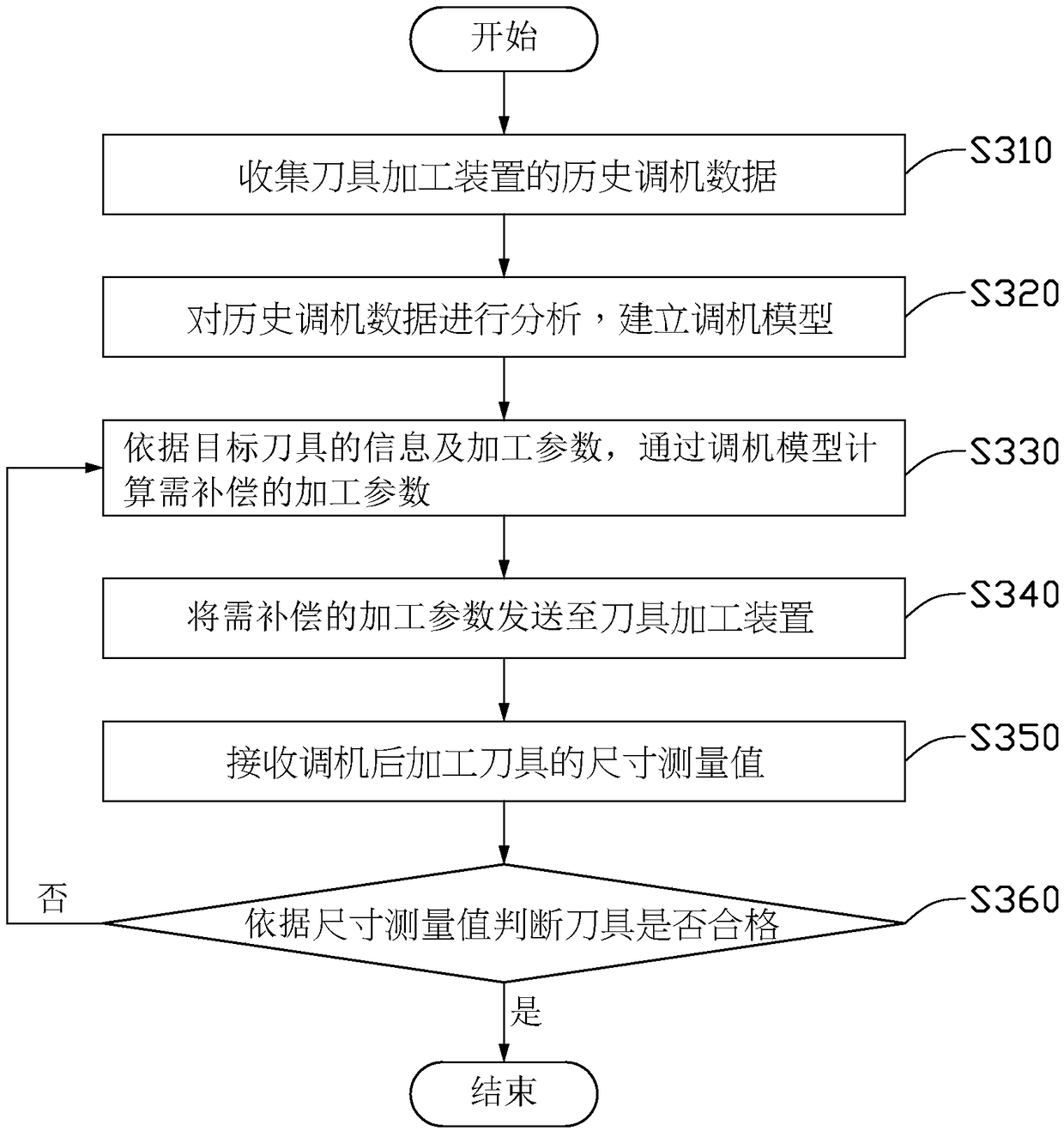

The invention provides a machine adjusting device for tool machining. The machine adjusting device for tool machining comprises at least one processor and a memory, wherein a plurality of modules arestored in the memory, and the plurality of modules are executed by at least one processor; the plurality of modules comprise a data collection module, a model establishing module, a parameter calculation module and a communication module, wherein the data collection module is used for collecting historical machine adjusting data of a tool machining device, the historical machine adjusting data comprises tool information in the machine adjusting process multiple times, corresponding machining parameters and tool size measuring values, the model establishing module is used for analyzing the historical machine adjusting data and establishing a machine adjusting model, the parameter calculation module is used for calculating machining parameters to be compensated through the machine adjustingmodel based on the tool information and the machining parameters of a target tool, and the communication module is used for sending the machining parameters needing to be compensated to the tool machining device so that the tool machining device can be used for machining the target tool according to the machining parameters needing to be compensated. The invention further provides a machine adjusting method for tool machining. According to the machine adjusting device and method for tool machining, the machine adjusting efficiency of tool machining can be improved.

Owner:深圳富联智能制造产业创新中心有限公司

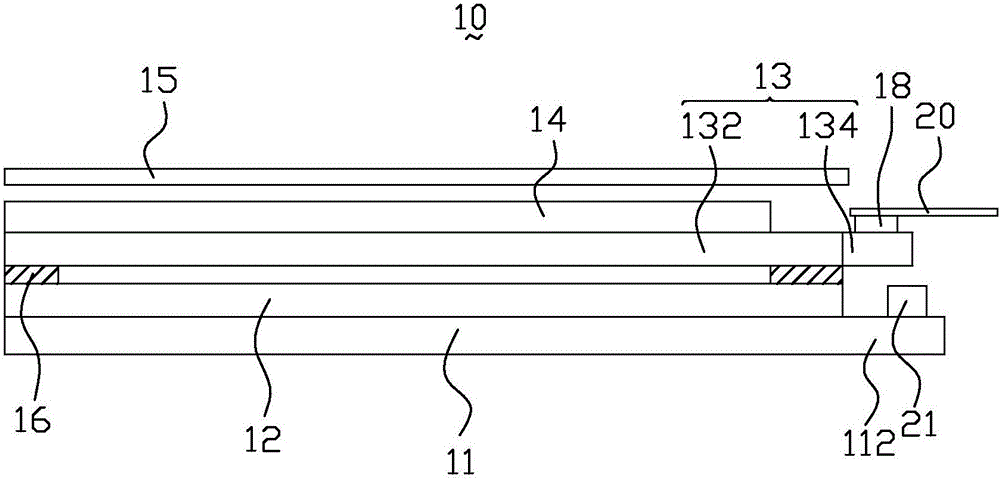

Touch display panel

ActiveCN106055159ALower requirementReduce manufacturing costInput/output processes for data processingFlexible circuitsComputer science

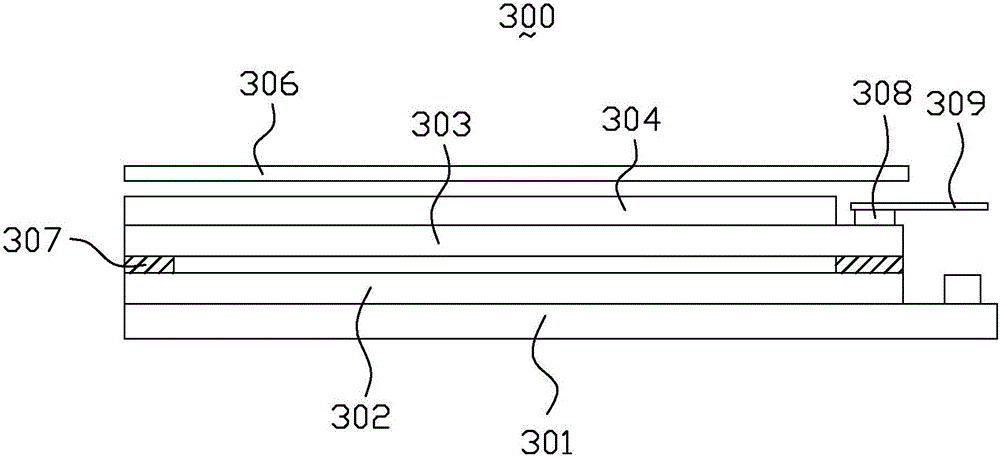

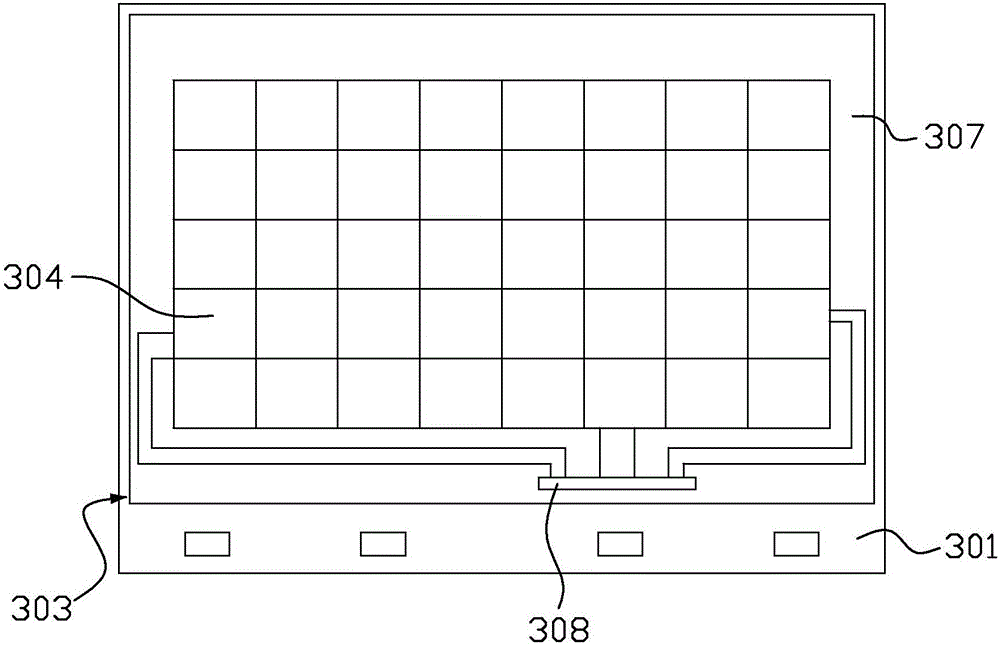

The invention provides a touch display panel which sequentially comprises a TFT (Thin-Film Transistor) substrate, a liquid crystal layer, a special-shaped CF (Color Filter) substrate and a touch sensor from bottom to top. The CF substrate comprises a rectangular CF mainboard region and at least one CF externally expanded region; a black matrix of a certain width is arranged on the periphery of the CF mainboard region; the CF externally expanded regions are convexly arranged at one side of the CF mainboard region and above a terminal region of the TFT substrate; a touch flexible circuit board bonding region is arranged on one CF externally expanded region; the touch sensor is led to the touch flexible circuit board bonding region by routing of inclined wires in the black matrix region; and then the touch flexible circuit board bonding region is electrically connected with a touch flexible circuit board. According to the touch display panel, due to arrangement of the CF externally expanded regions and increase of an available space, the touch flexible circuit board bonding region is arranged in the CF externally expanded regions and a routing space of the inclined wires in the black matrix region is increased; and meanwhile, the requirements of the touch flexible circuit board are weakened, and cost of the touch flexible circuit board is reduced.

Owner:KUSN INFOVISION OPTOELECTRONICS

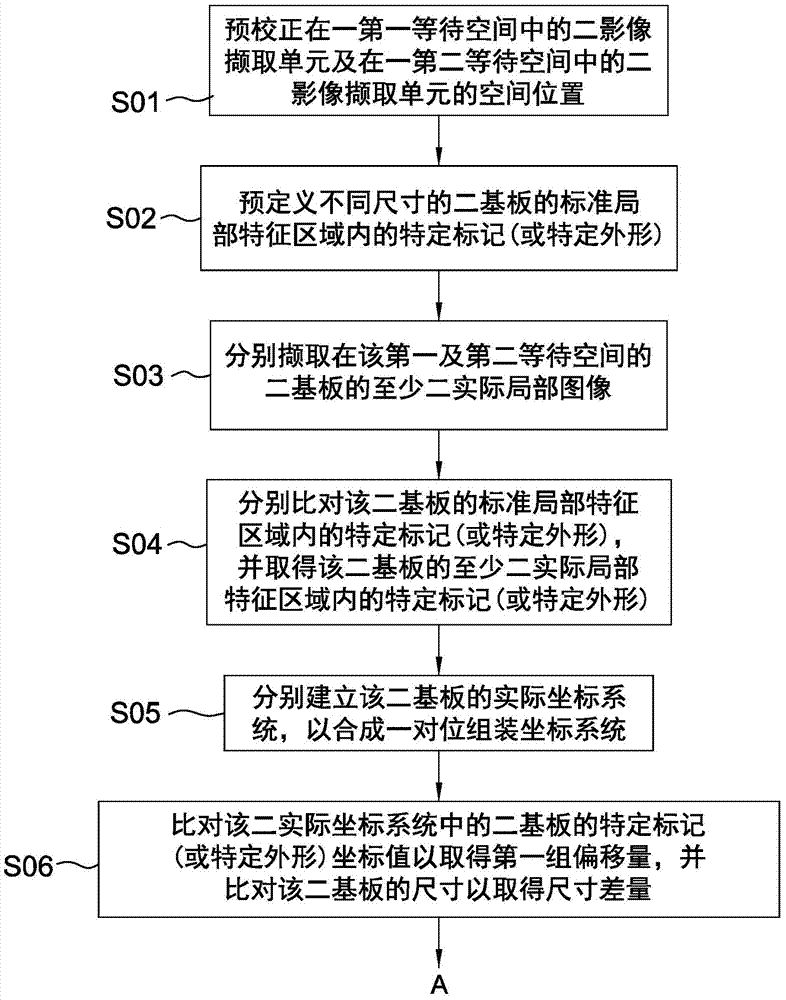

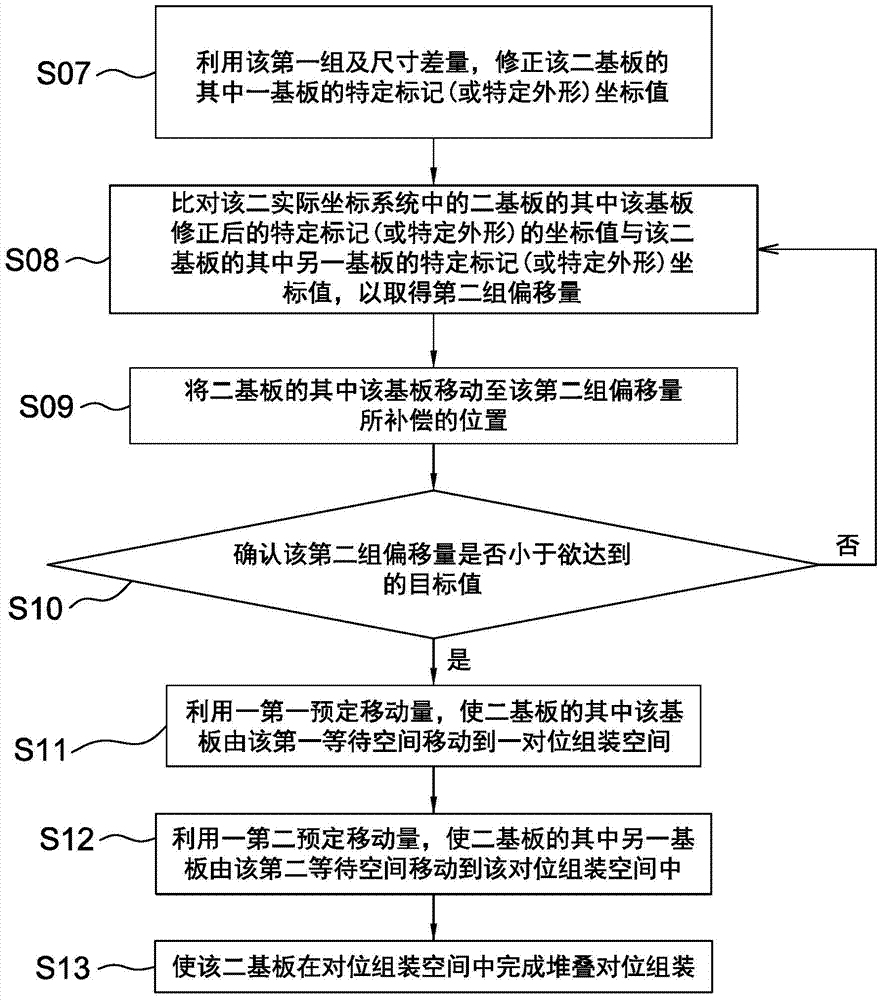

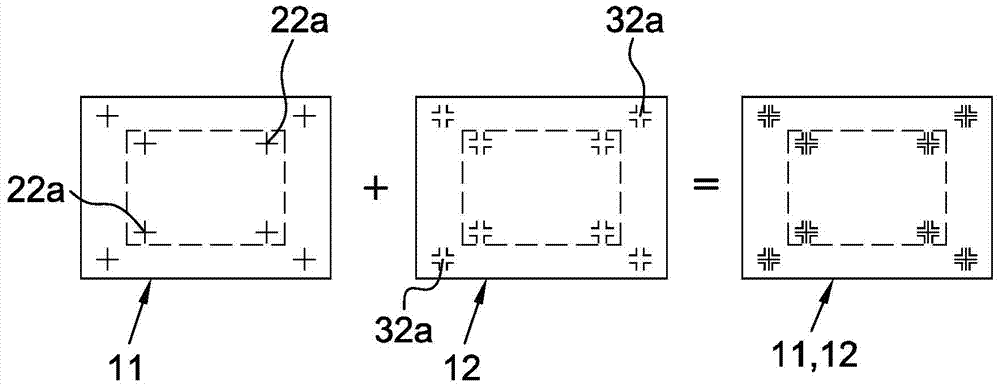

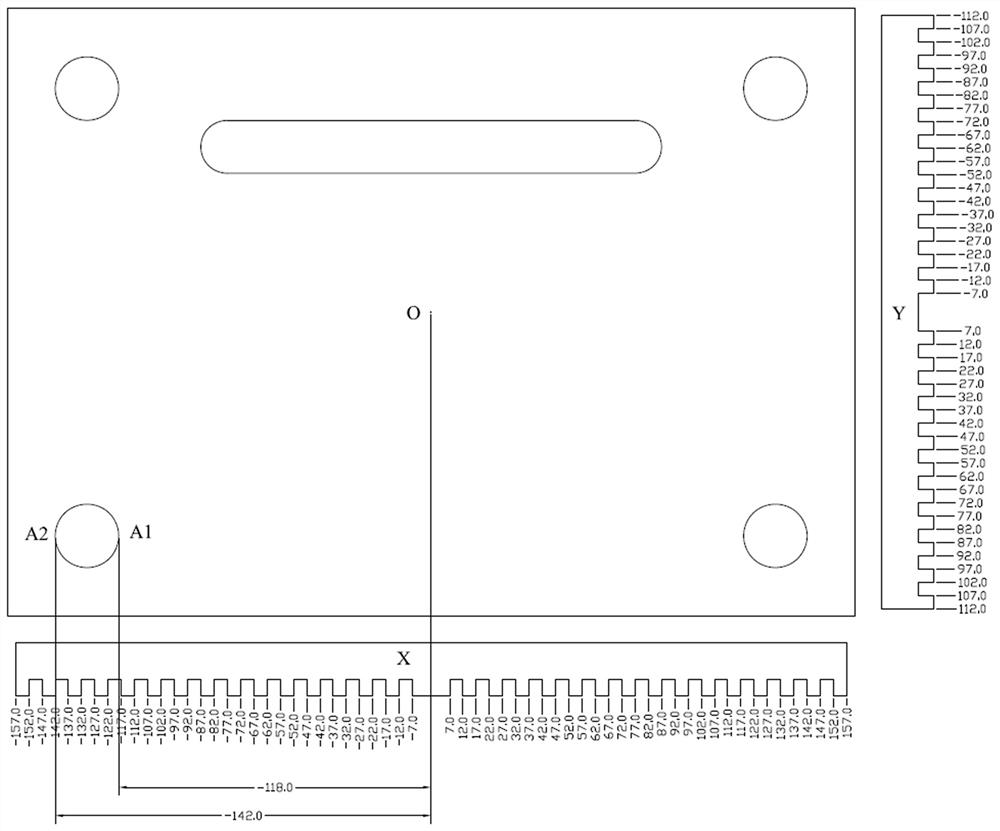

Different-space different-size substrate alignment method

ActiveCN104730871AIncrease elasticityReduce math calculationsPhotomechanical treatmentSize differenceComputer science

The invention relates to a different-space different-size substrate alignment method, which comprises: capturing actual local images of two substrates with different sizes; comparing the particular labels of the two substrates within the standard local character regions, and acquiring the particular labels of the two substrates within the actual local character regions; respectively establishing actual coordinate systems of the two substrates so as to synthesize an alignment assembly coordinate system; comparing the coordinate values of the particular labels of the two substrates within the two actual coordinate systems so as to acquire a first group of offsets, and comparing the sizes of the two substrates so as to obtain the size difference; using the first group of the offsets and the size difference to correct the coordinate value of the particular label of one of the two substrates; comparing the coordinate values of the particular labels of the two substrates so as to acquire a second group of offsets; and moving the substrate to the position compensated by the second group of the offsets.

Owner:METAL INDS RES & DEV CENT

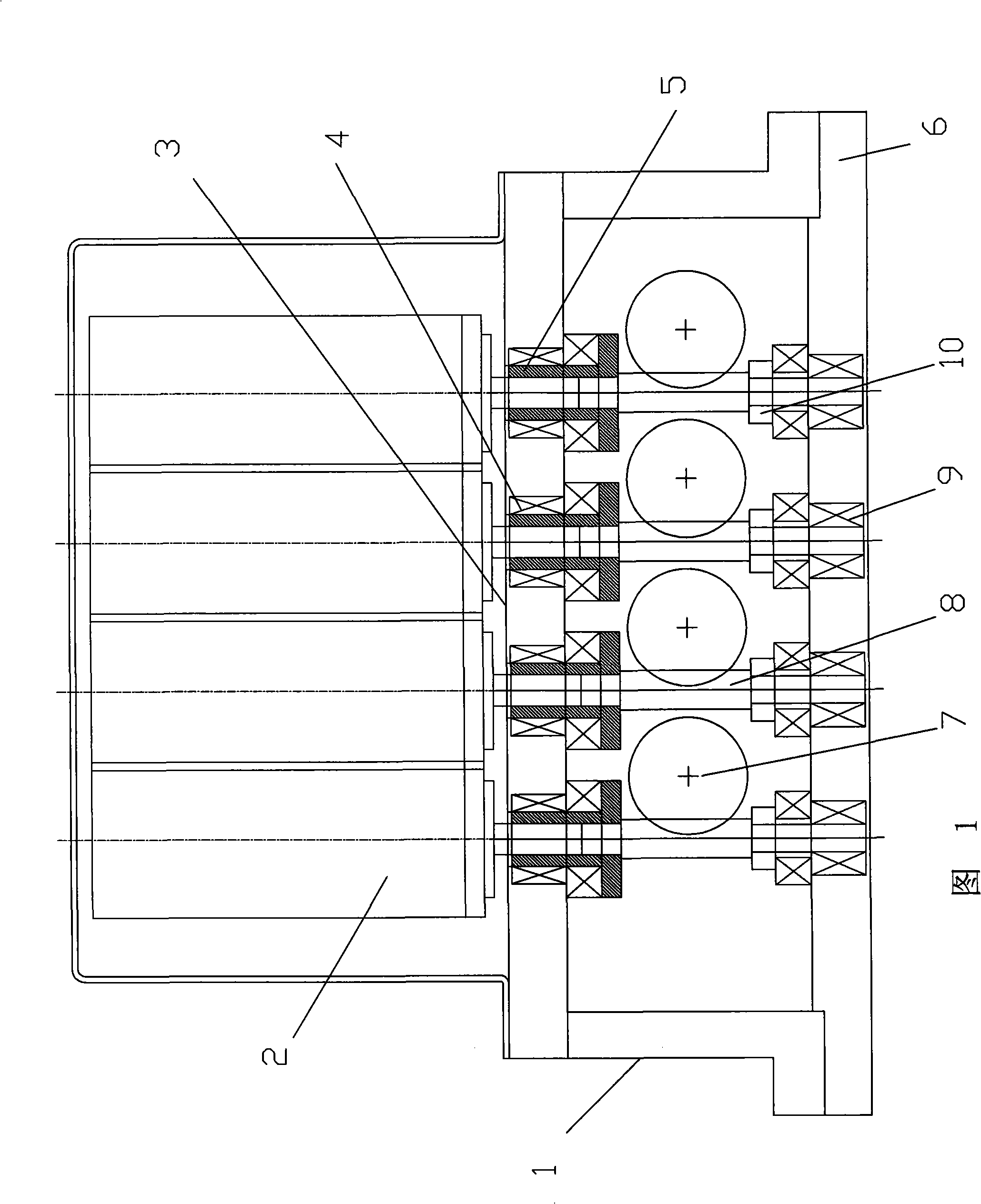

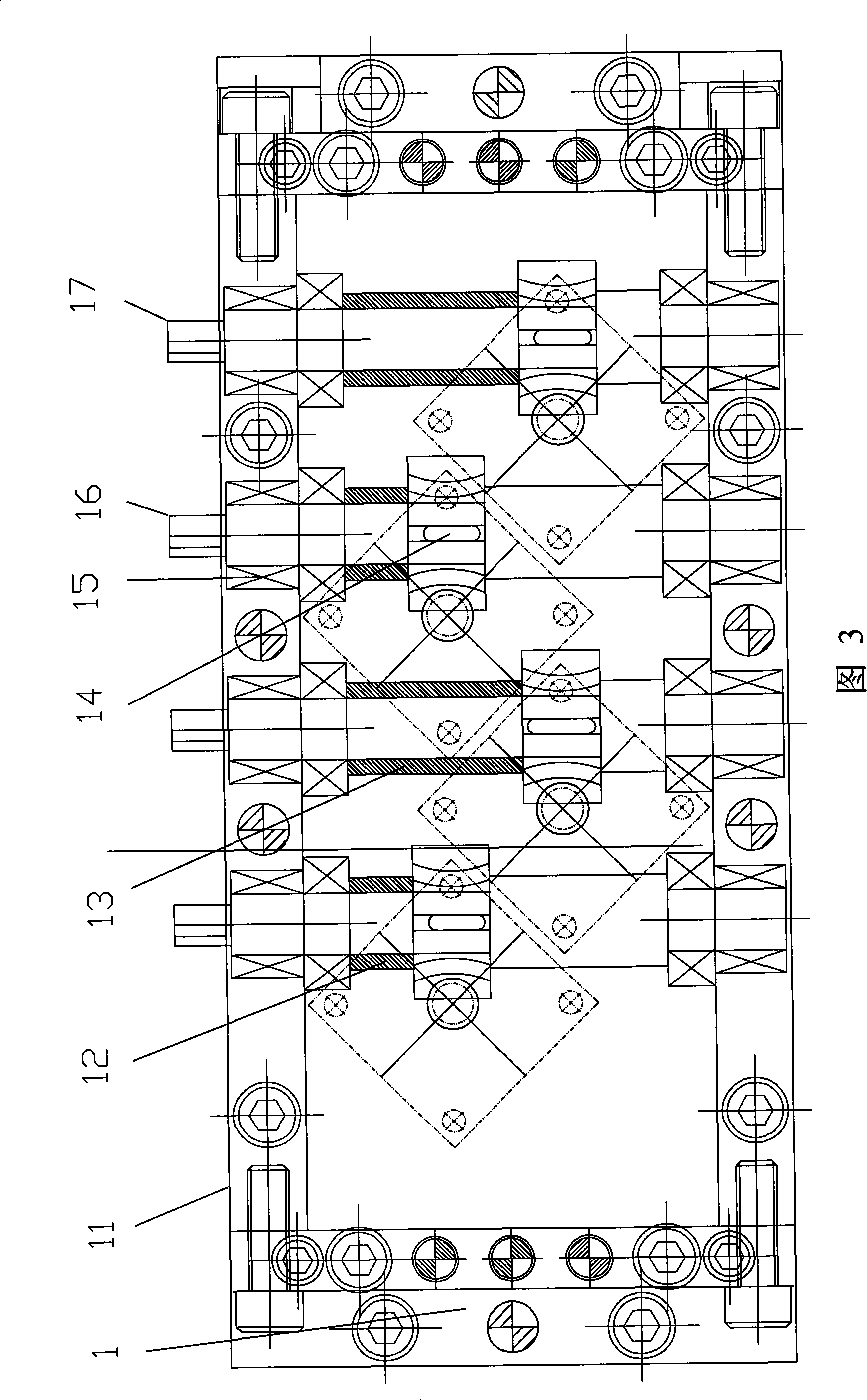

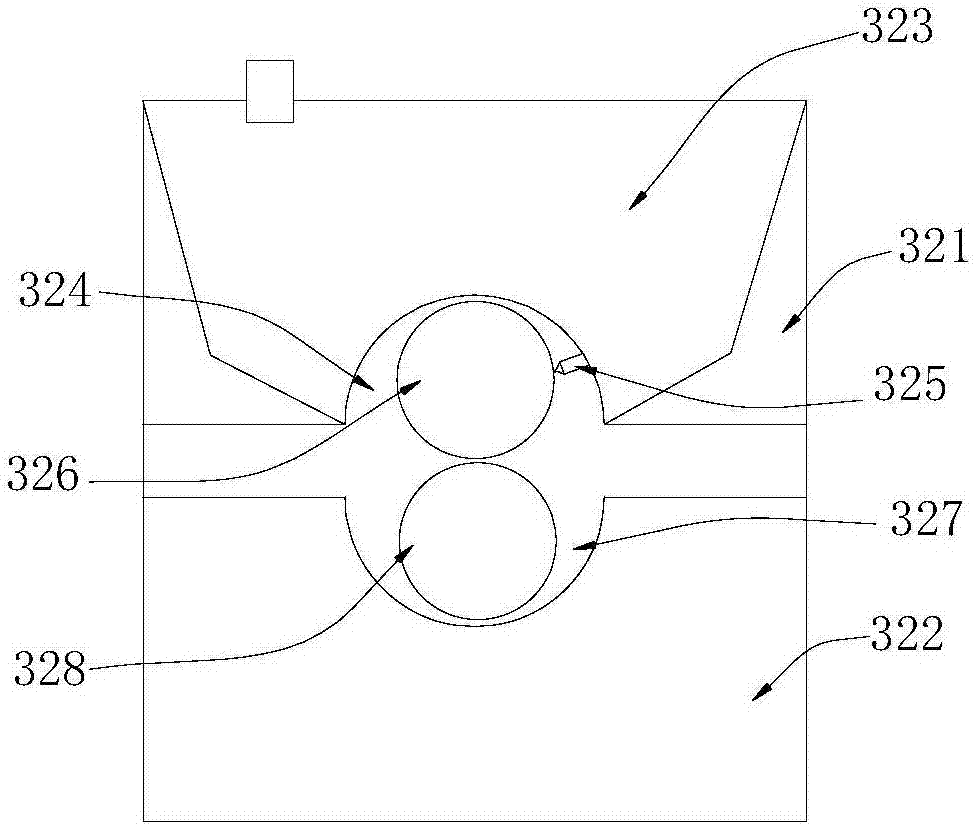

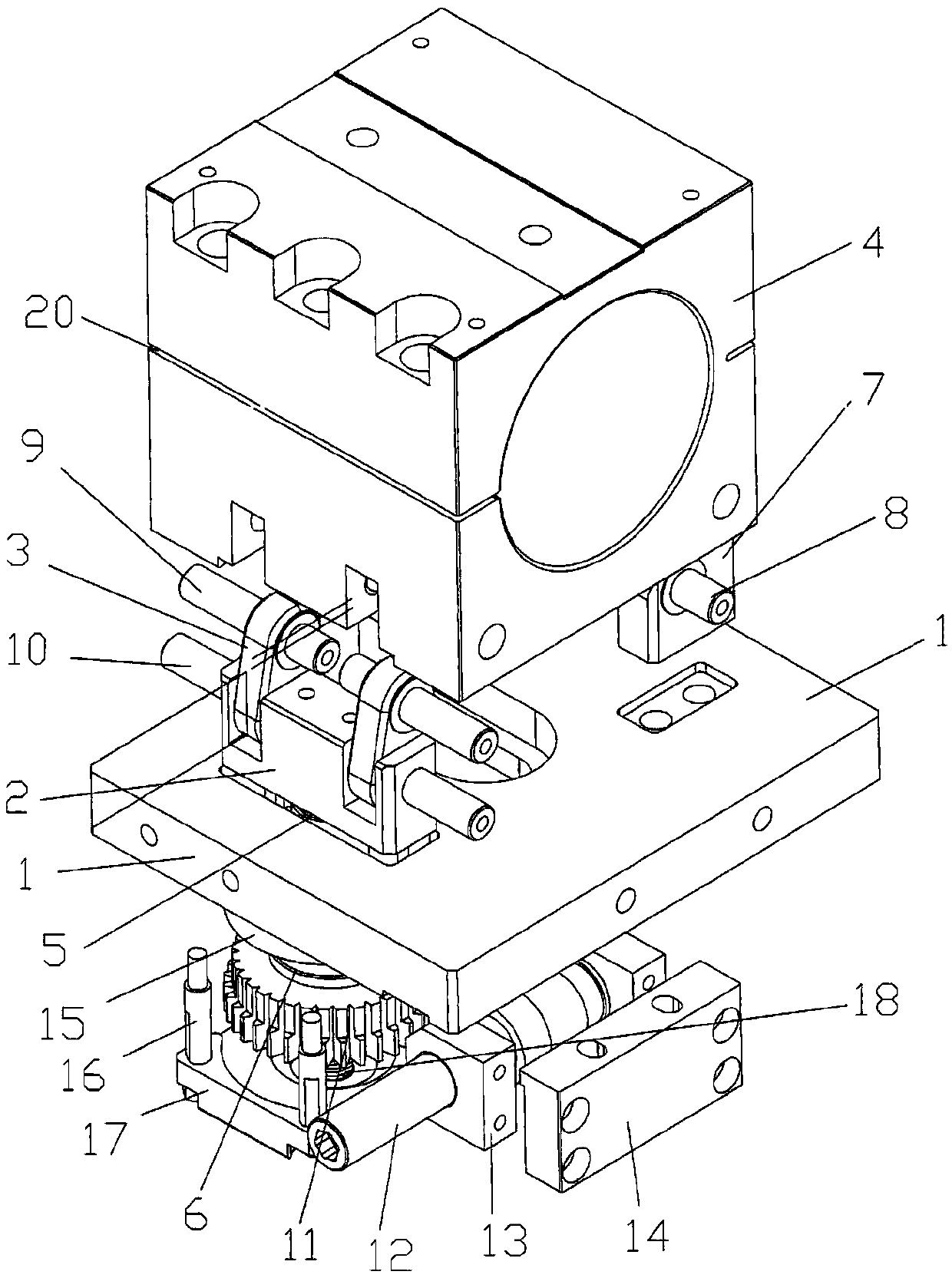

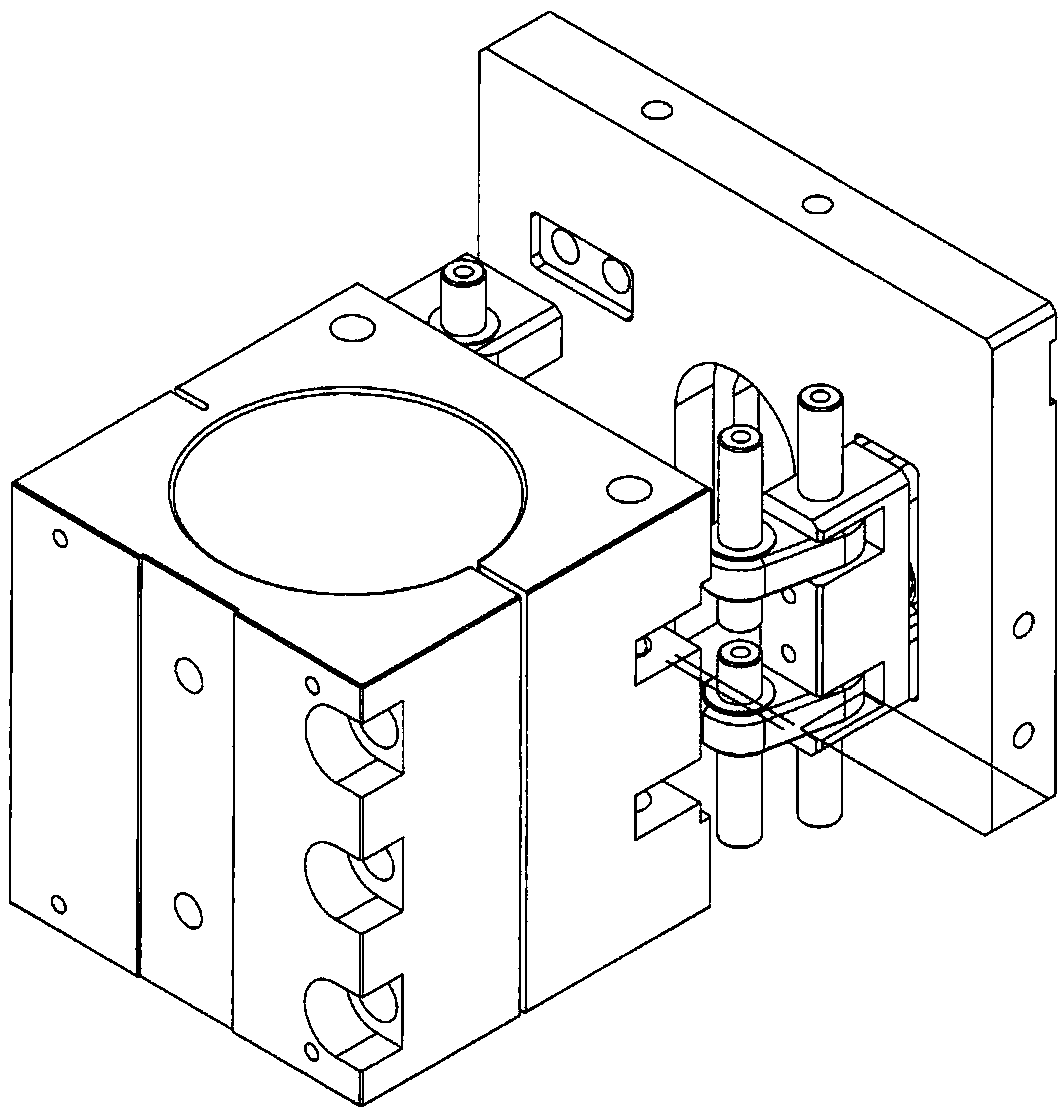

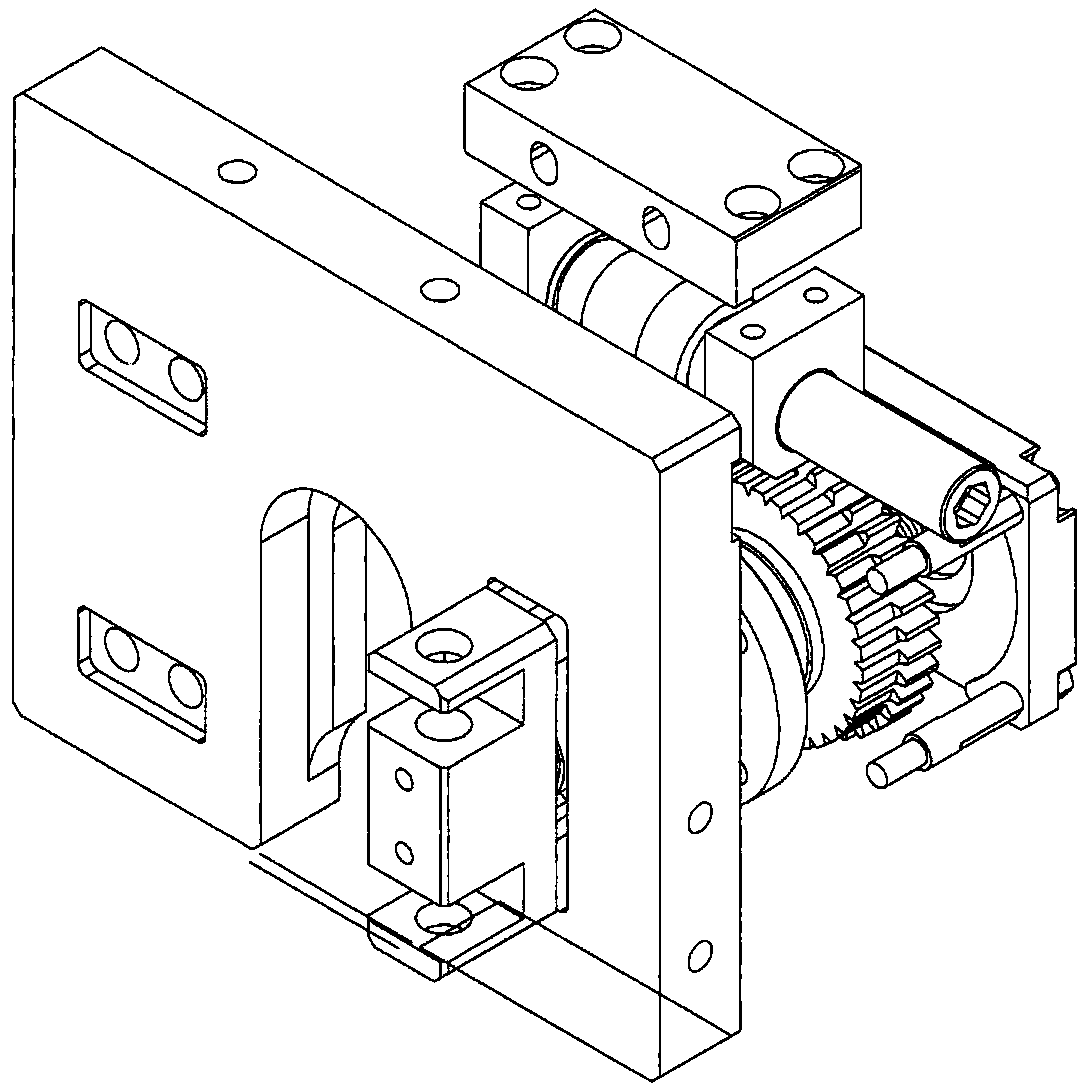

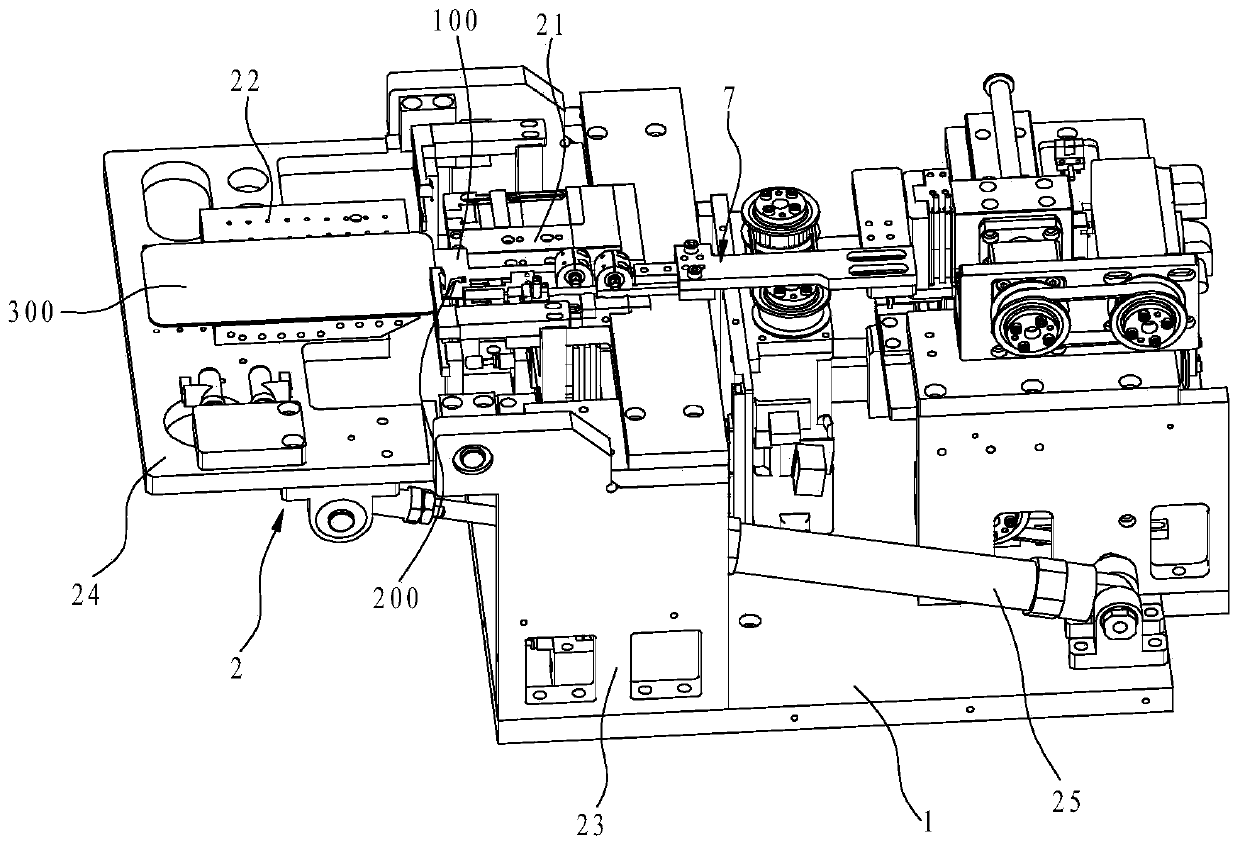

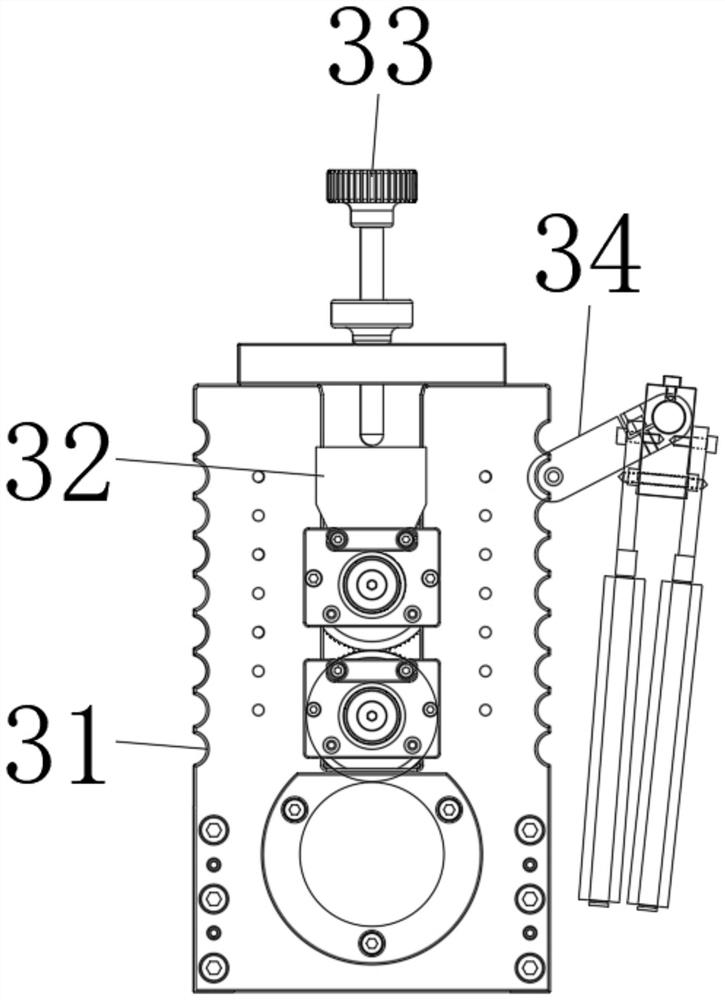

Intelligentized regulation system of air-conditioner fin die

InactiveCN101284293AReduce damage rateExtended maintenance cycleShaping toolsElectric machineryChassis

The invention relates to a mould for producing an air conditioner wing piece, particularly to the intellectualized regulating system of an air conditioner wing piece mould. According the technical proposal provided by the invention, a plurality of servo motors are arranged on a chassis, the output end of each servo motor is connected with a retarding mechanism, the output end of each retarding mechanism is connected with a connecting screw rod, connecting nuts are respectively matched on each connecting screw rod, each nut is installed on a downwardly gliding block with an inclined plane, and the position of the mould is vertically adjusted through the downwardly gliding block. The mould can improve the service life of the mould, improve product quality and reduce production cost.

Owner:WUXI MICRO RES

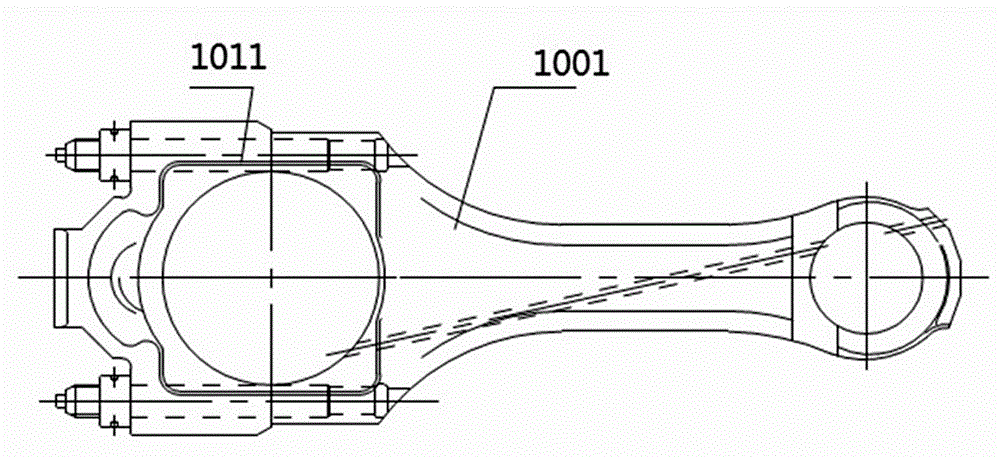

Group technology machining method of connecting rods

ActiveCN104907766AReduce machine set-up timeReduce production lead timeConnecting rodsOther manufacturing equipments/toolsEngineeringGroup technology

The invention discloses a group technology machining method of connecting rods. The method comprises the steps that according to the connecting rods to be machined, the connecting rods are classified based on the same or similar appearance, and the unified locating reference of following machining is achieved; and the connecting rods comprising the same machining elements are arranged on the same machining equipment for machining, a corresponding group technology is selected for machining the connecting rods, furthermore, the appearance of the connecting rods to be machined is used as the unified locating reference, a workblank side face is subjected to finish machining, the size is controlled to be in the workblank tolerance range, and based on a workblank subjected to side face finish machining, a connecting rod machining clamp matched with the shape of the workblank subjected to side face finish machining is used for fixing. According to the method, large risks are avoided, technology debugging time is shortened, and the process design time and a large amount of energy of technologists are saved.

Owner:SHANNXI DIESEL ENGINE HEAVY IND

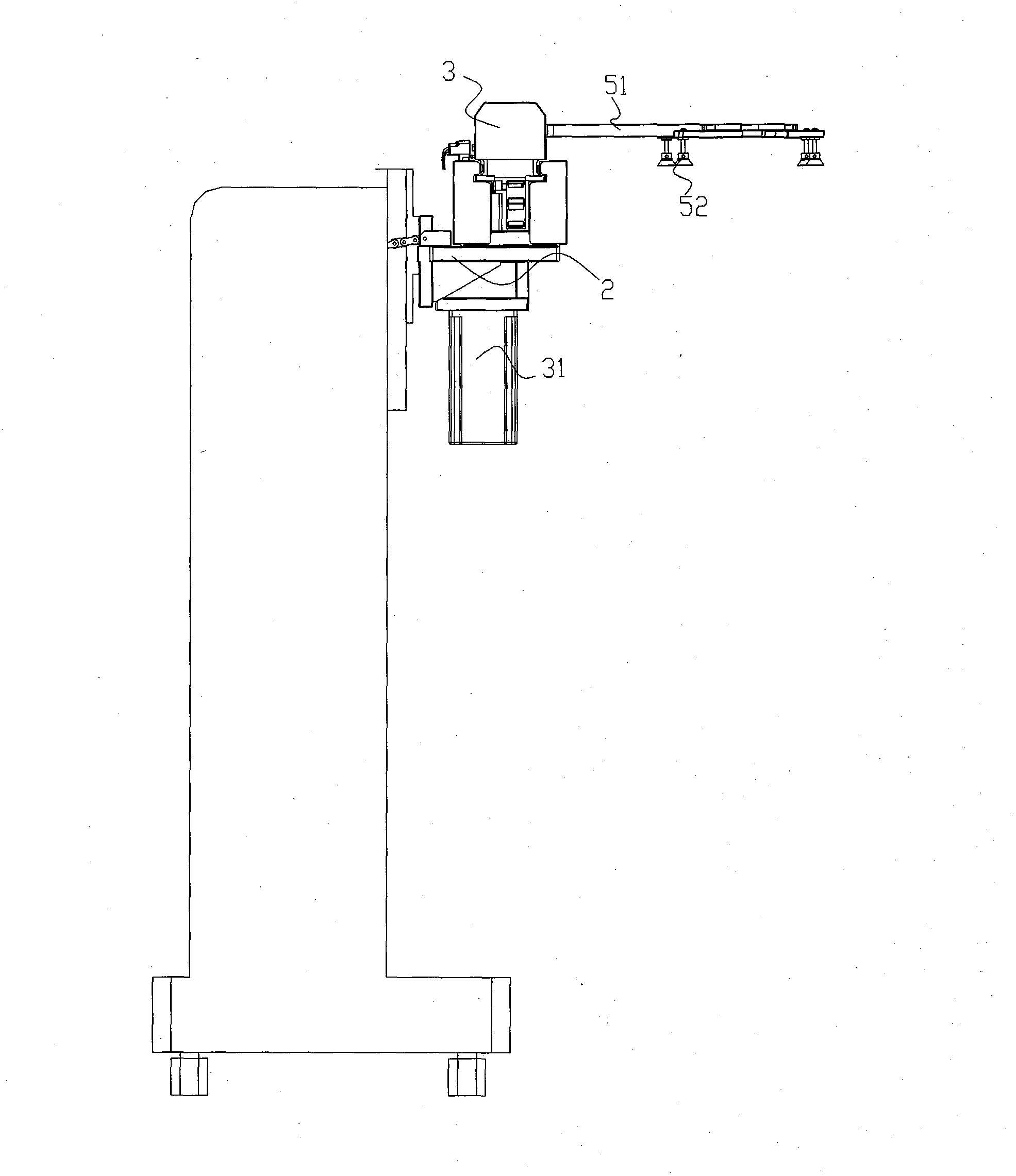

Mechanical arm

InactiveCN103447408AIncrease movement speedSave equipment spaceProgramme-controlled manipulatorMetal-working feeding devicesProcessing accuracyManipulator

The invention discloses a mechanical arm comprising a rack, a Z-axis moving component, an X-axis moving component and a hand grab. The Z-axis moving component is arranged on the rack and can move up and down, the X-axis moving component is arranged on the Z-axis moving component and can move to the left and the right, and the hand grab is arranged on the X-axis moving component comprising a main shaft and an auxiliary shaft. The main shaft can move to the left and the right around the X axis, the auxiliary shaft is assembled on the main shaft and can move to the left and the right on the main shaft along the X axis, and corresponding driving devices are arranged on the Z-axis moving component, the main shaft and the auxiliary shaft. The X-axis moving component is designed to be a double-shaft moving structure with the main shaft and the auxiliary shaft, relative moving speed of a single hand grab on the auxiliary shaft is greatly increased, long-distance X-axis travel equipment space is greatly reduced, the mechanical arm is superior to and can replace a traditional middle material grabbing switching mode, a middle switching procedure is omitted, setup time are saved, and working efficiency and processing accuracy are improved.

Owner:何芳

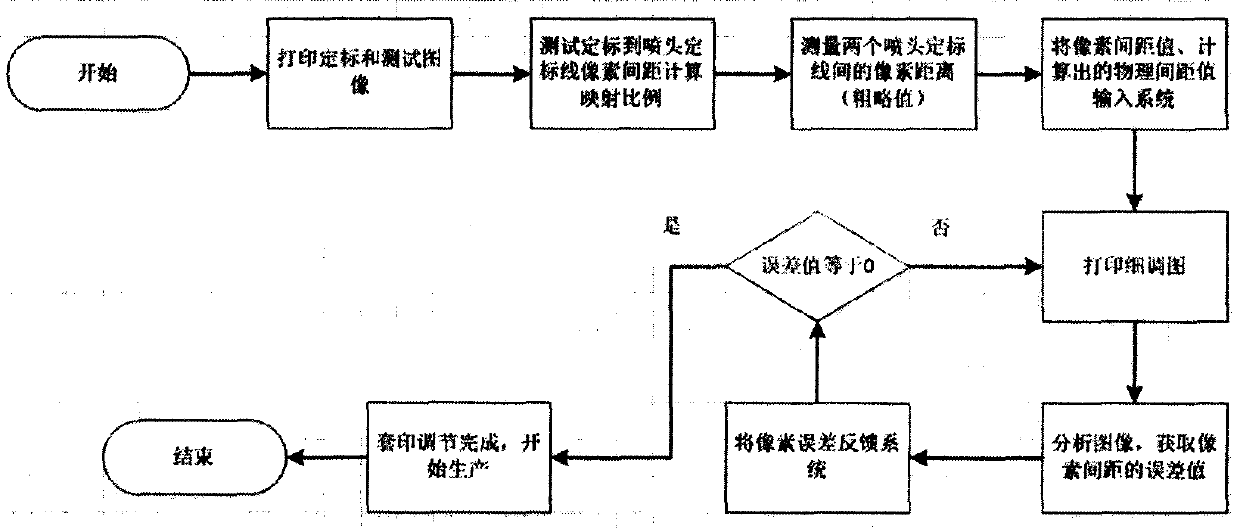

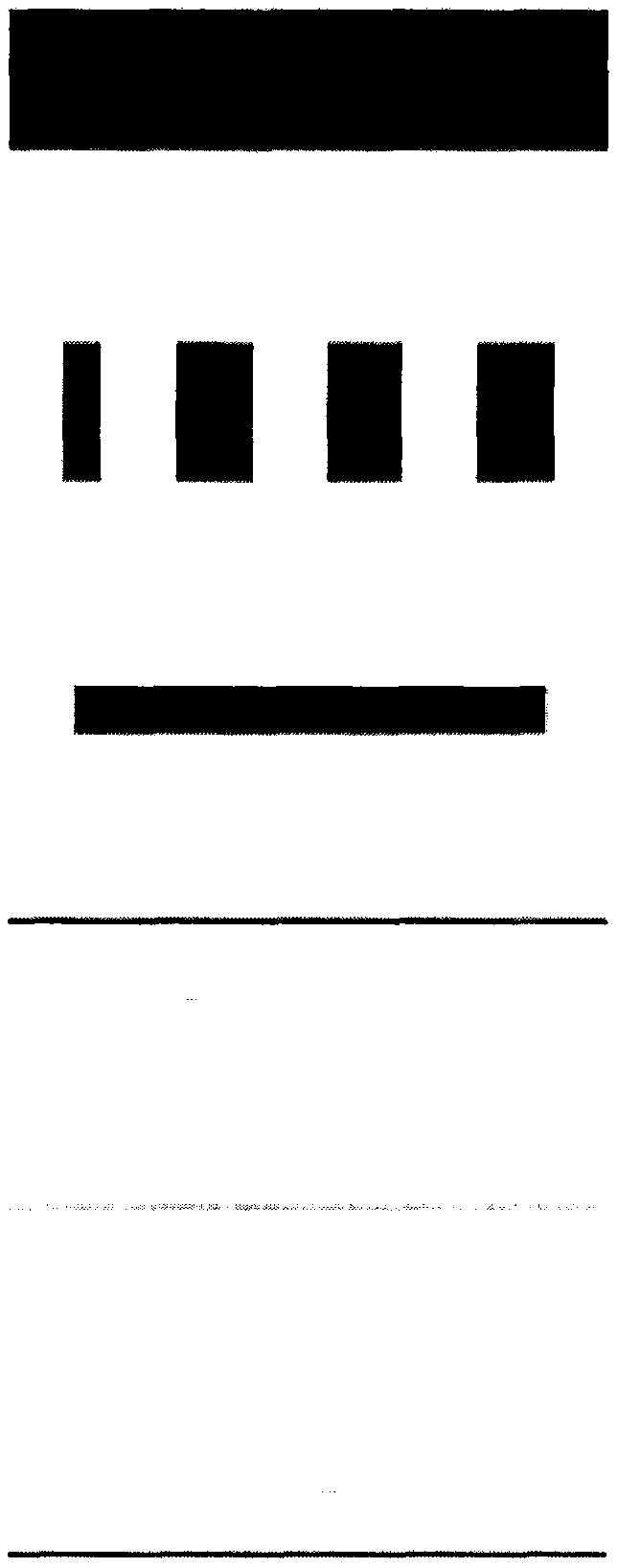

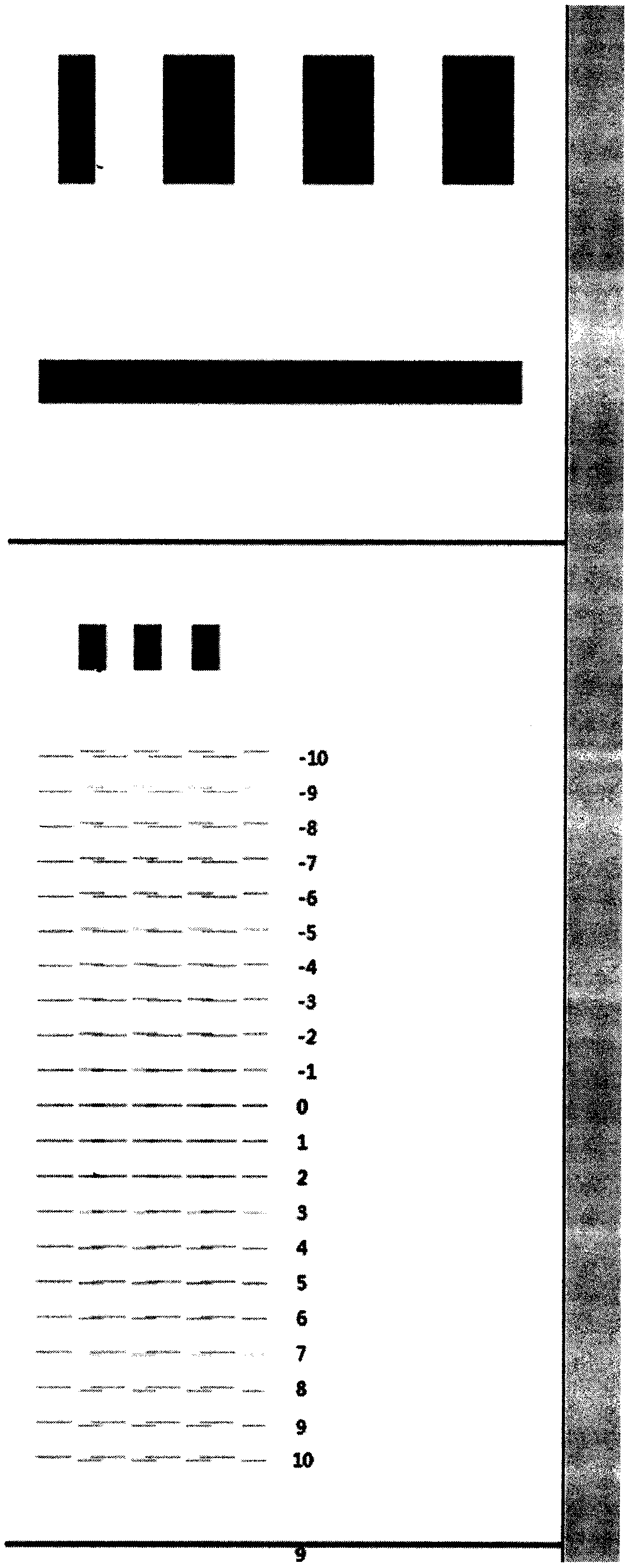

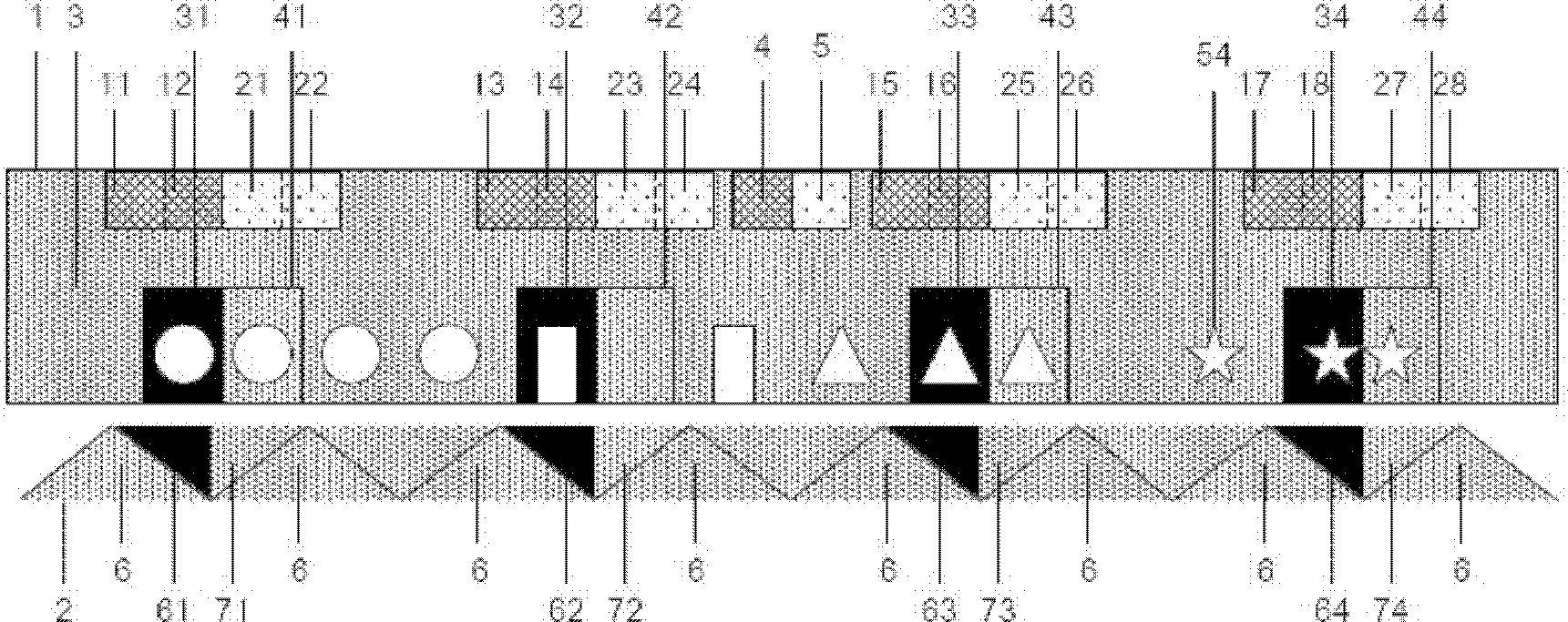

Multi-nozzle adjusting method for overprinting

ActiveCN110065309AHigh degree of automationNo manual adjustment requiredOther printing apparatusEngineeringDigital printing

The invention belongs to the field of digital printing, and particularly relates to a multi-nozzle adjusting method for overprinting. The method comprises the following steps: (1), in coarse adjustment stage: printing a calibration chart and a test chart, calculating the actual distance of adjacent spray heads according to the calibration chart and the test chart, and inputting the actual distanceinto a spray printing system for preliminary parameter correction; and 2, in fine adjustment stage: printing a fine adjusting chart, and inputting the calculated deviation into the spray printing system for further parameter correction. The method has the following beneficial effects: 1, high automation degree, specifically, front and back splicing effects and parameters of the spray heads are directly adjusted by equipment without manual adjustment, so that manual work is reduced; and 2, quick adjustment, specifically, adjustment and preparation time are reduced.

Owner:深圳圣德京粤科技有限公司

Group machining method for panel-type furniture parts

InactiveCN104608227AGuaranteed quality and accuracyGuaranteed dimensional accuracyWood working apparatusEngineeringMachining process

The invention provides a group machining method for panel-type furniture parts, relates to the field of machining, in particular to the group machining method for panel-type furniture parts. The group machining method includes the following step of cutting, wherein panels of the same type are unceasingly cut through a panel cutting center, and the number of boxing times can be reduced; a plurality of same panels can be stacked up within the permitted range and sawn and cut into plates of the same specification at the same time according to a plate cutting drawing; the comprehensive discharge method is used, and when the lengths and the widths of the plates are consistent, the design of the plate cutting drawing can be simplified, the time of steering times can be reduced in the cutting process, and efficiency is improved; when the number of the specifications of the plates in the same plate cutting drawing is large, the number of installation times of the plate cutting work can be increased, or saw lines need to be unceasingly cleaned when edging excess materials are too thin and too long. The machining process is simple, procedures are reasonable, the machining quality and size accuracy of workpieces are ensured, the production efficiency is improved, and the production cost is reduced.

Owner:王玉伟

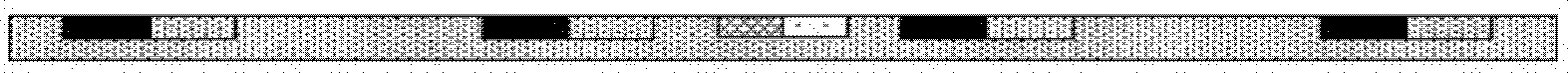

Printing color and latitude visual inspection system device and application method thereof

ActiveCN103600583AUnderstanding Production Physical ChangesAchieve the ultimate goal of standardized productionPrinting press partsLower limitMeasuring instrument

The invention discloses a printing color and latitude visual inspection system device and an application method thereof. The printing color and latitude visual inspection system device is composed of a rectangular ruler-shaped main body and monitoring color bars, the main body is a neutral gray color value region and is formed by combining every primary color and every secondary color in percentage; the main body and a plurality of replaceable color lumps are all functional areas with visual inspection hue contrast information, the main body is also provided with color monitoring information areas for comparing an upper limit and a lower limit visually, the color monitoring information areas can directly provide hue latitude information, the monitoring color bars are provided with a series of monitoring overprinting indication functional areas which are closely connected, and the paralleling and the ranking correspond to a system main body. The printing color and latitude visual inspection system device utilizes a gray balance technology, accords with printing standard data and is applicable to mechanical and digital printing processes, measuring instruments are not needed in the application method, a scheme can be modified by directly comparing a set color value visually, rapidly and in a point to point mode, the production changes can be known timely, loss can be reduced, and the aim of controlling the operation in a high-quality production environment with the lowest error rate can be achieved.

Owner:任德坚 +1

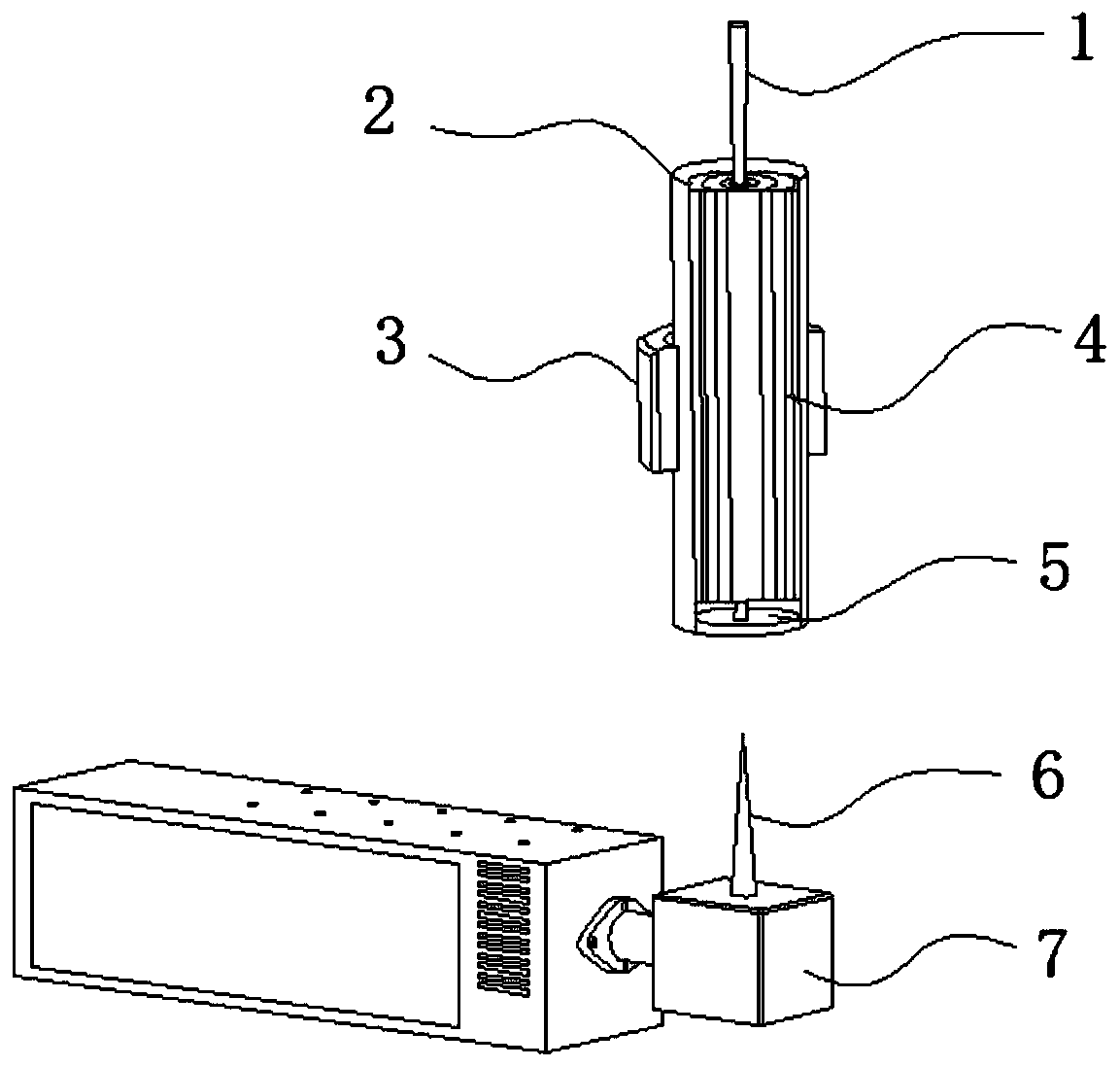

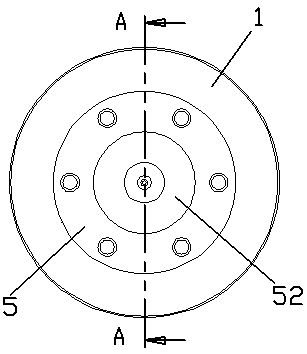

Laser welding technology for negative pole ear and battery case of cylindrical lithium-ion battery

InactiveCN110497082AImprove consistencyLower internal resistanceFinal product manufactureCylindrical casing cells/batteryEngineeringUltimate tensile strength

The invention provides a laser welding technology for a negative pole ear and a battery case of a cylindrical lithium-ion battery. The laser welding technology is implemented by a unit comprising thebattery case, wherein a press bar is mounted on one side of the top of the battery case, a battery holder is mounted on the surface of one side of the outer wall of the battery case, a roll core is mounted in an inner cavity of the battery case, the negative pole ear is mounted on one side of the bottom of the roll core, a laser welding device is mounted on one side of the bottom of the battery case, and laser beams are emitted from the output end of the laser welding device. By means of laser welding of the negative pole ear and the battery case, the bottleneck problem of the welding processis solved, the welding is more firm and more reliable, welding intensity and welding consistency are improved, the welding process is carried out more automatically, the process and the defective rateof products are reduced, production and manufacturing cost and labor cost are reduced, and production efficiency is improved.

Owner:崔少华

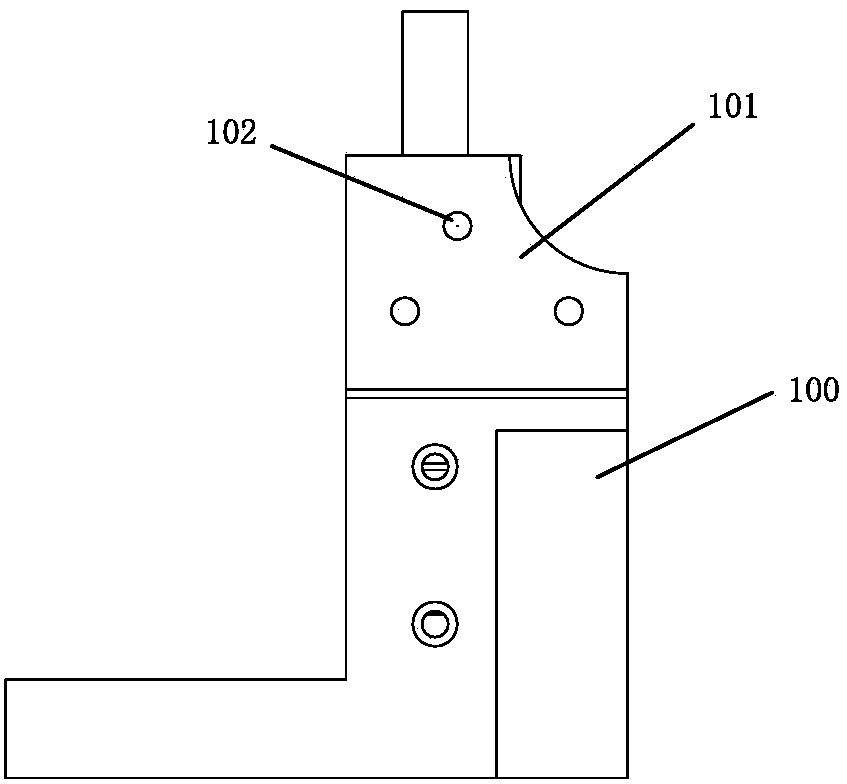

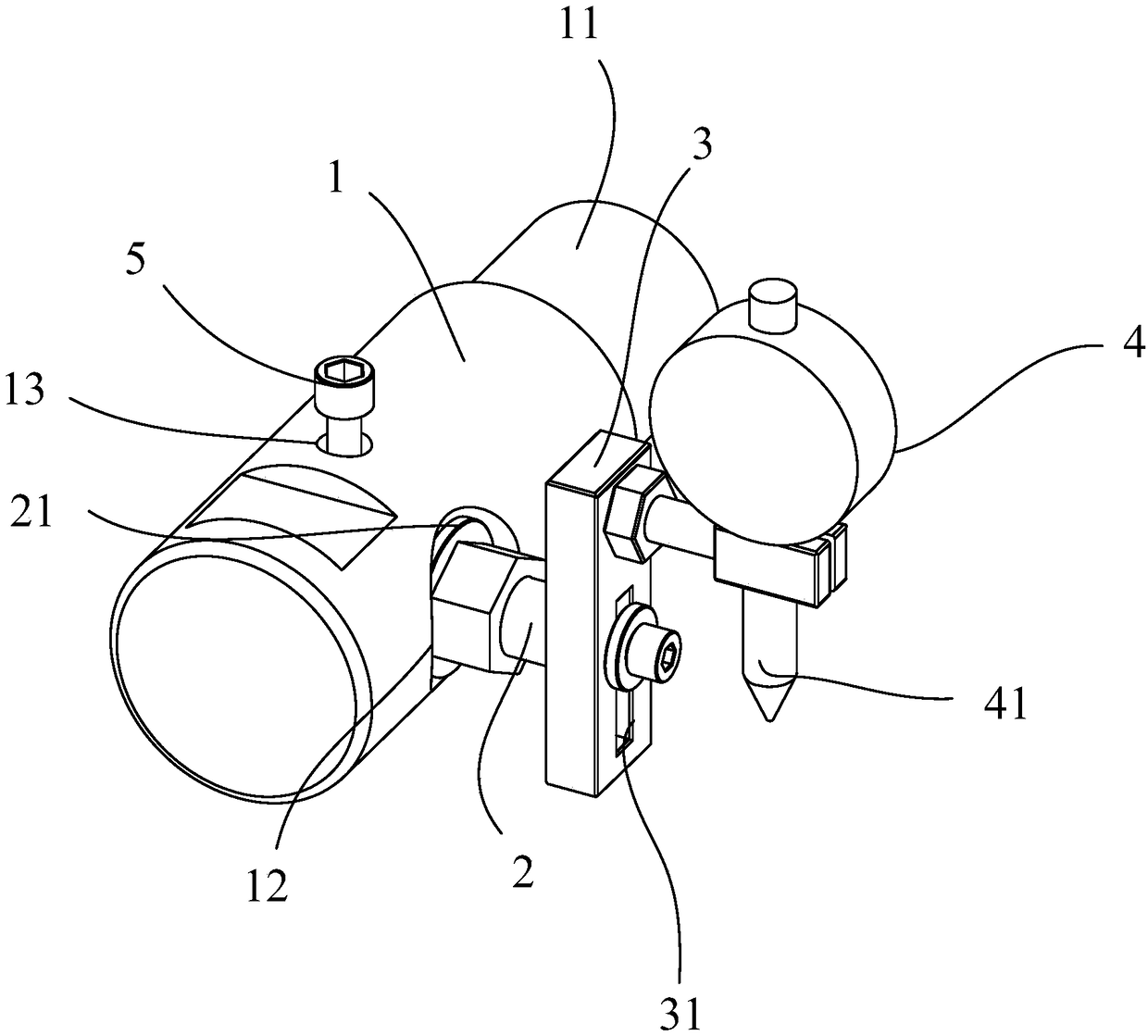

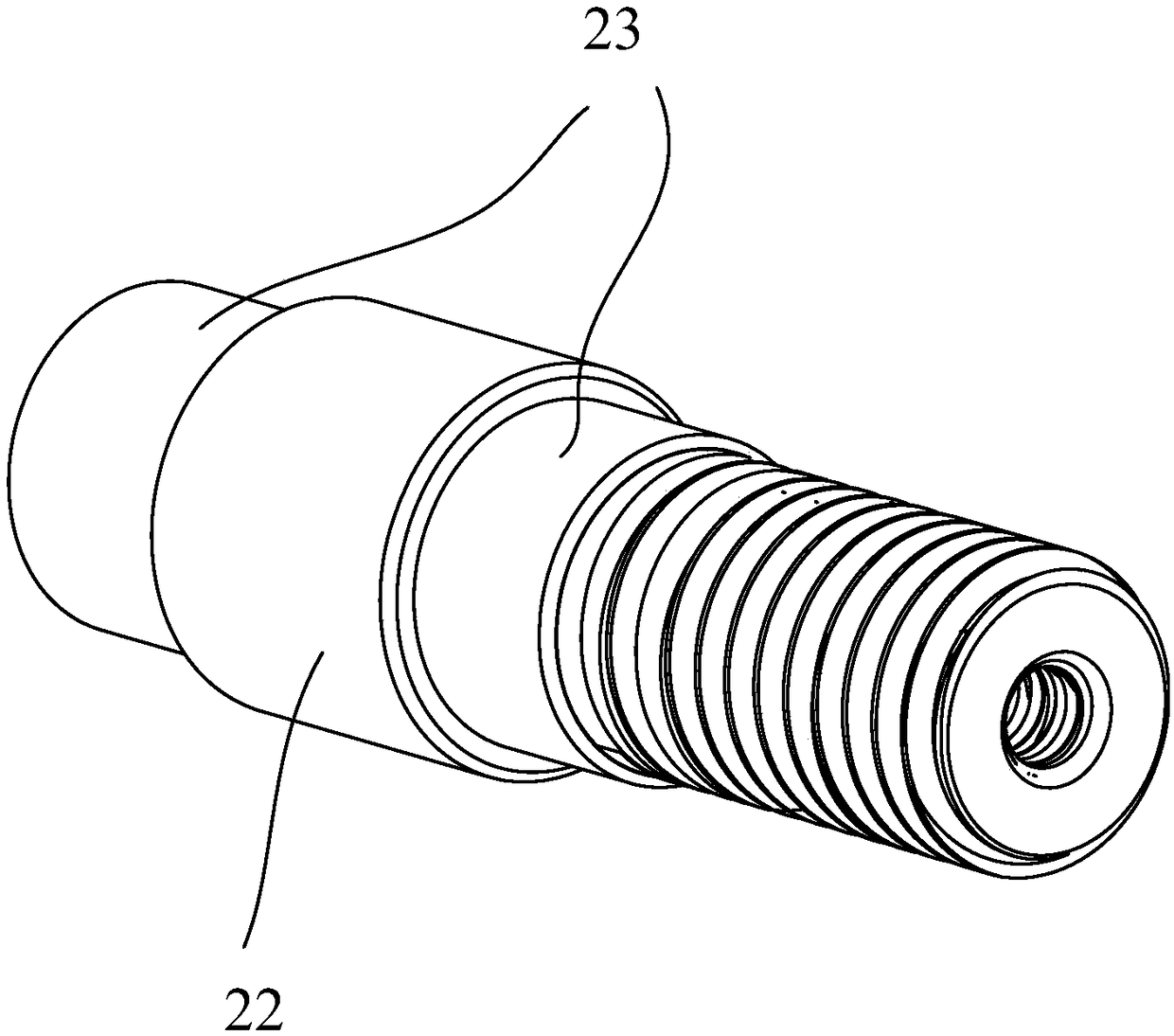

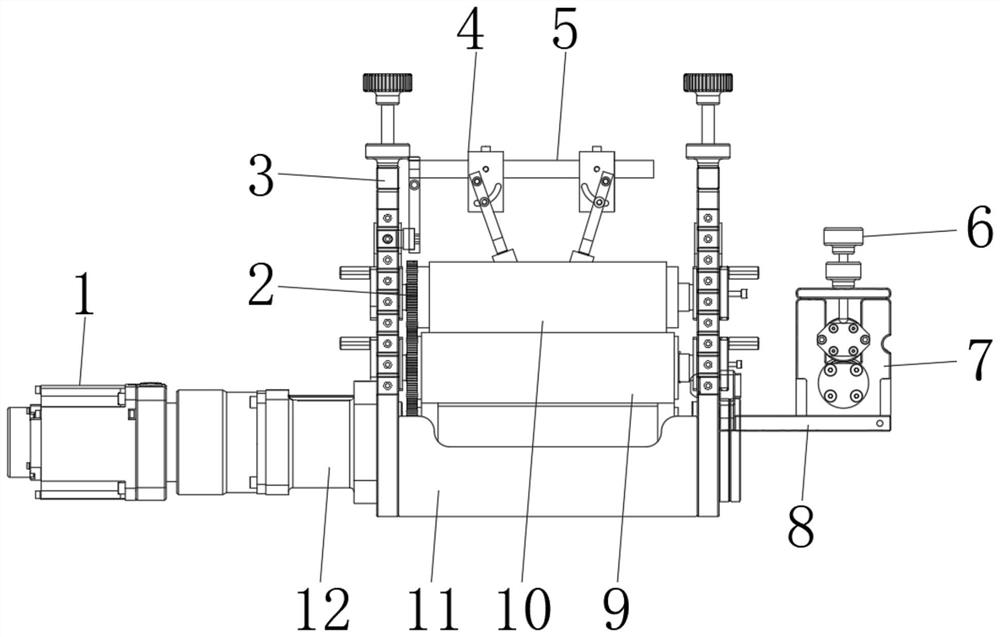

Centering adjustment method of V block center and work head center of grinding machine tool

ActiveCN103962962AEasy to determineReduce machine set-up timeGrinding machine componentsMilling cuttersMachine toolIndustrial engineering

The invention discloses a centering adjustment method of a V block center and a work head center of a grinding machine tool. The method includes the steps that standard tools, namely a standard block and a standard rod, are adopted, the standard rod clamped on a work head is matched with the standard block mounted on a supporting cylinder, the optimal mounting position of the supporting cylinder is found out, the supporting cylinder is well fixed, then the standard block is removed, a V block is arranged on the supporting cylinder with the position determined already, the high-low position of the V block is regulated, and the V block center and the work head center are made to be coaxial. According to the centering adjustment method, an auxiliary positioning method is adopted, a traditional mounting mode for the V block is changed, machine debugging personnel can determine the position of the V block center and the position of the work head center easily, the machine debugging time is shortened to be within ten minutes, and the machine debugging efficiency is improved to more than ten times.

Owner:XIAMEN TUNGSTEN

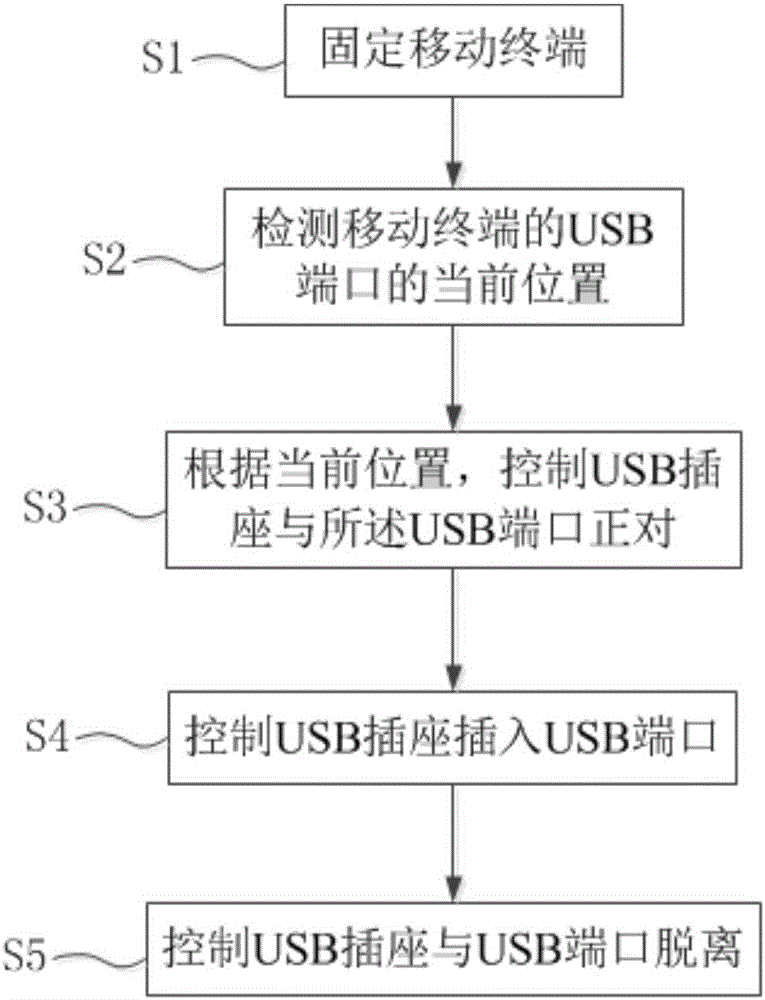

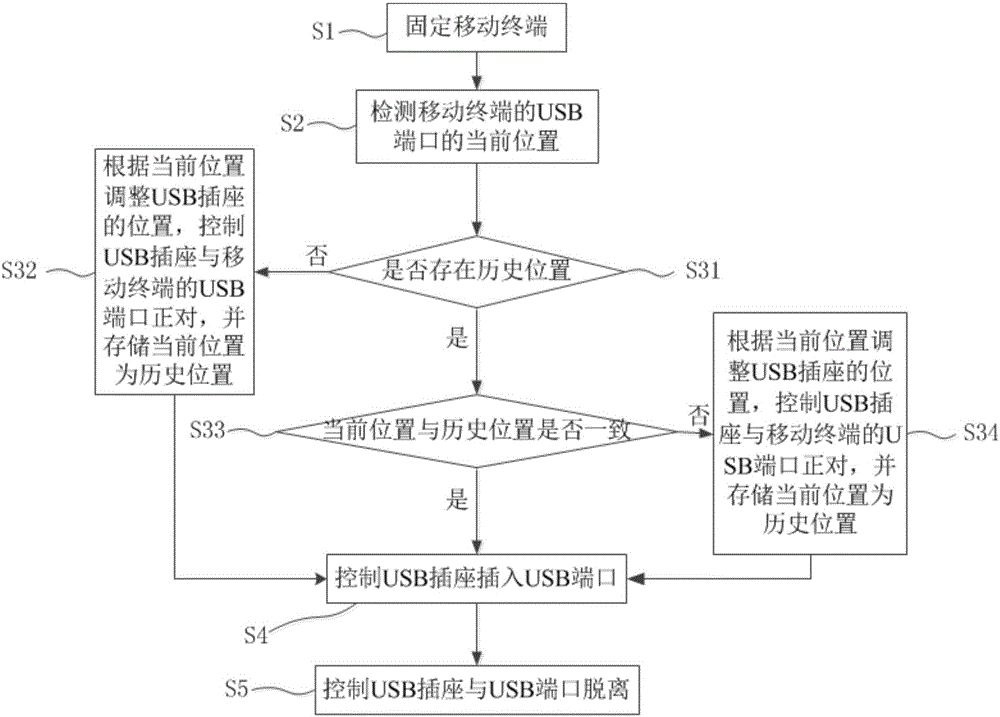

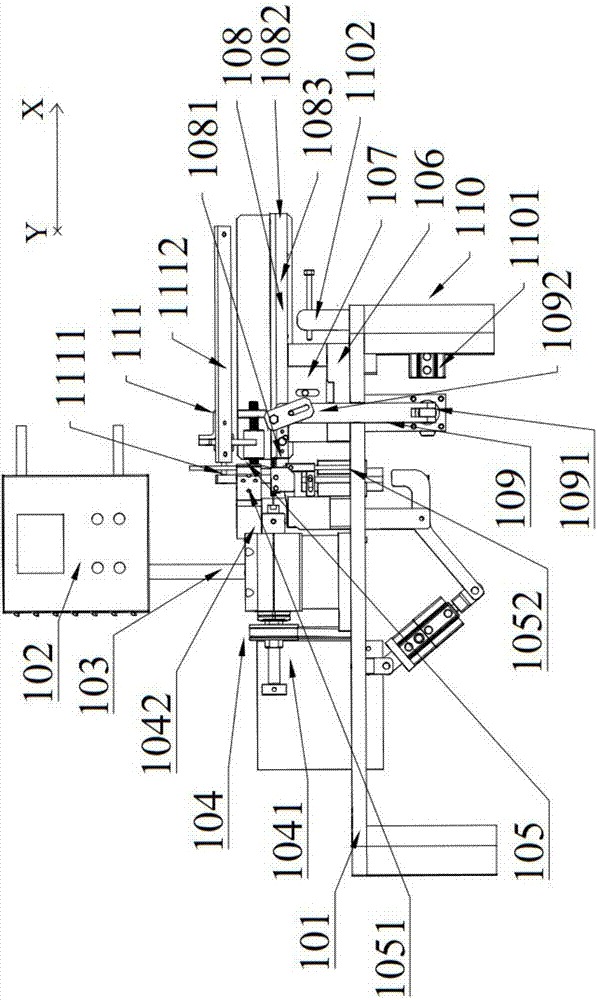

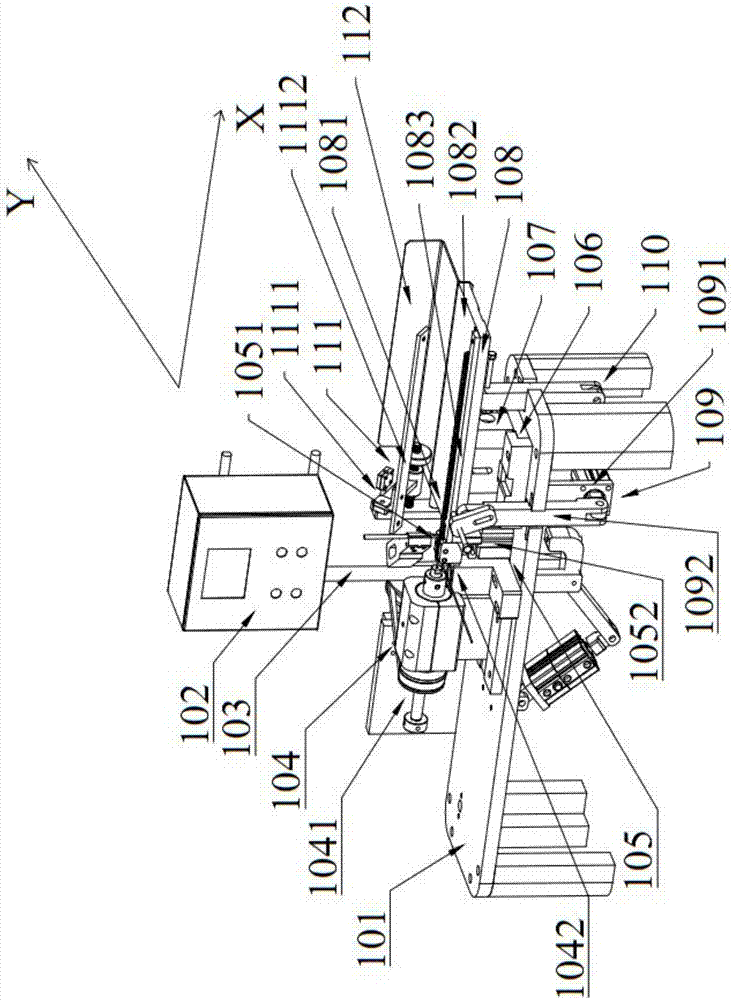

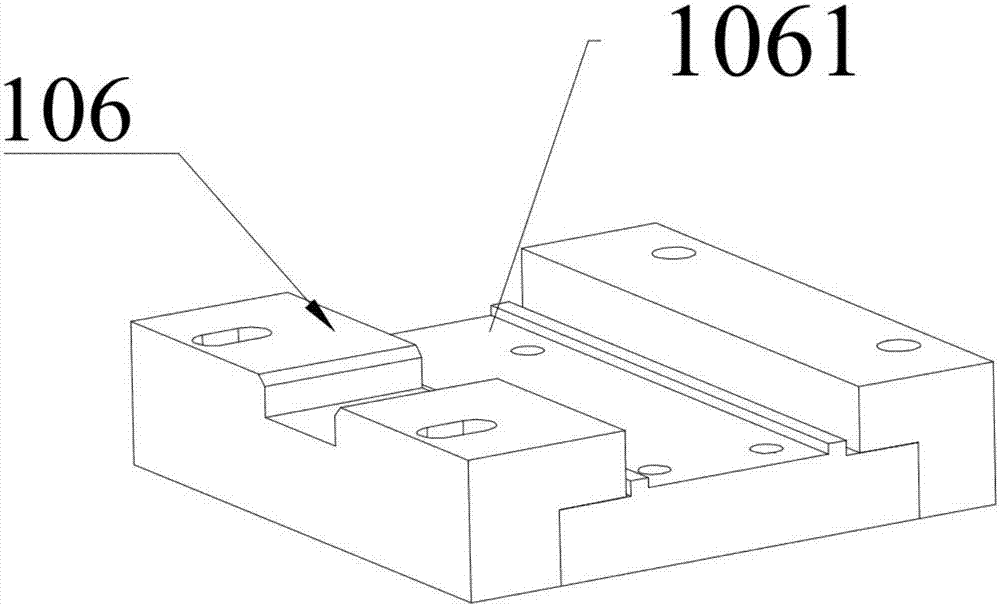

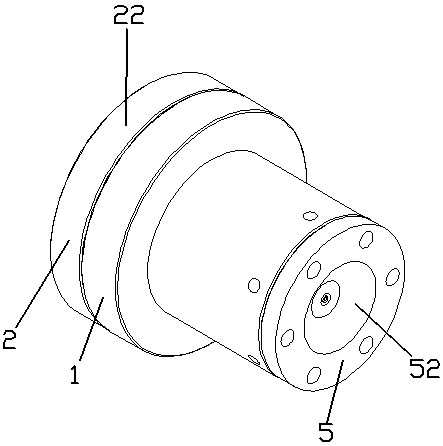

USB plug-in method and system for mobile terminal

ActiveCN106294263AClearly adjust the positionIncrease the detection linkElectric digital data processingComputer terminalUSB

The invention relates to the technical field of mobile terminal production, in particular to a USB plug-in method and system for a mobile terminal. The USB plug-in method comprises the following steps: fixing the mobile terminal; detecting the current position of the USB port of the mobile terminal; according to the current position, controlling a USB socket to face the USB port directly; controlling the USB socket to be inserted into the USB port; controlling the USB socket to be disengaged from the USB port. According to the USB plug-in method, firstly, the current position of the USB port on a clamp is detected, then the USB socket is adjusted according to the current position to face the USB port directly, and finally, the USB socket is inserted into the USB port. As the USB plug-in method further has a detection step, the adjusting position of the USB socket can be definite, the setup time is shortened, and the work efficiency is improved.

Owner:唯科终端技术(深圳)有限公司

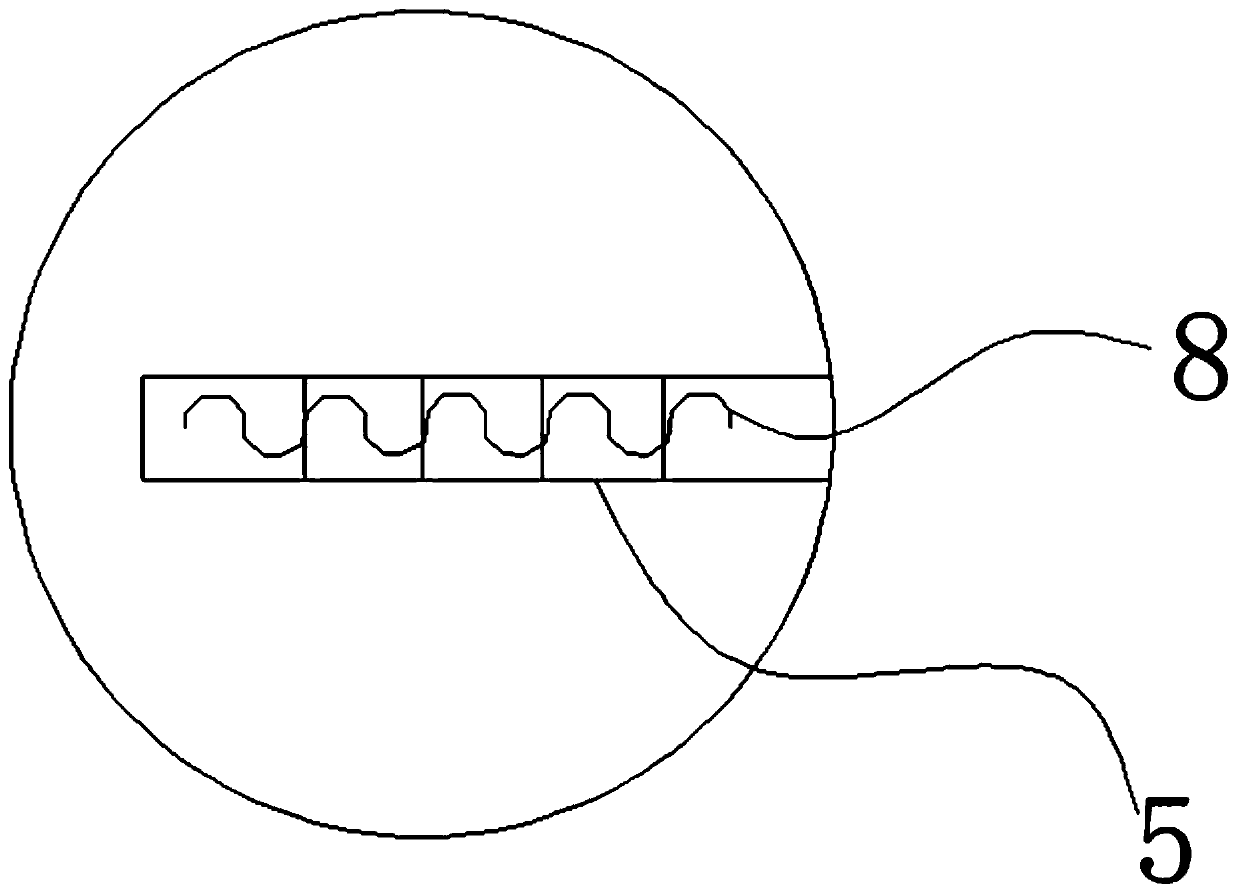

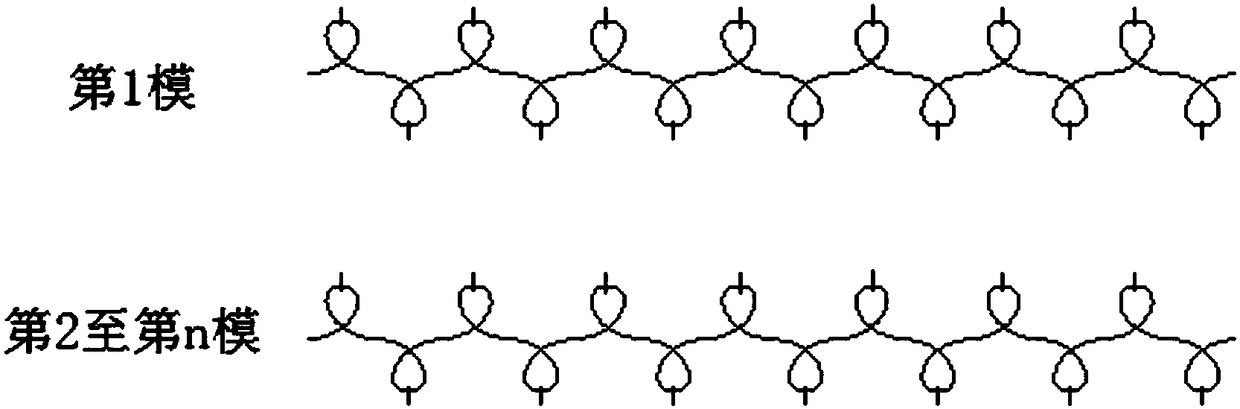

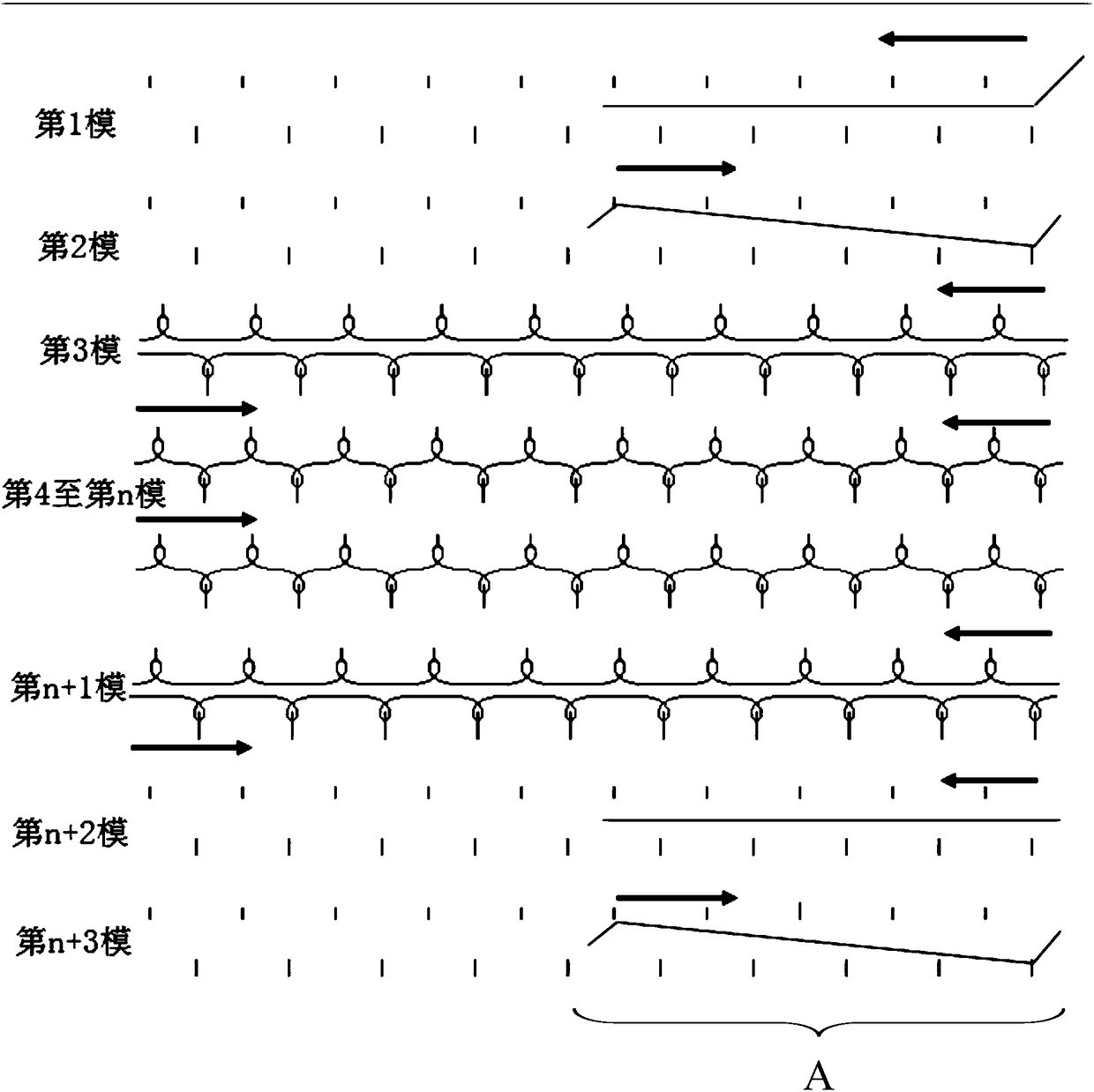

Weft-knitted rib fabric, knitting method and application thereof, and collar made of weft-knitted rib fabric

The invention relates to weft-knitted rib fabric, a knitting method and application thereof, and a collar made of the weft-knitted rib fabric. The knitting method includes floater knitting of first travel, tuck knitting of second travel, single-edge looping knitting of third travel, looping knitting of fourth travel, single-edge looping knitting of fifth travel, floater knitting of sixth travel, and tuck knitting of seventh travel. According to the characteristics of the rib fabric, after start and end floaters are cut off, left ends may automatically retract into the weft-knitted rib fabric and hide in the same, so that a collar hooking step is omitted. The knitting method has no need for arrangement of high and low needles, machine adjusting time is shortened, and production efficiency is improved.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

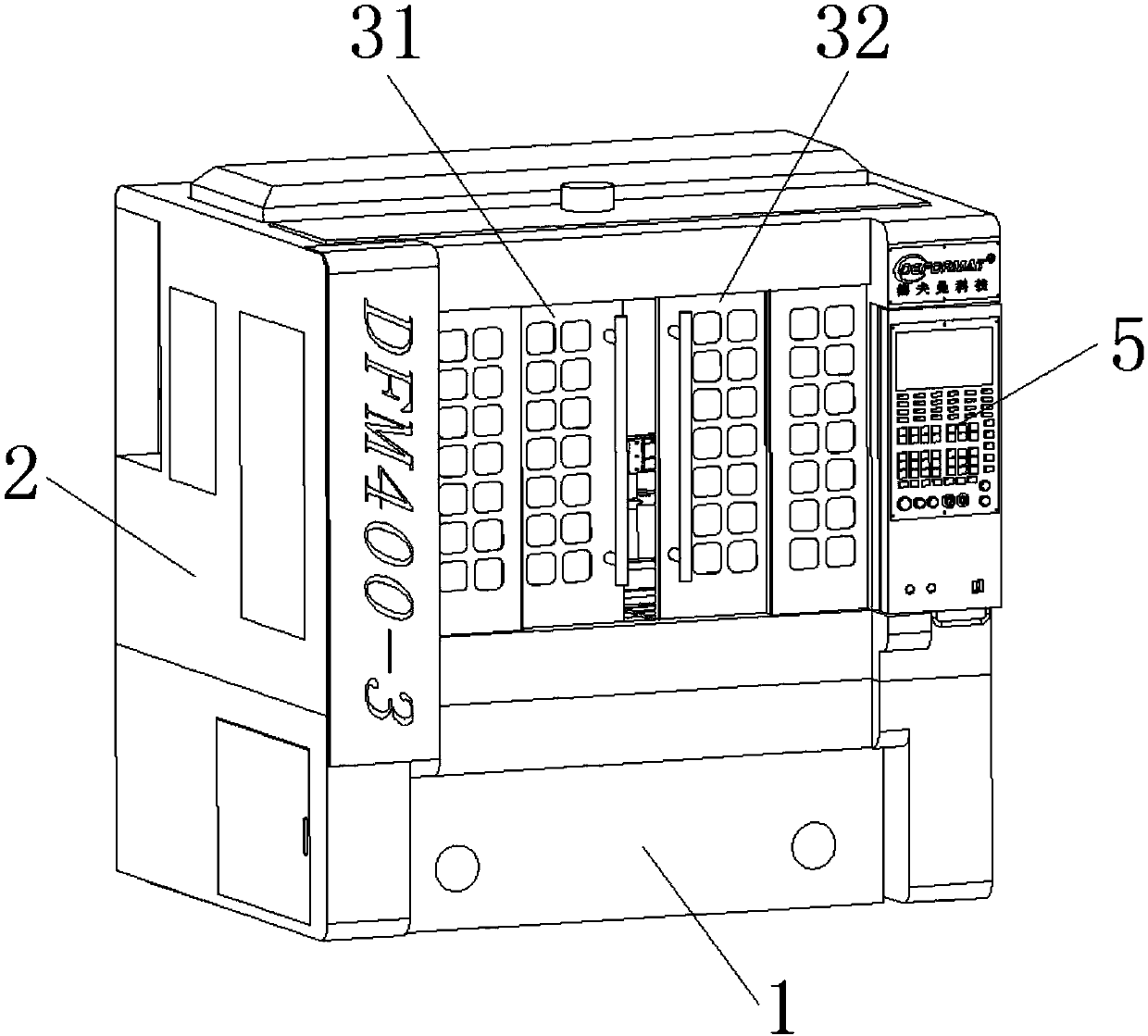

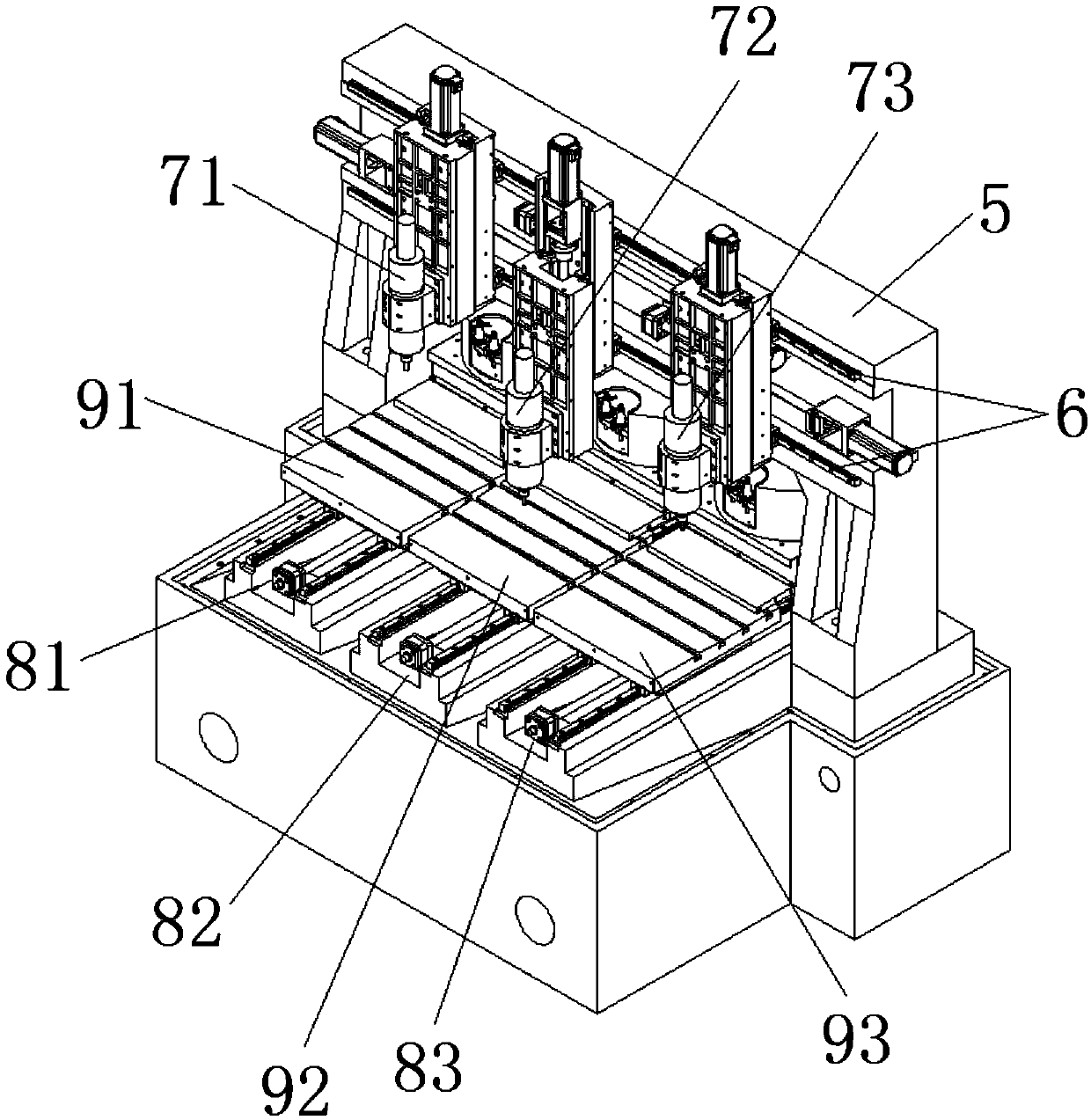

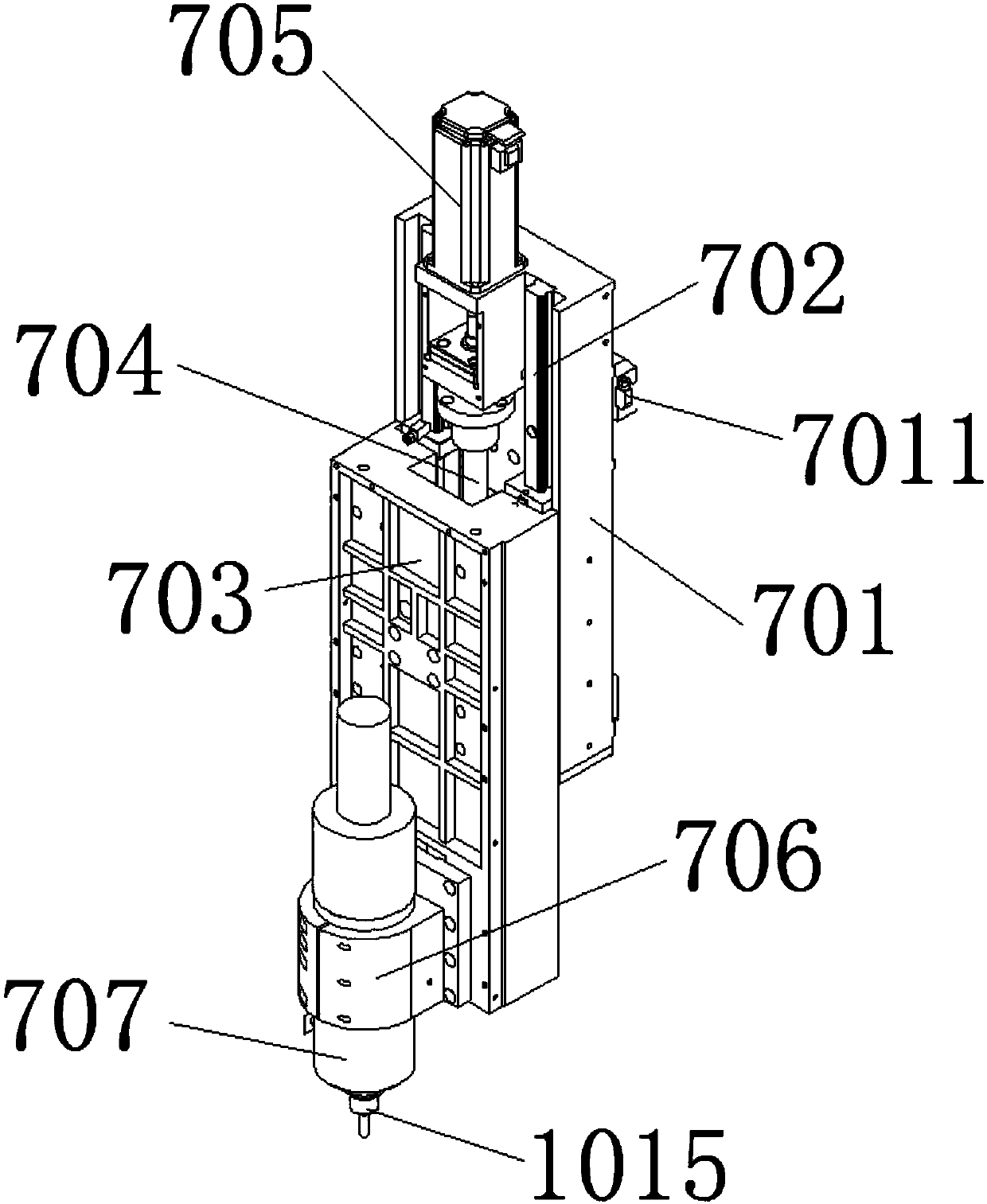

Separately controlled multichannel carving and milling machine

PendingCN107825226ALower purchase costReduce intensityLarge fixed membersMetal working apparatusNumerical controlControl system

The invention relates to a separately controlled multichannel carving and milling machine. The separately controlled multichannel carving and milling machine comprises a machine tool, a case, a left sliding door, a right sliding door, a control panel, a CNC (Computer Numerical Control) control system, a portal cross beam, a linear guide rail, a plurality of X-axis sliding plate mechanisms, a plurality of Z-axis sliding plate mechanisms, a plurality of Y-axis mechanisms, a plurality of workbenches and a plurality of tool changer disks. According to the separately controlled multichannel carvingand milling machine, main shafts and the workbenches can be separately controlled respectively, so that products can be synchronously or asynchronously processed by the main shafts, the products canalso be separately processed by the main shafts in multichannel different procedures, and the universality is good; the machining error of each shank cutter can be separately adjusted through the CNCcontrol system, so that the size of the produced products reaches the uniform standard, and the rate of good products is high; and the shank cutters of different specifications can be automatically replaced by the main shafts through the adjustment of the Y-axis mechanisms, so that the labor intensity of workers and the labor cost are reduced, the production cycle of the products is shortened, andthe production efficiency is high.

Owner:东莞市德夫曼科技实业有限公司

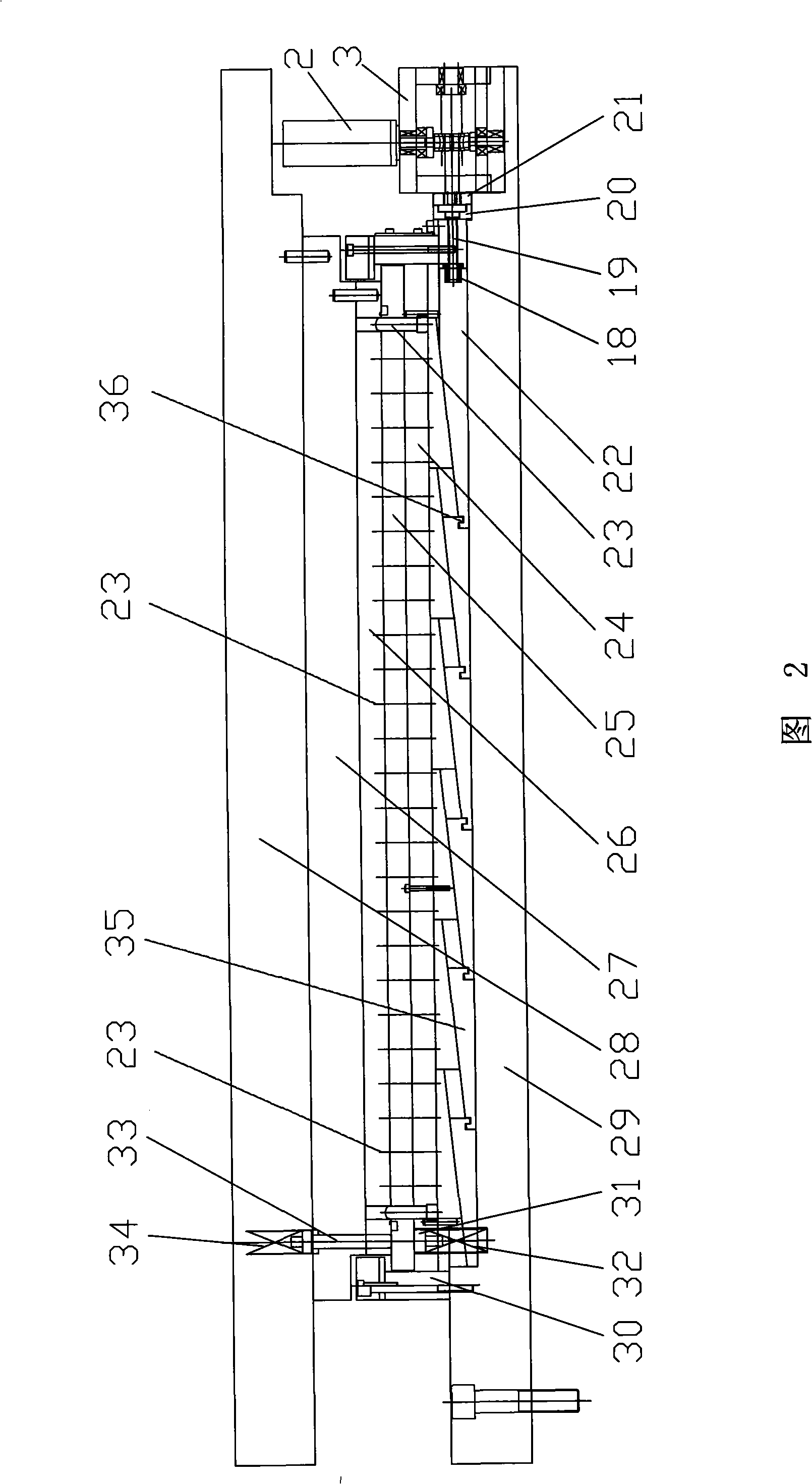

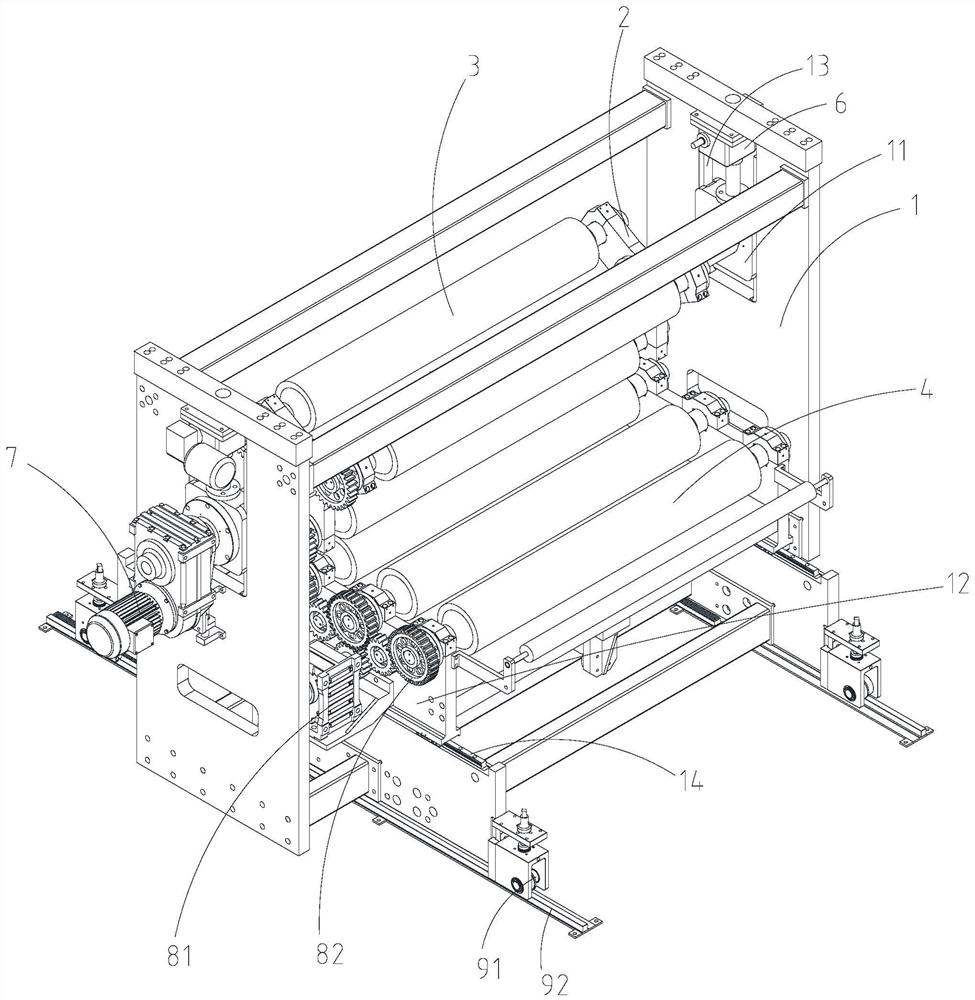

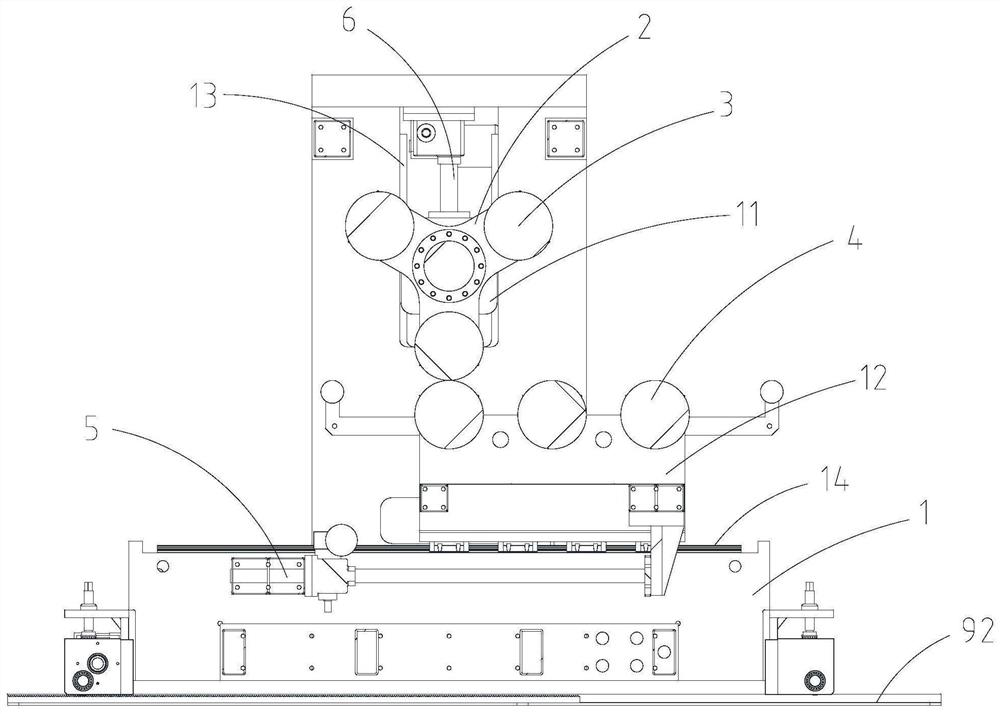

Plastic plate multi-roller embossing machine

The invention discloses a plastic plate multi-roller embossing machine. The machine comprises a rack, an upper pattern roller assembly, a lower pattern roller assembly and an upper pattern roller lifting driving mechanism, and a sliding block and a sliding frame are arranged on the rack in a sliding fit manner. The upper pattern roller assembly comprises a rotating frame rotationally supported onthe sliding block, at least two upper pattern rollers arranged in the circumferential direction of the rotating frame and rotationally supported on the rotating frame, and an upper pattern roller turnover mechanism connected with the rotating frame so as to drive the rotating frame to rotate to the corresponding angle. The lower pattern roller assembly comprises at least two kinds of lower patternrollers which are horizontally arranged and are respectively and rotatably supported on the sliding frame, and a lower pattern roller movement driving mechanism which is connected with the sliding frame so as to drive the sliding frame to horizontally move to a corresponding position; and the upper pattern roller lifting driving mechanism is connected with the sliding block to drive the sliding block to lift. According to the plastic plate multi-roller embossing machine, patterns can be conveniently replaced, the combination of various patterns is realized, the replacement is convenient, andthe trouble of replacing the roller by halting is avoided.

Owner:常州金纬片板设备制造有限公司

Medicine bottle cap punch forming equipment with synchronization of punching and discharging

InactiveCN107377807ASimple structureSimplify the blanking structureSievingMetal-working feeding devicesPunchingMedicine bottle cap

The invention relates to the field of processing of bottle caps, in particular to medicine bottle cap punch forming equipment with synchronization of punching and discharging. The medicine bottle cap punch forming equipment comprises a frame, a punching mechanism, a feeding mechanism and a discharging mechanism; the punching mechanism, the feeding mechanism and the discharging mechanism are arranged on the frame. The punching mechanism comprises a punching slide rail fixed to the frame, a punching platform slidably arranged on the punching slide rail and a driving motor driving the punching platform to move along the punching slide rail. The discharging mechanism comprises a blowing assembly and a receiving assembly; the blowing assembly comprises a blowing tube arranged beside the punching station and a blowing cylinder connected with the blowing tube and fixed at the position above the punching mechanism; the inside of the blowing cylinder is provided with an air cavity, the body of the blowing cylinder is provided with an air inlet, a piston is arranged in the air cavity, and an external rod of the piston is connected to the punching platform of the punching mechanism. The medicine bottle cap punch forming equipment realizes linkage synchronization of the punching procedure and the discharging procedure, thereby simplifying structure and saving time for regulation.

Owner:浙江冠利新材料股份有限公司

Cutter compensation and correction method and system of machine tool

ActiveCN111113268AImprove processing outputReduce machine set-up timeProgramme controlComputer controlCorrelation factorMachine tool control

A cutter compensation and correction method of a machine tool comprises the following steps that an abrasion wheel wear trend coefficient S is calculated; a correlation factor coefficient P of the influence of cutting force changes and abrasion wheel deflection on the machine tool control accuracy is calculated; a correlation factor M1 of the influence of the mechanical factor of the machine toolon the machining size is calculated; a first part actual compensation value M2 is calculated according to the effective machining diameter, deflection data and rigid deformation data of an existing abrasion wheel installed on the machine tool; the size of a product to be machined is measured, and the size deviation of the product is calculated; a cutter compensation value X is calculated through acompensation and correction algorithm according to the abrasion wheel wear trend coefficient S, the correlation factor coefficient P, the correlation factor M1, the first part actual compensation value M2 and the size deviation of the product; and when the product is machined by the machine tool, the cutter position is compensated and corrected according to the cutter compensation value X. By theadoption of the cutter compensation and correction method of the machine tool, the cutter position can be automatically compensated and corrected, the time adjustment time is shortened, the product yield can be improved, and the machining output of a machining facility is improved.

Owner:福建省嘉泰智能装备有限公司

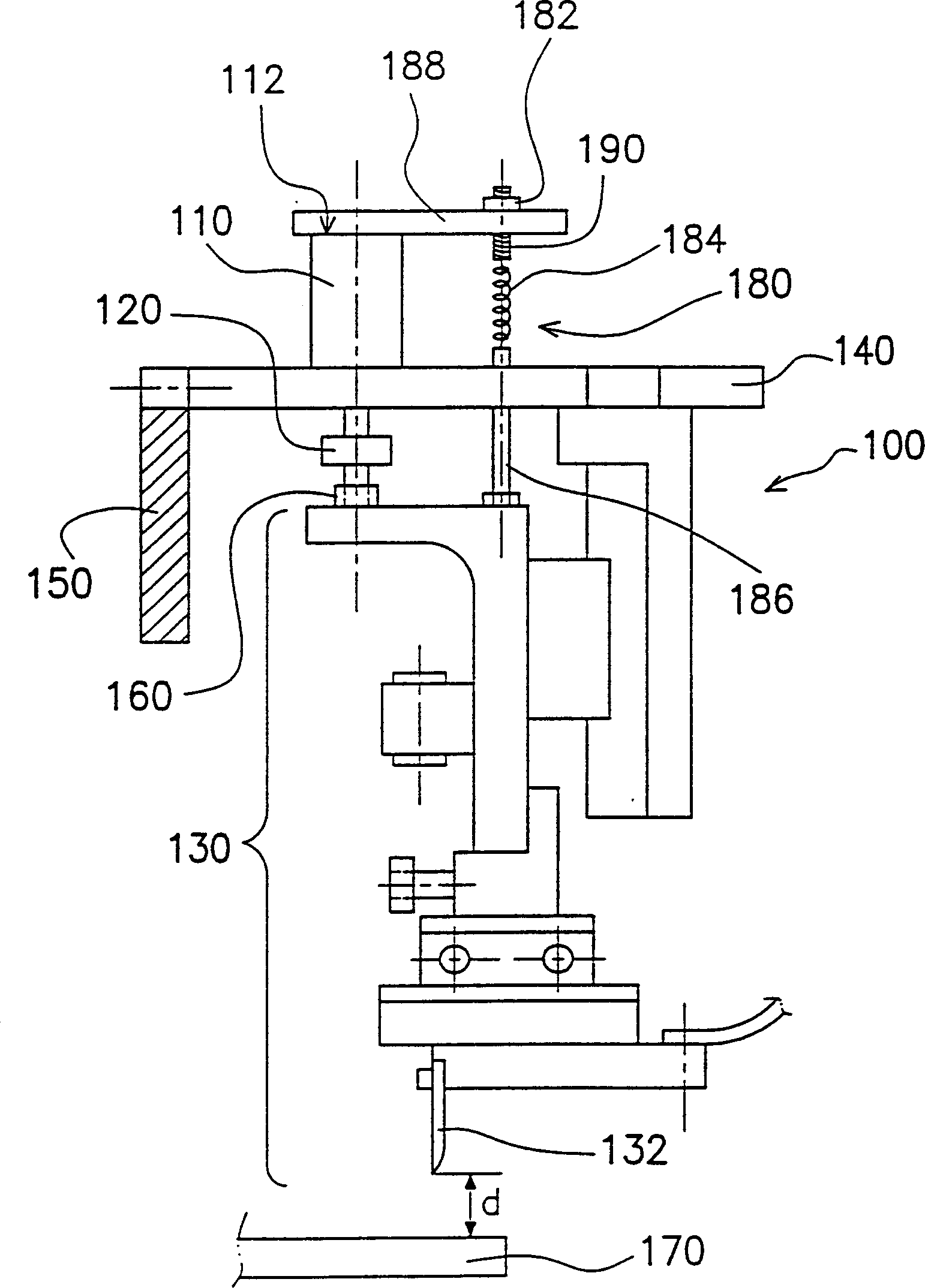

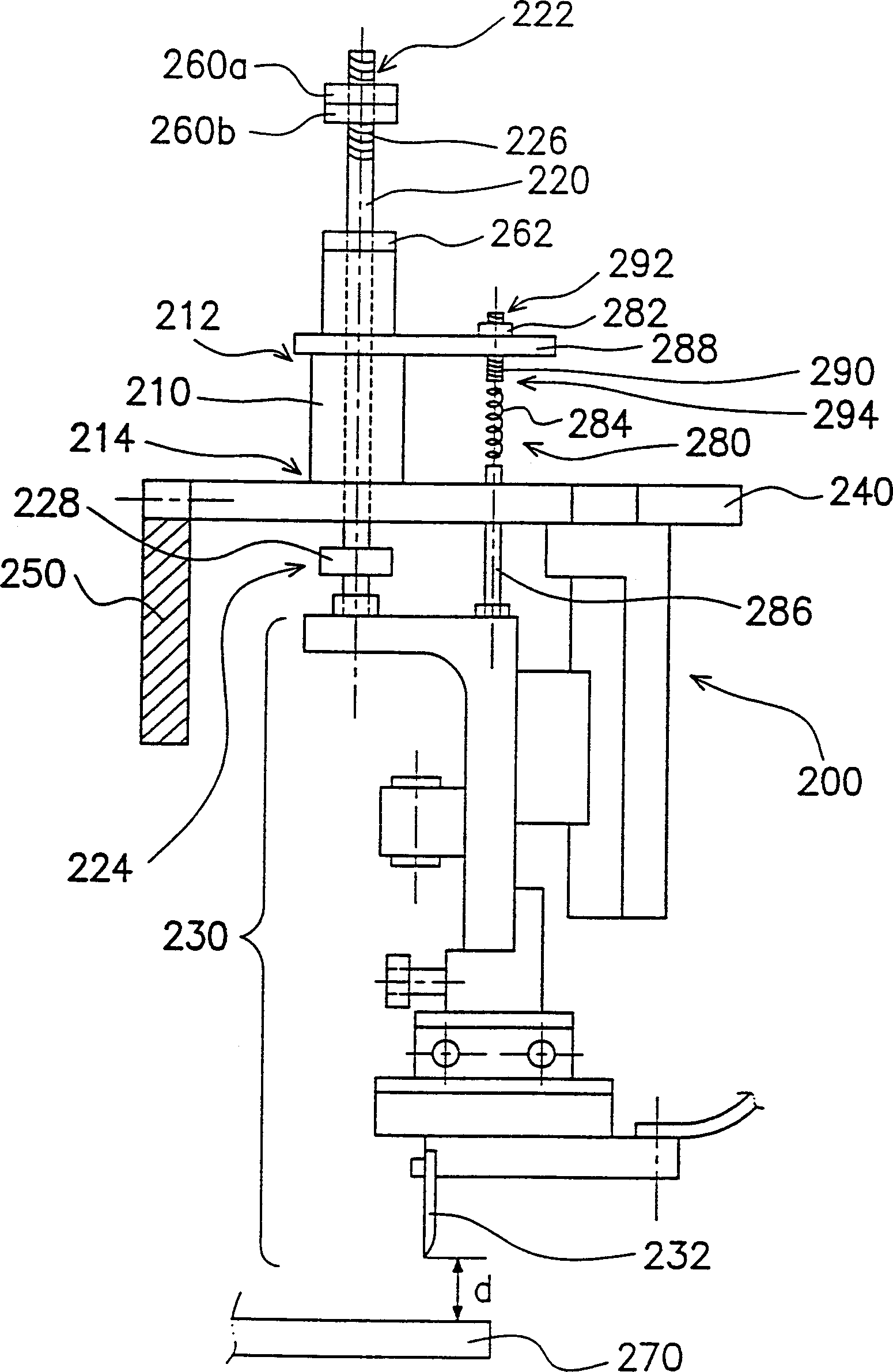

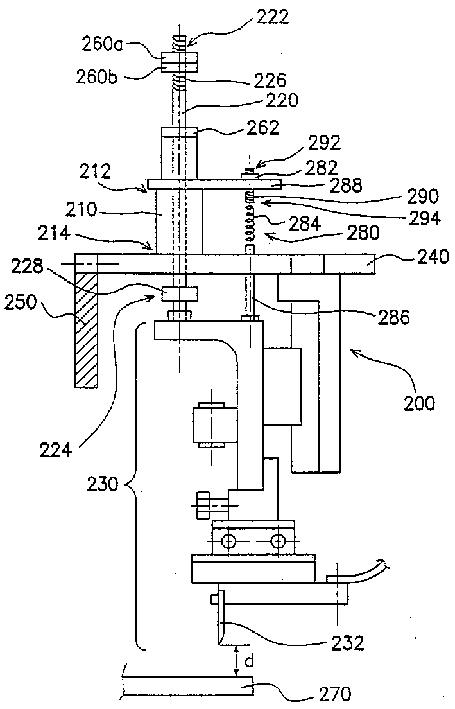

Film packaged external pin pressing device

InactiveCN1395303AIncrease activity spaceEasy to adjust machine operationSemiconductor/solid-state device manufacturingNon-linear opticsEngineeringScrew thread

The invented device for clamping the outer pins for the film encapsulation includes at least the one cylinder, one connecting rod and the clamping head assembly. The cylinder possesses the first end and the second end. The connecting rod is throughout the cylinder. The connecting rod also possesses the first end and the second end. The first end of the rod is extended to the outside of the first end of the cylinder, and the second end of the rod is extended to the outside of the second end of the cylinder. The screw thread structure is on the first end of the rod. There is the spacer between the adjusting nut and the cylinder. The floating joint constitutes the second end of the rod. The clamping head assembly is connected to the floating joint of the rod.

Owner:HANNSTAR DISPLAY CORPORATION

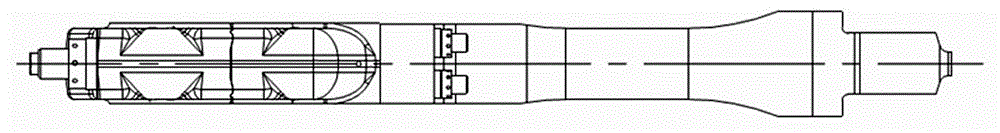

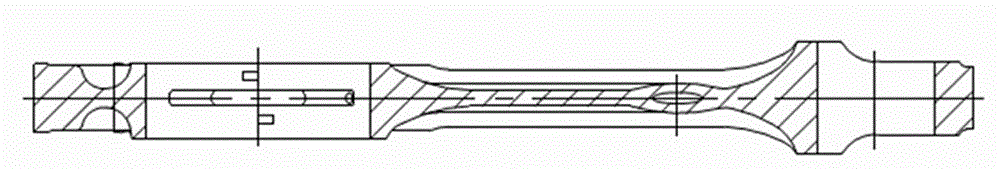

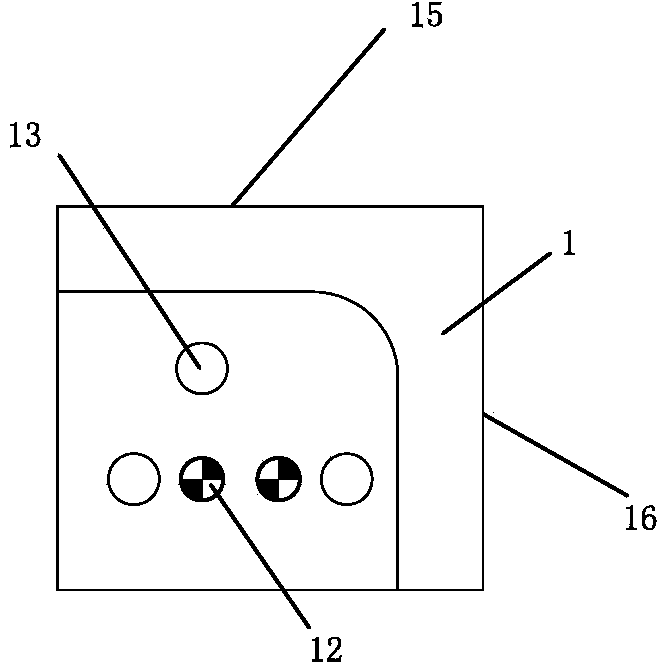

Numerical control lathe power shaft center correcting device

PendingCN109396472AEasy to adjustReduce machine set-up timeAuxillary equipmentNumerical controlFixed frame

The invention discloses a numerical control lathe power shaft center correcting device. The numerical control lathe power shaft center correcting device comprises a clamping main shaft, a connecting shaft, a fixing frame and a dial indicator, wherein the clamping main shaft comprises a clamping part and a rotating hole, the axis of the clamping part and the axis of the rotating hole are perpendicular to each other and in the same plane, the connecting shaft is arranged in the rotating hole, the connecting shaft can rotate in the rotating hole, the connecting shaft and the rotating hole are coaxial, the fixing frame is used for fixing the dial indicator on the connecting shaft, the dial indicator is provided with a gauge rod, the dial indicator can be horizontally moved along the axis of the gauge rod, and the axis of the gauge rod and the axis of the connecting shaft are perpendicular to each other and in the same plane. According to the numerical control lathe power shaft center correcting device, a power shaft is directly verified through the dial indicator, the numerical control lathe power shaft center correcting device is convenient and fast, the center of a power tool is accurately adjusted, the machine adjusting time is saved, and the requirements of the product are guaranteed.

Owner:上海阿为特精密机械股份有限公司

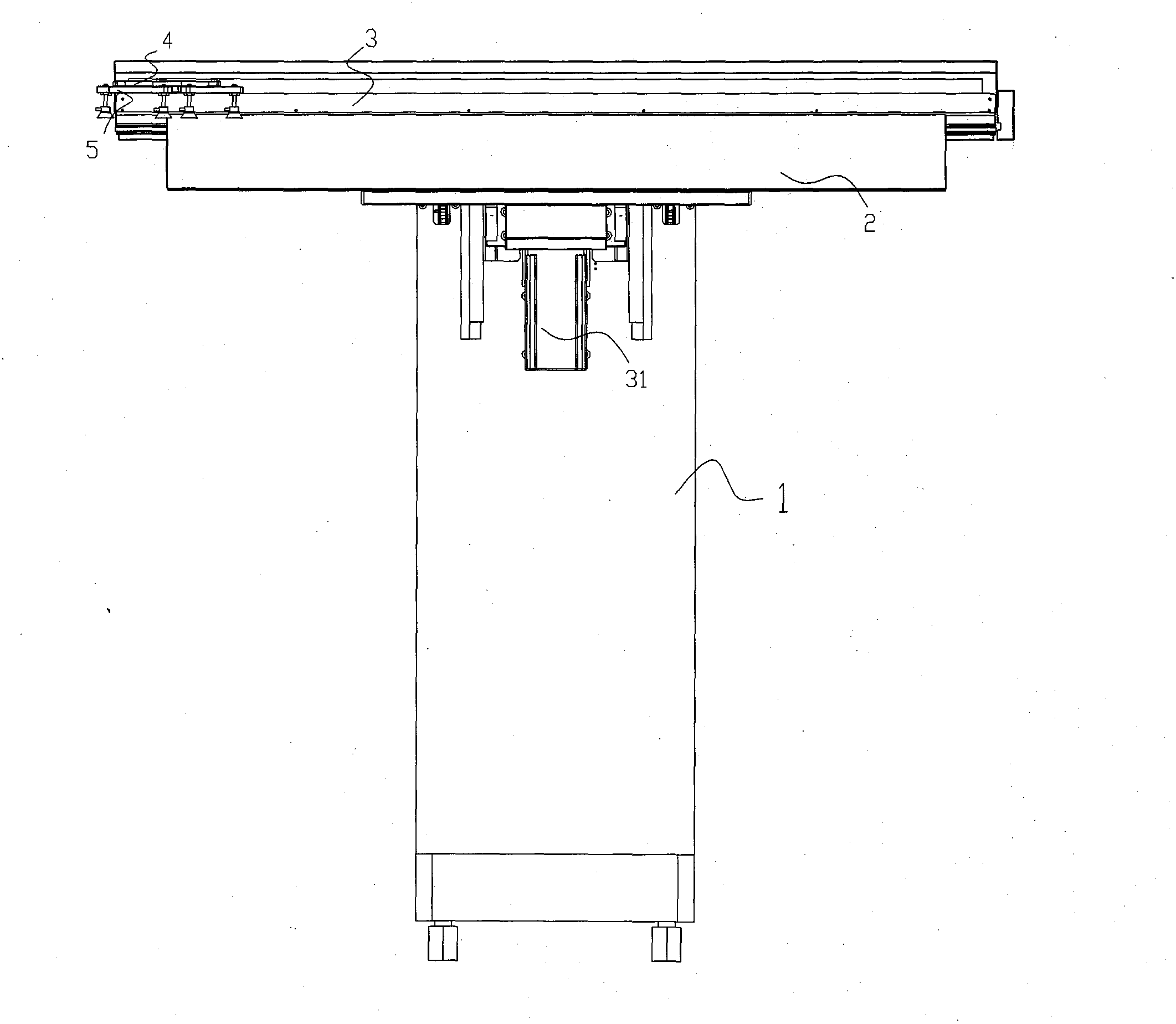

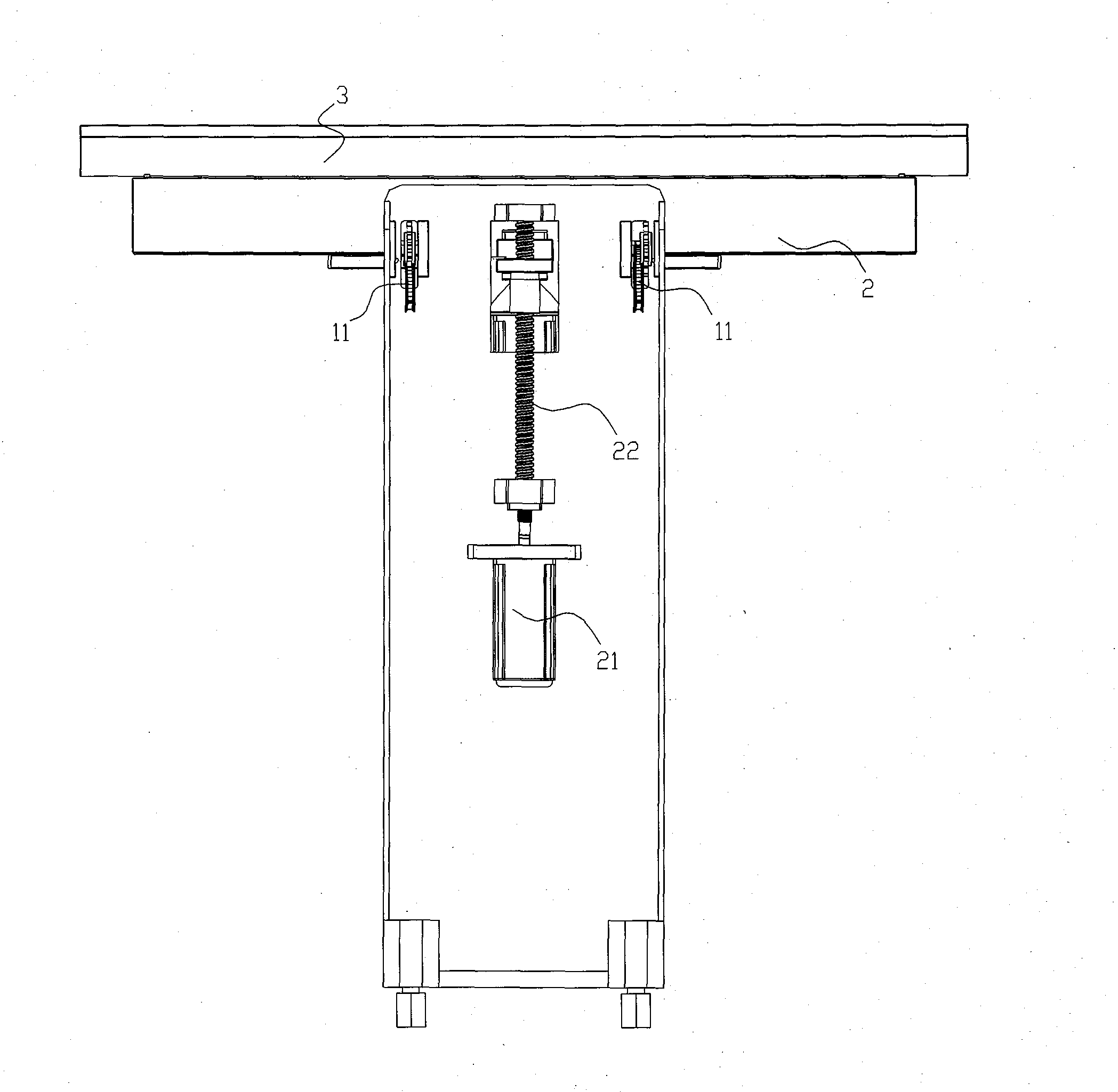

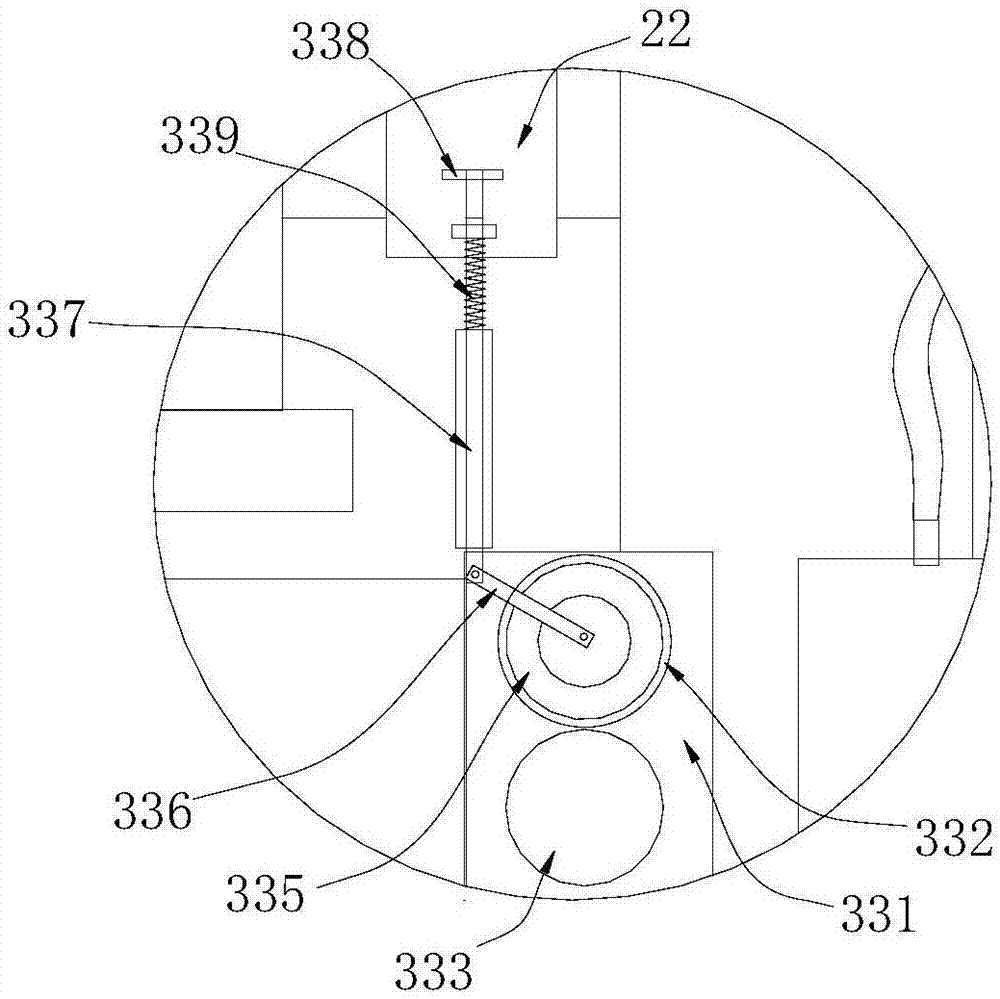

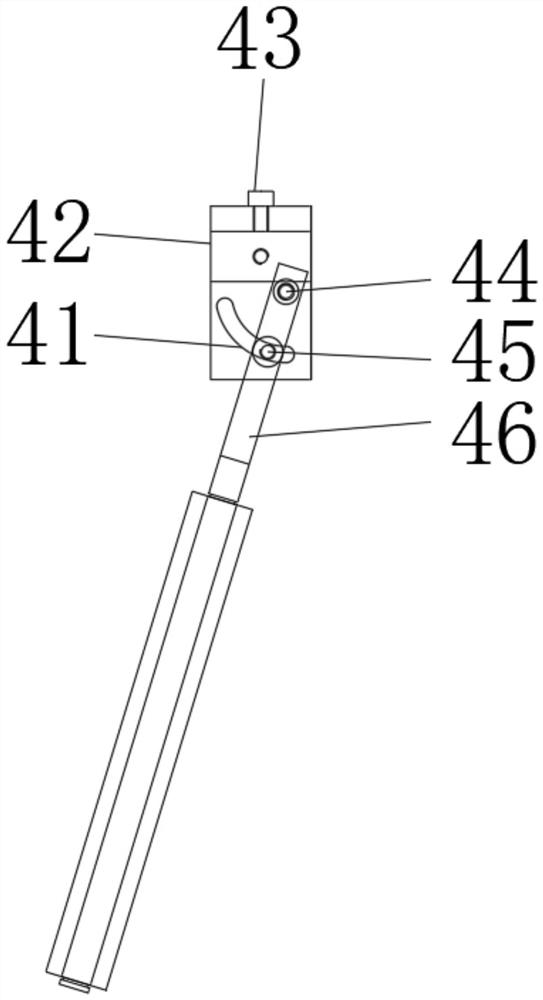

Leveling device

PendingCN110744185AEasy to adjustMeet the parallelism requirementNon-electric welding apparatusUltrasonic weldingEngineering

The invention discloses a leveling device which can be used for leveling a welding spot of an ultrasonic spot welder. The leveling device comprises a slider-crank mechanism and an indexing mechanism,wherein the slider-crank mechanism comprises a rack, a slider, a connecting rod and a sleeve acting as a crank, reciprocating movement of the slider drives the sleeve to do rotary swing in a certain angle, the sleeve is used for fixing a component needing to be leveled, the indexing mechanism comprises a lead screw and nut mechanism and a worm and gear mechanism, the lead screw and nut mechanism comprises a lead screw fixedly connected with the slider and a nut mounted on the lead screw, the worm and gear mechanism is used for driving the nut to rotate, and the slider is driven to move throughthe lead screw. When the scheme of the leveling device is applied to ultrasonic welding, rapid adjustment of the parallelism of a welding head and the welding spot relative to a bottom die can be achieved, the machine adjusting time during replacement of the welding head is shortened, the parallelism requirement of the welding head and the welding spot relative to the bottom die is met, and higher efficiency and higher welding quality of ultrasonic welding are achieved.

Owner:深圳市深发源精密科技有限公司

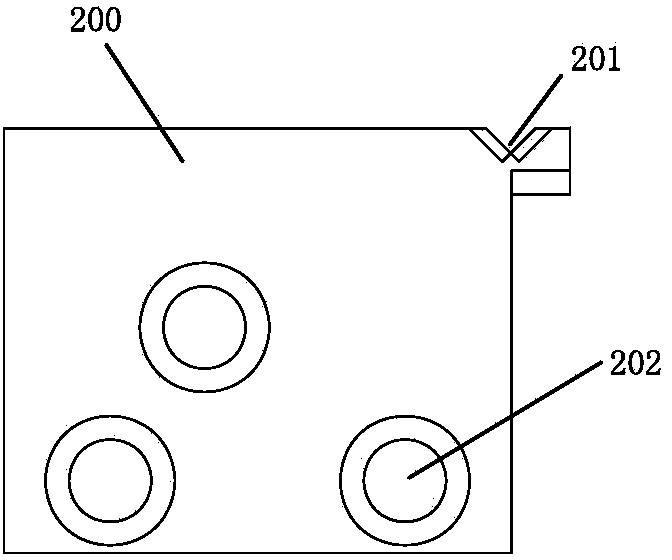

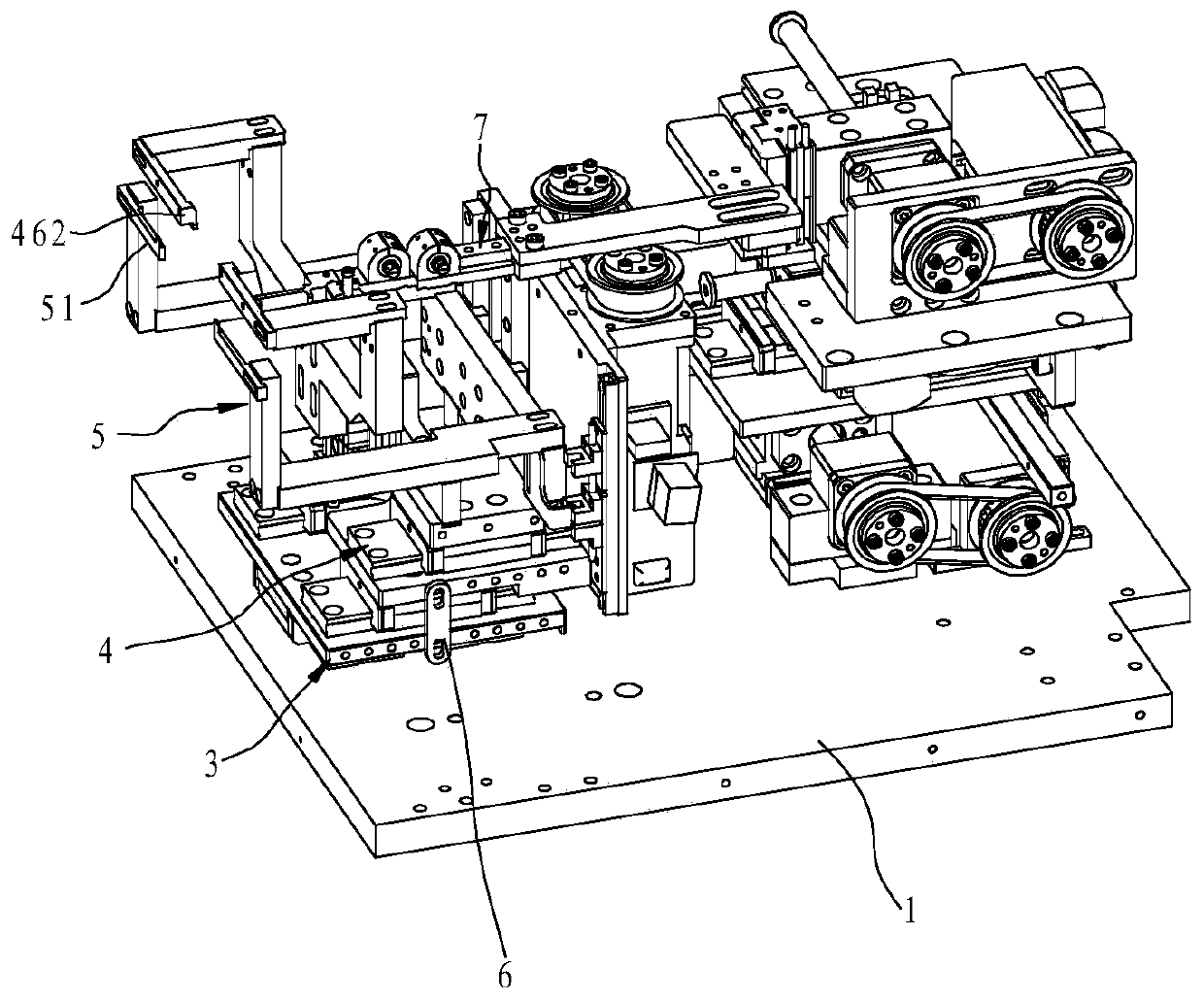

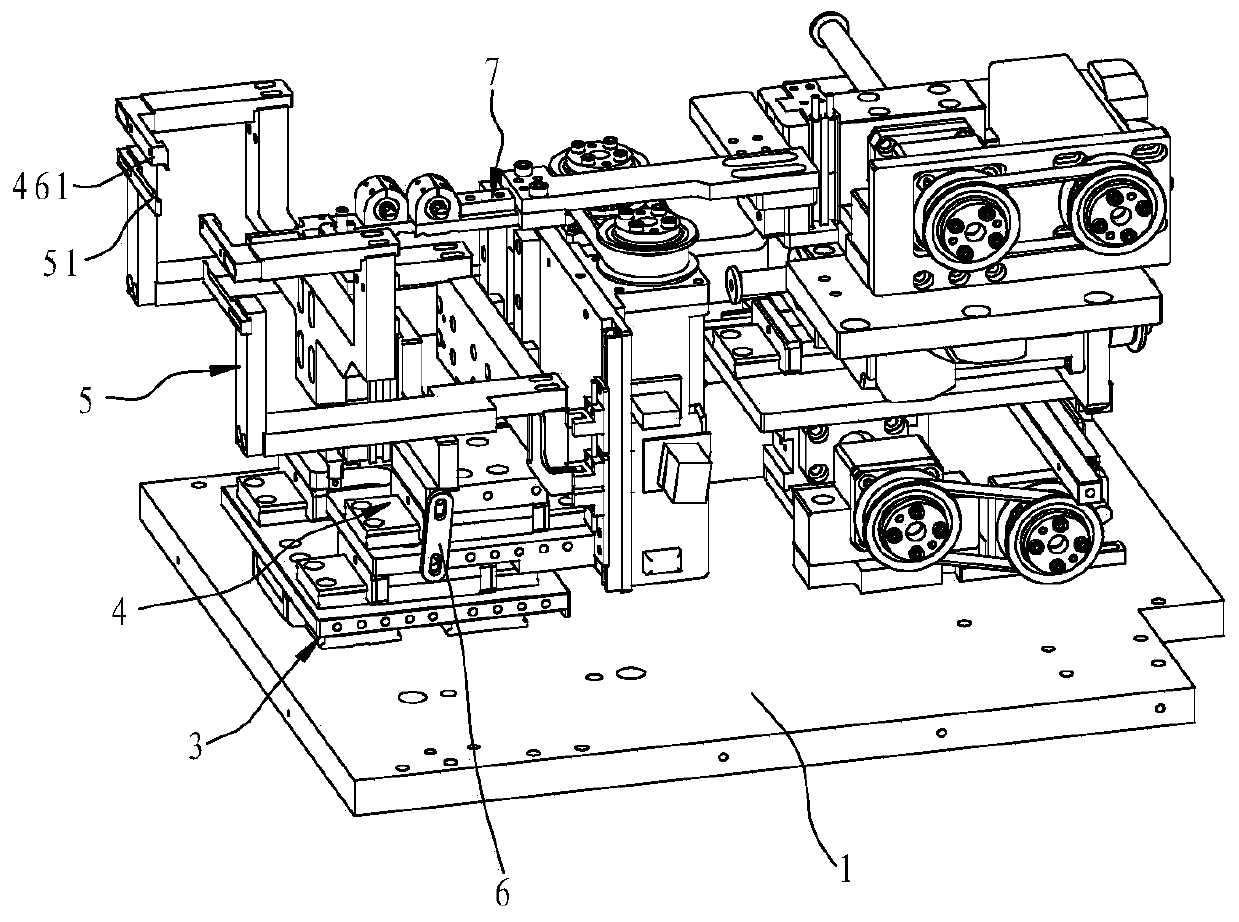

Backlight module and FPC welding alignment device

PendingCN110621120AFast switching speedReduce machine set-up timePrinted circuit assemblingNon-linear opticsComputer moduleEngineering

The invention discloses a backlight module and FPC welding alignment device. The device comprises a mounting bottom plate, an adsorption mechanism, an X-direction alignment driving mechanism, a Y-direction alignment mechanism, a Z-direction movement mechanism and a switching connection piece; the X-direction alignment driving mechanism comprises a first movement module sliding in an X direction and a first driving device connected with the first movement module; the Y-direction alignment mechanism comprises a second movement module, a third movement module, a second driving device, and an upper alignment part, wherein the second movement module and the third movement module slide in a Y direction, the second driving device is connected with the second movement module, and the upper alignment part is connected with the second driving device; a third driving device can drive the upper alignment part to move in a Z direction; a second connecting piece is fixedly connected with the third movement module; the upper alignment part is an upper clamping jaw or a friction rod; the Z-direction movement mechanism is fixedly connected with the second movement module and comprises a lower clamping jaw and a fourth driving device; and the switching connection piece is selectively and fixedly connected with the first movement module and the second movement module or the second movement moduleand the third movement module. The device has a friction alignment mode and a clamping alignment mode, and can be quickly switched between the two alignment modes.

Owner:SHENZHEN JIYIN TECH

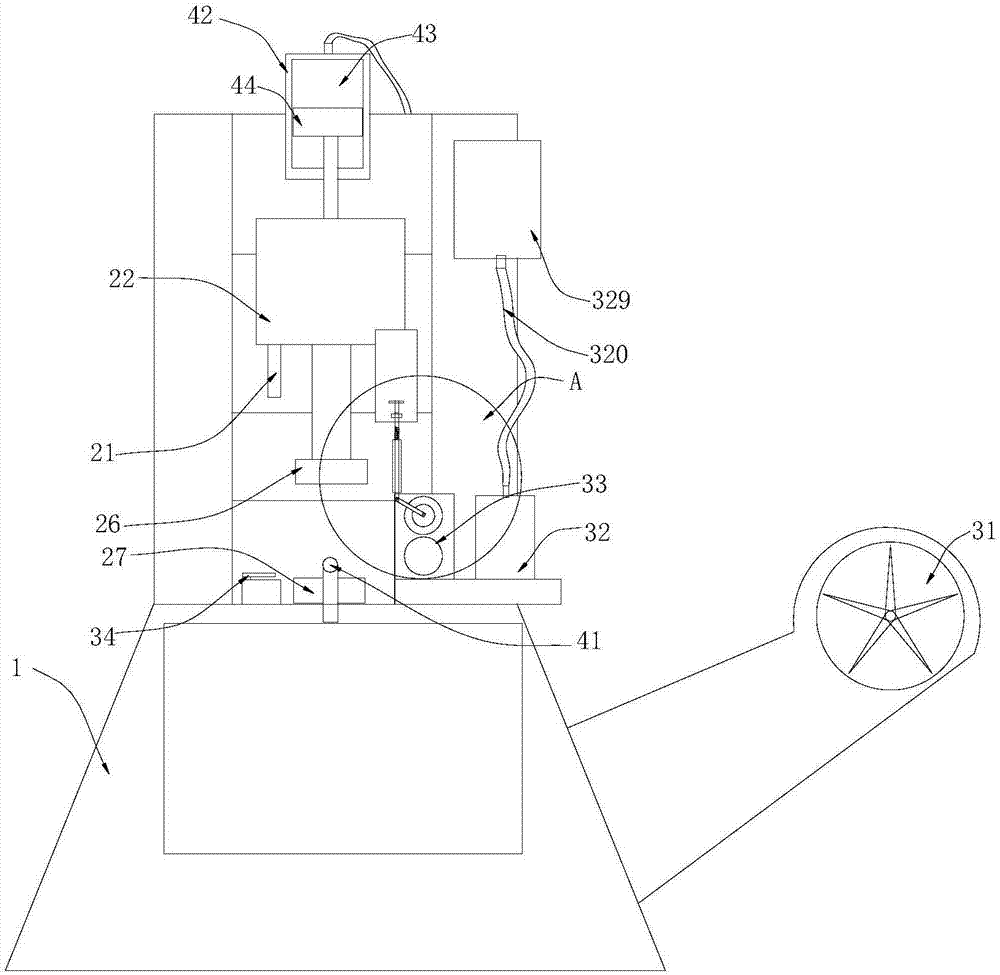

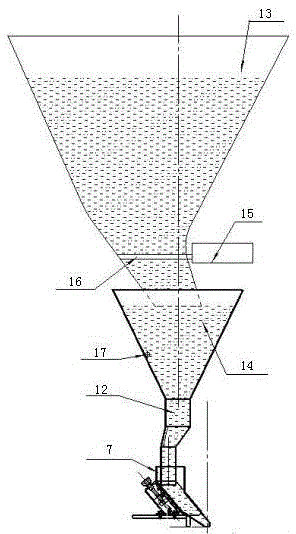

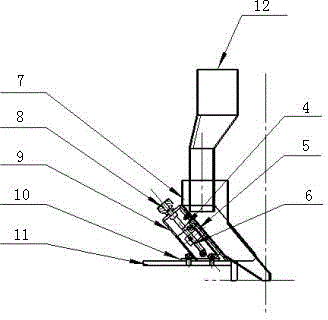

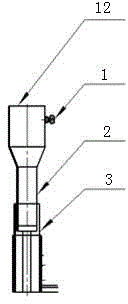

Quantitative feeding device for looping machine

The invention discloses a quantitative feeding device for a looping machine. The quantitative feeding device for the looping machine comprises a first stock bin, a second stock bin, a conveying hose, a material receiving opening, an inclined hopper, an adjustable discharging device and a fixed base, wherein the second stock bin is arranged at the upper end of the first stock bin, and the lower end of the first stock bin is fixedly connected with the conveying hose; the upper end of the material receiving opening is fixedly connected with the conveying hose, and the lower end of the material receiving opening is fixedly connected with the adjustable discharging device; the inclined hopper is arranged inside the adjustable discharging device, and an adjusting seat is welded on the bevel edge at the bottom of the inclined hopper; the fixed base is fixedly arranged on a fixed support through a screw, a slide base is fixedly arranged on the upper left side of the bottom of the fixed base in an upward slantwise manner, an adjusting rod is arranged inside the slide base, the adjusting rod is fixed with the adjusting seat through the screw to adjust the opening height of the inclined hopper. The quantitative feeding device for the looping machine has the benefits of good mechanism stability, accurate feeding target, precise feeding amount, convenience for control, uniform discharging, automatic feeding, uniform feeding and no blocking in the stock bins.

Owner:DANYANG QIRUI MACHINERY

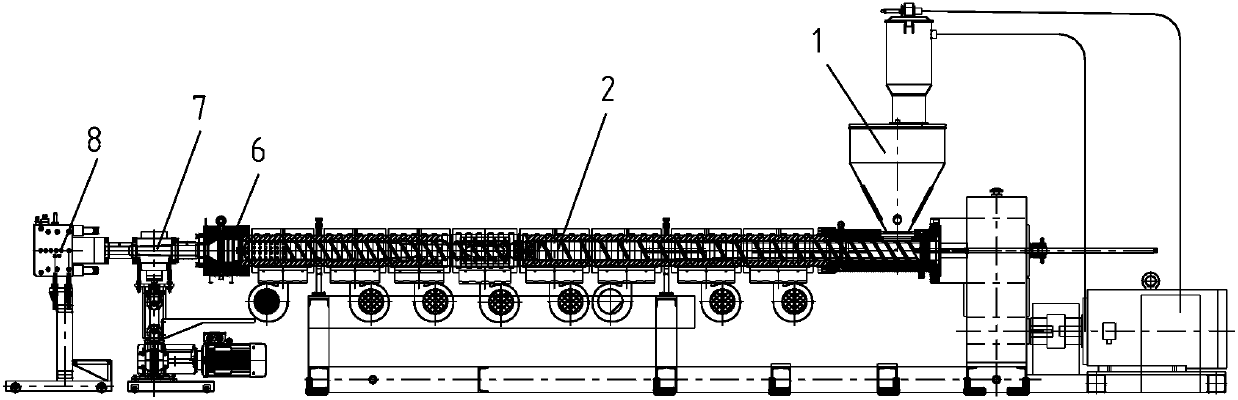

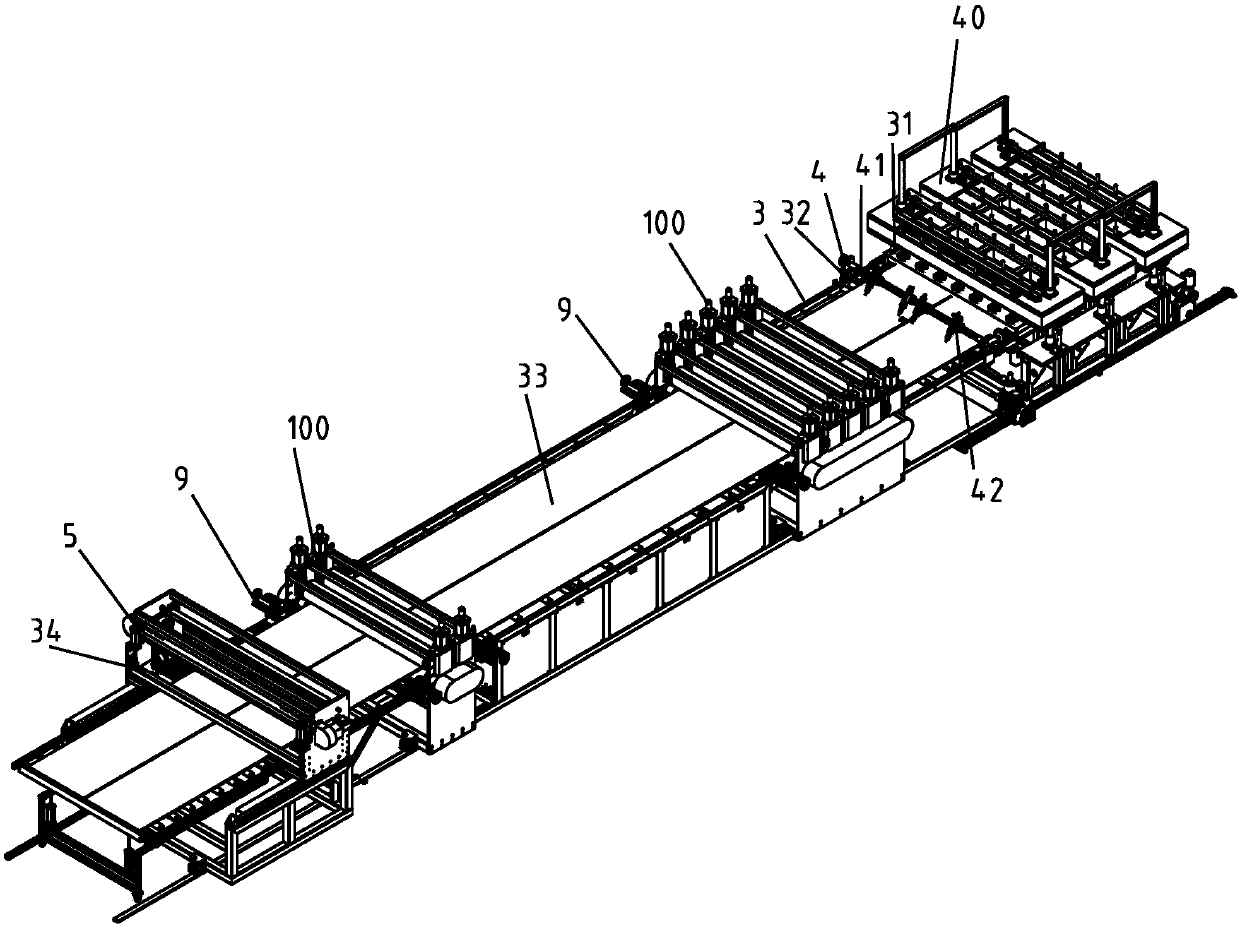

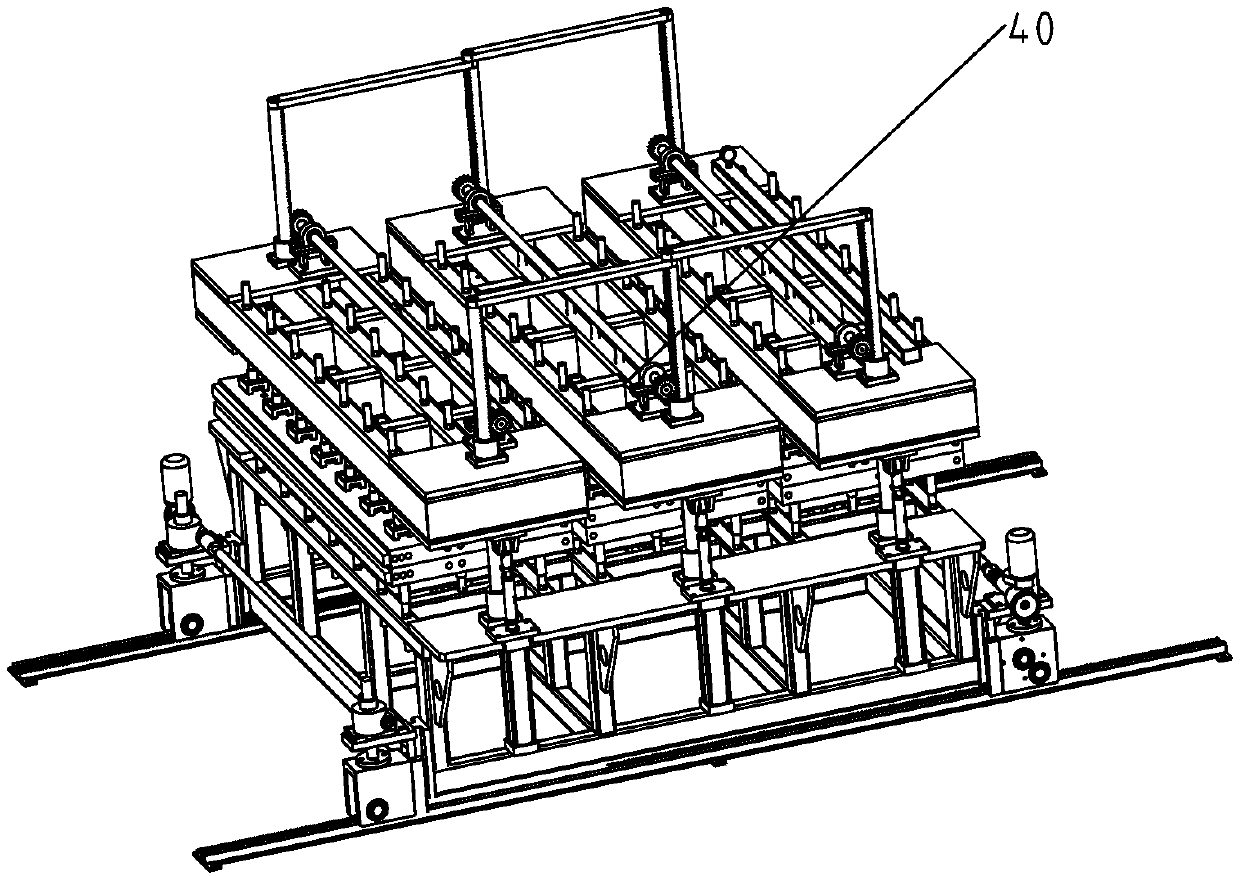

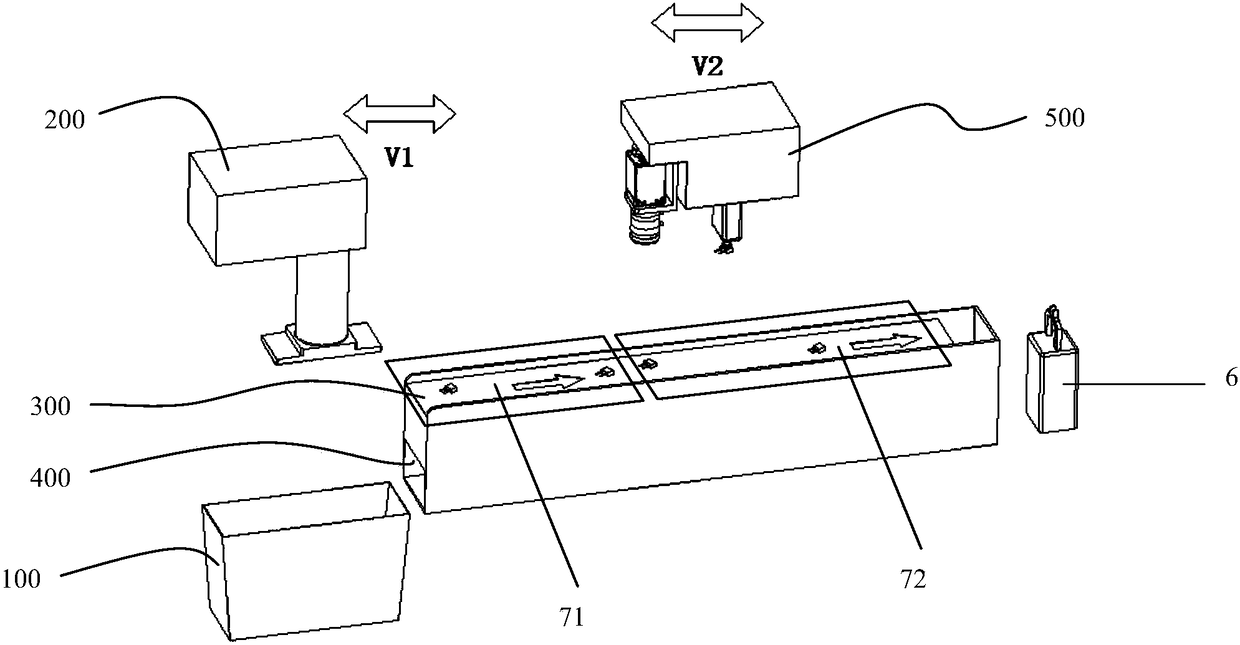

Building template production line and building template production method using same

PendingCN107639802AImprove practicalityHighlight humanityDomestic articlesProduction lineUser Friendly

The invention discloses a building template production line and a building template production method using the building template production line. The building template production line comprises a material extruding part, a material cooling and conveying platform, a shaping platform, a fixed-width longitudinal cutting component, a dragging component used for dragging longitudinally-cut blanks andenabling the longitudinally-cut blanks to be conveyed forwards, and a fixed-length transversal cutting component, wherein the material extruding part comprises a material loader and an extruder; a shaping platform mounting part, a fixed-width longitudinal cutting component mounting part, a cooling and conveying part and a fixed-length transversal cutting component mounting part are successively arranged on the material cooling and conveying platform from back to front; the shaping platform is mounted on the shaping platform mounting part; the fixed-width longitudinal cutting component is arranged on the fixed-width longitudinal cutting component mounting part; the dragging part is mounted on the cooling and conveying part; the fixed-length transversal cutting component is mounted on the fixed-length transversal cutting component mounting part. The building template production line can replace the low-productivity outdated forming process at present to complete production of building templates; meanwhile, the building template production line is high in automation degree of equipment and high in continuous production capability; the productivity of the equipment is effectively improved; the labor is reduced; the operation of the equipment is user-friendly.

Owner:常州金纬片板设备制造有限公司

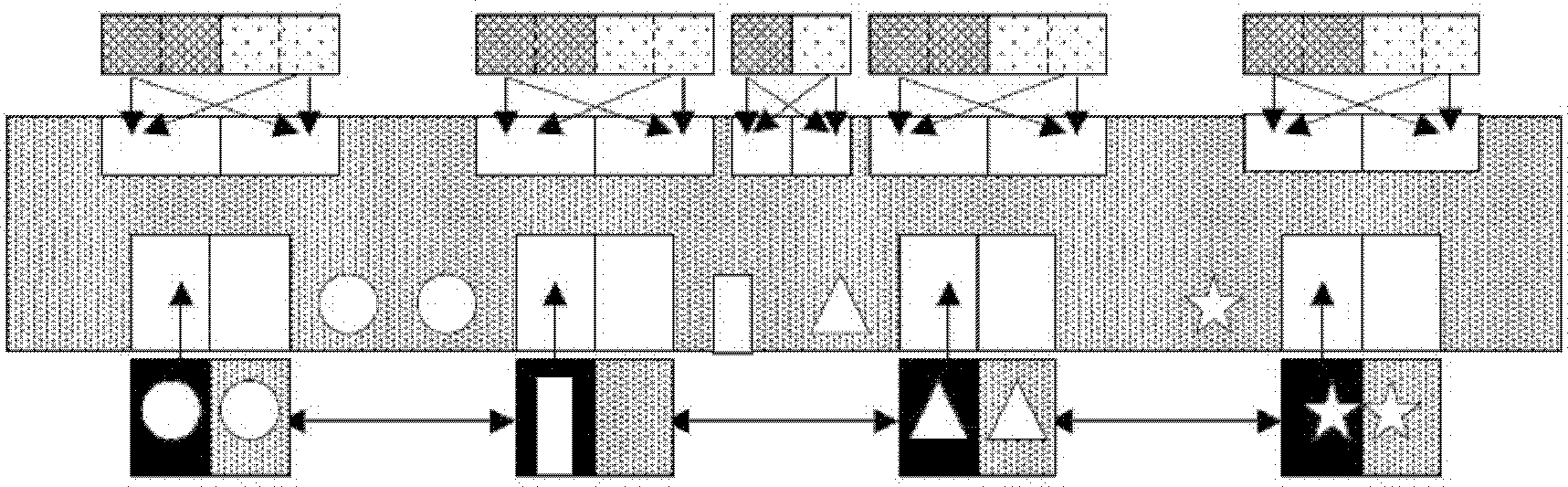

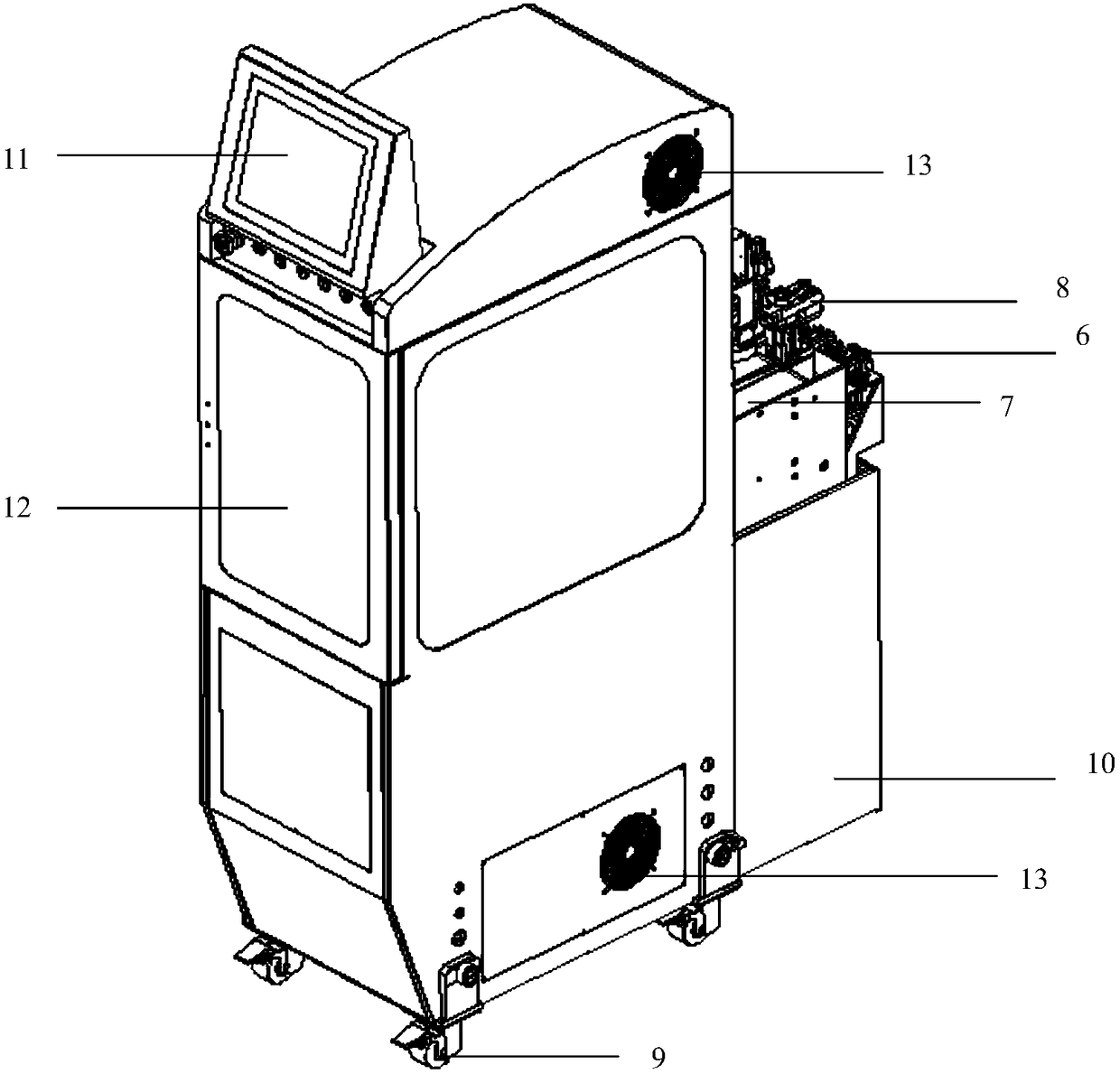

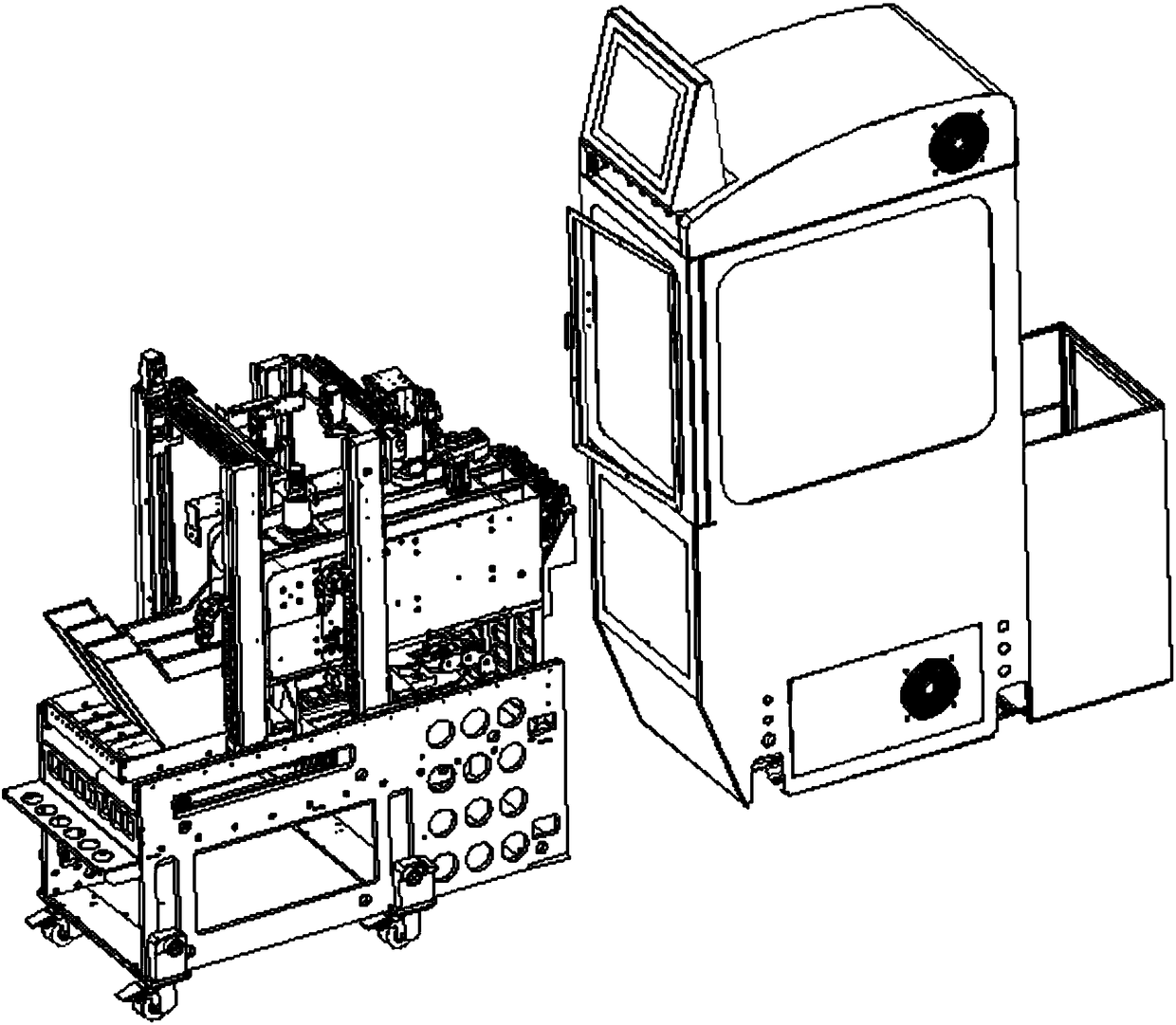

Bulk material feeding machine

PendingCN108328322AImprove general performanceImprove automationConveyorsControl devices for conveyorsDistribution systemEngineering

The invention discloses a bulk material feeding machine which comprises a storage module, a feeding module, a conveying module, a backflow module and a recognition and distribution system. The feedingmodule is arranged above the storage module, the recognition and distribution system, the conveying module and the backflow module are arranged from top to bottom, the conveying module and the backflow module are in opposite conveying directions, the feeding module obtains workpieces from the storage module and places the workpieces on the conveying module in one layer, the recognition and distribution system recognizes the workpieces recognized in a correct state on the conveying module and obtains the workpieces in the correct state, and the workpieces not obtained by the recognition and distribution system are conveyed into the storage module through the backflow module. According to the bulk material feeding machine, within a certain size range, all electric device elements or parts with regular geometrical shapes can be sorted, and universality is high.

Owner:SHENZHEN HANJIANG AUTOMATION SCI & TECH CO LTD

Folding device for RFID folding label production and using method thereof

ActiveCN113173452AReduce usageLow costFolding thin materialsArticle deliveryElectric machineryStructural engineering

The invention discloses a folding device for RFID folding label production and a using method thereof. The folding device comprises a first motor, a folding machine, a folding clamping roller, a limiting rod, a waste discharging machine and a base, the base is arranged at the bottom end of the folding machine, a first pressing roller and a second pressing roller are rotationally installed on the base, the first motor is installed on one side of the base, a connecting rod is installed on one side of the folding machine through an installation groove, the folding clamping rod is movably installed on the connecting rod through a limiting rod, a walking belt is folded along an edge line of a sponge after passing through the folding clamping rod, a folded material is isolated by silicone oil PET, the material cannot be bonded together temporarily, the waste discharging machine is installed on the folding machine through the installation groove, and when the walking belt passes through the folding machine, the silicone oil PET is pulled out by the waste discharging machine, so that the glue surface of the sponge is completely exposed to facilitate subsequent pressing. The device has the advantages that an RFID folding tag can be produced on a common multi-station die-cutting machine, and the capability of producing the anti-metal folding tag is realized at the lowest cost.

Owner:GUANGZHOU CONFIDEX ELECTRONICS SCI & TECH

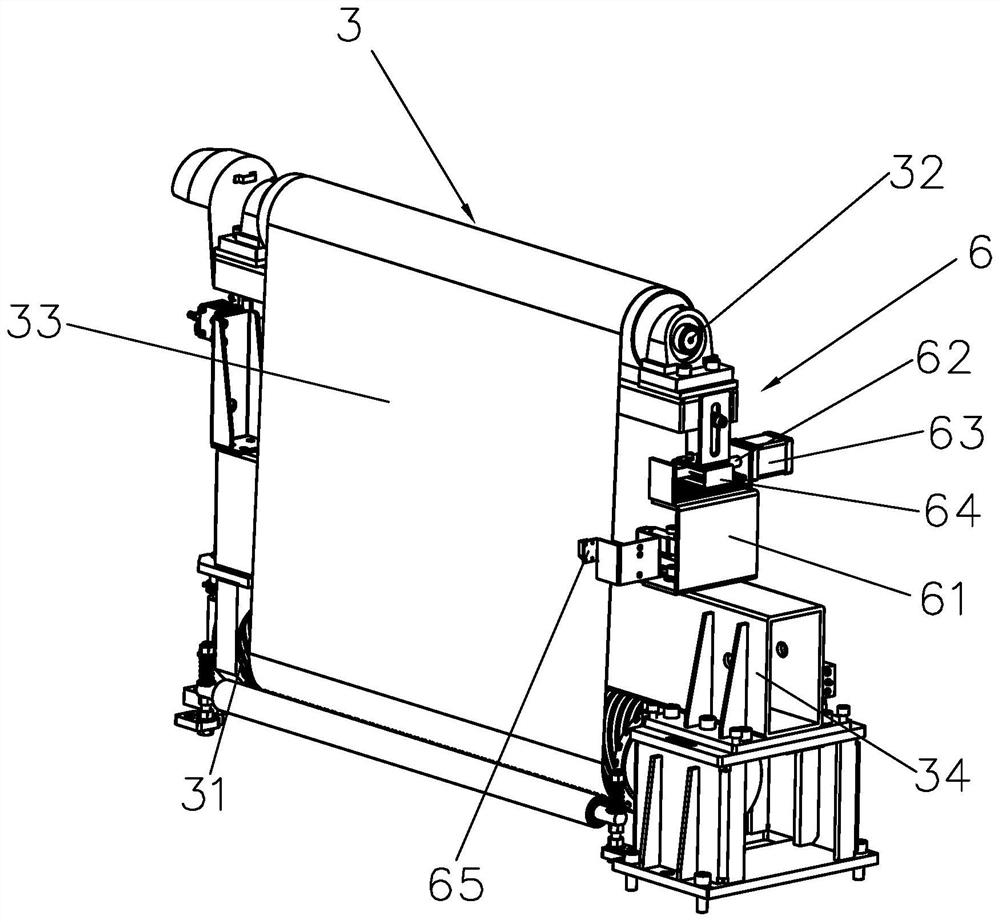

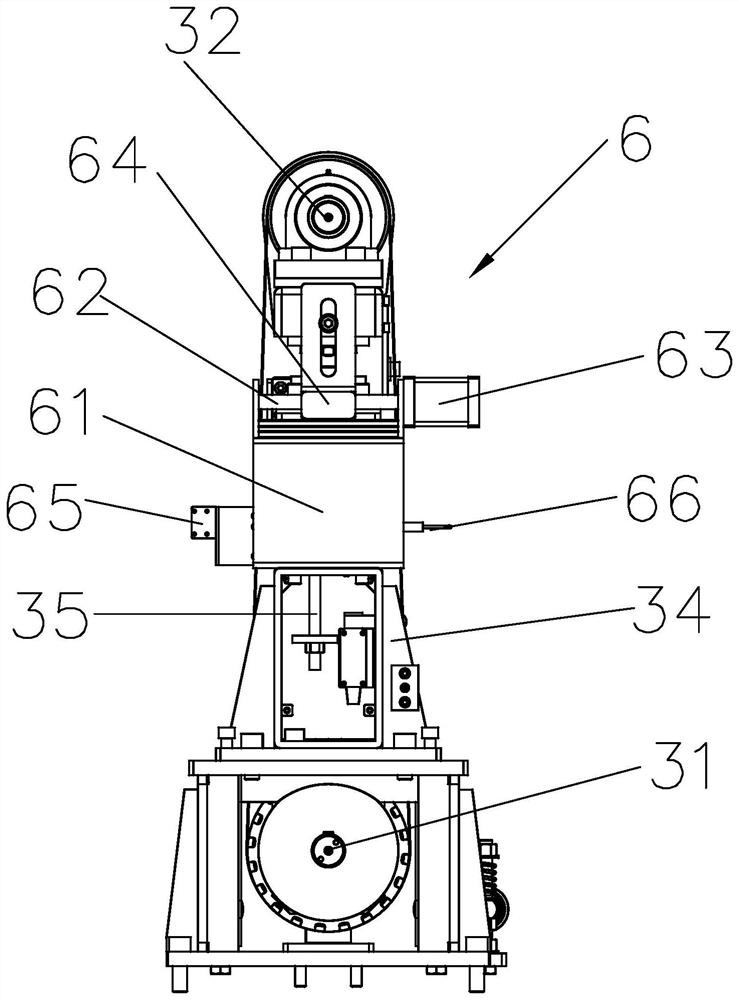

Intelligent deviation rectifying structure for wide abrasive belt

The invention discloses an intelligent deviation rectifying structure for a wide abrasive belt. The intelligent deviation rectifying structure comprises a machine frame, a controller, a wire drawing contact roller arranged on the machine frame, a wire drawing tensioning roller and the wire drawing abrasive belt arranged between the wire drawing contact roller and the wire drawing tensioning rollerin a winding mode, wherein a fixing cross beam is fixed on the machine frame, the fixing cross beam is located between the wire drawing contact roller and the wire drawing tensioning roller, the wiredrawing tensioning roller is rotationally arranged on the fixing cross beam through an adjusting shaft with the axis extending in the vertical direction, and a deviation rectifying device used for adjusting the wire drawing tensioning roller is arranged between the fixing cross beam and the wire drawing tensioning roller. According to the intelligent deviation rectifying structure, the automaticdeviation rectifying device reduces the process that workers need to conduct actual operation, saves the machine adjusting time, improves the production efficiency, and reduces the factory operation cost, the effect of the automatic deviation rectifying device is good, wire drawing lines are finer and smoother, and twisting lines are less.

Owner:苏州锃道研磨技术有限公司

Automatic net weaving machine

ActiveCN107282831AIncrease productivityImprove consistencyWire networkMechanical engineeringIndustrial engineering

The invention discloses an automatic net weaving machine. The automatic net weaving machine comprises a machine table, a thread weaving mechanism, a net cutting mechanism, a first permanent seat, a first sliding block, a first sliding groove, a material conveying plate, a lateral movement mechanism, a front and back movement mechanism and a material pressing mechanism, wherein the thread weaving mechanism is used for weaving net belt semi-finished products; the net cutting mechanism is used for cutting off the net belt semi-finished products with the fixed length; the material pressing mechanism is used for fixing the net belt semi-finished products on the material conveying plate; the lateral movement mechanism is used for pushing the net belt semi-finished products on the top surface of the material conveying plate; and the front and back movement mechanism drives the first sliding block to move frontwards and backwards in the first sliding groove so as to drive the material conveying plate to move frontwards and backwards. The automatic net weaving machine has the beneficial effects that the net belt semi-finished products with different lengths can be produced in a full-automation manner; the production efficiency is high; the influence of artificial factors is reduced; the products have high consistency; the product quality is improved; the ordered discharging, sequencing and initial net shaping of the net belt semi-finished products are realized through the lateral movement mechanism and the front and back movement mechanism; the product conveying is facilitated; and the production efficiency is improved.

Owner:美盛表业制品(惠州)有限公司

Single-layer plastic pipe extrusion fine adjustment die

A single-layer plastic pipe extrusion fine adjustment die comprises an outer die body, a core die body, a deflection adjusting module, a plurality of adjusting screws and a die locking plate. The outer die body is a rotation body, and a horn-mouth-shaped containing groove is formed in the center of the outer die body, wherein the diameter of the containing groove is gradually increased from the front end to the rear end. A cylinder-shaped installing groove is formed in the front end of the outer die body, and the installing groove communicates with the containing groove. An installing disc isarranged at the rear end of the core die body, and the installing disc is installed and fixed to the rear end of the outer die body. A horn-mouth-shaped forming die body is arranged towards the frontin a protruding manner from the installing disc, and the diameter of the forming die body is gradually increased from the front end to the rear end. The forming die body is inserted in the containinggroove. A horn-mouth-shaped storage groove is formed in the deflection adjusting module and communicates with the containing groove. The forming die body is inserted in the storage groove. A forming channel is formed among the inner wall face of the containing groove of the outer die body, the inner wall face of the storage groove of the deflection adjusting module and the outer wall face of the forming die body. By means of the single-layer plastic pipe extrusion fine adjustment die, the machine adjusting time is shortened, and raw material waste is reduced.

Owner:CHANGYUAN ELECTRONICS DONGGUAN +4

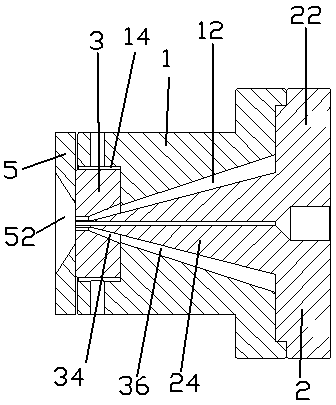

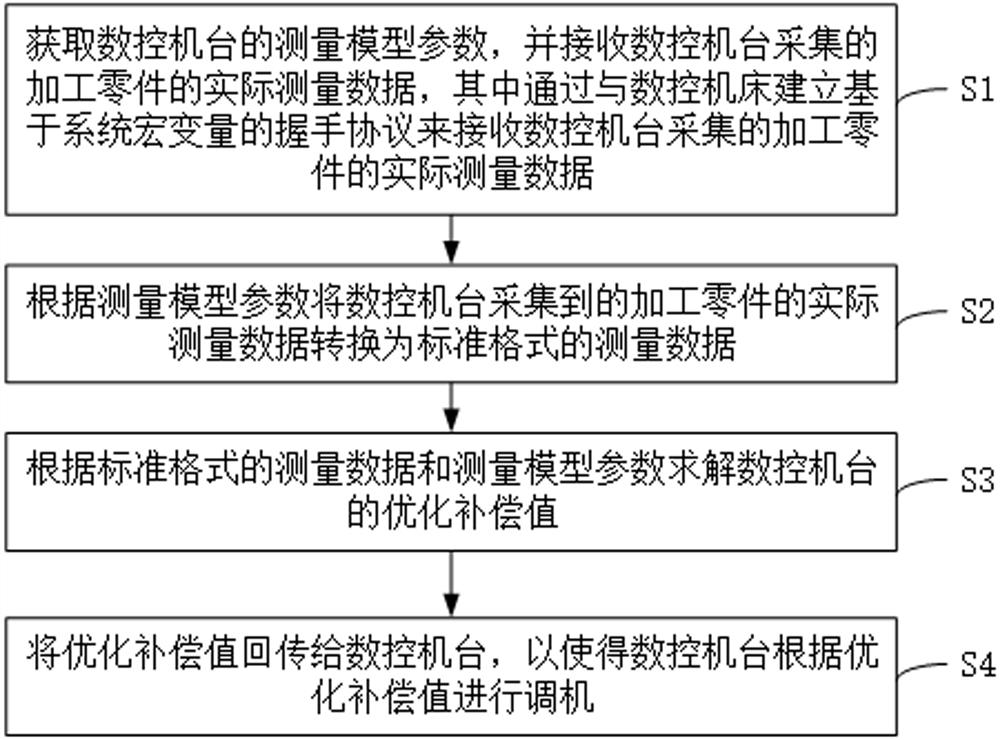

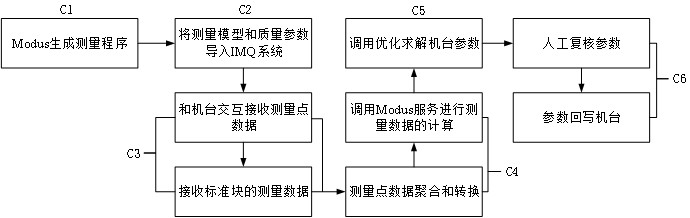

Intelligent debugging method and system based on handshake protocol

ActiveCN113589759ADoes not affect normal processingReduce machine set-up timeProgramme controlComputer controlNumerical controlMachine parts

The invention discloses an intelligent debugging method and system based on a handshake protocol, and the method is used for carrying out the intelligent debugging of at least one numerical control machine, and comprises the following steps: S1, obtaining the measurement model parameters of the numerical control machine, and receiving the actual measurement data of a machining part collected by the numerical control machine, wherein a handshake protocol based on a system macro variable is established with a numerical control machine table to receive actual measurement data, collected by the numerical control machine table, of a machined part; S2, according to the measurement model parameters, converting actual measurement data, collected by the numerical control machine, of the machined part into measurement data in a standard format; S3, solving an optimized compensation value of the numerical control machine according to the measurement data in the standard format and the measurement model parameters; and S4, transmitting the optimized compensation value back to the numerical control machine, so that the numerical control machine is adjusted according to the optimized compensation value. According to the invention, the problem of machine adjustment in the prior art is solved.

Owner:INREVO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com