Printing color and latitude visual inspection system device and application method thereof

A system device and wide-ranging technology, applied to the general parts of printing machinery, printing, printing machines, etc., can solve the problems of high error rate, no unified color value correction scheme, messy color information, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

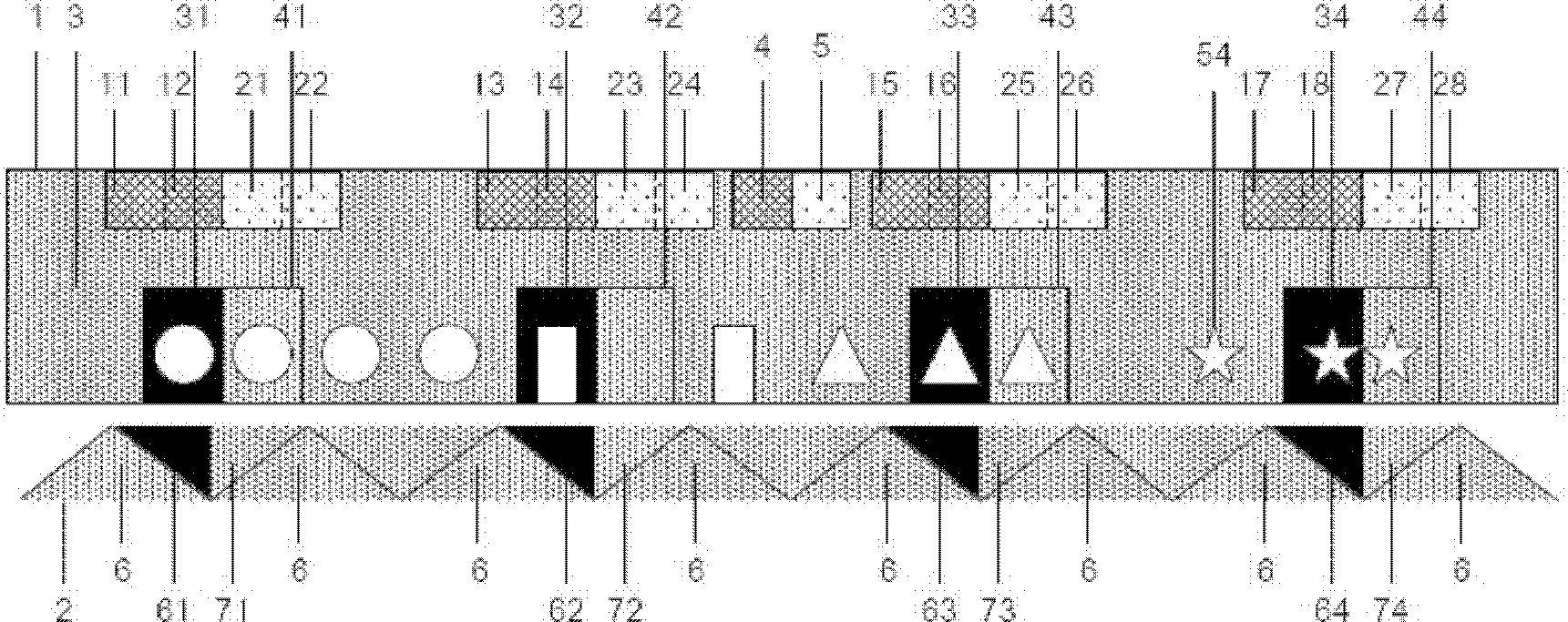

[0110] Embodiment 1: A kind of printing color and latitude visual inspection system device and using method, such as figure 1 As shown, it is a schematic diagram of the system main body and the monitoring color bar of the device. The main functional ruler-shaped plate of the external device is compared with the special monitoring color control color bar. The material of the ruler-shaped plate (1) can be paper (board), metal, For wood, plastics, glass, synthetic thick materials, pottery, etc., the main part of the surface is to be coated with neutral gray (3), which is the basis of the neutral gray tone of the present invention as standardized color management. The color scale samples of each primary color and black solid color are (31, 32, 33, 34); the mid-halftone color scale samples are (41, 42, 43, 44), and the reference provided by these two areas matches the visual guide is a standardized color Manage the set color value and color gamut dot value-added rate. As long as th...

Embodiment 2

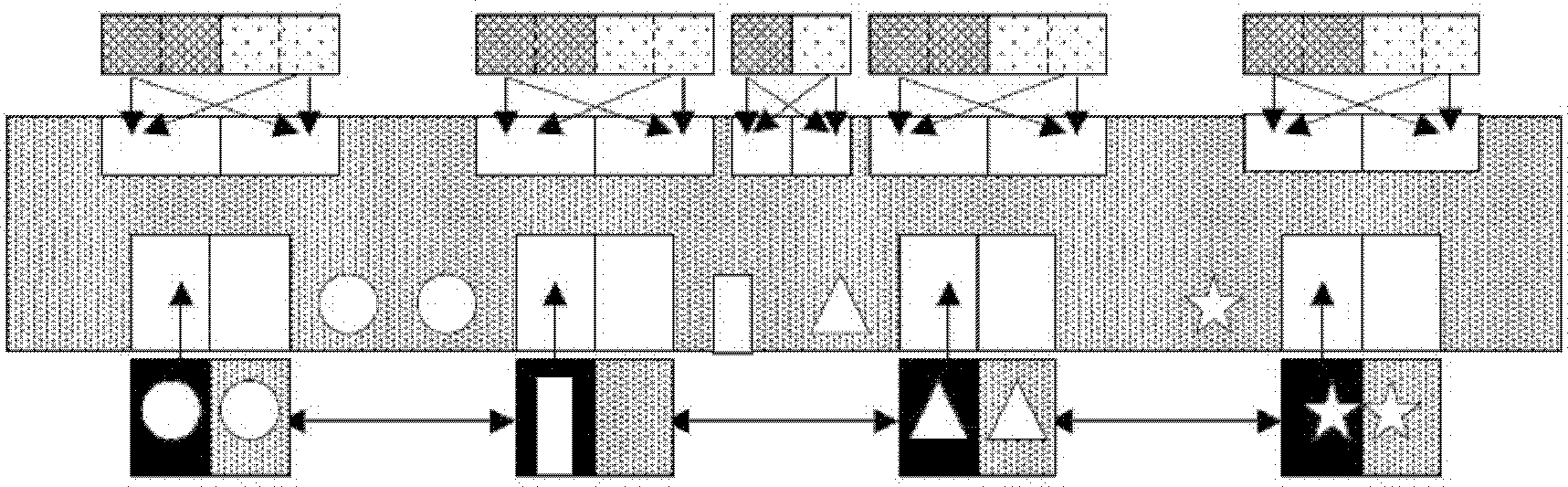

[0114] Embodiment 2: a kind of printing color and latitude visual inspection system device, such as Figure 5 As shown, it is a schematic diagram of the comprehensive structure of each primary color of the system main body of the device and the standard color area of black and tolerance. The color blocks on the device main body (1) are all fixed color blocks, and one of the primary colors of the ruler-shaped plate of the external device main body and mid-halftones are merged with the color latitude ribbon into ( Figure 5 ). The standardized primary color solid color (31) and the standard dark color area (11) and the standard light color area (12) of the color tolerance are arranged on both sides; the standardized primary color halftone (41) and the standard dark color area of the color tolerance (21) and the standard light-colored area (22) are arranged on both sides to become the merged functional area; Its standard tone depth (4) and light (5) such as neutral gray are ...

Embodiment 3

[0115] Embodiment 3: A printing color and latitude visual inspection system device, the main body of the system is divided into three parts: neutral gray tolerance scale, primary color and black tolerance scale, primary color, black and neutral gray standard color scale, see Figure 6-Figure 8 .

[0116] like Image 6 As shown, it is a schematic diagram of the gray tolerance structure of the system main body of the device, and a demonstration diagram of the gray tolerance structure of the ruler-shaped plate of the system of the device. The external plate is designed as an independent latitude visual inspection device. The color blocks for monitoring the upper limit (4) and lower limit (5) of the gray color value are constructed on the carrier (7) by printing, spray painting, dyeing, primary color casting, electroplating and coloring, and ceramic production. The carrier can be hard material or soft material. Manufactured from reversible material. The comparison method is to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com