Patents

Literature

5627 results about "Spray painting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Spray painting is a painting technique where a device sprays a coating (paint, ink, varnish, etc.) through the air onto a surface. The most common types employ compressed gas—usually air—to atomize and direct the paint particles. Spray guns evolved from airbrushes, and the two are usually distinguished by their size and the size of the spray pattern they produce. Airbrushes are hand-held and used instead of a brush for detailed work such as photo retouching, painting nails or fine art. Air gun spraying uses equipment that is generally larger. It is typically used for covering large surfaces with an even coating of liquid. Spray guns can be either automated or hand-held and have interchangeable heads to allow for different spray patterns. Single color aerosol paint cans are portable and easy to store.

Virtual coatings application system

ActiveUS7839416B2Improve realismSimulate the realLiquid surface applicatorsCathode-ray tube indicatorsSimulationMotion tracking system

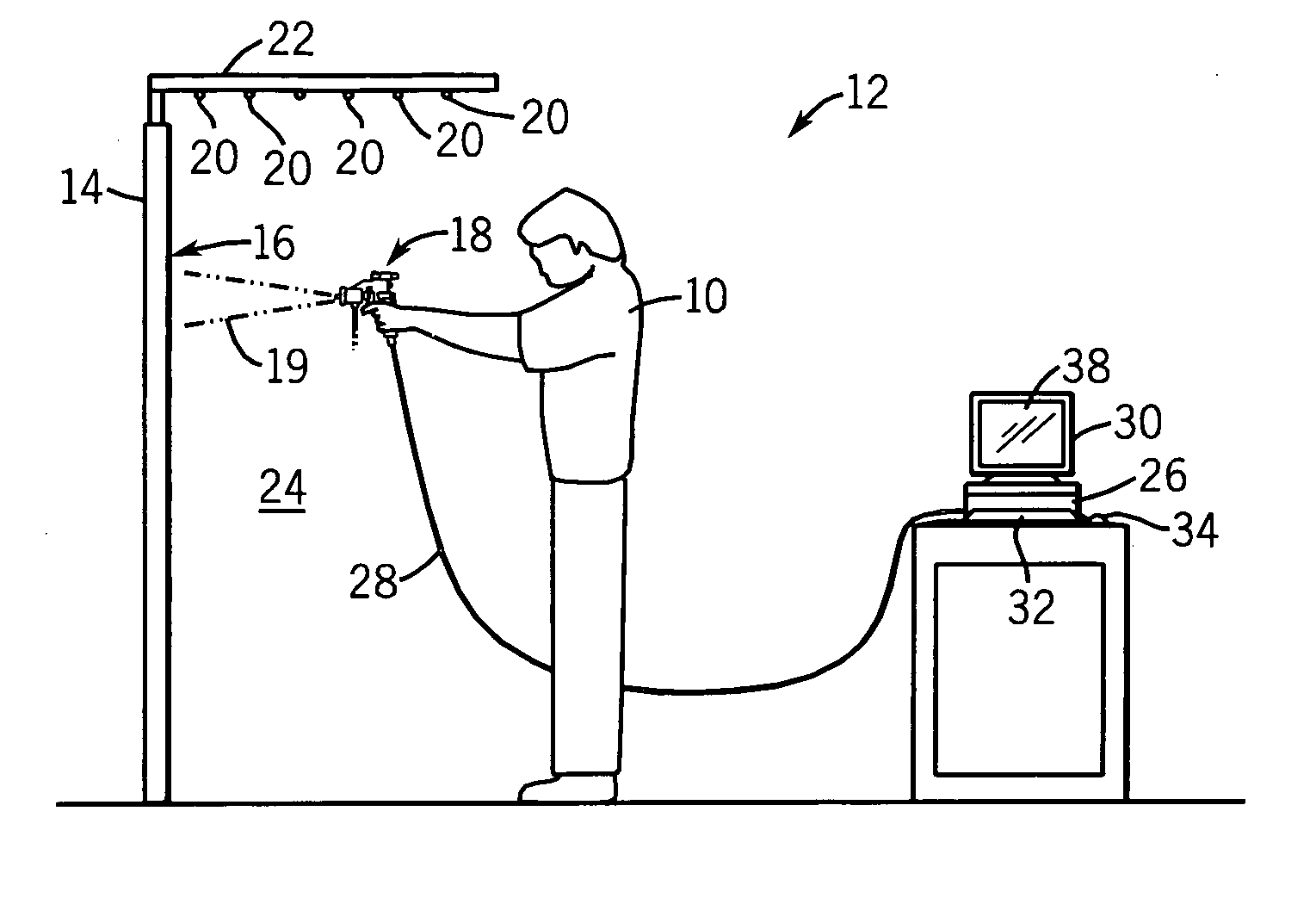

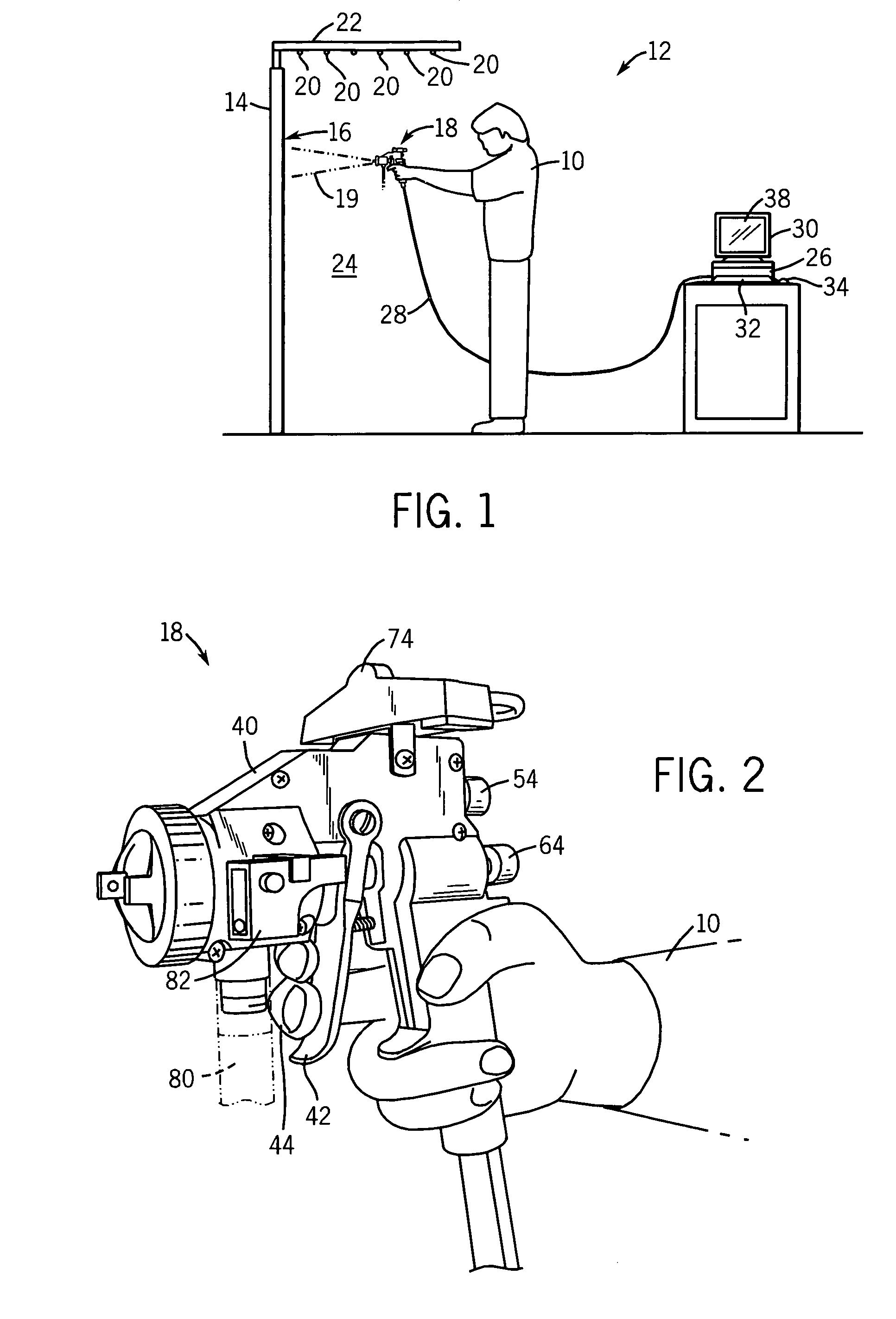

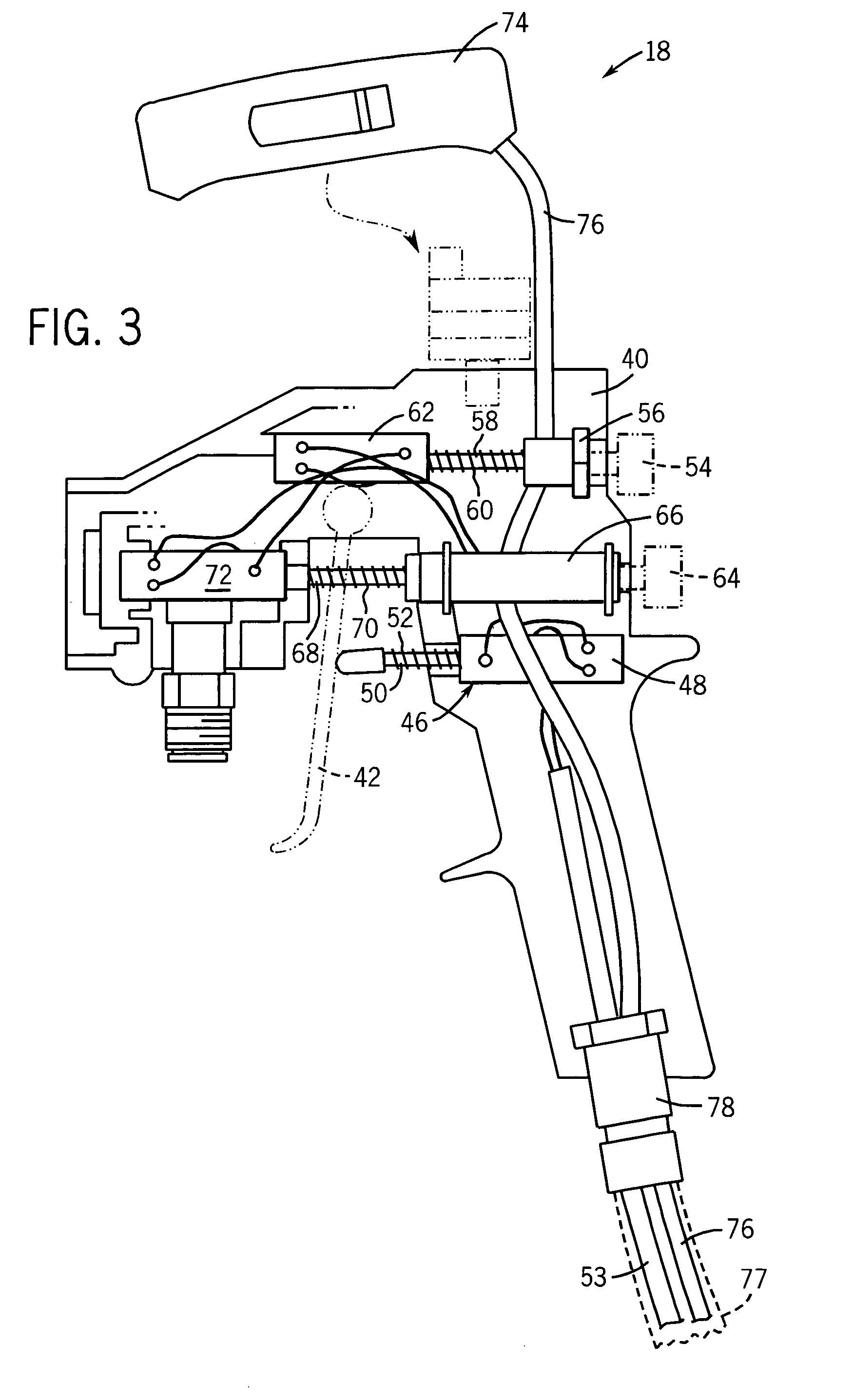

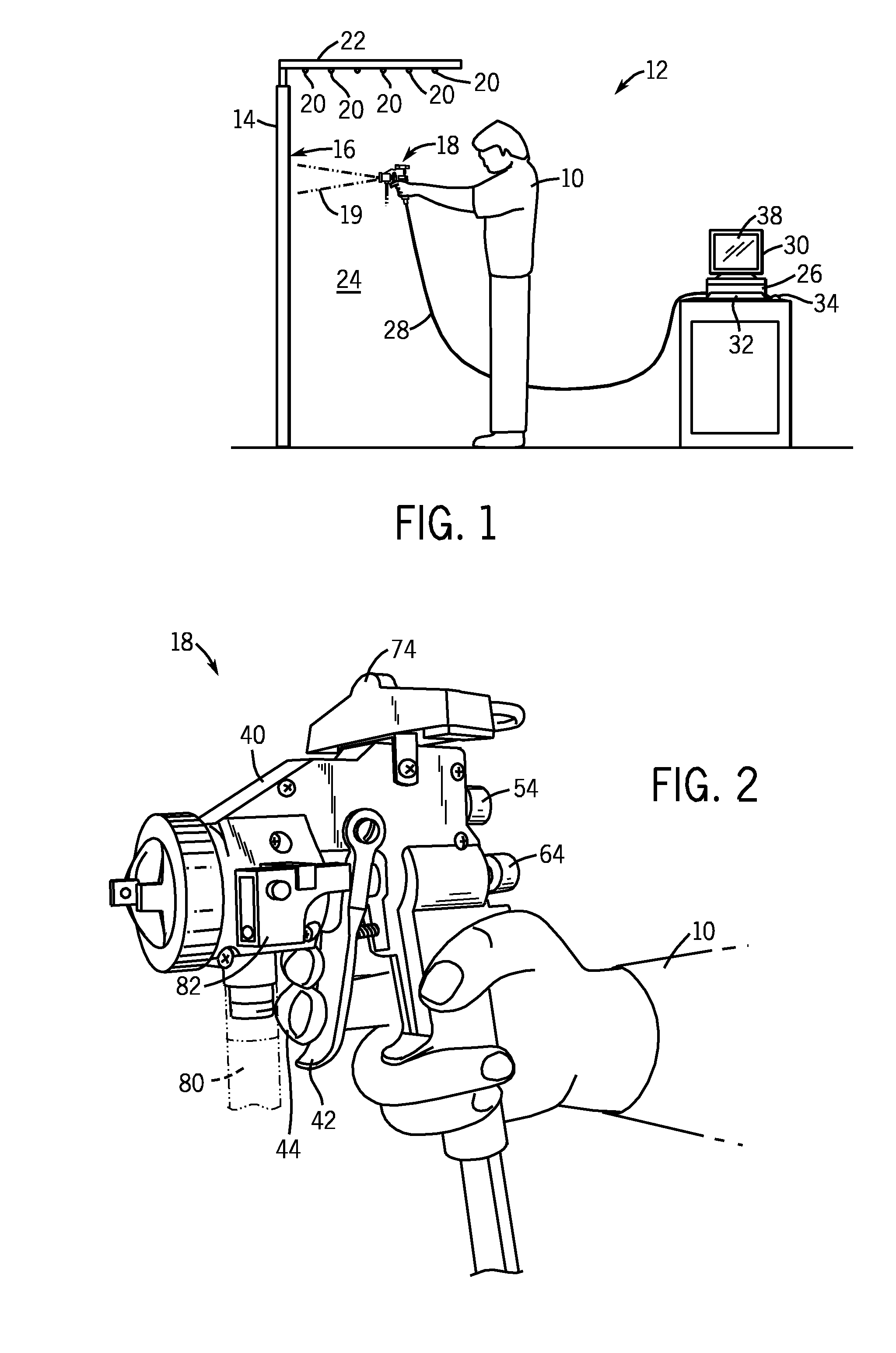

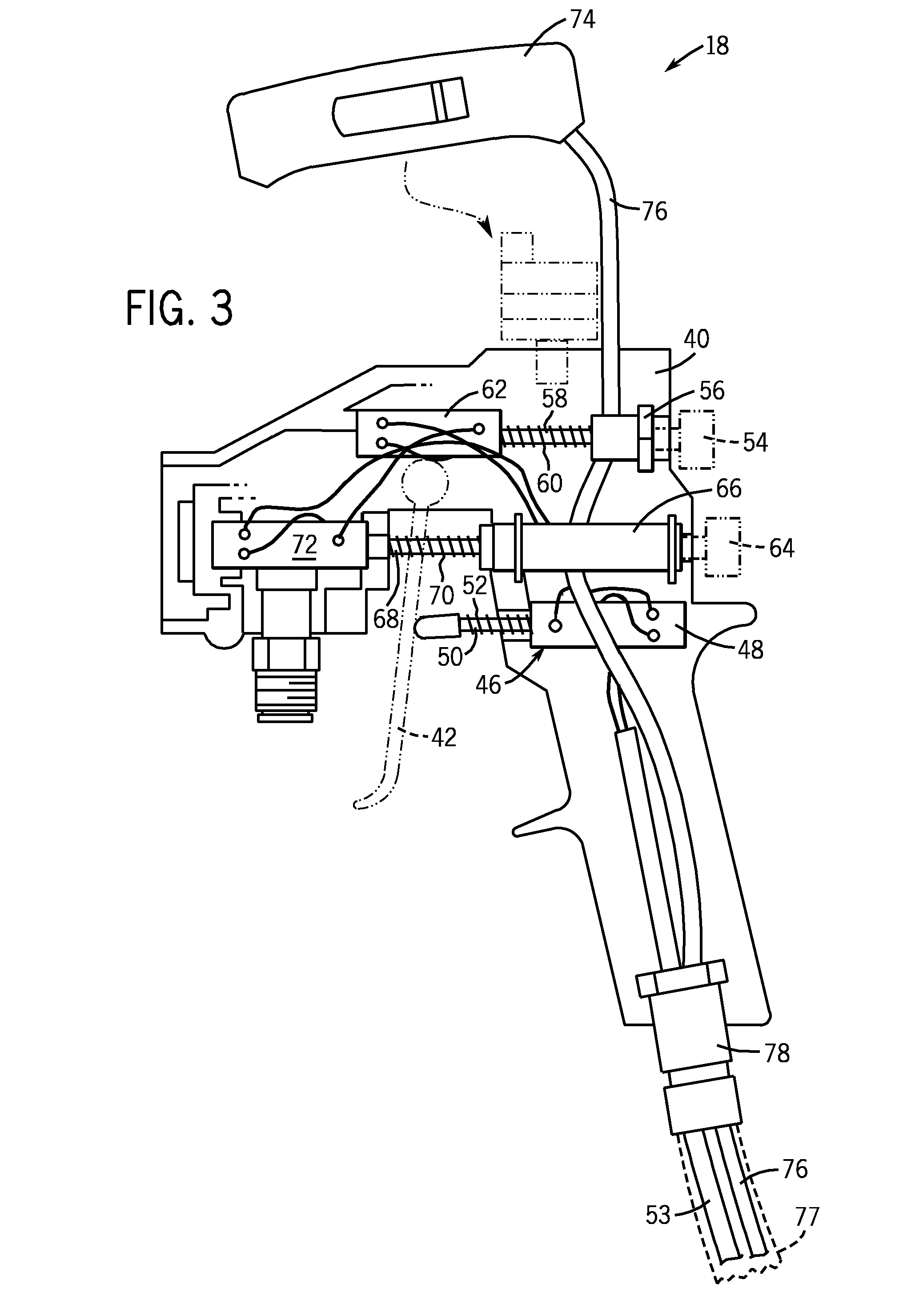

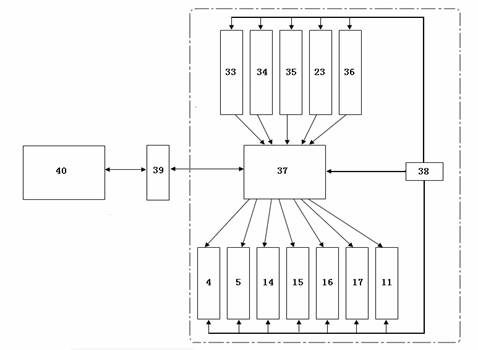

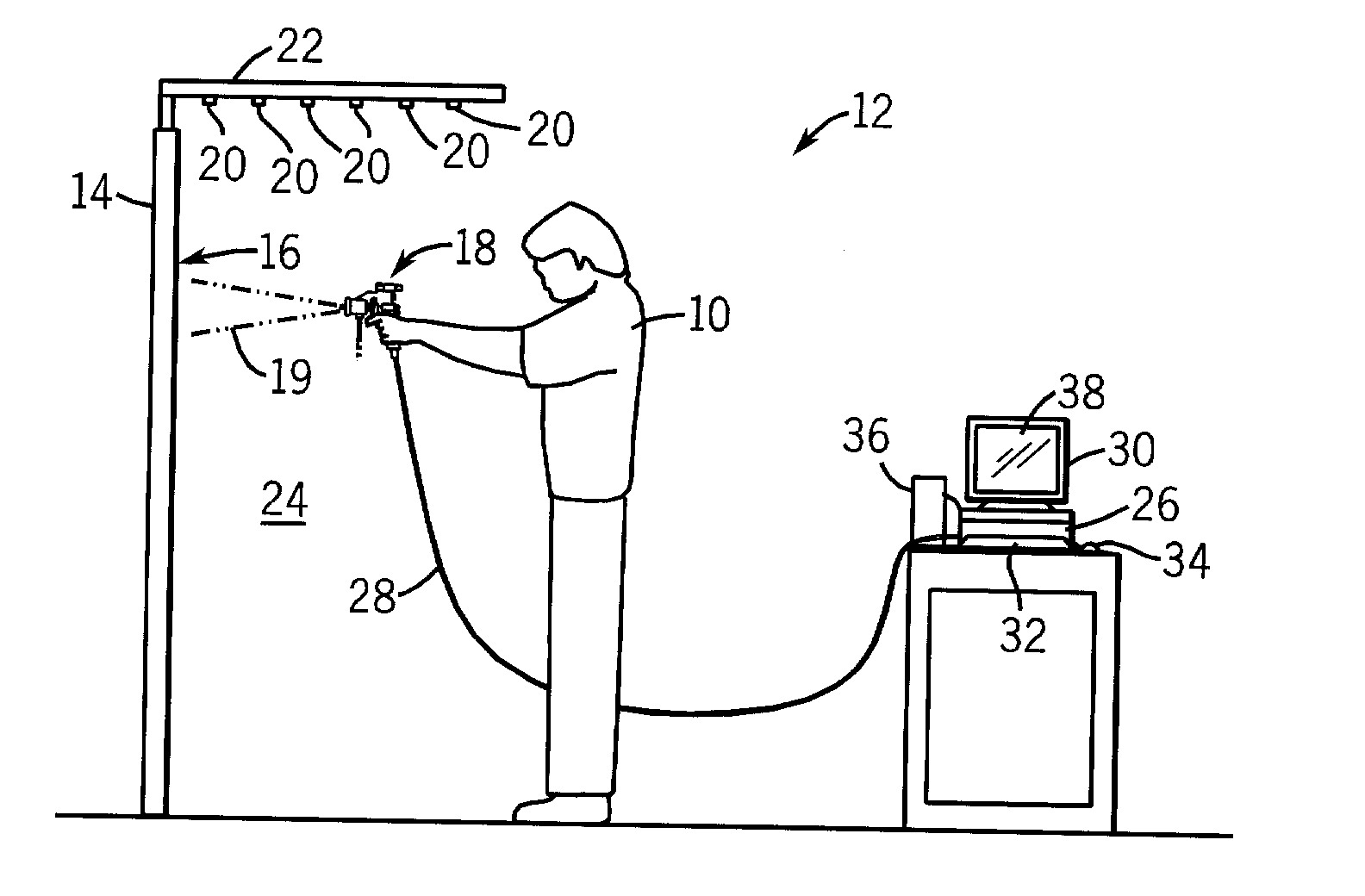

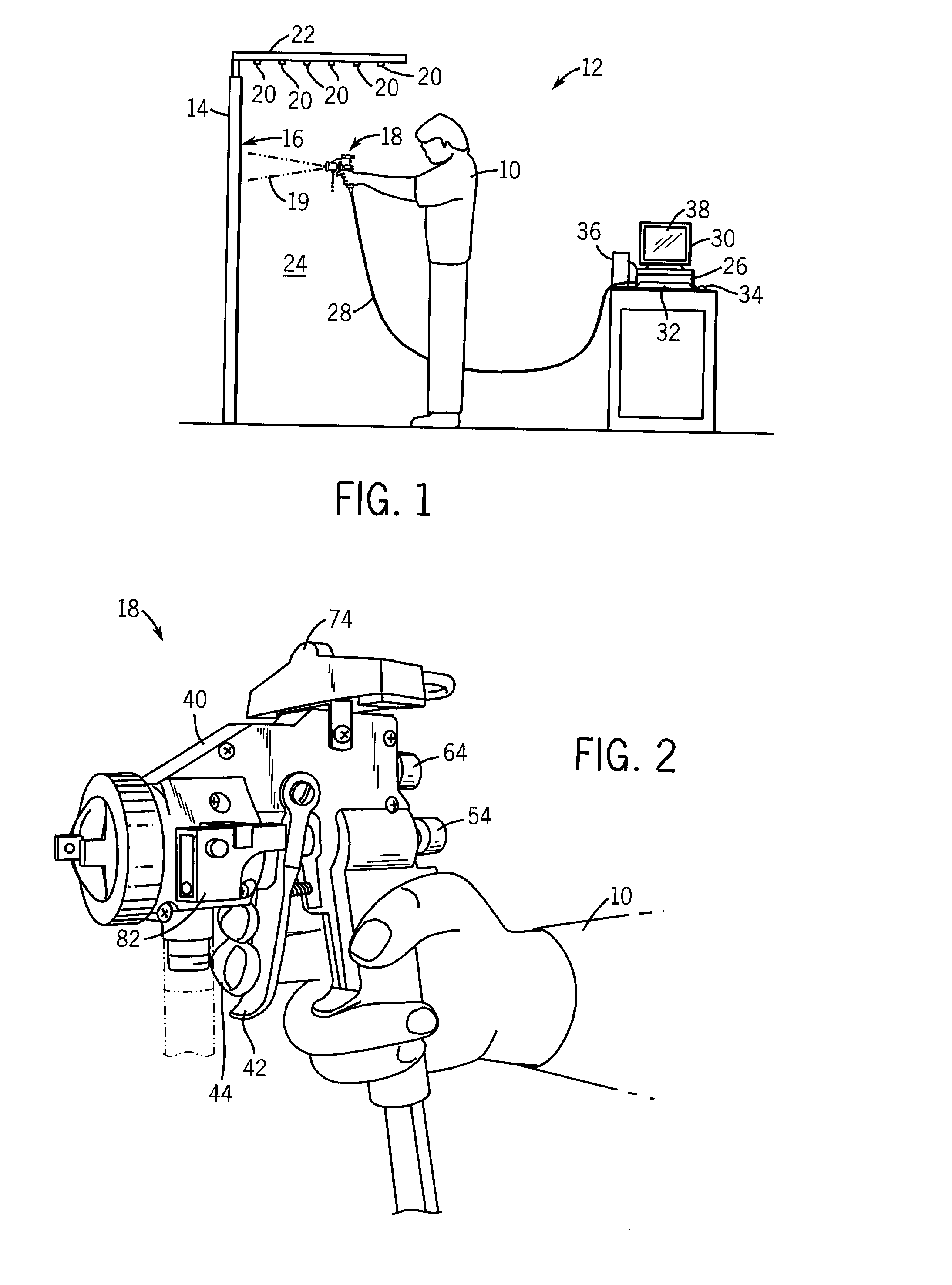

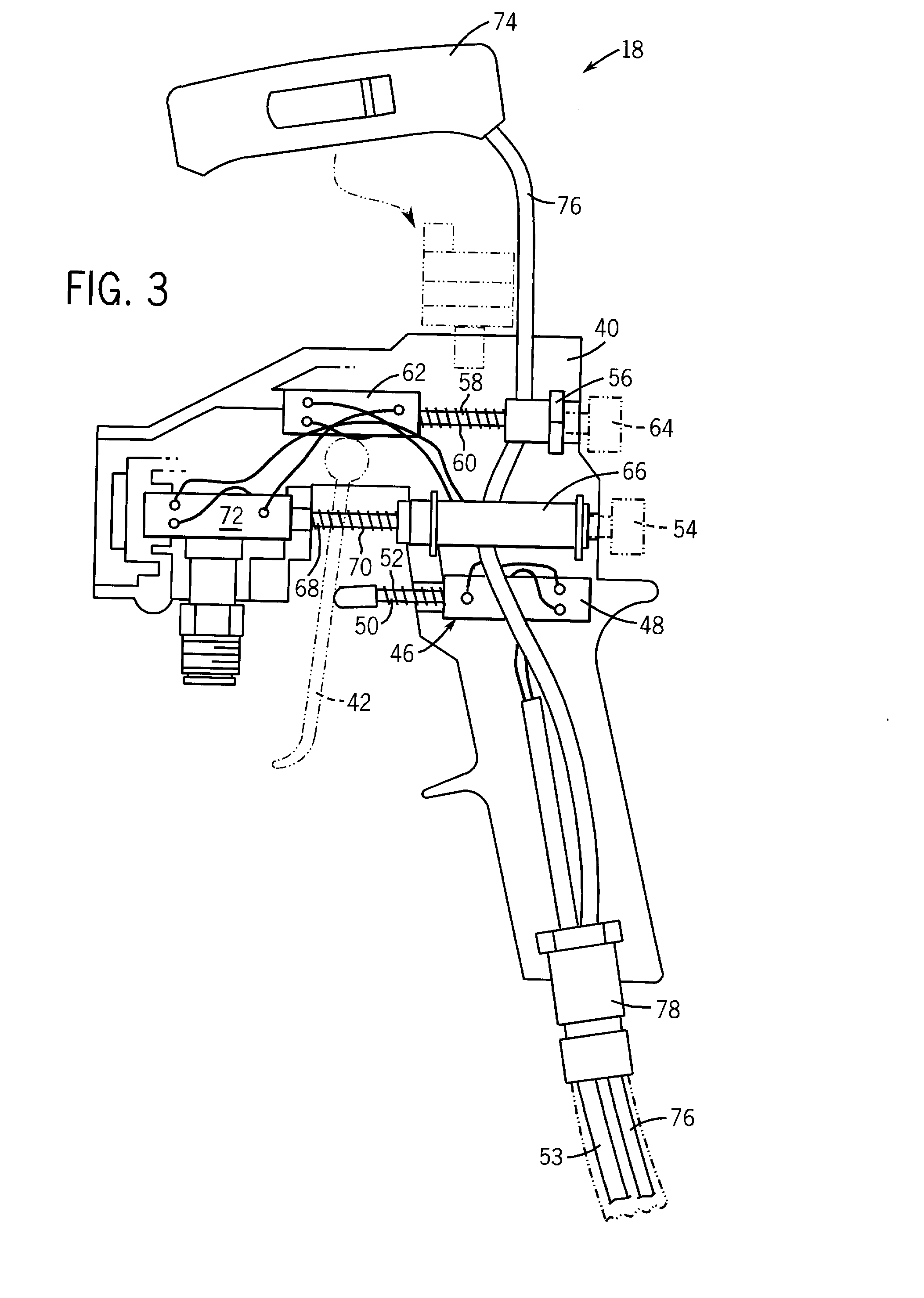

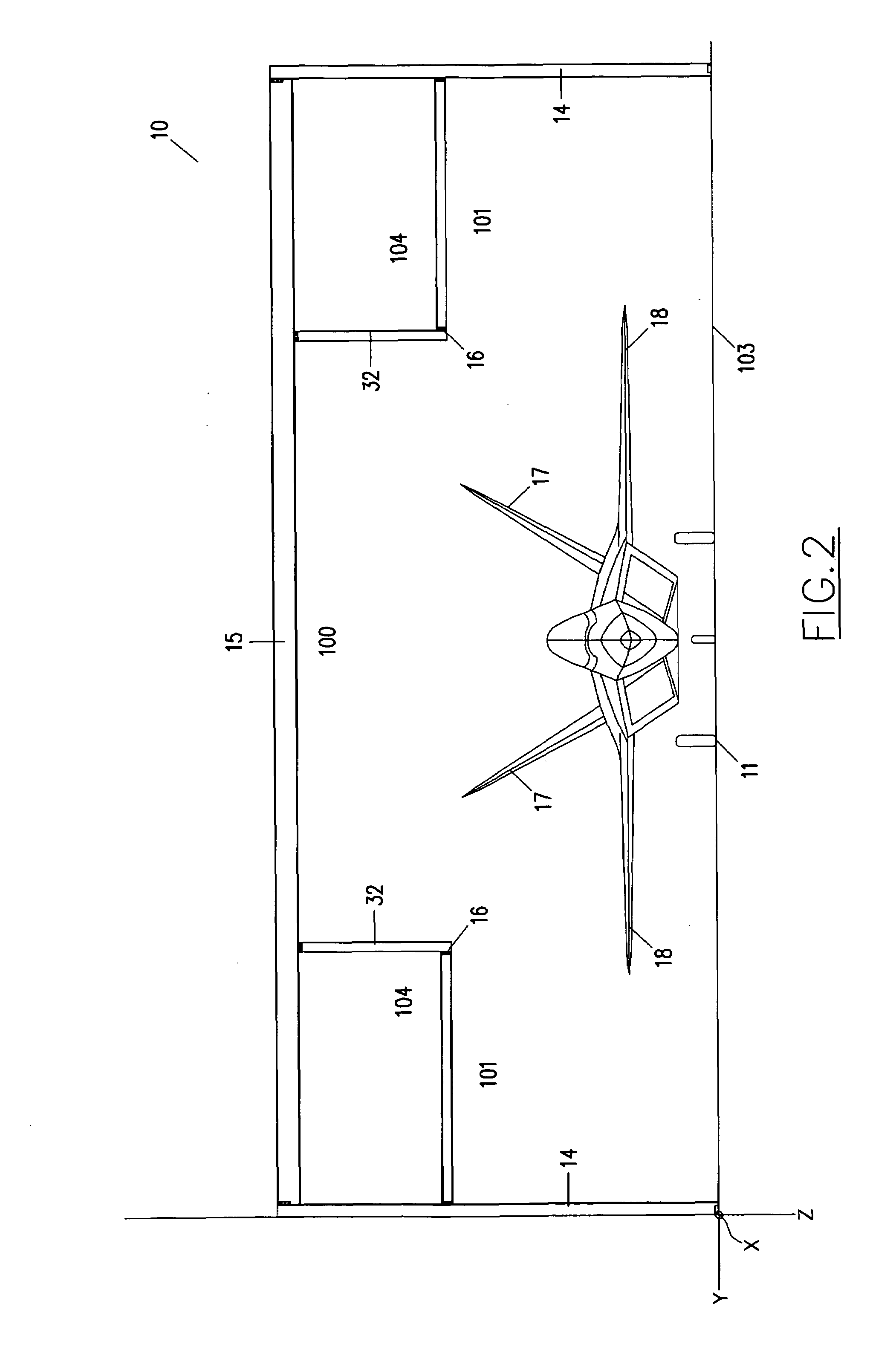

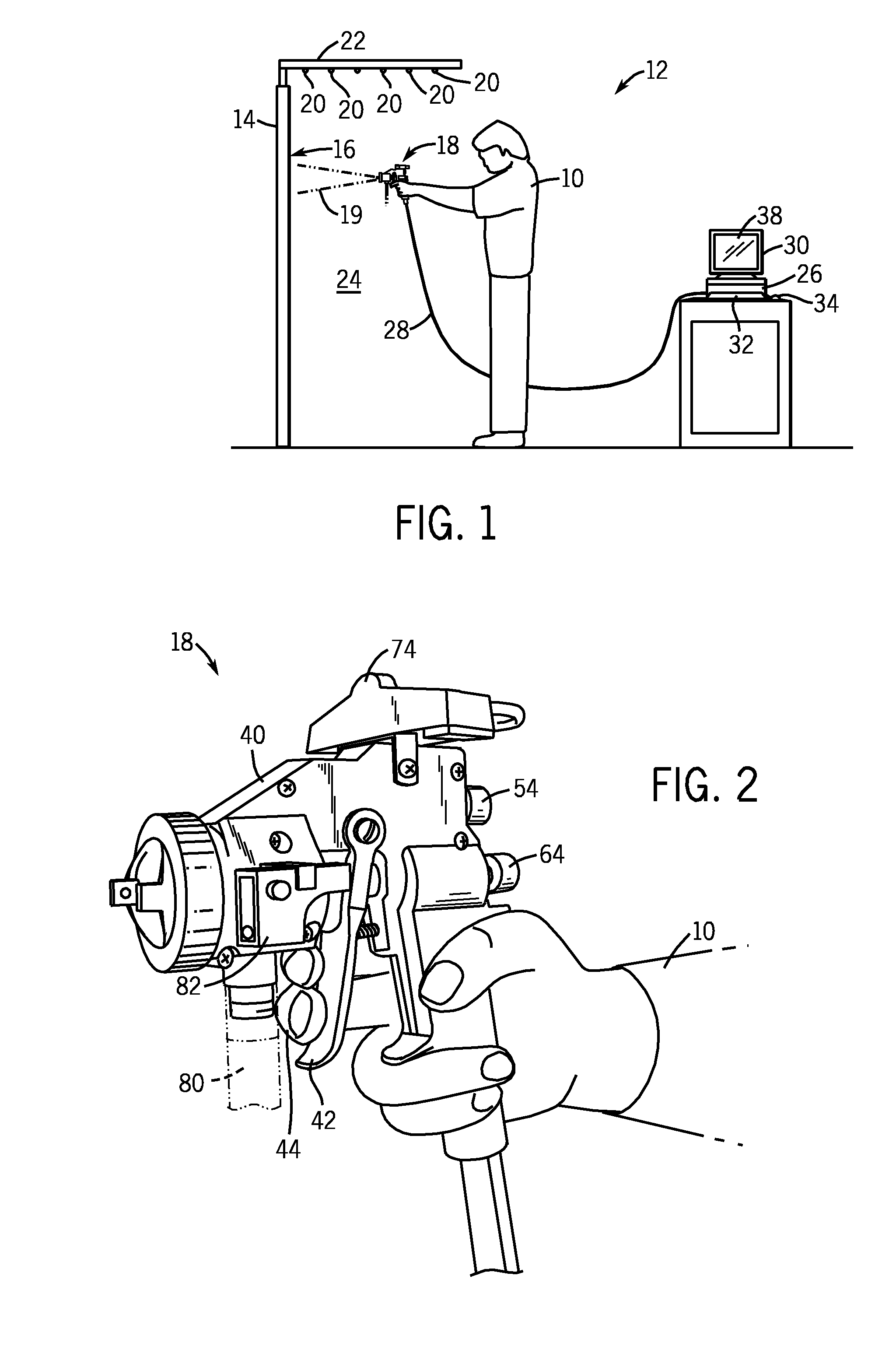

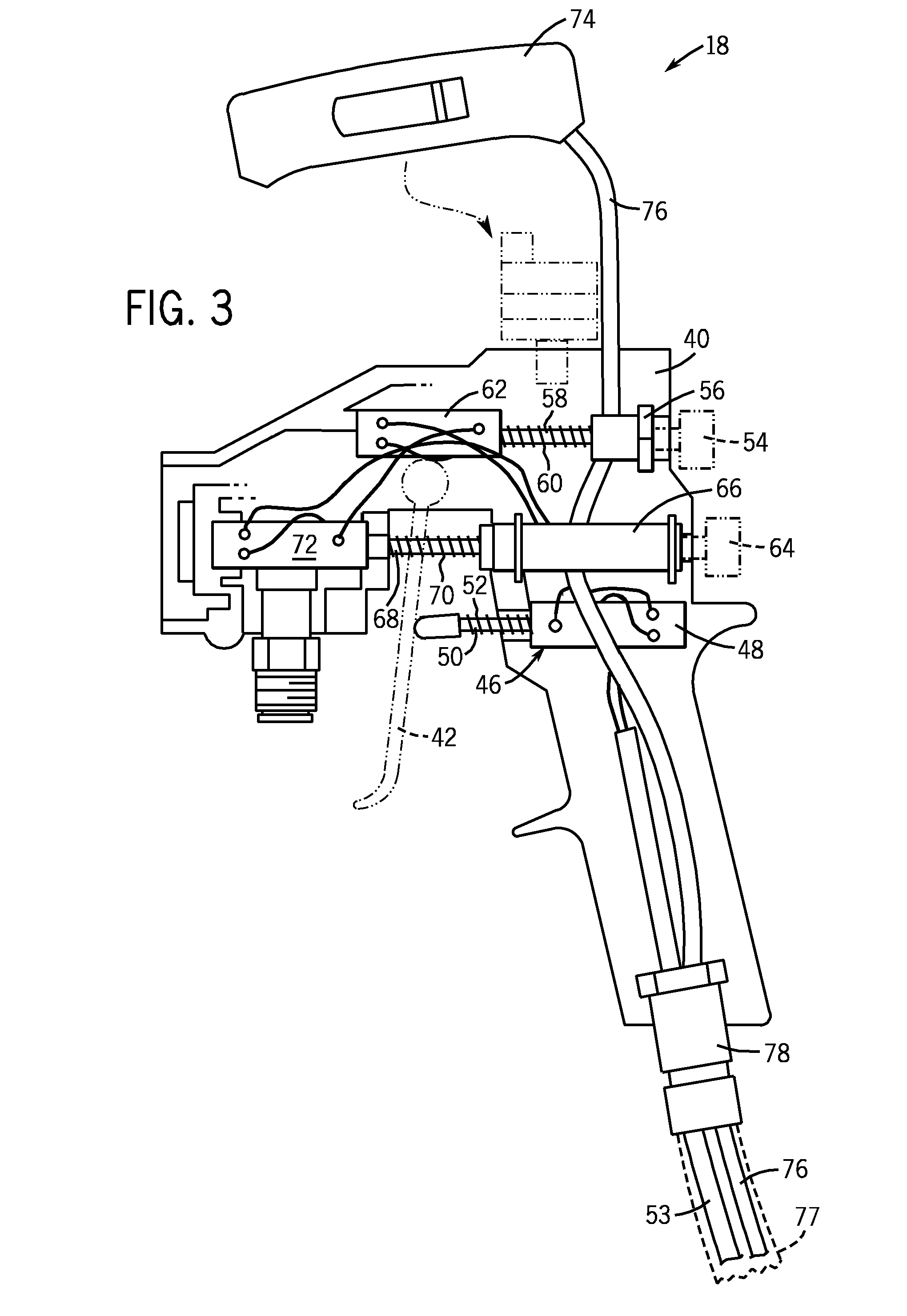

A virtual coatings application system has several features to enhance the realism of simulated spray painting. The system generally includes a display screen on which is defined a virtual surface (such as a truck door) that is intended to be virtually painted or coated by the user. The user operates an instrumented spray gun controller that outputs one or more signals representing data as to the status of the controls on the spray gun controller. The system also has a motion tracking system that tracks the position and orientation of the spray gun controller with respect to the virtual surface defined on the display screen. Simulation software generates virtual spray pattern data in response to at least the data from the spray gun controller and the position and orientation data received from the tracking system. Virtual spray pattern images are displayed in real time on the display screen in accordance with the accumulation of virtual spray pattern data at each location on the virtual surface.

Owner:UNIV OF NORTHERN IOWA RES FOUND

Virtual coatings application system

InactiveUS20070209586A1Accurate dataAvoid interferenceProgramme controlLiquid surface applicatorsSimulationMotion tracking system

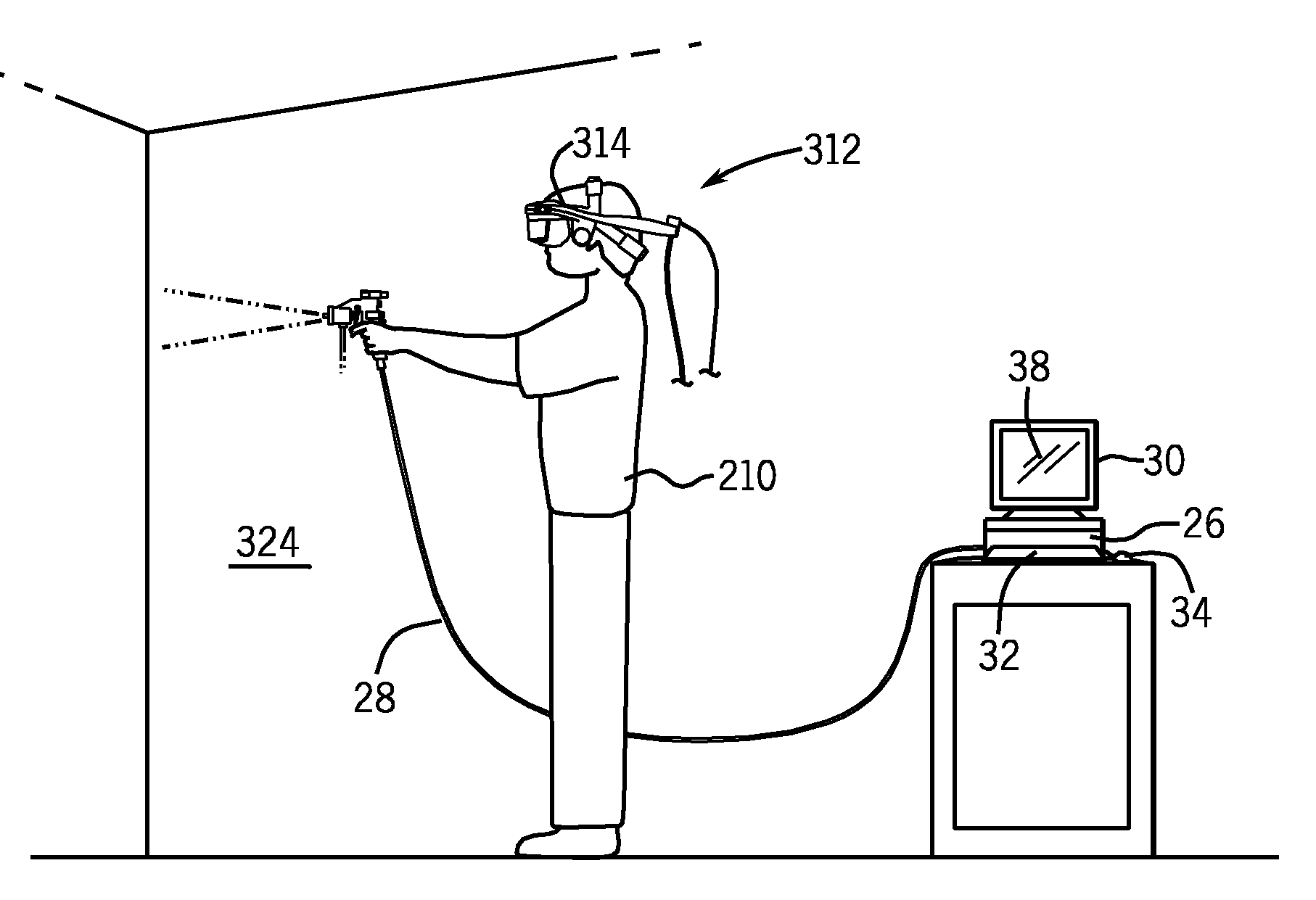

A virtual coatings application system has several features to enhance the realism of simulated spray painting. The system generally includes a display screen on which is defined a virtual surface (such as a truck door) that is intended to be virtually painted or coated by the user. Alternatively, the system includes a head-mounted display unit that displays a virtual spray painting environment in which the virtual surface is defined. The user operates an instrumented spray gun controller that outputs one or more signals representing data as to the status of the controls on the spray gun controller. The system also has a motion tracking system that tracks the position and orientation of the spray gun controller with respect to the virtual surface. Simulation software generates virtual spray pattern data in response to at least the data from the spray gun controller and the position and orientation data received from the tracking system. Virtual spray pattern images are displayed in real time on the virtual surface in accordance with the accumulation of virtual spray pattern data at each location on the virtual surface.

Owner:UNIV OF NORTHERN IOWA RES FOUND

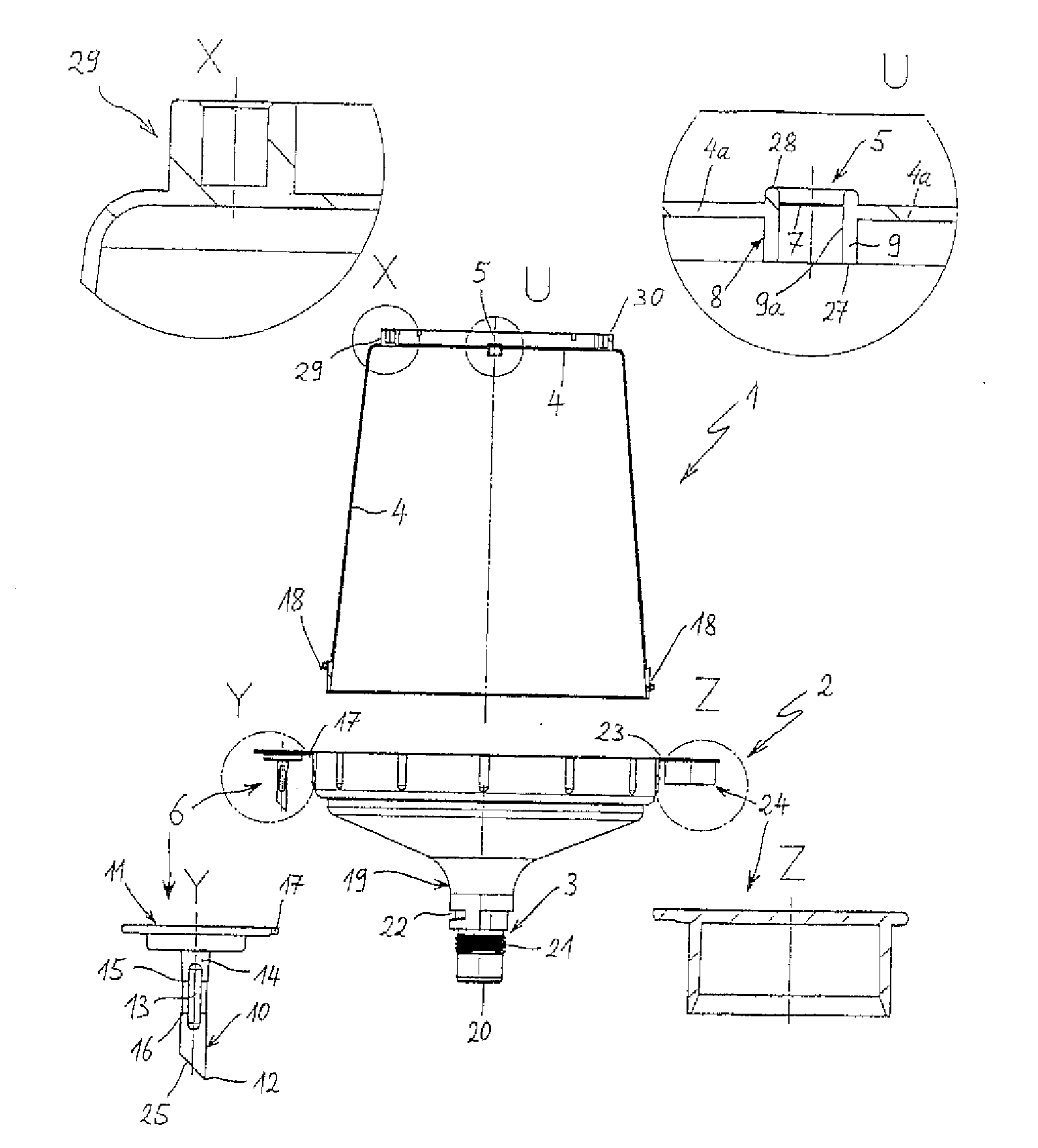

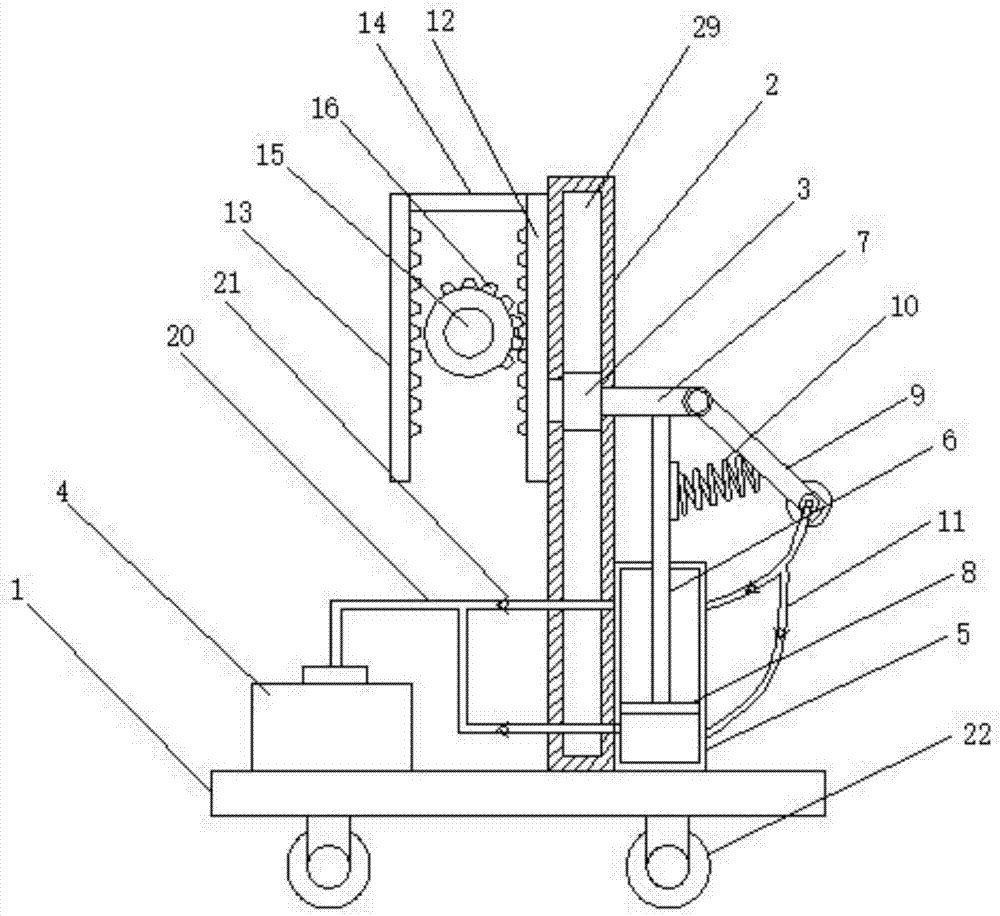

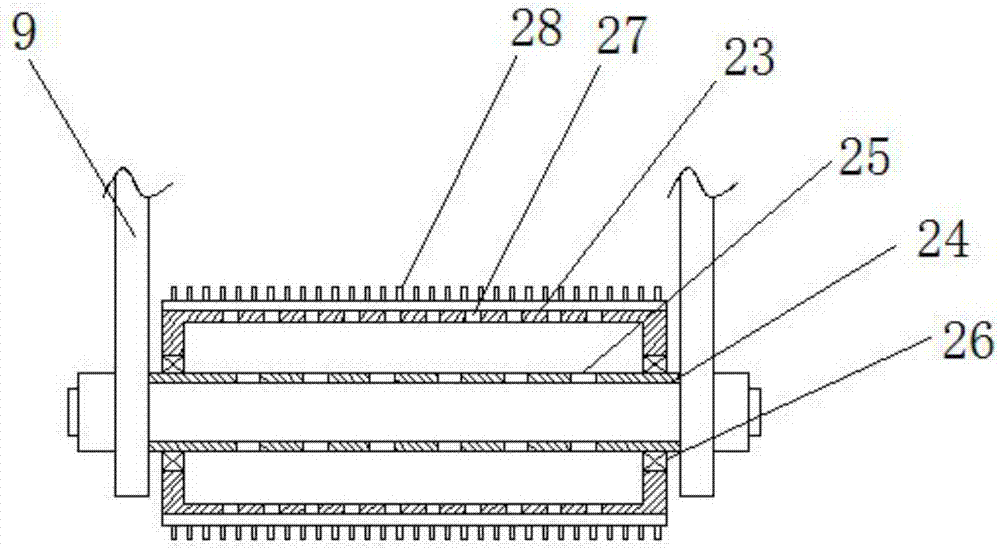

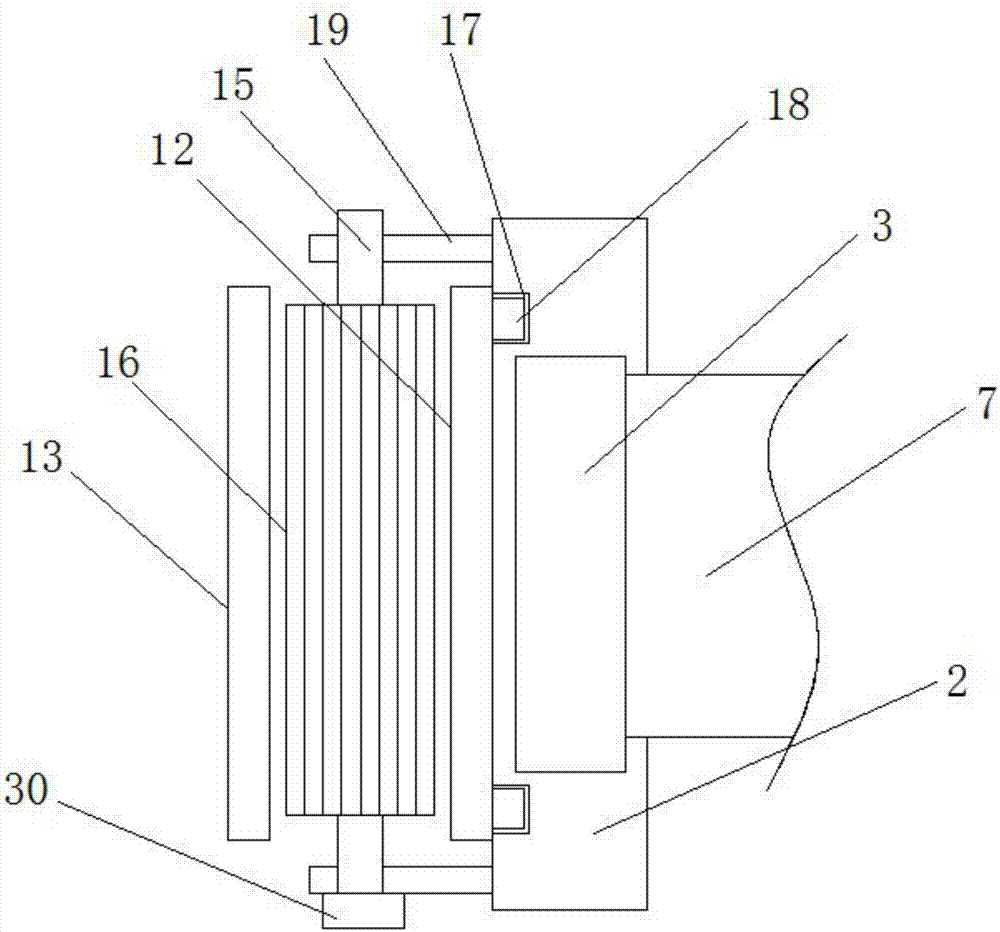

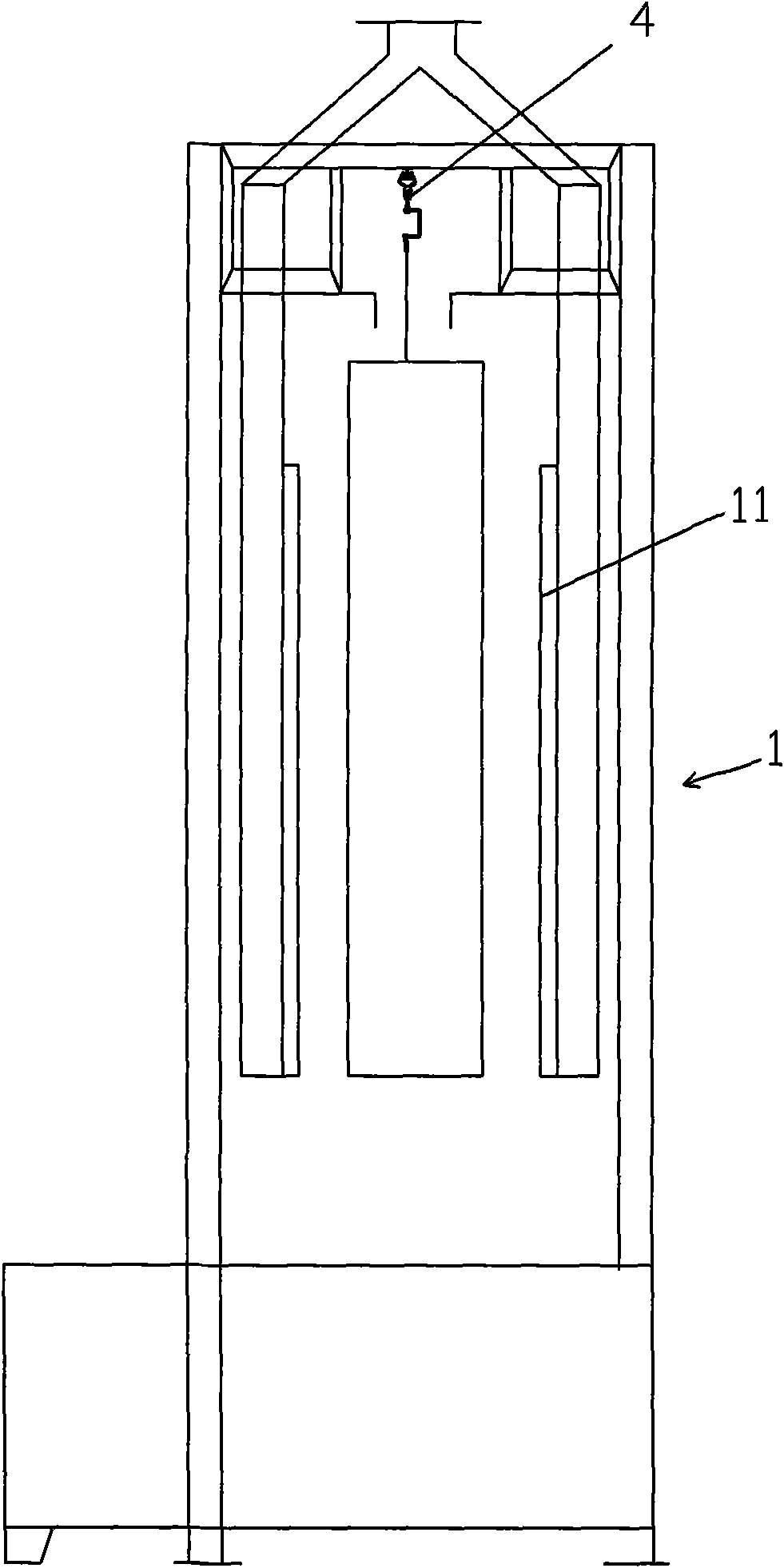

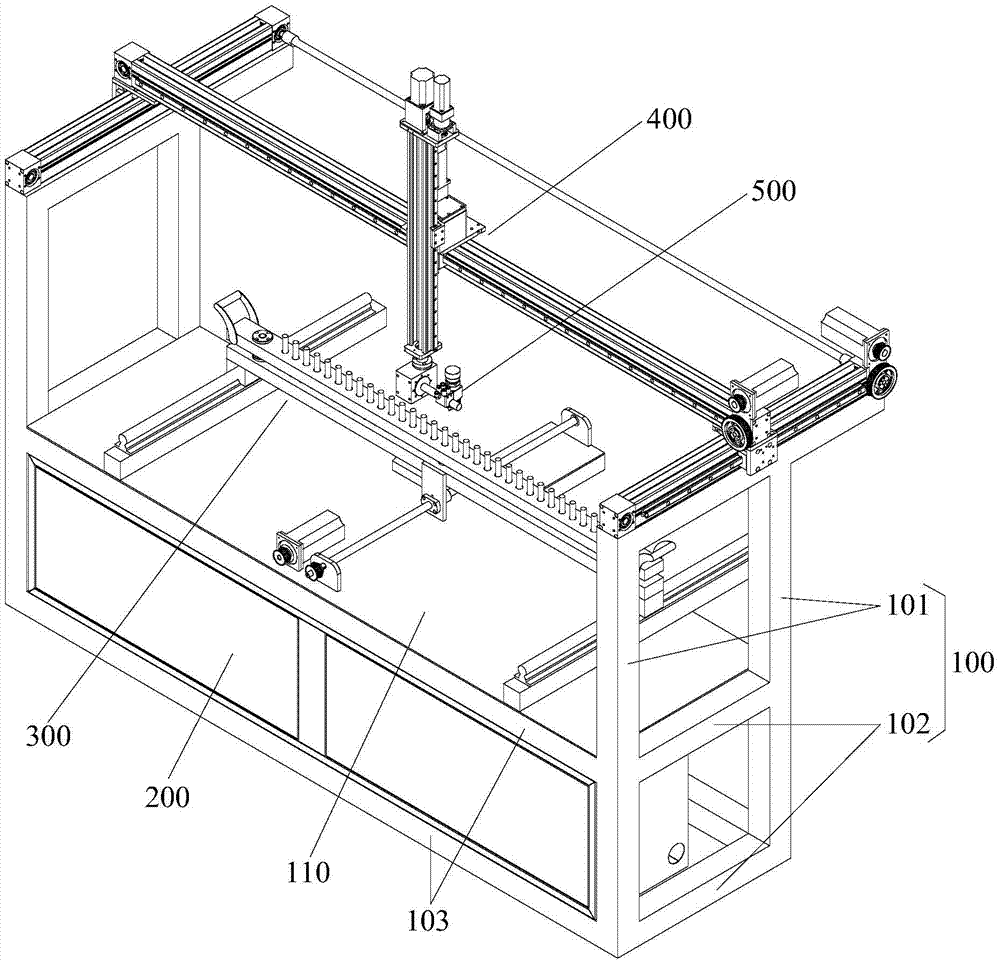

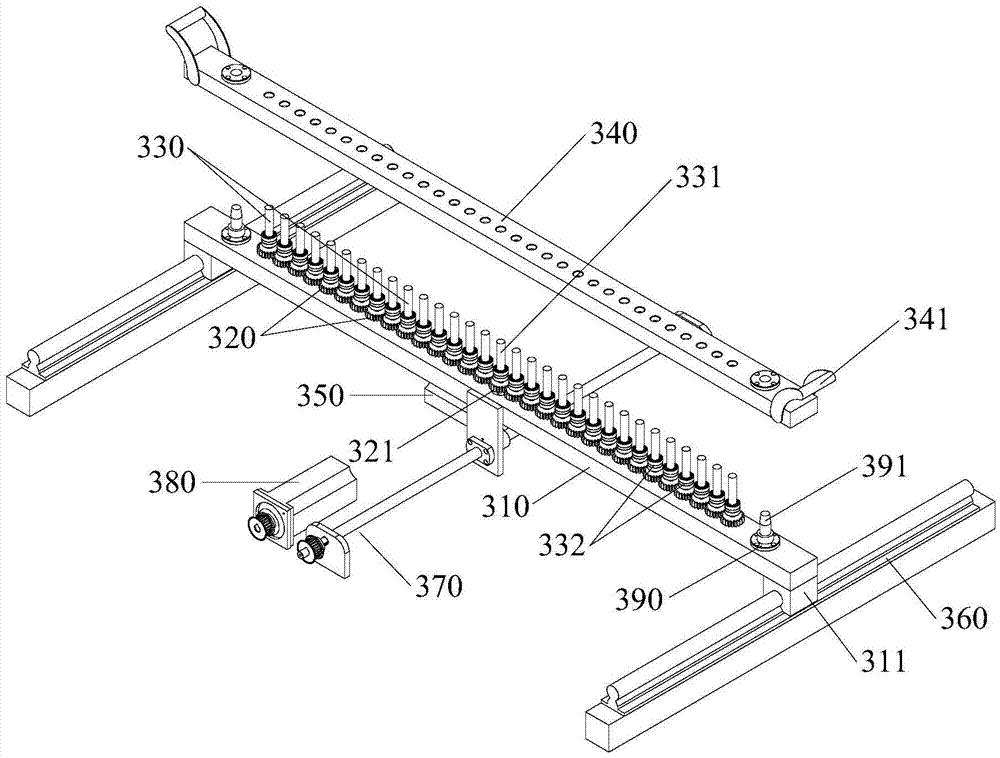

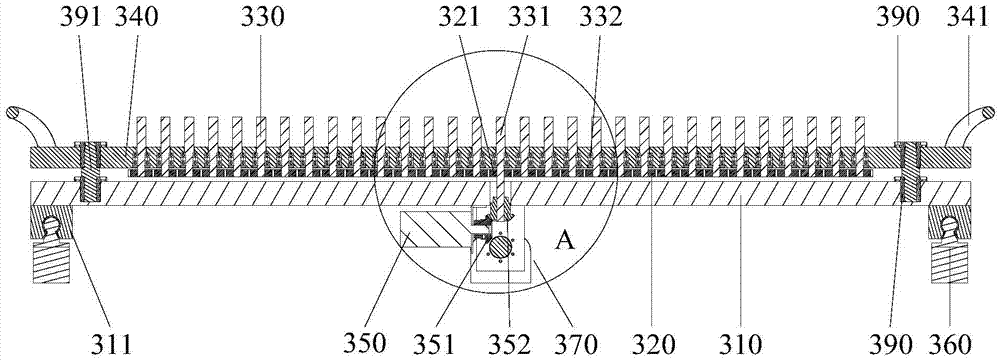

Intelligent tree trunk white paining robot

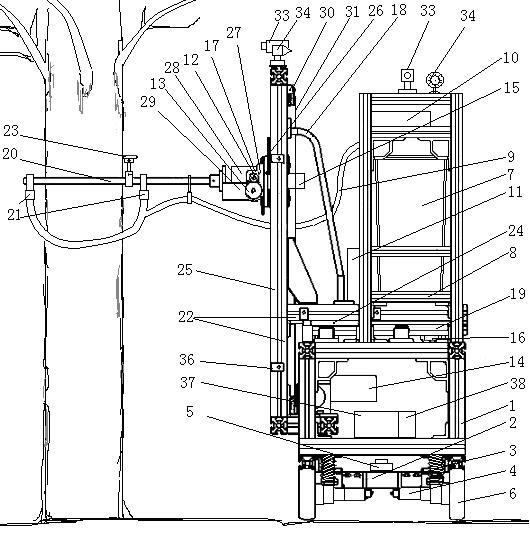

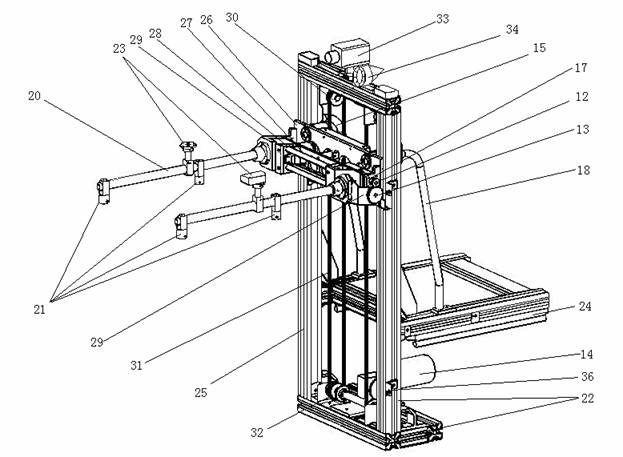

InactiveCN102151634AImprove work efficiencyQuality improvementLiquid spraying apparatusPlant protectionProgrammable logic controllerTree trunk

The invention discloses an intelligent tree trunk white painting robot and belongs to the related fields of urban and garden greening equipment. The intelligent tree trunk white painting robot comprises a machine frame system, a robot traveling system, a lime slurry supply system, an automatic white painting execution system and a real-time detection system. Adopting a spray painting mode for white painting of tree trunks, the robot can automatically walk along a side pavement and quickly and efficiently spray lime solution onto trees along the side pavement. In a real-time detection system, a digital compass, a laser sensor and a vision system are adopted to realize the semi-automatic searching of tree trunks and tree trunk automatic positioning, an ultrasonic transducer is adopted to realize automatic obstacle avoidance, and the whole-process real-time monitoring with a personal computer (PC) and a programmable logic controller (PLC) is realized. When the intelligent tree trunk white painting robot is used, coating is saved and the painting effect is optimized; and the robot automatically performs white painting of trees along the side pavement, the working efficiency is improved, labor force is saved, and the goals of intelligent control and green environmental sanitation are fulfilled.

Owner:SHANGHAI UNIV

Virtual coatings application system with structured training and remote instructor capabilities

InactiveUS20080124698A1Conveniently demonstrate proper spraying techniqueEducational modelsSimulatorsPassage planningVirtual reality

A computer simulation and virtual reality system for teaching proper spray painting techniques has features to foster structured training via planned lesson curriculum, and network capabilities that allow students to remotely view an instructor demonstrating technique on the system. The system also provides instructors software for developing lesson curriculum, managing classes, and reviewing lesson results of the students.

Owner:UNIV OF NORTHERN IOWA RES FOUND

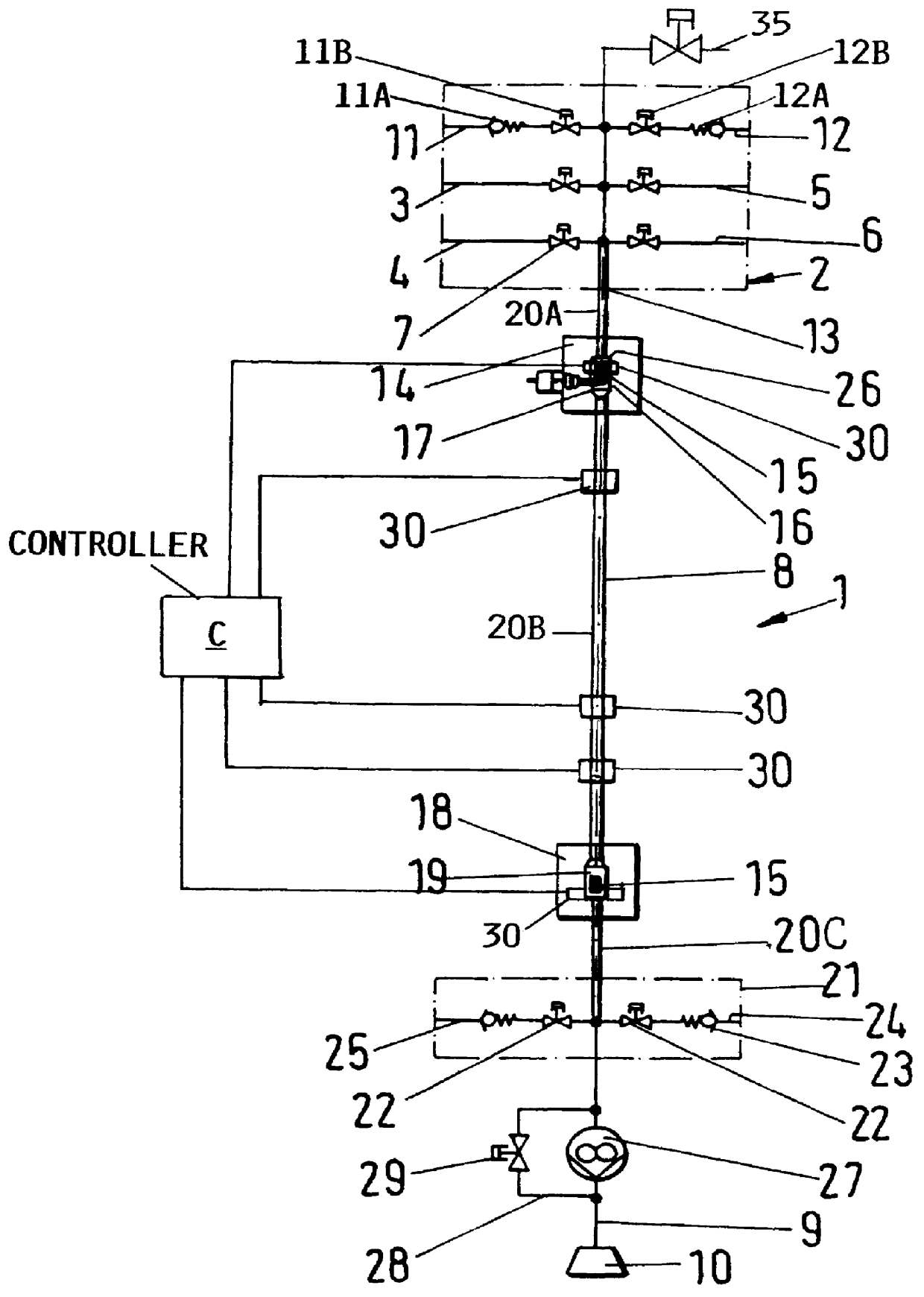

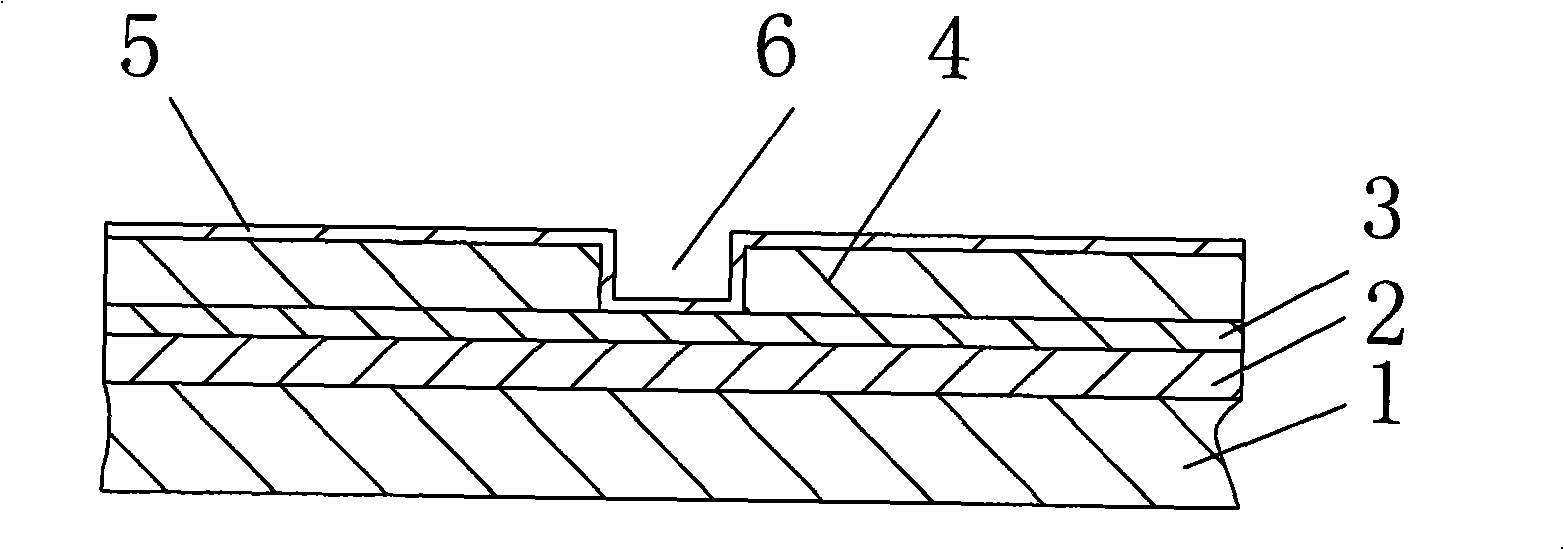

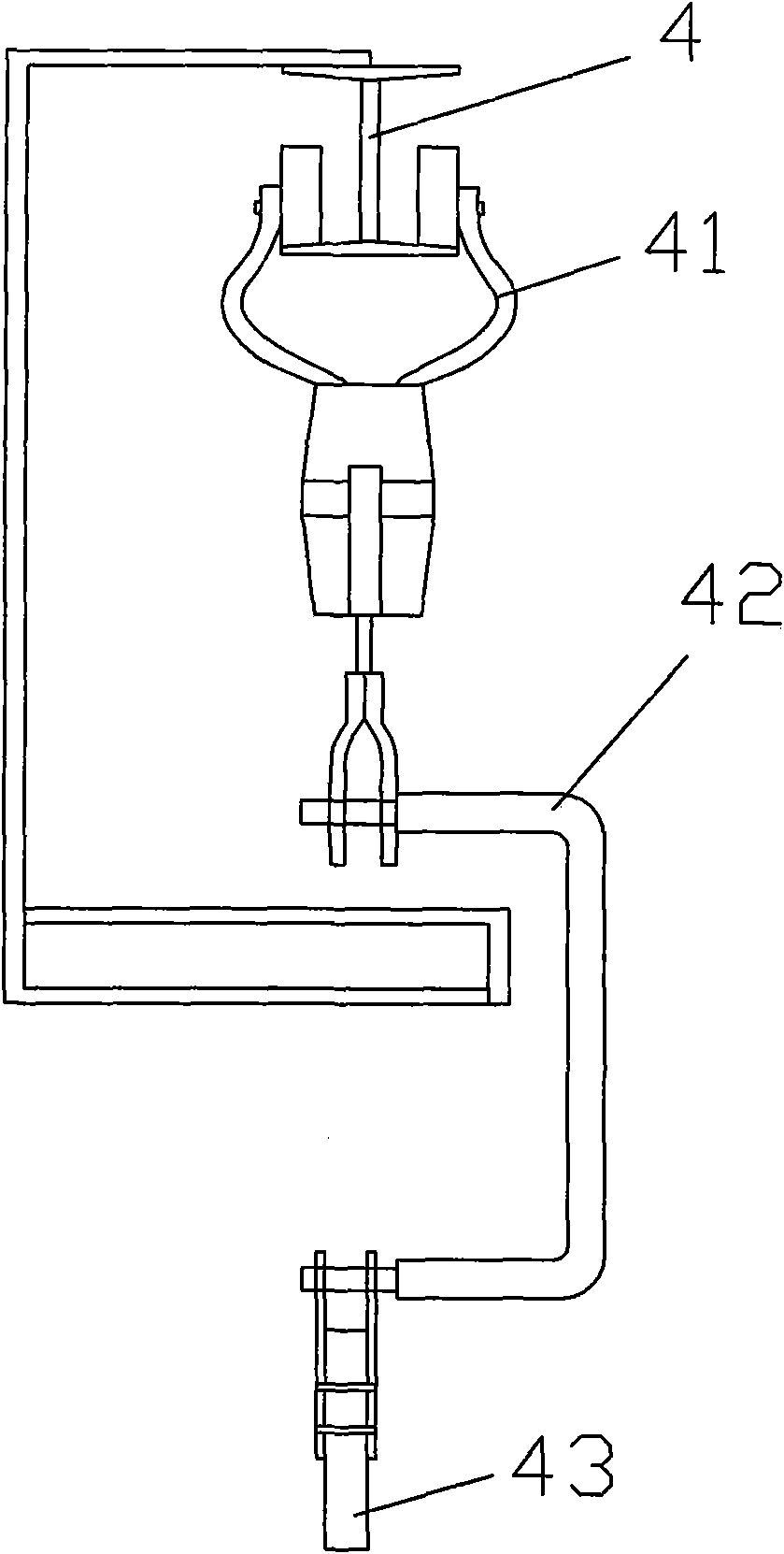

Method and apparatus for spray coating a workpiece

InactiveUS6090450ALiquid/solution decomposition chemical coatingSolid/suspension decomposition chemical coatingSpray nozzleFeed line

An apparatus and method for painting a workpiece while switching paint colors between successive painting cycles includes a paint supply switching device, a paint feed line connected to the paint supply switching device, a separating element adapted to move back and forth in at least a portion of the paint feed line, first and second receiver stations adapted to receive the separating element at the end positions of its travel in the paint feed line, and a paint spray nozzle at a terminal end of the paint feed line. The separating element is actively held in the first receiver station while paint of a first color is supplied through the paint feed line and sprayed from the nozzle onto a workpiece. To switch to a paint of a second color, the supply of the first paint is terminated, the separating element is released from the first receiver station, and a pushing medium pushes the separating element through the paint feed line, while residual paint is pushed from the paint feed line out through the spray nozzle. The separating element forms a sealing barrier between the pushing medium and the residual paint. Sensors detect the arrival of the separating element in the second receiver station, and the flow of pushing medium is terminated to avoid spraying the pushing medium out through the spray nozzle. Then a pushing medium pushes the separating element back into the first receiver station.

Owner:LACTEC GESELLSCHAFT FUR MODERNE LACKIERTECHNIK GMBH

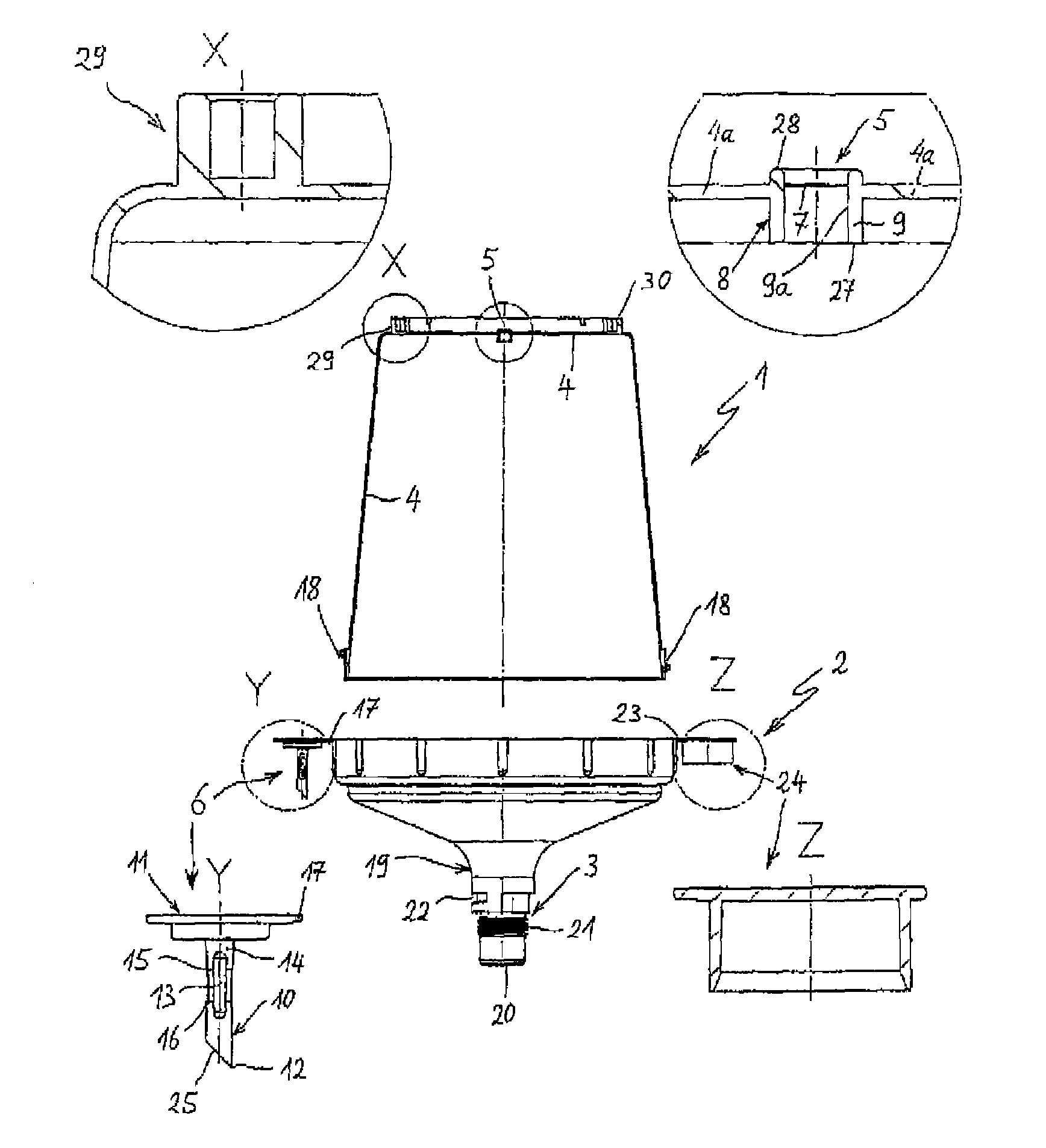

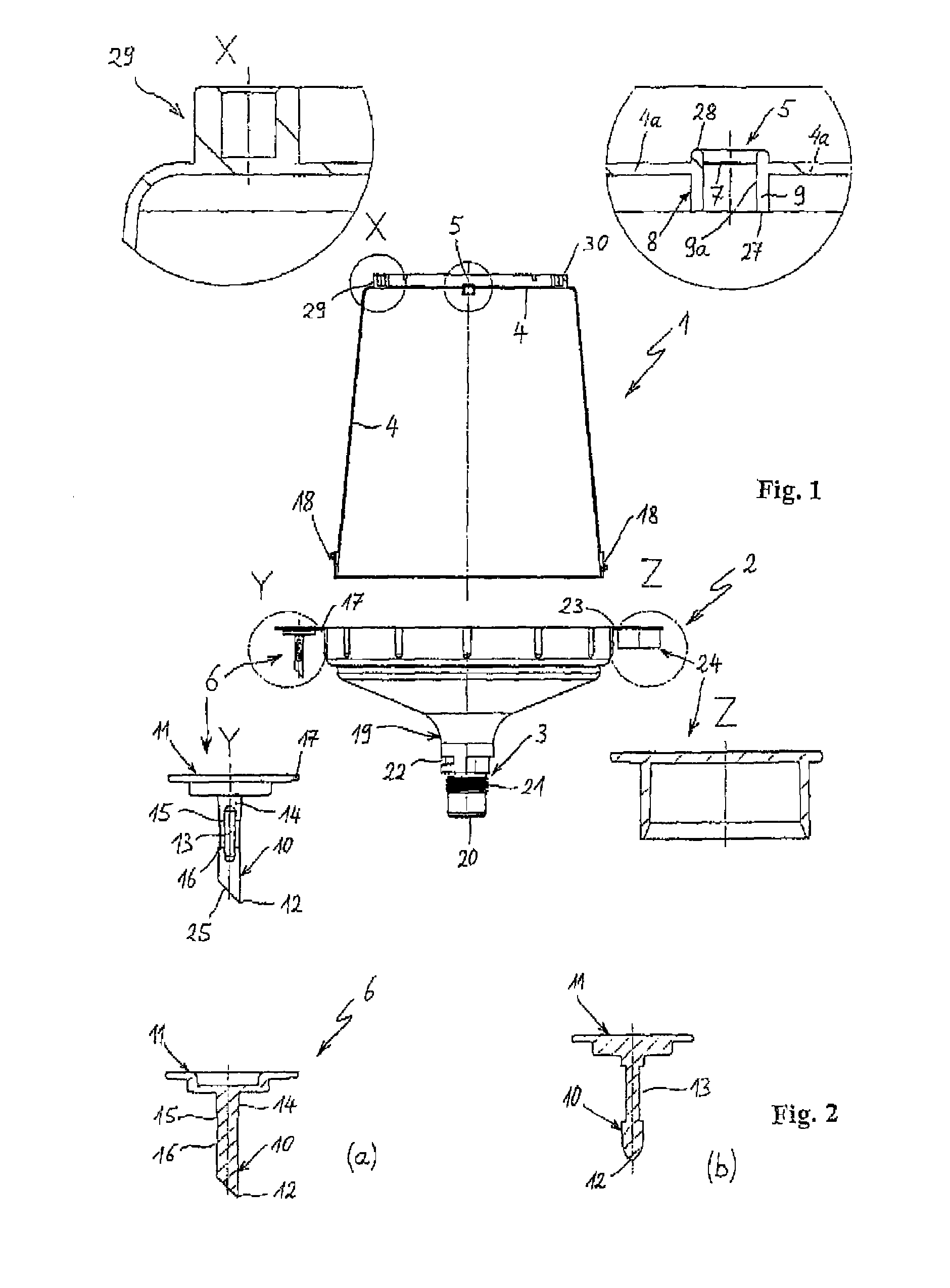

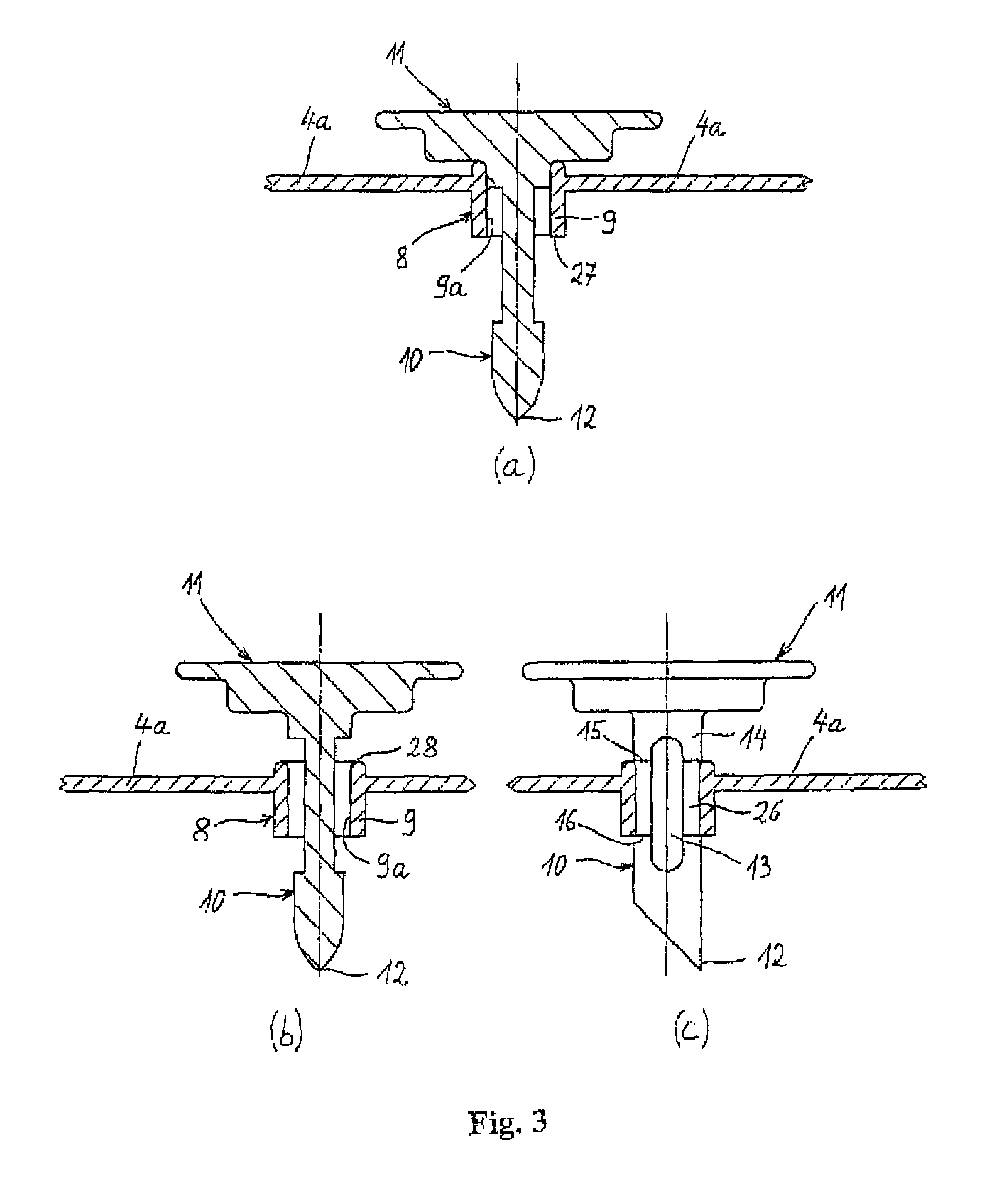

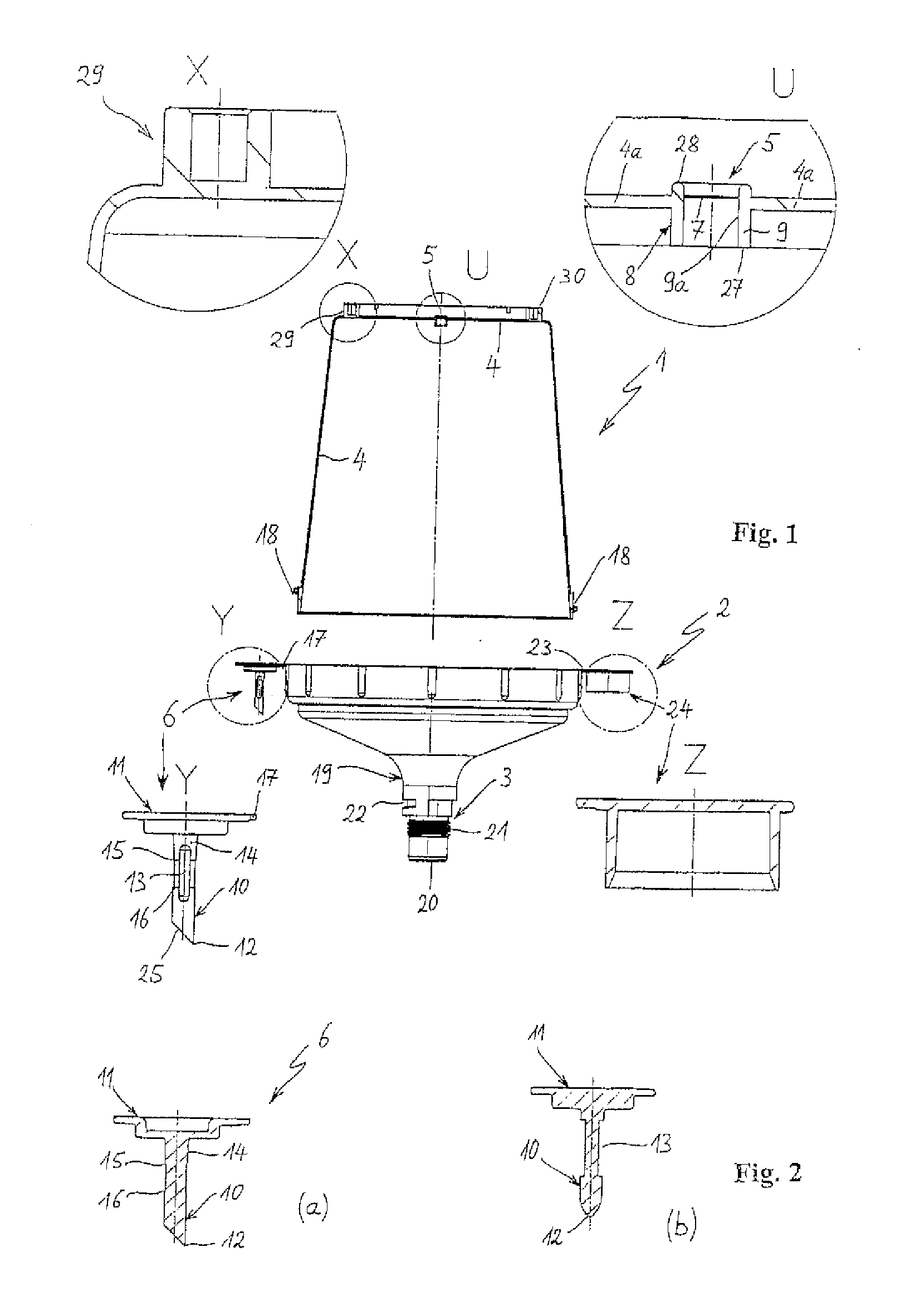

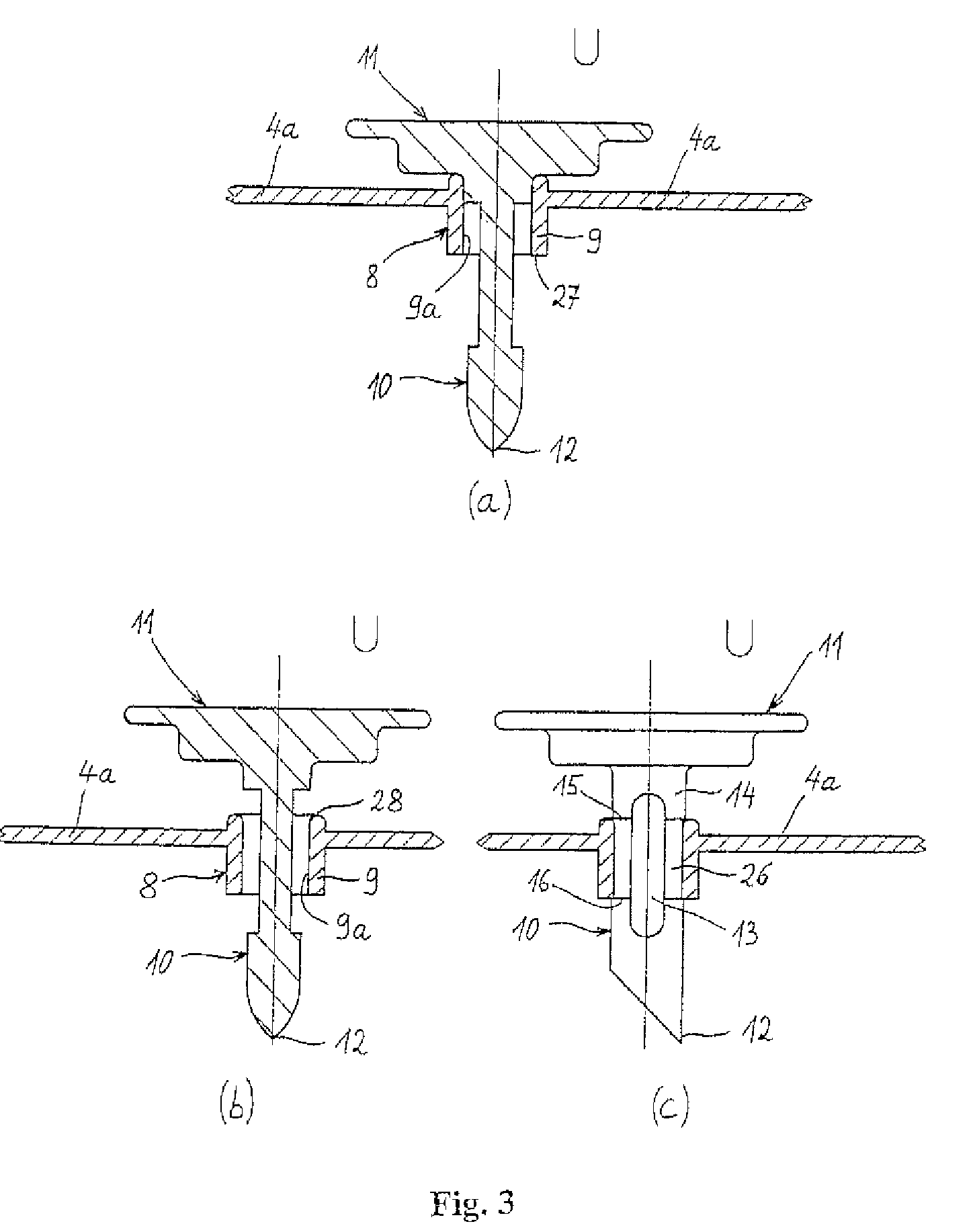

Paint reservoir system for a paint spray gun

ActiveUS7819341B2Simple and fast and uncomplicated formationLiquid flow controllersFire rescueWood shavingsThermodynamics

Owner:SATA GMBH & CO KG

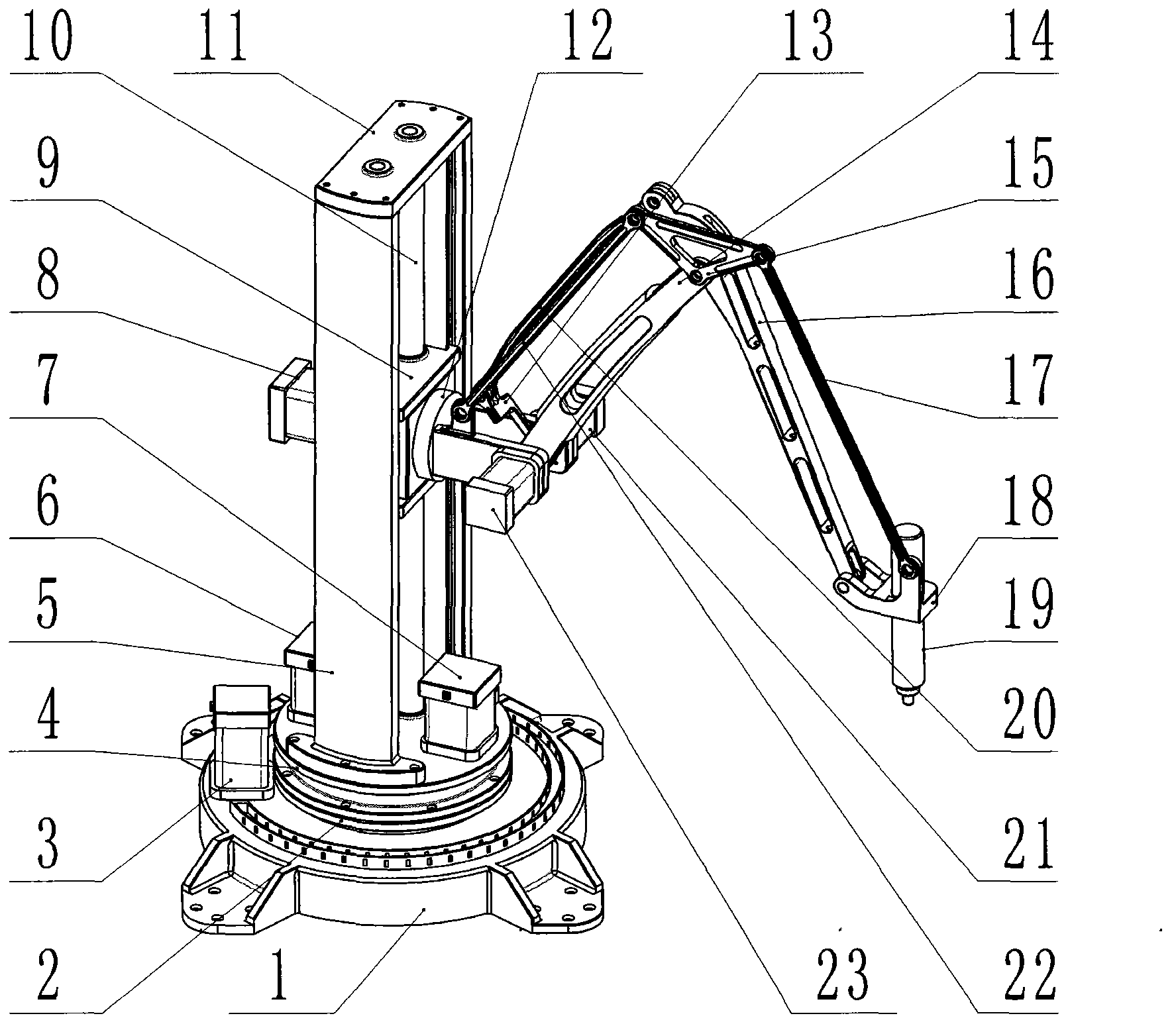

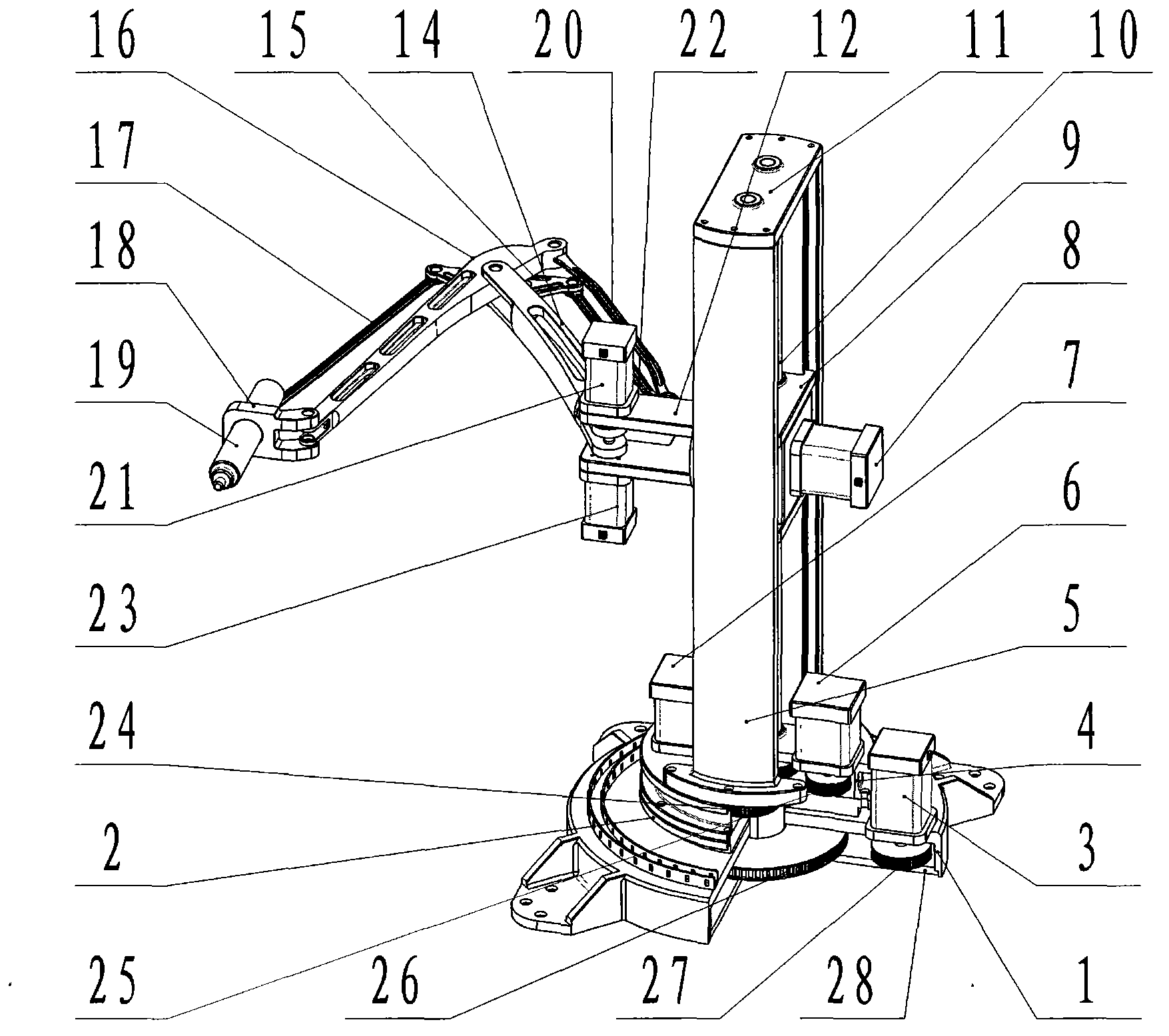

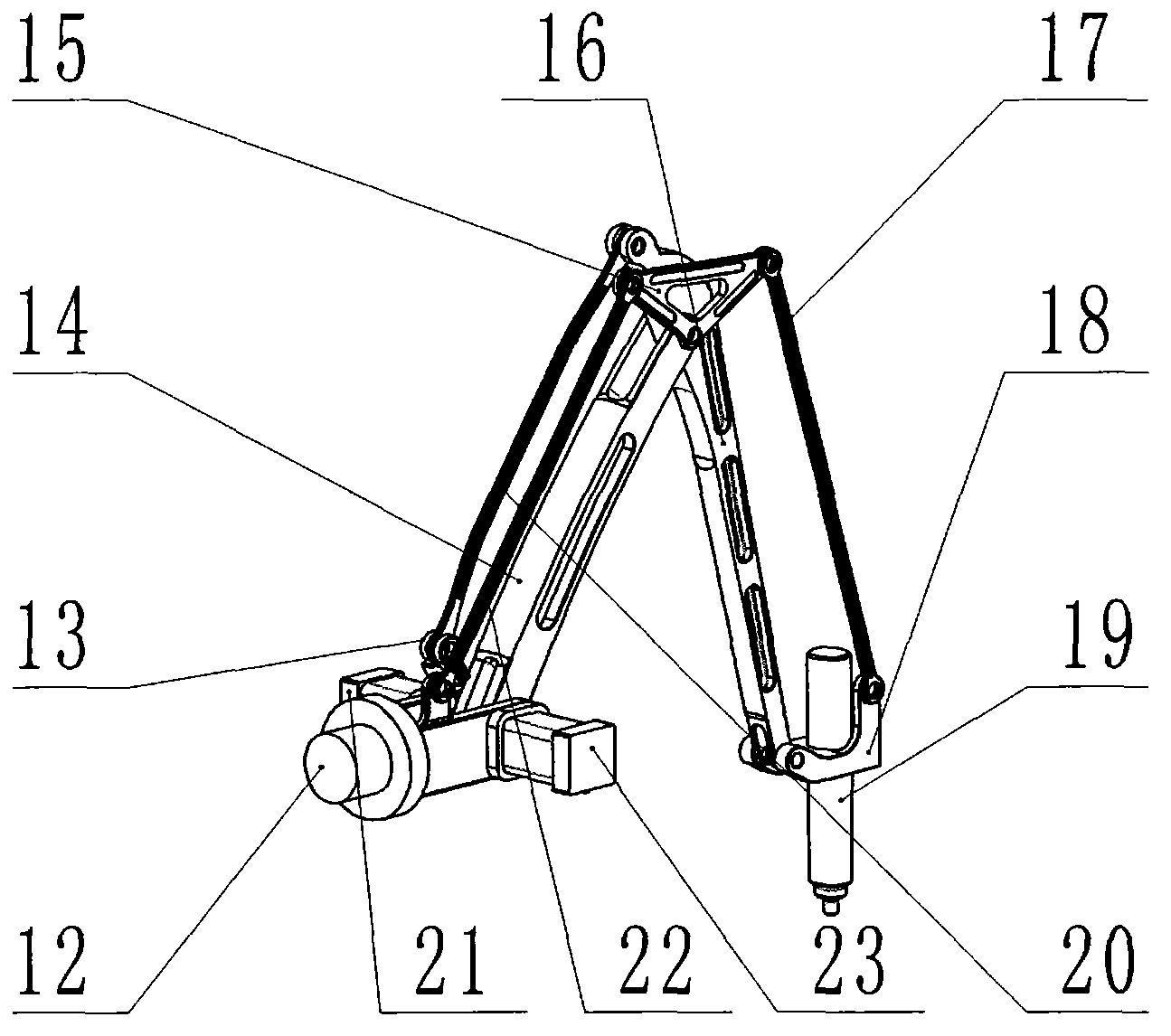

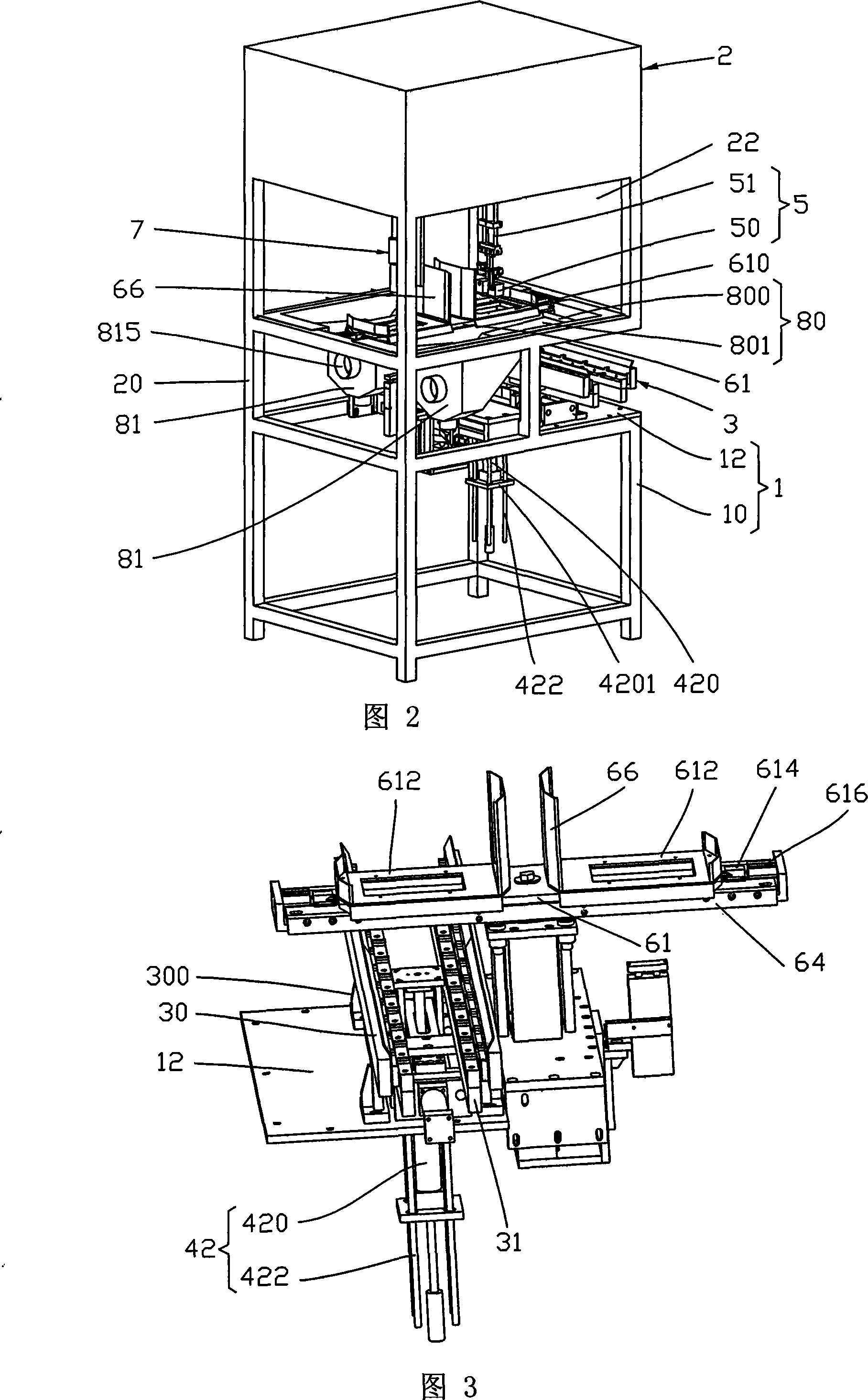

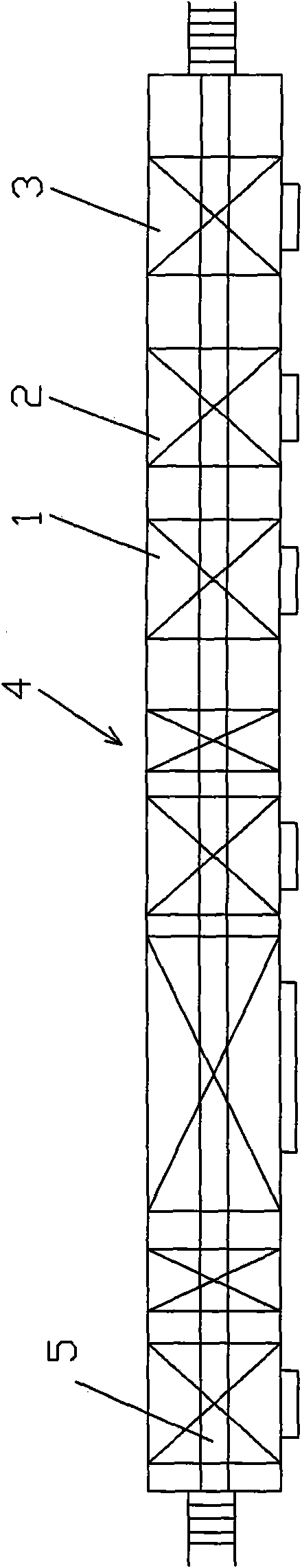

Rotary table upright type five-freedom-degree mixed-connecting spray painting robot

The invention relates to a rotary table upright type five-freedom-degree mixed-connecting spray painting robot which is large in work space and has certain flexibility. The rotary table upright type five-freedom-degree mixed-connecting spray painting robot comprises a foundational series-connection movement unit and a tail end parallel-connection spray painting operation unit. The foundational series-connection movement unit has two rotation freedom degrees and a movement freedom degree and is composed of a machine body rotation joint, a machine body lifting movement joint and a horizontal rotation joint. The tail end parallel-connection spray painting operation unit has two movement freedom degrees and is a plane parallel-connection mechanism composed of a large arm, a small arm, a connecting rod, a crank, a movable platform and the like. The rotary table upright type five-freedom-degree mixed-connecting spray painting robot has the advantages of being wide in work range, small in number of driving joints, compact in structure, easy to manufacture, convenient to control, capable of enabling the modularization to be achieved easily and the like.

Owner:JIANGSU CHANGHONG INTELLIGENT EQUIP CO LTD +1

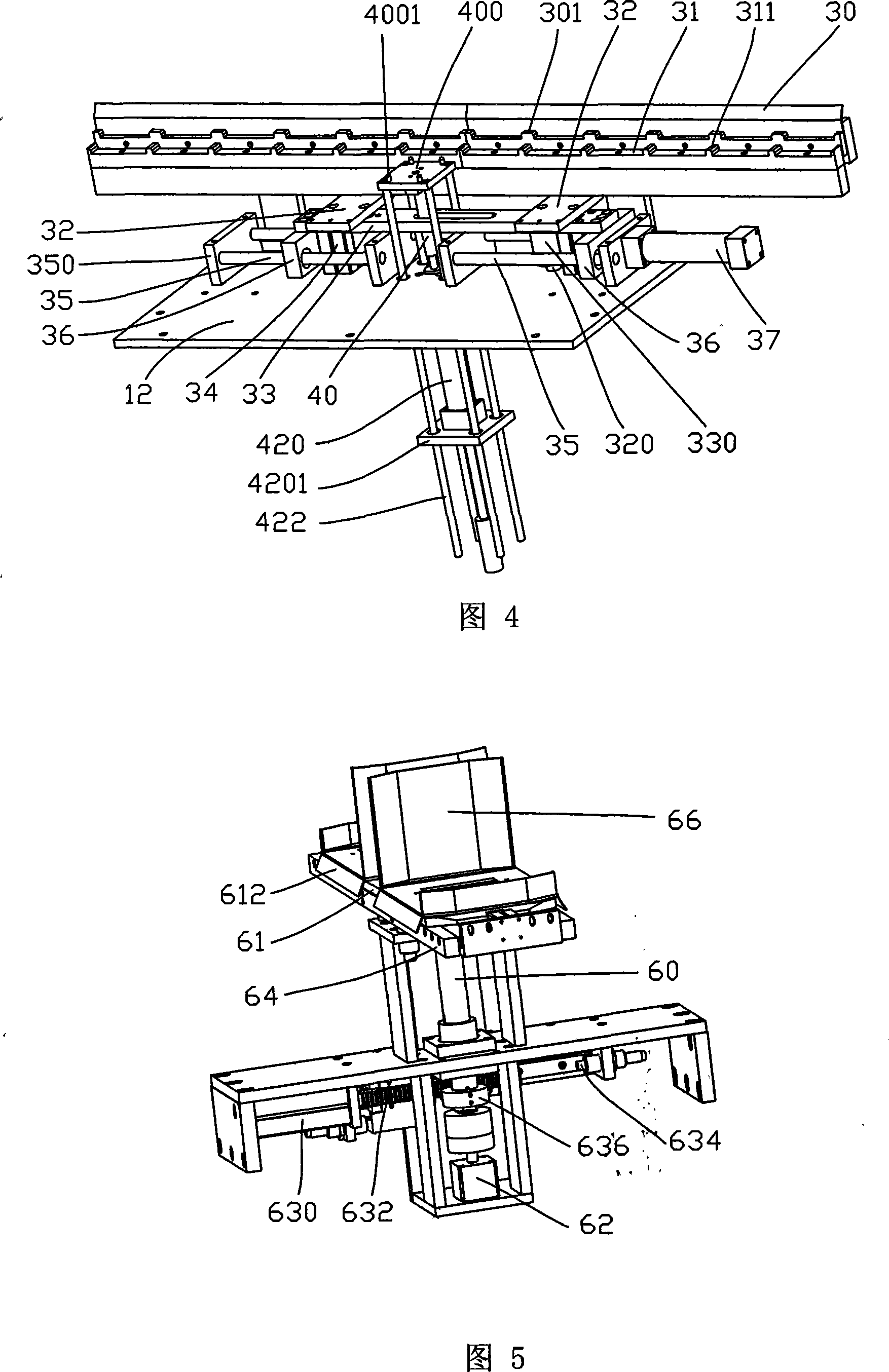

Automatic paint spraying machine

InactiveCN101185922ALow costTimely and pollution-free treatmentLiquid surface applicatorsSpraying apparatusControl systemEngineering

The invention relates to an automatic spray-painting machine, comprising a machine station, a spraying chamber, a work piece delivery device, a cover die device, a spraying device arranged in the spraying chamber, a rotating die device, a washing die device, a cleaning dirty device and a control system. The work piece delivery device is provided with a work piece loading plate; the cover die device comprises a cover die driving mechanism and an incremental launching column which can support the work piece loading plate and correspondingly lift and drop; the rotating die device comprises an upright column, a die base fixed on the top of the upright column, power elements for die base lifting and a rotating die driving mechanism. The die base is arranged in the spraying chamber and two ends of the die base are respectively positioned below the praying device and the washing die device. Two ends of the die base are respectively provided with dies and the middle part of the die base is provided with an isolation board. The invention can cover die automatically and do spraying and die washing work simultaneously. Only by rotating the die base, the position of the used die and the position of washed die can be exchanged, so as to realize high-speed and continual spraying process. The invention is high in automation degree and low in die cost. Due to the timely non-feculence treatment to the waste water and waster gas, the invention is also beneficial to environmental protection.

Owner:SHENZHEN KUNHAN TECH

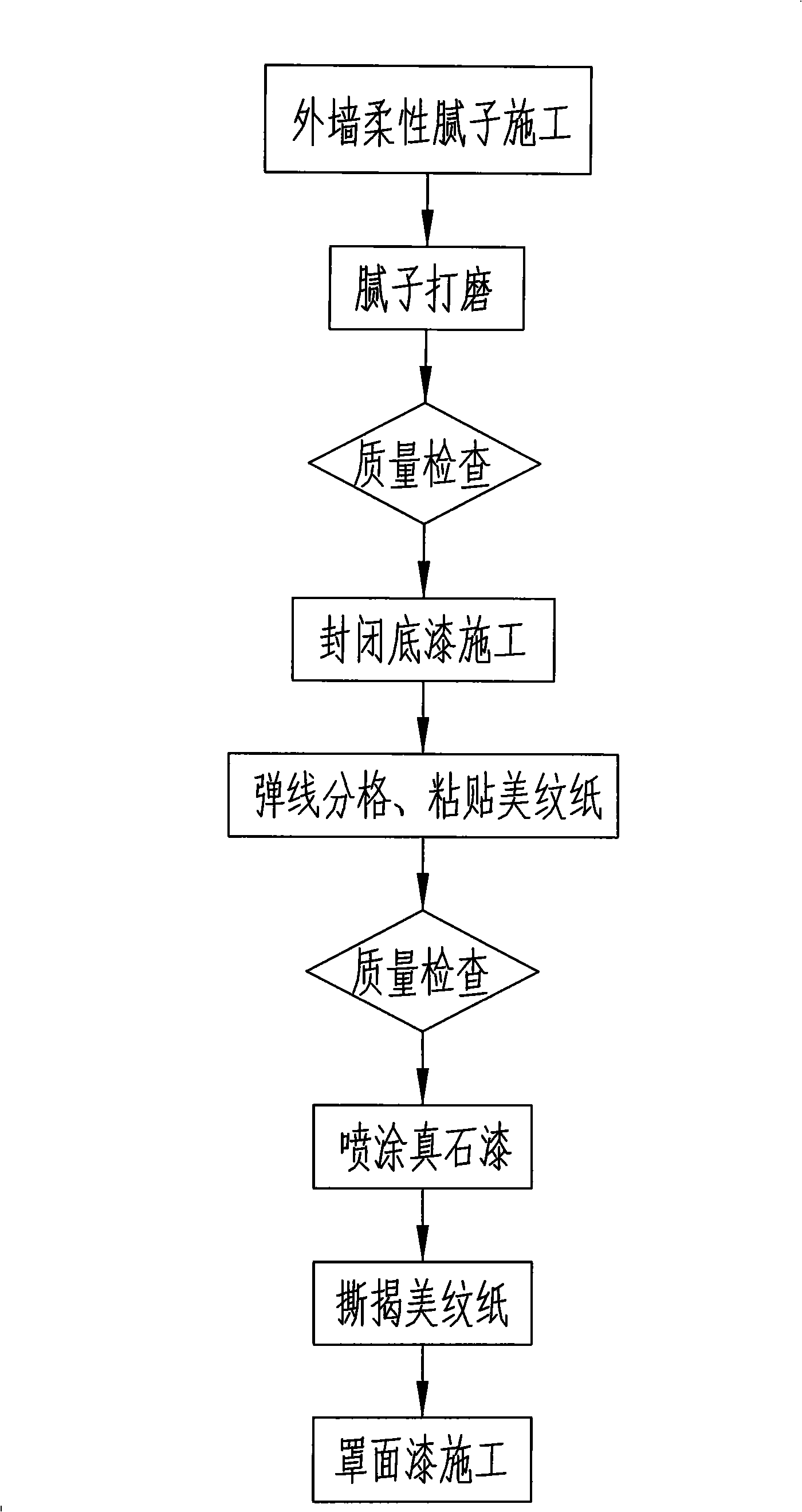

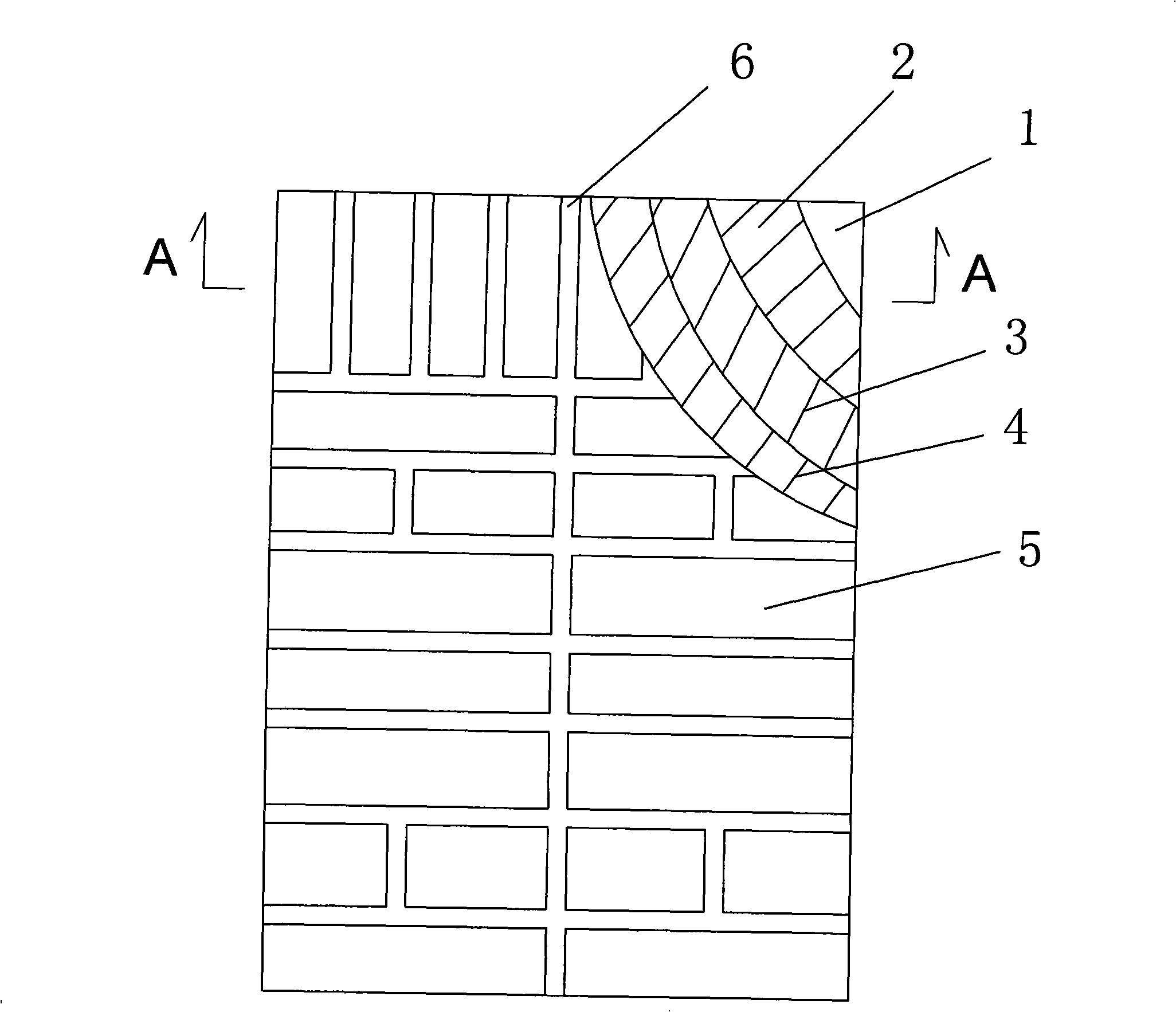

Construction method of ture mineral varnish face brick-imitation construction exterior wall

InactiveCN101319552ASolve the problem of decorative aesthetic effectSimple methodCovering/liningsBrickLacquer

The invention relates to a construction method for building external walls with real stone lacquer imitation tiles, which effectively solves the problem that the decoration of an external wall of a public building and a residential building not only realizes heat insulation and energy conservation but also can realize beautiful decorative effect. The technical proposal to be solved by the construction method is as follows: by adoption of the external wall as a fundamental plane, a base of the external wall is coated and rubbed down by filler plaster, and a primer layer is arranged on the base by primer; snapline division is performed on the primer layer, and beautiful paper tape is applied according to divided snaplines; real stone lacquer is sprayed, the beautiful paper tape is torn off in time after spray painting, and decorative grooves are left on the paper tape; and a layer of mask lacquer is sprayed finally. The method is simple, is easy to operate, has low cost, quick construction speed and good effect, and not only has good effects of energy conservation and heat insulation but also has beautiful decorative effect. The technique is not reported publicly until now, is an innovation architecturally, and has significant economic and social effects.

Owner:勾希杰 +1

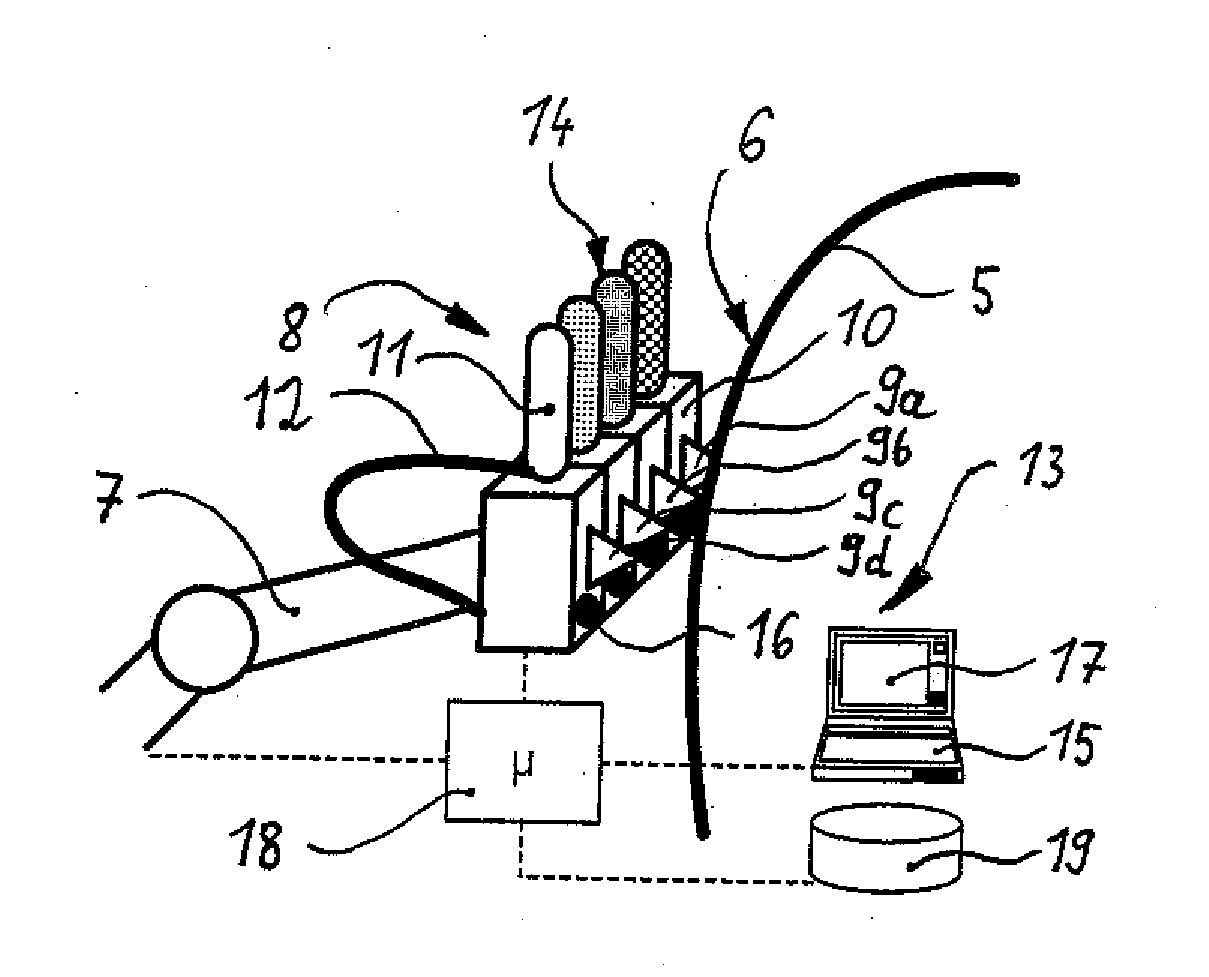

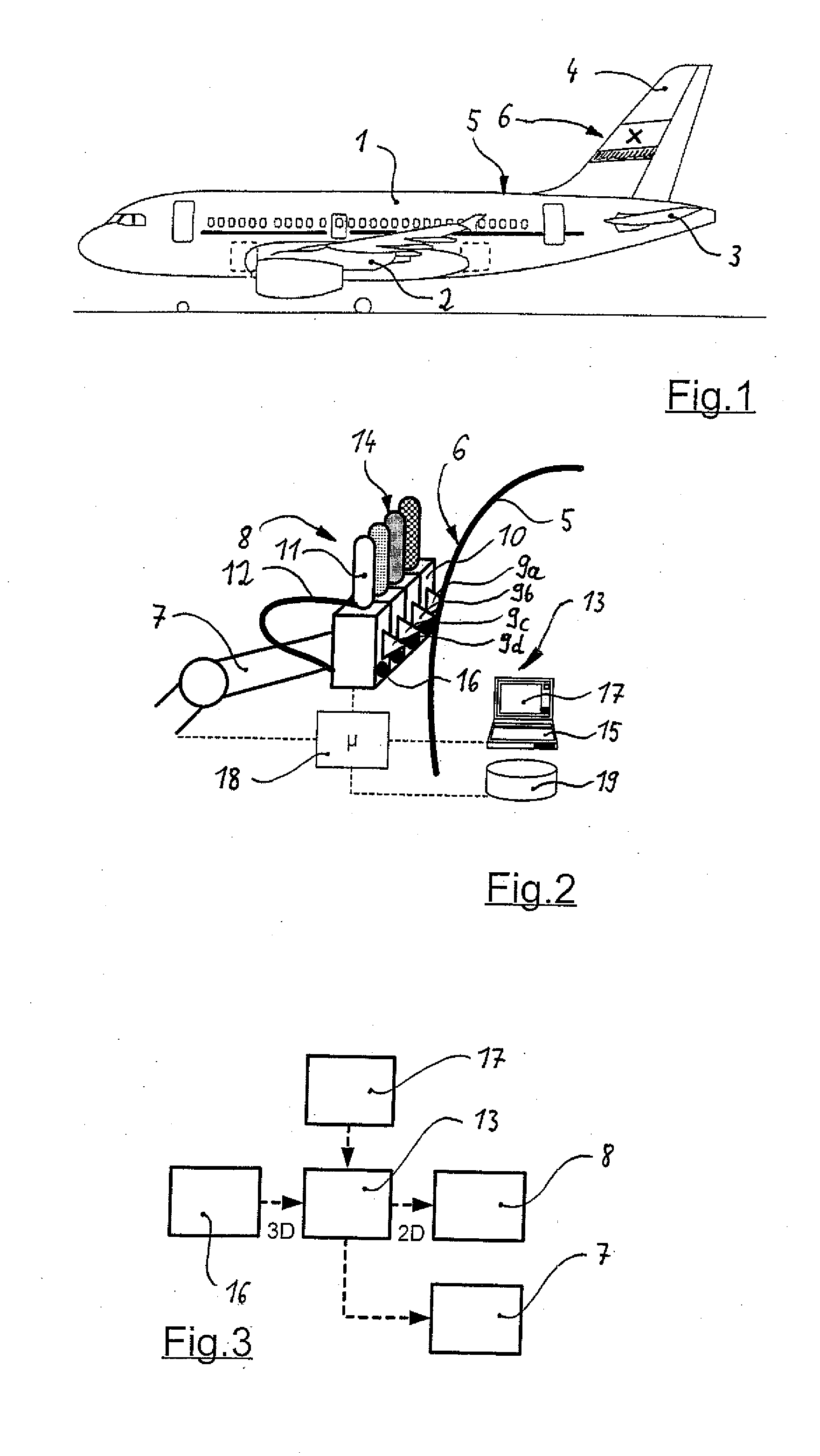

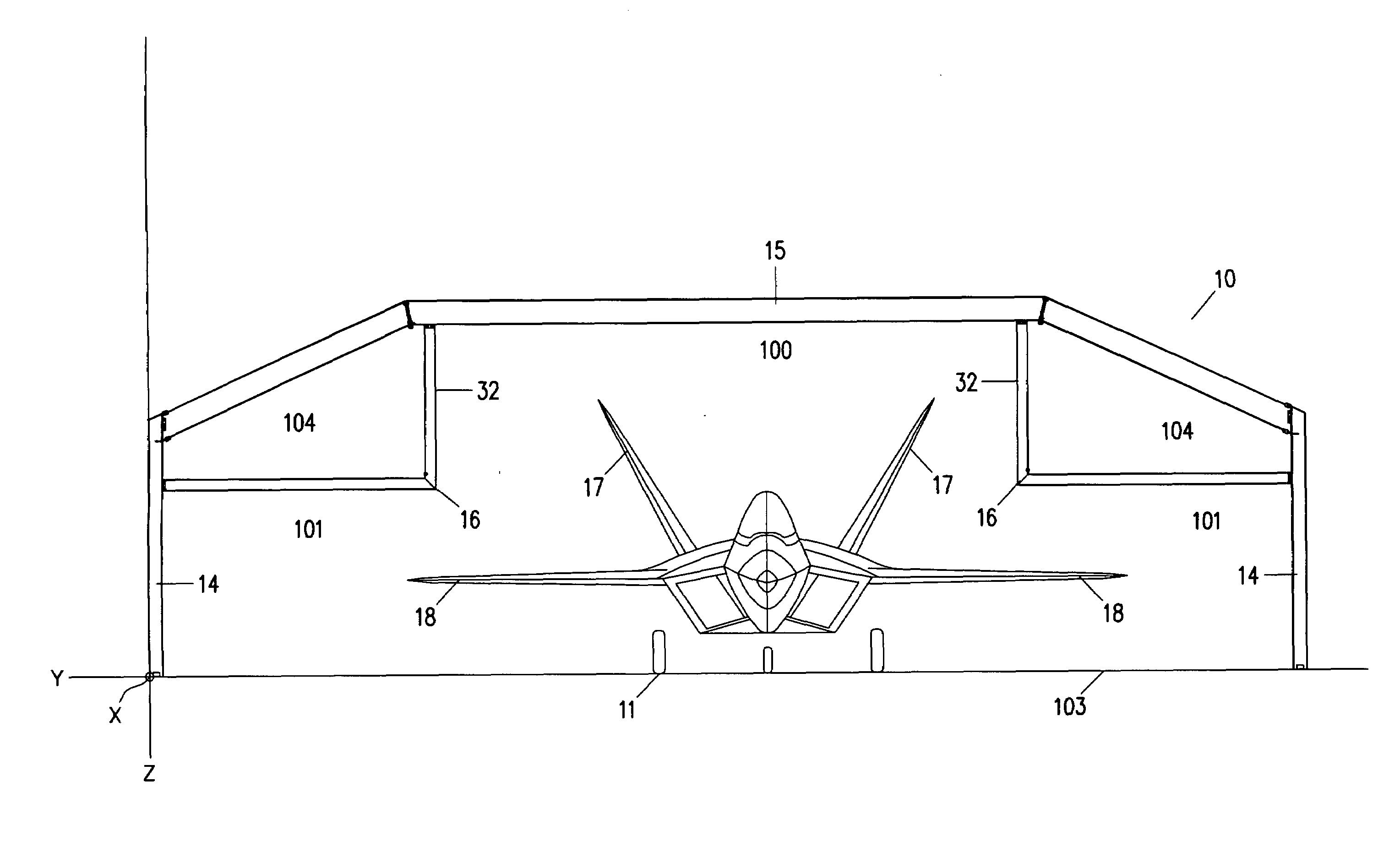

Device and method for painting curved outer surfaces of an aircraft

ActiveUS20100304009A1Durably applyShort production timeProgramme controlLiquid surface applicatorsEngineeringAirplane

A device for painting a curved outer surface of an aircraft includes a paint applicator having a plurality of spray painting heads each assigned to one of a plurality of different base color supply units containing one of polyurethane aircraft paint and ink. The device further includes a spatially adjustable positioning device configured to move the paint applicator relative to the curved outer surface and at least one sensor device configured to determine a three-dimensional geometry of the curved outer surface. The device also includes a control unit configured to coordinate a movement of the positioning device with a paint output of the paint applicator, wherein the control unit is configured to alternately activate each of the plurality of spray painting heads so as to produce a picture motif so as to derive a two-dimensional driving geometry based on the three-dimensional geometry.

Owner:AIRBUS OPERATIONS GMBH

Paint Reservoir System For A Paint Spray Gun

ActiveUS20080179763A1Simple and fast and uncomplicated formationLighting and heating apparatusUsing liquid separation agentWater reservoirEngineering

The invention relates to a gravity flow reservoir for a paint spraying gun having a container and a cover, which can be placed thereon and which has a connecting part in order to place the gravity flow reservoir onto the paint spraying gun or onto an adapter. Prior art reservoirs require a separate pointed tool, which serves to make a vent hole, is often unavailable and can lead to operating errors. The aim of the invention is to provide a paint reservoir system that enables a simple, rapid and uncomplicated insertion of a vent hole into the container wall of the gravity flow reservoir while preventing shavings or plastic parts from entering the gravity flow reservoir. To this end, a delimited area is provided in the wall of the container and can be penetrated by the pointed tool in order to make a vent hole.

Owner:SATA GMBH & CO KG

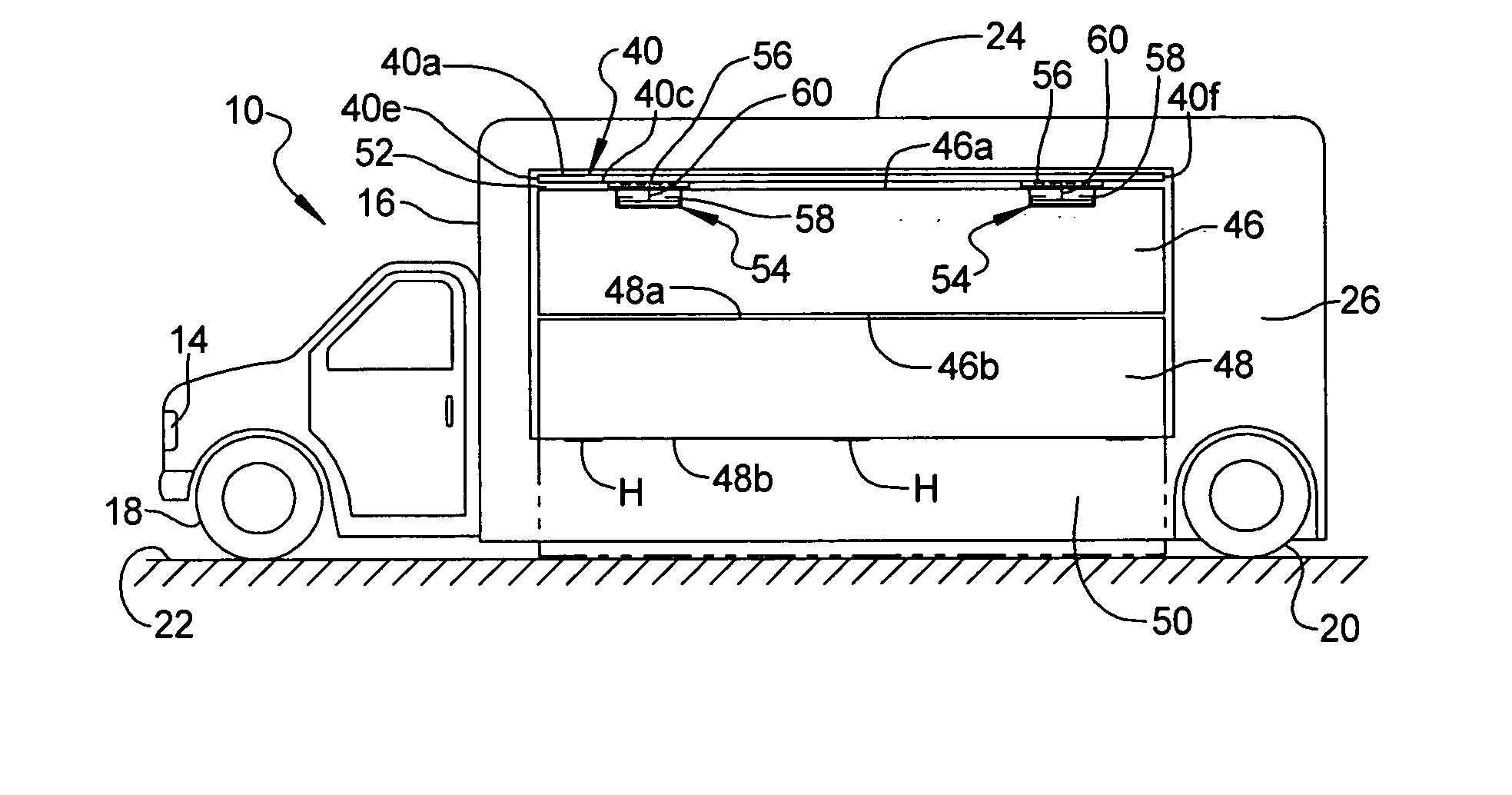

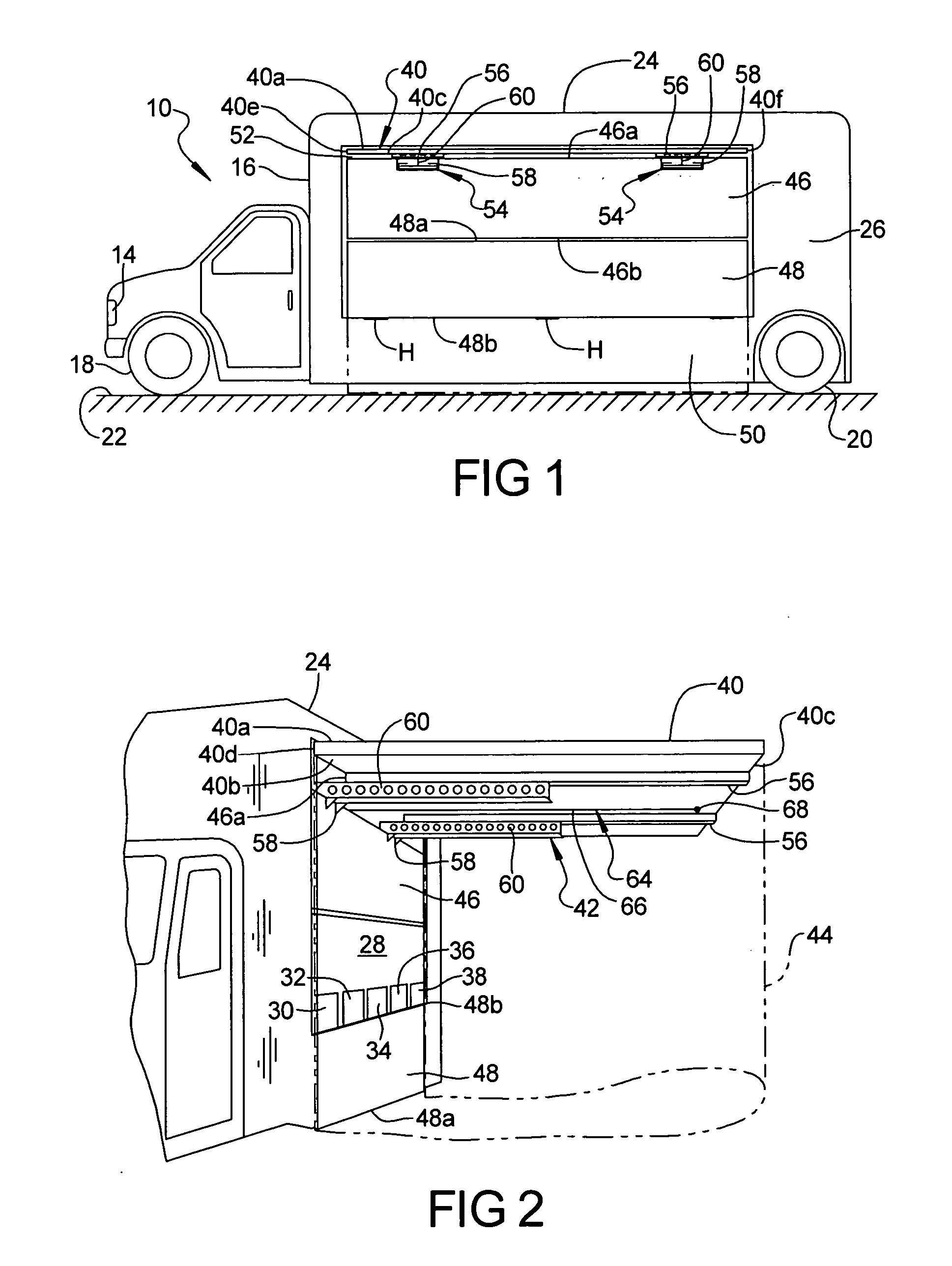

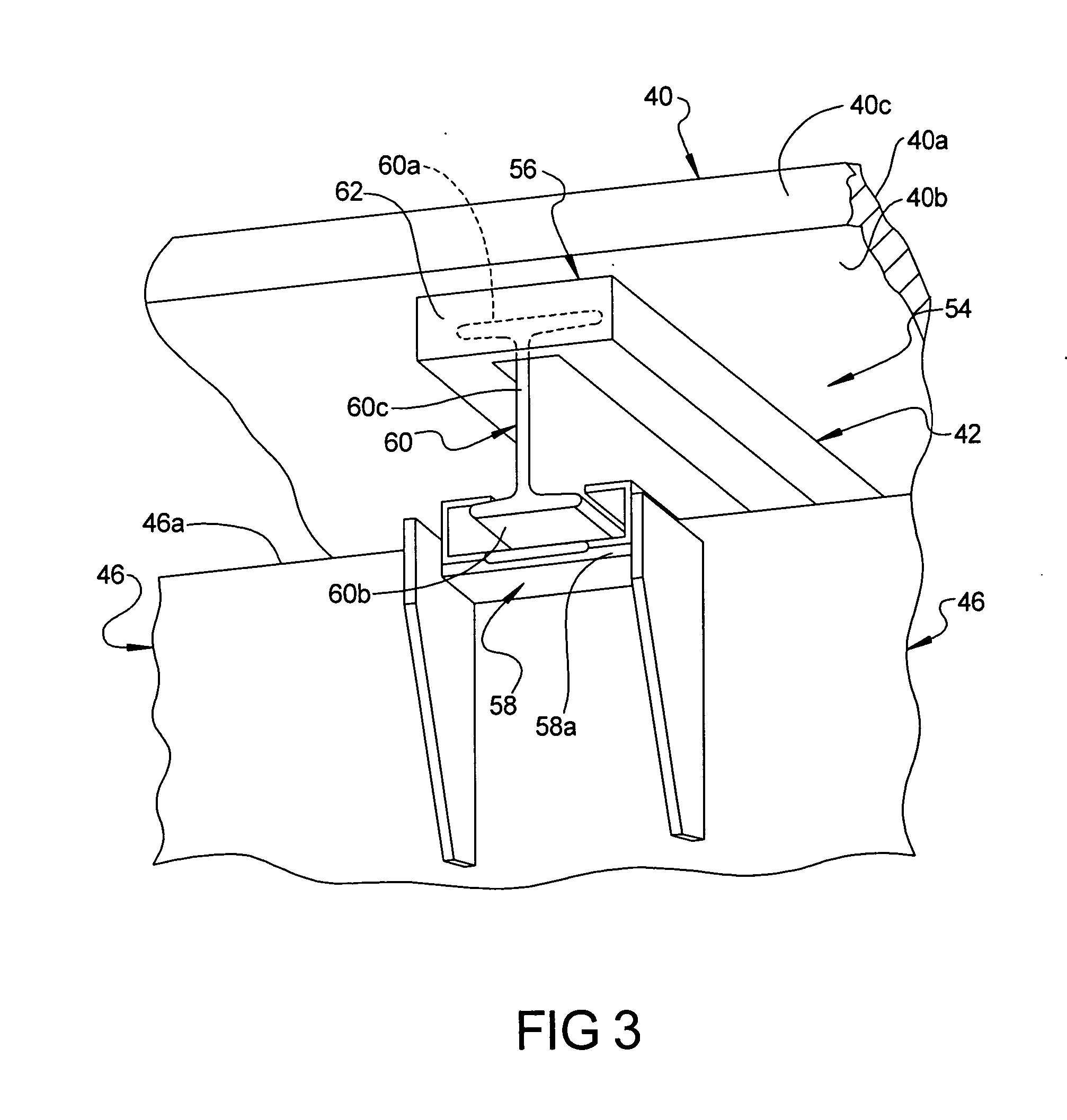

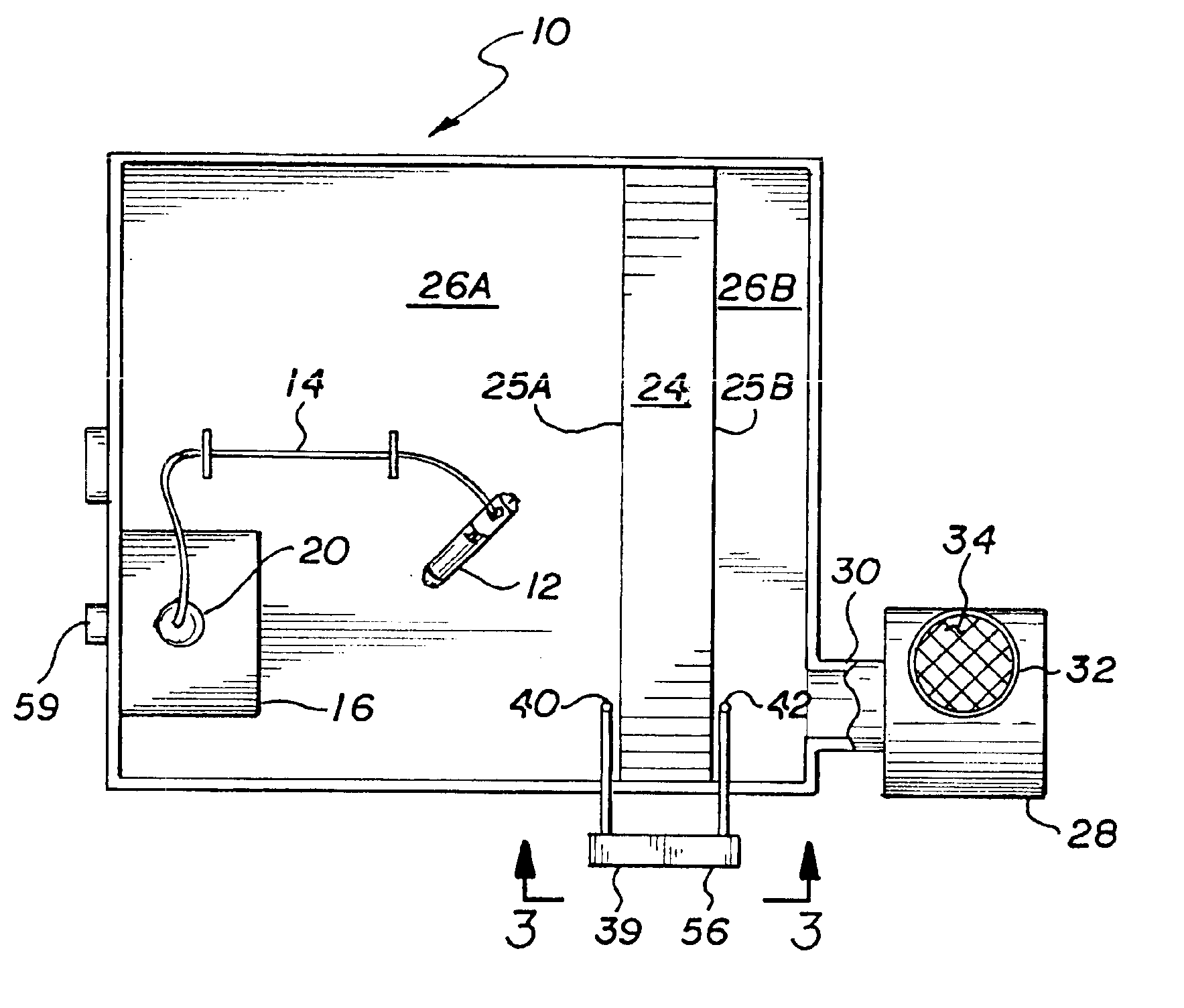

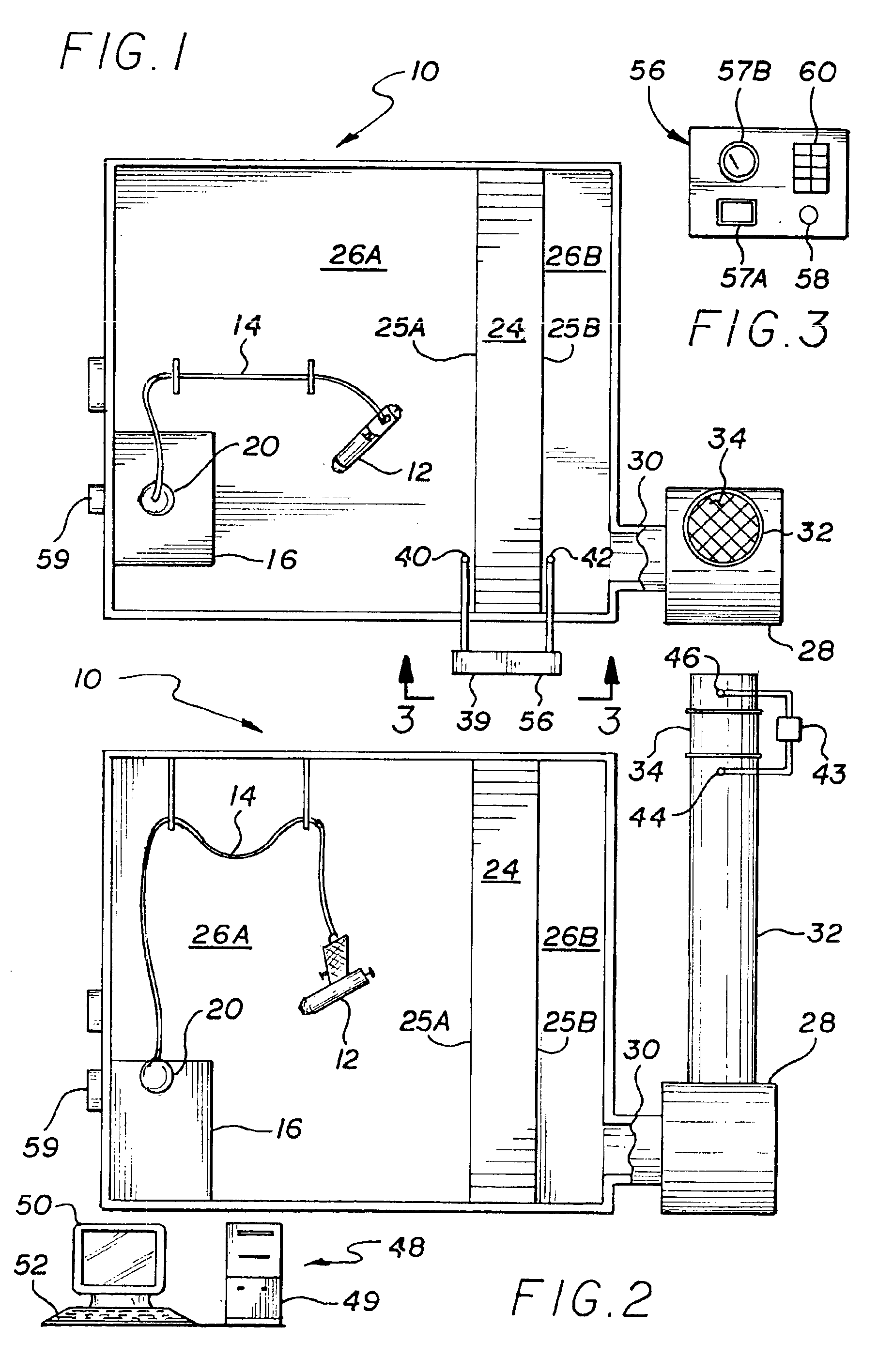

Portable paint booth

InactiveUS20070056510A1Reduce pressureQuick configurationLiquid surface applicatorsSpray nozzlesMobile vehicleStructural engineering

A mobile booth system, carried by a truck or like mobile vehicle, creates a portable, temporary in situ booth or enclosure at a remote location. A pair of side by side slide assemblies are formed by respective nests of C-channels and I-beams, each assembly extending and retracting through an opening in a sidewall of the truck wherein to deploy and retract a roof section outwardly from the truck. The roof section is deployed through a dedicated opening in the sidewall, which opening may be closed by a closure panel but opened by deployment of the roof section. When deployed, an enclosure is formed by attaching a drop cloth to the roof section. The enclosure when used as a paint booth enables rapid deployment of a drop cloth about irregular or difficult surfaces to be painted, as well as to contain overspray and fumes created by the spraying operation.

Owner:ANTAYA BRUCE C

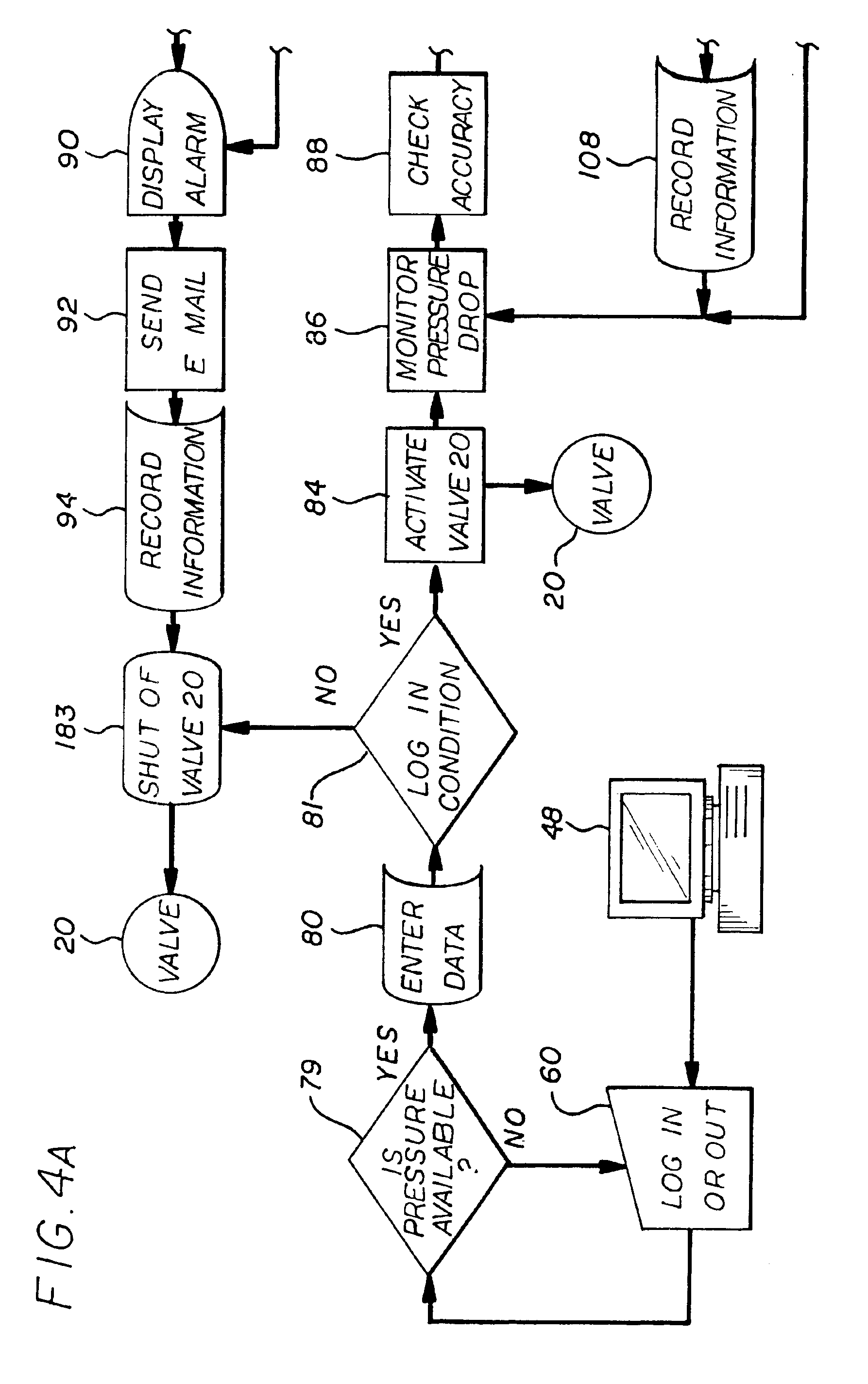

Method of monitoring a filter system for a paint spray booth

InactiveUS6887293B1Reduce usageGuaranteed normal operationCombination devicesAuxillary pretreatmentFilter systemEngineering

The invention is a method of monitoring a filter for absorbing paint particles produced during spray painting with a spray gun in a paint spray booth coupled to an exhaust pump, the method includes the steps of: 1) installing a filter between the booth and exhaust pump; 2) determining the initial pressure drop across a filter prior to use of the spray booth; 3) determining the maximum allowable pressure drop for the filter prior to the requirement that spraying activities must be terminated by adding the initial pressure drop of the filter to the maximum allowable increase in pressure drop across the filter before the of spraying activities must be terminated; 4) providing a warning when a first portion of the maximum allowable pressure drop is reached; and 5) preventing the use of the spray gun when a second portion, greater than the first portion, of the maximum allowable pressure drop is reached.

Owner:NORTHROP GRUMMAN SYST CORP

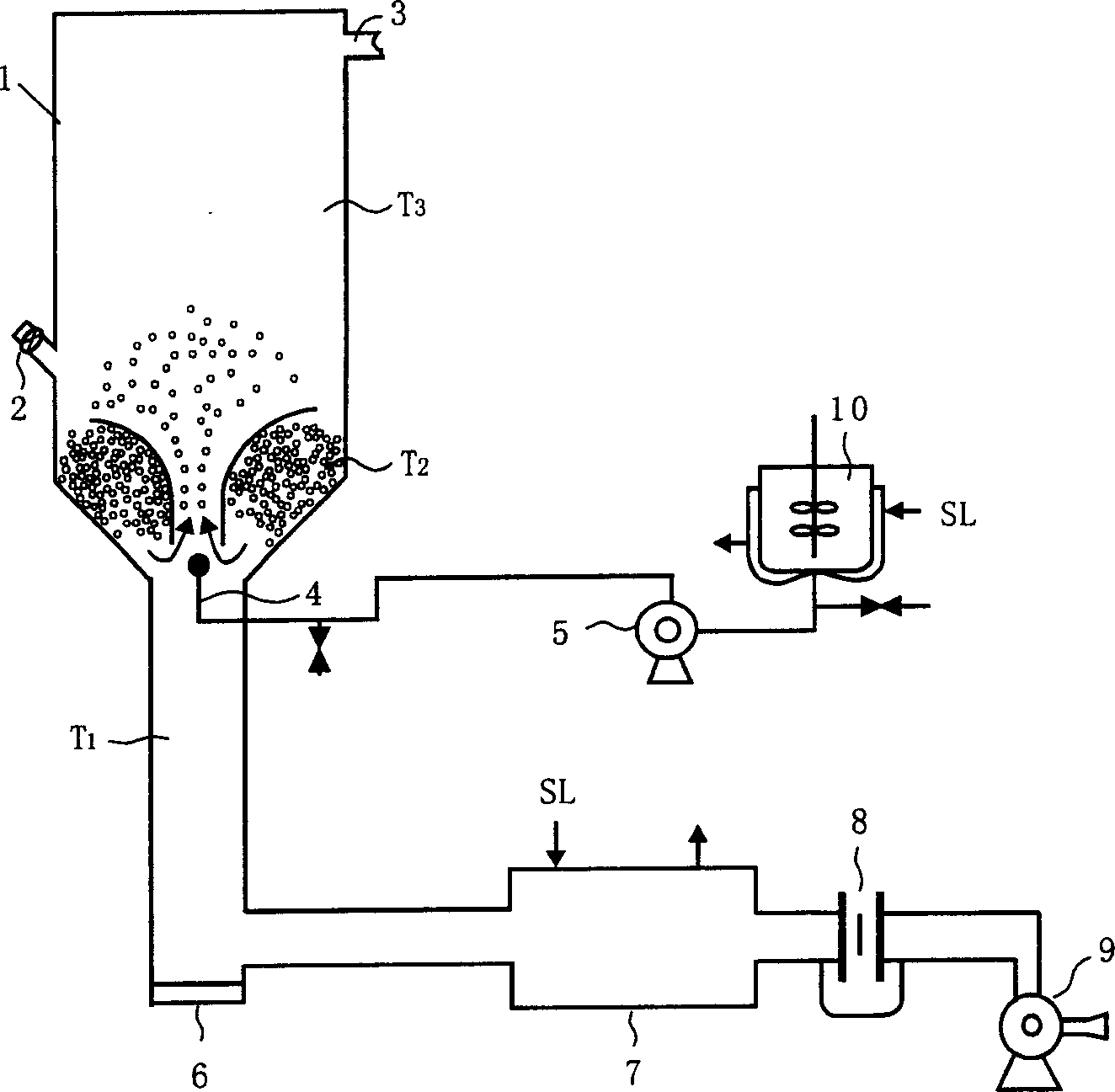

Pyromellitic dianhydride catalyst and preparation method thereof

InactiveCN102008971ASolve the problem of selectivityPhysical/chemical process catalystsOrganic chemistryAlkali metal oxideSlurry

The invention provides a pyromellitic dianhydride catalyst and a preparation method thereof, relates to a catalyst and the preparation method and solves the problems of low catalyst yield and low selectivity of the conventional gaseous oxidation method for preparing pyromellitic dianhydride. The catalyst consists of an active ingredients and a carrier, wherein the active ingredients consist of V2O5, TiO2, P2O5, Sb2O3 and alkali metal oxides. The method comprises the following steps of: 1, weighing; 2, adding an antimony source and a vanadium source into oxalic acid solution with stirring to obtain vanadyl oxalate solution; 3, adding a phosphorus source, the antimony source and alkali metal salt into the vanadyl oxalate solution, uniformly mixing, then adding a titanium source, adding polyvinyl acetate emulsion and then pulping and grinding to obtain size; and 4, adding the carrier into a revolving drum of spray painting equipment, heating and spraying the size on the carrier, putting into a Muffle furnace to carry out air purge and cooling to obtain the catalyst. The catalyst is used for catalysis and preparation of pyromellitic dianhydride.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

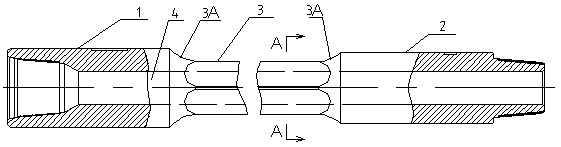

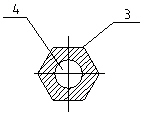

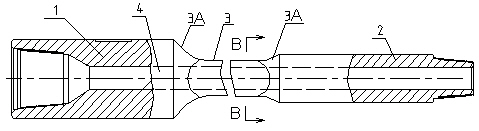

Production process of integral kelly stem

ActiveCN102059511ASimple structureMeet the use requirementsMetal-working drilling toolsFurnace typesWell drillingProcess engineering

The invention discloses a production process of an integral kelly stem, which comprises five procedures according to the operational sequence: smelting, forging, machining, thermally refining and refining, wherein slot milling and imprinting, imprinting, finished product check, paint spraying and packaging and then delivery can be carried out after the refining procedure is ended. The production process is more economic and scientific and has low production cost; and the produced integral kelly stem has good quality, meets the use requirement on the environment, is integrally manufactured, has the advantages of simple structure, no need of welding, no existence of welding stress inside the product, good quality and long service life, and is widely suitable for the field of petroleum drilling operation.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

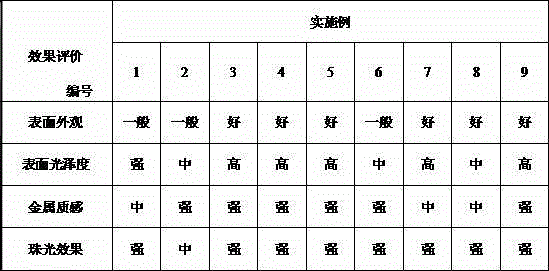

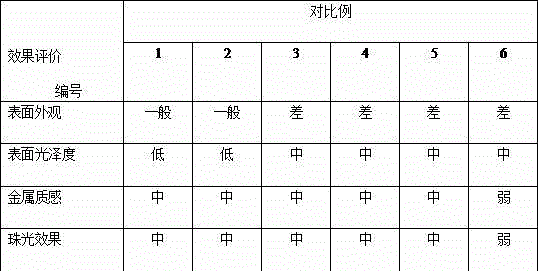

High-flowability high-glossiness no-surface-defect colored metallic-pearl-effect spraying-free polypropylene automobile material and preparation method thereof

The invention discloses a high-flowability high-glossiness no-surface-defect colored metallic-pearl-effect spraying-free polypropylene automobile material and a preparation method thereof. The material is composed of the following components in percentage by weight: 40.8-74.4% of polypropylene, 2-4% of toughener, 5-20% of mineral master batch, 5-10% of compatilizer, 0.4-0.6% of antioxidant, 0.4-0.6% of light stabilizer, 0.8-2% of lubricant, 6-10% of surface modifier, 3-6% of colored metallic pigment master batch and 3-6% of pearl color master batch. By using the high-melt-flow-rate polypropylene resin, compatilizer, surface modifier, mineral master batch, colored metallic pigment master batch and pearl color master batch, all the components can be uniformly dispersed, so that the material has the advantages of favorable glossiness, favorable pearl effect, favorable metallic sensation and no surface defect, and the appearance effect is infinitely approximate to the painting effect. The material can solve the problem of surface flow mark, tiger skin or fusion wire in the thin-wall complex-structure large-size product without especially customizing the ultrahigh-glossiness mirror surface mold or harsh injection molding technique, and can implement direct color-bearing injection molding of the part.

Owner:蔡勤勤

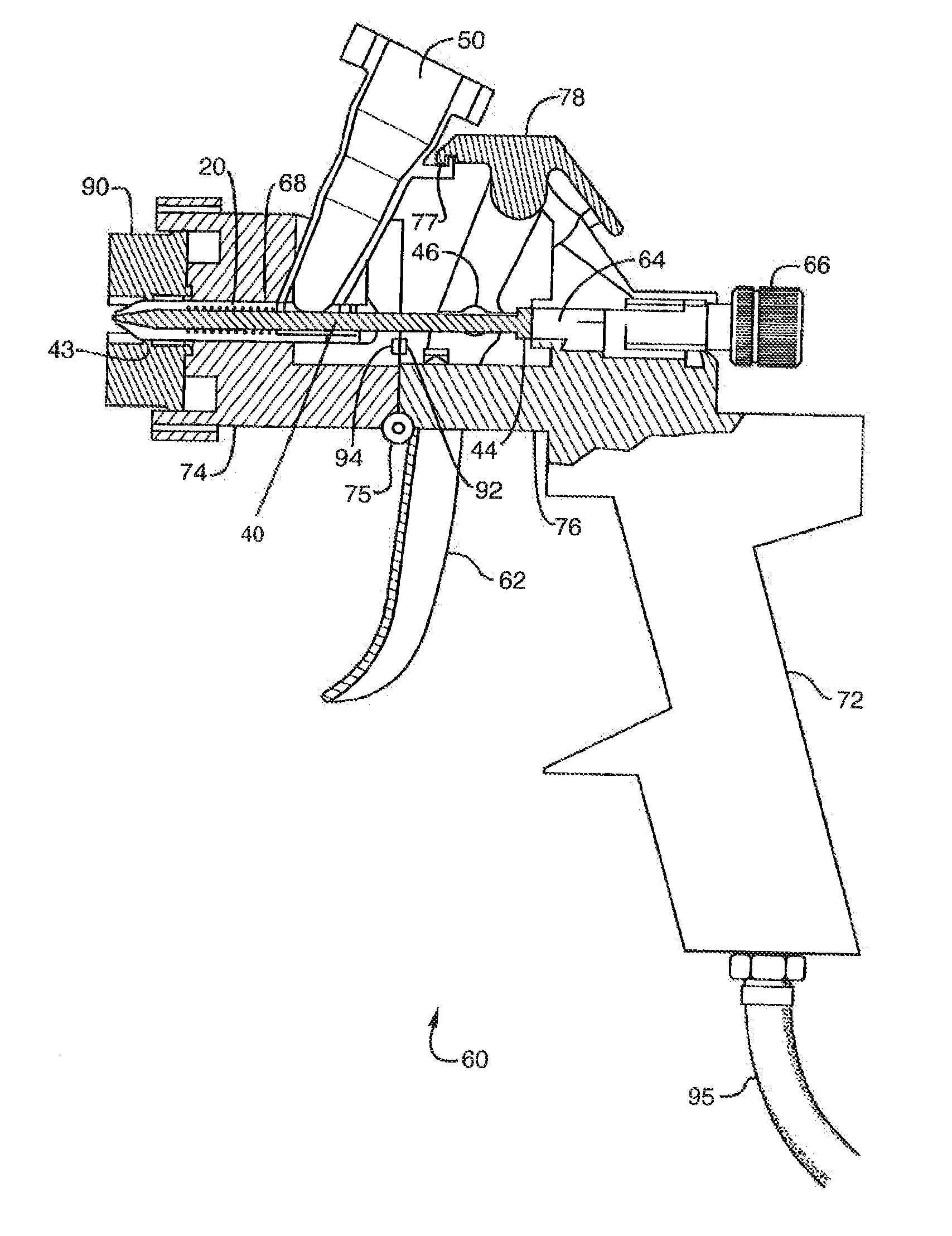

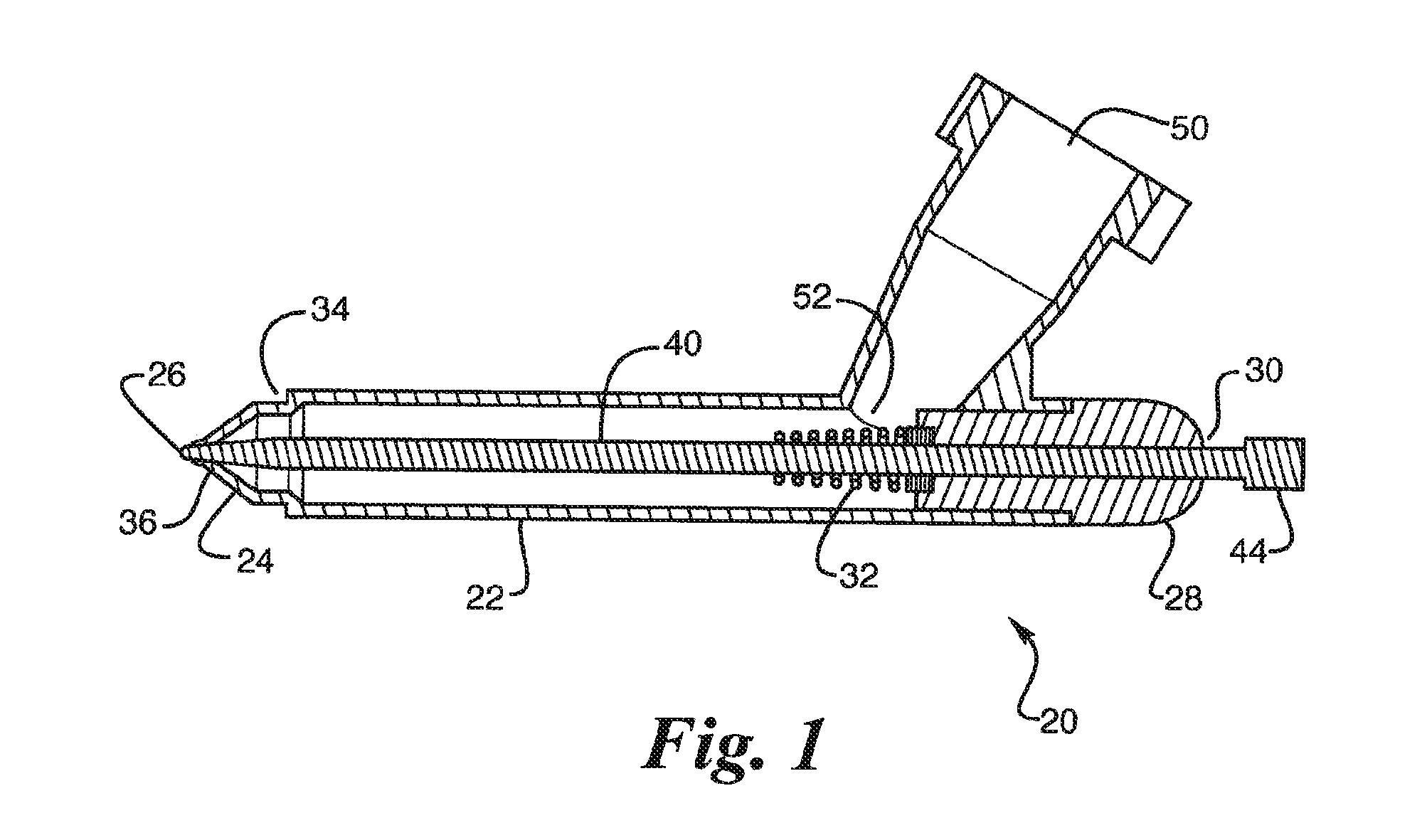

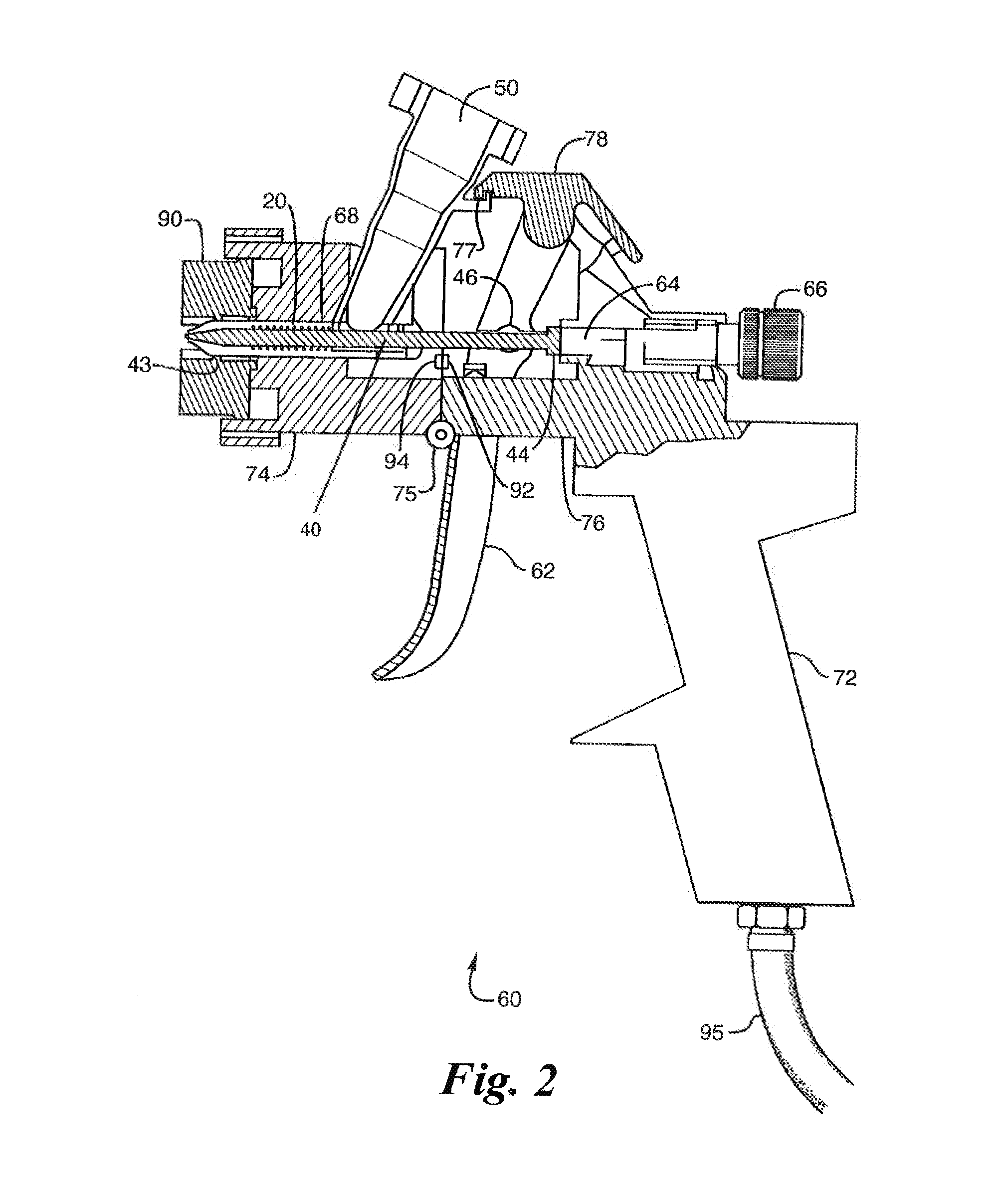

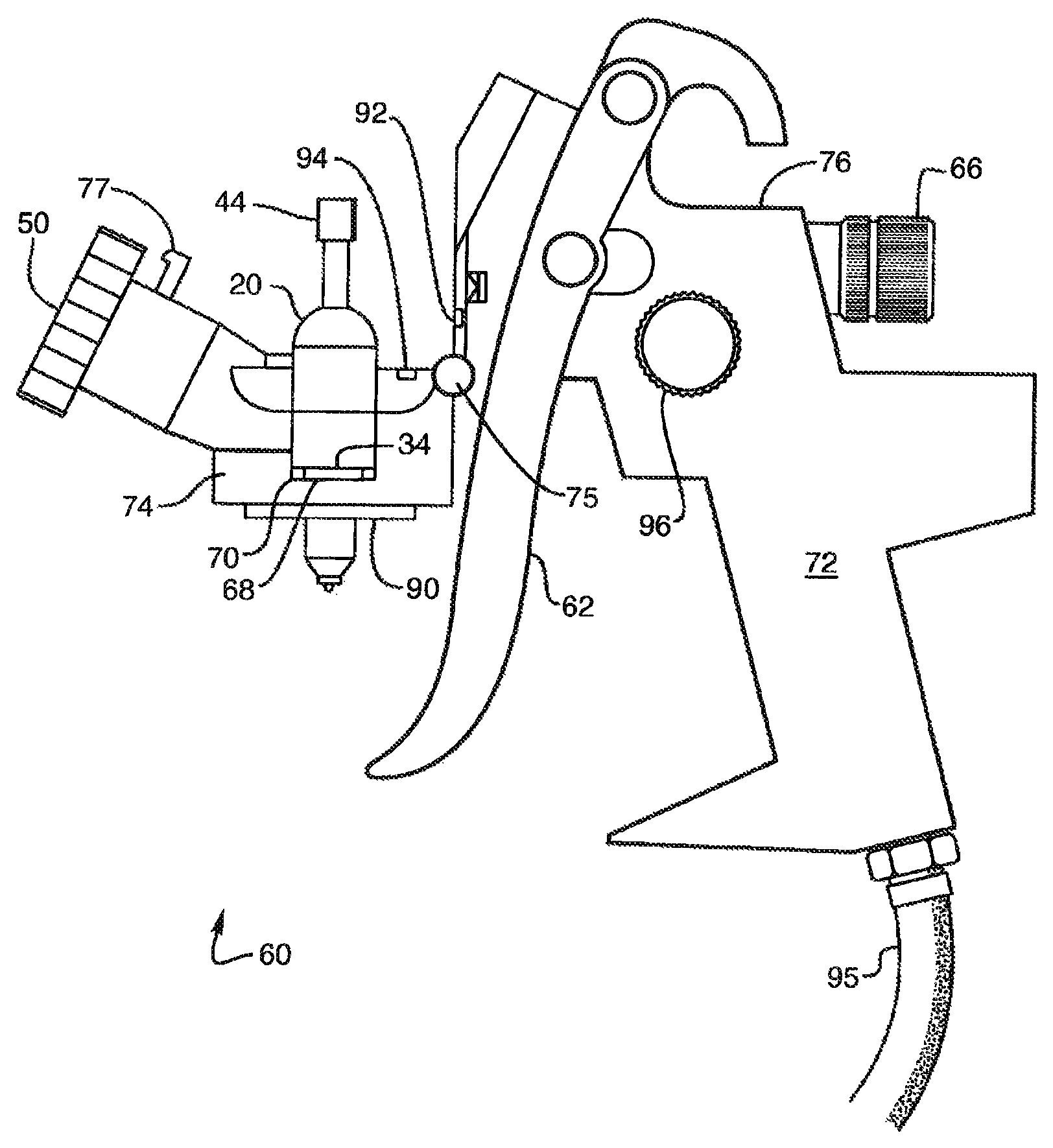

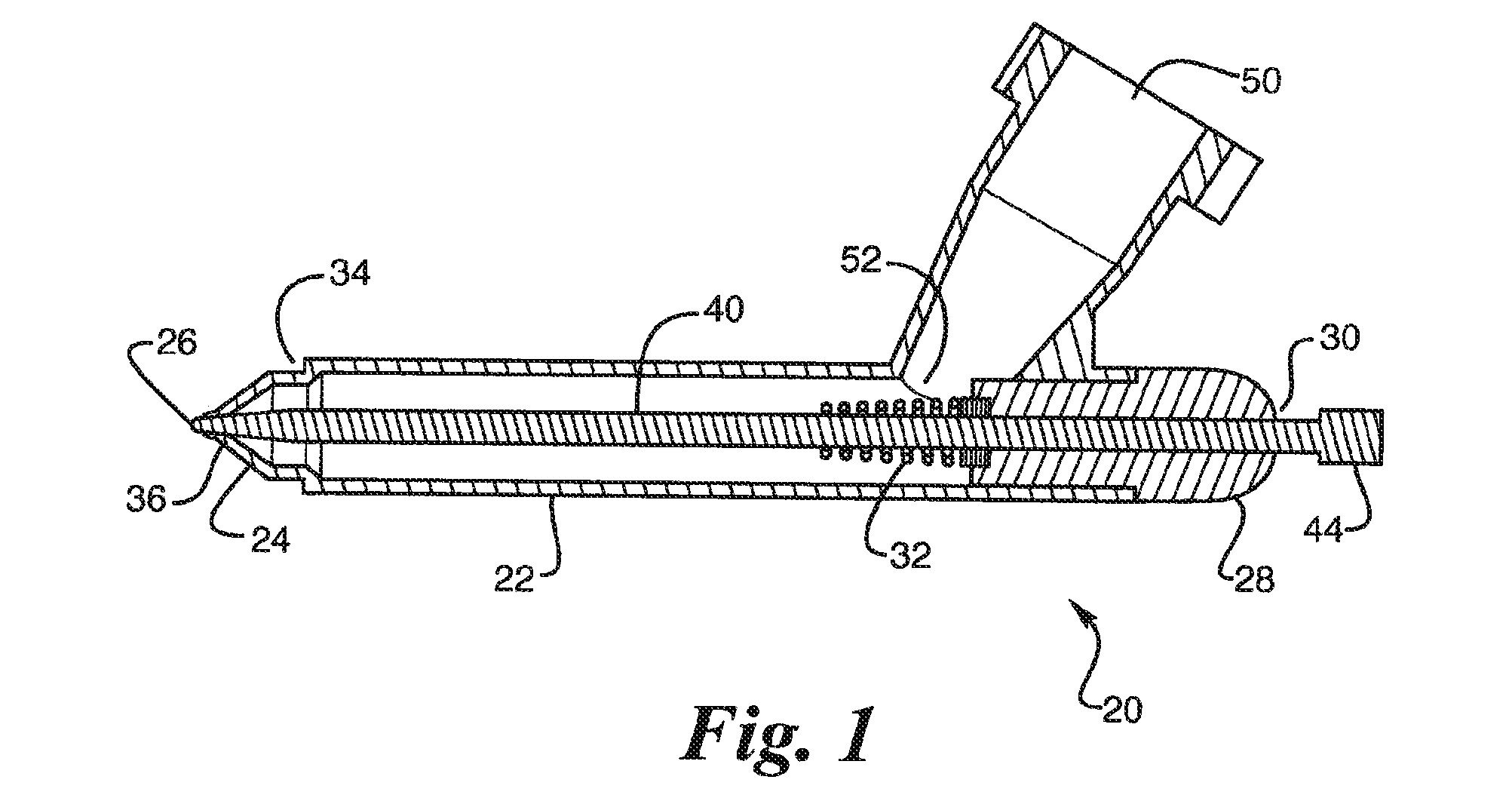

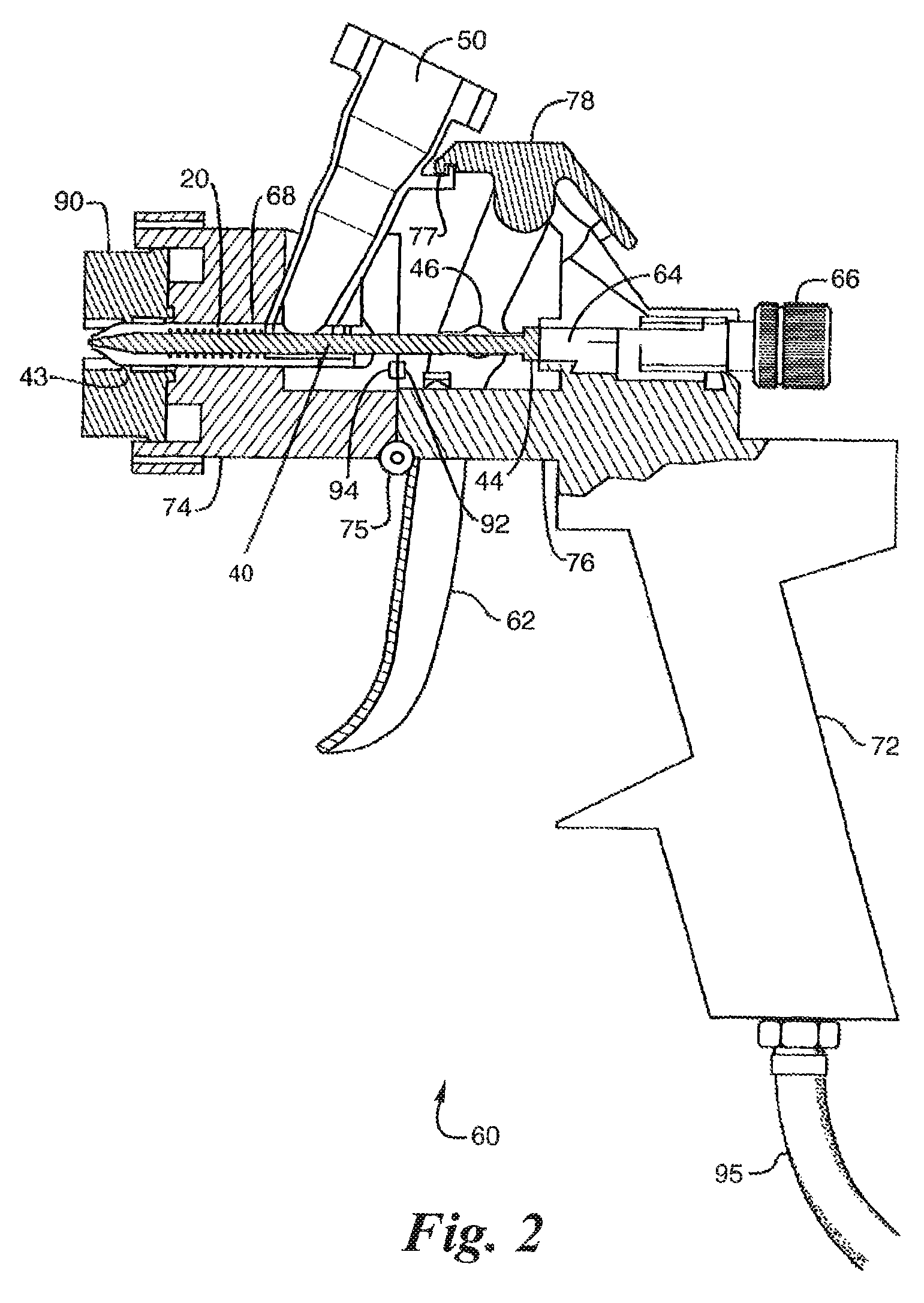

Spray Gun With Paint Cartridge

ActiveUS20110168811A1Reduce downtimeSpray nozzlesLiquid spraying apparatusSpray nozzleMechanical engineering

A spray paint gun having a disposable cartridge inserted therein such that paint can flow through the cartridge in the spray gun without touching the spray gun. Since no part of the spray gun has paint touching it, there is no cleaning of the spray gun or its components. The cartridges can be easily inserted into the spray gun and easily removed such that different color paints can be used in the spray gun in quick succession without down time for cleaning. There is no use of solvents for cleaning, making the cartridge spray gun environmentally friendly. The disposable cartridges eliminate expensive time consuming cleaning. The cartridges can be breach loaded into the front portion of a spray gun and front portion containing the cartridge can quickly snapped into place and ready for use by a hinged connection to the rear portion or by other connection means. The cartridge may include an integrally formed or otherwise attached gasket member to perfect an airtight seal at a joint in the air passage leading from the gun's handle portion to its spray nozzle.

Owner:SATA GMBH & CO KG

Continuous building wall painting device

InactiveCN107288320ASimple structureImprove painting efficiencyBuilding constructionsArchitectural engineeringPiston rod

The invention discloses a continuous building wall painting device. The continuous building wall painting device comprises a transverse plate. A vertical supporting plate, a paint box and a cylinder body are arranged on the transverse plate. Both the upper end and the lower end of the cylinder body communicate with the paint box through feed pipes. Two opposite lifting sliding grooves are further formed in the inner wall of the vertical supporting plate. A moving rod is arranged between the two lifting sliding grooves. The two ends of the moving rod are slidably connected with the lifting sliding grooves. A baffle is arranged on the right side of the moving rod. A mounting frame is arranged at the right end of the baffle. A piston is arranged in the cylinder body. A piston rod is arranged at the upper end of the piston, and the top end of the piston rod is fixedly connected with the baffle. A feed cylinder is mounted on the mounting frame. A painting cylinder is arranged on the outer side wall of the feed cylinder. One end of the feed cylinder is connected with the upper end and the lower end of the cylinder body through discharging pipes. The continuous building wall painting device is simple in structure, capable of achieving continuous spraying and painting, high in painting efficiency, uniform in painting, easy and convenient to operate, and high in practicability.

Owner:吴秀女

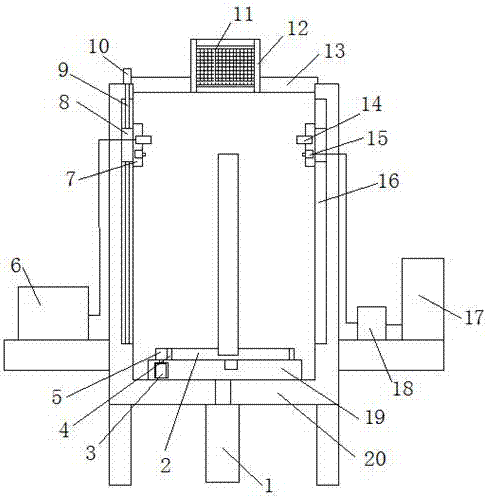

Industrial automation paint line

An industrial automation paint line comprises a conveying chain, an ultrasonic pretreatment production line, a drying room, a spraying room and a curing room; wherein, the conveying chain is hinged with a suspension bracket; the lower part of the suspension bracket is hinged with a C-shaped rack; the lower part of the C-shaped rack is hinged with a suspension balance beam which is provided with a suspension workpiece hole and a hinge hole; a flow equalization tube is fixed on the upper part of the spraying room; a flow equalization filter layer is fixed on the lower part of the flow equalization tube and a viscous flow device is arranged on the lower part of a worktable of the spraying room. A flow equalizing device ensures the spray painting effect free from the influence of uneven wind force; the viscous flow device can effectively treat the waste gas generated in the process of spray painting; the C-shaped rack can effectively prevent the viscous flow from generating. The industrial automation paint line has high degree of automation and shortens the running-in period in use of the system.

Owner:ZHEJIANG MINGQUAN INDAL COATING

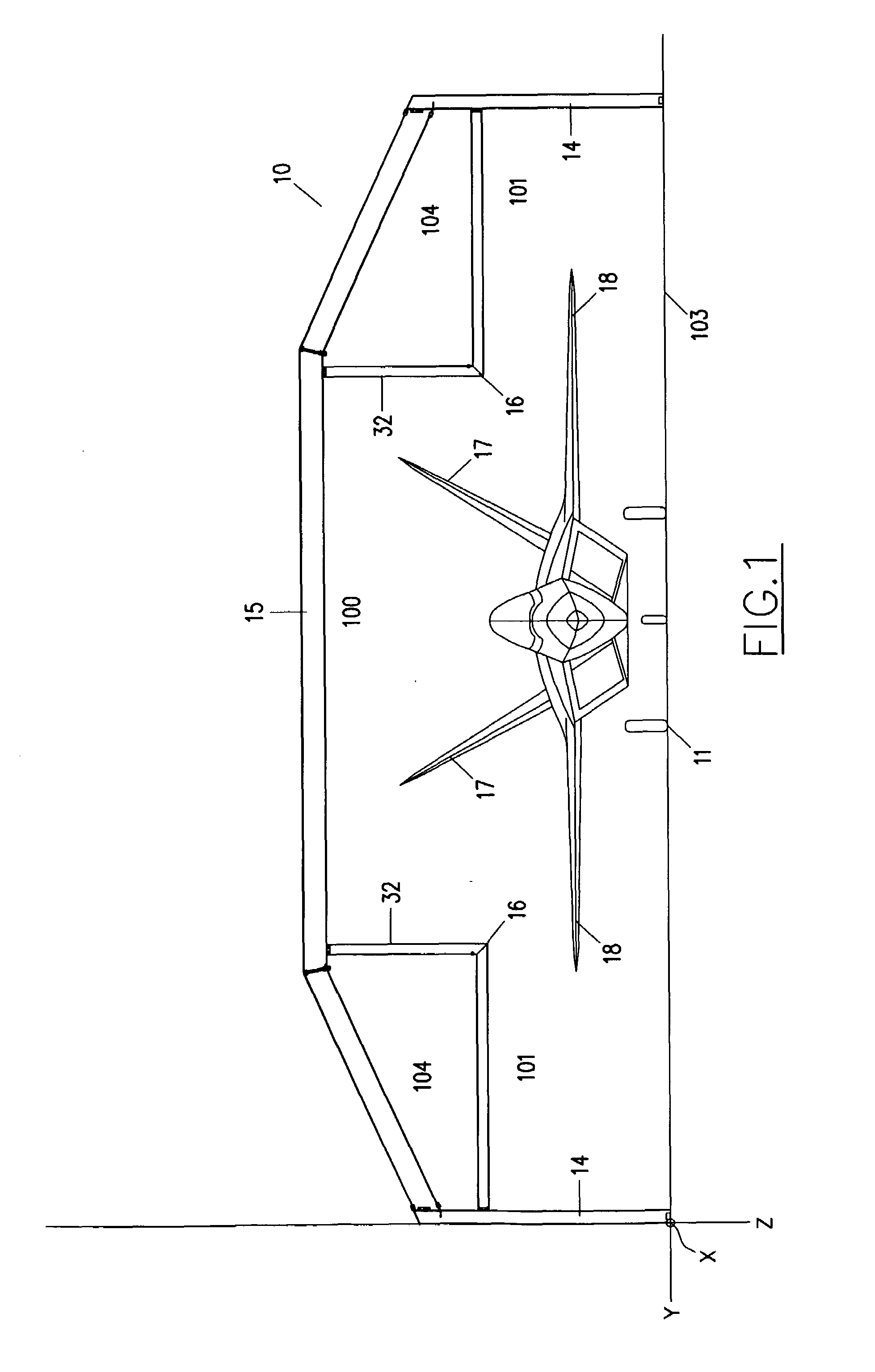

Paint booth arrangement and method for directing airflow

ActiveUS7666077B1High degree of structural strengthSmall additional costDucting arrangementsLiquid surface applicatorsAirflowEngineering

A paint booth arrangement maximizes floor space and efficiency of a painting operation. The arrangement comprises an equipment enclosing structure and certain air handling equipment specifically configured within the structure. The structure comprises forward and rearward sections, opposed wall sections, a centralized roof section, and opposed wall-to-roof sections, which sections define open space having varied elevation for receiving paintable equipment. The air handling equipment comprises an air intake and exhaust assemblies and an air replacement system. The air intake and exhaust assemblies extend coextensively intermediate the wall sections at the rearward section and function to support portions of the air replacement system. The air replacement system comprises conduit extending intermediate the forward and rearward sections as defined by the wall-to-roof sections. The air intake assembly communicates with the conduit for directing inlet airflow to the open space, and the air exhaust assembly comprises exhausts airflow from the open space.

Owner:GLOBAL FINISHING SOLUTIONS

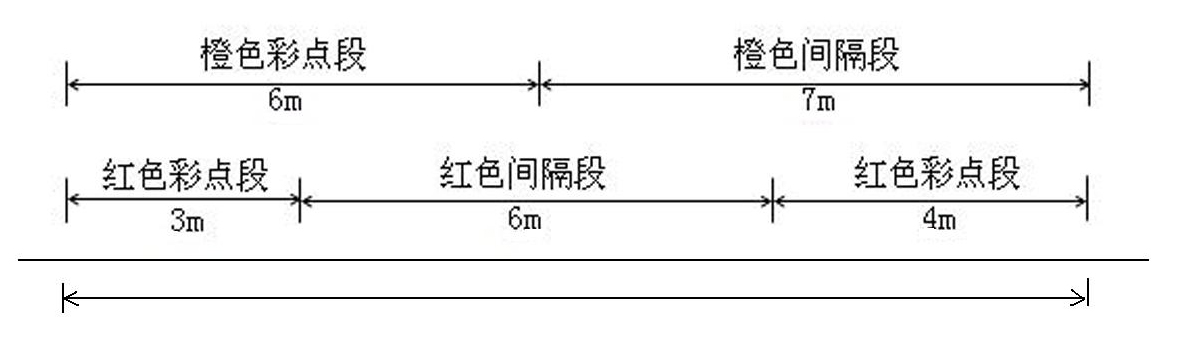

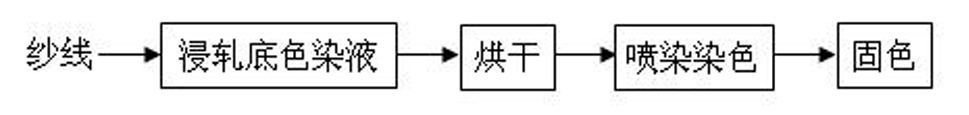

Production method of speck yarn

ActiveCN102011278ANot easy to fall offIncrease productivityTextile treatment with treating outlet contectLiquid/gas/vapor yarns/filaments treatmentYarnEngineering

The invention relates to a production method of speck yarn. The production method contains a speck machining process and the machining process contains a process that a plurality of parallel yarns pass through at least one nozzle in a progressive manner in turn; during the process, the nozzle sprays a staining solution to the yarns intermittently; in the spraying process of the nozzle, the spray-painting of at least one color is realized by controlling the color and concentration of the staining solution sprayed by each nozzle, the advancing lengths of the yarns under the spraying state and intermittent state relatively to each nozzle are controlled respectively to limit the speck section lengths sprayed by the corresponding nozzles and the intermittent section lengths on the yarns; and by controlling the ratio of the frequency of the back and forth movement of each nozzle to the advancing speed of the yarns respectively, the density of the specks sprayed by the nozzles on the yarns can be limited. The specks of the speck yarn prepared by the method in the invention are difficult to fade. In addition, the dyeing of the specks and the dyeing of the bottom color can be performed continuously, thus the cost is low and the comprehensive benefit is good.

Owner:ZHANGJIAGNAG SUNDELI DYEING & FINISHING

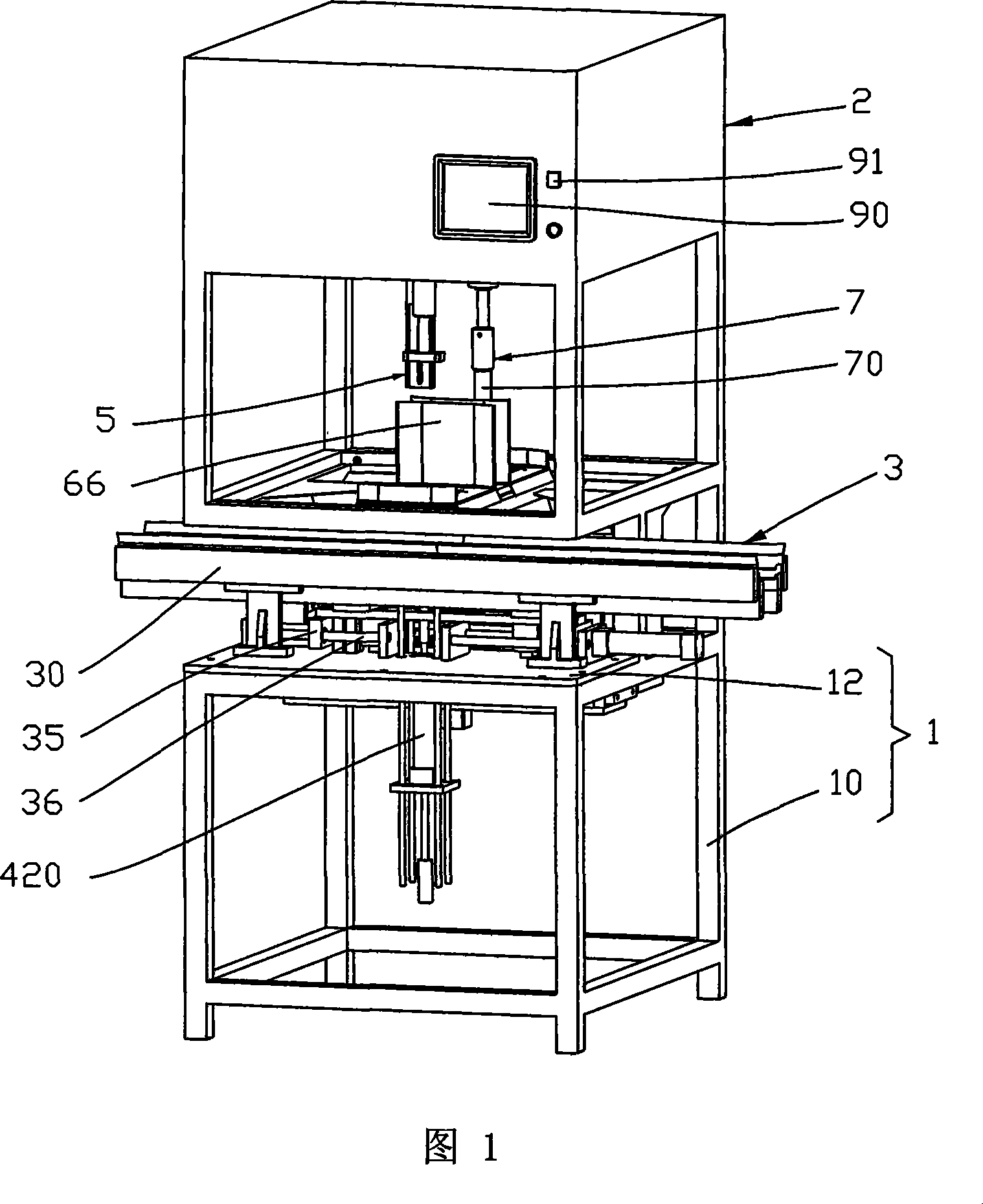

Spray painting machine

InactiveCN105435989AEnables simultaneous rotary spraying operationsMass production spraying effect is goodSpraying apparatusRotation functionEngineering

The invention discloses a spray painting machine. The spray painting machine comprises a spray gun, a machine frame, a control console arranged on the machine frame, and a horizontal electric box located below the control console. The spray painting machine further comprises a synchronous rotary table and a five-axis mechanism, wherein the synchronous rotary table is arranged on the control console, and a plurality of workpieces can be mounted on the synchronous rotary table at the same time; the five-axis mechanism is mounted at the top end of the machine frame and drives the spray gun. The five-axis mechanism comprises a Z-axis linear sliding table driving the spray gun to move up and down, an X-axis linear sliding table driving the Z-axis linear sliding table to move left and right, a Y-axis linear sliding table driving the X-axis linear sliding table to move front and back, a W-axis rotating mechanism and a P-axis rotating mechanism, wherein the W-axis rotating mechanism and the P-axis rotating mechanism are mounted on the Z-axis linear sliding table and drive the spray gun to rotate. According to the spray painting machine, the Z-axis linear sliding table and the station rotary table are innovated and improved, so that the spray gun has the two-direction rotating function, all the workpieces have the consistent rotating angle, the automation degree is improved, product surface quality and product consistency are improved, and synchronous rotating spray painting of the multiple workpieces is achieved.

Owner:SHENZHEN MATSUZAKL ROBOT AUTOMATION EQUIP CO LTD

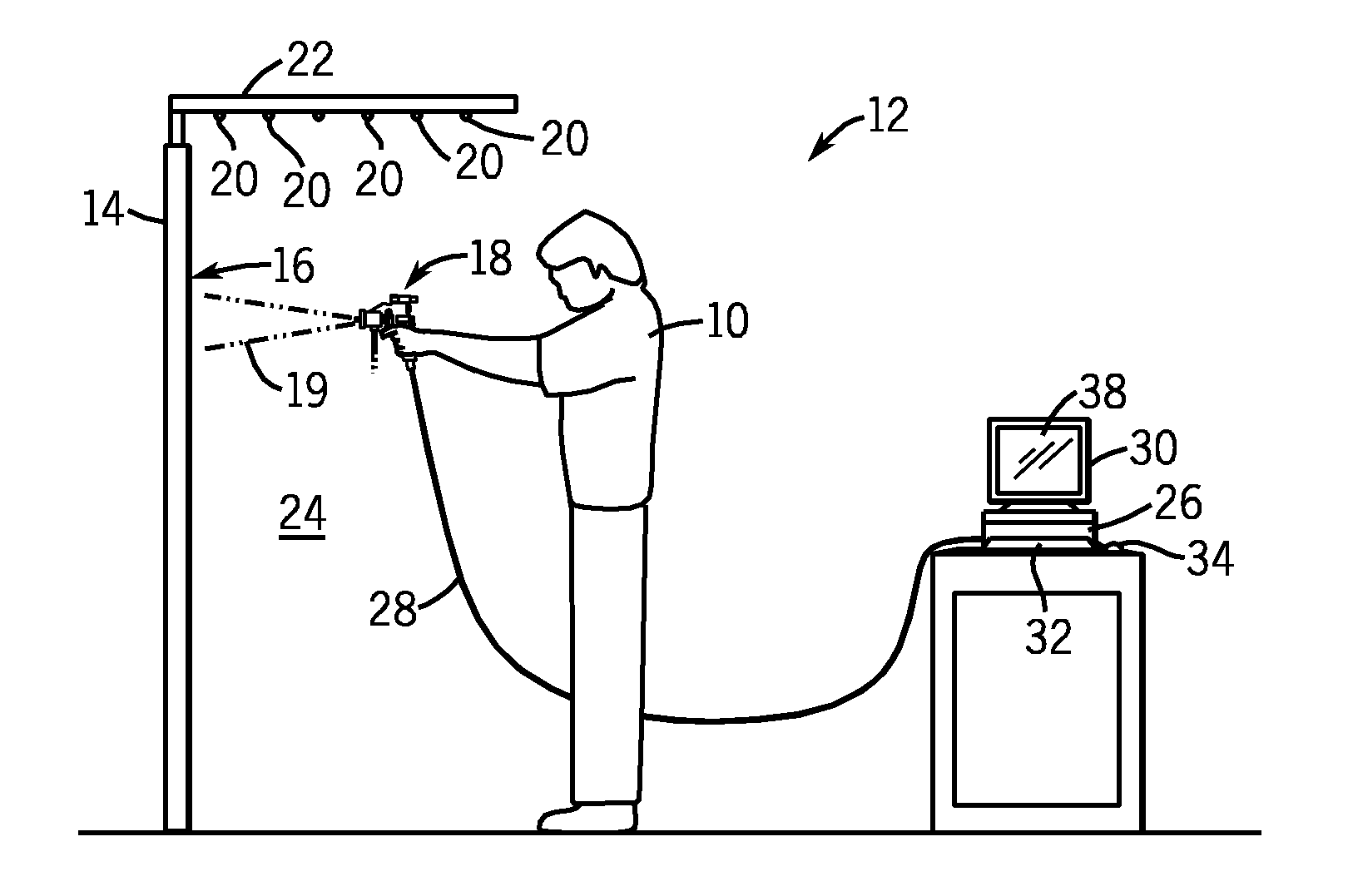

Virtual coatings application system

InactiveUS7839417B2Improve realismEnhance three-dimensional natureProgramme controlLiquid surface applicatorsSimulationMotion tracking system

A virtual coatings application system has several features to enhance the realism of simulated spray painting. The system generally includes a display screen on which is defined a virtual surface (such as a truck door) that is intended to be virtually painted or coated by the user. Alternatively, the system includes a head-mounted display unit that displays a virtual spray painting environment in which the virtual surface is defined. The user operates an instrumented spray gun controller that outputs one or more signals representing data as to the status of the controls on the spray gun controller. The system also has a motion tracking system that tracks the position and orientation of the spray gun controller with respect to the virtual surface. Simulation software generates virtual spray pattern data in response to at least the data from the spray gun controller and the position and orientation data received from the tracking system. Virtual spray pattern images are displayed in real time on the virtual surface in accordance with the accumulation of virtual spray pattern data at each location on the virtual surface.

Owner:UNIV OF NORTHERN IOWA RES FOUND

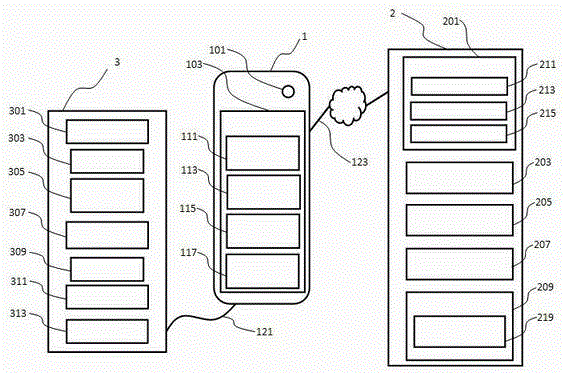

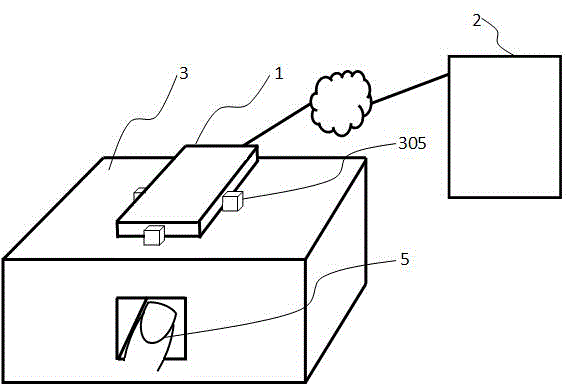

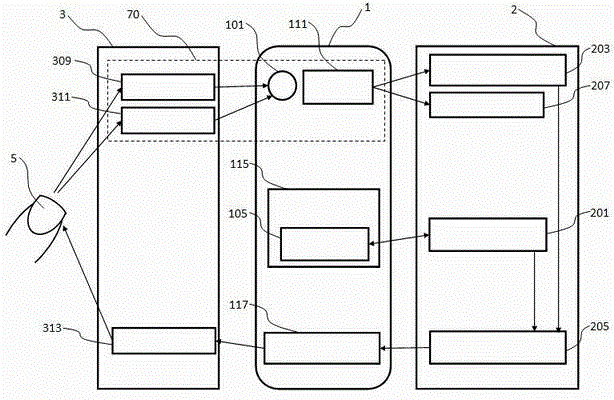

Manicure device and manicure, health management and information pushing method

PendingCN104382327ALow costEasy to implementProgramme controlPackaging toiletriesComputer moduleThe Internet

The invention relates to a manicure device and a manicure, health management and information pushing method based on the manicure device. The manicure device comprises at least one intelligent terminal equipment, at least one measuring and spray painting device, and at least one server end arranged on the Internet. At least one manicure application module is installed in each intelligent terminal equipment. Each manicure application module can be connected with the corresponding server end and controls the corresponding spray painting device to complete fingernail spray painting. Each manicure application module can judge the health condition of a user according to the fingernail information of the user. Each manicure application module can perform big data analysis on the user and pushes information to the user.

Owner:NANJING MEIXIAOJIA TECH CO LTD

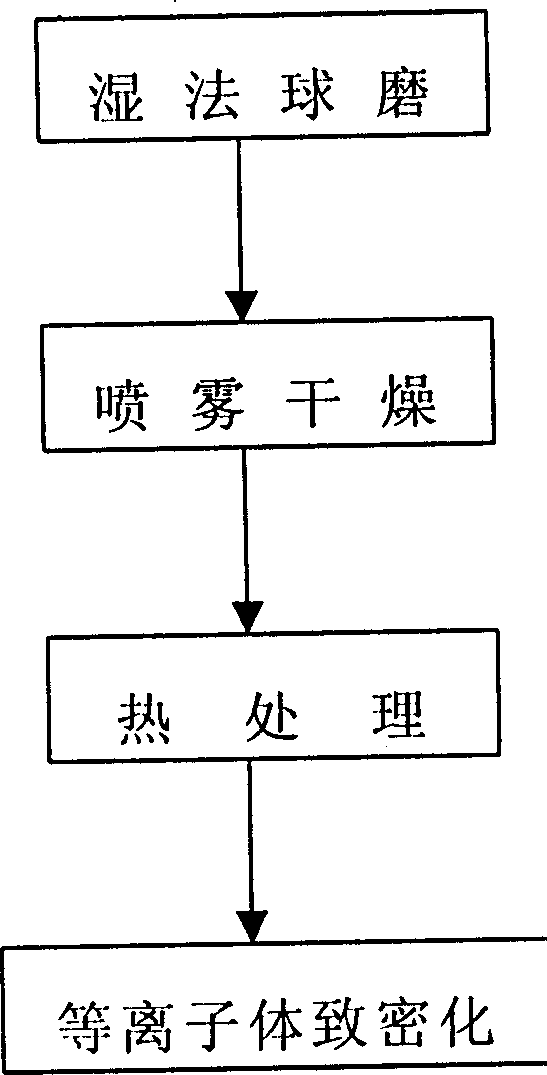

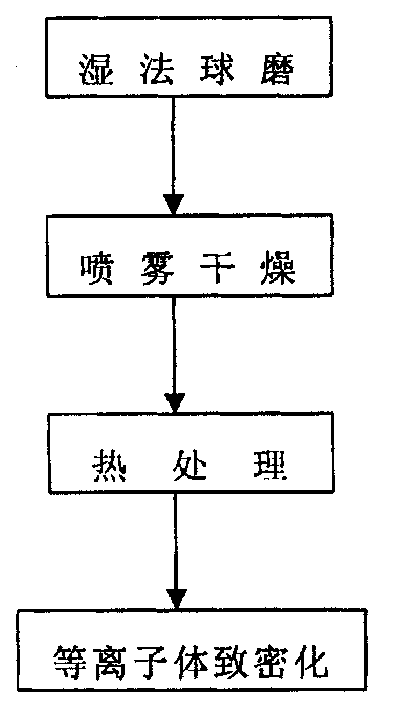

Method for producing and using large particle ball nano ceramic powder

InactiveCN1377857AUniform tissue structureImprove performanceCeramic layered productsThermal sprayingHigh density

The production process of nano ceramic powder includes the steps of: wet ball milling to obtain water-thinned nano colloid; spray drying to obtain large particle spheircal nano ceramic powder; heat treatment; and plasma densifying the large particle spherical nano ceramic powder after being heat treated. The nano ceramic powder thus produced has good flowability and high density and may be used through hot spray painting and sintering to form. The present invention reduce fragility of ceramic and raise the performance of hot spray painted and sintered ceramic products.

Owner:BAIFURUI MATERIAL HUNAN

Spray coating-free propene polymer (PP) material with high gloss and metal or pearly-lustre flashing effect and preparation method thereof

The invention provides a spray coating-free propene polymer (PP) material with high gloss and a metal or pearly-lustre flashing effect. The material consists of the following substances by weight percent: 97-99% of PP, 0.1-0.3% of antioxidant 168, 0.1-0.5% of antioxidant 1010, 0.1-1% of lubricating dispersing agent TAF and 0.3-1.5% of effect pigment. The invention further provides a method for preparing the PP material. The PP material has the advantages that the PP material can be directly injected without spray coating, so that high gloss, pearly-lustre flashing and a metal painting effect can be obtained, and the PP material is attractive in appearance; compared with a painting technology, the cost is saved, and the depainting problem during the use process of a produce is avoided; and through the coordination of a highlight mirror plane die and high die temperature forming conditions, the problems of the welding lines and flow lines of the product can also be solved, and the spray coating is really not needed, so that the PP material has a wide application prospect in the fields of household appliances, automobiles, sports goods and the like.

Owner:上海日之升科技有限公司

Automatic paint spraying device for metal castings

PendingCN107214035AEasy to installEasy to unloadLiquid surface applicatorsLiquid spraying apparatusPiston rodSpray painting

The invention discloses an automatic paint spraying device for metal castings. The automatic paint spraying device comprises a paint spraying barrel with an opening in the top end. Support columns are correspondingly mounted on the four corners of the bottom end of the paint spraying barrel. An air cylinder vertically arranged is fixedly arranged on the side wall of the bottom end of the paint spraying barrel through bolts. A movable plate is welded to a piston rod of the air cylinder. The movable plate is located on the inner wall of the bottom end of the paint spraying barrel. The top end of the movable plate is rotationally connected with a mounting plate horizontally arranged. A first electric motor is embedded into the movable plate. An output shaft of the first electric motor is connected with a gear. The gear is located on one side of the mounting plate. Tooth mouths distributed in an array manner are mounted on the side walls of the periphery of the mounting plate. The tooth mouths are engaged with the gear. A fixing ring is slidably connected into the paint spraying barrel. An annular air outlet pipe and a liquid spraying pipe are mounted on the inner wall of the fixing ring. The air outlet pipe is located above the liquid spraying pipe. By the adoption of the automatic paint spraying device, the multi-angle paint spraying of the metal castings can be achieved, the paint spraying effect is good, the quick mounting and discharging of the metal castings are achieved, and the air pollution is reduced.

Owner:JIANGSU SUGAO FLUID MACHINERY

Spray gun with paint cartridge

A spray paint gun having a disposable cartridge inserted therein such that paint can flow through the cartridge in the spray gun without touching the spray gun. Since no part of the spray gun has paint touching it, there is no cleaning of the spray gun or its components. The cartridges can be easily inserted into the spray gun and easily removed such that different color paints can be used in the spray gun in quick succession without down time for cleaning. There is no use of solvents for cleaning, making the cartridge spray gun environmentally friendly. The disposable cartridges eliminate expensive time consuming cleaning. The cartridges can be breach loaded into the front portion of a spray gun and front portion containing the cartridge can quickly snapped into place and ready for use by a hinged connection to the rear portion or by other connection means. The cartridge may include an integrally formed or otherwise attached gasket member to perfect an airtight seal at a joint in the air passage leading from the gun's handle portion to its spray nozzle.

Owner:SATA GMBH & CO KG

Release control fertilizer and method for producing same

InactiveCN1666971AReduce degradationEasy to fixAgriculture gas emission reductionFertilizer mixturesAcrylic resinNitrification inhibitors

This invention relates to controlled release fertilizer, to be specific, it is a control efficiency fertilizer and its manufacturing technique. The control efficiency fertilizer is composed by capsule and fertilizer core, the core is nitrogen compound fertilizer with nitrification inhibitor, the capsule is acrylic resin or compound of acrylic resin and ethyl cellulose. The core is produced by blending comminution granulation; fluidized bed spray painting is used on capsule technique. Acrylic resin or compound of acrylic resin and ethyl cellulose is dissolved in ethanol solution. Inorganic membrane amendment and plasticizer are added to the solution, then fluidized state capsule surface is sprayed coated to form smoothing, continuous, uniform capsule. It can control nutrition release and transformation of fertilizer nitrogen efficiently, greatly evaluate the availability of azophoska, and the manufacturing cost is below high molecular polymer capsule compounding fertilizer which has equal fertilizer efficiency.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

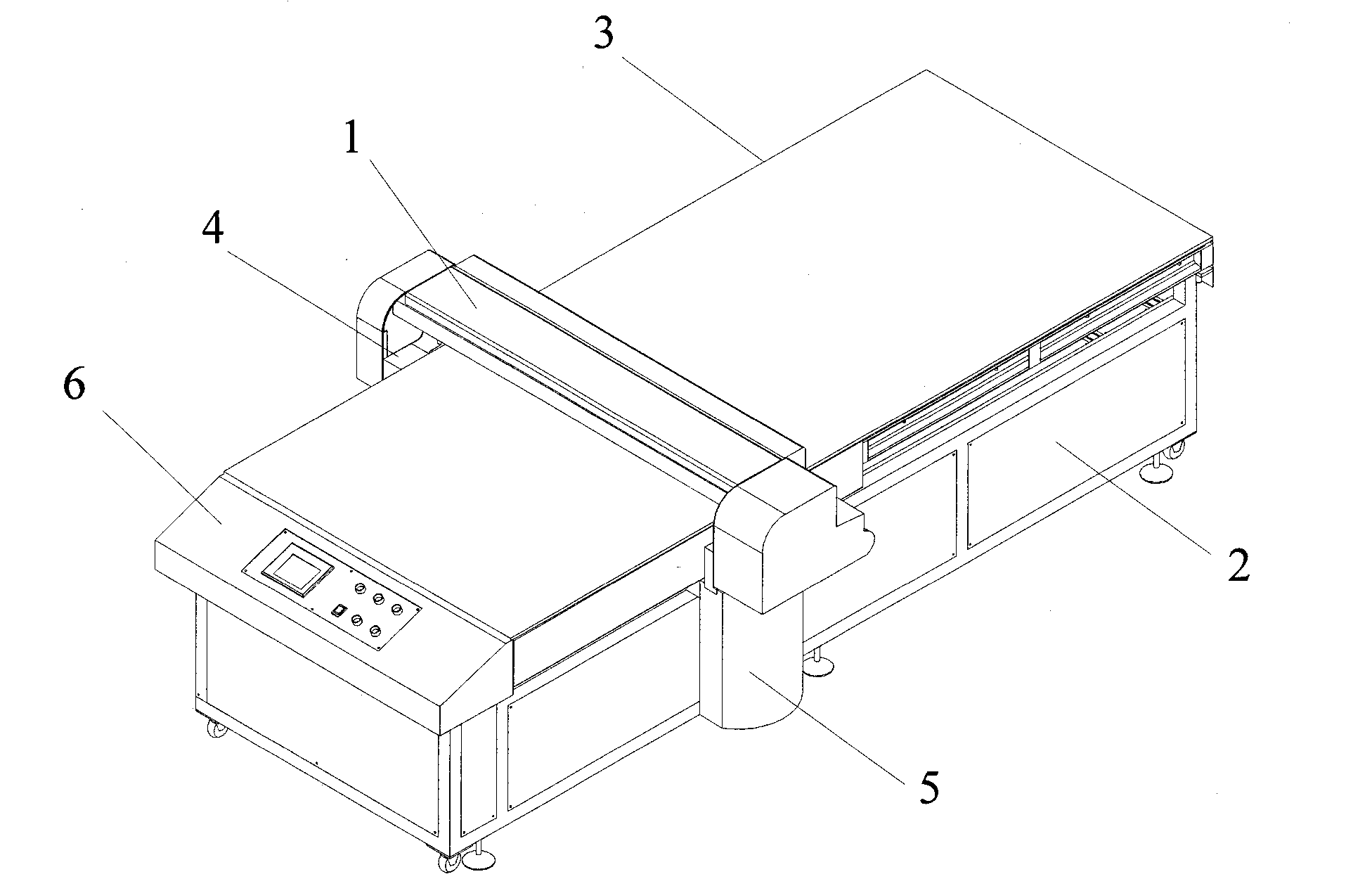

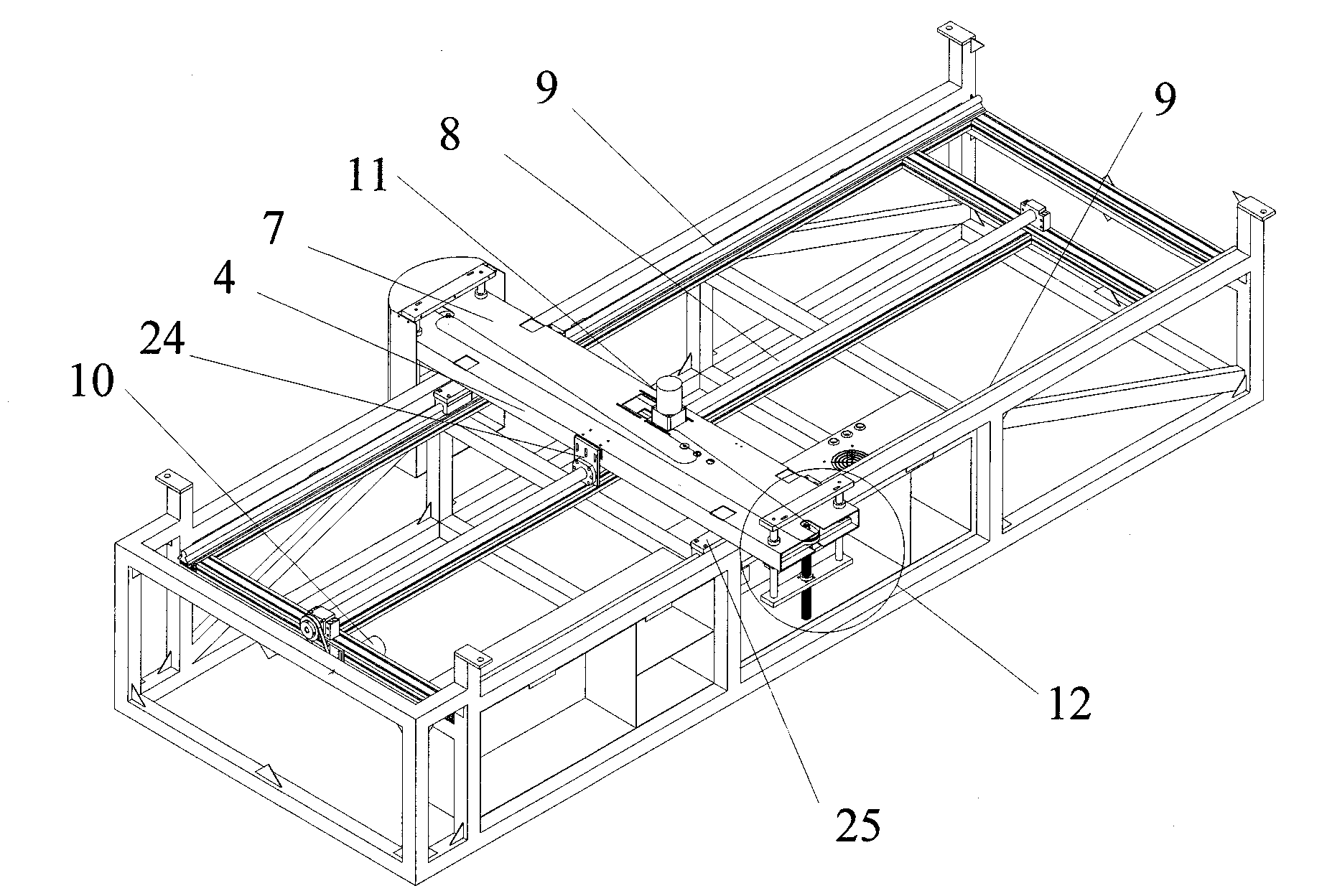

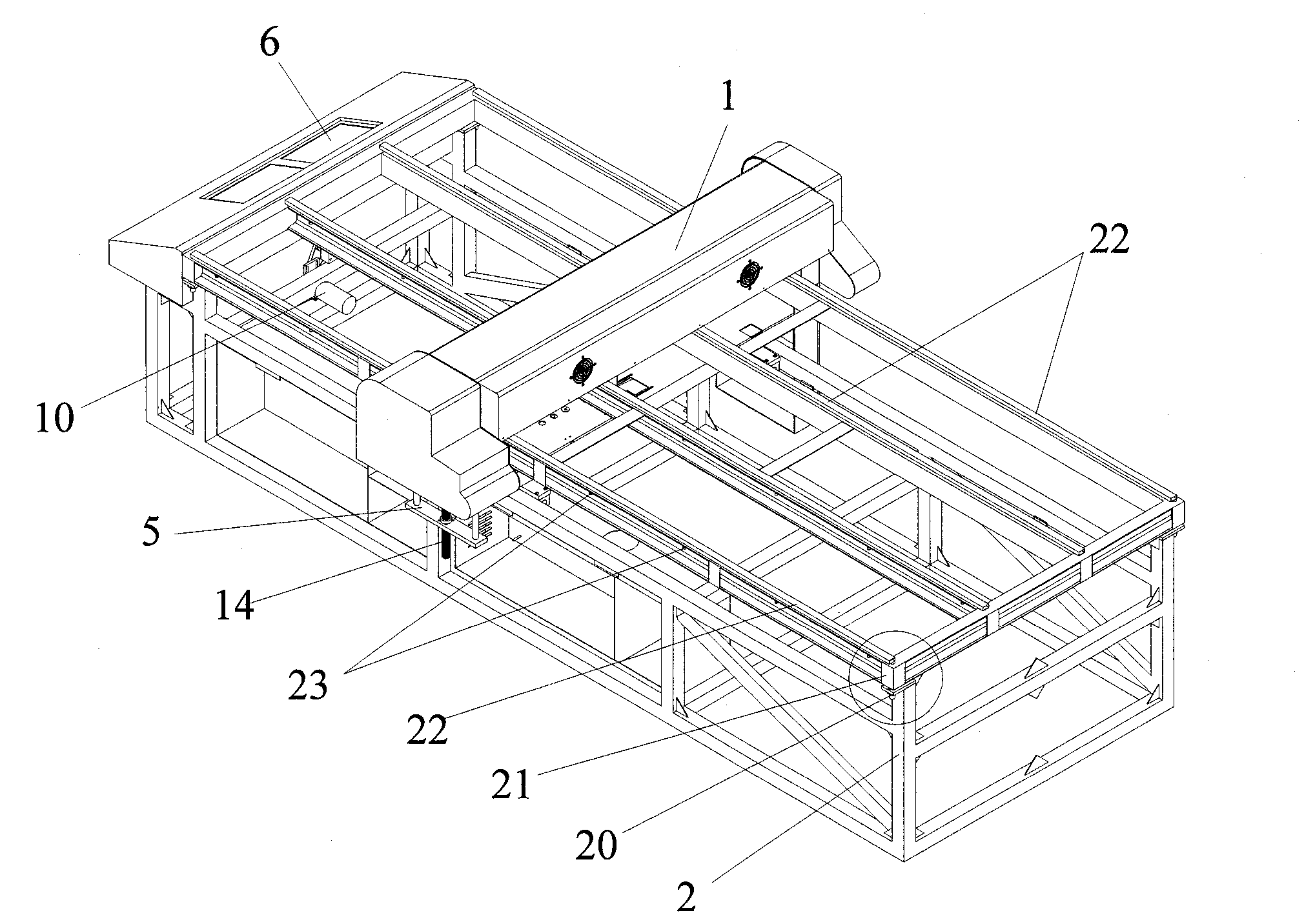

Large-size platform type digital colored printer

Owner:DONGGUAN XIANGYU DIGITAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com