Patents

Literature

243results about "Textile treatment with treating outlet contect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

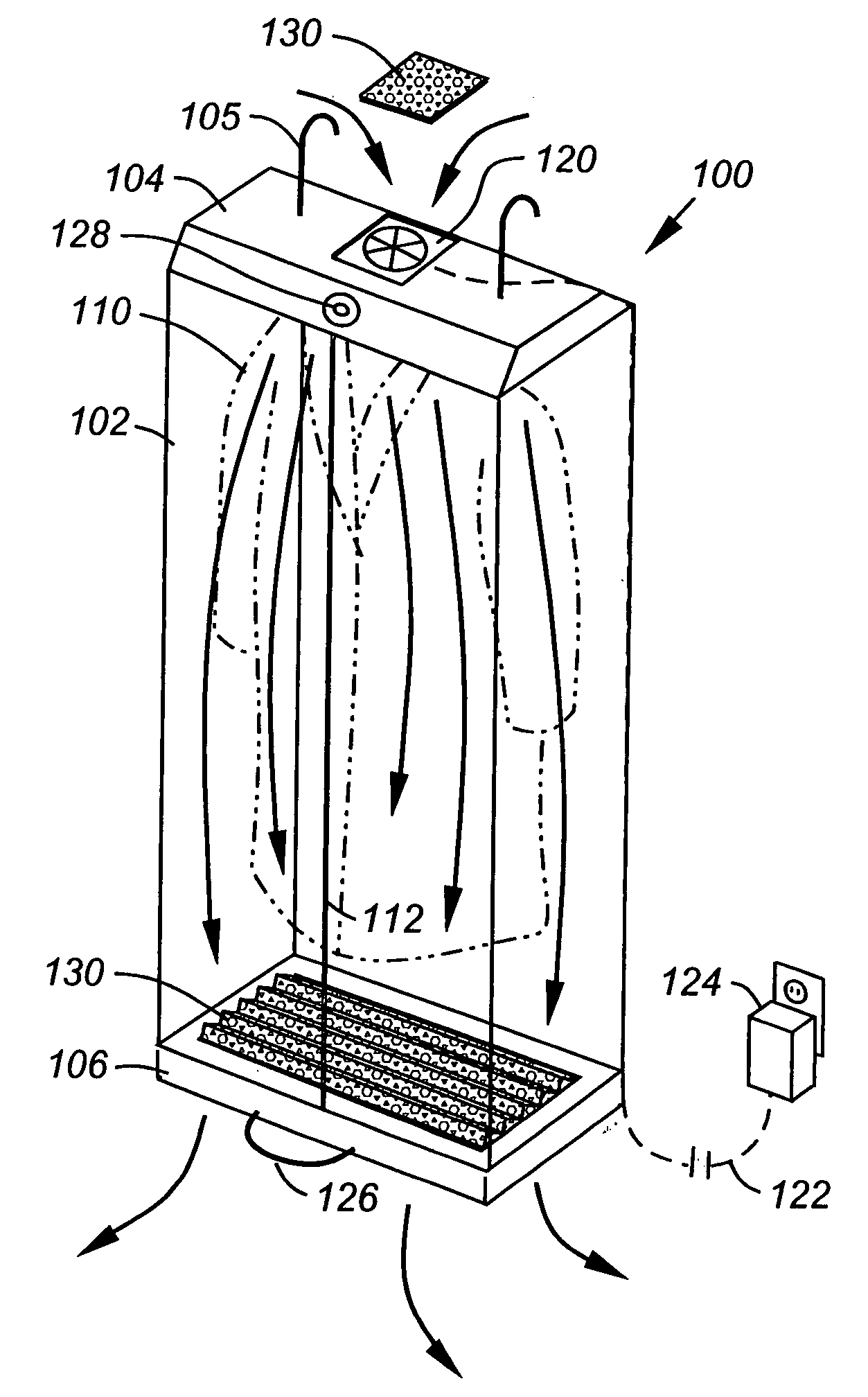

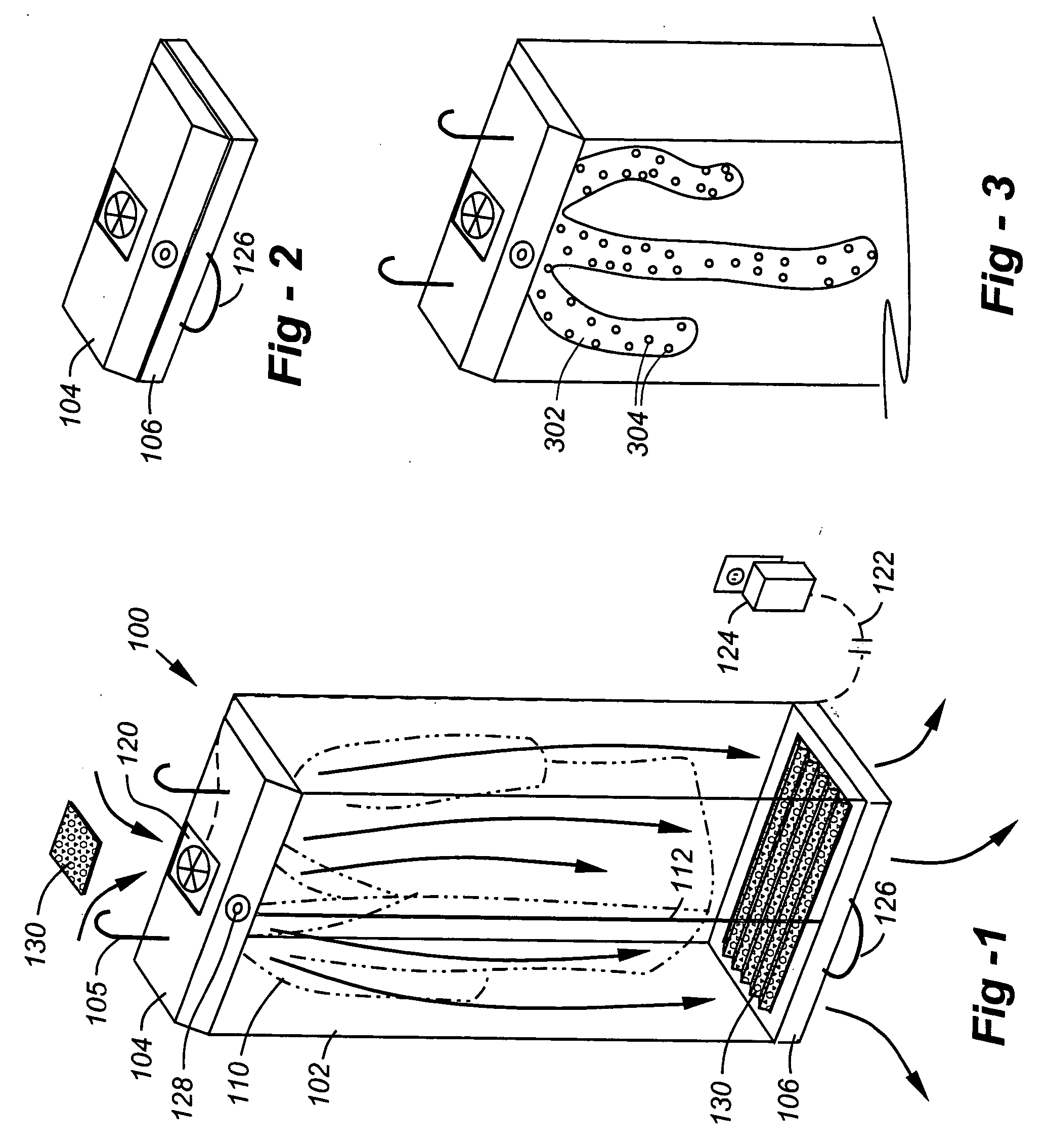

Garment refreshing apparatus and method

InactiveUS20050120757A1Easy to useHand rubbing apparatusTextile treatment machine partsLow voltageEngineering

A garment refreshing system includes an enclosure having a top, a bottom, a sidewall, an air inlet and an air outlet, and a hook or other element on the top to facilitate hanging in a closet or other location. An electrical fan at the air inlet is operative to bring air into the enclosure and past the clothing to the air outlet, and a filter supported at the air outlet for collecting odors removed from the clothing: The preferred configuration further includes a support within the enclosure to receive clothing on hangers, and the sidewall includes a closable opening to place clothing into, and remove clothing from the enclosure. The use of a low-voltage D.C. fan, such as a 12-VDC fan, facilitates use in a vehicle. As a further option, a material associated with the air inlet to introduce a deodorizer or fragrance into the enclosure. For example, an absorbent material may be provided to receive a deodorizer or fragrance in liquid form.

Owner:JACKSON W SHAUN

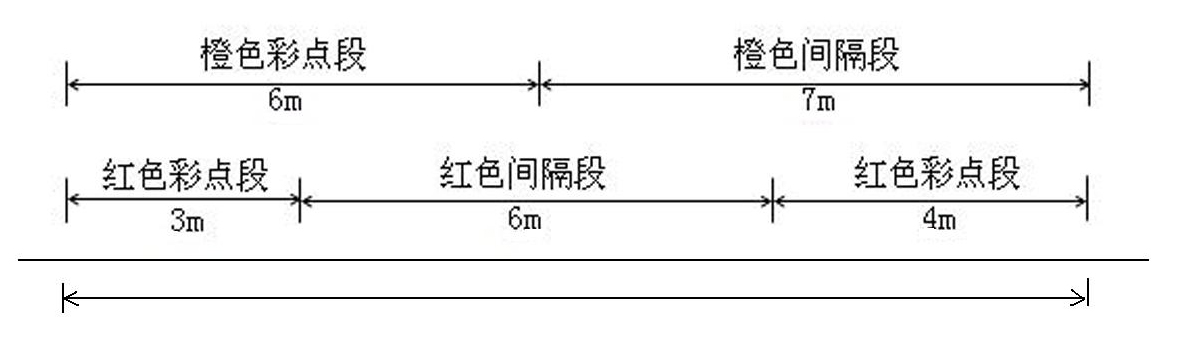

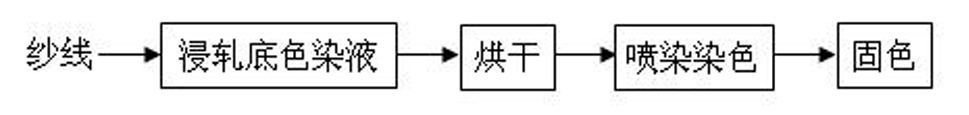

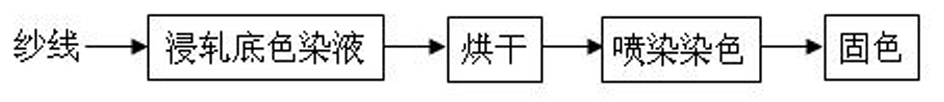

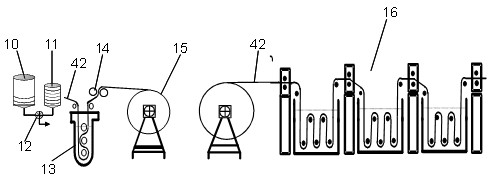

Production method of speck yarn

ActiveCN102011278ANot easy to fall offIncrease productivityTextile treatment with treating outlet contectLiquid/gas/vapor yarns/filaments treatmentYarnEngineering

The invention relates to a production method of speck yarn. The production method contains a speck machining process and the machining process contains a process that a plurality of parallel yarns pass through at least one nozzle in a progressive manner in turn; during the process, the nozzle sprays a staining solution to the yarns intermittently; in the spraying process of the nozzle, the spray-painting of at least one color is realized by controlling the color and concentration of the staining solution sprayed by each nozzle, the advancing lengths of the yarns under the spraying state and intermittent state relatively to each nozzle are controlled respectively to limit the speck section lengths sprayed by the corresponding nozzles and the intermittent section lengths on the yarns; and by controlling the ratio of the frequency of the back and forth movement of each nozzle to the advancing speed of the yarns respectively, the density of the specks sprayed by the nozzles on the yarns can be limited. The specks of the speck yarn prepared by the method in the invention are difficult to fade. In addition, the dyeing of the specks and the dyeing of the bottom color can be performed continuously, thus the cost is low and the comprehensive benefit is good.

Owner:ZHANGJIAGNAG SUNDELI DYEING & FINISHING

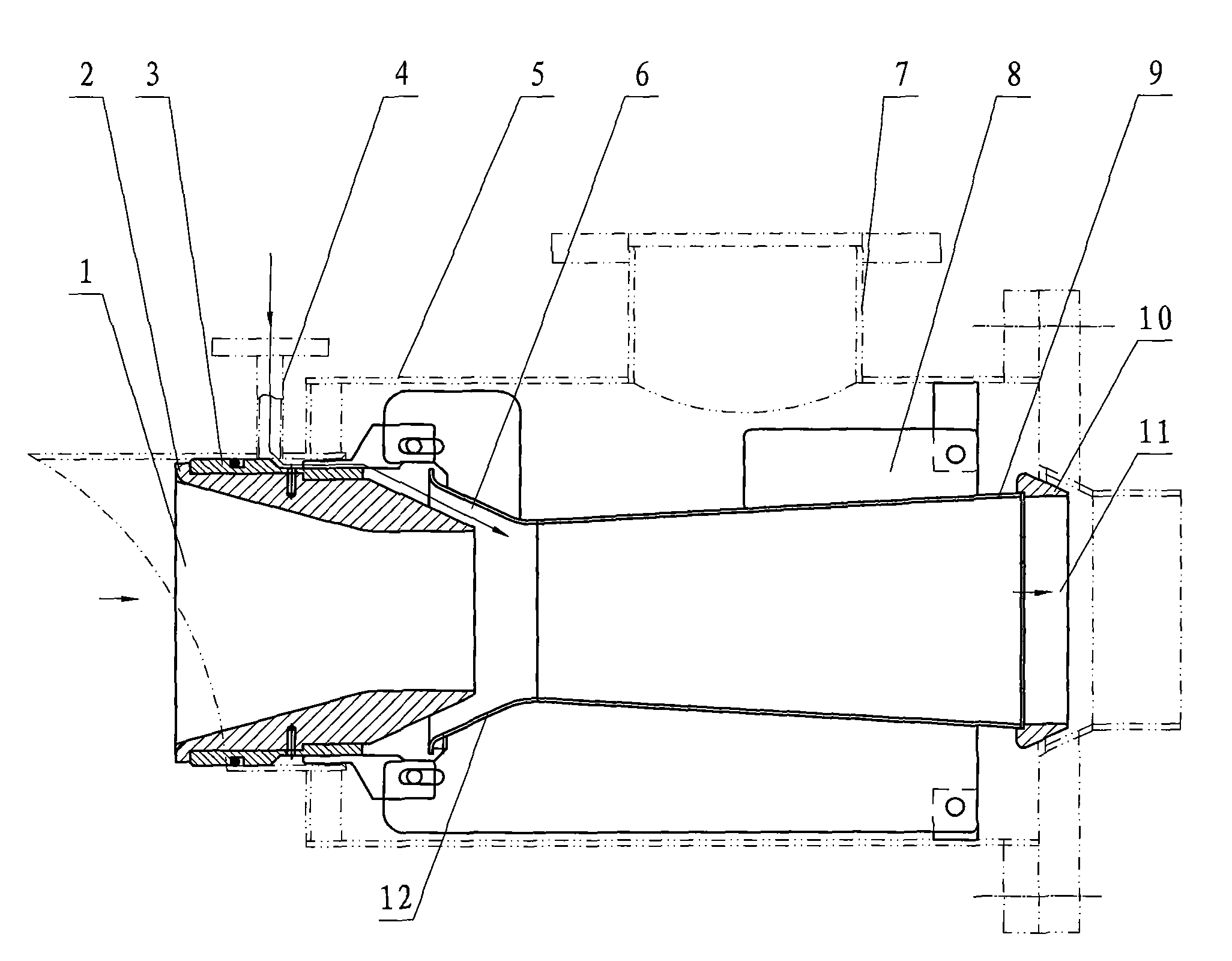

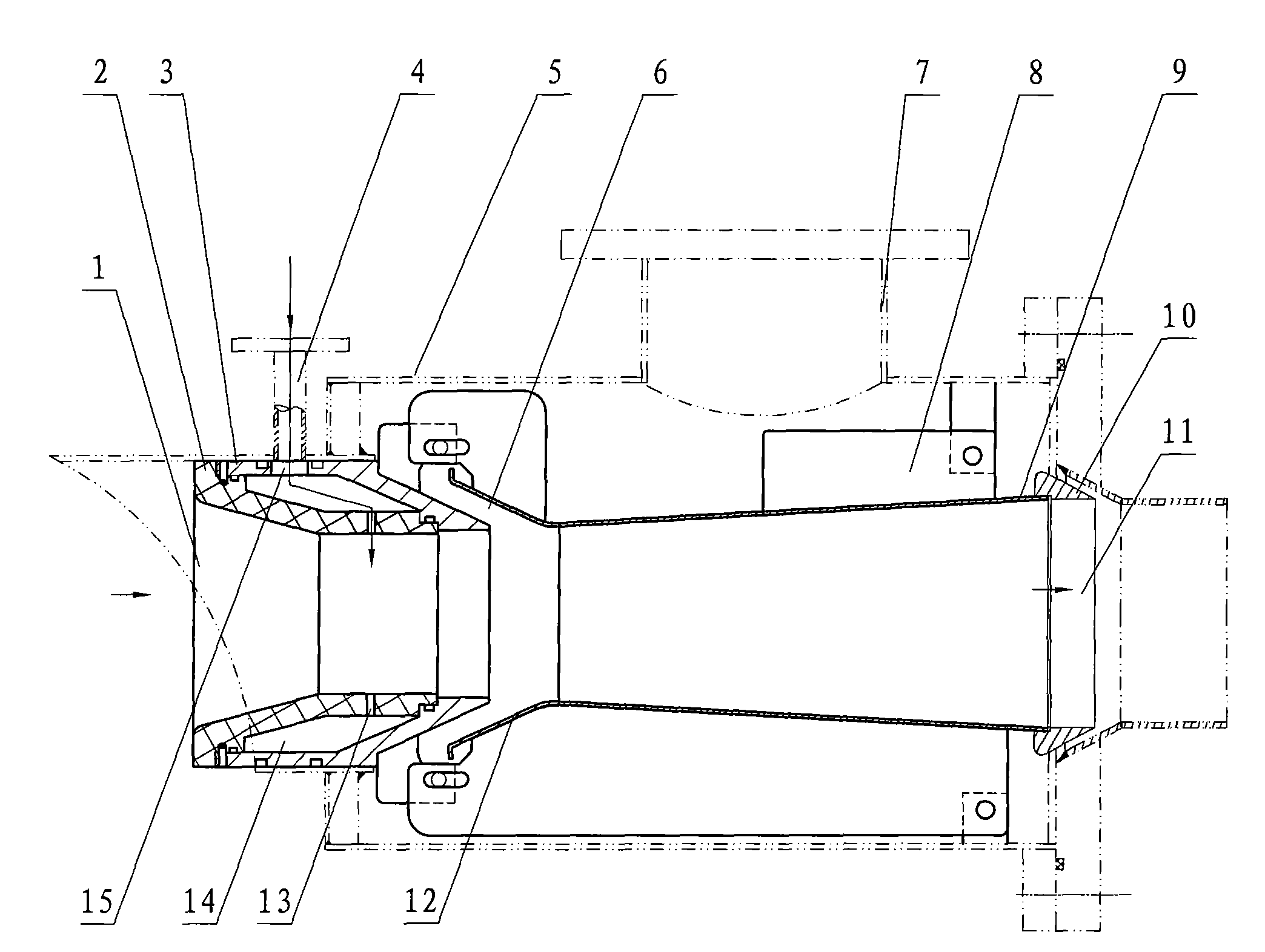

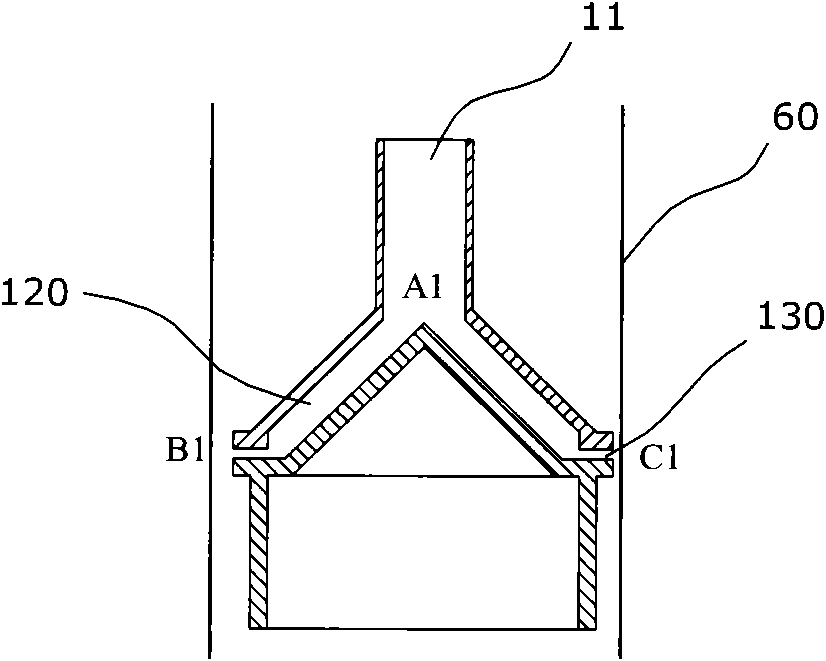

Atomizing nozzle structure of high-temperature high-voltage air flow dyeing machine and control method thereof

InactiveCN102080318AGood level dyeingSuitable for processing environmentLiquid/gas/vapor treatment of propelled fabricsTextile treatment machine partsSpray nozzleHigh pressure

The invention discloses an atomizing nozzle structure of a high-temperature high-voltage air flow dyeing machine and control method thereof. The nozzle structure comprises a front nozzle cover, an inner main stream pipe, a rear nozzle head and a sleeve, wherein the sleeve is sleeved outside the inner main stream pipe, and two ends of the sleeve are respectively connected with the front nozzle cover and the rear nozzle head through a connecting piece; the sleeve is provided with an air inlet which is connected with a fan; and the sleeve and the inner main stream pipe form a circular outer chamber atomizing region; a nozzle head is arranged in the outer chamber atomizing region and is fixed on the outer wall of the inner main stream pipe, and the nozzle head is connected with a dye liquid pipeline; and the outer chamber atomizing region is provided with two outlets which are connected with a channel through which the cloth to be dyed passes in the inner main stream pipe. The invention also provides a control method based on the atomizing nozzle structure of the high-temperature high-voltage air flow dyeing machine. According to the types of the cloth to be dyed, the number of the nozzle heads started in the nozzle structure, the flow rate of the nozzle heads, the air flow of the fan and the temperature process curves adopted are defined. According to the invention, the levelling property is high, and the problem of cloth blocking can not happen.

Owner:高勋绿色智能装备(广州)有限公司

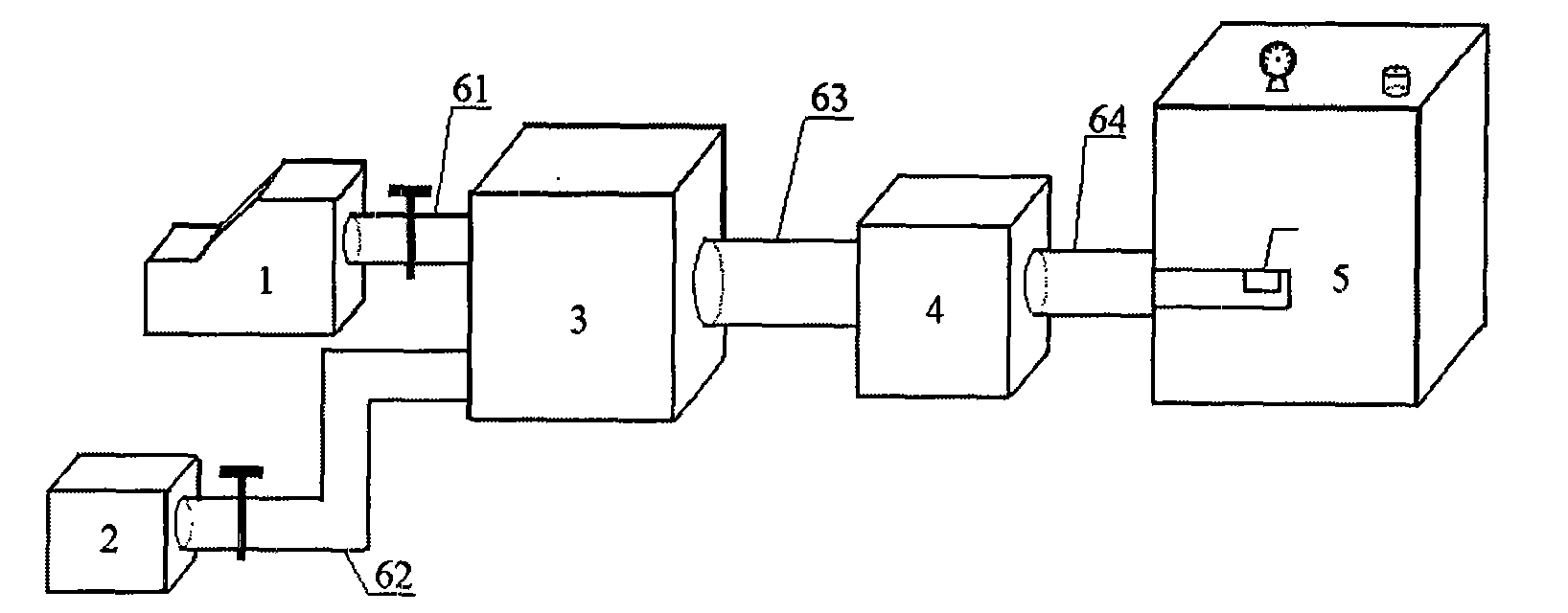

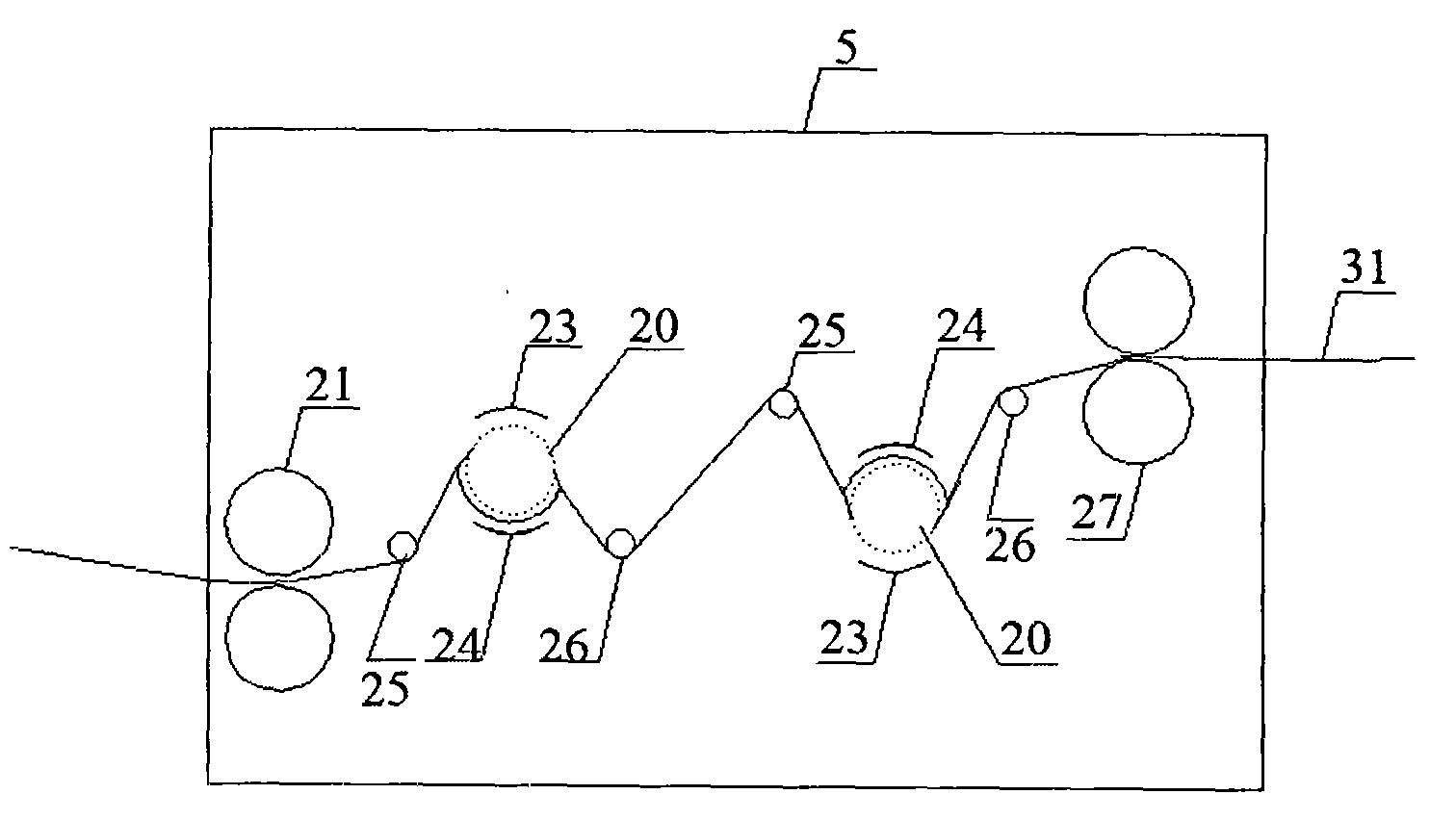

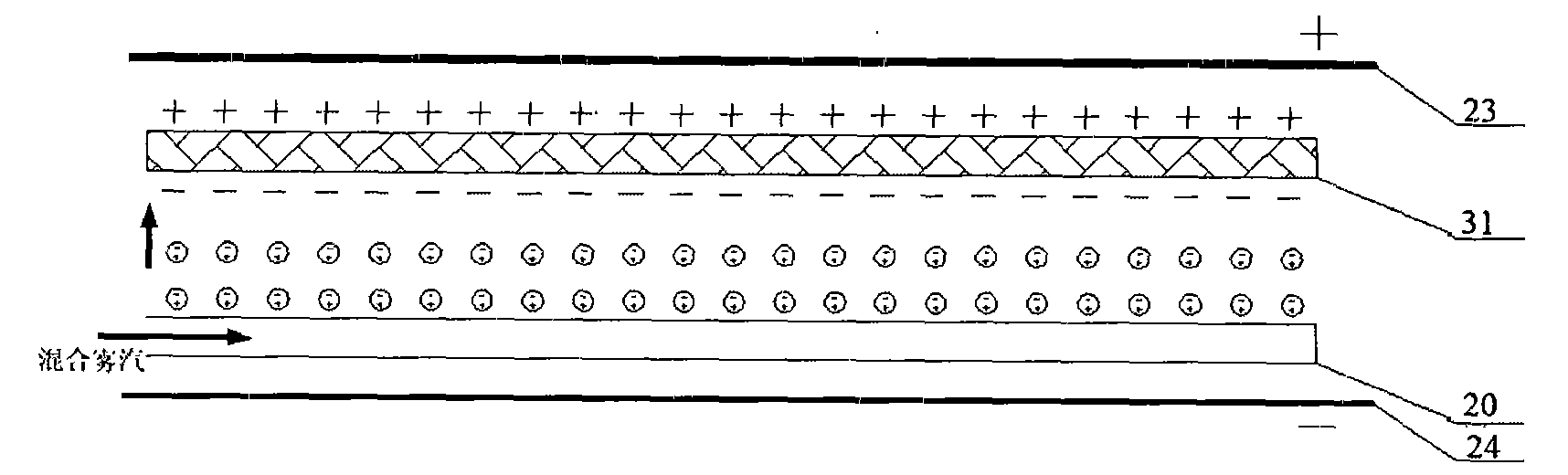

Textile dyeing method

InactiveCN102002834AIncrease profitSmall particle sizeTextile treatment containersTextile treatment with treating outlet contectFiberTextile printer

The invention relates to a method for dyeing textile materials and products thereof, and belongs to the field of textile printing and dyeing processing. In the method, prepared dye solution is subjected to ultrasonic atomization to form dye solution microbeads, and the dye solution microbeads directionally infiltrate the textile under the action of certain pressure and an electric field so as to complete the dyeing process. Due to the adoption of the technical scheme, dye solution atomized microbeads prepared from the dye solution through a high-frequency ultrasonic atomizer have smaller grain size, a small dispersion range on the textile and more fine and smooth dyeing effect; the dye solution atomized microbeads enter fibers more easily under the action of the air pressure and the electric field, and have better dyeing effect; and the atomized microbeads carry less solution, the utilization rate of the dye is high, water can be saved and the environmental pollution is lightened. The dyeing method has a wide application range, low energy consumption and light pollution, and is suitable for small-batch and multi-variety printing technology development direction.

Owner:WUHAN TEXTILE UNIV

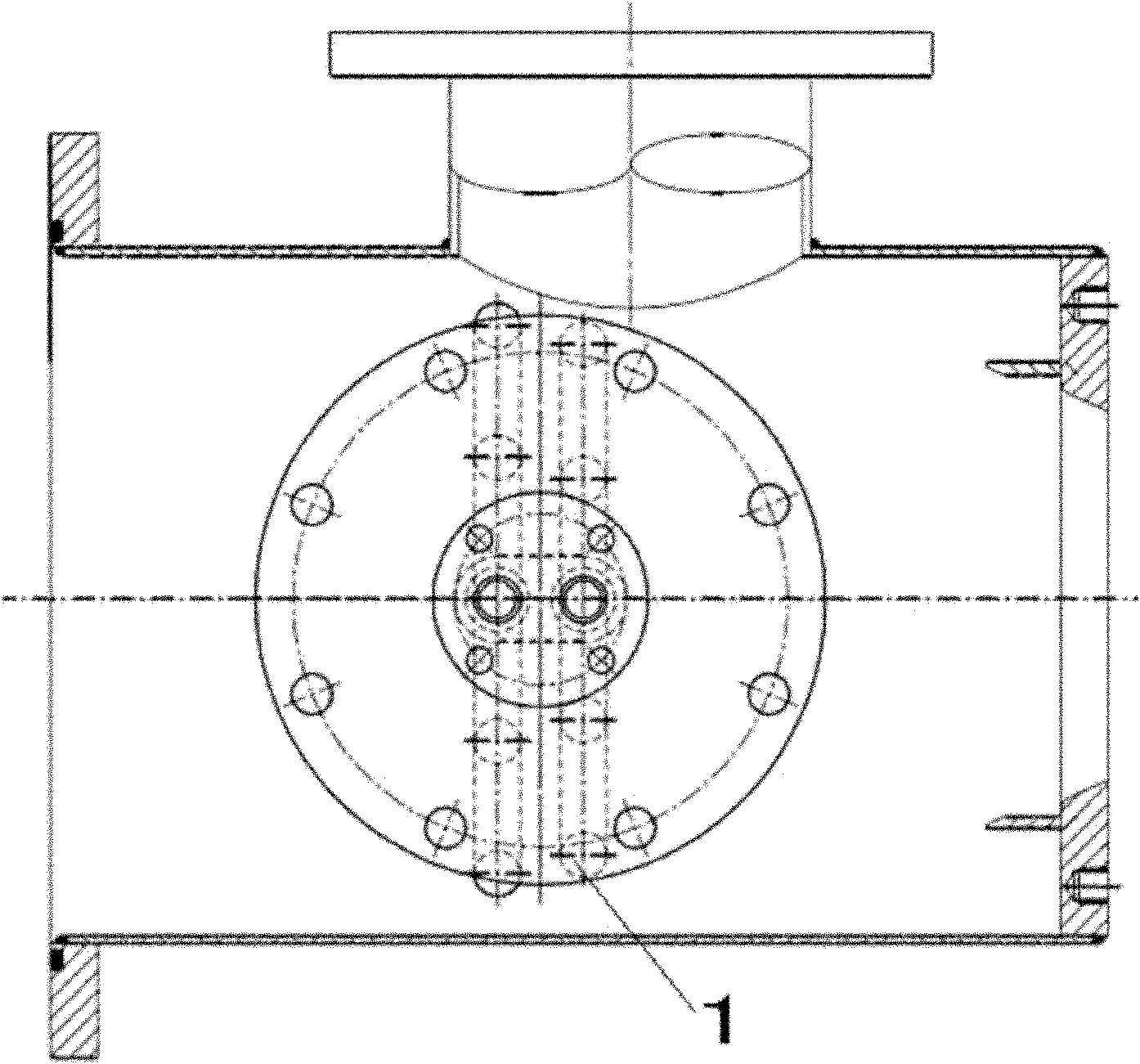

Nozzle of airflow dyeing machine

ActiveCN101613919AIncrease fluid pressureSpray evenlyLiquid/gas/vapor treatment of propelled fabricsTextile treatment machine partsEngineeringPulp and paper industry

The invention relates to a nozzle of an airflow dyeing machine, which comprises a front nozzle cover, a positioning sleeve, a nozzle body and a back nozzle head; the front end of the nozzle body is provided with a front guide nozzle; the positioning sleeve is sleeved on the front nozzle cover, and is connected with the nozzle body through a connecting piece; an airflow inlet is arranged between the back end of the positioning sleeve and the front guide nozzle; a dye liquor chamber is arranged between the front nozzle cover and the positioning sleeve; the front nozzle cover is provided with a dye liquor outlet; the positioning sleeve is provided with a dye liquor inlet; and the dye liquor outlet and the dye liquor inlet are respectively communicated with the dye liquor chamber. The dye liquor chamber is arranged between the front nozzle cover and the positioning sleeve, and dye liquor is stored in the dye liquor chamber, so that the fluid pressure of the dye liquor is increased; and the front nozzle cover is provided with the dye liquor outlet, and the dye liquor is directly ejected onto cloth, not interfered by airflow and is ejected evenly.

Owner:WUXI DONGBAO MACHINERY MFG

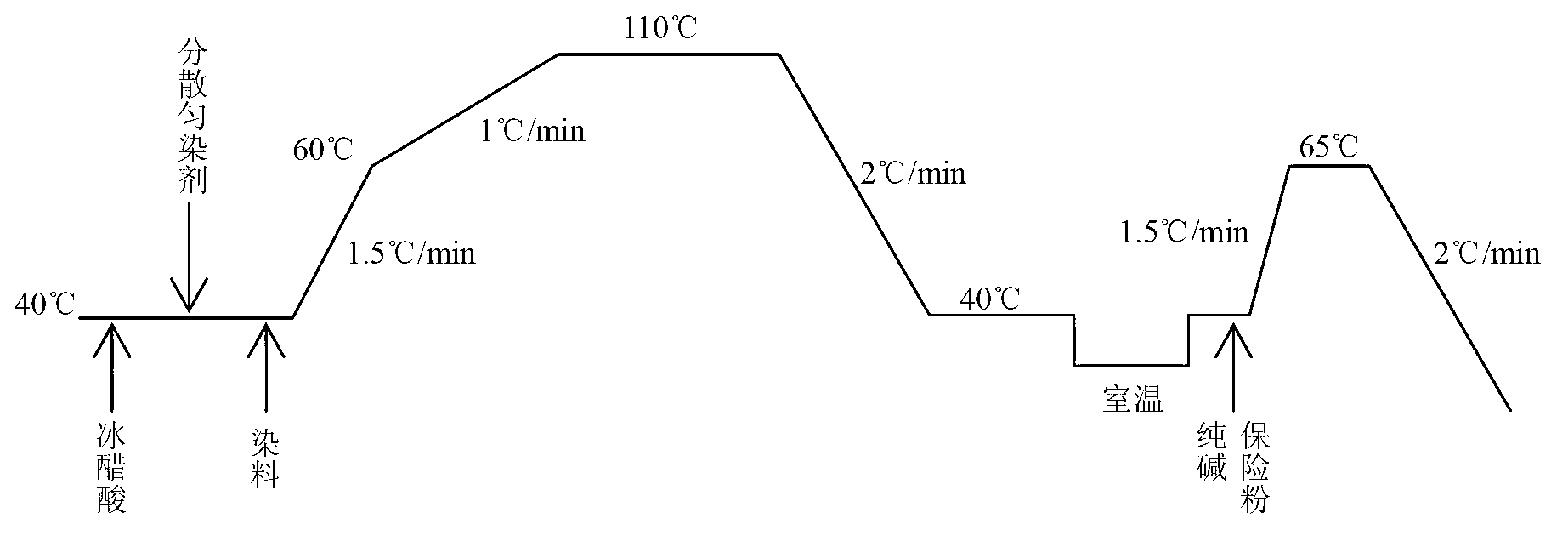

Processing method of Sorona and silk clothes fabric

ActiveCN102797104AGood smooth feelEnvironmentally friendlyWeft knittingTextile treatment with treating outlet contectAdhesiveEngineering

The invention provides a processing method of a Sorona and silk clothes fabric, relating to a processing method of a knitting fabric. The method comprises the following steps of: selecting raw materials; splicing threads; weaving to obtain a gray fabric; washing with water; sizing a finished product; and decating. The characteristics of ecological environmental protection, excellent rebound elasticity and the like of Sorona are fully utilized, and excellent moisture absorption, air permeability and chromatophilia of adhesives and smooth hand feel of mulberry silk are combined, so that the fabric has the advantages of functionality, environmental protection and high grade. A knitting fabric rather than a woven fabric is obtained by processing.

Owner:劲霸男装(上海)有限公司

Ultralow liquor ratio zipper dyeing machine and dyeing process thereof

InactiveCN103088574AHollow volume reductionReduced cavity cross-sectional areaPump componentsTextile treatment machine arrangementsPolymer scienceEngineering

The invention discloses an ultralow liquor ratio zipper dyeing machine and dyeing process thereof. The dyeing machine comprises a tube cylinder, a cylinder cover and a zipper warp beam plate frame embedded into the tube cylinder. The zipper warp beam plate frame comprises a zipper plate seat, a hollow water drum, a zipper woven belt, a zipper tube sleeve, a locking bolt, and a zipper frame lifting ring. The lower end of the hollow water drum is fastened on the zipper plate seat, the zipper tube sleeve is sleeved on the outer side of the hollow water drum, and a diversion inlet and a diversion outlet are arranged below the zipper plate seat and connected with an infusion pump through a horn-shaped pipe sleeve. The dyeing process comprises the stages of scouring and bleaching, dyeing and water scrubbing. According to the ultralow liquor ratio zipper dyeing machine and the dyeing process thereof, a lift range required by zipper woven belt dyeing water level can be achieved when the height of dye liquor in the dyeing machine is lower than the zipper plate seat, the effect of ultralow liquor ratio zipper dyeing is achieved, the dyeing machine has a lower dying liquor ratio than a traditional zipper dying machine, and the purposes of saving electric energy, steam and the dye liquor, shortening dyeing and finishing periods, and saving energy and reducing emission are achieved.

Owner:高勋绿色智能装备(广州)有限公司

Low-shrinkage pure-cotton oil fouling resistant hot-melting bonding lining and production method thereof

ActiveCN101962848AEnvironmental protection is goodEasy to operateDry-cleaning apparatus for textilesBleaching apparatusSize changeDry heat

The invention discloses a low-shrinkage pure-cotton oil fouling resistant hot-melting bonding lining and a production method thereof. The low-shrinkage pure-cotton oil fouling resistant hot-melting bonding lining is characterized in that the warp-direction and weft-direction washing size change rate is not less than minus 0.6 percent, the oil resistance is not less than120 scores, the lining cloth formaldehyde release amount is not more than 40mg / kg, the peeling strength is not less than 12N and the warp-direction and weft-direction dry heat size change rate is not less than minus 0.8 percent. The production method of the invention sequentially comprises the steps of turned sewing, singeing, desizing, boiling, bleaching, re-bleaching or dyeing, aftertreatment, liquid ammonia finishing, oil fouling and shrinkage resistant finishing, post baking, powder point coating and mechanical pre-shrinkage. The invention has the advantages of large warp-direction and weft-direction washing size change rate, high oil fouling resistance, high peeling strength, high environmental-friendly performance and easy operation of the production method.

Owner:曹平

Foam spraying dyeing method adopting reactive dyes

ActiveCN102650097AReduce dosageIncrease profitTextile treatment with treating outlet contectReactive dyeEnvironmental geology

The invention relates to a foam spraying dyeing method adopting reactive dyes, which comprises the following steps: mixing a reactive dye liquor and a color fixing liquid; applying the mixed liquor to a fabric; and carrying out water washing after fixing the color of the fabric. The method is characterized in that the mixed liquor is foamed before being applied to the fabric, and is applied to the fabric in a foamed manner. The foam spraying dyeing method has the advantages that the stability for controlling the dyeing process is improved; the process flow is short; energy and dye utilization ratios are improved; table salt, glauber salt or urea is not required; and unfixed dyes and the pollution discharge during the dyeing process are reduced.

Owner:上海虹馨管理咨询有限公司

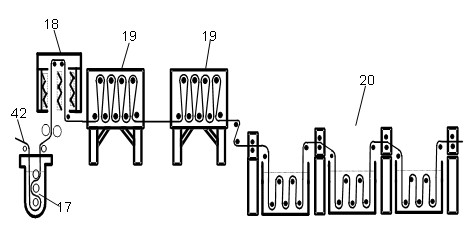

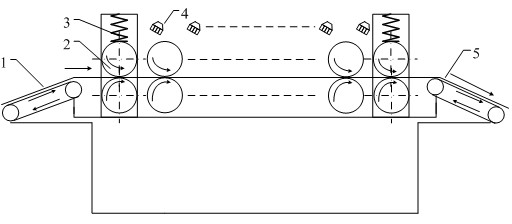

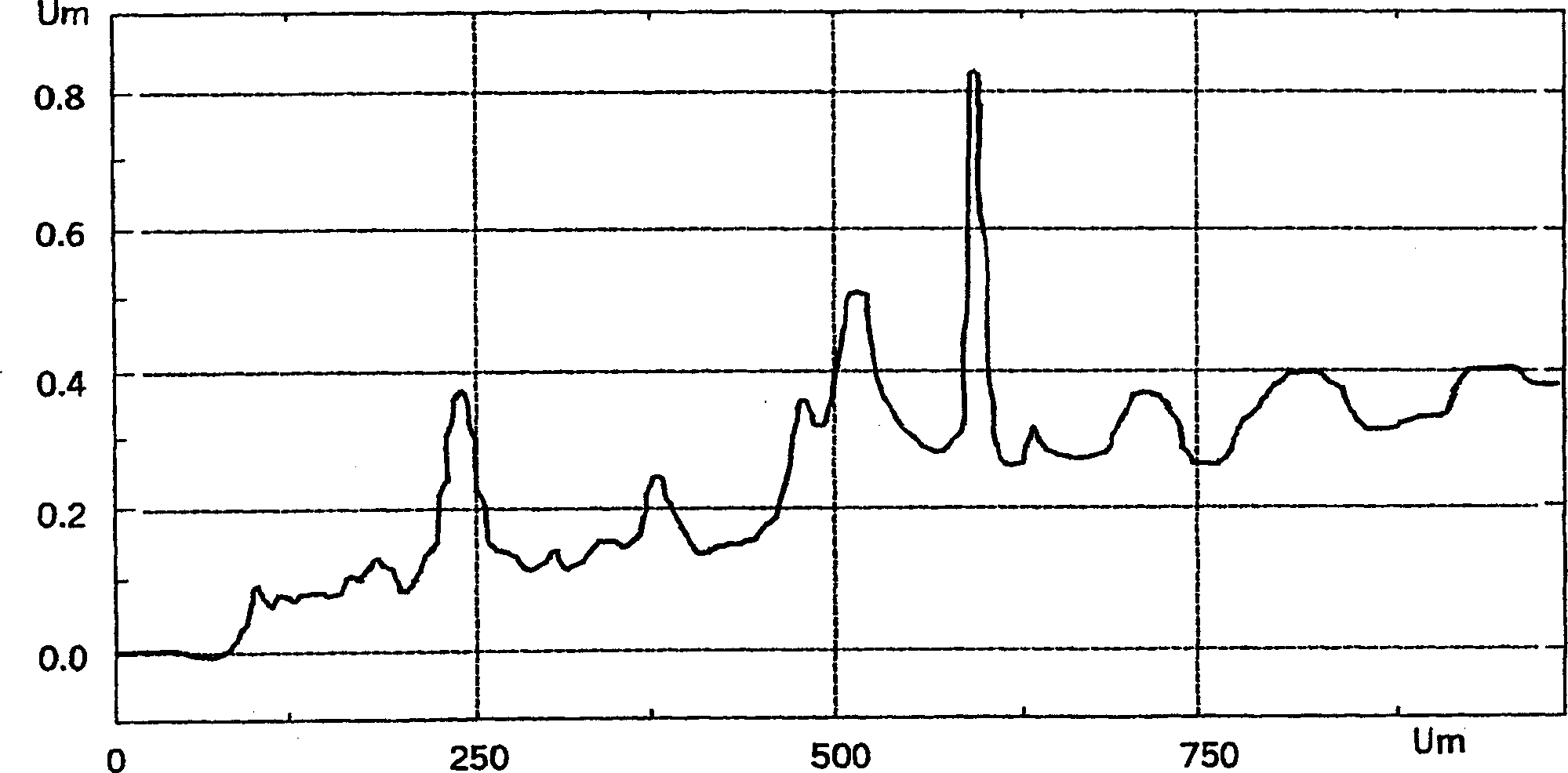

Roller extrusion type releasing and separating device and method for ramie

InactiveCN101974805ASqueeze evenlyKnead evenlyDrafting machinesTextile treatment with treating outlet contectRamieSelf weight

The invention relates to a roller extrusion type releasing and separating device and method for ramie. The device comprises a feeding apron and a discharging apron, wherein 5-14 pairs of linearly arranged rollers with grooves are arranged between the feeding apron and the discharging apron, compression springs are arranged on the upper sides of the rollers, the rollers are connected with a transmission device, and spray pipes are arranged above the rollers. The method is characterized by comprising the following specific steps of: laying boiled or biologically degummed ramie bundles on the feeding apron to be fed, holding and extruding the ramie bundles by the upper rollers and the lower rollers under the self weight of the upper rollers and the compression of the compression springs, delivering forward, and effectively removing colloid on the fiber surface through water washing. The invention has the advantages of labor saving, more uniform and sufficient releasing effect, fewer fiber damages and high manufacturing rate; moreover, because the overall ramie bundles make linear movement and the speed between every two rollers is gradually increased during processing, fibers can be conveniently straightened, and the mutual tangling of fibers is greatly reduced.

Owner:DONGHUA UNIV

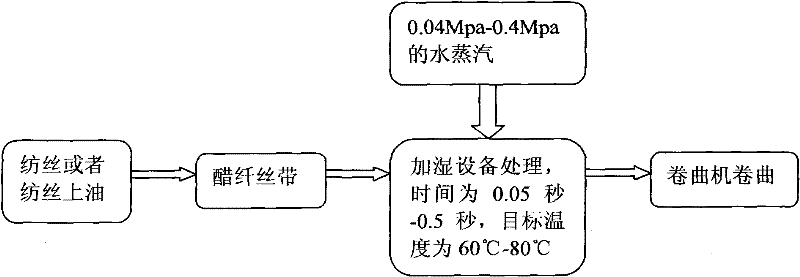

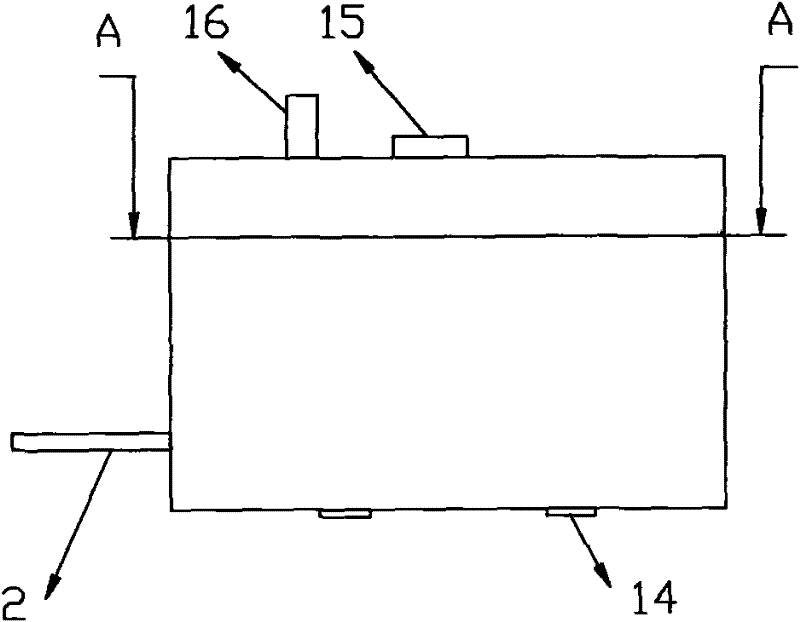

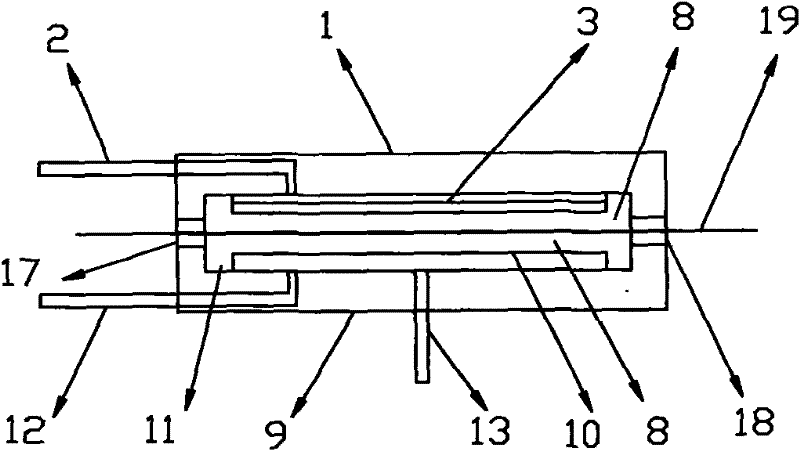

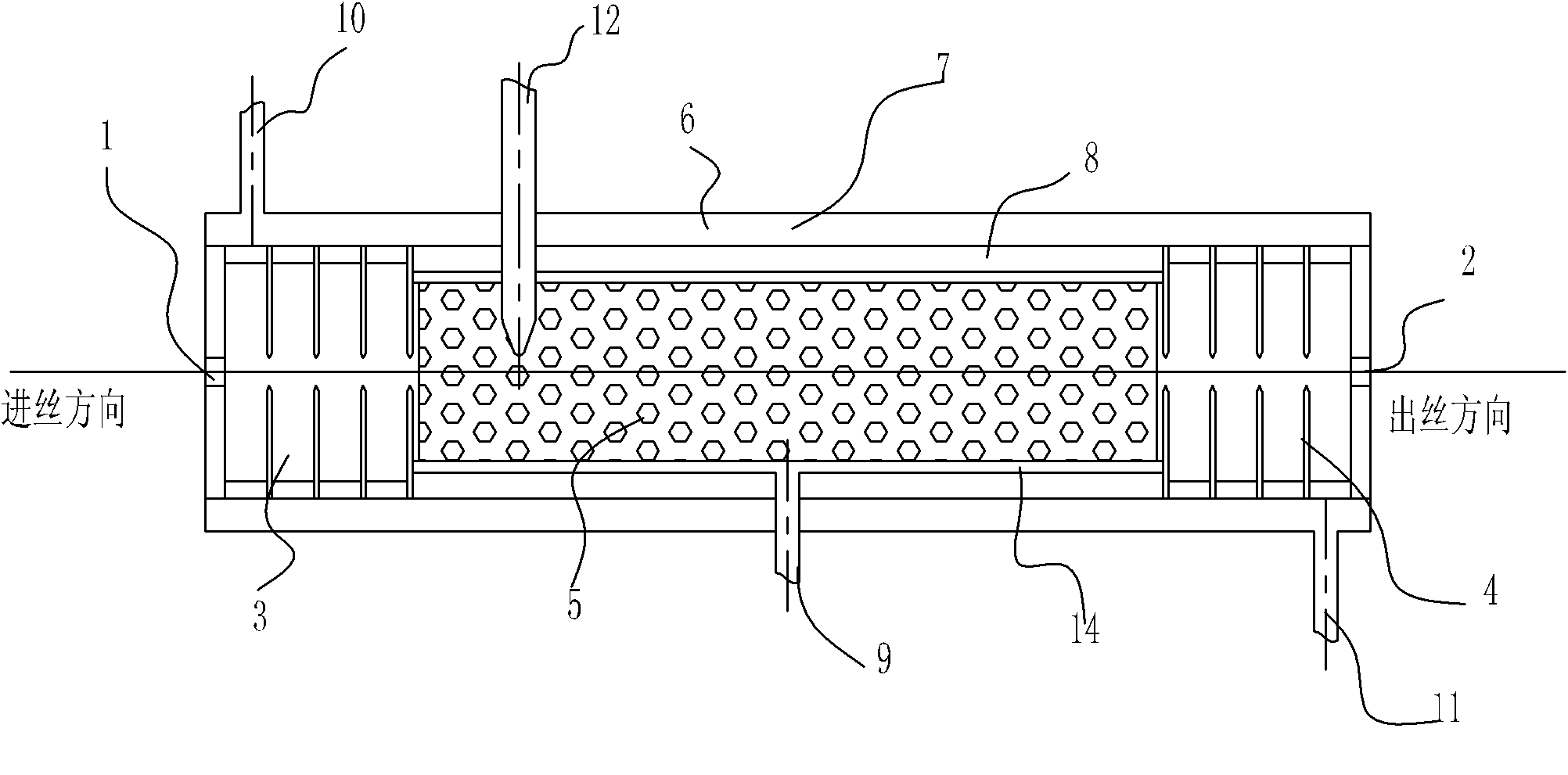

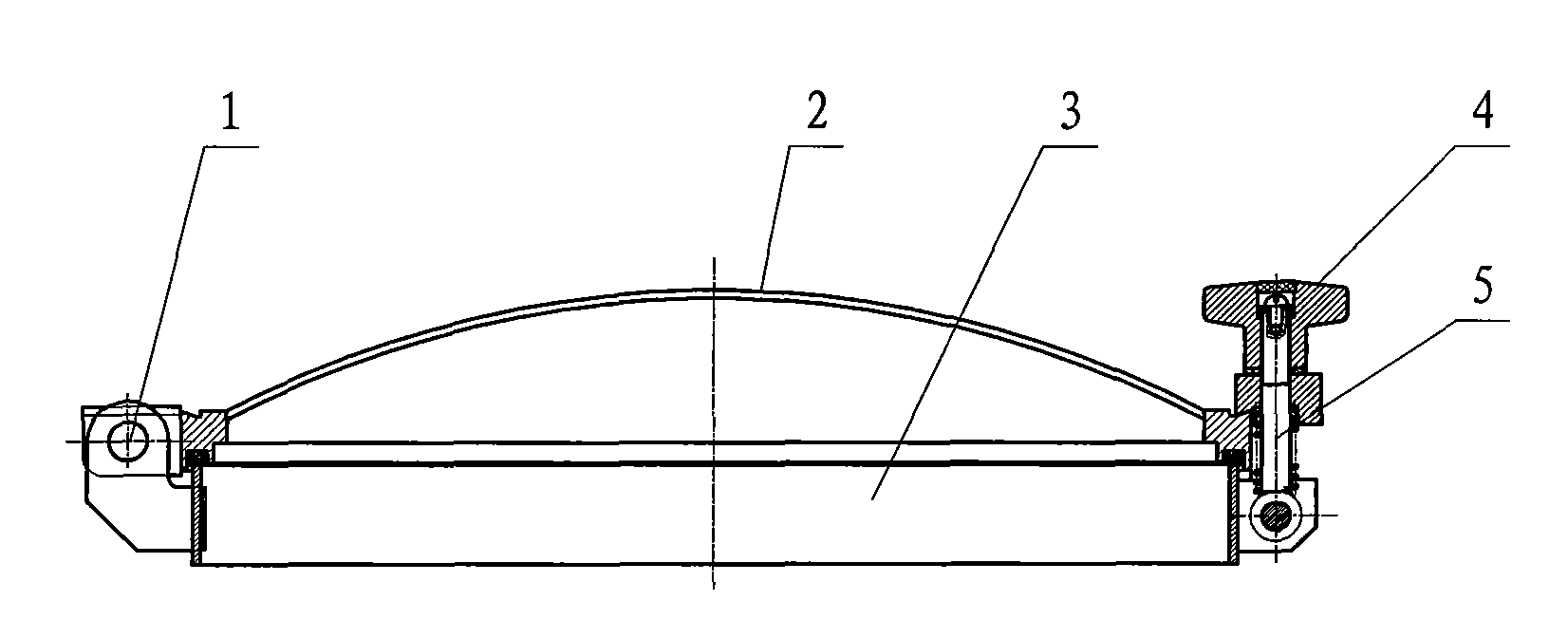

Humidifying method of acetate fibre and humidifying device of acetate fibre

ActiveCN102677414AIncrease humidityGood flexibilityTextile treatment machine partsTextile treatment with treating outlet contectVena contracta diameterEngineering

The invention provides a humidifying method of acetate fibre and a humidifying device of the acetate fibre. The humidifying device is additionally arranged before an acetate fibre ribbon is fed to a crimper for crimping operation in a production line, and the acetate fibre ribbon is humidified and warmed. Water vapour of which the pressure is 0.02-0.8Mpa is introduced into the humidifying device; the time of the acetate fibre ribbon passing through the humidifying device is 0.05-0.5 seconds, and the processed target temperature is 50-95 DEG C. The humidifying device is of a box structure and contains an upper part of a humidifying box, a lower part of the humidifying box, a ribbon operation chamber and a vapour chamber; an upper vapour jet orifice plate on the upper part of the humidifying box is inclined or arch-shaped; the position of a condensed water tank at the lower part of the humidifying box is lower than the vapour jet orifice plate; and the upper vapour jet orifice plate and the lower vapour jet orifice plate respectively comprise jet orifices, and a temperature detection device is also arranged in the ribbon operation chamber. According to the humidifying device of the acetate fibre disclosed by the invention, the strength of the acetate fibre ribbon is improved, the damage of the crimper to the ribbon is reduced, the flying of the ribbon is reduced, simultaneously the content of acetone in the ribbon is decreased, and subsequent processing load is lowered.

Owner:NANTONG CELLULOSE FIBERS CO LTD

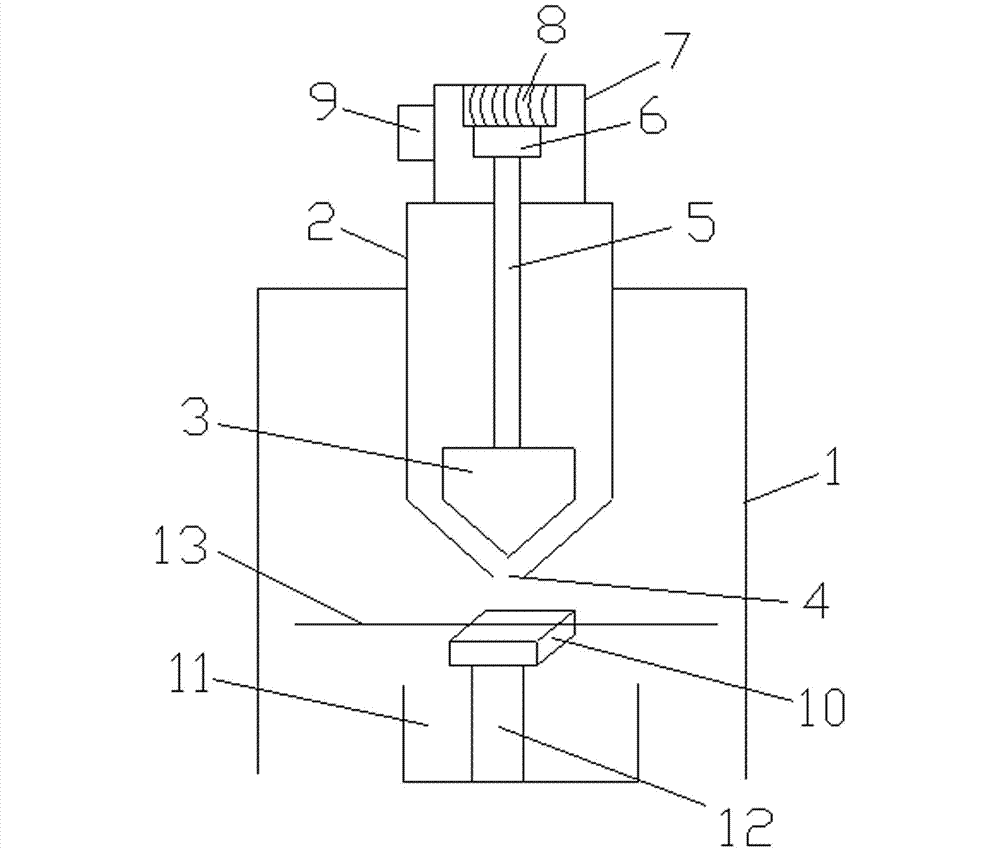

Lubricating device for spinning

InactiveCN102864577AQuality improvementSimple structureTextile treatment with treating outlet contectBraidYarnForce sensor

The invention relates to a lubricating device for spinning. The lubricating device for spinning comprises a bench, an oil storage device disposed on the bench, and a rubber plug disposed in the oil storage device. The lower end of each of the oil storage device and the rubber plug is conical. The lower end of the oil storage device is provided with an oil orifice. The lower end of the rubber plug is as tapered as the lower end of the oil storage device. A support bar is perpendicularly connected to the upper end of the rubber plug. The top end of the support bar extends out of the oil storage device and is connected with a metal block. A support frame is disposed at the top end of the oil storage device, and an electromagnet and a controller connected with the same are disposed on the support frame. A force sensor is disposed below the oil storage device and is connected with the controller. The lubricating device for spinning is simple in structure. Yarns can evenly and continuously pass under the oil storage device. Oil drops drop onto the yarns for lubricating through the oil orifice. When no yarn passes under the oil storage device, the force sensor sends a signal to plug the oil orifice under control of the controller, so that waste is avoided.

Owner:NANTONG KESTER TEXTILE

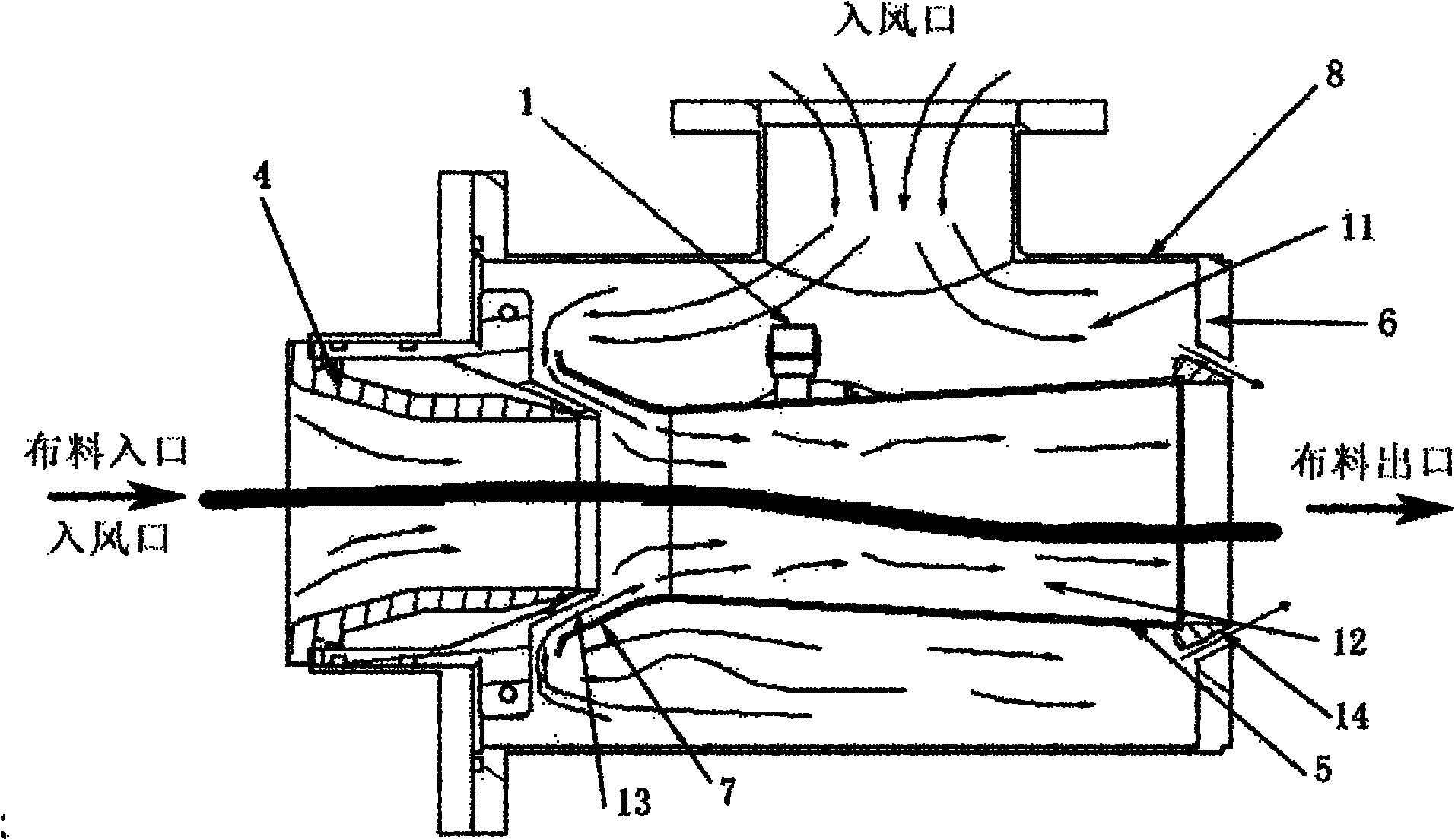

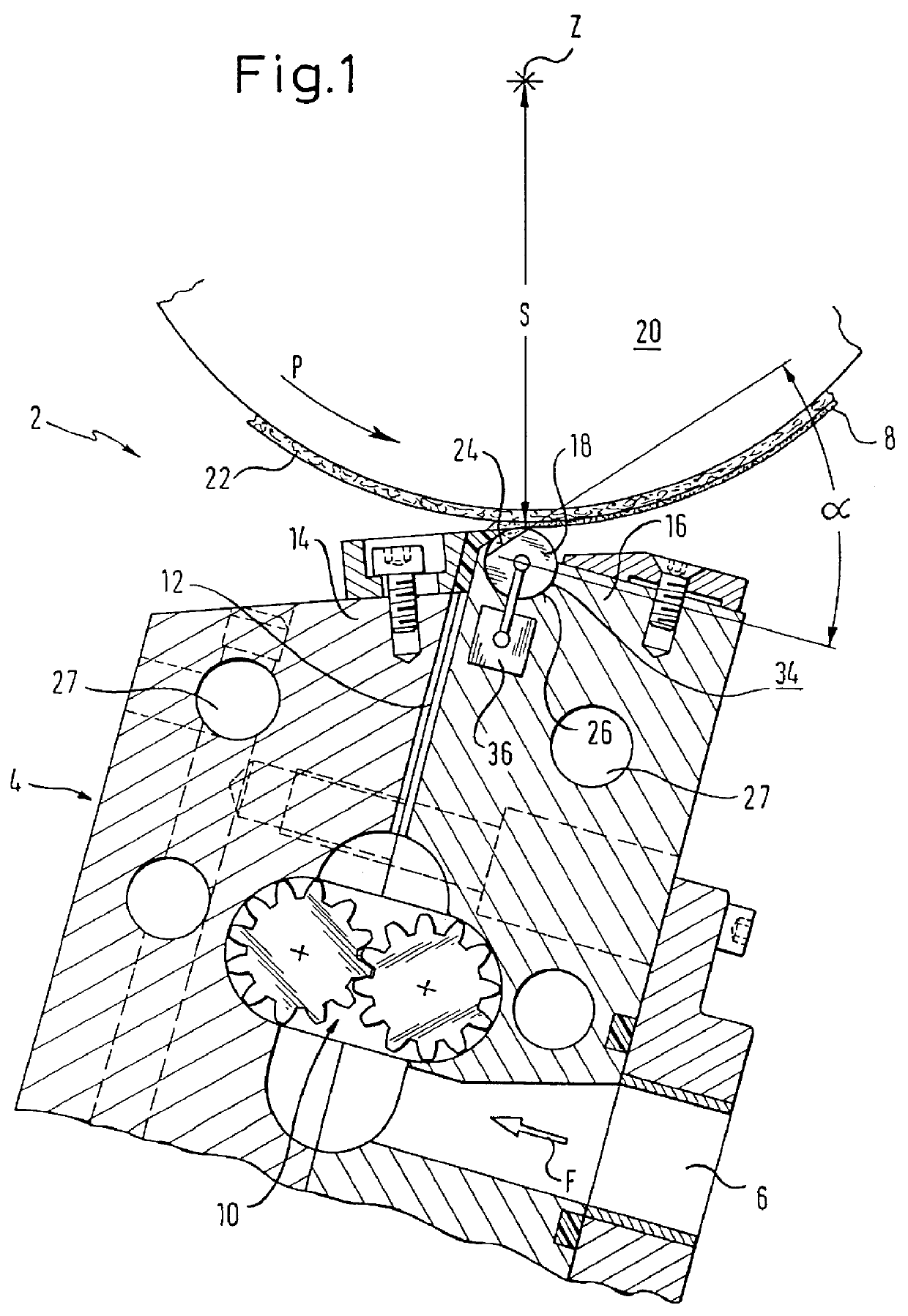

Pressurized steam drawing machine for drawing fibers

InactiveCN102011233AUniform and constant draftStable temperatureTextile treatment machine arrangementsTextile treatment with treating outlet contectFiberWater vapor

The invention relates to a pressurized steam drawing machine for drawing fibers, which comprises a box body, filament bundle inlet and outlet windows arranged at the two ends of the box body, an inlet steam seal part arranged in the box body close to the filament bundle inlet window, an outlet stem seal part arranged in the box body close to the filament bundle outlet window, and a drawing chamber arranged in the box body and positioned between the inlet steam seal part and the outlet steam seal part, wherein the drawing chamber is formed by filling with a porous material; the box body comprises main thermal-insulation layer for keeping the temperature in the drawing chamber; a steam chamber is arranged between the main thermal-insulation layer and the drawing chamber; and the box body is provided with a steam pipe which connects the steam chamber and an external steam source. In the invention, that fiber protofilament bundles are drawn at a uniform and constant is ensured, and the high orientation and high strength of the protofilaments are improved effectively.

Owner:西安航科等离子体科技有限公司

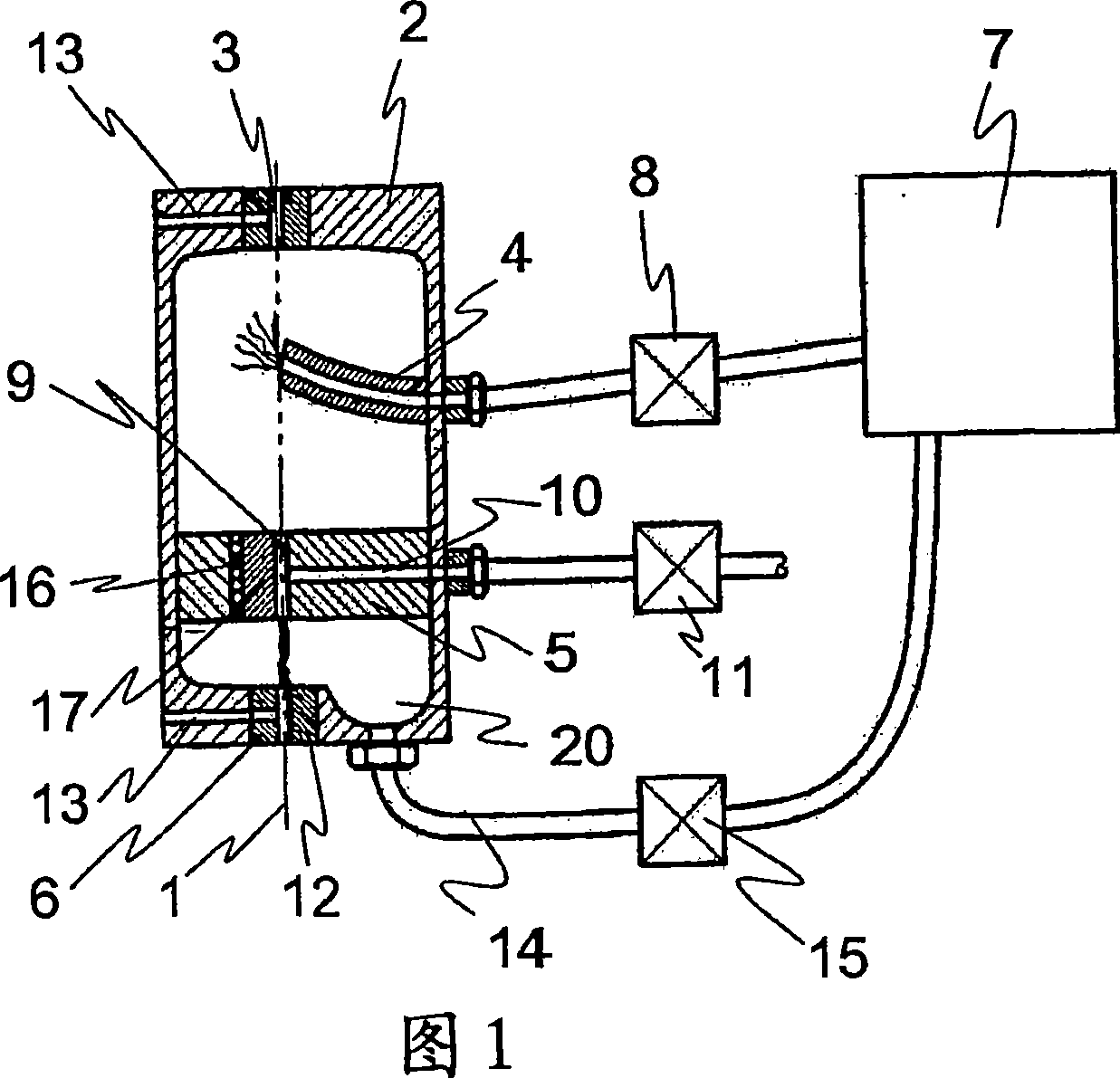

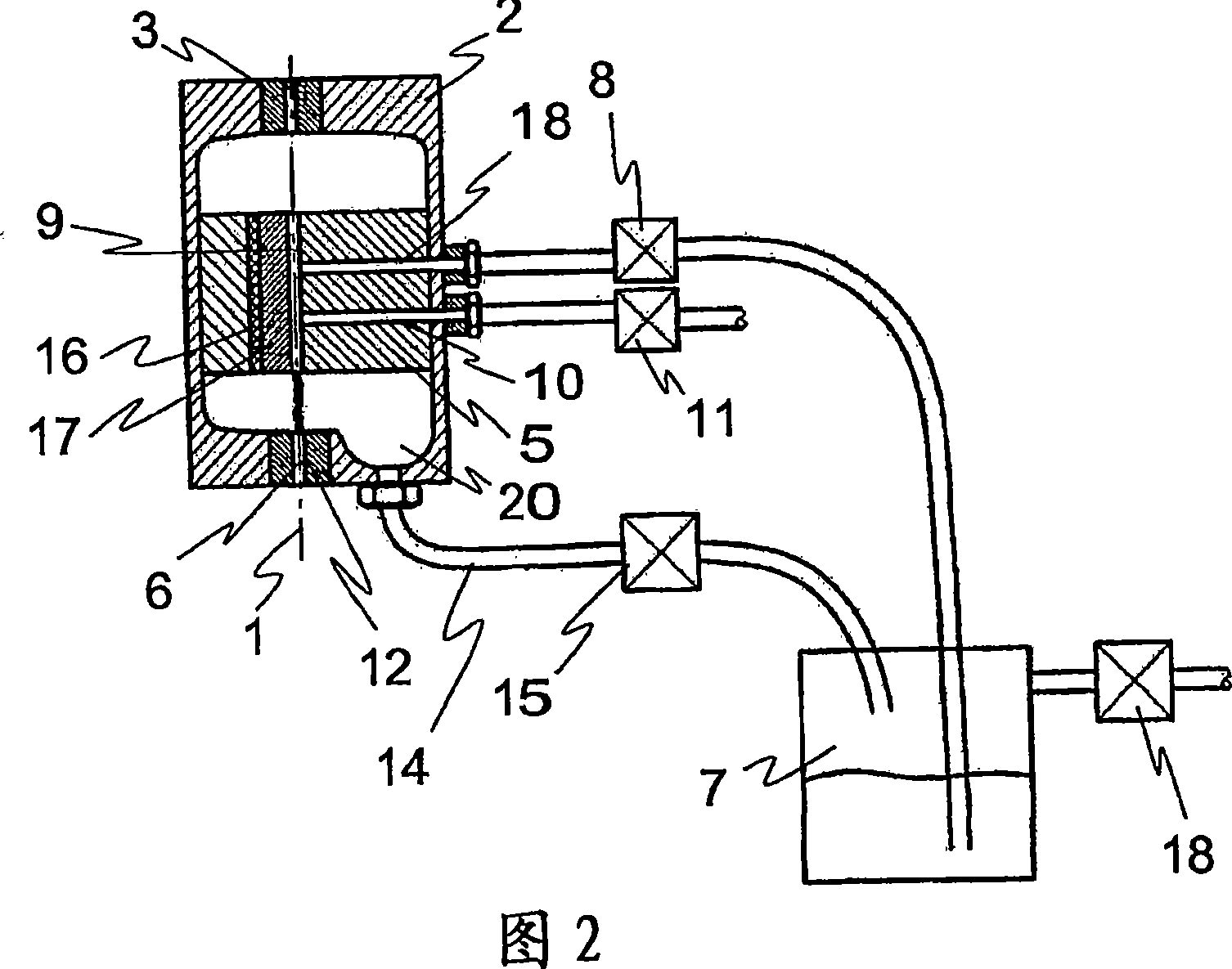

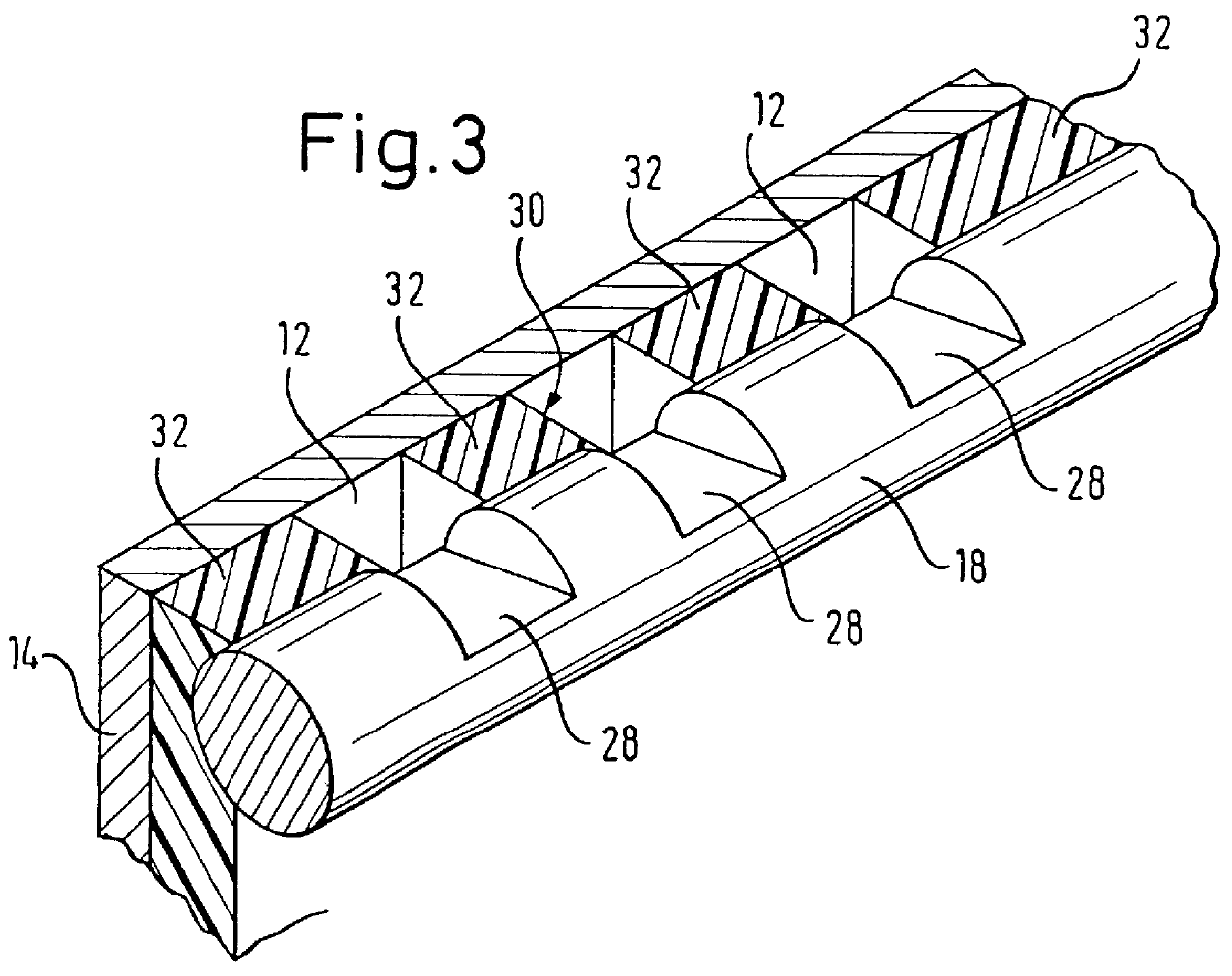

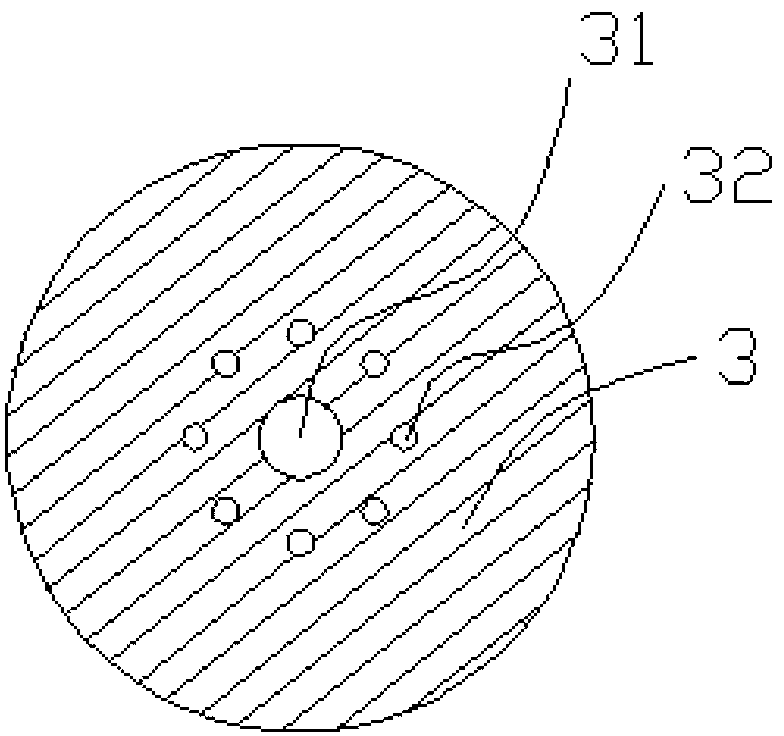

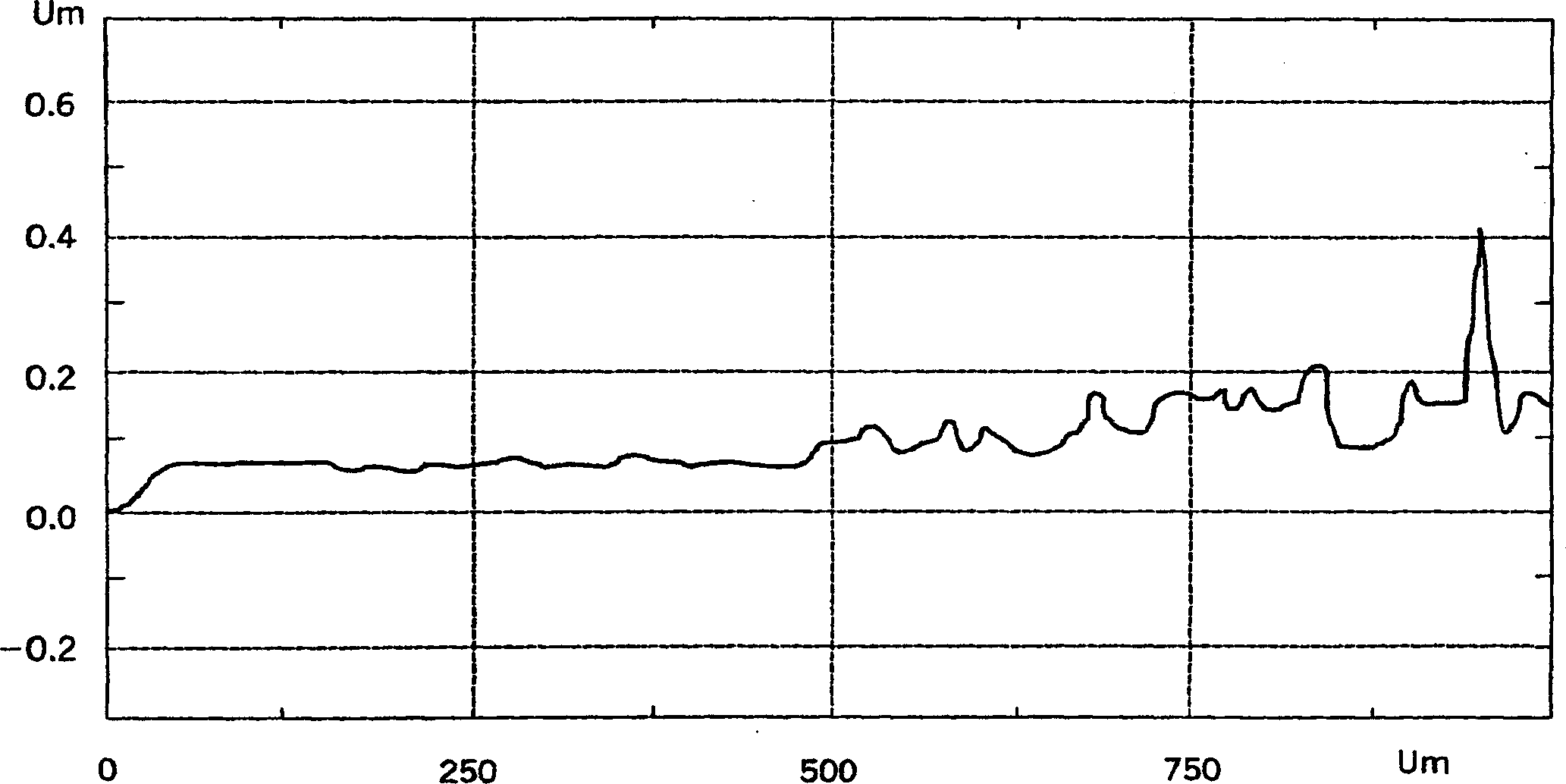

Liquid circulation processing device and method for bast fibers

ActiveCN101838895AReduce dosageGuaranteed normal needsTextile treatment machine arrangementsTextile treatment with treating outlet contectYarnAfter treatment

The invention relates to a liquid circulation processing device and a liquid circulation processing method for bast fibers. The method comprises the following steps of: 1) hanging the bast fibers or yarns in bunches on an extension bar of a yarn hanging device in parallel; 2) serially connecting a plurality of yarn hanging devices, and putting the yarn hanging devices in a main vat; 3) adding chemical agents into the main vat through an auxiliary vat, and opening a main pump and a heat exchange device; and 4) after treatment fluid is pumped into a hollow column of each yarn hanging device, spraying the treatment fluid on the bast fibers or yarns through holes on each extension bar and spraying holes on each extension bar. The device used by the liquid circulation processing method for the bast fibers and yarns is characterized by comprising a barrel-shaped main vat; the yarn hanging devices are arranged inside the main vat; the main pump is arranged outside the main vat; a water inlet of the main pump is connected with a water outlet of the main vat; a water outlet of the main pump is connected with the heat exchange device; a water outlet of the heat exchange device is connected with a water inlet of each yarn hanging device inside the main vat; and the auxiliary vat is arranged outside the main vat. The liquid circulation processing device and the liquid circulation processing method for the bast fibers can be widely applied to degumming, washing, bleaching and dyeing the bast fibers, scouring, dyeing, bleaching and washing the yarns, and other processes.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +3

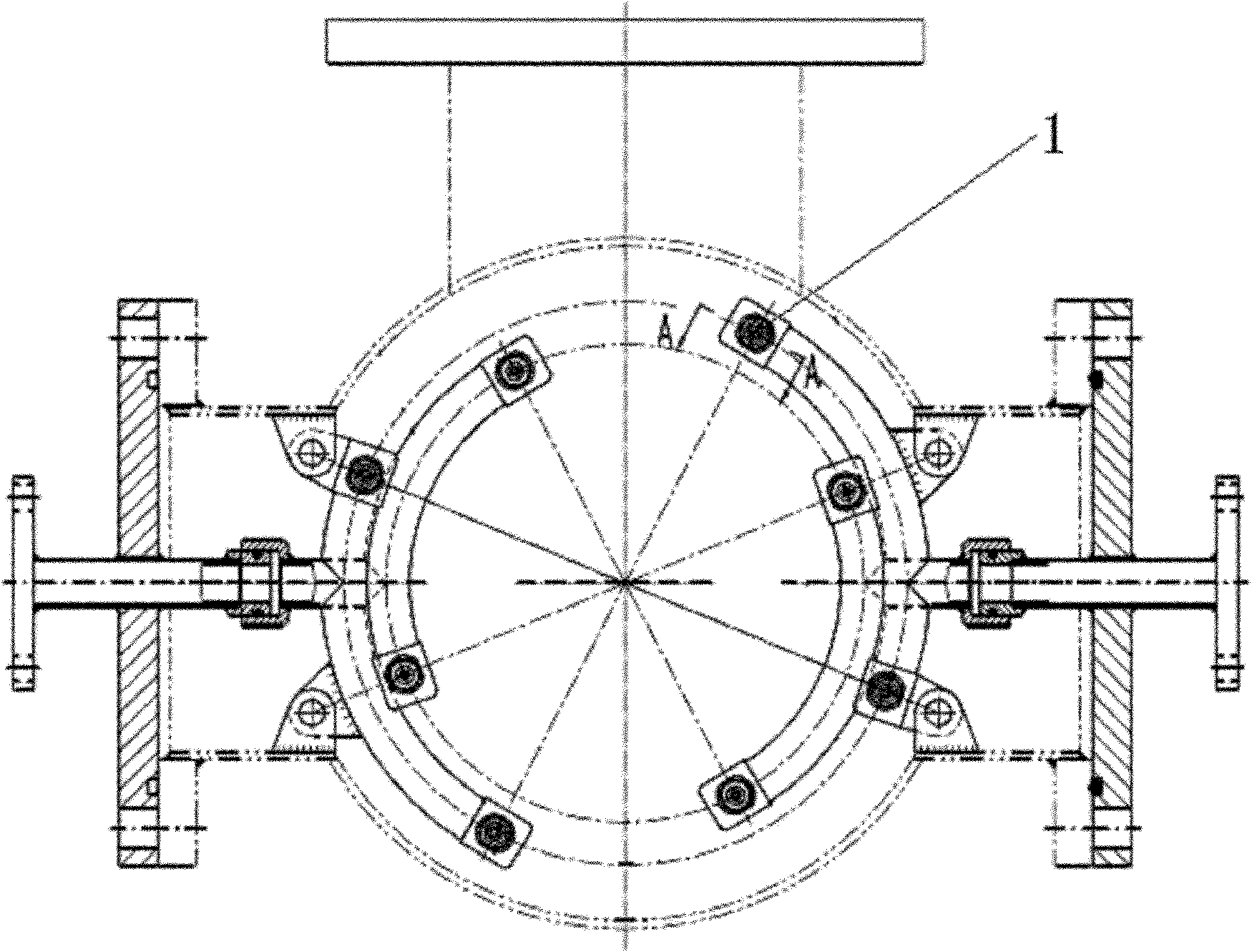

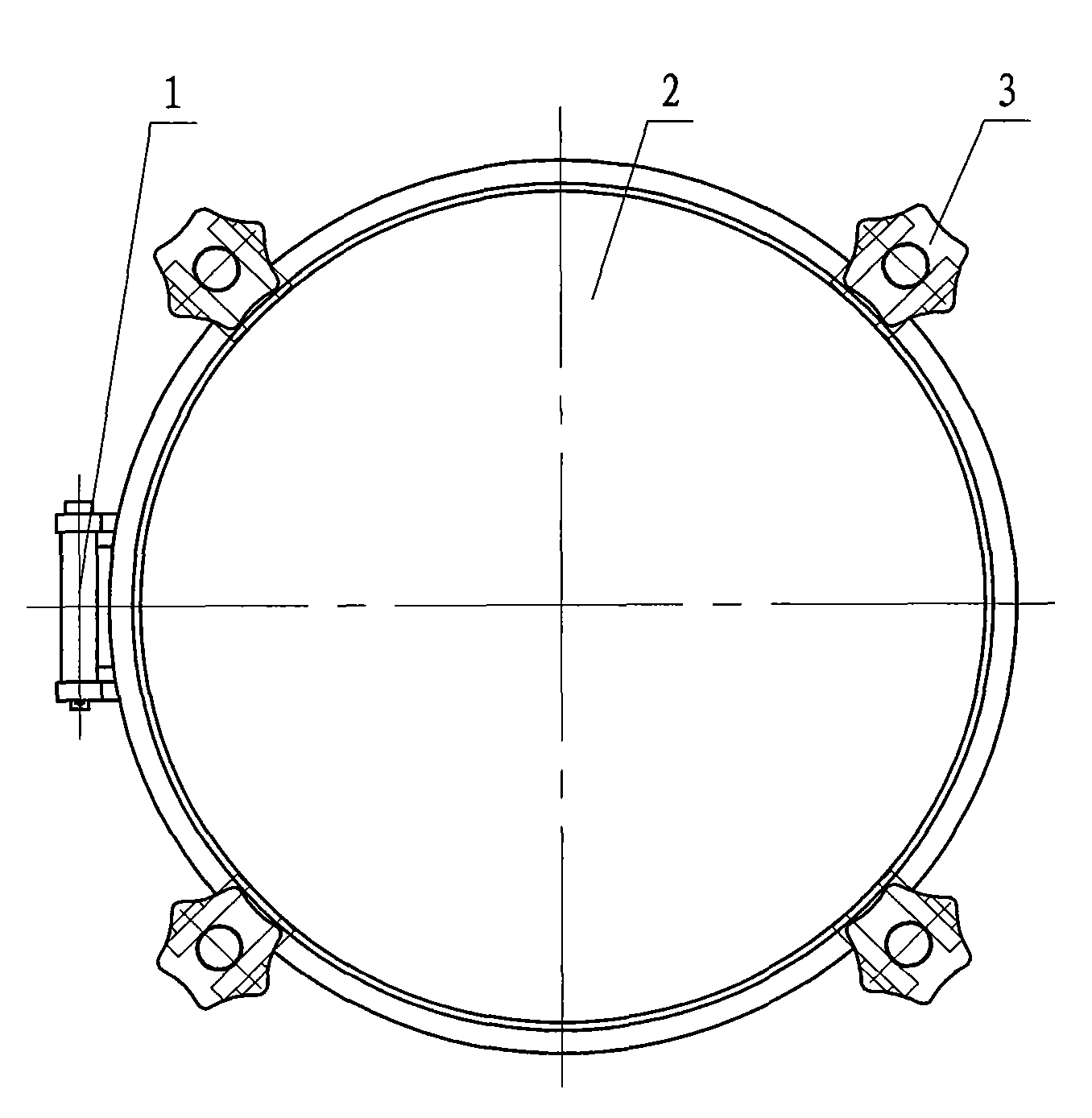

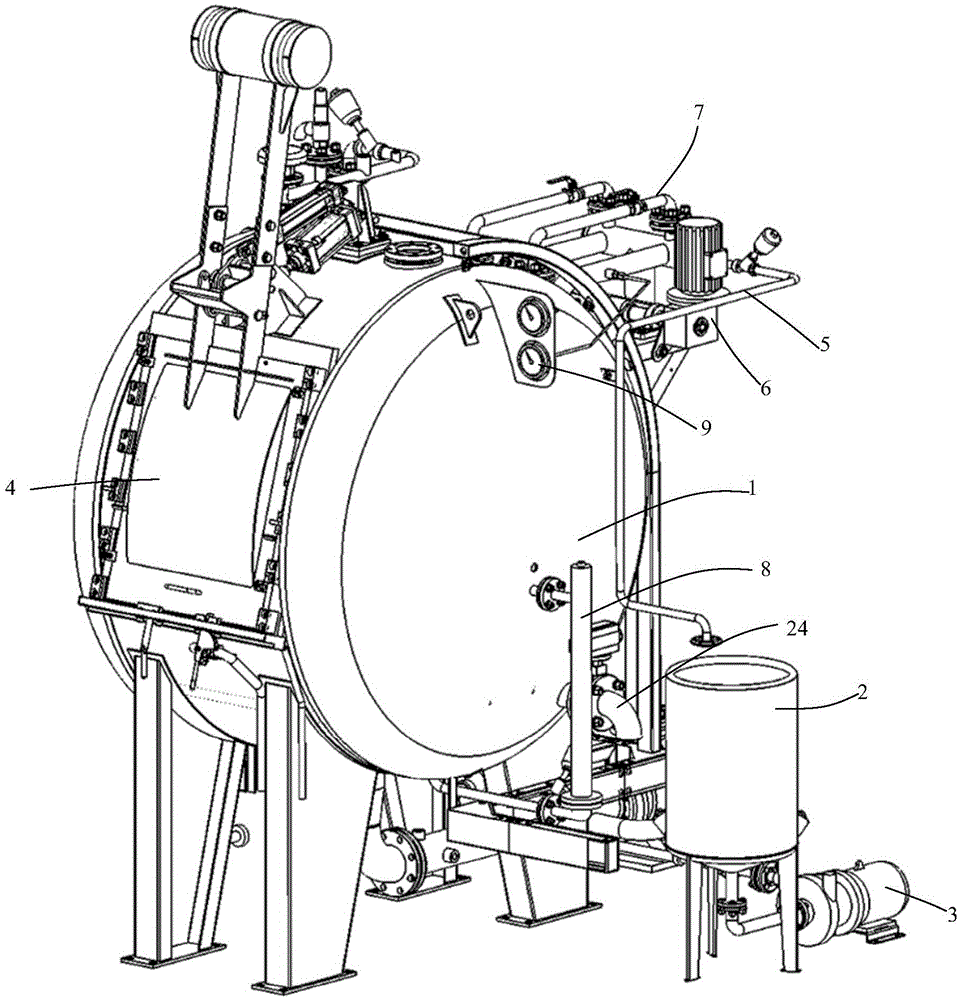

Quick-opening device of airflow dyeing machine

ActiveCN101613924ARealize safety interlock functionEasy to switchTextile treatment containersLiquid/gas/vapor treatment of propelled fabricsEngineeringSafety Interlock

The invention relates to a quick-opening device of an airflow dyeing machine, which comprises a manhole flange and a manhole cover, wherein the manhole flange is hinged with a door ring; the manhole cover is rotationally arranged on the door ring, and is provided with a handle; the inner wall of the manhole flange is provided with internal teeth; the outer wall of the manhole cover is provided with external teeth; the number of the internal teeth is the same as that of the external teeth; the manhole cover is rotationally clamped in the manhole flange through the fit of the internal teeth andthe external teeth; the manhole flange is provided with a cylinder; a piston rod of the cylinder is matched with a fixed hole on the manhole cover; and a manual safety interlocking device is arrangedbetween the manhole flange and the manhole cover. The teeth structure is arranged between the manhole cover and the manhole flange, and the manhole cover can be opened by rotating by a tooth so as tohave convenient opening and closing and quick speed; and the manual safety interlocking device is matched with the cylinder to realize the safety interlocking function of the quick-opening device.

Owner:WUXI DONGBAO MACHINERY MFG

Device and method for applying a preparation to threads

InactiveCN1969069AWill not polluteUniform atomizationTextile treatment containersFilament/thread formingEngineeringBiomedical engineering

Owner:天科部件有限公司

Coating porous carriers

InactiveUS6077351ASimple and flexibleEasy to adjustLiquid surface applicatorsTextile treatment with treating outlet contectDevice formThin layer

The invention relates to an apparatus for applying, by means of a slotted nozzle device formed between a stationary incoming nozzle lip and a trailing nozzle lip, a thin layer of coating material to a porous material web that passes over a counterpressure roll, wherein a doctor bar with an essentially circular cross-sectional shape is disposed on the trailing nozzle lip; this doctor bar has on its periphery at least one flattened section that runs across the entire longitudinal extension of the doctor bar and is rotatably supported within a doctor support so that the flattened section is adjustable at a setting angle relative to the counterpressure roll.

Owner:BEMATEC

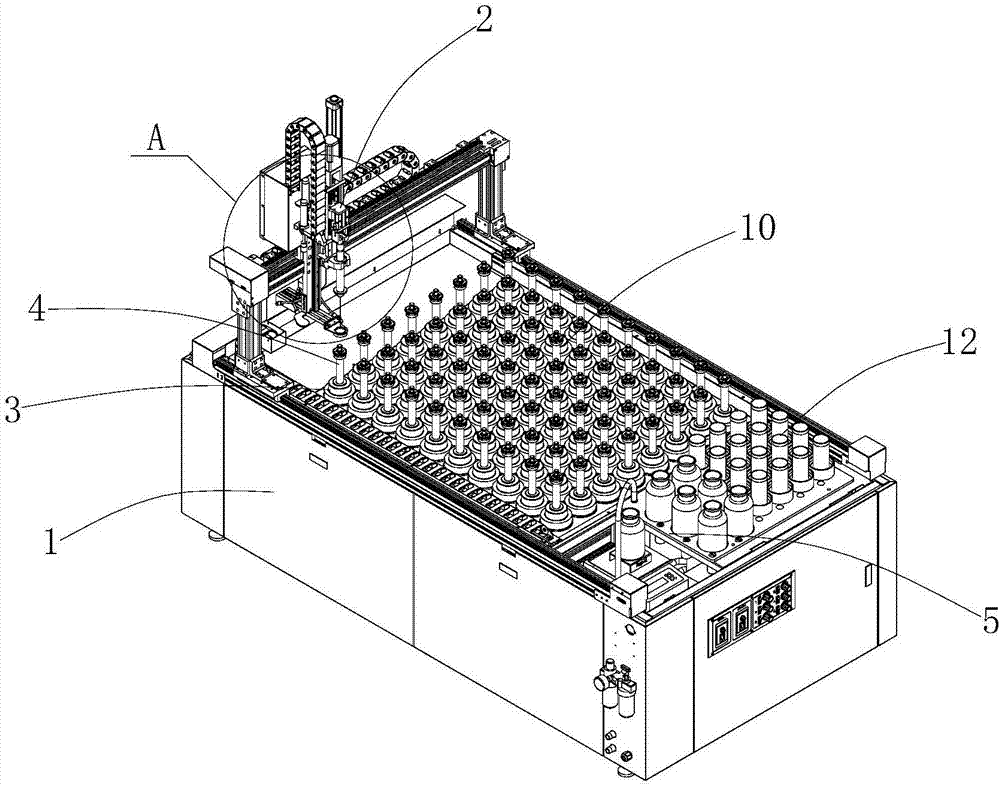

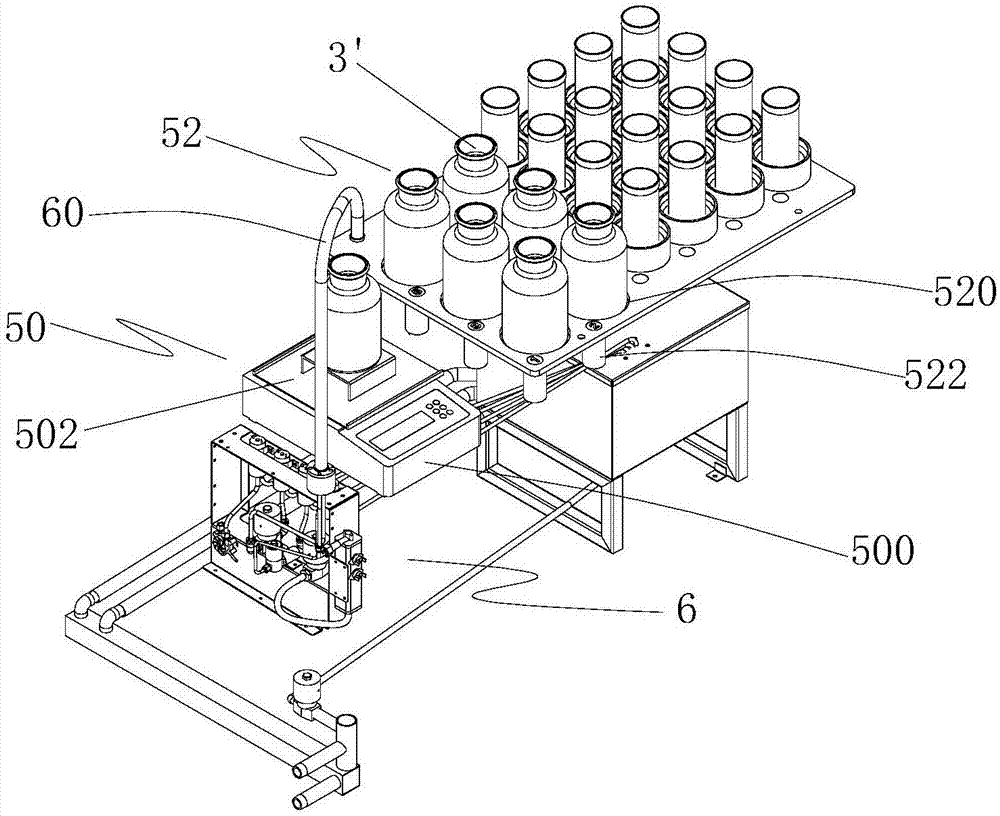

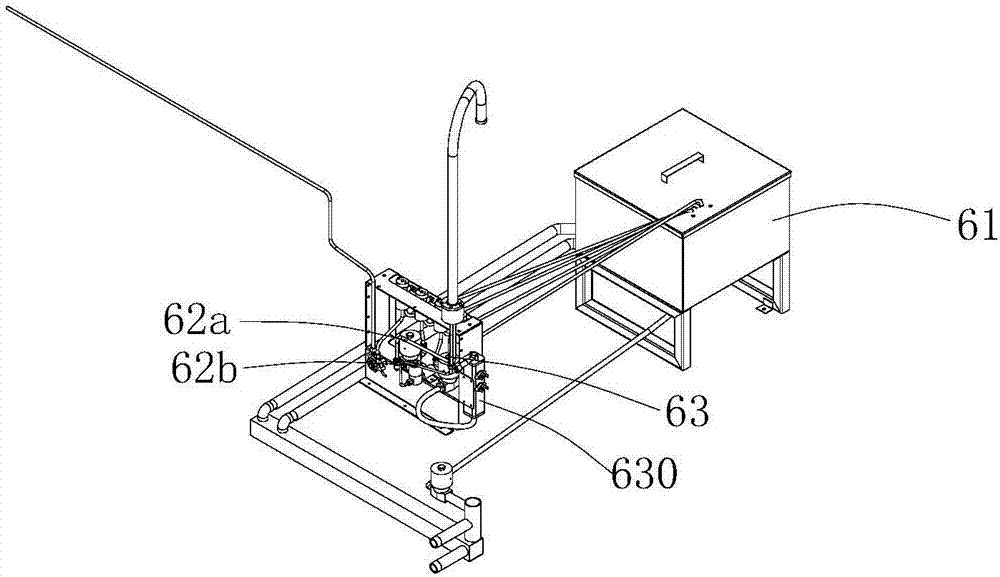

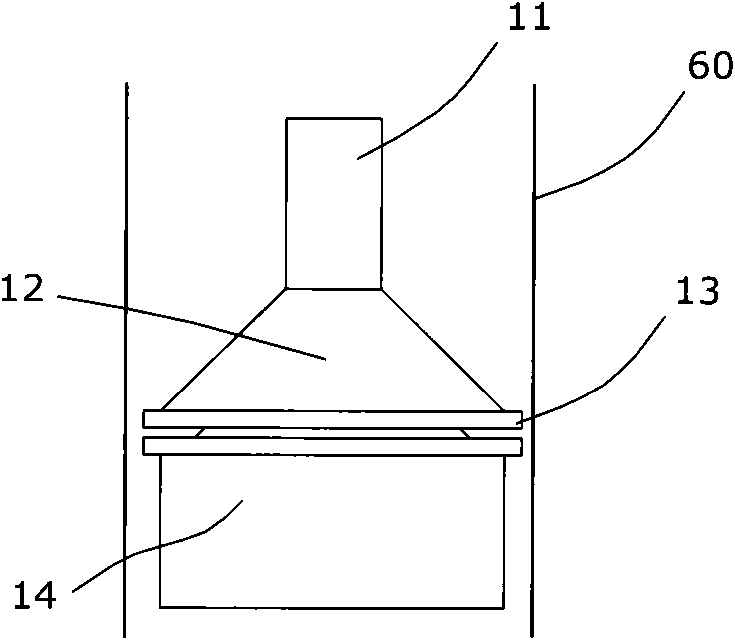

Printing and dyeing drip machine

InactiveCN107366105ALow costReduced placement spaceTextile treatment machine arrangementsTextile treatment with treating outlet contectEngineeringMagnetic stirrer

The invention relates to a printing and dyeing drip machine which comprises a machine body. A liquid taking area used for placing mother liquid bottles and a liquid blending area used for placing dyeing cups are arranged on the machine body, a triaxial manipulator is arranged above the liquid taking area, the triaxial manipulator and injectors are cooperatively used to deliver mother liquid to the dyeing cups in the liquid blending area, and the injectors are inserted into the corresponding mother liquid bottles; a liquid soaking area and a water charging system are further arranged on the machine body, the liquid soaking area includes a weighing area and a stirring area, a weighing unit is arranged in the weighing area, a plurality of positioning holes used for placing the mother liquid bottles are arranged in the stirring area, one magnetic stirrer is arranged correspondingly under each positioning hole, the water charging system is provided with a water outlet pipe, the water outlet of the water outlet pipe is arranged correspondingly to the weighing unit in the weighing area. By the arrangement, the problem that an existing drip machine does not have liquid soaking and stirring functions is solved.

Owner:厦门瑞比精密机械有限公司

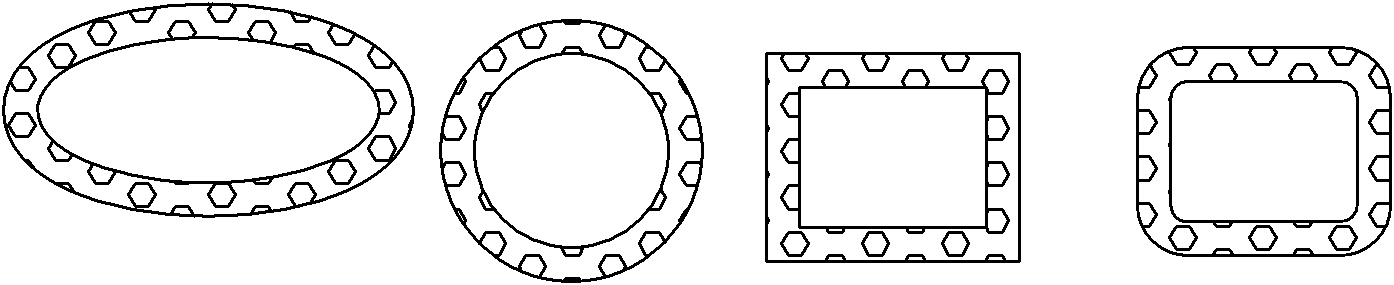

Foam application device for knitted fabric

ActiveCN101974835AUniform tensionNo edge curlingTextile treatment with treating outlet contectTextile treatment carriersUltrasound attenuationMaterials science

The invention discloses a foam application device for a knitted fabric. The device comprises a foam main pipe, a foam distribution part, a foam application part and a support body, wherein the foam distribution part is communicated with the foam main pipe, and a foam flow passage is formed in the foam distribution part; the foam application part is communicated with the foam distribution part and provided with an outlet; and the outlet of the foam application part is an integrally circular slit and is close to the peripheral surface of the support body, and the length of the path between the foam main pipe and any point on the circumference of the circular outlet is equal. By adopting the application device of the invention, the fabric can be finished before scotching, the tension of the treated fabric is uniform, and hemming is avoided. The path of the foam flow passage in the foam distribution part is kept equal, so the foam attenuation degree is consistent, and the treated degree of each part of the fabric is uniform.

Owner:上海虹馨管理咨询有限公司

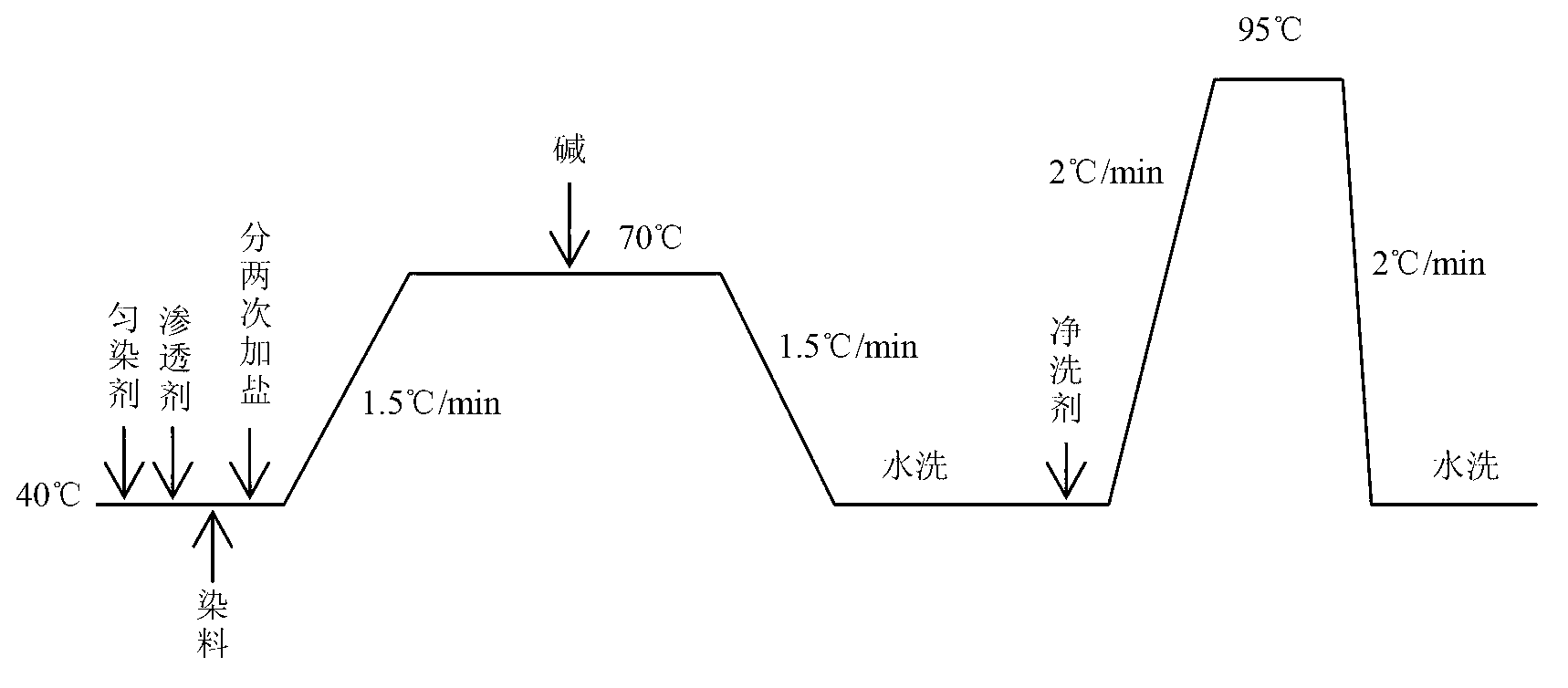

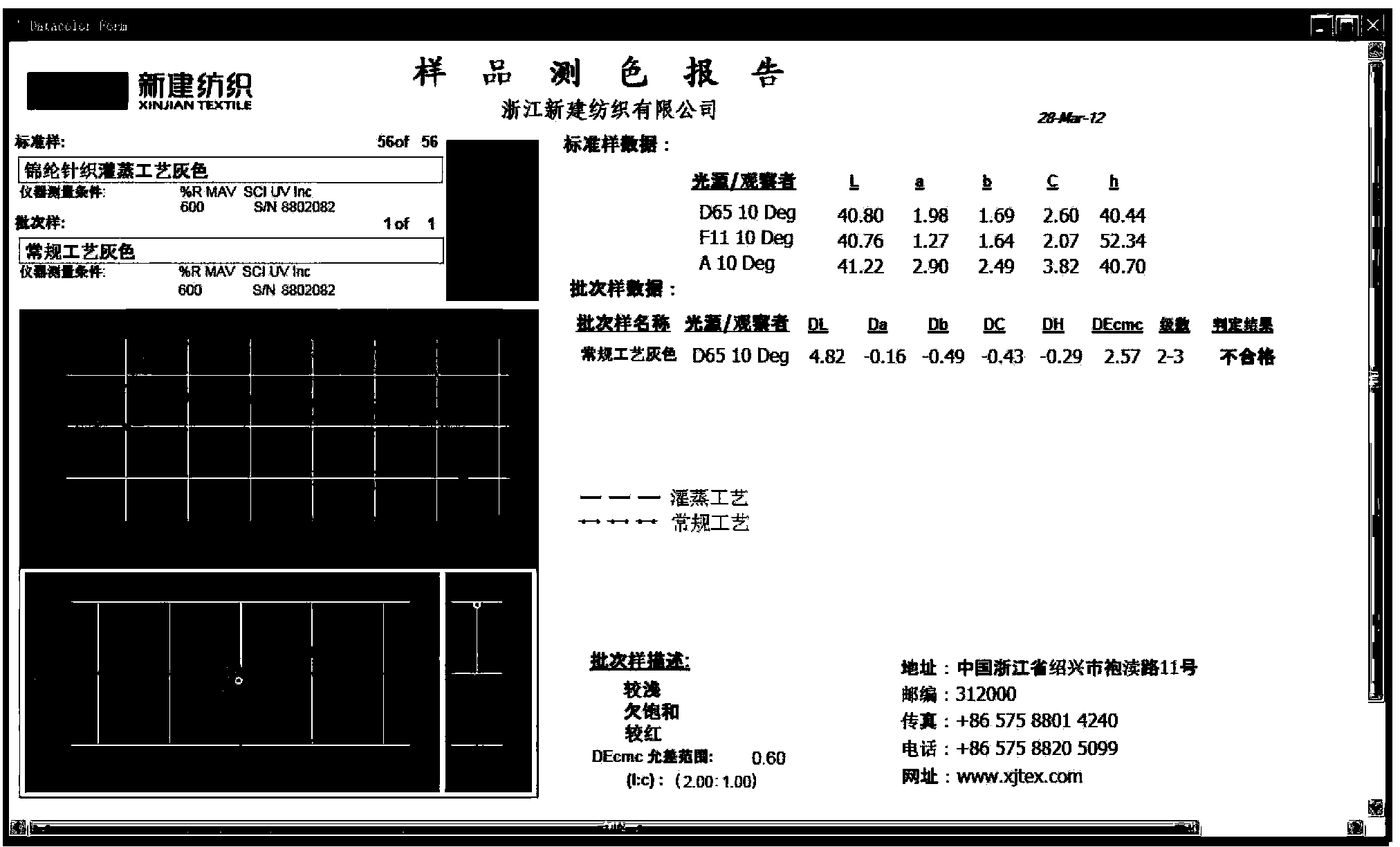

Chinlon or chinlon/cotton blended printed fabric and preparation method thereof

ActiveCN103572580AIncrease widthDoes not affect swathBleaching apparatusTextile treatment with treating outlet contectEngineeringVat dye

The invention discloses a chinlon or chinlon / cotton blended printed fabric and a preparation method thereof. The preparation method comprises the steps of (1) boiling and bleaching a gray fabric which is a chinlon fabric or chinlon / cotton blended printed fabric; (2) printing the gray fabric subjected to boiling and bleaching, wherein when the gray fabric is the chinlon fabric, a printing paste for printing is a neutral dye, and when the gray fabric is the chinlon / cotton blended printed fabric, the printing paste for printing is a mixture of the neutral dye and a reduced dye; (3) steaming and soaping the fabric obtained after printing treatment, and then drying to obtain a product. The printed fabric provided by the invention is full, rich and bright in color and high in color fastness, and has a clean cloth cover, clear pattern outlines and stable product quality.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME +1

Oscillatory water current type water washing machine

InactiveCN102808297AImprove laundry qualityImprove decontamination abilityTextile treatment with treating outlet contectTextile treatment rollersWater flowPulp and paper industry

The invention discloses an oscillatory water current type water washing machine, which comprises a fabric guiding roll, an outer barrel, an inner shaft barrel, a water tank, a tensioning roll, an impregnating mangle and a frame. The frame is connected with the impregnating mangle to form a rectangular framework; the water tank is mounted in the frame; and the fabric guide roll and the tensioning roll are arranged inside and outside the water tank to form a water washing structure in a routine driving condition. The outer barrel and the inner shaft barrel which are coaxially sleeved are mounted at the middle part of the water tank; through holes are uniformly distributed on the wall of the outer barrel; concave-convex alternate ridges are uniformly distributed around the outer wall of the inner shaft barrel; two shaft ends of the inner shaft barrel stretch out from the middle parts of two end surfaces of the outer barrel to be matched with a shaft seat; and the inner shaft barrel forms a rotating structure driven by external power. In a rotation process, the volume of a section between the concave-convex ridges uniformly distributed around the outside of the inner shaft barrel and the inner wall of the outer barrel generates regular change, so that water current comes in and out from the through holes on the wall of the outer barrel alternately, and a washing effect is strengthened by oscillatory round-trip water current. According to the oscillatory water current type water washing machine, two washing structures are arranged in the same water tank in total; the weak washing transits to the strong washing; the washing quality is good; the efficiency is high; and the oscillatory water current type water washing machine is suitable to wash various grey fabrics.

Owner:泰州科世茂工程设备有限公司

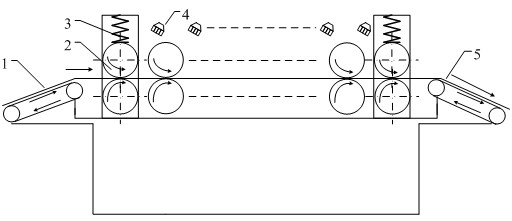

Sizing machine

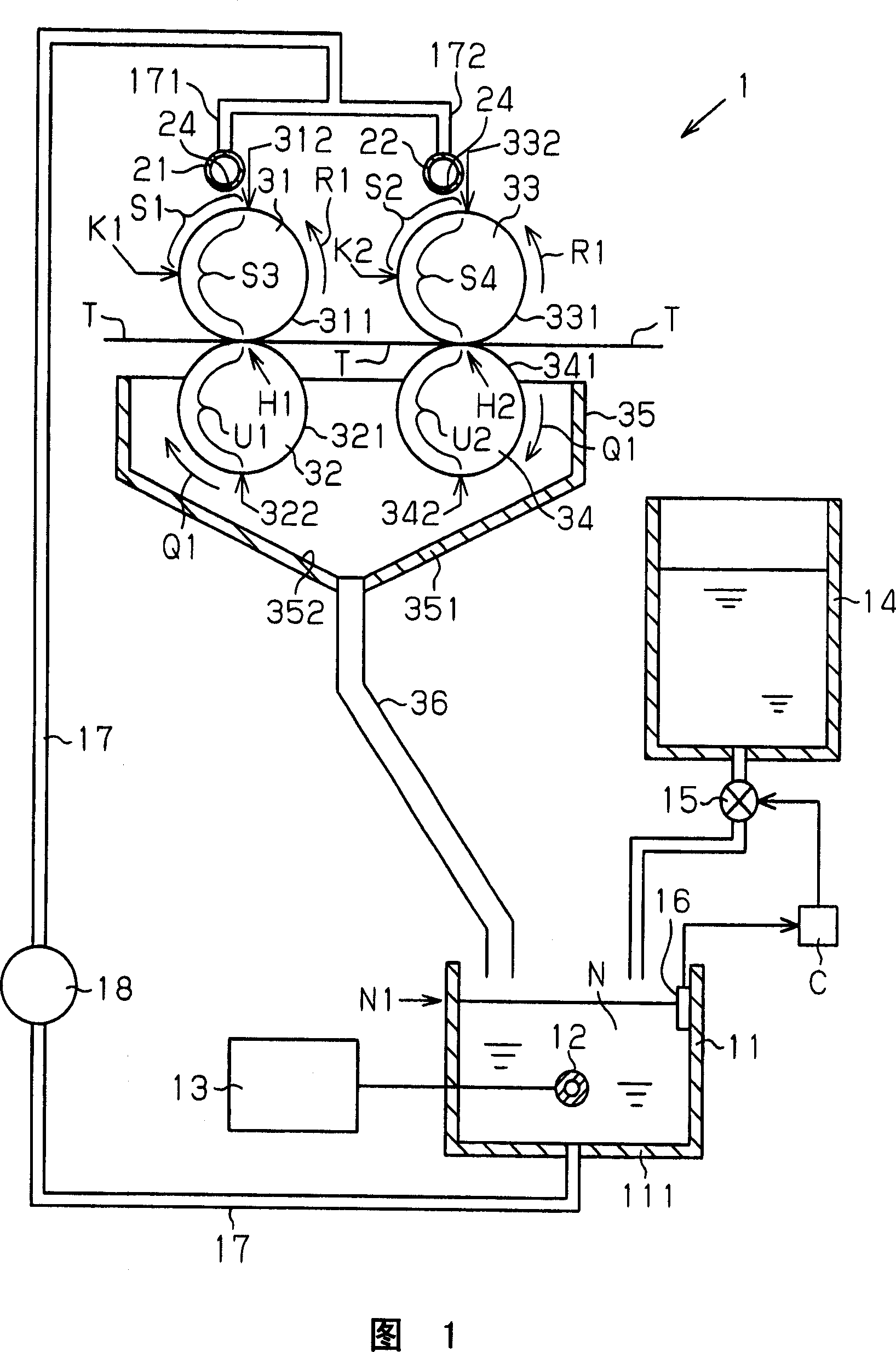

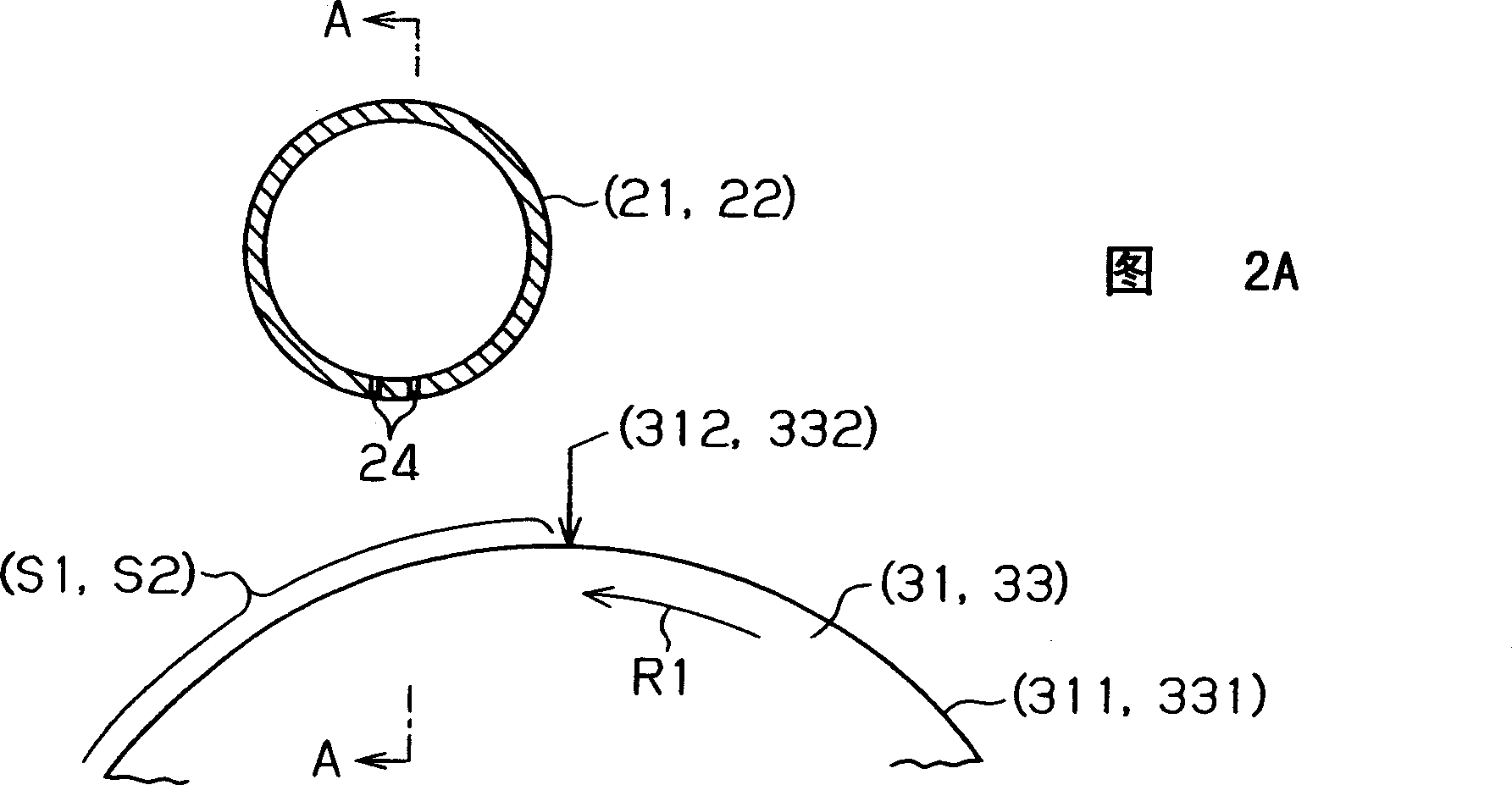

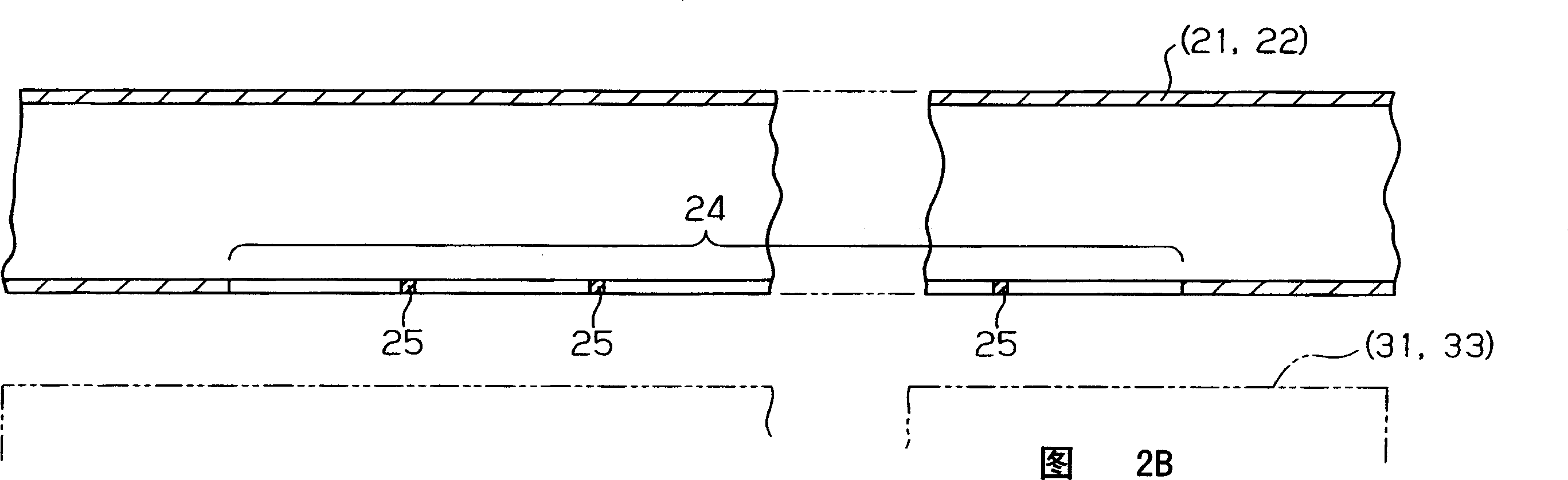

The present invention relates to a sizing machine that performs sizing by passing warp threads to which sizing solution has been applied through a pair of cylindrical squeeze rollers, thereby squeezing the sizing solution from the warp threads by means of squeezing effect of the squeeze rollers. The sizing machine includes a cylindrical size supplying device. The size supplying device supplies sizing solution either to a circumferential surface of the roller that is located above the warp threads passing through between the pair of rollers or to an upper side of the warp threads located upstream of the rollers. The size supplying device has discharge holes for discharging the sizing solution. Each discharge hole is formed as a slit that extends along an axial direction of the size supplying device.

Owner:TOYOTA IND CORP +1

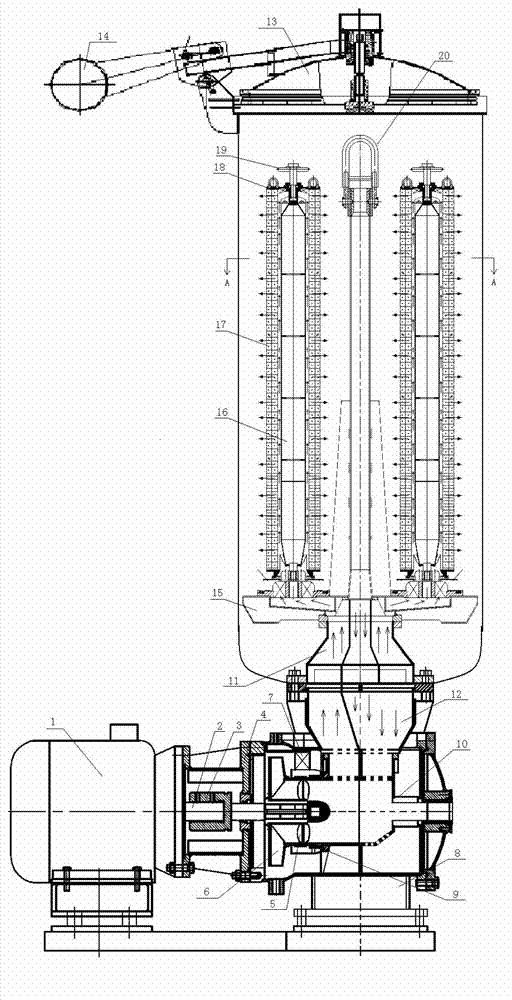

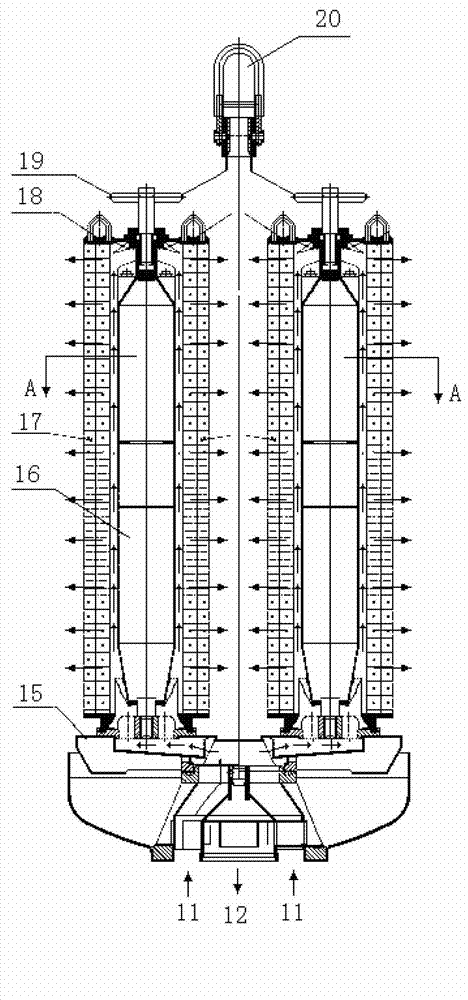

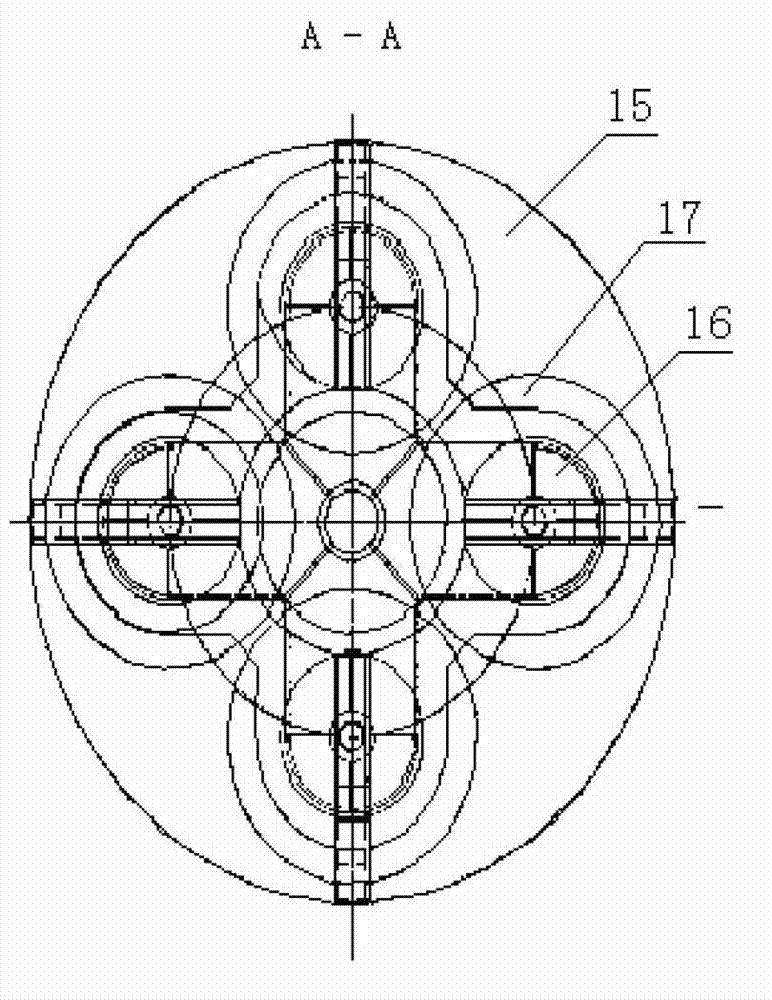

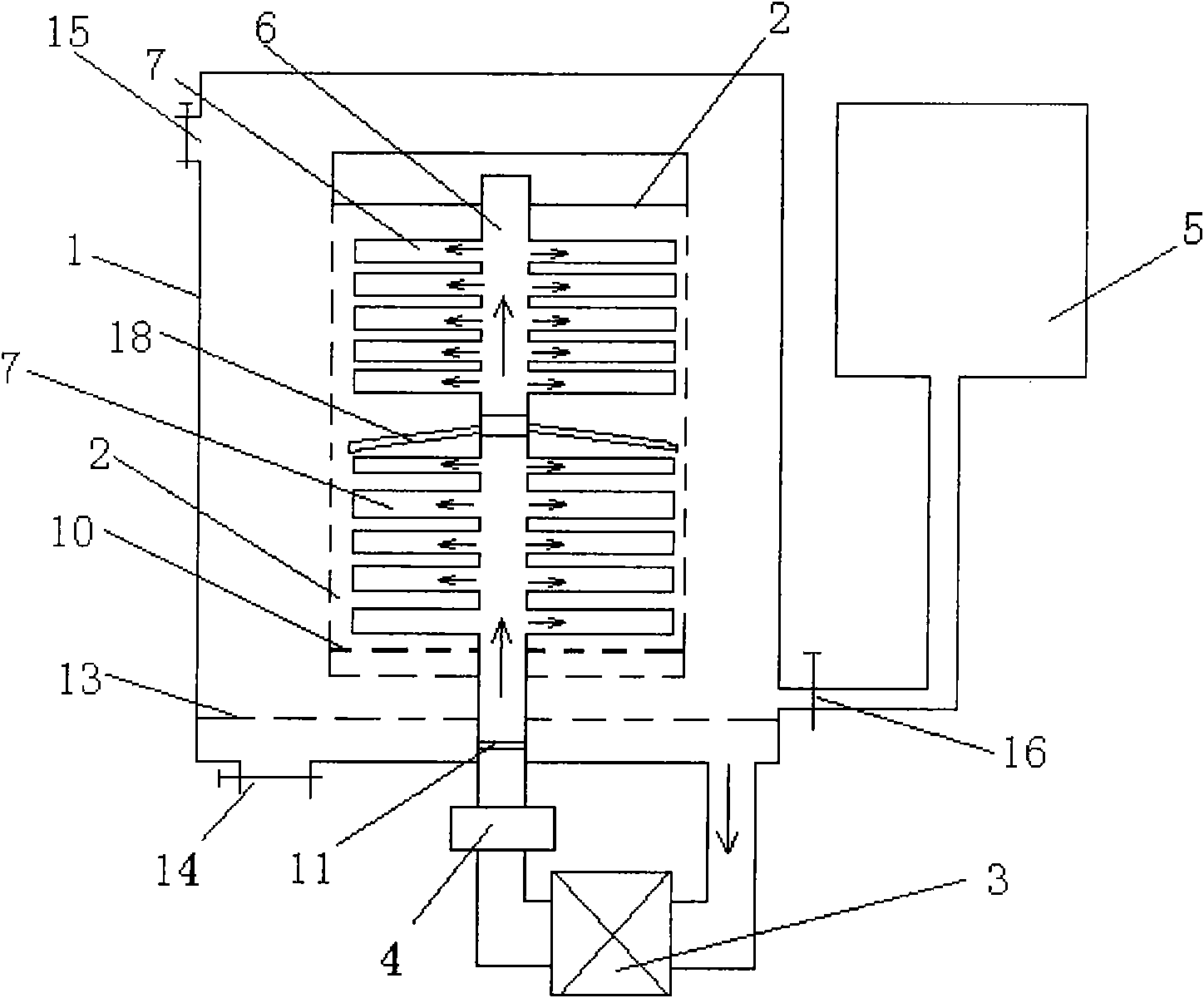

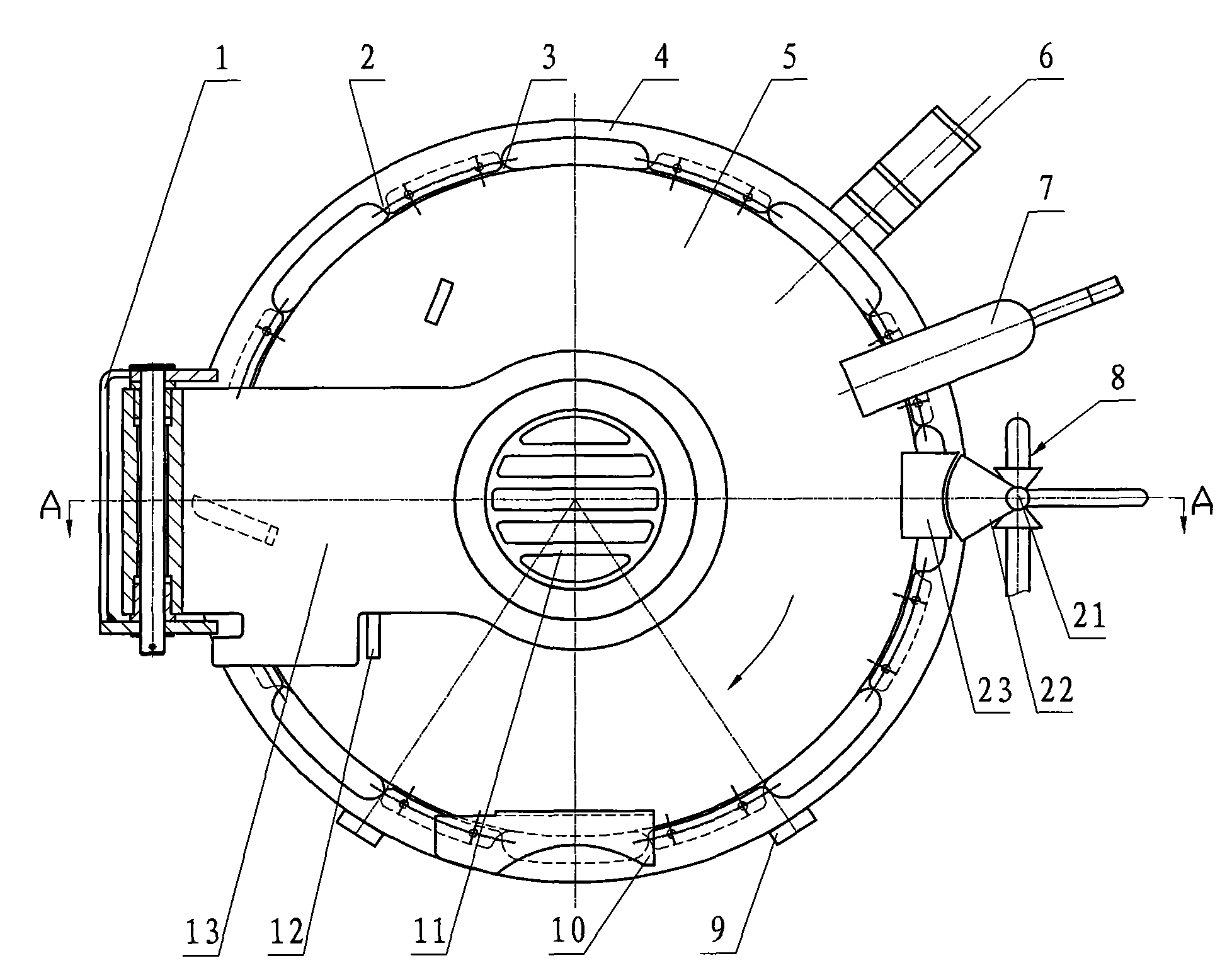

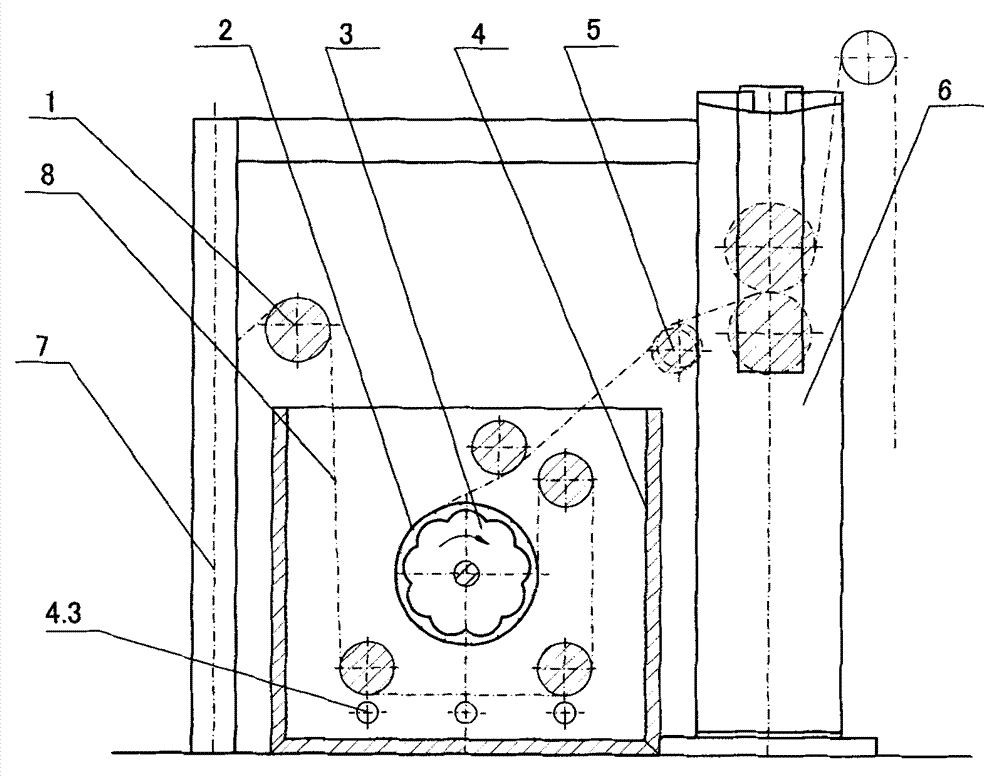

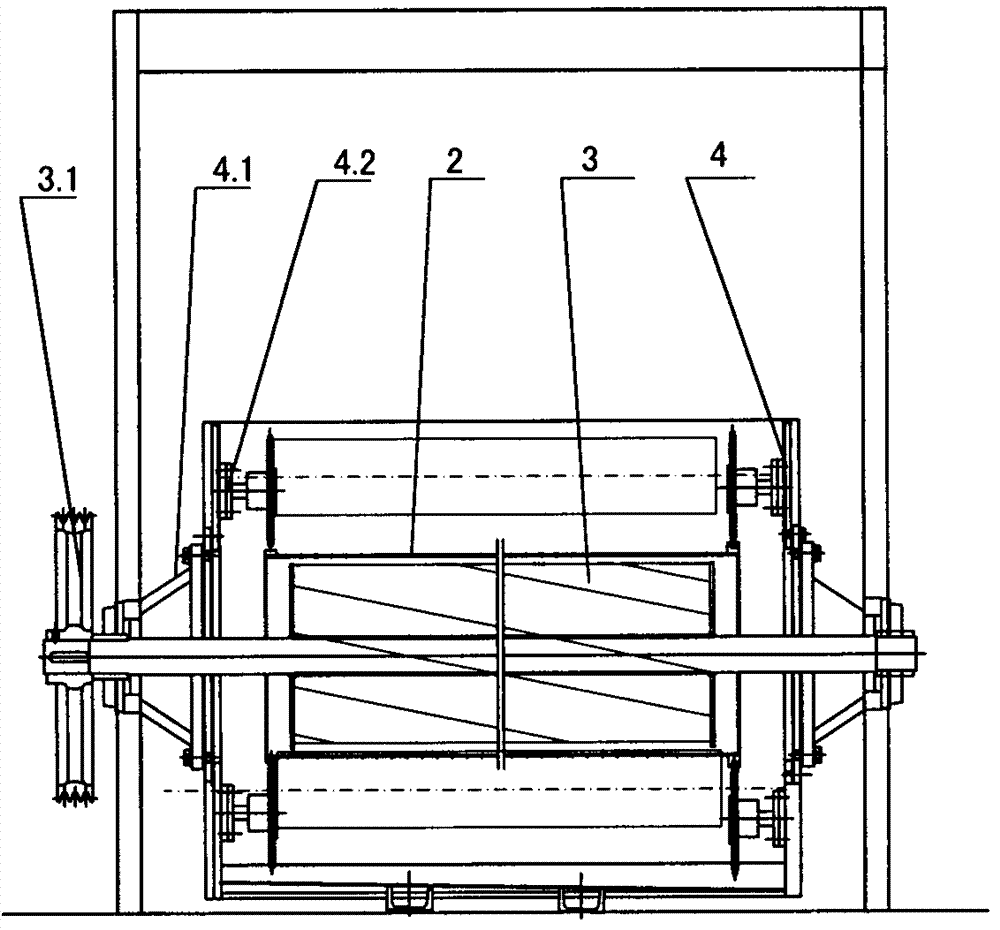

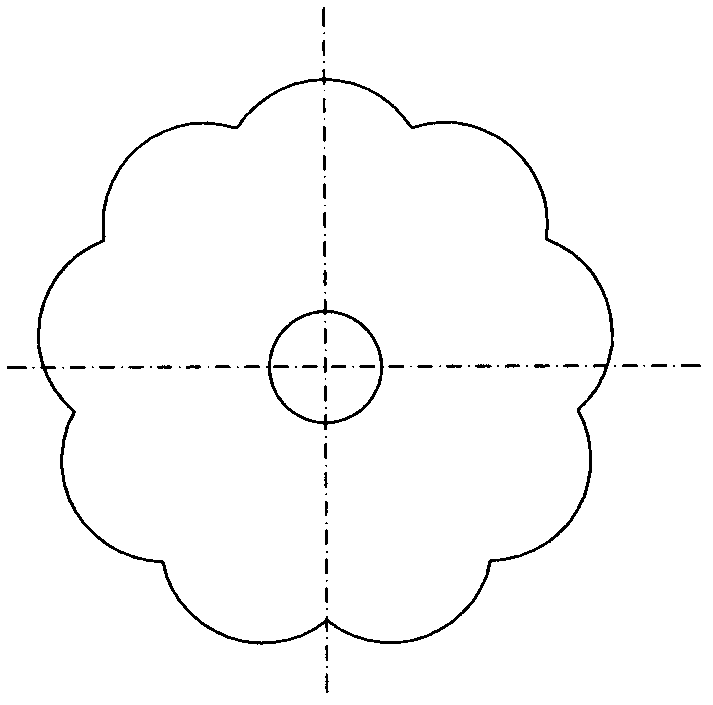

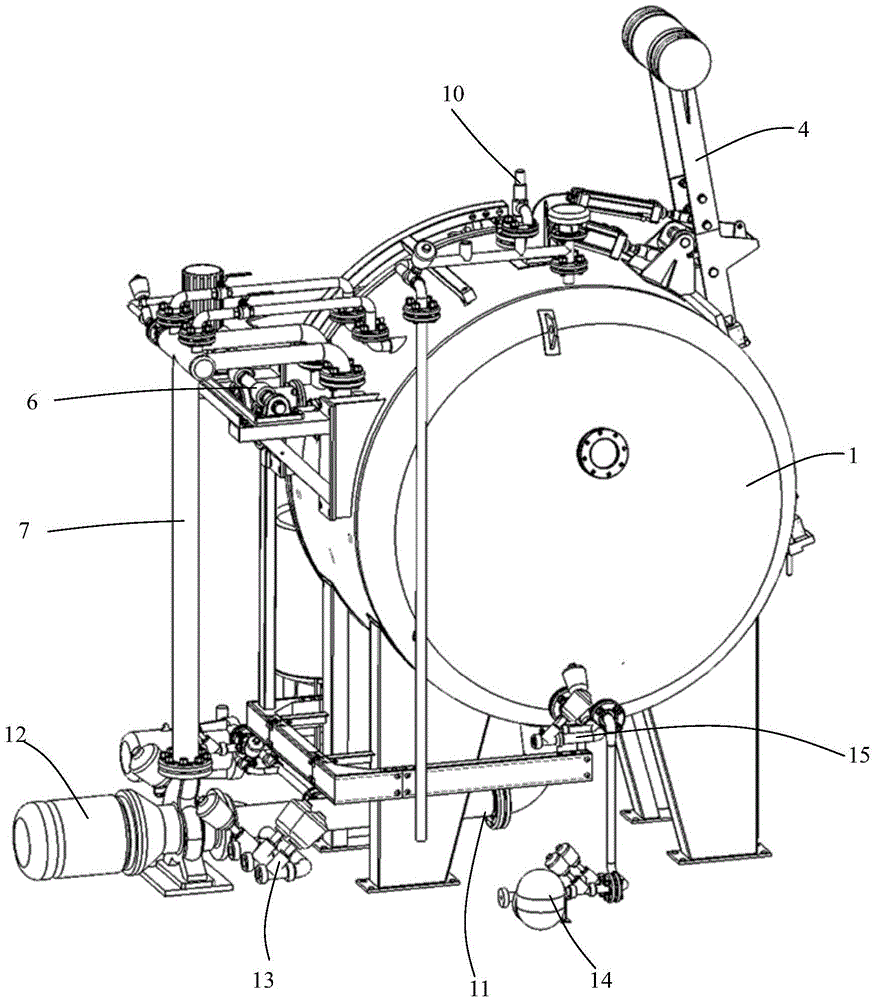

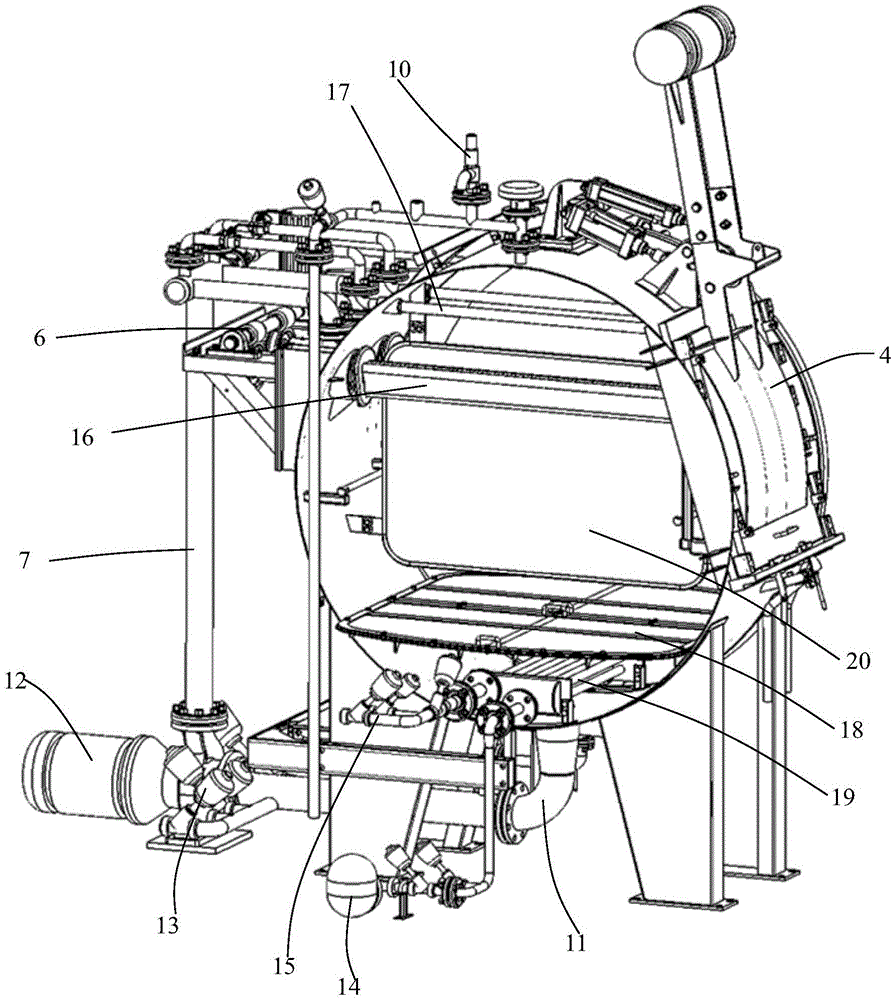

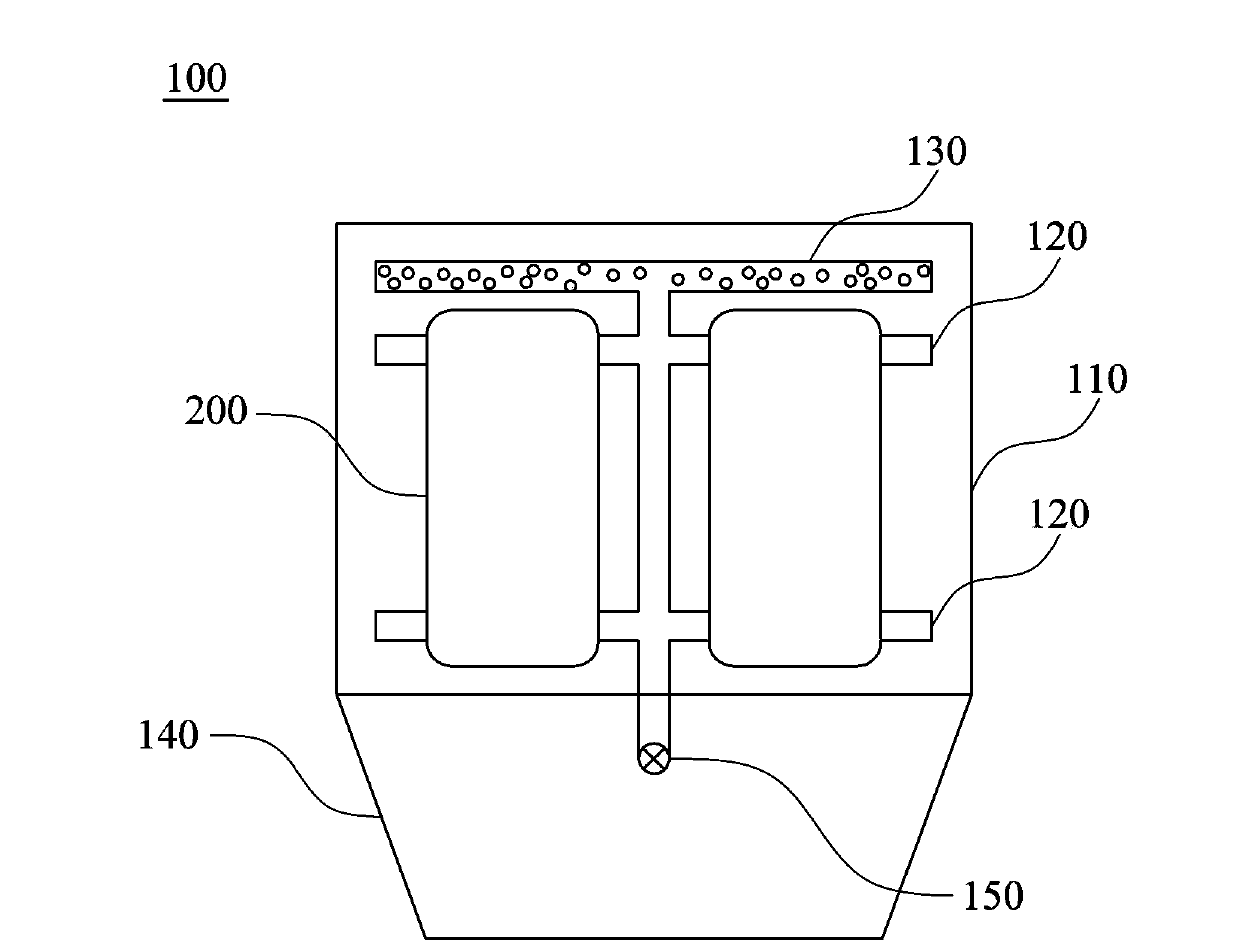

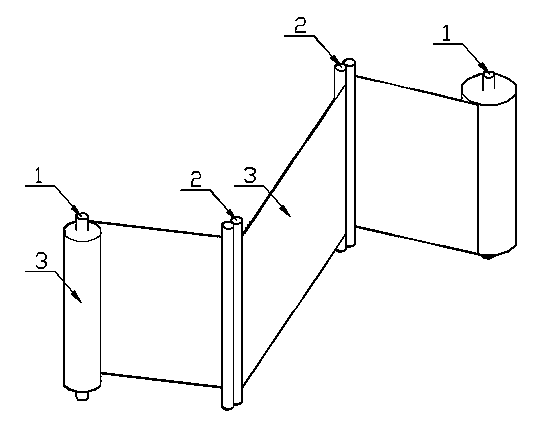

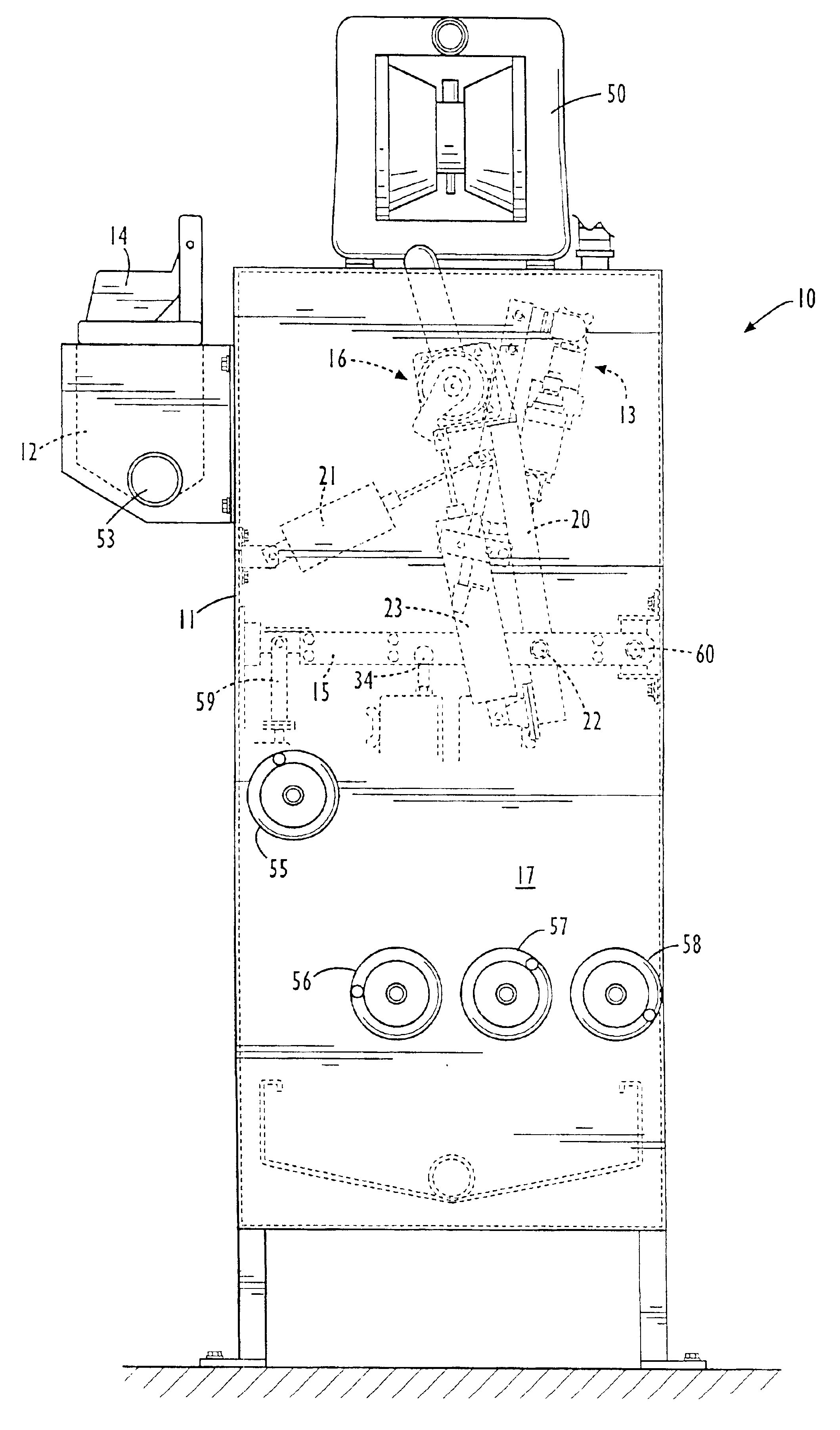

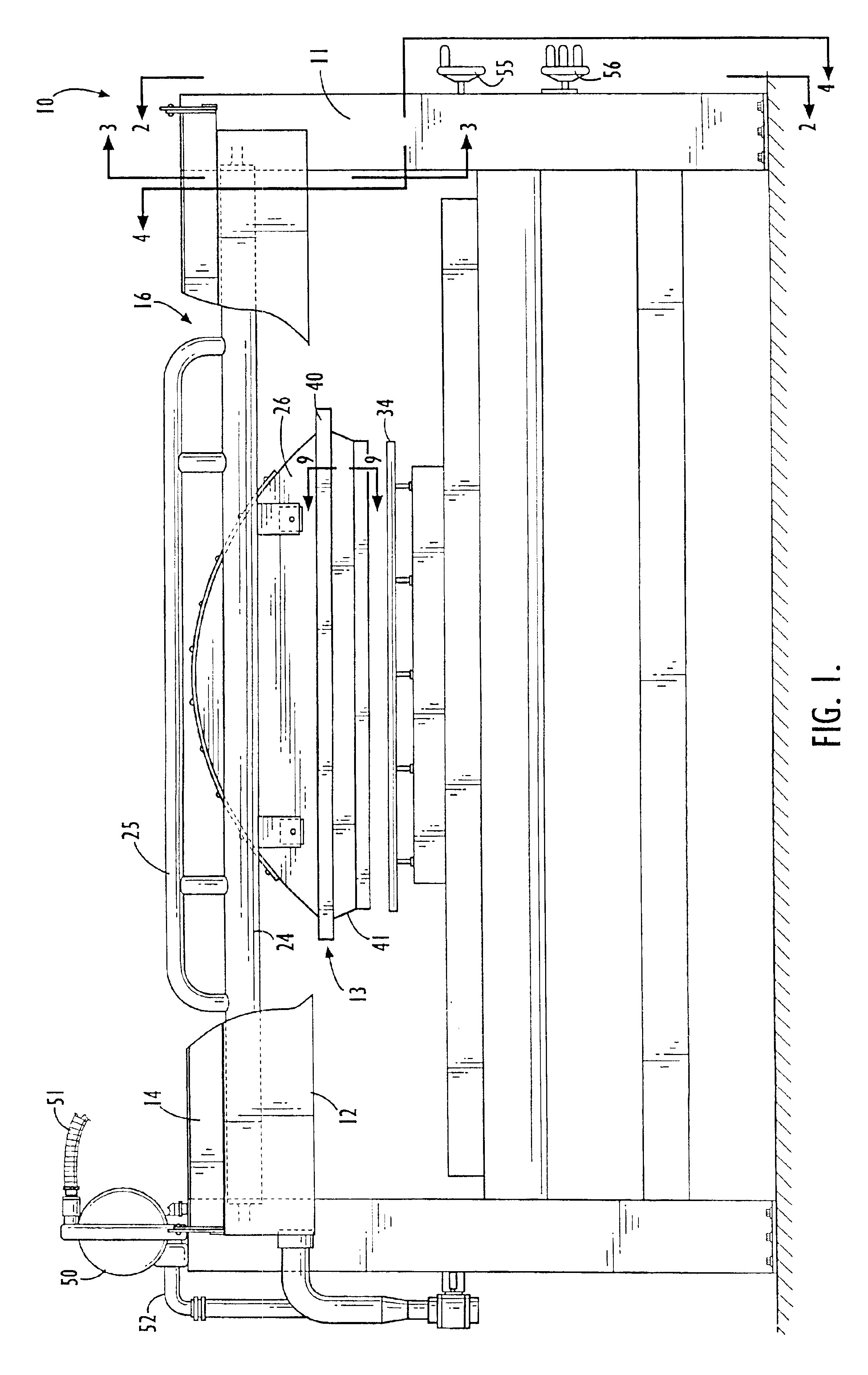

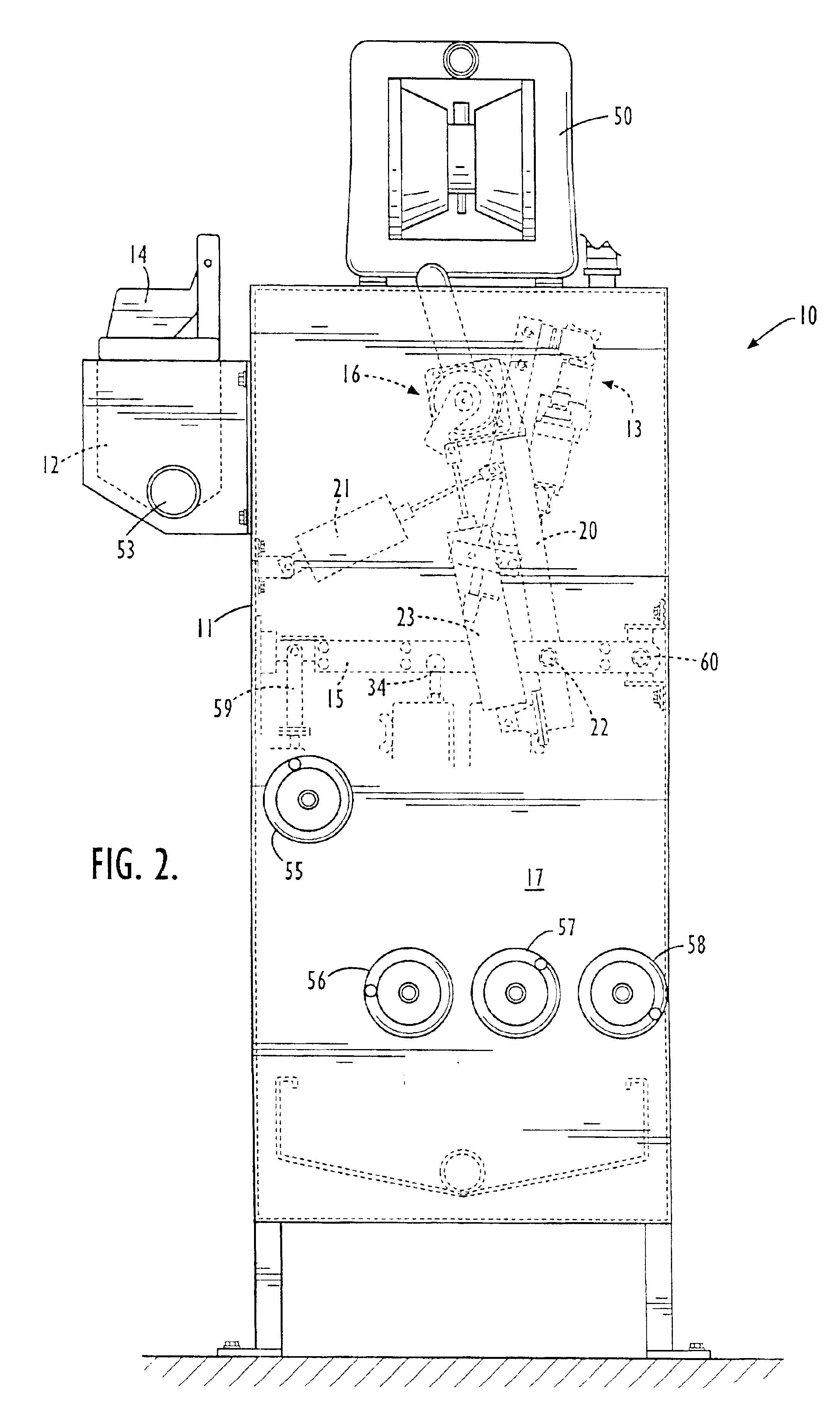

Low-bath-ratio high-temperature pulse type jet dyeing machine

ActiveCN105603654AControl flowControl pressureTextile treatment containersTextile treatment machine arrangementsSocial benefitsJet flow

The invention provides a low-bath-ratio high-temperature pulse type jet dyeing machine. The jet dyeing machine mainly comprises a main cylinder, an auxiliary cylinder, a liquid adding pump, a cylinder cover assembly, an auxiliary cylinder liquid return pipe, a movement system, a dye flow dividing pipe, a liquid level meter, a pressure meter, a decompression valve, a main cylinder liquid return pipe, a main pump, an adding valve set, a steam trap assembly, a coiled pipe steam inlet, a star-shaped spraying pipe, a sprinkler spraying pipe, a filter screen, a heat exchanger, a partition board, a spraying pipe support, a center pipe, a transmission shaft and other parts. According to the pulse type high-temperature jet dyeing machine, spray dyeing is conducted on fabric from the upper direction and the lower direction by means of the star-shaped spraying pipe and the sprinkler spraying pipe, and dyeing uniformity can be effectively improved. A central control system controls the jet flow and pressure of dye liquid according to properties of the fabric and fabric winding thickness, and accordingly dyeing quality can be effectively controlled. The jet dyeing machine can obviously save auxiliaries and dye, reduces waste liquid discharge, and has extremely remarkable economic and social benefits.

Owner:高勋绿色智能装备(广州)有限公司

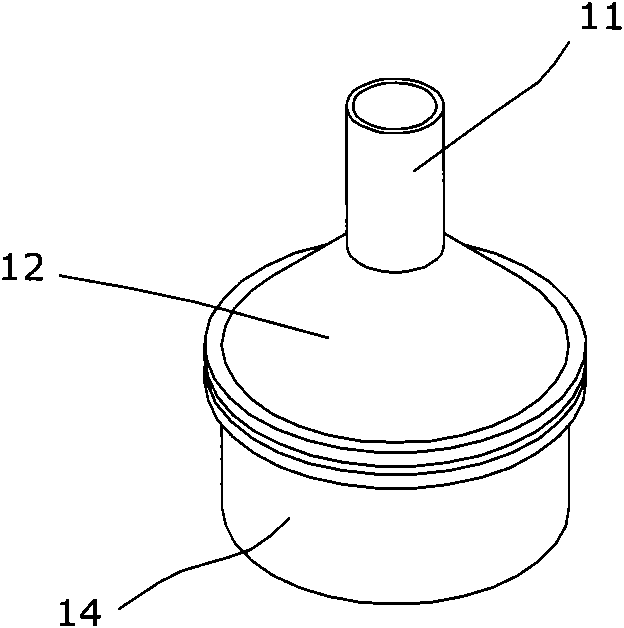

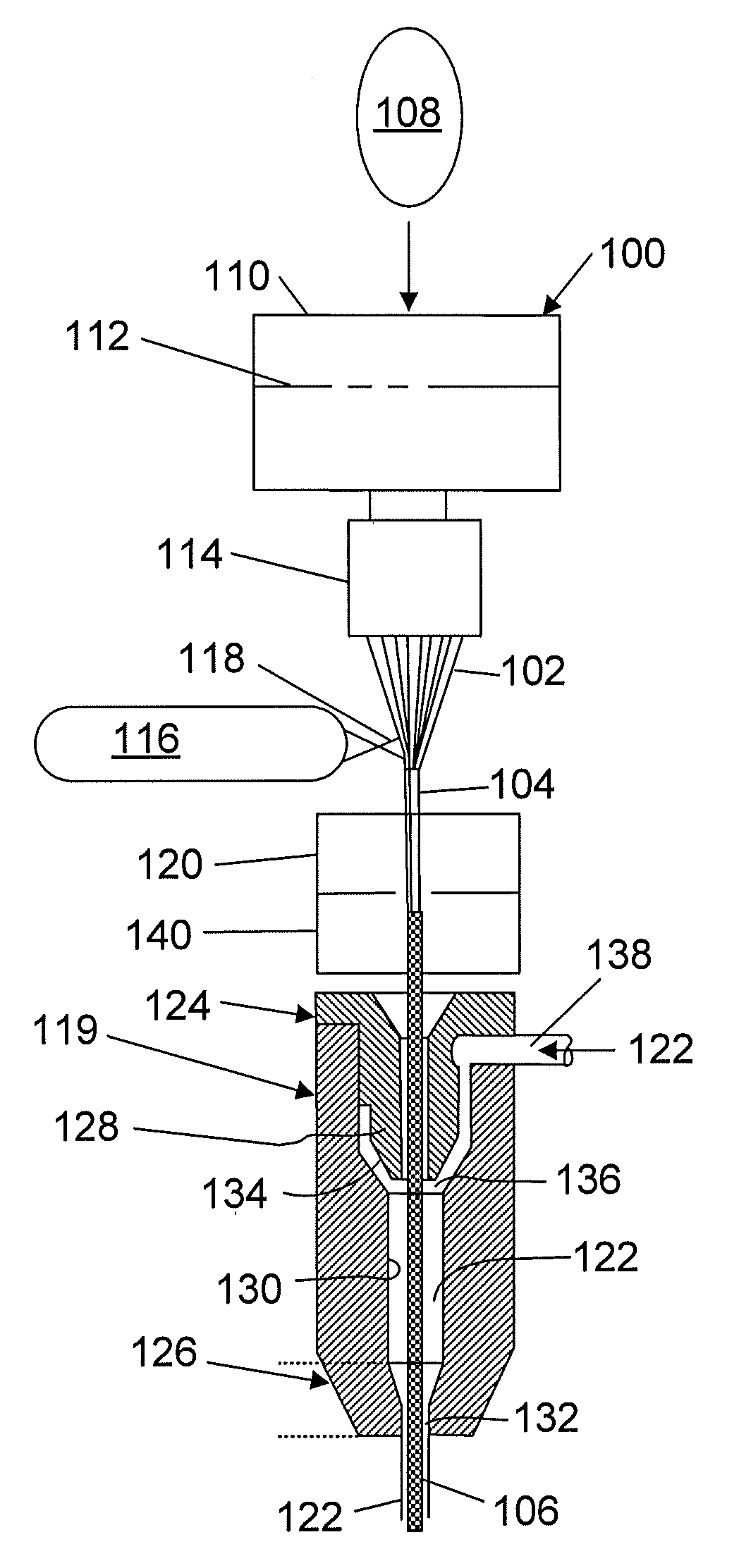

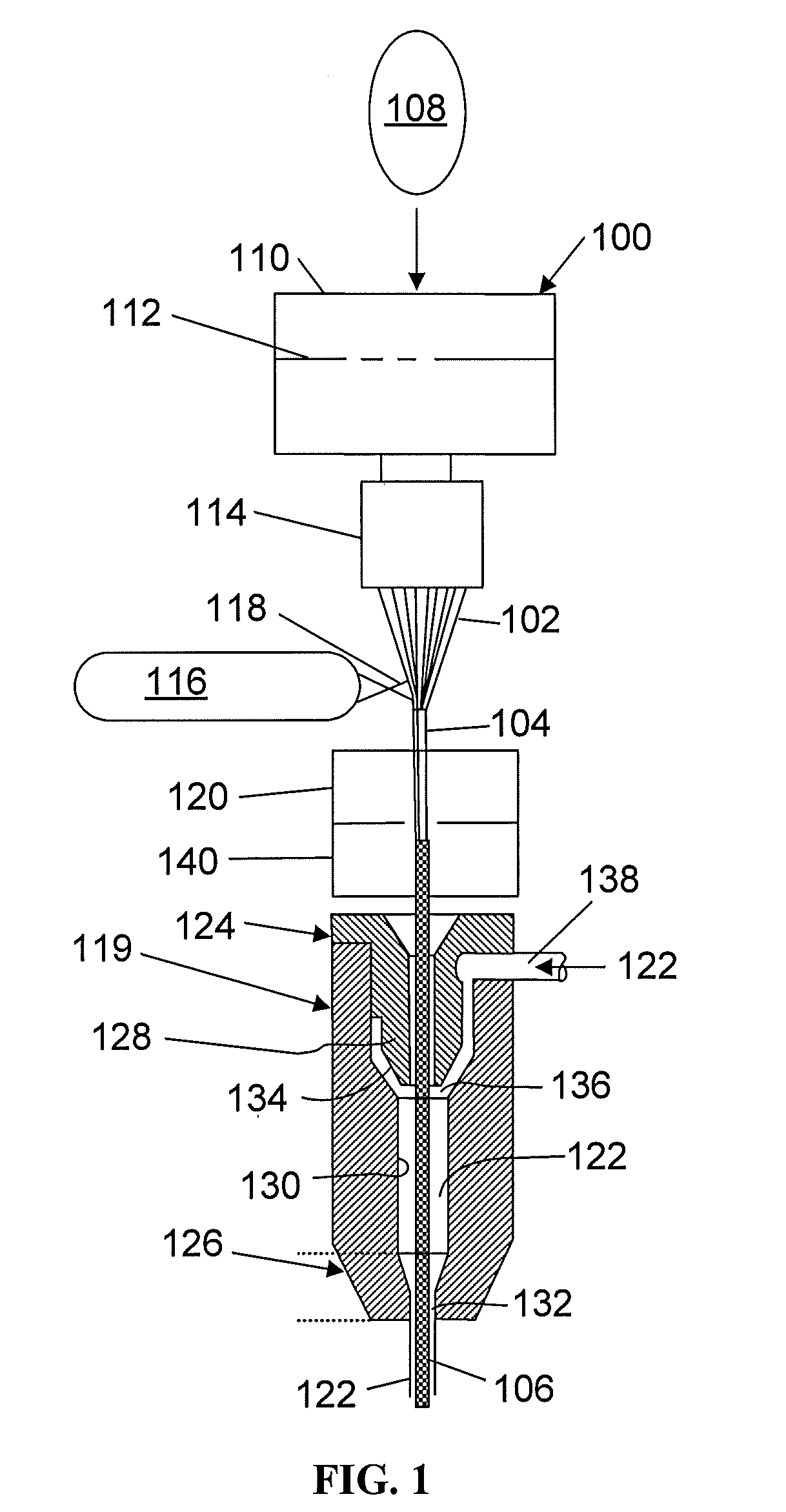

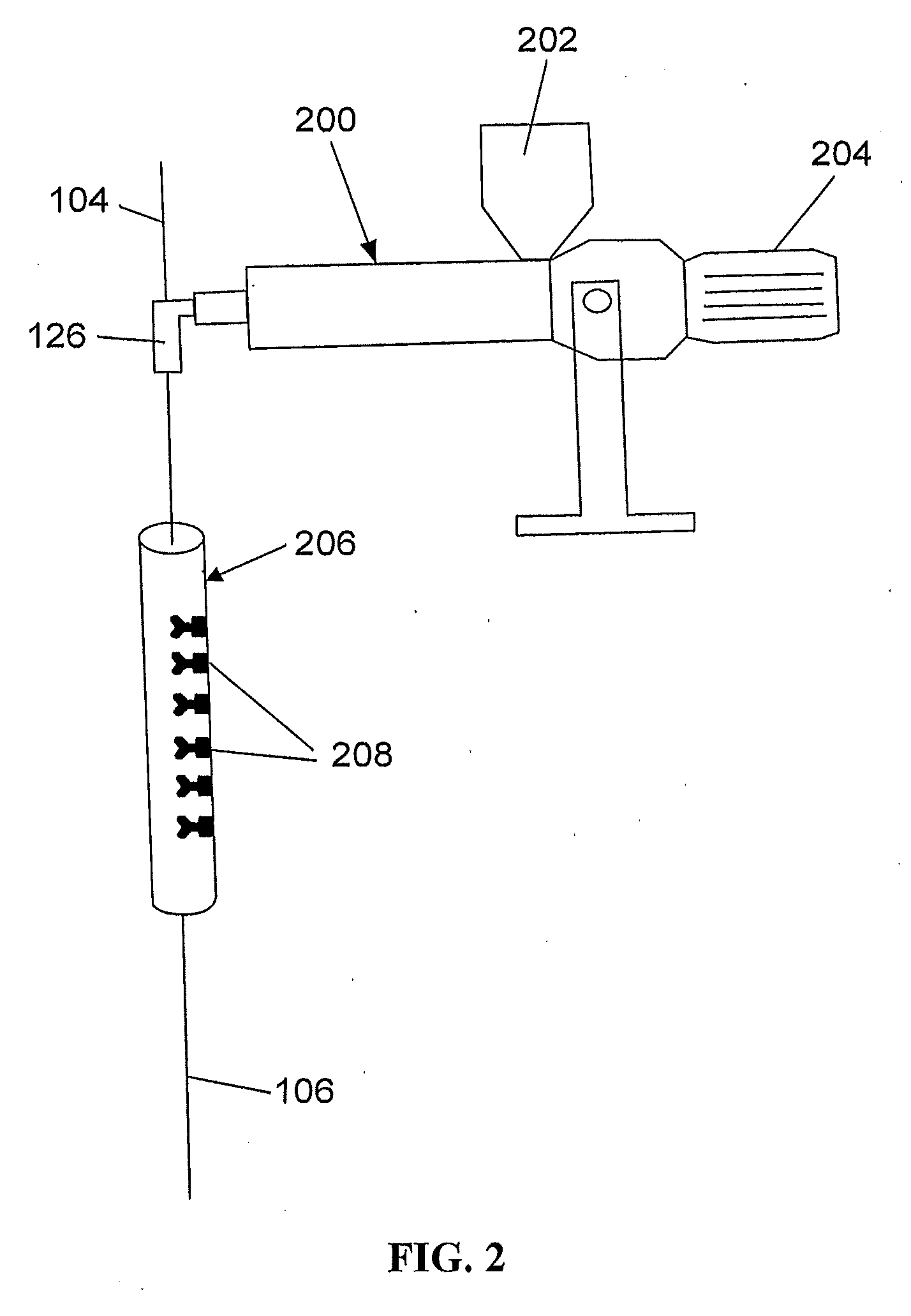

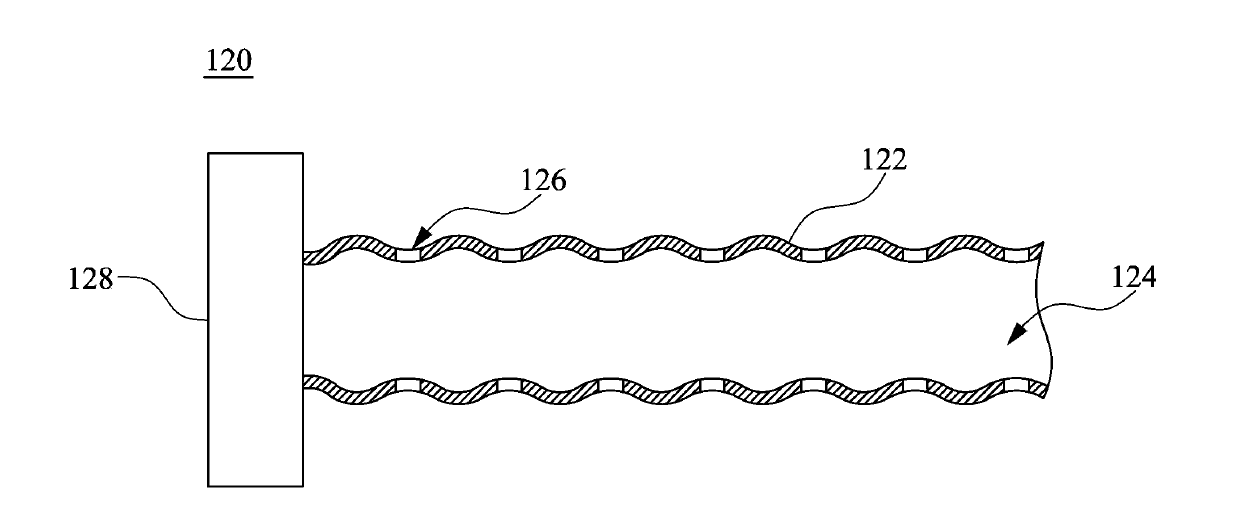

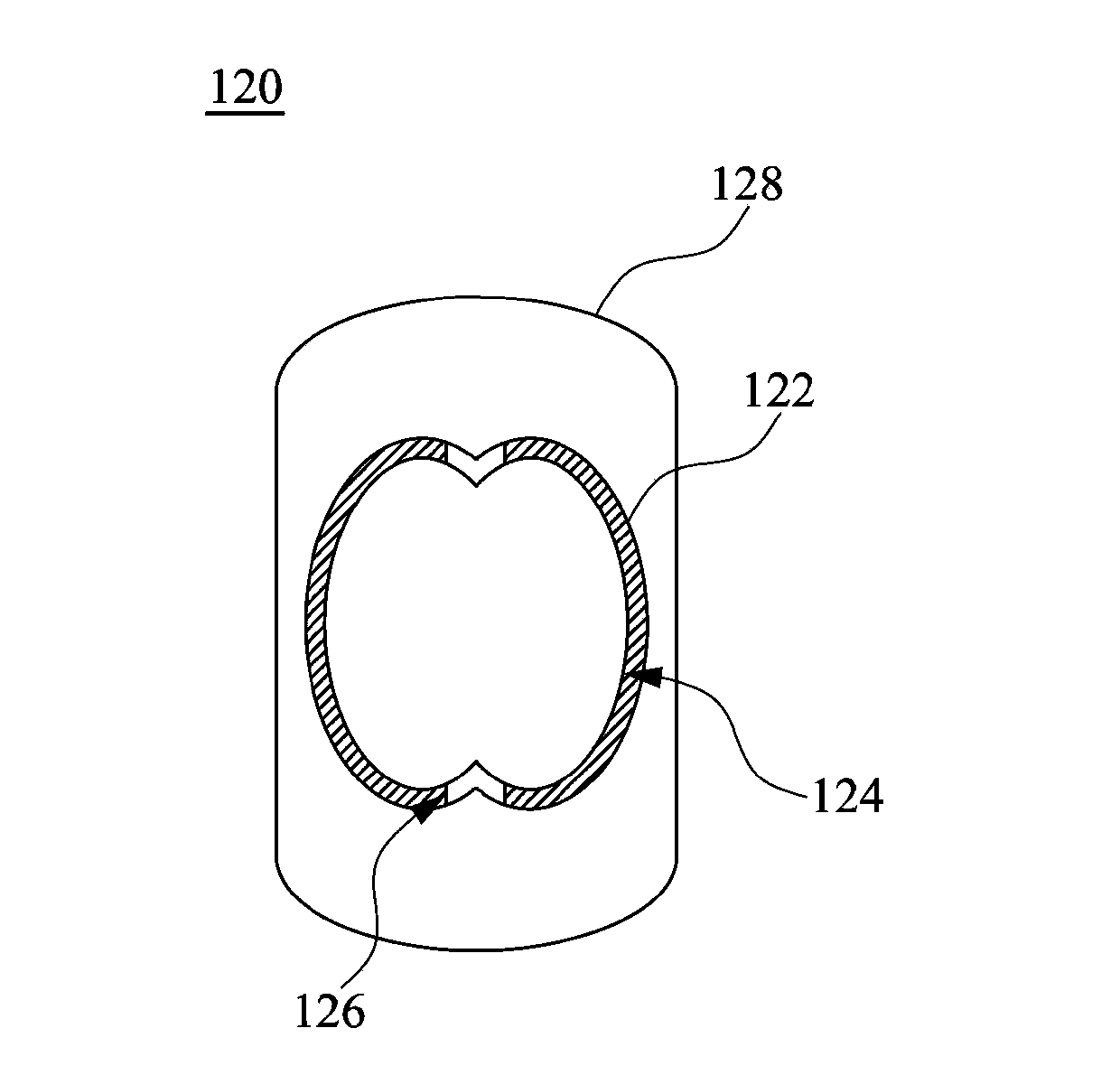

Spinning head and method for preparing braided tube/polymer composite membrane by using spinning head

ActiveCN103015082AUniform thicknessImprove bindingSemi-permeable membranesTextile treatment with treating outlet contectBurst pressureCASK

The invention discloses a spinning head and a method for preparing a braided tube / polymer composite membrane by using the spinning head. The spinning head comprises a shell and a cover plate, wherein the cover plate is arranged at the top part of the shell; the cover plate is provided with a fiber braided tube inlet, a pressurizing hole and a film casting liquid inlet; the fiber braided tube inlet is connected with an internal catheter extending to the bottom part of the shell; the bottom part of the shell is provided with a film casting liquid outlet; the film casting liquid outlet is connected with a spinning jet; the shell is of a double-layer cask-shaped structure; an inner layer cask forms a film casting liquid cavity; a cavity between an outer layer cask and the inner layer cask forms a circulating bath heating cavity; and side walls of the outer layer cask are respectively provided with a circulating bath inlet and a circulating bath outlet. According to the spinning head disclosed by the invention, through the centralized positioning and pre-coating action of the internal catheter and a braided tube channel on the spinning jet on the braided tube, the evenness of a polymer coating on the surface of the braided tube is effectively improved, and a binding force between the braided tube and the coating is enhanced. Moreover, the discharge rate of film casting liquid is controlled through nitrogen pressurization, and thus, the coating uniformity can be further ensured. The prepared braided tube / polymer composite membrane is higher in mechanical strength and burst pressure.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

Extrusion coated non-twisted yarn

The present invention provides a non-twisted yarn and an extrusion coated reinforcement yarn and their methods of manufacture, by coating non-twisted glass filaments with a sizing composition and combining the filaments together side-by-side to provide a sized non-twisted yarn, wherein the sizing composition becomes ductile in a molten thermoplastic resin to free the non-twisted glass filaments for radially inward movement while in the molten thermoplastic resin to provide the non-twisted yarn with an essentially round cross-section suitable for extrusion coating with the molten thermoplastic resin.

Owner:SAINT GOBAIN ADFORS CANADA LTD

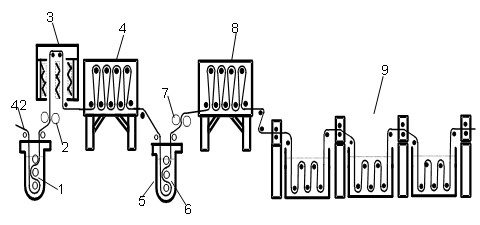

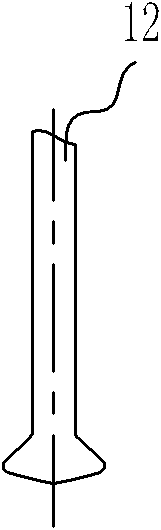

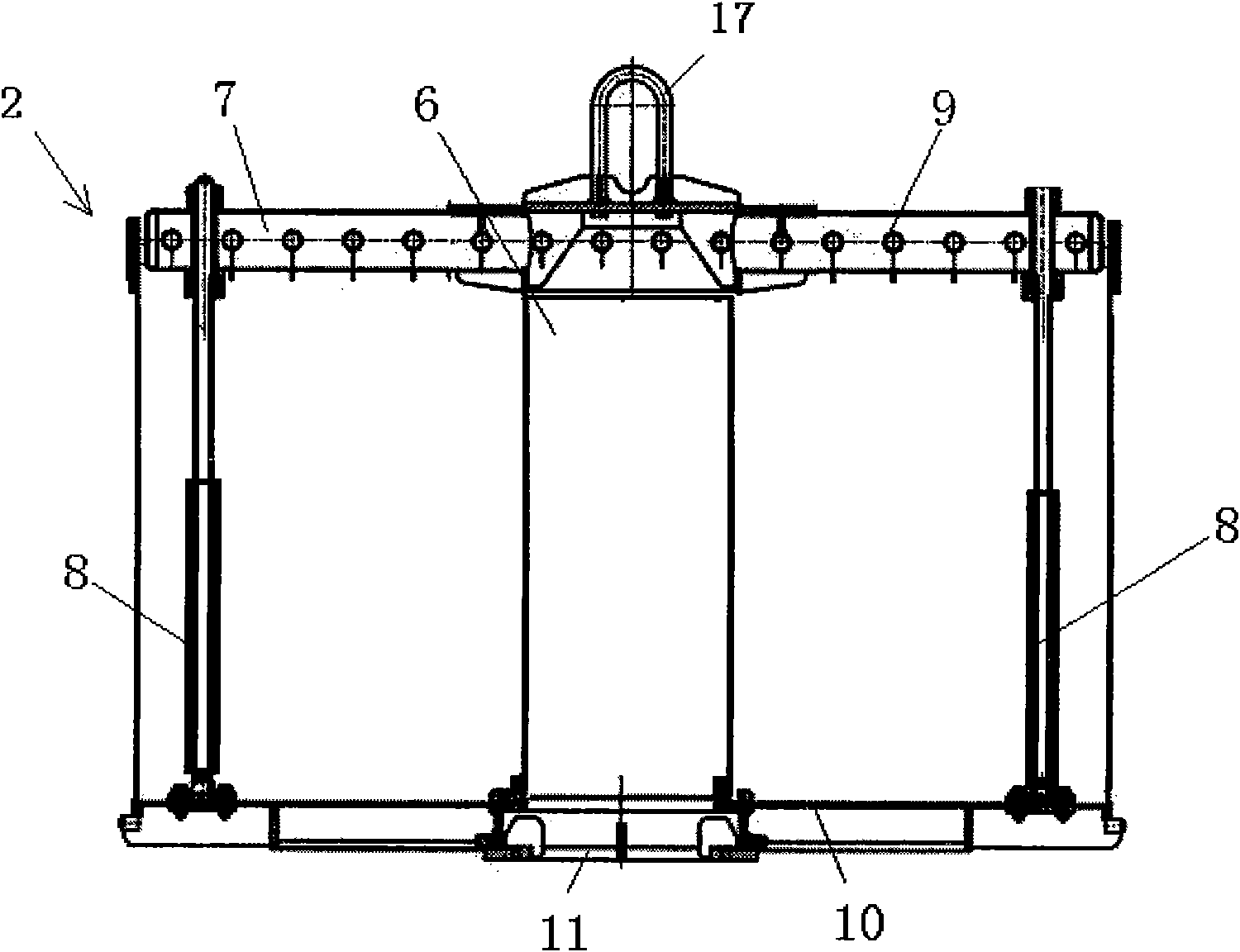

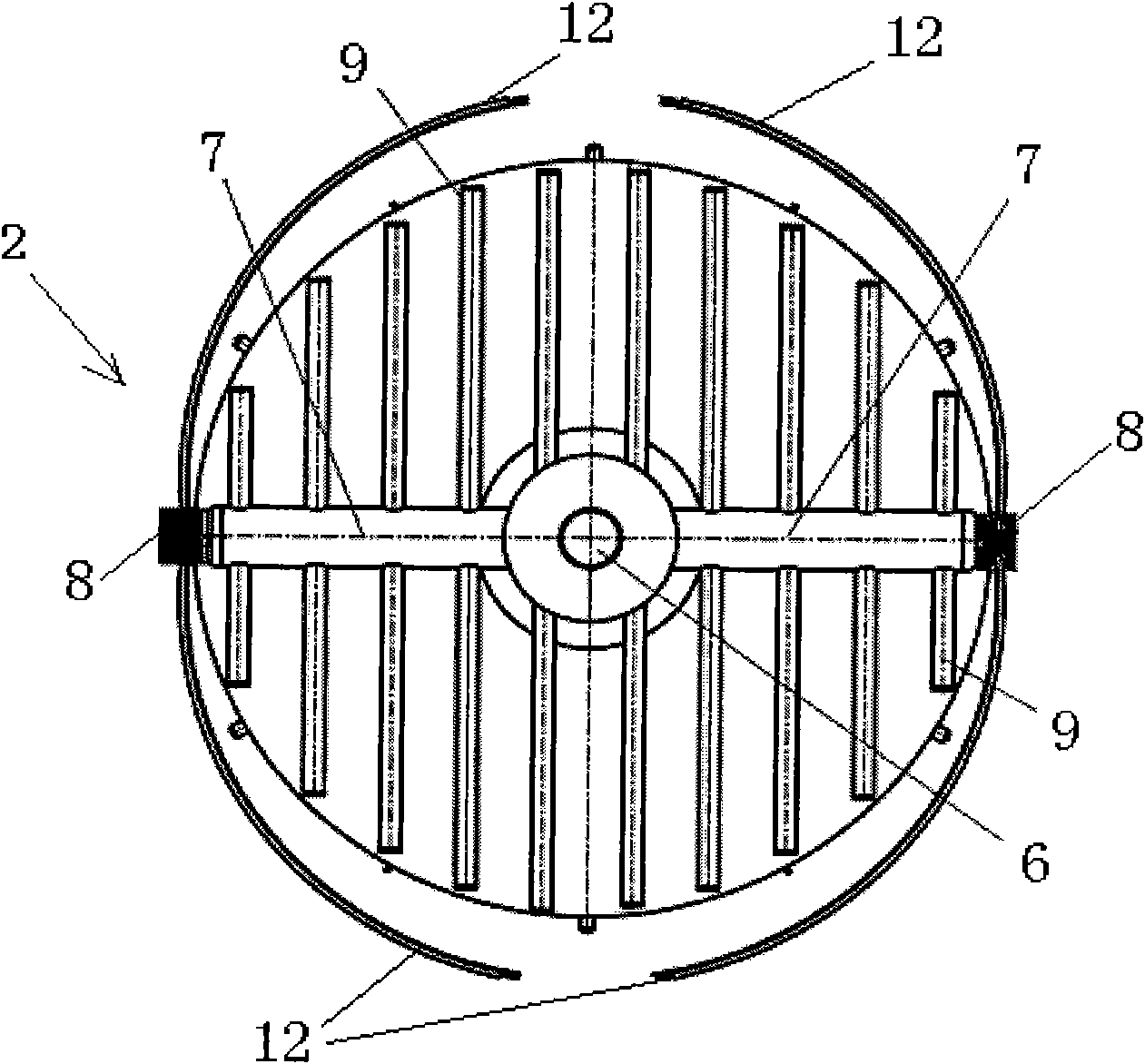

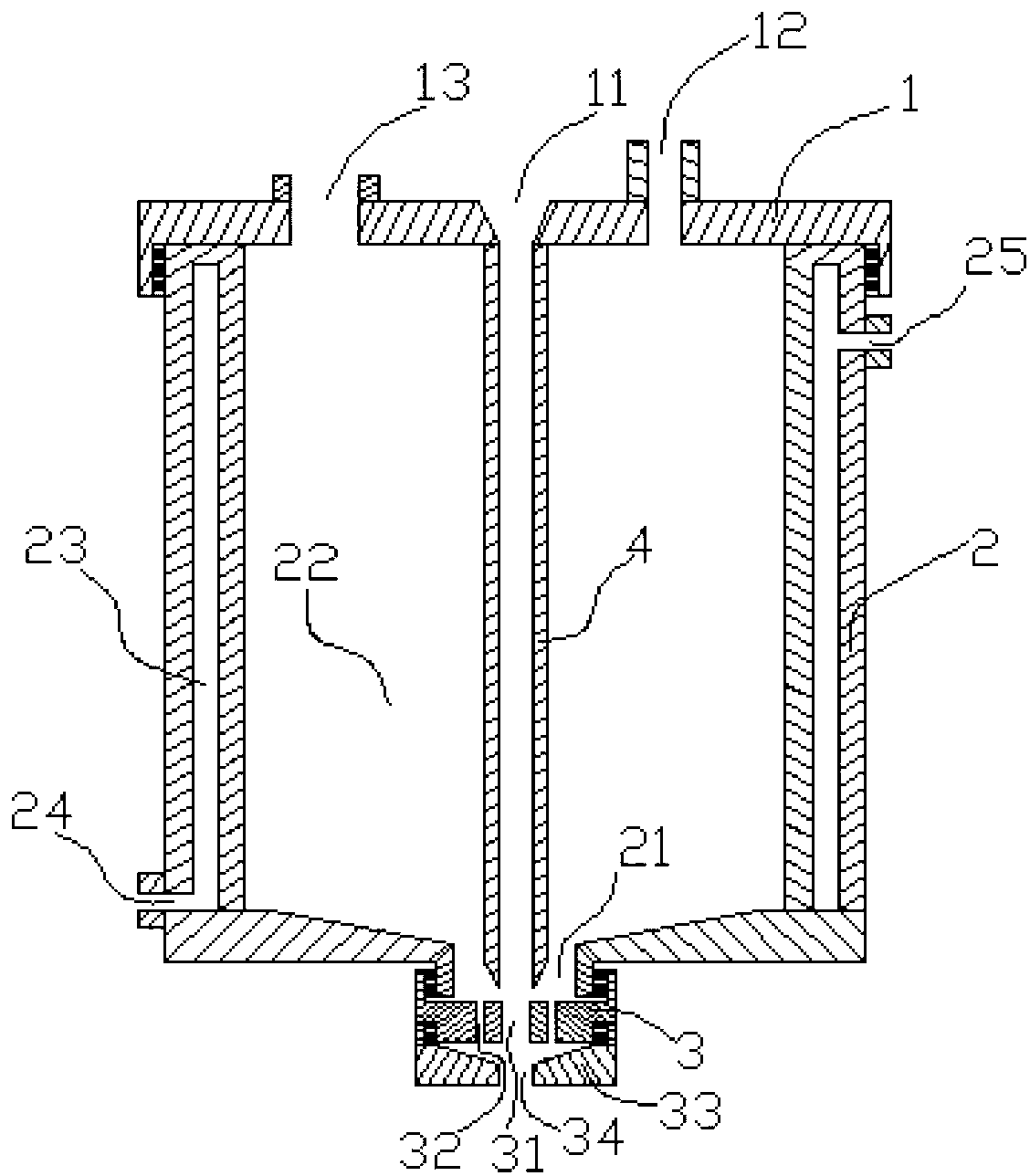

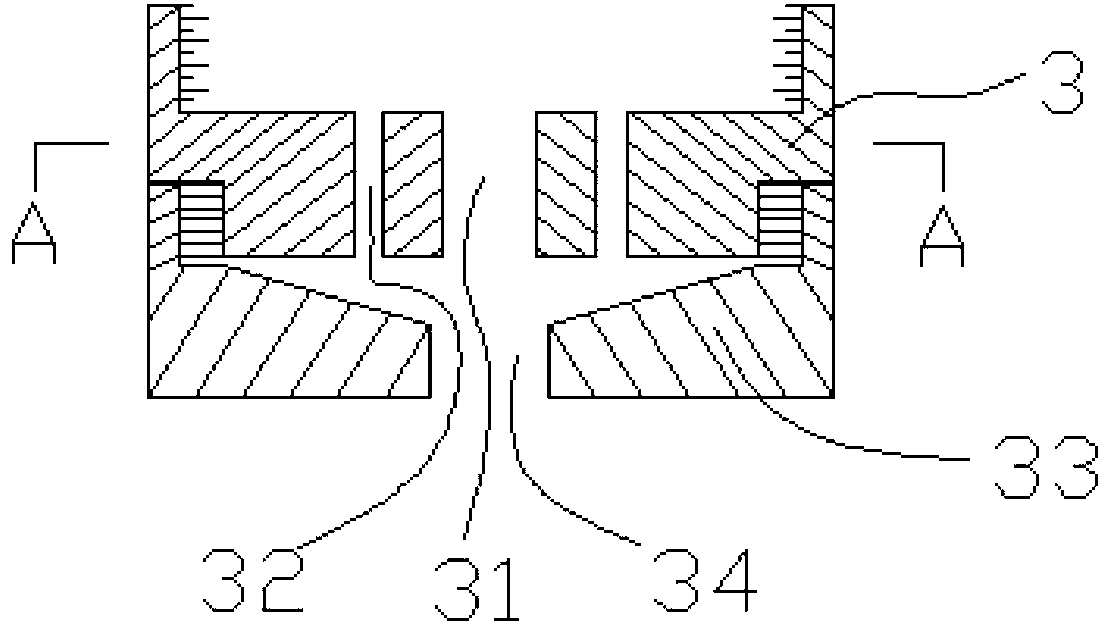

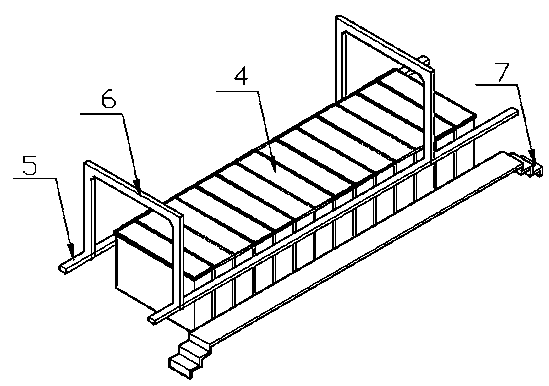

Liquid flow type skein dyeing machine

ActiveCN103866511ATextile treatment machine arrangementsTextile treatment with treating outlet contectEngineeringVertical cylinder

The invention discloses a liquid flow type skein dyeing machine. The skein dyeing machine comprises a vertical cylinder, at least a pair of skein fixing rods, a spraying mechanism, a dye liquor tank and a liquid flow pump. The skein fixing rods are located in the vertical cylinder and are used for fixing at least one skein in the vertical cylinder; at least one of the skein fixing rods is a hollow pipe, and the hollow pipe is provided with a pipe wall; a flow channel is defined by the pipe wall, and the pipe wall is provided with a guide hole in the flow channel; the guide hole penetrates through the pipe wall and is communicated with the flow channel; the spraying mechanism is located in the vertical cylinder and is located above the skein fixing rods; the dye liquor tank is located in the vertical tank and is located below the skein fixing rods; a liquid flow pump is communicated with the dye liquor tank, the flow channel and the spraying mechanism, is used for delivering one part of dye liquor in the dye liquor tank to the spraying mechanism, and delivering another part of dye liquor in the dye liquor tank to the flow channel.

Owner:TAIWAN TEXTILE RESEARCH INSTITUTE

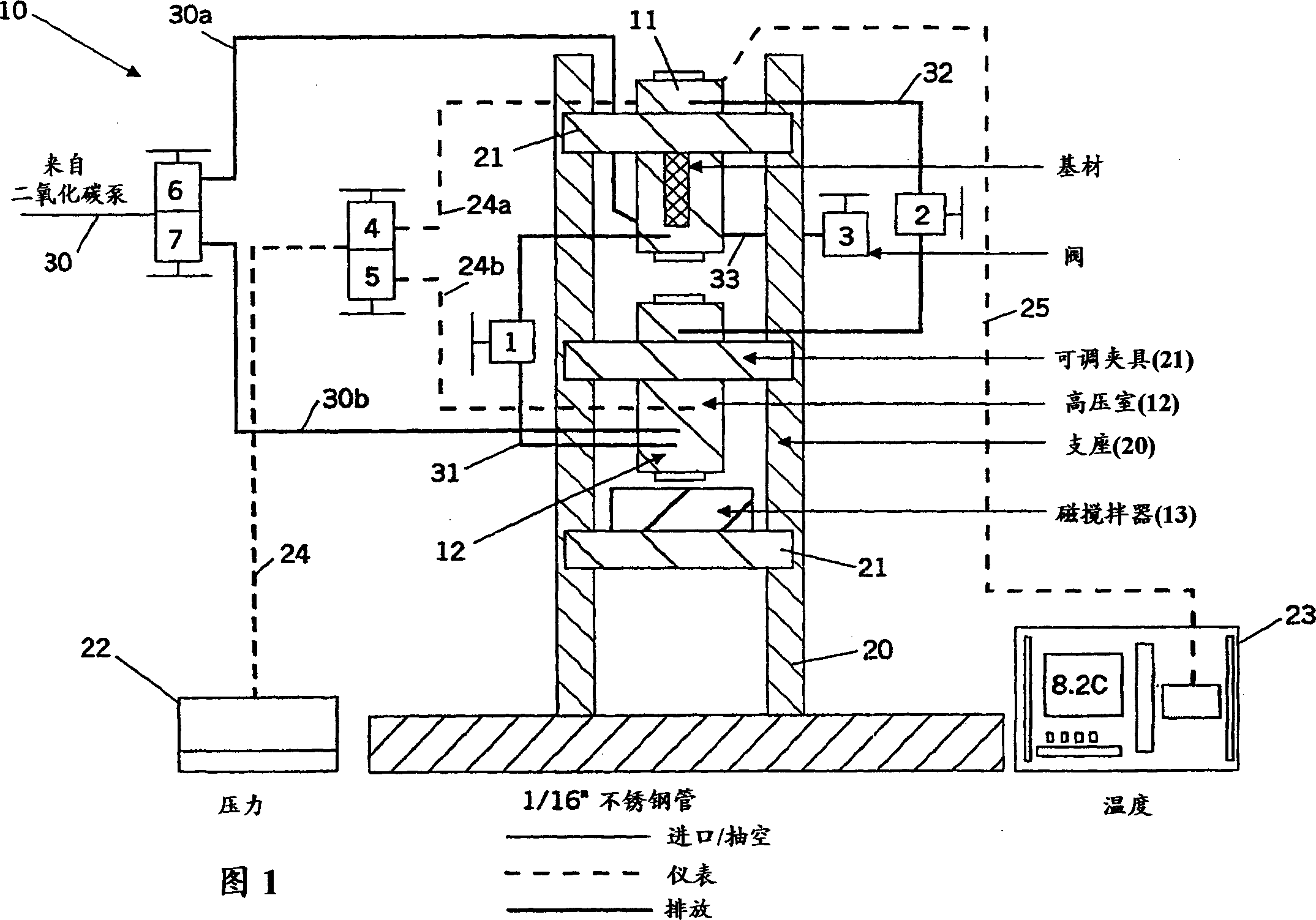

Method and apparatus for coating with liquid or supercritical carbon dioxide

A method of coating a substrate comprises immersing a surface portion of a substrate in a liquid or supercritical first phase. The first phase comprises carbon dioxide and a coating component such as a polymer. The substrate is then withdrawn from the first phase into a distinct second phase such as a gas atmosphere so that the coating component is deposited on said surface portion. The withdrawal step is followed by separating the carbon dioxide from the coating component (e.g., by evaporation, venting, heating, etc.) so that the coating component is retained as a coating layer formed on the surface portion. Apparatus for carrying out the method by free meniscus coating, or employing a metering element such as a knife, blade, or roll, are also disclosed.

Owner:NORTH CAROLINA STATE UNIV

Preparation method for novel TPU (Thermoplastic Polyurethane) aramid fiber coated fabric

InactiveCN103015184ASucessive textile treatmentsSolvent-treatmentPolyurethane elastomerThermoplastic polyurethane

The invention relates to a preparation method for novel TPU (Thermoplastic Polyurethane) aramid fiber coated fabric. The preparation method comprises the steps of firstly, conducting heat treatment, sizing and surface treatment on high-strength aramid fiber fabric; secondly, adding a polyurethane elastomer into a hopper, sealing, drying and dehumidifying; thirdly, adjusting the direction of a handpiece; fourthly, preheating the handpiece, opening a traction machine every 20 minutes to pull the aramid fiber fabric out of the handpiece for 190-210mm; fifthly, drying the aramid fiber fabric subjected to the surface treatment; and sixthly, when the temperature of the handpiece reaches to be a certain value, starting an extrusion machine and conducting the traction so as to enable the aramid fiber fabric to pass through a mouth of the handpiece and enable polyurethane granules to enter a screw extruder, moving the granules towards the direction of the handpiece, heating the granules to achieve the temperature being 200 DEG C-210 DEG C at the mouth of the handpiece, driving the granules to enter the extrusion handpiece in a melted viscous flow state, coating the granules on the upper surface and the lower surface of the aramid fiber fabric, cooling, drawing and curling the polyurethane aramid fiber fabric to form the high-strength ultra oil-resistance TPU aramid fiber coated fabric.

Owner:凯迪西北橡胶有限公司

Vertical winding type continuous chemical silver-plating method and device for flexible fabric

ActiveCN103966838AImprove washabilityEasy to handleFibre treatmentLiquid/gas/vapor removalUltrasonic assistedSilver plate

The invention provides a vertical winding type continuous chemical silver-plating method and device for a flexible fabric. The method comprises the following steps: sensitizing, cleaning, pre-plating, cleaning, performing ultrasonic-assisted chemical silver-plating, cleaning, and drying, wherein treatment liquid is replenished continuously or in one time before next workpiece enters a tank in the sensitizing and pre-plating steps and can be recycled for multiple times, so that the problems of simplicity for decomposition as well as low production efficiency and environmental pollution caused by a large amount of waste liquid, difficulty for treatment, serious pollution and the like after one-time use of conventional chemical plating liquid are solved; a winding supporting device in the method can be used for performing vertical winding type chemical silver-plating on the flexible fabric with large area, so that the shortcomings of inconvenience for extension, simplicity for local color difference and influence on appearance in a treatment process of an existing fabric with large specific surface area are overcome. According to the method, the continuous and uniform coating of a sliver layer is achieved, the production efficiency is high, less waste liquid is generated, and the waste liquid is easily recycled.

Owner:BEICHUAN TIANXUN NEW MATERIALS

Apparatus for applying foamed coating material to a traveling textile substrate

InactiveUS6858256B2Facilitate conductionProcess cleaningPretreated surfacesTextile treatment using short bath ratio liquorStop flowViscosity

A coater for applying foamed coating material to a traveling textile substrate including a frame, a flush pan, an applicator having an open slot, a pivot shaft journaled in a pair of support arms that are pivotally mounted to the frame and piston-cylinder mechanisms to move the applicator between an operating position wherein the open slot is adjacent the traveling substrate and a flush position wherein the open slot is adjacent the flush pan by pivoting the support arms and rotating the pivot shaft. Foamed coating material is applied by supporting the traveling substrate between two spaced support elements, contacting the traveling substrate with a foam applicator, and forcing a metered amount of foamed material at least partially into the interstices of the textile substrate before the foamed coating material collapses. A metered amount of foamed coating material is applied onto or into a textile substrate regardless of textile substrate structure and regardless of the viscosity of the coating material. The foamed coating material may be flushed from the coater by stopping flow of foamed material through the applicator, moving the applicator to the flush position, and commencing flow of a flushing fluid through the applicator and into the flush pan. Foamed coating material may also be flushed from the applicator by stopping flow of foamed material through the applicator, commencing flow of a flushing foam through the applicator, stopping flow of flushing foam through the applicator, and commencing flow of a flushing fluid through the applicator.

Owner:GASTON SYST INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com