Foam application device for knitted fabric

An application device and a technology for knitted fabrics, which are applied in the direction of processing textile material carriers, textile materials in contact with export textile materials, etc., can solve the problems of high liquid retention rate, low productivity, difficult processing, etc., and achieve uniform tension and consistent degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific implementation of the present invention is described by taking the finishing process of knitted fabrics as an example. The traditional knitted fabric finishing process is: fabric opening, padding, stacking, and drying. The invention can combine the fabric opening and padding, and apply foam to the fabric before the fabric is opened, and solve the problem of uneven padding treatment caused by the curling of the fabric after opening.

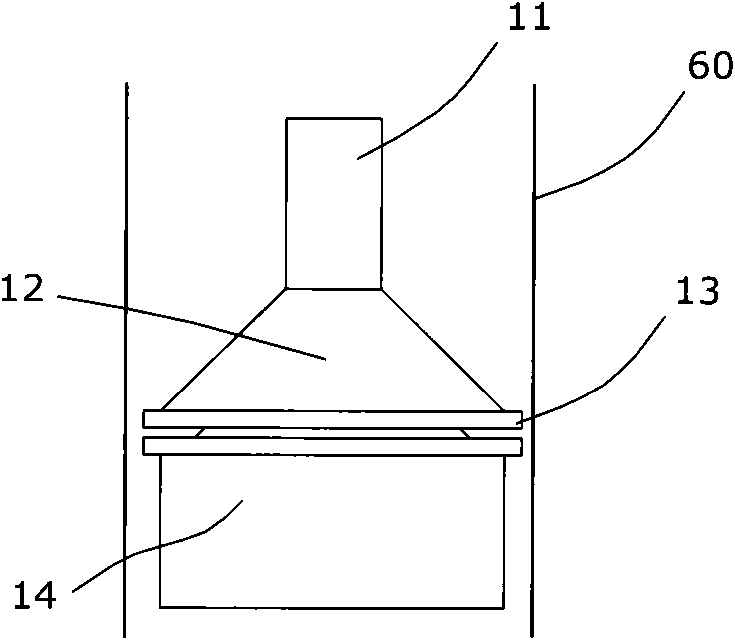

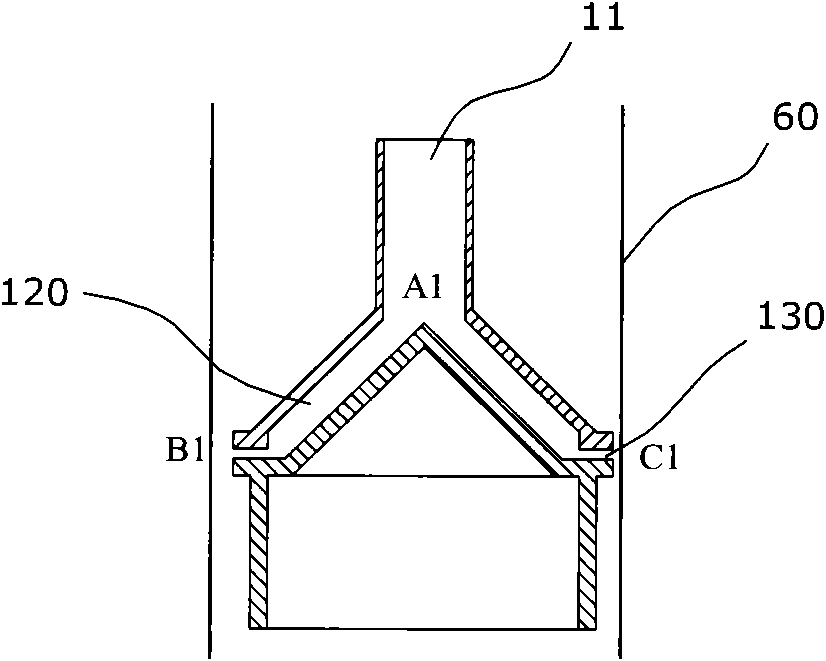

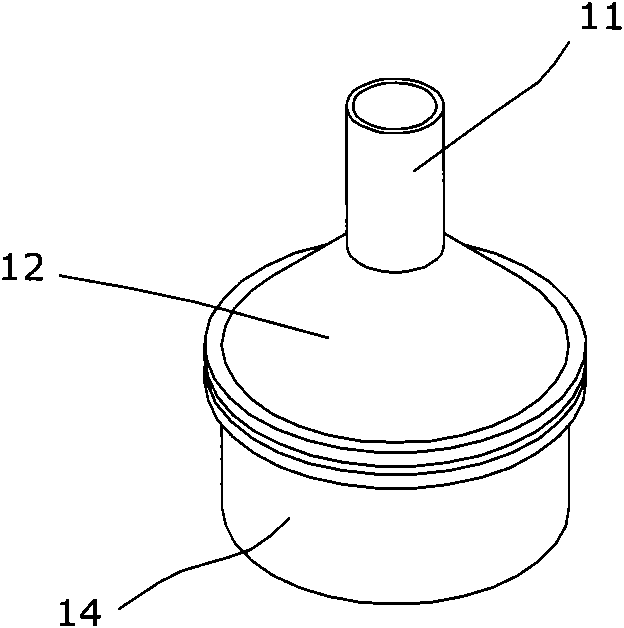

[0048] Such as Figure 1a-1cAs shown, the foam applicator 10 of the first embodiment of the present invention includes a foam manifold 11 , a foam distribution device 12 , a foam applicator 13 and a support 14 . One end of the foam main pipe 11 is connected to a foam generator (not shown in the figure), and the other end is connected to a foam distribution device 12 . In this embodiment, the foam distribution device 12 is conical, and a foam flow channel 120 is formed inside it. The foam delivery main pipe 11 is located abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com