Patents

Literature

117results about How to "Improve rolling precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

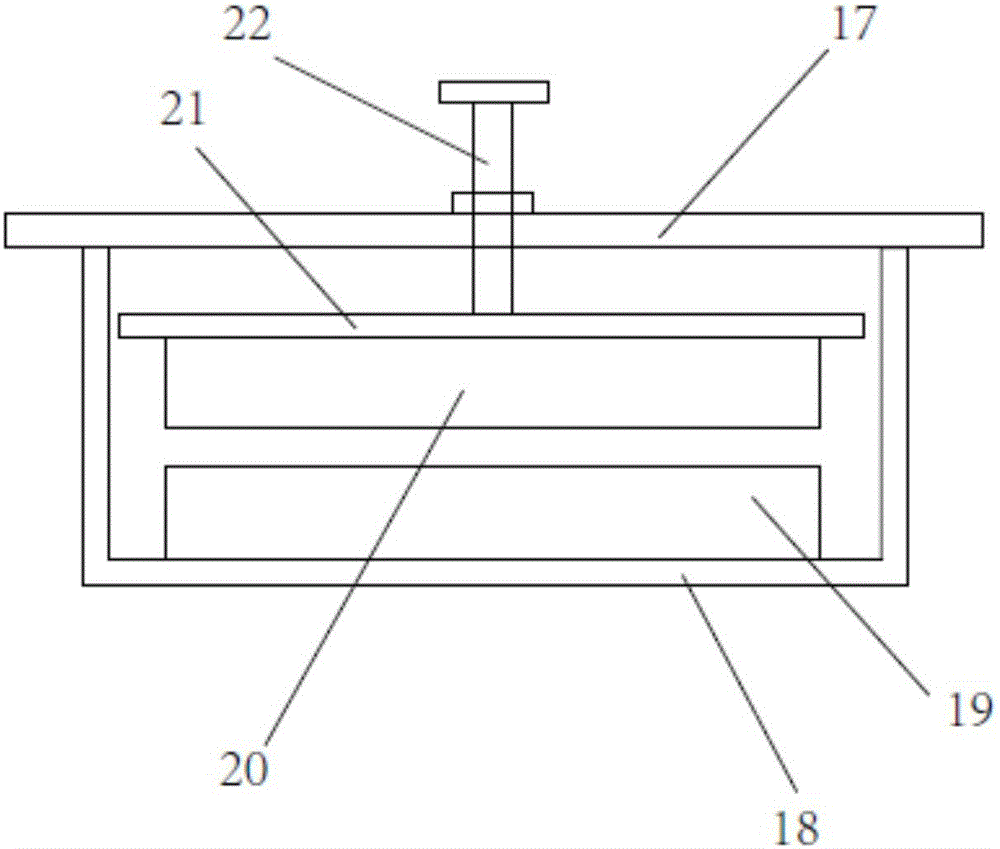

Device and method for rolling laser stereo formed part layer by layer

InactiveCN108655402AImprove organizational performanceDecreased organizational performanceAdditive manufacturing apparatusIncreasing energy efficiencyDislocationMechanical property

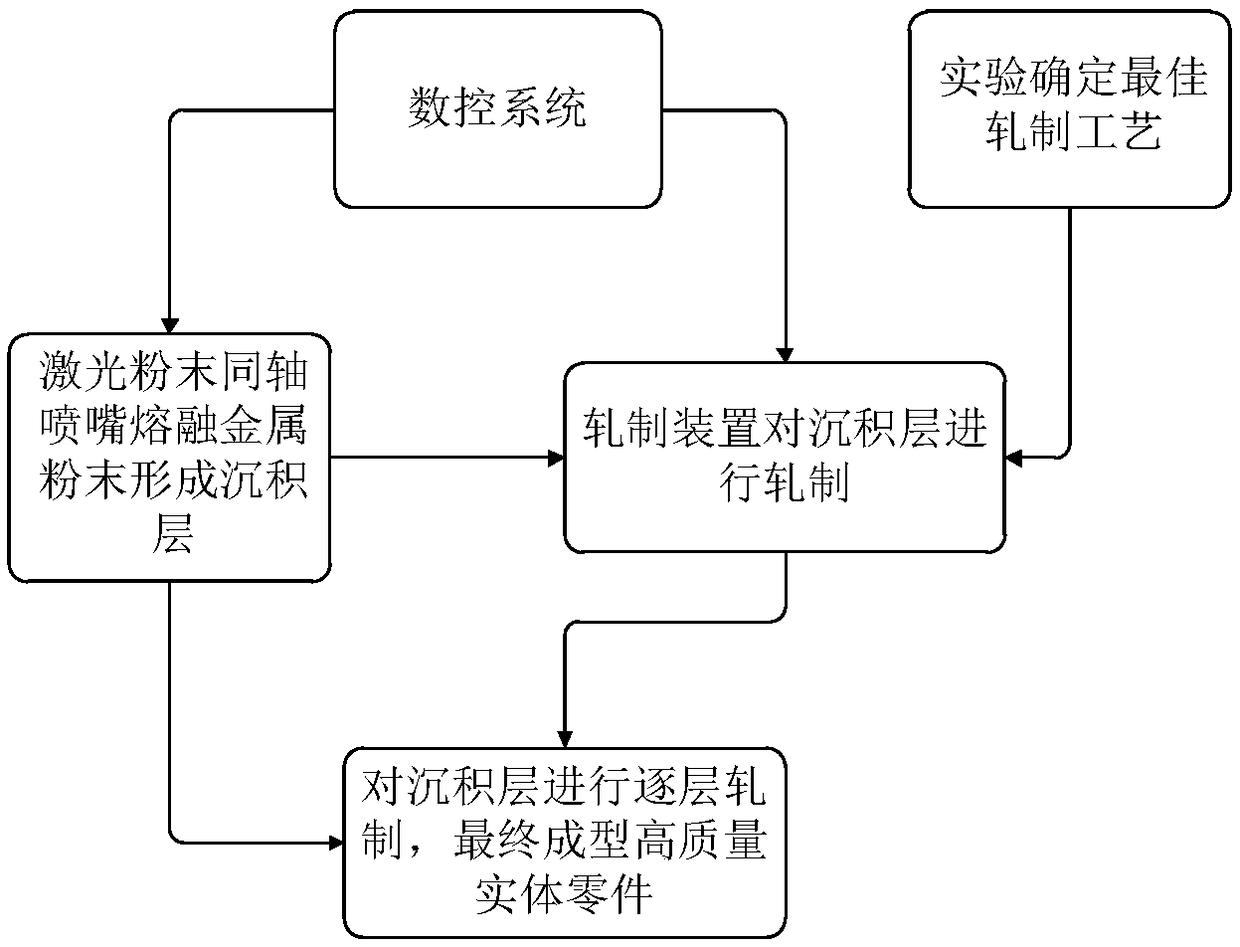

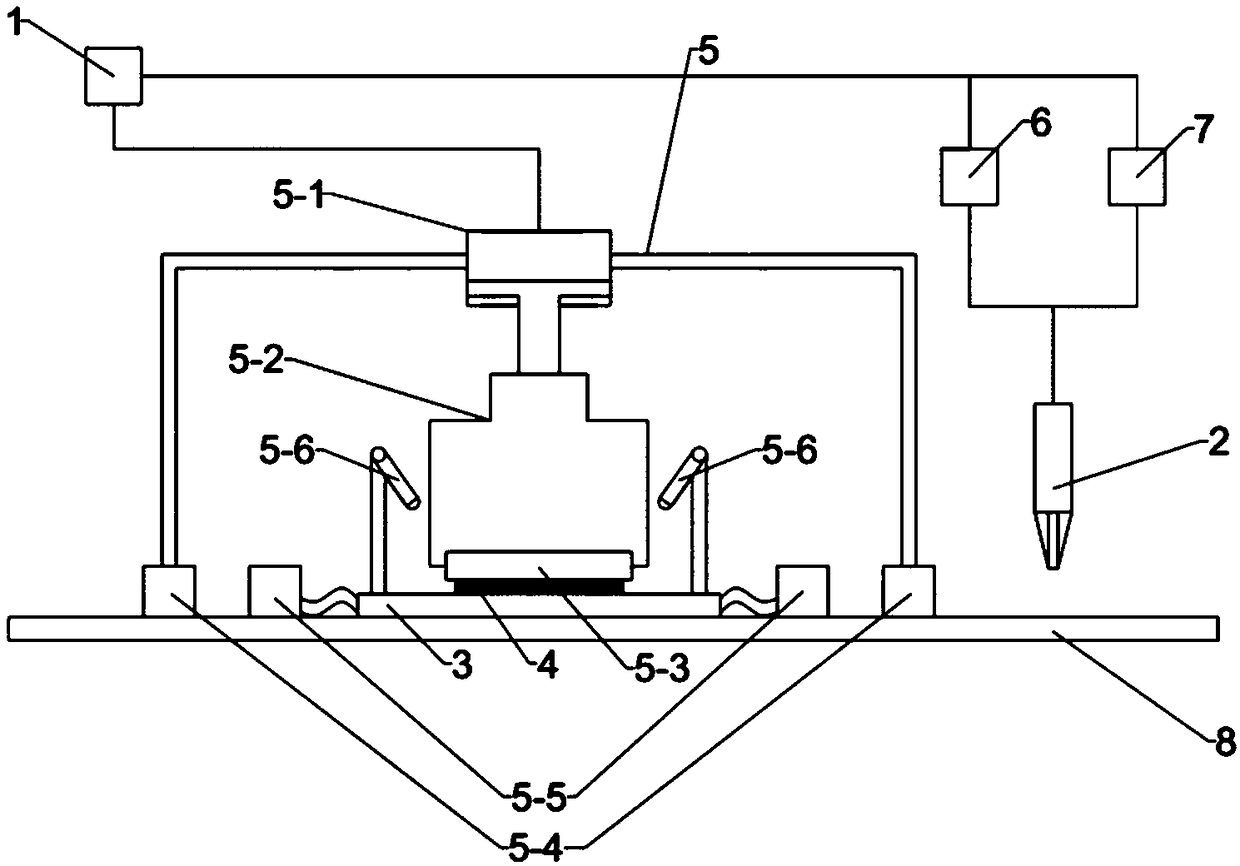

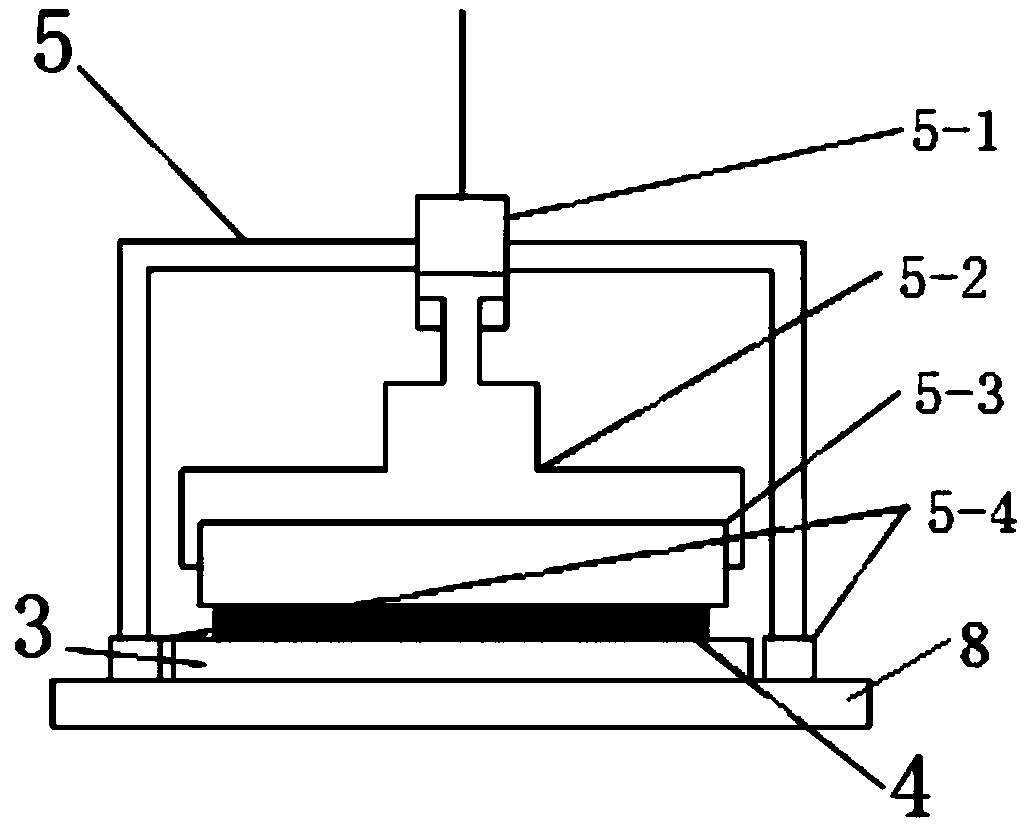

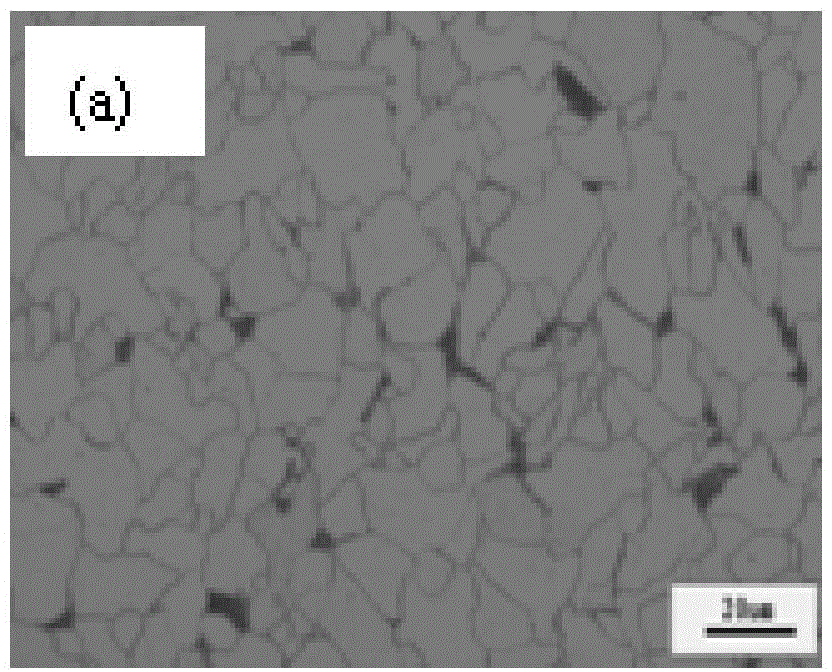

The invention discloses a device and method for rolling a laser stereo formed part layer by layer. The device comprises a numerical control system, a working table, a base plate, laser powder coaxialnozzles located above the base plate and a rolling device. By adopting the scheme that the numerical control system controls the rolling device to roll a metal deposition layer, the rolling frequencyand rolling deformation of a rolled area can be freely adjusted, the problems of high residual stress and severe warping deformation produced due to the high temperature gradient in the laser stereo forming process of the part are solved, and meanwhile by means of the rolling force of rollers, grains are refined, dislocation is increased, cracks are reduced, and part compactness is improved. The size precision and mechanical property of the laser stereo formed part can be improved, the metal part with the high quality is formed, and follow-up machining treatment for the part is reduced.

Owner:SHANGI INST FOR ADVANCED MATERIALSNANJING CO LTD

Hot rolling method for wide and thin size high-strength cold-rolled base plate for automobile

InactiveCN105478472AGuaranteed MicrostructureGuaranteed mechanical propertiesMetal rolling arrangementsStructure propertySheet steel

The invention discloses a hot rolling method for a wide and thin size high-strength cold-rolled base plate for an automobile. After continuous casting billets are assembled in a heating furnace in a hot state, the Cu accumulation amount of iron oxide scales and steel substrates is reduced by adopting high-temperature preheating and high-temperature rapid heating technologies; after rough rolling, the thickness of an intermediate billet is reduced, a heat holding cover is used for reducing temperature drop and temperature differences of all parts, so that the finish rolling entry temperature of the intermediate billet is increased; and loads of all racks for finish rolling are reduced, and the stability of finish rolling is improved. In the process from finish rolling to steel belt coiling, a controlled rolling and controlled cooling technology is adopted, so that the cold-rolled base plate has excellent uniformity between the shape and the structure property. According to the method, the cold-rolled base plate with the thickness of 1.5-2.5 mm and the width of 1650-2000 mm can be obtained; the convexity degree of a steel belt is controlled to be in a range between 45-15 mu m and 45+15 mu m; the straightness is controlled to be 30I; the thickness accuracy is in a range between -30 mu m and +30 mu m; the structure property of different edges of the head, the middle, the tail of the steel belt is uniform; and the yield and the production efficiency of the wide and thin size high-strength cold-rolled base plate can be increased and improved, so that the cold-rolled base plate meeting the requirements of the actual product quality and the performance is provided for steel plates with the grade of 450-590 MPa for automobile covering parts.

Owner:ANGANG STEEL CO LTD

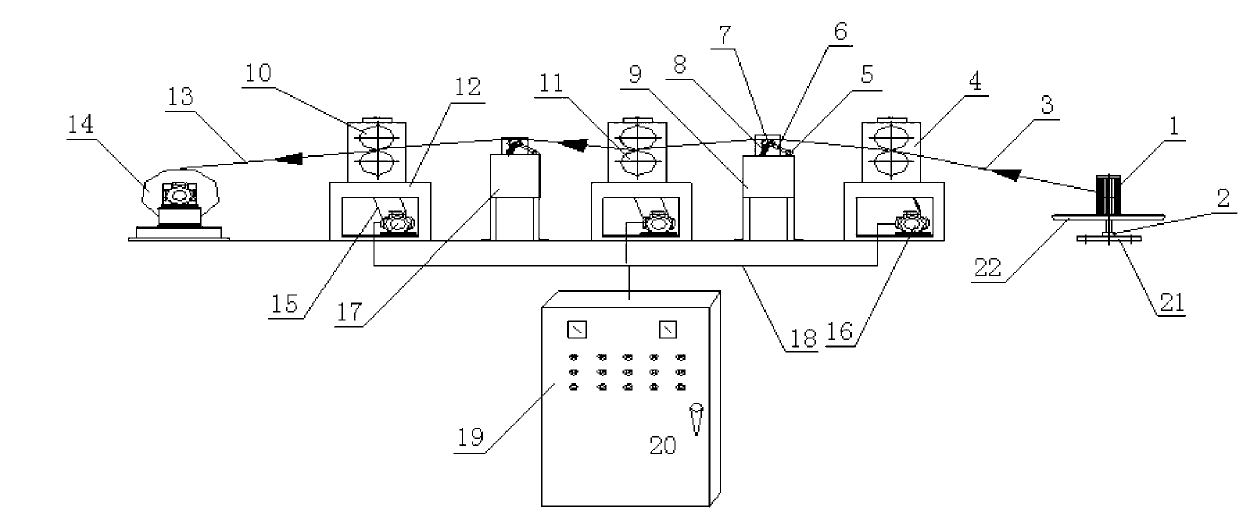

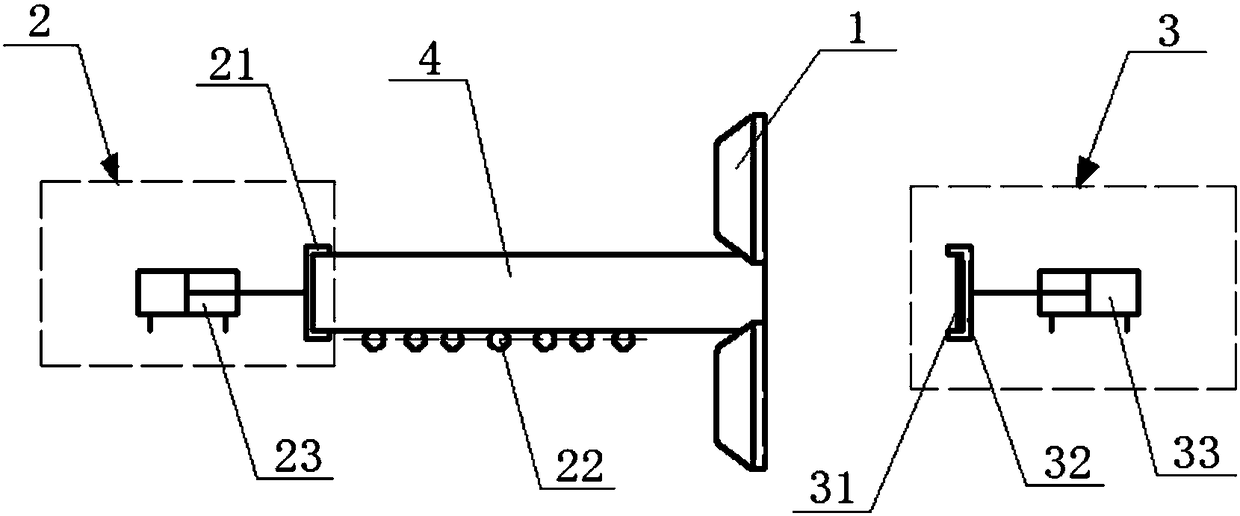

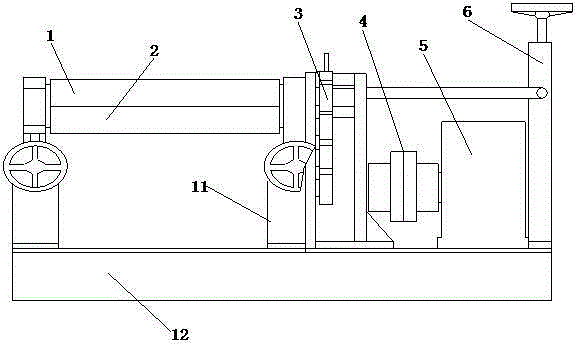

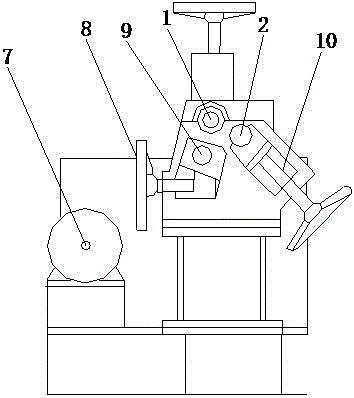

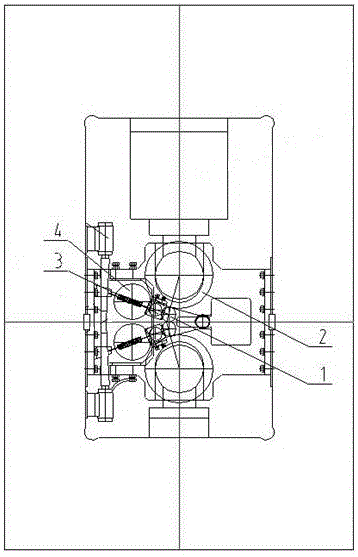

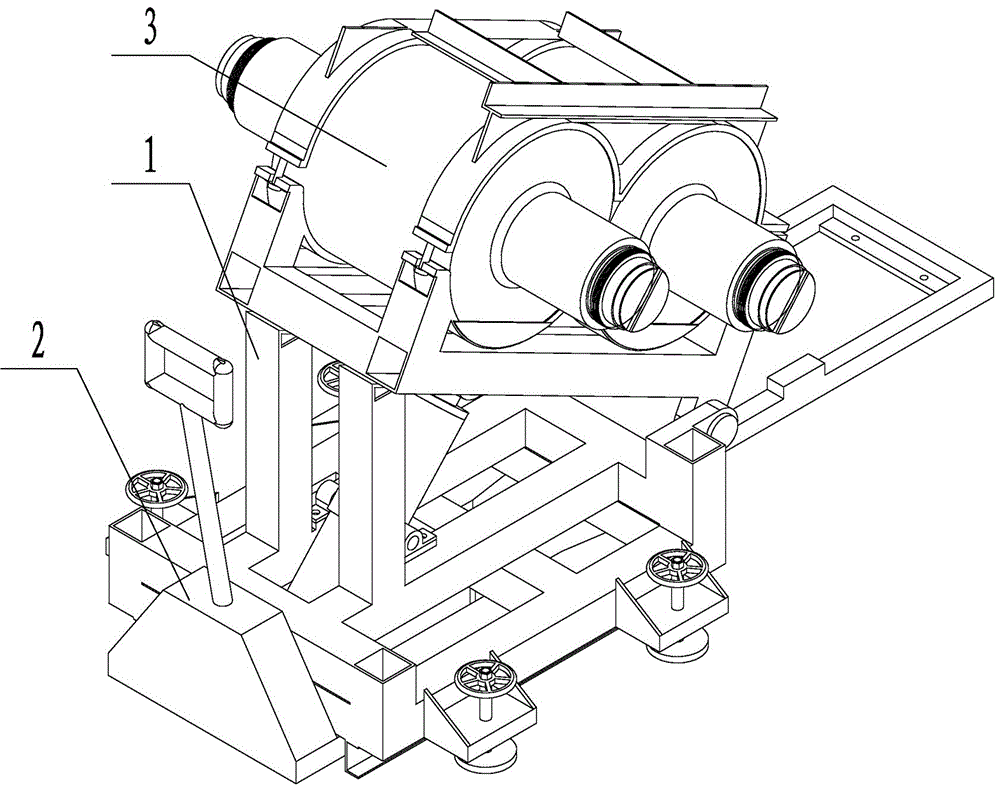

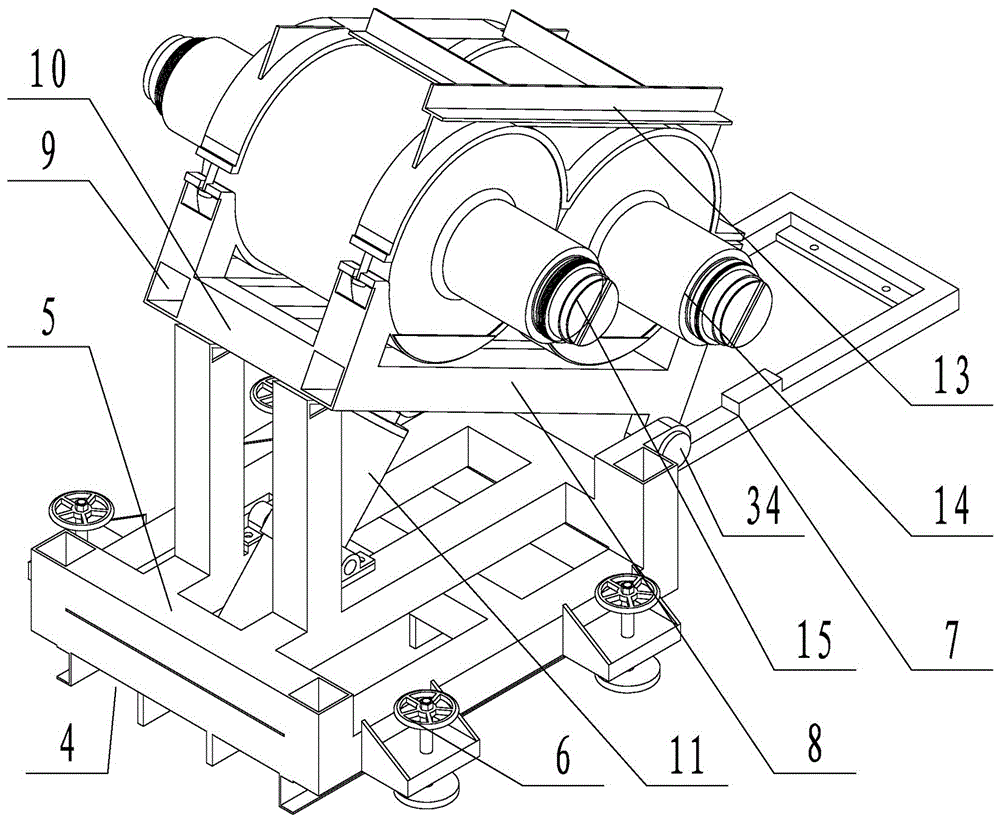

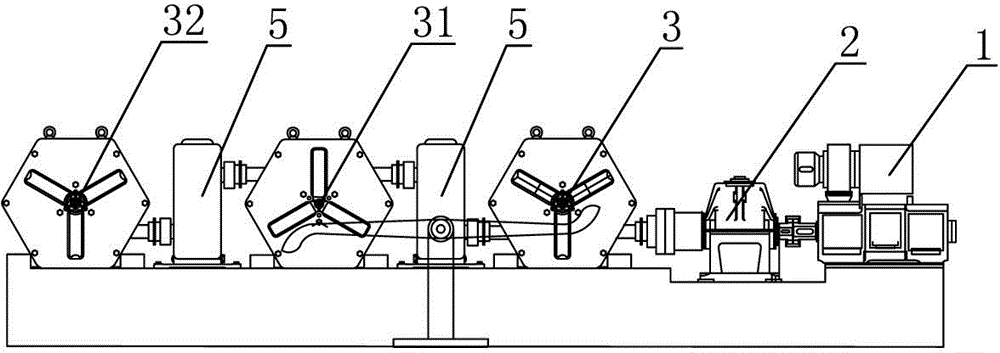

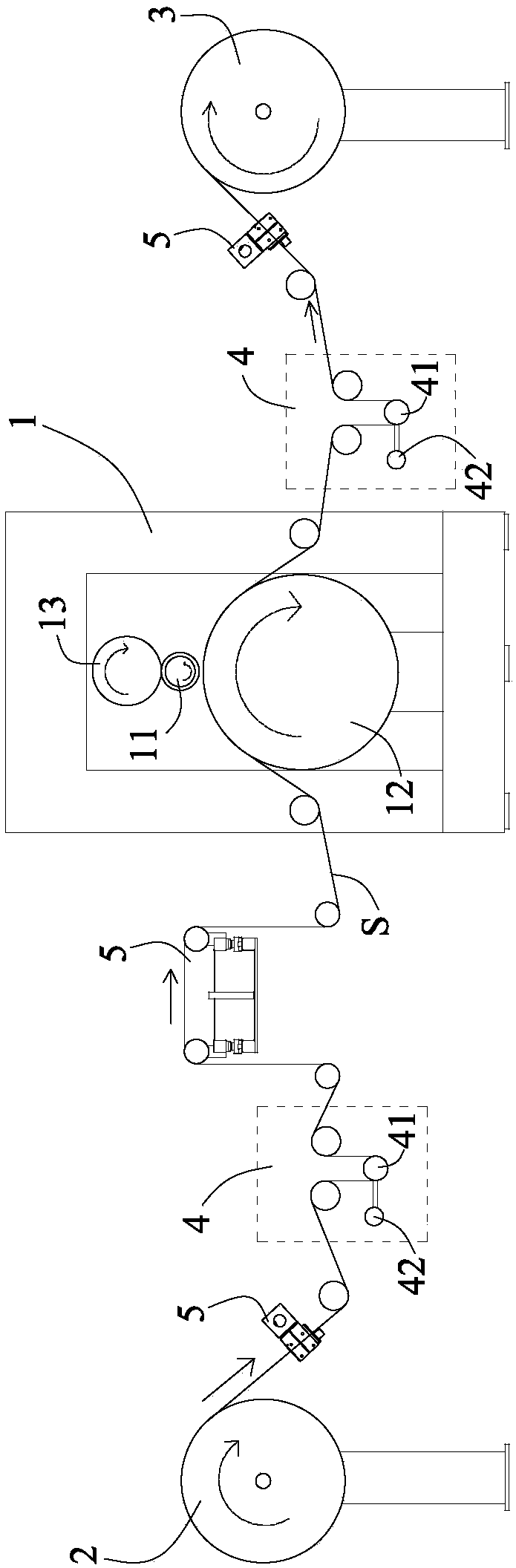

Rolling device for forming of copper alloy flat wires

InactiveCN103272840AImprove rolling precisionDimensionally stableMetal rolling arrangementsControl systemElectrical control

The invention discloses a rolling device for forming of copper alloy flat wires. The rolling device comprises a wire-unwinding mechanism, a plurality of sets of rolling mills, a synchronous tension mechanism, an electrical control system and a wire-rewinding machine. The wire-unwinding mechanism comprises a wire-unwinding plate and a halt air brake device. The rolling mills are composed of more than two stand-alone mills, and each rolling mill is composed of a rolling roller, a support, an electromotor and a belt. The synchronous tension mechanism is composed of a potentiometer, a connection rod, a guide wheel and a spring support. The electrical control system is composed of an electric cabinet, an electrical element, electric wires and cables and provides power for each rolling mill. According to the rolling device, a multi-channel continuous rolling method is utilized, the rolling device is high in accuracy, processing procedures of the copper alloy flat wires are shortened, operation speed is 1.5-2.0 times that of a conventional stand-alone mill, and production efficiency is improved. Meanwhile, as gradual rolling during a rolling process is utilized, the rolling size is very stable, the surfaces of the flat wires are smooth and bright, the fact that grooves and roughness of the surfaces of the flat wires occur in a drawing process of a traditional mould is avoided, and product quality is improved.

Owner:WUHU CHUJIANG ALLOY COPPER

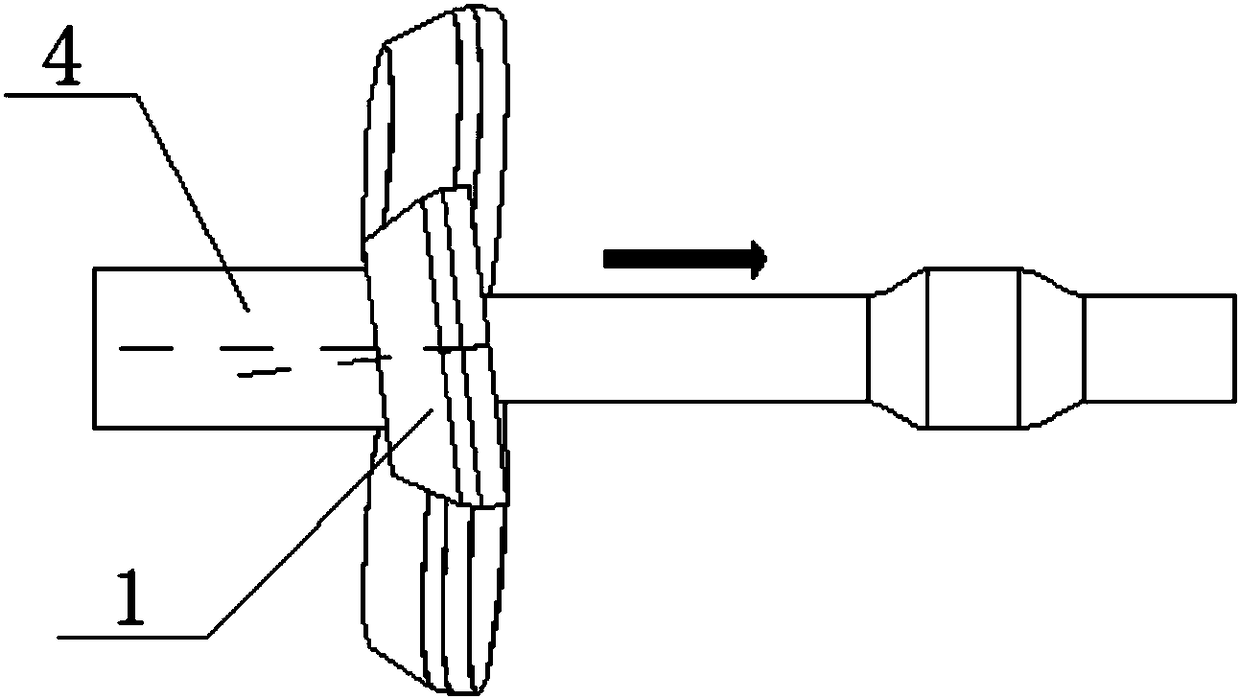

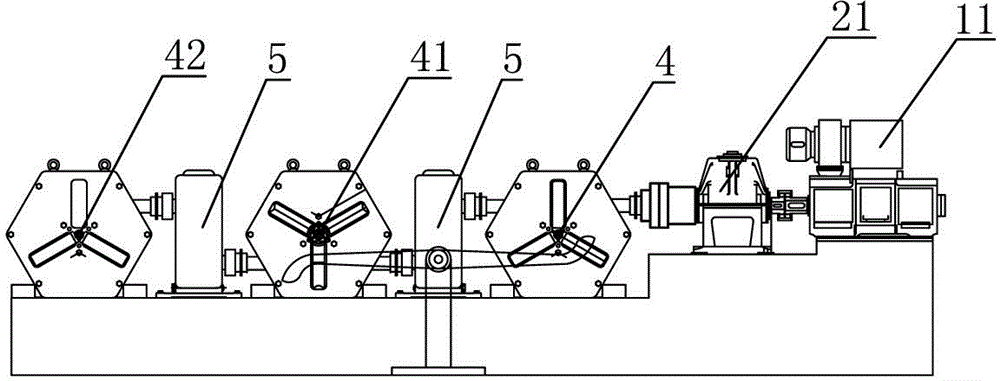

Three-roller inclined rolling forming method of rail vehicle axles

The invention discloses a three-roller inclined rolling forming method of rail vehicle axles. The method is characterized in that rods are heated and fed into a three-roller inclined rolling machine through an axial pushing device; three inclined rollers are engaged with the rods at the same time, and drive the rods to rotate; meanwhile, the axial pushing device pushes the rods to axially move ata constant speed; a radial driving mechanism controls radial movement of the inclined rollers according to diameter requirements of rail vehicle axles needing to be machined; when the rods axially move to contact with an axial guide device, the axial guide device tows the rods to continuously move axially at a constant speed; meanwhile, the rods are deviated from the axial pushing device; and after machining is finished, large-diameter long step shafts-rail vehicle axles are obtained. The method has the advantages of simple mold manufacturing, uniform distribution of force on the surfaces of rolled parts, capability of effectively reducing wear of the rollers in the inclined rolling process, capability of realizing light construction of the rolling machine and effective prolonging of the service life of the rolling machine.

Owner:NINGBO UNIV

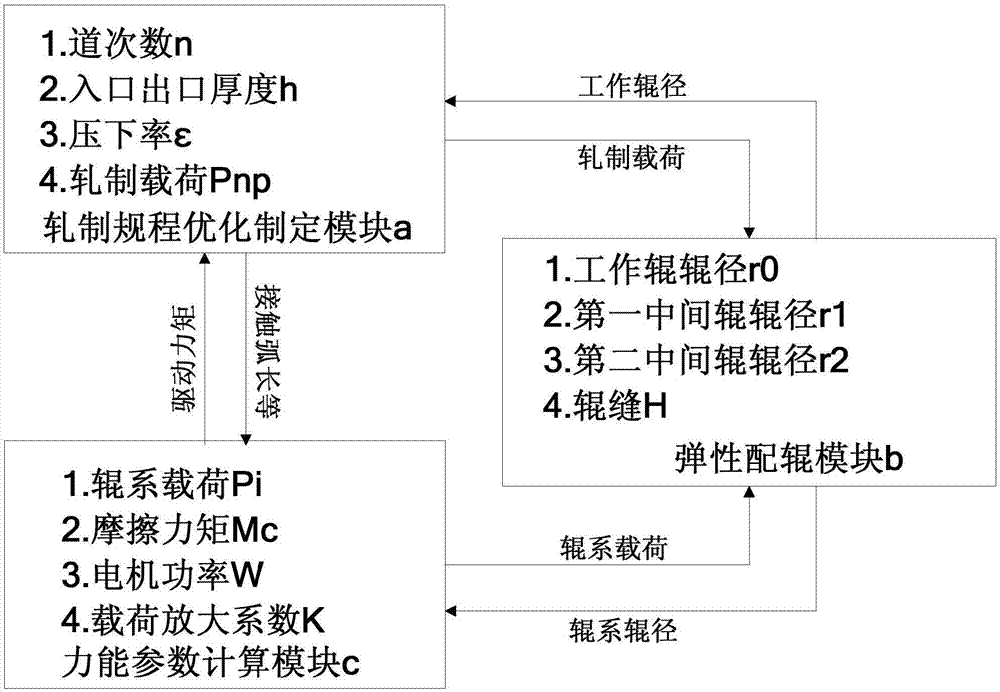

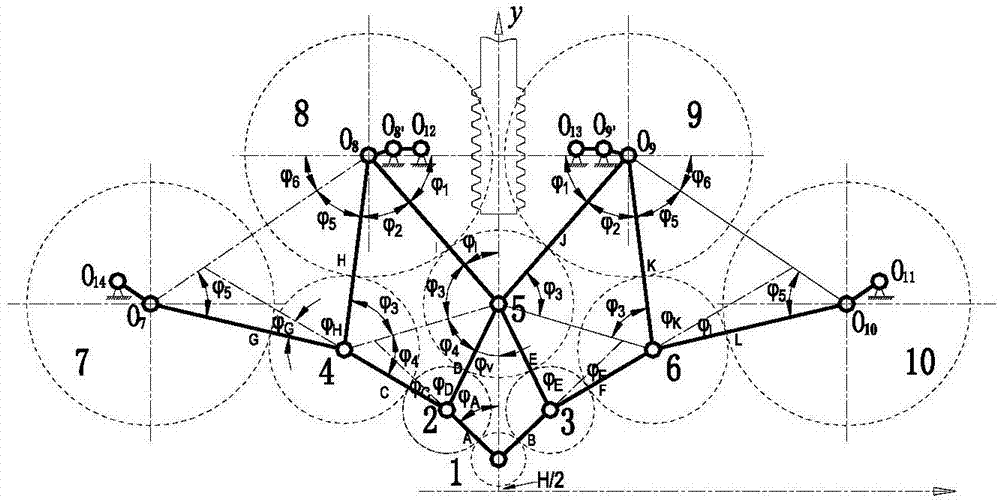

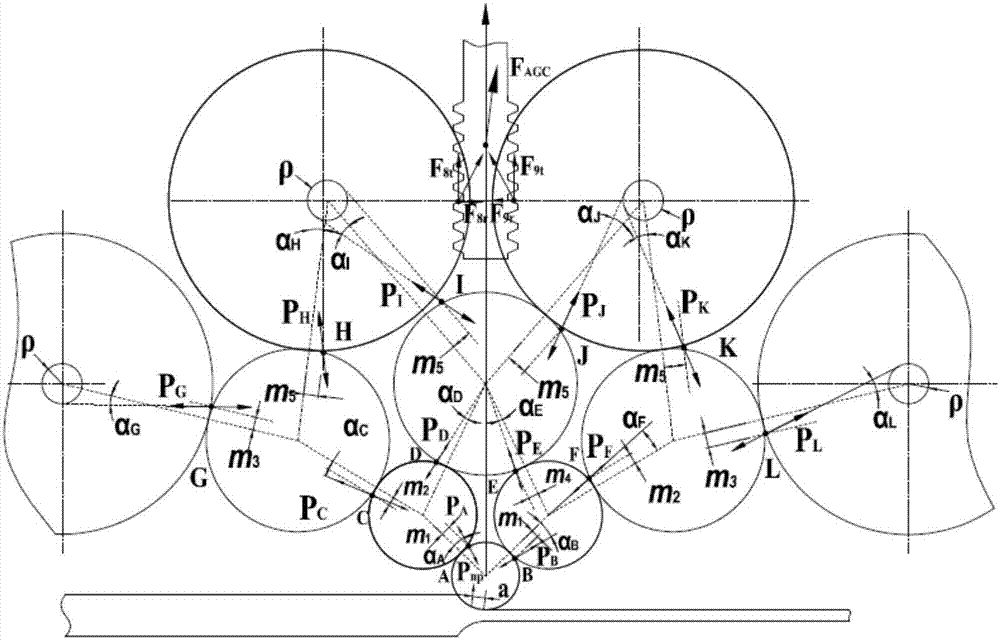

Novel parameter setting integrated system of twenty-high rolling mill control technology

ActiveCN107321799AOptimizing Process ParametersExtended service lifeRoll mill control devicesMetal rolling arrangementsIntegrated systemsEngineering

The invention provides a novel parameter setting integrated system of a twenty-high rolling mill control technology. The novel parameter setting integrated system of the twenty-high rolling mill control technology comprises a rolling schedule optimization setting module, an elastic roll diameter roll-arranging module, an energetic parameter calculating module and a mill roll system. After the incoming material thickness, the finished product thickness, the strip material width, the maximal rolling force, a maximal rolling reduction ratio and the work roll diameter are input into the rolling schedule optimization setting module, the rolling pass, the total rolling reduction ratio, the rolling reduction ratio of each pass, the rolling force, the forward tension and the backward tension, the rolling speed, the rolling power and the rolling pass outlet thickness are output; and after the roller diameter compensation eccentric distance, the rolling reduction adjusting eccentric distance and the rolling pass outlet thickness are input into the elastic roll diameter roll-arranging module, the work roll diameter, a first middle roll diameter, a second middle roll diameter and the rolling reduction adjusting angle are output. According to the novel parameter setting integrated system of the twenty-high rolling mill control technology, setting of parameters of the rolling mill control technology can be conducted by adopting the incoming material thickness, the finished product thickness and the like without the need of accumulating long-term production data.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

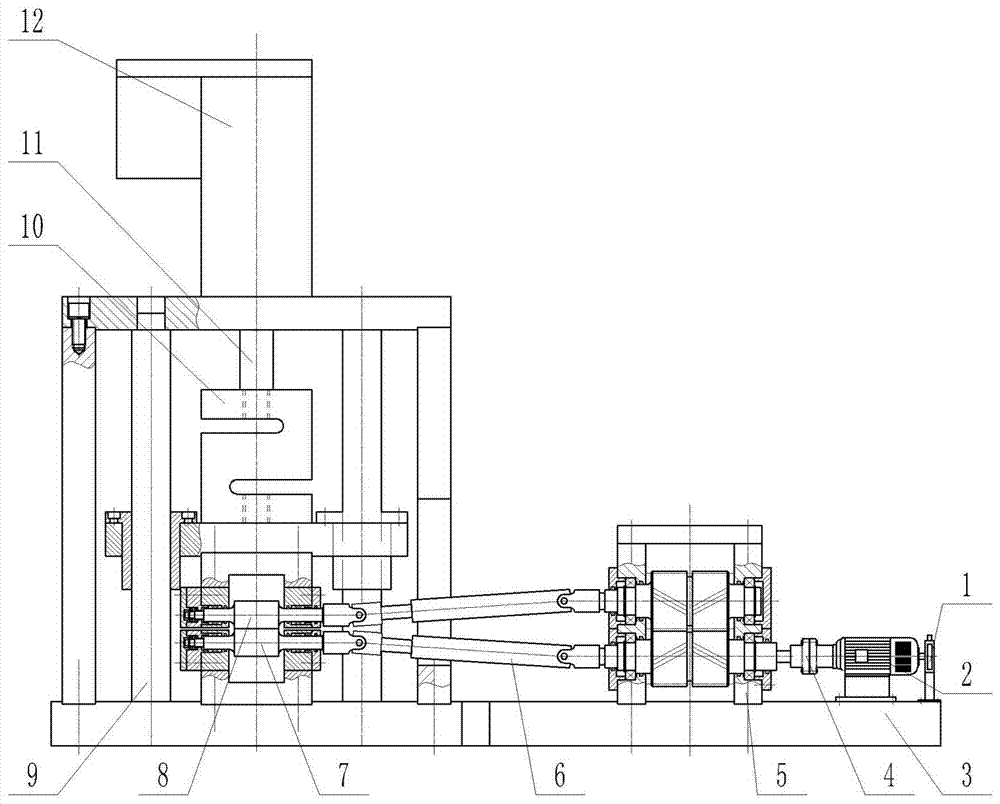

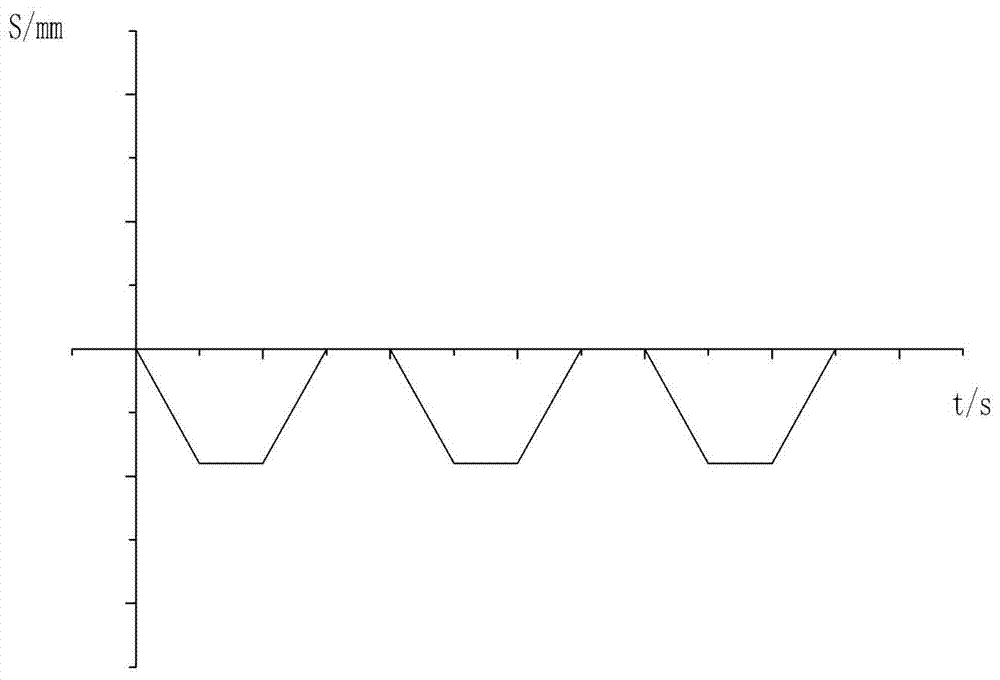

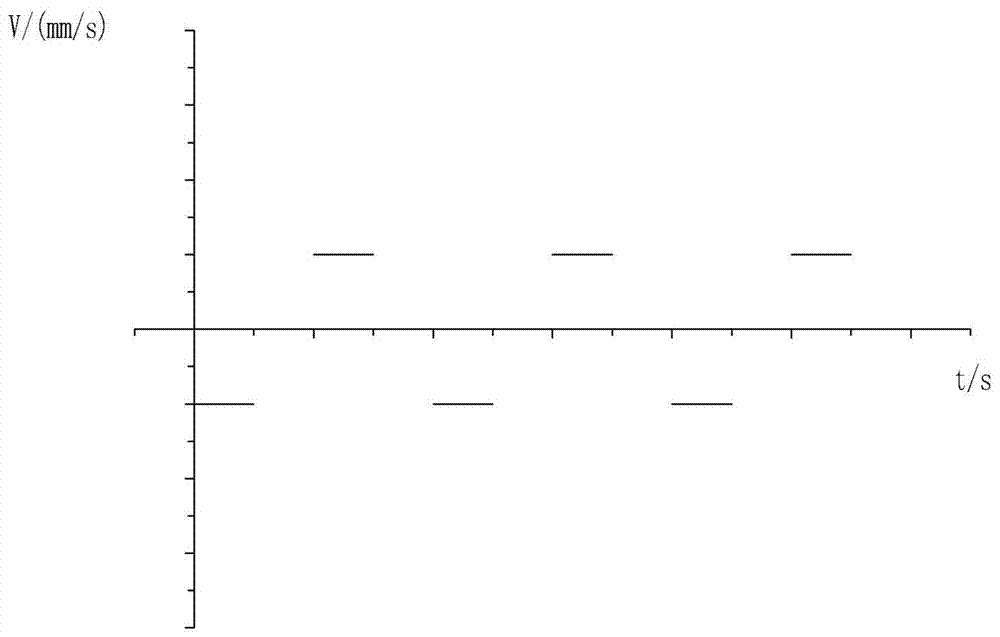

Micro-rolling method for extra-thin variable-thickness strip

InactiveCN106975664AImprove reliabilityImprove mechanical propertiesRoll force/gap control deviceMetal rolling stand detailsVariable thicknessAutomatic control

The invention discloses a micro-rolling method for an extra-thin variable-thickness strip, and the micro-rolling method solves the problems that operations in the prior art are complex, the needed thickness can be reached by needing multi-pass rolling and the production efficiency is low. The method comprises the following steps of: firstly, determining a deformation-thickness ratio as H2 / H3, thereby determining a roll gap Hgap; in case of determining rolling speed V, setting an initial rolling roll gap as H2, length of a to-be-rolled thick region as S1 and length of a to-be-rolled thin region as S2; selecting a rolling direction and a rolling control way, opening the roll gap, putting a to-be-rolled strip onto a roll, closing the roll gap, pressing the roll by initial pressure of closing the roll gap, and clamping and pressing the head part of the strip; and enabling a rolling mill to start operation and rolling according to set roll gap amount. The micro-rolling method disclosed by the invention can realize variable-thickness micro rolling on the extra-thin strip, precisely controls thickness of a thin region and a thick region as well as length of a transition region, and completes regulation on the roll gap through automatic control; and single-pass pressing amount is increased by a hydraulic type pressing system, so that once forming of a variable-thickness rolled piece is realized.

Owner:UNIV OF SCI & TECH LIAONING

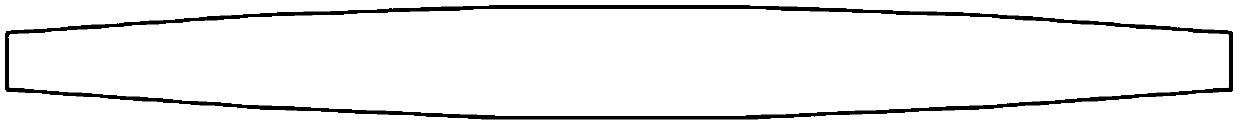

Deep-drawing production technique for stainless steel shuttle-shaped artware

InactiveCN105946432AEasy to useImprove rolling precisionLiquid surface applicatorsSpecial ornamental structuresSolid solutionDeep drawing

The invention discloses a deep-drawing production technique for stainless steel shuttle-shaped artware. The deep-drawing production technique for the stainless steel shuttle-shaped artware comprises the steps of material selection, solid solution treatment, polishing, deep drawing, cutting, cleaning, primer spraying, surface paint spraying and the like. First-time cold deep drawing is conducted on a polished blank, the step of solid solution treatment is conducted after first-time cold deep drawing, then second-time cold deep drawing is conducted, third-time hot deep-drawing correction is conducted on the blank subjected to second-time cold deep-drawing, pressure maintaining treatment is conducted during third-time hot deep drawing correction, and thus the production efficiency and attractiveness degree of the shuttle-shaped artware are effectively improved.

Owner:CHENGDU RUIDA KEHENG TECH

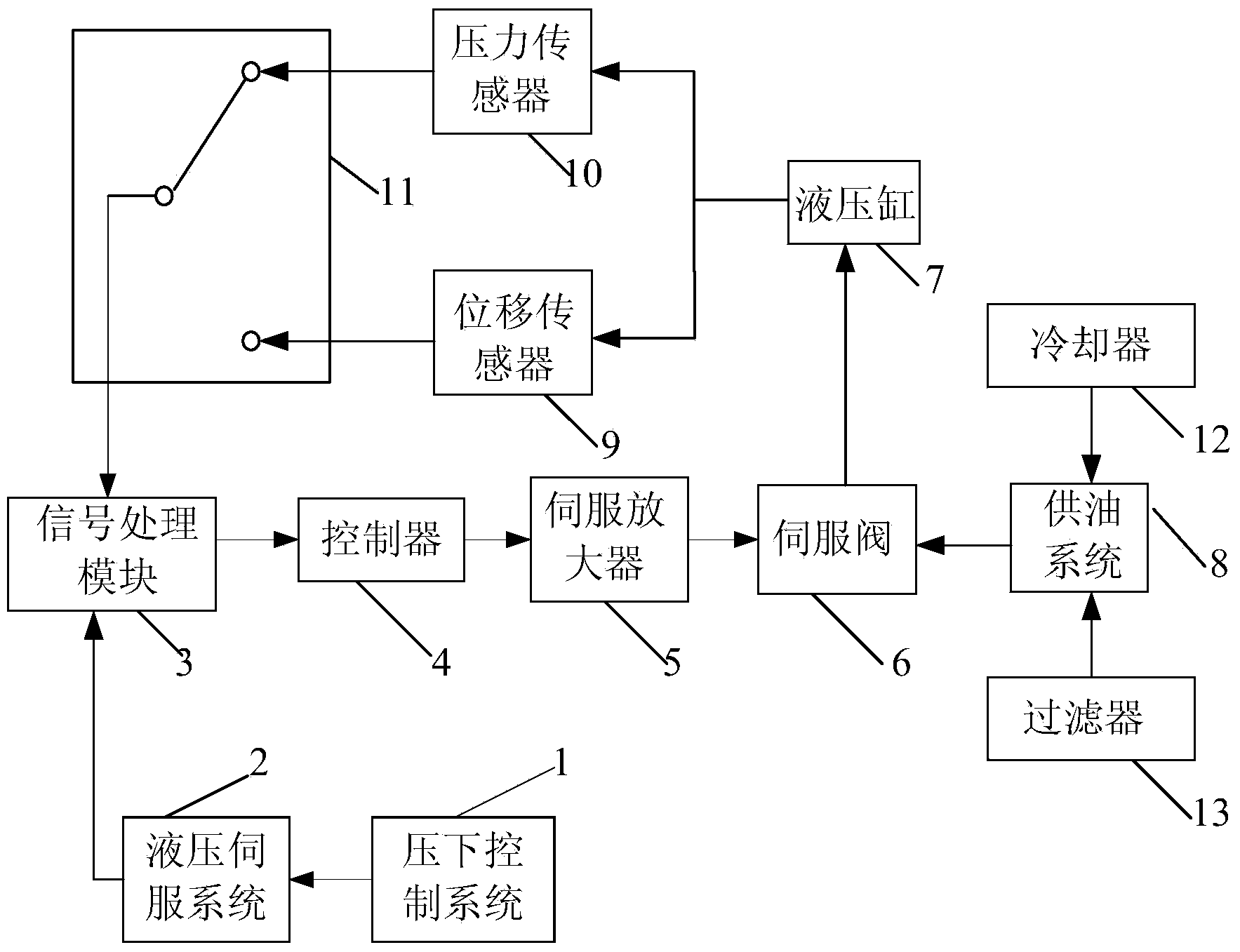

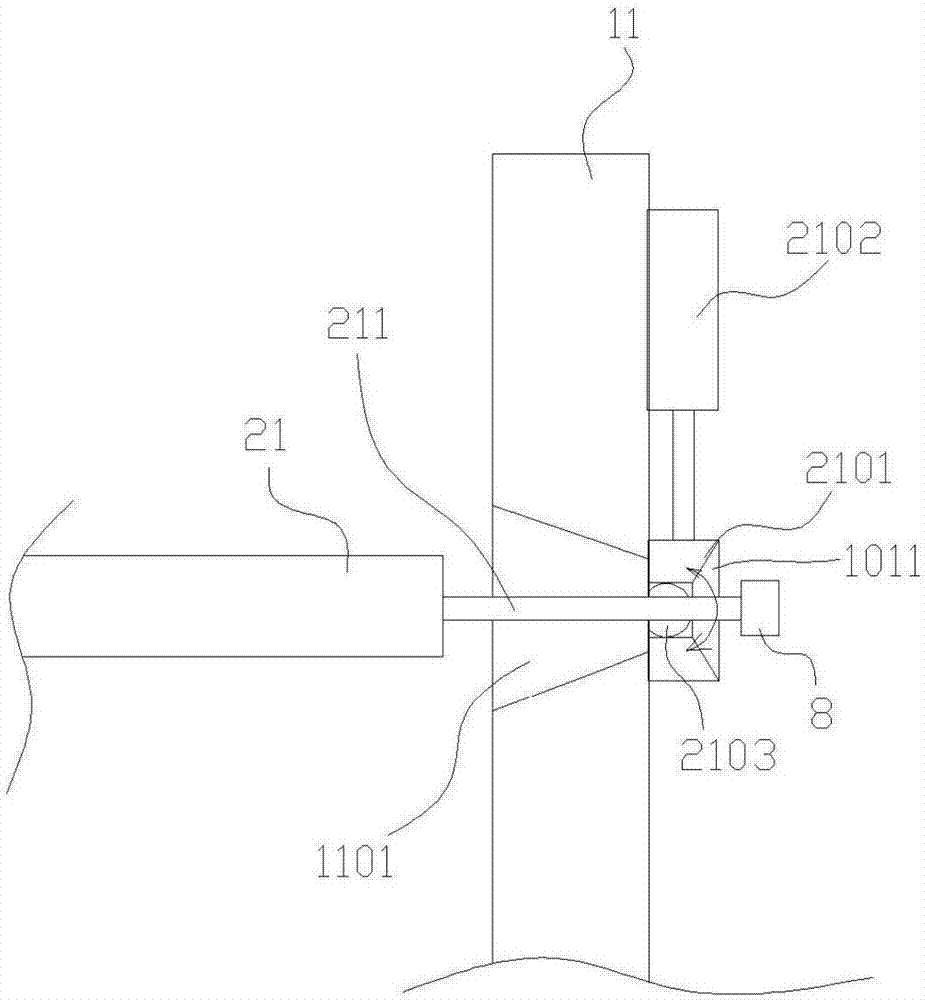

Hot rolling mill rolling control system used for improving rolling accuracy

InactiveCN103511365AImprove rolling precisionPrecise Control of DisplacementServomotorsFluid-pressure actuator componentsSignal onTraffic volume

The invention provides a hot rolling mill rolling control system used for improving rolling accuracy, and relates to a hot rolling mill control system. The hot rolling mill rolling control system used for improving rolling accuracy solves the problems that an existing hot rolling mill control system can not realize constant roll bit rolling under manual control, so that control accuracy is low. The hot rolling mill rolling control system used for improving rolling accuracy can detect the displacement of a piston inside a hydraulic cylinder through a displacement sensor, and compares detected displacement signals with roll bit control signals to obtain a displacement difference, a servo valve carries out conversion between electrical signals and flow signals on the received displacement difference, oil feeding amount of an oil tank to the hydraulic cylinder is controlled, the displacement of the piston of the hydraulic cylinder is further accurately controlled, constant roll bit rolling is finally achieved, and the rolling accuracy of a hot rolling mill is improved by 40%.

Owner:NORTHEAST LIGHT ALLOY CO LTD

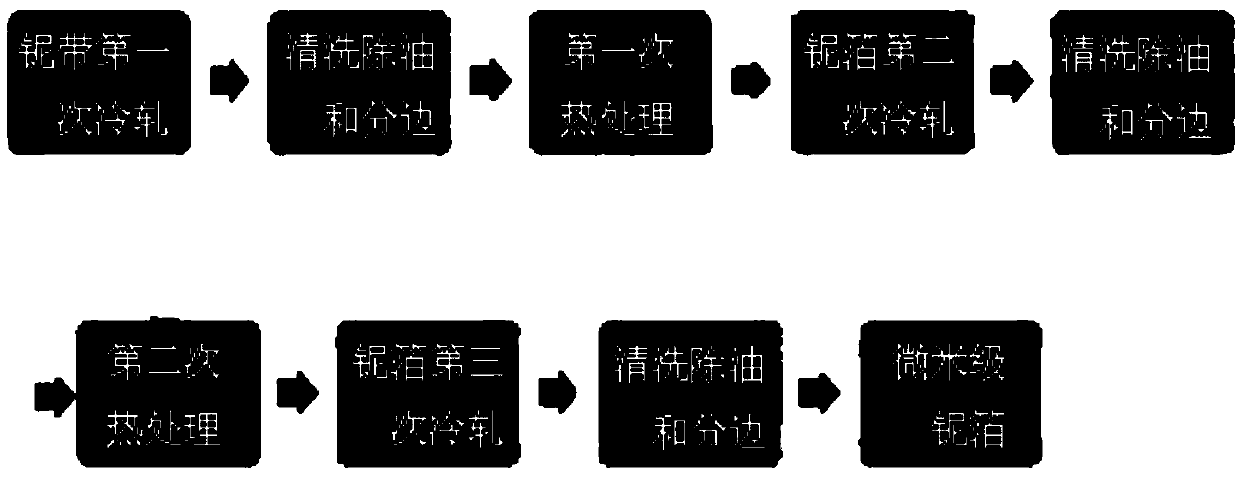

Preparation method of micro order niobium foil

The invention discloses a preparation method of a micro order niobium foil. According to the method, three rolling process reversible type rolling is performed on a niobium belt by utilizing a Sendzimir twenty-roller cold rolling machine, the obtained niobium foil is cleaned, and subjected to edge splitting and heat treatment after each rolling process reversible type rolling, and finally, the micro order niobium foil is obtained. According to the method, three rolling process rolling is performed on the niobium belt with the width being 100 mm to 120 mm and the thickness being 0.15 mm to 0.2mm by adopting the Sendzimir twenty-roller cold rolling machine. Due to the beneficial effects that the Sendzimir twenty-roller cold rolling machine is large in rolling force and high in rolling precision, by designing a reasonable rolling process, the thickness precision of the micro order niobium foil is greatly guaranteed; meanwhile, through a reasonable annealing process, the structure internal stress of the niobium foil is eliminated in time, influences on the niobium foil in the rolling process are reduced, and finally, the micro order niobium foil with the thickness being 0.007 mm to 0.009 mm is obtained.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Manufacturing method of titanium shuttle-shaped component

The invention discloses a method for manufacturing a titanium shuttle-shaped part, which includes the steps of material selection, mold fixing, mold trial, annealing, grinding, deep drawing and cutting, cleaning, primer spraying, surface paint spraying, etc. Carry out the first cold drawing, and then carry out the above solution treatment step after the first cold drawing, and then carry out the second cold drawing, and then carry out the third hot drawing to shape the blank after the second cold drawing, Carry out pressure-holding treatment during the third hot drawing and shaping. Effectively improve the production efficiency and aesthetics of shuttle-shaped parts.

Owner:CHENGDU RUIDA KEHENG TECH

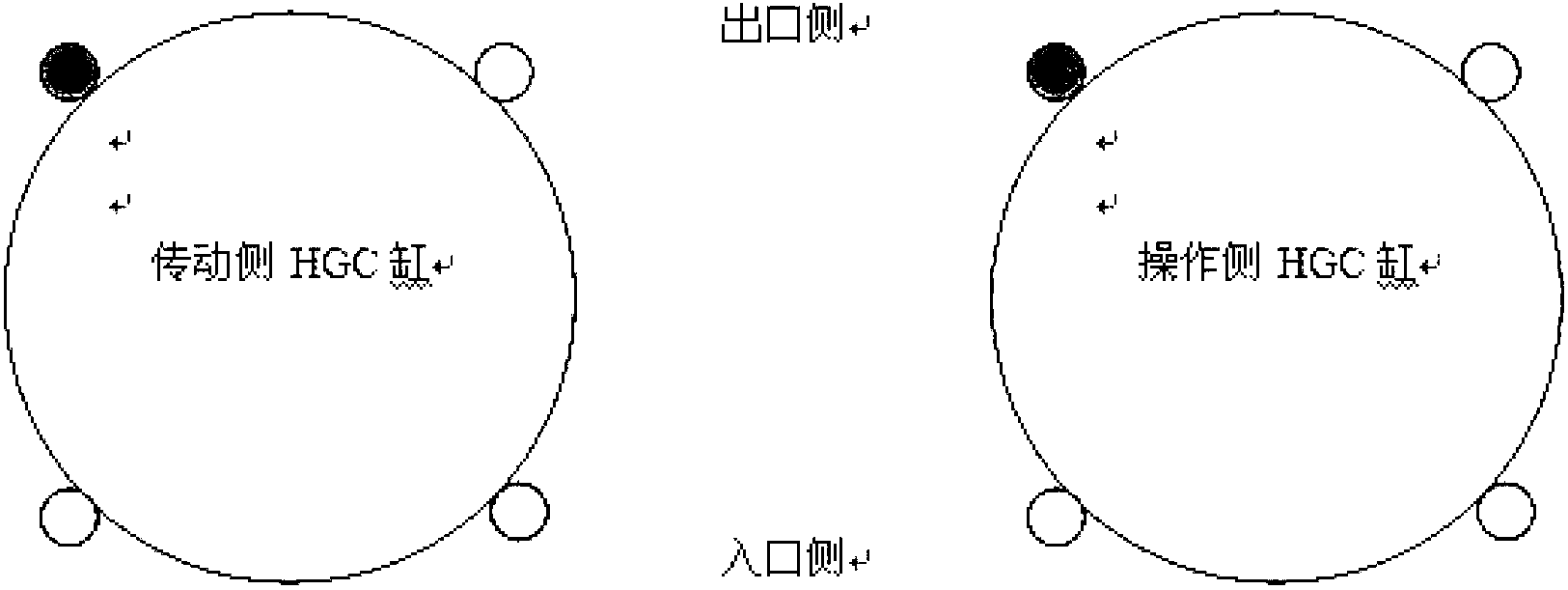

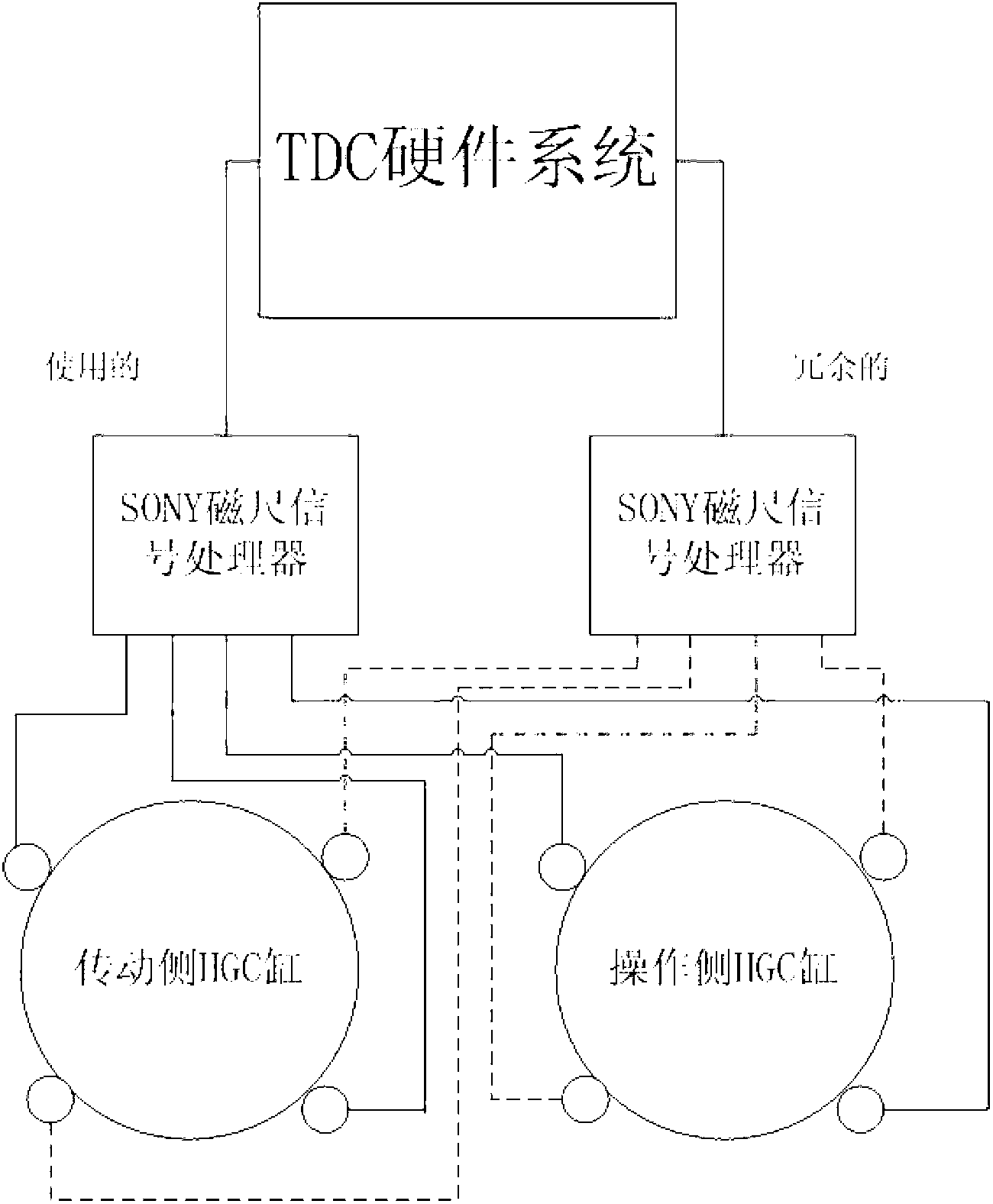

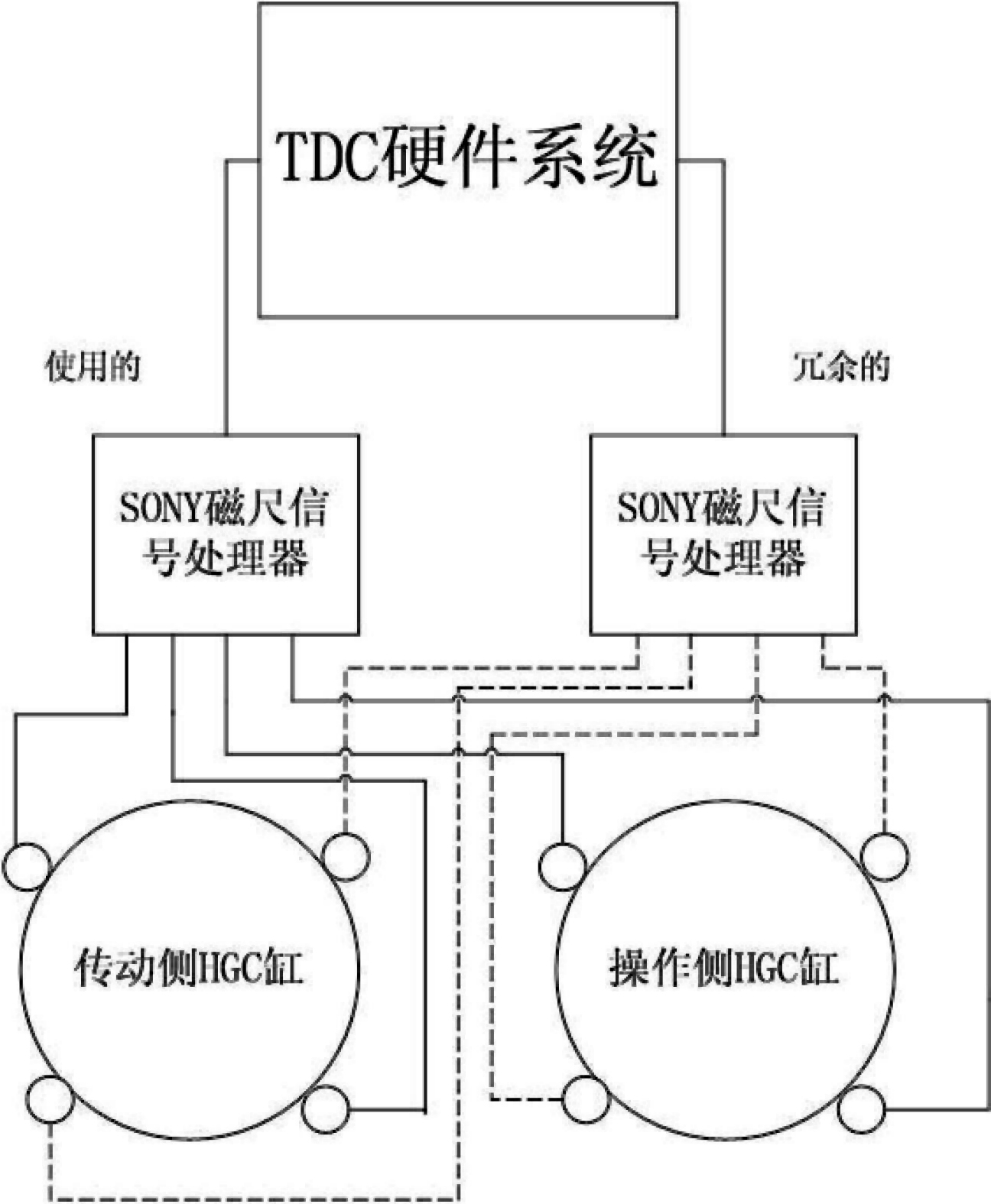

Rolling mill SONY magneto-scale online redundancy method

ActiveCN102699033AImprove stabilityImprove rolling precisionRolling equipment maintainenceMetal rolling arrangementsFault handlingIndustrial engineering

A rolling mill SONY magneto-scale online redundancy method belongs to the technical field of heavy and medium plate rolling mills. Aiming at sensitivity of a rolling mill roll gap adjusting system for signal adjusting stability, two SONY magneto-scales are newly added in a diagonal mode, signal collection is carried out by aid of four sensors with the same work principle in advantage complementation and combination mode, and the average value of the four sensors is taken from the system to serve as an actual position of a hydraulic gap control (HGC) cylinder. In the production process, if one sensor breaks down, the system can switch to the other group of sensors to continue production, accordingly stability of the milling roll adjusting system is enhanced, fault processing time can be shortened to the maximum limit, and smooth operation of production is ensured.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

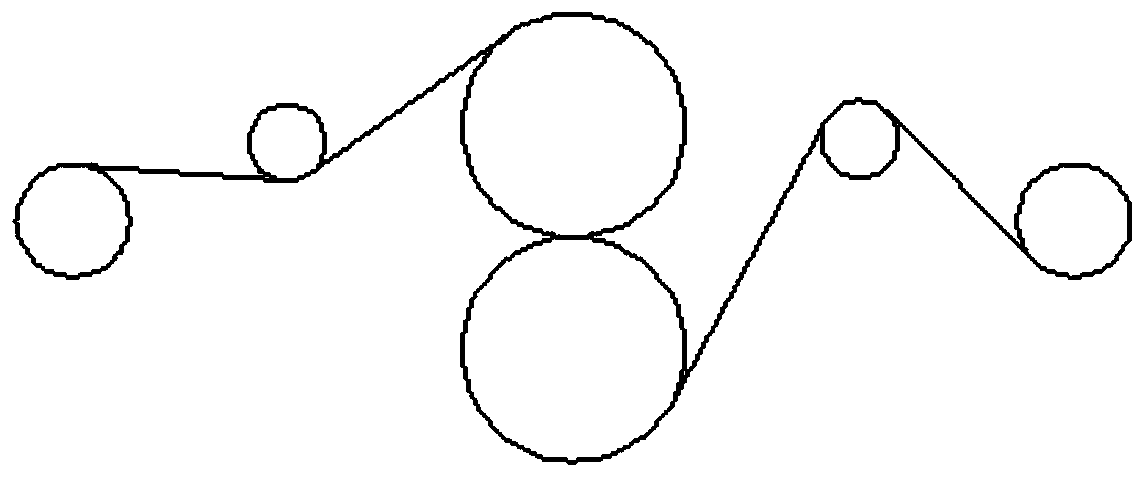

Plate rolling machine

The invention discloses a plate rolling machine which comprises an upper roller, a side roller, a transmission mechanism, a coupler, a speed reducer, a pressing rod mechanism, a motor, a lower roller adjusting mechanism, a lower roller, a side roller adjusting mechanism, supports and a base. The supports are arranged on the base. The upper roller, the side roller and the lower roller are arranged between the supports. The side roller is connected with the side roller adjusting mechanism. The lower roller is connected with the lower roller adjusting mechanism. The upper roller and the side roller are connected with the coupler through the transmission mechanism. The coupler is connected with the motor through the speed reducer. The pressing rod mechanism is arranged at a position above and outside the speed reducer. The plate rolling machine is simple in structure, capable of conveniently taking out rolled cylindrical workpieces, more convenient and reliable to operate, high in rolling precision and high in practicability.

Owner:浙江德清森朗装饰材料有限公司

Metal foil rolling device

InactiveCN106269866AImprove rolling effectReduce contact surfaceMetal rolling arrangementsMetal foilElectric machinery

The invention discloses a metal foil rolling device which comprises a base. Two support plates are symmetrically arranged on the base, a rolling space is formed between the two support plates, adjusting open holes are formed in the support plates, a large upper power roller, a small upper driving roller, a small lower driving roller and a large lower power roller are sequentially arranged in the rolling space from top to bottom, a first bearing seat is arranged at two ends of the large upper power roller and two ends of the large lower power roller respectively, a second bearing seat is arranged at two ends of the small upper driving roller and two ends of the small lower driving roller respectively, the first bearing seats and the second bearing seats are arranged in the adjusting open holes, inner threaded sleeves are further arranged on the support plates above the adjusting open holes, threaded rods are arranged in the inner threaded sleeves, one end of the threaded rod is in abut joint with the corresponding first bearing seat of the large upper power roller, the other end of the threaded rod is connected with a worm wheel, and the worm wheels are connected with a pushing motor through worms. The metal foil rolling device is compact in structure, convenient to adjust and high in production precision.

Owner:JIANGSU YOUZHA MACHINE CO LTD

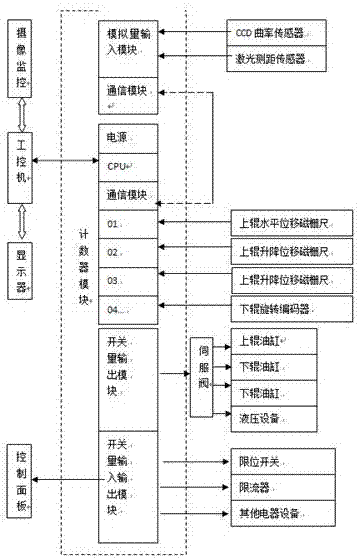

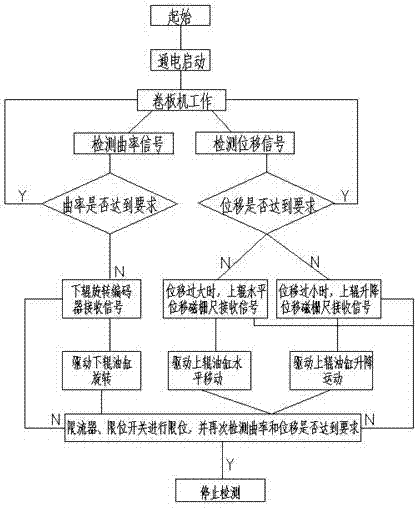

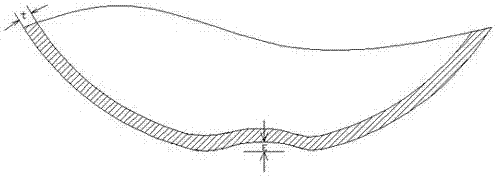

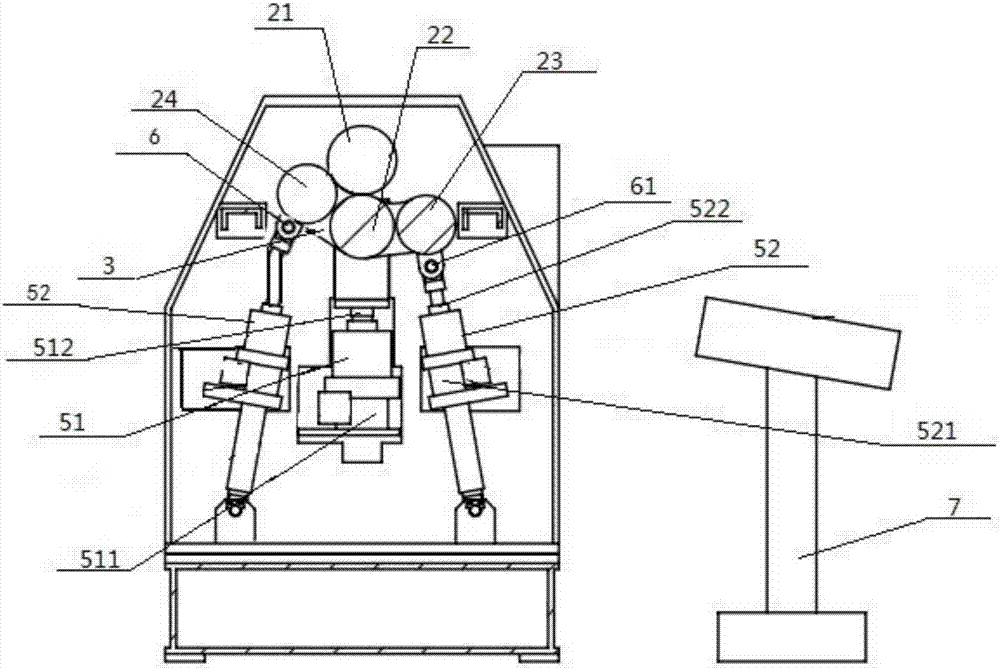

Light sensation monitoring and control system of plate winding machine and wind power steel pipe pile cylinder winding process applying system

ActiveCN106975675AGood image reproducibilityStrong anti-interference ability on siteMetal working apparatusAutomatic controlInformation quantity

The invention discloses a light sensation monitoring and control system of a plate winding machine and a wind power steel pipe pile cylinder winding process applying the system. The light sensation monitoring and control system of the plate winding machine comprises an online monitoring system and a feedback control system. The wind power cylinder winding process applying the system comprises sample plate manufacturing, steel plate inspection, steel plate prewinding, winding formation, longitudinal gap cleaning, longitudinal gap adjustment, welding, cylinder lifting, secondary circle correction and cylinder repair. The light sensation monitoring and control system of the plate winding machine has the following advantages: the light sensation monitoring and control system fuses such modern sciences and technologies as optoelectronics, computer technology, laser technology, image processing technology and automatic control technology as a whole to form a light, machine and electricity comprehensive online measurement control system with optical detection as basis, has the advantages of no contact, high speed, wide dynamic range and rich information quantity, monitors the radian and continuously winds a wind power cylinder in the winding process, improves the automation degree, and greatly improves the winding precision and efficiency.

Owner:上海泰胜(东台)电力工程机械有限公司

Asynchronous cold rolling forming process of aluminum alloy stainless steel composite plate

ActiveCN110883093AIncrease rolling capacityImprove rolling precisionTemperature control deviceWork cooling devicesComposite plateLine heating

The invention discloses an asynchronous cold rolling forming process of an aluminum alloy stainless steel composite plate. The process comprises the following process steps: 1, rolling and compoundinga stainless steel plate and an aluminum alloy plate in an asynchronous rolling mode, and 2, after asynchronous rolling, diffusing and annealing the composite plate, specifically, in the step 1, online heating is carried out on the opposite surface of the composite plate surface of the stainless steel plate, online cooling is carried out on the opposite surface of the composite plate surface of the aluminum alloy plate online, and the heating temperature is 350 DEG C-850 DEG C; the temperature of the composite plate surface of the stainless steel plate from which the composite plate is rolledis lower than 650 DEG C, and the temperature of the composite plate surface of the aluminum alloy plate from which the composite plate is rolled is lower than 300 DEG C; the rolling reduction rate is20%-90%; the different speed ratio of a roller for asynchronous cold rolling is 1.05-1.50; the thickness ratio of the aluminum alloy plate to the stainless steel plate is 1.5-4.0; and in the step 2, the annealing temperature is 250 DEG C-500 DEG C and the annealing time is 15-120 min. The single-side online heating process for rolling the composite plate is creatively provided so as to improve theinterface bonding strength of the composite plate and realize rolling compounding in an interface semi-melting state.

Owner:JIANGYIN KANGRUI MOLDING TECH CO LTD

Hot drawing technology for 410# steel cylinders

InactiveCN105081707AAvoid shortened service lifeEffective anti-corrosion and oxidationSizingMaterials science

The invention discloses a hot drawing technology for 410# steel cylinders. The hot drawing technology comprises the steps of material selection, die fixing, annealing, polishing, drawing, closing-in, cleaning and the like; a polished blank is subjected to primary hot drawing, annealing, secondary hot drawing and tertiary hot drawing sizing in sequence, and pressure is maintained in the third hot drawing sizing process. The overall quality of the steel cylinders is ensured through repeated drawing and annealing treatment.

Owner:SINOMA SCI & TECH CHENGDU CO LTD

Machining technology of seat ring for engineering wheel

InactiveCN108274203AIncrease profitImprove welding qualityVehicle componentsNumerical controlButt welding

The invention provides a machining technology of a seat ring for an engineering wheel. The machining technology comprises the steps of section steel rolling, double dimension shearing, edge coiling, aligning and spot welding, flash butt welding, welded joint milling, finishing, knurling, turning, packaging and the like. By means of the machining technology, the material utilization rate and welding quality can be improved, and the production cost can be reduced. In the process of the machining technology, a short stress rolling mill controlled by a microprocessor is adopted for rolling, and the rolling precision is high; high-pressure water is adopted for dephosphorization, and the surface quality is good; a punching machine is adopted for double dimension shearing, and the shearing efficiency is high; during turning, a robot and numerical control machine tool full-automatic assembly is adopted for machining, omni-directional machining of workpieces can be achieved, the equipment assembly is operated by only one person, manpower is saved, electricity consumption and the manual cost are reduced, and the machining efficiency can be improved by 3 times; and a dedicated knurling machine is adopted, and the knurling efficiency is 6-8 times that of a common lathe.

Owner:HONGYUAN JINGGONG WHEEL CO LTD

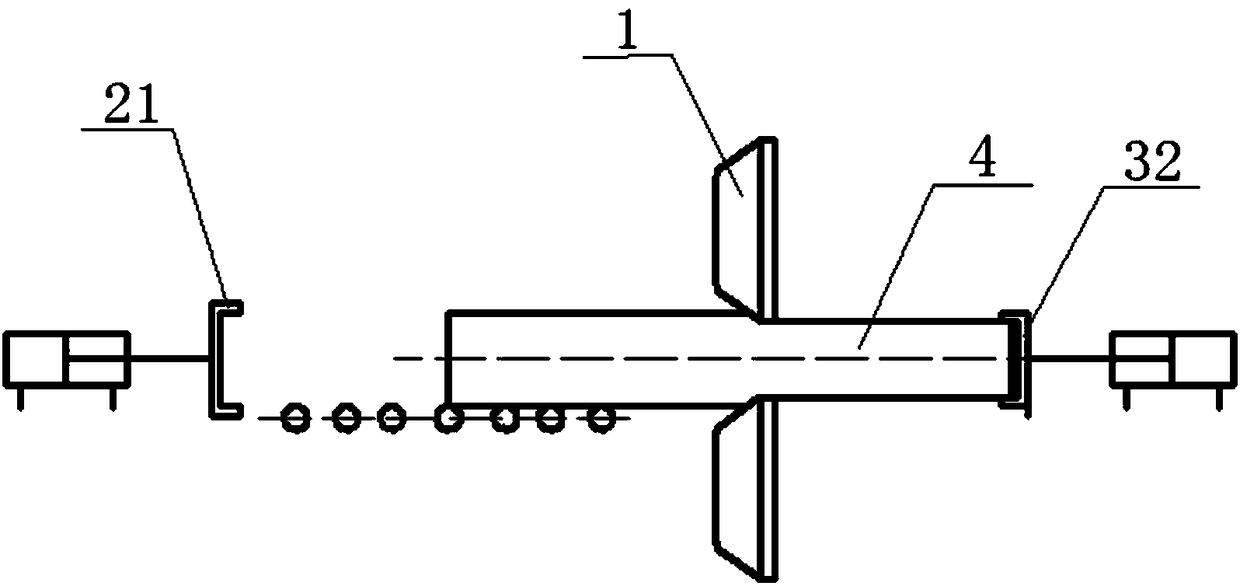

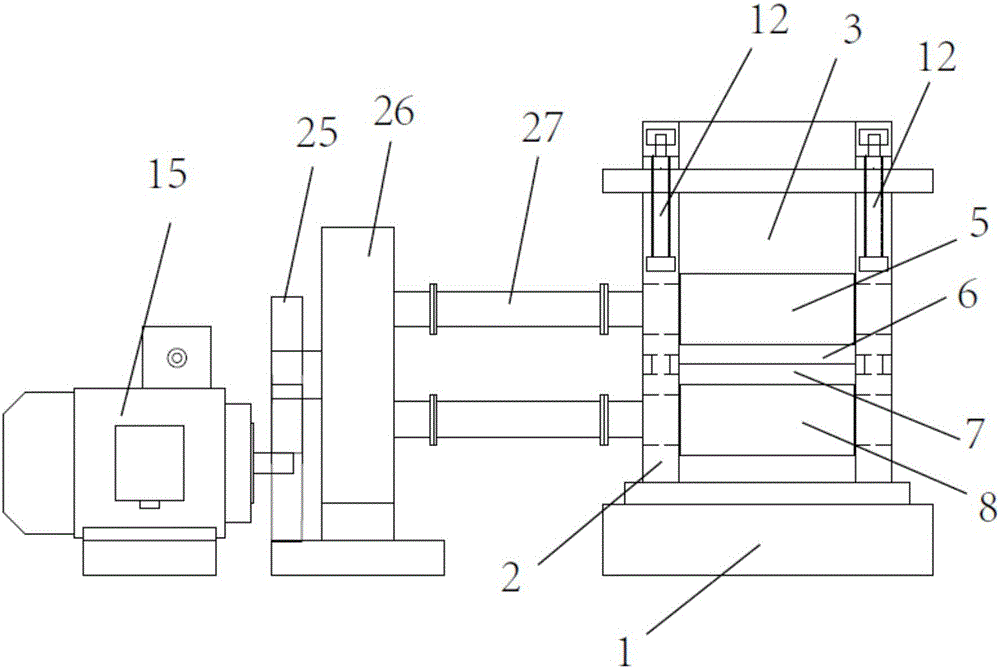

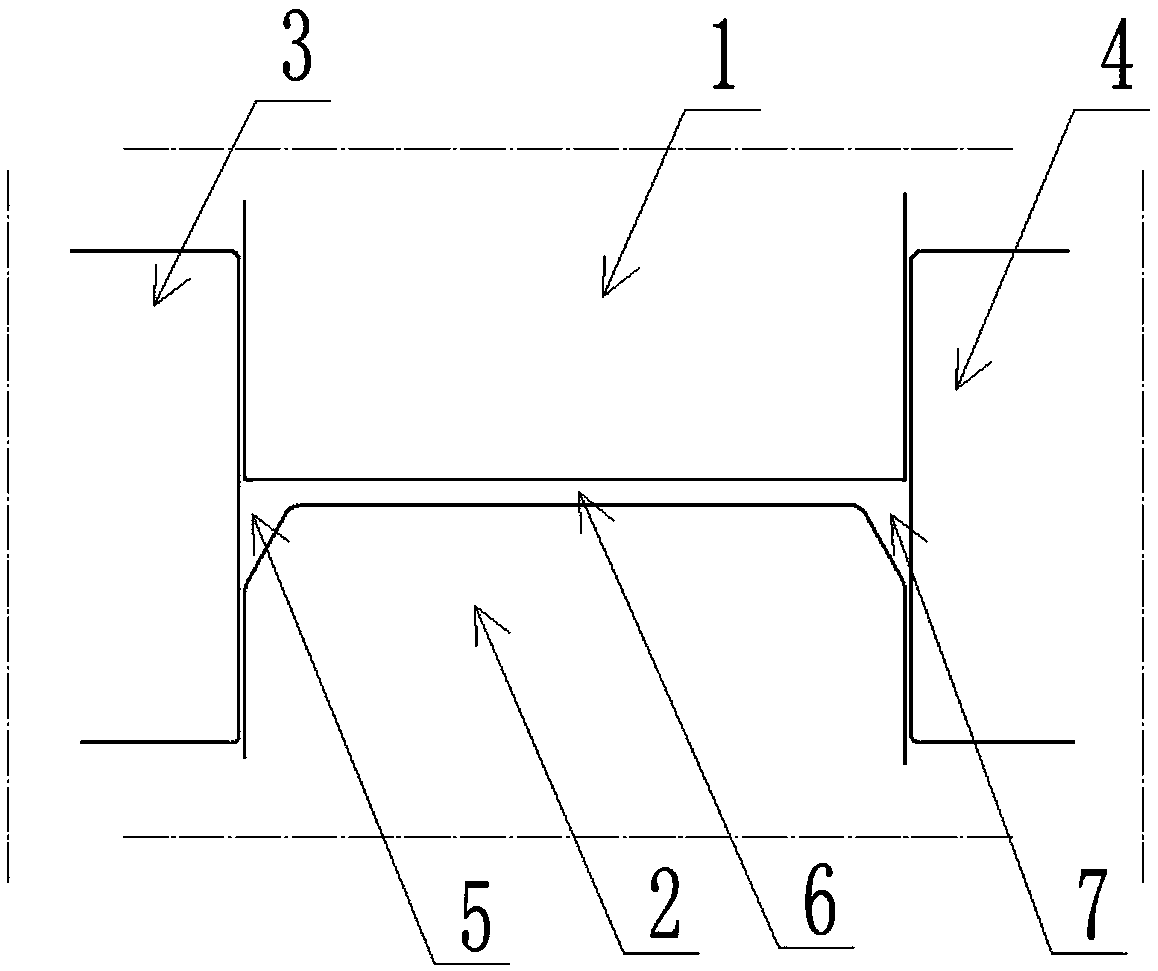

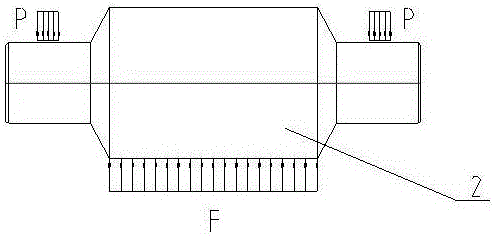

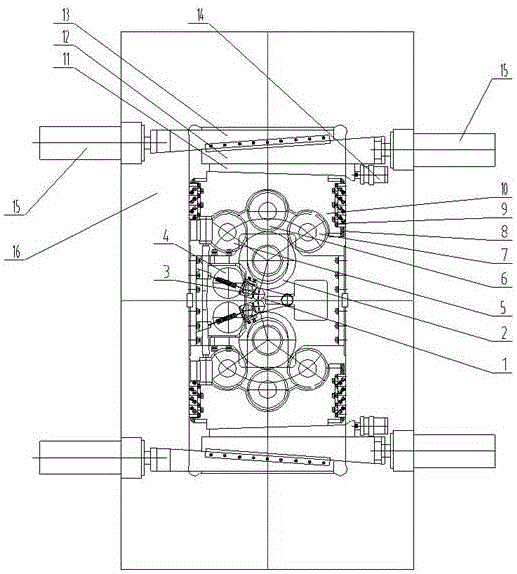

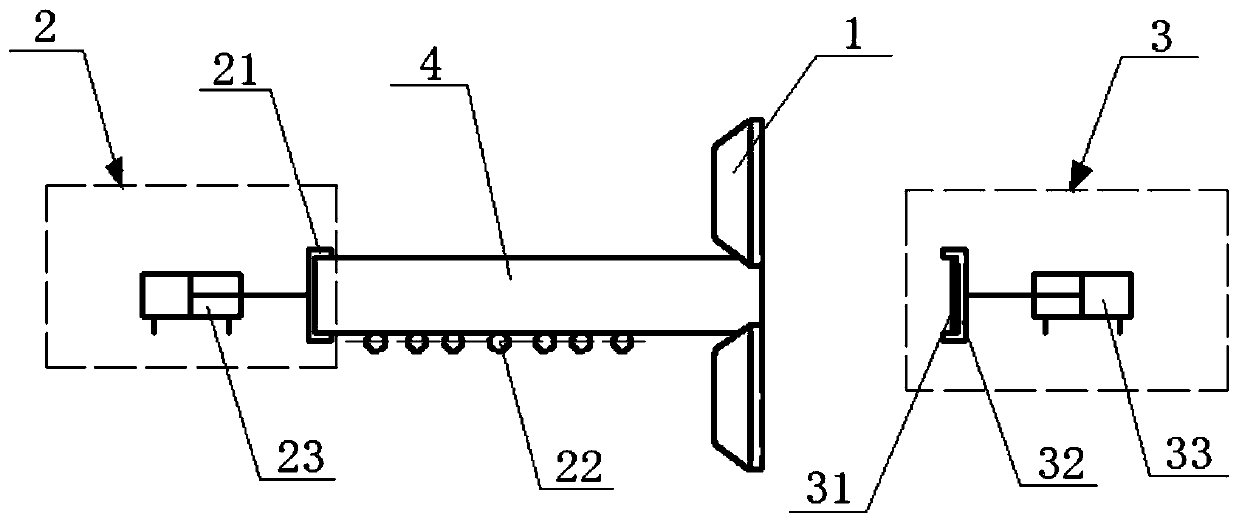

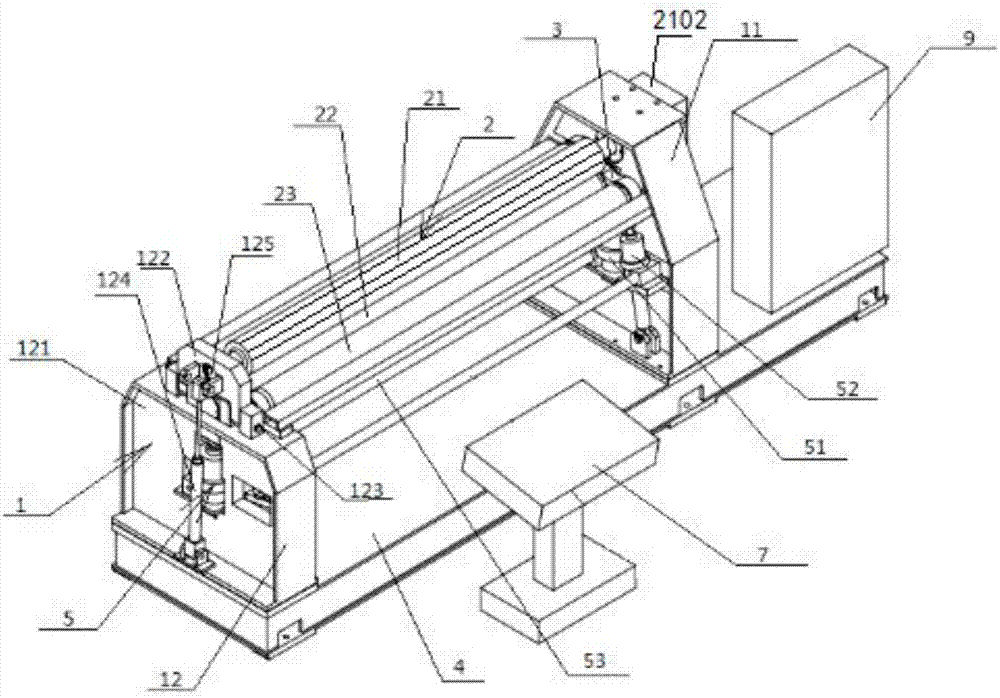

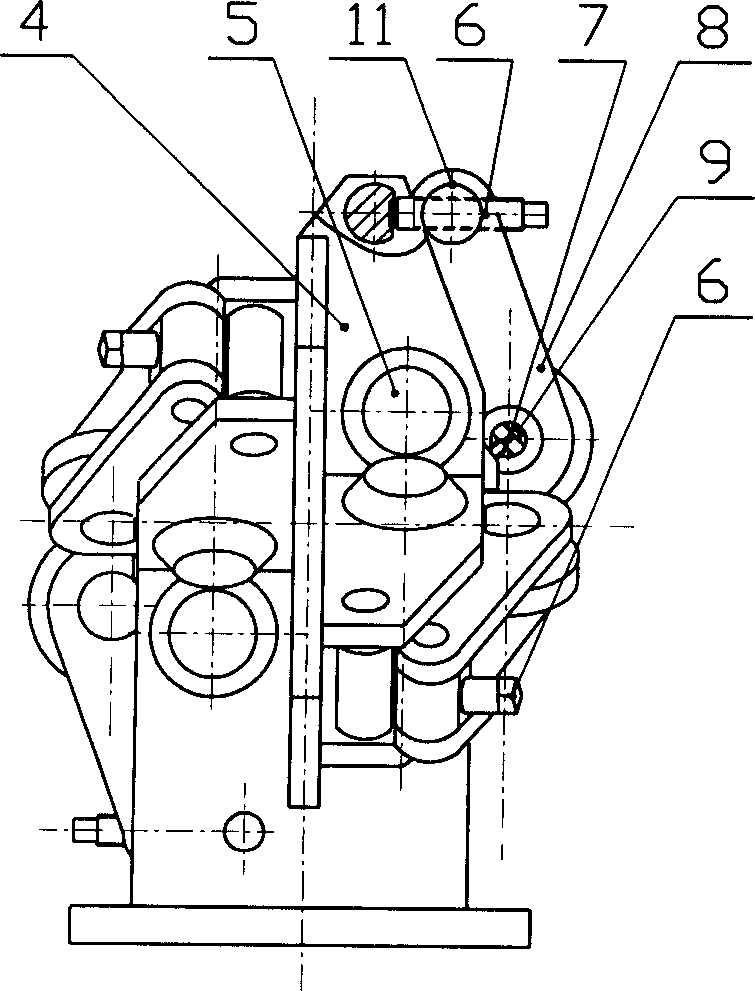

Universal rolling device of ball flat steel and rolling method

PendingCN107824613AIncrease rolling batchImprove rolling precisionMetal rolling stand detailsMetal rolling arrangementsSteel ballEngineering

The invention discloses an universal rolling device of ball flat steel and a rolling method. The universal rolling device comprises an universal rolling mill unit; the universal rolling mill unit consists of 3-6 universal rolling mills; any universal rolling mill is provided with an upper horizontal roller (1), a lower horizontal roller (2), an operation side vertical roller (3) and a transmissionside vertical roller (4); two ends of the lower horizontal roller (2) are chamfered, so that the upper horizontal roller (1), the lower horizontal roller (2), the operation side vertical roller (3) and the transmission side vertical roller (4) are combined to form a combined ball flat steel rolling hole; the combined ball flat steel rolling hole is in a shape of combining two ball flat steels; web plates of the two ball flat steels are connected to form a combined web plate (6); and bulbs are respectively positioned on the same sides of the connected web plates as a left leg (5) and a right leg (7). The universal rolling device can roll axisymmetric combined ball flat steels, and has the characteristics of high rolling precision, prominent improvement of the rolling batches and low rollerconsumption.

Owner:SHANDONG IRON & STEEL CO LTD

Cold rolling method of TC4 titanium alloy wires

PendingCN110976512AAvoid inhalationRealize continuous cold rollingFurnace typesMetal rolling arrangementsWire rodGraphite

The invention provides a cold rolling method of TC4 titanium alloy wires. By reasonably distributing the cold rolling deformation amount of each pass and using the mode of small deformation accumulative large deformation, continuous cold rolling of the TC4 titanium alloy wires is realized, the rolling precision is high, the speed is high, and the method is suitable for continuous machining of thecoiled wires large in piece weight (>=30 kilograms per coil). Proper heat treatment is used in the cold rolling process, so that on the basis of ensuring the machining performance of the wires, the metallographic structure and mechanical property of the material are well matched. The machining process is stable, the mechanical property and size precision consistency of the produced wires are good,the production effect and the product quality stability are greatly improved compared with a traditional cold drawing technology, and the product precision, performance and stability completely meetcustomer requirements; and multiple times of heat treatment and graphite emulsion lubricant coating are not needed in the early stage of wire rolling, and harmful gas is prevented from being absorbedby the wires. The method is low in cost and simple in process, and can realize large-scale industrial production.

Owner:宝鸡鑫诺特材股份有限公司

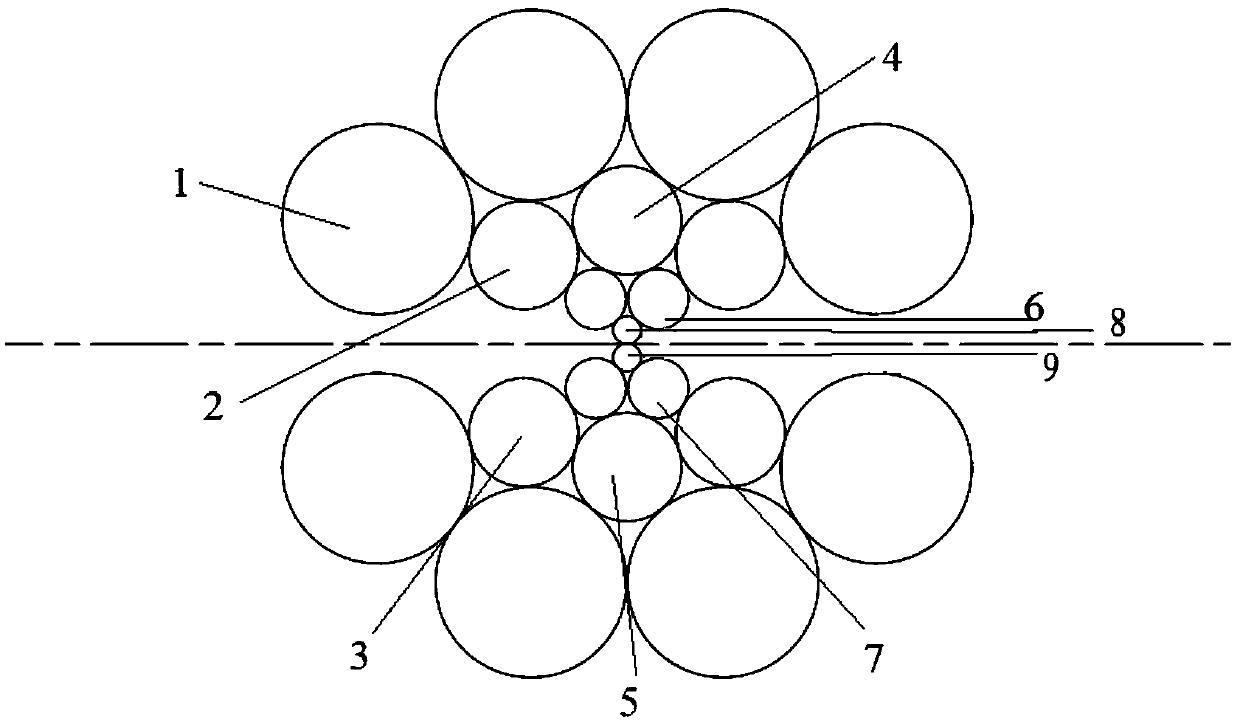

Novel partial fourteen-roller steel plate cold rolling mill structure

ActiveCN105728463ASmall diameterStable rolling processMetal rolling stand detailsMetal rolling arrangementsRolling millBending moment

The invention provides a novel partial fourteen-roller steel plate cold rolling mill structure. A roller system is arranged in a J form; the structure comprises a set of working rollers, three sets of support rollers, three sets of back lining bearing rollers and a set of pressing devices symmetrically arranged up and down along a roller center line; the working rollers are deviated from the roller center lien by a certain distance, are supported by middle support rollers in the vertical direction, and are supported by transition support rollers and side support rollers in the side direction; the three sets of back lining bearing rollers are arranged on the peripheral surfaces, far from one sides of the working rollers, of the support rollers in sequence; multiple back lining bearings are respectively arranged in axial directions of three back lining bearing rollers; the bearings are arranged in a staggered manner; indentations cannot be generated among the rollers; and the pressing devices are clamped on shafts among bearings of the back lining bearing rollers. The roller system in rolling work is stable in structure, excellent in rigidity and capable of adjusting the convexity of the working rollers at any time to finish the plate shape adjustment; the rolling force and the deformation resistance of rolled steel are both directly acted in a roller surface range of the rollers; and the support rollers are not suffered from the bending moment, and generate no bending deformation, so that the plate rolling precision is higher.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Method for processing profiled bar with asymmetrical cross section

InactiveCN103386416AImprove rolling conditionsRolling realizationMetal rolling arrangementsWork in processEngineering

The invention discloses a method for processing a profiled bar with an asymmetrical cross section. The method is characterized in that a to-be-rolled profiled bar with the asymmetrical cross section is subjected to mirror pairing and combining in the direction of a vertical axis (Y axis), converting the asymmetrical cross section into a symmetrical cross section, improving the rolling condition, then rolling the bar with a symmetrical cross section by a four-roll universal mill, and finally dissecting the rolled semi-finished product with the symmetrical cross section by a metal dissecting device, so as to obtain two qualified finished bars which have the asymmetrical cross sections and are the same in size and shape. The method has the advantages that the rolling condition of the profiled bar with the asymmetrical cross section is improved, so the rolling by the four-roll universal mill is realized; and the rolling speed is high, the rolling efficiency is high, and the production capability is greatly improved.

Owner:钱奕峰

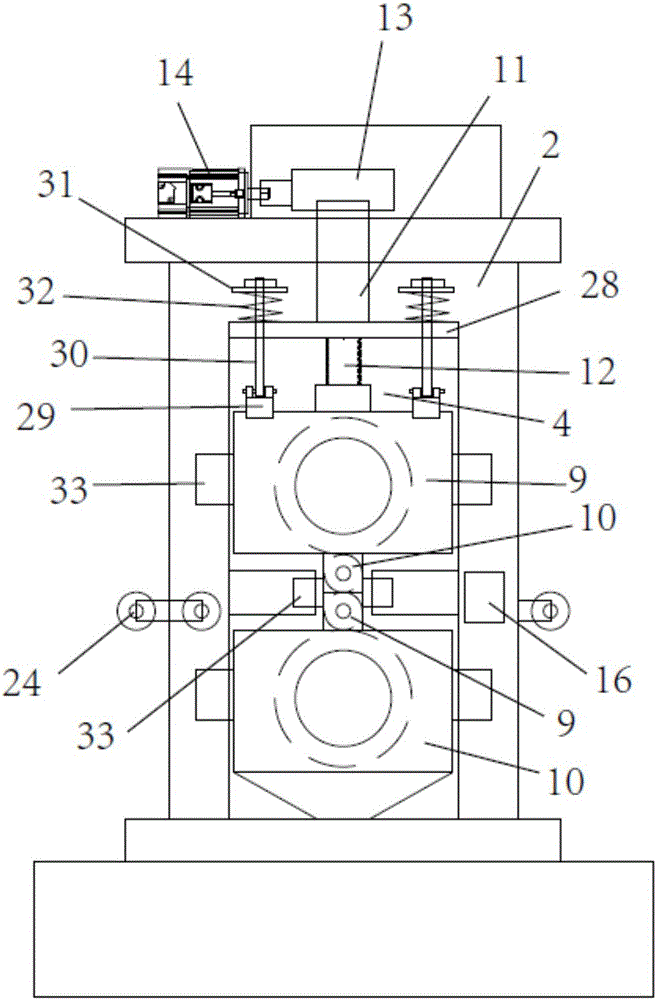

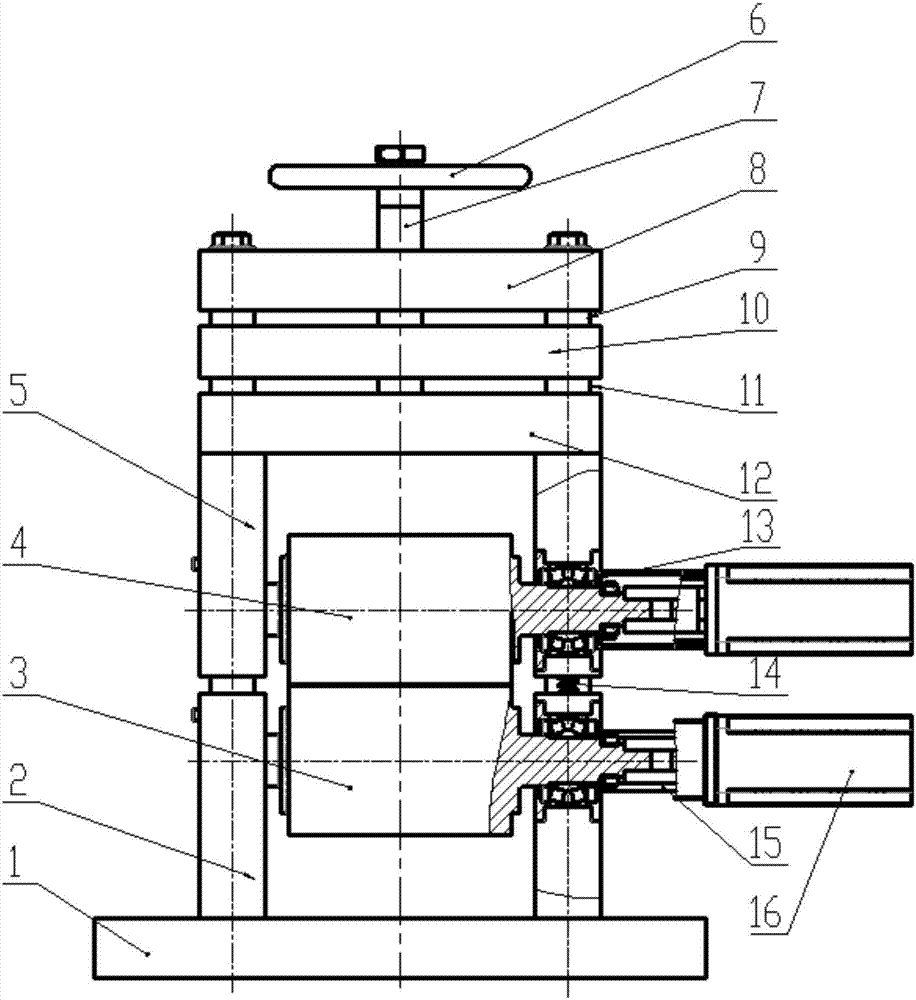

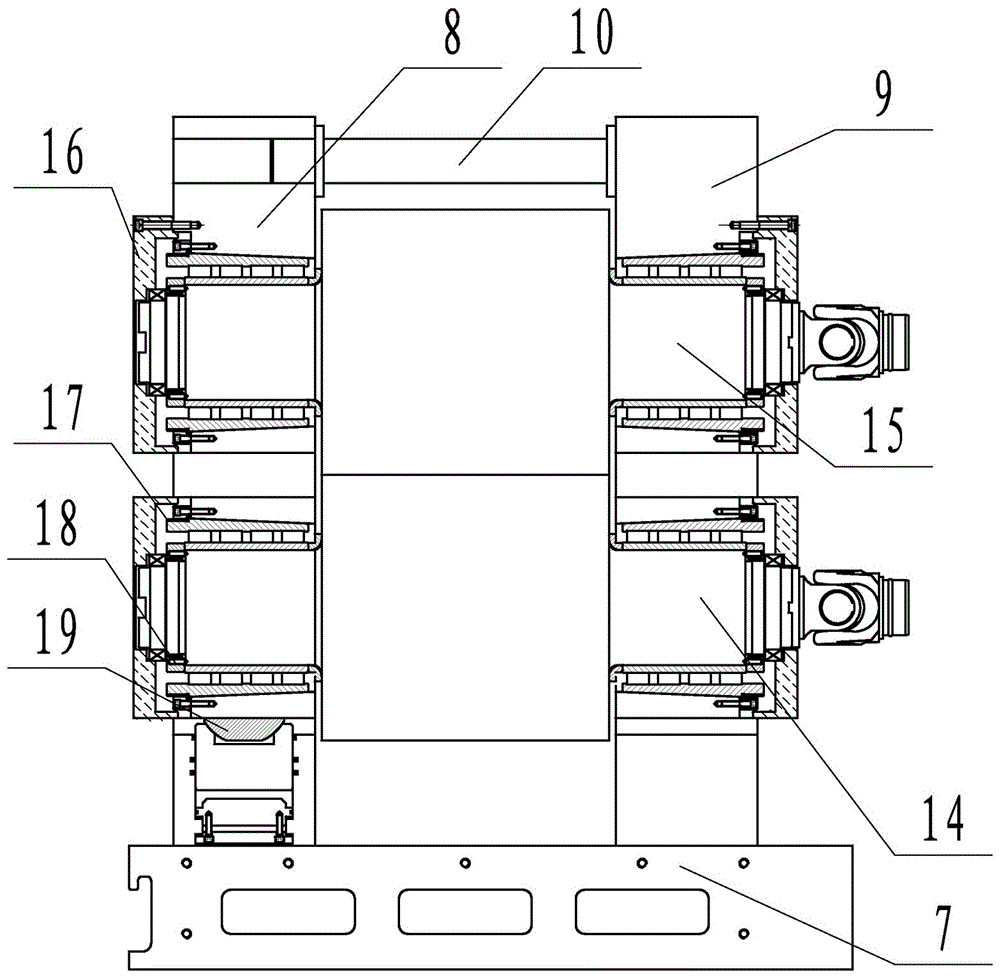

Short stress line type pole piece rolling press

InactiveCN107020764ASimple structureCompact structureCell electrodesRotary pressEngineeringMechanical engineering

The invention provides a short stress line type pole piece rolling press. The short stress line type pole piece rolling press comprises an upper roller mechanism, a lower roller mechanism, an upper bearing seat, a lower bearing seat and a roller gap adjustment mechanism; the upper roller mechanism is connected with the upper bearing seat; the lower roller mechanism is connected with the lower bearing seat; the upper bearing seat is connected with the lower bearing seat through a guide shaft; the roller gap adjustment mechanism is connected with the upper roller mechanism and is used for adjusting a roller gap between the upper roller mechanism and the lower roller mechanism. The short stress line type pole piece rolling press is simpler and more reliable in structure; a stress loop line is shorter when a pole piece is rolled and pressed; the rolling and pressing precision and the rolling and pressing quality can be improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Drawing process for steel cylinder made of 410 stainless steel

InactiveCN105127688AAvoid shortened service lifeEffective anti-corrosion and oxidationMaterials scienceMaterial selection

The invention discloses a drawing process for a steel cylinder made of 410 stainless steel. The drawing process comprises steps of material selection, annealing, polishing, drawing, closing-up, washing and the like, wherein polished blank is subjected to first-time cold drawing, annealing is performed after first-time cold drawing, and then second-time cold drawing is performed; the blank subjected to second-time cold drawing is subjected to third-time hot drawing and shaping, and pressure-maintaining processing is performed during third-time hot drawing and shaping. The overall quality of the steel cylinder is guaranteed through multiple times of drawing and annealing processing.

Owner:SINOMA SCI & TECH CHENGDU CO LTD

Automobile arbor efficient and environment-friendly rolling process

InactiveCN109648020AImprove plasticityEliminate or mitigate defectsMetal rollingHeating furnaceMaterials science

The invention discloses an automobile arbor bar material efficient and environment-friendly rolling process. The automobile arbor bar material efficient and environment-friendly rolling process comprises the following steps that S1, a steel blank is selected; S2, the steel blank is put into a conveyor and is fed into a heating furnace to be heated through the conveyor; S3, a furnace outlet rollerpassage conveys the steel blank after heating treatment to a rough rolling machine set; S4, a material after rough rolling is conveyed to a cold scattering roller passage; S5, the cold scattering roller passage conveys the cooled material to a finish rolling vertical roller machine set to be subjected to finish rolling; S6, specified-length shearing is performed on the material by a shearing machine arranged at the material output end of the finish rolling vertical roller machine set; and S7, check and accept are performed on the arbor bar material. The automobile arbor bar material efficientand environment-friendly rolling process is free of pollution, environment friendly, efficient in rolling and suitable for large-scale promotion.

Owner:柳州国福科技有限公司

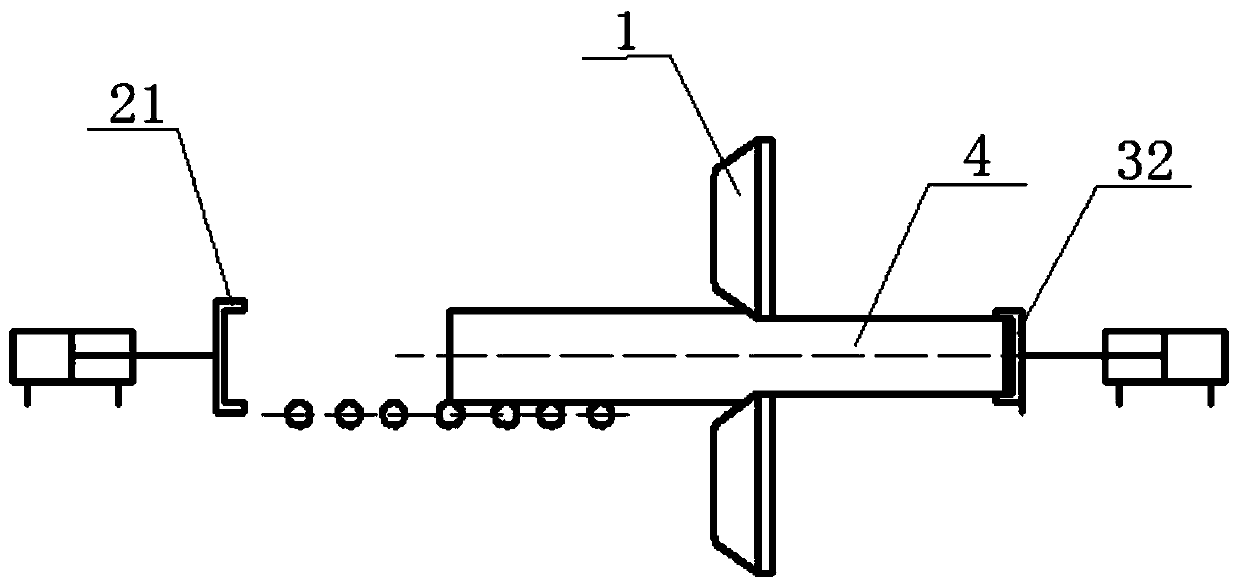

A three-roll skew rolling forming method for a railway vehicle axle

The invention discloses a three-roll cross-rolling forming method for railway vehicle axles, which is characterized in that the bar is heated, and the bar is sent into a three-roll cross-rolling machine through an axial pushing device, and three cross-rollers are simultaneously engaged with the bar , and drive the bar to rotate. At the same time, the axial pusher pushes the bar to move axially at a constant speed. The radial drive mechanism controls the radial movement of the skew roll according to the diameter of the railway vehicle axle to be processed. When it moves to contact with the axial feeding device, the axial feeding device pulls the bar and continues to move axially at a constant speed, and at the same time the bar is separated from the axial pushing device, and a long step with a large diameter is obtained after processing Axle—the railway vehicle axle; the advantage is that the mold is simple to manufacture, and the force is evenly distributed on the surface of the rolled piece, which can effectively reduce the wear of the roll during the skew rolling process, enable the rolling mill to carry out lightweight construction, and effectively increase the service life of the rolling mill.

Owner:NINGBO UNIV

Linkage adjusting mechanism for plate rolling machine working rollers

The invention discloses a linkage adjusting mechanism for plate rolling machine working rollers. The linkage adjusting mechanism comprises a side roller linkage mechanism body. The side roller linkage mechanism body comprises a first linkage arm and a second linkage arm. The first linkage arm is clamped into the second linkage arm and is in rotating connection with the second linkage arm. The first linkage arm and the second linkage arm are provided with moving bases in an embedded mode correspondingly. Side roller bases are formed in the corresponding moving bases. The first side roller and the second side roller are installed in the corresponding side roller bases. A lower roller base is arranged at the coincided position of the first linkage arm and the second linkage arm, and the lower roller is installed in the lower roller base. The moving bases are connected with the first linkage arm or the second linkage arm through corresponding moving base drive mechanisms. The linkage adjusting mechanism for the plate rolling machine working rollers is compact in structure, stable and reliable. Meanwhile, the first side roller and the second side roller can be adjusted in the front-back direction and the up-down direction, and the flexibility, adaptability and universality of equipment are enhanced; and meanwhile, the adjusted first side roller and second side roller are positioned, and thus the rolling precision is further improved.

Owner:JIANGSU ZHONGHAI HEAVY MACHINE TOOL

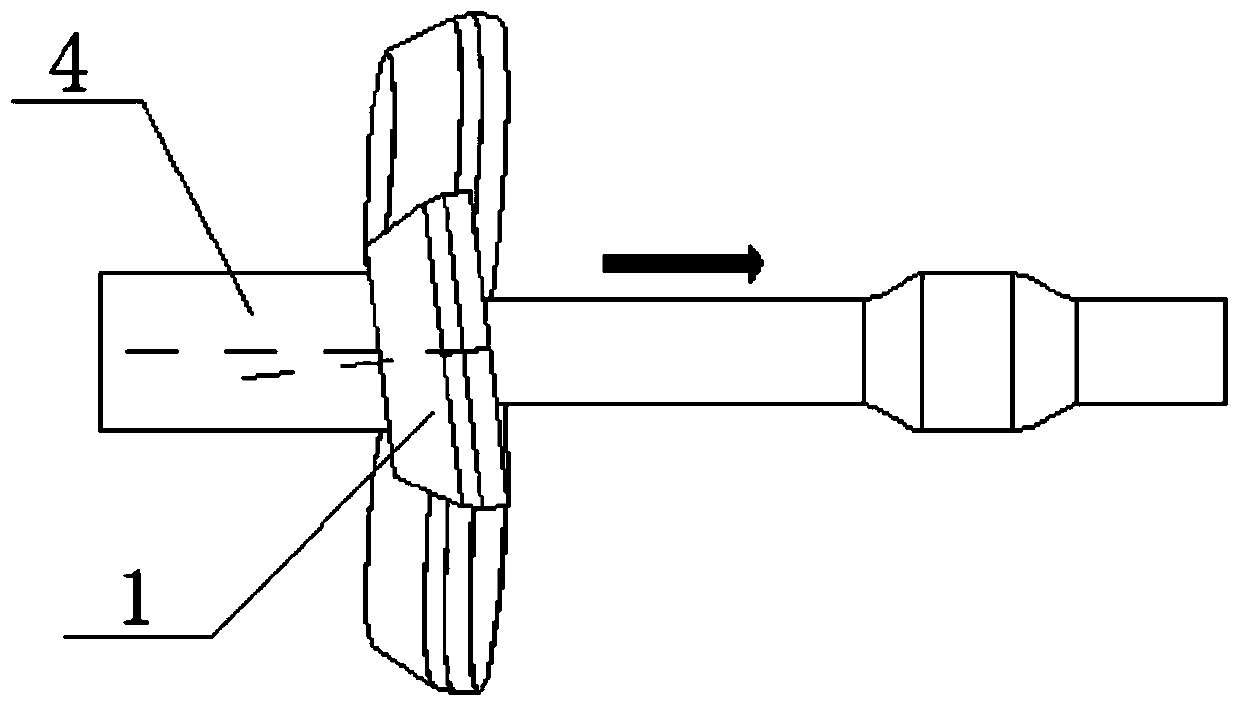

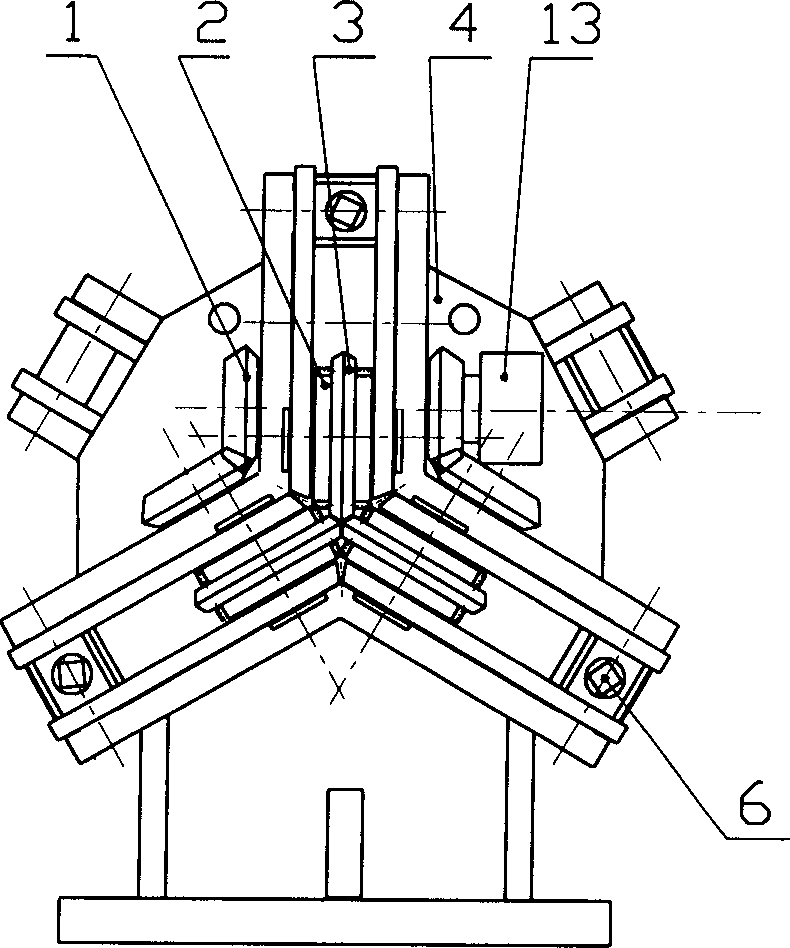

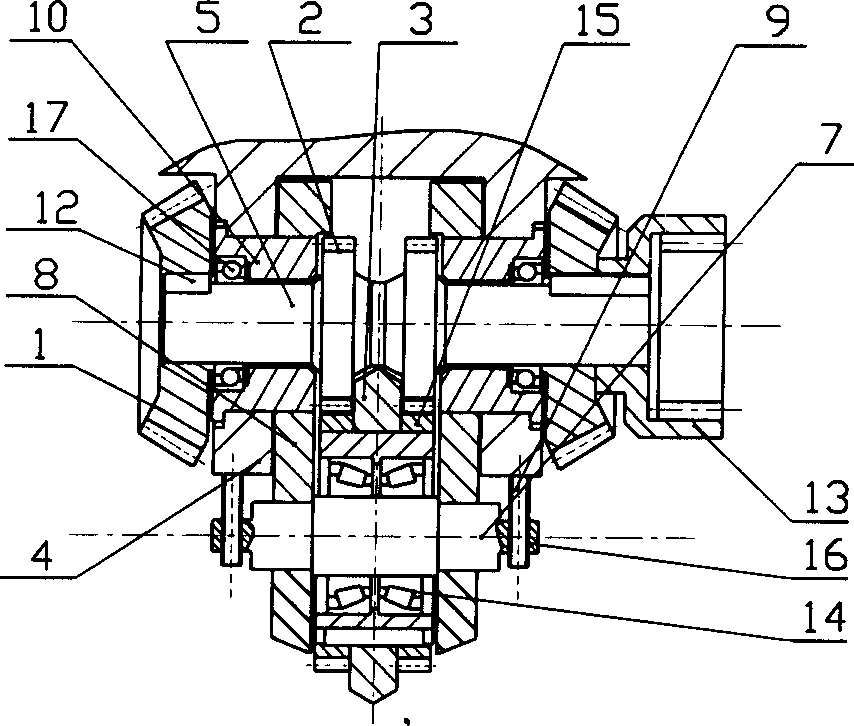

Three-roller Y shaped prestressed rolling mill

InactiveCN1669689ASmall diameterEasy to rollMetal rolling stand detailsRolling mill drivesGear wheelFixed frame

The invention relates to a three-high Y-pattern initial stress mill, belongs to the milling machinery technique fields, characterized in that it sets the positive Y-pattern and the reverse Y-pattern rolling units on the same fixed frame 4, each unit set three flat shafts 10 in the upper hole of the frame 4 as the mechanical gearing system, inside the shaft 10 sets the drive shaft 5 which has gears in the middle and angle gears in the ends, the movable frame 8 with a roll bearing 7on it covers the flat shafts 10, the roll 3 and gear 15 is set on the roll bearing 7, the bolt 6 whose left interfere with the fixed frame 4 is fitted with the bolt 11 set on the movable frame 8, the two ends of the rolling bearing 7 has the screwed hole 16 fitted with the bolt 9.

Owner:山西贝特科贸有限公司

Battery pole piece rolling equipment

ActiveCN105921517ARealize rollingAchieve regulationMetal rolling stand detailsRollsElectrical batteryEngineering

The invention relates to battery pole piece rolling equipment. The battery pole piece rolling equipment comprises a rack set and a roller set hinged to the rack set. The rack set comprises an oblique supporting bottom frame and a vertical supporting bottom frame connected with the oblique supporting bottom frame. The roller set comprises a first vertical column, a second vertical column, a lower battery pole piece roller, an upper battery pole piece roller and two movable connecting frames, wherein the first vertical column and the second vertical column are symmetrically arranged on the vertical supporting bottom frame, the lower battery pole piece roller and the upper battery pole piece roller are arranged between the first vertical column and the second vertical column, and the movable connecting frames are connected with the first vertical column and the second vertical column correspondingly. The battery pole piece rolling equipment is compact in structure, reasonable in design, safe, reliable, low in cost, capable of saving time and effort, high in machined battery pole piece quality and suitable for large-scale popularization.

Owner:HEBEI DELE MACHINERY TECH

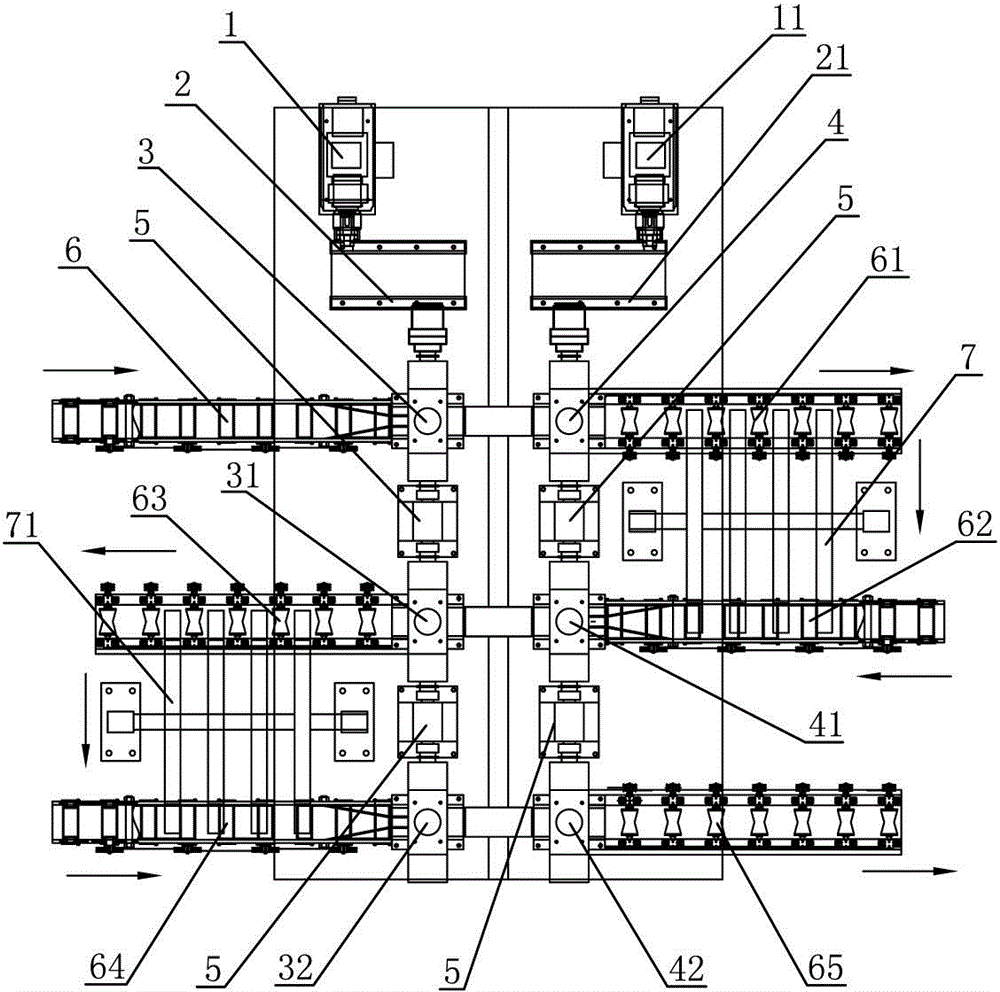

Metal bar rolling production line

ActiveCN102728613BCompact structureReduce temperature dropMetal rolling arrangementsProduction lineMaterials science

The invention discloses a metal bar rolling production line for rolling metal bars. The production line comprises at least two rolling mill columns arranged longitudinally, each rolling mill column comprises at least two transverse three-roll Y-shaped rolling mills, namely the transverse Y-shaped rolling mills in all the rolling mill columns are transversely arranged in at least two rows of rolling mill units; each rolling mill column is driven by a transmission device, and the rotating directions of the two adjacent transverse three-roll Y-shaped rolling mills in each rolling mill column are opposite; a conveying roll table for conveying rolled pieces is arranged at an inlet or an outlet of each transverse three-roll Y-shaped rolling mill in each row of rolling mill unit, the rolling rotating directions of the transverse three-roll Y-shaped rolling mills in each row of rolling mill unit are the same, and the rolling rotating directions of the transverse three-roll Y-shaped rolling mills in two adjacent rows of rolling mill units are opposite. The production line has the advantages of saving occupied area and equipment investment, improving the rolling speed and reducing temperature drop of the rolled pieces, and is high in rolling precision.

Owner:ZHANGJIAGANG CHANGLI MACHINERY

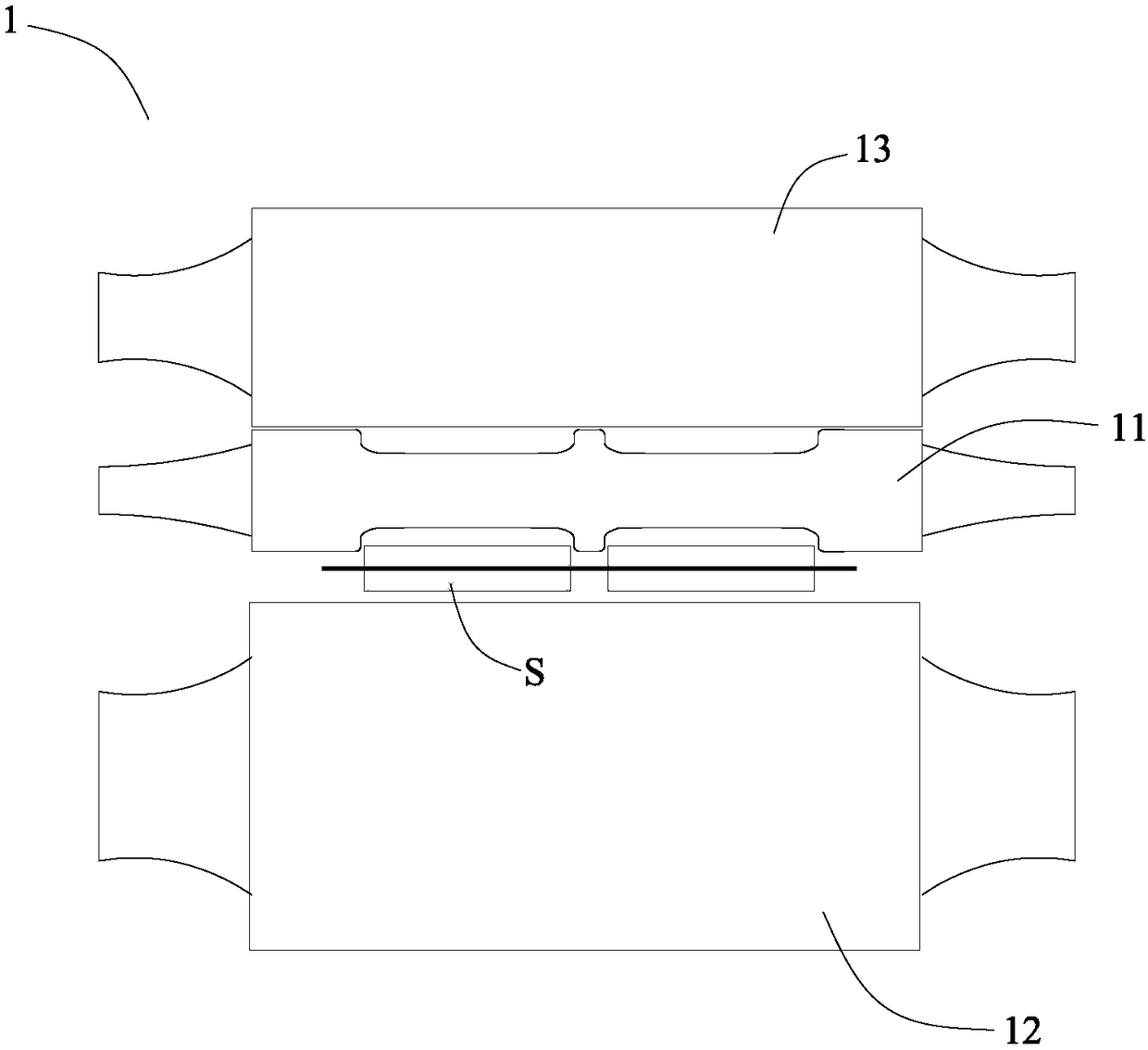

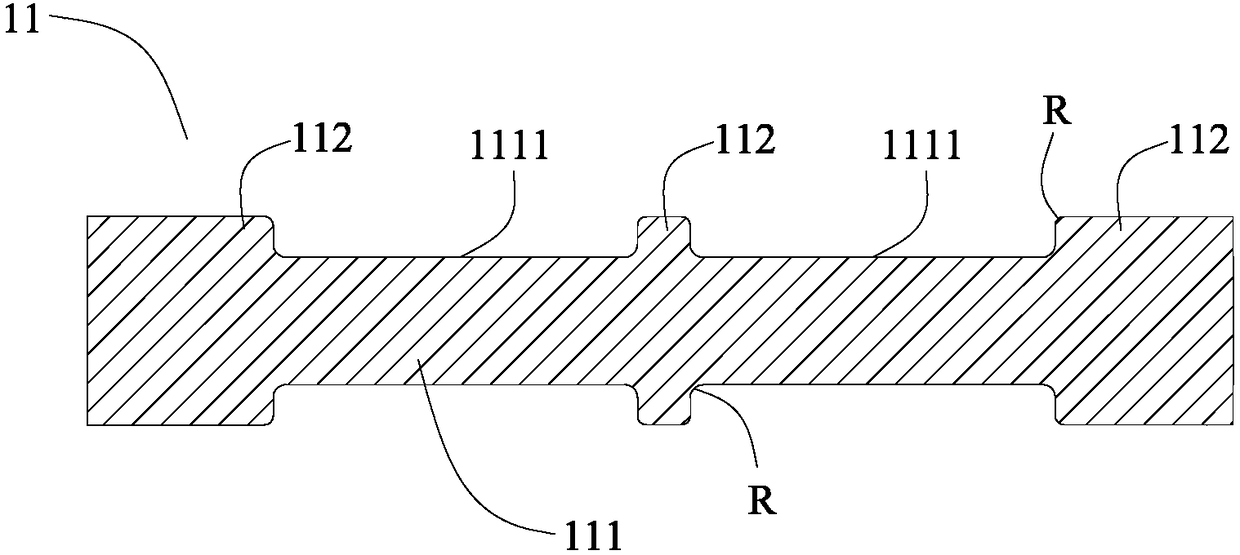

Rolling device

PendingCN109382410AAvoid wrinklesAvoid liftingRollsMetal rolling arrangementsMechanical engineeringCoating

The invention provides a rolling device, which comprises a rolling mechanism for rolling a strip, wherein the rolling mechanism comprises a first pressing roller and second pressing roller which are oppositely arranged. The strip comprises a substrate and a coating layer, wherein the substrate is provided with an exposed blank area and a covered area covered by the coating layer; the blank area and the covered area both extend in the longitudinal direction and alternate in the transverse direction. And the diameter of the second pressing roller is larger than that of the first pressing roller.The first pressing roller comprises a roller body with an annular rolling area formed on the outer peripheral surface; and an annular convex part arranged on the roller body and protrudes outwards relative to the outer peripheral surface of the roller body. The rolling area and the annular convex part are alternately arranged; the annular convex part of the first pressing roller and the second pressing roller are used for rolling the blank area of the substrate, and the rolling area of the roller body and the second pressing roller are used for rolling the covered area of the substrate and the coated layer of the strip.

Owner:CONTEMPORARY AMPEREX TECH CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com