Patents

Literature

862results about "Rolling equipment maintainence" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

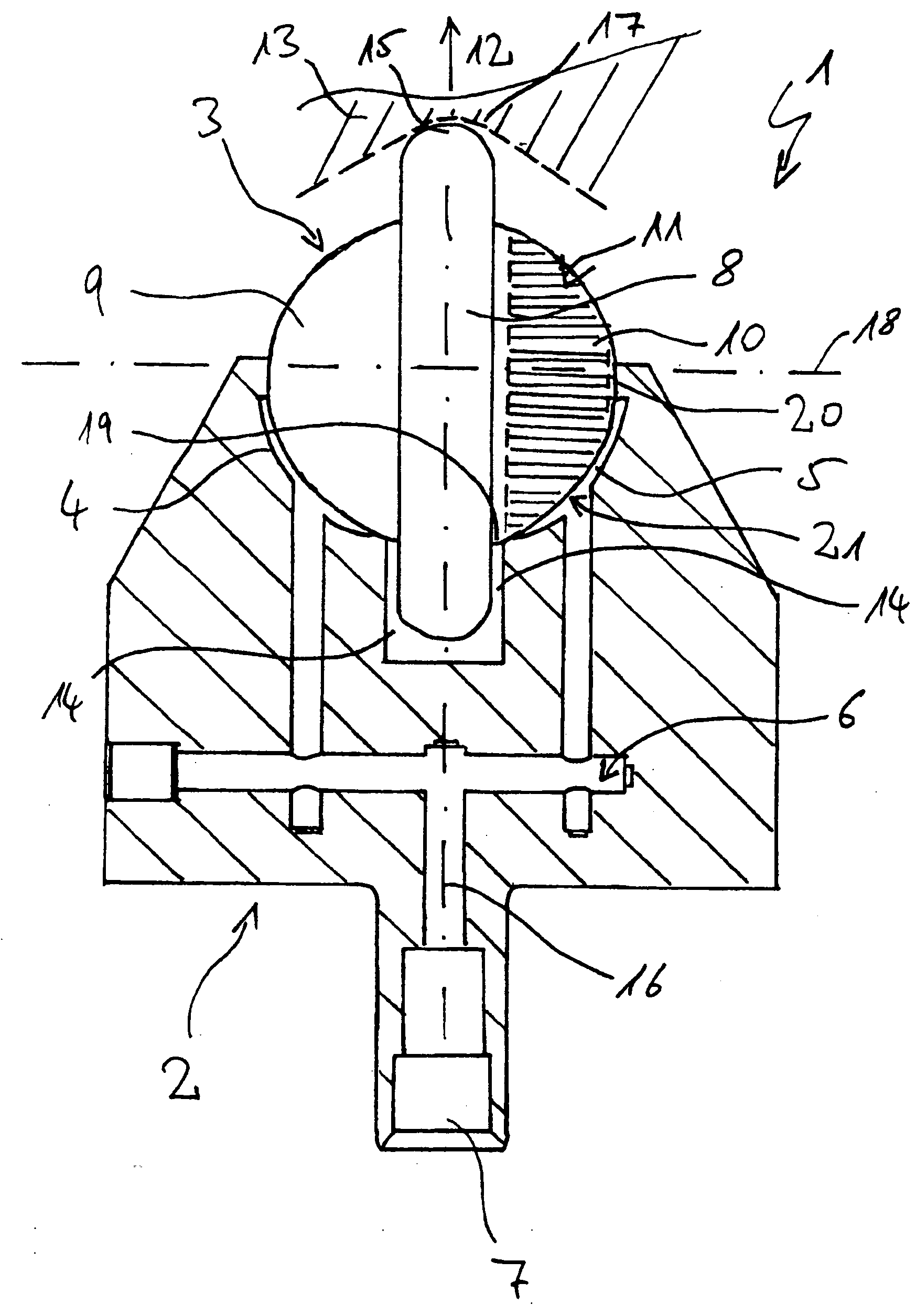

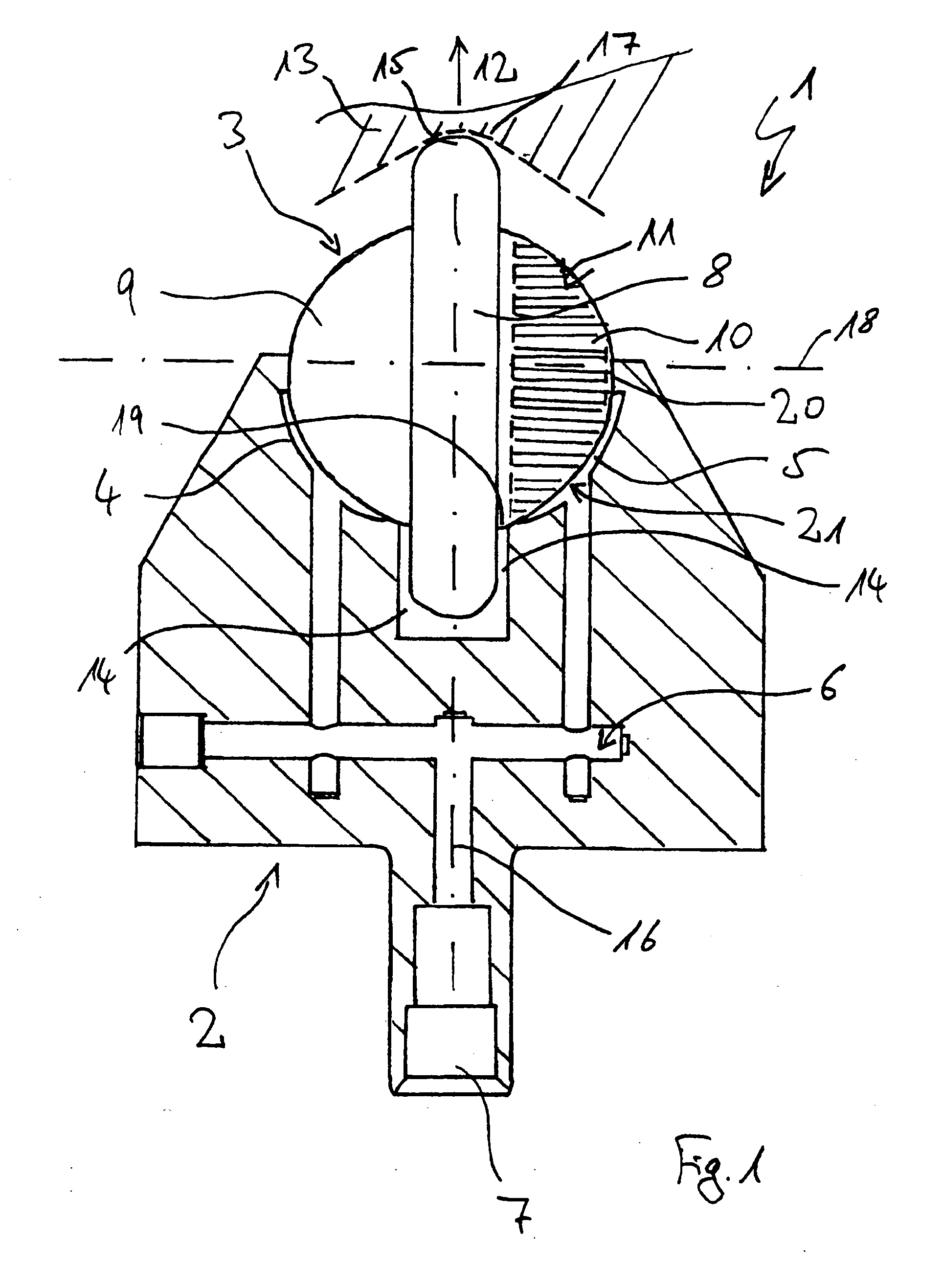

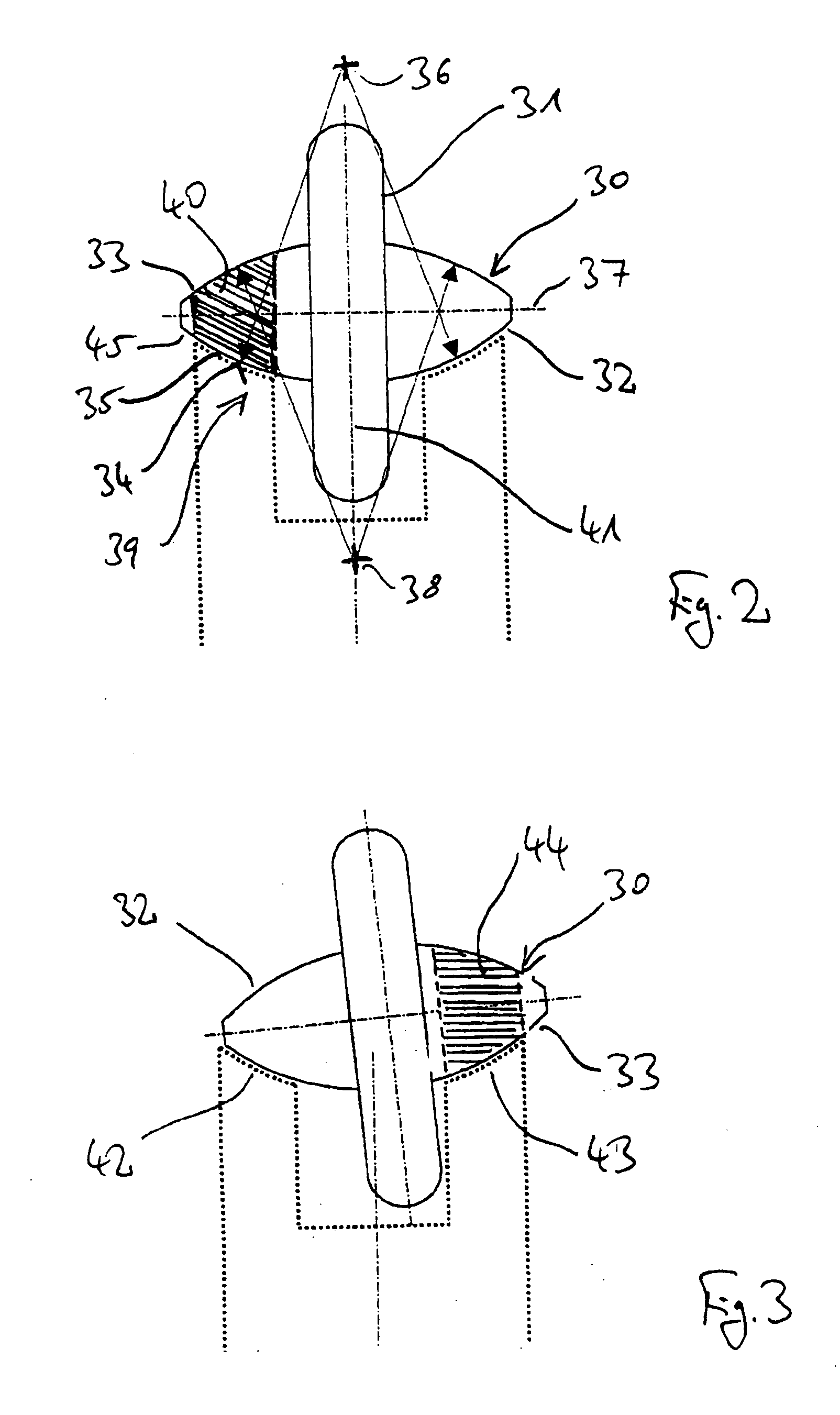

Rolling tool and roller for rolling, particularly deep rolling, a work piece

InactiveUS20050107230A1High quality and reproducibilityRolling force can be constantRolling equipment maintainenceBurnishing machinesEngineeringMechanical engineering

Owner:ECOROLL WERKZEUGTECHN

Large rooler hard-surface build-up welding repairing method

InactiveCN1438088ALow costGood effectRolling equipment maintainenceArc welding apparatusTransition layerMaterials science

Owner:上海宝山热喷涂厂

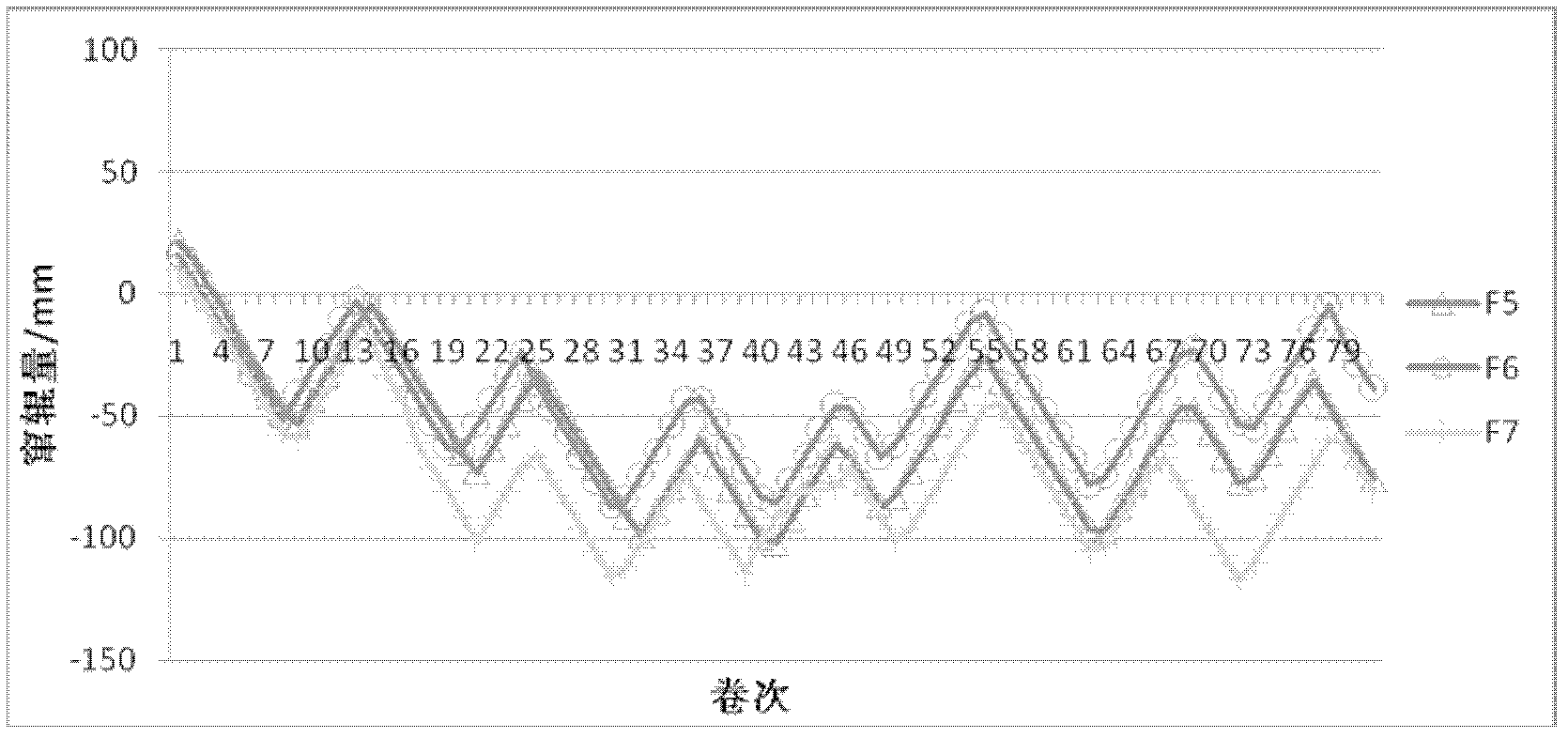

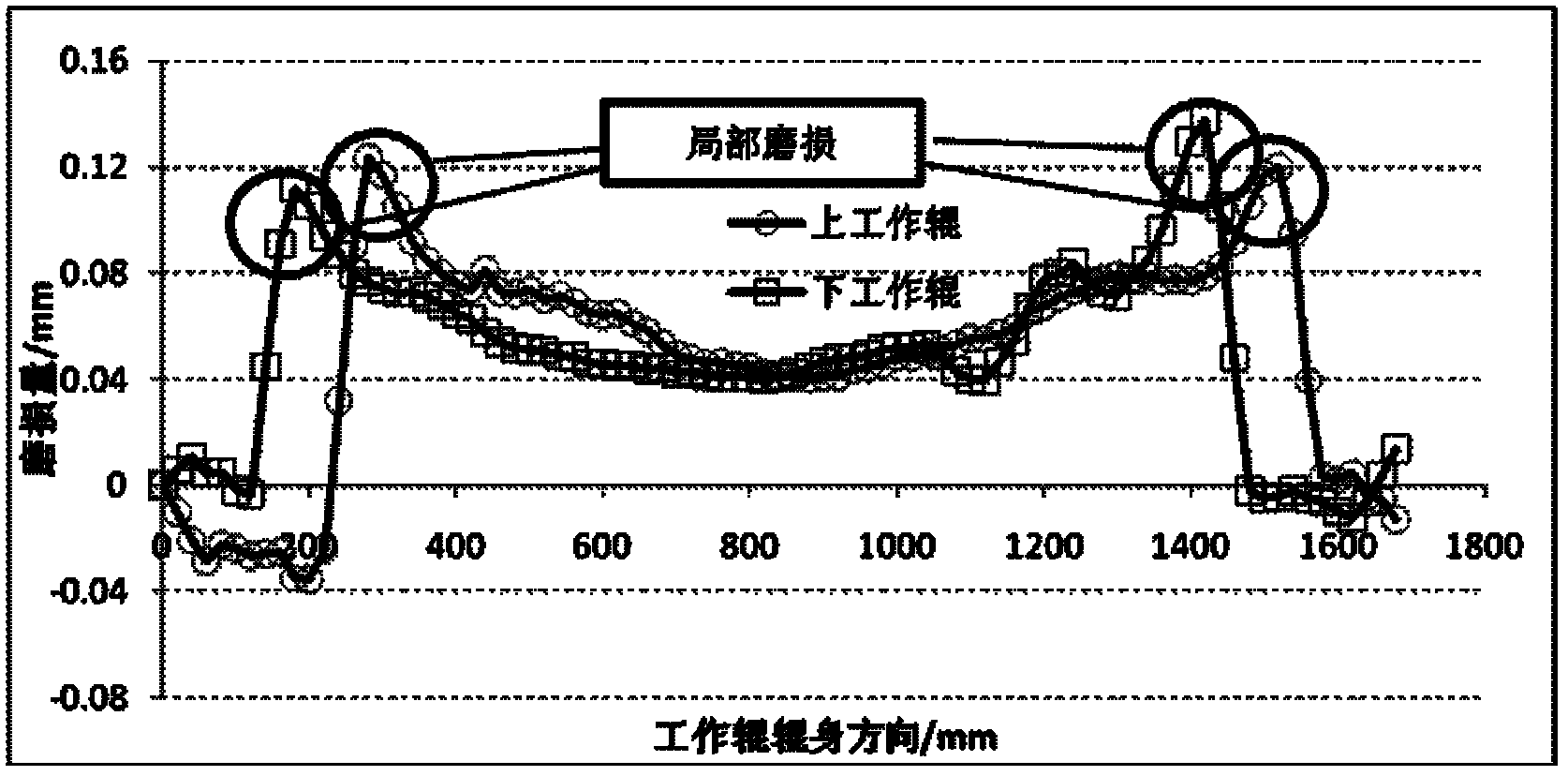

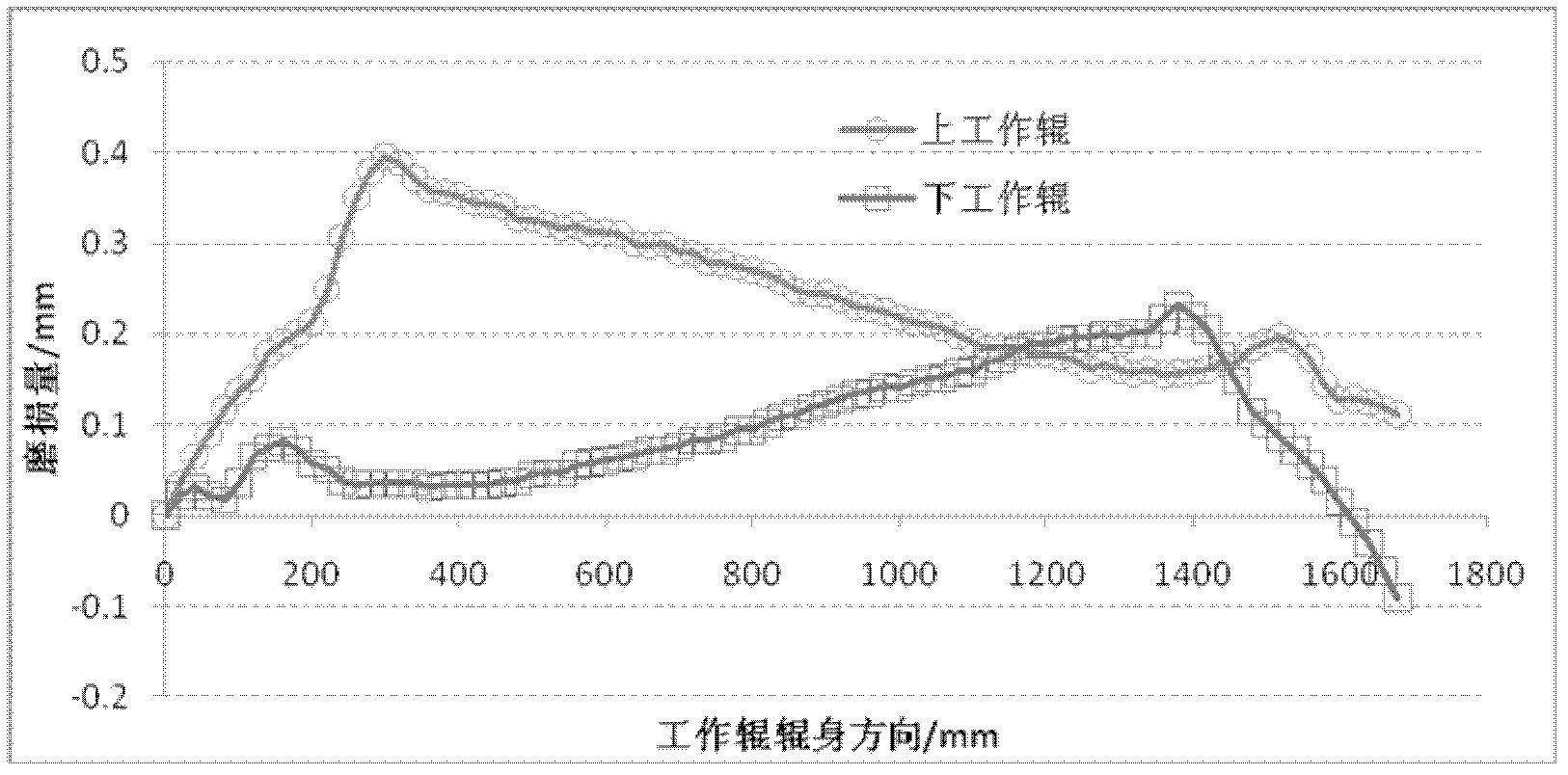

Method for eliminating local wear of working roller of CVC (continually variable crown) mill

ActiveCN102310089ADoes not affect programmingChange local highsRolling equipment maintainenceRoll mill control devicesEngineeringStrip steel

The invention relates to the technical field of steel rolling, in particular to a method for eliminating local wear of a working roller of a CVC (continually variable crown) mill, which comprises the following steps: (1) setting the shifting step, the upper bending force compensation limit and the lower bending force compensation limit of the working roller, given that the shifting increment of the working roller deltaD = Delta; (2) calculating the set bending force value F(i) of the ith roll of strip steel; (3) judging whether F(i) exceeds the bending force compensation limit; (4) outputtingthe set shifting value D(i) and the set bending force value F(i) of the working roller of the ith roll of strip steel; and (5) given that i = i +1,, carrying out presetting calculation of control parameters of a following roll of strip steel sheet. The periodic shifting frequency and amplitude of the working roller can be changed through changing the shifting step, the bending force compensation limits and other parameters, the effects of eliminating the local wear of the working roller and controlling local high points of edges of a hot-rolled sheets can be achieved, the promotion and application on CVC mills of the same category can be easily realized.

Owner:SHOUGANG CORPORATION

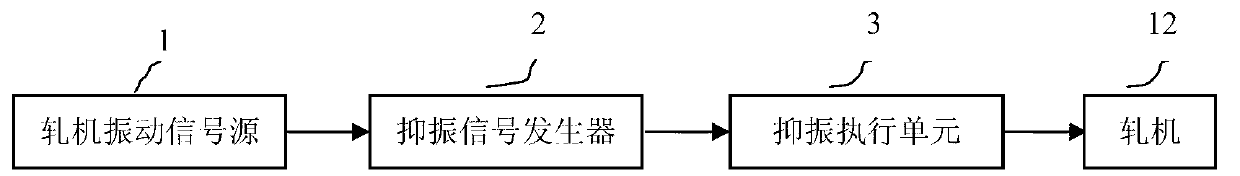

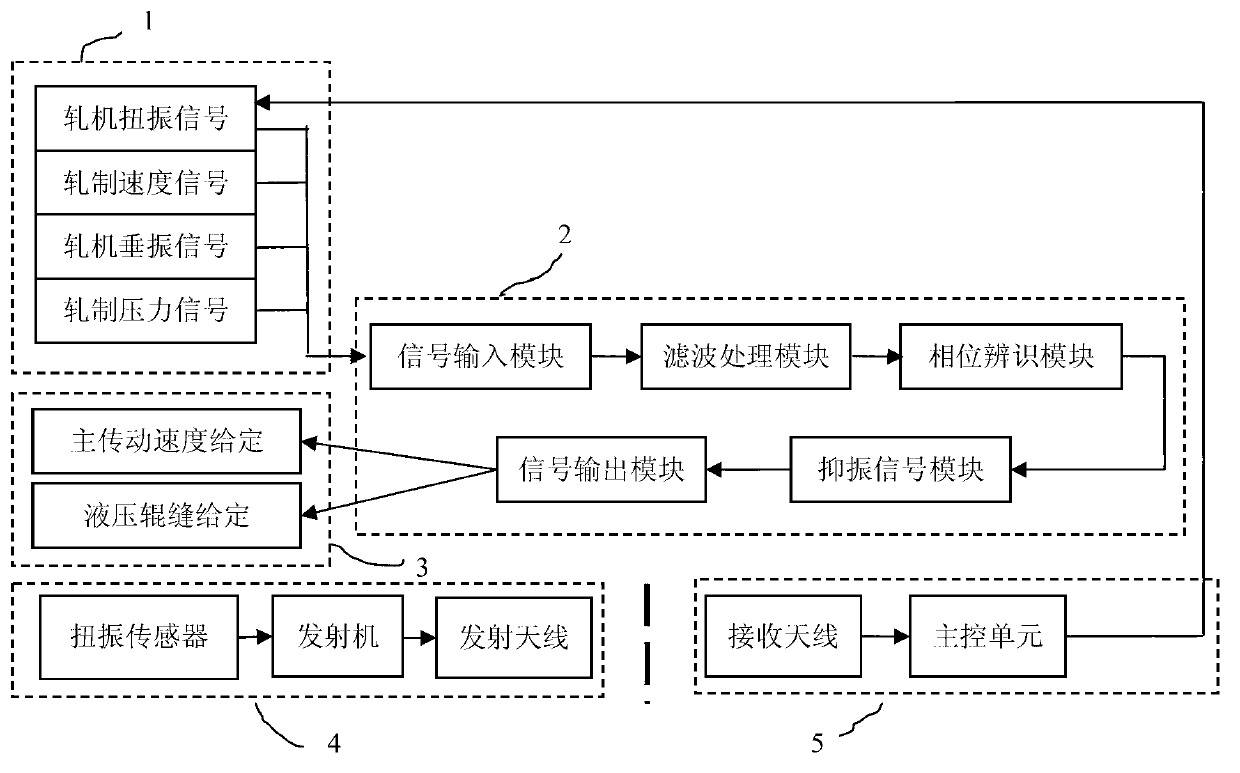

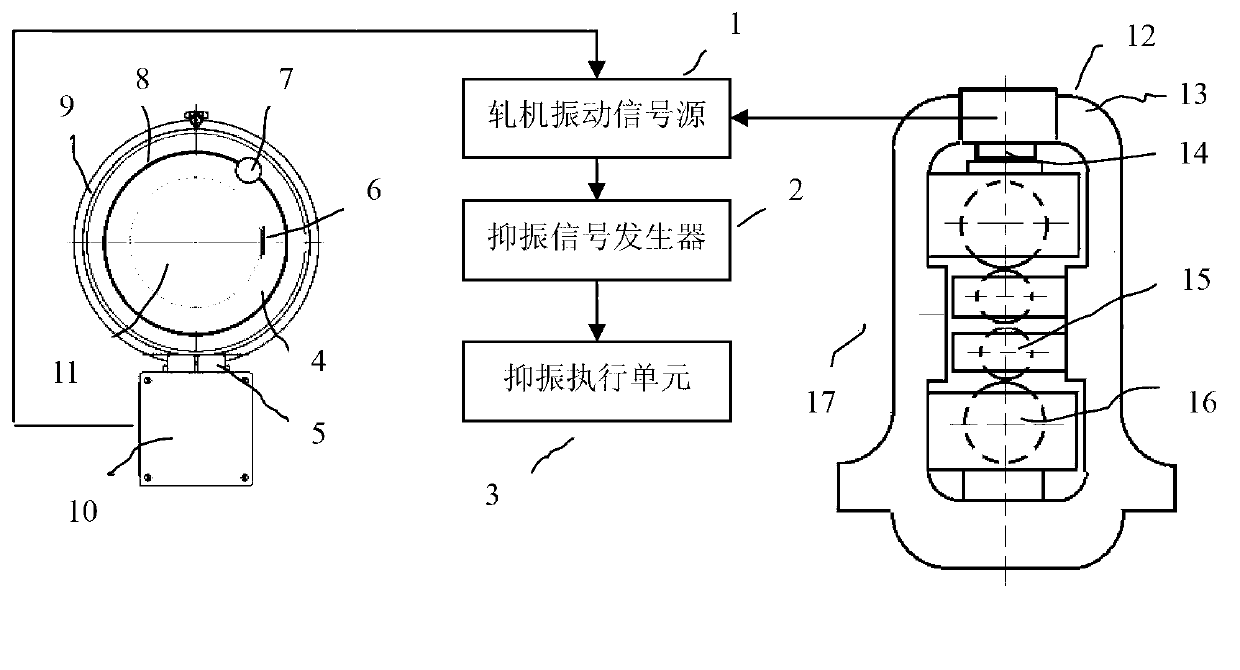

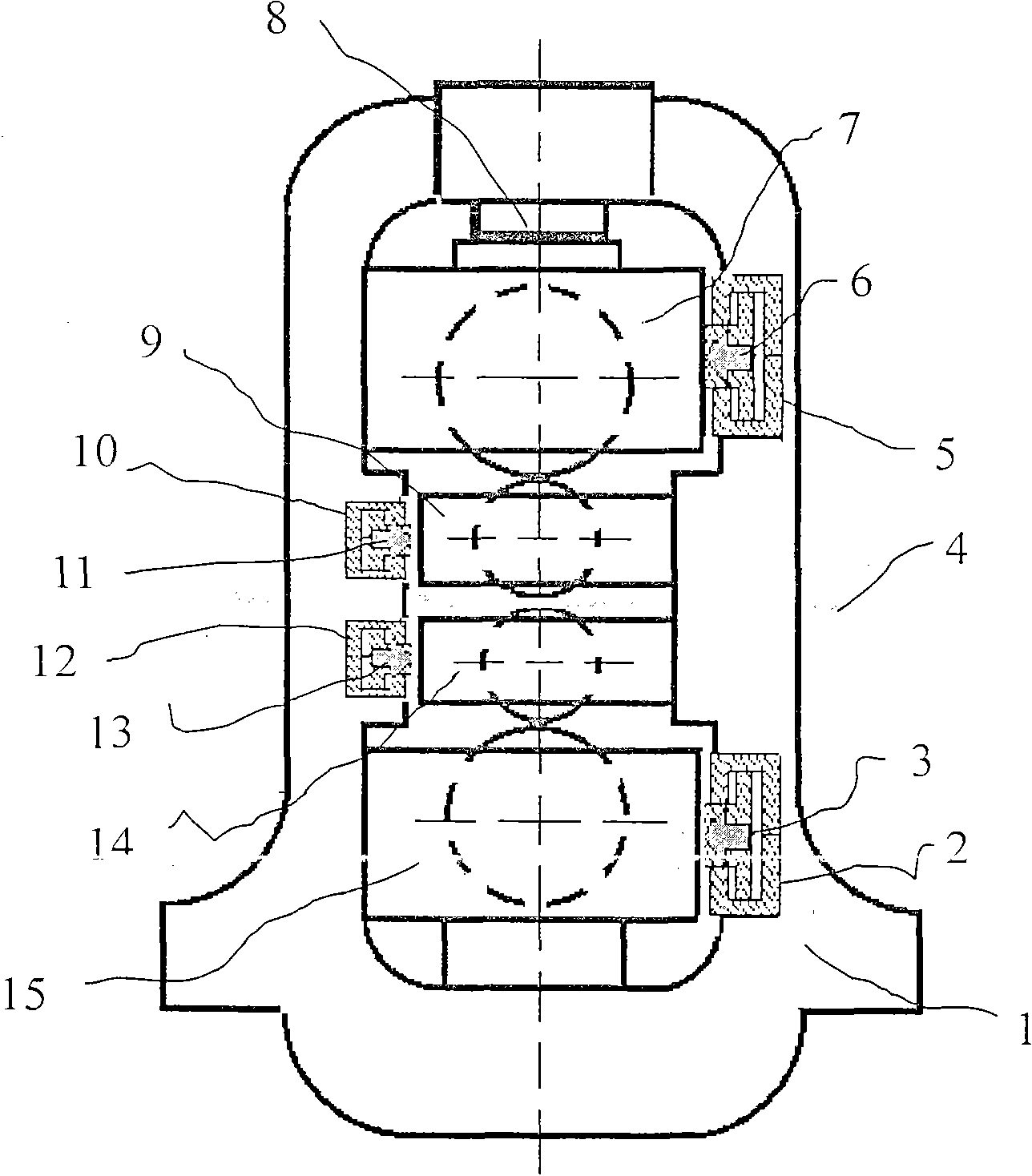

Device for suppressing vibration of rolling mill

InactiveCN103121037AReduce vibrationReduce vibrational energyRolling equipment maintainenceMetal rolling arrangementsVertical vibrationSetter

The invention belongs to the field of signal detection and automation control of rolling mills, and relates to a device for suppressing vibration of a rolling mill. The device for suppressing the vibration of the rolling mill is characterized by comprising a rolling mill vibration signal source, a vibration suppression signal generator, a vibration suppression actuating unit and the rolling mill, wherein the rolling mill vibration signal source is composed of rolling mill torsion vibration signals, rolling speed signals, rolling mill vertical vibration signals and rolling pressure signals, the vibration suppression signal generator is composed of a signal input module, a filter processing module, a phase recognition module, a vibration suppression signal module and a signal output module, and the vibration suppression actuating unit is composed of a main drive speed setter and a hydraulic roll gap setter. The device for suppressing the vibration of the rolling mill has the advantages that vibration suppression damping signals are generated by the vibration suppression signal generator according to the rolling mill vibration signal source and sent to the main drive speed setter and the hydraulic roll gap setter of the vibration suppression actuating unit so as to participate in control of the rolling mill to reduce the vibration energy of the rolling mill, so that the rolling mill can be prevented from vibrating severely, chatter marks on a roller and the surfaces of strips are eliminated, and therefore the surface quality of products is improved, and the on-line service life of the roller is prolonged.

Owner:UNIV OF SCI & TECH BEIJING

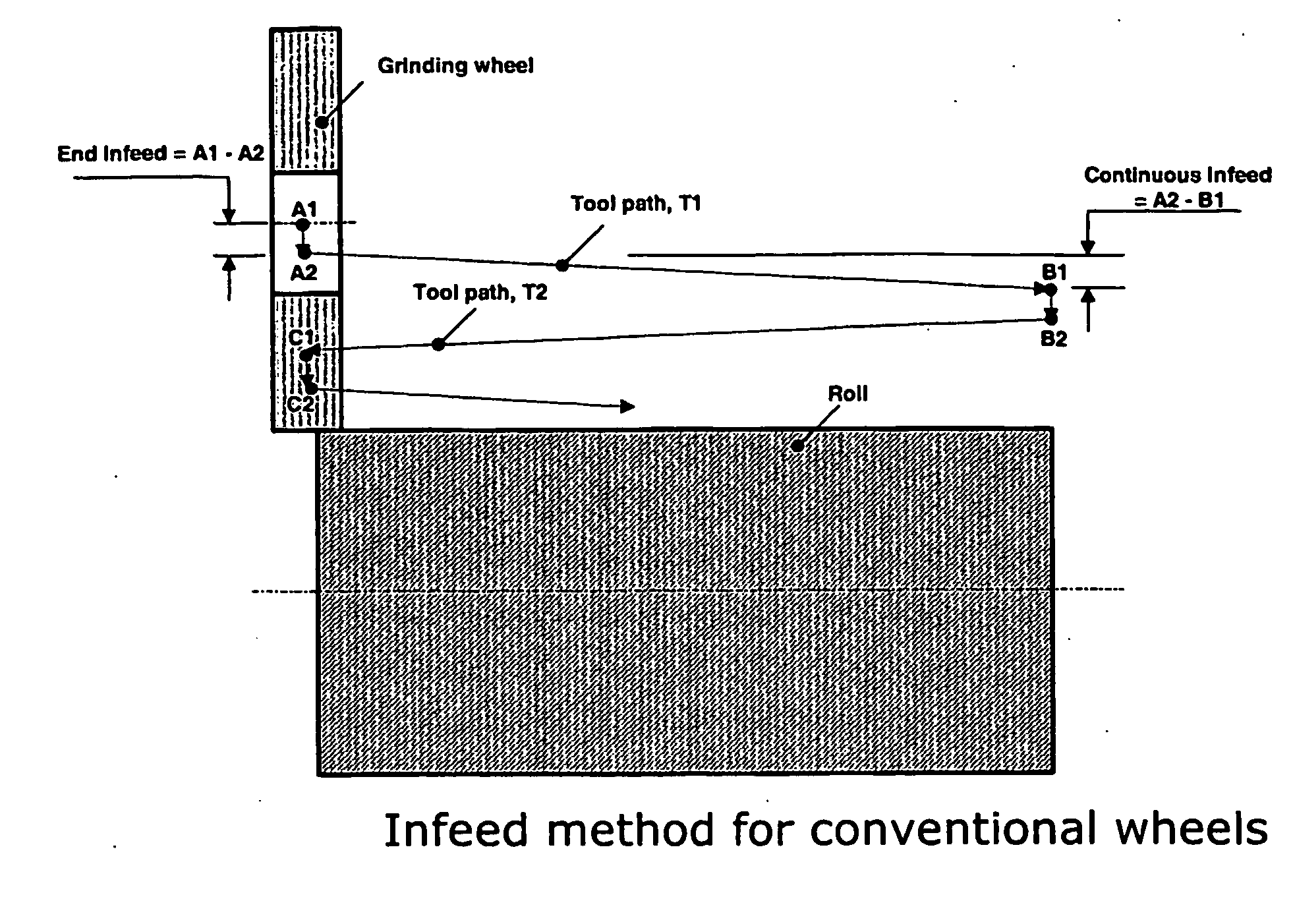

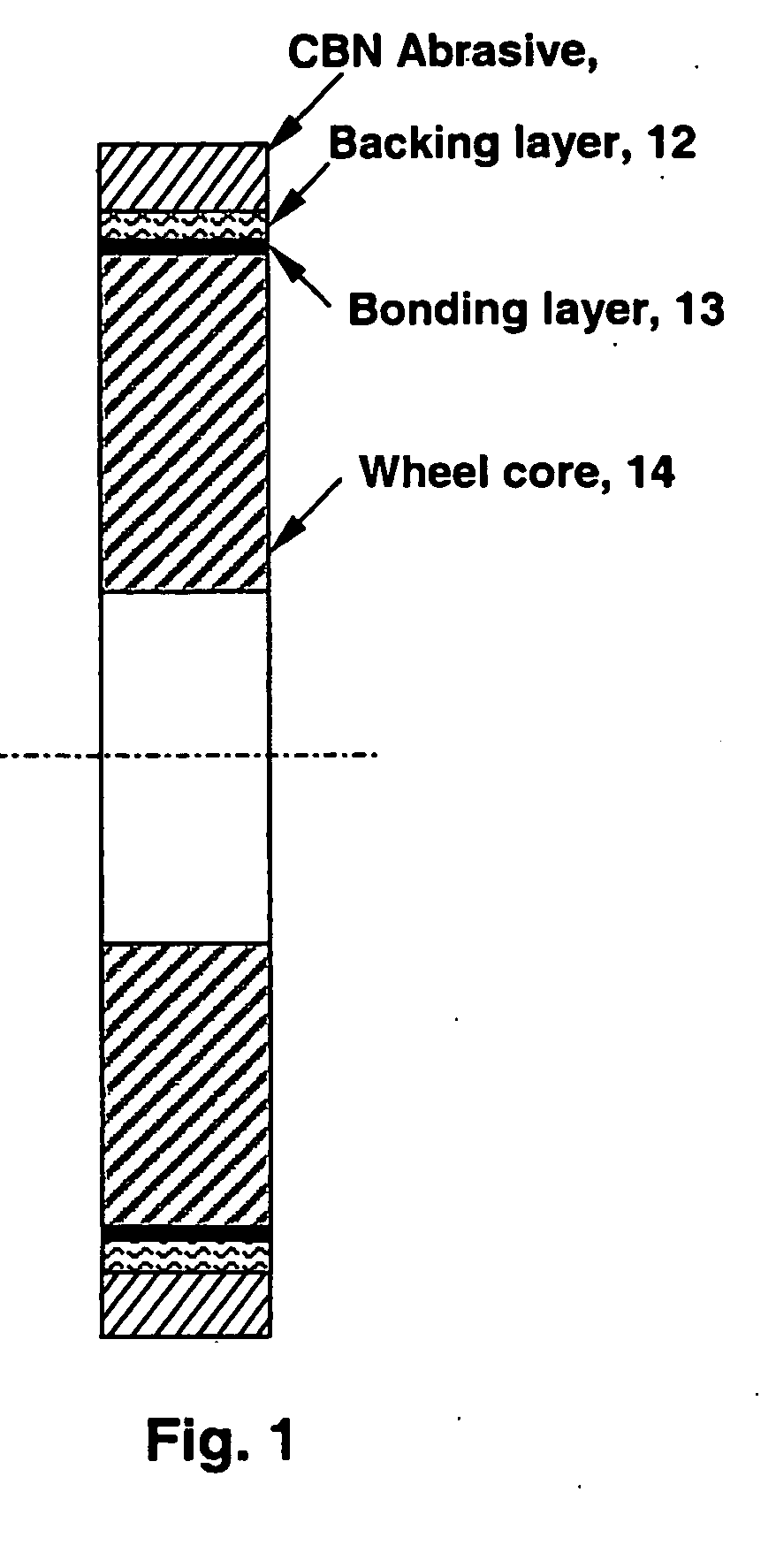

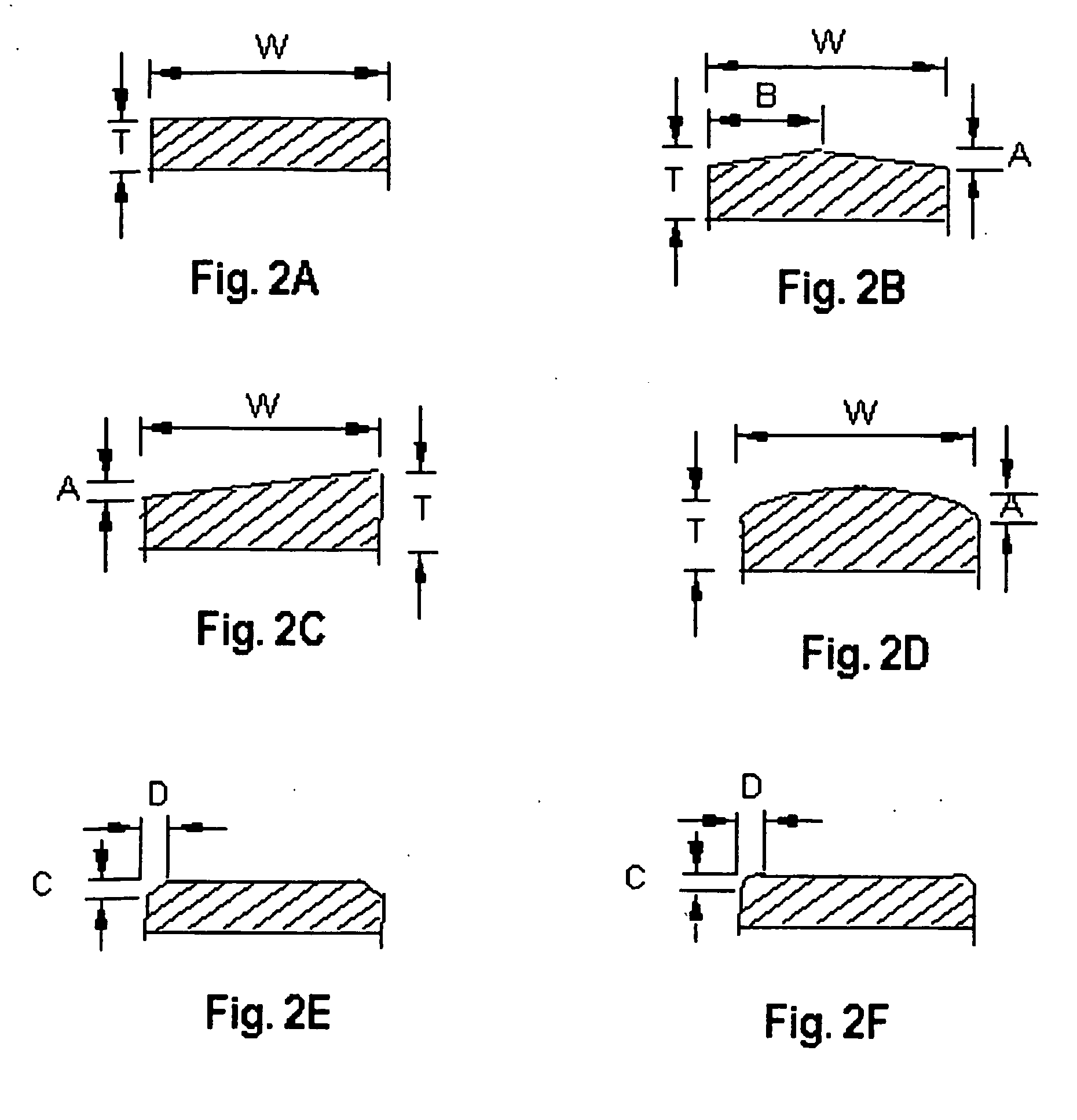

Grinding wheel for roll grinding application and method of roll grinding thereof

ActiveUS20070099548A1Constant speed ratioLong grinding lifeRevolution surface grinding machinesRolling equipment maintainenceBoron nitrideWheel wear

Iron and steel rolls are ground to production quality requirements with a grinding wheel that requires minimal wheel wear compensation, profile error compensation or taper error compensation during the grinding process. The grinding wheel consists essentially of a superabrasive material selected from the group of natural diamond, synthetic diamond, cubic boron nitride, and mixtures thereof, in a bond system, for a grinding wheel with extended wheel life, and which removes minimum amount of stock off the roll to achieve desired roll geometry.

Owner:DIAMOND INNOVATIONS INC

Automatic roll data acquisition system

InactiveUS20050197044A1Protect from harmSafer environmentRolling equipment maintainenceAutomatic grinding controlWork rollMachine control

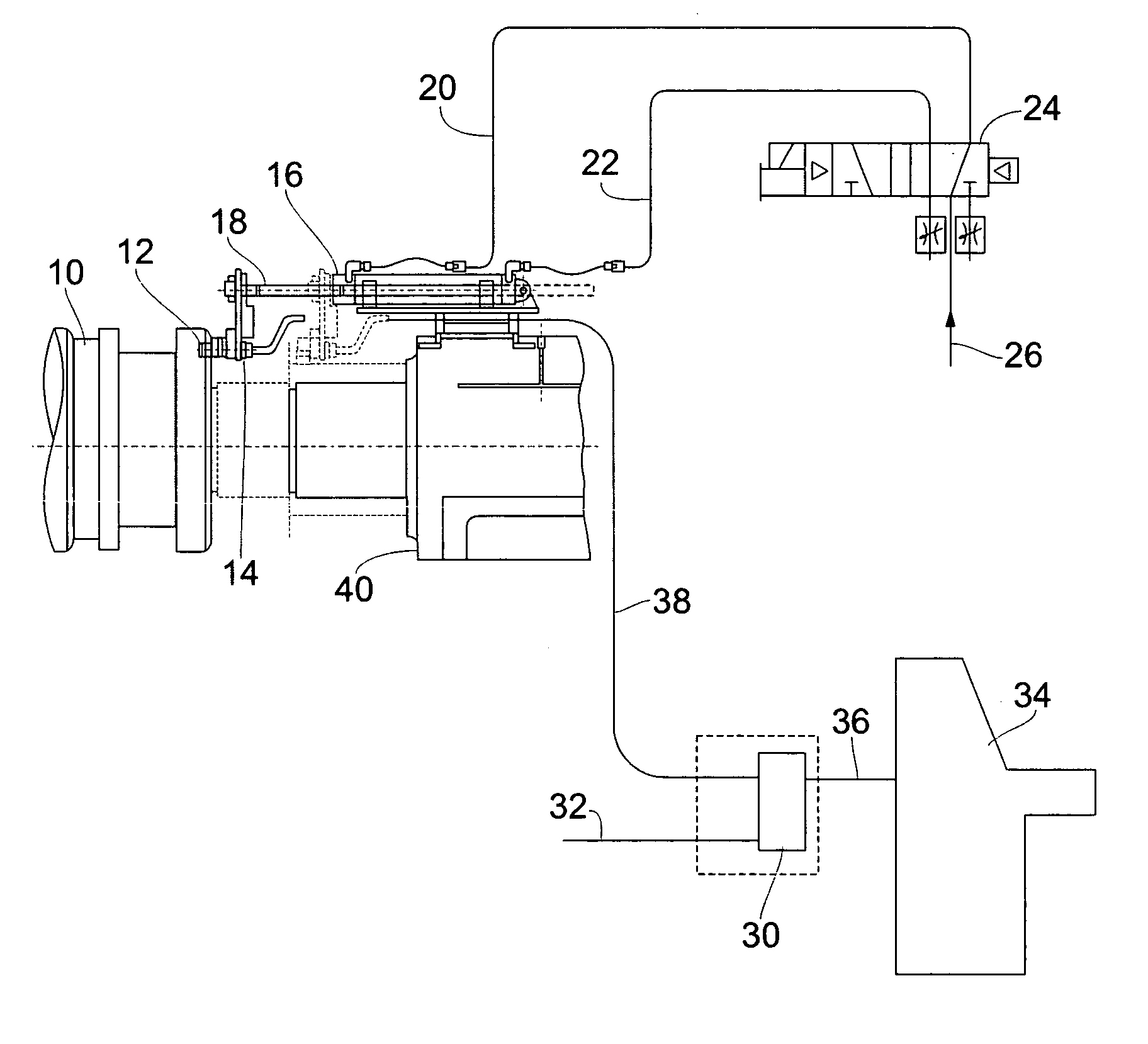

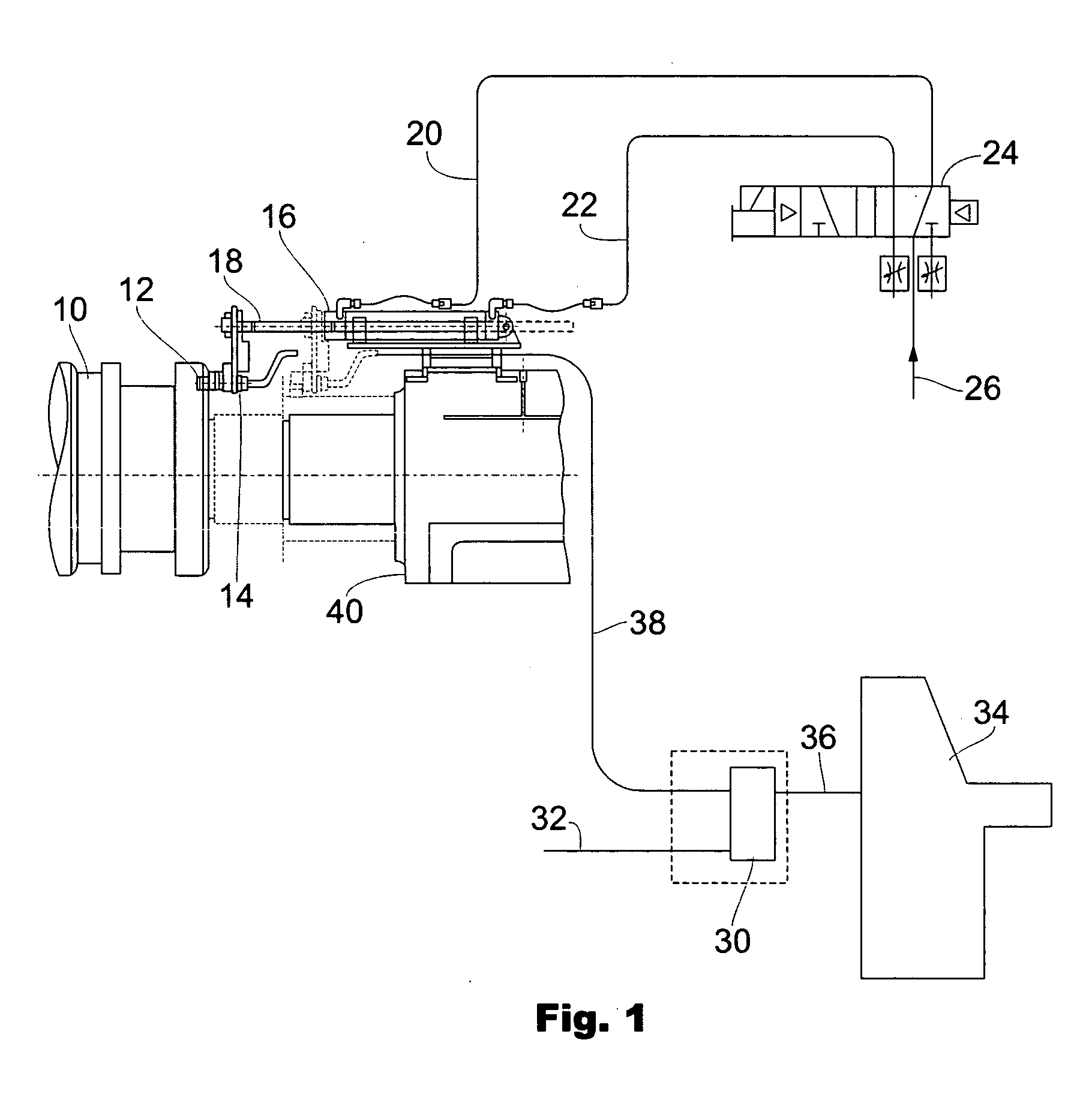

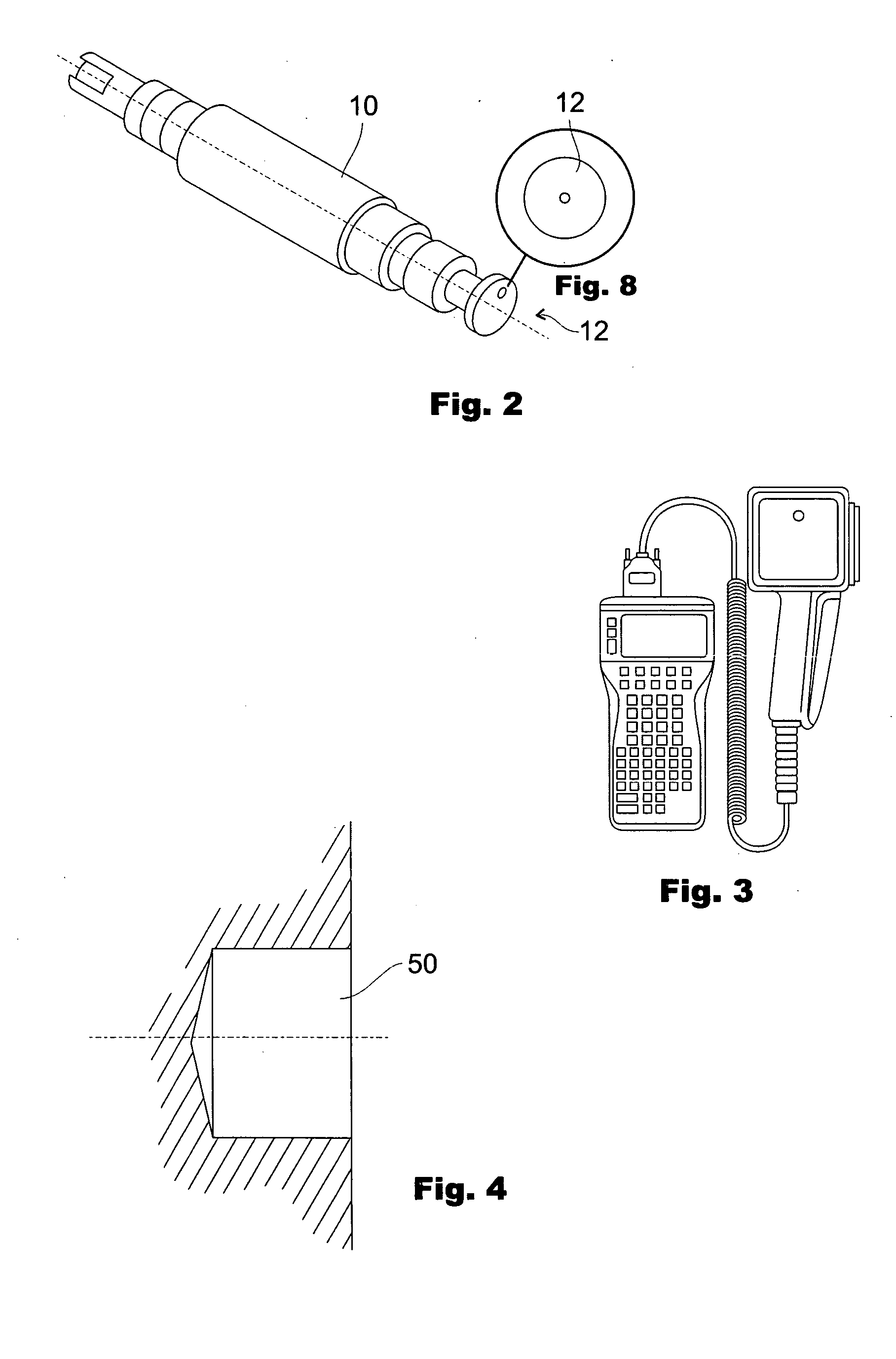

The present invention discloses a method, system and apparatus for use in a roll grinding machine. Data is read from an RFID tag automatically by providing an RF read / write sensor on a movable cylinder rod. The RF sensor is held away from the work roll area while the work roll is loaded or removed. When the work roll is placed in the position for grinding, a signal to rotate the roll is sent to the grinding machine, and also operates to advance the cylinder rod. An RFID tag embedded in the work roll and containing identification and other data related to the work roll, is read by a read / write sensor, and the data is then transferred from the sensor to a serial control interface, which converts the data and transmits the information to the grinding machine control desk and the computer control management data base. The work roll identification information is transmitted automatically to the grinding machine, eliminating errors in transposing information manually and avoiding potential injury to personnel from having to scan the RFID tag using handheld RF read / write modules.

Owner:USX CORP

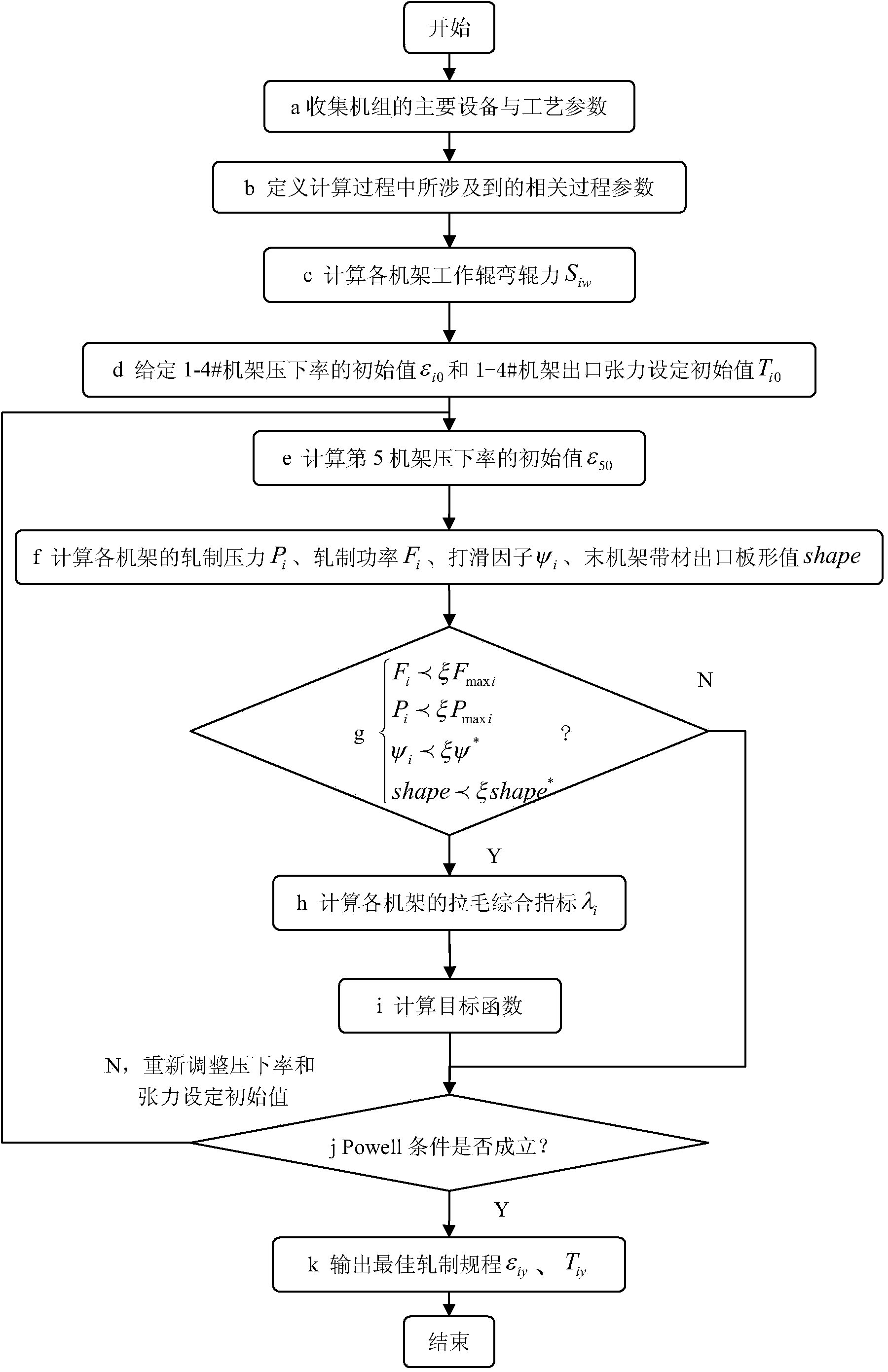

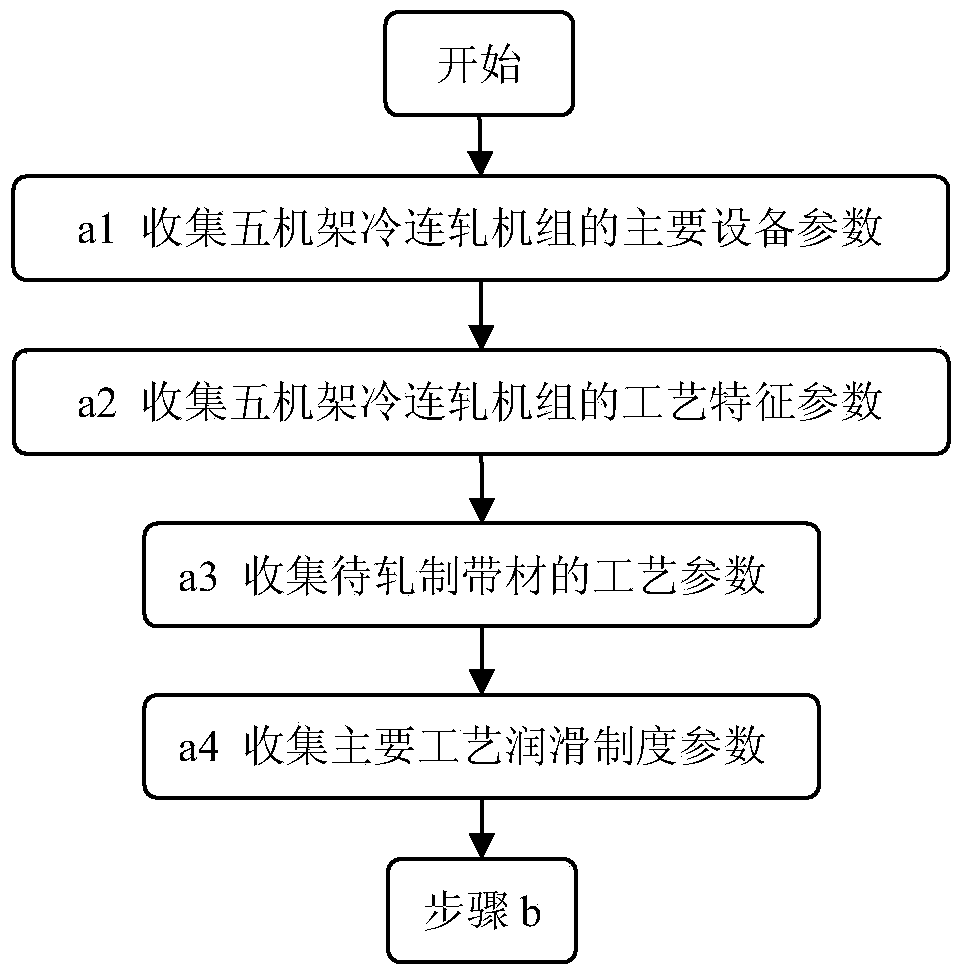

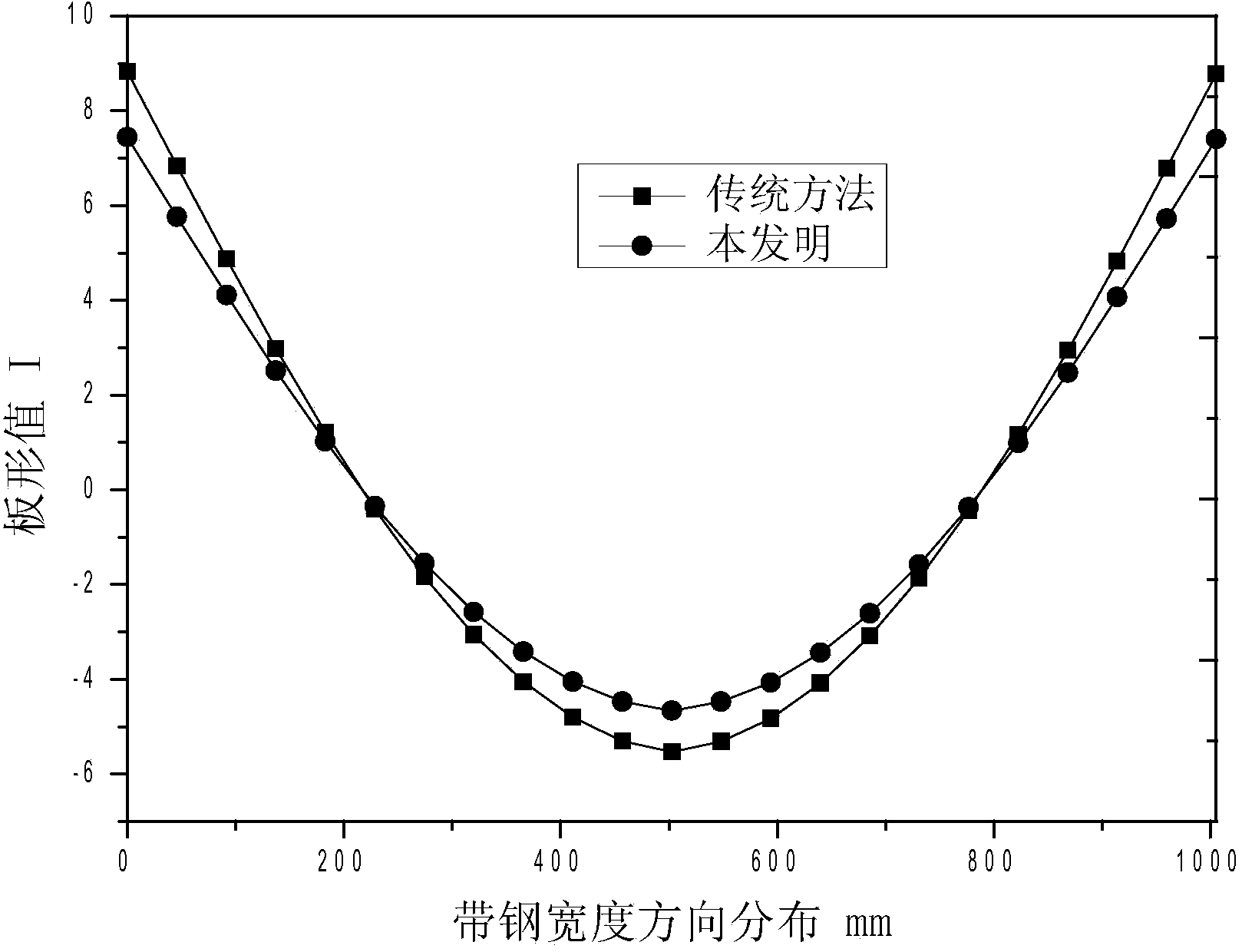

Rolling schedule comprehensive optimization method for cold continuous rolling unit taking scratch prevention as objective

InactiveCN103586286AEvenly distributed relative power headroomEvenly distributedRolling equipment maintainenceMeasuring devicesReduction rateStrip steel

A rolling schedule comprehensive optimization method for a cold continuous rolling unit taking scratch prevention as an objective mainly comprises the following steps that 1, main equipment and technological parameters of the cold continuous rolling unit with five machine frames are collected; 2 procedure parameters involved in a rolling schedule optimization procedure are defined; 3, the ability of the unit to regulate the outlet plate shapes is improved; 4, initial values of reduction rates epsilon<i0> of the first machine frame, the second machine frame, the third machine frame and the fourth machine frame and initial values of outlet tension force T<i0> of the first machine frame, the second machine frame, the third machine frame and the fourth machine frame are given; 5, an initial value of the reduction rate of the fifth machine frame is calculated; 6, rolling pressure, rolling power, slipping factors, and the outlet plate shape value of each machine frame are calculated; 7, the value of a scratch comprehensive judgment index lambada of each machine frame is calculated; 8, an optimized objective function is calculated; 9 the optimal rolling schedule is output; the steps are executed through a computer. By means of the rolling schedule comprehensive optimization method, the scratch comprehensive judgment index of each machine frame can be predicted accurately, the occurrence possibility of scratch defects is reduced to the greatest extent, production efficiency is increased, and outlet surface quality of strip steel is improved.

Owner:山东冠洲股份有限公司

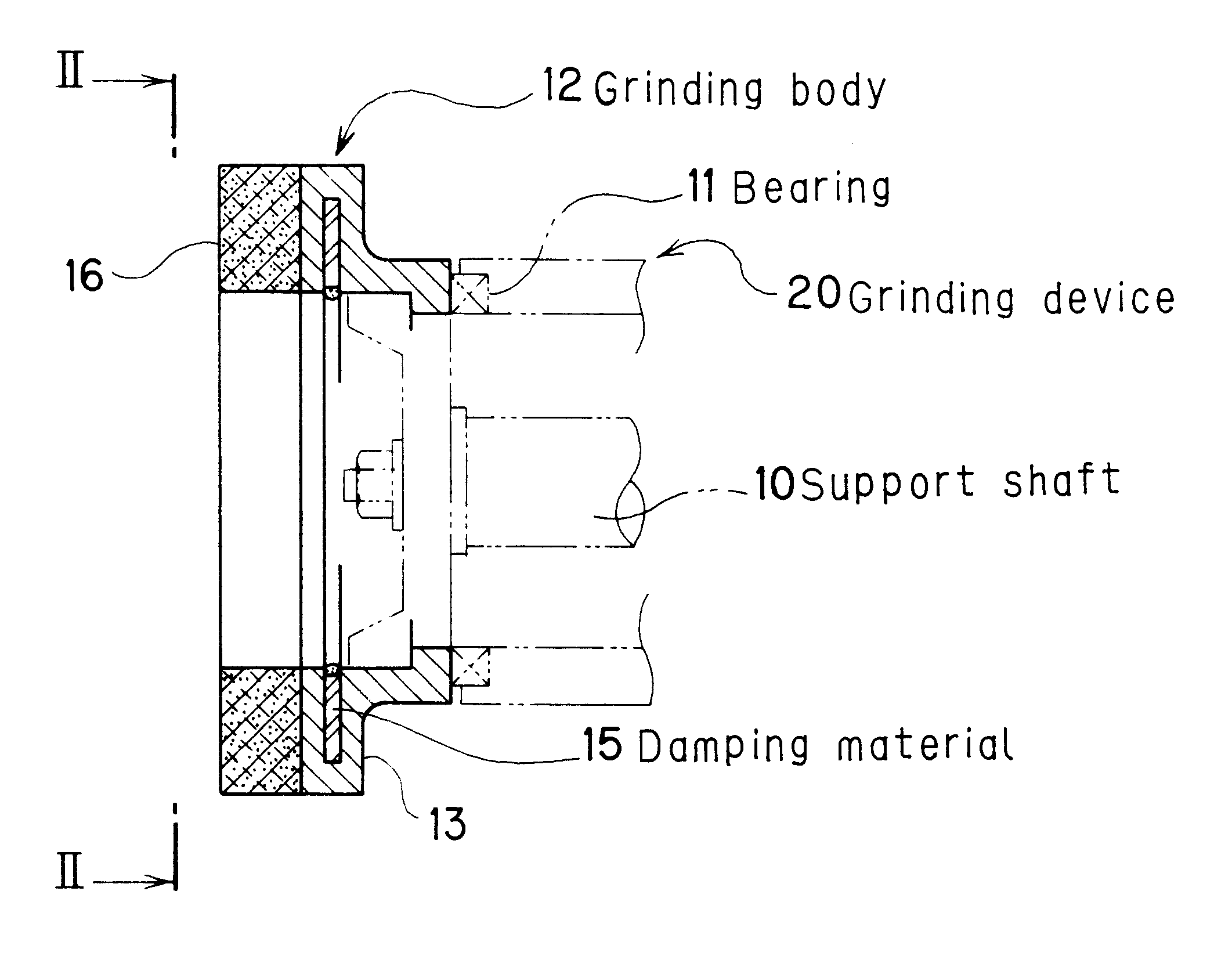

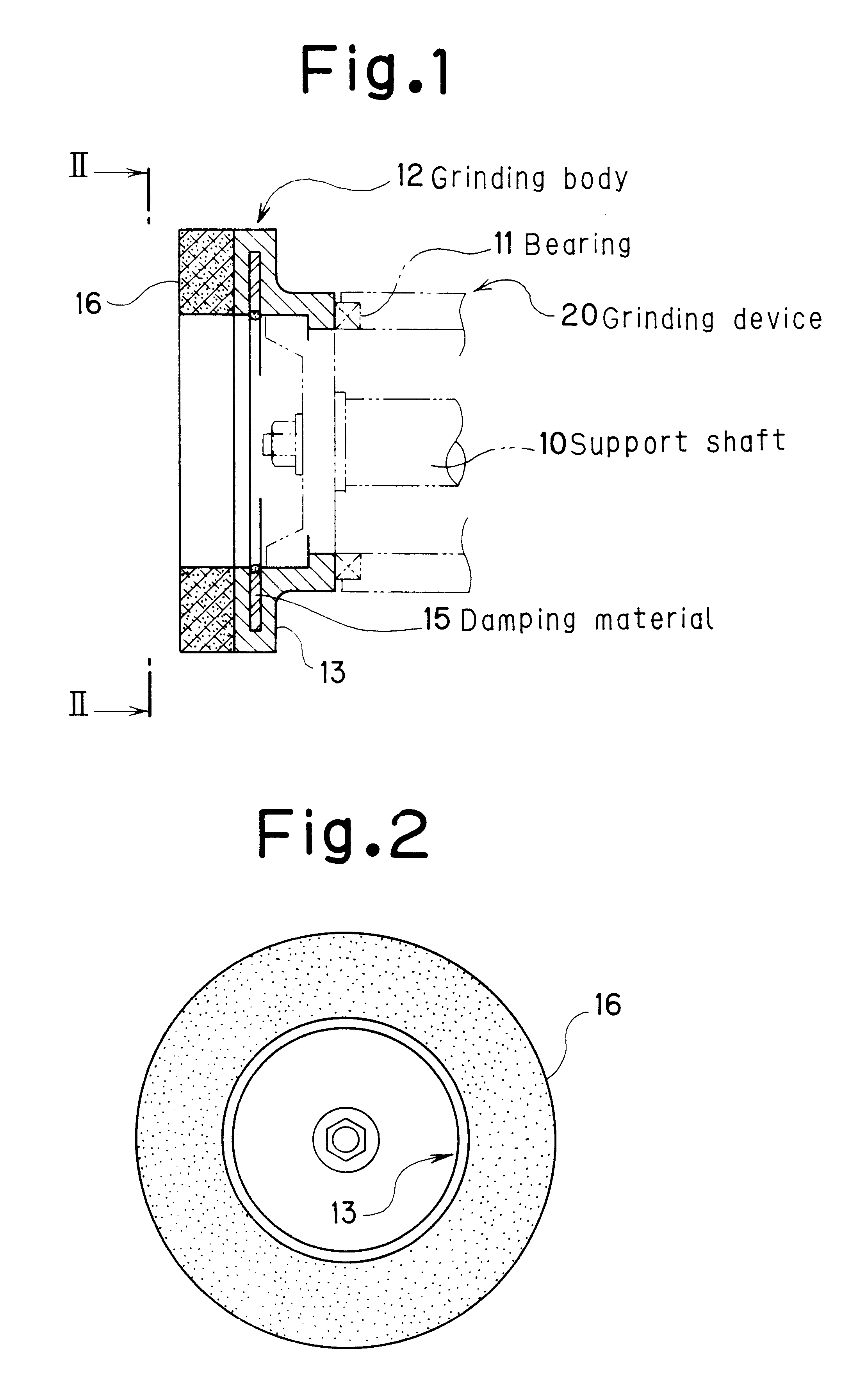

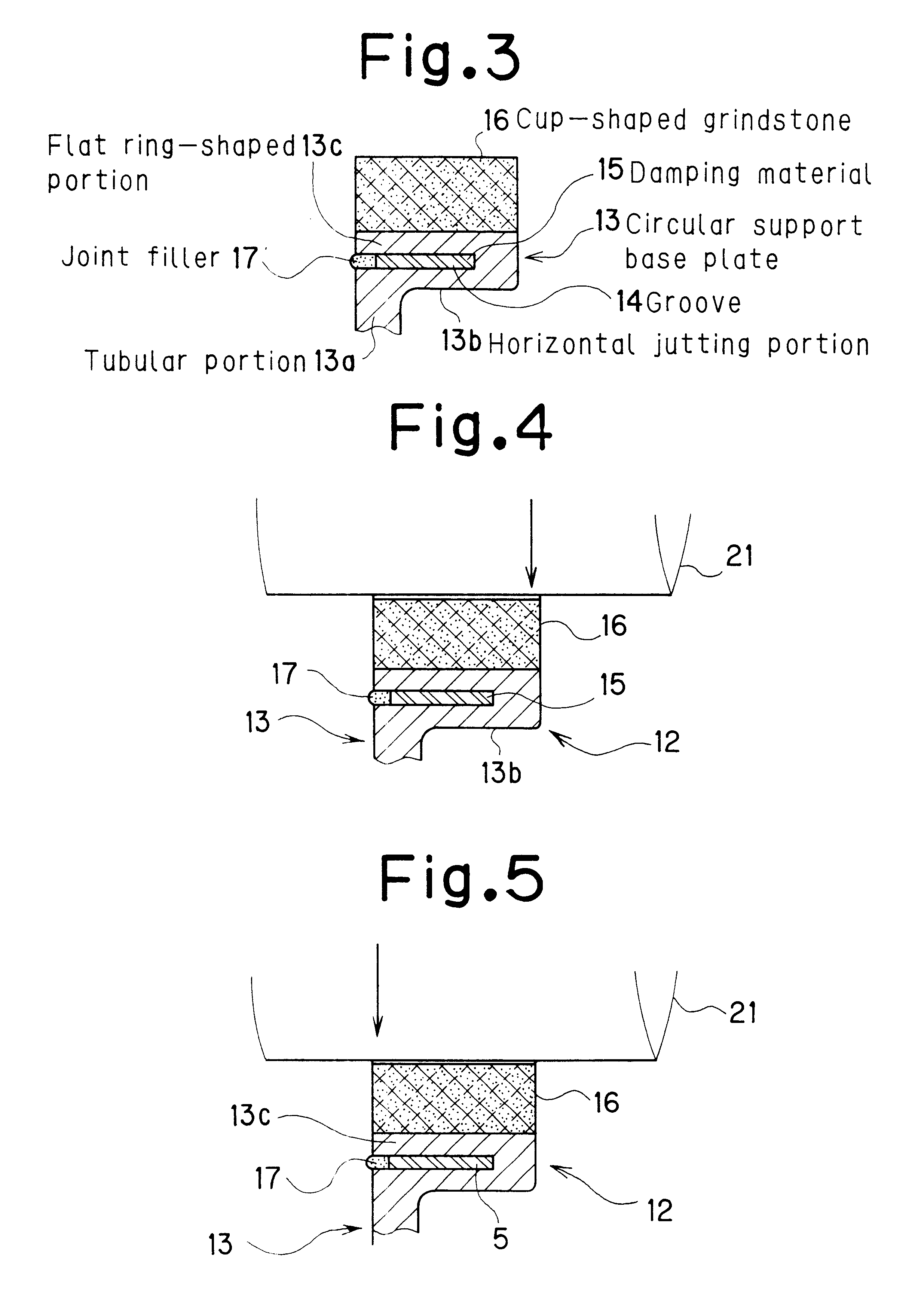

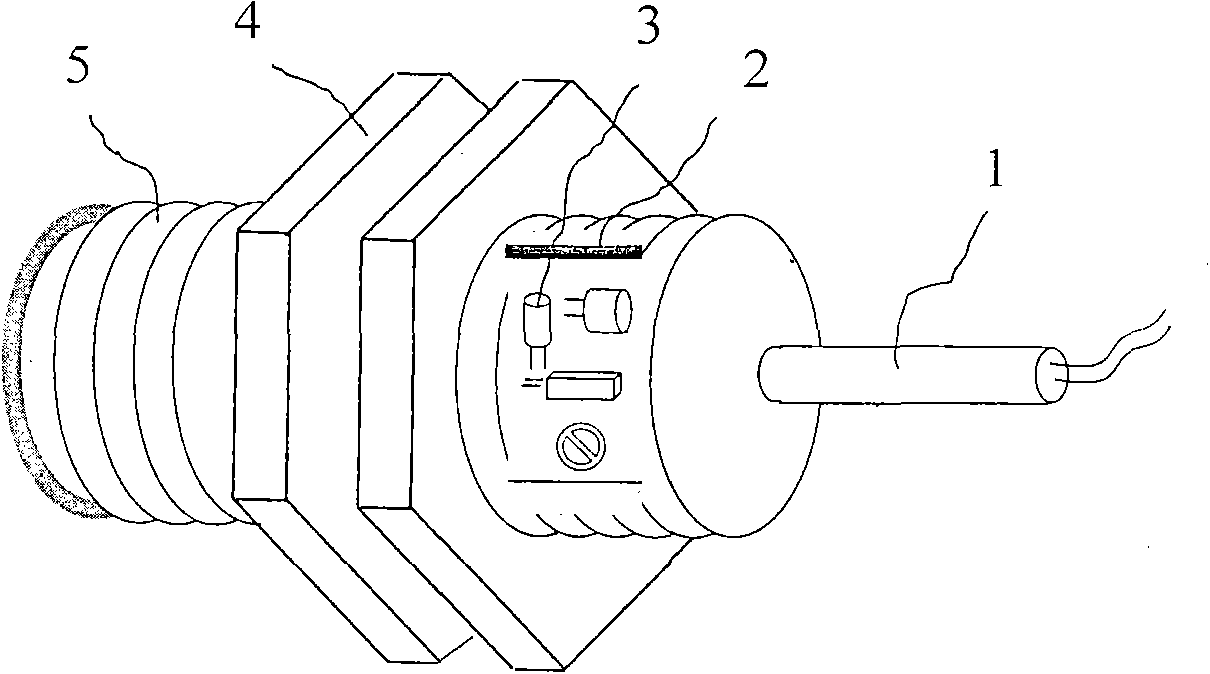

Grinding body for on-line roll grinding

InactiveUS6220949B1Edge grinding machinesRevolution surface grinding machinesEngineeringMechanical engineering

A grinding body for on-line roll grinding has a grindstone of a cup shape. The grindstone is on a surface portion, and near a peripheral edge, of a circular support base plate, so that a peripheral edge portion of the circular support base plate has on a surface side thereof a two-layer structure. This two-layered structure includes a flat ring-shaped portion jutting toward an inner periphery so as to define a groove opening inward. The grindstone is mounted on the flat ring-shaped portion; and a damping material is filled and mounted into the groove. This grinding body can effectively prevent the formation of a spiral mark and a pitching surface mark, improve the grinding power and grinding accuracy, and prolong the life of the grindstone.

Owner:MITSUBISHI HITACHI METALS MASCH INC +2

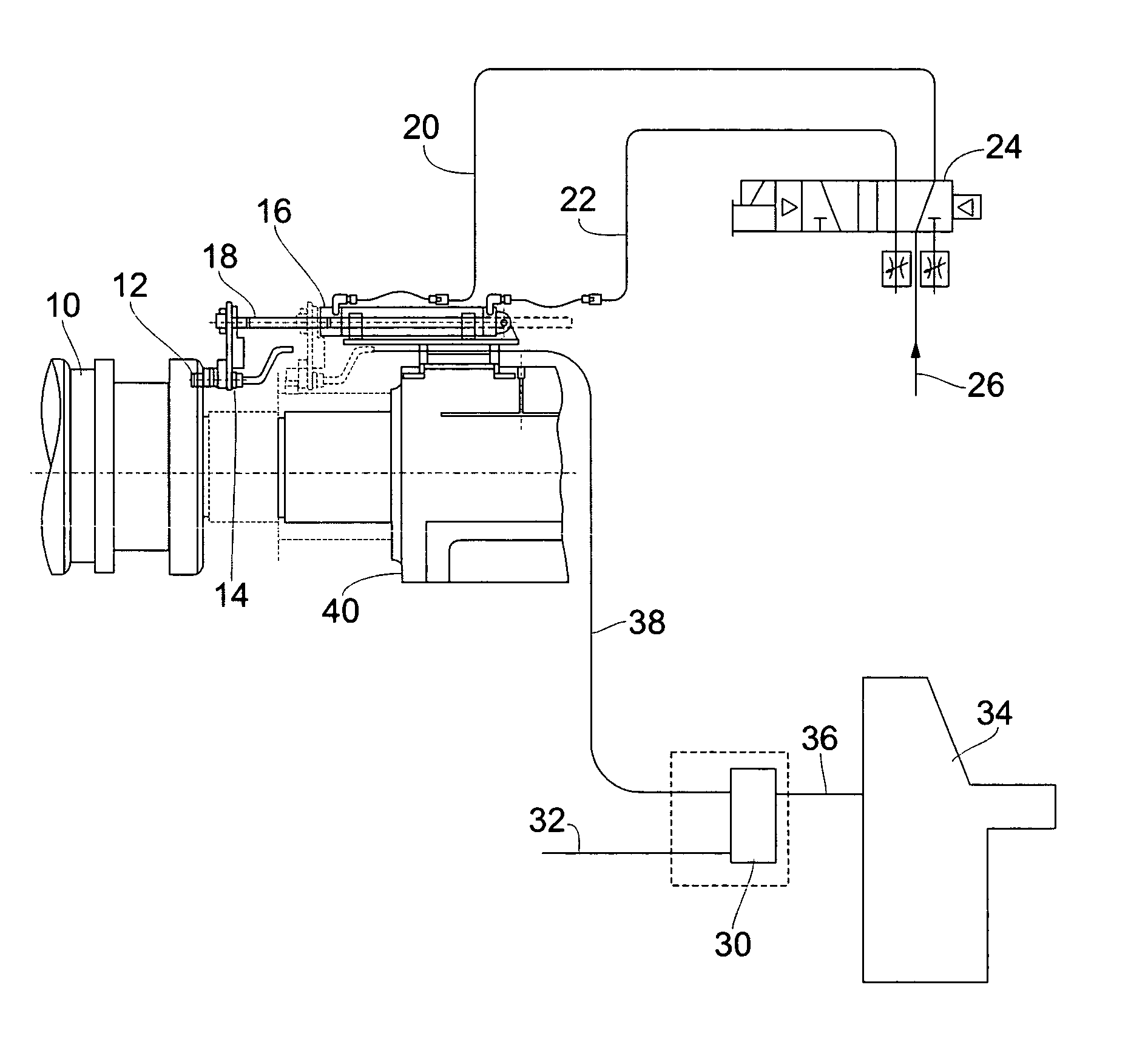

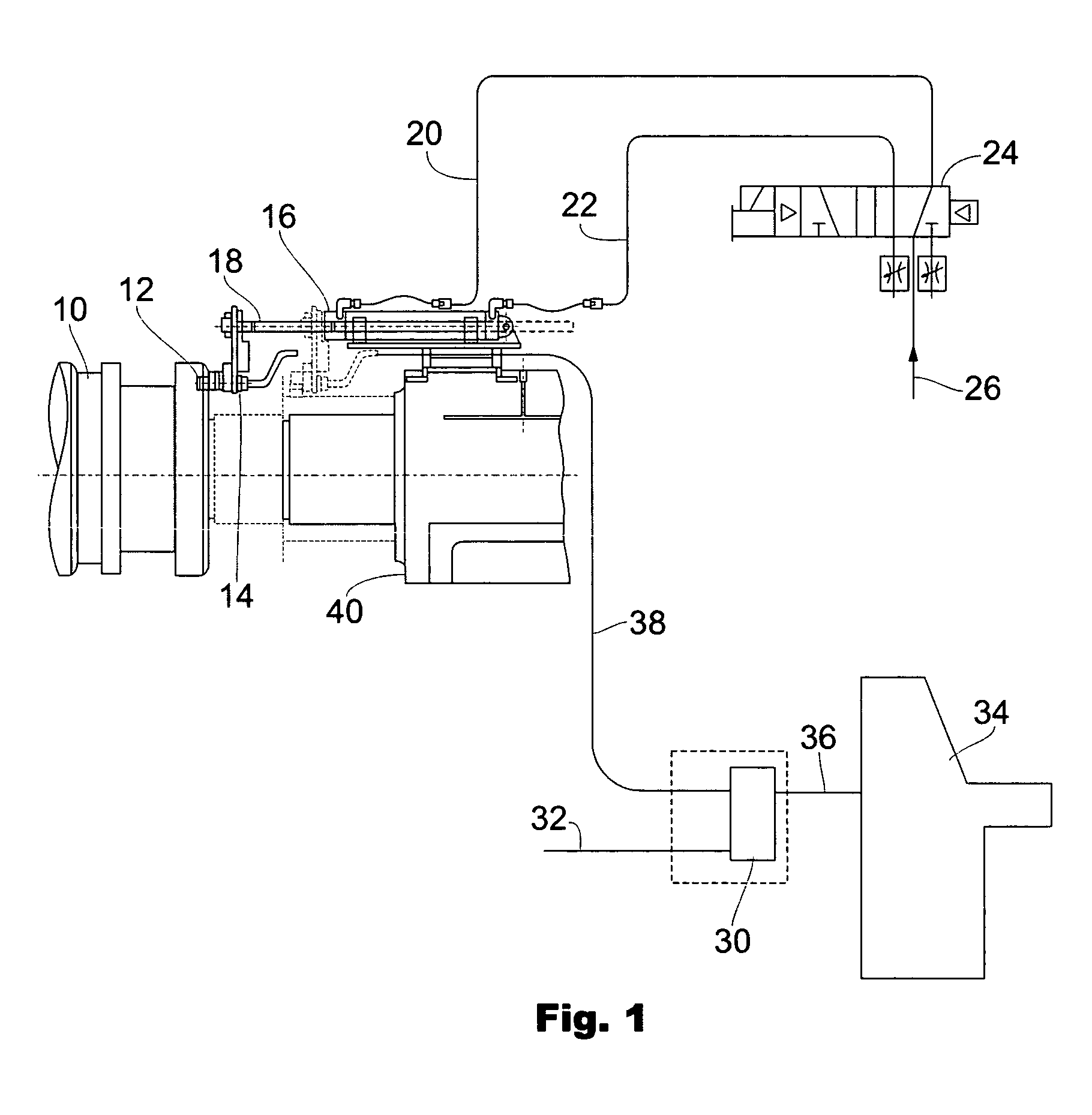

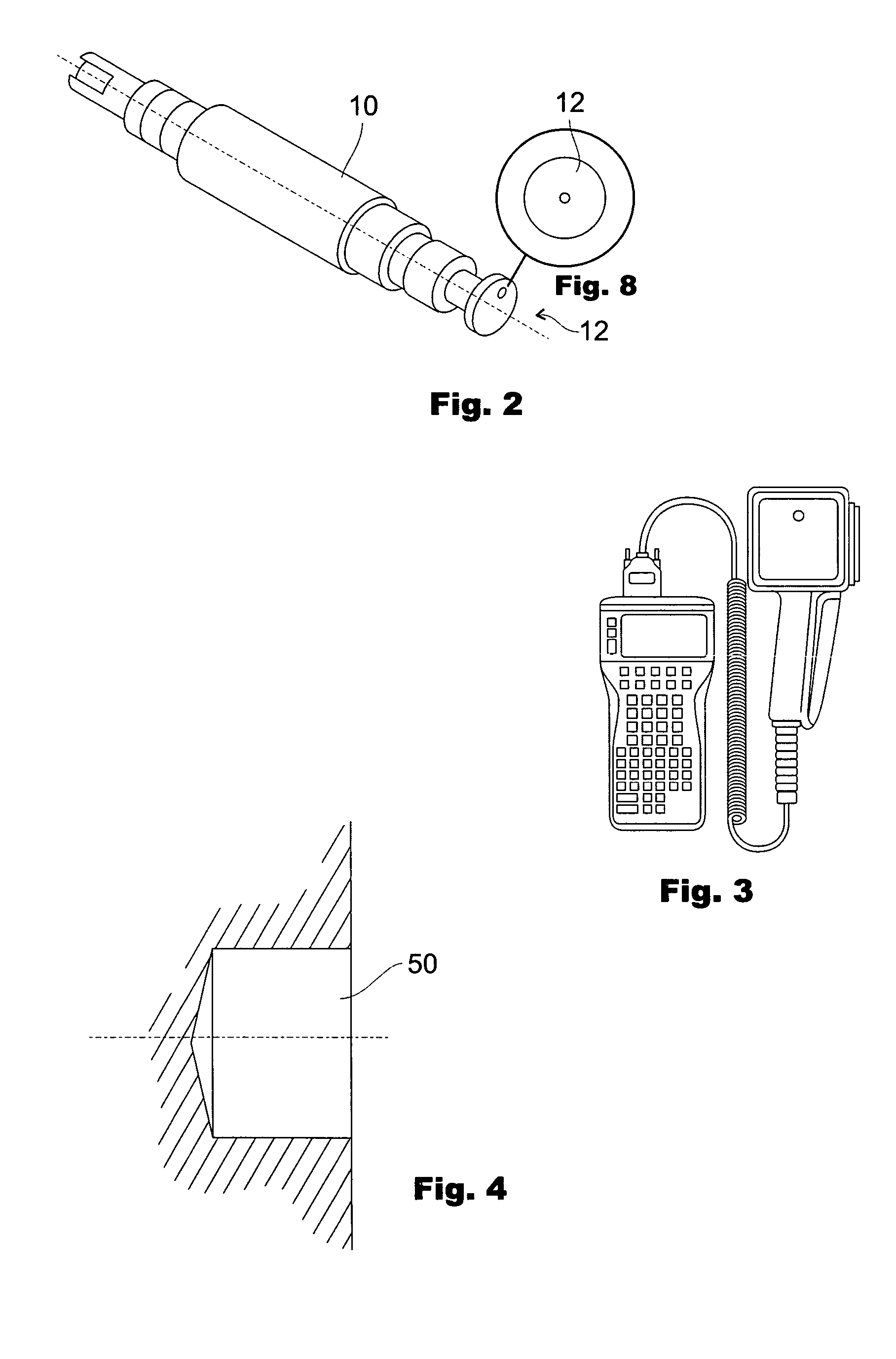

Automatic roll data acquisition system

InactiveUS6976900B2Improve integrityImprove securityRolling equipment maintainenceAutomatic grinding controlWork rollMachine control

The present invention discloses a method, system and apparatus for use in a roll grinding machine. Data is read from an RFID tag automatically by providing an RF read / write sensor on a movable cylinder rod. The RF sensor is held away from the work roll area while the work roll is loaded or removed. When the work roll is placed in the position for grinding, a signal to rotate the roll is sent to the grinding machine, and also operates to advance the cylinder rod. An RFID tag embedded in the work roll and containing identification and other data related to the work roll, is read by a read / write sensor, and the data is then transferred from the sensor to a serial control interface, which converts the data and transmits the information to the grinding machine control desk and the computer control management data base. The work roll identification information is transmitted automatically to the grinding machine, eliminating errors in transposing information manually and avoiding potential injury to personnel from having to scan the RFID tag using handheld RF read / write modules.

Owner:NITED STATES STEEL CORP

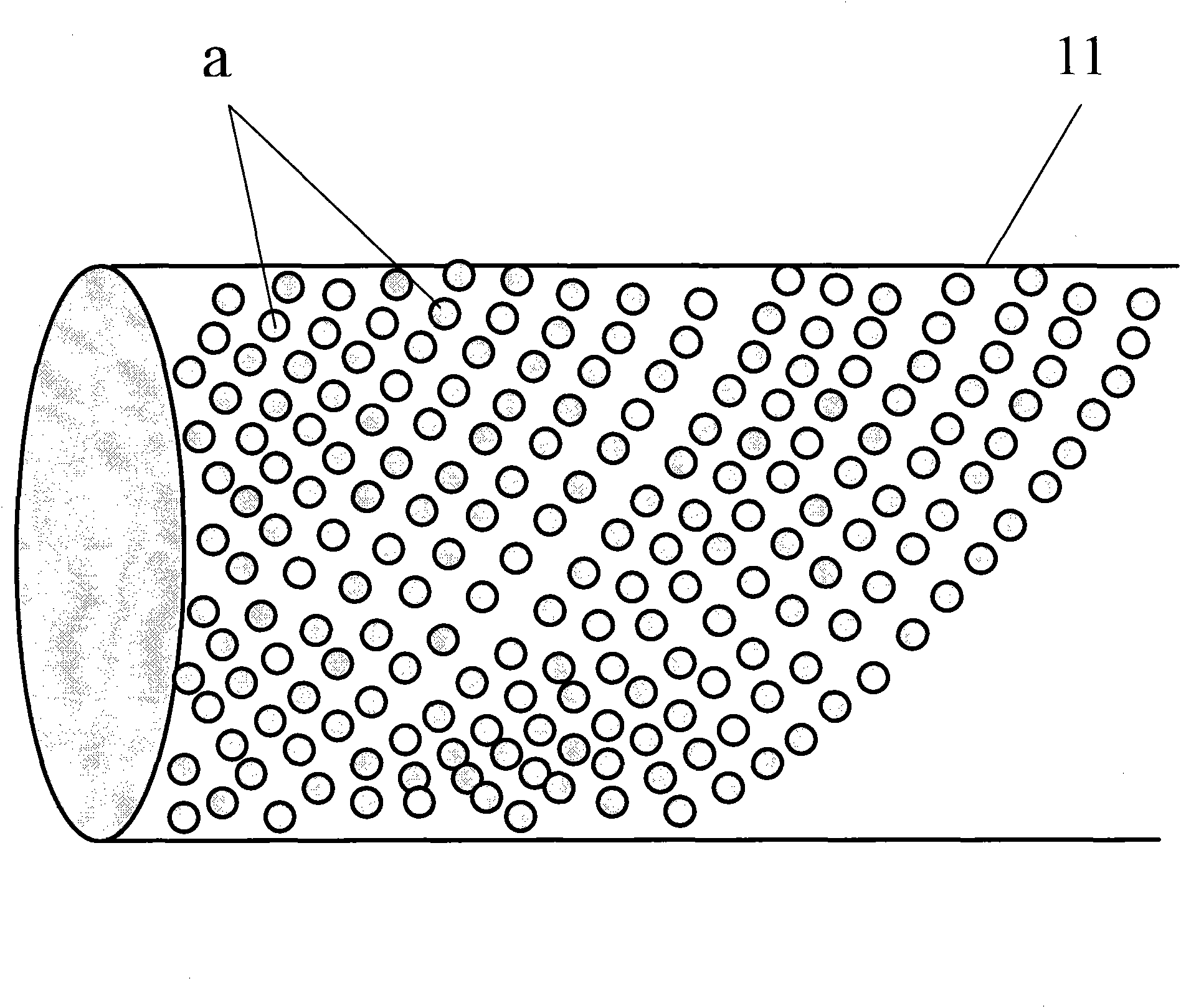

Laser texturing processing method on surface of roller

InactiveCN101642778AImprove rolling qualityImprove wear resistanceRolling equipment maintainenceLaser beam welding apparatusHelical lineSheet steel

The invention discloses a laser texturing processing method on the surface of a roller, comprising the following steps: leading the roller to rotate with uniform velocity along self axes; simultaneously, leading a laser texturing head to move with uniform velocity along the axial direction of the roller; and periodically transmitting laser beam to the surface of the roller and forming texturing spots on the surface of the roller. The method is characterized in that by accelerating the moving speed V of the laser texturing head along the axial direction of the roller, the texturing spots are distributed along the high inclination-angle helical line with the thread pitch of delta being equal to 2-200mm on the roller. As the roller has no smooth straight line between the two rows of the texturing spots on the circumference of the surface of the roller, when rolling a steel plate, the roller and the steel plate can prevent from jointing at those parts, the iron slag grains can be absorbedby texturing concave holes crisscross distributed on the peripheral direction of the roller, scratch can not be produced on the length direction of the steel plate, and the iron slag grains can not fray and break the texturing spots, thereby greatly improving the rolling quality of the steel plate and the wearing resistance of the roller, and prolonging the service life of the roller.

Owner:苏州市博海激光科技有限公司

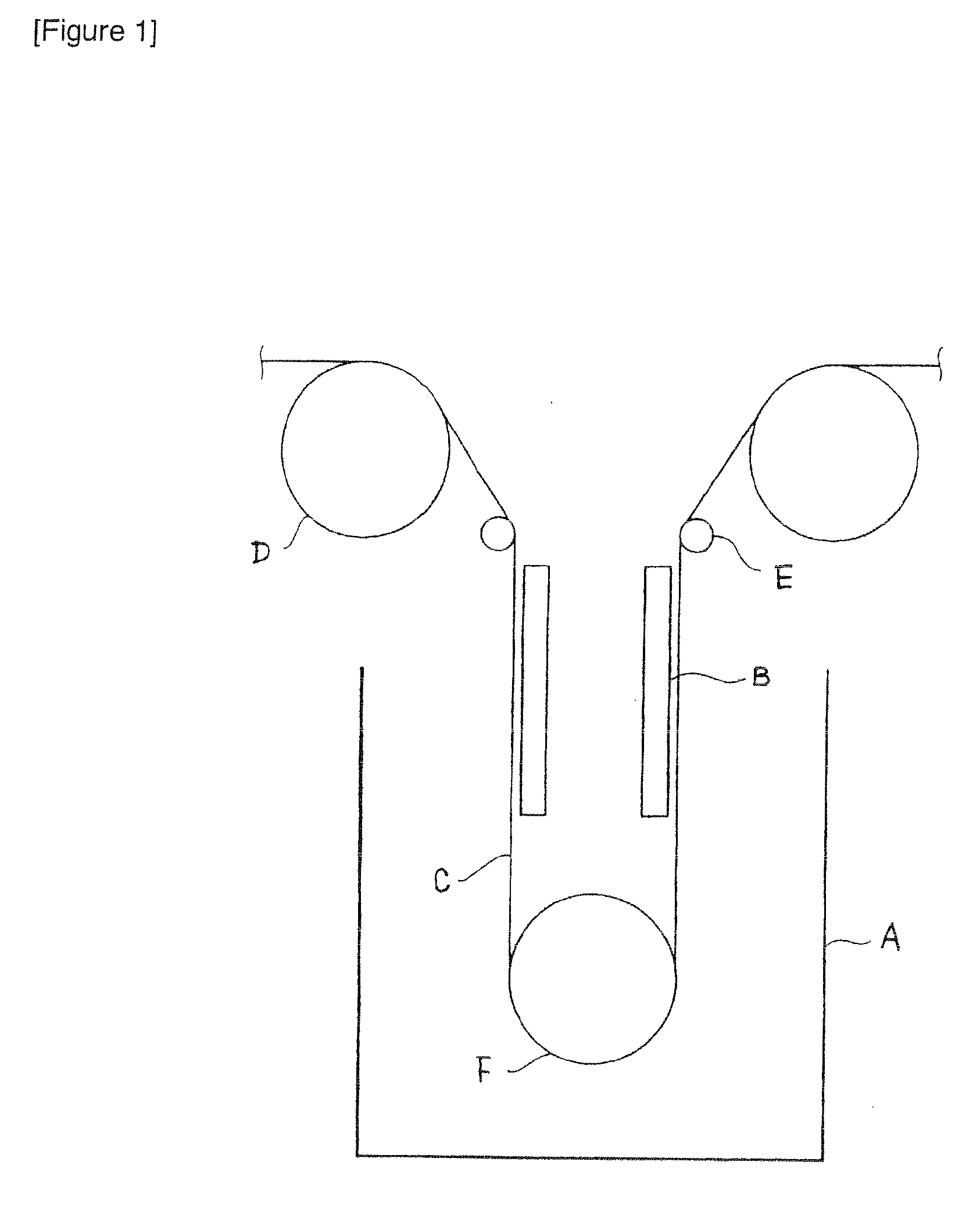

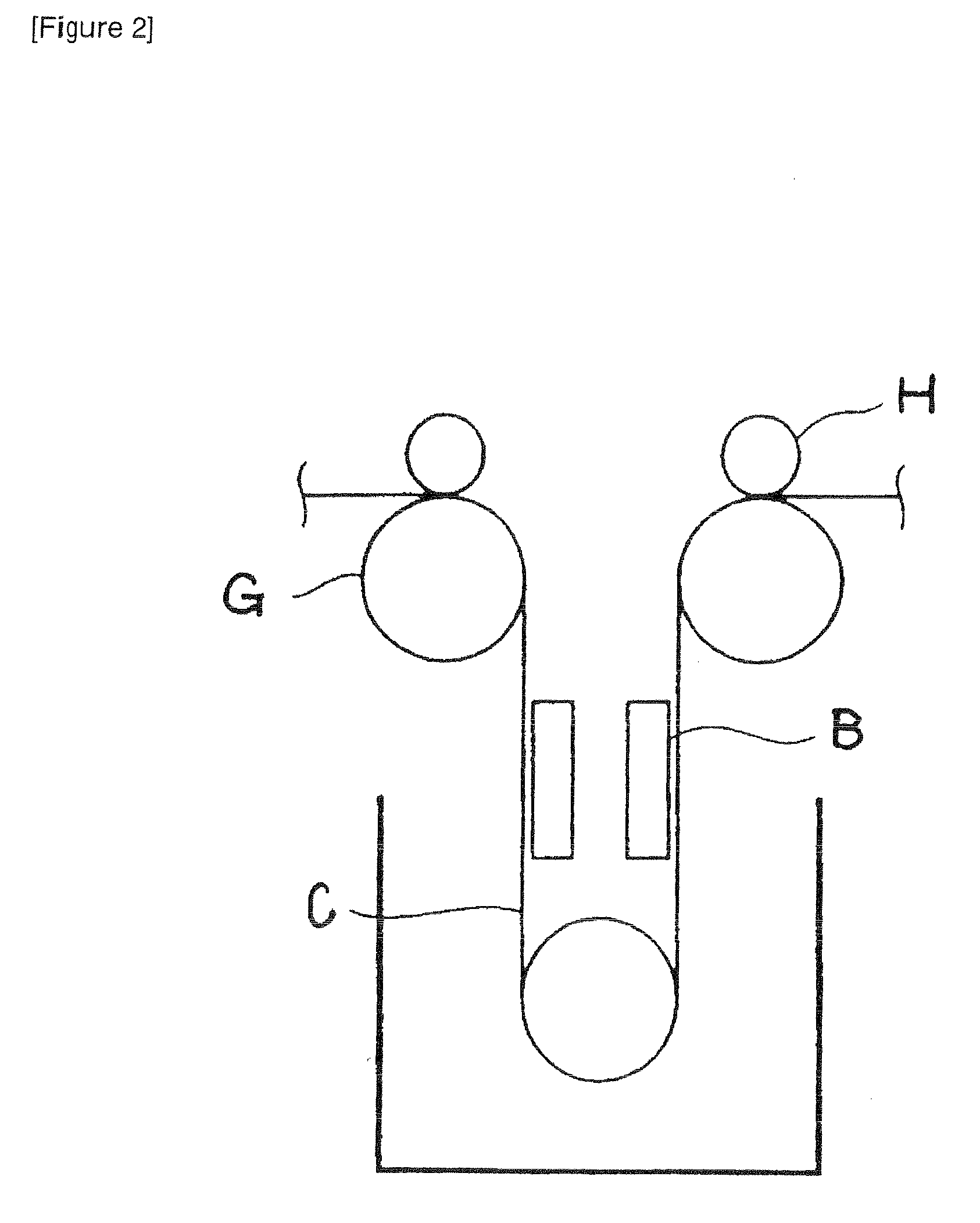

Roll Unit for use in Surface Treatment of Copper Foil

InactiveUS20100018273A1Easy to replaceImprove productivityMetal rolling stand detailsRolling equipment maintainenceElectrolysisSurface oxidation

Provided is a roll unit for use in a surface treatment of a copper foil, wherein shaft sleeves are fitted to a roll shaft of a roll so that the roll shaft is rotatably supported by a bearing via the shaft sleeves. Additionally provided is a roll unit wherein the shaft sleeves consist of two sleeves, namely a roll-side sleeve arranged on a roll main body side and a tapered sleeve arranged on a shaft end side, an oil seal is arranged between the roll-side sleeve and a bearing box, and the tapered sleeve is supported by a bearing disposed in the bearing box. Thus, this invention relates to a roll unit to be used in electrochemical surface treatments, such as roughening treatment, rust prevention treatment and surface oxidation treatment, to be continuously performed on a surface of a rolled copper foil or an electrolytic copper foil, and in particular relates to a roll unit capable of inhibiting the abrasion and corrosion of the roll shaft of such roll unit and capable of simple replacement of the bearing box, bearing and other components.

Owner:JX NIPPON MINING& METALS CORP

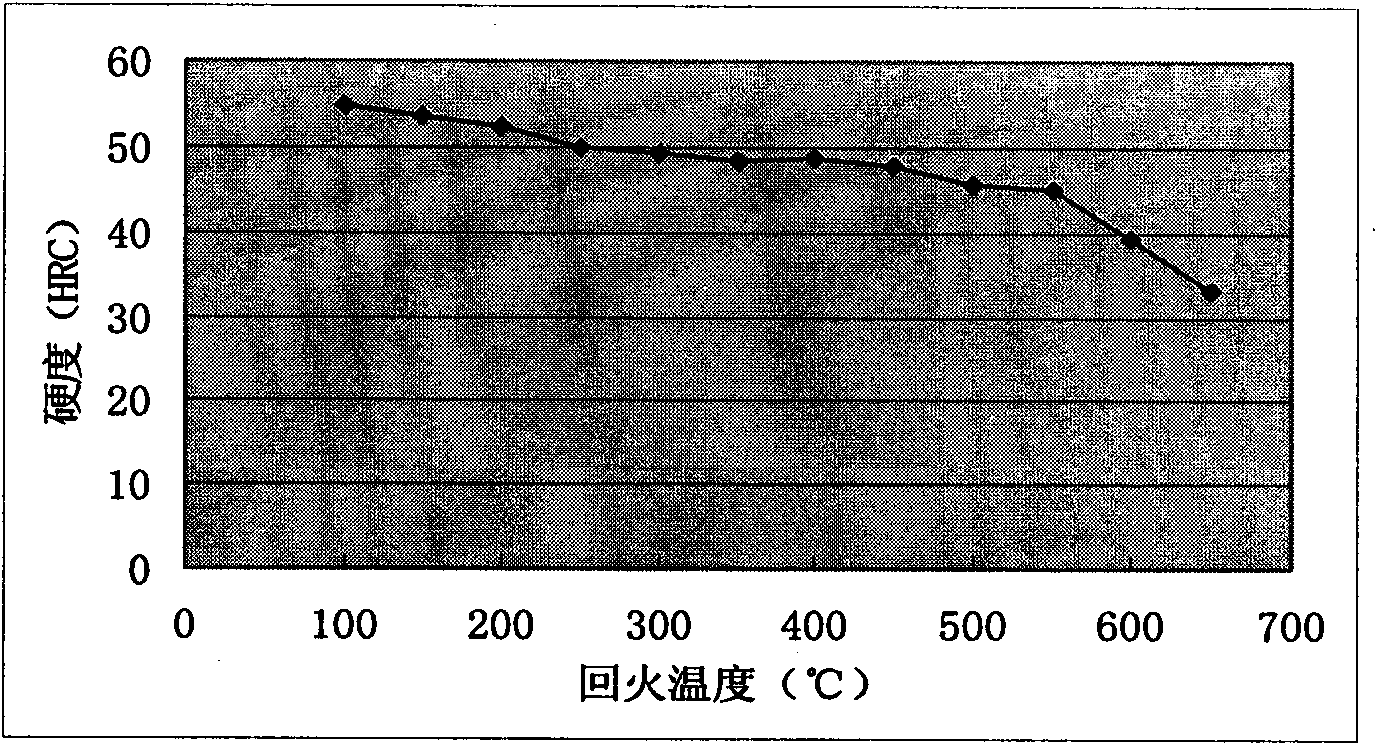

Method for producing textured surface accurate stainless steel band

InactiveCN101244427AHigh hardnessImprove wear resistanceRevolution surface grinding machinesRolling equipment maintainenceAbrasive blastingGranularity

The invention relates to a production method of precision stainless steel band with roughened surface, which comprises the following steps: (1) grinding with roller, wherein, the material of the roller is W6Mo5Cr4V; (2) sandblasting and roughening with roller; (3) rolling with twenty rollers. The production method is characterized in that the roller enables to roll continuously over 3000 meters to produce obvious change in roughness; the roughness of the roughened surface of roller is controlled through changing the granularity of the blasting sand. The production method adopts the sand with 46 to 100 granularity, wherein, the higher the granularity of the blasting sand, the lower the surface roughness of the roughened roller, and the surface roughness of the rolled steel band is also lower. The production method has the advantages of simple method, low cost and controlling range of 0.50 to 1.0 Mum for the surface roughness of the precision stainless steel band with roughened surface.

Owner:NINGBO YONGZHENG PRECISION STAINLESS STEEL

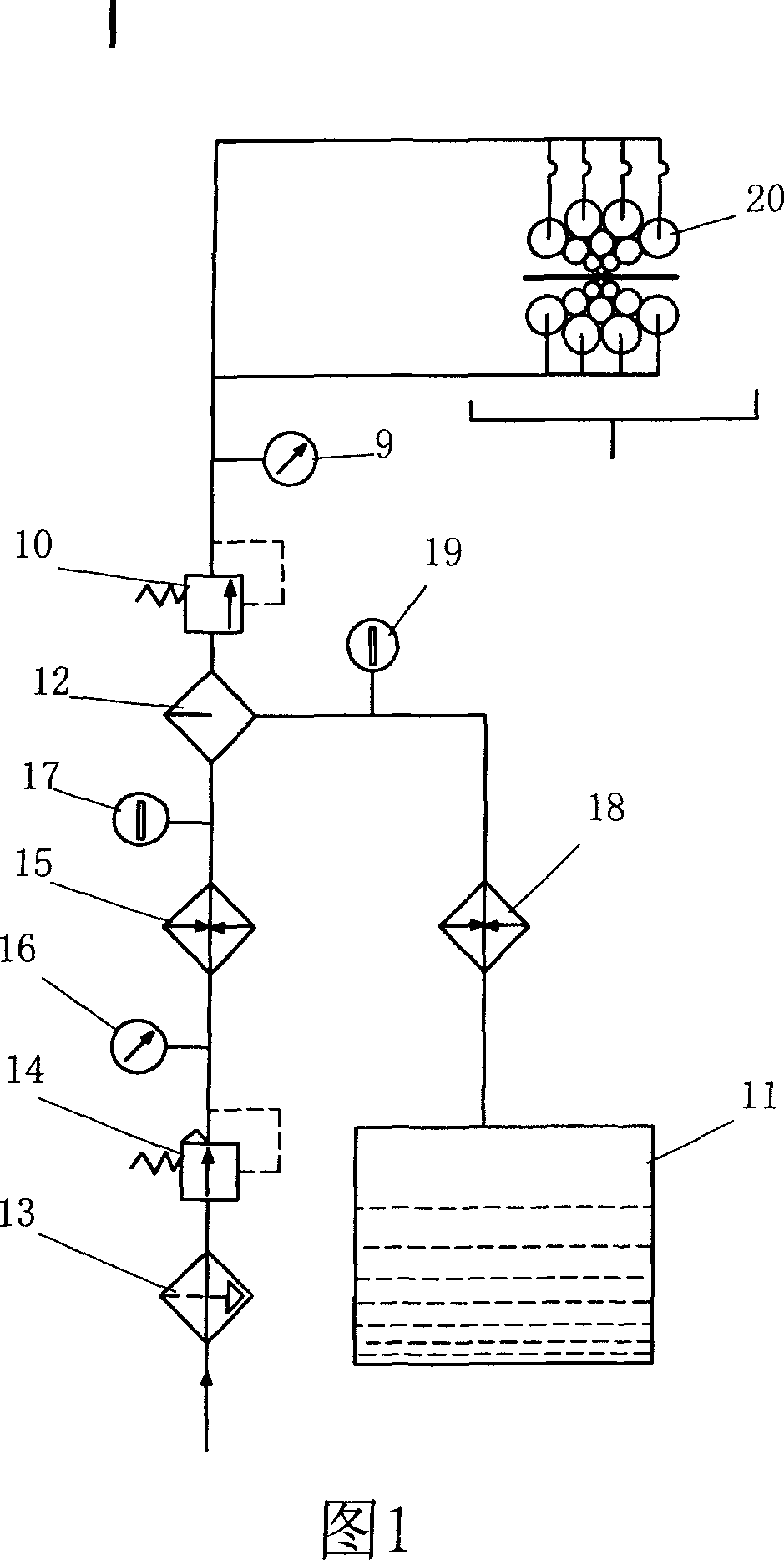

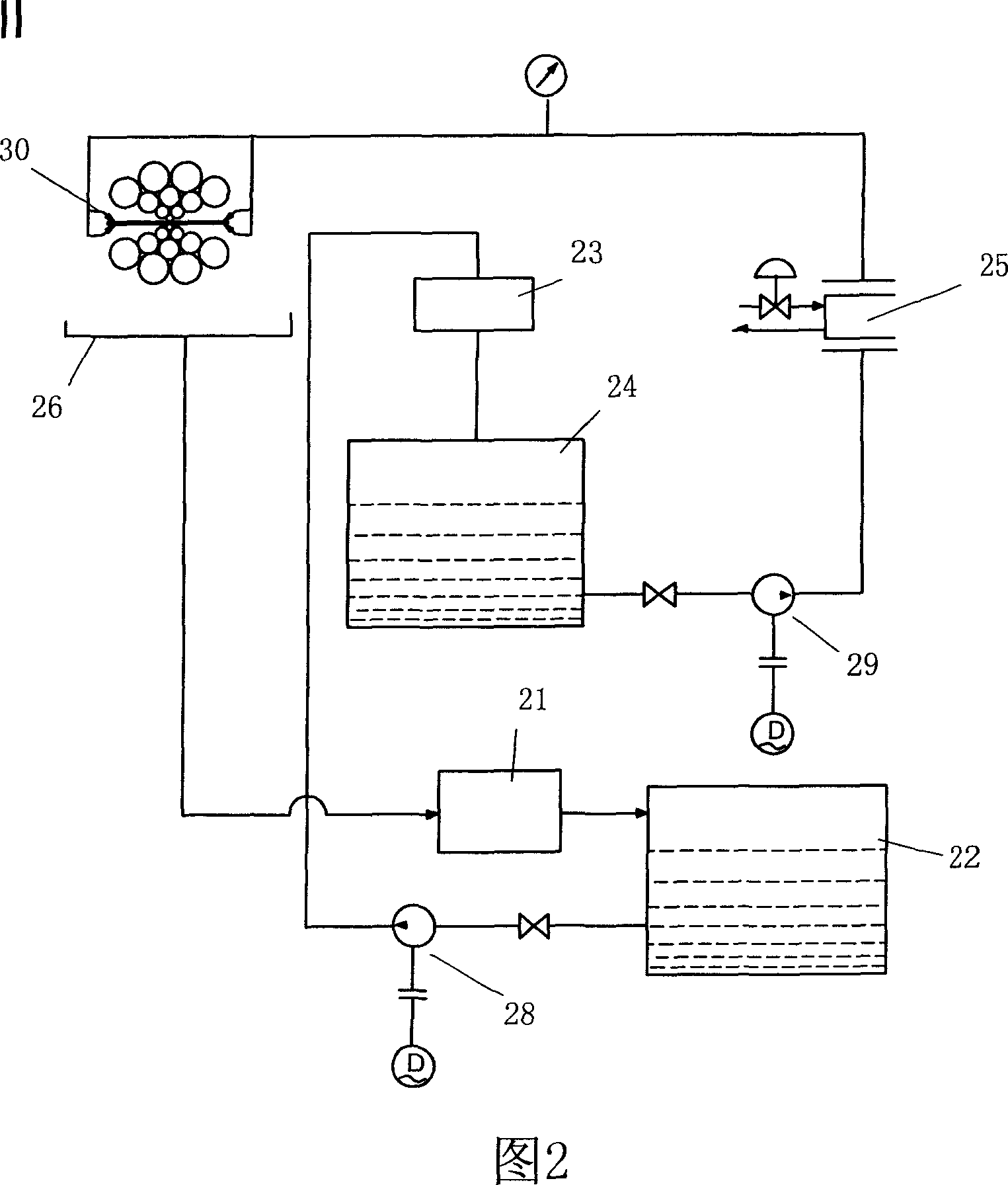

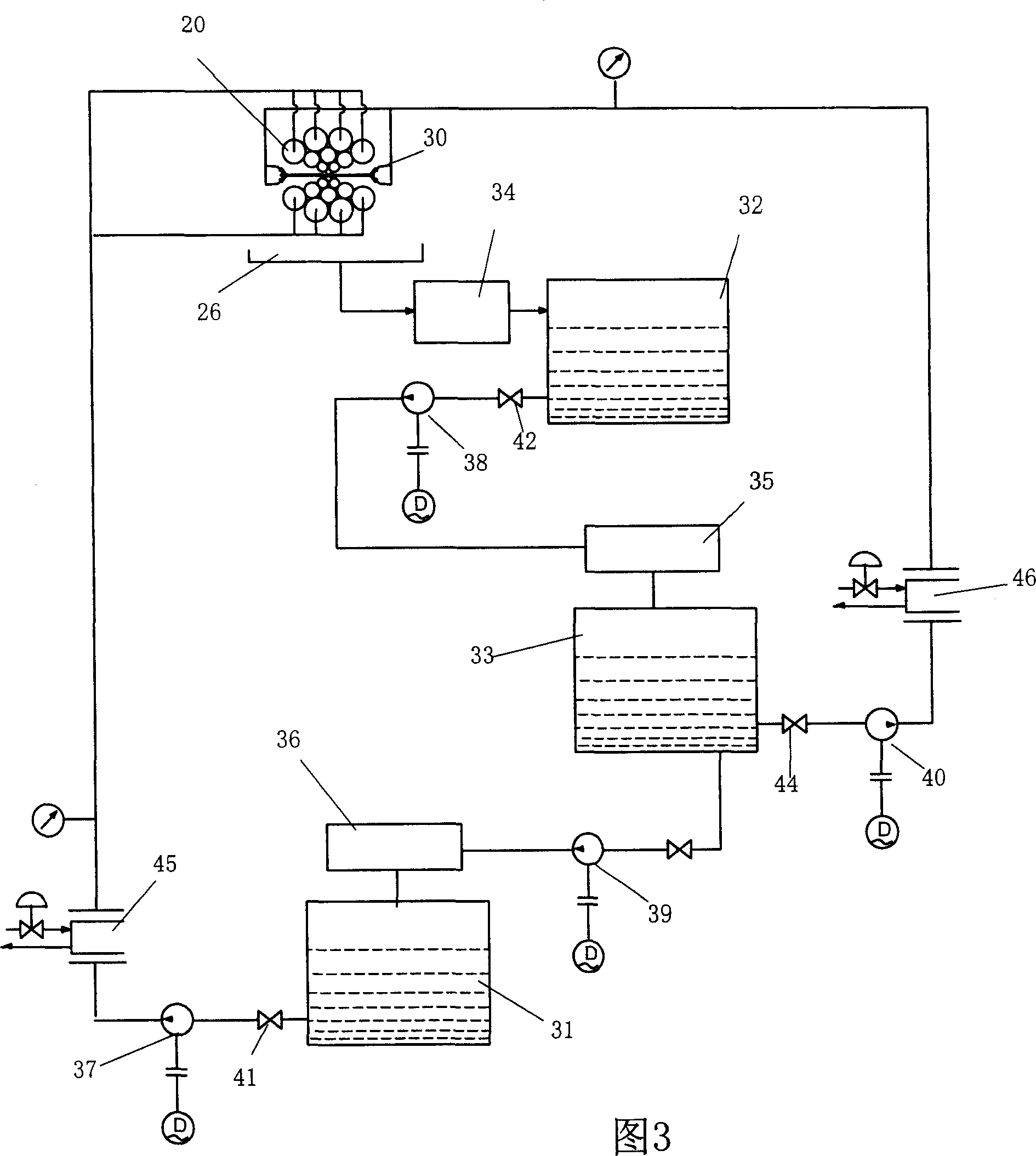

Bearing lubricating and cooling method and device

ActiveCN1931459AImprove the lubrication effectImprove cooling effectRolling equipment maintainenceWork treatment devicesEmulsionBelt filter

The present invention is bearing lubricating and cooling method and device, and features utilizing emulsion as lubricating and cooling medium and adopting an emulsion circulating device to provide the bearing, roller and the rolled plate with emulsion. The present invention can meet different lubricating and cooling requirements of rolling process in a two-stage paper belt filtering mode and has the pressure, flow rate, temperature, concentration and other parameters of the emulsion separately adjustable. The present invention can cool bearing, roller and the rolled plate effectively, save lubricating and cooling medium, improve rolled plate quality, prolong the service life of the bearing and make best use of the rolling machine.

Owner:BEIJING WEISHIJIE HYDRAULIC EQUIP +1

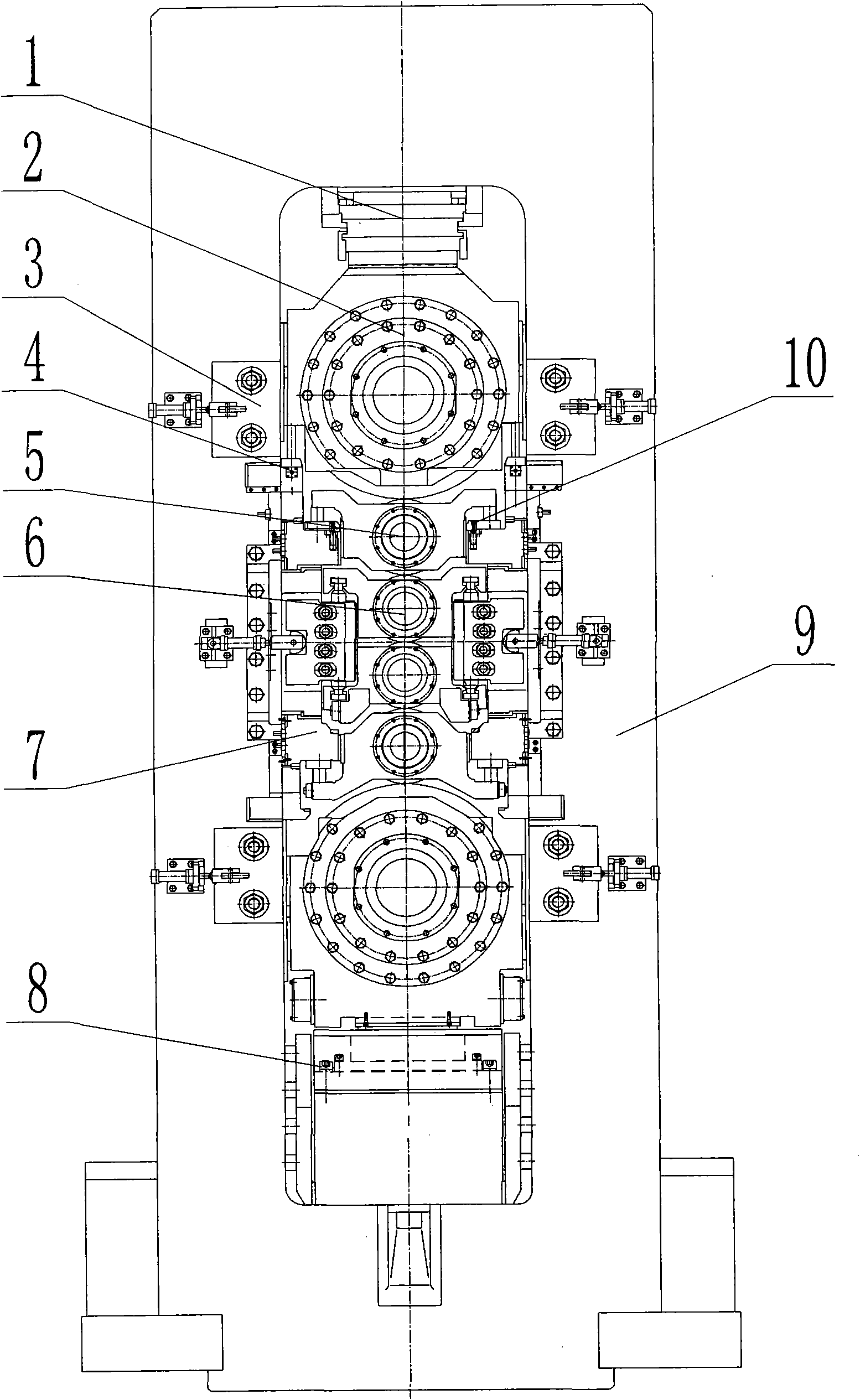

Six-roller mill

ActiveCN101549354AHigh dimensional accuracyExtended service lifeMetal rolling stand detailsRolling equipment maintainenceStrip steelCarbon steel

The invention relates to cold mill machinery, in particular to a six-roller mill which belongs to the forming technical field. In the invention, an axial locking device and supporting rollers are connected and installed at the operation sides of the upper part and the lower part of a housing; a supporting roller balancing device is connected with an upper supporting roller; a hydraulic pressing fine adjustment device is installed at the bottom of the housing, and a lower supporting roller is directly placed on the top of the hydraulic pressing fine adjustment device; an axial moving device is installed outside the transmission side of the housing and connected with a middle roller through another axial moving device; an axial moving locking device is installed on a bowed roller block at the transmission side; and a roller system compensating device is installed at the upper part of the housing. The invention improves the dimensional precision of cold-rolled steel strip products and improves the automatic degree in the production process; the device pressing mechanism has simple structure and compact arrangement and improves the service life of bearings; and the roller replacement is fast, flexible, stable, reliable and convenient in operation. The six-roller mill is suitable for rolling steel strip products such as straight carbon steel, quality carbon steel, low alloyed steel, stainless steel, and the like.

Owner:CISDI ENG CO LTD

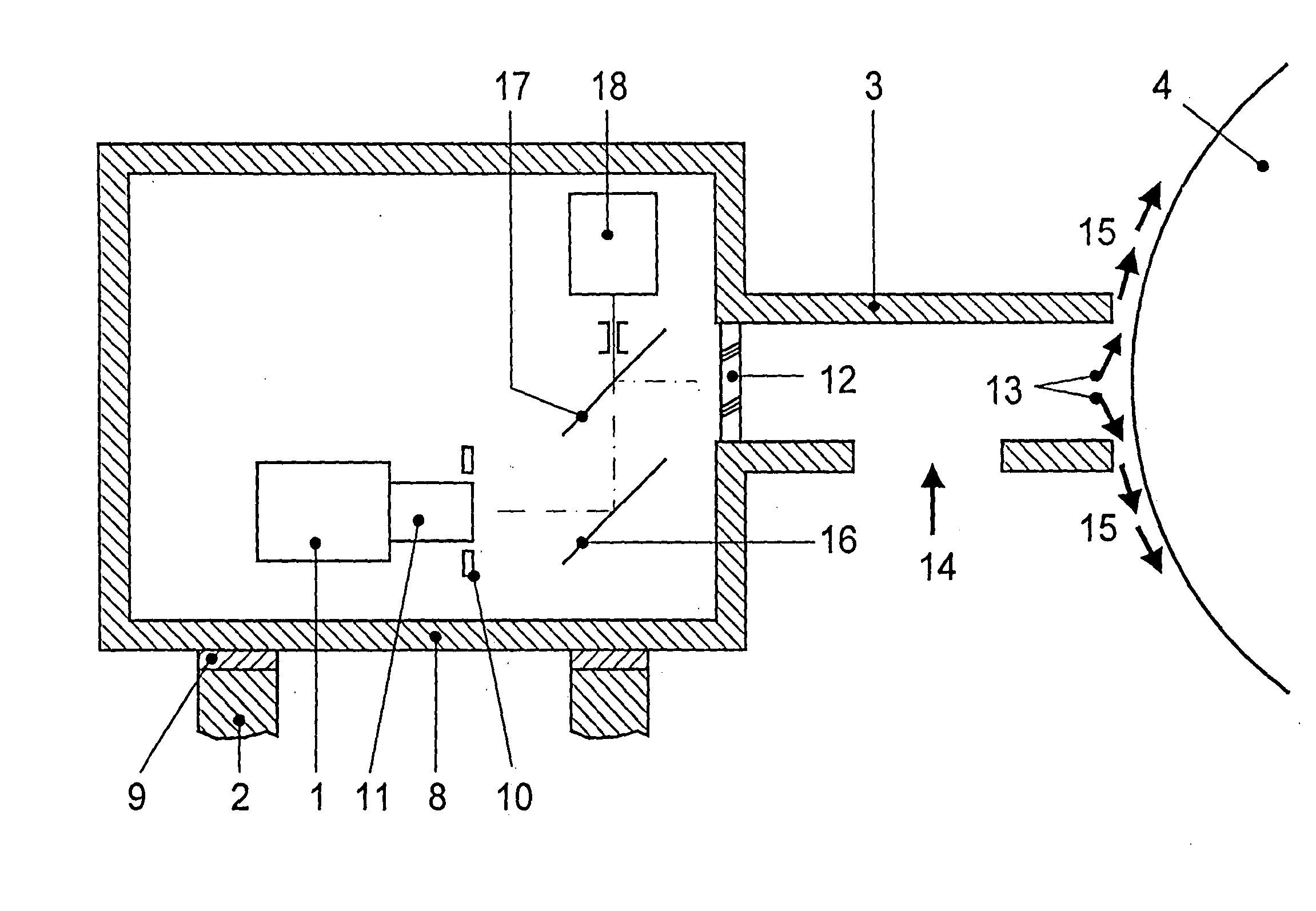

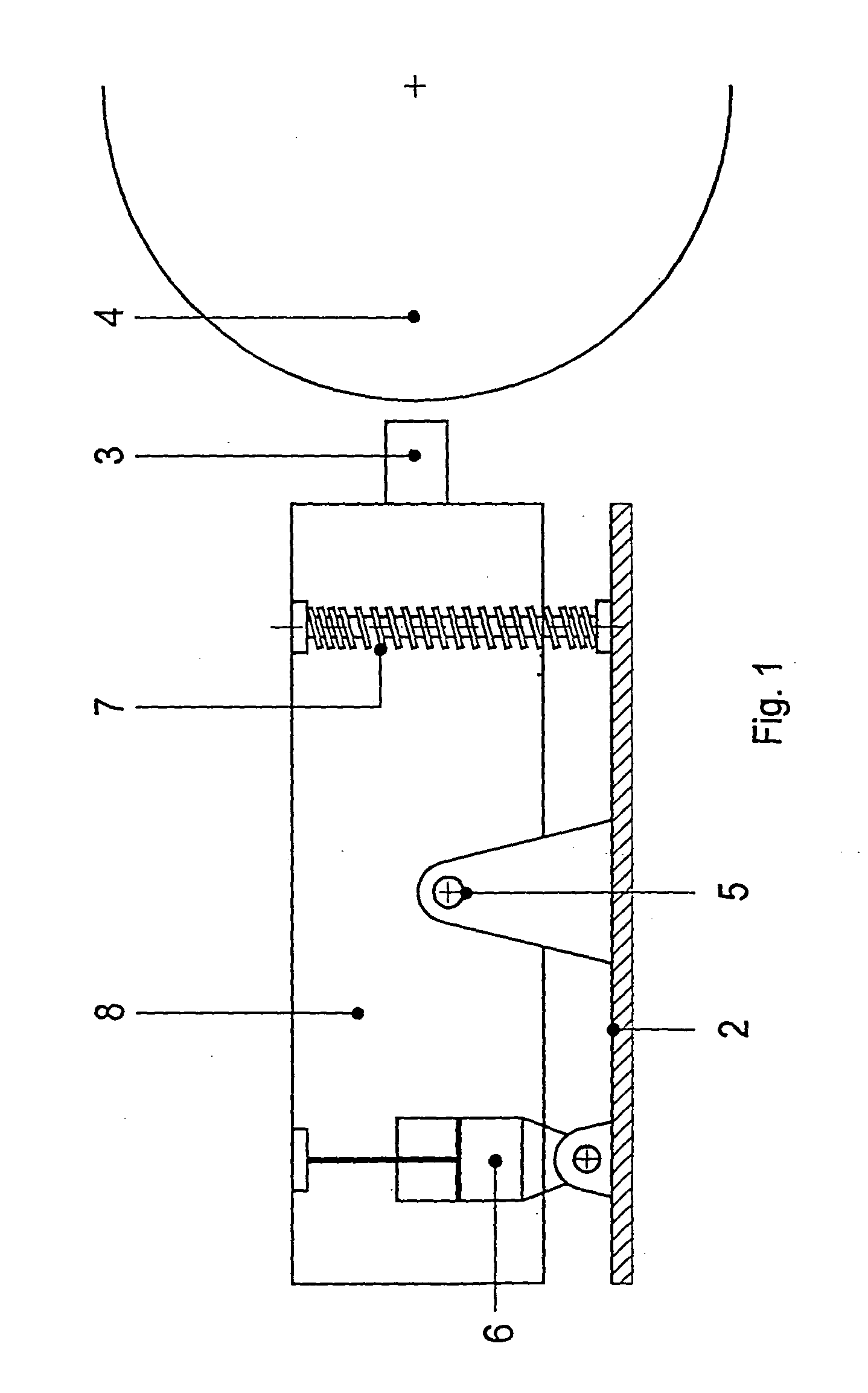

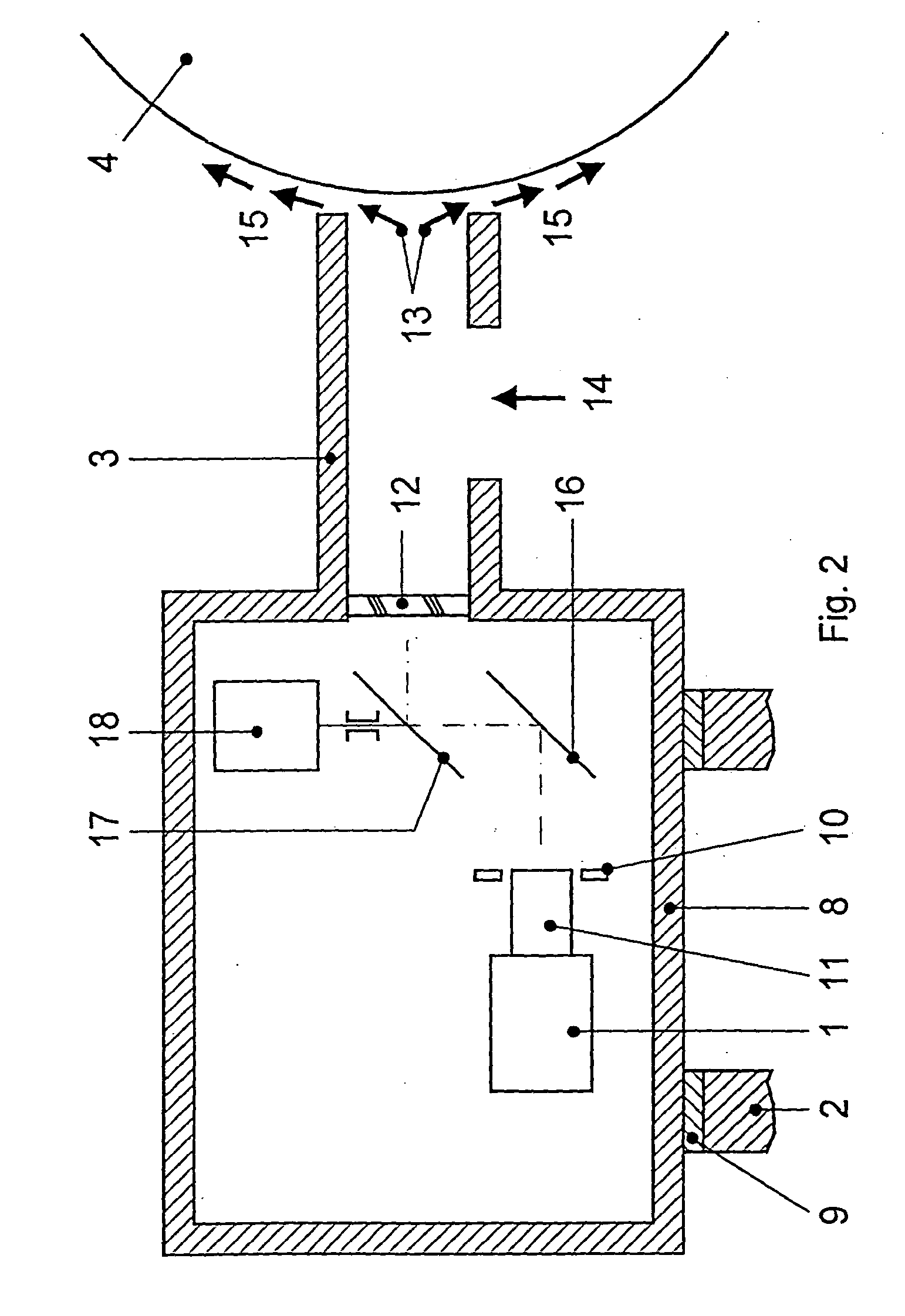

Method for inspecting the surface of a roll cylinder and device therefor

InactiveUS20040022430A1Large in illuminationIncrease awarenessMechanical counters/curvatures measurementsRolling equipment maintainenceOptical axisReference image

In a process for the inspection of the surface of a cylindrical body and more especially that of a mill roll, at least one zone of the surface is observed by means of an inspection device having an optical axis oriented towards this zone of the surface with a view to determining the state of the surface. To this end, at least one image of the zone supplied by the inspection device is captured, at least one of the images captured is analysed, the analysis of the image or images captured is compared with the analysis of a reference image, the differences between the analysis of the image or images captured and the analysis of the reference image are detected, and at least the orientation of the optical axis is adjusted so as at least to reduce and preferably to eliminate the differences found. The device can include mechanical and / or optical means of adjusting the orientation of the optical axis.

Owner:CENT DE RECH METALLURGIQUES CENT VOOR RES IN DE METALLURGIE

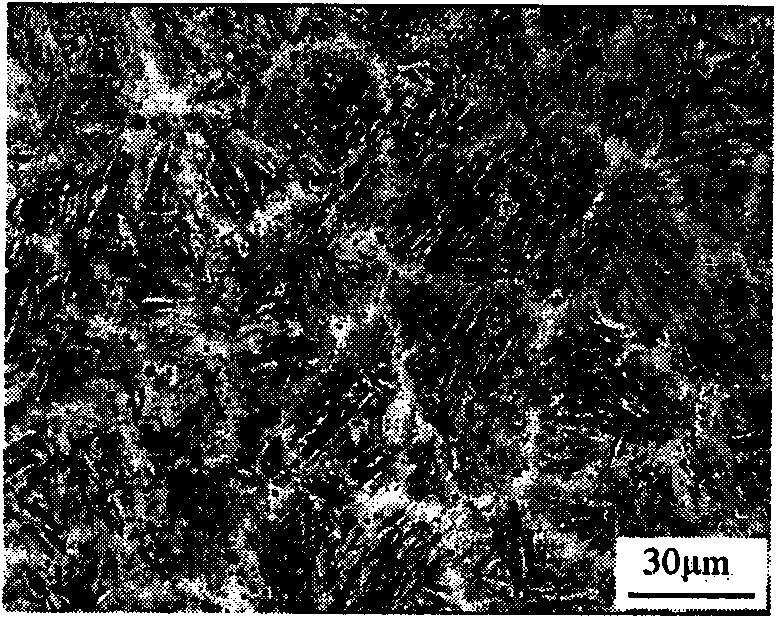

Build-up welding rod for repairing Cr3 roller and build-up welding method

InactiveCN101658986AImprove wear resistanceMeet repair requirementsRolling equipment maintainenceArc welding apparatusCrack resistanceHigh carbon

The invention relates to a build-up welding rod for repairing a Cr3 roller and a build-up welding method, which belong to the technical field of welding materials and welding. The build-up welding rodcomprises a welding core and a coating, the welding core is H08A steel and the coating of the welding rod comprises, by mass percent, 36 to 42 marble, 20 to 26 fluorite, 1.5 to 4 low-carbon ferromanganese, 1 to 4 ferromolybdenum, 13 to 17 high carbon ferro-chrome, 0 to 1.5 calcined soda, 1 to 4 rare earth alloy, 4 to 8 titanium dioxide, 0.5 to 1.5 graphite, 3 to 5 No,45 silicoferrite and 4 to 7 silicon dioxide. The build-up metal has no crack, good crack resistance, good wear resistance, high hardness and plasticity and good tempering stability. The welding method is simple and convenient, and the connection of the melt-applying metal and the roller is firm to excellently satisfy the repairing requirement of the Cr3 support roller.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

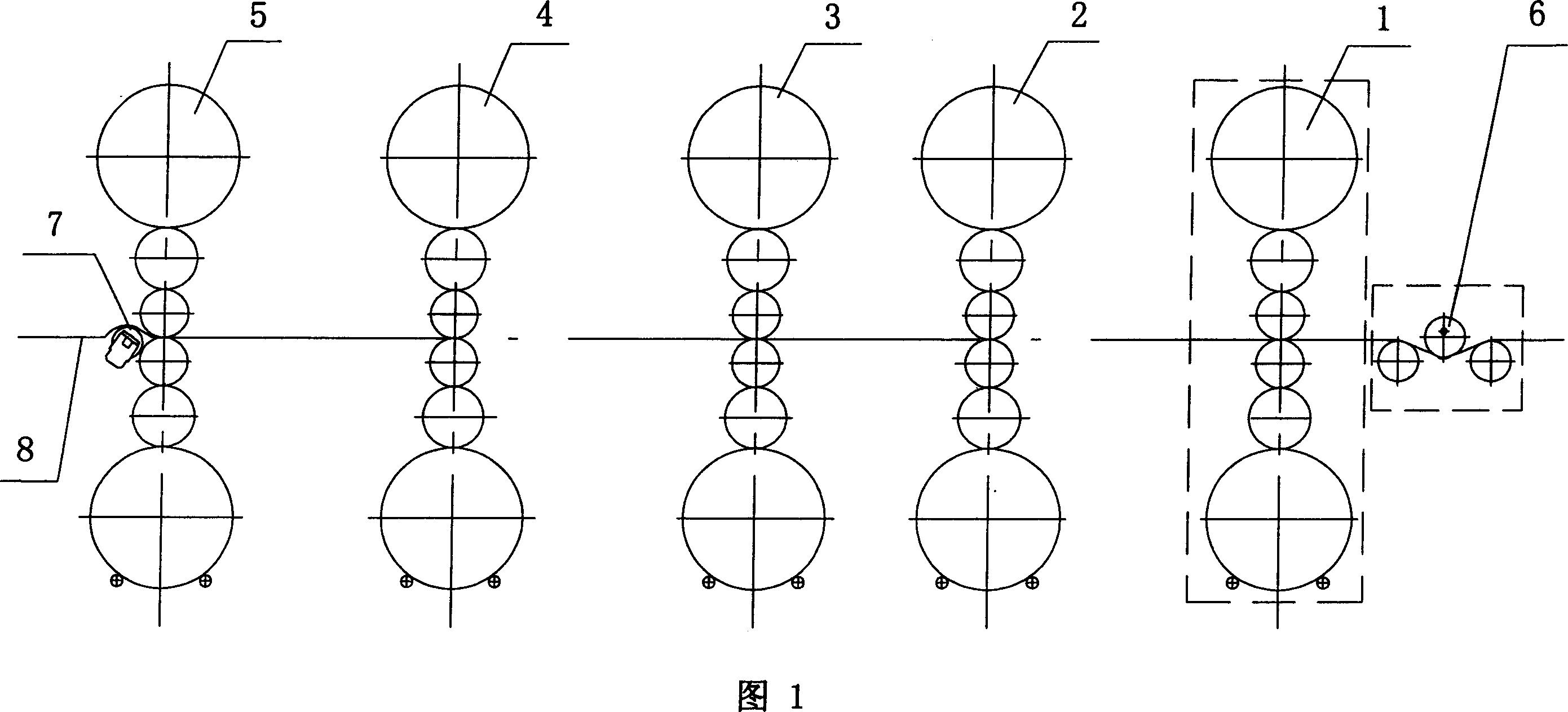

Method for preventing vibration of steel bar under high-speed rolling station of ultra-thin plate

ActiveCN1962103AReduce driveGood effectGuiding/positioning/aligning arrangementsRolling equipment maintainenceHydraulic cylinderStrip steel

The invention relates to a method for the vibration of band steel in high-speed rolling process, wherein said method is characterized in that: the first frame inlet of cold rolling machine is arranged with three-roller stabilizer which comprise left low roller, right low roller and upper middle roller; the upper middle roller is above the left and right low rollers, and above the rolling line; the left and right low rollers are under the rolling line; the band steel is through between the upper middle roller and left low roller and right low roller, the upper middle roller is lifted by hydraulic cylinder; when in normal rolling, the upper middle roller compresses the band steel; the last frame outlet of machine has single-roller vibration resistor; when in normal rolling, the vibration-resistant roller extends out driven by the hydraulic cylinder, to tension the bane steel.

Owner:WISDRI ENG & RES INC LTD

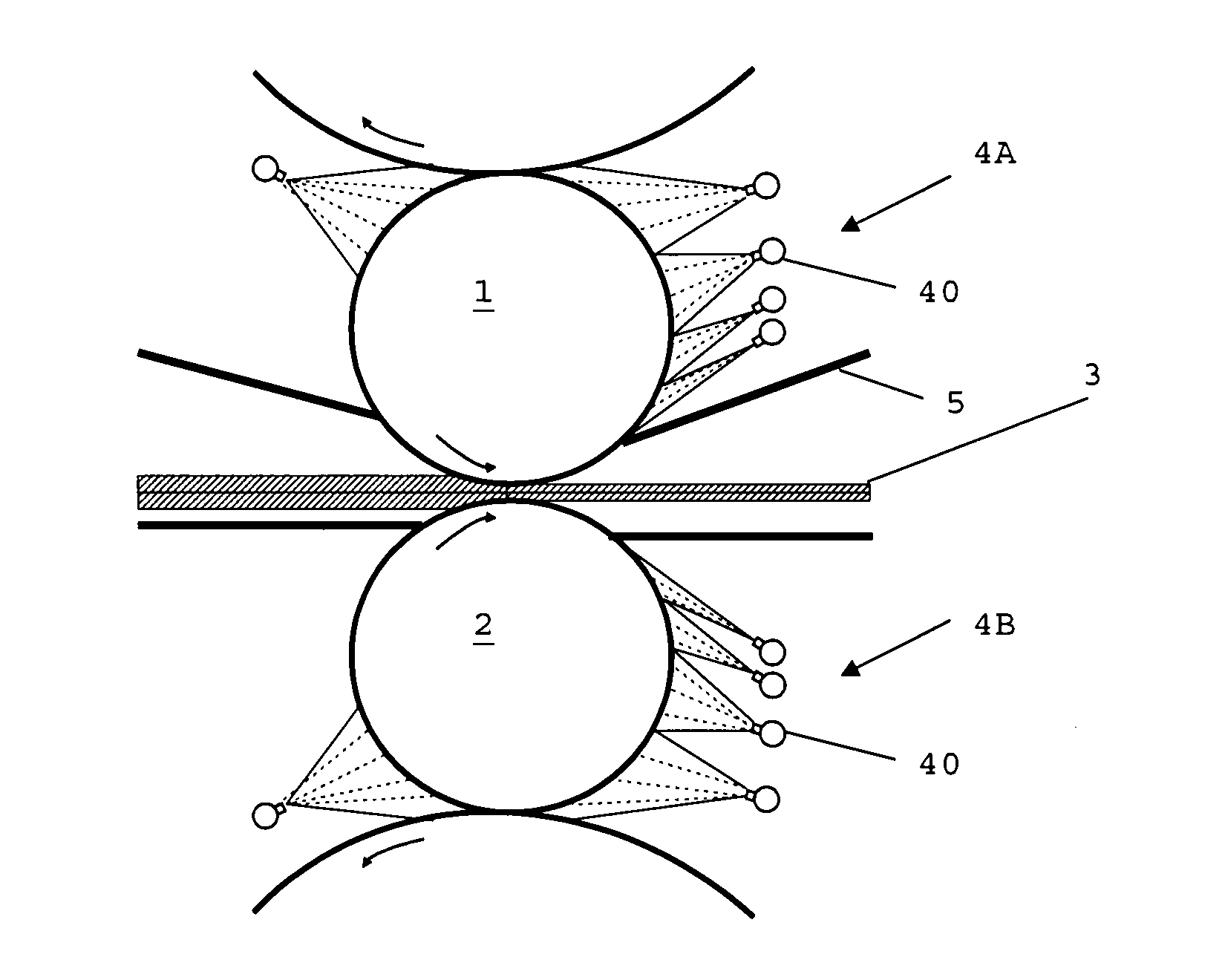

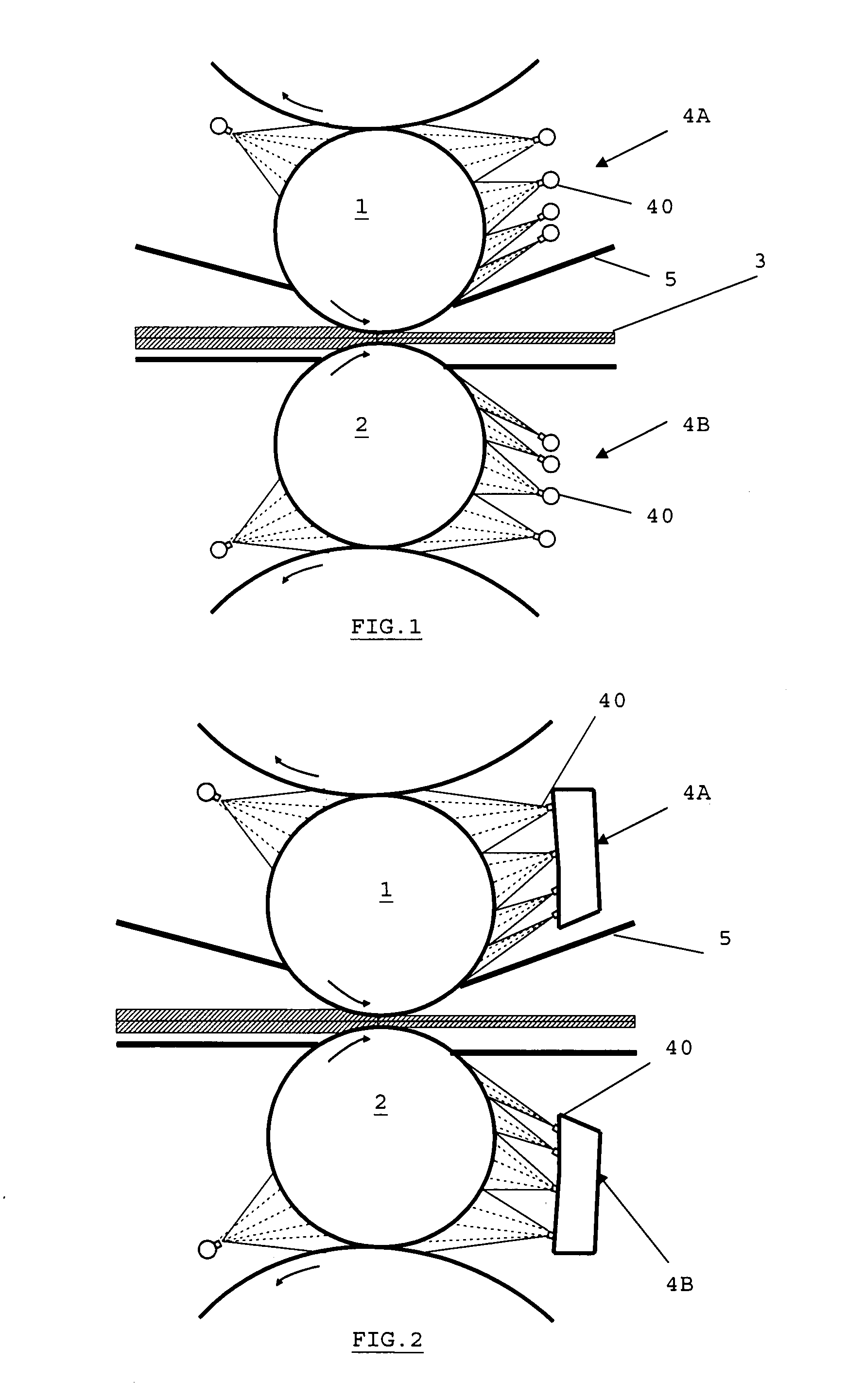

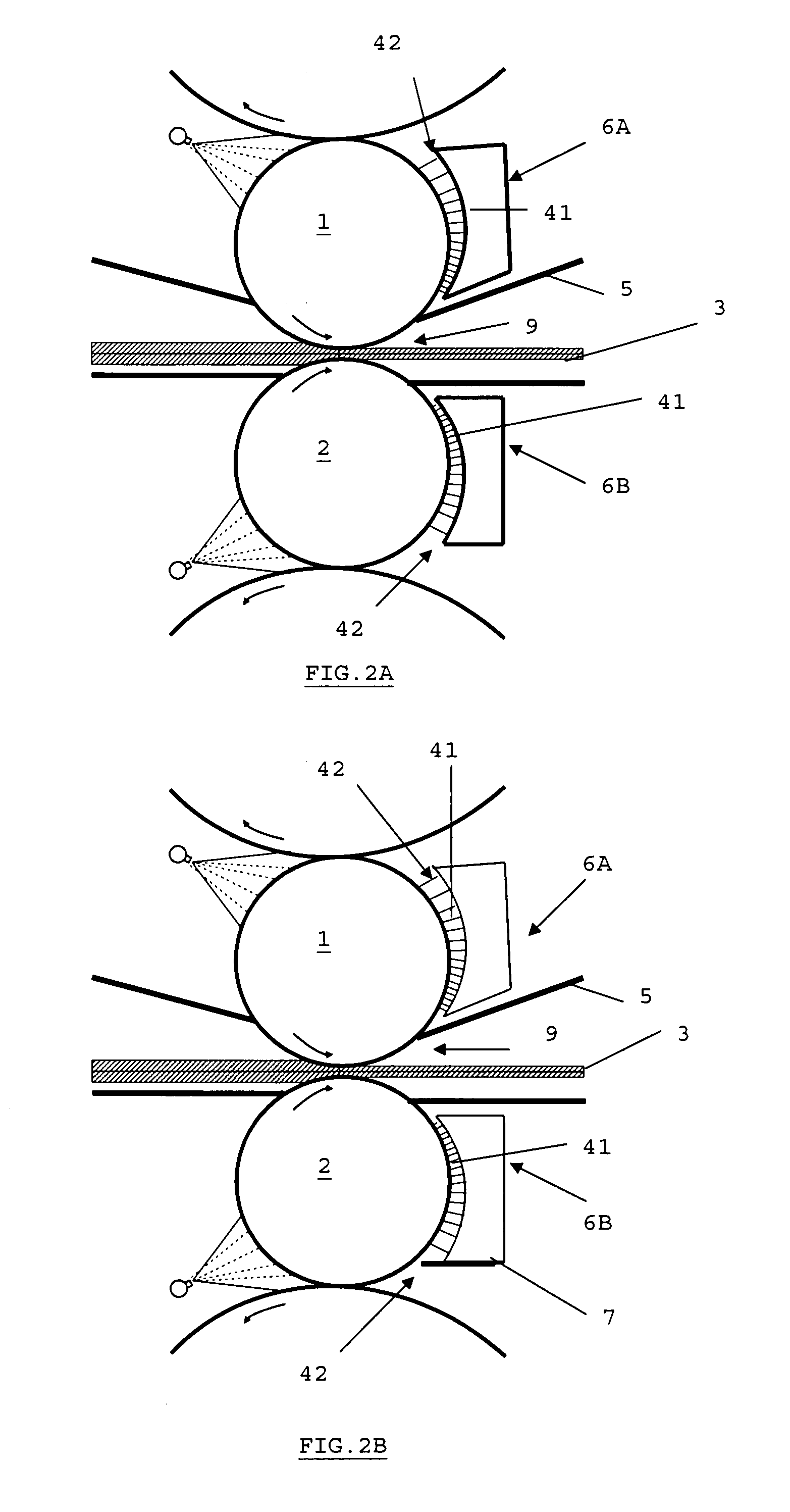

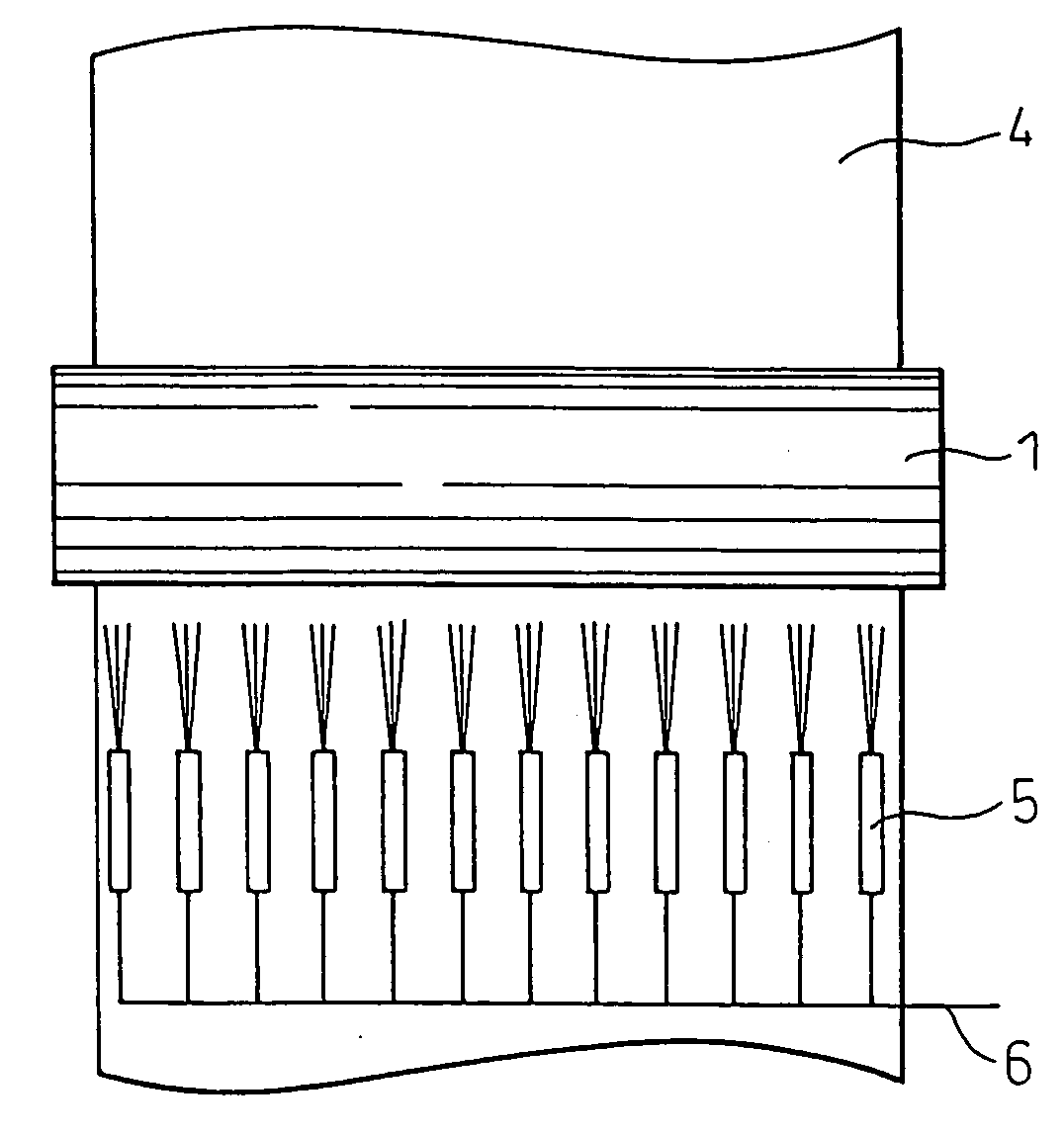

Device and Method for Cooling Rollers Used for Rolling in a Highly Turbulent Environment

ActiveUS20100089112A1Ensure controlLess deteriorationMetal rolling stand detailsWatering devicesShortest distanceEngineering

(EN) The present invention relates to a device for cooling a working roll (1, 2) belonging to a rolling stand used for rolling a long or flat product (3), characterized in that it comprises a cooling head in the form of a box section (6A, 6B) that is sealed except along a front face (42) lying a short distance from said roll (1, 2), and in which face a plurality of nozzles (41) has been machined or positioned in a determined pattern, said box section (6A, 6B) being concave and cylindrical at its front face (42). The box section (6A, 6B) is also fitted with transverse (5, 7) and lateral (8) plates which collaborate with the front face (42) of the box section so as to control the flow of cooling liquid and confine said liquid in the form of a highly turbulent flow. This then yields optimal cooling of the roll both in terms of the uniformity of the cooling across the surface thereof and in terms of the reduction in temperature as a result of the turbulent effect created.

Owner:CENT DE RECH METALLURGIQUES CENT VOOR RES IN DE METALLURGIE

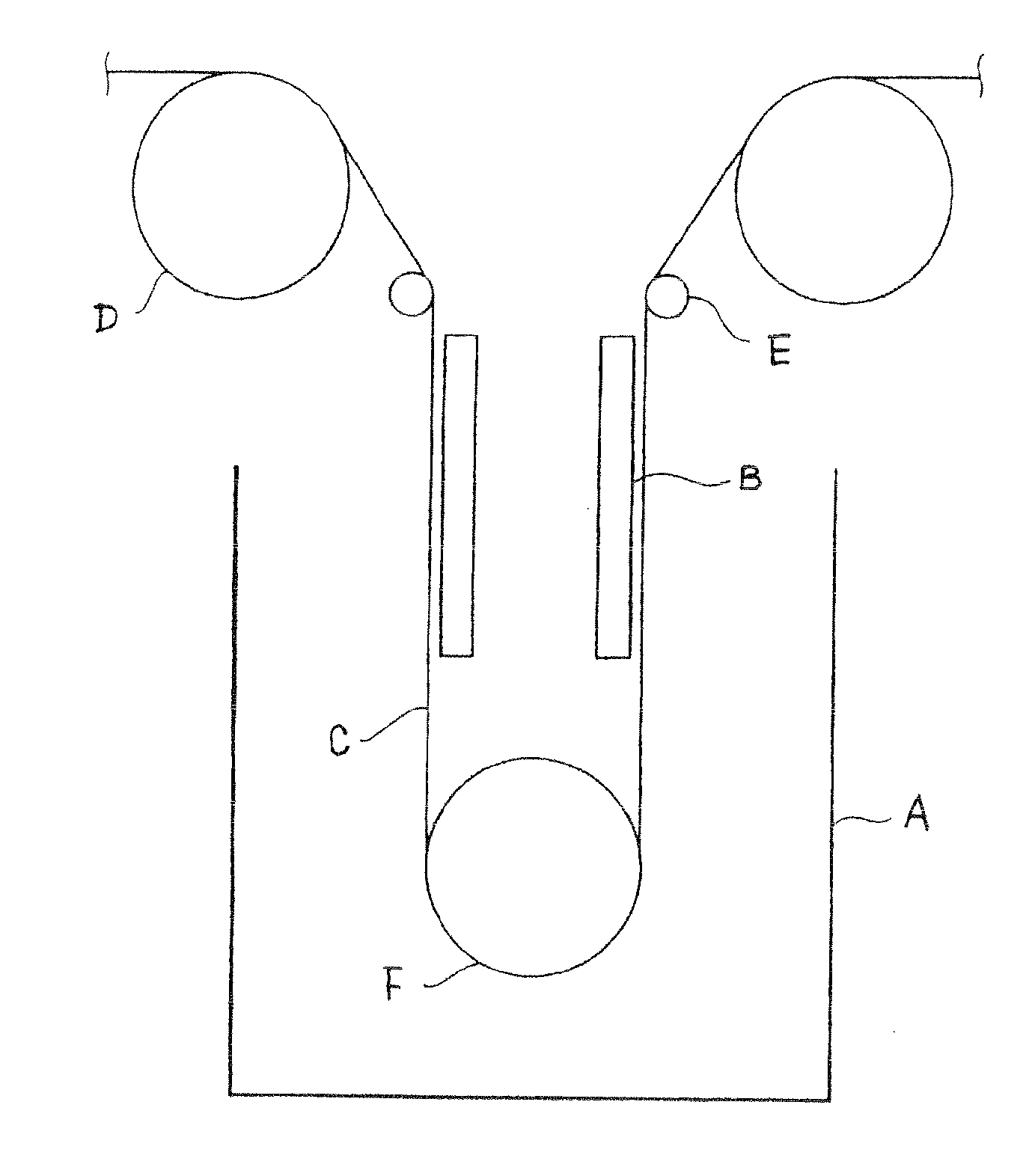

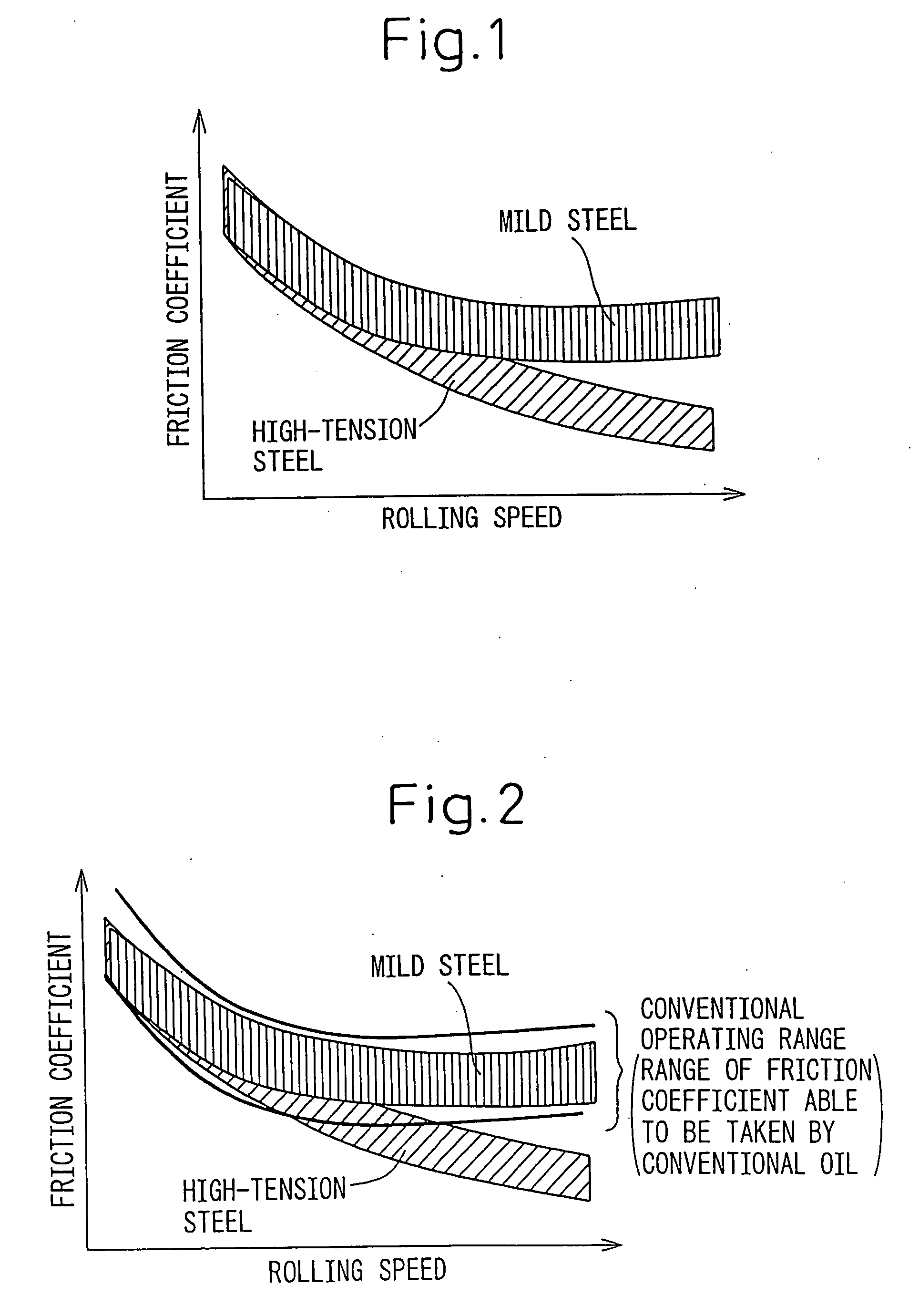

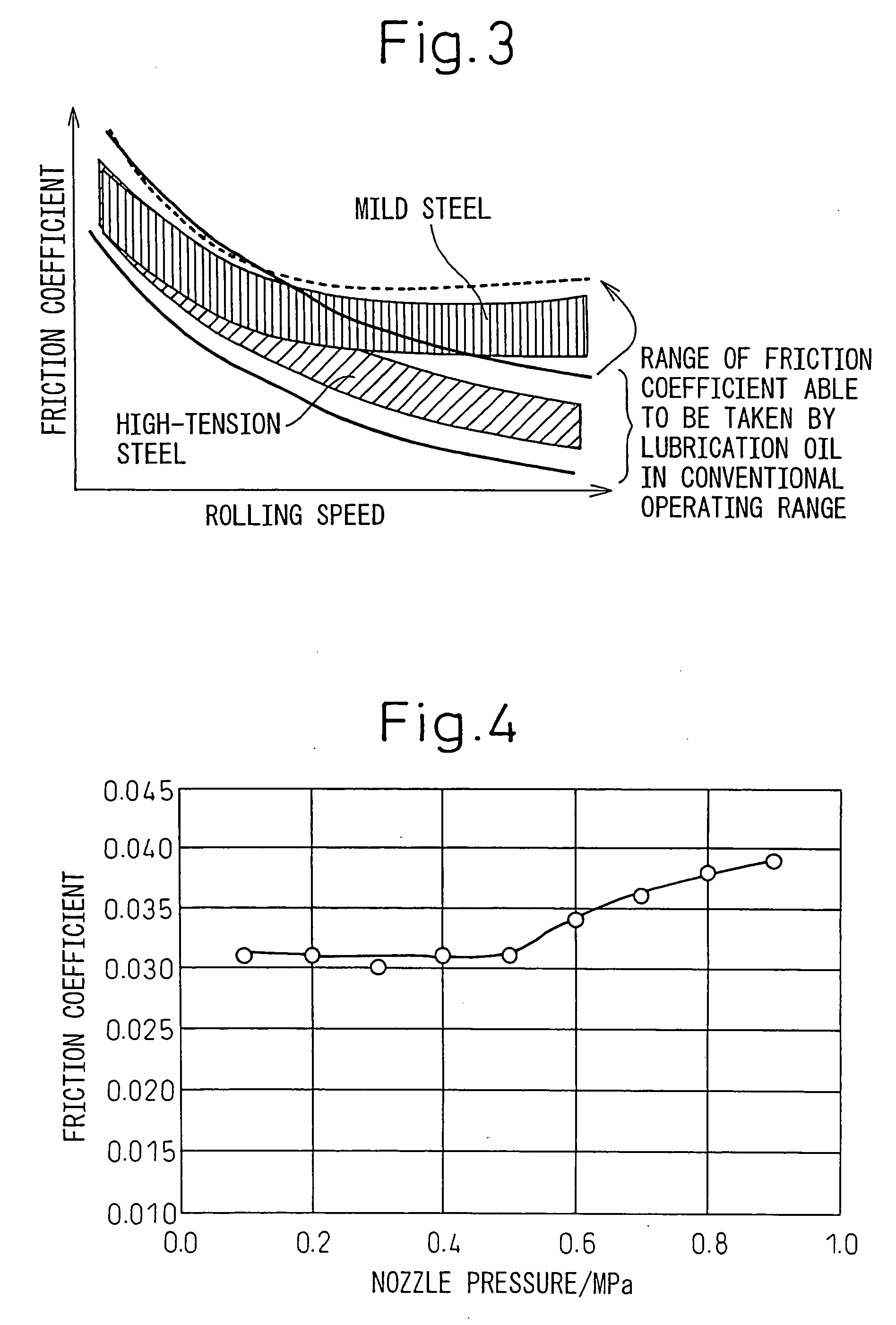

Method of Supplying Lubrication Oil in Cold Rolling

ActiveUS20080116011A1Improve productivityIncrease consumptionRolling equipment maintainenceRollsProduction rateEmulsion

The present invention provides a method of supplying lubrication oil in cold rolling for stable rolling without heat scratches or slip and realizing high productivity and improvement of the specific consumption of lubrication oil, that is, a method of supplying lubrication oil in cold rolling for lubricating rolling in cold tandem rolling of metal sheet by supplying a predetermined kind of emulsion lubrication oil comprised of a mixture of rolling oil and water at the rolling stand inlet side from nozzles, the method of supplying lubrication oil in cold rolling characterized by measuring or estimating the pressure in the lubrication nozzle pipe (lubrication nozzle pressure), controlling the lubrication nozzle pressure of any rolling stand where lubrication is liable to become excessive with the predetermined emulsion lubrication oil to 0.5 MPa or more, and, while doing so, supplying the lubrication oil to the roll bite inlet of the stand by direct injection.

Owner:NIPPON STEEL CORP +1

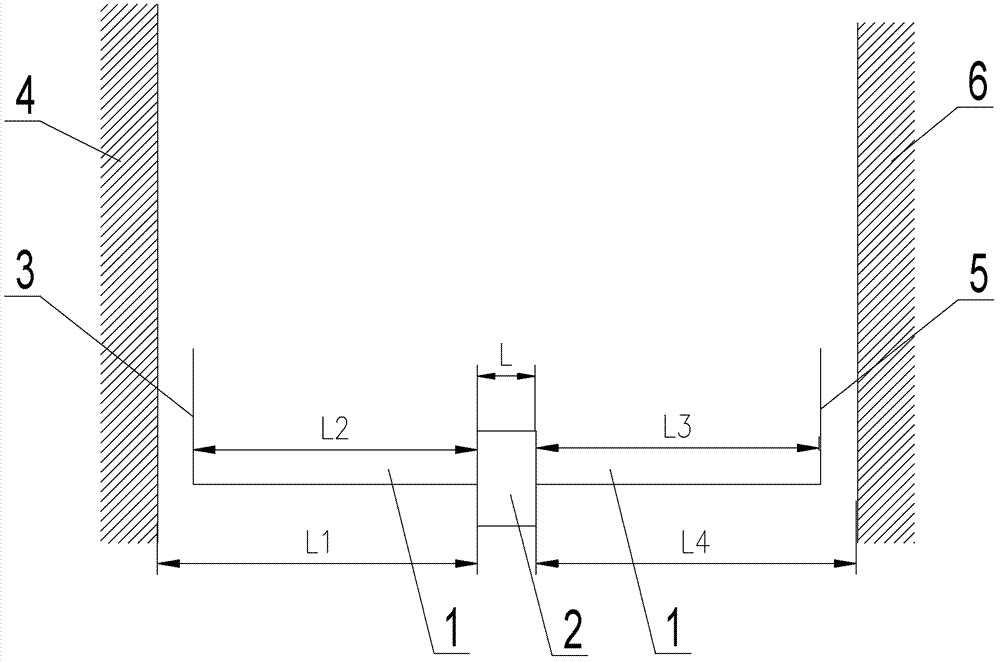

Method for calibrating center line of guide ruler

ActiveCN103191924AAvoid wear and tearReduce defective productsRolling equipment maintainenceGuiding/positioning/aligning arrangementsWaxEngineering

The invention relates to the field of hot rolled strip guide ruler centering, in particular to a method for calibrating the center line of a guide ruler. The method is characterized in that after maintenance is finished every time or strip steel with the thickness of 18 mm is rolled every time, the deviation of a transmission side and an operation side of the guide ruler is corrected in time to ensure the centering of the guide ruler. The method comprises the following specific operation steps: (1) measuring the width L of an extension strip at the middle part of the guide ruler, the distance L2 between the edge of the transmission side to a guiding plate on the transmission side of the extension strip, the distance L1 between the edge of the transmission side of the extension strip and an archway on the transmission side, the distance L3 between the edge of the operation side of the extension strip and the guiding plate on the operation side, and the distance L4 between the edge of the operation side of the extension strip and the archway on the operation side; (2) determining the deviation of the center of the extension strip; and (3) calibrating the center of the guide rule. Compared with the prior art, the method has the benefits that through in time correction of the deviation of the transmission side and the operation side of the guide rule after maintenance is finished every time or strip steel with the thickness of 18 mm is rolled every time, the wear and wax hanging phenomena of one side of the guide ruler, which is resulted from deviation of the guide ruler, are avoided.

Owner:ANGANG STEEL CO LTD

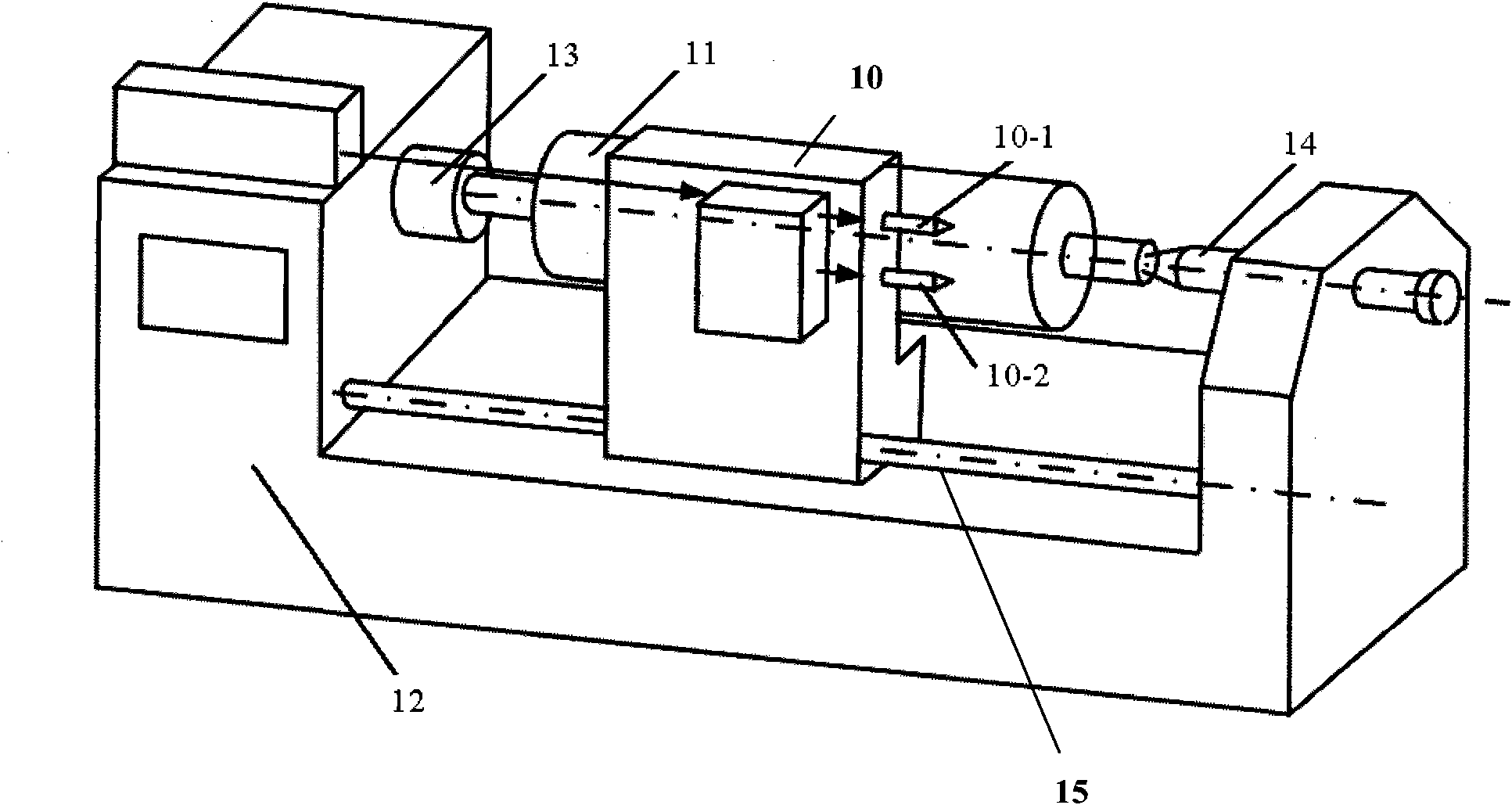

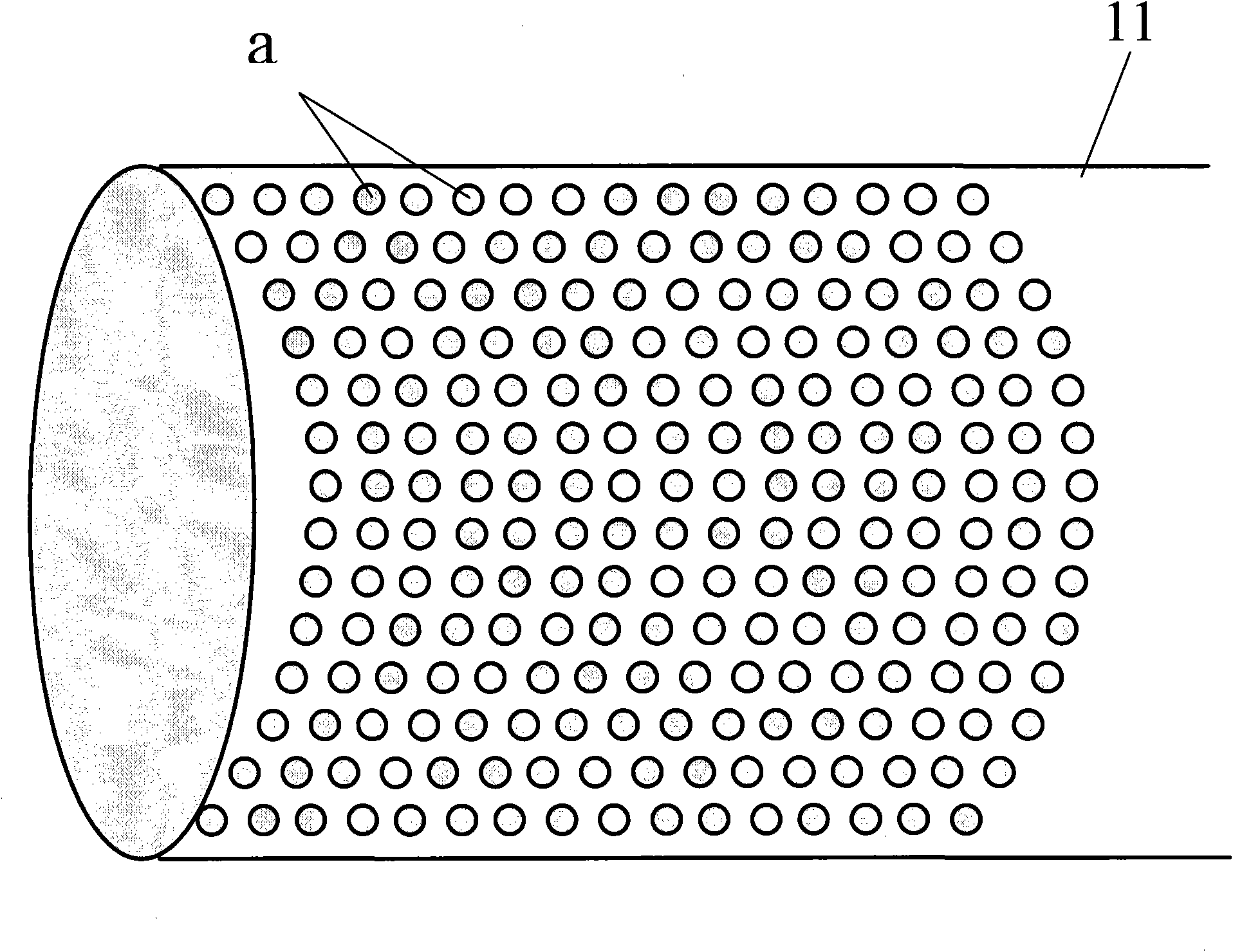

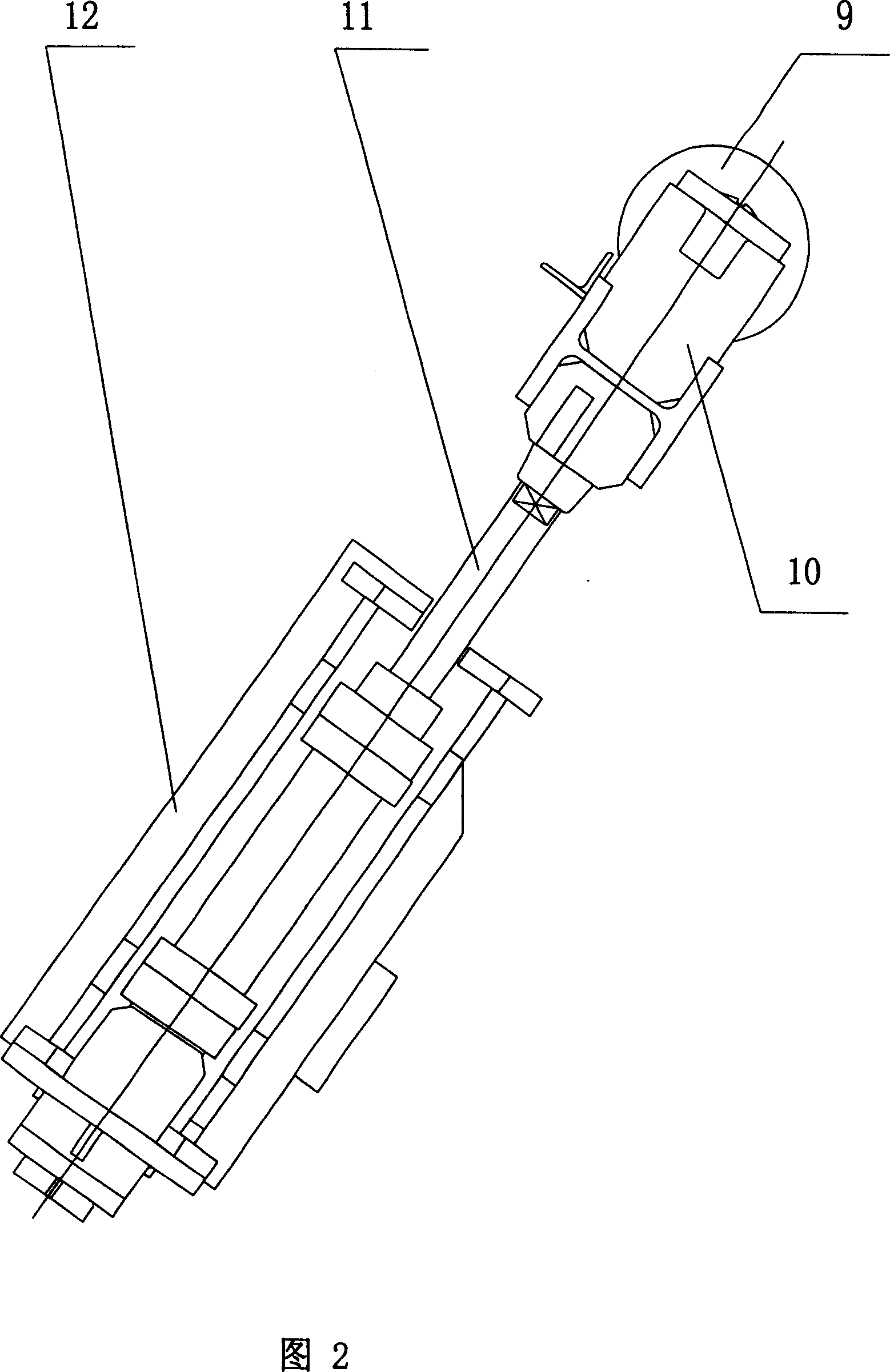

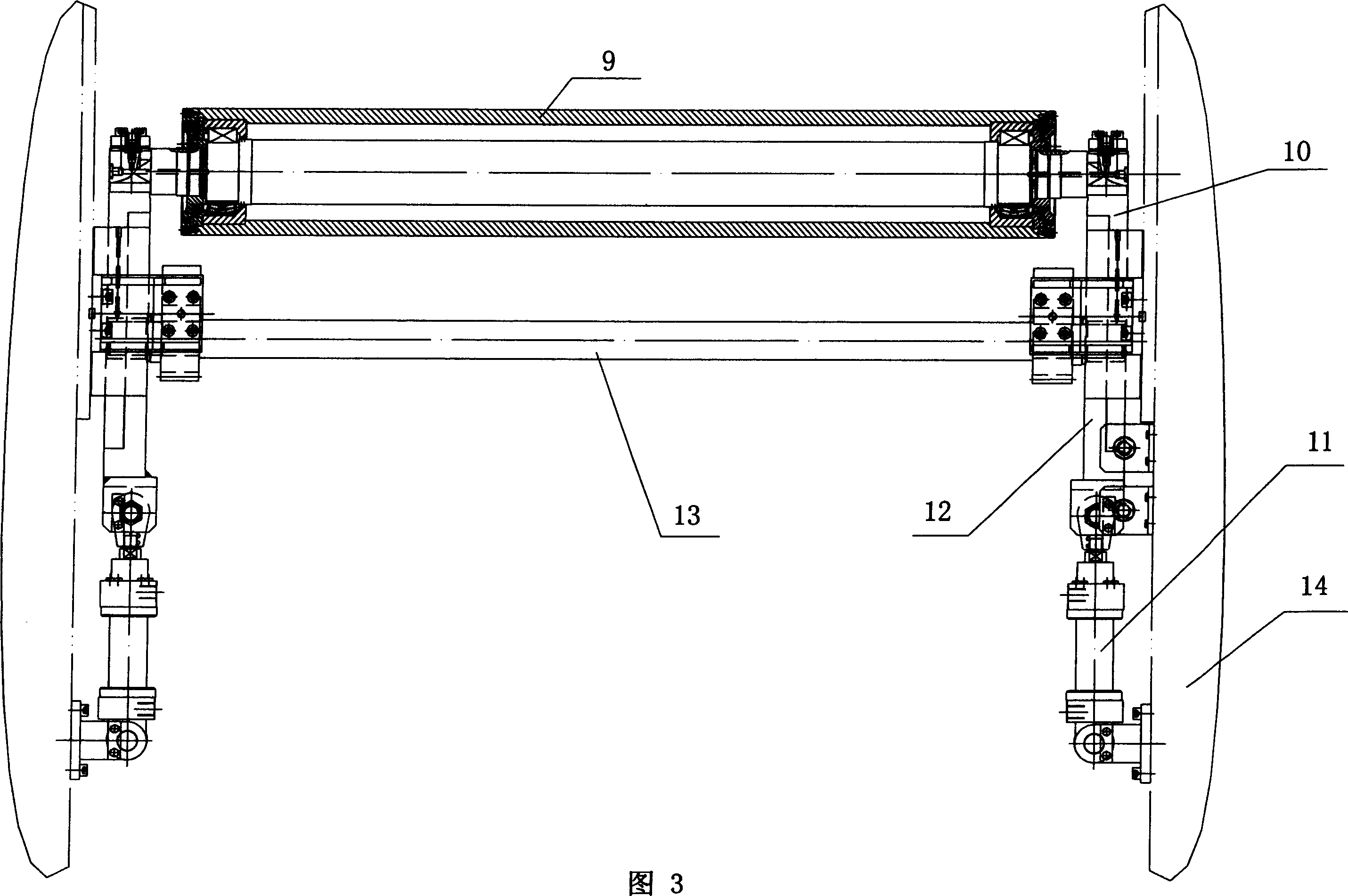

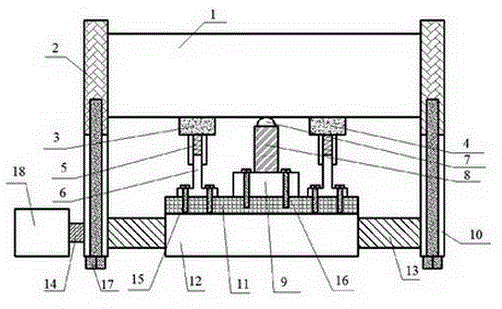

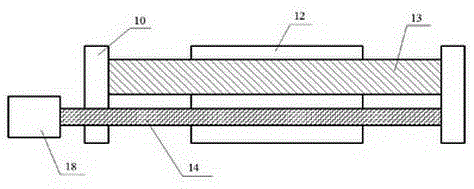

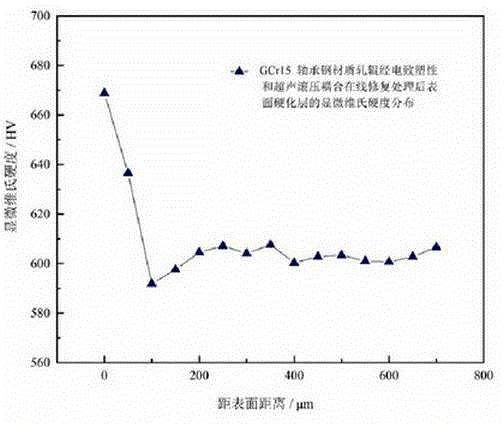

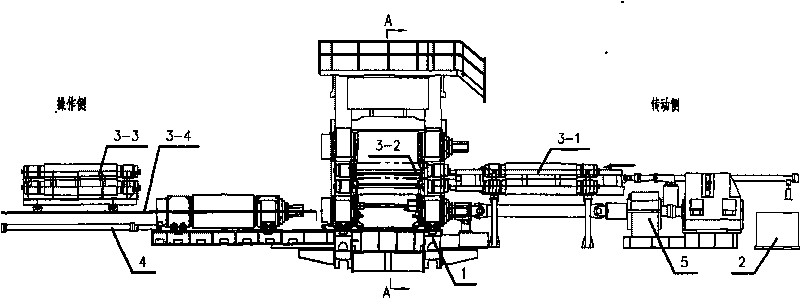

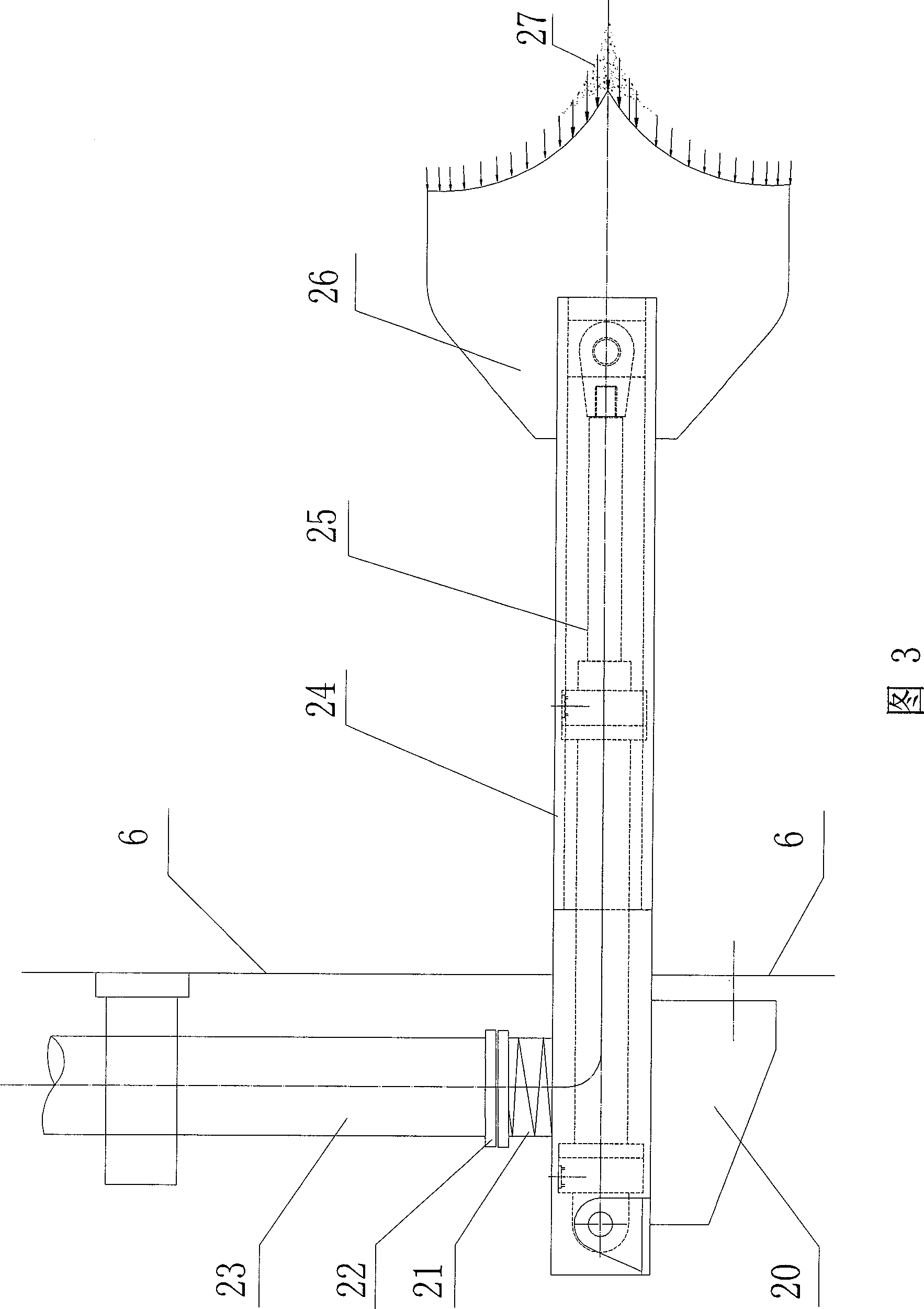

Electroplastic and ultrasonic rolling pressing coupling roller on-line repairing system and method

ActiveCN104826869AImprove utilization efficiencyQuality improvementRolling equipment maintainenceMetal rolling arrangementsEngineeringPulse power supply

The invention provides an electroplastic and ultrasonic rolling pressing coupling roller on-line repairing system and method. The system comprises a pair of support frames, a lead screw, a guide rail, a slide block, an air cylinder, a left electric brush device, a right electric brush device and a pulse power supply, wherein the support frames are arranged on a machine body of a rolling machine in front of a roller; the lead screw, the guide rail and the slide block are driven by an electric motor; the lead screw and the guide rail are arranged between the pair of support frames; the slide block is driven by the lead screw and can flatly move along the guide rail; the air cylinder, the left electric brush device and the right electric brush device are arranged on the slide block in an insulated way, the air cylinder is provided with an ultrasonic rolling pressing device; a rolling pressing head of the ultrasonic rolling pressing device can be in tight contact with the roller surface of the roller; a left electric brush of the left electric brush device and a right electric brush of the right electric brush device are in sliding contact with the roller surface of the roller; the output end of the pulse power supply is respectively connected with the left electric brush and the right electric brush. The system and the rolling machine are combined, the on-line restoration of the roller can be realized, and the electroplastic effect, the ultrasonic impact and the rolling pressing simultaneously act on the roller surface of the roller, so that the roller surface crystal particles are refined, a pressure stress reinforcing layer is formed, and the on-line restoration of the roller is fast realized.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Method for repairing cold roll

InactiveCN1394703AEasy to useReduce manufacturing costRolling equipment maintainenceMetal rolling arrangementsEngineeringDye penetrant inspection

The method for repairing working roll for cold-rolling includes the following steps: using the combination of dye penetrant inspection and crack depth detector to define crack position and crack depth; turning working roll for cold-rolling, after it is turned, using dye penetrant inspection method to make inspection, checking and confirming that said working roll has no crack and transferring it into next procedure, if said working roll also has the crack, making secondary turning, low-temp. tempering treatment of crackless roll, further grinding so as to make it reach to requirements for use.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

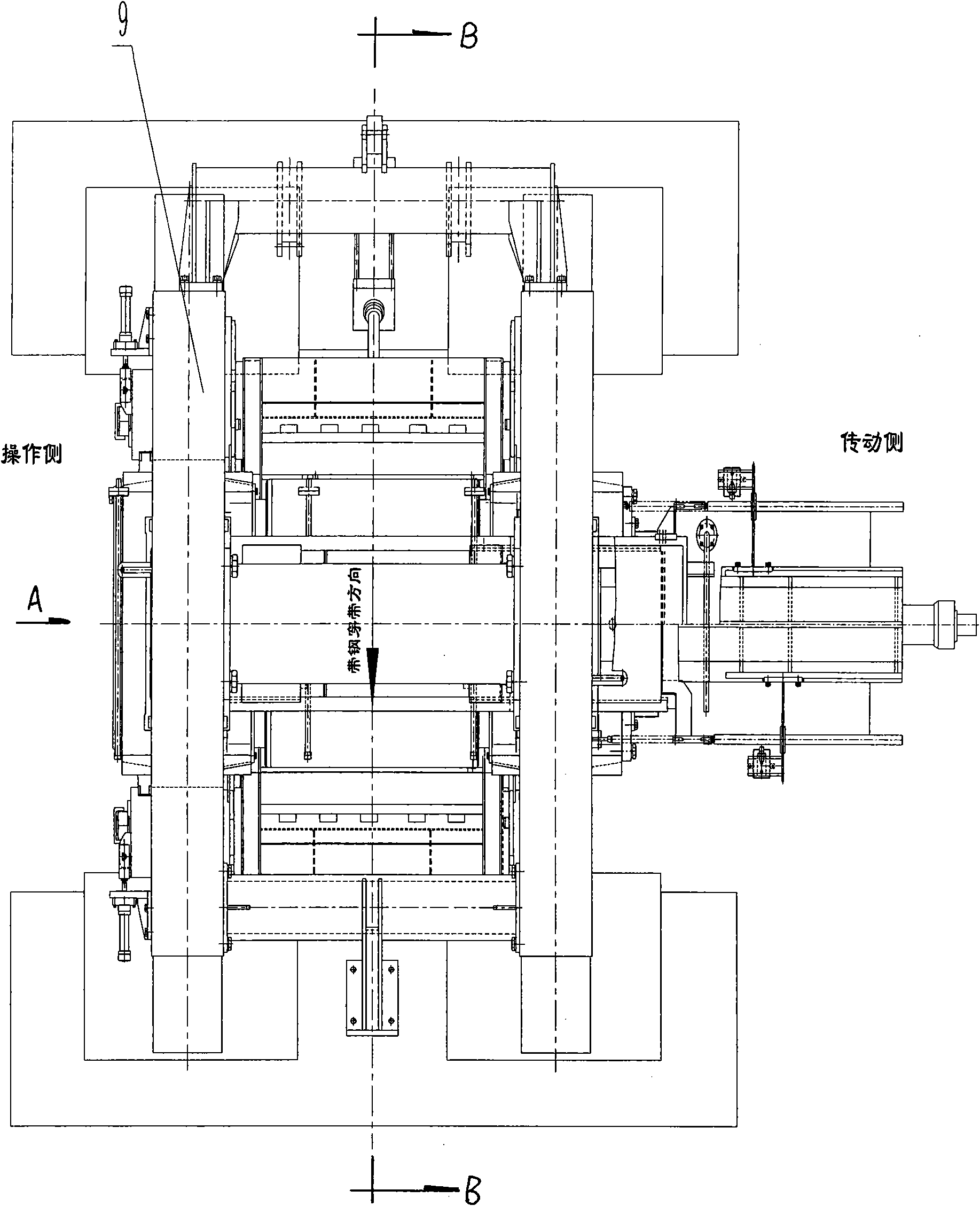

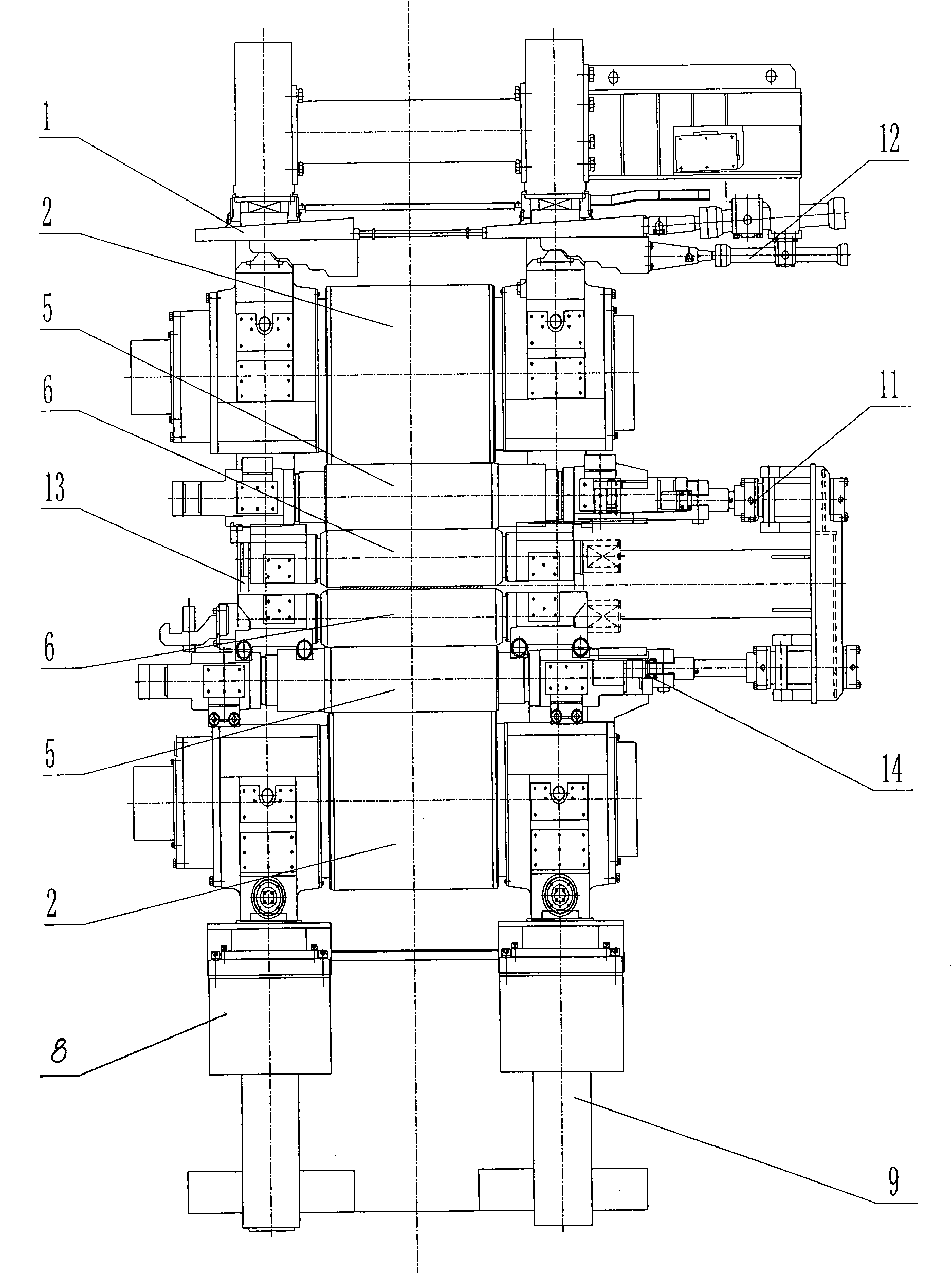

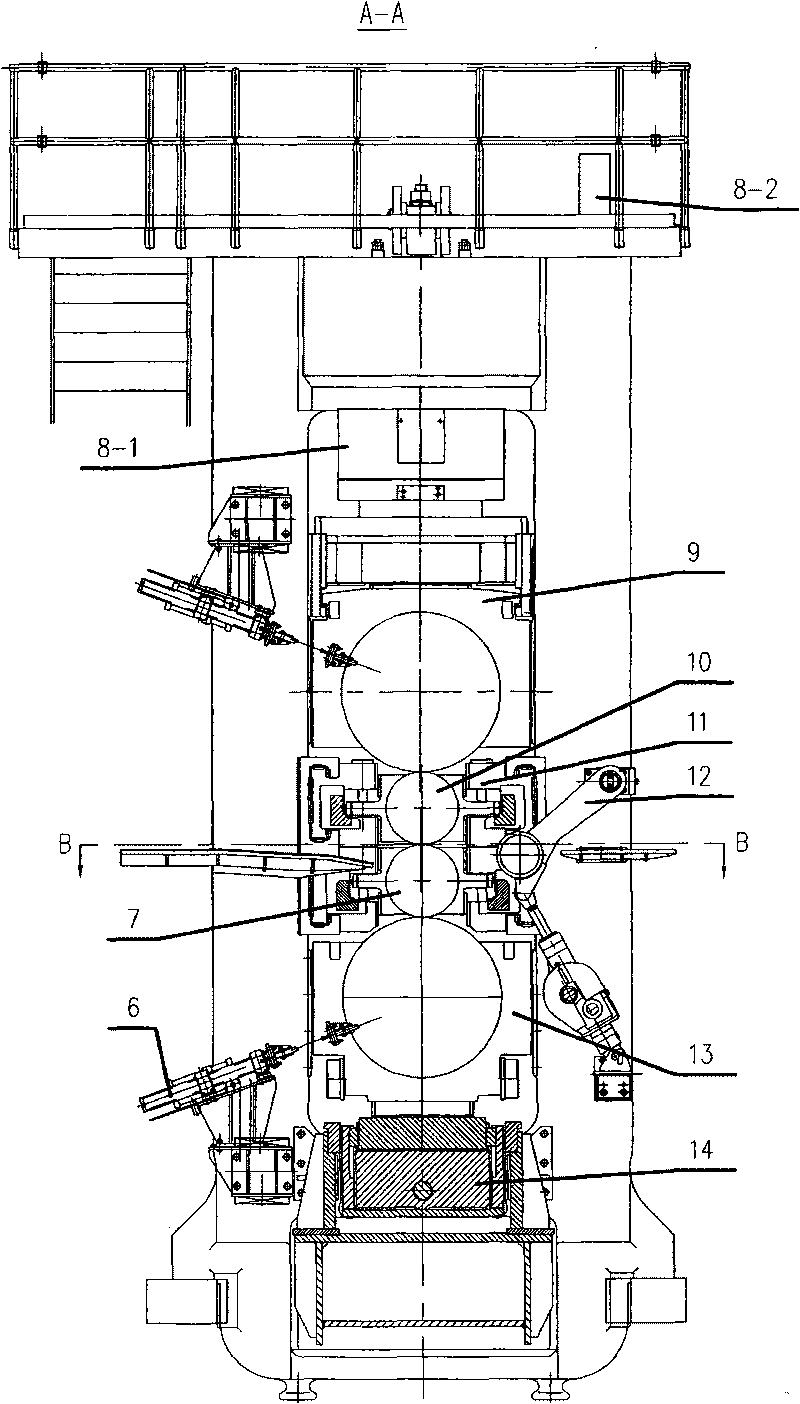

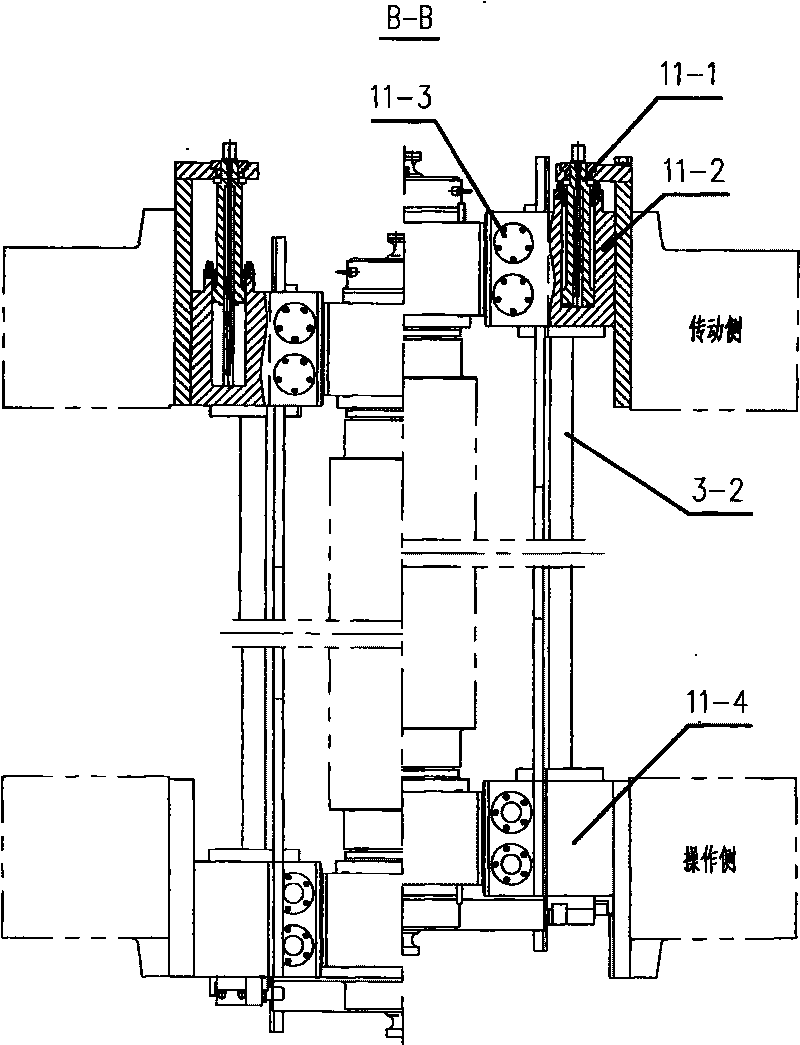

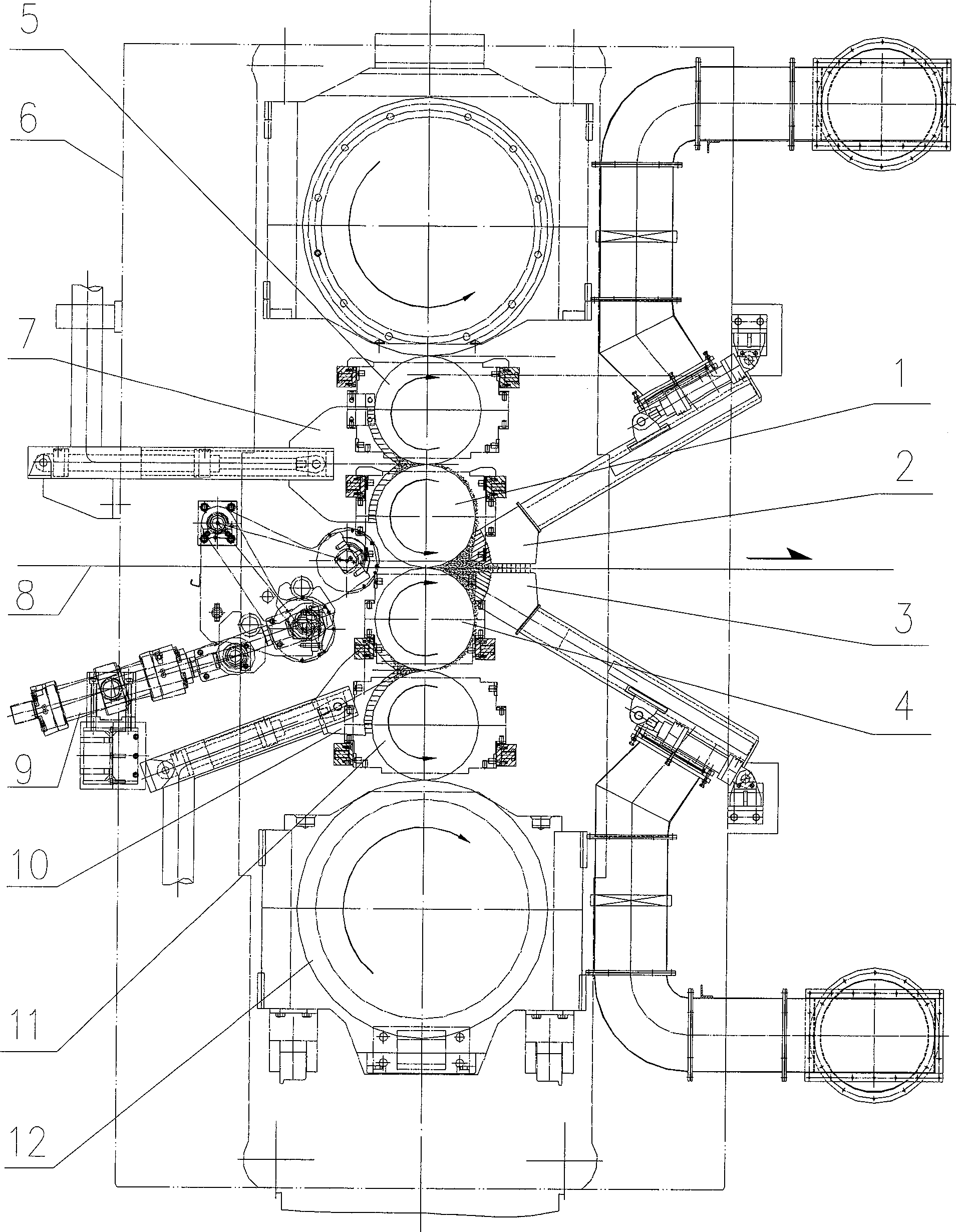

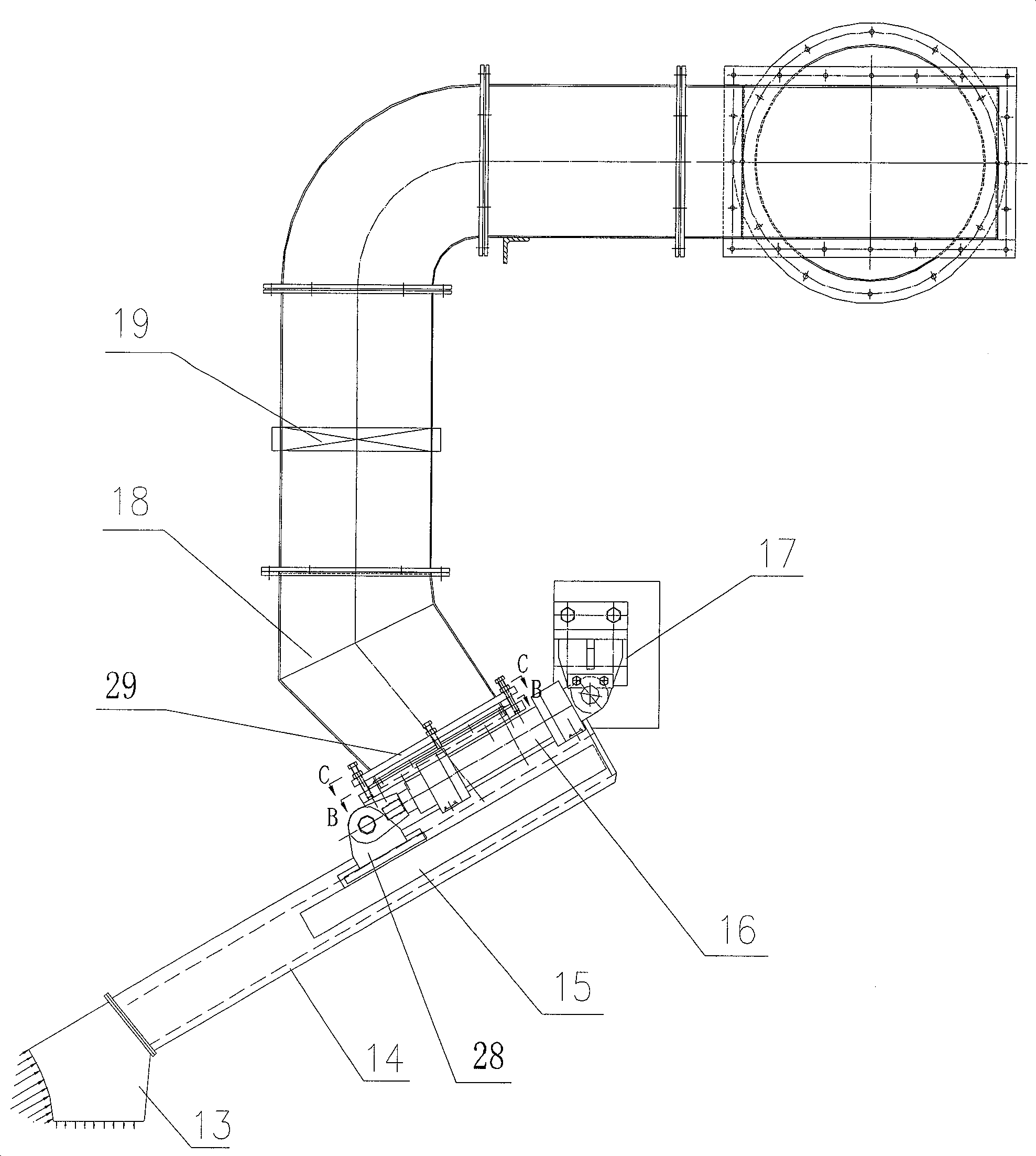

Temper mill with roll bending and shifting functions

ActiveCN101733285AImprove effective utilizationCompact structureMetal rolling stand detailsRolling equipment maintainenceStanding frameWork roll

The invention belongs to the technical field of forming and discloses a temper mill with the roll bending and shifting functions. The temper mill mainly comprises a stand frame, a working roll changing device, a back-up roll changing device, a main transmission gear, upper and lower working roll fittings, a thickness control device, upper and lower back-up roll fittings and a rolling line elevation adjusting device. A working roll shifting and bending device is inlaid in a housing window of the temper mill. Positive and negative roll bending cylinder bodies at the transmission side and a roll shifting cylinder body are integrated on a bending and shifting integrated block. A piston rod of the roll shifting cylinder is fixedly mounted on a housing by an E-shaped block. Positive and negative roll bending cylinders at the operating side are integrated on a roll bending integrated block, without roll shifting cylinders. The integrated blocks at the transmission side and the operating side are connected together by a roll changing rail in the housing of the temper mill to form the working roll shifting and bending device. The invention ensures the means of adjusting the roll gaps to be more flexible, can prolong the service life of the working roll, realize rapid roll changing, shorten roll changing time and reduce the production cost. The invention can be widely applied to strip temper mills.

Owner:CISDI ENG CO LTD

Dry-type planishing mill non-contact type roller cleaning method

ActiveCN101433914AGuaranteed strip surface qualityQuality assuranceRolling equipment maintainenceMetal rolling arrangementsStrip steelPlanishing

The invention belongs to the filed of cleaning and leveling of strip steel, in particular to a non-contact roll cleaning method for a dry planishing mill. The non-contact roll cleaning method for the dry planishing mill is characterized in that: 1) a first dust suction hood and a second dust suction hood are arranged on a roll gap of an upper working roll and a lower working roll on the outlet side of the dry planishing mill in the flying direction of metallic dust, and suck away the metallic dust, wherein the first dust suction hood is positioned above a strip steel passing line, and the second dust suction hood is positioned below the strip steel passing line; and 2) a third dust suction hood is arranged on a roll gap of the upper working roll and an upper intermediate roll on the inlet side of the dry planishing mill in the flying direction of the metallic dust, and suck away the metallic dust; and a fourth dust suction hood is arranged on a roll gap of the lower working roll and a lower intermediate roll on the inlet side of the dry planishing mill in the flying direction of the metallic dust, and suck away the metallic dust. The method can improve the surface quality of strip steel and cleaning of the rolls and avoid surface damage to the rolls.

Owner:WISDRI ENG & RES INC LTD

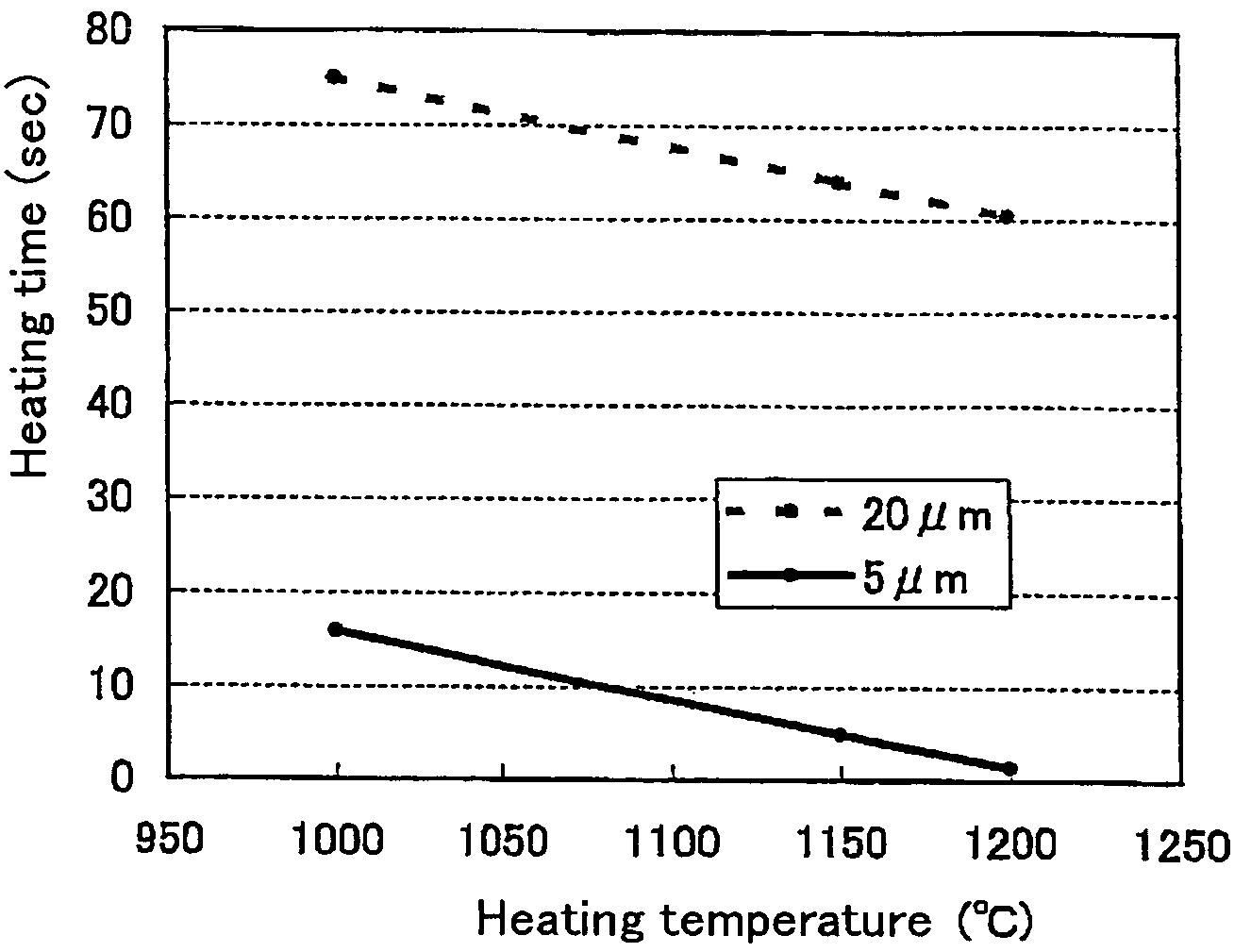

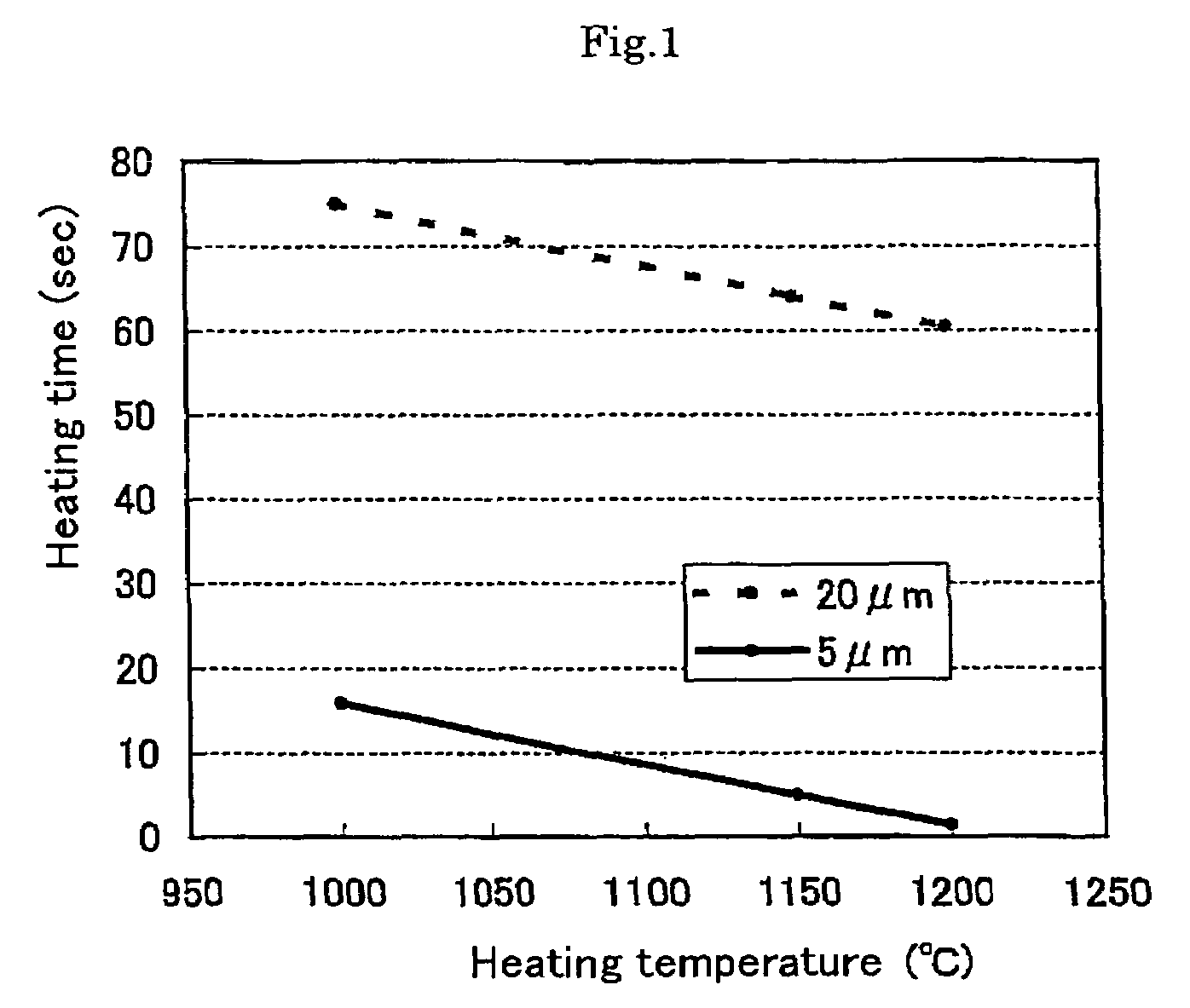

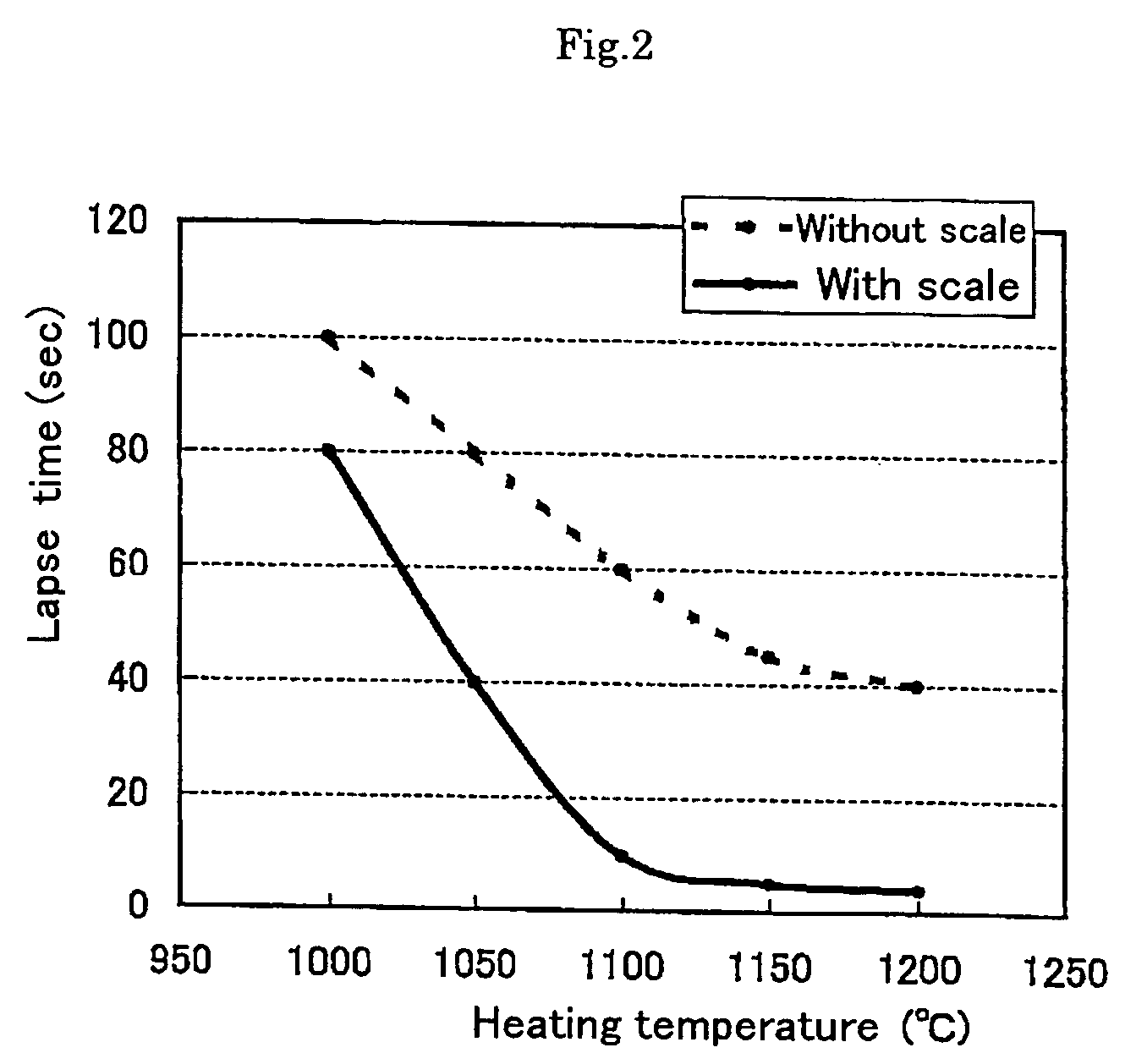

Method for preventing surface oxide film of nichrome roller from being peeling-off

InactiveCN101003053AReduce deformation rateReduce loadTemperature control deviceRolling equipment maintainenceChromium nickelSurface roughness

A method for preventing the surficial oxide film of Ni-Cr roller from being stripped includes such steps as blooming the conticast billet of ferritic stainless steel at 1150 + / - 50 deg.C to become intermediate billet at 1020-1050 deg.C and with a thickness less than 35 mm, arranging an insulating hood between blooming and finish rolling, and finishing rolling of stainless steel band at a temp higher than 950 deg.C by three passes with relative surface roughness of rollers (0.9 microns, 0.6 microns and 0.6 microns) and relative maximal deformation rate (42%, 38% and 36%).

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Process for producing seamless steel pipe

ActiveUS7308812B2Reduce coefficient of frictionImprove wettabilityRolling equipment maintainenceWork treatment devicesGraphiteLubricant

A process for producing a seamless steel pipe, in which the occurrence of inner surface flaws in the pipe can be reduced through the lowering of the friction coefficient during the elongation rolling by means of a mandrel mill is provided. The reduction of inner surface flaws is accomplished through the use of a lubricant composed mainly of either or both of graphite and mica coated to the surface of a mandrel bar, and another lubricant composed mainly of an alkali metal borate that is applied onto the inner surface of the hollow stock pipe. The temperature of the pipe prior to receiving the lubricant, during lubricant application, and prior to elongation rolling is controlled. The time between descaling or piercing and lubricant application and between lubricant application and elongation rolling is also controlled.

Owner:NIPPON STEEL CORP

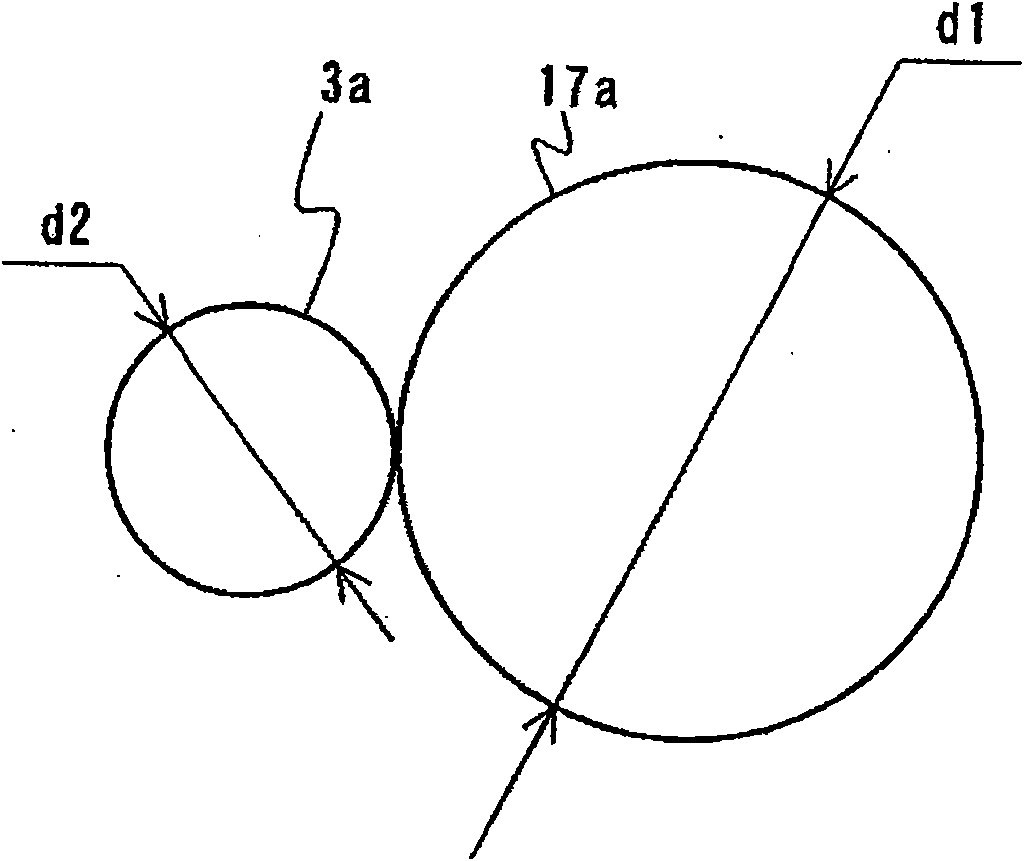

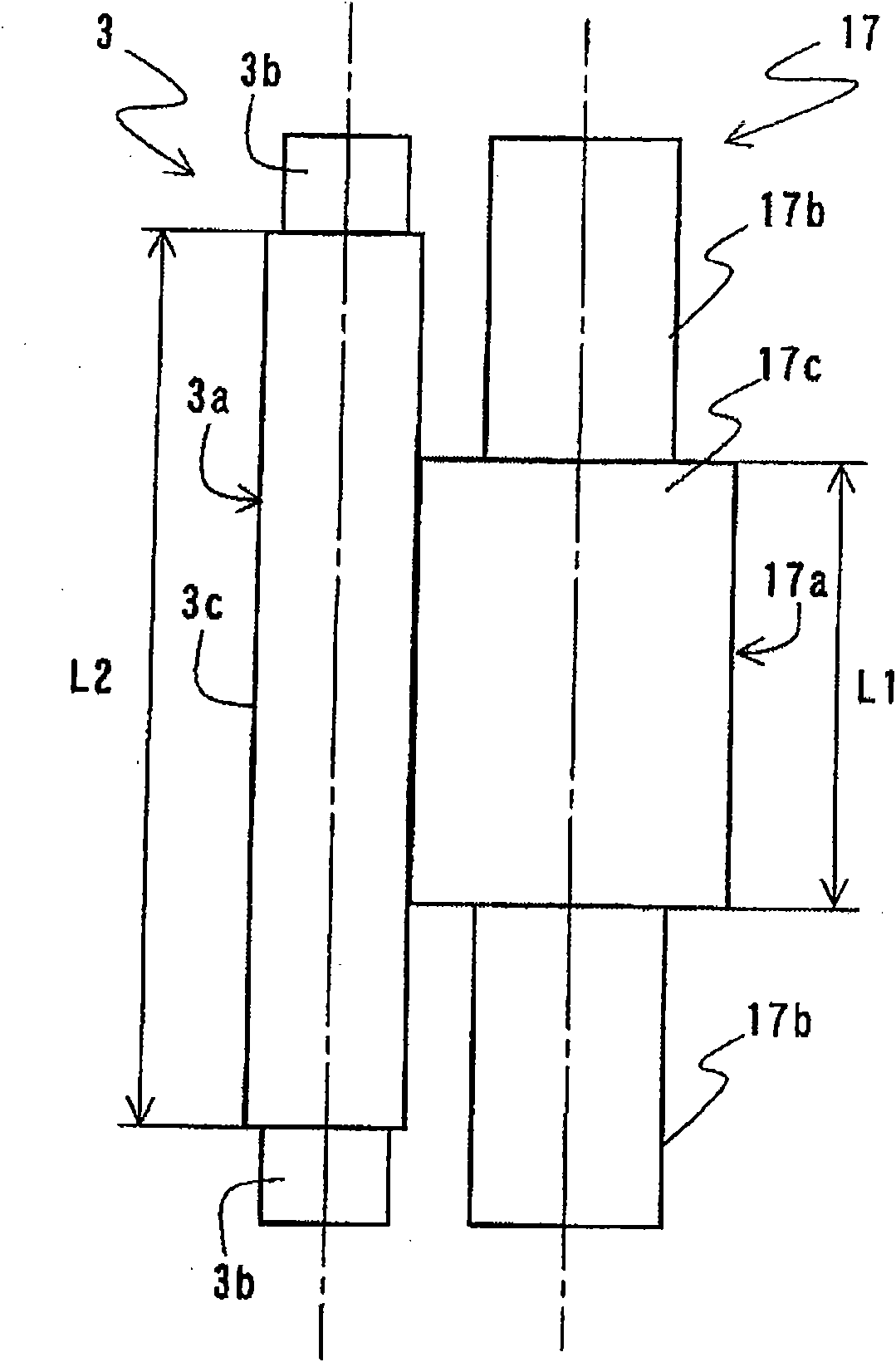

Roller grinding method

InactiveCN101767298AImprove roundnessReduced rotational runoutRevolution surface grinding machinesSupport wheelsRoom temperatureAgricultural engineering

The present invention provides a roller grinding method for obtaining rollers with good circular degree. The method comprises the first process that the center of first roller (17) is determined, the external surface (17c) and two ends of a bearing part (17b) of the first roller (17) are grinded to control the circular degree of the first roller (17) under the room temperature within 25 micron, the second process that the bearing part (17b) is installed with a bearing (19) and a bearing housing (23), the third process that the bearing housing (23) is fixed on a base plate (5), the fourth process that the first roller (17) is rotated, and the fifth process that the second roller (3) having a circular degree within 3 micron and is provided with a grinding mechanism (29) on the external surface (3c) is rotated, the second roller (3) is pressed on the external surface (17c) of the first roller (17) for grinding the external surface (17c).

Owner:NORDSON CORP

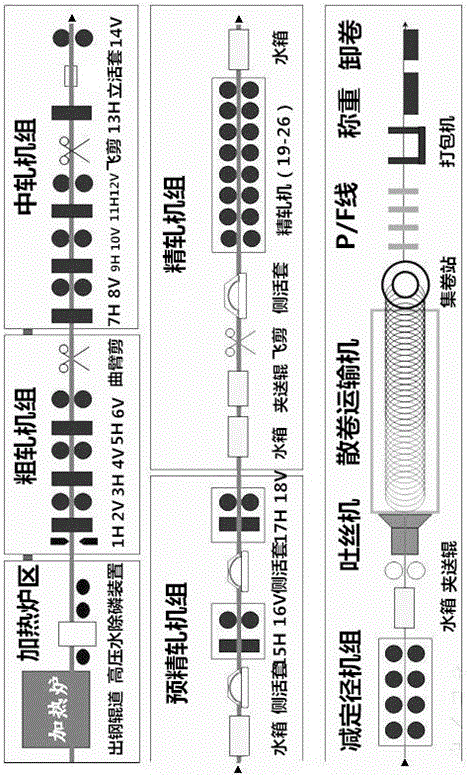

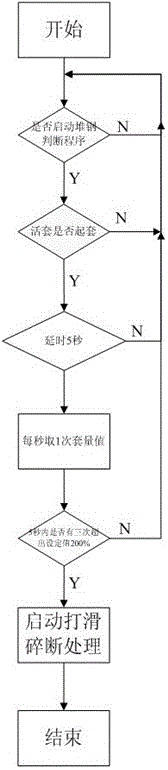

Detection system for high-speed wire rod steel heaping and judgment method

ActiveCN106040752AAccurate judgmentShorten the timeRolling equipment maintainenceMeasuring devicesWire rodProduction line

The invention discloses a detection system for high-speed wire rod steel heaping and a judgment method of the detection system. The detection system comprises a PLC control system, detection loops, loop detectors and accident shears. The loop detectors are mounted on the detection loops. The detection loops are correspondingly mounted on a pre-finishing mill group and a finishing mill group of a rolling production line. The loop detectors and the accident shears are connected to the PLC control system through circuits. The detection system for high-speed wire rod steel heaping and the judgment method mainly aim at the steel heaping failure of a segment from a pre-finishing mill to a finishing mill in the large-scale steel rolling process; and in the type of steel heaping failure, the finishing line failure cannot be judged in time, excessive steel heaping is caused, so that whether steel heaping happens or not is judged by detecting the loop quantity between the pre-finishing mill and the finishing mill, accordingly the judgment can be made in advance, the judgment is precise, and the failure treatment time is shortened.

Owner:JIANGSU YONGGANG GROUP CO LTD

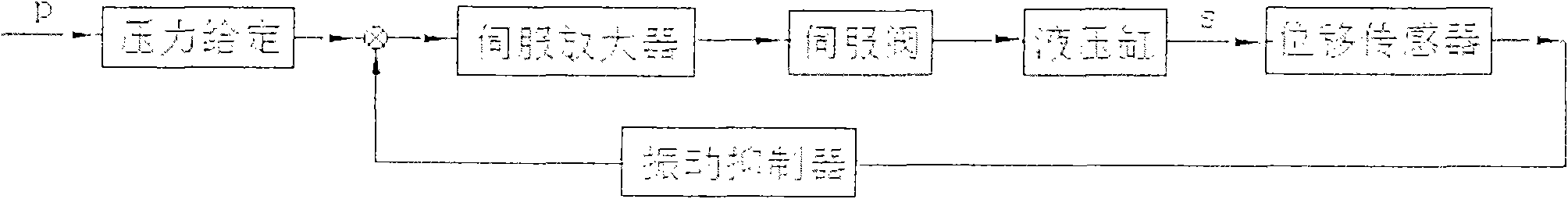

Vibration suppression device for rolling mill roller system

InactiveCN102755995AReduce vibrationRolling equipment maintainenceMetal rolling arrangementsHydraulic cylinderAutomatic control

The invention provides a vibration suppression device for a rolling mill roller system, belonging to the field of automatic control of a rolling mill. The vibration suppression device comprises a vibration suppressor, a pressure setter, a servo amplifier, a servo valve, a hydraulic cylinder and a displacement sensor, when the rolling mill roller system vibrates, a vibration damping hydraulic cylinder vibrates together with the rolling mill roller system, the displacement sensor in the hydraulic cylinder outputs a vibration signal and sends the vibration signal to the vibration suppressor; after receiving the vibration signal from the hydraulic cylinder, the vibration suppressor processes and converts the vibration signal so as to output an oscillation signal to a feedback input end of the servo amplifier to control the action of the servo valve, so that oil entering the hydraulic cylinder oscillates, the oscillation of the oil is same as the original vibration in frequency and amplitude and opposite to the original vibration in phase, so as to suppress the vibration of the hydraulic cylinder; therefore, the vibration of the roller system is reduced and the chatter marks generated by a roller and band steel are suppressed.

Owner:通化钢铁股份有限公司 +1

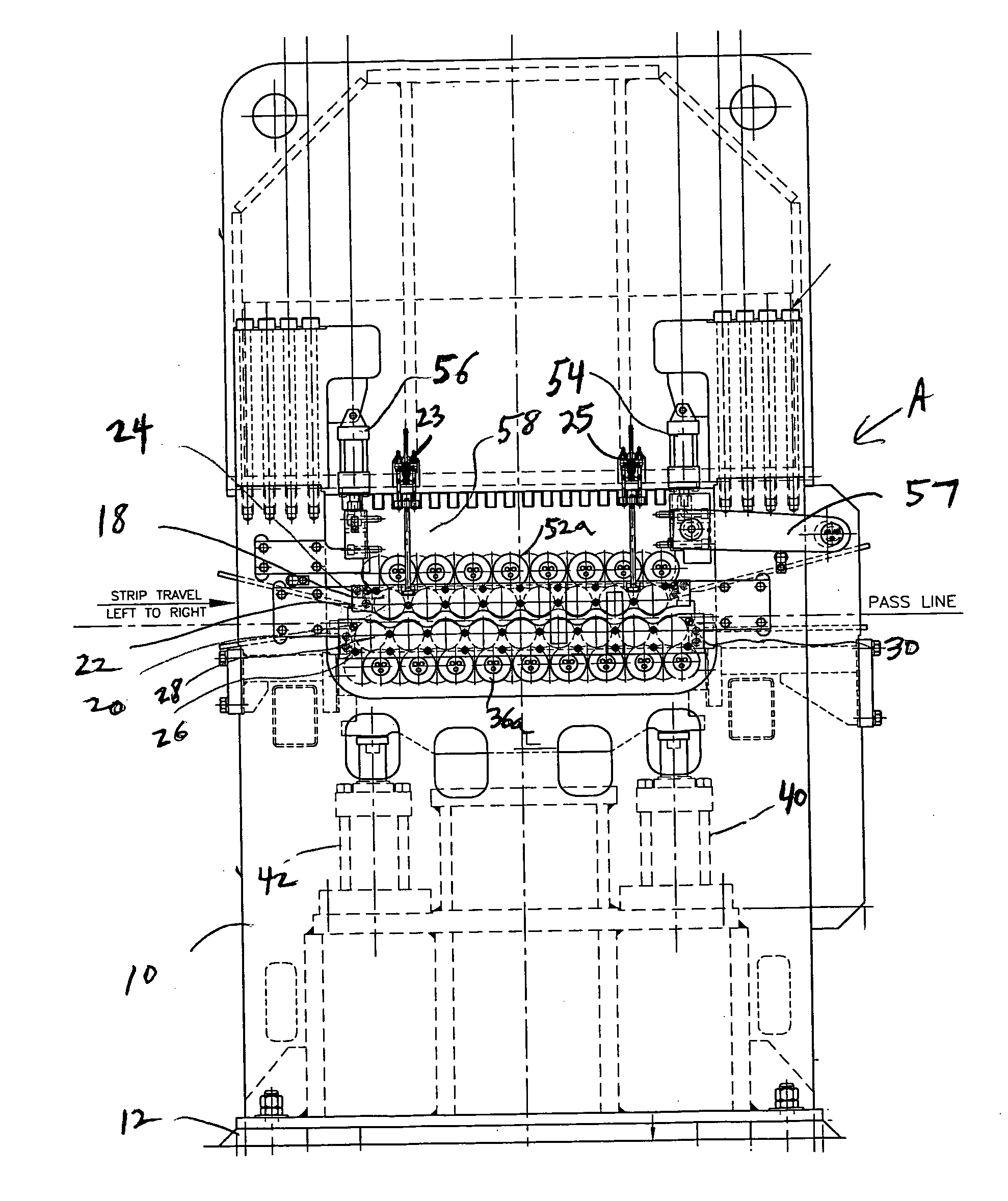

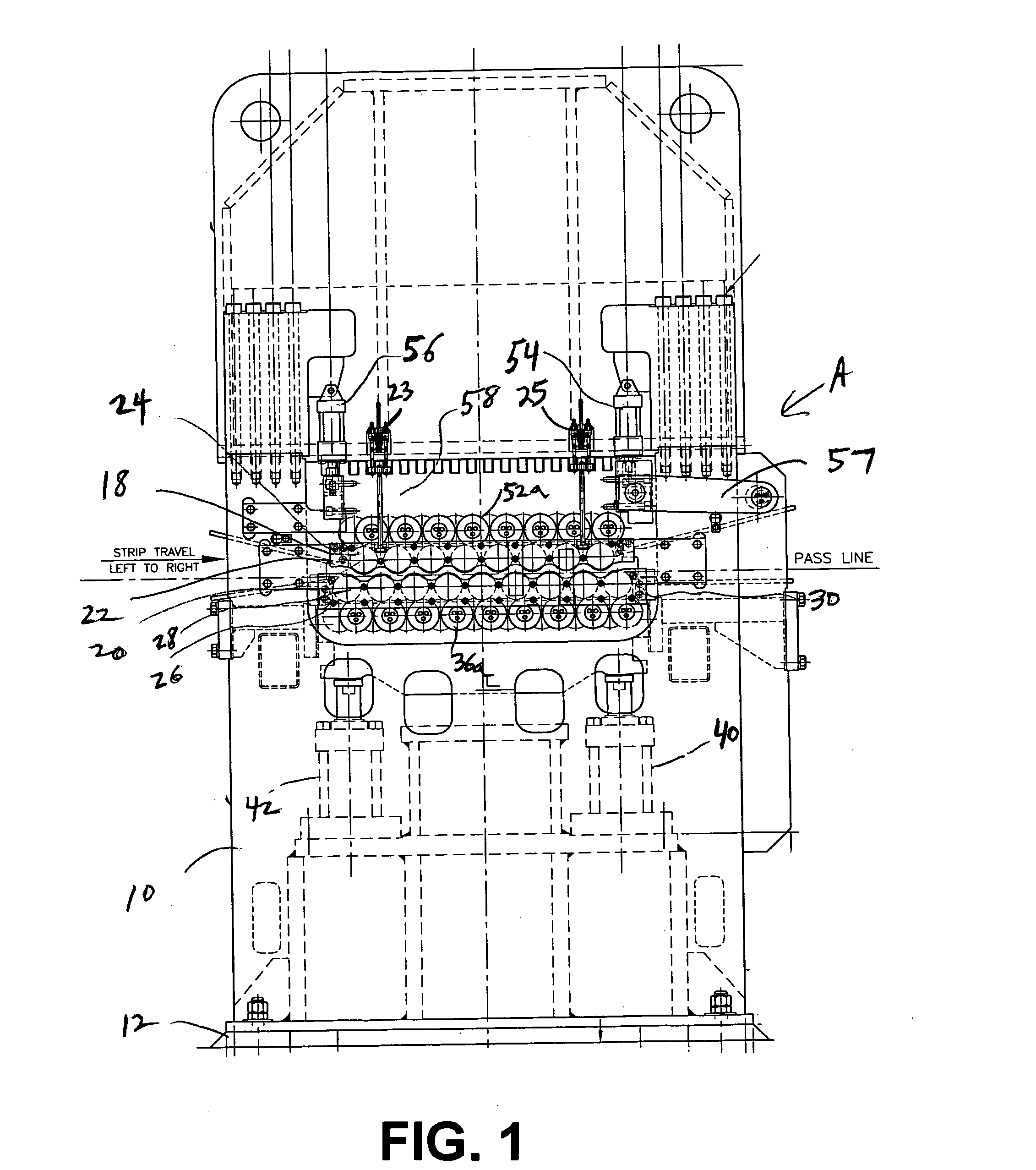

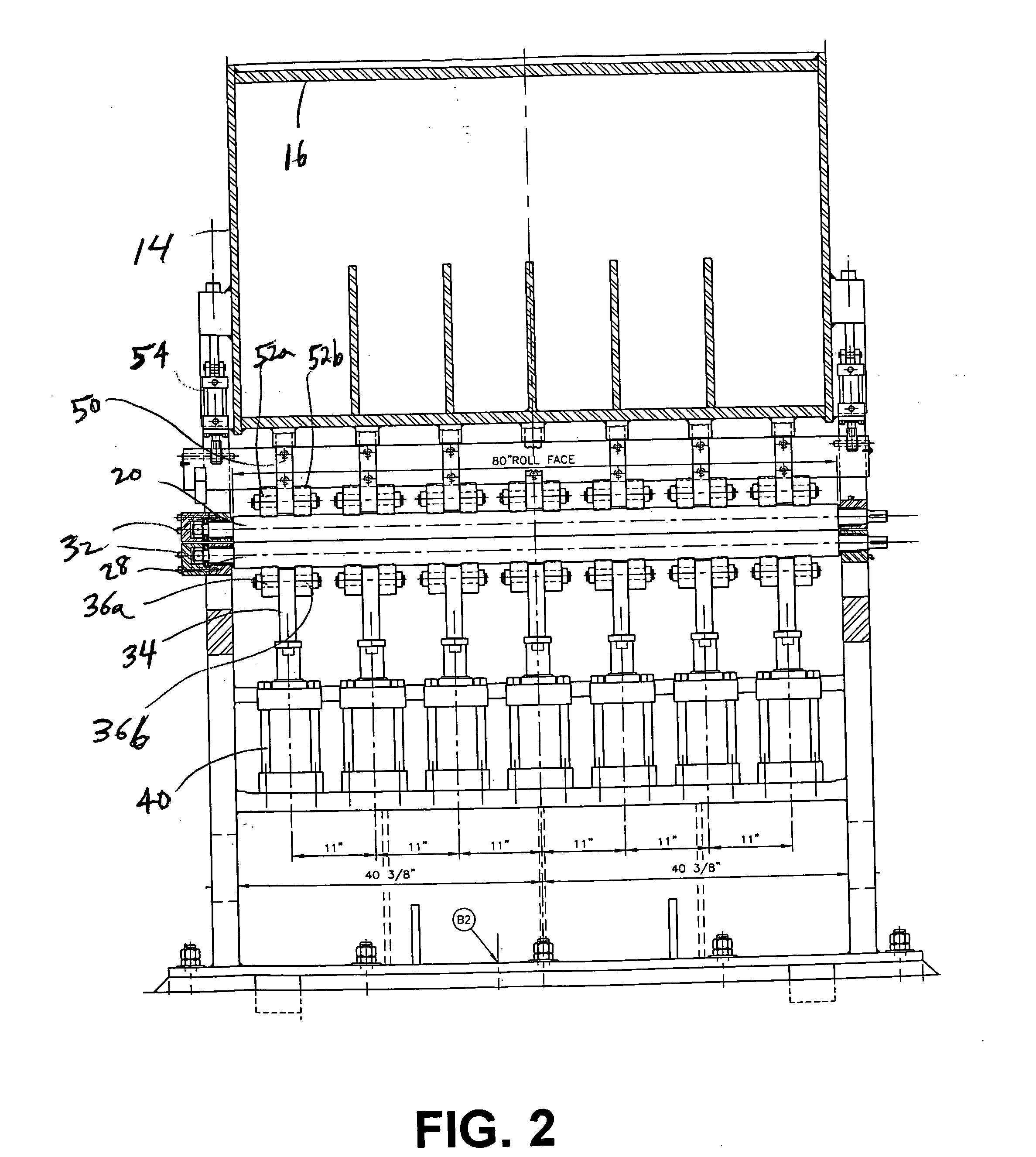

Work roll scraper for roller levelers

InactiveUS20070180879A1Easy to installContinuous cleaningRolling equipment maintainenceBrushesWork rollLeveler

A self-retaining scraping device for continuously cleaning work rolls of a roller leveler assembly has a first wall having two angled or curved portions and a straight portion extending between the angled portions; and a second wall having two angled or curved portions and a straight portion extending between the angled portions.The first wall and second wall are connected to each other via the straight portions. The angled or curved portions of the first wall extend in an opposite direction from the angled or curved portions of the second wall. The scraping device is inserted between adjacent work rolls and has multiple scraping edges contacting outer surfaces of the work rolls to continuously clean the work rolls. The scraping device is supported by the work rolls.

Owner:BUTECH BLISS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com