Dry-type planishing mill non-contact type roller cleaning method

A non-contact, skin pass mill technology, applied in the direction of keeping the roll equipment in an effective state, metal rolling, metal rolling, etc. Achieve the effect of ensuring the surface quality of the strip, avoiding damage to the surface of the roll, and high dust collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

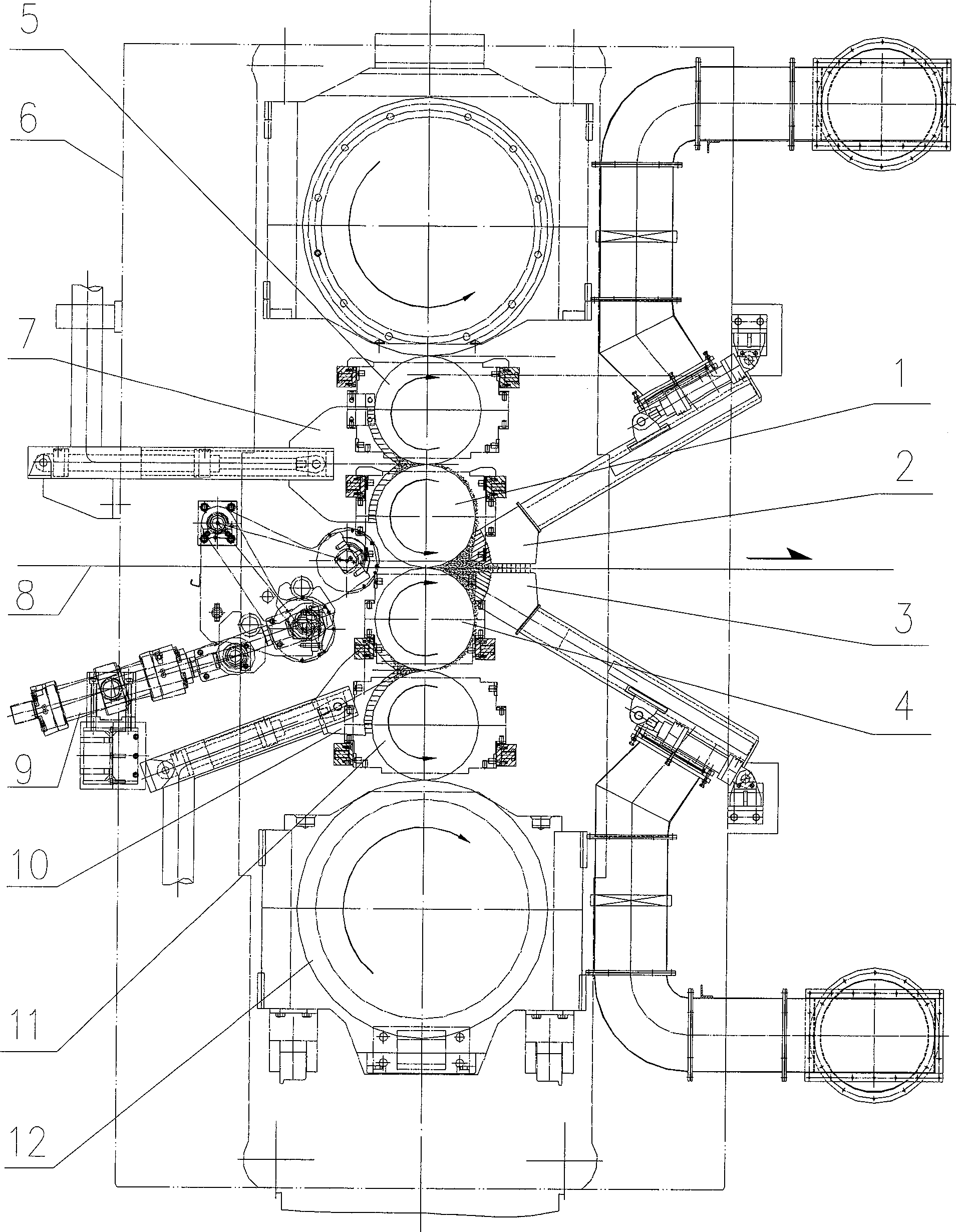

[0026] Such as figure 1 As shown, the non-contact roll cleaning method of dry tempering machine includes the following steps:

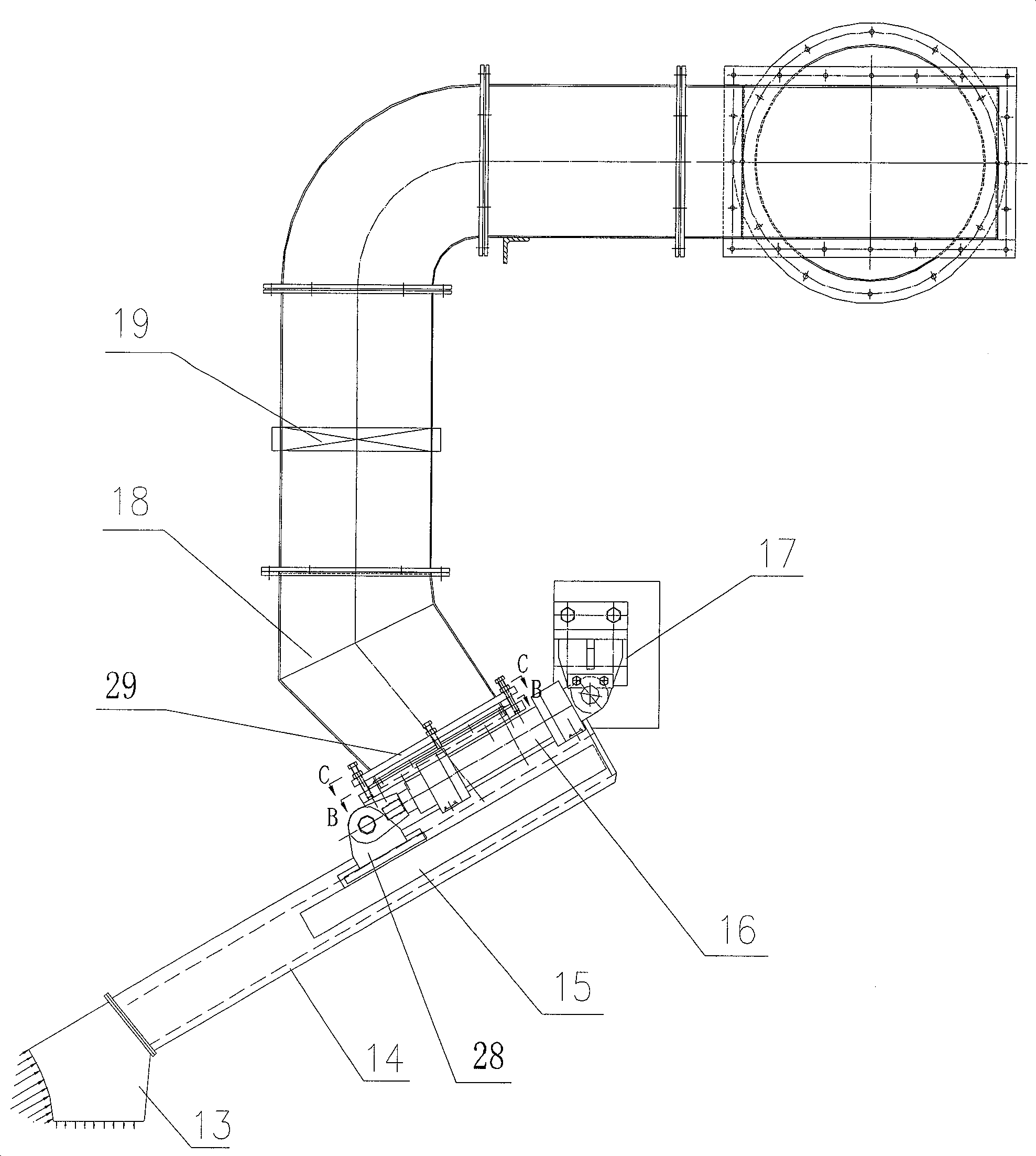

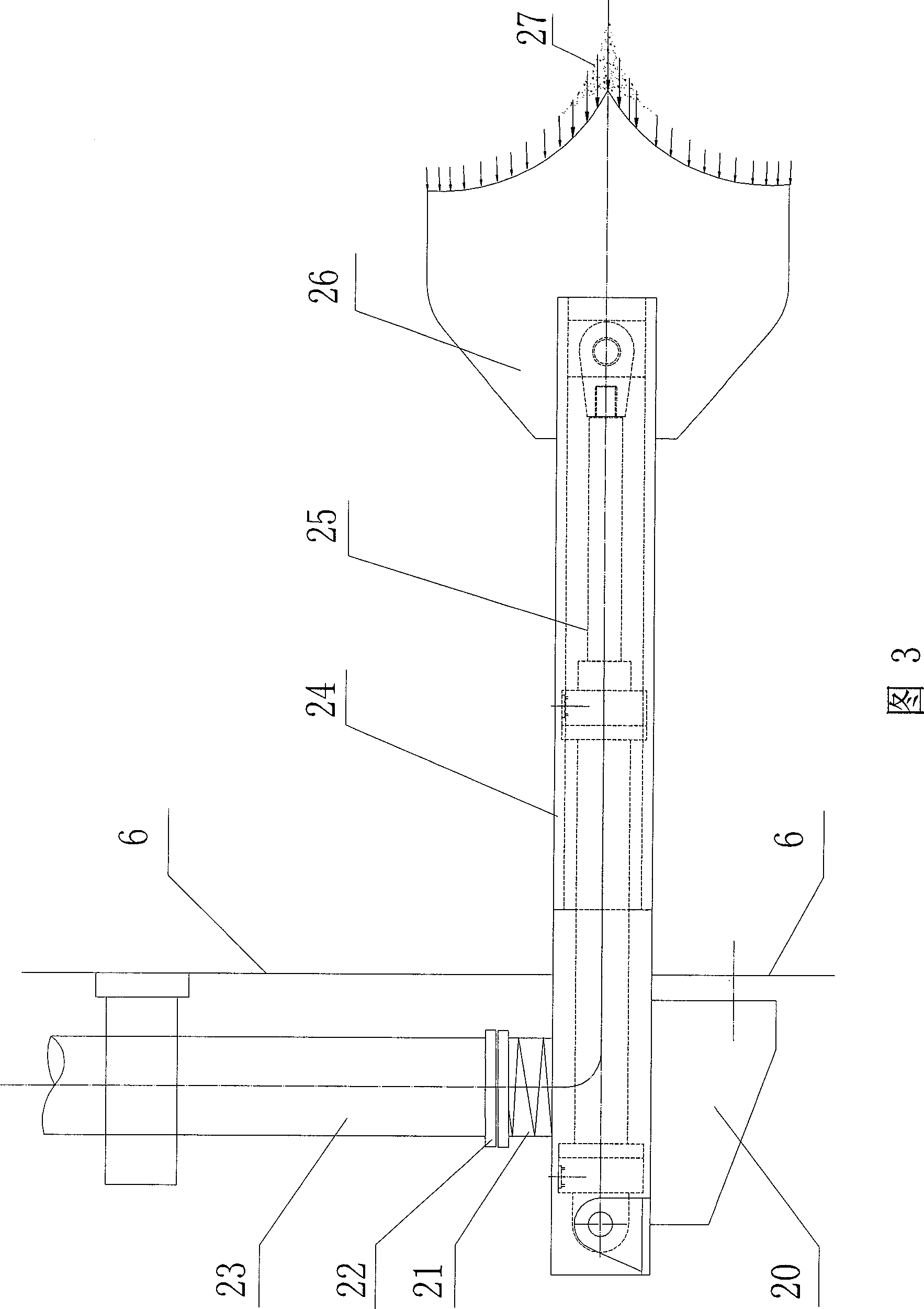

[0027] 1) On the outlet side of the dry tempering machine ( figure 1 The first dust suction hood (the dust suction port of the first dust suction hood faces the flying of metal dust at the roll gap) out direction) and the second dust collection hood (the dust suction port of the second dust collection hood faces the flying direction of the metal dust at the roll gap) to suck away the metal dust; the first dust collection hood is located above the strip passing line 8 , the second vacuum hood is located below the strip passing line;

[0028] 2) On the inlet side of the dry tempering machine ( figure 1 In the left side of the figure), the third dust suction hood is arranged on the roll gap of the upper work roll 1 and the upper intermediate roll 5 in the direction of the metal dust flying out (the dust suction port of the third dust suction hood f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com