Patents

Literature

560 results about "Metal dust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

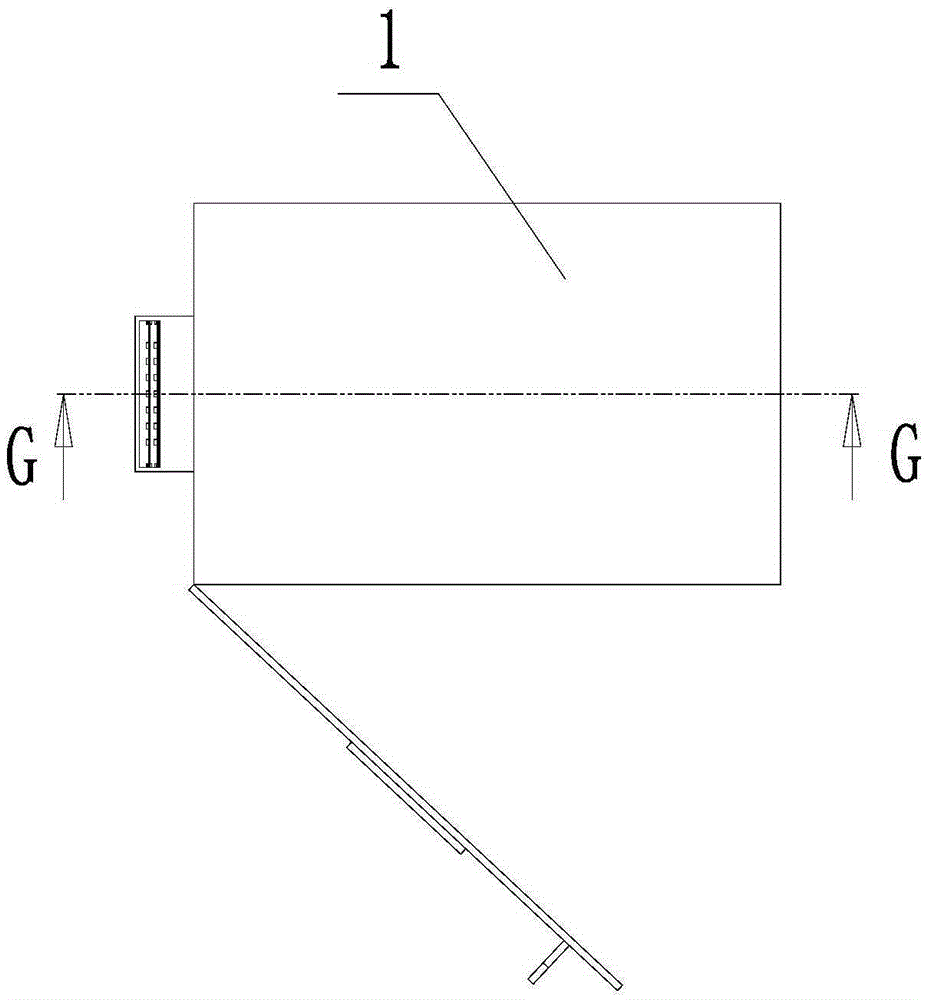

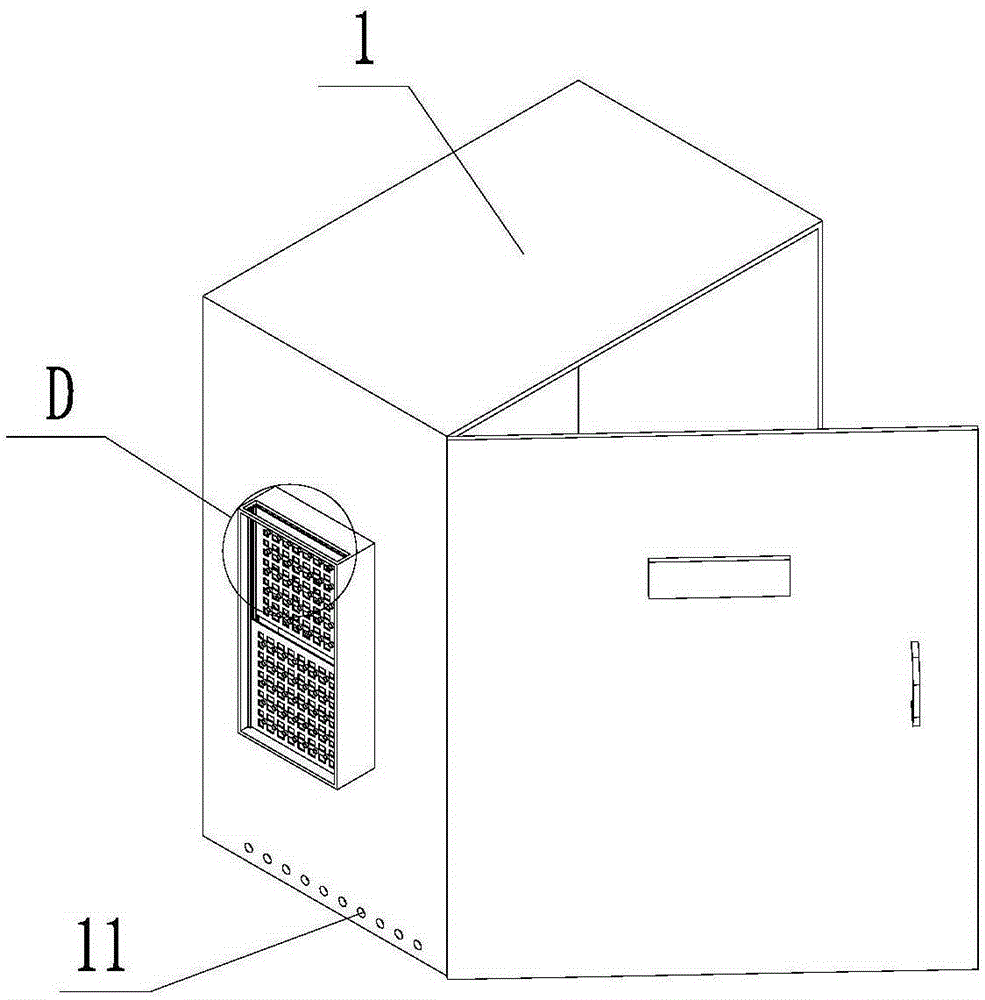

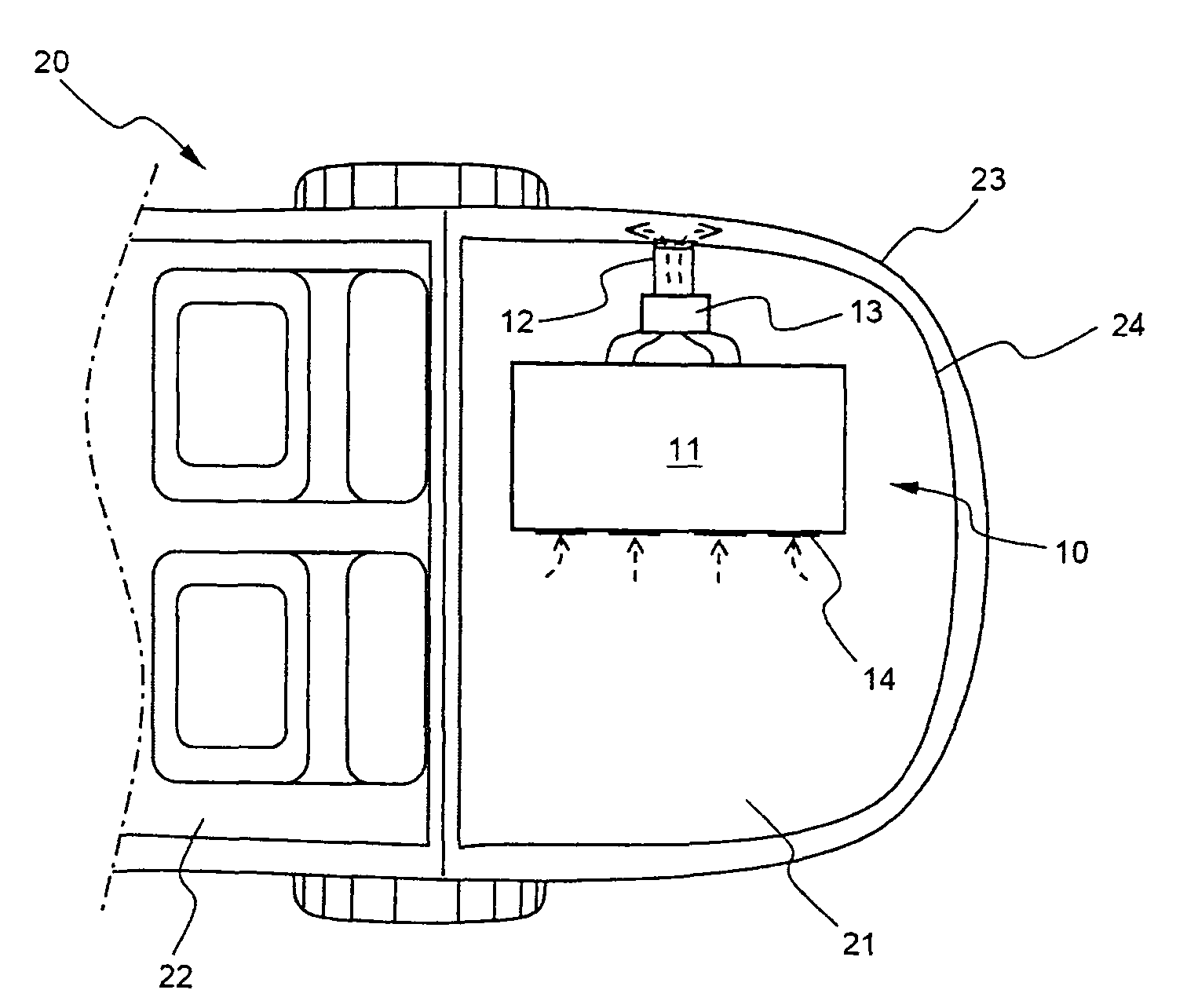

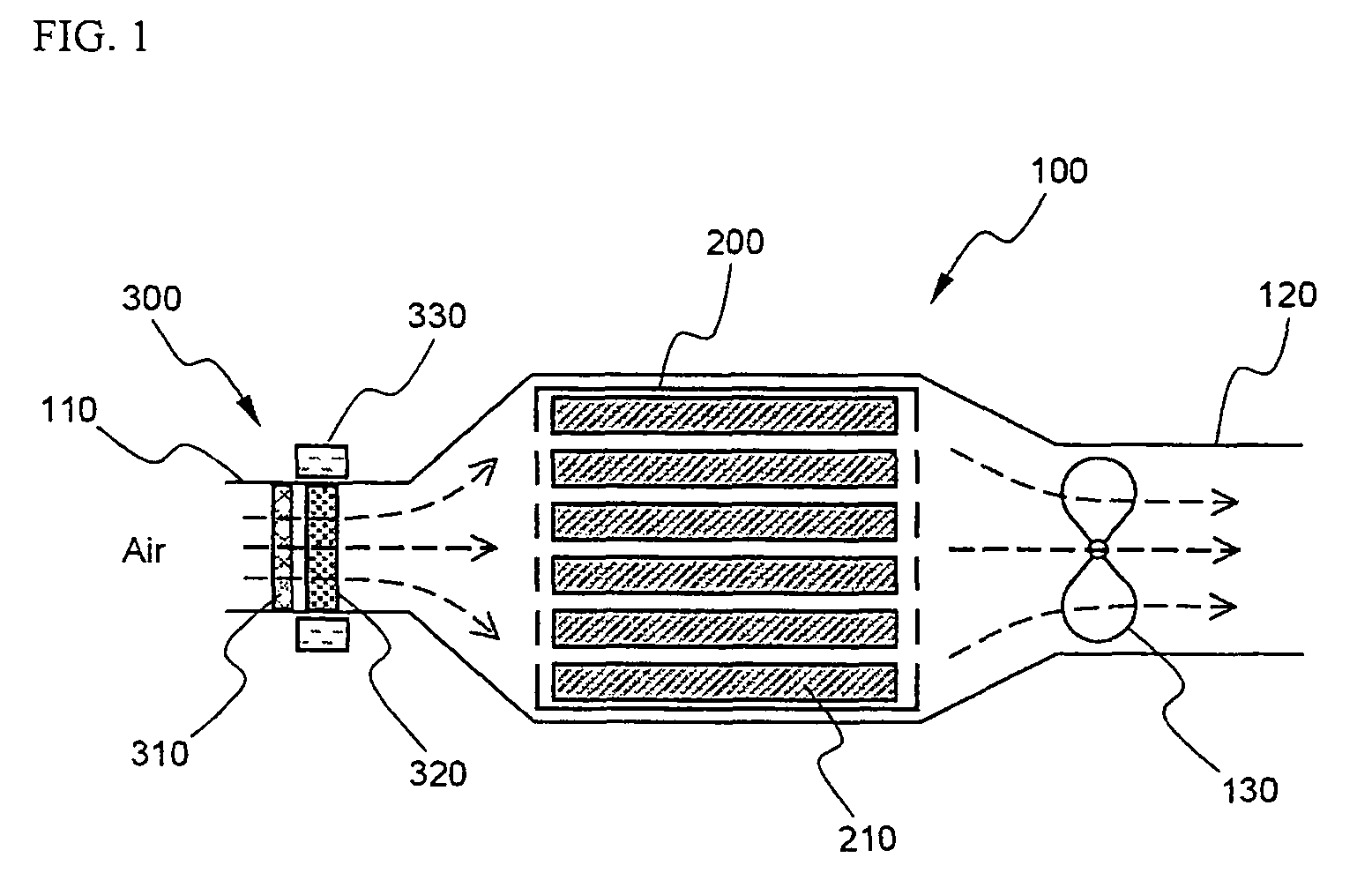

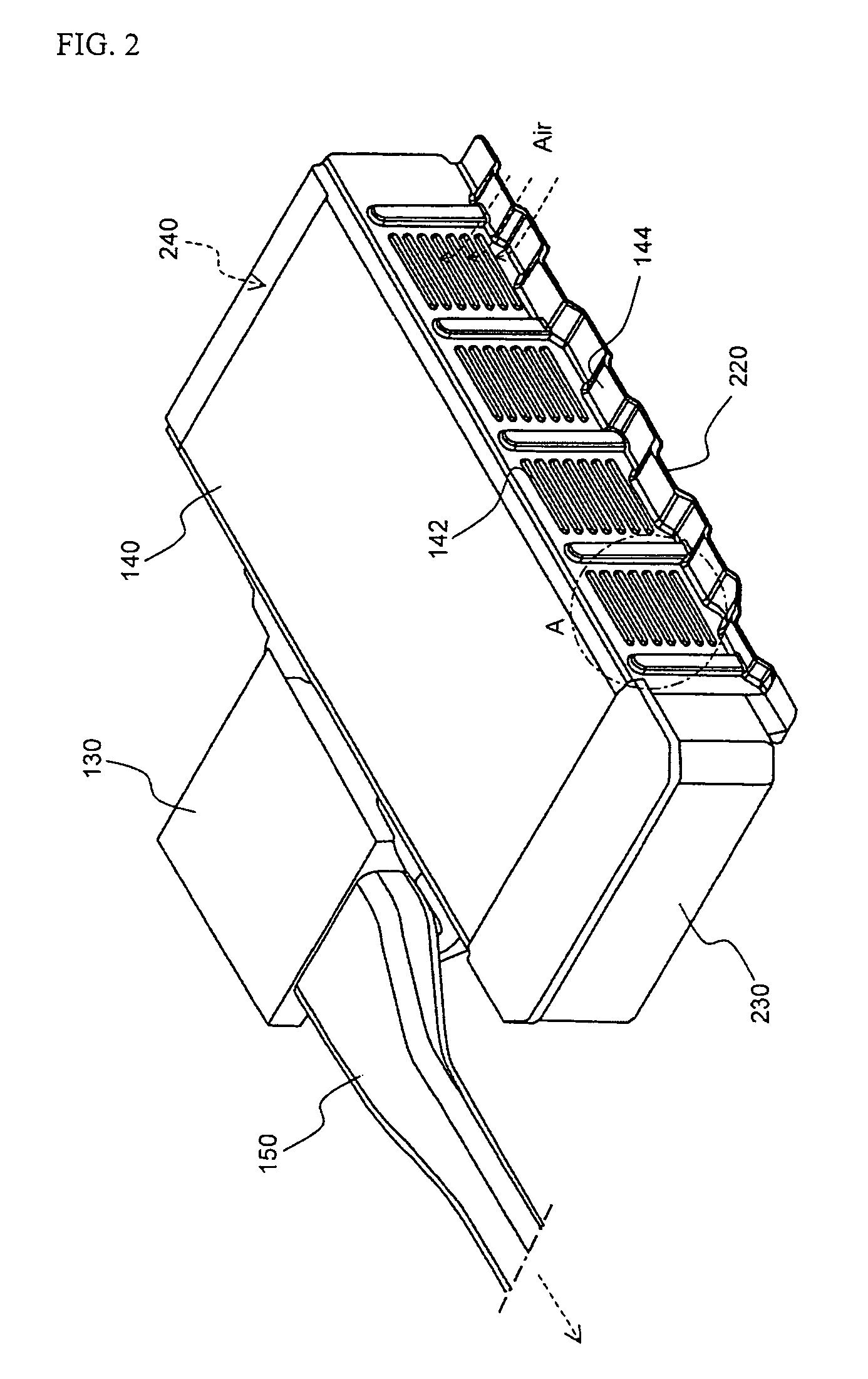

Cooling system for vehicle battery pack containing double filter device

ActiveUS20070196728A1Improve cooling efficiencyReduce the possibilityAir-treating devicesCell temperature controlToxic gasMedia filter

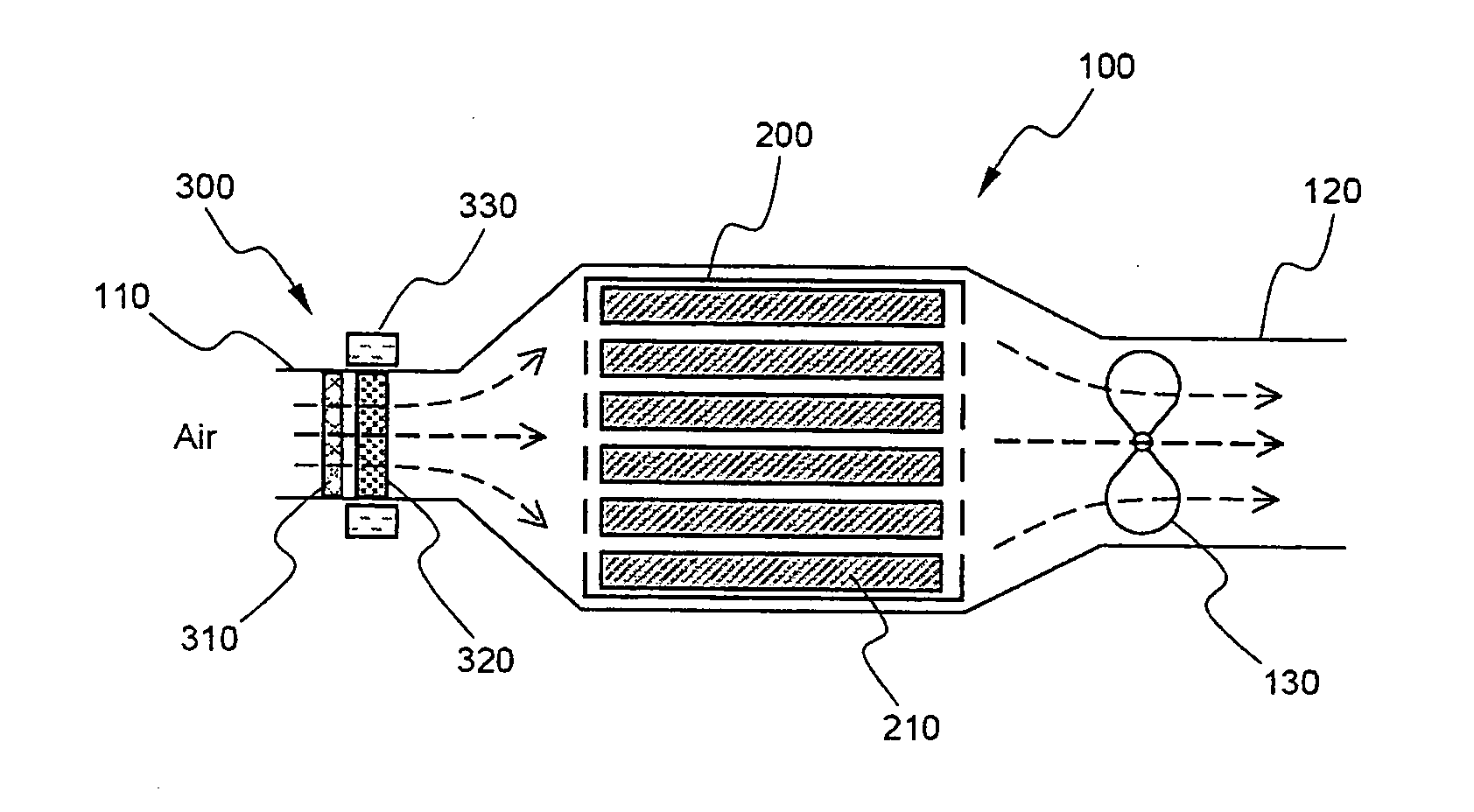

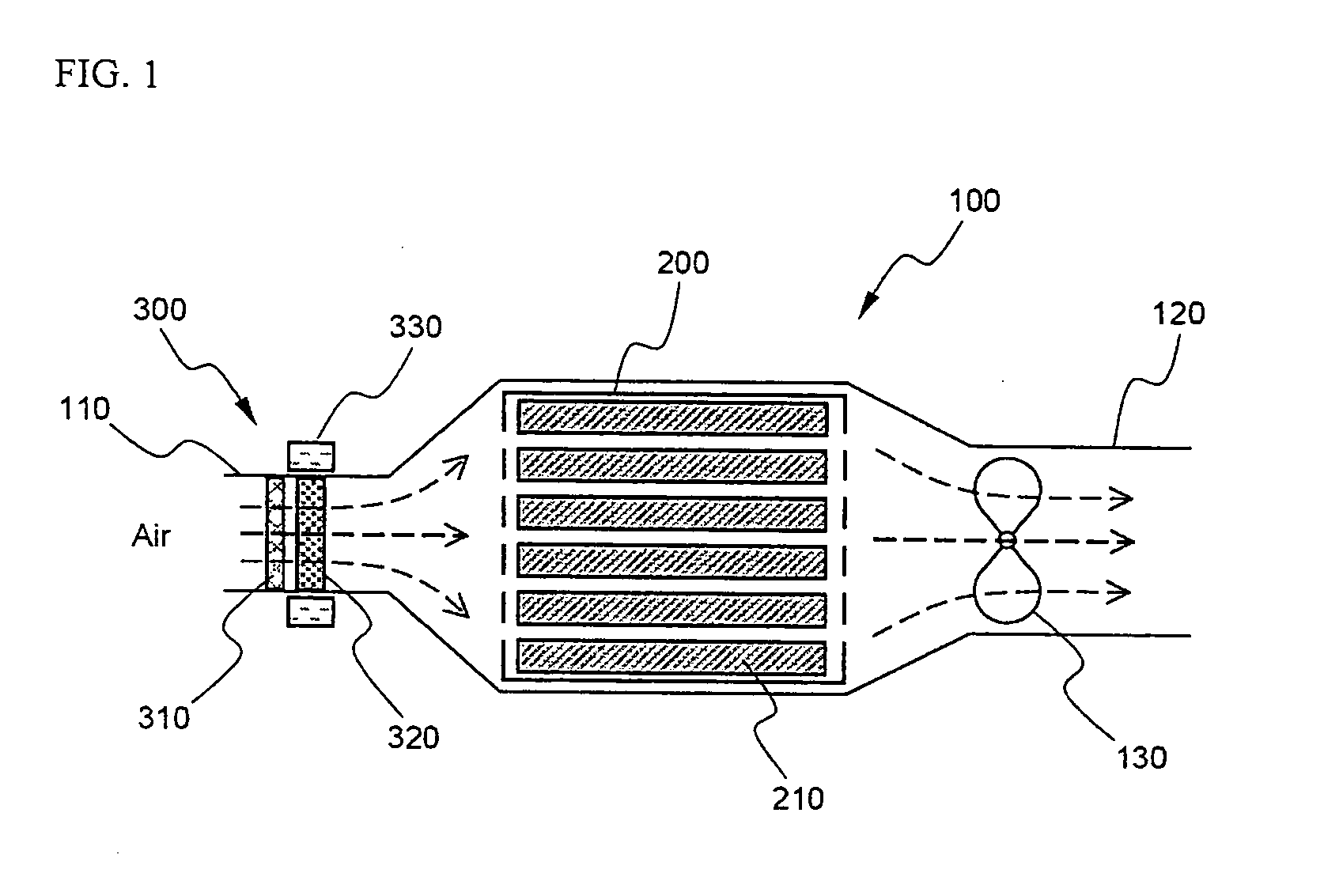

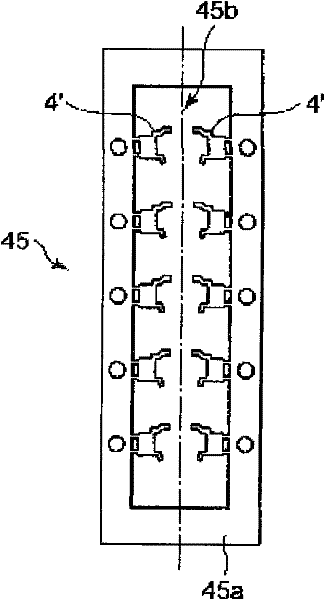

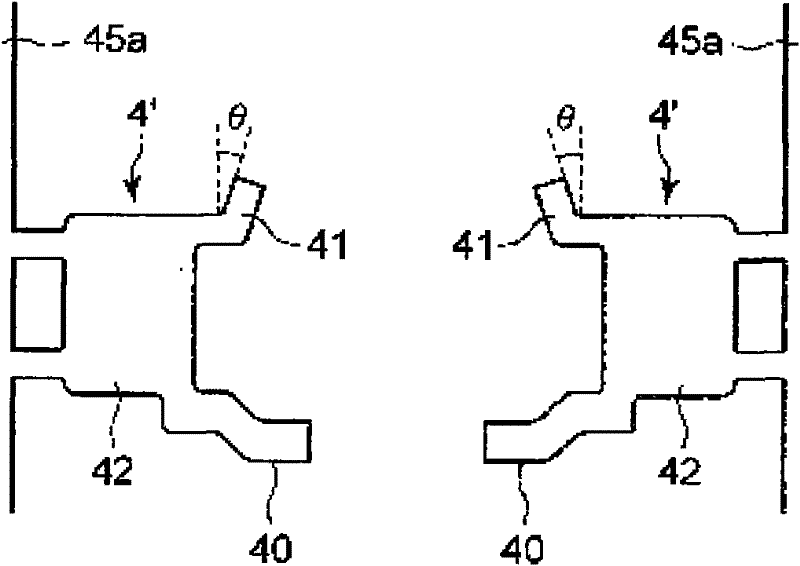

Disclosed herein is a cooling system for vehicle battery packs, including a double filter device mounted at an air inlet part, through which air for cooling the battery pack is introduced from the outside and / or the inside of the vehicle. The double filter includes a pre-filter having relatively large air holes, the pre-filter having high frequency of replacement, and a medium filter having relatively small air holes, the medium filter having low frequency of replacement. The pre-filter is located before the medium filter in the direction in which the air is introduced. Consequently, dust is removed from air, and therefore, the cooling efficiency of the battery pack is increased. In a preferred structure, metal dust is also effectively removed by the magnetic force applied to the medium filter. Consequently, the malfunction or short circuits of the battery pack are prevented. Also, air surrounding the battery pack is directly introduced through the through-type intake ports without passing through any pipe-shaped intake duct. Consequently, generation of noise, which is a problem caused when air in the cabin is used, and backward flow of flames and toxic gas, which are generated during a fire, are prevented. Furthermore, the battery pack is constructed in a compact structure.

Owner:LG ENERGY SOLUTION LTD

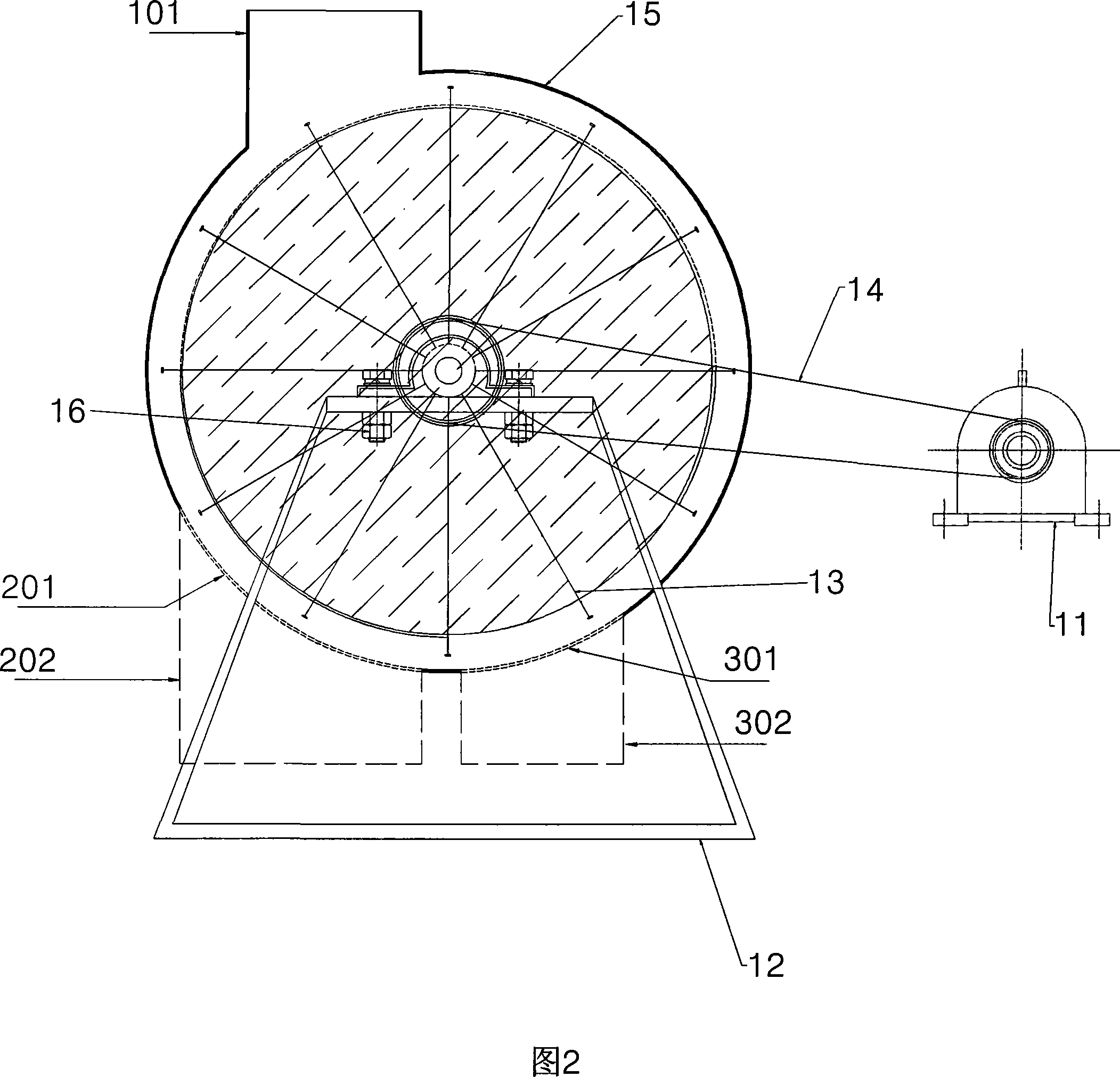

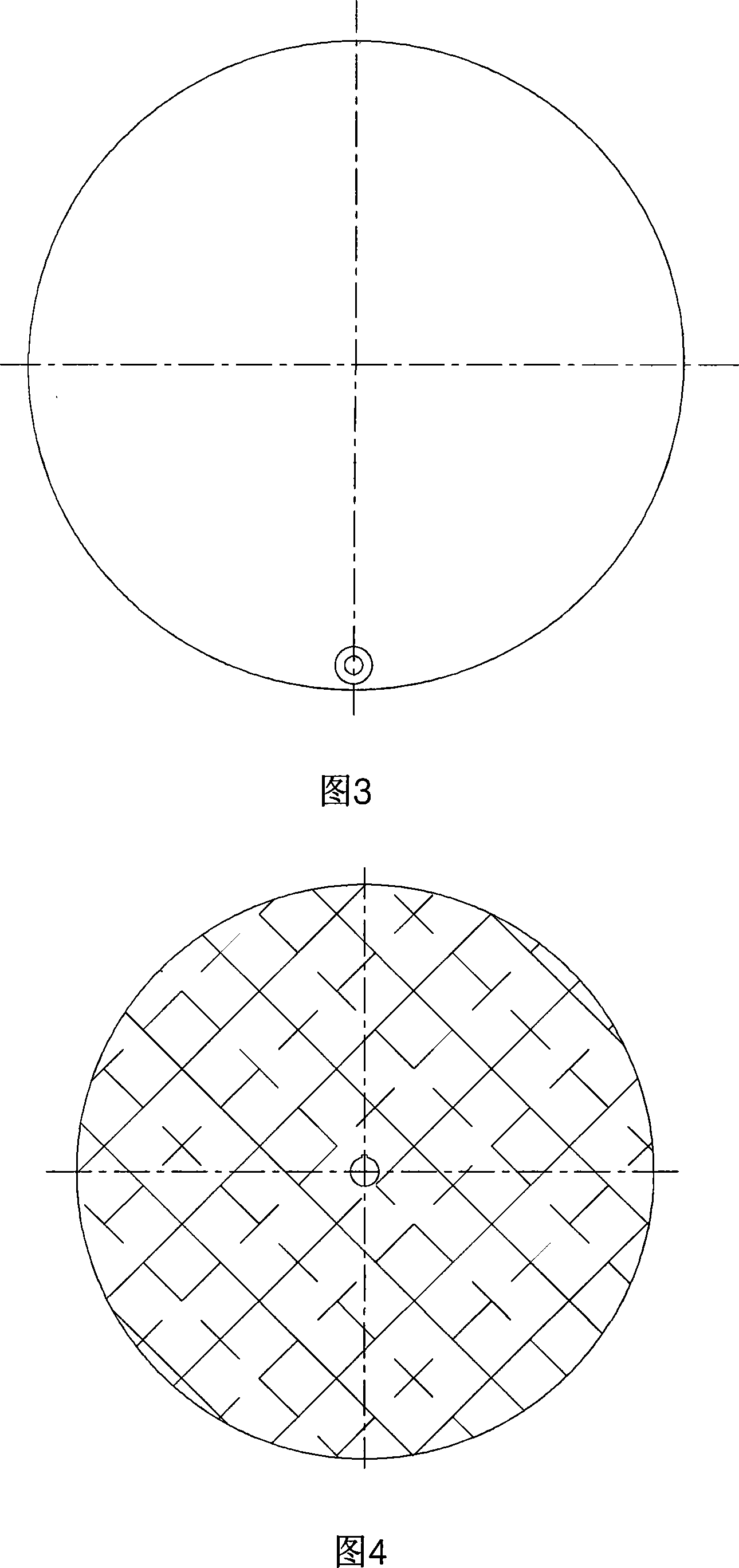

Method and apparatus for recovering solid waste material containing metal

InactiveCN101185935ACause damageHigh failure rateGas current separationElectrostatic separationElectric machineEnvironmental engineering

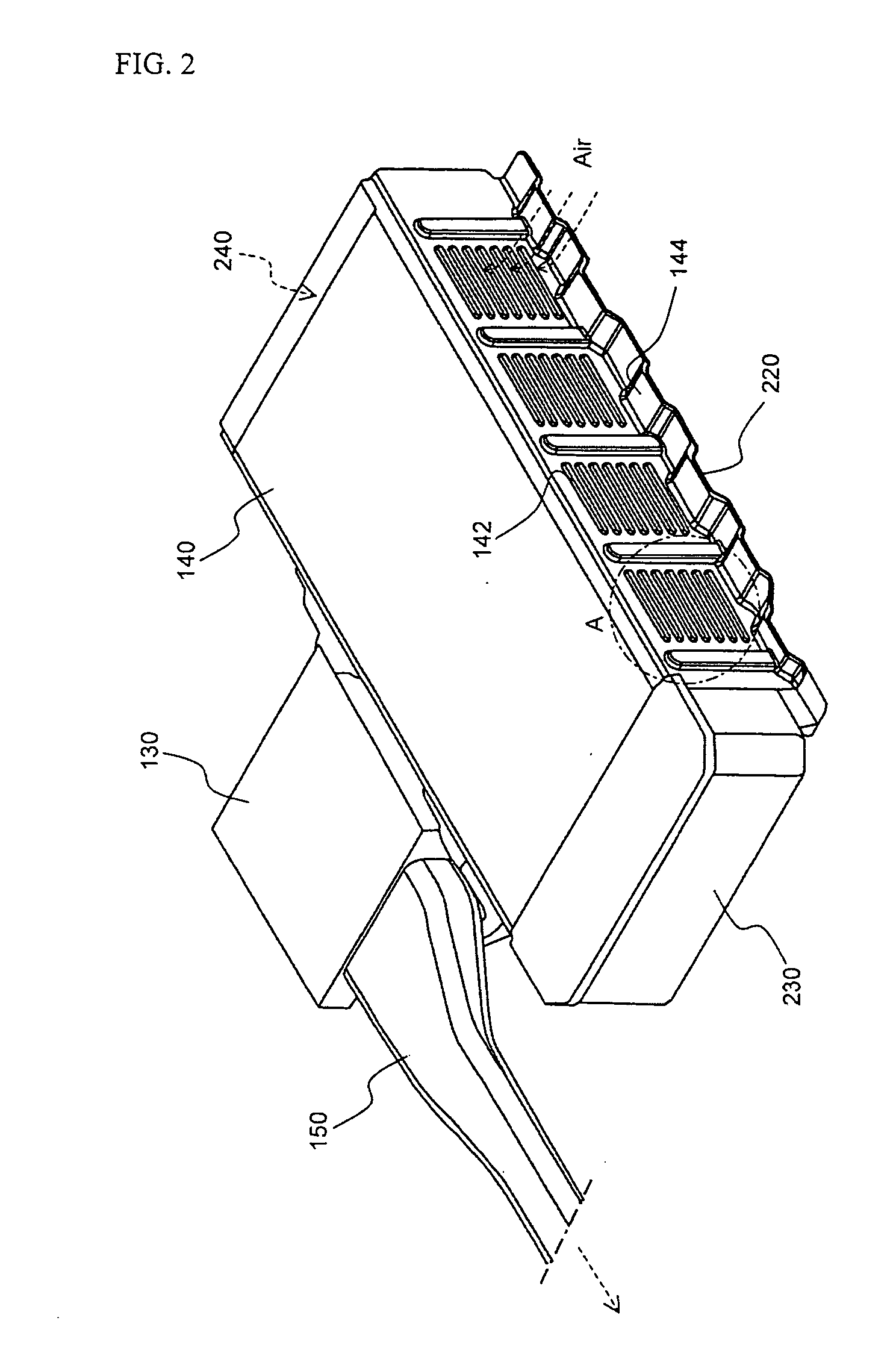

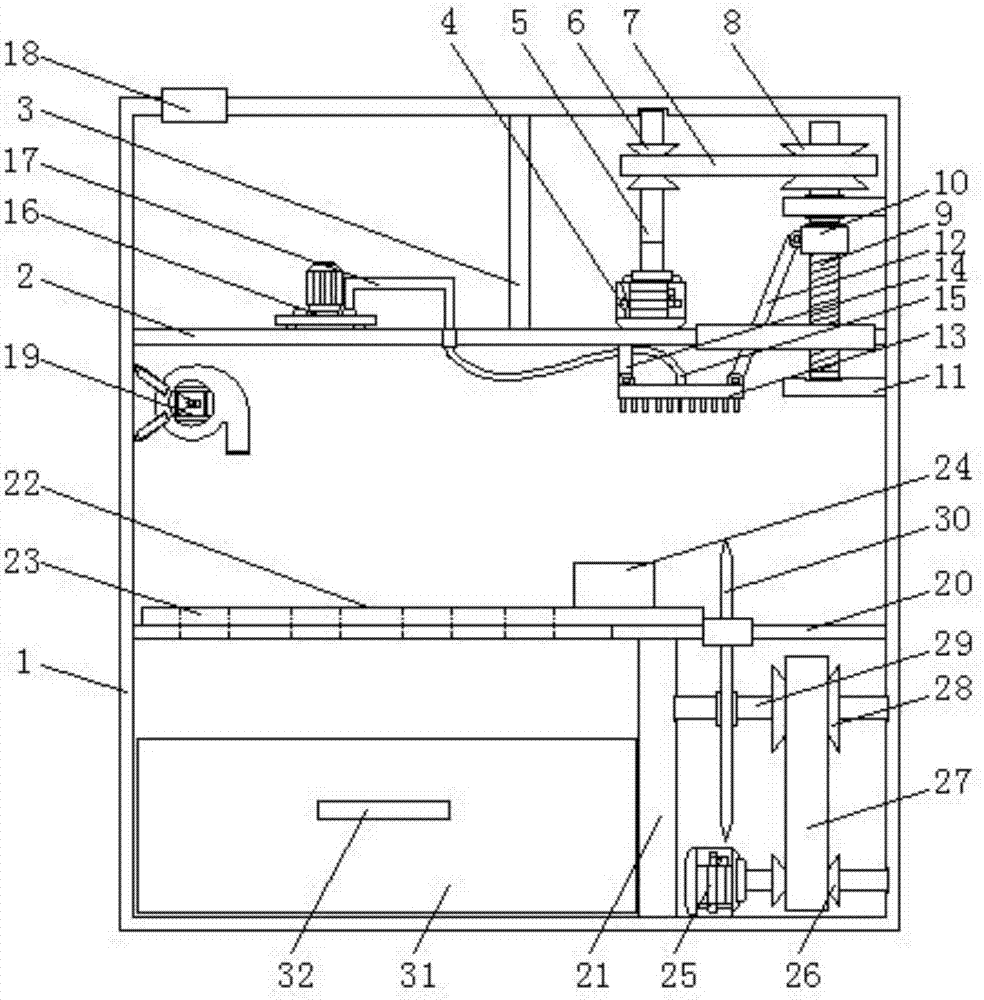

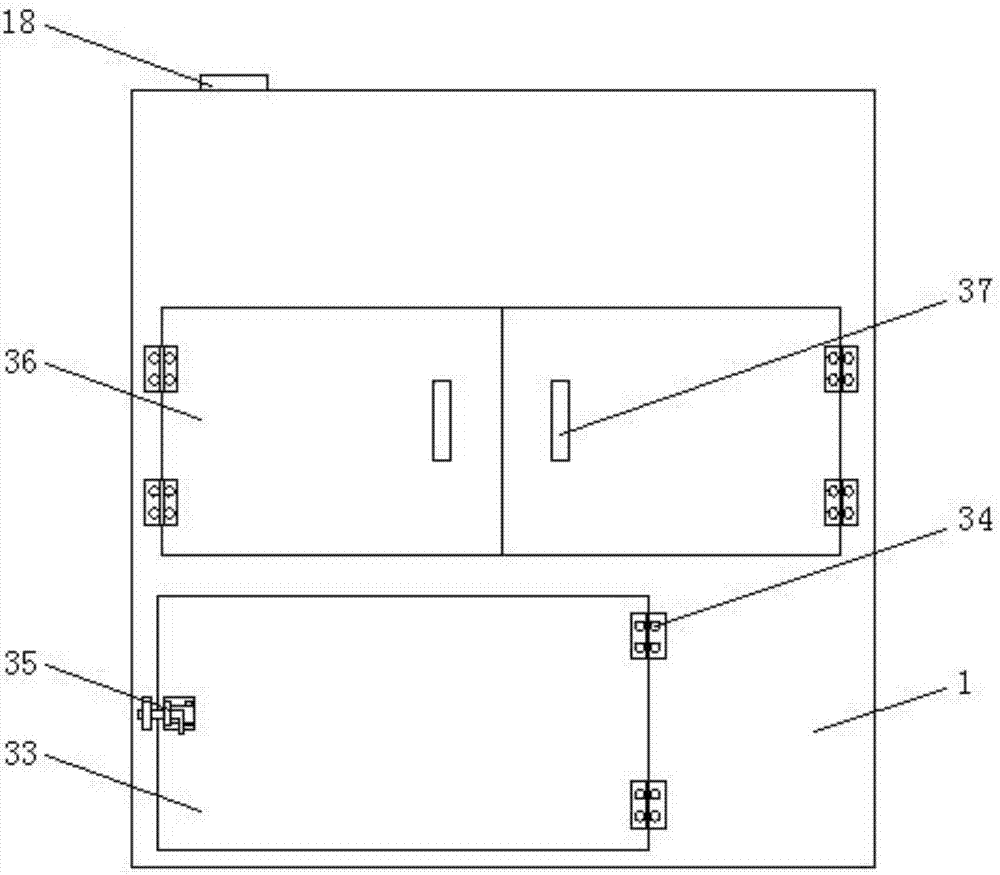

The invention discloses a method and an equipment of recycling solid waste with metals. The invention comprises the procedures as follows: (1) the solid waste with metals is rough shattered by a slicer, a primary crushed is carried out by a shear mode crusher and a second crushed is carried out by a speed variable hammer crusher; (2) the material is extracted into a gravity separator and a cyclone separator by a centrifugal fun after being second shattered. (3) Dust with metal which is less than 60 meshes is sent into a vibrating screen after falling into a dust collecting hopper of the cyclone separator. (4) Material powder which is more than 60 meshes goes into the vibrating screen. The separation of metal from nonmetal can be realized by a high pressure electrostatic separator. The high pressure electrostatic separator which is used in the invention comprises a body and dust collecting polar plates which can continuously rotate. A plurality of dust collecting polar plates are fixed and connected in series by central axis. The central axis is connected with a motor. A discharge electrode and a scraper are arranged between every two dust collecting polar plates. The invention has high metal recovery rate and the system of the invention operates automatically, which is harmless to the environment and has obviously economical benefit.

Owner:曹时宜

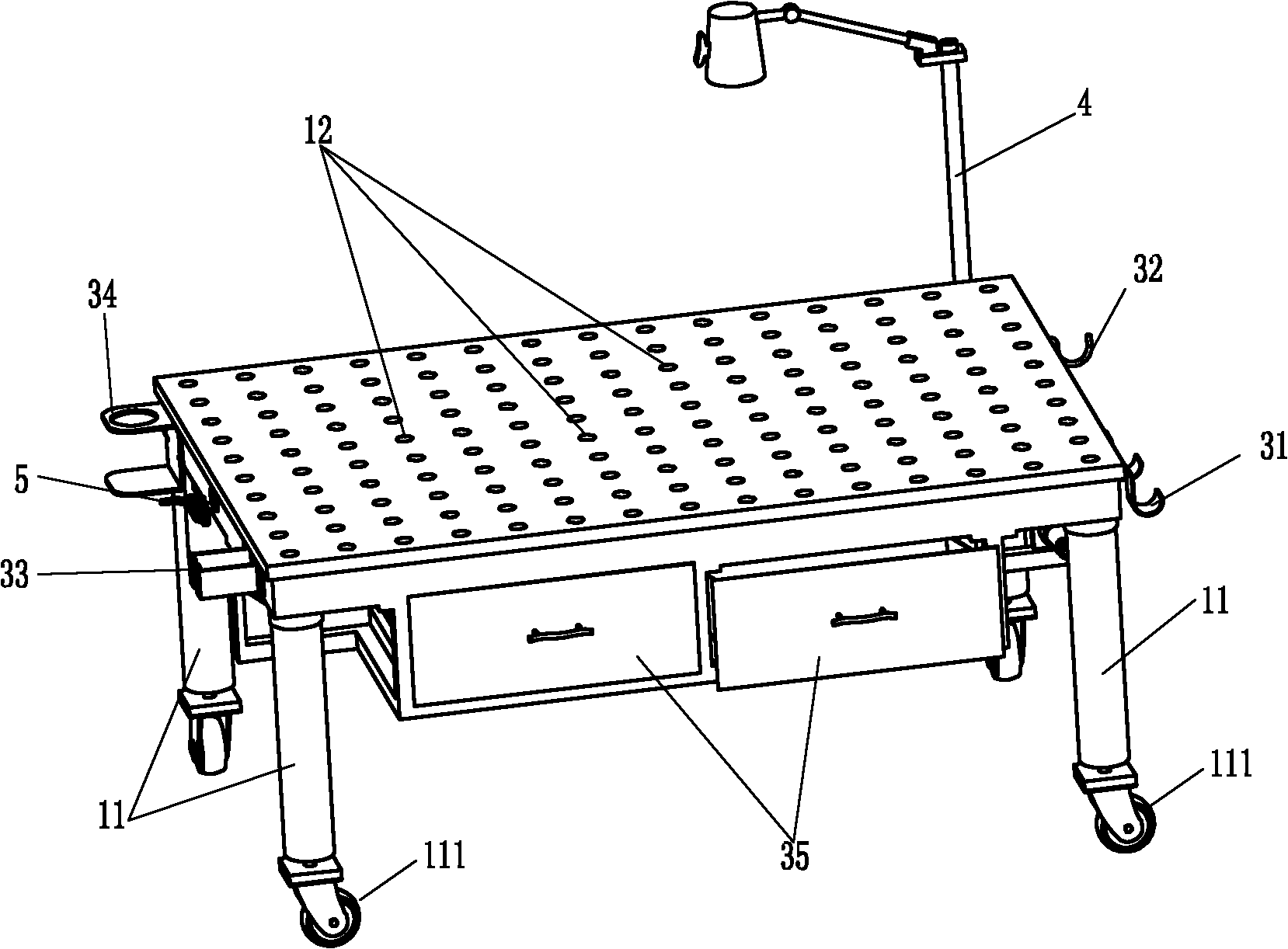

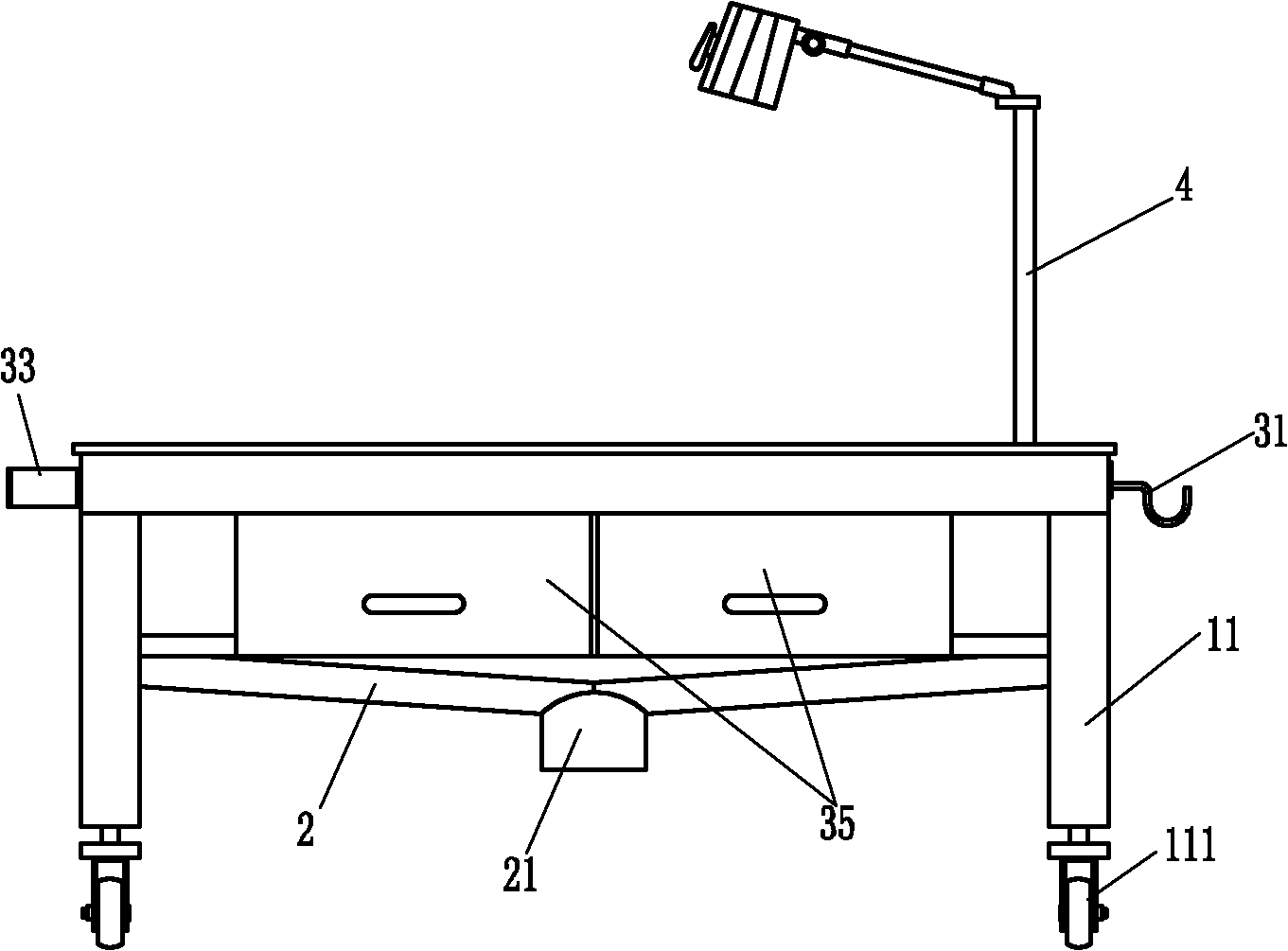

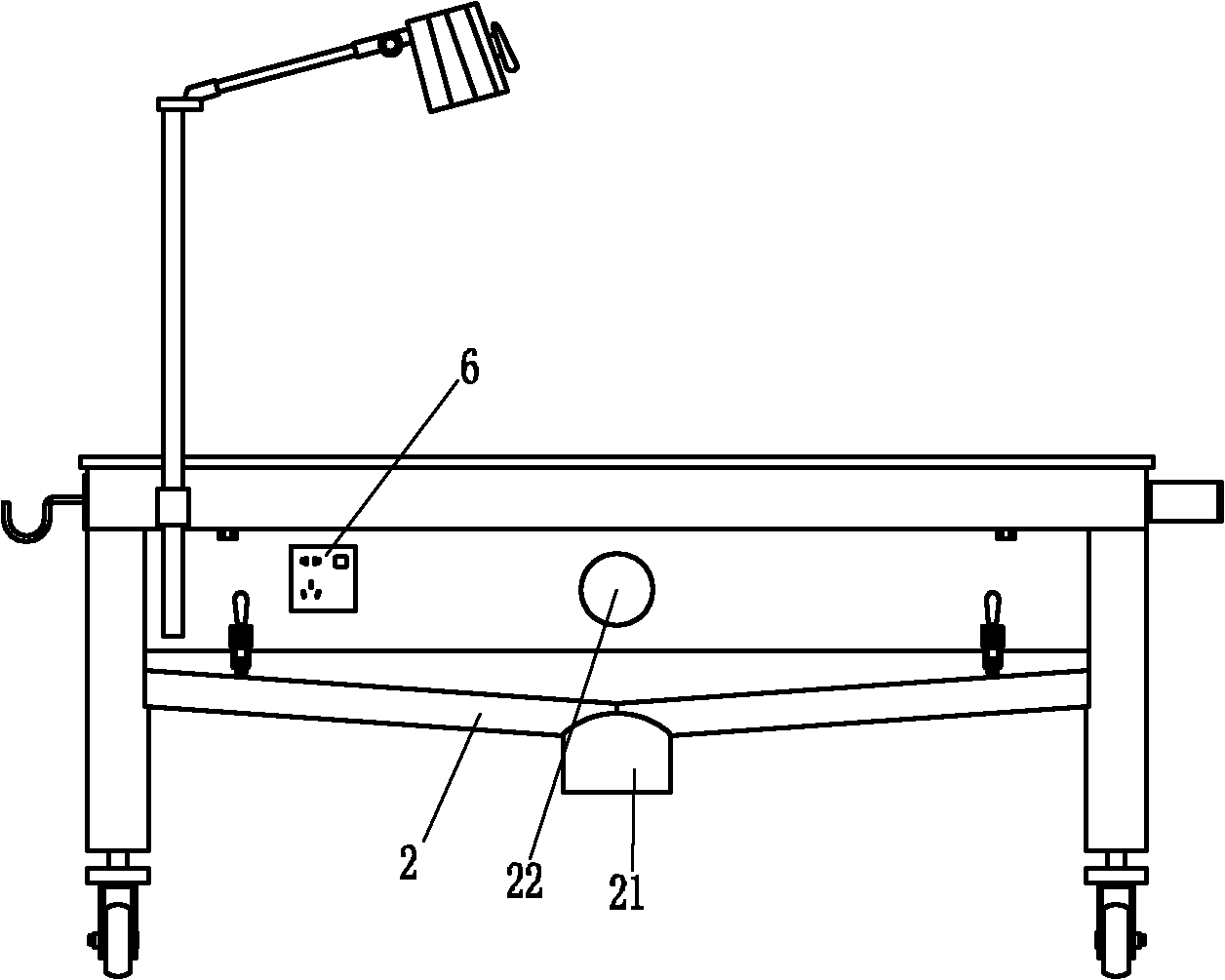

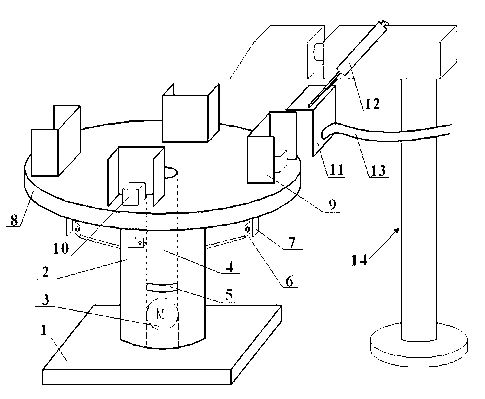

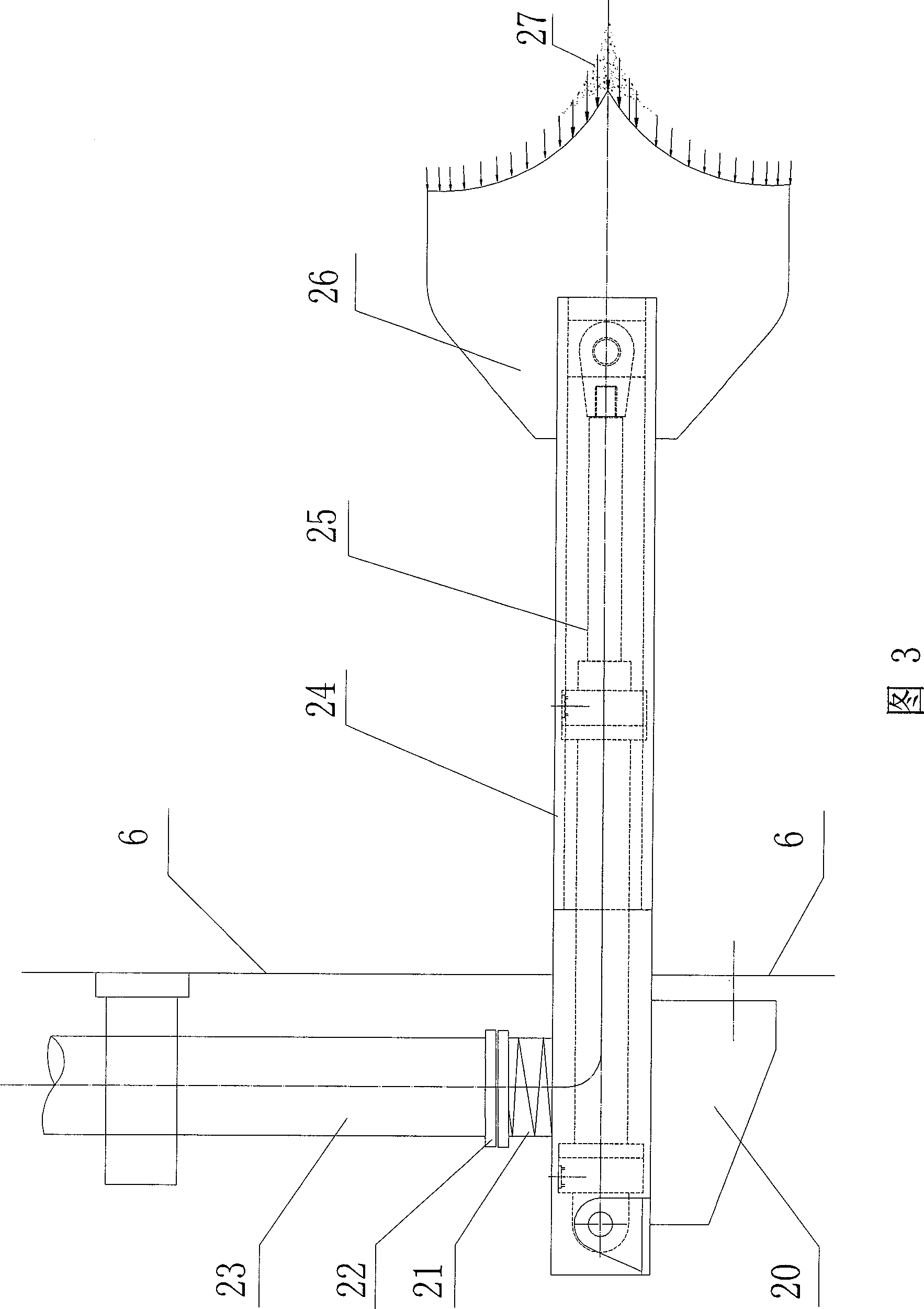

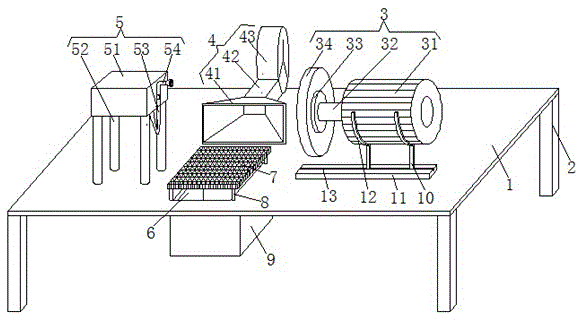

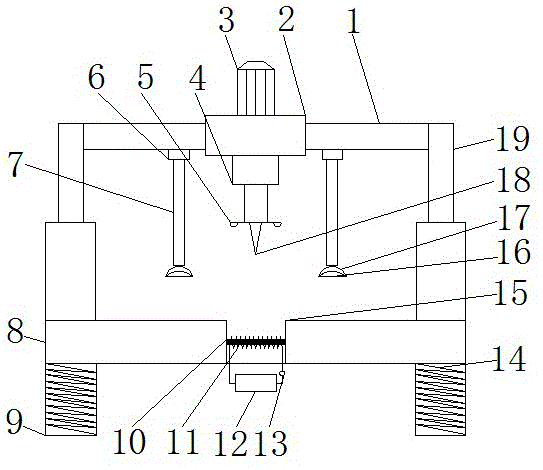

Welding fixture platform

InactiveCN102039507AIncrease profitLow costWelding/cutting auxillary devicesAuxillary welding devicesToxic gasSlag

The invention provides a welding fixture platform, relating to the technical field of auxiliary welding devices, in particular to environment improvement of a welding site. In the invention, the technical problems of the existing welding site is severe, fixture cost is high and utilization rate is low are solved. The platform comprises a table board, the table board is a three-dimensional flexible fixture plate structure, table board through holes which can contain welding slag and is used for locating the fixture are arranged on the table board, and a hopper which collects welding slags dropped into the through holes on the table board is arranged below the table board. The welding slag drops into through holes of the table board and is collected by the hopper, thus optimizing the work environment; fixture units are modularized, the unit modules are assembled into a required fixture when fixing welding parts, and the fixture is fixed in the through holes of the table board, thus improving utilization factor of the fixture. An air extractor can suck harmful gas and metal dust produced by welding from the through holes of the table board, thus purifying the air of the welding site and preventing human body from sucking harmful and toxic gas.

Owner:陈凌

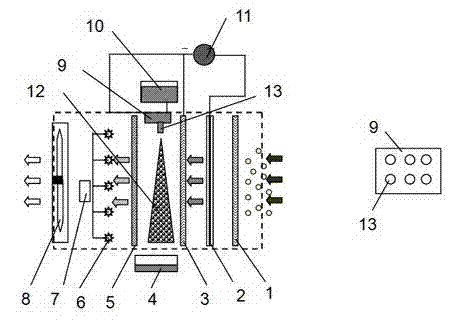

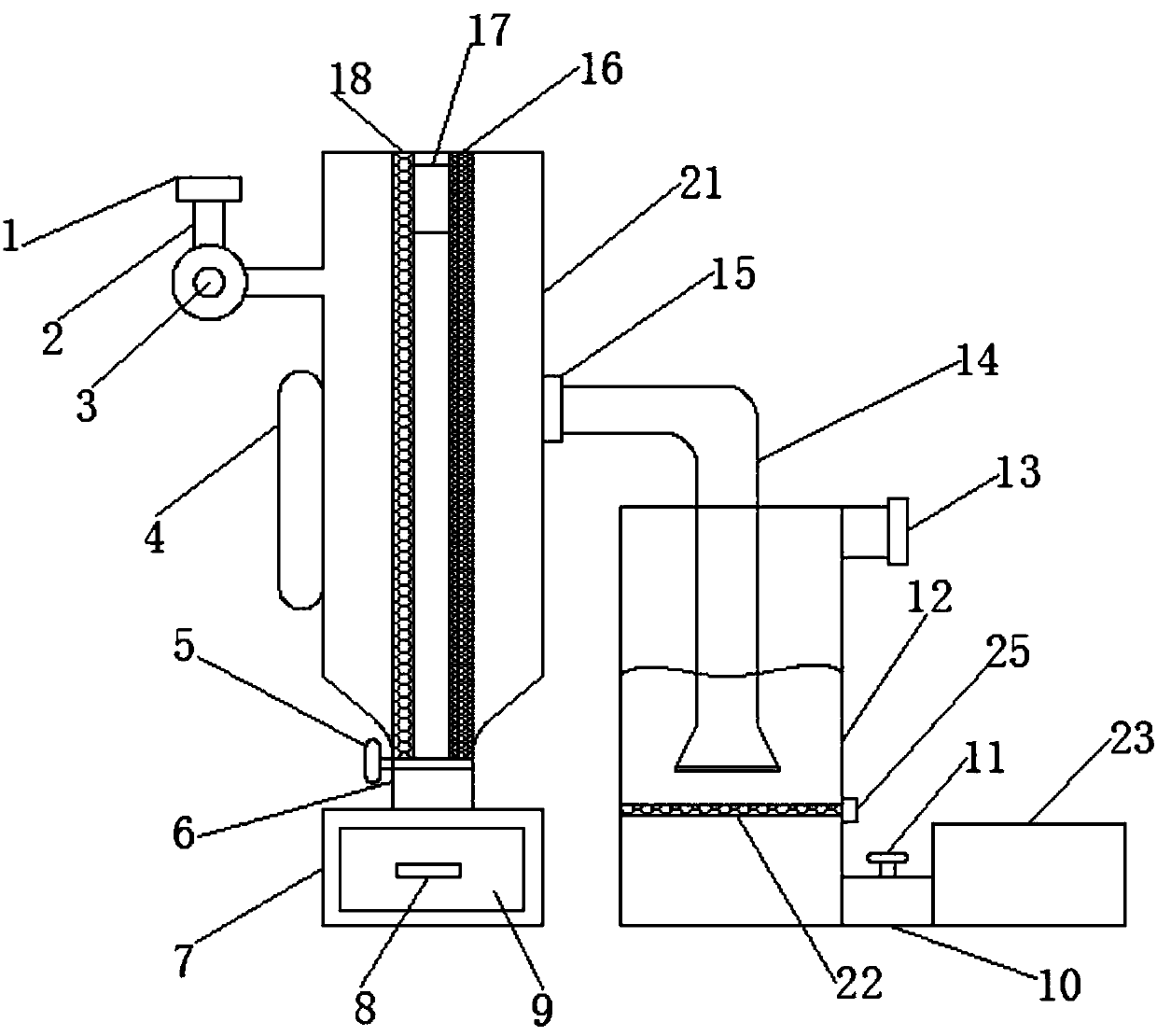

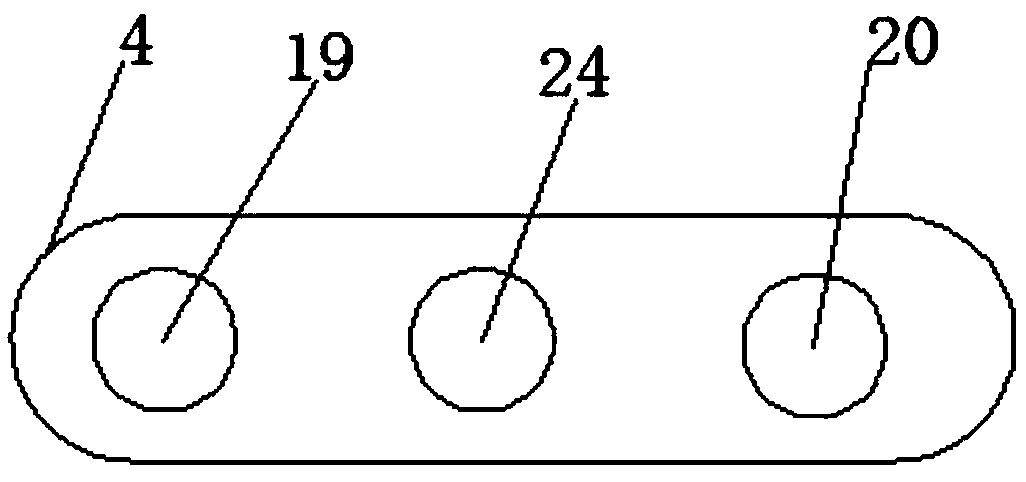

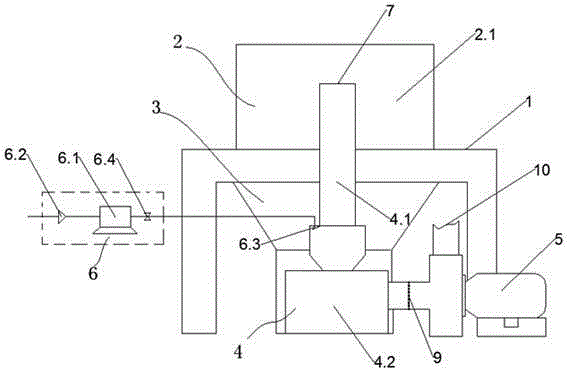

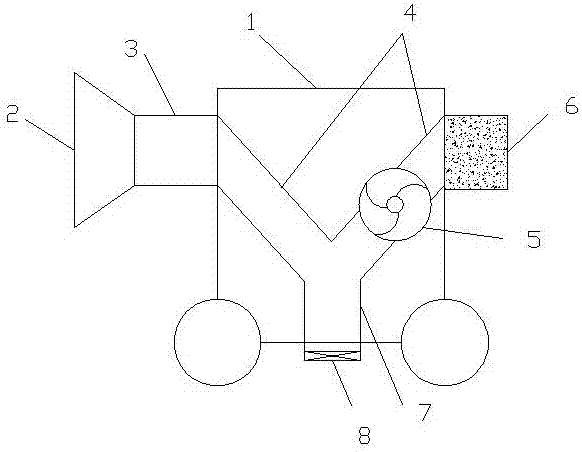

Device and method for purifying indoor air through electrostatic atomization

InactiveCN103586131ATo achieve the purpose of high-efficiency purification of the cycleDeodrantsExternal electric electrostatic seperatorAir cycleEngineering

he invention discloses a device and a method for purifying indoor air through electrostatic atomization. The purification device comprises a filter screen (1), a corona electrode (2), a metal dust collecting net (3), a water-collecting tank (4), a photocatalyst filter screen (5), an LED source (6), a negative ion generation device (7) and a drainage blower fan (8). The purification device also comprises an electrostatic atomizer (9) forming an electrostatic spraying field (12). The method combines static dust collection purification with electrostatic atomization water washing purification. First air goes through the filter screen and the strong electric field zone formed by high-voltage corona, harmful gases are decomposed by the strong electric field. Then the air goes through the charged water atomization zone formed through electrostatic atomization, harmful gases are dissolved further and dust particles are adsorbed. Then the air goes through the photocatalyst filter screen for deep purification. Combined with negative ion generation and air-flow guidance, the purpose of circulation and high-efficiency purification of air in a room is achieved.

Owner:JIANGSU UNIV +1

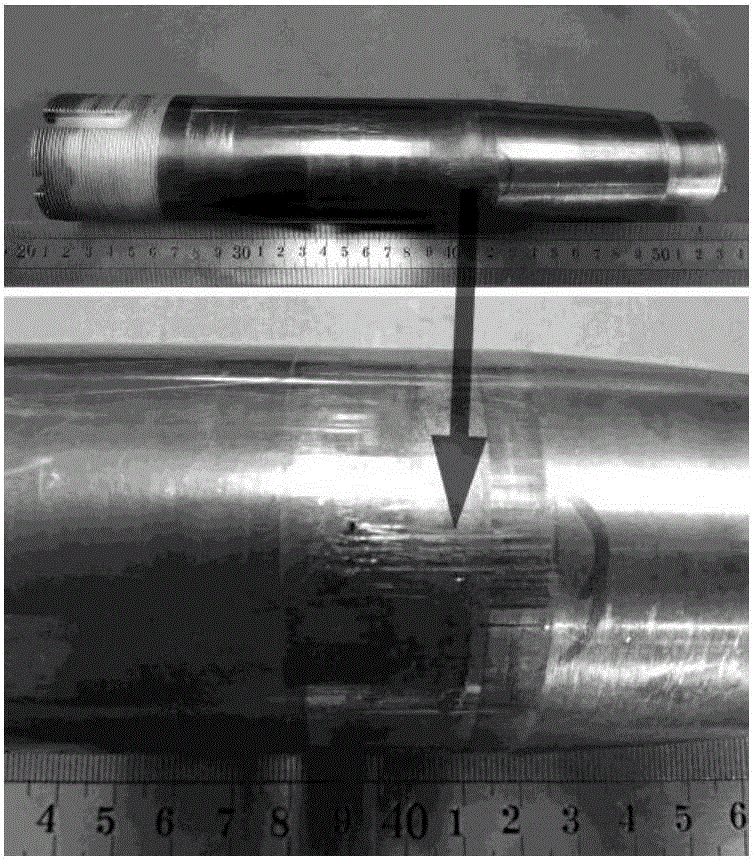

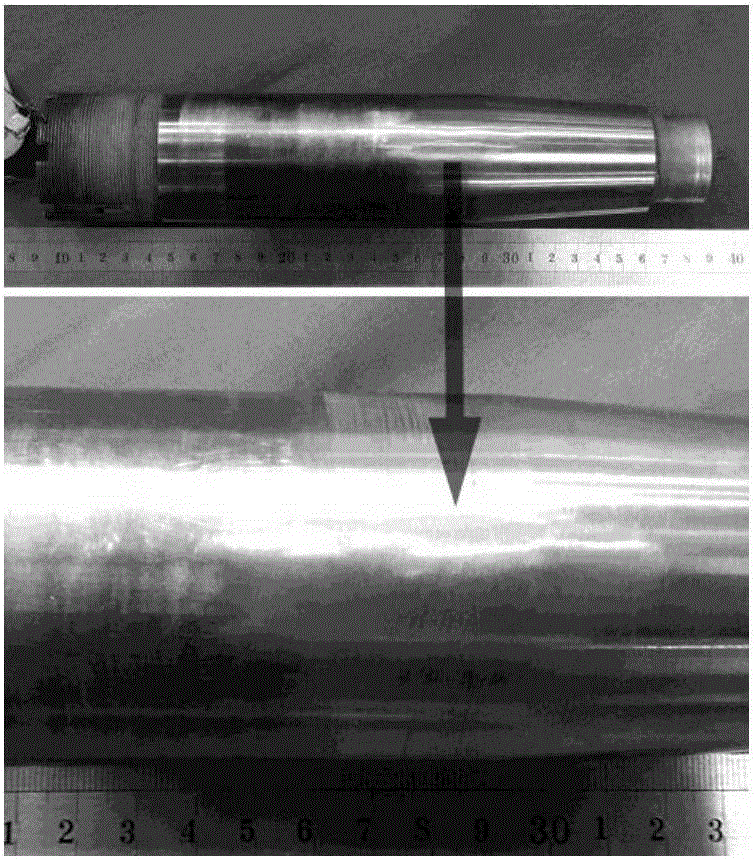

Laser cladding repairing method for aircraft end-journal part surface

InactiveCN105256249AShorten maintenance timeReduce maintenance costsMetallic material coating processesHeat-affected zoneSlag

The invention belongs to the technical field of laser cladding, relates to a laser cladding repairing method for aircraft end-journal part surface, particularly to a method for repairing the mechanical wear and scrape malfunction of an aircraft end-journal part after long-time service by adopting the laser fused deposition technology. The method aims at mechanical wear, scrape and other defects on the surface of the part, selects spherical precipitation to harden stainless steel metal dust, adopts reasonable laser cladding technological parameters, and removes residual stress of the part after cladding through the specific heat treatment technology to recover the performance of the aircraft end-journal and realize repairing of lengthening the service life. The repaired end-journal part hardly deforms, and the depth of a heat affected area is no more than 0.5mm; the repairing area does not have the defects of cracks, incomplete fusion and slag inclusion; the serviceability of the repaired end-journal is recovered.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Laser marking device with environment protection function

InactiveCN103008890AReduce noiseAvoid pollutionLaser beam welding apparatusProgrammable logic controllerWorking environment

The invention discloses a laser marking device with environment protection function. The laser marking device comprises a base, a cylindrical stand column is fixedly arranged on the base, a servo motor is arranged inside the stand column and connected with a shaft through a bearing, and the top of the shaft is fixedly connected with a turnplate. Four evenly distributed proximity switches are arranged on the periphery of the outer surface of the upper part of the stand column, four lower baffles are arranged on the upper surface of the turnplate at equal intervals and correspond to the four proximity switches in position, four limiting baffles are arranged on the lower surface of the turnplate and correspond to the lower baffles in position, a cylinder and an exhaust pipe are arranged on an upper baffle, and a PLC (Programmable Logic Controller) is respectively connected with the servo motor, the four proximity switches, the cylinder and a laser marker through electric signals. According to the laser marking device, the environment noise can be effectively reduced, the pollution of metal dust produced in laser burning of workpieces to the working environment can be avoided, and the automation of equipment can be realized.

Owner:CHINA NTAIONAL NUCLEAR TIANJIN MACHINERY

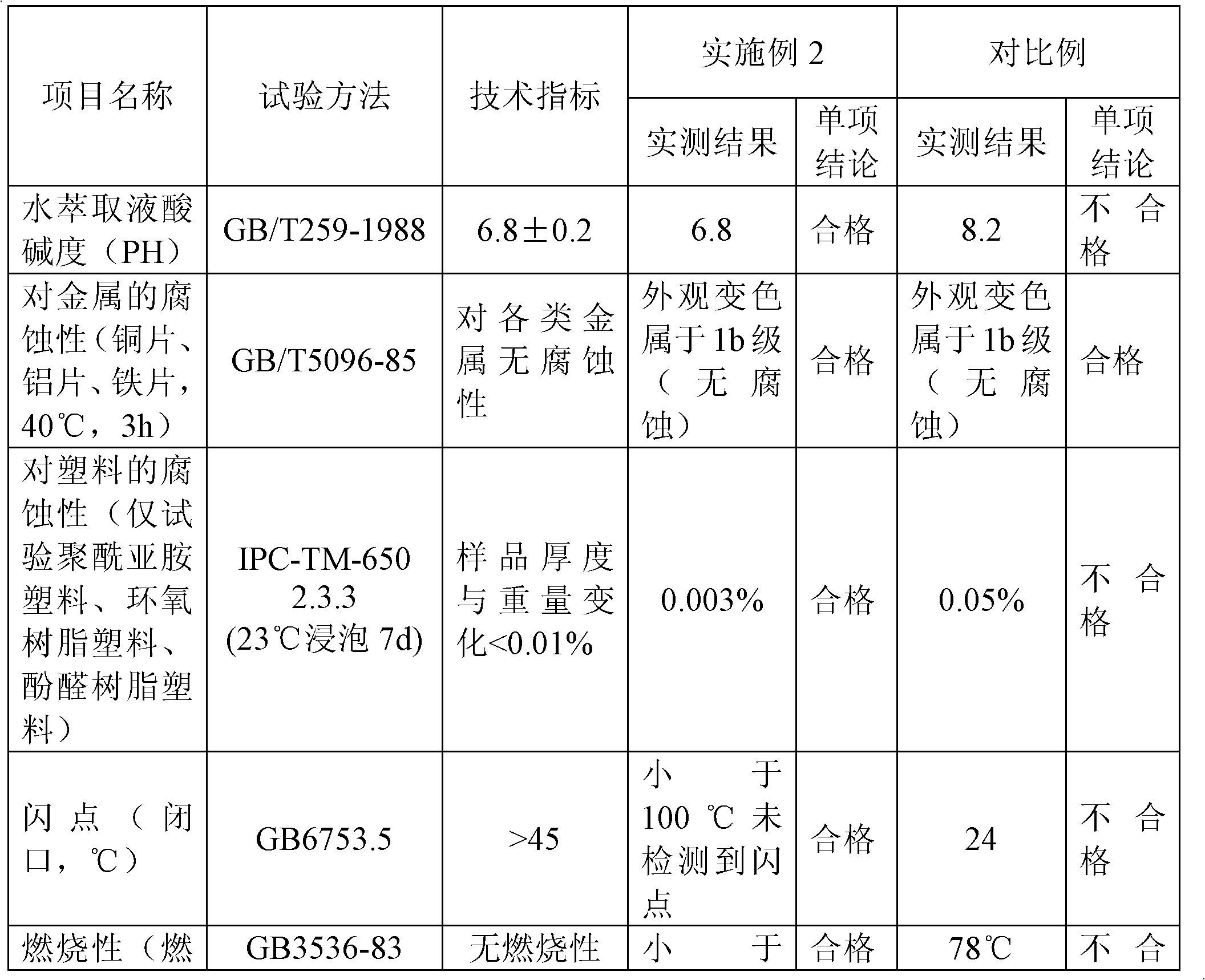

Method for realizing live cleaning of secondary equipment

ActiveCN102580937AMeet cleaning requirementsImprove insulation performanceInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsNon toxicityEngineering

The invention relates to a method for cleaning, dedusting and descaling secondary equipment, in particular to a method for realizing live cleaning of secondary equipment. During live operation of the secondary equipment, live cleaning agents are used for flushing or spray-washing the secondary equipment through a cleaning device, and a recovery device is used for recovering dirt. On the premise that the secondary equipment is not powered off and does not stop running, various dirt such as dust, greasy dirt, moisture, salt, metal dust, carbon stains and the like on the surface and in a deep layer of the equipment can be safely and efficiently cleaned, high safety of high insulation, non-toxicity, non-combustibility, corrosion resistance and the like is achieved, and the gap of safely cleaning the secondary equipment in live operation in the prior art is filled. The method makes a great breakthrough, and has fine application prospect in the field of secondary equipment maintenance.

Owner:广州华盈电气科技有限公司

Conductive plastic material and its preparation method and application

InactiveCN1995128AImprove conductivityImprove mechanical propertiesOther chemical processesMagnetic/electric field screeningPlastic materialsMetallic materials

The invention discloses a conductive plastic material which comprises (by weight ratio) the following materials (by weight percent): carbon black, conductive substance consisting of metal dust and conductive high polymers 10-50%, plastic resin 40-70%, filler 5-10% and auxiliary agent 5-10%. The invention also discloses the process for preparing the material.

Owner:JIANGMEN KANHOO IND

Special cleaning agent for insulators and preparation method thereof

ActiveCN101629129ANo environmental pollutionLess corrosiveNon-ionic surface-active compoundsDetergent compounding agentsPhenyl EthersDecomposition

The invention provides a special cleaning agent for insulators, which comprises the following components in percentage by mass: 1 to 20 percent of polyethyleneglycol octyl phenyl ether, 1 to 20 percent of nonylphenol polyoxyethylene ether, 1 to 3 percent of dichloromethane, 5 to 20 percent of C5H2F10, 10 to 30 percent of C3HCl2F5, and 5 to 15 percent of C2Cl3H3. The invention also provides a preparation method for the special cleaning agent for the insulators, which comprises the following steps: filling the components into a closed container according to the proportion, and reacting the mixture for 1 hour under normal pressure at the temperature of between 20 and 30 DEG C. The cleaning agent has the advantages of non environment pollution, low erosion, strong physical decomposition capacity and safe and reliable use, and can quickly and thoroughly clean various insulators, deep dust, oil stain, impregnated carbon, salinity, moisture and metal dust and various charged particles, effectively eliminate 'flexible fault', ensure the optimal working state of equipment and reduce the maintenance cost.

Owner:SHANGHAI SHENJIE ENVIRONMENTAL PROTECTION TECH DEV

Preparation method of nano tourmaline modified dust removal filter material

ActiveCN107261641AHigh pyroelectric coefficientImprove charging capacityDispersed particle filtrationMembrane filtersEmulsionTest sample

The invention discloses a preparation method of a nano tourmaline modified dust removal filter material, which belongs to the technical field of high-temperature smoke dust removal. The preparation method comprises the following steps: carrying out heat treatment for nano tourmaline powder; weighing sodium hexametaphosphate and sodium polyacrylate, and mixing the sodium hexametaphosphate and sodium polyacrylate with water; weighing nano tourmaline powder, adding water, and mixing with PTFE emulsion; adding the sodium hexametaphosphate and sodium polyacrylate into a mixed solution of the nano tourmaline powder and PTFE emulsion, and obtaining a nano tourmaline treatment solution; soaking a filter material test sample in the nano tourmaline treatment solution, and obtaining a nano tourmaline filter material; and polarizing the nano tourmaline filter material by virtue of electrets, and obtaining the nano tourmaline modified dust removal filter material. By adopting the preparation method, not only is electrets performance high, small dust can be trapped, the dust filter efficiency can be improved, the dust removing rate can be increased, and the equipment resistance is reduced.

Owner:南京际华三五二一环保科技有限公司

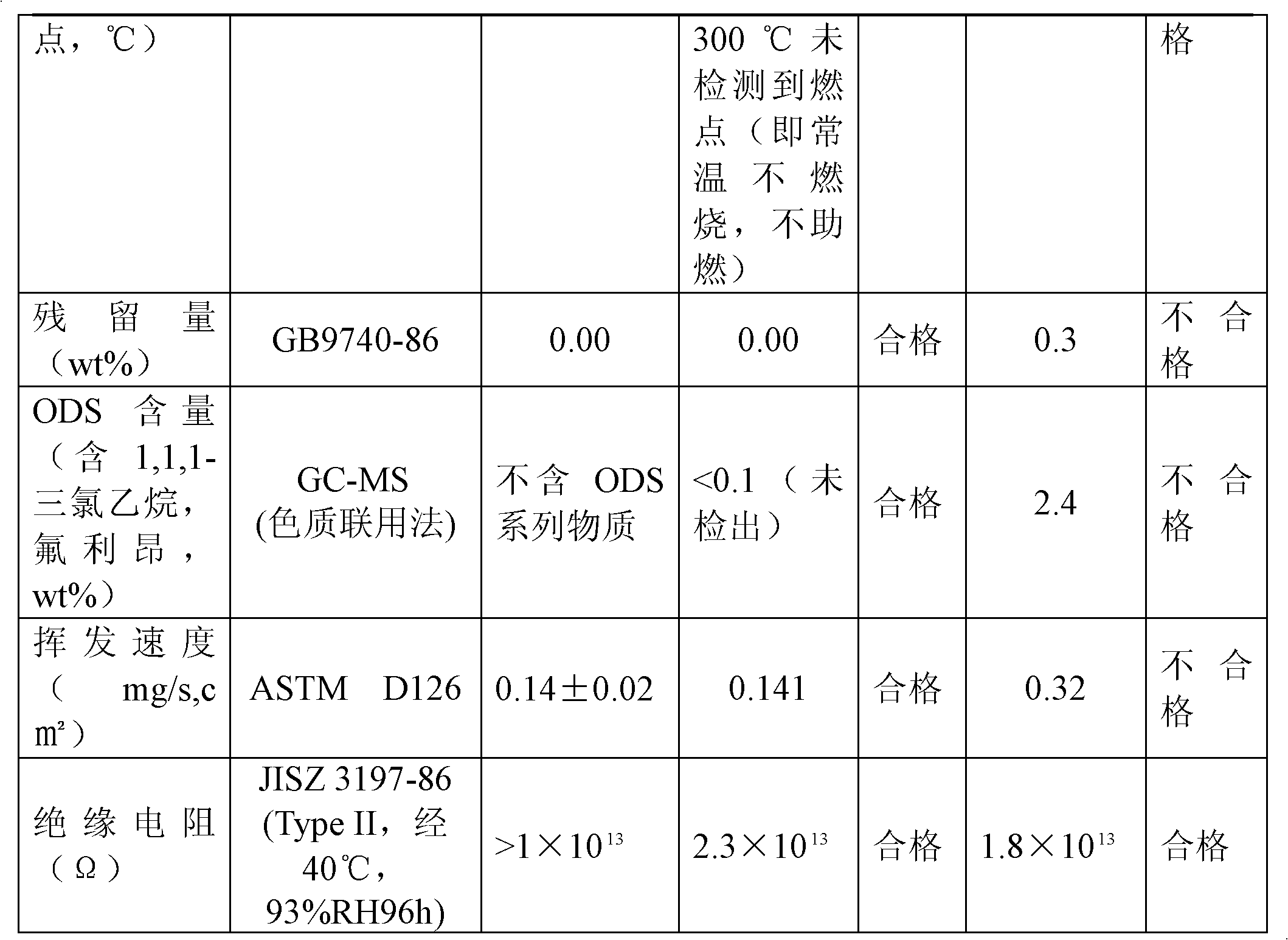

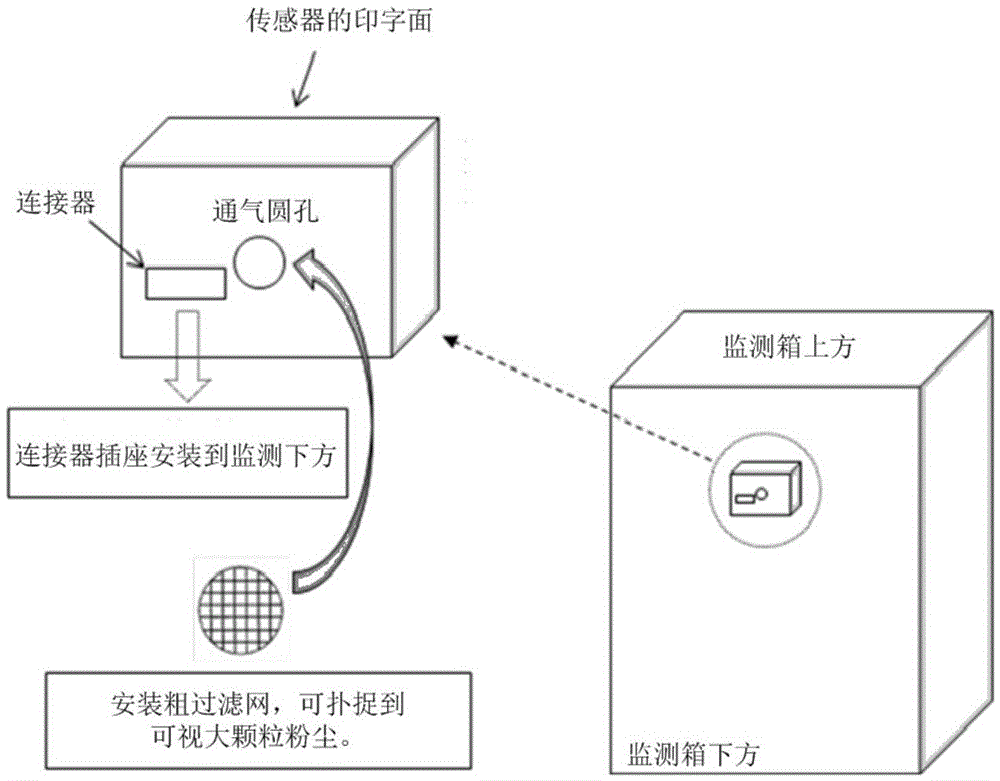

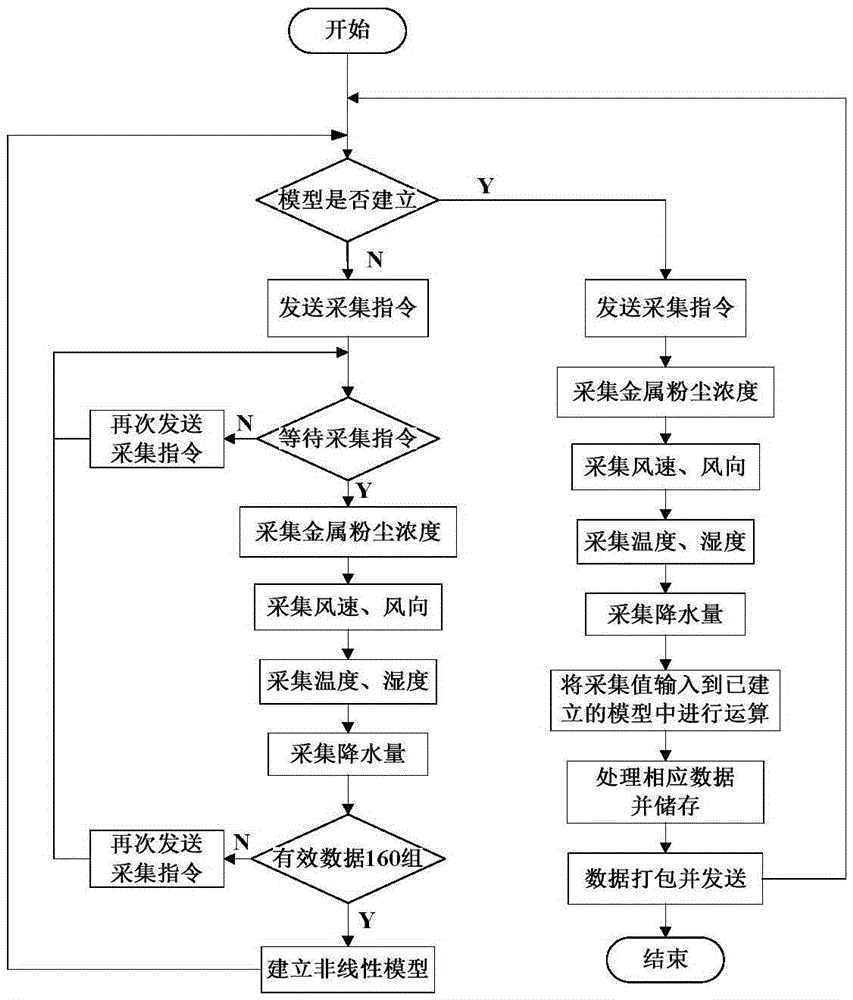

Metal dust pollution on-line monitoring device for insulator, and monitoring method thereof

ActiveCN105571644AWith automatic collection functionWith controlled collection functionParticle suspension analysisMicrocontrollerEngineering

The invention discloses a metal dust pollution on-line monitoring device for an insulator. The metal dust pollution on-line monitoring device for an insulator comprises a state monitoring device, a wind speed and wind direction sensor, a rainfall sensor and a temperature and humidity sensor, wherein the wind speed and wind direction sensor, the rainfall sensor and the temperature and humidity sensor are connected with the state monitoring device; the state monitoring device includes a microcontroller, a data storage unit and a dust concentration sensor; the data storage unit and the dust concentration sensor are connected with the microcontroller; the state monitoring device is also connected with a system power supply and a GPRS / 3G communication module; the GPRS / 3G communication module is connected with a background monitoring center and the system power supply; and the wind speed and wind direction sensor, the rainfall sensor and the temperature and humidity sensor are connected with the microcontroller. The metal dust pollution on-line monitoring device for an insulator solves the problems that a leakage current method in the prior art is easily interfered by electromagnetism so that misdeclaration and declaration failure is easy to occur, or a fiber salt deposit density monitoring method cannot reflect the accumulated degree of metal dust for the special environment of steel works, and cannot accurately monitor the pollution degree of an insulator of the steel works. The invention discloses a monitoring method by using the metal dust pollution on-line monitoring device for an insulator.

Owner:XI'AN POLYTECHNIC UNIVERSITY

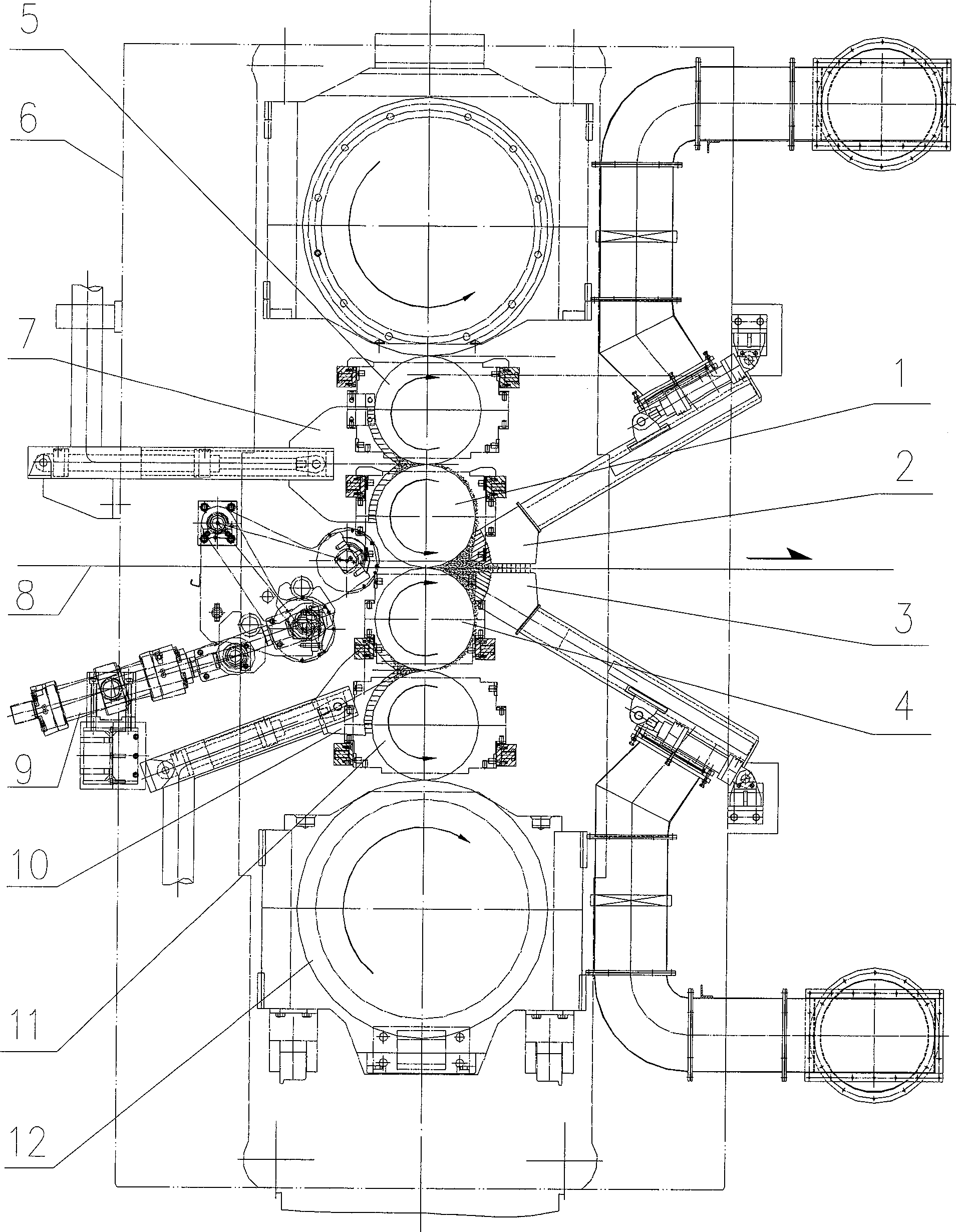

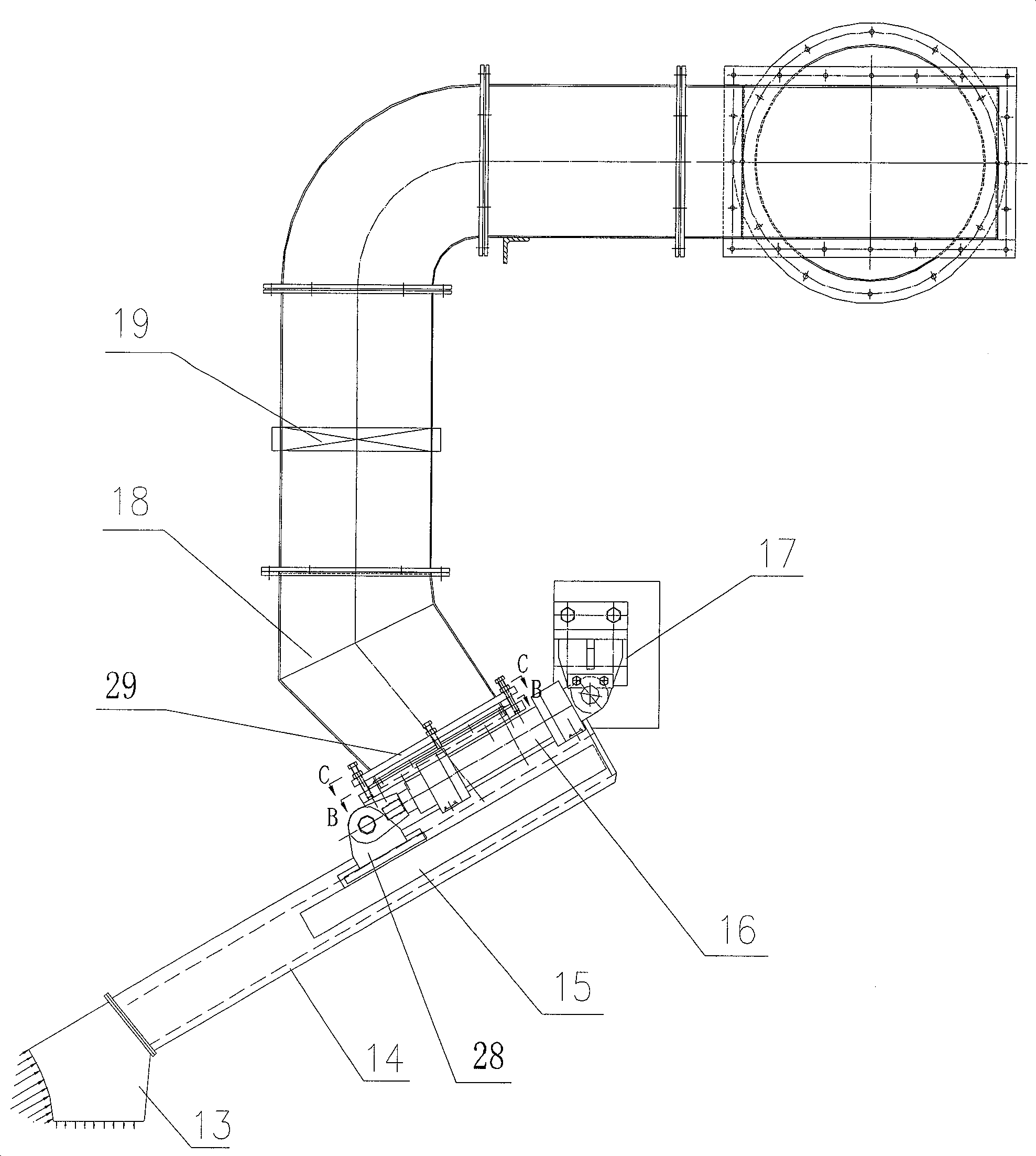

Dry-type planishing mill non-contact type roller cleaning method

ActiveCN101433914AGuaranteed strip surface qualityQuality assuranceRolling equipment maintainenceMetal rolling arrangementsStrip steelPlanishing

The invention belongs to the filed of cleaning and leveling of strip steel, in particular to a non-contact roll cleaning method for a dry planishing mill. The non-contact roll cleaning method for the dry planishing mill is characterized in that: 1) a first dust suction hood and a second dust suction hood are arranged on a roll gap of an upper working roll and a lower working roll on the outlet side of the dry planishing mill in the flying direction of metallic dust, and suck away the metallic dust, wherein the first dust suction hood is positioned above a strip steel passing line, and the second dust suction hood is positioned below the strip steel passing line; and 2) a third dust suction hood is arranged on a roll gap of the upper working roll and an upper intermediate roll on the inlet side of the dry planishing mill in the flying direction of the metallic dust, and suck away the metallic dust; and a fourth dust suction hood is arranged on a roll gap of the lower working roll and a lower intermediate roll on the inlet side of the dry planishing mill in the flying direction of the metallic dust, and suck away the metallic dust. The method can improve the surface quality of strip steel and cleaning of the rolls and avoid surface damage to the rolls.

Owner:WISDRI ENG & RES INC LTD

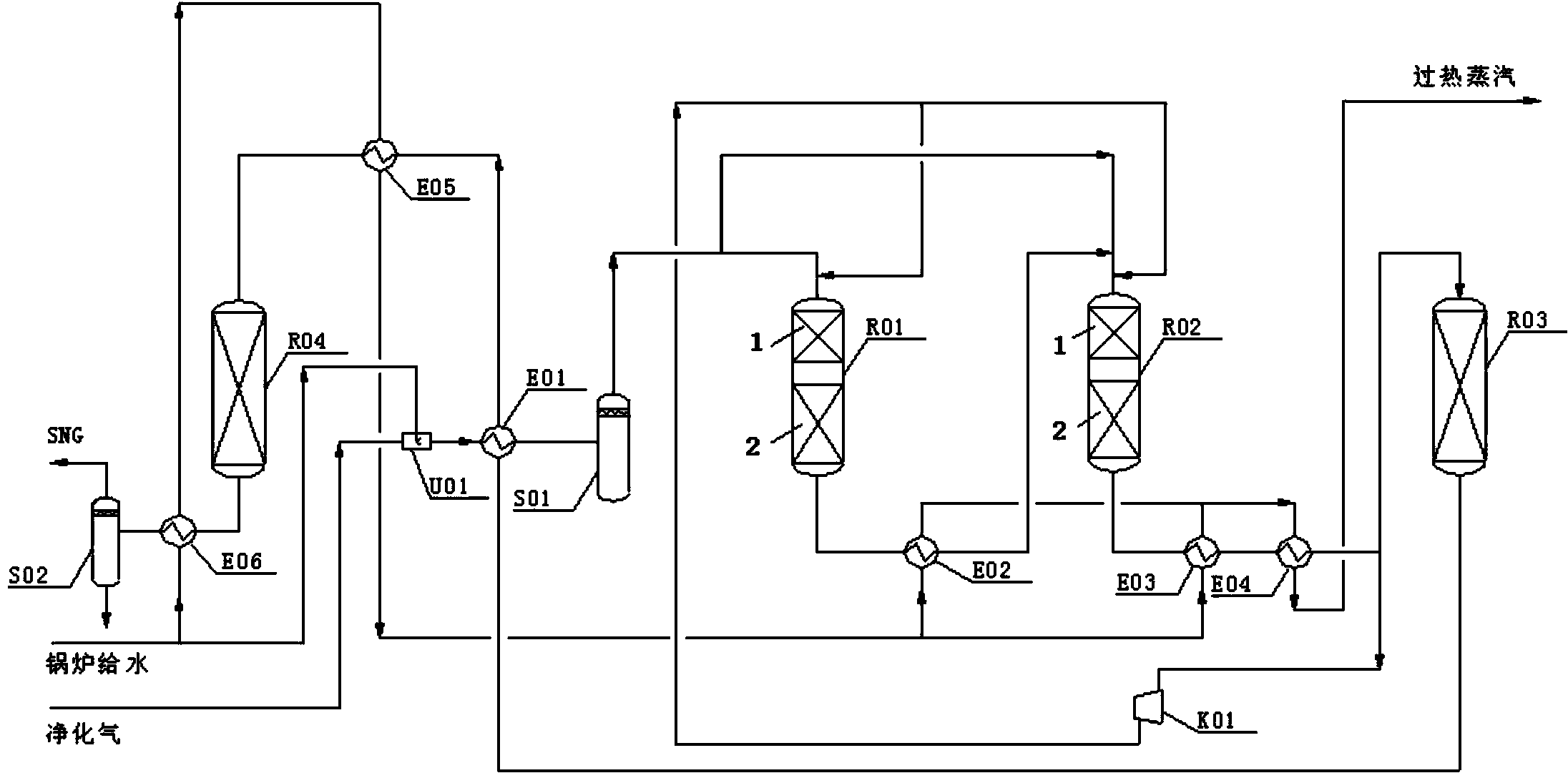

Coal natural gas methanation technology and system thereof

ActiveCN103450960AGuarantee product qualityExtended service lifeGaseous fuelsMethanationReaction temperature

The invention relates to a coal natural gas methanation technology and a system thereof. The problems that in the existing methanation technology, system operation reliability awaits improvement, reaction temperature and reaction balance control is hard, catalyst service life is short, and a metal dust reaction is easy to happen are solved. The coal natural gas methanation technology comprises the steps that purified gas from an upstream purifying device sequentially passes four series-connection methane reactors, a number2 boiler water supply preheater and a number2 separator to obtain synthetic natural gas, the purified gas and boiler supplied water which is supplied at intervals are sprayed by an ejector in a mixed mode, then the temperature of the purified gas rises to 280-350 DEG C through a purified gas preheater, and the purified gas and steam after separation through a number1 separator are mixed and then sent to the four series-connection methane reactors. The technology is simple, device operation and investment cost is low, energy is saved, the environment is protected, and the system is high in operation stability, long in service life of catalysts, and good in heat energy recovery effect.

Owner:WUHUAN ENG

Dust removal device for spring production

The invention discloses a dust removal device for spring production. The dust removal device comprises a dust removal chamber, a dust collection hopper and an air inlet, wherein an air inlet pipe is arranged at the bottom of the air inlet; an air blower is arranged on the air inlet pipe; the air inlet pipe penetrates through the air blower; one end of the air inlet pipe is connected with the dustremoval chamber; a control panel is arranged at the left middle of the dust removal chamber; a first filter screen and a second filter screen are arranged on the left and right sides of the top of thedust removal chamber respectively; a dust falling port is formed in the bottom of the dust removal chamber; a valve A is arranged on the dust falling port; an air outlet is formed in the middle of the right side of the dust removal chamber. According to the dust removal device disclosed by the invention, relatively large metal dust particles are subjected to primary filtration through the firstfilter screen and the second filter screen in the dust removal chamber; adsorption settlement is formed at the moment of sufficient contact between metal dust and water through a water storage tank atone end of the air guide pipe, thus, thorough removal of the metal dust is facilitated, the using effect of the dust removal effect is improved, and the dust removal device is relatively practical and suitable for wide popularization and application.

Owner:NANJING LISHUI LIHUA SPRING FACTORY

Metallization of substrate(s) by a liquid/vapor deposition process

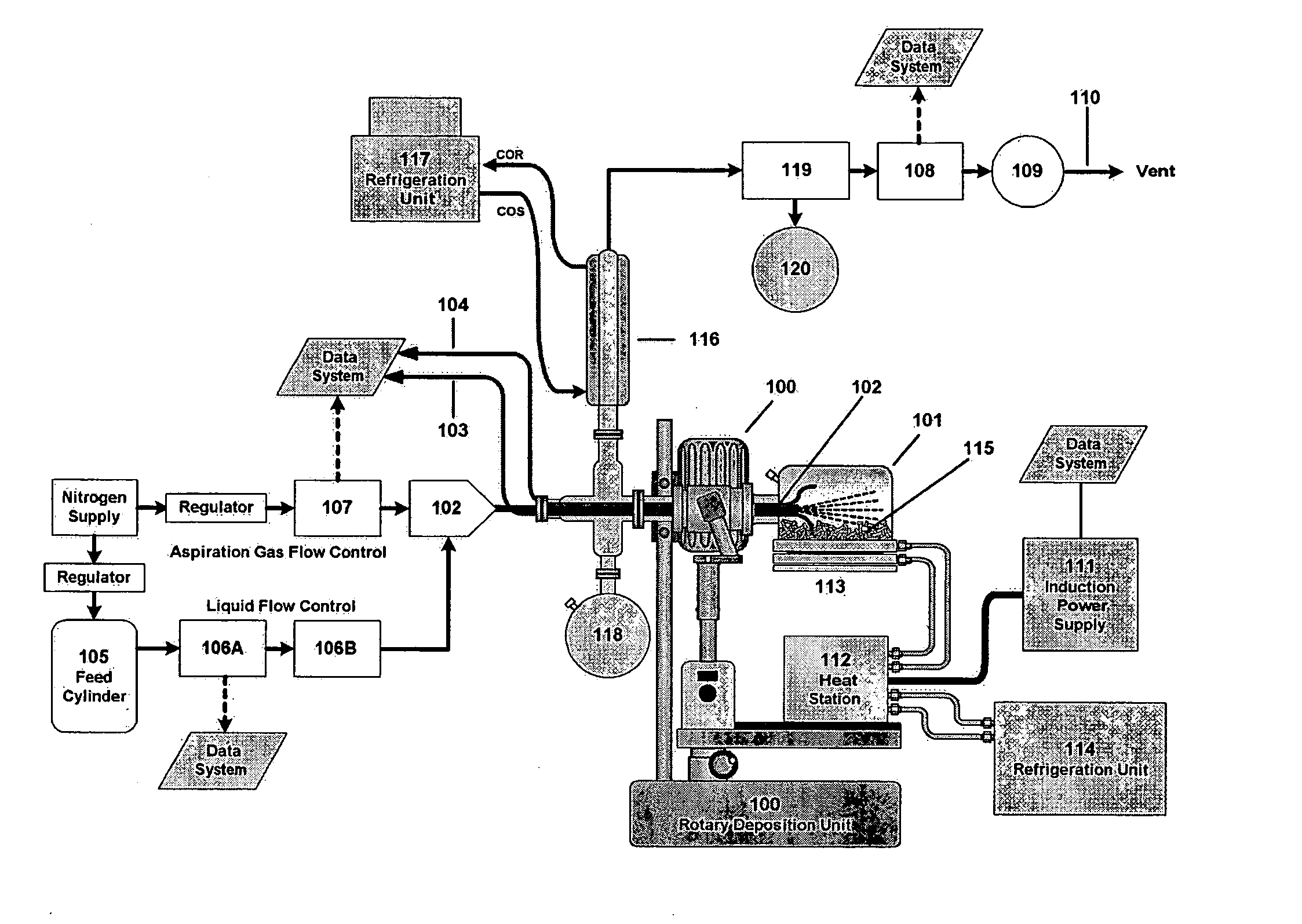

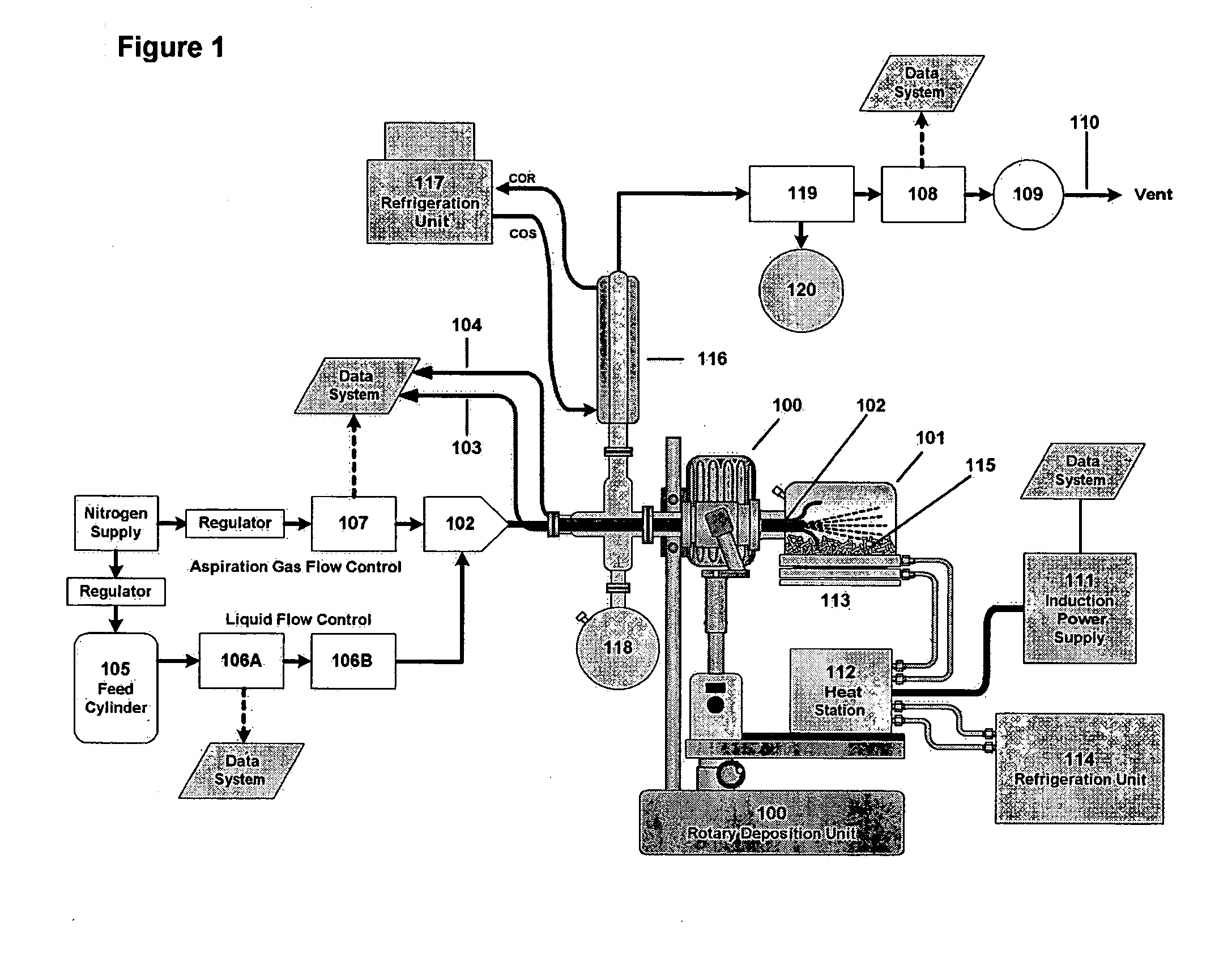

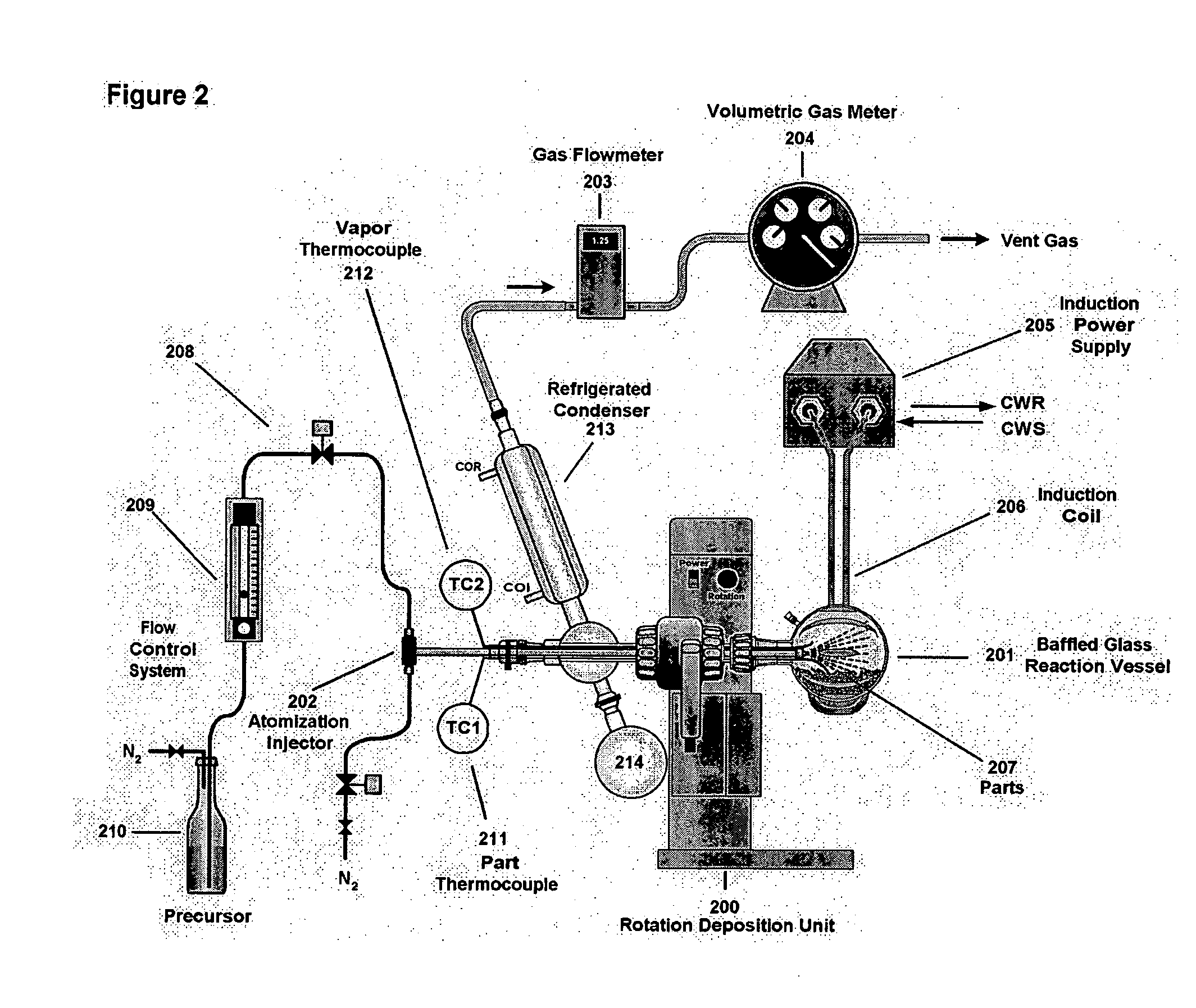

InactiveUS20050064211A1Improve deposition qualityReduce productionDielectric heatingInduction heatingTemperature controlGas phase

A process for depositing a substantially pure, conformal metal layer on one or more substrates through the decomposition of a metal-containing precursor. During this deposition process, the substrate(s) is maintained at a temperature greater than the decomposition temperature of the precursor while the surrounding atmosphere is maintained at a temperature lower than the decomposition temperature of the precursor. The precursor is dispersed within a transport medium, e.g., a vapor phase. The concentration of the metal-containing precursor(s) in the vapor phase, which also contains liquid therein, can be at a level to provide conditions at or near saturation for the metal precursor(s). In ensuring the aforementioned temperature control between the transport media and substrate, and in maintaining saturation conditions for the transport media, the quality of the deposited metal thin film is markedly improved and the production of by-product metal dust is greatly reduced or substantially eliminated.

Owner:AKZO NOBEL NV

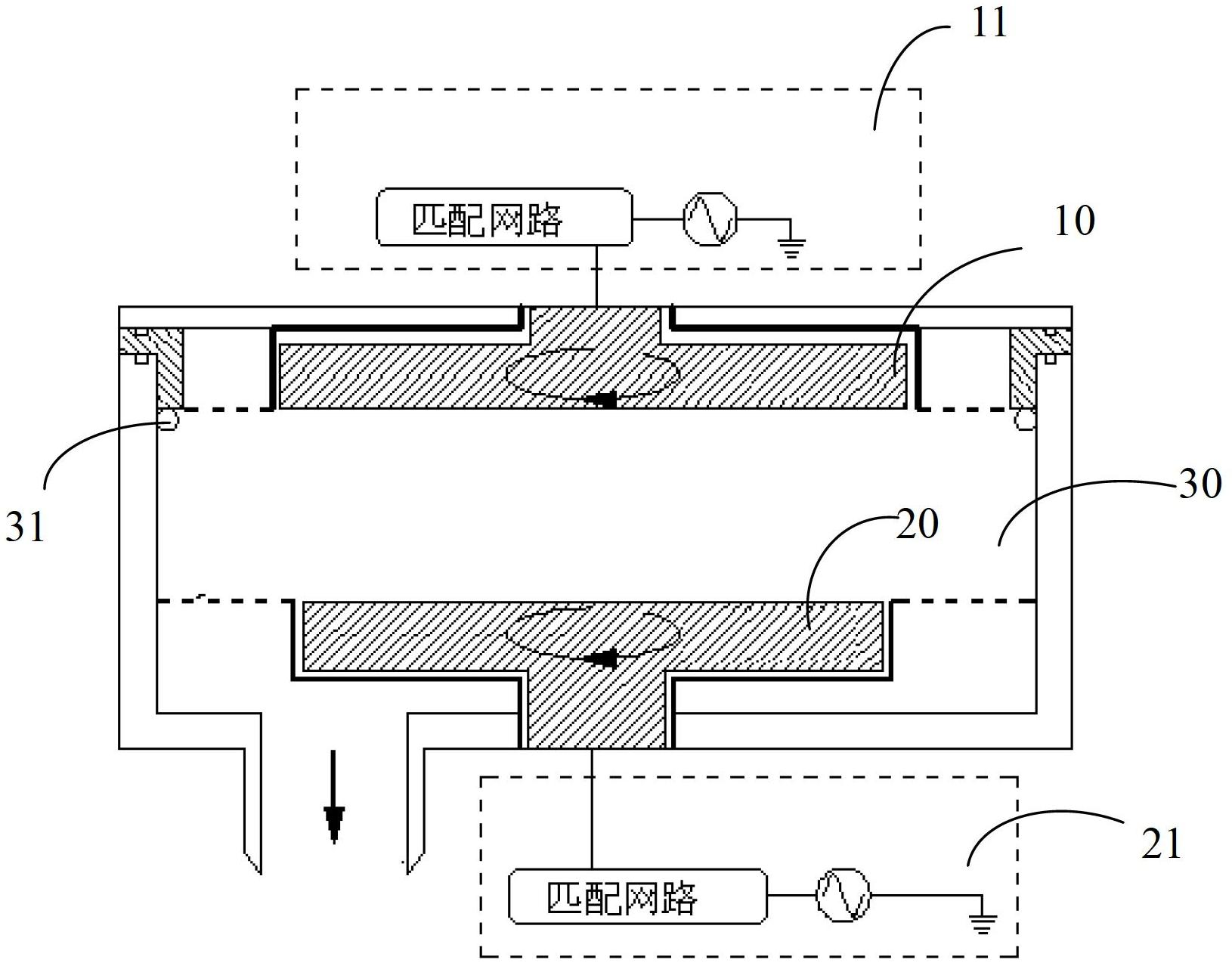

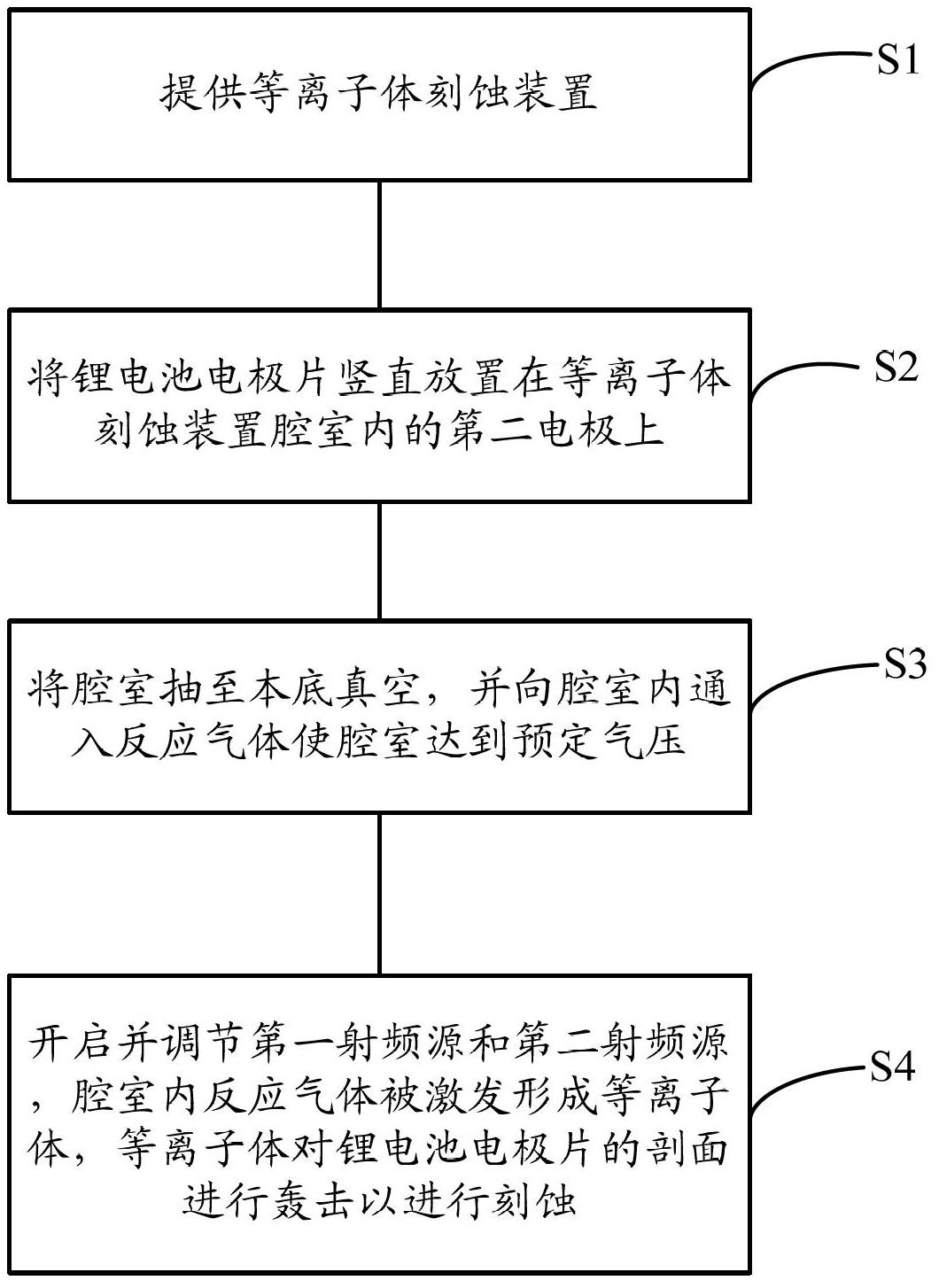

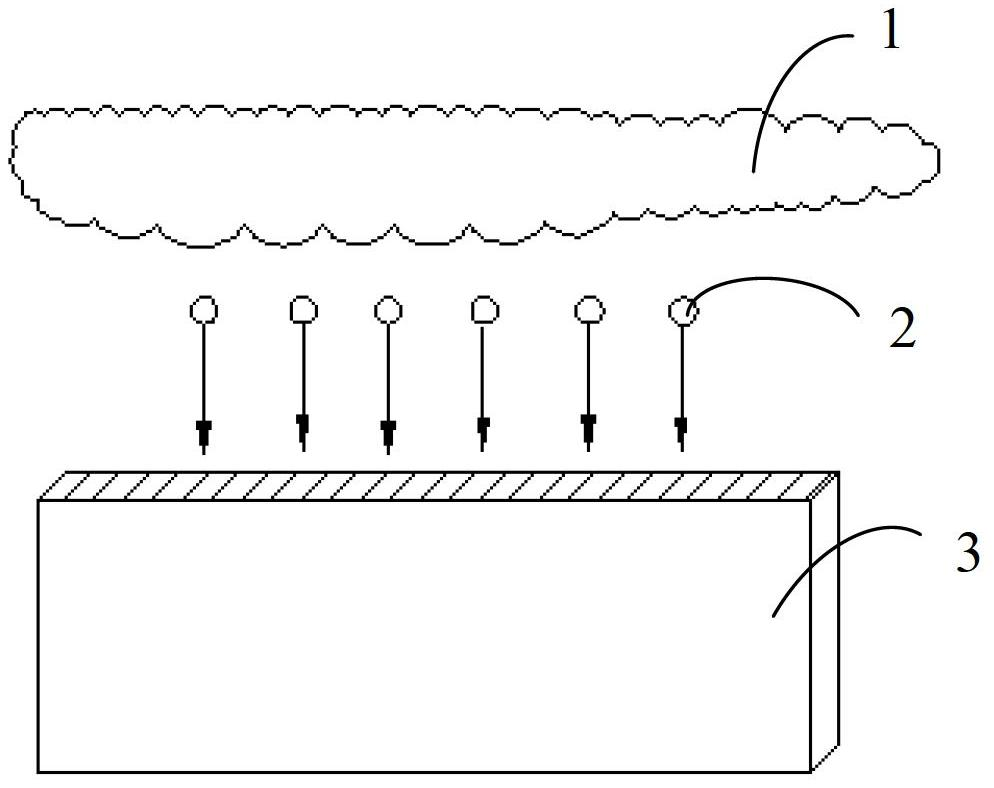

Method and device for treating burrs of electrode plate of lithium battery

InactiveCN102691066AEliminates the risk of internal short circuitsAlkaline accumulator electrodesHigh energyEngineering

The invention discloses a method and a device for treating burrs of an electrode plate of a lithium battery. The method comprises the following steps of: S1, providing a plasma etching device; S2, vertically placing the electrode plate of the lithium battery on a second electrode in a cavity of the plasma etching device; S3, pumping the cavity to reach background vacuum, and introducing reaction gas in the cavity, so that the cavity reaches a pre-set air pressure; and S4, turning on and adjusting a first radio frequency source and a second radio frequency source; forming a plasma by exciting the reaction gas in the cavity, and etching by forcing out a section of the electrode plate of the lithium battery. According to the method and device provided by the invention, the section of the electrode plate of the lithium battery is etched by using a dry plasma etching method; and the section of the electrode plate of the lithium battery is forced out by high-energy ions in a plasma in a treating process, and an etching effect is generated, so as to remove metal burrs and metal dust at the edge of the electrode plate. Therefore, the potential safety hazard of internal short circuit, caused by the burrs at the edge of the electrode plate of the lithium battery, is eliminated.

Owner:SUZHOU UNIV

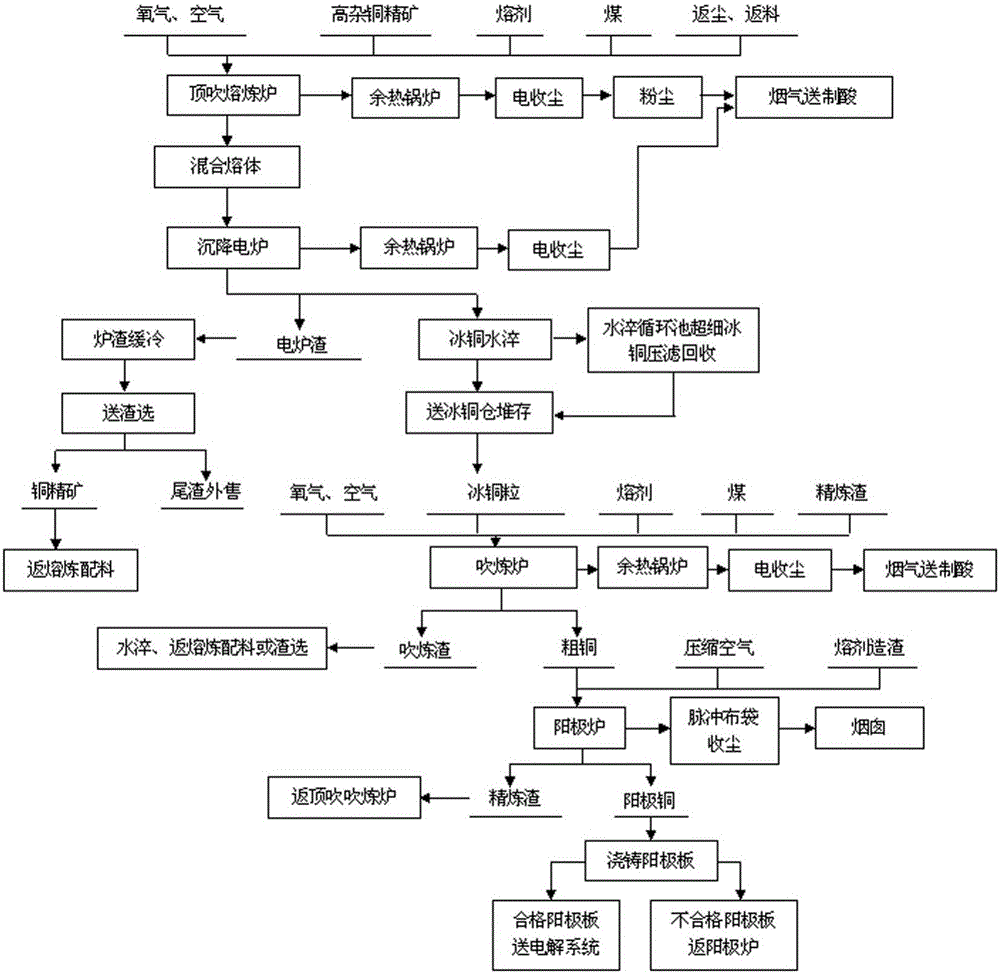

Method for recovering valuable metal from high-impurity-content copper-contained materials through double-top-blowing smelting

The invention discloses a method for recovering valuable metal from high-impurity-content copper-contained materials through double-top-blowing smelting. The method comprises the steps of mixing high-impurity-content copper concentrate with quartz sand flux, coal, returned charge and / or returned dust in a matched mode, directly adding the mixture to a top-blowing smelting furnace, blowing oxygen into the smelting furnace for smelting, and feeding obtained mixed melt into a sedimentation electric furnace to obtain electric furnace slag and high-impurity-content copper matte through sedimentation and separation; conducting water quenching on the high-impurity-content copper matte to obtain copper matte particles; mixing the high-impurity-content copper matte, the quartz sand flux, the coal and refining slag in a matched mode, adding the mixture into a top-blowing converting furnace, and blowing oxygen into the converting furnace for converting to obtain blister copper and converting slag; mixing the electric furnace slag with the converting slag according to the weight ratio of 3:1-5:1, feeding the mixture into a slag mineral separation system to recover copper concentrate; placing the blister copper into an oxygen-rich combustion type anode furnace to be refined, and conducting casting to obtain a copper anode plate. By the adoption of the method, the adaptability of smelting equipment to the copper-contained materials such as the high-impurity-content copper concentrate can be improved, valuable metal in the high-impurity-content copper concentrate or / and the high-impurity-content copper matte can be effectively recovered, valuable metal dust contained in smoke generated during smelting can be effectively recovered, the technology is simple, and environment pollution is light.

Owner:YUNNAN TIN

Grinding device for hardware

InactiveCN105538082AImprove processing efficiencySimple structureEdge grinding machinesGrinding drivesEngineeringHardness

Owner:WUXI FUMEI LIGHT ALLOY TECH

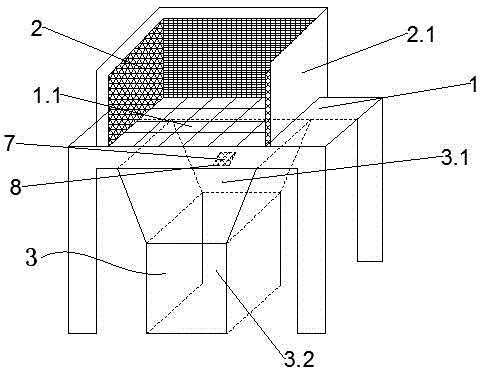

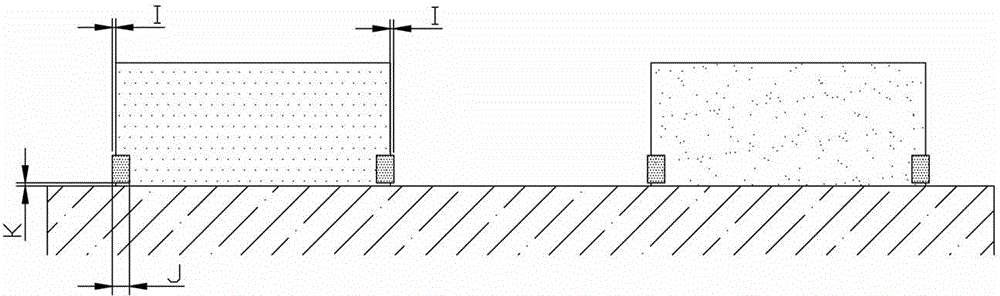

Device for controlling and collecting aluminum and magnesium powder generated by polishing, grinding and wiredrawing on platform

InactiveCN104588387APrevent proliferationReduce the likelihood of an explosionSievingPolishing machinesParticulatesLow voltage

The invention discloses a device for collecting aluminum and magnesium powder generated by polishing, grinding and wiredrawing. The device comprises an operating platform, fine grid filter screen baffles, a large particle collecting device, a small particle collecting device, a fan and a low voltage fine mist device, wherein the table board of the operating platform consists of a grid of large aperture; the large particle collecting device is arranged below a middle area of the working platform and is used for collecting large particles; the fine grid filter screen baffles are distributed at three sides of the operating platform, are connected with the small particle collecting device through a ventilating pipe and are used for collecting fine and easily-floating metal powder generated caused by grinding and blocking larger metal particles; one end of the low voltage fine mist device is connected with the small particle collecting device, and the other end of the small particle collecting device is connected with a tap water pipe; the low voltage fine mist device is used for preventing a condition that powder explosion is formed by the raising and suspending of the fine metal powder. According to the device provided by the invention, the aluminum and magnesium powder generated by polishing, grinding and wiredrawing can be effectively prevented from being diffused in the air, the possibility of the powder explosion can be reduced, and the environment of operating personnel in manufacturing shops can be improved.

Owner:SHANGHAI INST OF TECH

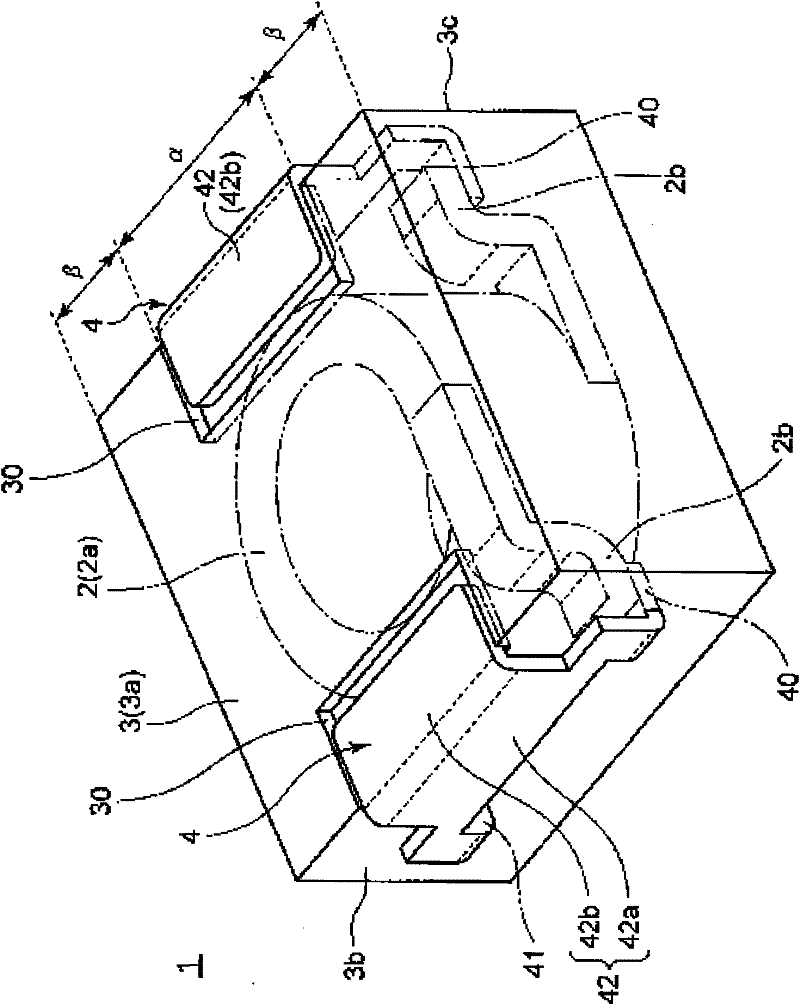

Coil encapsulated powder magnetic core and manufacturing method thereof

ActiveCN102290208AHigh strengthAvoid crackingTransformers/inductances coils/windings/connectionsThick wallEngineering

The invention provides a coil-embedded dust magnetic core and its manufacturing method, wherein the strength of the compact dust body is enhanced, when a terminal electrode is processed by bending, no crack is generated on the compact dust body. The coil embedded in the compact dust magnetic core possesses the following: the compact dust body of strong magnetic metal dust, wherein a hollow coil is embedded; a terminal electrode, which possesses a connection terminal portion connected with the edge portion of the hollow coil in the compact dust body and a terminal portion protruding to the outside of the compact dust body for external connection, wherein the terminal portion of the terminal electrode is bended along the surface of the compact dust body, and is accommodated at the surface of the compact dust body to form a terminal accommodation concave portion, and the connection terminal portion of the terminal electrode is positioned in the thick wall portion of the compact dust body wherein no terminal accommodation concave portion form.

Owner:ALPS ALPINE CO LTD

Cutting device with automatic cleaning function

InactiveCN107443155AWith automatic cleaning functionWith adjustment functionMaintainance and safety accessoriesCouplingSprayer

The invention discloses a cutting device with an automatic cleaning function, and relates to the technical field of mechanical equipment. The cutting device comprises a box. A first partition plate is fixedly connected between the two sides of the inner wall of the box. The top of the first partition plate is fixedly connected with a first motor. An output shaft of the first motor is fixedly connected with a first rotation shaft through a coupler. The end, away from the first motor, of the first rotation shaft is fixedly connected with a first belt wheel, and the surface of the first belt wheel is in transmission connection with a second belt wheel through a first belt. The axis of the second belt wheel is fixedly connected with a screw shaft, and the surface of the screw shaft is in threaded connection with a movable block. According to the cutting device with the automatic cleaning function, metal dust generated after cutting can be rapidly washed away, a sprayer has an adjusting function, dust at every place of a machine can be washed away, the surface of the machine can be rapidly blown dry after washing, and the machine has a very good automatic washing and dust removing function.

Owner:合肥众望电气科技有限公司

Process for separating iron from other metals in iron containing feed stocks

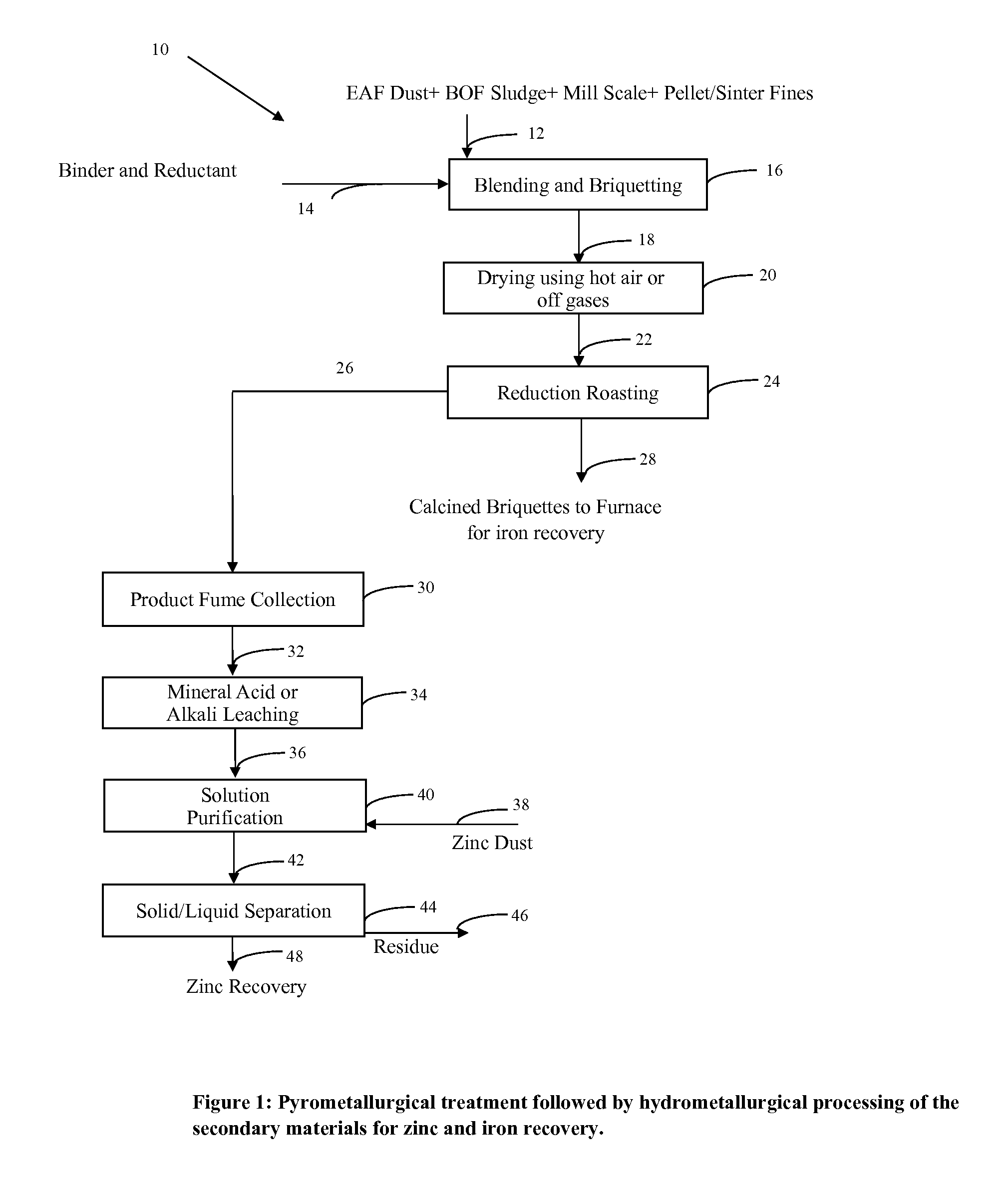

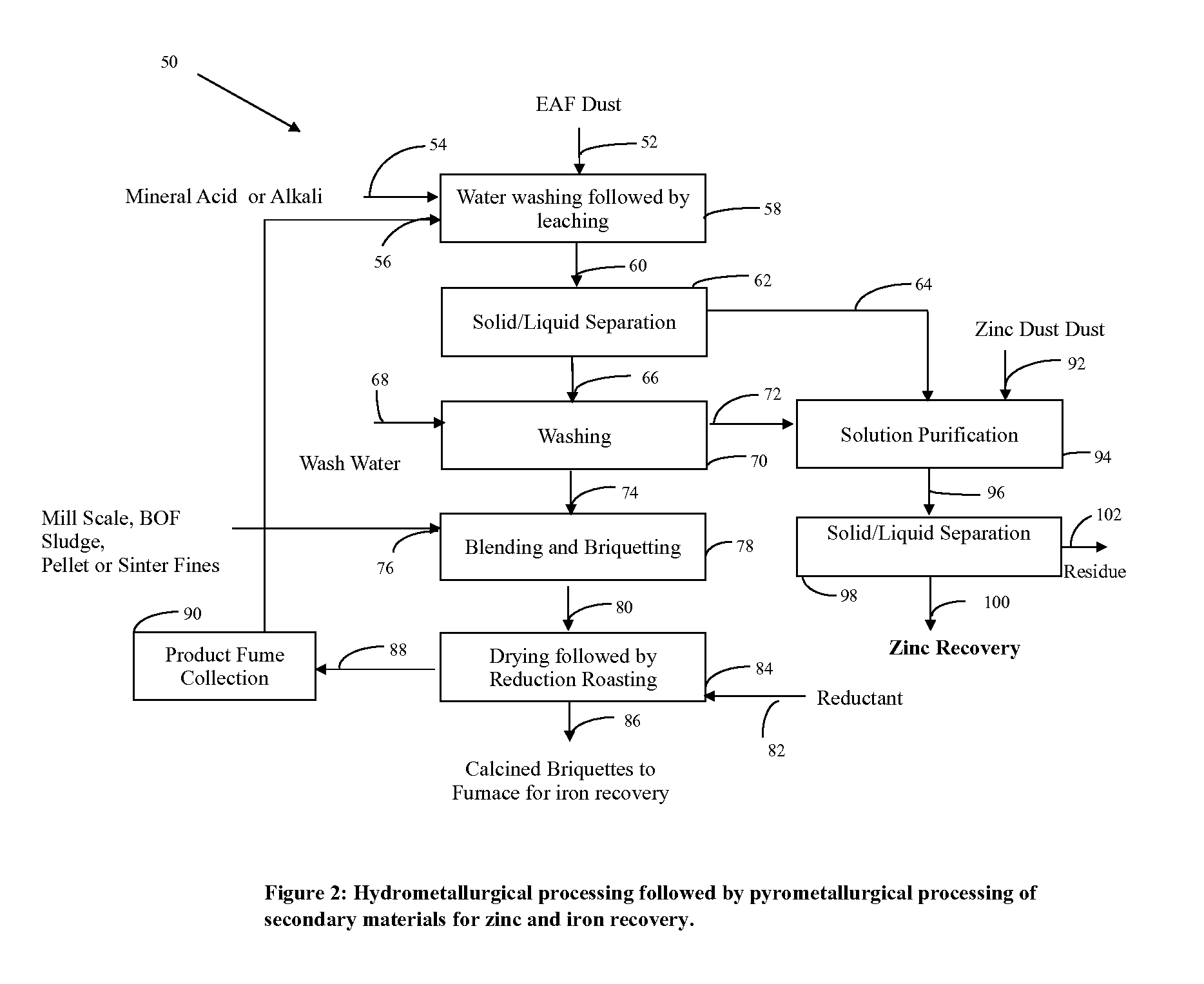

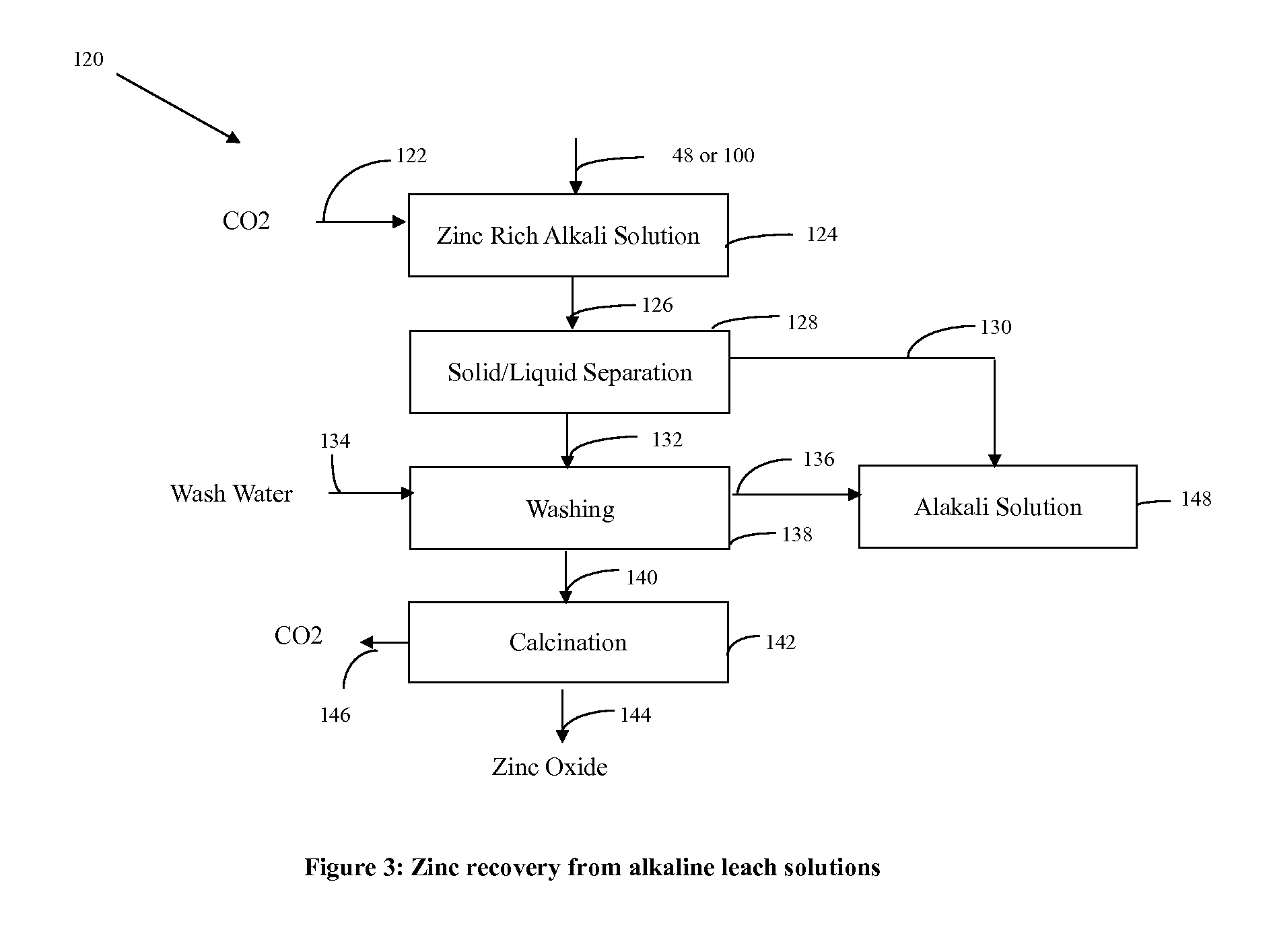

The invention is a method of separating metals such as zinc, lead and cadmium from iron in secondary feed stocks such as EAF Dust, BOF Sludge, mill scale, iron fines, tire dust and other iron and zinc containing residues and dusts. The method includes the steps of reduction roasting the feed stocks at a volatizing temperature sufficient to volatilize the zinc and other metals into metal fumes but insufficient to volatize iron and then collecting the metal fumes as a metal dust. The metal dust is then leached with a leaching liquid to form a leach liquor and a leach residue. The leach liquor is then purified by zinc dust cementation to form a purified liquor and a zinc dust cement residue. The purified liquor is then separated from the zinc dust cement residue, and a zinc recovery step is then performed on the purified liquor.

Owner:PUVVADA GEORGE

Flexible package battery lug welding method

The invention discloses a flexible package battery lug welding method. To achieve the purpose, the technical scheme adopted by the invention is that the flexible package battery lug welding method is characterized by comprising the following steps: firstly, respectively fixing positive plate exposed aluminum lug foil and negative plate exposed copper lug foil by using an aluminum piece and a nickel piece, secondly, cutting the positive plate exposed aluminum lug foil and the negative plate exposed copper lug foil, and finally welding an aluminum strip adhesive lug and a nickel strip adhesive lug on the cut positive plate exposed aluminum lug foil and the negative plate exposed copper lug foil in an ultrasonic manner. By adopting the flexible package battery lug welding method, the manufacturing cost of a flexible package battery is reduced, the metal dust pollution caused by ultrasonic vibration is reduced, the pass percent of the battery is increased, the charge / discharge property of the battery is improved, and the welding effect of the battery lugs is improved.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

Electromagnetic type metal dust collecting device

PendingCN107971133AEnsure hygieneEasy to handleCombination devicesMagnetic separationAir filterWorking environment

The invention discloses an electromagnetic type metal dust collecting device including a tank body, the bottom portion of the tank body is provided with rollers, the tank body is connected with a dust-suction inlet through a metal hose, a V-shaped pipeline is arranged in the tank body, and the inflection point of the pipeline faces down; the pipeline is provided with a fan, one end of the pipelinecommunicates with the metal hose, the other end of the pipeline is connected with an air filter element, and the inflection point position of the pipeline communicates with a metal dust collecting tank; and the lower end of the metal dust collecting tank extends out of the bottom of the tank body, a dust-discharging valve is arranged below the metal dust collecting tank, the pipeline wall is composed of electromagnets and is connected with a power supply through a guiding line, and power-on and power-off of the pipeline is controlled by a switch. Compared with the prior art, the electromagnetic type metal dust collecting device has the beneficial effects that the collecting of the metal dust can be completed, the preliminary classification can also be performed, and the hygiene of the work environment can be ensured.

Owner:江苏飞视文化发展有限公司

High-low-voltage switch cabinet having dust removing function

InactiveCN105244784AImprove securityImprove reliabilitySubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsDust controlStructural engineering

The invention discloses a high-low-voltage switch cabinet having a dust removing function. The high-low-voltage switch cabinet comprises a switch cabinet body which is horizontally arranged, wherein an installation empty cavity is formed inside the switch cabinet body, a bracket is arranged on a side wall of the switch cabinet body, a support is arranged inside the bracket, an axial flow fan is arranged on the support, the bracket is provided with a ventilation net on the outer side of the axial flow fan, the surface of the ventilation net is provided with a plurality of magnets, and a plurality of air outlets are formed in the switch cabinet body. the high-low-voltage switch cabinet is simple in structure and convenient in operation, can reduce temperature inside the switch cabinet, prolongs the service life of the switch cabinet, has a function of absorbing metal dust, greatly reduces the metal dust entering into the switch cabinet, ensures the normal operation of internal electrical components, avoids safety problems of causing short circuit and the like, is stable and reliable in operation, and reduces costs.

Owner:鼎圣集团有限公司

Iron plate punching equipment

InactiveCN106734532ANo deviationImprove punch qualityMetal-working feeding devicesDirt cleaningPunchingPhysical health

The invention discloses iron plate punching equipment which comprises a bracket. The middle of the bracket is provided with a motor base. The top of the motor base is connected with a motor. The bottom of the motor base is connected with a telescopic cylinder. The bottom of the telescopic cylinder is connected with a punching plunger chip. A fixing block is connected with each of the two sides of the bottom of the bracket. The bottoms of the fixing blocks are connected with supporting columns. The bottoms of the supporting columns are connected with suction discs. The two sides of the bracket are each provided with a telescopic stand column. The bottoms of the telescopic stand columns are provide with a worktable. The middle of the worktable is provided with a dust collection trough. An inner cavity of the dust collection trough is provided with an iron core. The surface of the iron core is connected with a coil in a winding mode. The bottom of the coil is connected with a power supply. The right side of the coil is provided with a switch. By adoption of the iron plate punching equipment, metal dust in the air is reduced and prevented from affecting physical health conditions, deviation cannot occur when the punching plunger chip punches an iron plate, and the punching quality of the iron plate is improved.

Owner:WUXI CAIYUN MACHINERY & EQUIP

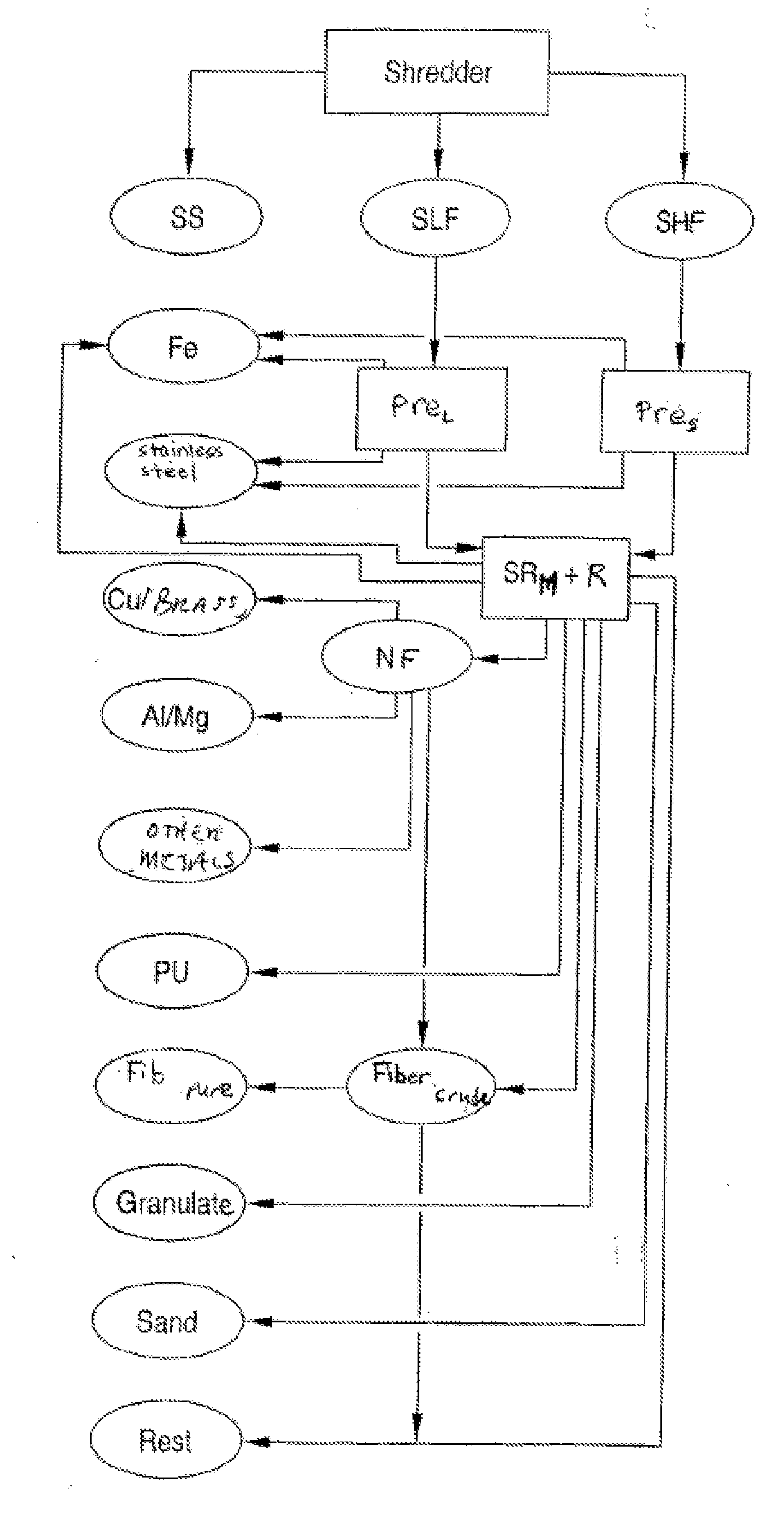

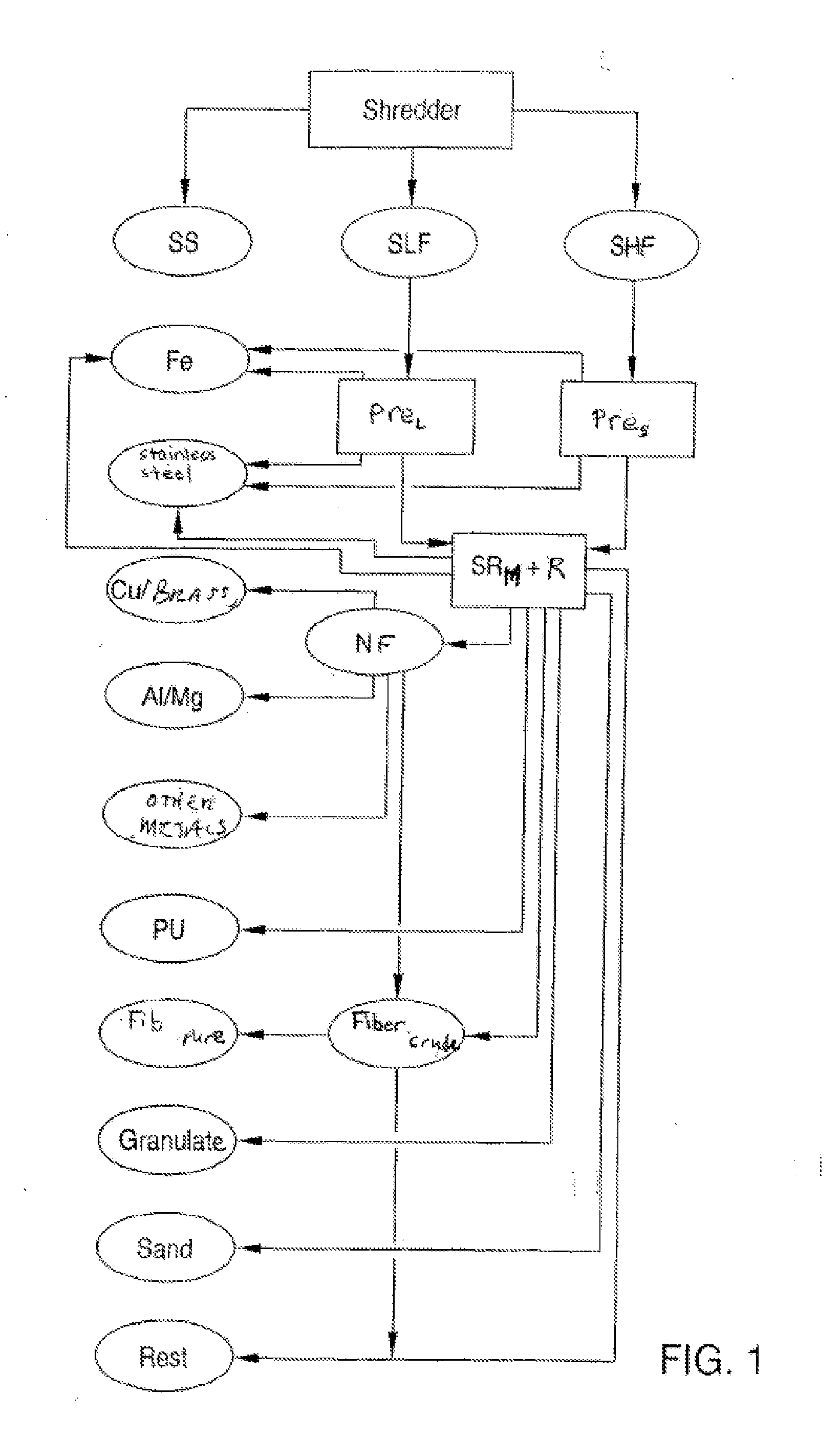

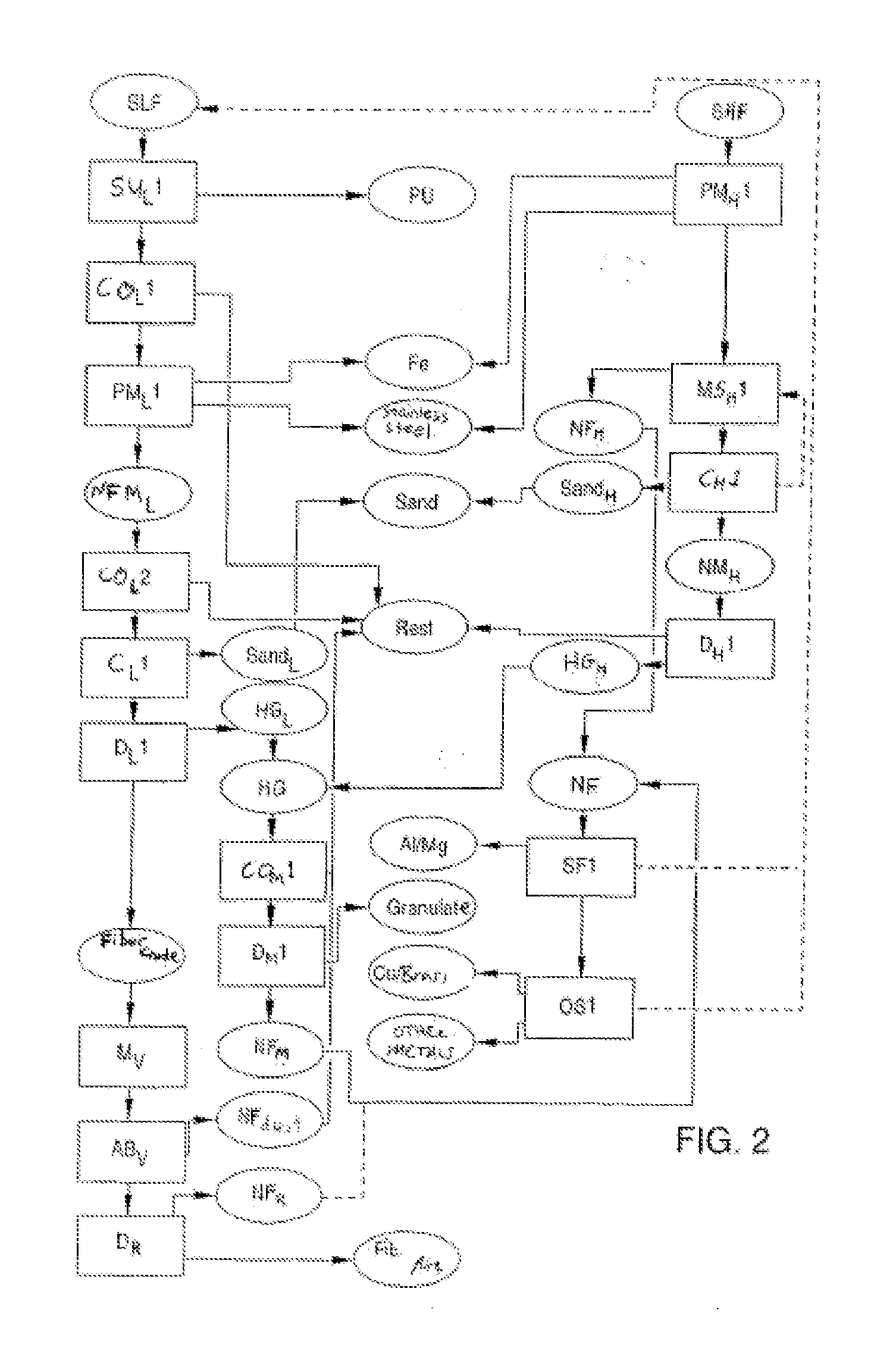

System and method for treating shredder residues and utilizing a produced fiber fraction

InactiveUS20070158242A1Reduce operating costsGas current separationSolid waste disposalMetal fiberCrude fibre

In a method for sorting shredder residues of metal-containing wastes, in particular of vehicle bodies, where the shredder residues are separated into a shredder light fraction and a non-ferromagnetic fraction) and a system for implementing the method, (a) a crude-fiber fraction being generated during the processing of the shredder light fraction and the shredder heavy fraction in preliminary processes and a main process, by extracting at least a ferromagnetic fraction, a fraction containing nonferrous metals, a granulate fraction, and a sand fraction, and (b) the crude-fiber fraction being separated into a metal-containing dust fraction, a fiber fraction depleted in metals, and a metallic fraction in a refining process, using the successive process steps of metal-balling, dust removal, and density separation.

Owner:VOLKSWAGEN AG

Battery pack cooling system for vehicle

ActiveUS8048554B2Improve cooling efficiencyReduce the possibilityCell temperature controlPropulsion by batteries/cellsToxic gasMedia filter

Disclosed herein is a cooling system for vehicle battery packs, including a double filter device mounted at an air inlet part, through which air for cooling the battery pack is introduced from the outside and / or the inside of the vehicle. The double filter includes a pre-filter having relatively large air holes, the pre-filter having high frequency of replacement, and a medium filter having relatively small air holes, the medium filter having low frequency of replacement. The pre-filter is located before the medium filter in the direction in which the air is introduced. Consequently, dust is removed from air, and therefore, the cooling efficiency of the battery pack is increased. In a preferred structure, metal dust is also effectively removed by the magnetic force applied to the medium filter. Consequently, the malfunction or short circuits of the battery pack are prevented. Also, air surrounding the battery pack is directly introduced through the through-type intake ports without passing through any pipe-shaped intake duct. Consequently, generation of noise, which is a problem caused when air in the cabin is used, and backward flow of flames and toxic gas, which are generated during a fire, are prevented. Furthermore, the battery pack is constructed in a compact structure.

Owner:LG ENERGY SOLUTION LTD

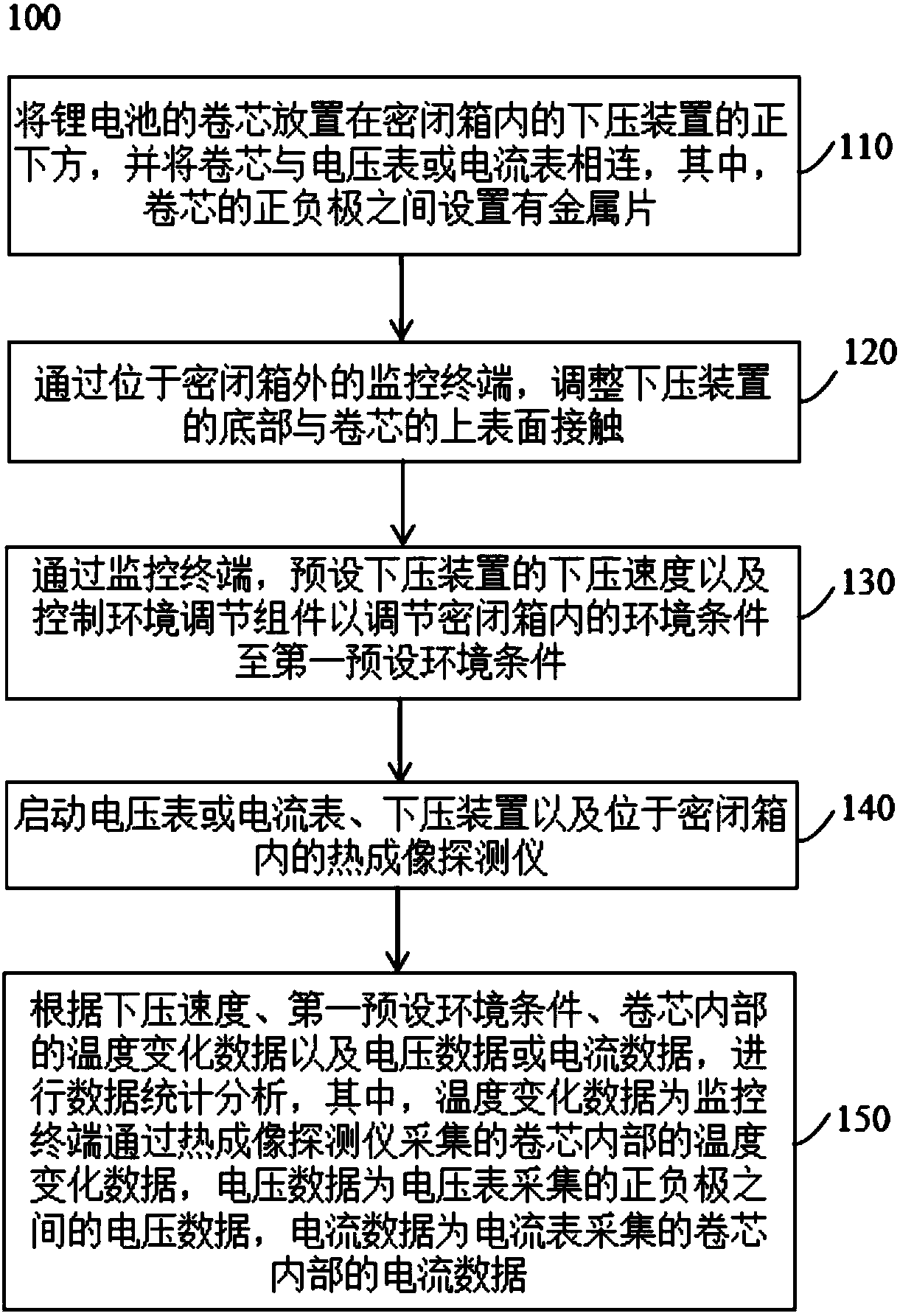

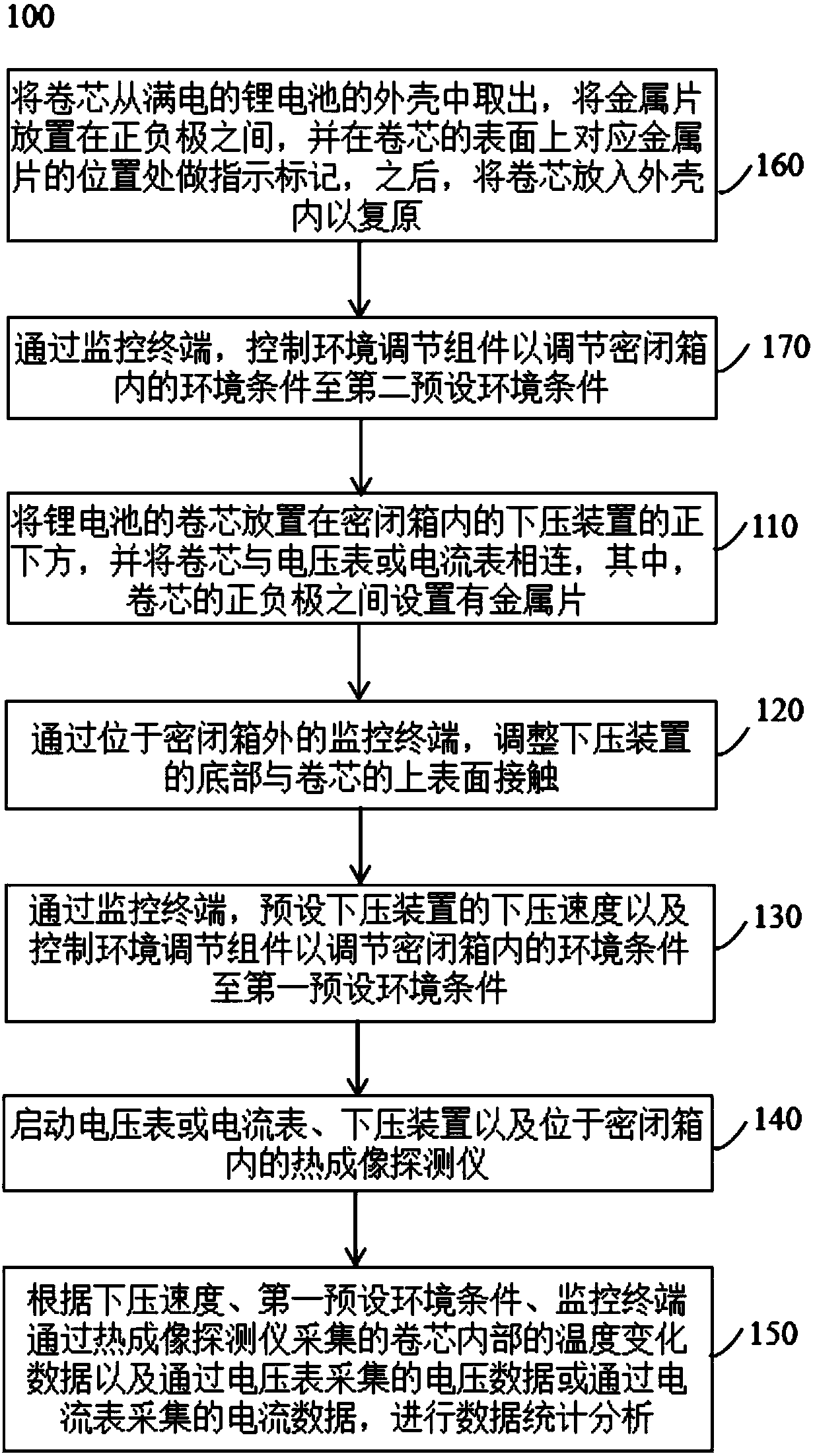

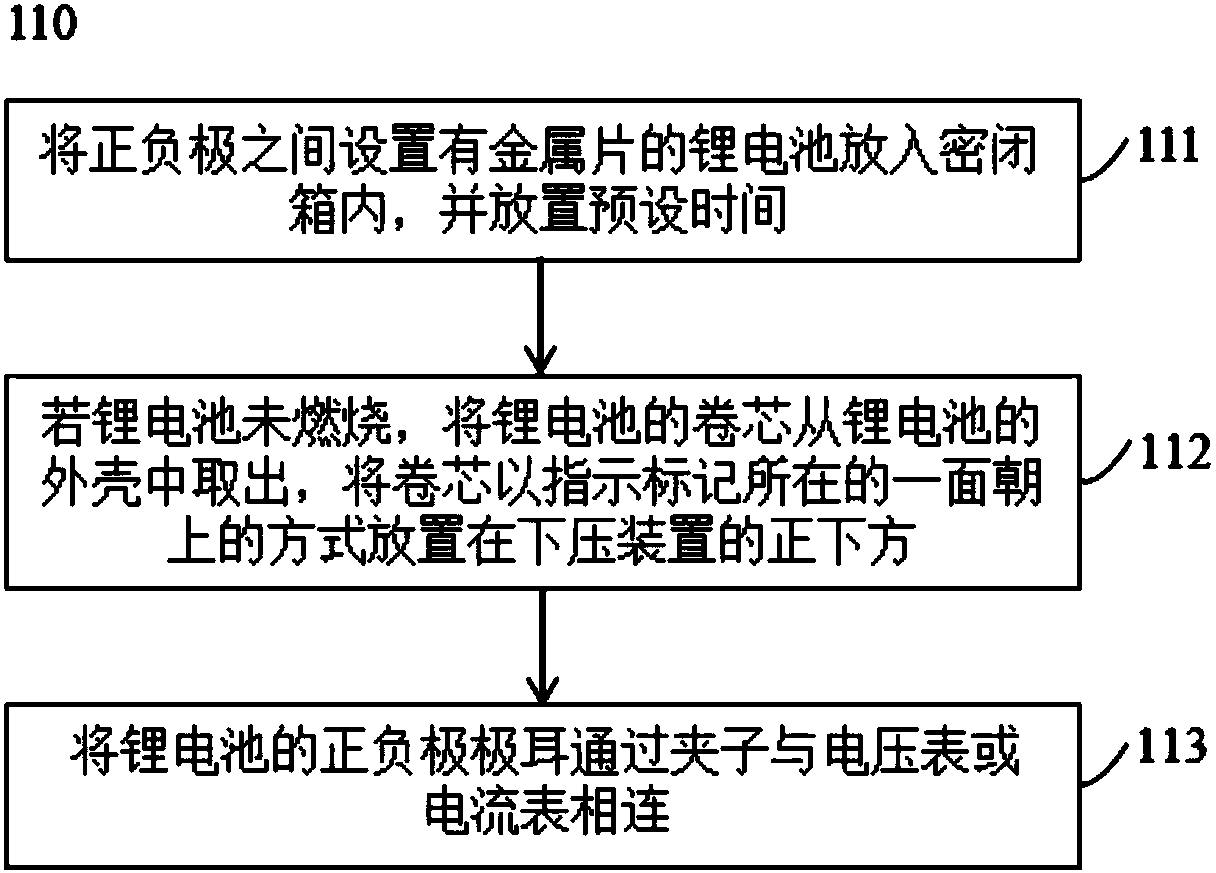

Analysis and test method based on forced internal short circuit of lithium battery

ActiveCN108267695AImprove the protective effectEasy to operateElectrical testingElectrical batteryEngineering

The invention relates to an analysis and test method based on forced internal short circuit of a lithium battery. The method comprises that the lithium battery provided with sheet metal is placed below a press-down device in a closed cabinet, different test conditions are controlled to record internal change of the lithium battery, and data is concluded and summarized to analyze concrete relationbetween the forced internal short circuit and related factors. According to the method, the phenomenon that impurities including metal dusts and particles may enter in the manufacturing process of anelectrical core is simulated, a thermo-imaging principle is used, and the internal short circuit process is reflected indirectly; and a monitoring terminal records the conditions and process of the forced internal short circuit, help is provided for conclusion and summarization of the system, and it is ensured that the safety of the battery is protected in the production process.

Owner:湖南领湃科技股份有限公司 +4

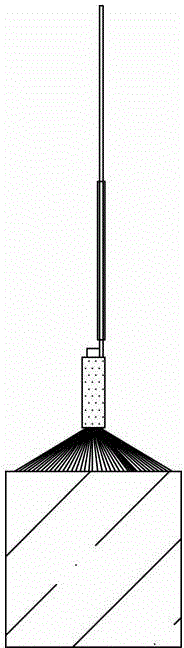

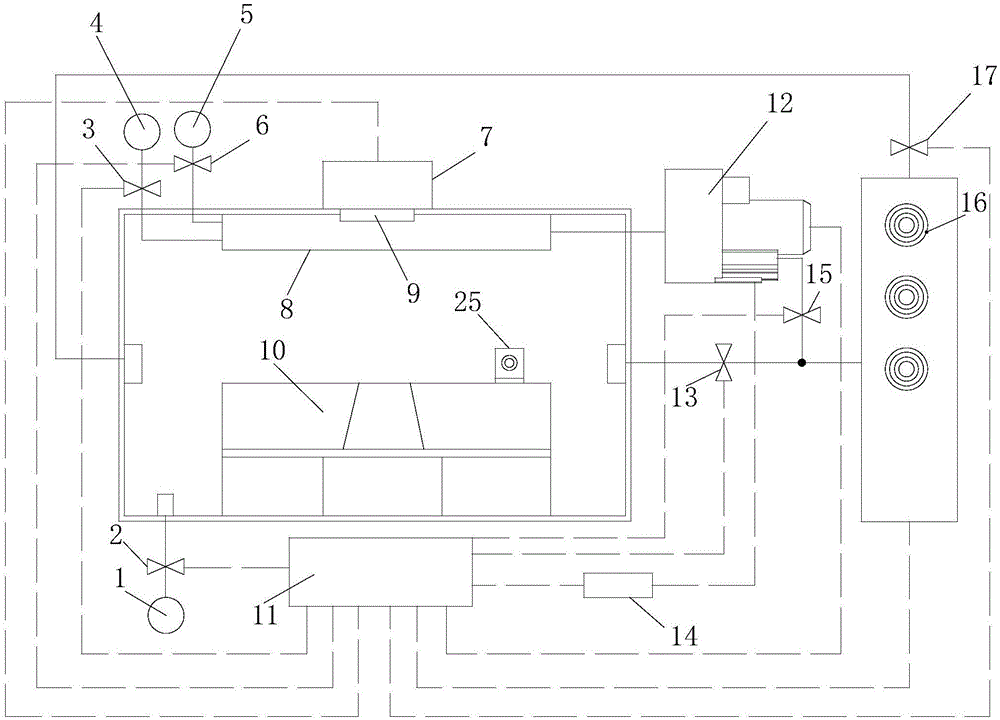

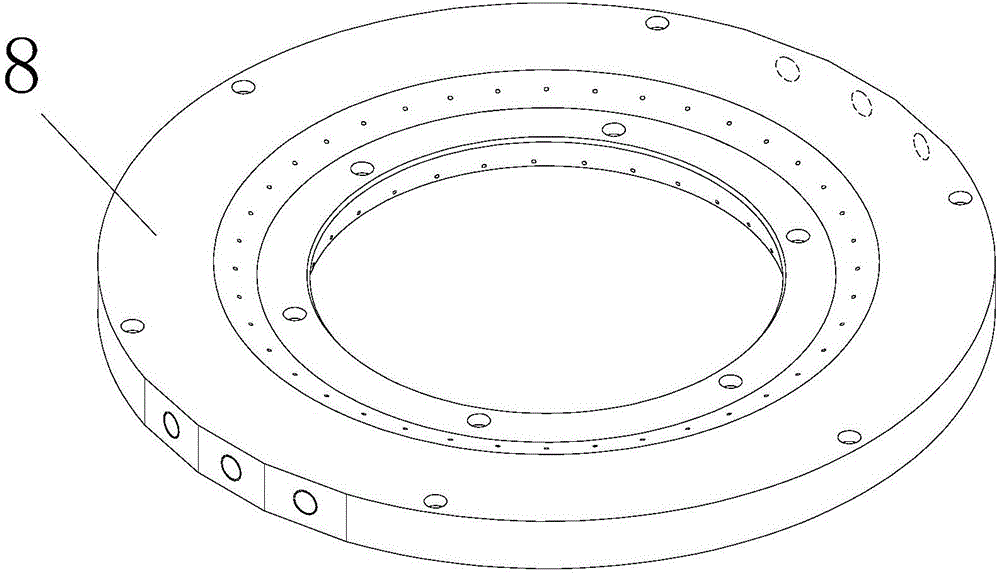

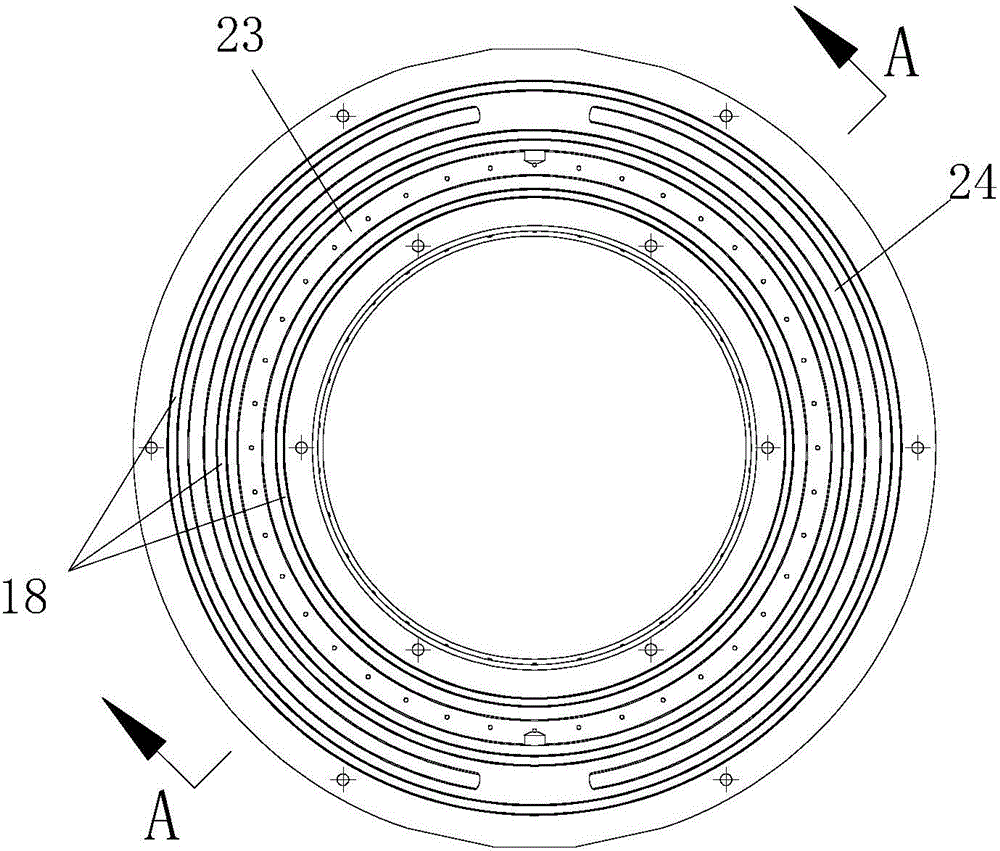

Selective laser sintering and melting equipment

ActiveCN106392073AAvoid stickingReduce oxygen contentAdditive manufacturing apparatusIncreasing energy efficiencySelective laser sinteringMetallurgy

The invention discloses selective laser sintering and melting equipment which comprises a sealing forming bin, a laser galvanometer arranged outside the sealing forming bin, a lens arranged on the surface of the sealing forming bin and used for enabling the laser projected from the laser galvanometer to enter the sealing forming bin, a part machining platform arranged in the sealing forming bin, a powder paving scraper used for paving powder on the machining platform, an annular gas curtain device fixed to the inner wall of the sealing forming bin and corresponding to the lens, and a gas source used for providing gas for the annular gas curtain. According to the selective laser sintering and melting equipment, a cone high-speed gas curtain wall can be formed around the inner surface of the lens, a clean space is formed around the inner surface of the lens, and metal powder in the forming bin can be effectively prevented from adhering to the surface of the lens. Meanwhile, the lens is prevented against dust and cooled through inert gas in the forming bin during the machining process of the equipment, so that a large amount of inert gas is saved, and the production cost is lowered.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com