Flexible package battery lug welding method

A soft-packed battery and tab welding technology, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of high battery production cost, high welding cost, damage to pre-soldered solder joints, etc., to reduce metal dust pollution, The effect of improving welding effect and saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] The present invention adopts the following technical solutions.

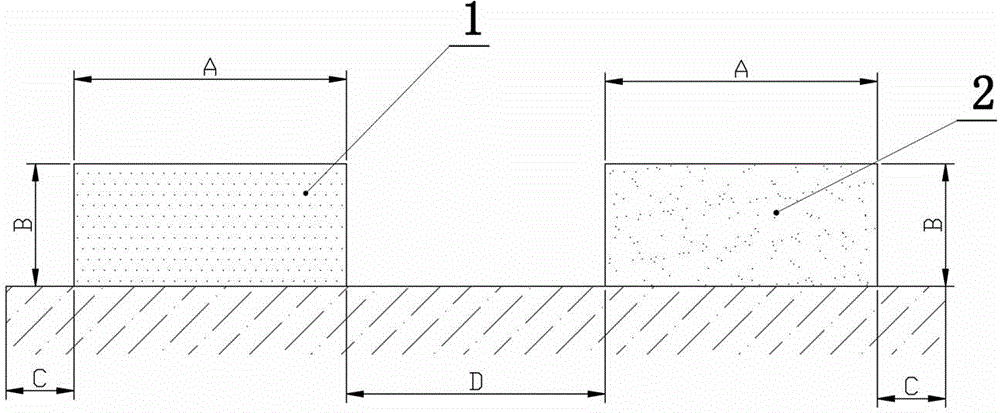

[0029] The plan view of the ear end of the laminated flexible package cell is as follows figure 1 As shown, the one on the left is the exposed aluminum tab foil 1 for the positive electrode, and the one on the right is the exposed copper tab foil 2 for the negative electrode. The range is 10mm-50mm, the gap C between the edge of the battery cell and the tab foil material is applicable to the range of 0mm-100mm, and the gap D between the positive and negative tab foil materials is applicable to the range of 20mm-200mm. The applicable range of cell thickness after lamination is 3.0mm-20mm.

[0030] The tab welding method adopts the following steps.

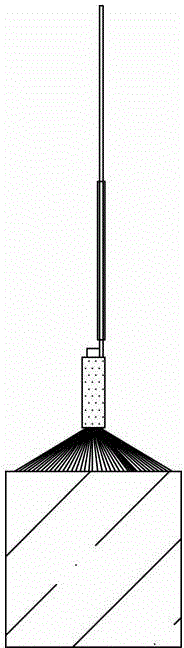

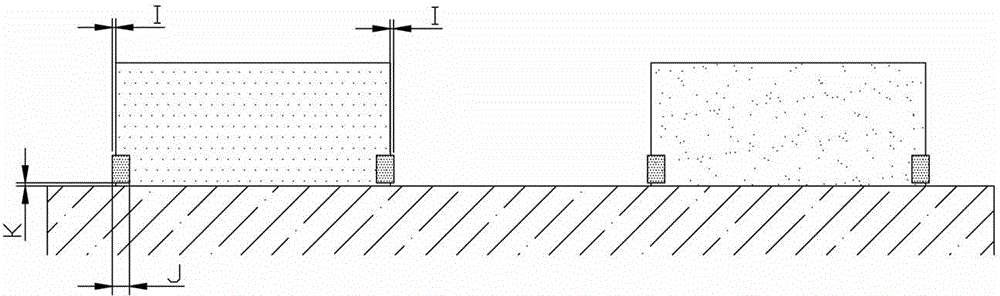

[0031] Firstly, the aluminum sheet and the nickel sheet are respectively fixed on the exposed aluminum tab foil of the positive electrode sheet and the exposed copper tab foil of the negative electrode sheet. Aluminum sheet and nickel sheet have the same str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com