Patents

Literature

3298 results about "Ultrasonic welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrasonic welding is an industrial technique whereby high-frequency ultrasonic acoustic vibrations are locally applied to workpieces being held together under pressure to create a solid-state weld. It is commonly used for plastics and metals, and especially for joining dissimilar materials. In ultrasonic welding, there are no connective bolts, nails, soldering materials, or adhesives necessary to bind the materials together. When applied to metals, a notable characteristic of this method is that the temperature stays well below the melting point of the involved materials thus preventing any unwanted properties which may arise from high temperature exposure of the materials.

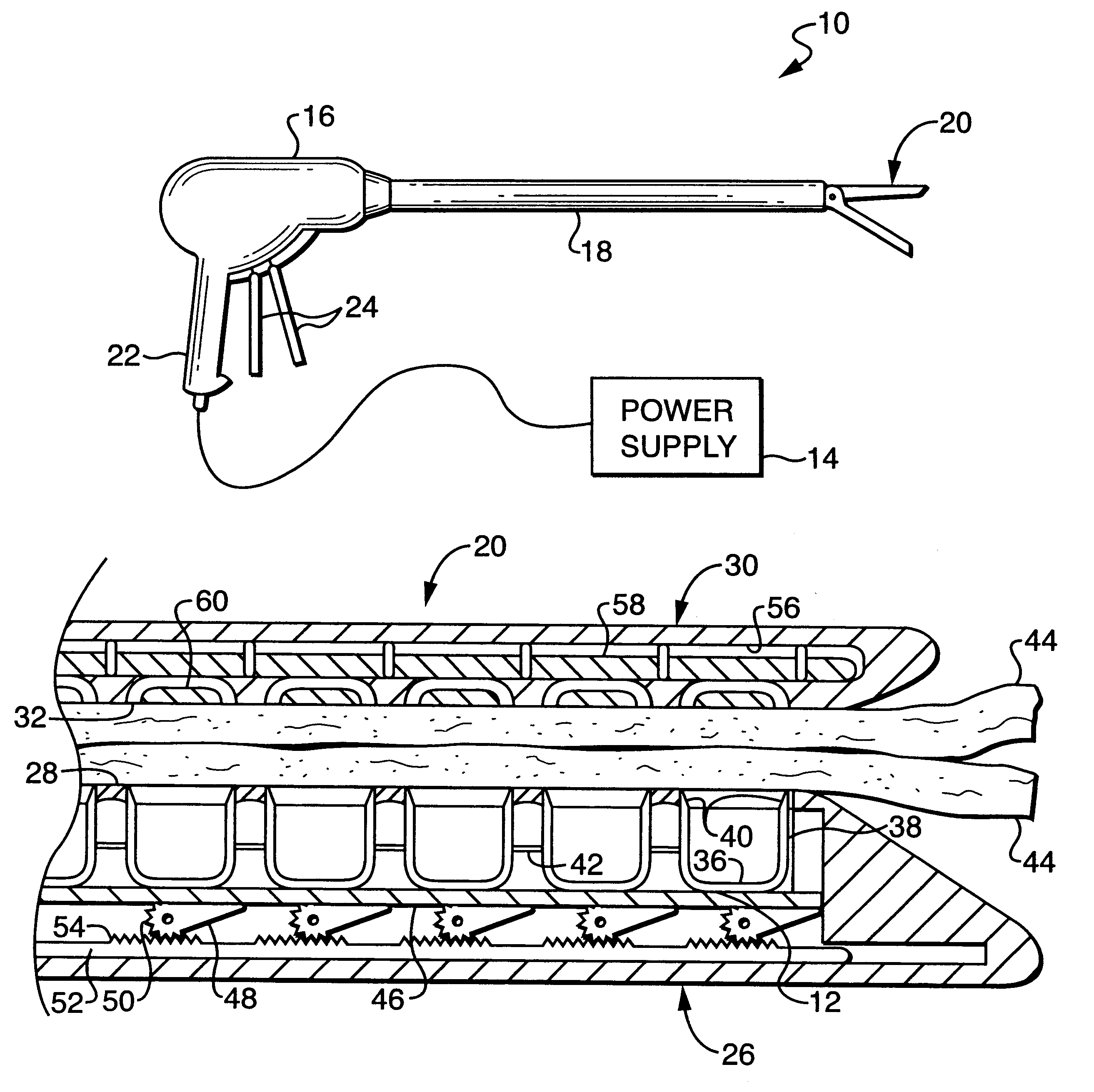

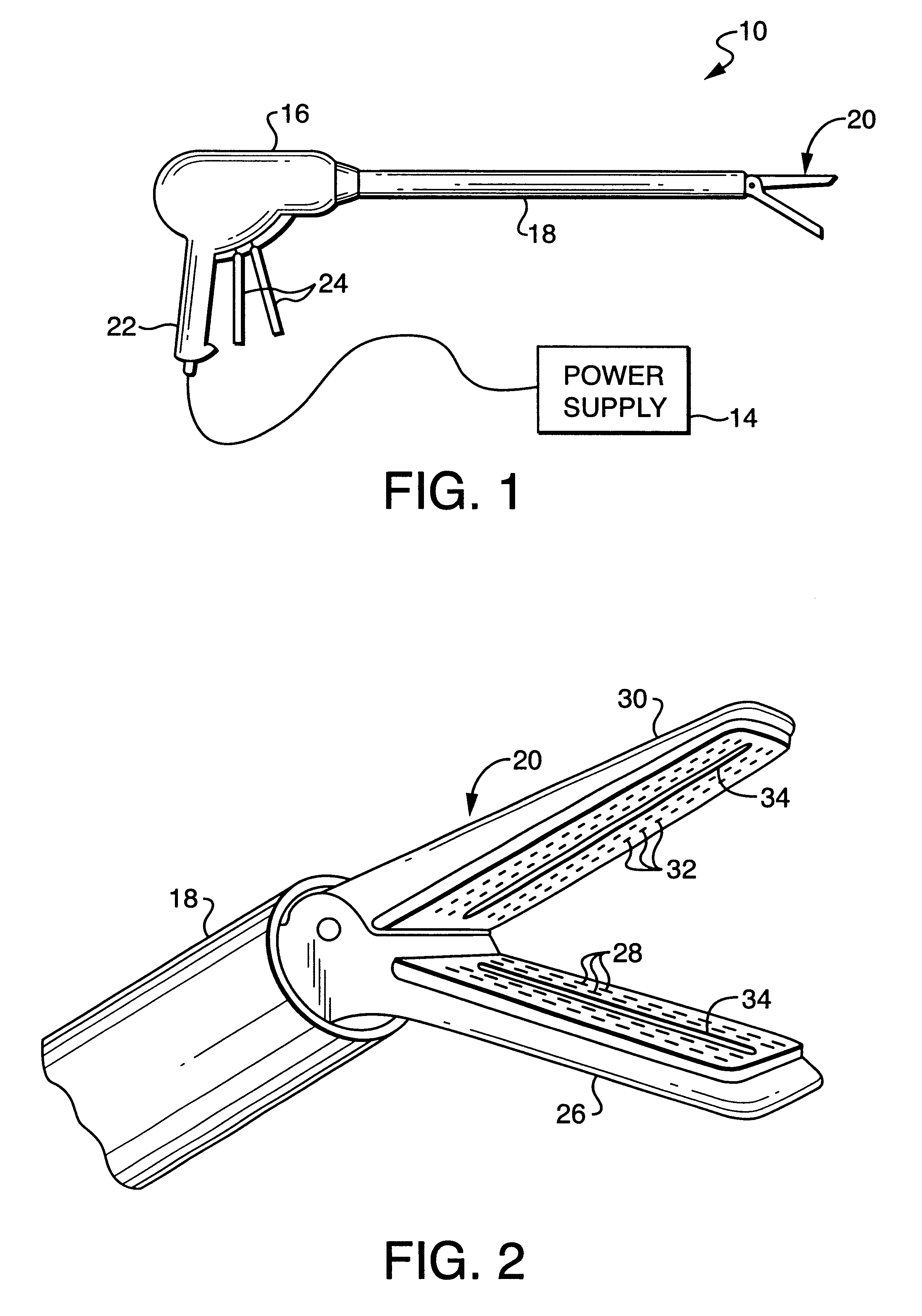

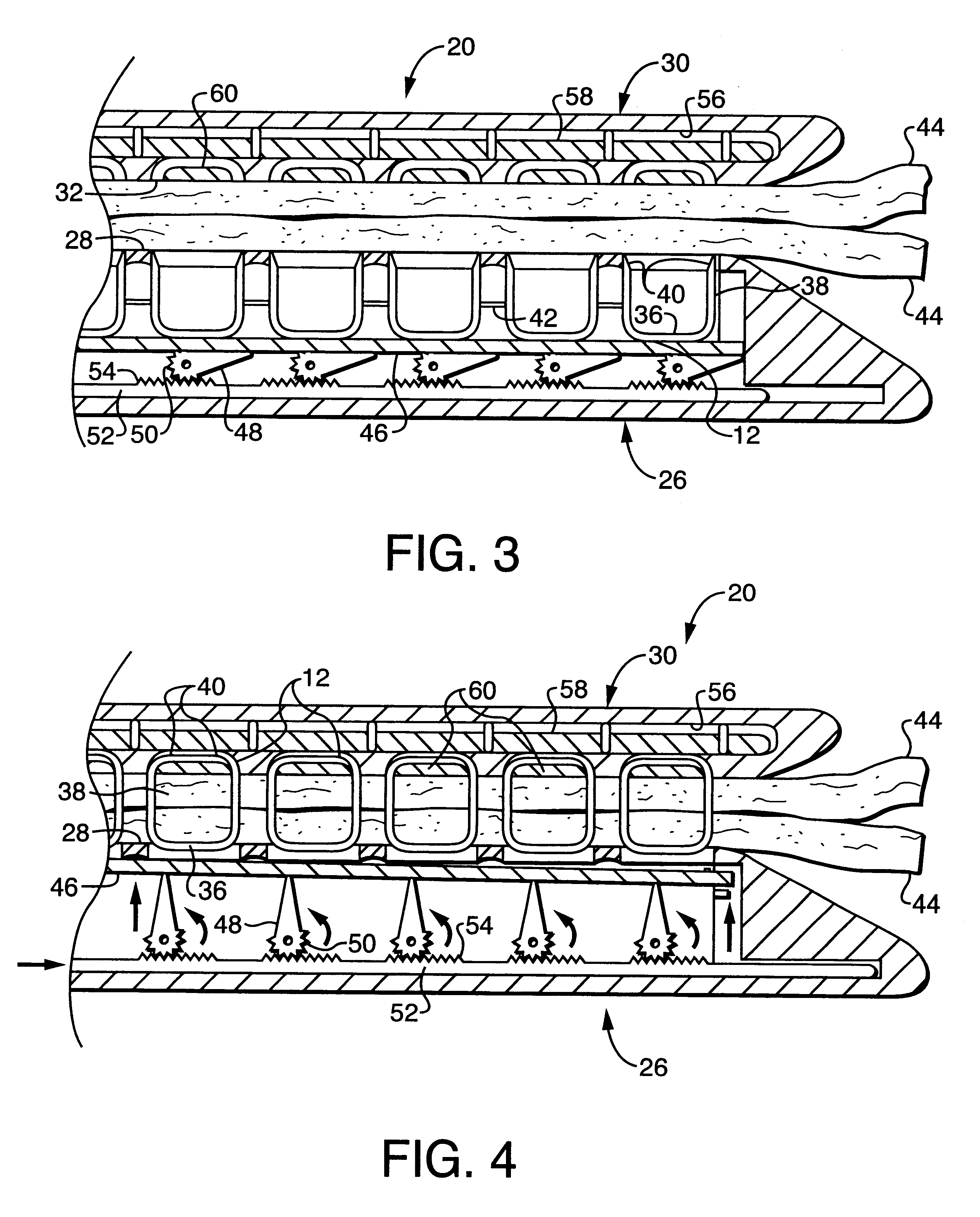

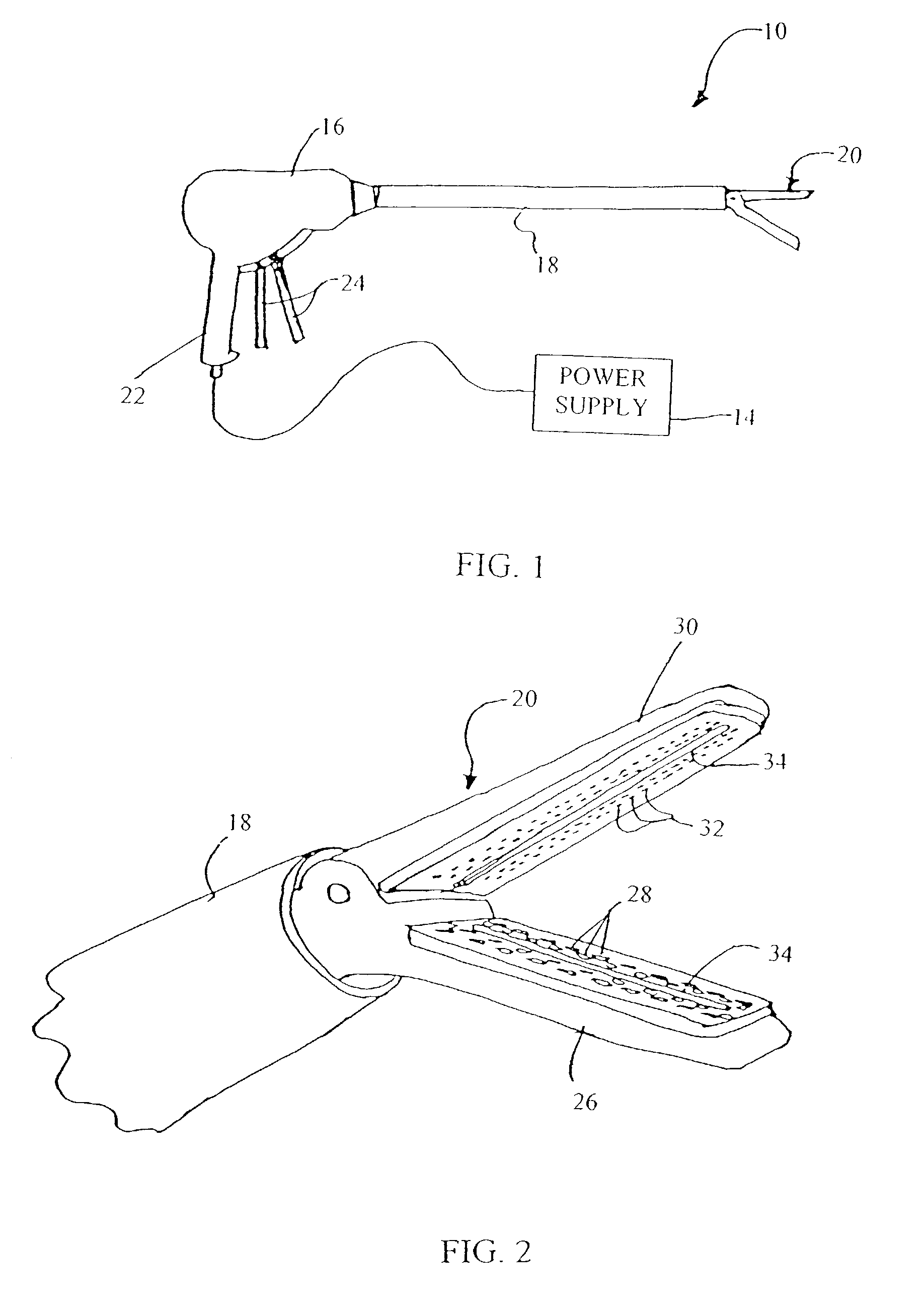

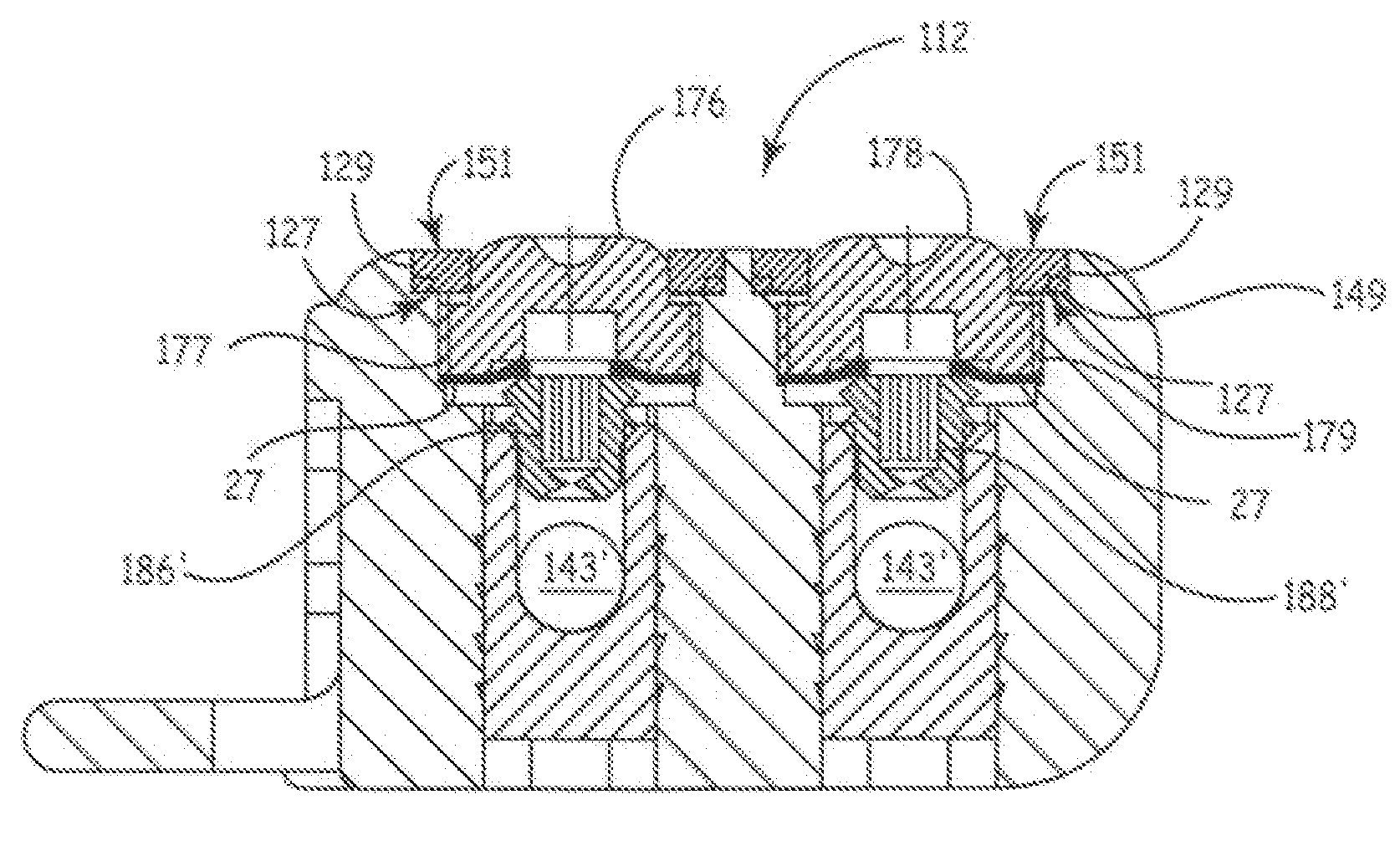

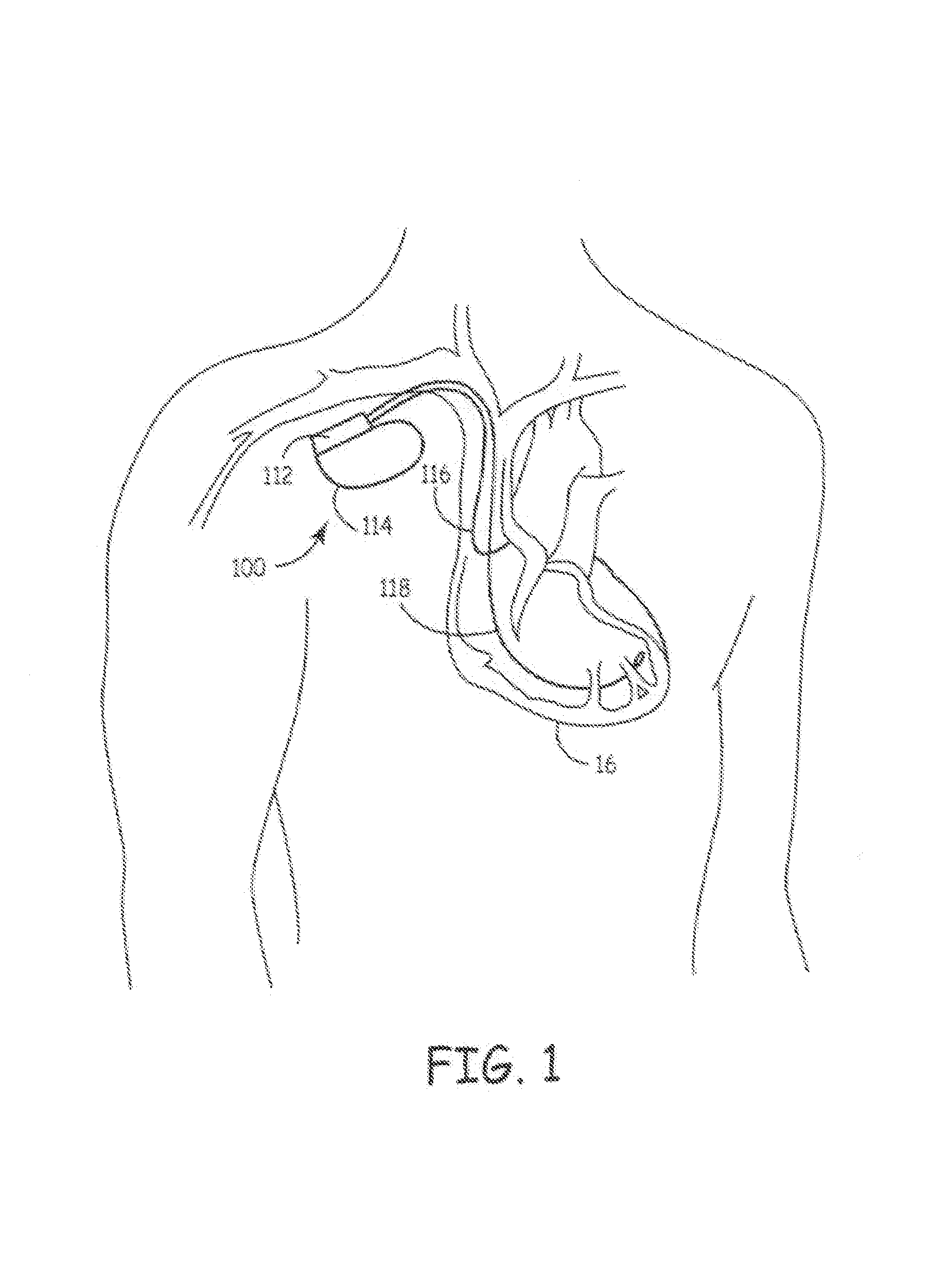

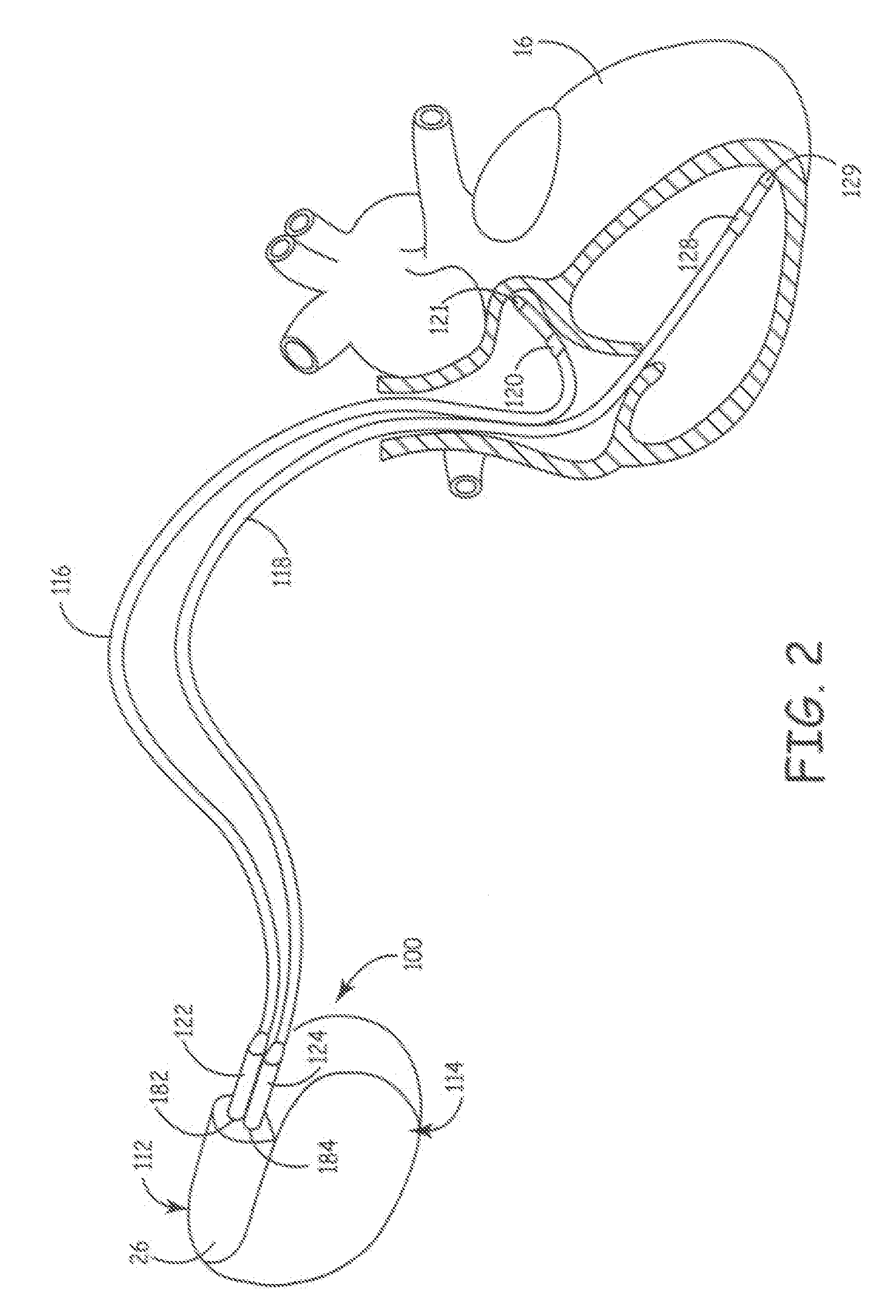

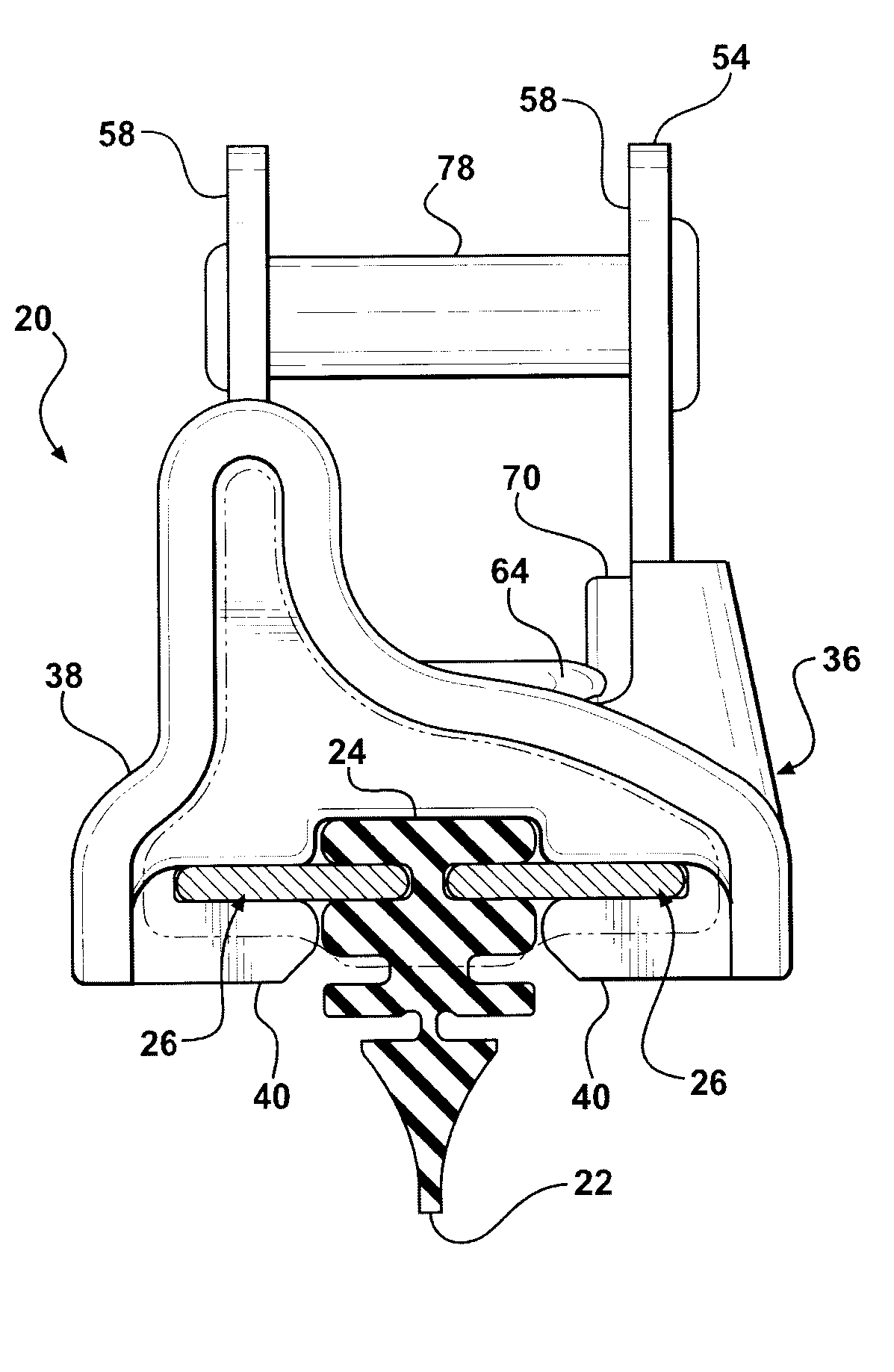

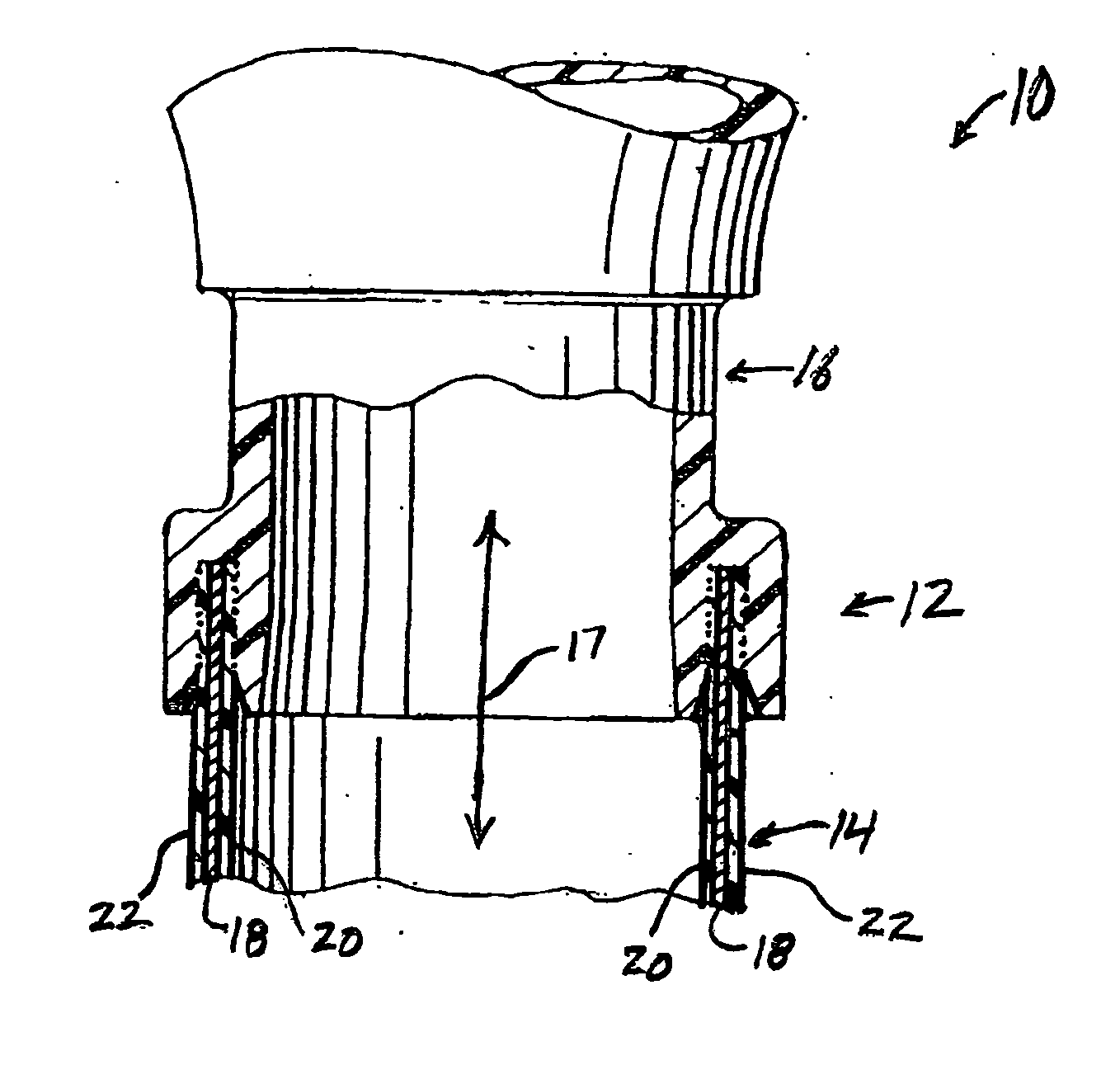

Surgical stapler and method of applying plastic staples to body tissue

A surgical stapler utilizing plastic staples and ultrasonic welding to secure the staples in body tissue. The stapler includes a pair of jaws movable between open and closed positions, a handle and trigger assembly for controlling operation of the jaws, and an elongated tubular structure connecting the handle and trigger assembly to the jaws. The stapler also includes an ejection assembly for ejecting at least one staple from one of the jaws against the other of the jaws. An anvil and a horn are positioned in the other of the jaws and are arranged to receive ends of the ejected staple such that the ends overlap between the anvil and the horn. The horn is for melting and bonding at least a portion of the overlapping ends of the staple upon being energized by a predetermined form of energy, and one of the anvil and the horn is movable from within the bonded staple to allow the jaws to be moved to an open position.

Owner:AXYA MEDICAL INC

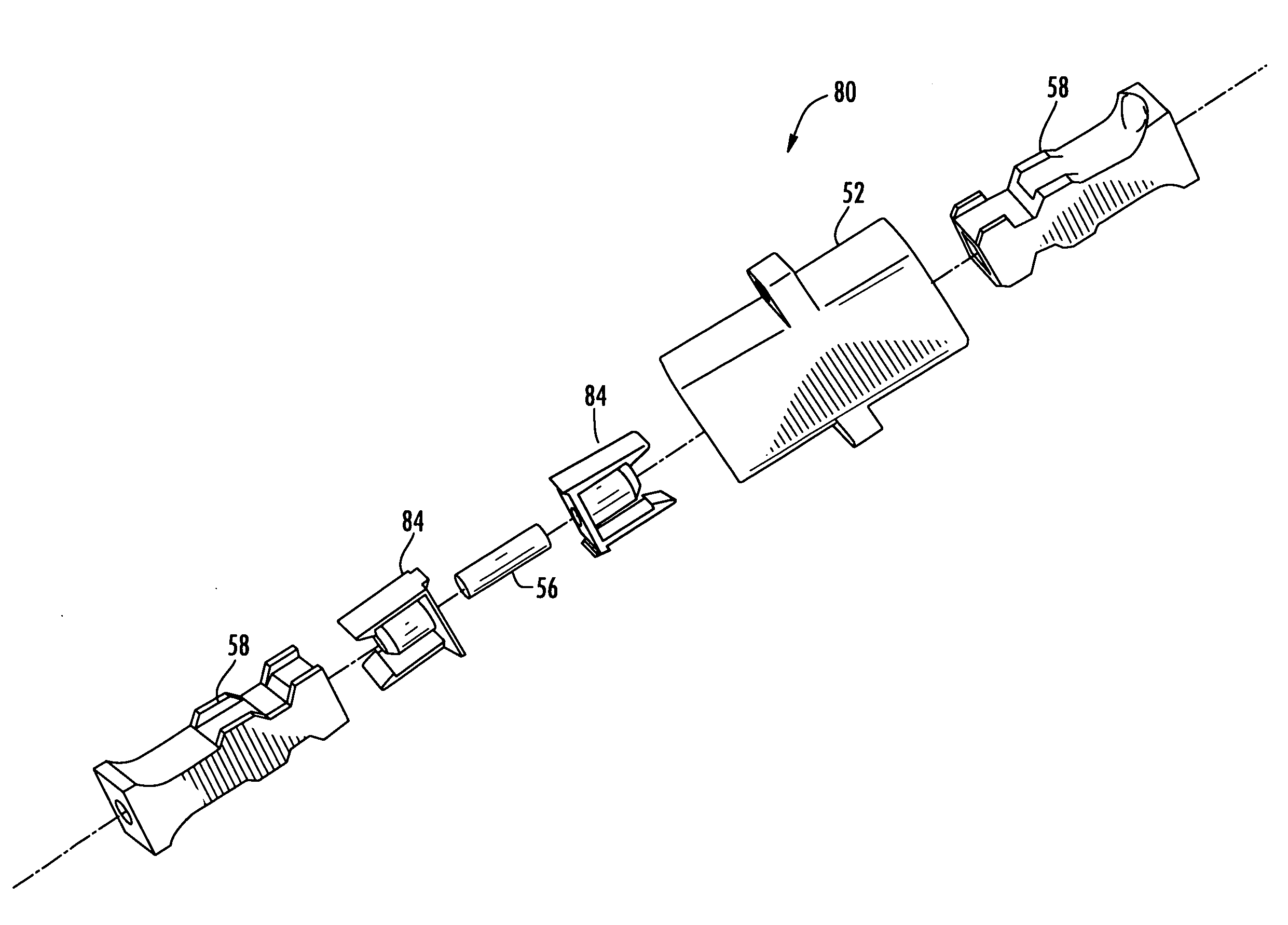

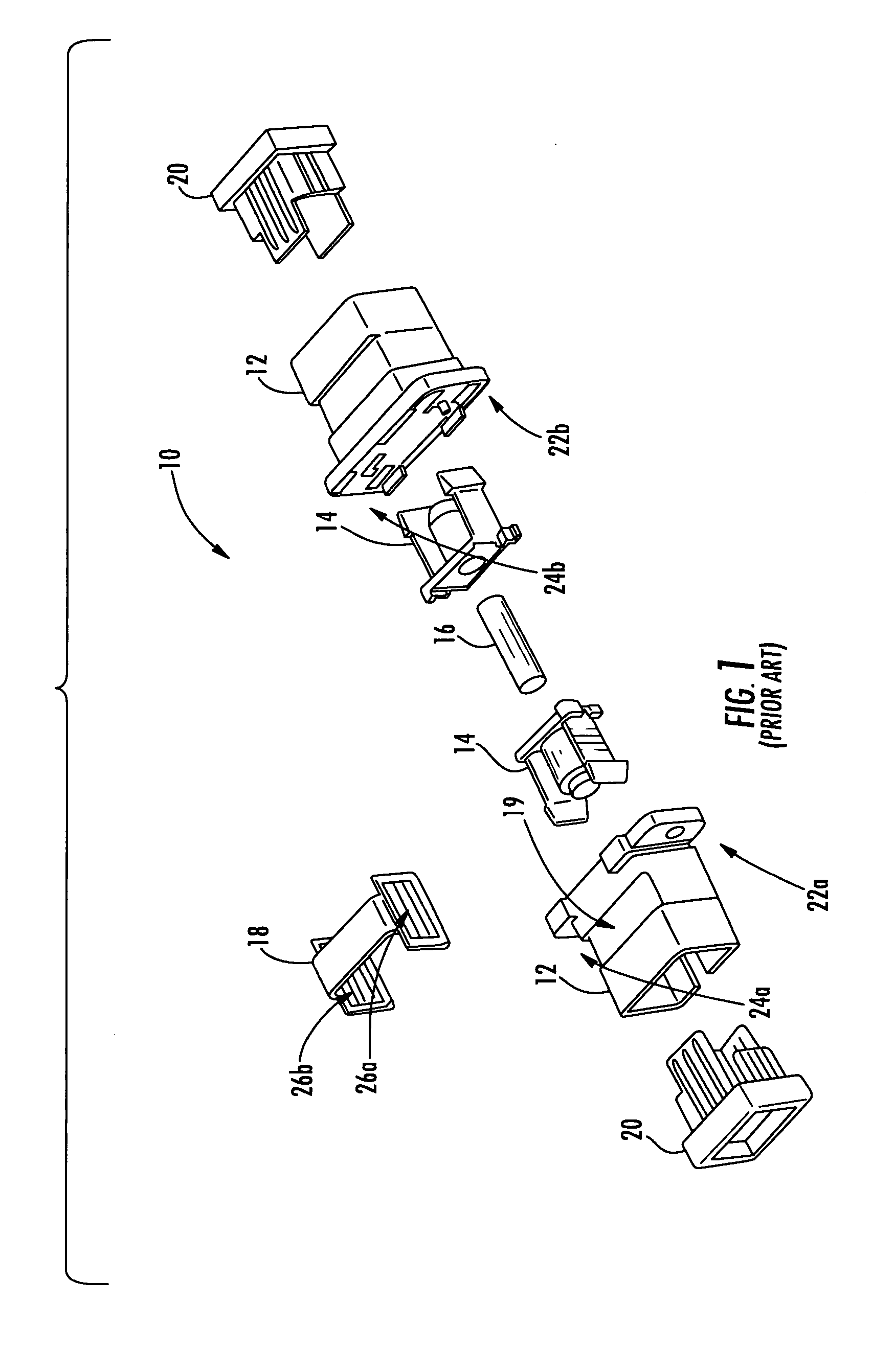

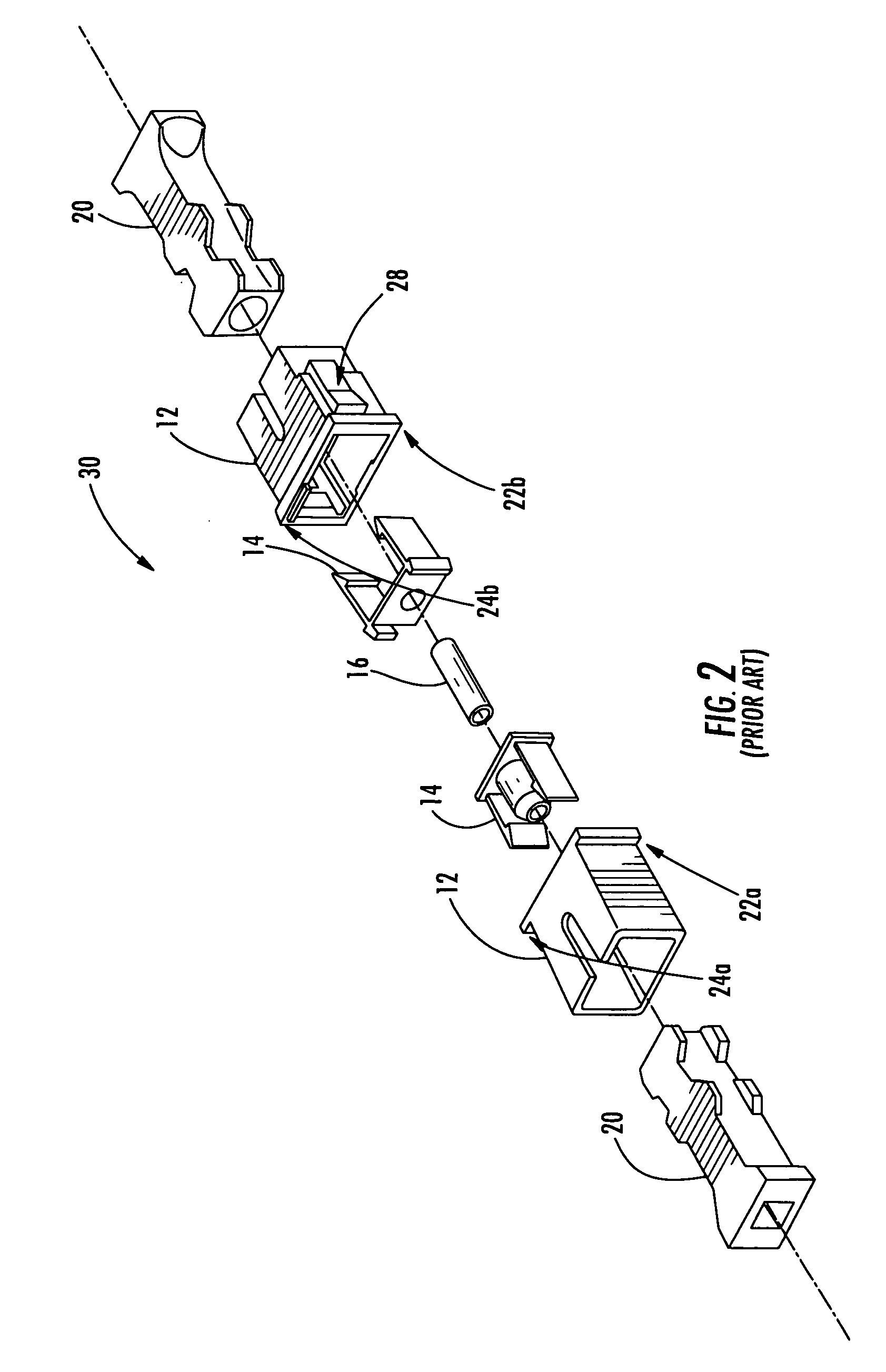

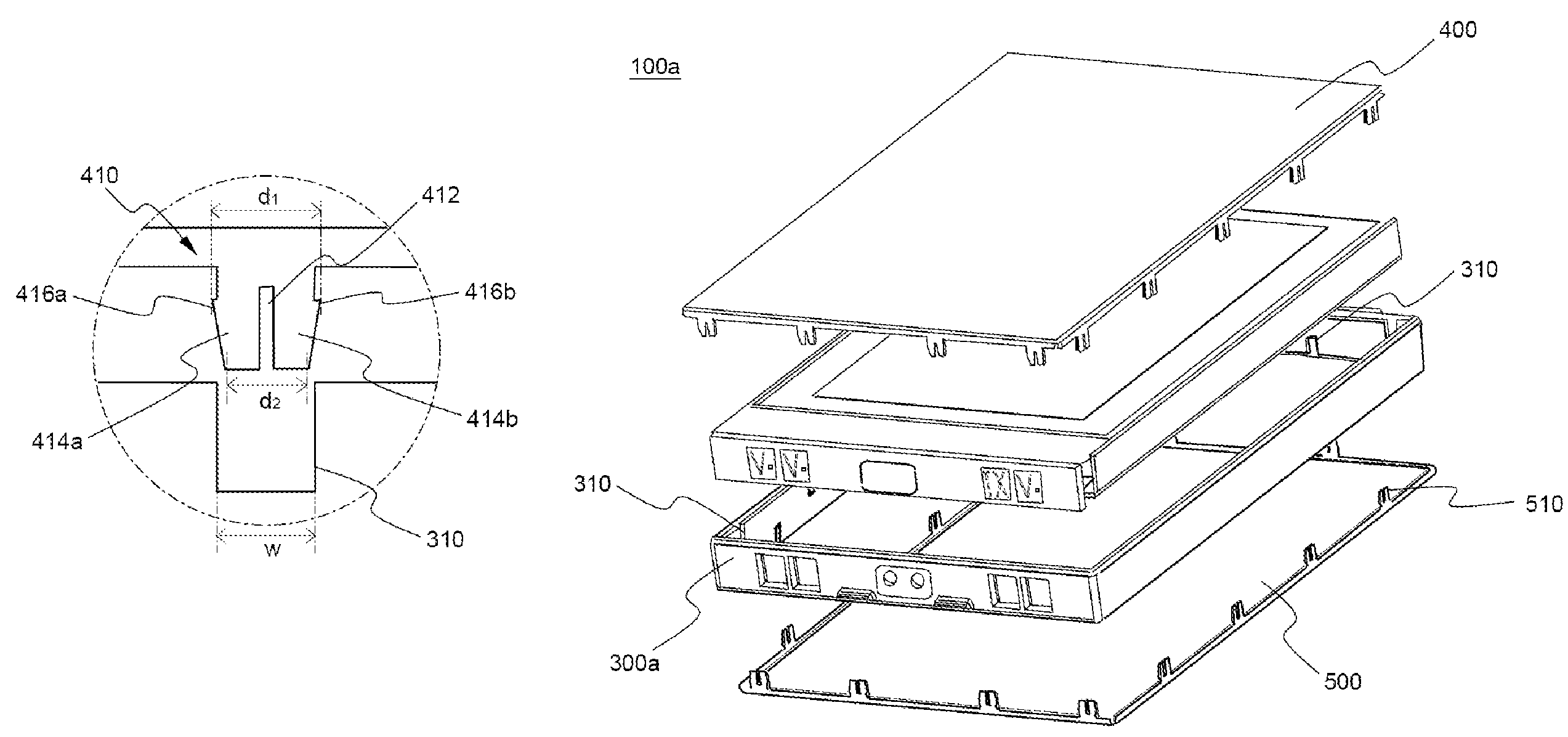

Fiber optic adapter with integrated shutter

InactiveUS20090028507A1Reduce in quantityLower component costsCoupling light guidesFiberUltrasonic welding

The present invention relates generally to fiber optic connectors and adapters, and more specifically to a simplified fiber optic adapter assembly and integrated shutter mechanism. In various embodiments, the simplified fiber optic adapter assembly includes a one-piece outer housing, a one or two-piece inner housing, and several different clip arrangements, reducing the number of parts associated with conventional fiber optic adapter assemblies and eliminating the need for ultrasonic welding or the like. In various embodiments, the integrated shutter mechanism includes one or more shutter doors that are opened internally via the motion required for connector installation.

Owner:CORNING CABLE SYST LLC

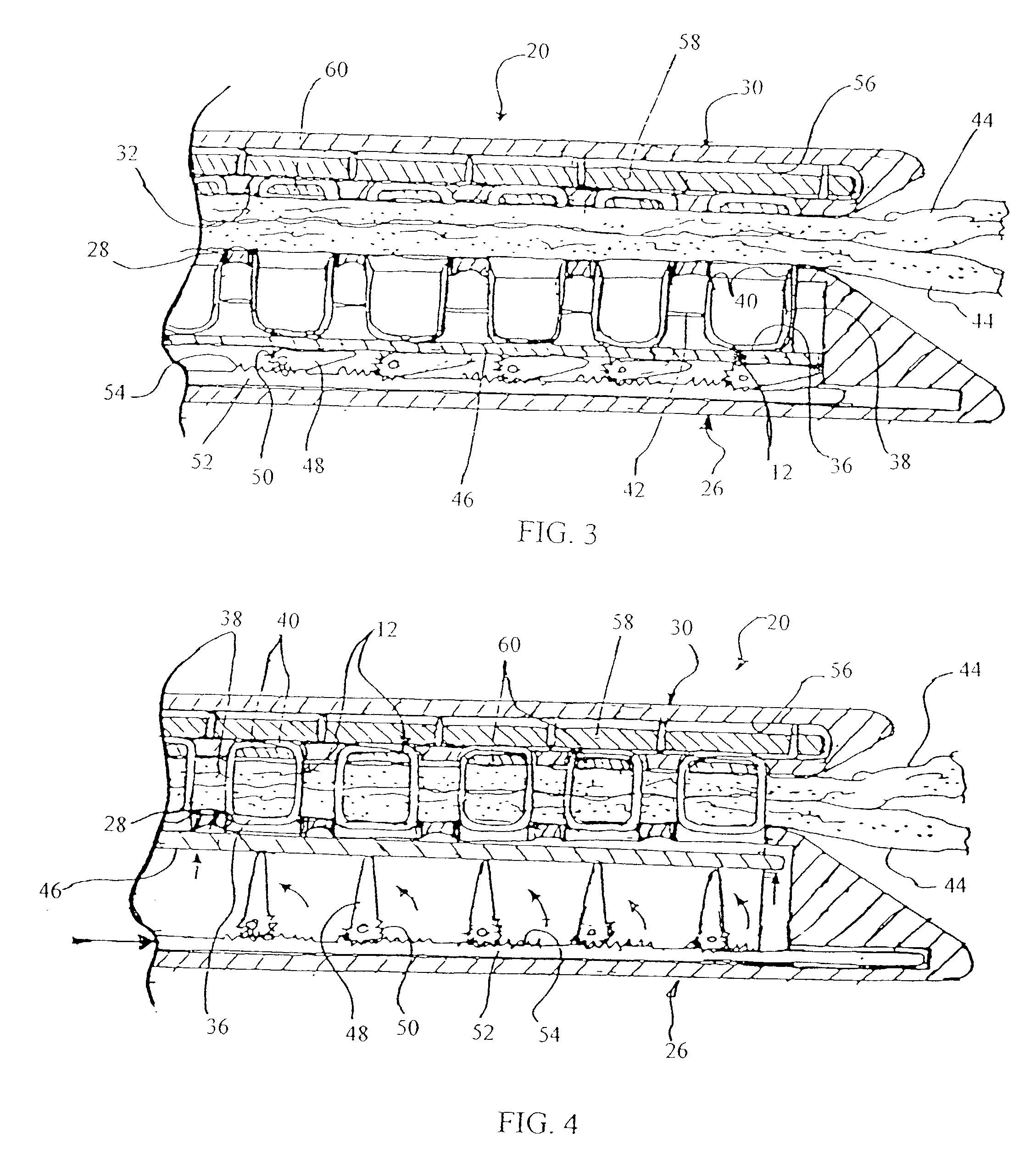

Surgical stapler and method of applying plastic staples to body tissue

A surgical stapler utilizing plastic staples and ultrasonic welding to secure the staples in body tissue. The stapler includes a pair of jaws movable between open and closed positions, a handle and trigger assembly for controlling operation of the jaws, and an elongated tubular structure connecting the handle and trigger assembly to the jaws. The stapler also includes an ejection assembly for ejecting at least one staple from one of the jaws against the other of the jaws. An anvil and a horn are positioned in the other of the jaws and are arranged to receive ends of the ejected staple such that the ends overlap between the anvil and the horn. The horn is for melting and bonding at least a portion of the overlapping ends of the staple upon being energized by a predetermined form of energy, and one of the anvil and the horn is movable from within the bonded staple to allow the jaws to be moved to an open position.

Owner:TORNIER INC

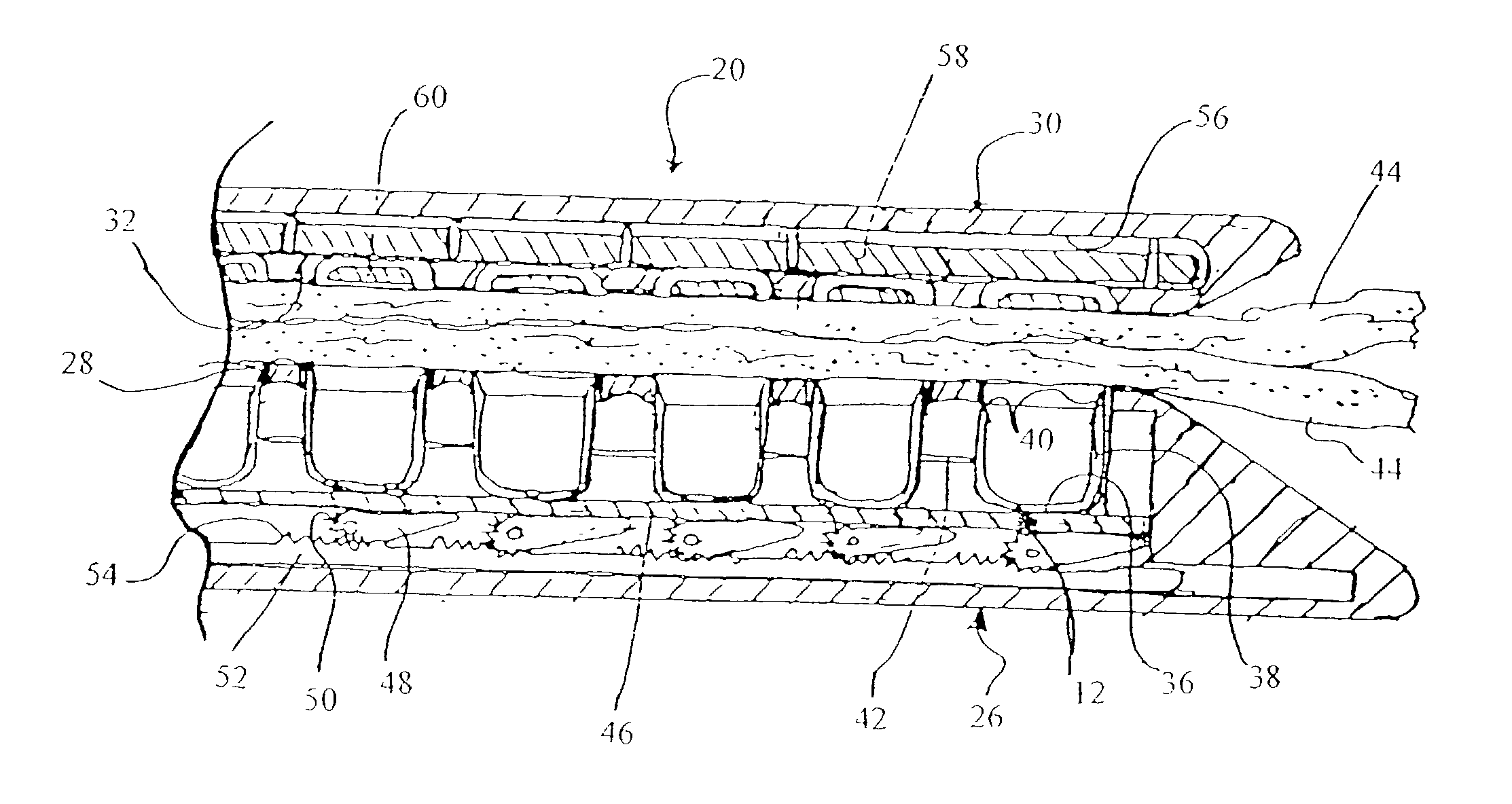

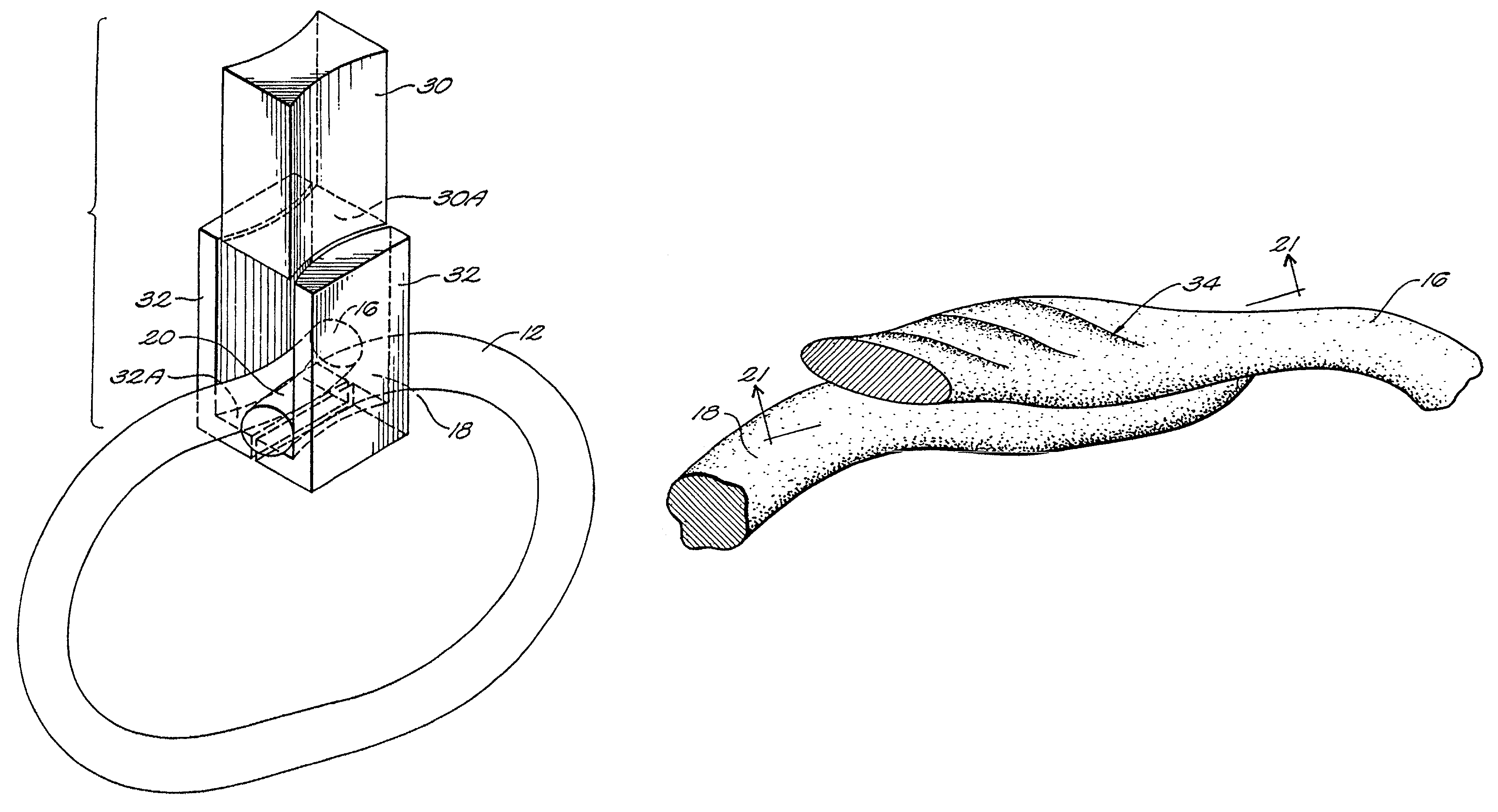

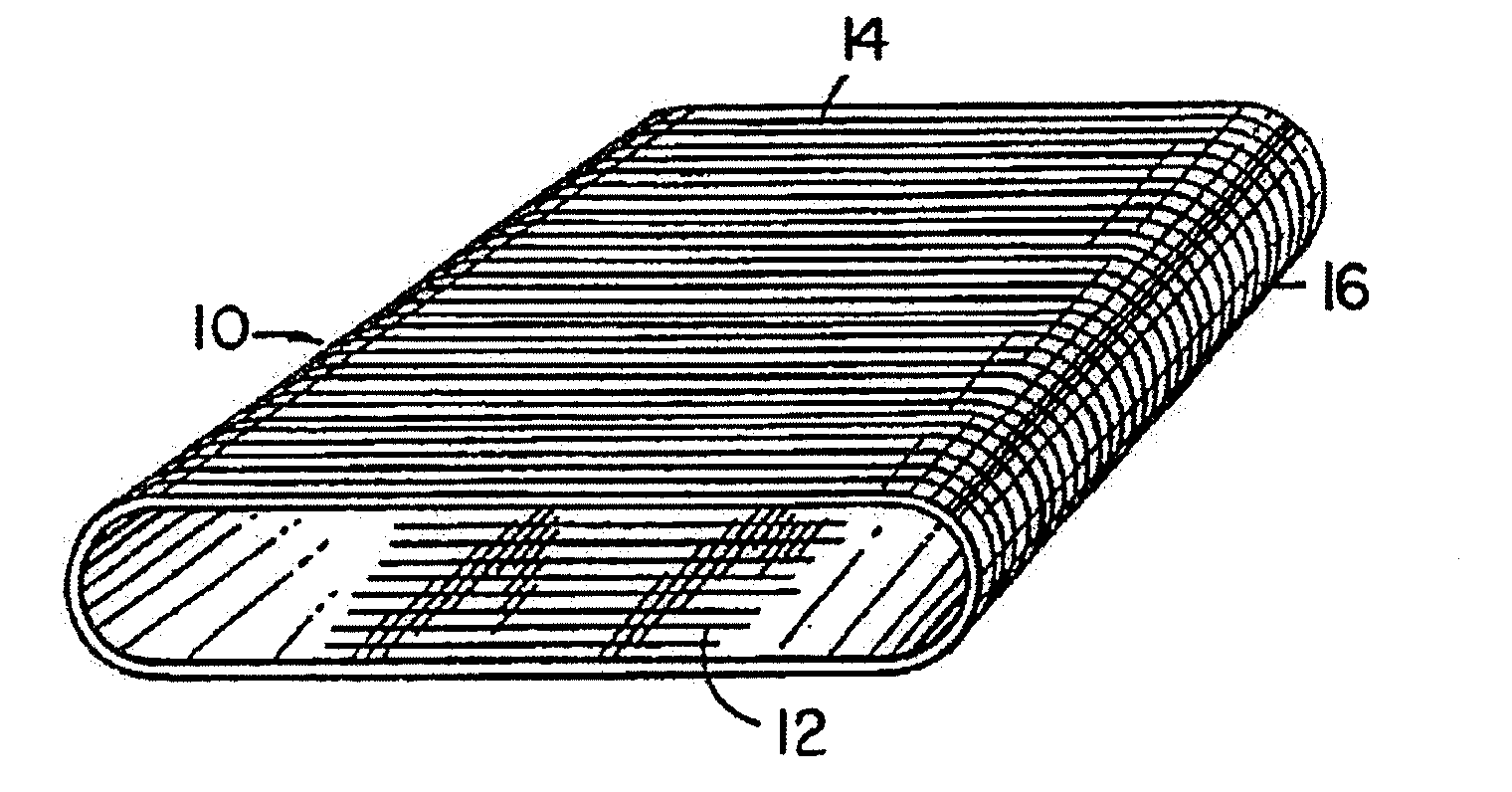

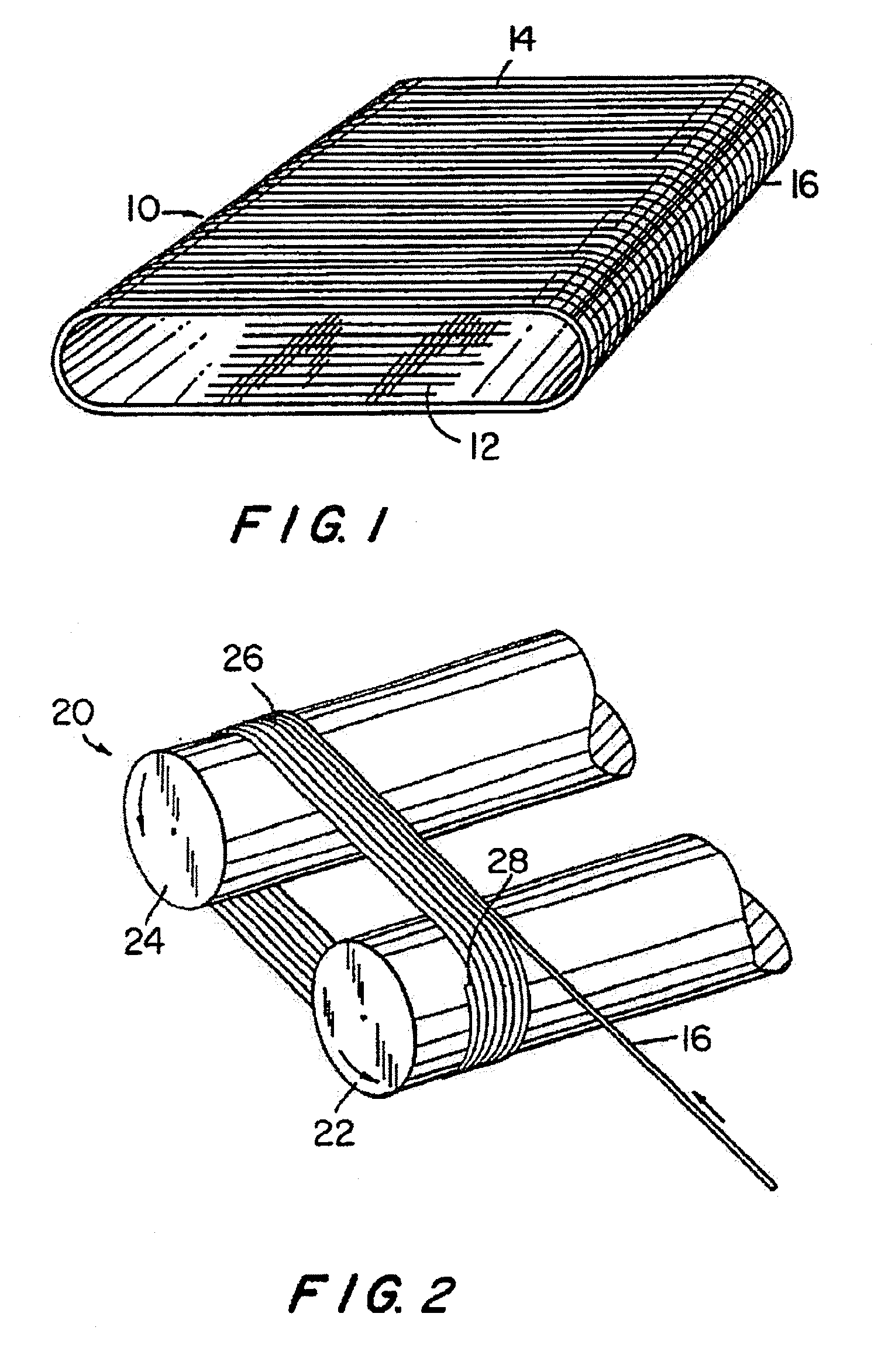

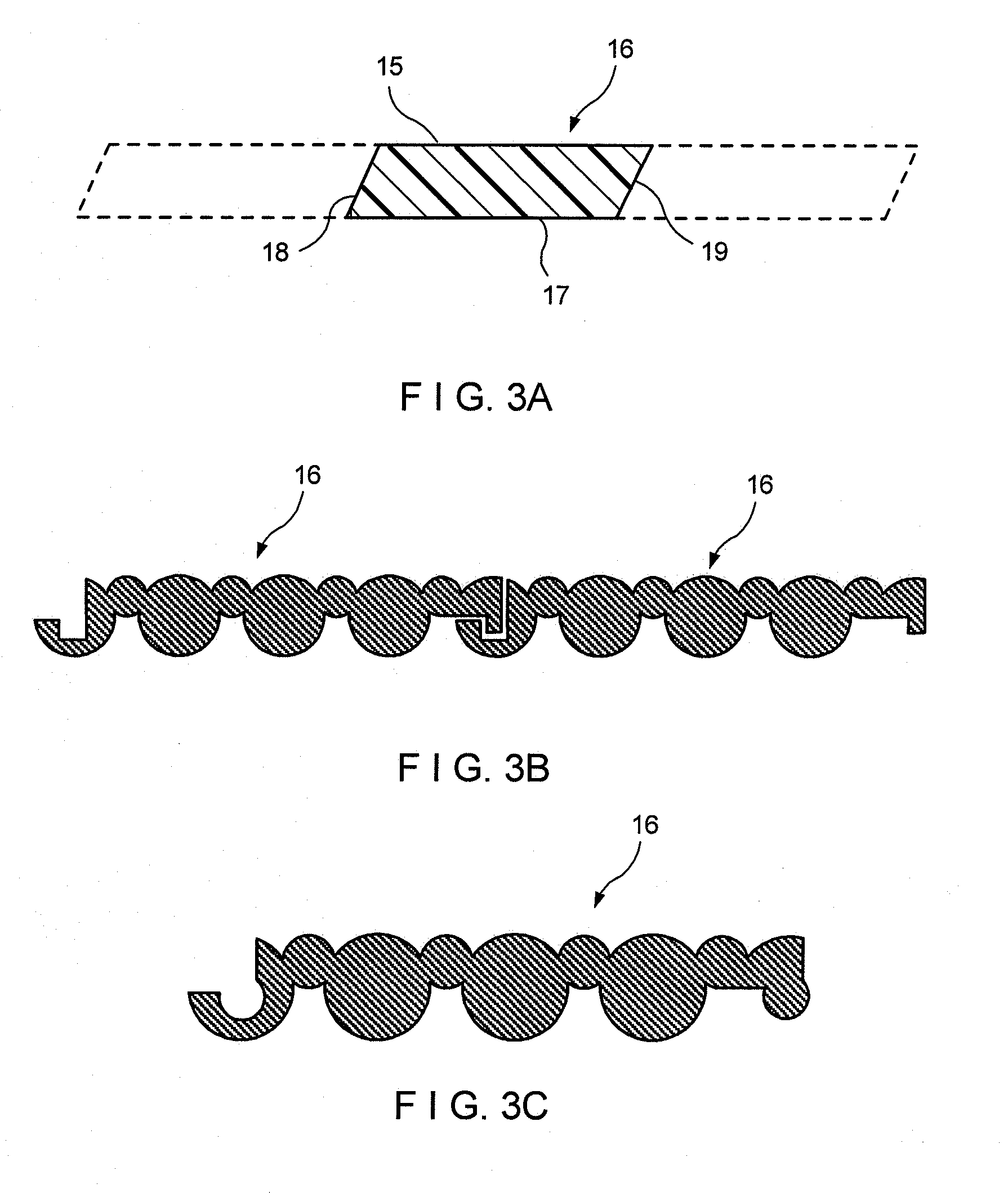

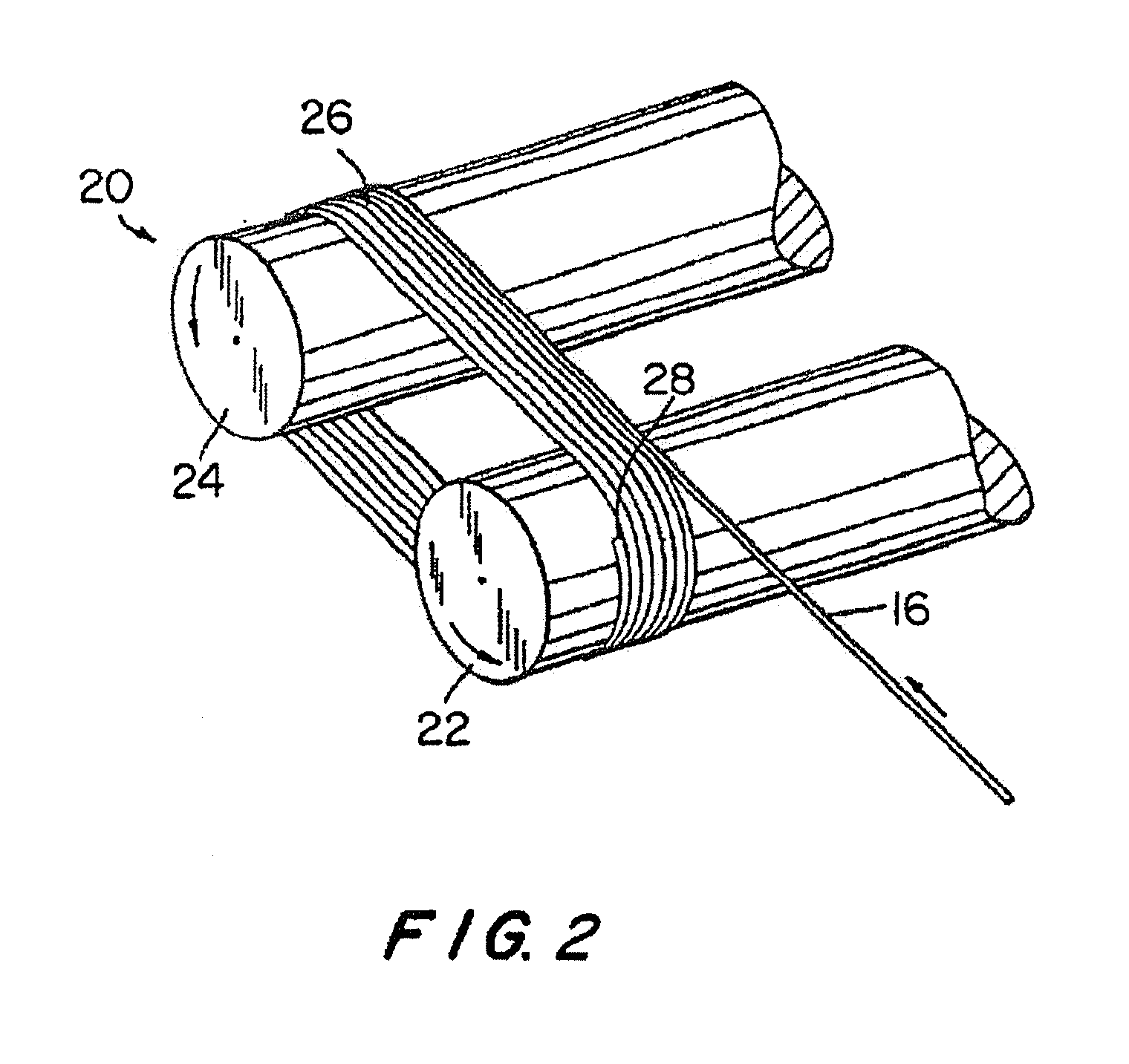

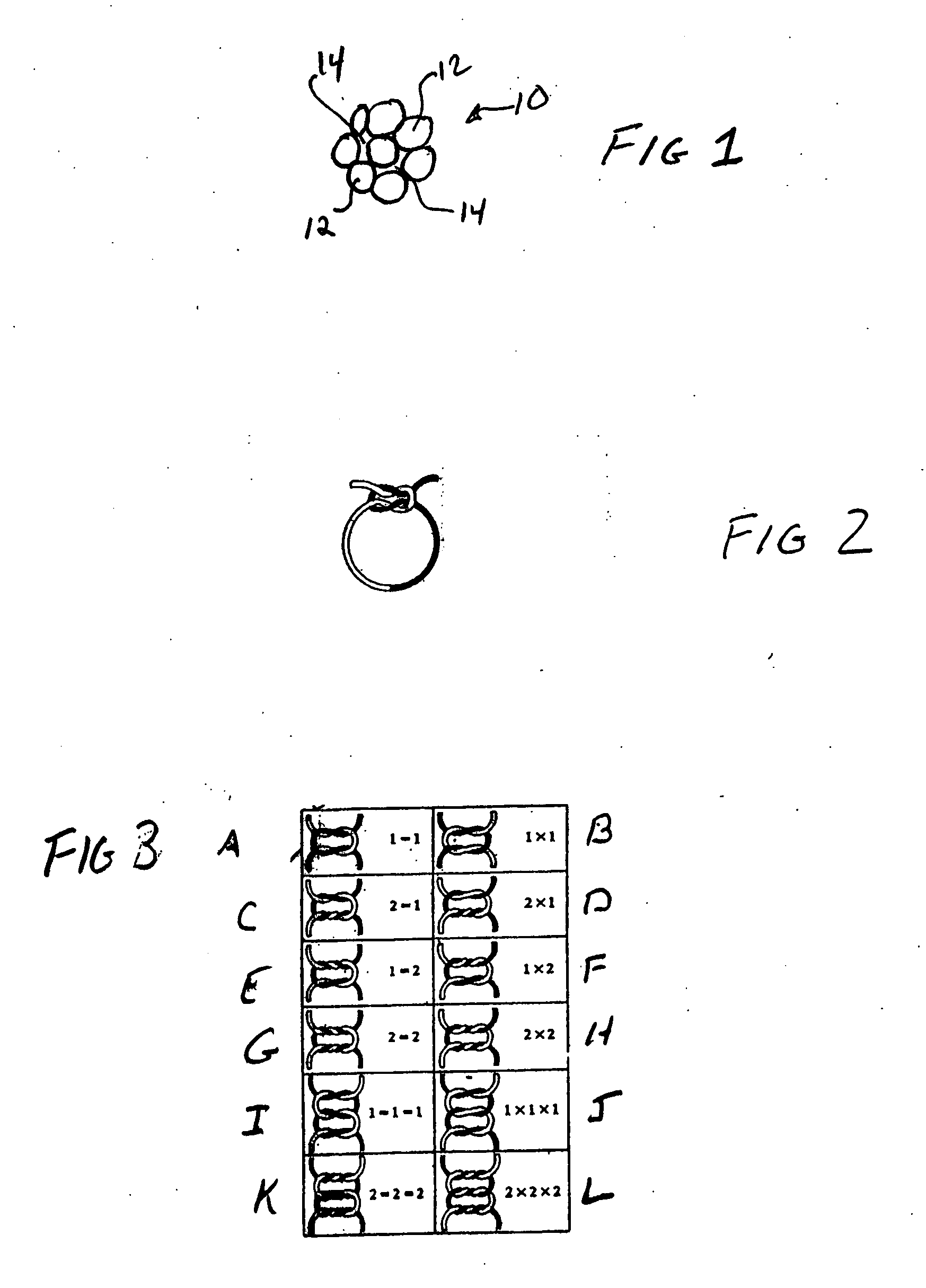

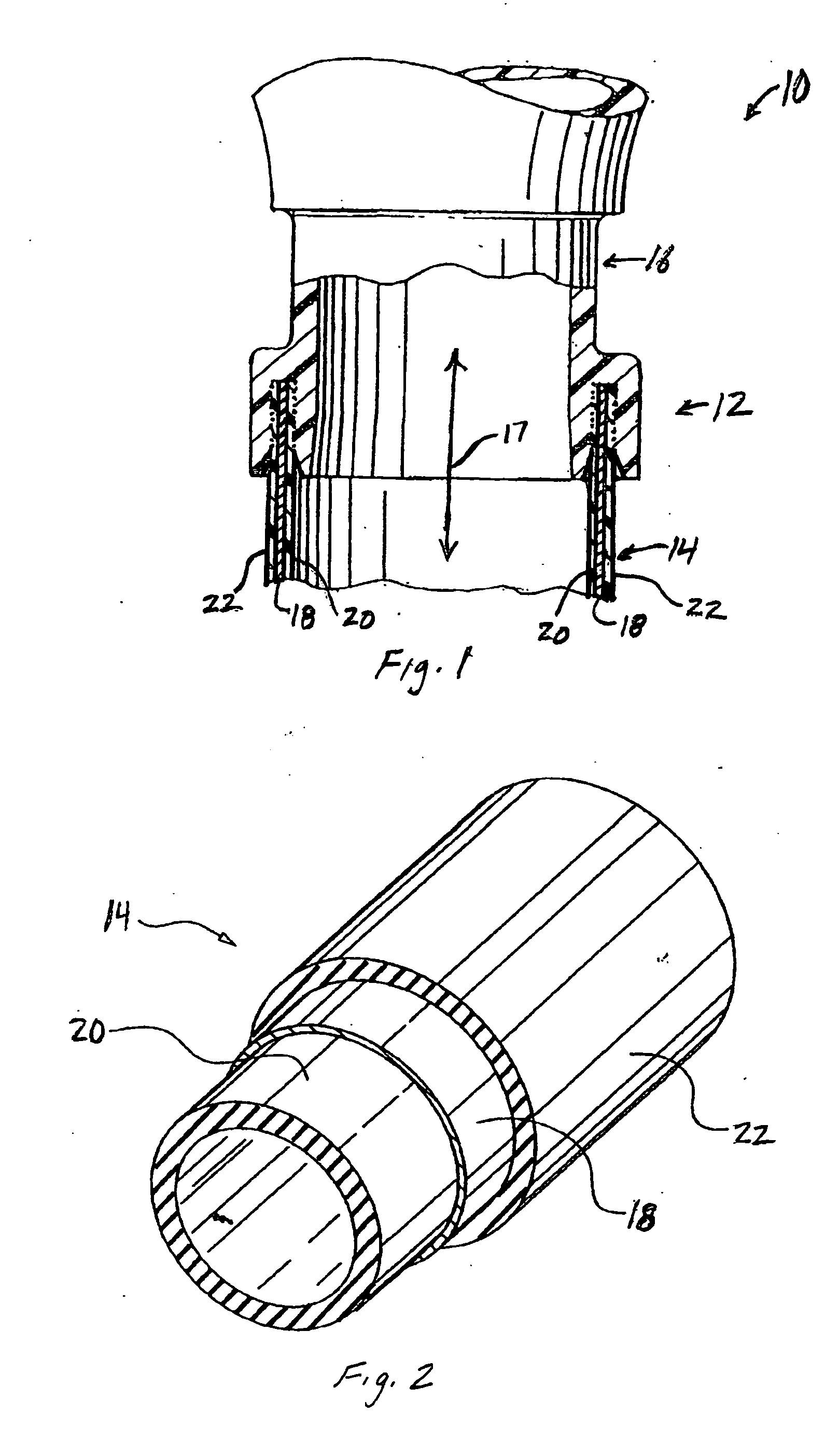

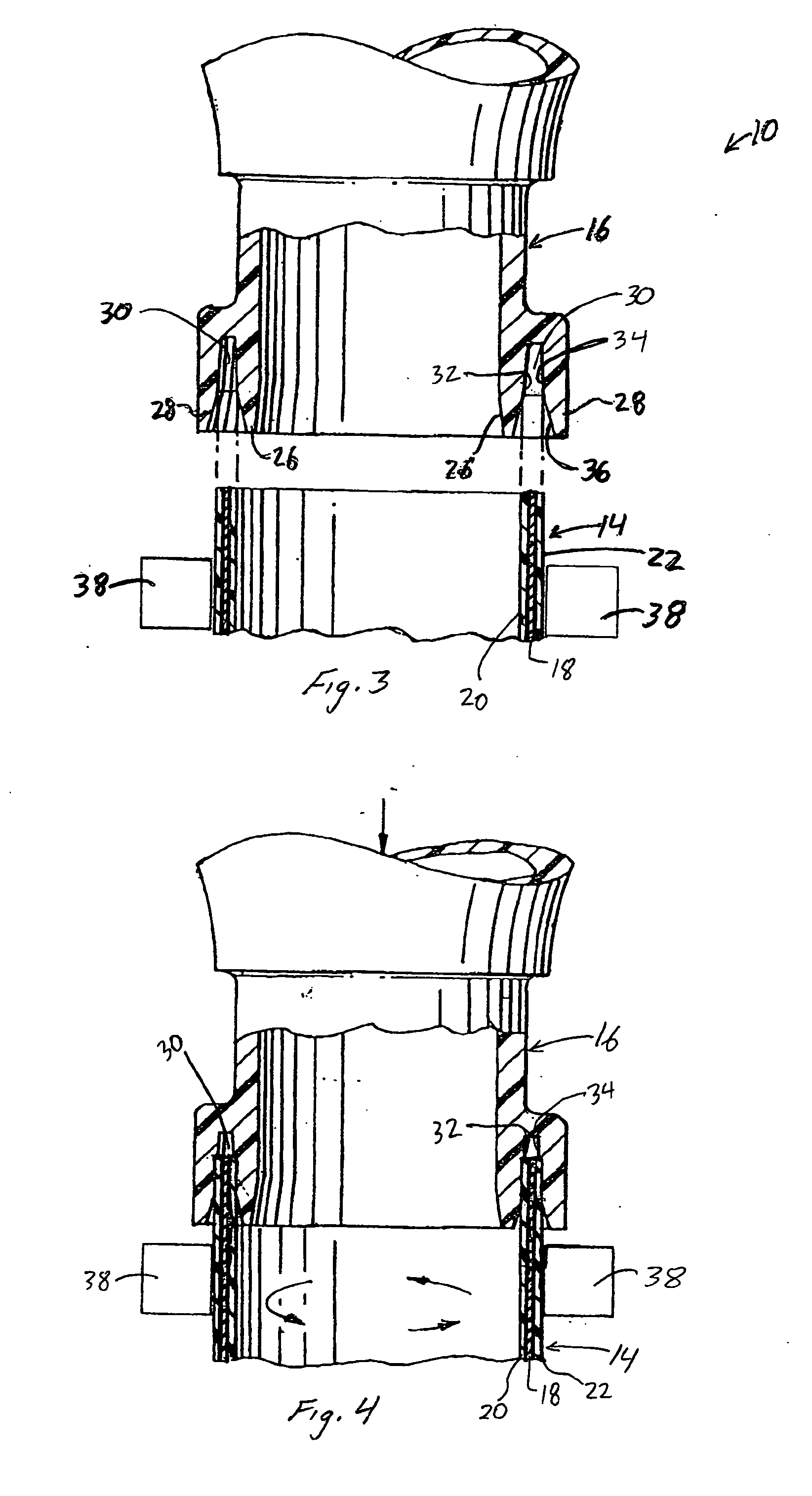

Fused loop of filamentous material and apparatus for making same

InactiveUS7090111B2Maximize joint strengthSuture equipmentsSurgical needlesSurface patternUltrasonic welding

A welding apparatus that includes a first member having a first suture-contacting surface, a second member having a second suture-contacting surface, and a device for moving the first member relative to the second member to define a gap between the respective suture-contacting surfaces. The first member is capable of vibrating and delivering mechanical energy at ultrasonic frequencies. The second member is stationary relative to the first member. A fixture element is adapted to receive and maintain two or more segments of a material to be welded in a predetermined alignment in the gap between the first and second surfaces of the first and second members during a welding operation. According to another aspect of the invention, an ultrasonic welding apparatus includes first and second members with patterned first and second suture-contacting surfaces. The patterned surfaces can be complementary or non-complementary and the surface patterns on each member may vary in either a periodic or a non-periodic manner.

Owner:TORNIER INC

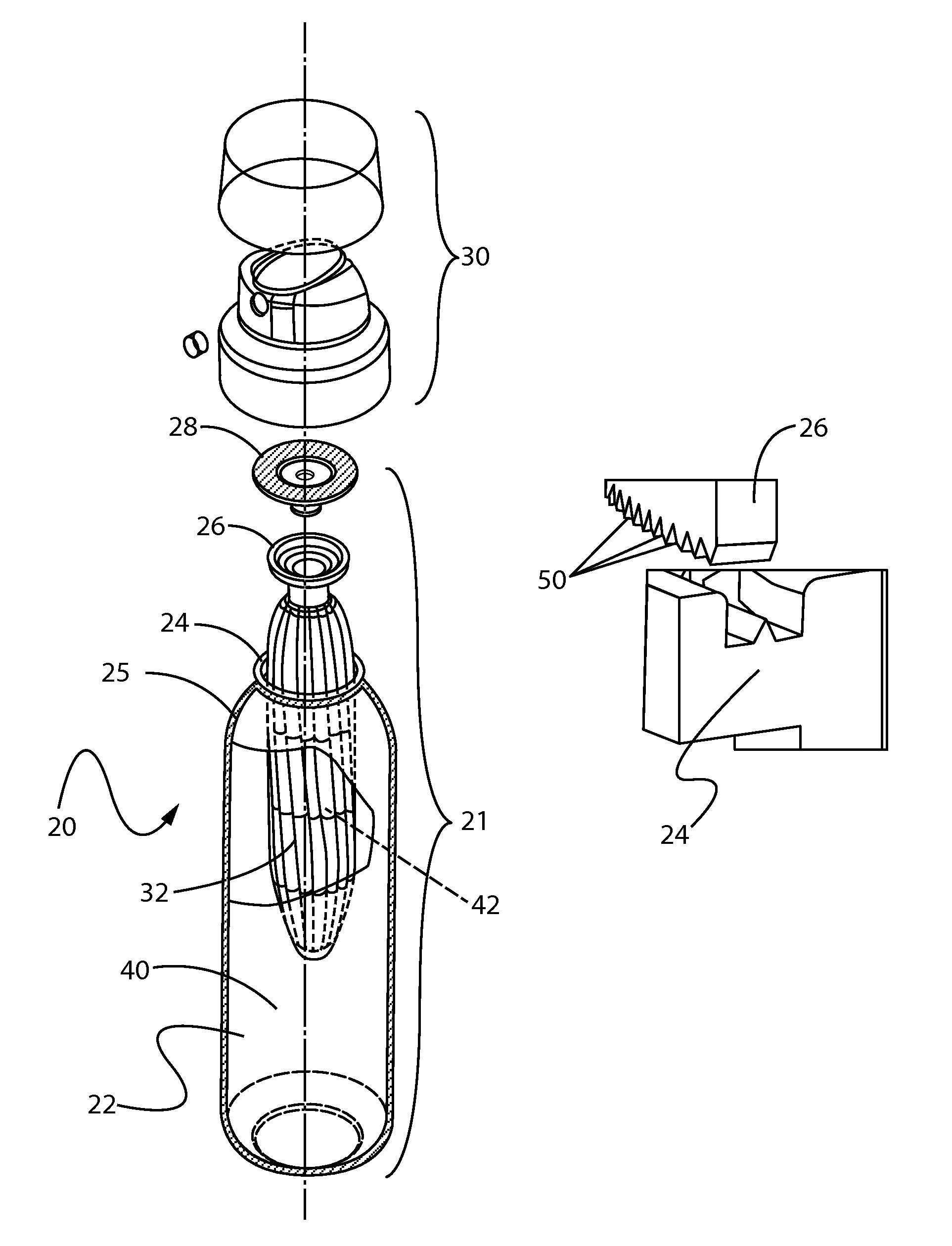

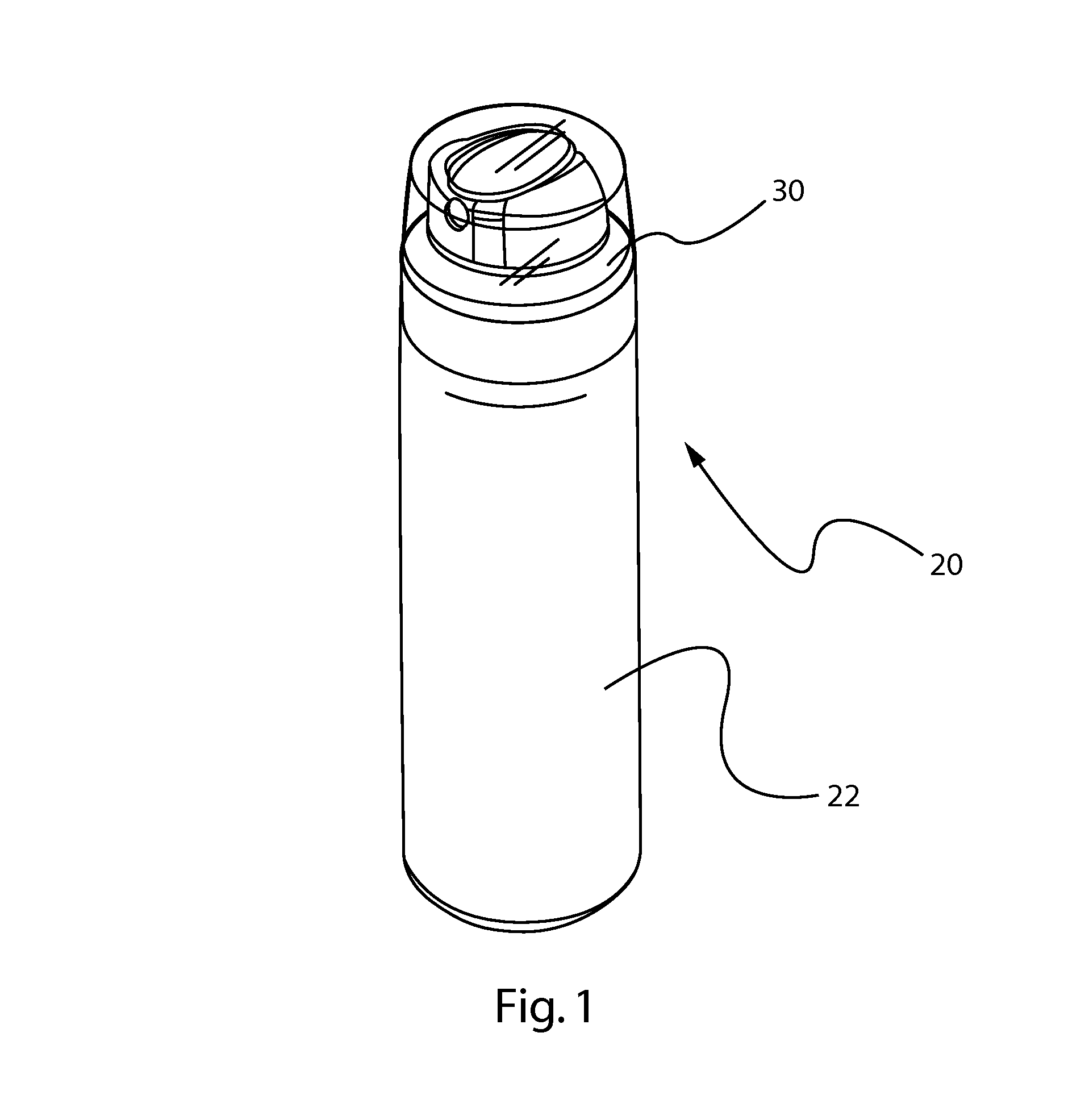

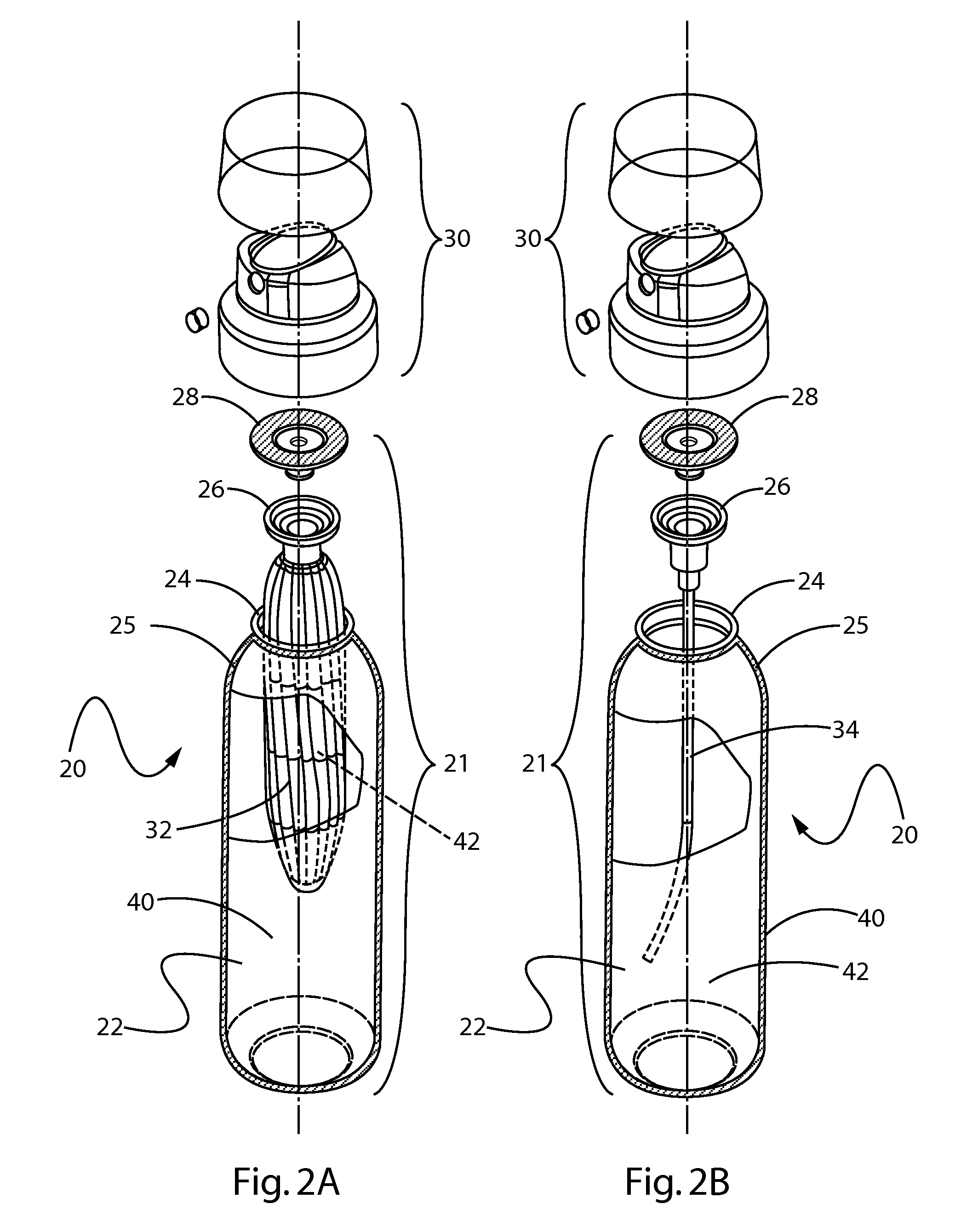

Method of filling and sealing an aerosol dispenser

A method of pressurizing a container usable for an aerosol dispenser. The method comprises providing a pressurizeable outer container and complementary valve cup, at least one having a channel into the container. A manifold is brought into sealing relationship with the channel of the container. Propellant is supplied from the manifold, goes through the channel and into the container. While the manifold is still sealed to the container, the channel is sealed shut to maintain the pressure. Sealing may be accomplished by sonic or ultrasonic welding.

Owner:PROCTER & GAMBLE CO

Manufacturing within a single-use container

ActiveUS20160068793A1Function increaseProgramme-controlled manipulatorBioreactor/fermenter combinationsNumerical controlThree degrees of freedom

A manufacturing assembly has at least a sterilizable chamber containing at least one of a three-dimensional printing device (additive manufacturing), a Computer Numerical Controlled (CNC) finishing head (subtractive manufacturing), a vacuum-forming unit, an injection-molding unit, a laser-cutting unit, a ultrasonic-welding unit, a robotic arman analysis device, a sampling device or a combination thereof. A plurality of individual sterilizable chambers may be aseptically connected into a network of sterilizable chambers that provides additional functionality for the manufacturing assembly. A sterilizable printer assembly may include at least one printing head, a printing platform, and a driving mechanism adapted to perform a movement of the at least one printing head relative to the printing platform along three degrees of freedom; a printer housing enclosing the printer assembly in a sterile manner, at least one aseptic connector fluidly connected to a corresponding one of the at least one printing head.

Owner:SARTORIUS STEDIM BIOTECH GMBH

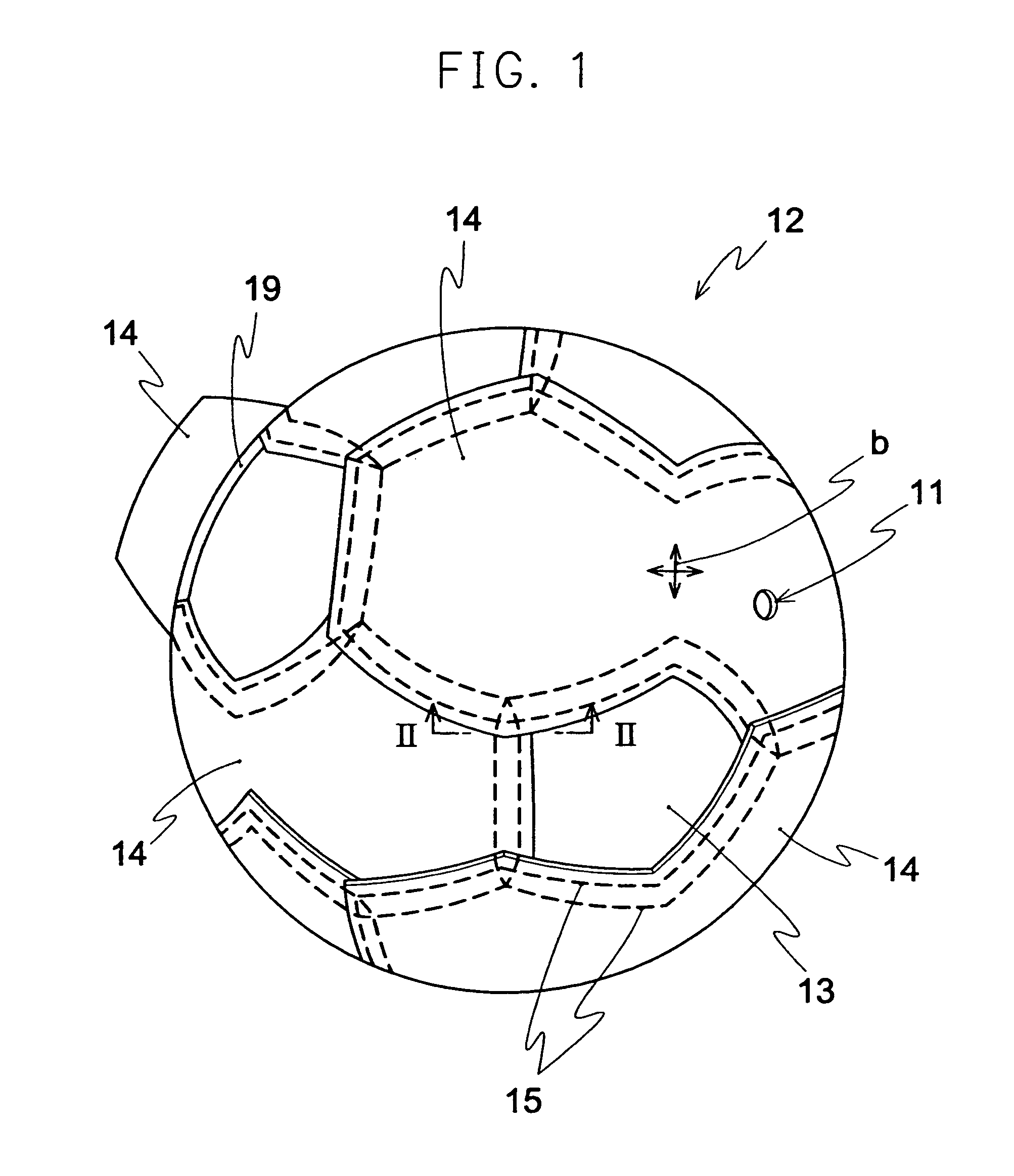

Ball for ball game and method for manufacturing the same

InactiveUS6971965B1Increase the number ofMaintain tensile strengthHollow inflatable ballsHollow non-inflatable ballsBall gameSpherical shaped

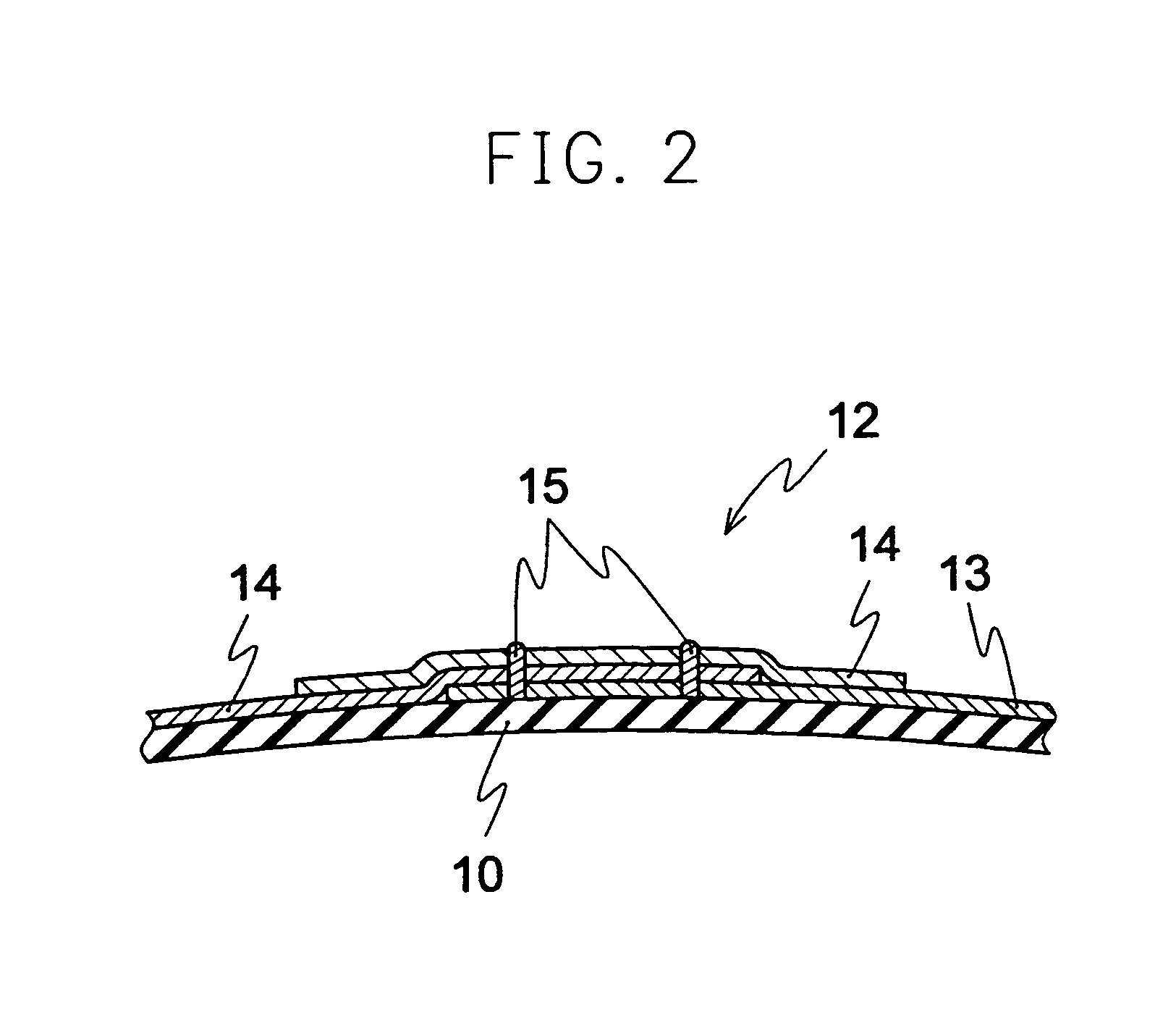

To provide a ball for ball game and a method for manufacturing the ball having superior sphericity, an ability to retain its original shape, durability, and soft feel. The fabric layer (12) is formed by sewing with a sewing machine for instance pentagonal first fabric pieces (13) together with composite shaped second fabric pieces (14) in which two hexagons are connected with each other, so that a spherical shape is formed. The marginal edge of the first and second fabric pieces are superimposed in the spherical surface direction, so that corner portions thereof are temporarily attached. Temporary attachment is achieved by inserting the needle into the needle through hole formed in the corner of the first and second fabric pieces, and welding by means of ultra sonic wave, such that the first and second fabric pieces (13, 14) are accurately aligned. The temporarily attached fabric pieces sewn together using a sewing machine along the guiding line (17) for sewing printed beforehand on the surface of the fabric pieces (13, 14).

Owner:MOLTEN CORPORATION +1

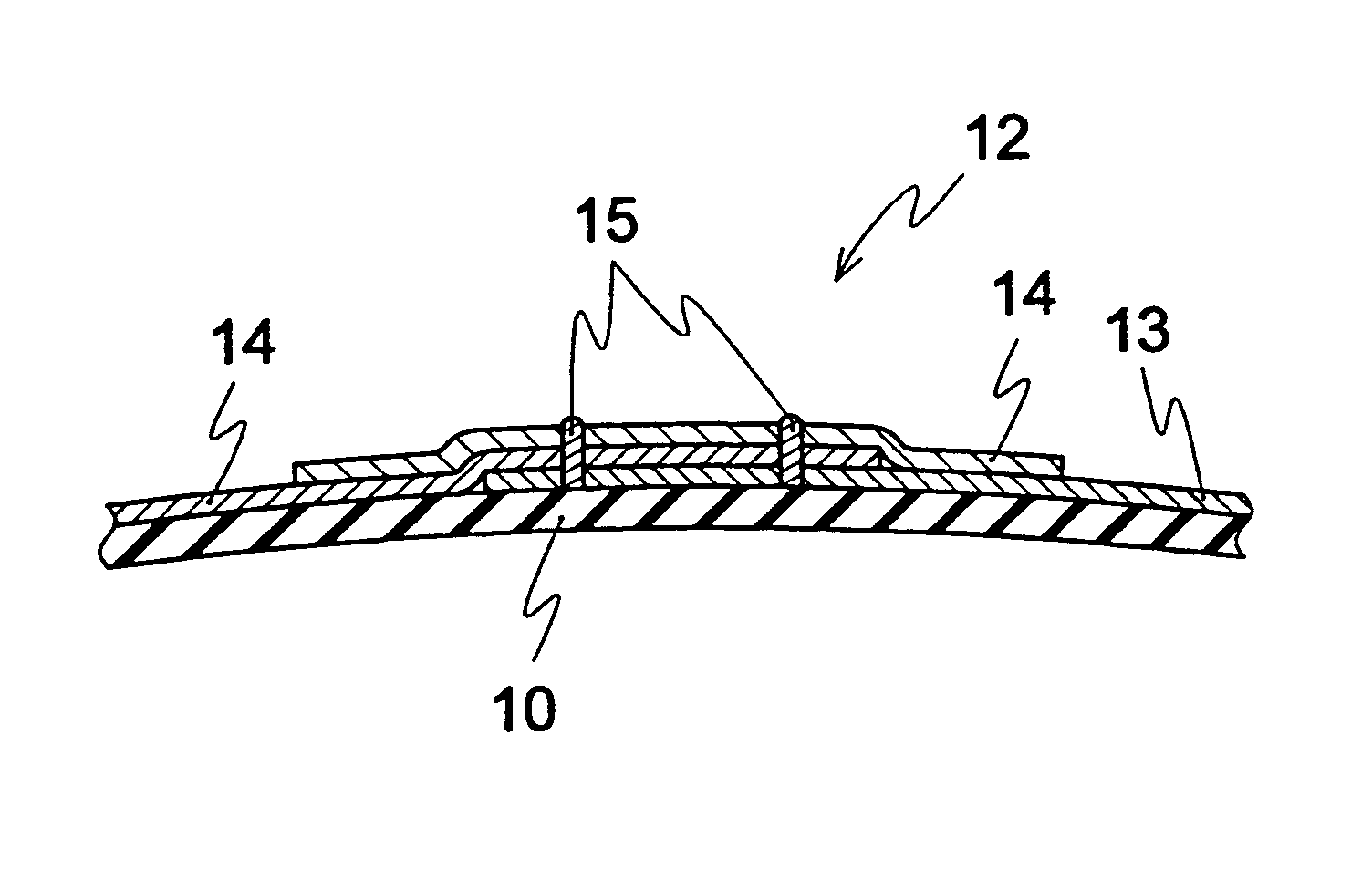

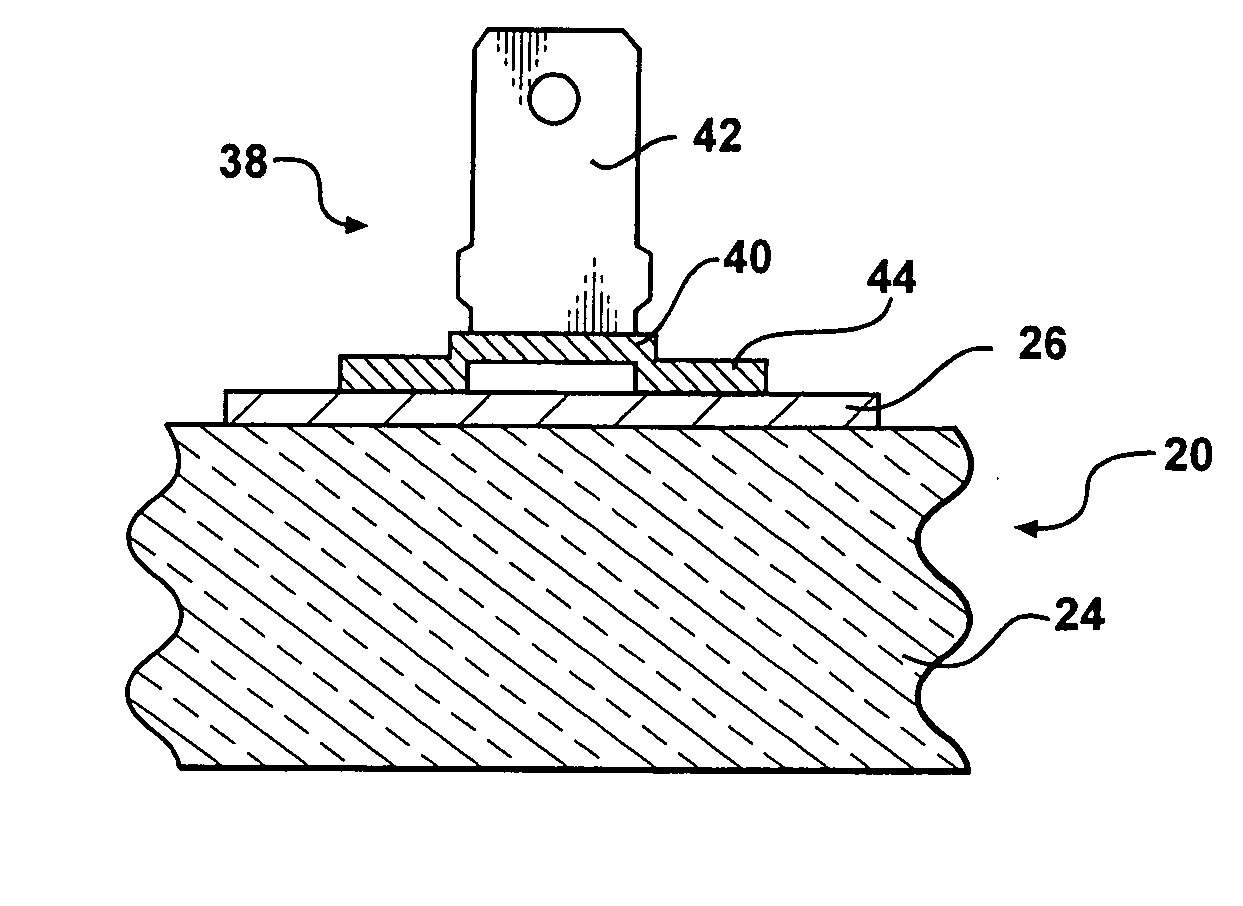

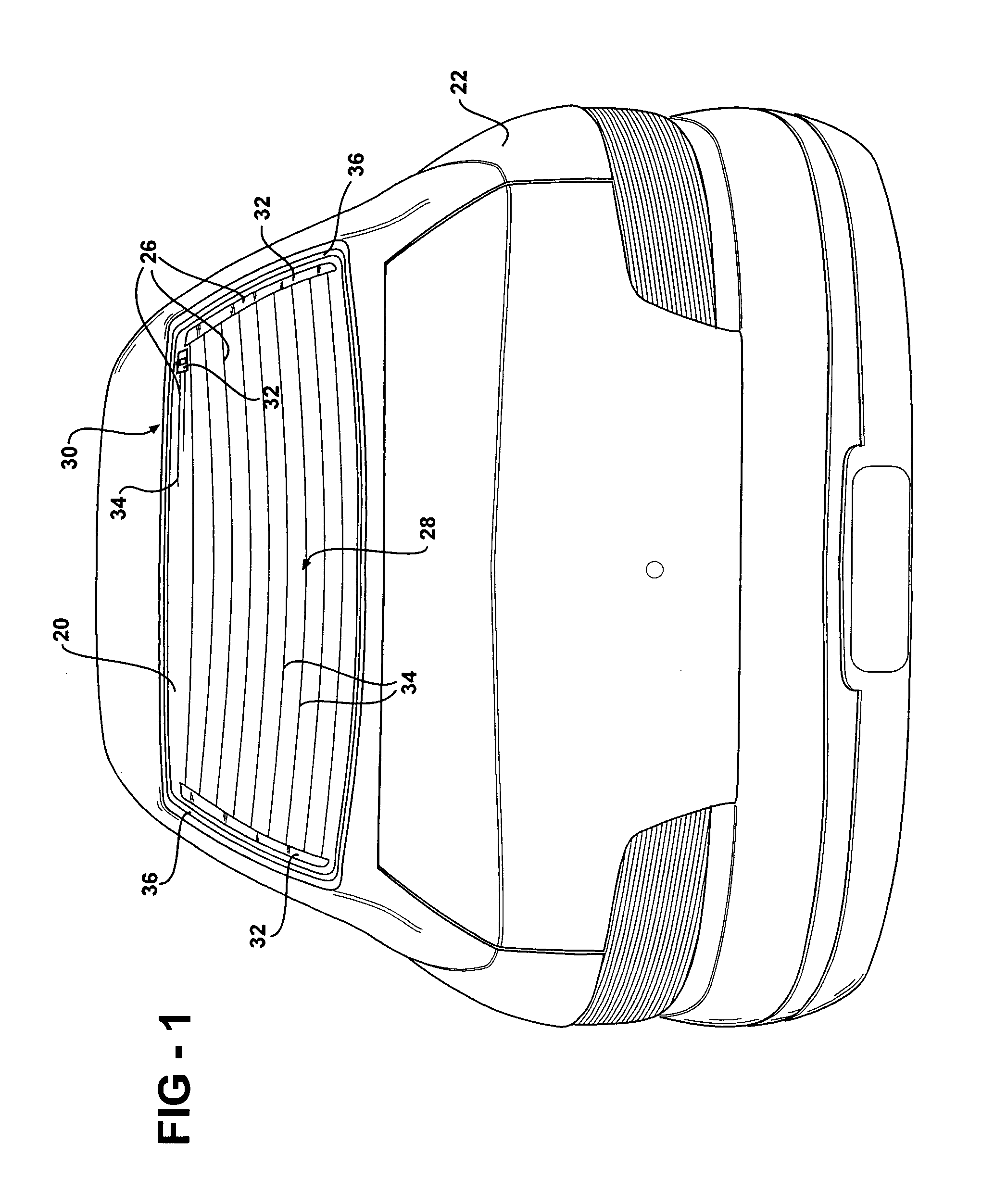

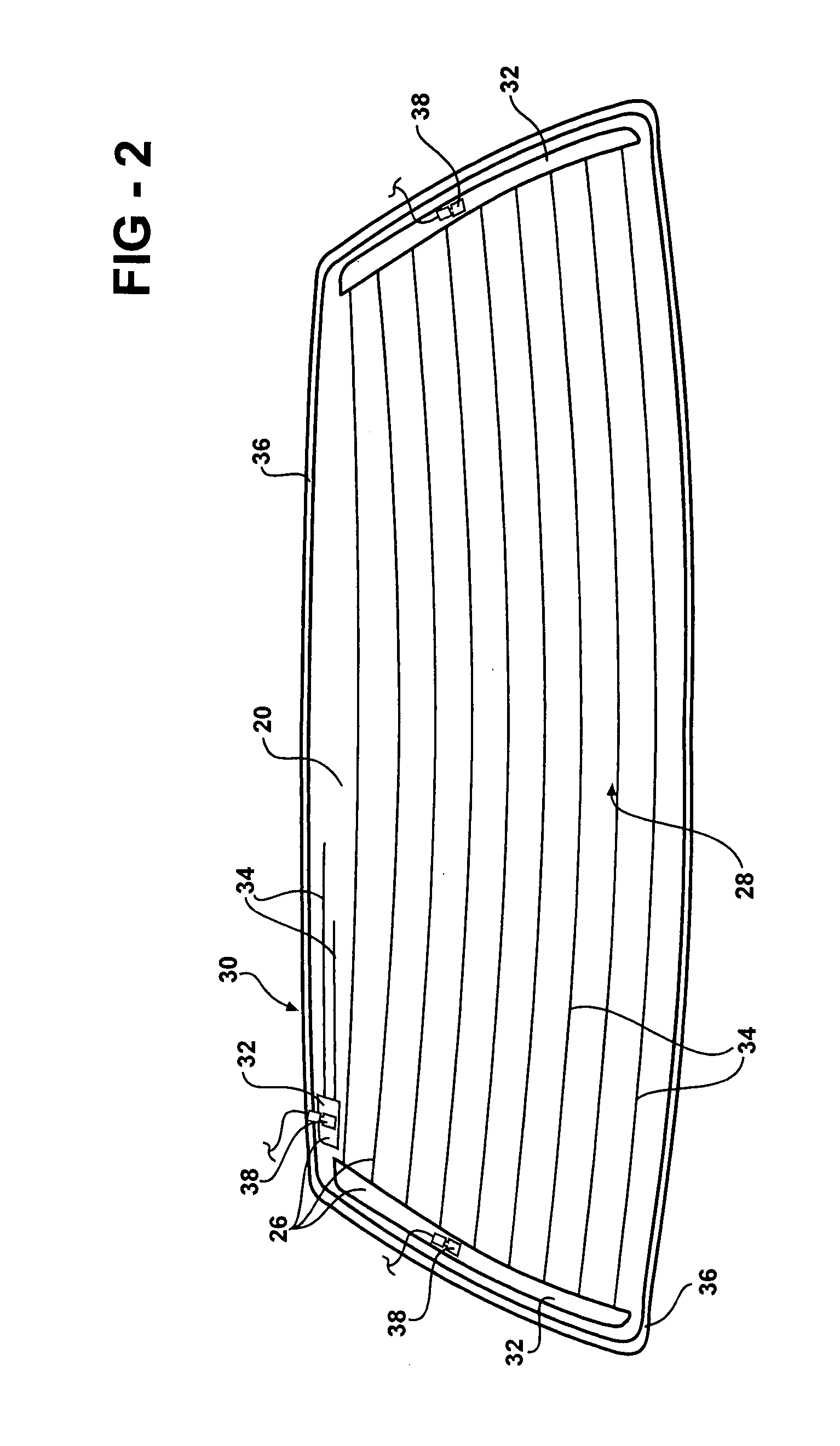

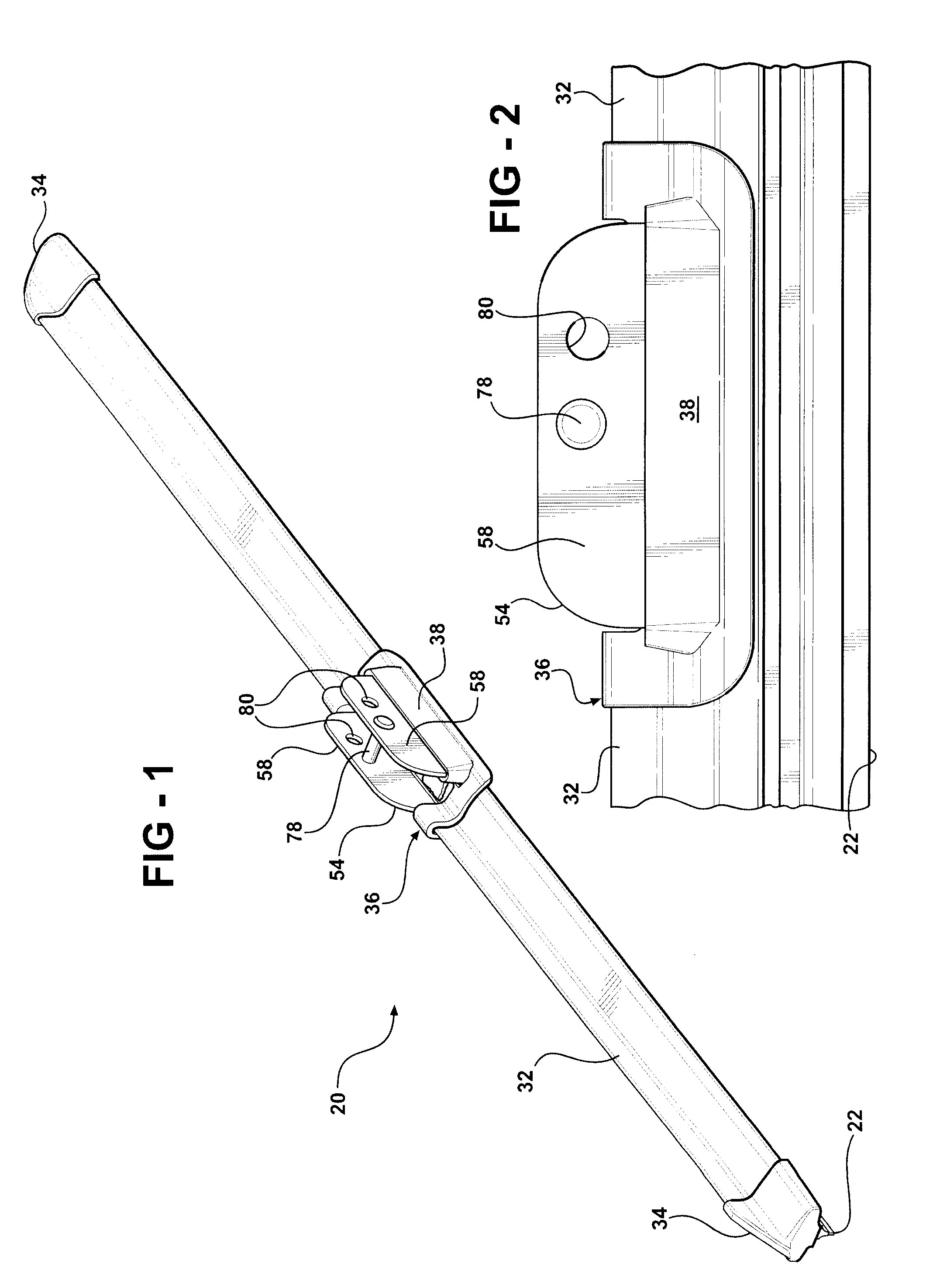

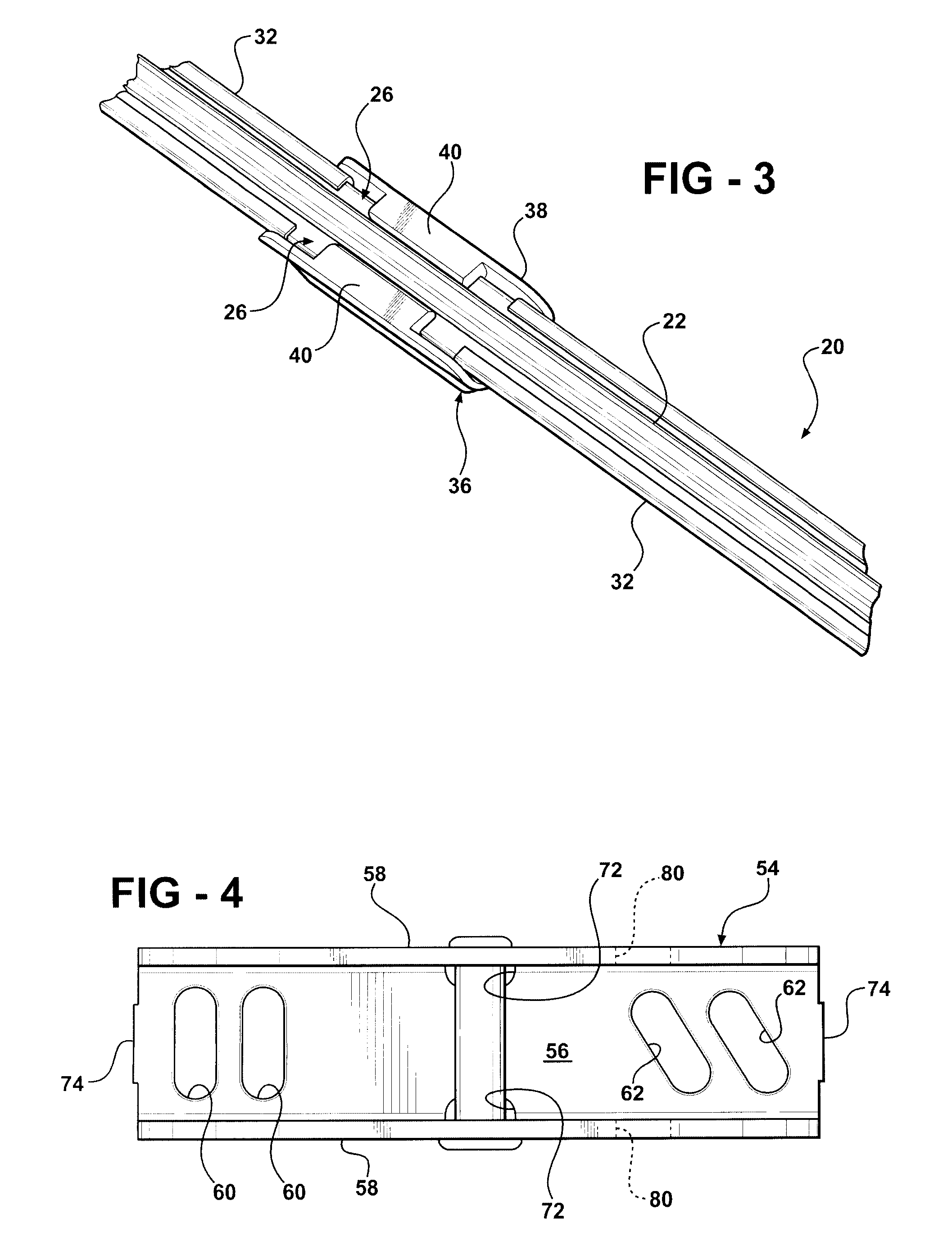

Two-piece connector for flat blade windshield wiper

ActiveUS7523522B2Easy to manufactureEasy to assembleWindow cleanersVehicle cleaningUltrasonic weldingHot melt

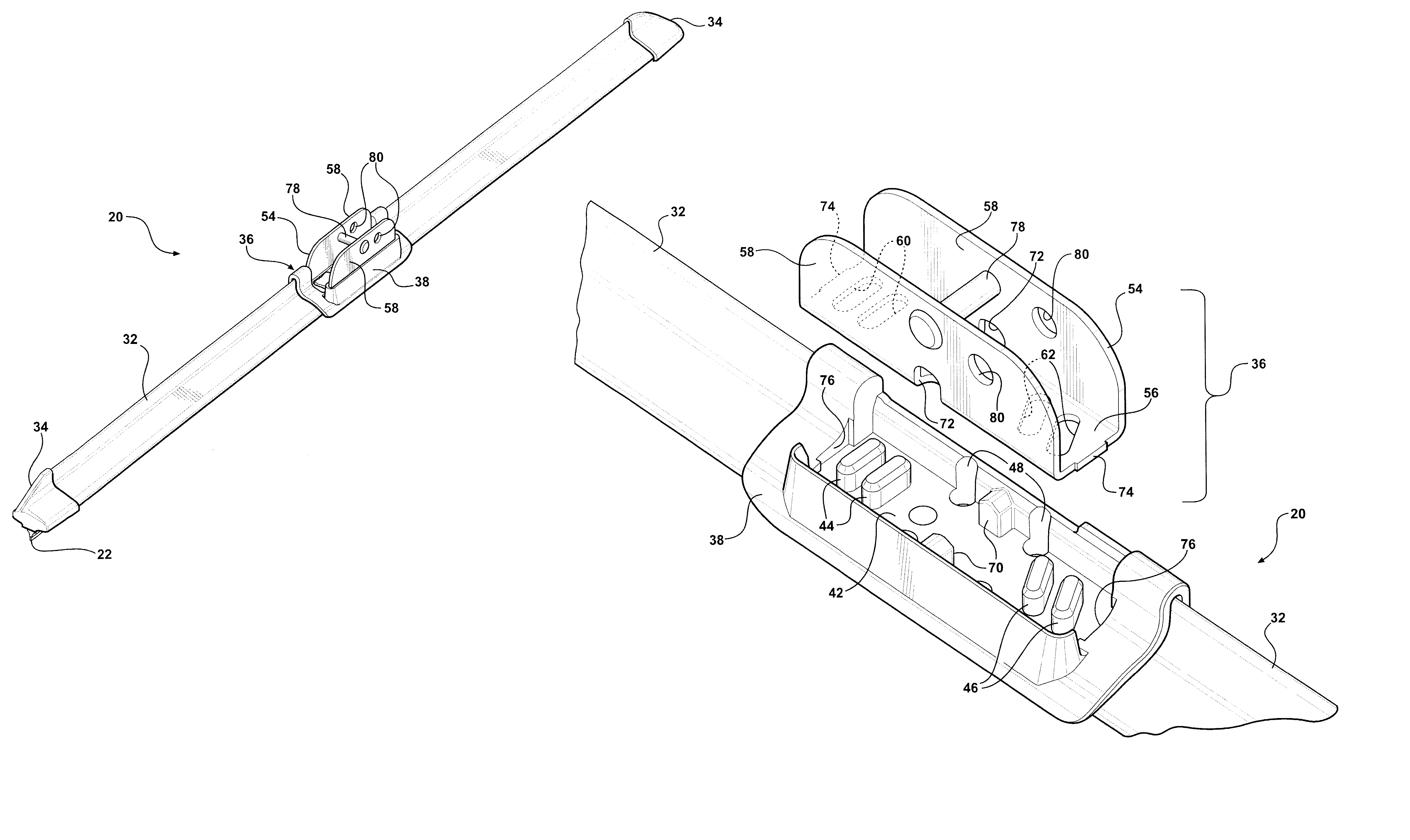

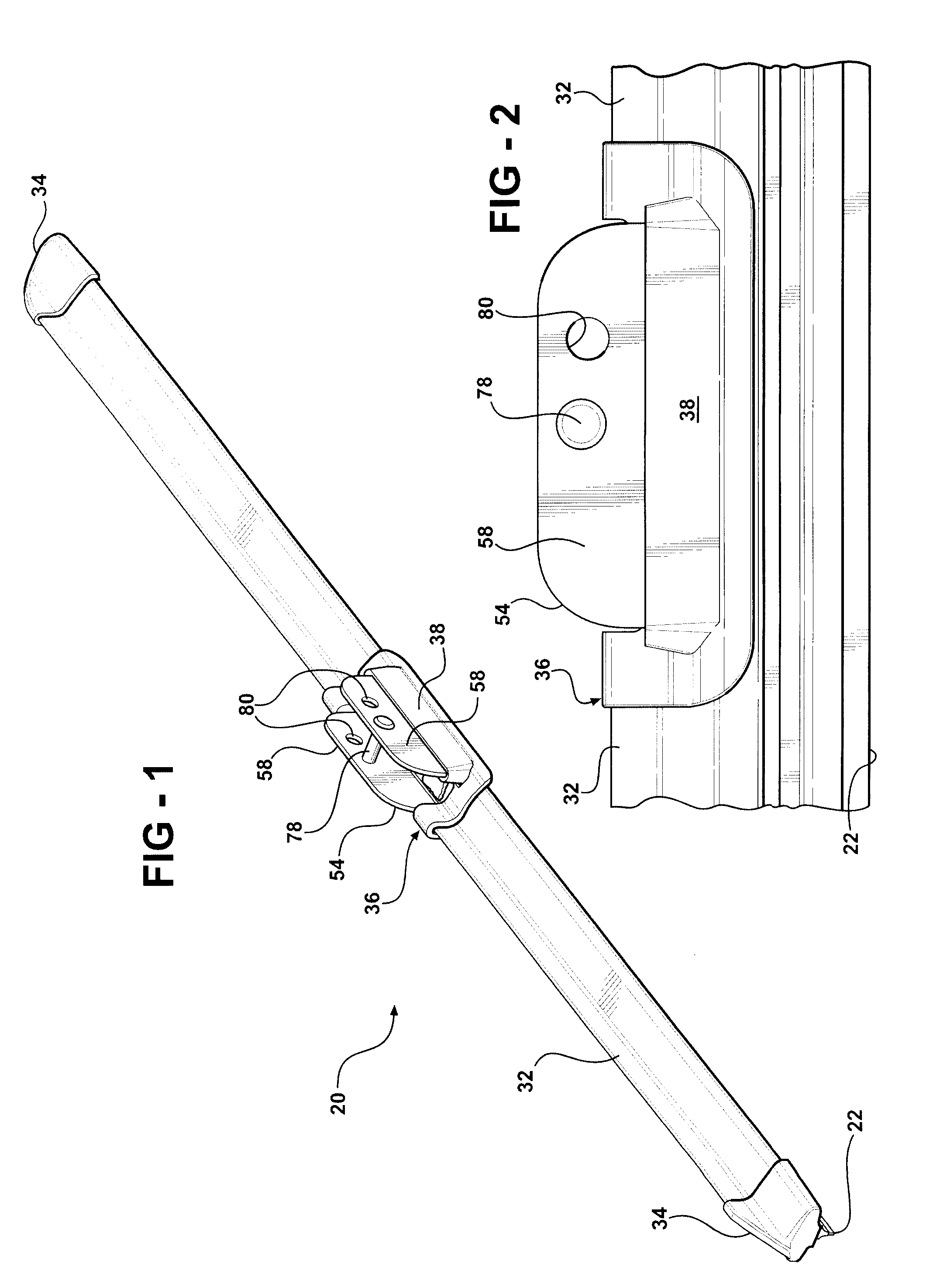

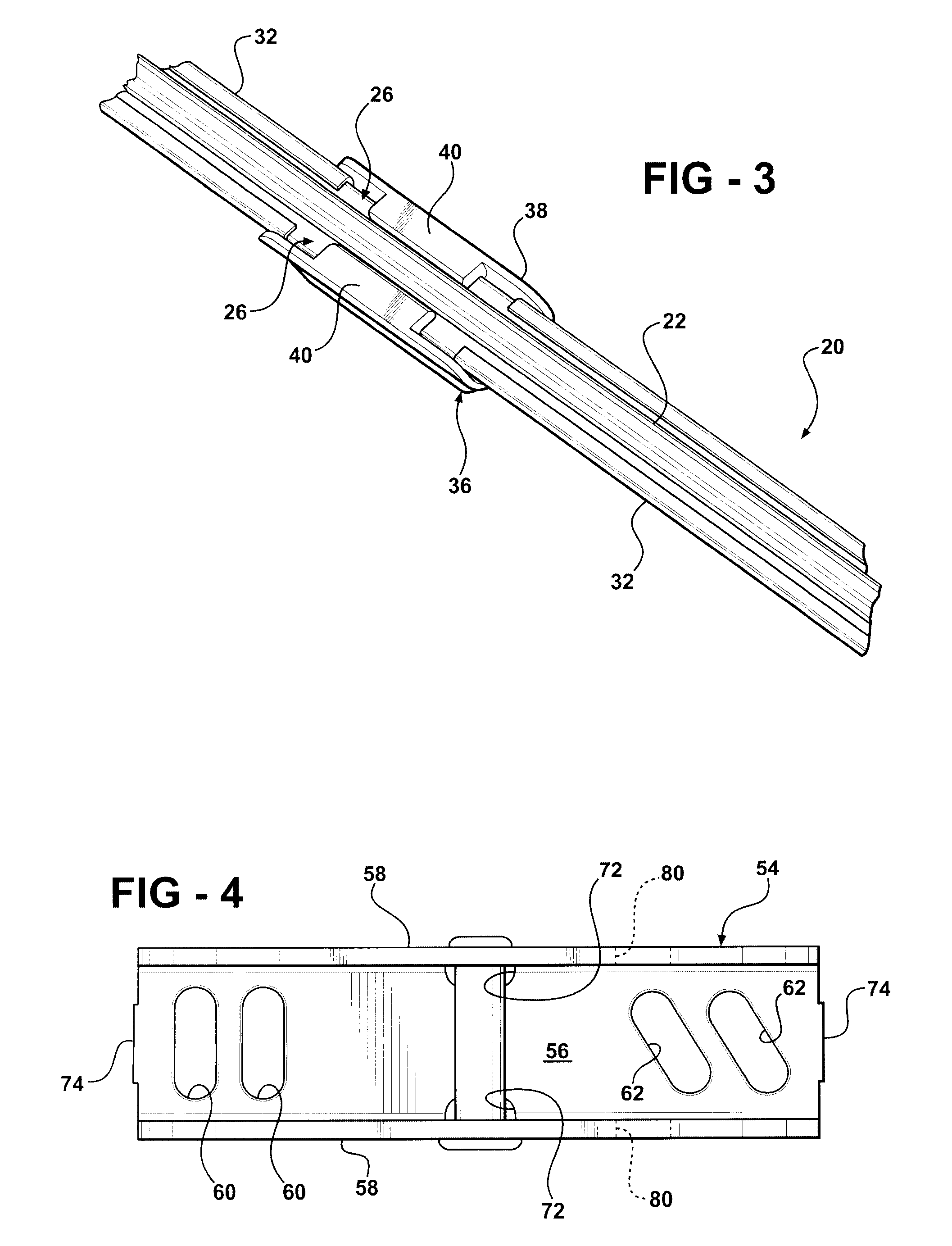

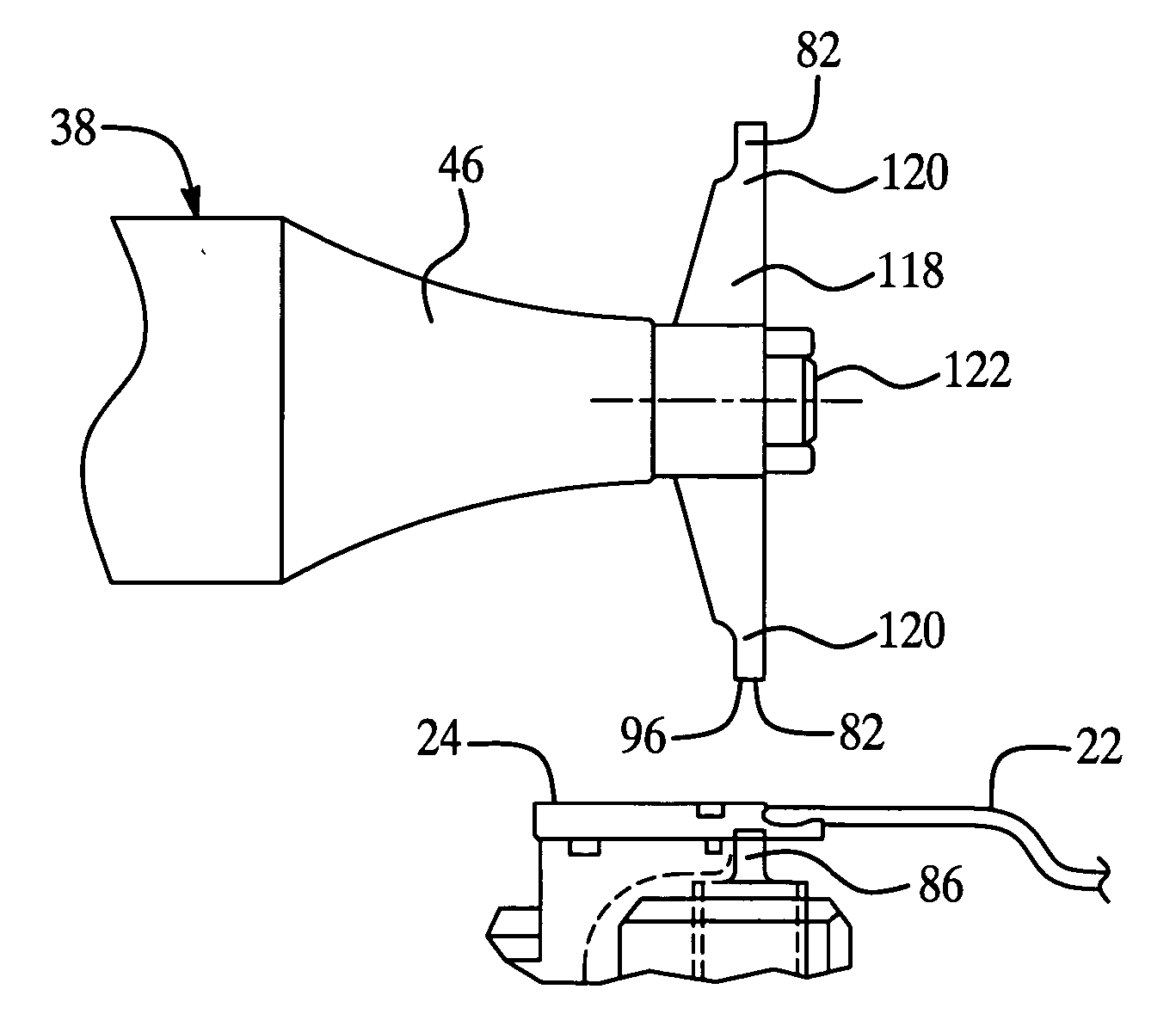

A central connecting device (36) for a flat blade style wiper blade assembly (20) includes a plastic intermediate base (38) that is fixed, such as by ultrasonic welding, to a pair of flexors (26) extending the length of the wiper blade assembly (20). The intermediate base (38) includes a recessed deck section (42) for receiving a metallic housing (54). The housing (54) is heat-staked in position to the intermediate base (38) to secure the two elements together as an integral unit. A rivet (78) extends transversely across the sidewalls (58) of the housing (54) for adjoining to a universal connector (82) or other suitable adaptor or by direction connection to the end of a wiper arm.

Owner:TRICO PROD CORP

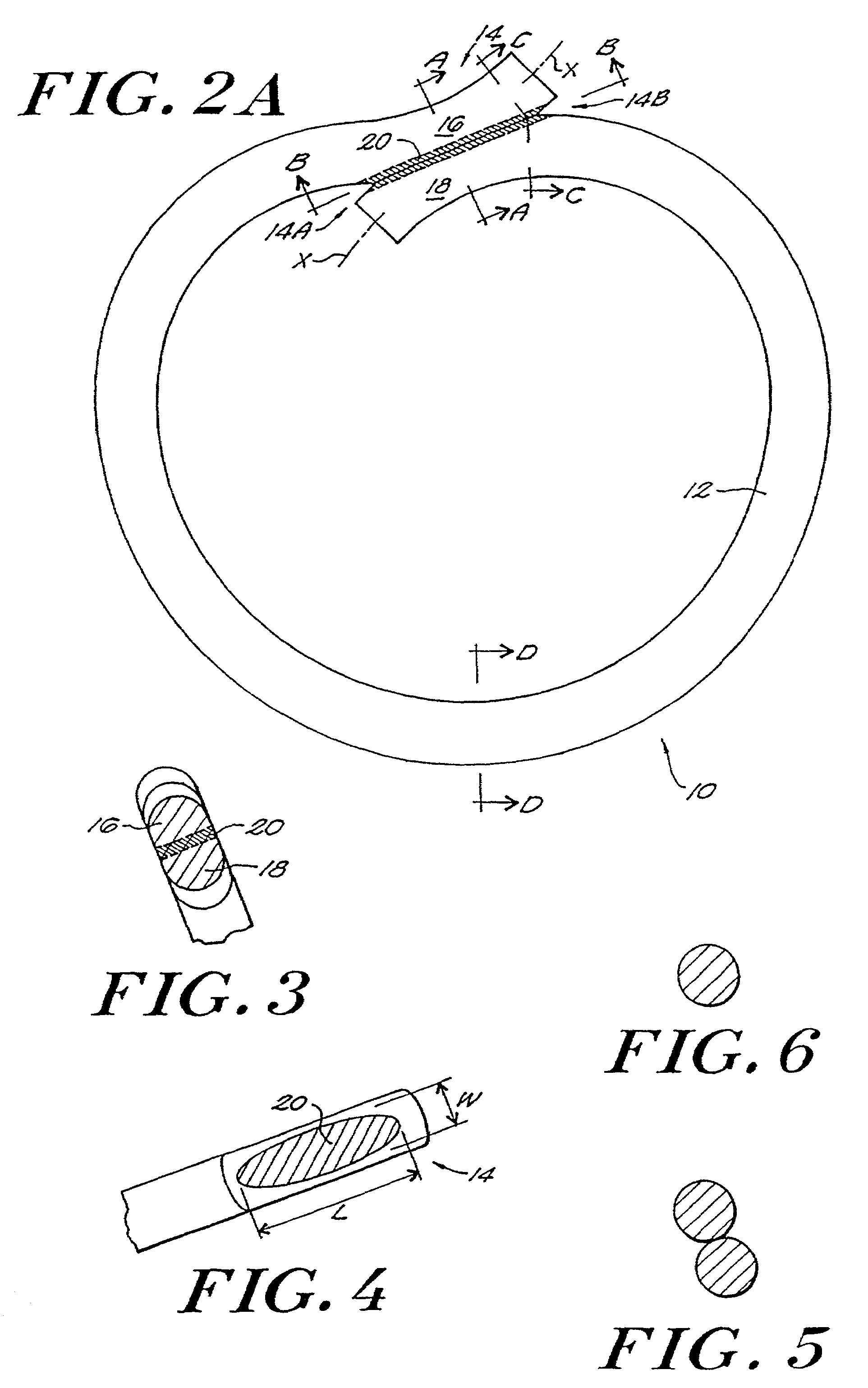

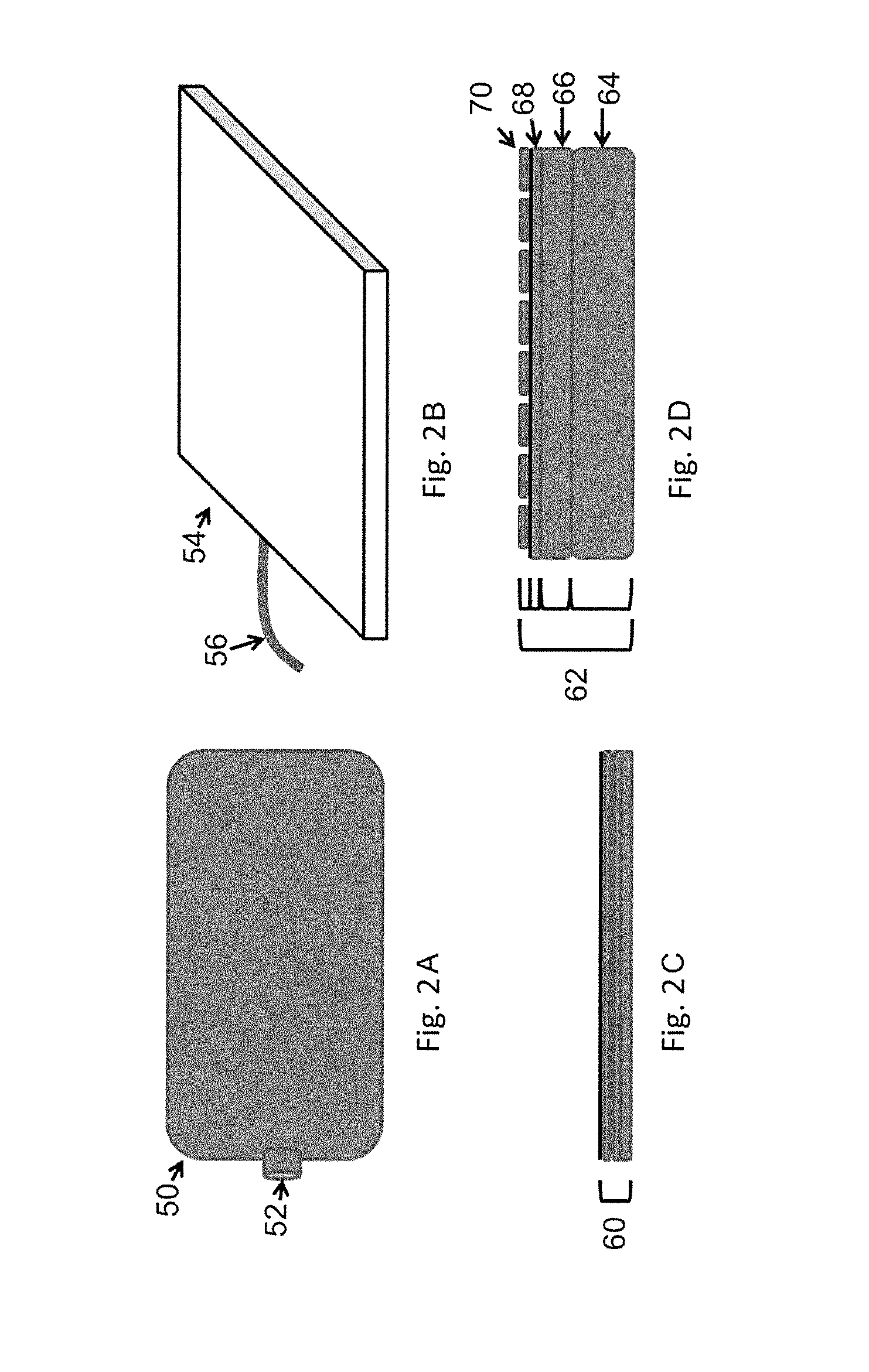

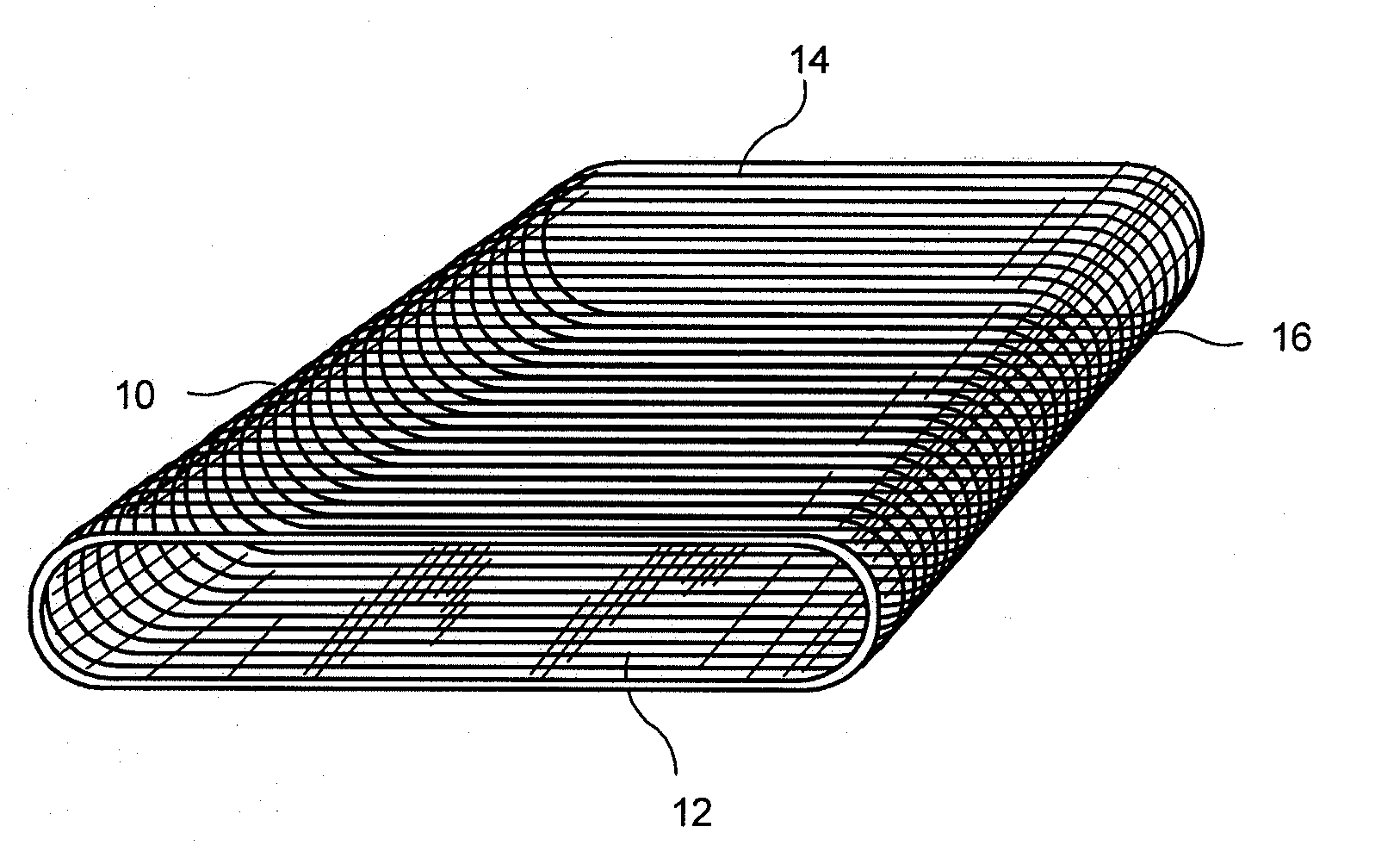

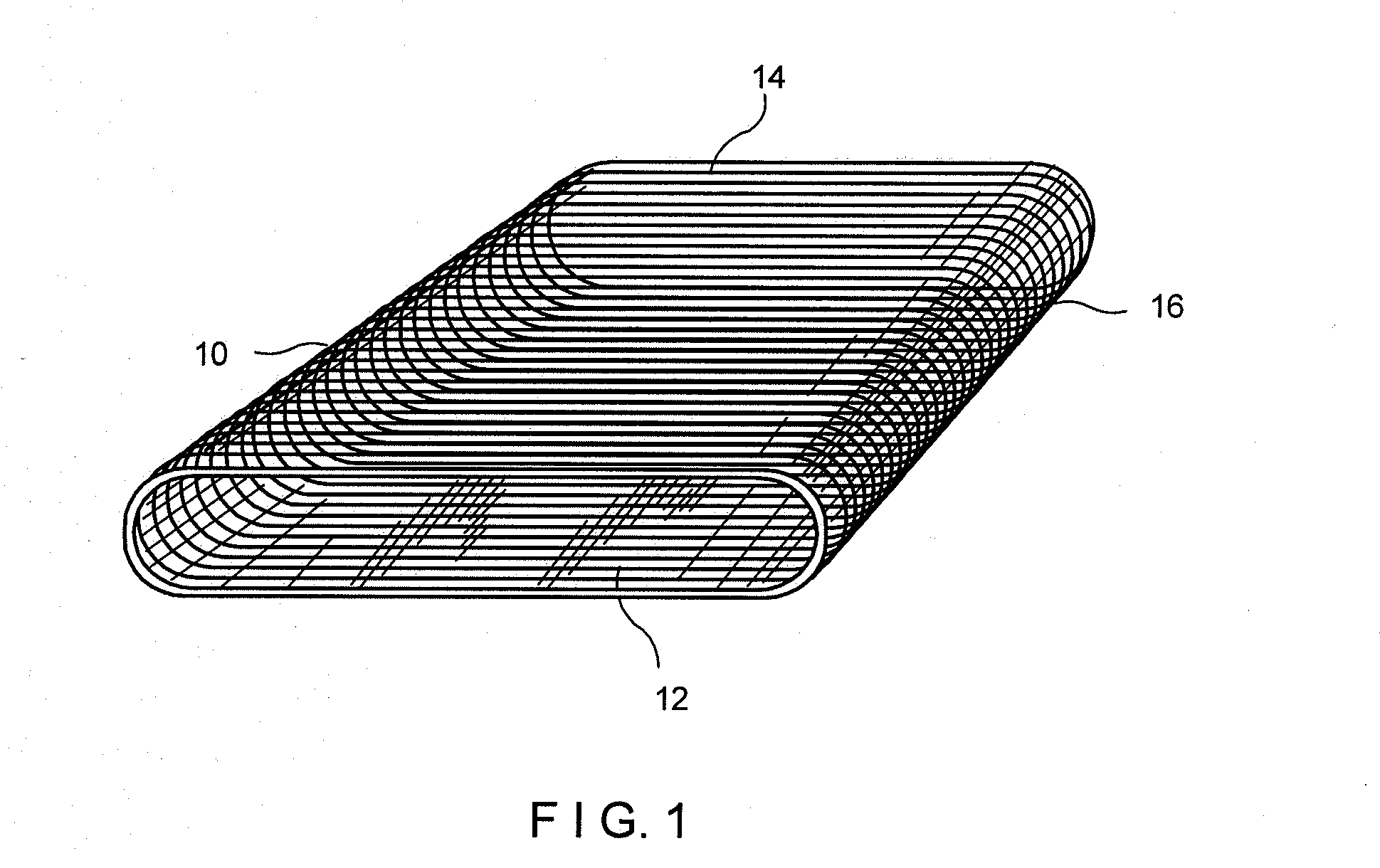

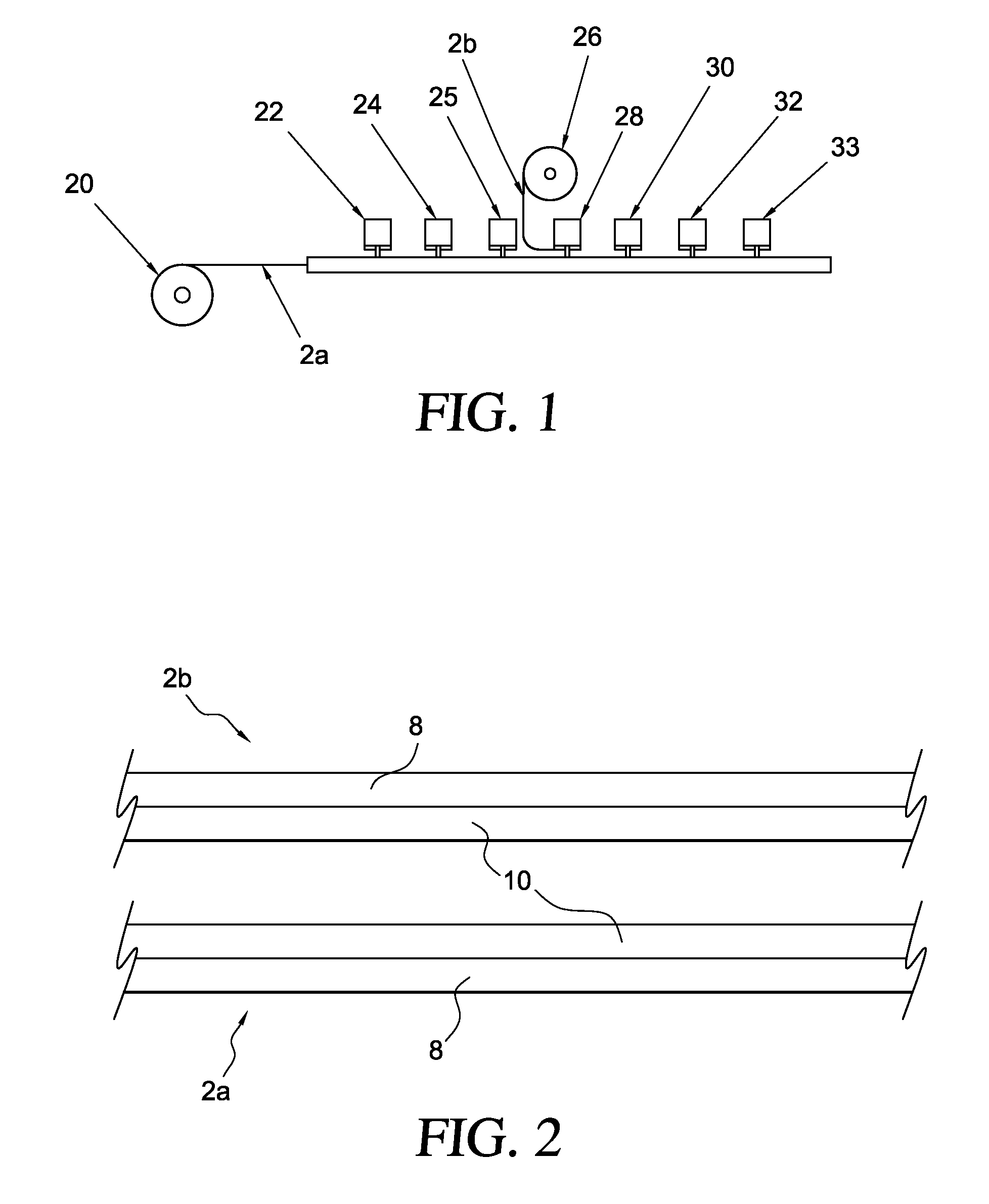

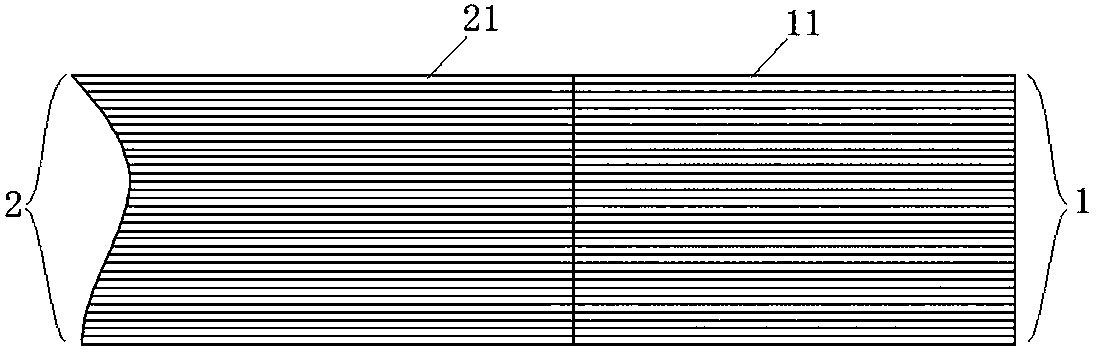

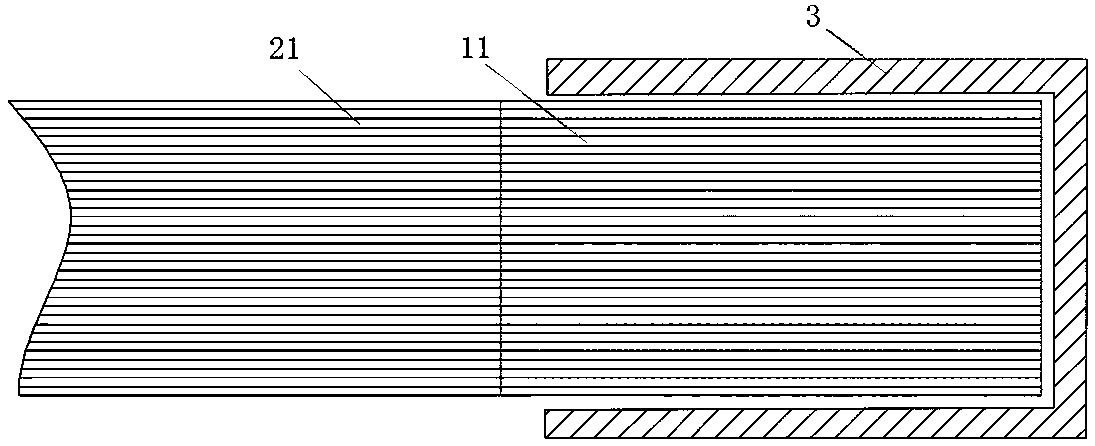

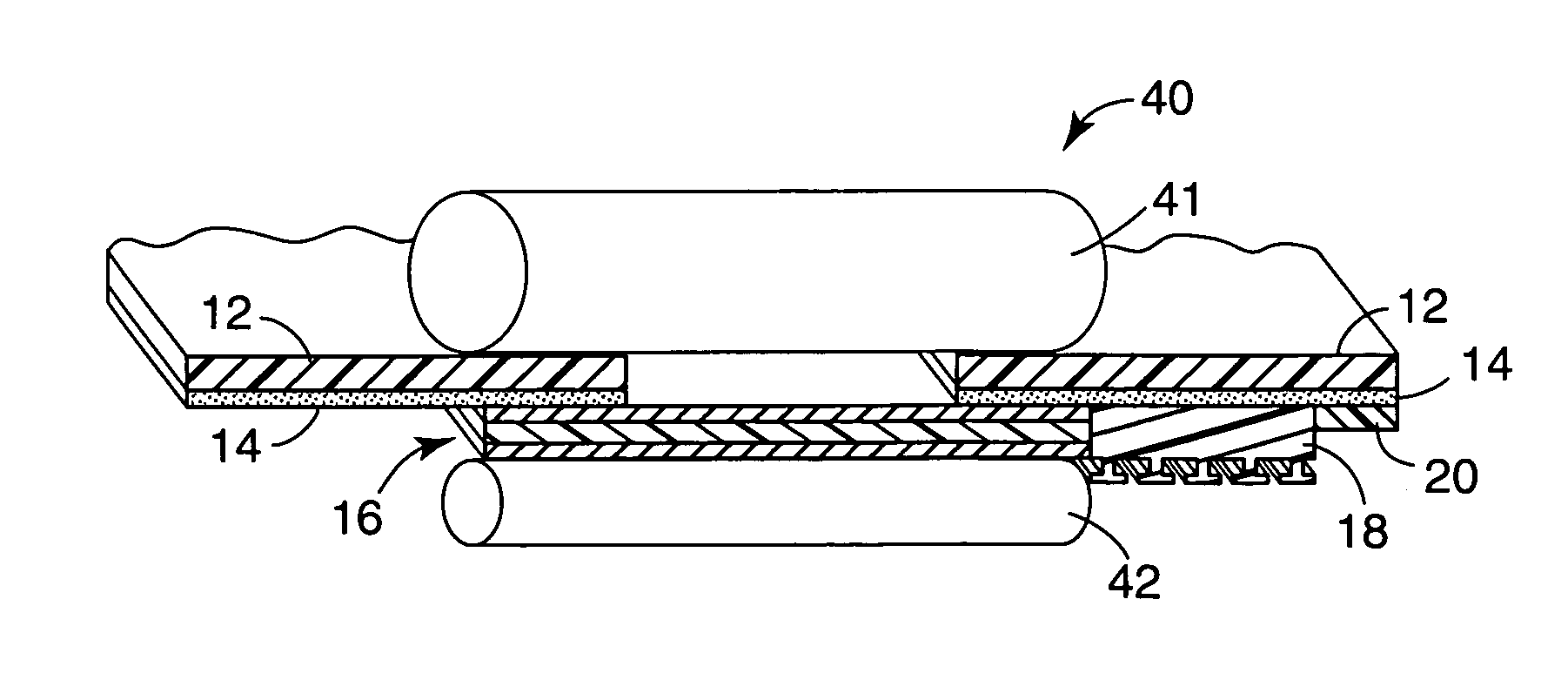

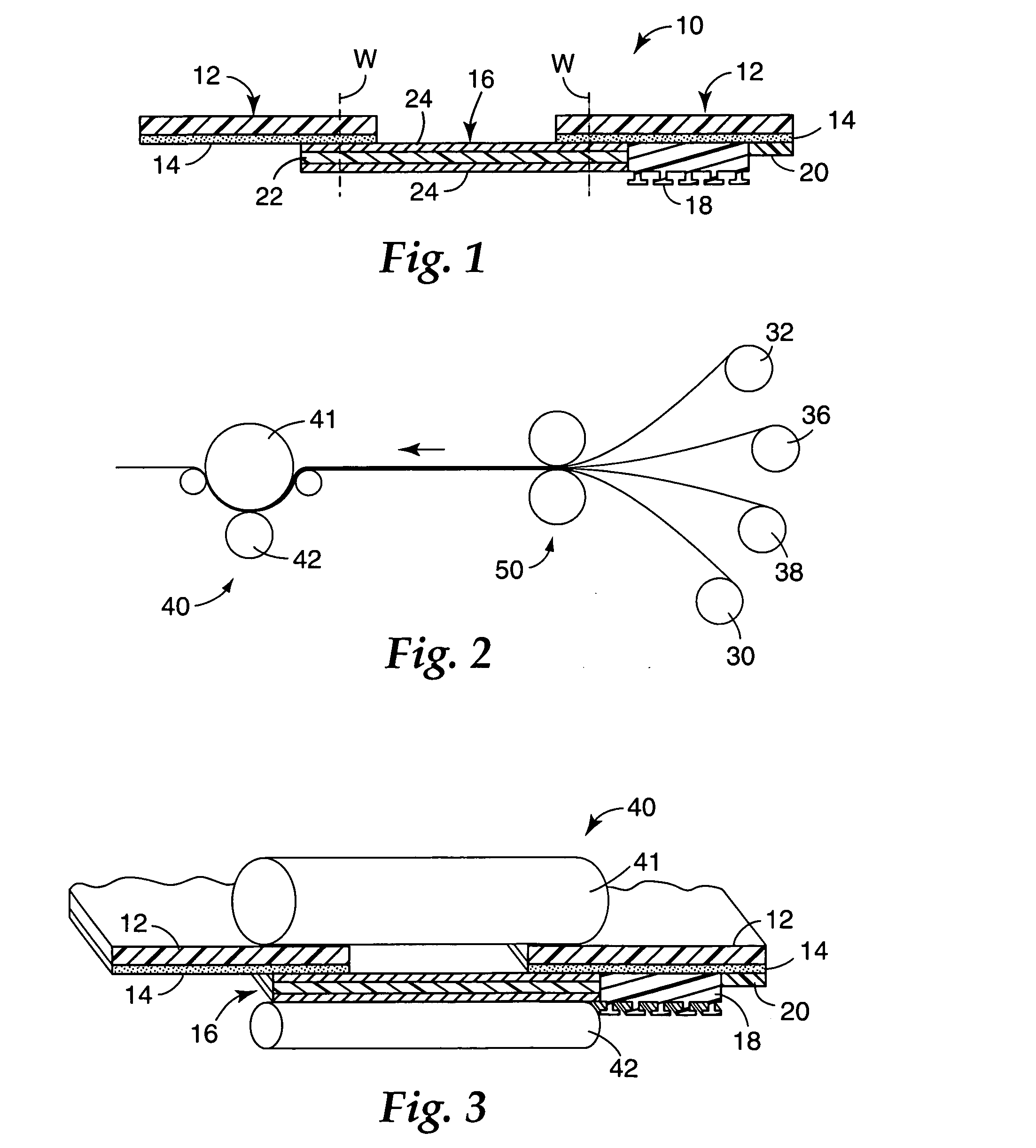

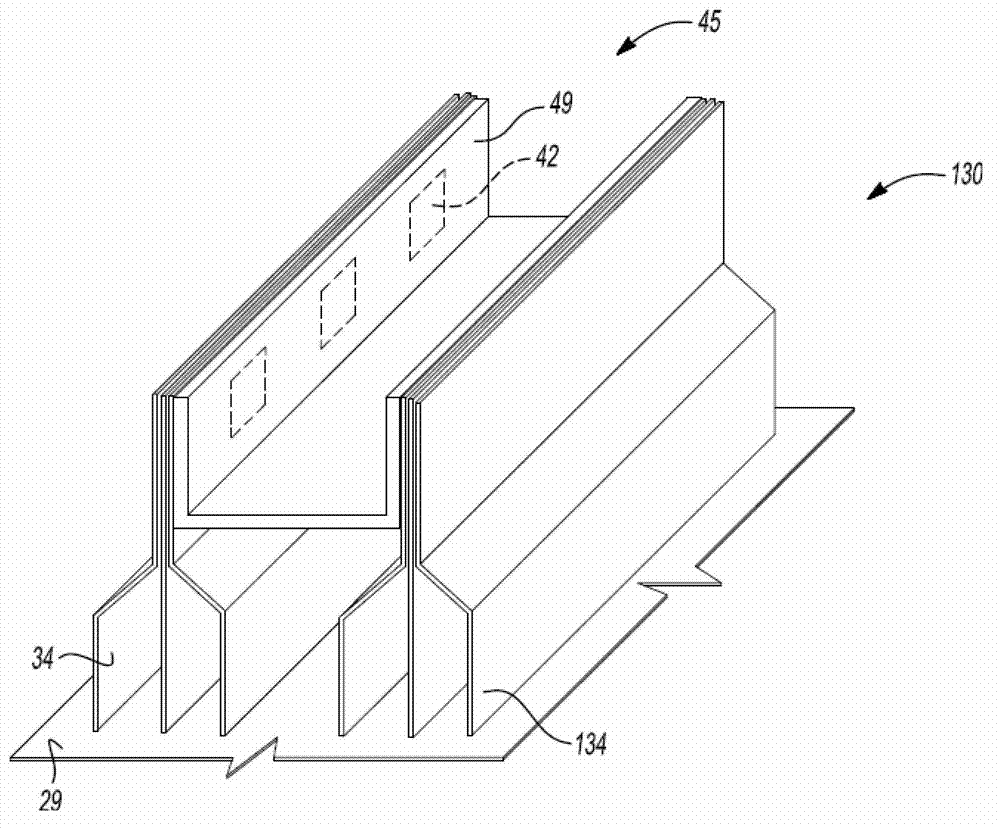

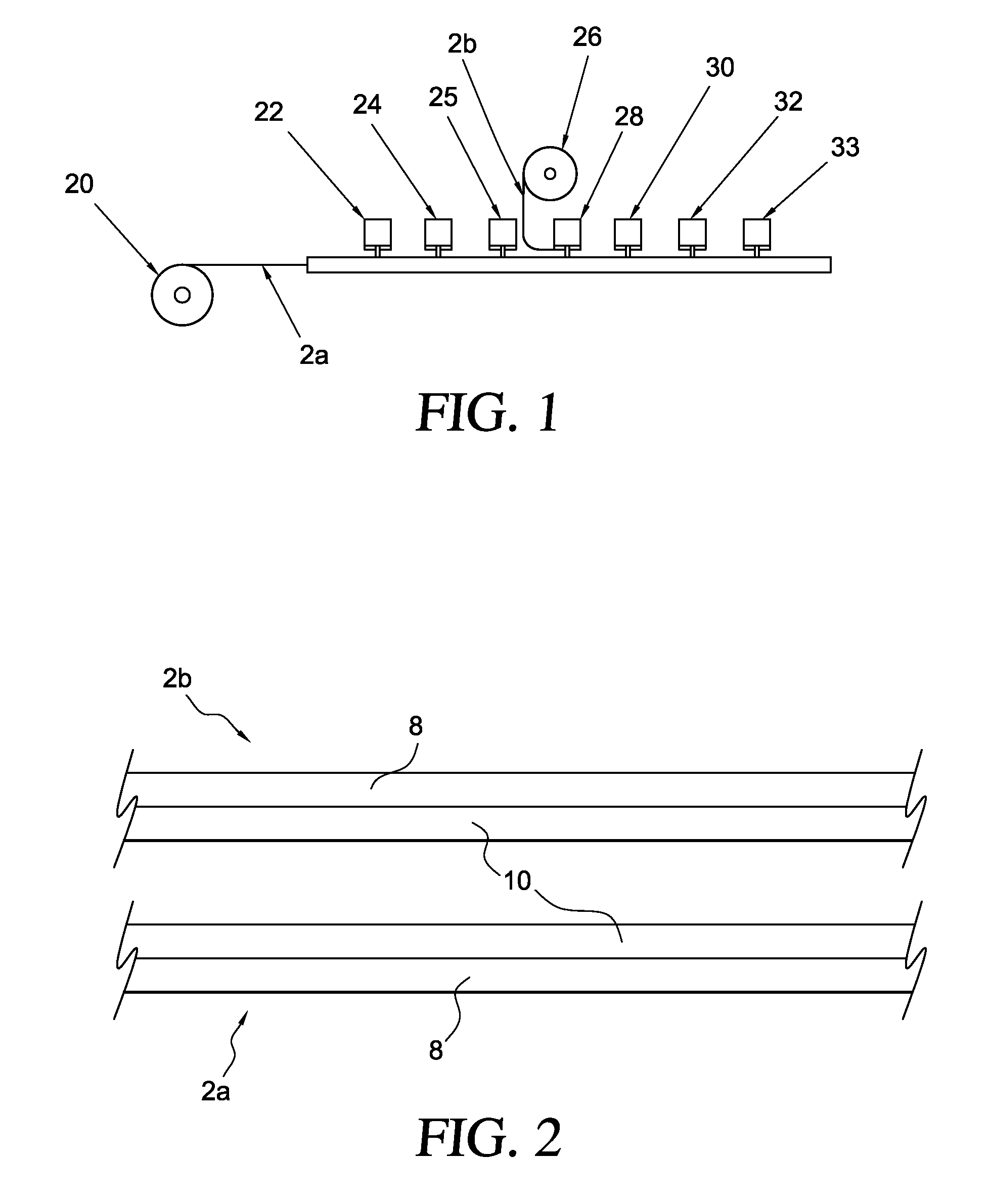

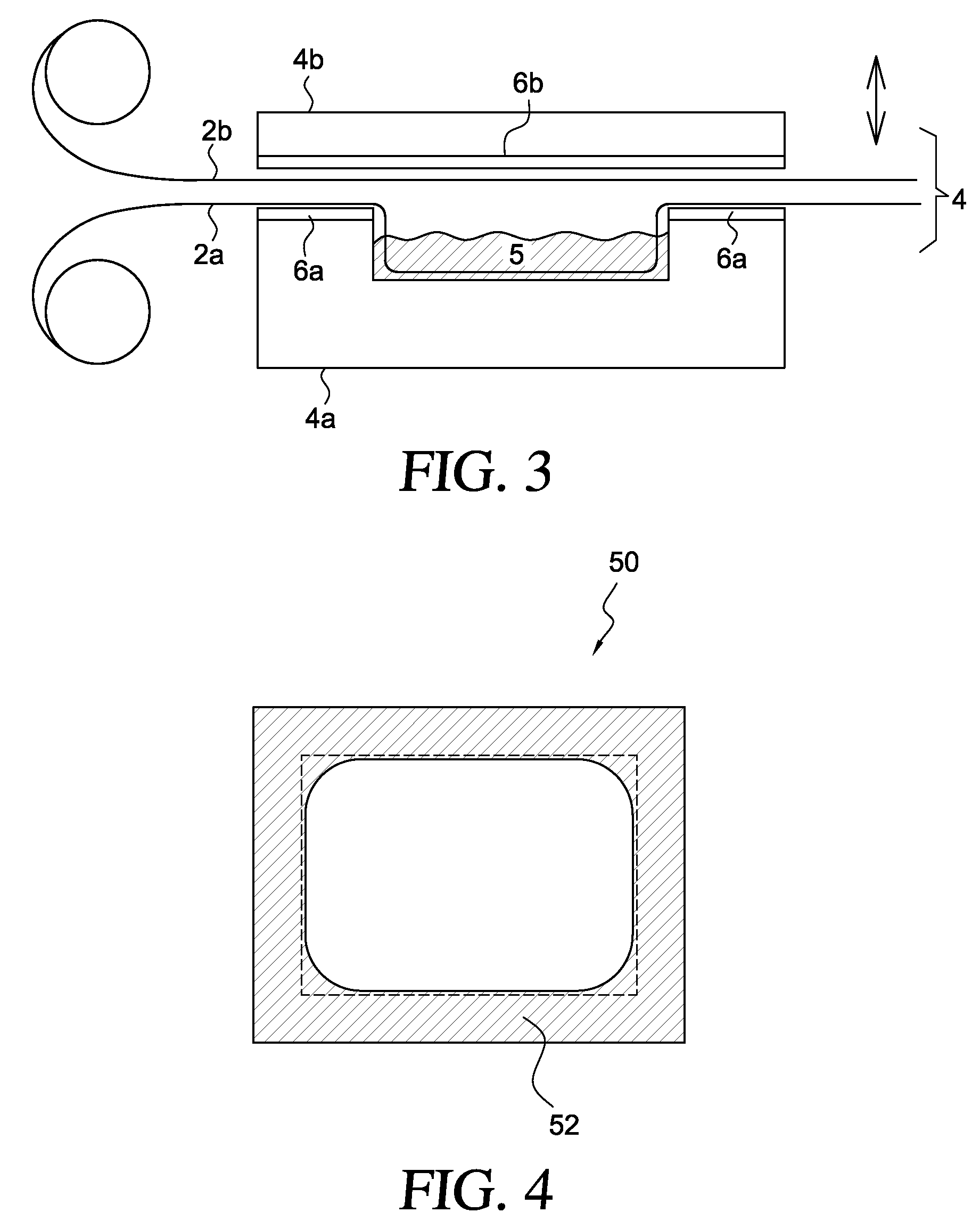

Industrial fabric including spirally wound material strips

ActiveUS20100230064A1Improved fiber supportFacilitated releaseFilament handlingNeedling machinesStrappingUltrasonic welding

An industrial fabric, belt or sleeve and a method of making the fabric, belt or sleeve are disclosed. The industrial fabric, belt or sleeve is produced by spirally winding strips of polymeric material, such as an industrial strapping or ribbon material, and joining the adjoining sides of the strips of material using ultrasonic welding or laser welding techniques. The fabric, belt or sleeve may then be perforated using a suitable technique to make it permeable to air and / or water.

Owner:ALBANY INT CORP

Industrial fabric including spirally wound material strips

ActiveUS20100236034A1Facilitated releaseStable supportNon-fibrous pulp additionNatural cellulose pulp/paperUltrasonic weldingStrapping

An industrial fabric such as an endless belt or sleeve for use in the production of nonwovens, and a method of making thereof are disclosed. The industrial fabric is produced by spirally winding strips of polymeric material, such as an industrial strapping or ribbon material, and joining the adjoining sides of the strips of material using ultrasonic welding or laser welding techniques. The fabric may then be perforated using a suitable technique to make it permeable to air and / or water.

Owner:ALBANY INT CORP

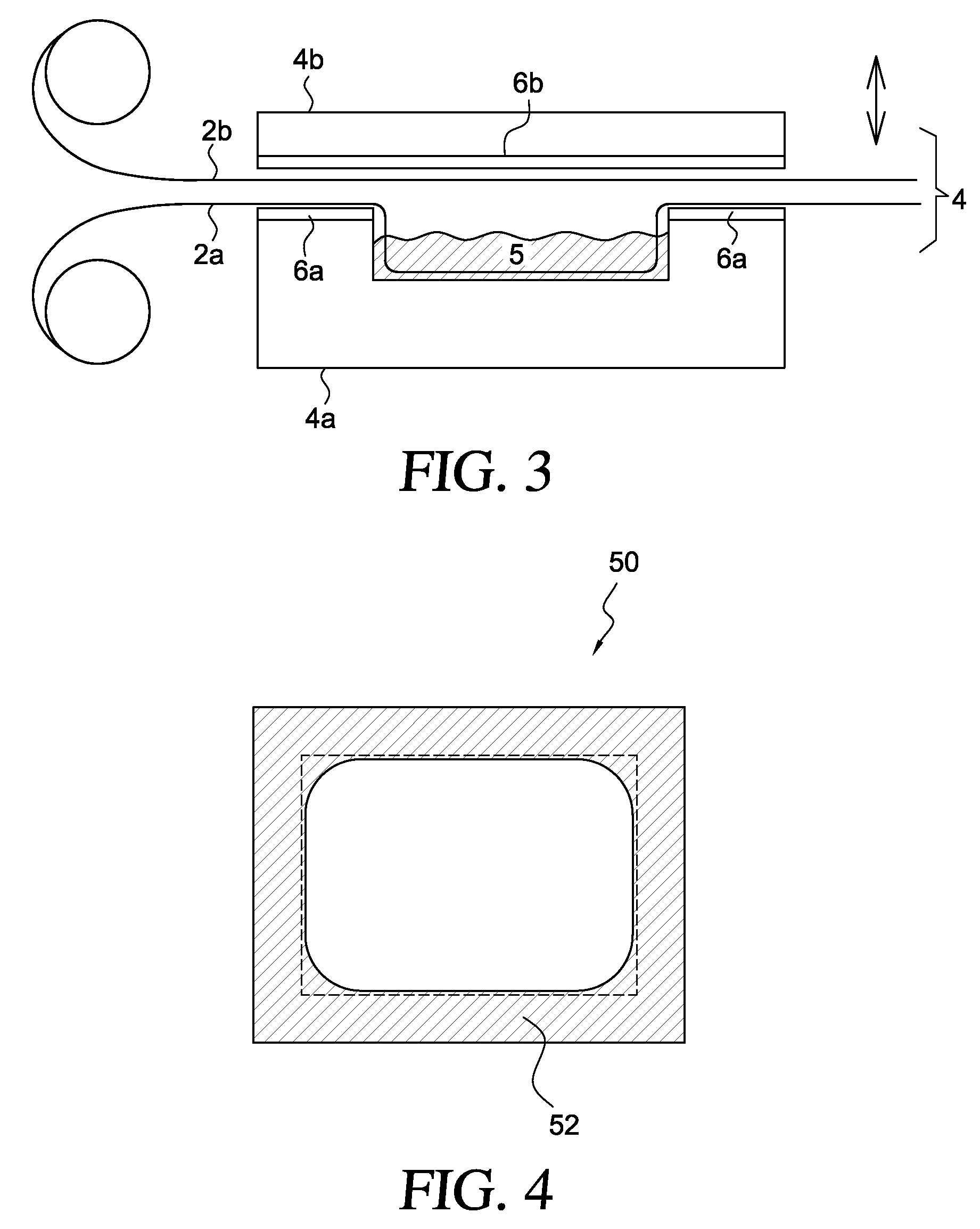

Ultrasonically welded, staked or swaged components in an implantable medical device

InactiveUS7187974B2Inherent modular configurationReduce thicknessElectrotherapyHermetic sealUltrasonic welding

The present invention generally relates to an improved implantable medical device (IMD) and more particularly to an ultrasonically weld perforated lid for an IMD to form a hermetic seal between the IMD and the perforated lid. Appropriately configured perforated lids retain one or more components within a cavity or port formed in a part of an IMD. Such lids preferably secure a pierceable resilient grommet, septum or other resilient member in a cavity or port. When an adjustment instrument, a pull tool or a syringe is temporarily inserted therethrough and later extracted, the resilient member heals (i.e., seals and / or reseals). Preferably, the resilient member abuts a mechanical stop and is compressed slightly during assembly and ultrasonic welding of the lid. The resilient member preferably has a lateral dimension like the cavity or port so that when the lid compresses the resilient member it expands slightly and contacts the interior cavity surfaces thus improving the seal.

Owner:MEDTRONIC INC

Fluid-containing pouches with reduced gas exchange and methods for making same

ActiveUS8216529B2Reduce penetrationReduce solubilityReagent containersClosure using stoppersUltrasonic weldingProduct gas

Owner:ABBOTT POINT CARE

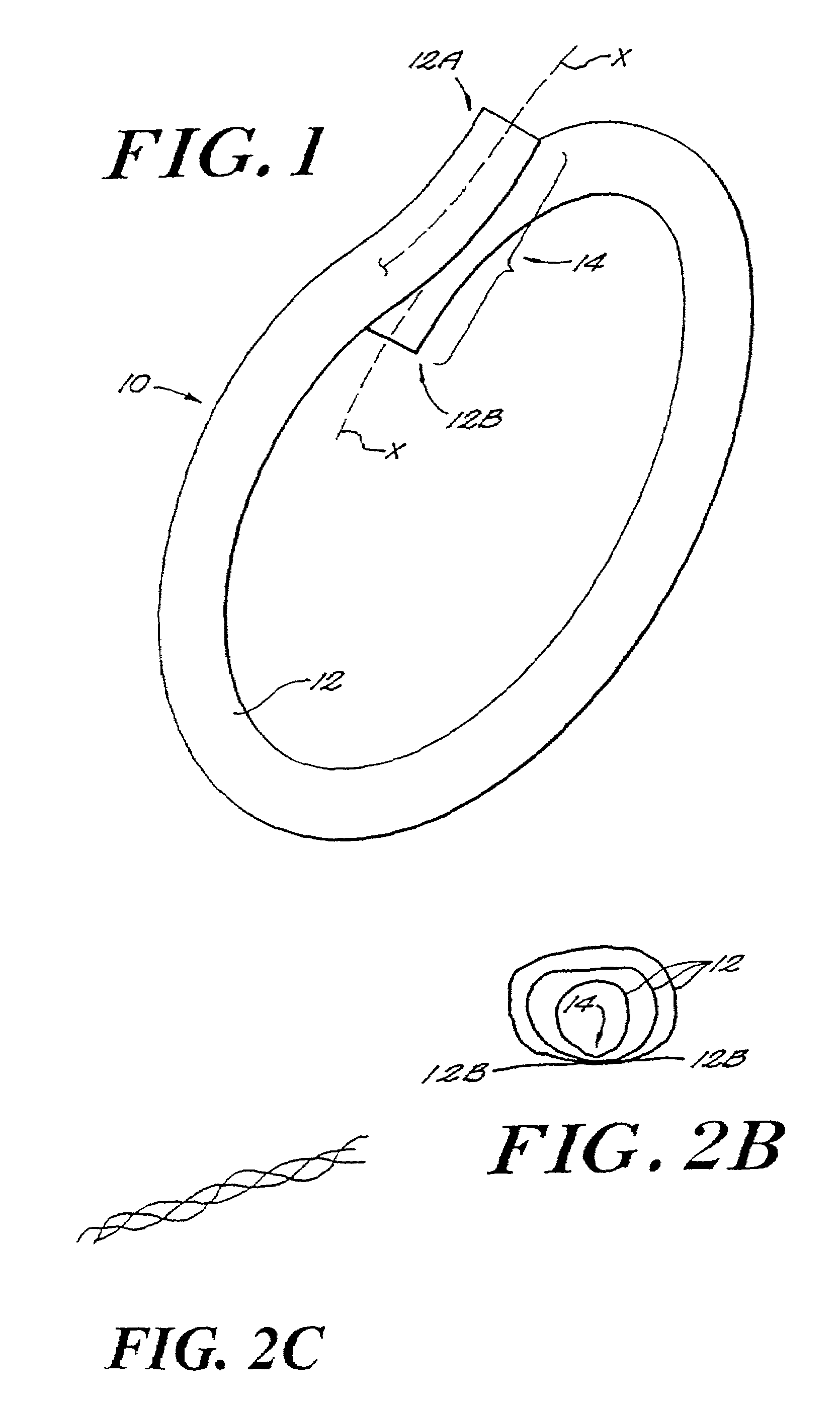

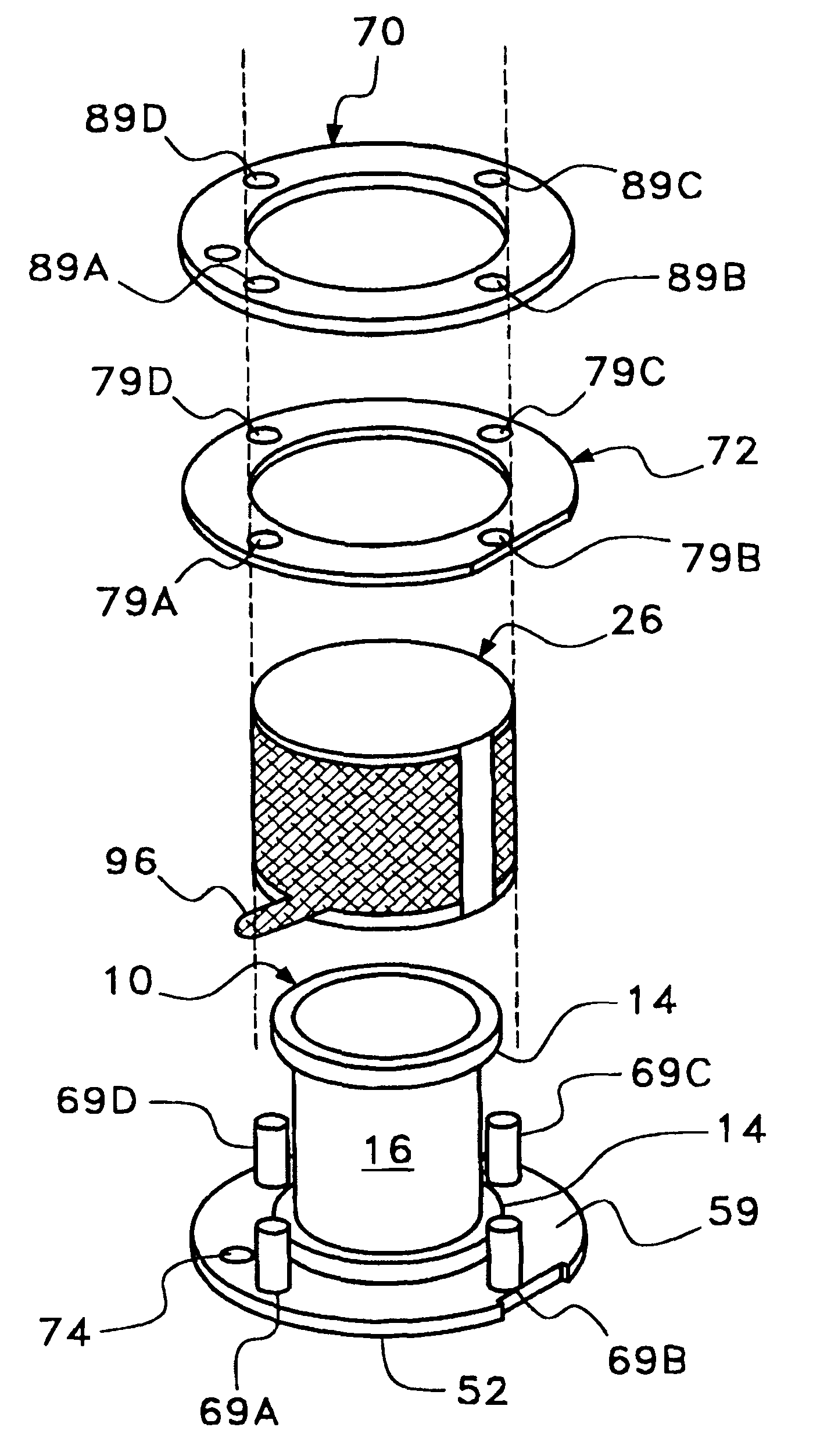

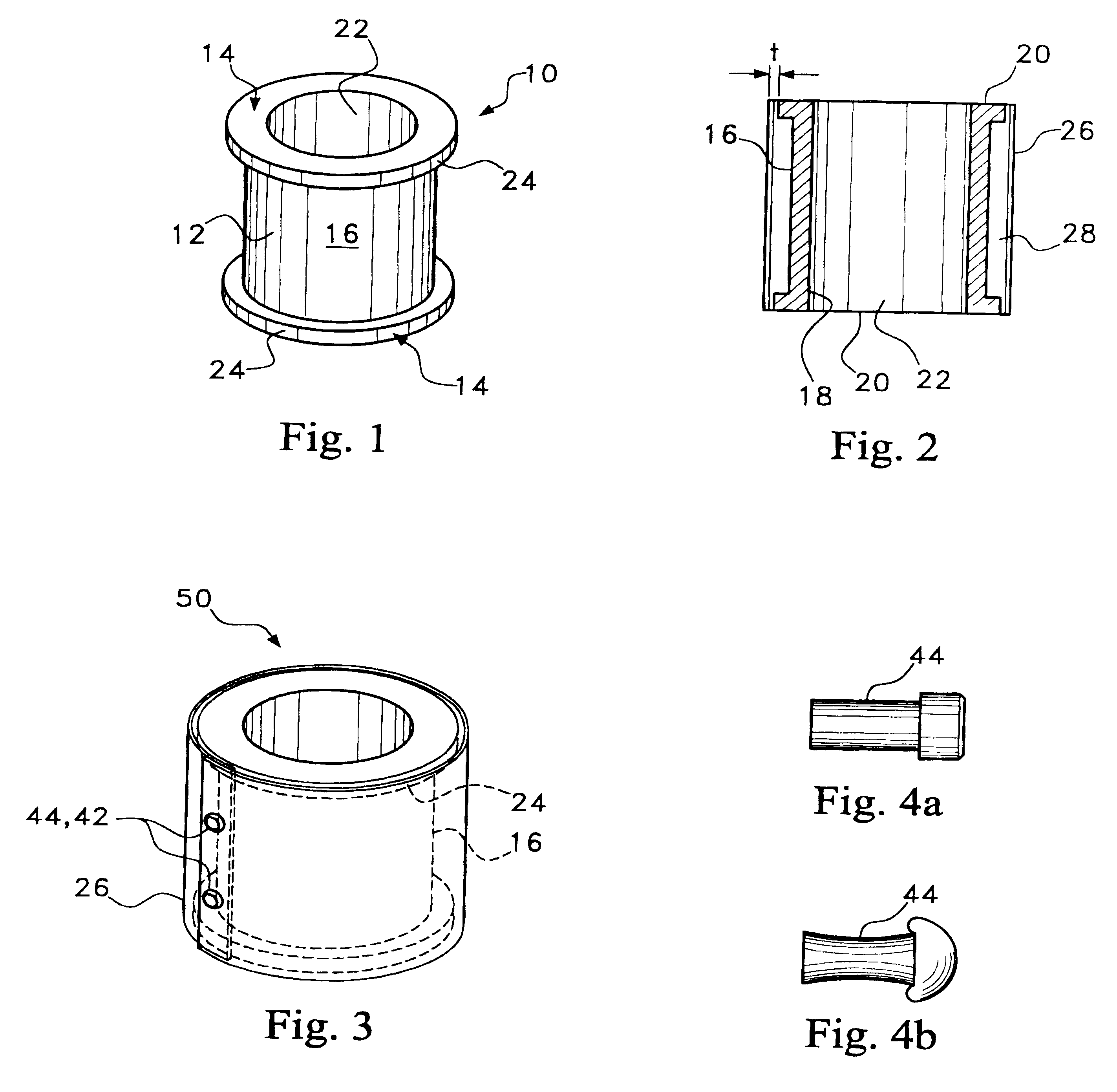

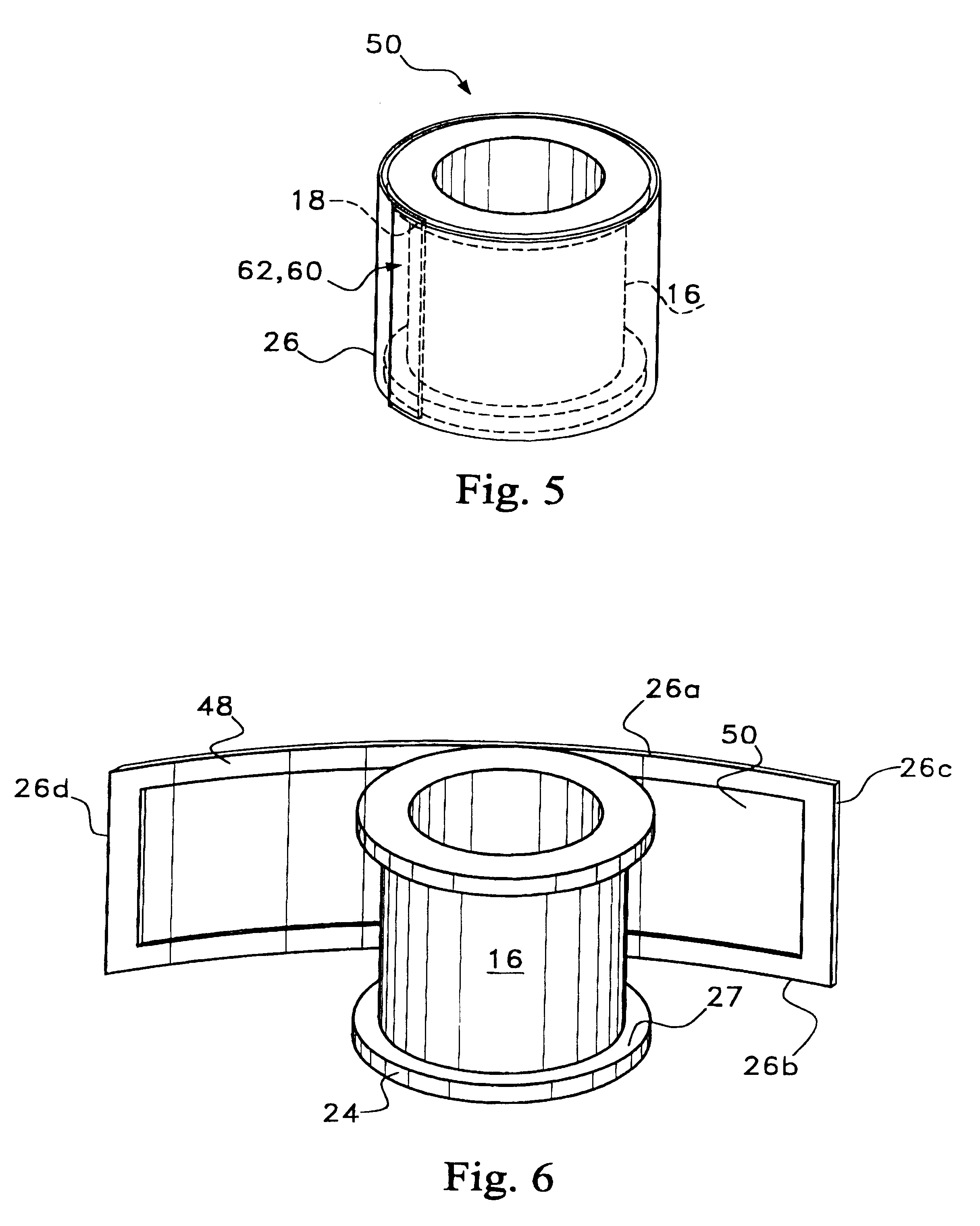

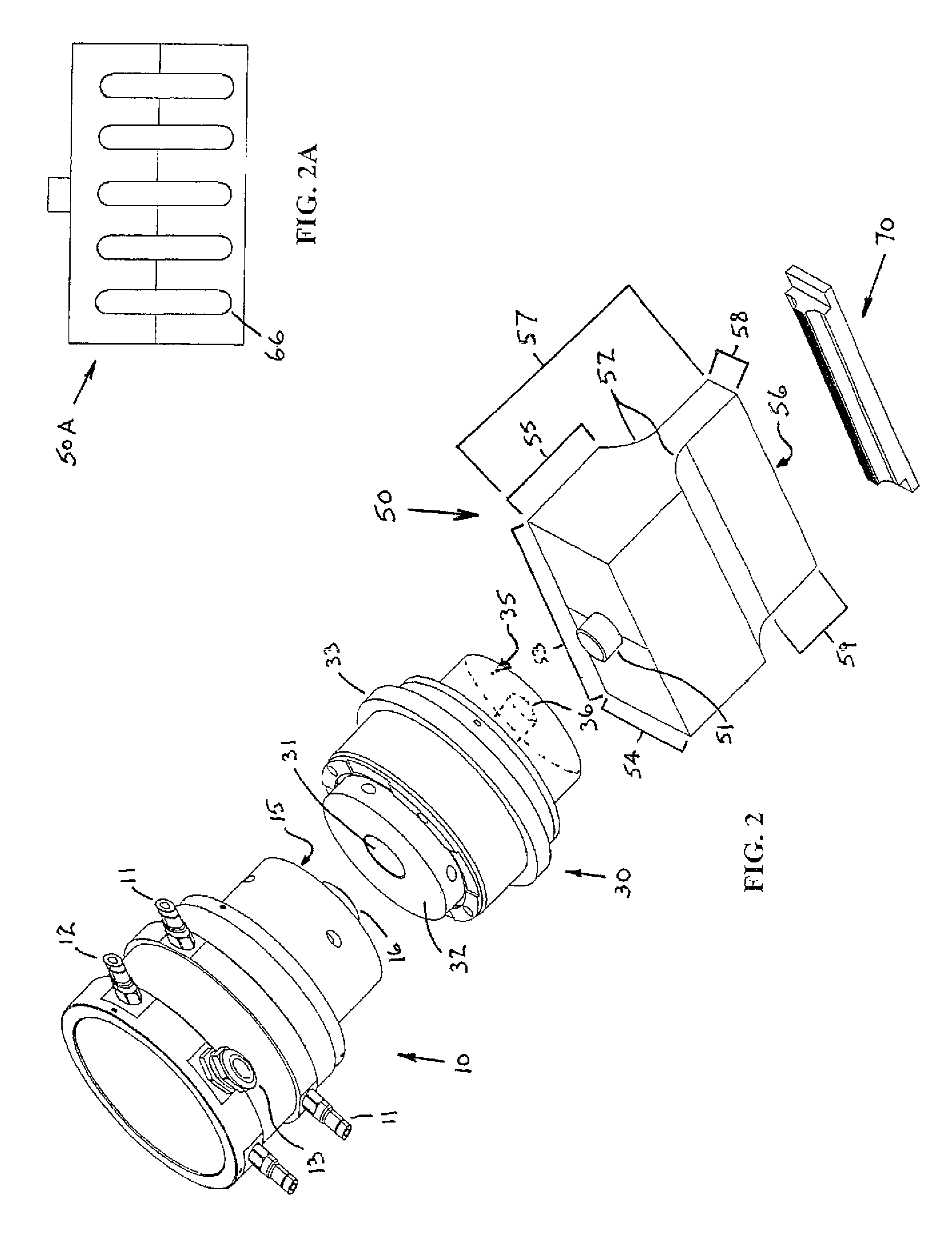

Omni-directional ultrasonic transducer apparatus and staking method

InactiveUS6400065B1Good vibesCost effectivePiezoelectric/electrostriction/magnetostriction machinesMechanical vibrations separationUltrasonic weldingAdhesive

A transducer apparatus is disclosed having a spool member with a body portion and first and second elevated regions formed on the body portion. A PVDF film surrounds the spool member, the film including an inner surface facing the spool member and an outer surface opposite the inner surface. The film as surrounding the spool member has a predetermined frequency of resonance. Lateral ends of the film are secured together by a securing material. The securing material is such that the secured ends of the film will have substantially the same resonance frequency as a remainder of the film. The film includes a non-electrode area at a perimeter of the inner surface and an electrode material formed on a remainder of the inner surface. Upon securing the lateral edges of the film together, the securement is at overlapping non-electrode lateral edges of the film. The securing material may be any one of an adhesive in combination with screws or thermally deformable nails, adhesive alone, tape, or ultrasonic welding.

Owner:MEASUREMENT SPEC

Lithium ion battery lead ultrasonic welding method and lead welding protection method

ActiveCN107671414AMetal working apparatusNon-electric welding apparatusVibration amplitudeUltrasonic welding

The invention relates to a lithium ion battery lead ultrasonic welding method and a lead welding protection method. A protection piece is arranged on an overlaid lead foil piece ultrasonic welding area, and a welding head of an ultrasonic welding device is pressed on the protection piece for ultrasonic welding. The protection piece is arranged on overlaid lead foil pieces, and the protection piecemakes direct contact with the welding head so as to bear ultrasonic vibration of the welding head and transmit vibration to the lead foil pieces; through arrangement of the protection piece, the leadfoil pieces can be prevented from being broken under vibration; through arrangement of the protection piece, the ultrasonic welding parameters such as energy, pressure and vibration amplitude can beadjusted to be slightly high correspondingly, so that the welding effect is improved and welding is firmer, and the effect on batteries with few lead foil piece layers is particularly obvious; and through arrangement of the protection piece, the surfaces of leads are free of damage, and the consistency of the welding effect is high.

Owner:CHINA AVIATION LITHIUM BATTERY LUOYANG

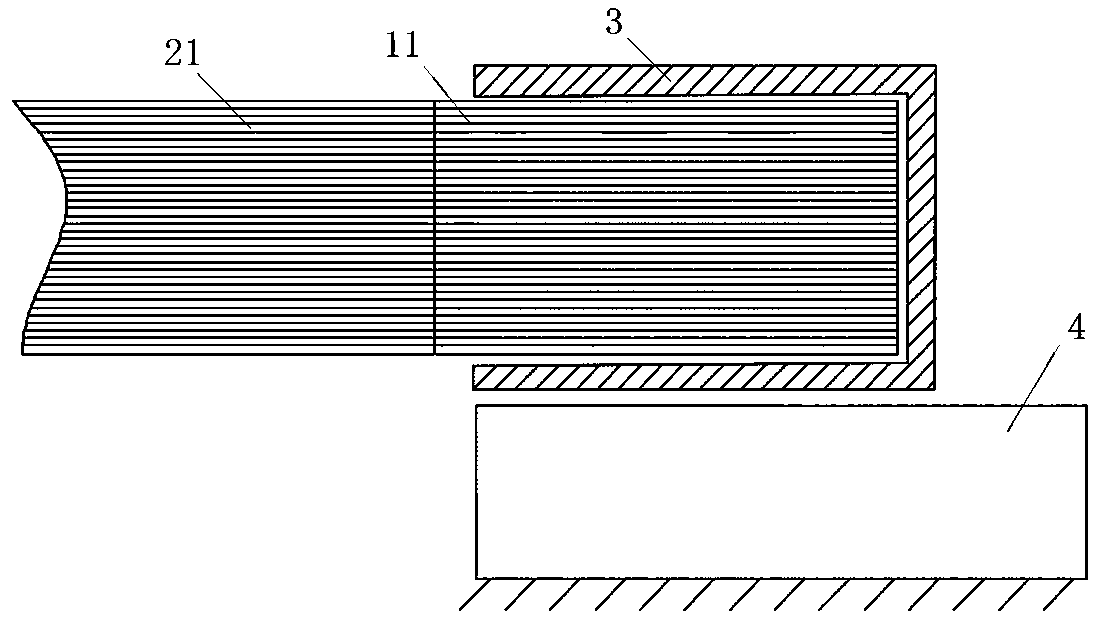

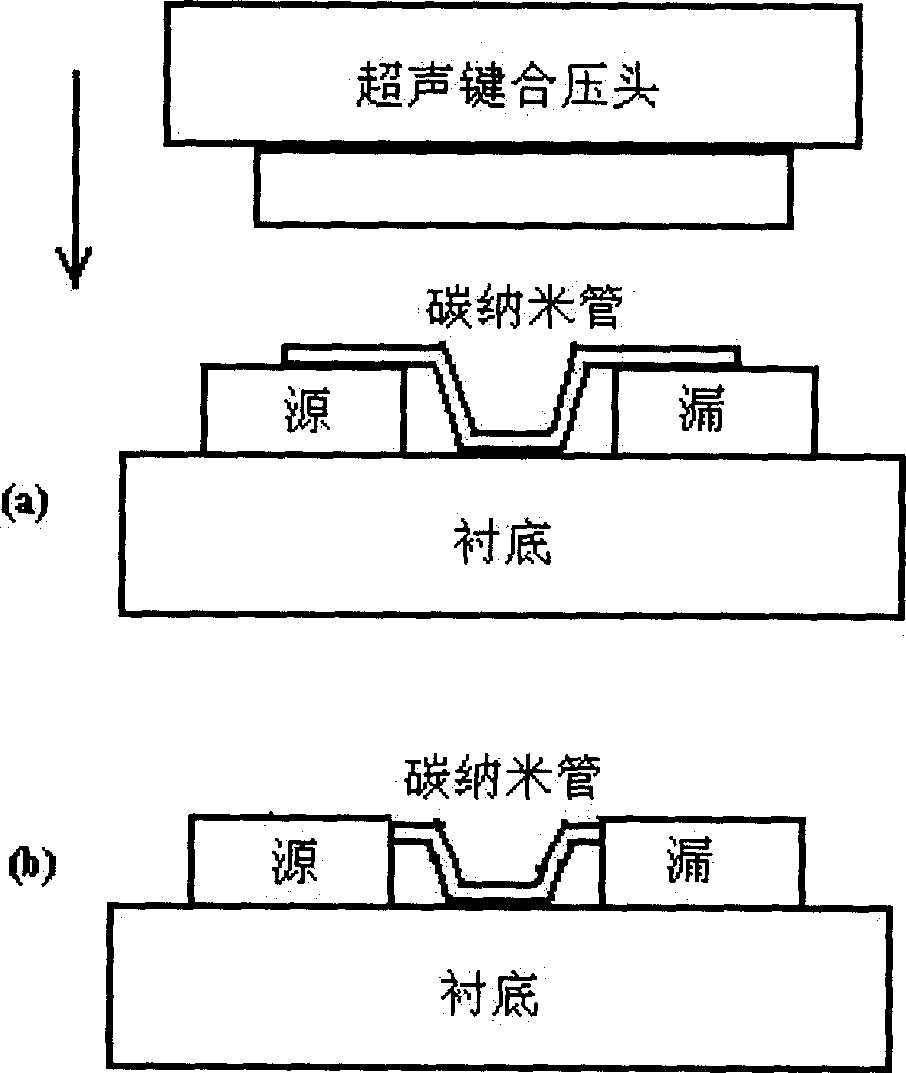

Method for bonding nanometer material on metal electrode

InactiveCN1738018AReliable contactReduce contact resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical resistance and conductanceUltrasonic welding

Disclosed a method for bonding nanometer material on the metal electrode, belongs to the nanometer technique filed. Wherein, connecting the one-dimensional nanometer material between the metal electrodes of chip, to make its end part on the face of metal electrode or under its low surface; using the ultrasonic wave header which carries ultrasonic wave to press and weld the one-dimensional nanometer material and the contact part of metal electrode as a whole. The invention reaches the reliable contact between the one-dimensional nanometer material and metal electrode to reduce the contact resistance significantly; since the device for ultrasonic welding belongs to the integrated circuit packaging processing, the one-dimensional nanometer material of a plurality of metal electrodes can be fast welded in batch; and has simple device and lower cost compared to other method which also can reduce the contact resistance.

Owner:SHANGHAI JIAO TONG UNIV

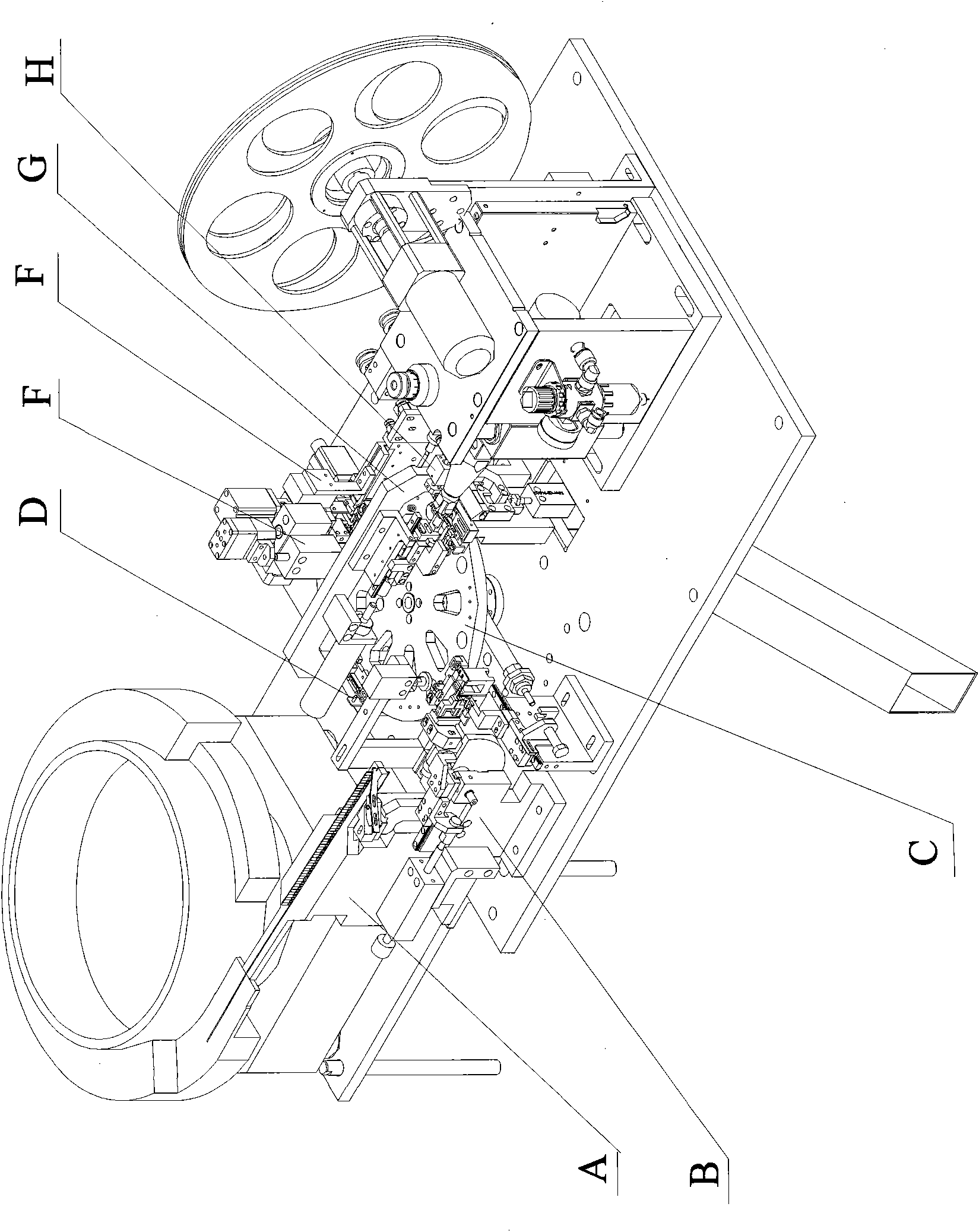

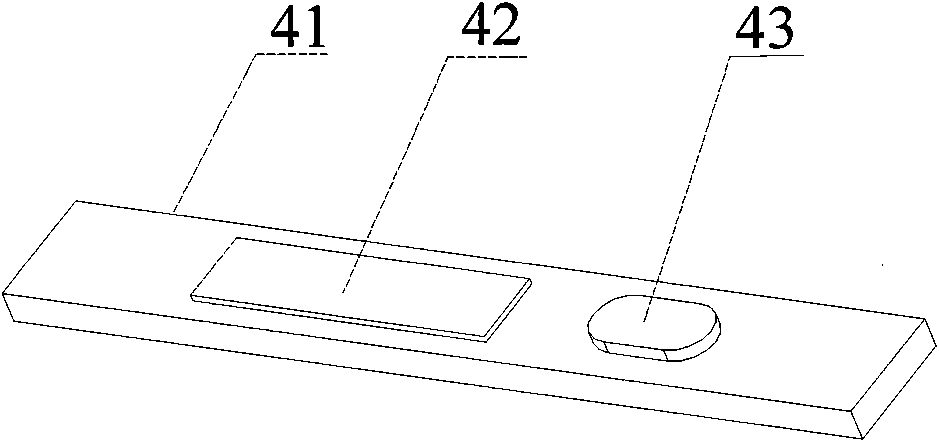

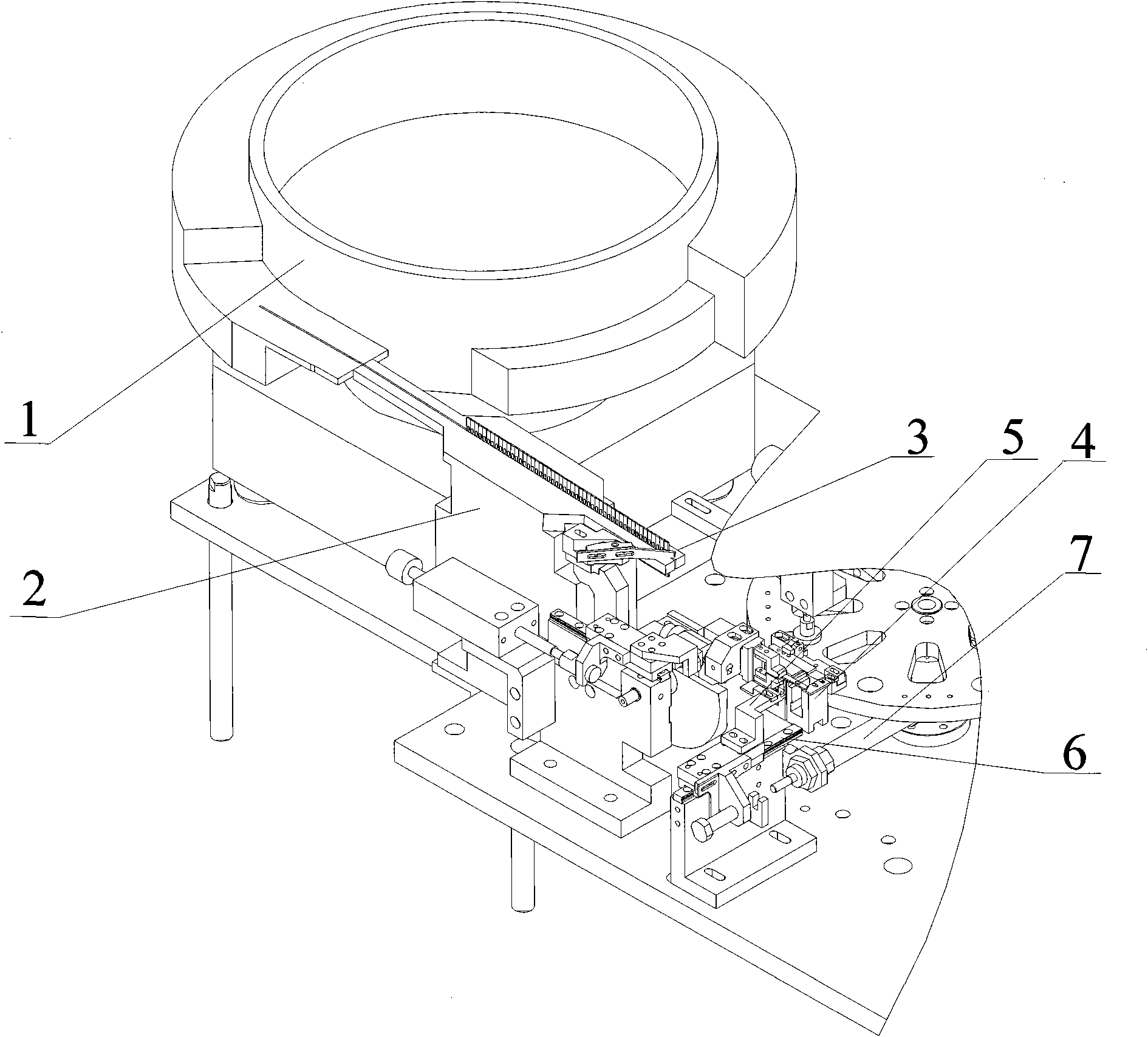

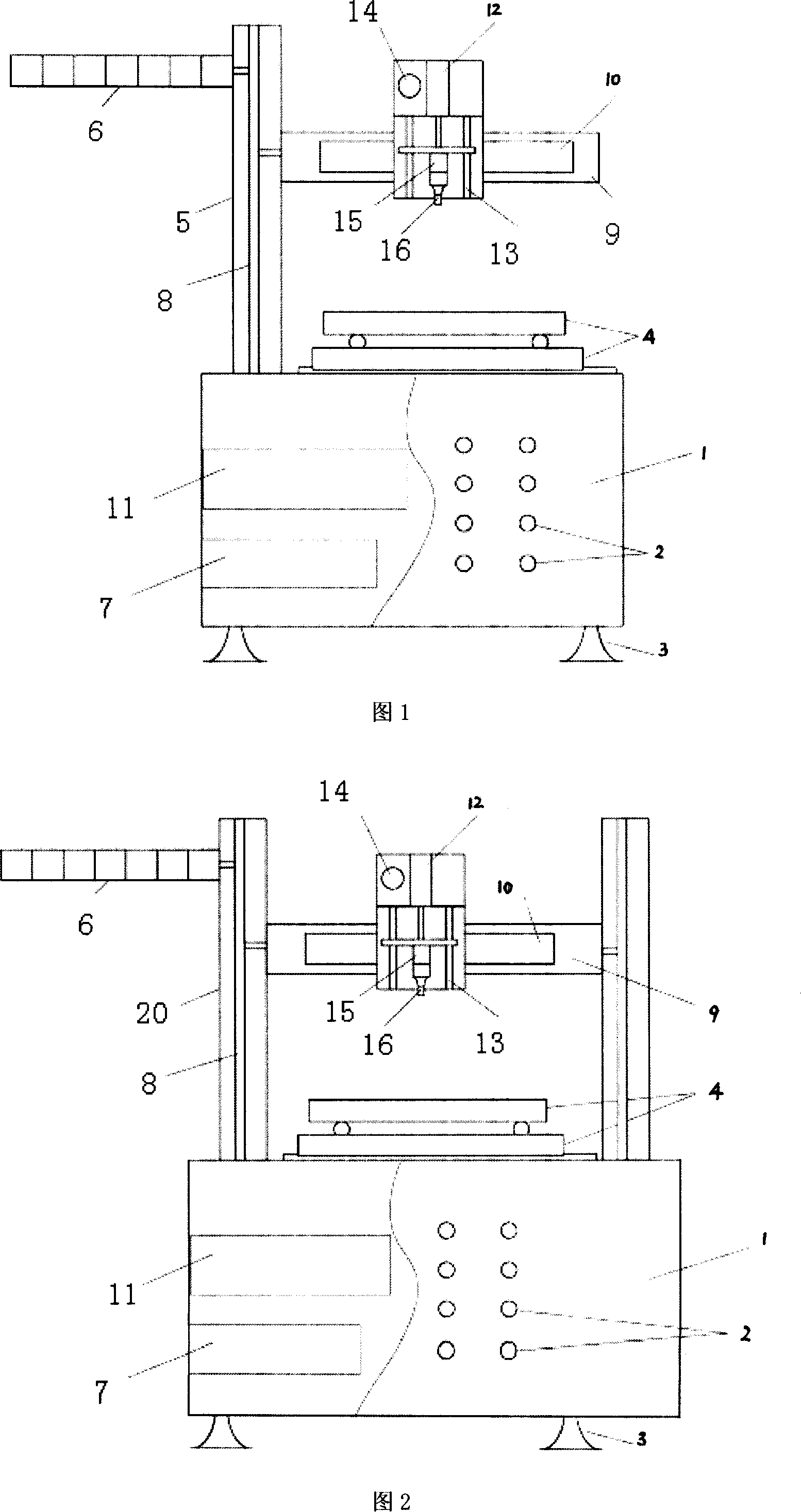

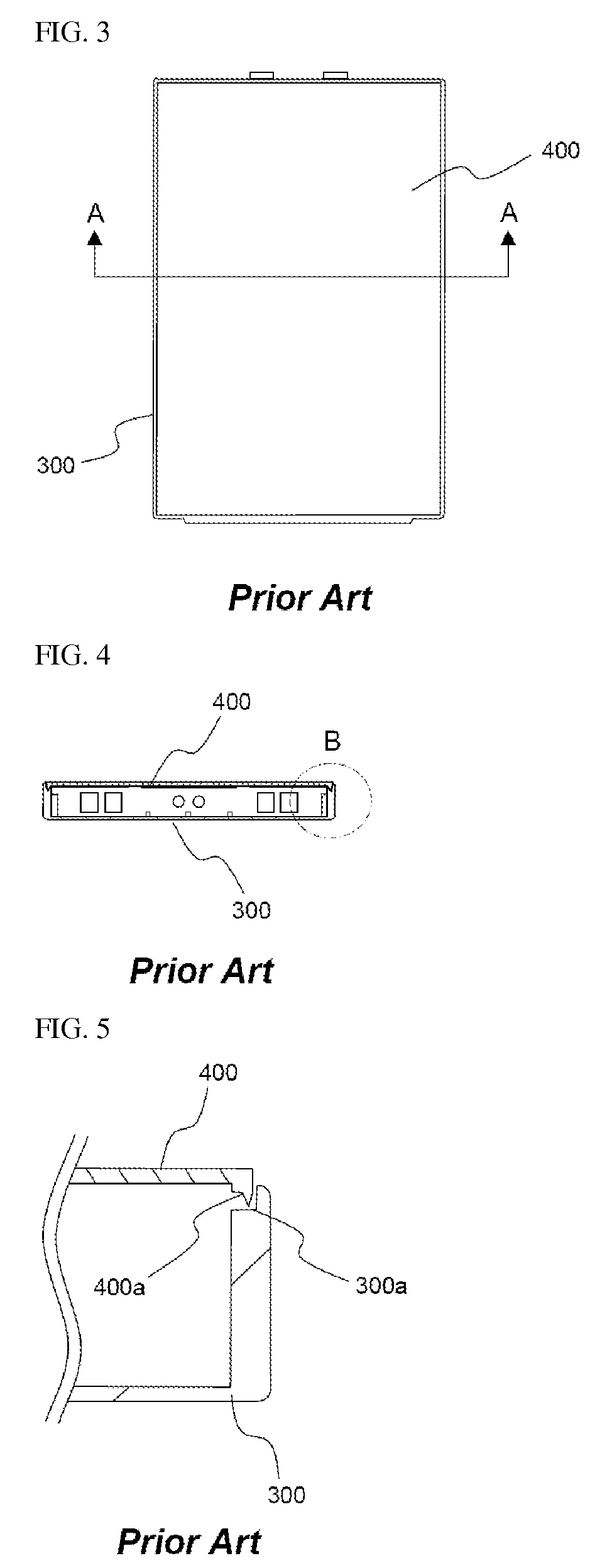

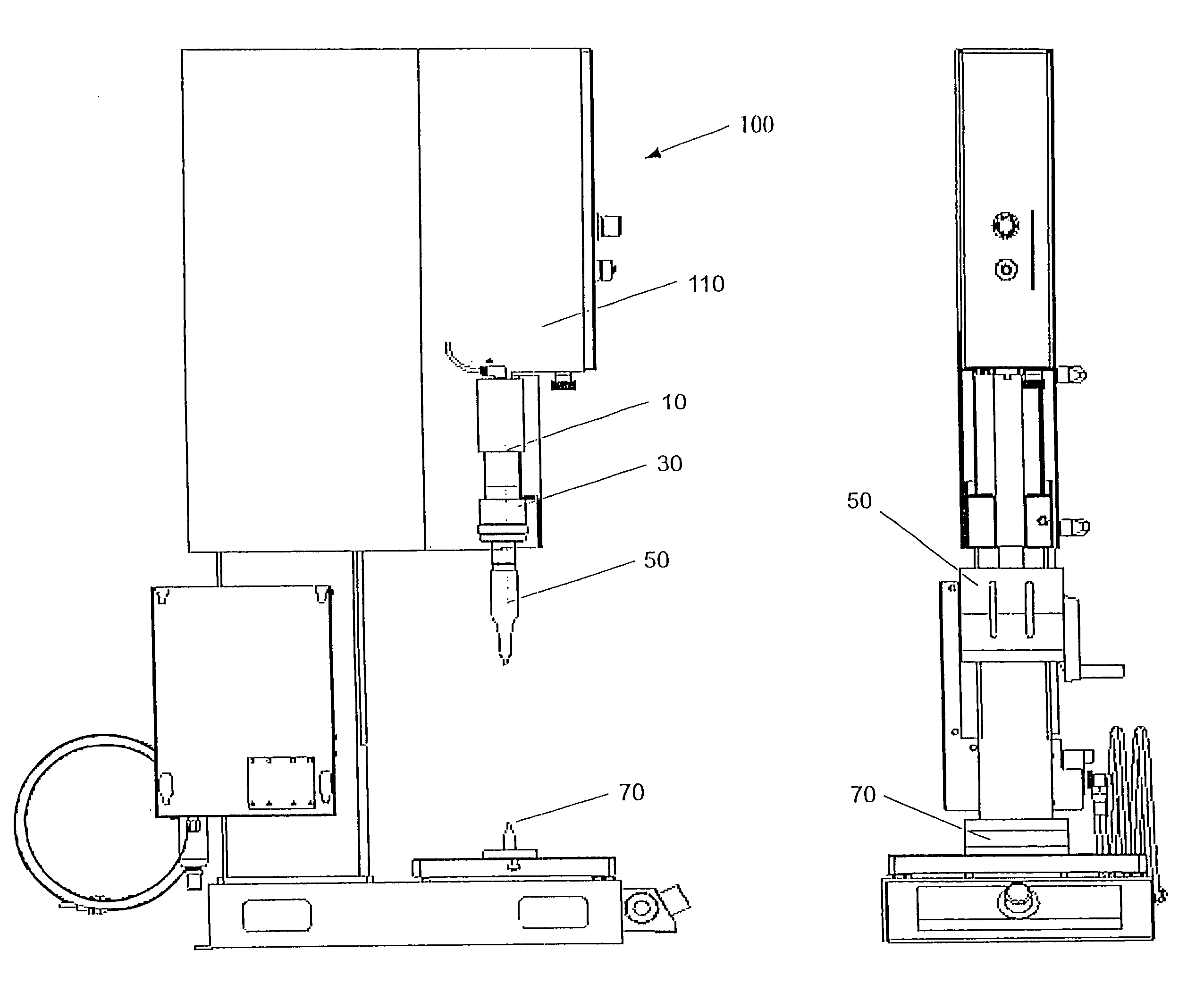

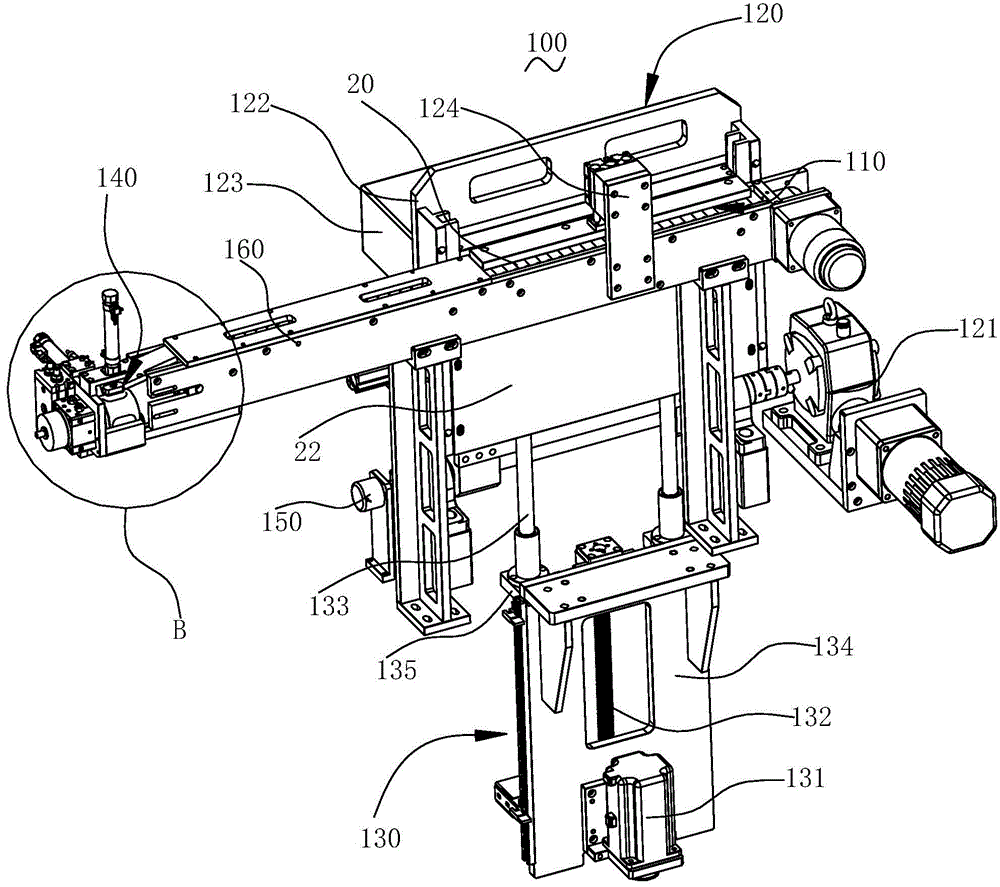

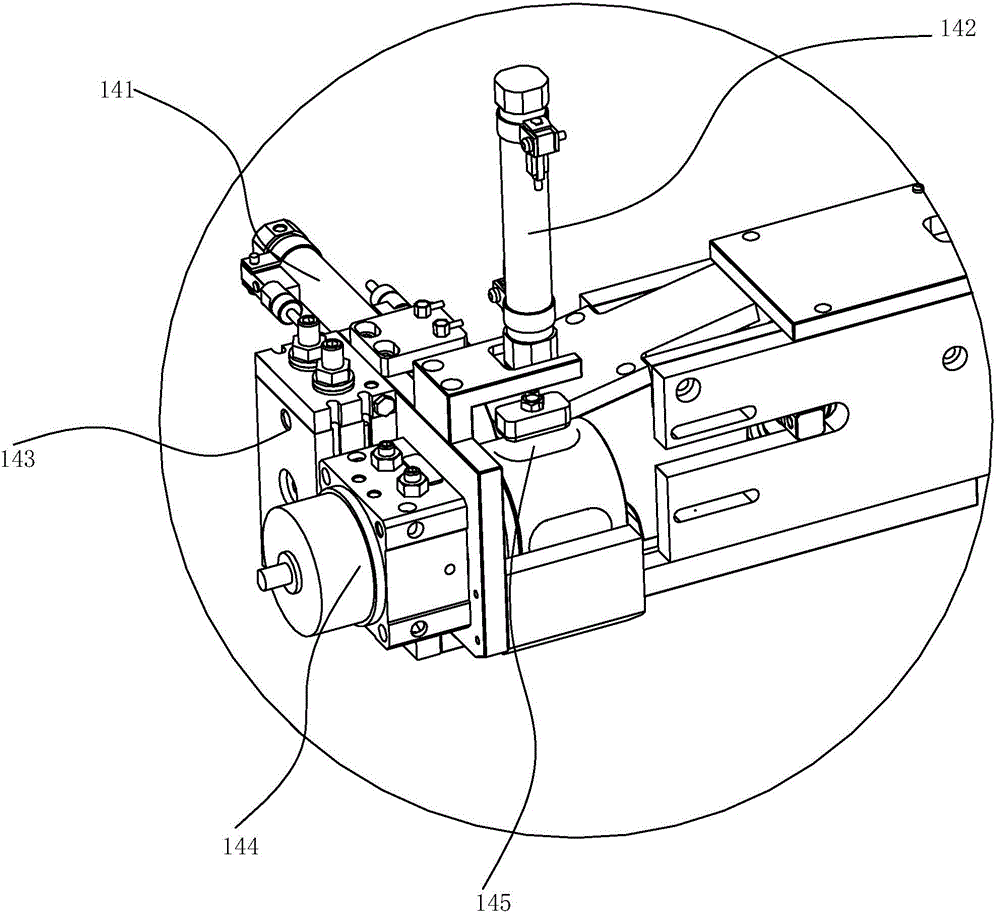

Automatic welding machine of aluminum-nickel compound piece of lithium ion battery cover plate

ActiveCN101913029AChange choresSave human effortWelding apparatusAutomatic controlUltrasonic welding

The invention provides an automatic welding machine of an aluminum-nickel compound piece of a lithium ion battery cover plate, consisting of a feeding mechanism A, a feeding turnover mechanism B, a turnplate mechanism C, a detection mechanism D, a nickel piece feeding mechanism E, a spot-welding machine F, an ultrasonic welding mechanism G, a banking mechanism H and an automatic control mechanism, wherein the feeding mechanism A, the feeding turnover mechanism B, the turnplate mechanism C and the detection mechanism D are arranged on the tabletop of the automatic welding machine; the nickel piece feeding mechanism E, the spot-welding machine F, the ultesonic welding mechanism G and the banking mechanism H are arranged on the turnplate mechanism C; the aluminum-nickel compound piece is placed on the lithium ion battery cover plate through the feeding mechanism A, the feeding turnover mechanism B, the turnplate mechanism C, the detection mechanism D and the nickel piece feeding mechanism E; and the lithium ion battery cover plate is automatically welded with the aluminum-nickel compound piece through the spot-welding machine F, the ultrasonic welding mechanism G and the banking mechanism H. The invention ensures that the whole process flow realizes the automation, changes the traditional mode for manually finishing miscellaneous work, librates the large amount of labor force, greatly improves the work conditions, greatly increases the yield, greatly reduces the manufacturing cost and simultaneously and effectively ensures the quality of products.

Owner:HUNAN HUAHUI NEW ENERGY

Window pane and a method of bonding a connector to the window pane

InactiveUS7134201B2Eliminate useAvoid defectsVehicle connectorsElectrically conductive connectionsElectrical conductorUltrasonic welding

Owner:AGC AUTOMOTIVE AMERICAS

Elastic laminate material, and method of making

InactiveUS20060169387A1Reduce complicationsIncrease line speedSynthetic resin layered productsLaminationUltrasonic weldingEngineering

An ultrasonic welding apparatus, such as a rotary welding apparatus, and methods of using the same for making a laminate material are disclosed. The multi-layered laminate material has a nonwoven material ultrasonically welded to a base layer, which can include elastic.

Owner:3M INNOVATIVE PROPERTIES CO

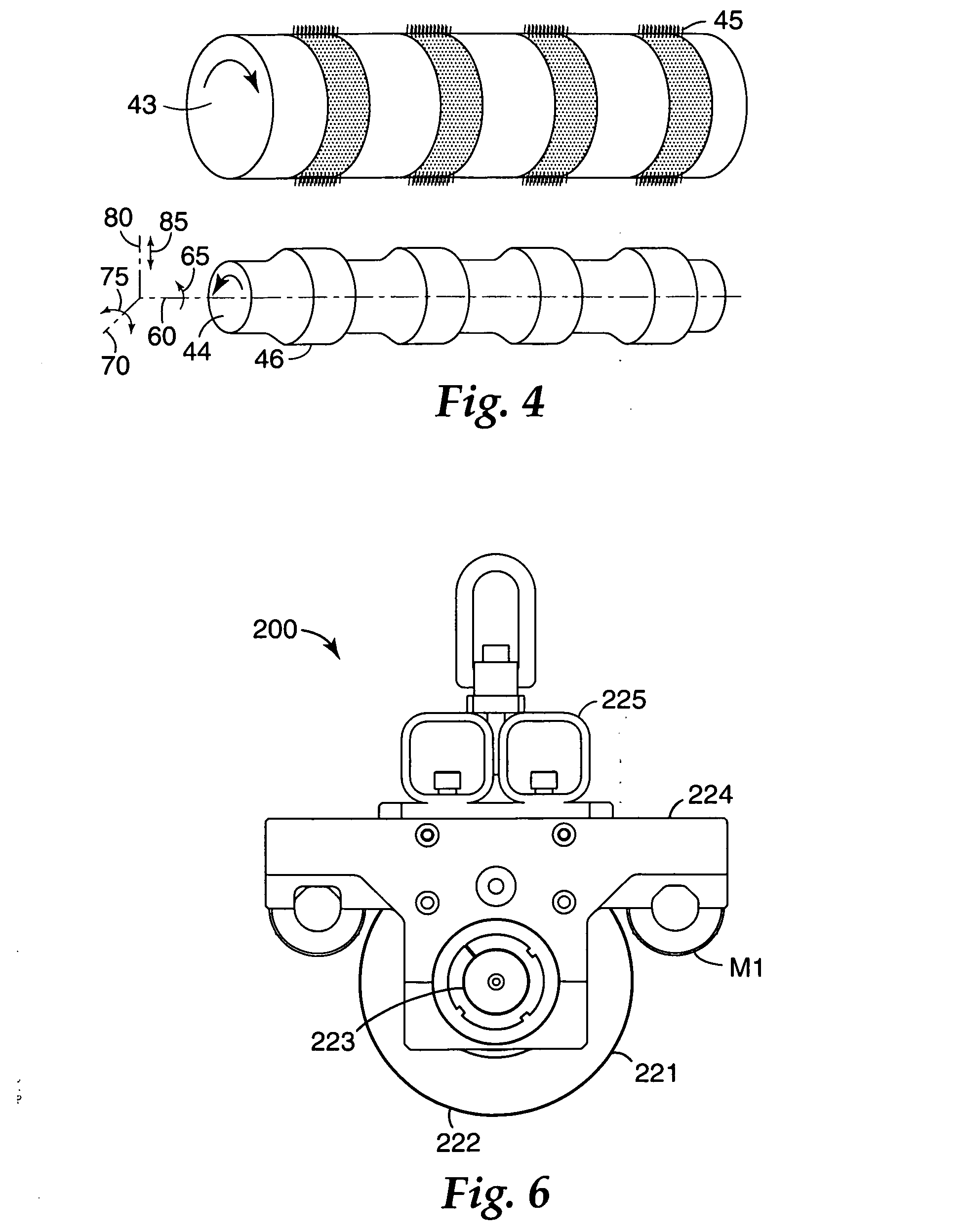

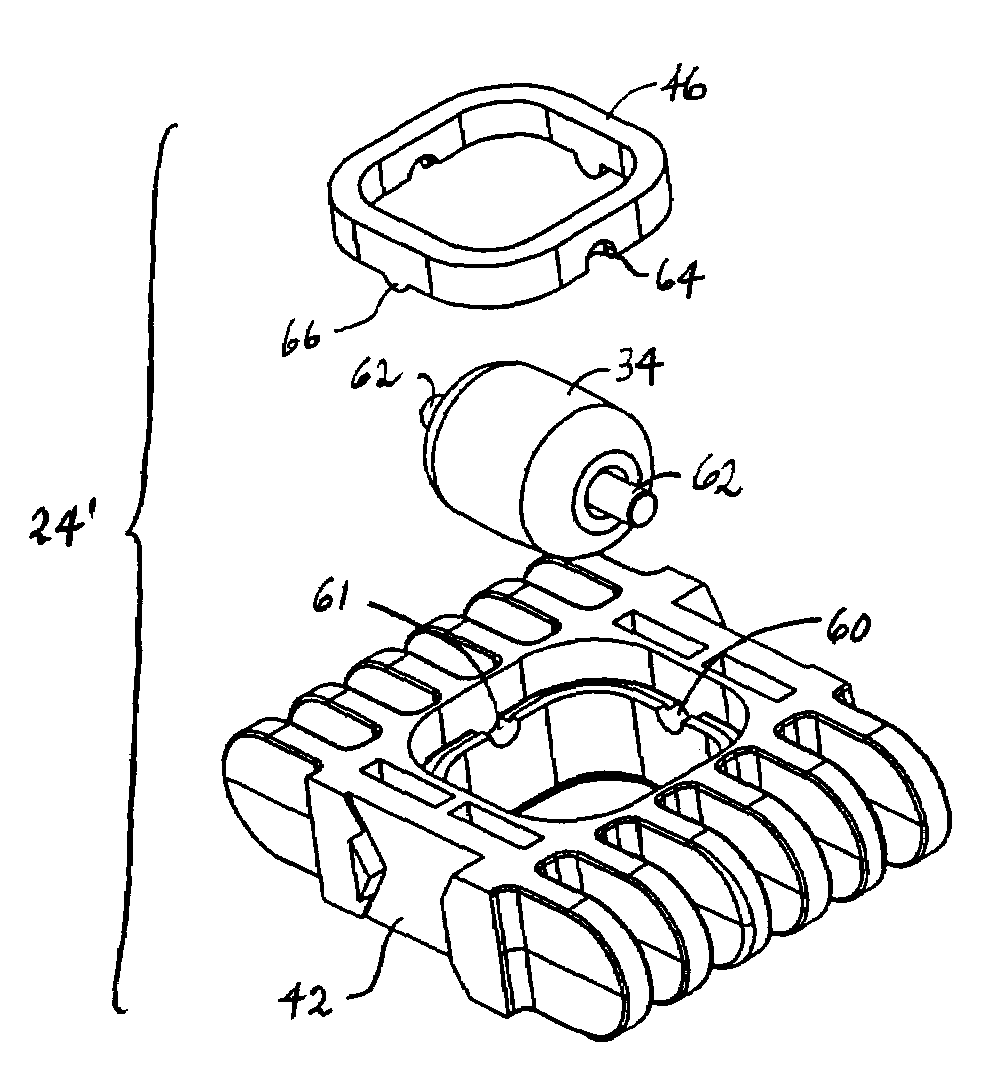

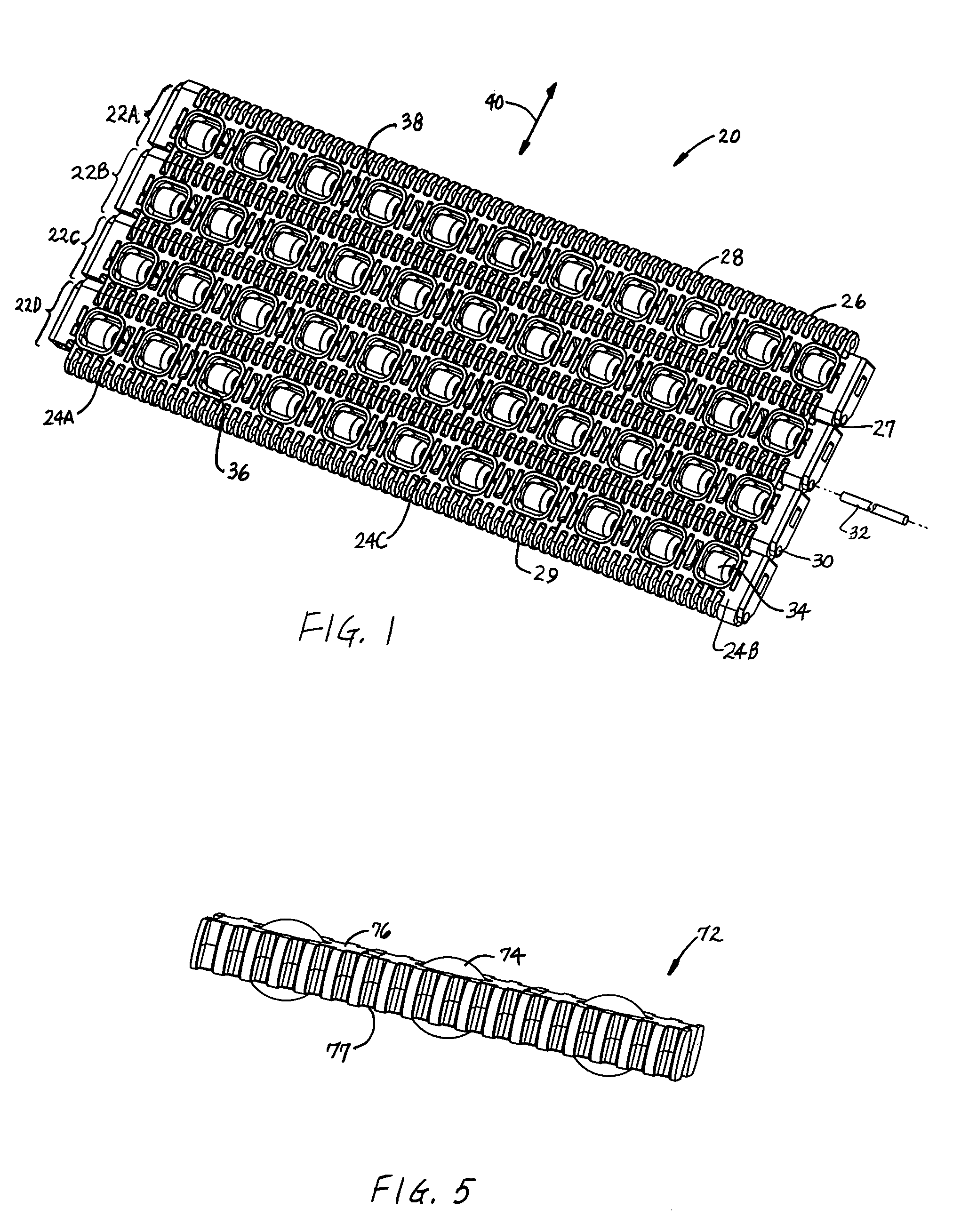

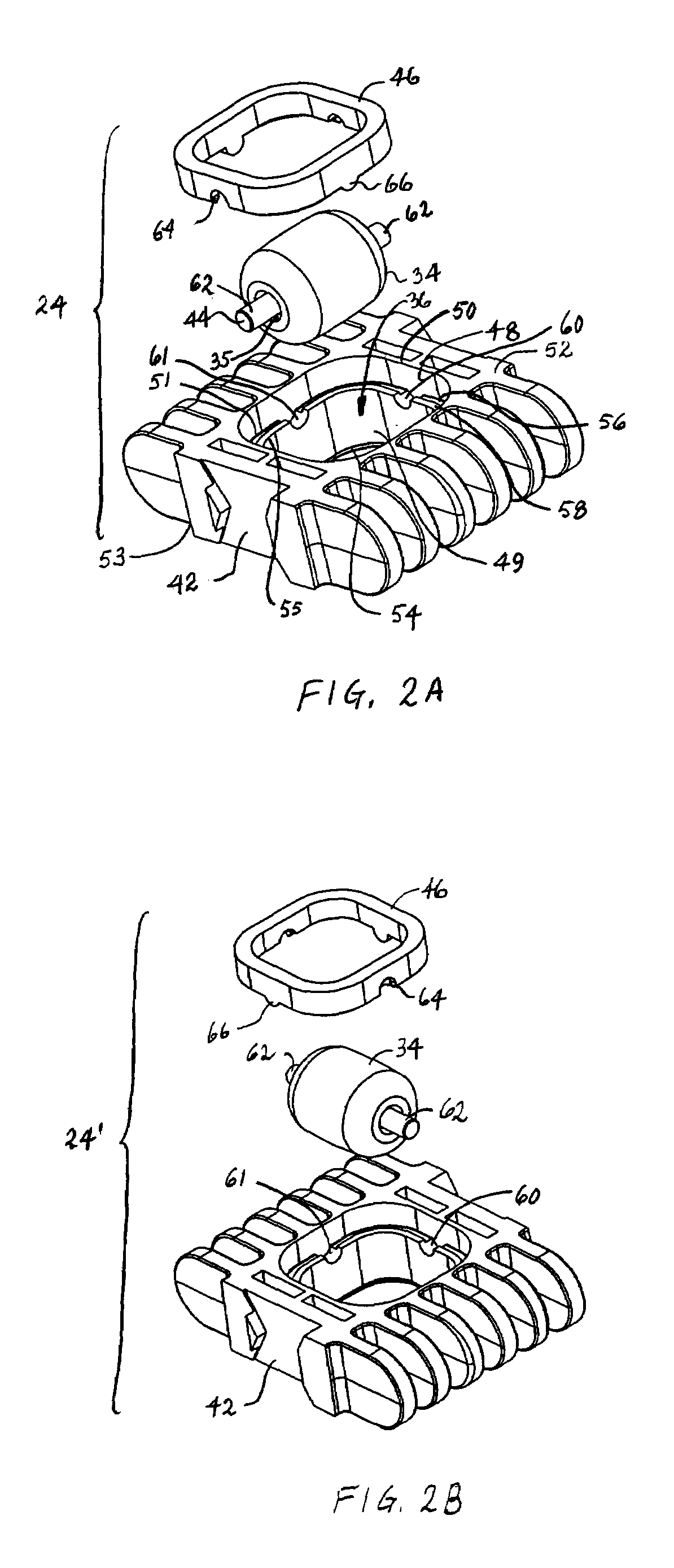

Conveyor belt modules with embedded rollers retained in the modules and associated method

A plastic conveyor belt module with embedded rollers retained in the module and a method for making such a module. The module includes a module body forming a cavity, a roller in the cavity, and a retainer received in the cavity to hold the roller rotatably in place. A salient portion of the roller extends outward from the cavity through the retainer past an outer surface of the module. The retainer is attached to the module body by ultrasonic welding, epoxy- or solvent-bonding, spin welding, electromagnetic welding, staking, screwing, or locking.

Owner:LAITRAM LLC

Aluminum, aluminum alloy and composite material ultrasonic vibration liquid phase welding equipment therefor

InactiveCN101011776AFlexible welding operationConvenient welding operationMechanical vibrations separationWelding/soldering/cutting articlesTemperature controlUltrasonic welding

The invention provides an ultrasonic vibrating liquid phase welding device for aluminum, aluminum alloy and other composite material, which comprises control box installed with ultrasonic generator inside, control knob and wire connecting post on the panel, clipping working bench on the upper surface of the control box, bracket on the top of the control box, temperature display panel and ultrasonic welding head installed on the bracket, one end of the electrical thermocouple connecting with the inspecting work piece, the other connecting with the temperature control module inside the control box through the wire connecting post on the control panel, temperature control module connecting with the temperature display panel, displaying the temperature from the display, ultrasonic welding head connecting with the ultrasonic generator through signal wire, with pressurizing device, energy changing device, width changing bar on the ultrasonic welding head, with the rear two connected and to connect with the first. Without using brazing flux, it can realize the welding of aluminum, aluminum alloy and other composite material.

Owner:HARBIN INST OF TECH

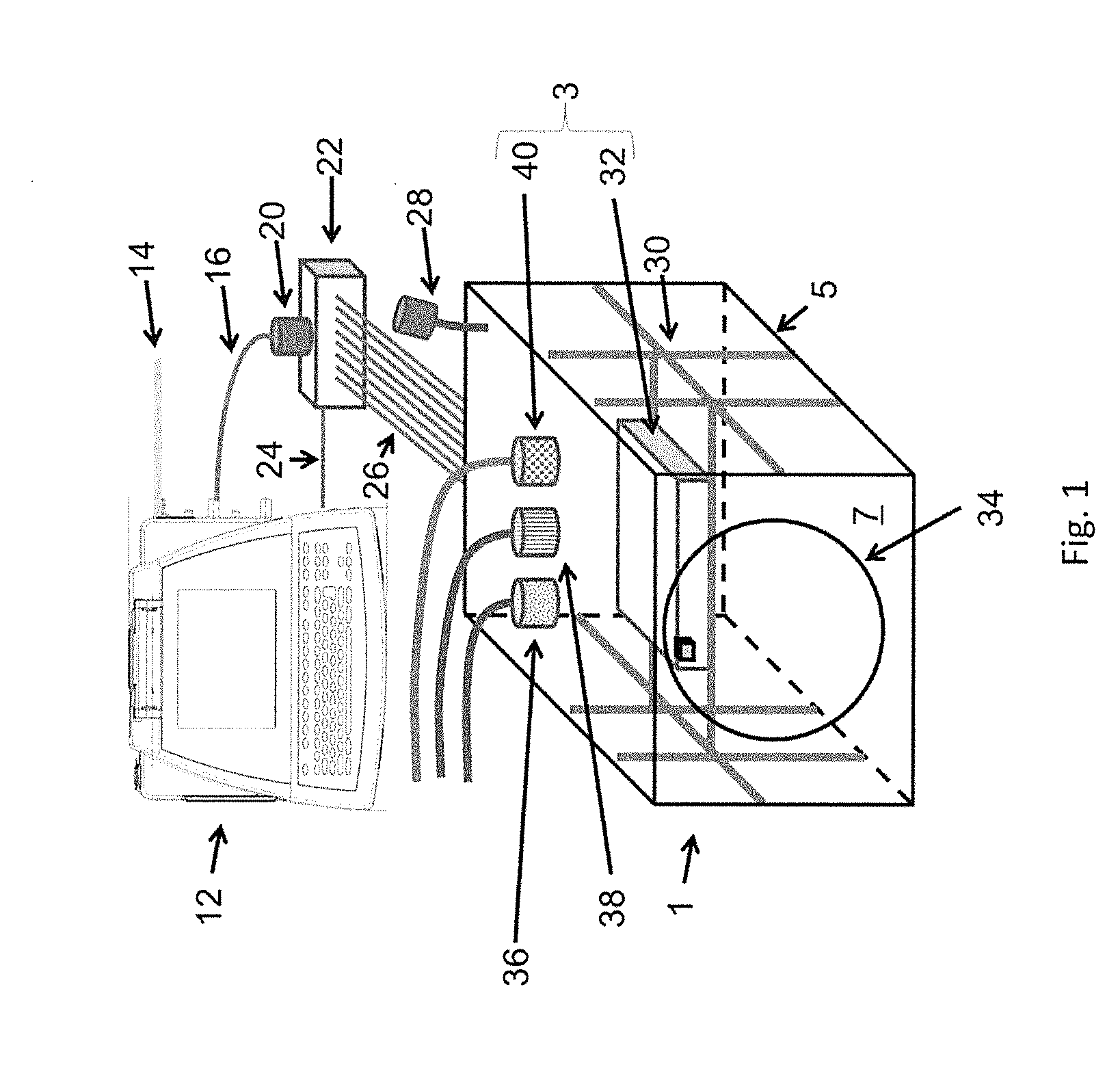

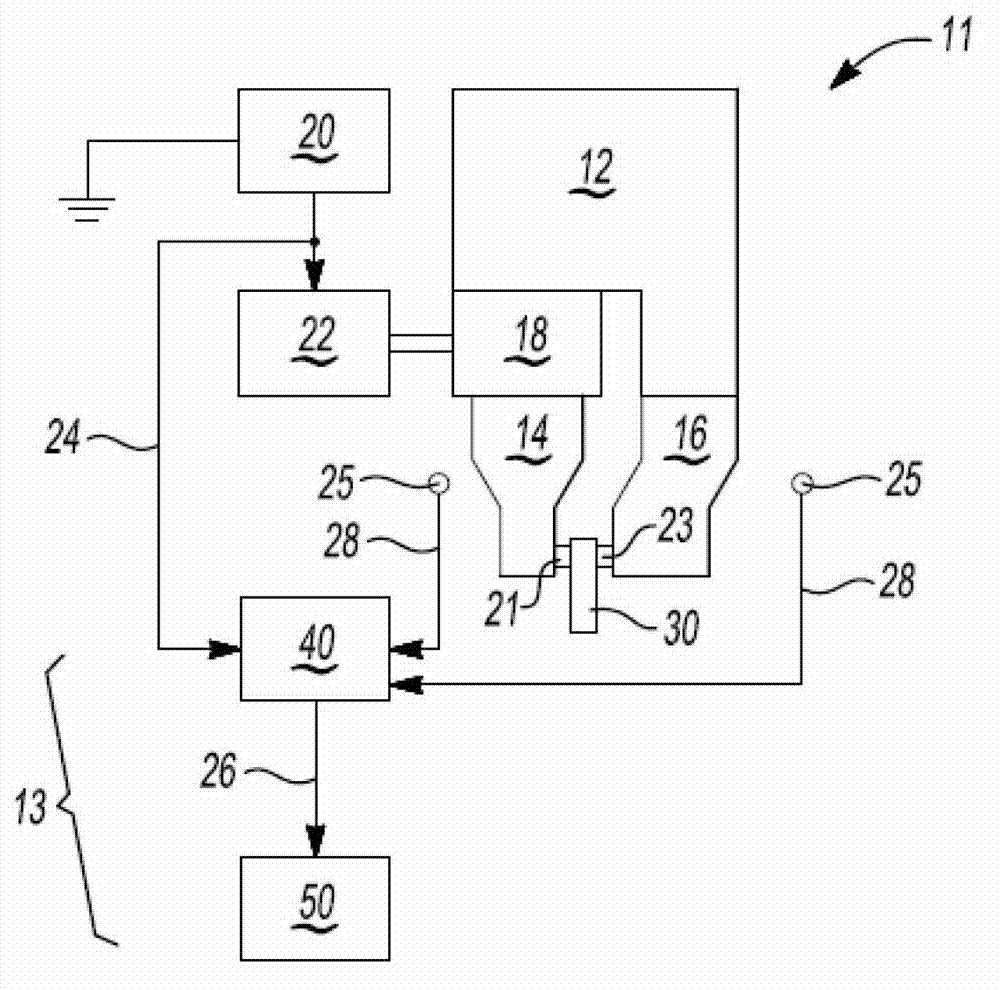

Ultrasonic welding system

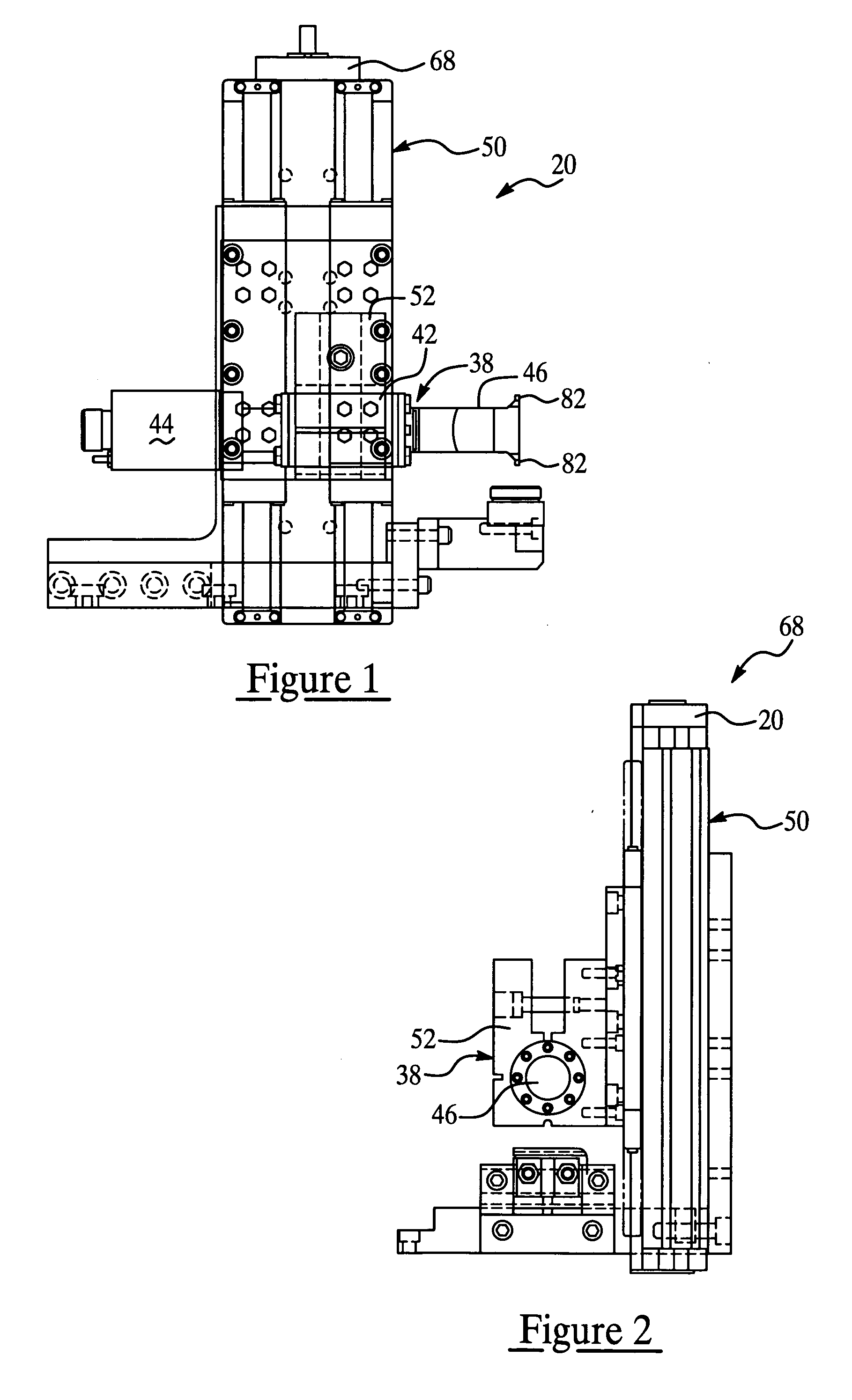

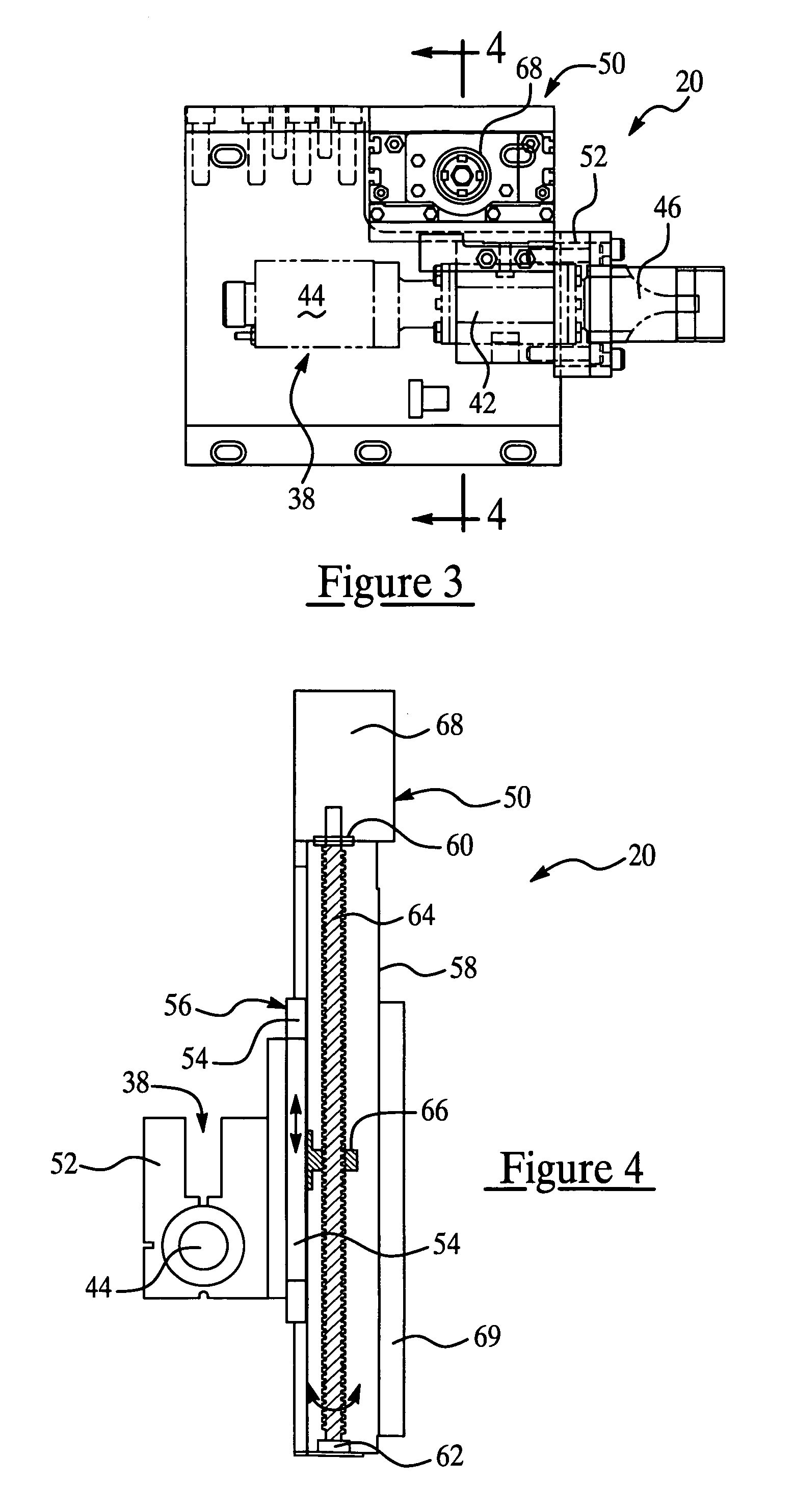

InactiveUS20070068991A1Highly versatileRobust systemElectrically conductive connectionsWelding/cutting auxillary devicesUltrasonic weldingTransducer

The present invention is an ultrasonic welding system having an ultrasonic welder integrated with a servo press for galling and ultrasonic welding of a first workpiece to a second workpiece. The first and second workpieces are substantially disposed between a confronting tip and stationary anvil of the ultrasonic welder. Prior to welding, the servo press preferably quickly moves the tip toward and generally against the first workpiece. During welding, a variable speed motor of the servo press preferably slowly moves the tip toward the anvil compressing the workpieces together while a transducer of the ultrasonic welder transmits mechanical vibration to the tip for welding the workpieces together.

Owner:DELPHI TECH INC

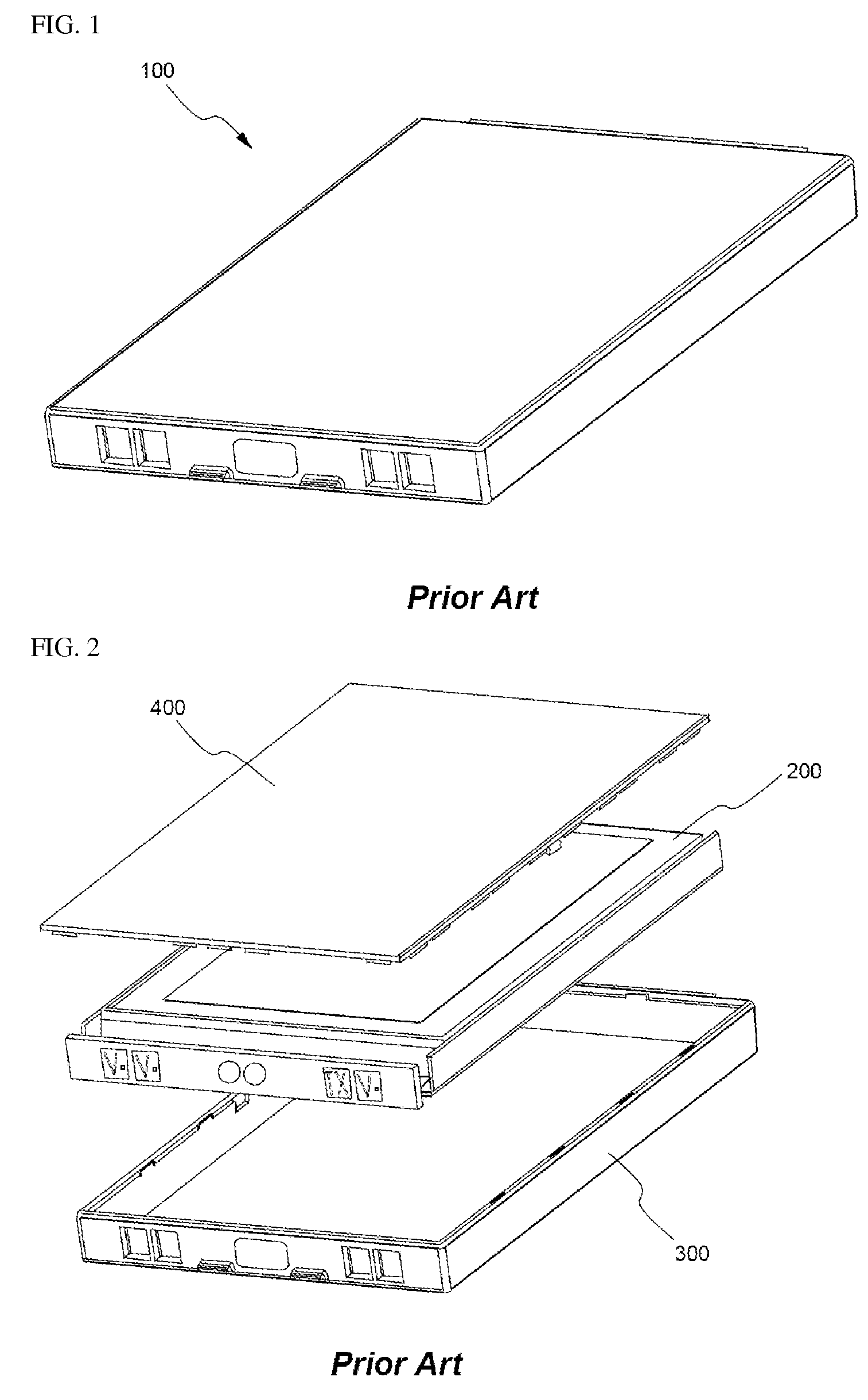

Battery pack casing with lock type connector

ActiveUS7479758B2Reduce thicknessHigh strength and elasticityBatteries circuit arrangementsFinal product manufactureUltrasonic weldingCoupling

Owner:LG ENERGY SOLUTION LTD

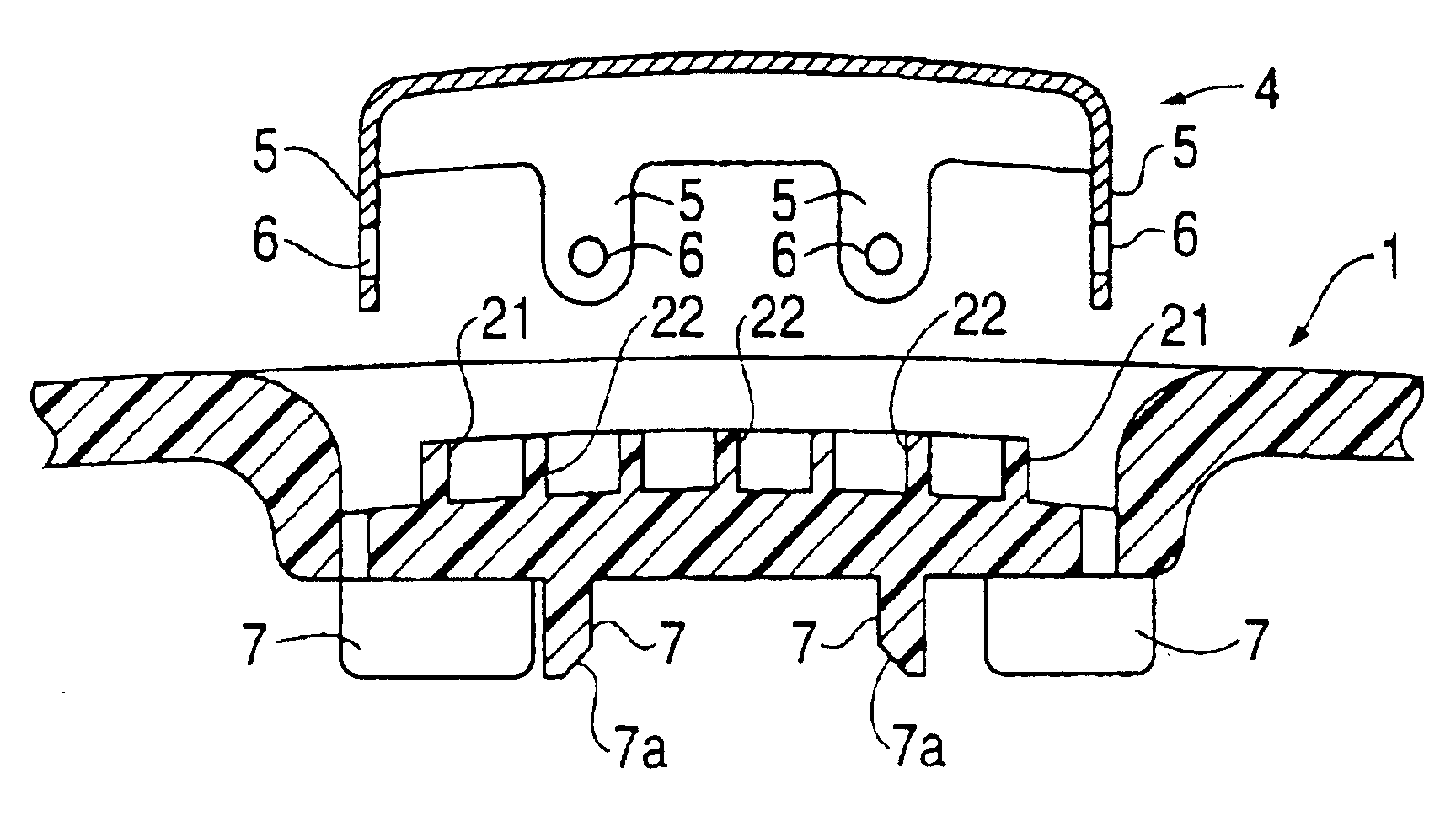

Sonotrode and anvil energy director grids for narrow/complex ultrasonic welds of improved durability

InactiveUS9278481B2Reduce material costsAdd equipmentLaminationLamination apparatusGrid patternEnergy control

A specially designed sonotrode and anvil are adapted to be used in combination for ultrasonic welding of work pieces, to produce a narrower weld region, but one exhibiting greater durability, thereby permitting use of less packaging material. The contact surfaces comprise a surface of the anvil having a plurality of energy directors, where the plurality of energy directors are arranged into a three-dimensional grid pattern to be capable of distributed vibration-transmissive contact. The energy directors may comprise a series of plateau surfaces being regularly spaced apart from each other in a first direction, and in a second direction that is orthogonal to the first direction, to form the grid pattern. The rectangular-shaped plateaus may be spaced apart by valleys. Engagement of the energy directors of the anvil with the corresponding surface of the sonotrode may cause minor elastic deformation of work pieces positioned therebetween prior to ultrasonic welding.

Owner:RINCO ULTRASONICS USA

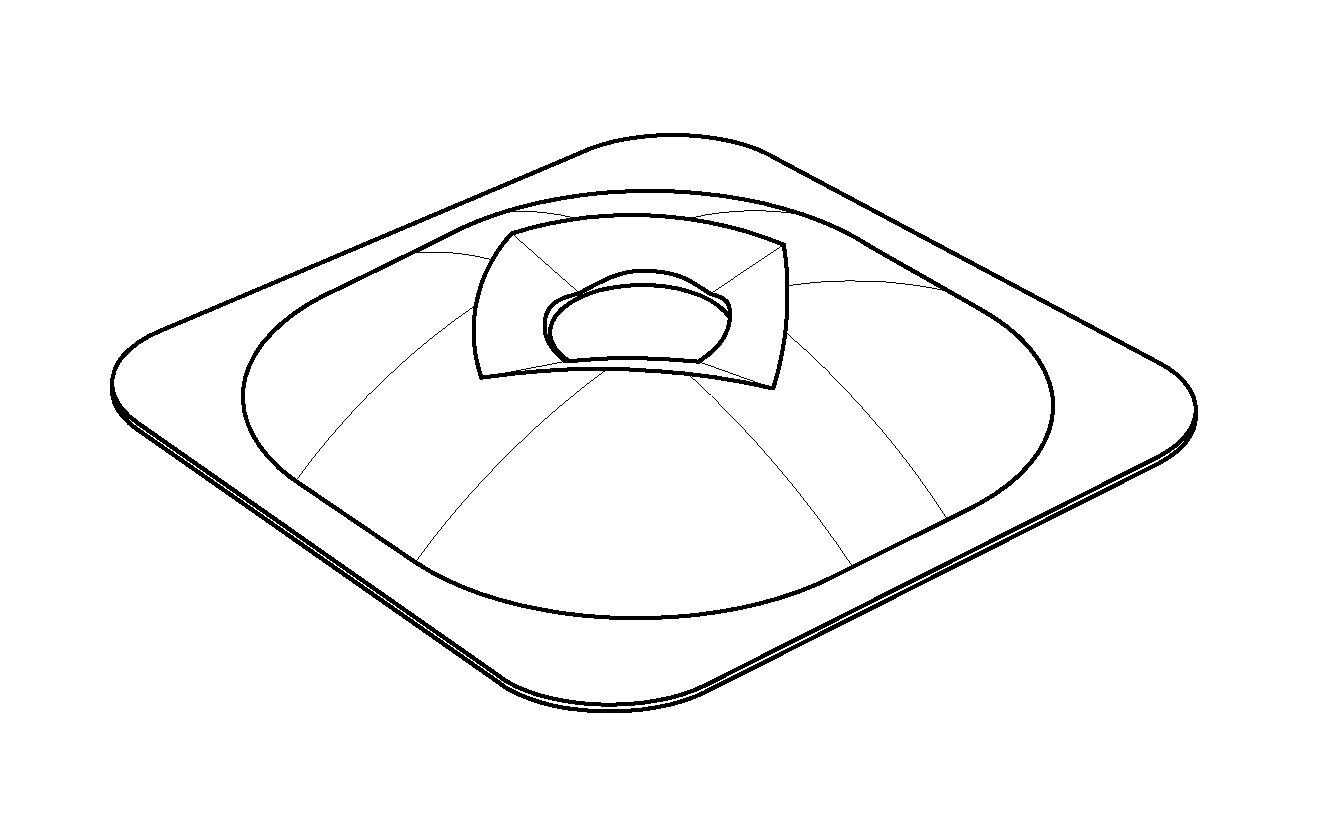

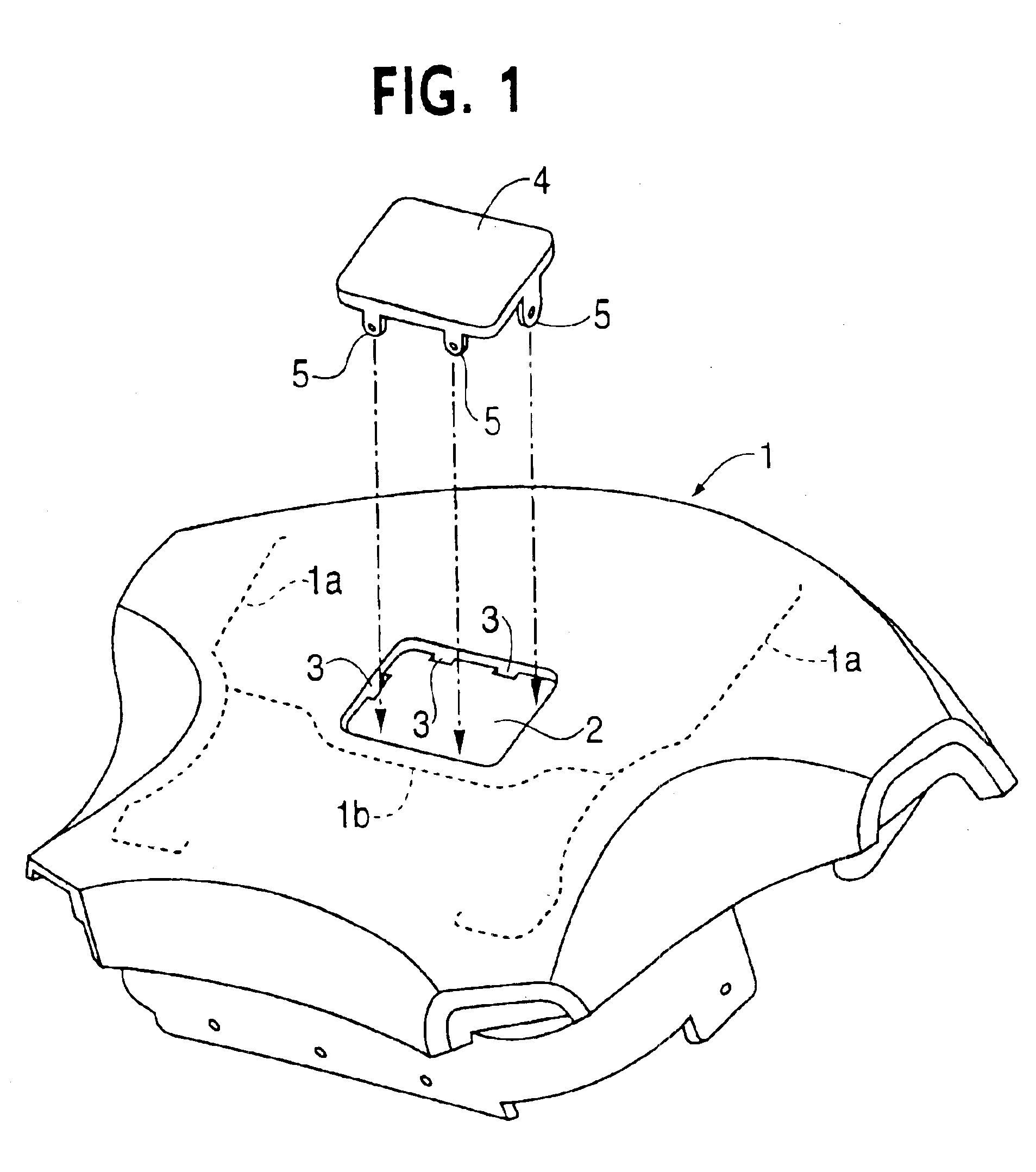

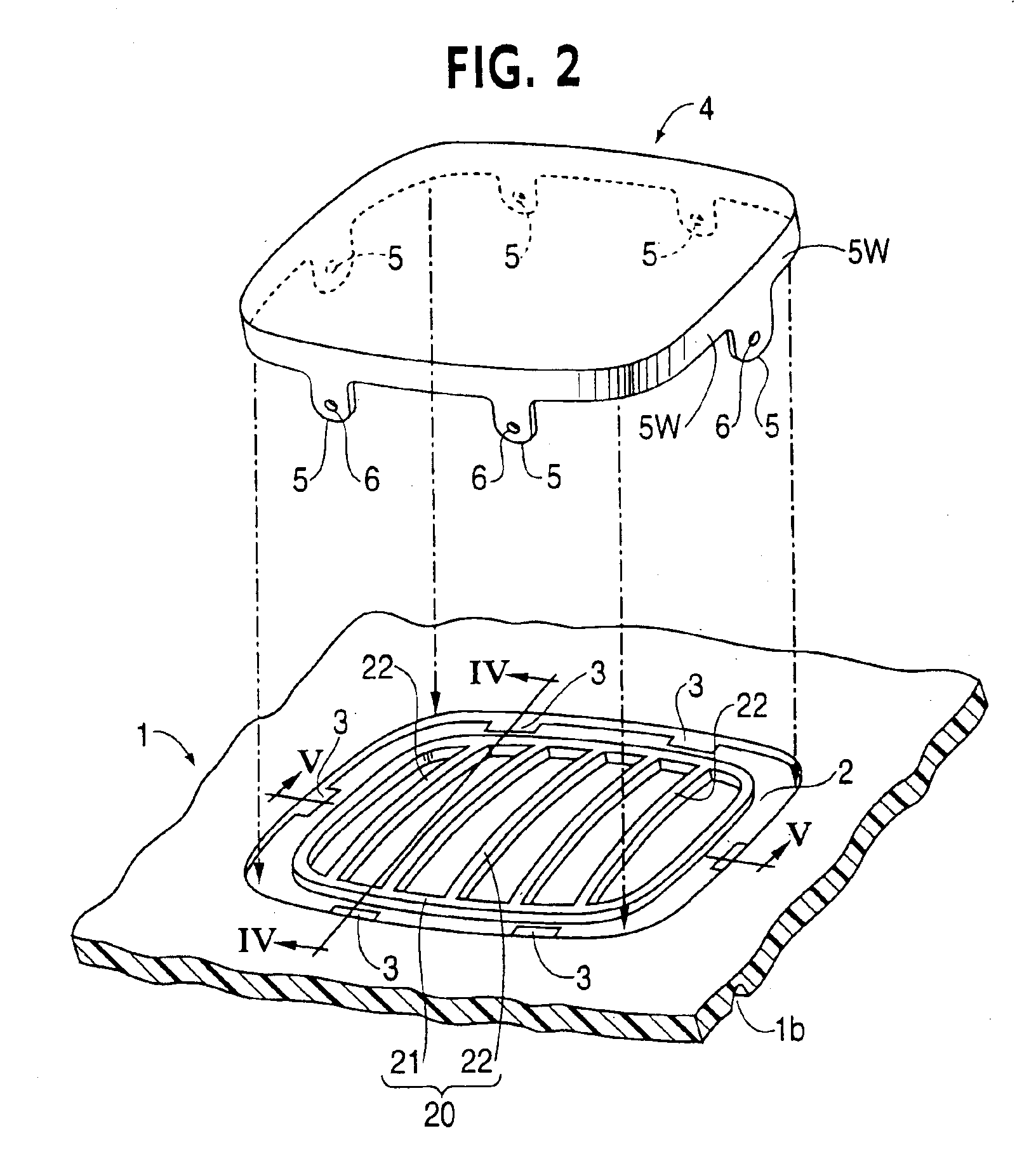

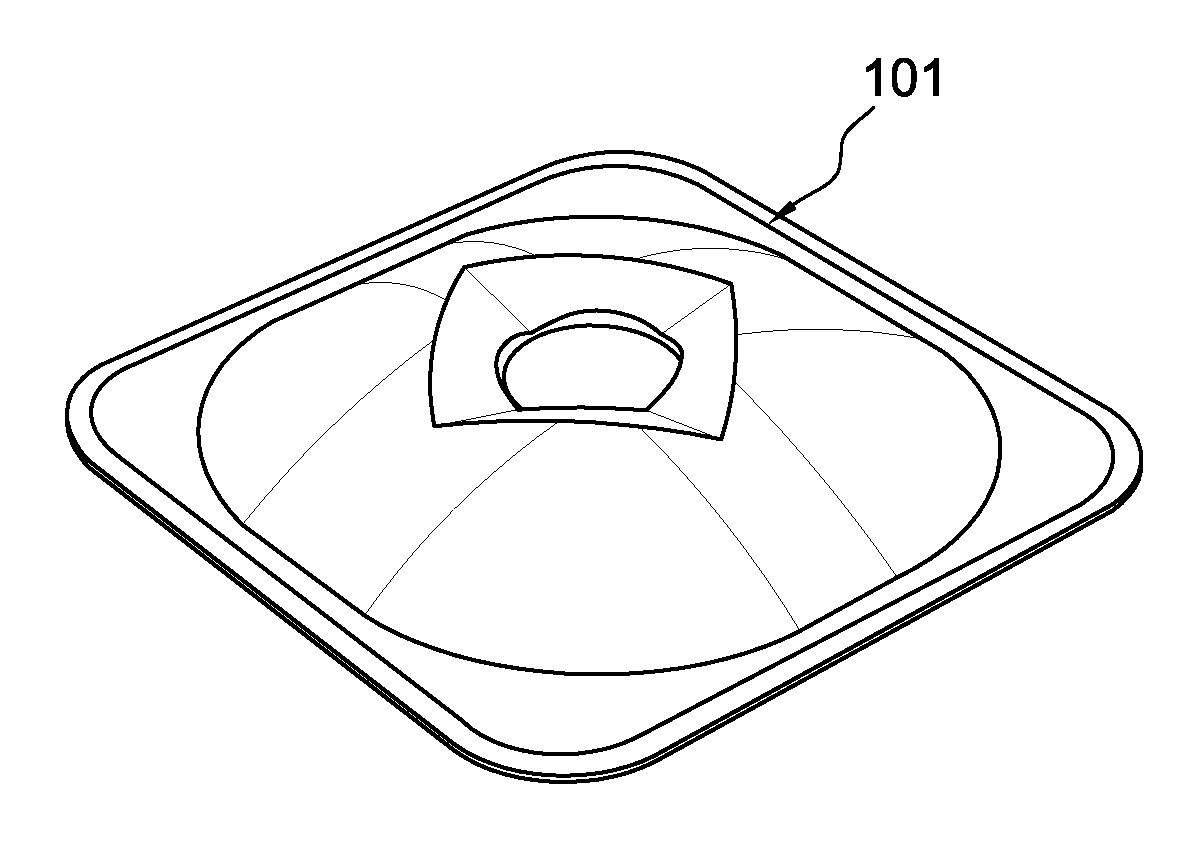

Cover for air bag device

InactiveUS6951349B2Good adhesionPrevent looseningPedestrian/occupant safety arrangementHand wheelsUltrasonic weldingEngineering

A cover for an air bag device that enables an emblem to be secured to the cover in an extremely simple manner. The cover (module cover) has a recess for receiving the emblem. An extension of the emblem is extended through a hole in the cover. A distal end of the extension is bent along a rear side of the cover. A rib is pressed and welded by a thermal or ultrasonic welding element to form a welding body. The welding body covers the distal end of the extension.

Owner:JOYSON SAFETY SYST JAPAN KK

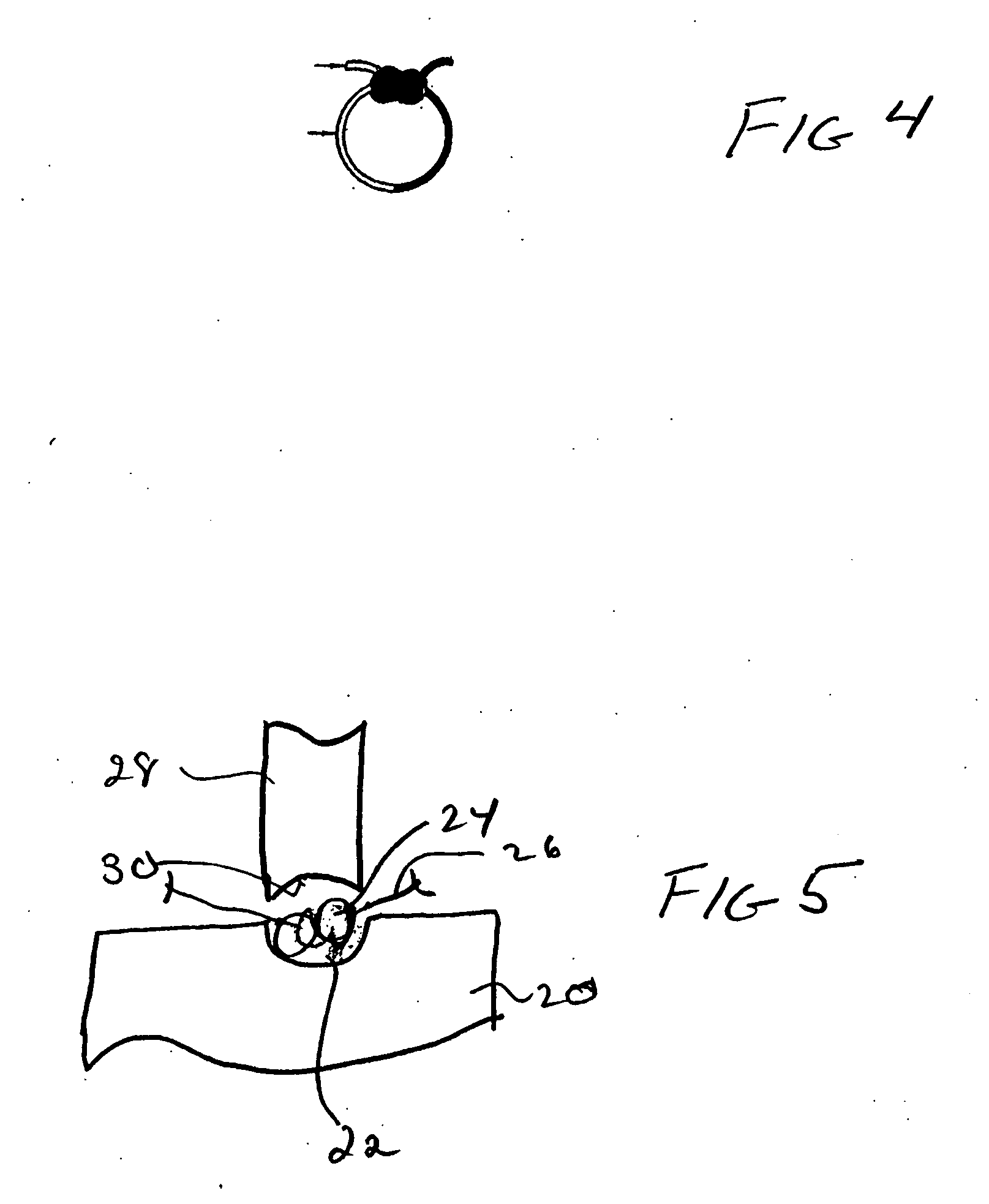

Fused suture knot

InactiveUS20050209639A1Decreases knot diameterReduce the overall diameterSuture equipmentsSurgical needlesUltrasonic weldingUltimate tensile strength

A securement location on a polymer thread structure includes the tying of a knot. In order to secure the knot, the knot is ultrasonically welded. Multifilament suture knots may be welded. The ultrasonic welding technique also tends to decrease the diameter of the knot from its pre-fused diameter. The resultant fused knot exhibits increased tensile and peel strength.

Owner:BOSTON SCI SCIMED INC

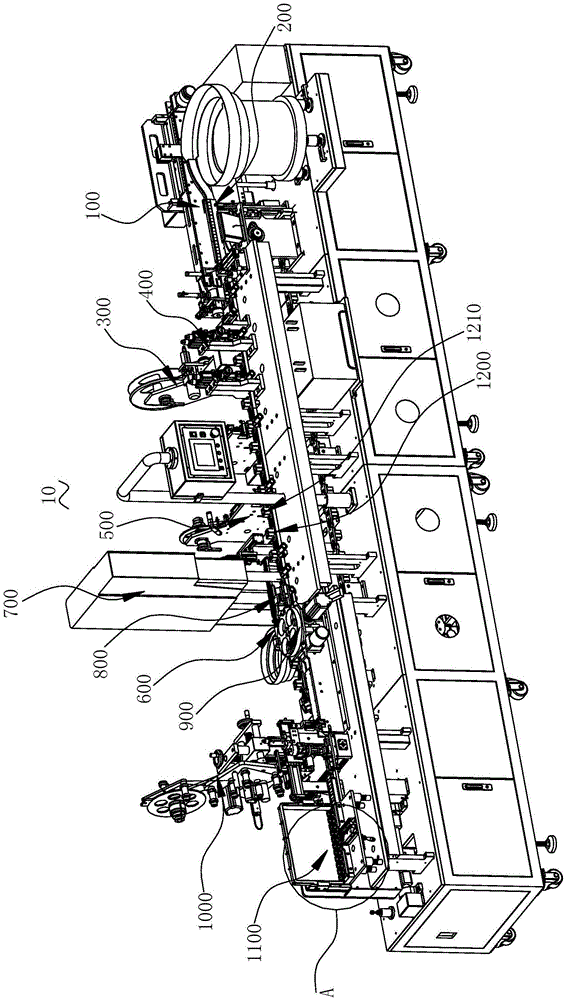

Battery production equipment

ActiveCN104485472APrimary cell manufactureAssembling battery machinesUltrasonic weldingAssembly line

The invention discloses battery production equipment. The battery production equipment is used for assembling a cell on a tray into a glue shell, welding a resistor on a resistance material strap to the cell, pasting a buffer glue on the cell, covering the glue shell with a cover plate, welding the cover plate and the glue shell, screening good and bad products, pasting a brand on the surface of the glue shell, and panning finished products. The battery production equipment comprises a cell loading mechanism, a glue shell loading mechanism, a resistor conveying mechanism, a resistor welding mechanism, a buffer glue pasting mechanism, a cover plate assembling mechanism, an ultrasonic welding mechanism, a detection mechanism, a detaching mechanism, a brand pasting mechanism, a panning mechanism and an assembly line, the battery production equipment finishes the operations of loading the cell into the glue shell, welding the resistor, pasting the buffer glue, loading the cover plate and performing sealing weld, screening the good and bad products, pasting the brand and panning by virtue of the cell loading mechanism, the glue shell loading mechanism, the resistor conveying mechanism, the resistor welding mechanism, the buffer glue pasting mechanism, the cover plate assembling mechanism, the ultrasonic welding mechanism, the detection mechanism, the detaching mechanism, the brand pasting mechanism and the panning mechanism, so that the standardized, mechanized, and automated production is finished.

Owner:EVE ENERGY CO LTD

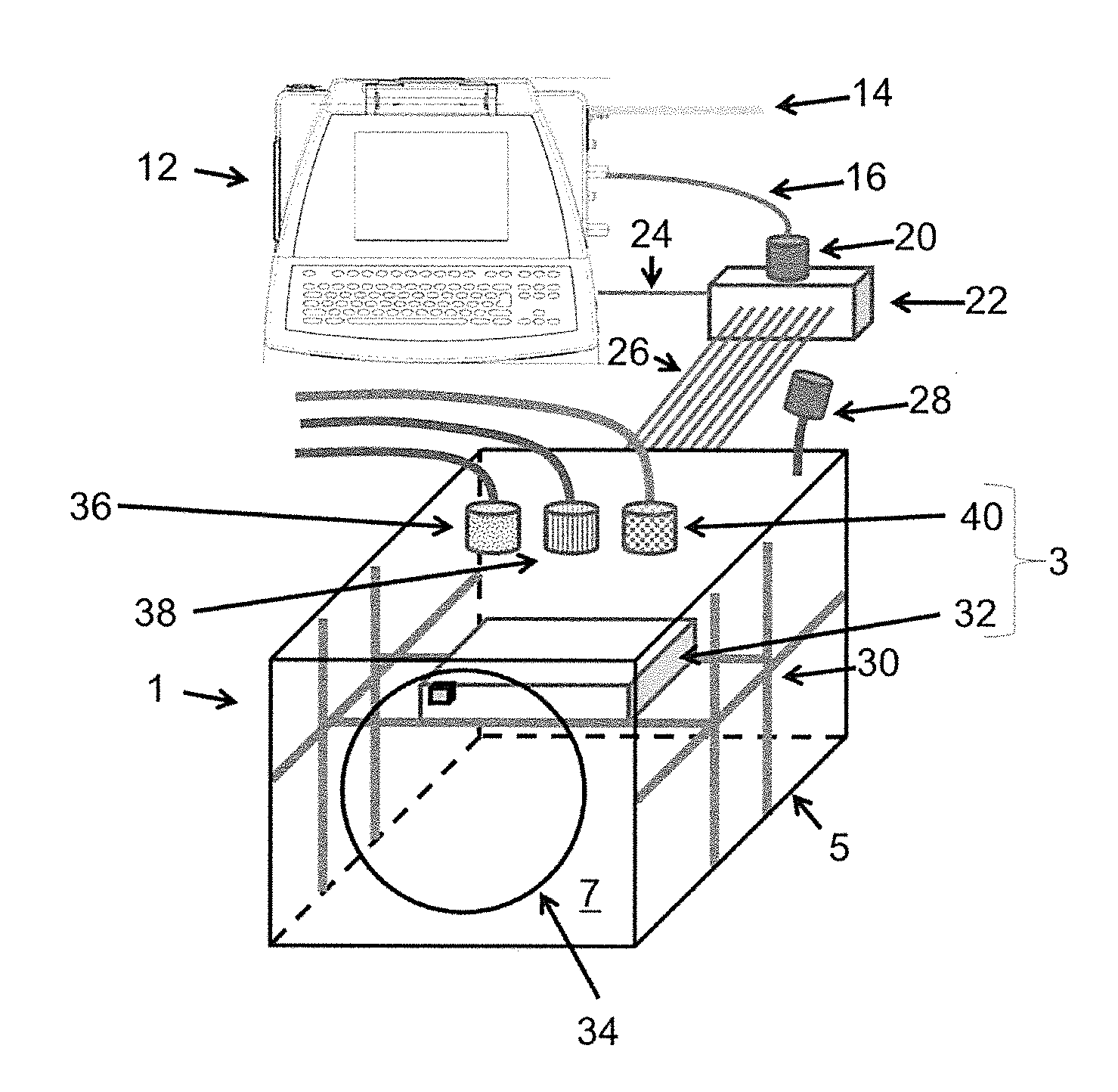

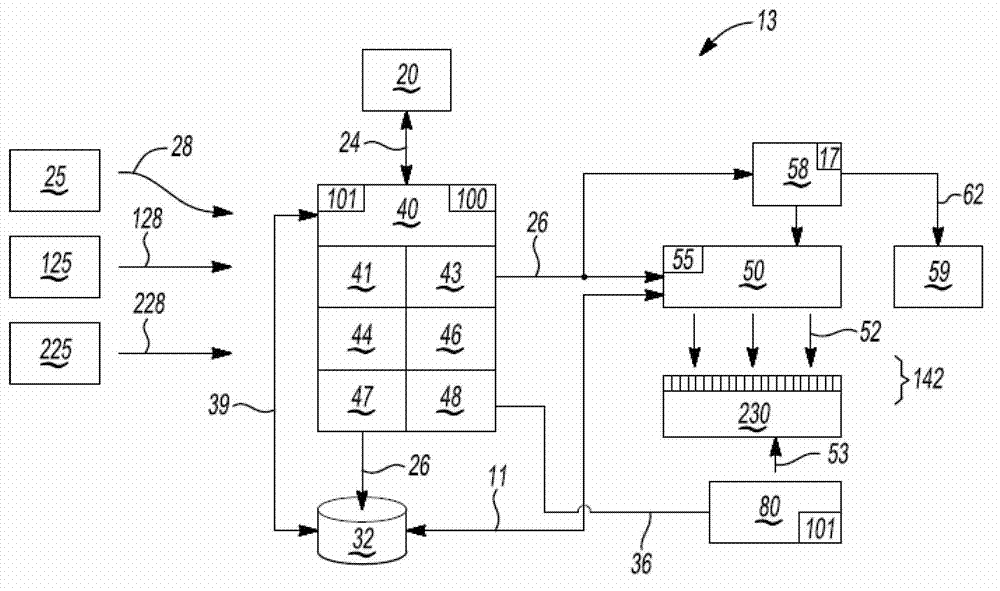

Real-time detection and weld quality prediction in vibration welding process

A system includes a host machine and a status projector. The host machine is in electrical communication with a collection of sensors and with a welding controller that generates control signals for controlling the welding horn. The host machine is configured to execute a method to thereby process the sensory and control signals, as well as predict a quality status of a weld that is formed using the welding horn, including identifying any suspect welds. The host machine then activates the status projector to illuminate the suspect welds. This may occur directly on the welds using a laser projector, or on a surface of the work piece in proximity to the welds. The system and method may be used in the ultrasonic welding of battery tabs of a multi-cell battery pack in a particular embodiment. The welding horn and welding controller may also be part of the system.

Owner:GM GLOBAL TECH OPERATIONS LLC

Two-piece connector for flat blade windshield wiper

ActiveUS20080078051A1Easy to manufactureEasy to assembleWindow cleanersVehicle cleaningUltrasonic weldingRivet

A central connecting device (36) for a flat blade style wiper blade assembly (20) includes a plastic intermediate base (38) that is fixed, such as by ultrasonic welding, to a pair of flexors (26) extending the length of the wiper blade assembly (20). The intermediate base (38) includes a recessed deck section (42) for receiving a metallic housing (54). The housing (54) is heat-staked in position to the intermediate base (38) to secure the two elements together as an integral unit. A rivet (78) extends transversely across the sidewalls (58) of the housing (54) for adjoining to a universal connector (82) or other suitable adaptor or by direction connection to the end of a wiper arm.

Owner:TRICO PROD CORP

Fluid-containing pouches with reduced gas exchange and methods for making same

ActiveUS20100068097A1Reduce penetrationReduce solubilityHollow inflatable ballsHollow non-inflatable ballsUltrasonic weldingEngineering

The invention is directed to fluid-containing pouches and to methods for forming fluid-containing pouches. In one embodiment, the invention is to a fluid-containing pouch, comprising first and second opposing sheets, and a fluid (e.g., a calibrant fluid, a reactant fluid or a wash fluid) disposed between the first and second opposing sheets. The first sheet and the second sheet have a substantially liquid and gas impermeable perimeter seal. The sheets may be sealed, for example, by one or more of heat crimping, pressure crimping, heat and pressure crimping, ultrasonic welding, metal-to-metal welding or laser welding. Fluid-containing pouches sealed according to the disclosed methods and apparatuses show substantially improvement in terms of reduced gas exchange, notably CO2 pressurization levels.

Owner:ABBOTT POINT CARE

Gas impermeable tube joint and method of forming same

A method of forming a gas impermeable joint in a fluid system includes: providing a tube having a metallic barrier layer disposed between an inner plastic layer and an outer plastic layer; forcing at least one of the inner plastic layer and the outer plastic layer into contact with a plastic surface of a component; and welding the at least one of the inner plastic layer and the outer plastic layer with the plastic surface to form the gas impermeable joint. The welding may include: spin welding, hot plate welding, vibration welding, and ultrasonic welding. The metallic barrier layer extends substantially to the component, thus improving the gas impermeability of the joint between the tube and the component.

Owner:FLUID ROUTING SOLUTIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com