Patents

Literature

333 results about "Sonotrode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

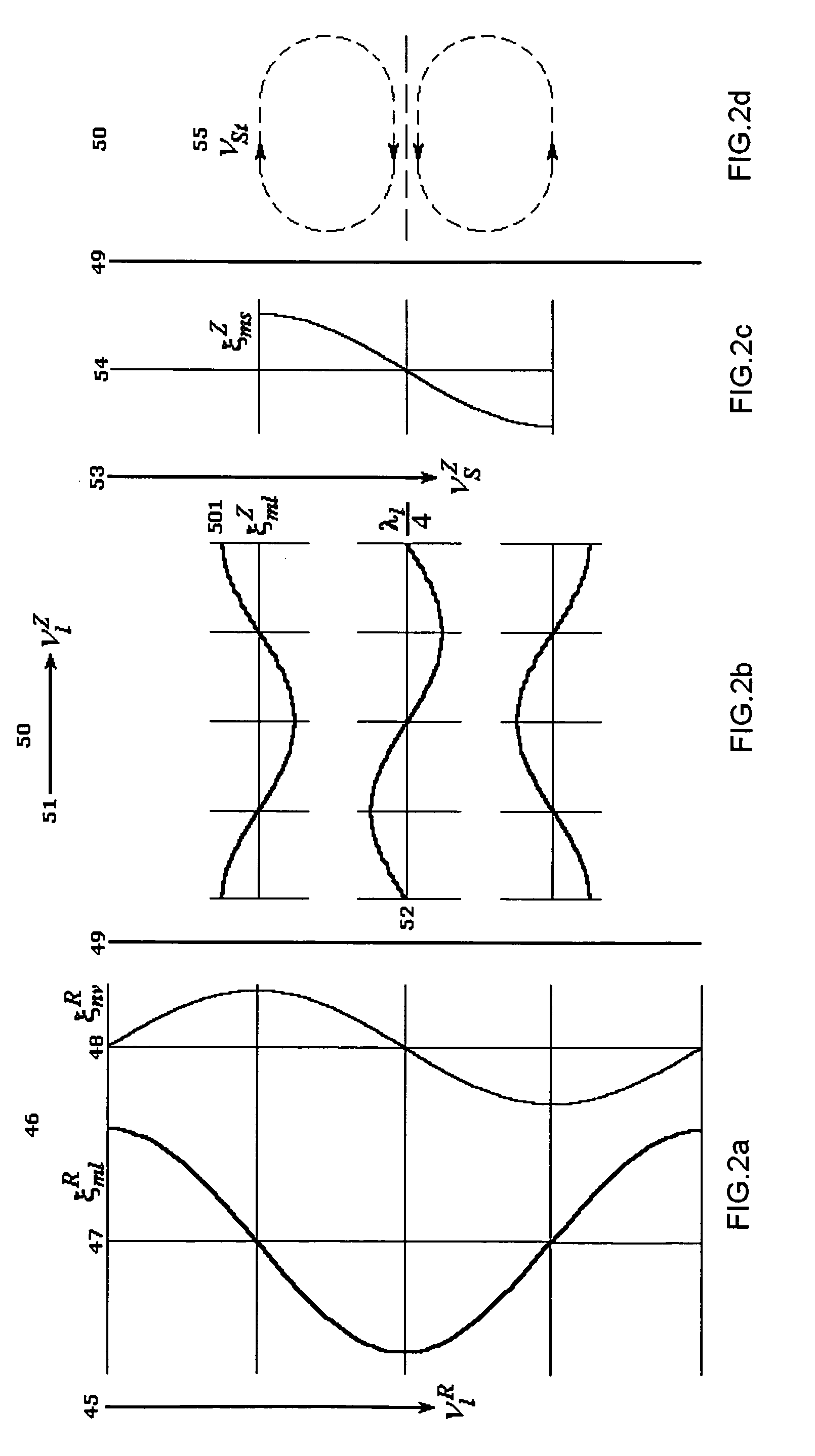

In ultrasonic machining, welding and mixing, a sonotrode is a tool that creates ultrasonic vibrations and applies this vibrational energy to a gas, liquid, solid or tissue. A sonotrode usually consists of a stack of piezoelectric transducers attached to a tapering metal rod. The end of the rod is applied to the working material. An alternating current oscillating at ultrasonic frequency is applied by a separate power supply unit to the piezoelectric transducers. The current causes them to expand and contract. The frequency of the current is chosen to be the resonant frequency of the tool, so the entire sonotrode acts as a half-wavelength resonator, vibrating lengthwise with standing waves at its resonant frequency. The standard frequencies used with ultrasonic sonotrodes range from 20 kHz to 70 kHz. The amplitude of the vibration is small, about 13 to 130 micrometres.

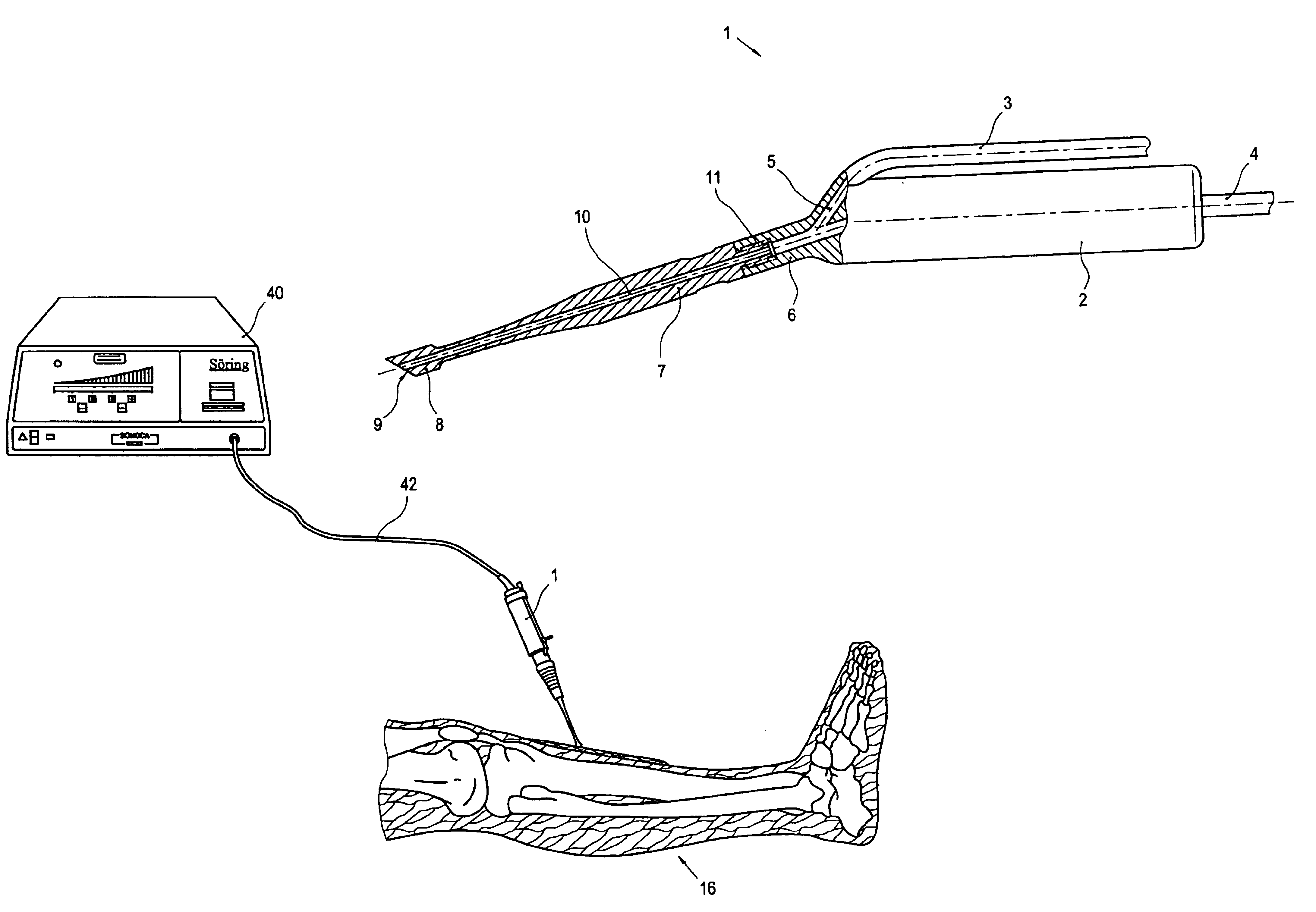

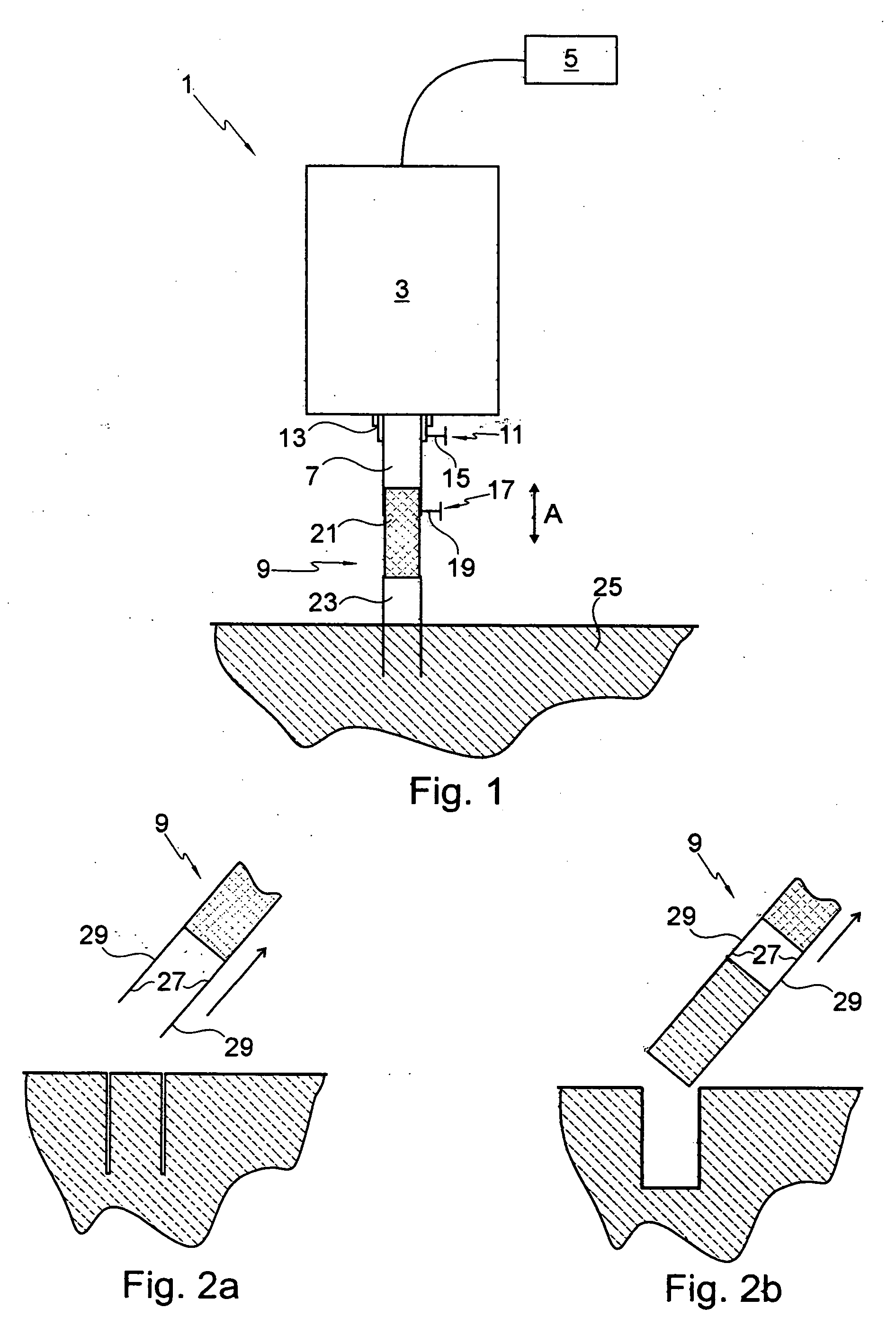

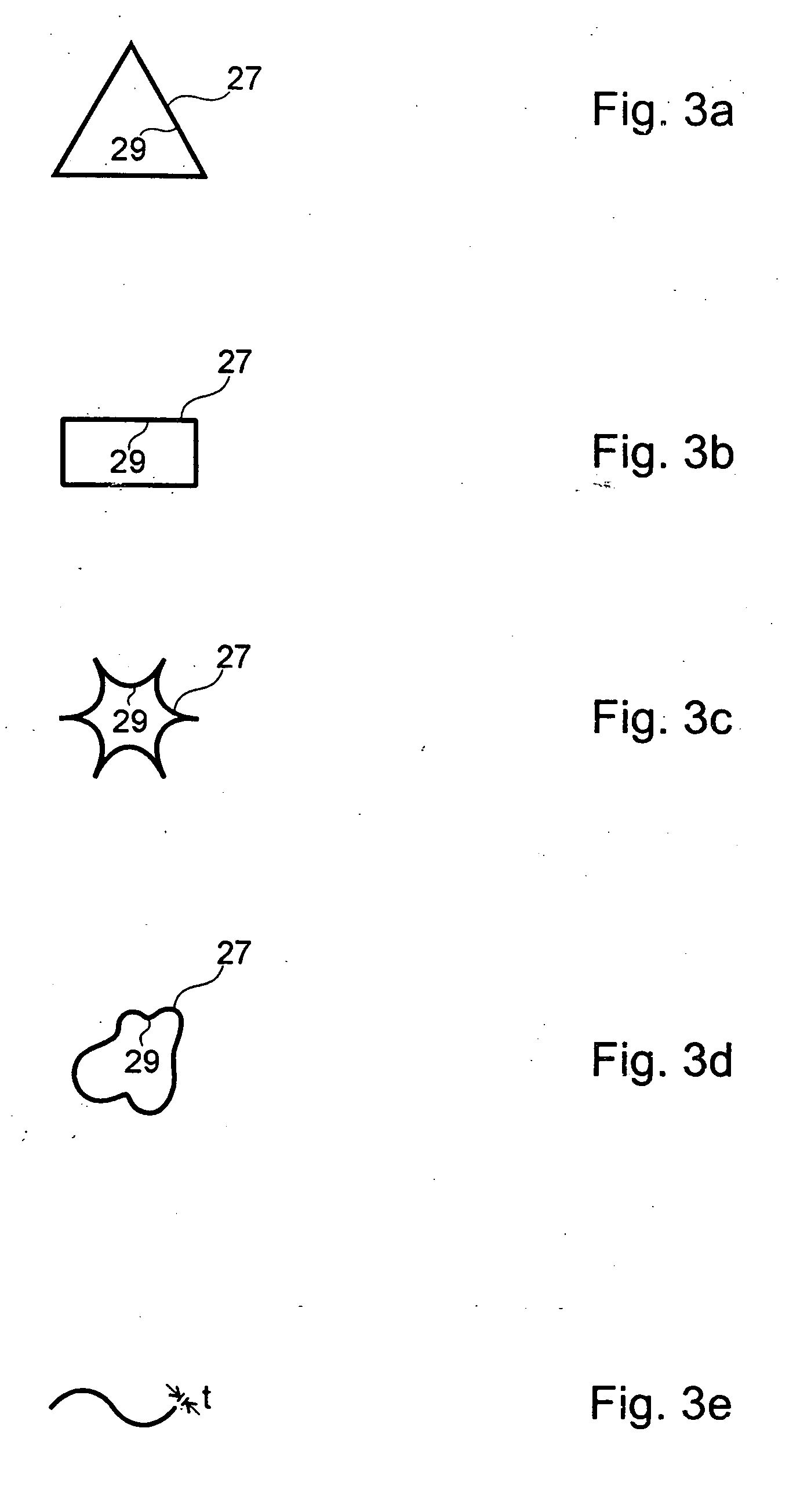

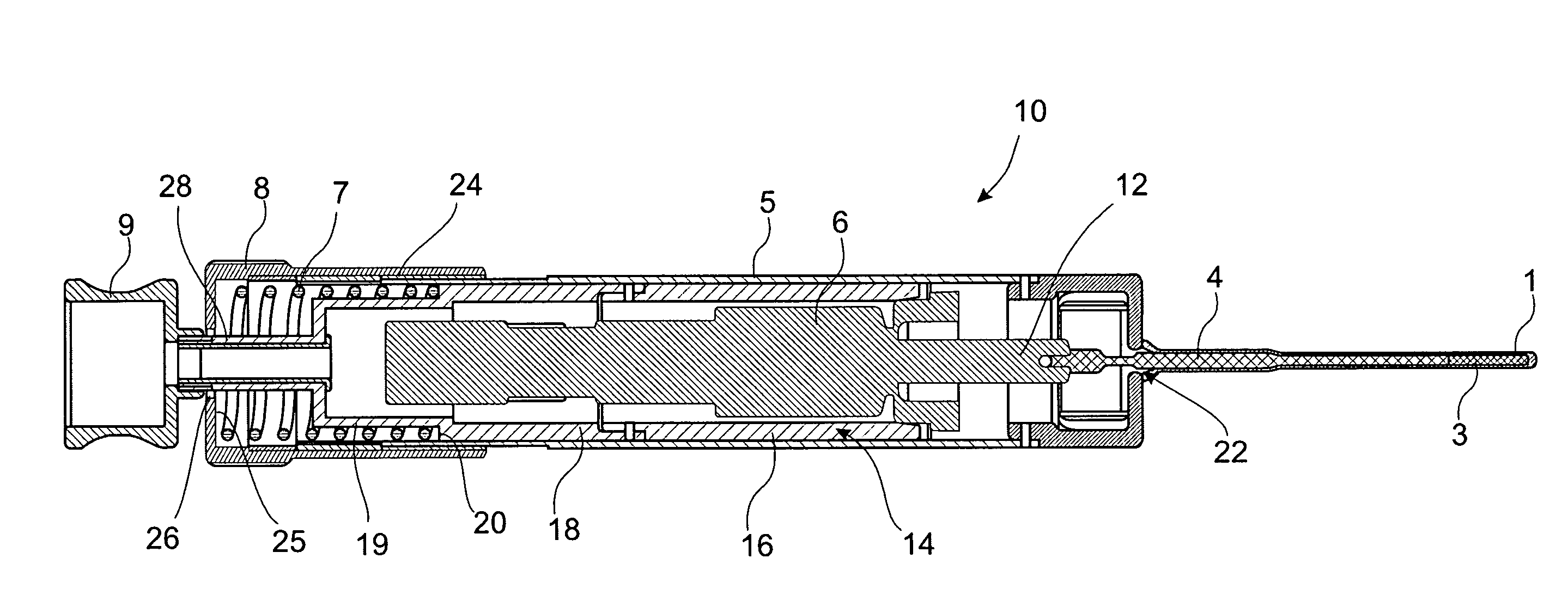

Medical treatment apparatus

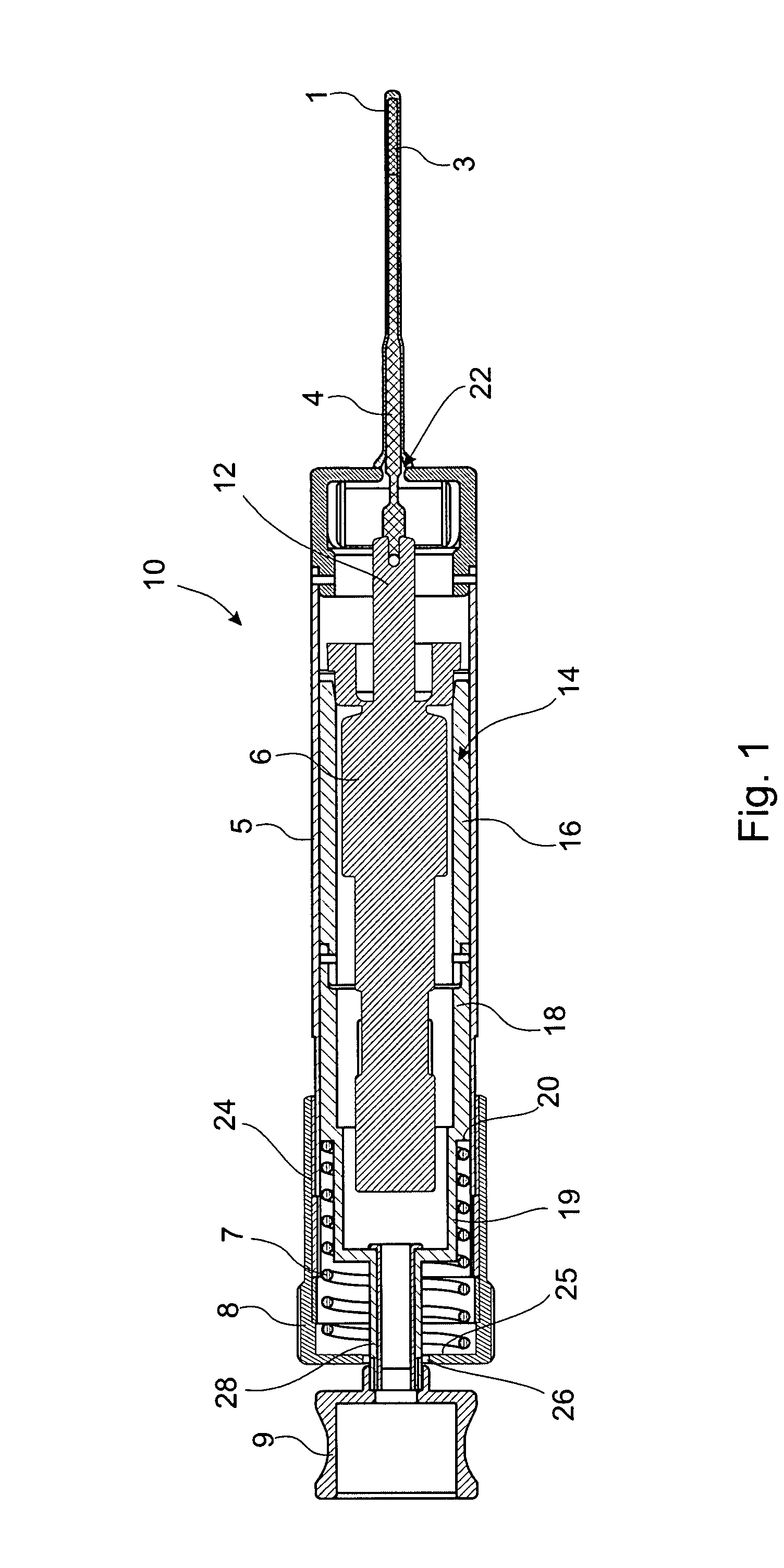

InactiveUS7608054B2Guaranteed to workIntravenous devicesSuction irrigation systemsMedical deviceBiomedical engineering

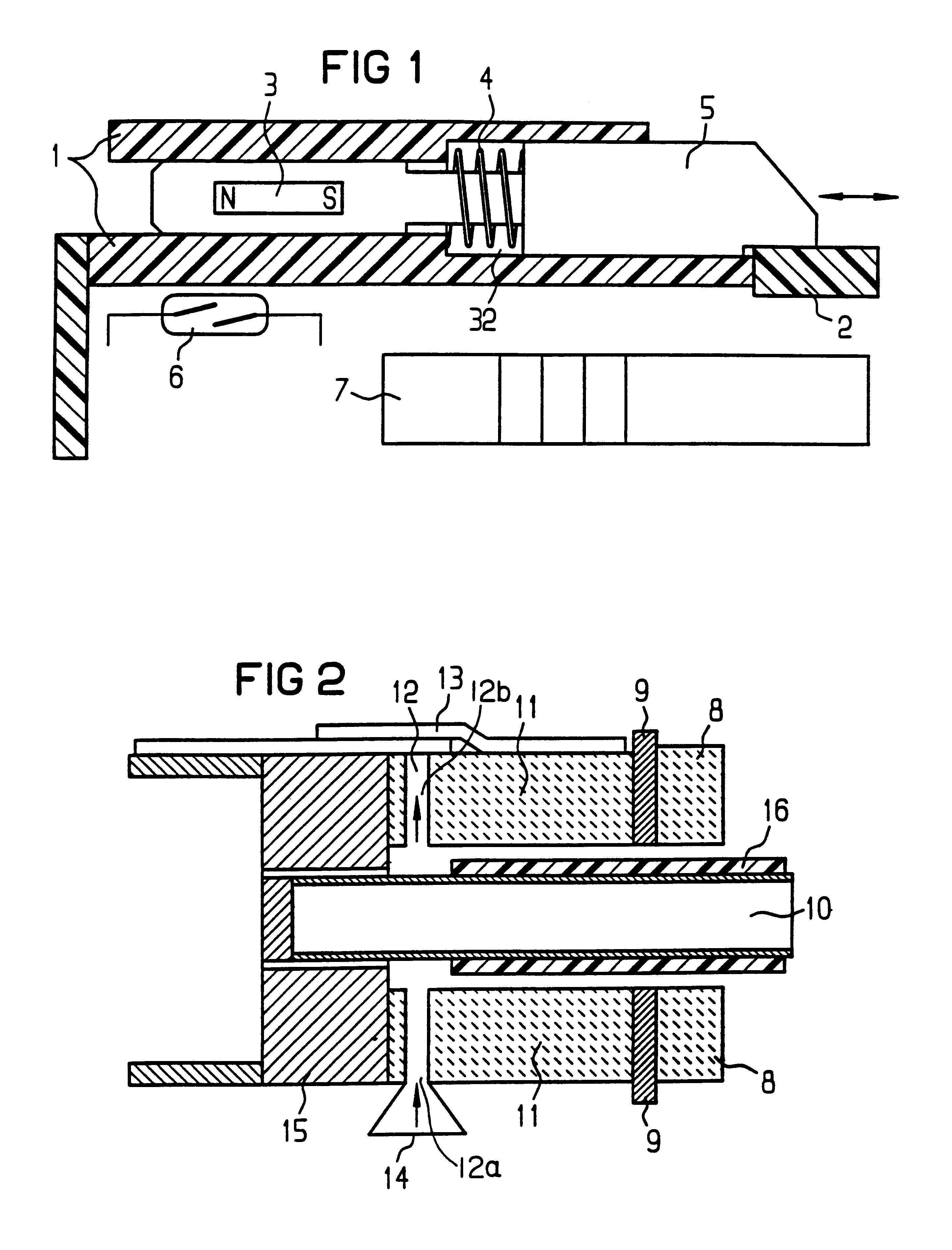

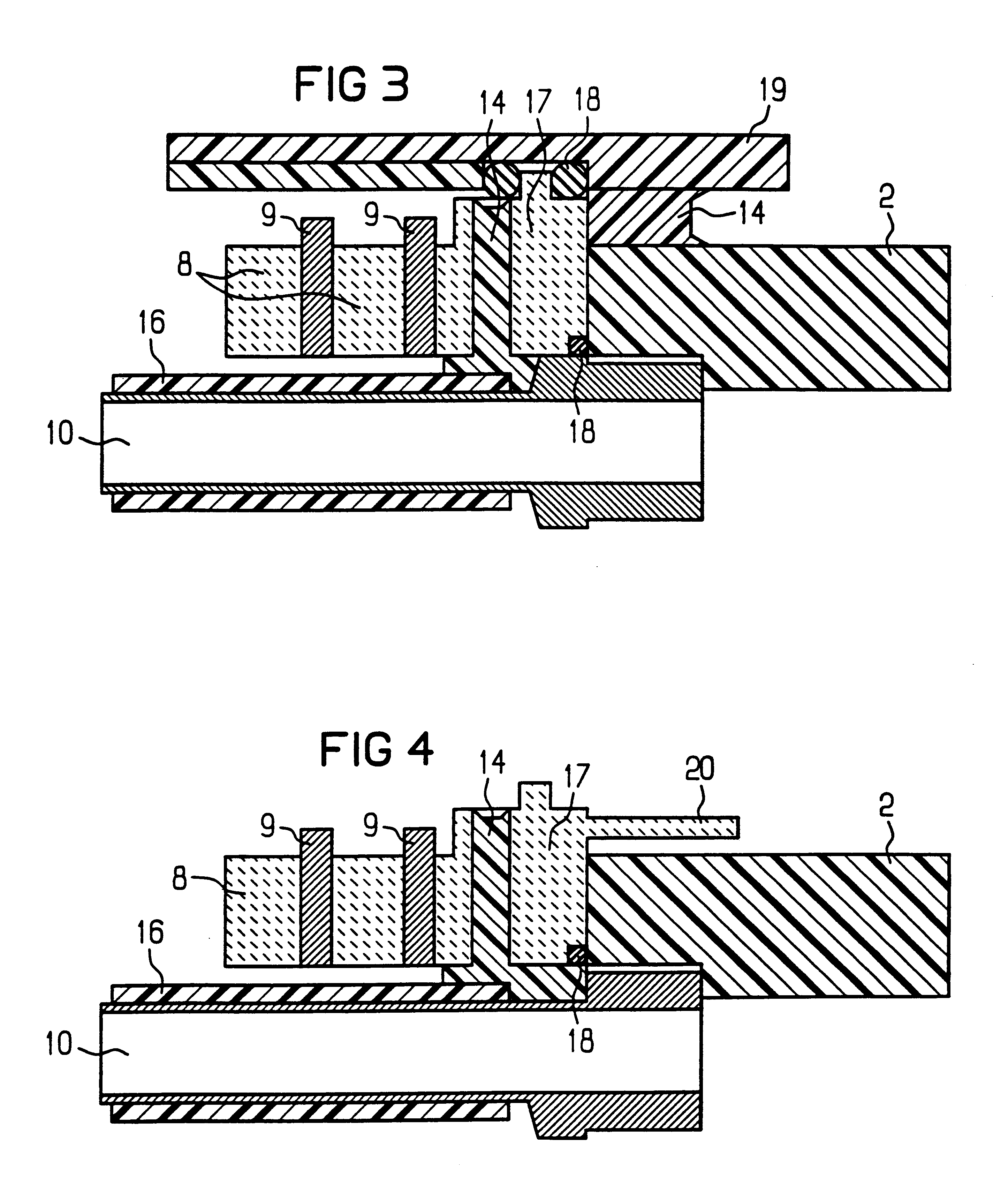

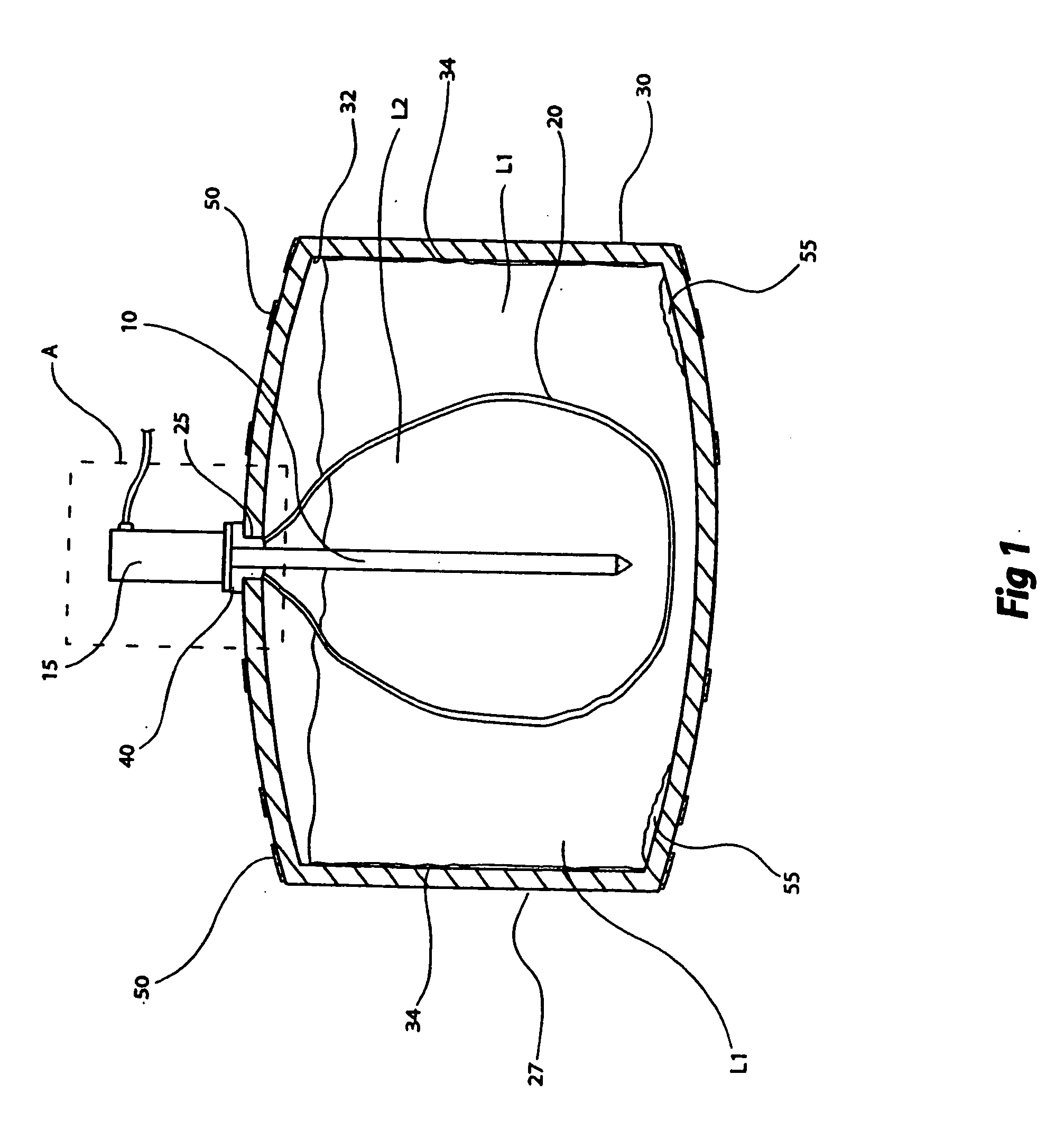

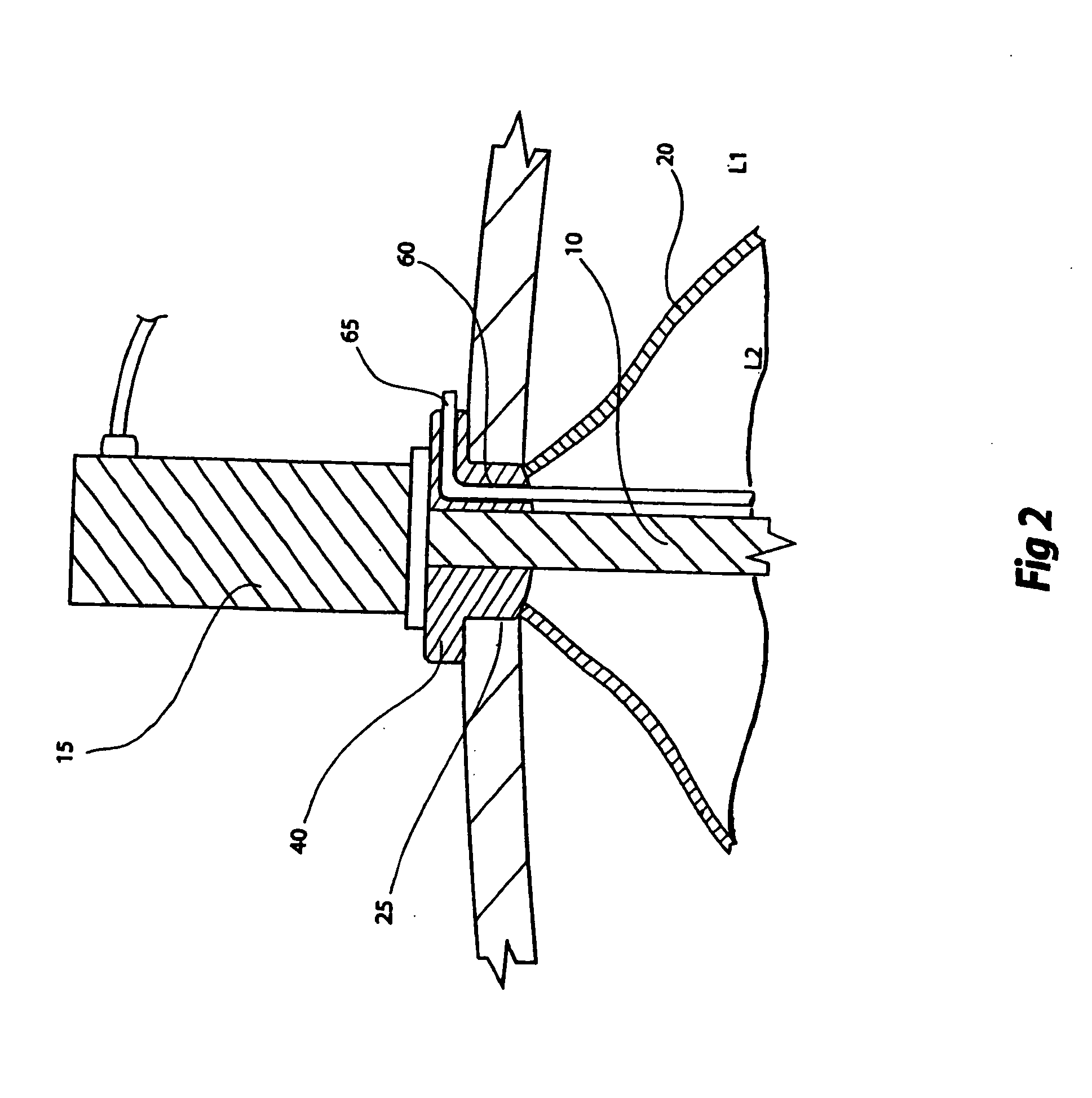

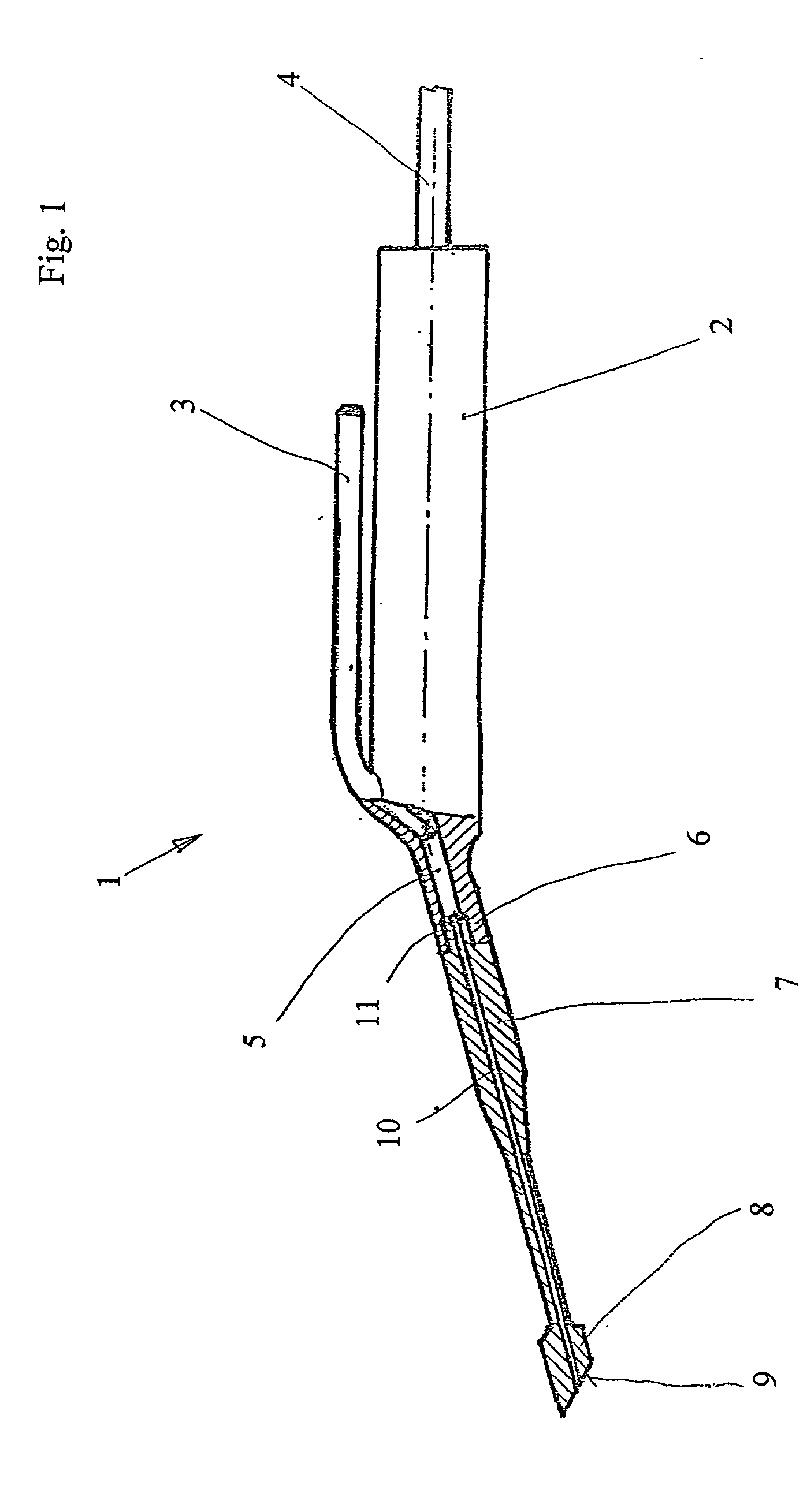

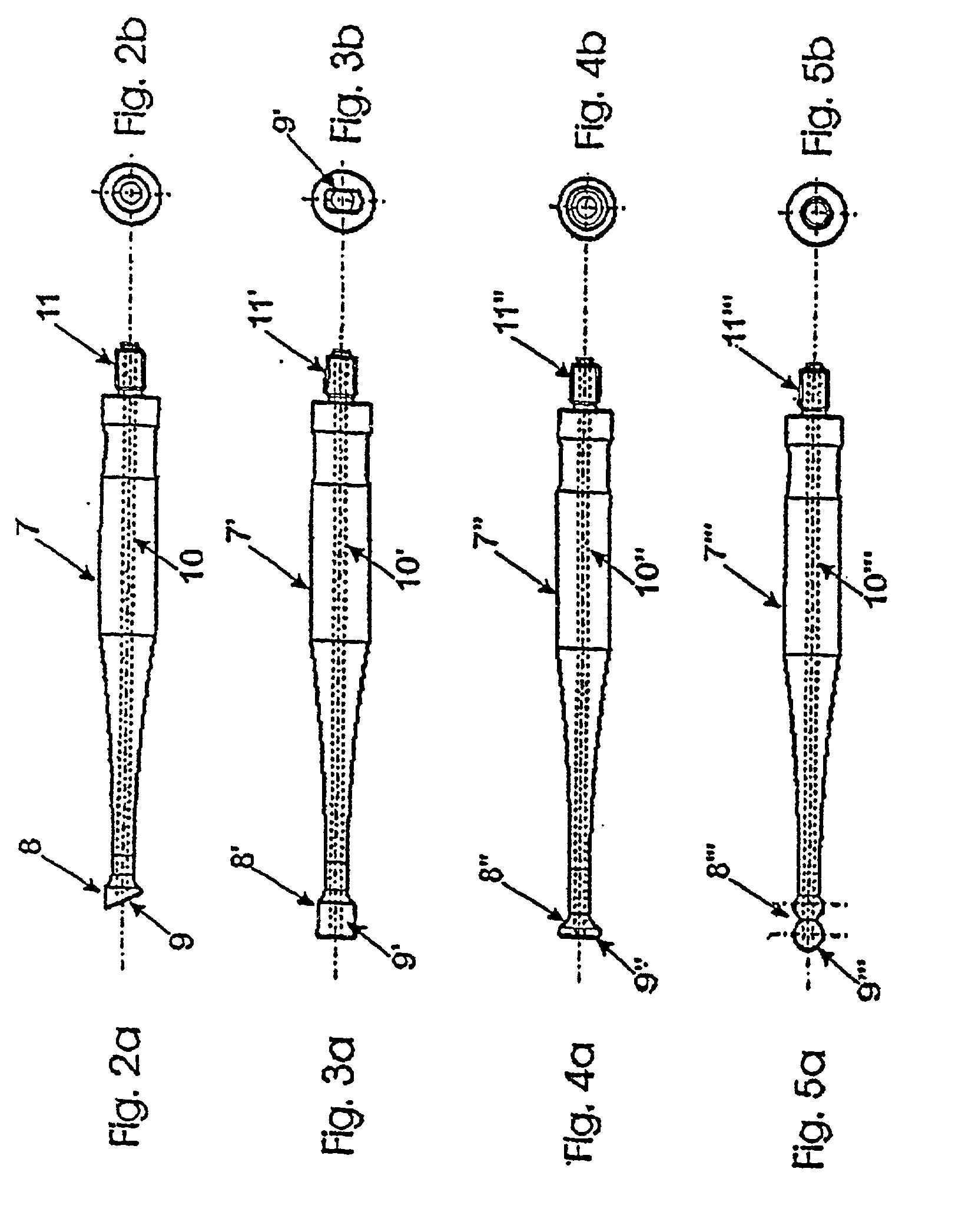

A medical treatment apparatus includes a hand piece (1) equipped with an ultrasound vibration generator and a sonotrode (3) attached to the hand piece (1). An adaptation sleeve (10) can be slid over the sonotrode (3) of the medical treatment apparatus. The adaptation sleeve (10) can be attached at the hand piece (1), wherein the adaptation sleeve (10) is equipped with a connector (12, 13) for receiving a suction hose (14). A separator (15) is furnished between a suction apparatus (A) and the suction hose (14).

Owner:SORING

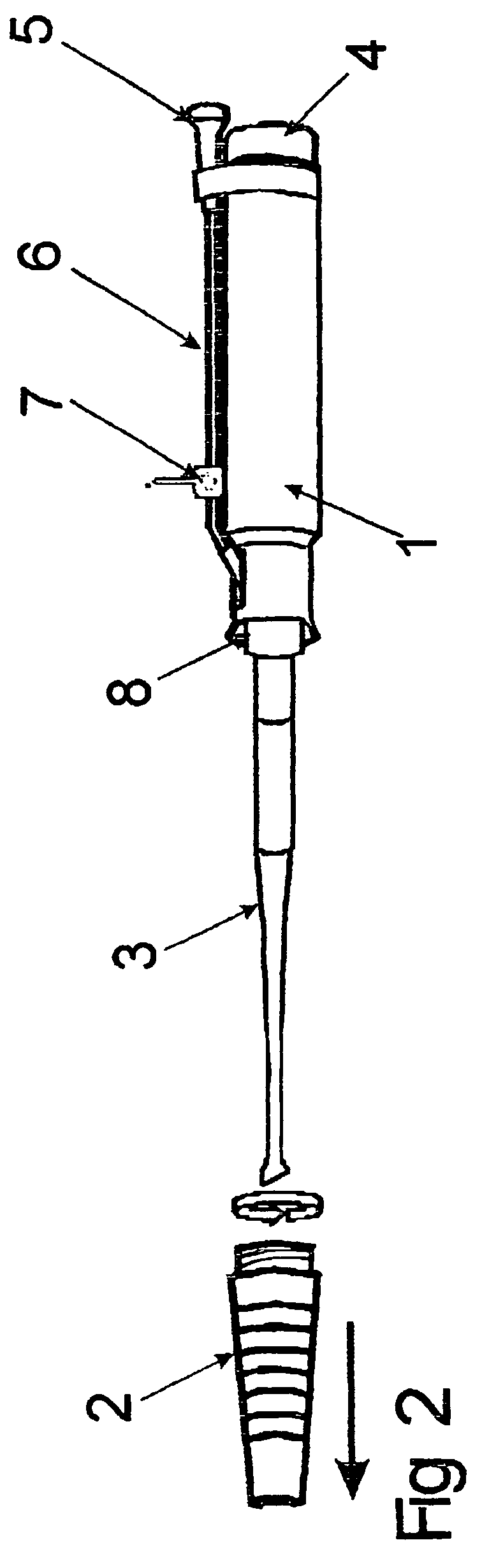

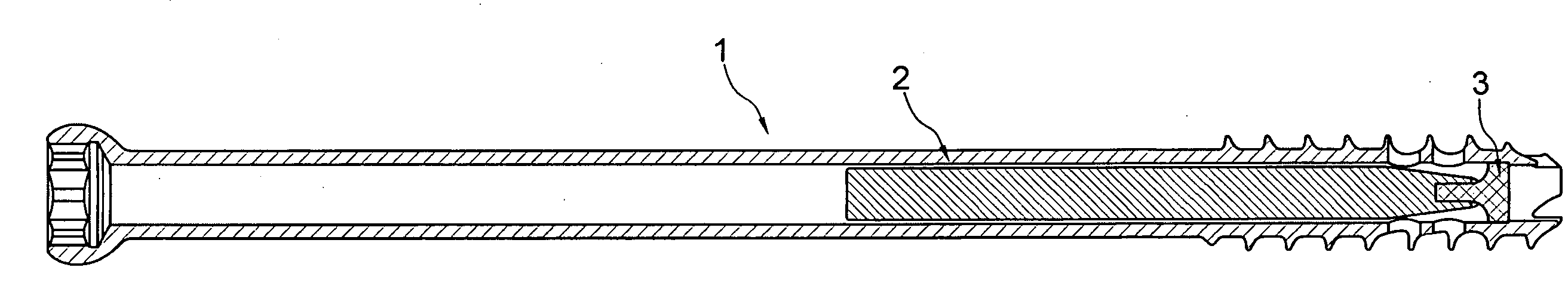

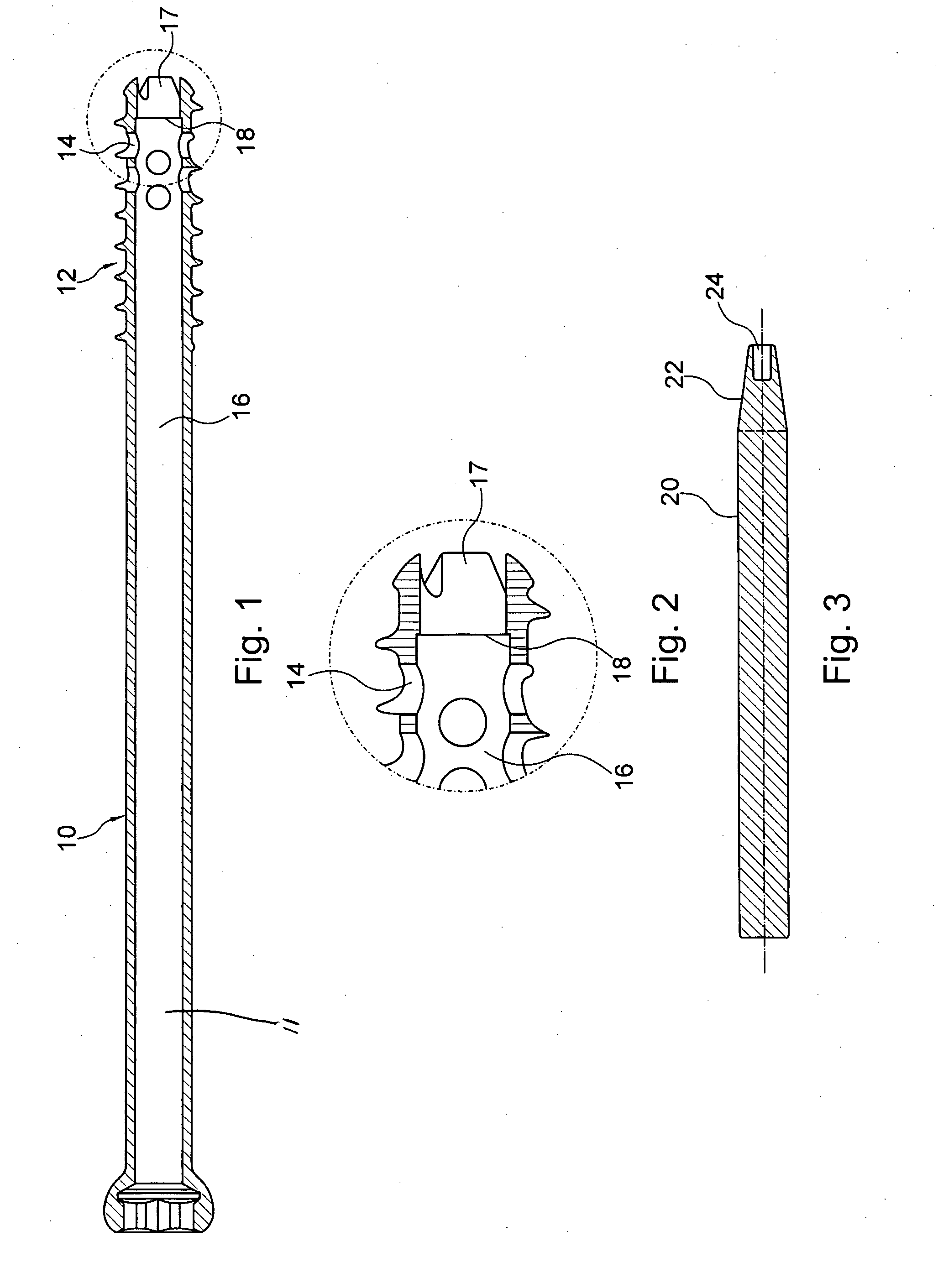

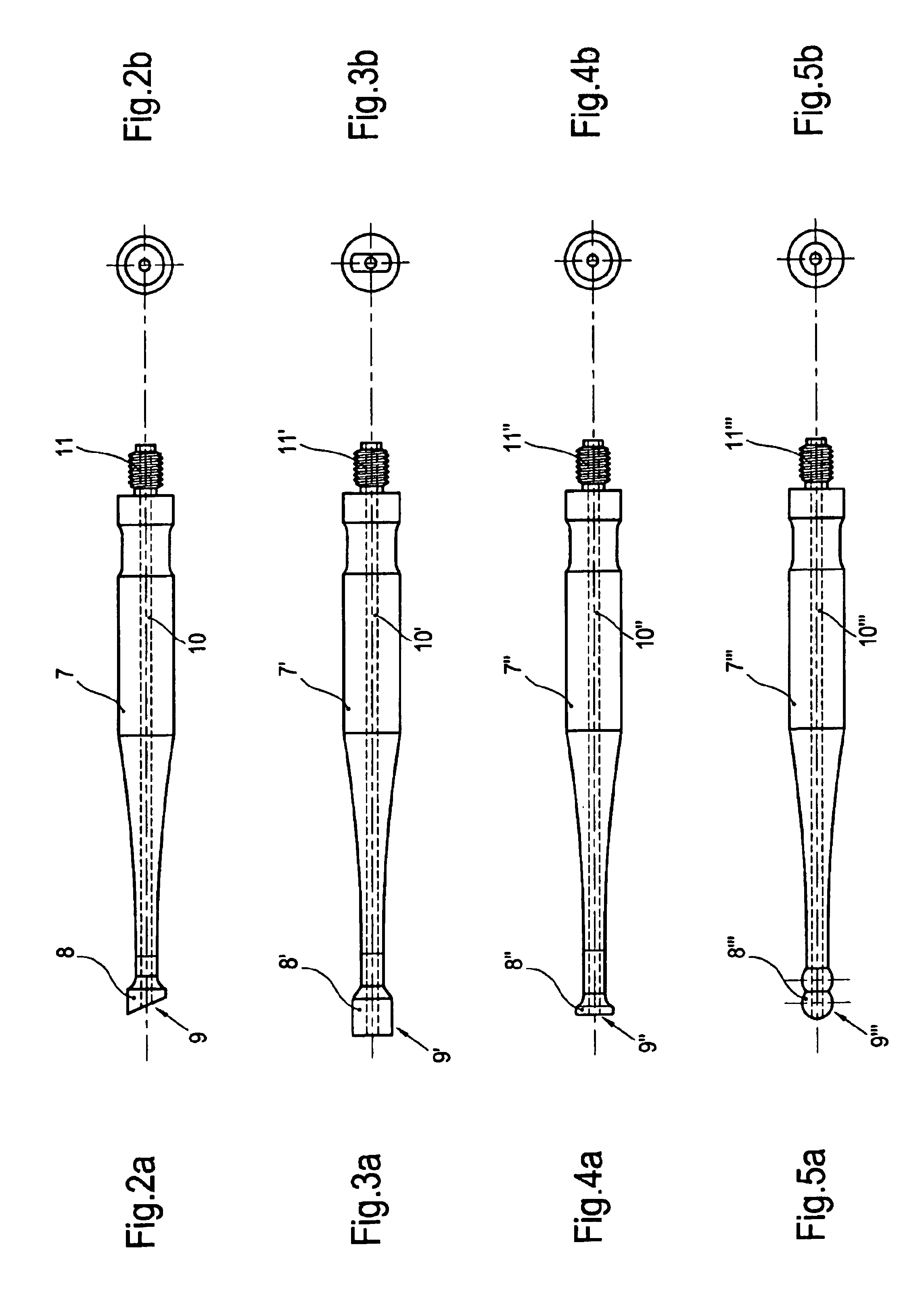

Device for fixation of bone fractures

A device and method for fixation of bone fractures has a bone screw comprising a shank with a threaded end portion, on the outer surface. The screw has a through bore with two bore portions differing in diameter. A step in the diameter is formed between these bore portions and is located within the end of the screw having the thread. This step in diameter can support a metal insert which in turn supports a polymer pin when the latter if pressurized with a sonotrode in the bone screw. Together with an applied ultrasonic vibration the pressure fluidizes the polymer pin and presses the material through holes configured in the wall of the bone screw and into surrounding bone.

Owner:WOODWELDING +1

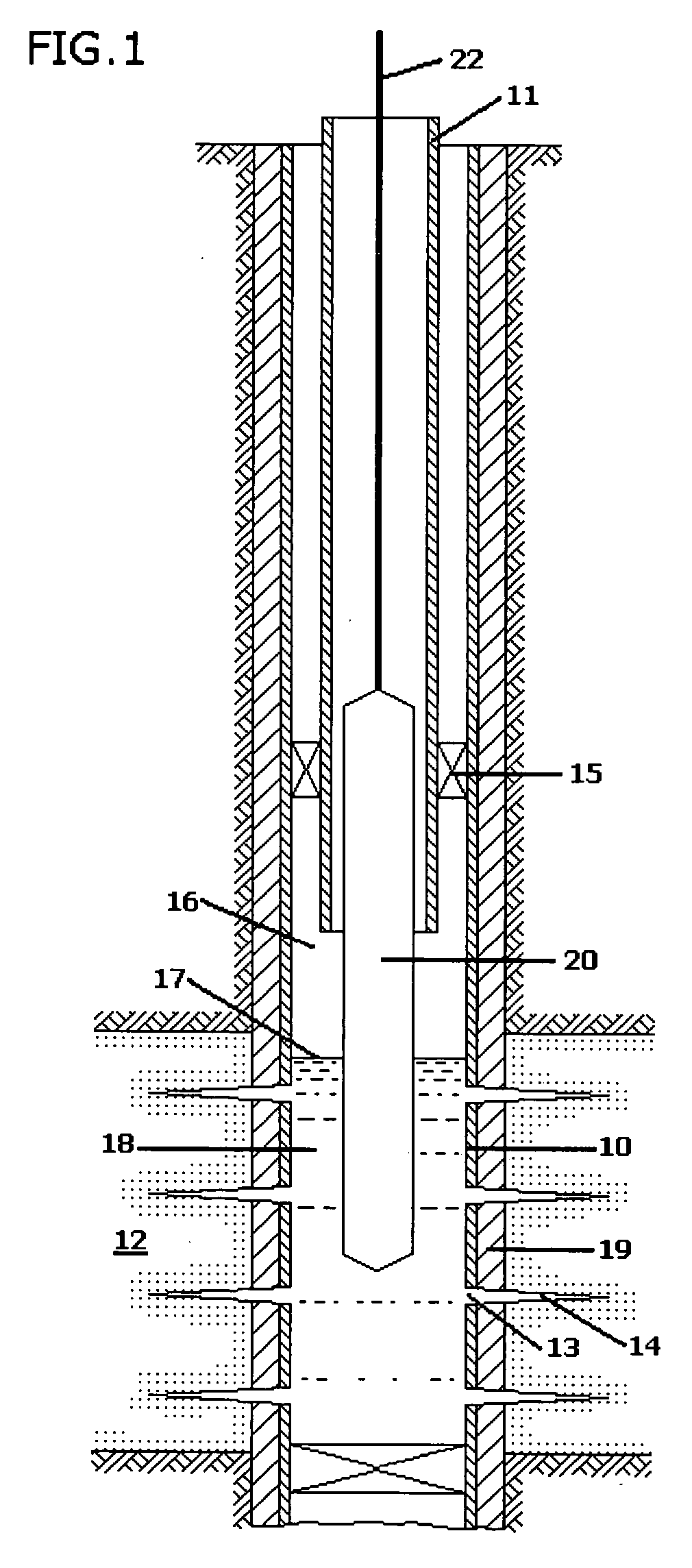

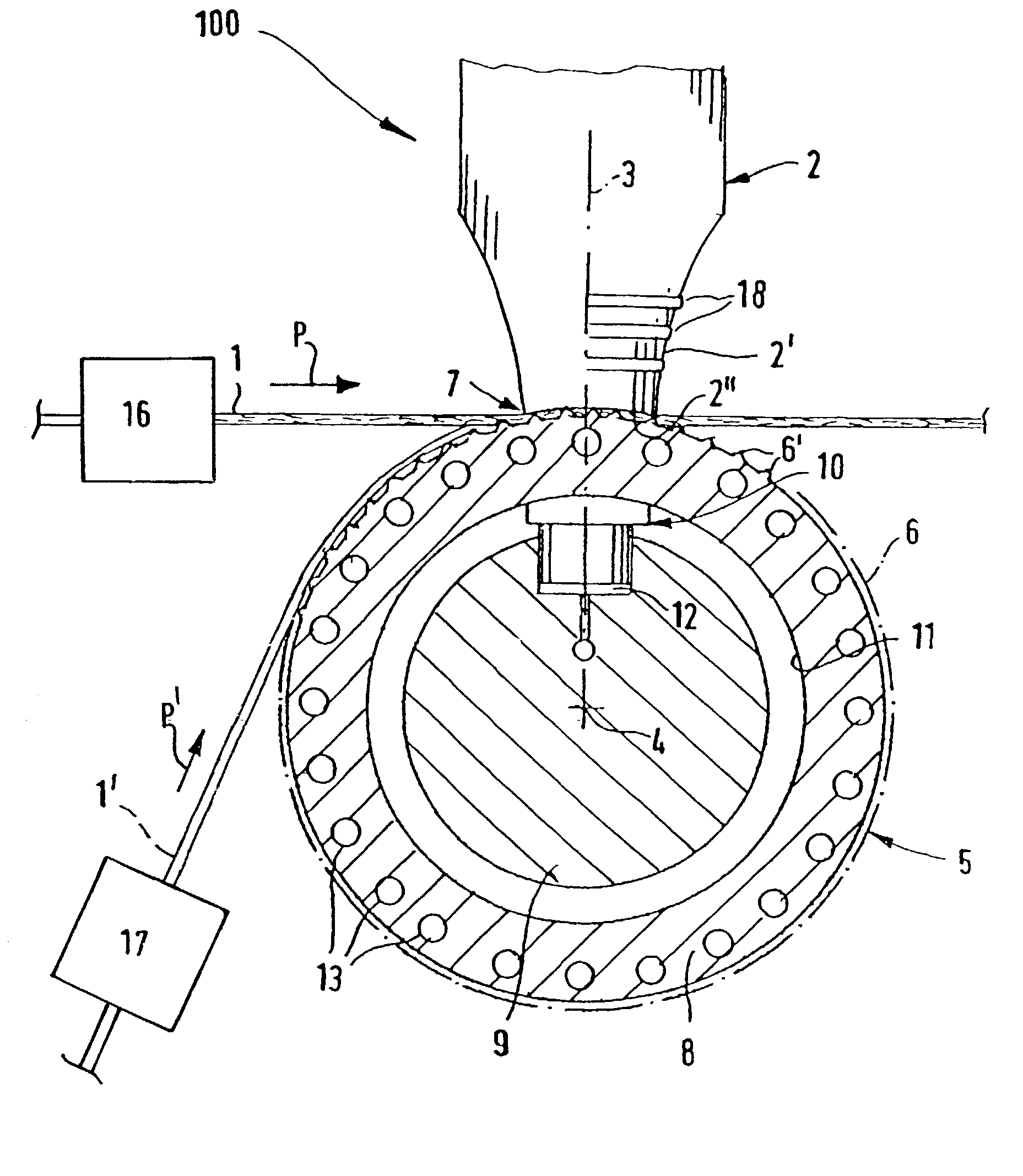

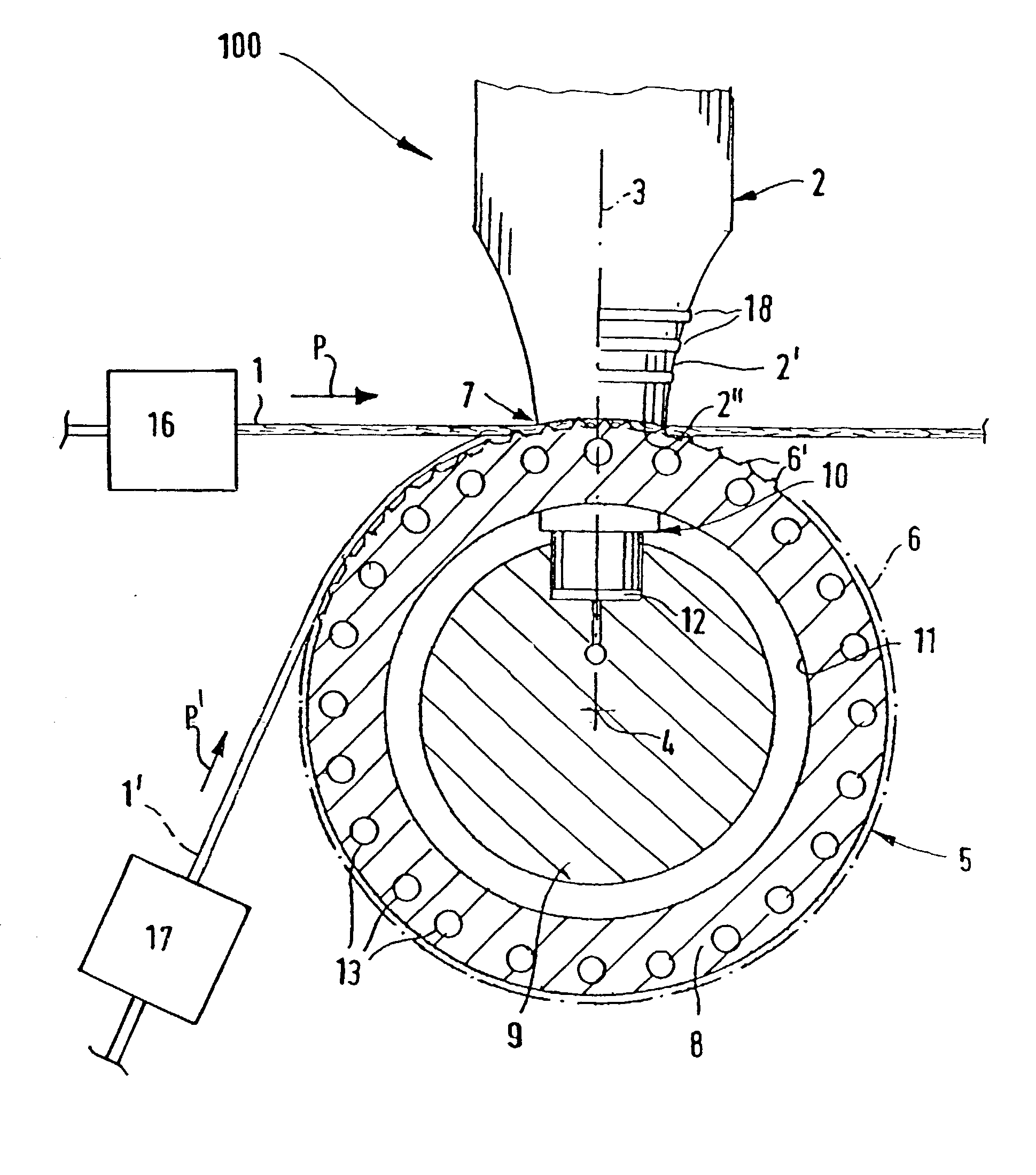

System for antiseptic surgery

InactiveUS6916296B2Cost advantageAlleviate patient painUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyMedicineProsthesis

A method is furnished for a treatment of septic wounds. A hand piece of a sonotrode is connected to a liquid storage. Access to a wound is furnished to the sonotrode. A liquid atomized by ultrasound is delivered to the wound through a sonotrode channel disposed in the sonotrode. Bacteria in the area of the wound are destroyed by the ultrasound emitted by the sonotrode. The method allows to remove a prosthesis not longer desired from a patient. The area left open by the removed prosthesis and / or a bone is filled with a liquid. The sonotrode is then entered into the liquid for propagating ultrasound through the liquid and thereby destroying bacteria present in the liquid.

Owner:SORING MEDIZINTECHN

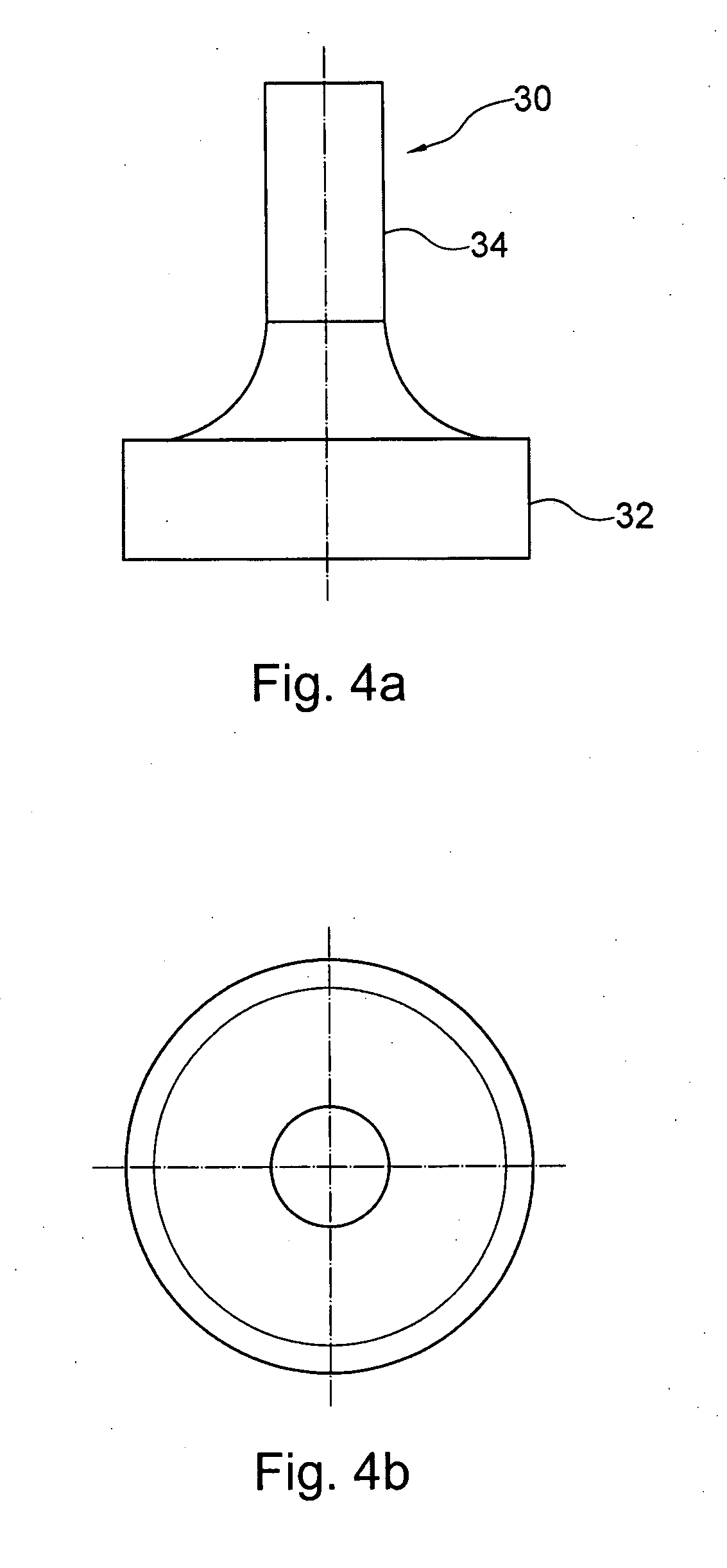

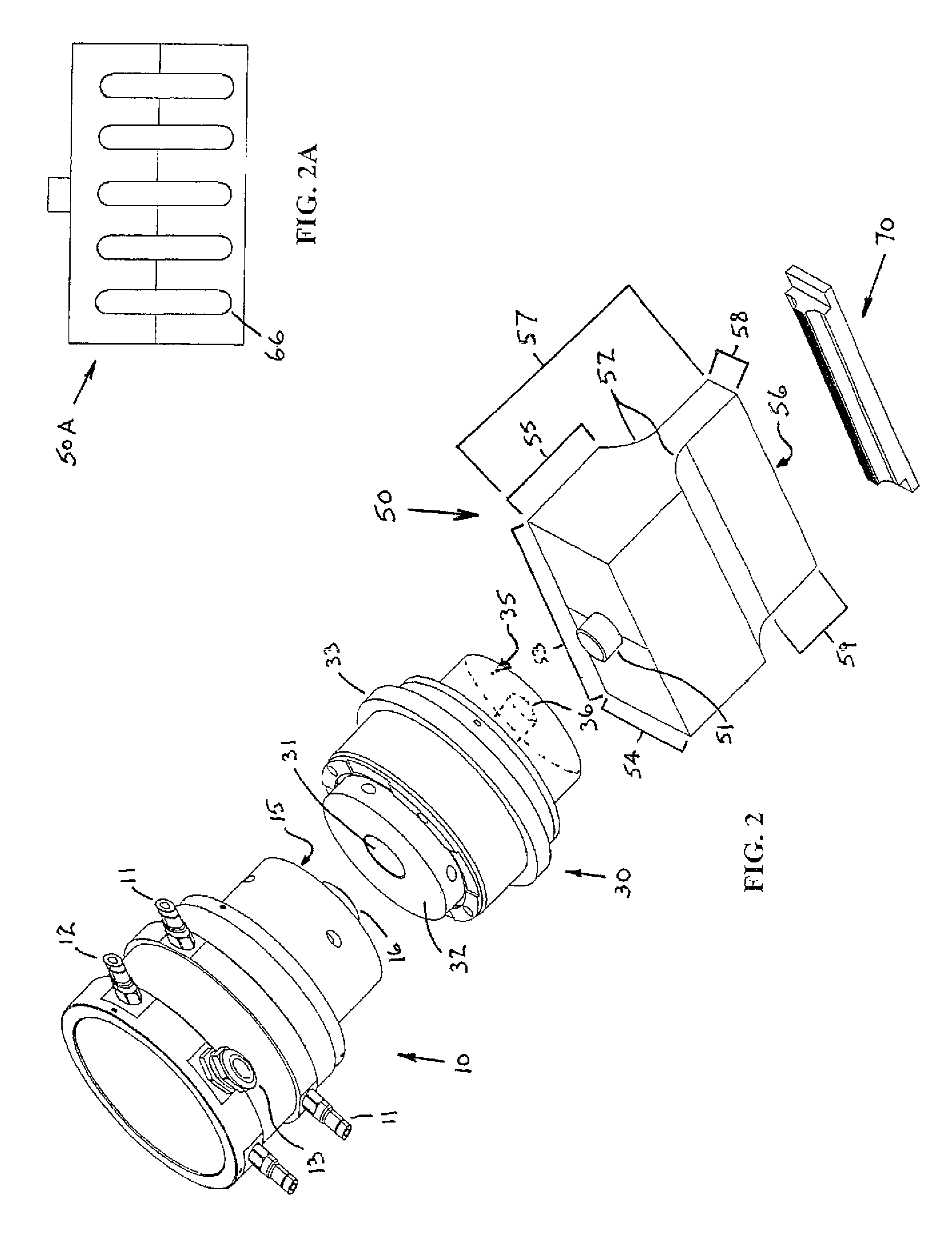

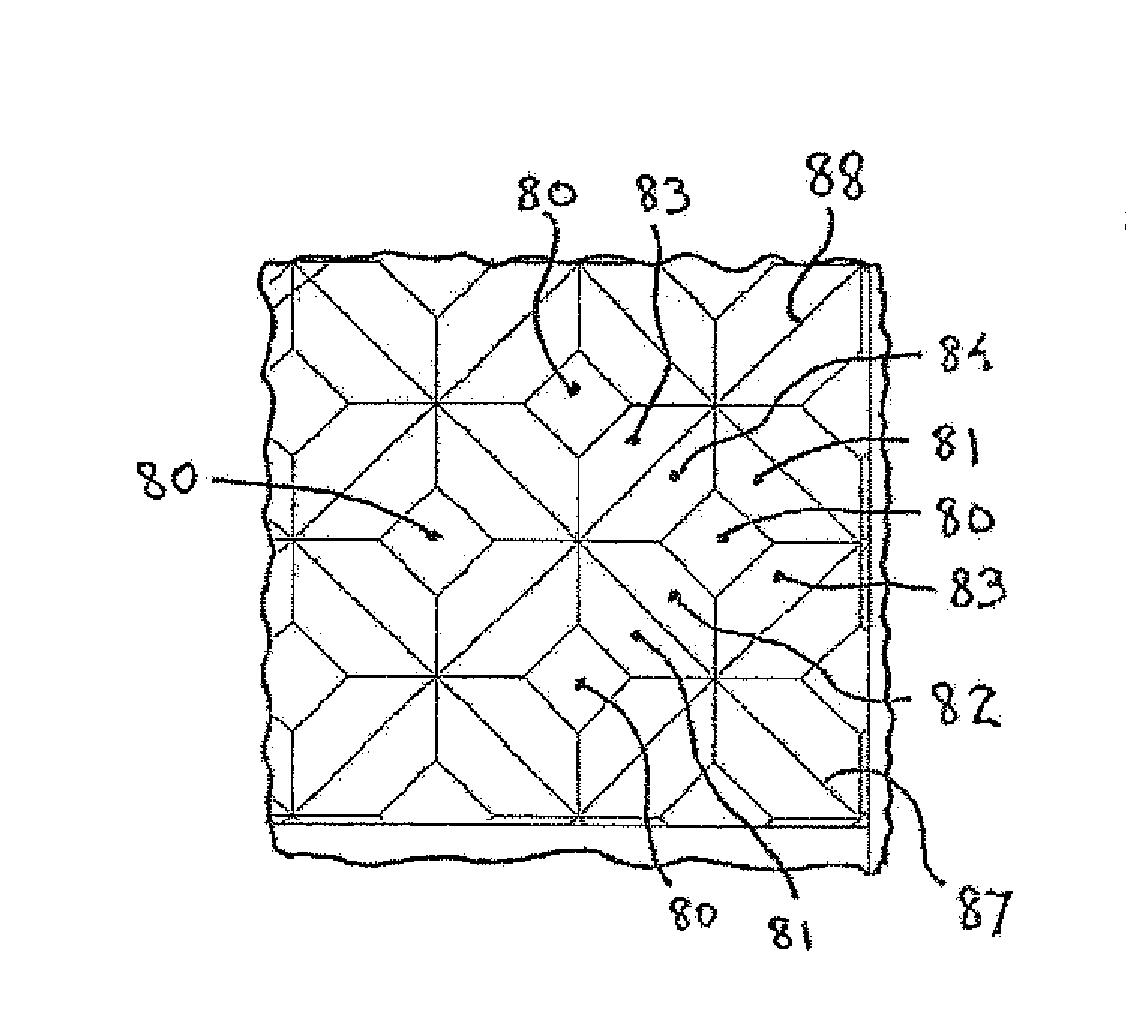

Sonotrode and anvil energy director grids for narrow/complex ultrasonic welds of improved durability

InactiveUS9278481B2Reduce material costsAdd equipmentLaminationLamination apparatusGrid patternEnergy control

A specially designed sonotrode and anvil are adapted to be used in combination for ultrasonic welding of work pieces, to produce a narrower weld region, but one exhibiting greater durability, thereby permitting use of less packaging material. The contact surfaces comprise a surface of the anvil having a plurality of energy directors, where the plurality of energy directors are arranged into a three-dimensional grid pattern to be capable of distributed vibration-transmissive contact. The energy directors may comprise a series of plateau surfaces being regularly spaced apart from each other in a first direction, and in a second direction that is orthogonal to the first direction, to form the grid pattern. The rectangular-shaped plateaus may be spaced apart by valleys. Engagement of the energy directors of the anvil with the corresponding surface of the sonotrode may cause minor elastic deformation of work pieces positioned therebetween prior to ultrasonic welding.

Owner:RINCO ULTRASONICS USA

Apparatus for producing scored lines in a film

InactiveUS20050209076A1Reduce operating costsReduce investmentEnvelopes/bags making machineryMechanical working/deformationBearing surfaceBiomedical engineering

The present invention makes it possible to produce at least one scored line in at least one plastic outer layer of a film. The device of the invention includes bearing surface for the film and at least one projection for forming the scored line by penetration of the projection into the plastic layer when the film is in position against the said bearing surface. The projections may be arranged in the form of ribs on one or more coaxial rollers. The projections may form the scored line by ultrasonic plastic flow, the film being compressed between a sonotrode and the rollers. The invention provides methods using these devices and it also provides films having scored lines, and packages having scored lines.

Owner:MARS INC

Device and method for preparing a recess in a bone

InactiveUS20080269649A1Avoid necessityAvoid interferences from occurringChiropractic devicesVaccination/ovulation diagnosticsPunchingEngineering

A punching device for preparing a recess in a bone has a punching tool usable for such a punching device. An implant usable with the punching tool is provided and a method for preparing a recess in a bone are disclosed. The punching device comprises an ultrasonic sonotrode and a punching tool which is fixable to the sonotrode at its proximal extremity. At its distal extremity, the punching tool has a thin-walled portion having a non-rotational symmetric cross-section. By ultrasonic vibration of the punching tool, the thin-walled portion can be forced into a bone thereby preparing a recess of which is not rotationally symmetric. Subsequently, an implant can be held in such recess. Due to its lack of rotational symmetry, the implant may absorb rotational forces around its longitudinal axis.

Owner:STRYKER EURO OPERATIONS HLDG LLC +1

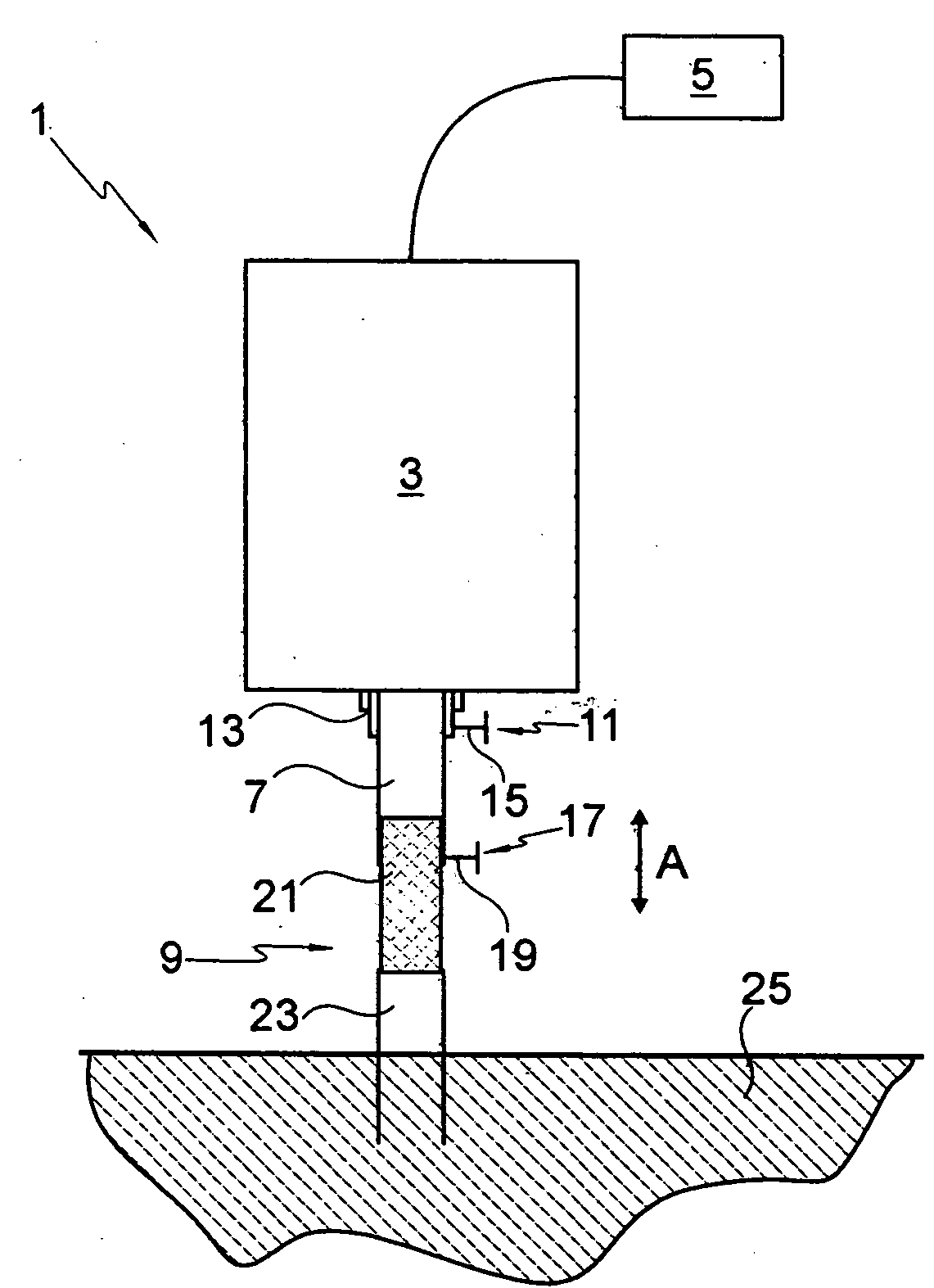

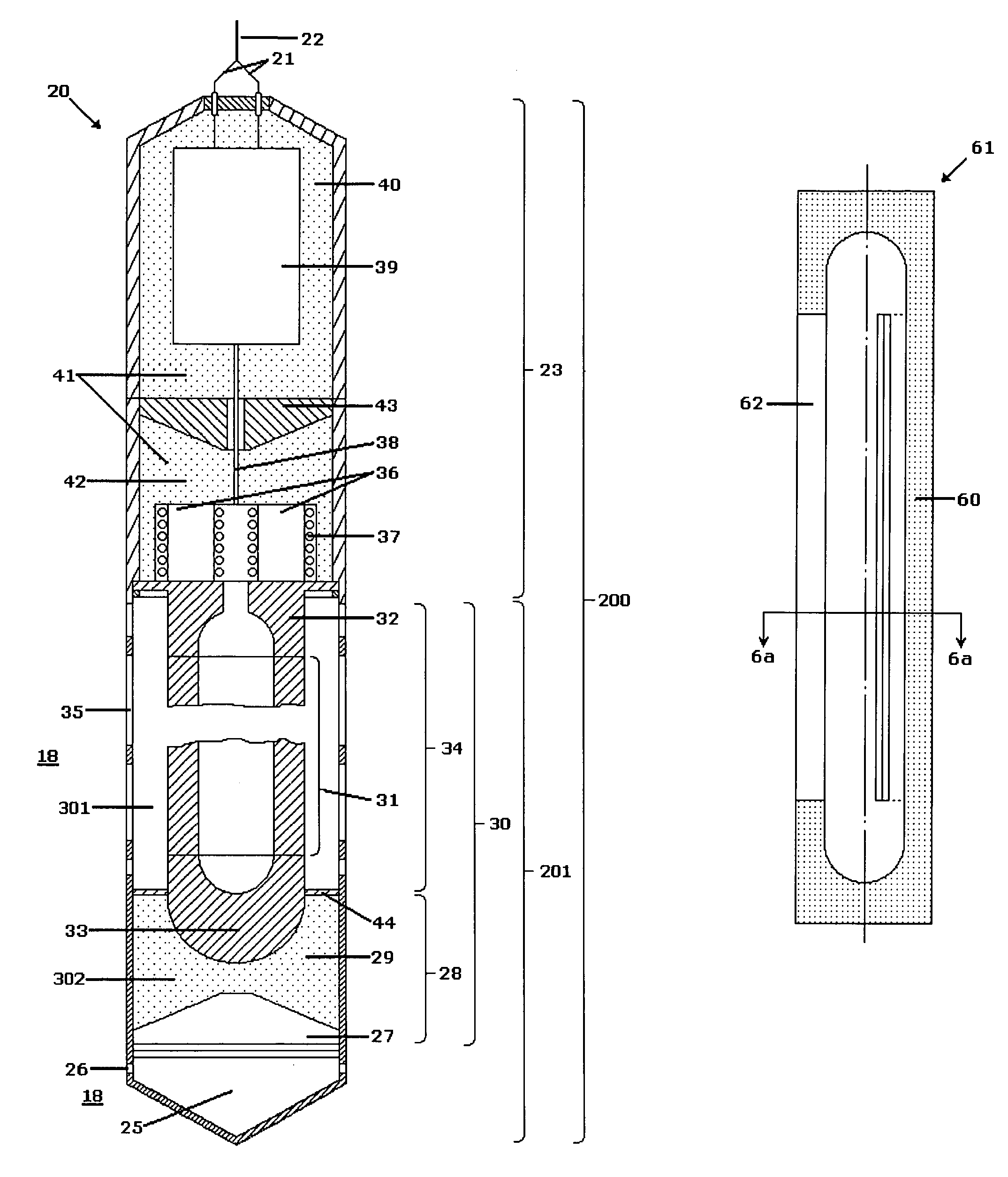

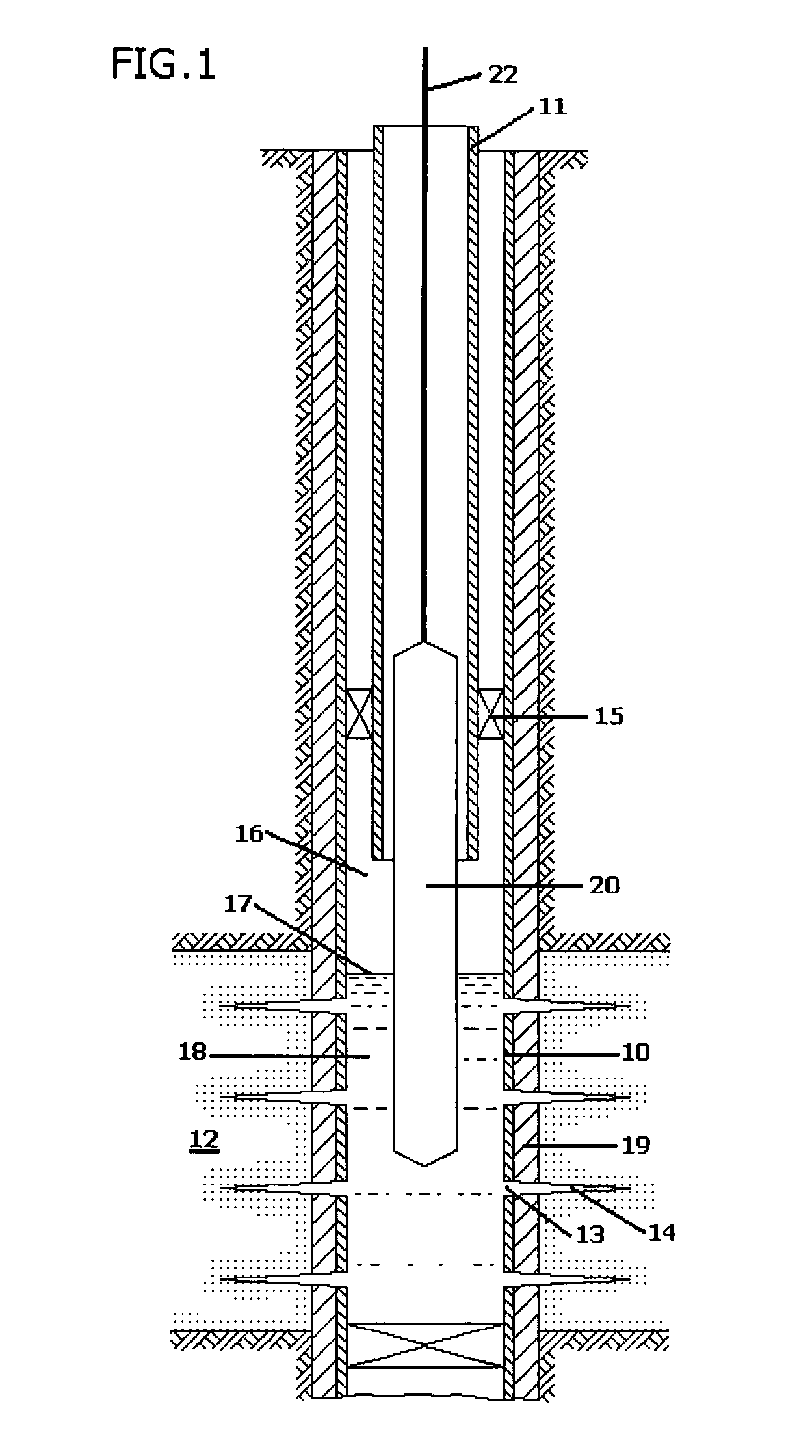

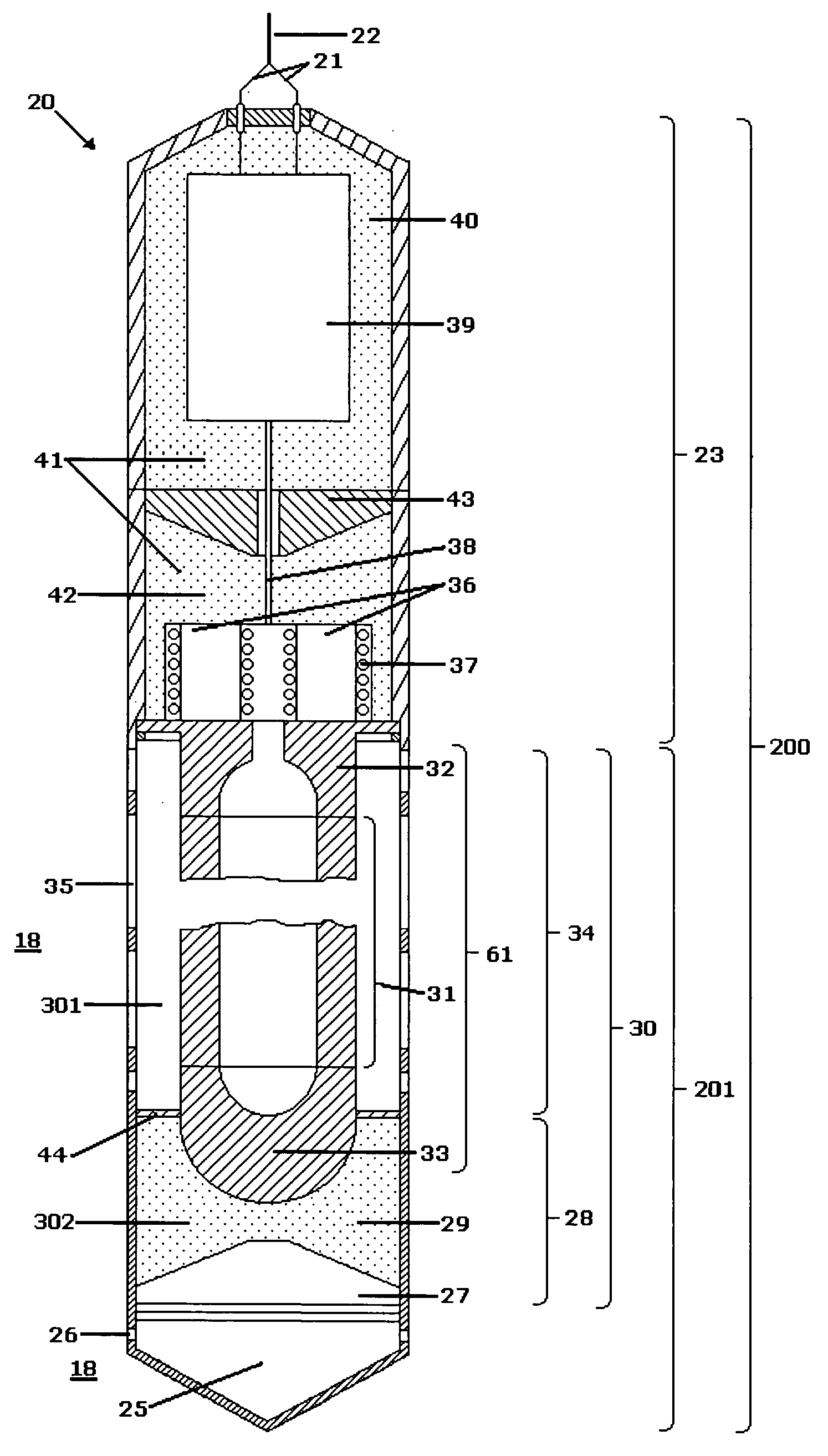

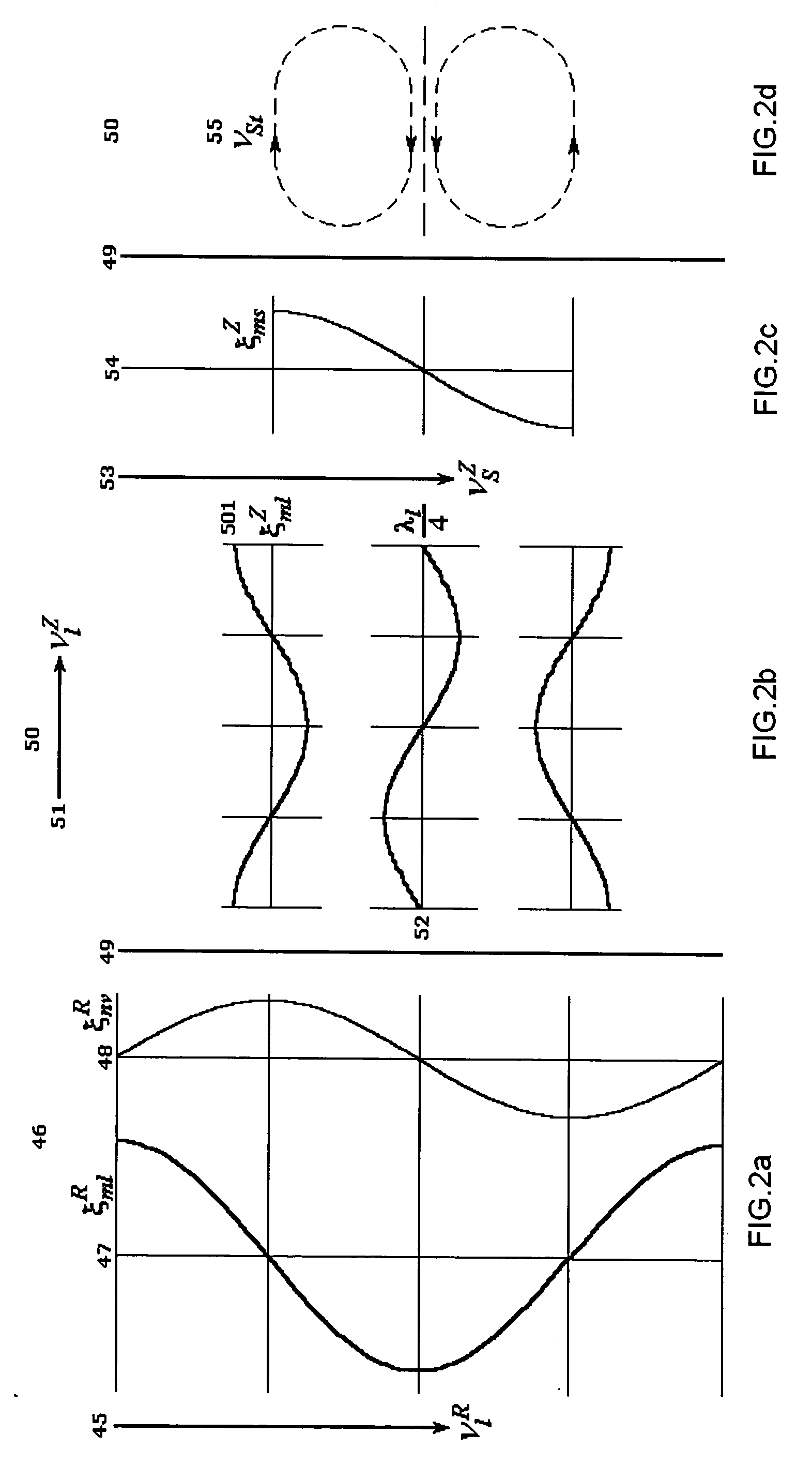

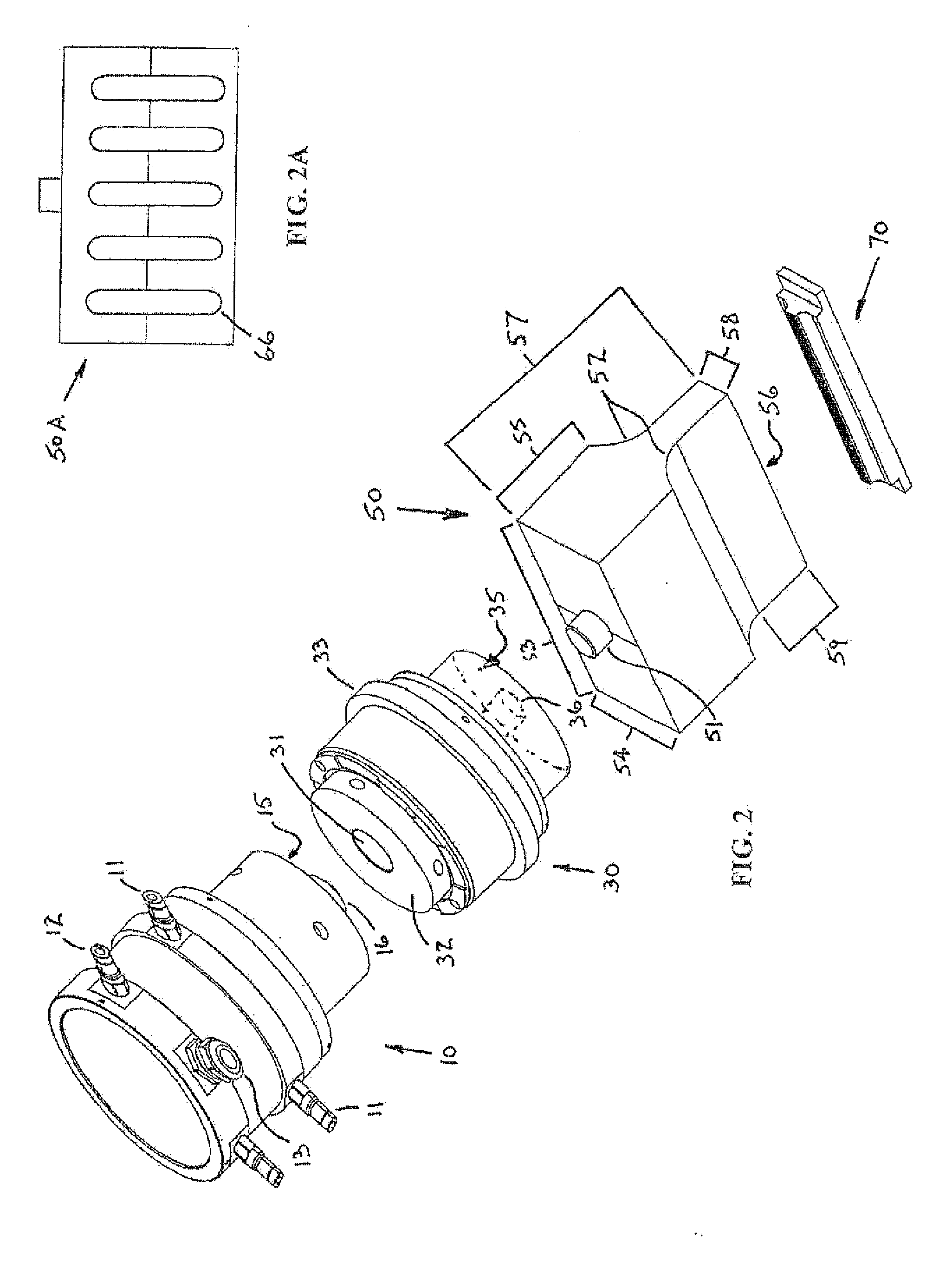

Acoustic well recovery method and device

InactiveUS7063144B2Highly efficient acousticImprove liquidityFluid removalVibration devicesRecovery methodRestoration method

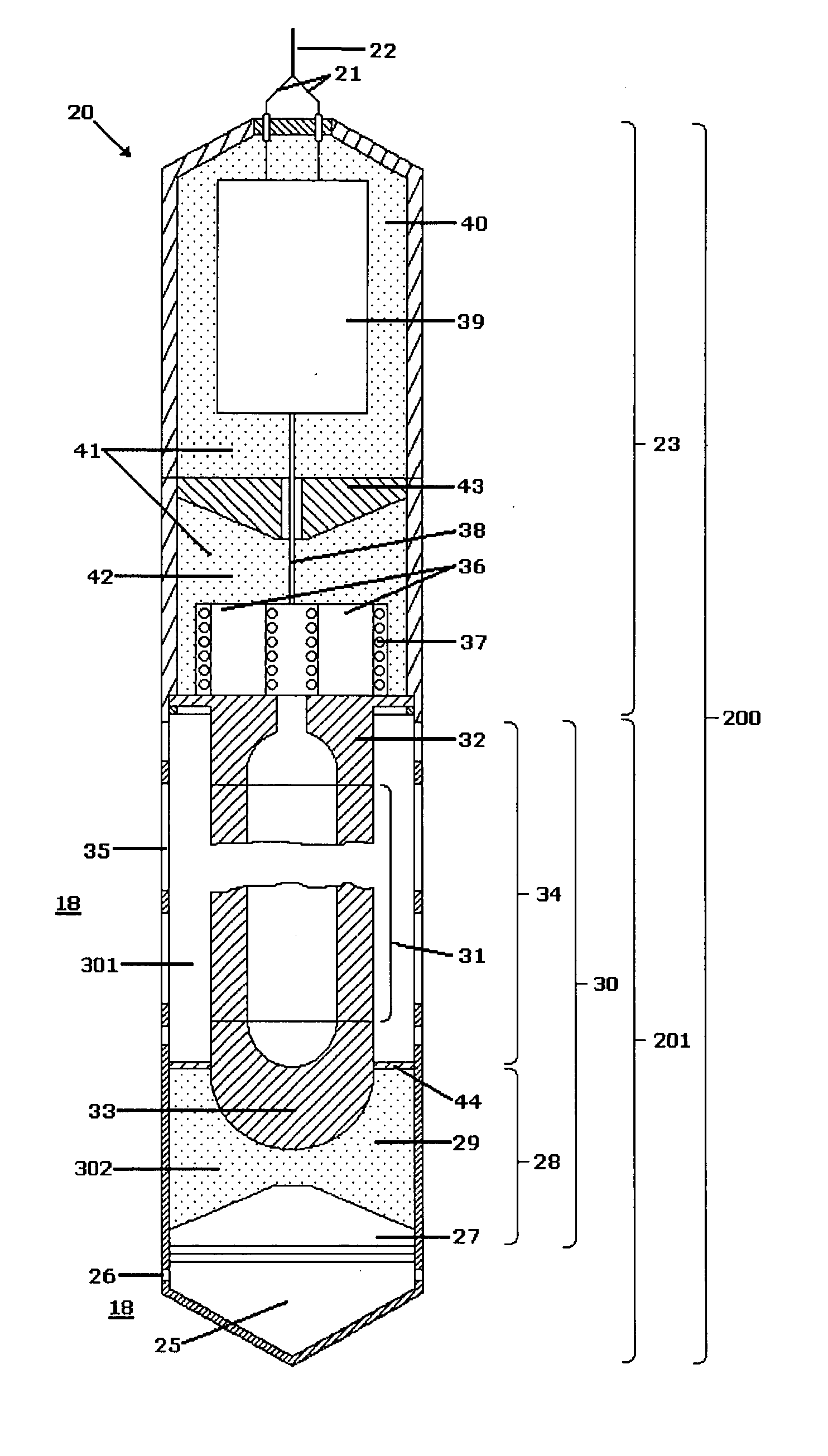

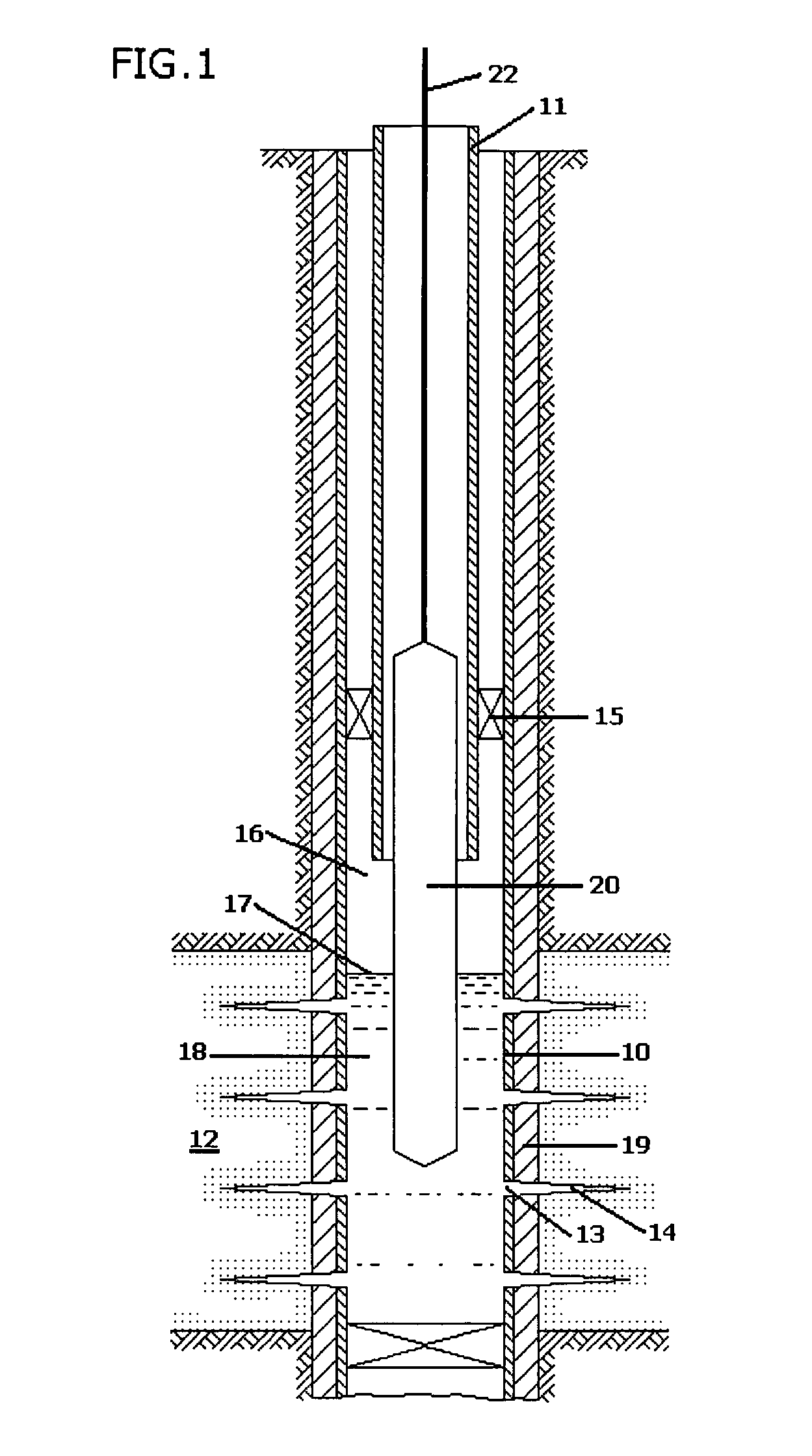

An electro acoustic device and related method for increasing the production capacity of wells that contains oil, gas and / or water is disclosed. The electro acoustic device is submerged in the well producing zone, and includes an electric generator, one or more electro acoustic transducers, and one or more wave guide systems (sonotrodes) that include radiators which transmit vibrations into the medium under treatment. The electro acoustic device produces vibrations that stimulate the occurrence of mass transfer processes within the well. According to one or more embodiments, shear vibrations are produced in the well bore region due to the phase displacement of mechanical vibrations produced along the axis of the well, achieving alternate tension and pressure due to the superposition of longitudinal and shear waves.

Owner:SONOPLUS

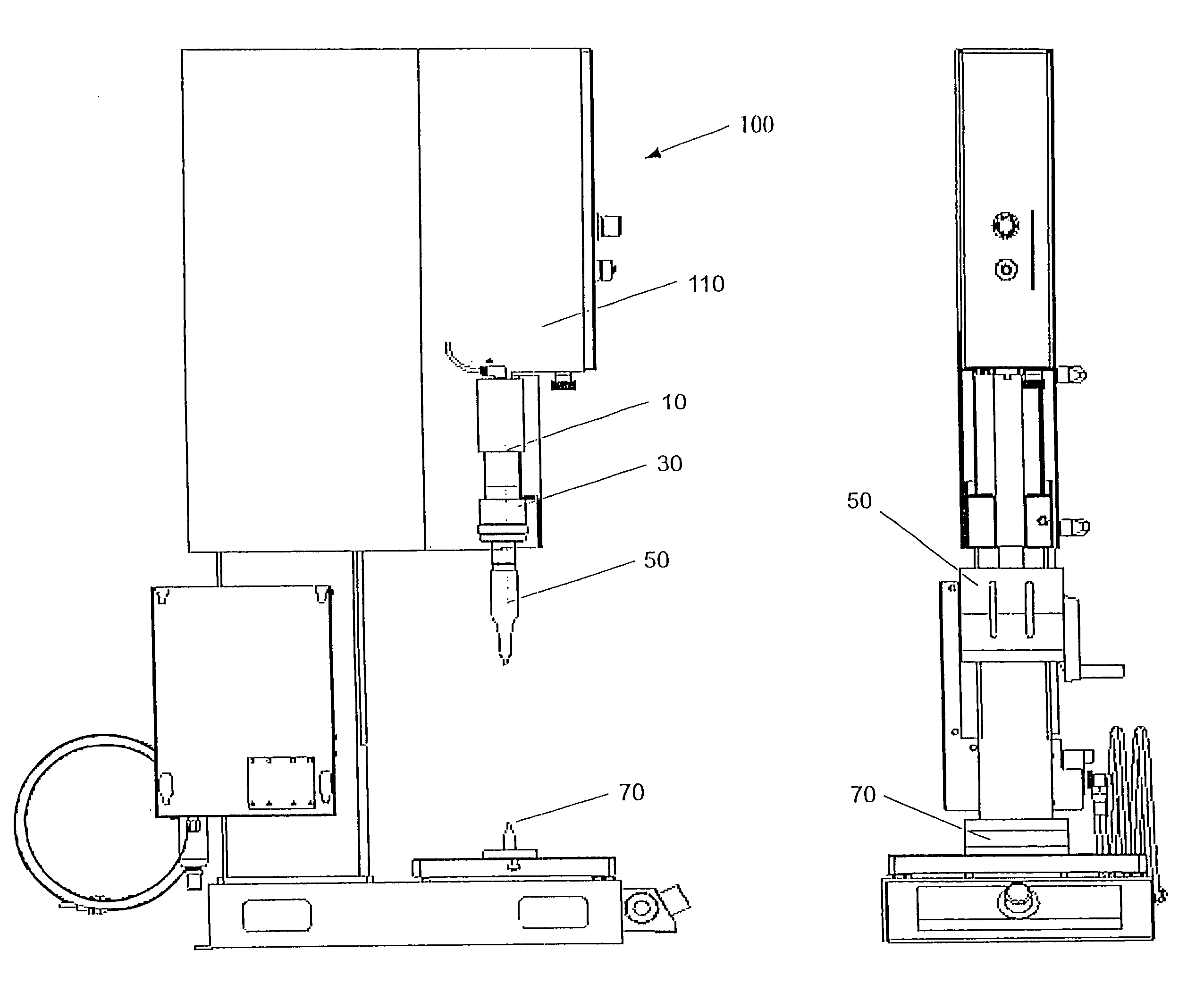

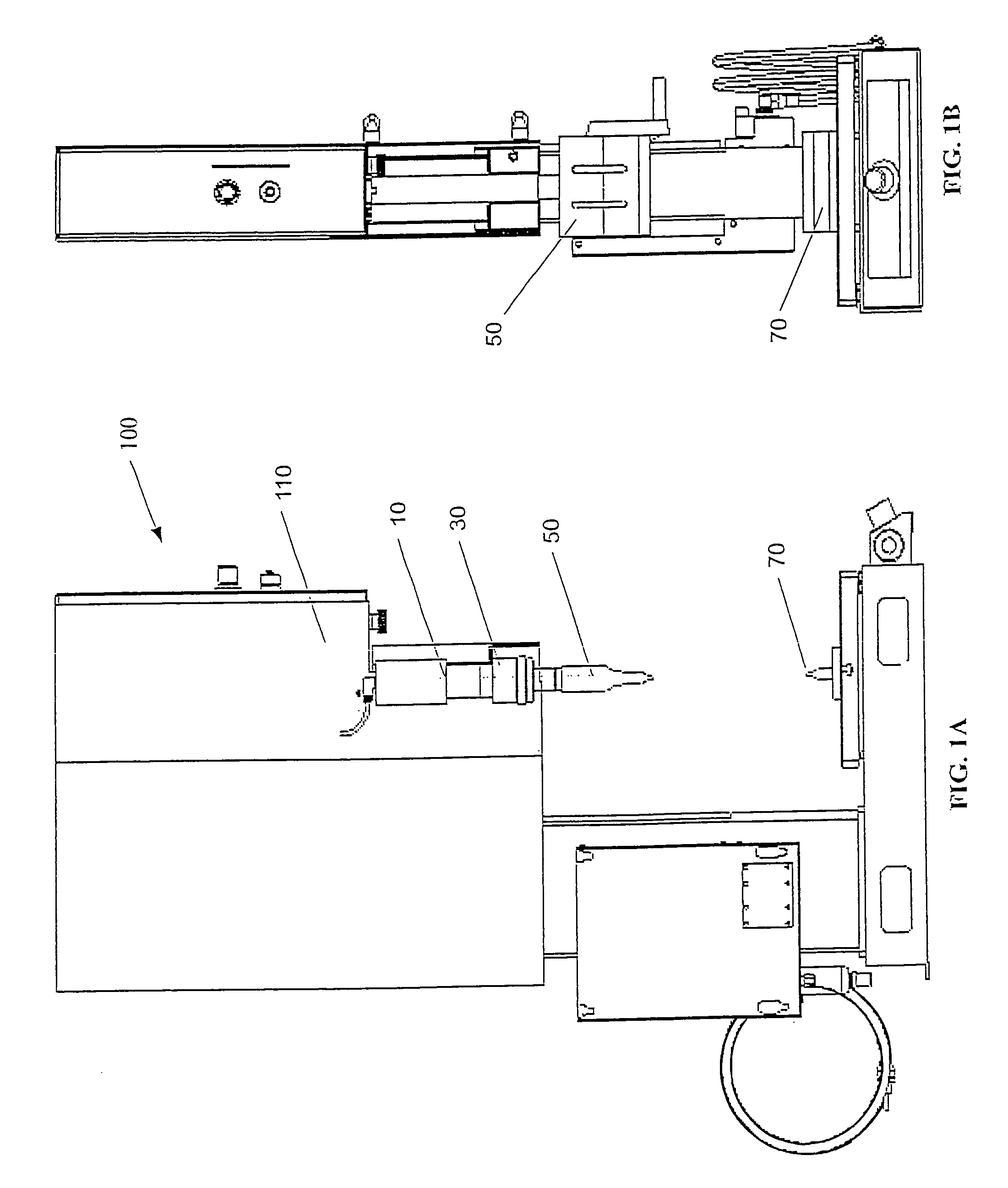

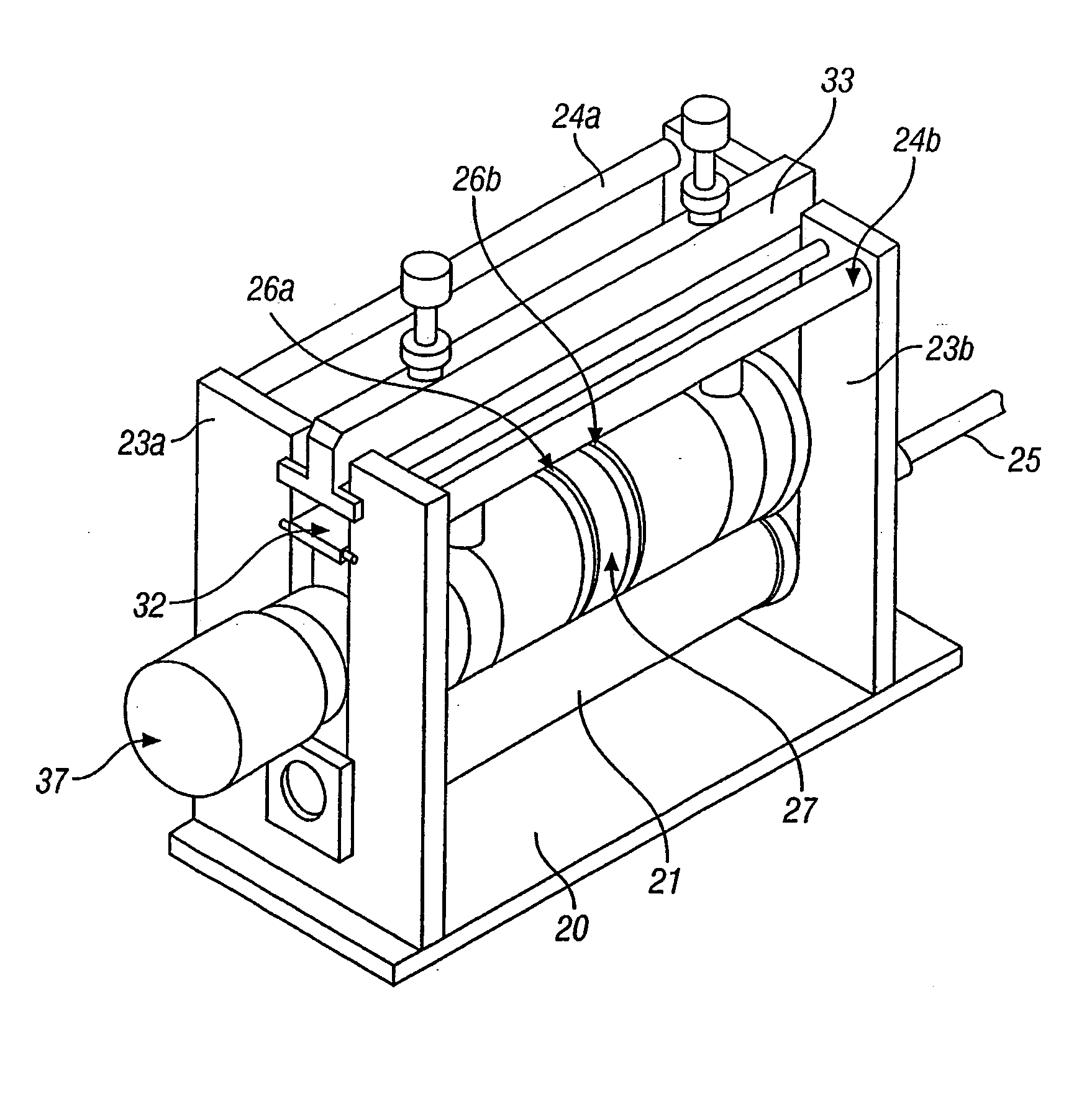

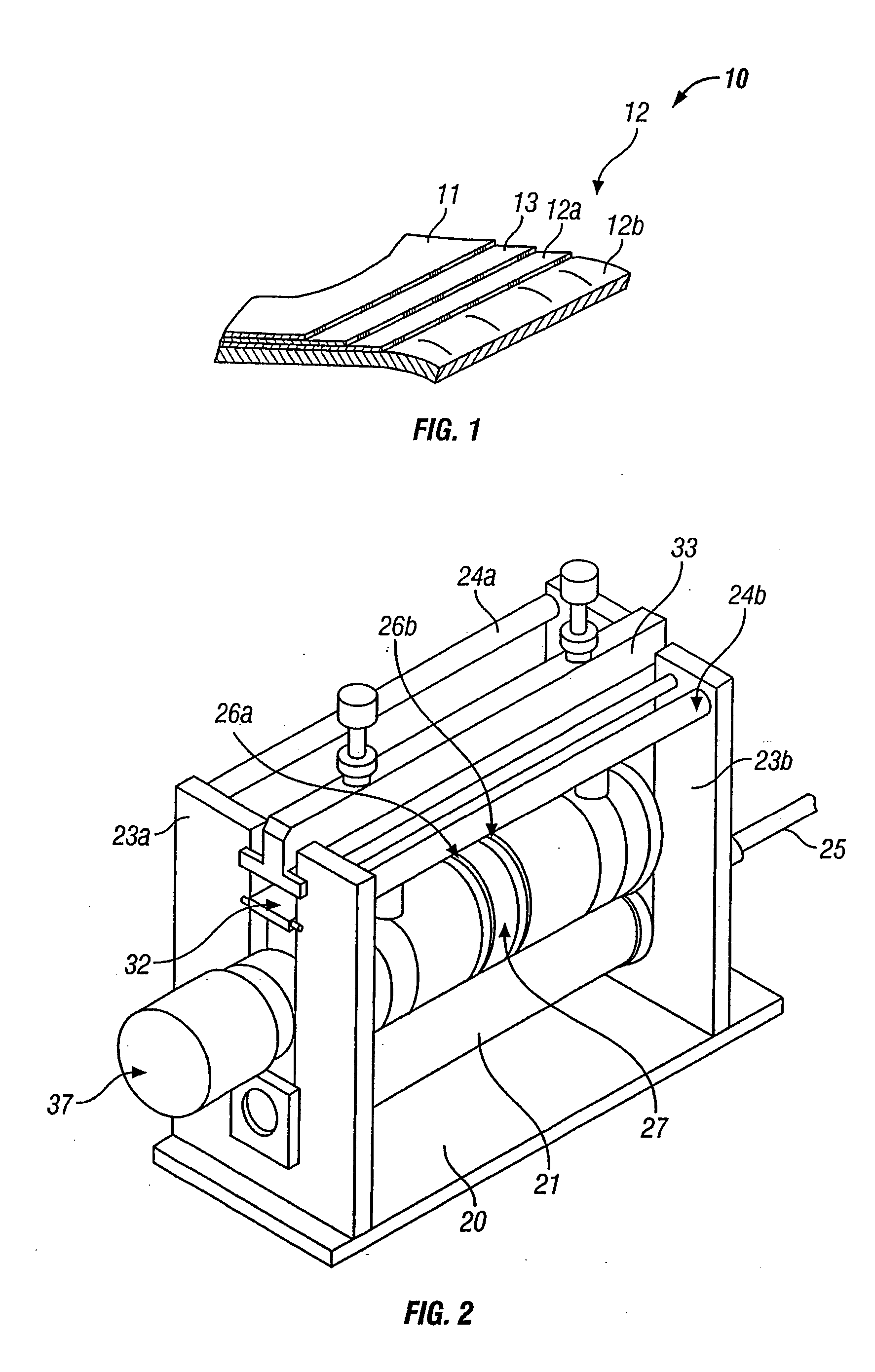

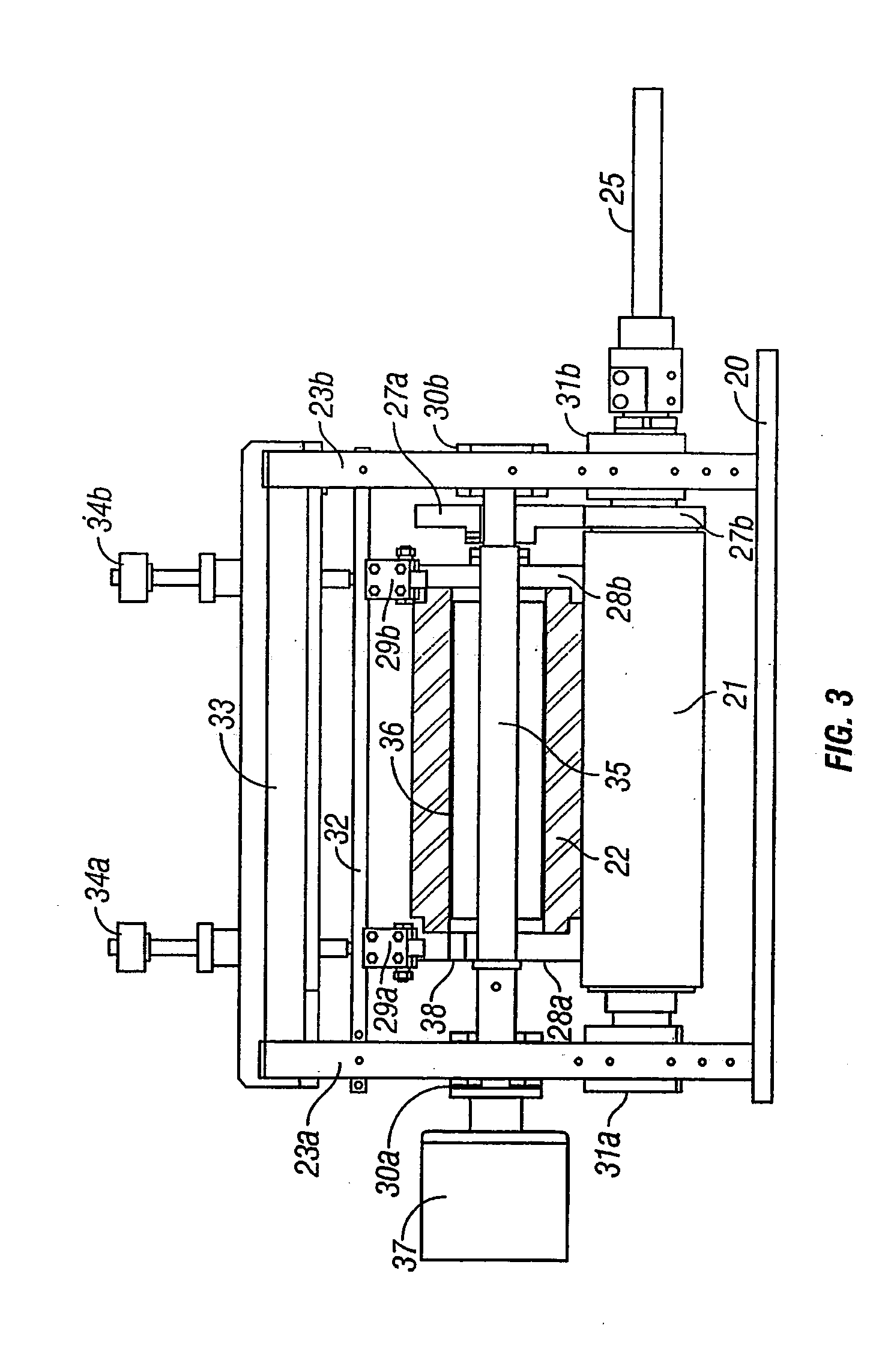

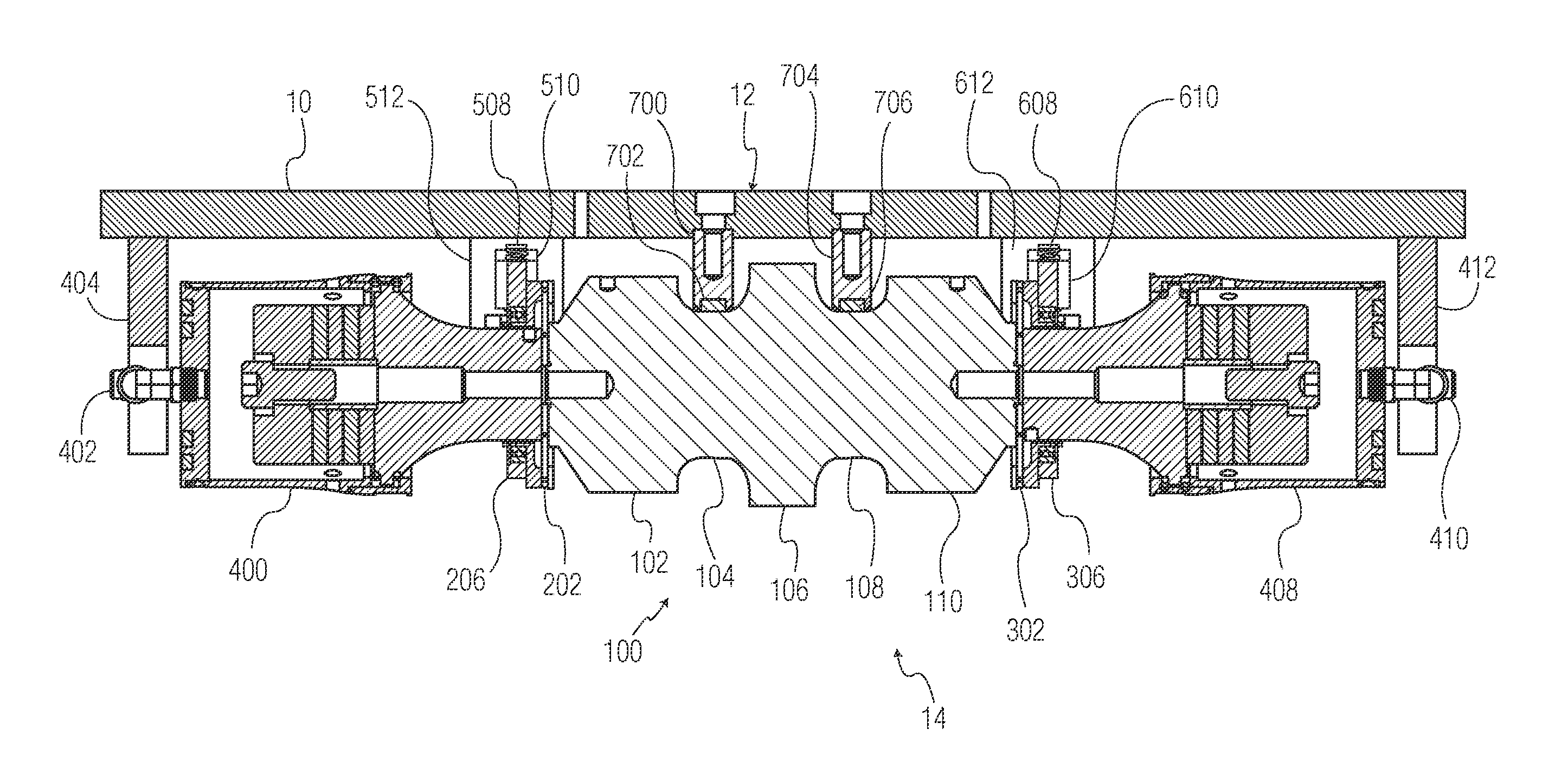

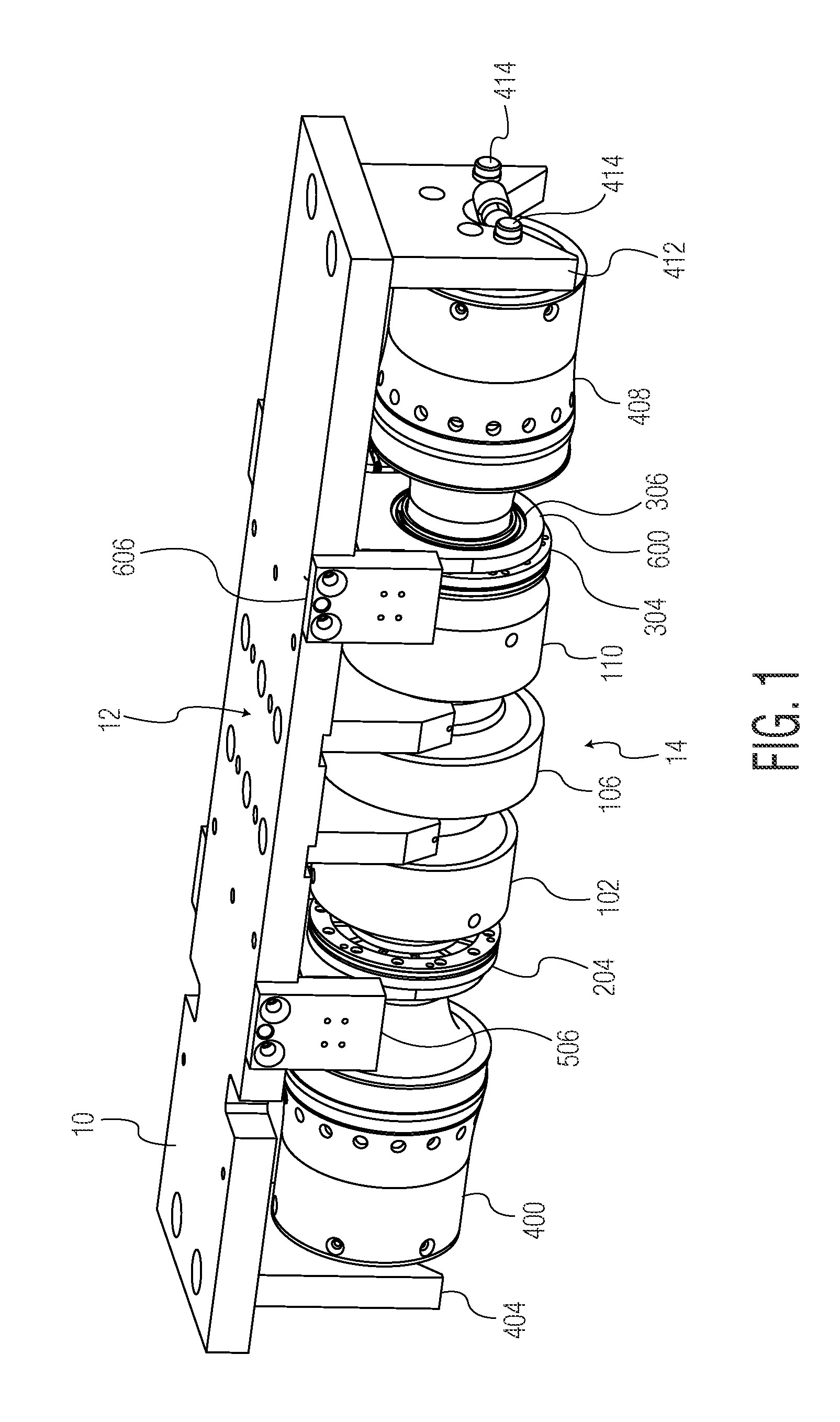

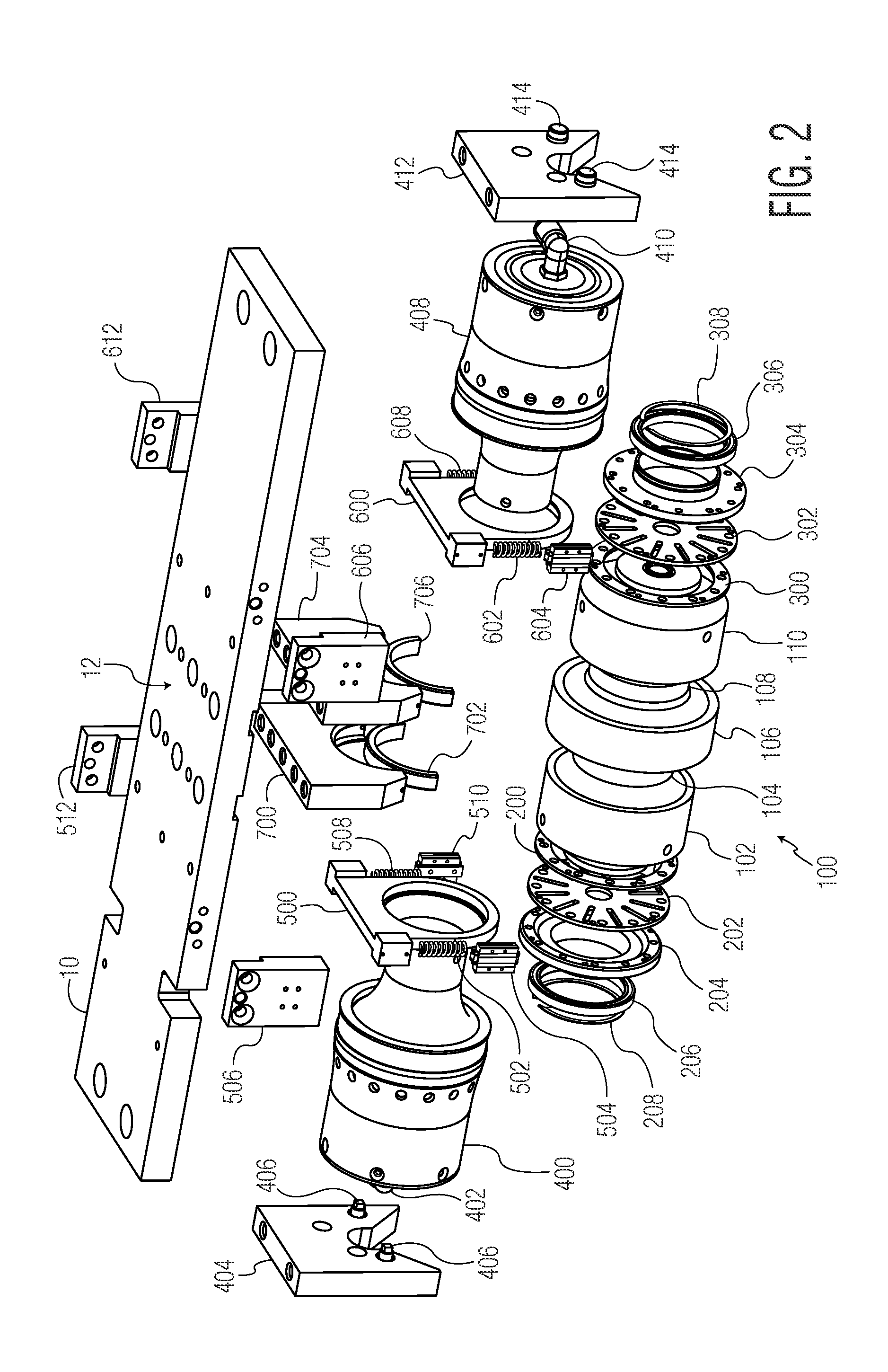

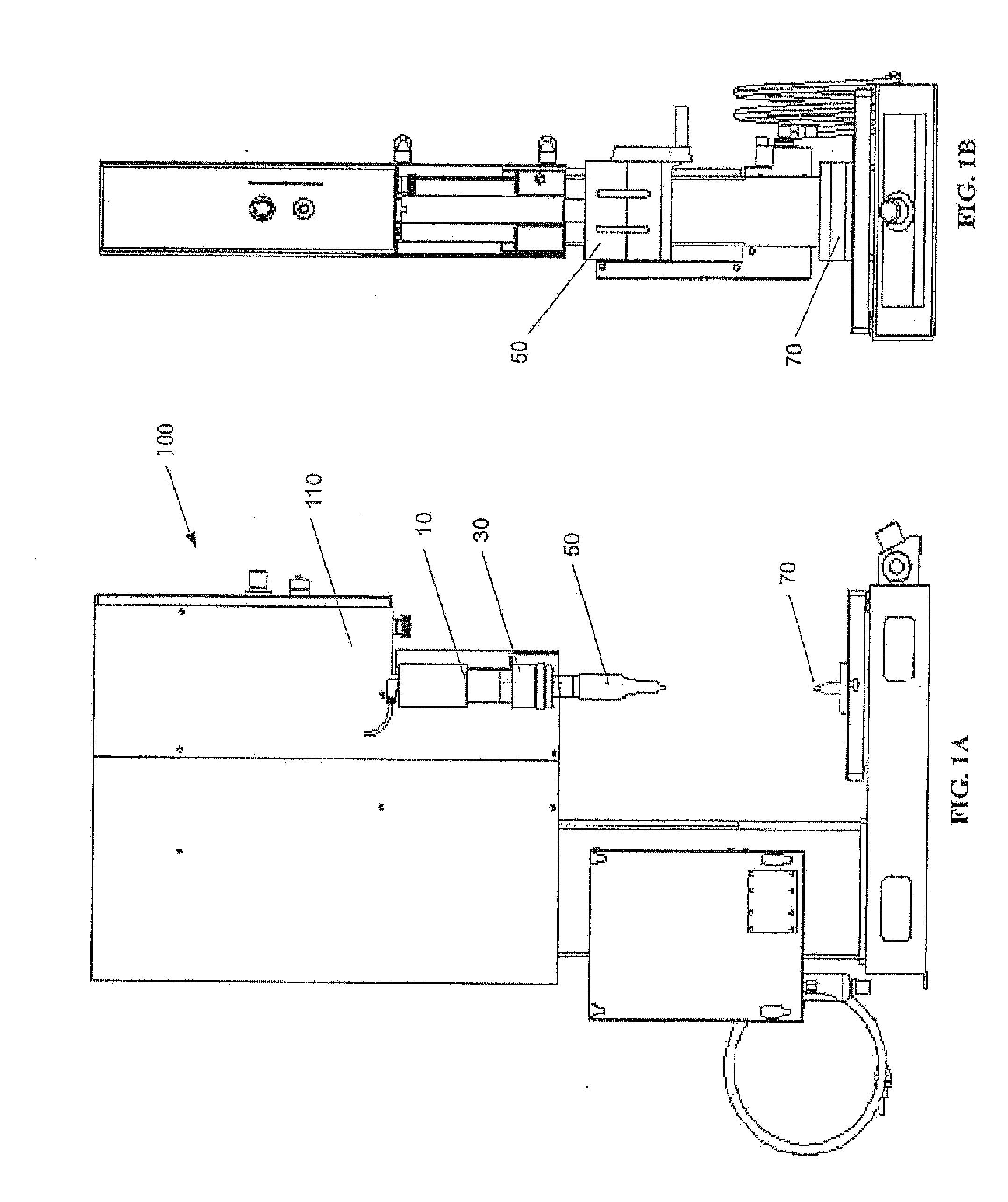

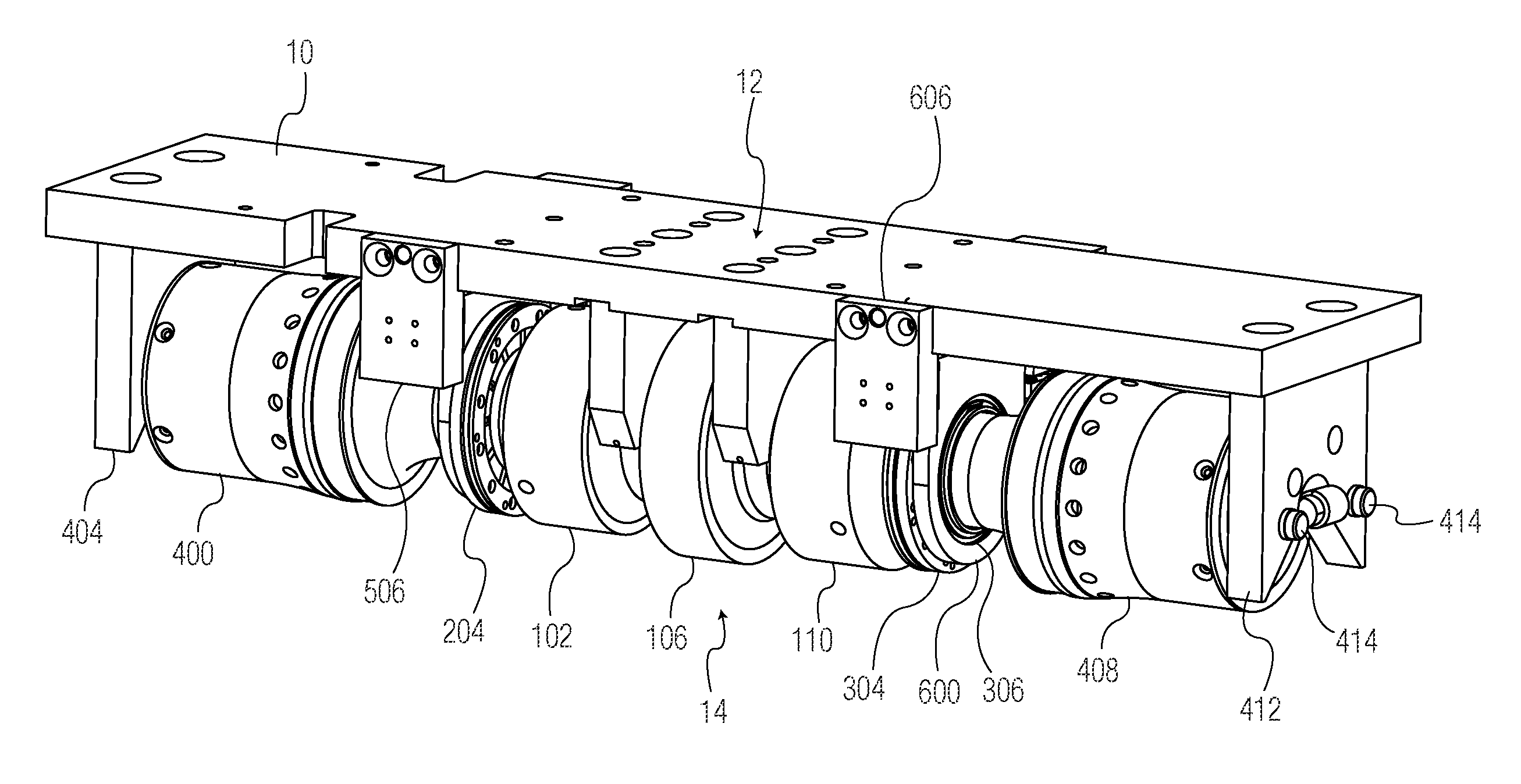

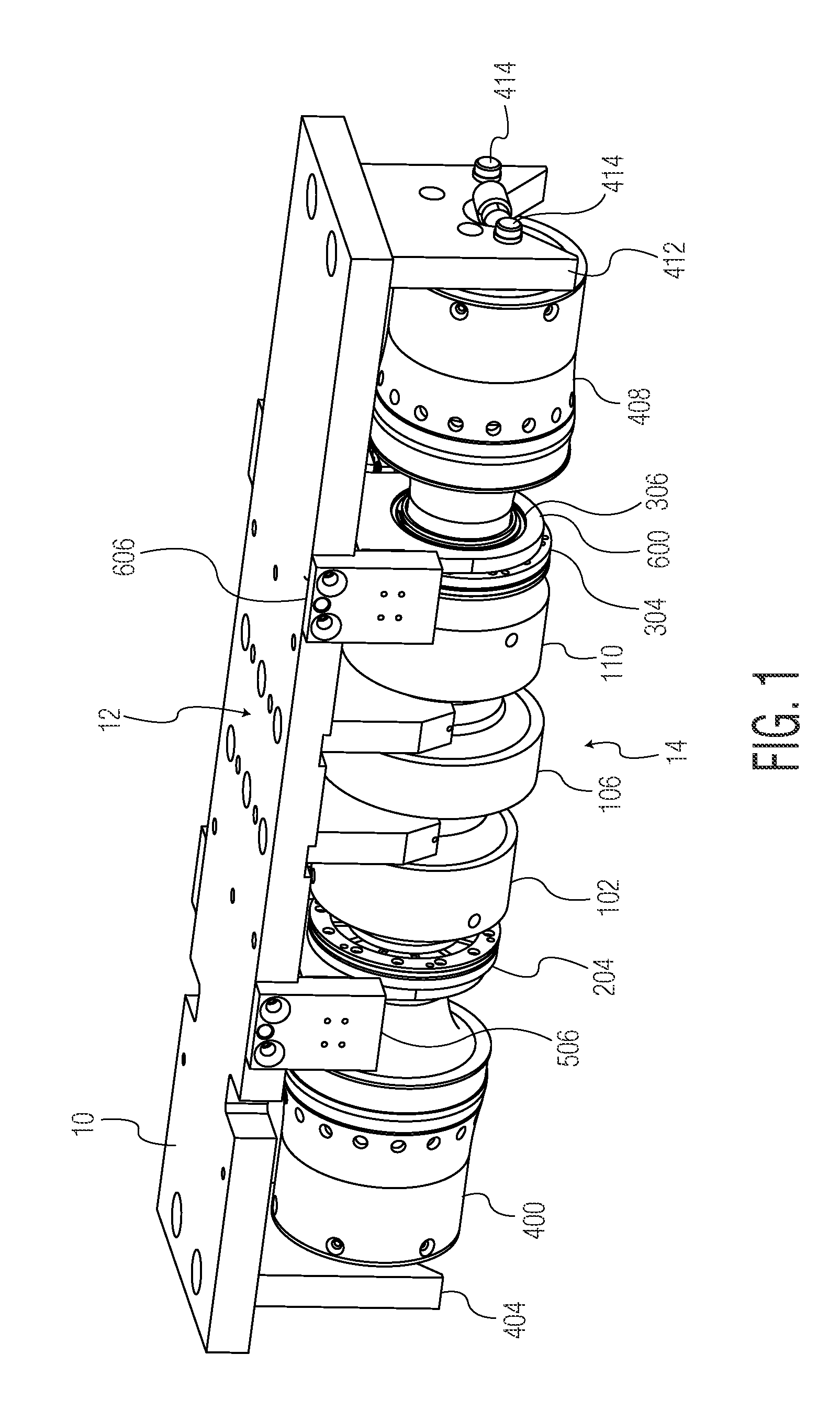

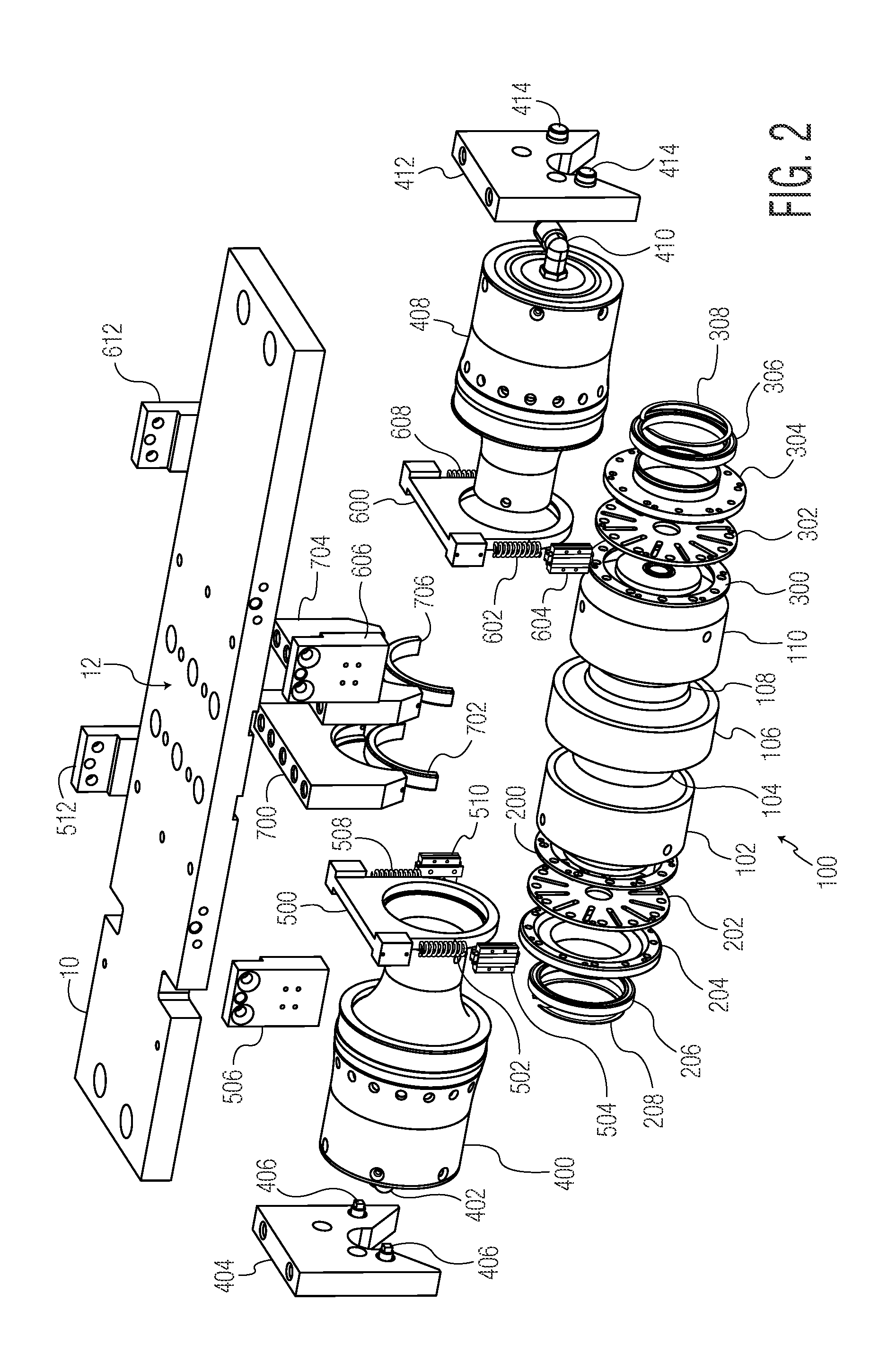

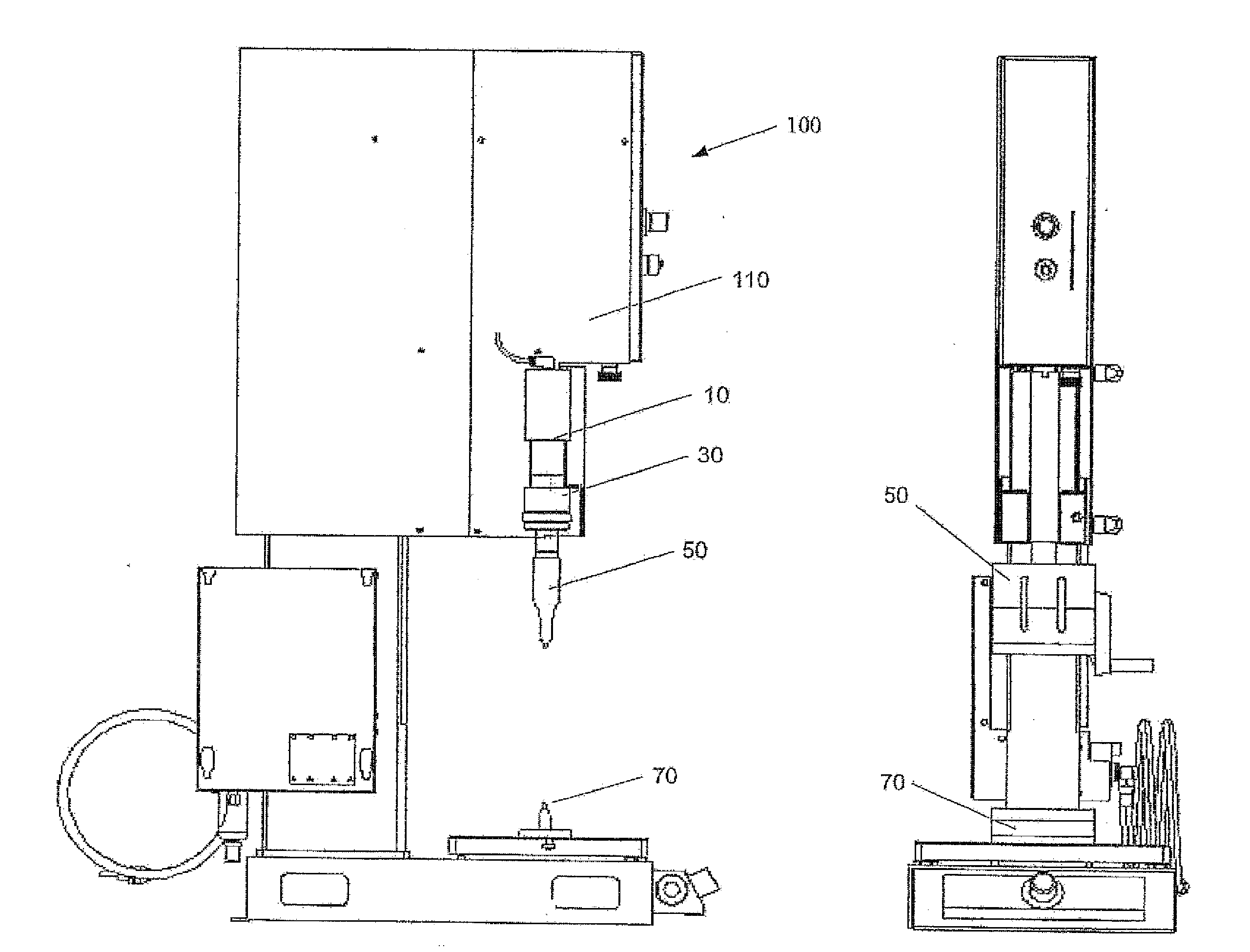

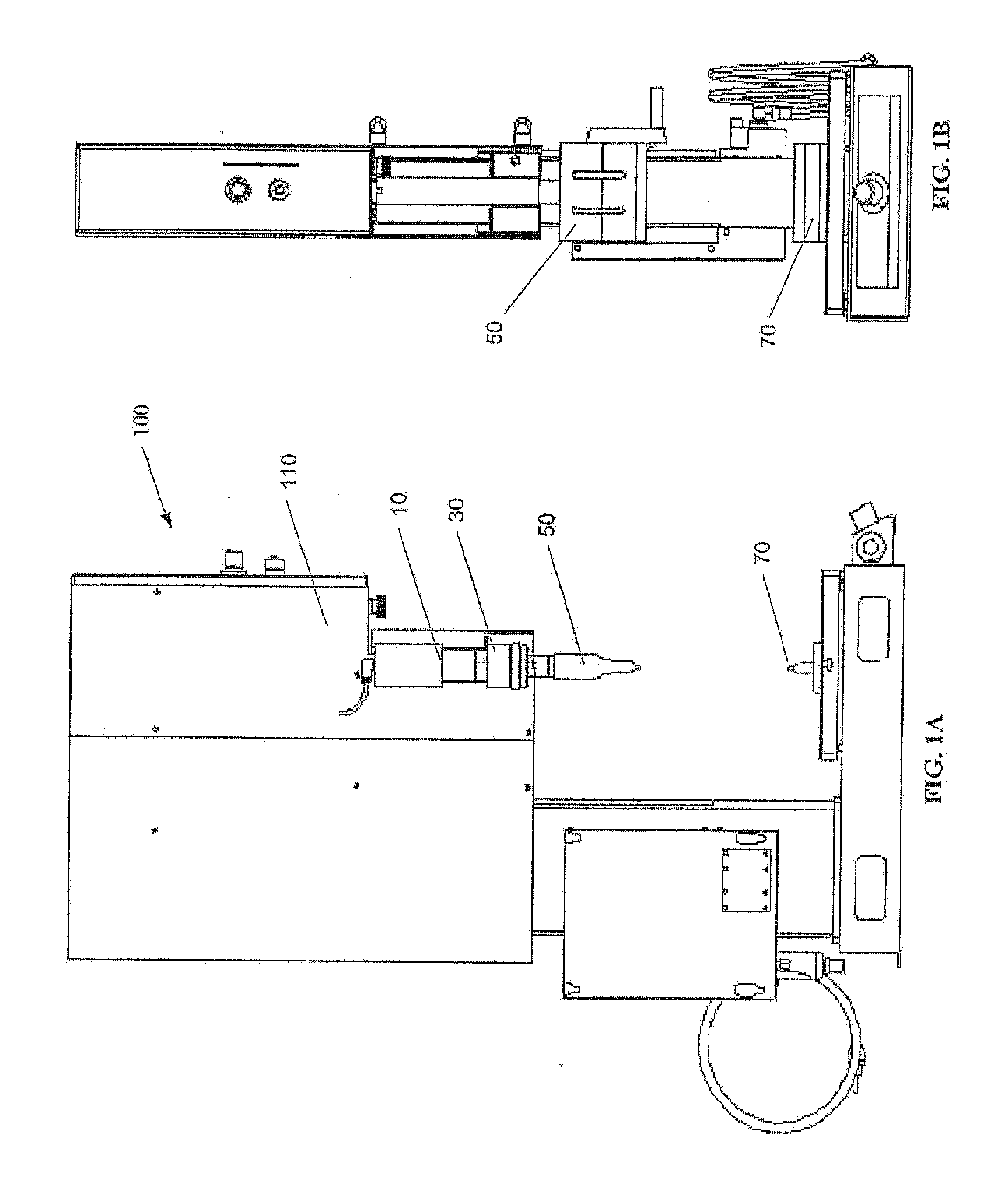

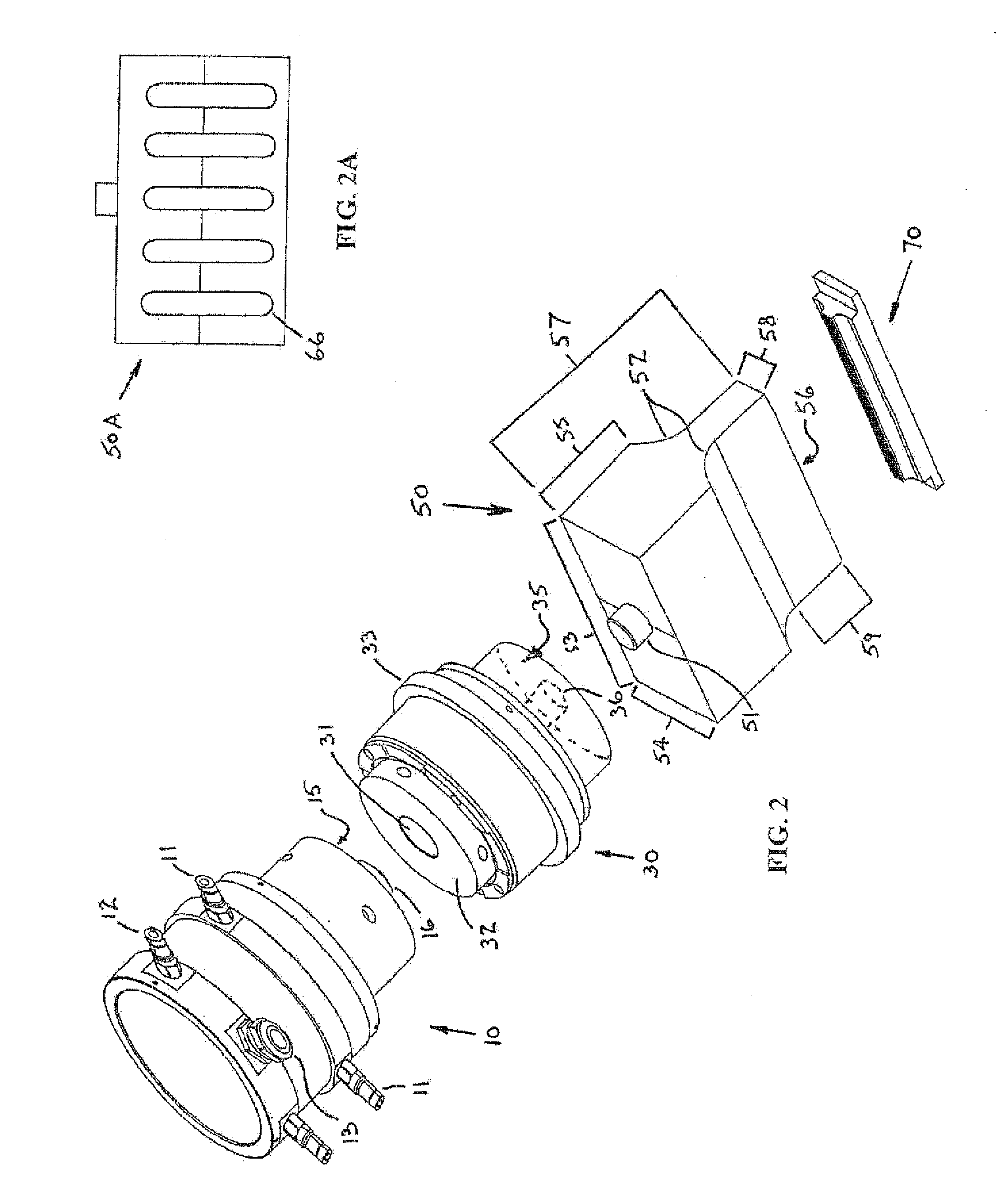

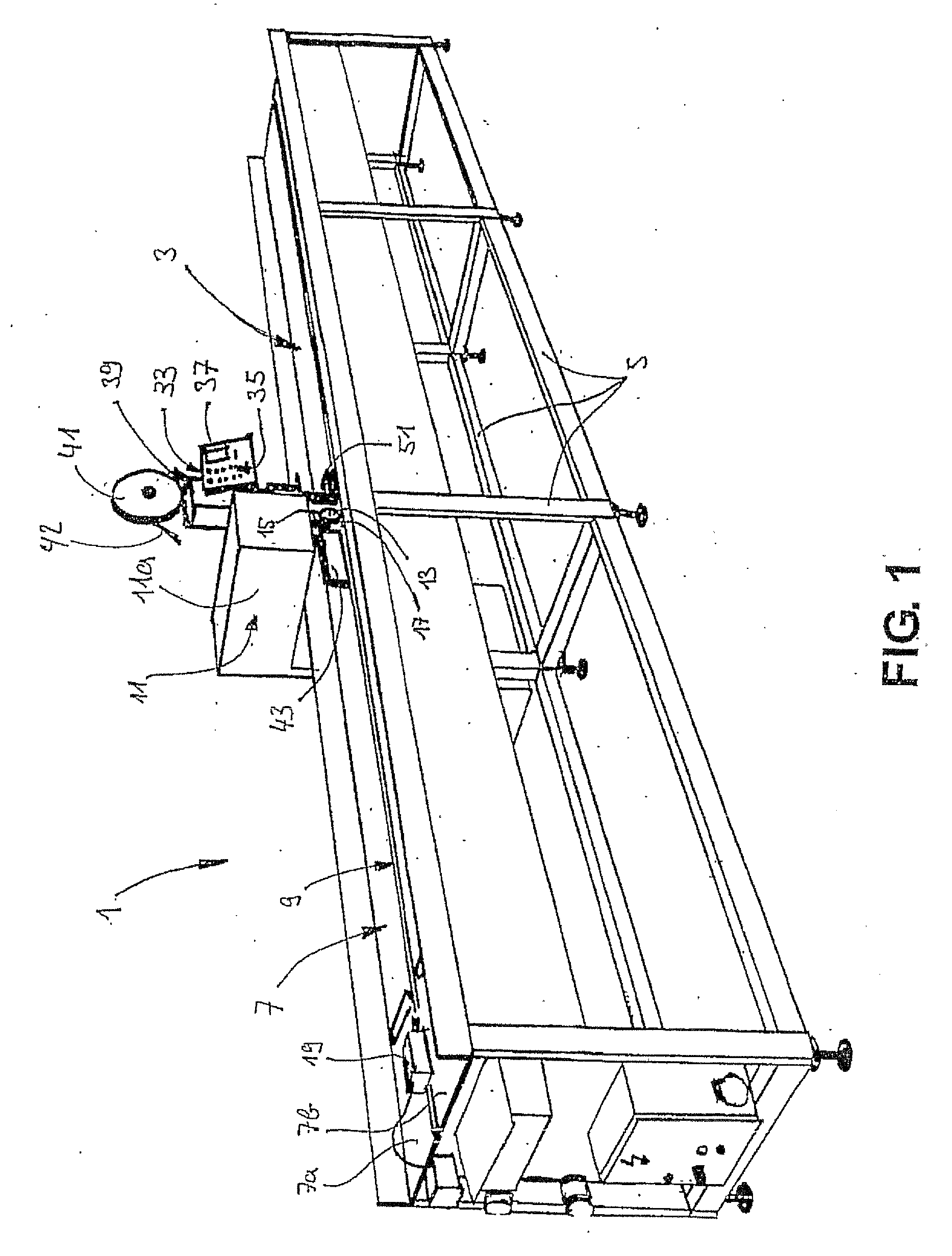

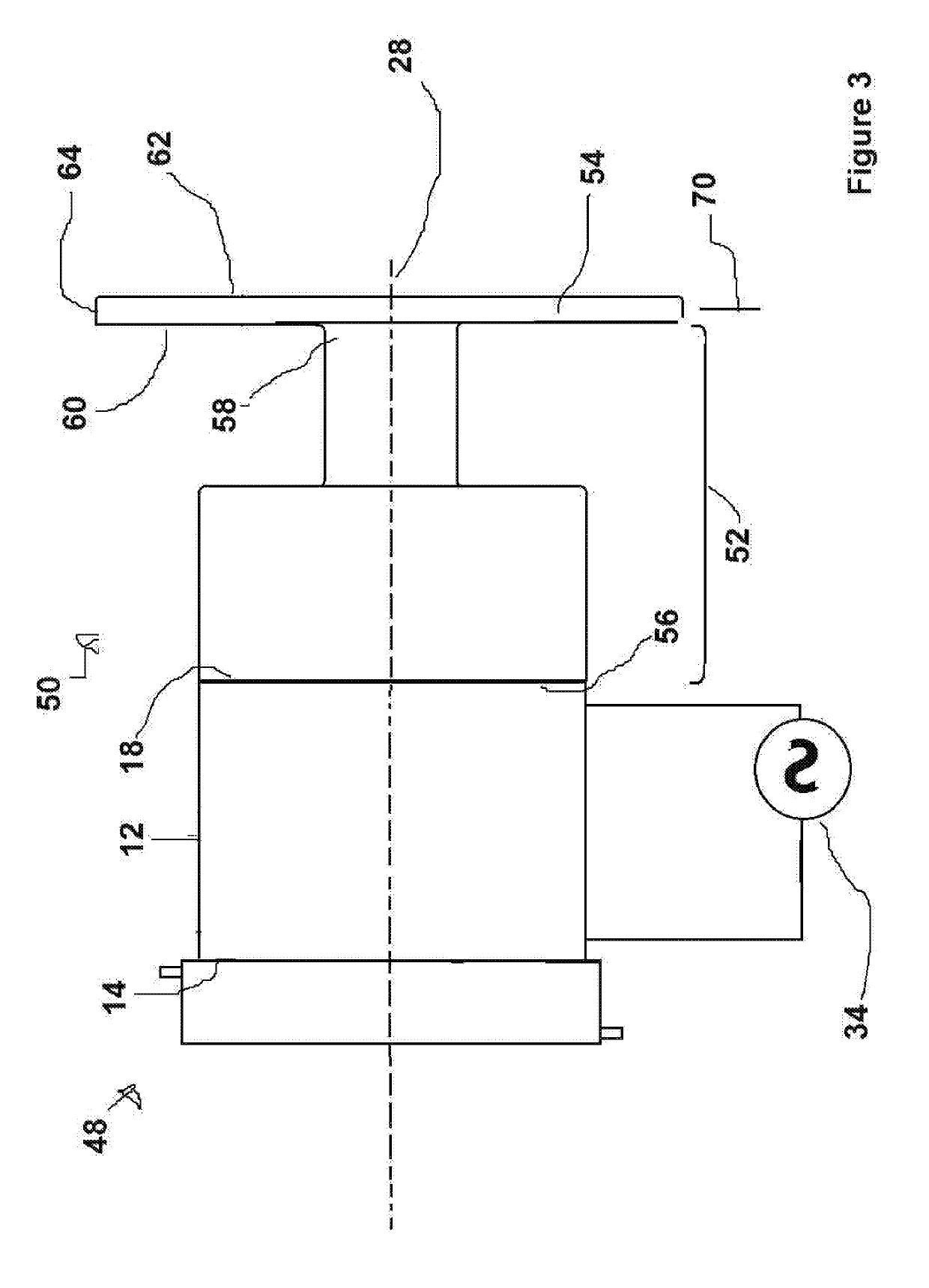

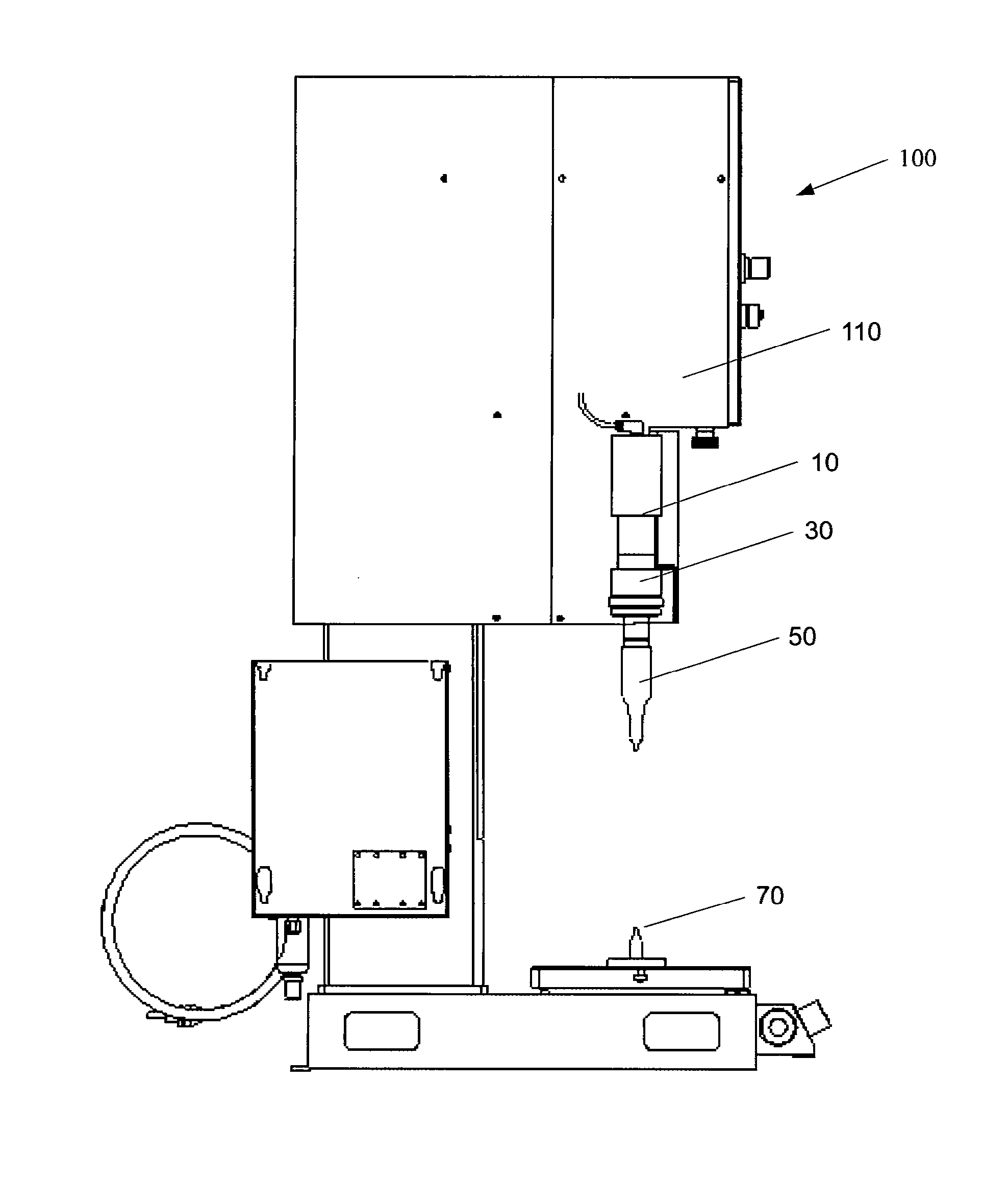

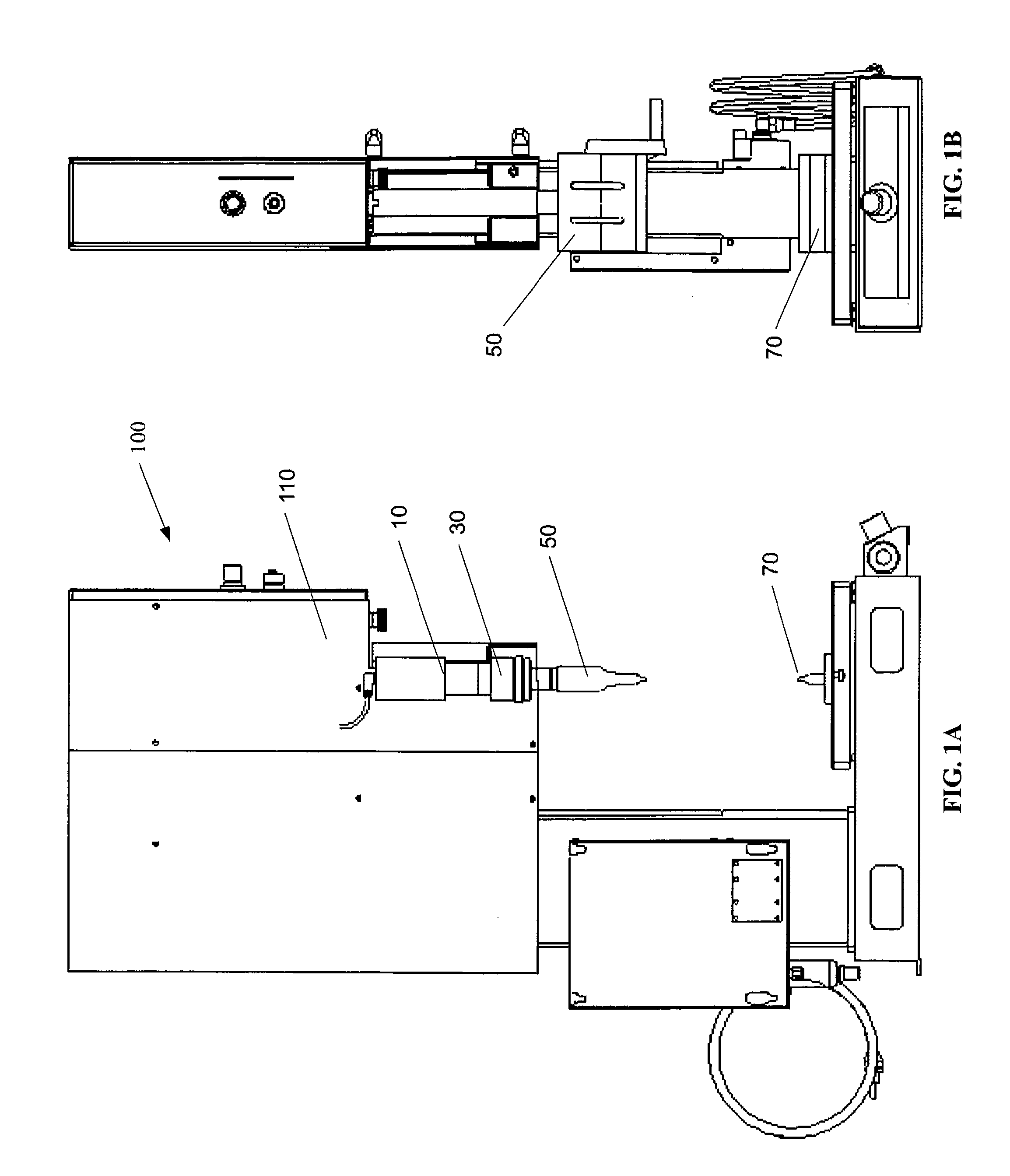

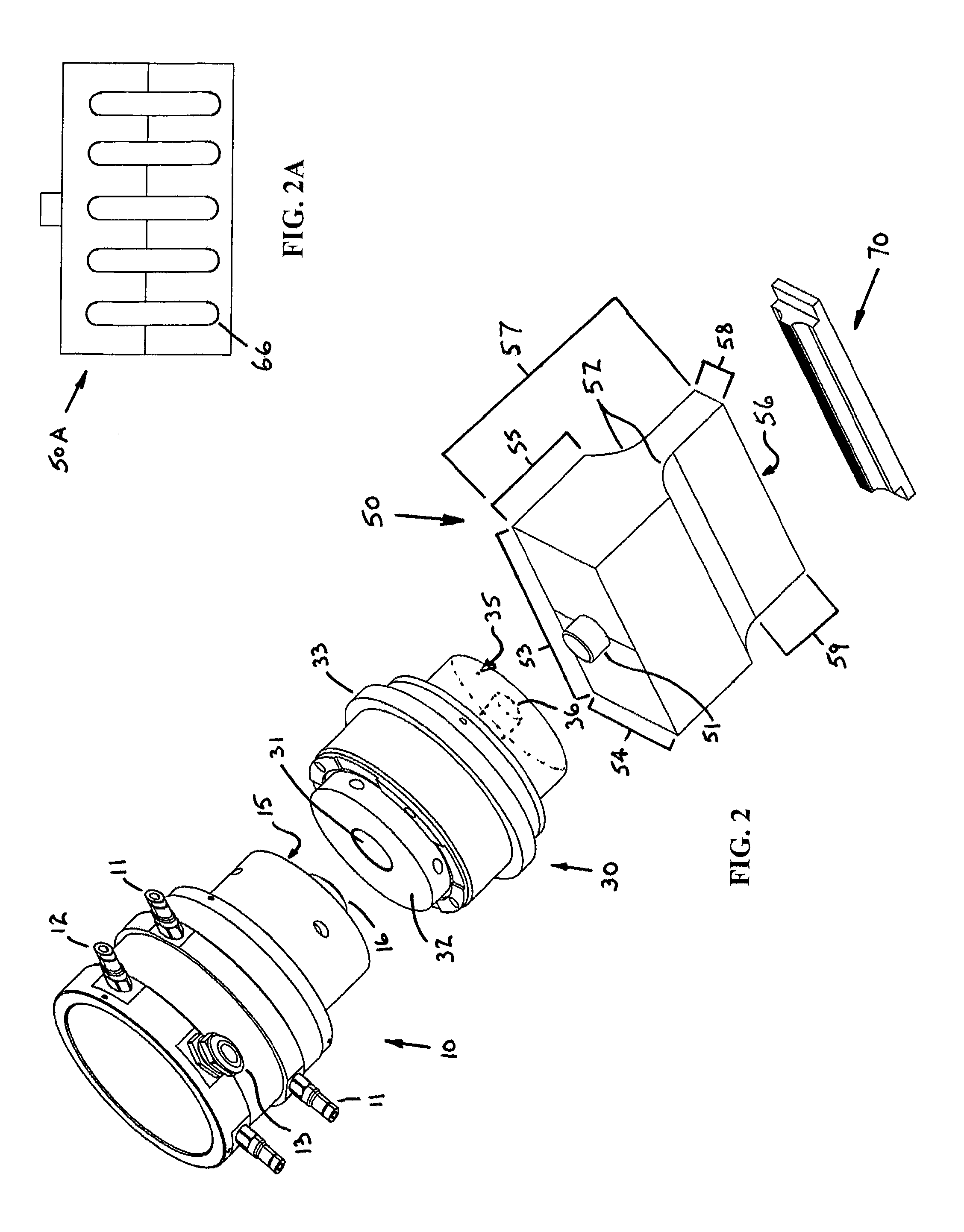

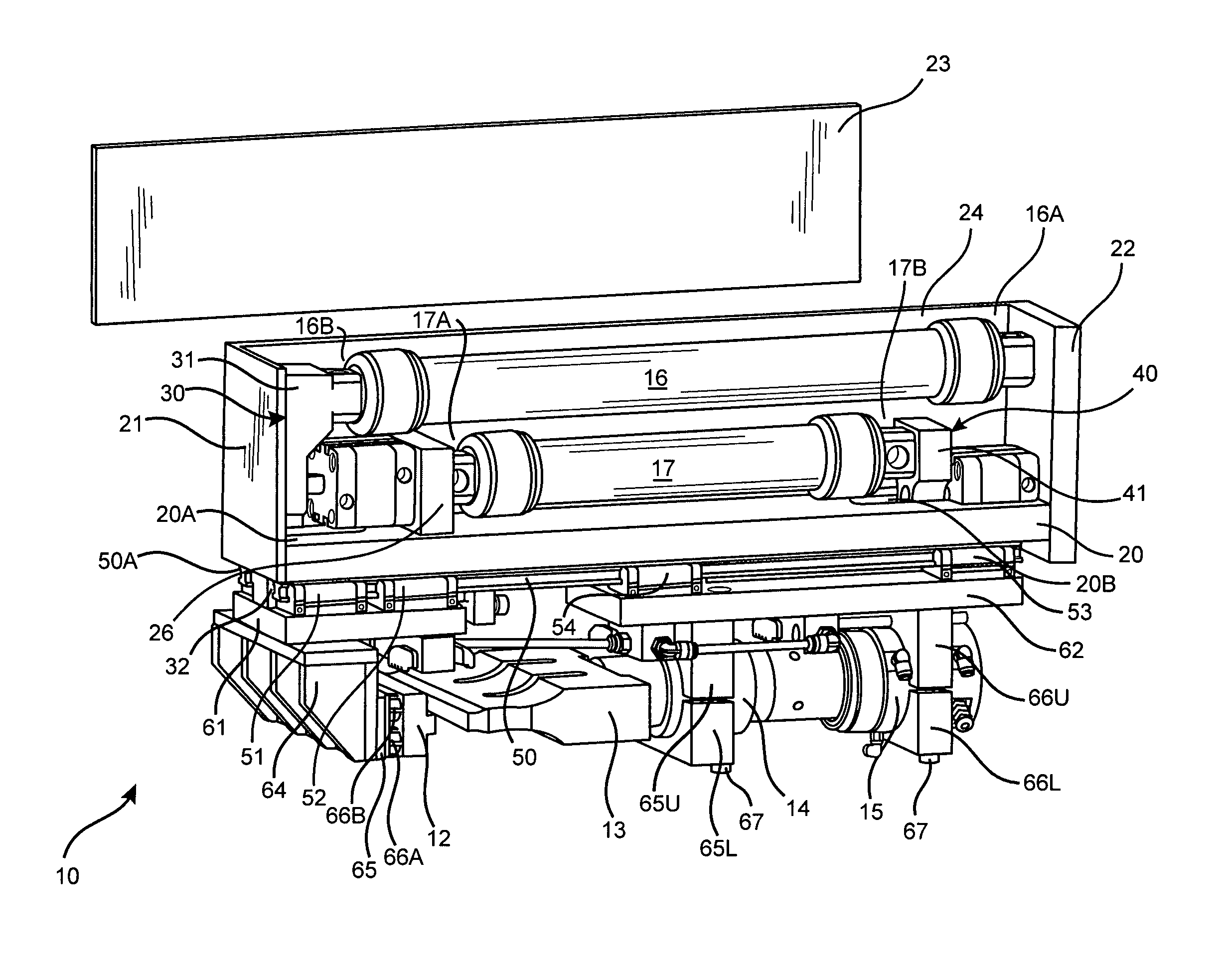

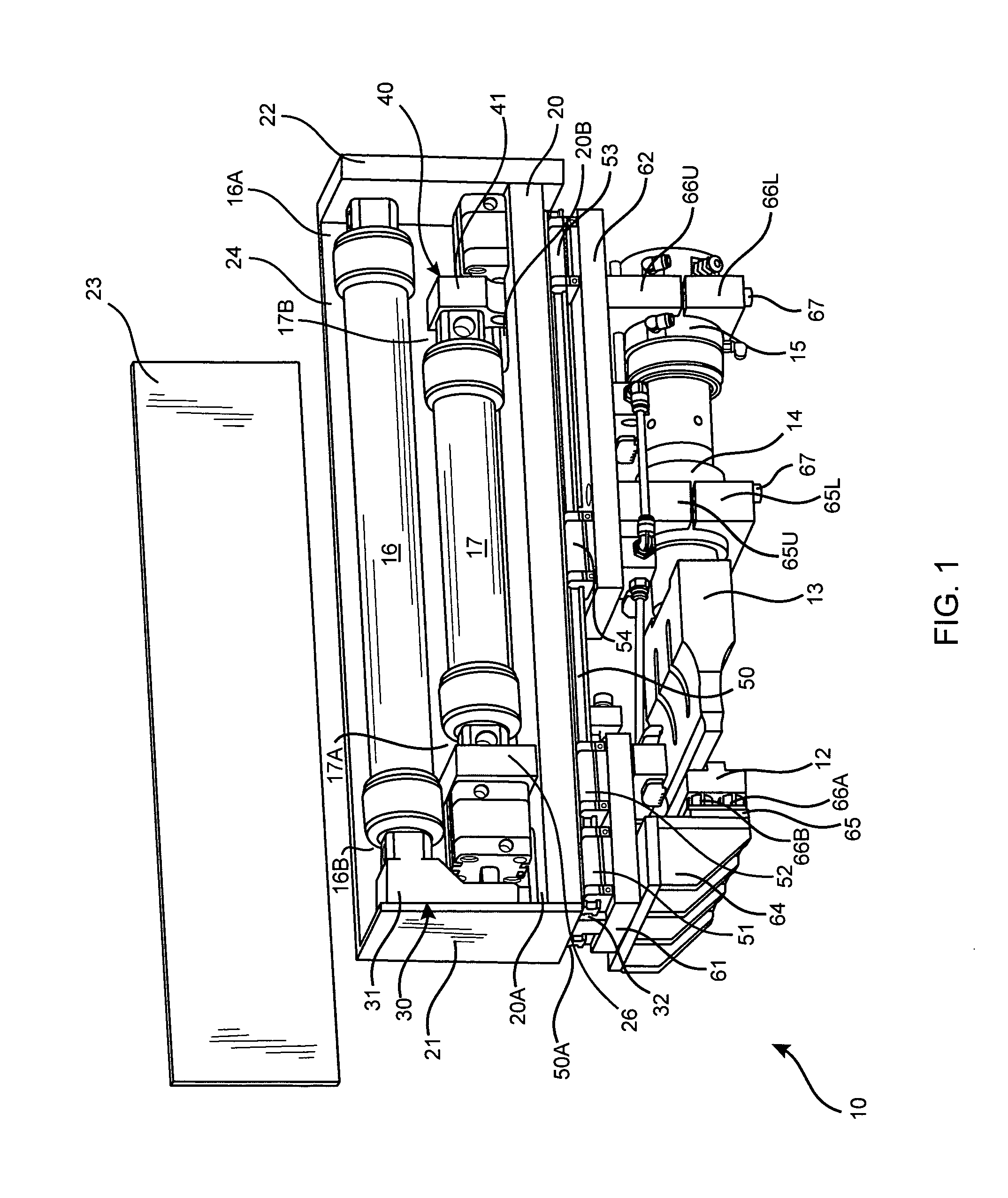

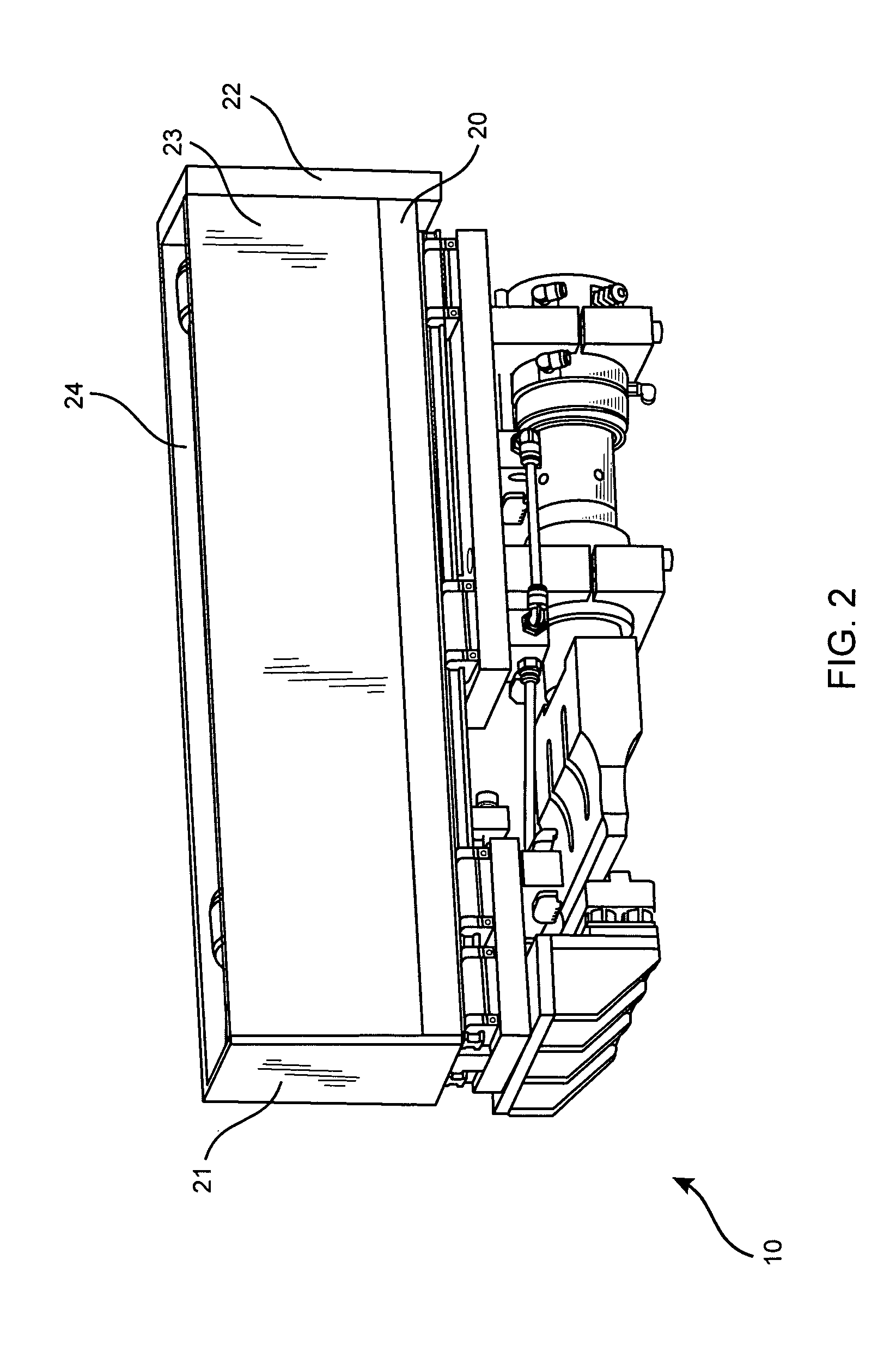

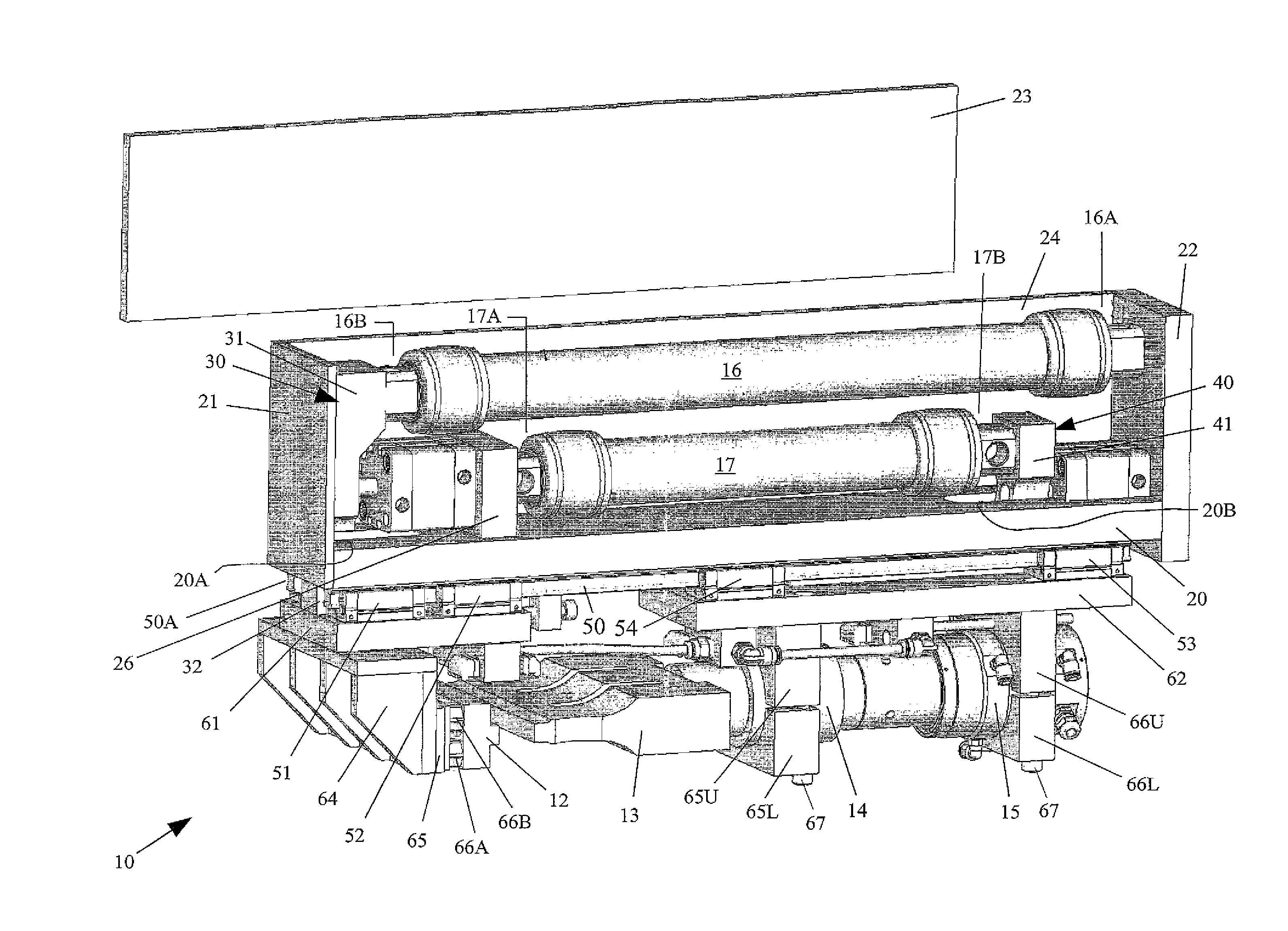

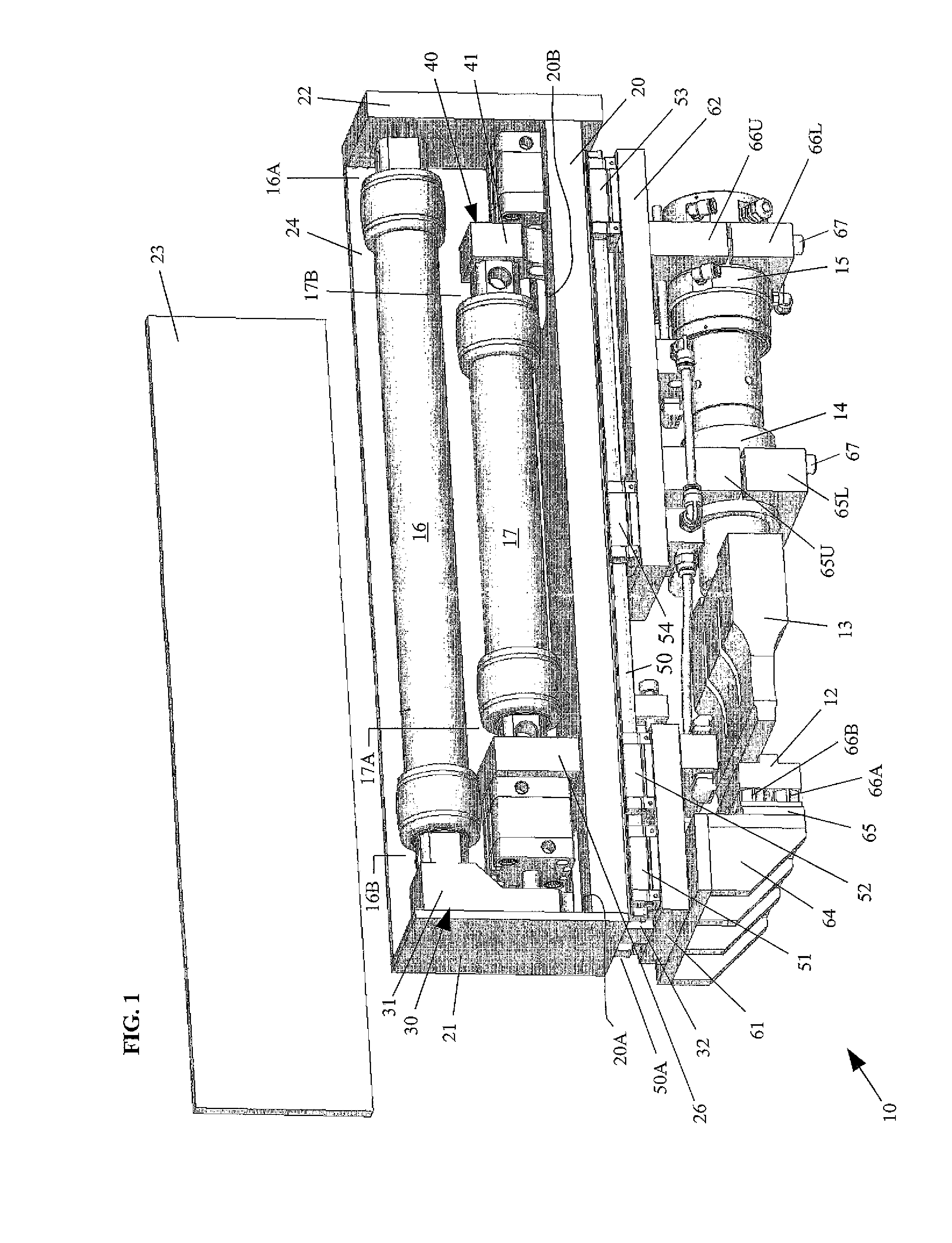

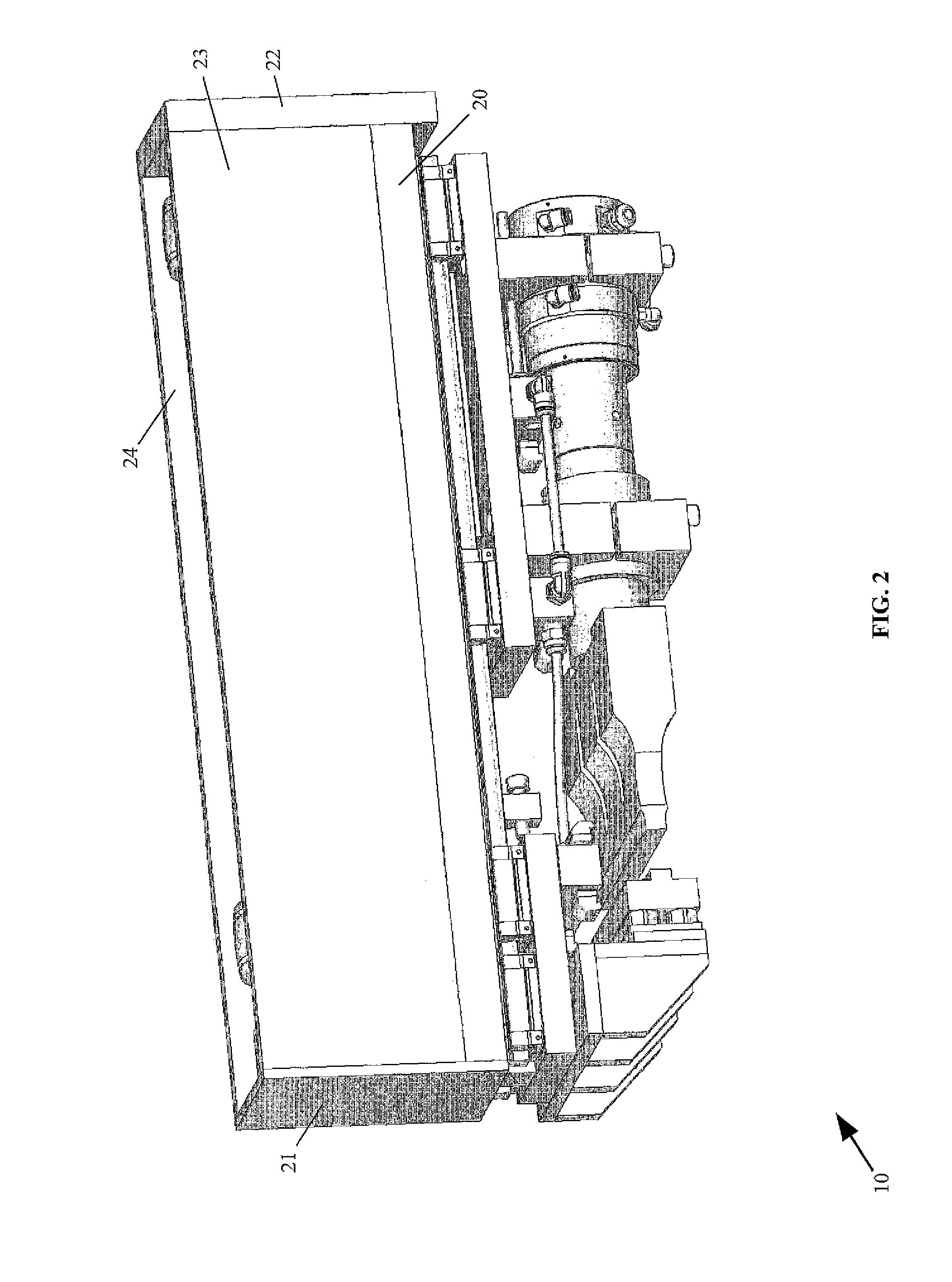

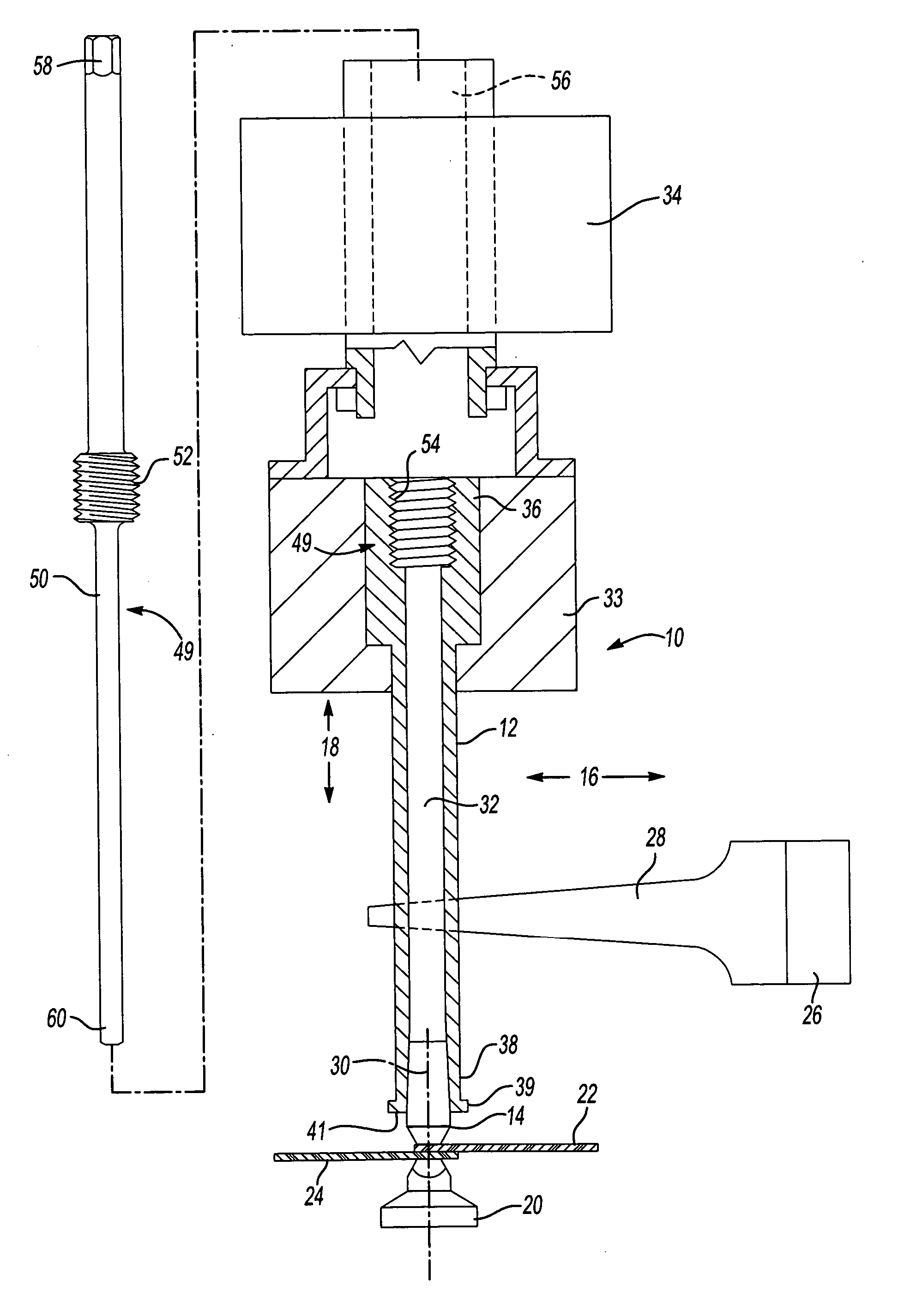

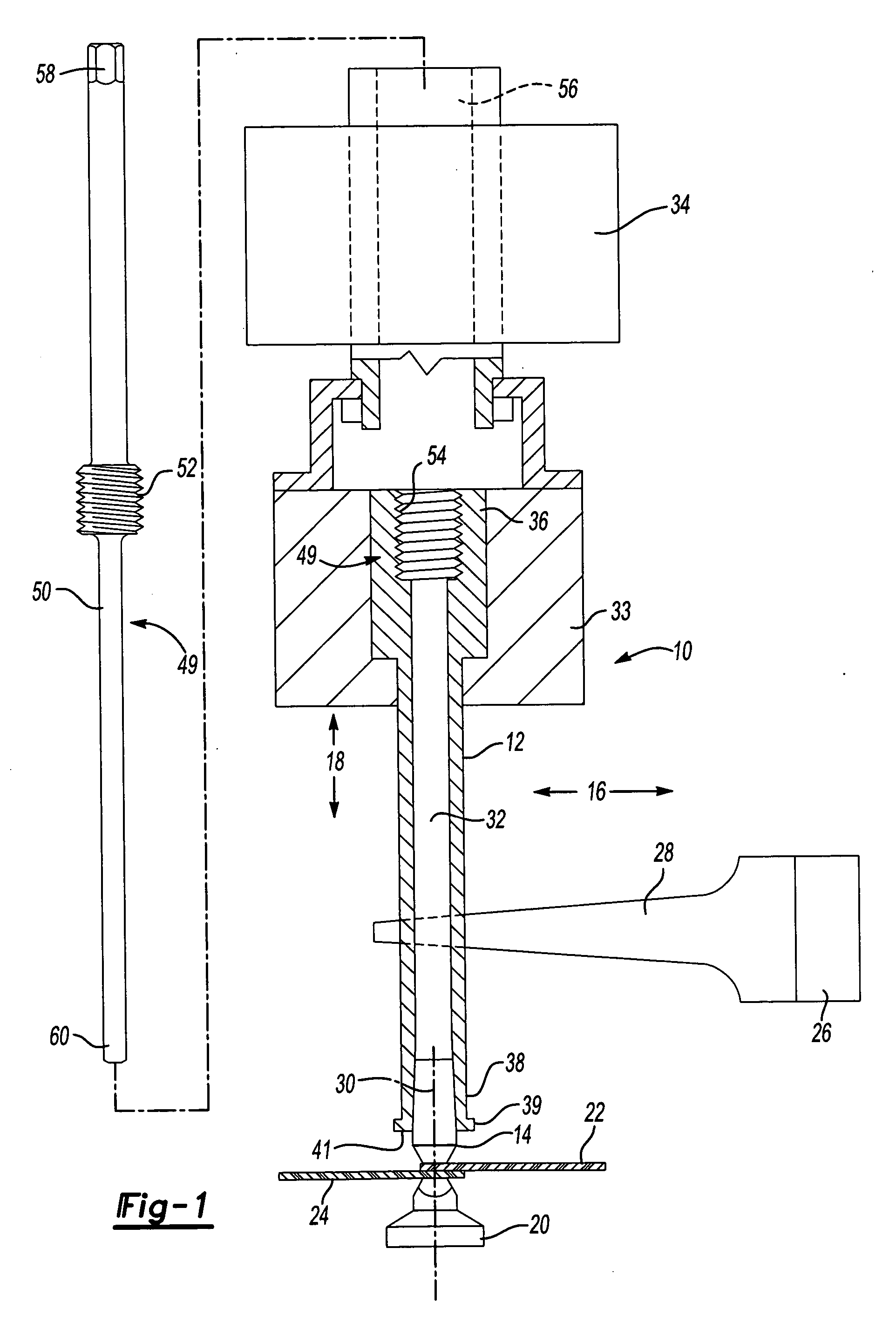

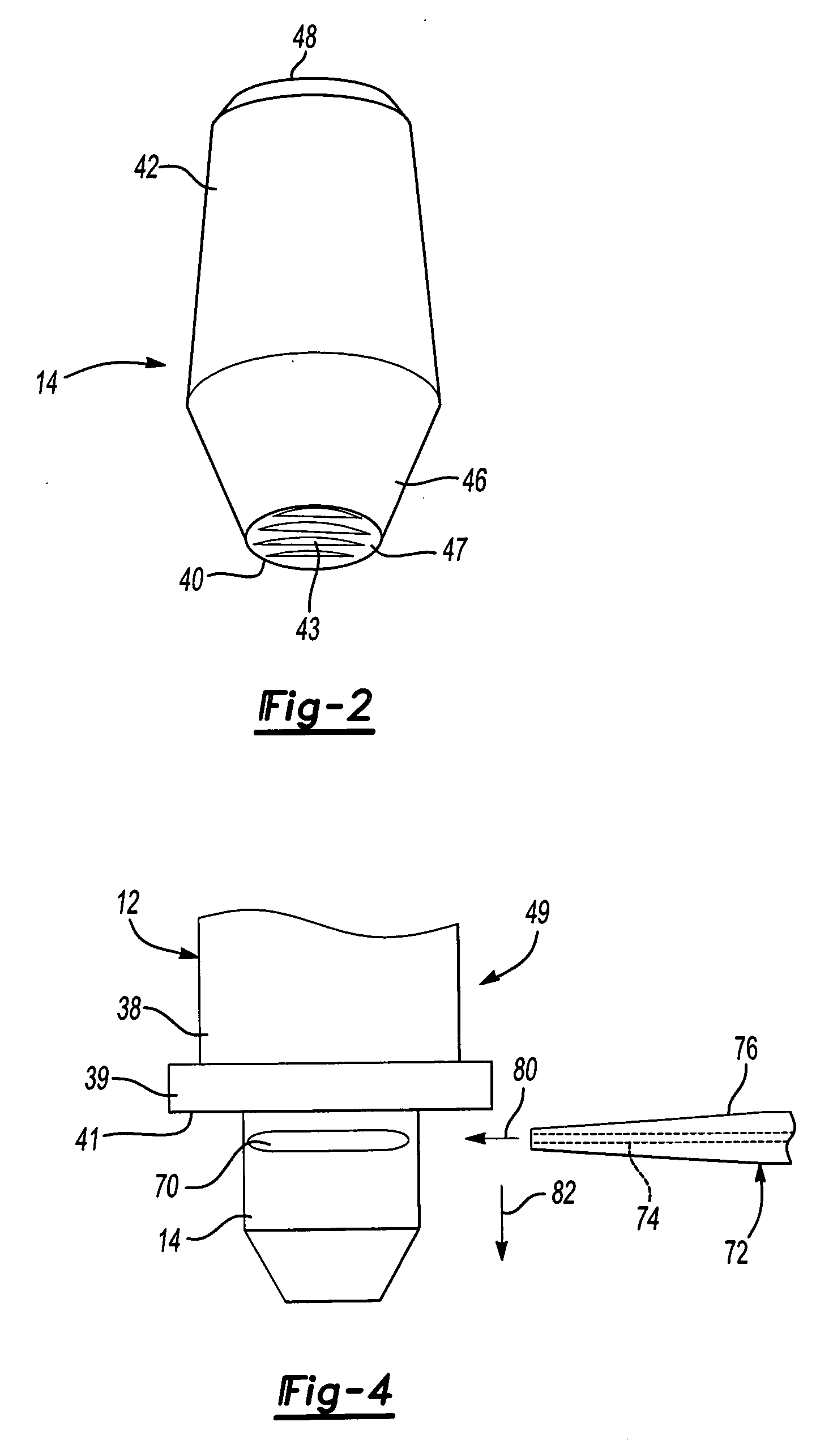

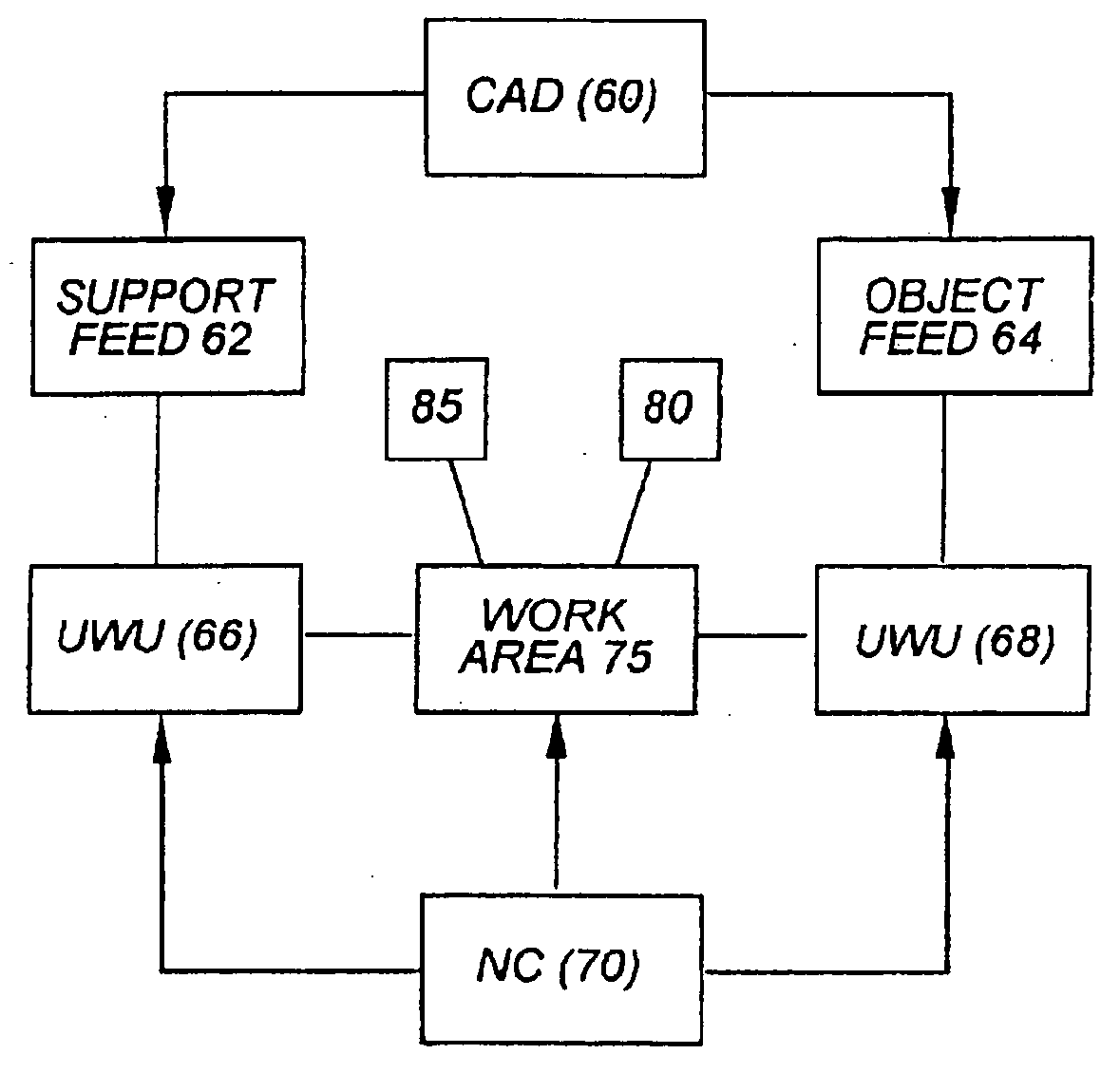

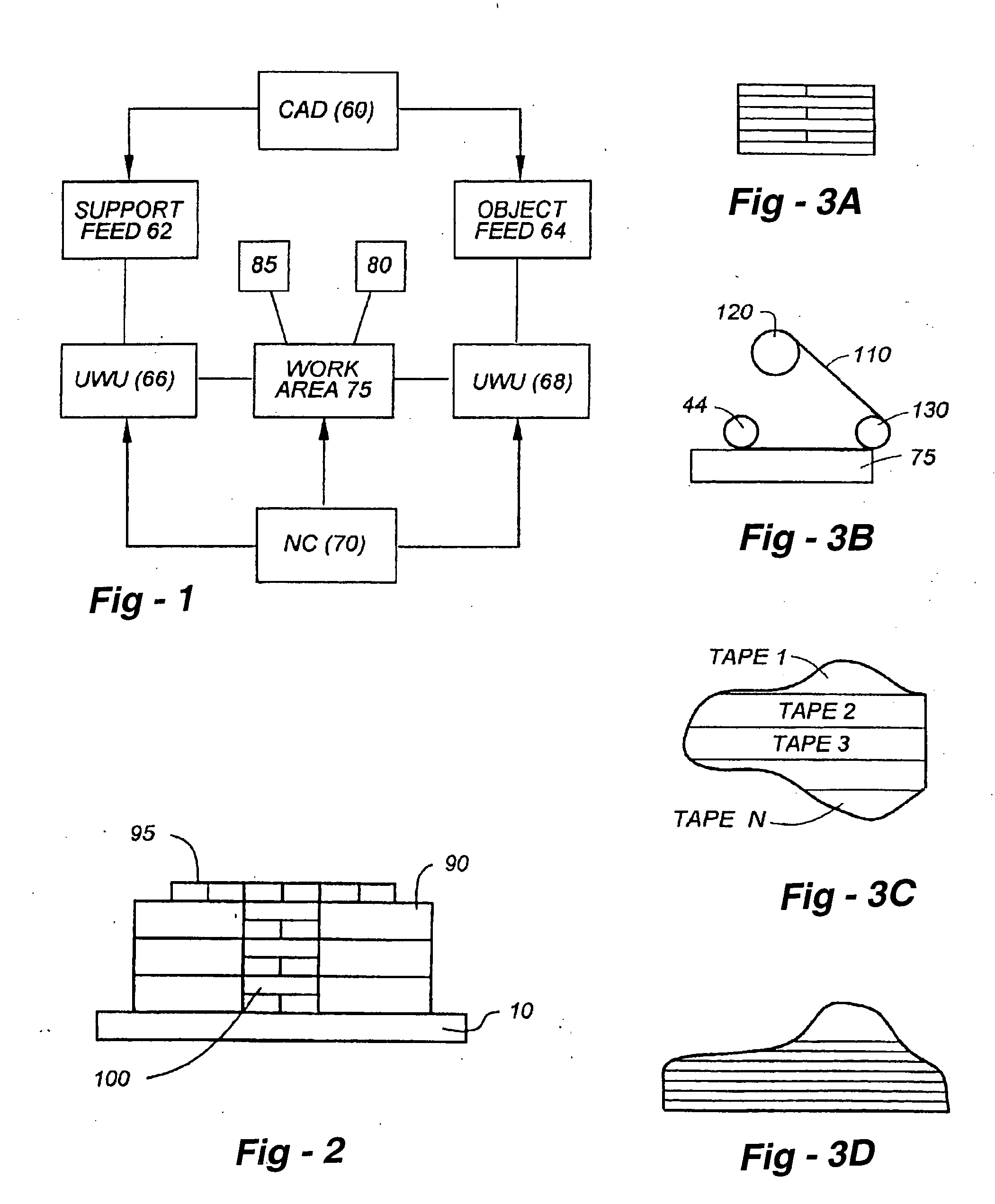

System for enhancing sonotrode performance in ultrasonic additive manufacturing applications

ActiveUS20110220292A1Additive manufacturing apparatusRolling contact bearingsUltrasonic weldingEngineering

An ultrasonic welding assembly, comprising: a sonotrode having a single welding region and two nodal regions formed on either side of the welding region; a mounting plate for supporting the sonotrode having a force application region on the upper surface thereof; at least one ultrasonic transducer connected to the sonotrode; at least one diaphragm spring disposed between the ultrasonic transducer and the sonotrode; at least one roller bearing connected to the diaphragm spring; at least two linear guides connected to the roller bearing, wherein the at least two linear guides are connected to the mounting plate and support the roller bearing and the sonotrode in a flexible manner; and first and second low-friction linear bearings in contact with nodal regions for the application of downward force to the sonotrode, wherein the first and second linear bearings are connected to the mounting plate.

Owner:FABRISONIC

Method of treatment of vegetable matter with ultrasonic energy

InactiveUS20060110503A1Producing viscosityIncrease contentMilk preservationDough treatmentVegetable matterCavitation

A method for modifying the viscosity of pureed vegetable matter, said method including the step of applying relatively low-frequency ultrasonic energy (having a frequency in the range from about 16 kHz to 100 kHz) to said puree via a sonotrode in a manner such that cavitation of a water fraction in said puree is induced, and the cellular structure and cell wall material of the vegetable matter are degraded, thereby to increase the viscosity of said puree.

Owner:MARS INC

Electroacoustic method and device for stimulation of mass transfer processes for enhanced well recovery

ActiveUS20060096752A1Highly efficient acousticImprove liquidityFluid removalVibration devicesPorous mediumAcoustic energy

An electro acoustic device and related method for increasing production capacity of wells that contain oil, gas and / or water is disclosed. The electro acoustic device produces vibrations stimulating occurrence of mass transfer processes within the well. The resultant acoustic flow generated in porous media, produced by superposition of longitudinal and shear waves, is developed over a characteristic frequency threshold value specific to water, normal oil and heavy oil, with an acoustic energy density capable of establishing higher fluidity zones in the porous media, promoting mobility and recovery of desired fluid and formation damage reduction in a wellbore. The down hole electro acoustic device is a submerged unit placed in the well producing zone, and consists of an electric generator, one or more electro acoustic transducers, and one or more waveguide systems (sonotrodes) that include tubular type radiators which provide transmission of elastic vibrations into the medium under treatment.

Owner:SONOPLUS

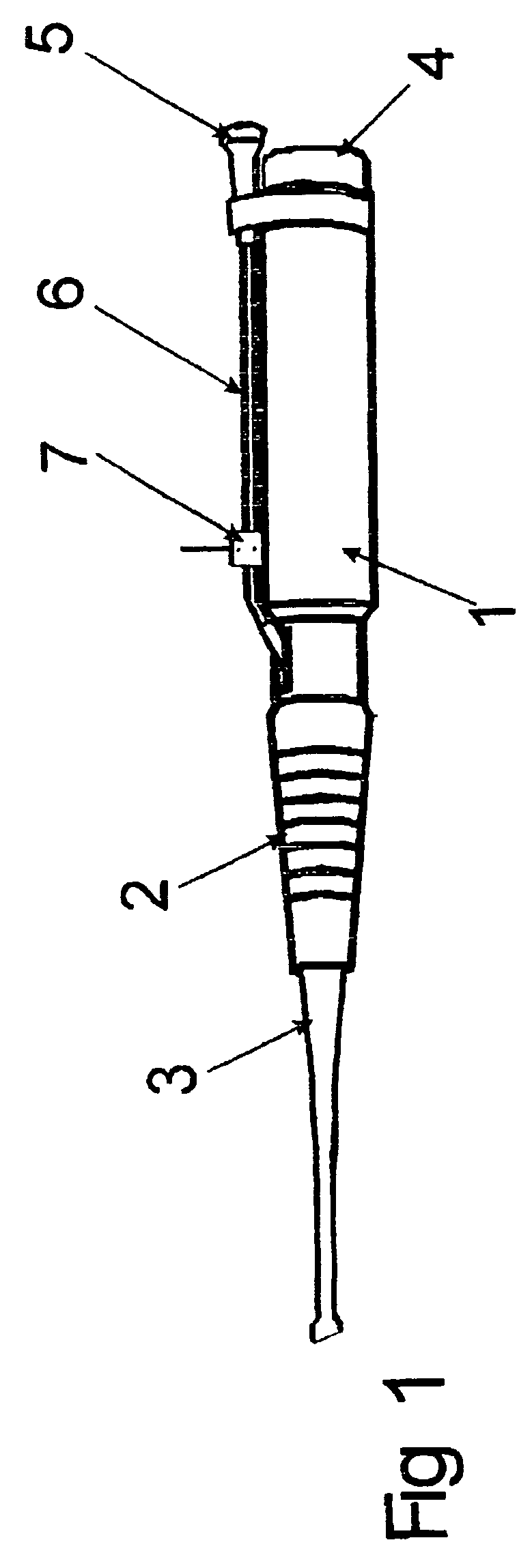

Ultrasonic handpiece

ActiveUS20090018471A1Reliable fluidizationUltrasound therapyInternal osteosythesisBiomedical engineeringBone screws

An ultrasonic handpiece is used for augmenting a bone screw. The handpieces comprise a housing, an ultrasonic converter shiftingly accommodated in the housing, and a sonotrode connected to one end of the ultrasonic converter. The sonotrode protrudes from the housing into the bone screw. An adjuster wheel is adjustably connected to the housing. A spring is provided the ends of which are supported by the ultrasonic converter and the adjuster wheel, respectively. The ultrasonic converter is preloaded in the direction away from the adjuster wheel by setting the adjuster wheel, thereby the sonotrode is urged with a selected force into the bone screw and the augmentation material is pressed out of the bone screw and into the bone.

Owner:WOODWELDING +1

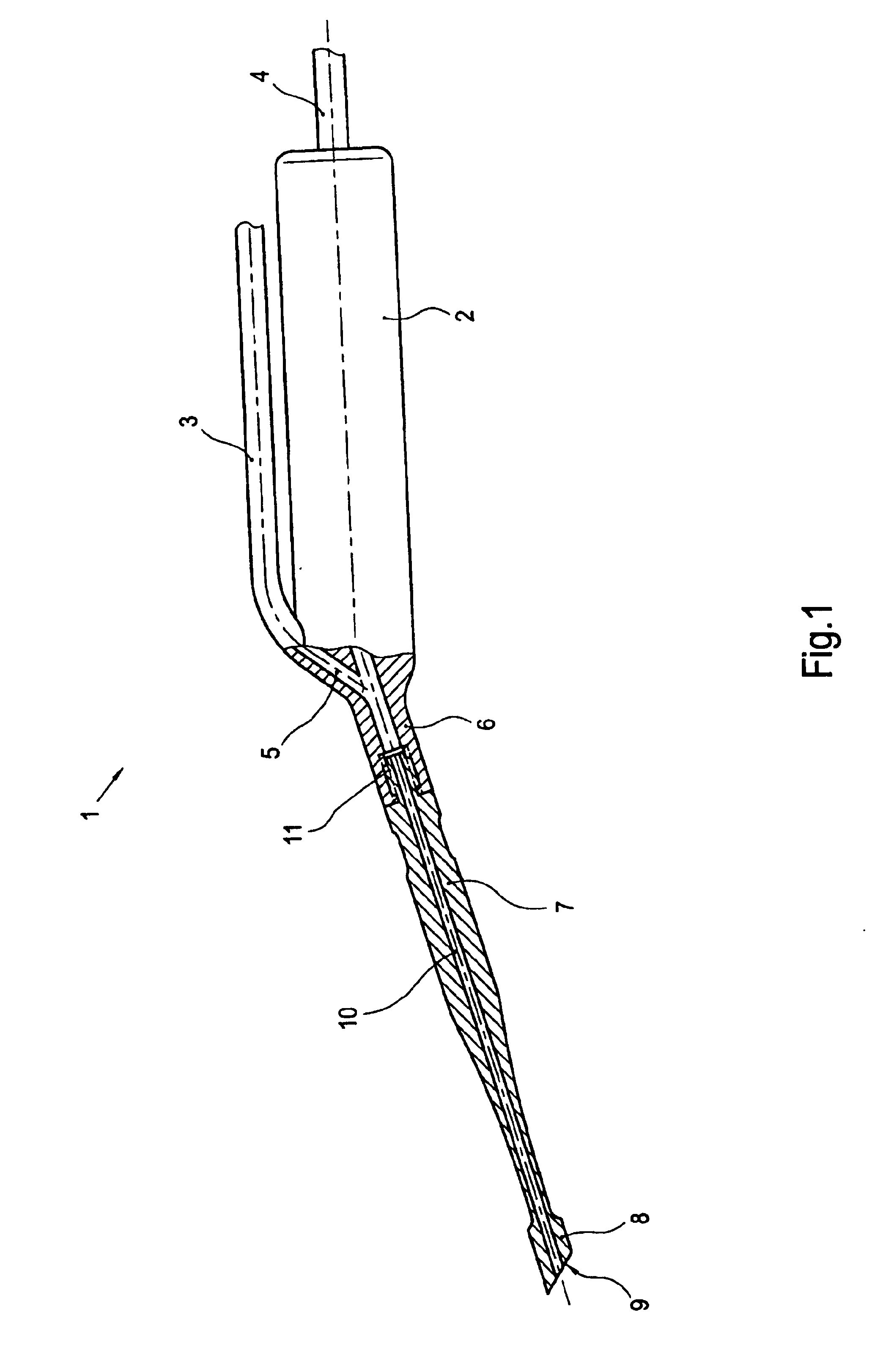

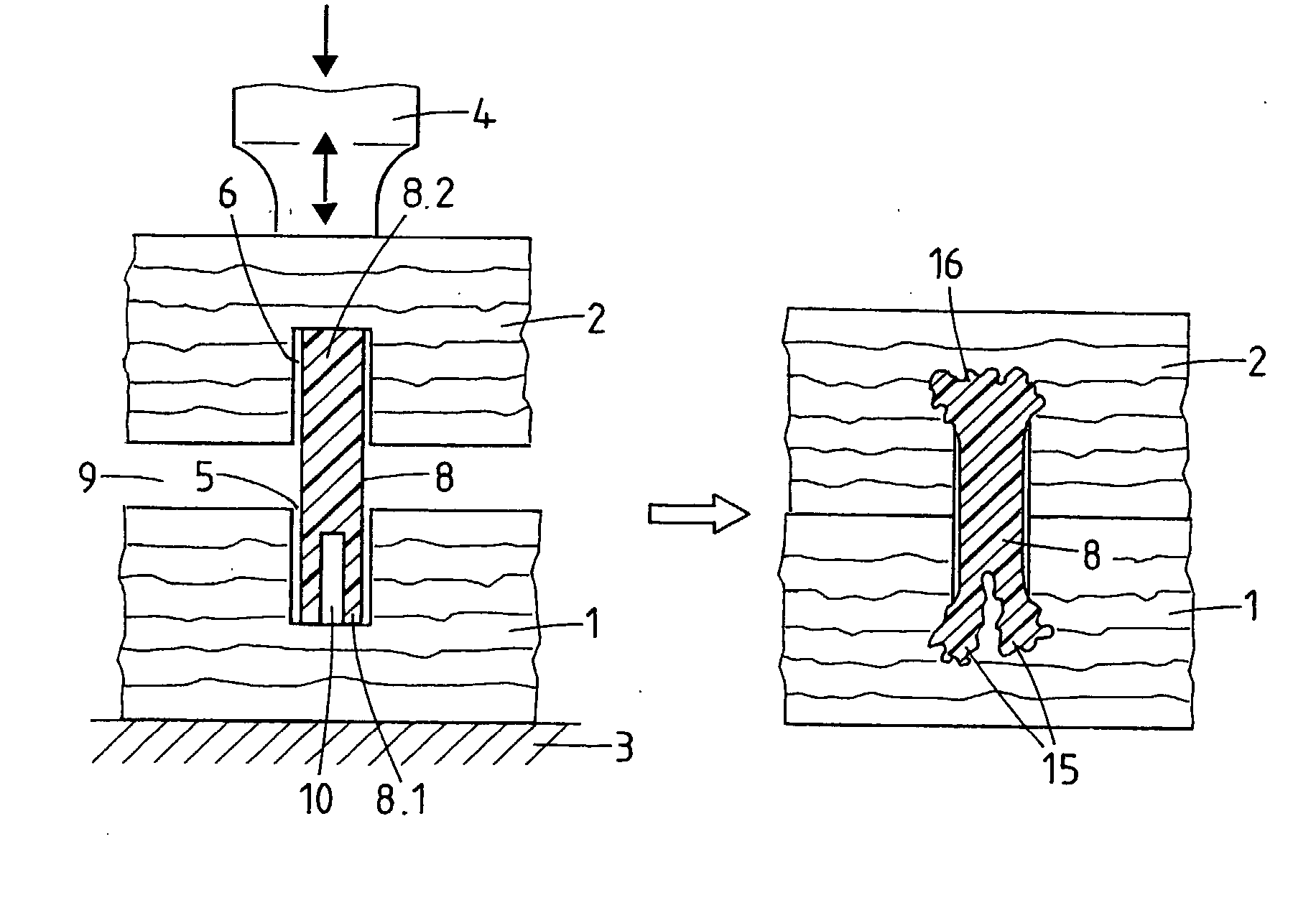

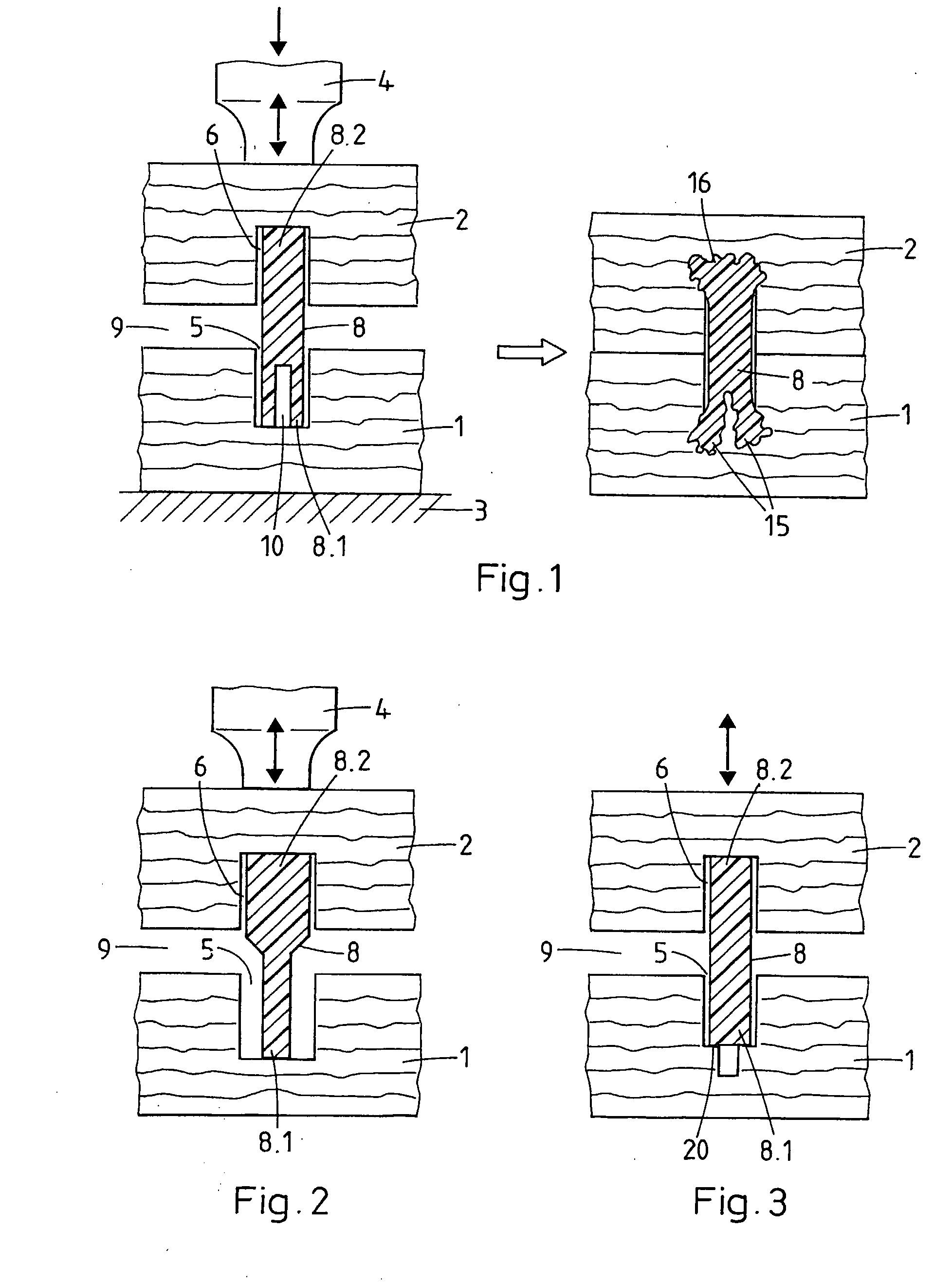

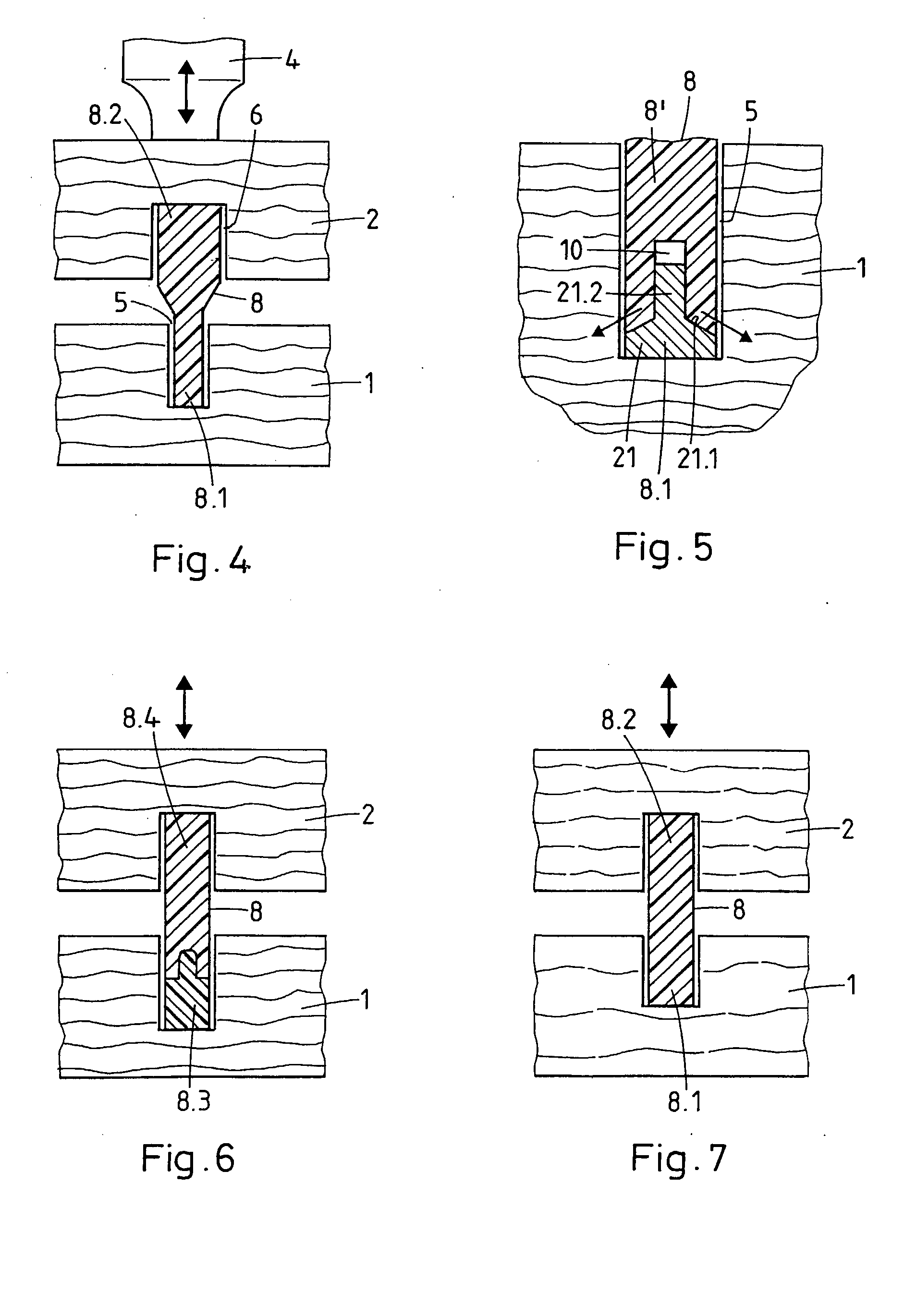

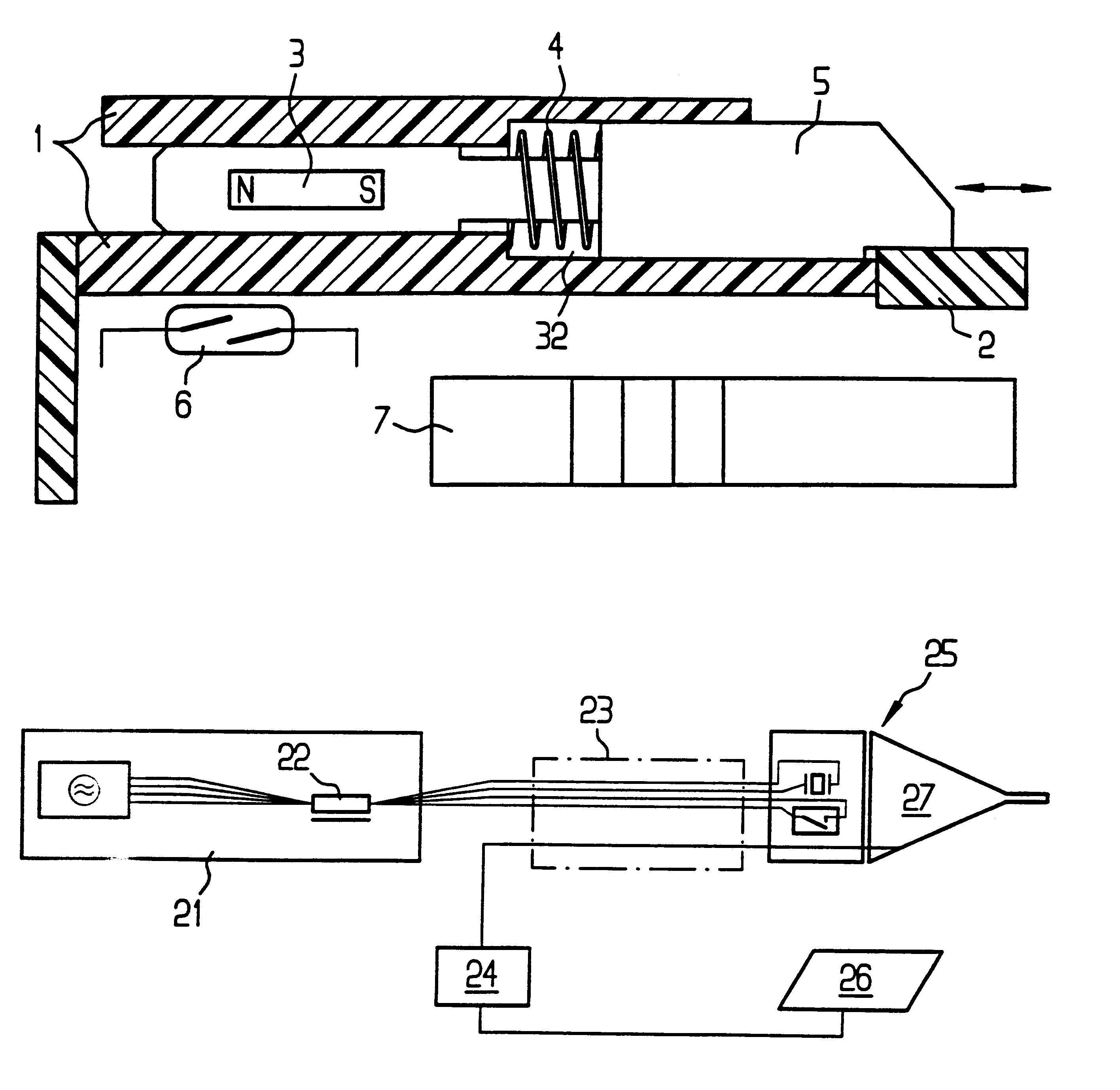

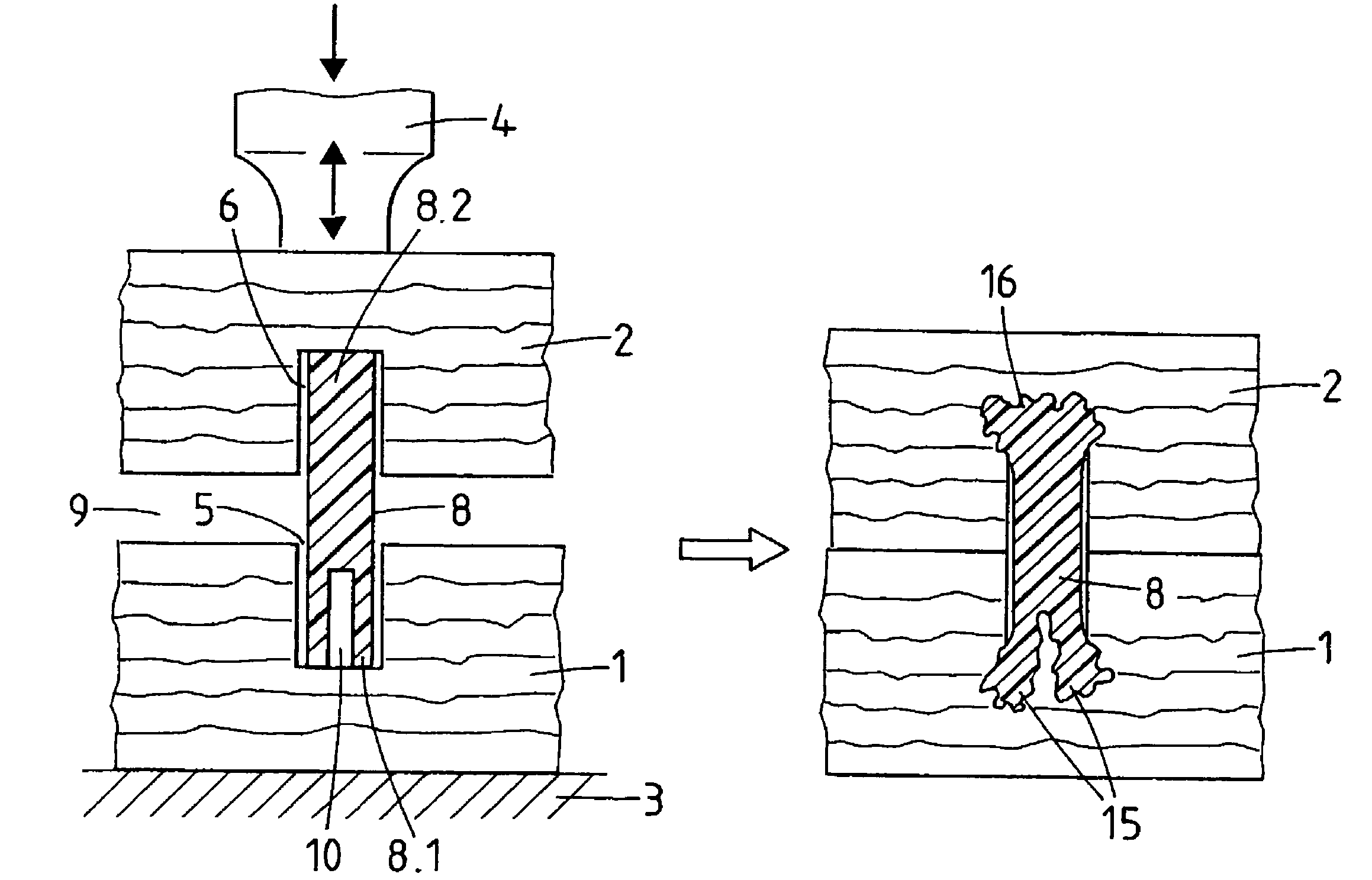

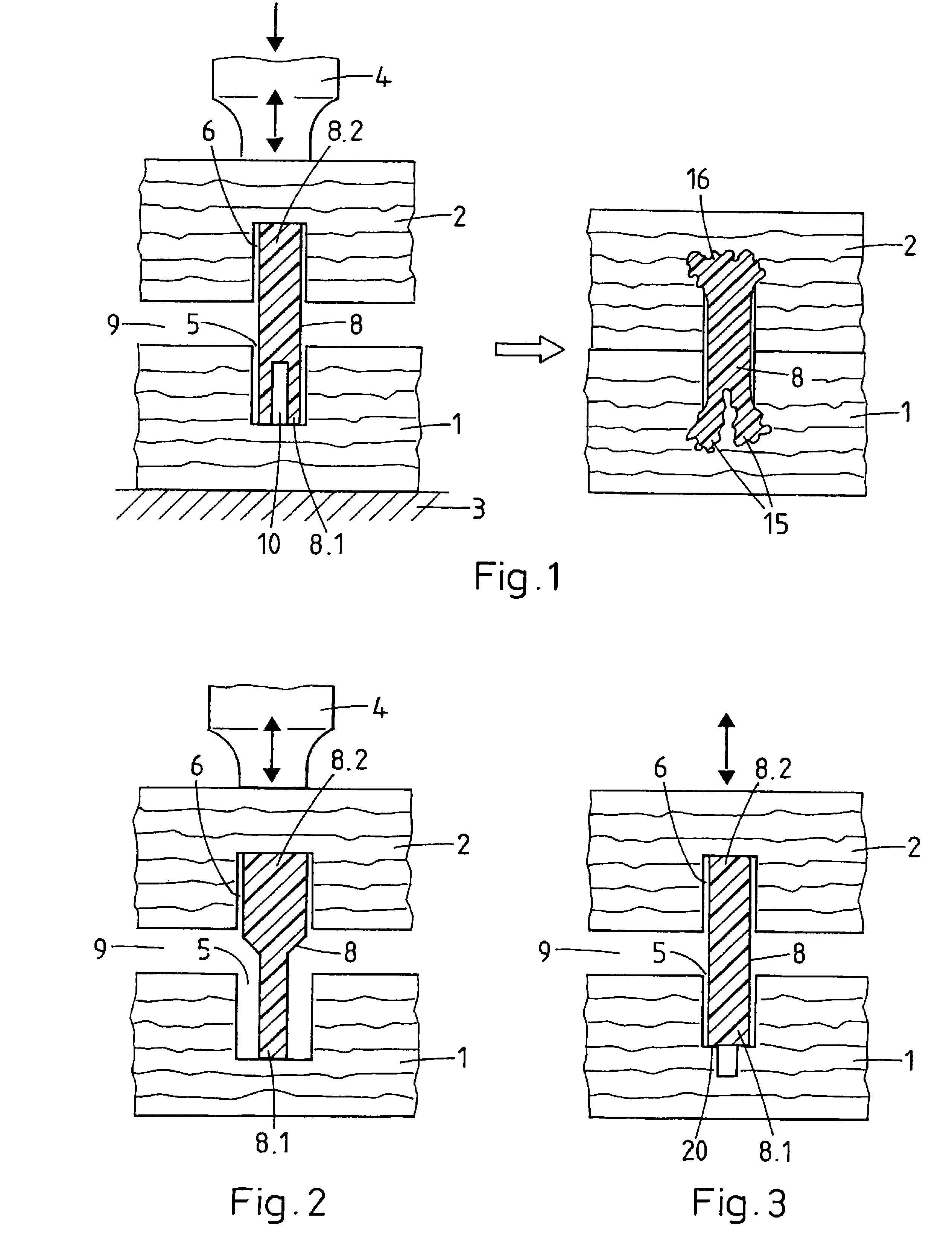

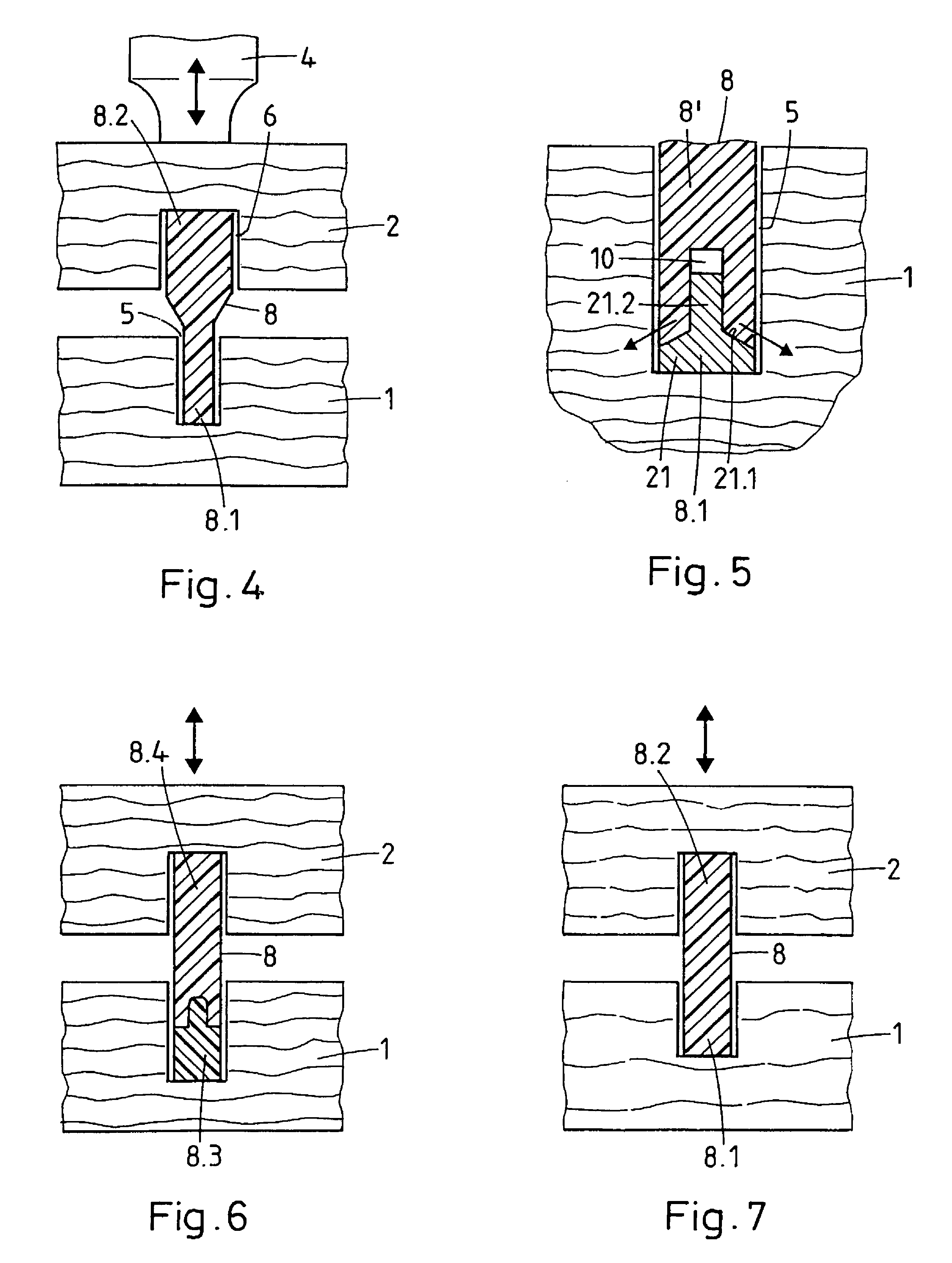

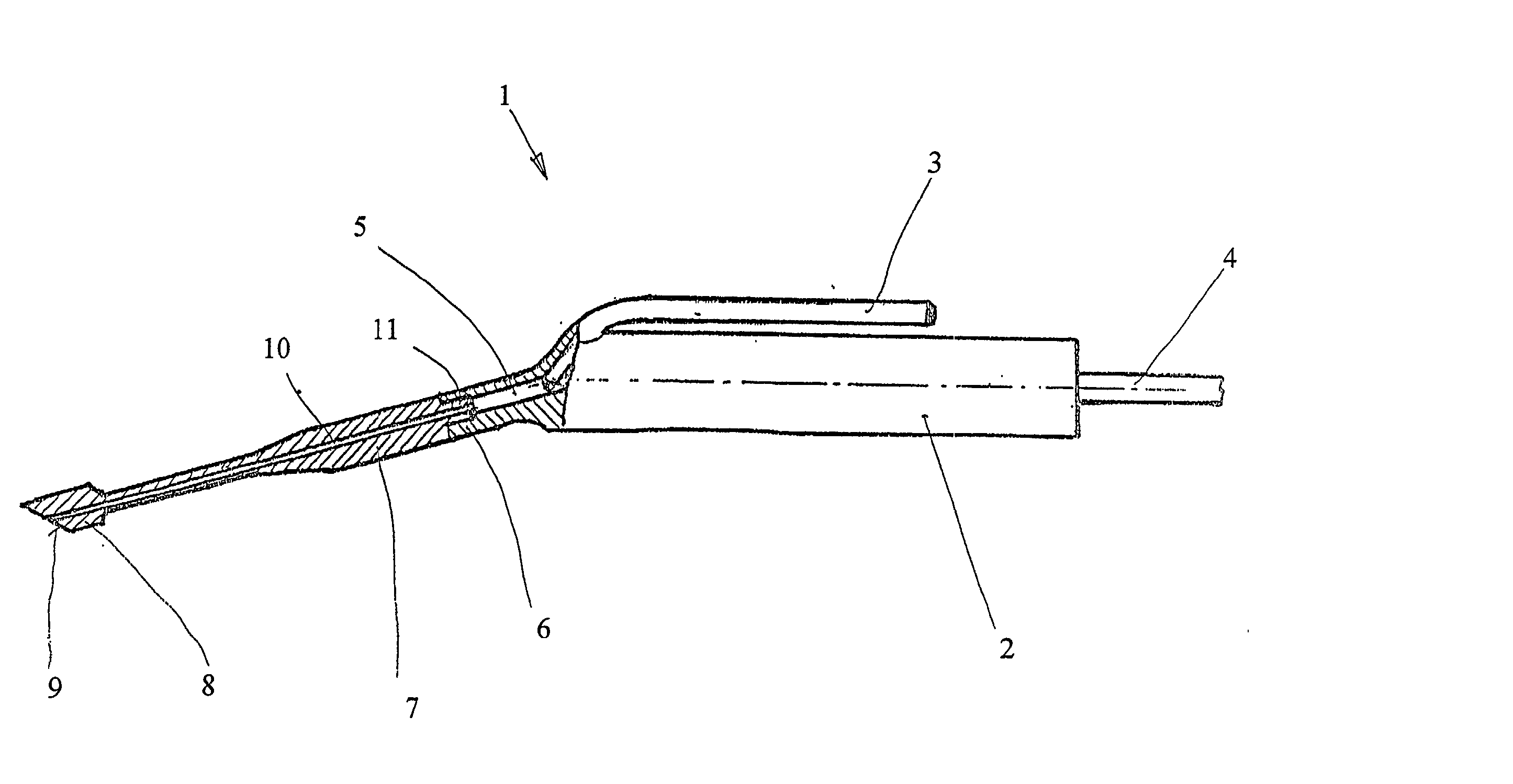

Method for Joining Two Objects and Corresponding Joining Element

ActiveUS20080047107A1Enhanced couplingSatisfactory jointWing handlesPicture framesEngineeringMechanical engineering

A first and a second object (1 and 2) are joined with the aid of a joining element (8) including at least in the region of its distal and proximal ends (8.1 and 8.2) a thermoplastic material. Two blind holes (5 and 6) facing each other are provided in the two objects (1 and 2) and the joining element (8) is positioned in the blind holes such that its distal and proximal ends (8.1) are in contact with the bottom faces of the blind holes and such that there is a gap (9) between the two objects (1 and 2). This assembly is then positioned between a support (3) and a sonotrode (4). The sonotrode (4) and the support (3) are forced towards each other, while the sonotrode (4) is vibrated, thereby liquefying at least part of the material having thermoplastic properties, there, where the joining element ends (8.1 and 8.2) are pressed against the bottom faces of the holes (5 and 6) and allowing the liquefied material to infiltrate into pores of the hole surfaces or unevennesses or openings provided in the hole surfaces.

Owner:WOODWELDING

Stepped Sonotrode and Anvil Energy Director Grids for Narrow/Complex Ultrasonic Welds of Improved Durability

InactiveUS20150090405A1Increased durabilityReduce total usageLaminationLamination apparatusGrid patternUltrasonic welding

A sonotrode and anvil are adapted for ultrasonic welding of work pieces, to produce a narrower weld region that exhibits greater durability, permitting use of less material per package. The horn-to-anvil contact is through a plurality of energy directors arranged into a three-dimensional grid pattern to be capable of distributed vibration-transmissive contact. The energy directors include a series of plateau surfaces regularly spaced apart in a first direction, and in a second direction that is orthogonal to the first direction, to form the grid pattern. The energy directors of the horn are configured to interlock with the energy directors of the anvil. The rectangular-shaped plateaus are spaced apart by angled side-surfaces that form valleys. A stepped transition to a corresponding region of reduced height for the energy directors of the sonotrode and anvil may form a cosmetic seal region with a lesser integrity, in addition to the main barrier seal.

Owner:RINCO ULTRASONICS USA

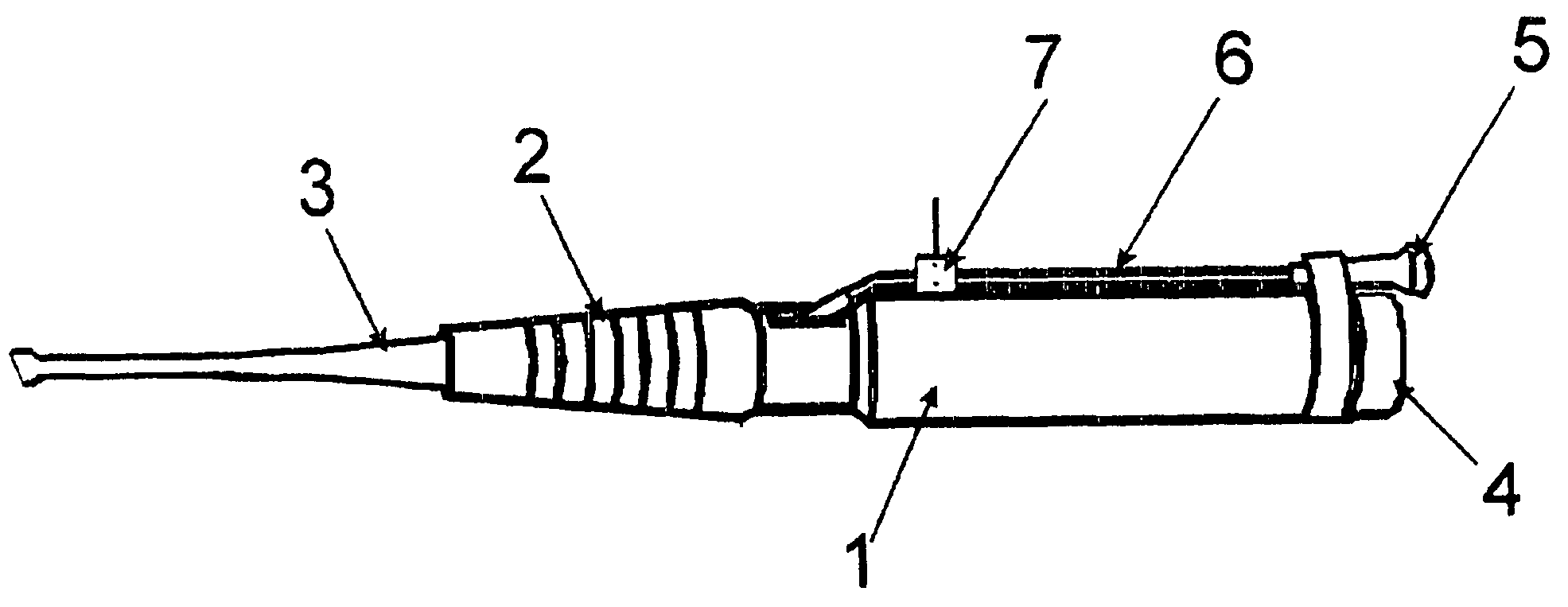

Handpiece for use with a multifunctional operating endoscopic instrument

A handpiece is disclosed for a multifunctional instrument for endoscopic surgery. The handpiece comprises a case; a connector disposed on the case and adapted to be connected to connecting lines such as electrical lines, liquid supply and discharge lines, and the like; at least one ultrasonic transducer arranged in the case; an ultrasonic sonotrode transmitting the ultrasonic energy; and at least one switch for controlling functions of the handpiece. The handpiece is characterized by, among other things, the provision that the sonotrode includes a long and thin probe section with a duct composed of several segments which are welded to each other.

Owner:STORZ ENDOSKOP

Ultrasonic vibration unit

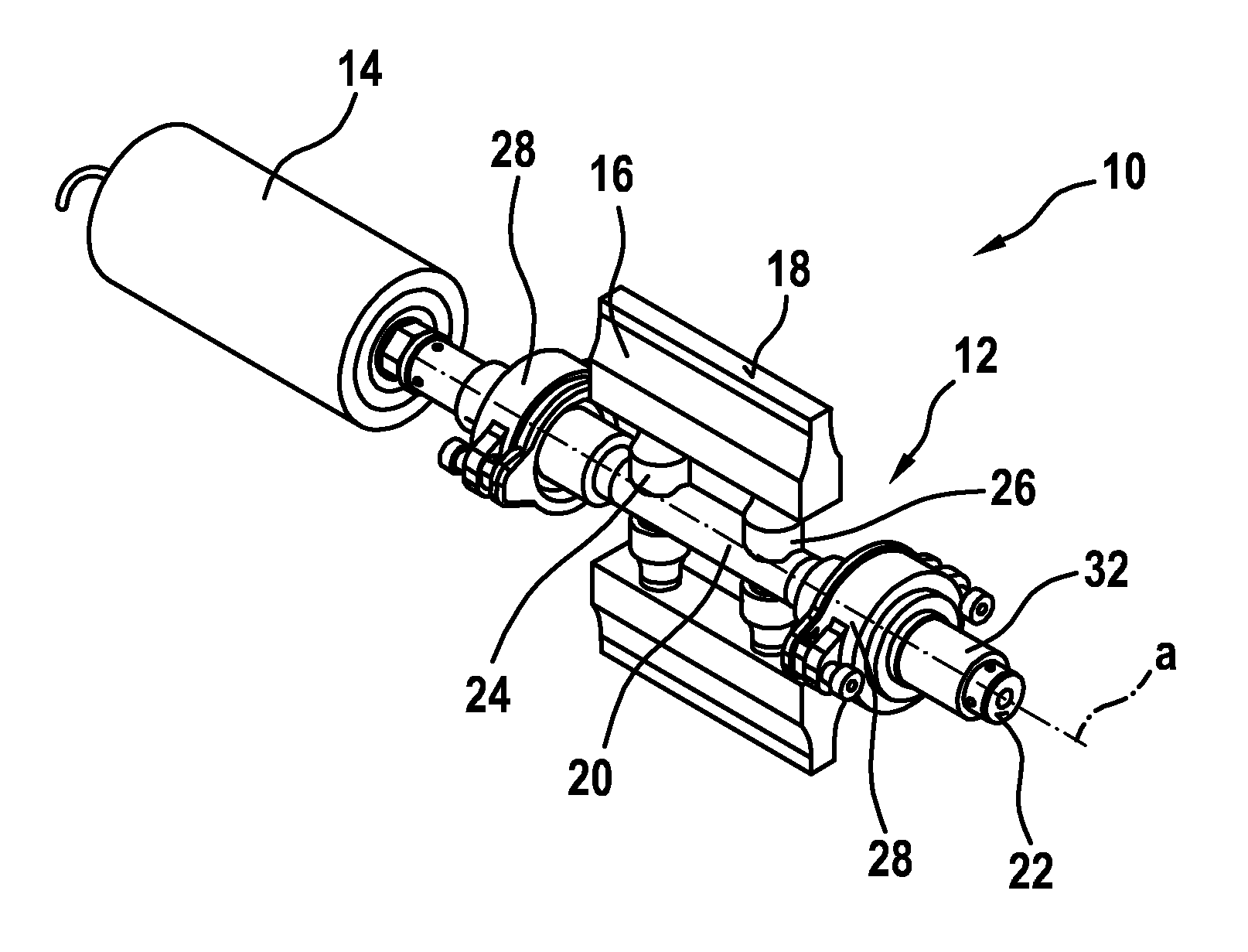

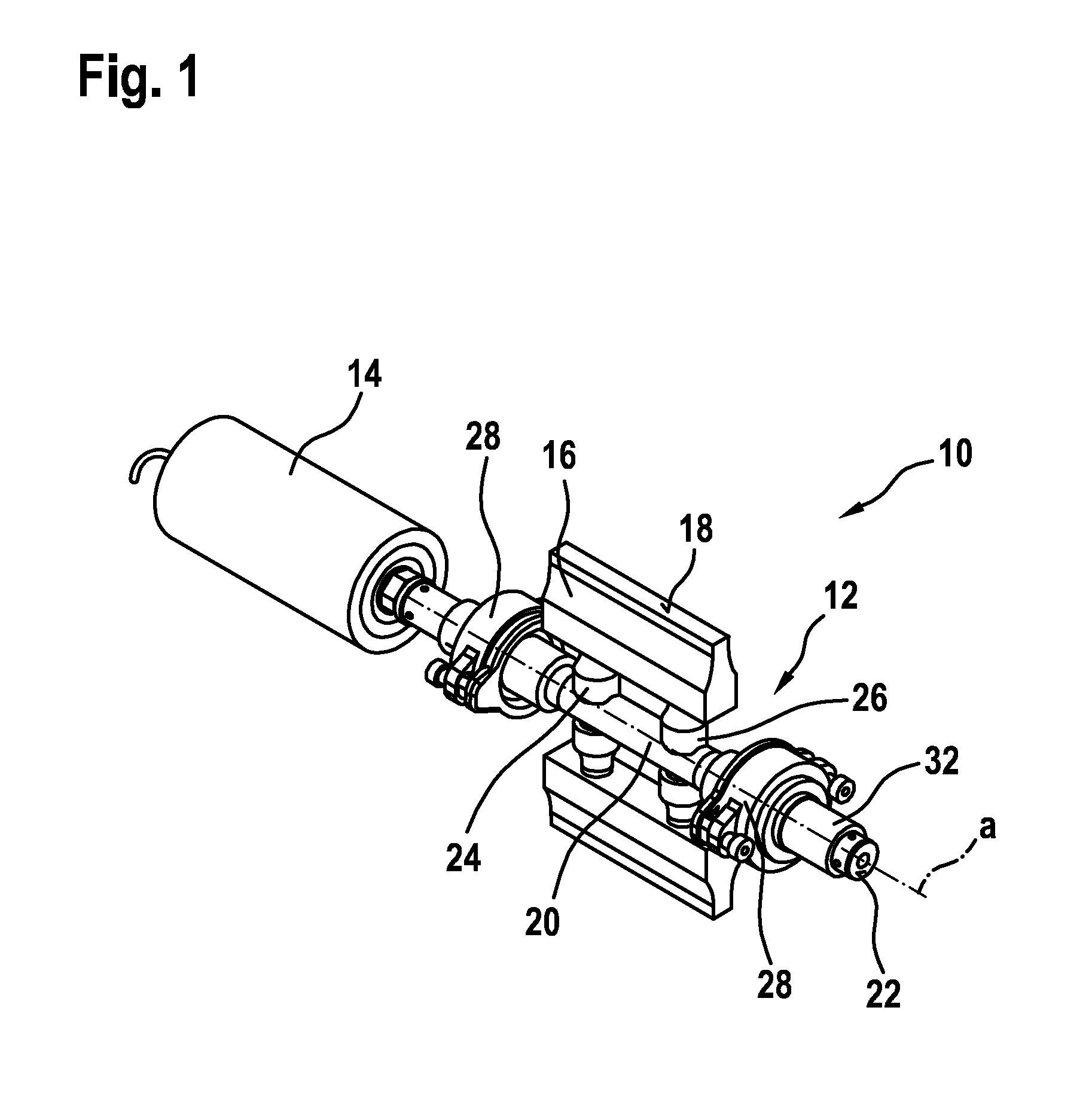

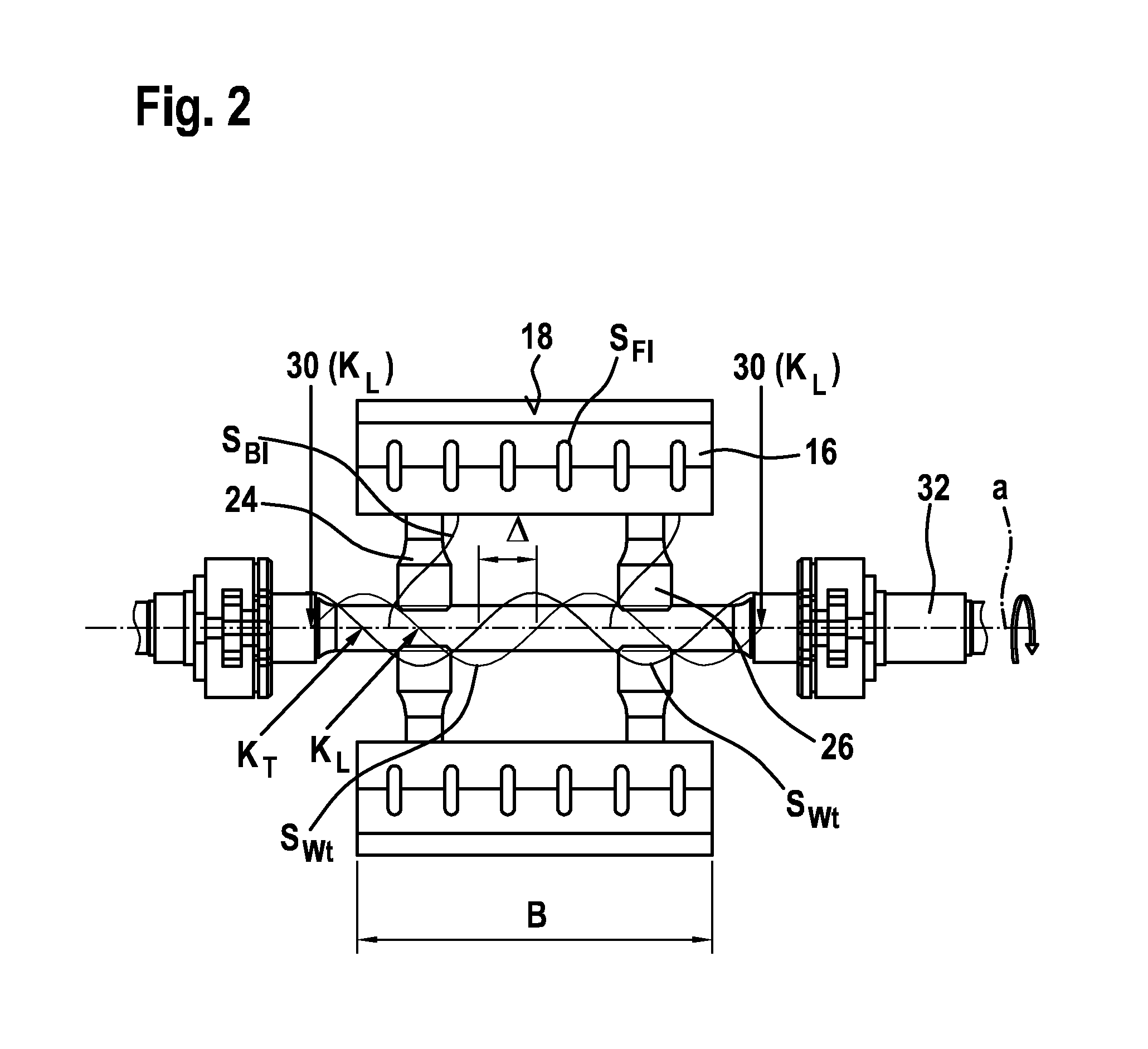

ActiveUS20130213580A1Easy to replaceGood flexibilityLaminationLamination apparatusUltrasonic weldingUltrasonic vibration

The invention relates to an ultrasonic vibration unit (10) for an ultrasonic welding device for sealing and welding material webs, comprising a sonotrode (12) connected to a converter (14) and having at least one sealing horn (16) radially protruding from an axis of rotation (a) and rotatable about the axis of rotation (a) and having a free end forming a sealing surface (18). The sonotrode (12) comprises a sonotrode shaft (20) having the axis of rotation (a). One or both end faces (22) of the sonotrode shaft (20) are connected to a converter (14) and the sealing horns (16) are attached to the sonotrode shaft (20) directly or by means of boosters (24, 26) when vibrational nodes (KL) of a longitudinal vibration (SWI) of the sonotrode shaft (20) are present.

Owner:SYNTEGON PACKAGING SYST AG

Acoustic well recovery method and device

ActiveUS20050006088A1Reduce spacingReduce trafficFluid removalVibration devicesRecovery methodRestoration method

An electro acoustic device and related method for increasing the production capacity of wells that contains oil, gas and / or water is disclosed. The electro acoustic device is submerged in the well producing zone, and includes an electric generator, one or more electro acoustic transducers, and one or more wave guide systems (sonotrodes) that include radiators which transmit vibrations into the medium under treatment. The electro acoustic device produces vibrations that stimulate the occurrence of mass transfer processes within the well. According to one or more embodiments, shear vibrations are produced in the well bore region due to the phase displacement of mechanical vibrations produced along the axis of the well, achieving alternate tension and pressure due to the superposition of longitudinal and shear waves.

Owner:SONOPLUS

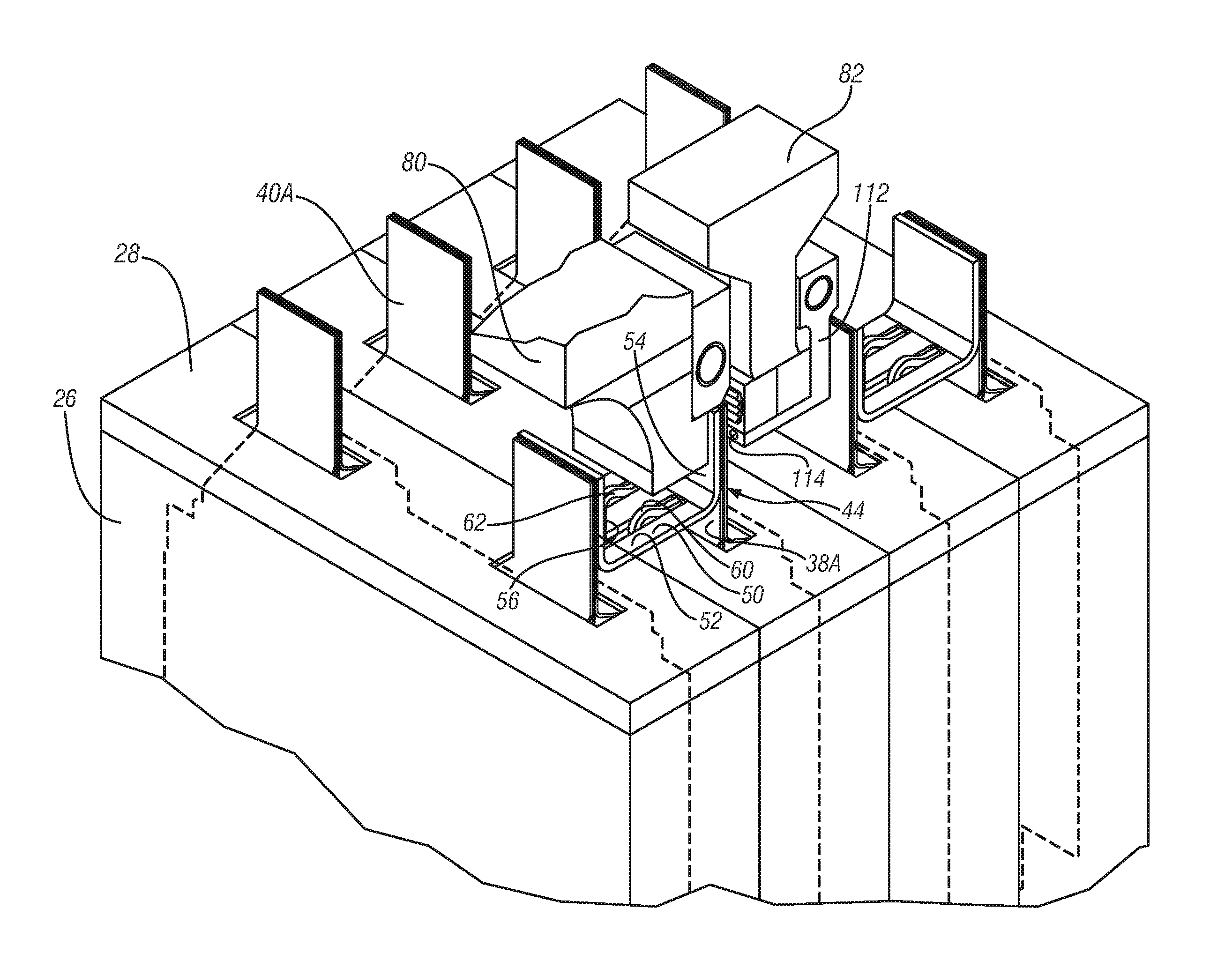

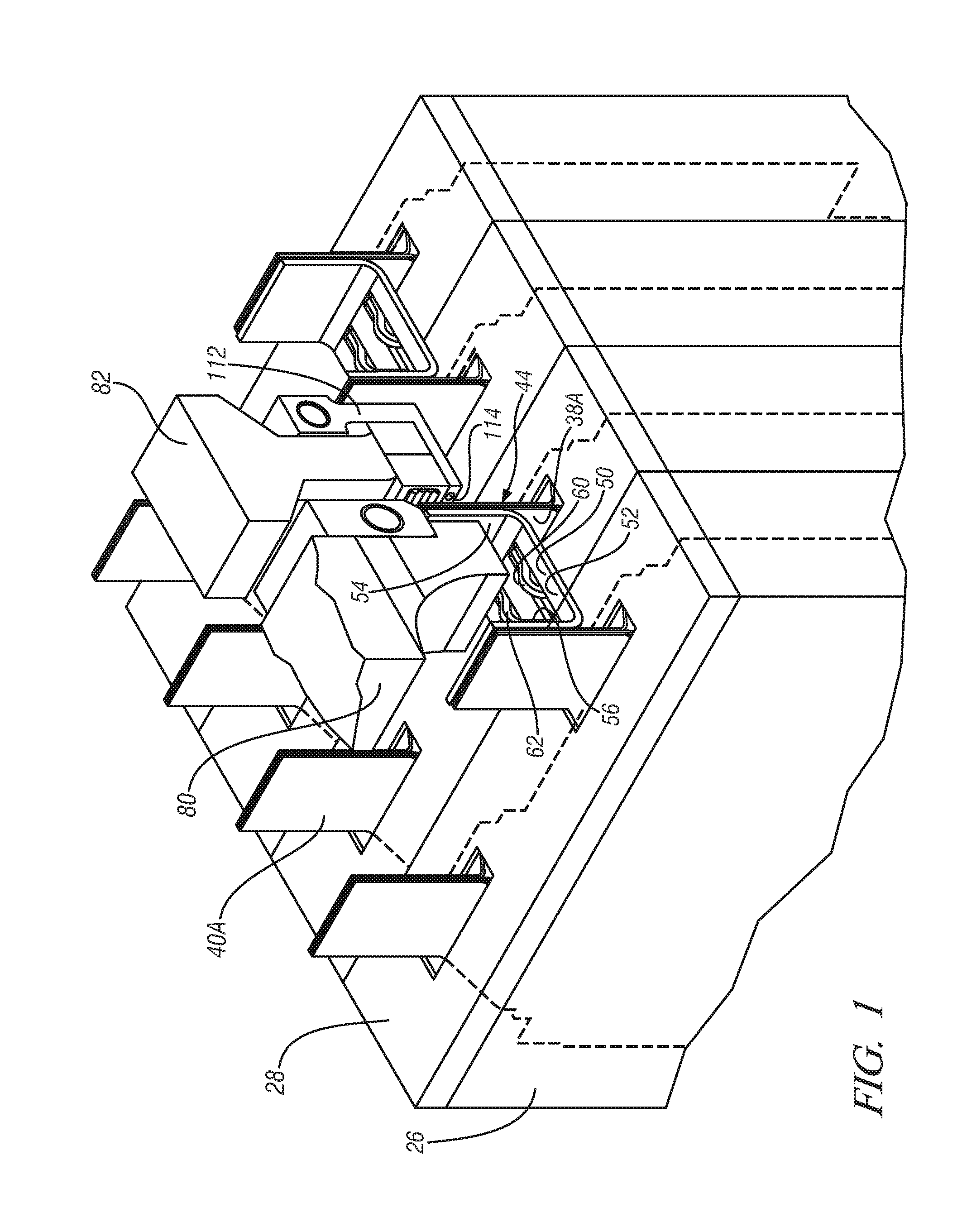

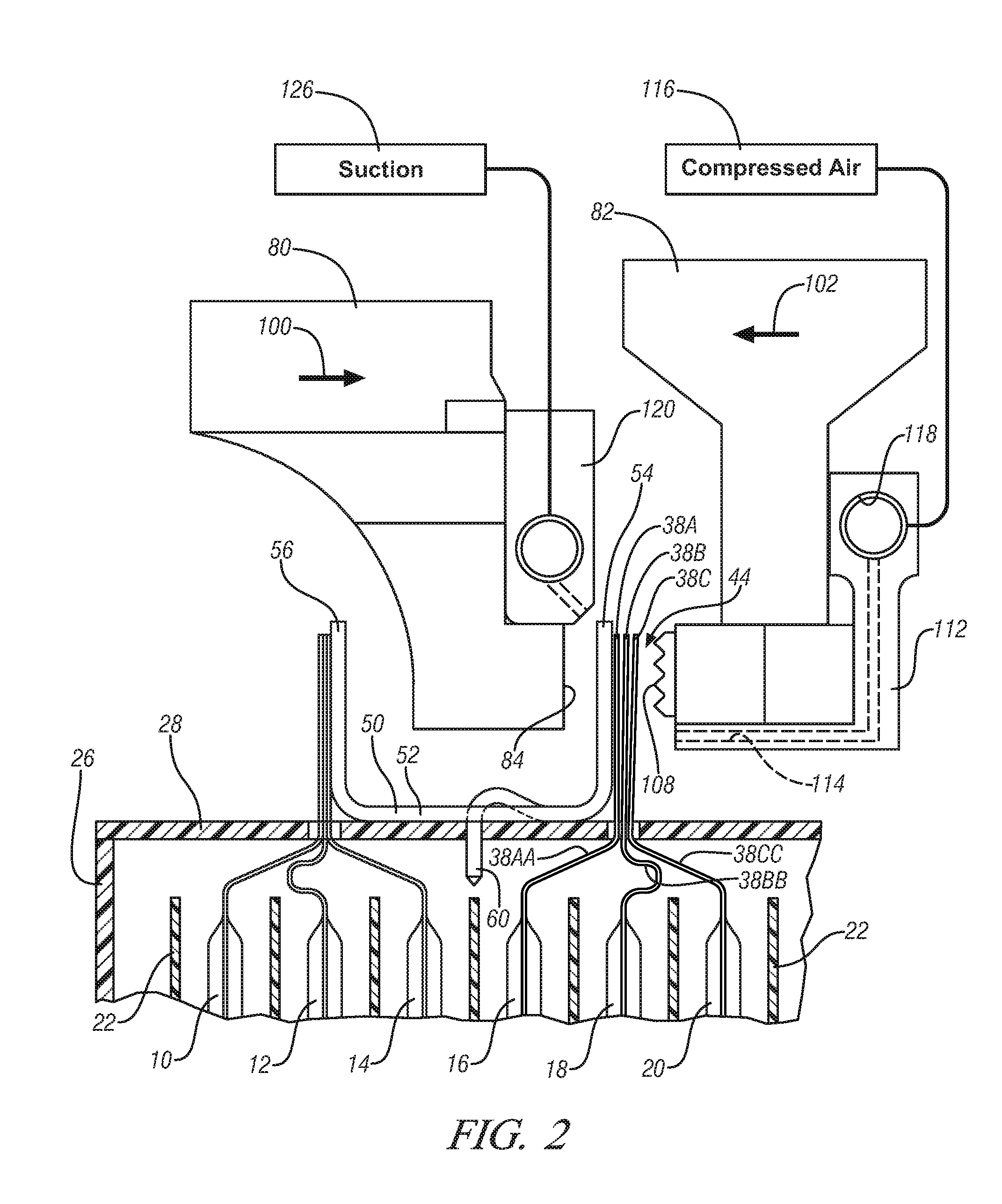

Method and Apparatus for Ultrasonic Welding of Terminals

InactiveUS20100224671A1Welding/cutting auxillary devicesAuxillary welding devicesUltrasonic weldingEngineering

A method and apparatus for welding of battery terminals to an interconnect includes: juxtaposing two or more battery cell terminals to each other to create a terminal stack including an innermost terminal and an outermost terminal; juxtaposing a battery cell interconnect with the innermost terminal of the stack; positioning an anvil in contact with the interconnect; directing an air stream against the outermost terminal so that the air stream compresses the terminal stack and urges the innermost terminal into contact with the interconnect; positioning a sonotrode horn in contact with the outermost terminal; and energizing the sonotrode horn to vibrate the terminal stack and thereby make an ultrasonic weld between the stacked terminals of the terminal stack and the interconnect. The air stream is directed at the terminal below the sonotrode horn to capture any debris and a suction removes the debris.

Owner:GM GLOBAL TECH OPERATIONS LLC

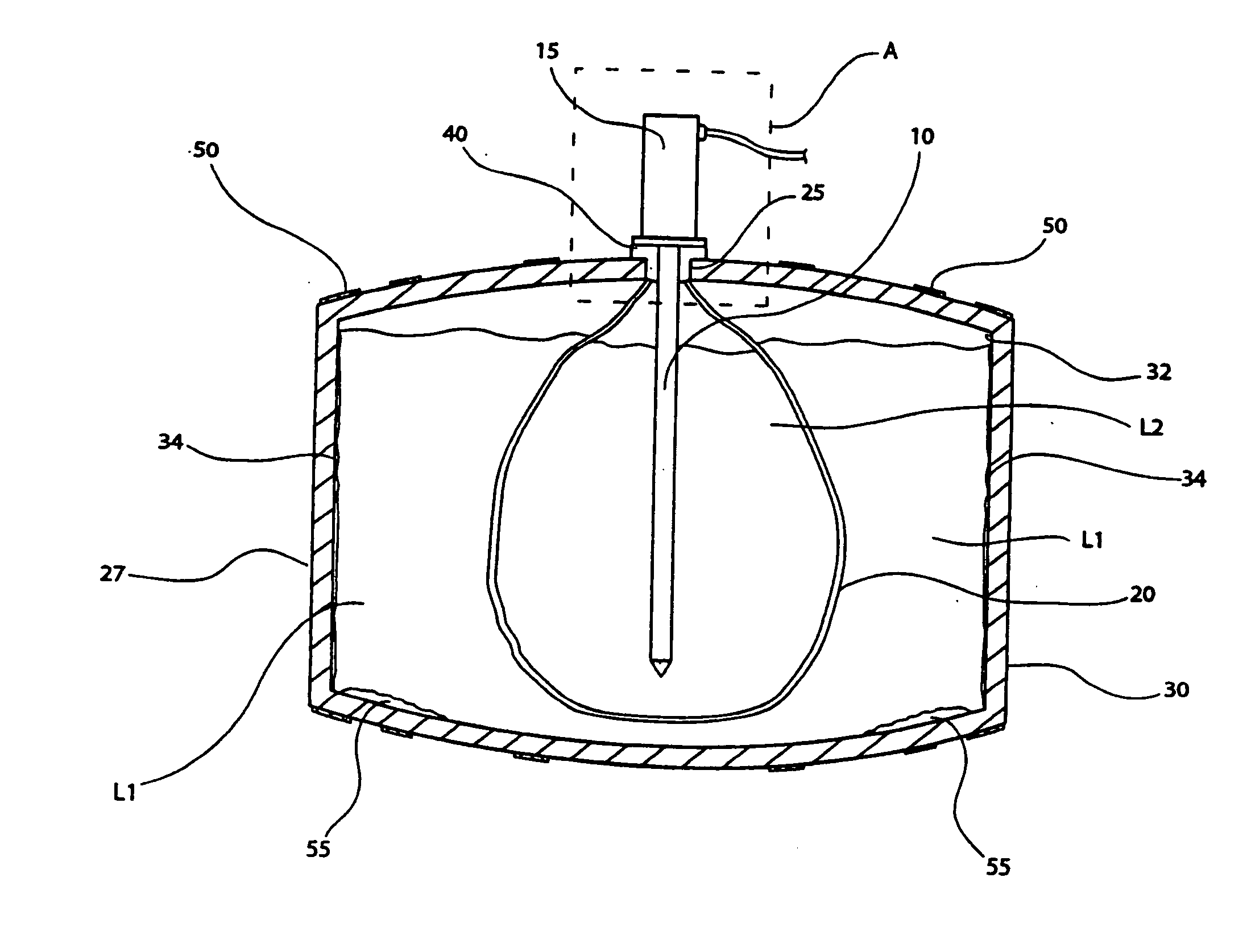

Apparatus and method of ultrasonic cleaning and disinfection

InactiveUS20060191424A1Effective cavitationLower the volumeMilk preservationSpecific water treatment objectivesEngineeringBiomedical engineering

An apparatus for and method of disinfecting the interior surfaces of barrels and destroying microorganisms is disclosed. In one embodiment, an ultrasonic apparatus includes a sonotrode encased in a sheath, placed within a bunghole of a barrel. An ultrasonic generator is connected to the sonotrode. The ultrasonic apparatus also includes an ultrasonic transducer connected to the ultrasonic generator and associated with the sonotrode.

Owner:CAVITUS PTY LTD

System for enhancing sonotrode performance in ultrasonic additive manufacturing applications

ActiveUS8082966B2Additive manufacturing apparatusRolling contact bearingsUltrasonic weldingEngineering

An ultrasonic welding assembly, comprising: a sonotrode having a single welding region and two nodal regions formed on either side of the welding region; a mounting plate for supporting the sonotrode having a force application region on the upper surface thereof; at least one ultrasonic transducer connected to the sonotrode; at least one diaphragm spring disposed between the ultrasonic transducer and the sonotrode; at least one roller bearing connected to the diaphragm spring; at least two linear guides connected to the roller bearing, wherein the at least two linear guides are connected to the mounting plate and support the roller bearing and the sonotrode in a flexible manner; and first and second low-friction linear bearings in contact with nodal regions for the application of downward force to the sonotrode, wherein the first and second linear bearings are connected to the mounting plate.

Owner:FABRISONIC

Method for joining two objects and corresponding joining element

A first and a second object (1 and 2) are joined with the aid of a joining element (8) including at least in the region of its distal and proximal ends (8.1 and 8.2) a thermoplastic material. Two blind holes (5 and 6) facing each other are provided in the two objects (1 and 2) and the joining element (8) is positioned in the blind holes such that its distal and proximal ends (8.1) are in contact with the bottom faces of the blind holes and such that there is a gap (9) between the two objects (1 and 2). This assembly is then positioned between a support (3) and a sonotrode (4). The sonotrode (4) and the support (3) are forced towards each other, while the sonotrode (4) is vibrated, thereby liquefying at least part of the material having thermoplastic properties, there, where the joining element ends (8.1 and 8.2) are pressed against the bottom faces of the holes (5 and 6) and allowing the liquefied material to infiltrate into pores of the hole surfaces or unevennesses or openings provided in the hole surfaces.

Owner:WOODWELDING

Stepped Sonotrode and Anvil Energy Director Grids for Narrow/Complex Ultrasonic Welds of Improved Durability

InactiveUS20140338842A1Reduce material costsAdd equipmentLaminationLamination apparatusGrid patternEnergy control

A specially designed sonotrode and anvil are adapted to be used in combination for ultrasonic welding of work pieces, to produce a narrower weld region, but one exhibiting greater durability, thereby permitting use of less packaging material. The contact surfaces comprise a surface of the anvil having a plurality of energy directors, where the plurality of energy directors are arranged into a three-dimensional grid pattern to be capable of distributed vibration-transmissive contact. The energy directors may comprise a series of plateau surfaces being regularly spaced apart from each other in a first direction, and in a second direction that is orthogonal to the first direction, to form the grid pattern. The rectangular-shaped plateaus may be spaced apart by valleys. Engagement of the energy directors of the anvil with the corresponding surface of the sonotrode may cause minor elastic deformation of work pieces positioned therebetween prior to ultrasonic welding.

Owner:RINCO ULTRASONICS USA

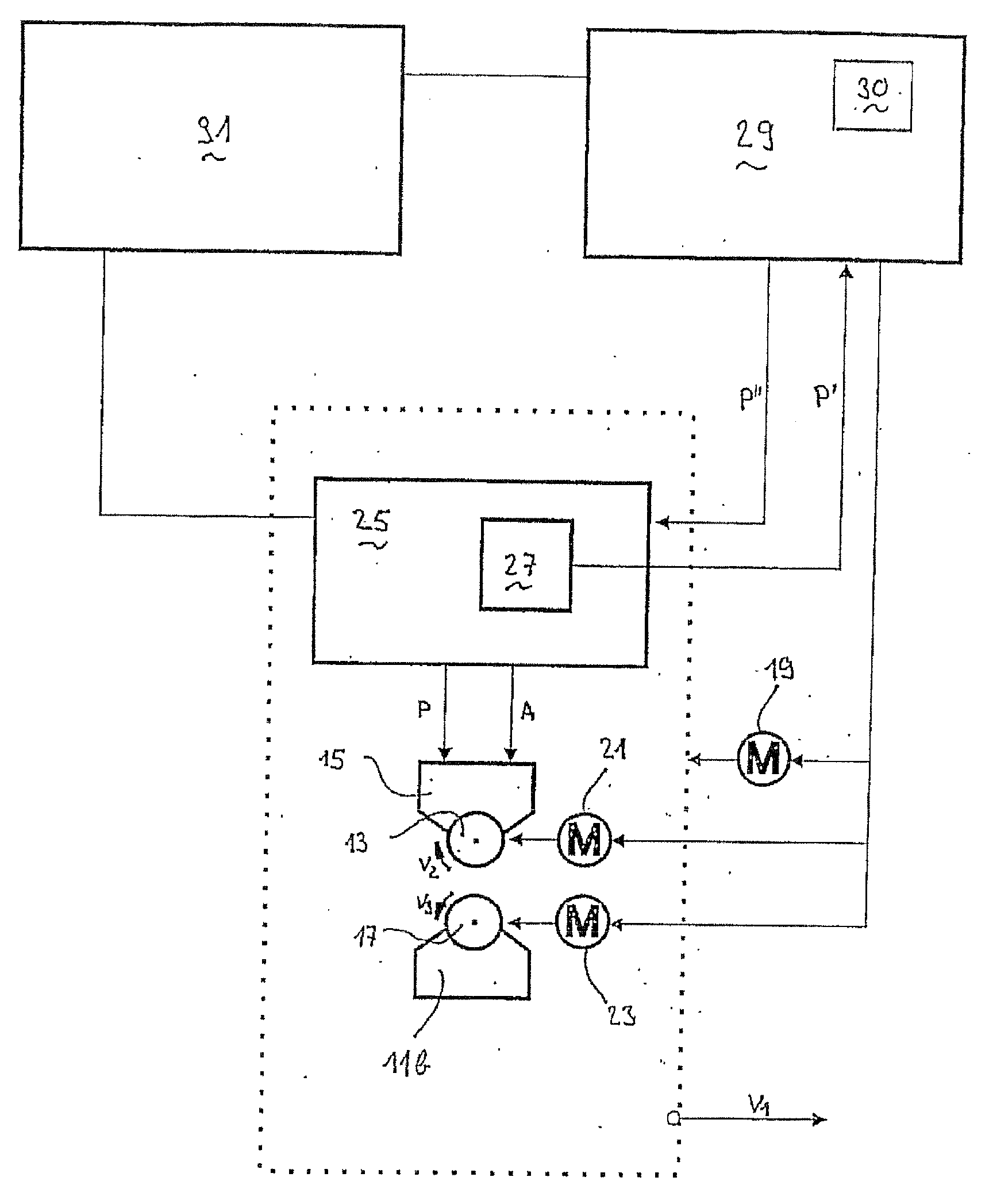

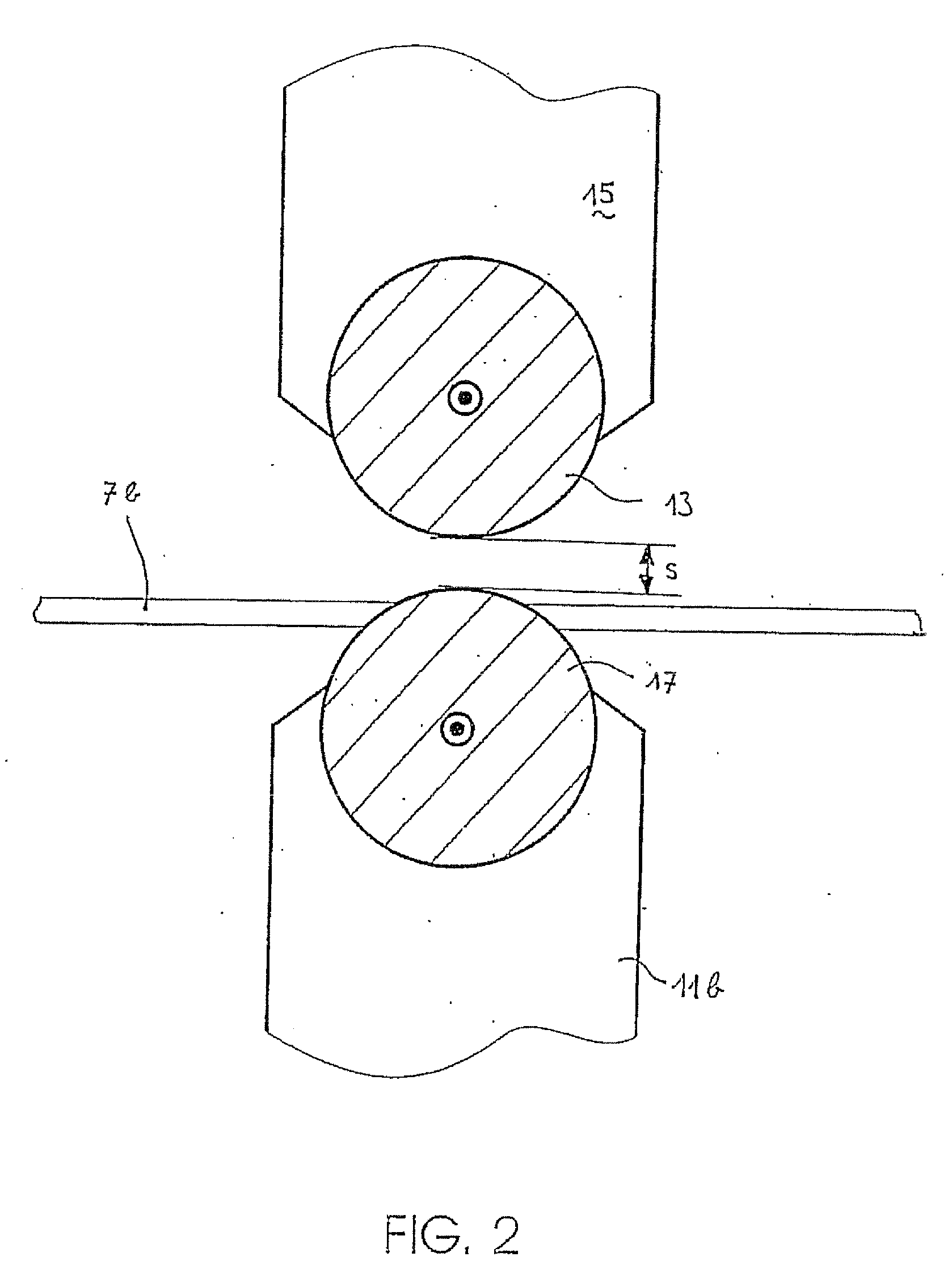

Ultrasound welding device

InactiveUS20070158012A1Reduce energy consumptionPower peakMechanical working/deformationLaminationLoop controlUltrasonic welding

The ultrasonic welding device (1) comprises a continuously operable roller sonotrode (13). The power of the roller sonotrode (13) may be closed-loop controlled depending on other welding parameter in a manner such that long welding seams or adhesive seam with a uniform quality may be manufactured. The method may be used for manufacturing canopies, tarpaulins, or pieces of clothing

Owner:JENTSCHMANN ZURICH

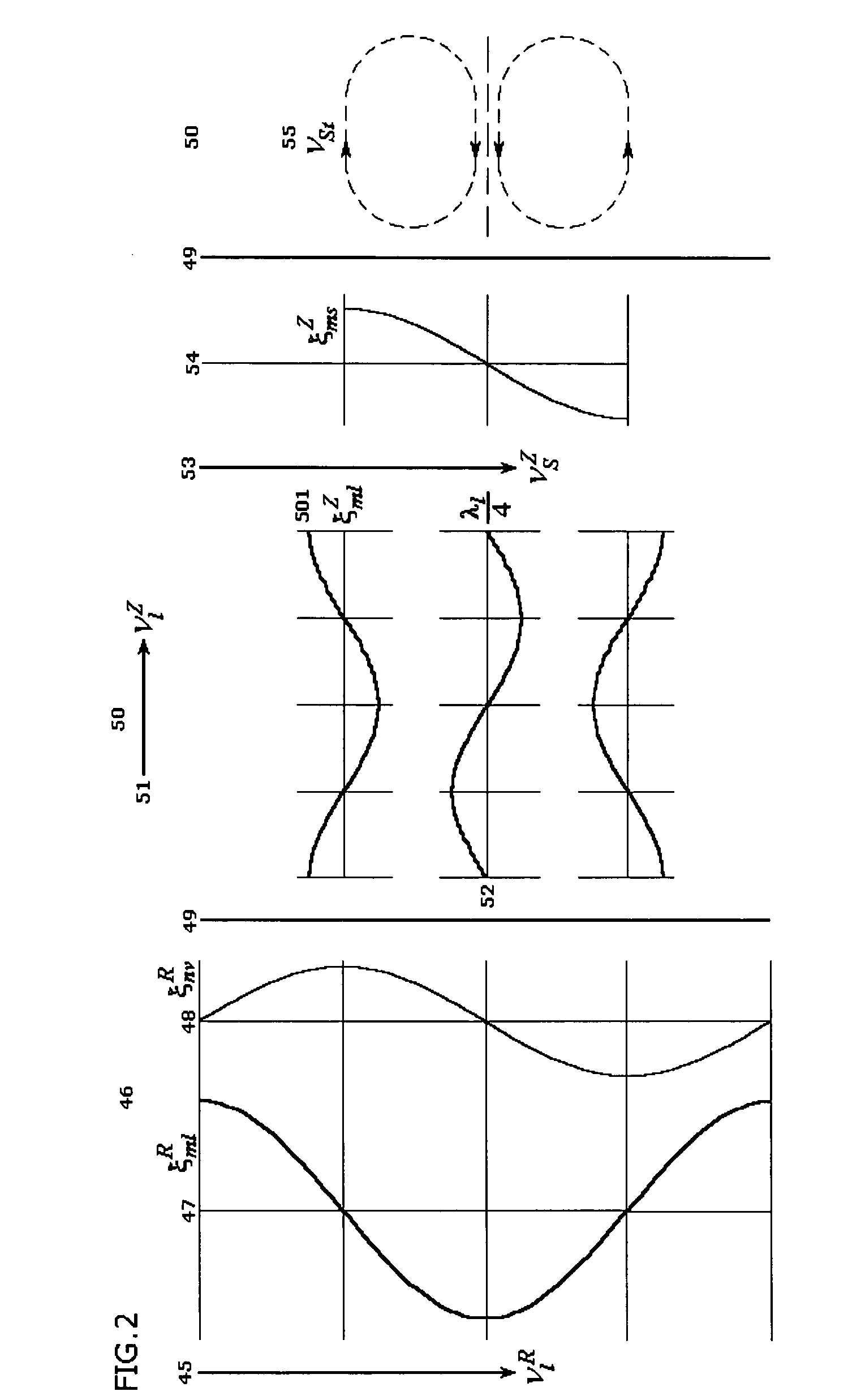

Sonotrode

ActiveUS20190091490A1Ultrasound therapySurgical instruments for heatingReduced subcutaneous fatLongitudinal vibration

Disclosed are methods and devices for treatment of subcutaneous fat by simultaneously transdermally inducing both ultrasonic transverse vibrations and ultrasonic longitudinal vibrations in subcutaneous tissue, for example for reduction of subcutaneous fat.

Owner:ALMA LASERS LTD

Sonotrode and anvil energy director grids for narrow/complex ultrasonic welds of improved durability

InactiveUS8376016B2Reduce material costsAdd equipmentLaminationLamination apparatusGrid patternEnergy control

A specially designed sonotrode and anvil are adapted to be used in combination for ultrasonic welding of work pieces, to produce a narrower weld region, but one exhibiting greater durability, thereby permitting use of less packaging material. The contact surfaces comprise a surface of the anvil having a plurality of energy directors, where the plurality of energy directors are arranged into a three-dimensional grid pattern to be capable of distributed vibration-transmissive contact. The energy directors may comprise a series of plateau surfaces being regularly spaced apart from each other in a first direction, and in a second direction that is orthogonal to the first direction, to form the grid pattern. The rectangular-shaped plateaus may be spaced apart by valleys. Engagement of the energy directors of the anvil with the corresponding surface of the sonotrode may cause minor elastic deformation of work pieces positioned therebetween prior to ultrasonic welding.

Owner:RINCO ULTRASONICS USA

Pedestal mounted ultrasonic welding device

The sonotrode and anvil of co-pending application Ser. No. 12 / 925,652, for advanced ultrasonic welding of work pieces, are readily incorporated into new form-fill-seal machines, but existing machines with heat-seal stations pose difficult problems for swapping of the sealing packages. Kits enabling heat station replacement, with the further improved sonotrode and anvil disclosed herein, comprise: a housing; a linear rail fixed thereto; anvil and sonotrode support members; and a parallel gripper. Each of the anvil and sonotrode support members is slidably attached to the rail(s) and are also connected to a respective piston of the gripper, permitting actuation of each through cycling of the gripper pistons. The improved sonotrode / anvil combination each comprise a corresponding plurality of energy directors arranged into a three-dimensional grid pattern to produce a narrower weld region, but one exhibiting greater durability, thereby permitting use of less packaging material, and which may also weld a company logo into the workpieces.

Owner:RINCO ULTRASONICS USA

Retrofit of a form-fill-seal machine heat station with an advanced ultrasonic welding kit

Advanced ultrasonic welding components of co-pending application Ser. No. 12 / 925,652 are readily incorporated into new form-fill-seal machines, but owners of existing machines utilizing heat-seal stations were unsuccessful at swapping the sealing packages. Retrofit kits to a replace heat sealing station with an advanced ultrasonic sonotrode and anvil comprise: a housing; a linear rail fixed thereto; first and second bearing carriages being slidable upon the rail; and first and second fluidic muscles. Each of the fluidic muscles is mounted with a first end fixed to a respective housing wall, and a second end fixed to a respective bearing carriage, permitting actuation of each carriage through pressurization and depressurization of the muscles. The advanced anvil and sonotrode may be secured to respective carriages. In-line arrangements of anvil / sonotrode, bearing carriages, the first fluidic muscle, and the second fluidic muscle provides a narrow profile, permitting side-by-side kit installations for retrofits accomplishing duplex sealing on a horizontal machine.

Owner:RINCO ULTRASONICS USA

Method and device for ultrasound treatment of a fabric

A method for ultrasound treatment of at least one fabric. The fabric is passed through a working gap between a sonotrode connected with an ultrasound vibration unit and a counter-tool, and is exposed to an ultrasound effect in the working gap. The fabric or fabrics to be treated are subjected to pretreatment in a device before passing through the working gap.

Owner:EDUARD KUSTERS MASCHFAB GMBH & CO KG

Ultrasonic welding apparatus

InactiveUS20060255091A1Reduce manufacturing costEffective installationWelding/cutting auxillary devicesLaminationUltrasonic weldingEngineering

An ultrasonic welding apparatus having an extractable sonotrode. The sonotrode having a non-threaded outer peripheral surface and a tapered mating surface that meets with a correspondingly tapered aperture formed in the end of the reed of the ultrasonic welding apparatus. In the preferred embodiment the ultrasonic welding apparatus includes a sonotrode removal mechanism for extracting the sonotrode from the reed.

Owner:FORD MOTOR CO +2

System for antiseptic surgery

InactiveUS20030023193A1Optimum energy flowGood body shapeUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyProsthesisSeptic wound

A method is furnished for a treatment of septic wounds. A hand piece of a sonotrode is connected to a liquid storage. Access to a wound is furnished to the sonotrode. A liquid atomized by ultrasound is delivered to the wound through a sonotrode channel disposed in the sonotrode. Bacteria in the area of the wound are destroyed by the ultrasound emitted by the sonotrode. The method allows to remove a prosthesis not longer desired from a patient. The area left open by the removed prosthesis and / or a bone is filled with a liquid. The sonotrode is then entered into the liquid for propagating ultrasound through the liquid and thereby destroying bacteria present in the liquid.

Owner:SORING MEDIZINTECHN

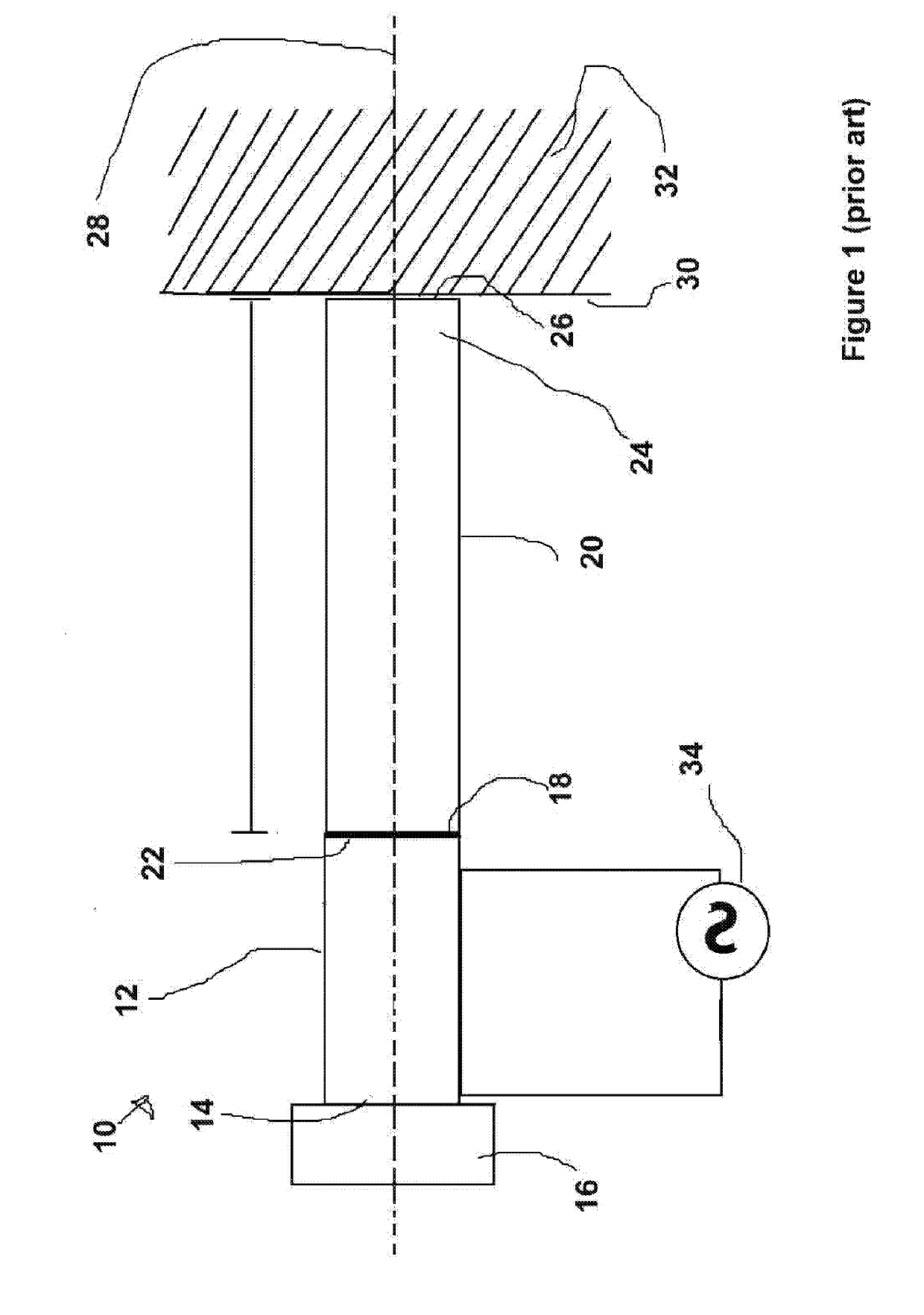

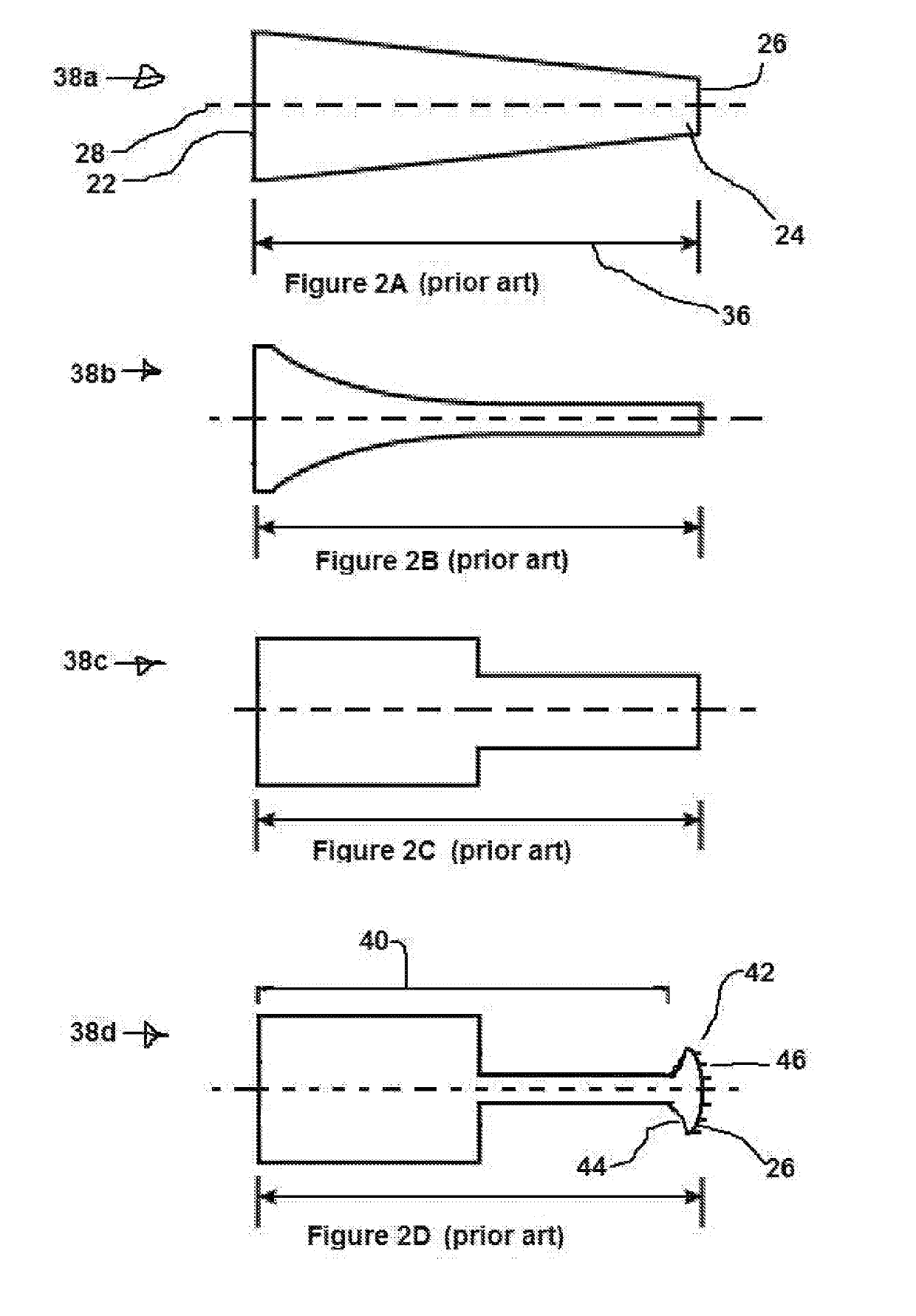

Closed-loop control of power used in ultrasonic consolidation

Disclosed is method of enhancing bond quality in an ultrasonic consolidation process using a sonotrode having a power output level. The preferred embodiment includes the steps of inputting a plurality of process parameters associated with a localized geometry over which the ultrasonic consolidation is occurring, and varying the relationship between these parameters to control the power output level to optimize bond quality between layers of material as they are consolidated. The process parameters, alone or in combination, may include the speed of the consolidation; the amplitude of the ultrasonic energy; applied force; and / or temperature.

Owner:SOLIDICA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com