Patents

Literature

630results about How to "Improve bonding quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

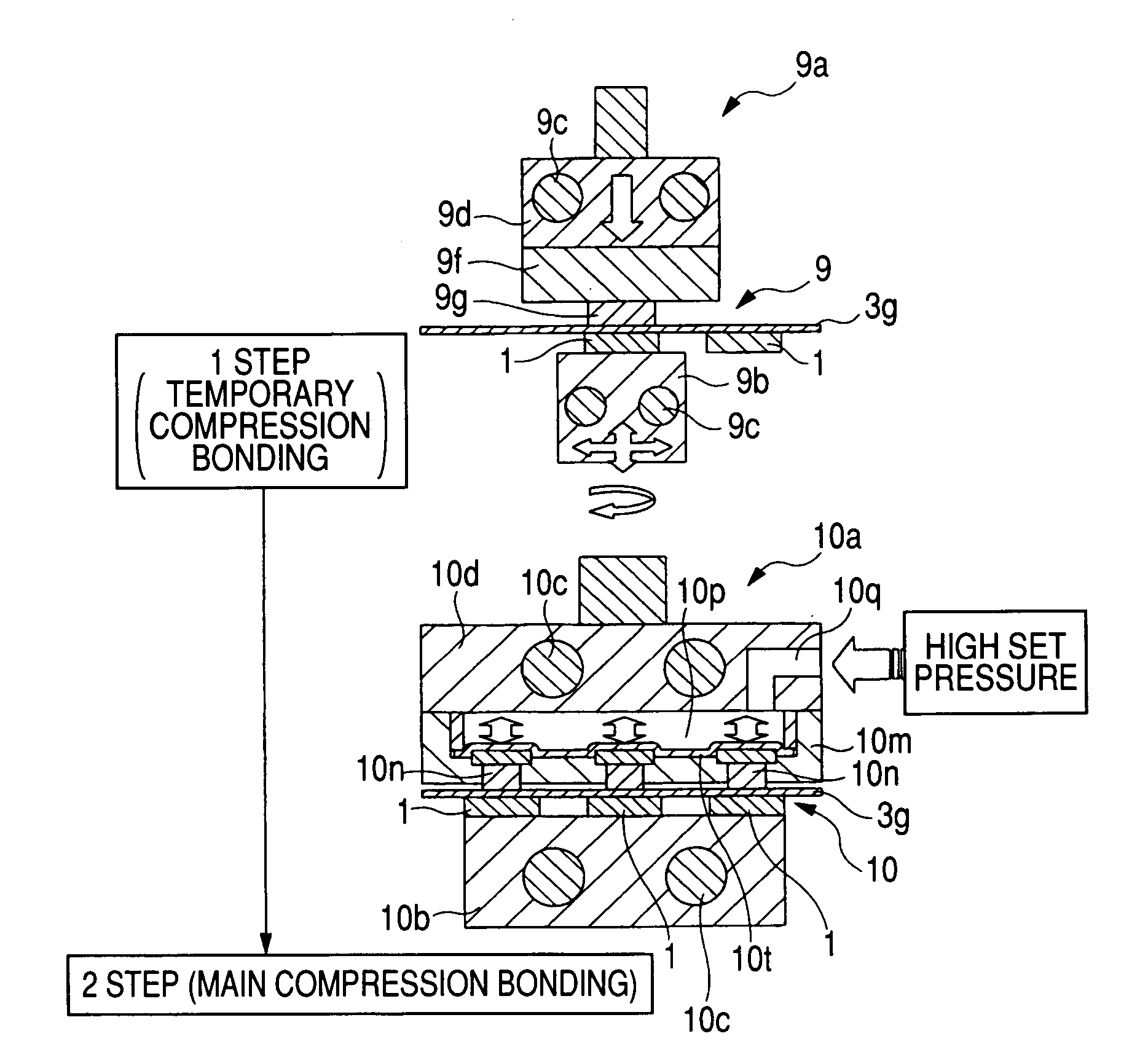

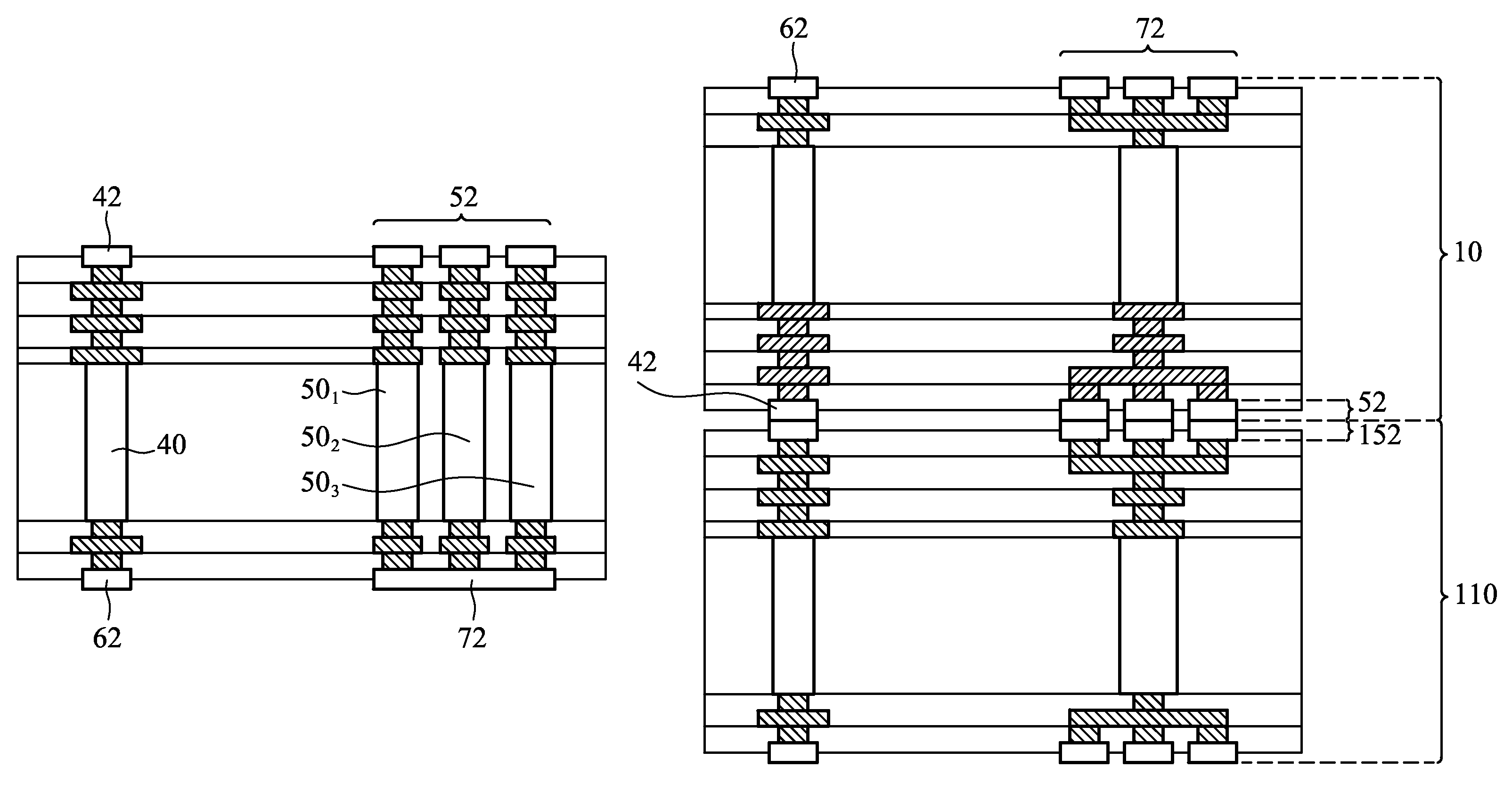

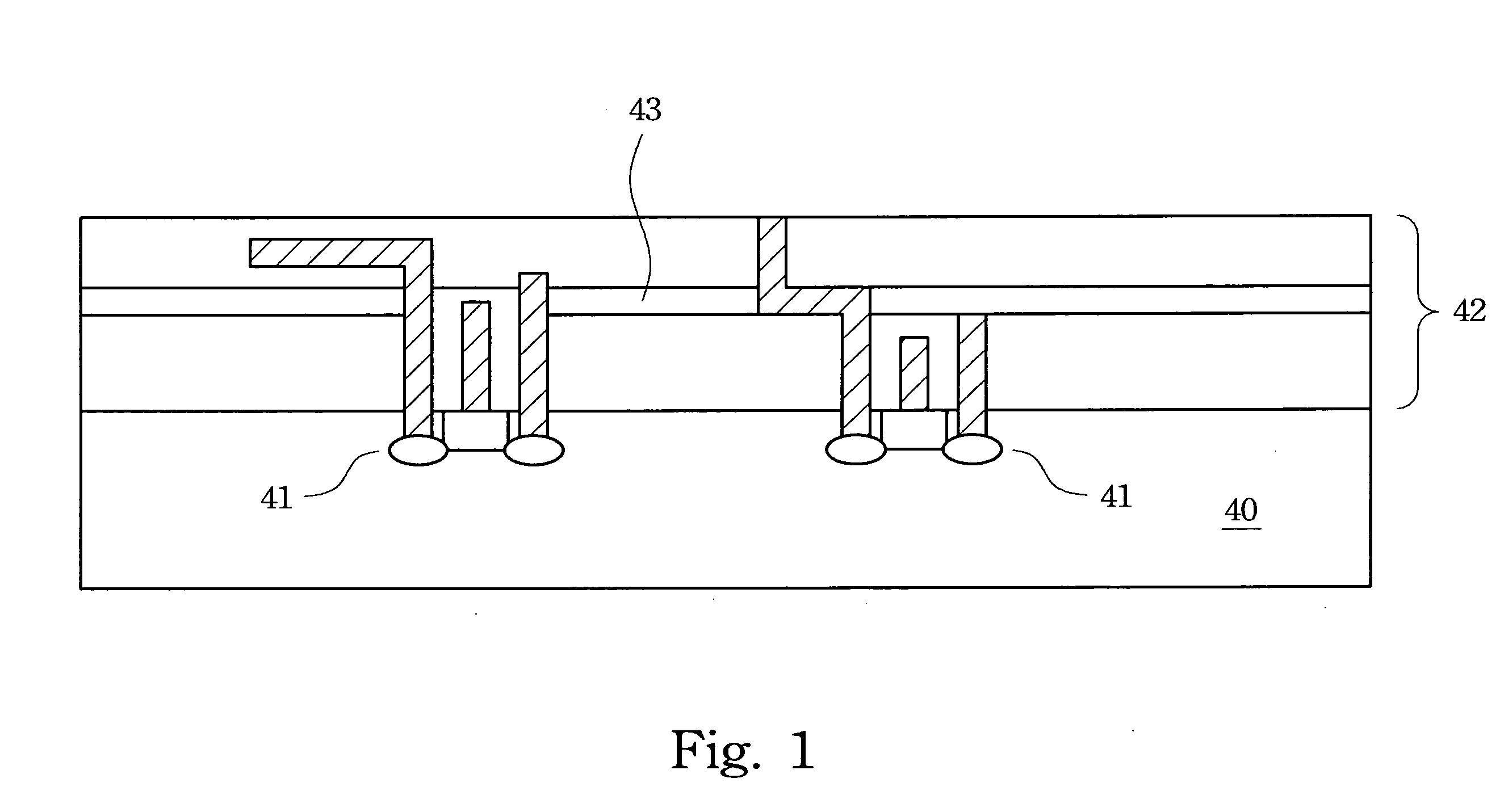

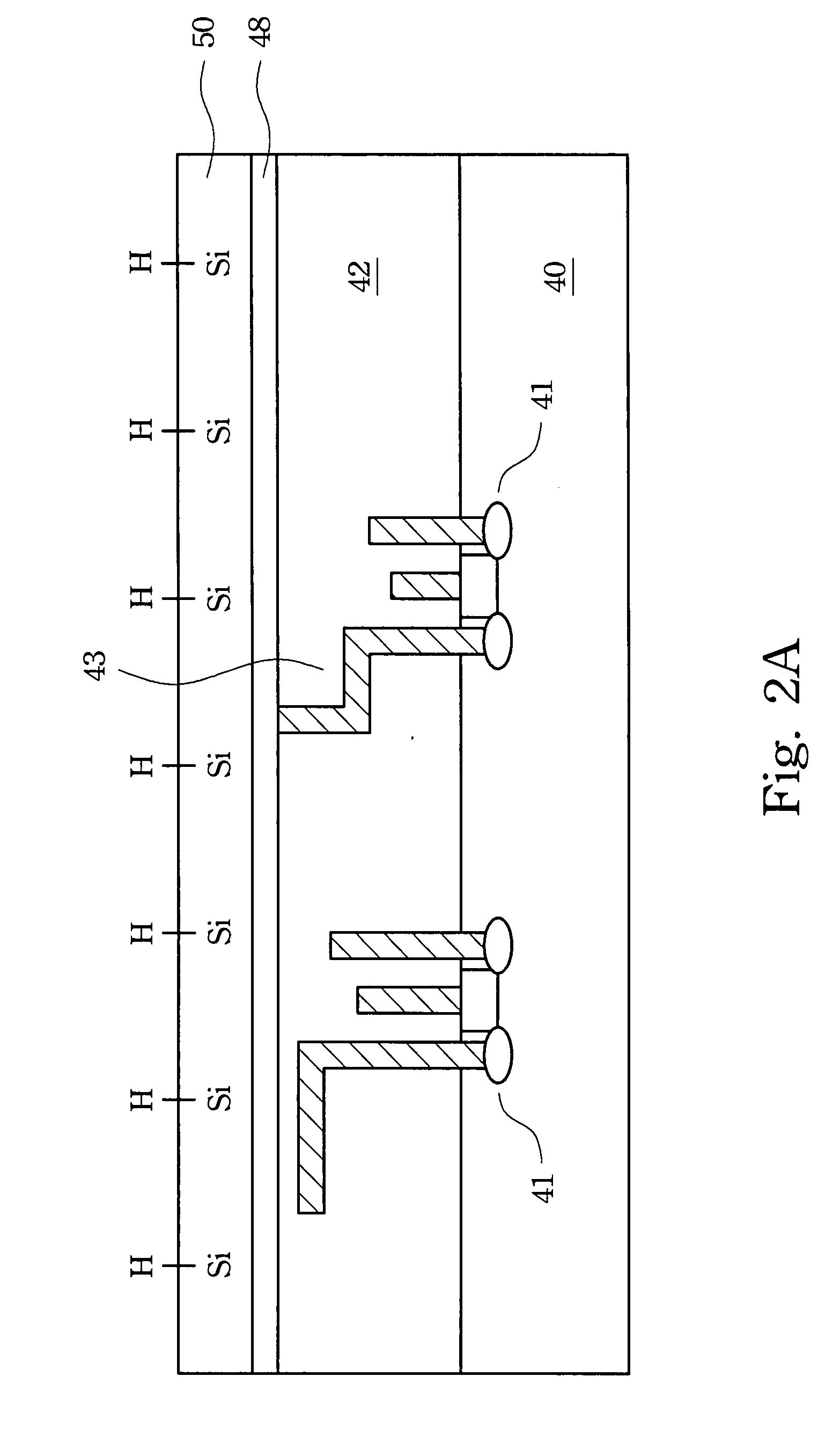

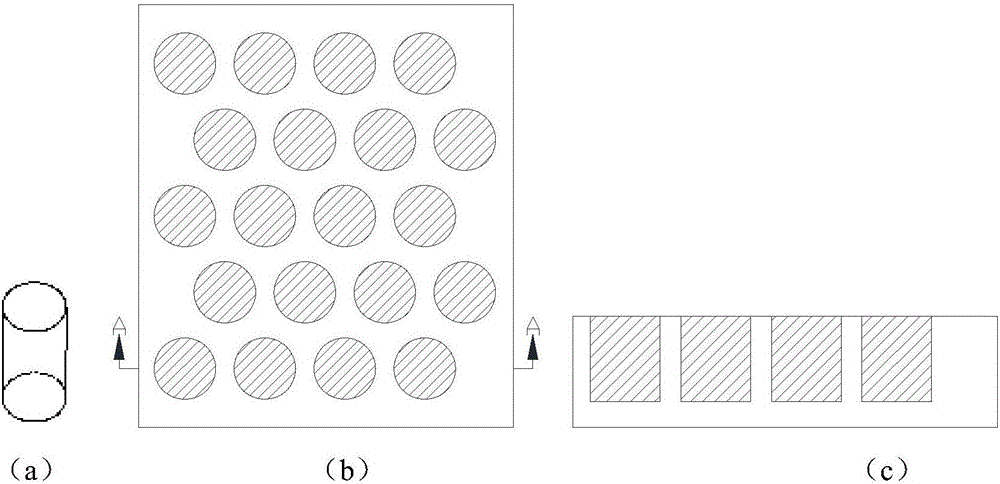

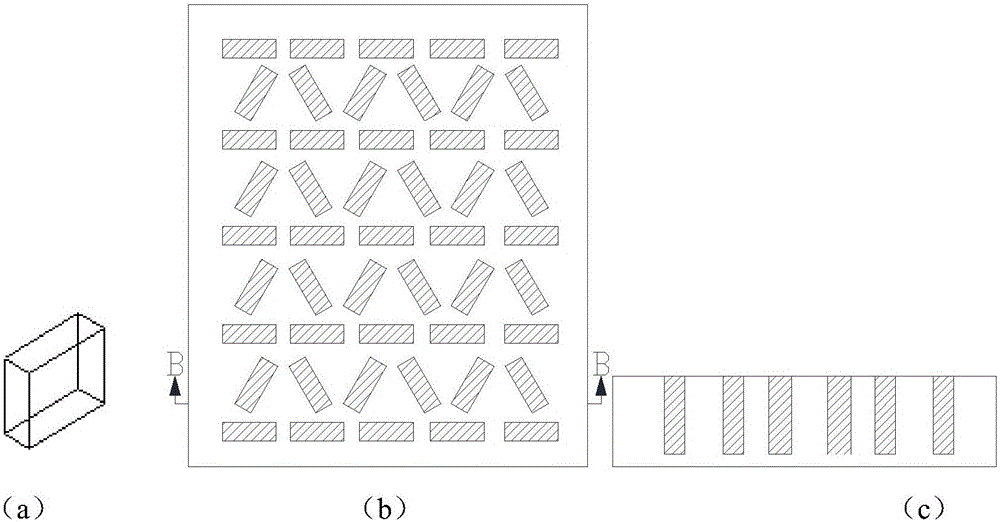

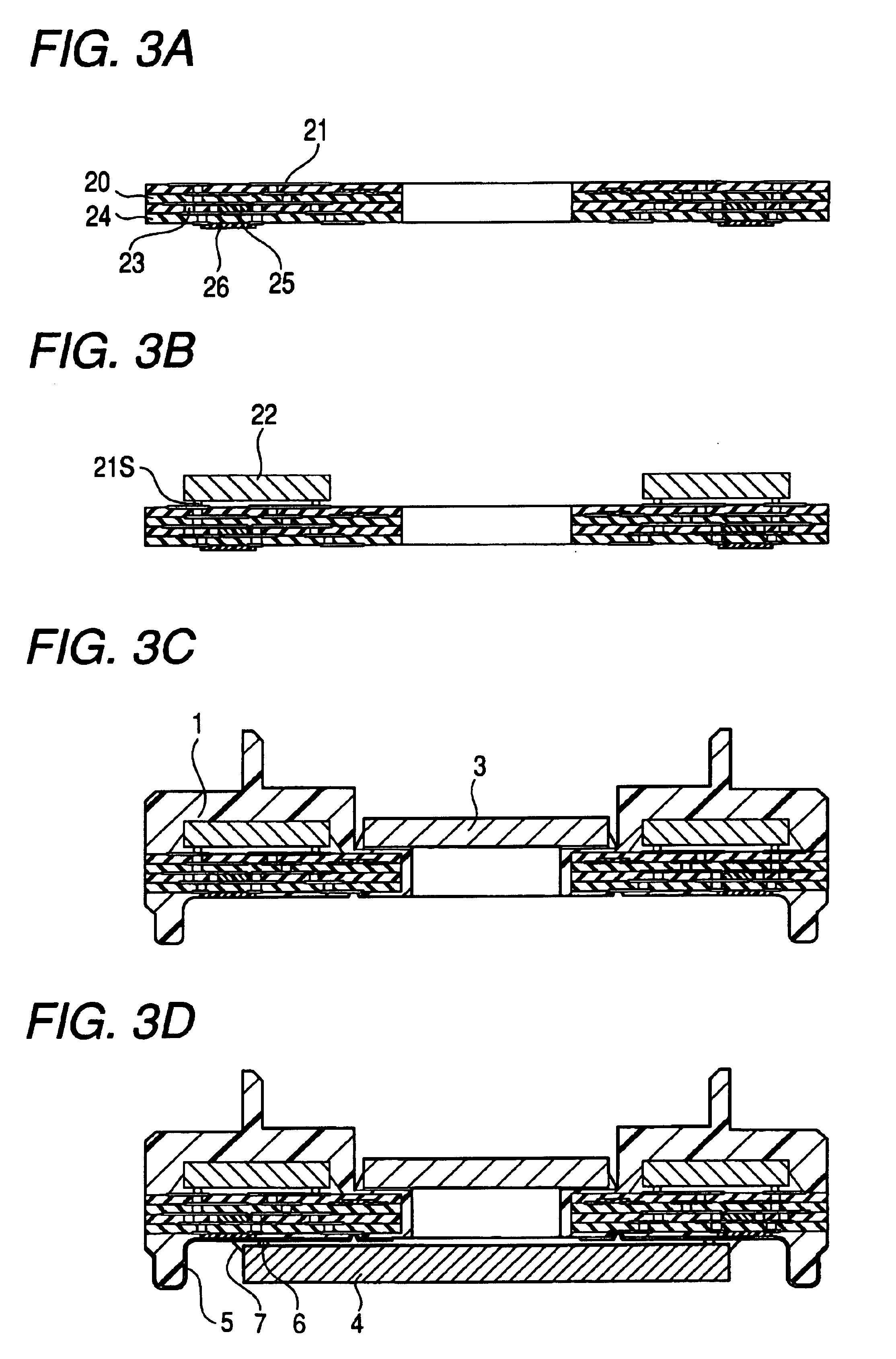

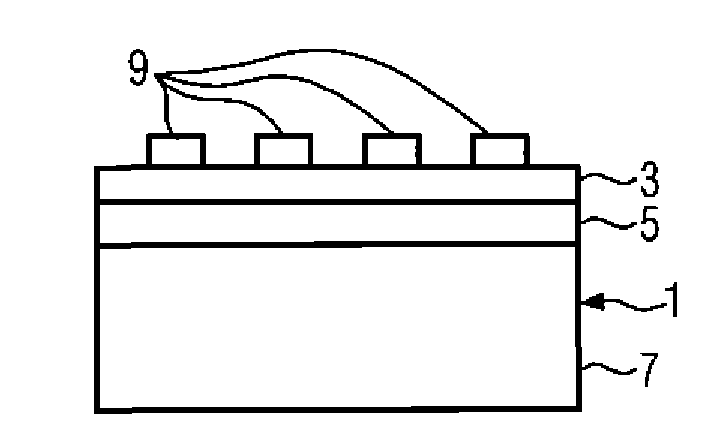

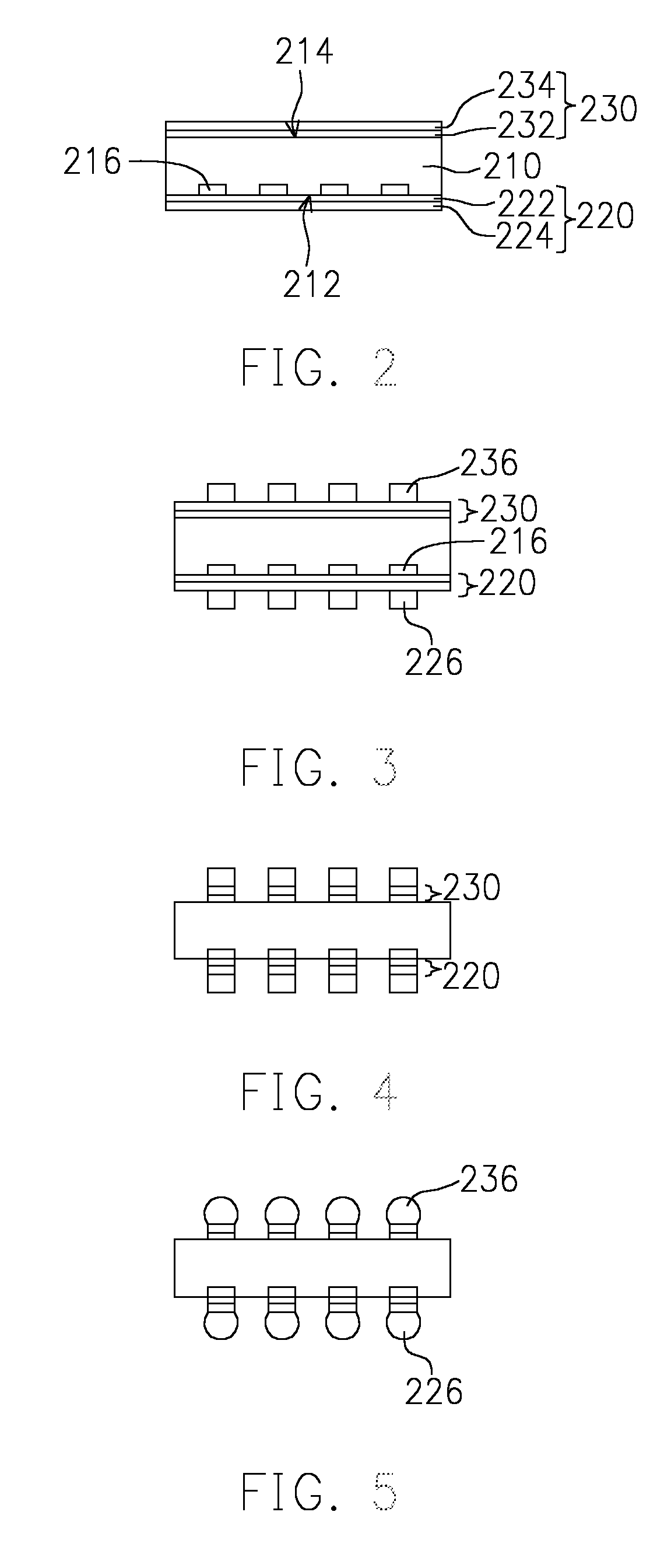

Fabrication method of semiconductor integrated circuit device

InactiveUS20050061856A1Improve productivityImprove bonding qualitySemiconductor/solid-state device detailsSolid-state devicesProduction rateSemiconductor chip

Productivity is to be improved in assembling a semiconductor integrated circuit device. A matrix substrate is provided and semiconductor chips are disposed on a first heating stage, and then the matrix substrate is disposed above the semiconductor chips on the first heating stage. Subsequently, the semiconductor chips and the matrix substrate are bonded to each other temporarily by thermocompression bonding, while heating the chips directly by the first heating stage. Thereafter, the temporarily bonded matrix substrate is disposed on a second heating stage adjacent to the first heating stage, and then, on the second heating stages, the semiconductor chips are thermocompression-bonded to the matrix substrate, while being heated directly by the second heating stage.

Owner:RENESAS ELECTRONICS CORP +1

Adhesive tape for outdoor use

InactiveUS20030113534A1Improve initial viscosityReduce adhesionThin material handlingPressure sensitive film/foil adhesivesUltravioletChemistry

Transparent, UV and heat resistant adhesive compositions and associated methods of manufacturing using such compositions are provided. Exemplary methods of use include the utilization of the provided adhesive compositions as part of tape to be used outdoors where UV exposure is high. The present invention also provides a simple one-pass calendering process whereby the UV resistant adhesive compositions may be formed and extruded directly onto tape backing.

Owner:SCAPA NORTH AMERICA

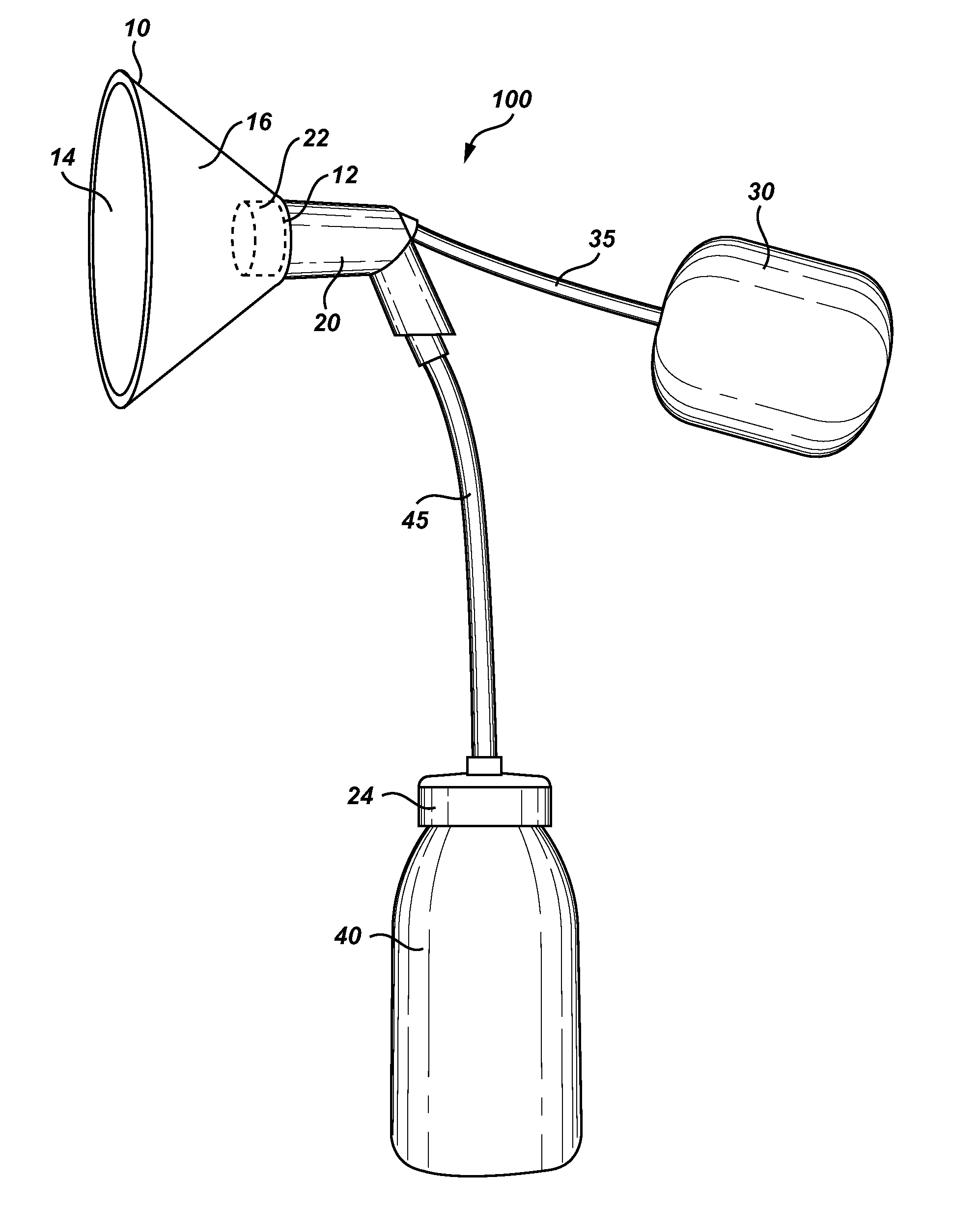

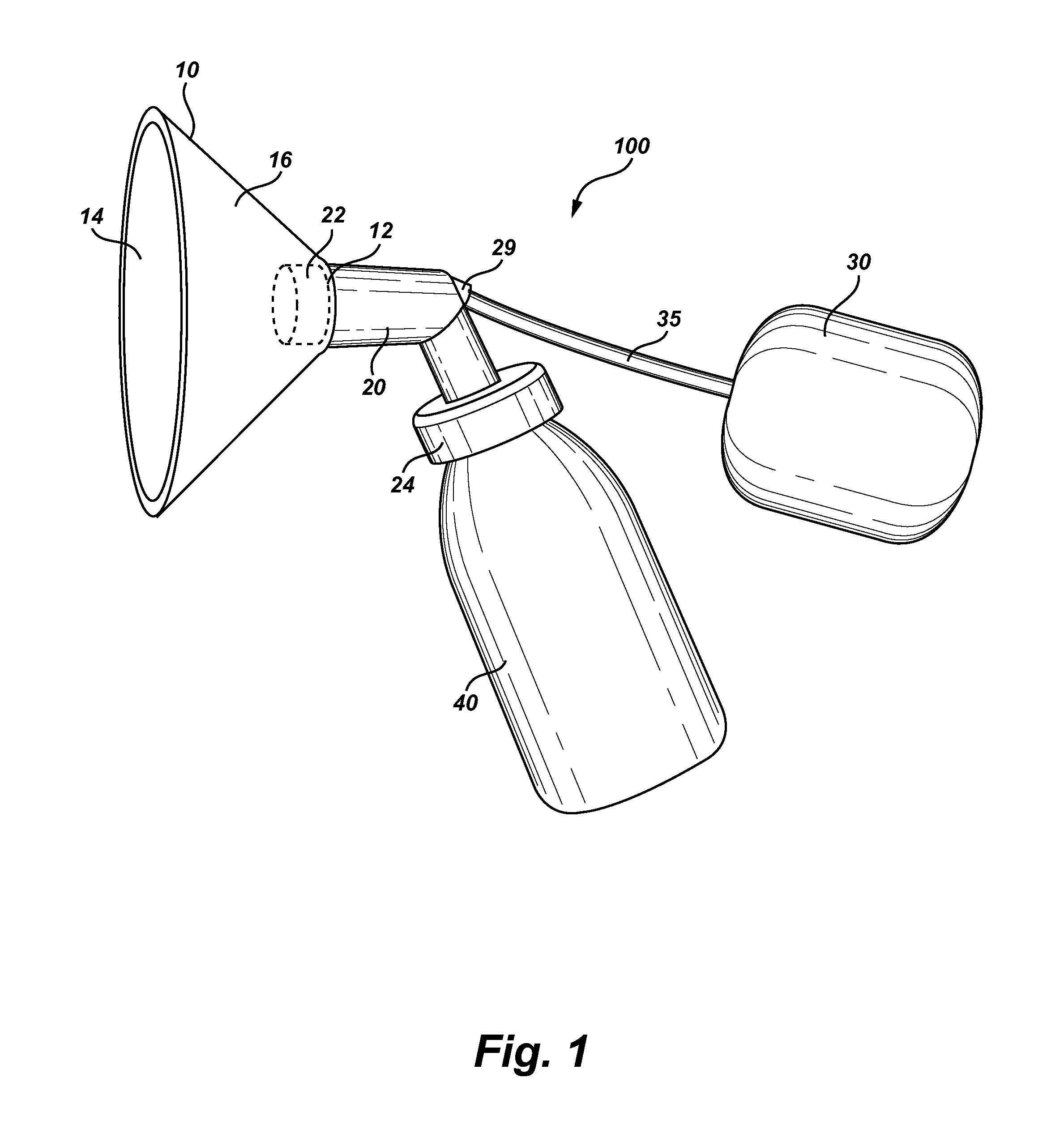

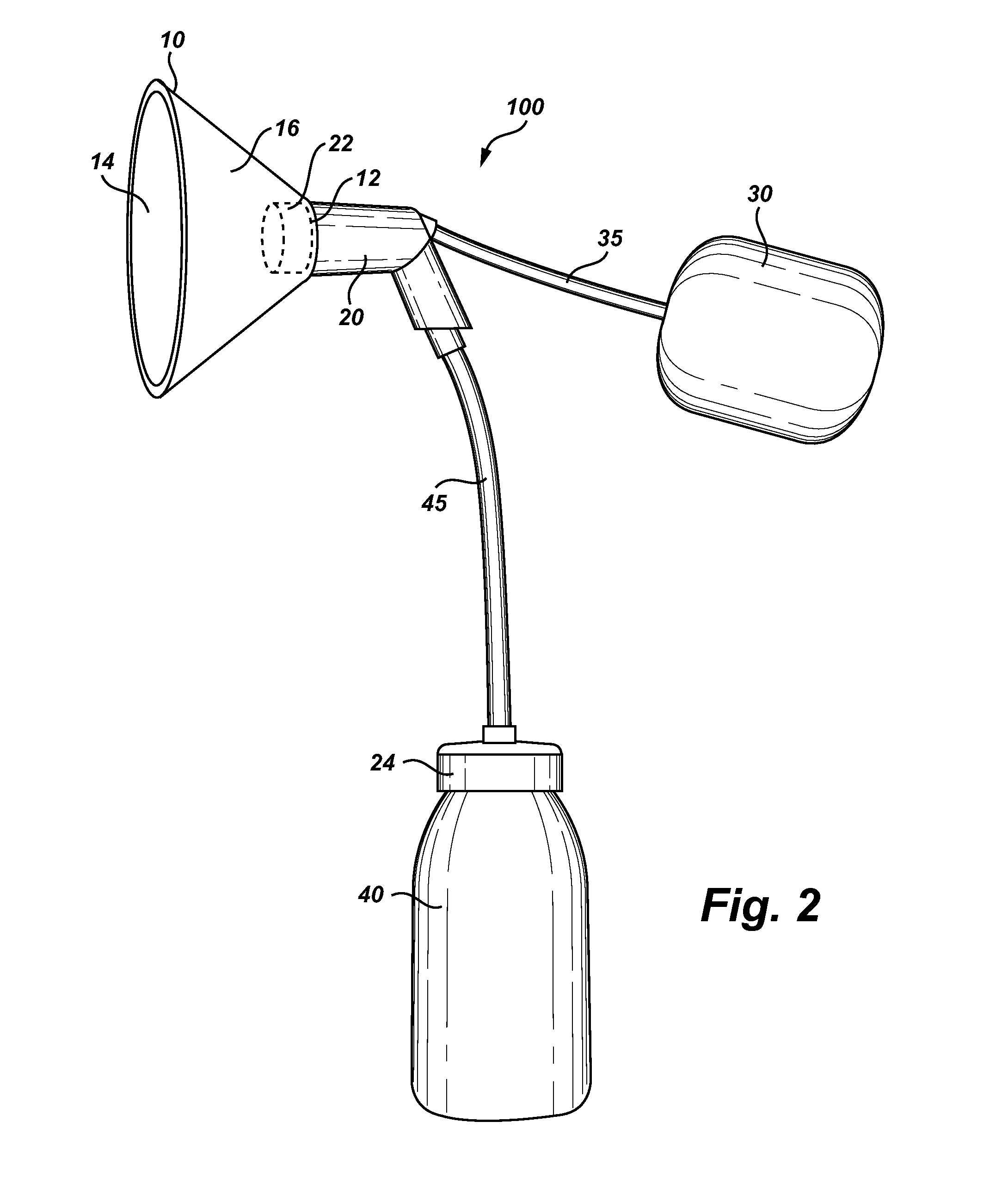

Hands-free breast pump system

A hands-free breast pump system is disclosed. A breast shield having an adhesive inner surface for adhering to a woman's breast is disclosed. The breast shield may be connected to an adapter for transferring a vacuum generated by a pump to the breast. The adapter also allows milk expressed from the breast to drain from the adapter to a container. In the alternative, the breast shield may form part of a breast shield adapter system which is connected to a conventional breast shield by a drain line so that a conventional breast pump system is used to supply a vacuum and to collect the milk.

Owner:OAK TREE IP LLC

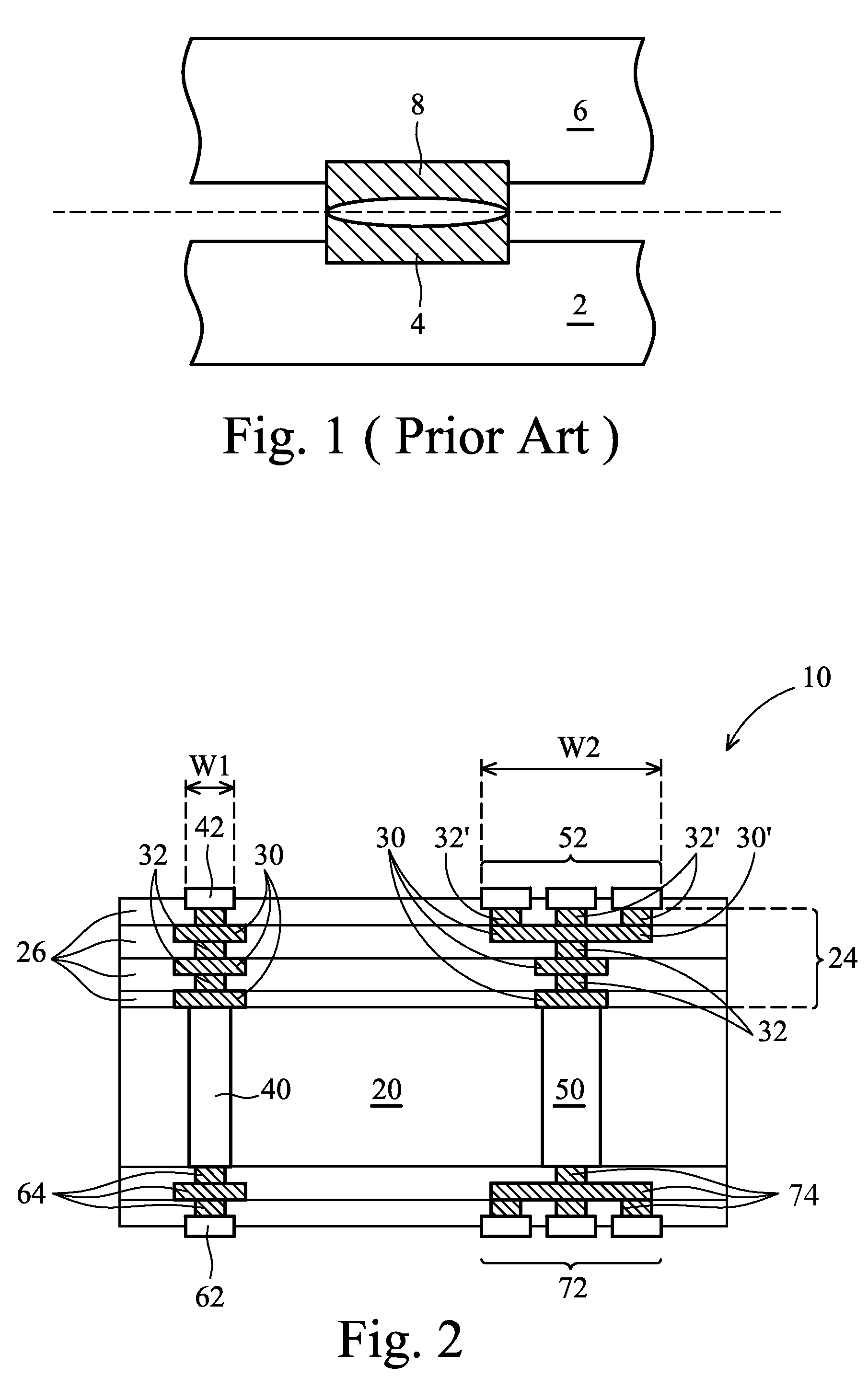

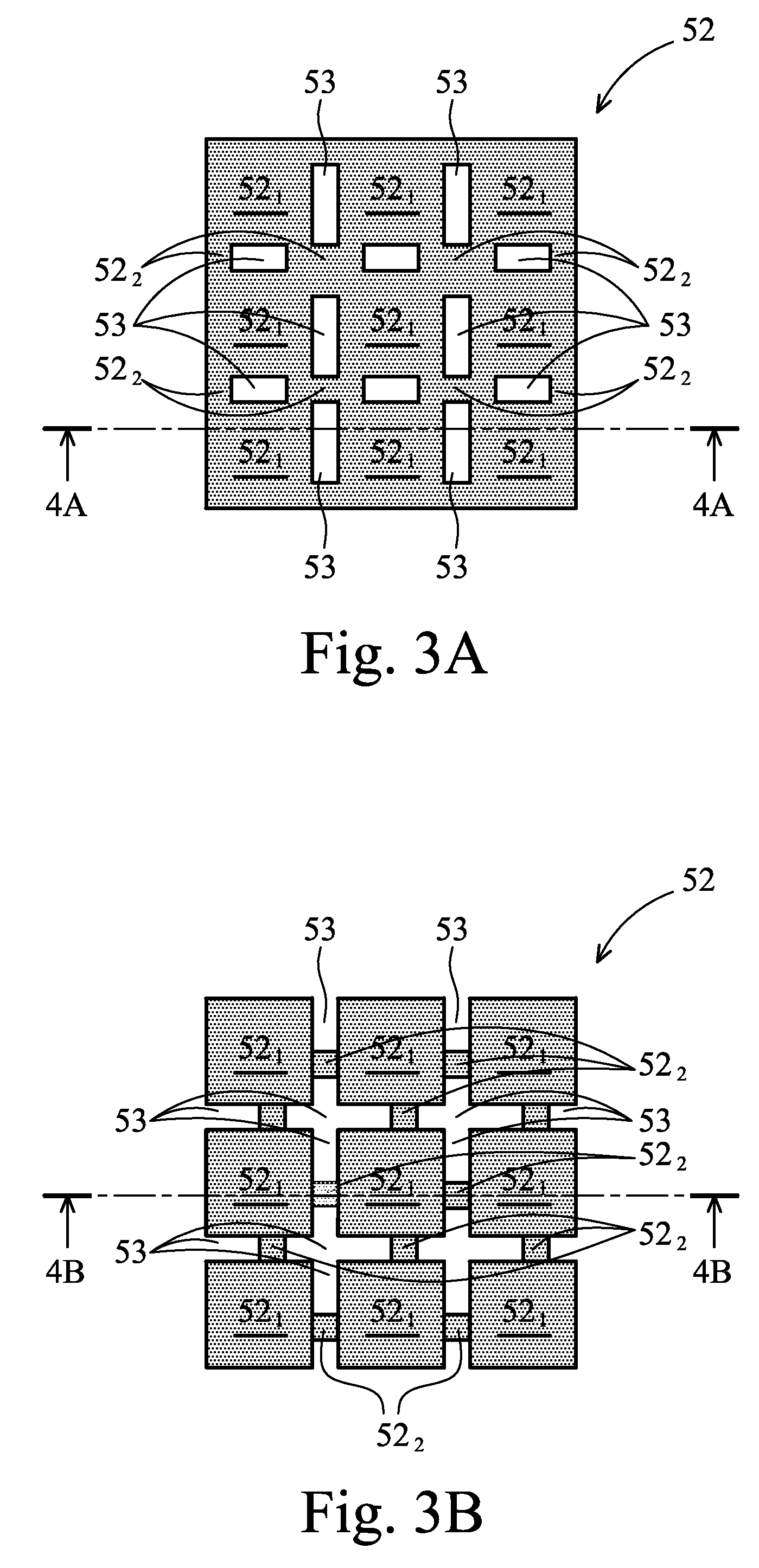

Through-substrate vias (TSVs) electrically connected to a bond pad design with reduced dishing effect

ActiveUS8053900B2Reduce impactImprove bonding qualitySemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

Owner:TAIWAN SEMICON MFG CO LTD

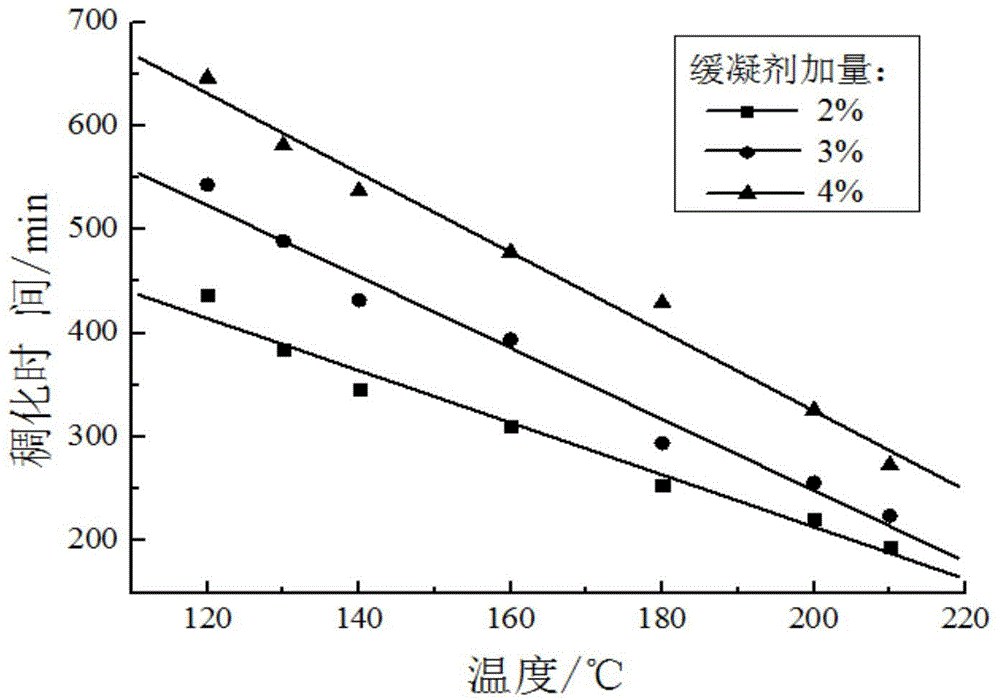

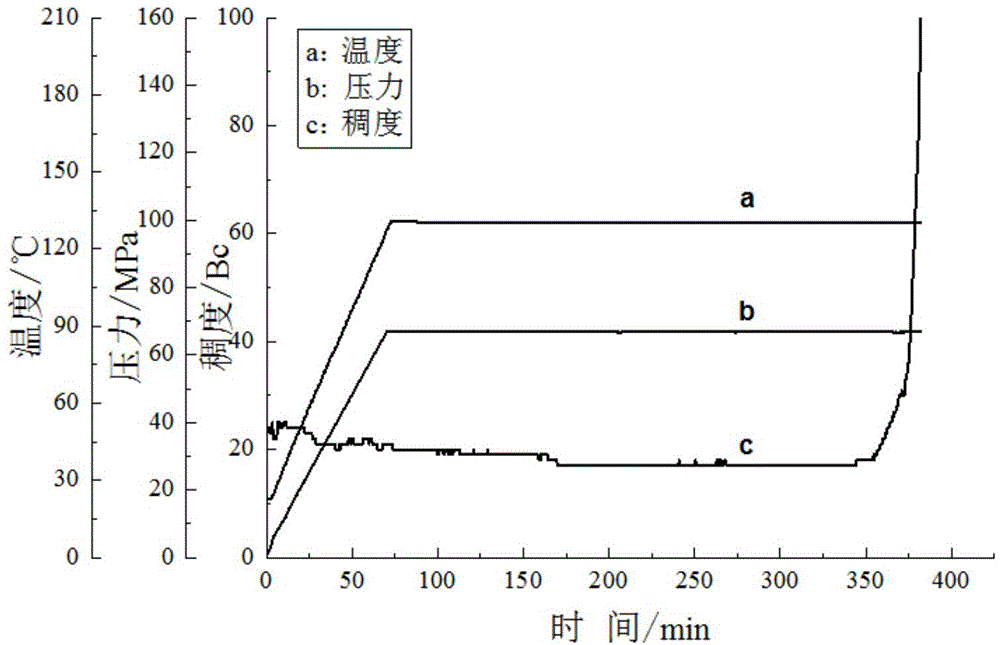

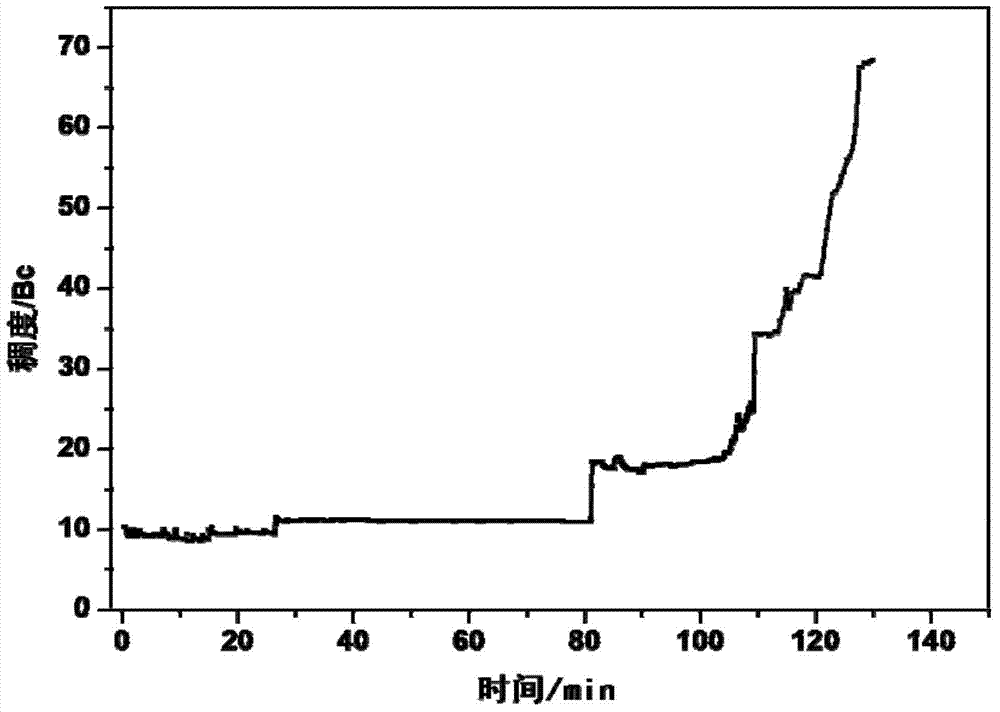

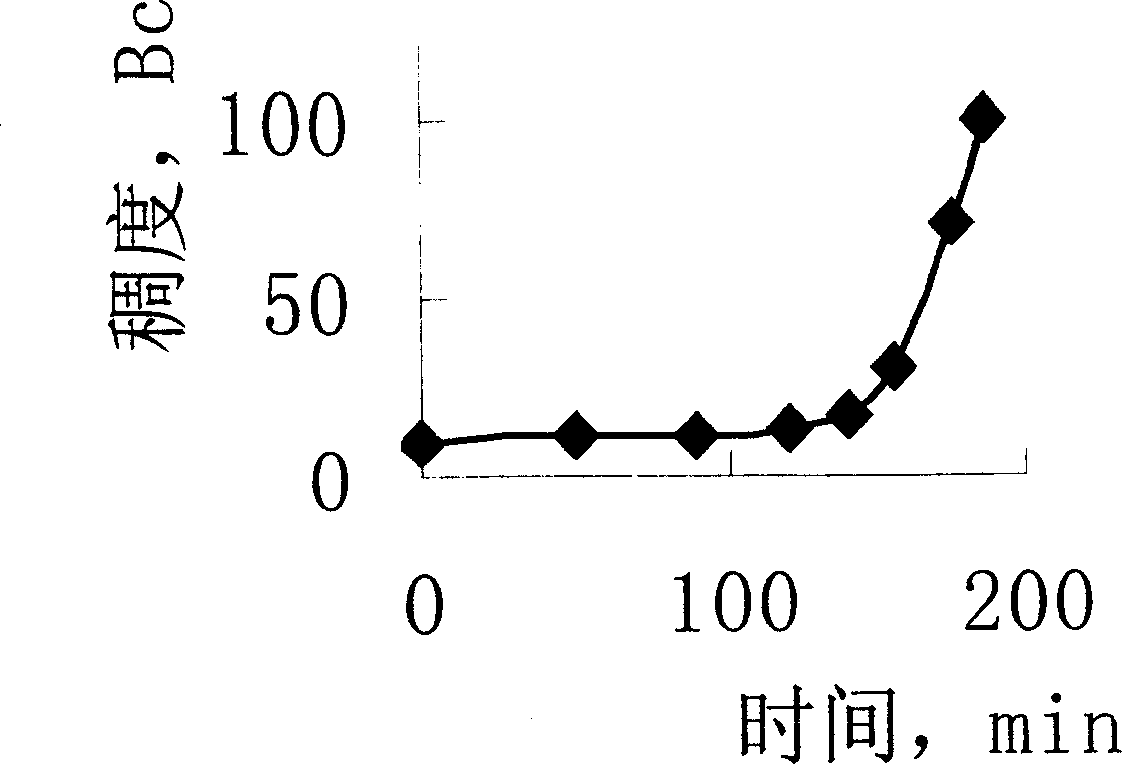

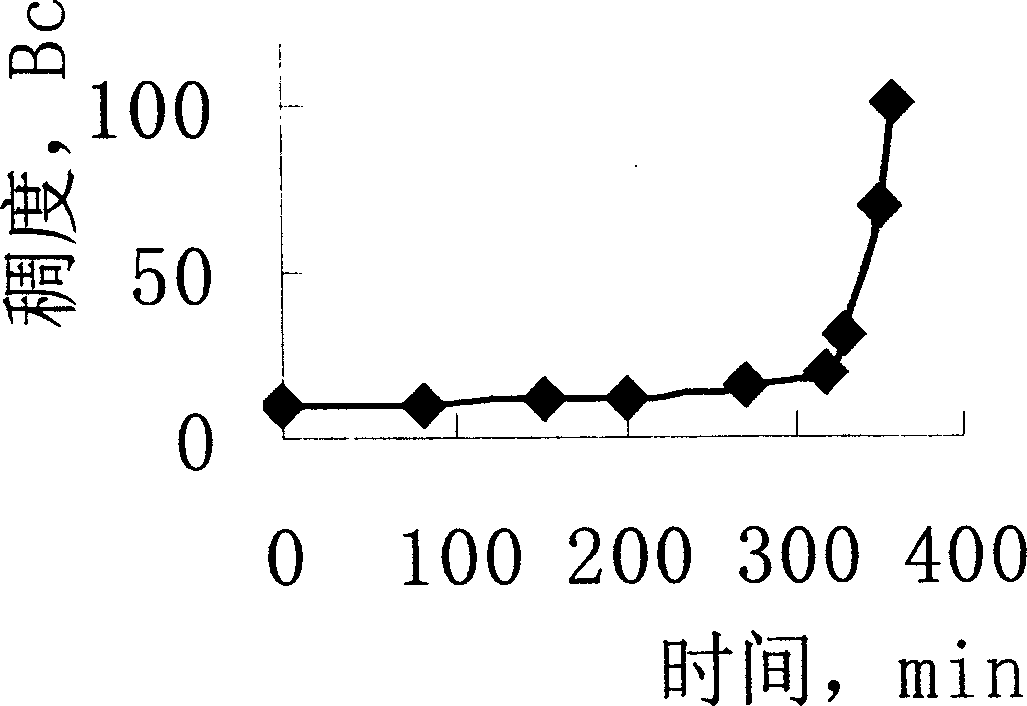

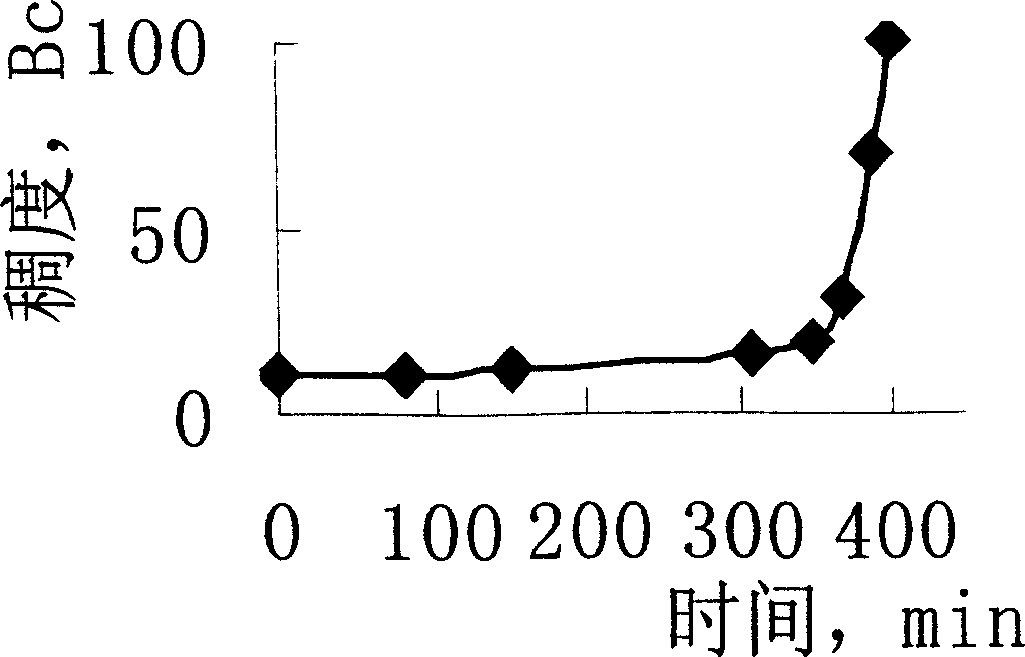

High-temperature-resistant copolymer oil well cement retarder and preparation method thereof

ActiveCN104403056AImprove performanceSolve the problem of severe subsidence at high temperatureDrilling compositionPolymer scienceFumaric acid

The invention relates to a high-temperature-resistant copolymer oil well cement retarder and a preparation method thereof. The preparation method comprises: respectively weighing four polymerization monomers such as 2-acrylamide-2-methylpropanesulfonic acid, diallyldimethylammonium chloride, maleic anhydride or itaconic acid or fumaric acid, and acrylic acid or methacrylic acid according to the mass ratio of 45-80:5-17:7-18:8-20, dissolving the first three monomers in water, then adding sodium polyphosphate and diphenylcarbazide, then successively adding a chain transfer reagent and an initiator, and finally dropwise adding the forth monomer, performing heating reaction and adjusting the pH value, so as to obtain the copolymer retarder. The invention also provides the high-temperature-resistant copolymer oil well cement retarder prepared by the above preparation method. The retarder is resistant to a high temperature up to 230 DEG C and is weak in dispersibility at a high temperature, the cement paste strength develops fast at a low temperature, the addition amount of the retarder has good linear relation with the cement paste hardening time, and the cement paste comprehensive performance is good.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

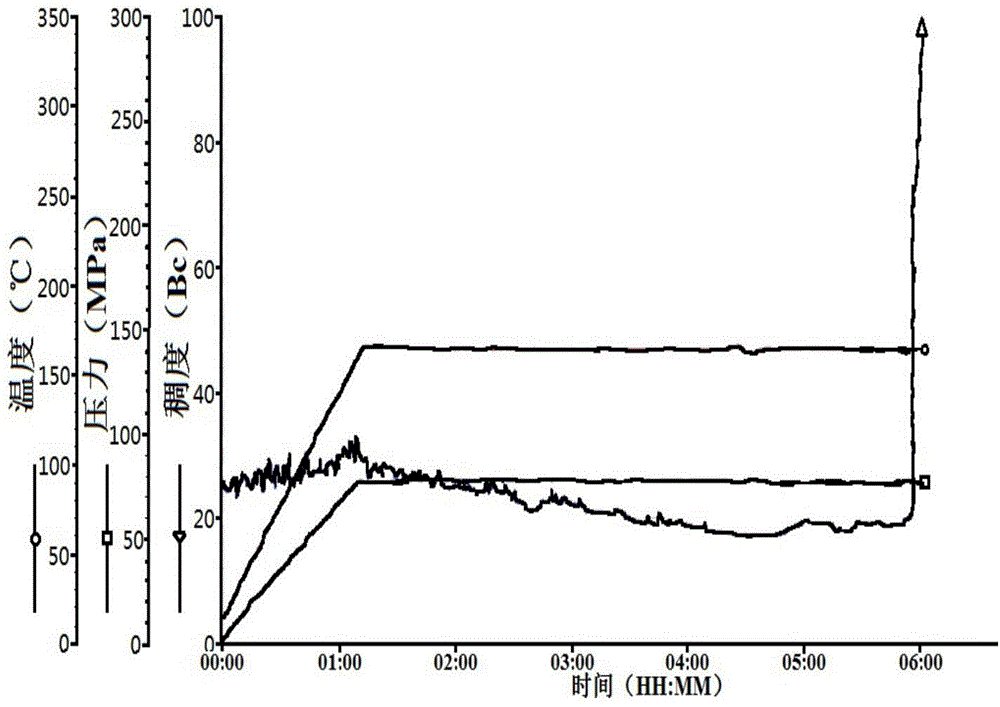

Solid-free anti-salt cleaning type well cementation spacer fluid and preparation method thereof

InactiveCN103756653AGood settlement stabilityImprove bonding qualityDrilling compositionSludge cakeEthylenediamine

The invention discloses a solid-free anti-salt cleaning type well cementation spacer fluid and a preparation method thereof. The spacer is prepared from the following components in parts by weight: 100 parts of water, 20-350 parts of soluble weighting agent, 0.1-1.0 part of additive, 0.2-0.5 part of thickening agent, 0.5-3.0 parts of fluid loss agent, 5-10 parts of non-ionic surfactant, 1.5-2.5 parts of anionic surfactant, 0.1-0.3 part of pH adjusting agent and 0.1-0.5 part of defoaming agent, wherein the additive is sodium tripolyphosphate, ethylenediamine tetraacetic acid disodium or ethylenediamine tetraacetic acid sodium. The solid-free anti-salt cleaning type well cementation spacer fluid is free of solid phase, so that virtual thick sludge cake cannot be formed on a well wall, the function of effectively spacing a drilling liquid from cement slurry is achieved, and meanwhile the well cementation is improved. In the preparation process, the substances are added to reaction in different batches, so that the operation method is simple.

Owner:CNPC BOHAI DRILLING ENG

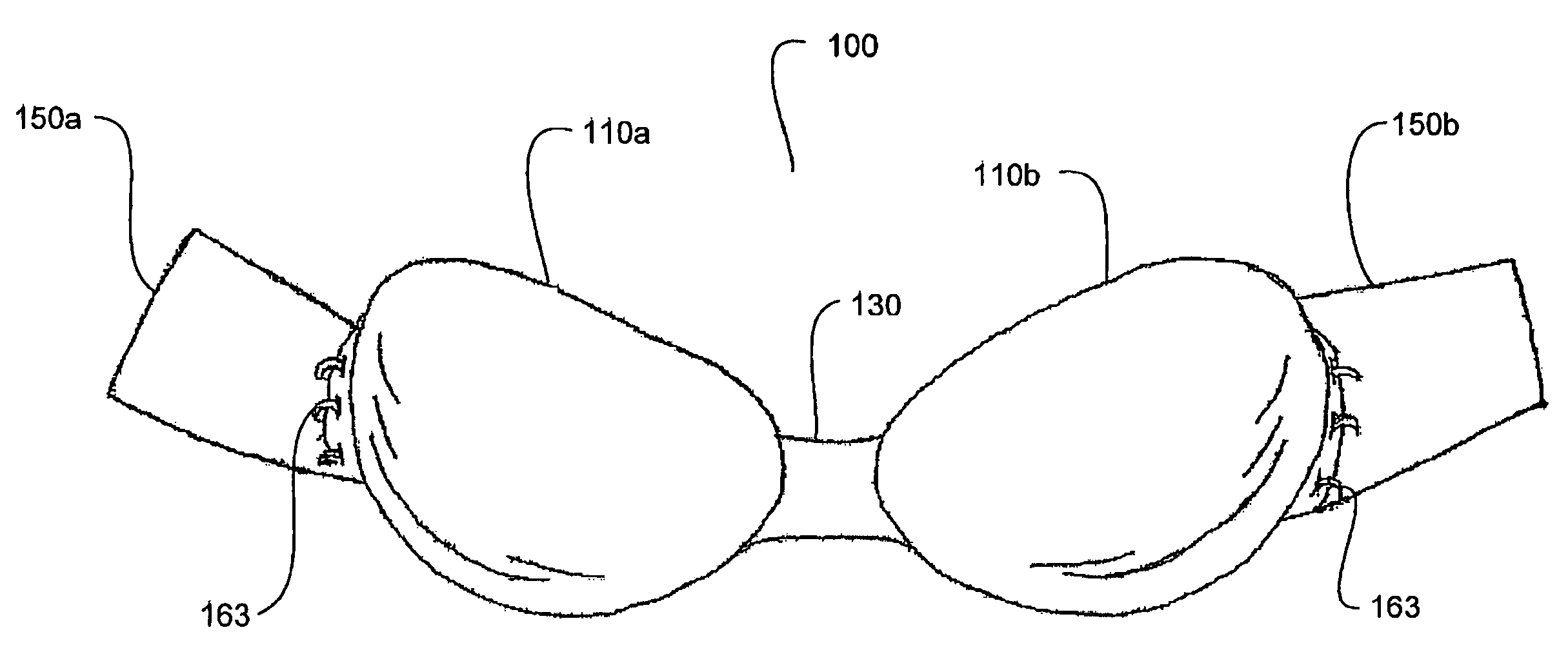

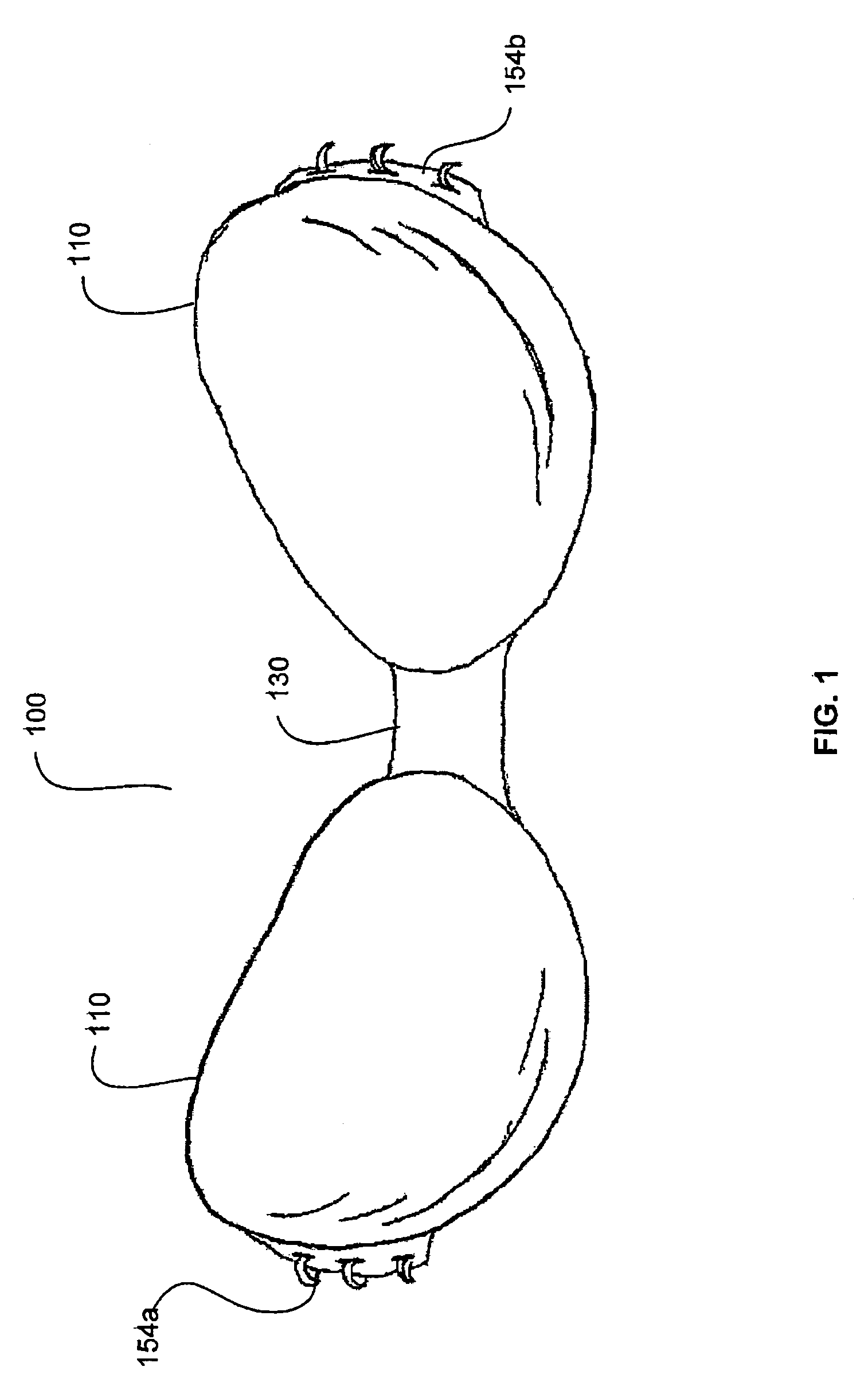

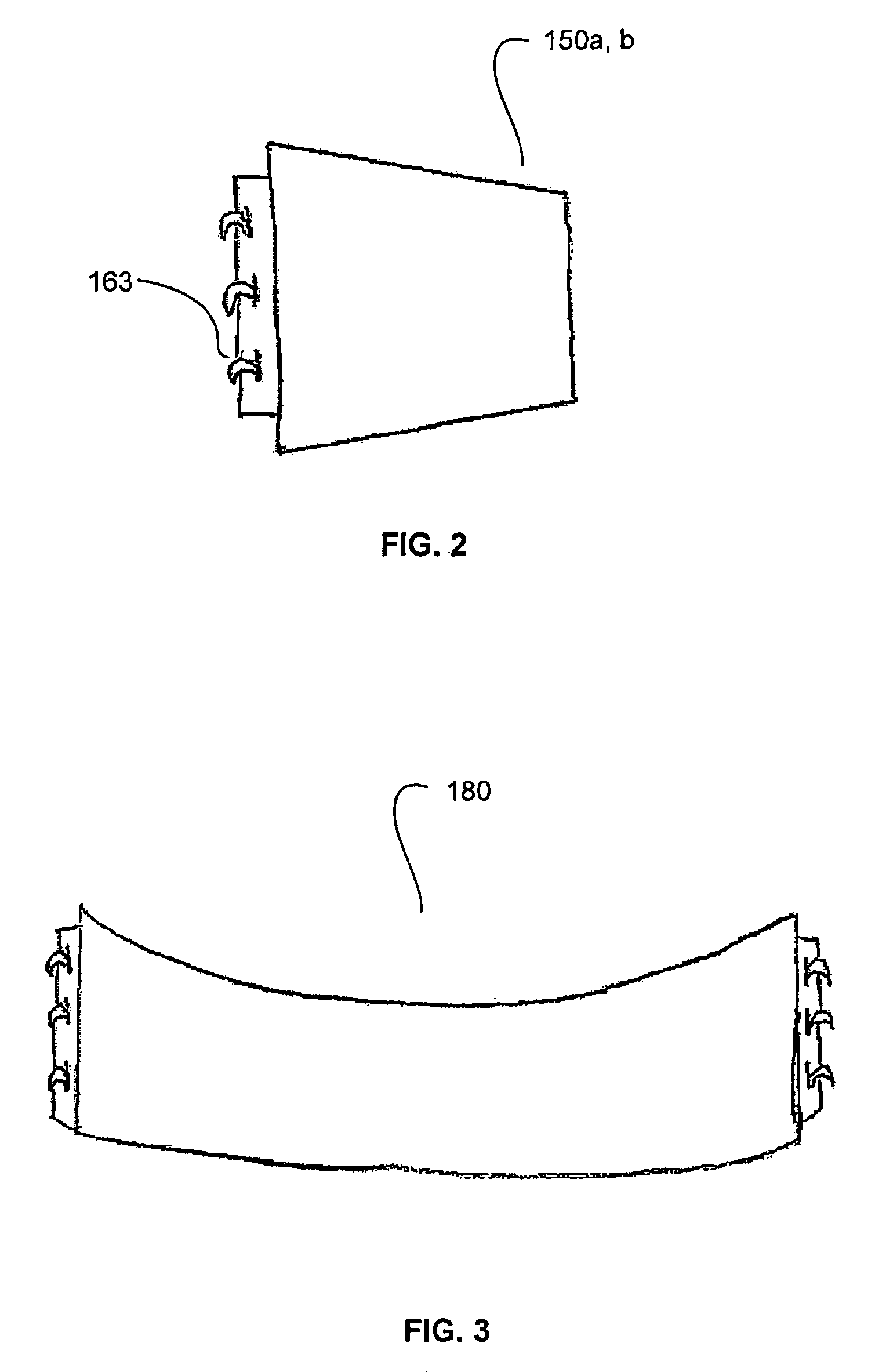

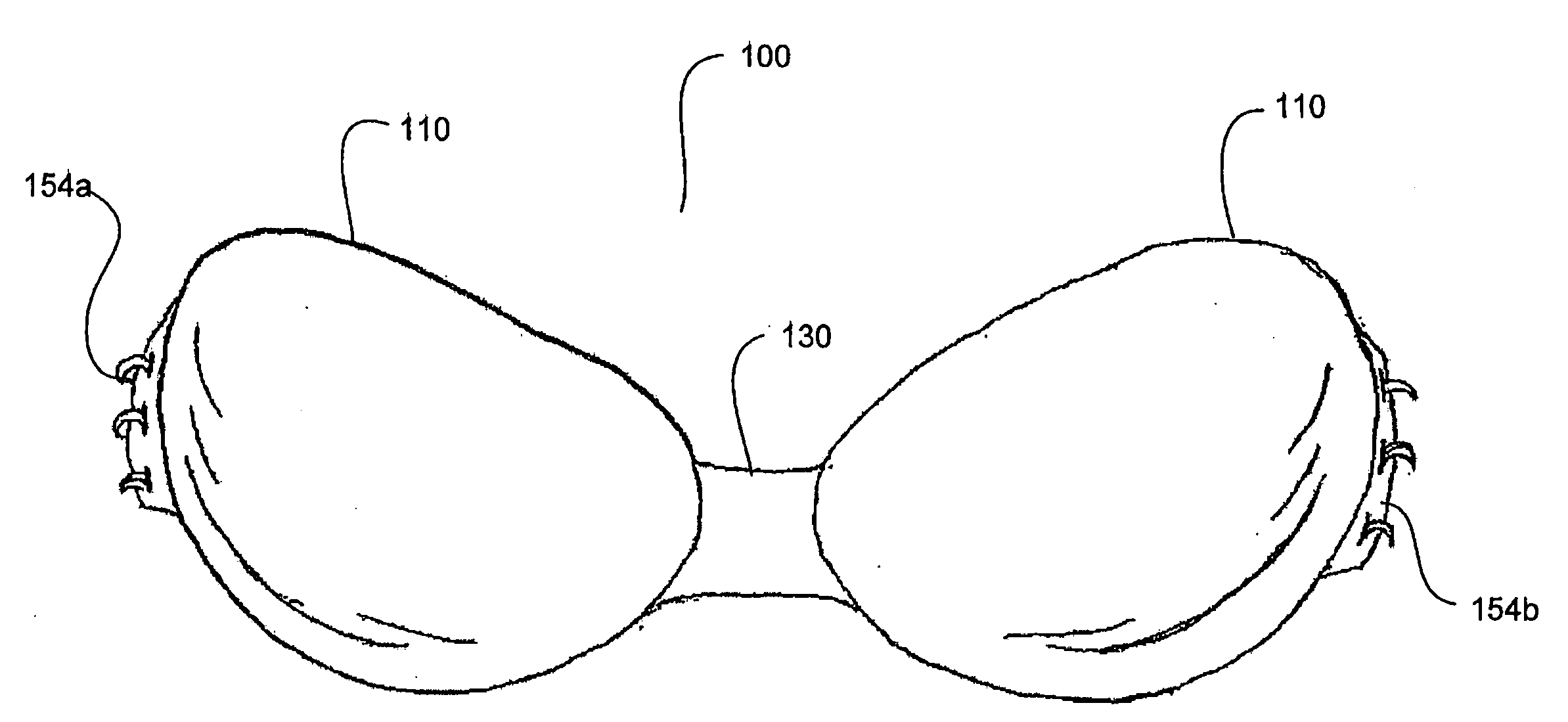

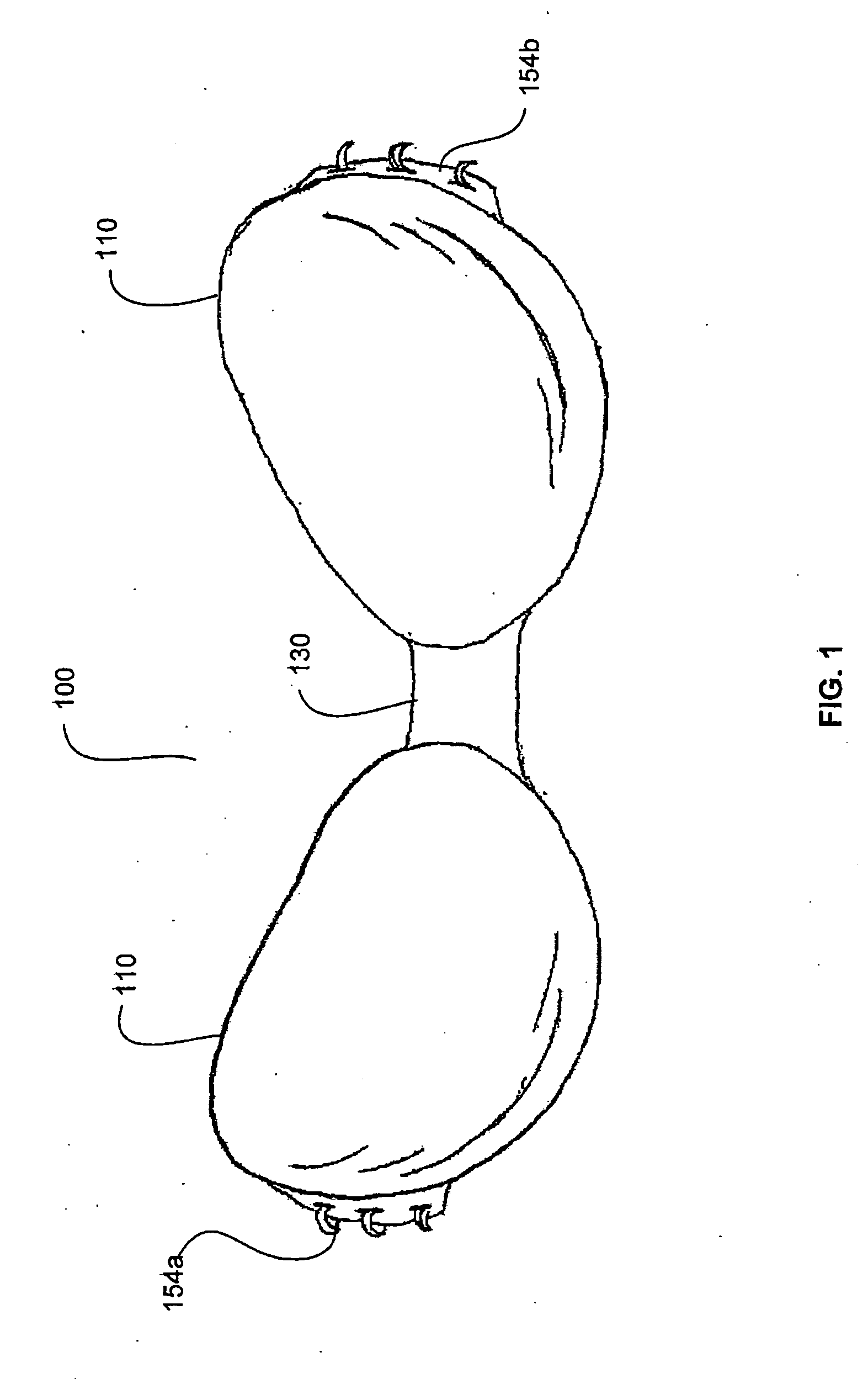

Supportive, washable adhesive bra with detachable support structures

InactiveUS7677952B2Area maximizationIncrease surface areaBrassieresGirdlesAdhesiveBiomedical engineering

A strapless brassiere having winged support structures to maximize surface area of the bra to which an extended-wear adhesive is applied over substantially all of the undersurface of the bra.

Owner:WOOLEY SUSAN

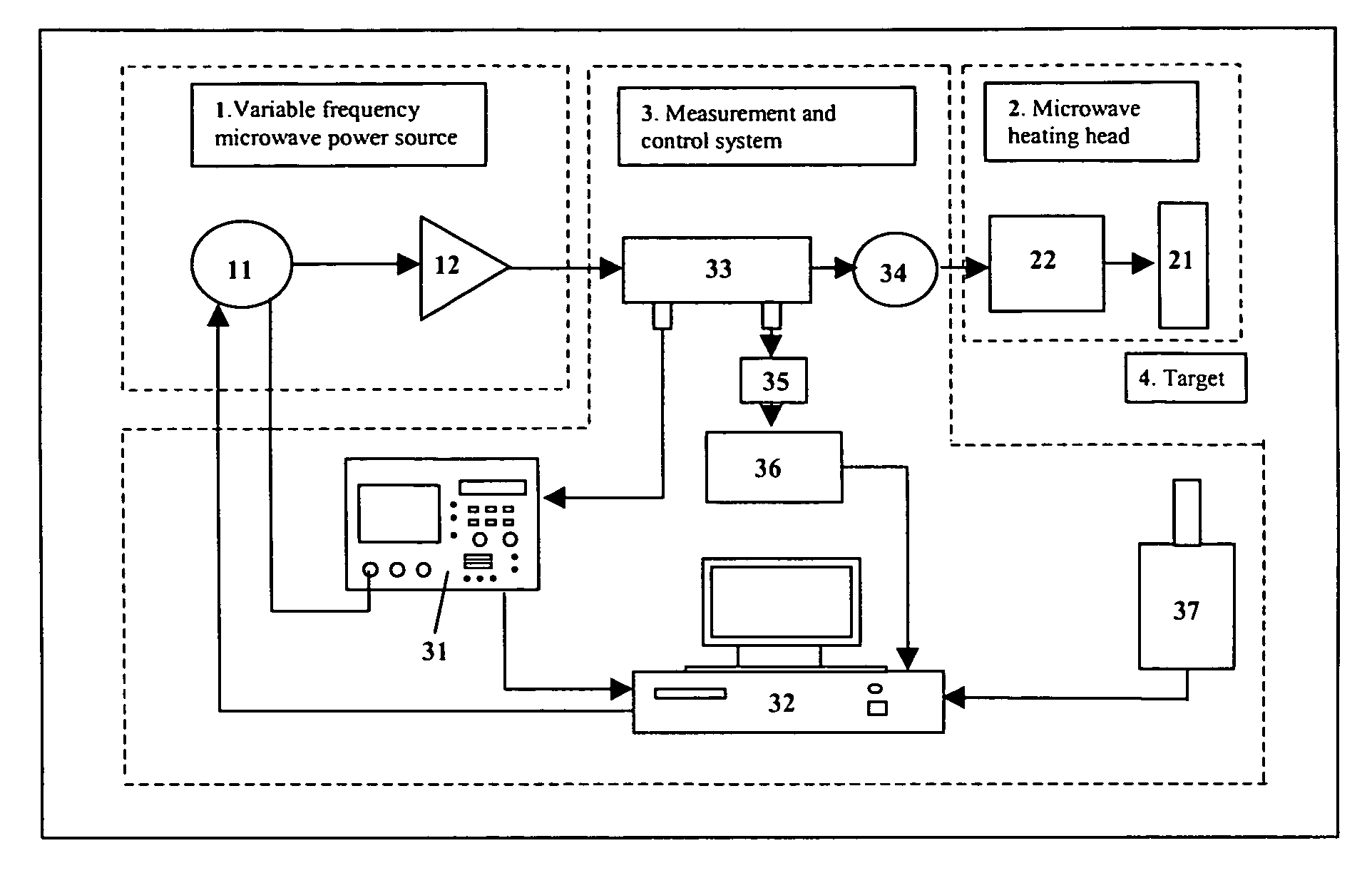

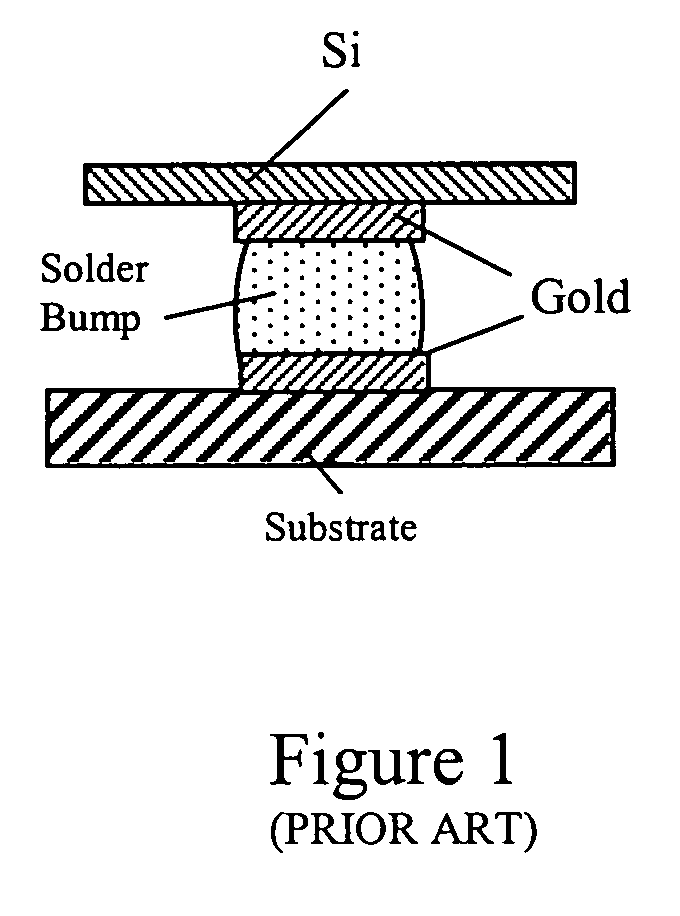

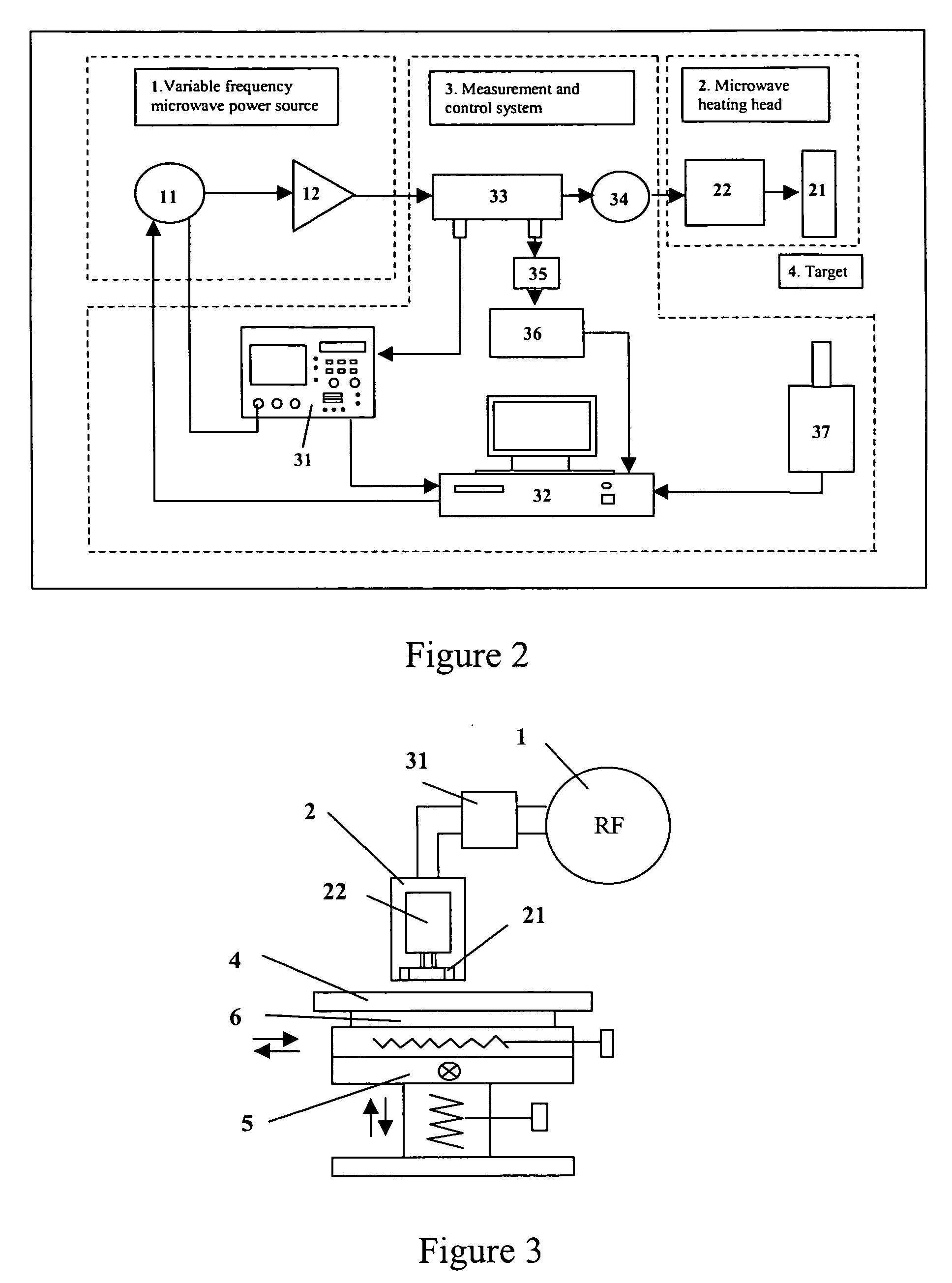

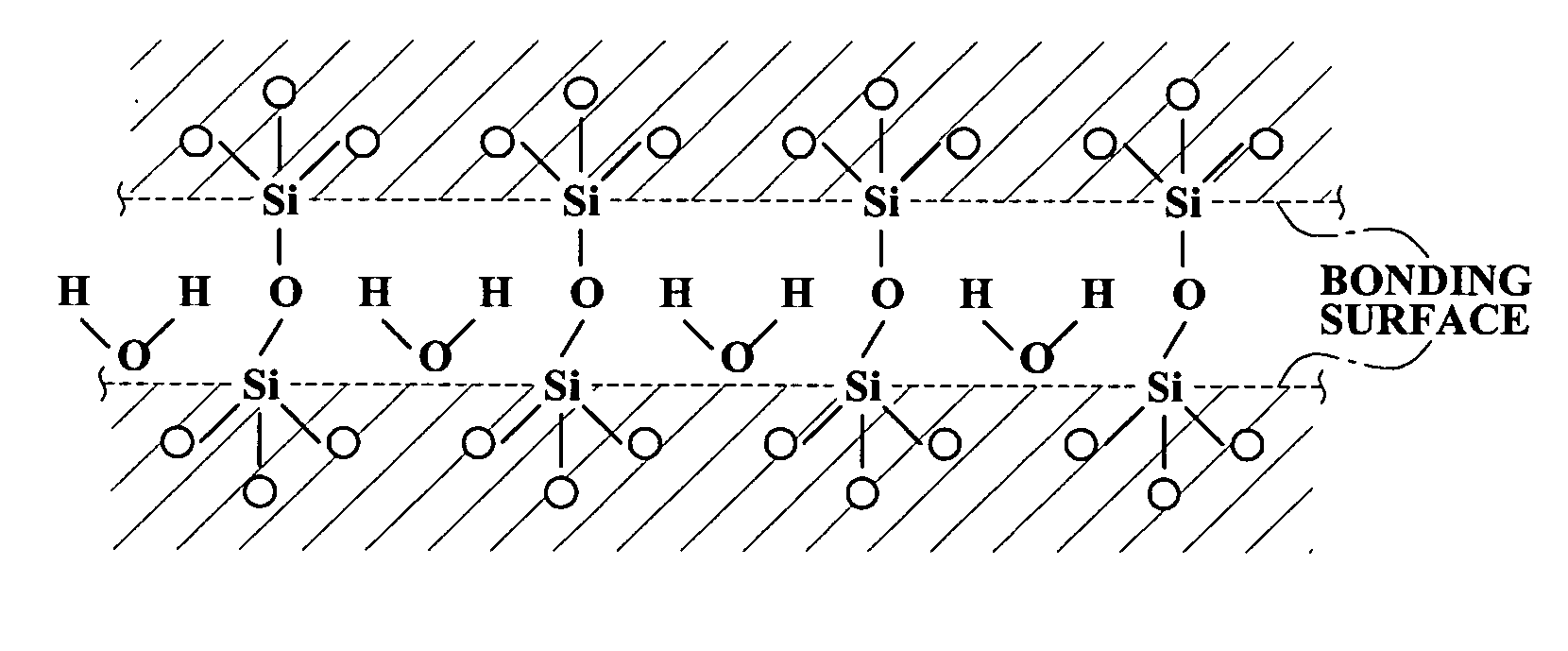

Method and apparatus for rapid thermal processing and bonding of materials using RF and microwaves

ActiveUS20070108195A1Heating fastMicrowave heating is fastSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceInterconnection density

A method and apparatus for rapid and selective heating of materials using variable frequency RF and microwaves. The apparatus uses variable frequency solid state electronics as a microwave power source, a novel microwave heating head to couple microwave energy to the target materials and a match-up network to tune the frequency and impedance match between the microwave source and the load. An electronic and computer measurement and control system is employed to monitor and control the microwave heating process. The method teaches the use of inductive microwave coupling for thin conductive materials such as metal film and impurity doped silicon wafers. The method also teaches the use of capacitive microwave coupling for dielectric material such as glass and ceramics. The method further teaches the use of rapid and selective heating of heterostructure for bonding and sealing of mems and integrated circuits. The method and apparatus can provide ultra-high heating speed along with ultra-high heating temperatures for rapid thermal processing of semiconductors and other materials. It also allows the use of bonding materials with high melting temperature for strong bonding and sealing of mems and IC devices. The apparatus further provides for high interconnection density of integrated circuits as connections are made without the use of solder bumps.

Owner:TIAN YONGLAI +1

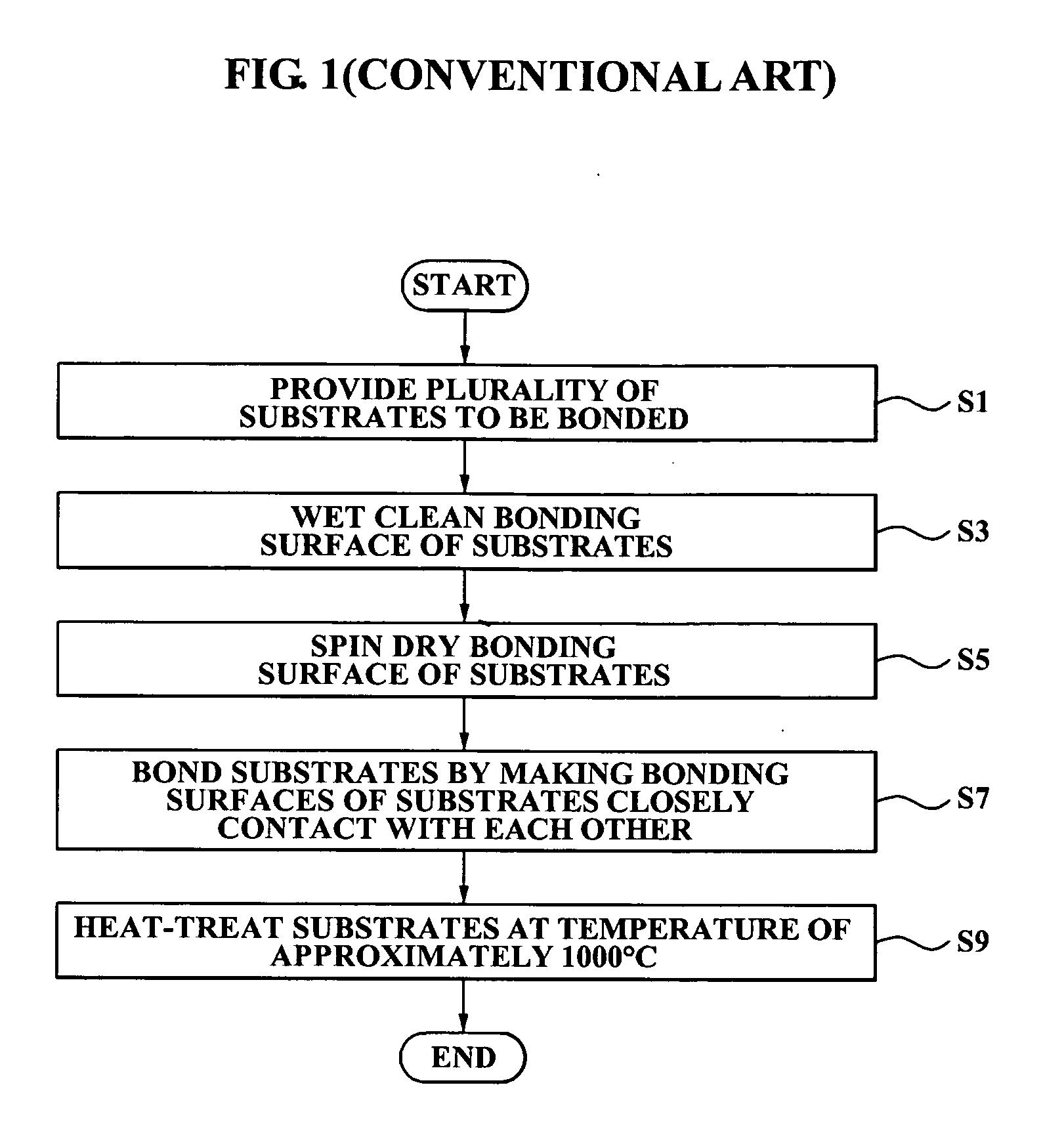

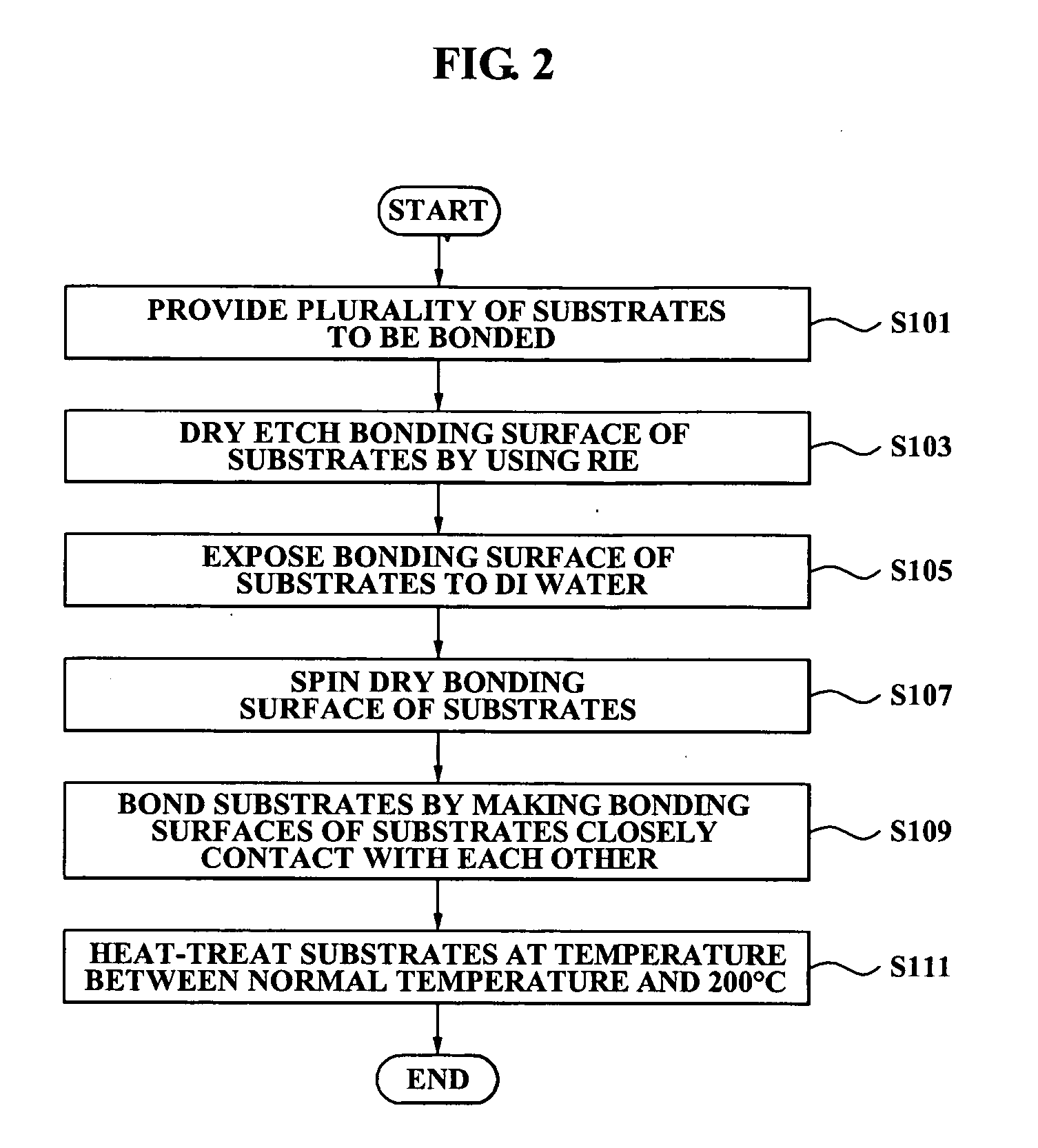

Substrate bonding method

InactiveUS20080006369A1Improve manufacturing productivityShorten the time periodAdhesive processes with surface pretreatmentSemiconductor/solid-state device manufacturingProduction rateEngineering

A substrate bonding method using dry etching is disclosed. The substrate bonding method according to the exemplary embodiments of the present invention may notably reduce an amount of time required for bonding the substrates, and increase a manufacturing productivity.

Owner:SAMSUNG ELECTRONICS CO LTD

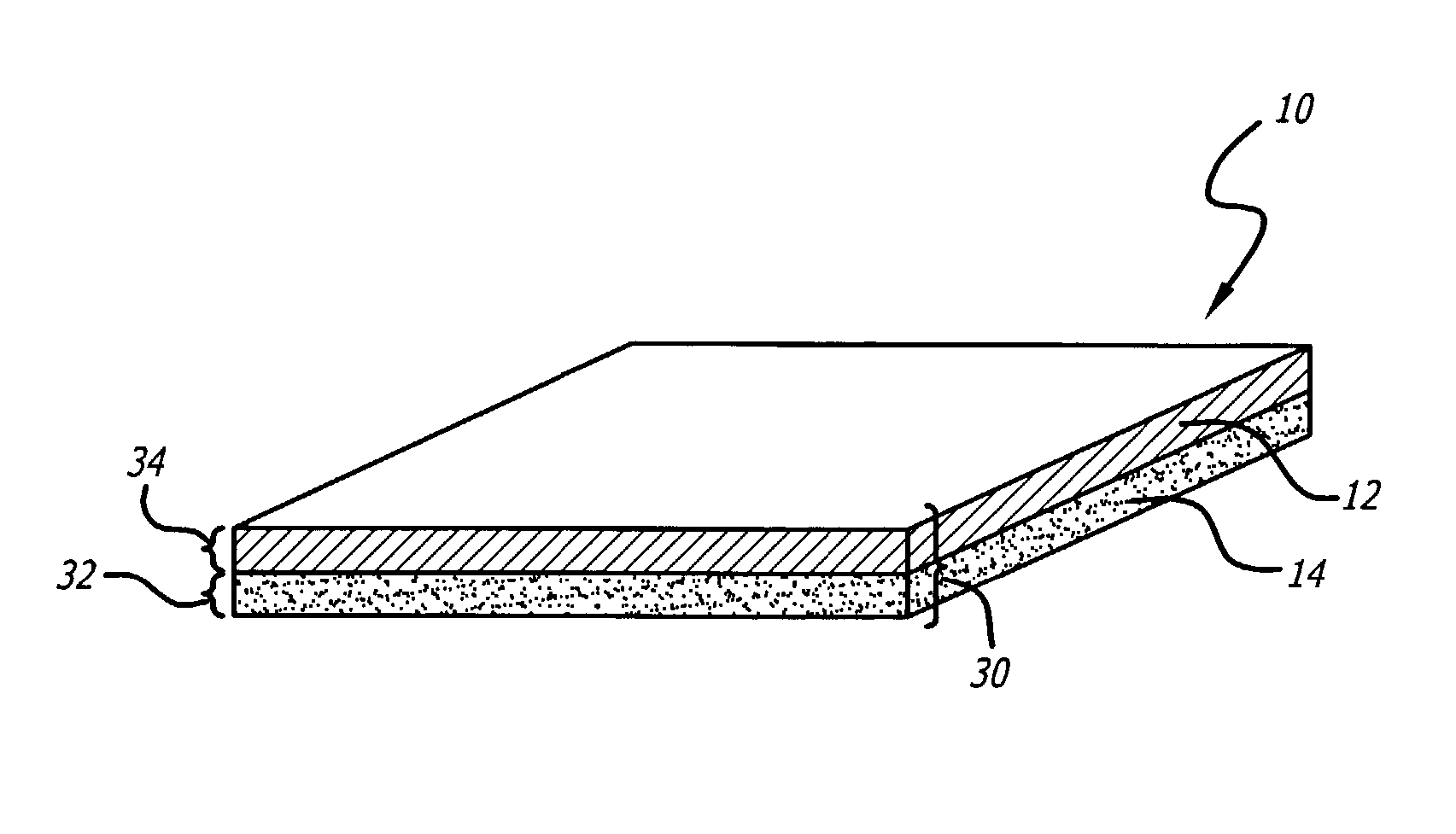

Manufacturing and assembly of structures using shims

InactiveUS6907651B1Avoid disadvantagesImprove bonding qualityMeasurement/indication equipmentsFuselage bulkheadsEngineeringAirframe

The invention relates to a method of assembling a structure, particularly those structures requiring very tight tolerances. The structure may be assembled by positioning shim material on at least part of a sub-structure, curing the shim material in situ, machining the cured shim material to a desired thickness, and then assembling outer layer parts to the sub-structure such that the shim material is situated between the substructure and the outer parts. The shim material may be machined to different thicknesses at different locations on the sub-structure, so that, when assembled, the outer layer parts together conform to a predetermined profile. This is especially advantageous in the manufacture of airframes, where the outer layer panels must provide a smooth surface to avoid unwanted aerodynamic effects.

Owner:BAE SYSTEMS PLC +1

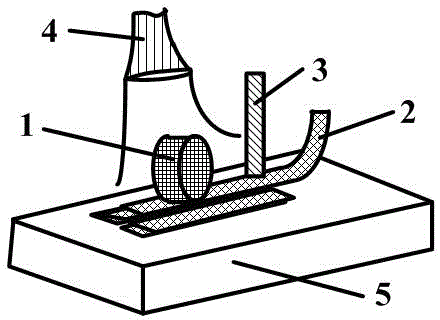

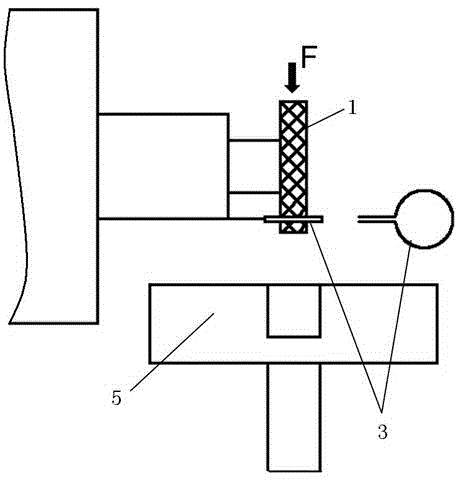

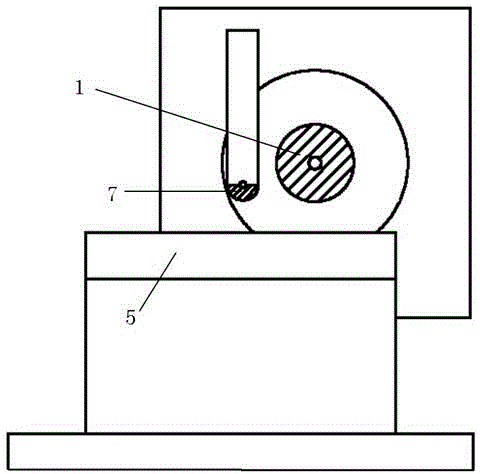

Method and device for auxiliary heating type ultrasound rapid forming

ActiveCN103600166AAvoid formingGuaranteed solid phase junction propertiesNon-electric welding apparatusNumerical controlMetal foil

The invention belongs to the technical field of rapid forming, and particularly relates to a method for achieving multilayer bead welding of metal foil strips through combination of extra auxiliary heating and ultrasonic welding. According to the method, preheating is conducted on metal foil or a base body material in rapid forming, the metal foil or the base body material is softened through preheating conducted by an external heating field, good gas protection is provided, and the welding thickness and width of a metal foil sheet are increased under the condition that the ultrasonic welding power is limited, so that multilayer one-time ultrasonic bead welding or multilayer multi-time ultrasonic bead welding of the metal foil is achieved and a three-dimensional solid block is formed in the solid-phase connection mode. Finally, a machining platform controlled by a numerical control program is applied, so that geometrical characteristic machining of a needed part is achieved. A metal piece obtained according to the method has the advantages of being low in cost, high in efficiency, compact in organization, free of casting-state structure, capable of achieving rapid forming of a functionally gradient material and the like.

Owner:WEIHAI WANFENG MAGNESIUM IND DEV

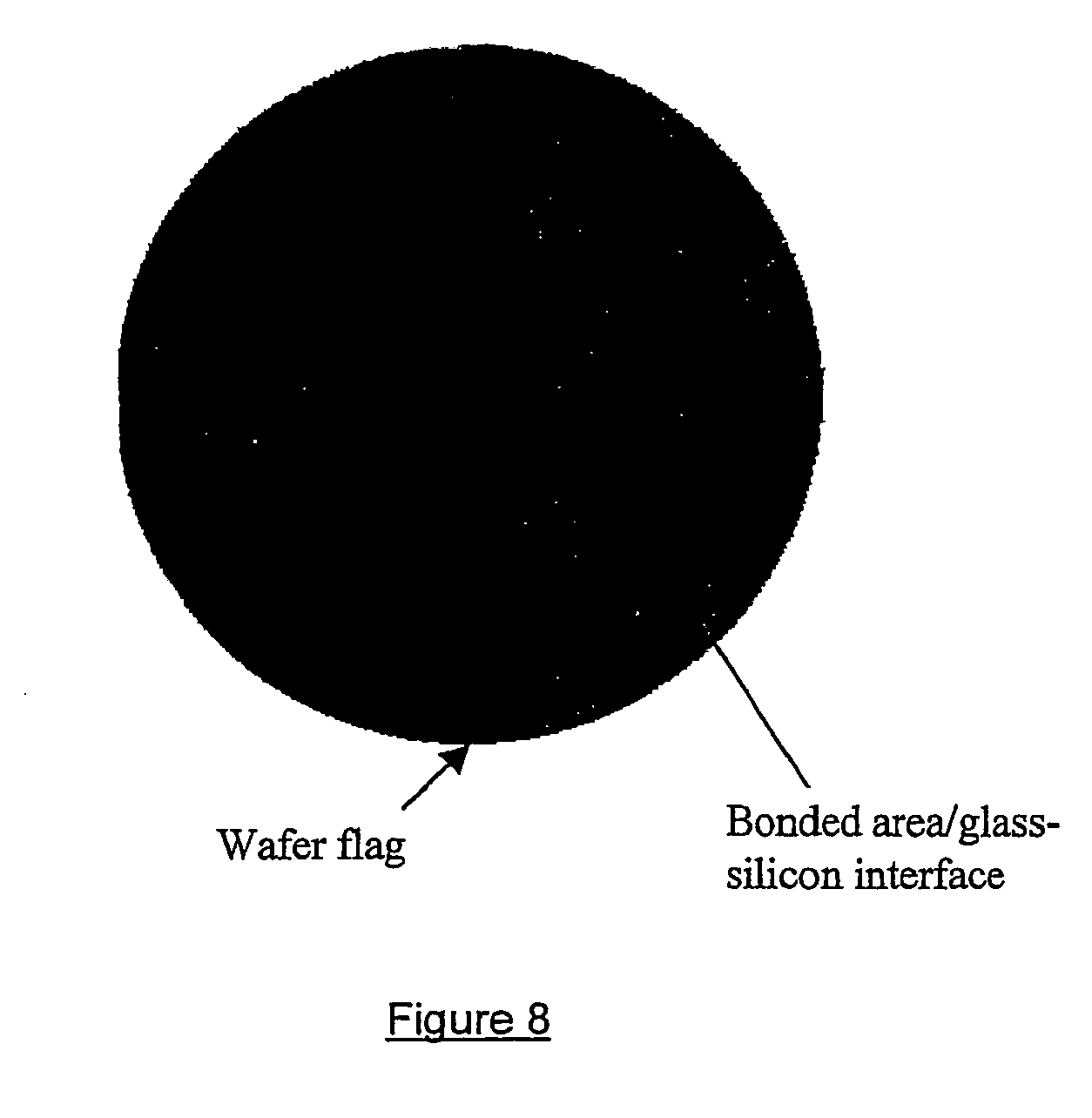

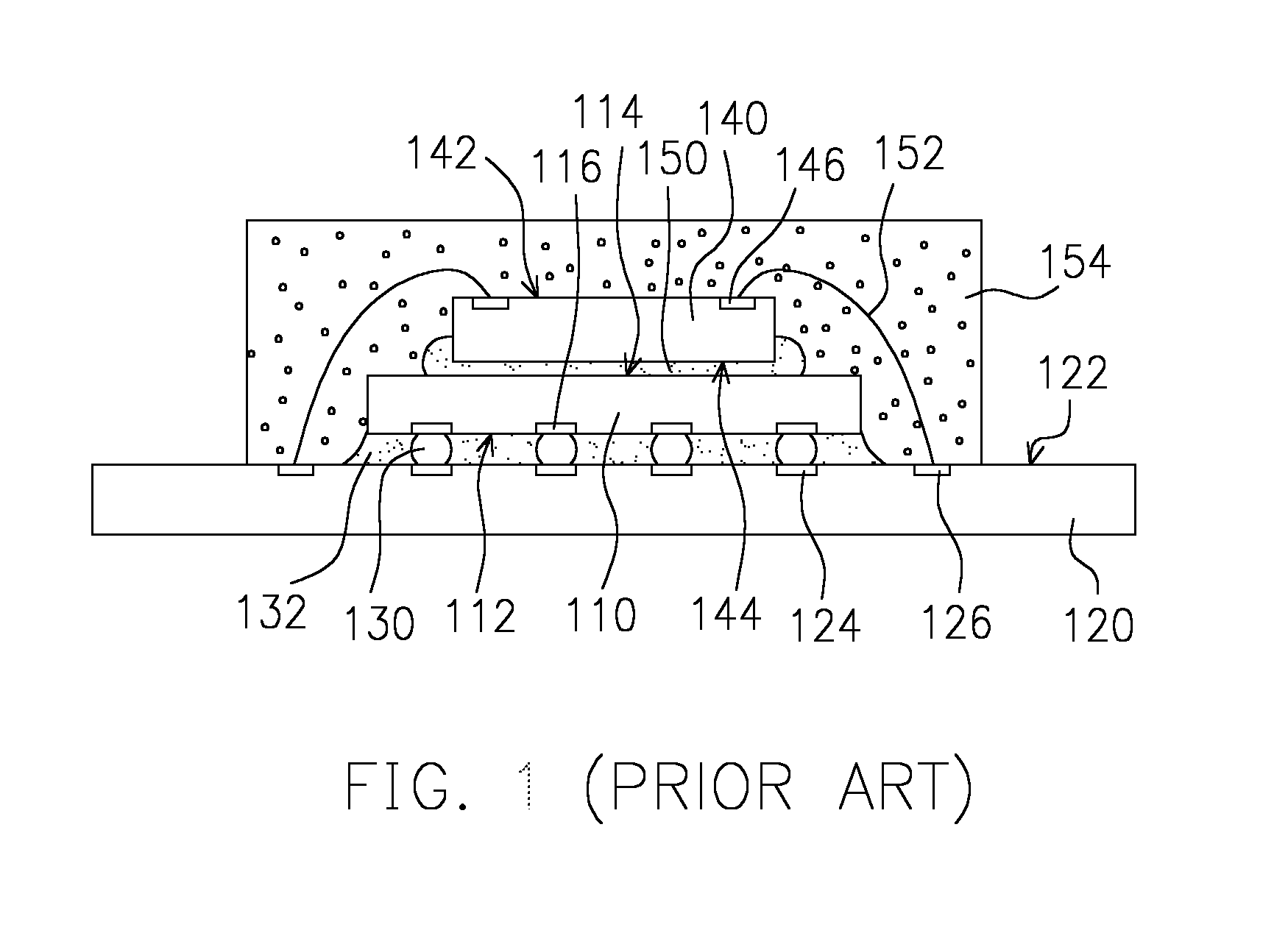

By-product removal for wafer bonding process

InactiveUS20080191310A1Improve bonding qualitySolid-state devicesSemiconductor/solid-state device manufacturingDevice formBonding process

A three-dimensional (3D) integrated circuit structure includes a first wafer and a second wafer, each comprising a substrate having devices formed thereon and an interconnect structure over the substrate; a composite layer comprising a first dielectric layer bonded to a second dielectric layer, wherein the composite layer is bonded to the first and the second wafers; a first plurality of openings extending from an interface of the first and the second dielectric layers into the first dielectric layer, wherein each opening of the first plurality of openings is in scribe lines of the first wafer; and vias connecting devices in the first and the second wafers.

Owner:TAIWAN SEMICON MFG CO LTD

Composition for promoting adhesion between rubber and textiles

InactiveUS6046262ALimited shelf lifeStable aqueous dispersion/solutionAdhesive processesImpression capsSilane compoundsPolyester

A composition for the promotion of adhesion between a rubber formulation and a textile substrate is provided. The inventive composition comprises either a mixture of specific amine functional silanes and organo-functional silanes having reactive groups or groups with an affinity for rubber. The inventive method entails the use of the inventive composition or a silane compound having both an amine moiety and a reactive group having an affinity for rubber formulations, particularly an unsaturated carbon-carbon bond. The composition may be utilized to adhere any standard reinforcement-type textile, such as polyester or polyamide, to a standard rubber composition, such as SBR, NBR, or EPDM. A method for adhering textiles to rubber formulations is also provided involving a pre-dip, -spray, -coat, and the like, of the inventive composition on a reinforcement-type textile surface followed by the contacting of the rubber formulation. Optionally, and preferably, the process involves the extra utilization of resorcinol-formaldehyde latex as an effective bonding agent to improve the adhesion between the two layers. The resulting textile-reinforced rubber product may be utilized as an automobile fan or timing belt, an automobile tire component, and any other rubber article which requires long-lasting, durable textile reinforcement.

Owner:MILLIKEN & CO

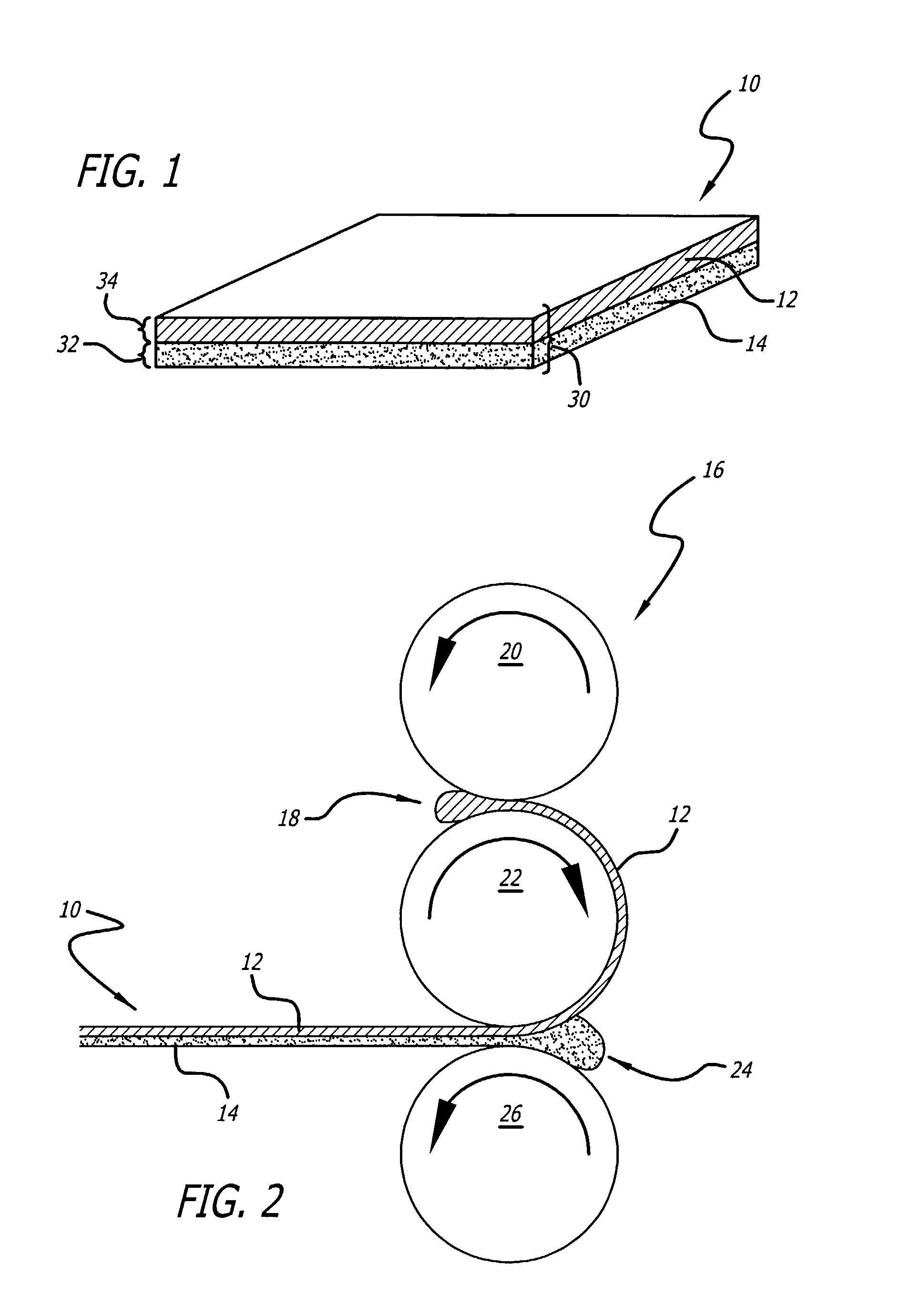

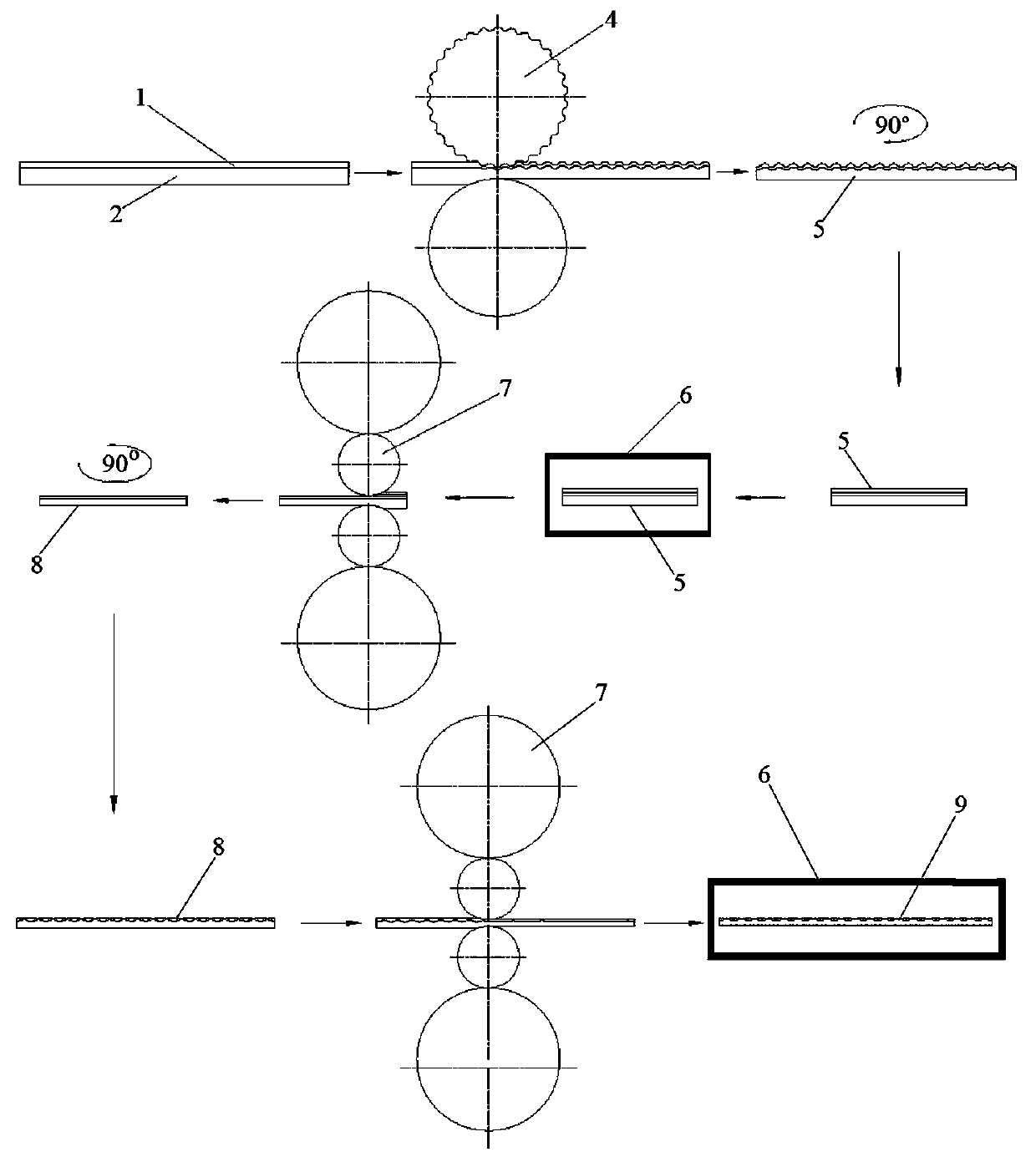

Method for continuously rolling metal composite substrate by corrugated roll and a flat roll

ActiveCN108672494AReduce warpageFacilitates continuous rollingAuxillary arrangementsMetal rolling arrangementsComposite substrateHigh intensity

The invention belongs to the technical field of material processing of metal composite plates, and particularly relates to a method for continuously rolling a metal composite substrate by a corrugatedroll and a flat roll. The method comprises the following steps: rolling a blank by using the corrugated roll to obtain a corrugated composite plate; and then flattening the corrugated-shaped composite plate by using a flat roll. In the process, high-strength combination of the composite plate from a local part to a whole surface can be realized by stress peaks at two different positions. Comparedwith a method for directly flattening in the original rolling direction, the method comprises the advantages that the elongation of metal in the plate width direction can be reduced by flattening after the corrugated composite plate rotates at an angle of 90 degrees, damage to positions which have been combined originally is reduced, extrusion at positions of wave peaks is obvious, the combination strength of portions which are originally combined weakly relatively is improved favorably, and thus, the combination quality of the whole surface is improved; and warping in a direction perpendicular to corrugations can also be prevented from being generated in a corrugated composite plate flattening process by flattening after the corrugated composite plate rotates at an angle of 90 degrees, and continuity of a follow-up thinning process is facilitated.

Owner:TAIYUAN UNIV OF TECH

Method for producing modified soybean albumen adhesive

InactiveCN101255328AImprove bonding qualityImprove water resistanceProtein adhesivesGlue/gelatin preparationAlcoholOrganic solvent

The invention provides a preparation method of modified soybean protein adhesive. Any one selected from soybean protein concentrate, soybean protein isolate, defatted soybean flour, soybean pulp and soybean cake is used as raw material and then organic solvent alcohol is added. The hydrophobicity group of alcohol immerges into the soybean molecule to break the molecule structure and denature the soybean, the hydrophobicity amino acid residues of protein molecule are bare, therefore the bond strength and water resistance is increased. The object of the invention is to solve the problem that the bond strength of soybean protein adhesive is low and the water resistance is bad. The soybean protein adhesive has good bond strength without pollution and the alcohol has the same function of antifoaming agent, so that the soybean protein adhesive has higher bonding strength and water resistance, compared with the soybean protein adhesive which is not modified.

Owner:SHENYANG POLYTECHNIC UNIV

Method of manufacturing a wind turbine blade and a wind turbine blade

InactiveUS20130189114A1Uniform and controllable flowImprove bonding qualityFinal product manufactureMetal-working apparatusVacuum assistedTurbine blade

The invention relates to a method for manufacturing a wind turbine blade, comprising the steps of pre-manufacturing a first blade member, positioning said pre-manufactured first blade member in a joining mold and bonding said first blade member with a second blade member using a vacuum assisted infusion process so as to form an integrated blade part.

Owner:MITSUBISHI HEAVY IND LTD

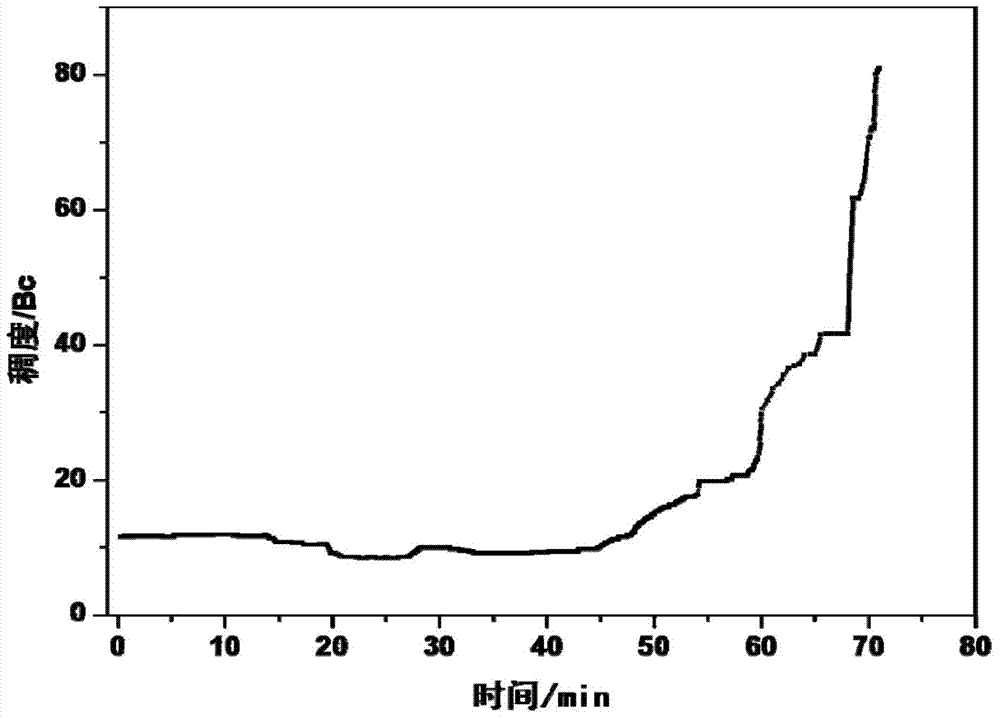

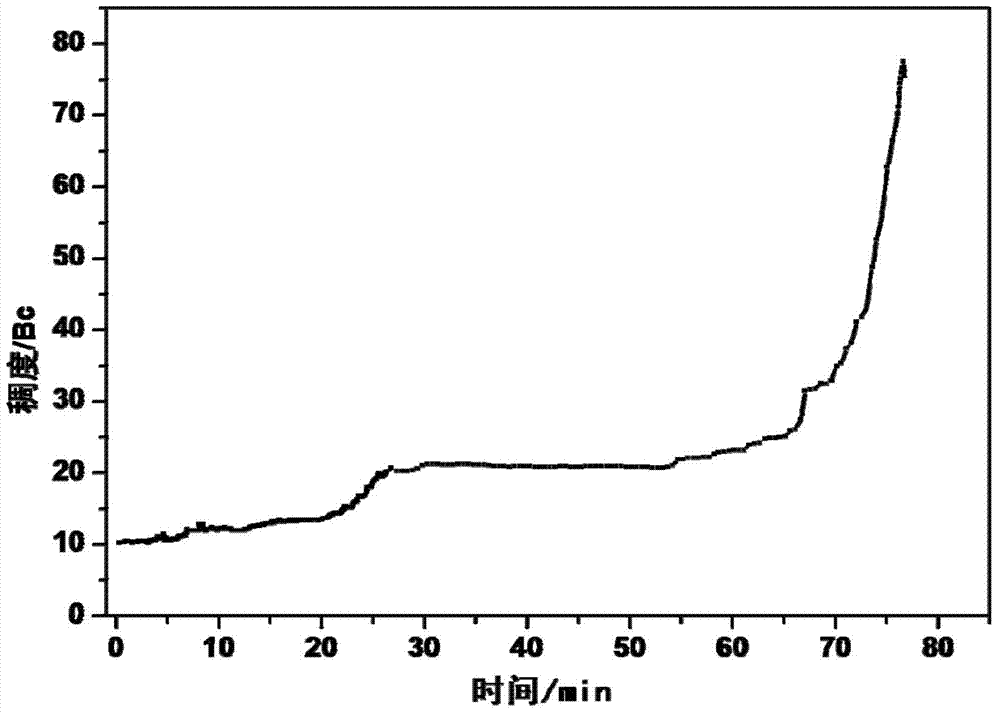

Anti-pollution high efficiency isolation liquid and preparing method

The present invention relates to anti-pollution high efficiency isolating liquid for shaft wall cementing operation and its preparation process. The isolating liquid is compounded through adding suspension stabilizer, water reducing agent, tackifier, diluent, viscosity and shearing force increasing agent, weight additive and pH regulator in certain weight proportion into water. One compounding process is a water base process through throwing the said components successively into water in a slurry tank apparatus. One other compounding process is one dry mixture process in a cementing tank apparatus. The isolating liquid has flexible compounding process, high anti-pollution capacity and effective eliminating effect on well wall interface pollutant.

Owner:SOUTHWEST PETROLEUM UNIV

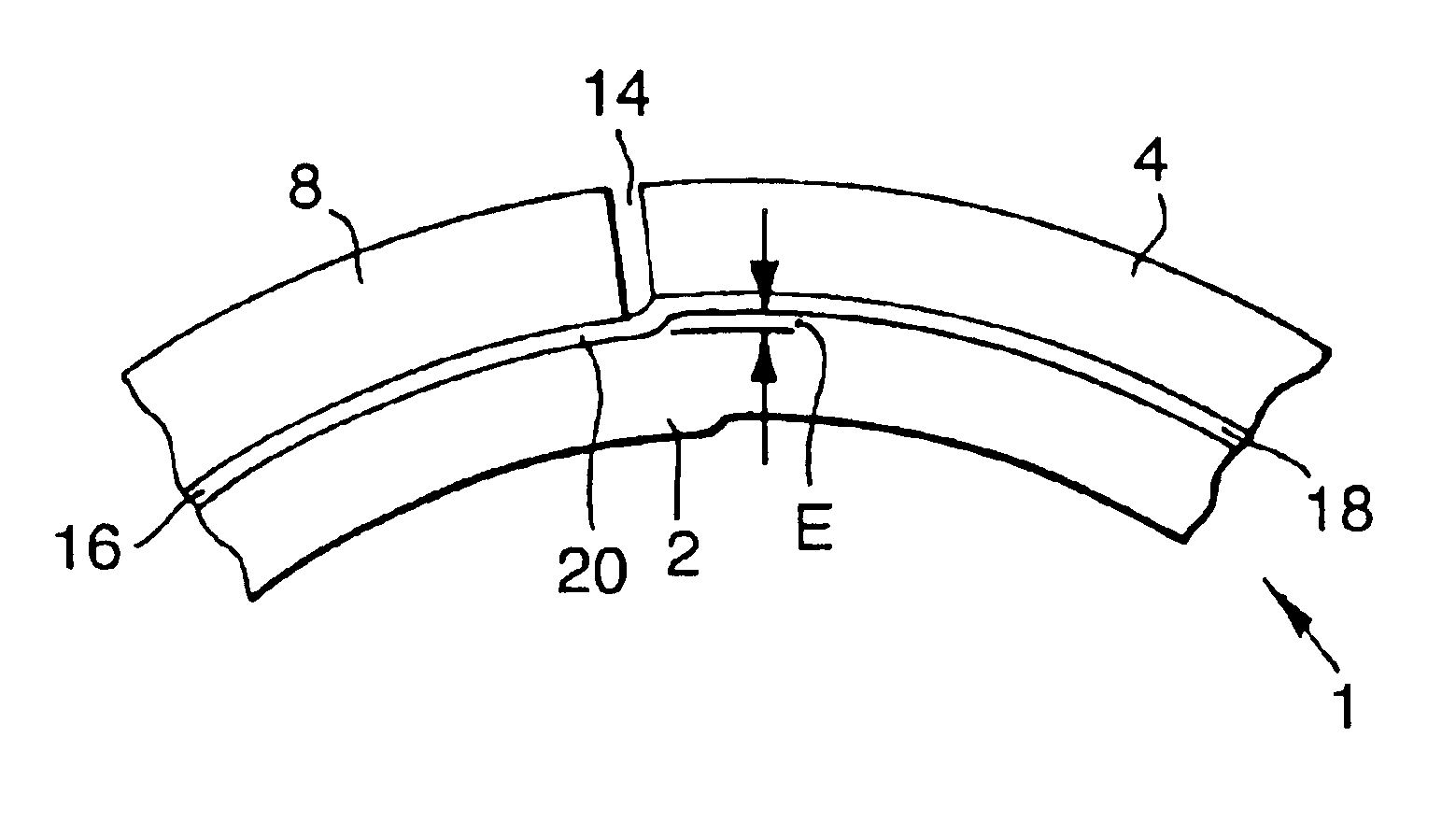

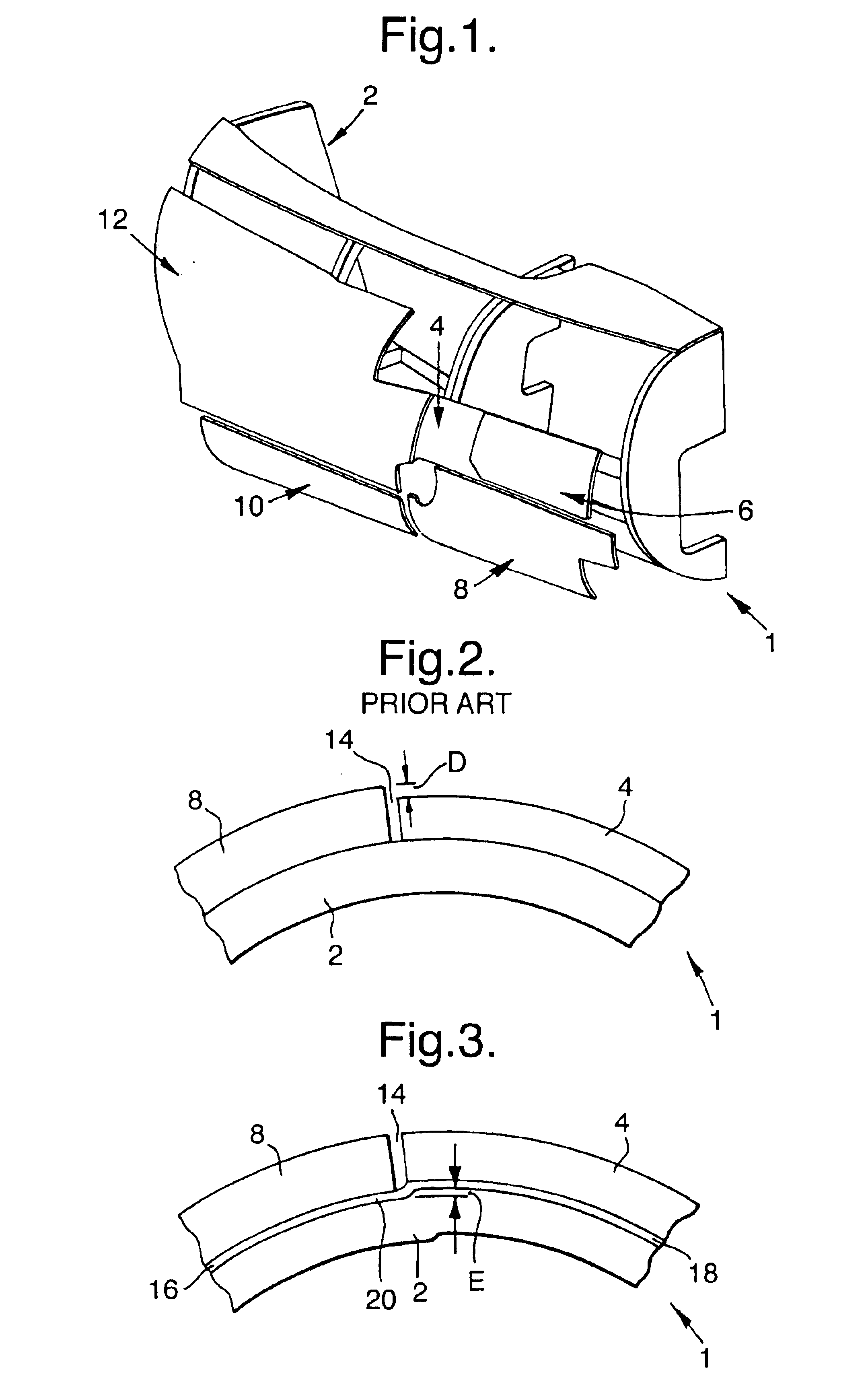

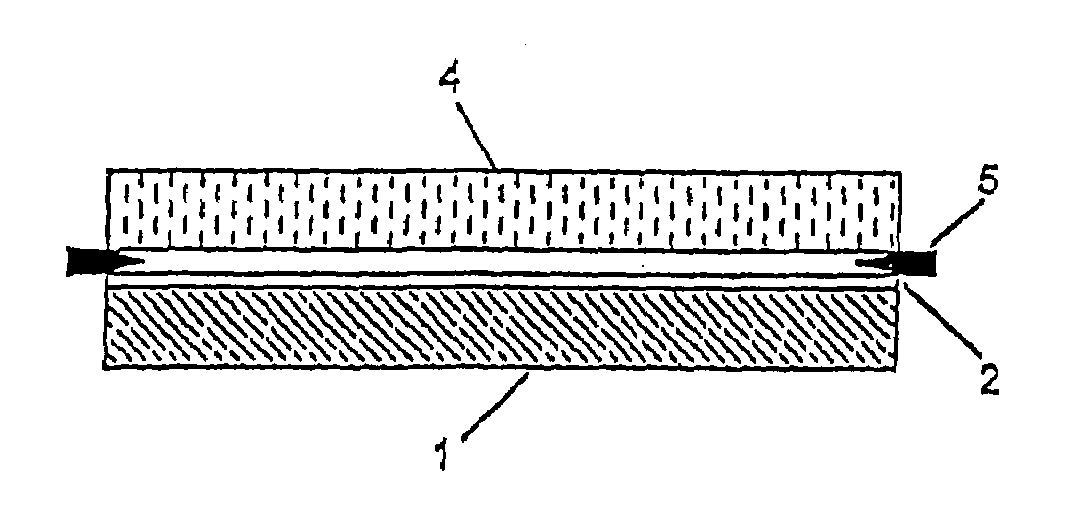

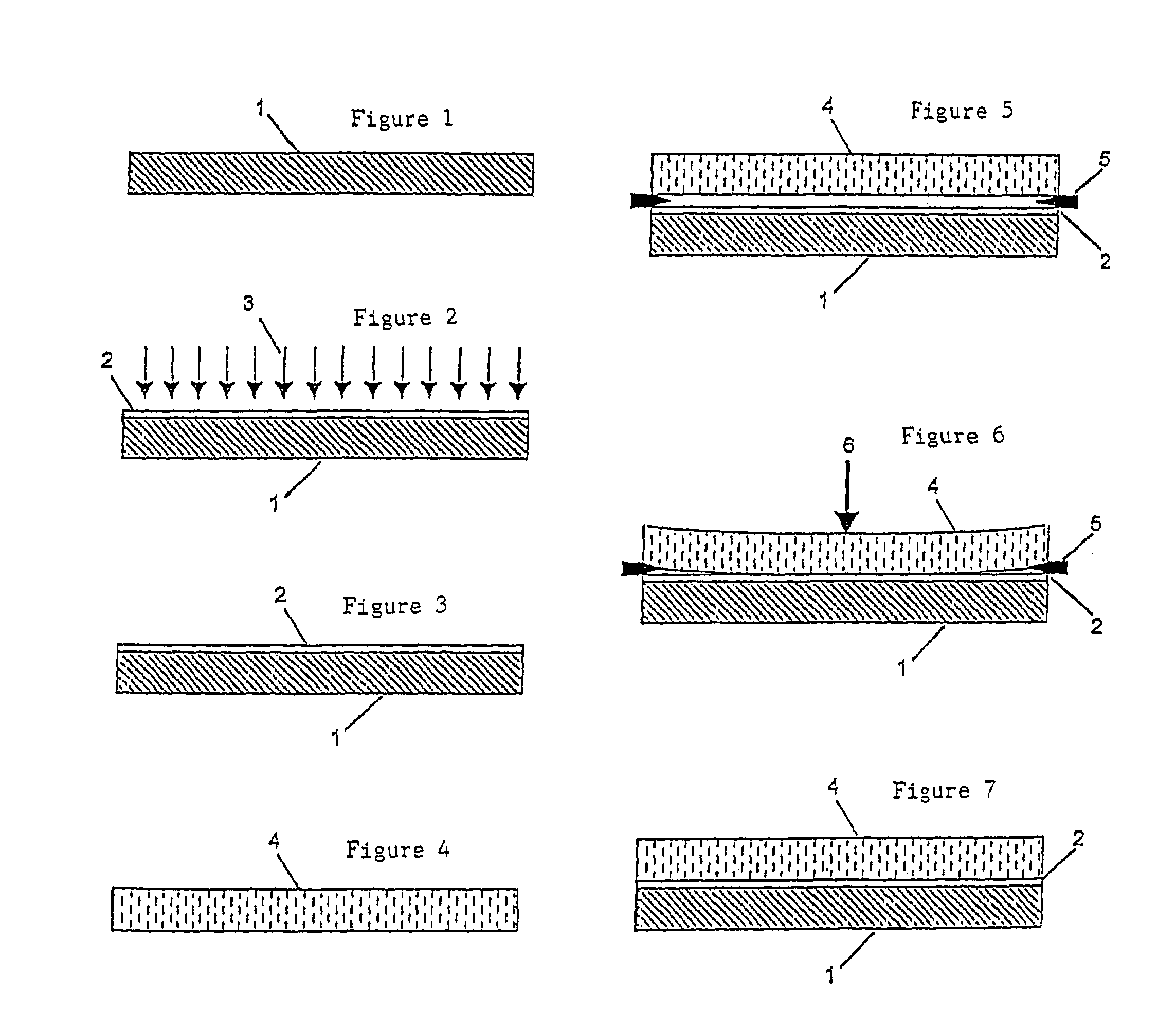

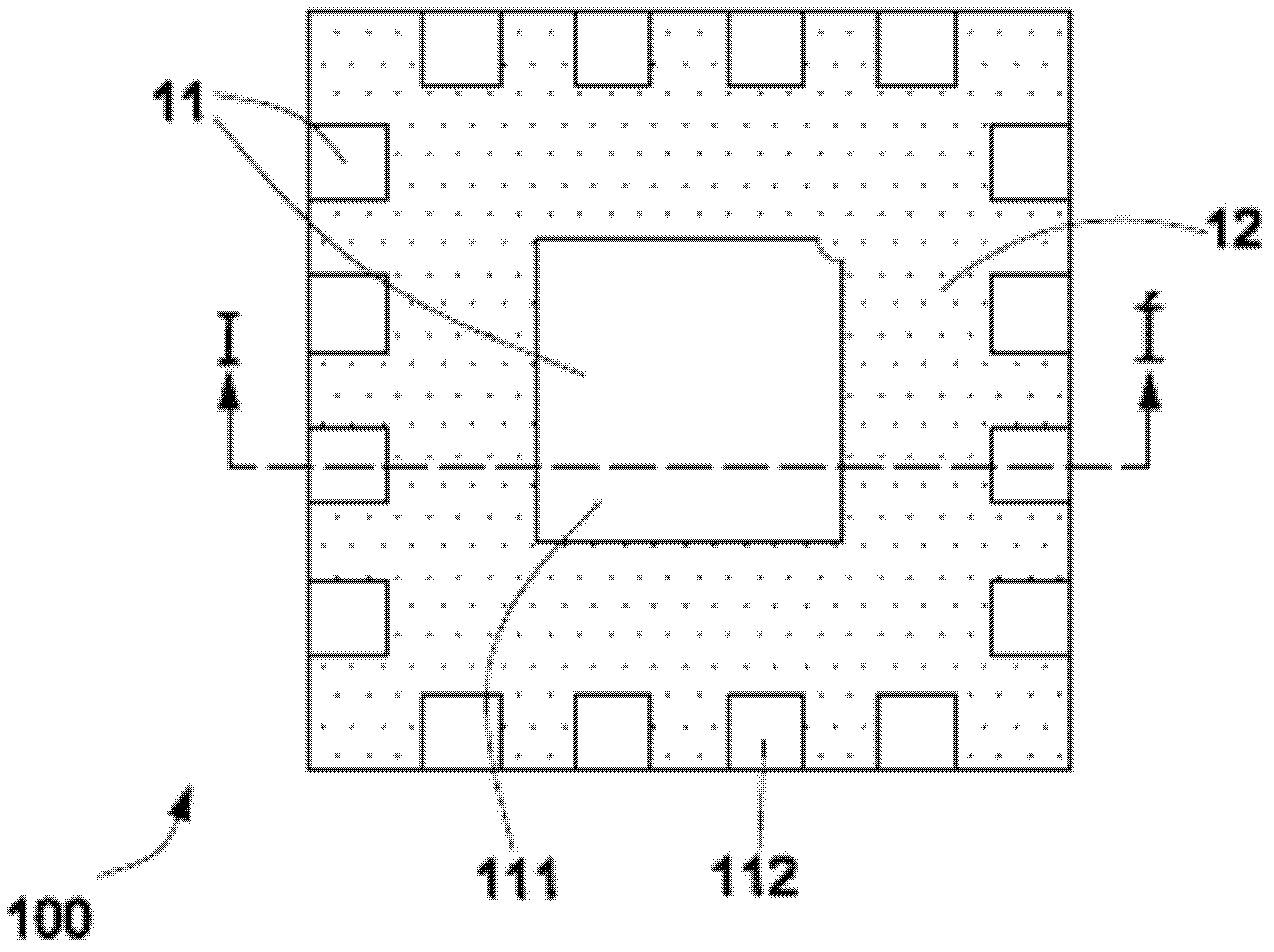

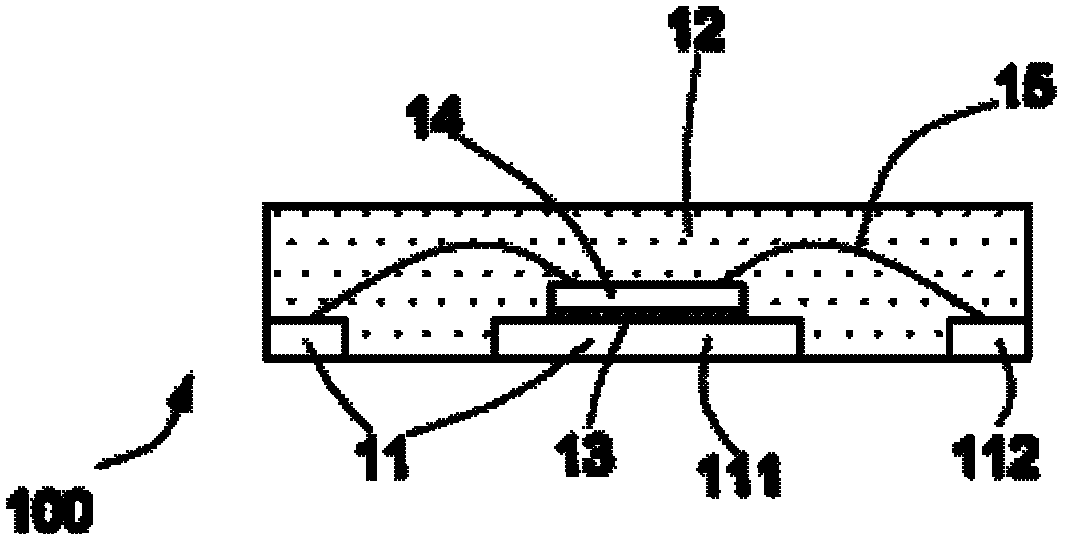

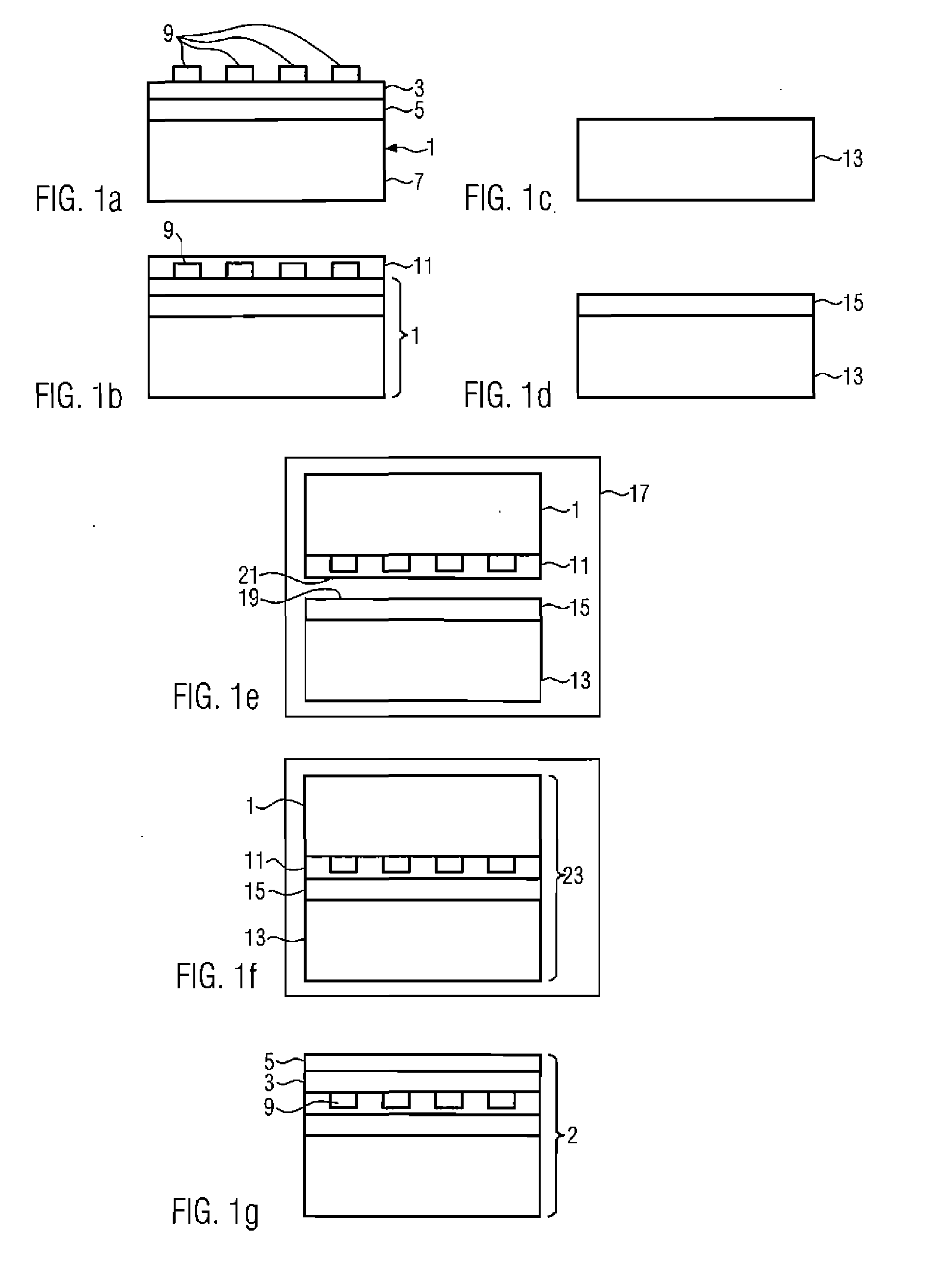

Method of wafer/substrate bonding

InactiveUS7192841B2Improve bonding qualityHigh bonding strengthSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringVoltage

A method of bonding two components by depositing an amorphous and non-hydrogenated intermediate layer (2) on one of the components (1,4) and arranging the components (1,4) in spaced relationship with the intermediate layer (2) therebetween. The method further comprises heating one or both of the components (1,4) before bringing the components (1,4) into contact. Finally, a voltage is applied to the components (1,4) to create a permanent bond between the two components.

Owner:AGENCY FOR SCI TECH & RES

Supportive, washable adhesive bra with detachable support structures

InactiveUS20090093190A1Sufficient surface areaArea maximizationBrassieresGirdlesExtended wearBiomedical engineering

A strapless brassiere having winged -support structures to maximize surface area of the bra to which an extended-wear adhesive is applied over substantially all of the undersurface of the bra.

Owner:WOOLEY SUSAN

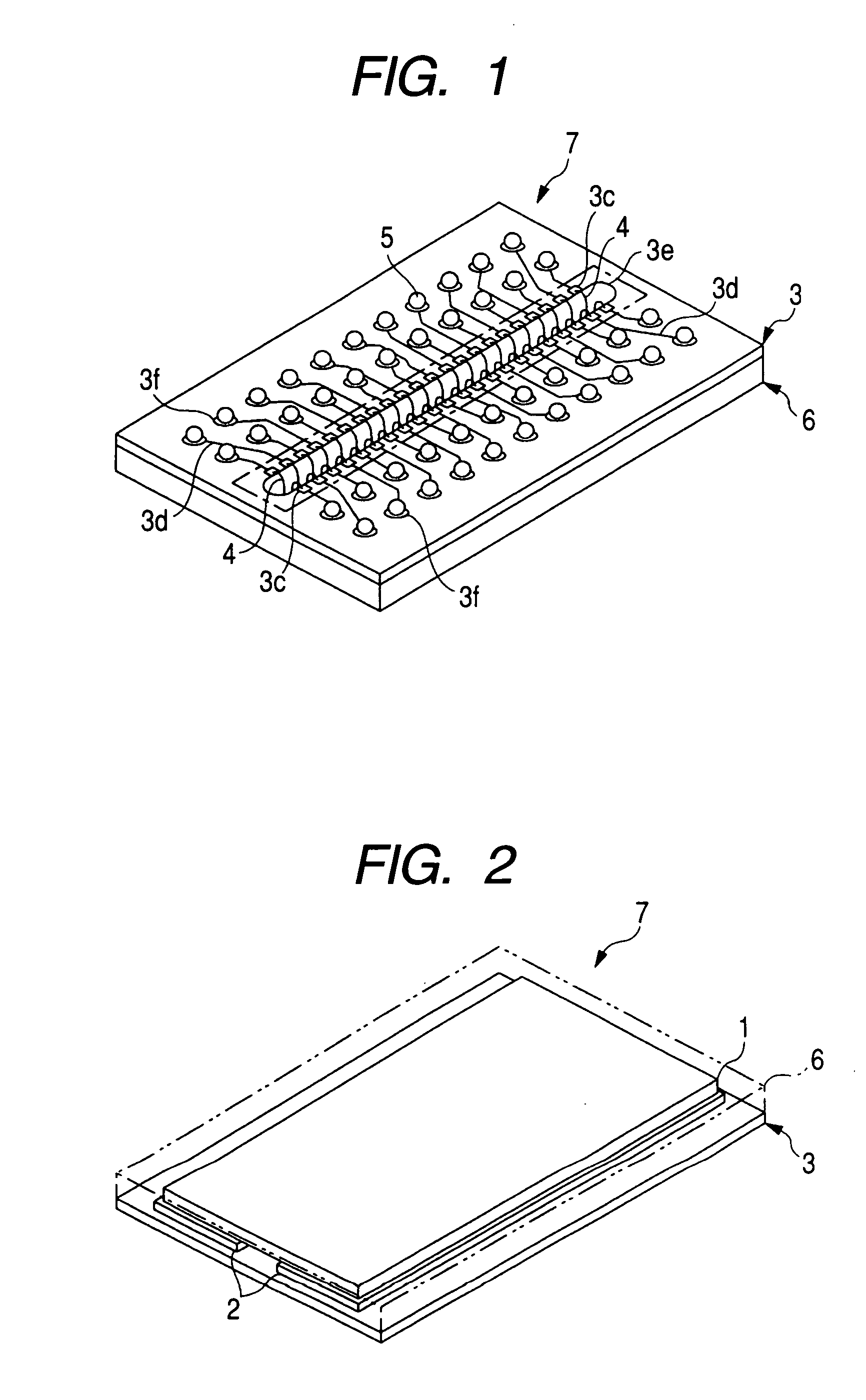

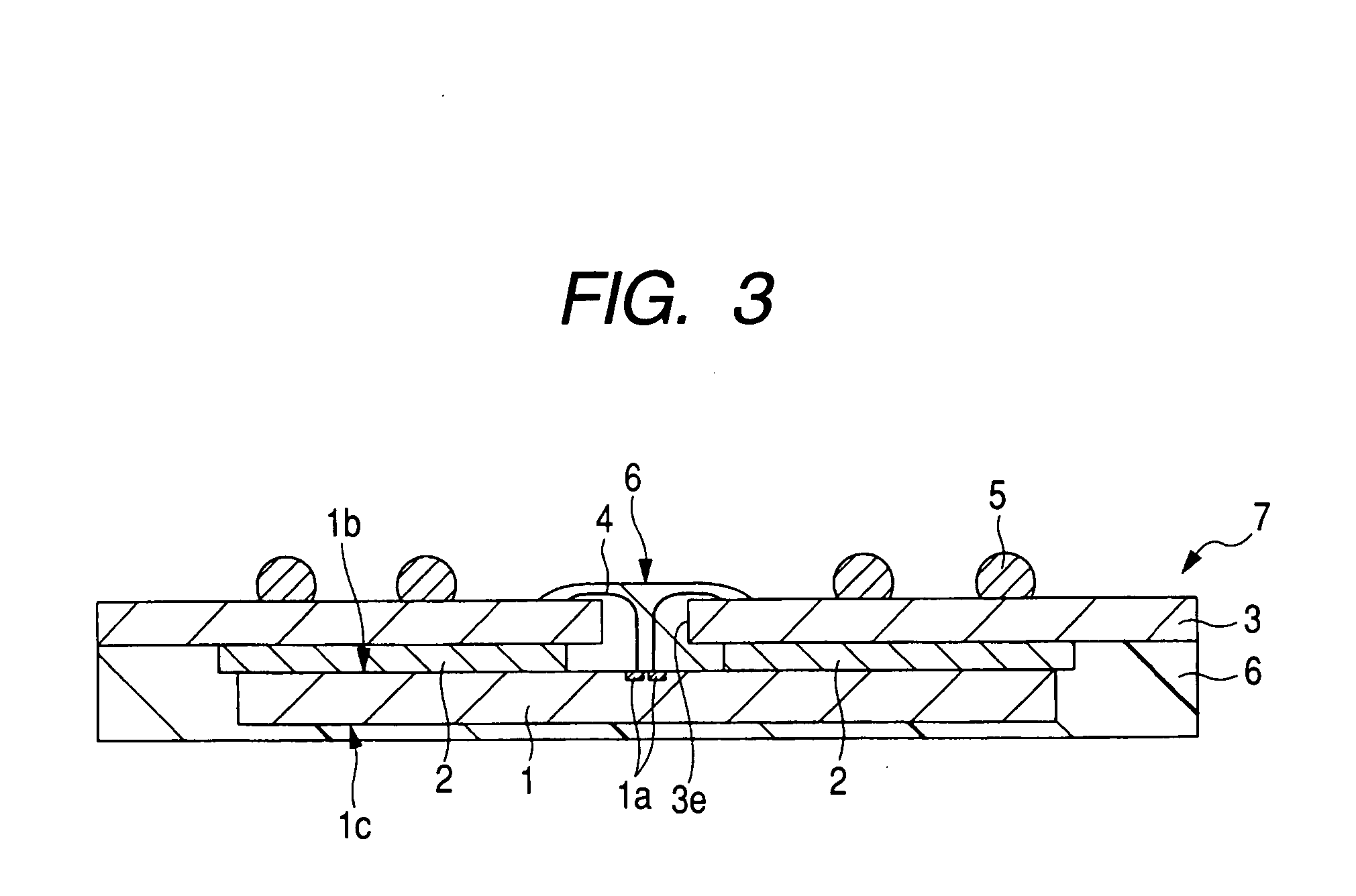

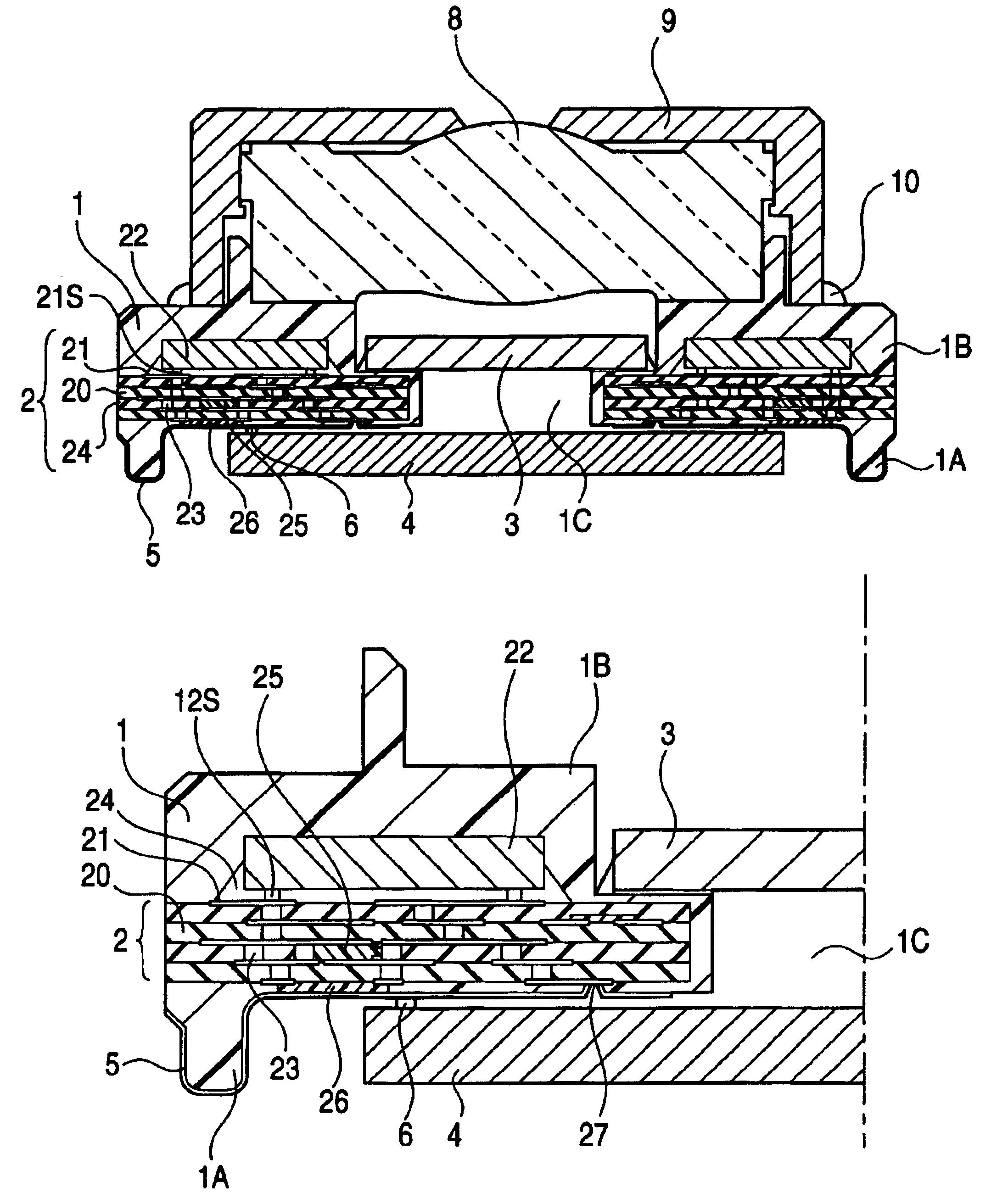

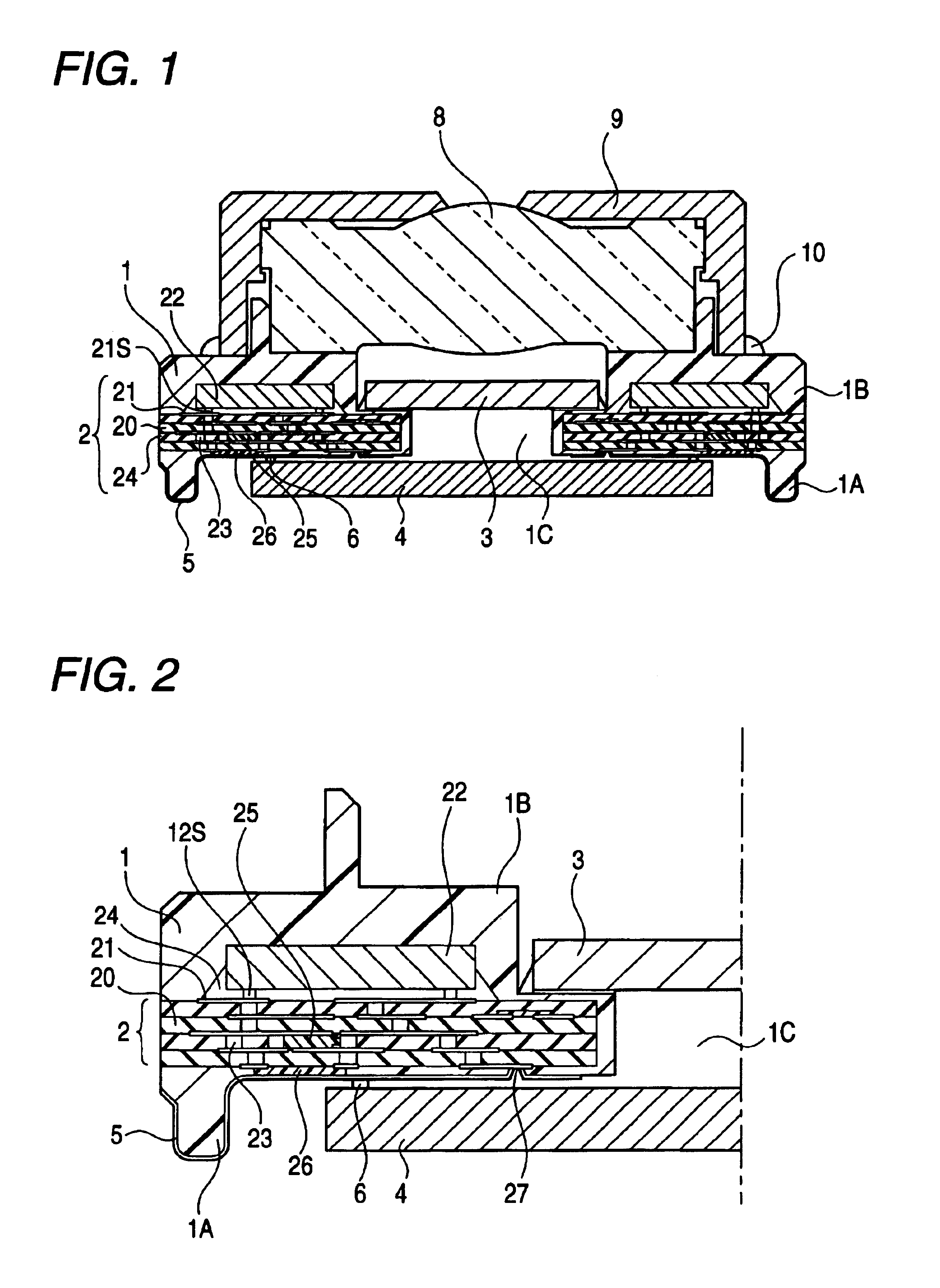

Solid-state imaging apparatus and manufacturing method thereof

InactiveUS6949808B2Easy to transformSmall thermal deformationTelevision system detailsSolid-state devicesSolid-stateStructural element

A structure member is used wherein a circuit board is connected to a solid-state image pickup element and placed between a portion of the structure member to which the solid-state image pickup element is attached, and another portion to which a light-transmitting member is attached, and the circuit board is sealed integrally into the structure member. The solid-state image pickup element is attached to a through-opening portion 1C, and a light-transmitting member is attached so as to cover the through-opening portion 1C with being separated from the solid-state image pickup element by a predetermined distance. In a process of molding the structure member, the circuit board is integrally molded, whereby the manpower can be reduced, and the structures of the attaching portions can be simplified to miniaturize the device.

Owner:PANASONIC CORP

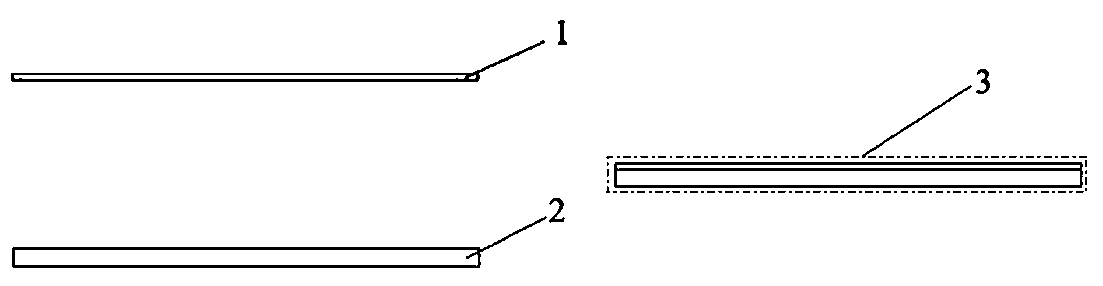

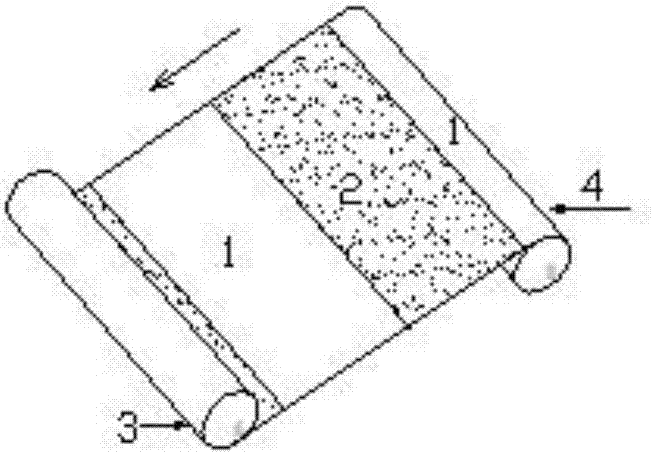

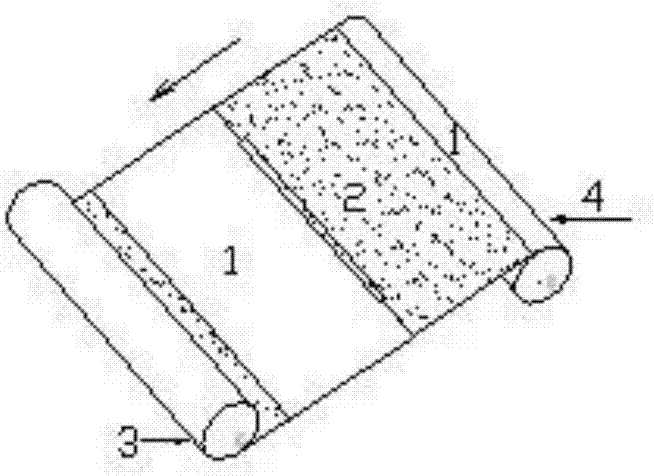

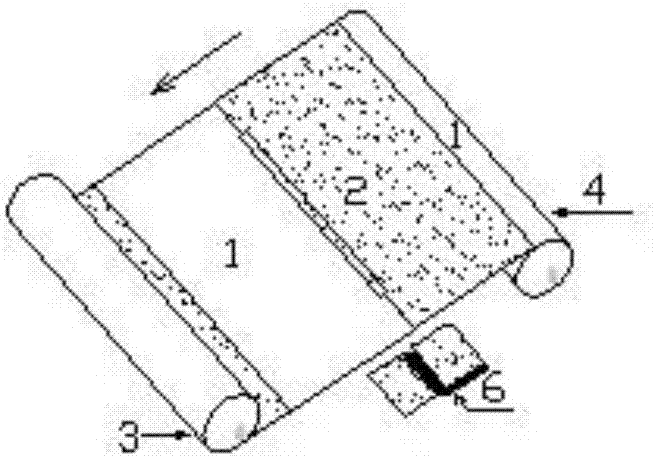

Automatic packaging roll film and preparation method thereof

ActiveCN107142033ASolve technical problems with complex processImprove efficiencyFlexible coversWrappersEngineeringMechanical engineering

The invention aims to provide an automatic packaging roll film and a preparation method thereof. According to the roll film, sticky regions (2) parallel to one another are formed in the transverse direction of the same side of a roll film base material at intervals; a non-sticky region (1) is formed between two adjacent sticky regions (2); each non-sticky region (1) and an adjacent sticky region (2) form a packaging section; between adjacent packaging sections, the non-sticky region (1) of the previous packaging section and the sticky region (2) of the latter packaging section are connected through a separable adhesive tape; and all packaging sections are connected through the separable adhesive tapes so as to form an integral continuous automatic packaging roll film (3). According to the automatic packaging roll film provided by the invention, the technical problem that automatic packaging fails due to film clamping and breaking even shutdown occurring in the automatic packaging process is solved.

Owner:HAIAN XIN FU YUAN OF AGRI SCI & TECH CO LTD

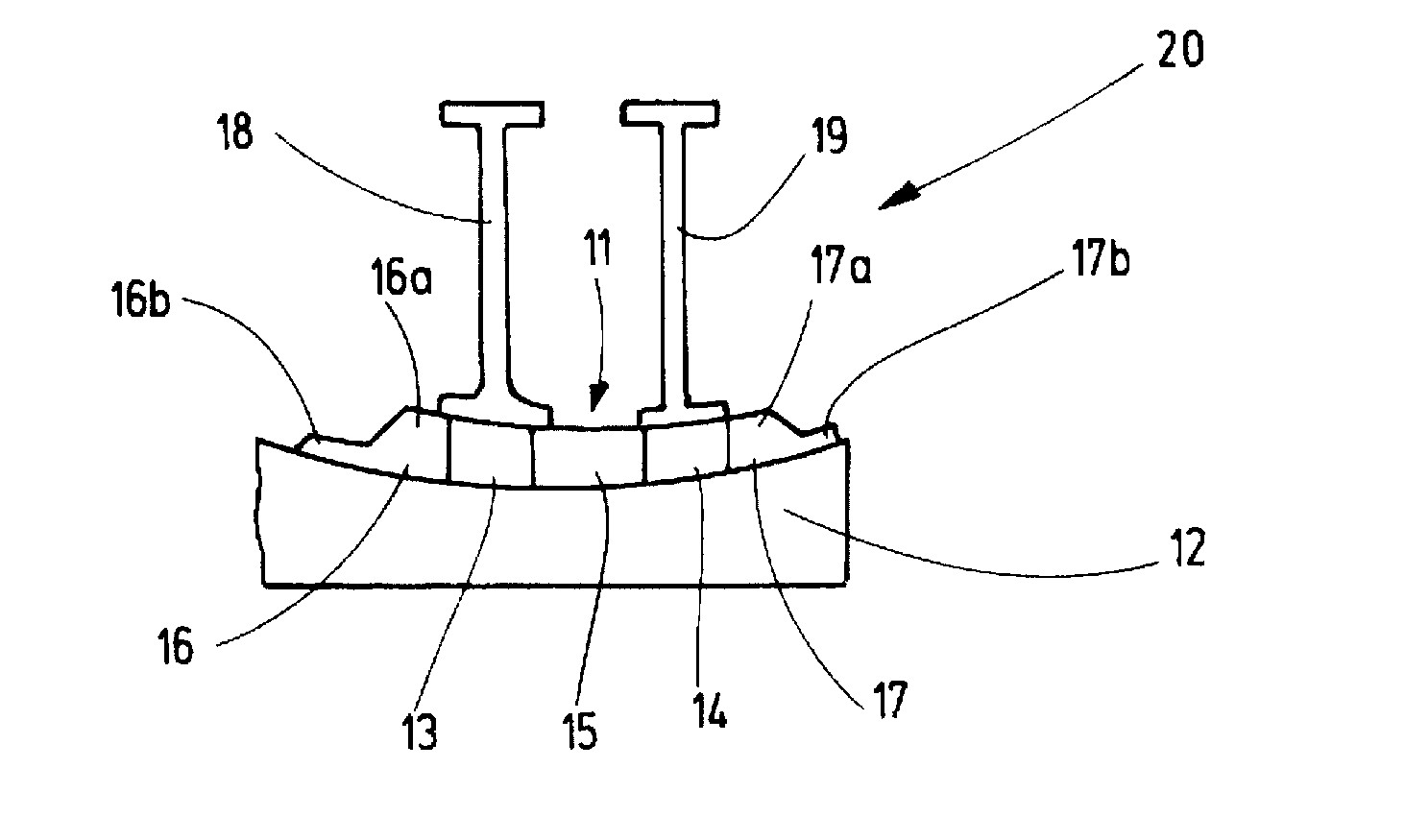

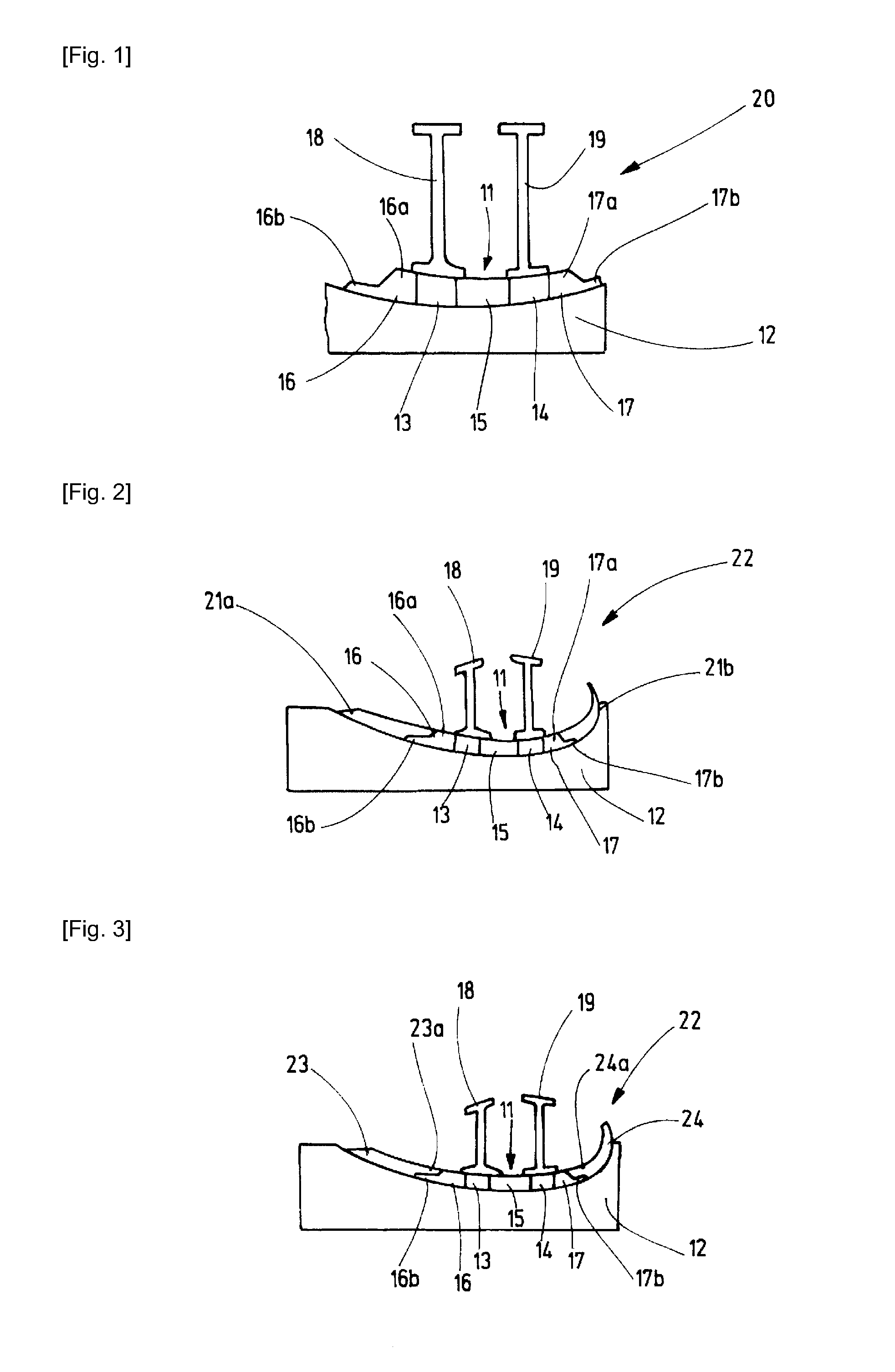

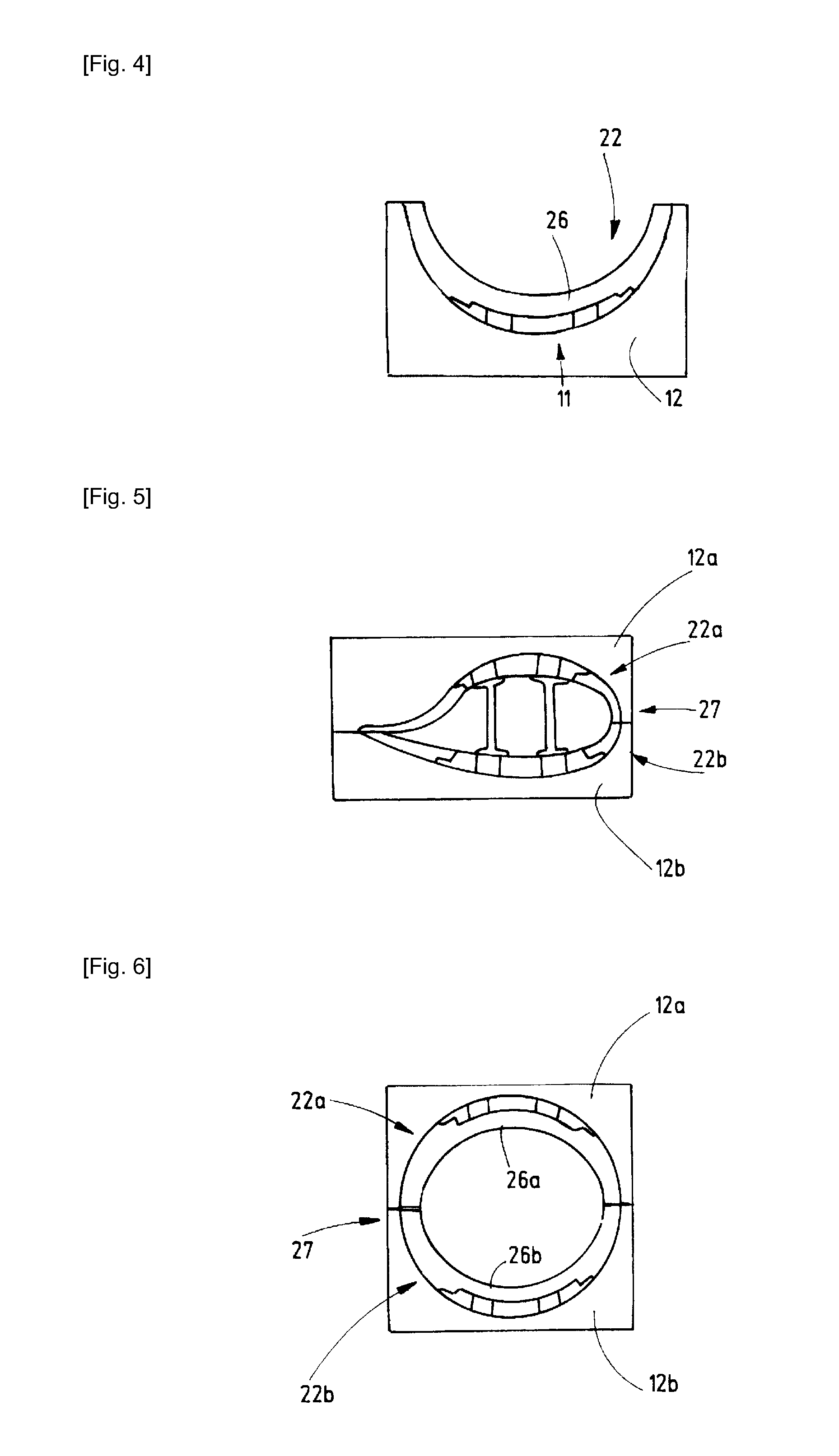

Quad flat non-lead (QFN) package with high density and manufacturing method

InactiveCN102354691AHigh I/O densityPrevent falling offSemiconductor/solid-state device detailsSolid-state devicesFilling materialsMetallic materials

The invention discloses a quad flat non-lead (QFN) package with high density and a manufacturing method. The package comprises a lead frame 201, metal material layers 25, an IC chip 27, insulating filling materials 23, bonding materials 26, metal conductors 28 and plastic package materials 29, wherein the lead frame comprises a chip carrier 202 and a plurality of leads 203 arranged in multiple circles around the chip carrier; the metal material layers are arranged on the upper and lower surfaces of the lead frame; the IC chip is arranged on a metal material layer on the upper surface of the lead frame; the insulating filling materials are arranged below stepped structures 22b of the lead frame; the bonding materials are arranged between the IC chip and the metal material layer on the upper surface of the lead frame; the IC chip is connected to the inner leads of the multiple circles of leads and the upper surface of the chip carrier respectively by the metal conductors; the plastic package materials wrap and seal the IC chip, the bonding materials, the metal conductors, partial regions of the lead frame and partial metal material layers; and the chip carrier and the outer leads exposed out of the bottom surface of a package structure, are provided with raised parts. The package and the manufacturing method have the following beneficial effects: the bottleneck of low I / O quantity is broken through and the package reliability is improved.

Owner:BEIJING UNIV OF TECH

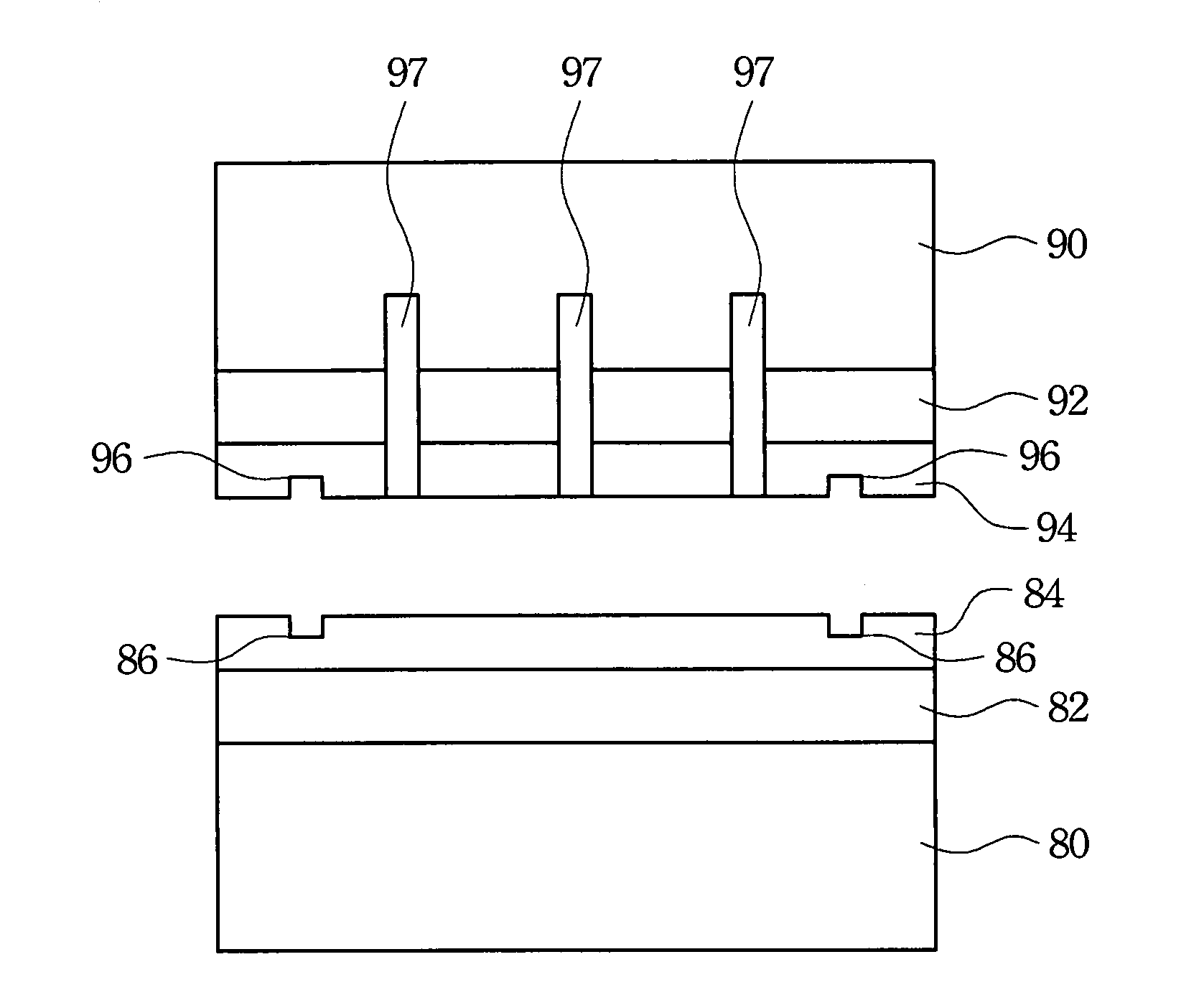

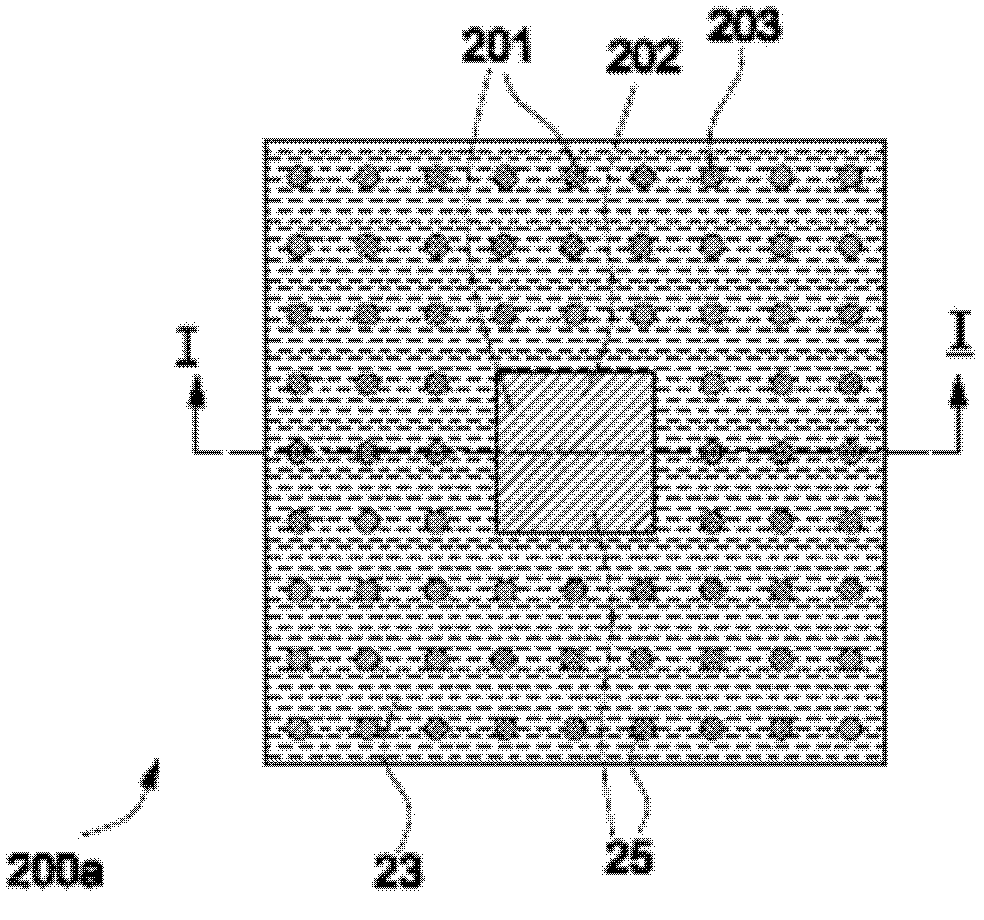

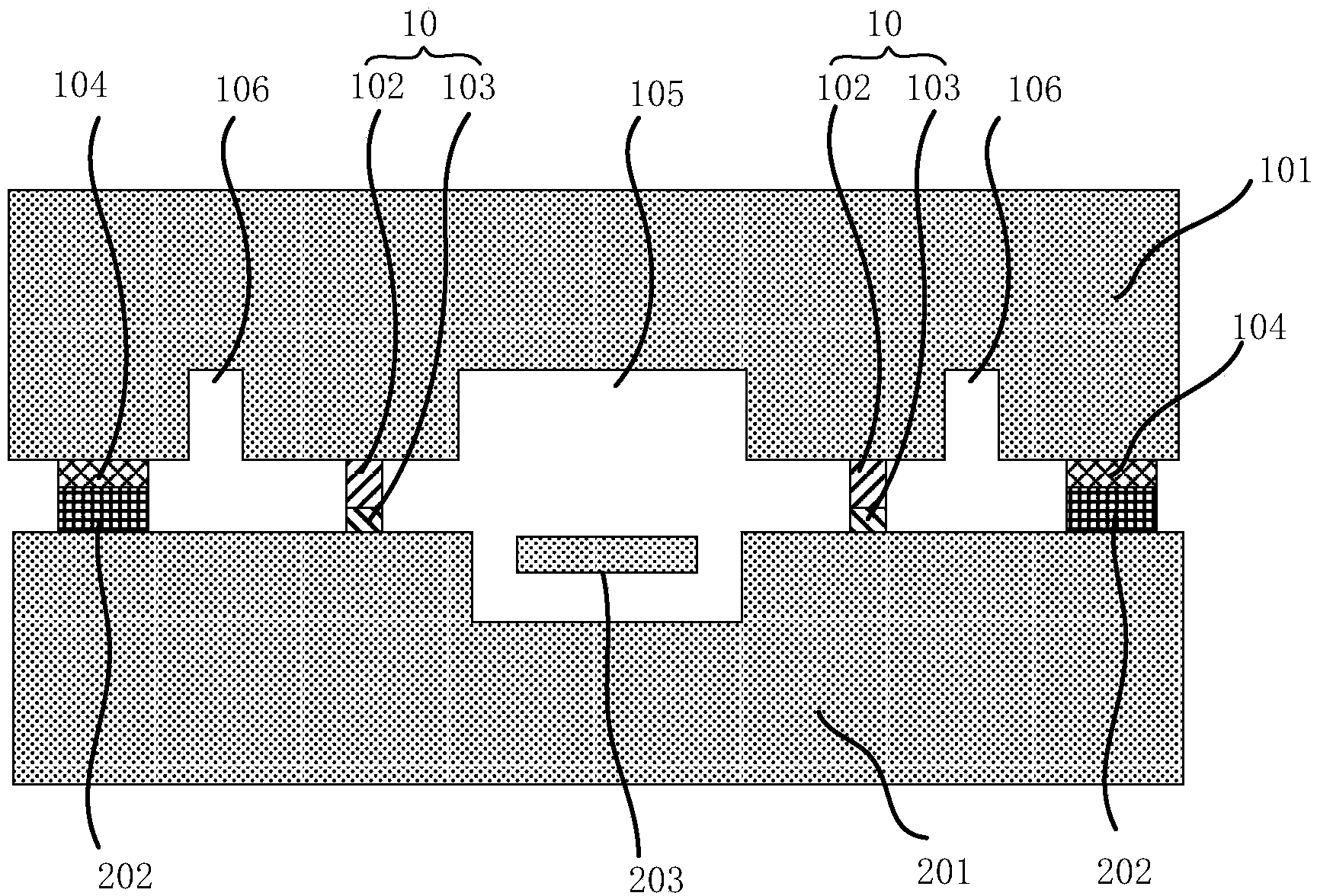

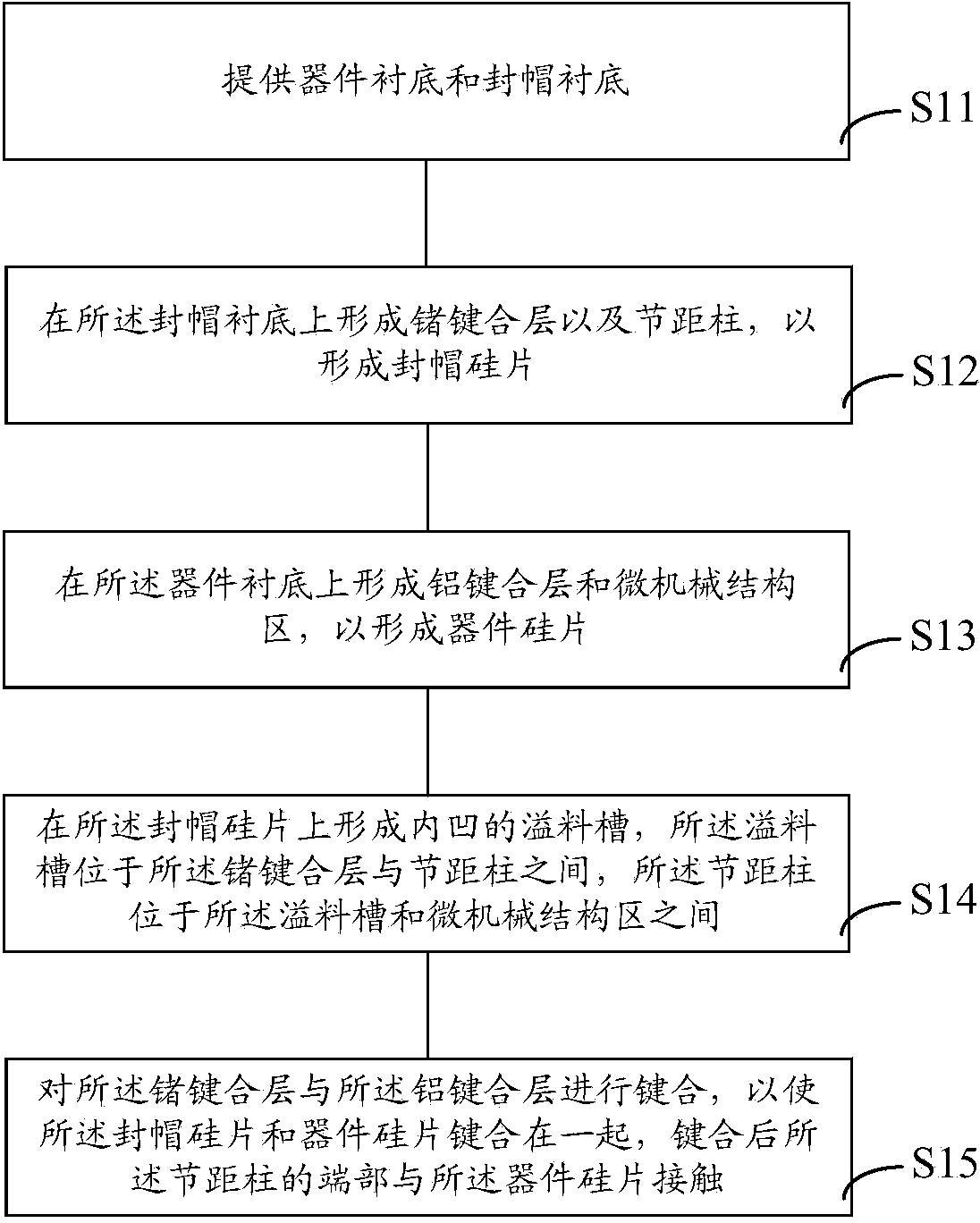

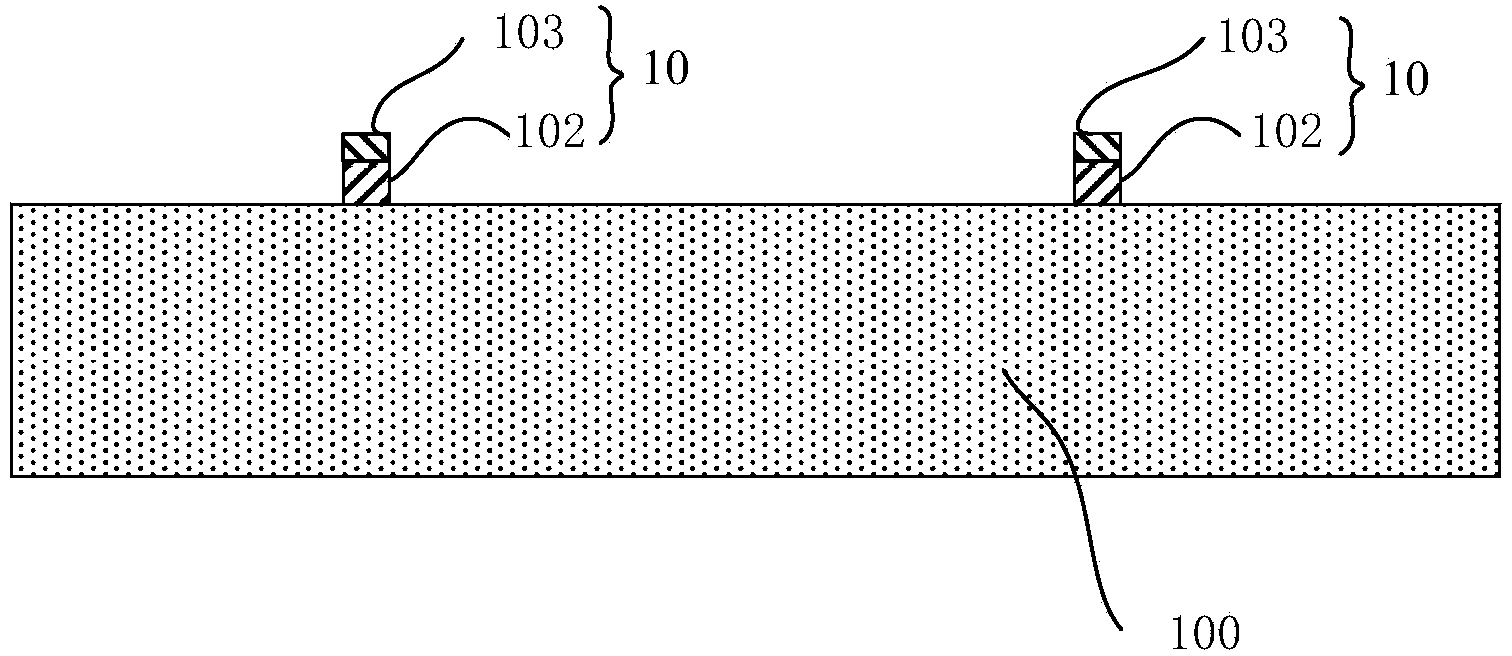

MEMS aluminum and germanium bonding structure and manufacturing method thereof

ActiveCN103979481AUniform pressureGuaranteed tightnessTelevision system detailsPrecision positioning equipmentBonding processOptoelectronics

The invention provides an MEMS aluminum and germanium bonding structure and a manufacturing method thereof. The structure comprises a device silicon chip and a sealing cap silicon chip, wherein the device silicon chip is provided with a micro mechanical structure area and an aluminum bonding layer; the sealing cap silicon chip is provided with a germanium bonding layer, and the germanium bonding layer is in bonding with the aluminum bonding layer. The sealing cap silicon chip is further provided with a pitch column extending out of the sealing cap silicon chip, and the end of the pitch column is in contact with the device silicon chip. The MEMS aluminum and germanium bonding structure can control aluminum and germanium horizontal extension quantity caused by bonding pressure in the bonding process, and an aluminum and germanium bonding layer with a preset thickness is obtained.

Owner:HANGZHOU SILAN INTEGRATED CIRCUIT

Method for bonding two substrates

InactiveUS20100155882A1Reduce in quantityFast and easy to carry-outSolid-state devicesSemiconductor/solid-state device manufacturingBiological activationTwo step

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

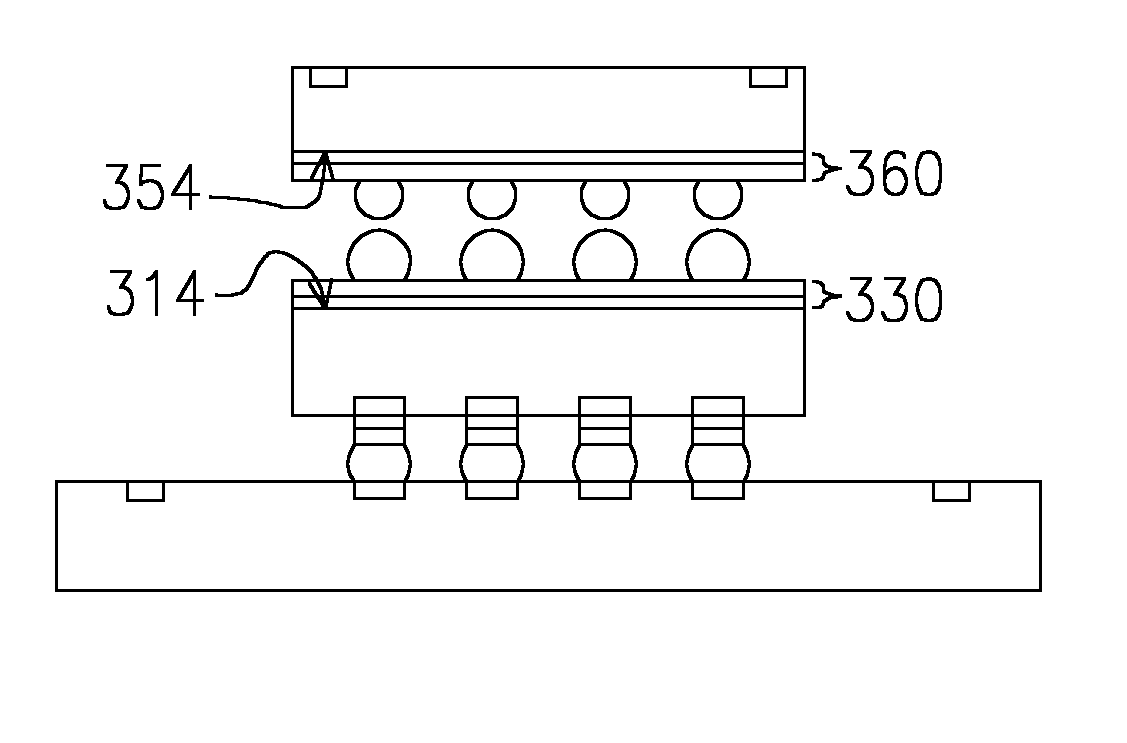

Multi-chip stack package and fabricating method thereof

InactiveUS20030127720A1Improve bonding qualitySemiconductor/solid-state device detailsSolid-state devicesFilling materialsEngineering

Abstract of Disclosure A multi-chip stack package having a substrate, a first chip, a second chip, a plurality of bumps, a plurality of junction interface bumps, a plurality of conductive wires, a first filler material, a second filler material and an encapsulating material is provided. The substrate has a substrate surface with a plurality of first contacts and a plurality of second contacts. The first chip has a first active surface with a plurality of bonding pads thereon and a first chip back surface. The first chip is positioned over the substrate surface. The second chip has a second active surface with a plurality of bonding pads thereon and a second chip back surface. The second chip is positioned over the first chip back surface. The bumps are positioned between the first bonding pads and the first contacts. The junction interface bumps are positioned between the first chip back surface and the second chip back surface. The conductive wires electrically connect the second bonding pads and the second contacts. The first filler material encloses the bumps and the second filler material encloses the junction interface bumps. The encapsulating material encloses the first chip, the second chip and the conductive wires.

Owner:ADVANCED SEMICON ENG INC

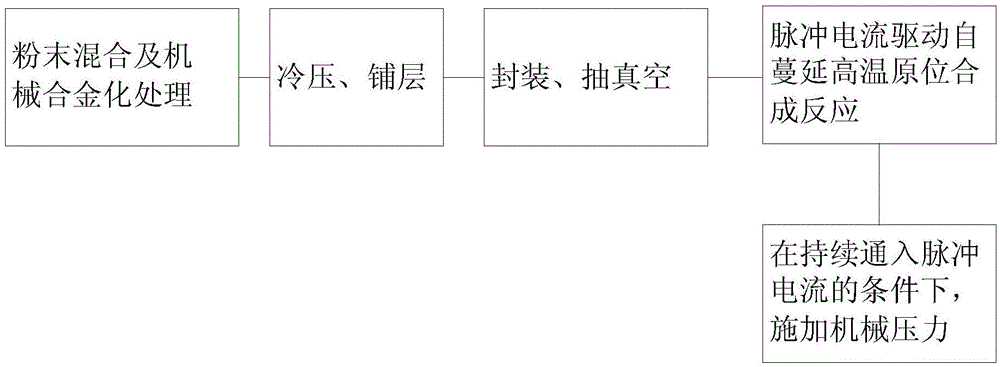

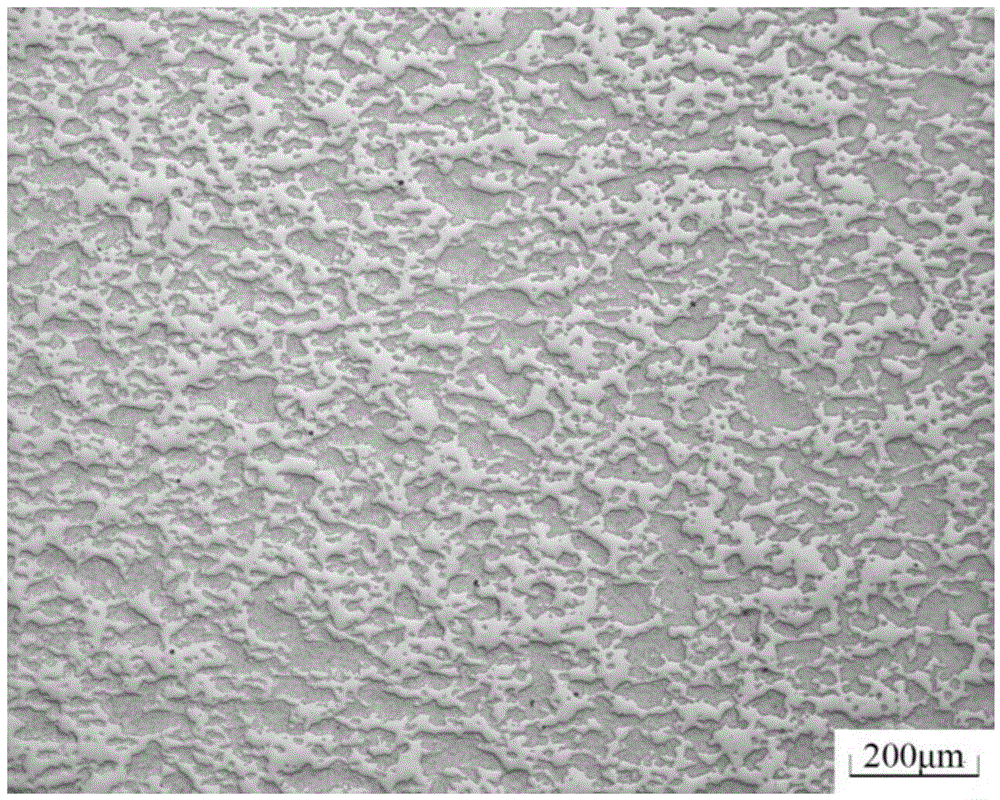

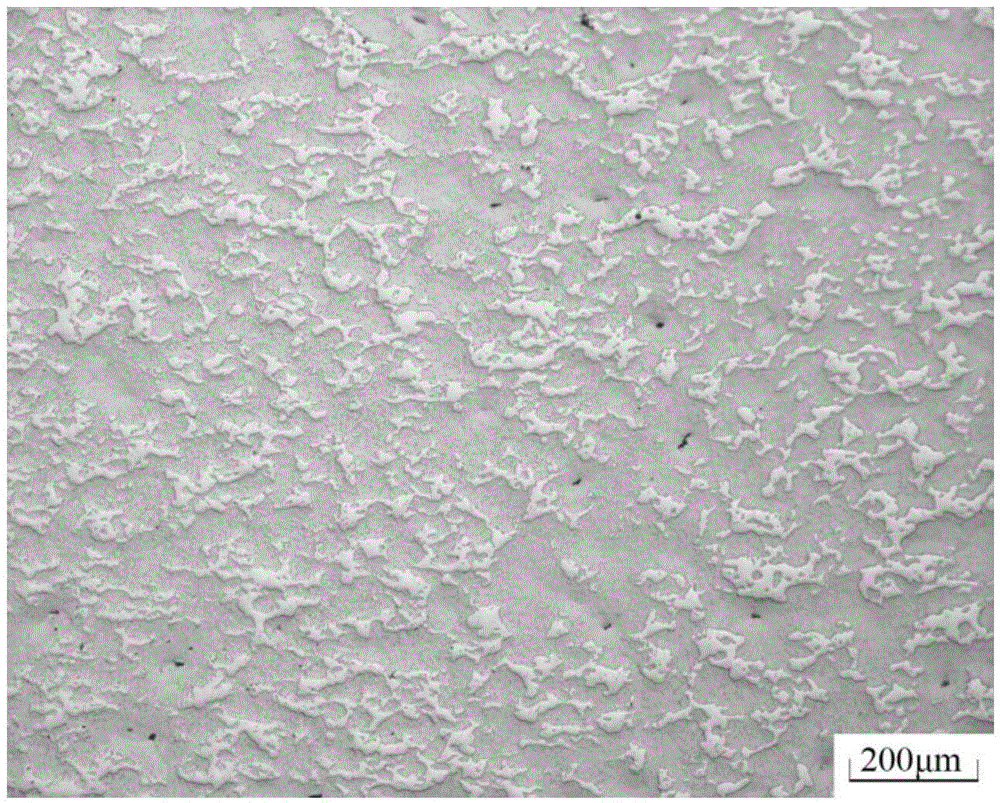

Metal/ceramic gradient material and preparation method thereof

The invention provides a metal / ceramic gradient material and a preparation method thereof. The method comprises the steps that metal powder needed for each layer and element powder needed for ceramic synthesis are fully mixed and are subjected to mechanical alloying treatment according to designed gradient components, the number of gradient layers and the component content in each layer, and mixed powder needed for each layer is obtained; the mixed powder needed for each layer is subjected to cold pressing, and semi-densified powder blanks are obtained; the semi-densified powder blanks are laid up according to the designed gradient components, the number of gradient layers and the component content in each layer, and pre-formed blanks are obtained; the pre-formed blanks are vacuumized after being packaged through metal sheaths, and the packaged pre-formed blanks are obtained; and after the packaged pre-formed blanks are preheated, pulse current is applied to the packaged pre-formed blanks, so that a self-propagating high-temperature in-situ synthesis reaction is driven, and the metal / ceramic gradient material is obtained after the reaction finishes. The prepared metal / ceramic gradient material is full in reaction, high in density and good in bonding quality between gradient interfaces.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

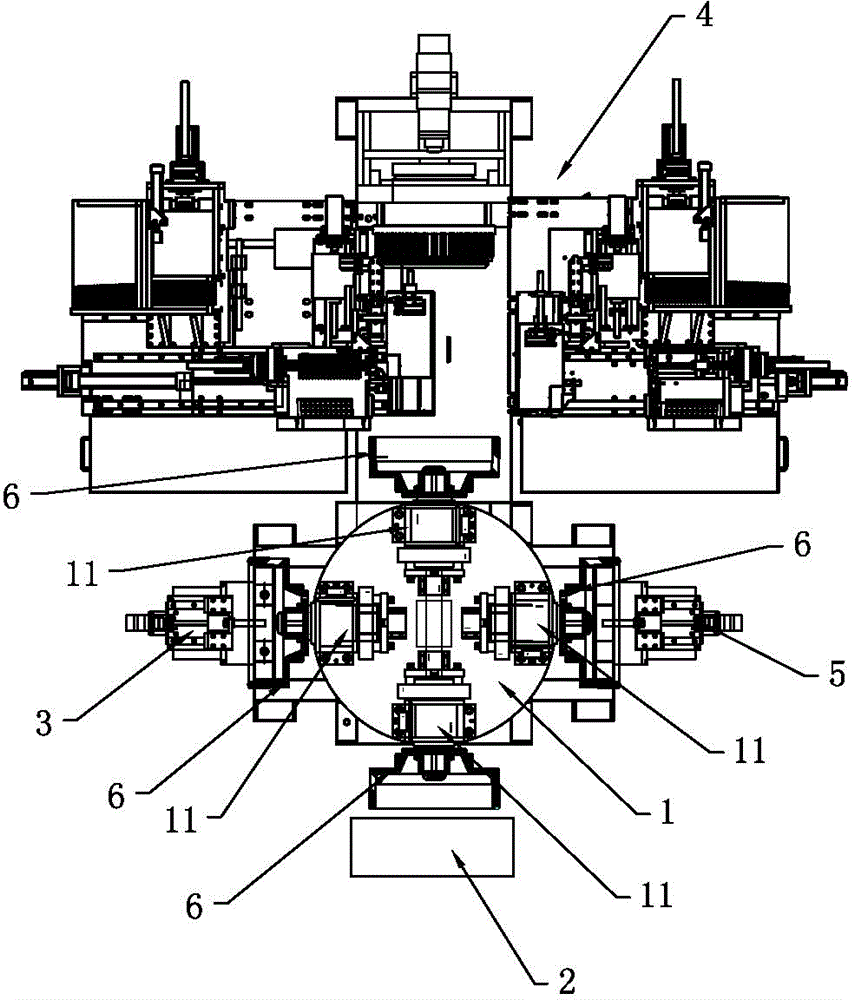

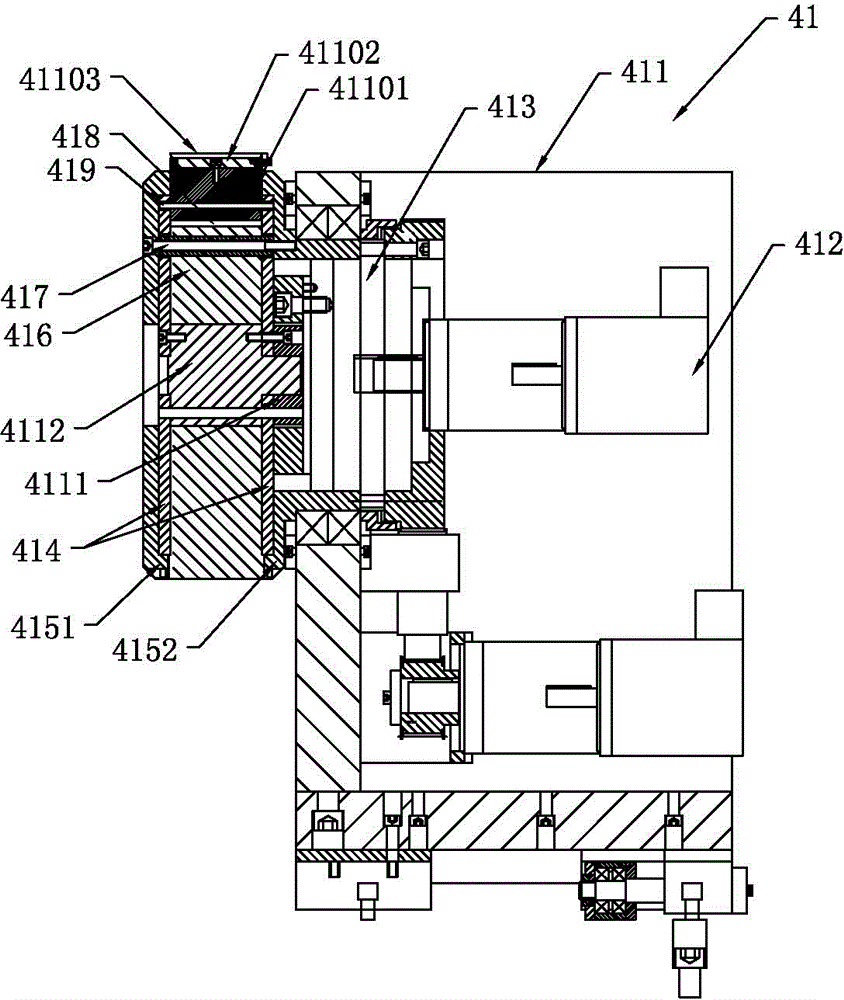

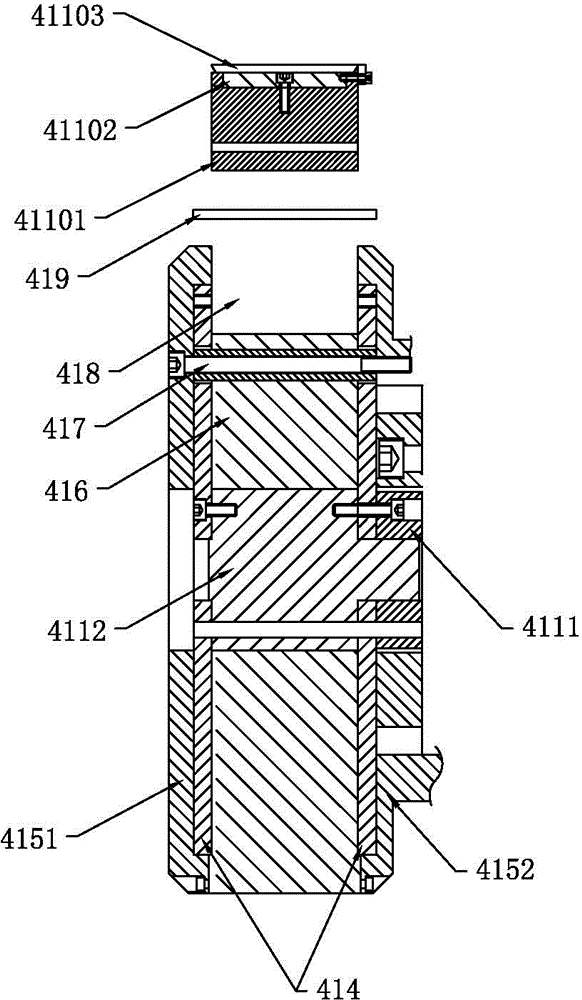

Full-automatic magnetic tile sticking machine

ActiveCN104795947AImprove efficiencyAvoid errorsManufacturing stator/rotor bodiesControl systemStructural engineering

The invention relates to a full-automatic magnetic tile sticking machine which comprises a control system, a rotatable turnplate mechanism, a feeding mechanism, a discharging mechanism, a gluing mechanism, a magnetic tile sticking and mounting mechanism and a filling glue coating mechanism. The feeding mechanism, the discharging mechanism, the gluing mechanism, the magnetic tile sticking and mounting mechanism and the filling glue coating mechanism are arranged sequentially, the magnetic tile sticking and mounting mechanism comprises a magnetic tile library driving device, an intermediate wheel, two driving plates, multiple pins and multiple loading units capable of adsorbing magnetic tiles, the magnetic tile library driving device can drive the driving plates to rotate, the intermediate wheel is fixedly arranged between the driving plates, multiple guide grooves are formed between the outer wall of the periphery of the intermediate wheel and the side walls of the driving plates, each loading unit is mounted in the corresponding guide groove, each driving plate is provided with multiple pin driving mechanisms corresponding to the loading units, and the pin driving mechanism are used for pushing the pins to move. The magnetic tile sticking and mounting mechanism adopts a magnetic tile library to adsorb the magnetic tiles needed by a rotor to the loading units of the magnetic tile library, and the loading units move outwards at the same time to stick the magnetic tiles to the inner wall of the rotor at the same time when the driving plates rotate, so that the full-automatic magnetic tile sticking machine is high in efficiency and quality.

Owner:GUANGZHOU FIRESTEP SELF CONTROL SPECIAL PURPOSE EQUIP +1

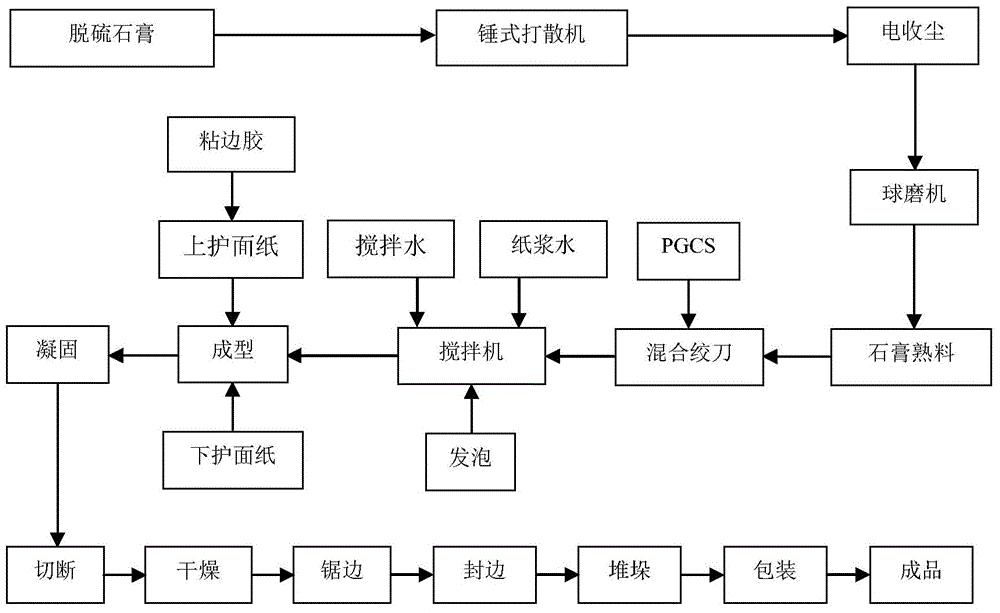

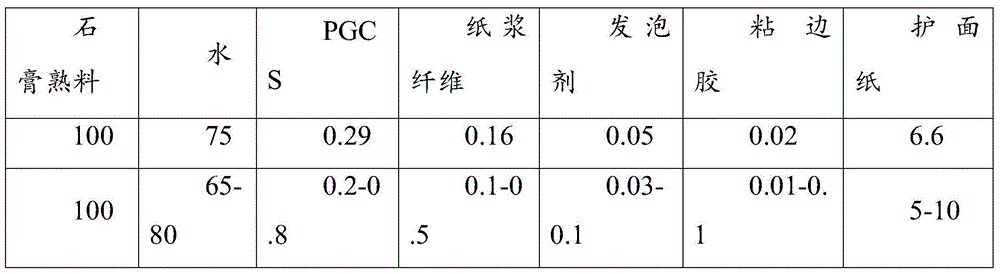

Preparation method of paper-surface gypsum board

InactiveCN104973882AImprove bonding qualityAchieve self-consumptionCeramicwareSlurryToxic industrial waste

The invention discloses a preparation method of a paper-surface gypsum board. The method comprises the following steps: after being metered, gypsum clinker and PGCS are fully mixed, and then the mixture enters a mixer; paper pulp, mixing cement and foam respectively enter the mixer; the above dry and wet materials are fully stirred in the mixer to prepare uniform slurry, the slurry is continuously poured between two layers of covering paper, and a wet gypsum board is prepared by extrusion molding; and the wet gypsum board undergoes solidification, cutting, drying, final trimming, edge banding, stacking and packaging so as to prepare the paper-surface gypsum board finished product. According to the invention, bonding quality and strength of the board are enhanced; raw materials can be saved, energy consumption is reduced, and production cost is decreased; and dependence of bonding quality of the covering paper on operation and drying system is reduced. The scheme of drying the paper-surface gypsum board by the use of waste heat from a power plant or a steel mill is feasible. Energy conservation and emission reduction as well as automatic disposal of industrial waste residues are realized. In addition, the aggregate resources conservation purpose of ''low energy, low pollution and high return'' is achieved.

Owner:BEIJING NEW BUILDING MATERIALS PLC

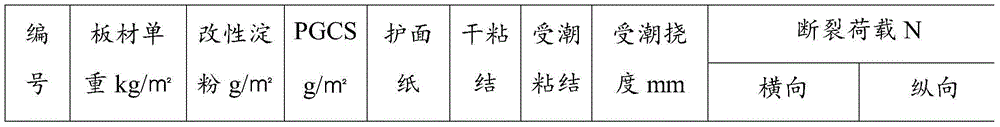

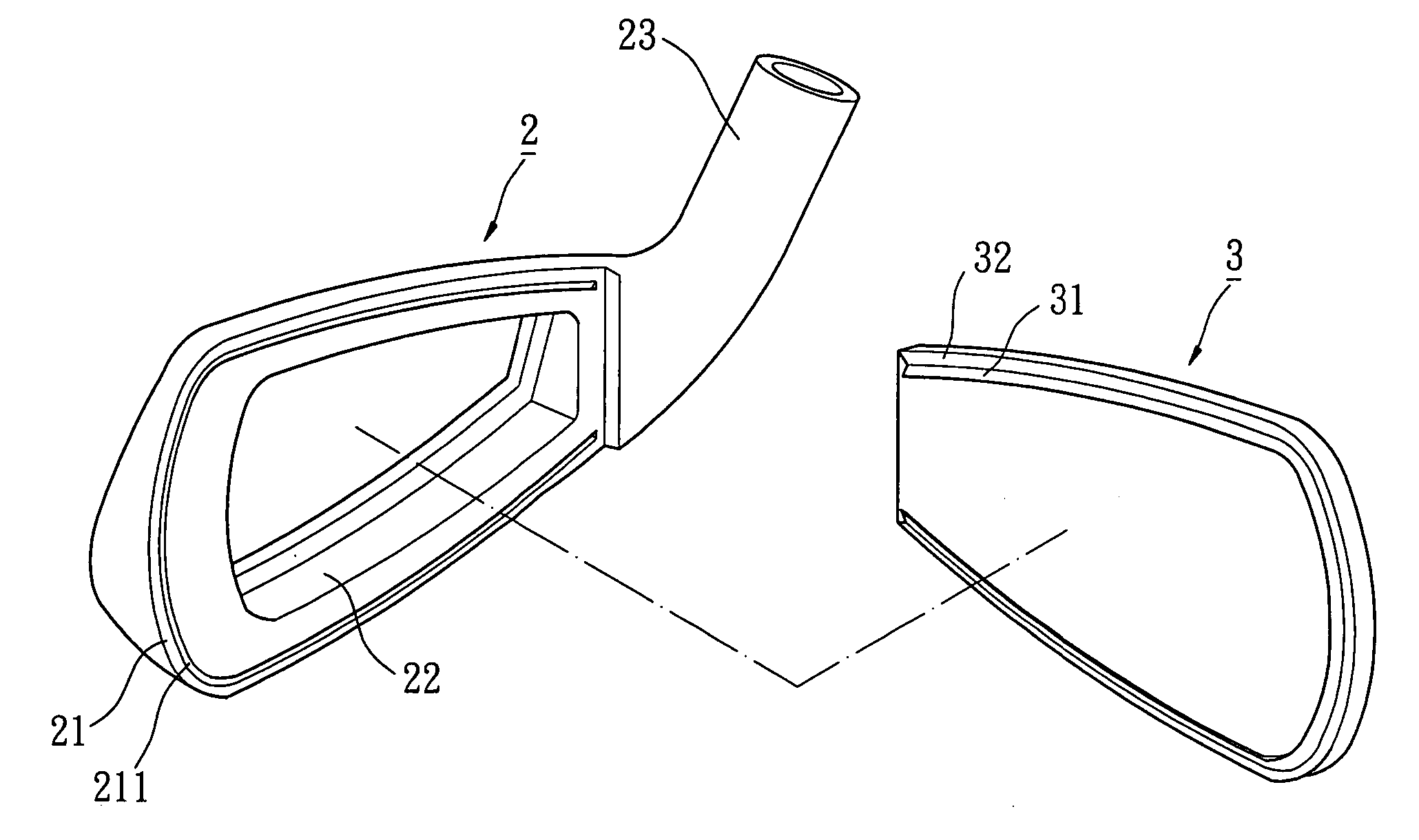

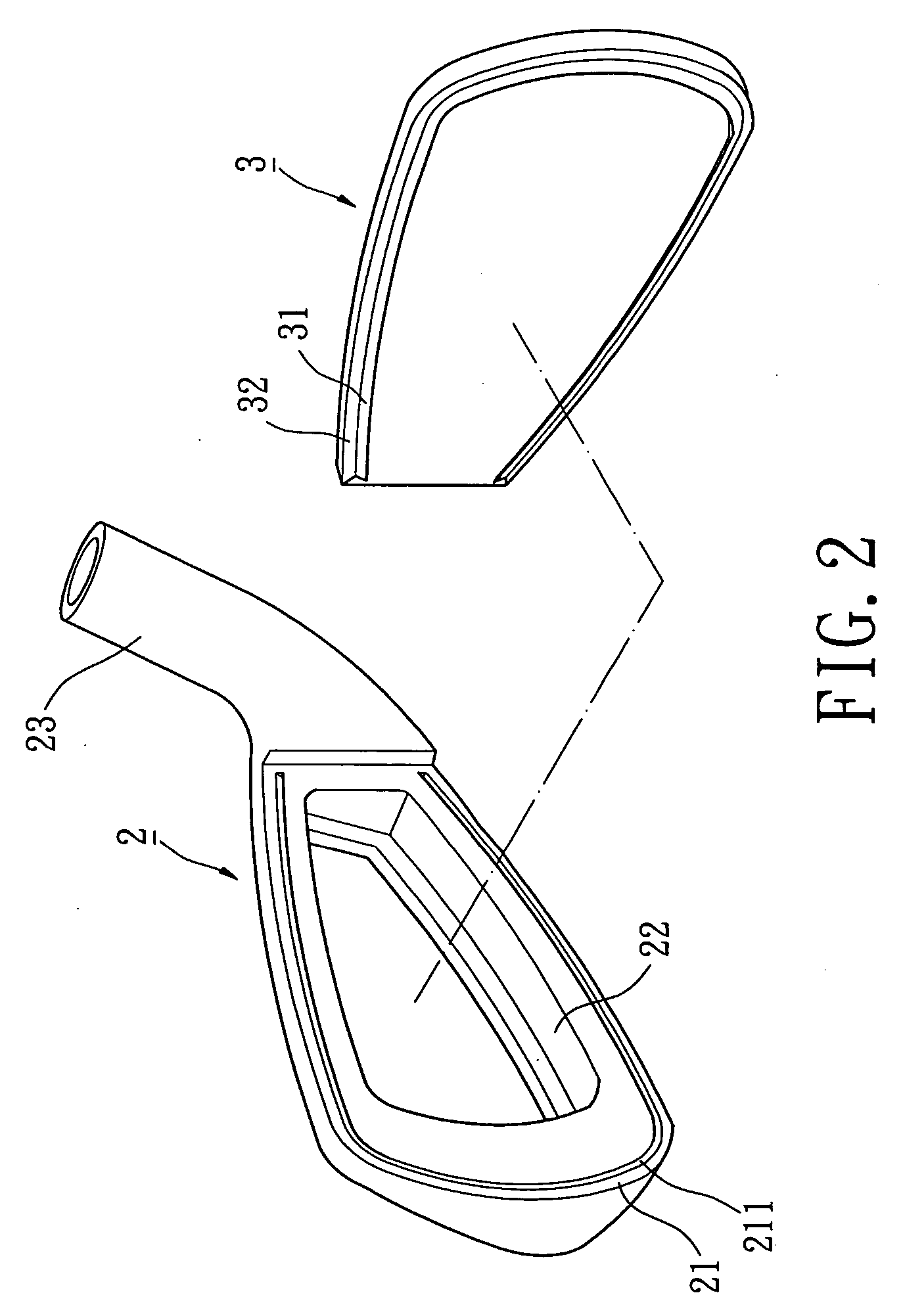

Combination of body and striking plate for golf club head

InactiveUS20060073912A1Reduced precision requirementsSimple processGolf clubsRacket sportsEngineeringGolf Ball

A golf club head includes a body and a striking plate. The body includes a front side having a recessed portion. The striking plate includes a front side for striking golf balls and a rear side. At least one groove is defined in one of the front side of the body and the rear side of the striking plate. At least one plastic protrusion is formed on the other of the front side of the body and the rear side of the striking plate. When assembling the striking plate and the body, the plastic protrusion deforms under pressure to form an engaging portion that is engaged in the groove, thereby securely engaging the striking plate with the body.

Owner:NELSON PRECISION CASTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com