Patents

Literature

353results about How to "Improve cementing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

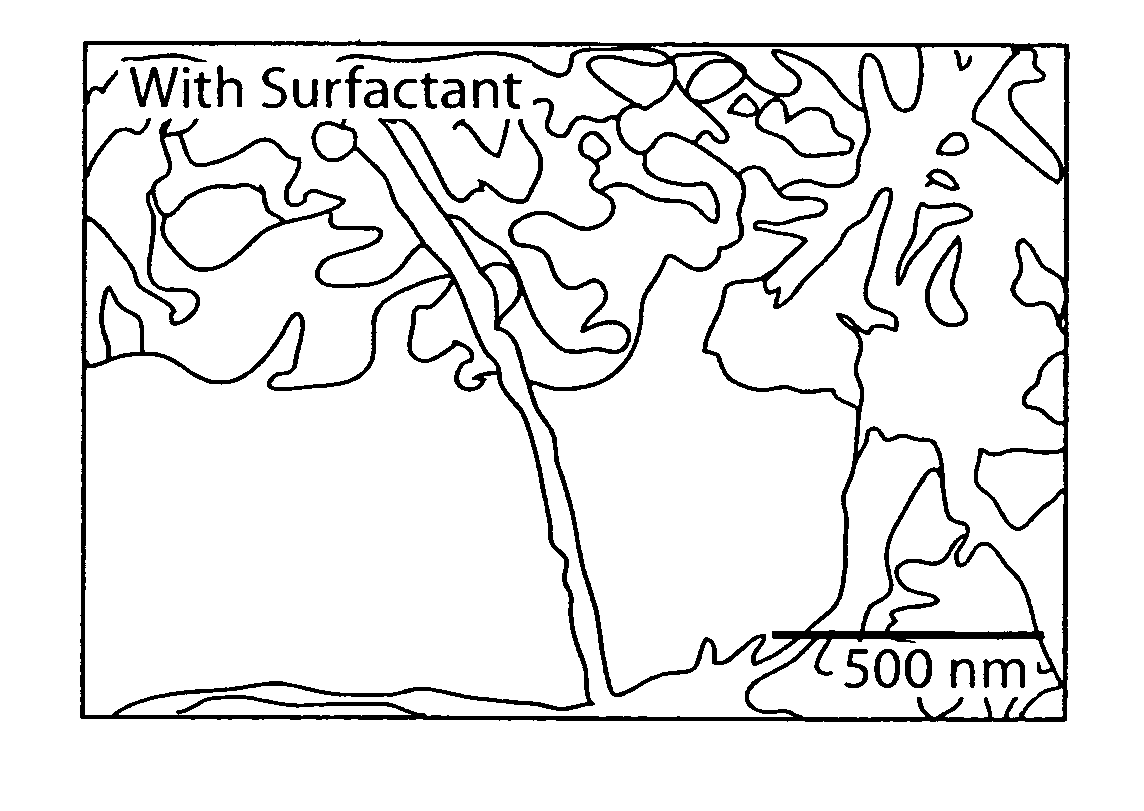

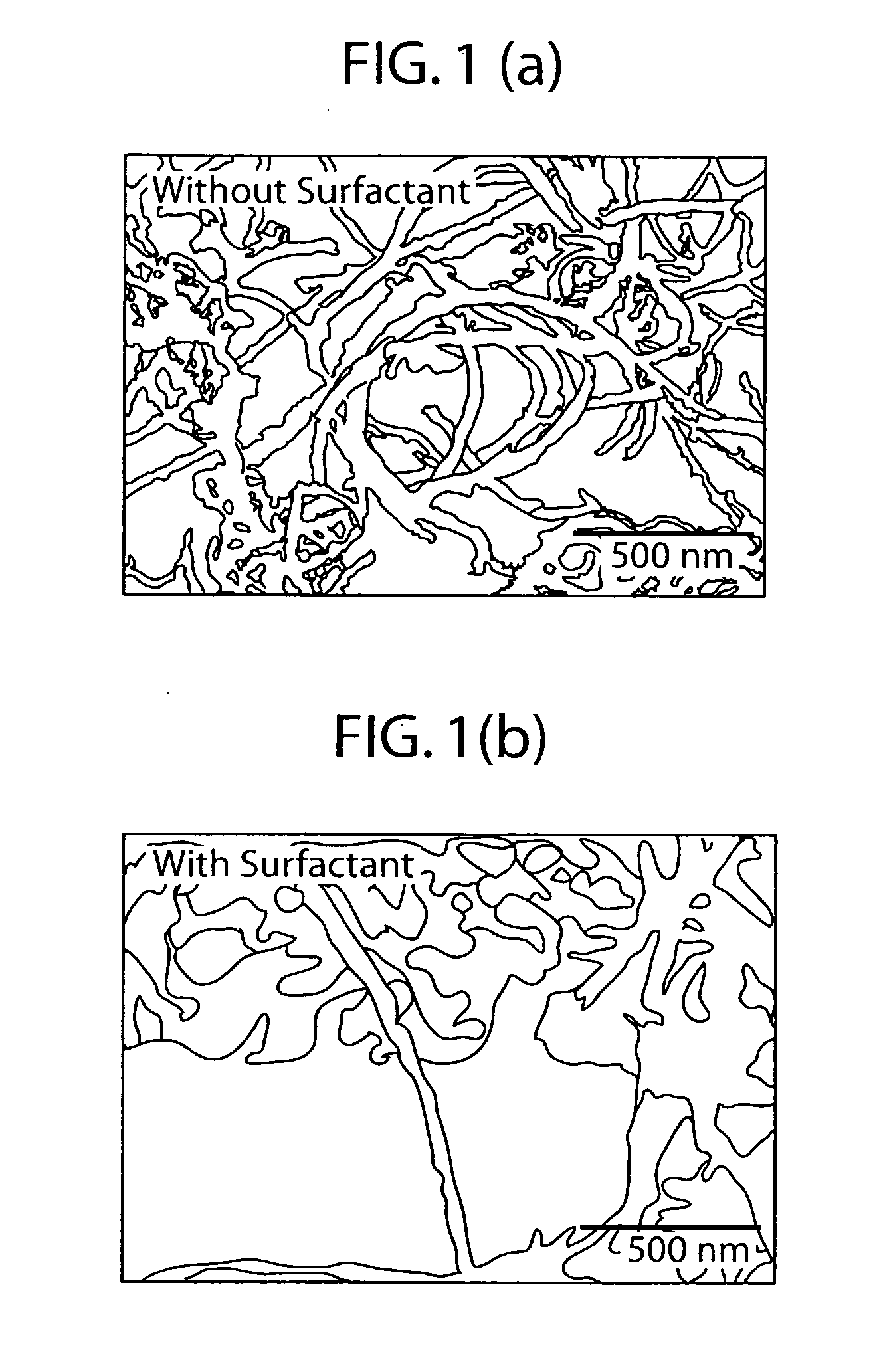

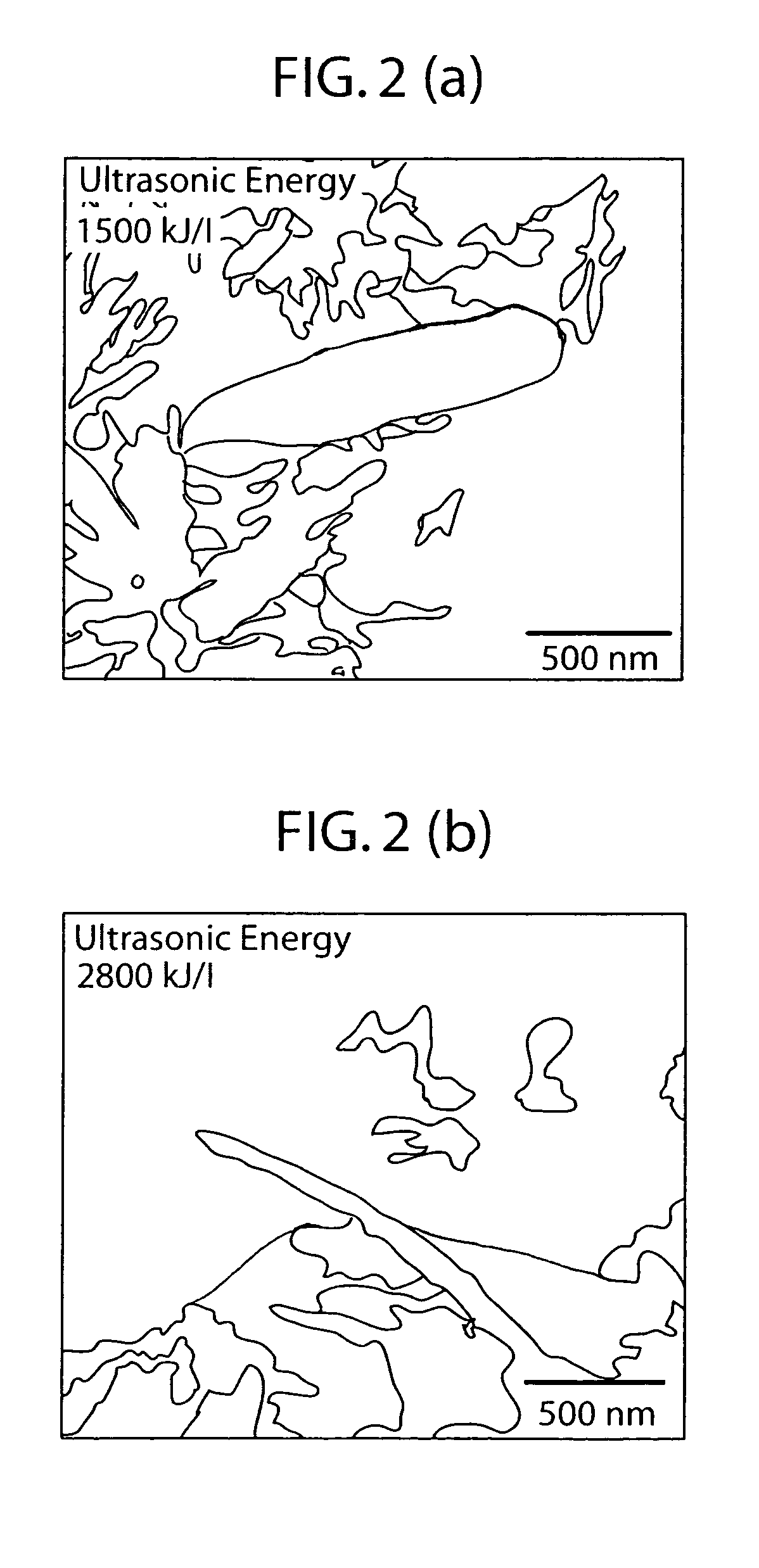

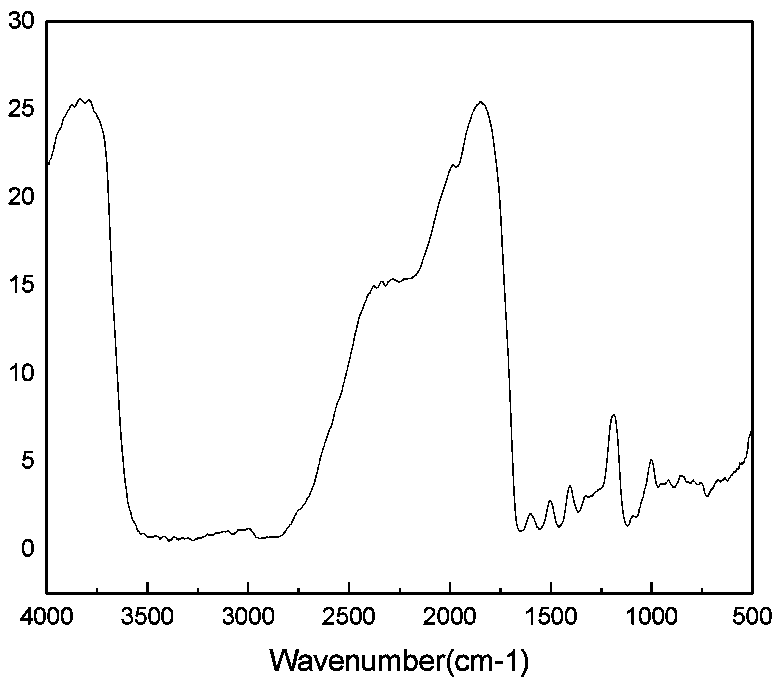

Highly-dispersed carbon nanotube-reinforced cement-based materials

A composite cement material is prepared from cement material and carbon nanotubes, wherein the carbon nanotubes are present from about 0.02 wt % to about 0.10 wt % based on weight of cement material. The process for preparing such cement compositions includes sonicating a mixture of a surfactant, water, and carbon nanotubes; and blending the dispersion and the cement material to form a cementitious paste. The process may also include curing the cementitious paste. The composite cement materials are useful in a variety of cement applications where a reduction in nanoscale flaws and fractures is desired.

Owner:NORTHWESTERN UNIV

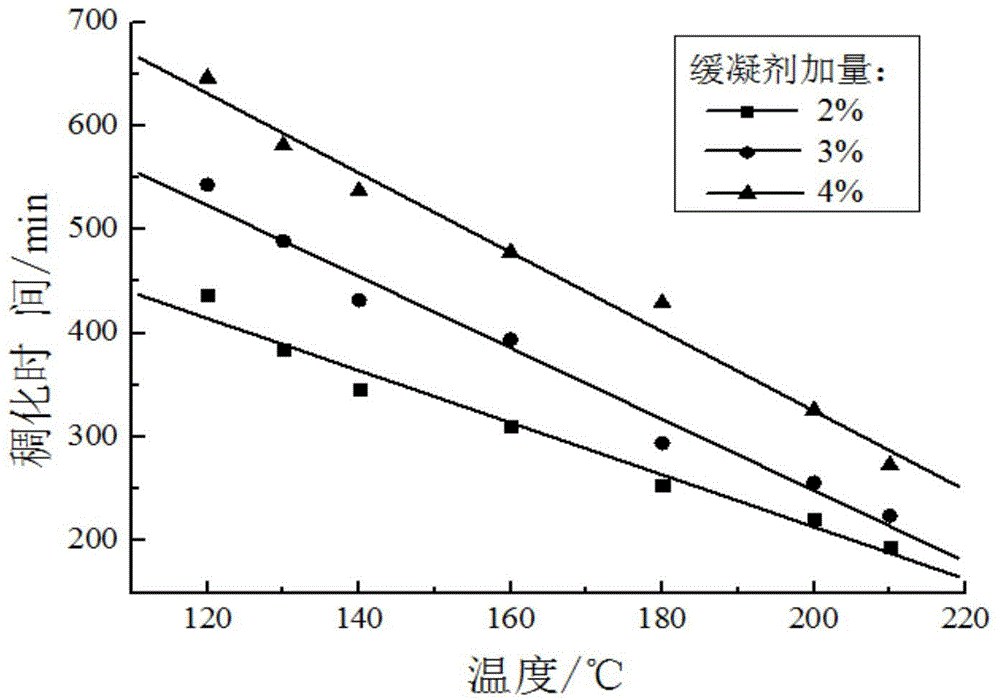

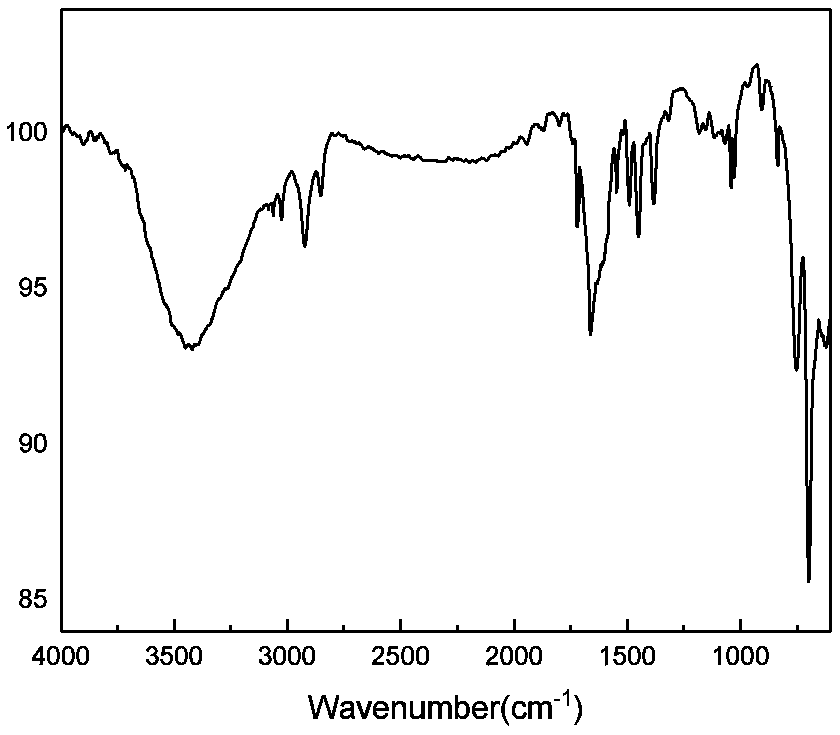

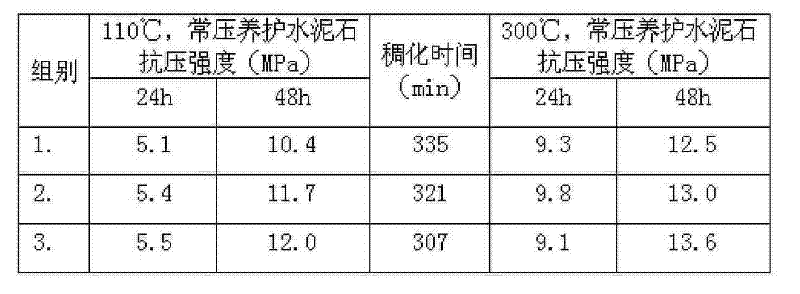

High-temperature-resistant copolymer oil well cement retarder and preparation method thereof

ActiveCN104403056AImprove performanceSolve the problem of severe subsidence at high temperatureDrilling compositionPolymer scienceFumaric acid

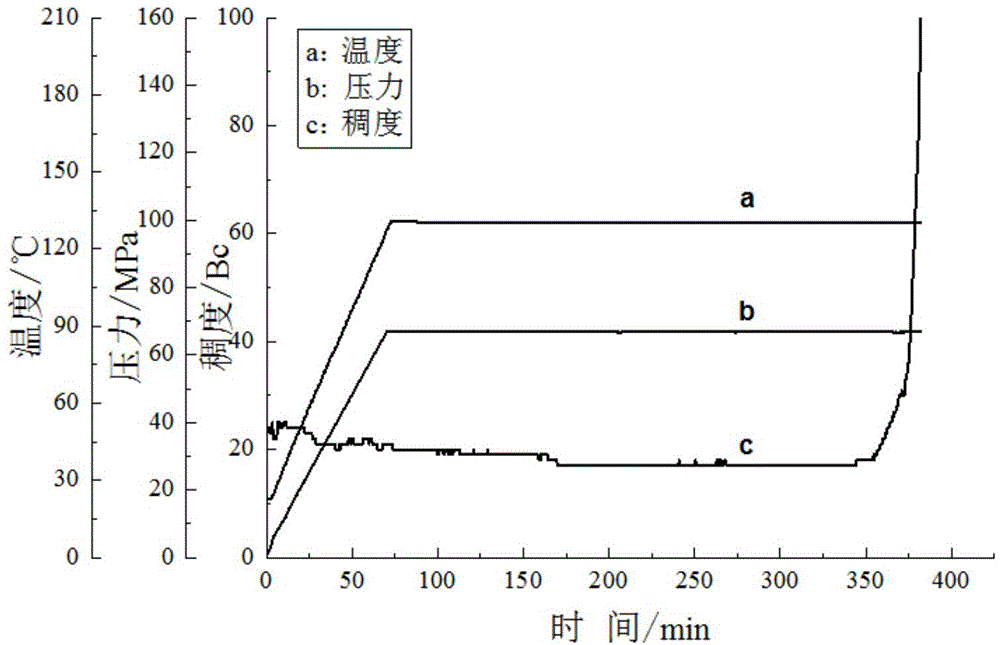

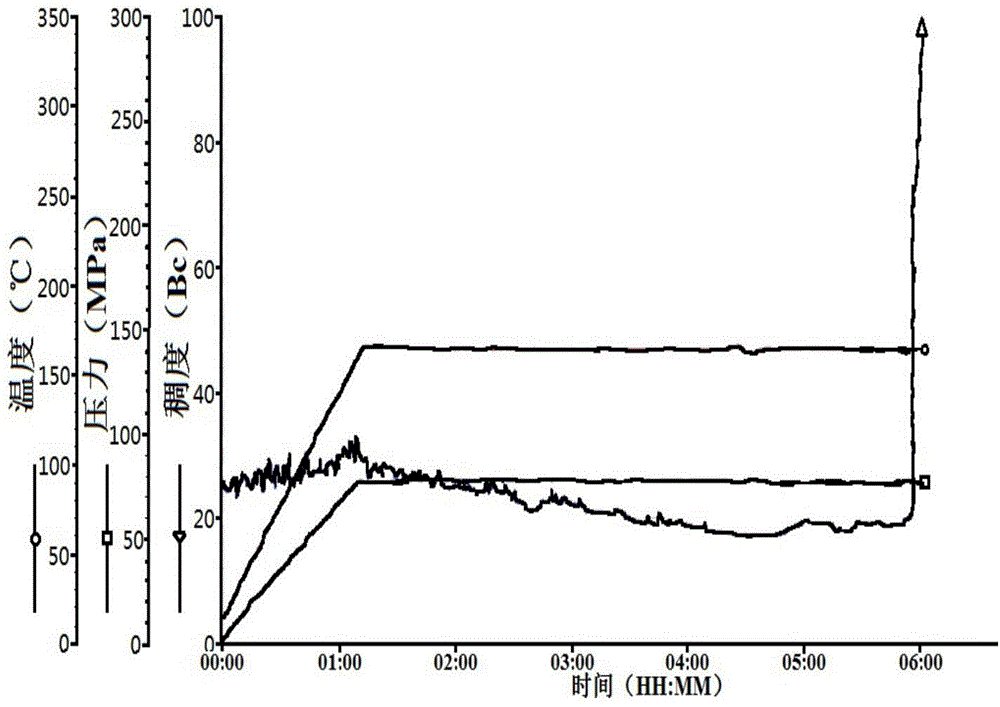

The invention relates to a high-temperature-resistant copolymer oil well cement retarder and a preparation method thereof. The preparation method comprises: respectively weighing four polymerization monomers such as 2-acrylamide-2-methylpropanesulfonic acid, diallyldimethylammonium chloride, maleic anhydride or itaconic acid or fumaric acid, and acrylic acid or methacrylic acid according to the mass ratio of 45-80:5-17:7-18:8-20, dissolving the first three monomers in water, then adding sodium polyphosphate and diphenylcarbazide, then successively adding a chain transfer reagent and an initiator, and finally dropwise adding the forth monomer, performing heating reaction and adjusting the pH value, so as to obtain the copolymer retarder. The invention also provides the high-temperature-resistant copolymer oil well cement retarder prepared by the above preparation method. The retarder is resistant to a high temperature up to 230 DEG C and is weak in dispersibility at a high temperature, the cement paste strength develops fast at a low temperature, the addition amount of the retarder has good linear relation with the cement paste hardening time, and the cement paste comprehensive performance is good.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Solid-free anti-salt cleaning type well cementation spacer fluid and preparation method thereof

InactiveCN103756653AGood settlement stabilityImprove bonding qualityDrilling compositionSludge cakeEthylenediamine

The invention discloses a solid-free anti-salt cleaning type well cementation spacer fluid and a preparation method thereof. The spacer is prepared from the following components in parts by weight: 100 parts of water, 20-350 parts of soluble weighting agent, 0.1-1.0 part of additive, 0.2-0.5 part of thickening agent, 0.5-3.0 parts of fluid loss agent, 5-10 parts of non-ionic surfactant, 1.5-2.5 parts of anionic surfactant, 0.1-0.3 part of pH adjusting agent and 0.1-0.5 part of defoaming agent, wherein the additive is sodium tripolyphosphate, ethylenediamine tetraacetic acid disodium or ethylenediamine tetraacetic acid sodium. The solid-free anti-salt cleaning type well cementation spacer fluid is free of solid phase, so that virtual thick sludge cake cannot be formed on a well wall, the function of effectively spacing a drilling liquid from cement slurry is achieved, and meanwhile the well cementation is improved. In the preparation process, the substances are added to reaction in different batches, so that the operation method is simple.

Owner:CNPC BOHAI DRILLING ENG

Oil-based mud flushing liquor and preparation method thereof

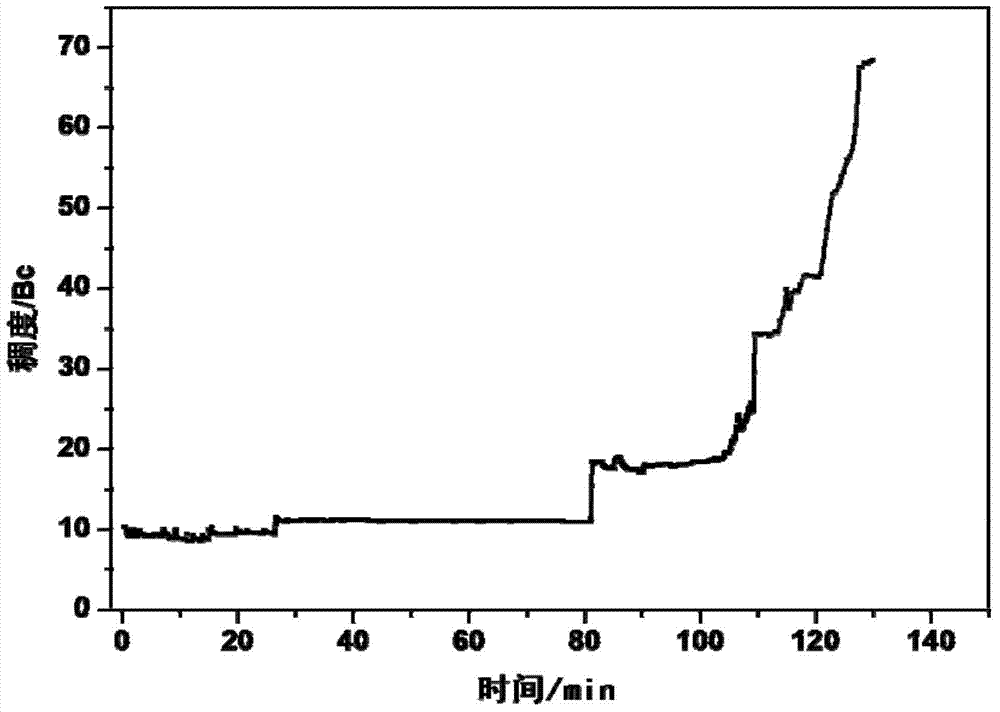

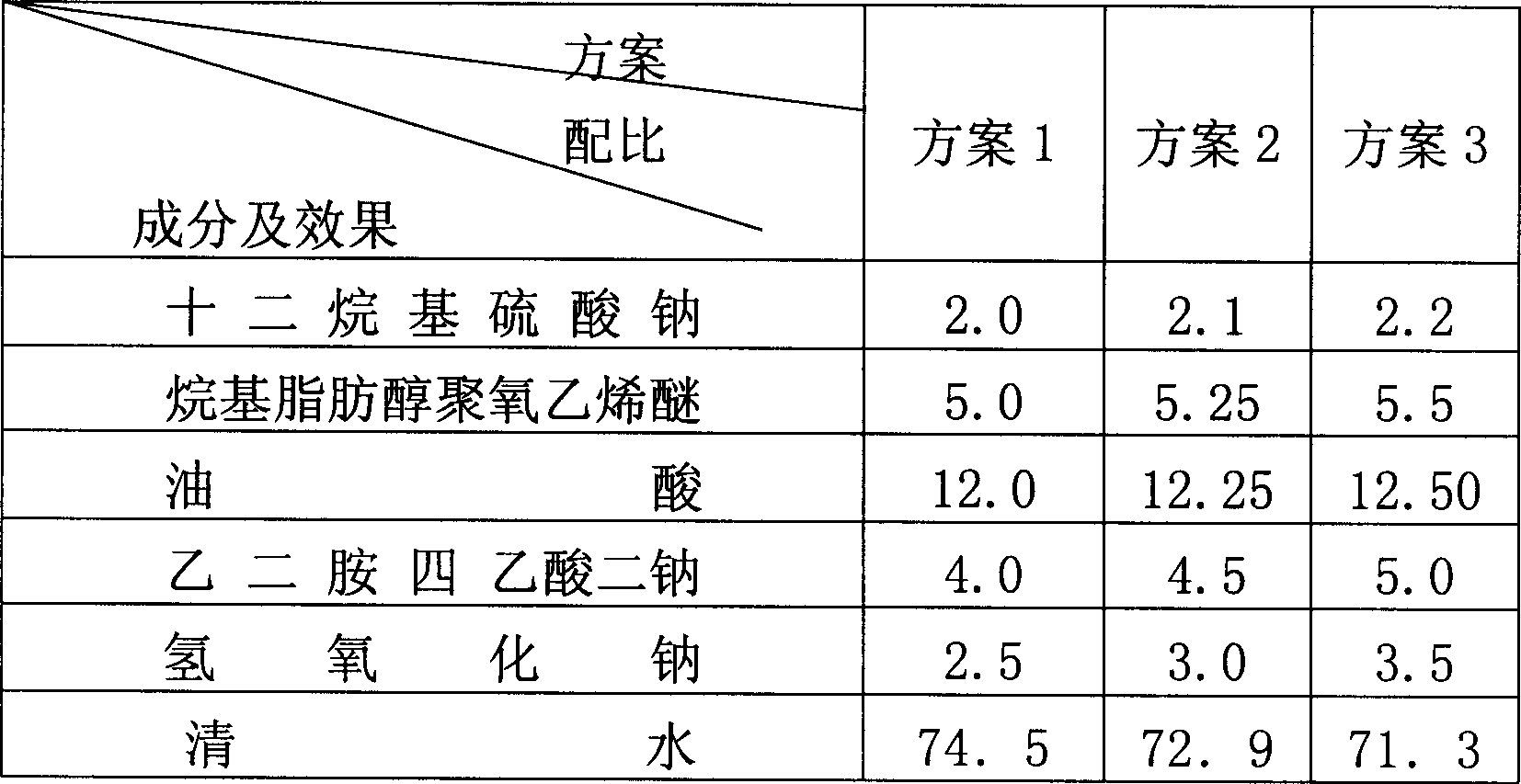

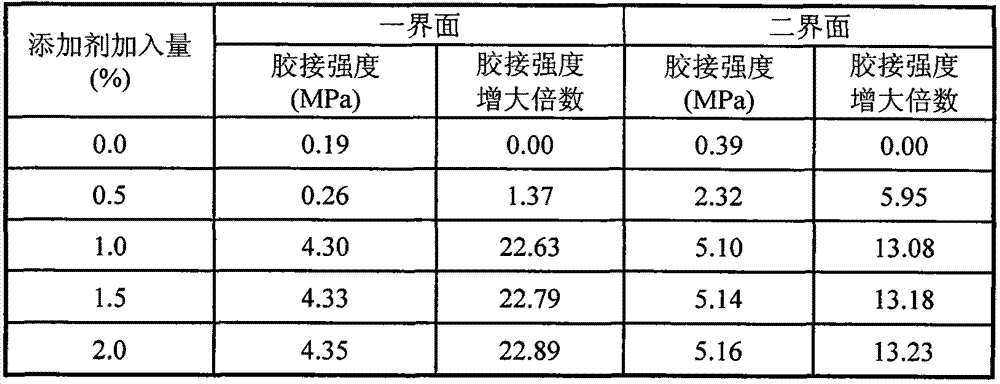

The invention refers to an oil rinse liquid for mud and the manufacturing method. It resolves the problem that the second interface cementation is bad. Its character lies in: add 2.5-3.5 shares sodium hydroxide and 4.0-5.0 shares ethyl diamine fourthacetic acid to clean water and blend to make them dissolve completely, then add 12.0-12.5 share oleic acid and blend for 20-30 minutes, add 2.0-2.2 shares dideakly natrium sulphate and 5.0-5.5 shares alkyl fatty ethanol poly-oxy ethene aether and blend for 55-65 minutes, finally add in the organic silicon anti-foamer. It can change the "oil wet" into "water wet", improve the cementation of cement interface and enhance the quality of fixing mine.

Owner:DAQING PETROLEUM ADMINISTRATION

Special horizontal well track control method for oil reservoir with top water and edge water

InactiveCN101424166APrevent intrusionImprove cementing qualityDirectional drillingWell drillingWell cementing

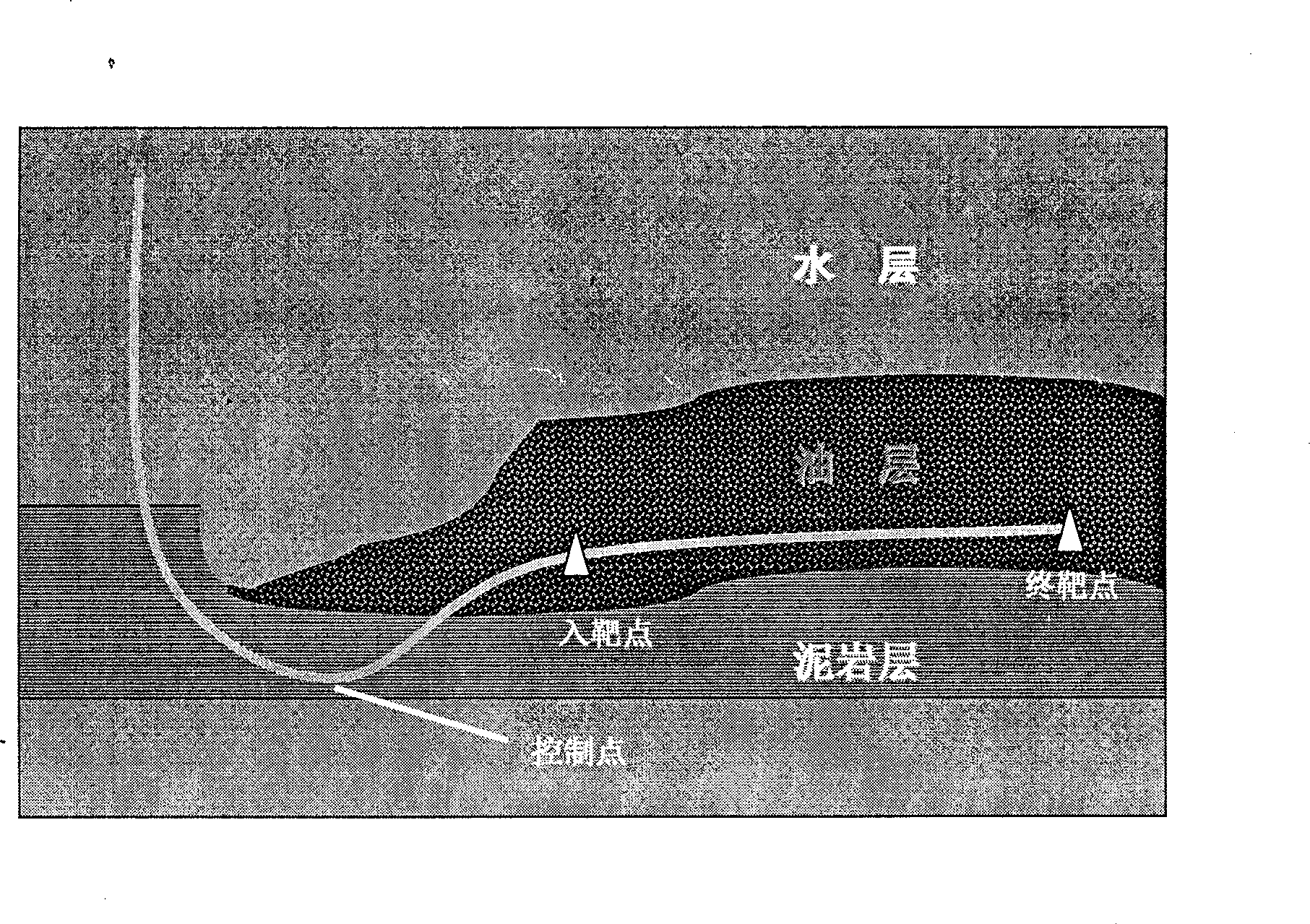

The invention relates to a method for controlling a track of a well hole of a special horizontal well of an edge-top water reservoir. The method comprises the following steps: a fishhook-shaped well hole track is adopted in the drilling construction process of the horizontal well and a sidetrack horizontal well of the edge-top water reservoir; the well hole is drilled to mudstone of the lower part of the reservoir; well completion in the middle part of the mudstone realizes effective packing of the edge-top water of the upper part and ensures the safe drilling of the horizontal well section of the lower part. The method has main advantages that as a technical sleeve runs to a mudstone layer, the method can effectively prevent the edge-top water from invading an oil layer and can improve the well fixing quality of the technical sleeve in the middle well completion; and as the track of the well hole of the horizontal well is smooth, the normal running of the sleeve and a sieve tube is ensured.

Owner:CNPC GREATWALL DRILLING ENG

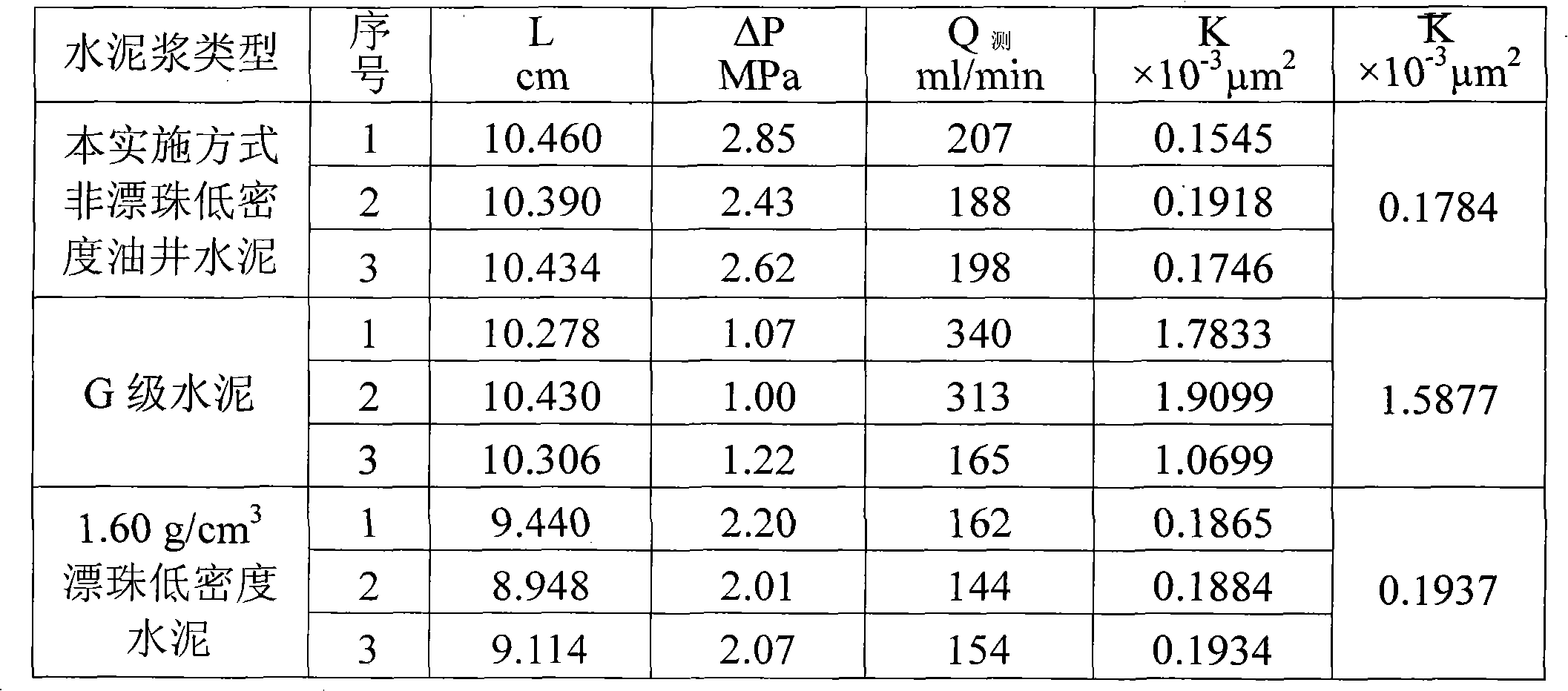

Non-floating bead low-density oil-well cement

The invention relates to low-density oil-well cement, in particular to non-floating bead low-density oil-well cement. The invention solves the problems of low early strength, poor slurry flowability and stability and short service life of the traditional non-floating bead pulverized fuel ash low-density cement. The non-floating bead low-density oil-well cement comprises oil-well cement, pulverized fuel ash, an aldosterone sulfonate condensate dispersing agent, nano silicon ash stone and an early strength agent, and the mass content of SiO2 in the nano silicon ash stone is larger than or equalto 96 percent. The cement has good stability, good compactness, high early strength, long service life, good rheological property and controllable densification time and meets the requirement of a low-pressure stratum oil field cementation well on the performance of the cement.

Owner:哈尔滨太行兴隆水泥有限公司

Low-density cement slurry

ActiveCN102994059AHigh compound compressive strengthHigh compressive strengthDrilling compositionSolid componentFiber

The invention provides a low-density cement slurry. The water-solid ratio of the cement slurry is (58-65):100, and the cement slurry comprises the following solid components in parts by weight: 112-118 parts of cement, 35-45 parts of lightening admixture microbeads and 5-12 parts of stabilizer micro-silicon, wherein the cement comprises 100 parts of cement first component with the average particle size of 12-14 mu m and 12-18 parts of cement second component with the average particle size of 6-7 mu m; calculated by the volume of the cement slurry, each liter of the cement slurry comprises 0.1-0.25g of fiber; and the density of the cement slurry is 1.29-1.31g / cm<3>. By applying a cement slurry system disclosed by the invention, cementing quality of a formation, which is easy to drop out due to the development of cracks of limestone and dolostone can be greatly improved.

Owner:CHINA PETROLEUM & CHEM CORP

Swelled perlite and its preparation method, its uses as modified microbead in producing high intensity low density oil well cement

ActiveCN1970484AImprove cementing qualityStrong pressure capacityDrilling compositionPearlitePerlite

The invention discloses a bulking pearlite and making method and application in the high-strength low-density oil well cement, which is characterized by the following: adopting low-temperature bulking and high-temperature glass technique; allocating raw material sequently; heating to form powder; bulking under low-temperature; glassifying under high temperature; cooling; making the grain size at 100-120 order with obturator foramen rate not less than 98% and sucking rate not more than 30%; possessing bearing pressure and excellent slurry fluidity.

Owner:JIAHUA SPECIAL CEMENT

Low-density high-strength leak-resistant slurry method for sealing leakage producing formation

ActiveCN101870862AImprove mechanical propertiesImprove the pressure bearing capacity of the formationDrilling compositionCement slurryVolumetric Mass Density

The invention belongs to the technical field of oilfield cementing, in particular to a low-density high-strength leak-resistant slurry method for sealing leakage producing formation in a well drilling area. The method is characterized in that: cement, micro silicon, hollow micro spheres, a fluid loss agent, an expanding agent, and water are mixed in a certain ratio according to the grain composition principle, and the mixture is mixed with the water in a certain ratio, wherein the ratio of water to solid is 0.67 to 0.46, the cement slurry density is between 1.25 and 1.45g / cm<3>, and the cement slurry thickening time is between 110 and 240 minutes. The invention provides a low-density high-strength leak-resistant slurry method for sealing the leakage producing formation, which realizes balanced pressure well cementation and solves the problems of serious leaker cementing quality and cement top in a bed of interest.

Owner:CHANGQING GUJING OF CNPC CHUANQING DRILLING ENG

Oil well cement flexibilizer

The invention discloses an oil well cement flexibilizer. The oil well cement flexibilizer can be used as an admixture for oil well cement of oil-gas well cementing, and is prepared from the following components in parts by mass: 15-50 parts of a temperature-resistance rubber material, 0-20 parts of surface modified fibers, 10-20 parts of a stabilizer and 10-50 parts of a rheolobic modifier. The flexibilizer can be used for reducing the elasticity modulus of annulus set cement and improving the impact resistance of set cement, and is well compatible with other cement admixtures. The flexibilizer has stable normal-temperature and high-temperature performances, and can be used for improving the rheological property of cement paste, solving the problem that the annulus set cement in an oil-gas well has poor stress resistance and cannot adapt to big-frac treatment in the oil and gas exploitation process, and prolonging the service life of the oil-gas well.

Owner:CNPC BOHAI DRILLING ENG

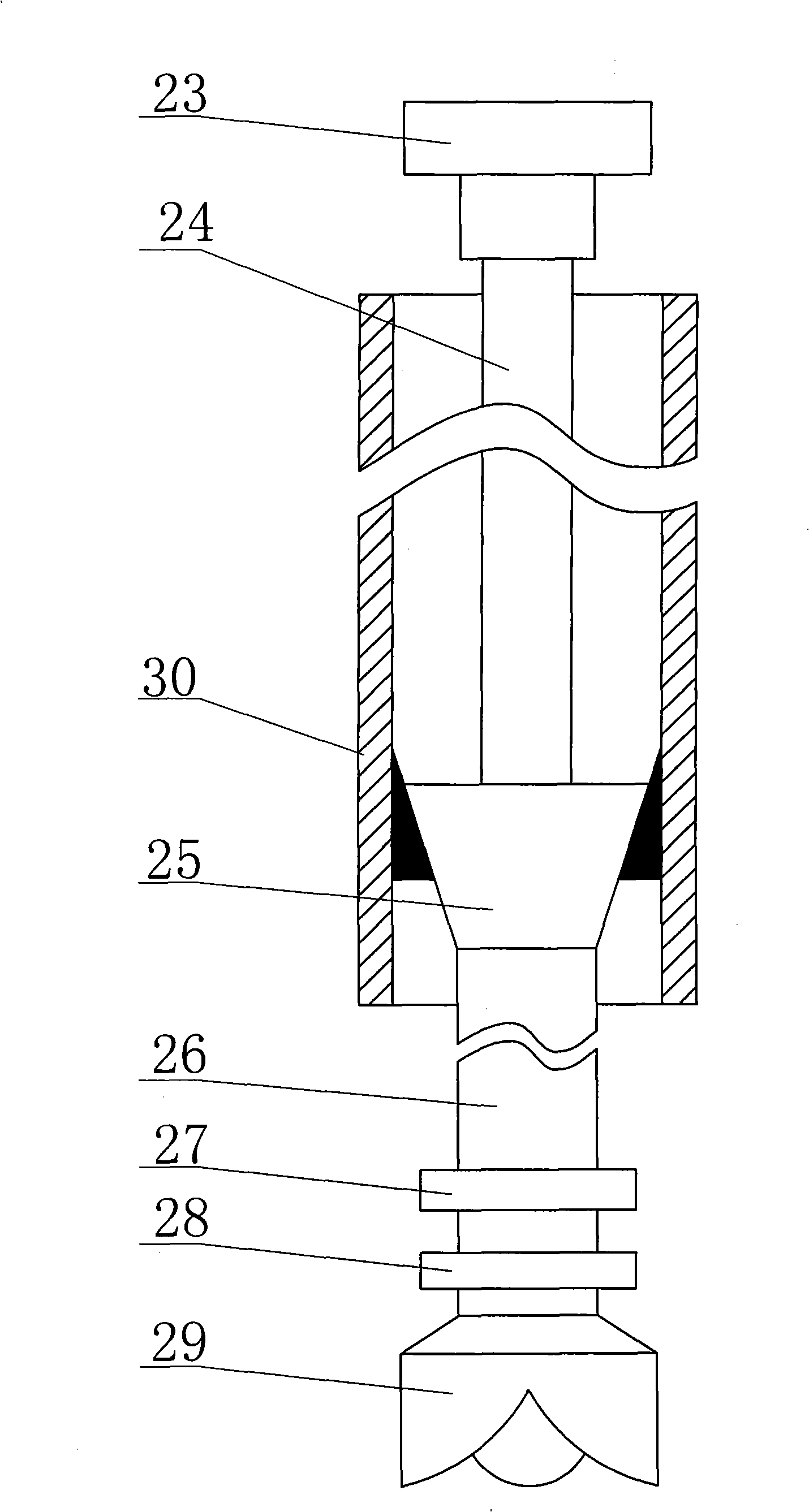

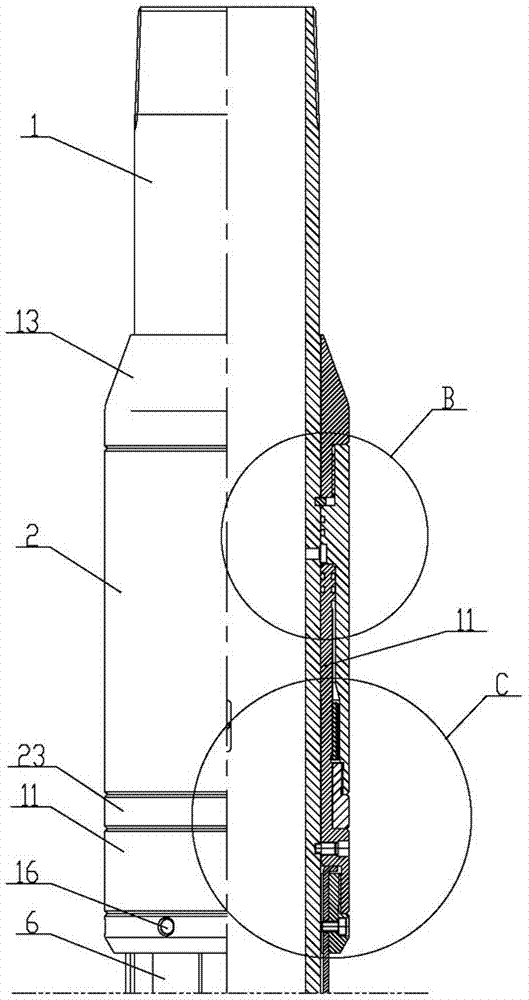

Hydraulic chambering device for drilling

ActiveCN102654024ADoes not affect normal circulationLarge diameterDrilling machines and methodsUpper jointWell cementing

The invention relates to a hydraulic chambering device for drilling, and the device comprises an upper joint, a shell, a lower shell, a lower joint, a spindle, a sealing pipe and a blade which are connected in sequence, wherein the sealing pipe and the blade are connected with the spindle. The device is characterized in that a piston is arranged between the shell and the spindle and connected with a locking and unlocking mechanism; one end of the locking and unlocking mechanism is connected with a baffle plate; a blade reset adjusting mechanism is arranged between the spindle and the shell; one end of the blade reset adjusting mechanism is connected with the baffle plate; the a blade is mounted between two baffle plates on the two mechanisms; a suspension joint is arranged at one end of the spindle between the upper joint and the shell; an upper ball base is arranged inside one end of the spindle; and a lower ball base is arranged inside one end of the sealing pipe. The device provided by the invention is suitable for back reaming, forward reaming and drilling reaming in the drilling process, and can be used for effectively enlarging the well diameter, improving the drilling efficiency, enhancing the annular space between a sleeve and a well wall, improving the quality of wells, and greatly improving the sand prevention quality and oil drainage area in wells requiring naked eye gravel filling sand prevention operation.

Owner:CHINA NAT OFFSHORE OIL CORP +1

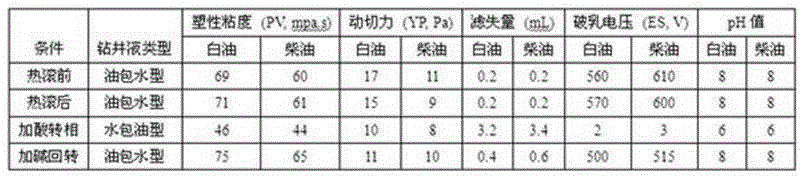

High-temperature-resistant high-density reversible water-in-oil/oil-in-water drilling fluid and preparation method thereof

ActiveCN109097010AGood reversalComparable performanceOrganic compound preparationCarboxylic acid amides preparationOil phasePolyamine

The invention provides high-temperature-resistant high-density reversible water-in-oil / oil-in-water drilling fluid which is composed of the following raw materials in parts by weight: 30-70 parts of an oil phase, 30-70 parts of an aqueous phase, 2-5 parts of a reversible emulsifier, 1-3 parts of an auxiliary emulsifier, 0-2 parts of organic soil, 1-4 parts of a filtrate reducer, 0-1 part of an alkalinity regulator, 0-0.5 part of a wetting agent, 0-2 parts of an enhancer and 0-800 parts of weighting materials. The reversible emulsifier is fatty acyl polyamines and derivatives thereof, and has astructural general formula of R1(CH2)m(CONH)n(C6H4)x(NH)y(NH2)zR2; the filtrate reducer is an amphiphilic filtrate reducer. The amphiphilic filtrate reducer comprises but is not limited to an amphiphilic polymer filtrate reducer, a hydrophilic modified asphalt filtrate reducer and a hydrophobic modified humic acid filtrate reducer. The compounded auxiliary emulsifier is a high HLB (Hydrophile-Lipophile Balance) value surfactant. The drilling fluid disclosed by the invention has directly adjustable density of 0.8-1.8g / cm<3>, and has excellent properties such as rheological property, suspensionstability, filter cake clearance, filter loss control, environment friendliness and stable reversibility of water-in-oil emulsion and oil-in-water emulsion in a range of 100-180 DEG C.

Owner:SOUTHWEST PETROLEUM UNIV

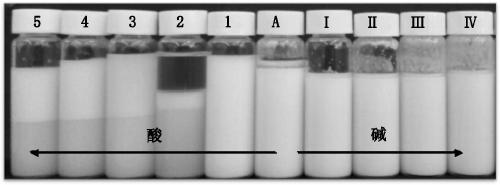

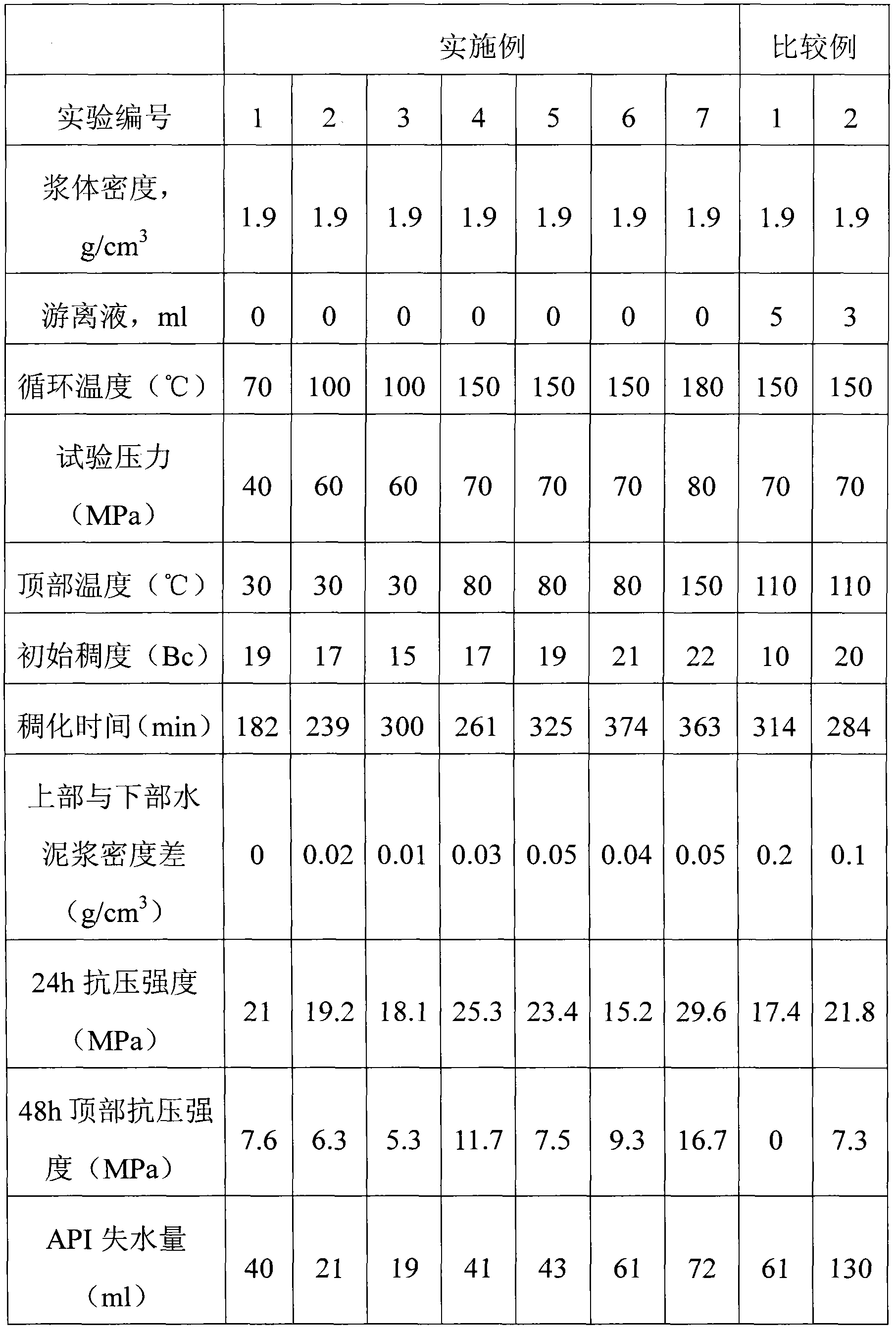

Cementing slurry system suitable for large range of temperature

ActiveCN102127404AImprove performanceRapid development of strengthDrilling compositionPhosphateDiethylenetriamine

The invention relates to a cementing slurry system suitable for large range of temperature. The cementing slurry system comprises the following components in parts by weight: 100 parts of cement, 0-40 parts of high temperature stabilizer, 2-6 parts of filtrate reducer, 0.3-3 parts of retarder and 40-55 parts of water, wherein the cement is G-grade high sulfate-resistant oil well cement; the filtrate reducer is 2-acrylamido-2-methylpropane sulfonic acid (AMPS)-acrylamide polymer, the molar ratio of AMPS to acrylamide polymer monomer is 7:3 and the number average molecular weight is 0.7-1.5 millions; the retarder is a diethylenetriamine derivative with carboxyl groups, phosphate groups and sulfonate groups, the molar ratio of the carboxyl groups to the phosphate groups and sulfo groups is 3:2:1; and the high temperature stabilizer is amorphous silica of which purity is more than 95% and average diameter is 0.1-0.15 micron. The circulating temperature range of the cementing slurry is 70-180 DEG C; under high temperature, the cementing slurry has good slurry stability, low fluid loss water amount and no free liquid; and the cementing slurry system can meet the deep well cementing construction requirement and can be used to increase the cementing quality.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

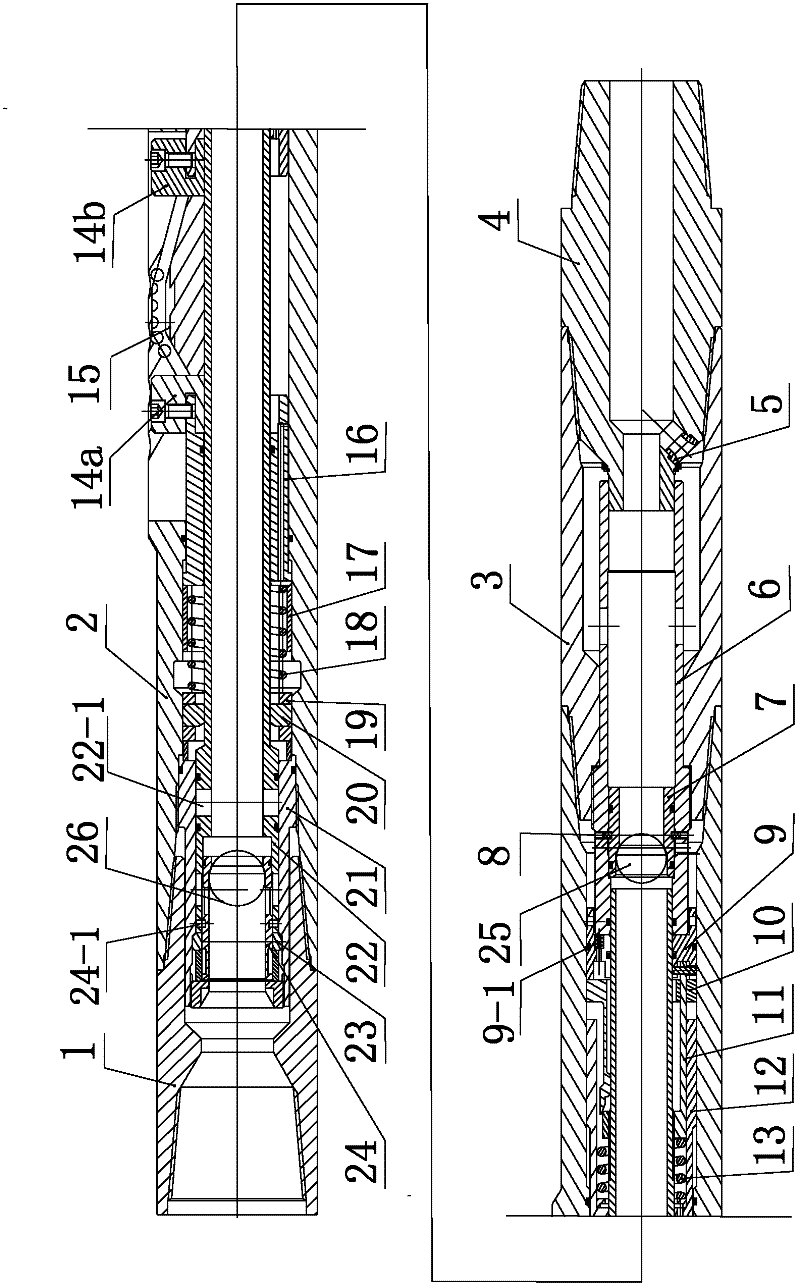

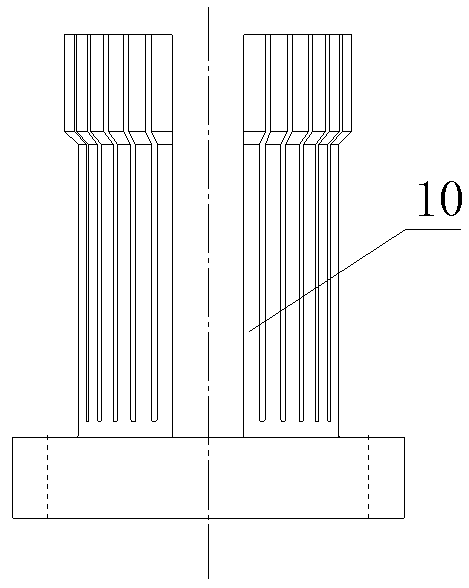

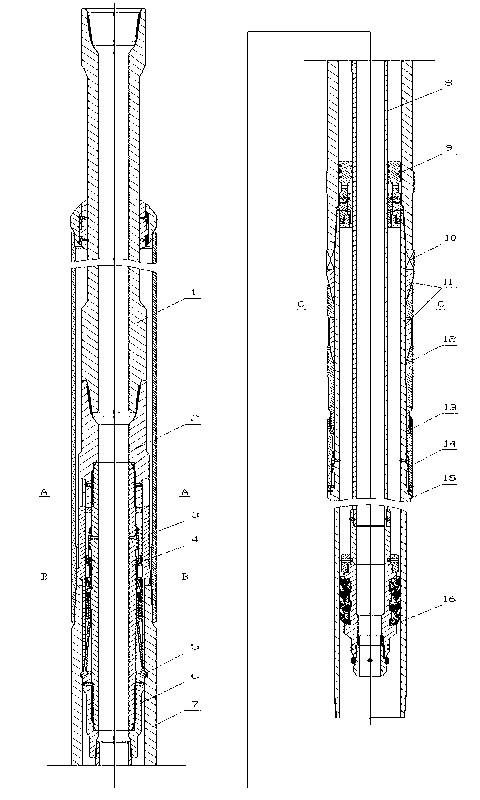

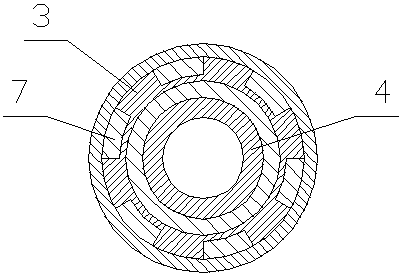

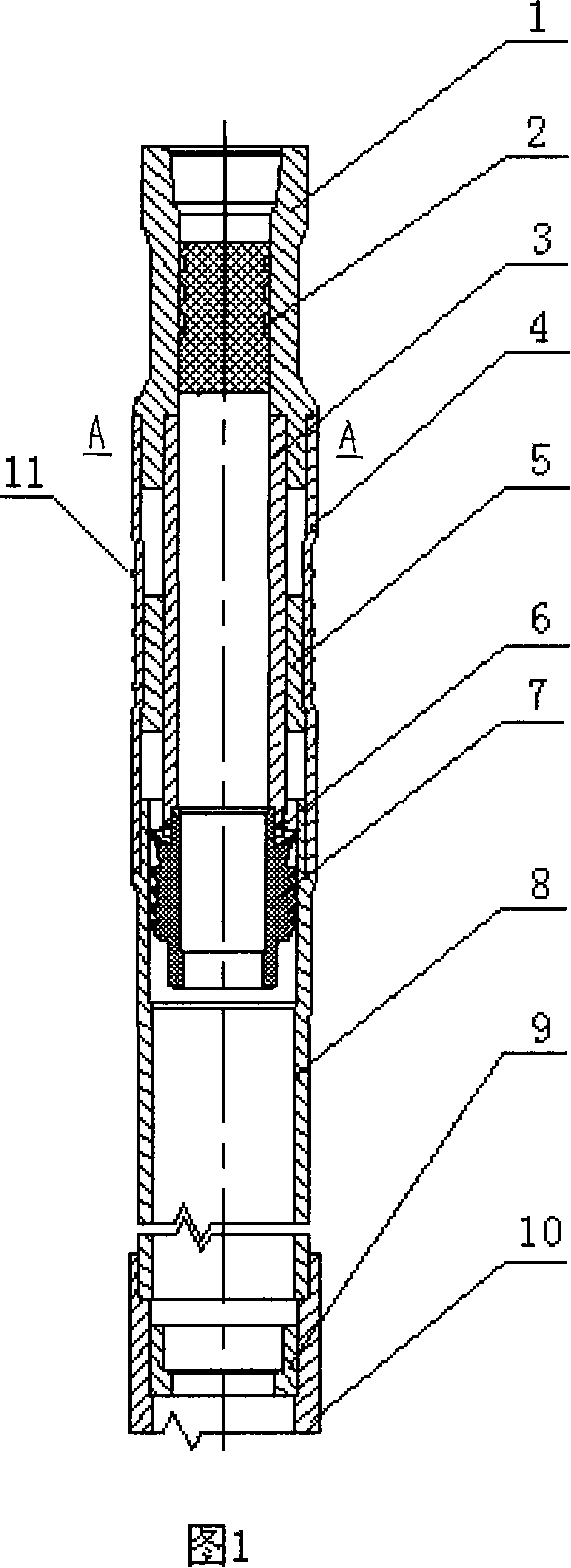

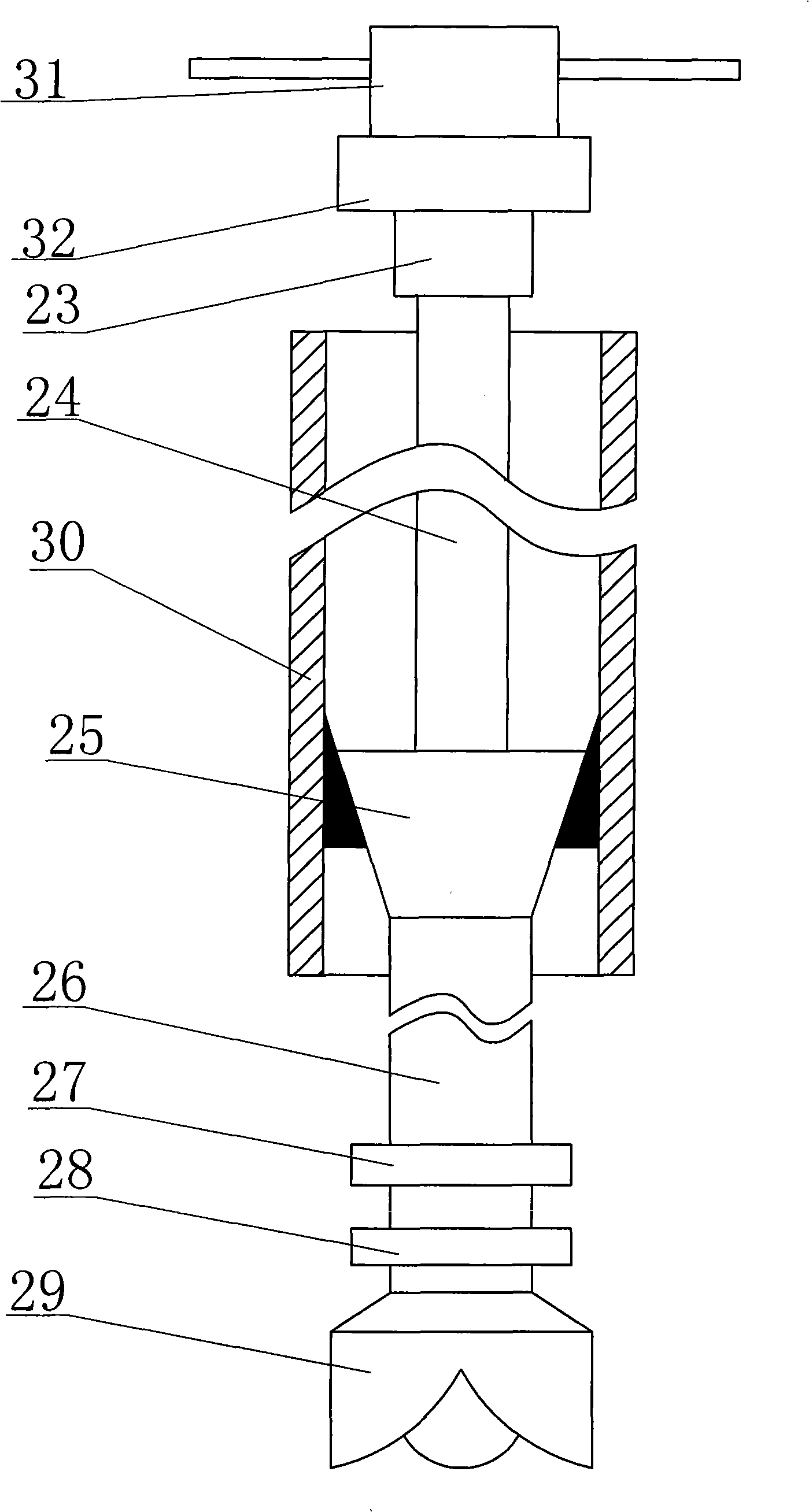

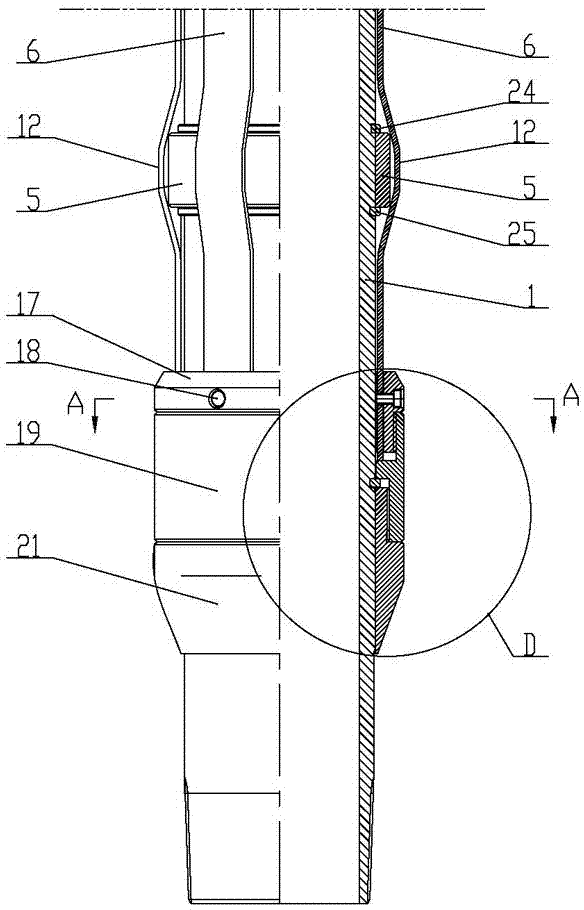

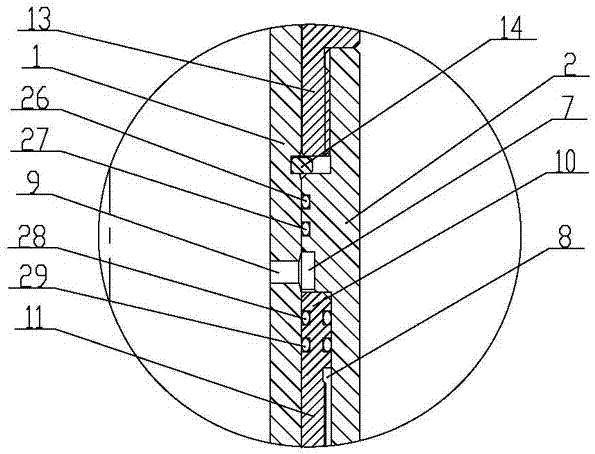

Mechanical-hydraulic double-acting release rotary tail pipe hanger

The invention discloses a mechanical-hydraulic double-acting release rotary tail pipe hanger, and belongs to the technical field of manufacturing downhole tools for oil and gas well cementing operations in oil and gas development. The mechanical-hydraulic double-acting release rotary tail pipe hanger comprises a short drill pipe, an upper joint, a release mechanism, a double male joint, a male and female joint and a lower joint. The short drill pipe, the upper joint, the double male joint and the lower joint are connected in a threaded manner from up to down sequentially. The mechanical-hydraulic double-acting release rotary tail pipe hanger further comprises a loading mechanism comprising a hanger set hydraulic cylinder, a light-load bearing, conjoined twin slips, a conjoined twin cone, a heavy-duty bearing and a central pipe. The hanger set hydraulic cylinder, the light-duty bearing, the conjoined twin slips, the conjoined twin cone and the heavy-duty bearing are arranged on the central pipe from down to up sequentially. The central pipe is connected at the lower end of the male and female joint. The heavy-duty bearing is arranged between the male and female joint and the conjoined twin cone. By the aid of the mechanical-hydraulic double-acting release rotary tail pipe hanger, a tail pipe can rotate when the a tube pillar enters, after the hanger is set and is separated from a releasing release, the slips and the bearings bear the hanger, and functions of rotating and well cementing of a heavy-duty tail pipe is realized.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

Drilling liner cementing method for controlling annulus equivalent density of pressure-sensitive stratum

ActiveCN108240196AReduce riskReduce chance of lost circulationSealing/packingWell drillingCement slurry

The invention discloses a drilling liner cementing method for controlling the annulus equivalent density of a pressure-sensitive stratum. Based on the minimum equivalent density for keeping shaft stability and the maximum equivalent density for avoiding formation leakage, the density of a drilling fluid is decreased before cementing, accordingly, the leakage risk is reduced, and the cement slurrydisplacement efficiency is improved; and after finishing drilling, on the basis of hydraulic parameters and leakage and the oil-gas-water display situation in the drilling process, the annulus pressure is calculated, and the minimum equivalent density phimin for keeping the shaft stability and the maximum equivalent density phimax for avoiding formation leakage are determined. Cementing construction designing is conducted based on phimin and phimax, and for the purpose that the annulus cement slurry displacement efficiency is larger than 90%, the pressure stabilizing and leakage preventing effects are achieved by decreasing the density of the drilling fluid, applying back pressure to a wellhead and reasonably designing injection displacement.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

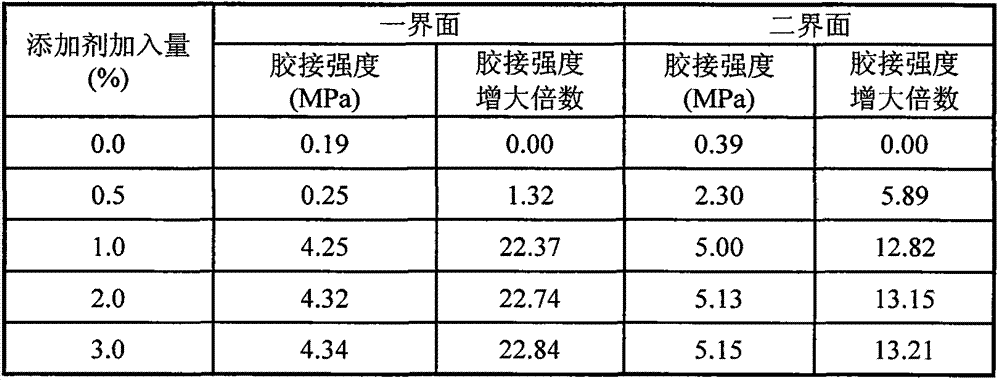

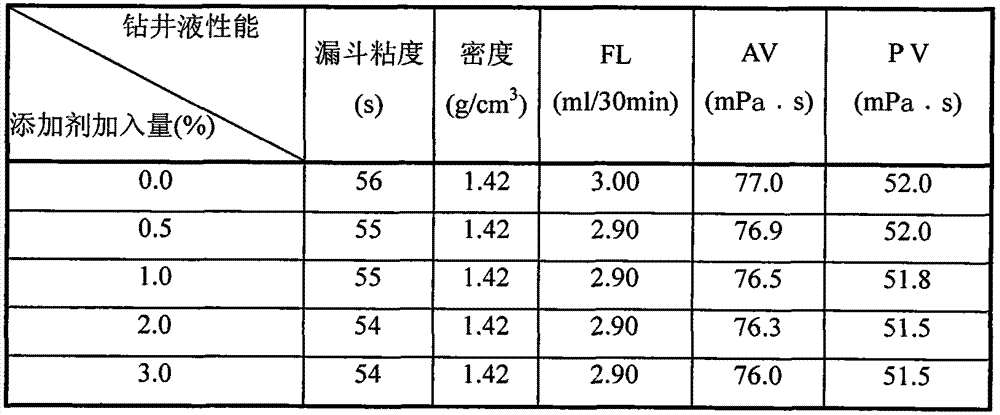

Drilling fluid additive capable of improving oil well cementing quality

InactiveCN104513651AImprove cementing qualityImprove structural performanceDrilling compositionFiberCleansing Agents

The invention discloses a drilling fluid additive capable of improving oil drilling engineering well cementing quality, the drilling fluid additive is a mixture comprising superfine inorganic short fiber, nano superfine crystal, semi rigid fiber, flexible particles, a surface modification agent and other components, according to the mechanism of action, the components comprise 10%-90% by mass of a mud cake curing agent, 5%-70% by mass of an interface affinity agent and 2%-10% by mass of an interface cleaning agent. The interface affinity agent comprises 30%-90% by mass of the nano superfine crystal, 10%-50% by mass of semi rigid fiber and 1%-20% by mass of flexible particles. The drilling fluid additive can enhance the bond strength of cement formation interface, and effectively improves the cementing quality of oil wells. The oil drilling fluid additive is less in addition amount, convenient in construction, and almost free of influence on the main performance of drilling fluid.

Owner:NORTHEAST GASOLINEEUM UNIV

Efficient composite defoaming agent for oil well cement and preparation method thereof

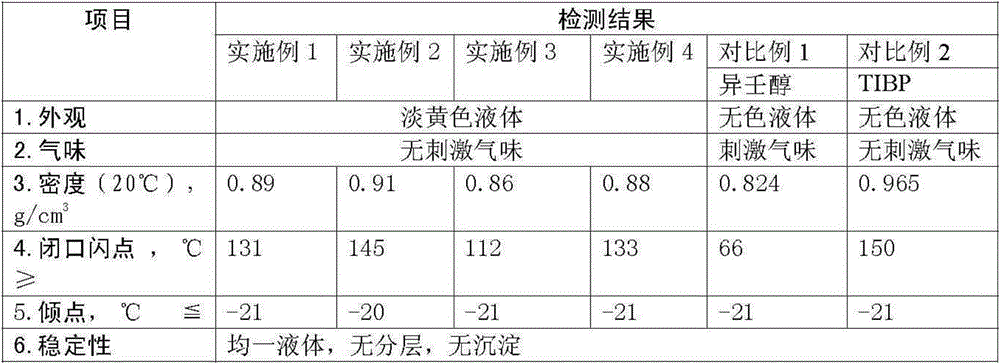

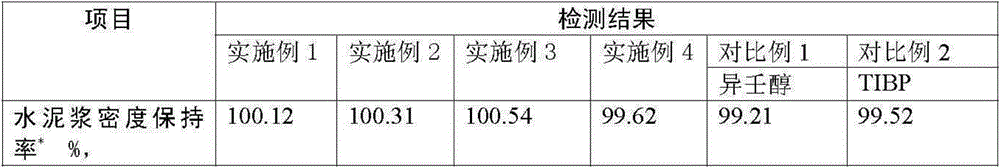

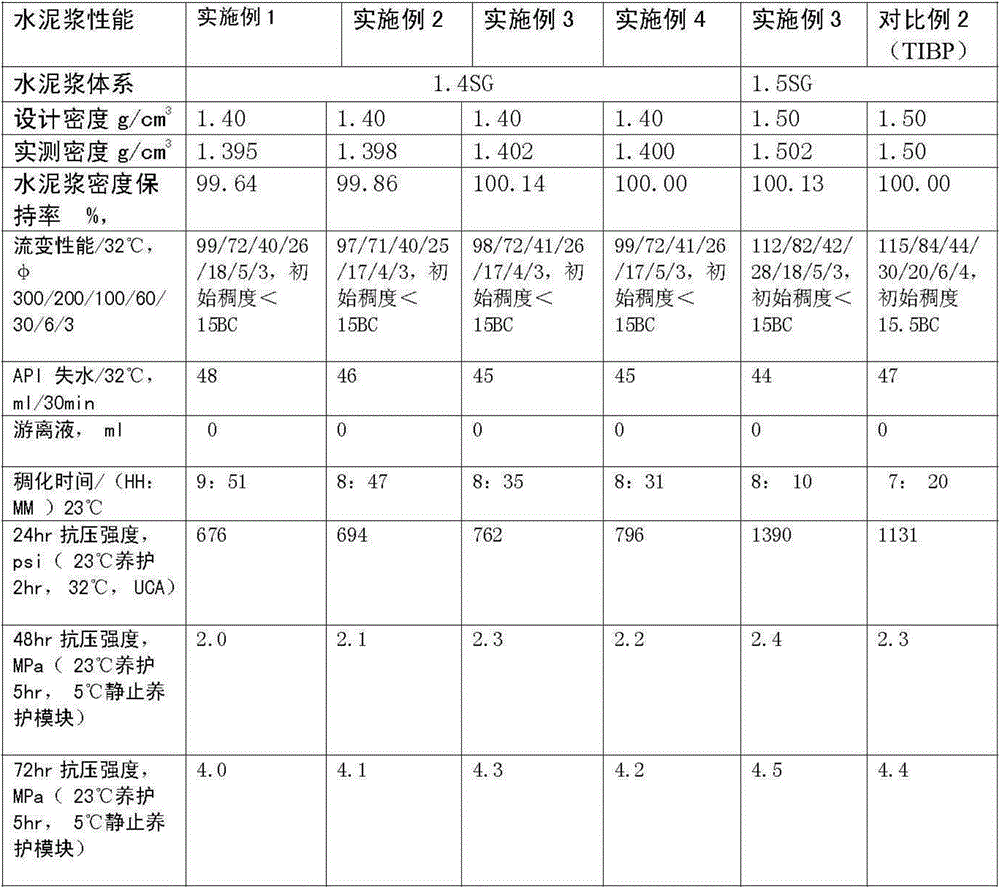

The invention discloses an efficient composite defoaming agent for oil well cement and a preparation method thereof. The defoaming agent is applied to the defoaming and foam inhibition of various admixtures containing cement paste for well cementation in the processes of high-speed shearing and mixing. The defoaming agent comprises the following components in percentage by mass: 15-59.5% of mineral oil, 40-84.5% of polyol fatty acid ester, 0-15% of polyacid fatty alcohol ester and 0.5-15% of a defoaming auxiliary component, wherein the defoaming auxiliary component contains one or two of polyether and tri-isobutyl phosphate. The preparation method of the defoaming agent comprises the following steps: under the condition of stirring at room temperature, sequentially adding the mineral oil, the polyol fatty acid ester, the polyacid fatty alcohol ester and the defoaming auxiliary component into a batching kettle; mixing for 0.5-2.0 hours; filtering the obtained mixture, and discharging the obtained object; and carrying out measurement packing on the obtained product. Compared with common defoaming agents for oil well cement, the defoaming agent disclosed by the invention is low in cost and simple in manufacturing process, products are uniform and stable, and the defoaming agent concurrently has the functions of defoaming and foam inhibition, and does not affect the rheological property and thickening property of cement paste and the compressive strength and the like of cement.

Owner:NANJING YUNYUE NEW MATERIAL TECH CO LTD

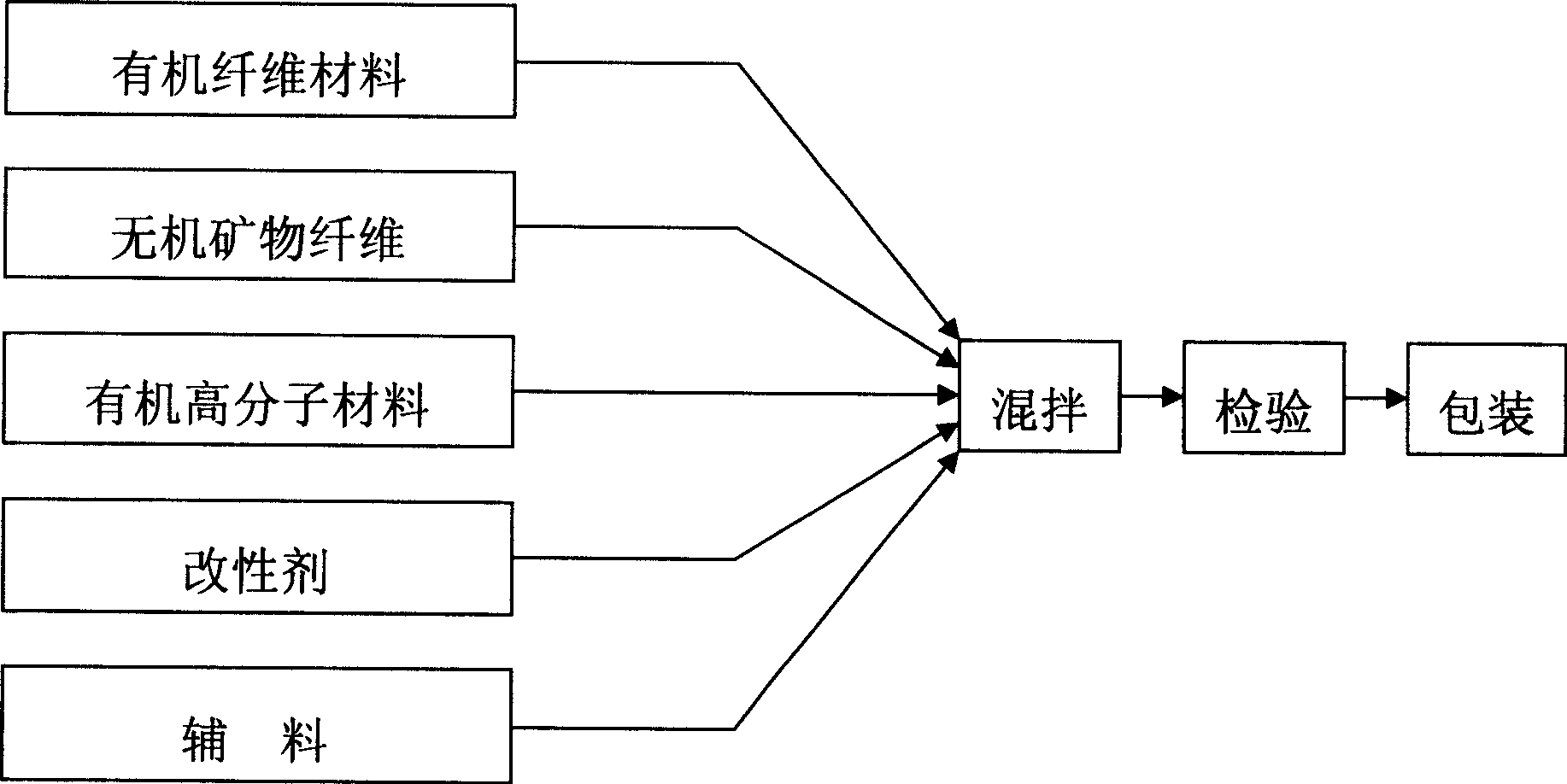

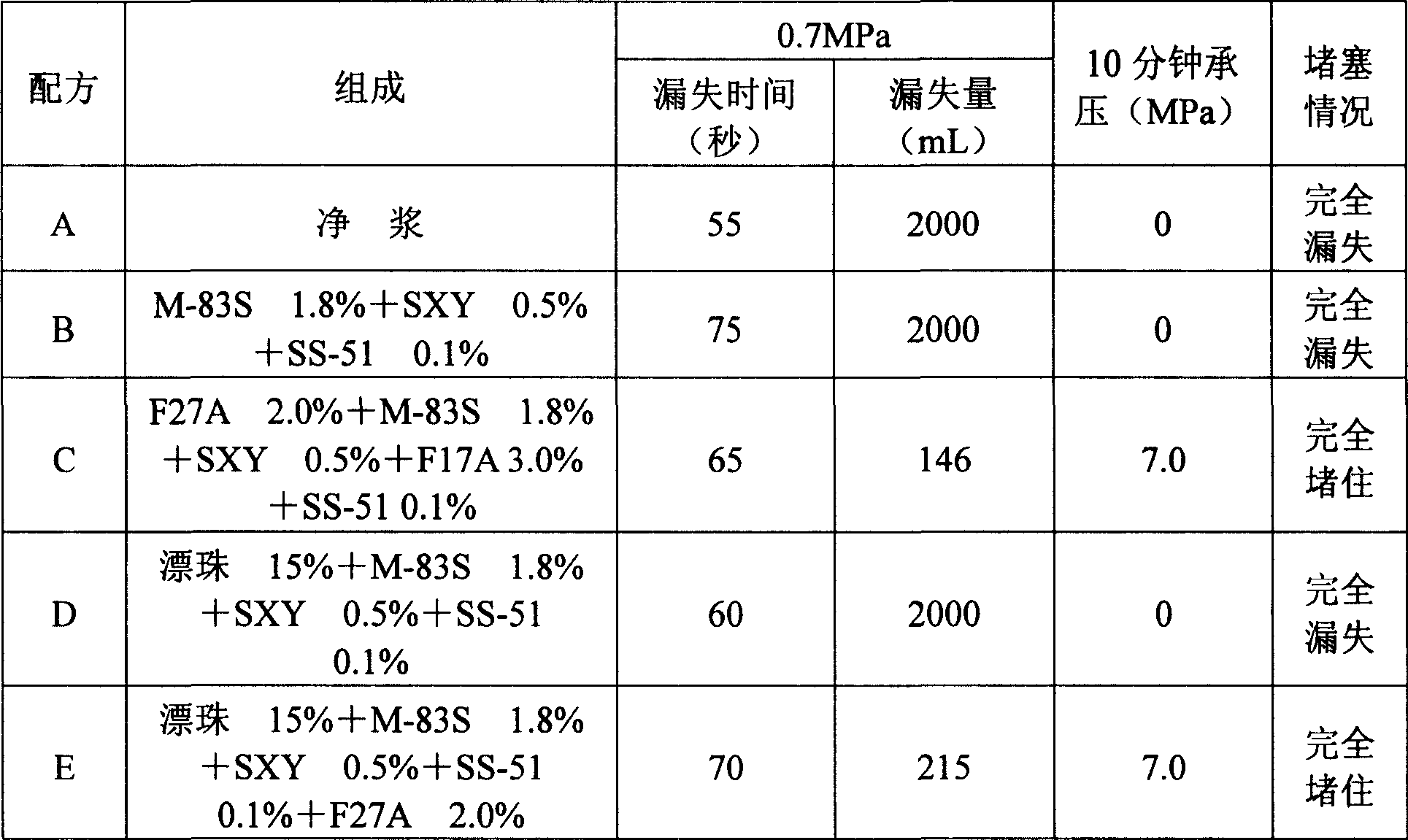

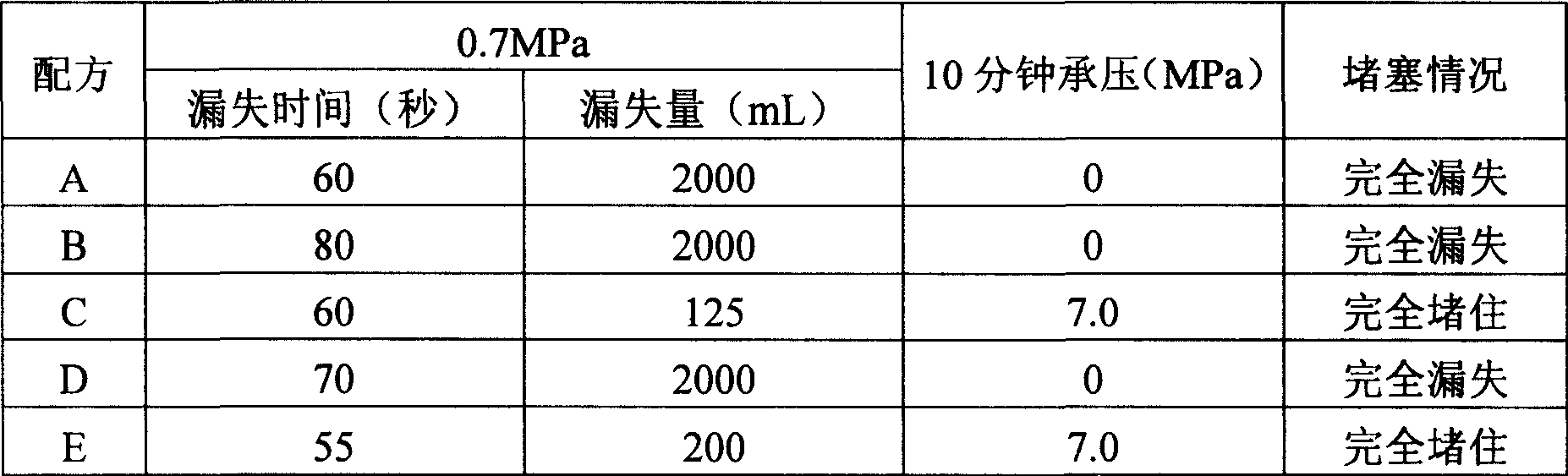

Oil well cement leak-proof toughening agent

The invention discloses an oil-well cement leakage-proof toughener which not only has leakage-proof function and improves the toughness of cement rocks, but also has good multiple-purpose project performance, so as to have double effects and solve the technical problems of slurry loss and the inherent brittleness of the cement rocks in the process of well cementation; the oil-well cement leakage-proof toughener comprises the components based on the weight percentage: 5-30% of organic fiber material, 35-70% of special type inorganic fiber, 1.0-10% of organic polymer material, 5.0-15% of modifying agent and 1.0-10% of auxiliary material.

Owner:NANJING UNIV OF TECH +1

Preparation method of high-temperature-resistant reversible emulsifier and application thereof in drilling fluid

ActiveCN105385423AImprove stabilityEnhanced inhibitory effectDrilling compositionEthylene oxidePolyethylene glycol

The invention discloses a preparation method of a high-temperature-resistant reversible emulsifier and an application thereof in drilling fluid. The technical scheme is as follows: the preparation method comprises the following steps: adding a mixture including 8 parts of dodecanamine, 72 parts of hexadecylamine and 180 parts of octadecylamine into a spray type reaction kettle; displacing the air in the kettle by using nitrogen to remove all the air; then heating to 100 DEG C while vacuumizing; sucking out materials from the inside of the reaction kettle and spaying the materials into the reaction kettle; adding 90 parts of ethylene oxide into the kettle while spraying for reacting for 4 hours; then preserving the heat for 1 hour, cooling to 70 DEG C and discharging; pouring obtained reactants into a stirring type reaction vessel; and keeping the temperature at 70 DEG C, adding 100 parts of white oil, further stirring for 0.5h; and adding 50 parts of a polyol type surfactant and 50 parts of a polyethylene glycol type surfactant, further stirring, and discharging after cooling to obtain the high-temperature-resistant reversible emulsifier. The high-temperature-resistant reversible emulsifier has the beneficial effects of good stability, strong inhibitive capability and easy maintenance.

Owner:中石化石油工程技术服务有限公司 +2

High-temperature low-density cement and applications thereof

ActiveCN101747009AHigh strengthHigh compressive strengthSolid waste managementDrilling compositionOil productionTemperature resistance

The invention relates to a high-temperature low-density cement and applications thereof, belonging to the field of building materials. The high-temperature low-density cement provided by the invention has excellent high temperature resistance and comprises the following components in percentage by weight: 30%-70% of cement substrate, 14%-40% of lightening material, 14%-30% of high-temperature strength stabilizer and 0.02%-0.10% of high-temperature retarder, wherein the high-temperature retarder is organic acid sodium salt, and the high-temperature strength stabilizer material is one of micro silicon and silicon powder or the combination of micro silicon and silicon powder. The cement has the characteristics of simple construction processes, high pulping rate, excellent high temperature resistance and the like, can be applied to special environments such as oil well cementing and the like, and can obviously improve well cementing quality and crude production rate. When the cement of the invention is used for well cementing operation and high-temperature oil production operation, the well cementing construction performance can be ensured, and the unabated performance of the strength of the cement stone at high temperature can be ensured.

Owner:JIAHUA SPECIAL CEMENT

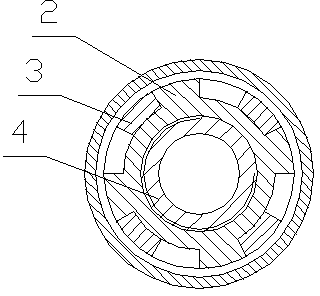

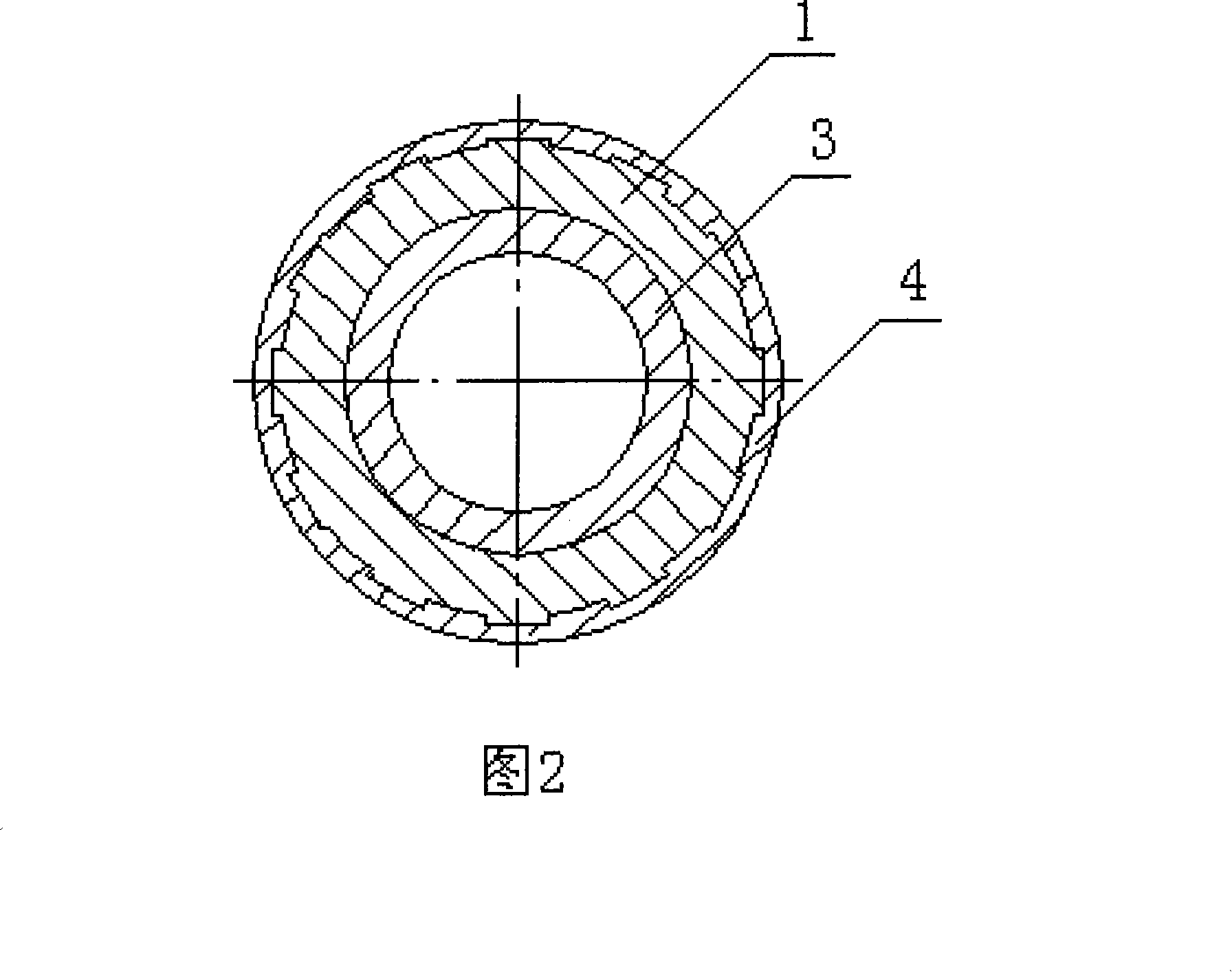

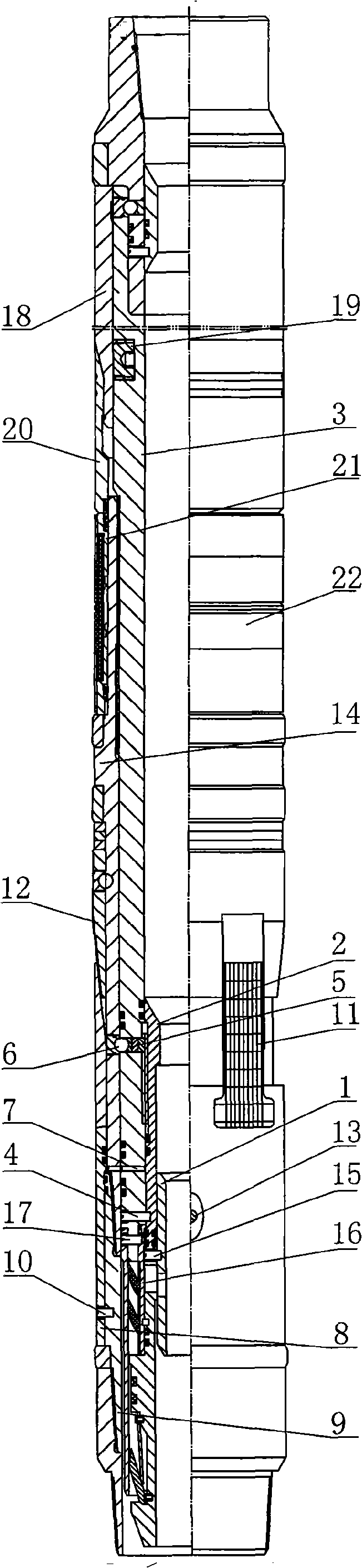

Rotatable hydraulic expanding type tail pipe hanger

A rotatable hydraulically expandable liner hanger is used in liner cementing construction. The feature is that the upper end of the feed-in joint is threaded and can be connected with a drilling tool. The outer wall of the lower end of the feeding joint is splined with the expansion pipe; the inner wall of the lower end of the feeding joint is screwed into the central pipe. The lower end of the central tube is fixed with a sealing rubber plug by shear nails; the expansion plug is in the annular space between the central tube and the expansion tube; the rubber plug conduit is connected to the lower end of the expansion tube; the lower end of the rubber plug conduit is threadedly connected to the lower connecting pipe; the blocking ring is placed on the inner shoulder of the lower connecting pipe. The diameter of the central hole at the upper part of the blocking ring is the same as the outer diameter of the lower end of the sealing rubber plug, and the diameter of the central hole at the lower part of the blocking ring is smaller than the outer diameter of the lower end of the sealing rubber plug. The effect is that the tailpipe is suspended by utilizing the hydraulic pressure to expand the expansion pipe to closely contact with the casing inner wall. High hanging success rate, good sealing quality; large internal diameter of the pipe string. The spline connection between the feeding joint and the expansion pipe can be drilled with the drill bit rotating during the lowering process.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Tail pipe well drilling and well completion technique

ActiveCN101403281AAvoid situations where it cannot be pulled outImprove protectionDrilling machines and methodsWell drillingPetroleum engineering

The invention discloses a liner drilling and well completion process, which mainly solves the problems of difficult guarantees of cementing quality to the liner drilling process, easy occurrence of serious drilling troubles, complex processes, a plurality of related tools, poor reliability and short maximum drilling length. The process is characterized in that: after the well completion of an intermediate casing: (1) a liner drilling string is connected; (2) the liner drilling is carried out; (3) the drilling is finished; (4) then a hanging liner and a running tool are disentangled from a liner hanger; (5) a well completion string is connected; (6) the liner is rotated to carry out well cementation; (7) the liner is set; and (8) a drill rod and the running tool are taken out. The liner drilling and well completion process is characterized by good well cementation quality, safety and reliability, simple process, fewer related tools and longest maximum drilling length.

Owner:DAQING PETROLEUM ADMINISTRATION +1

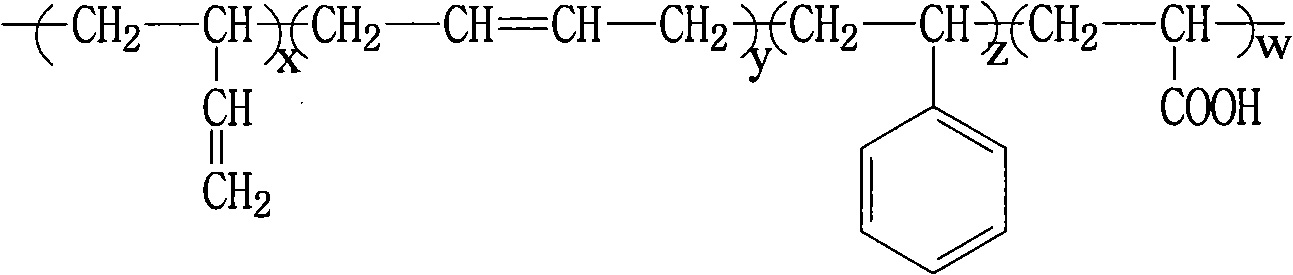

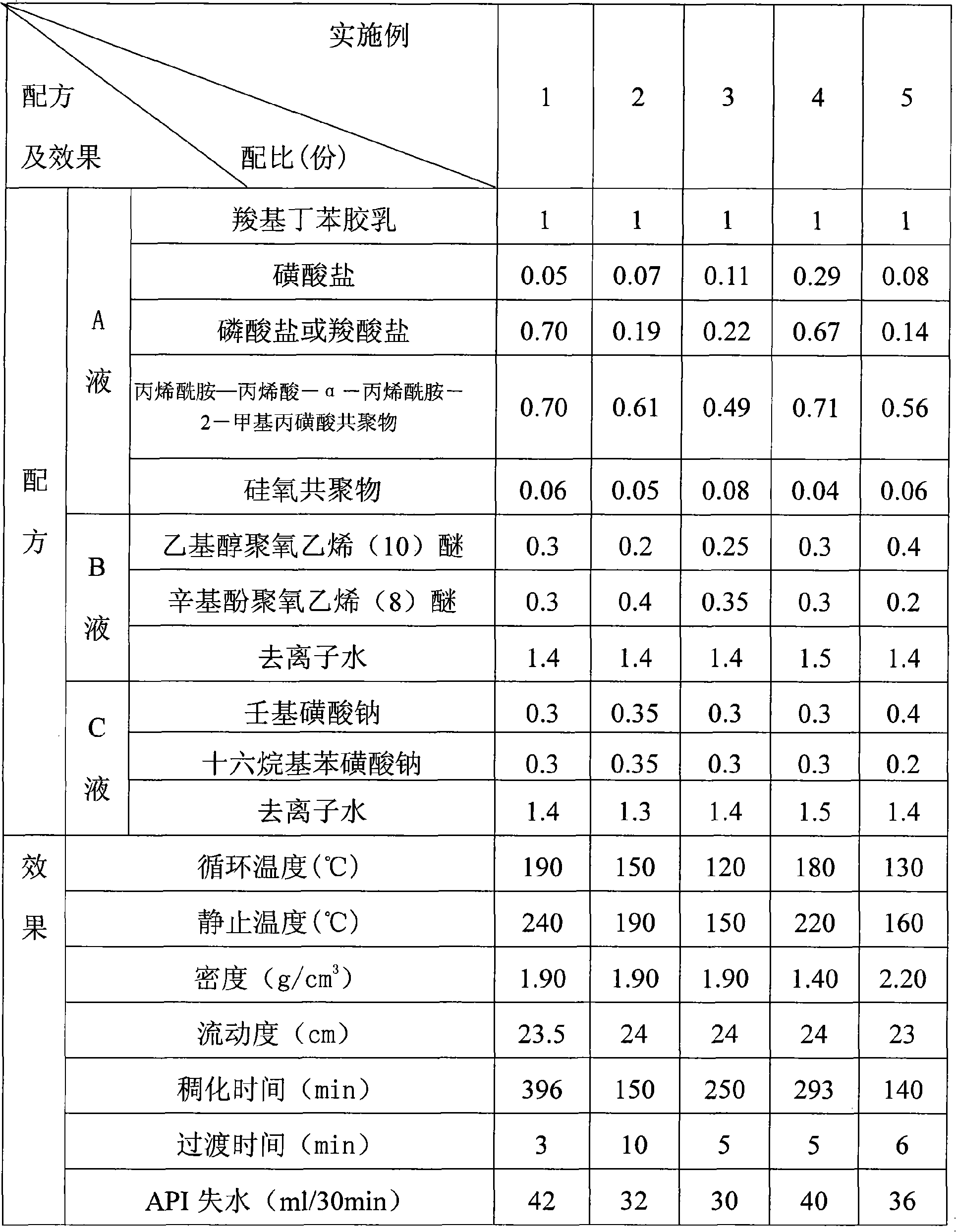

High temperature toughcementing carboxyl butadiene-styrene latex additive

ActiveCN101328401AHigh compressive strengthReduce water lossDrilling compositionPhosphateButadiene-styrene rubber

The invention relates to a high temperature ductility well cementing carboxylic styrene butadiene latex additive. The additive consists of 1 portion of a liquid A, 0.067 to 0.133 portion of a liquid B and 0.067 to 0.133 portion of a liquid C. The liquid A comprises 1 portion of carboxylic styrene butadiene latex, 0.03 to 0.3 portion of sulfonate, 0.0 to 0.8 portion of phosphate, carboxylate or a mixture thereof, and 0.1 to 0.8 portion of an acrylamide-acrylic acid-alpha-acrylamide-2-methylpropanesulfonic acid copolymer; the liquid B contains two nonionic surfactants and deionized water; and the liquid C contains two anionic surfactants and the deionized water. When a well bottom temperature reaches between 190 and 240 DEG C, cement slurry is also characterized in low water loss, adjustable thickening time and high compressive strength; and the hardened cement formed by the cement slurry can ensure good well cementing quality with ductility.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

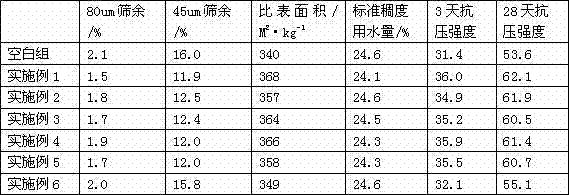

Cement composite grinding aid

The invention discloses a cement composite grinding aid which is characterized by comprising the following components in parts by weight: 10-30 parts of polyol amine, 10-30 parts of polyol, 5-15 parts of molasses, 5-15 parts of lignosulphonate, 2-6 parts of sodium metasilicate pentahydrate, 3-7 parts of sodium hexametaphosphate and 20-30 parts of water. The cement composite grinding aid disclosed by the invention is stable in raw material source, environmental-friendly, low in toxicity and easy to produce, and ensures that the components achieve preferable synergistic effect by confirming the components and a content range, thus optimizing the efficacy of a powder grinding process and improving the power granule distribution and morphology of cement without adverse effect on cement quality. The cement composite grinding aid disclosed by the invention has the advantages of preferably increasing the yield increase and enhancing the cement quality and has the effects of saving the electricity consumption, improving the powder efficiency and the cement strength, reducing the free calcium oxide contained in the cement and enhancing the early strength and later strength of the cement.

Owner:湖州华仑助剂科技有限公司

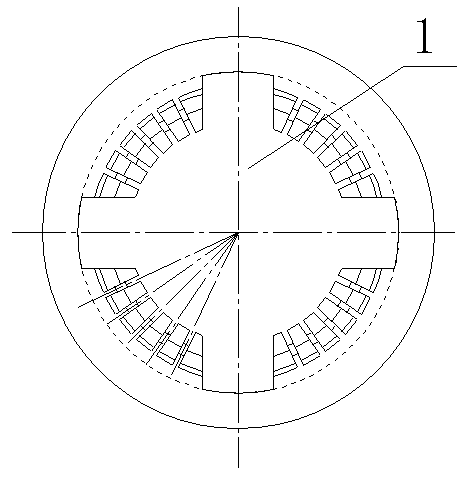

Hydraulic type sleeve pipe centralizer

InactiveCN107120073AWon't scratchStable supportDrilling rodsDrilling casingsHydraulic cylinderControl engineering

The invention relates to the technical field of oil-gas field down-hole tools and provides a hydraulic type sleeve pipe centralizer. The hydraulic type sleeve pipe centralizer comprises a core shaft, a hydraulic cylinder sleeve, a shearing dowel, an expanding assisting block and a centralizer plate spring; the upper portion of the hydraulic cylinder sleeve is mounted on the upper portion of the core shaft through a first fixing assembly, a liquid inflow hole is formed in the side wall of the core shaft, and a piston cylinder is mounted in a second annular cavity; a piston rod is mounted at the lower end of the piston cylinder; the lower end of the piston rod is mounted on the outer wall of the core shaft through the shearing dowel; the upper end of the centralizer plate spring is fixedly connected with the lower end of the piston rod through a second fixing assembly; the expanding assisting block is fixedly mounted on the outer wall of the middle of the core shaft; and the lower end of the centralizer plate spring is fixedly mounted on the outer wall of the lower portion of the core shaft through a third fixing assembly. The hydraulic type sleeve pipe centralizer is compact in structure, and stabbing and scraping over the well wall cannot be caused when the device is placed into a drill hole; hydraulic expanding seal is adopted, the outer diameter after expanding seal is large, the centering effect is better, center of a down-hole horizontal-section sleeve pipe is achieved, a cement loop is uniform, and improvement of the well cementation quality is facilitated.

Owner:CNPC XIBU DRILLING ENG

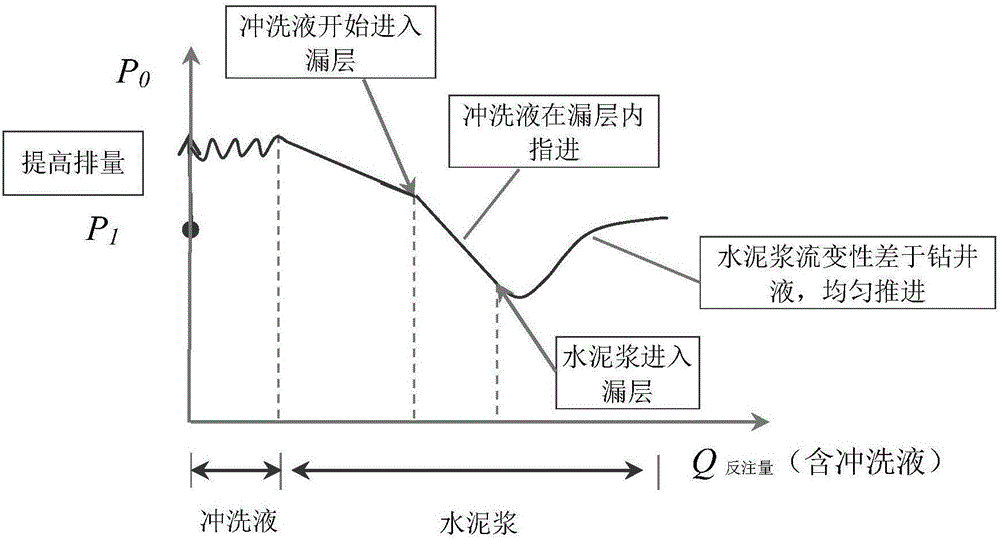

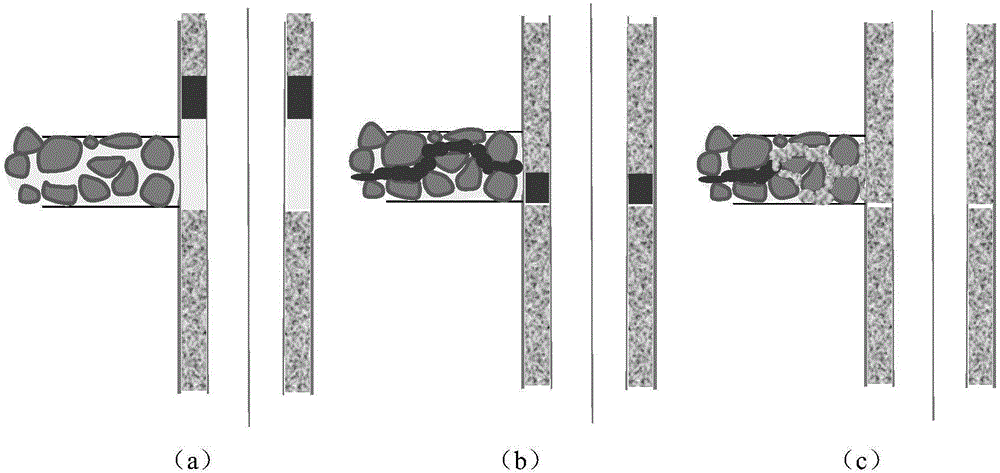

Positive injection back squeeze well cementation method for low pressure and leaky well

The invention relates to a positive injection back squeeze well cementation method for a low pressure and leaky well. The method comprises the steps that 1) drilling fluid section circulating is carried out during a casing running process; 2) after casing running, drilling fluid in the well goes to the top, and if normal cycle can be established, fixed displacement cycle is carried out at least two periods, otherwise positive drilling fluid injection is carried out to ensure unobstructed hohlraum; 3) cement slurry is positively injected and sealed to the bottom of a leak layer or the formation to bear ensured cement back height; 4) small displacement test squeeze is carried out to squeeze the leak layer through. In the step 4), if the pressure of the squeezed wellhead exceeds P, construction is stopped; and if the pressure of the squeezed wellhead does not exceed P, back squeeze construction is carried out according to the designed back squeeze cement slurry amount and the slurry column structure. According to the well cementation method, the problems of insufficient cement back height and low replacement efficiency of a sealing section, which are caused by well cementation leak, are effectively solved; cement slurry waste caused by leak is reduced; and obvious cost increasing caused by used ultra-low density cement slurry and hidden production dangers caused by loose grading hoop sealing are avoided.

Owner:中石化石油工程技术服务有限公司 +1

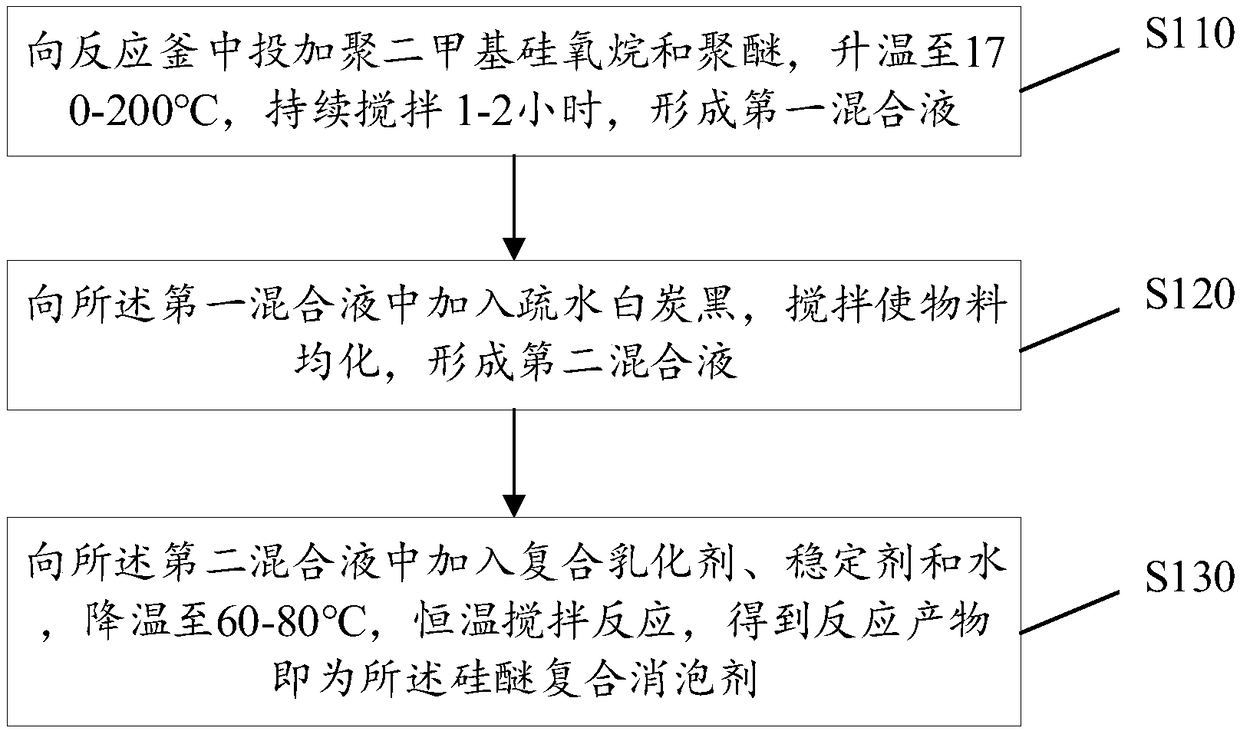

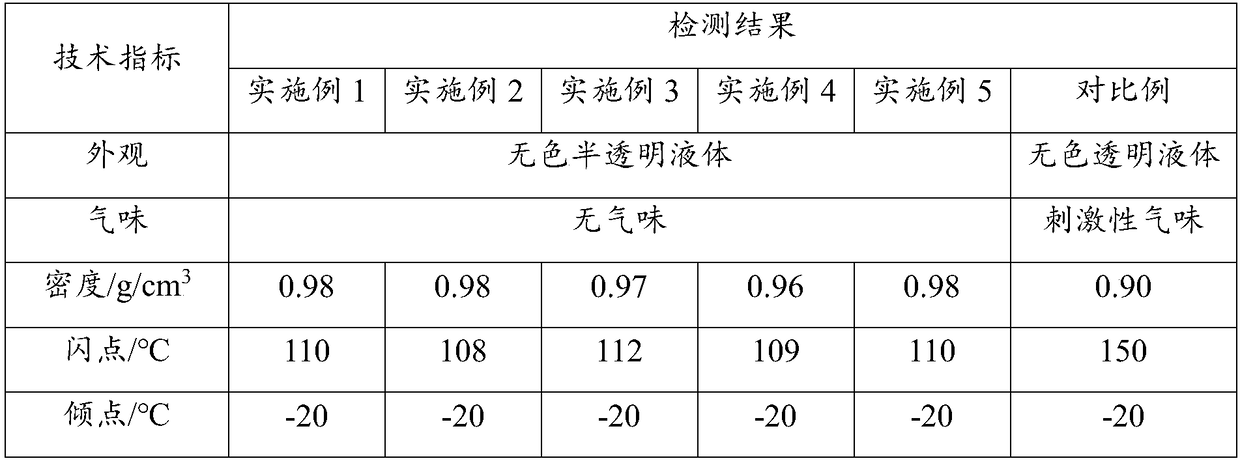

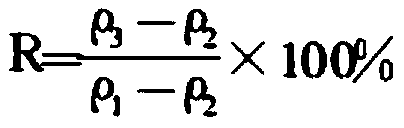

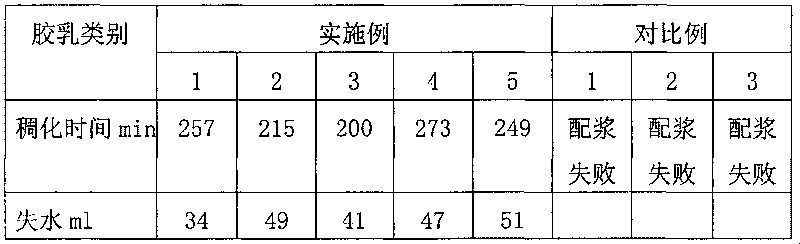

Silyl ether composite defoaming agent as well as preparation method and application thereof

ActiveCN108726913AGood defoamingImprove cementing qualityDrilling compositionChemical industryDefoaming Agents

The invention discloses a silyl ether composite defoaming agent as well as a preparation method and an application thereof, and belongs to the technical field of oilfield chemical industry. The composite defoaming agent is prepared from components in percentage by mass as follows: 15%-25% of polysiloxane, 15%-25% of polyether, 2%-5% of hydrophobic white carbon black, 2%-5% of a compound emulsifier, 1%-2% of a stabilizer and the balance of water. The preparation method comprises steps as follows: polydimethylsiloxane and polyether are added to a reaction kettle, the temperature is increased to170-200 DEG C, and the materials are continuously stirred for 1-2 h; hydrophobic white carbon black is added and stirred to be homogenized; the compound emulsifier, the stabilizer and water are added,the temperature is reduced to 60-80 DEG C, a stirring reaction is performed at constant temperature, and the silyl ether composite defoaming agent is obtained. The composite defoaming agent is used for defoaming and foam inhibition in a stirring process of well cementing slurry containing an admixture. The composite defoaming agent is high in defoaming and foam inhibition capacity, can be appliedto various cement slurry systems, and is good in compatibility with common admixtures, safe and environmentally friendly.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +1

Carboxylated styrene-butadiene rubber latex special for oil and gas field cementing well

InactiveCN101759825AMeet the dehydration requirementImprove cementing qualityDrilling compositionFunctional monomerPolymer science

The invention relates to a synthetic method of carboxylated styrene-butadiene rubber latex special for an oil and gas field cementing well by using butadiene and styrene as main monomers, using carboxylic acid containing unsaturated links or / and sulfuric acid and sulphonate as functional monomers and adopting a composite emulsifier system as a nonionic emulsifier of C8-C20 sodium alkyl sulfate-c8-c20 sodium alkylbenzene sulfonate at a polymerization temperature of 50-90 DEG C in a polymerization mode, i.e. the main monomers are added in one step, and the other assistants can be added in one step or a plurality of times. The carboxylated styrene-butadiene rubber latex obtained by the method of the invention is compounded with cement and other related assistants into well-cementing liquid so as to satisfy the grout-dehydrating requirement in the well-cementing operation, i.e. the water loss is controlled within 50ml / 30min. The rubber latex is suitable for cementing wells and has favorable economic benefits and social benefits.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

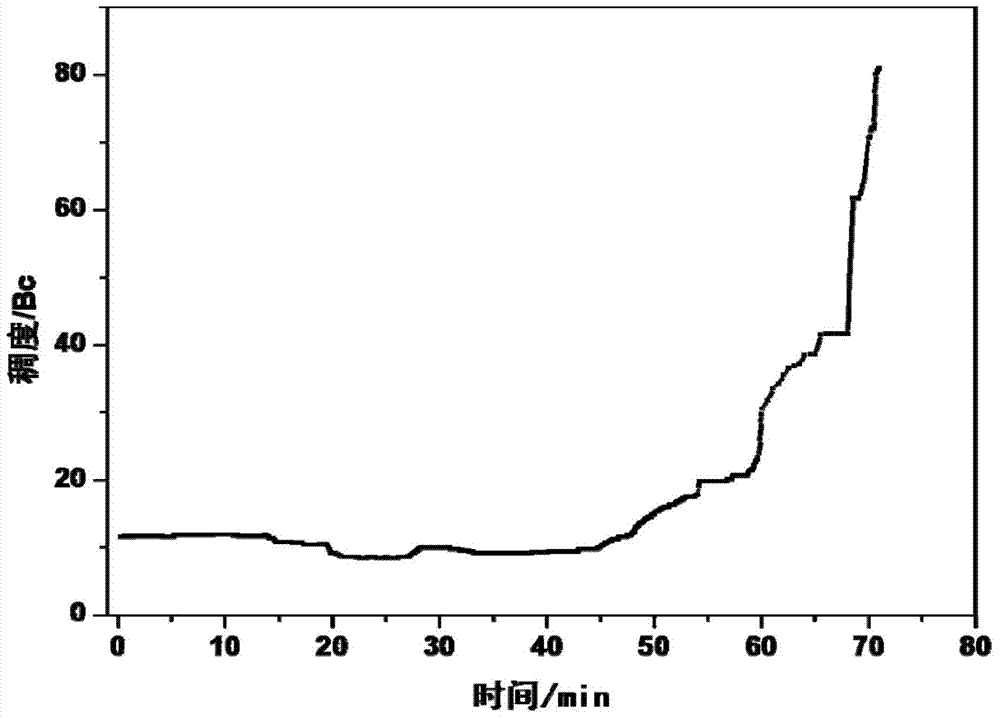

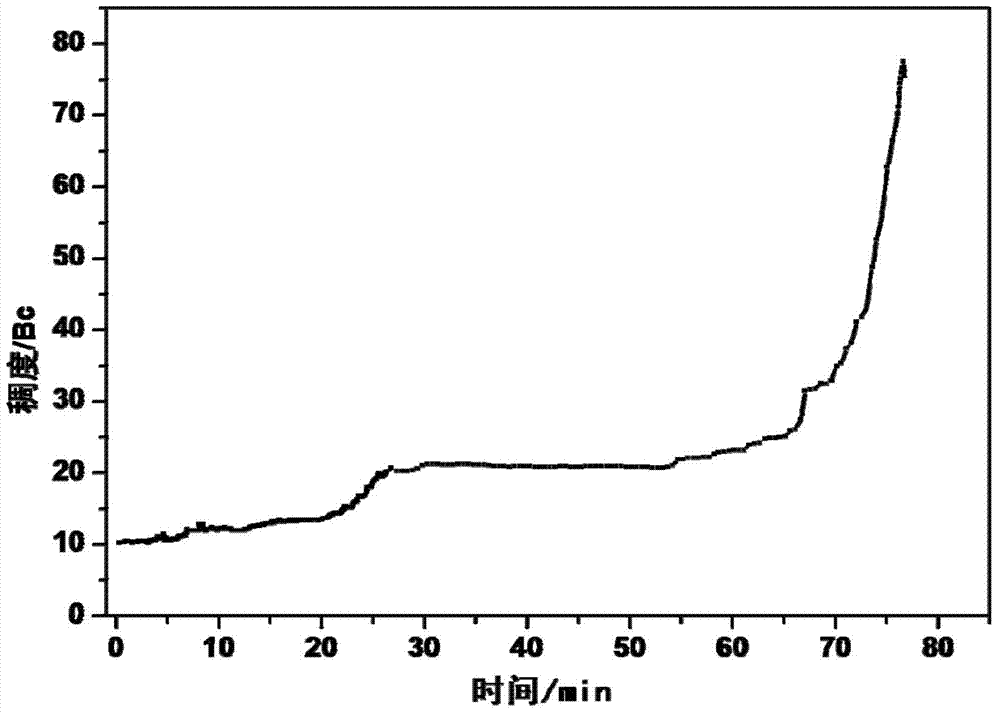

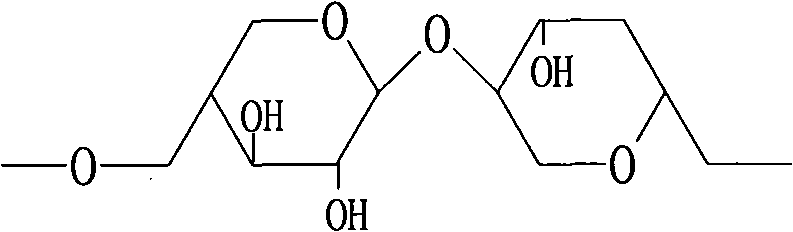

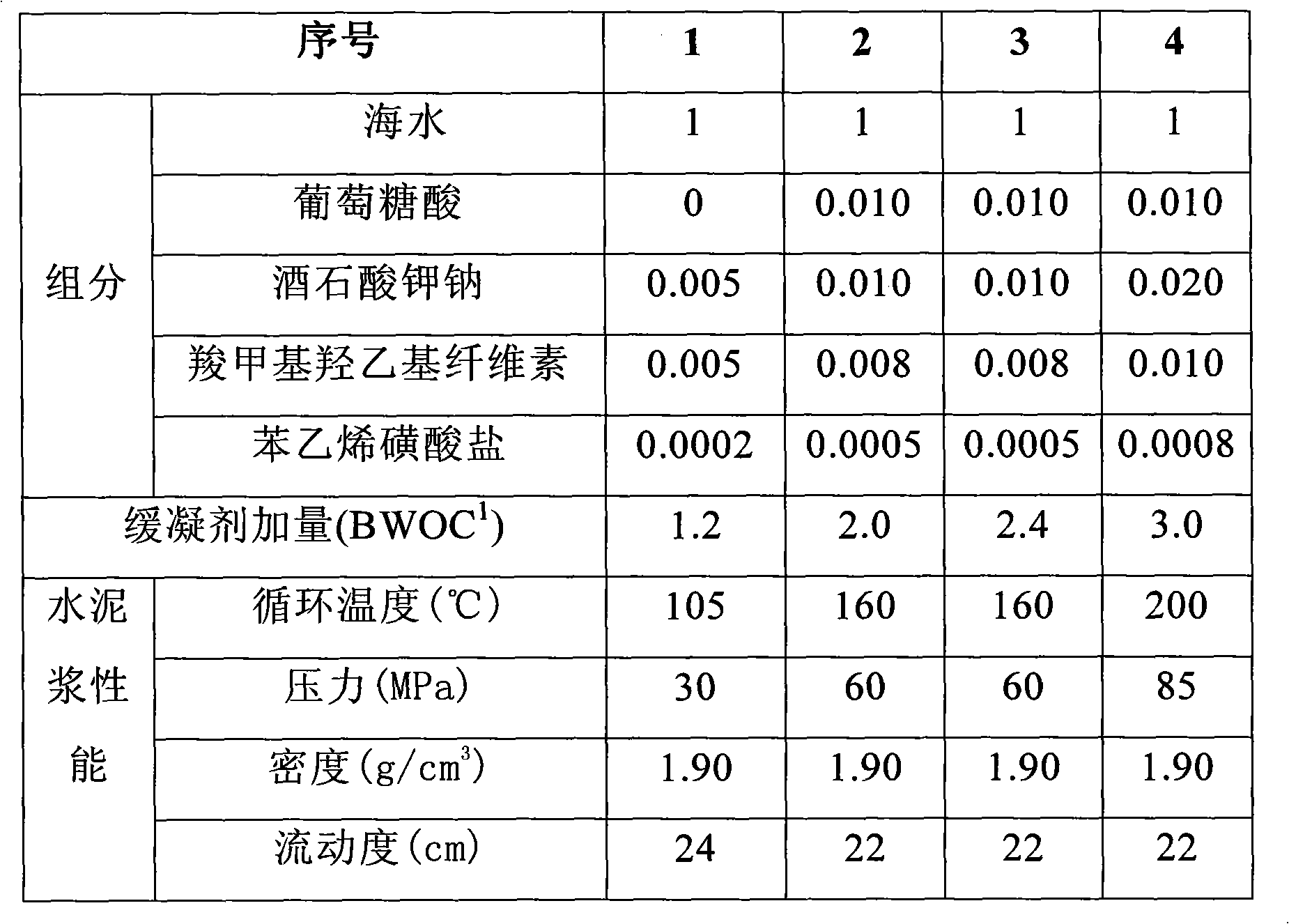

Oil well cement high temperature retarder

ActiveCN101597487ASuitable for a wide temperature rangeMeet the needs of drilling and completion engineeringDrilling compositionSulfonateWell drilling

The invention relates to an oil well cement high temperature retarder applied to the technical field of oil field well drilling and completion. The invention is characterized in that: the retarder is composed of 1 part by weight of water, 0.005-0.030 part by weight of hydroxycarboxylic acid and salt thereof, 0.005-0.010 part by weight of cellulose derivative and 0.0001-0.0010 part by weight of sulfonate. The high temperature retarder has wide applicable temperature range, can be applied to cement paste systems with various densities, has strong compatibility with a plurality of admixture systems, and does not influence the performance of cement paste. The cement paste prepared by the retarder is stable, the thickening transition time is short, and the thickening time is adjustable; the hardened cement paste has rapidly developed compression strength and is suitable for the requirement of well cementation engineering.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

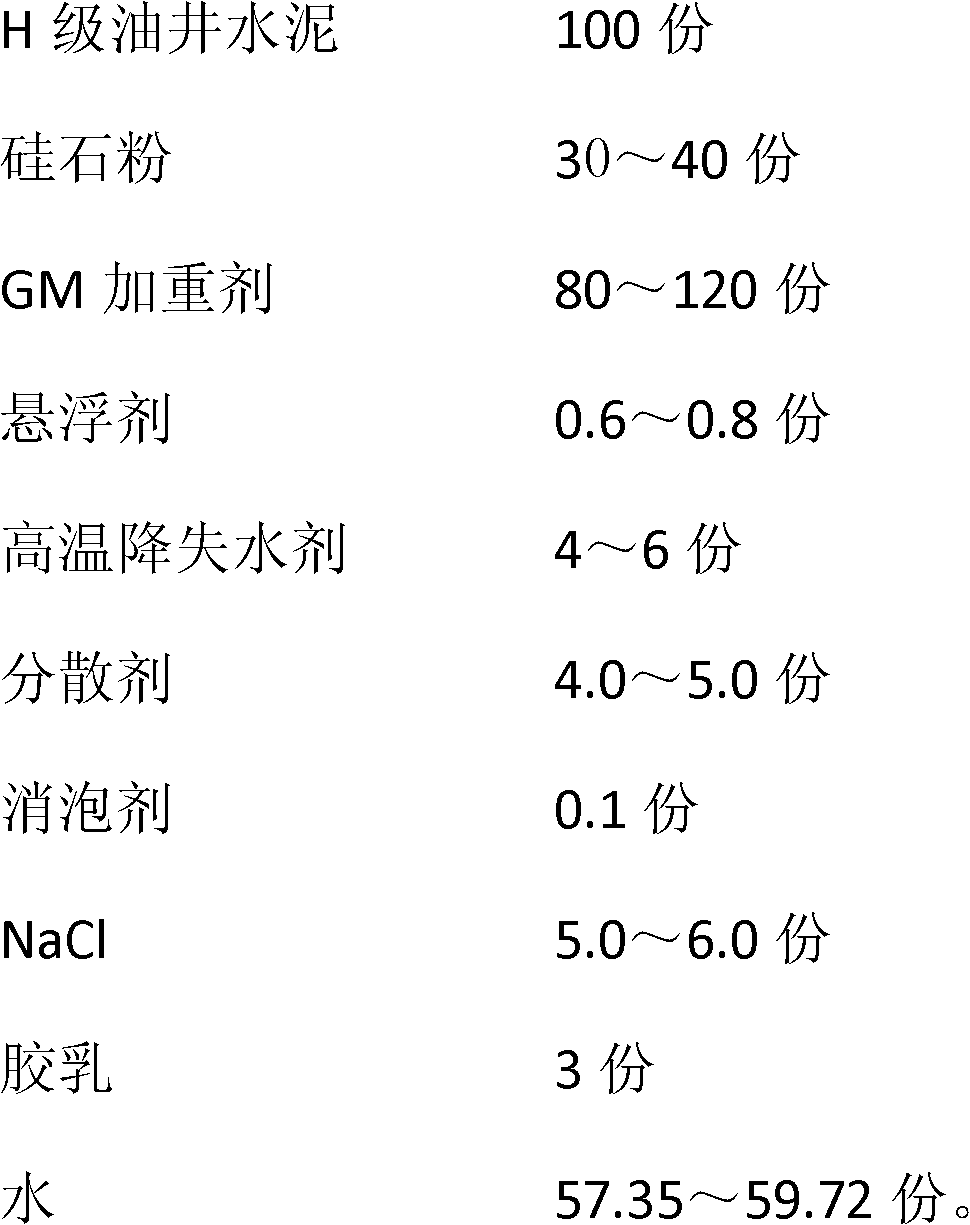

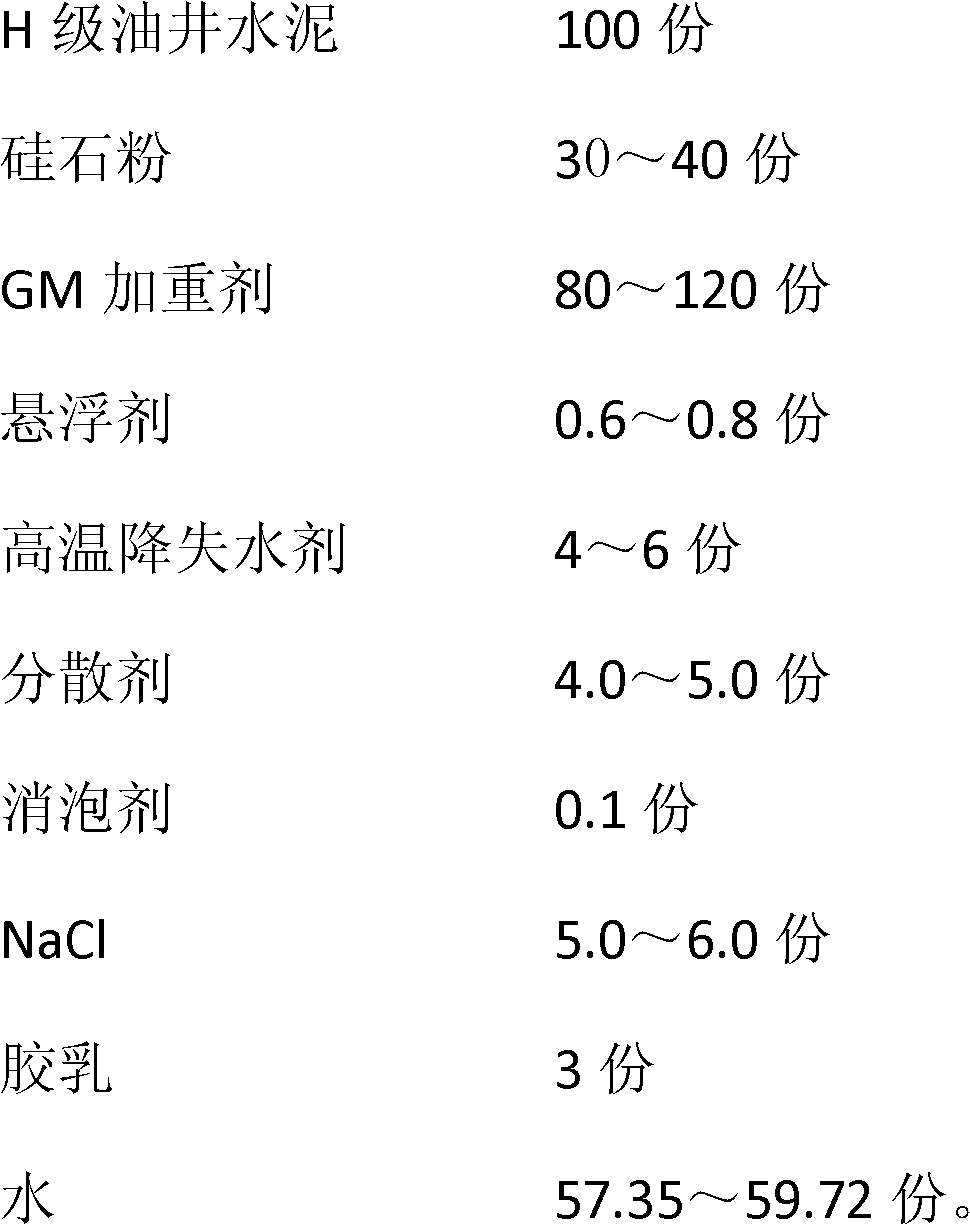

Cementing slurry with high temperature, high density and high toughness

ActiveCN102516965AHigh densityGood settlement stabilityDrilling compositionHigh densitySuspending Agents

The invention discloses a cementing slurry with high temperature, high density and high toughness, which comprises the following ingredients by weight 100 parts of H grade oil well cement, 30-40 parts of silicon powder, 80-120 parts of a GM weighting agent, 0.6-0.8 parts of a suspending agent, 4-6 parts of a high temperature fluid loss reducer, 4.0-5.0 parts of a dispersant, 0.1 parts of an antifoaming agent, 5.0-6.0 parts of NaCl, 3 parts of latex and 57.35-59.72 parts of water. The density of the cementing slurry can reach 2.40-2.50gcm3, the cementing slurry can resist a temperature of 160 DEG C, and the cementing slurry has the advantages of good rheological property under high temperature, good settlement stability and good cement stone toughness, is suitable for cementing depth wellsand ultra-deep wells, and is in favor of improving the sealing quality and raising the quality of the wells.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com