Non-floating bead low-density oil-well cement

A technology of oil well cement and low non-bleeding beads, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of poor slurry fluidity, low early strength, short service life, etc., and achieve thickening time Controllable, high early strength and long life effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

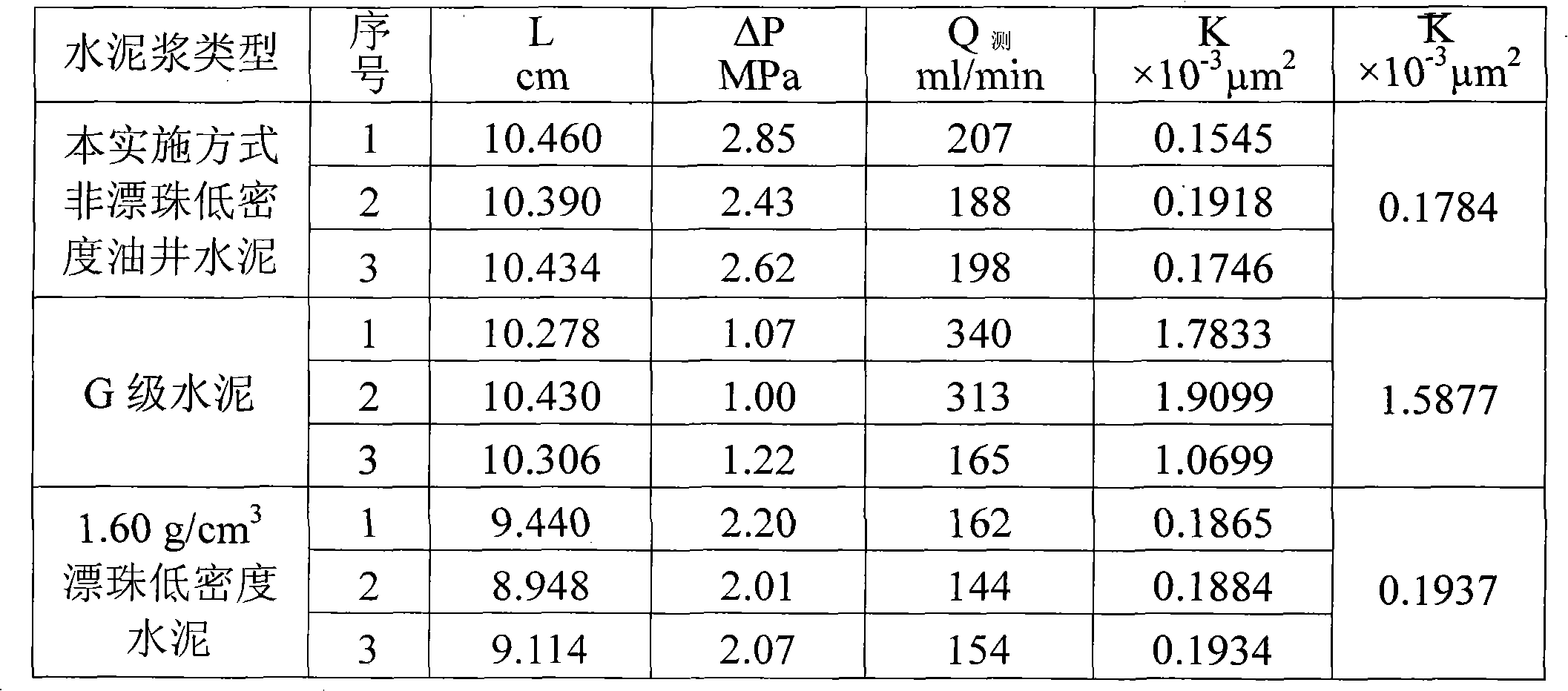

Examples

specific Embodiment approach 1

[0012] Embodiment 1: In this embodiment, the non-floating pearl low-density oil well cement consists of 100 parts of oil well cement, 12 to 20 parts of nano wollastonite, 120 to 180 parts of fly ash, and 3 to 6 parts of early strength agent and 4 to 8 parts of cement dispersant, of which SiO in nano wollastonite 2 The mass content of ≥96%.

specific Embodiment approach 2

[0013] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the non-floating bead low-density oil well cement is composed of 100 parts of oil well cement, 14 to 18 parts of nano wollastonite, and 140 to 160 parts of pulverized coal by weight. Ash, 4-5 parts of early strength agent and 5-7 parts of cement dispersant. Others are the same as in the first embodiment.

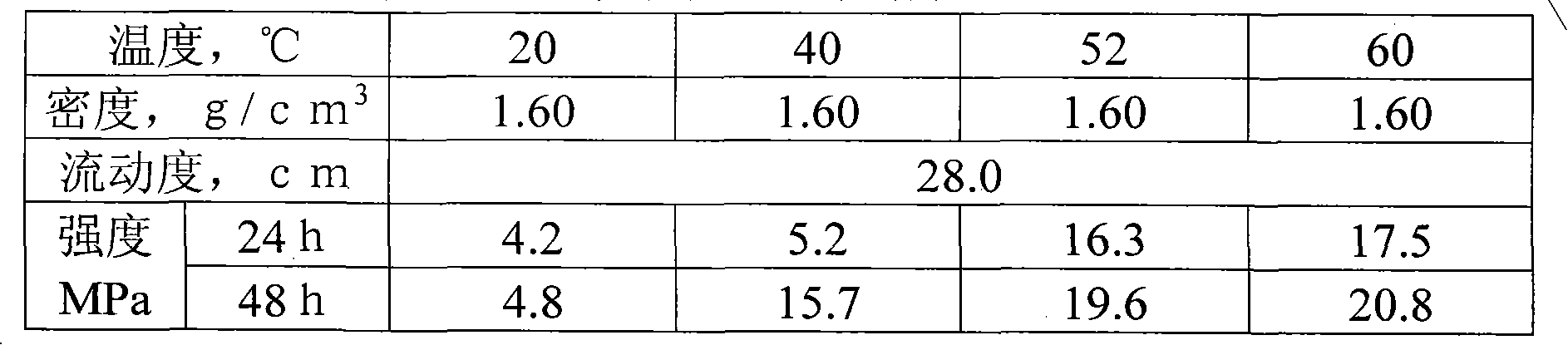

[0014] The cement preparation method described in this embodiment is as follows: mixing each component according to the above-mentioned ratio. When mixing the cement described in this embodiment, the water consumption accounts for 60% of the total weight of the dry ash, and the resulting cement slurry has a density of 1.60±0.02g / cm 3

specific Embodiment approach 3

[0015] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the non-floating pearl low-density oil well cement is composed of 100 parts of oil well cement, 16 parts of nano wollastonite, 150 parts of fly ash, 4.5 parts by weight Early strength agent and 6 parts cement dispersant. Others are the same as the specific way one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com