Patents

Literature

2793results about How to "Improve early strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cement-based composite material used for 3D printing technology as well as preparation method and application thereof

ActiveCN104310918AEasy to get materialsLow costSolid waste managementHouse buildingConstruction 3D printing

The invention provides a cement-based composite material used for a 3D printing technology as well as a preparation method and application thereof. The cement-based composite material is prepared from the following raw materials based on the total weight of the composite material: 33%-40% of cement, 0%-8% of inorganic powder, 32%-38% of tailing machine-made sand, 2.5%-3% of a high-molecular polymer, 0.1%-0.5% of a water reducing agent and 16.7%-20% of mixing water; a composite thickening time control agent, a thixotropic agent, a volume stabilizer and the like are added into a mixture to prepare an inorganic composite material; and then the inorganic composite material can be directly pumped into a 3D printer for building to be applied to construction. The cement-based composite material is an inorganic material and the materials are easily available; a lot of industrial waste materials can be used; therefore, the cement-based composite material is low in cost, energy-saving and environment-friendly; the condensation time can be flexibly controlled, and the material has super early strength, good caking property and strong stability; the requirements of 3D printing construction continuity of the building and the building strength are met so that the house building has good global stability and use safety; and the application and popularization of 3D printing technology can be greatly promoted.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

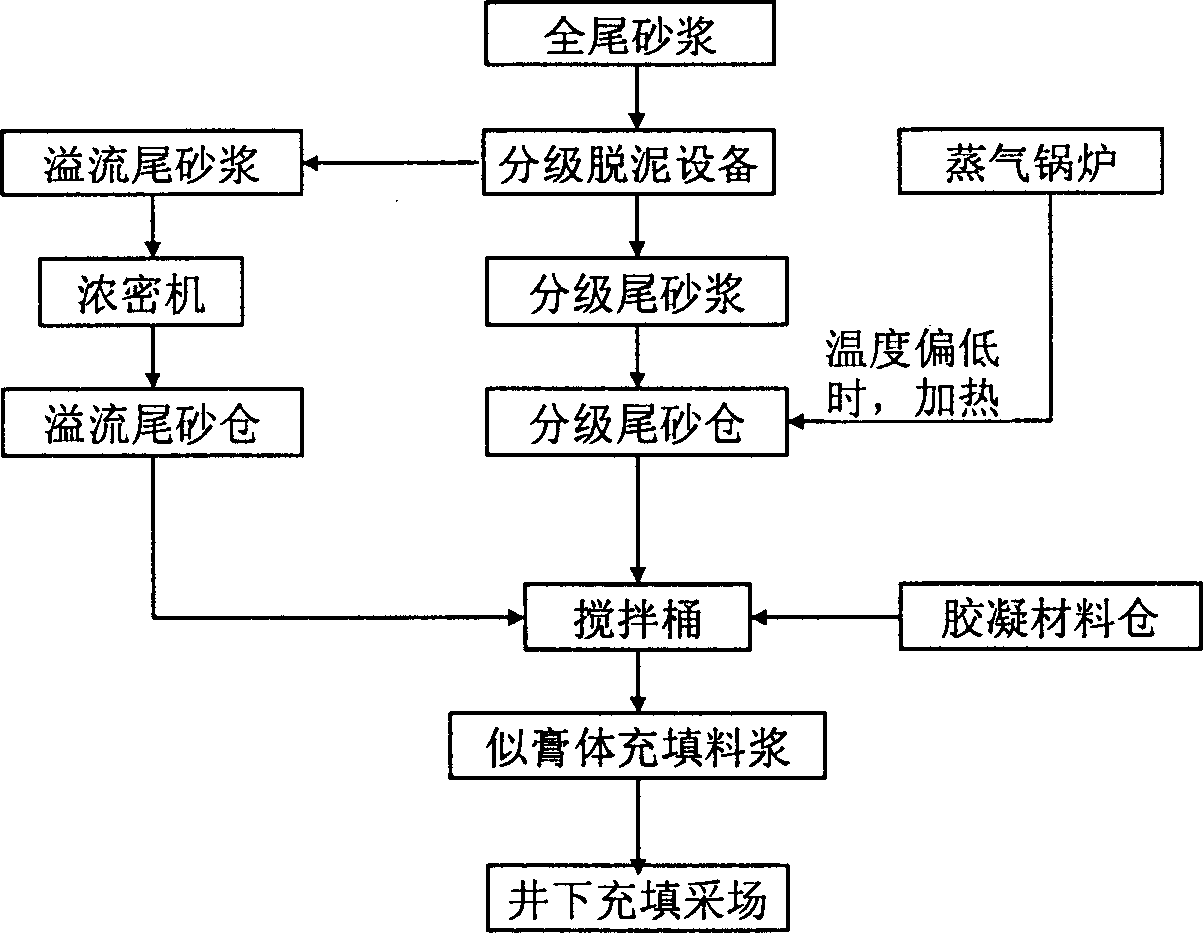

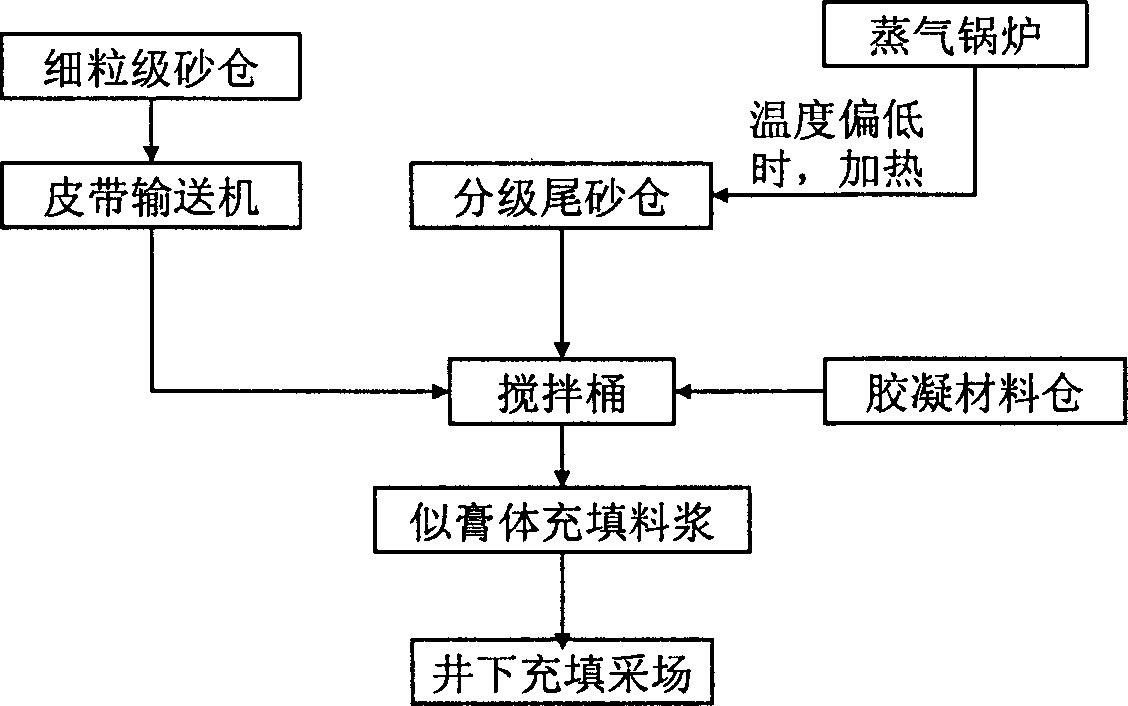

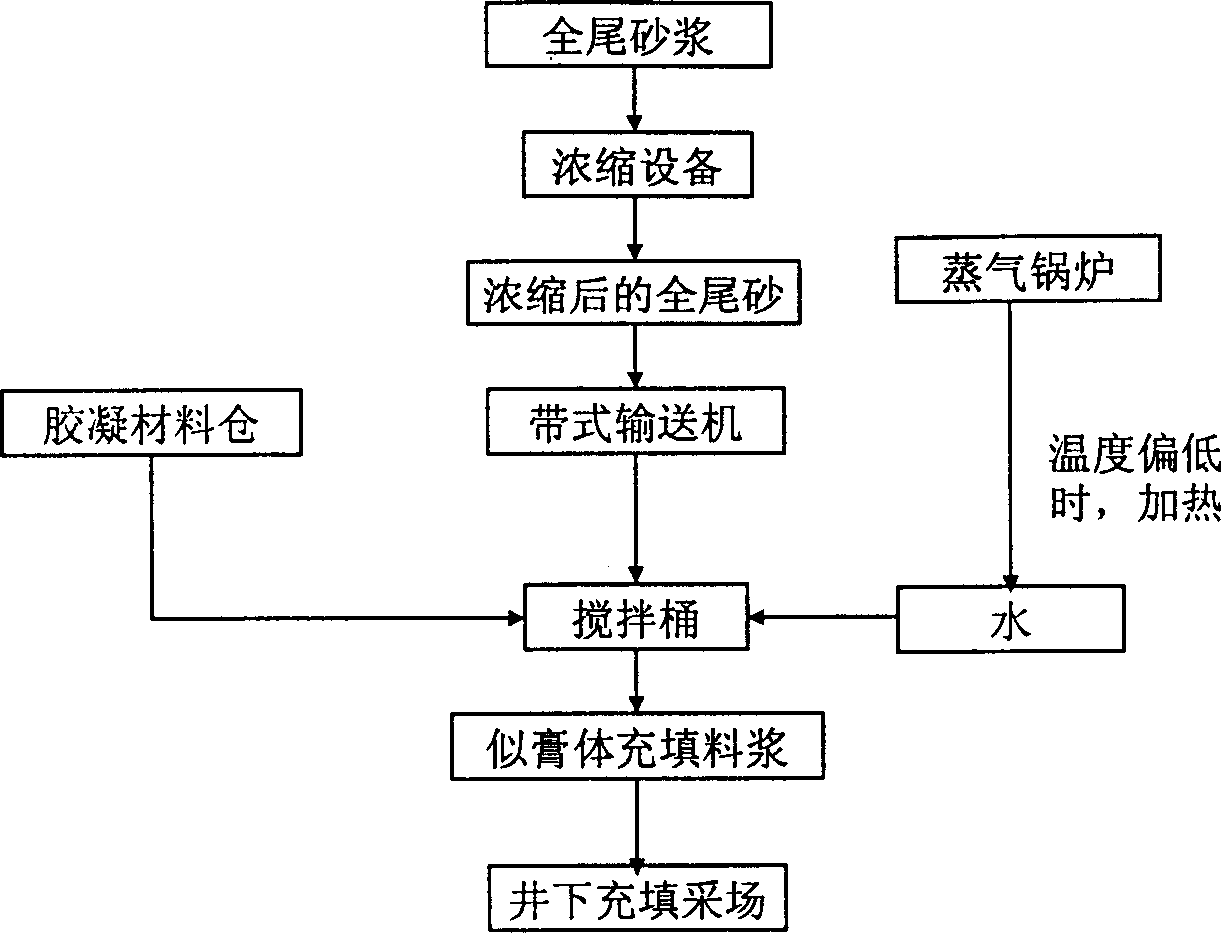

Cementing materials for filling, slurry and preparing and filling processes

InactiveCN1424275AReduce manufacturing costLess investmentSolid waste managementMaterial fill-upSlurrySulfur containing

A gelatining material similar to cream for filling underground working surface is preapred from the Ca-contained non-crystal and microcrystal material, alkali and / or sulfur contained exciting material, active material, aggregate and regulator. A filling slurry is prepared from said gelatining material, filling aggregate, fine particles, regulator and water through heating to at least 18 deg.C and proportional mixing.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +2

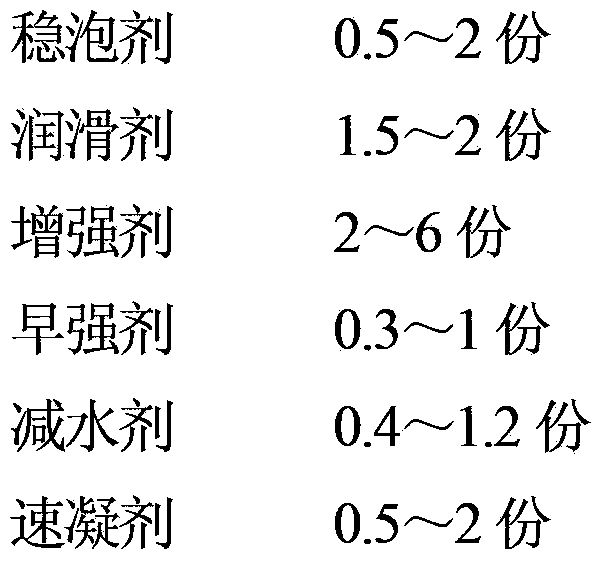

Lightweight high-performance foam concrete and preparation method thereof

ActiveCN104108912AHigh CaO contentHigh glass bead contentSolid waste managementCeramicwareFoam concreteFiber

The invention discloses a lightweight high-performance foam concrete, which is composed of the following components in parts by weight: 50 to 60 parts of cement, 20 to 35 parts of mineral slag, 15 to 20 parts of fly ash, 5 to 10 parts of gypsum, 60 to 80 parts of fine aggregate, 2.7 to 7.3 parts of additive, 0.1 to 0.2 part of fiber, 32 to 45 parts of water, and 5 to 25 parts of foam. The invention also discloses a preparation method of the foam concrete. The foam concrete has the advantages of small volume-weight, high strength, low water absorption, and small contraction rate, and has the waterproof and anti-cracking functions at the same time.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD

Concrete super instant coagulant

The invention discloses a concrete early-strength agent, which is characterized in comprising the following components according to weight percentage: inorganic salt early-strength component 35-55 percent, organic early-strength component 5-10 percent, water reducing component 15-25 percent, wherein the inorganic salt early-strength component is prepared by at least two among sulfate, carbonate, nitrate, and nitrite; the organic early-strength component selects any one among calcium formate, sodium acetate, calcium oxalate, triethanolamine, tri-iso-propanolamine and carbamide; the water reducing component selects one among naphthalenesulfuric acid type, melamine type and polycarboxylate type. The invention makes the concrete be coagulated and hardened rapidly under the condition of low temperature, so that the early strength of the concrete is greatly improved as well as later strength is ensured.

Owner:ZHONGYIFENG CONSTR GRP +1

Epoxy emulsion modified quick repair mortar for concrete roads and bridges and preparation method for mortar

The invention discloses epoxy emulsion modified quick repair mortar for concrete roads and bridges and a preparation method for the mortar, and belongs to the technical field of chemical construction materials. The prepared epoxy emulsion modified quick repair mortar for the concrete roads and bridges is good in construction performance, high in early strength and stable in later strength, does not shrink, and can be formed by selecting a proper formula according to different engineering requirements; the early strength is increased quickly, the repair speed is high, the traffic can be openedin 4 hours, the 4H compressive strength is more than 25MPa, and the 4H breaking strength is more than 3.5MPa; and the mortar is highly bonded to an old concrete base layer, and the positive pulling bonding strength in 28 days is more than 2.5MPa; and the mortar is good in freezing resistance and impermeability. The mortar mainly solves the problems of long traffic opening time, low bonding strength with the old concrete base material, poor durability and the like of the conventional quick repair mortar for the concrete roads and bridges.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

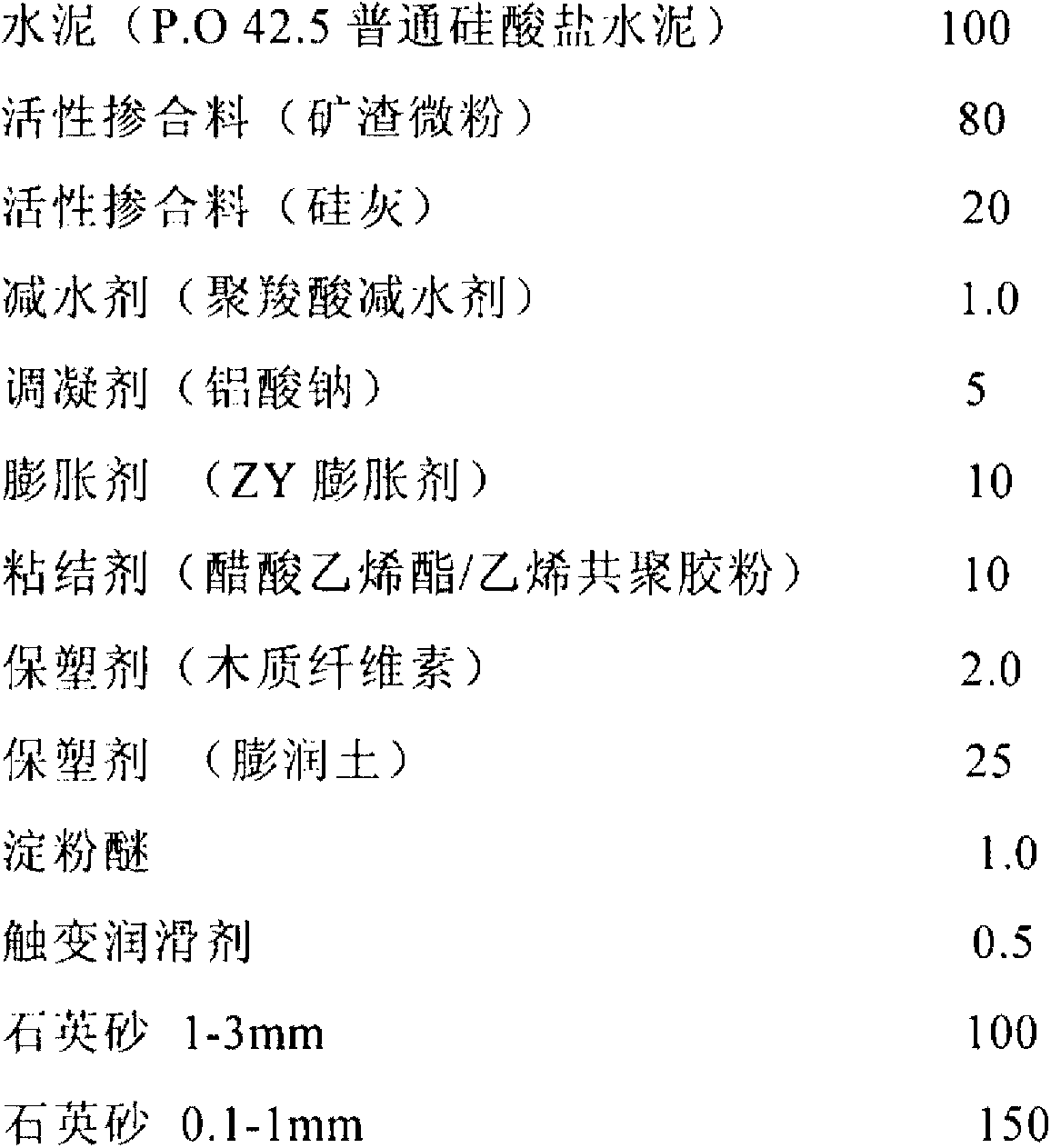

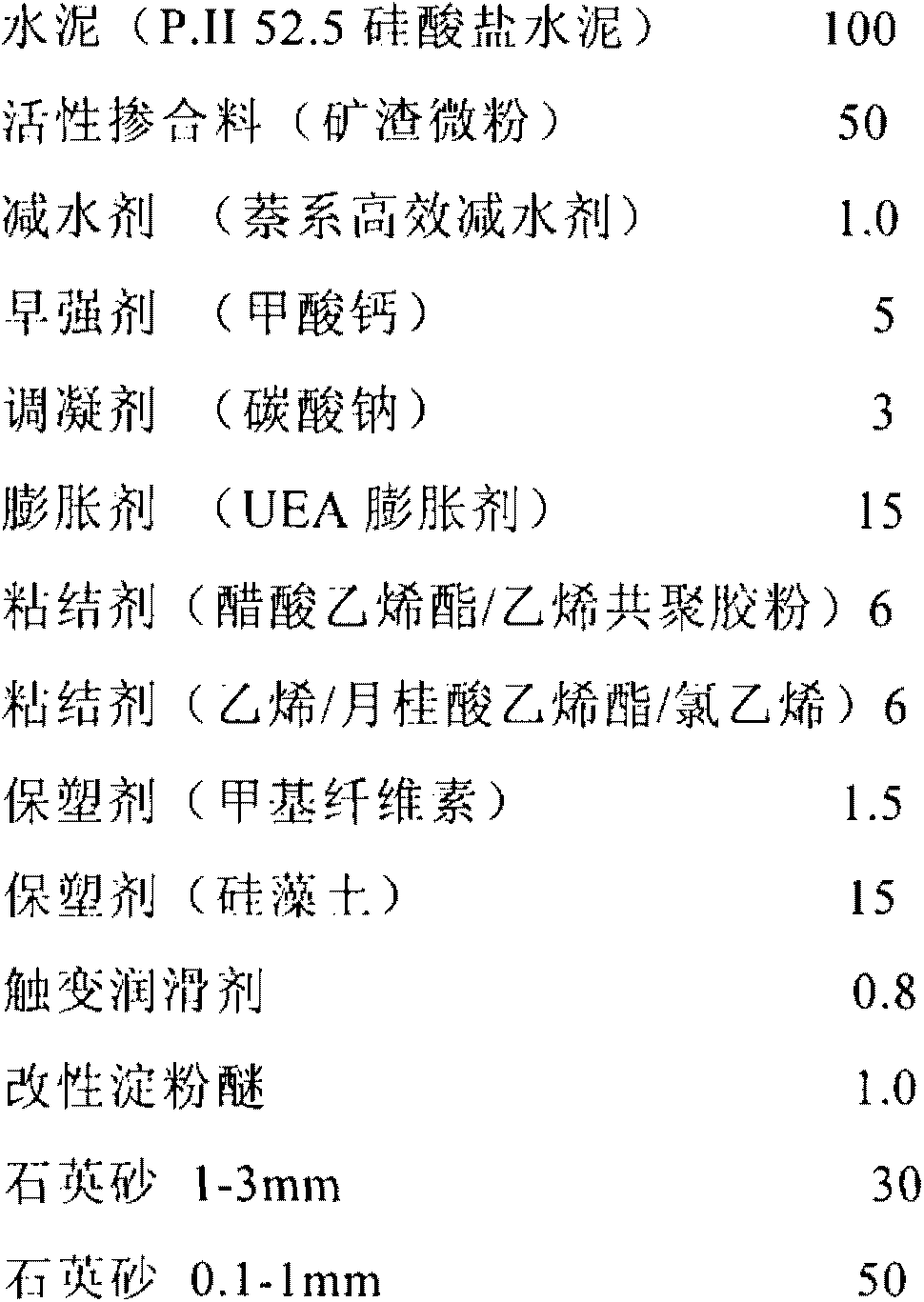

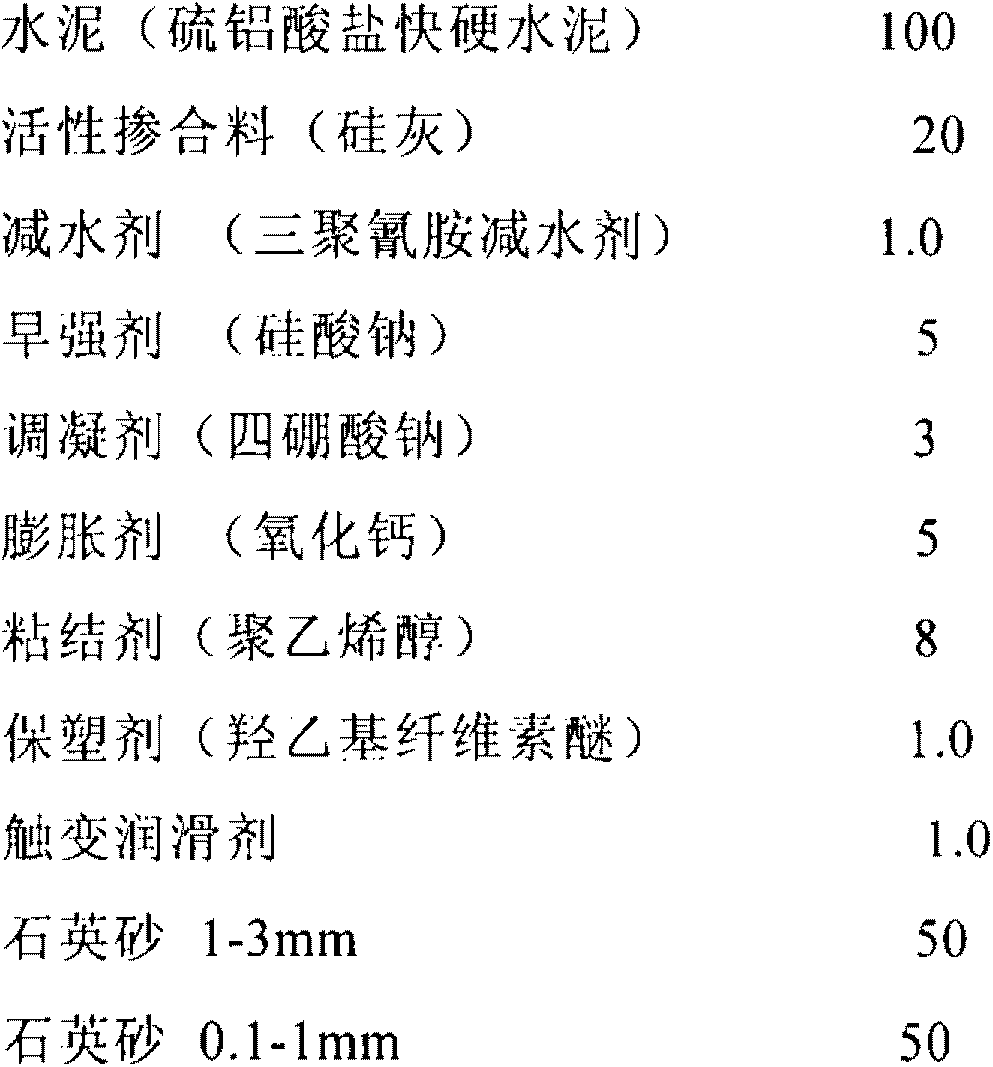

Assembled splicing joint sealing material for building components and application thereof

The invention relates to an assembled splicing joint sealing material for building components and an application thereof. The sealing material is prepared from raw materials in parts by weight as follows: 100 parts of cement, 0-150 parts of active admixture, 0.01-10 parts of water reducer, 0.01-10 parts of early strength agent, 0-10 parts of thickening time control agent, 0.1-30 parts of expanding agent, 0-30 parts of bonder, 0.01-30 parts of plastic retaining agent, 0.01-10 parts of starch ether, 0-10 parts of thixotropic lubricant and 0-300 parts of quarts sand. The sealing material can be applied to sealing joint of concrete components spliced. Compared with the prior art, the sealing material is good in construction performance, and can be used by adding water to stir. The sealing material can be quickly constructed by a caulking gun or an electric caulking device, and the operating time is long. Newly mixed slurry has good plasticity, adhesive force and resistance to falling. The sagging phenomenon is further avoided when a vertical direction is spliced. The condensing time is adjusted according to the project demand, the early strength is high and the later strength is continuously increased.

Owner:TONGJI UNIV

Single-component high-performance mortar for repairing and reinforcing concrete

InactiveCN101935201AShrinkage controlImprove bindingSolid waste managementFlexural strengthPollution

The invention provides single-component t high-performance mortar for repairing and reinforcing concrete, which comprises the following components in part by mass: 200g of sand, 55 to 75 parts of ordinary portland cement, 10 to 30 parts of sulphate aluminium cement, 3 to 7 parts of siliceous dust, 8 to 12 parts of flyash, 0.18 to 0.22 part of water reducing agent, 2 to 4 parts of flexibilizer, 0.04 to 0.06 part of water-retaining agent, 1.0 to 2.0 parts of swelling agent and 0.1 to 0.2 part of polymer synthetic fiber. The single-component t high-performance mortar has the advantages of high initial strength, good adhesion, excellent cracking resistance, low ratio of compressive strength to flexural strength, excellent toughness, simple and convenient construction, single component, no toxin or smell, no harm to human bodies, and environmental protection without pollution.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Light energy conservation insulating concrete

The invention relates to a lightweight energy-saving insulating concrete, belonging to building materials. The invention comprises the master batches and accessories in accordance with the following parts by weight: master batches: 30-70 parts of cementing materials, 25-60 parts of fillers, 5-10 parts of strength activators, and accessories: 1-3 parts of waterproof agents, 2.0-3.0 parts of bleeding agents, 2.0-5.0 parts of suspending agents, 0.1-0.5 part of foam stabilizer, 38-60 parts of honeycomb agents, 0.5-1.5 parts of rusty retardant agents, 0.02-10 parts of reinforcing agents, 1.2-4.2 parts of early strength agents and expanding agents and 0.6-1.4 parts of acid and alkali resistant fibers. The concrete has the advantages of high early tensile and compressive strength, no decrease and crack of later strength and simple manufacturing process. According to the requirement of the building structure, the technical target of the concrete can be realized by regulating the mixing proportion. The concrete can be used for manufacturing various products at normal temperature and is widely applied to insulating and self-waterproof building engineering.

Owner:徐东亮 +4

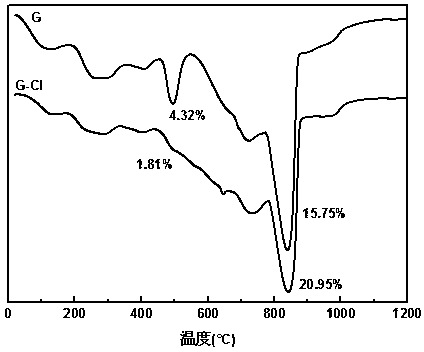

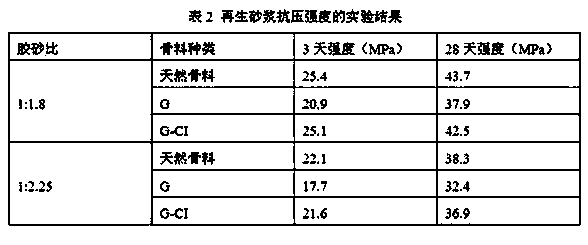

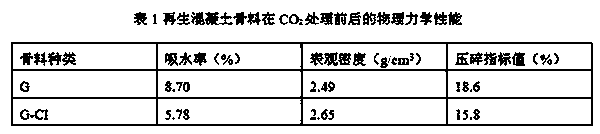

Method for carbon dioxide strengthening of recycled concrete aggregate

ActiveCN104045251AImprove physical and mechanical propertiesImprove early strengthSolid waste managementCarbonizationAbsorption rate

A method for carbon dioxide strengthening of a recycled concrete aggregate comprises the following steps: (1) crushing and sieving waste concrete; (2) placing the sieved recycled concrete aggregate in a sealed container, controlling the relative humidity of 30-90% and the CO2 concentration of 5-90%, and carrying out carbonization treatment; and (3) making the treated recycled concrete aggregate particles into recycled mortar and concrete. Compared with mortar prepared from a recycled concrete aggregate without treatment, the mortar prepared from the obtained recycled concrete aggregate after CO2 strengthening treatment enables the mortar early strength to be improved by 20.1%-22.0% and the later strength to be improved by 12.1%-13.9%; the 28 d drying shrinkage value can be reduced by 7.8%-16.7%; and the 28 d water absorption rate can be reduced by 7.7%-13.3%.

Owner:HUNAN UNIV

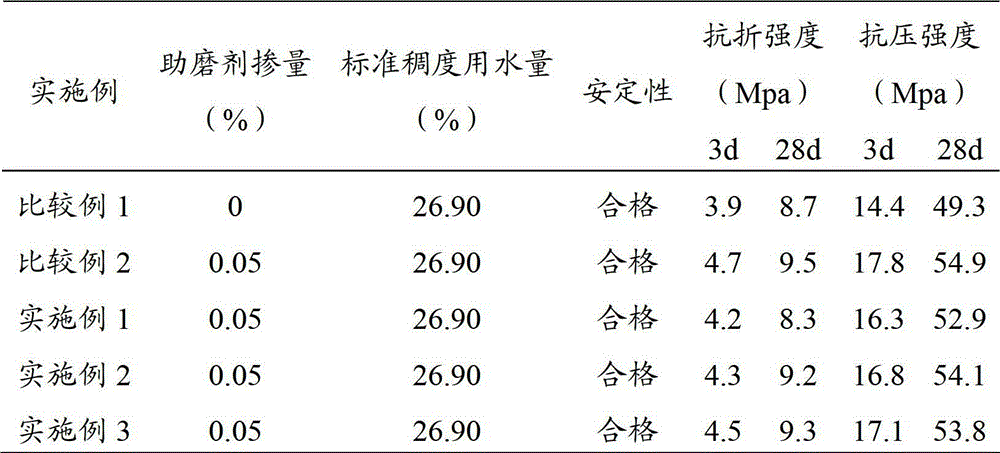

Grinding aid for slag cement

The invention provides a grinding aid for slag cement. The grinding aid provided by the invention comprises the following components by weight percent: 5-20wt% of alcohol amine compound, 0.1-5wt% of hydroxypropyl methyl cellulose, 5-30wt% of polyhydric alcohol compound, 0.5-10wt% of sodium hexametaphosphate, 1-10wt% of soluble sulfate, 1-8wt% of sodium dodecyl benzene sulfonate and the balance of water. In the grinding agent provided by the invention, the hydroxypropyl methyl cellulose is beneficial for stimulating the activity of the slag, forming stable hydrous products in the reaction process, improving the property of the cement, improving the strength of the cement and improving the stability of the liquid grinding aid at the same time. Experimental result shows that the grinding aid is capable of increasing the breaking strength of the cement to 9.5MPa and increasing the compressive strength to about 55MPa.

Owner:SHANDONG HONGYI TECH +1

Construction material produced by utilizing industrial residue

The invention discloses a construction material produced from industrial residue, aims to provide a construction material having the advantages of light weight, sound insulation, heat insulation, low cost, fire resistance, dense products, high rigidity and the like, and solves the problems with land occupation and pollute environment of phosphate slag and phosphogypsum at the same time. the invention is realized through the following technical scheme: phosphate slag and phosphogypsum are used as raw materials for producing the construction material, which comprises the following components by the weight part: 35 to 65 parts of phosphate slag, 10 to 40 parts of phosphogypsum, 5 to 15 parts of lime, 15 to 28 parts of cement, 0.1 to 0.4 part of light aggregate, 0.02 to 0.05 part of soluble glass, 0.02 to 0.05 part of water-reducing agent, 0 to 0.004 part of retarding agent, 0 to 0.005 part of early-strength admixture, and 0 to 0.008 part of foam killer; the components are weighed by the formula weight part and added to a blender; water is added to the blender with the water-to-material proportion being 4 to 10 and mixed evenly with the materials; and the solution is cast into a die and natural air dried after molding. Dies with different structures can be used according to purposes to conduct cast molding. The construction materials such as wall plates, guardrail decoration pillars, door and window sleeves, vase sleeves and the like can be produced.

Owner:张勇飞

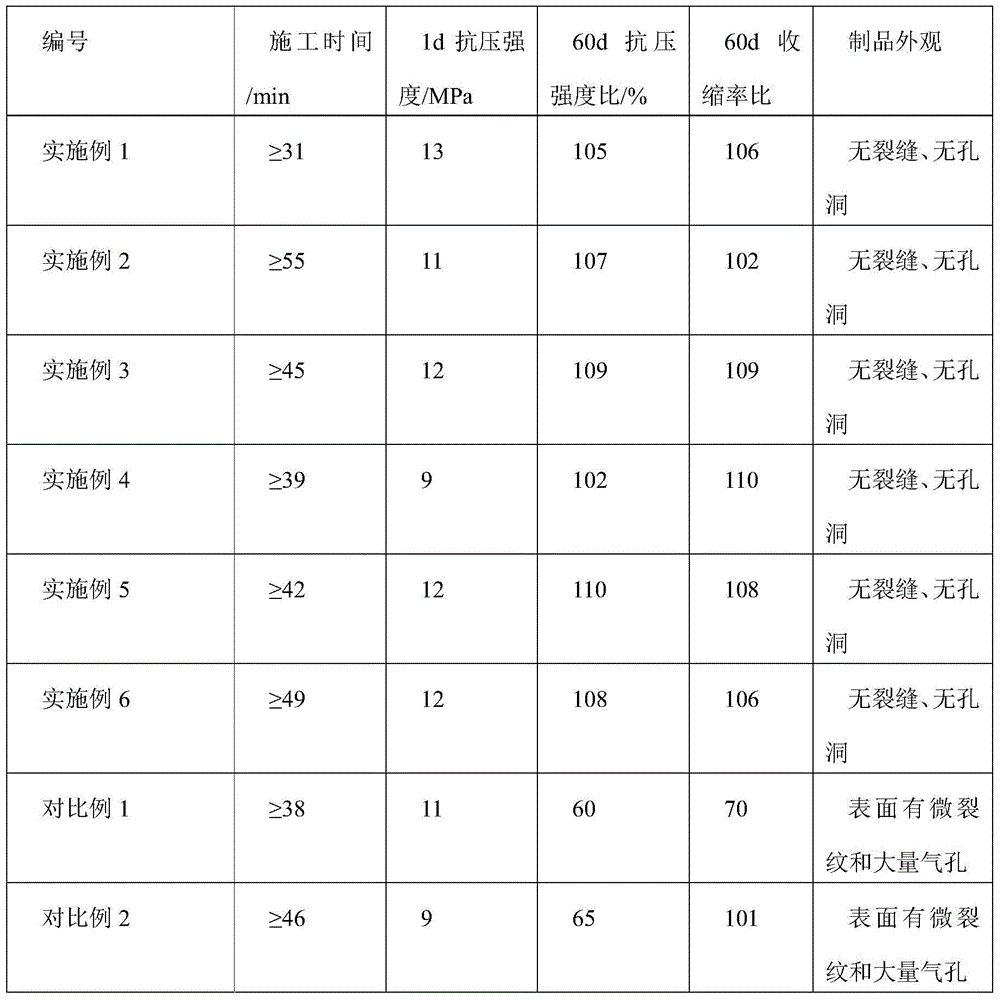

Cement-based composite material used for 3D printing as well as preparation method and application thereof

ActiveCN105731942AGood lookingGreat tasteAdditive manufacturing apparatusSolid waste managementAggregate (composite)Alkali free

The invention discloses a cement-based composite material used for 3D printing as well as a preparation method and application thereof, and belongs to the field of building materials. The cemented-based composite material comprises the following components in percentage by weight: 19-25% of a composite gel material, 0.2-0.6% of a shrinkage inhibitor, 1-2% of an anti-carbonization agent, 57-66% of aggregates, 0.3-1.1% of fiber-reinforced materials, 0.9-1.8% of a liquid alkali-free accelerating agent, 0.8-1.7% of a retarder, 0.02-2% of a thickening agent, 0.2-0.4% of a plastic retaining agent, 0.04-0.09% of a defoaming agent, 0.04-0.2% of a water reducer and 5-14% of water. A cement product printed by the cement-based composite material has no holes and pitted surface in appearance.

Owner:CHINA BUILDING MATERIALS ACAD

High-performance sand-soil consolidation material, as well as preparation method and using method thereof

The invention relates to a high-performance sand-soil consolidation material, as well as a preparation method and a using method thereof. The high-performance sand-soil consolidation material belongs to a mortar composition and is characterized by comprising the following raw materials in parts by weight: 5-40 parts of cement clinker, 3-6 parts of gypsum, 4-10 parts of alkali additive, 0.5-6 parts of compound activating agent, 1-4 parts of early strength agent, 2-10 parts of mineral activating agent, 3-8 parts of expansion agent and 22-77 parts of micro-powder formed by fine grinding of blast furnace water-quenched slag. The invention provides the high-performance sand-soil consolidation material which has the advantages of simple operation, convenient construction, good water resistance, fast consolidation, high early strength, stable improvement of post-strength, resistance to erosion of underground inorganic salt water, excellent anti-seepage performance and low production cost, as well as the preparation method and the using method thereof. The high-performance sand-soil consolidation material is suitable for consolidating mine tailings, natural weathered sand, fly ash, gravel, stone chips, stone powder, soil, sludge, construction waste, coal gangue and phosphorus slag into a solid material, and can be used for laying a subgrade, constructing a wall body and constructing a site foundation.

Owner:淄博乾耀固结材料有限公司

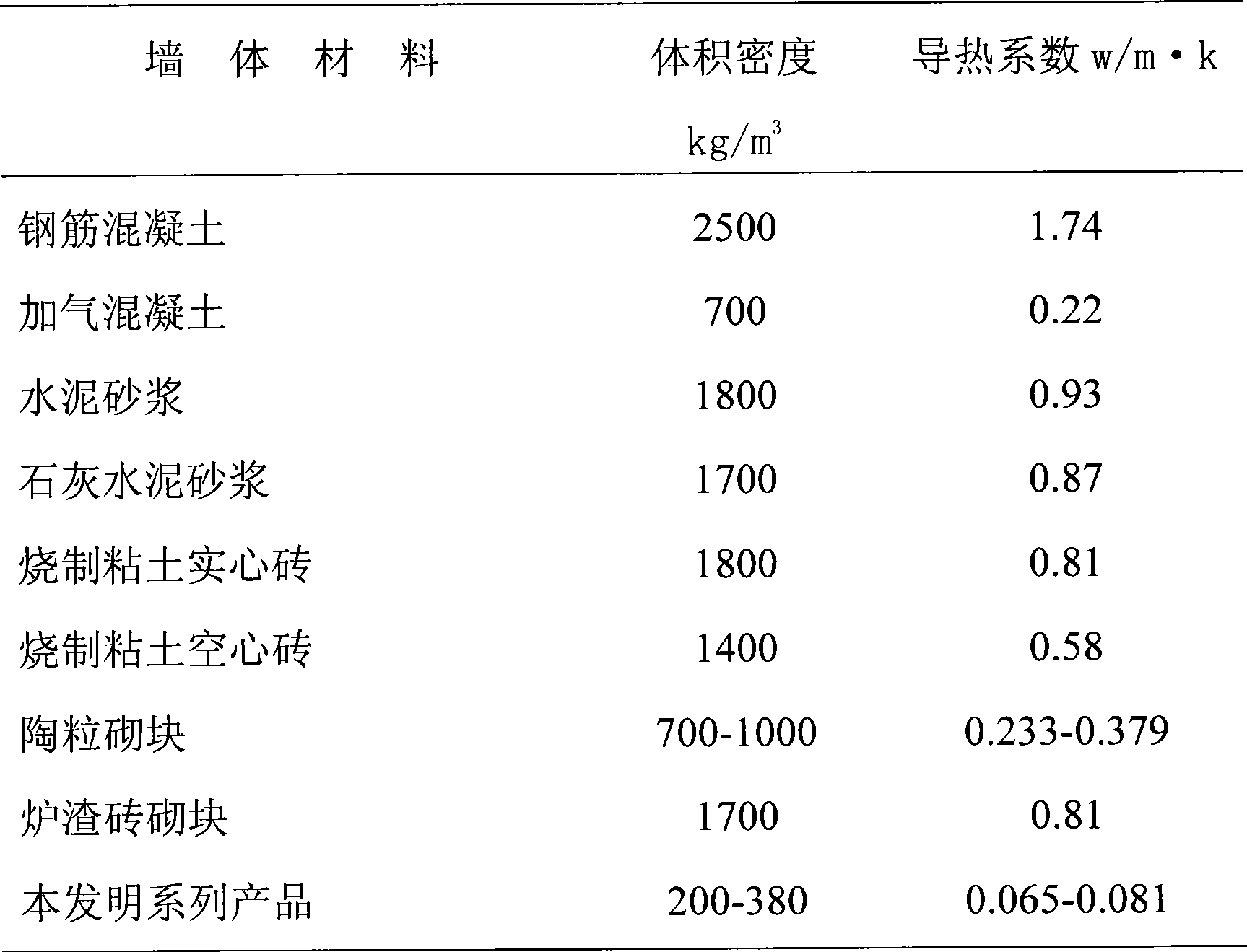

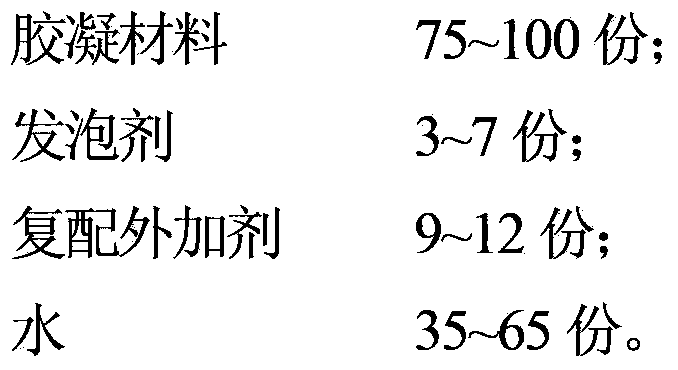

Chemical foamed concrete and preparation method thereof

The invention discloses a chemical foamed concrete and a preparation method thereof. The concrete product is prepared by using a cementing material, a foaming agent, a compounded additive and water as raw materials through a chemical foaming principle, and the added compounded additive realizes stable foaming speed stability, uniform bubble diameter and controllability. The chemical foaming preparation method has the advantages of simplicity, low production investment cost, and convenient construction. The foamed concrete product prepared in the invention has the advantages of fireproof property, waterproof property, sound insulation, heat insulation, light weight, high compressive strength and environmental protection. The bulk density, the compressive strength and the heat conduction coefficient of the obtained product are less than 400kg / m<3>, more than 3.5MPa and less than or equal to 0.07W / (M.K) respectively. The above formula adopting alkaline ash comprising alkaline furnace ashes, alkaline slag, alkaline furnace slag and other wastes as raw materials realizes comprehensive utilization of resources, changes wastes into valuables, and accords with the demands of sustainable development of national circular economy.

Owner:LIAONING JIJIA ENERGY SAVING WALL EQUIP

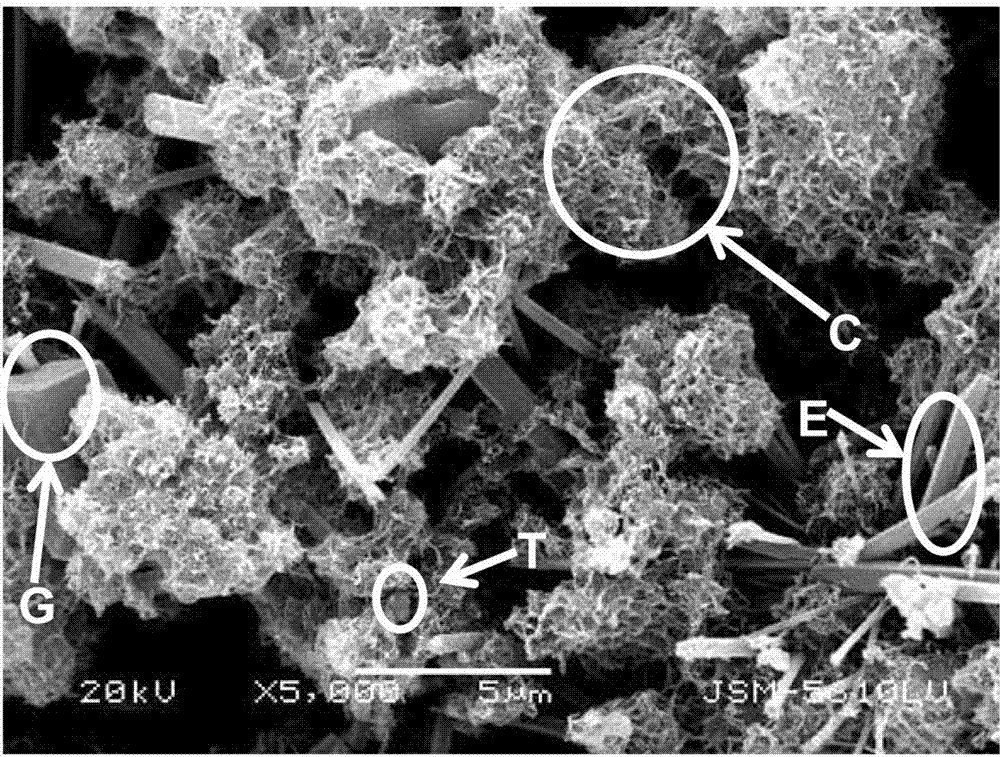

Geopolymer grouting material

InactiveCN101712546AImprove early strengthImprove liquiditySolid waste managementCement productionSlagGeopolymer

The invention discloses a geopolymer grouting material, which is prepared from the following components in parts by weight: 10-30 parts of waste concrete powder, 5-15 parts of desulfurization gypsum, 10-20 parts of steel slag powder, 20-40 parts of scoria powder, 3-8 parts of high calcium fly ash, 20-50parts of coal ash and 5-10 parts of alkali-activator. The geopolymer grouting material has the advantages of high early strength, good flowing property, low production cost, and the like; moreover, the geopolymer grouting material has self-hardening property, can react with soil, and enable soil bodies to become a plate-shaped structure, thereby improving the bearing capacity of a soil roadbed.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

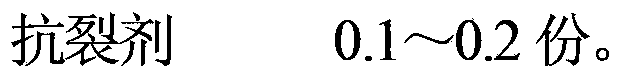

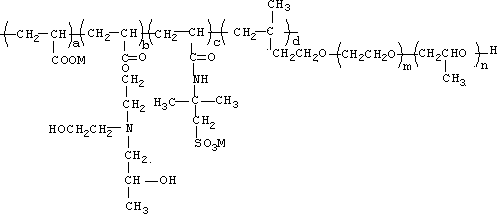

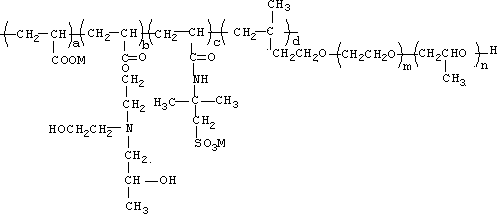

Ethers early strength type polycarboxylate water reducer and preparation method thereof

The invention discloses an ethers early strength type polycarboxylate water reducer and a preparation method thereof. The water reducer regards unsaturated esters, N,N-bis(2-hydroxyethyl)isopropanolamine (DIEPA), 2-acrylamide-2-methylpropanesulfonic acid (AMPS), methyl allyl polyoxyethylene polyoxypropylene ether (TPEG) and the like as main chemical synthesis raw materials, and the main chemical synthesis raw materials are subjected to amidation and copolymerization in certain conditions under the action of a catalyst, an initiator, a chain transfer agent and the like, so that a high-molecular polymer with an amphoteric structure is obtained. The molecular structure of the water reducer comprises hydrophilic hydroxyl, hydrophilic carboxyl, hydrophilic acylamino, hydrophilic sulfonyl, hydrophobic carbon chains and a polyoxyethylene polyoxypropylene ether long-chain structure with certain stereo-hindrance effects, wherein an N containing group can improve early strength of concrete obviously. Therefore, the ethers early strength type polycarboxylate water reducer is applicable to pre-cast concrete components which need improvement of early strength.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Emulsified asphalt

InactiveCN101153118AEasy to control air contentEasy to control fluidityBuilding insulationsLight railCement mortar

The present invention provides emulsified asphalt made of asphalt, surfactant, additive and water. Wherein, the contents of each component are: 38 percent to 58 percent of asphalt, 1 percent to 15 percent of ionic surfactant and 2.5 to 19 percent of non-ionic surfactant of the surfactant, 0.5 to 8 percent of additive; and the left is water; all are calculated according to a weight percentage. The product of the present invention is the emulsified asphalt of good stability and simple production process. In the actual use, the CA mortar can avoid eduction and contraction; thus the CA mortar has appropriate work time and high strength in the early period, which can fully meet the requirements of plate type ballastless track. Therefore, the product of the present invention can be effectively used in emulsified asphalt cement mortar (also known as CA mortar) for plate type ballastless track of high-speed railway or urban light rail.

Owner:张洪武

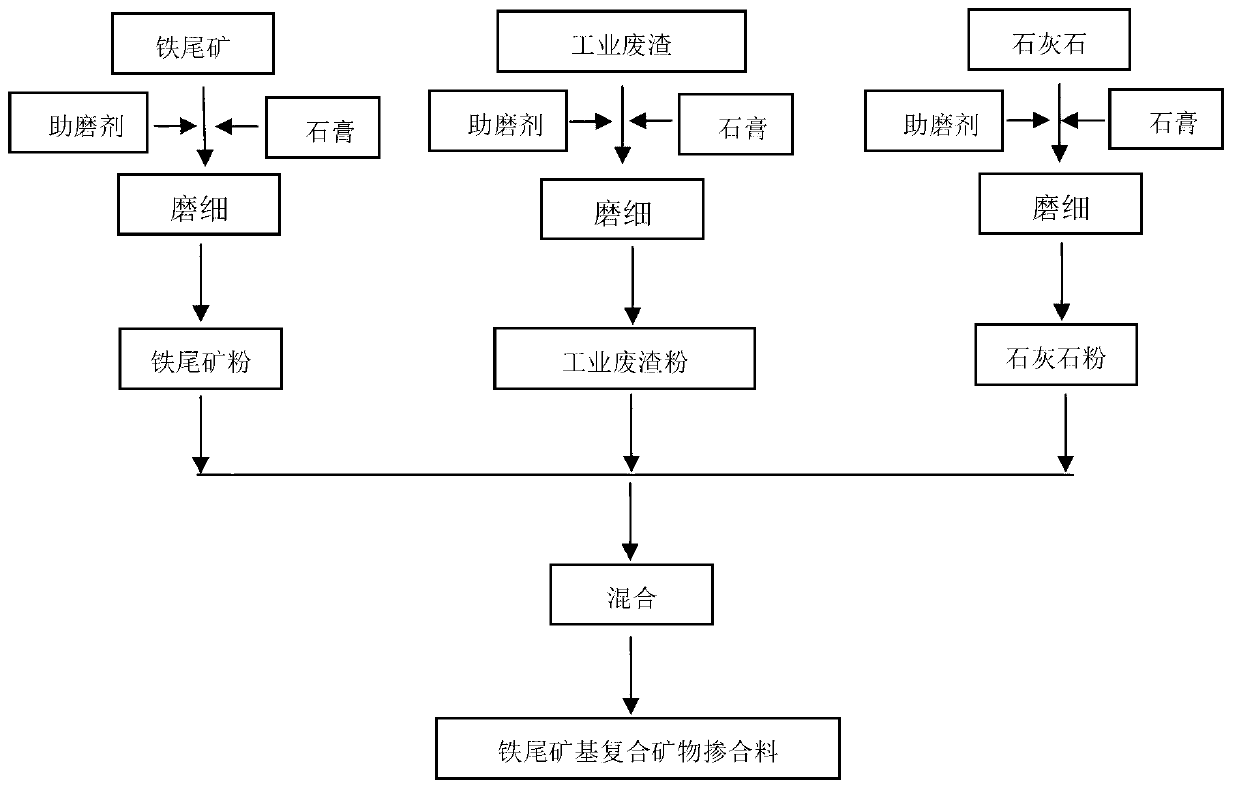

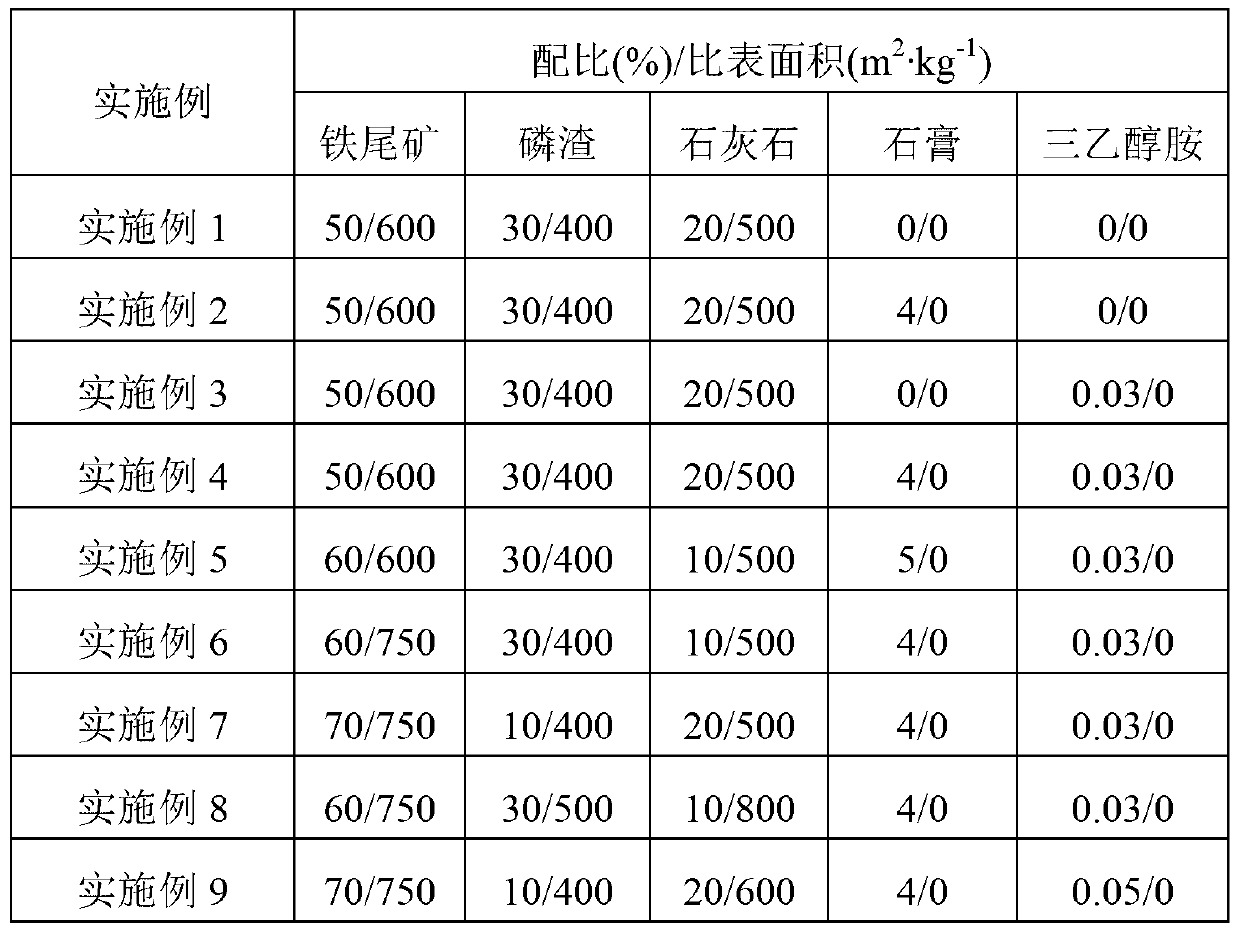

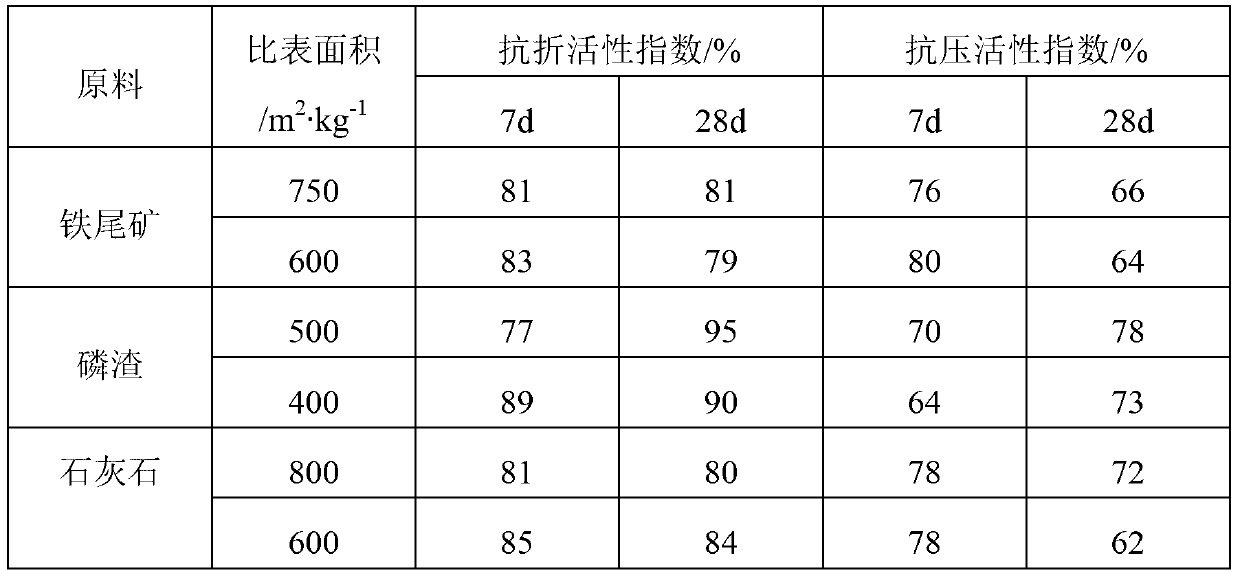

Iron tailing-based complex mineral admixture and preparation process thereof

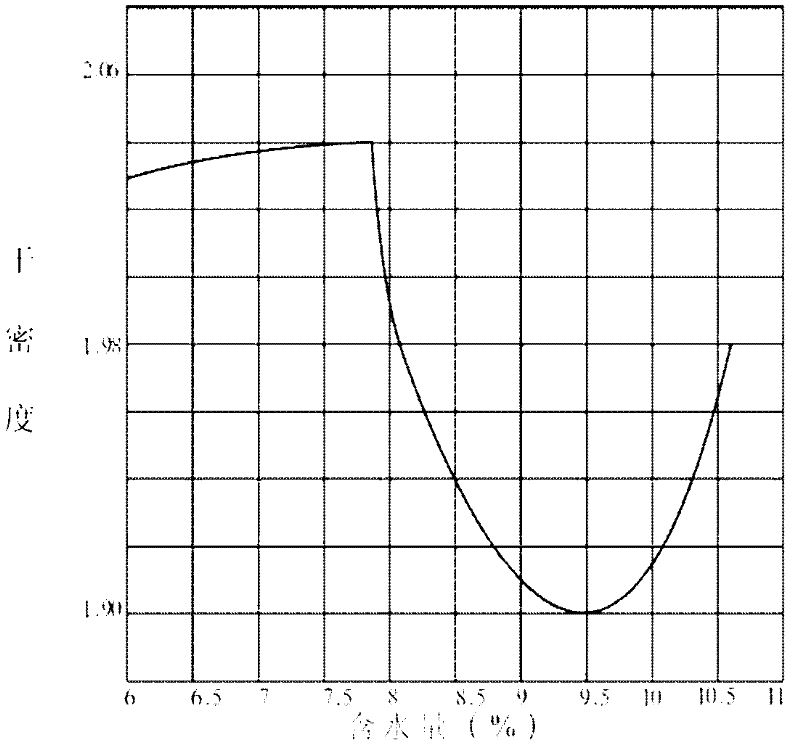

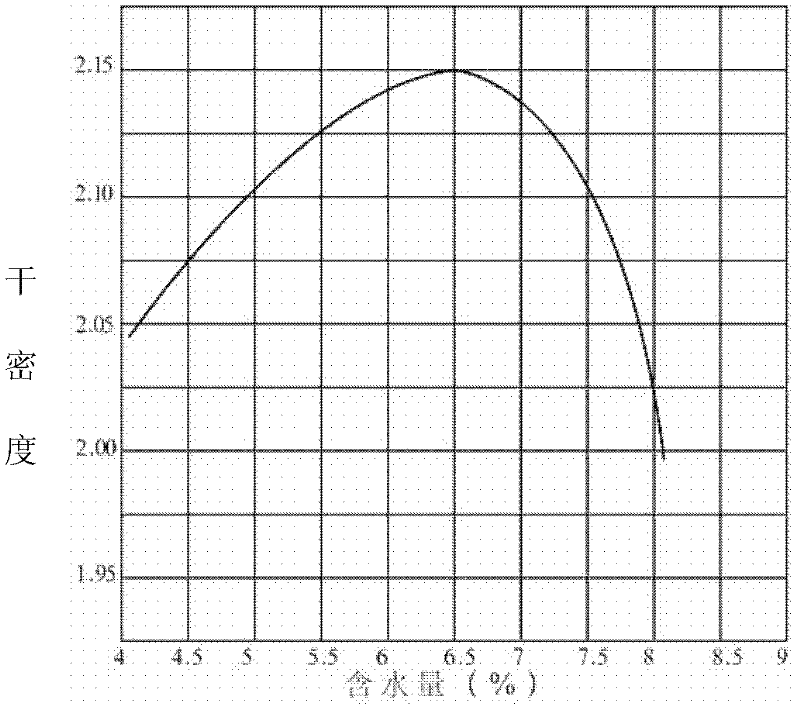

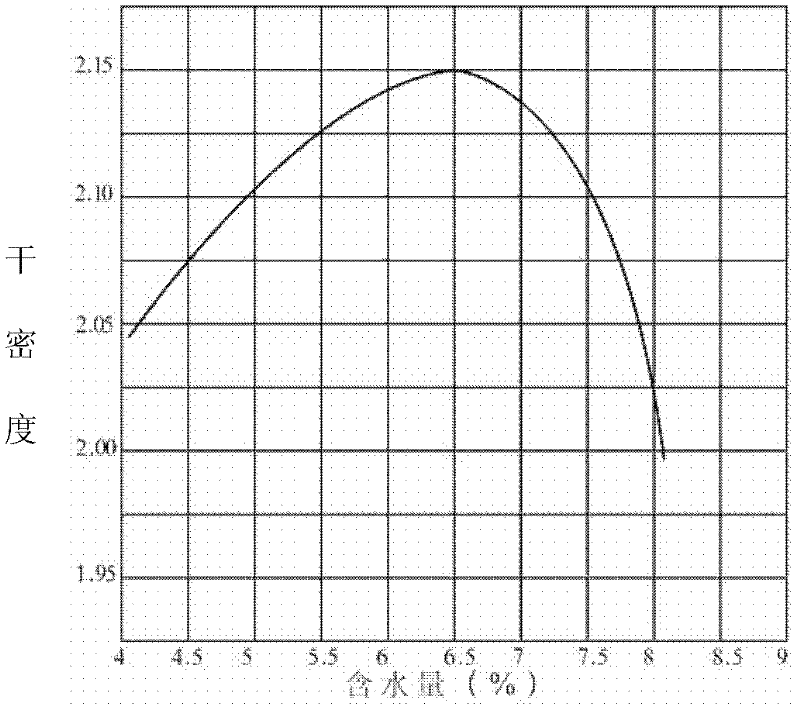

InactiveCN103342491AExcellent performanceImprove pore structureSolid waste managementWater contentSlag

The invention relates to an iron tailing-based complex mineral admixture and a preparation process thereof. The preparation process comprises the following steps of: respectively drying iron tailing sand, industrial waste slag and limestone till water content is not more than 1% for later use; adding gypsum to match with iron tailings, the industrial waste slag and the limestone after drying, then sending into a ball grinding machine to perform powder grinding, and adding grinding aids during the powder grinding process; and uniformly mixing the obtained iron tailing powder, industrial waste slag powder and limestone powder to obtain the iron tailing-based complex mineral admixture. The iron tailing-based complex mineral admixture disclosed by the invention has the beneficial effects that 1) the iron tailings are matched with other industrial waste slag, the admixture for concrete is prepared by simple mechanical fine grinding, and the performance is better; 2) the performance is good, and the iron tailing-based complex mineral admixture can be used for preparing the concrete with the strength grade of C50-C80; 3) a variety of industrial wastes are scientifically and effectively compounded, the activity and particle size synergy of each component against cement and the concrete can be fully exerted to enable the advantages of all the components to complement each other, and the over-superimposed effect is further realized; and 4) the production process is simple and conductive to industrial production, popularization and application.

Owner:WUHAN UNIV OF TECH

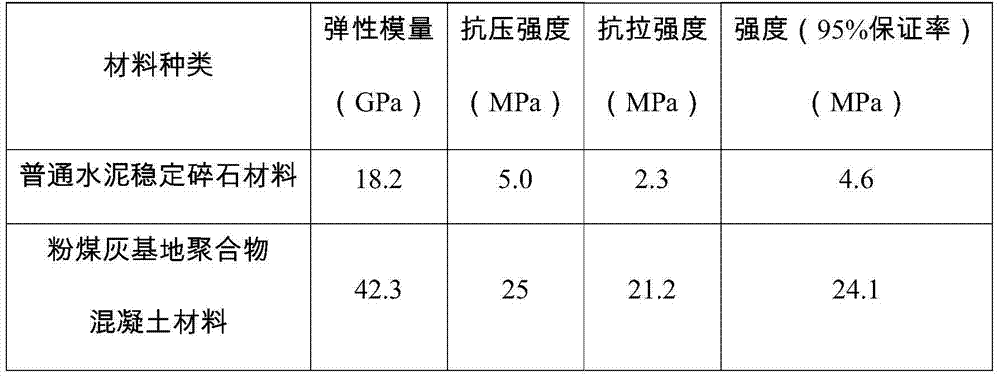

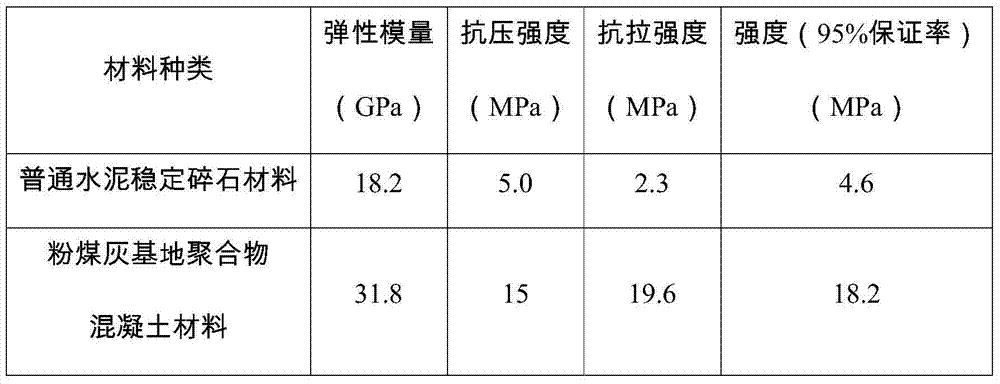

Flyash-based polymer concrete material and preparation method thereof

ActiveCN104496333APromote environmental protectionImprove mechanical propertiesPolymer sciencePolymer concrete

The invention discloses a flyash-based polymer concrete material and a preparation method and an application thereof. The flyash-based polymer concrete material comprises the following components in percentage by mass: 25%-45% of flyash, 0-15% of metakaolin, 10%-15% of cement, 0-5% of coal gangue and slag, 25%-35% of an alkali activator, 0.5%-1% of a retarder and 1%-5% of deionized water. An alkali-activated flyash-based polymer is adopted as a main gel material, so as to prepare an inorganic polymer concrete material; the polymer concrete material has the characteristics of high environmental protection property, good mechanical property and high early strength.

Owner:SHANGHAI PUDONG NEW AREA CONSTR GRP CO LTD

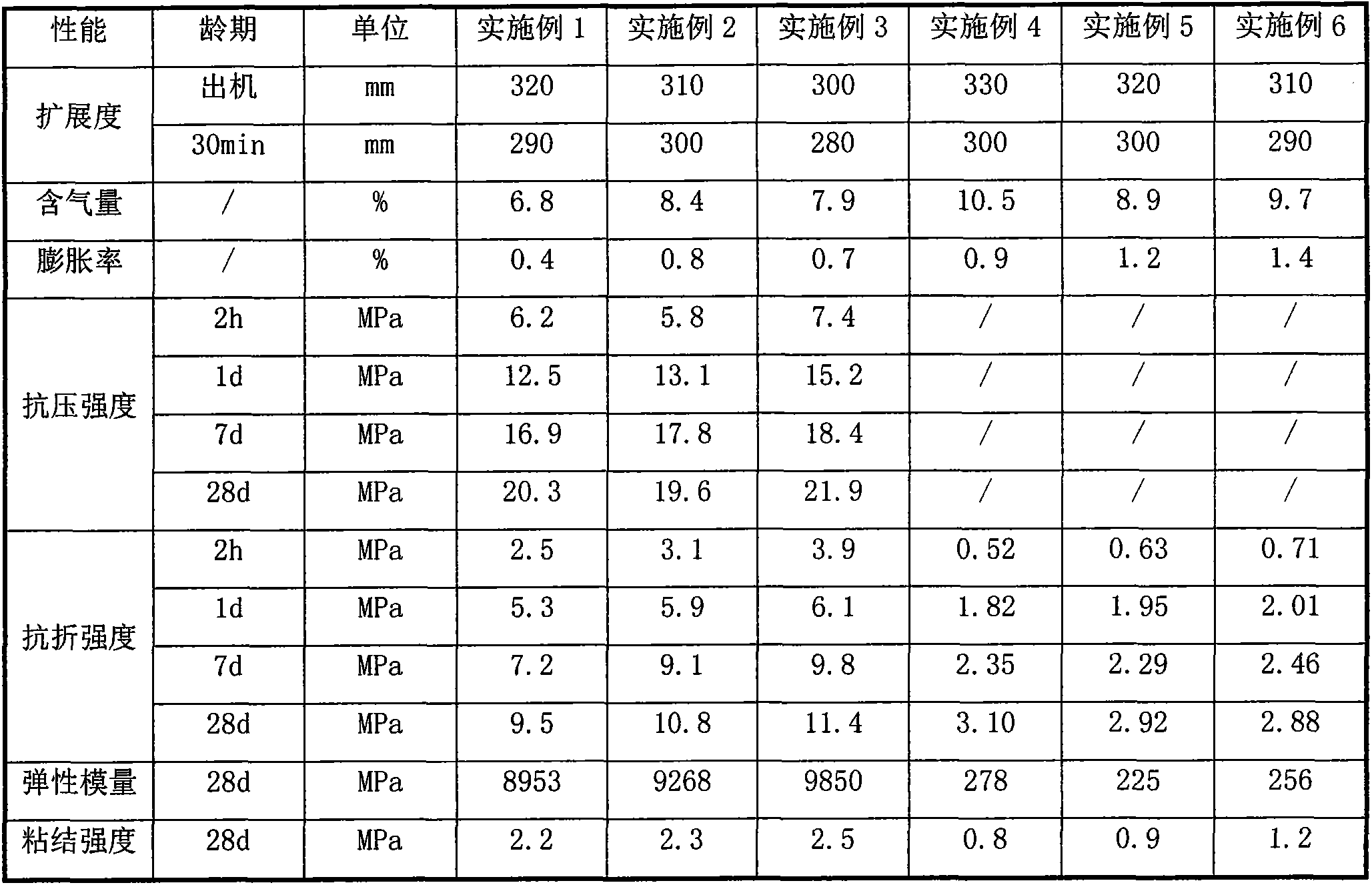

Polymer cement mortar for slab ballastless track of high-speed railway

The invention discloses polymer cement mortar for a slab ballastless track of a high-speed railway. The polymer cement mortar a comprises a dry raw material and a liquid raw material, wherein the dry raw material comprises a binding material component, an elastic adjusting component, an expanding component, an internal curing component, an aggregate component and a coagulation adjusting component; the liquid raw material comprises a polymer emulsion, a water reducing agent, a defoaming agent, an air entraining agent and water; and the weight ratio of the dry raw material to the liquid raw material is 100:(15-25), and the dry raw material and the liquid raw material are uniformly mixed in a proportion to prepare the polymer cement mortar. The polymer cement mortar has the advantages of controllable coagulation time, high adhering strength, adjustable elastic modulus, good elasticity and toughness, high durability and the like, and is capable of replacing cement emulsified asphalt mortar to be applied to a packing material of the slab ballastless track or can be used as a quick repairing material of a filling layer of cement emulsified asphalt mortar.

Owner:BEIJING TIEKE SPECIAL ENG TECH CO LTD +1

Phosphogypsum-based gelling material and its application in mine tailing filling

ActiveCN104211313ARealize high-quality utilizationWide variety of sourcesMaterial fill-upRed mudPhosphogypsum

The invention relates to a gelling material for mine tailing filling. The gelling material for mine tailing filling used for improving the early stage strength of a filler and having good water segregation performance is obtained through the steps of respectively milling phosphogypsum, red mud, phosphorus residues and clinker to 800m<2> / kg, 700m<2> / kg, 300m<2> / kg and above 300m<2> / kg respectively, uniformly mixing the above milled raw materials, and adding an exciting agent. The gelling material is used to carry out mine tailing filling, and the raw materials are from various industrial waste residues, so the gelling material has the advantages of low cost, simple technology, strong maneuverability, low filling cost, effective utilization of various industrial waste residues of the metallurgy industry, energy saving, emission reduction and environmental protection.

Owner:CHINA THREE GORGES UNIV

Environment-friendly colorful tile joint mixture and preparation method thereof

ActiveCN103172330AReduce consumptionImprove early strengthSolid waste managementEmulsionShrinkage coefficient

The invention discloses an environment-friendly colorful tile joint mixture. The environment-friendly colorful tile joint mixture is characterized by comprising the following components in percentage by weight: 35%-40% of white cement, 40.73%-47.75% of waste porcelain powder, 0-15% of quartz powder, 0-10% of titanium dioxide, 1%-1.5% of re-dispersible emulsion powder, 0.1% of water repellent, 0.15% of water-retaining agent, 0.4% of lignin fiber, 0.1%-0.25% of water reducing agent and 0-2% of pigment. The invention further discloses a preparation method of the environment-friendly colorful tile joint mixture. The consumption of quartz sand and heavy calcium powder is reduced by using the waste porcelain powder as the joint mixture filler; the early strength of the joint mixture is improved by virtue of early strength function of the white cement, so that the construction process requirements are satisfied. The waste porcelain powder is sintered at a high temperature, so that the physical and chemical performances are stable, the volume is stable, and the expansion-shrinkage coefficient is close to that of the tile; the material with the same expansion-shrinkage coefficient is used as the filler, so that the possibility that the tile joint mixture generates cracks can be further reduced.

Owner:厦门路桥翔通股份有限公司

Formula of early strength type polycarboxylic acid series high-performance dehydragent and method for manufacturing same

The invention proposes a compounding formula and manufacture method of an early-strength polyocarboxy acid high performance water reducing agent. The compounding formula is as follows: (1) the mass ratio of 37 61.5percent allyl polyethyleneoxide ether water-soluble fluid with polymerization degree 37, allyl polyethyleneoxide ether, acrylic acid, 27.7percent acrylic amide water-soluble fluid, 26.2percent methyl propylene sulfonic acid sodium water-soluble liquid is 2321:882:311:276.7:542.2; (2) the consumed amount of the initiator hydrogen peroxide is 0.2percent of a monomer mole number; (3) the initiator Sodium bisulfoxylate is 0.06percent of a monomer mole number; (4) the five elements copolymerization is carried on in the 60percent density system under 55 DEG C. The invention synthesizes carboxylic acid series product with strong early-strength performance, which especially are used for increasing the early-strength of the concrete largely under the low temperature of the winter to speed up the concrete construction progress and enhance the use efficiency of the construction template though the adjustment of the formula and craft. The invention is suitable for the concrete project with high requirements for the concrete early-strength (within 2 days).

Owner:LETS HLDG GRP CO LTD +1

Emulsified asphalt modified by epoxy resin

The present invention relates to emulsified asphalt modified by adopting water-base epoxy resin. It is characterized by that it utilizes water-base epoxy resin emulsion and solidifying agent to modify the emulsified asphalt, in which the general emulsified asphalt content is 100 portions, water-base epoxy resin emulsion content is 3-15 portions and the solidifying agent content is 20%-25% of water-base epoxy resin emulsion content.

Owner:GUANGDONG UNIV OF TECH

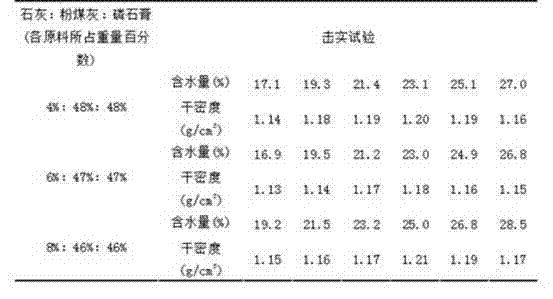

Roadbed filler for road and preparation method of roadbed filler

InactiveCN102690098AImprove early strengthImprove water stabilityRoadwaysPhosphogypsumPulverized fuel ash

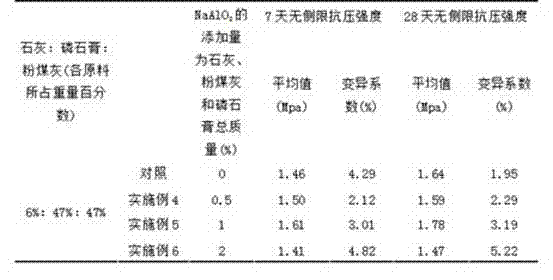

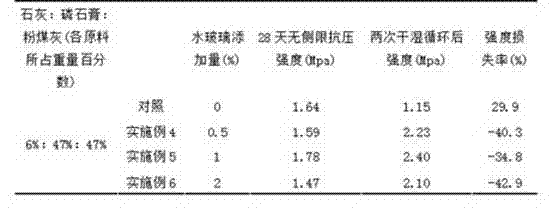

The invention relates to a roadbed filler for a road and a preparation method of the roadbed filler. The roadbed filler for the road is characterized by being prepared from lime, pulverized fuel ash, phosphogypsum and stabilizer. The weight percentage of each material in the lime, the pulverized fuel ash and the phosphogypsum is 15% of lime, 30-50% of pulverized fuel ash and 35-60% of phosphogypsum; the sum of the weight percentages of the materials is 100%; the stabilizer is water glass or NaAlO2 (sodium metaaluminate); the adding amount of the water glass is 2-6% of total mass of the lime, the pulverized fuel ash and the phosphogypsum, and the adding amount of the NaAlO2 is 0.5-2% of total mass of the lime, the pulverized fuel ash and the phosphogypsum. Due to the roadbed filler for the road prepared by the method, not only can the early strength be improved, but also the problem of water stability can be solved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +2

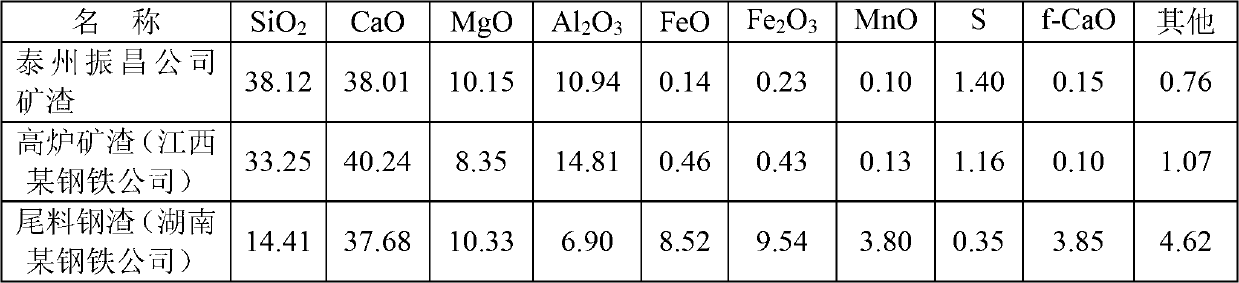

Aerated concrete block produced through using specially-made mineral waste residue and tailings steel slag and production method of aerated concrete block

The invention provides an aerated concrete block produced through using specially-made mineral waste residue and tailings steel slag and a production method of the aerated concrete block. The aerated concrete block is produced through the following steps: adding an additive A, an additive B and water in components as follows: 40 to 50% of specially-made mineral waste residue obtained in a such way that cinder is obtained through the production process of recycling steel slag discharged from Taizhou Zhenchang Industrial Waste Residue Comprehensive Utilization LTD and metallurgical and chemicalferrous waste residue, and then is water-quenched, 35 to 45% of tailings steel slag, 2 to 4% of cement clinker, 1 to 3% of gypsum, and 8 to 12% of modified wood, wherein the grain size of the specially-made mineral waste residue is less than or equal to 5 mm, the grain size of the tailings steel slag is less than or equal to 20 mm, the additive A accounts for 1% of the total weight of the components, the additive B accounts for 0.05% of the total weight of the components, and water accounts for 0.5 to 0.6 times of the total weight of the components; and conducting mixing, heating, air-entrapping, steaming and pressing, and curing in sequence. The aerated concrete block produced by adopting the production method is high in strength, and small in drying shrinkage value, and can meet the block standards of the A3.5 grade and the B09 grade in the JC1062-2007 foam concrete block standard.

Owner:TAIZHOU ZHENCHANG IND RESIDUE COMPREHENSIVE UTILIZATION +1

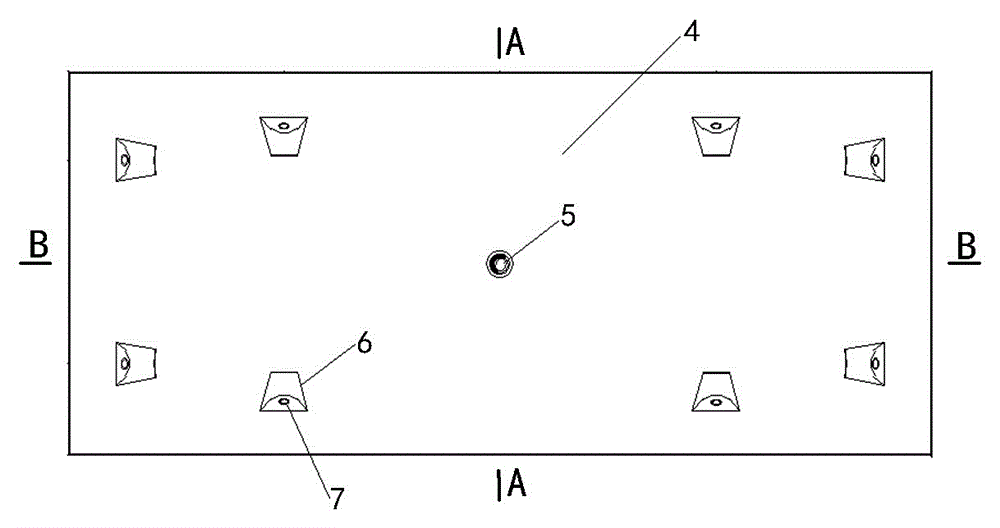

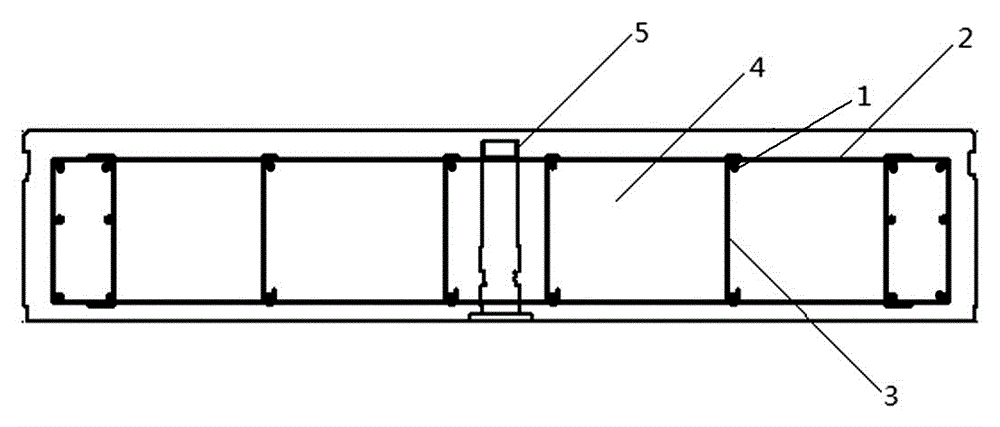

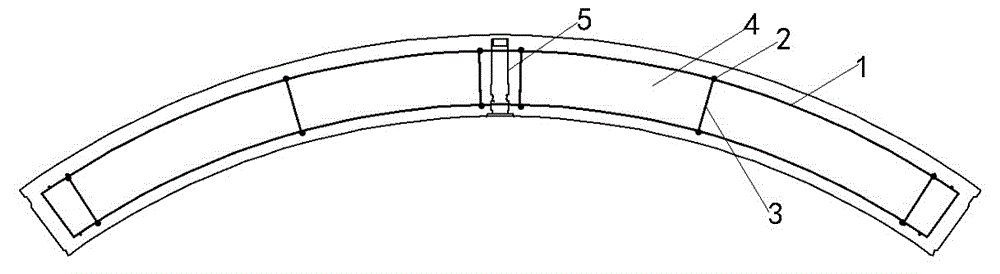

Ultra-high performance hybrid fiber concrete shield segment and preparation method thereof

InactiveCN105041336AReduce dosageReduce consumptionUnderground chambersTunnel liningCrack resistanceReinforced concrete

The invention discloses an ultra-high performance hybrid fiber concrete shield segment and a preparation method thereof. The ultra-high performance hybrid fiber concrete shield segment is of a reinforced concrete structure which consists of a steel skeleton and concrete, wherein the reinforcement ratio of used main reinforcements is 0.5%-1.0%, the distances of the main reinforcements are 150-300mm, the grades of steel reinforcements are not less than three, the smallest steel reinforcement distance of distributed reinforcements is 400mm, the biggest steel reinforcement distance of used distributed reinforcements is 2000mm, and the grades of the steel reinforcements are not less than two. The ultra-high performance hybrid fiber concrete shield segment is made from ultra-high performance hybrid fiber concrete, and comprises cementitious materials, sands, crushed stones, steel fibers, synthetic fibers, water reducer, defoamer and water. The ultra-high performance hybrid fiber concrete shield segment is less in dosage of the steel reinforcements and concrete and high in early strength, can prevent steam preservation, reduces energy consumption, and is green, energy-saving and environmentally friendly. The ultra-high performance hybrid fiber concrete shield segment is strong in anti-burst performance when having a fire, excellent in toughness and crack resistance and excellent in durability, enables edge joints not to easily break, and overcomes the defects of traditional segments.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +2

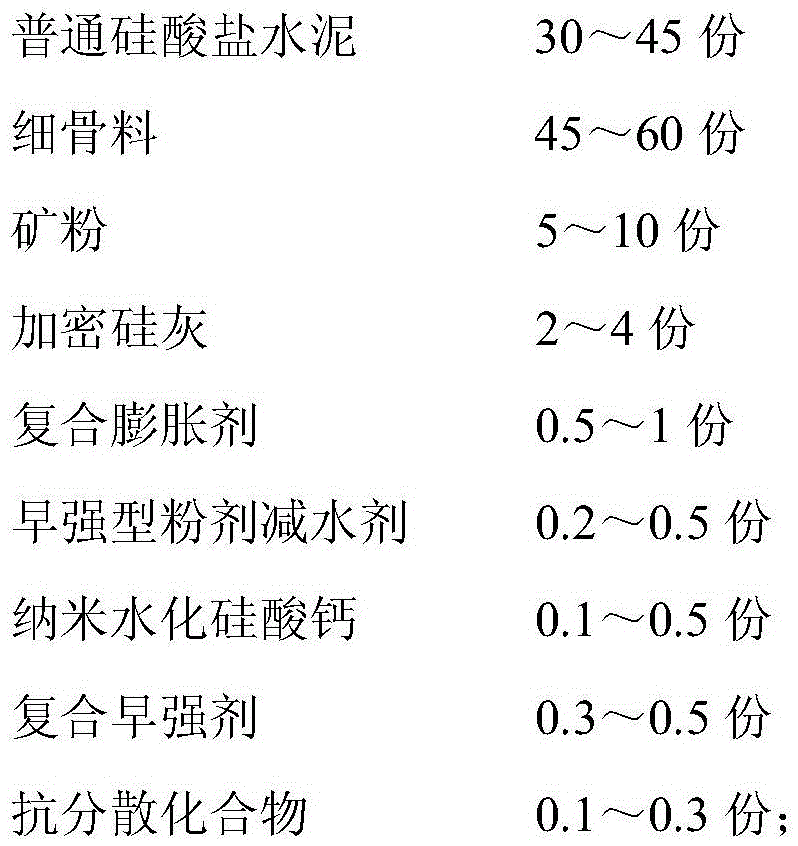

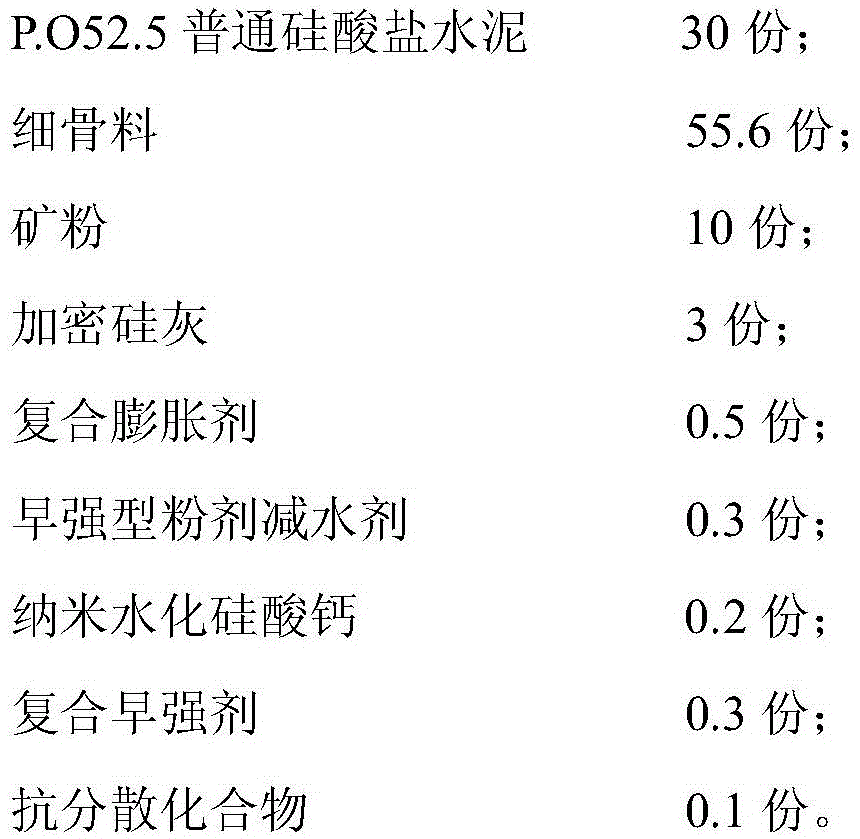

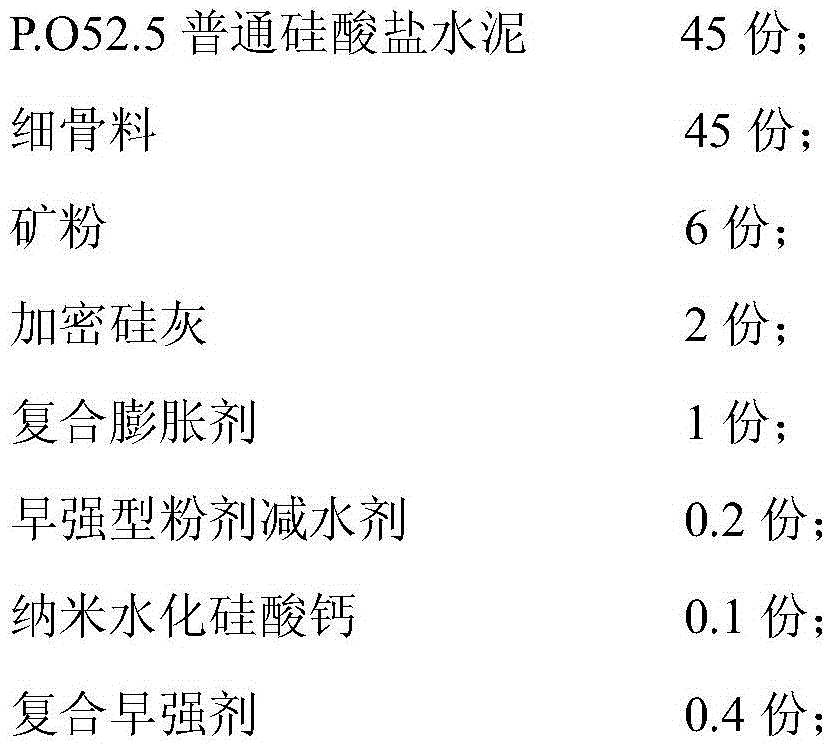

Low-temperature early-strength high-strength underwater grouting material

ActiveCN105622006AEnhance early compressive strengthImprove early strengthCalcium silicateWater reducer

The invention provides a low-temperature early-strength high-strength underwater grouting material. The low-temperature early-strength high-strength underwater grouting material consists of the following ingredients in parts by weight: 30-45 parts of ordinary Portland cement, 45-60 parts of fine aggregate, 5-10 parts of mineral powder, 2-4 parts of encryption silica fume, 0.5-1 part of a compound expanding agent, 0.2-0.5 part of an early-strength powdery water reducer, 0.1-0.5 part of nano hydrated calcium silicate, 0.3-0.5 part of a compound early-strength agent and 0.1-0.3 part of a dispersion-resistant compound. The low-temperature early-strength, low-temperature high-strength and dispersion resistant properties of the low-temperature early-strength high-strength underwater grouting material in water are improved at the same time in the four aspects of reducing the void ratio of the aggregate, optimizing the expanding components and improving the nano early strength and the dispersion resistance, the construction performance, such as the water holding performance and the viscosity, of the grouting material are remarkably improved, the 1d strength and the 28d strength of the grouting material under the undersea low-temperature condition are effectively improved, and the underwater dispersion resistance of the grouting material can be greatly improved. The low-temperature early-strength high-strength underwater grouting material has favorable low-temperature early-strength, low-temperature high-strength and underwater dispersion resistant functions.

Owner:JIANGSU SOBUTE NEW MATERIALS

Cement grinding aid and preparation method thereof

InactiveCN101125742AImprove grinding efficiencyReduce grinding power consumptionCement grindingTriisopropanolamine

The invention discloses a cement grinding aid and a preparation method thereof. Raw materials of the cement grinding aid consists of 10-30 percent of triethanolamine, 12-30 percent of tirisopropanolamine, 5-20 percent of ethylene glycol, 3-10 percent of propanediol, 15-40 percent of water, 1-5 percent of sodium dodecyl benzene sulfonate, 3-10 percent of lignin and 2-5 percent of anhydrous sodium sulfate; water is poured into a reactor and heated to 40-50 DEG C to be reserved; the sodium dodecyl benzene sulfonate is added to be stirred for 15min; the anhydrous sodium sulfate is added and stirred for 10min, then the lignin is added and stirred for 30min; materials in the reactor are filtered by a 150 mesh screen; the ethylene glycol and the propanediol are added and stirred for 20min; the triethanolamine and the tirisopropanolamine are added and stirred for 30min and the grinding aid products are obtained. The cement grinding aid can improve grinding efficiency and early and later strength of cement and reduce cement cost.

Owner:洛阳万顺建材有限公司

Soil curing agent suitable for salinized soil

InactiveCN1743563AHigh strengthExcellent resistance to freeze-thaw cyclesSoil preservationAlkaline earth metalSlag

An earth curing agent used in curing salinized soil with heavy salt is manufactured by ordinary silicate cement, water quenched blast furnace slag, fly-ash, active mineral doped material, lime hydroxides of alkali metal or alkali earth metal and chemical dispersing agent in proper proportion. The middle and strong salinized soil of sulfate can be cured effectively by doping 8%-12% earth curing agents.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com